SECTION 7C1 - AUTOMATIC TRANSMISSION (4L30-E)

CAUTION

When fasteners are removed, always reinstall

them at the same location from which they

were removed. If a fastener needs to be

replaced, use the correct part number fastener

for that application. If the correct part number

fastener is not available, a fastener of equal

size and strength (or stronger) may be used.

Fasteners that are not reused, and those

requiring thread locking compound, will be

called out. The correct torque values must be

used when installing fasteners that require

torque. If the above conditions are not

followed, parts or system damage could

result.

General Description

Construction

Electronic Control Diagram

Transmission Control Module (TCM)

Control System Diagram

Functions of Input/Output Components

Range Reference Chart

Normal Operation of 4L30-E Transmission

Diagnosis

Introduction

Driver Information

General Diagnosis Procedure

Preliminary Inspection Chart

Checking Transmission Fluid Level and Condition

Test Driving

Mechanical/Hydraulic Diagnosis

Check Trans Indicator Chart

Mechanical/Hydraulic Diagnosis Symptoms Index

Stall Test

Line Pressure Test

Shift Speed Chart

Lock-up Speed Chart

Electronic Diagnosis

Check Trans Indicator

Diagnostic Check

”Check Trans“ Check

Flashing Codes

TECH2 Connection

Clear DTC

DTC Check

F0 : Data List Quick Check

Chart 1 : Diagnosis Connector and Voltage Supply Test

Chart 2 : Diagnostic Trouble Code (DTC)

Chart 3 : Transmission and TCM Identification

Chart 5 : F5 : Actuator Test Quick Check

Without DTC Set

TCM Precautions

Intermittent Conditions

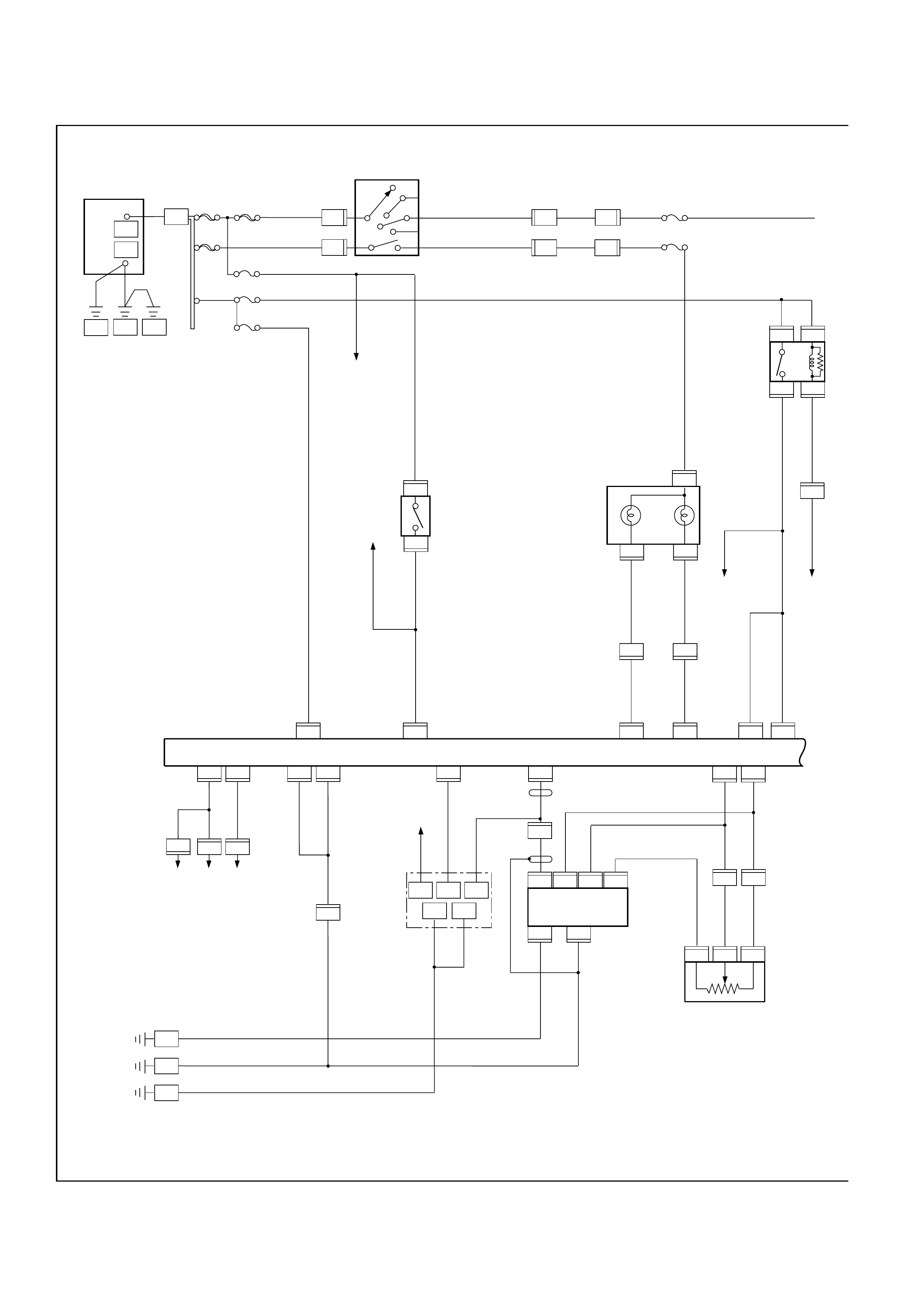

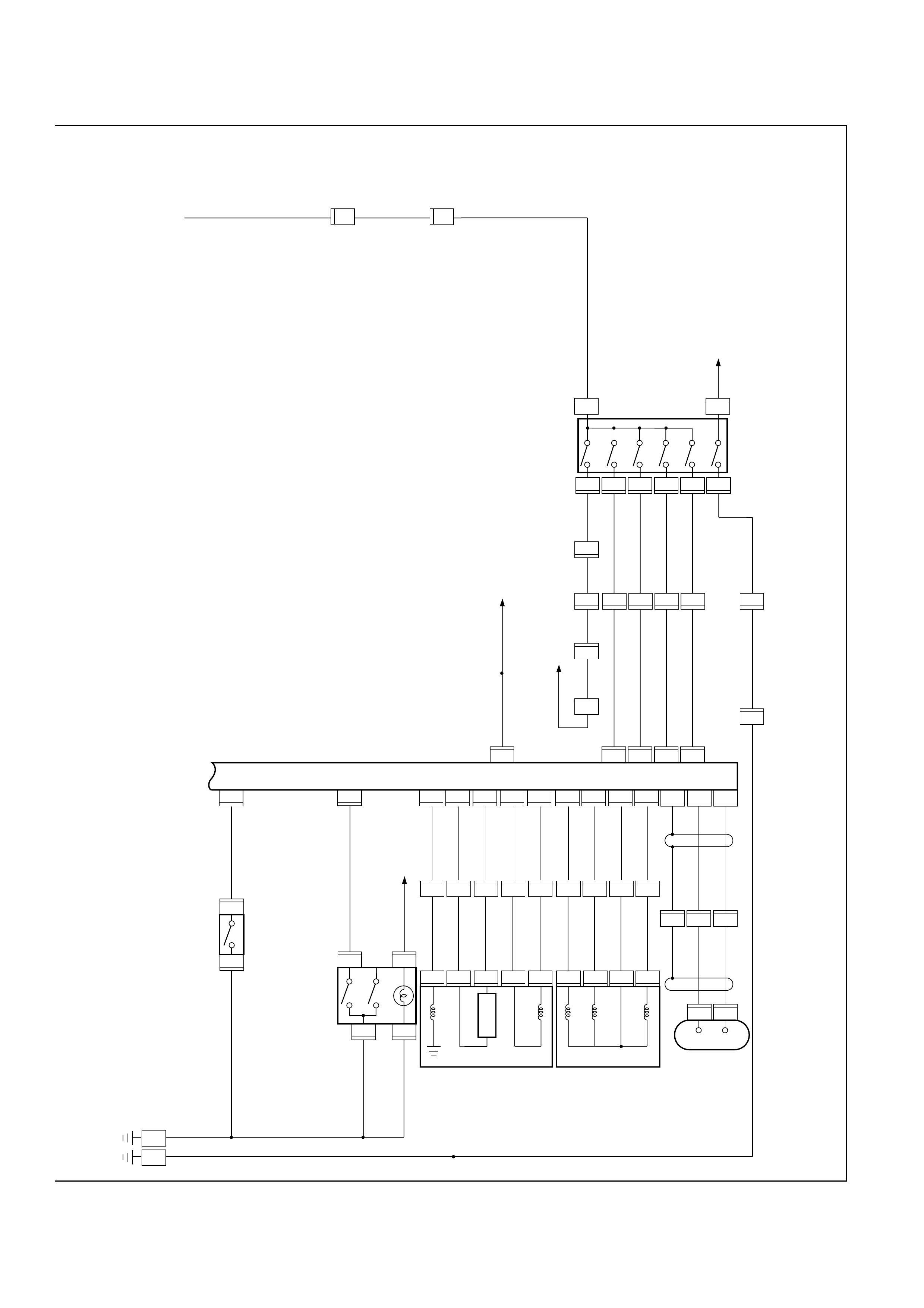

Wiring Diagram

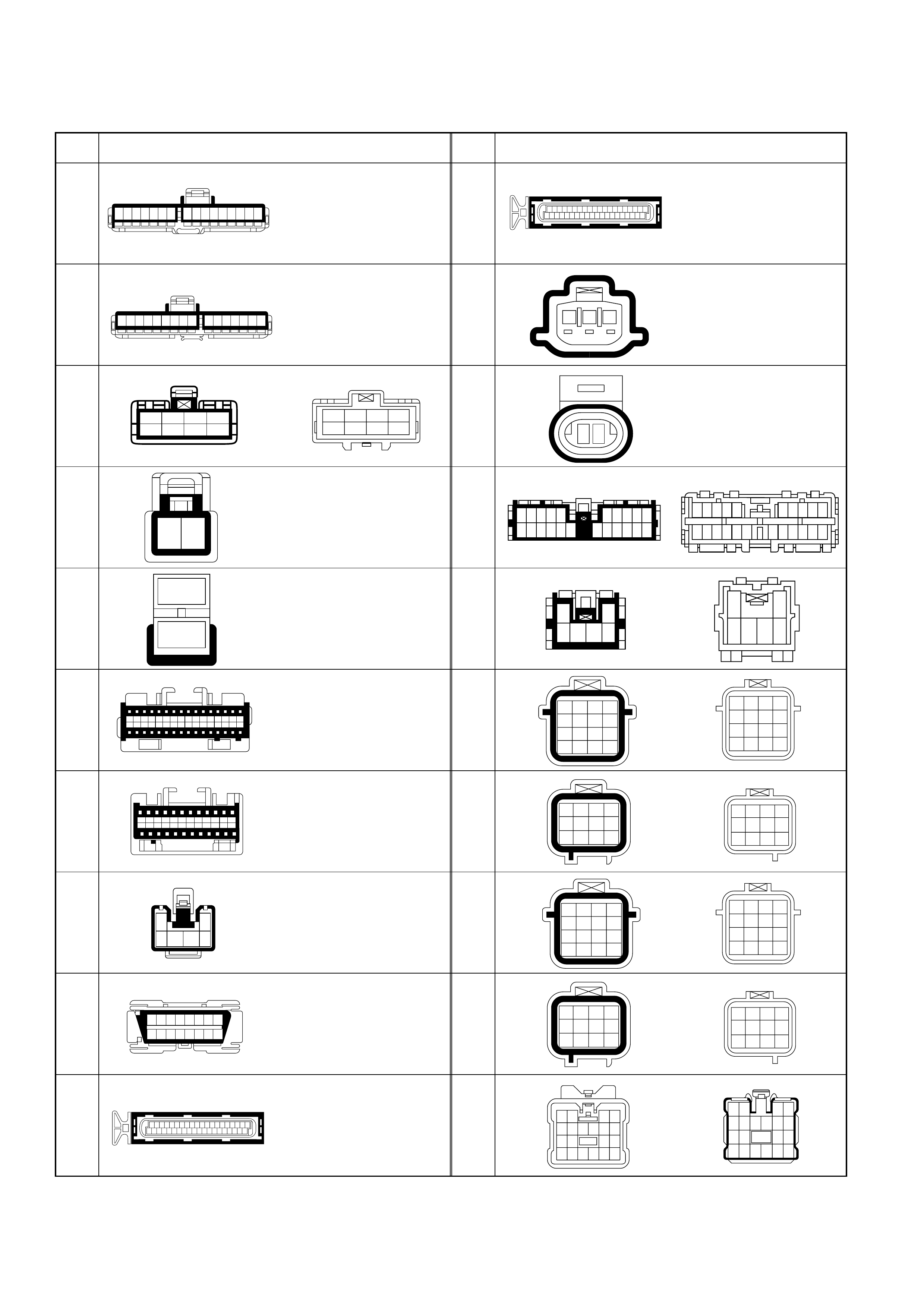

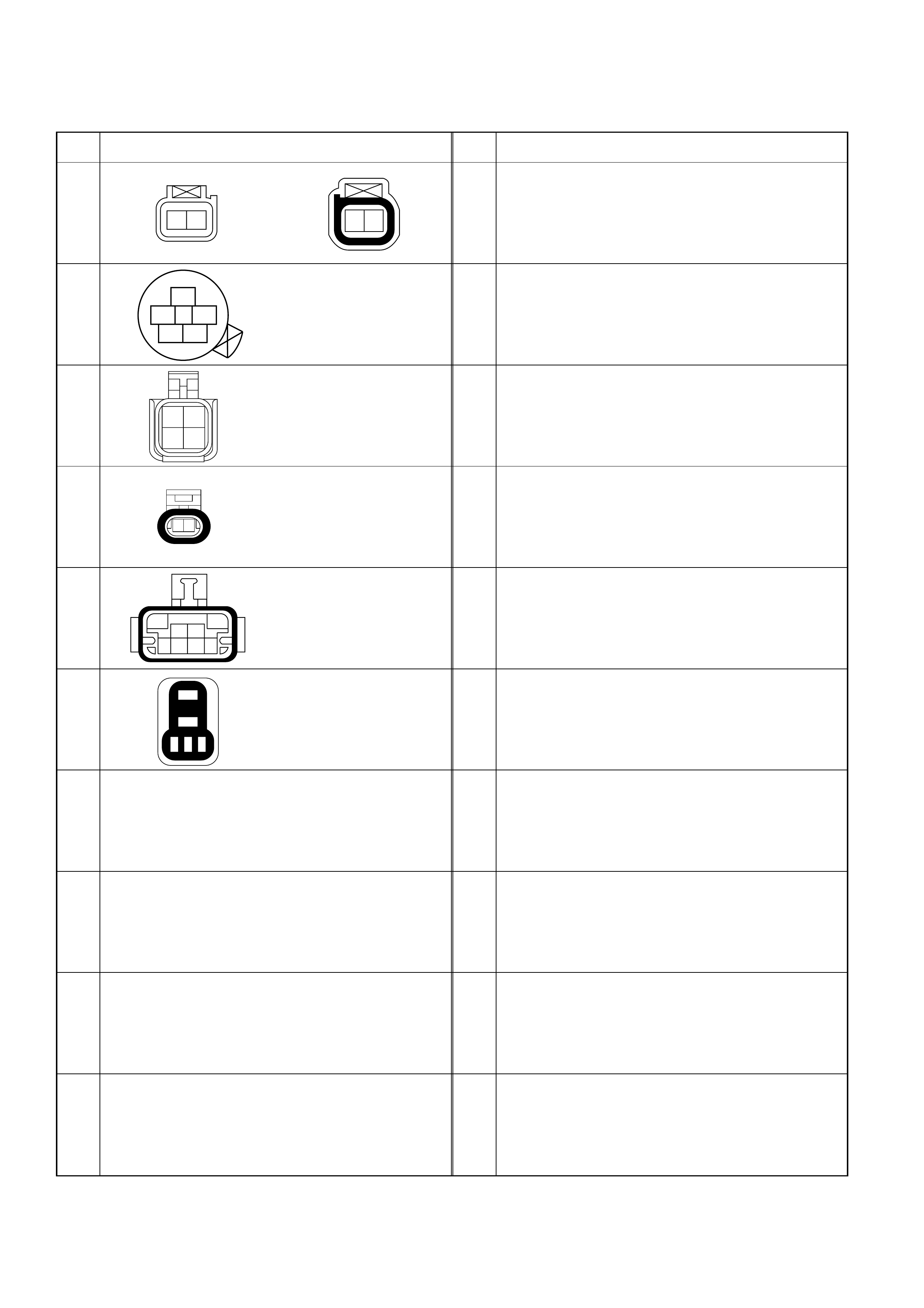

Connector Location

Connector List

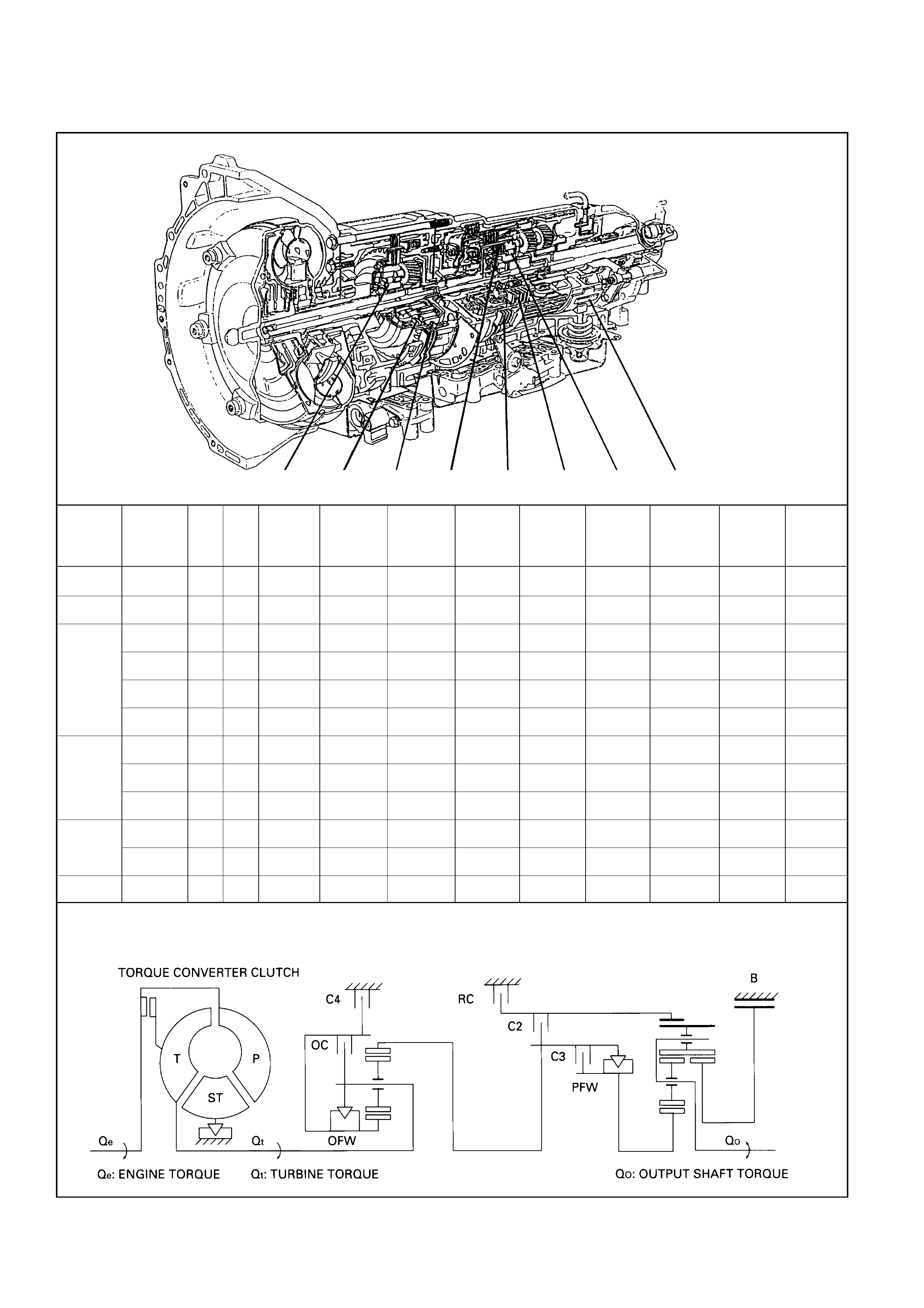

GENERAL DESCRIPTION

The 4L30-E is a 4-speed automatic transmission. It consists primarily of a 4-element torque converter,

an oil pump, two planetary gear sets, 5 multi-plate clutch packs, a brake band, 2 one-way clutches, 2

valve bodies, sensors, actuators and a Transmission Control Module (TCM).

The torque converter acts as a fluid coupling to transmit power from the engine to the, transmission. It

also provides torque multiplication when required and the lock-up function of the pressure plate

eliminates slip by providing a mechanical coupling between the engine and transmission.

The two planetary gear sets, clutches and brake band provide the 4 forward gears and reverse.

Changing of the forward gear ratios is fully automatic – sensors provide input signals to the TCM. The

TCM interprets these signals and actuates the various solenoids inside the transmission. By using

electronics, the TCM controls shift points, shift feel and torque converter clutch operation, to provide the

correct gear ratios for all conditions of vehicle operation.

Control of shift feel is achieved by providing TCM control over a Force Motor, which is a precision

electronic pressure regulator that controls line oil pressure. Electronic pressure regulation provides

excellent shift feel by a precise match between line oil pressure and engine power output.

The TCM provides three transmission-operating modes:

· Normal Mode – normal shift pattern.

· Power Mode – delayed upshift time for maximum acceleration.

The mode of operation is selected by the driver through the Power Switch mounted to the rear of the

centre console.

A third mode, ‘Fail-safe', is provided by the transmission to allow restricted operation in the event of

electrical failure.

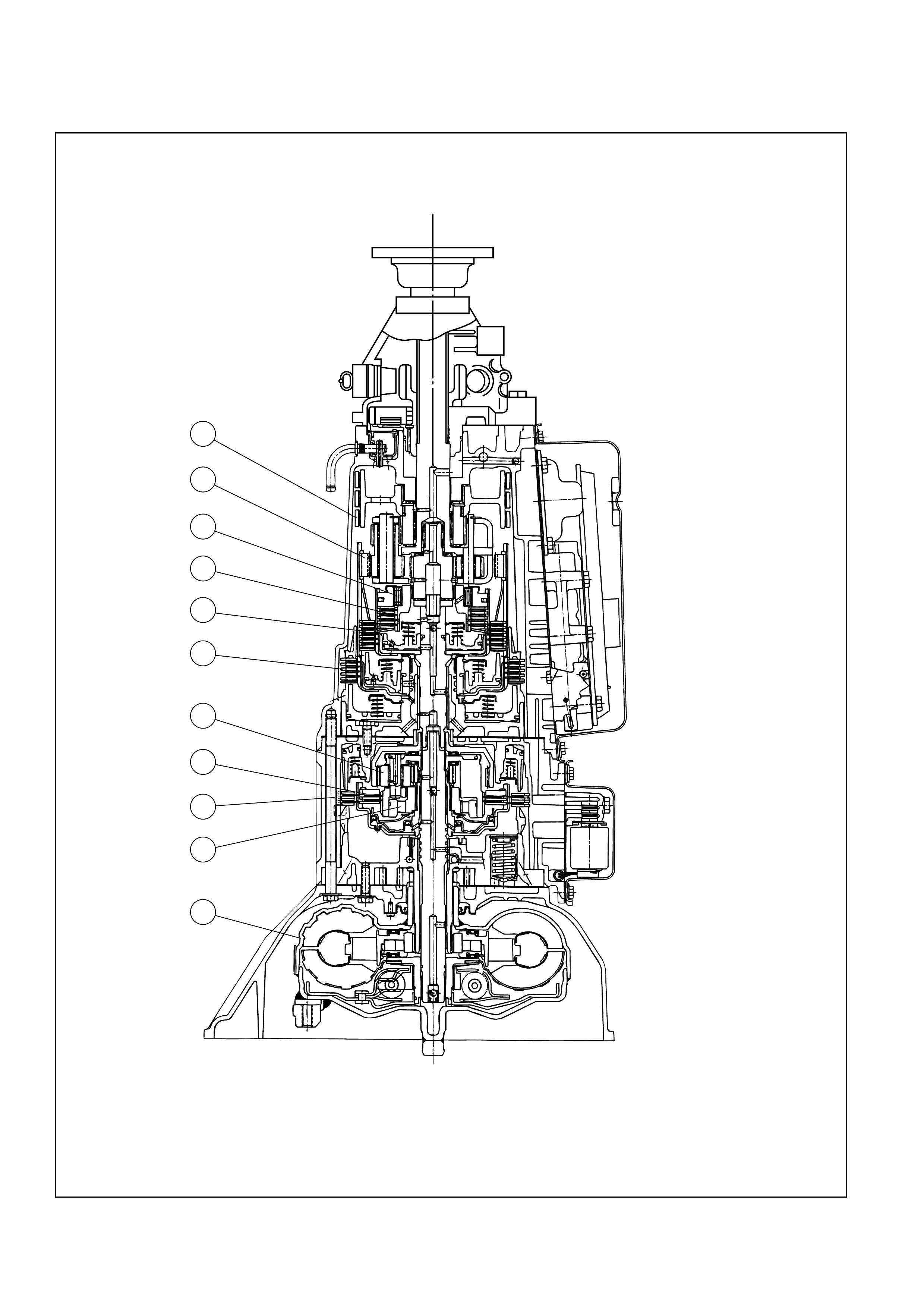

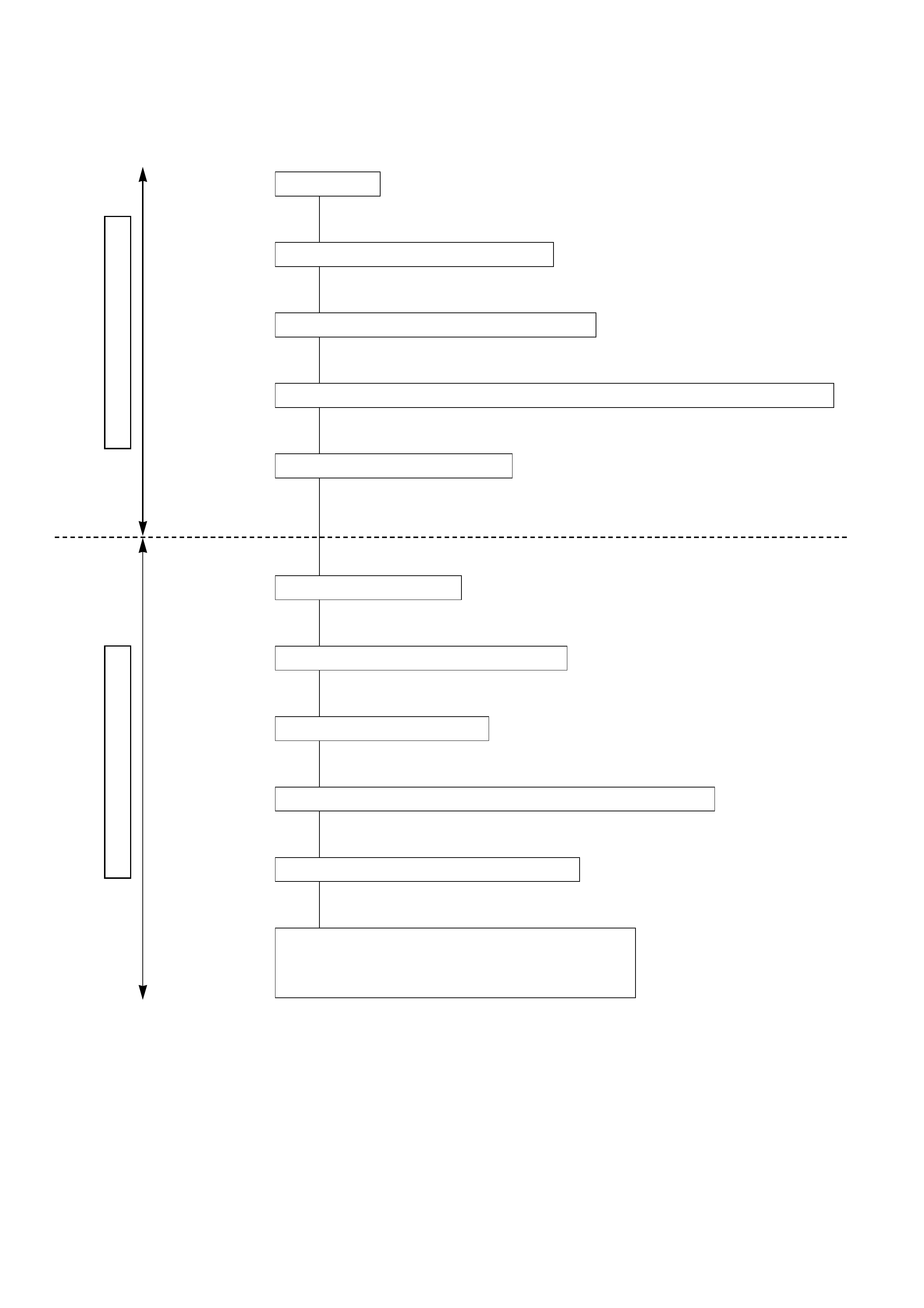

CONSTRUCTION

89

56711

10 234

1

1. TORQUE CONVERTER-CLUTCH (TCC)

2. FOURTH CLUTCH (C4)

3. OVERRUN CLUTCH (OC)

4. OVERDRIVE UNIT

5. REVERSE CLUTCH (RC)

6. SECOND CLUTCH (C2)

7. THIRD CLUTCH (C3)

8. RAVIGNEAUX PLANETARY GEARSET

9. BRAKE BAND (B)

10. OVERDRIVE FREE WHEEL

(ONE WAY CLUTCH) (OFW)

11. SPRAG FREE WHEEL

(ONE WAY CLUTCH) (PFW)

