Remarks

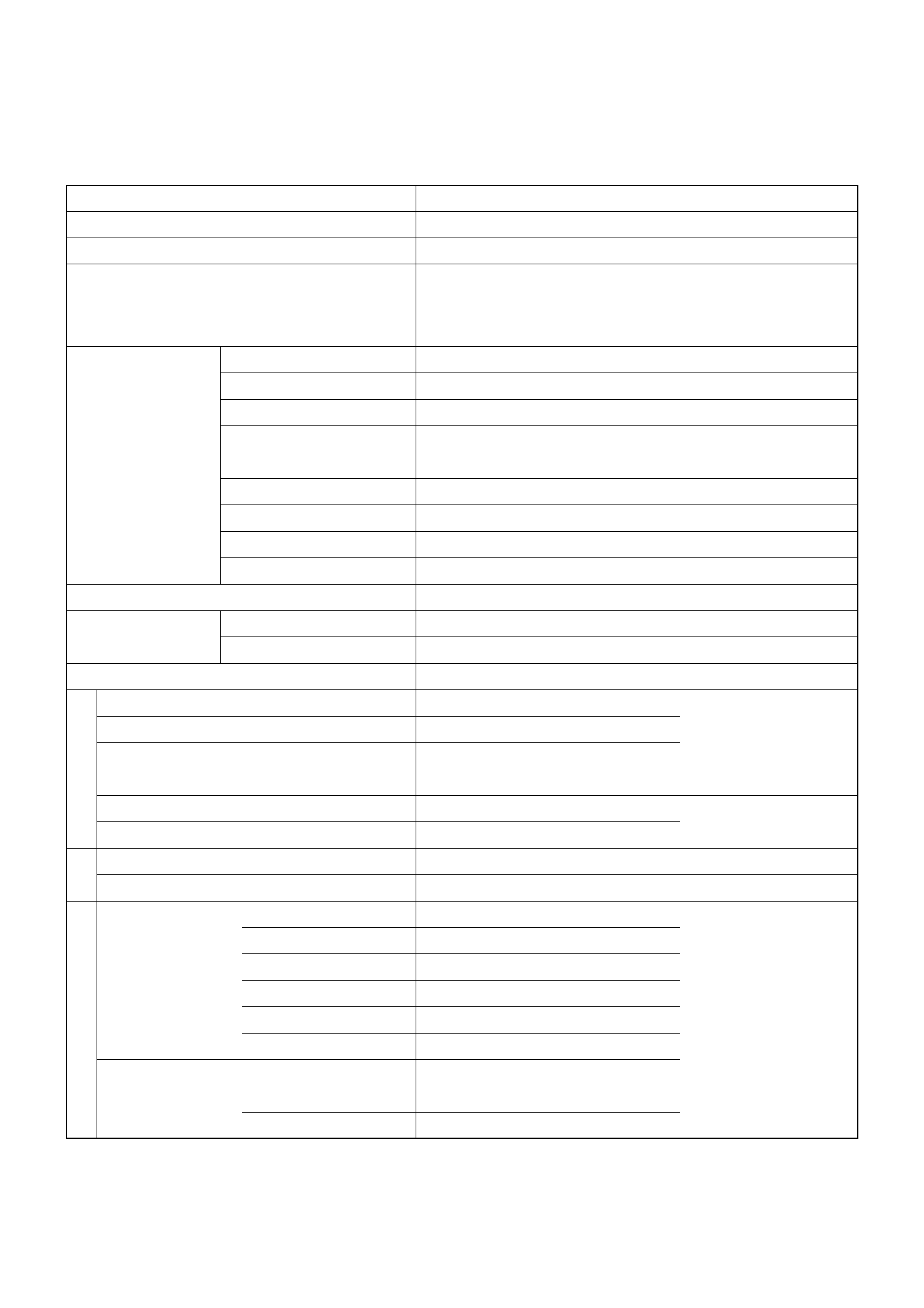

Model 4L30-E

Engine V6 3.2L 6VD1 DOHC

Automatic four speed

overdrive in 4th gear

Type lock-up clutch torque

converter

Shift control Hydraulic

Shift pattern Electronic

Control systems Shift quality Electronic

Lock-up clutch Electronic

1st 2.856

2nd 1.618

Gear ratio 3rd 1.000

4th (O/D) 0.723

Reverse 2.000

Gear set Noiseless, high torque capability

Name ATF DEXRON-III

Oil used Q’ty lit (Imp qt / US qt) 8.6 (7.6 / 9.1)

