SECTION 6B - ENGINE COOLING

Main Data and Specifications

General Description

Coolant Flow

Water Pump

Thermostat

Radiator

Coolant Specification

Coolant Capacity

Diagnosis

Draining and Refilling Cooling System

Engine Coolant Filling Procedure

Water Pump

Removal

Inspection and Repair

Installation

Thermostat

Removal

Inspection and Repair

Installation

Radiator

Radiator and Associated Parts

Removal

Inspection and Repair

Installation

Fan Clutch with Cooling Fan

Inspection and Repair

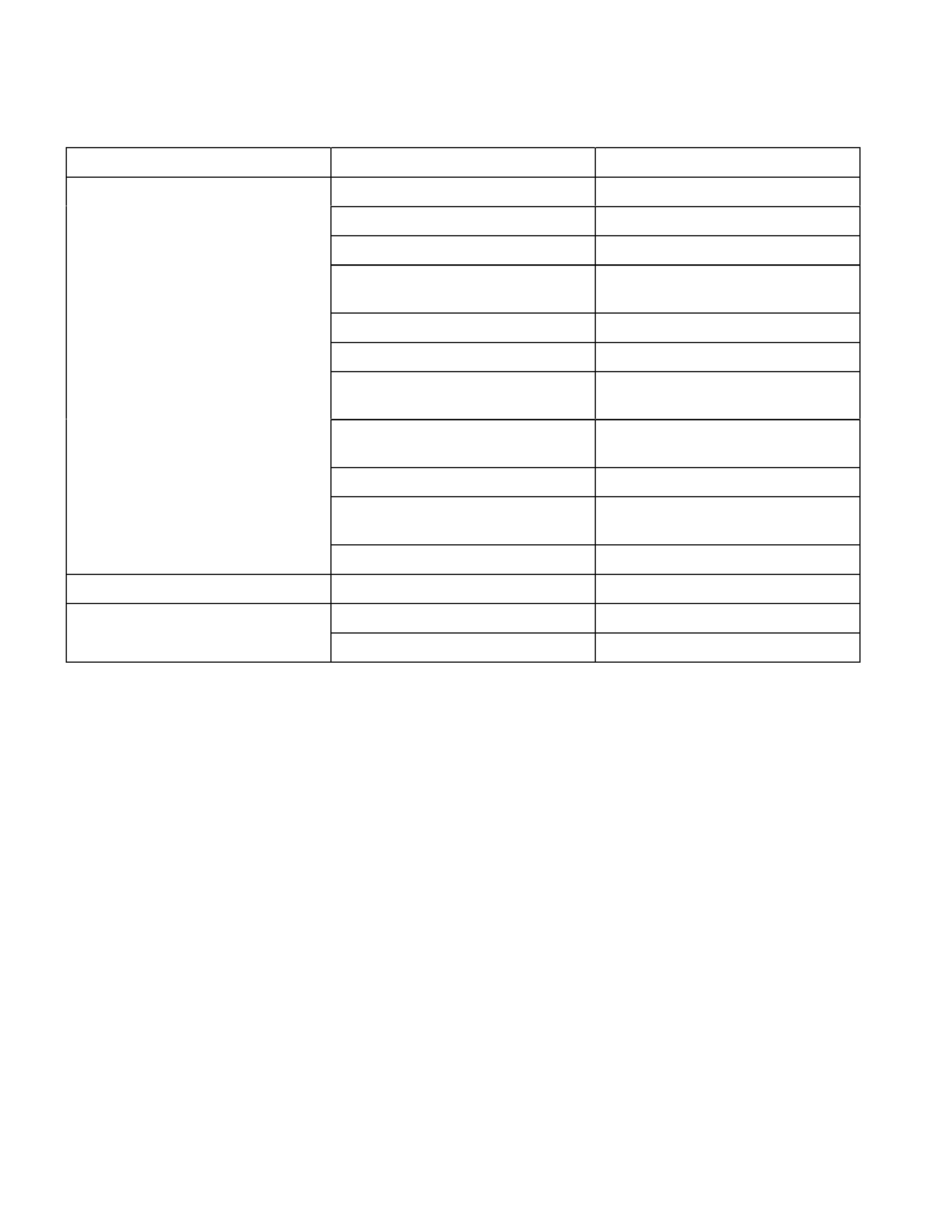

MAIN DATA AND SPECIFICATIONS

Description

Item M/T A/T

Cooling system

Water pump type

Pump to crankshaft speed ratio (To 1)

Delivery volume lit (US/UK gal)/min

Pump speed at 3000 rpm

Water temperature at 30°C (86°F)

Pump bearing type

Thermostat type

Valve initial opening temperature °C (°F)

Valve full opening temperature °C (°F)

Valve lift at fully open position mm (in)

Engine coolant forced circulation

Centrifugal impeller type

1.2

100 (26.3/22.2)

Double row shaft

Wax pellet with jiggle valve

82 (180)

95 (203)

9.5 (0.37)

Radiator Tube type corrugated

Heat radiation capacity 93.0 kw (79,980 kcal/h)

Heat radiation area 11.63 m2 (1.081 ft2)

Radiator front area 0.28 m2 (0.026 ft2)

Radiator dry weight 52 N (5.3 kg/11.7 lb) 53 N (5.4 kg/11.9 lb)

Radiator cap valve opening pressure 93.3 ∼ 122.7 kpa (13.5 ∼ 17.8 psi)

Engine coolant total capacity 10.1 litres 10.0 litres

GENERAL DESCRIPTION

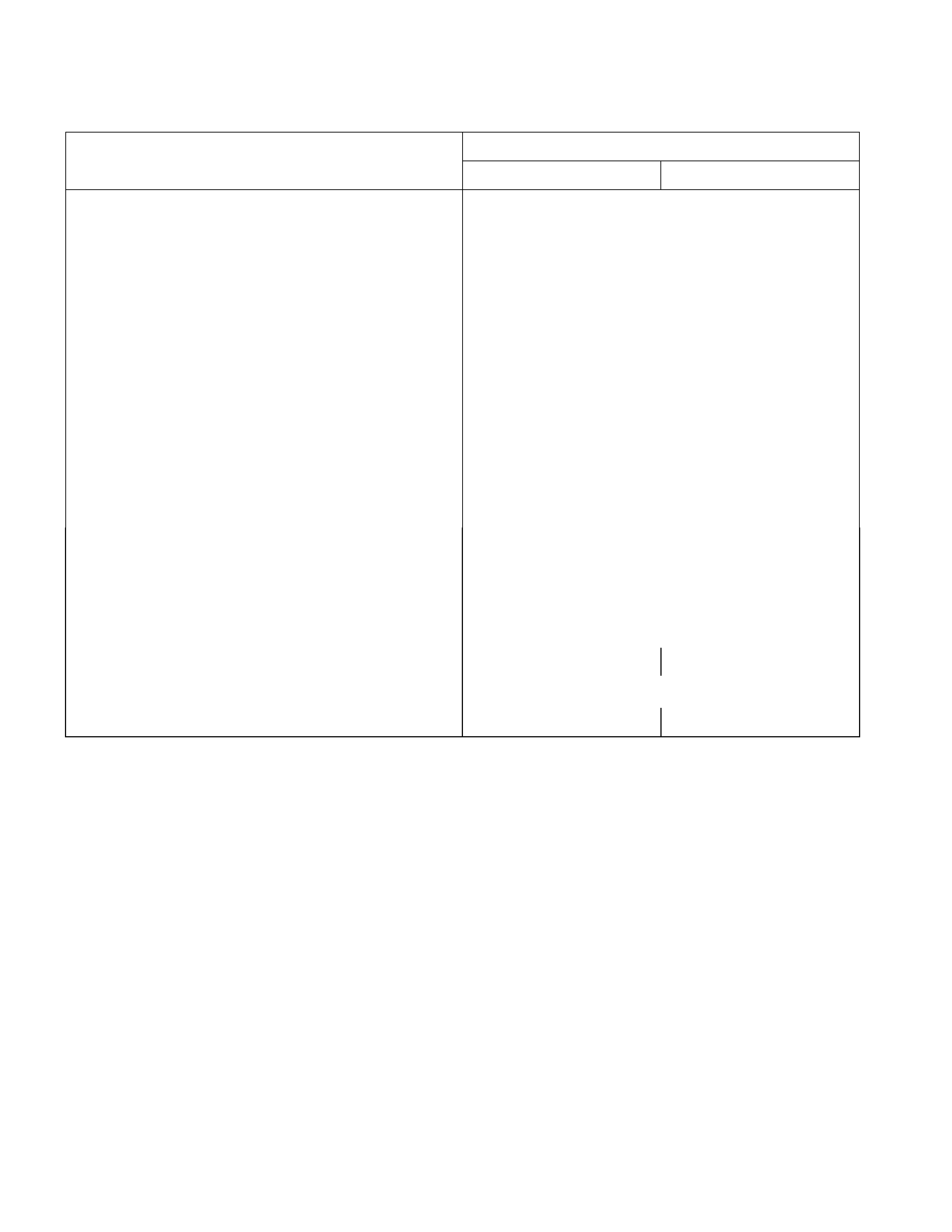

COOLANT FLOW

The engine cooling system consists of the radiator, the water pump, the cooling fan, and the thermostat.

