MAIN DATA AND SPECIFICATIONS

Description

Item 60A 80A

Generator

Type

AC generator with IC regulator and vacuum pump

Hitachi LR160-503E Hitachi LR180-513B

Voltage V

Drive and rotation

Ground polarity

12

V-belt, clockwise viewed from the drive pulley

Negative

Maximum output A 60 80

Engine speed ratio to 1 1.788

Maximum speed rpm 11,000

Weight with vacuum pump kg (lb) 5.8 (12.8) 6.4 (14.1)

Vacuum Pump

Delivery volume cm3/rev

Exhaust Characteristic

Maximum vacuum

50

-66.7 kPa (-500 mm Hg) build up time 21 seconds or less at 1,000

rpm

7 seconds or less at 5,000 rpm

-90.7 kPa (-680 mmHg) or more

Starter Motor

Type

Solenoid controlled

Hitachi S13-555

12

2.3

8.76

300

Rated voltage V

Rated output kW

Load characteristics

Terminal voltage V

Load current A

Weight kg (Ib) 4.7 (10.4)

GENERAL DESCRIPTION

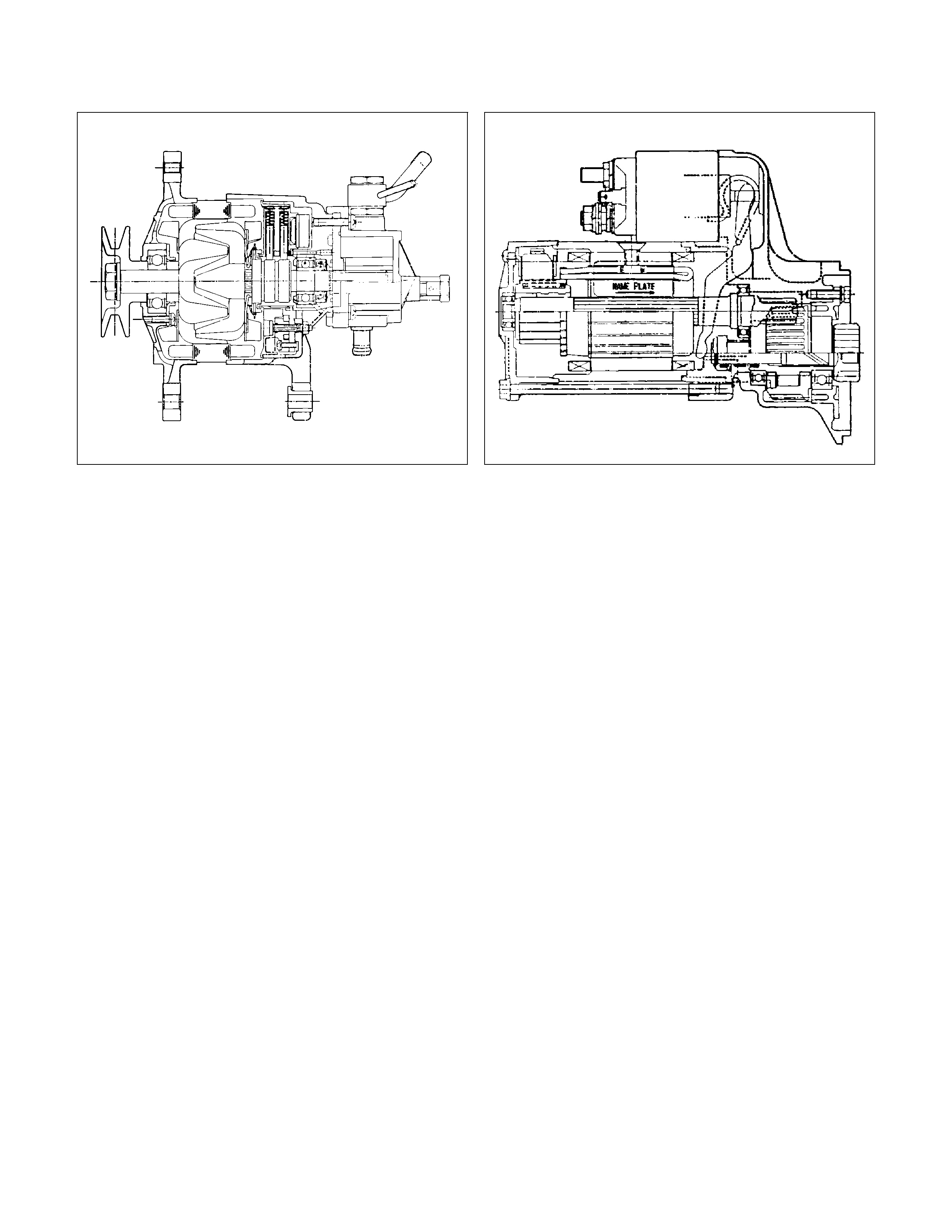

GENERATOR STARTER MOTOR

066L300004 065L300002

The basic charging system is the IC integral regulator charging system. The internal components are connected

electrically as shown in charging circuit diagram.

The generator features a solid state regulator that is mounted inside the generator. All regulator components are

enclosed into a solid mould, and this unit along with the brush holder assembly is attached to the slip ring end frame.

The generator voltage setting cannot be adjusted.

The starter motor circuit is composed of a 4-pole 4-brush type direct current series motor. The starter motor circuit

utilizes negative ground polarity.

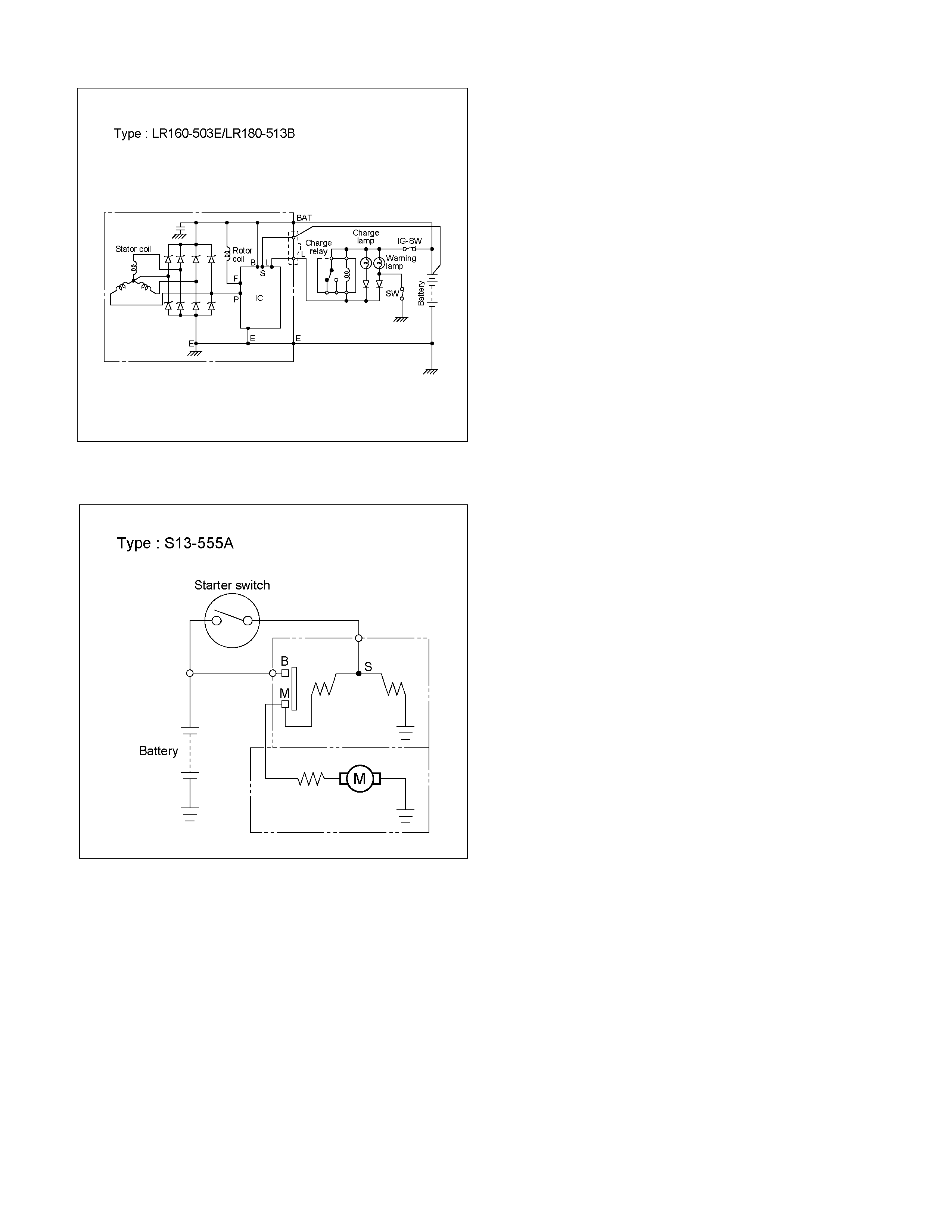

CHARGING CIRCUIT DIAGRAM

RTW46DSH005101

STARTING CIRCUIT DIAGRAM

RTW46DSH005501

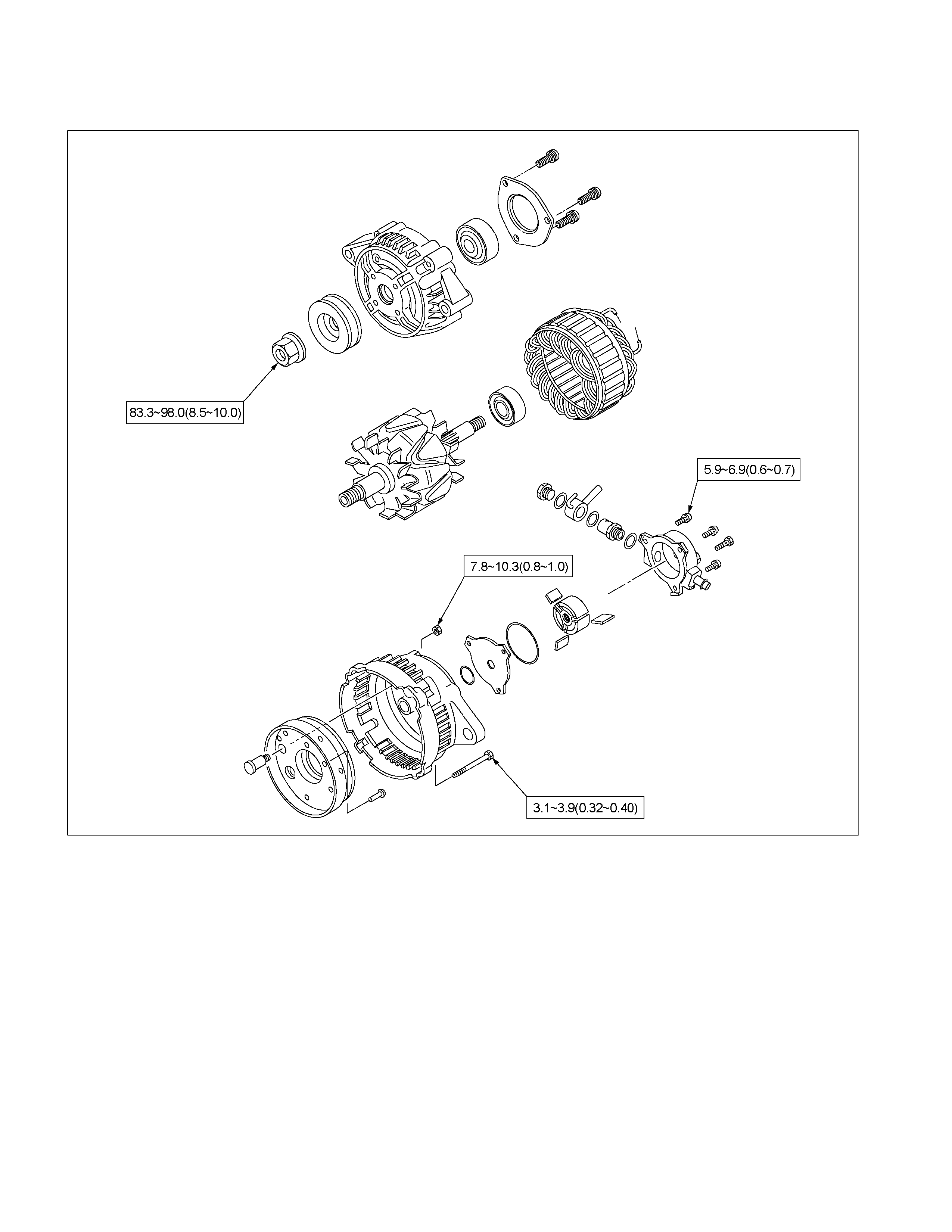

TORQUE SPECIFICATIONS

GENERATOR

Nm (kgm/Ib ft)

RTW46DLF000201

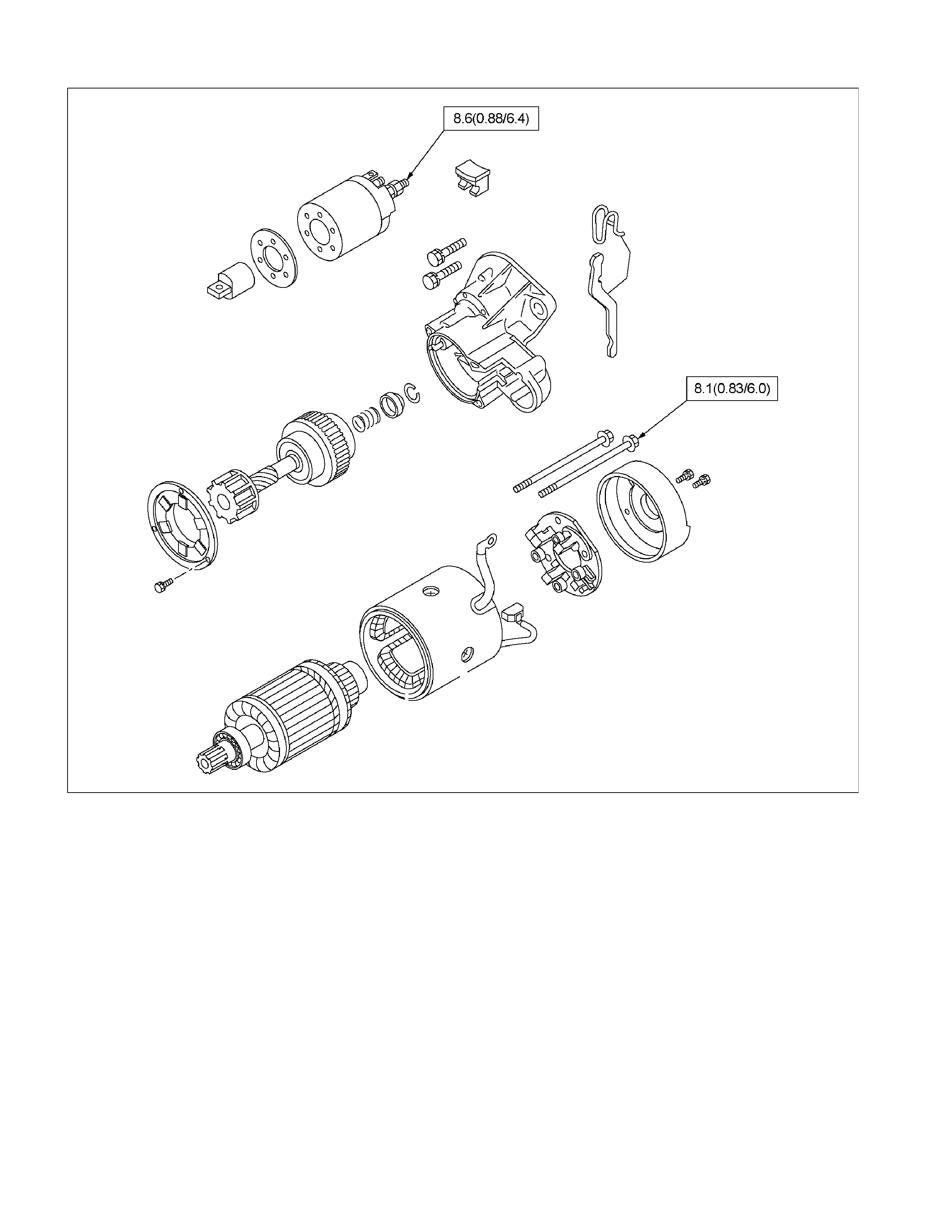

STARTER MOTOR

Nm (kgm/Ibft)

RTW46DLF000301

GENERATOR

Read this Section carefully before performing any removal and installation procedure. This Section gives you important

points as well as the order of operation. Be sure that you understand everything in this Section before you begin.