Torque converter 2200 ± 150 Stall speed (rpm)

Reverse clutch RC 4

Second clutch C2 6 Number of discs

Third clutch C3 6

Brake band Double wrap

Fourth clutch C4 2Number of discs

Overrun clutch OC 1

Overdrive OFW 10 Number of rollers

Principal PFW 26 Number of sprags

Input sun gear 30

Pinion gear 19

Long pinion 23

Ravigneaux Ring gear 90

Long pinion 19 Number of teeth

Output sun gear 46

Sun gear 31

Overdrive Pinion gear 24

Ring gear 81

MAIN DATA AND SPECIFICATIONS

AUTOMATIC TRANSMISSION

SERVICE STANDARD

AUTOMATIC TRANSMISSION

ITEMS SERVICE STANDARD SERVICE LIMIT

PLANETARY CARRIER

Planetary Carrier Pinion End Play mm (in) 0.13 – 0.89 (0.005 – 0.035) –

SECOND CLUTCH

Second Clutch End Play mm (in) 0.36 – 0.79 (0.014 – 0.031) –

OVERDRIVE CLUTCH

Overdrive Clutch End Play mm (in) 0.1 – 0.8 (0.004 – 0.031) –

MAIN CASE

Main Case End Play mm (in) 0.36 – 0.80 (0.014 – 0.031) –

OVERDRIVE CARRIER

Overdrive Carrier Pinion End Play mm (in) 0.24 – 0.64 (0.0094 – 0.025) –

CHECKING TRANSMISSION FLUID LEVEL AND

CONDITION

Checking fluid level and condition (color and odor) at

regular intervals will provide early diagnosis

information about the transmission. This information

may be used to correct a condition that, if not

detected early, could result in major transmission

repairs.

IMPORTANT:

When new, automatic transmission fluid is red in

color. As the vehicle is driven, the transmission fluid

will begin to look darker in color. The color may

eventually appear light brown.

A DARK brown color with burnt odor may indicate

excessive fluid deterioration and signal a need for

fluid change.

FLUID LEVEL

When adding or changing fluid, use only DEXRON®-

III

.

Refer to the Maintenance and Lubrication (Section 0)

for maintenance information and servicing interval.

CAUTION:

DO NOT CHECK FLUID LEVEL UNDER THESE

CONDITIONS:

• Immediately after driving at sustained highway

speeds.

• In heavy city traffic during hot weather.

– If vehicle is towing a trailer.

If the vehicle has been operated under these conditions,

shut the engine off and allow the vehicle to “cool” for

thirty (30) minutes. After the cool-down period, restart the

vehicle and continue from step 2 above.

