SECTION 6 - TROUBLESHOOTING

BASIC INSPECTION PROCEDURE

1. HARD STARTING

1-1.Starter Motor Inoperative

1-2. Starter Motor Operates But Engine Does Not Turn Over

1-3. Engine Turns Over But Does Not Start

2. UNSTABLE IDLING

3. INSUFFICIENT POWER

4. EXCESSIVE FUEL CONSUMPTION

5. EXCESSIVE OIL CONSUMPTION

6. OVERHEATING

7. WHITE EXHAUST SMOKE

8. DARK EXHAUST SMOKE

9. OIL PRESSURE DOES NOT RISE

10. ABNORMAL ENGINE NOISE

10-1. Engine Knocking

10-2. Gas Leakage Noise

10-3. Continuous Noise

10-4. Slapping Noise

10-5. Excessive Turbocharger Noise

11. ROTATING PARTS OF TURBOCHARGER ARE WORN

12. OIL LEAKAGE FROM TURBOCHARGER

13. INSUFFICIENT ACCELERATION AND/OR LACK OF POWER DUE TO TURBOCHARGER FAULT

14. BATTERY CHARGING AND NOISE PROBLEM

14-1. Battery Not Charging

14-2. Battery Overcharging

14-3. Battery Under Charging

14-4. Battery Unstable Charging Current

14-5. Charging System Noise

15. STARTER MOTOR PROBLEM

15-1. Starter Motor Pinion Engages to Ring Gear But Engine Does Not Turn Over

15-2. Incorrect Pinion And Ring Gear Engagement

15-3. Starter Motor Continues To Run After The Starter Switch Is Turned Off

15-4. Excessive Commutator Sparking

Techline

Techline

Techline

Techline

Techline