CROSS SECTION

A07LW004

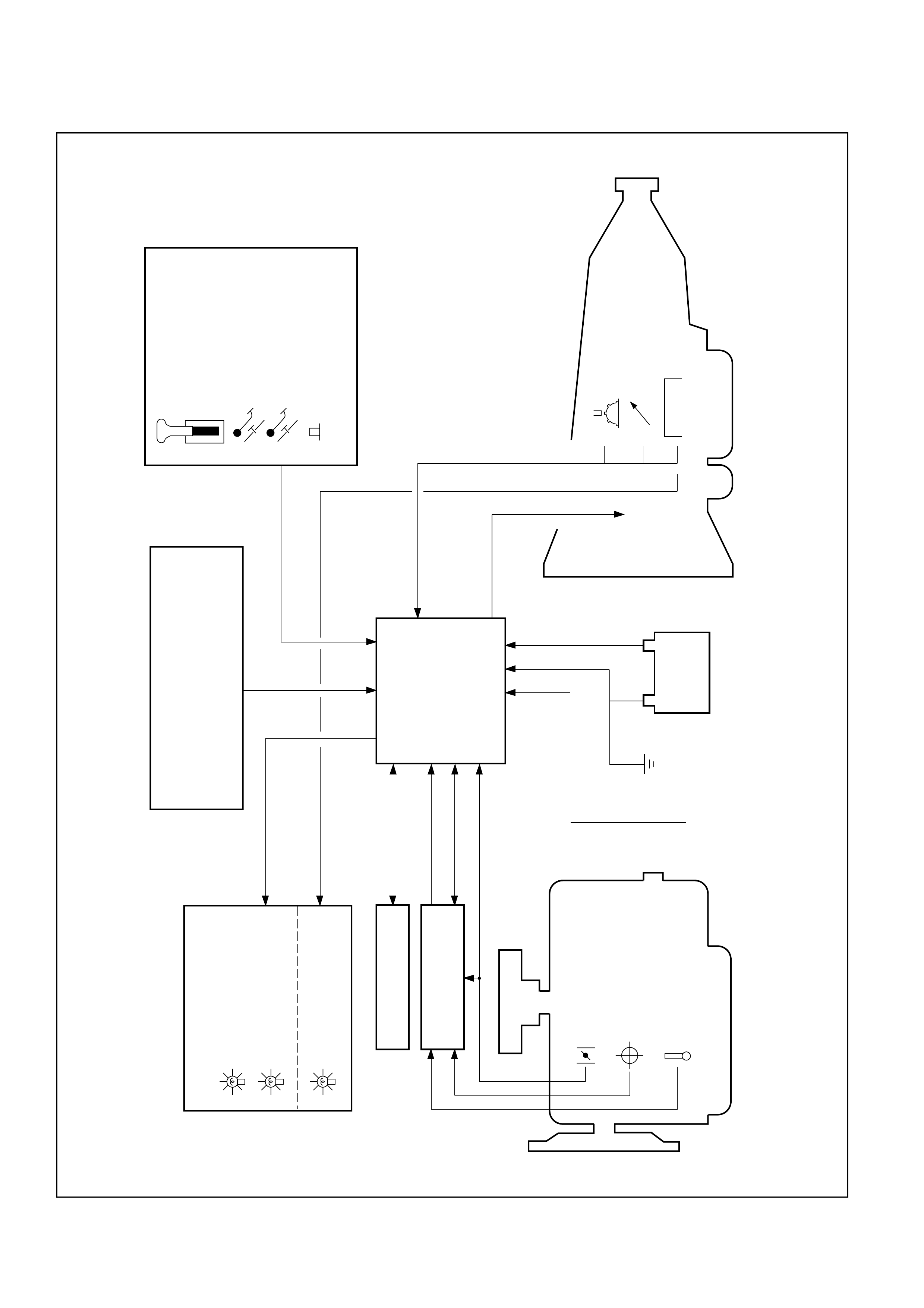

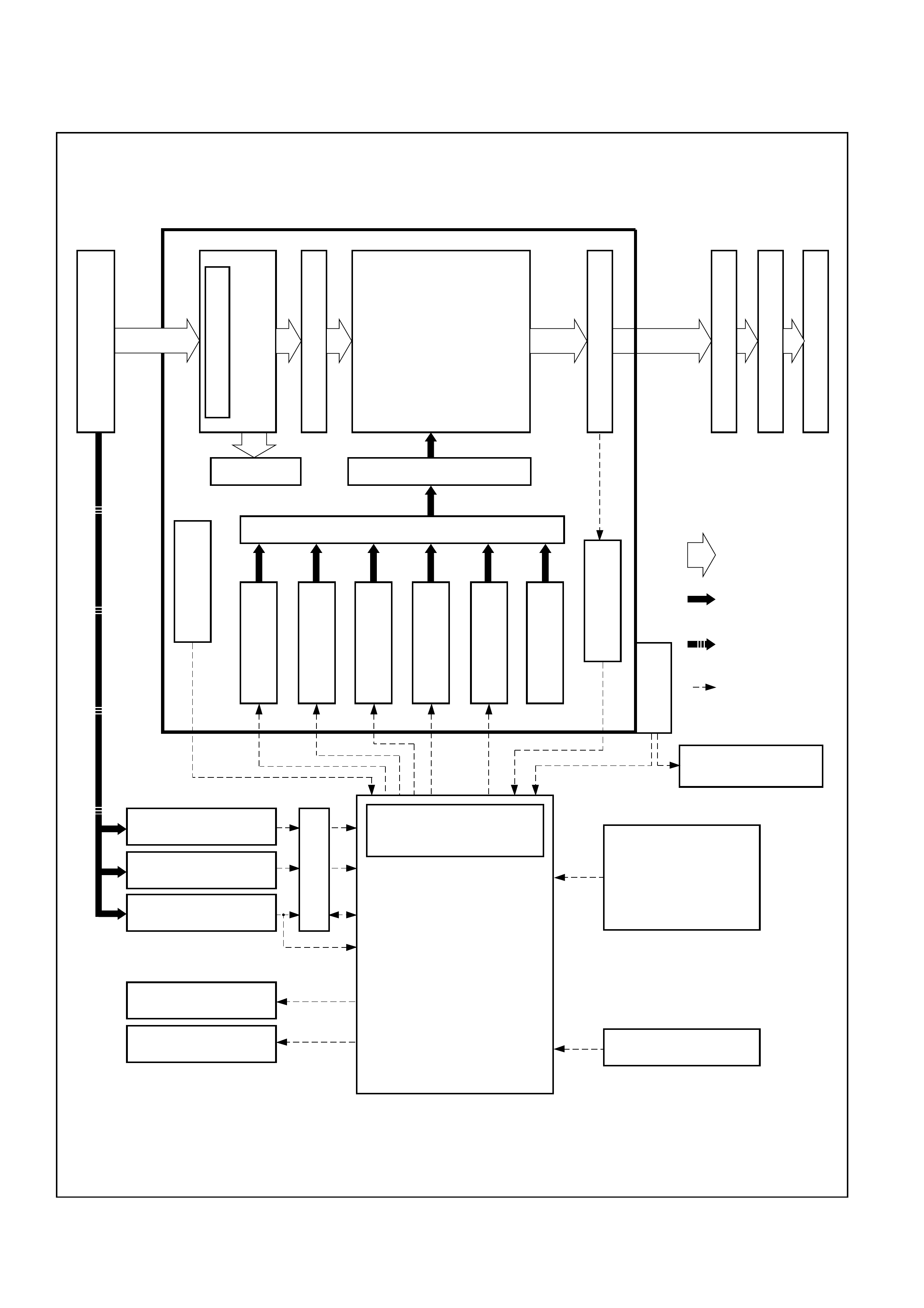

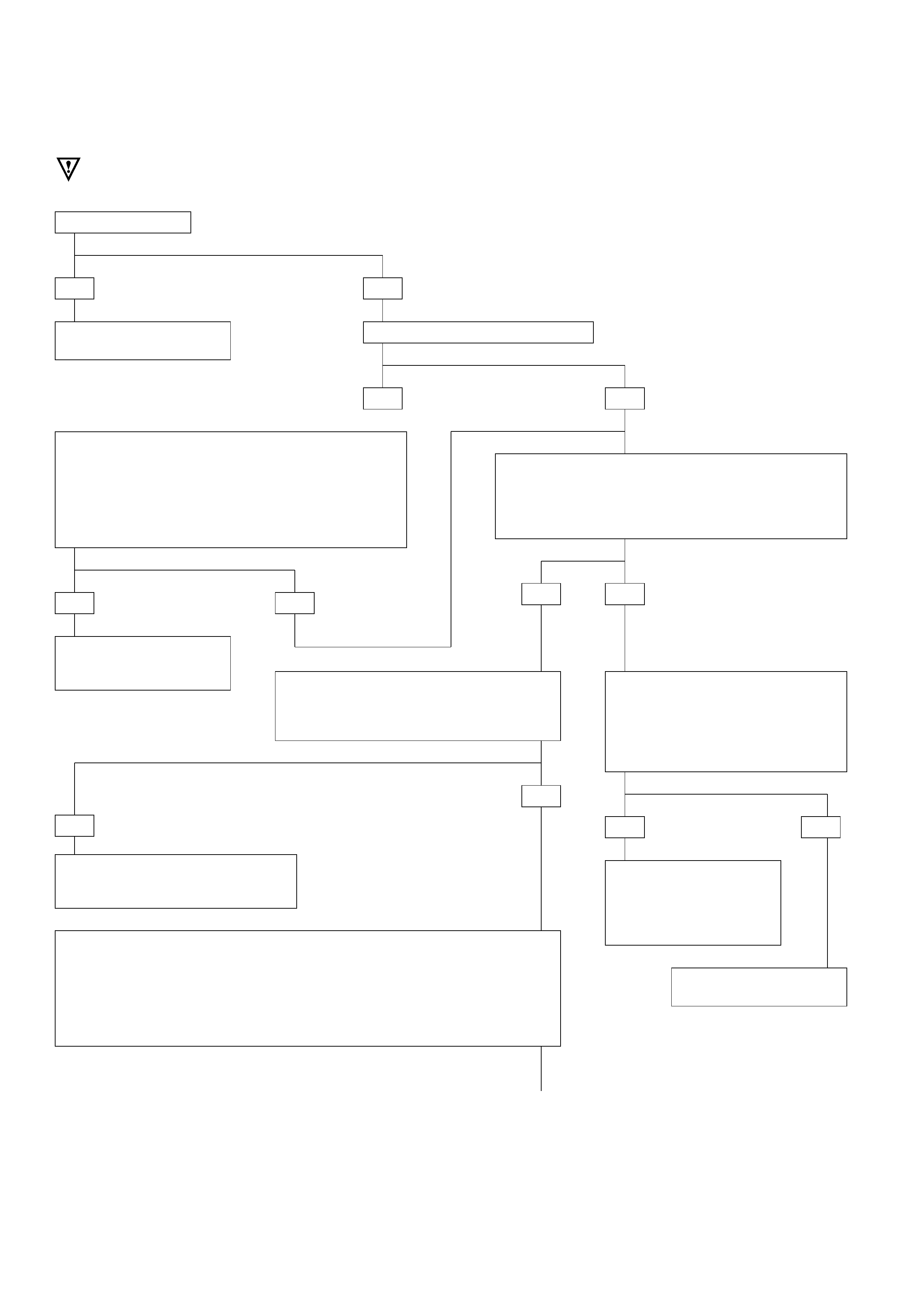

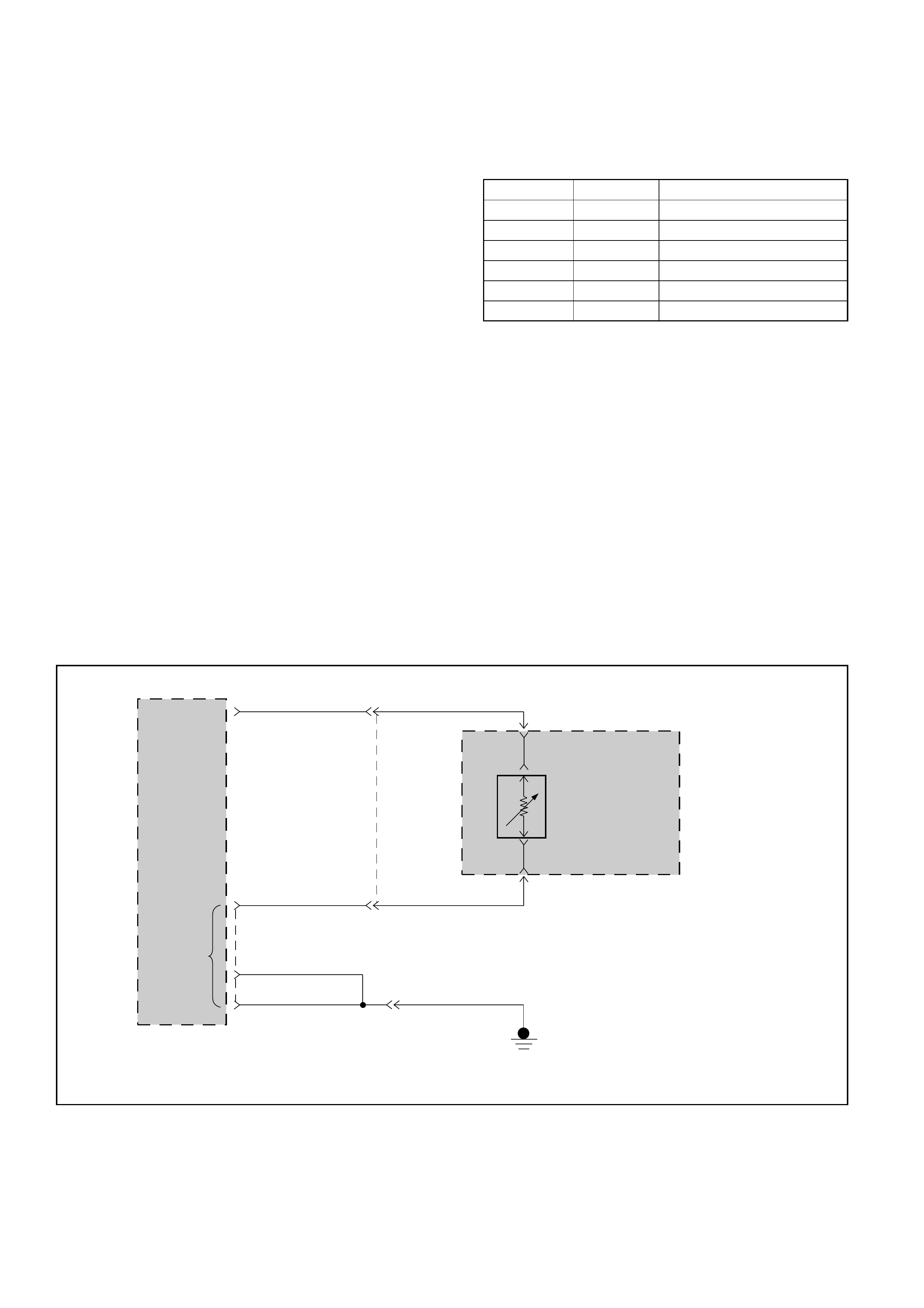

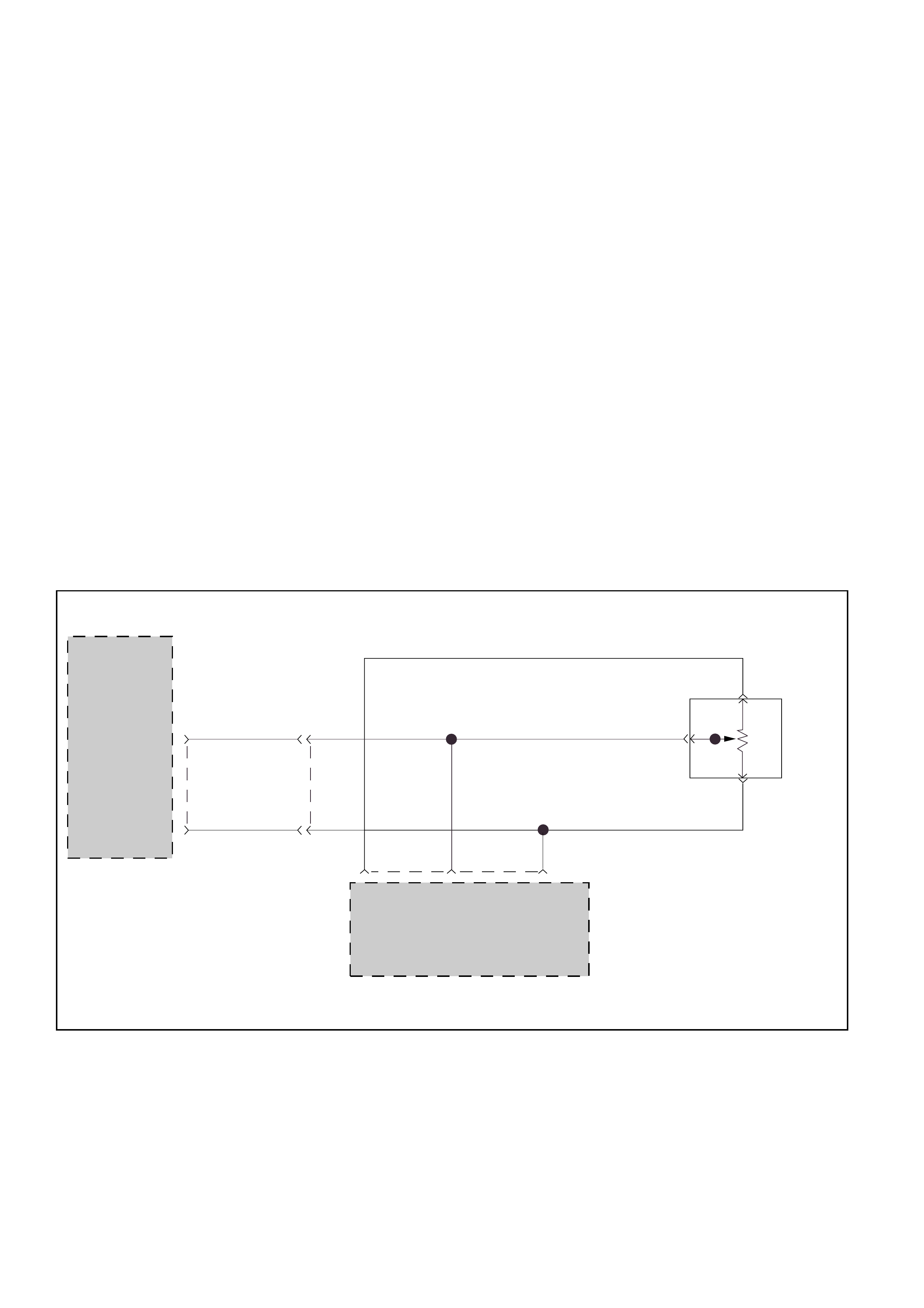

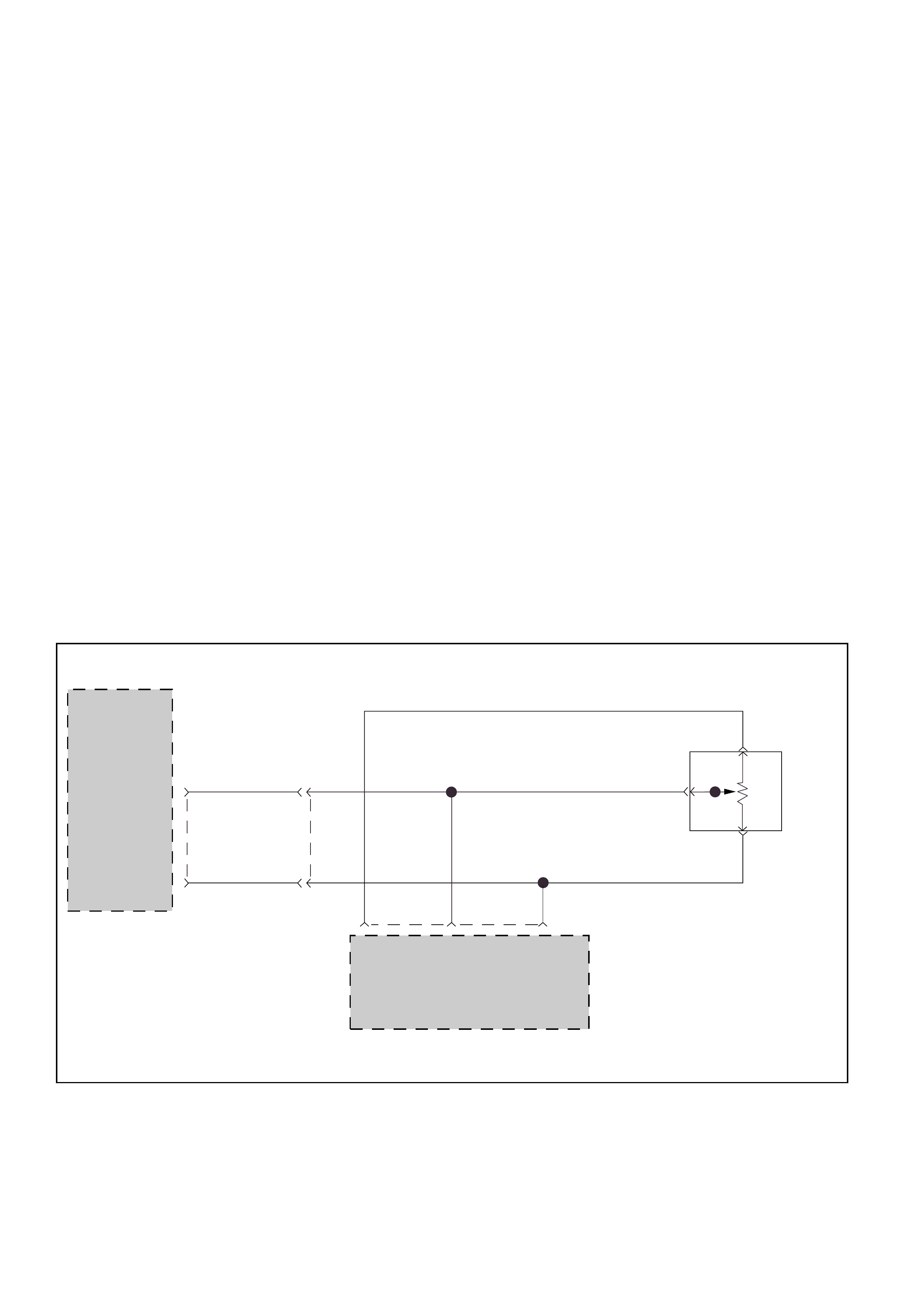

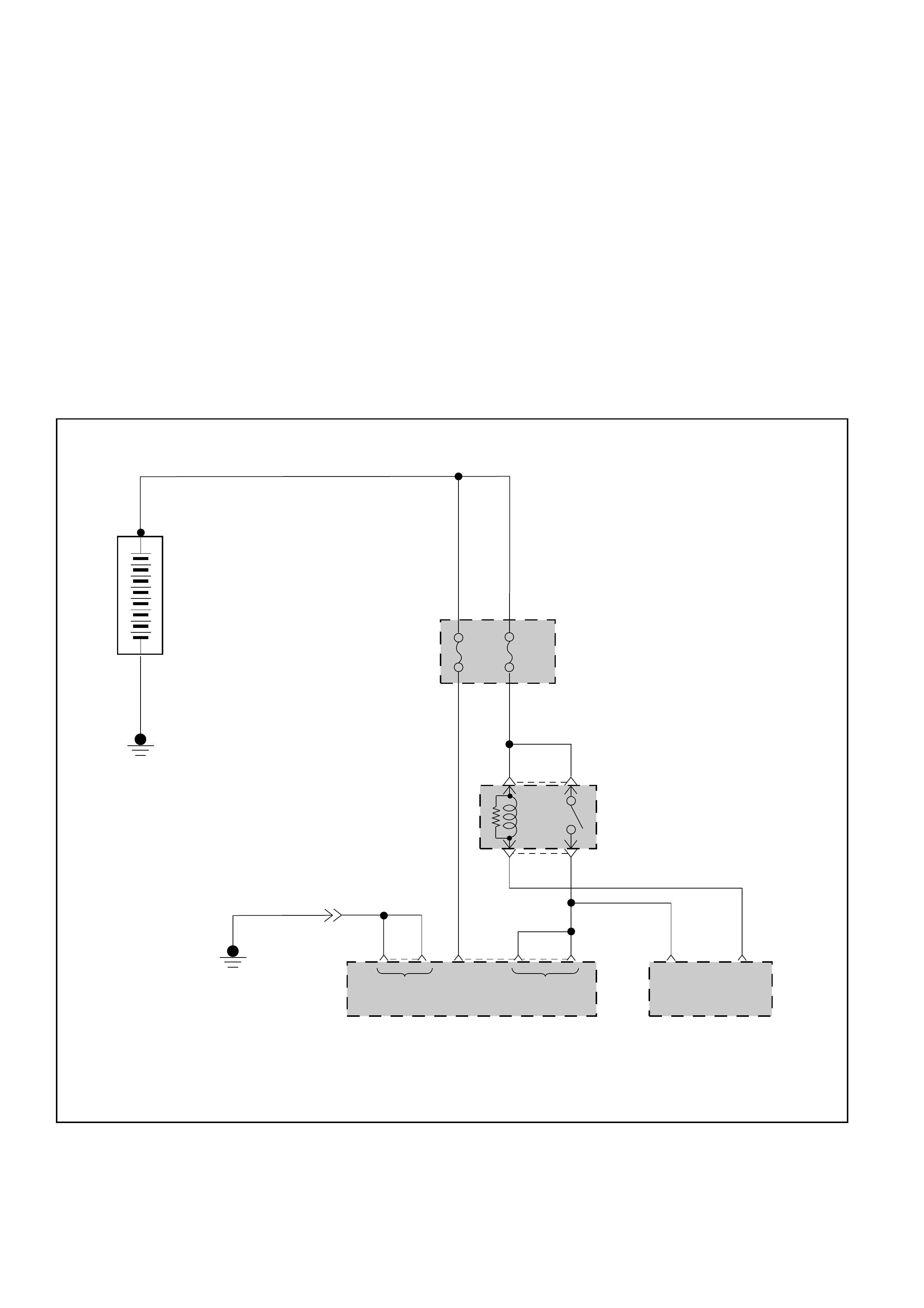

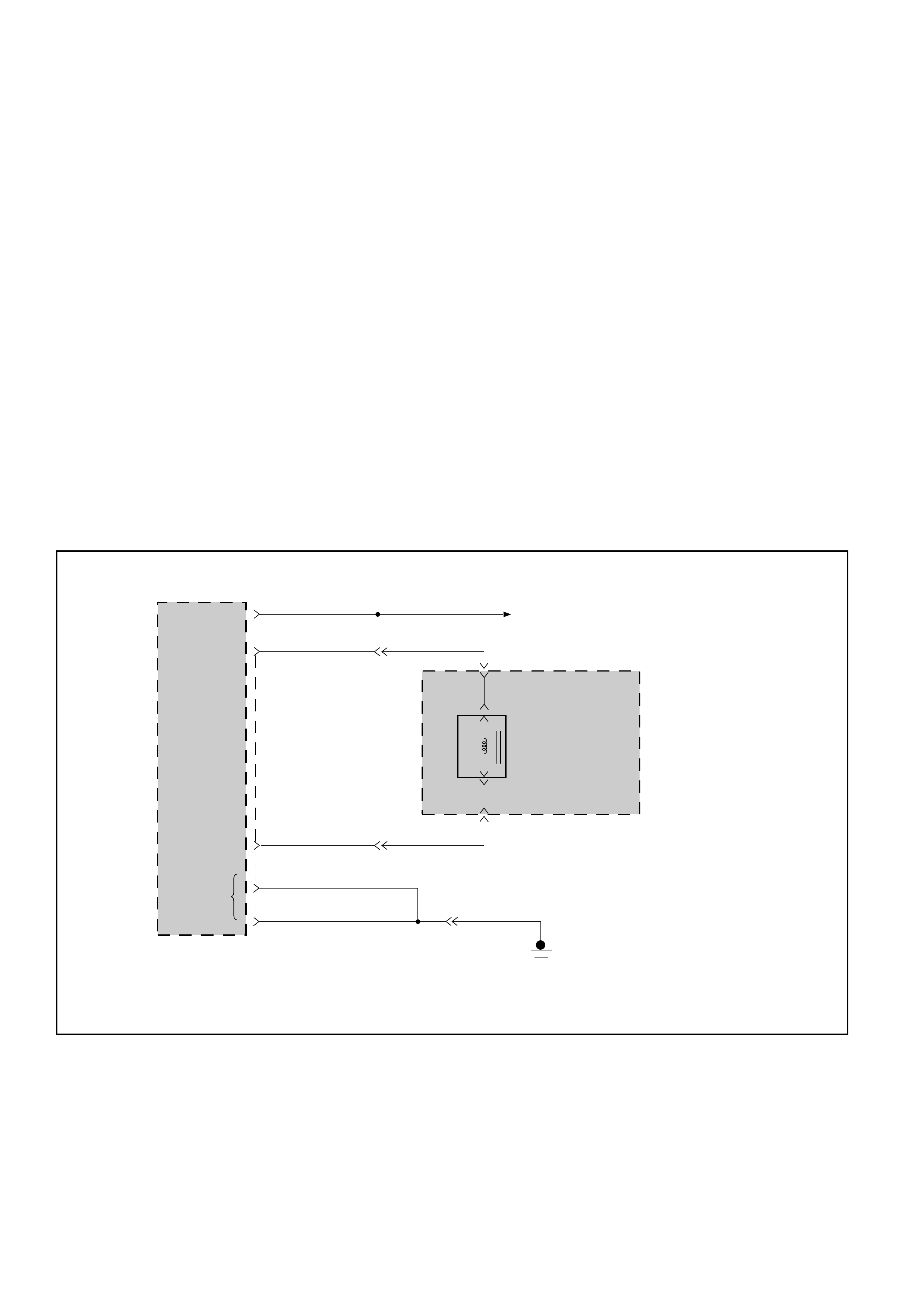

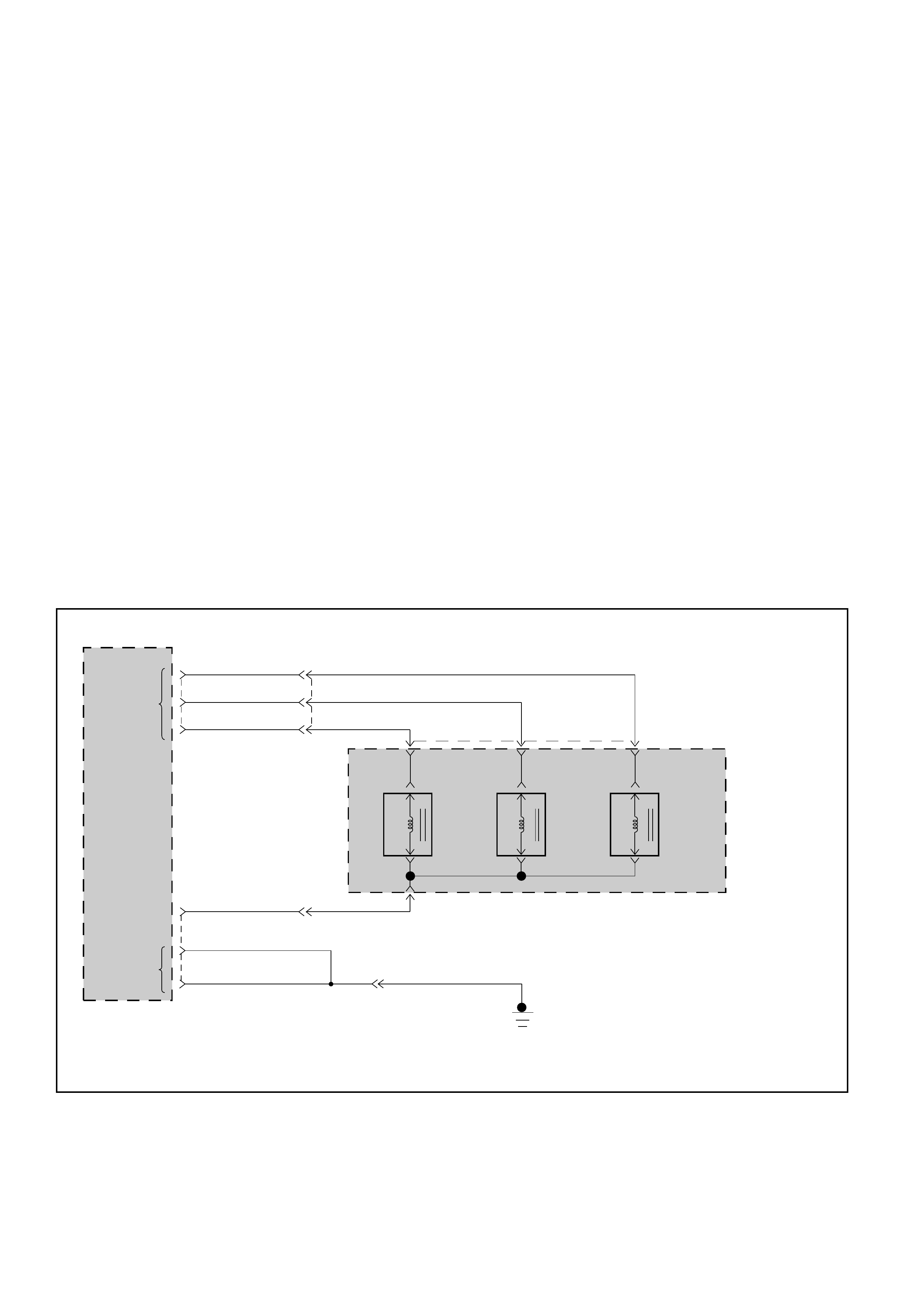

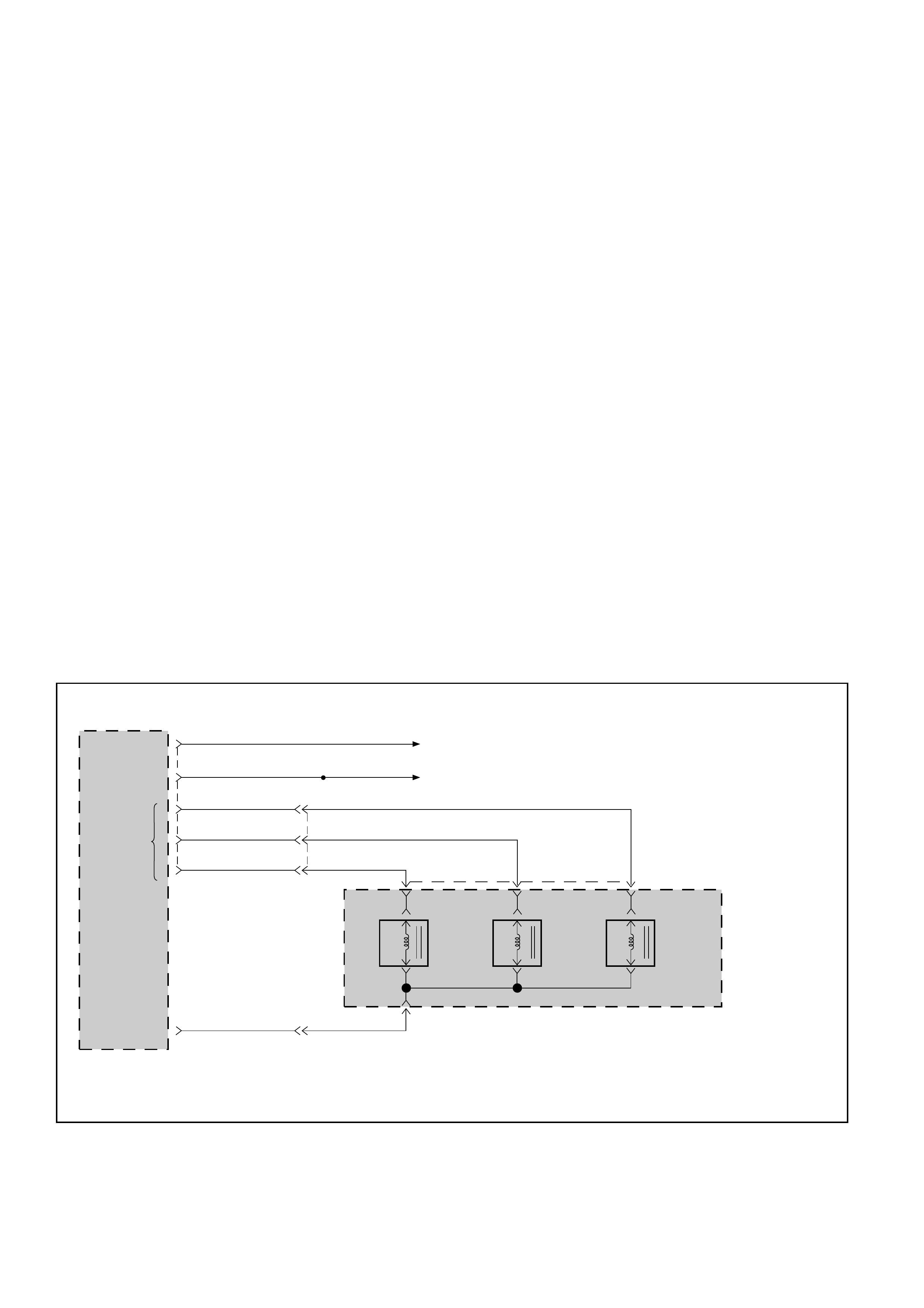

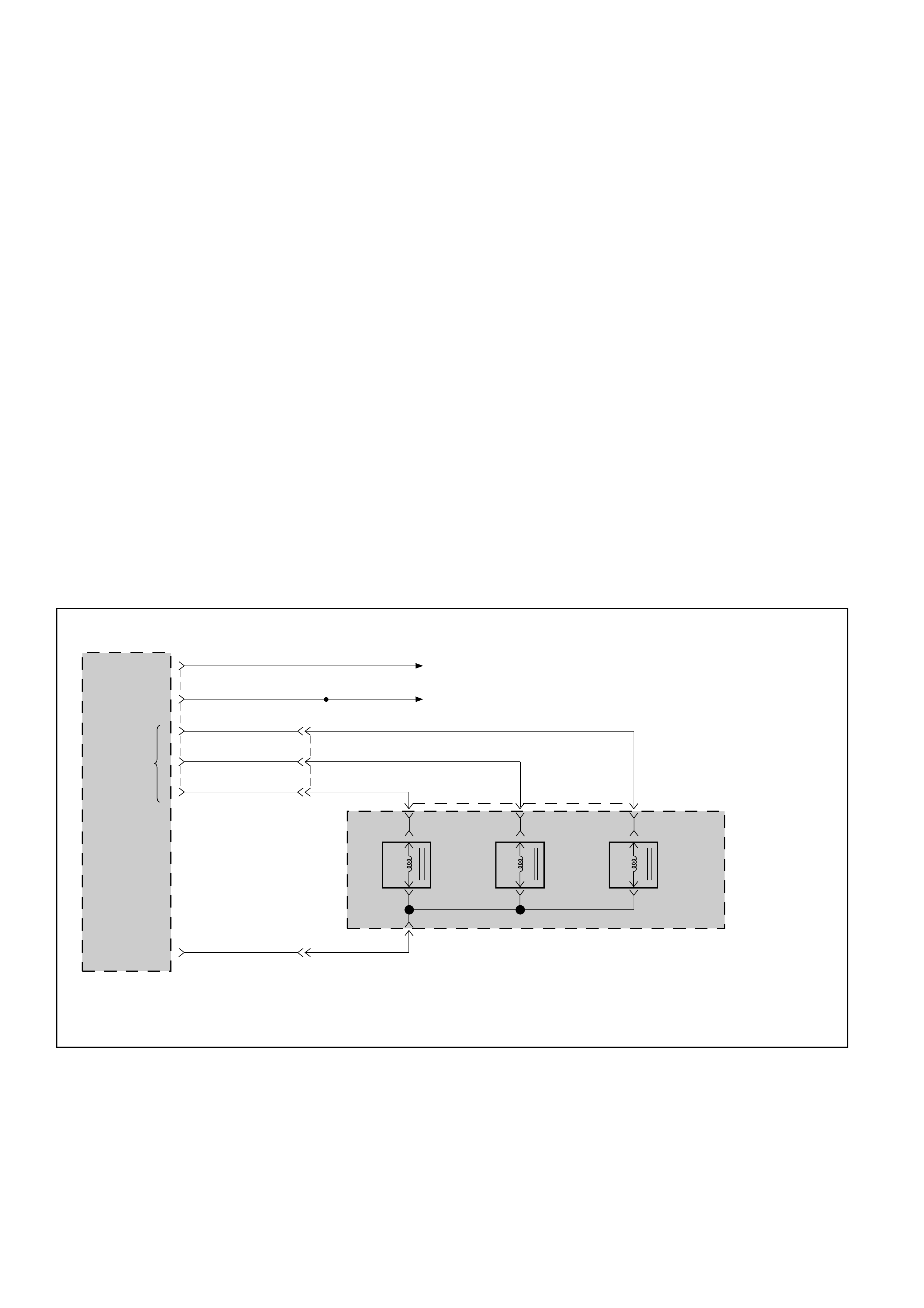

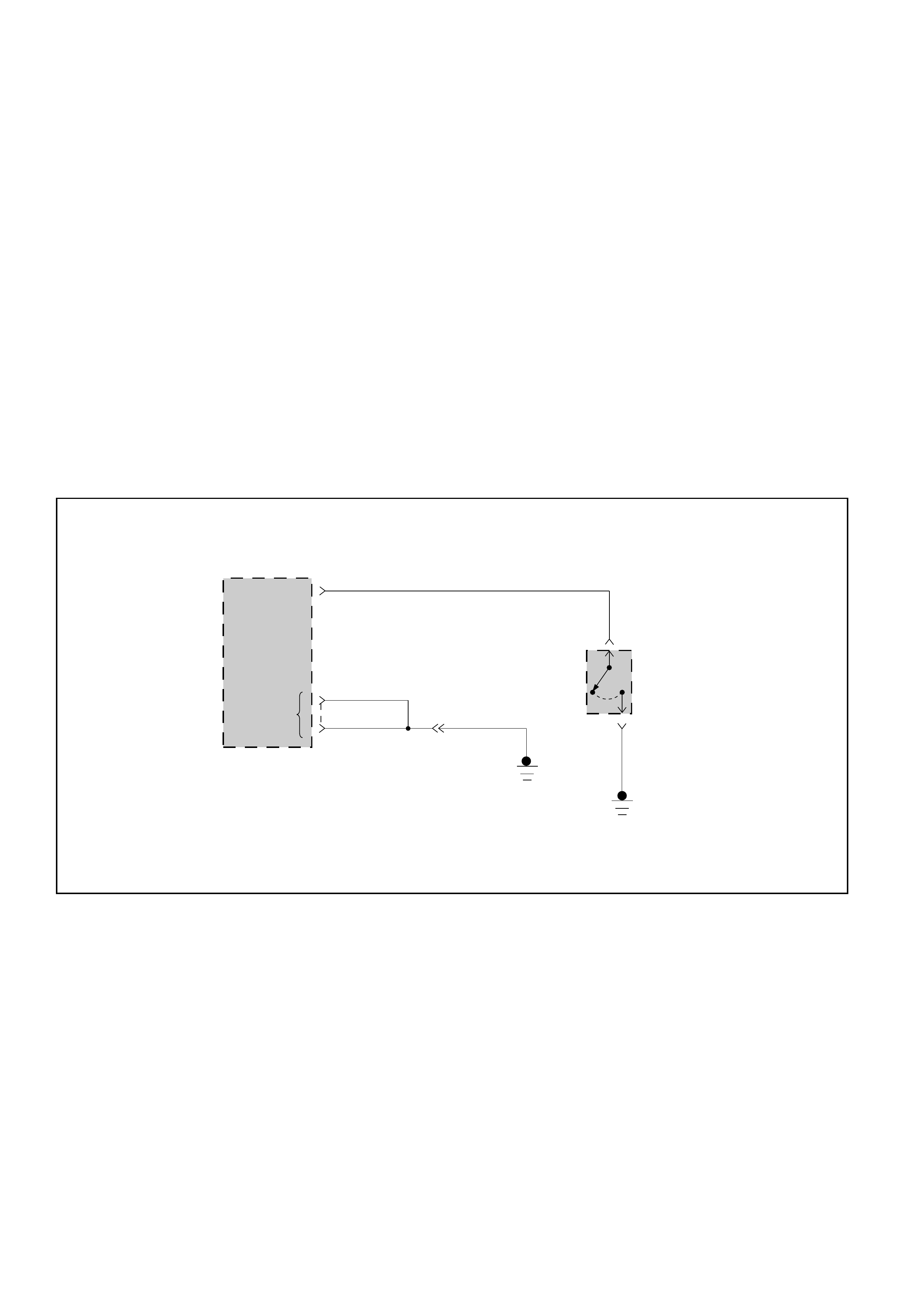

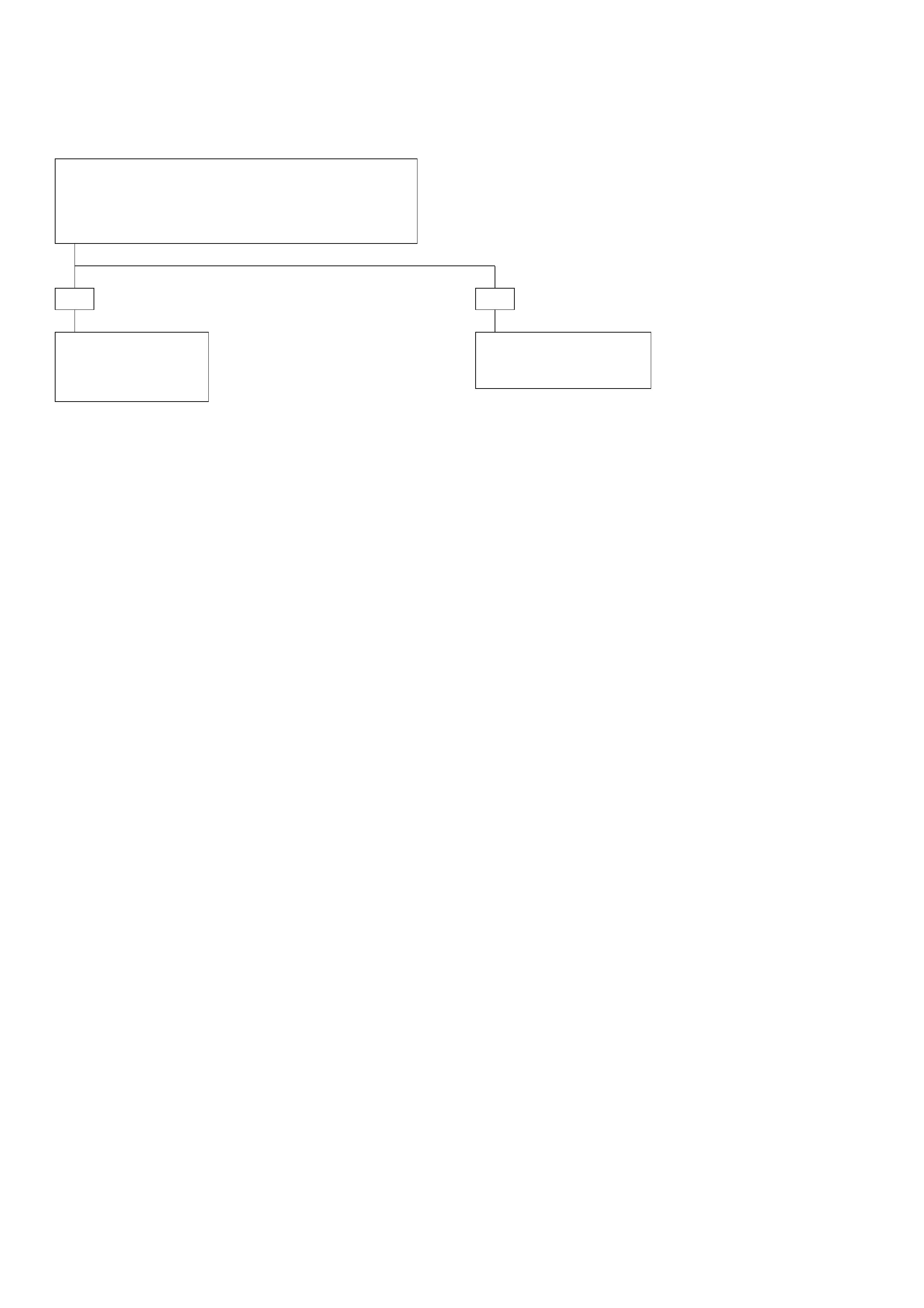

ELECTRONIC CONTROL DIAGRAM

DRIVER'S INPUT

MANUAL SELECTOR

KICKDOWN SWITCH

BRAKE SWITCH

PUSH BUTTON FOR

NORMAL/POWER

DRIVE MODE

VEHICLE SPEED

SENSOR

ATF TEMPERATURE

SENSOR

MODE SWITCH

PRND32L

5 SOLENOID

VALVES

BATTERY

+12

IGNITION

TRANSMISSION

CONTROL

MODULE

(TCM)

COMPENSATION FOR ENGINE LOAD

AIR CONDITIONING SWITCH

ON-BOARD DIAGNOSTIC

ENGINE CONTROL

MODULE(ECM)

THROTTLE POSITION

SENSOR

CRANK ANGLE SENSOR

ENGINE COOLANT

TEMPERATURE SENSOR

DASH BOARD DISPLAY

POWER DRIVE MODE

LAMP

SHIFT INDICATOR LAMP

A/T SHIFT INDICATOR

CONTROL UNIT

(

(

CHECK TRANS LAMP

C07LW003

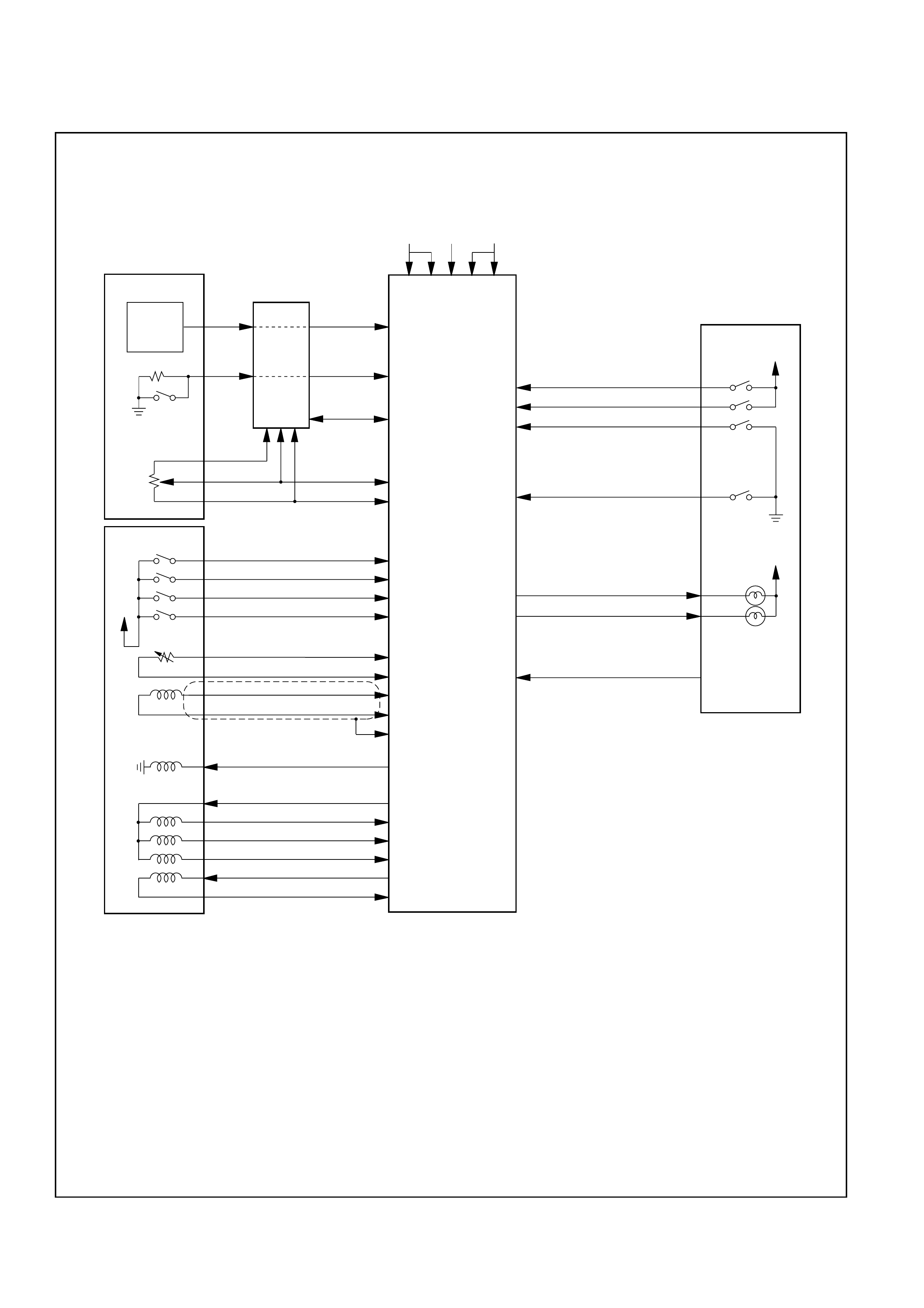

TRANSMISSION CONTROL MODULE (TCM)

C07LW002

ENGINE

VEHICLE

A7

TPS

4L30-E

Ac

Ad

Aa

Mc

Md

Ma

Mb

Ab

Ac

X2

X1

Xa

Xb

Xc

Xg

IGN

A8 A4 C1 D1

IGN

IGN

IGN BATT GND

D14

C5

C6

D7

D6

D5

D4

B3

C14

A12

B12

B11

C7

C12

A2

A3

A9

C15

C16

TCM

D9

D8

B8

B5

C10

B9

OUT

MODE SW A

MODE SW B

MODE SW C

MODE SW G

OIL TEMP

OUTPUT SPEED HI

OUTPUT SPEED LO

TCC HI

SHIFT SOL. HI

SHIFT SOL. A

SHIFT SOL. B

BAND APPLY SOL.

FORCE MOTOR HI

FORCE MOTOR LO

BRAKE SW

A/C REQUEST

POWER SW

KICKDOWN SW

CHECK TRANS LAMP

POWER LAMP

+

–

ECM:

TPS:

TCC:

Engine Control Module

Throttle Position Sensor

Torque Converter Clutch

D16 DIAG SW

CRANK

ANGLE

SENSOR

ECM D12

ENGINE

SPEED

SERIAL DATA

TORQUE

MANAGEMENT

ENGINE

COOLANT

TEMP SW

C8

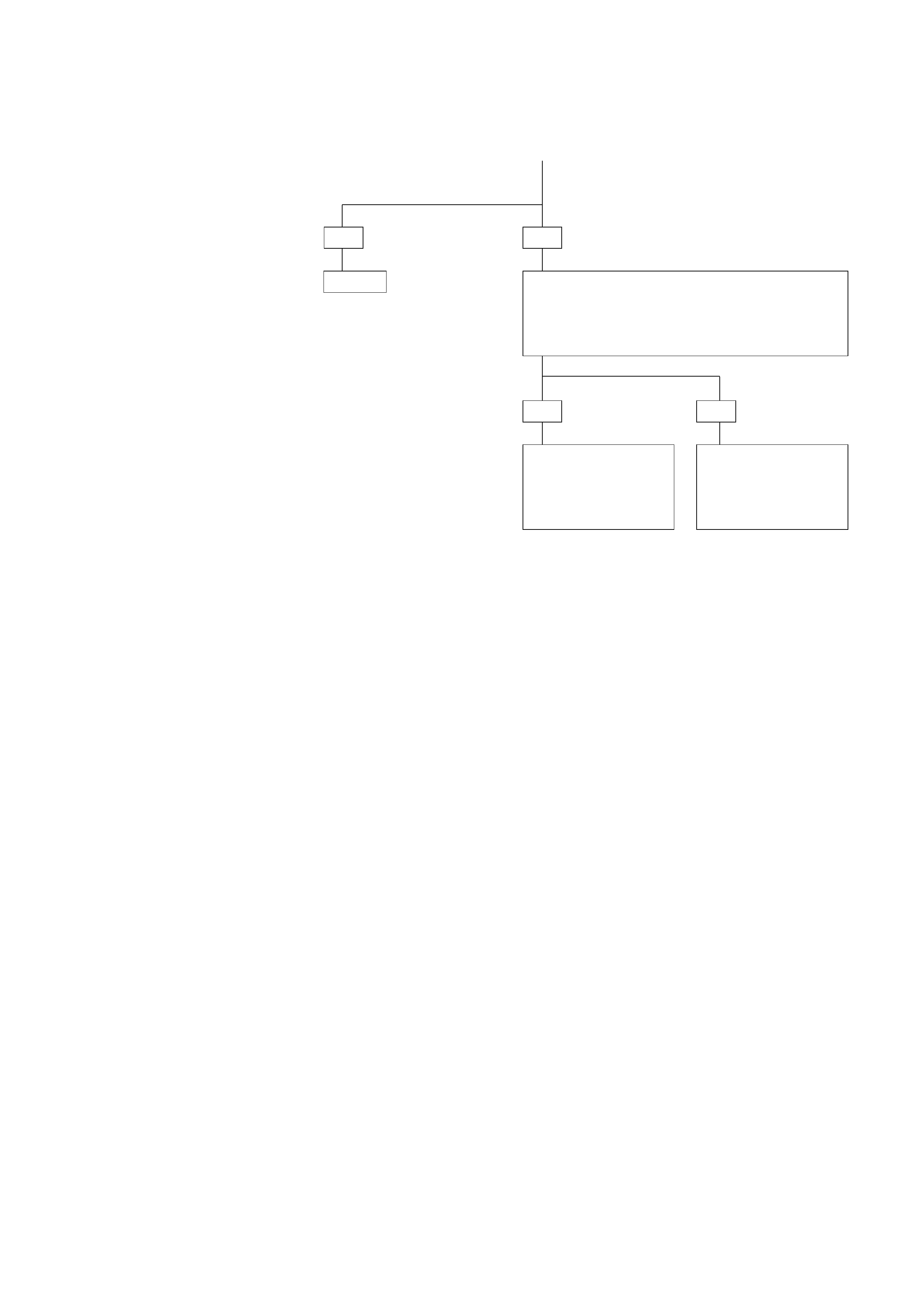

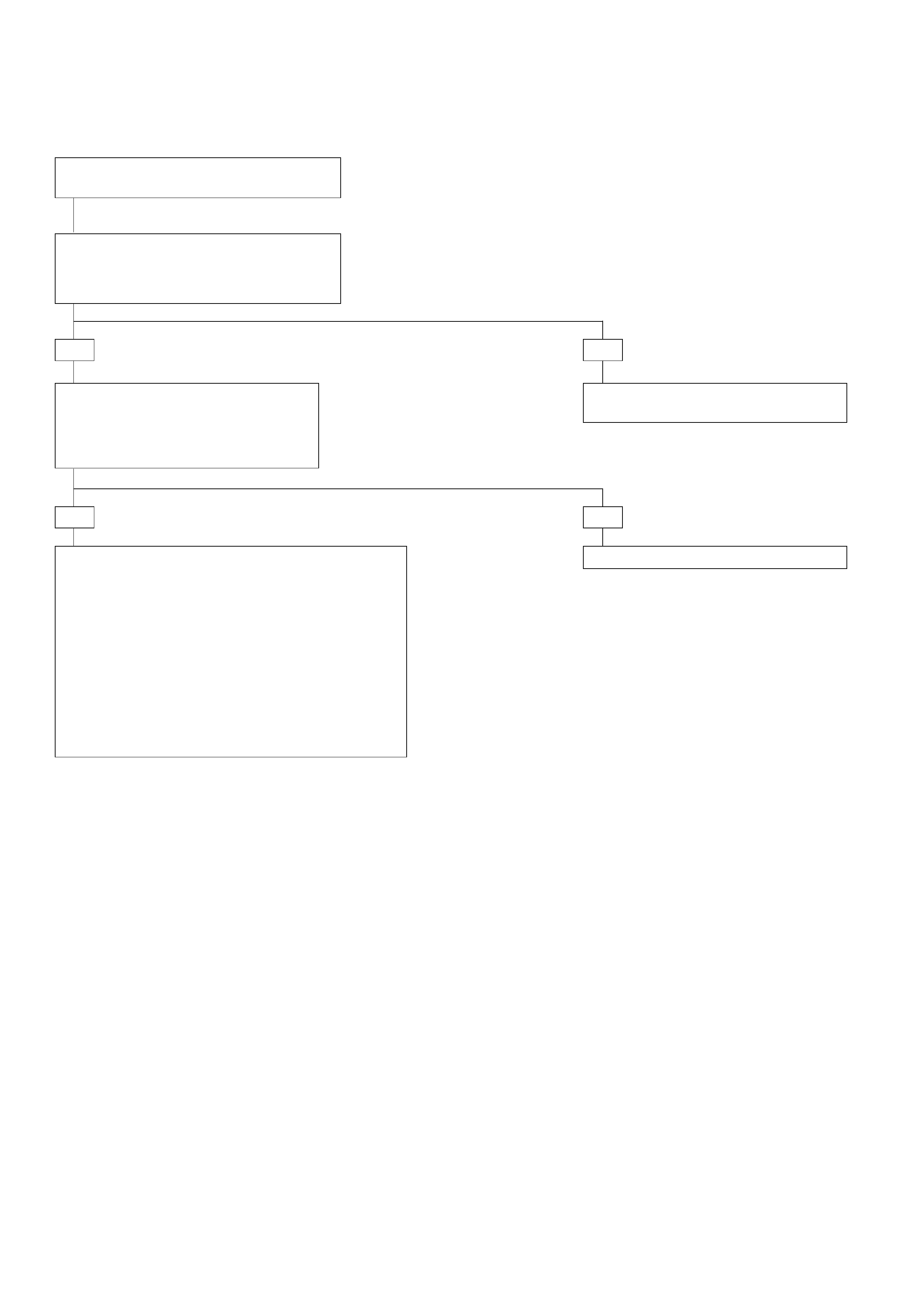

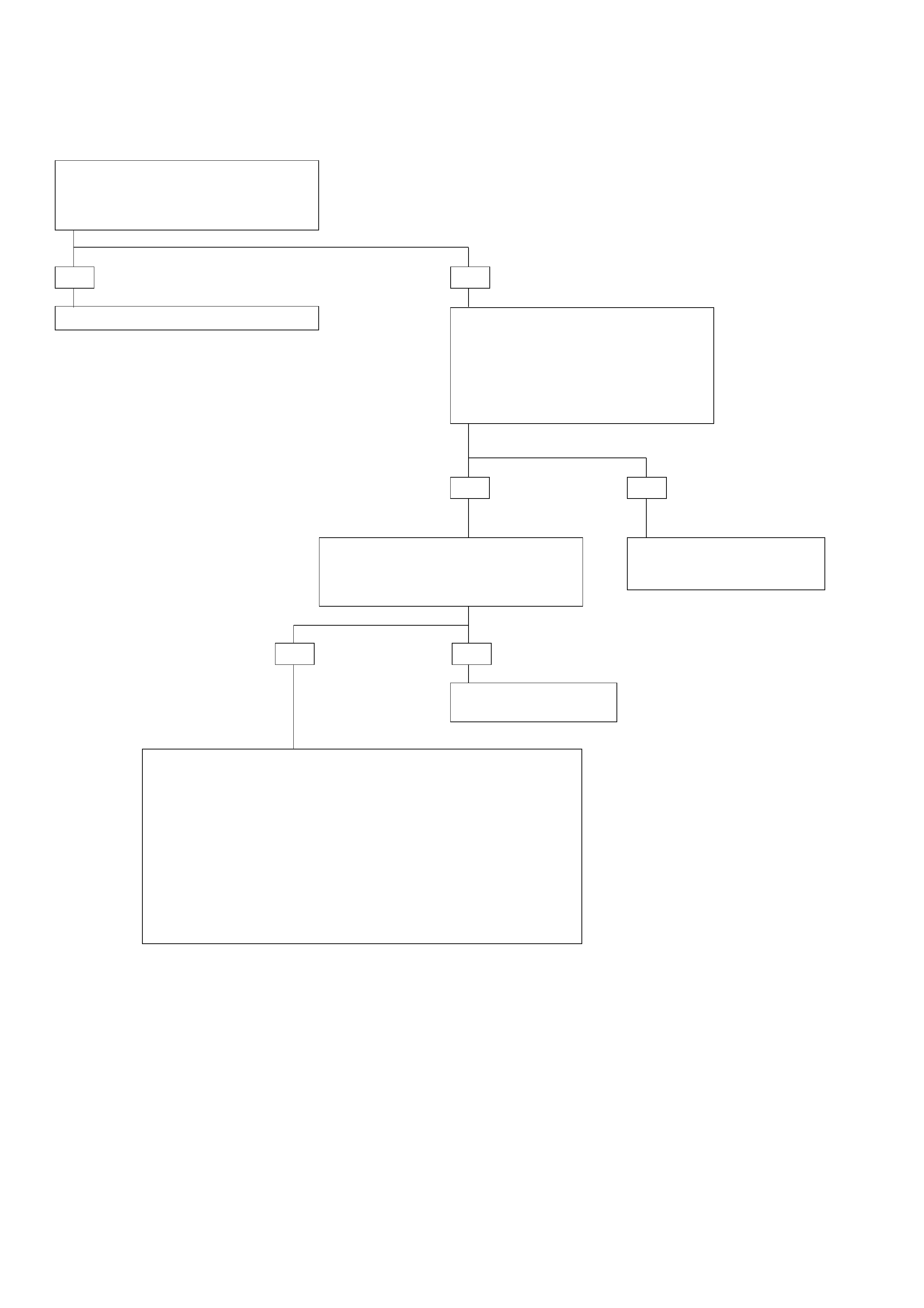

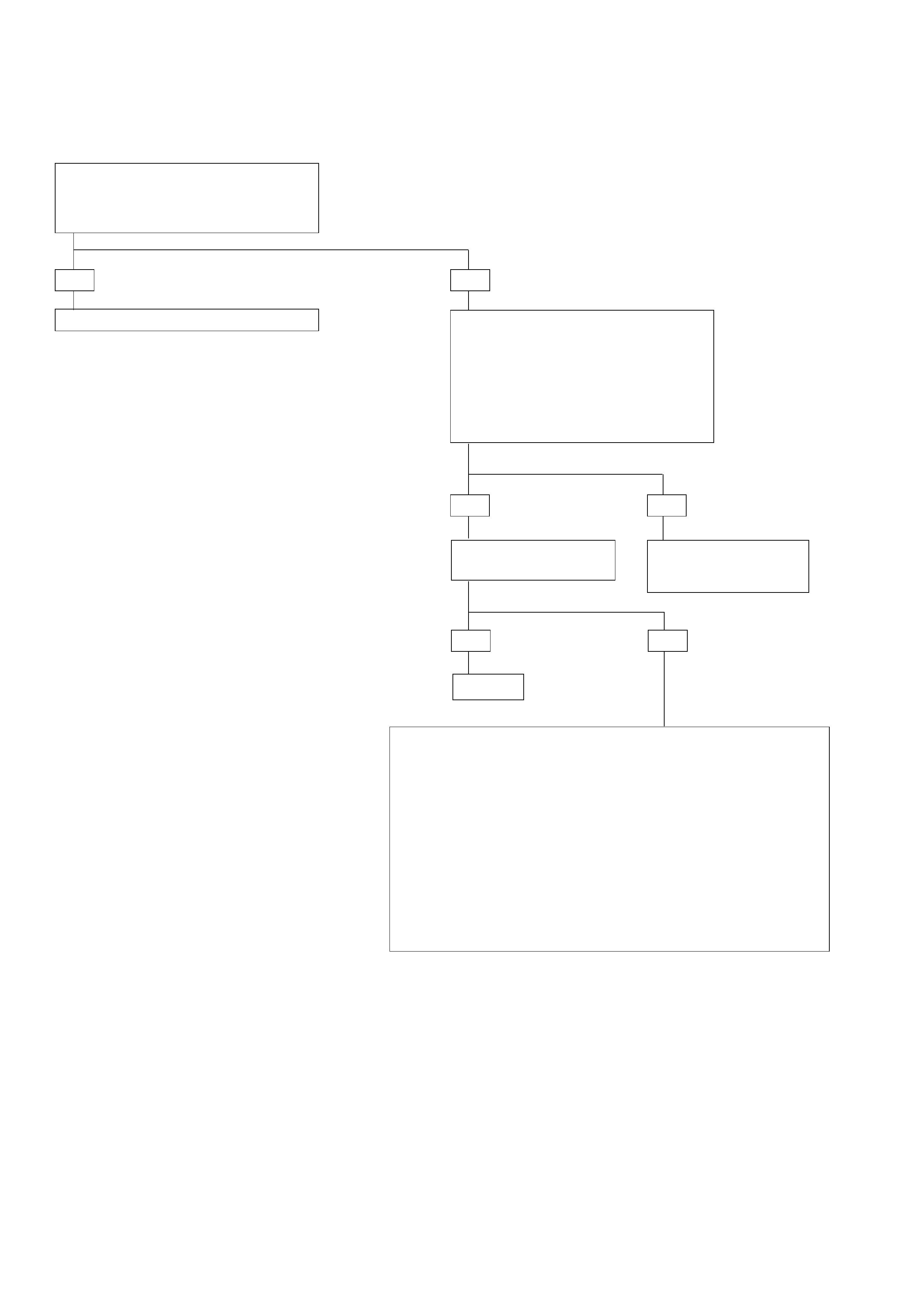

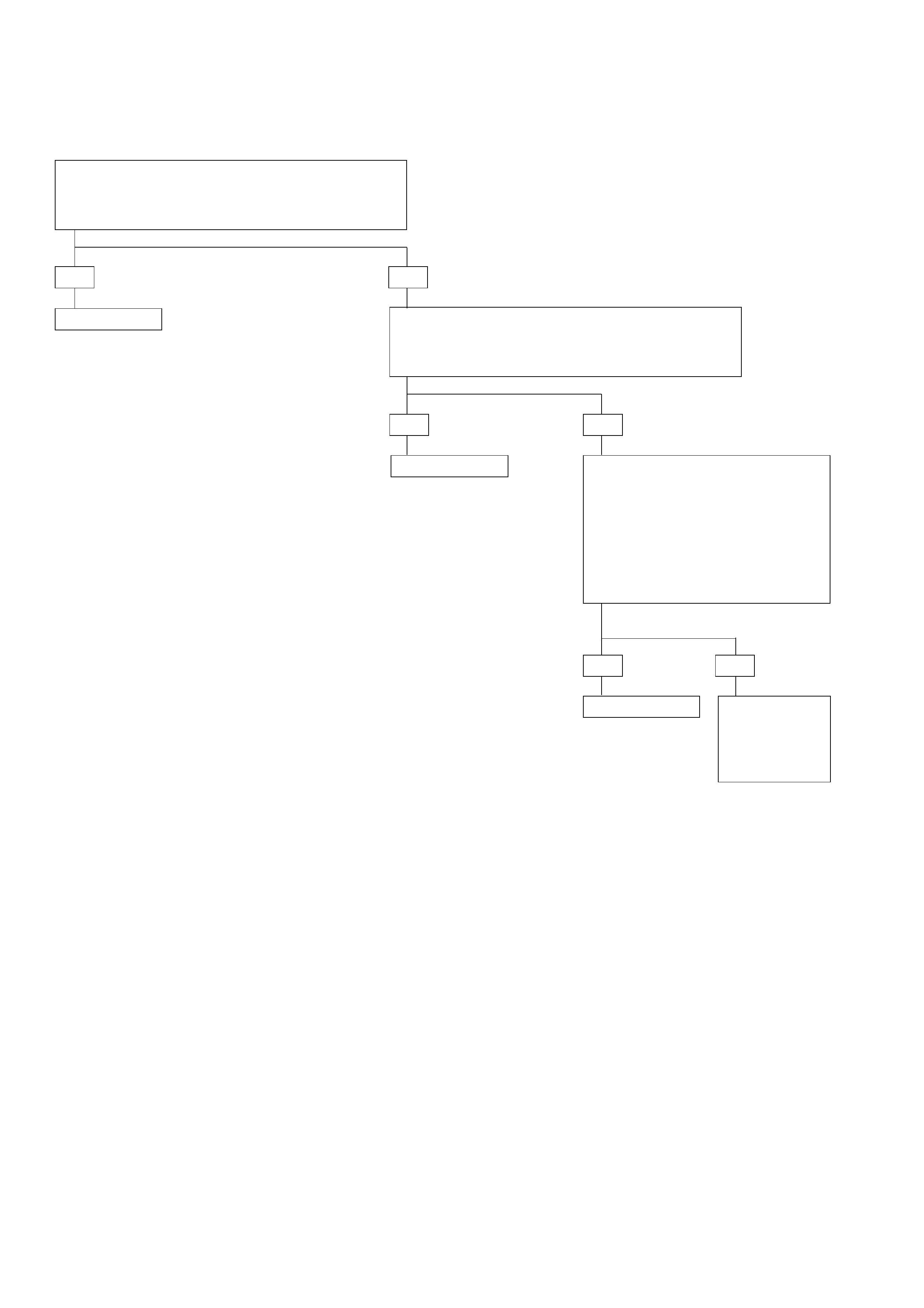

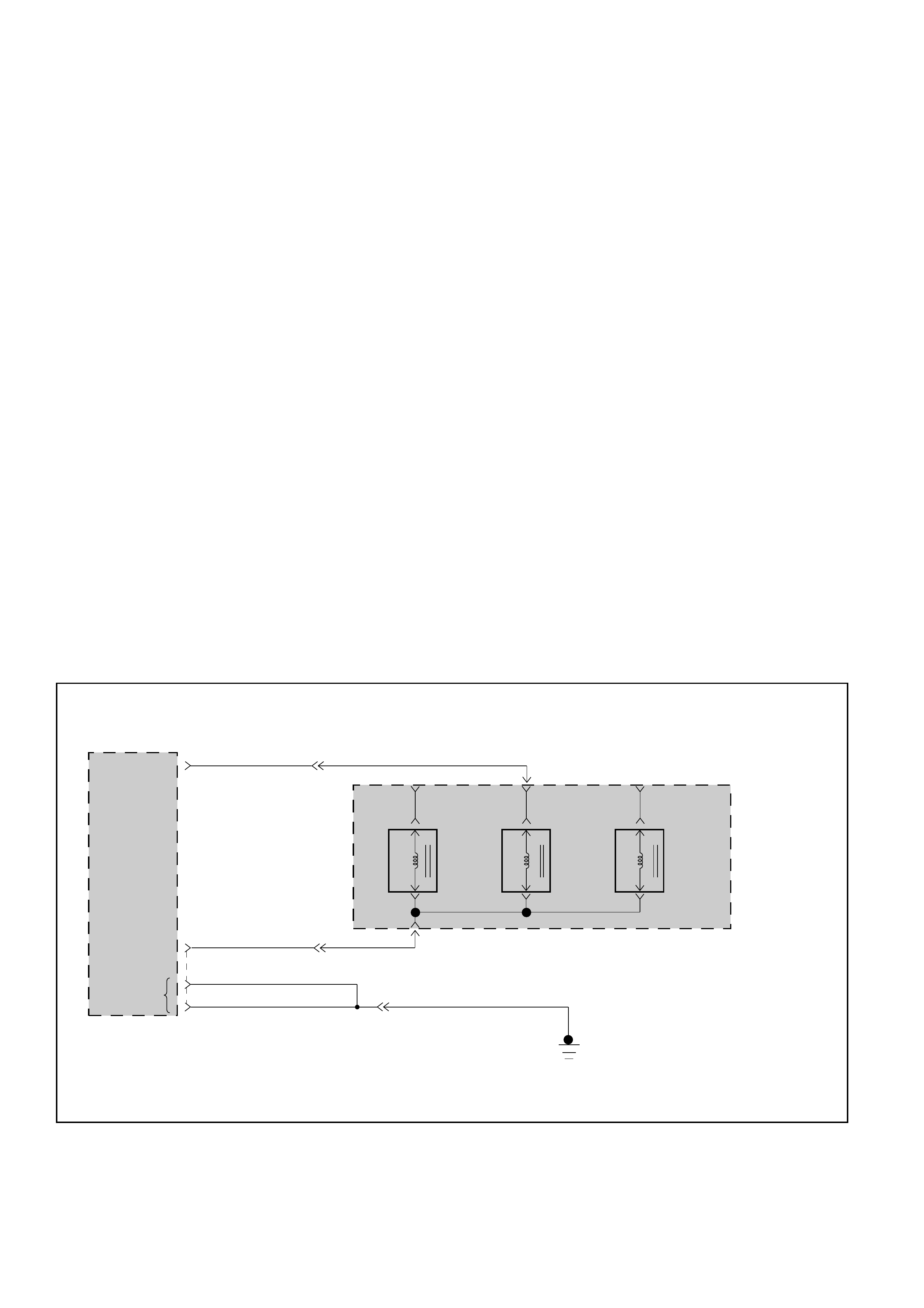

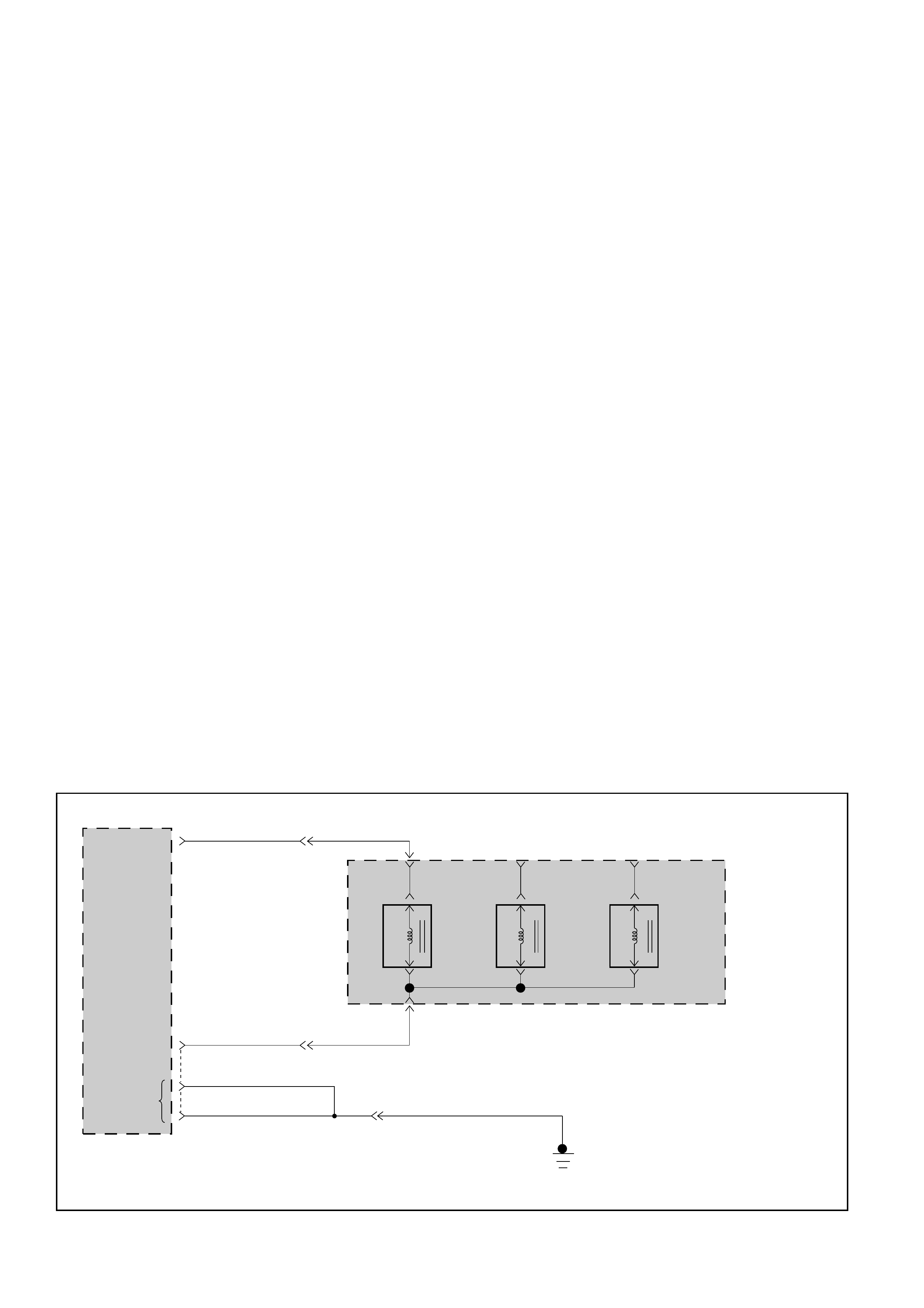

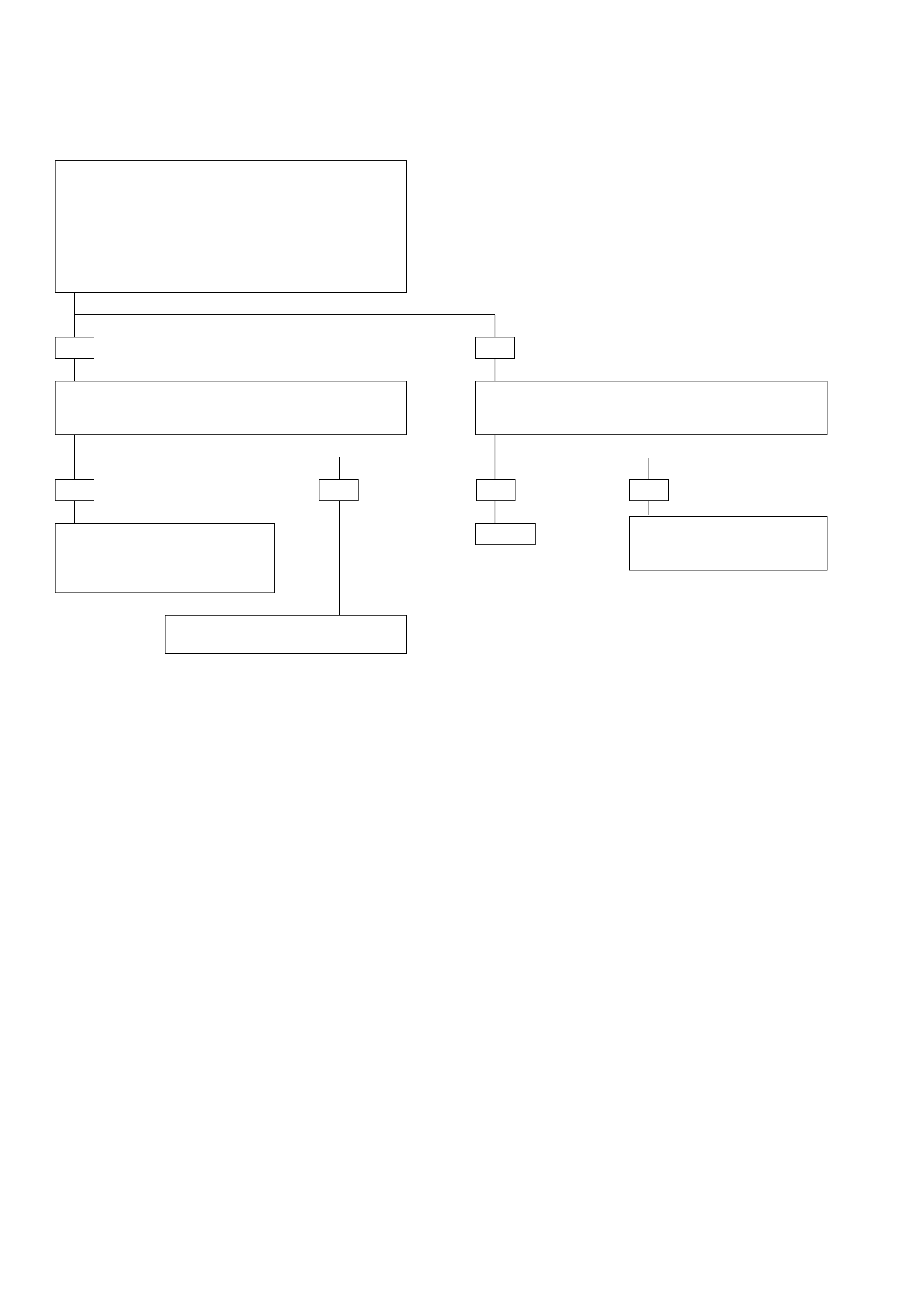

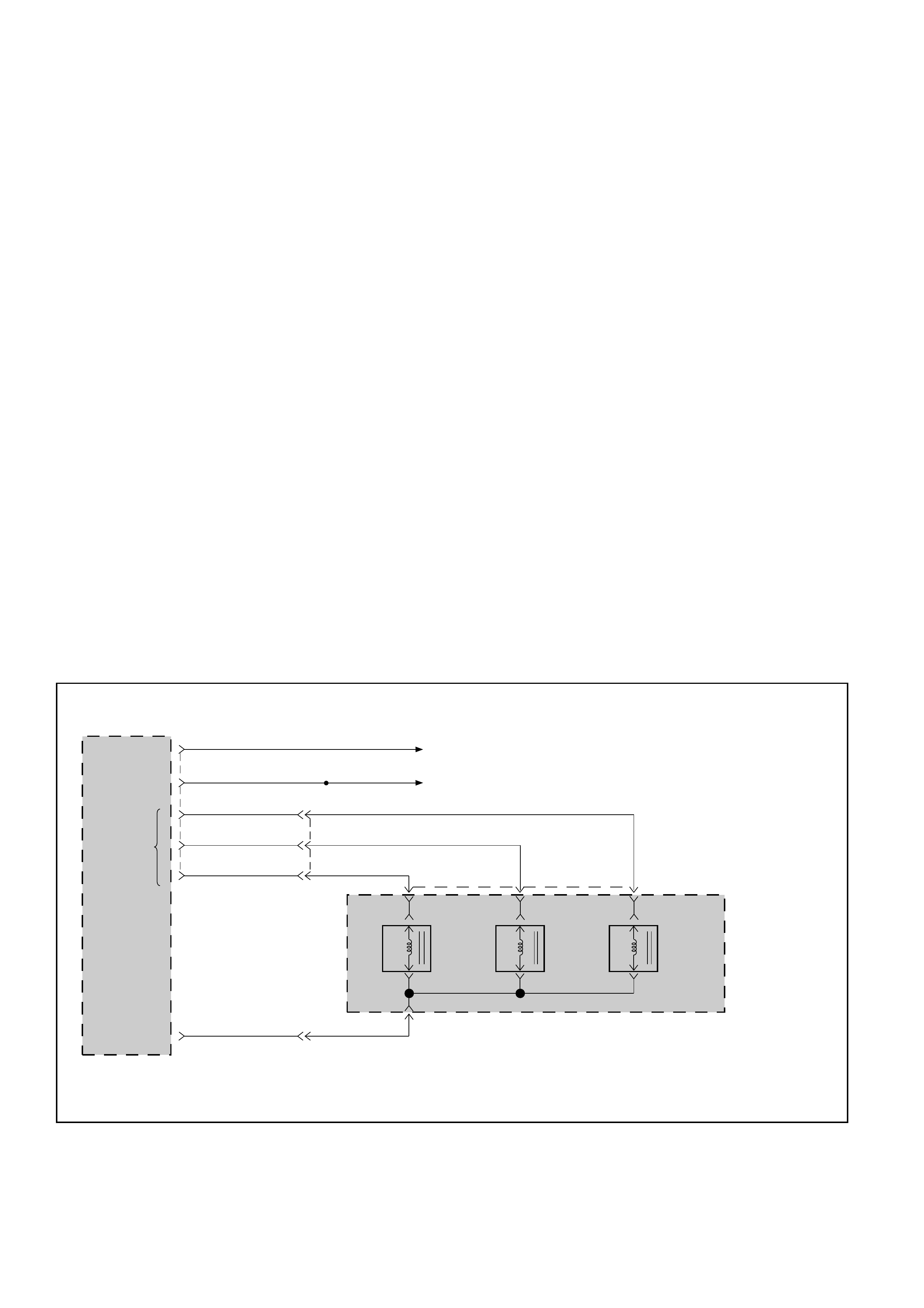

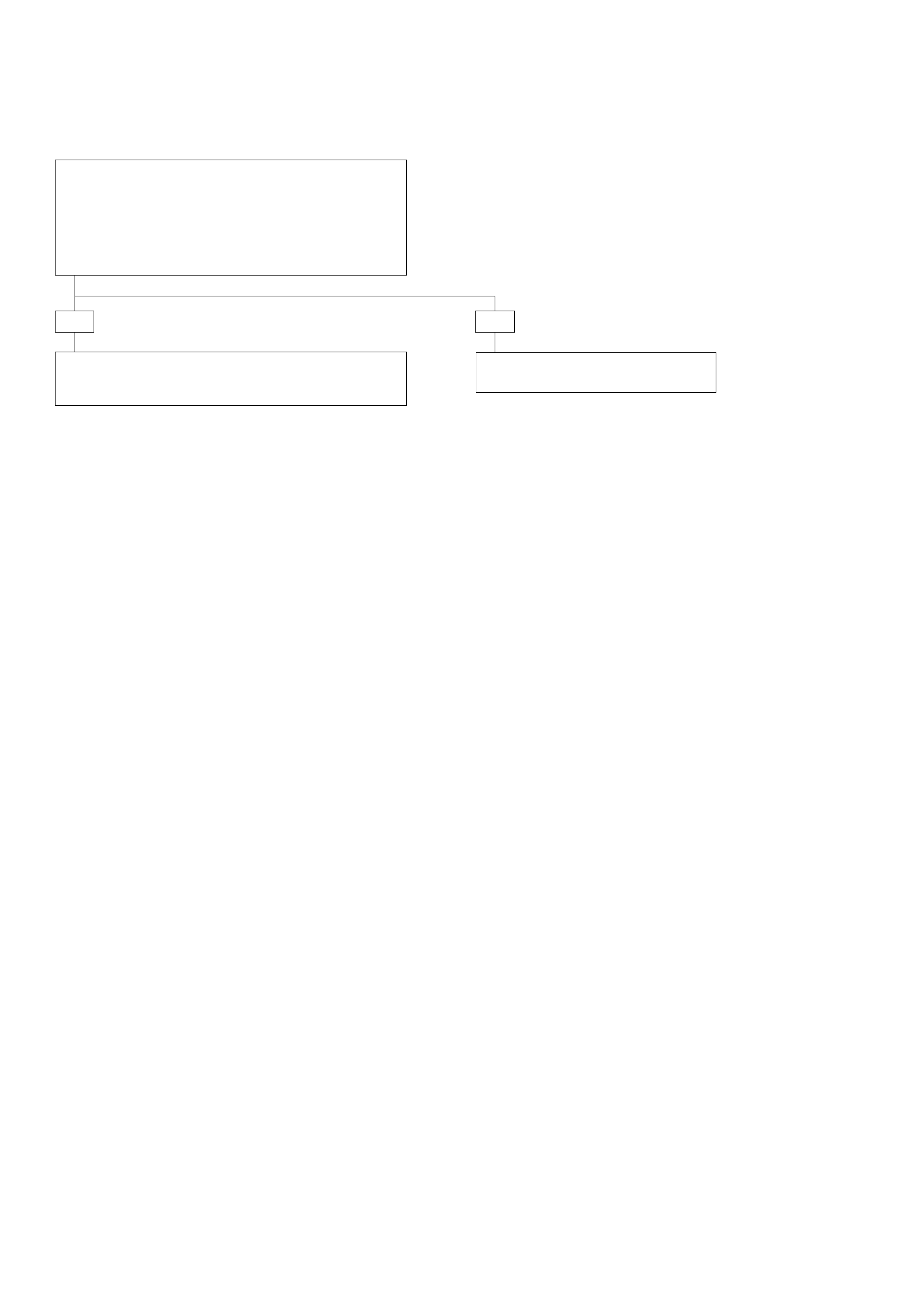

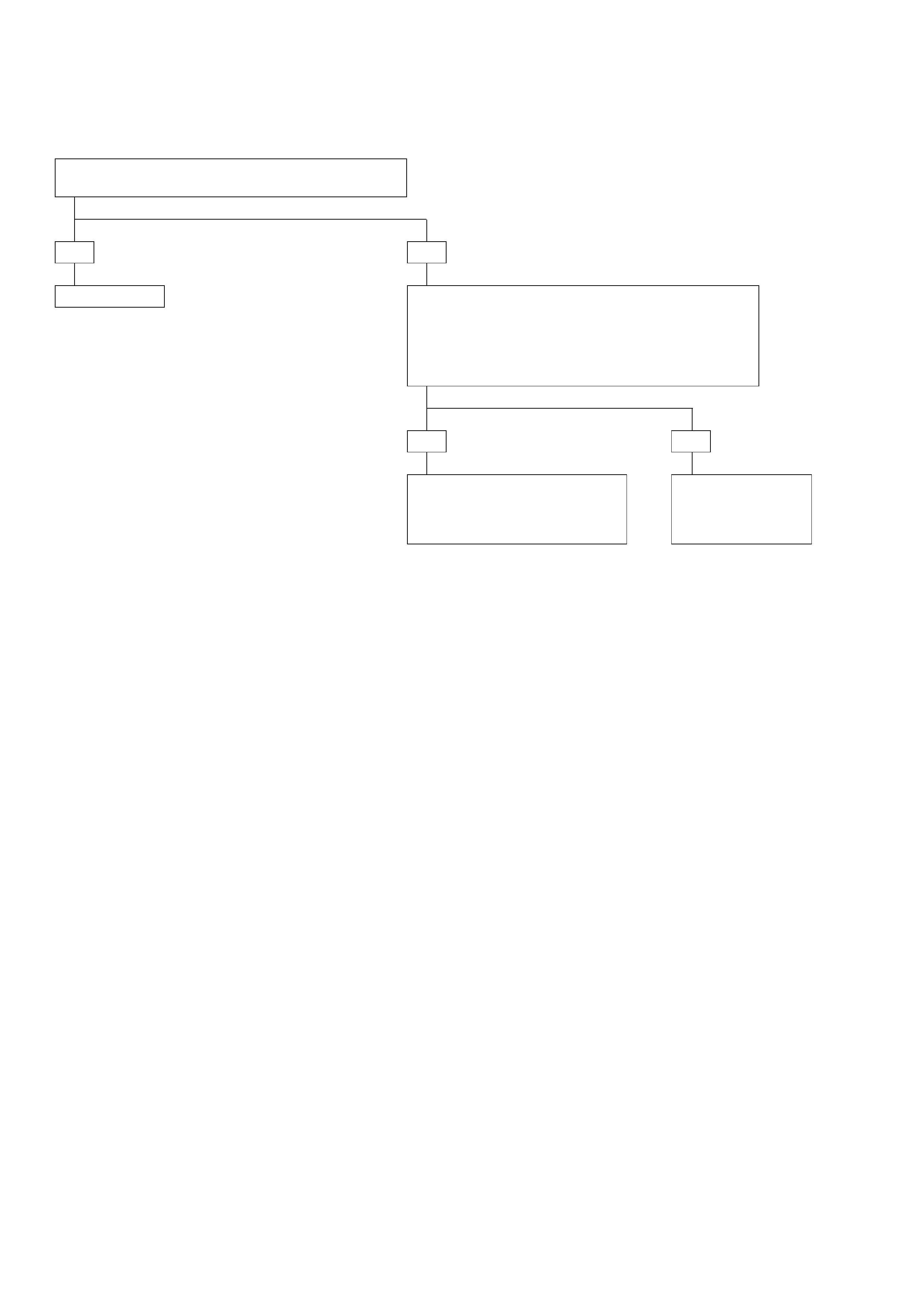

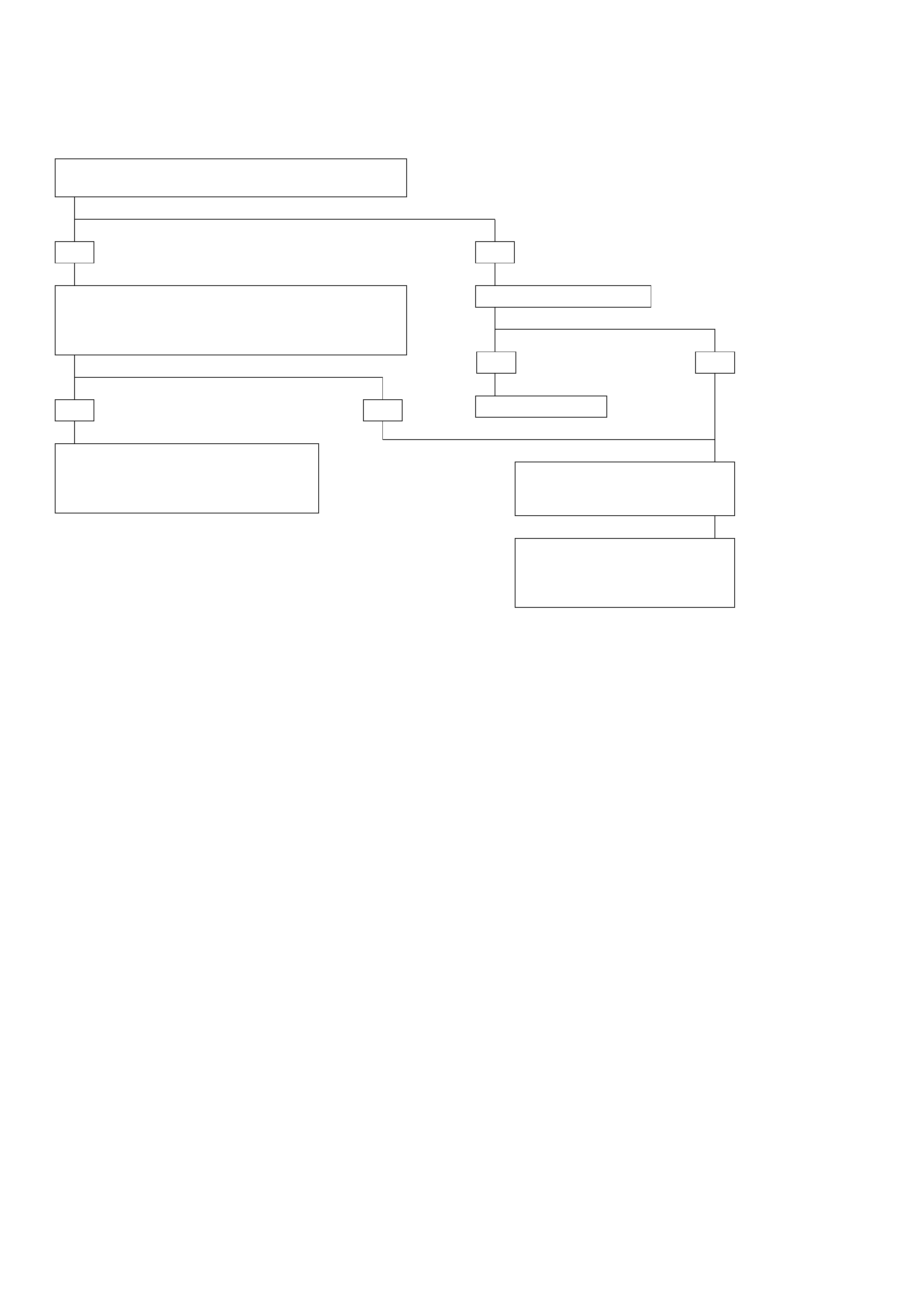

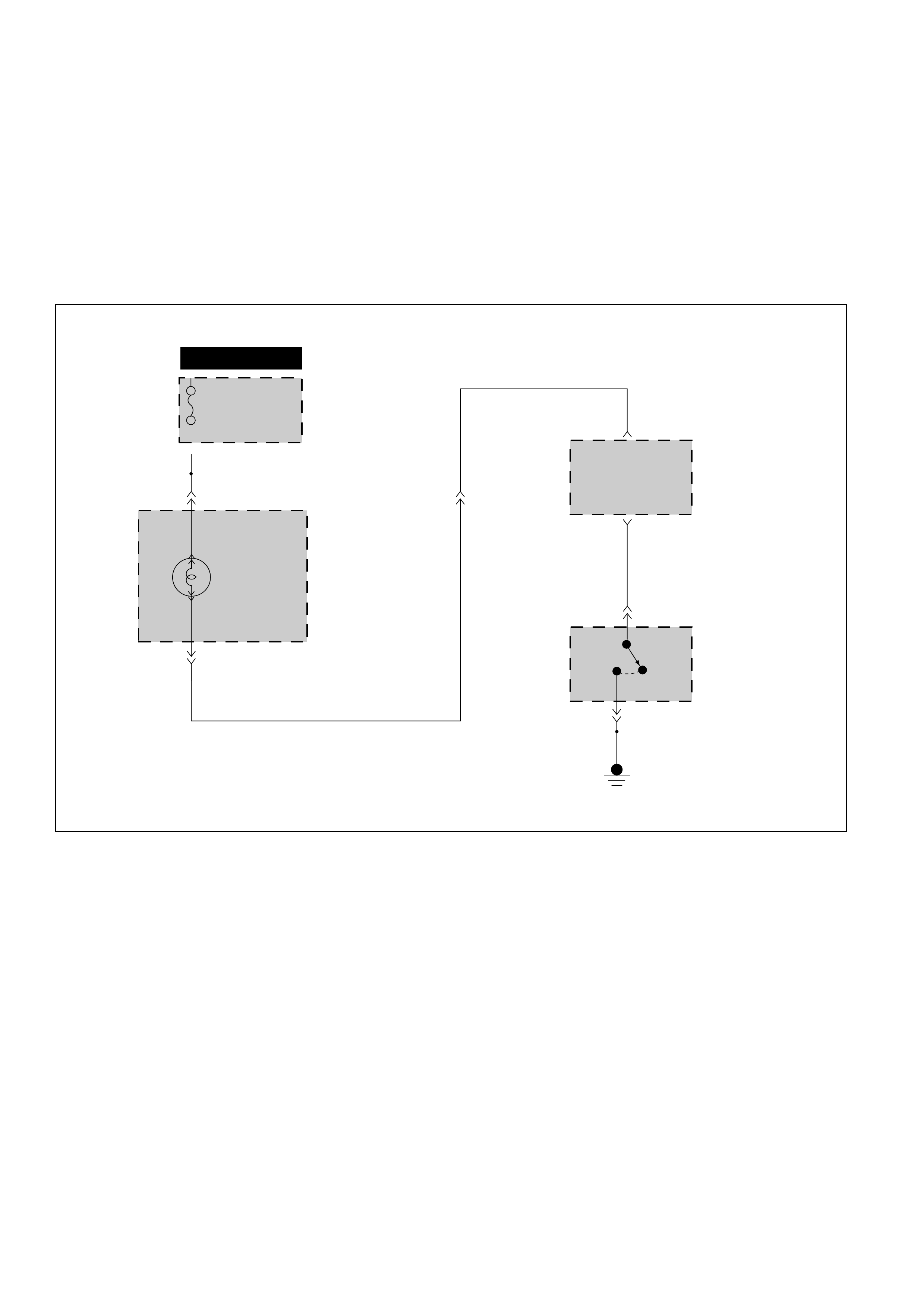

CONTROL SYSTEM DIAGRAM

AUTOMATIC TRANSMISSION ASSEMBLY

ENGINE

LOCKUP PISTON

TORQUE

CONVERTER

INPUT SHAFT

PLANETARY GEAR

MULTIPLATE CLUTCH

MULTIPLATE BRAKE

BRAKE BAND

ONE WAY CLUTCH

OUTPUT SHAFT

TIRE

FINAL DRIVE GEAR

DRIVE SHAFT

OIL PUMP SERVO MECHANISM

CONTROL VALVE

:POWER

TRANSMIT

:OIL PRESSURE

CONTROL

:MECHANICAL

SIGNAL

:ELECTRONIC

SIGNAL

OIL TEMP.

SENSOR

TORQUE CONVERTER

CLUTCH SOLENOID

SHIFT SOLENOID A

SHIFT SOLENOID B

BAND APPLY

SOLENOID

FORCE MOTOR

MANUAL VALVE

VEHICLE SPEED

SENSOR

MODE

SWITCH

CHECK TRANS LAMP

POWER LAMP

KICKDOWN SWITCH

BRAKE SWITCH

POWER MODE SWITCH

AIR CONDITIONING

SWITCH

TRANSMISSION CONTROL

MODULE (TCM)

• SHIFT CONTROL

• BAND APPLY CONTROL

• TORQUE CONVERTER CLUTCH

CONTROL

• LINE PRESSURE CONTROL

• SAFETY MODE

• ON-BOARD DIAGNOSTIC

SYSTEM

• TORQUE MANAGEMENT

SHIFT INDICATOR LAMP

A/T SHIFT INDICATOR

CONTROL UNIT

(

(

CRANK ANGLE SENSOR

THROTTLE POSITION

SENSOR

ENGINE COOLANT

TEMPERATURE SENSOR

ECM

C07LW001

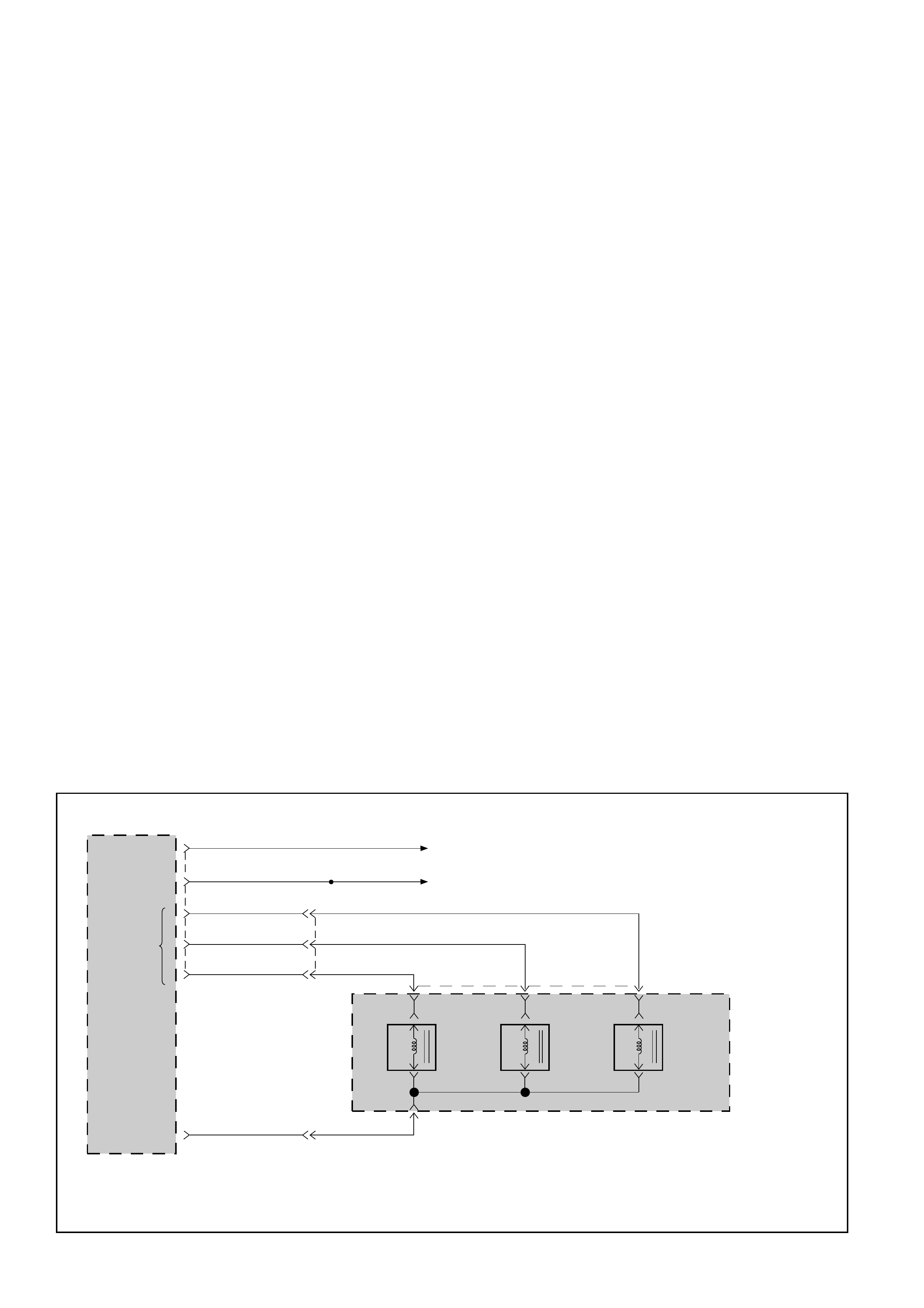

Shift Control

The 4L30E transmission uses two electronic shift

solenoids to control upshift and downshift points in all

forward gear ranges. These shift solenoids operate

together in a combination of ‘OFF’ and ‘ON’ sequences

to control the position of the 1-2/3-4 and 2-3 shift valves.

The Transmission Control Module (TCM) monitors the

numerous input signals to determine the solenoid status

required for the current vehicle operating conditions.

The shift solenoids are ’Low-side Driven’, that is, the

TCM provides the ground path to energise the solenoid.

Band Apply Control

The Band Apply Solenoid is a normally open solenoid

valve located on the rear of the main valve body. The

solenoid controls the rate of brake band apply and

release in response to a Pulse Width Modulated (PWM)

signal from the TCM by regulating the flow of oil to and

from the band servo.

Varying the rate of band apply and release reduces low

speed shift-shock and provides a measure of engine

poverrun protection on a 3-2 downshift.

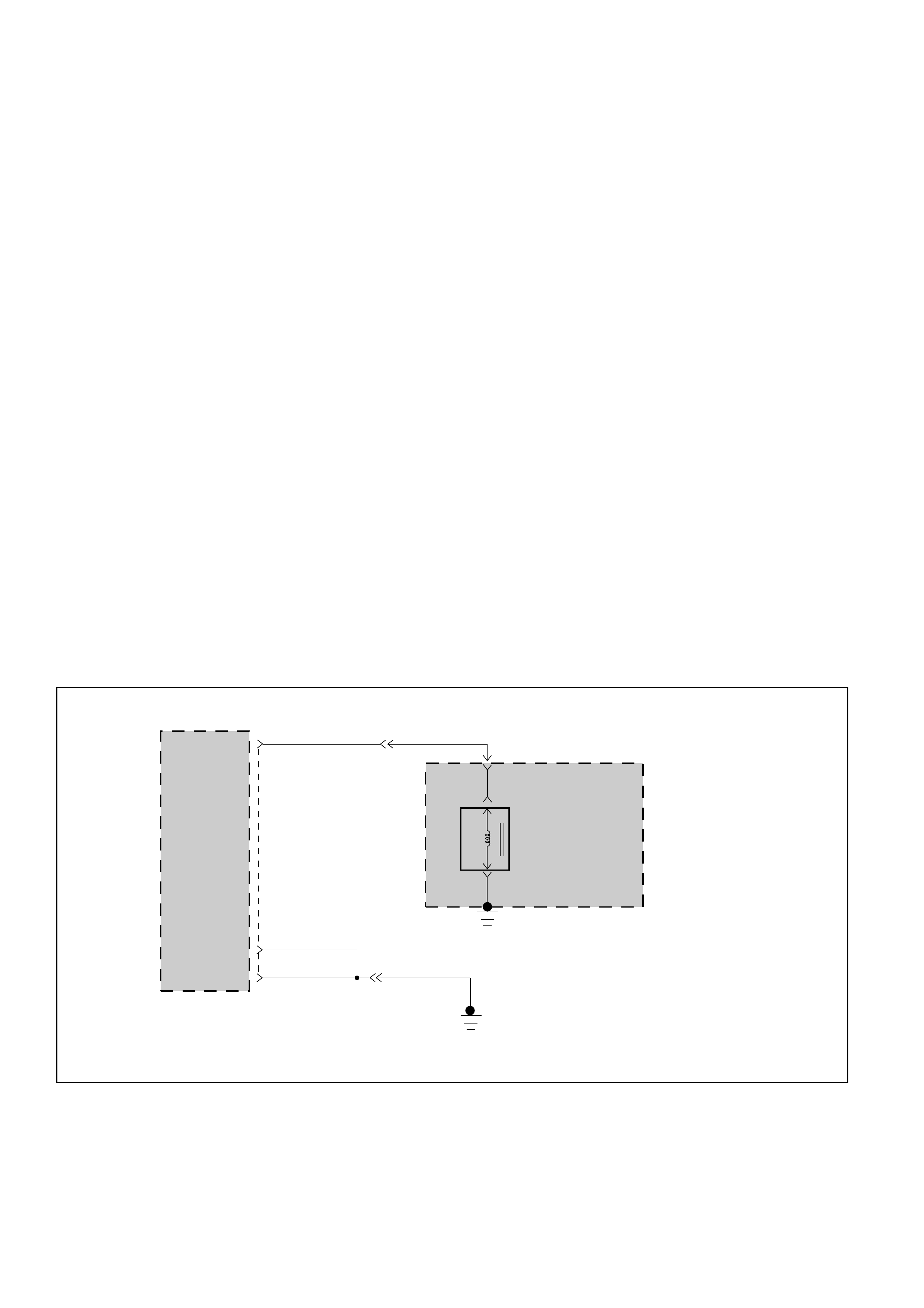

Torque Converter Clutch Control

The Torque Converter Clutch (TCC) solenoid is a

normally open solenoid valve, located in the Adapter

Case valve body. When the solenoid is de-energised,

the TCC is released. Energising the solenoid allows

fluid fluid pressure to move the TCC Control Valve into

the apply position, initiating TCC apply.

The TCC is normally applied in 3rd and 4th gear,

although it may apply in 2nd gear during a downshift, or

as part of the transmission ‘overheat’ strategy.

Line Pressure Control

Line pressure varies in response to the operation of the

Force Motor. The Force Motor (or Pressure Control

Solenoid) is a precision electronic pressure regulator

valve, controlled by a 600Mz PWM signal from the

TCM. The Force Motor regulates the flow of Feed Limit

fluid into the Throttle Signal pressure circuit, hence Line

Oil pressure.

Force Motor duty cycle and Line Oil pressure are

inversely proportional. That is, as duty cycle (current

flow) decreases, Line Oil pressure increases.

Under normal operating conditions - between minimum

and maximum throttle, the TCM will vary the duty cycle

signal Force Motor duty cycle signal between 60% and

0%.

In the event of electrical system failure, the current flow

to the Force Motor will 0.0 amps. This creates maximum

Line Oil pressure to prevent any apply components from

slipping until the condition can be corrected.

On–Board Diagnostic System

The TCM has a built-in diagnostic system that

recognises and identifies possible transmission

operational issues and alerts the driver by flashing the

CHECK TRANS lamp mounted in the instrument panel.

Below the RH edge of the instrument panel is the J1962

Diagnositc Link Connector (DLC). The DLC allows

access to the diagnostic system with the TECH 2 scan

tool for both active testing and Diagnostic Trouble Code

(DTC) retrieval.

Fail Safe Mechanism

Should a major electrical system failure occur which

may either adversly affect vehicle safety or damage the

transmission, the transmission will enter ‘Fail-saf’e or

‘Default’ mode.

In this mode, the transmission operates with both shift

solenoids, the TCC solenoid and the Force Motor

turned OFF. The driver maintains some manual control

over gear selection, but with some shift-shock during

selection and harsh garage shifts.

Torque Management Control

The 4L30E transmisssion utilises a ‘Torque

Management’ system to improve transmission

component durability and shift quality under medium to

full throttle operation.

Provididng a means to occur to reduce engine torque

during the shift-overlap period reduces the stress on

bands and clutches while improving the shift ‘feel’. The

process of limiting engine torque during shiting is called

Toque Management. The technique calls for a

momentary reduction (or retardation) of the spark

advance and may effectively retard the ignition timing to

0º TDC.

ATF Warning Control

The ATF warning lamp will illuminate when transmission

fluid temperature exceeds 145ºC and will extinguish

when the fluid temperature falls below 125ºC.

ABS Control (If equipped)

When the select lever is at “L” or “R” range, a signal is

sent to the ABS Modulator, resulting in a recalibration of

the ABS operation to suit the current operating

conditions.

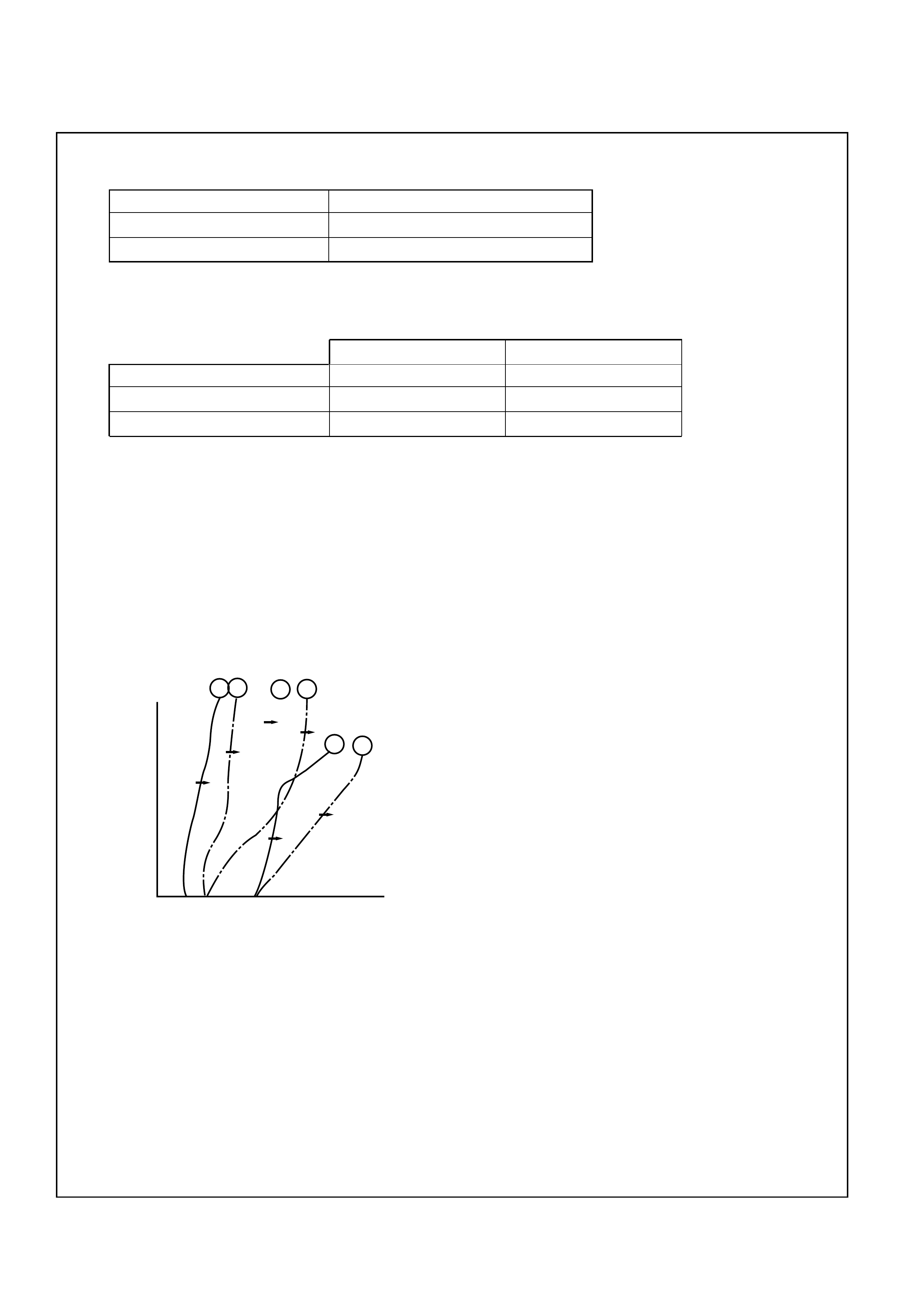

SHIFT MODE CONTROL

1Mode type

Mode type Select lever position

Normal drive mode (NOR) Entire range (excluding “R”)

Power drive mode (PWR) Entire range (excluding “R”)

2Mode selection

SWITCH (SW) LAMP

Mode type

PWR/NOR. SW POWER DRIVE LAMP

Normal drive mode (NOR)

OFF OFF

Power drive mode (PWR)

ON ON

3Comparison of mode

(1) The normal drive mode is set at the normal shift points.

(2) The shift points of the power drive mode are shifted to the higher speed side, compared to the

normal drive mode.

Shift diagram

23

3

4

1

2

2

12

3

4

3

N: Normal drive mode

P: Power drive mode

Amount of

throttle

opening

Speed mph(km/h)

NPP

P

N

N

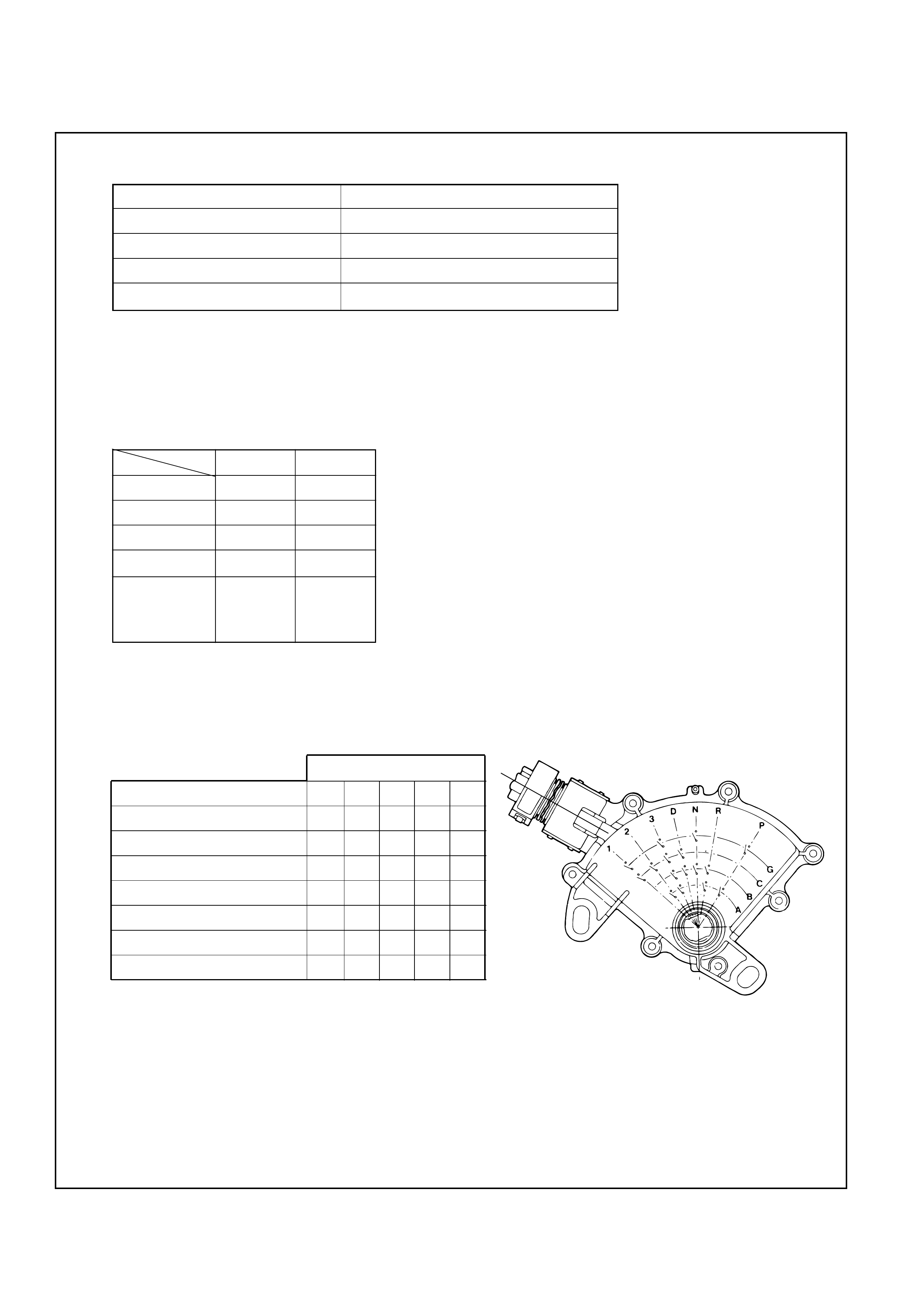

GEAR SHIFT CONTROL

1Shift pattern

2Gear position

The gear is selected by ON/OFF of two solenoids.

3Selecting gear position

Seven types of positions can be selected according to 5 signals from the mode switch as shown

below.

SELECT LEVER RANGE SHIFT PATTERN

D (Drive) 1 2TCC 3TCC 4TCC

3 (Third) 1 2TCC 3TCC 4TCC

2 (Second) 1 2TCC 3TCC

L (First) 1 2

→

←→

←

←

←

←

→

←

→

←

→

←

→

←

TCC = Torque Converter Clutch

GEAR SOL AB

4 (Fourth) ✕✕

3 (Third) ●●✕

2 (Second) ●●●●

1 (First) ✕●●

P (Park)

R (Reverse) ✕●●

N (Neutral)

●●= ON

✕= OFF

SOLENOID A ON →PRESSURE TO

(Normally closed) SHIFT VALVE

SOLENOID B OFF →PRESSURE TO

(Normally open) SHIFT VALVE

MODE SW TERMINALS

SELECT LEVER RANGE 5(D) 8(A) 7(B) 6(C) 3(G)

P (Park) •• •

R (Reverse) •••

N (Neutral) •••

D (Drive) •••

3 (Third) •••••

2 (Second) •• •

L (First) •••

•= Continuity

BACKUP MODE

If a major system failure occurs which could affect safety or damage the transmission under normal

vehicle operation, the diagnostic system detects the fault and overrides the TCM.

The “CHECK TRANS” light flashes to alert the driver, and the transmission must be manually shifted

as follows:

Select lever position Gear Ratio Selected

D 4 (Fourth)

Manual 3 4 (Fourth)

Manual 2 3 (Third)

Manual L 1 (First)

R Reverse

Shifts are firmer to prevent clutch slip and consequent wear. The fault should be corrected as soon as

possible.

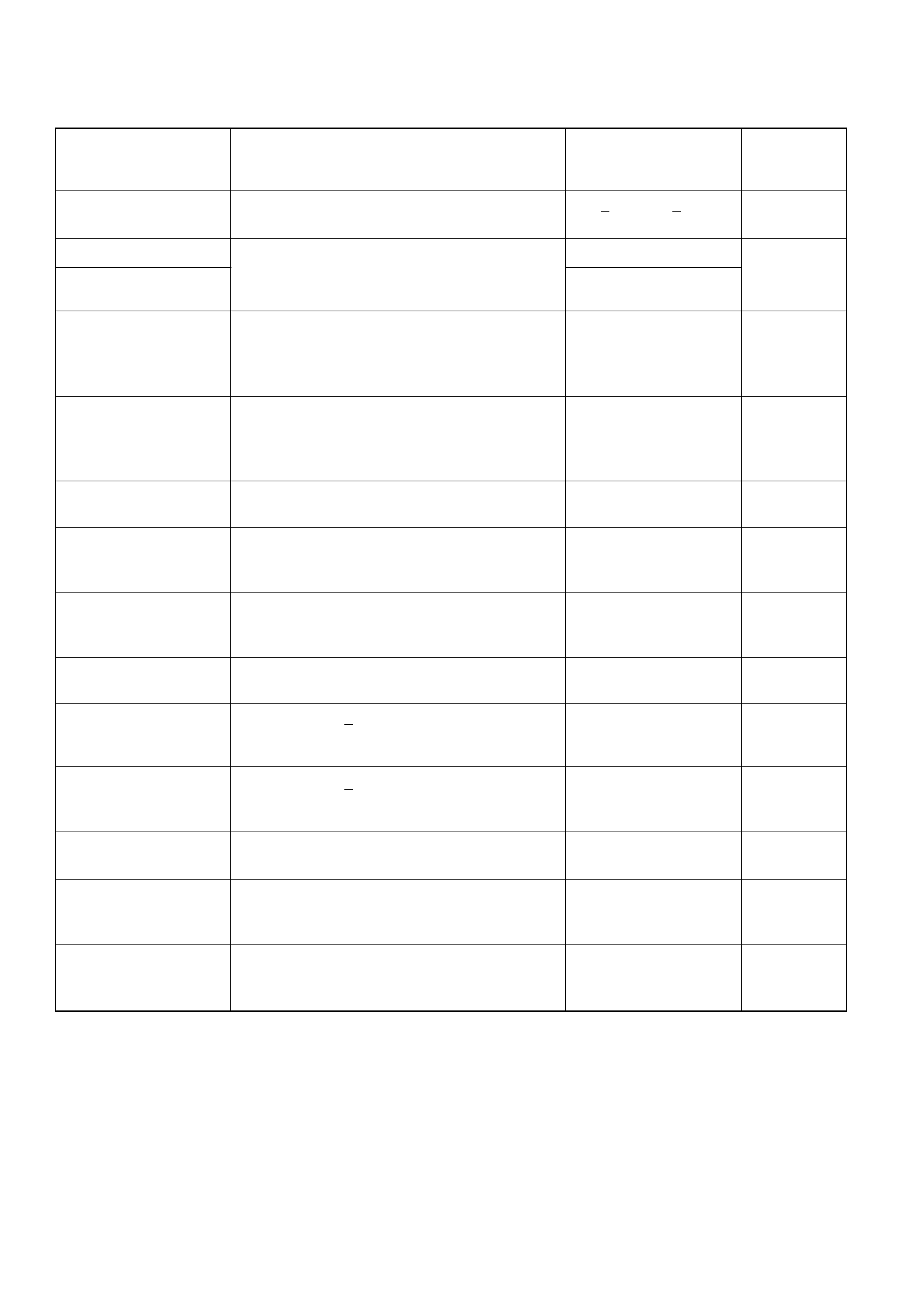

FUNCTIONS OF INPUT/OUTPUT COMPONENTS

Components Function

Speed sensor Senses rotation of output shaft and feeds the data to Transmission

(fixed to transmission T/M) Control Module (TCM)

Throttle Senses the extent of throttle valve opening and the speed of the throttle

position sensor (TPS) valve lever motion to open the valve and feeds the data to TCM (fed to

(fixed to engine) Engine Control Module (ECM) also)

Brake Switch (SW) Senses whether the driver has pressed the brake pedal or not and feeds

(fixed to brake pedal) the information to TCM

Kick-down SW (fixed to Senses whether the driver has pushed the accelerator pedal fully or not

accelerator pedal) and feeds the information to TCM

Mode SW (fixed to T/M) Senses the select lever position and feeds the information to TCM

Power drive SW Senses whether the driver has selected the power mode and feeds the

(fixed to front console) information to TCM

T/M oil temp. sensor Senses the T/M oil temperature and feeds the data to TCM

Engine coolant Senses the engine cooling water temperature and feeds the data to TCM

temperature SW (feeds the signal from ECM)

Engine speed signal Feeds the signals monitoring engine speed to TCM from crank angle sensor

(feeds the signal from ECM)

Air conditioning Senses whether the air conditioner has been switched on or not and

information feeds the information to TCM

On-board diagnostic input By monitoring the Ground (GND), the location of failure is shown on the

T/M monitor lamp (“CHECK TRANS”) by flashing the diagnostic trouble

code

Shift solenoid A, B Selects shift point and gear position suited to the vehicle running con-

dition on the basis of TCM output

Band apply solenoid Controls oil flow suited to the vehicle running condition on the basis of

TCM output

Torque Converter Controls clutch engagement/disengagement suited to the vehicle

Clutch solenoid running condition on the basis of TCM output

Force motor Adjusts the oil pump delivery pressure to line pressure suited to the

(Pressure regulator vehicle running condition on the basis TCM output

valve)

Power drive mode lamp Informs the driver whether the vehicle is in power mode or not

T/M monitor lamp Informs the driver of failure in the system. It also displays the self diag-

(“CHECK TRANS”) nosis code.

Data Link Connector (DLC) When connected with TECH2 or tester, can communicate the data for

function check, etc. (fed to ECM also). When TECH2 is not connected,

can communicate the signal for torque management with ECM.

When short-circuited with the bipolar connector, the T/M monitor lamp

displays a failure by code.

S

O

L

E

N

O

I

D

O

U

T

P

U

T

S

I

G

N

A

L

I

N

P

U

T

S

I

G

N

A

L

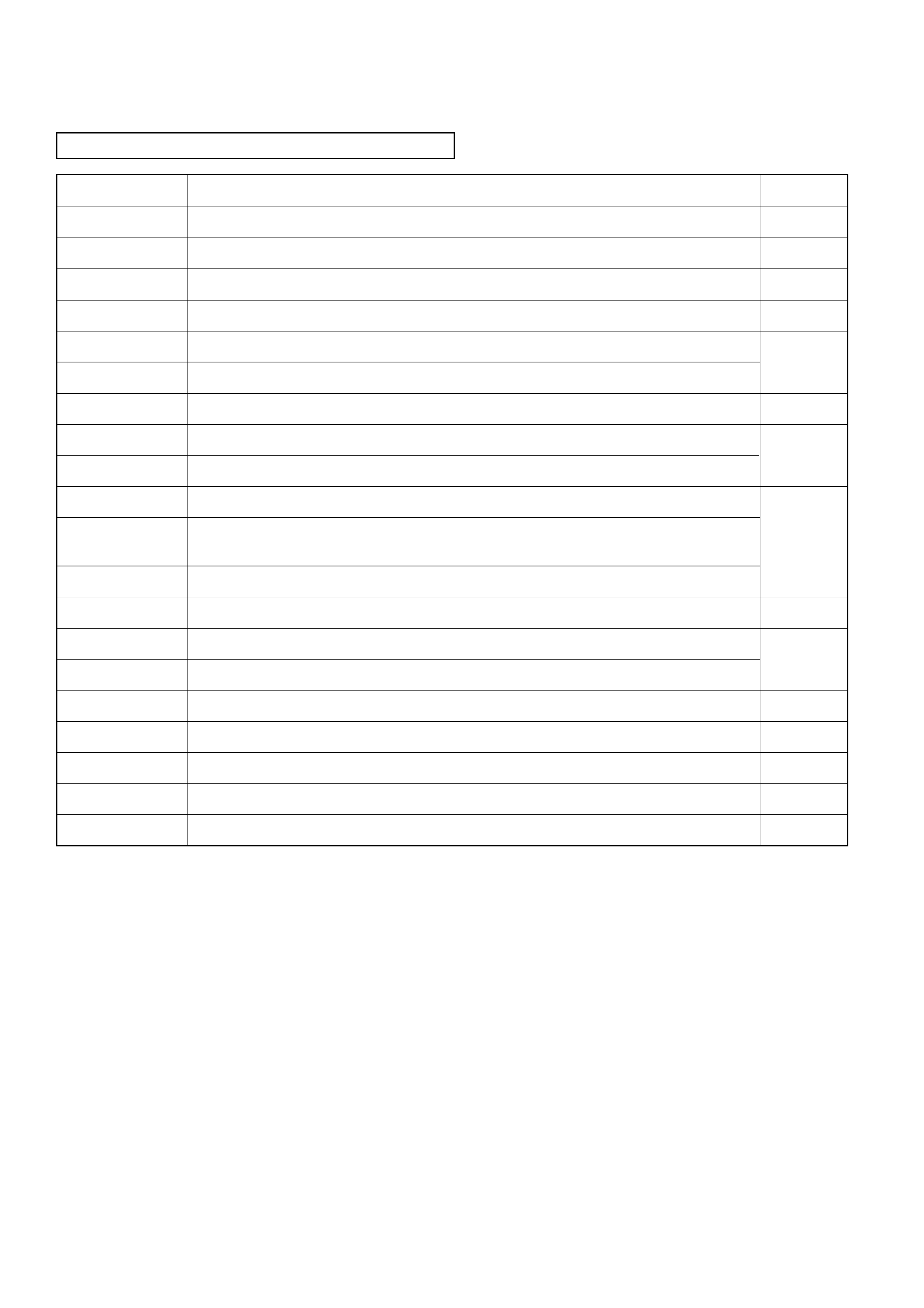

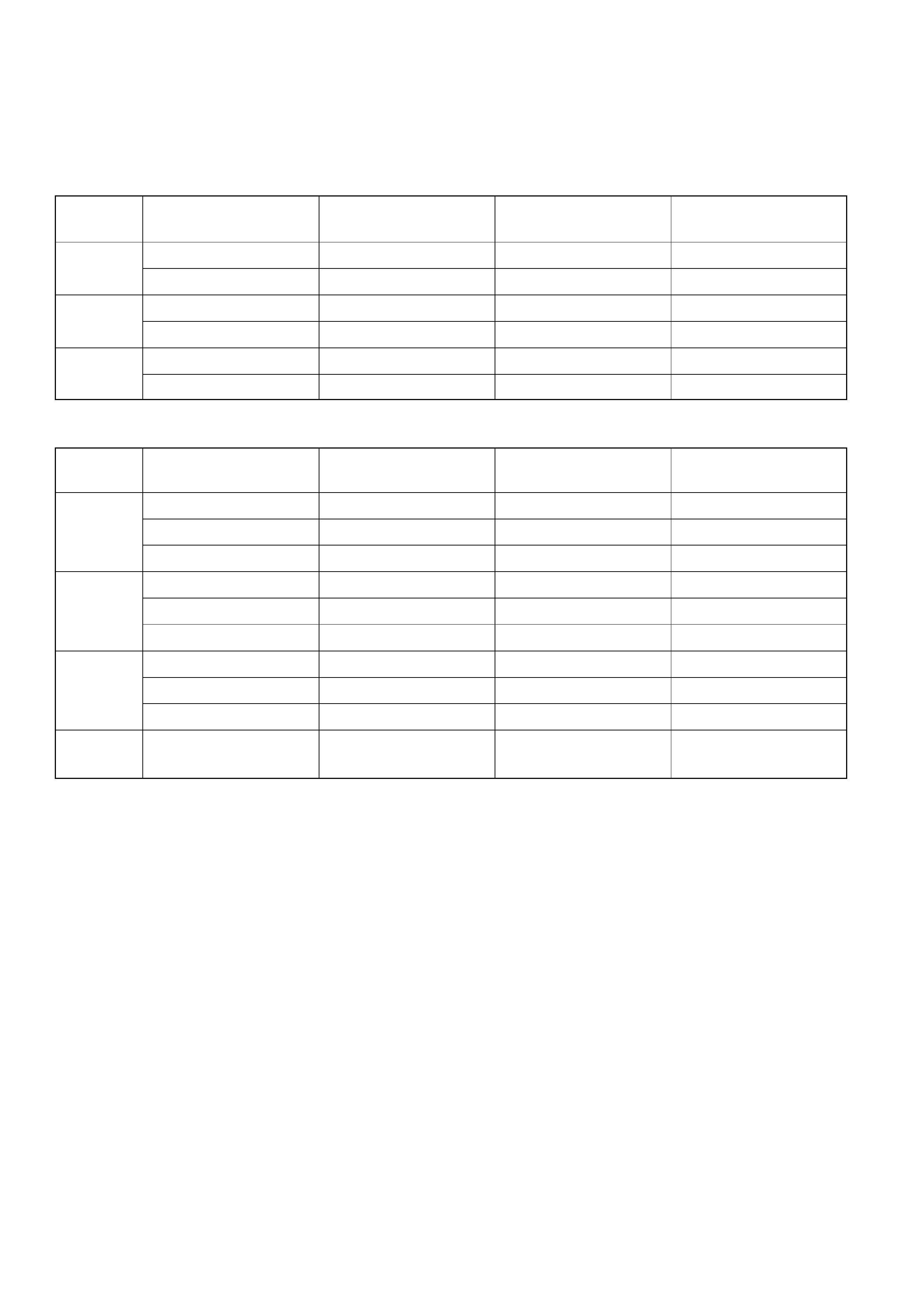

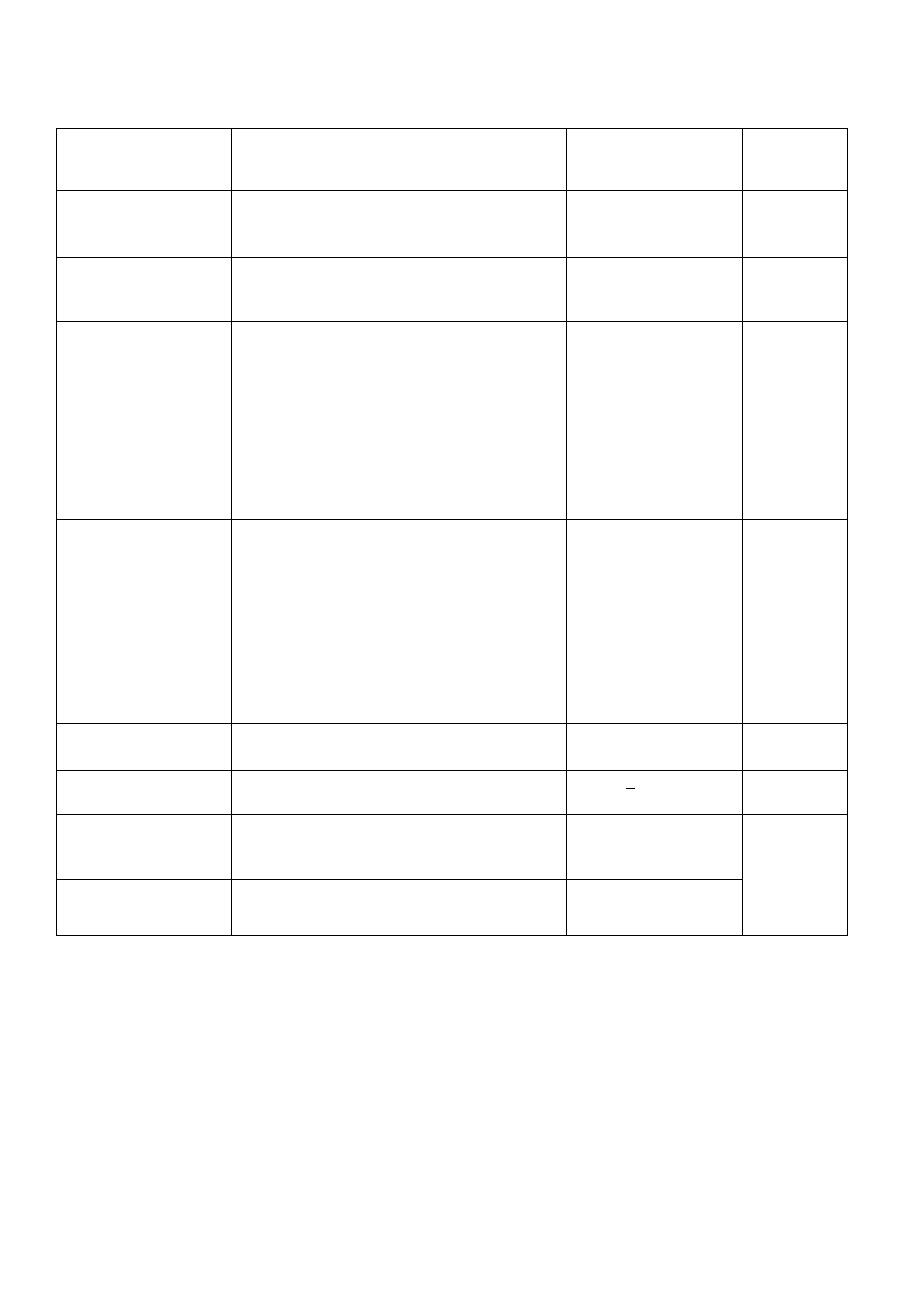

RANGE REFERENCE CHART

1-2/3-4

2-3 O/DRIVE OVERRUN FOURTH THIRD REVERSE SECOND PRINCIPLE BAND

RANGE GEAR SOL SOL ROLLER CLUTCH CLUTCH CLUTCH CLUTCH CLUTCH SPRAG

ASSEMBLY

ENGINE

N.C. N.O. CLUTCH (OC) (C4) (C3) (RC) (C2)

ASSEMBLY

(B) BRAKING

(OFW) (PFW)

P-N OFF ON APPLIED NO

RREVERSE OFF ON LD APPLIED APPLIED LD NO

1ST OFF ON LD APPLIED LD APPLIED NO

2ND ON ON LD APPLIED APPLIED FW APPLIED YES

D3RD ON OFF LD APPLIED APPLIED APPLIED NE YES

4TH OFF OFF FW APPLIED APPLIED APPLIED NE YES

1ST OFF ON LD APPLIED LD APPLIED NO

32ND ON ON LD APPLIED APPLIED FW APPLIED YES

3RD ON OFF LD APPLIED APPLIED APPLIED NE YES

1ST OFF ON LD APPLIED APPLIED LD APPLIED YES

22ND ON ON LD APPLIED APPLIED FW APPLIED YES

L1ST OFF ON LD APPLIED APPLIED LD APPLIED YES

LD : LOCKED IN DRIVE FW : FREEWHEELING NE : NOT EFFECTIVE

C07RT010

NORMAL OPERATION OF 4L30-E

TRANSMISSION

1. TORQUE CONVERTER CLUTCH (TCC)

APPLICATION CONDITIONS:

The TCC is normally applied in 2nd, 3rd and 4th

gears only when all of the following conditions

exist:

ÐThe engine coolant temperature is above 70º C

(158ºF).

Ð The brake pedal is released.

Ð The shift pattern requests TCC apply.

Moreover, TCC is always applied in 2nd, 3rd and

4th gears when the transmission oil temperature is

above 135º C (275º F).

This mode should be canceled at 125ºC (257ºF).

2. SPECIAL SHIFT P ATTERN WHEN THE

ENGINE IS COLD:

The TCM inhibits TCC apply and delays transmission

upshifts until engine coolant temperature rises above

70ºC.

DIAGNOSIS

INTRODUCTION

The systematic trouble shooting information covered by this Section offers a practical and systematic

approach to diagnosing 4L30-E transmission, using information that can be obtained from road tests,

electrical diagnosis, oil pressure checks or noise evaluation.

The key to correcting a complaint is to make use of all of the available symptoms and logically letting them

direct you to the cause.

When dealing with automatic transmission complaints, it is best to gather as many symptoms as possible

before making the decision to remove the transmission from the vehicle.

Frequently, the correction of the cause of the complaint does not require removal of the transmission from

the vehicle.