To quickly increase cold engine coolant temperature for smooth engine operation, the coolant is circulated by the water

pump and thermostat through the bypass hose and back to the cylinder body.

The coolant does not circulate through the radiator.

When the coolant temperature reaches specified value, the thermostat will begin to open and a gradually increasing

amount of coolant will circulate through the radiator.

The thermostat will be fully open when the coolant temperature reaches specified value. All of the coolant is now

circulating through the radiator for effective engine cooling.

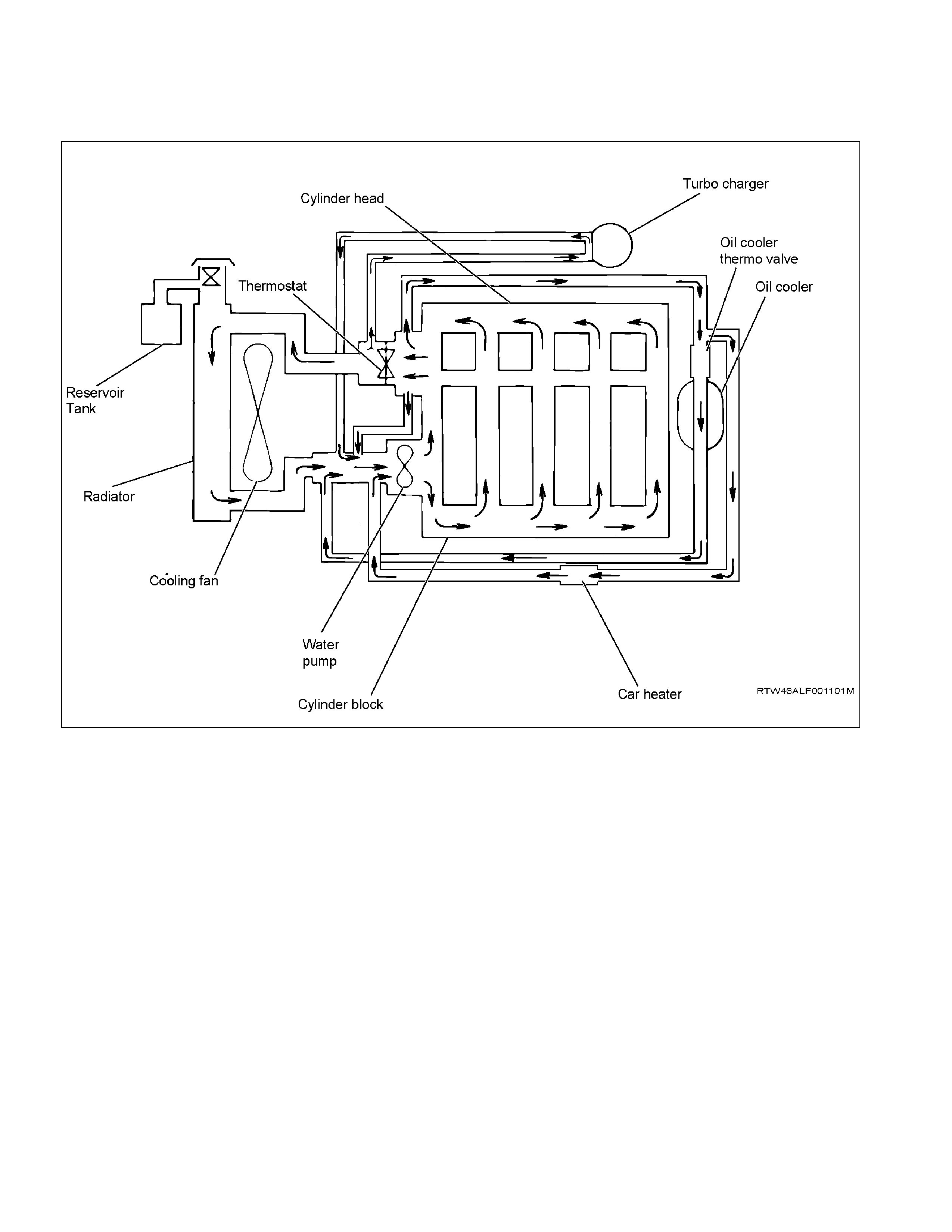

WATER PUMP

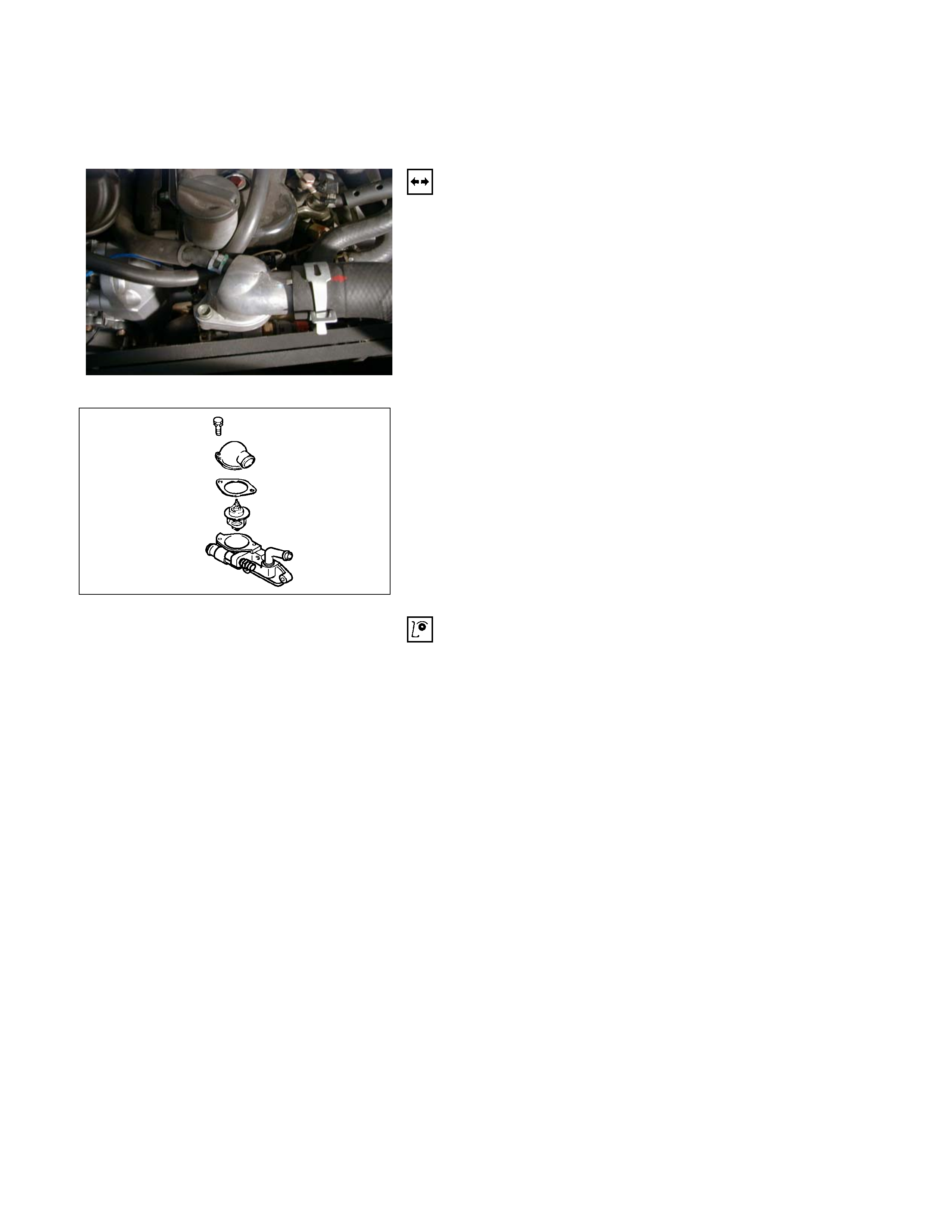

RTW36BSF000101

A centrifugal type water pump forcefully circulates the coolant through the cooling system.

