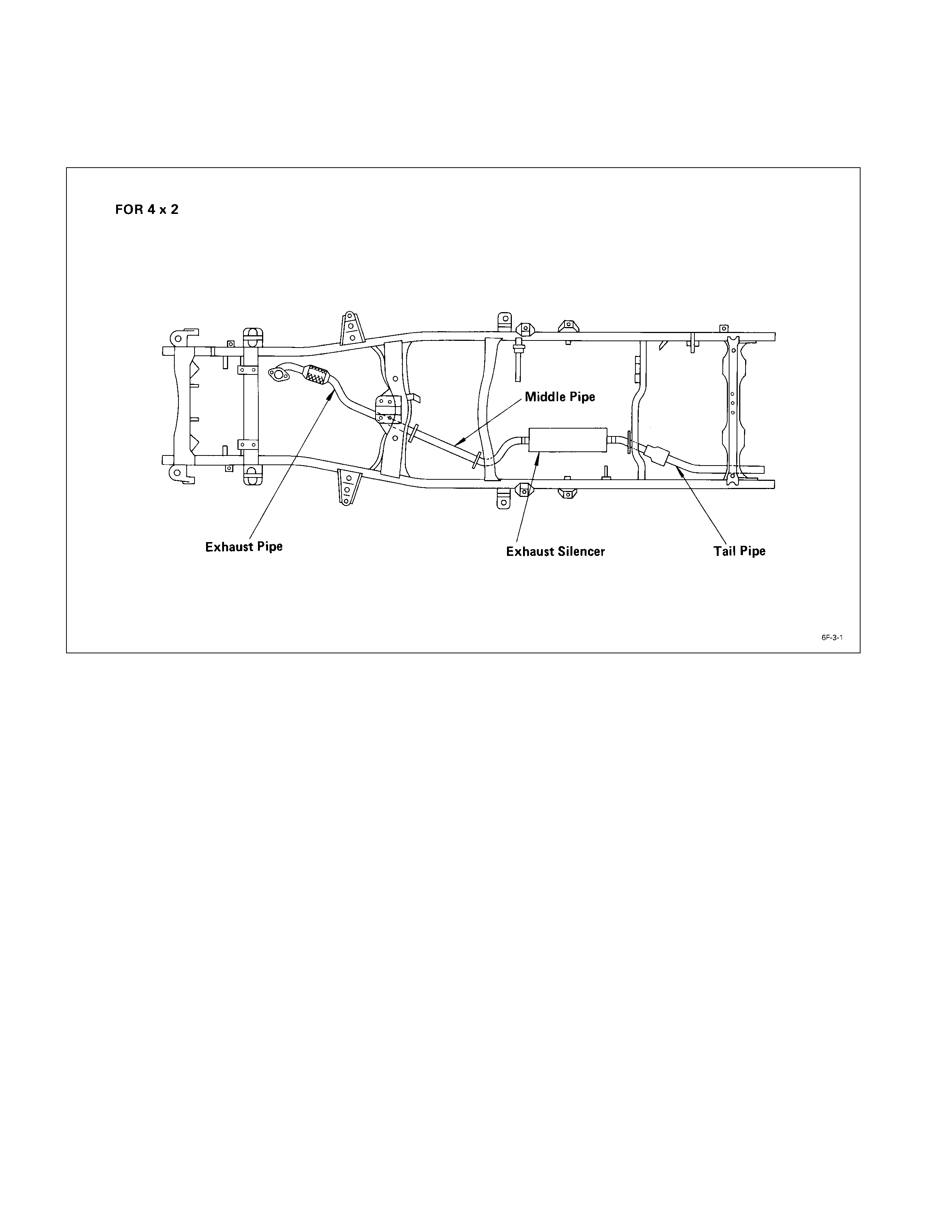

Exhaust System

General Description

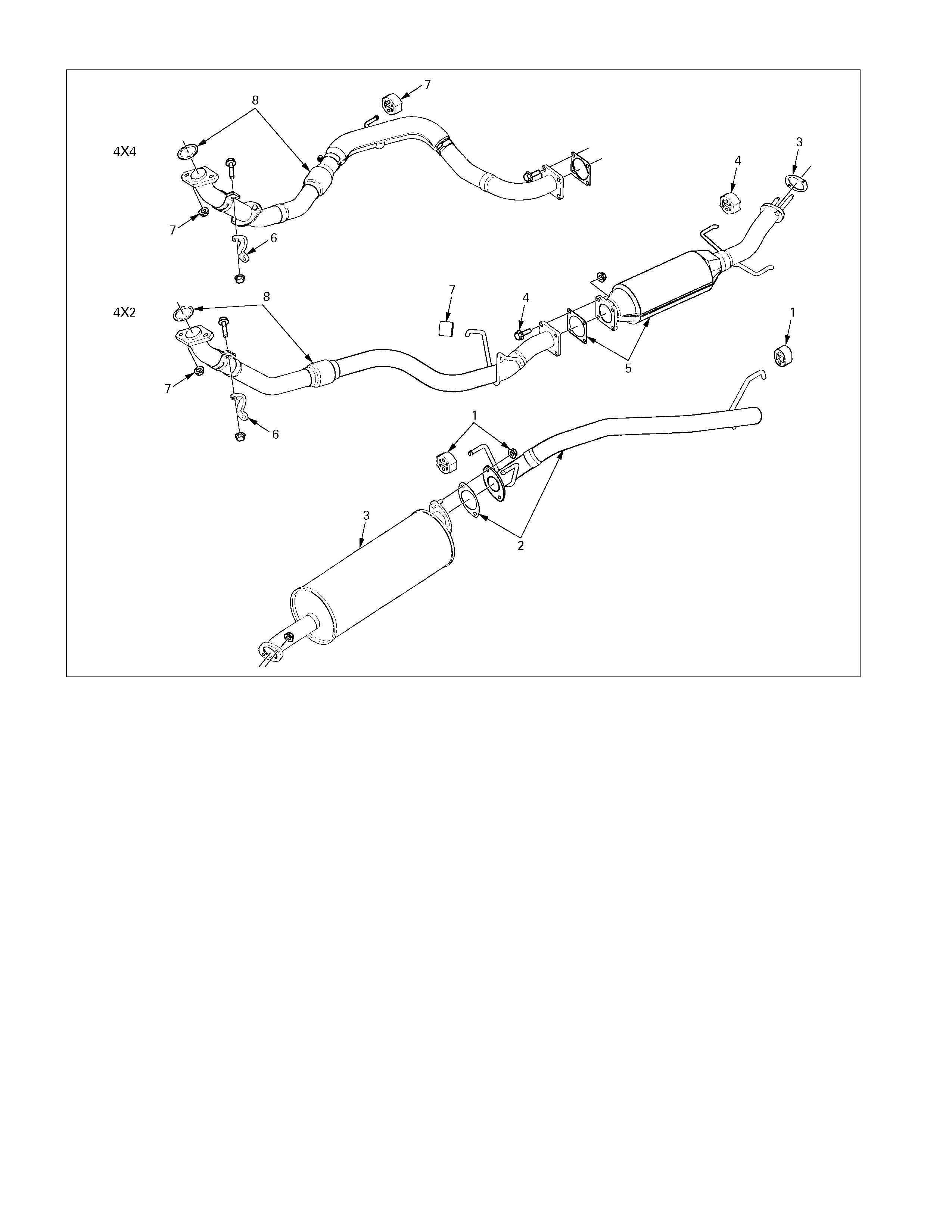

150L200007

4JH1TC

The exhaust system consists of a front exhaust pipe, a catalytic converter, a silencer and a tail pipe.

When inspecting or replacing exhaust system components, make sure there is adequate clearance from all points on

the underbody to prevent overheating of the floor pan and possible damage to the passenger compartment insulation

and trim materials.

Check complete exhaust system and nearby body areas and rear compartment lid for broken, damaged, missing or

mispositioned parts, open seams, holes, loose connections or other deterioration which could permit exhaust fumes to

seep into the rear compartment or passenger compartment. Dust or water in the rear compartment may be an

indication of a problem in one of these areas. Any faulty areas should be corrected immediately.

OXIDIZING CATALYTIC CONVERTER

The oxidizing catalytic converter is an emission control

device added to the exhaust system to reduce pollutants

from the exhaust gas stream.

Periodic maintenance of the exhaust system is not

required. If the vehicle is raised for other service, it is

advisable to check the condition of the complete exhaust

system.

A dual bed monolith catalytic converter is used in

combination with oxidizing catalytic converter.

GASKET

The gasket must be replaced whenever a new exhaust

pipe, muffler or catalytic converter is installed.