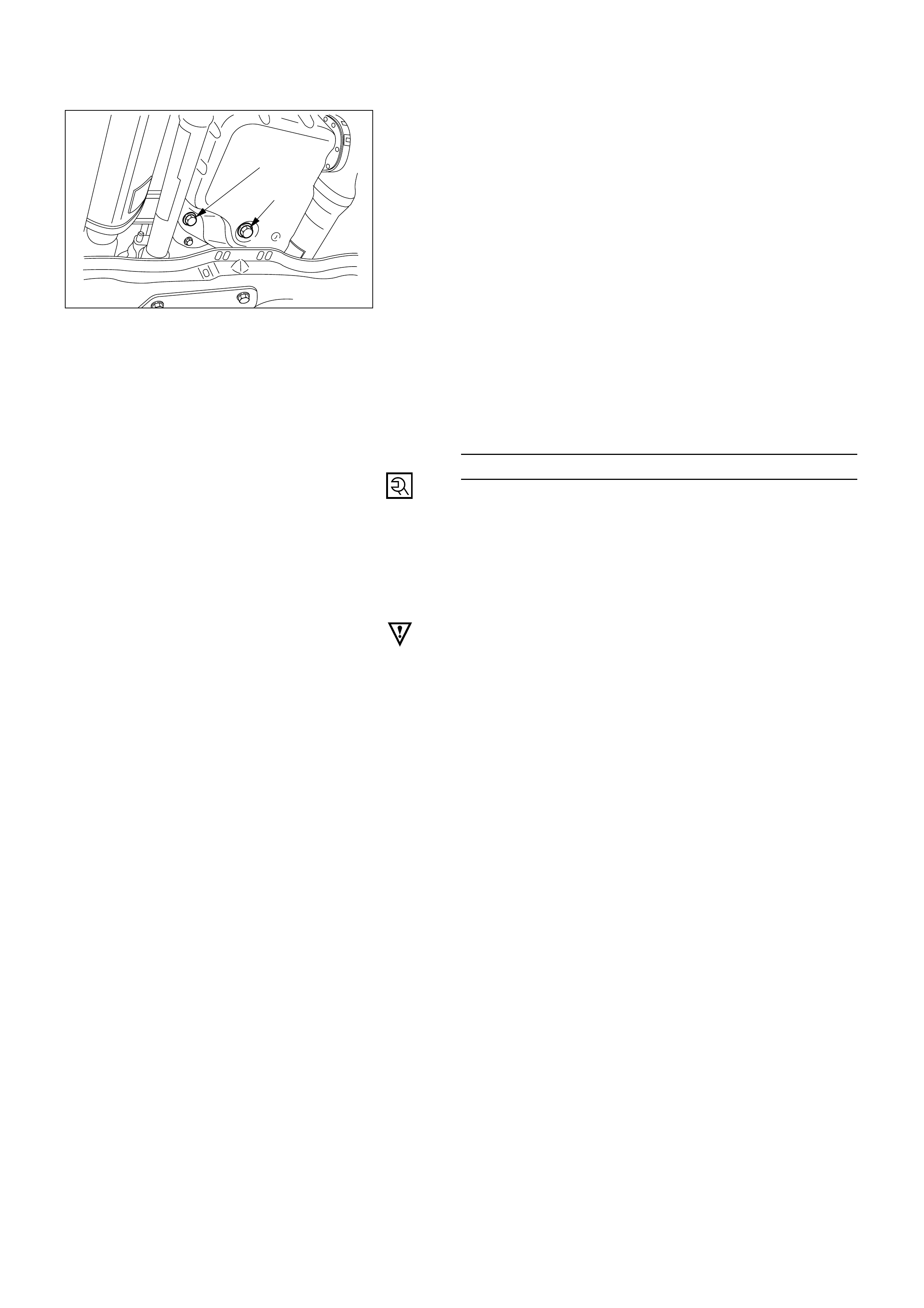

SERVICING

AUTOMATIC TRANSMISSION

CAUTION: Do not overfill.

Overfilling will cause foaming, loss of fluid, abnormal

shifting and possible damage to the transmission.

Techline

1. Parking the vehicle on level ground and apply the

parking brake firmly.

2. Check fluid level with engine running at idle.

NOTE:

Be sure that transmission fluid temperature is below 30°C

(86°F).

3. Move through all gear ranges the selector lever.

4. Move the selector lever to “Park”.

5. Let engine idle for 3 minutes and open the overfill

screw.

6. Let engine idle until a fluid temperature between 32°C

(90°F) and 57°C (135°F) is reached.

7. Add transmission fluid until it flows out over the

overfill screw-opening, then close the overfill screw.

Overfill Screw Torque N·m(kg·m/lb·ft)

38 (3.9 / 28)

NOTE:

Transmission fluid temperature to be check with

service tool.

Minimum fluid level →57°C (135°F)

Maximum fluid level →32°C (90°F)

CAUTION:

Do not open overfill screw with engine stopped.

