SECTION 6E2 - ENGINE DRIVEABILITY AND EMISSIONS

ABBREVIATION CHARTS

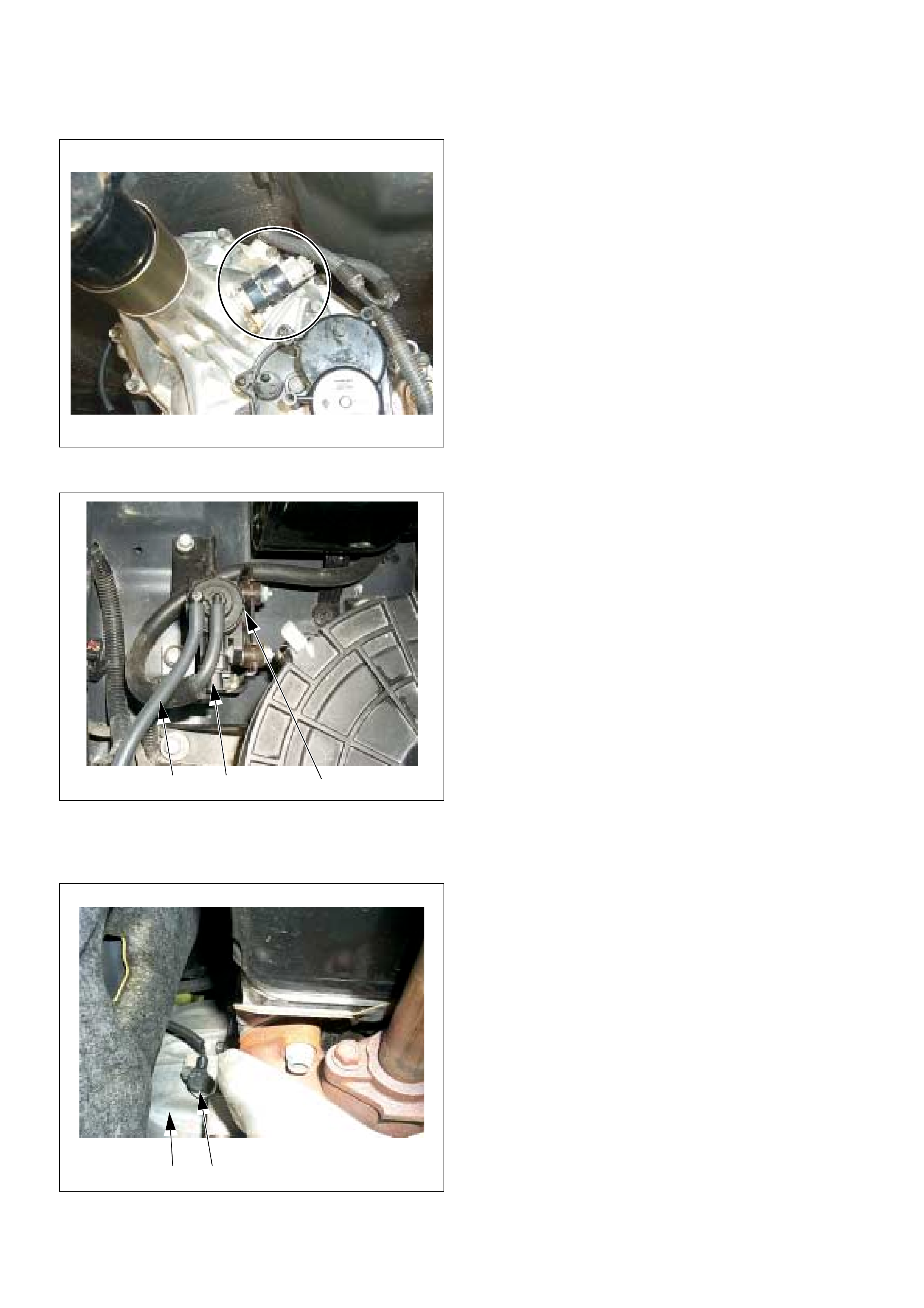

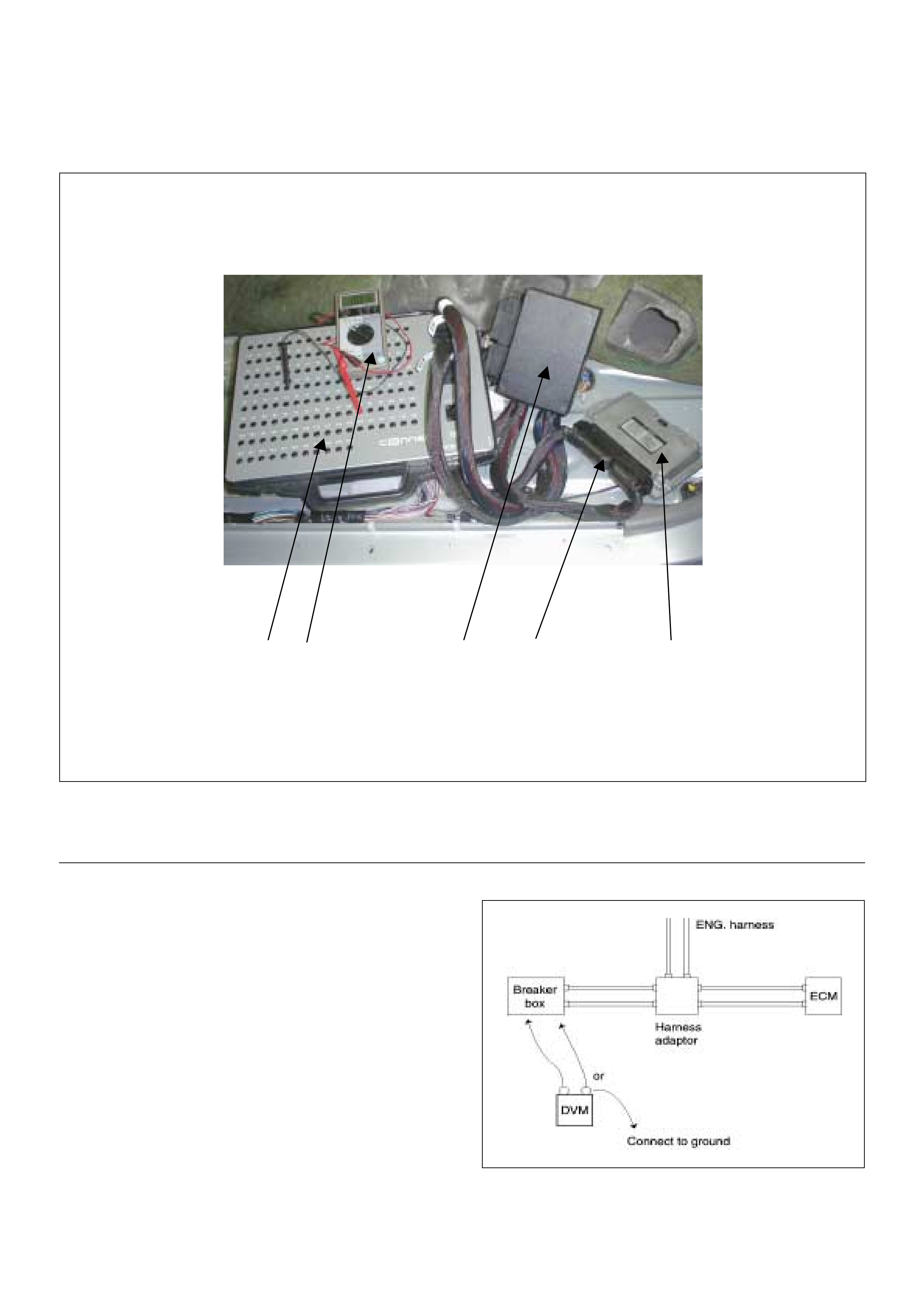