Techline

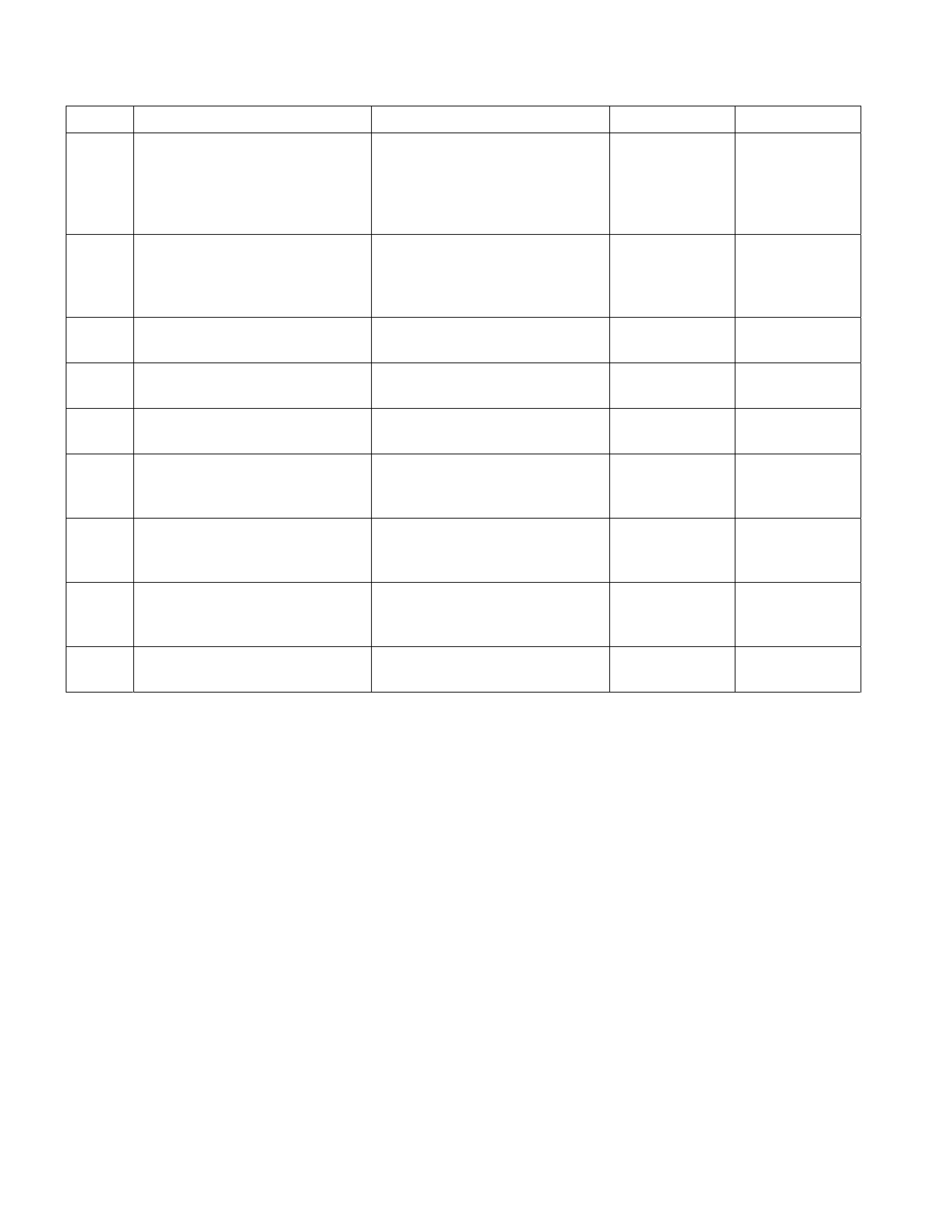

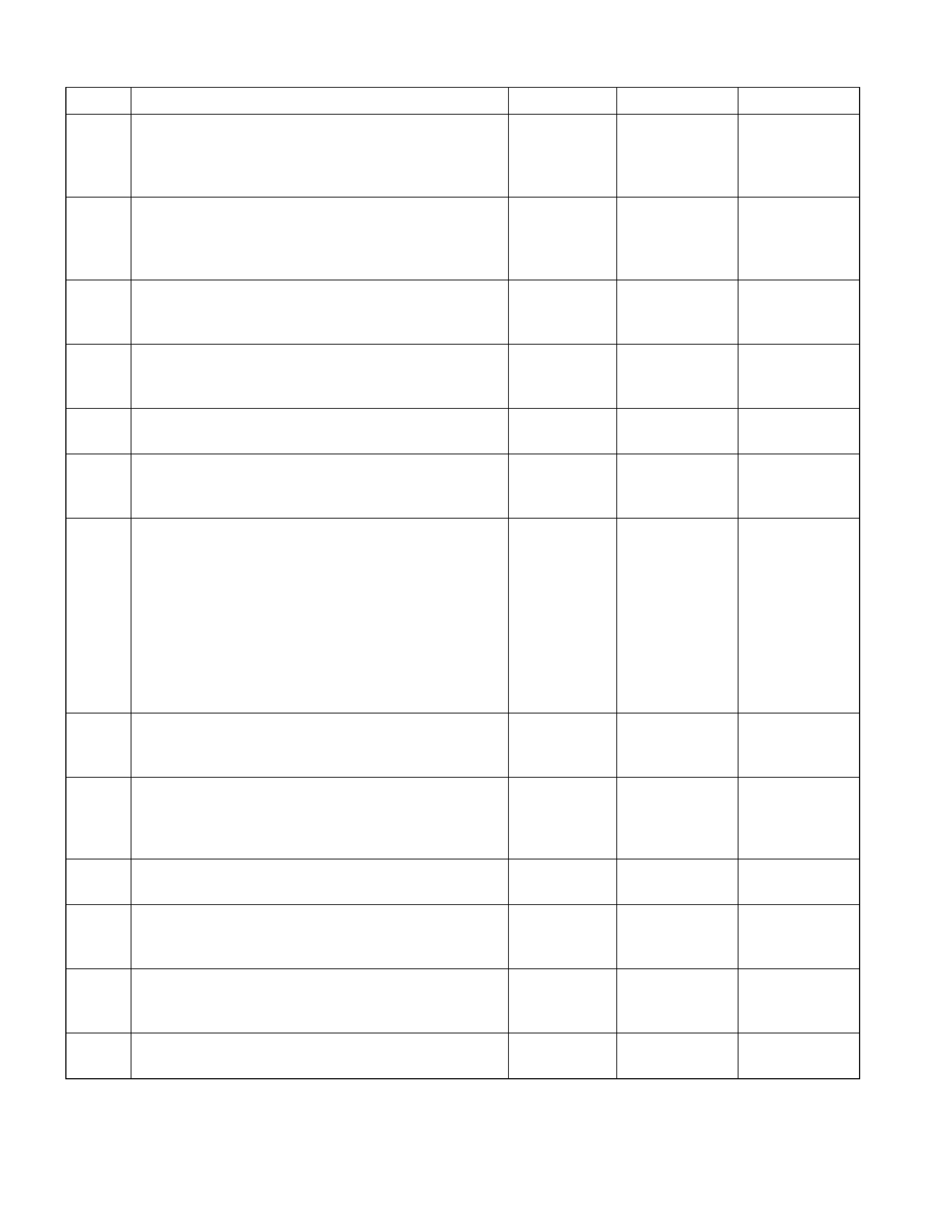

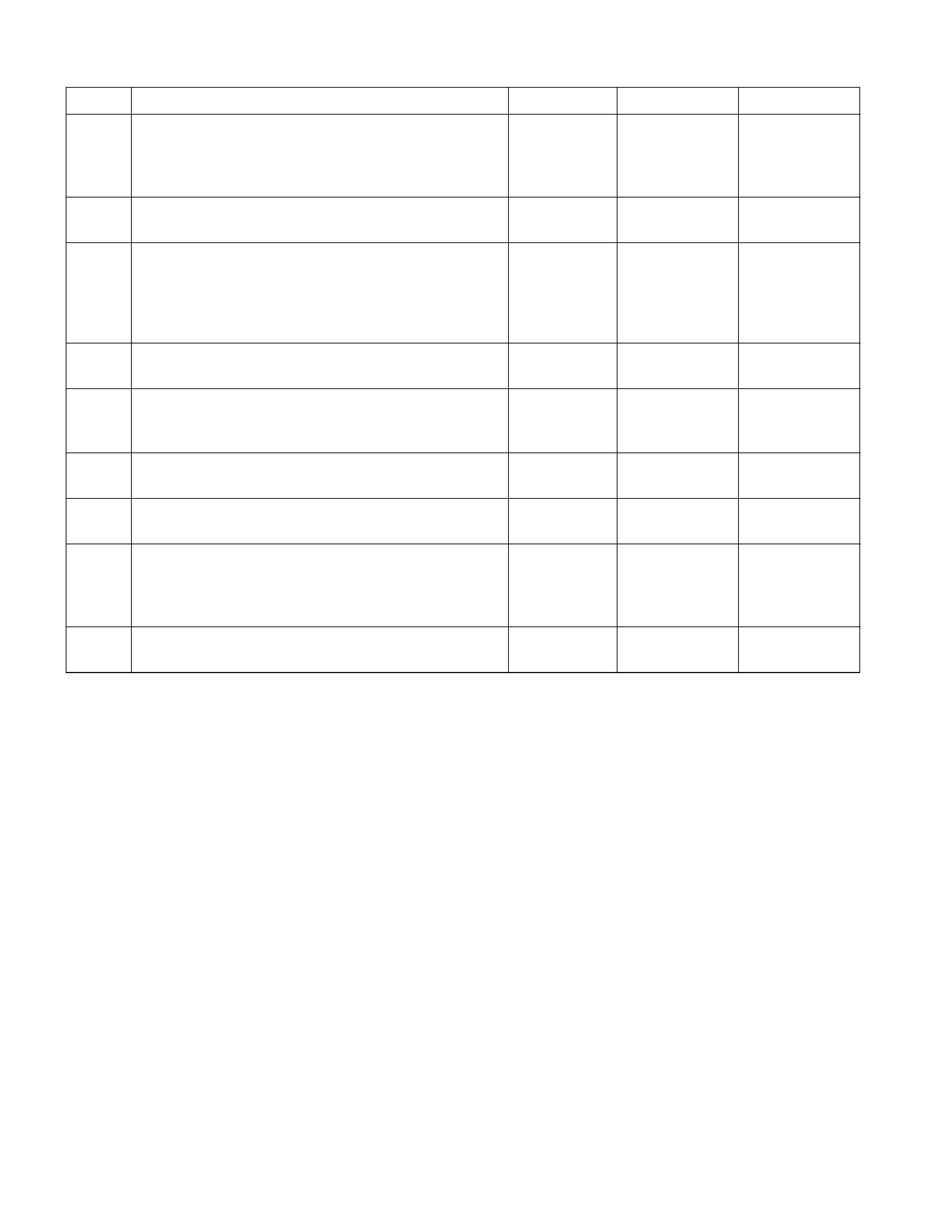

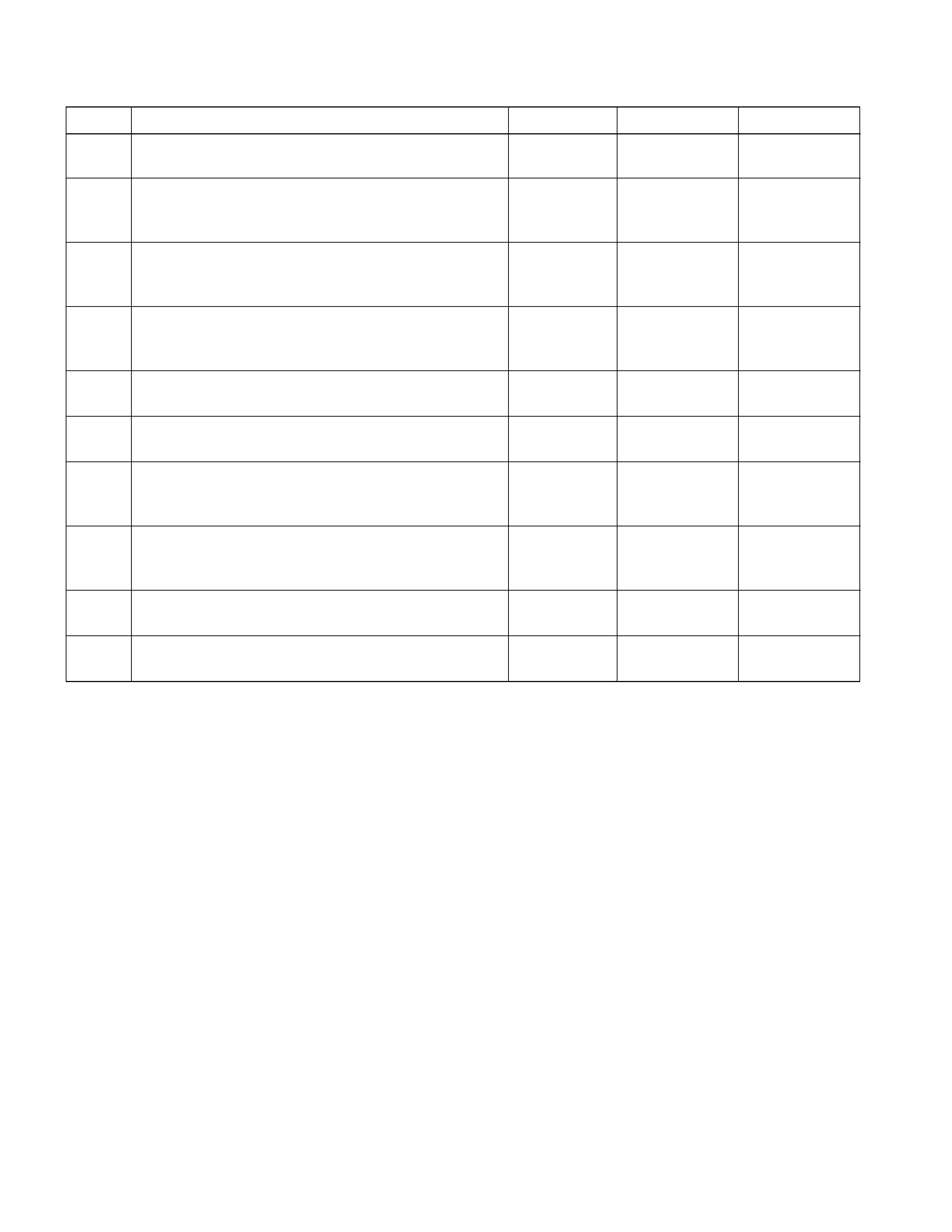

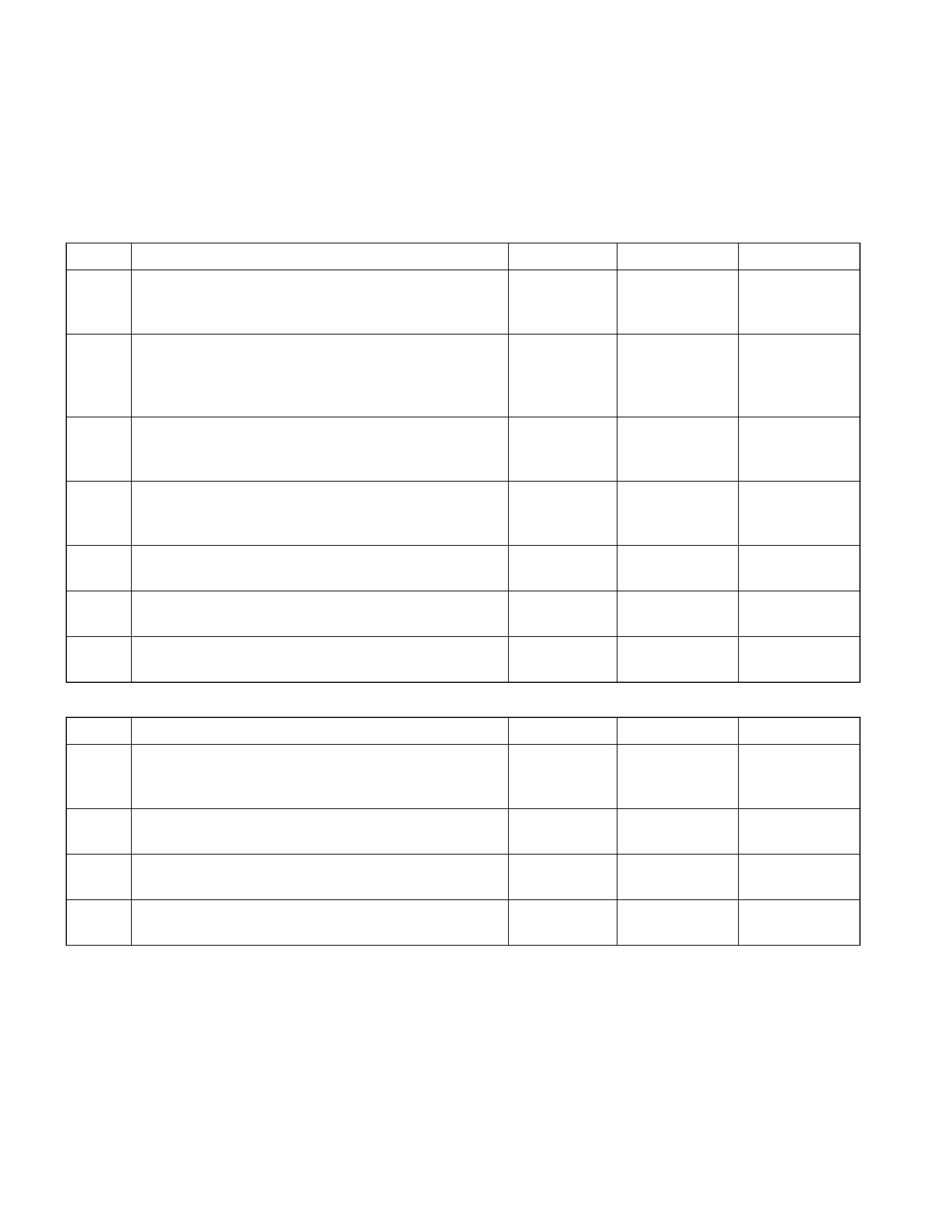

Basic Inspection Procedure

Follow the inspection procedure below, when the problem vehicle comes into the workshop.

Step Inspection point Inspection result YES NO

1 Inspect the check engine lamp Is the check engine lamp ON? Go to section

6E “On Board

Diagnostic

(OBD) System

Check" Go to Step 2

2 The battery fluid level and the

specific gravity Was the problem found? Re-charge the

battery or

replace the

battery Go to Step 3

3 The engine coolant level Was the problem found? Replenish the

engine coolant Go to Step 4

4 The engine oil level Was the problem found? Replenish the

engine oil Go to Step 5

5 The air cleaner element Was the problem found? Clean or

replace Go to Step 6

6 The piping fixing condition (oil,

vacuum and fuel piping) Was the problem found? Return to

normal

condition Go to Step 7

7 The drive belt tension and

security Was the problem found? Re-adjust the

tension or

replace Go to Step 8

8 Go to section 6E “On Board

Diagnostic (OBD) System

Check”

Was the problem found?