P1010002

Important Operations-Removal

Cooling Fan Belt

1. Disconnect the battery cables at the battery terminals.

2. Loosen and remove the fan belt adjusting plate bolts.

3. Remove the fan belt from the generator drive pulley.

Generator

1. Remove the vacuum pump hose.

2. Remove the generator bolt and the generator from the

bracket.

Important Operations-Installation

Follow the removal procedure in the reverse order to

perform the installation procedure. Pay careful attention to

the important points during the installation procedure.

Generator

1. Install the generator to the bracket.

2. Tighten the generator bolt to the specified torque.

3. Install the vacuum pump hose.

Generator Bolt Torque Nm (kgm/Ibft)

40 (4.1/30)

033RY00009

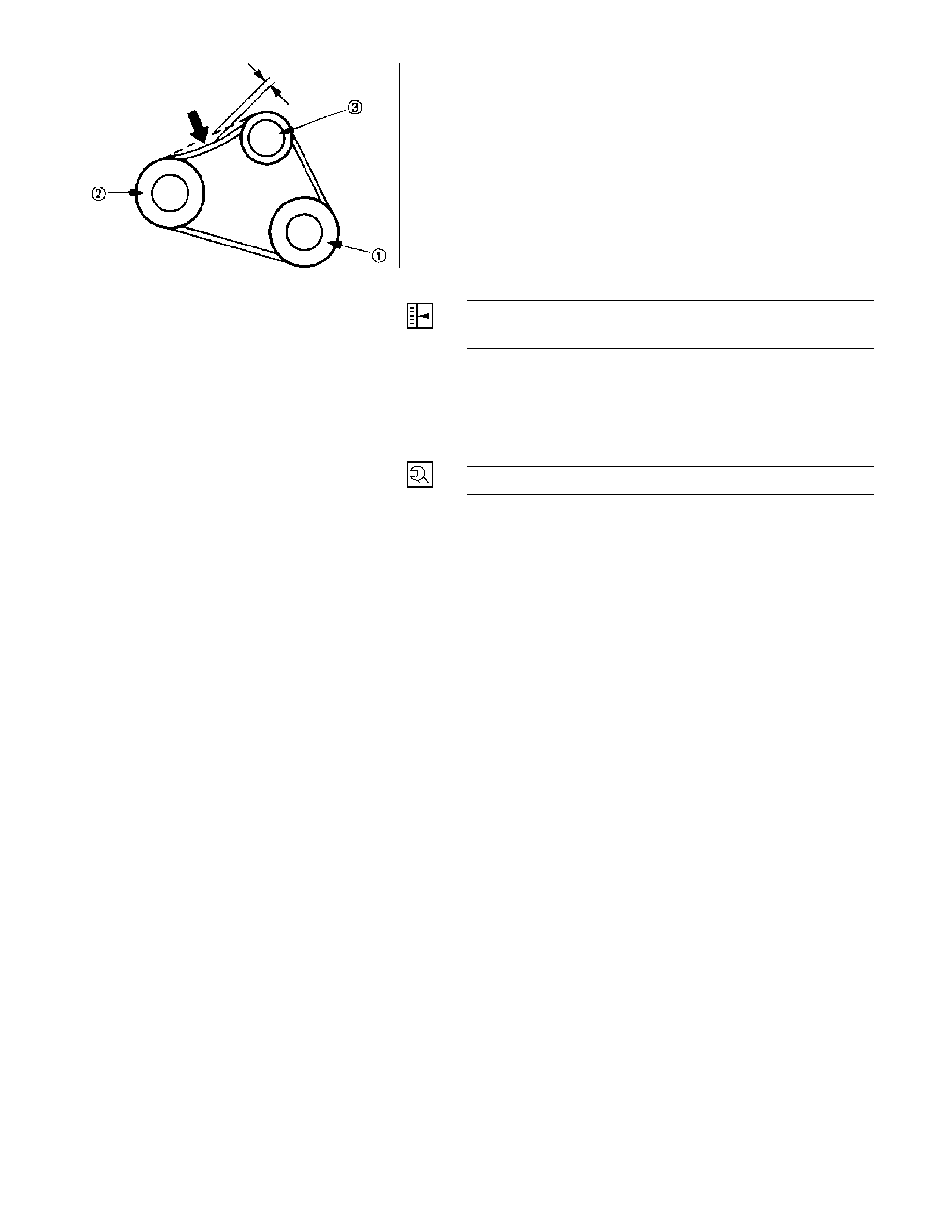

Cooling Fan Drive Belt

1. Hold the generator toward the engine.

2. Install the fan belt to the three pulleys.

1) Crankshaft pulley

2) Generator pulley

3) Cooling fan drive pulley

3. Adjust the fan belt tension

Fan belt tension is adjusted by moving the generator.

Depress the drive belt mid-portion with a 98 N (10

kg/22 Ib) force.

Cooling Fan Drive Belt Deflection mm (in)

New belt 4 - 7 (0.16 - 0.28)

Used belt 6 - 9 (0.24 - 0.35)

4. Tighten the adjusting plate bolts to the specified

torque.

Adjusting Plate Bolt N·m (kg·m/lb·ft)

19 (1.9/14)

Reconnect the battery cable to the battery after the completion

of work.

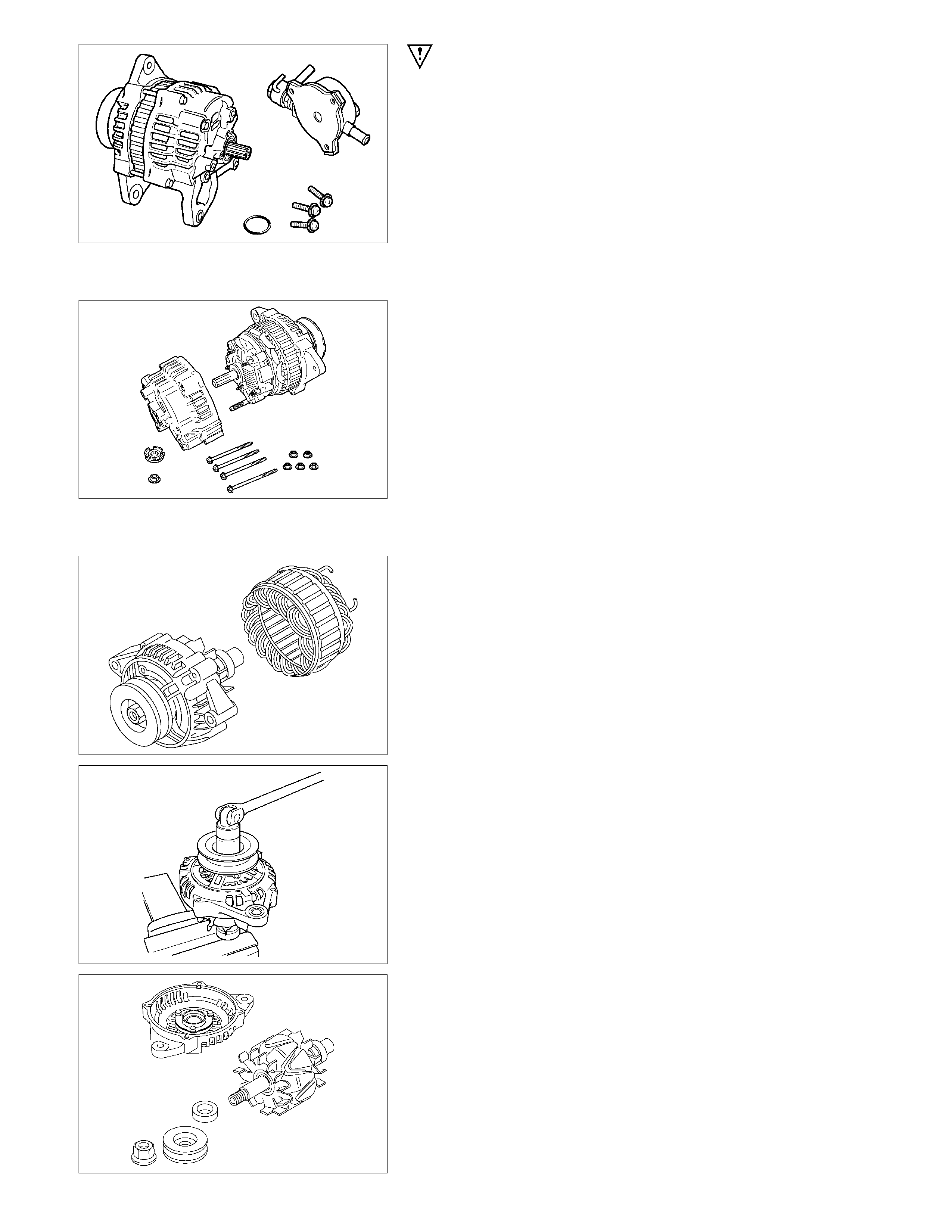

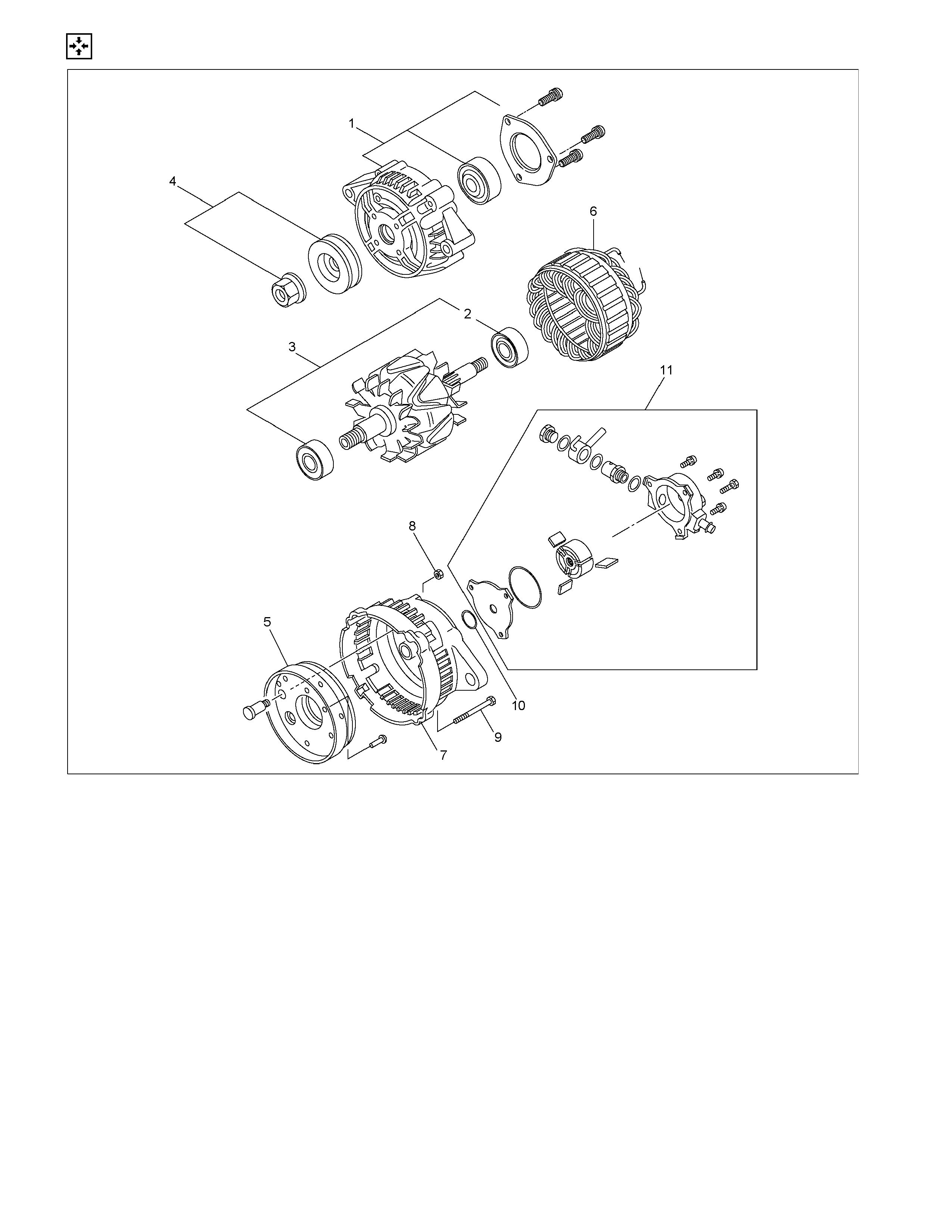

DISASSEMBLY

RTW46DLF000401

Disassembly Step

1. Vacuum pump

2. O-ring

3. Through bolt

4. B Terminal nut

5. Rear cover

6. Pulley

7. Rotor assembly

8. Front cover assembly

9. Rear rotor bearing

10. Rectifier assembly

11. Stator assembly

RTW46DSH000101

Important Operations

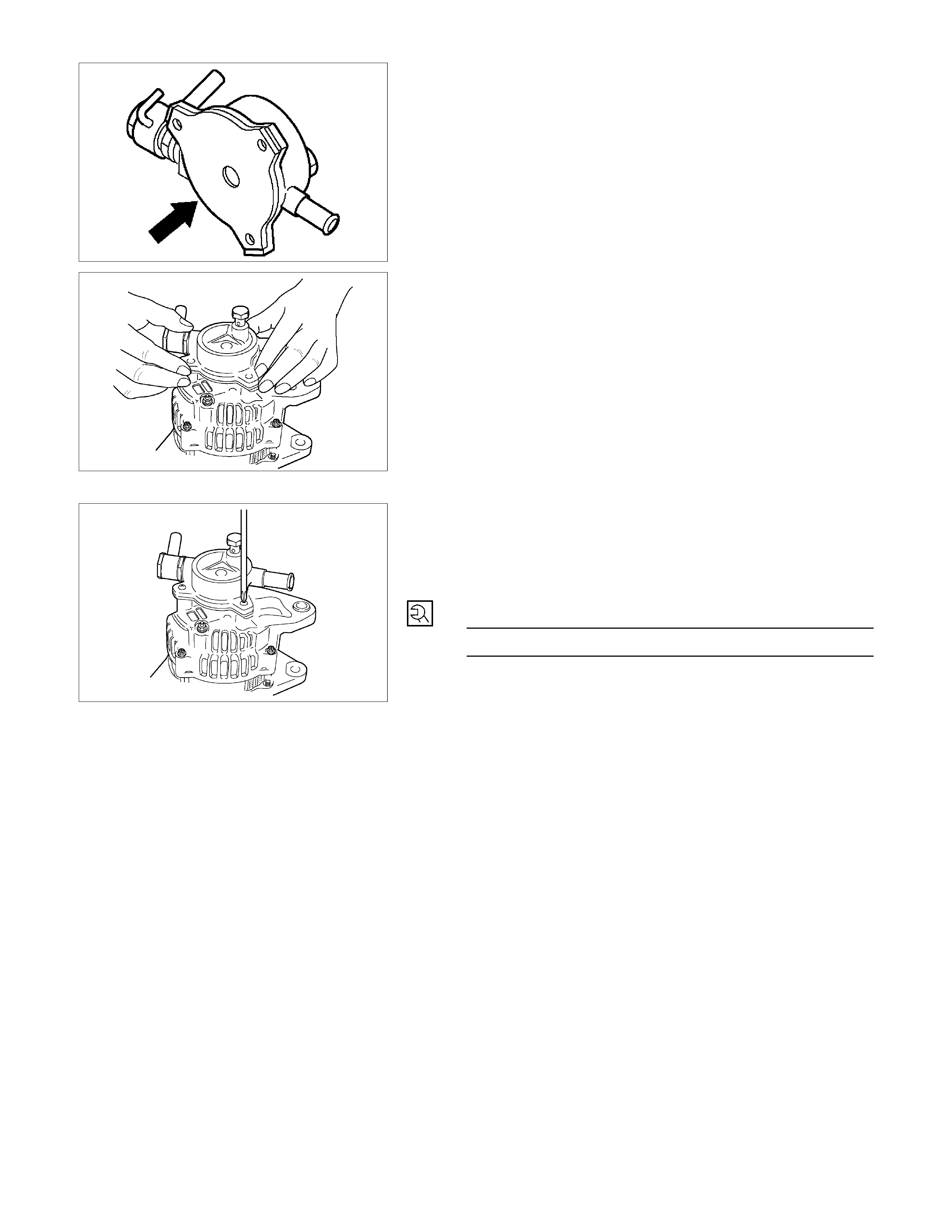

1. Vacuum Pump

1) Loosen the vacuum pump fixing screws.