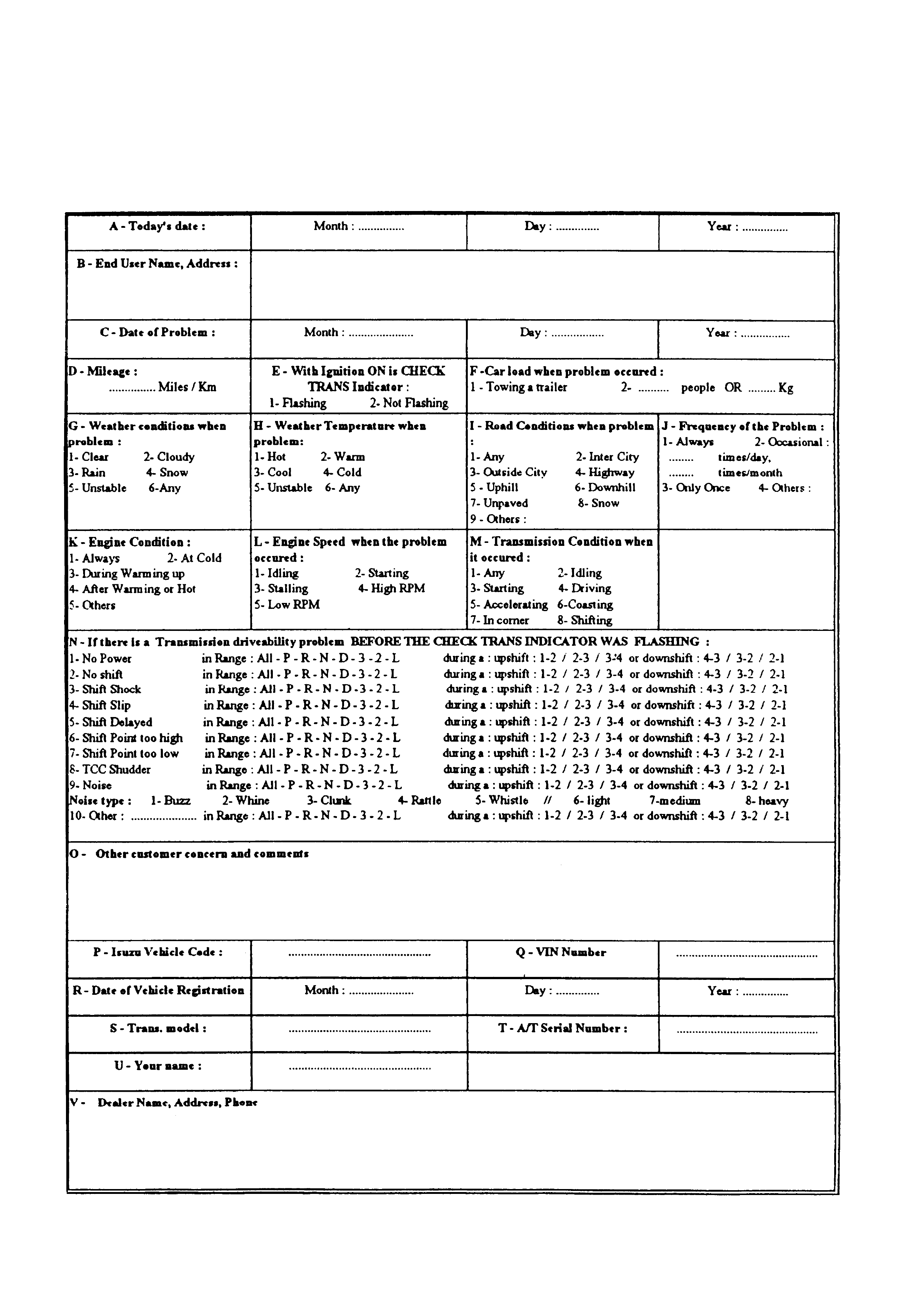

DRIVER INFORMATION

To analyze the problem fill a complete description of the owner’s complaint.

Please draw a circle around the right information and complete the following form. (Find next page an

example of form completed). You can draw a circle around many numbers if you are not sure.

Example of form completed.

