MAIN DATA AND SPECIFICATIONS

Exhaust system

Pipe outside diameter × thickness

Front pipe mm (in)

Middle pipe mm (in)

Rear pipe mm (in)

Silencer

Type

Inside diameter mm (in)

Length mm (in)

Mounting

Number of suspension points

Type

50.8 × 1.6 (2.0 × 0.063)

50.8 × 1.6 (2.0 × 0.063)

50.8 × 1.6 (2.0 × 0.063)

Circular section-shell construction

of triple skin and end plates,

internal construction of baffles

and perforated tubes.

Approximately 180 (7.1)

Approximately 525 (20.7)

5

Rubber and metal

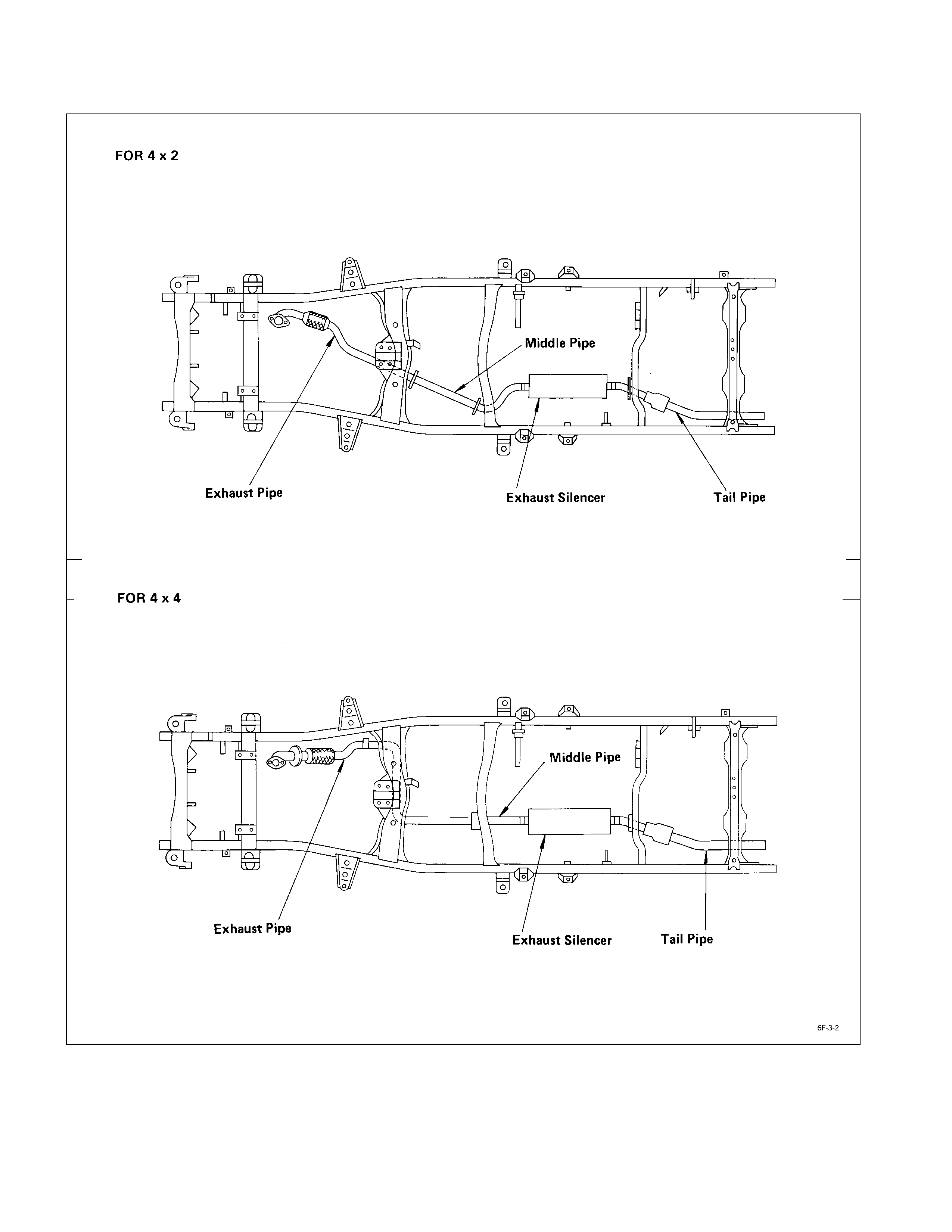

GENERAL DESCRIPTI O N

REMO VAL AND INSTALLATI ON

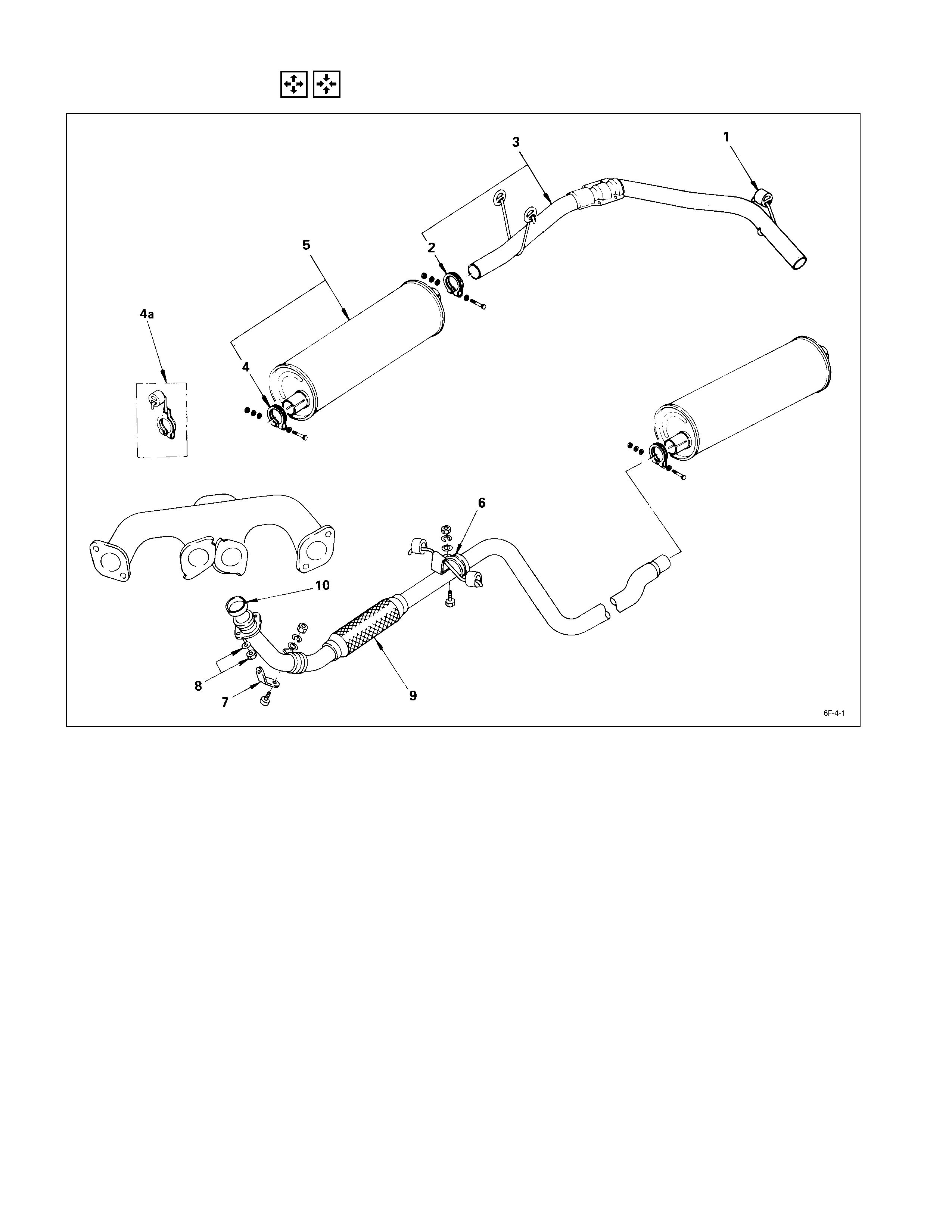

REMOVAL STEPS INSTALLATION STEPS

1. Rear hanger clamp 10. Exhaust pipe gasket

2. Silencer rear clamp 9. Front exhaust pipe

3. Rear exhaust pipe

J

8. Exhaust pipe nut and washer

4. Silencer front clamp 7. Exhaust front bracket

4a. Silencer front clamp 6. Front hanger clamp

(For long wheel base)