The water pump is not disassembled type.

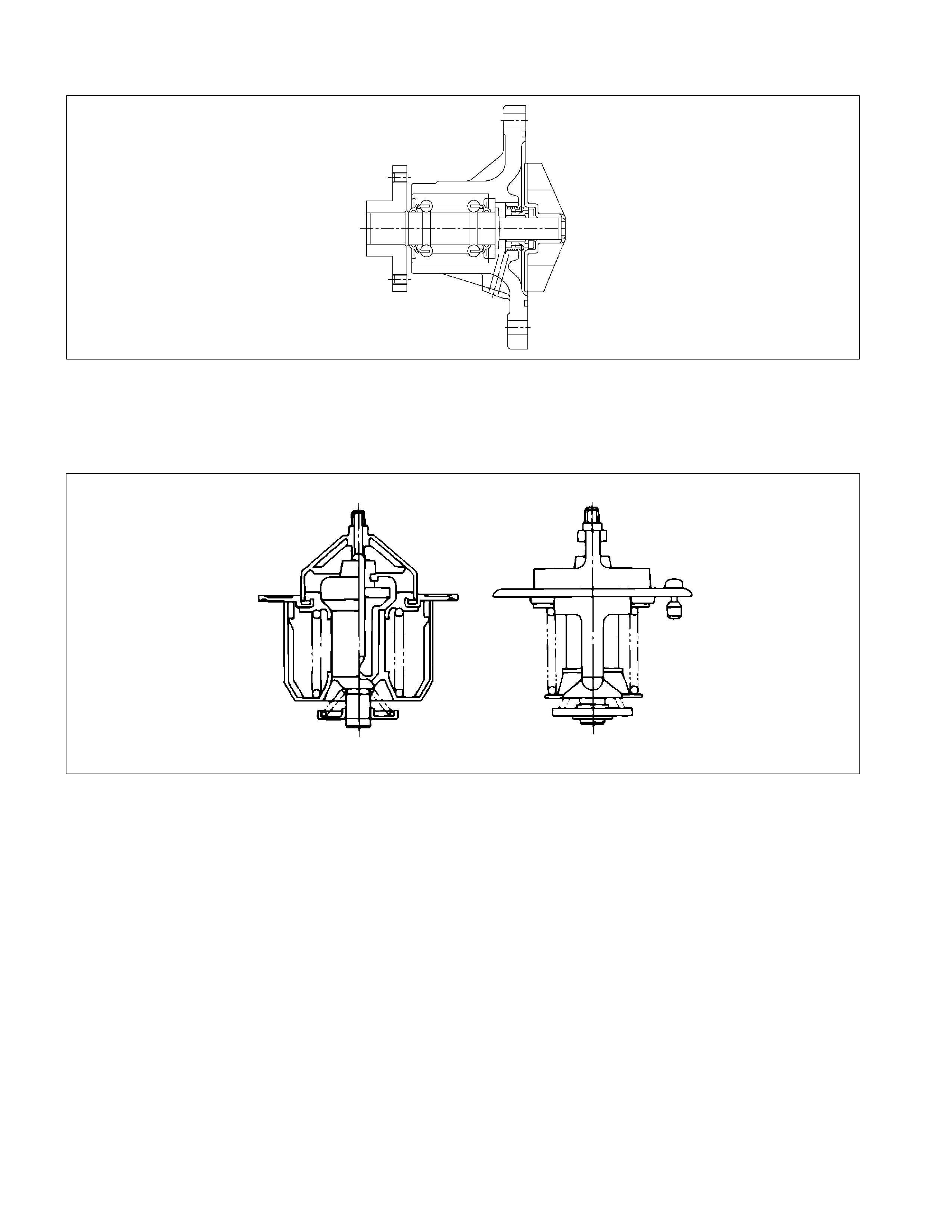

THERMOSTAT

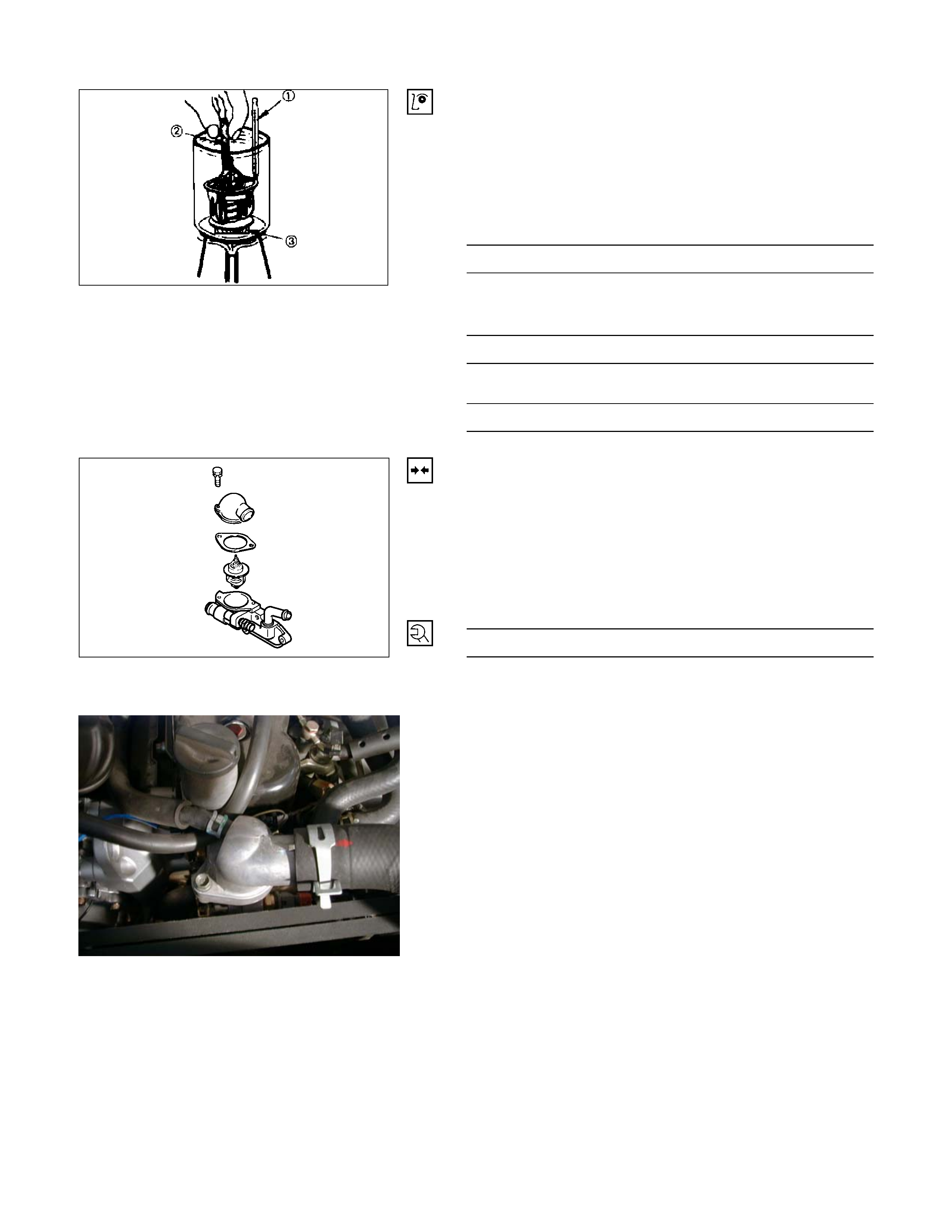

030RY00005

A wax pellet type thermostat is used.

The jiggle valve accelerates engine warm-up.