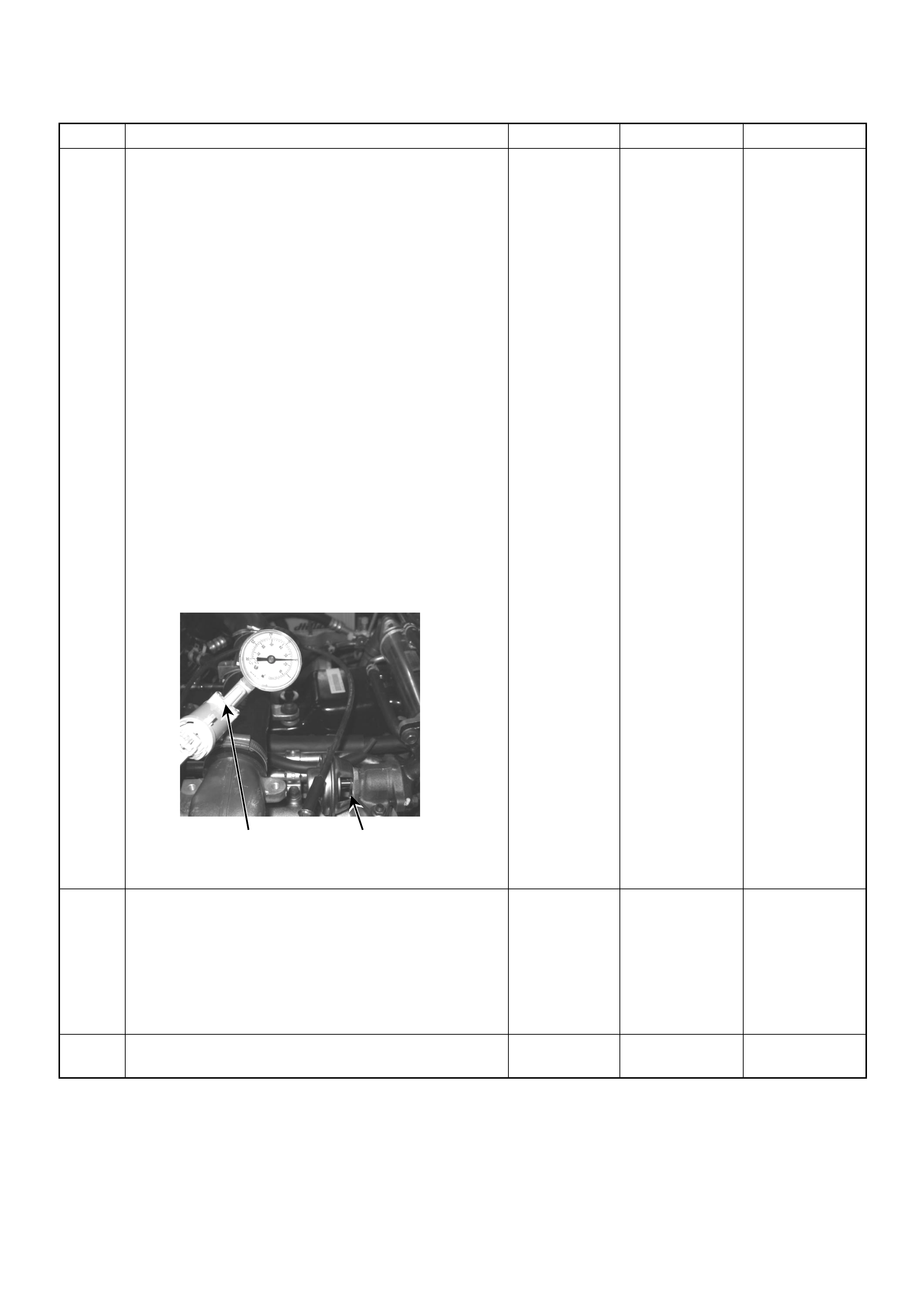

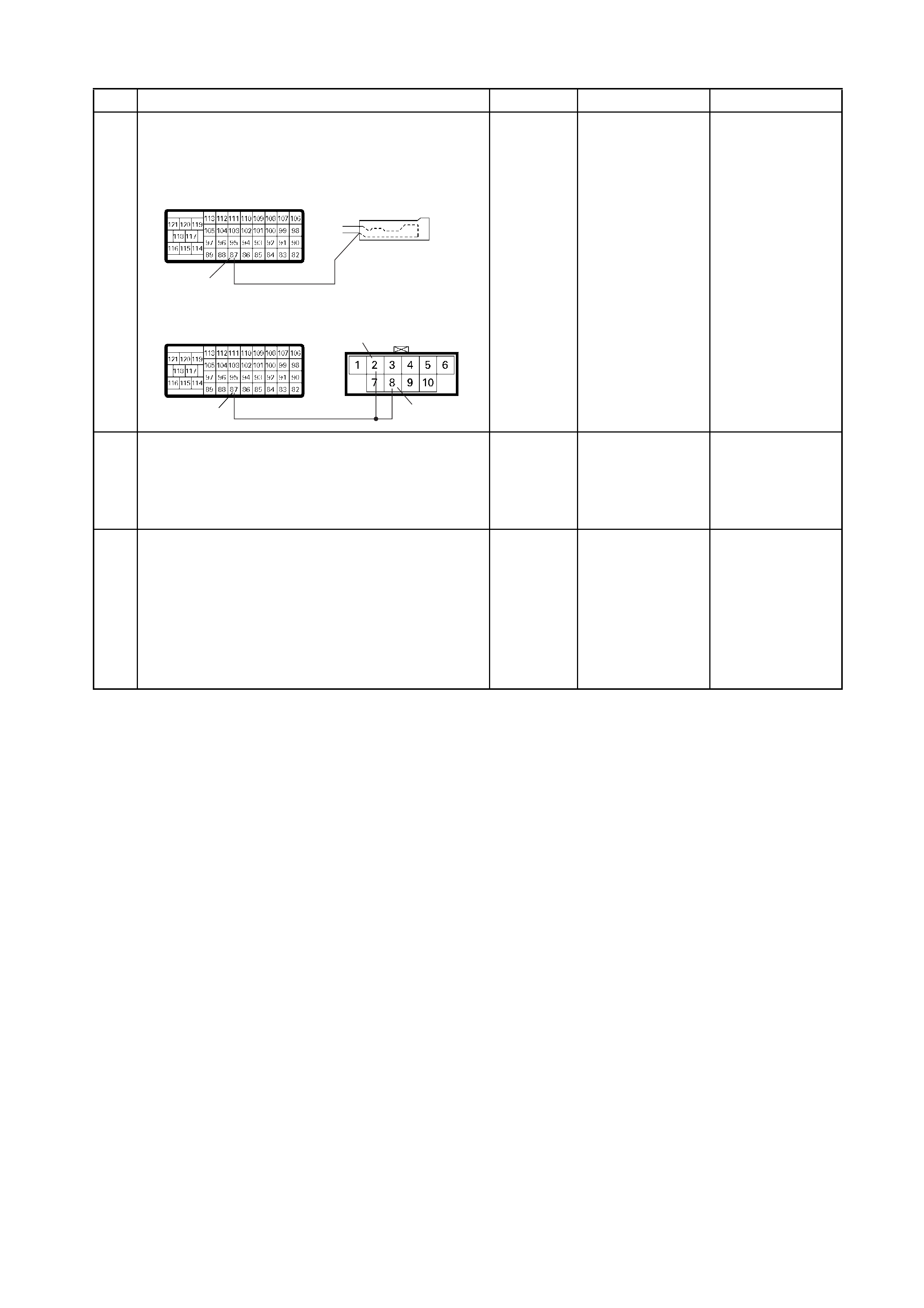

COMPONENT LOCATOR

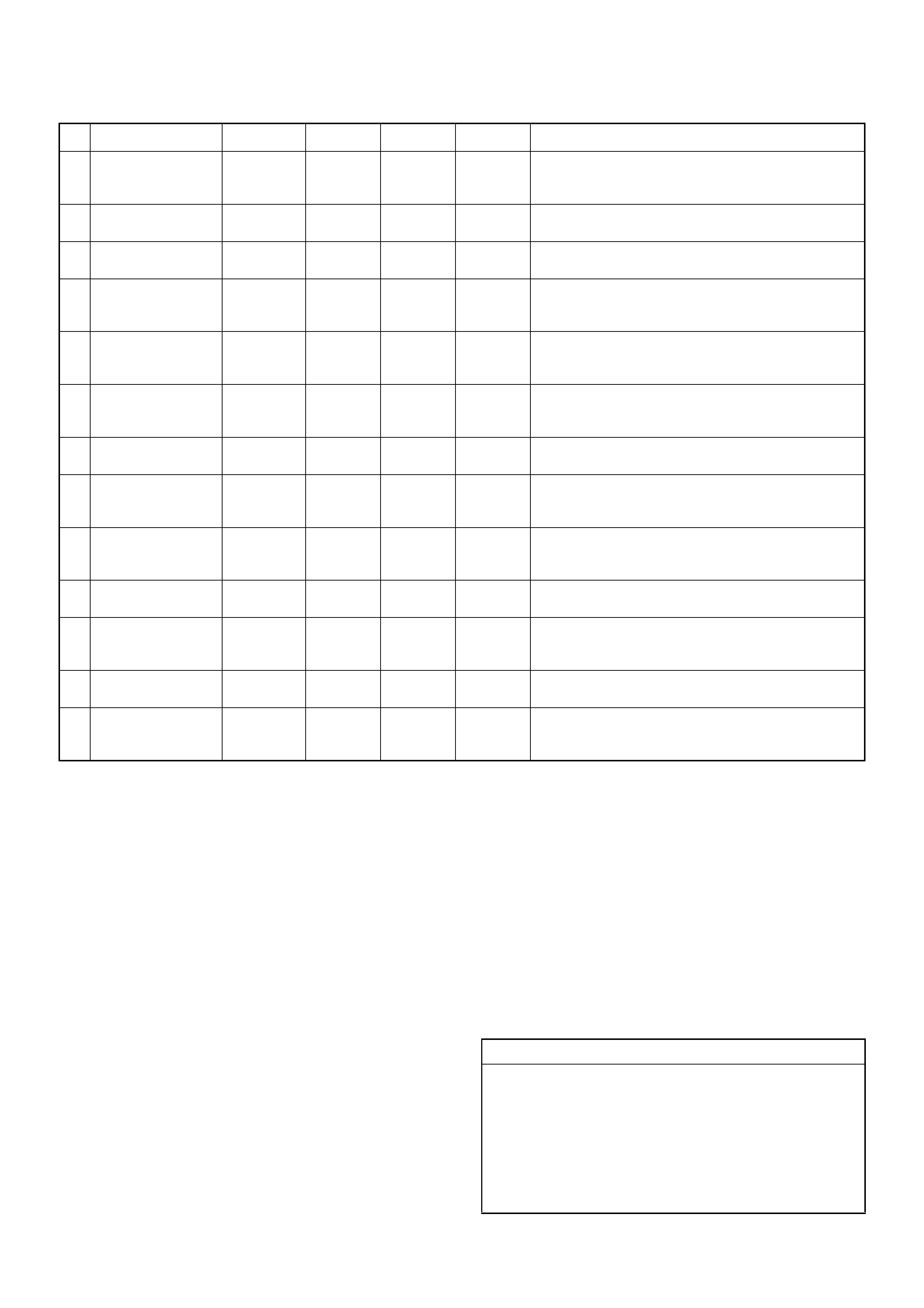