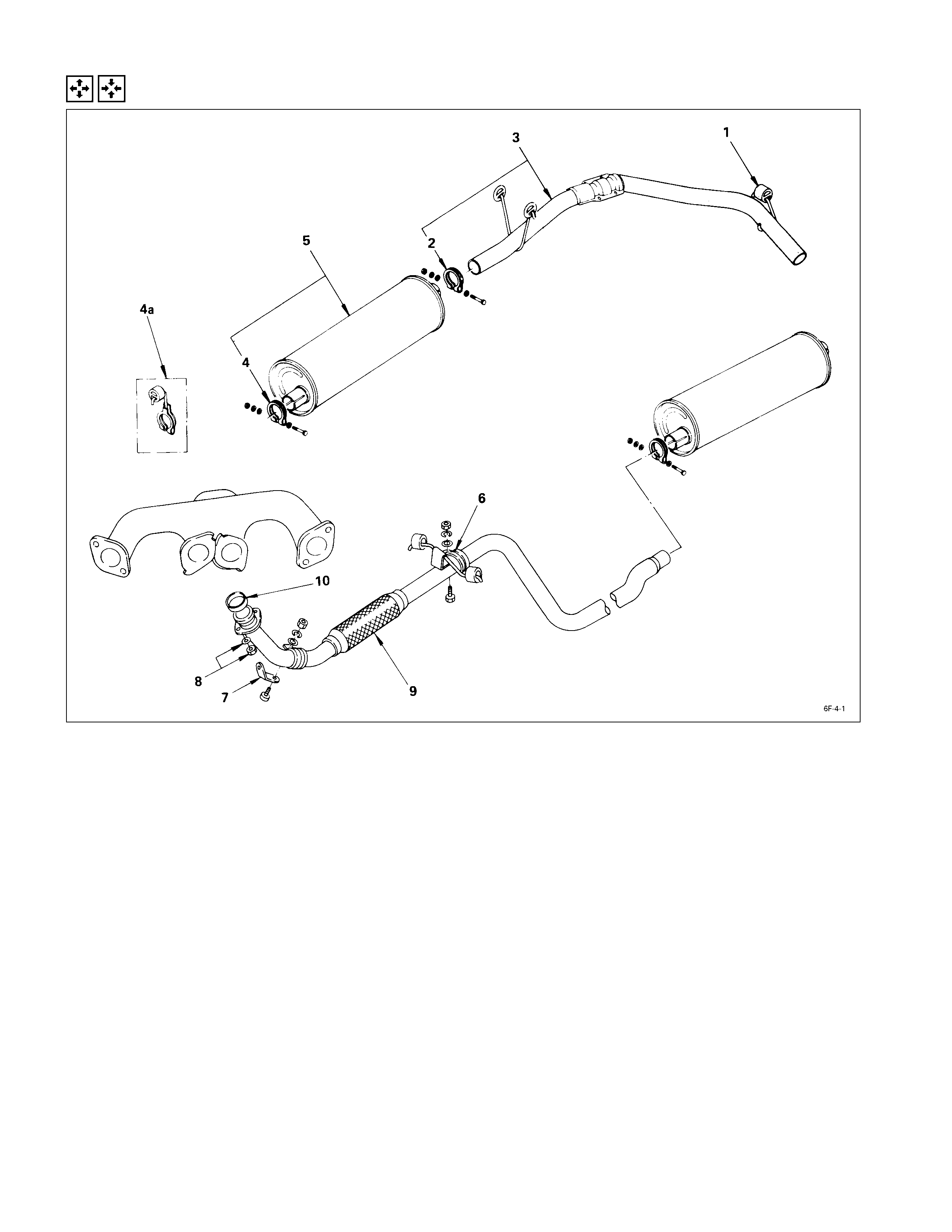

Removal & Installation

REMOVAL STEPS INSTALLATIO N STEPS

1. Rear hanger clamp 10. Exhaust pipe gasket

2. Silencer rear clamp 9. Front exhaust pipe

3. Rear exhaust pipe

J

8. Exhaust pipe nut and washer

4. Silencer front clamp 7. Exhaust front bracket

4a. Silencer front clamp 6. Front hanger clamp

(For long wheel base)

J

5. Exhaust silencer

5. Exhaust silencer 4. Silencer front clamp

6. Front hanger clamp 4a. Silencer front clamp

7. Exhaust front bracket (For long wheel base)

8. Exhaust pipe nut and washer 3. Rear exhaust pipe

9. Front exhaust pipe 2. Silencer rear clamp

10. Exhaust pipe gasket 1. Rear hanger clamp

IMPORTANT OPERATIONS – INSTALLATION

Follow the removal procedure in the reverse order to

perform the installation procedure. Pay careful attention to

the important points during the installation procedure.

8. Exhaust Pipe Nut and Was her

Connect the exhaust pipe to the exhaust manifold.

Torque kg·m (lb·ft/N·m)

6.8 ± 0.5 (49 ± 3.6/67 ± 5)

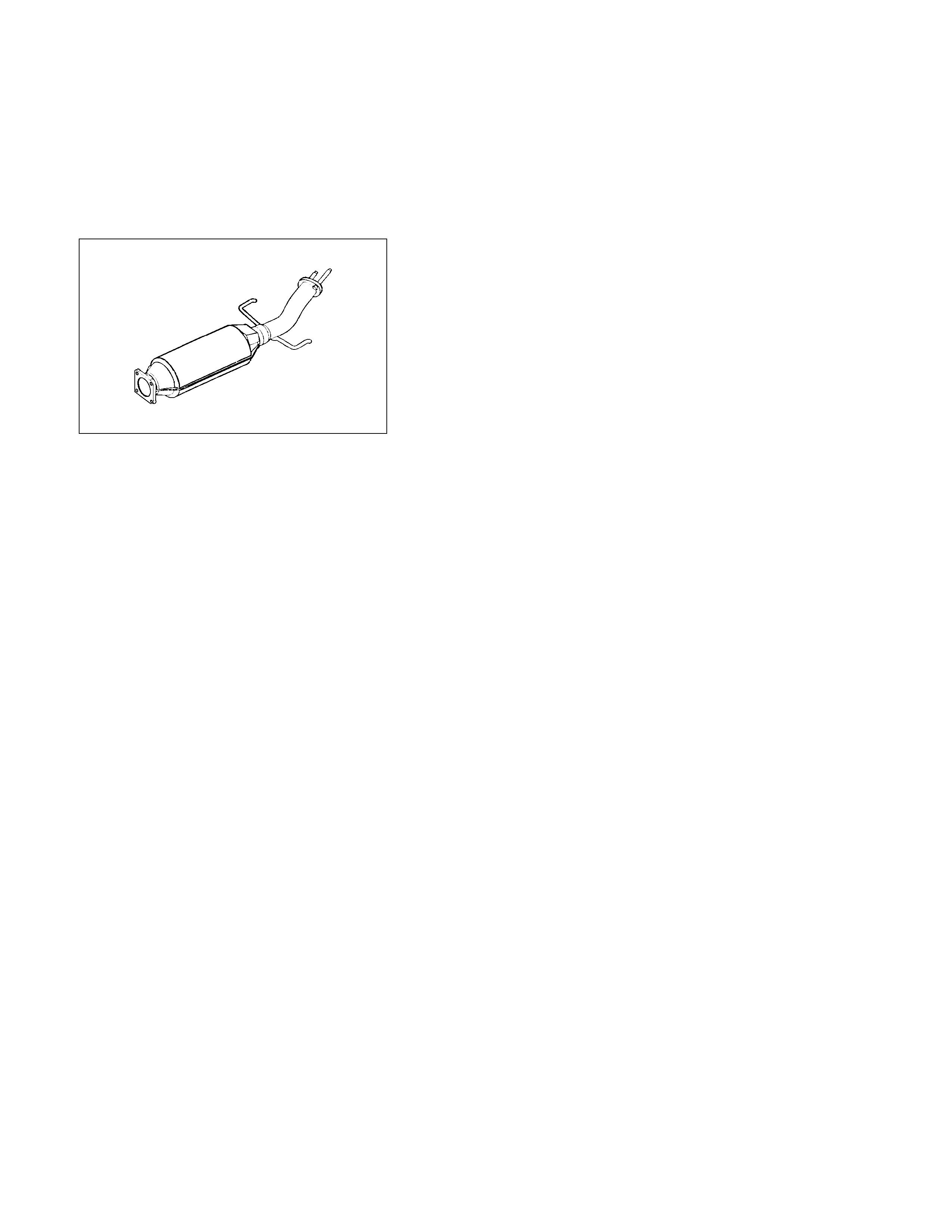

5. Exhaust Silencer

Apply muffler sealer to the joining portion of the pipes.