J

5. Exhaust silencer

5. Exhaust silencer 4. Silencer front clamp

6. Front hanger clamp 4a. Silencer front clamp

7. Exhaust front bracket (For long wheel base)

8. Exhaust pipe nut and washer 3. Rear exhaust pipe

9. Front exhaust pipe 2. Silencer rear clamp

10. Exhaust pipe gasket 1. Rear hanger clamp

IMPORTANT OPERATIONS – INSTALLATION

Follow the removal procedure in the reverse order to

perform the installation procedure. Pay careful attention to

the important points during the installation procedure.

8. Exhaust Pipe Nut and Washer

Connect the exhaust pipe to the exhaust manifold.

Torque kg·m (lb·ft/N·m)

6.8 ± 0.5 (49 ± 3.6/67 ± 5)

5. Exhaust Silencer

Apply muffler sealer to the joining portion of the pipes.

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is discovered during

inspection.

Front Exha ust Pipe

Rear Exhaust Pipe

Exhaust Silencer

Check the pipes for corrosion, cracking, damage or misalignment and repair as required.

Check the rubber rings for deterioration or damage and repair as required.

TURBOCHARGER

MAI N DATA AND SPECIFICATIONS

Engine model 4JB1T

Turbocharger model IHI RHF 4H

Turbine type

Compressor type

Radial inflow

Radial outflow

Maximum permissible speed rpm 180,000

Wastegate opening pressure mmHg (inHg)

Safety valve opening pressure mmHg (inHg)

189 – 887

850 - 910

Weight kg (lb) 4.2 (9.3)

IHI : Ishikawajima Harima Heavy Industries., Ltd.

GENERAL DESCRIPTI O N

The turbocharger internal mechanism consists of the turbine wheel, the compressor wheel, and the radial bearings. The

bearing housing supports these parts.

The turbocharger external mechanism consists of the compressor housing air intake port and the turbine housing air

exhaust port.

The turbocharger increases air intake efficiency. This results in increased engine power, reduced fuel consumption, and

minimal engine noise.

The turbocharger operates at very high speeds and temperatures. Part materials have been carefully selected and

machined to extremely high precision.

Turbocharger servicing requires great care and expertise.

If reduced performance is noted, check the engine for damage or wear. If there is no apparent engine damage or wear,

trouble with the turbocharger is indicated.