Engine Component Locator Table

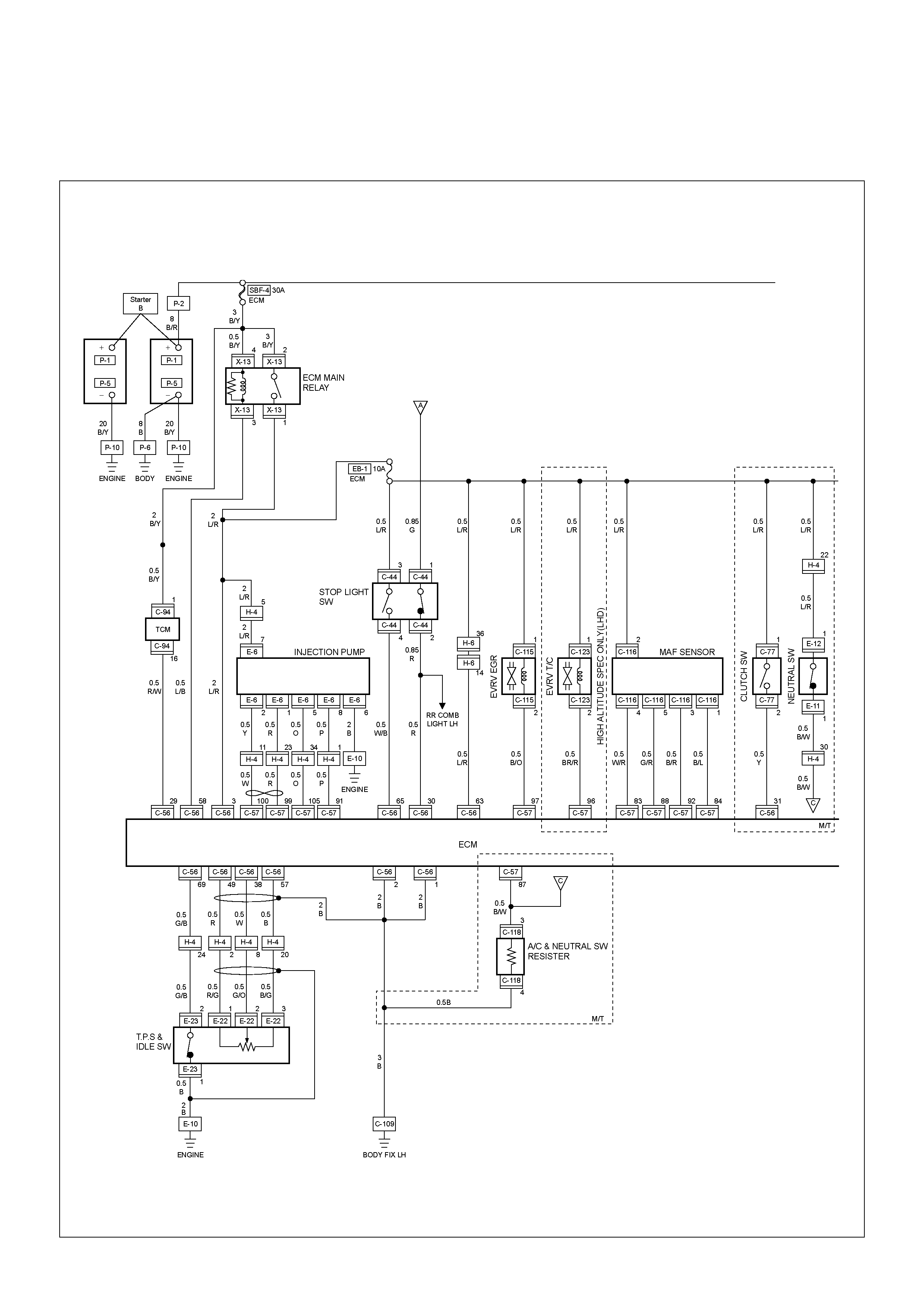

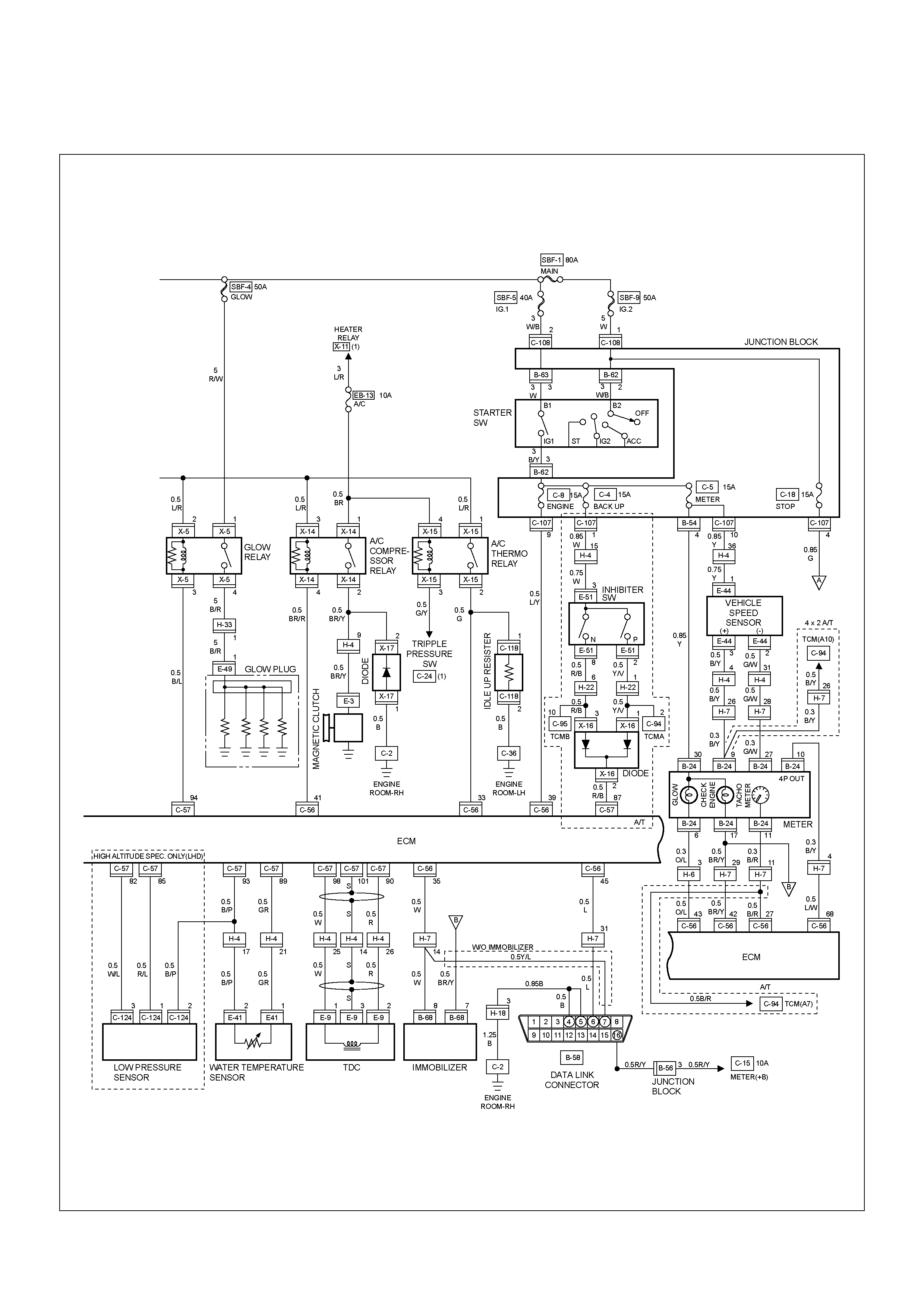

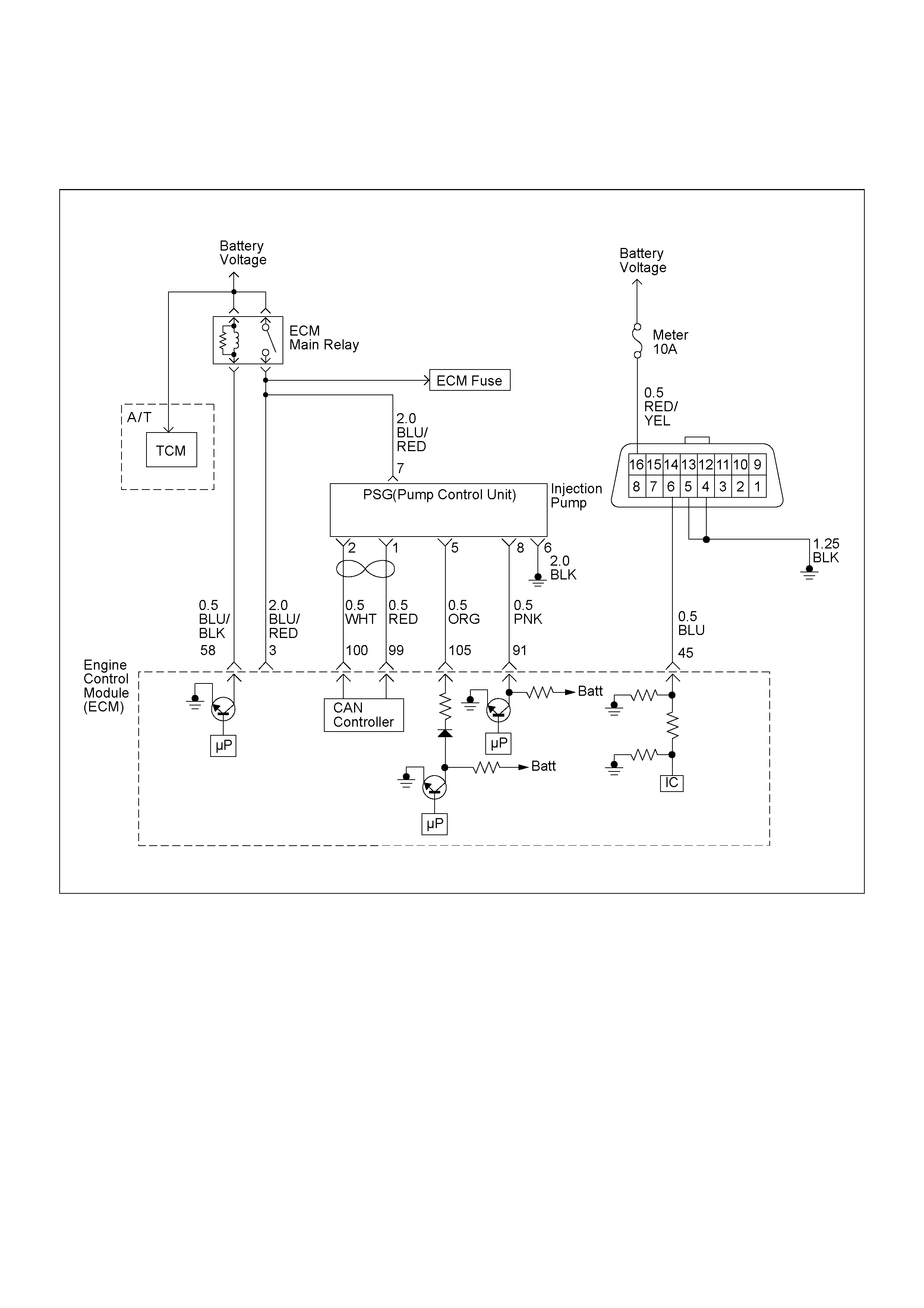