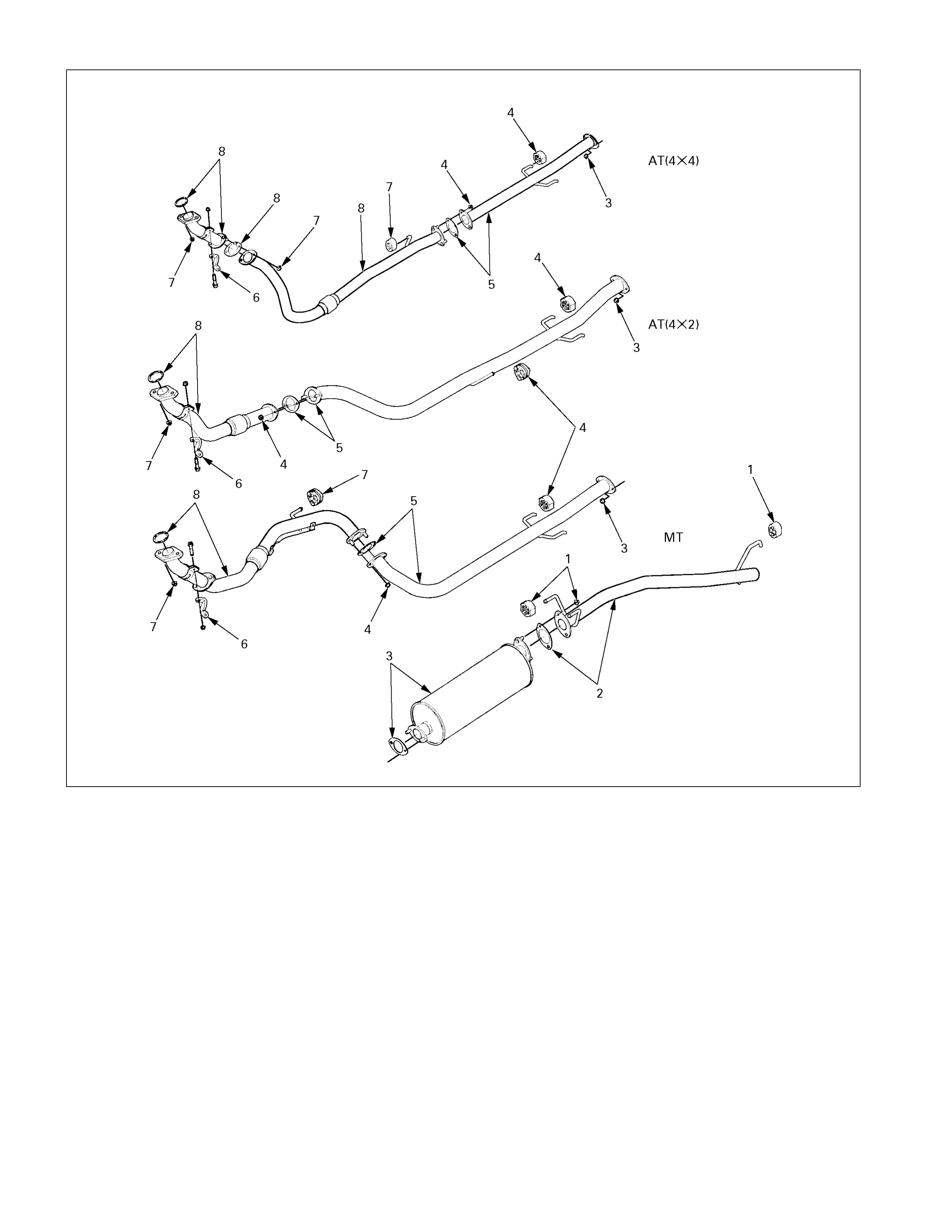

150L200006

REMOVAL STEPS INSTALLATIO N STEPS

1. Tail pipe hanger clamp and nuts

J

8. Front pipe with gasket

2. Tail pipe with gasket 7. Front pipe hanger clamp and nuts

3. Silencer with gasket

J

6. Front pipe BRKT

4. Oxidizing Catalytic converter hanger

clamp and bolts

J

5. Oxidizing Catalytic converter with gasket

5. Oxidizing Catalytic converter with

gasket 4. Oxidizing Catalytic converter hanger

clamp and bolts

6. Front pipe BRKT

J

3. Silencer with gasket

7. Front pipe hanger clamp and nuts

J

2. Tail pipe with gasket

8. Front pipe with gasket 1. Tail pipe hanger clamp and nuts

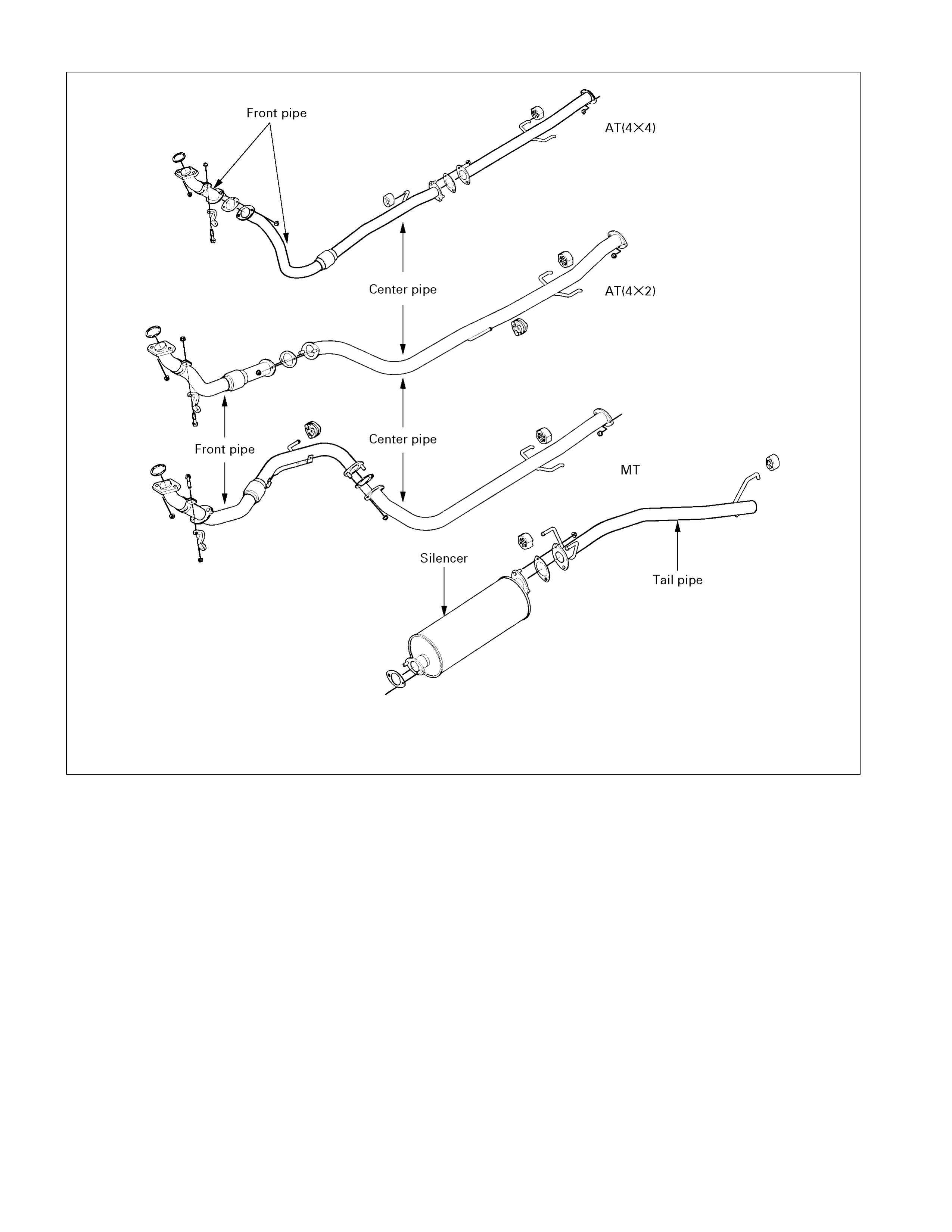

4JA1TC

150L200008

REMOVAL STEPS INSTALLATIO N STEPS

1. Tail pipe hanger clamp and

nuts

J

8. Front pipe with gasket

2. Tail pipe with gasket 7. Front pipe hanger clamp and nuts

3. Silencer with gasket and nuts

J

6. Front pipe BRKT

4. Center pipe hanger clamp and

nuts

J

5. Center pipe with gasket

5. Center pipe with gasket 4. Center pipe hanger clamp and nuts

6. Front pipe BRKT

J

3. Silencer with gasket

7. Front pipe hanger clamp and

nuts

J

2. Tail pipe with gasket

8. Front pipe with gasket 1. Tail pipe hanger clamp and nuts

4JH1TC

IMPORTANT OPERATIONS – INSTALLATION

Follow the removal procedure in the reverse order to

perform the installation procedure. Pay careful attention to

the important points during the installation procedure.

8. Front Pipe With Gasket

Connect the front pipe to the exhaust manifold.