110RS001

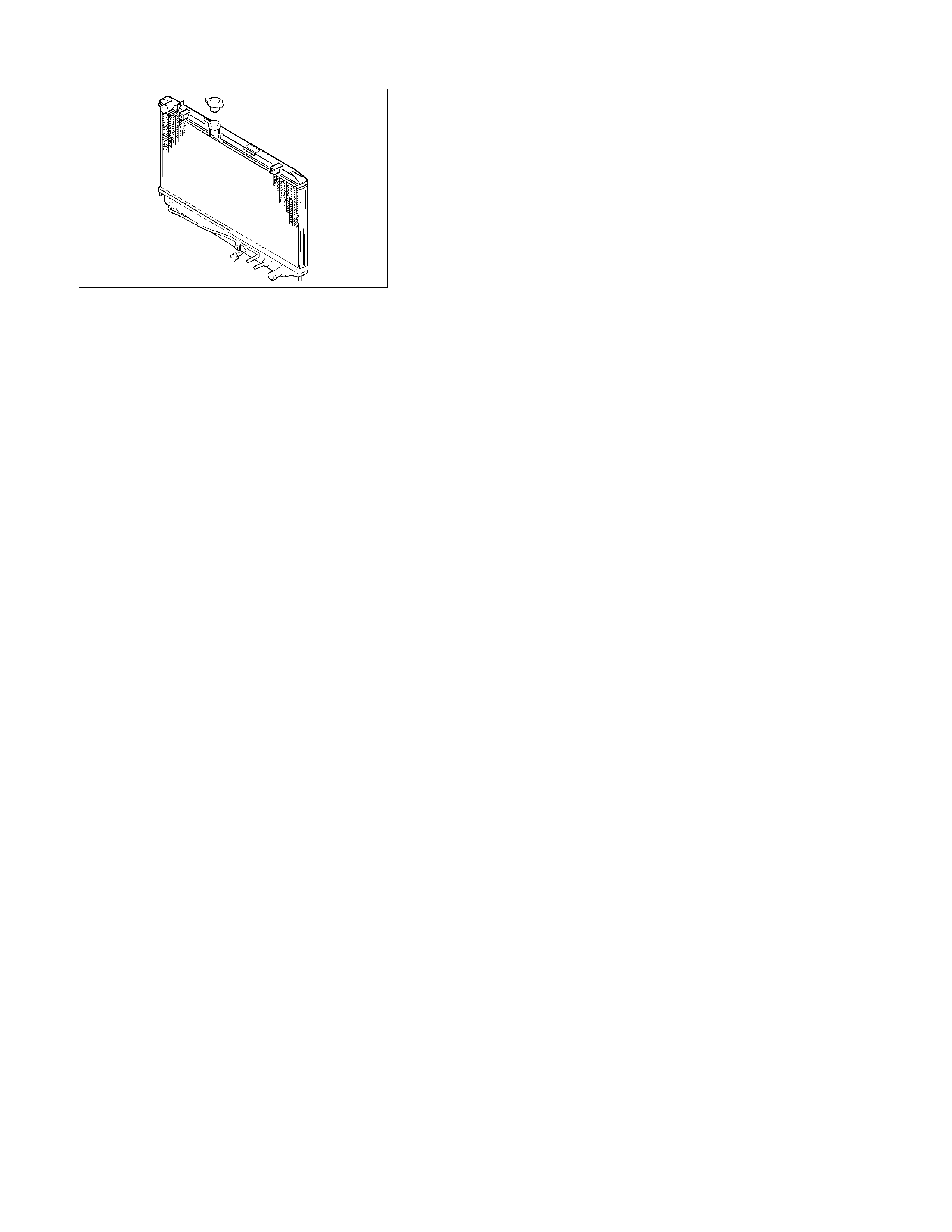

RADIATOR

The radiator is a tube type with corrugated fins. In order to

raise the boiling point of the coolant, the radiator is fitted with a

cap in which the valve is operated at 93.3 ∼ 122.7 kPa (13.5 ∼

17.8 psi) pressure. (No oil cooler provided for M/T).

COOLANT SPECIFICATION

To Holden Specification. Refer to Section 0B

COOLANT CAPACITY

Automatic Transmission: 10.0 litres

Manual Transmission: 10.1 litres

DIAGNOSIS

Engine Cooling Trouble

Symptom Possible Cause Action

Low engine coolant level Replenish

Thermo meter unit faulty Replace

Faulty thermostat Replace

Faulty engine coolant temperature

sensor Repair or replace

Clogged radiator Clean or replace

Faulty radiator cap Replace

Low engine oil level or use of

improper engine oil Replenish or change oil

Clogged exhaust system Clean exhaust system or replace

faulty parts

Faulty throttle position sensor Replace throttle valve assembly

Open or shorted throttle position

sensor circuit Repair or replace

Engine overheating

Damaged cylinder head gasket Replace

Engine overcooling Faulty thermostat Replace

Faulty thermostat Replace

Engine slow to warm–up

Thermo unit faulty Replace

Draining and Refilling Cooling System

Before draining the cooling system, inspect the system and

perform any necessary service to ensure that it is clean, does

not leak and is in proper working order. The engine coolant

(EC) level should be between the “MIN" and “MAX" lines of

reserve tank when the engine is cold. If low, check for leakage

and add EC up to the “MAX" line.

There should not be any excessive deposit of rust or scales

around the radiator cap or radiator filler hole, and the EC

should also be free from oil.

Replace the EC if excessively dirty.

P1010064

1. Completely drain the cooling system by opening the

drain plug at the bottom of the radiator.

2. Remove the radiator cap.

WARNING: To avoid the danger of being burned, do not

remove the cap while the engine and radiator are still hot.

Scalding fluid and steam can be blown out under

pressure.

3. Disconnect all hoses from the EC reserve tank.

Scrub and clean the inside of the reserve tank with

soap and water. Flush it well with clean water, then

drain it. Install the reserve tank and hoses.

4. Refill the cooling system with the EC using a solution

that is to Holden Specification. Refer Section 0B.

Engine Coolant Filling Procedure

NOTE:

Use only 50% water with 50% coolant to Holden HN2217

Specification.

1. Make sure that the engine is cool.

WARNING:

When the coolant is heated to a high temperature, be

sure not to loosen or remove the radiator cap,

otherwise you might get scalded by hot vapour or

boiling water. Wait until the coolant has become

cooler before opening the cap.

To open the radiator cap, put a piece of thick cloth on

the cap and loosen the cap slowly to reduce the

pressure.

2. Remove the radiator cap and add coolant up to the

filler neck.

3. Pour coolant into the reservoir tank up to “MAX” line.

4. Set the heater adjustment to the highest temperature

position to allow the coolant to circulate through the

heater system.

5. Tighten the radiator cap and start the engine. After

idling for 2 to 3 minutes, stop the engine and reopen

the radiator cap. If the coolant level is lower than the

filler neck, replenish the coolant level.

6. After replenishing the coolant, refit and tighten the

radiator cap. Warm up the engine at approximately

2000 rpm.

7. Continue to monitor the coolant temperature gauge.

When the coolant temperature gauge indicates that

the thermostat has opened, idle the engine for 5

minutes, then stop the engine.

8. When the engine has cooled, remove the radiator cap

and inspect that the coolant level is up to the filler

neck. Replenish if required. If there is an extreme

shortage of coolant, check the coolant system,

including the reservoir tank and hose, for leaks.

9. Pour coolant into the reservoir tank up to “MAX” line.

WATER PUMP

Read this Section carefully before performing any removal and installation procedure. This Section gives you important

points as well as the order of operation. Be sure that you understand everything in this Section before you begin.

6B_1

Removal

1. Radiator Upper Hose

1) Partially drain the engine coolant.

2) Remove the radiator upper hose.

2. Upper Fan Shroud

3. Fan and Fan Clutch

1) Loosen the fan clutch nuts.

2) Remove the fan together with the fan clutch. Take

care not to damage the radiator core.

4. Fan Drive Belt and Pulley

1) Loosen the tension adjust bolt on the generator.

2) Remove the fan drive belt with the fan pulley.