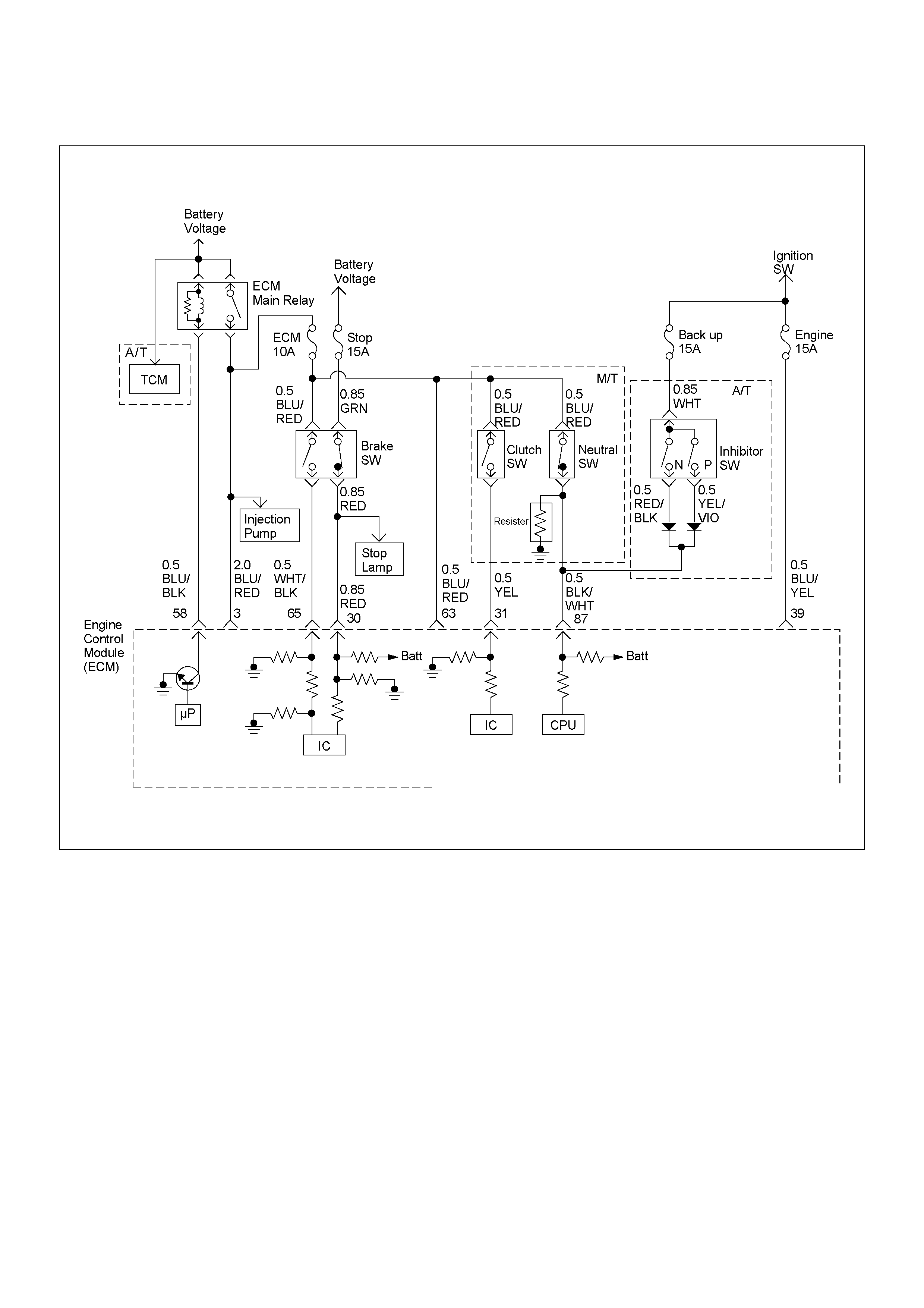

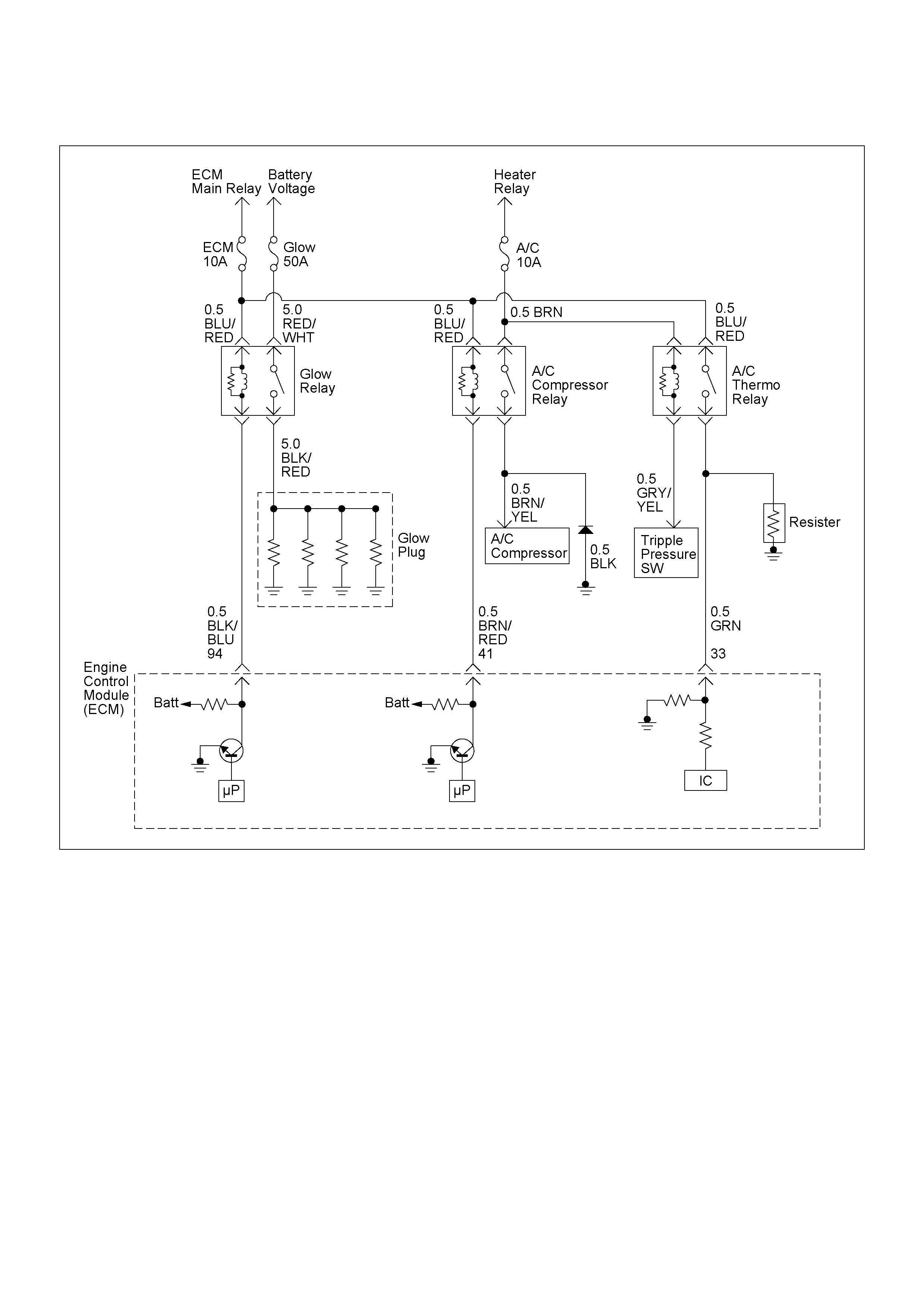

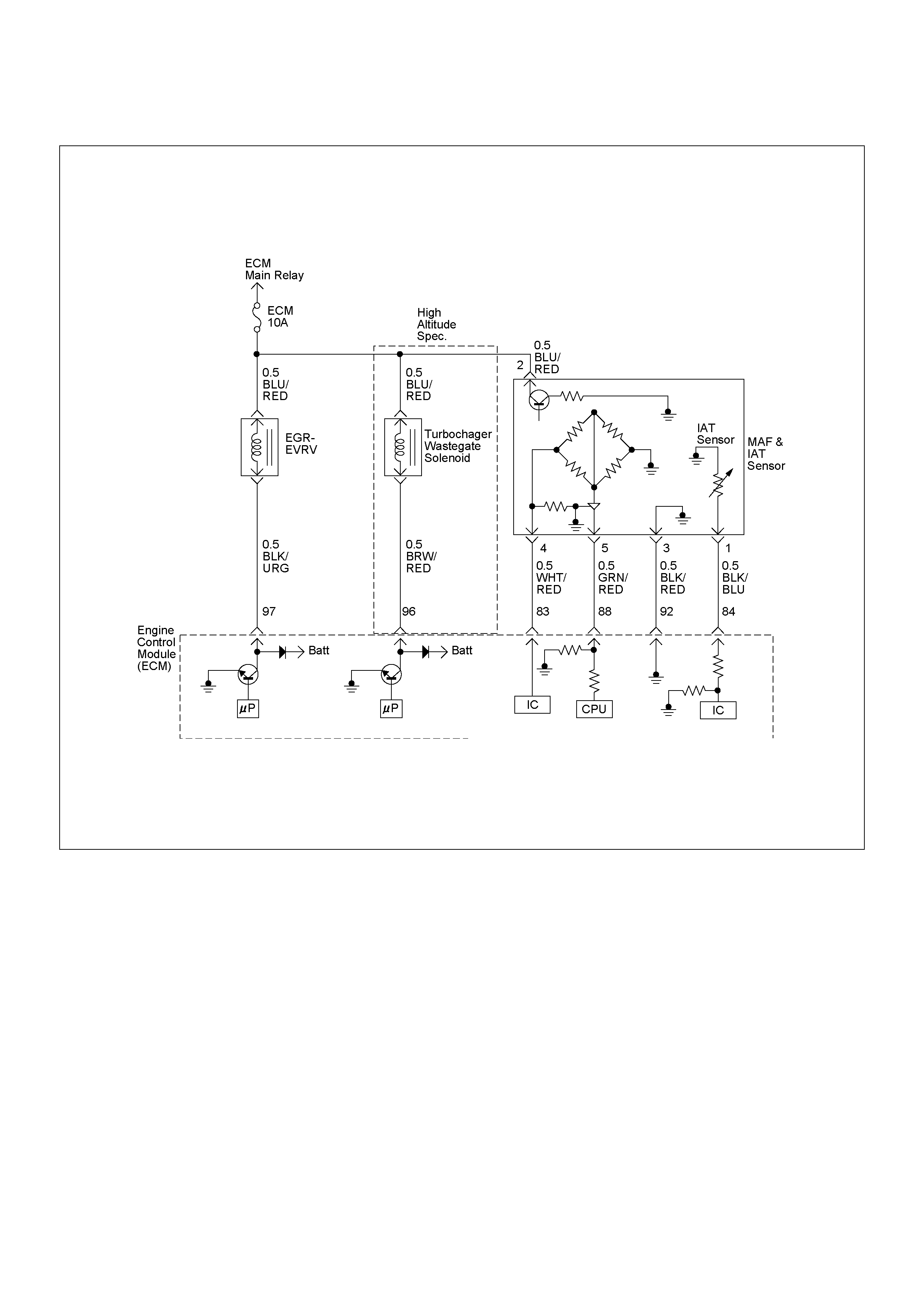