Verify repair Go to Step 9

9 Go to mechanical

troubleshooting chart Was the problem found? Verify repair —

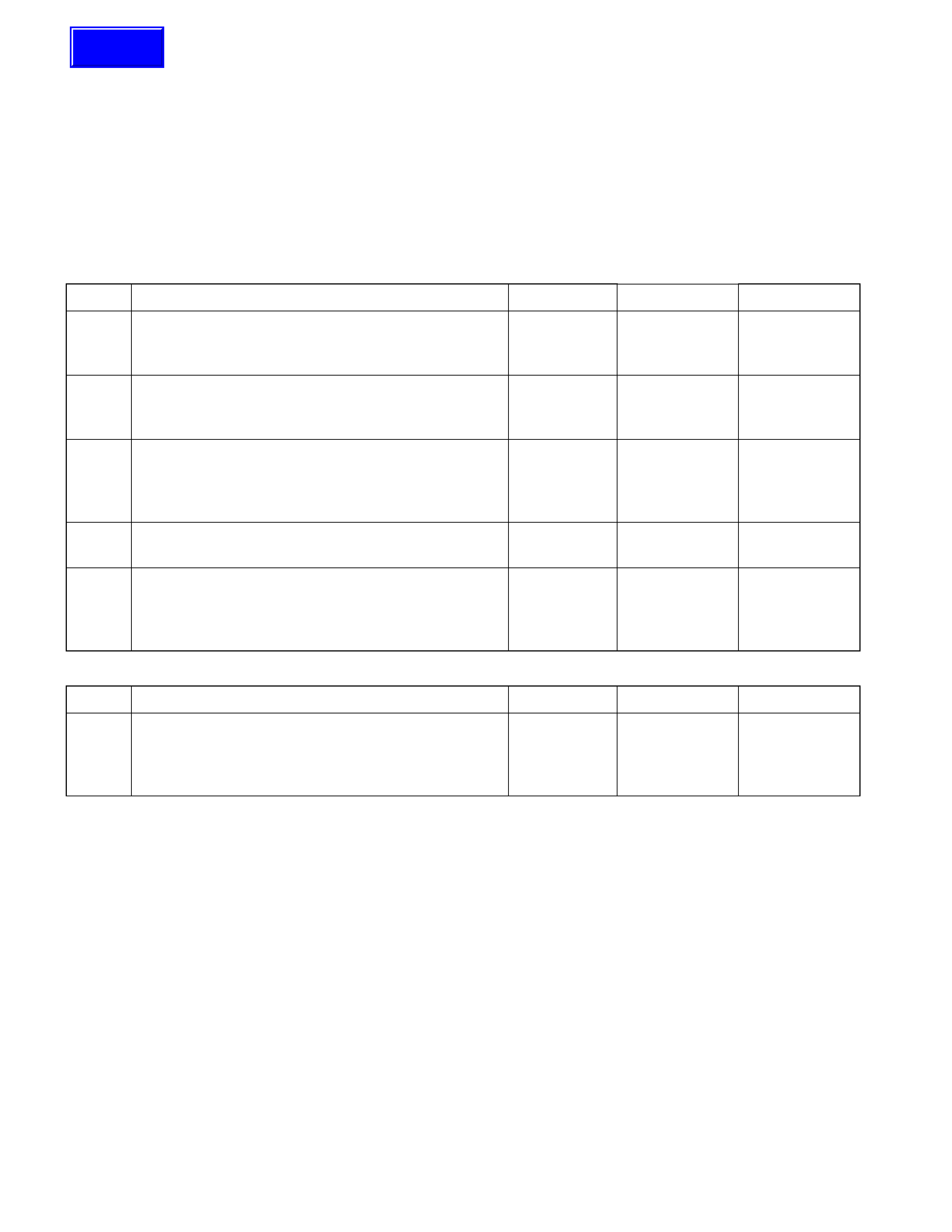

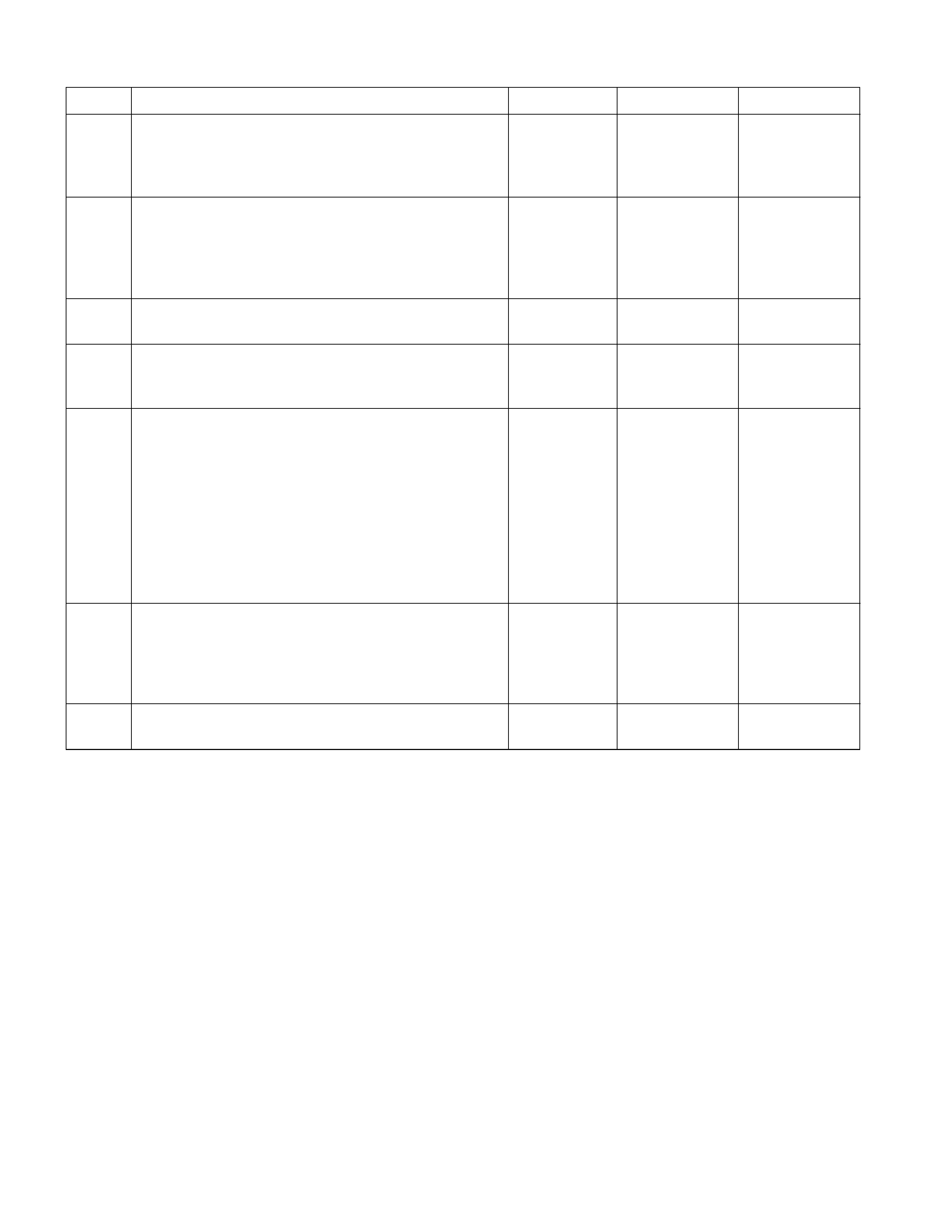

1. Hard Starting

Inspect the following items before diagnosis.

1. The battery condition.

The condition of the terminal connections.

The state of charge of the battery.