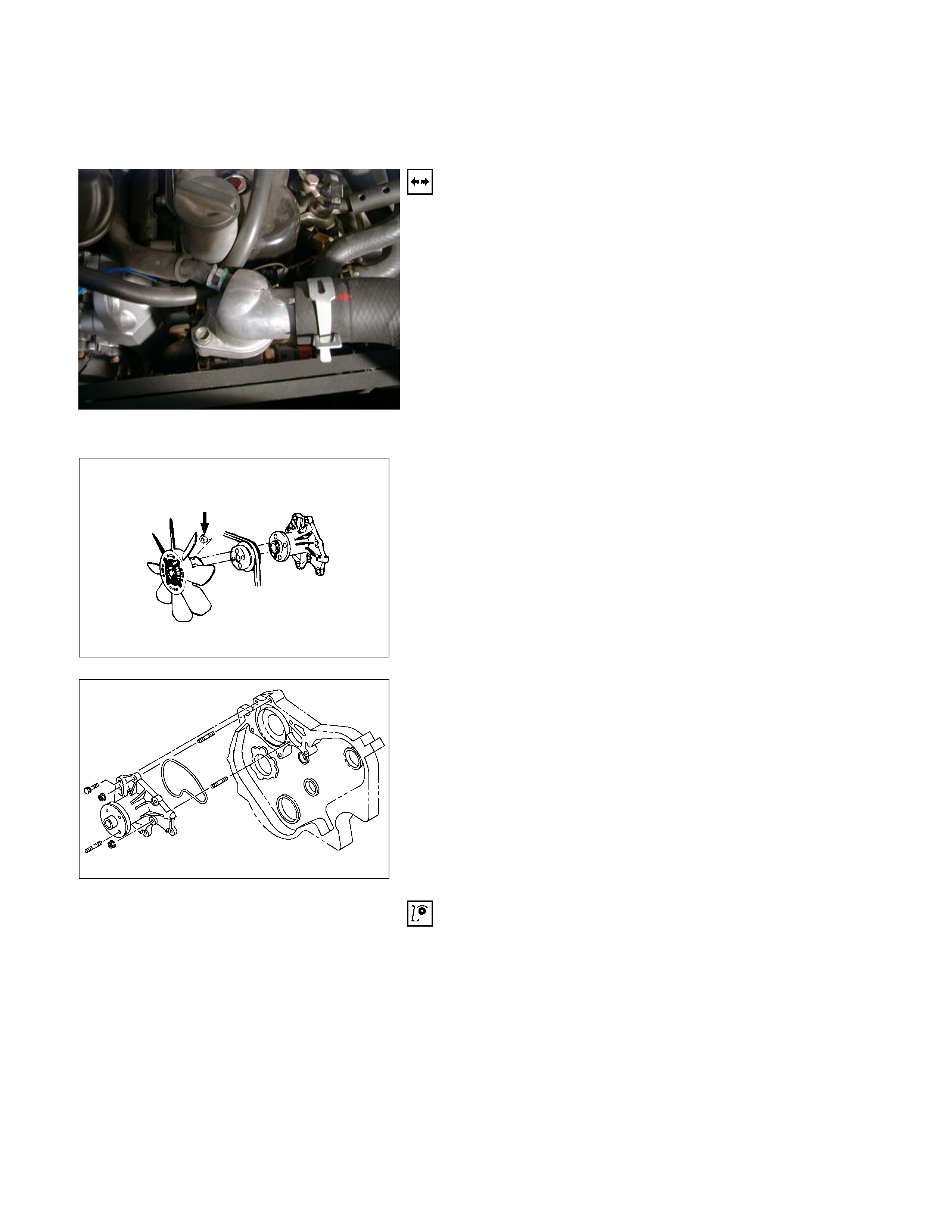

030R300001

5. Water Pump

1) Remove the water pump bolts.

2) Remove the water pump.

030R300002

Inspection and Repair

The water pump is not disassembled type.

Make necessary parts replacement if extreme wear or

damage is found during inspection. Should any of the

following problems occur, the entire water pump assembly

must be replaced.

Cracks in the water pump body

Coolant leakage from the seal unit

Excessive radial play or abnormal noise in the fan centre

when rotated by hand

Excessive thrust play in the fan centre (Standard play: less

than 0.2mm)

Cracks or corrosion in the impeller

Installation

1. Water Pump

1) Install the water pump with new gasket.

2) Tighten bolts and nuts to specified torque.

Water Pump Bolt/Nut Torque N·m (kg·m/lb·ft)

20 (2.0/14)

2. Fan Drive Belt and Pulley

1) Install the fan drive belt and fan pulley.

2) Apply tension to the fan drive belt by moving the

generator.

3) Apply a force of 98 N (10 kg/22 lb) to the drive belt

mid-portion to check the drive belt deflection.

Fan Drive Belt Deflection mm (in)

New belt: 4-7 (0.16-0.28)

Reuse belt: 6-9 (0.24-0.35)

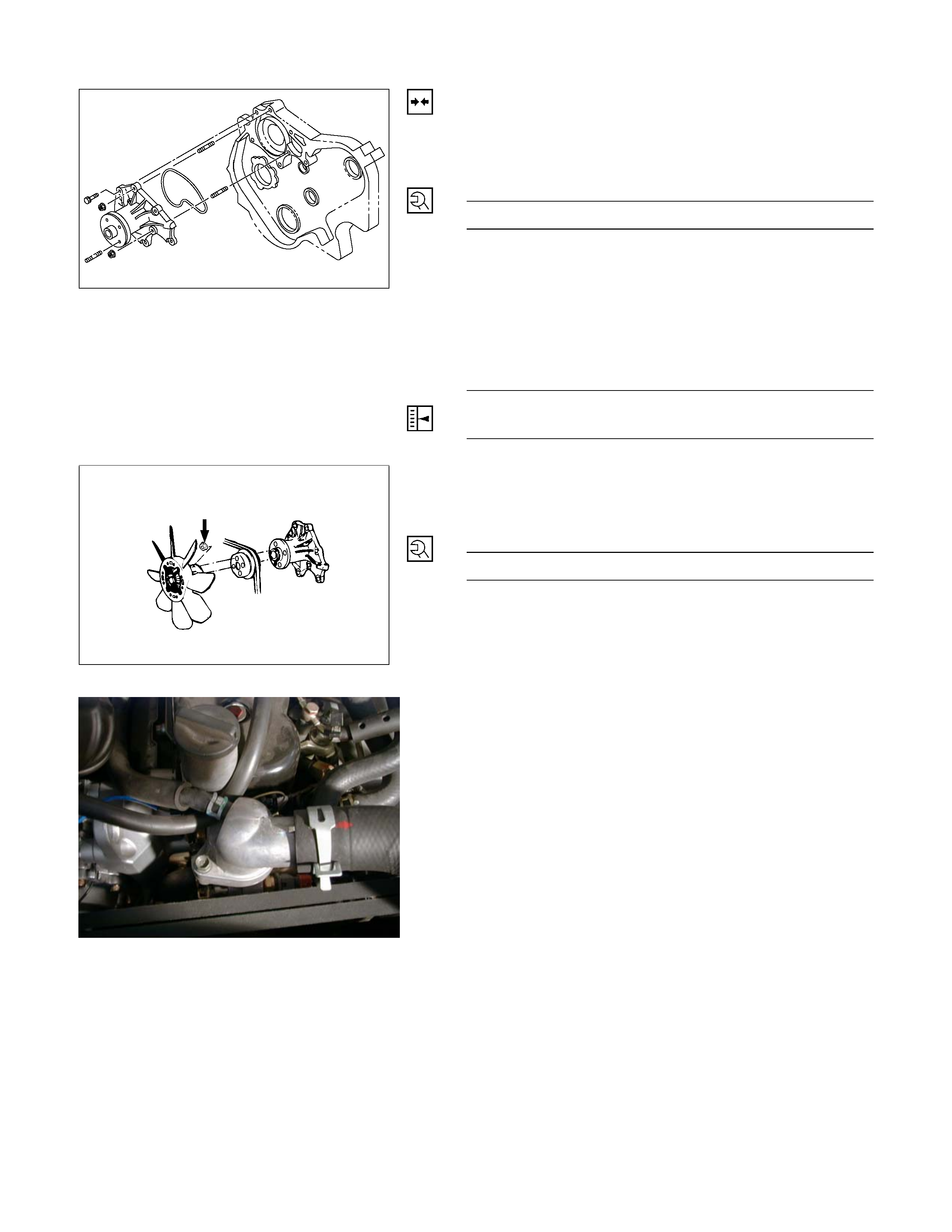

030R300002

030R300001

3. Fan and Fan Clutch

1) Install the fan and fan clutch to pulley.