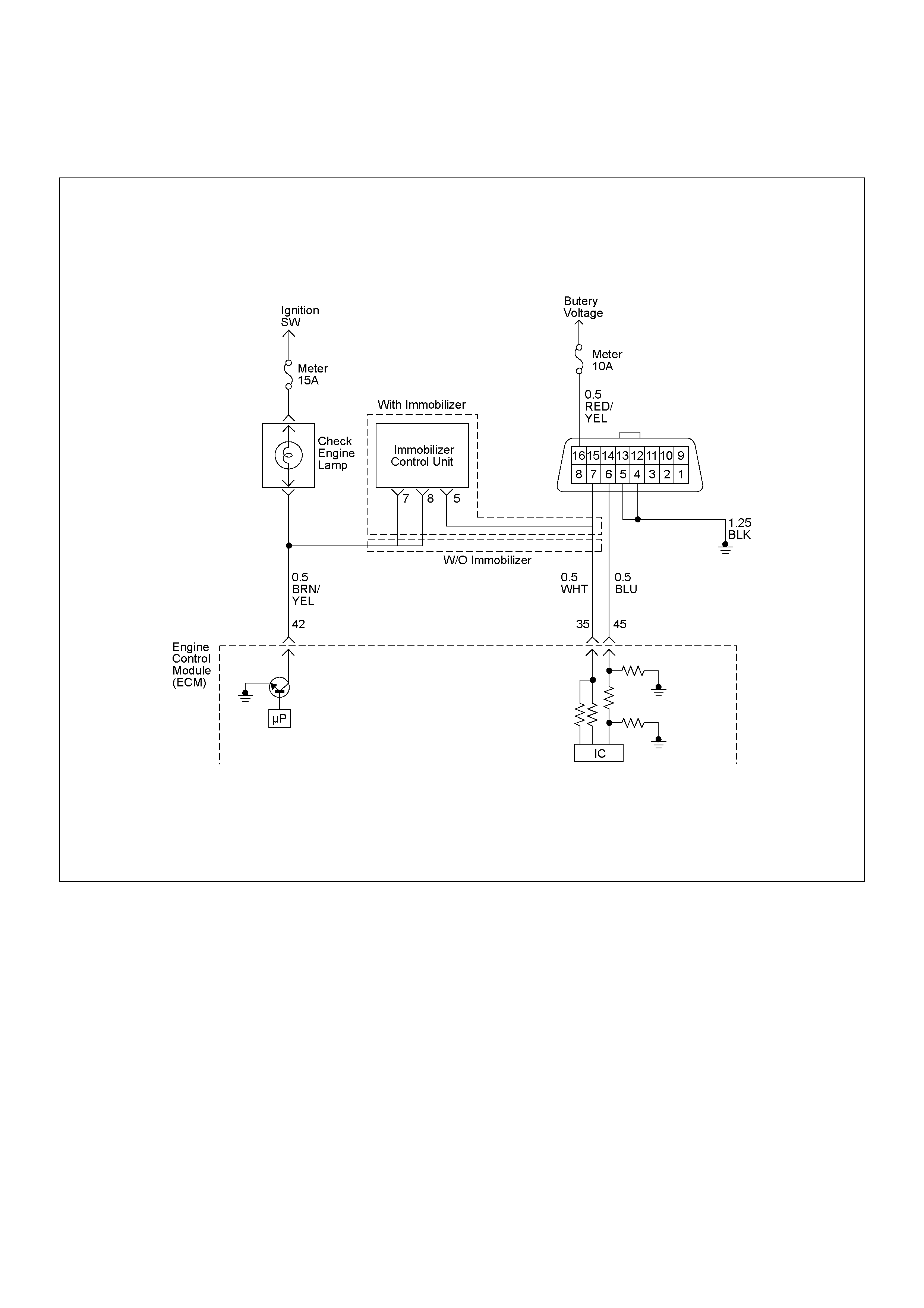

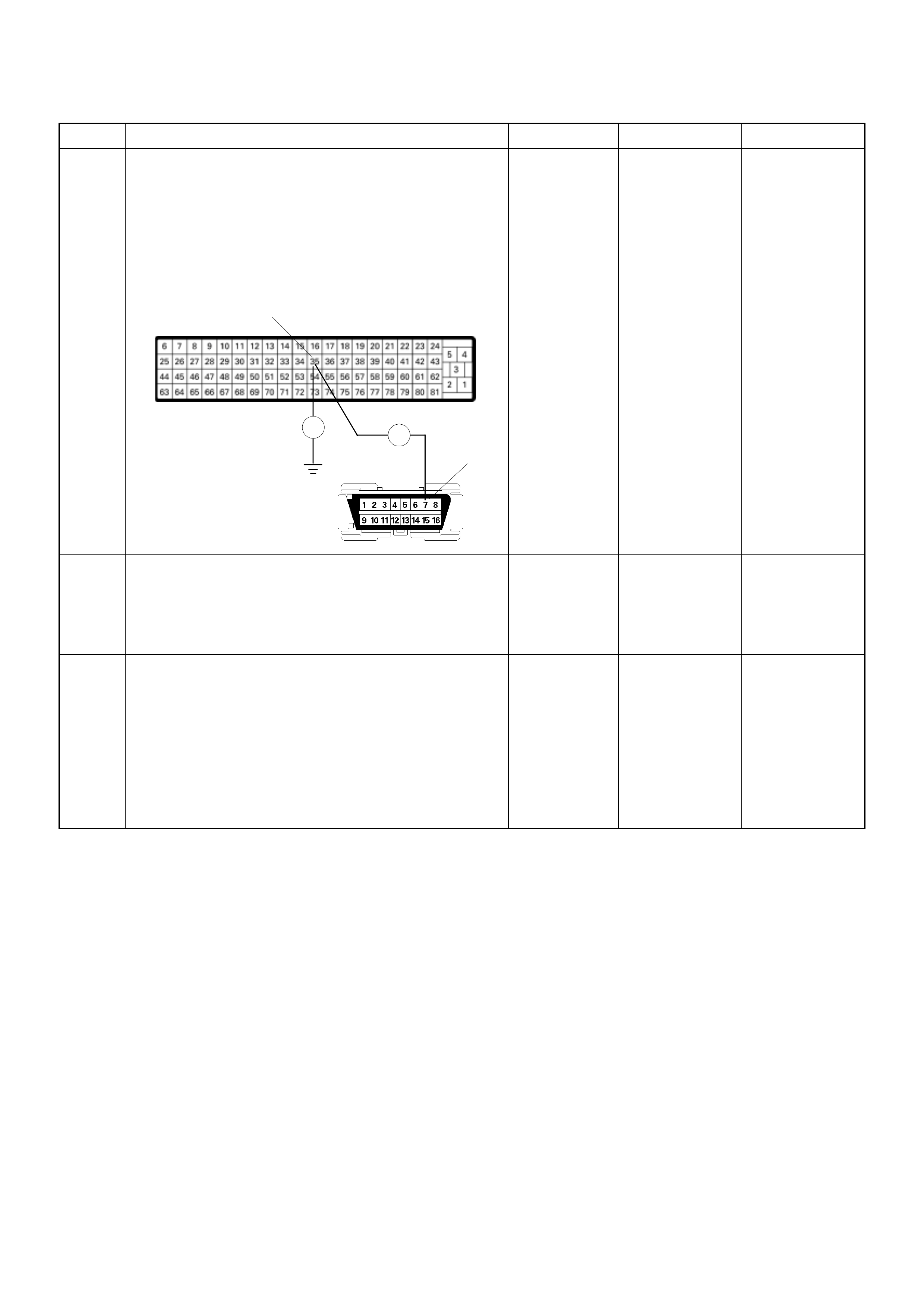

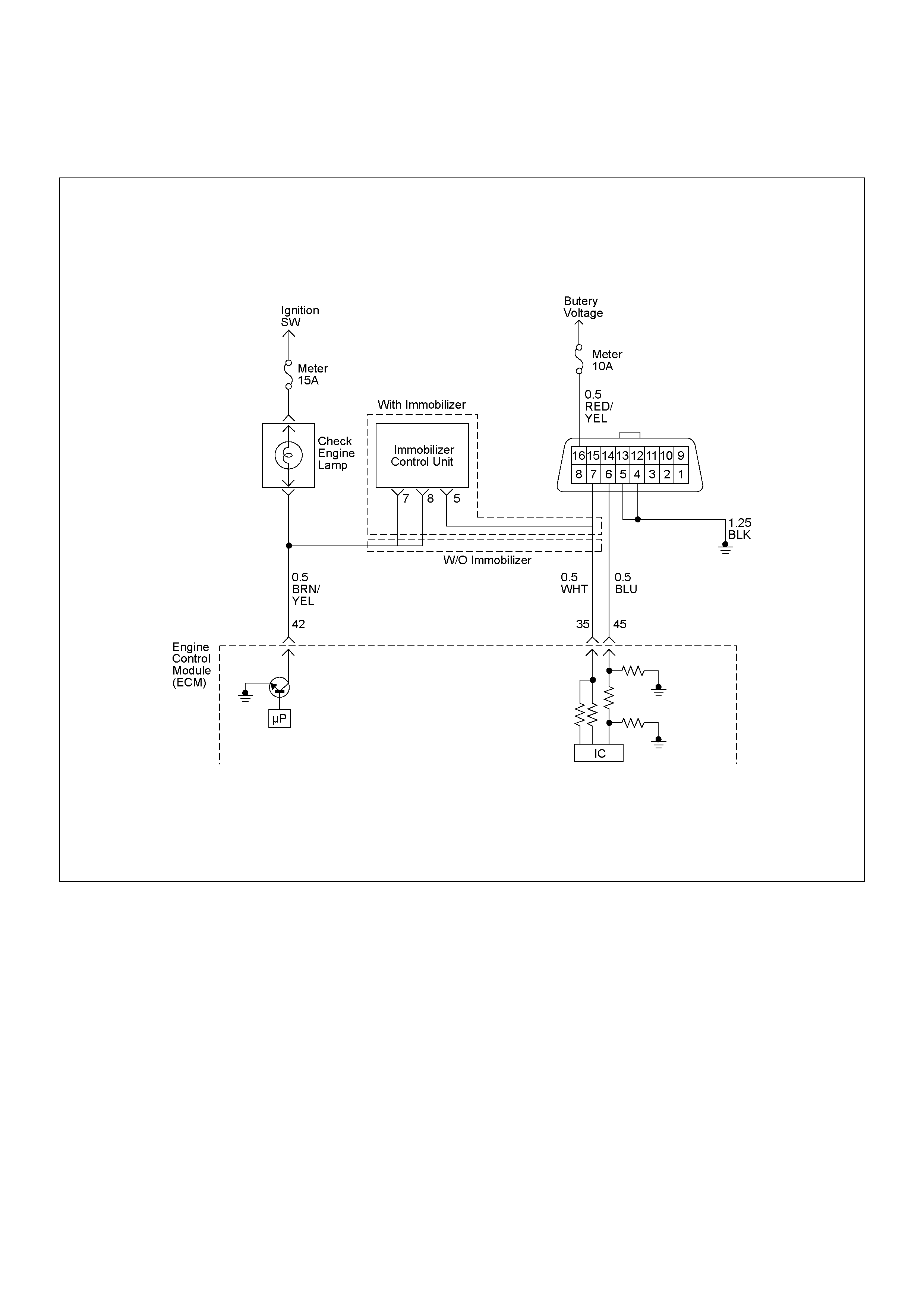

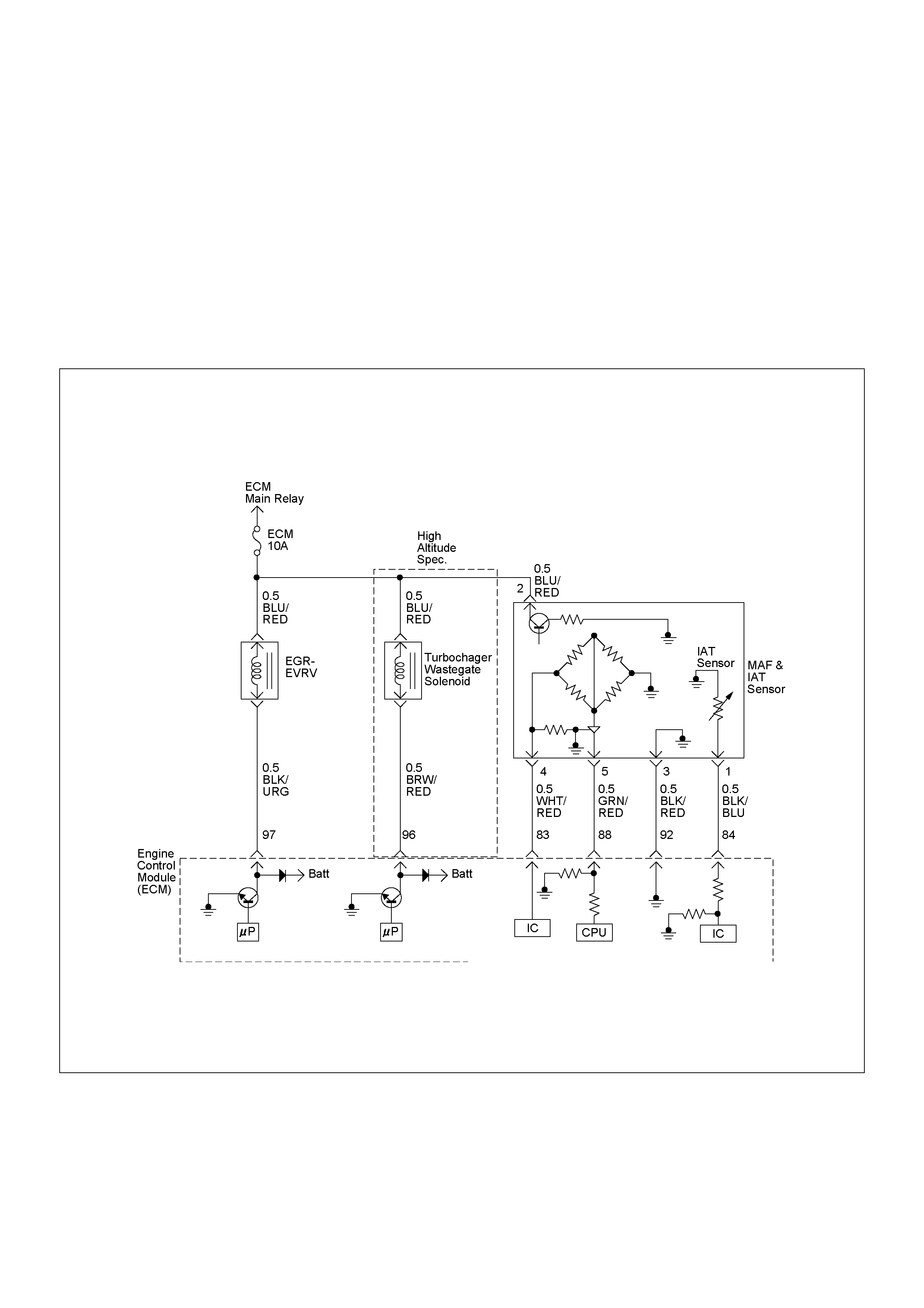