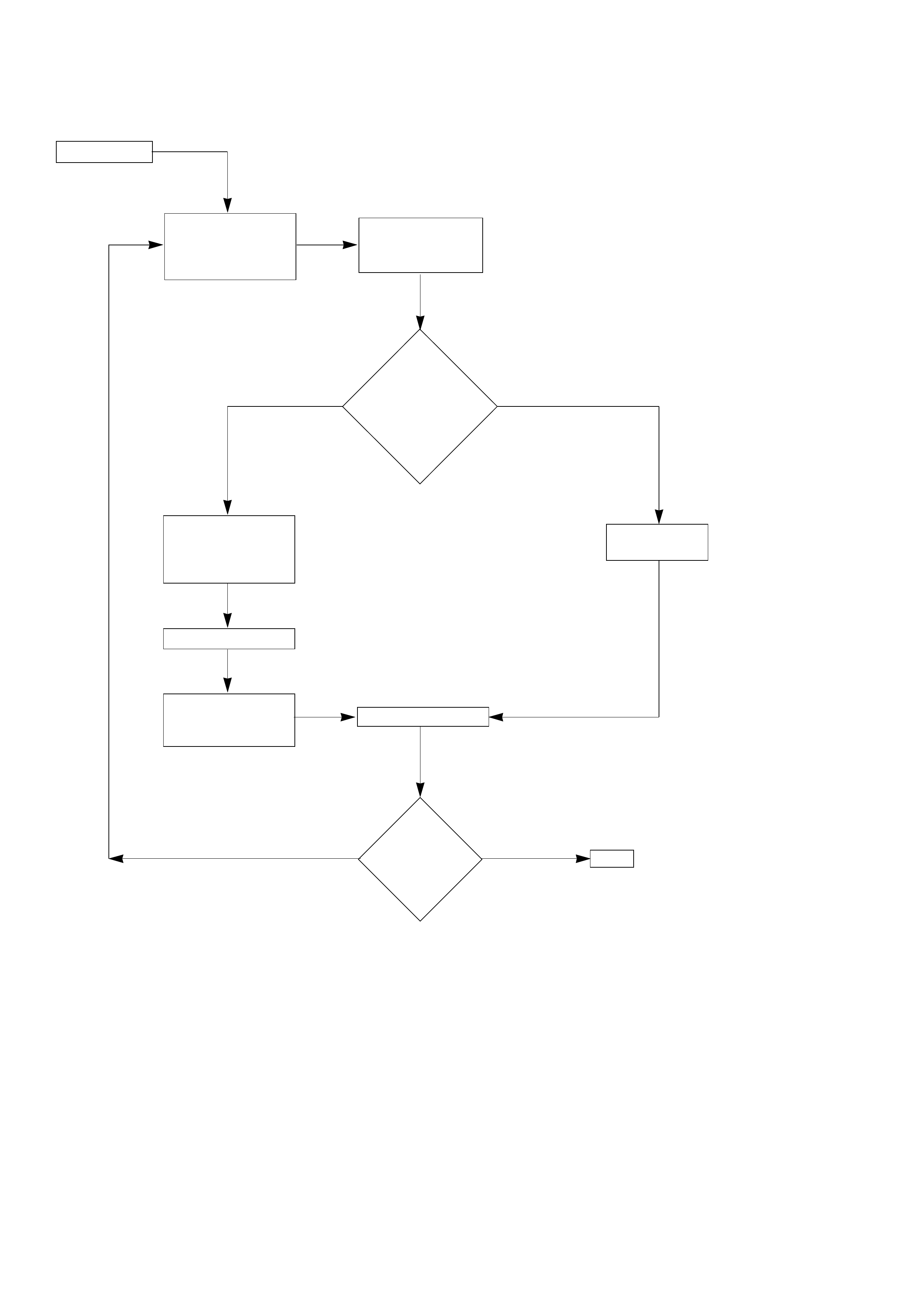

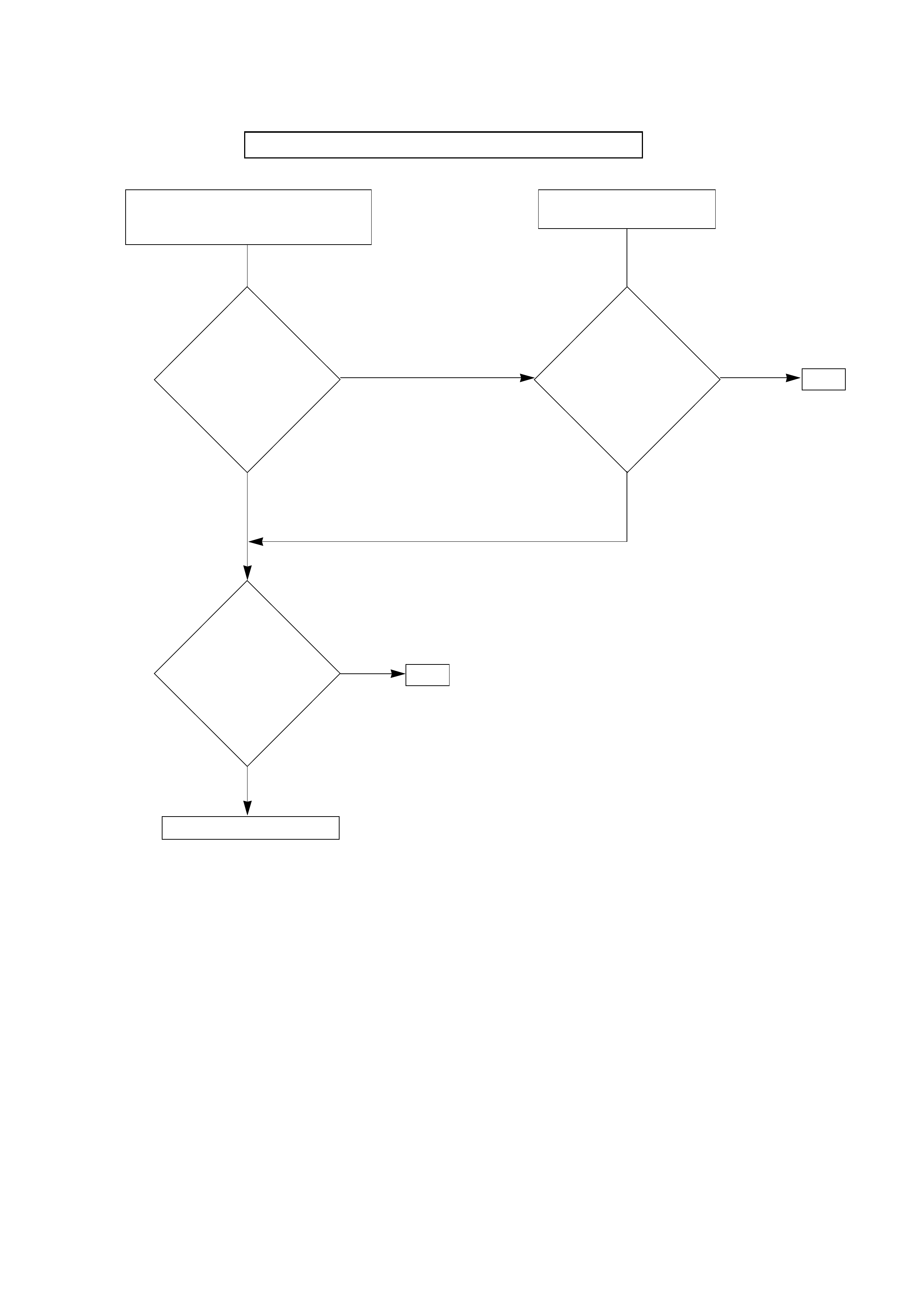

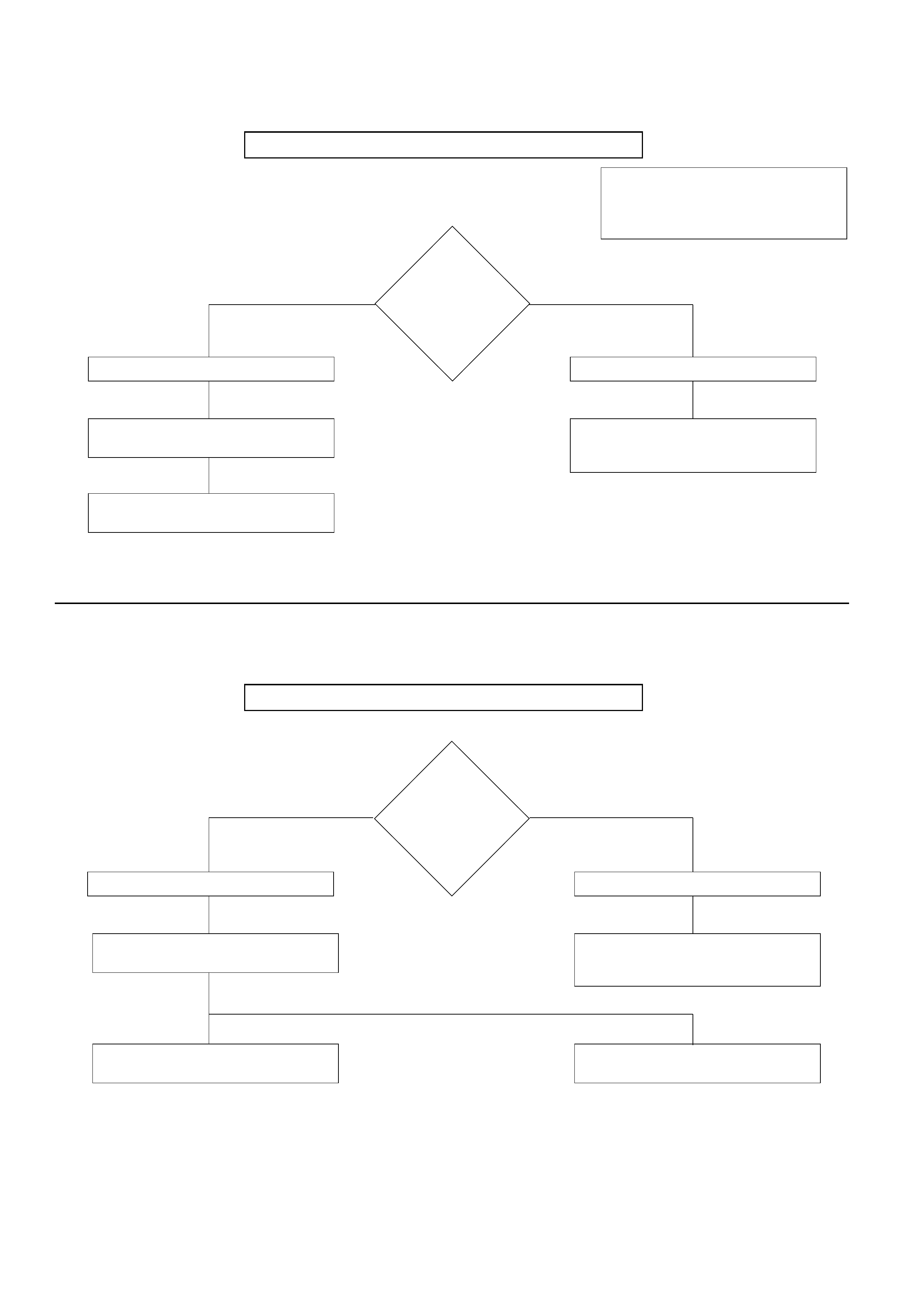

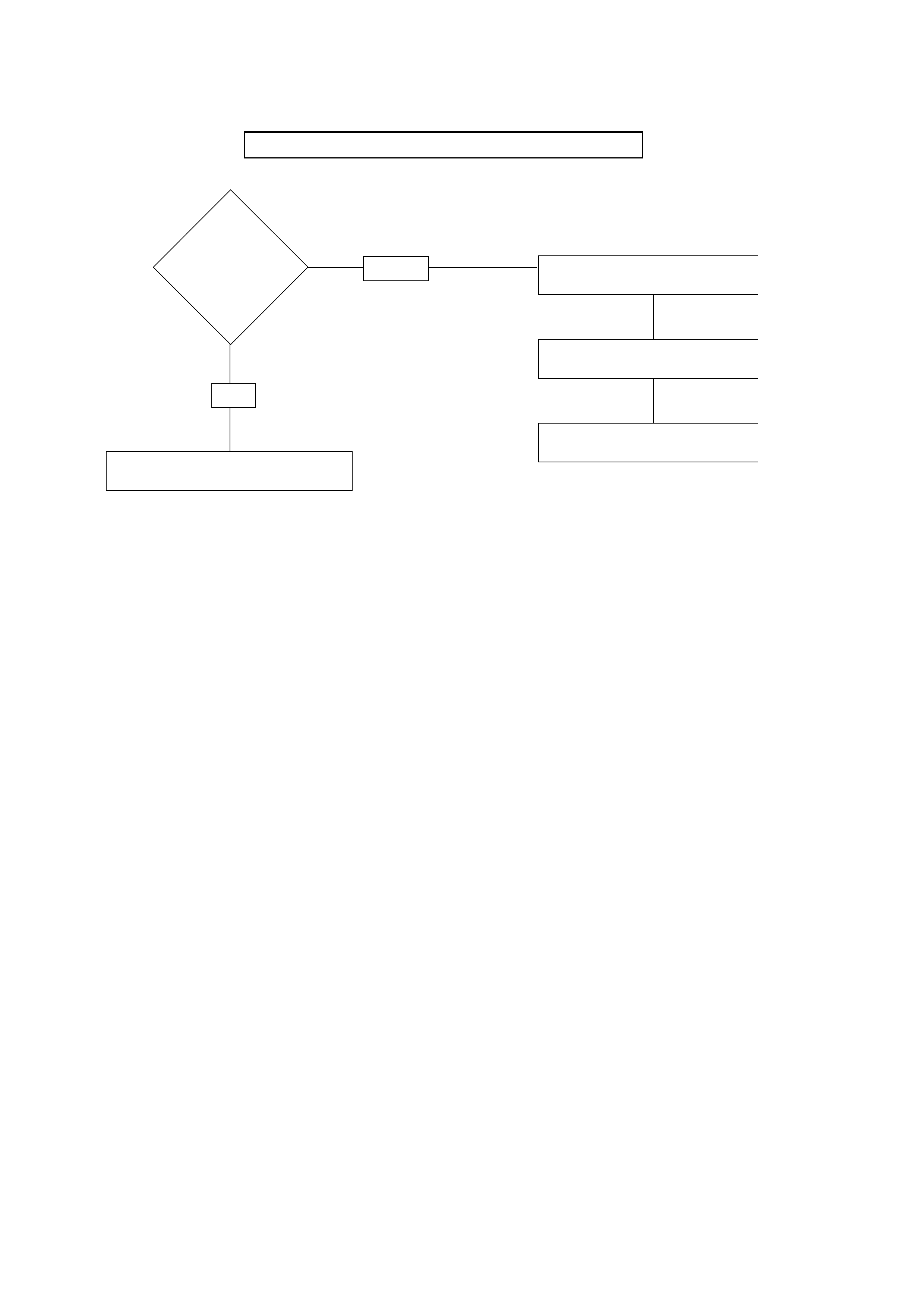

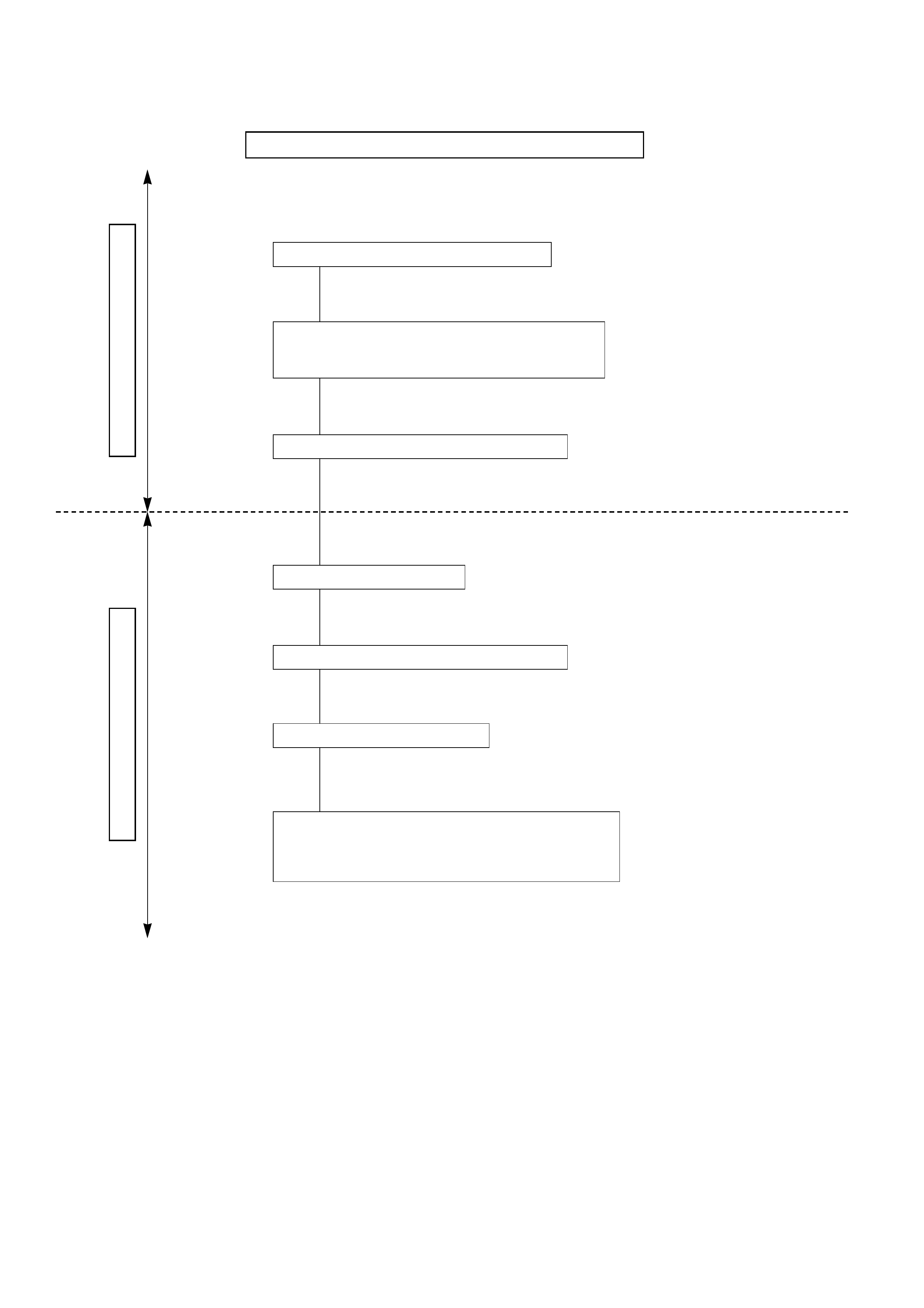

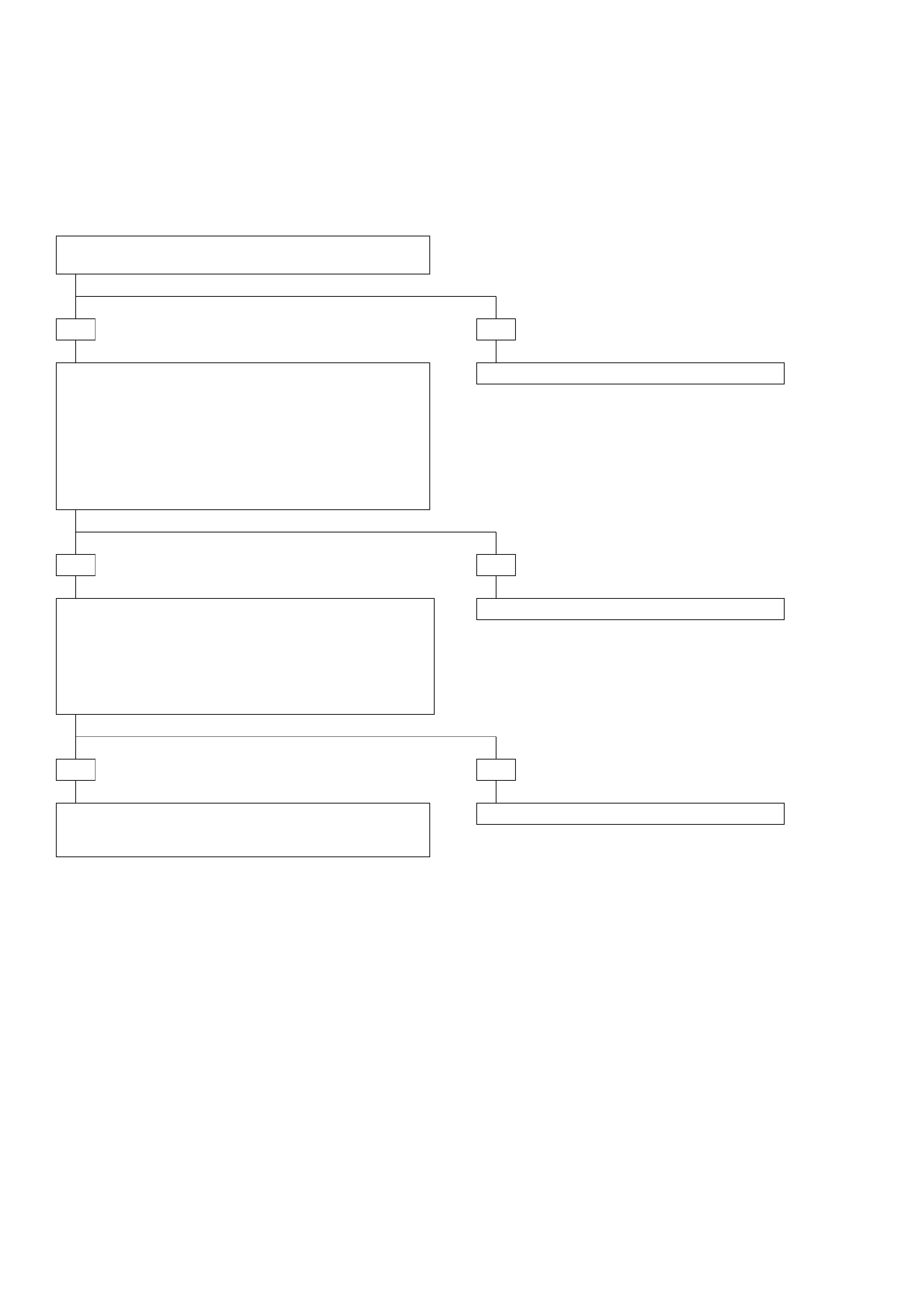

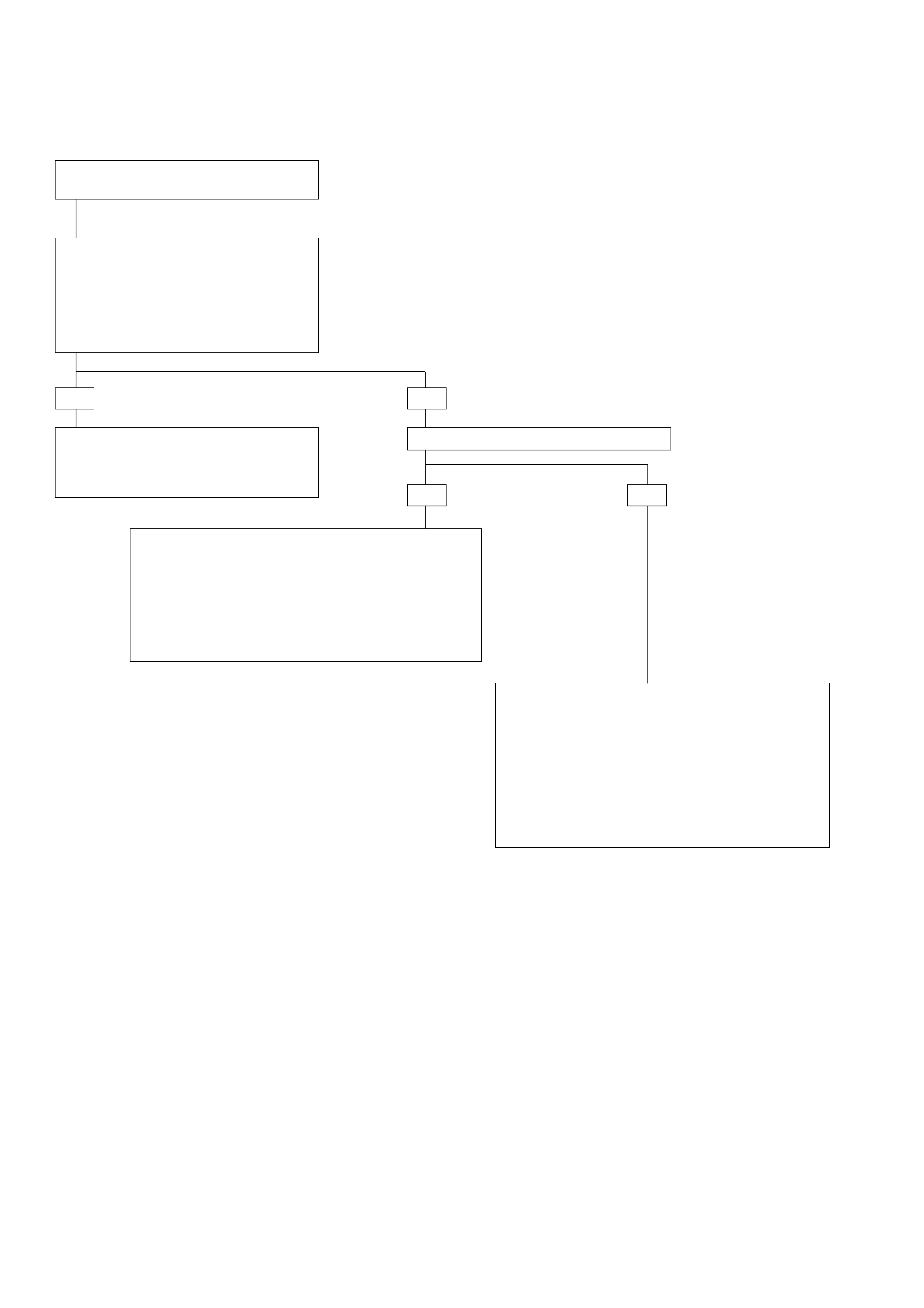

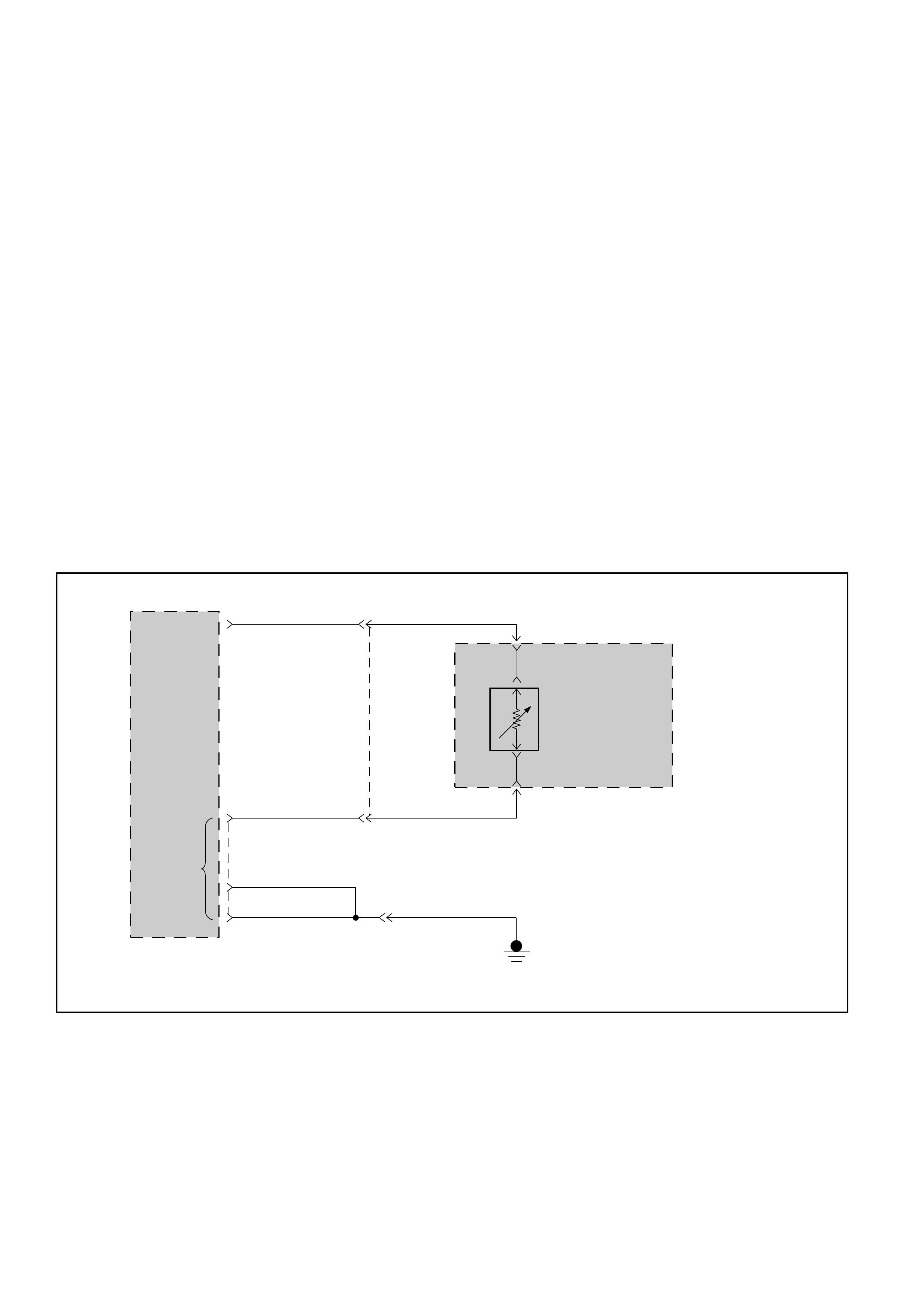

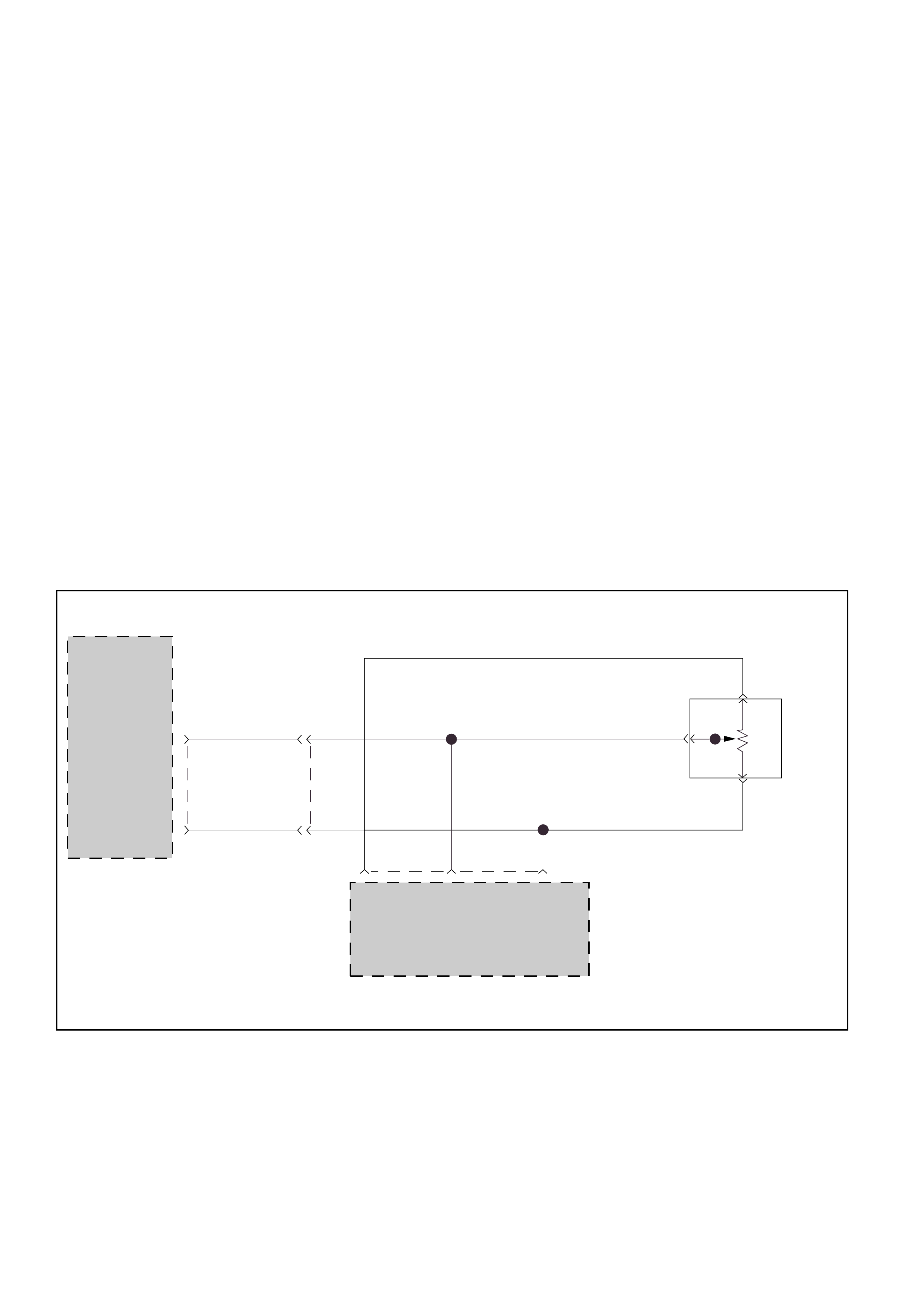

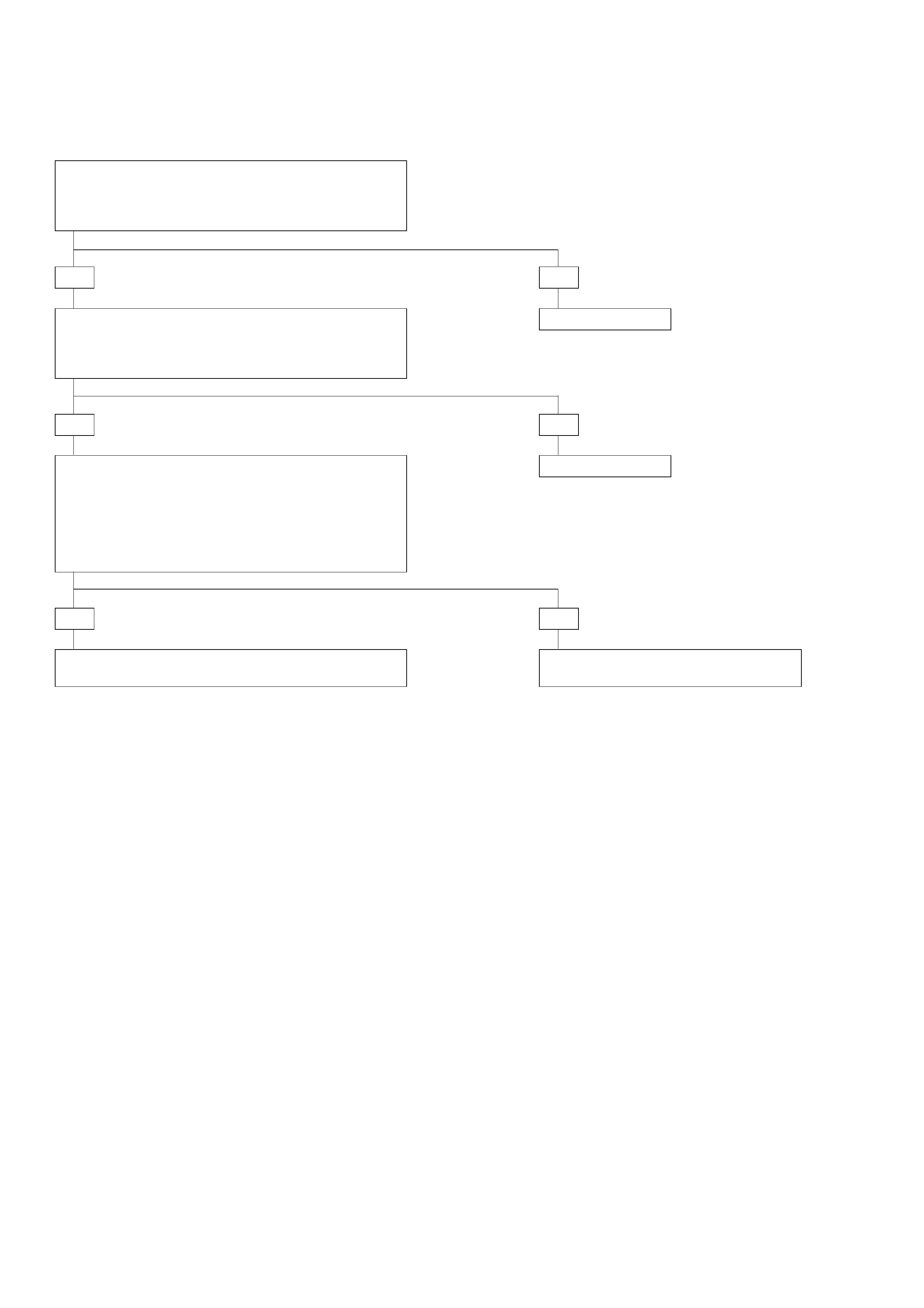

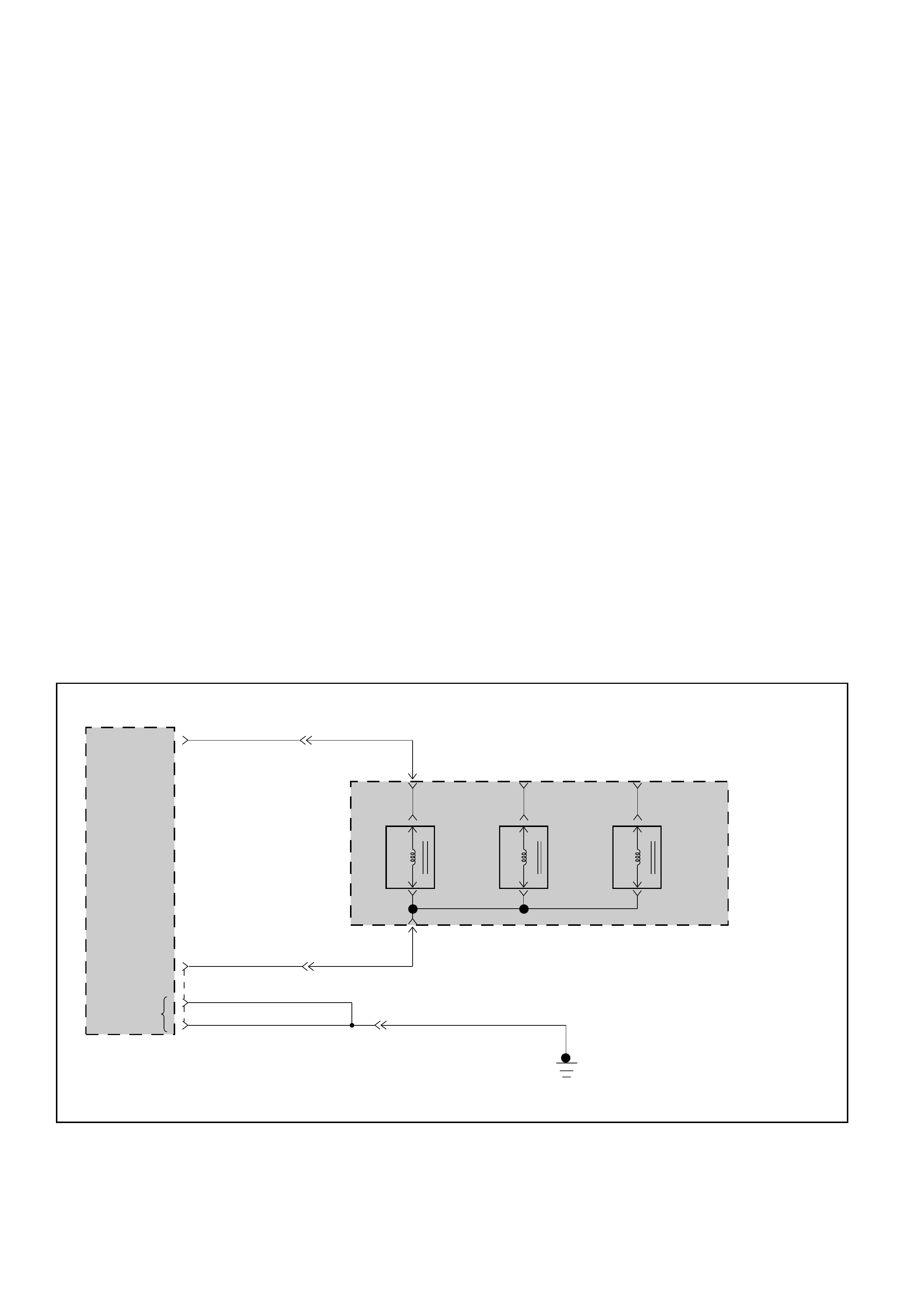

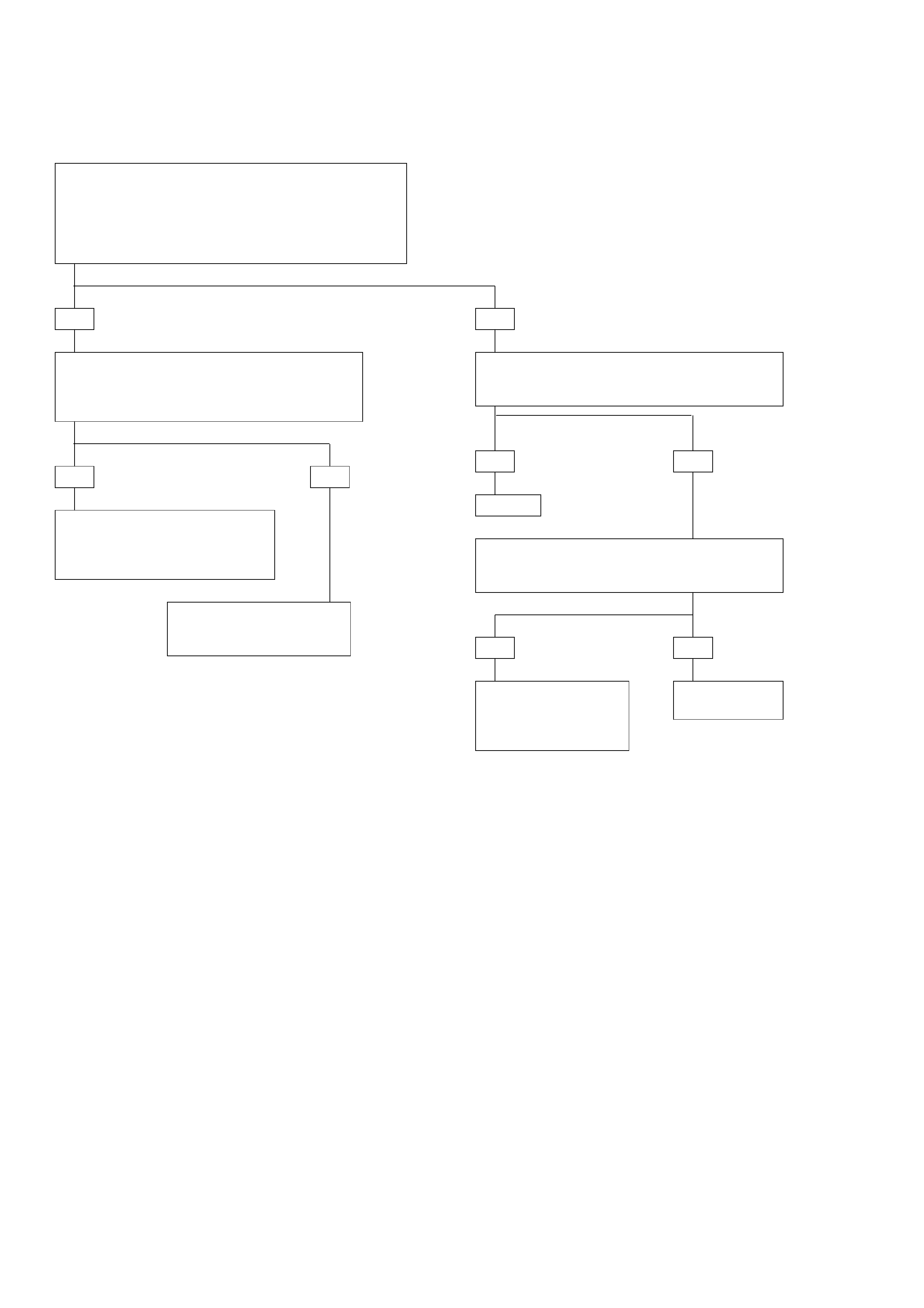

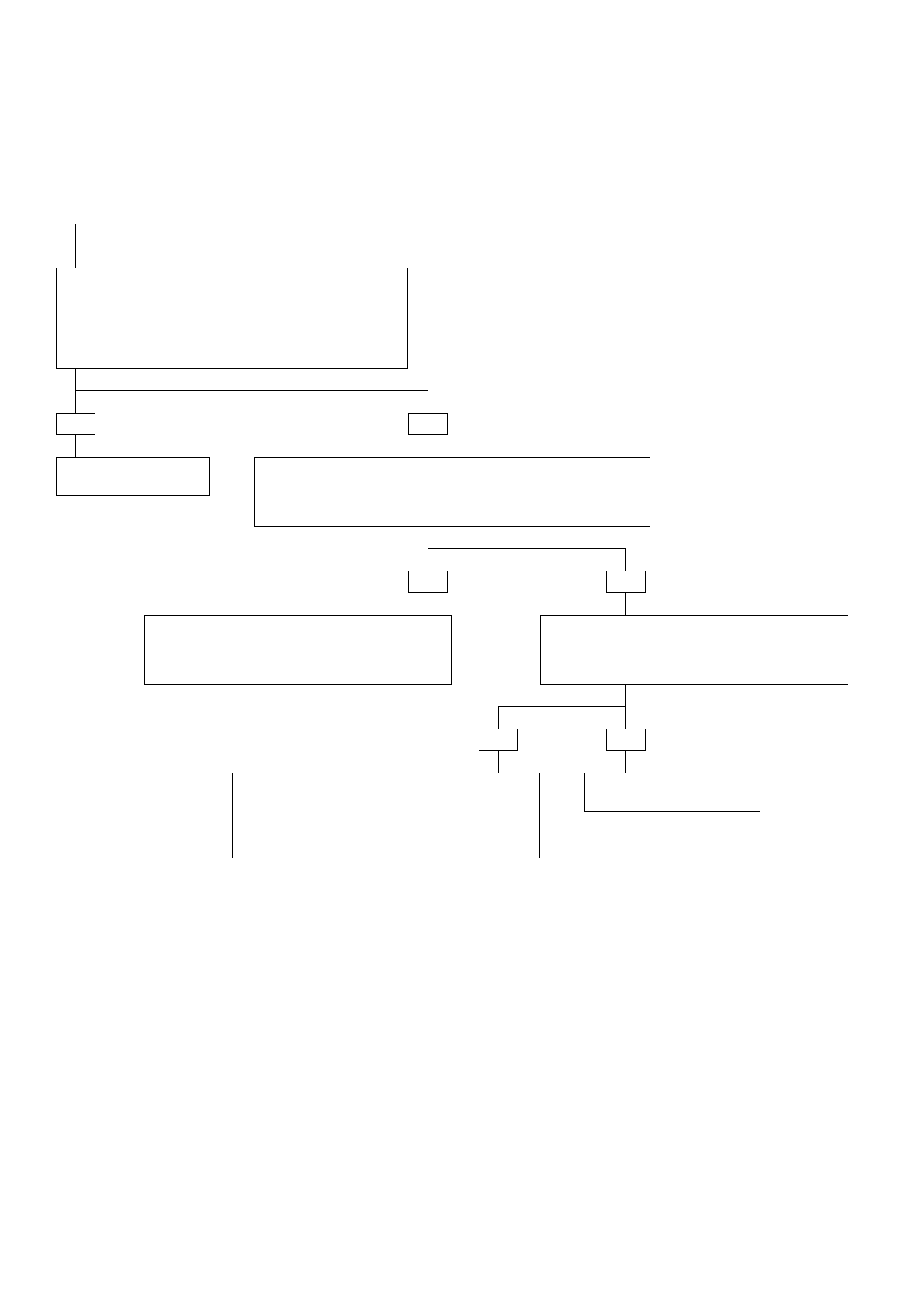

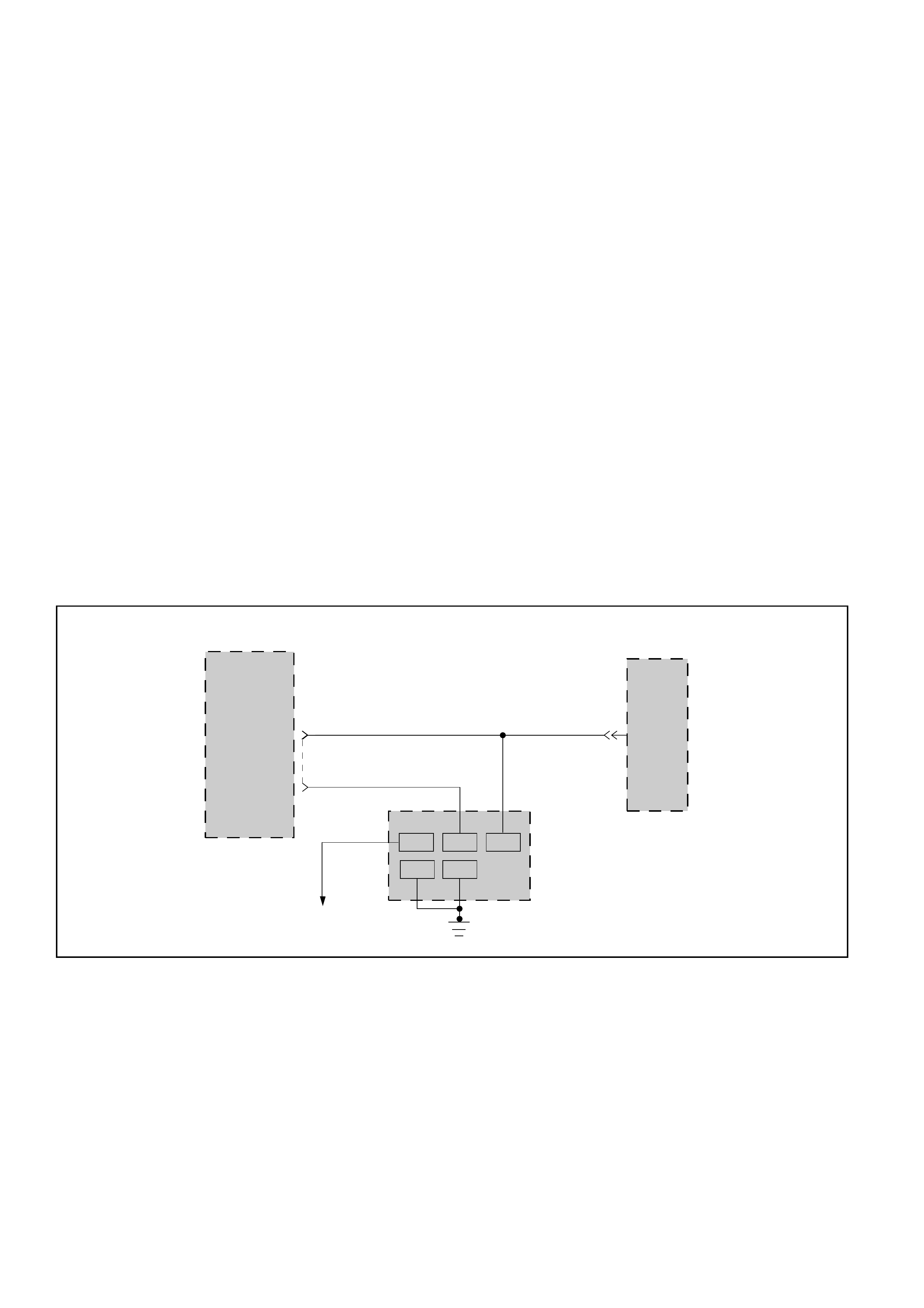

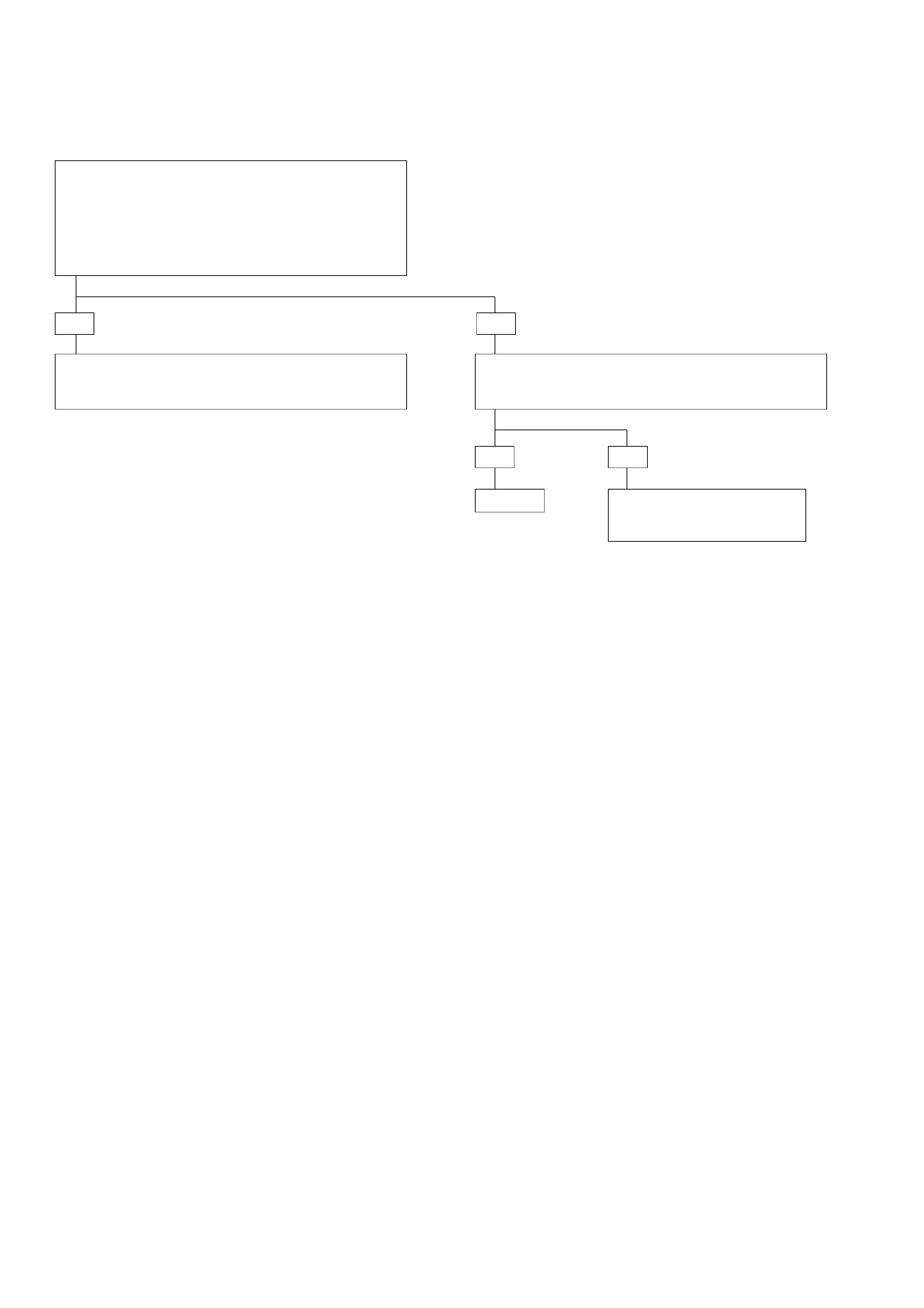

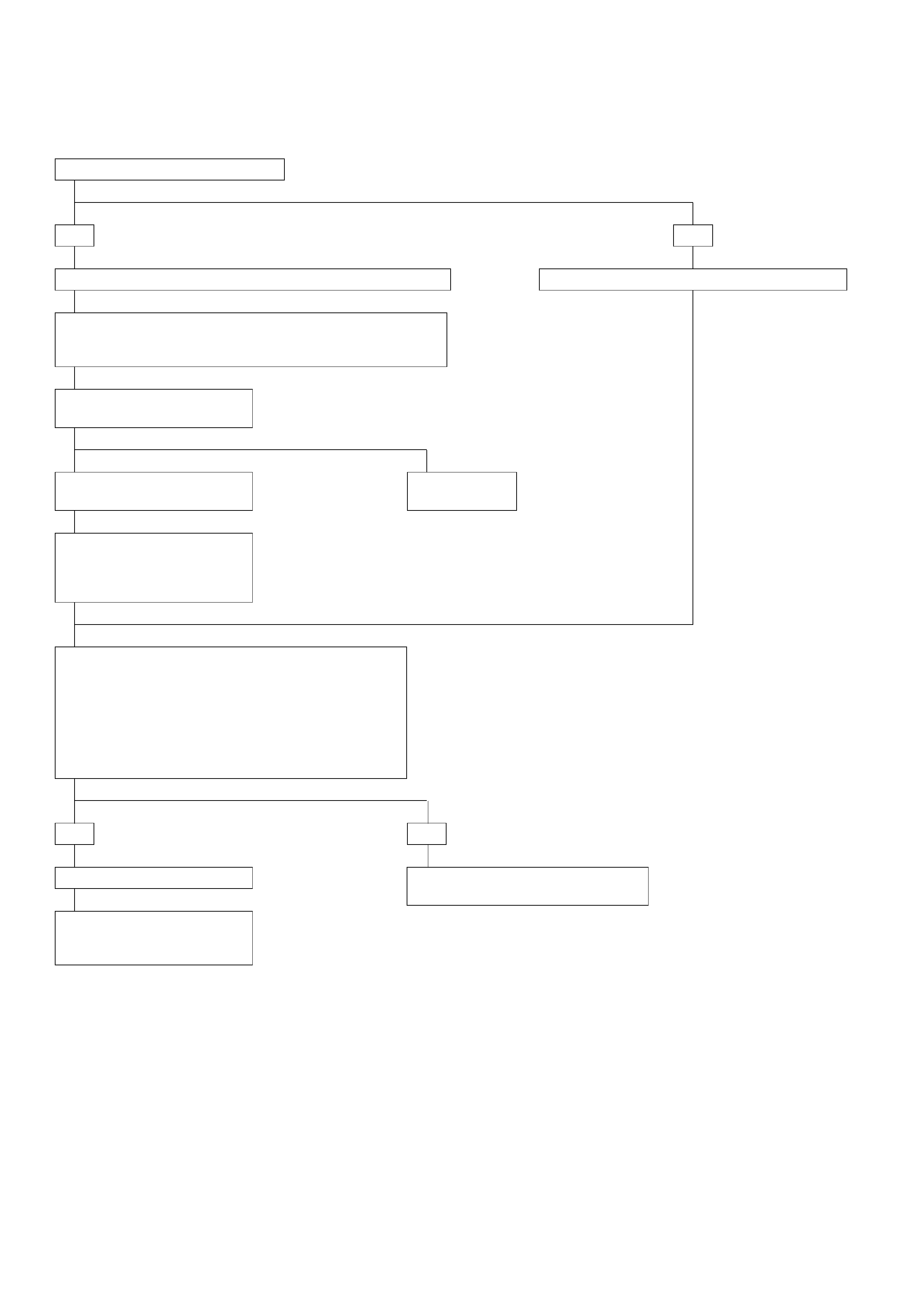

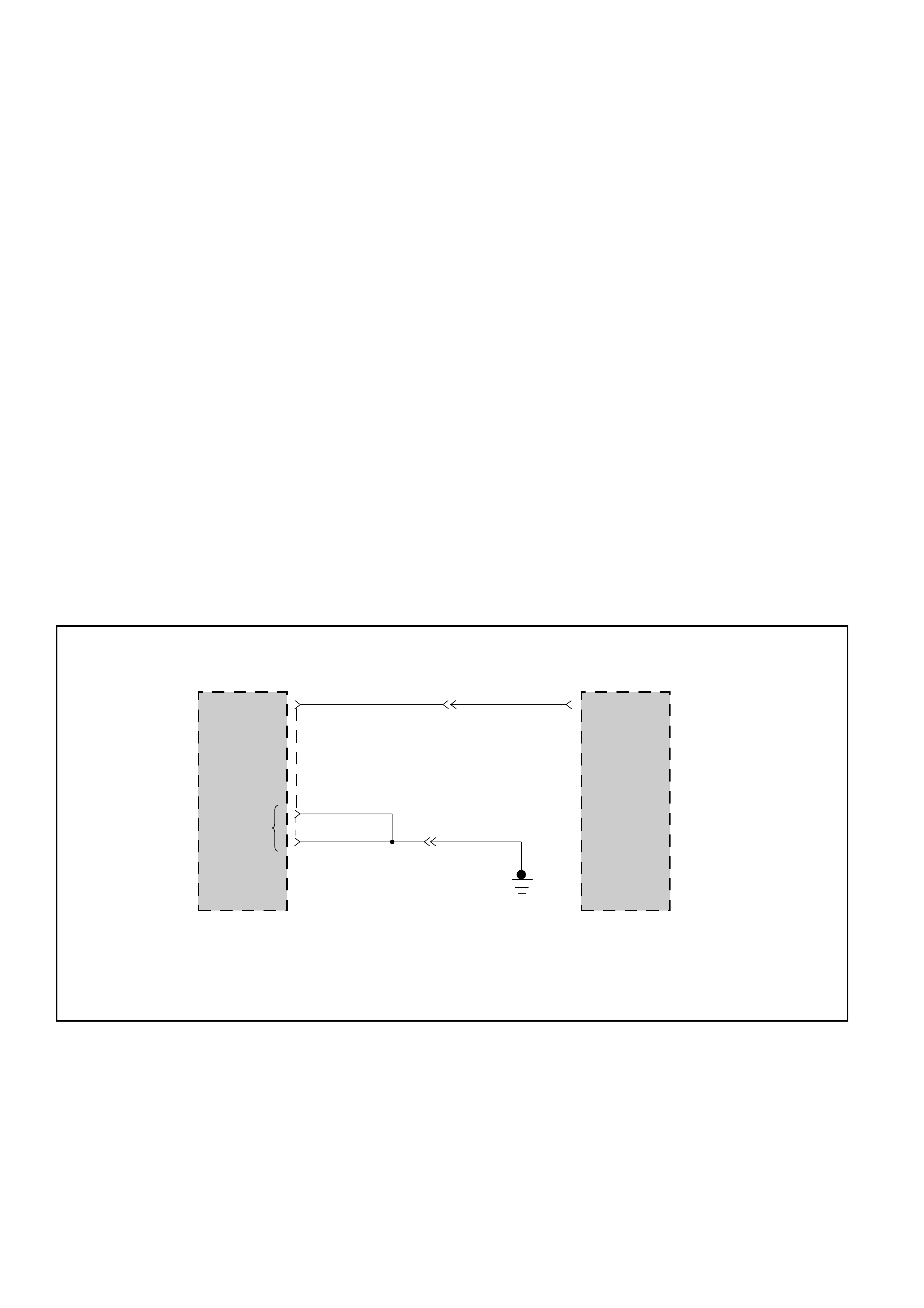

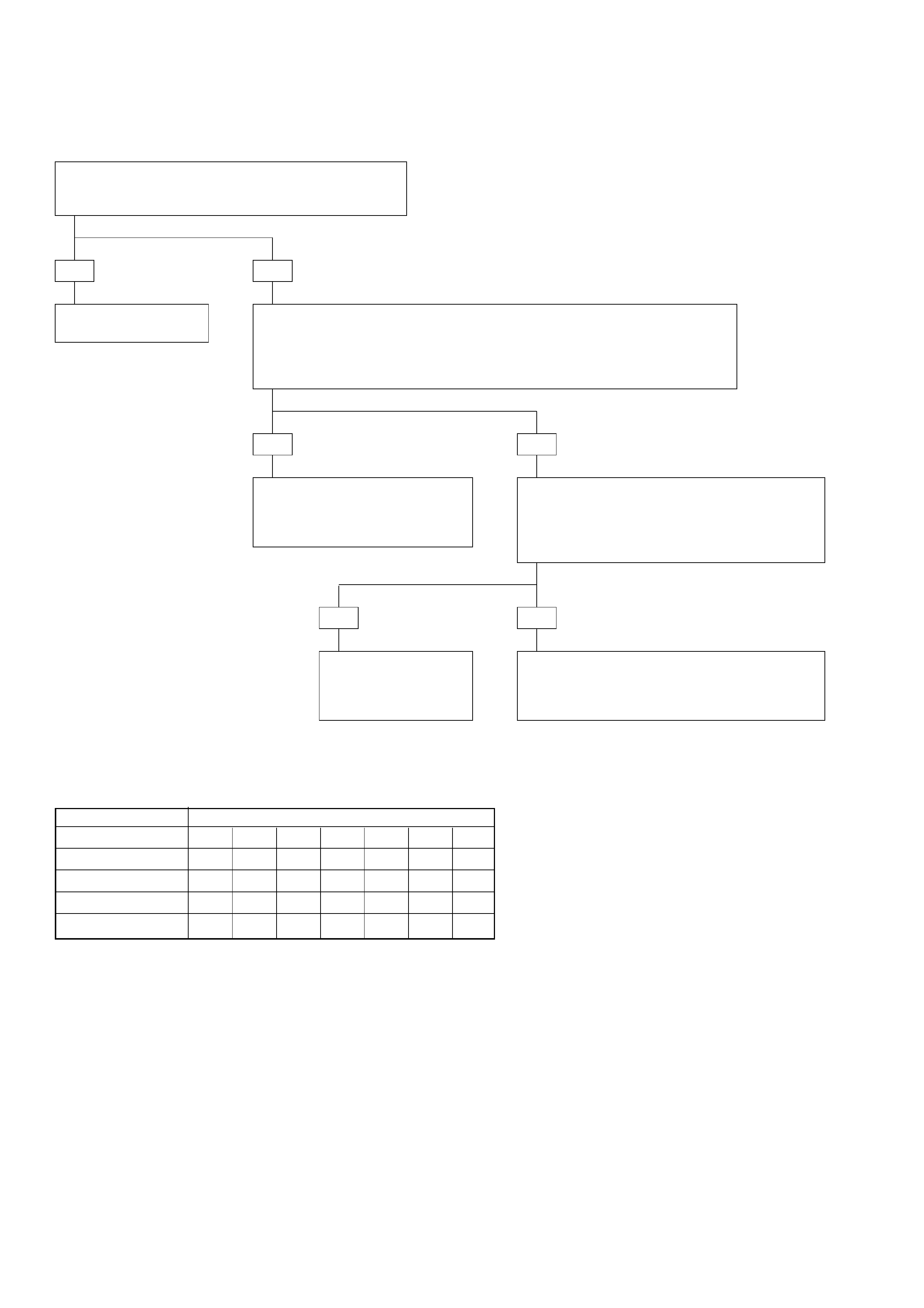

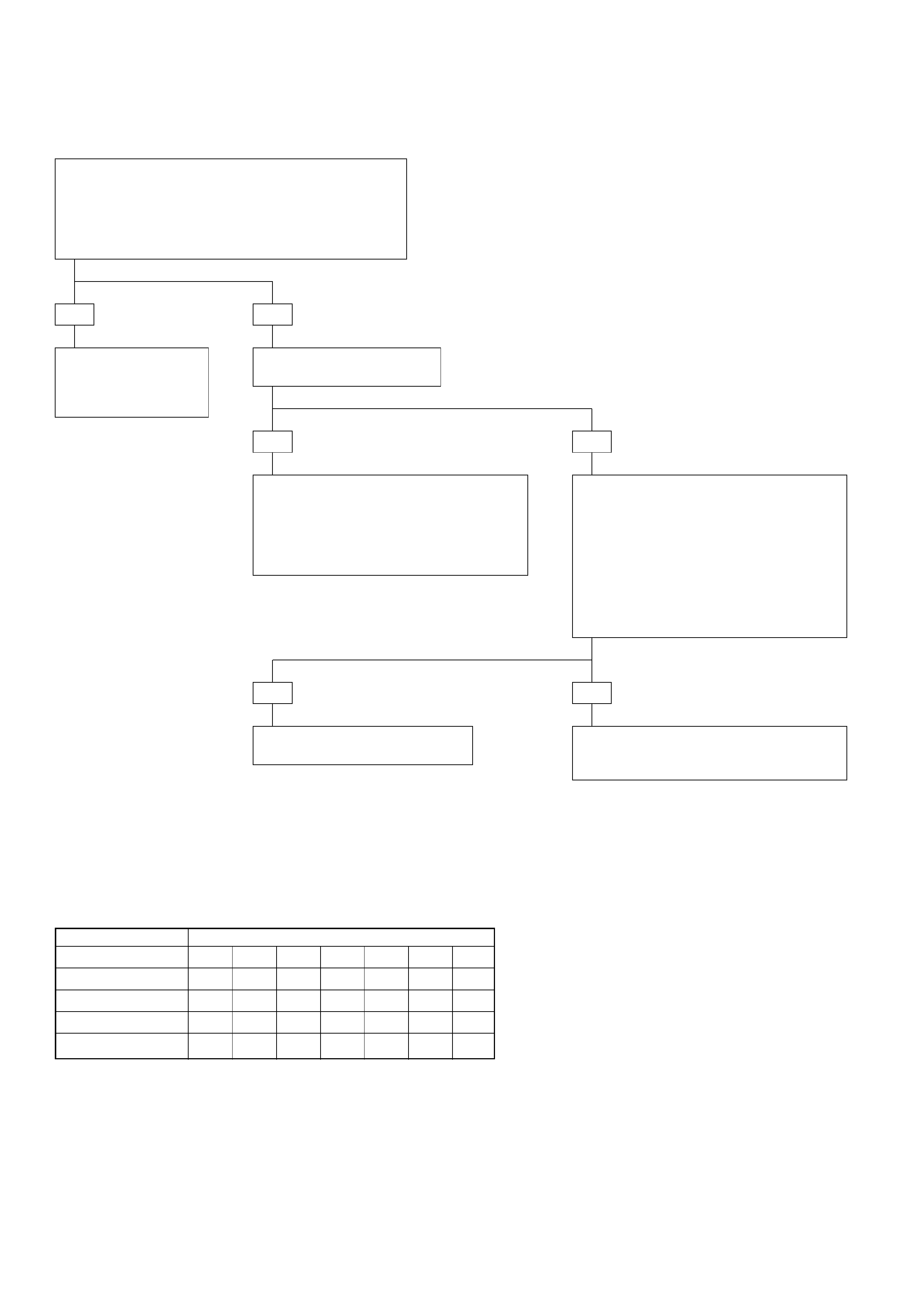

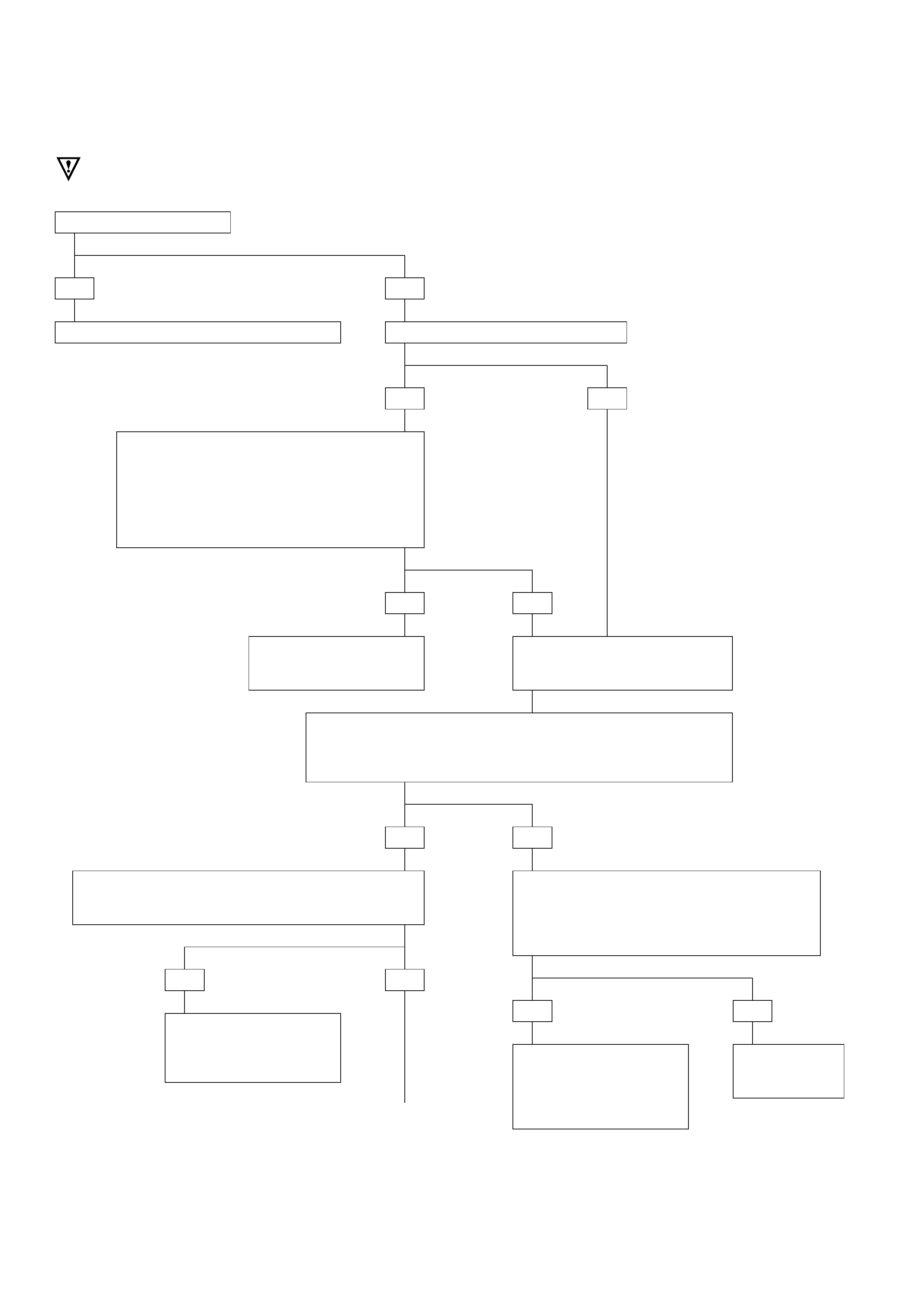

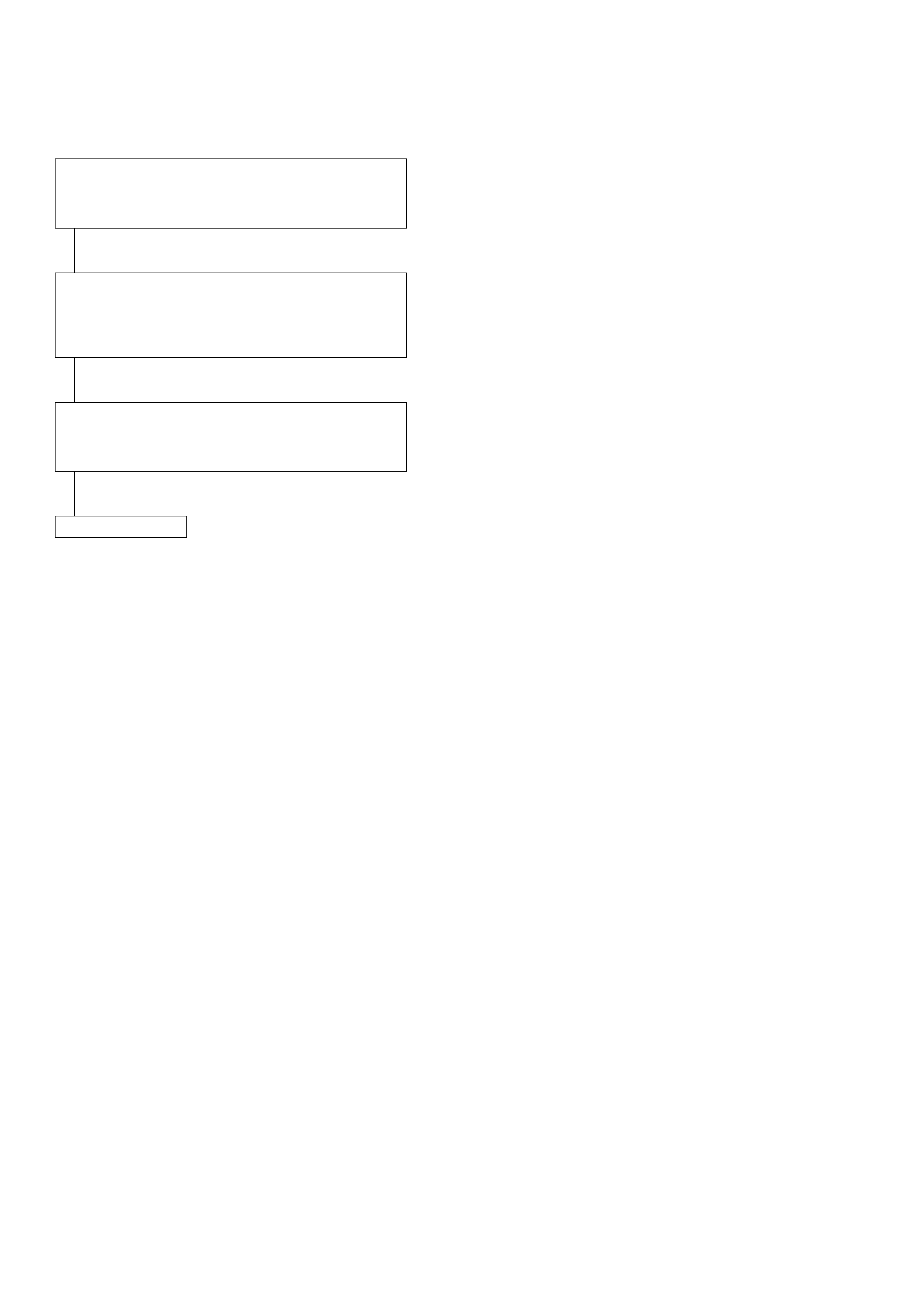

GENERAL DIAGNOSIS PROCEDURE

END

Complaint

Follow

PRELIMINARY

INSPECTION

CHART

Remove trans-

mission assembly

and repair/replace

as required

Reinstall

transmission

assembly TEST DRIVING

Flush cooler lines

Perform repair

per

SYMPTOMS CHART

Replace

component

Can

fault

be corrected

by on-car

component

replacement?

Problem

fixed?