2. The fan belt tension and security.

3. The main fuse condition.

4. The quantity of fuel in the fuel tank.

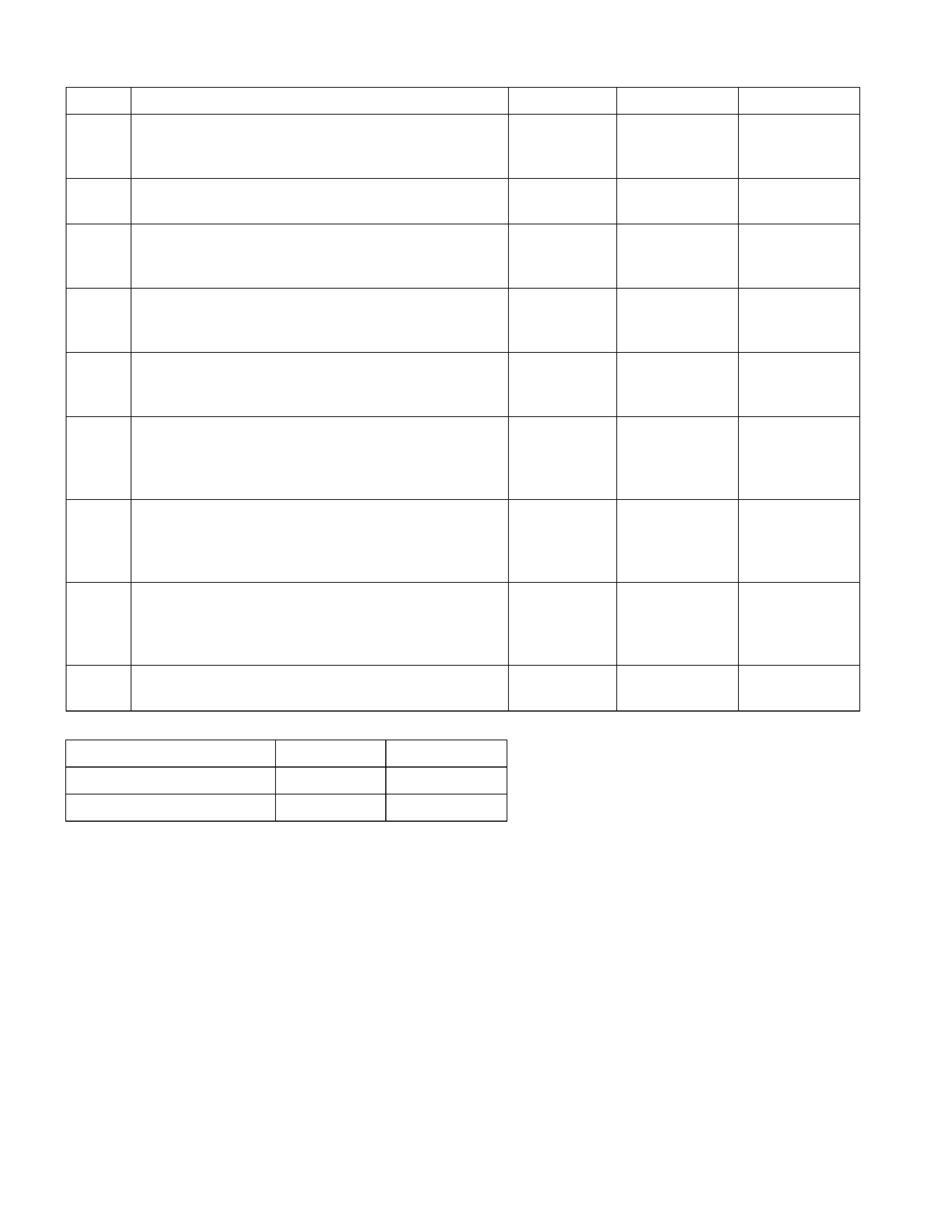

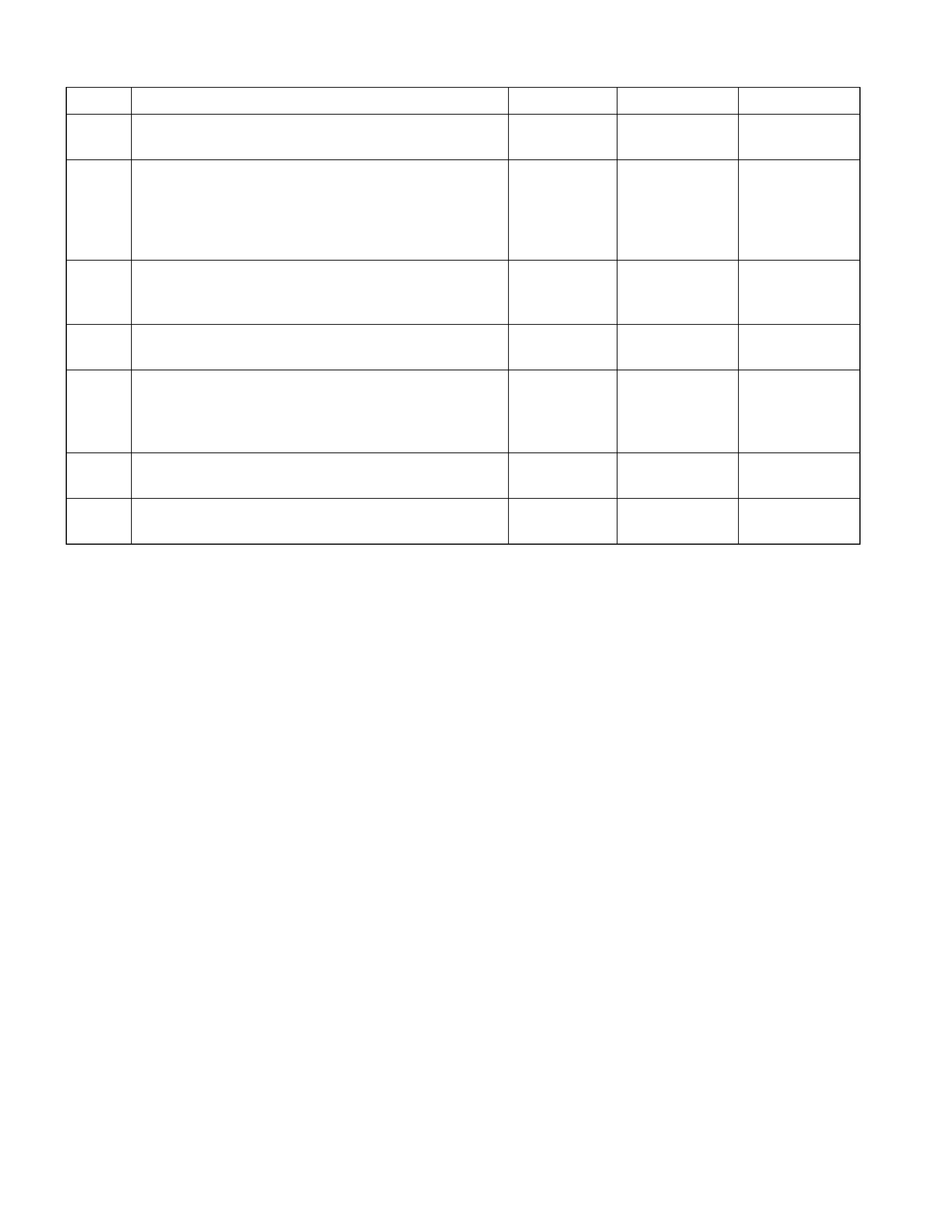

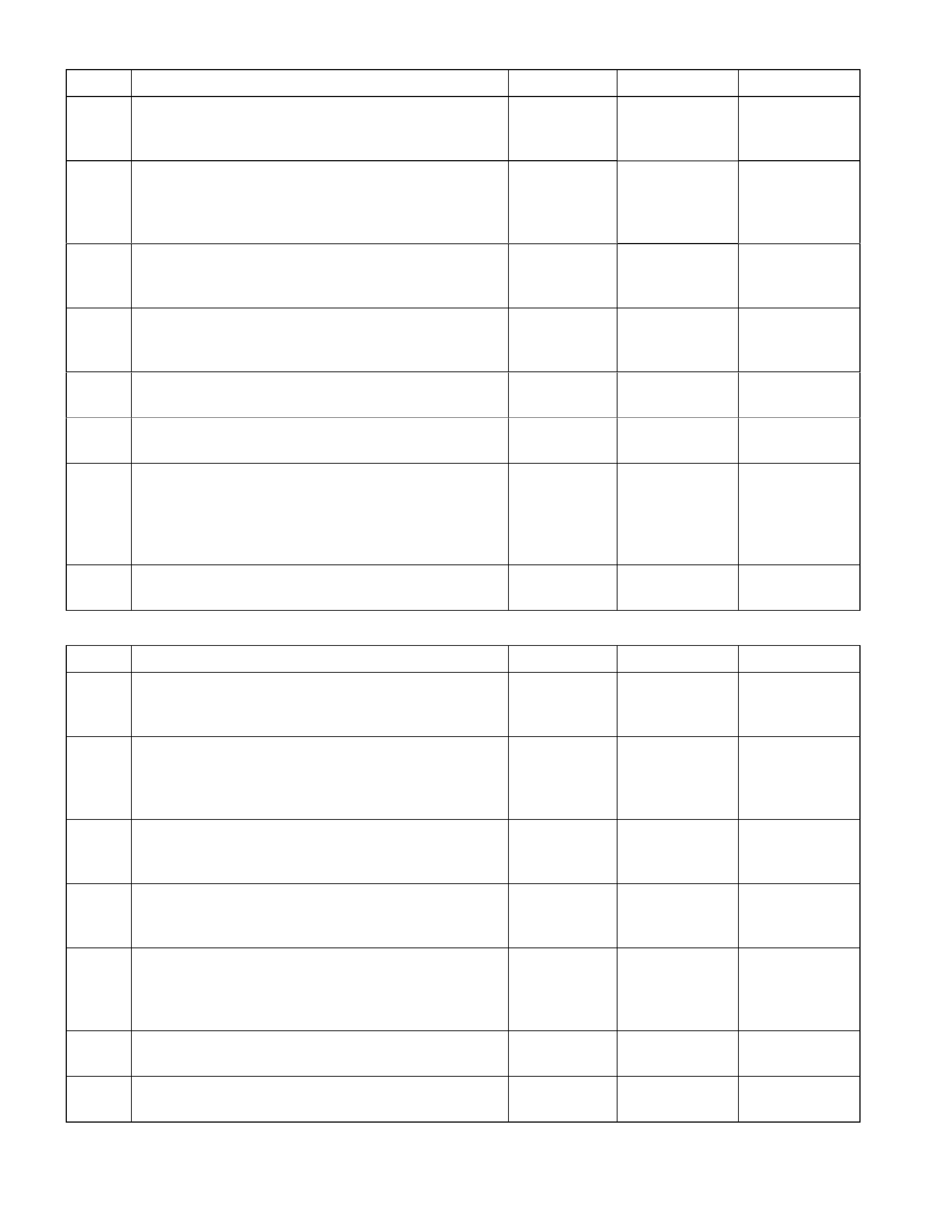

1–1 Starter Motor Inoperative

Step Action Value(s) Yes No

1 Check the starter switch.

Does the starter switch work? —

Go to Step 2

Repair or

replace the

starter switch

2 Check the starter relay.

Does the starter relay work? —

Go to Step 3

Repair or

replace the

starter relay

3 Check the magnetic switch.

Does the magnetic switch work? —

Go to Step 4

Repair or

replace the

magnetic

switch

4 Check the pinion gear condition on the starter motor.

Is the condition normal? — Go to Step 5 Replace the

pinion gear

5 Check the brush wear or brush spring weakness.

Is the condition normal? — Replace the

starter motor

assembly

Repair or

replace the

brush or brush

spring

1-2 Starter Motor Operates But Engine Does Not Turn Over

Step Action Value(s) Yes No

1 Check the engine for internal seizure.

Is the engine seized? — Repair or

replace seized

parts

Check other

DTC by Tech2

and go to

indicated DTC

Techline

1-3 Engine Turns Over But Does Not Start

When fuel is not being delivered to the injection pump

Step Action Value(s) Yes No

1 Check for clogged or damaged fuel piping, or loose

connections.

Are there any problems?

— Repair replace

faulty parts Go to Step 2

2 Is the over flow valve on the fuel filter closed? — Repair or

replace the

over flow valve Go to Step 3

3 Is the fuel filter element clogged? — Replace the

fuel filter

element Go to Step 4

4 Is the fuel line air bled? — Go to Step 5 Bleed the air

5 Are any DTCs stored? — Go to indicated

DTC Solved

When fuel is being delivered to the injection pump

Step Action Value(s) Yes No

1 Does the fuel contain any water? — Replace the

fuel Go to Step 2

2 Is the fuel line air bled? — Go to Step 5 Bleed the air

3 Are the injection spray patterns satisfactory? —

Go to Step 4

Replace the

injection

nozzle(s)

4 Are the injection nozzle injection starting pressures

OK? (See below)

Go to Step 5

Replace the

injection

nozzle(s)

5 Are any injection nozzles sticking? — Replace the

injection

nozzle(s) Go to Step 6

6 Are any DTCs stored? — Go to indicated

DTC Solved

Injection nozzle opening pressure

1st = 19.5 MPa (199 kg/cm2, 2828 psi)

NOTE: The injectors fitted to the 4JH1-TC engine are not serviceable at the time of publication of this Service

Information. It is advised to check the current situation with Robert Bosch Aust. Pty., Ltd., or your local Bosch

Service Agent.