2) Support the vacuum pump centre plate.

3) Carefully remove the vacuum pump.

2. O-ring

1) The O-ring must be renewed.

RTW46DSH000201

3. Through Bolt

1) Remove the M5 through bolt.

2) Separate the front and rear sides of the vacuum

pump.

3) Insert the tips of 2 flat-blade screwdrivers into the

space between the front cover and the stator core.

Remove the front cover and rotor together with the

rear cover and stator.

If removal is difficult, push the rear cover to the side and

lightly tap the end of the shaft with a plastic hammer to

loosen it.

• The front cover oil seal must be replaced with a new

one when the front cover is removed.

• Take care not to damage the stator core with the

screwdriver tips.

RTW46DSH000601

RTW46DSH002101

6. Pulley

1) Carefully clamp the rotor assembly in a vice.

2) Loosen the pulley nut.

3) Remove the pulley and the front cover from the rotor.

RTW46DSH000301

7. Rotor Assembly

1) Remove the rotor from front cover assembly.

2) Remove the front cover stator and rectifier.

RTW46DSH000701

8. Front Cover Assembly

1) Remove the front cover bearing retainer screws.

2) Remove the bearing.

RTW46DSH000801

9. Rear rotor bearing

• Re-use improper parts.

10. Rectifier

1) Disconnect the stator coil leads between each rectifier

by melting the solder connection.

Hold the lead wire between the solder and the rectifier

with a pair of long nose pliers.

This will prevent heat transfer and resultant damage to the

rectifier.

RTW46DSH000401

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacement if excessive wear or damage is discovered during

inspection.

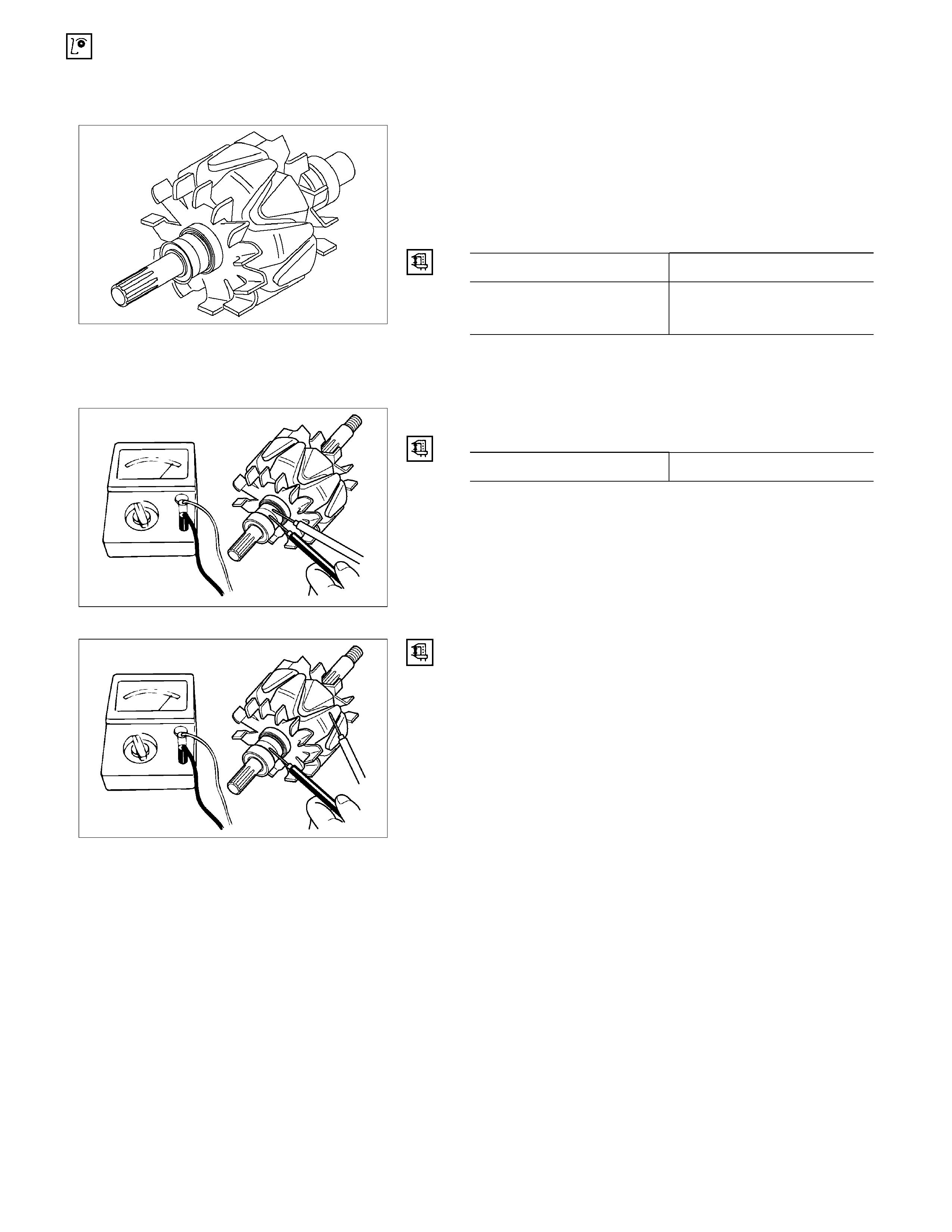

ROTOR ASSEMBLY

1. Inspect the slip ring faces for dirt and pitting.

Wipe away any dirt with a clean cloth soaked in

alcohol.

2. Measure the slip ring diameter.

Slip Ring Diameter mm (in)

Standard Limit

RTW06DSH000101

31.6 (1.245) 30.6 (1.183)

If the slip ring diameter is less than the specified limit, the

slip rings must be replaced.

3. Measure the rotor coil resistance.

Rotor Coil Resistance at 20°C (68°F) ohms

Standard 3.8

RTW46DSH001001

RTW46DSH001101

4. Check for continuity between the slip rings and the

rotor core or shaft.

If there is continuity, the entire rotor assembly must be

replaced.

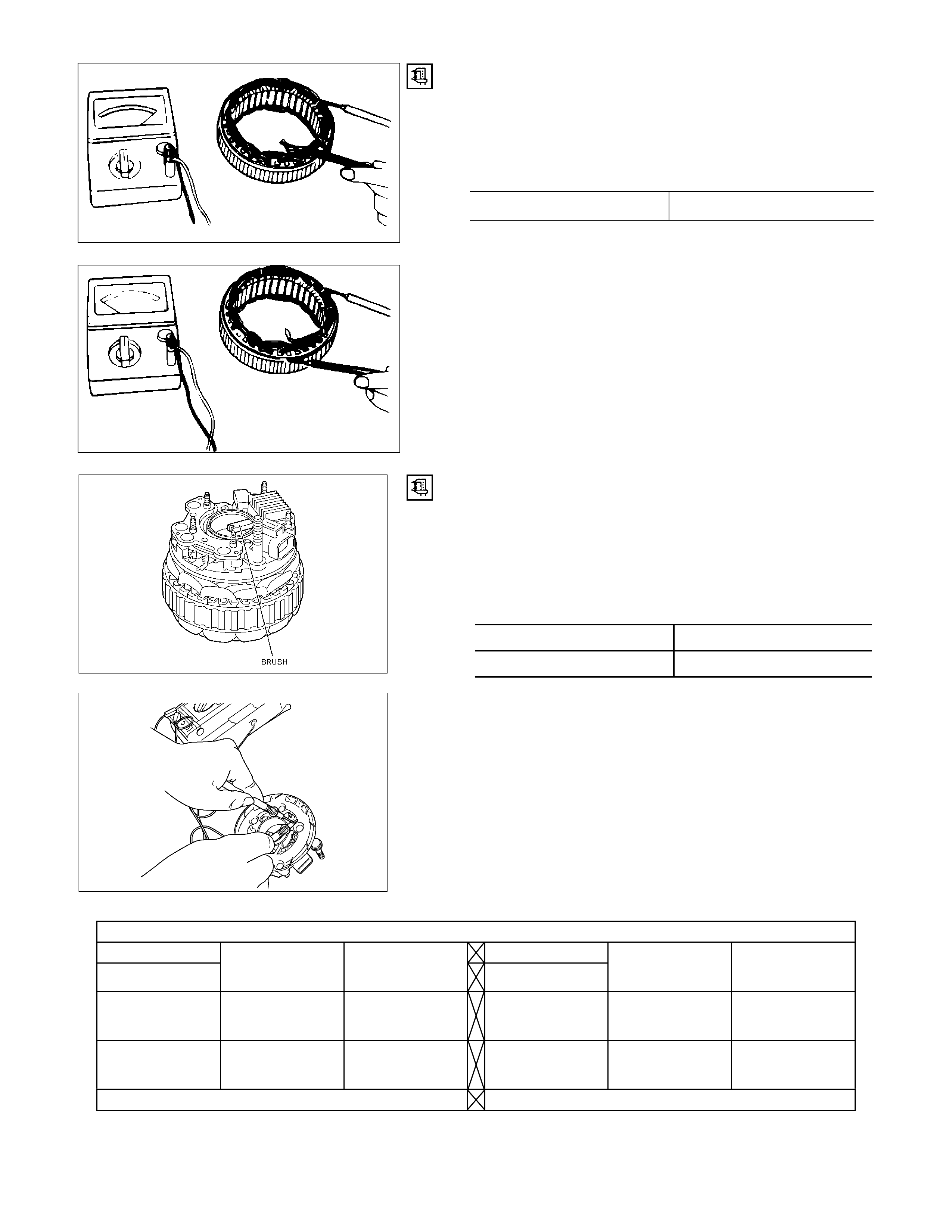

STATOR COIL ASSEMBLY

1. Check for continuity across the stator coils.

If there is no continuity, the stator coils must be

replaced.

Resistance Between The Terminal “N” and the Coil Ends

(Reference) ohms

Standard 0.1

066RY00022

2. Check for continuity between each stator coils and the

stator core.

If there is continuity, the stator coils must be replaced.

066RY00023

RTW46DSH004801

BRUSH

Measure the length of the brush. If abrasion has reduced

the brush length to less than 6.5 mm, the brush must be

replaced with a new one.

A wear line is inscribed in the brush. If the line is not

visible, the brush must be replaced.

Brush Length (Reference) mm (in)

Standard Limit

25 (1.0) 6.5 (0.25)