2) Tighten the nuts to specified torque.

Fan Clutch Nut Torque N·m (kg·m/lb·in)

8 (0.8/69)

4. Upper Fan Shroud

6B_1

5. Radiator Upper Hose

1) Connect the radiator upper hose to the water outlet

pipe.

2) The knob of clamp shall be directed to horizontal side.

3) Replenish the engine coolant.

THERMOSTAT

Read this Section carefully before performing any removal and installation procedure. This Section gives you important

points as well as the order of operation. Be sure that you understand everything in this Section before you begin.

6B_1

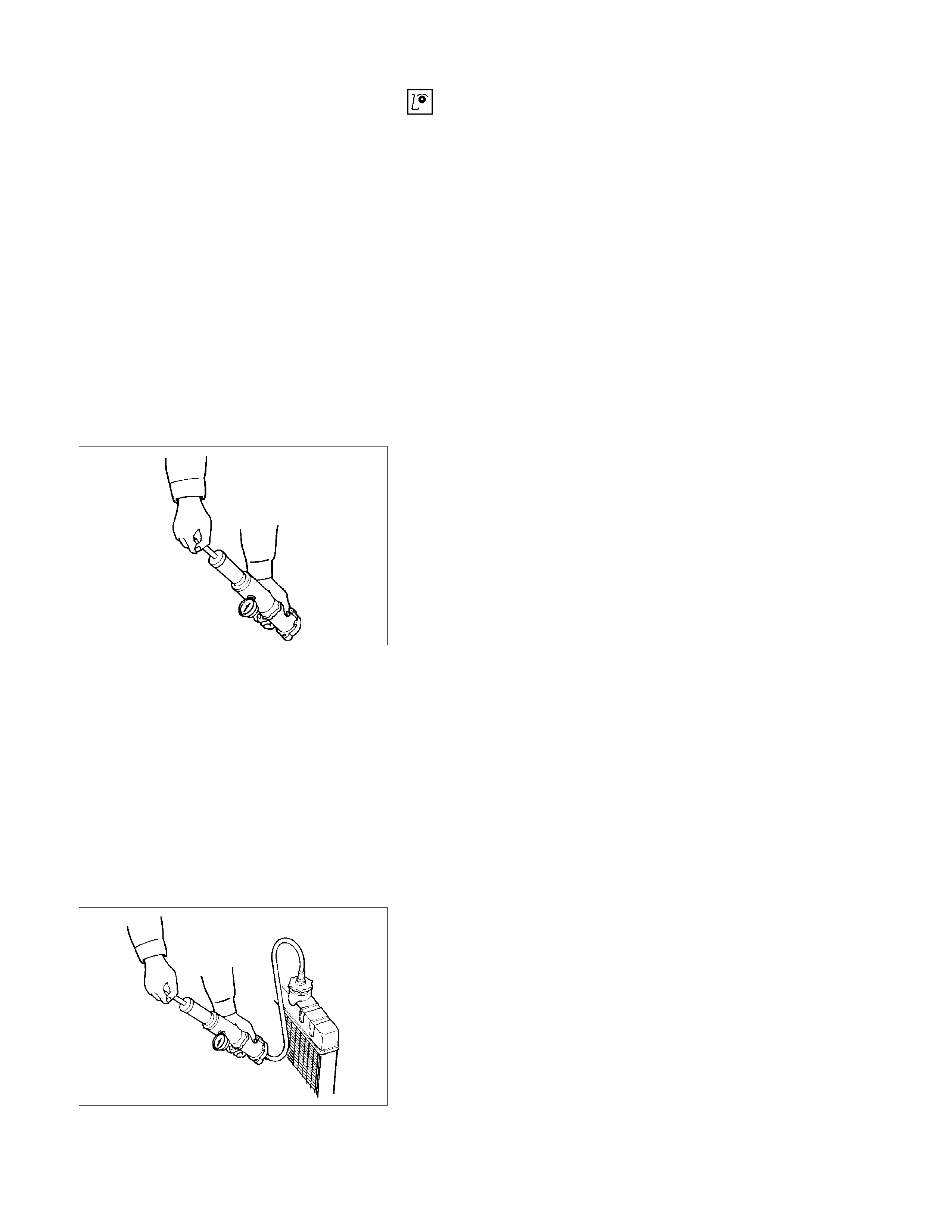

Removal

1. Radiator Upper Hose

1) Partially drain the engine coolant.

2) Remove the radiator upper hose.

2. Water Outlet Pipe

1) Disconnect the turbocharger-cooling pipe from outlet

pipe.

2) Loosen the fixing bolts and remove the water outlet

bolts.

3. Thermostat

Remove the thermostat from the thermostat housing.

Take care not to damage the thermostat.

031R300003

Inspection and Repair

Make the necessary adjustments, repairs, and part

replacements if excessive wear or damage is discovered

during inspection.

031RY00005

c Thermometer

d Agitating rod

e Wooden piece

Operating Test of Thermostat

1. Completely submerge the thermostat in water.

2. Heat the water.

Stir the water constantly to avoid direct heat being

applied to the thermostat.

3. Check the thermostat initial opening temperature.

Thermostat Initial Opening Temperature °C (°F)

82 (180)

4. Check the thermostat full opening temperature.

Thermostat Full Opening Temperature °C (°F)

95 (203)

Valve Lift At Fully Open Position mm (in)

9.5 (0.37)

Installation

1. Thermostat

Install the thermostat to the thermostat housing.

2. Water Outlet Pipe

1) Install the water outlet pipe with new gasket to the

thermostat housing.

2) Tighten the outlet pipe bolt to specified torque.

Outlet Pipe Bolt Torque N·m (kg·m/lb·ft)

19 (1.9/14)

3) Connect the turbocharger-cooling pipe to outlet pipe.

031R300003

3. Radiator Upper Hose

1) Connect the radiator upper hose to the water outlet

pipe.

2) The knob of clamp shall be directed to horizontal side.

3) Replenish the engine coolant.