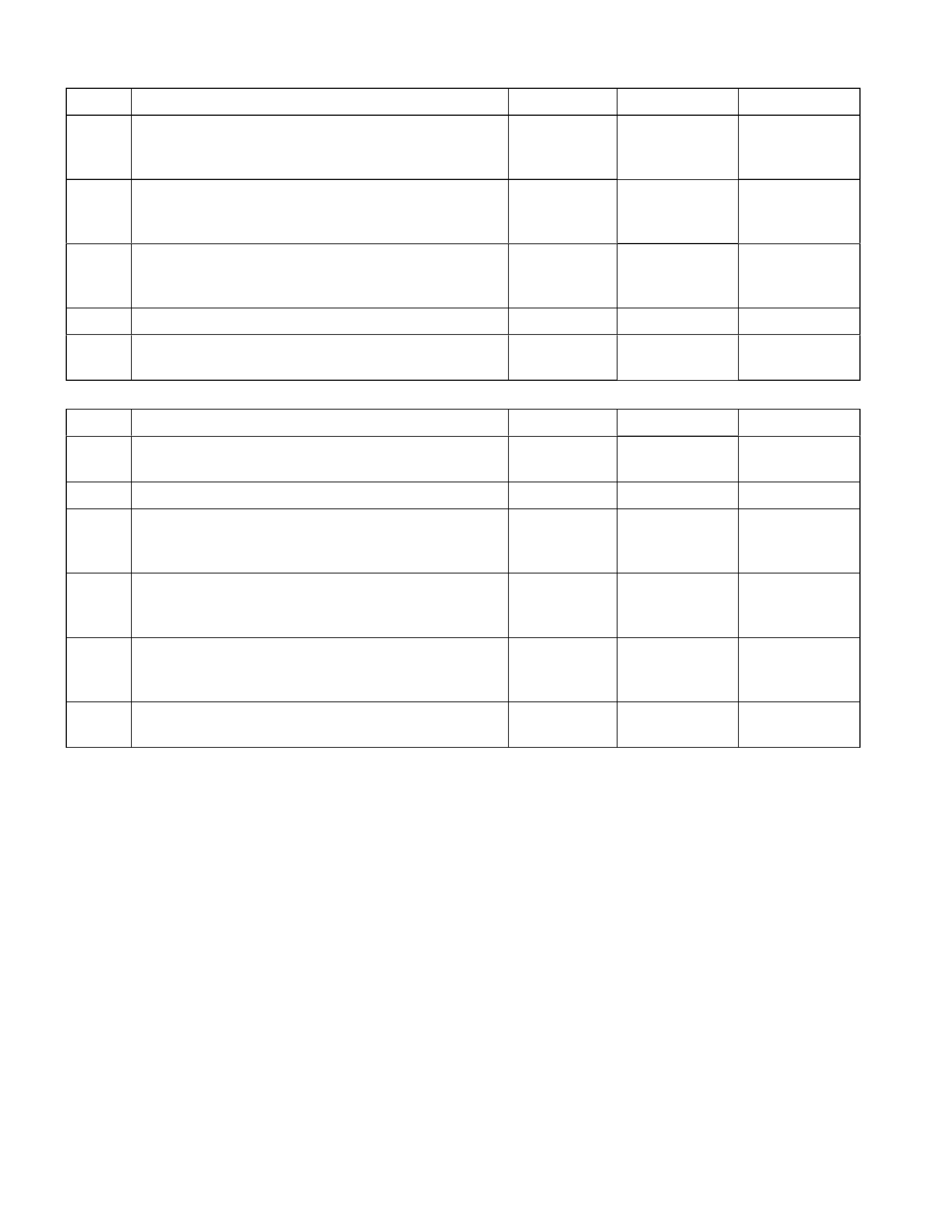

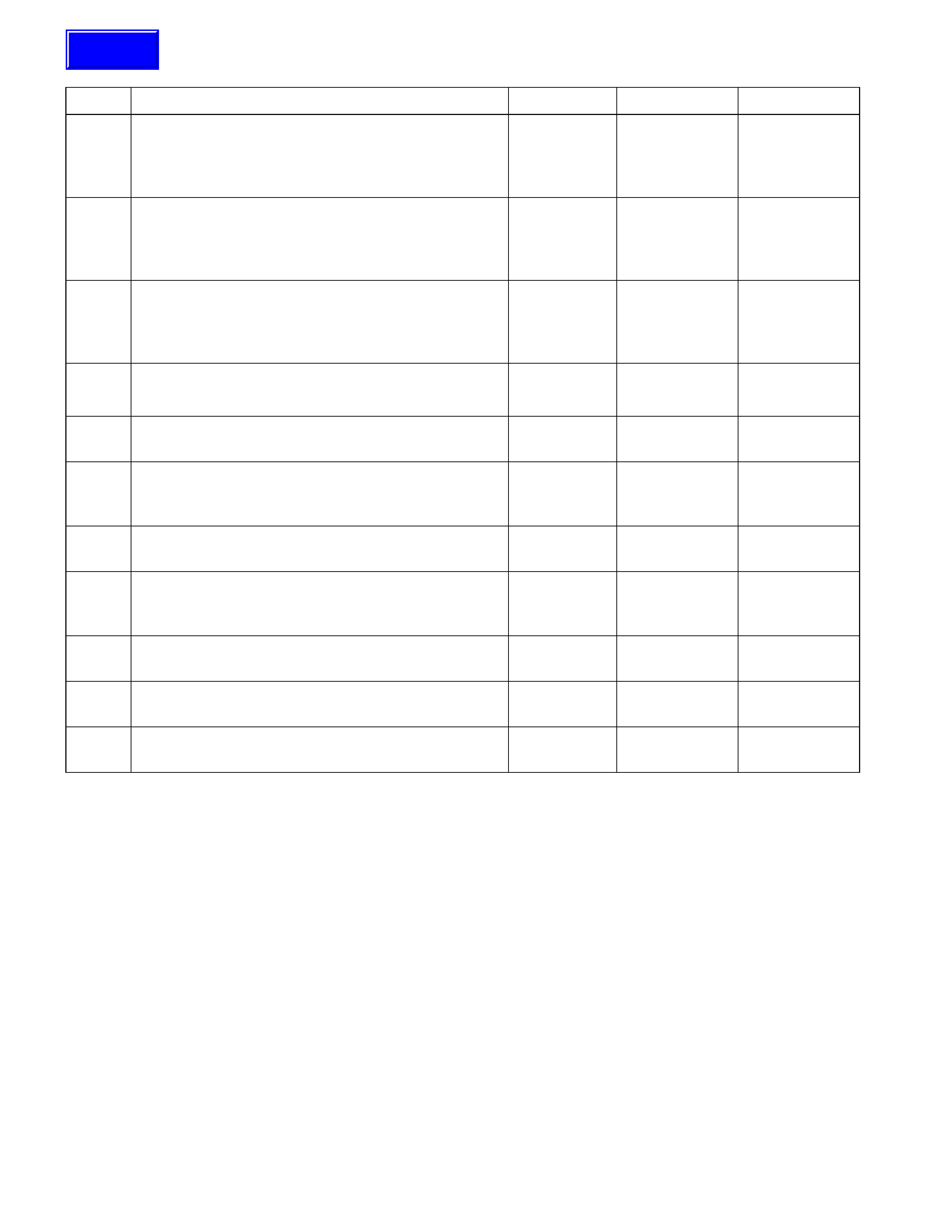

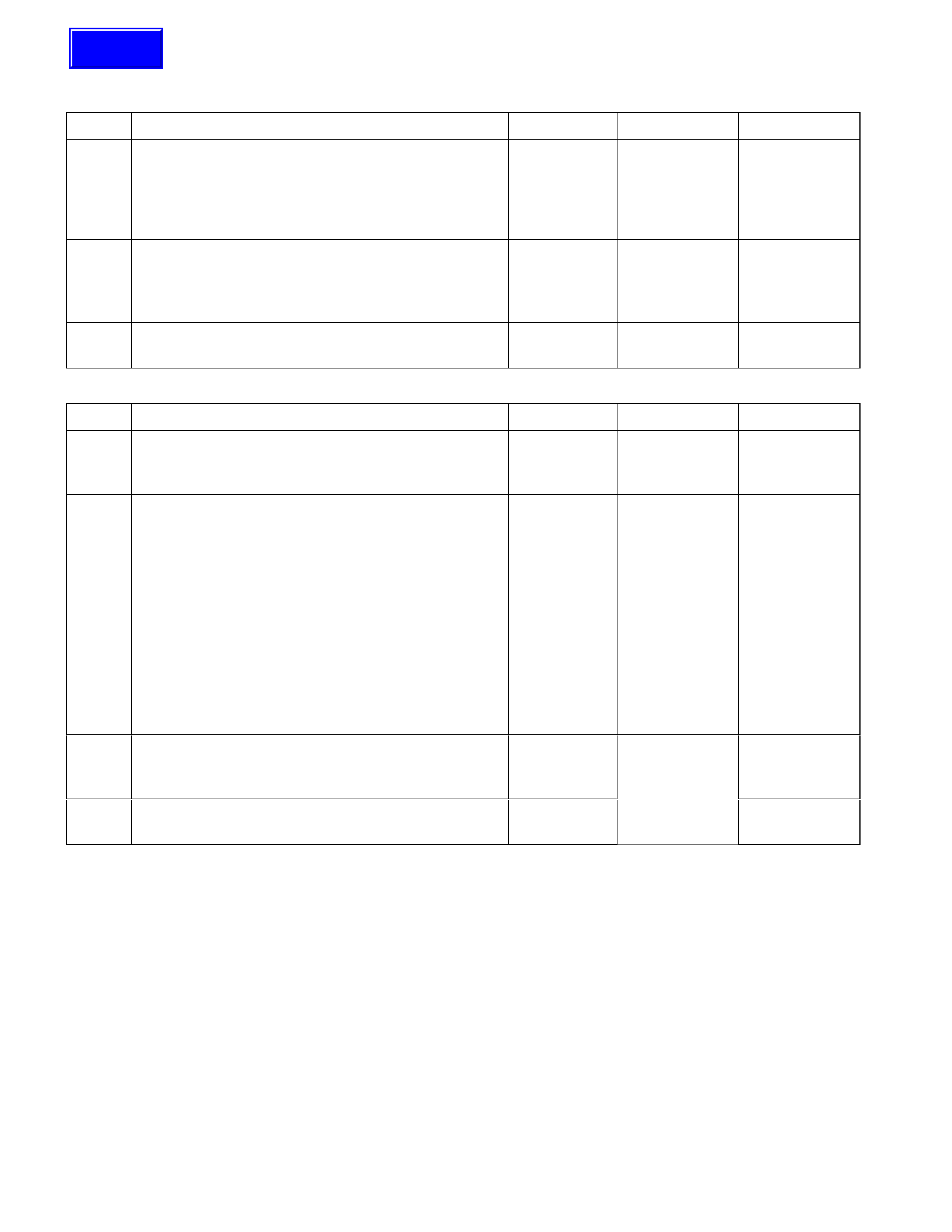

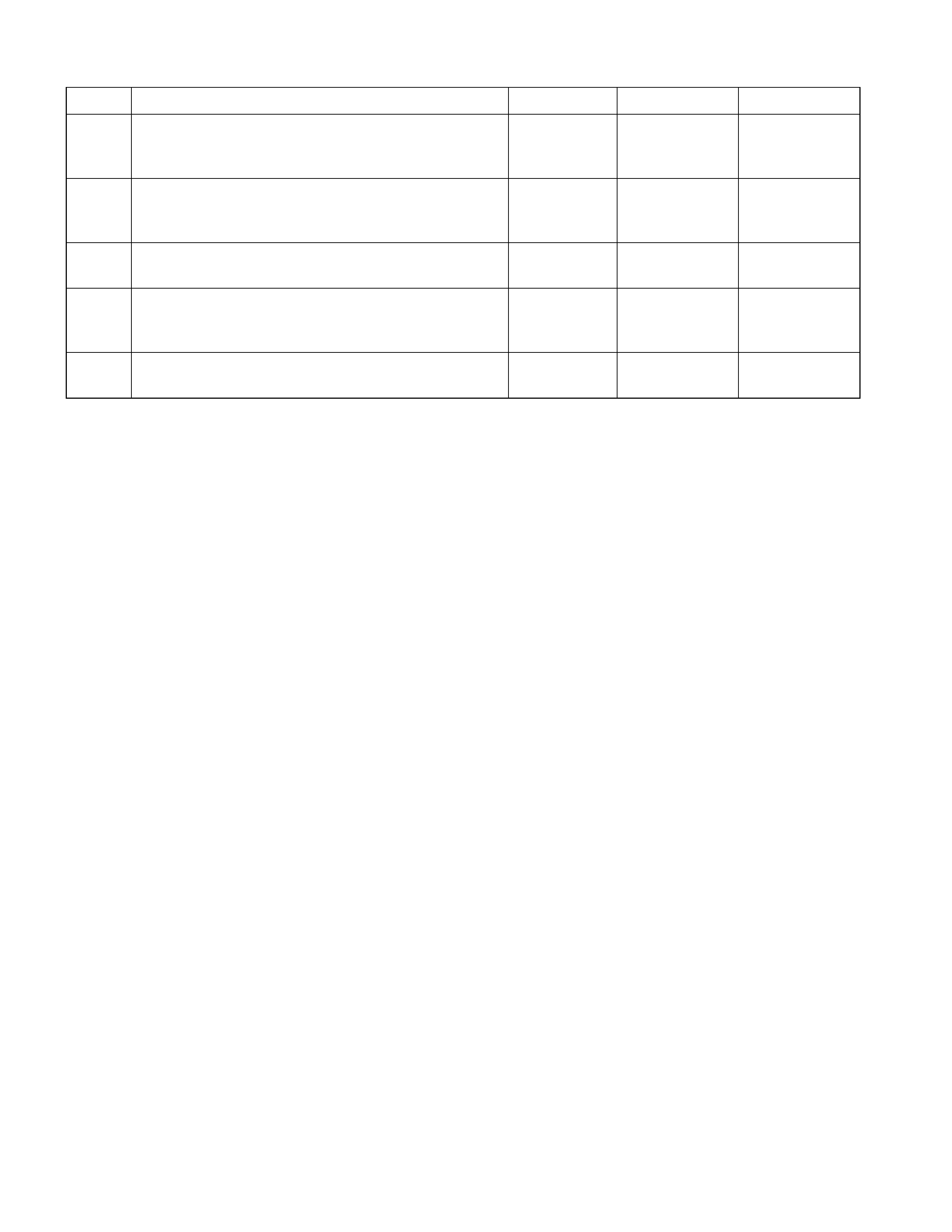

2. Unstable Idling

Step Action Value(s) Yes No

1 Is the fuel line air bled completely? — Go to Step 3 Bleed the air

2 Check for fuel line leaks or blockages — Repair or

replace

appropriate

parts Go to Step 4

3 Does the fuel contain any water? — Replace the

fuel Go to Step 5

4 Is the fuel filter element clogged? — Replace the

fuel filter

element Go to Step 6

5 Are the injection starting pressures and the injection

spray patterns OK? (See below)

Go to Step 7

Replace the

injection

nozzle(s)

6 Are any injection nozzles sticking? See Step 5 Replace the

injection

nozzle(s) Go to Step 8

7 Check the throttle valve condition.

Is the idling port clogged in the throttle valve? — Repair or

replace the

throttle valve Go to Step 9

8 Are the valve clearances adjusted correctly? 0.4 mm

(0.016 in)

both intake

and exhaust

valves Go to Step 10

Adjust the

valve

clearances

9 Is the compression pressure OK? 3,040 kPa

(31 kg/cm2,

441 psi) at

200rpm

Go to Step 11

Readjust the

valve

clearance or

replace the

cylinder head

gasket or

cylinder liner or

piston or piston

ring or valve

and valve seat

10 Are any DTCs stored? — Go to indicated

DTC Solved

Injection nozzle opening pressure

1st = 19.5 MPa (199 kg/cm2, 2828 psi)

NOTE: The injectors fitted to the 4JH1-TC engine are not serviceable at the time of publication of this Service

Information. It is advised to check the current situation with Robert Bosch Aust. Pty., Ltd., or your local Bosch

Service Agent.

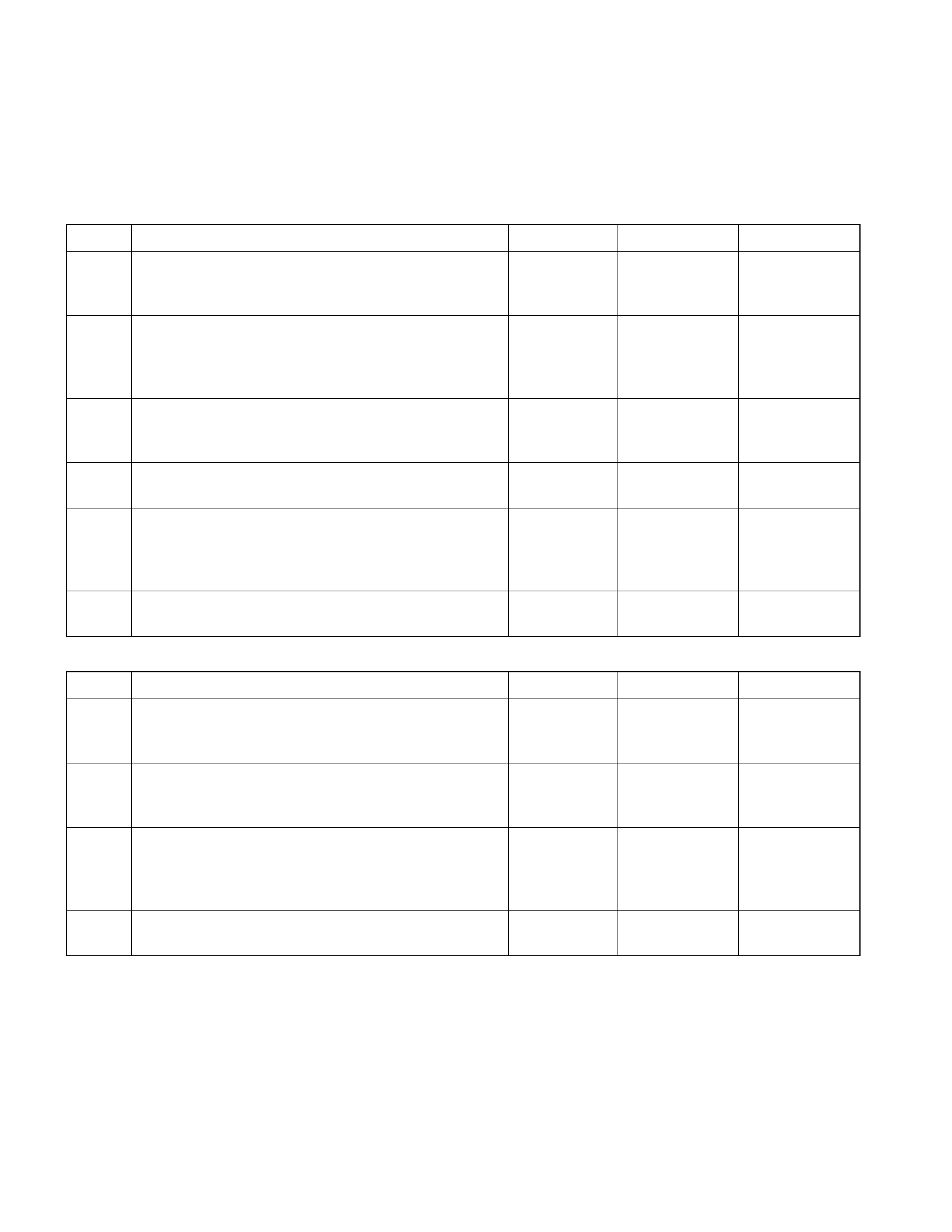

3. Insufficient Power

Step Action Value(s) Yes No

1 Is the air cleaner element condition OK? —

Go to Step 2

Clean or

replace the air

cleaner

element

2 Does the intake system have any leaks? — Repair or

replace the

intake air

system Go to Step 3

3 Is the fuel filter element condition OK? —

Go to Step 4

Clean or

replace the fuel

filter element

4 Check the fuel injection pipes.

Do the injection pipes have any obstructions or

damage?