NO

NO

YES

YES

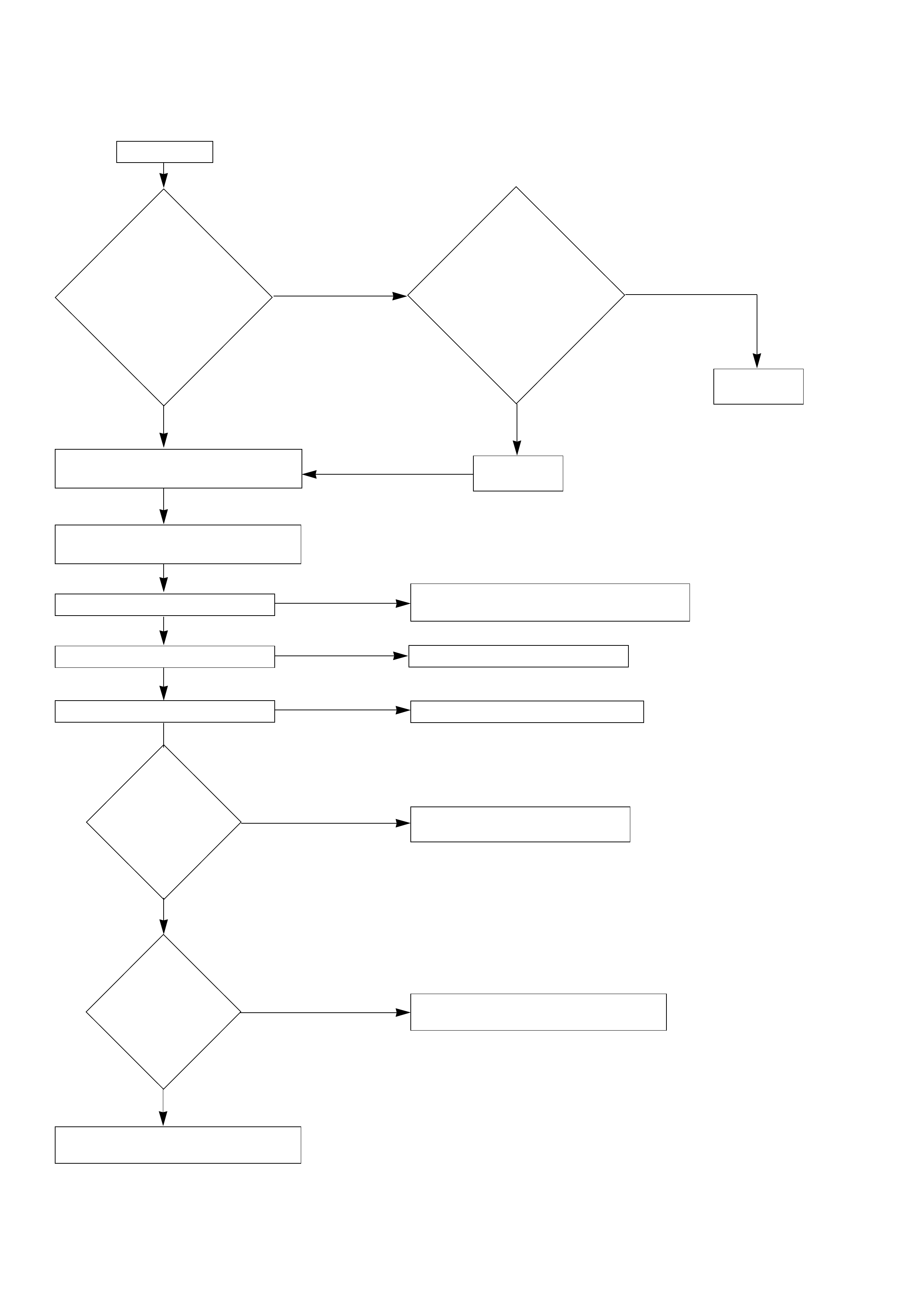

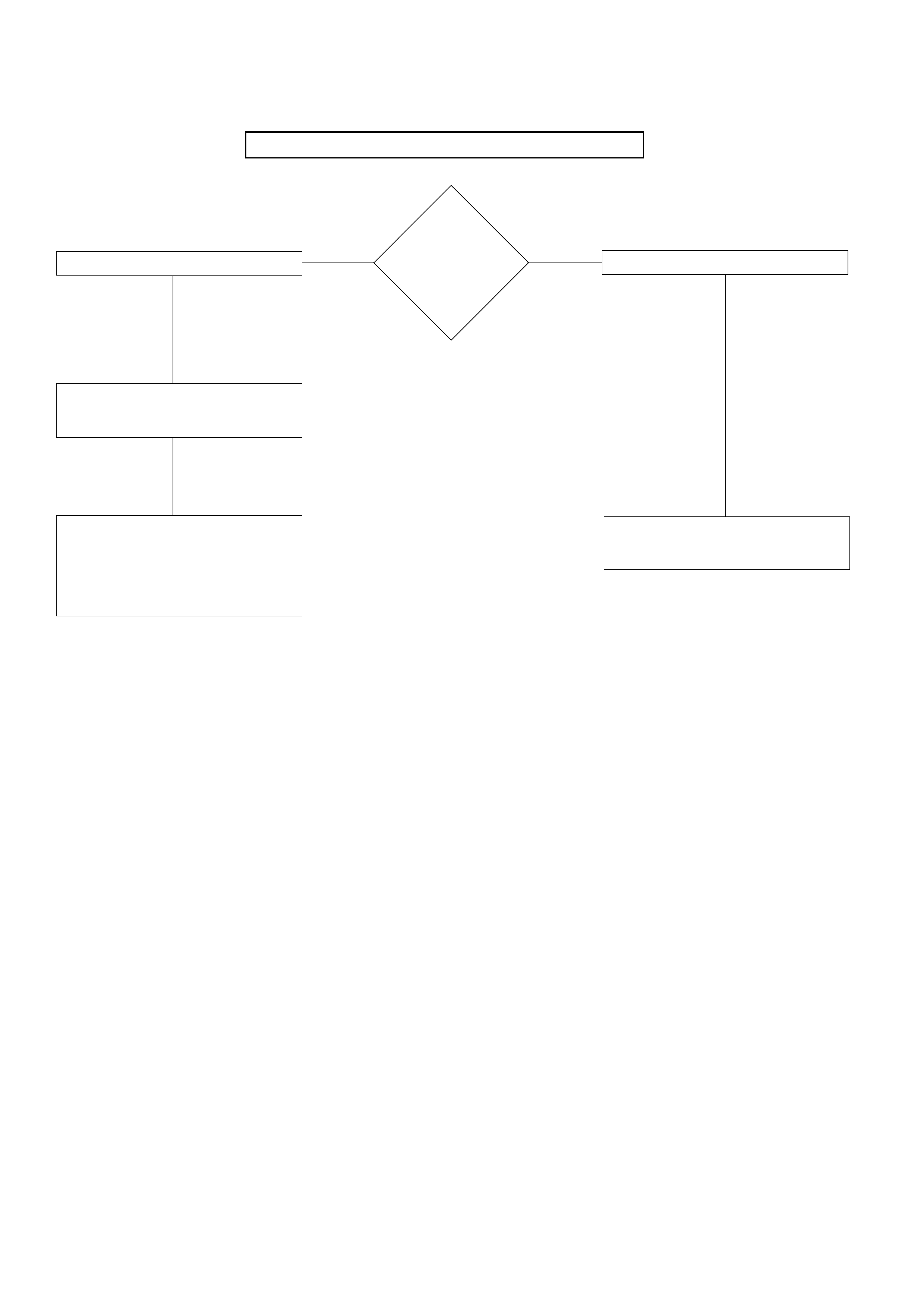

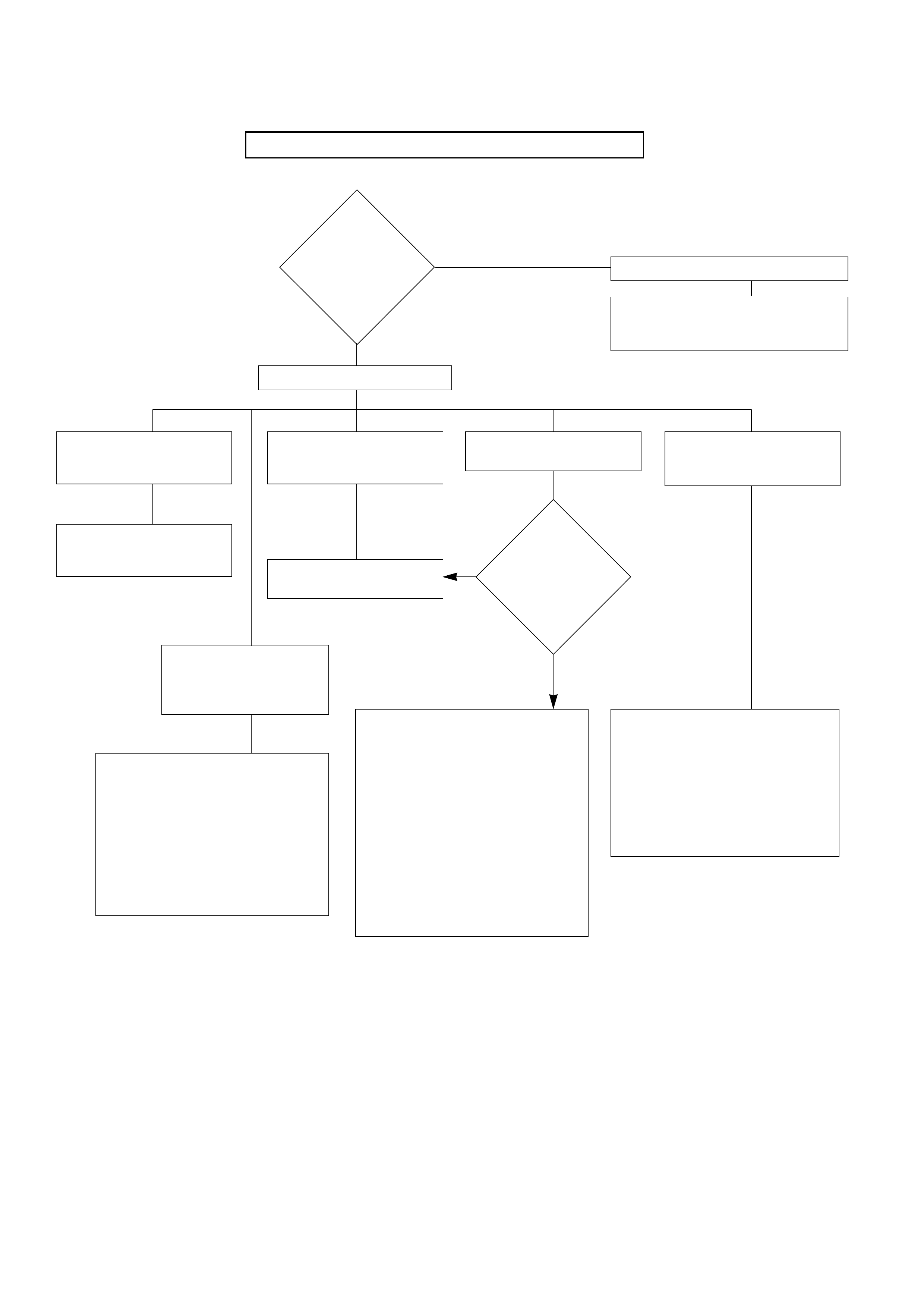

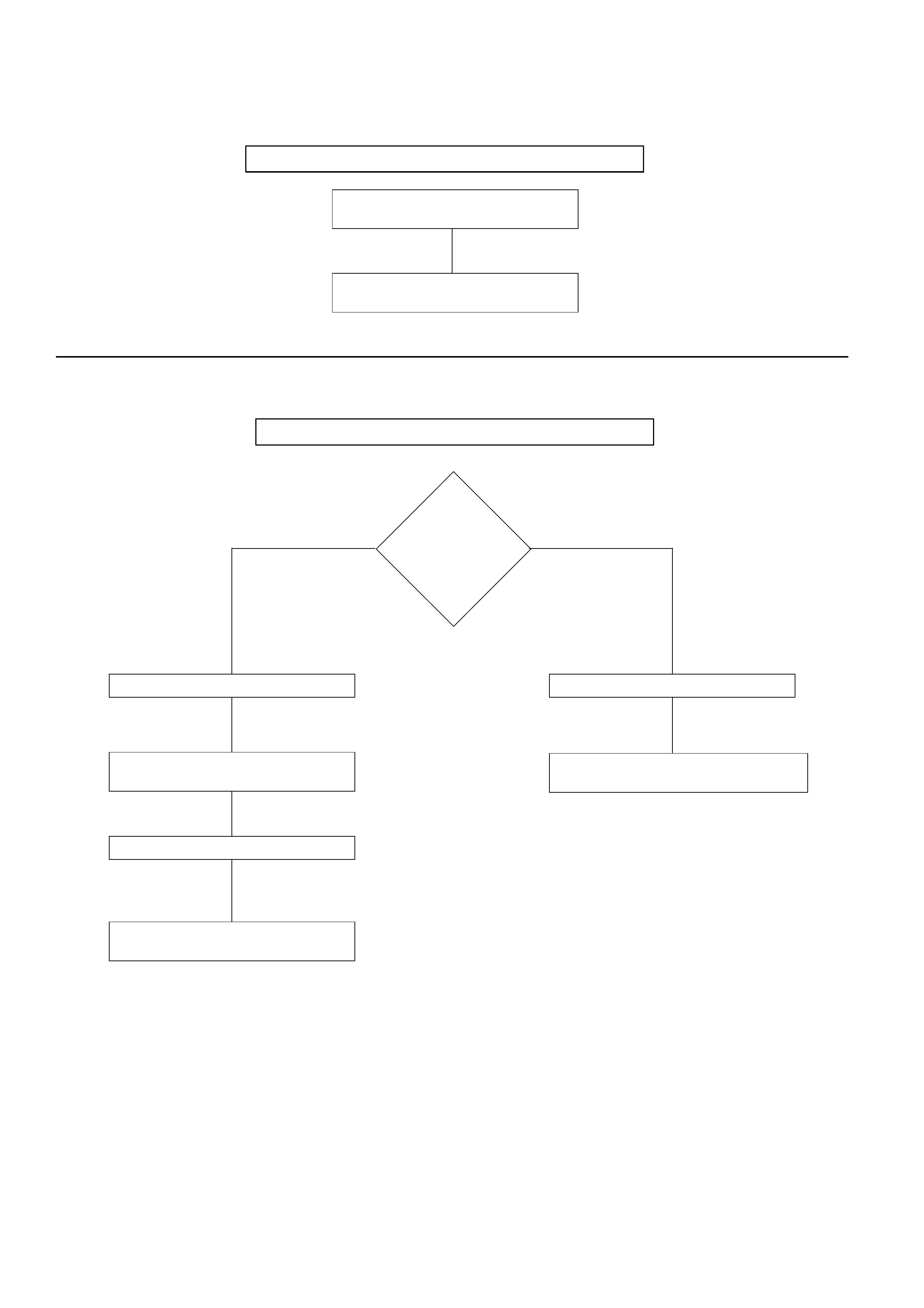

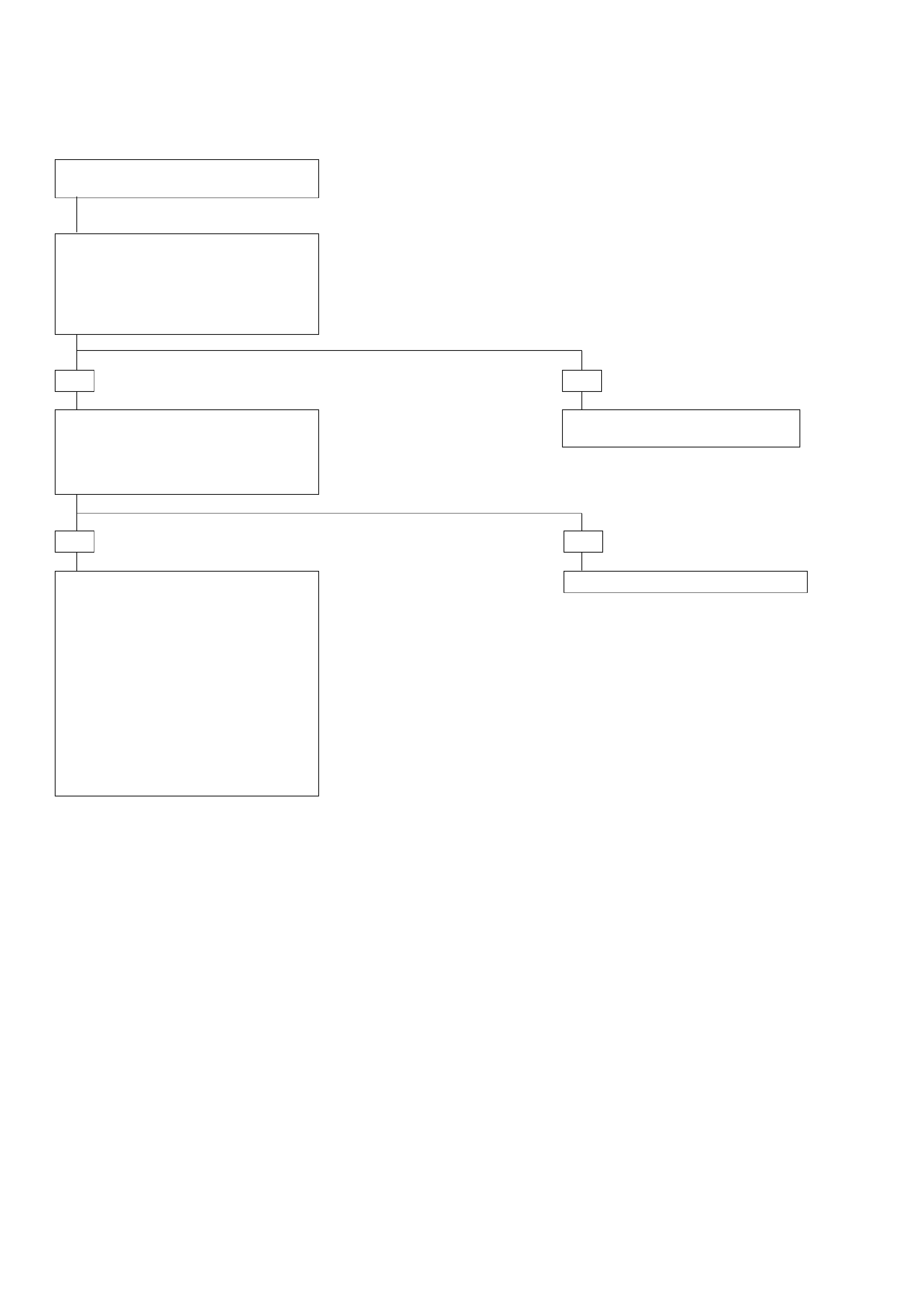

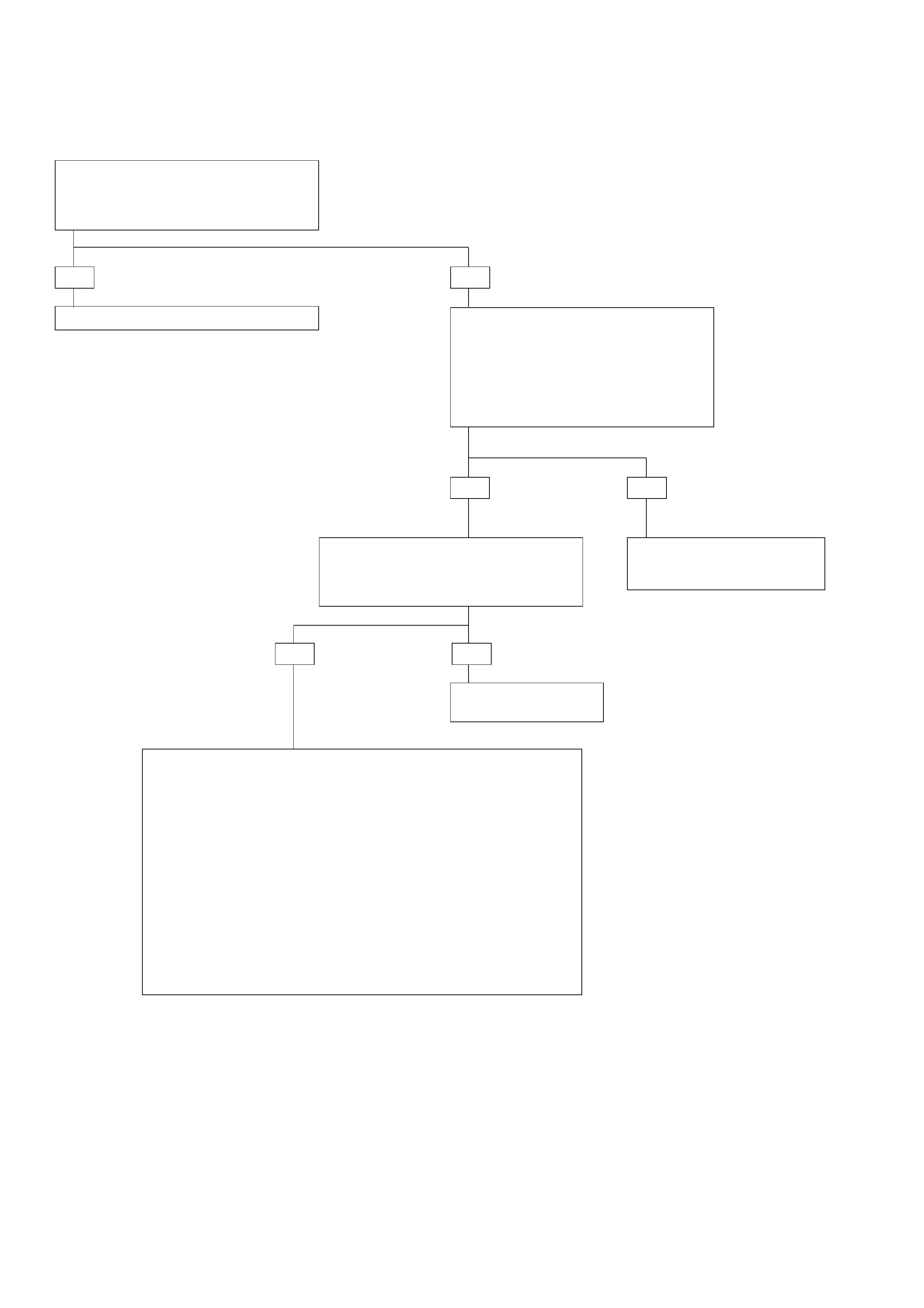

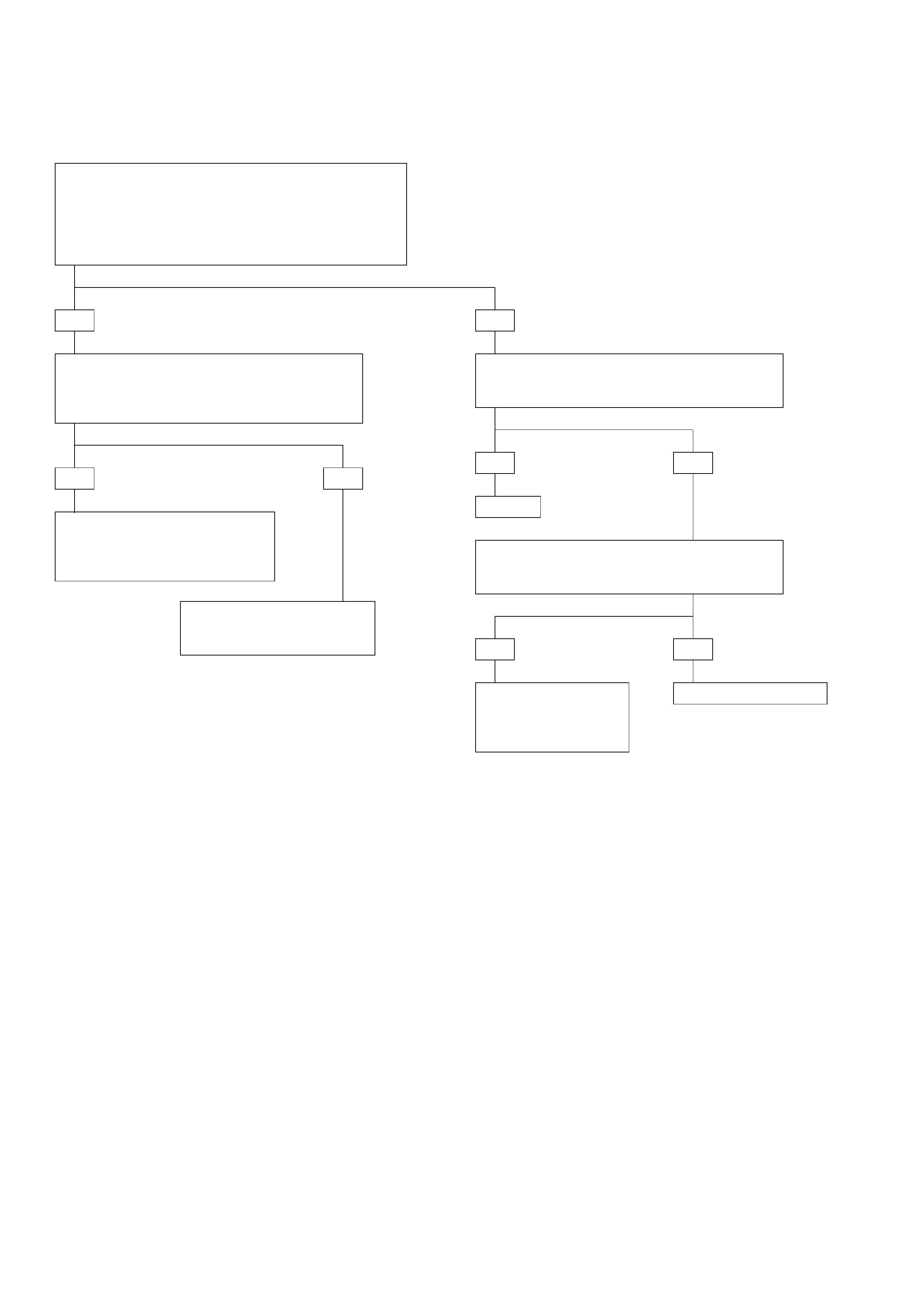

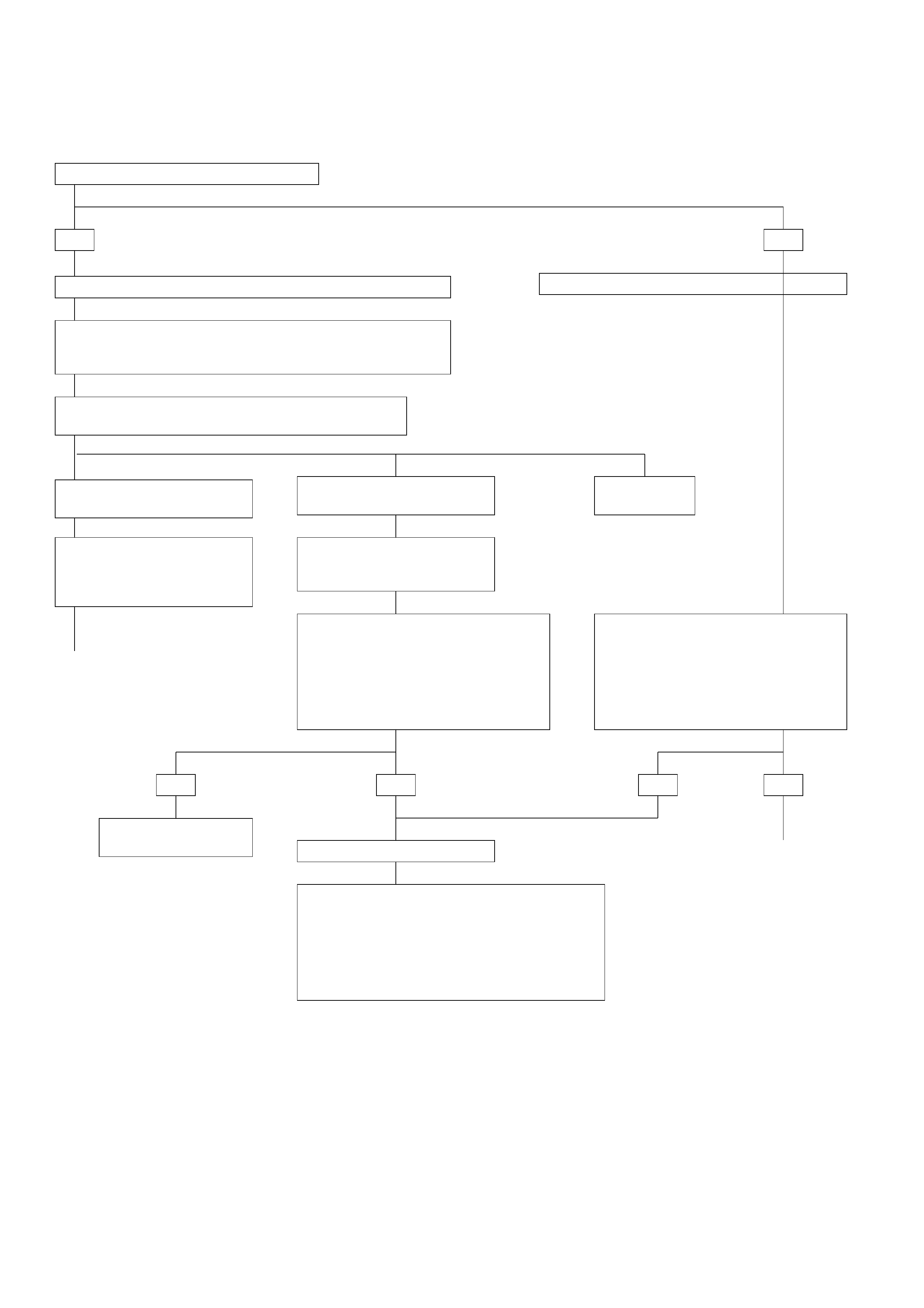

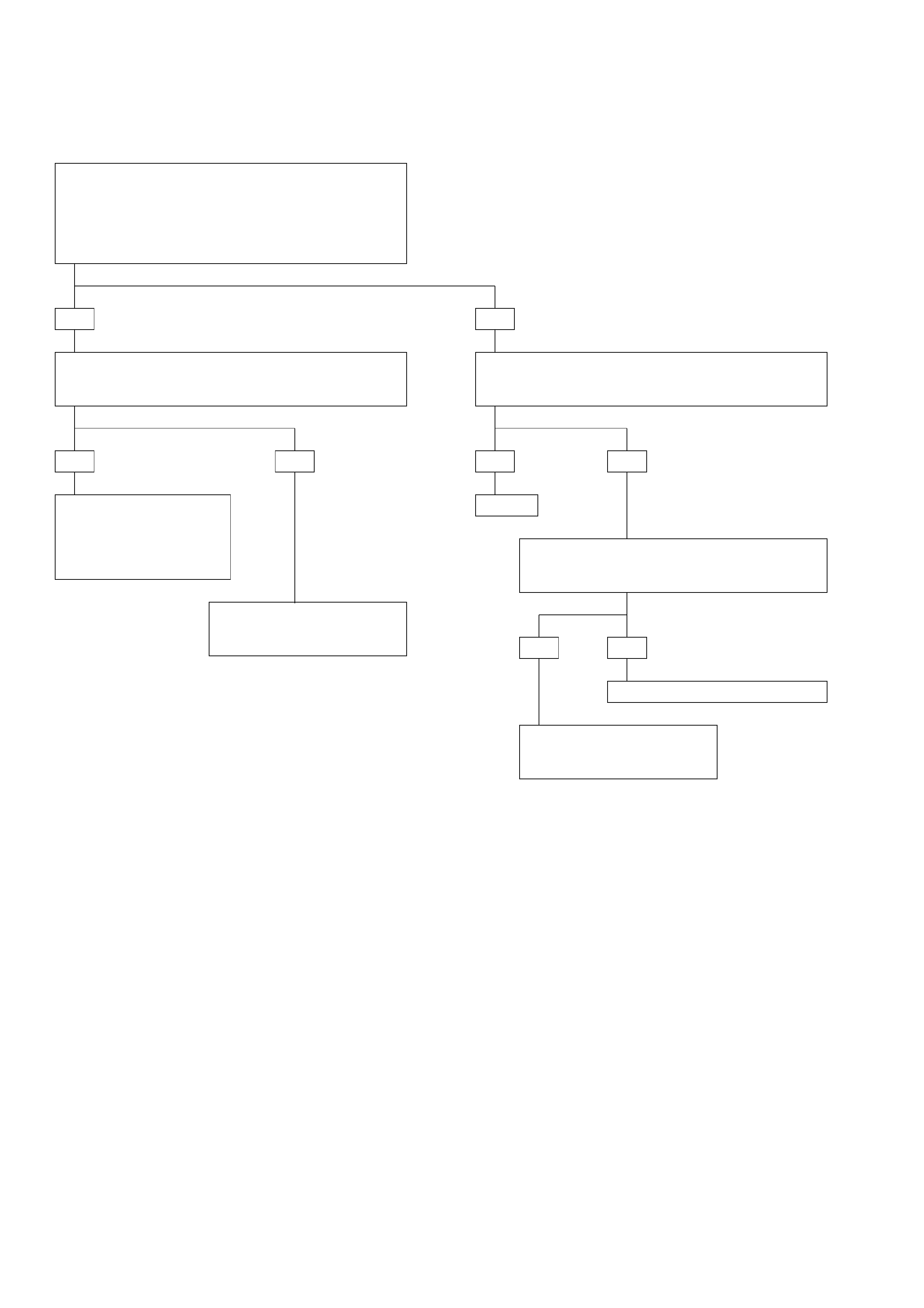

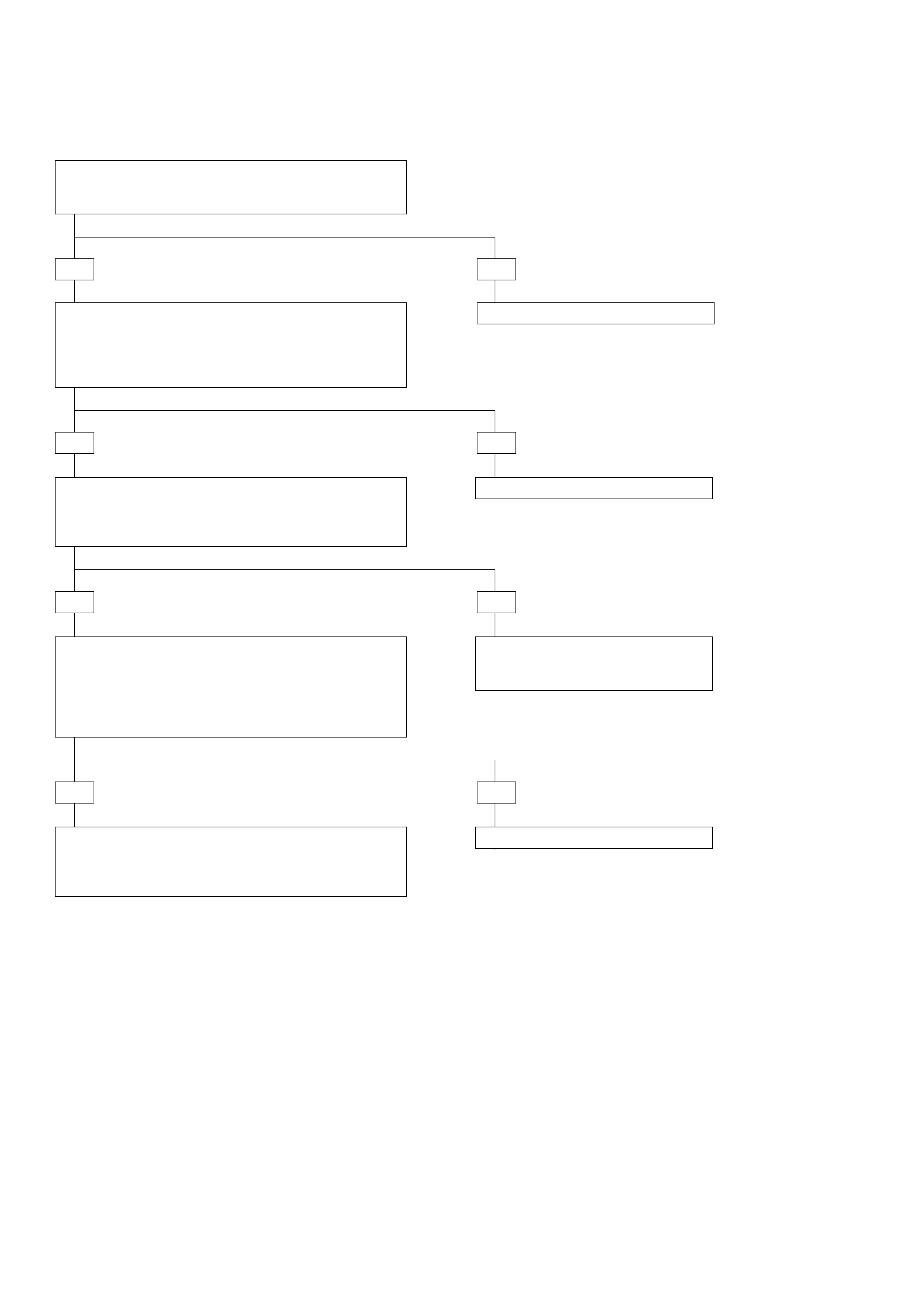

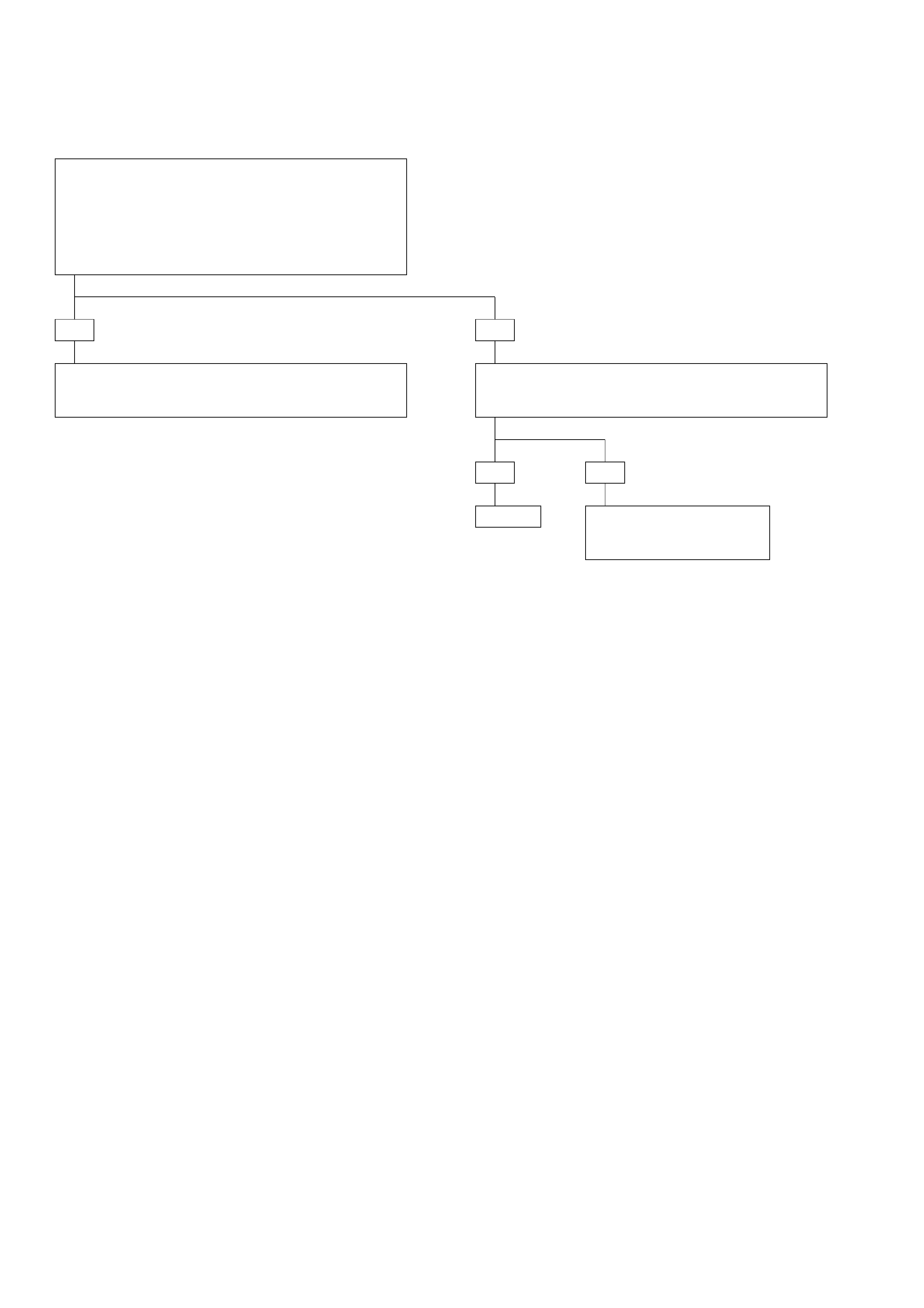

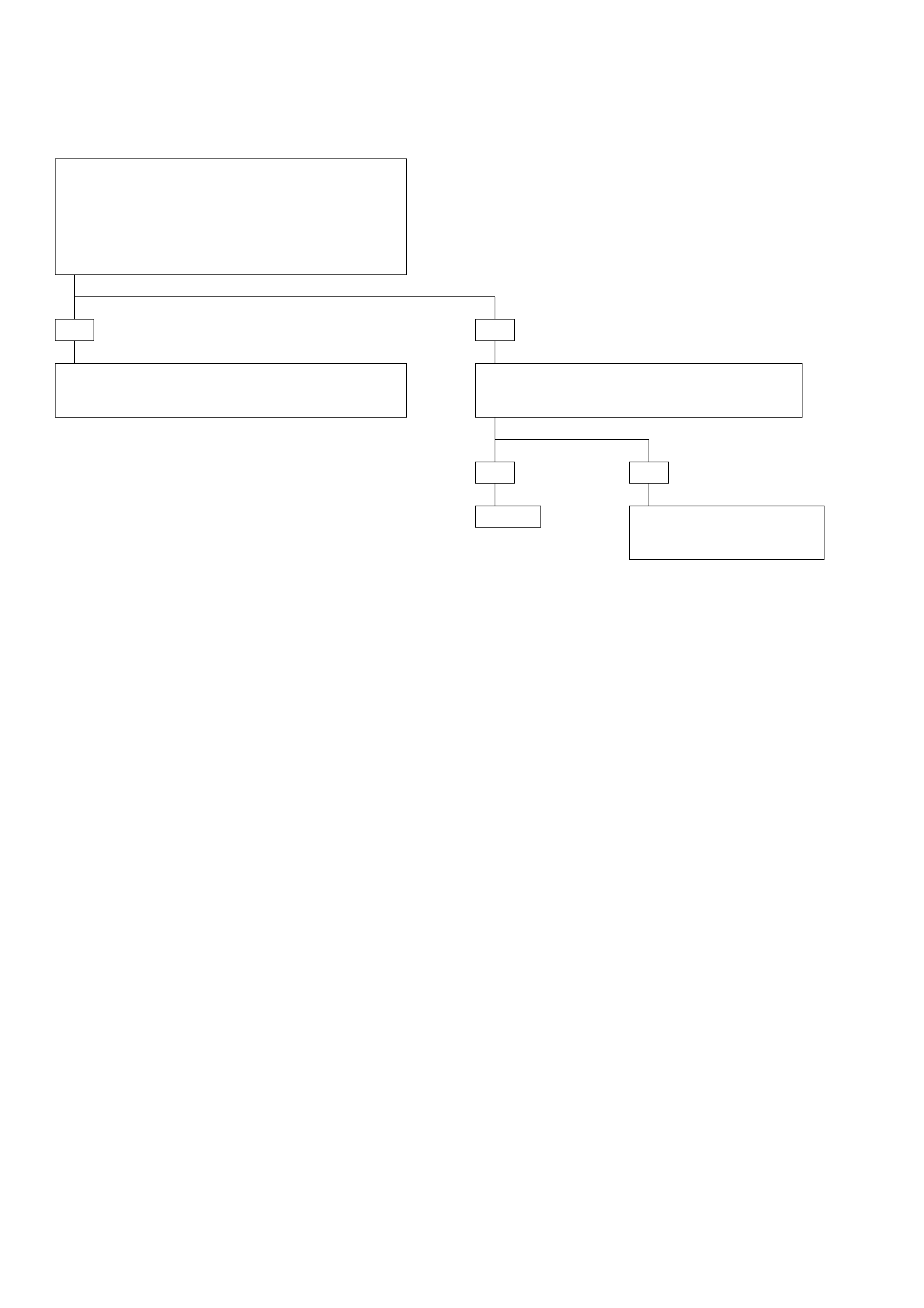

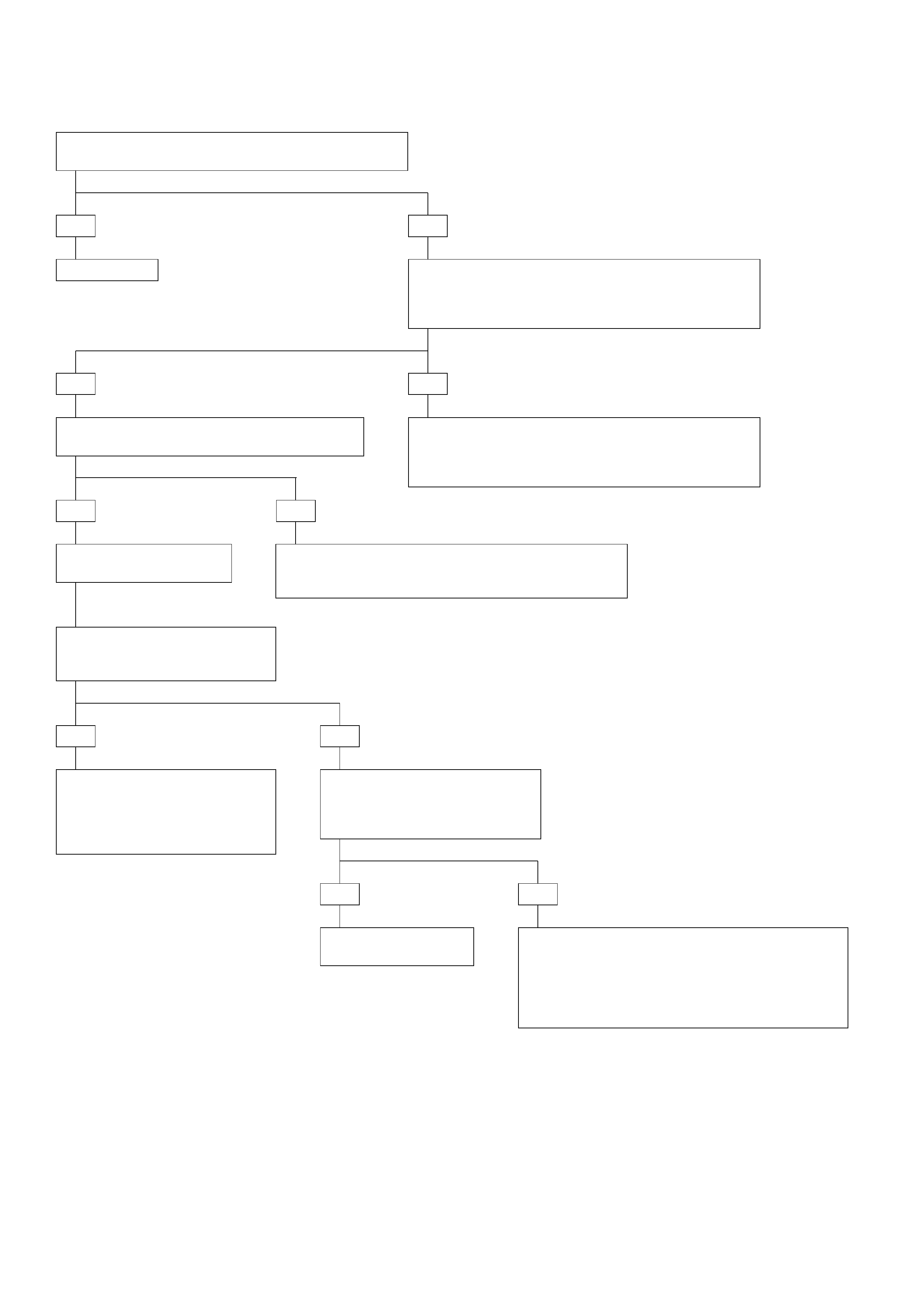

PRELIMINARY INSPECTION CHART

Complaint

Check CHART3: TRANSMISSION AND

TCM IDENTIFICATION on page 7A1-64.

Check TRANSMISSION FLUID LEVEL

and CONDITION. See page 00-4.

Check manual linkage.

Verify engine performance. Refer to Engine Section

Road test vehicle to verify concern.

See CHECK TRANS INDICATOR

CHART on page 7A1-25.

See ELECTRONIC DIAGNOSIS

Section of this manual on page 7A1-47.

See page 7A1-23 for TEST DRIVING

Refer to SELECTOR LEVER in this manual.

See page 7A1-145.

System

OK

Note

codes

Does

symptom reflect

NORMAL

OPERATIONS

OF 4L30-E

TRANSMISSION?

(See page 7A1-15)

“CHECK TRANS”

flashing

Any

Trouble Codes

stored by

TCM?

Hydraulic

system appears

OK!

Are any DTC’s

stored in

TCM?

YES

YES

YES

YES

NO

NO

NO

NO

TCM: Transmission Control Module

See MECHANICAL/HYDRAULIC

DIAGNOSIS Section on page 7A1-26.

TEST DRIVING

Some 4L30-E automatic transmission complaints

vehicles will require a test drive as a part of the

diagnostic procedure. Some codes will not set

unless the vehicle is moving. The purpose of the

test drive is to duplicate the customer’s complaint

condition and set a current Transmission Control

Module (TCM) trouble code. Perform this procedure

before each 4L30-E automatic transmission repair,

and again after repairs are made.

IMPORTANT:

• Duplicate the condition under which the

customer’s complaint was observed.

• Depending on the complaint, line pressure

gauge and the scan tool may be required

during the test drive.

• During the test drive, it is important to record

all necessary data from the areas being

monitored, for use in diagnosis. Also listen for

and note any unusual noises.

The following procedure should be used to test

drive 4L30-E automatic transmission complaint

vehicles:

1. Turn the ignition ON without starting the

engine. Check that the “CHECK TRANS” lamp

comes on for approximately 2 to 3 seconds

and then goes out and remains out.

• If the lamp is flashing, GOTO CHECK TRANS

INDICATOR.

• If no serial data is present, see Chart 1:

DIAGNOSTIC CONNECTOR AND VOLTAGE

SUPPLY TEST.

• If the lamp stays ON or stays OFF, GOTO

“CHECK TRANS” CHECK.

2. Drive the vehicle. During the test drive be sure

that the transmission achieves normal

operating temperature (approx. 20 minutes).

Allow the transmission to go through all of its

gear ranges, checking shift timing and

firmness. Duplicate the owner’s complaint

condition as closely as possible during the test

drive.

3. If, during the test drive, the “CHECK TRANS”

lamp comes on, use the scan tool to check for

trouble codes.

4. If, during the test drive, a problem is felt, but

the “CHECK TRANS” lamp does not come on

and no trouble codes are present, drive the

vehicle with the TCM disconnected (manually

shifting the vehicle).

• In Manual L, the vehicle operates in first

gear.

• In Manual 2, the vehicle operates in third

gear.

• In Manual 3 or “D”, the vehicle operates in

fourth gear.

If the problem still exists with the TCM

disconnected, refer to the MECHANICAL/

HYDRAULIC DIAGNOSIS in this Section.

5. If no problem has been found at this point,

check all underhood connections that supply

power to the TCM and ignition fuses.

Physically and visually inspect all the TCM

harness connectors for loose or corroded

terminals. Inspect the TCM ground points.

PERFORM PRELIMINARY INSPECTION FIRST!

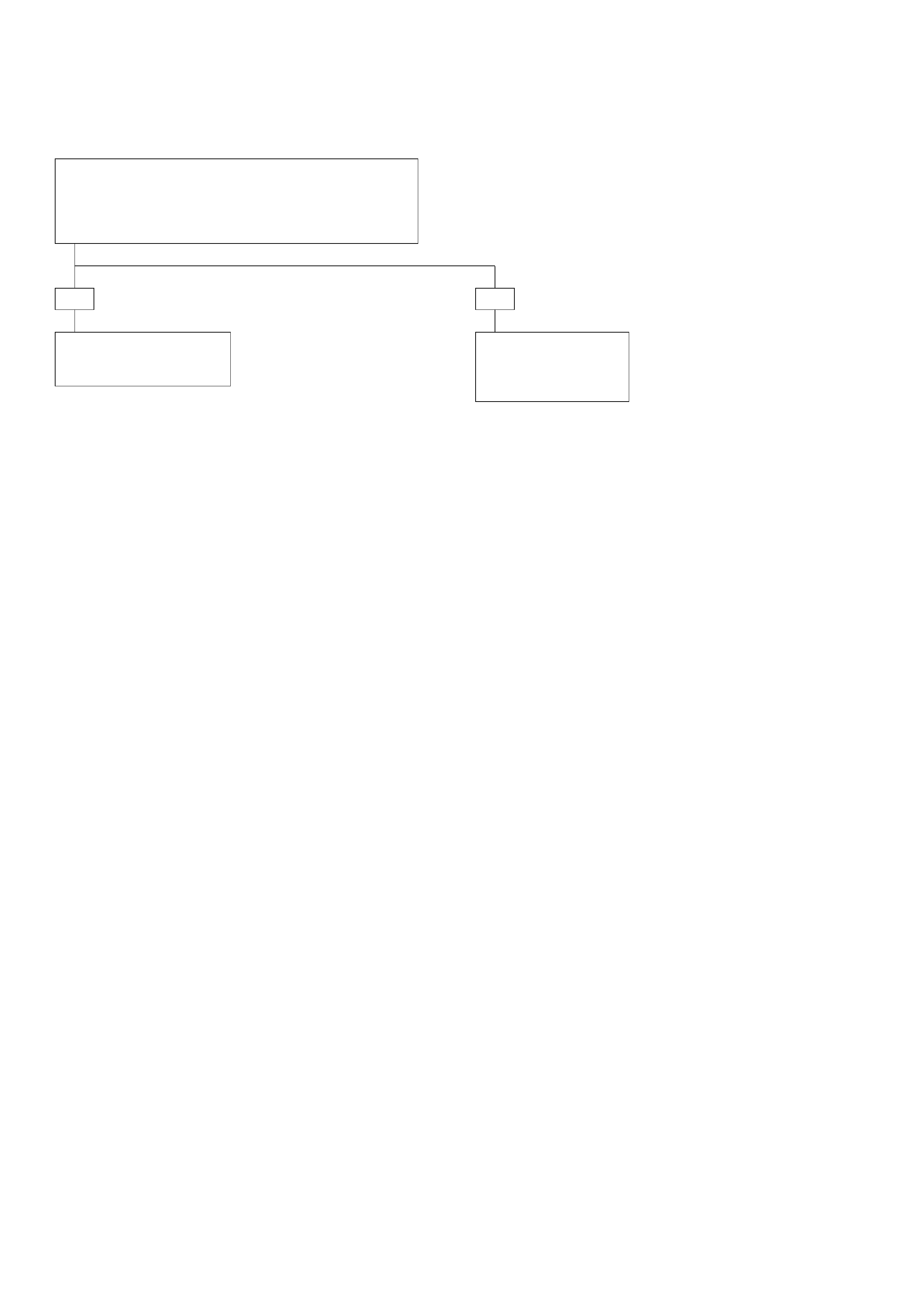

When the “CHECK TRANS” indicator is flashing, it

indicates that a problem related to the trans-

mission, the Transmission Control Module (TCM),

or the vehicle harness has occurred:

The system is now operating in a “BACKUP MODE”

where the risk of further damaging the transmission

has been reduced. The vehicle may be shifted

manually.

If the initial problem is intermittent or seldom,

switching OFF/ON the engine might allow normal

operation again until the problem re-occurs.

“CHECK TRANS” indicator flashing

Use “CHECK TRANS” CHECK in

Electronic Diagnosis section in this

manual

Refer to appropriate DTC chart in

Electronic Diagnosis section in this

manual.

NO DTC ANY DTC

Read and record the Diagnostic

Trouble Codes (DTC) stored by TCM.

WARNING:

Disconnecting battery or TCM will

result in loss of stored trouble code(s).

BACKUP MODE PATTERN:

- No automatic shifting

- Manual shifting only

- “CHECK TRANS” Flashing

SHIFT LEVER GEAR

POSITION SELECTED

PP

RR

NN

D4

34

23

L1

MECHANICAL/HYDRAULIC DIAGNOSIS

CHECK TRANS INDICATOR CHART

MECHANICAL/HYDRAULIC DIAGNOSIS SYMPTOMS INDEX

PERFORM PRELIMINARY INSPECTION FIRST!

CHART SYMPTOMS PAGE

1 NO ENGINE START IN NEUTRAL OR PARK 7C1-27

2 NO FORWARD GEARS IN ANY RANGE/NO REVERSE 7C1-28

3 NO ENGINE BRAKE IN ANY RANGE 7C1-29

4 POOR SHIFTING IN ALL GEARS (ALL HARSH OR ALL SOFT) 7C1-30

5a DELAYS IN DRIVE AND REVERSE 7C1-31

5b DELAYS IN REVERSE ONLY

6 DIAGNOSTIC TROUBLE CODE (DTC) 61 7C1-32

7 HARSH 1-2 SHIFT 7C1-33

8 HARSH 3-4 SHIFT

9a 3-2 DOWNSHIFT COMPLAINT

9b HARSH SHIFT WHEN SHIFTING INTO “D” OR ACCELERATING

FROM STOP 7C1-34

9c COASTDOWN HARSH SHIFT OR CLUNK AT 3-2 DOWNSHIFT

10 INTERMITTENT 4TH TO 2ND GEAR DOWNSHIFT AT STEADY SPEED 7C1-35

11 ENGINE FLARE AT SHIFTING DURING TURNING ONLY 7C1-36

12 ENGINE FLARE DURING 1-2 OR 2-3 SHIFT

13 SHUDDER ONLY DURING TORQUE CONVERTER CLUTCH (TCC) APPLYING 7C1-37

14 POSSIBLE CAUSES OF TRANSMISSION NOISE 7C1-38

15a POSSIBLE CAUSES OF LOW LINE PRESSURE 7C1-39

15b POSSIBLE CAUSES OF HIGH LINE PRESSURE 7C1-40

16 POSSIBLE CAUSES OF TRANSMISSION FLUID LEAKS 7C1-41

NOTE:

Numbers with parenthesis on the following charts refer to Parts List at end of Section 7C2.

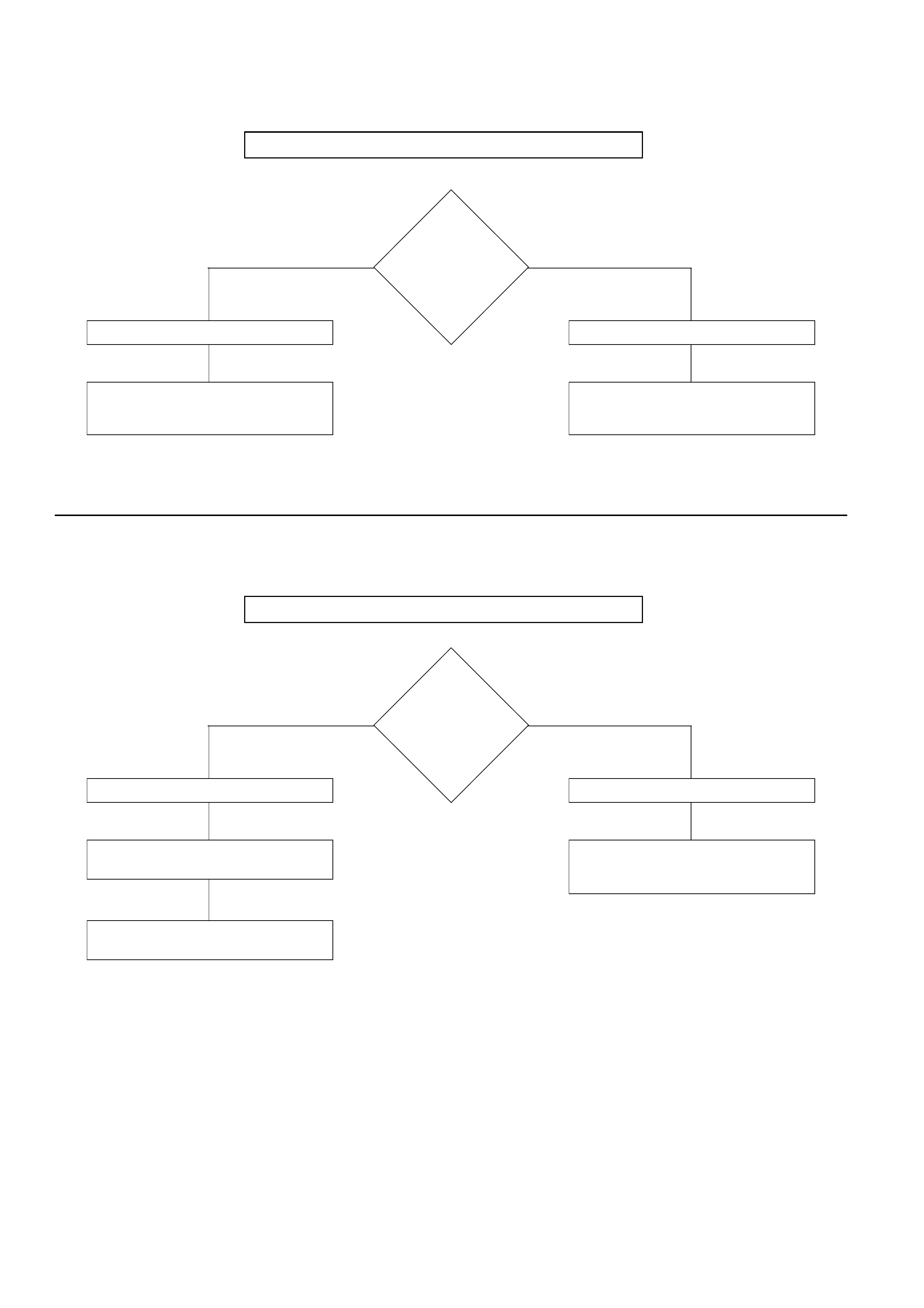

NO

NO

NO

YES

YES

YES

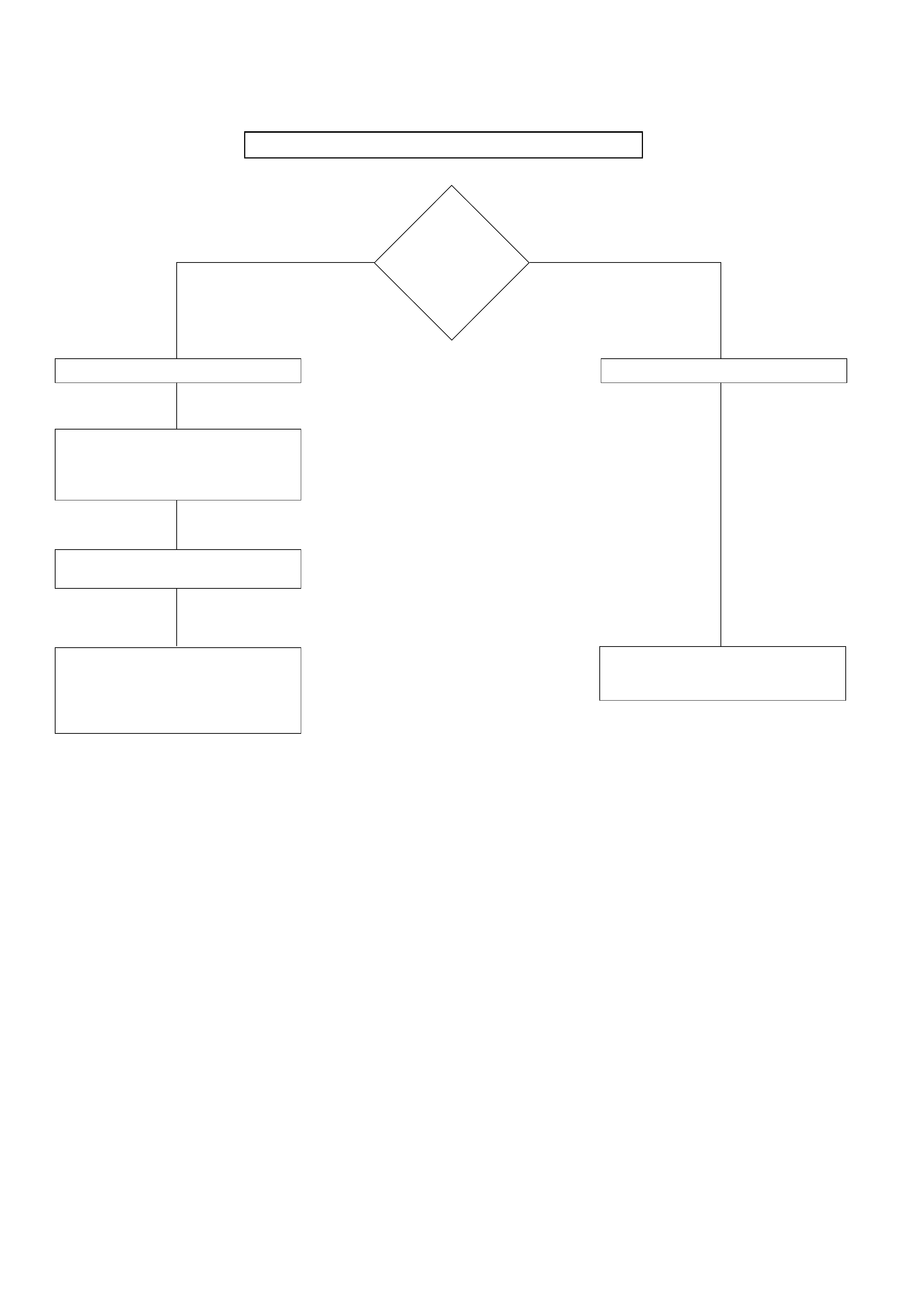

NO ENGINE START IN NEUTRAL

When shift lever moved from drive to

neutral mostly in hot condition

NO START IN P

(Any condition)

Replace mode switch (63)

END

END

Does

engine also not

start in neutral when

shift lever moved from

park to neutral?

Open

in neutral

start circuit of mode

switch (63)

Check

mode switch

(63) setting. Readjust

if necessary.

Problems

fixed?

( ) Refer to Parts List at the end of this Section.

CHART 1: NO ENGINE START IN NEUTRAL OR PARK

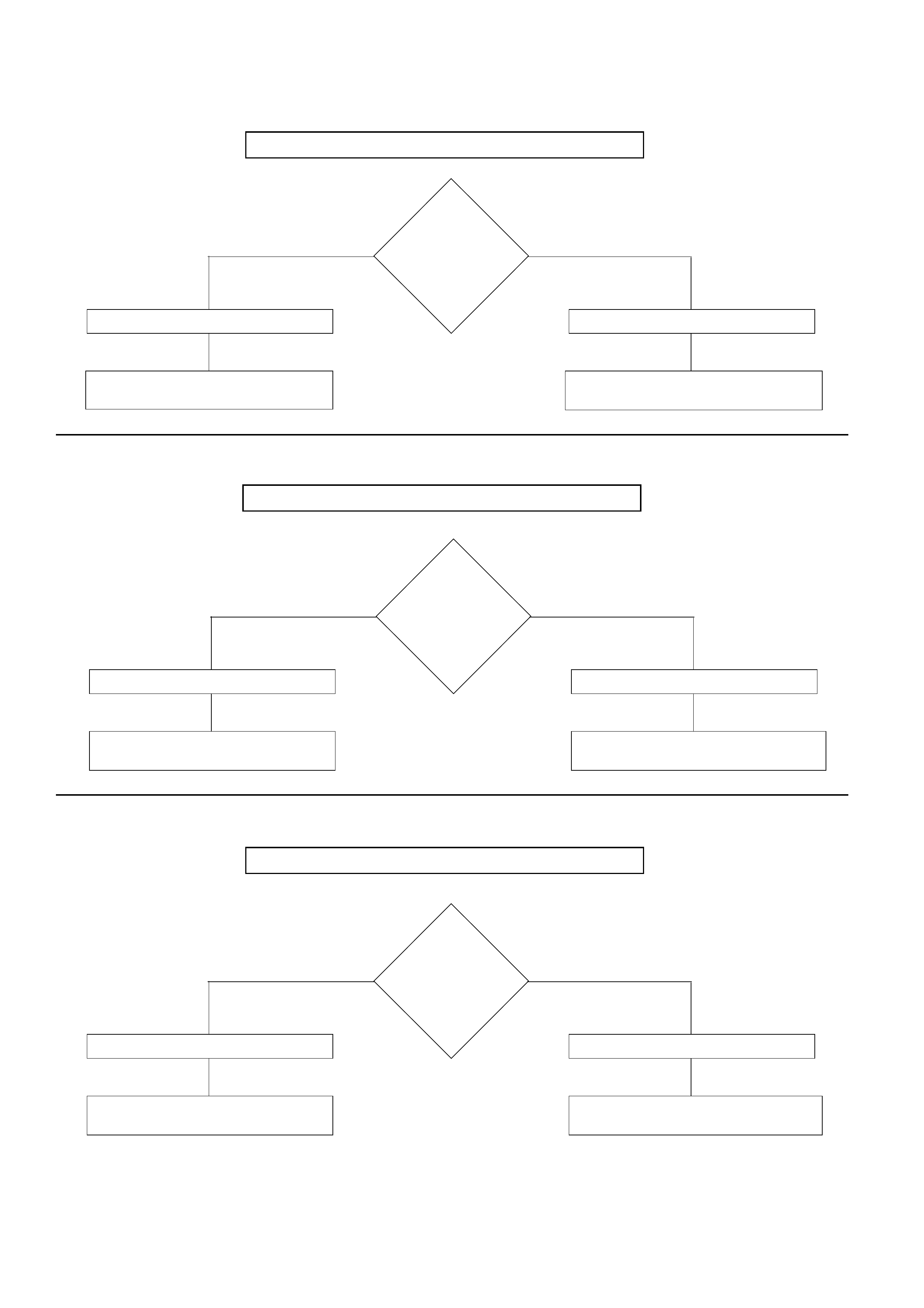

PERFORM PRELIMINARY INSPECTION FIRST!

Normal line pressure

Check internal linkage:

– Manual linkage (58) not moving

manual valve (326)

Check for internal mechanical

damage:

– Turbine shaft (506) broken loose

– Overrun roller clutch (516) broken

loose

– Etc.

Low line pressure

Use CHART 15a: POSSIBLE CAUSES

OF LOW LINE PRESSURE on page

7A1-39

Check

line pressure

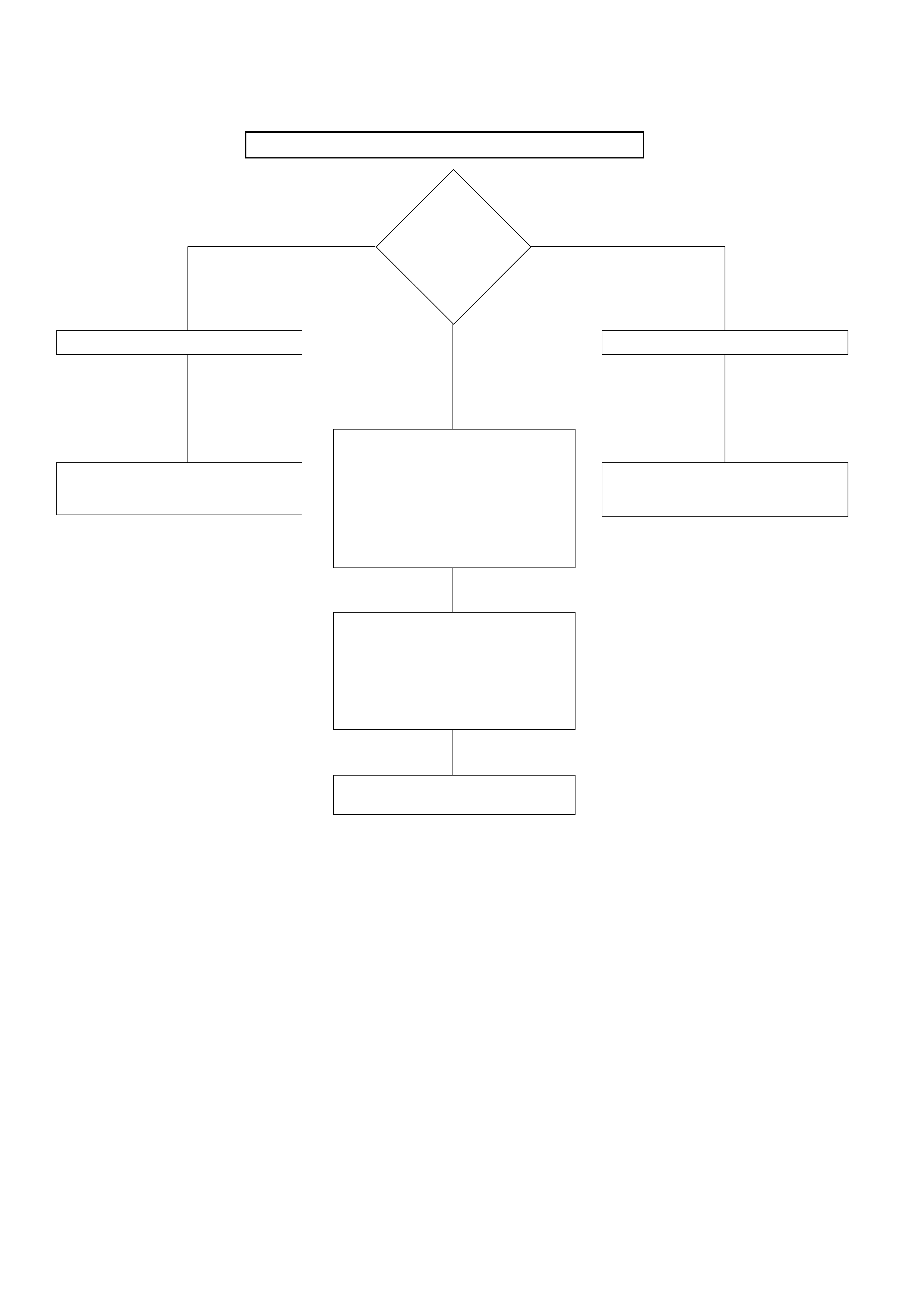

CHART 2: NO FORWARD GEARS IN ANY RANGE/NO REVERSE

PERFORM PRELIMINARY INSPECTION FIRST!

Refer to Line Pressure chart

(

in this Section.

)

( ) Refer to Parts List at the end of this Section.

Check

line pressure

CHART 3: NO ENGINE BRAKE IN ANY RANGE

PERFORM PRELIMINARY INSPECTION FIRST!

Refer to Line Pressure chart

(

in this Section.

)

( ) Refer to Parts List at the end of this Section.

Low line pressure

Use CHART 15a: POSSIBLE CAUSES

OF LOW LINE PRESSURE on page

7A1-39

Normal line pressure

Check for overrun clutch leaks caused

by:

– Damaged piston lip (513)

– Check ball defective (504)

Check for overrun lockout valve (705)

stuck by foreign material

Check for leaks at turbine shaft (506)

Caused by:

– Teflon seal rings damaged (508)

– Excessive wear of turbine shaft

bearing surfaces

( ) Refer to Parts List at the end of this Section.

CHART 4: POOR SHIFTING IN ALL GEARS (ALL HARSH OR ALL SOFT)

PERFORM PRELIMINARY INSPECTION FIRST!

Check

line pressure

Low line pressure

Use CHART 15a: POSSIBLE CAUSES

OF LOW LINE PRESSURE on page

7A1-39

High line pressure

Use CHART 15b: POSSIBLE CAUSES

OF HIGH LINE PRESSURE on page

7A1-40

Check for these conditions which

could affect clutch apply time:

•Defective band apply solenoid

(323)

•Defective servo or/and

accumulator piston

•Excessive clutch piston travel

Check of possible causes of internal

leaks:

– Cut or damaged sealing ring(s)

– Damaged sealing gasket (s)

– Check ball missing or out of

location in 2nd and 3rd clutch

pistons

Check for causes of burned clutch

plates or band

Refer to Line Pressure chart

(

in this Section.

)

( ) Refer to Parts List at the end of this Section.

CHART 5a: DELAYS IN DRIVE AND REVERSE

PERFORM PRELIMINARY INSPECTION FIRST!

CHART 5b: DELAYS IN REVERSE ONLY

PERFORM PRELIMINARY INSPECTION FIRST!

Check

line pressure

Normal line pressure

More than 3 second delay in drive and

reverse with engine off 1 hour or less

Teflon seals (508) on turbine shaft

damaged

Low line pressure

Use CHART 15a: POSSIBLE CAUSES

OF LOW LINE PRESSURE on page

7A1-39

NOTE: A short delay (less than 3

seconds) when first engaging drive or

reverse after allowing vehicle to sit

overnight is normal.

Refer to Line Pressure chart

(

in this Section.

)

Check

line pressure

Refer to Line Pressure chart

(

in this Section.

)

Normal line pressure

Main case to valve body gasket (88)

damaged

Reverse check ball (85) in valve body

(84) missing or out of location

Low line pressure

Use CHART 15a: POSSIBLE CAUSES

OF LOW LINE PRESSURE on page

7A1-39

Check for restrictions at valve body

transfer plate orifice

CHART 6: DIAGNOSTIC TROUBLE CODE (DTC) 61

PERFORM PRELIMINARY INSPECTION FIRST!

DTC 61 sets.

Check line

pressure

Check

3rd gear in “D”

in winter mode.

Does vehicle

move?

Check for suspected conditions

modifying delays to clutch apply:

– Overrun clutch seal damaged

– Excessive overrun clutch piston

travel

– Defective 3-4 accumulator piston

– Causes of internal leaks

– Causes of burned clutch plates

Low line pressure

Use CHART 15a: POSSIBLE CAUSES

OF LOW LINE PRESSURE on page

7A1-39

Refer to Line Pressure chart

(

in this Section.

)

Normal line pressure

1st and 4th gear missing

or 2nd and 3rd gear

missing

Shift solenoid A stuck.

Replace shift solenoid A.

1st and 2nd gear missing

or 3rd and 4th gear

missing

Check appropriate shift

valve

If OK replace solenoid

DTC 61 is set in “D” range

1st gear above 3500 rpm

Check for suspected conditions

modifying delays to clutch apply:

– 2nd clutch seal damaged

– Excessive 2nd clutch piston travel

– Defective accumulator piston

– Causes of internal leaks

– Check ball missing or out of

location in 2nd clutch

– Seals cut, damaged or missing

– Gaskets defective

– Causes of burned clutch plates

DTC 61 is set in “D” range

3rd gear between 55-80

mph *

Check for suspected conditions

modifying delays to clutch apply:

– 4th clutch seal damaged

– Excessive 4th clutch piston travel

– Defective 3-4 accumulator piston

– Causes of internal leaks

– Causes of burned clutch plates

No engine brake in any

range

(All ranges in Drive &

Reverse are OK)

YES

NO

* Perform this test within safe and legal limits.

CHART 7: HARSH 1-2 SHIFT

PERFORM PRELIMINARY INSPECTION FIRST!

CHART 8: HARSH 3-4 SHIFT

PERFORM PRELIMINARY INSPECTION FIRST!

( ) Refer to Parts List at the end of this Section.

Check

line pressure

Refer to Line Pressure chart

(

in this Section.

)

Normal line pressure

Check for 1-2 accumulator valve (320)

stuck by foreign material in main case

valve body

Use CHART 15b: POSSIBLE CAUSES

OF HIGH LINE PRESSURE on page

7A1-40

High line pressure

Check

line pressure

Refer to Line Pressure chart

(

in this Section.

)

Normal line pressure

Check for 3-4 accumulator valve (407)

stuck in adapter case valve body (401) Use CHART 15b: POSSIBLE CAUSES

OF HIGH LINE PRESSURE on page

7A1-40

High line pressure

Check for 3-4 accumulator piston (18)

stuck in adapter case (20)

CHART 9a: 3-2 DOWNSHIFT COMPLAINT

PERFORM PRELIMINARY INSPECTION FIRST!

CHART 9b: HARSH SHIFT WHEN SHIFTING INTO "D" OR ACCELERATING FROM STOP

PERFORM PRELIMINARY INSPECTION FIRST!

CHART 9c: COASTDOWN HARSH SHIFT OR CLUNK AT 3-2 DOWNSHIFT

PERFORM PRELIMINARY INSPECTION FIRST!

( ) Refer to Parts List at the end of this Section.

Check

line pressure

Refer to Line Pressure chart

(

in this Section.

)

Normal line pressure

Replace band apply solenoid (PWM)

(323) Use CHART 15a: POSSIBLE CAUSES OF

LOW LINE PRESSURE on page 7A1-39

Low line pressure

Check

line pressure

Refer to Line Pressure chart

(

in this Section.

)

Normal line pressure

Replace band apply solenoid (PWM)

(323) Use CHART 15b: POSSIBLE CAUSES OF

HIGH LINE PRESSURE on page 7A1-40

High line pressure

Check

line pressure

Refer to Line Pressure chart

(

in this Section.

)

Normal line pressure

Replace band apply solenoid (PWM)

(323) Use CHART 15b: POSSIBLE CAUSES OF

HIGH LINE PRESSURE on page 7A1-40

High line pressure

CHART 10: INTERMITTENT 4TH TO 2ND GEAR DOWNSHIFT AT STEADY SPEED

PERFORM PRELIMINARY INSPECTION FIRST!

Check for

consistent speed

sensor reading

with TECH2

OK

OK

Check for wiring harness damage

or short to ground

Check transmission speed sensor

connections

Replace transmission speed

sensor

NOT OK

OK

Replace mode switch for intermittent

contact

CHART 11: ENGINE FLARE AT SHIFTING DURING TURNING ONLY

(USUALLY WITH WARM ENGINE)

PERFORM PRELIMINARY INSPECTION FIRST!

PERFORM PRELIMINARY INSPECTION FIRST!

CHART 12: ENGINE FLARE DURING 1-2 OR 2-3 SHIFT

Check

line pressure

( ) Refer to Parts List at the end of this Section.

Leak at transmission oil filter, gasket,

or wrong filter type

Replace transmission oil filter and

gasket

Check for band apply solenoid (323)

stuck

Check for servo piston (106) leaks

Check for 1-2 accumulator valve (320)

stuck

Normal line pressure

Use CHART 15a: POSSIBLE CAUSES OF

LOW LINE PRESSURE on page 7A1-39

Low line pressure

Refer to Line Pressure chart

(

in this Section.

)

CHART 13: SHUDDER ONLY DURING TORQUE CONVERTER CLUTCH (TCC) APPLYING

PERFORM PRELIMINARY INSPECTION FIRST!

YES

NO

Replace transmission fluid and filter (remove both pans) and flush

cooler lines.

Replace converter assembly and O-ring on turbine shaft.

Drive until whole drivetrain is at normal operating temperature.

– Shudder is a SHORT BURST OF NOISE NORMALLY LESS THAN 1

SECOND IN DURATION, and can be induced by the following

maneuver:

TCC shudder is one of the most commonly misdiagnosed conditions in

an automatic transmission. The key to diagnosing TCC shudder is to

note when it happens and under what conditions. Once the TCC has

been fully applied, it is nearly impossible to make it shudder. TCC

shudder (short burst of noise normally less than 1 second) will only

occur during clutch applying. It is not a steady state condition.

From coast condition at 50 mph in “D” range (Normal mode), depress

the throttle to 1/4-1/3 throttle.

If present, shudder (short burst of noise normally less than 1 sec.) will

occur within 5 seconds together with TCC applying.

(TECH2 may be used to determine the exact time of TCC applying)

Perform mechanical inspection of

other drivetrain components.

CHART 14: POSSIBLE CAUSES OF TRANSMISSION NOISE

PERFORM PRELIMINARY INSPECTION FIRST!

CAUTION:

Before checking transmission for what is believed to be transmission noise,

ensure presence and positioning of insulating plugs, pads etc. Also make

sure that noise does not come from other drivetrain components.

1. WHINE OR BUZZ:

– Oil level low

– Plugged or restricted oil filter

– Damaged oil filter gasket

2. KNOCKING NOISE FROM FRONT OF TRANSMISSION:

– Loose bolts (Converter to flex plate)

– Cracked or broken flex plate

– Converter damaged

3. KNOCKING NOISE WHILE DRIVING - MOSTLY ON ACCELERATION:

– Transmission mount loose or broken

– Cooler line mounts loose or broken

– Cooler lines touching body or frame

4. KNOCKING NOISE WHEN VEHICLE IS STATIONARY:

– Loose flex plate mounting bolts

– Cracked or broken flex plate

– Damaged converter

CHART 15a: POSSIBLE CAUSES OF LOW LINE PRESSURE

ON-VEHICLE SERVICE

TRANSMISSION REMOVED

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

Small

valve

body

Oil

pump

( ) Refer to Parts List at the end of this Section.

Check for loose bolts (4 & 5)

Check for pressure regulator valve (208) stuck

Check for boost valve (205) stuck

Check for intermediate oil passages to pressure regulator valve blocked

Check for defective oil pump (9, 201, 202 & 209)

Check for internal leaks

– Check balls missing or out of location in valve bodies

– Seals cut or damaged

– Gaskets defective, etc.

Check oil level

Check for defective throttle position sensor

Check for plugged, loose, or damaged oil filter (79)

Check for force motor plunger (404) stuck. (Remove force motor. Shake and listen for rattle.)

Check for feed limit valve (412) stuck

CHART 15b: POSSIBLE CAUSES OF HIGH LINE PRESSURE

PERFORM PRELIMINARY INSPECTION FIRST!

ON-VEHICLE SERVICE

TRANSMISSION REMOVED

Small

valve

body

Oil

pump

OK

OK

OK

( ) Refer to Parts List at the end of this Section.

NOTE: If transmission is operating in back-up mode, high line pressure will be

present.

Check for defective throttle position sensor

OK

Check for loose bolts (4 & 5)

OK

OK

Check for pressure regulator valve (208) stuck

Check for boost valve (205) stuck

Check for force motor plunger (404) stuck

(Remove force motor. Shake and listen for rattle.)

(Open circuit/Intermittent)

Check for feed limit valve (412) stuck

Check for internal leaks

– Check balls missing or out of location in valve bodies

– Seals cut or missing

– Gaskets defective, etc.

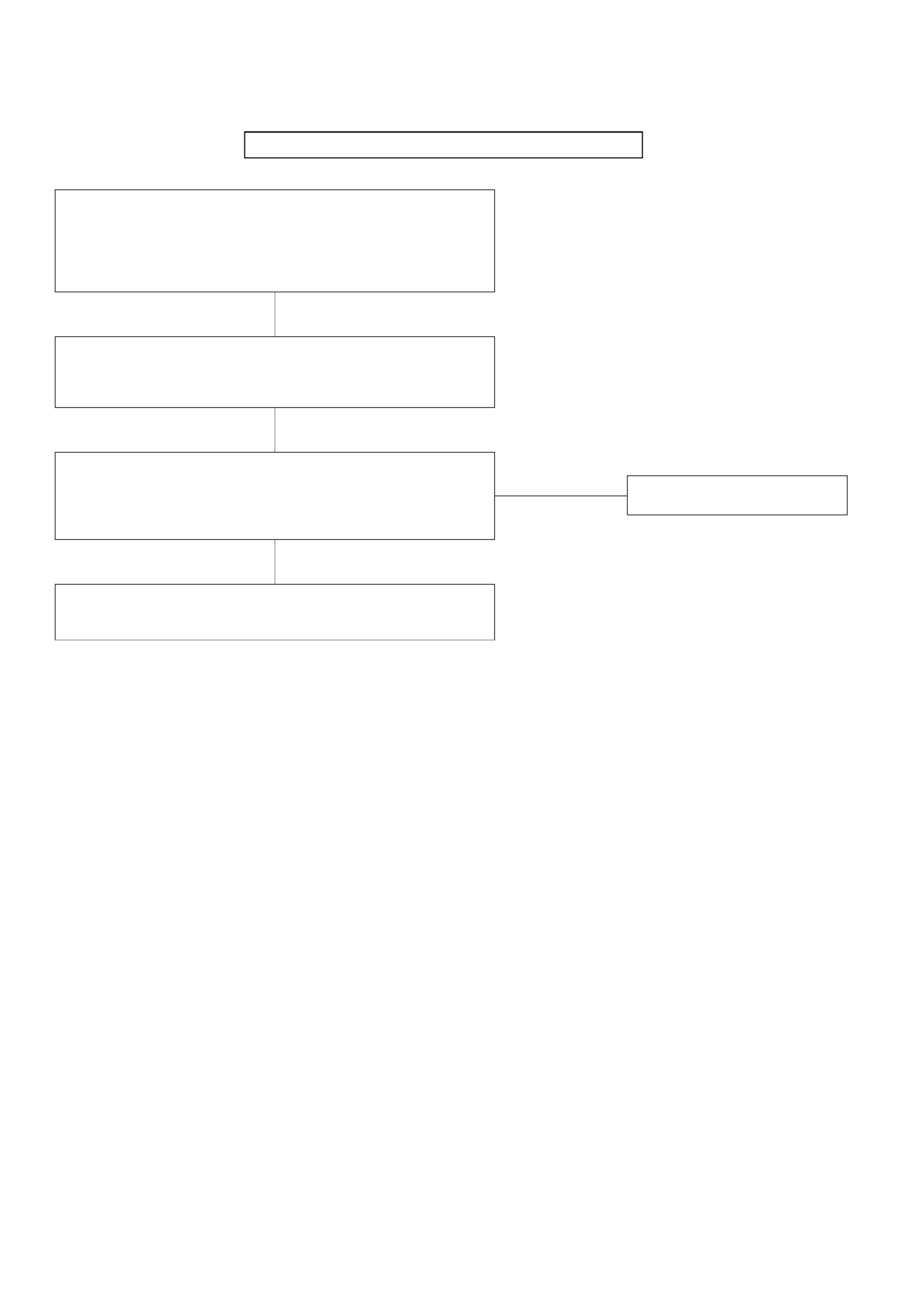

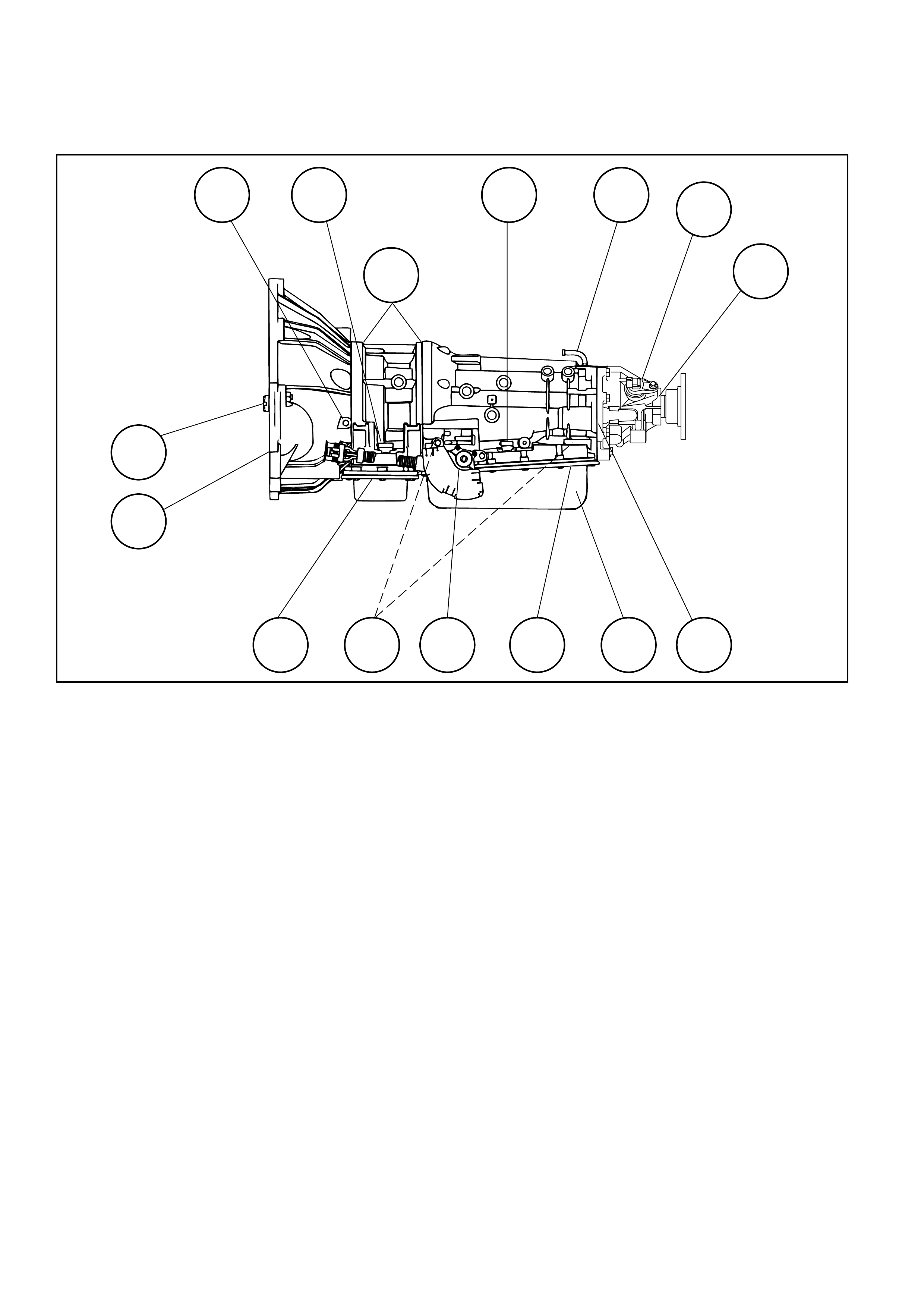

CHART 16: POSSIBLE CAUSES OF TRANSMISSION FLUID LEAKS

Before attempting to correct an oil leak, the actual source of the leak must be determined. In many cases,

the source of the leak may be difficult to determine due to “wind flow” around the engine and

transmission.