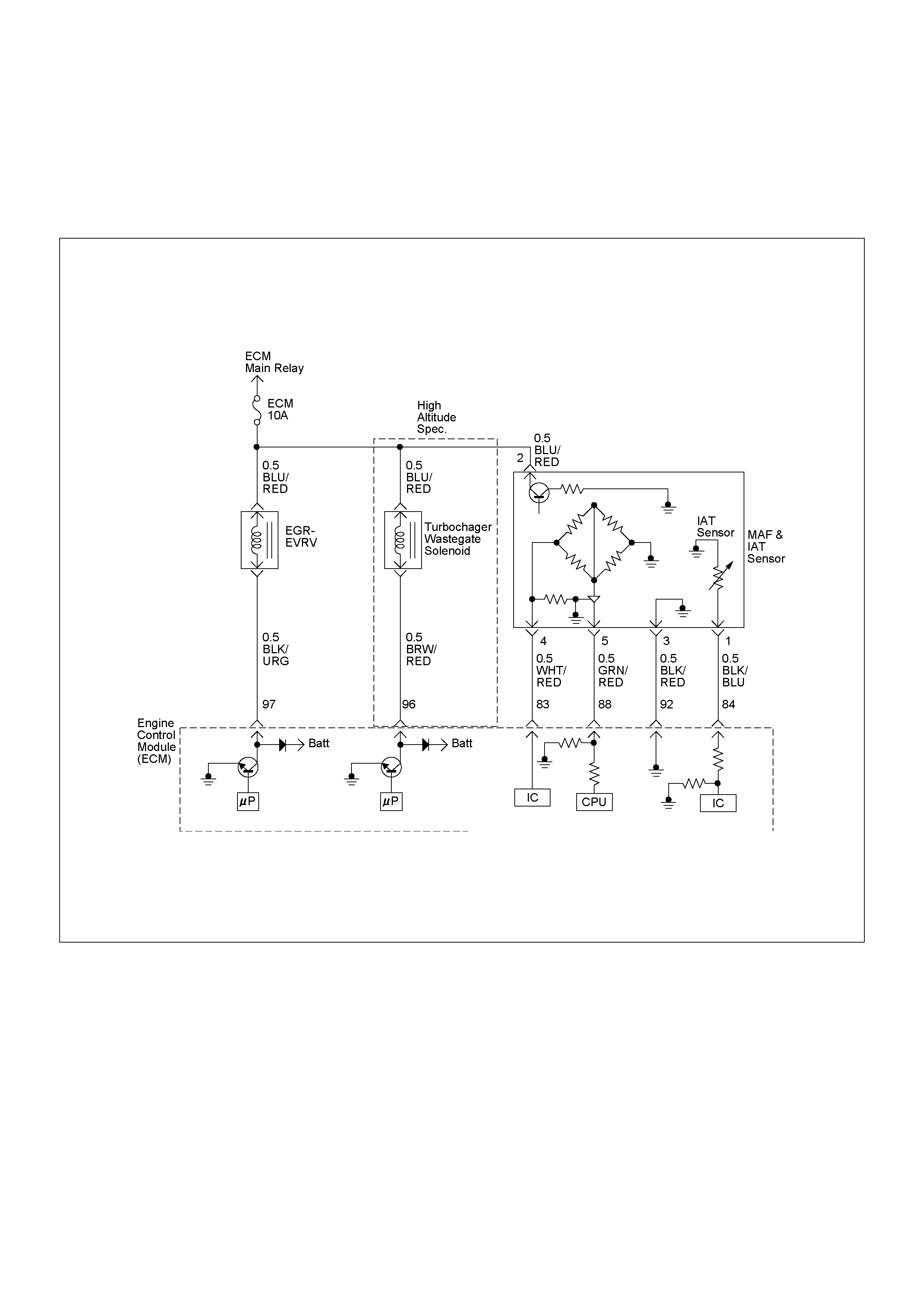

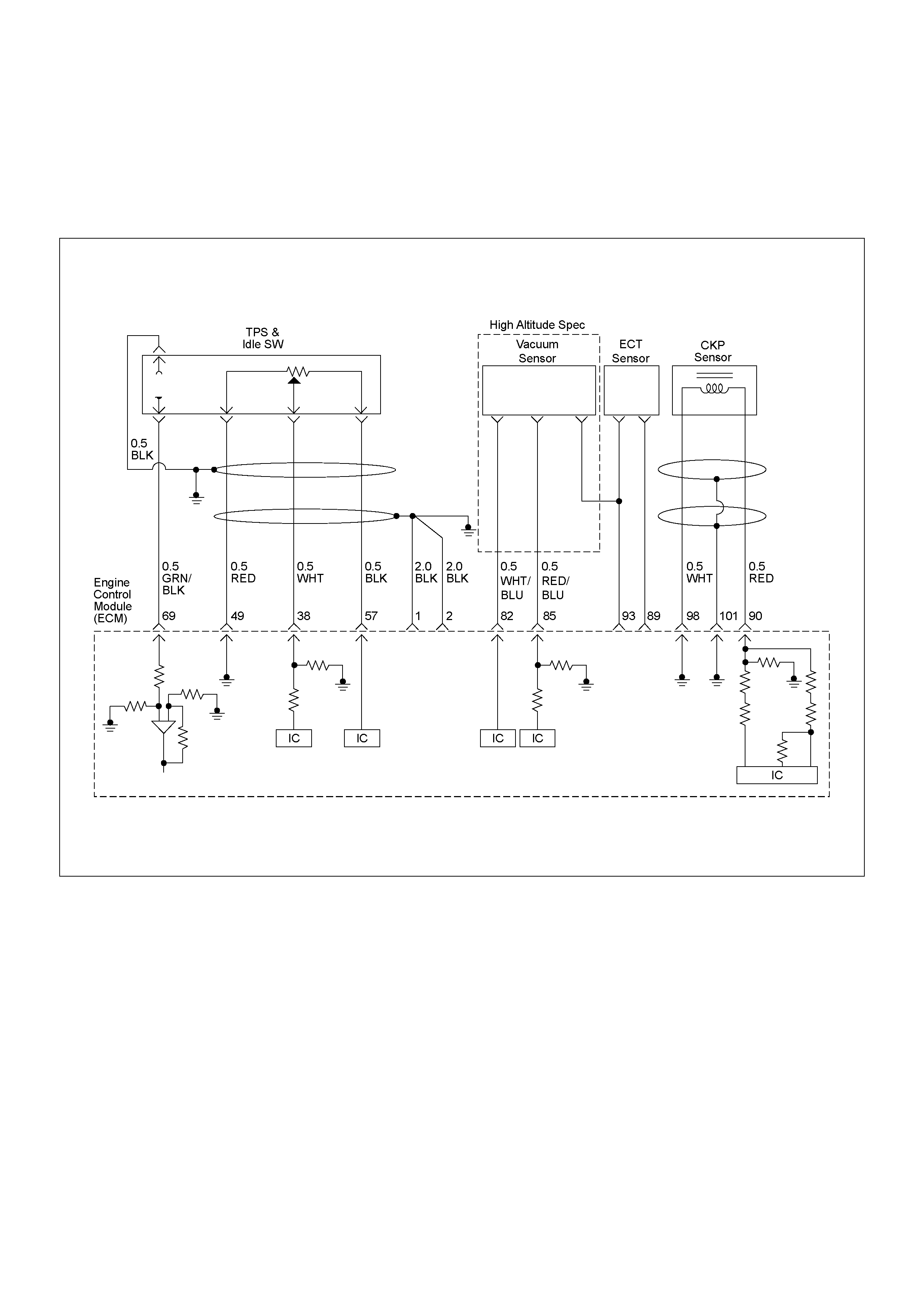

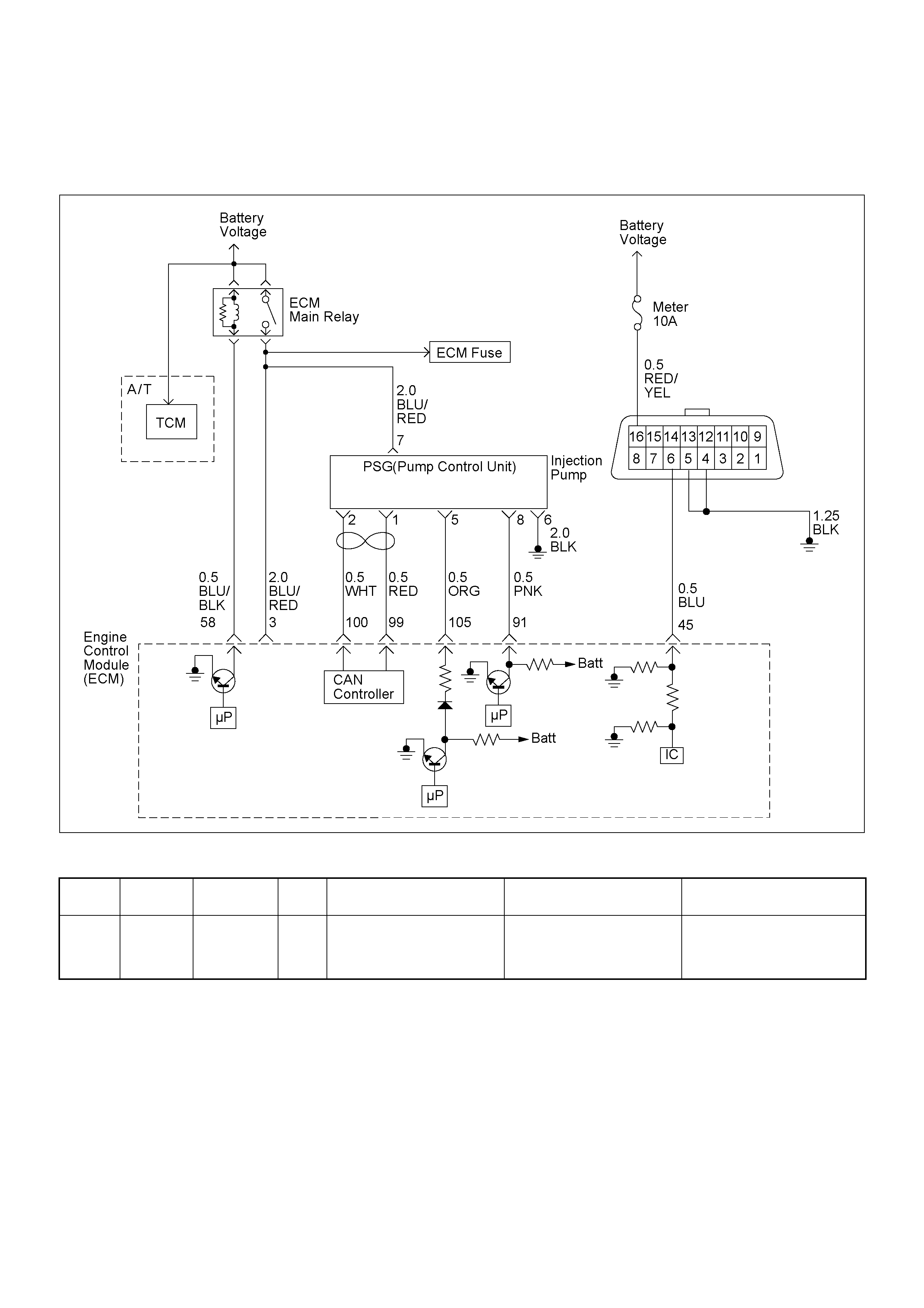