— Repair or

replace the fuel

injection pipes Go to Step 5

5 Does the fuel contain any water? — Replace the

fuel Go to Step 6

6 Are the injection starting pressures and the injection

spray patterns OK? —

Go to Step 7

Replace the

injection

nozzle(s)

7 Is the compression pressure OK? 3.0 MPa

(31.0 kg/cm2,

441 psi) at

200 rpm

Go to Step 8

Readjust the

valve

clearance or

replace the

cylinder head

gasket or

cylinder liner or

piston or piston

ring or valve

and valve seat

8 Is the exhaust pipe clogged? — Repair or

replace the

exhaust pipe Go to Step 9

9 Does the exhaust system leak any exhaust gas? — Repair or

replace the

exhaust system Go to Step 10

10 Is the waste gate control actuator hose broken or

cracked? — Replace the

hose Go to Step 11

11 Is the waste gate working correctly? —

Go to Step 12

Replace the

turbocharger

assembly

12 Is turbocharger working correctly? —

Go to Step 13

Replace the

turbocharger

assembly

13 Are any DTCs stored? — Go to indicated

DTC Solved

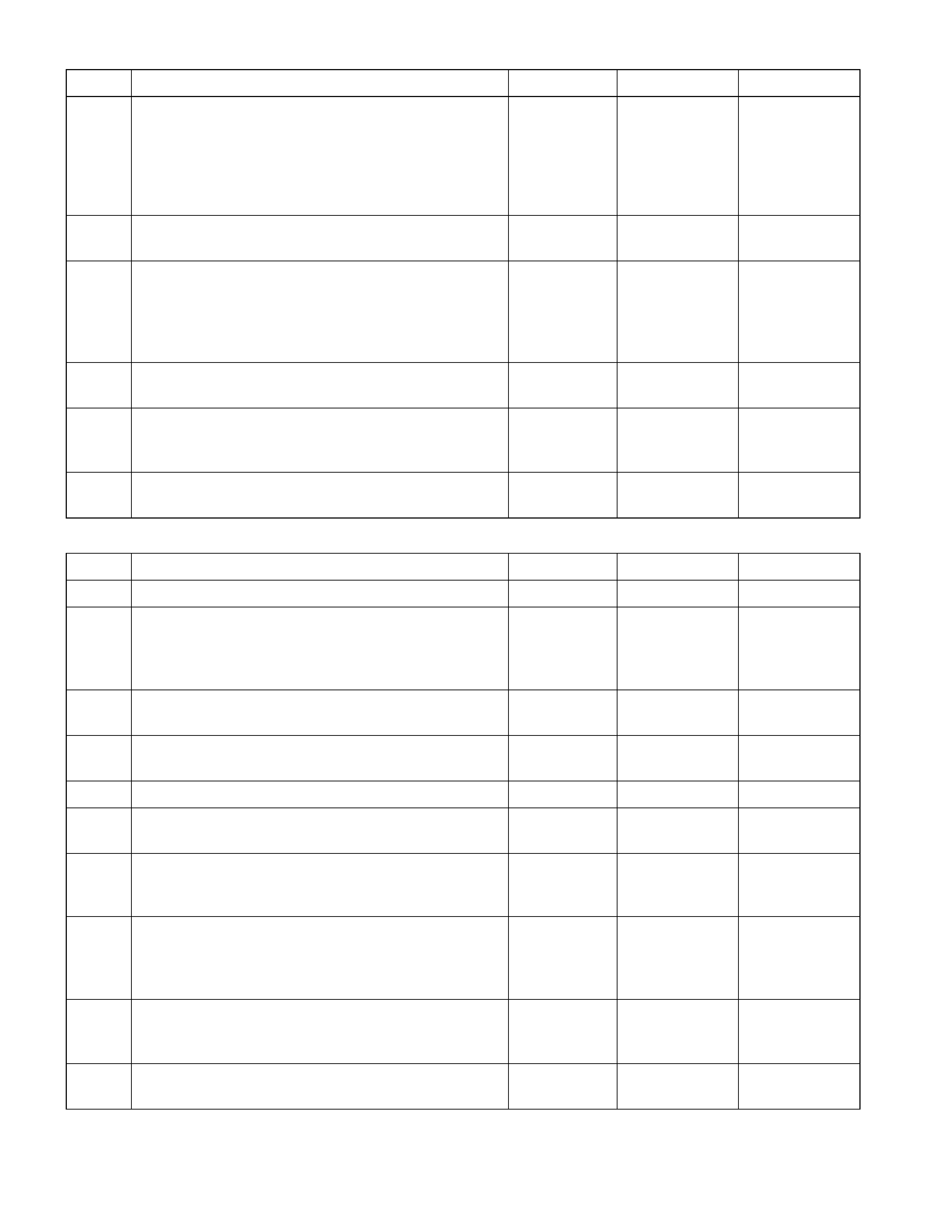

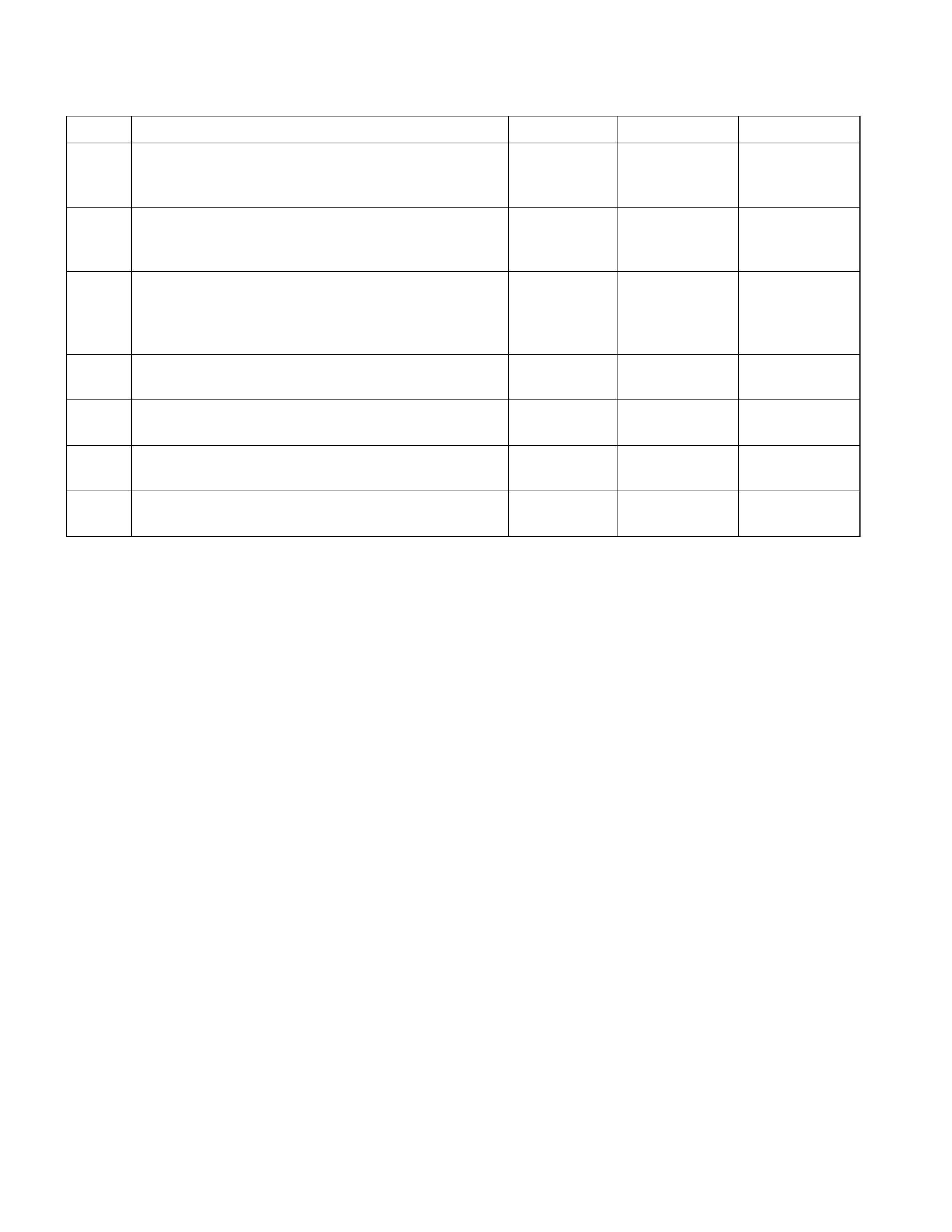

4. Excessive Fuel Consumption

Step Action Value(s) Yes No

1 Is the air cleaner element clogged? — Clean or

replace the air

cleaner

element Go to Step 2

2 Is there any air leaking from the air intake side of the

turbocharger? — Repair or

replace the air

intake side of

the

turbocharger Go to Step 3

3 Is the turbocharger working correctly? — Go to Step 4 Replace the

turbocharger

4 Are there any fuel leaks? — Repair or

replace the

leaking part Go to Step 5

5 Is the compression pressure OK? 3.0 MPa

(31.0 kg/cm2,

441 psi) at

200 rpm

Go to Step 6

Readjust the

valve

clearance or

replace the

cylinder head

gasket or

cylinder liner or

piston or piston

ring or valve

and valve seat

6 Are the injection starting pressures and the injection

spray patterns OK? —

Go to Step 7

Replace the

injection

nozzle(s)

7 Are any DTCs stored? — Go to indicated

DTC Solved

NOTE: The injectors fitted to the 4JH1-TC engine are not serviceable at the time of publication of this Service

Information. It is advised to check the current situation with Robert Bosch Aust. Pty., Ltd., or your local Bosch

Service Agent.