Torque kg⋅m(lb⋅ft/N⋅m)

6.8 ± 0.5 (49 ± 3.6/67 ± 5)

6. Front Pipe BRKT

Tighten the fixing bolt to the specified torque.

Torque kg⋅m(lb⋅ft/N⋅m)

Front pipe side 2.4 ± 0.5 (17 ± 3.6/23 ± 5)

Transmission side 4.1 ± 1.0 (30 ± 7/40 ± 1)

5. Oxidizing Catalytic Converter With Gasket (4JA1TC)

Center Pipe With Gasket (4JH1TC)

Tighten the fixing nuts to the specified torque.

Torque kg⋅m(lb⋅ft/N⋅m)

4.4 ± 1.3 (32 ± 9.4/43 ± 13)

3. Silencer With Gasket

Tighten the fixing nuts to the specified torque.

Torque kg⋅m(lb⋅ft/N⋅m)

4.4 ± 1.3 (32 ± 9.4/43 ± 13)

2. Tail Pipe With Gasket

Tighten the fixing nuts to the specified torque.

Torque kg⋅m(lb⋅ft/N⋅m)

4.4 ± 1.3 (32 ± 9.4/43 ± 13)

• Connect battery ground cable.

• After assembling each part, start the engine to check

for any leakage of gas at each connection.

Inspection & Repair

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is discovered during

inspection.

Front Exha ust Pipe

Rear Exhaust Pipe

Exhaust Silencer

Check the pipes for corrosion, cracking, damage or

misalignment and repair as required.

Check the rubber rings for deterioration or damage and repair

as required.

Turbocharger

Main Data & Speci fications

Engine model 4JB1T, 4JH1TC

Turbocharger model IHI RHF 4H RHF5H

Turbine type

Compressor type

Radial inflow

Radial outflow

Wastegate opening pressure mmHg (inHg)

Safety valve opening pressure mmHg (inHg)

189 – 887

850 - 910

Weight kg (lb) 4.2 (9.3) 4.6 (10.1)

IHI : Ishikawajima Harima Heavy Industries., Ltd.