6B_1

RADIATOR

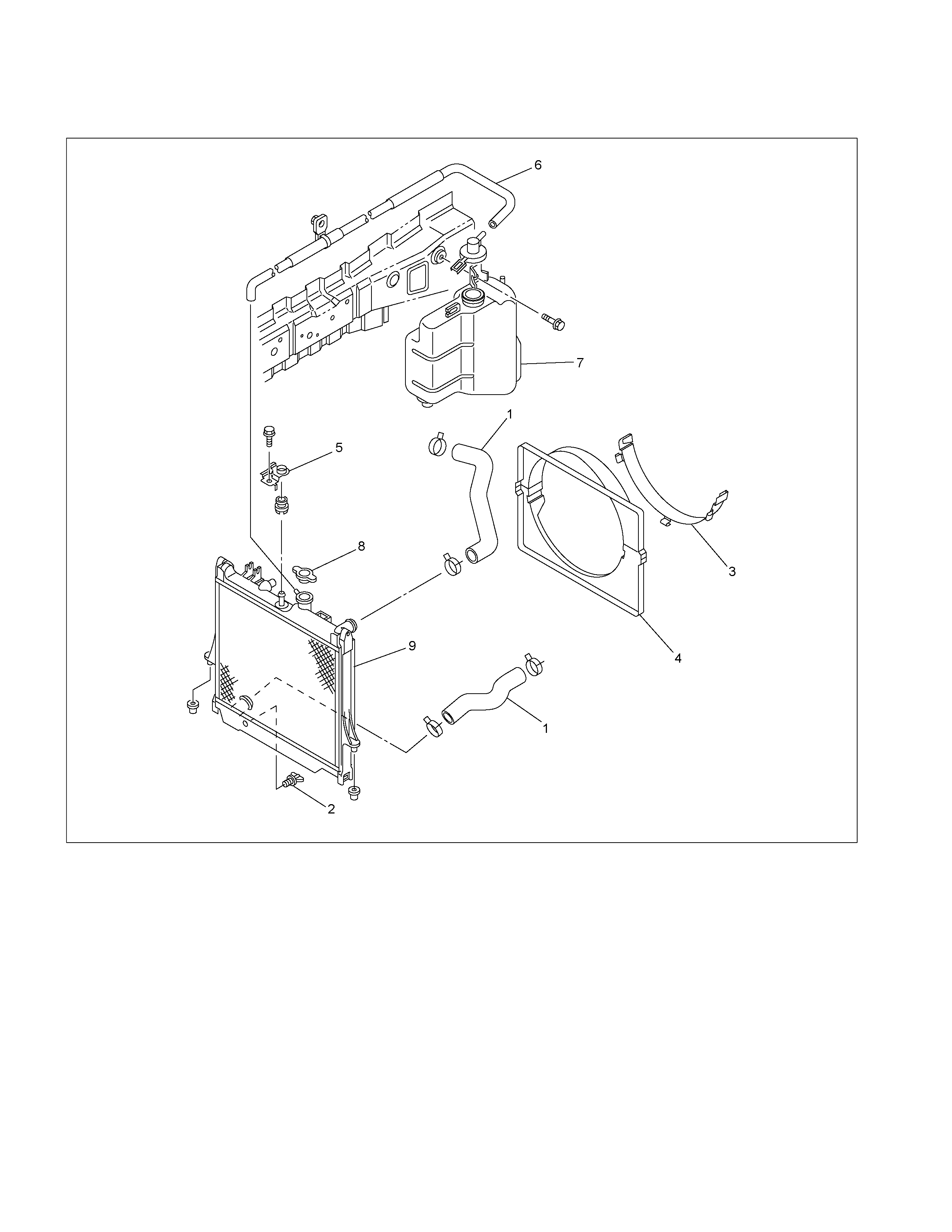

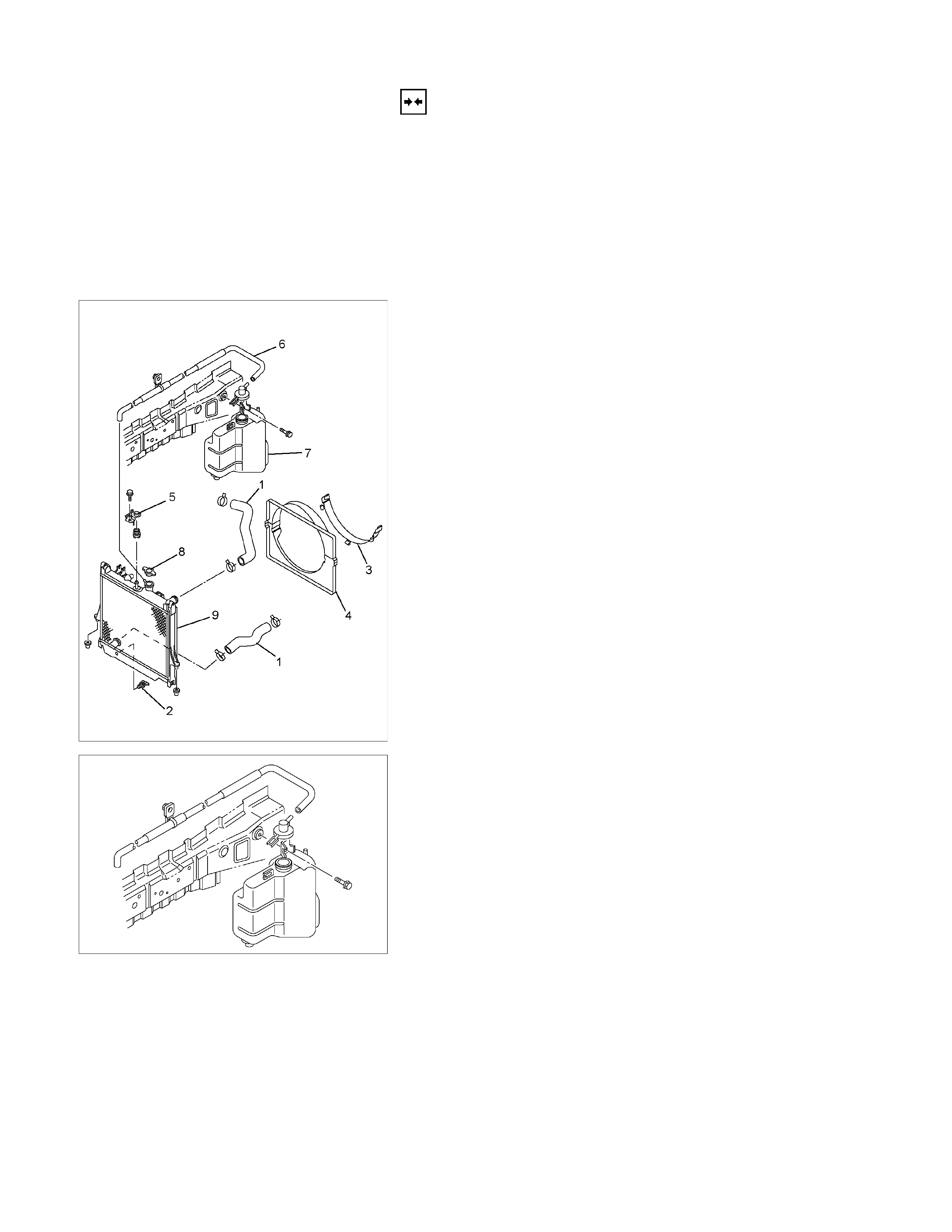

Radiator and Associated Parts

RTW36BLF000101

Legend

1. Radiator Hose

2. Drain Plug

3. Fan Guide, Lower

4. Fan Guide

5. Bracket

6. Reserve Tank Hose

7. Reserve Tank

8. Radiator Cap

9. Radiator Assembly

P1010064

Removal

1. Disconnect battery ground cable.

2. Loosen the drain plug to drain EC.

3. Disconnect oil cooler hose on automatic transmission

(A/T).

4. Disconnect radiator inlet hose and outlet hose from

the engine.

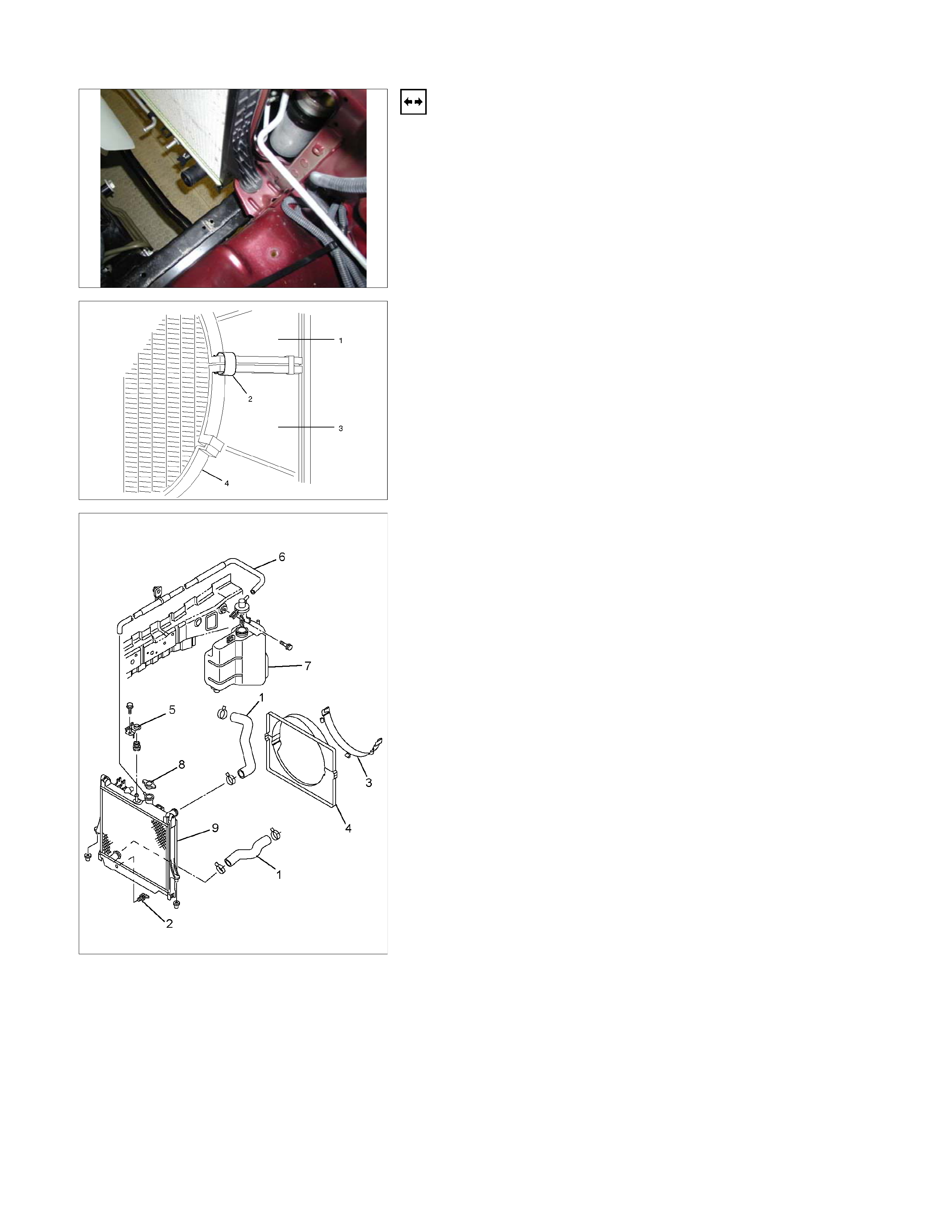

110RW001

5. Remove fan guide (1), clips (2) on both sides and the

bottom lock, then remove lower fan guide (3) with fan

shroud (4).