The suspected area should be wiped clean of all oil before inspecting for the source of the leak.

Oil leaks around the engine and transmission are generally carried toward the rear of the car by the air

stream. In determining the source of an leak, the following two checks should be made:

1. With the engine running, check for external line pressure leaks.

2. With the engine off, check for oil leaks due to the raised oil level caused by drainback of converter oil

into the transmission.

POSSIBLE CAUSES OF FLUID LEAKS

DUE TO SEALING MALFUNCTION

1) Electrical connector (Main case) seal

2) Transmission vent (Breather)

3) Speed sensor O-ring

4) Extension (Adapter) lip seal

5) Extension (Adapter) to main case gasket

6) Oil drain plug gasket

7) Oil pan gasket (Main case)

8) Selector shaft seal

9) Oil cooler connectors (2)

10) Oil pan gasket (Adapter case)

11) Converter housing attaching bolts not correctly

torqued

12) Converter housing lip seal

13) Line pressure tap plug

14) Electrical connector (Adapter case) seal

15) Adapter case seal rings (2)

67 5910 8

11

12

23

4

1

1413

15

240LW004

STALL TEST

The stall test allows you to check the transmission for

internal abrasion and the oneway clutch for slippage.

Torque converter performance can also be evaluated.

The stall test results together with the road test results will

identify transmission components requiring servicing or

adjustment.

Stall Test Procedure:

1. Check the level of the engine coolant, the engine oil,

and the automatic transmission fluid.

Replenish if necessary.

2. Block the wheels and set the parking brake.

3. Connect a tachometer to the engine.

4. Start the engine and allow it to idle until the engine

coolant temperature reaches 70 - 80°C (158 - 176°F).

5. Hold the brake pedal down as far as it will go.

6. Place the selector in the “D” range.

7. Gradually push the accelerator pedal to the floor.

The throttle valve will be fully open.

Note the engine speed at which the tachometer

needle stabilizes.

Stall Speed

Standard

2200 ± 150 rpm

NOTE:

Do not continuously run this test longer than 5

seconds.

8. Release the accelerator pedal.

9. Place the selector in the “N” range.

10. Run the engine at 1,200 rpm for one minute.

This will cool the transmission fluid.

11. Repeat Steps 7-10 for the “3”, “2”, “L” and “R”

ranges.

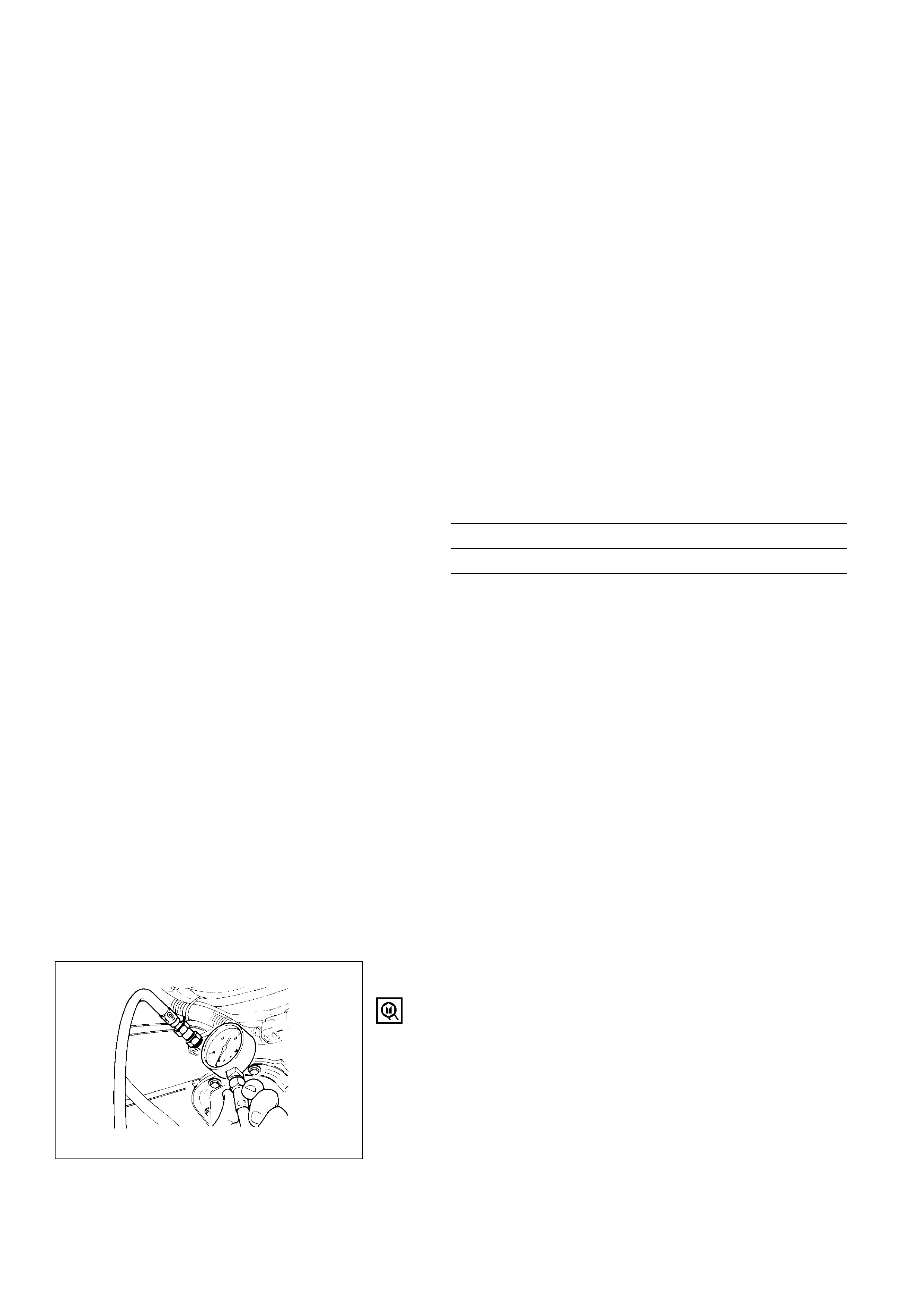

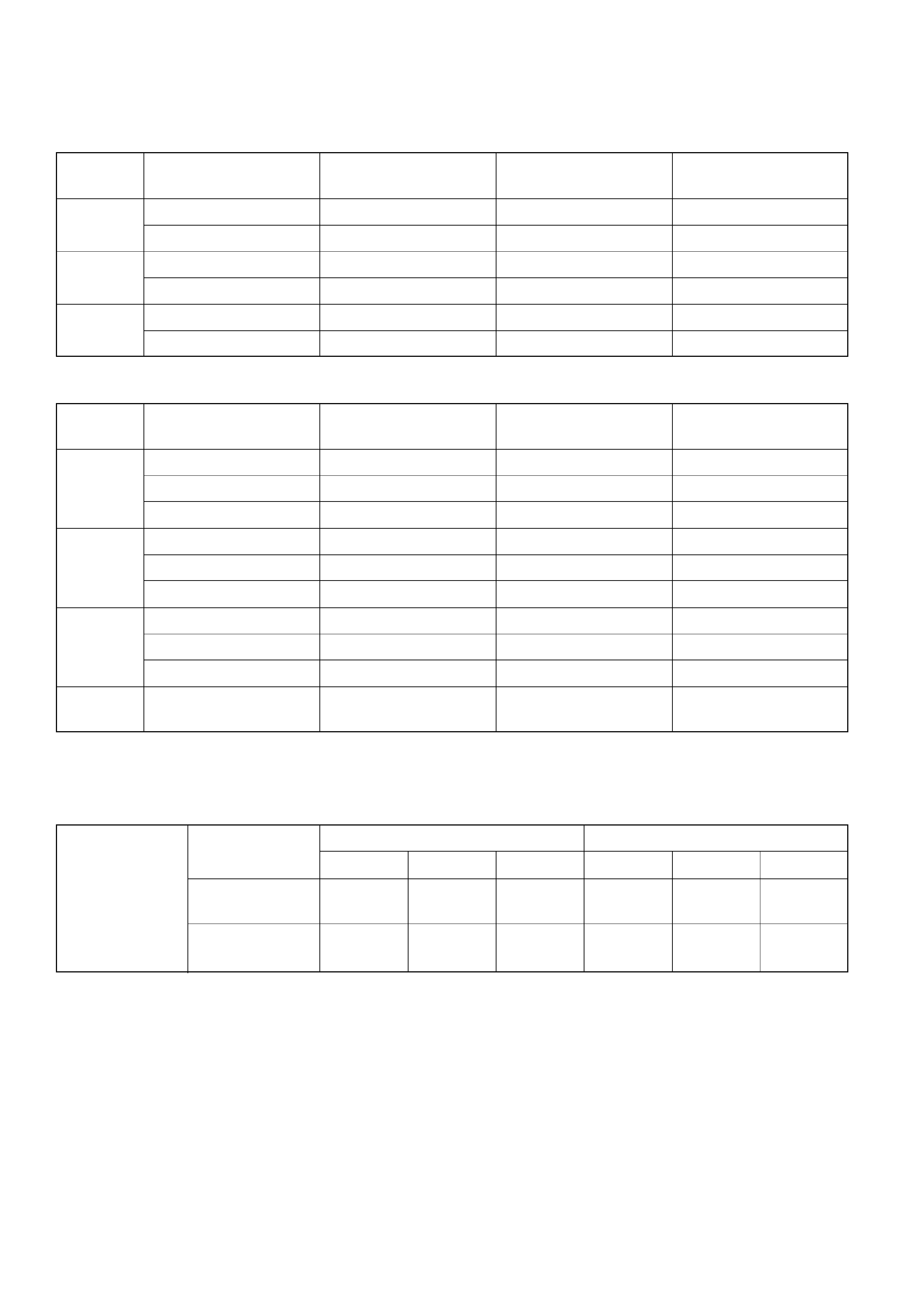

LINE PRESSURE TEST

The line pressure test checks oil pump and control valve

pressure regulator valve function. It will also detect oil

leakage.

Line Pressure Test Procedure:

1. Check the level of the engine coolant, the engine oil,

and the automatic transmission fluid.

Replenish if required.

2. Block the wheels and set the parking brake.

3. Remove the pressure detection plug at the left side of

the transmission case.

Set pressure gauge, adapter to the pressure detection

plug hole.

Gauge and adapter: 5-8840-0004-0 (J-21867)

Line Pressure and Force Motor Current KPa (kg/cm2/ PSI)

4. Start the engine and allow it to idle until the engine

coolant temperature reaches 70 - 80°C (158- 176°F).

5. Hold the brake pedal down as far as it will go.

6. Place the selector in the “D” range.

7. Note the pressure gauge reading with the engine

idling.

8. Gradually push the accelerator pedal to the floor. The

throttle valve will be fully open.

Note the pressure gauge reading with the accelerator

pedal fully depressed.

NOTE:

Do not continuously run this test longer than 5

seconds.

9. Release the accelerator pedal.

10. Place the selector in the “N” range.

11. Run the engine at 1,200 rpm for one minute.

This will cool the transmission fluid.

12. Repeat Steps 7 - 11 for the “3”, “2”, “L”, and “R”

ranges.

13. Install a pressure detection plug to the transmission

case, applying recommended thread locking agent

(LOCTITE 242) or its equivalent to thread of plug.

Make sure that thread is cleaned before applying

locking agents.

14. Tighten the pressure detection plug to the specified

torque.

Pressure Detection Plug Torque N·m (kg·m / lb·ft)

9 – 14 (0.9 – 1.4 / 7 – 10)

LEVER ENGINE FORCE

MODE LINE PRESSURE MOTOR

POSITION SPEED CURRENT

NORMAL/POWER D, 3, 2, L IDLE 312 – 363 (3.2 – 3.7 / 45.2 – 52.6) VARIABLE

NORMAL/POWER REVERSE IDLE 419 – 486 (4.3 – 5.0 / 60.7 – 70.5) 0.9 – 1.0A

NORMAL/POWER D, 3, 2, L STALL SPEED 1236 – 1320 (12.6 – 13.5 / 179.3 – 191.4) 0.1 – 0.2A

NORMAL/POWER REVERSE STALL SPEED 1634 – 1743 (16.7 – 17.8 / 236.9 – 252.8) 0.1 – 0.2A

SHIFT SPEED CHART Transfer gear ratio: High: 1.000

(

Rear axle ratio: 4.555

)

“Normal mode”

Downshift Km/h (mph)

Upshift Km/h (mph)

Range Throttle opening 1 →22 →33 →4

(First Gear) (Second Gear) (Second Gear) (Third Gear) (Third Gear) (Fourth Gear)

DFully opened 41 ~ 47 (25 ~ 29) 84 ~ 90 (52 ~ 56) 127 ~ 133 (79 ~ 83)

(Drive) Half throttle 33 ~ 39 (20 ~ 24) 60 ~ 66 (37 ~ 41) 117 ~ 123 (73 ~ 76)

3Fully opened 49 ~ 55 (30 ~ 34) 99 ~ 105 (62 ~ 66) –

(Third) Half throttle 32 ~ 38 (20 ~ 24) 58 ~ 64 (36 ~ 40) –

2Fully opened 49 ~ 55 (30 ~ 34) – –

(Second) Half throttle 32 ~ 38 (20 ~ 24) – –

Range Throttle opening 1 ←22 ←33 ←4

(First Gear) (Second Gear) (Second Gear) (Third Gear) (Third Gear) (Fourth Gear)

DFully opened 16 ~ 22 (10 ~ 14) 62 ~ 68 (39 ~ 42) 104 ~ 110 (65 ~ 68)

(Drive) Half throttle 15 ~ 21 (9 ~ 13) 34 ~ 40 (21 ~ 25) 67 ~ 73 (42 ~ 46)

Fully closed 14 ~ 20 (9 ~ 12) 21 ~ 27 (13 ~ 17) 29 ~ 35 (18 ~ 22)

3Fully opened 39 ~ 45 (24 ~ 28) 87 ~ 93 (54 ~ 58) –

(Third) Half throttle 15 ~ 21 (9 ~ 13) 34 ~ 40 (21 ~ 25) –

Fully closed 13 ~ 19 (8 ~ 12) 15 ~ 21 (9 ~ 13) –

2Fully opened 40 ~ 46 (25 ~ 29) 94 ~ 100 (59 ~ 63) –

(Second) Half throttle 15 ~ 21 (9 ~ 13) 94 ~ 100 (59 ~ 63) –

Fully closed 13 ~ 19 (8 ~ 12) 82 ~ 88 (51 ~ 55) –

L– 50 ~ 56 (31 ~ 35) – –

(First)

“Power mode”

Upshift Km/h (mph)

Downshift Km/h (mph)

Range Throttle opening 1 →22 →33 →4

(First Gear) (Second Gear) (Second Gear) (Third Gear) (Third Gear) (Fourth Gear)

DFully opened 49 ~ 55 (30 ~ 34) 99 ~ 105 (62 ~ 66) 169 ~ 175 (105 ~ 109)

(Drive) Half throttle 37 ~ 43 (23 ~ 27) 74 ~ 80 (46 ~ 50) 124 ~ 130 (77 ~ 81)

3Fully opened 49 ~ 55 (30 ~ 34) 99 ~ 105 (62 ~ 66) –

(Thire) Half throttle 37 ~ 43 (23 ~ 27) 74 ~ 80 (46 ~ 50) –

2Fully opened 49 ~ 55 (30 ~ 34) – –

(Second) Half throttle 37 ~ 43 (23 ~ 27) – –

Range Throttle opening 1 ←22 ←33 ←4

(First Gear) (Second Gear) (Second Gear) (Third Gear) (Third Gear) (Fourth Gear)

DFully opened 40 ~ 46 (25 ~ 29) 90 ~ 96 (56 ~ 60) 160 ~ 166 (100 ~ 104)

(Drive) Half throttle 21 ~ 27 (13 ~ 17) 53 ~ 59 (33 ~ 37) 98 ~ 104 (61 ~ 65)

Fully closed 13 ~ 19 (8 ~ 12) 24 ~ 30 (15 ~ 19) 46 ~ 52 (29 ~ 32)

3Fully opened 40 ~ 46 (25 ~ 29) 90 ~ 96 (56 ~ 60) –

(Third) Half throttle 21 ~ 27 (13 ~ 17) 53 ~ 59 (33 ~ 37) –

Fully closed 13 ~ 19 (8 ~ 12) 24 ~ 30 (15 ~ 19) –

2Fully opened 40 ~ 46 (25 ~ 29) 94 ~ 100 (59 ~ 63) –

(Second) Half throttle 21 ~ 27 (13 ~ 17) 94 ~ 100 (59 ~ 63) –

Fully closed 13 ~ 19 (8 ~ 12) 82 ~ 88 (51 ~ 55) –

L– 50 ~ 56 (31 ~ 35) – –

(First)

LOCK-UP SPEED CHART Transfer gear ratio: High: 1.000

(

Rear axle ratio: 4.555

)

Km/h (mph)

Mode Lock-Up ON Lock-Up OFF

2nd 3rd 4th 2nd 3rd 4th

Normal 75 ~ 81 55 ~ 61 67 ~ 73 70 ~ 76 47 ~ 53 62 ~ 68

(47 ~ 50 ) (34 ~ 38) (42 ~ 45) (43 ~ 47) (29 ~ 33) (39 ~ 42)

Power 72 ~ 78 77 ~ 83 77 ~ 83 67 ~ 73 68 ~ 74 72 ~ 78

(45 ~ 48 ) (48 ~ 52) (48 ~ 52) (42 ~ 45) (42 ~ 46) (45 ~ 48)

D range

Throttle

opening

9%

ELECTRONIC DIAGNOSIS

HOW TO DIAGNOSE THE PROBLEM

1. To avoid incorrect diagnostics: this book needs to be

followed accurately. Unless stated: do not jump

directly to a section that could contain the solution:

some important information may be missed.

2. The sections in CAPITALS and bold are the main

sections that can be found in the contents.

3. The GOTO “SECTION” means to continue to check

going to the “section”.

4. The GOTHROUGH “SECTION” means to go through

the “section” and then to go back to the place the

GOTHROUGH was written.

5. BASIC ELECTRIC CIRCUITS:

You should understand the basic theory of electricity.

This will include the meaning of voltage, amps,

ohms, and what happens in a circuit with an open or

shorted wire. You should also be able to read and

understand wiring diagrams.

6. IGNITION CYCLE:

When the car is driven a malfunction can occur due to

a car wiring harness problem, in this case the driver

can reset the system (as on a personal computer). To

reset the computer he must:

(1) Stop the car and the engine.

(2) Turn the key ignition OFF.

(3) Turn the key ignition ON.

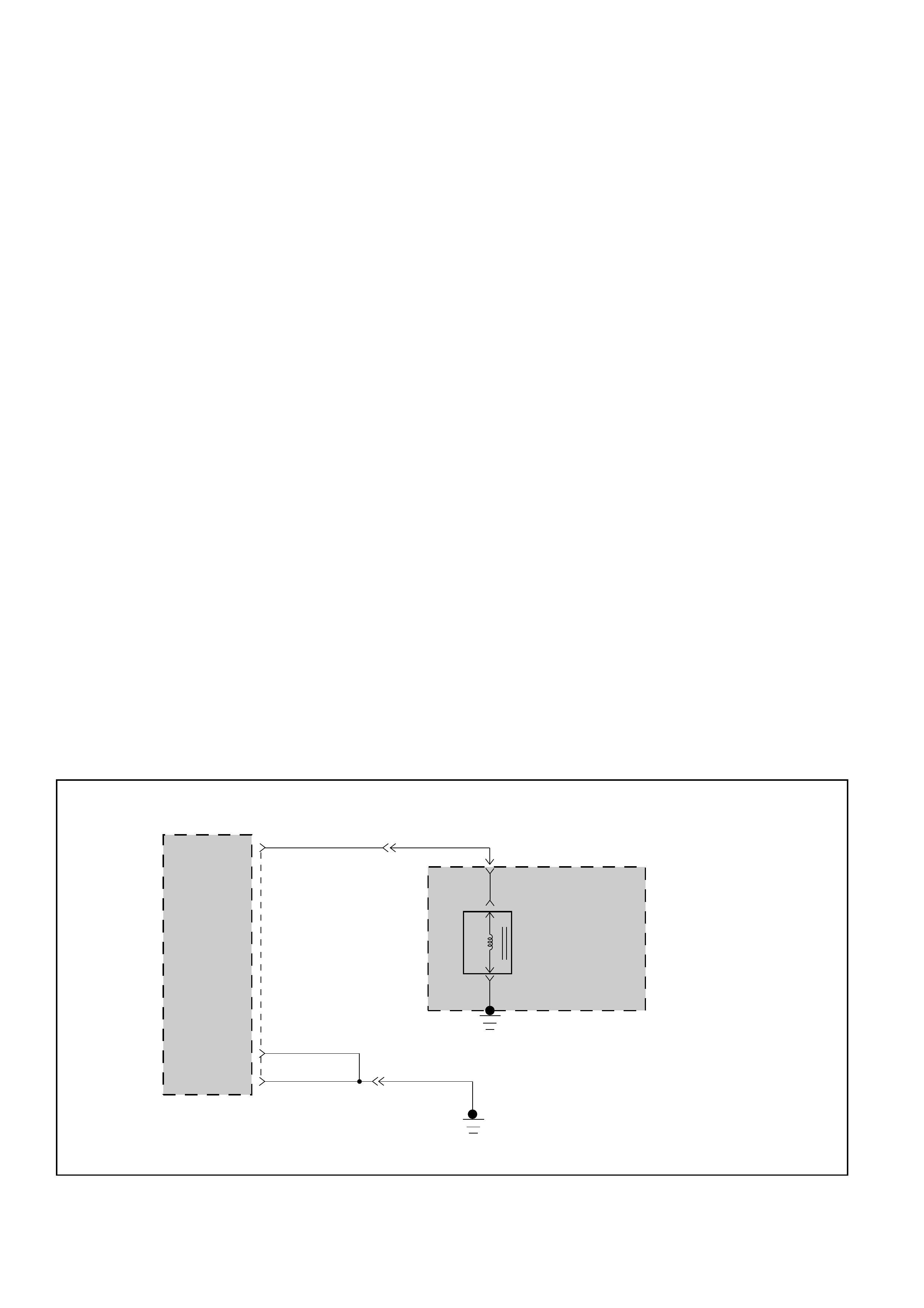

CHECK TRANS INDICATOR

Find CHECK TRANS indicator and verify if it is:

A. Flashing: GOTO DIAGNOSTIC CHECK.

B. Staying on: GOTHROUGH CHECK TRANS CHECK.

C. Is never ON when the ignition key is turned on:

GOTHROUGH CHECK TRANS CHECK

D. Is ON during 2 to 3 seconds at ignition but OFF after:

Normal operation. No DTC or malfunction.

CHECK

TRANS

821LW003

DIAGNOSTIC CHECK

This test determines if the transmission itself or its

inputs or outputs connections or sensors are failing.

1. Connect the TECH2: GOTHROUGH TECH2

CONNECTION.

2. Turn on the ignition but not the engine.

3. Push “F2” on TECH2 to see the Diagnostic Trouble

Codes (DTC):

4. IF you have DTC?

YES: write down all code numbers and do the DTC

CHECK

NO: the DTC can not help you finding the problem.

(1) GOTHROUGH “CHECK TRANS” CHECK

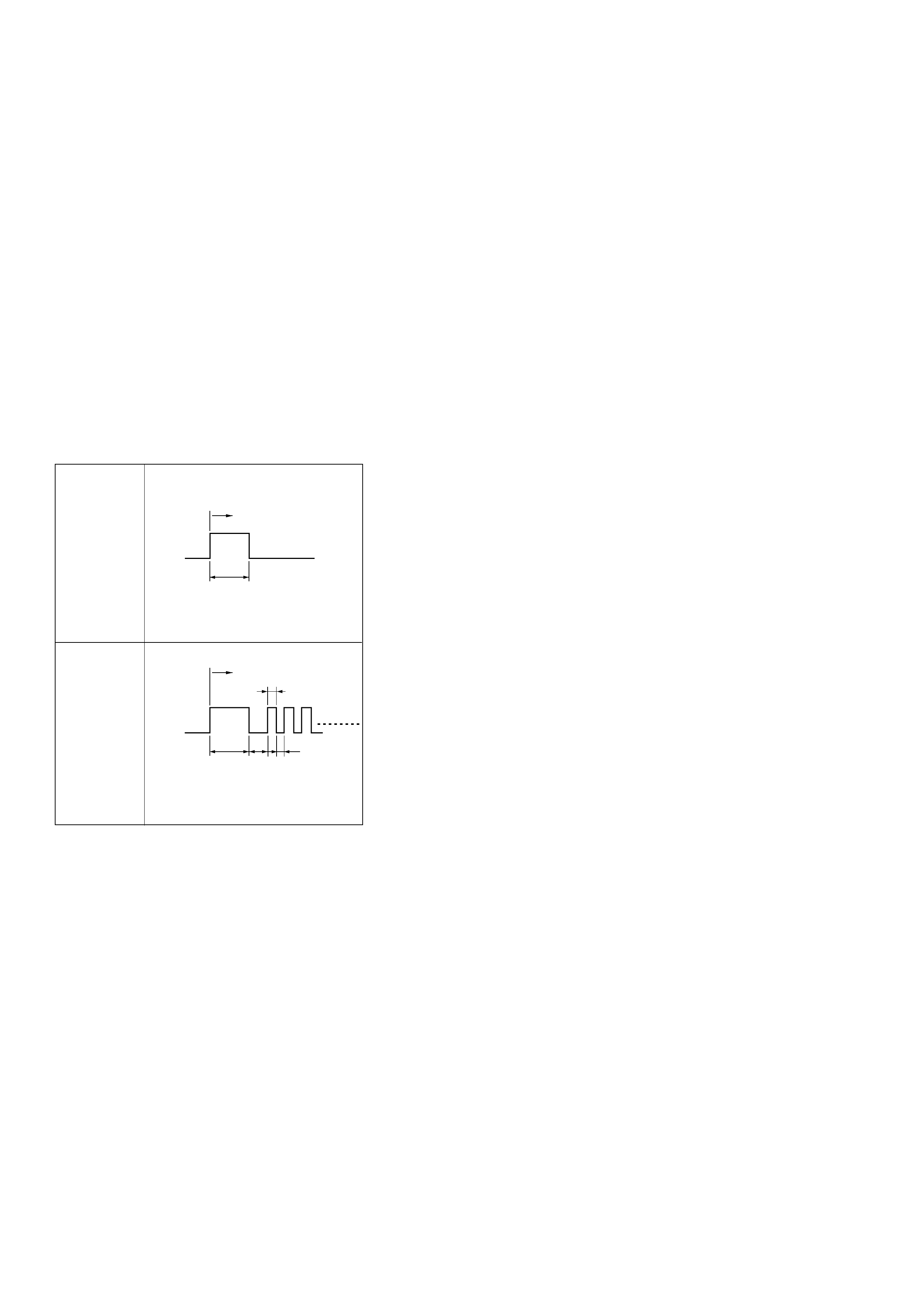

(2) IF it is flashing and the flash is 0.2 seconds ON

and 0.2 seconds OFF, this means that you should

have a DTC stored. Please recheck GOTO

DIAGNOSTIC CHECK

(3) IF the CHECK TRANS indicator is not flashing

GOTO WITHOUT DTC SET.

Normal

Abnormal

ON

OFF

IGN Key ON

3 Sec.

(Lamp check)

ON

OFF

IGN Key ON

3 Sec.

(Lamp check)

0.2 Sec.

(2.5 Hz)

3.2 Sec.

0.2 Sec.

“CHECK TRANS” CHECK

1. CASE it is ON during 2 to 3 seconds at ignition (or

when the engine is cranked) but it is OFF after. The

indicator is working normally GOTO DIAGNOSTIC

CHECK.

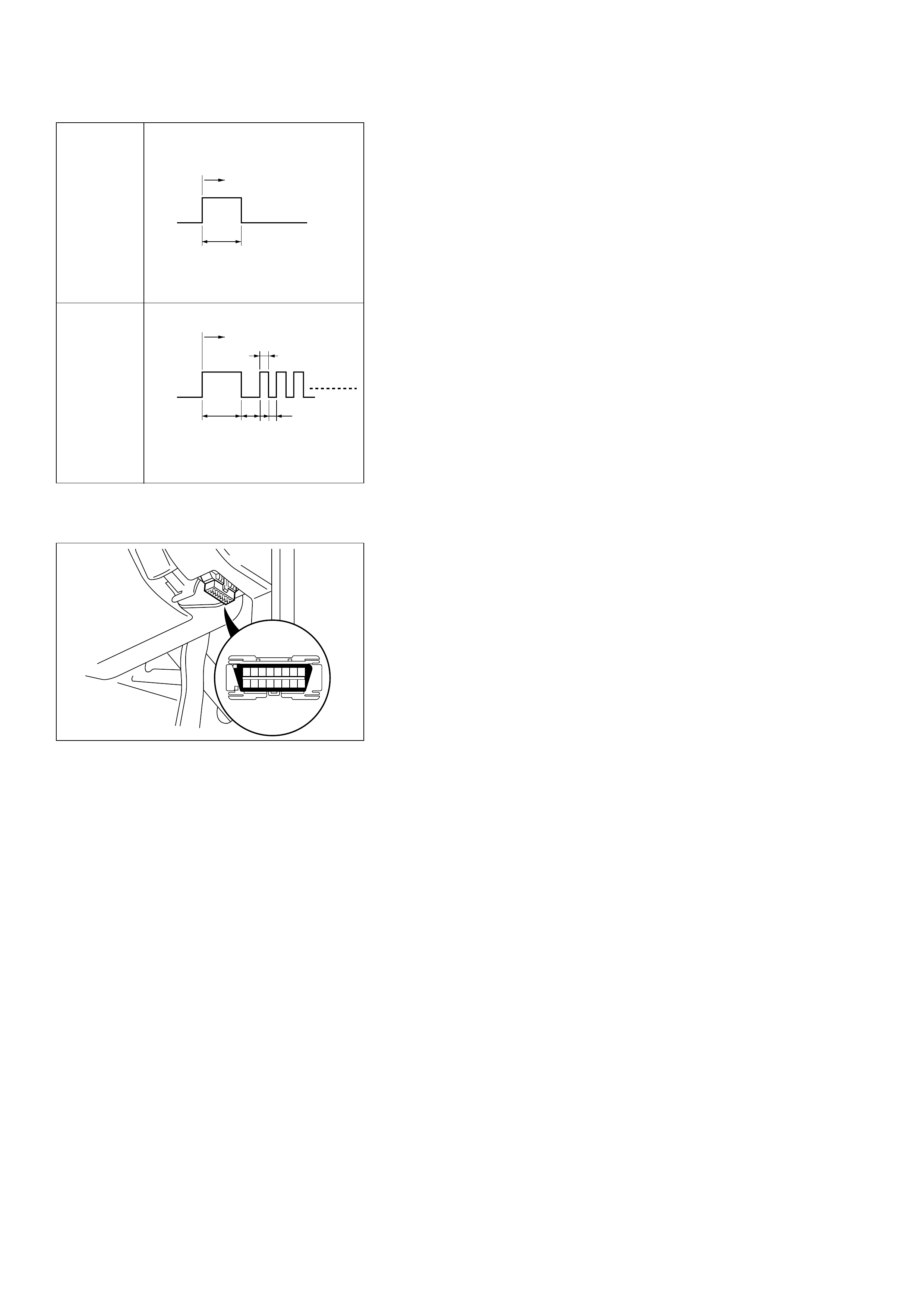

2. CASE it is flashing and the flash is 0.2 seconds ON

and 0.2 seconds OFF always when ignition is on

(engine cranked or not). This means that there is a

malfunction. GOTO DIAGNOSTIC CHECK.

3. CASE the CHECK TRANS indicator is flashing always

and the flash is 0.4 seconds ON and 0.4 second OFF.

(1) This means that the Transmission Control Module

(TCM) is in flashing code mode. This mode is only

used for service. This mode is set when the

terminal 11 of data link connector C-102 is set to

ground. To go out of this mode.

(2) Check if terminal 11 of data link connector C-102

is shorted to ground. (Voltage is about 0 volts

when there is a short to ground instead of 5

volts).

(3) Check if TCM terminal D16 has the same problem.

(4) Remove the short circuit to ground due to wiring

problems.

(5) IF problem solved: GOTO CHECK TRANS

INDICATOR.

ON

OFF

IGN Key ON

3 Sec.

(Lamp check)

ON

OFF

IGN Key ON

3 Sec.

(Lamp check)

0.2 Sec.

(2.5 Hz)

3.2 Sec.

0.2 Sec.

Normal

Abnormal

826RV061

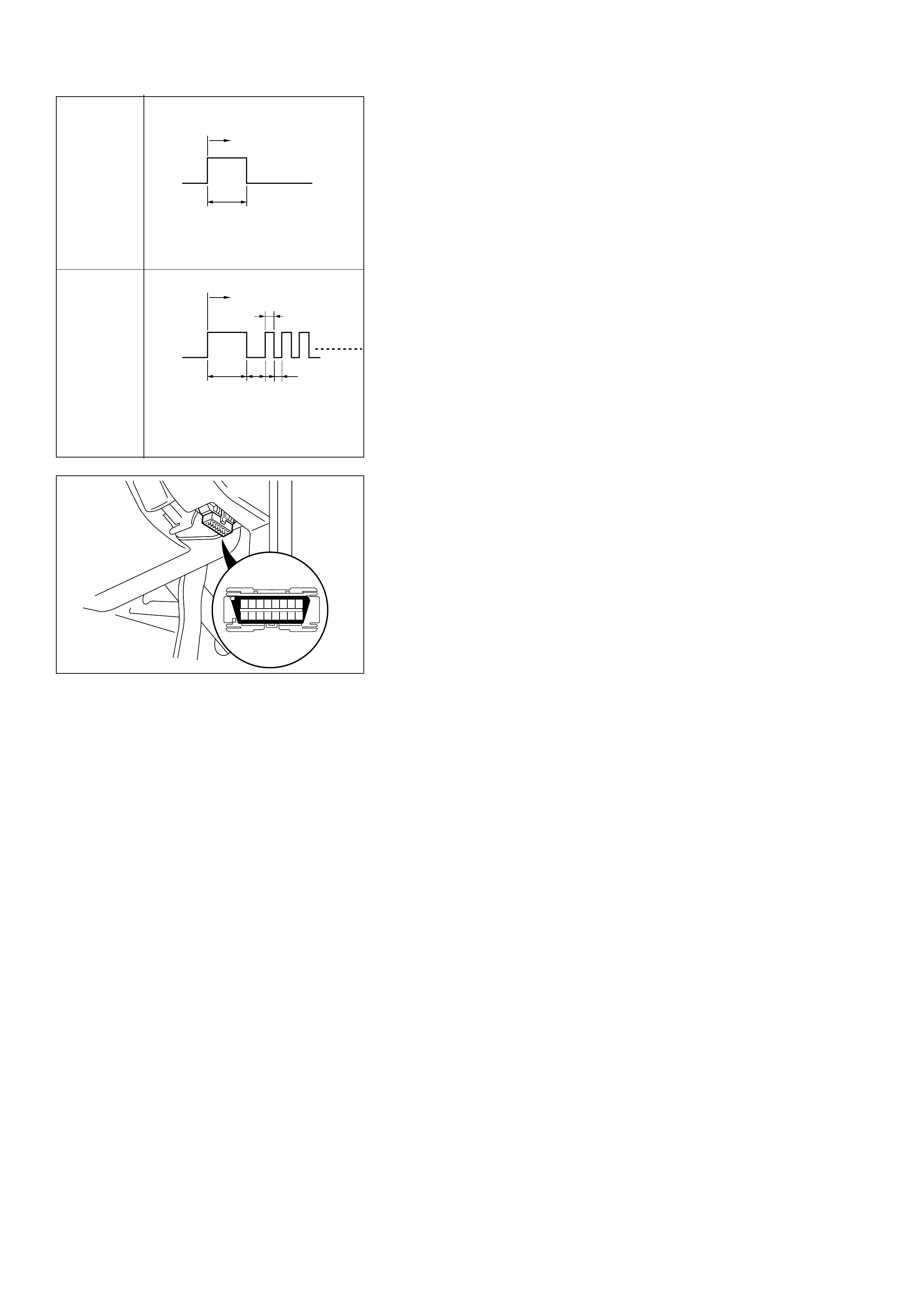

87654321

161514131211109

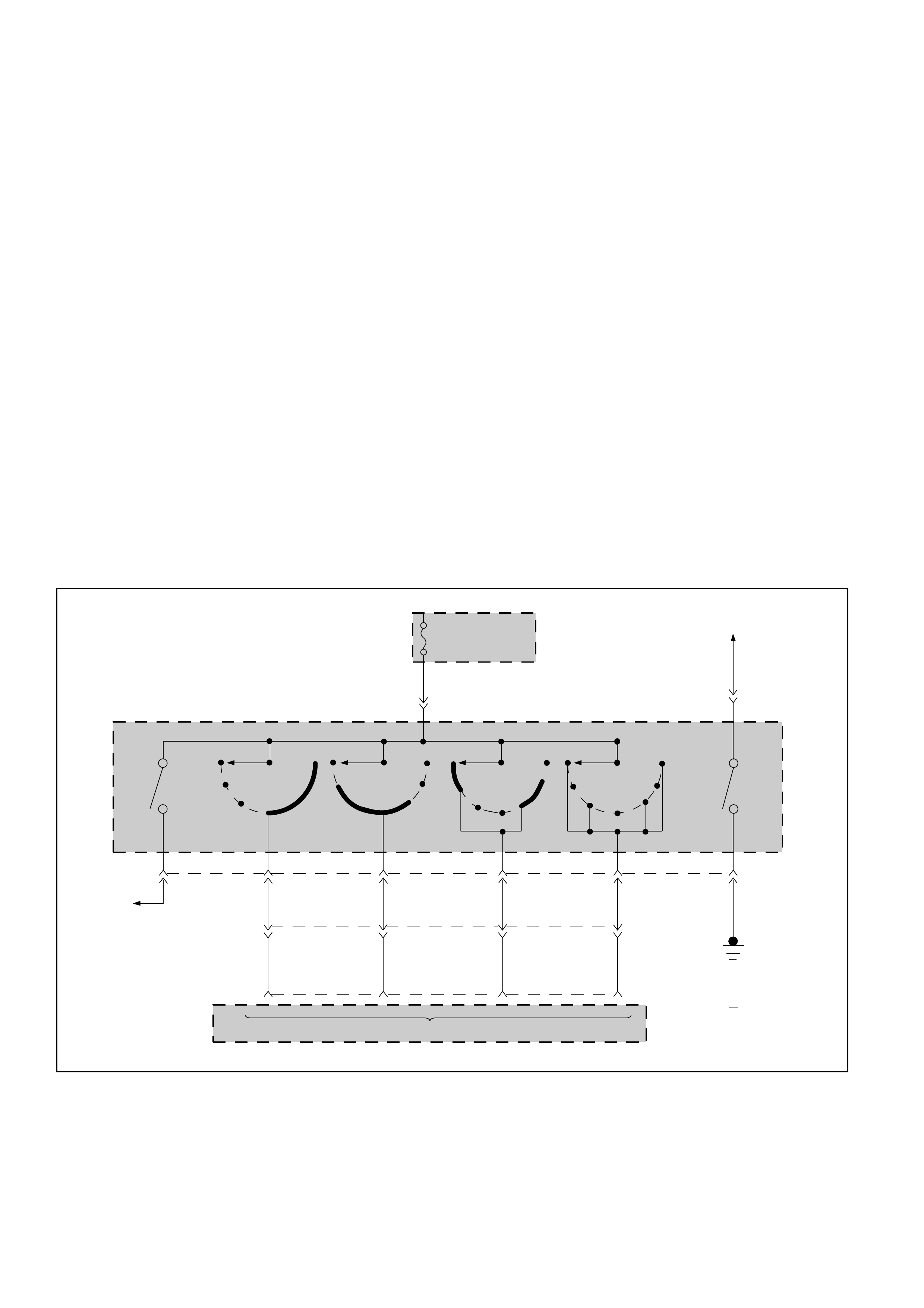

TRANSMISSION

CONTROL

MODULE

(TCM)

CHECK TRANS

INDICATOR

CONTROL

DIAGNOSTIC

INPUT

CHECK TRANS

(METER)

B-248

B-242

FUSE

CB-5

15A

FUSE BOX

ORN/BLU

H-26

7

D16(16) C-95

C10(10) C-95

YEL/BLK

11 45

DATA LINK

CONNECTOR

(C-102)

ORN/BLU

4. CASE it is staying ON always when Ignition is ON.

(1) This means that connection between the Lamp

and the TCM is shorted to ground.

(2) Verify if instrument panel terminal 8 of connector

B-24 is shorted to ground.

(3) Verify if the TCM connector C-95 terminal C10 is

shorted to ground.

(4) Verify that the instrument panel terminal 2 of con-

nector B-24 is connected to battery.

(5) IF problem solved: GOTO CHECK TRANS

INDICATOR.

5. CASE it is staying OFF with the ignition ON (engine

OFF).

(1) This means that connection between the lamp

and the TCM is shorted to battery or opened.

(2) Verify if instrument panel terminal 8 of connector

B-24 is shorted to battery or open.

(3) Verify if the TCM connector C-95 terminal C10 is

shorted to battery or open.

(4) Verify that the instrument panel terminal 2 of

connector B-24 is connected to battery. If not

check the fuses and the connections voltage.

(5) IF problem solved: GOTO CHECK TRANS

INDICATOR.

D07LW004

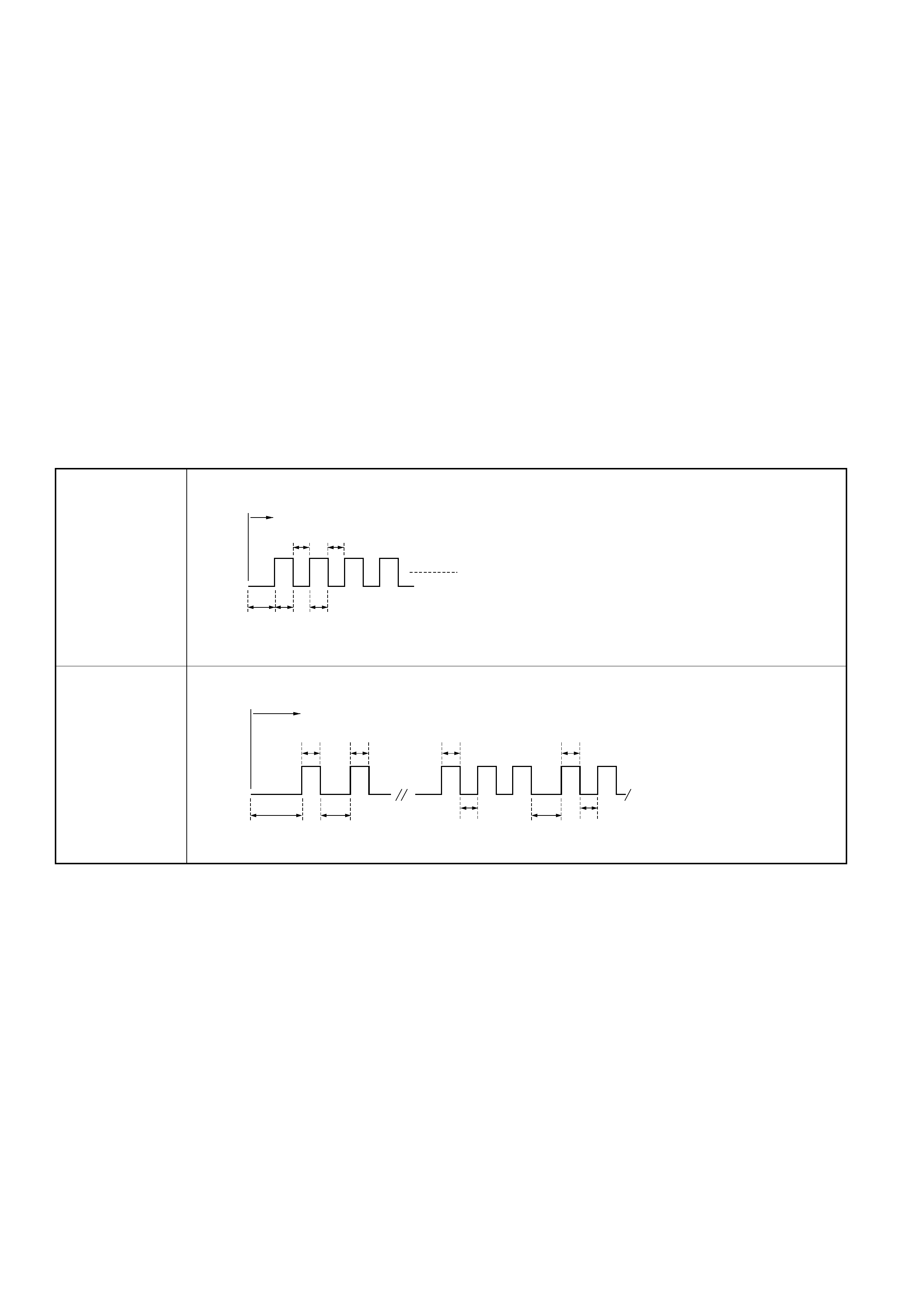

FLASHING CODES

1. ON BOARD DIAGNOSIS (SELF-DIAGNOSIS)

(1) The Transmission Control Module (TCM)

conducts a self-test of most of the wiring and

components in the system each time the key is

turned ON. If a fault is detected the TCM will store

a Diagnostic Trouble Code (DTC) in memory. It’s a

number that corresponds to a specific problem.

(2) When the problem detected is important: the

CHECK TRANS indicator is flashing (turned ON

0.2 seconds and OFF 0.2 seconds) until the fault is

repaired and the TCM memory is cleared.

ON

OFF

IGN Key ON

3 Sec.

(Lamp check)

ON

OFF

IGN Key ON

3 Sec.

(Lamp check)

0.2 Sec.

(2.5 Hz)

3.2 Sec.

0.2 Sec.

Normal

Abnormal

2. DIAGNOSTIC TROUBLE CODES (DTC)

(1) DTC can be displayed by the Transmission

Control Module (TCM) by shorting together

terminals 11 and 4 or 5 (ground) of the TCM

Diagnosis Connector (C-102) located driver

compartment.

(This grounds the TCM pin D16).

826RV061

87654321

161514131211109

ON

OFF

Diagnostic test start

0.4 Sec. 0.4 Sec.

3.2 Sec. 0.4 Sec. 0.4 Sec.

(1.25 Hz)

ON

OFF

The trouble code(s) will flash 3 times.

Example: DTC 11 x 3 (times), DTC 32 x 3 (times)

3.2 Sec.

0.4 Sec. 0.4 Sec. 0.4 Sec. 0.4 Sec.

0.4 Sec.

1.2 Sec. 1.2 Sec. 0.4 Sec.

Diagnostic test start

Normal

Abnormal

(2) After this, the CHECK TRANS Indicator will be OFF

for 3.2 second and then will flash each DTC 3

times.

1When there are more than 9 flashes this

means that the indicator is constantly flashing,

OFF for 0.4 seconds, ON for 0.4 seconds. In

this case there is no DTC stored in memory.

•To find the problem without a scan tool and

without DTC GOTO WITHOUT DTC SET.

2When there are less than 9 flashes you will

see DTC of 2 digits repeated 3 times each and

when all codes have been displayed they are

displayed again beginning from the first one.

3Do not care about the DTC order : if “21” is

before “22” it does not matter.

4Write down all codes numbers and GOTO DTC

CHECK.

(3) IF CHECK TRANS indicator is not flashing GOTO

“CHECK TRANS” CHECK.

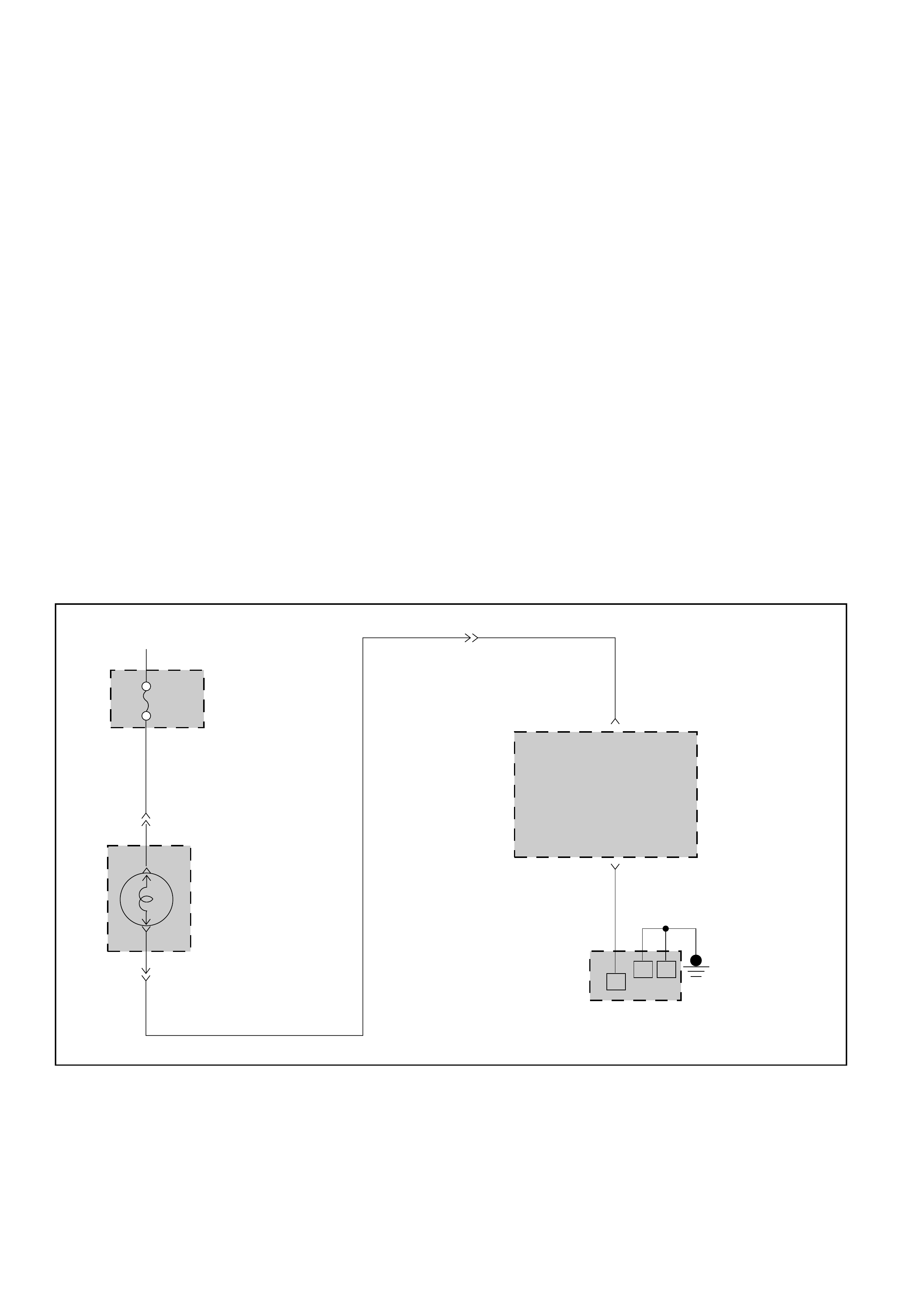

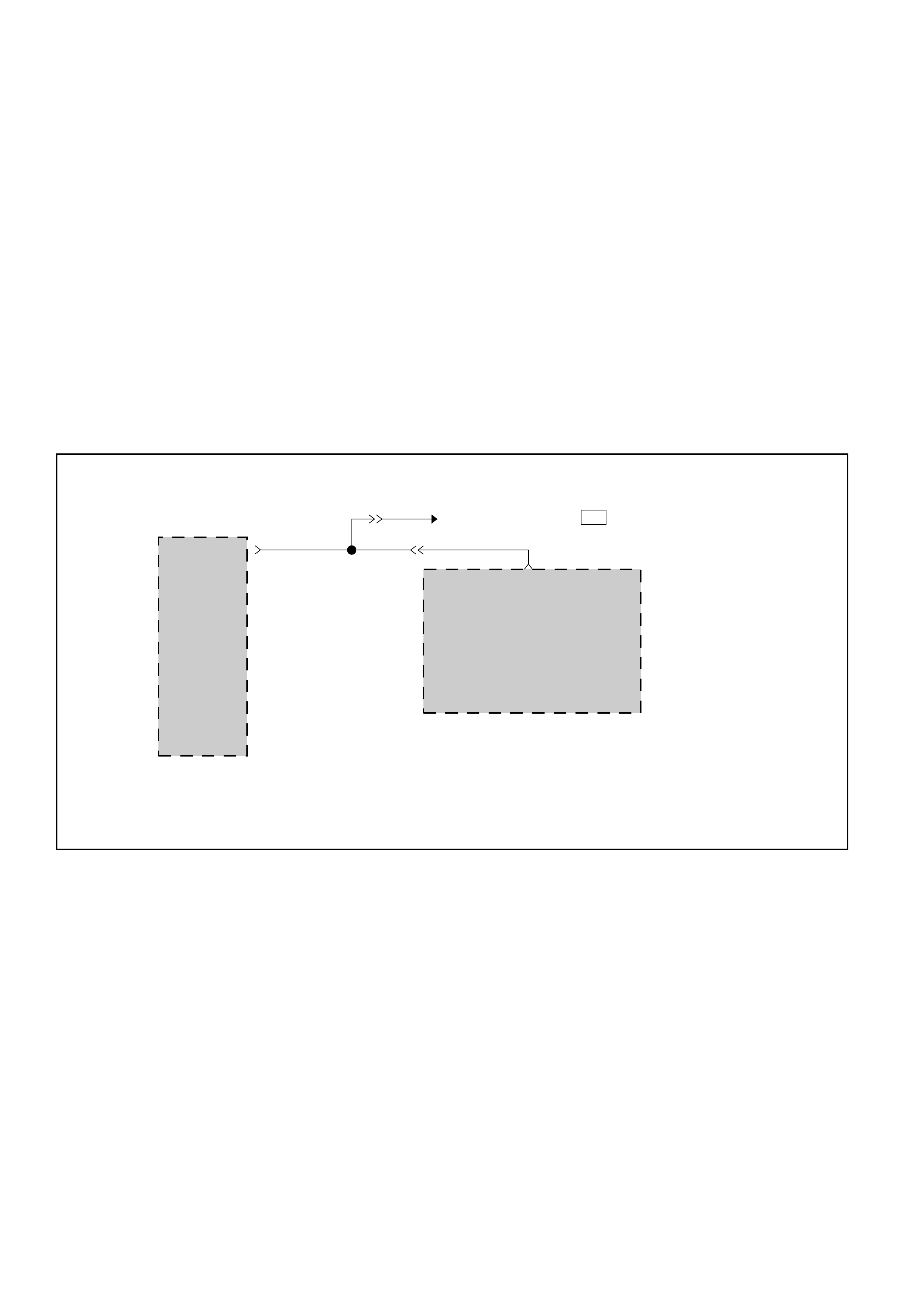

TECH2 CONNECTION

In order to access Transmission Control Module (TCM)

data, use of the TECH2 scan tool is required.

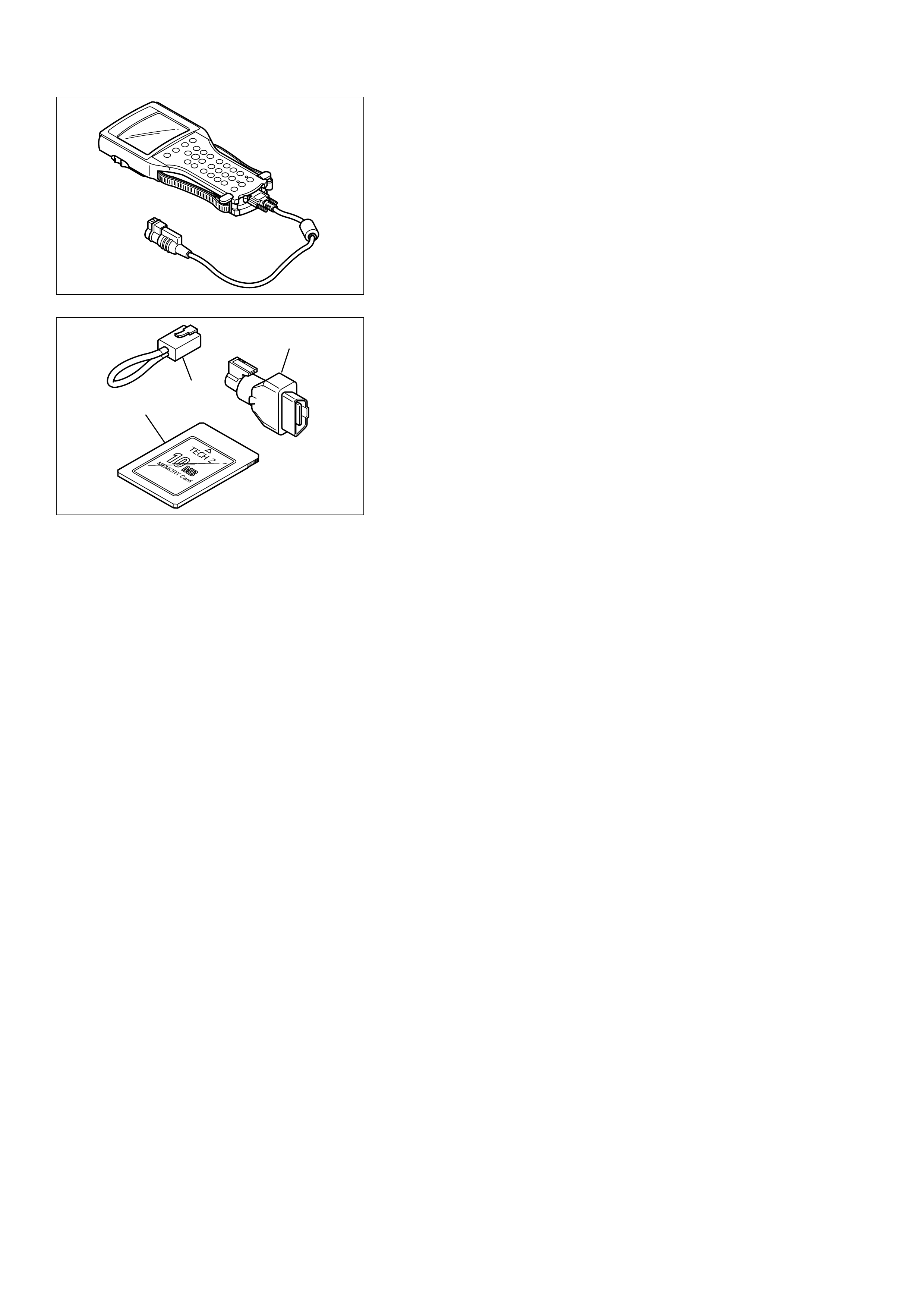

1. The electronic diagnosis equipment is composed of:

(1) TECH2 (3000094) hand-held scan tool, and DLC

cable (3000095).