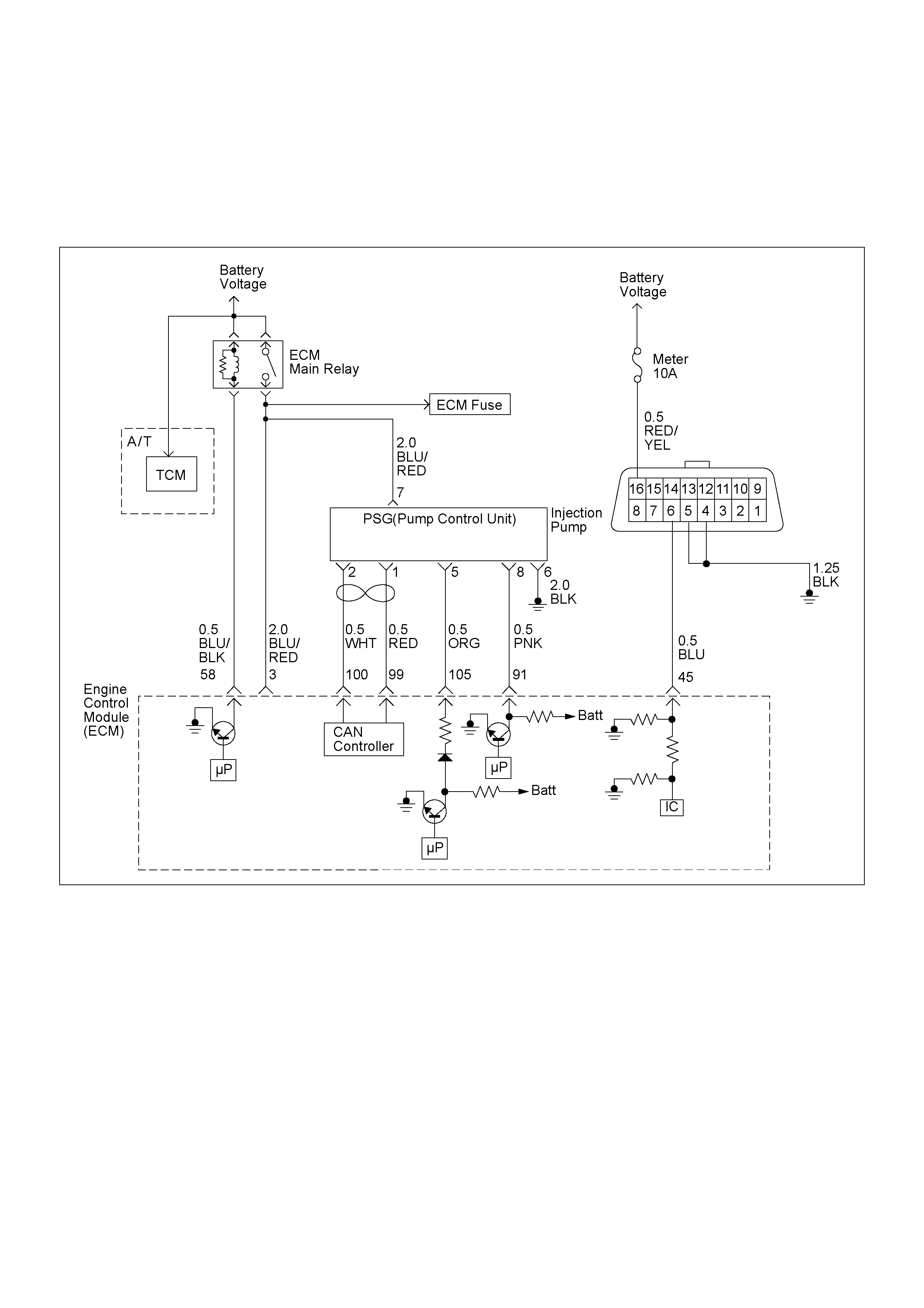

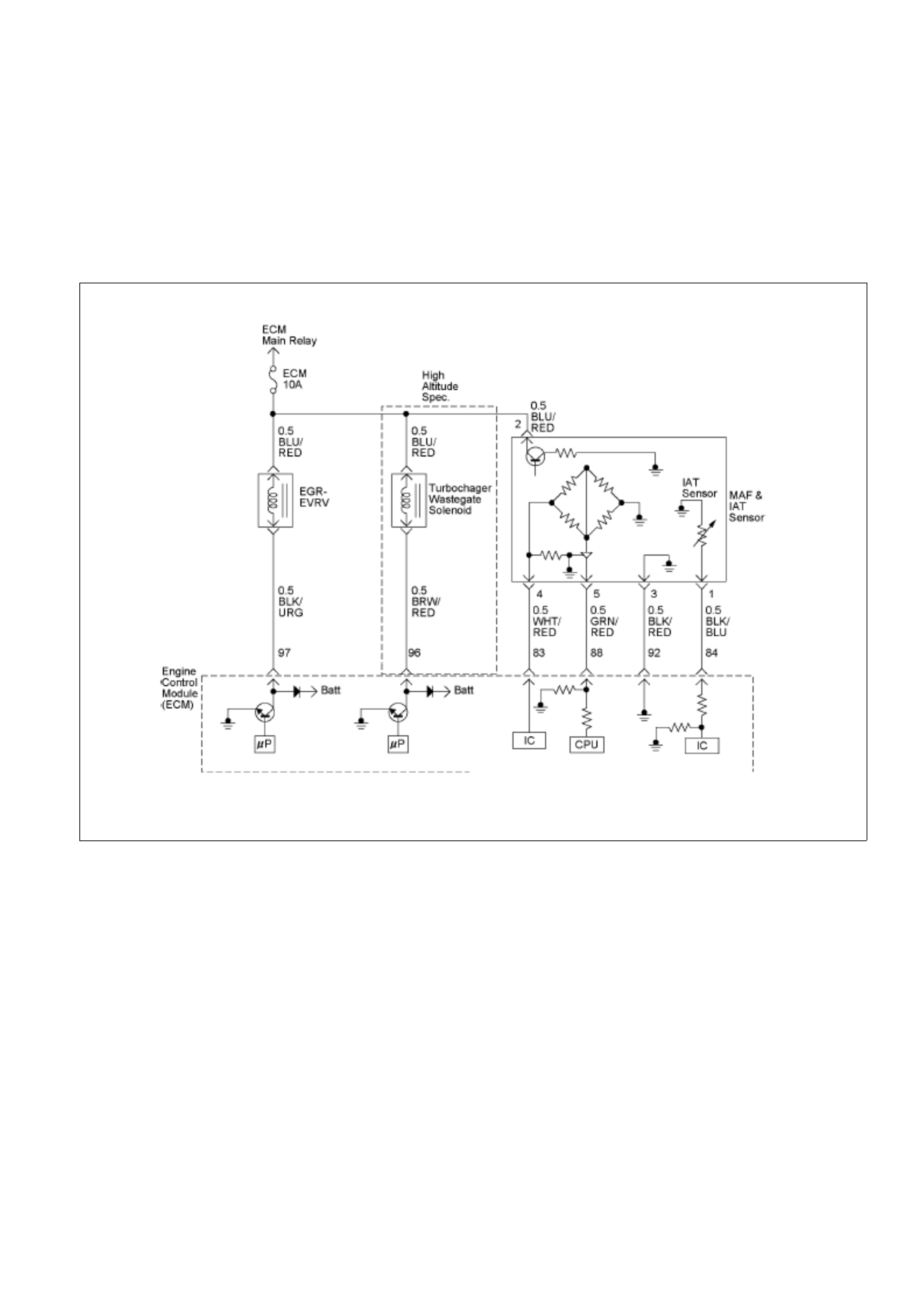

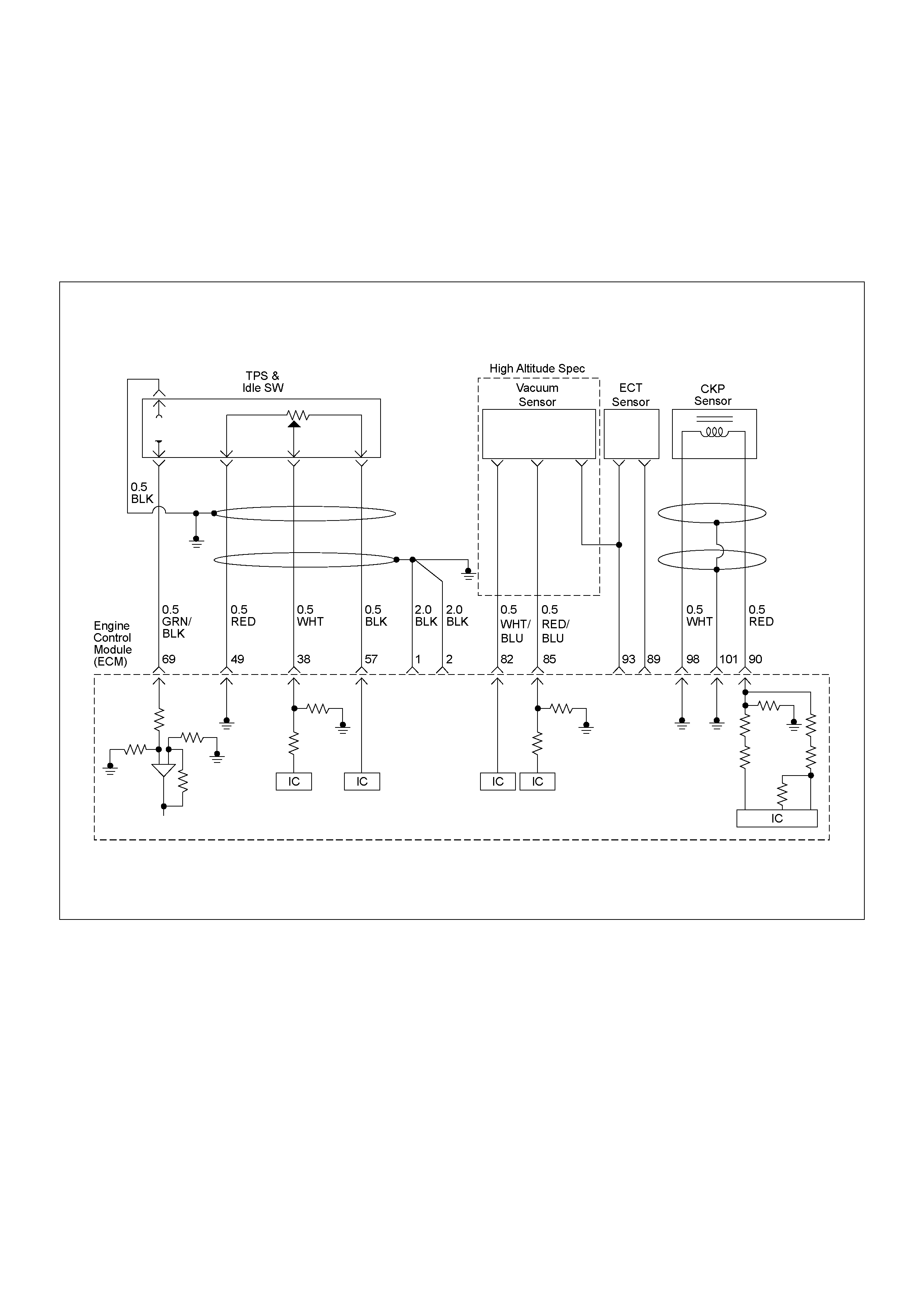

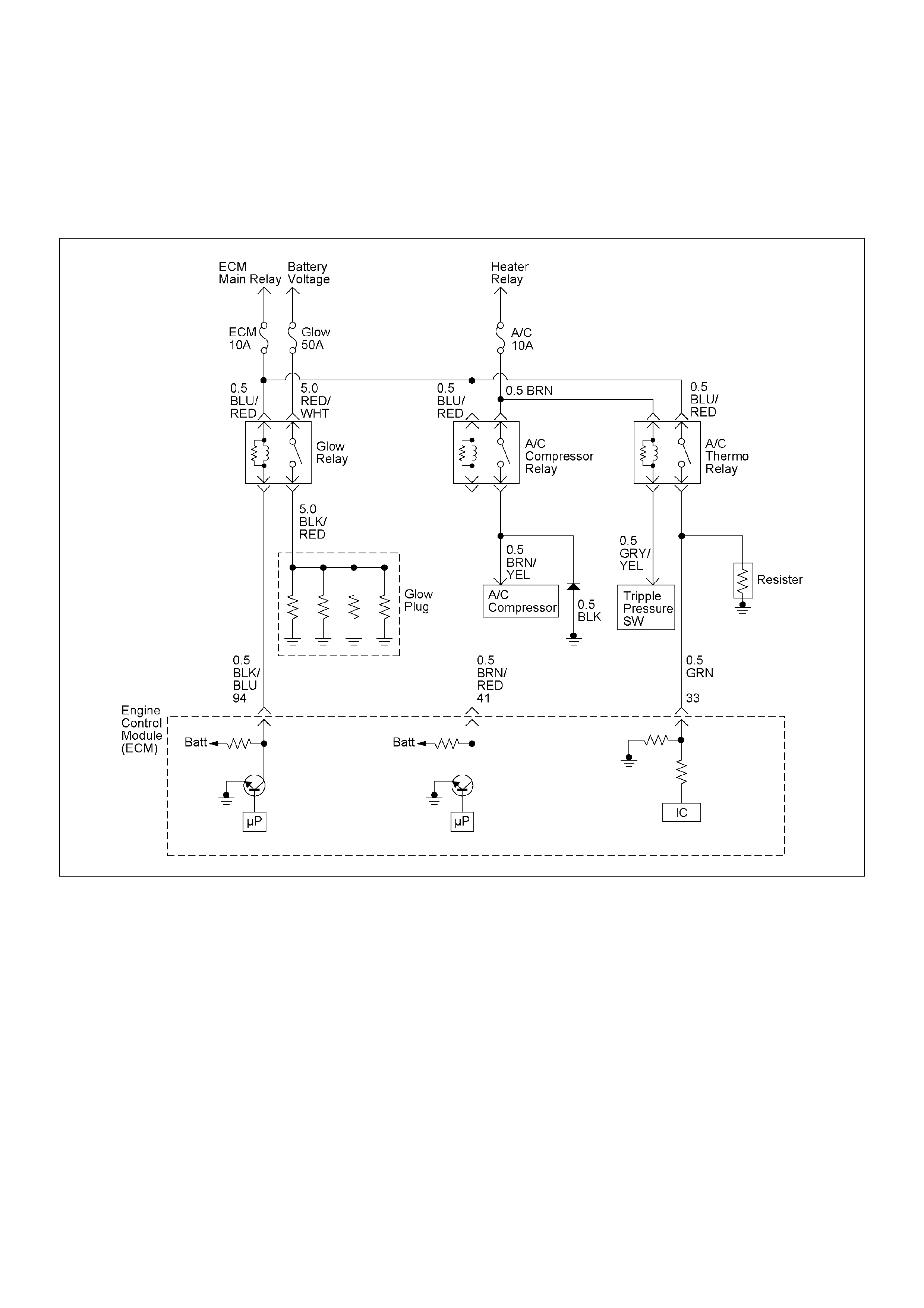