Overfill screw

Drain screw

242RT001

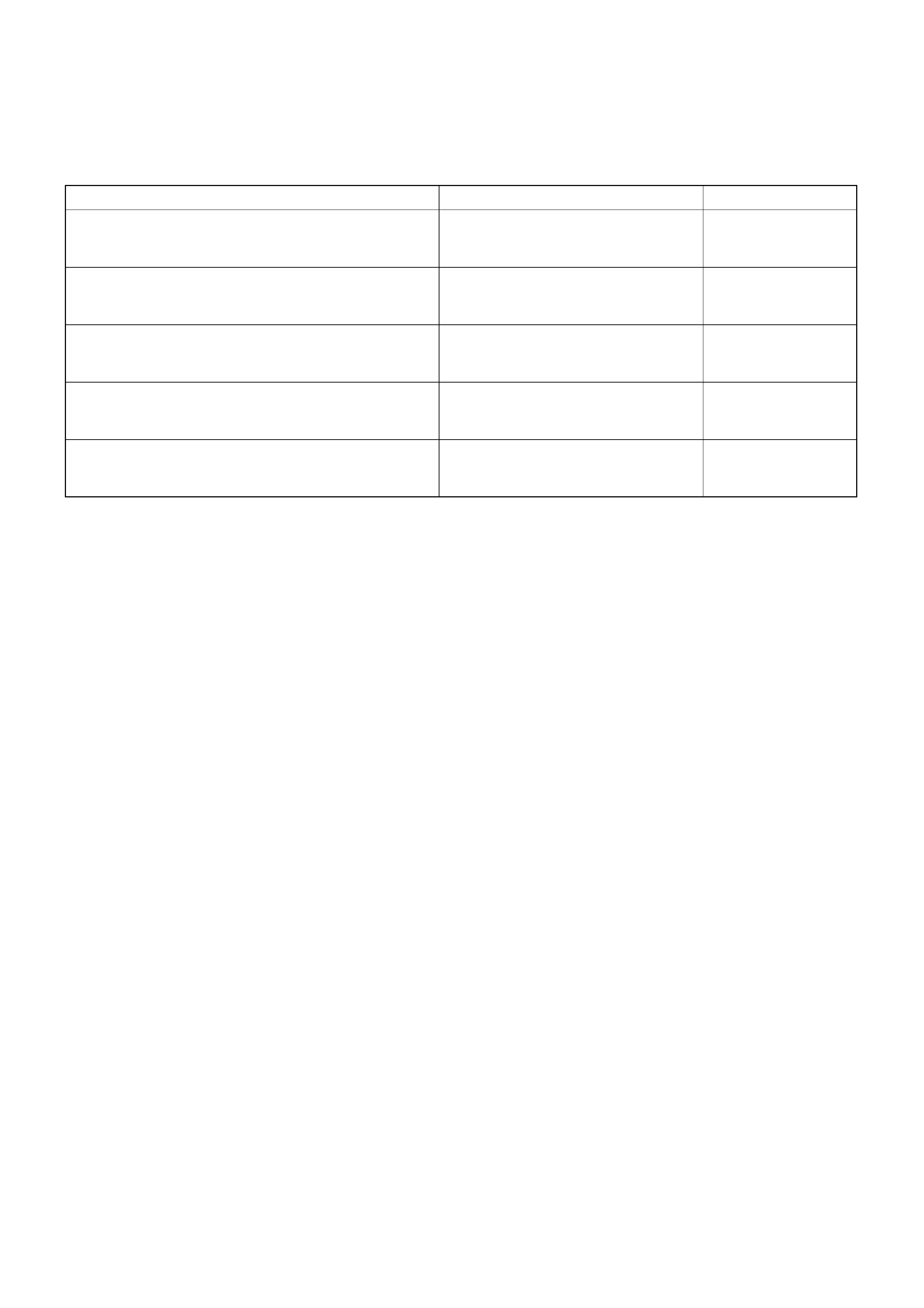

FLUID CONDITION

FLUID CONDITION

NORMAL* CONTAMINATED

COLOR RED BROWN

NON-TRANSPARENT

BROWN

OR LIGHT BROWN /PINK

DRAIN NO YES YES YES

REQUIRED?

CONTAMI- NONE

NATION Very small amount

of foreign material

in bottom of pan

CORRECT

LEVEL

&

CONDITION

Contamination by

coolant or other

source

Large pieces of

metal or other

foreign material in

bottom of pan

– Remove both pans

– Change filter

– Flush cooler

– Add new fluid

– Check level

1. LOW LEVEL:

A. Add fluid to

obtain proper

level & check

for external

leaks.

B. Correct cause

of leak.

2. HIGH LEVEL:

–Remove excess

fluid

–Repair/replace

radiator cooler

–Transmission

overhaul required

–Check for:

•Damaged plates

and seals

•Contaminated

solenoids

–Flush cooler

–Add new fluid

–Check level

–Transmission

overhaul required

–Flush cooler and

cooler lines

–Add new fluid

–Check level

* Fluid should be changed according to maintenance schedule.