6. Disconnect the reserve tank hose (6) from radiator.

RTW36BMH000101

7. Remove bracket (5).

8. Lift up and remove the radiator assembly with hose,

taking care not to damage the radiator core with the

fan.

Inspection and Repair

Make the necessary adjustments, repairs, and part

replacements if excessive wear or damage is discovered

during inspection.

Radiator Cap

Measure the valve opening pressure of the pressurizing

valve with a radiator filler cap tester.

Replace the cap if the valve opening pressure is outside

the standard range.

Valve opening pressure

kPa (psi) 93.3 ∼ 122.7 (13.5 ∼17.8)

Cap tester: 5–8840–0277–0

Adapter: 5–8840–2603–0

Check the condition of the vacuum valve in the centre of

the valve seat side of the cap. If considerable rust or dirt is

found, or if the valve seat cannot be moved by hand,

clean or replace the cap.

110RS006

Valve opening vacuum

kPa (psi) 1.96 ∼ 4.91 (0.28 ∼ 0.71)

Radiator Core

1. A bent fin may result in reduced ventilation and

overheating may occur. All bent fins must be

straightened. Pay close attention to the base of the fin

when it is being straightened.

2. Remove all dust, insects, and other foreign material.

Flushing the Radiator

Thoroughly wash the inside of the radiator and the engine

coolant passages with cold water and mild detergent.

Remove all signs of scale and rust.

110RS005

Cooling System Leakage Check

Use a radiator cap tester to force air into the radiator

through the filler neck at the specified pressure of 196 kPa

(28.5 psi) with a cap tester:

• Leakage from the radiator

• Leakage from the coolant pump

• Leakage from the water hoses

• Check the rubber hoses for swelling.

Cap tester: 5–8840–0277–0

Adapter: 5–8840–2603–0

Installation

1. Install radiator assembly (9) with hose, taking care not

to damage the radiator core with a fan blade.

2. Support the radiator upper tank with the bracket (5)

and secure the radiator.

3. Connect reserve tank hose (6).

4. Install lower fan guide (3).

5. Connect radiator inlet hose and outlet hose (1) to the

engine.

RTW36BMH000101

6. Connect oil cooler hose to automatic transmission.

7. Connect battery ground cable.

RTW36BSH000101

8. Pour engine coolant up to filler neck of radiator, and

up to MAX mark of reserve tank.

Refer to Draining and Refilling Cooling System in this

Section.

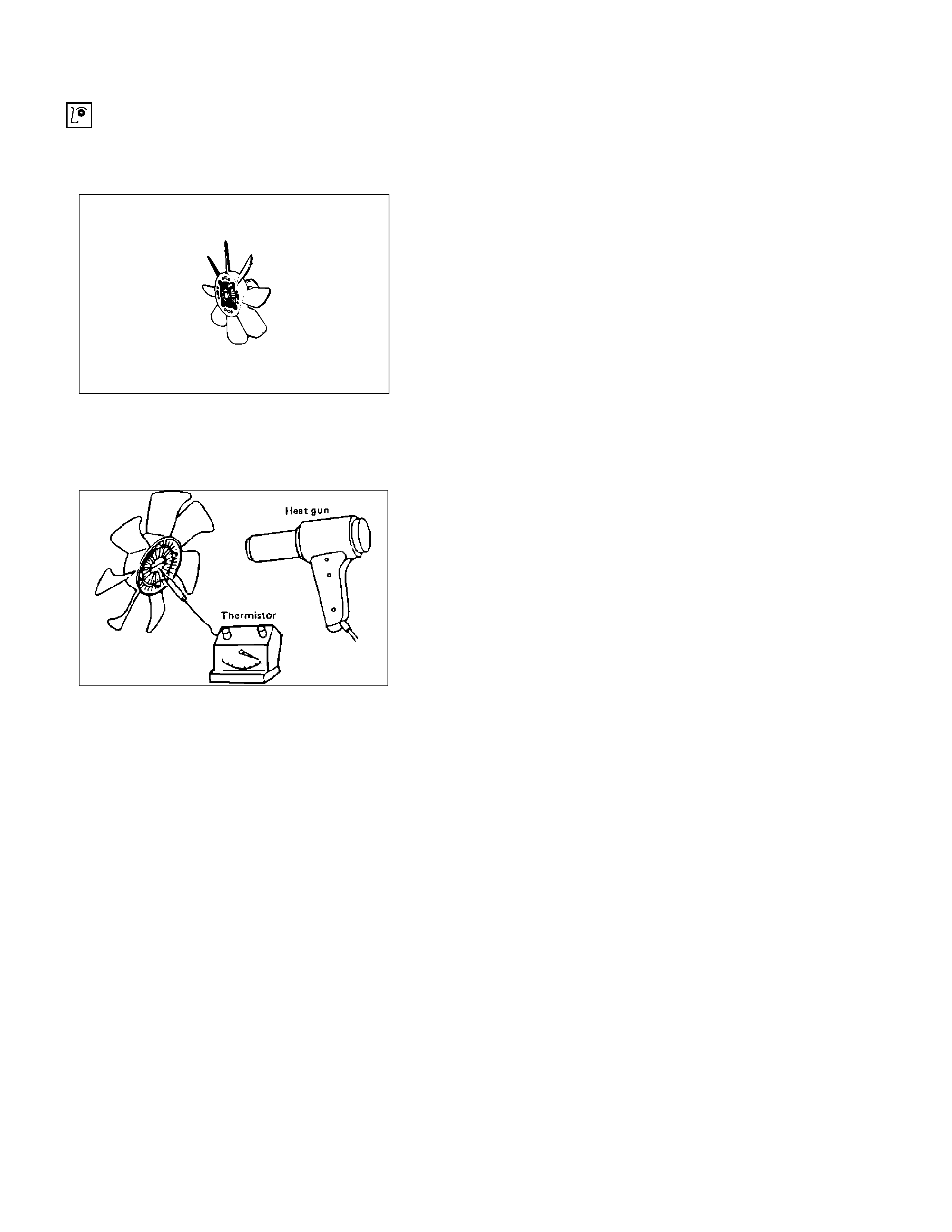

FAN CLUTCH WITH COOLING FAN

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear, damage or any other abnormal condition are found through

inspection.

033R300001

Visually inspect for damage, leak (silicon grease) or other

abnormal conditions.

1. Inspection (on-vehicle)

1) Turn the fan clutch by hand when in a low

temperature condition before starting the engine, and

confirm that it can be turned readily.

2) Start the engine to warm it up until the temperature at

the fan clutch portion gets to around 80°C. Then stop

the engine and confirm that the fan clutch can be

turned with considerable effort (clutch torque) when

turned by hand.

If the fan clutch rotates more readily, however, this

indicates that the silicone grease is leaking internally.

Replace the fan clutch with a new one.

033RY00011

2. Inspection (in unit)

Warm up the bimetal of the fan clutch by using the heat

gun until the temperature gets to about 80°C when

measured with the thermistor. Then confirm that the fan

clutch can be turned with considerable effort (clutch

torque).

If the fan clutch rotates more readily at this time, this

indicates that the silicone grease is leaking internally.

Replace the fan clutch with a new one.