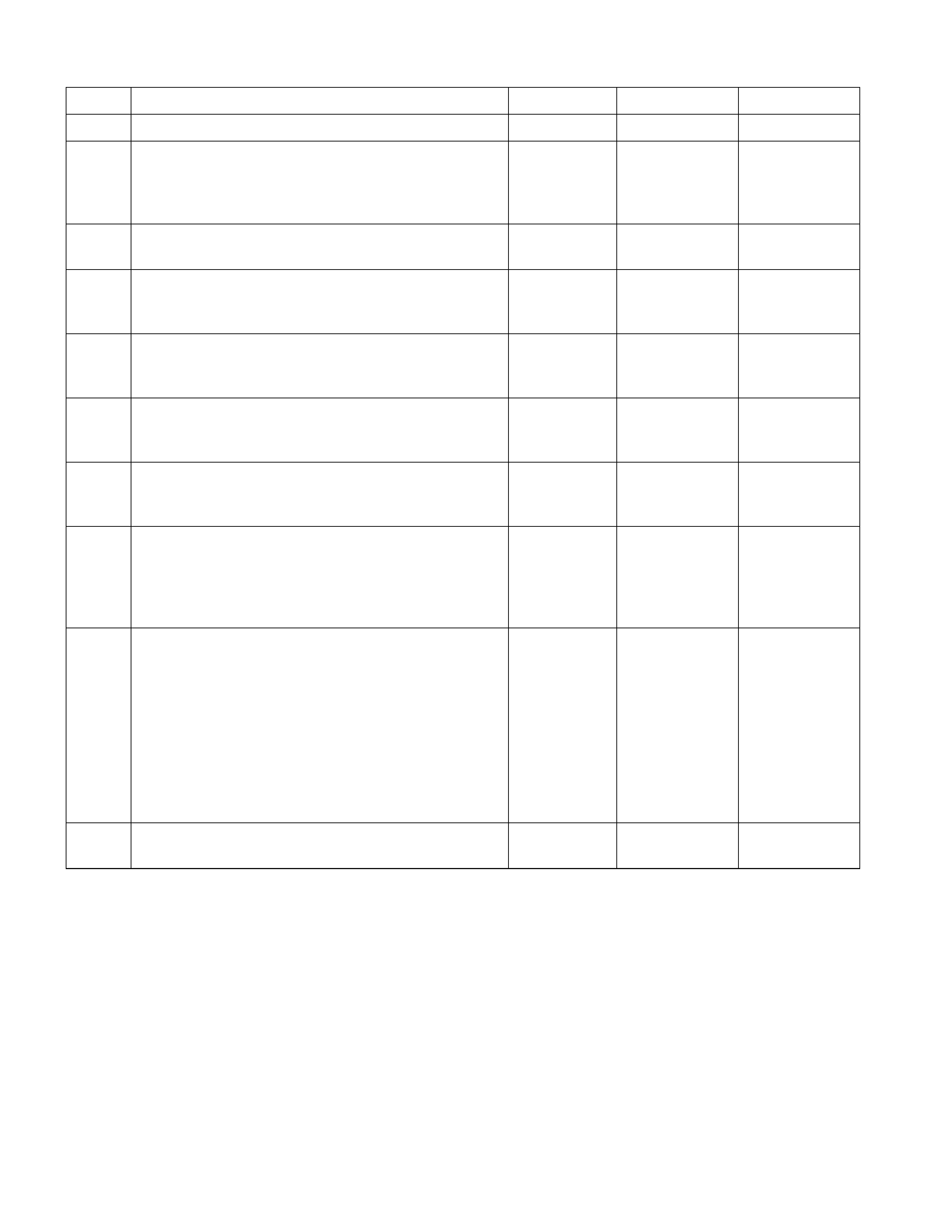

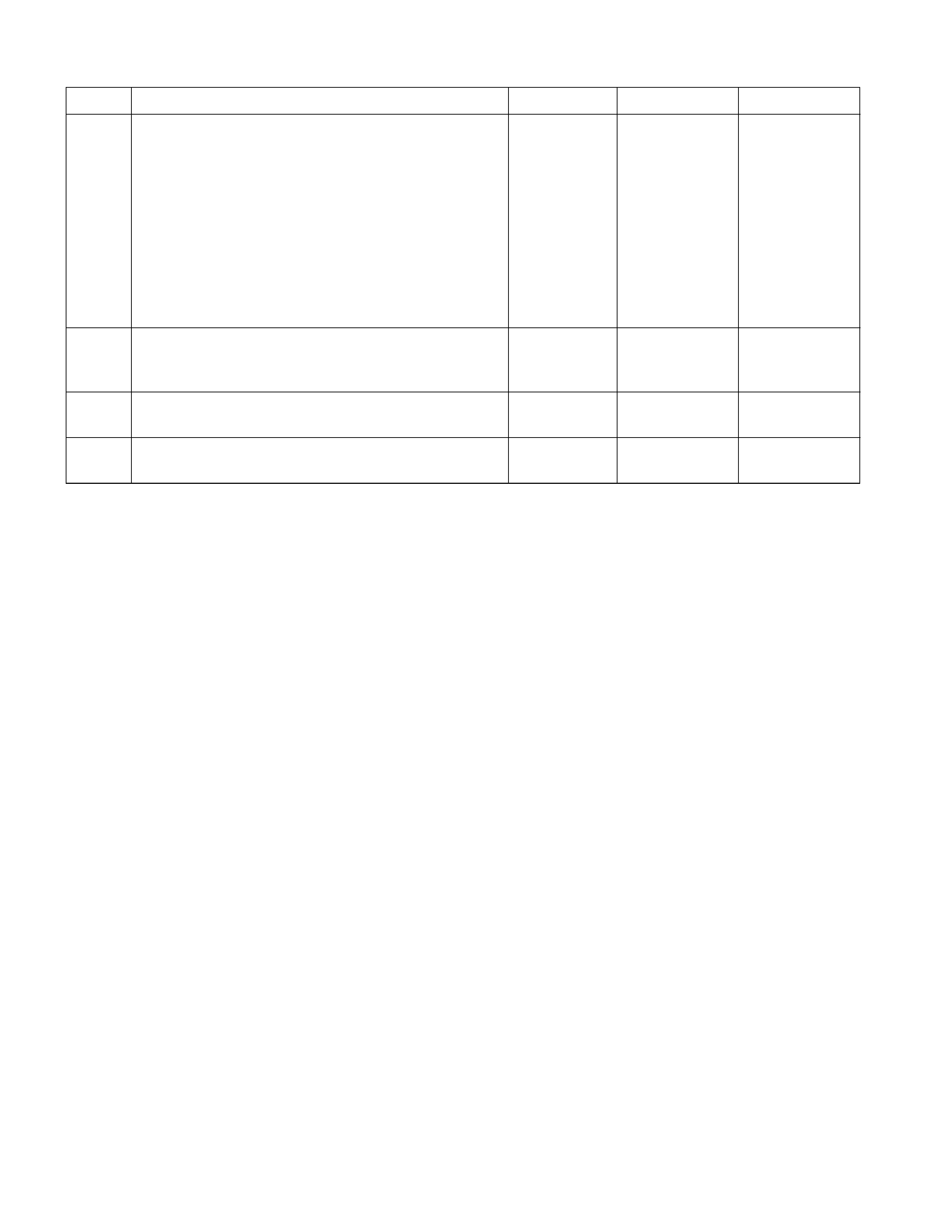

5. Excessive Oil Consumption

Step Action Value(s) Yes No

1 Is the air cleaner element condition OK? —

Go to Step 2

Clean or

replace the air

cleaner

element

2 Is the PCV (Positive Crankcase Ventilation) Valve

faulty? — Repair or

replace the

appropriate

parts Go to Step 3

3 Is the oil pressure value more than normal value? Less than

588 kPa (6.0

kg/cm2, 85

psi)

Repair or

replace the oil

relief valve Go to Step 4

4 Inspect the front and rear crankshaft oil seal.

Were any oil leaks found? — Replace the

faulty part Go to Step 5

5 Were any oil leaks found from any gasket? — Replace the

faulty gasket Go to Step 6

6 Inspect the valve stem seals, the valve stems, and

the valve guides, for excessive wear.

Are any parts worn?

— Replace the

worn part(s) Go to Step 7

7 Is there oil leaking from the turbocharger oil seal? — Replace the oil

seal Go to Step 8

8 Is the oil drain pipe of the turbocharger restricted? — Repair or

replace the oil

drain pipe Go to Step 9

9 Is the oil drain passage in the turbocharger center

housing restricted? — Clean the

center housing Go to Step 10

10 Does turbine wheel have any impact damage? — Replace the

turbocharger Go to Step 11

11 Are any DTCs stored? — Go to indicated

DTC Solved

Techline

6. Overheating

Step Action Value(s) Yes No

1 Is the engine coolant level OK? — Go to Step 2 Replenish the

coolant

2 Are there any coolant leaks (also check radiator

cap)? — Repair or

replace the

leaking part Go to Step 3

3 Is the fan belt slipping? — Tension or

replace the fan

belt Go to Step 4

4 Is the fan clutch working correctly? —

Go to Step 5

Replace the

fan clutch

assembly

5 Is the fan clutch leaking oil? — Replace the

fan clutch

assembly Go to Step 6

6 Is the thermostat working normally? — Go to Step 7 Replace the

thermostat

7 Is the water pump working OK? —

Go to Step 8

Replace the

water pump

assembly

8 Are there any restrictions in the cooling system? — Clean or

replace the

constricted part Go to Step 9

9 Is there any coolant leaking into the engine

cylinders? — Replace the

cylinder head

gasket and/or

other parts as

required Go to Step 10

10 Are any DTCs stored? — Go to indicated

DTC Solved

7. White Exhaust Smoke

Step Action Value(s) Yes No

1 Is the compression pressure OK? 3.0 MPa

(31.0 kg/cm2,

441 psi) at

200 rpm

Go to Step 2

Readjust the

valve

clearance or

replace the

cylinder head

gasket or

cylinder liner or

piston or piston

ring or valve

and related

parts

2 Does the PCV (Positive Crankcase Ventilation)

valve operate correctly? —

Go to Step 3

Repair or

replace the

PCV valve

3 Is the turbocharger working correctly? — Go to Step 4 Replace the

turbocharger

4 Are any DTCs stored? — Go to indicated

DTC Solved

8. Dark Exhaust Smoke

Step Action Value(s) Yes No

1 Is the air cleaner element condition OK? —

Go to Step 2

Clean or

replace the air

cleaner

element

2 Is the EGR valve sticking? — Replace the

EGR valve Go to Step 3

3 Are the injection starting pressures and the injection

spray patterns OK? —

Go to Step 4

Replace the

injection

nozzle(s)

4 Is there oil leaking from the turbocharger oil seal? — Replace the oil

seal Go to Step 5

5 Is the oil drain pipe of the turbocharger restricted? — Repair or

replace the oil

drain pipe Go to Step 6

6 Is the oil drain passage in the turbocharger center

housing restricted? — Clean the

center housing Go to Step 7

7 Does the turbine wheel have any impact damage? — Replace the

turbocharger Go to Step 8

8 Is the PCV (Positive Crankcase Ventilation) Valve

faulty? — Repair or

replace the

appropriate

parts Go to Step 9

9 Are any DTCs stored? — Go to indicated

DTC Solved

NOTE: The injectors fitted to the 4JH1-TC engine are not serviceable at the time of publication of this Service

Information. It is advised to check the current situation with Robert Bosch Aust. Pty., Ltd., or your local Bosch

Service Agent.

9. Oil Pressure Does Not Rise

Step Action Value(s) Yes No

1 Is the oil pressure warning lamp working OK? (See below)

Go to Step 2

Replace faulty

parts as

required

2 Is the oil filter element restricted? — Replace the oil

filter element Go to Step 3

3 Is the relief valve stuck open? — Repair or

replace the

relief valve Go to Step 4

4 Is the oil strainer restricted? — Clean or

replace the oil

strainer Go to Step 5

5 Is the oil pump faulty? (The pump and related parts

worn etc.) — Repair or

replace the oil

pump Go to Step 6

6 Is the rocker arm and/or related parts worn? — Replace the

rocker arm

and/or related

parts Go to Step 7

7 Is the camshaft and/or related parts worn? — Replace the

camshaft

and/or related

parts Go to Step 8

8 Is the crankshaft and/or related parts worn? — Replace the

crankshaft

and/or related

parts Go to Step 9

9 Are any DTCs stored? — Go to indicated

DTC Solved

Specifications for oil pressure switch circuit

Pressure – kPa (kg/cm2) 100 (1.0) 980 (10.0)

Resistance – Ω 81 30

Electric current – A 63.5 106.7

10. Abnormal Engine Noise

10–1 Engine Knocking

Step Action Value(s) Yes No

1 Are the injection starting pressures and the injection

spray patterns OK? —

Go to Step 2

Replace the

injection

nozzle(s)

2 Is the compression pressure OK? 3.0 MPa

(31.0 kg/cm2,

441 psi) at

200 rpm Go to Step 3

Replace the

cylinder head

gasket or

piston ring

3 Are any DTCs stored? — Go to indicated

DTC Solved

10–2 Gas Leakage Noise

Step Action Value(s) Yes No

1 Is the exhaust pipe loose or broken? — Retighten or

replace the

exhaust pipe Go to Step 2

2 Is the exhaust manifold loose? — Retighten or

replace the

exhaust

manifold, or

replace the

exhaust

manifold

gasket Go to Step 3

3 Is the injection nozzle loose? — Retighten or

replace the

injection nozzle

fixing bolt Go to Step 4

4 Is the cylinder head gasket broken? — Replace the

cylinder head

gasket Go to Step 5

5 Are any DTCs stored? — Go to indicated

DTC Solved

Techline

10–3 Continuous Noise

Step Action Value(s) Yes No

1 Is the fan belt tension OK? 9 – 13 mm

(0.35 – 0.51

in)

Go to Step 2 Adjust the fan

belt tension

2 Is the cooling fan loose? — Tighten the

cooling fan Go to Step 3

3 Is the noise coming from the generator? — Repair or

replace the

generator

and/or the

vacuum pump Go to Step 4

4 Is the noise coming from the water pump? — Replace the

water pump Go to Step 5

5 Is the noise coming from the cylinder head cover? — Readjust the

valve

clearance Go to Step 6

6 Are any DTCs stored? — Go to indicated

DTC Solved

10-4 Slapping Noise

Step Action Value(s) Yes No

1 Is the noise coming from the cylinder head cover? — Go to Step 2 Go to Step 4

2 Are the valve clearances correct? 0.4 mm

(0.016 in)

both intake

and exhaust Go to Step 3

Adjust the

valve

clearances

3 Are the rocker arms damaged? — Replace the

rocker arms Go to Step 4

4 Is the crankshaft damper fixing bolt loose? — Tighten the

fixing bolt Go to Step 5

5 Is the noise coming from the cylinder body? — Go to Step 6 Go to Step 10

6 Inspect the crankshaft bearing and/or crankshaft.

Is the crankshaft bearing and/or crankshaft worn? — Replace the

worn parts Go to Step 7

7 Inspect the connecting rod bearing and/or crankpin.

Is the connecting rod bearing and/or crankpin worn? — Replace the

worn parts Go to Step 8

8 Inspect the connecting rod small end bushing and/or

piston pin.

Is the connecting rod small end bushing and/or

piston pin worn?

—

Replace the

worn parts Go to Step 9

9 Inspect the piston and/or cylinder liner.

Is the piston and/or cylinder liner worn or damaged? — Replace the

worn or

damaged parts Go to Step 10

10 Are any DTCs stored? — Go to indicated

DTC Solved

10-5 Excessive Turbocharger Noise

It is normal for the turbocharger to create some noise when operating. Compare with a known good vehicle to confirm

excess operating noise.

Step Action Value(s) Yes No

1 Is the excess noise coming from the turbocharger? — Go to Step 2 Go to Step 10

2 Inspect the fixing bolts and bands on the

turbocharger.

Are there any problems?

— Tighten the

loose parts Go to Step 3

3 Is the intake or exhaust system gasket damaged? — Replace the

damaged

gasket Go to Step 4

4 Inspect the condition of the turbocharger rotating

parts.

Is the turbine wheel rotation rough?

— Replace the

turbocharger Go to Step 5

5 Inspect the turbine wheel.

Is the turbine wheel rubbing against housing? — Replace the

turbocharger Go to Step 6

6 Is the turbine wheel damaged? — Replace the

turbocharger Go to Step 7

7 Are there carbon deposits in the turbine or

compressor housing? — Clean or

replace the

turbocharger Go to Step 8

8 Inspect the oil supply.

Is the oil feed pipe restricted? — Repair or

replace the oil

feed pipe Go to Step 9

9 Is the turbine shaft bearing worn? — Replace the

turbocharger Go to Step 10

10 Are any DTCs stored? — Go to indicated

DTC Solved

11. Rotating Parts of Turbocharger are Worn

Step Action Value(s) Yes No

1 Inspect the engine oil.

Is it contaminated with foreign materials? — Replace the

engine oil Go to Step 2

2 Is the recommended engine oil grade/viscosity being

used? API CD or

ISUZU

genuine/

10W–30 Go to Step 3 Replace the

engine oil

3 Is the oil feed pipe restricted? — Clean or

replace the oil

feed pipe Go to Step 4

4 Is the oil seal of the turbocharger defective? — Replace the oil

seal Go to Step 5

5 Is the center housing oil drain passage restricted? — Clean center

housing or

replace the

turbocharger Go to Step 6

6 Is there oil sludge and/or coking on the turbine

shaft? — Replace the

turbocharger Go to Step 7

7 Are any DTCs stored? — Go to indicated

DTC Solved

12. Oil Leakage from Turbocharger

Step Action Value(s) Yes No

1 Inspect the oil leakage area.

Is the oil feed pipe eye bolt loose or the gasket

broken?