RTW46DSH001201

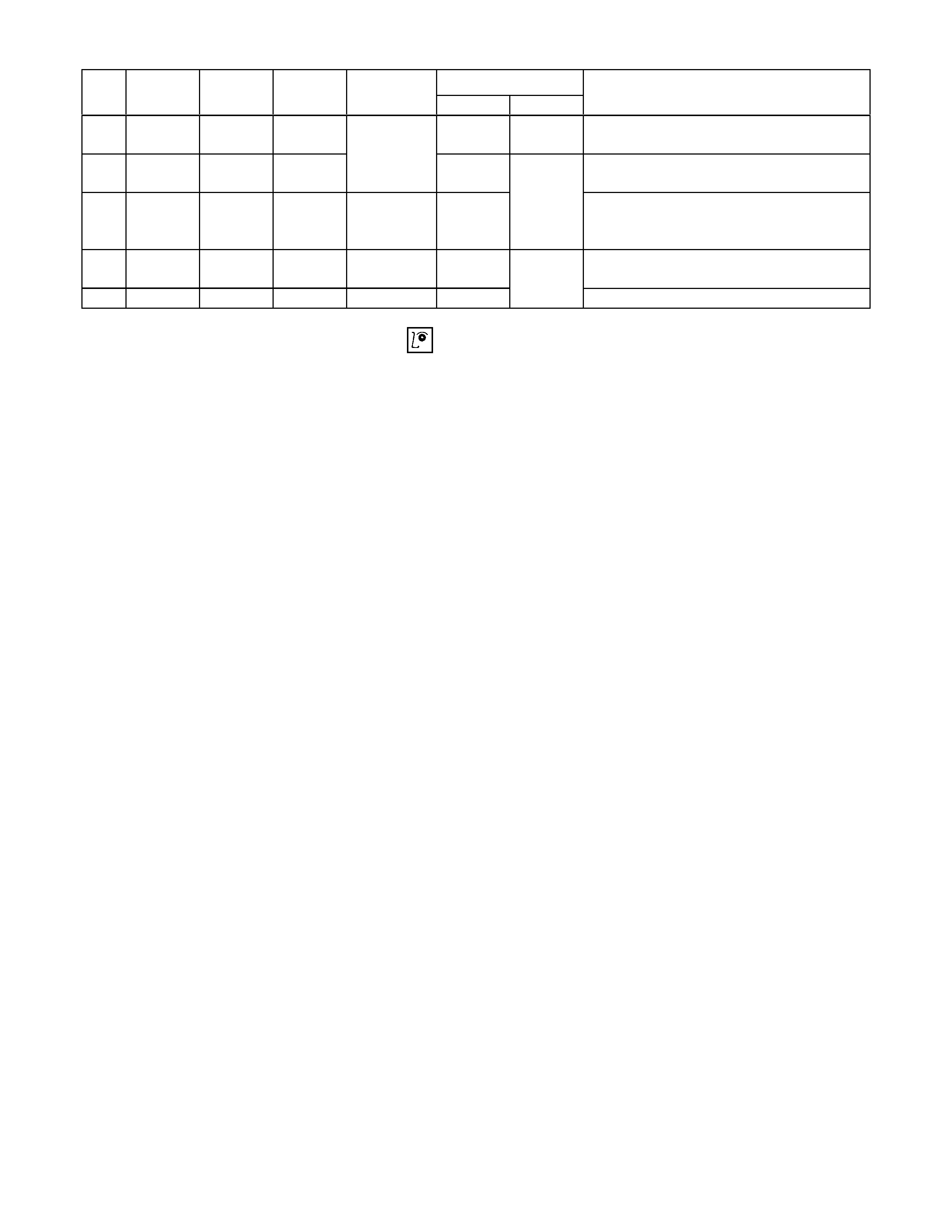

Rectifier

Tester wire

E BAT

U, V, and WN ⊕ ⊖ U, V, and WN ⊕ ⊖

⊕ ----- Conductivity ⊕ ----- No

conductivity

⊖ No

conductivity ----- ⊖ Conductivity -----

Negative side diode check Positive side diode check

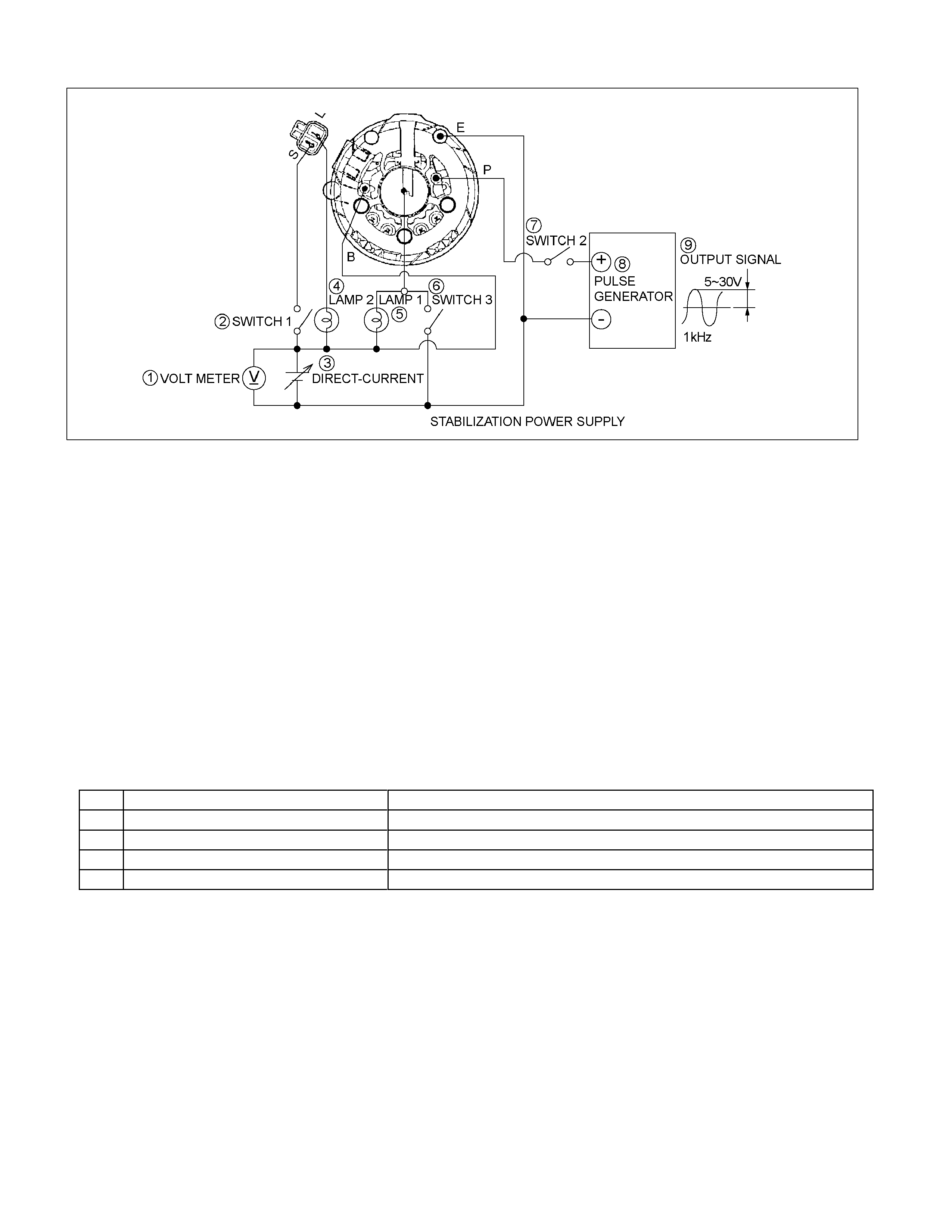

RECTIFIER ASSEMBLY

RTW46DSF000301

1. Voltmeter

2. Switch 1

3. DC regulated power supply

4. Lamp 2

5. Lamp 1

6. Switch 3

7. Switch 2

8. Pulse generator

9. Output signal

Test circuit

Refer to the judgment criteria shown in the Table below.

Carefully check Items 1~5. If all the items are OK, the IC

regulator is normal.

Circuit components

1 DC regulated power supply 0~20 volts variable with output of 1 ampere or more

2 Lamps (2) 12 volts, 1.4~3.4 watts

3 Switches (3) -----

4 DC voltmeter 0~30 volts, 0.5 grade

5 Pulse generator (Oscillator) 5~30 volt output at a frequency of 1kHz

Judgment criteria

Lamp condition

No. Switch

1 Switch

2 Switch

3 Voltmeter

reading Lamp 1 Lamp 2 Remarks

1 ON OFF OFF On

(dim) ON Initial excitation check

2 ON ON OFF 12V On or

flashing Full excitation check

3 ON ON OFF 16V Off or

on (dim)

OFF Lamp 1 off or dimly lit when the

voltmeter shows less than 12 volts or

16 volts

4 OFF ON OFF 12V On or

flashing Stator and brush separation check

5 ON ON ON 18V On ON Excess voltage check

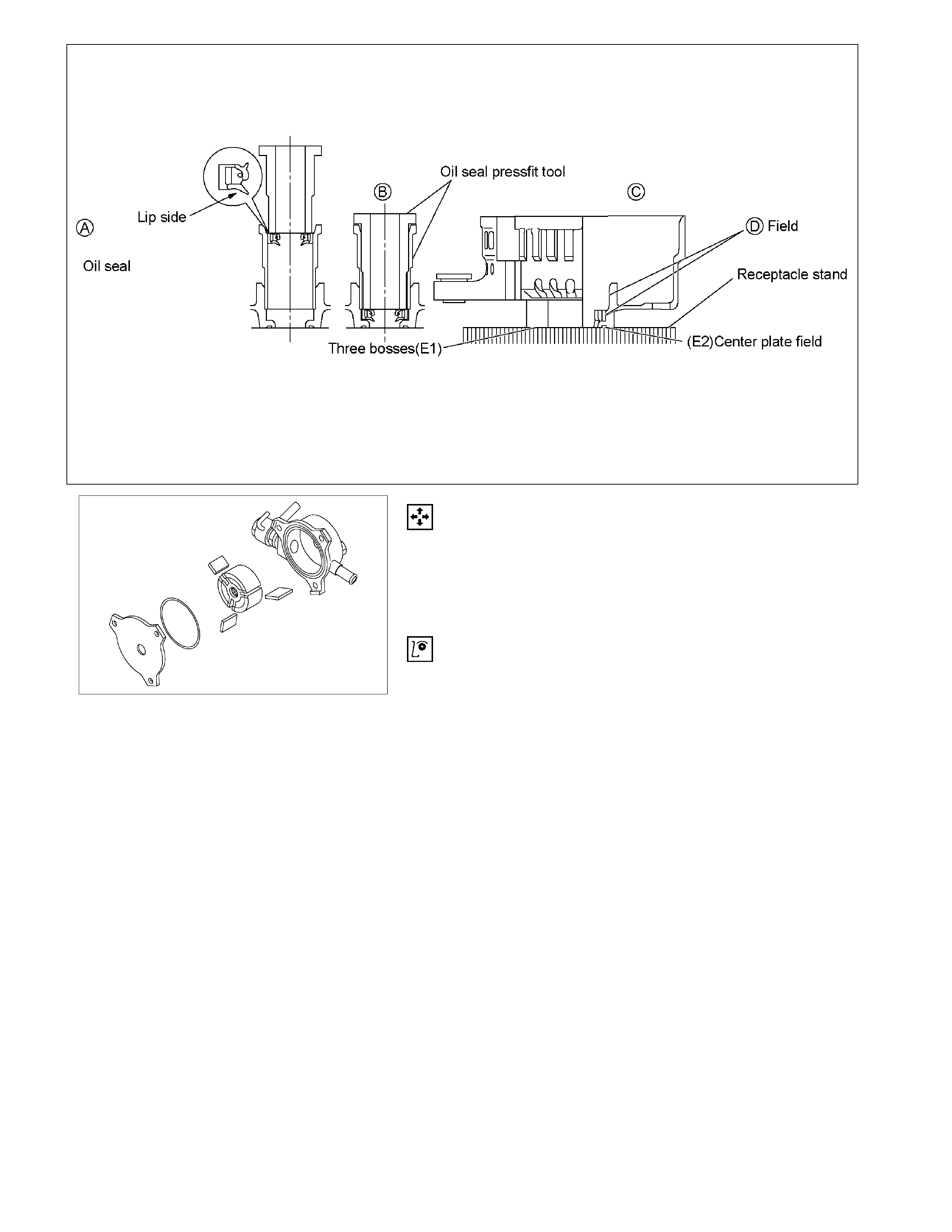

Oil seal

The oil seal must be replaced with a new one whenever

the alternator is disassembled.

Oil Seal Replacement

1. Push the old oil seal from the rear bracket outside

holes.

2. Use the insertion tool to press the new oil seal into

place. Follow the procedure shown in Figures A, B, C

and D.

Position the oil seal beneath the shaft and the

guide lip.

Position the cradle against the rear cover bosses

(3 points) so that the E1 and E2 surfaces fit into

the cradle. Take care not to damage the E1 and

E2 surfaces.

After completing the procedure, carefully check

the oil seal seating. Be absolutely sure that the

seal is evenly inserted (no warp) and level with the

surrounding surfaces.

CAUTION

• Be sure that no foreign material enters the

space between the oil seal and the rotor shaft

surfaces during the installation procedure.

• Take care not to damage the D surface.

• Under no circumstances may the original oil

seal be reused.

• The oil seal must be perfectly flat after being

pressed into place. If the oil seal is tilted, there

will be oil leakage.

RTW46DSF000101

RTW46DSH000901

Vacuum Pump

Vacuum Pump Disassembly

1. Remove the centre plate from the vacuum pump

housing.

2. Remove the vacuum pump rotor and the vanes from

the housing.

Inspection

Vacuum Pump Housing and Centre Plate

Inspect the vacuum pump housing and the centre plate for

excessive wear, abrasion, and scoring.

If any of these conditions are present, the vacuum pump

housing and centre plate must be replaced.

Vane

Inspect the vanes for excessive wear and damage.

Replace all four vanes if either of these conditions are

present.

Never replace only one vane.

Rotor

1. Inspect the rotor for excessive wear, abrasion, and

scoring.

Pay particular attention to the internal spline.

Replace the rotor if any of these conditions are

present.

2. Inspect the generator rotor shaft splines for backlash.

Replace the rotor if backlash is present.

RTW46DSH005201

Check Valve

1. Carefully force the valve from the side as shown in the

illustration.

The valve must move smoothly.

If it does not, the check valve must be replaced.

2. Apply compressed air to the side as shown in the

illustration.

Air Pressure kPa (kg/cm2/psi)

98 - 490 (1-5/14 – 71)

3. Check for air leakage from the check valve.

If there is air leakage, the valve must be replaced.

RTW46DSH001801

Vacuum Pump Reassembly

1. Install the vanes to the rotor slits.

The rounded side of the vanes must be facing the

rotor housing.

RTW46DSH001901

2. Install the rotor with the concave side facing the

centre plate.

RTW46DSH002001

3. Install the centre plate to the rotor housing.

Be sure to use a new O-ring.

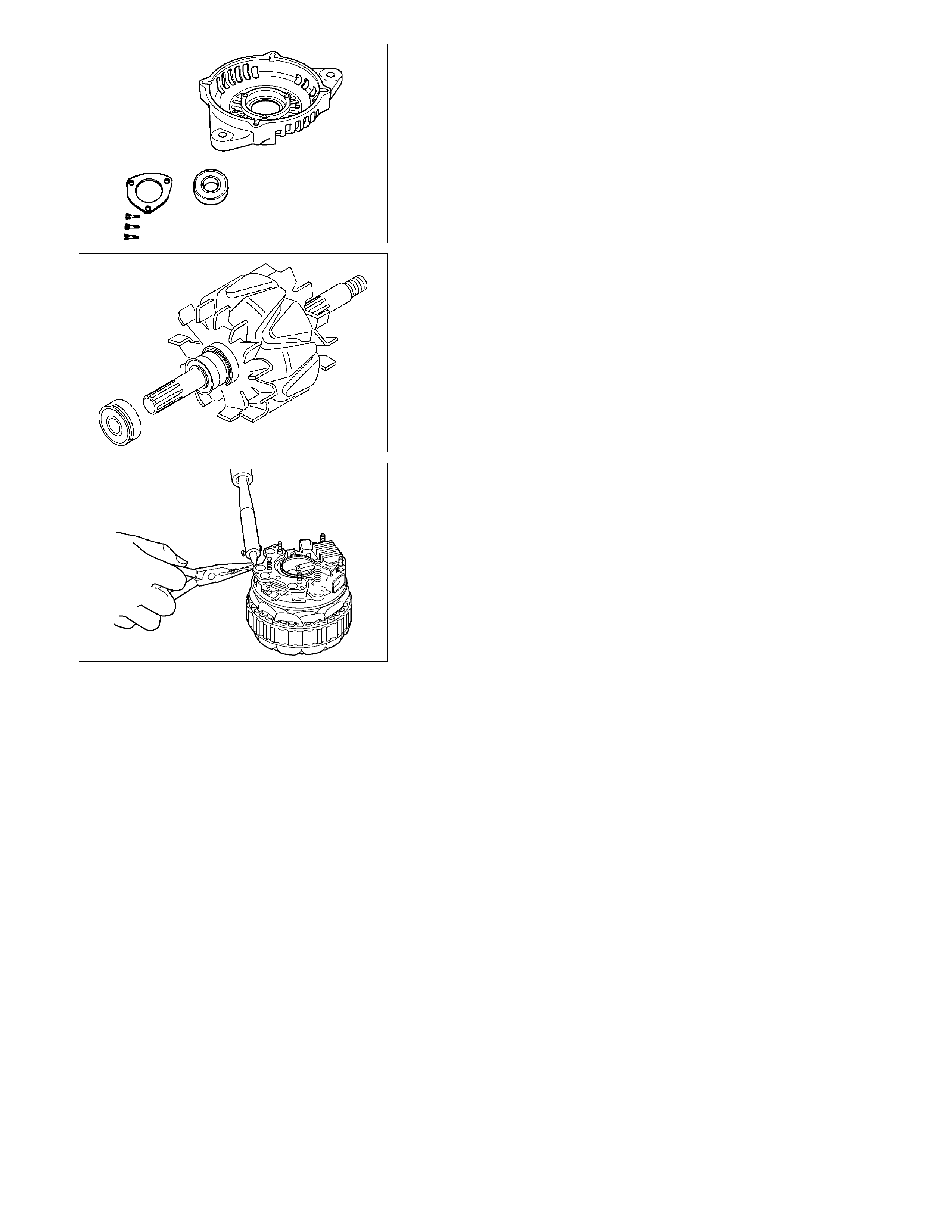

REASSEMBLY

RTW46DLF000501

Reassembly Step

1. Front cover

2. Rear rotor bearing

3. Rotor Assembly

4. Pulley

5. Rectifier Assembly

6. Stator Assembly

7. Rear cover

8. B Terminal nuts

9. Through bolt

10. O-ring

11. Vacuum pump

RTW46DSH000401

Important Operations

2. Rear rotor bearing

• Replace if the bearing condition is unsatisfactory.

5. Rectifier

6. Stator

Use a pair of long-nose pliers to connect the stator coil

leads and the rectifier leads.