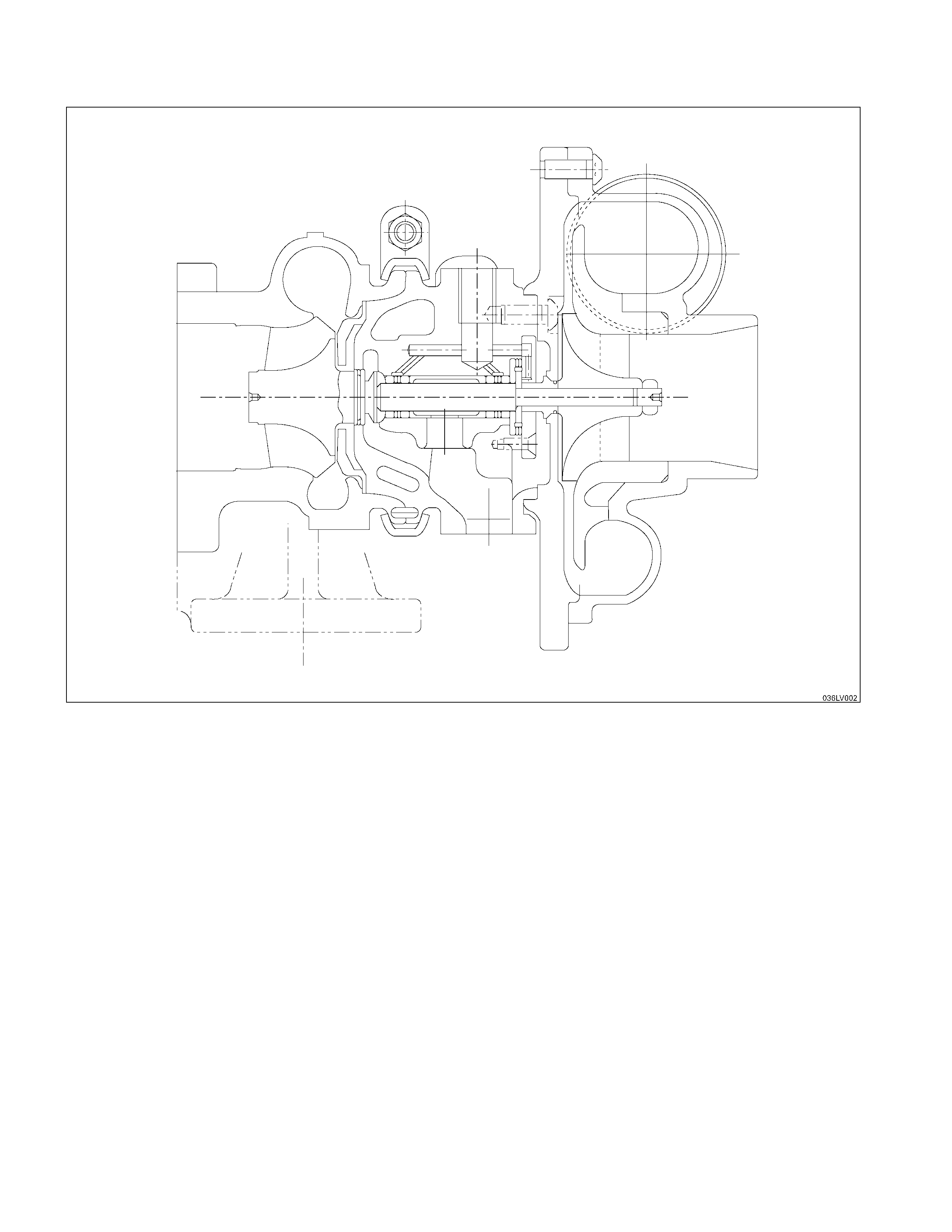

General Description

The turbocharger internal mechanism consists of the turbine wheel, the compressor wheel, and the radial bearings.

These parts are supported by the bearing housing.

The turbocharger external mechanism consists of the compressor housing air intake port and the turbine housing air

exhaust port.

The turbocharger increases air intake efficiency. This results in increased engine power, reduced fuel consumption, and

minimal engine noise.

The turbocharger operates at very high speeds and temperatures. Part materials have been carefully selected and

machined to extremely high precision.

Turbocharger servicing requires great care and expertise.

If reduced performance is noted, check the engine for damage or wear. If there is no apparent engine damage or wear,

trouble with the turbocharger is indicated.