— Tighten the eye

bolt or replace

the gasket Go to Step 2

2 Are the V band fixing faces tight? — Tighten band

or replace the

turbocharger Go to Step 3

3 Is there oil leaking from the flange of the turbine

housing? — Replace the

turbocharger Go to Step 4

4 Is there oil leaking from the flange of the compressor

housing? — Tighten the bolt

and/or hose

clamp Go to Step 5

5 Are any DTCs stored? — Go to indicated

DTC Solved

13. Insufficient Acceleration and/or Lack of Power due to

Turbocharger Fault

Step Action Value(s) Yes No

1 Inspect the air or exhaust piping.

Is the air and/or exhaust gas piping loose? — Tighten flange

bolts or hose

clamp Go to Step 2

2 Inspect the waste gate valve control.

Is there rust on the linkage rod or pin of the waste

gate valve?

— Replace the

turbocharger Go to Step 3

3 Is air leaking found from the actuator piping? — Repair or

replace the

actuator pipe

or hose Go to Step 4

4 Inspect the inside of the turbocharger.

Is the turbine shaft end nut loose? — Replace the

turbocharger Go to Step 5

5 Are the turbine blades bent? — Replace the

turbocharger Go to Step 6

6 Is the turbine wheel rubbing against housing? — Replace the

turbocharger Go to Step 7

7 Are any DTCs stored? — Go to indicated

DTC Solved

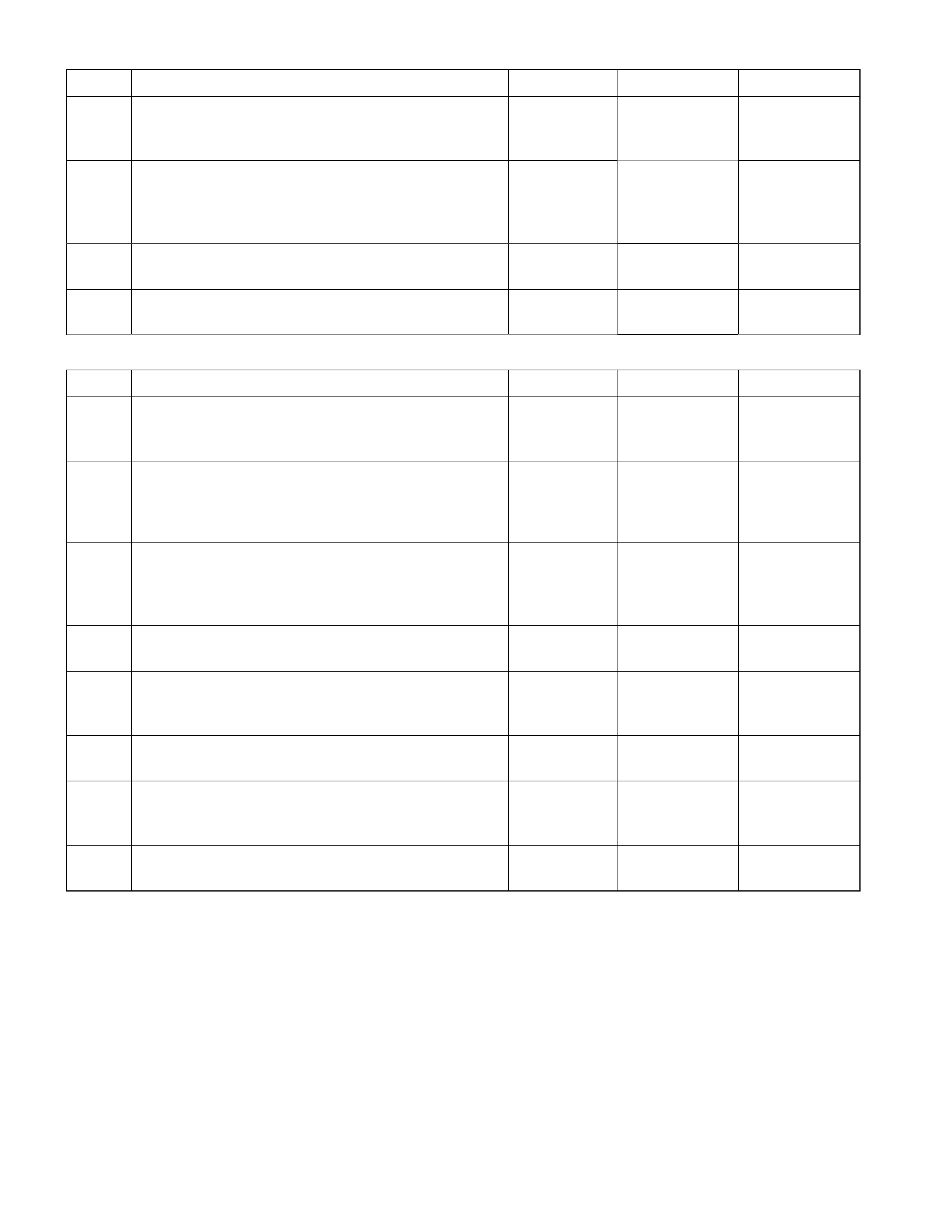

14. Battery Charging and Noise Problem

Perform a Visual/Physical Check of the following items before diagnosis:

The drive belt tension.

The condition of the battery terminals and connections.

The condition of the ground connections.

The condition of the generator and the battery fastener.

The battery fluid level and specific gravity.

14-1 Battery Not Charging

Step Action Value(s) Yes No

1 Was the “Visual/Physical Check" performed?

—

Go to Step 2

Go to

visual/physical

check

2 Inspect the brush contact condition on the generator.

Is there poor contact between the brush and the slip

ring?

— Repair or

replace the

brush and/or

the slip ring Go to Step 3

3 Inspect the stator coil on the generator.

Is there an open circuit or scorching on the stator

coil?

— Replace the

stator coil Go to Step 4

4 Inspect the rotor coil on the generator.

Is there an open circuit or scorching on the rotor

coil?

— Replace the

rotor coil Go to Step 5

5 Inspect the rectifier on the generator.

Is the rectifier defective? — Replace the

rectifier Go to Step 6

6 Inspect the IC regulator.

Is the IC regulator defective? — Replace the IC

regulator Go to Step 7

7 Are any DTCs stored? — Go to indicated

DTC Solved

14-2 Battery Overcharging

Step Action Value(s) Yes No

1 Was the “Visual/Physical Check" performed?

—

Go to Step 2

Go to

visual/physical

check

2 Inspect the terminal circuit.

Are the B and F terminals shorted? — Repair the

short circuit Go to Step 3

3 Check the regulating voltage.

Is the IC regulator voltage excessive? — Replace the IC

regulator Go to Step 4

4 Are any DTCs stored? — Go to indicated

DTC Solved

14-3 Battery Under Charging

Step Action Value(s) Yes No

1 Was the “Visual/Physical Check" performed?

—

Go to Step 2

Go to

visual/physical

check

2 Inspect the brush contact condition on the generator.

Is the contact between the brush and the slip ring

intermittent?

— Repair or

replace the

brush holder

assembly Go to Step 3

3 Inspect the rotor coil on the generator.

Is there a short circuit in the rotor coil? — Repair or

replace the

rotor coil Go to Step 4

4 Inspect the stator coil on the generator.

Is there an open circuit or the short circuit on the

stator coil?

— Repair or

replace the

stator coil Go to Step 5

5 Inspect the rectifier on the generator.

Is the rectifier defective? — Replace the

rectifier Go to Step 6

6 Inspect the IC regulator on the generator.

Is the IC regulator defective? — Replace the IC

regulator Go to Step 7

7 Is the electrical load excessive? — Reduce the

electrical load

or fit higher

capacity

generator Go to Step 8

8 Are any DTCs stored? — Go to indicated

DTC Solved

14-4 Battery Unstable Charging Current

Step Action Value(s) Yes No

1 Was the “Visual/Physical Check" performed?

—

Go to Step 2

Go to

visual/physical

check

2 Inspect the brush contact condition on the generator.

Is there poor contact between the brush and the slip

ring?

— Repair or

replace the

brush and/or

the slip ring Go to Step 3

3 Inspect the rotor coil on the generator.

Is there a short circuit or an open circuit in the rotor

coil?

— Repair or

replace the

rotor coil Go to Step 4

4 Inspect the stator coil on the generator.

Is there an open circuit or a short circuit in the stator

coil?

— Repair or

replace the

stator coil Go to Step 5

5 Inspect the connection between the rectifier and

stator coil on the generator.

Is there a loose connection between the rectifier and

stator coil ?

— Repair the

loose

connection Go to Step 6

6 Inspect the IC regulator on the generator.

Is the IC regulator defective? — Replace the IC

regulator Go to Step 7

7 Are any DTCs stored? — Go to indicated

DTC Solved

14-5 Charging System Noise

Step Action Value(s) Yes No

1 Was the “Visual/Physical Check" performed?

—

Go to Step 2

Go to

visual/physical

check

2 Is there an intermittent or continuous noise from the

generator that can be identified clearly by increasing

and decreasing engine speed?

— Replace the

bearing Go to Step 3

3 Is there a growling sound from the generator, and

does this sound stop when the connector is

disconnected?

— Replace the

stator coil Go to Step 4

4 Is an intermittent sound heard from the generator

when the generator is running? — Replace the

brush and/or

slip ring Go to Step 5

5 Is a frictional sound heard from the generator when

the generator is running? — Clean the slip

ring or replace

the brush Go to Step 6

6 Are any DTCs stored? — Go to indicated

DTC Solved

15. Starter Motor Problem

Perform a Visual/Physical Check of the following items before diagnosis:

The condition of the battery terminals and connections.

The condition of the ground connections.

The condition of the starter motor and the battery fastener.

The battery fluid level and specific gravity.

15-1 Starter Motor Pinion Engages To Ring Gear But Engine Does Not Turn Over

Step Action Value(s) Yes No

1 Was the “Visual/Physical Check" performed?

—

Go to Step 2

Go to

visual/physical

check

2 Check the condition of the contact between the

brush and the commutator.

Is the brush and the commutator contact

intermittent?

— Replace the

brush or repair

the commutator Go to Step 3

3 Are the brush and the commutator contact faces

dirty?

— Clean contact

faces Go to Step 4

4 Is the pinion clutch slipping? — Replace the

pinion clutch Go to Step 5

5 Inspect the armature field coil.

Is there an open circuit or a short circuit in the

armature field coil?

— Repair or

replace the

armature field

coil Go to Step 6

6 Are any DTCs stored? — Go to indicated

DTC Solved

15-2 Incorrect Pinion And Ring Gear Engagement

Step Action Value(s) Yes No

1 Was the “Visual/Physical Check" performed?

—

Go to Step 2

Go to

visual/physical

check

2 Inspect the pinion and the ring gear teeth.

Are the pinion and/or the ring gear teeth worn or

broken?

— Replace the

faulty part(s) Go to Step 3

3 Inspect the pinion gear return movement.

Is the pinion gear return movement incorrect? — Adjust or

replace the

appropriate

parts Go to Step 4

4 Are any DTCs stored? — Go to indicated

DTC Solved

15-3 Starter Motor Continues To Run After The Starter Switch Is Turned Off

Step Action Value(s) Yes No

1 Was the “Visual/Physical Check" performed?

—

Go to Step 2

Go to

visual/physical

check

2 Inspect the magnetic switch contact point.

Is the contact point seized? — Repair or

replace the

magnetic

switch Go to Step 3

3 Inspect the starter switch.

Is the starter switch defective? — Replace the

starter switch Go to Step 4

4 Are any DTCs stored? — Go to indicated

DTC Solved

15-4 Excessive Commutator Sparking

Step Action Value(s) Yes No

1 Was the “Visual/Physical Check" performed?

—

Go to Step 2

Go to

visual/physical

check

2 Inspect the condition of the contact between the

brush and the commutator.

Is the brush and commutator contact intermittent?

— Replace the

brush or repair

the commutator Go to Step 3

3 Is there the contamination on the contact face? — Clean the

contact face or

replace the

brush Go to Step 4

4 Is the brush holder loose? — Repair the

brush holder Go to Step 5

5 Inspect the commutator.

Is there excessive wear or pitting? — Repair or

replace the

commutator Go to Step 6

6 Is there loose solder on the commutator? — Clean and

repair Go to Step 7

7 Inspect the armature shaft.

Is the run-out of the armature shaft outside the

standard value due to worn bearings?

— Replace the

bearing Go to Step 8

8 Are any DTCs stored? — Go to indicated

DTC Solved