Finish the work as quickly as possible to prevent the

rectifier from heat transferred by the soldering.

RTW46DSH002101

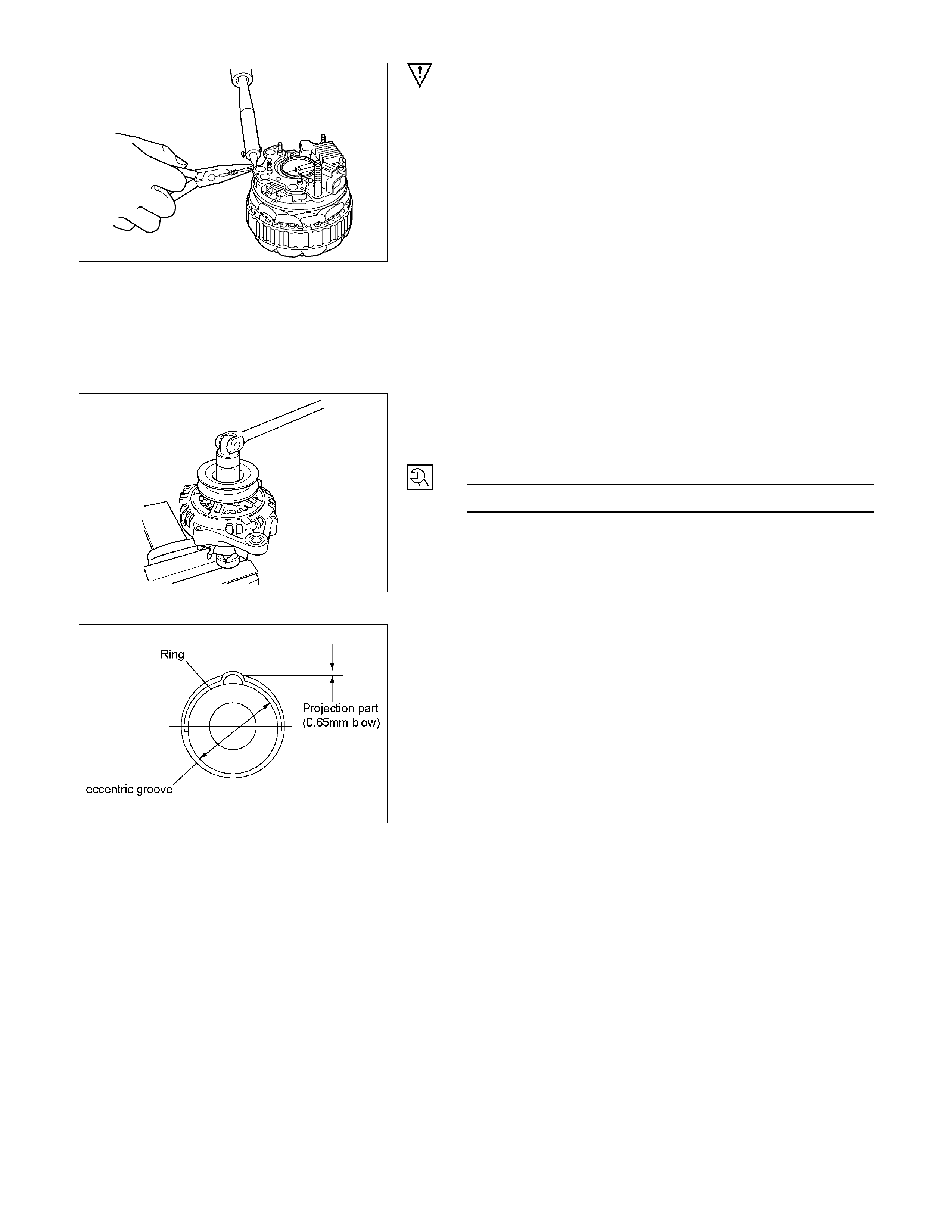

3. Rotor Assembly

4. Pulley Assembly

Clamp the rotor in a vice and install the pulley nut.

Pulley Nut Torque N⋅m (kg⋅m/lb⋅ft)

83.3 ∼ 98.0 (8.5 ∼ 10.0/61 ∼ 72)

RTW46DSH004901

The rear ball bearing is pressed into the wheel eccentric

groove. The bearing ring projects from the groove.

During installation, rotate the bearing to the point of

minimum bearing ring projection.

Inspect the rear cover bearing box and replace it if it is

damaged.

RTW46DSH002201

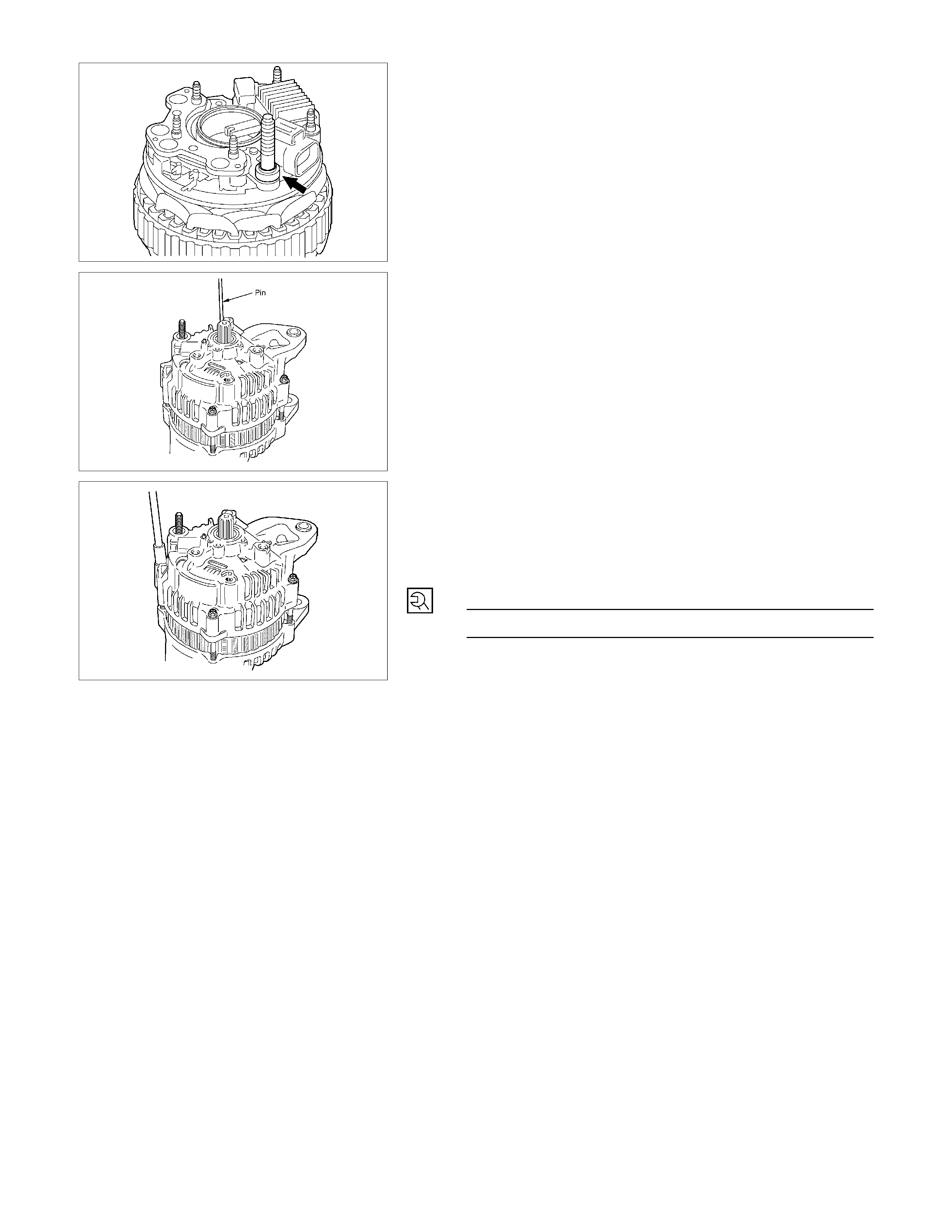

NOTE:

Be sure to attach the collar to the B terminal.

RTW46DSH005301

Insert the pin from the outside of the rear cover. Press the

brushes into the brush holder. Complete the assembly

procedure.

Remove the pin after completion of the assembly

procedure.

RTW06DSH000201

9. Through Bolt

1) Place a pilot bar into the through bolt hole to align the

front cover and the rear cover.

2) Install the through bolts and tighten them to the

specified torque.

Through Bolt Torque N⋅m (kg⋅m/lb⋅ft)

3.1 ∼ 3.9 (0.32 ∼ 0.41/2.6 ∼ 3.5)

11. Vacuum Pump

To install the generator -

1) Note the direction of the arrow on the vacuum pump.

2) Look forward from the base of the arrow to locate the

3 generator fixing points.

3) Twist the fixing points down and to the left to align

them with the middle of the centre plate and the rotor.

RTW46DSH006101

Install vanes into slits in rotor.

The vanes should be installed with the chamfered side

facing outward.

RTW46DSH002401

Install the vacuum pump housing.

Make sure that the O-ring is not projecting beyond the

slots of the centre plate.

Take care so that no scratching takes place on the vane

resulted by contact with the housing.

RTW46DSH002501

Install the housing in the generator and fix it with the three

bolts.

Supply engine oil (5cc or so) from the oil port and check

that the generator pulley can be turned smoothly with your

hand.

Generator Housing Bolt Torque N⋅m (kg⋅m/lb⋅ft)

5.9 ∼ 6.9 (0.6 ∼ 0.7/5.2 ∼ 6.1)

STARTER MOTOR

Read this Section carefully before performing any removal and installation procedure. This Section gives you important

points as well as the order of operation. Be sure that you understand everything in this Section before you begin.

Important Operations - Removal

Starter Motor

1. Disconnect the ground cable and the battery cable at

the battery terminals.

2. Disconnect the cable at the terminal on the magnetic

switch.

3. Disconnect the battery cable from the starter motor

and the ground cable from the cylinder body.

4. Remove the starter motor from the engine.

Important Operations – Installation

The installation procedure is the reverse of the removal

procedure. Pay careful attention to the important points

during the installation procedure.

Starter Motor

1. Install the starter motor to the rear plate.

2. Tighten the starter motor bolts to the specified torque.

Starter Motor Bolt Torque N⋅m (kg⋅m/lb⋅ft)

85 (8.7/63)

3. Reconnect the battery cable at the starter motor and

the ground cable at the cylinder body.

4. Reconnect the battery cable and the ground cable at

the battery terminals.