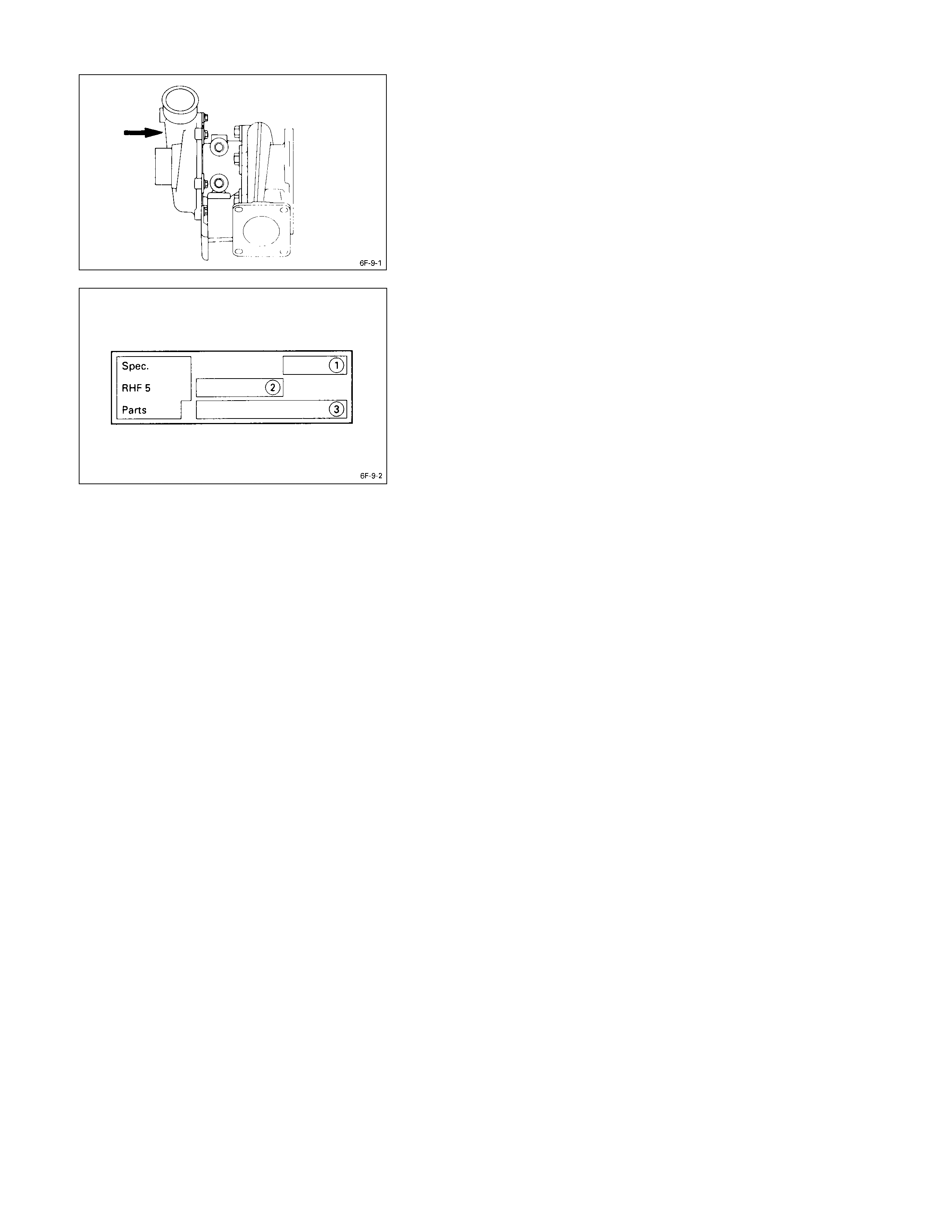

Identification Of Unit

The turbocharger nameplate gives the date of manufacture

and other important information required to identify the unit

when service inquiries are made.

The turbocharger nameplate has the following information

stamped on it.

Q Turbo Specification Number, Production Year and

Month

R Production Date, Daily Serial Number

S ISUZU Part Number

Inspection And Repair

Make the necessary adjustments, re pairs, and part replacements if excessive wear or damage is discovered durin g

inspection. Note that the quoted pressures ar e Absolute Pressure.

Turbocharger pressure check

(1) Remove the pressure switch connecting hose from

intake duct.

(2) Connect the pressure gauge.

(3) Start the engine and gradually increase the engine

speed (the vehicle must be stationary with no load

applied to the engine).

(4) Check to see that turbocharger pressure rises to

approximately 141.3 kPa (1060 mmHg).

Pressure Gauge : 5-8840-0075-0

Waste gate operation check

(1) Remove the hose between the waste gate and the

intake pipe.

(2) Connect the pressure gauge.

(3) Check to see that the rod begins to move whe n a

pressure of approximately 118 kPa (885 mm Hg) is

applied to the waste gate.

Note:

Do not apply a pressure greater than 150 kPa (1125

mm Hg) to the wastegate during this check.

Unit Inspection (Remove Turbo. from engine)

Check that the pressure required to stroke the control rod

c is at the correct value. kPa / mm Hg

4JB1-TC 147.7 / 1108

4JH1-TC 134.8 / 1101

Safety valve check

Operate the valve with your hand to check its operation.

Check the valve seal are for excessive wear or dama ge.

Contact the “ISUZU MOTORS LIMITED” Dealer service

department or “IHI SERVICE FACILITY” for major repairs

and maintenance.

Important wheel shaft end play and bearing clearance

standards and limits are included below for your

reference.