CHANGING TRANSMISSION FLUID

There is no need to change the transmission fluid unless

the transmission is used under one or more of the

following heavy duty conditions.

A: Repeated short trips

B: Driving on rough roads

C: Driving on dusty roads

D: Towing a trailer

If the vehicle is used under these conditions, change the

fluid every 27,000 miles (45,000 km.)

1. Place a large drain pan under the oil pan.

2. Remove the transmission oil drain screw and drain

fluid.

3. Tighten drain screw.

Drain Screw Torque N·m(kg·m/lb·ft)

38 (3.9 / 28)

4. Remove the transmission overfill screw and fill

transmission through overfill screw opening, using

DEXRON®-

III

ATF.

5. Let engine idle until a fluid temperature between 32°C

(90°F) and 57°C (135°F) is reached, then close the

overfill screw.

Overfill Screw Torque N·m(kg·m/lb·ft)

38 (3.9 / 28)

6. Add transmission fluid until it flows out over the

overfill screw opening.

NOTE:

Transmission fluid temperature to be check with

service tool.

Overfill screw

Drain screw

242RT001

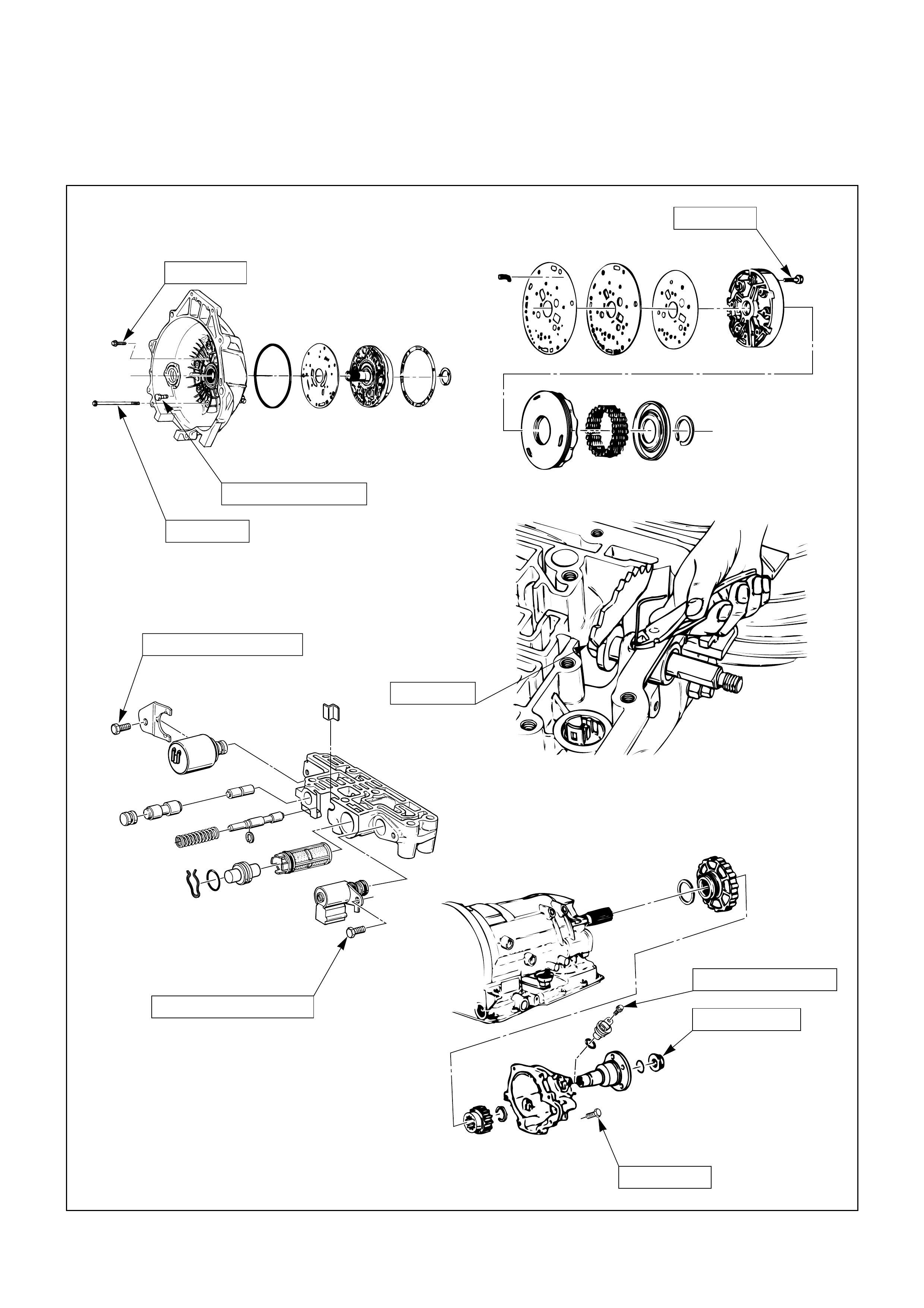

FIXING TORQUE

AUTOMATIC TRANSMISSION N·m (kg·m / lb·ft)

E07LW003

Non-reusable part

63(6.4/40)

See page 7A1-153

54(5.5/40)

55(5.6/41)

50(5.1/37)

40(4.1/30)

43(4.4/32)

67(6.8/49)

41(4.2/30)

8(80kg•cm/69 lb in)

6(60kg cm/52 lb in)

AUTOMATIC TRANSMISSION N·m (kg·m / lb·ft)

E07LW001

'97/ 11/ 28

10012

13(130kg·cm/113 lb.in)

23(2.3/17)

25(2.5/18)

20(2.0/15)

11(110kg·cm/96 lb.in)

38(3.9/28)

20(2.0/15)

20(2.0/15)

11(110kg·cm/96 lb.in)

13(130kg·cm/113 lb.in)

AUTOMATIC TRANSMISSION N·m (kg·m / lb·ft)

20 (2.0/15)

25 (2.5/18)

3 (30kg·cm/26 Ib·in)

39 (4.0/29)

10 (100kg·cm/87 Ib·in)

22 (2.2/16)

10 (100kg·cm/87 Ib·in)

9 (90kg·cm/78 Ib·in)

32 (3.3/24 )

103 (10.5/76 )