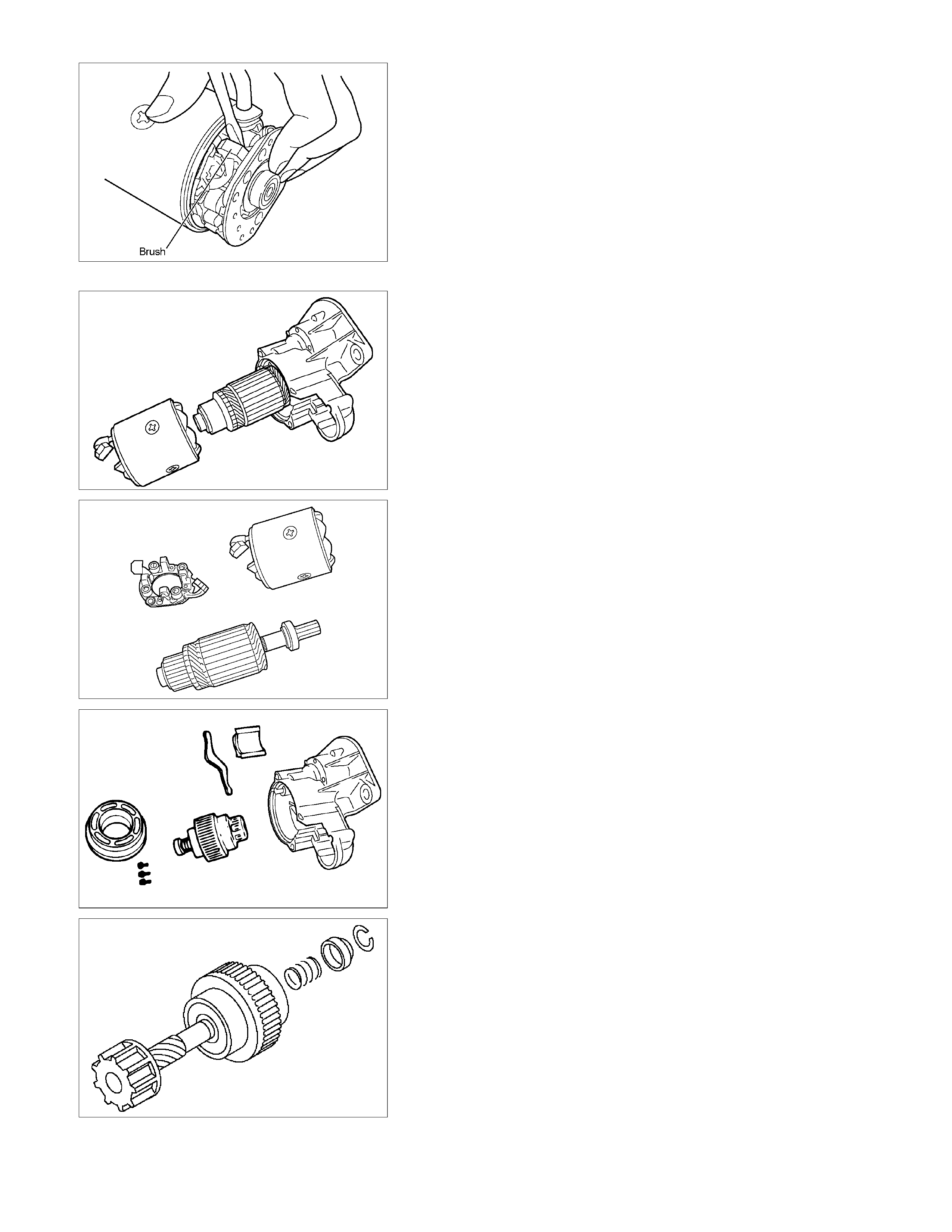

DISASSEMBLY

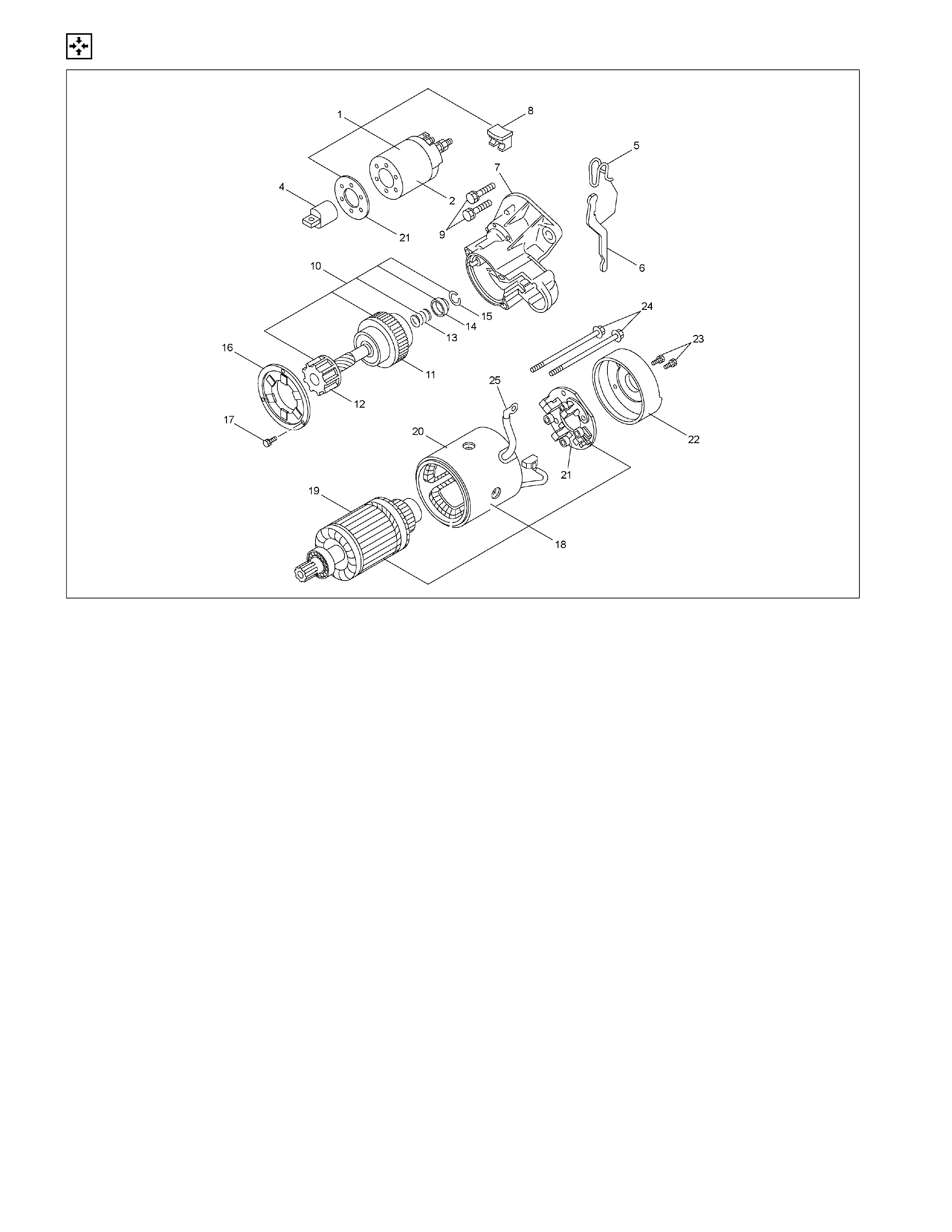

RTW460LF000201

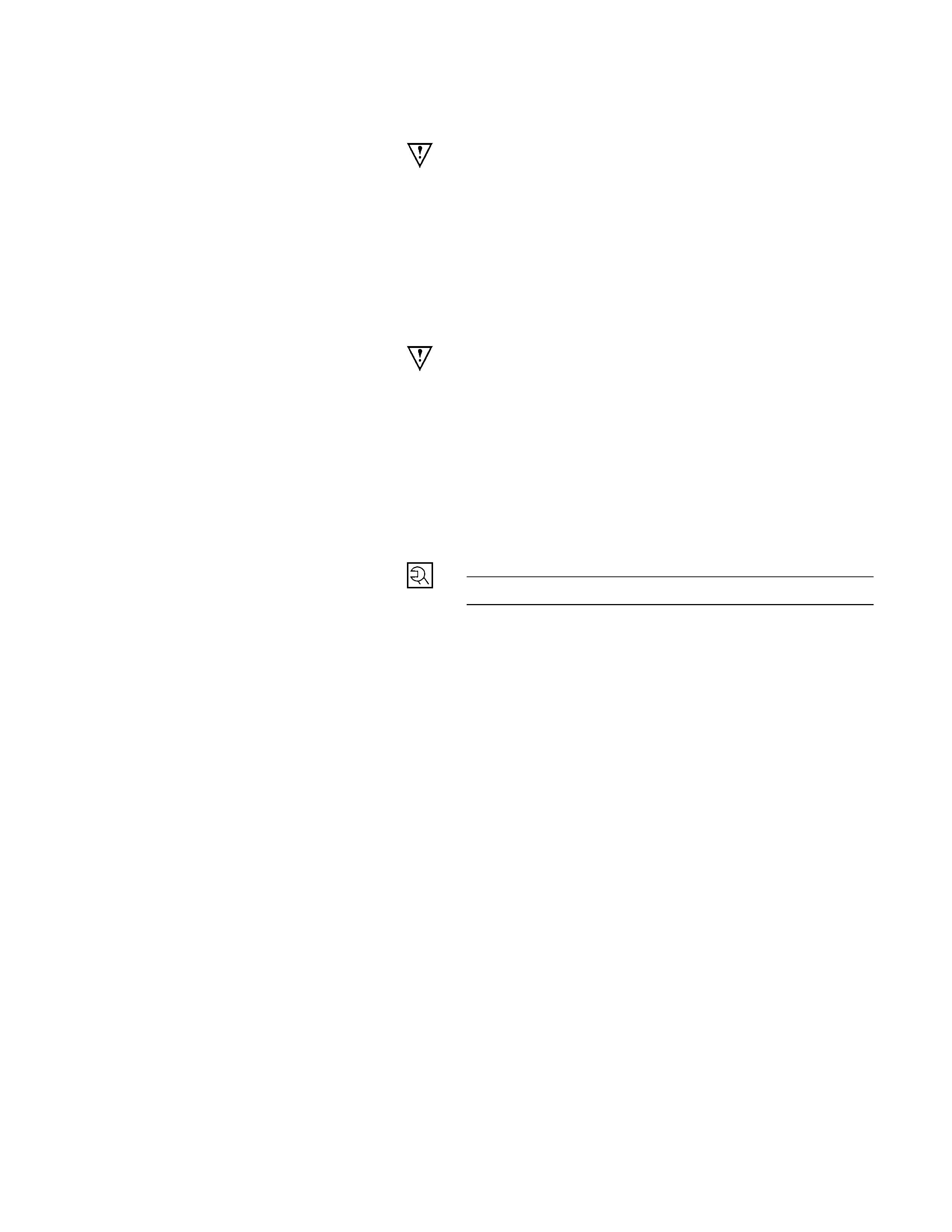

Disassembly Step

1. Lead wire 14. Armature

2. Bolt 15. Bolt

3. Magnetic switch assembly 16. Bearing retainer

4. Torsion spring 17. Pinion assembly

5. Plunger 18. Pinion stopper clip

6. Dust cover 19. Pinion stopper

7. Magnetic switch 20. Return spring

8. Screw 21. Pinion shaft

9. Through bolt 22. Clutch

10. Rear cover 23. Dust cover

11. Motor assembly 24. Shift lever

12. Brush holder 25. Gear case

13. Yoke

RTW46DSH002601

Important Operations

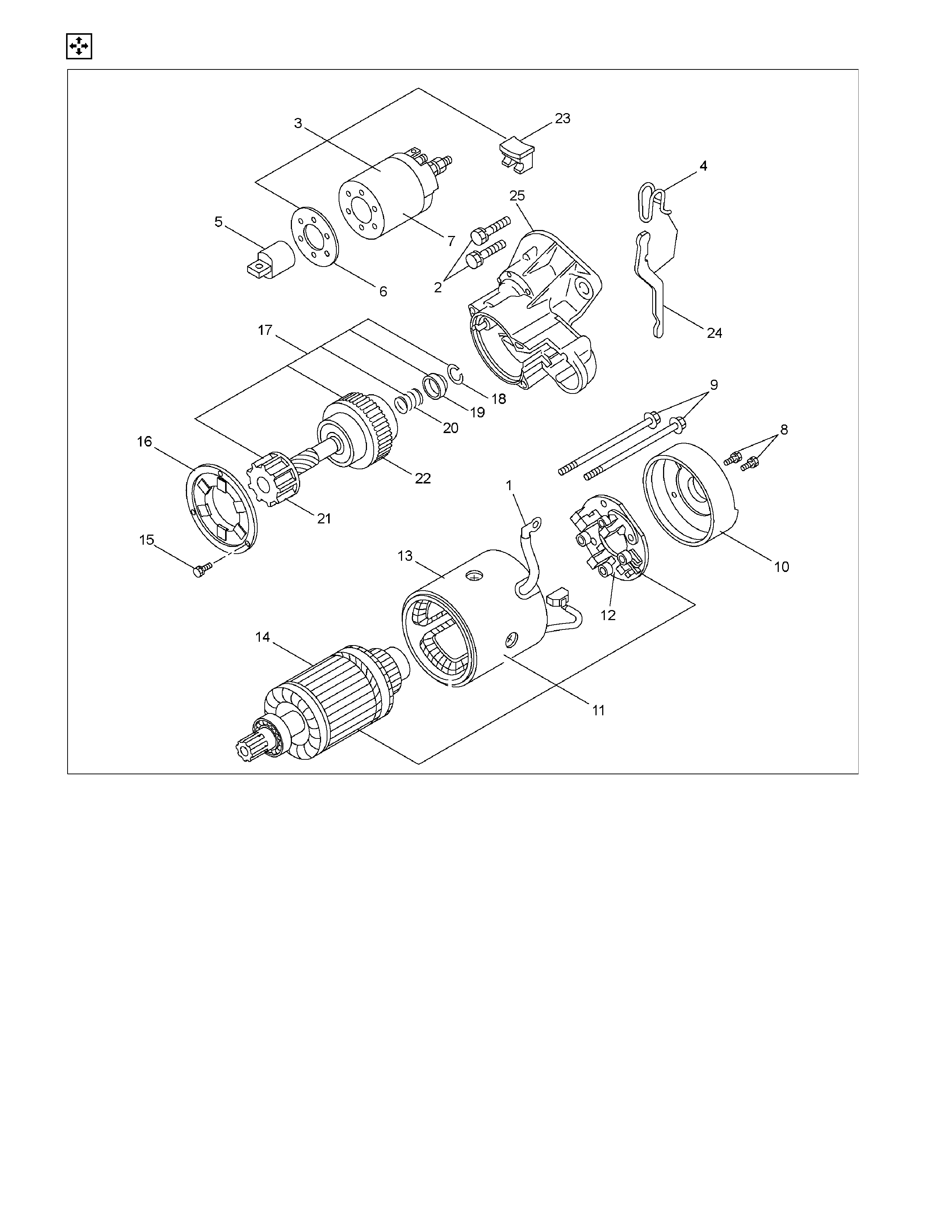

1. Lead Wire

Disconnect the lead wire at the magnetic switch.

RTW46DSH002701

3. Magnetic Switch Assembly

Remove the magnetic switch bolts, then remove the

switch from the shift lever.

RTW46DSH002801

Remove the torsion spring from the magnetic switch.

RTW46DSH002901

8. Screw

9. Through Bolt

10. Rear Cover

Remove the through bolts, then remove the rear cover.

RTW46DSH003001

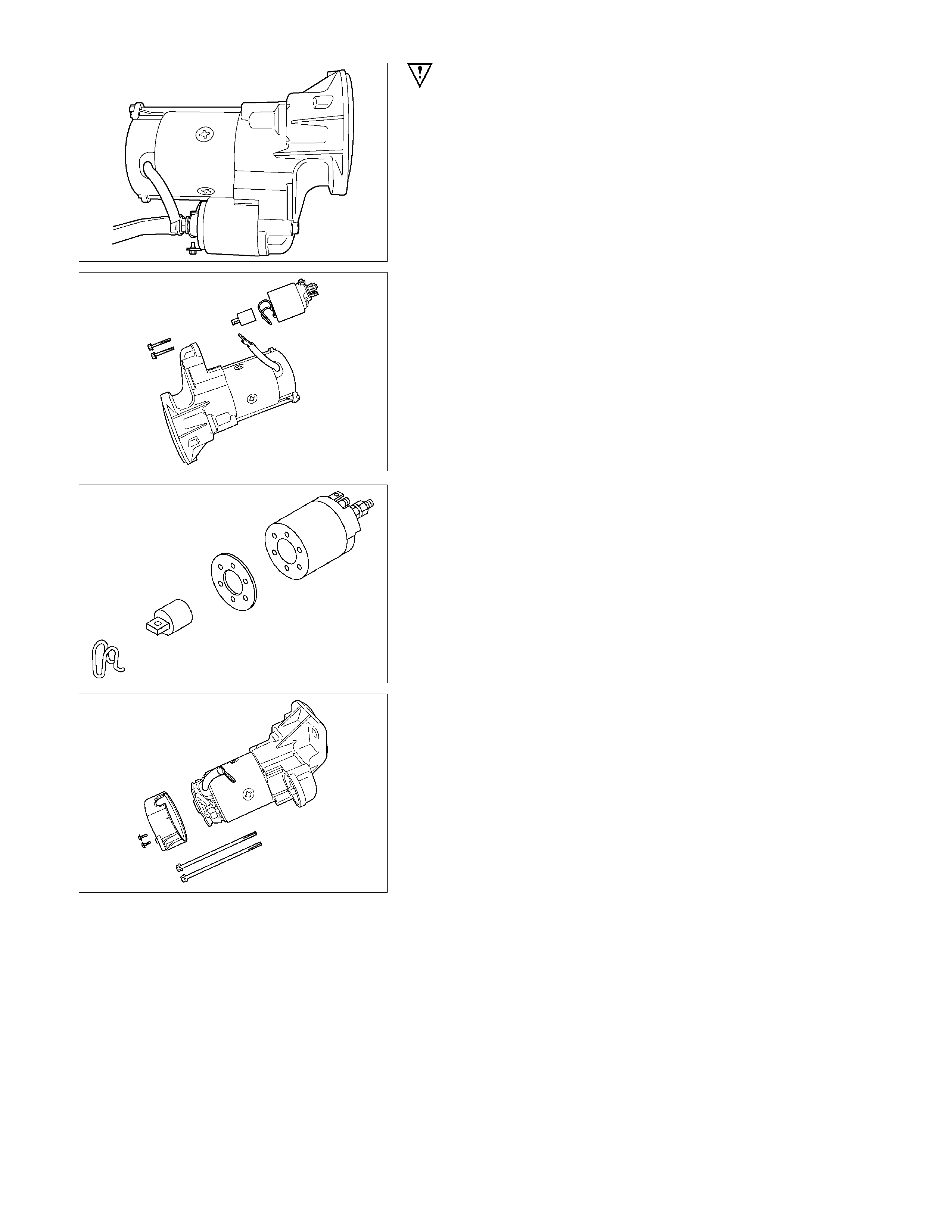

11. Motor Assembly

Remove the four brushes from the brush holders.

RTW46DSH003101

Remove the yoke along with the armature and the brush

holder from the gear case.

Remove the brushes and commutator carefully, to avoid

contact with adjacent parts.

RTW46DSH003201

12. Brush Holder

13. Yoke

14. Armature

Remove the brush holder and pull out the armature

assembly free from the yoke.

RTW46DSH003301

16. Bearing Retainer

17. Pinion Assembly

23. Dust Cover

24. Shift Lever

25. Gear Case

1) Remove the bearing retainer.

2) Remove the pinion from the gear case.

RTW46DSH003401

3) Use a screwdriver to remove the stopper clip. Then

disassemble the pinion assembly.

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacement if excessive wear or damage is discovered during

inspection.