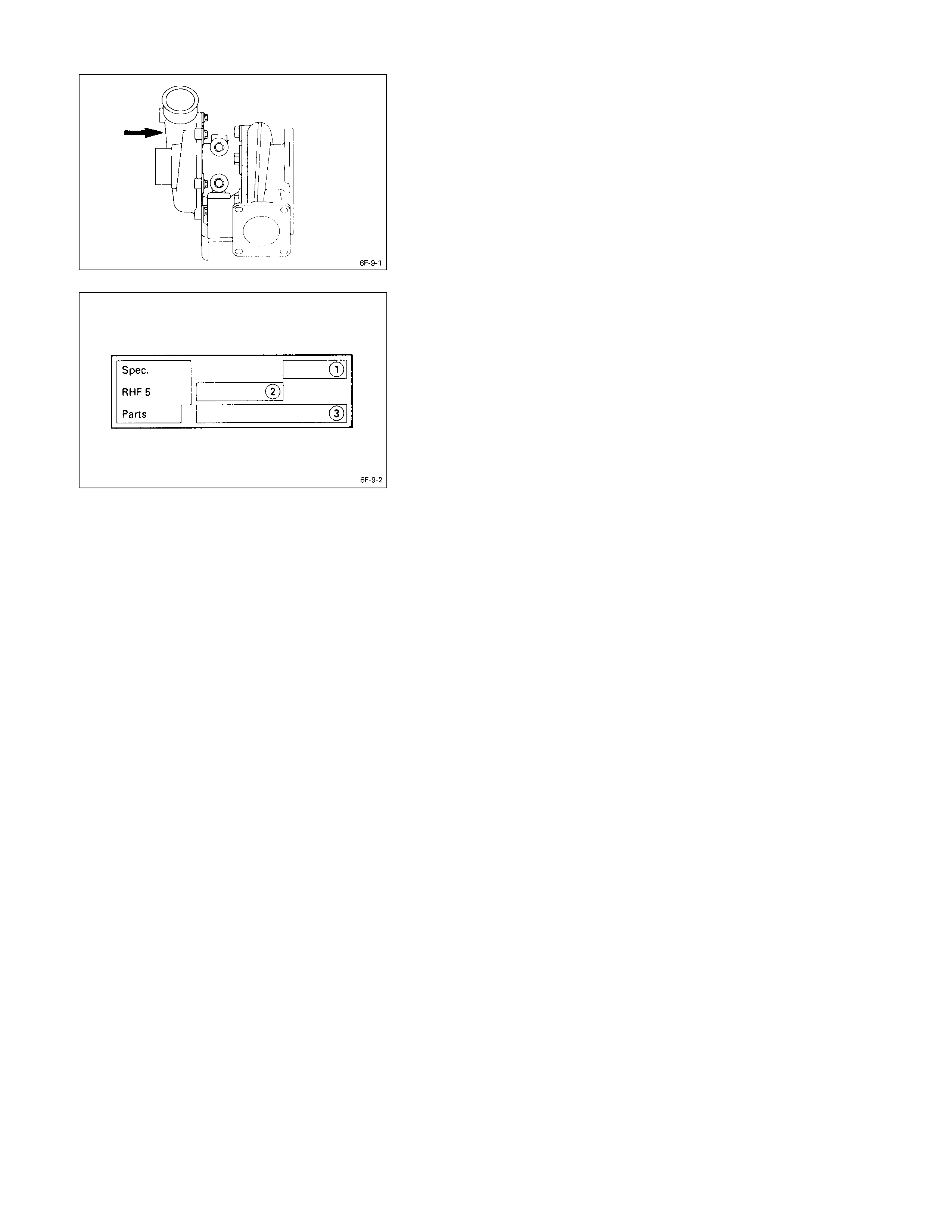

IDENTIFICATION OF UNIT

The turbocharger nameplate gives the date of manufacture

and other important information required to identify the unit

when service inquiries are made.

The turbocharger nameplate has the following information

stamped on it.

Q Turbo Specification Number, Production Year and

Month

R Production Date, Daily Serial Number

S HOLDEN Parts Number

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is discovered during

inspection.