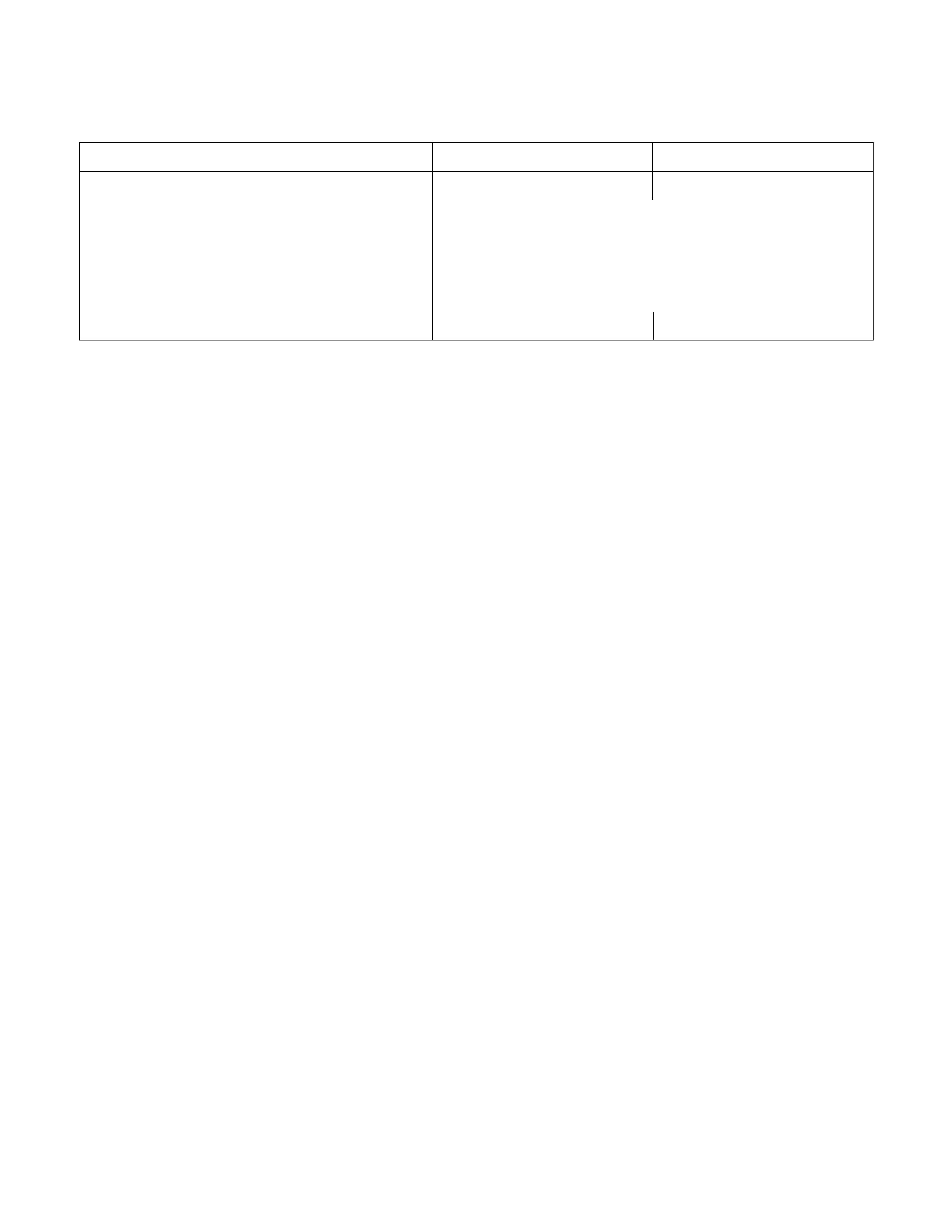

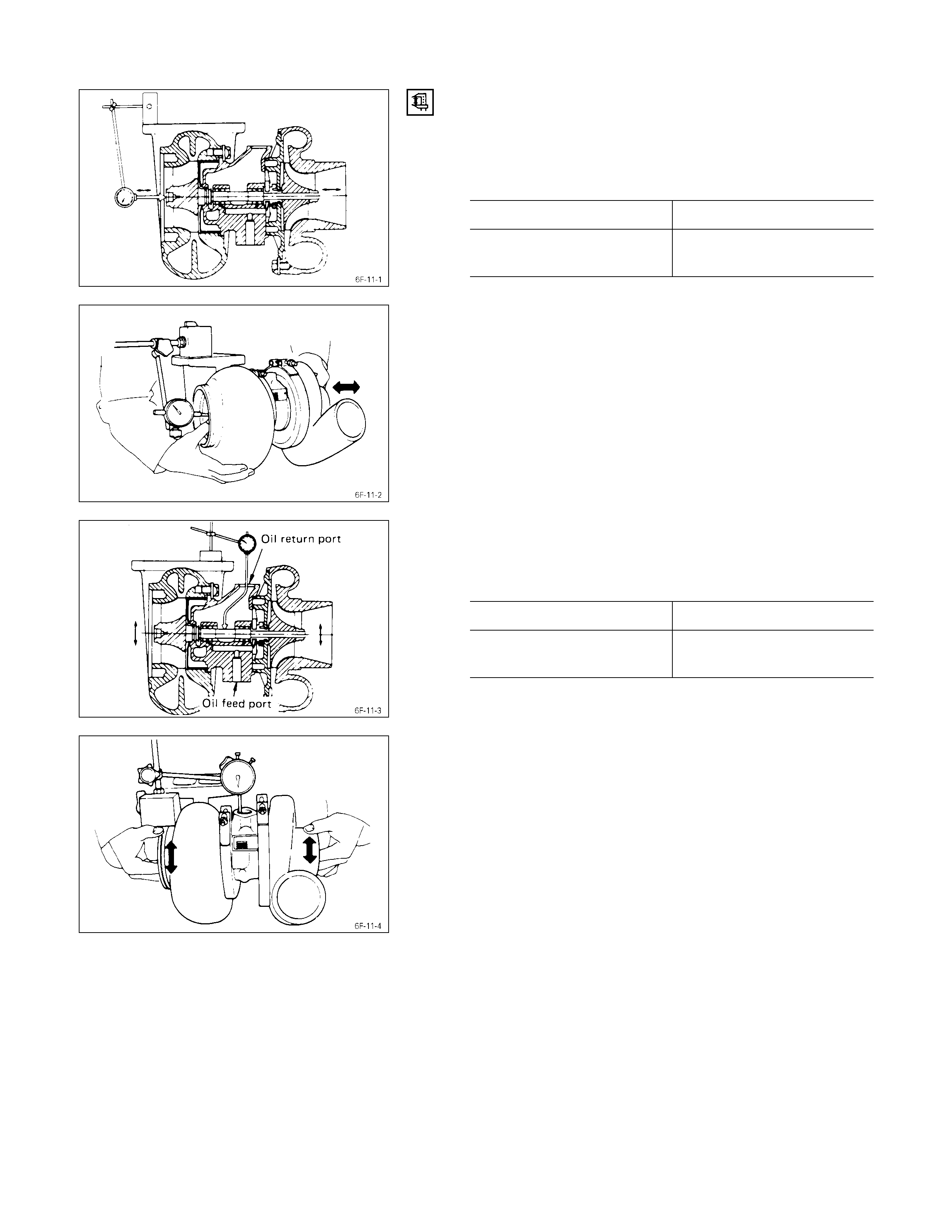

WHEEL SHAFT END PLAY

Use a dial indicator to measure the wheel shaft end play.

Apply a force of 1.2 kg (2.6 lb/11.8N) alternately to the

compressor wheel end and the turbine wheel end.

Wheel Shaft End Play mm (in)

Standard Limit

0.03 - 0.06

(0.001 - 0.002) 0.09 (0.004)

Wheel Shaft and Bearing Clearance

Use a dial indicator to measure the wheel shaft and

bearing clearance.

Wheel Shaft and Bearing Clearance mm (in)

Standard Limit

0.056 - 0.127

(0.0022 - 0.0050) 0.127 (0.0050)

Special Tool s

ILLUSTRATION TOOL NUMBER TOOL NAME

5-8840-0070-0 Pressure Gauge

IHI Service Netw ork

For inquiries relating to turbochargers, please contact your HOLDEN distributor or the nearest IHI Turbocharger Service

Facility.

HEADQUARTERS

ISHIKAWAJIMA HARIMA HEAVY INDUSTRIES CO., LTD.(IHI)

General Machinery Division

Tokyo Chuo Building 1-6-2 Marunouchi Chiyoda-ku

Tokyo 100-0005 JAPAN

TEL: 81-(3)-3286-2405 to 2407 (3 lines)

FAX: 81-(3)-3286-2430