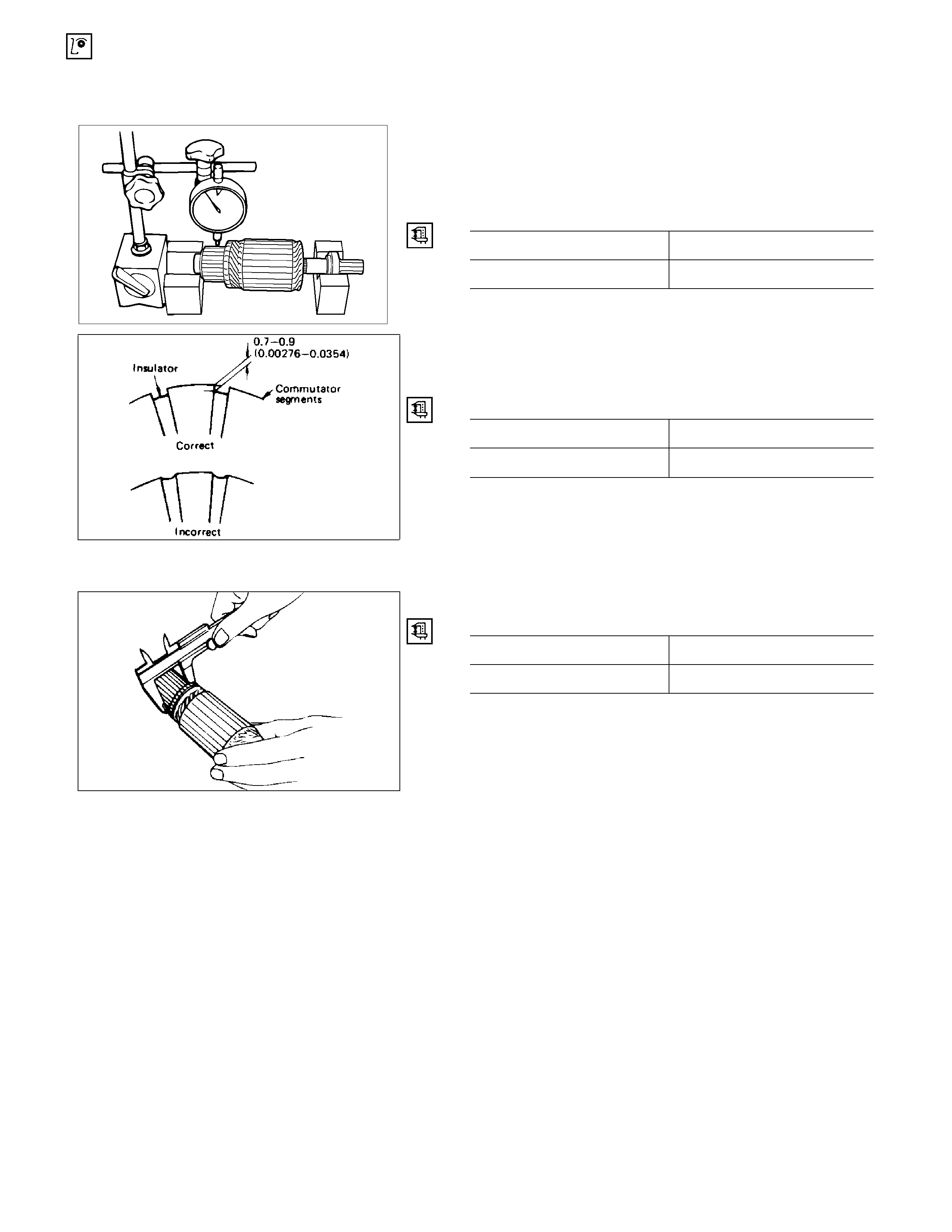

ARMATURE

1. Measure the commutator run-out.

Replace the commutator if the measured run-out

exceeds the specified limit.

Commutator Run-Out mm (in)

Standard Limit

0.05 (0.002) 0.2 (0.008)

RTW46DSH003501

2. Check the commutator mica segments for excessive

wear.

3. Measure the mica segment depth.

Mica Segment Depth mm (in)

Standard Limit

0.5 ∼ 0.8 (0.020 ∼ 0.030) 0.2 (0.008)

065RY00025

If the mica segment depth is less than the standard but

more than the limit, the commutator may be reground.

If the mica segment depth is less than the limit, the

commutator must be replaced.

4. Measure the commutator outside diameter.

Commutator Outside Diameter mm (in)

Standard Limit

36.5 (1.44) 35.5 (1.40)

If the measured outside diameter is less than the specified

limit, the commutator must be replaced.

065RY00026

RTW46DSH003601

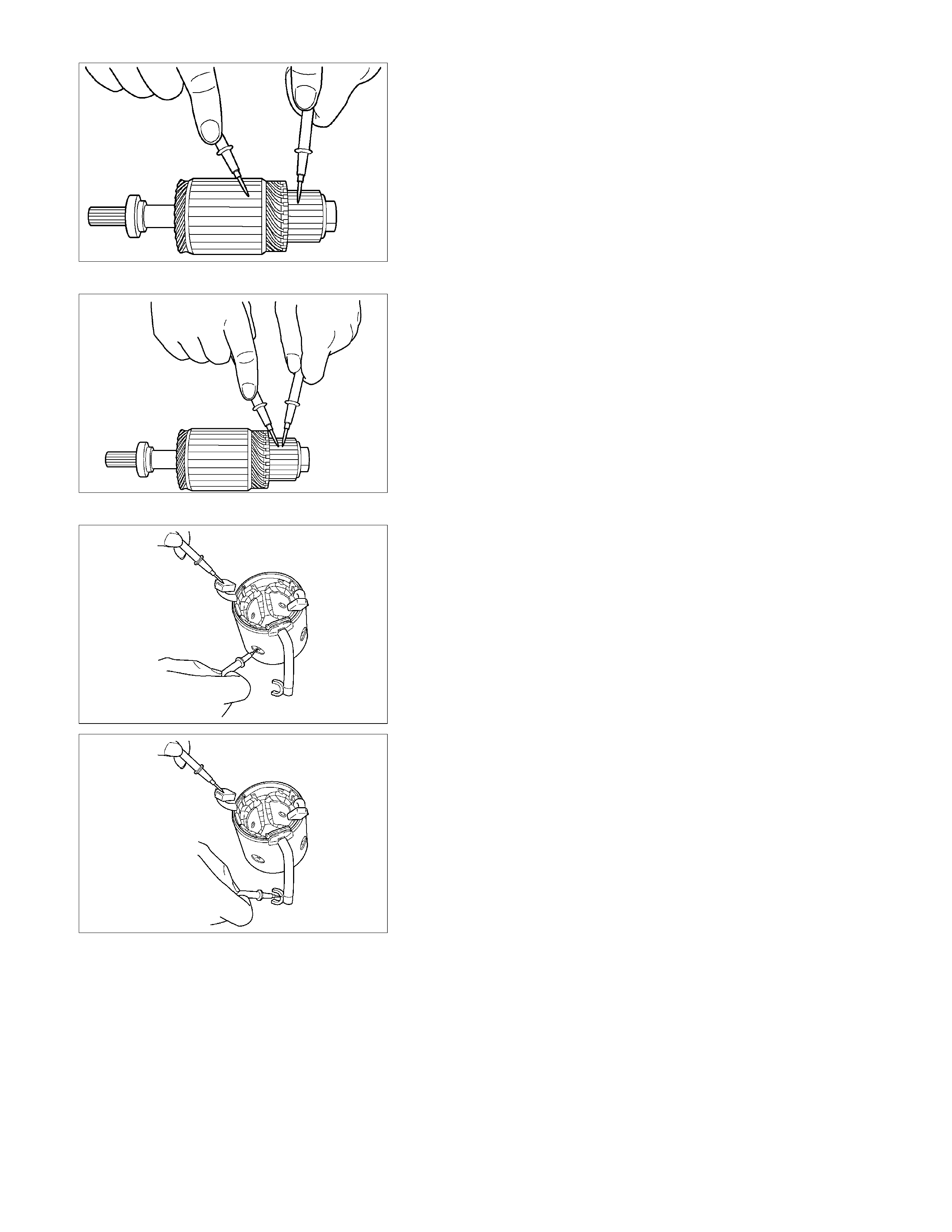

5. Use a circuit tester to check the armature for

grounding.

1) Hold one probe of the circuit tester against the

commutator segment.

2) Hold the other circuit tester probe against the

armature core.

If the circuit tester indicates continuity, the armature is

grounded and must be replaced.

RTW46DSH003701

6. Use the circuit tester to check the armature for

continuity.

1) Hold the circuit tester probes against two

commutator segments.

2) Repeat Step 1 at different segments of the

armature core.

There should be continuity between all segments of

the commutator.

If there is not, the armature must be replaced.

RTW46DSH003801

YOKE

1. Use a circuit tester to check the field winding ground.

1) Hold one circuit tester probe against the field

winding end or brush.

2) Hold the other circuit tester probe against the

bare surface of the yoke body.

There should be no continuity.

If there is continuity, the field coil is grounded, and

therefore the yoke must be replaced.

RTW46DSH003901

2. Use the circuit tester to check the field winding

continuity.

1) Hold one circuit tester probe against the “M”

terminal lead wire.

2) Hold the other circuit tester probe against the

field winding brush.

There should be continuity.

If there is no continuity, the yoke must be replaced.

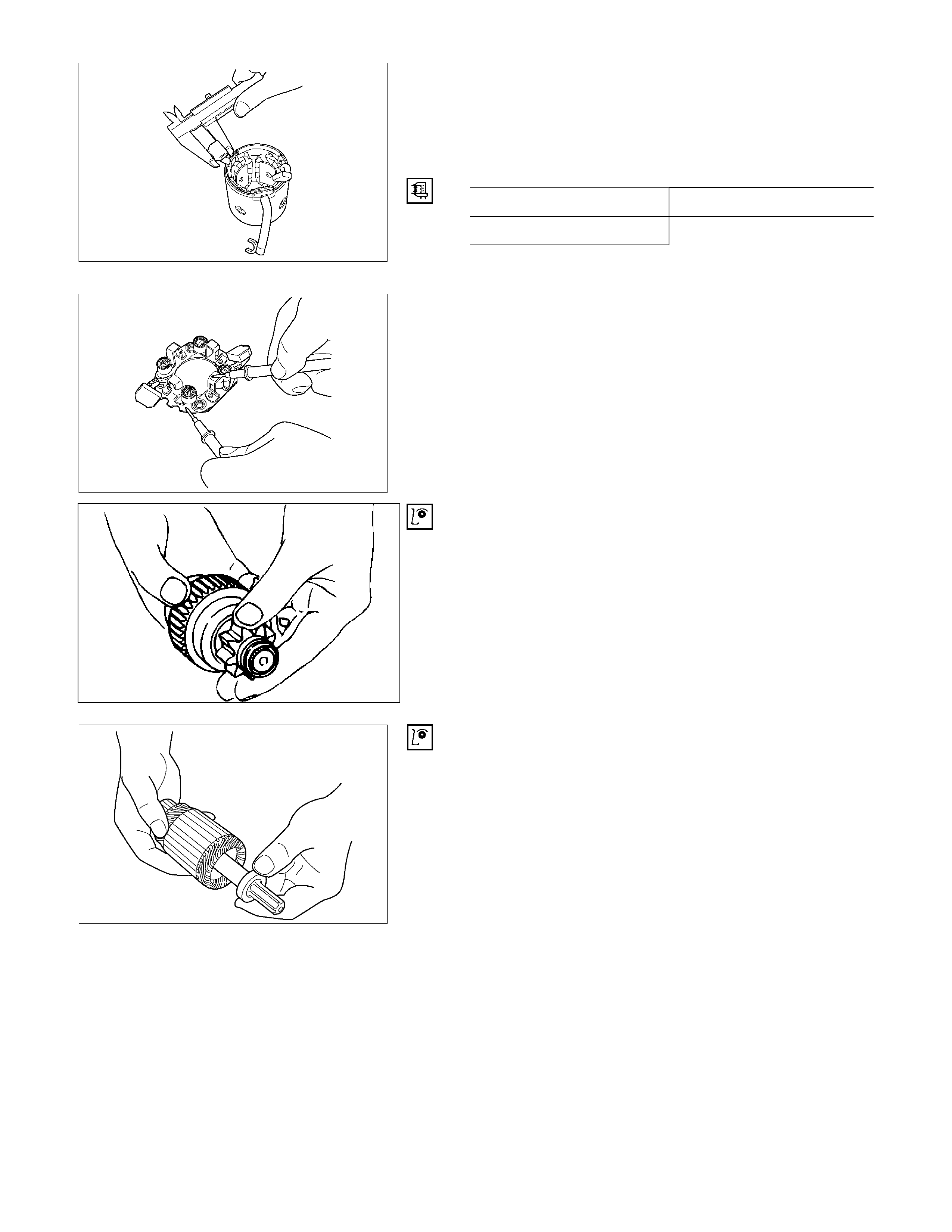

BRUSH AND BRUSH HOLDER

1. Use a vernier calliper to measure the brush length

(four brushes).

Replace the brushes as a set if one or more of the

brush lengths is less than the specified limit.

Brush Length mm (in)

Standard Limit

15 (0.59) 12 (0.47)

RTW46DSH004001

RTW46DSH004101

2. Use a circuit tester to check the brush holder

insulation.

Touch one probe to the holder plate and the other

probe to the positive brush holder.

There should be no continuity.

3. Inspect the brushes for excessive wear.

Replace parts as necessary.

OVERRUNNING CLUTCH

1. Inspect the overrunning clutch gear teeth for

excessive wear and damage.

Replace the overrunning clutch if necessary.

2. Rotate the pinion clockwise.

It should turn smoothly.

3. Try to rotate the pinion in the opposite direction.

The pinion should lock.

065RY00035

RTW46DSH004401

BEARING

Inspect the bearings for excessive wear and damage.

Replace the bearings if necessary.

REASSEMBLY

l

RTW46DLF000601

Reassembly Steps

1. Magnetic switch assembly 14. Pinion stopper

2. Magnetic switch 15. Pinion stopper clip

3. Dust cover 16. Bearing retainer

4. Plunger 17. Bolt

5. Torsion spring 18. Motor assembly

6. Shift lever

19. Armature

7. Gear case 20. Yoke

8. Dust cover 21. Brush holder

9. Bolt 22. Rear cover

10. Pinion assembly 23. Screw

11. Clutch 24. Through bolt

12. Pinion shaft 25. Lead wire

13. Return spring

RTW46DSH005601

Important Operations

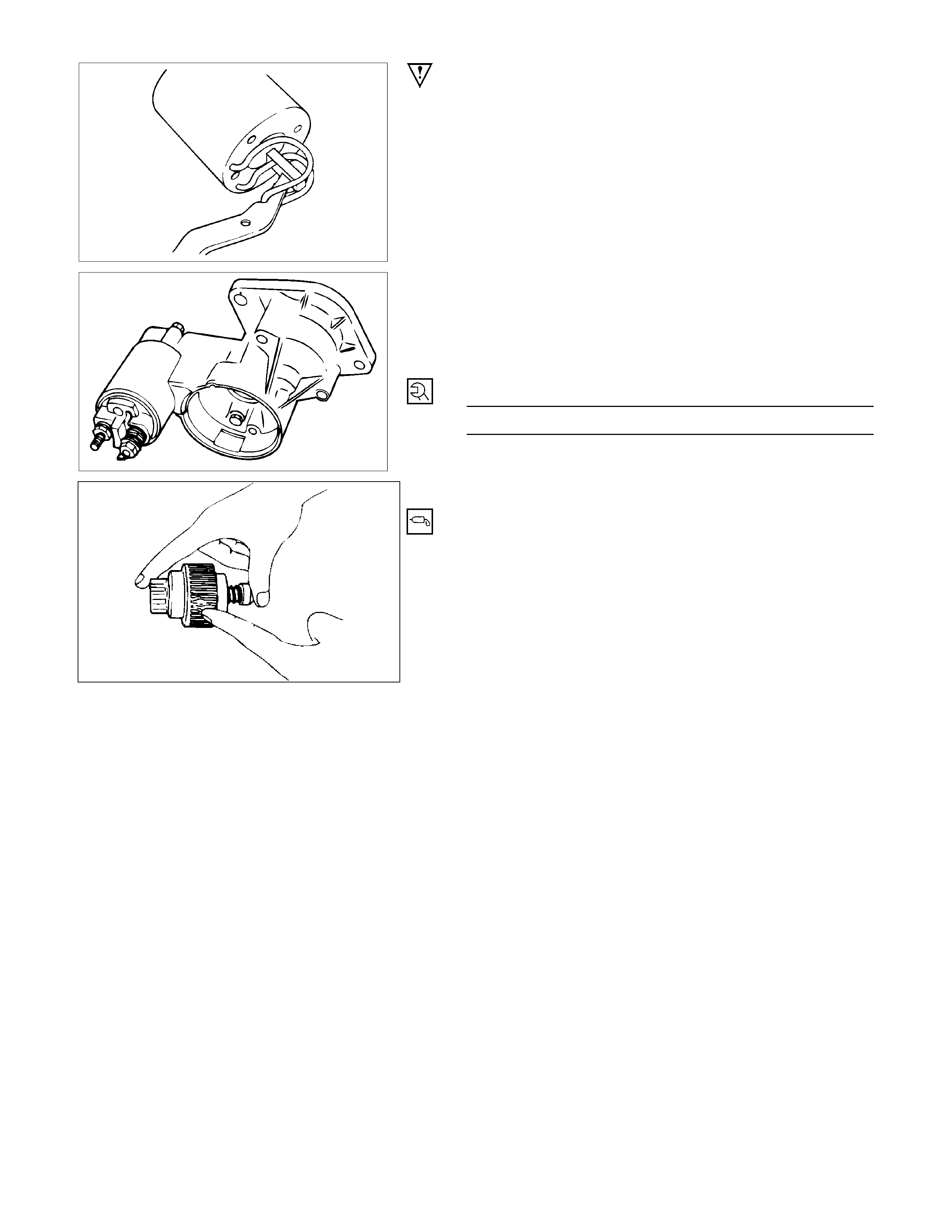

1. Magnetic Switch Assembly

1) Attach the torsion spring to the holes in the magnetic

switch as illustrated.