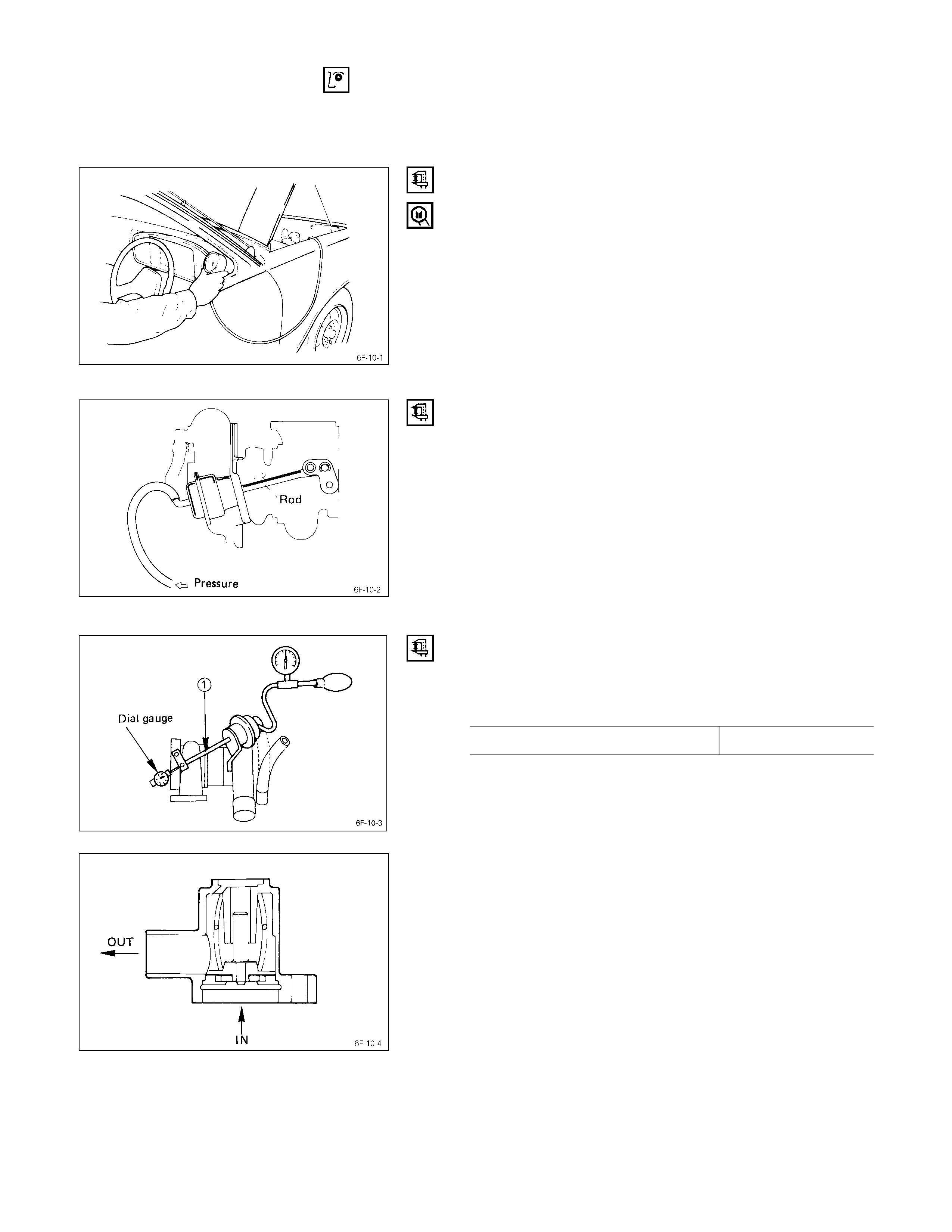

TURBOCHARGER PRESSURE CHECK

(1) Remove the pressure switch connecting hose from

intake duct.

(2) Connect the pressure gauge.

(3) Start the engine and gradually increase the engine

speed (the vehicle must be stationary with no load

applied to the engine).

(4) Check to see that turbocharger pressure rises to

approximately 300 mmHg.

Pressure Gauge : 5-8840-0075-0

WASTE GATE OPERATION CHECK

(1) Remove the hose between the waste gate and the

intake pipe.

(2) Connect the pressure gauge.

(3) Check to see that the rod begins to move when a

pressure of approximately 665 mmHg is applied to the

waste gate.

Note:

Do not apply a pressure greater than 1 kg/cm2 to the

wastegate during this check.

UNIT INSPECTION (REMOVE TURBO. FROM

ENGINE)

Check to see the pressure required to move the control

rod 2 mm is within the limits shown below.

Control Rod Operating Pressure Approx. 860 mmHg

SAFETY VALVE CHECK

Operate the valve with your hand to check its operation.

Check the valve seal are for excessive wear or damage.

Contact the “HOLDEN LIMITED” Dealer service

department or “IHI SERVICE FACILITY” for major repairs

and maintenance.

Important wheel shaft end play and bearing clearance

standards and limits are included below for your reference.

WHEEL SHAFT END PLAY

Use a dial indicator to measure the wheel shaft end play.

Apply a force of 1.2 kg (2.6 lb/11.8N) alternately to the

compressor wheel end and the turbine wheel end.

Wheel Shaft End Play mm (in)

Standard Limit

0.03 - 0.06

(0.001 - 0.002) 0.09 (0.004)

Wheel Shaft and Bearing Clearance

Use a dial indicator to measure the wheel shaft and

bearing clearance.

Wheel Shaft and Bearing Clearance mm (in)

Standard Limit

0.056 - 0.127

(0.0022 - 0.0050) 0.127 (0.0050)

SPECIAL TOOLS

ILLUSTRATION TOOL NUMBER TOOL NAME

5-8840-0070-0 Pressure Gauge