E07LW002

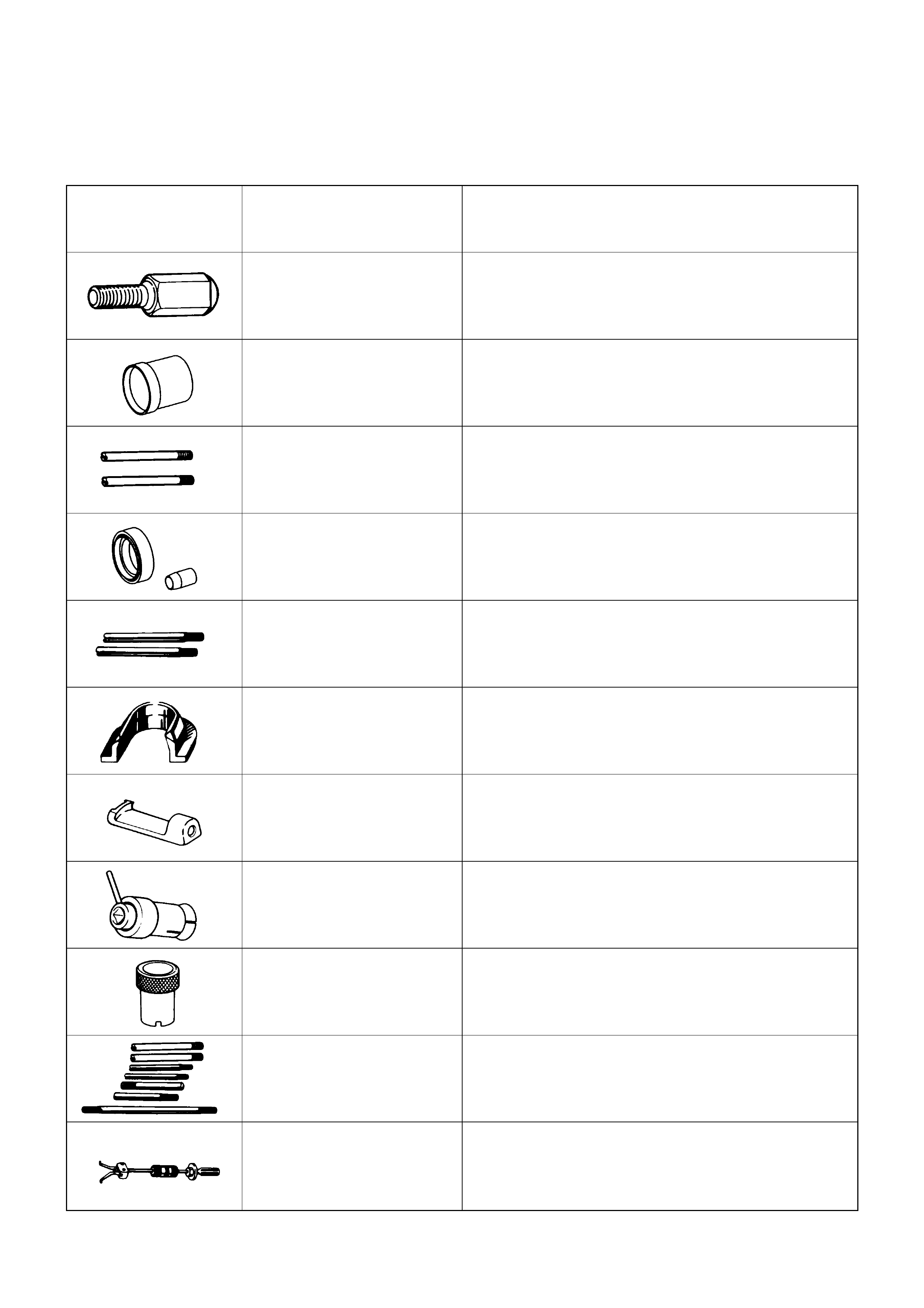

SPECIAL TOOLS

AUTOMATIC TRANSMISSION

ILLUSTRATION PARTS NO. PARTS NAME

5-8840-0501-0 Spring compressor (For servo piston)

(J-23075)

5-8840-2258-0 Third clutch retaining ring compressor

(J-38450)

5-8840-2259-0 Third clutch spring compressor adapter

(J-23075-12) (Use with 5-8840-0501-0 (J-23075))

5-8840-2260-0 Third clutch piston installer

(J-23084)

5-8840-0195-0 Spring compressor

(J-23327)

5-8840-2261-0 Second clutch piston installer

(J-23080-A)

5-8840-2262-0 Selective washer gaging tool

(J-23085-A)

5-8840-2263-0 Fourth clutch spring compressor

(J-23327-90) (Use with 5-8840-0195-0 (J-23327))

5-8840-2264-0 3/4 Accumulator piston fitter

(J-38553)

5-8840-2265-0 (’94) Cover remover

(J-38552) (Use with 5-8840-2266-0 (J-38584))

5-8840-2403-0 (’96) Cover remover

(J-41096) (Use with 5-8840-2266-0 (J-38584))