2) Insert the shift lever into the plunger hole of the

magnetic switch.

RTW46DSH005701

7. Gear Case

3,8. Dust Cover

1) Install the magnetic switch assembly in the gear case.

2) Install the dust cover.

Dust Cover Bolt Torque N⋅m (kg⋅m/lb⋅ft)

8 (0.8/5.4)

10. Pinion Assembly

Apply a coat of grease to the reduction gear and install

the pinion assembly to the armature shaft.

065RY00041

RTW46DSH004501

21. Brush Holders

1) Install the brushes into the brush holder while raising

the spring end of the brush spring.

Take care not to damage the commutator face.

2) Install the brush holder while aligning the edges of the

yoke and the brush holder.

24. Through Bolt

Install the through bolts in the rear cover and tighten them

to the specified torque.

Through Bolt Torque N⋅m (kg⋅m/lb⋅ft)

8.1 (0.83/6.00)

065RY00044

RTW46DSH002601

25. Lead Wire

Connect the lead wire in the magnetic switch and tighten

the terminal nut to the specified torque.

Lead Wire Terminal Nut Torque N⋅m (kg⋅m/lb⋅ft)

8.6 (0.88/6.40)

RTW46DSH005801

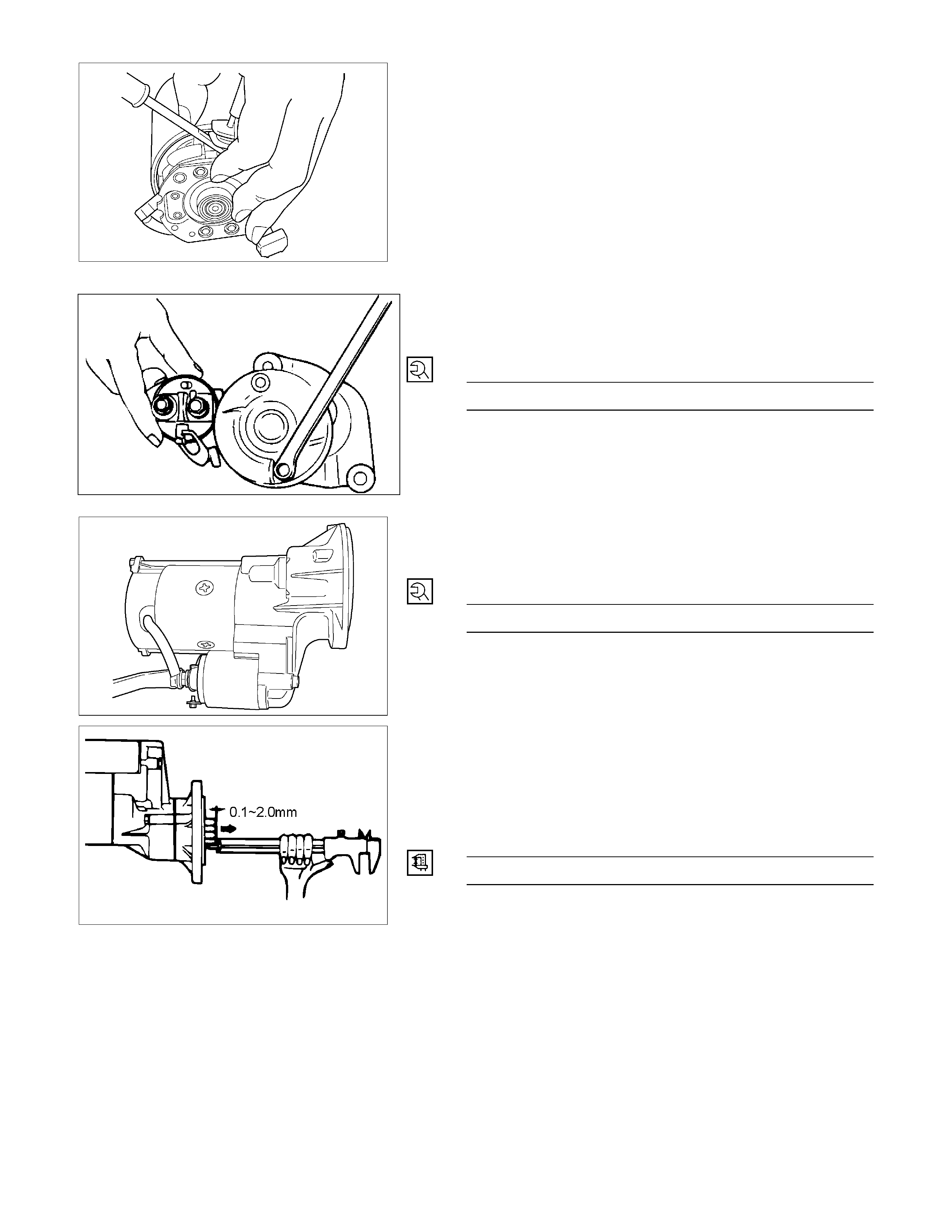

Inspection After Assembly

Use a vernier calliper to measure the pinion shaft thrust

play.

The pinion shaft thrust play is equal to the pinion shaft

end and pinion stopper clearance.

Pinion Shaft Thrust Play mm (in)

0.1 – 2.0 (0.004 – 0.078)

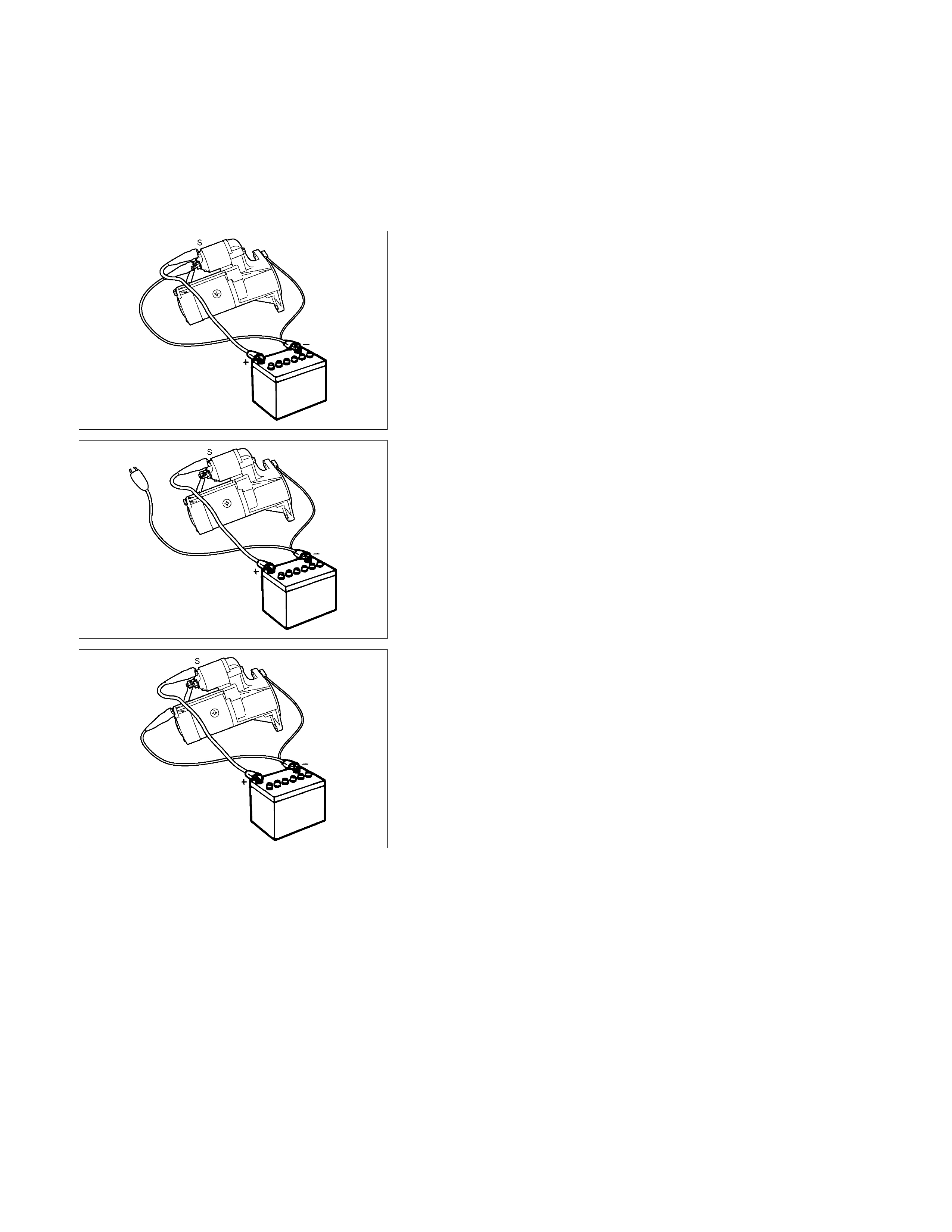

MAGNETIC SWITCH

The following tests must be performed with the starter

motor fully assembled.

The yoke lead wire must be disconnected from the “M”

terminal.

To prevent coil burning, complete each test as quickly as

possible (within three to five seconds).

RTW46DSH004601

Temporarily connect the solenoid switch between the

clutch and the housing and run the following test.

Complete each test within three to five seconds.

1. Pull-in Test

Connect the battery negative terminal with the solenoid

switch body and the M terminal. When current is applied

to the S terminal from the battery positive terminal, the

pinion should flutter.

RTW46DSH005901

2. Hold-in Maintenance Test

Disconnect the lead at the M terminal. The pinion should

continue to flutter.

RTW46DSH004701

3. Return Test

Disconnect the battery positive lead at the S terminal.

The pinion should return to its home position.

PRE-HEATING SYSTEM

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacement if excessive wear of damage is discovered during

inspection.

VISUAL CHECK

Check the main fuses and glow indicator for damage.

Replace the part(s) if required.

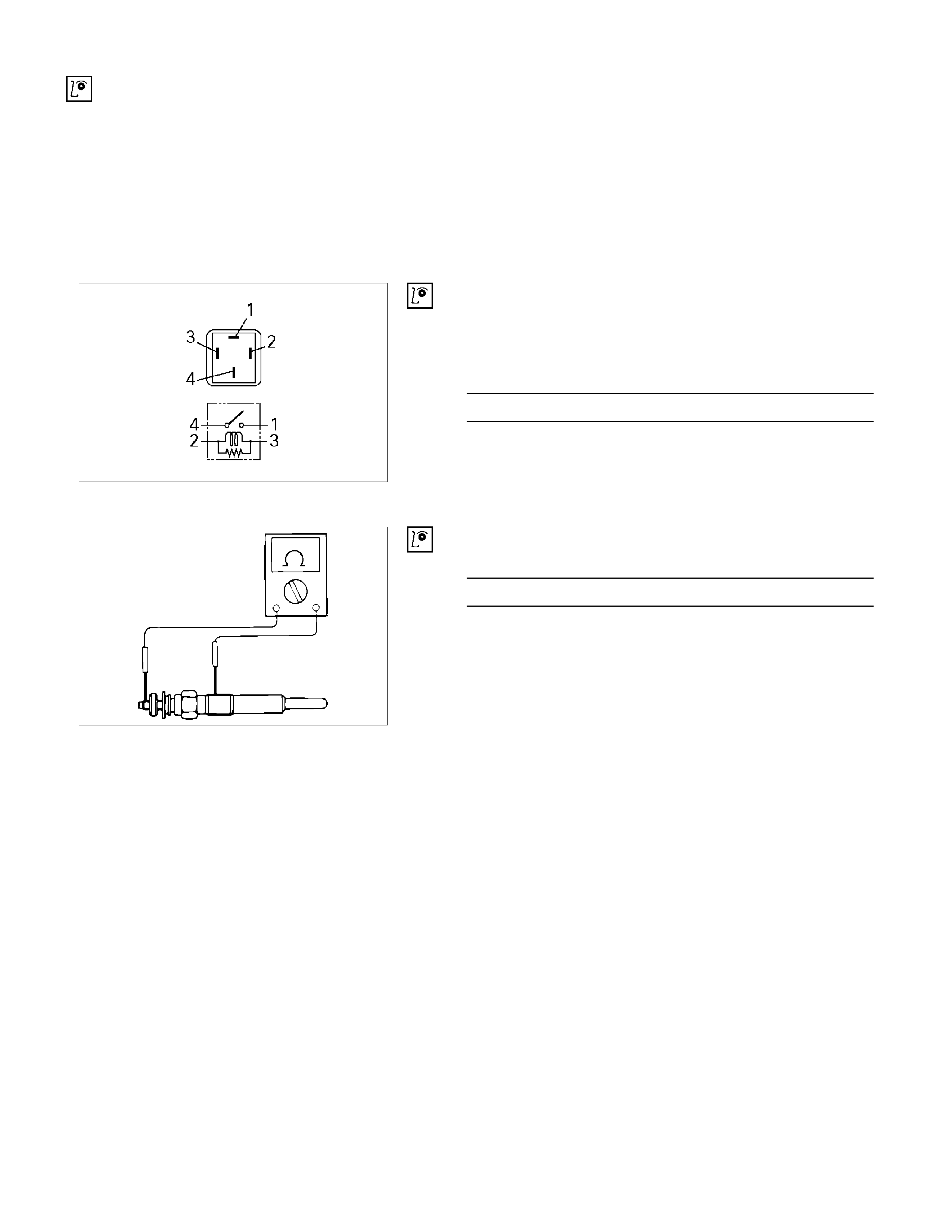

GLOW RELAY

The glow relay is located in the relay box in the engine

compartment.

825R300046

Use an ohmmeter to measure the resistance between

terminals No.2 and No.3.

If the measured value is outside the specified range, the

glow relay must be replaced.

Glow Relay Resistance Ohms

94 − 114

GLOW PLUG

LNW21KSH001401

Use a circuit tester to test the glow plugs for continuity.

Glow Plug Resistance (Reference) Ohms

Approximately 0.9