(2) SAE 16/19 adapter (3000098) (1), RS 232 loop back

connector (3000112) (2), and PCMCIA card

(3000117) (3).

901RW176

F07RW033

1

2

3

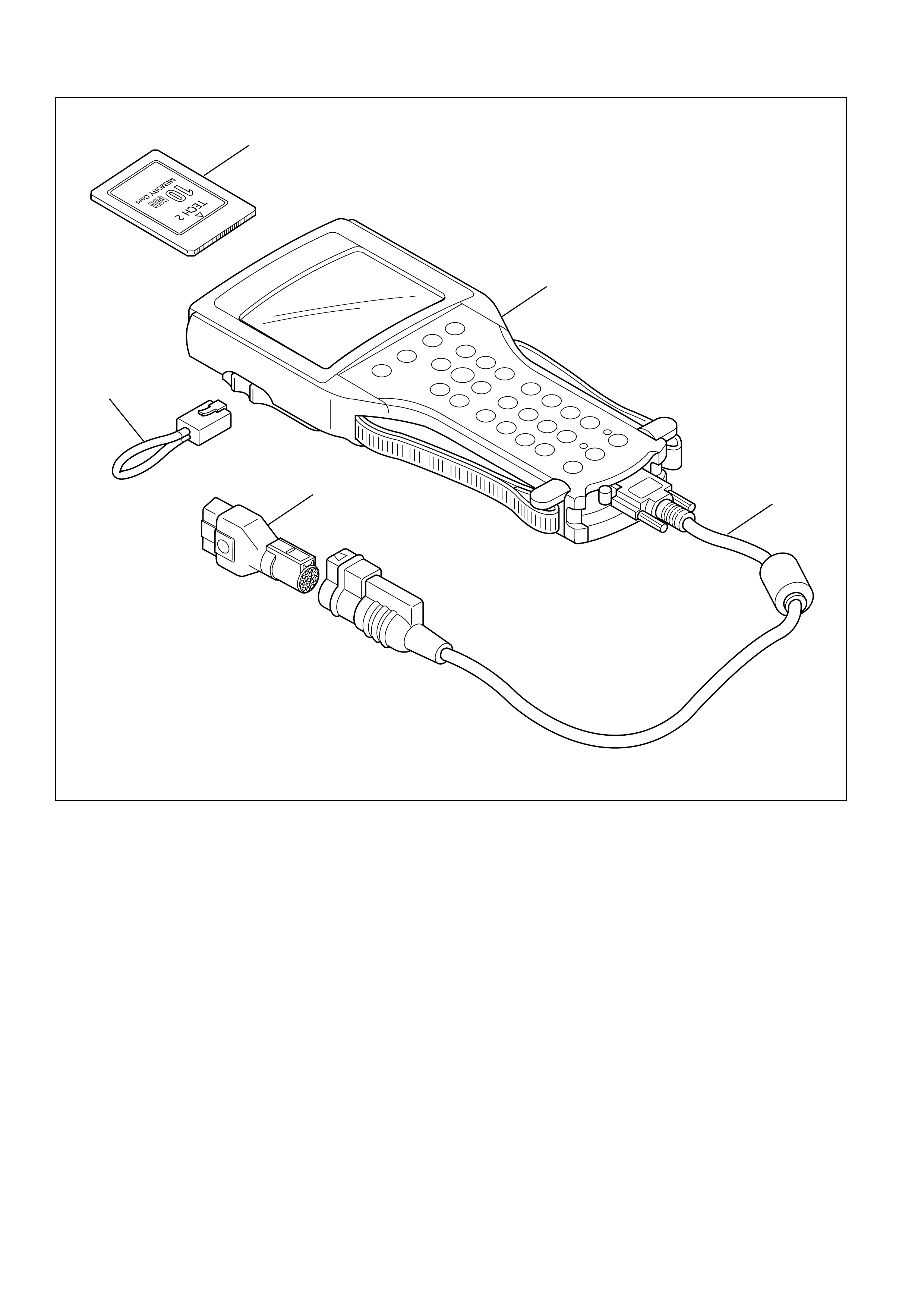

2. Connecting the TECH2

NOTE:

Always observe instructions in the TECH 2 and the Holden

Program PCMCIA card.

Before operating the Isuzu PCMCIA card with the TECH2,

the following steps must be performed:

1. The Holden Program PCMCIA card (1) inserts into the

TECH2 (5).

2. Connect the SAE 16/19 adapter (3) to the DLC

cable(4).

3. Connect the DLC cable to the TECH2 (5).

4.

CAUTION

Make sure the vehicle ignition is off.

Connecting TECH 2 with the engine running may

result in the transmission entering 'Fail- safe' mode.

Should this occur, cycle the ignition to perform a

system reset.

1

5

4

3

2

Legend

1. PCMCIA Card

2. RS232 Loop Back Connector

3. SAE 16/19 Adaper

4. DLC Cable

5. Tech2

901RW180

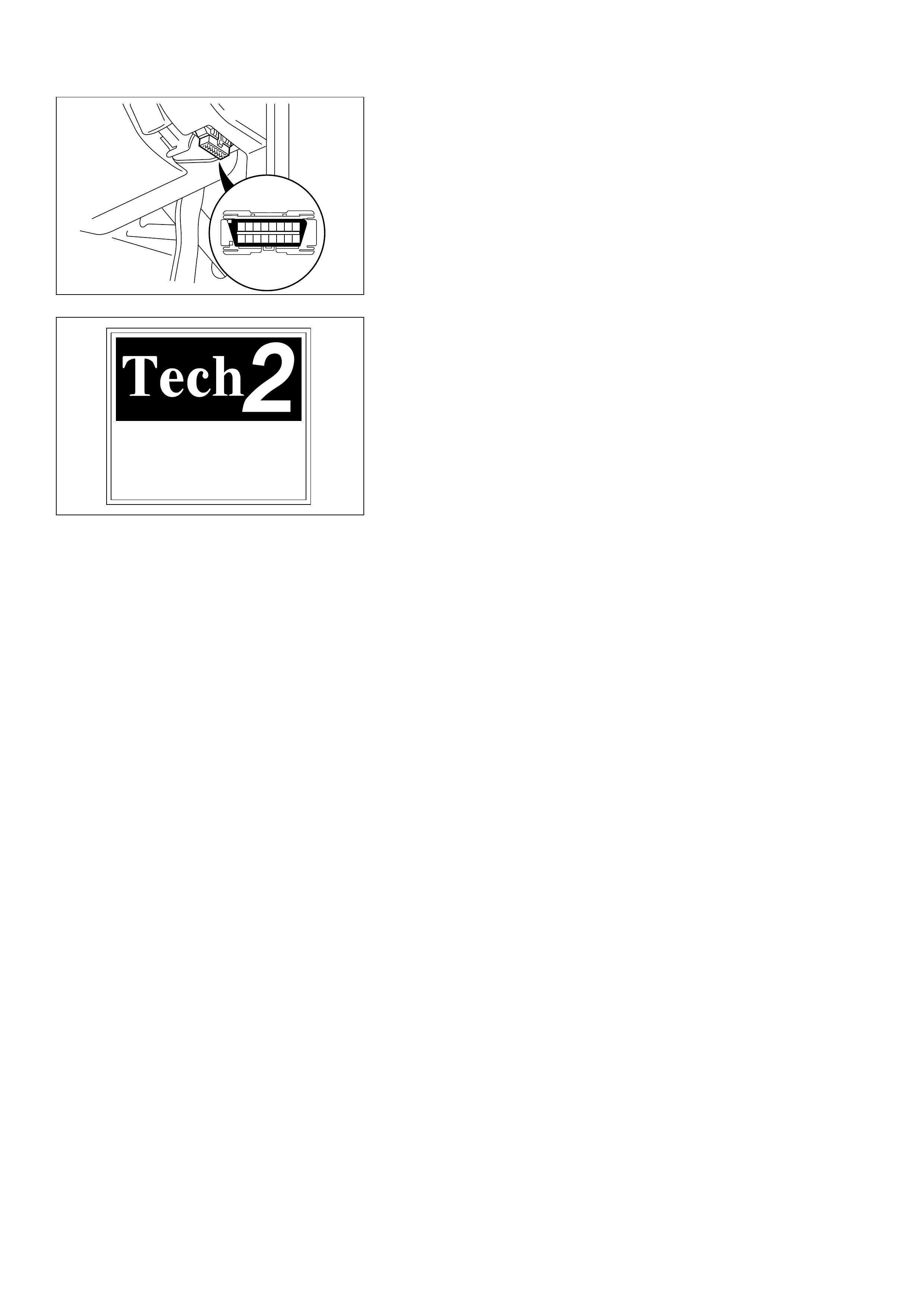

87654321

161514131211109

826RV061

Press (ENTER) To Continue

060RW009

5. Connect the TECH2 SAE 16/19 adaptor to the vehicle

DLC.

6. The vehicle ignition turns on.

7. Verify the TECH2 power up display.

NOTE:

The RS232 Loop back connector is only to use for

diagnosis of TECH2 and refer to user guide of the TECH2.

CLEAR DTC

Remark: If you clear the DTC (Diagnosis Trouble

Codes) you will not be able to read any codes

recorded during the last Trouble.

Remark: To be able to use the DTC again to identify a

problem you will need to reproduce the fault or the

problem. This may require a new test drive or just

turning the ignition on (this depends on the nature of

the fault).

1. IF you have a TECH2:

(1) Connect the TECH2 if it is still not connected

GOTHROUGH TECH2 CONNECTION.

(2) Push “F4” and answer “Yes” to the question “Do

you really want to clear the codes?”

1When a malfunction remains as it is the

TECH2 displays “4L30E CODES NOT

CLEARED”. This means that the problem is

still there or that the recovery was not done

please GOTO DTC CHECK.

2When a malfunction has been repaired and

the recovery is done the TECH2 displays

“4L30E CODES CLEARED”.

2. IF you have no TECH2:

(1) Short the Data Link Connector C-102 terminal 11

to terminal 4 or 5 (ground).

1IF it is flashing and the flash is 0.4 seconds ON

and 0.4 second OFF without interruption, this

means that there is no DTC. The DTCs are

already cleared.

(2) IF a code is flashed, wait until the lamp is

flashing.

(3) Push POWER SWITCH (do this within 3 second).

1If you continue to have malfunctions: This

means that the problem is still there or that

the recovery was not done please see DTC

CHECK.

(4) IF you can not clear the DTC:

1GOTHROUGH TCM PRECAUTIONS.

2Disconnect the TCM.

3Reconnect the TCM.

4IF the DTC is not cleared: GOTO TCM MEM-

CAL REPLACEMENT.

87654321

161514131211109

826RV061

DTC CHECK

1 Diagnosis Trouble Codes (DTC) have been identified

by TECH2 or FLASHING CODES.

2. You have written the list of the DTC. The order of the

malfunctions has no meanings for this TCM. Usually

only one or two malfunctions should be set for a

given problem.

3. Check directly the DTCs you identified. The DTC are

sorted by number. See Chart 2:

DIAGNOSTIC TROUBLE CODES (Page 7A1-63).

F0: DATA LIST QUICK CHECK

TECH2 DISPLAY CONDITONS CORRECT VALUE FOR

DIAGNOSIS

SEE*1

BATTERY VOLTAGE Ignition ON 9 V ≤voltage ≤15.5 V DTC 25

(V) or 26

FORCE MOTOR CUR. Engine at idle speed approx. 0.9 A DTC 35

CALCULAT. PRESS. Parking brake on approx. 4.0 bar

Selector lever position ”D“

SOLENOID A Vehicle traveling at a speed of: approx. ACTIVE DTC 31

50 km/h (32 mph) with selector lever in or 41

position ”2“ or approx. 70 km/h (44 mph)

with selector lever in position ”3“

SOLENOID B Vehicle traveling at a speed of: approx. ACTIVE DTC 32

10 km/h (6 mph) with selector lever in or 42

position ”L“ or approx. 30 km/h (18 mph)

with selector lever in position ”2“

BAND APPLY SOL. Engine at idle speed approx. 99% DC DTC 34

Selector lever position ”L“or 44

TCC SOLENOID Vehicle traveling at a speed of approx. ON DTC 33

80 km/h (50 mph) or 43

Selector lever position ”D“

TCC SLIP RPM Constant engine speed 0±10 RPM DTC 33

Selector lever position “D”or 43

TCC on

BRAKE SWITCH Ignition ON ACTIVE DTC 55

Brake pedal pressed or 56

AT INPUT SPEED Engine speed ≤200 rpm Engine speed: (RPM) DTC 13

Output speed > 1024 rpm or 62

Selector lever position ”D“, ”3“, ”2“, ”L“

AT OUTPUT SPEED Output speed ≤0 rpm Output speed: DTC 11

Engine speed > 3000 rpm (RPM) or 13

Selector lever position ”D“, ”3“, ”2“, ”L“

BAROMETER Engine at idle speed 0.9 ~ 1.0 bar –

SENSOR approx. 0.02 V

SELECTOR POS. Ignition ON Dependent on DTC 53

Shift through all selector lever positions selector lever position or 54

P, R, N, D, 3, 2, L

ACTUAL GEAR Vehicle traveling at a speed of approx. - 4 - DTC 61

100 km/h (62 mph)

Selector lever position ”D“

NOTE: (*1) FOR DIAGNOSIS OF A DTC SEE CHART 2: DIAGNOSTIC TROUBLE CODES (DTC)

(PAGE 63)

•IF ALL VALUES ARE CORRECT, CONTINUE DIAGNOSIS WITH F5: ACTUATOR TEST QUICK CHECK.

NOTE: (*1) FOR DIAGNOSIS OF A DTC SEE CHART 2: DIAGNOSTIC TROUBLE CODES (DTC)

(PAGE 63)

TECH2 DISPLAY CONDITONS CORRECT VALUE FOR

DIAGNOSIS

SEE*1

SELECTOR PIN A Ignition ON ACTIVE DTC 53

Selector lever position: or 54

”P“, ”R“, ”3“ or ”2“

SELECTOR PIN B Ignition ON ACTIVE DTC 53

Selector lever position: or 54

”R“, ”N“,”D“ or ”3“

SELECTOR PIN C Ignition ON ACTIVE DTC 53

Selector lever position: or 54

”D“, ”3“, ”2“ or ”L“

SELECTOR PIN P Ignition ON ACTIVE DTC 53

Selector lever position: or 54

”P“, ”N“, ”3“ or ”L“

TPS SIGNAL Ignition ON

Throttle body in idle speed position 0.1 V to 0.96 V (0%) DTC 21

Throttle body in full load position 4.9 V or less (99%) or 22

KICK DOWN SWITCH Ignition ON ACTIVE DTC 52

Depress accelerator pedal to stop

A/C REQUEST Engine running. Air conditioning ON. ACTIVE

CHECK WIRE

Compressor engaged. FROM TCM

CONNECTOR

C-91

TERMINAL

D8 FOR

OPEN

CIRCUIT.

TRANSM. OIL TEMP. Engine running 70 - 120°C/158 - 248°F DTC 15

approx. 1.00 ~ 3.10 V or 16

COOLANT TEMP SW. Ignition ON: Engine warm COLD (≤63°C) DTC 51

WARM (> 70°C)

POWER SWITCH Ignition ON ACTIVE TRANSMIS-

Press “POWER” switch SION

OPERATING

POWER LAMP Engine running ON MODE TEST

Press “POWER” switch SEE PAGE

133

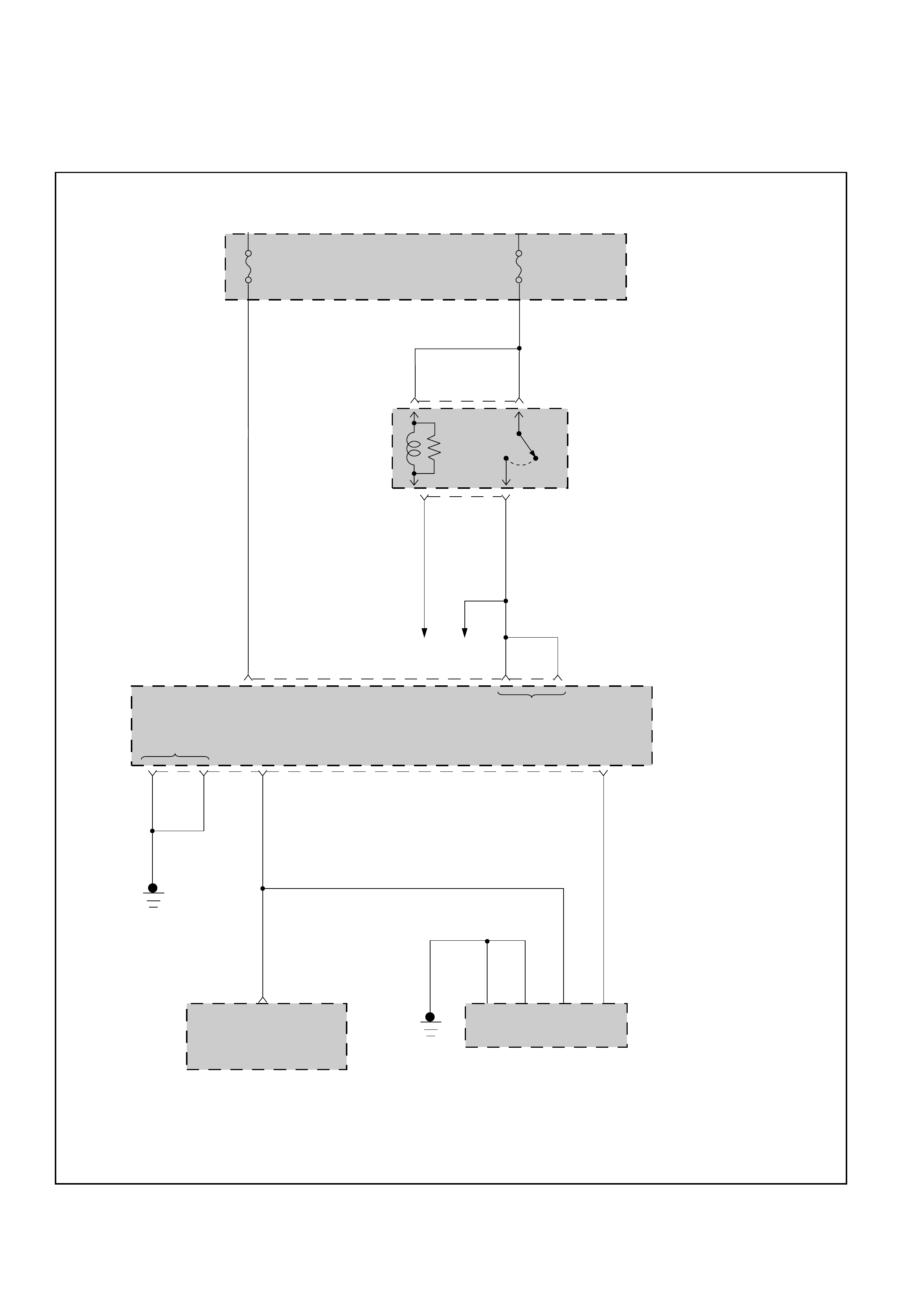

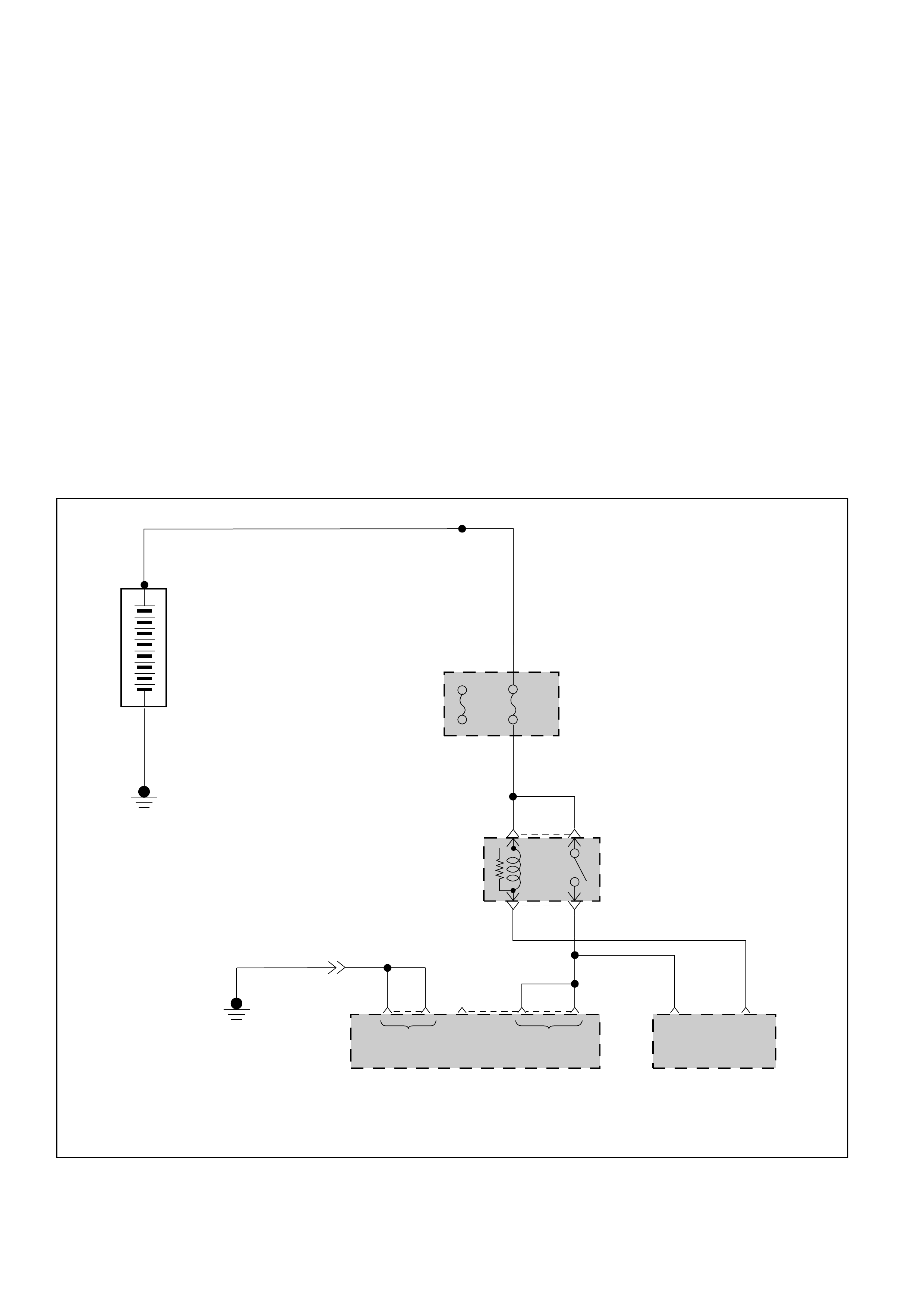

CHART 1: DIAGNOSIS CONNECTOR AND VOLTAGE SUPPLY TEST

FUSE

EB-12

10A

RELAY &

FUSE

BOX

FUSE

EB-14

20A

ECM

MAIN

RELAY

A4(4) A7(7) A8(8) C-96

TO ECM

TRANSMISSION

CONTROL

MODULE (TCM)

BATTERY

INPUT

GROUND

IGNITION

INPUT

DIAGNOSTIC

INPUT

51

X-18

3 2 X-18

RED/

GRN

GRN

SERIAL DATA

ENGINE CONTROL MODULE (ECM)

DATA LINK CONNECTOR (C-102)

35 E-61 54911

YEL YEL/BLK

BLK

C8

(8)

D1

(17)

C1

(1) C-95D16

(32)

BLU/

RED RED/

BLU

RED/BLU

YEL

BLK BLK

YEL

D07LW005

CHART 1: DIAGNOSIS CONNECTOR AND VOLTAGE SUPPLY TEST

TECH2 REFERS TO CHART 1 WHEN THE EQUIPMENT IS CORRECTLY CONNECTED, BUT NO DATA (WITH IGNITION ON) IS RECEIVED

FROM TECH2.

•PERFORM TECH2 SELF-TEST.

IS TECH2 OK?

•IGNITION SWITCH OFF.

•DISCONNECT TCM CONNECTOR C-95 AND C-96.

•IGNITION SWITCH ON.

•CONNECT VOLTMETER BETWEEN TERMINAL A4 AND

GROUND TERMINAL C1 OR D1 OF TCM CONNECTOR.

•THEN CONNECT VOLTMETER BETWEEN TERMINAL A7

OR A8 AND GROUND TERMINAL C1 OR D1 OF TCM

CONNECTOR.

DO BOTH DISPLAYS INDICATE BATTERY VOLTAGE?

•IGNITON SWITCH OFF.

•CONNECT OHMMETER BETWEEN TERMINAL 11 OF 16-PIN

DATA LINK CONNECTOR C-102 AND TERMINAL D16 OF

TCM CONNECTOR C-95.

•THEN CONNECT OHMMETER BETWEEN TERMINAL 4 OR 5

OF 16-PIN DATA LINK CONNECTOR C-102 AND GROUND.

DO BOTH DISPLAYS INDICATE APPROXIMATELY 0 OHMS?

•CHECK FOR SHORT BETWEEN TERMINAL D16 AND

GROUND AND BETWEEN TERMINAL D16 AND B+.

IF OK, REPLACE TCM

YES

YES

YES

NO

SEE TECH2 OPERATOR’S MANUAL.

NO

CHECK FUSE OR WIRE FOR OPEN.

NO

CHECK WIRE FOR OPEN.

CHART 2: DIAGNOSTIC TROUBLE CODE (DTC)

FOR

DTC MALFUNCTION DIAGNOSIS

SEE PAGE

11 OUTPUT SPEED FAILURE 7C1 - 66

13 ENGINE SPEED FAILURE 7C1 - 70

15 TRANSMISSION OIL TEMPERATURE SHORT TO PLUS OR OPEN 7C1 - 72

16 TRANSMISSION OIL TEMPERATURE SHORT TO GROUND 7C1 - 74

21 THROTTLE POSITION SENSOR SHORT TO PLUS 7C1 - 76

22 THROTTLE POSITION SENSOR SHORT TO GROUND OR OPEN 7C1 - 78

23 THROTTLE POSITION SENSOR CONNECTOR OPEN 7C1 - 80

25 SUPPLY VOLTAGE TOO LOW 7C1 - 82

26 SUPPLY VOLTAGE TOO HIGH 7C1 - 84

31 SOLENOID A SHORT TO GROUND OR OPEN 7C1 - 86

32 SOLENOID B SHORT TO GROUND OR OPEN 7C1 - 88

33 TCC HIGH SHORT TO PLUS OR OPEN 7C1 - 90

34 BAND APPLY SOLENOID SHORT TO GROUND OR OPEN 7C1 - 94

35 FORCE MOTOR OPEN OR SHORT TO PLUS OR GROUND 7C1 - 96

36 SHIFT HIGH SHORT TO GROUND OR OPEN 7C1 - 98

37 TORQUE MANAGEMENT SERIAL LINE FAULTY 7C1 - 100

41 SOLENOID A SHORT TO PLUS 7C1 - 102

42 SOLENOID B SHORT TO PLUS 7C1 - 104

43 TCC HIGH SHORT TO GROUND 7C1 - 106

44 BAND APPLY SOLENOID SHORT TO PLUS 7C1 - 108

46 SHIFT HIGH SHORT TO PLUS 7C1 - 110

51 ENGINE COOLANT SWITCH SHORT TO GROUND, PLUS OR OPEN 7C1 - 112

52 KICK DOWN ALWAYS ON OR SHORT TO GROUND 7C1 - 114

53 MODE SWITCH IN P OR N OR R BAD POSITION 7C1 - 116

54 MODE SWITCH ILLEGAL POSITION 7C1 - 118

55 BRAKE SWITCH SHORT TO GROUND OR OPEN 7C1 - 120

56 BRAKE SWITCH SHORT TO PLUS 7C1 - 122

61 GEAR ERROR 7C1 - 124

62 DOWNSHIFT PROTECTION 7C1 - 126

63 EPROM CSUM FAILURE 7C1 - 129

82 SHIFT OR BAND APPLY SOLENOIDS FAULTY DURING DRIVING 7C1 - 130

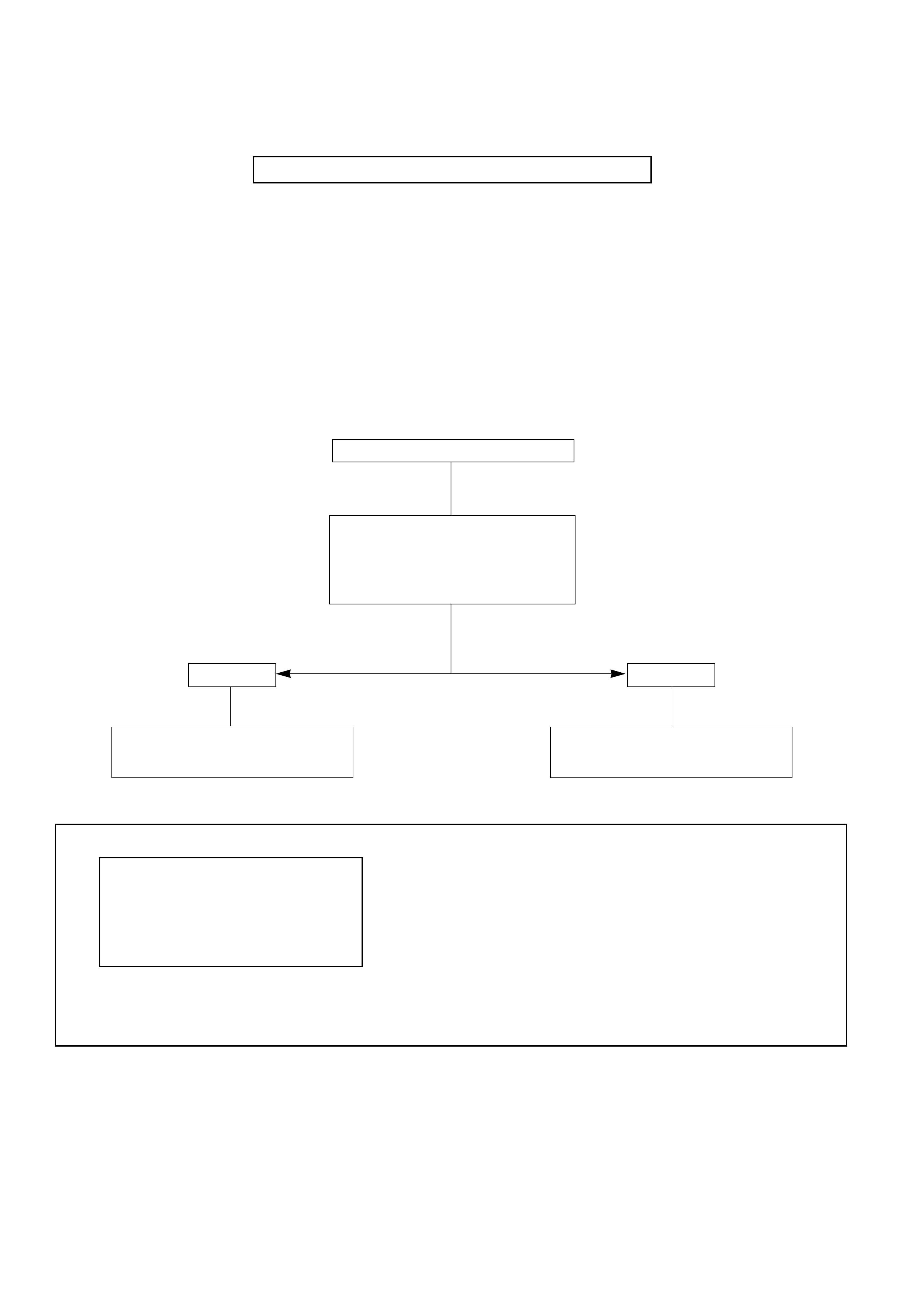

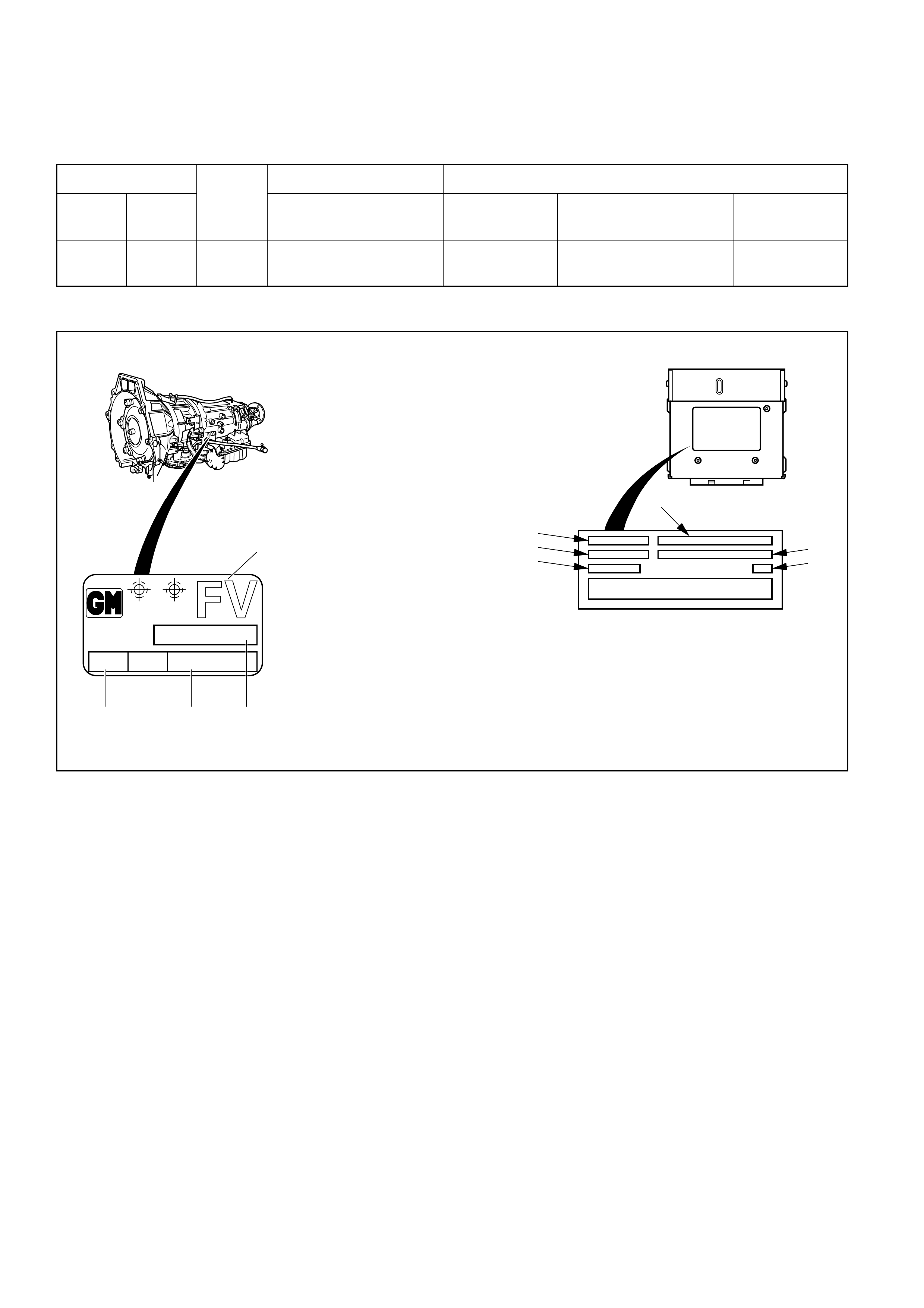

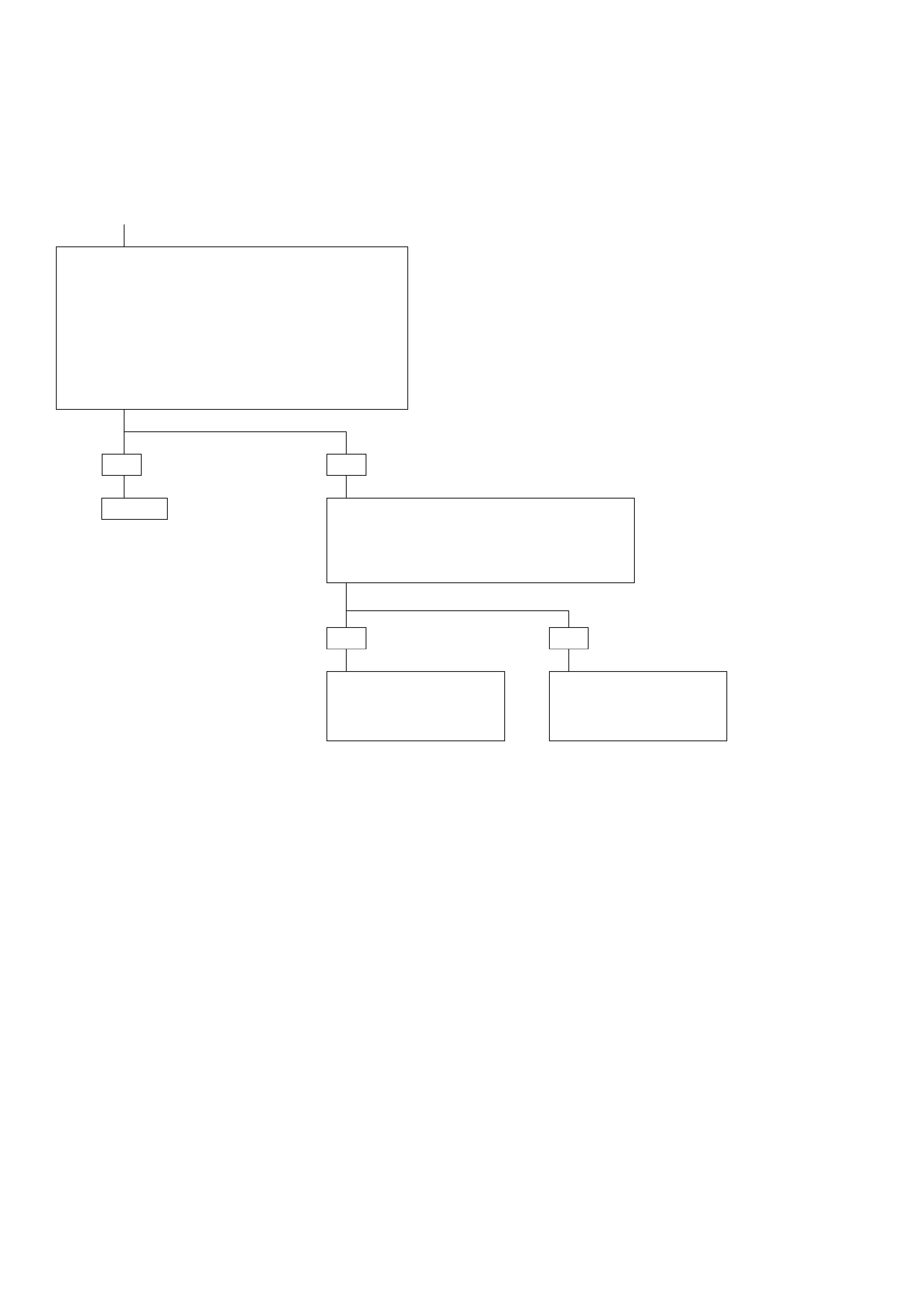

CHART 3: TRANSMISSION AND TCM IDENTIFICATION

Chart 3 contains a list of all important information concerning rear axle ratio, Transmission Control Module

(TCM), and transmission identification.

VEHICLE TCM TRANSMISSION

Type Engine Holden Part No. Calibration Holden Part No. Model Code

Code

Holden/ 3.2L V6 4.555

TFR 8-09350-909-0 G22 8-96018-434-0 FV (4X2)

Rr axle

Ratio

A

B

E

C

D

F

The idenification plate is

located on the left-hand side

of the transmission above the

mode switch.

AT Transmission identification on

vehicle identification plate :

1. Model code

2. Calibration code

3. Production serial number

4. Production part number

TCM IDENTIFICATION:

A. ISUZU part number

B. Model of car

C. DELCO part number

D. Application

E. Service TCM number

F. Broadcast code

G 22

96

0000 000

018 434

PART No.

SERIAL No.SAL

HYDRAMATIC

STRASBOURG

MADE IN FRANCE

1

234

F07LW001

CHART 5: F5: ACTUATOR TEST QUICK CHECK

Before carrying out the Actuator Test, the selector lever should be placed in selector position ”N“.

The ignition should be switched ON, and the engine not running.

FOR

TECH2 DISPLAY NOTES CORRECT RESULT DIAGNOSIS

SEE1

SOLENOID A Press arrow up (ON) “Click” heard from DTC 31

Press arrow down (OFF) transmission or 41

SOLENOID B Press arrow up (ON) “Click” heard from DTC 32

Press arrow down (OFF) transmission or 42

SHIFT SOLENOID Press arrow up (ON) “Click” heard from DTC 82

Press arrow down (OFF) transmission

TCC SOLENOID Not used ––

TCC HIGH (D) Press arrow up (ON) “Click” heard from DTC 33

Press arrow down (OFF) transmission or 43

POWER LAMP Press arrow up (ON) POWER lamp ON TRANSMISSION

Press arrow down (OFF) OPERATING

MODE TEST

(PAGE 133)

CHK. TRN. LAMP Press arrow up (ON) CHECK TRANS lamp CHECK TRANS

Press arrow down (OFF) ON CHECK (PAGE 50)

1FOR DIAGNOSIS OF A DTC SEE CHART 2: DIAGNOSTIC TROUBLE CODES (DTC) (PAGE 63)

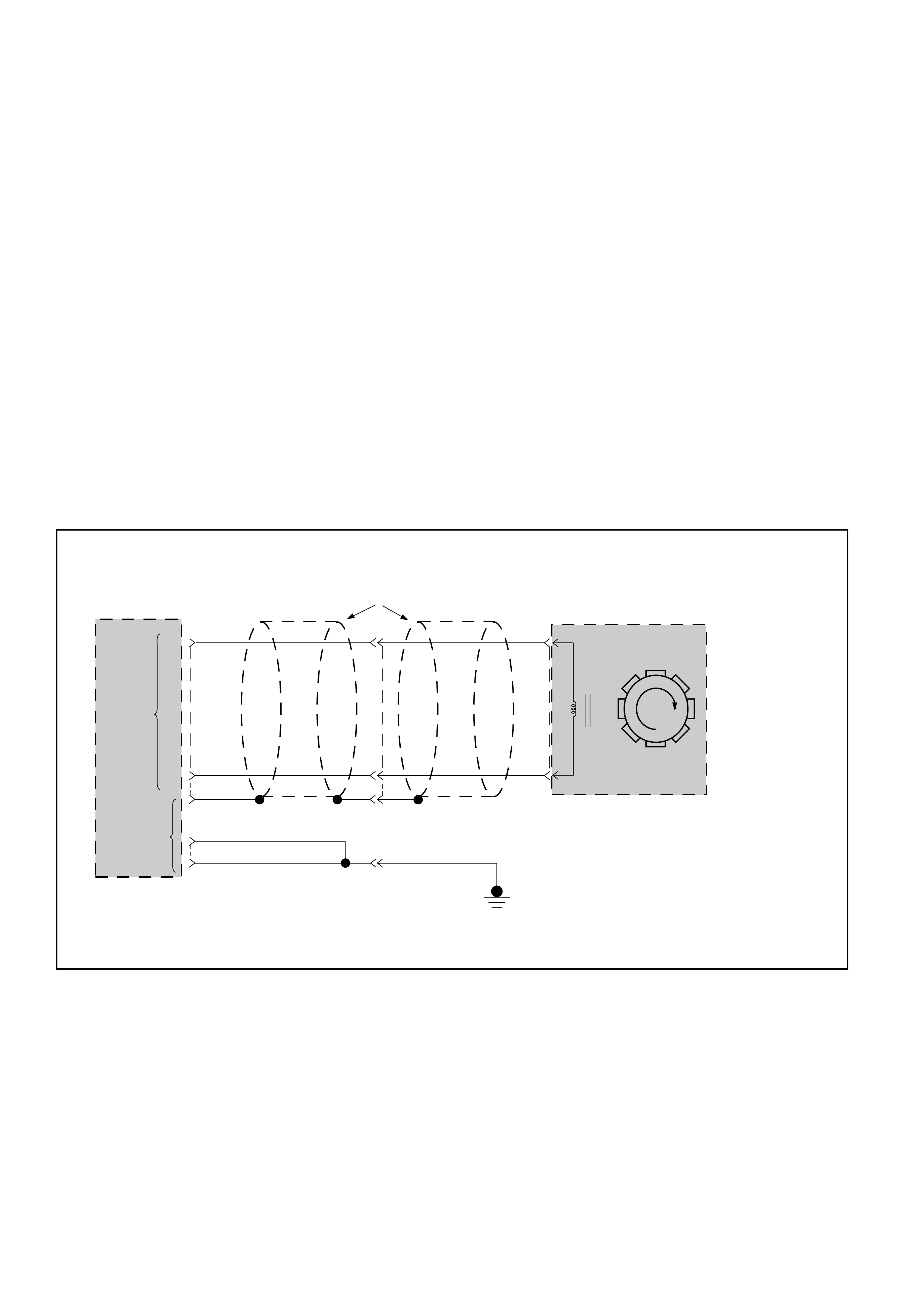

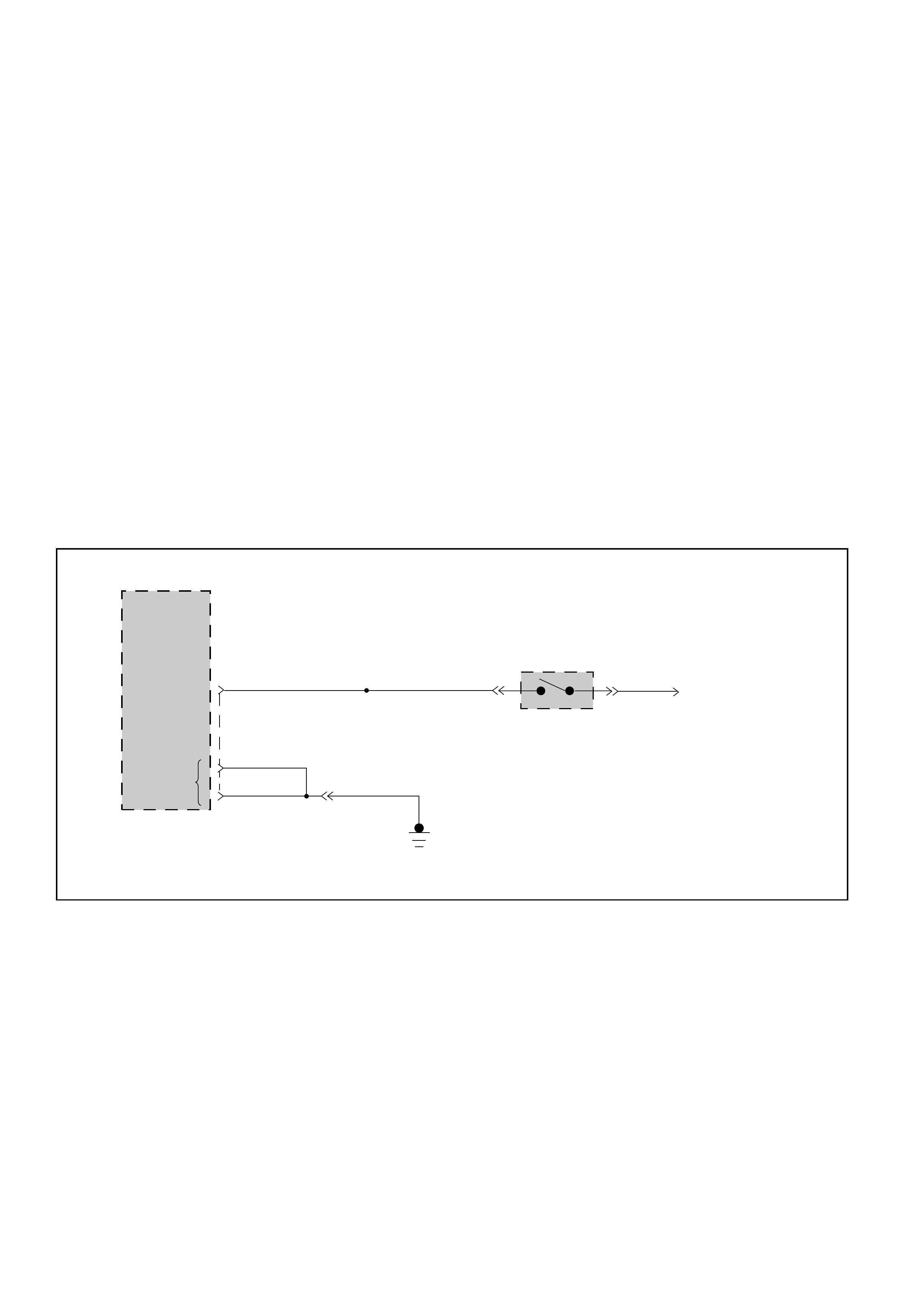

DIAGNOSTIC TROUBLE CODE (DTC) 11

OUTPUT SPEED FAILURE

This DTC flashes the CHECK TRANS indicator and

sets the BACKUP MODE.

Circuit Description:

The transmission output speed sensor provides

information on vehicle speed to the Transmission

Control Module (TCM). The speed sensor circuit

consists of a magnetic induction type sensor. The

sensor is mounted above a target wheel pressed on

the output shaft in the transmission extension. As

the output shaft turns, the target wheel teeth induce

a variable voltage in the magnetic pickup. This

alternating current (AC) signal is provided to the

TCM. The voltage increases with the speed of the

wheel but this is not used to define the speed of the

vehicle. As the vehicle moves faster, the signal

alternates faster between positive and negative

voltages. The Output speed information is

proportional to the frequency of the signal.

Diagnostic Aids:

•This diagnostic is not an electrical test done by

the TCM but a test between different information

(“logic test”).

•Detection conditions:

1Output Speed < or = 0 RPM.

2Engine Speed > 3000 RPM.

3No Malfunction: Engine Speed DTC 13. Mode

Switch DTC54.

4Selector lever not in Park, Reverse, or Neutral.

5The conditions need to be present for at least

5 seconds.

•Action after the detection time:

1CHECK TRANS Indicator is turned ON.

2TCM in BACKUP MODE

•Recovery conditions : To recover do an IGNITION

CYCLE.

TRANSMISSION

CONTROL

MODULE (TCM)

TRANSMISSION

SPEED SENSOR

A12(12)

C-96

C-95

C1(1)

D1(17)

1

M-15

2

TRANSMISSION SPEED

SENSOR SHIELDS

+

—

OUTPUT

SPEED

INPUT

H-23

10

11

9

PNK

B11(23)

B12(24)

GROUND

BLK BLK

7

H-25

PNK

BLU

BLK

BLU

D07LW006

IF the DTC 53 is set:

GOTHROUGH DTC 53 first

and do a test drive.

Problem is intermittent.

GOTO INTERMITTENT

CONDITIONS.

Check for faulty TCM connection.

IF OK, REPLAC TCM

YES

YES

YES

NO

NO

NO

IF you have a SCAN TOOL: TECH2?

• Raise drive wheels.

• Connect the TECH2 GOTHROUGH TECH2

CONNECTION.

• Push “F0”: DATALIST: DISPLAY. Read “AT OUTPUT

SPEED”.

IF: Output Speed different from 0 RPM when the wheels

are turning:

• Ignition switch OFF.

• Disconnect TCM connector C-95 and C-96.

• Connect ohmmeter between connector C-96 terminal

A12 and terminal B12.

IF: display is approx. 3K ohms:

• Connect ohmmeter between connector

C-96 terminal A12 and ground connector

C-95 terminal C1.

IF: display indicates an open circuit:

Replace transmission

speed sensor.

NO

YES

NO

YES NO

YES

• Disconnect transmission speed

sensor connector M-15.

• Connect ohmmeter between

terminals 1 and 2 of the speed

sensor.

IF: display approx. 3K ohms:

• Wires from Connector

C-96 to sensor

connector are open or

shorted together.

• Repair.

HINT: the wire between TCM terminal B12 and sensor connector M-15 terminal 2

can be shorted to ground or open without creating a problem because the TCM

B12 pin is connected to the TCM ground internally and the signal is detected only

on the A12 input.

• Check wire for a short to ground between terminal A12 and sensor connector

M-15 terminal 1.

IF: display indicates a short circuit:

DIAGNOSTIC TROUBLE CODE (DTC) 11

OUTPUT SPEED FAILURE

CAUTION:

If wire to connector C-96 terminal B12 is short to voltage, Transmission Control Module

(TCM) will be damaged.

A

CONTINUED

ON NEXT PAGE

CONTINUED FROM

PREVIOUS PAGE

A

NOYES

YES NO

•Connect voltmeter between connector C-96

terminal A12 and ground connector C-95

terminal C1.

•Ignition switch ON.

IF: display indicates approximately 0 volt:

Check for faulty TCM

connectors.

IF OK, REPLACE THE

TCM

Check wire for a short

to voltage between

terminal A12 and

speed sensor

connector M-15.

Repair.

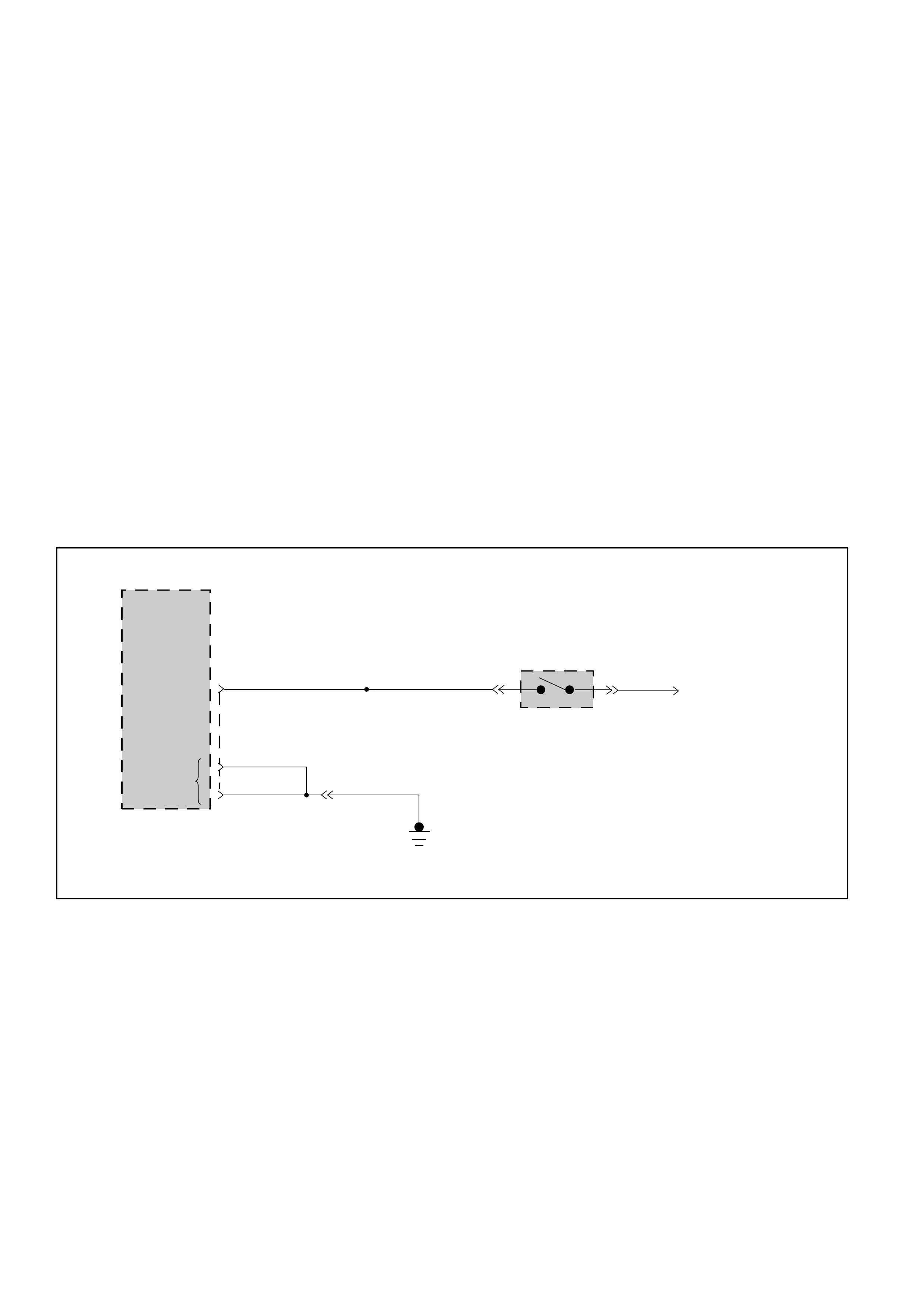

DIAGNOSTIC TROUBLE CODE (DTC) 13

ENGINE SPEED SIGNAL FAILURE

This DTC flashes the CHECK TRANS indicator and

set the BACKUP MODE.

Circuit Description:

The Engine Control Module (ECM) sends a signal to

the Transmission Control Module (TCM) that

indicates engine speed in RPM. When the vehicle is

in neutral gear and the engine is at idle, the engine

speed should be approximately 800 RPM.

Diagnostic Aids:

• This is not an electrical test performed by the

TCM, but a comparison of different information

signals (a “logic test”).

•Detection conditions:

1Engine speed < or = 200 RPM.

2 Output Speed > 1024 RPM.

3 Vehicle speed > 2 Kmh.

4No DTC: Output Speed DTC11, Downshift

Protection DTC62 or Mode Switch Illegal

Position DTC54.

5Selector Lever not in Park or Neutral.

6The conditions need to be present for at least

0.5 second.

•Action after the detection time: BACKUP MODE

• Recovery conditions: CYCLE IGNITION

ENGINE

RPM

INPUT

TRANSMISSION

CONTROL

MODULE (TCM)

ECM

TACHOMETER ( METER

C-95

D12(28)

ENGINE

RPM

OUTPUT

B-24 3 )

H-20

6 12 E-61

BLK/RED BLK/RED

H-6

16

D07LW007

DIAGNOSTIC TROUBLE CODE (DTC) 13

ENGINE SPEED FAILURE

Install scan tool.

GOTHROUGH TECH2 CONNECTION.

•Engine running at idle.

•Brake applied.

•Selector lever position “N” or “P”.

•Selector “F0: DATA LIST: AT INPUT

SPEED”.

IF: TECH2 DISPLAY approximately 800

RPM:

This system is functioning correctly.

The problem is probably intermittent.

GOTO

INTERMITTENT CONDITIONS.

IF: Tachometer displays engine speed?

•Check wire for open or short to ground or short to