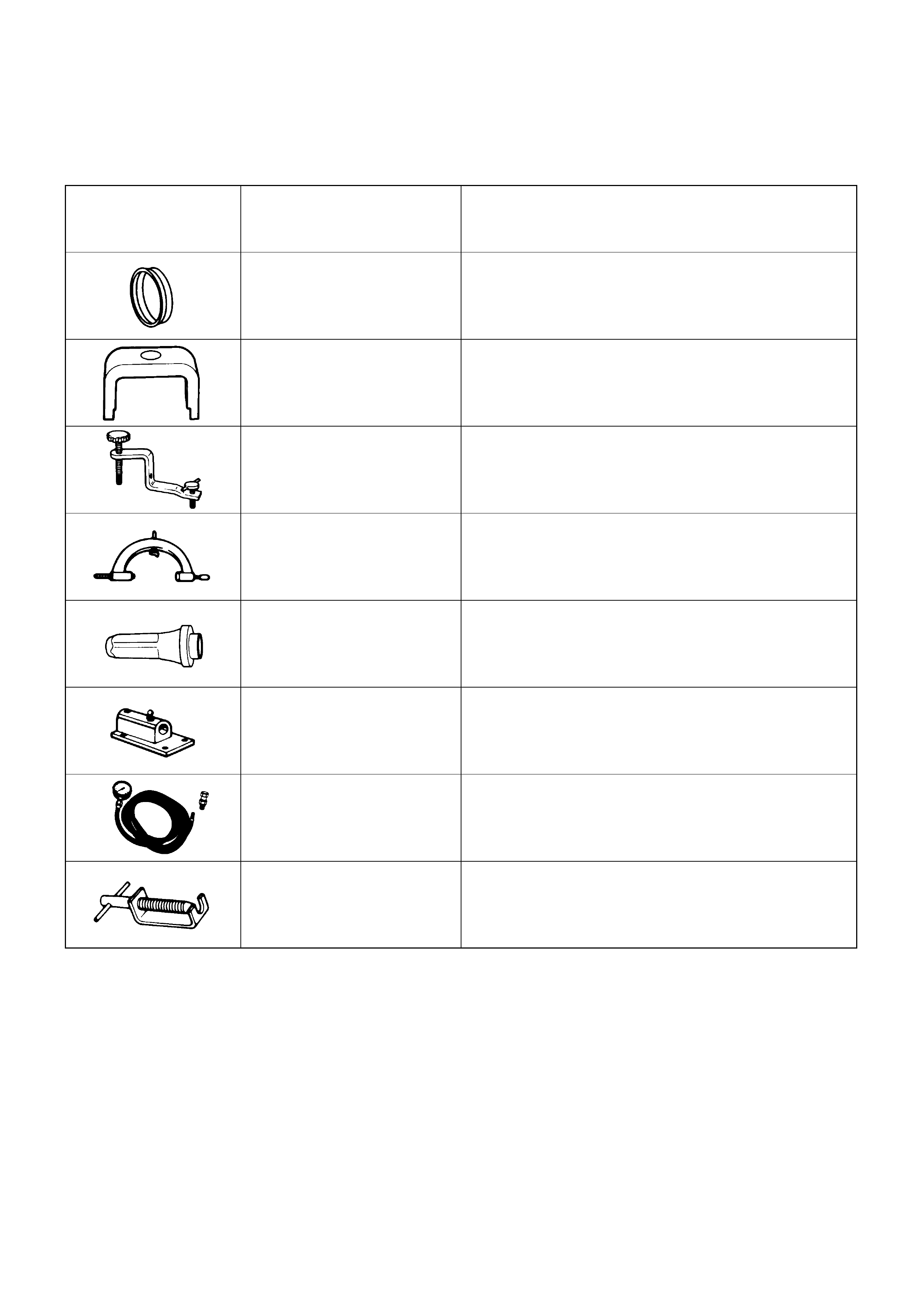

AUTOMATIC TRANSMISSION

ILLUSTRATION PARTS NO. PARTS NAME

5-8840-2266-0 Slide hammer adapter

(J-38584) (Use with 5-8840-0019-0 (J-23907))

5-8840-2267-0 Fourth clutch piston fitter

(J-38554)

5-8840-2268-0 Guide pins: adapter case to main case

(J-38588)

5-8840-2269-0 Overrun clutch piston seal installer set

(J-38555)

5-8840-2270-0 Guide pins: gasket and transfer plate to valve

(J-3387-2) body

5-8840-2271-0 Turbine shaft puller

(J-25022) (Use with 5-8840-0618-0 (J-24773-1))

5-8840-0196-0 Oil seal remover (Use with 5-8840-0019-0

(J-23129) (J-23907) and 5-8840-2266-0 (J-38584))

5-8840-2272-0 Oil pump centering tool

(J-38557)

5-8840-2273-0 Oil pump rotation tool

(J-23082-01)

5-8840-0022-0 Guide pins: valve body to main case

(J-25025-B)

5-8840-0019-0 &

5-8840-2000-0 Slide hammer

(J-23907)

AUTOMATIC TRANSMISSION

ILLUSTRATION PARTS NO. PARTS NAME

5-8840-2274-0 Servo piston fitter

(J-38428)

5-8840-2275-0 Overrun clutch spring compressor

(J-23327-91)

5-8840-2277-1 3/4 Accumulator piston cover compressor

(J-38559-A)

5-8840-2278-0 Holding fixture

(J-8763-02)

5-8840-2282-0 A/T extension housing oil seal installer (Inside)

(J-36797)

5-8840-0003-0 Holding fixture base

(J-3289-20)

5-8840-0004-0 Pressure gauge

(J-21867)

5-8840-0618-0 End play fixture

(J-24773-1) (Use with 5-8840-2271-0(J-25022))