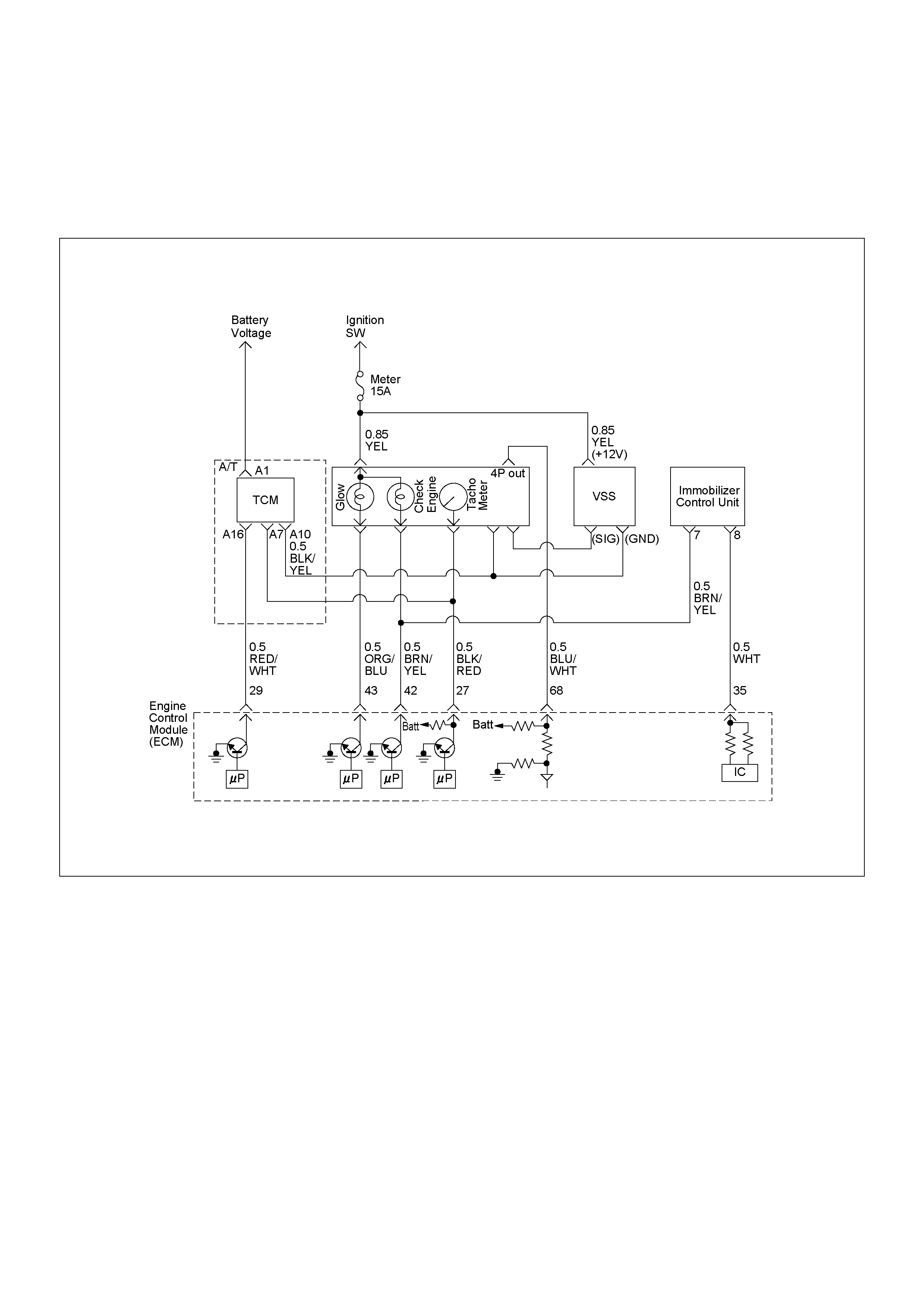

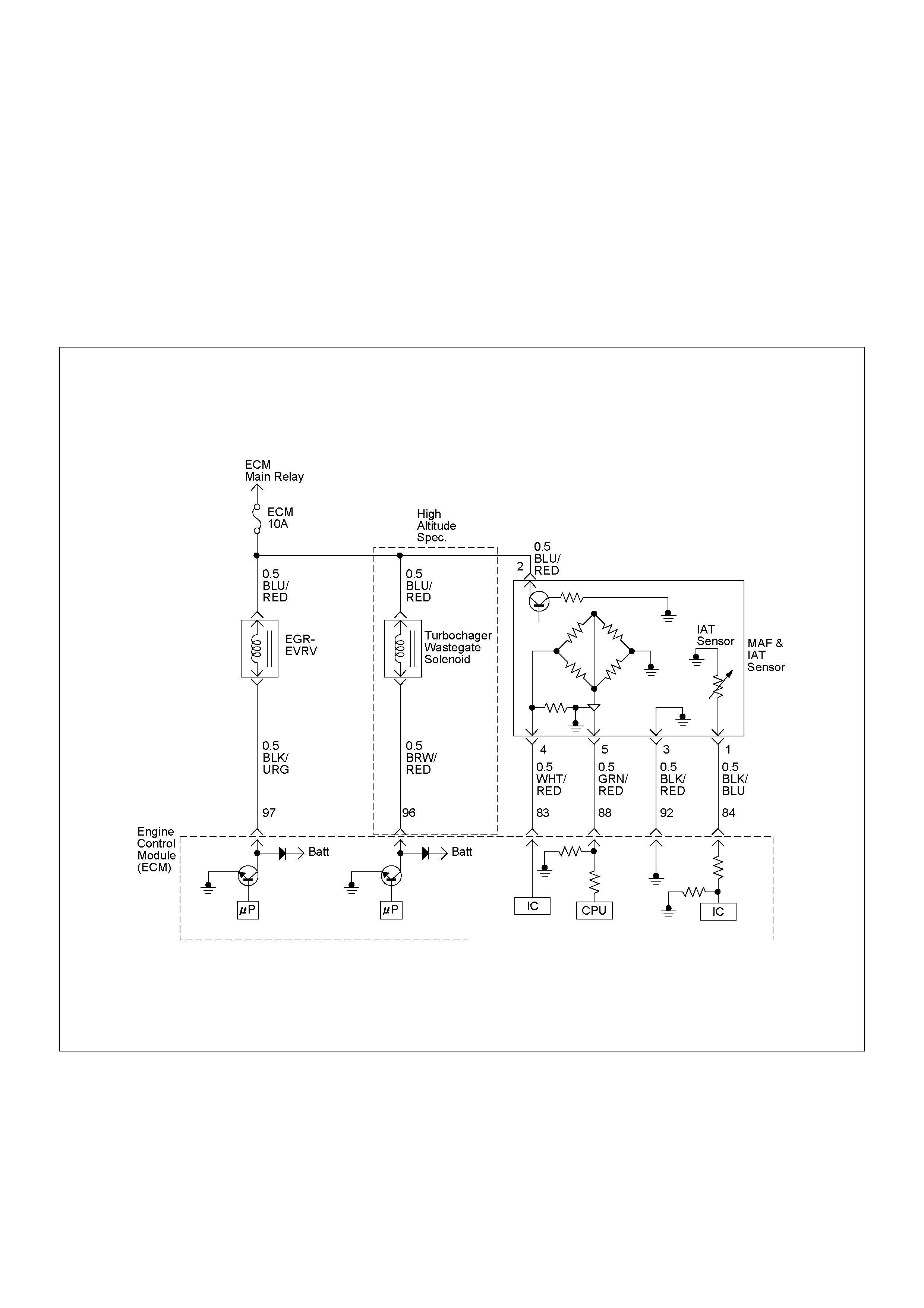

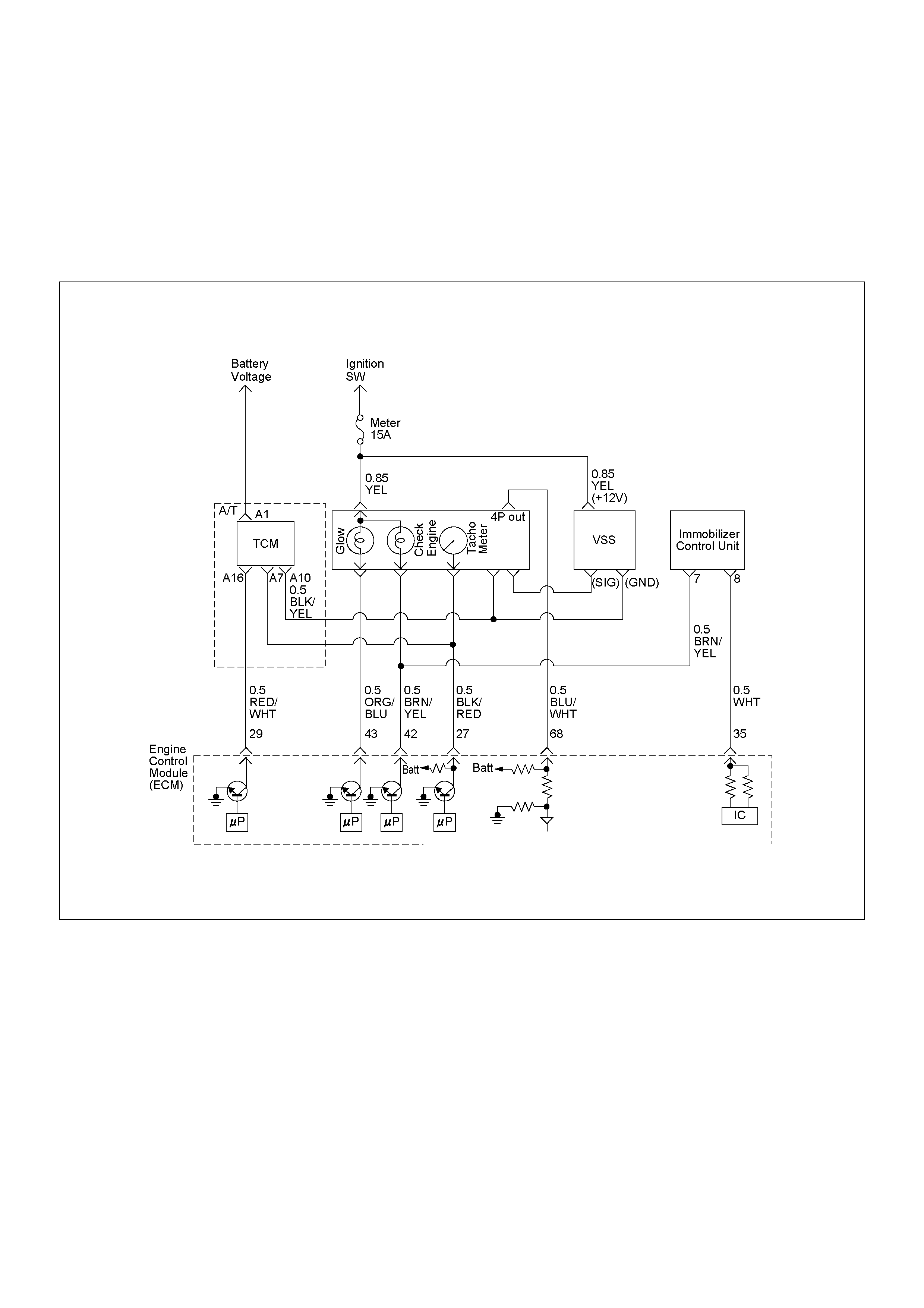

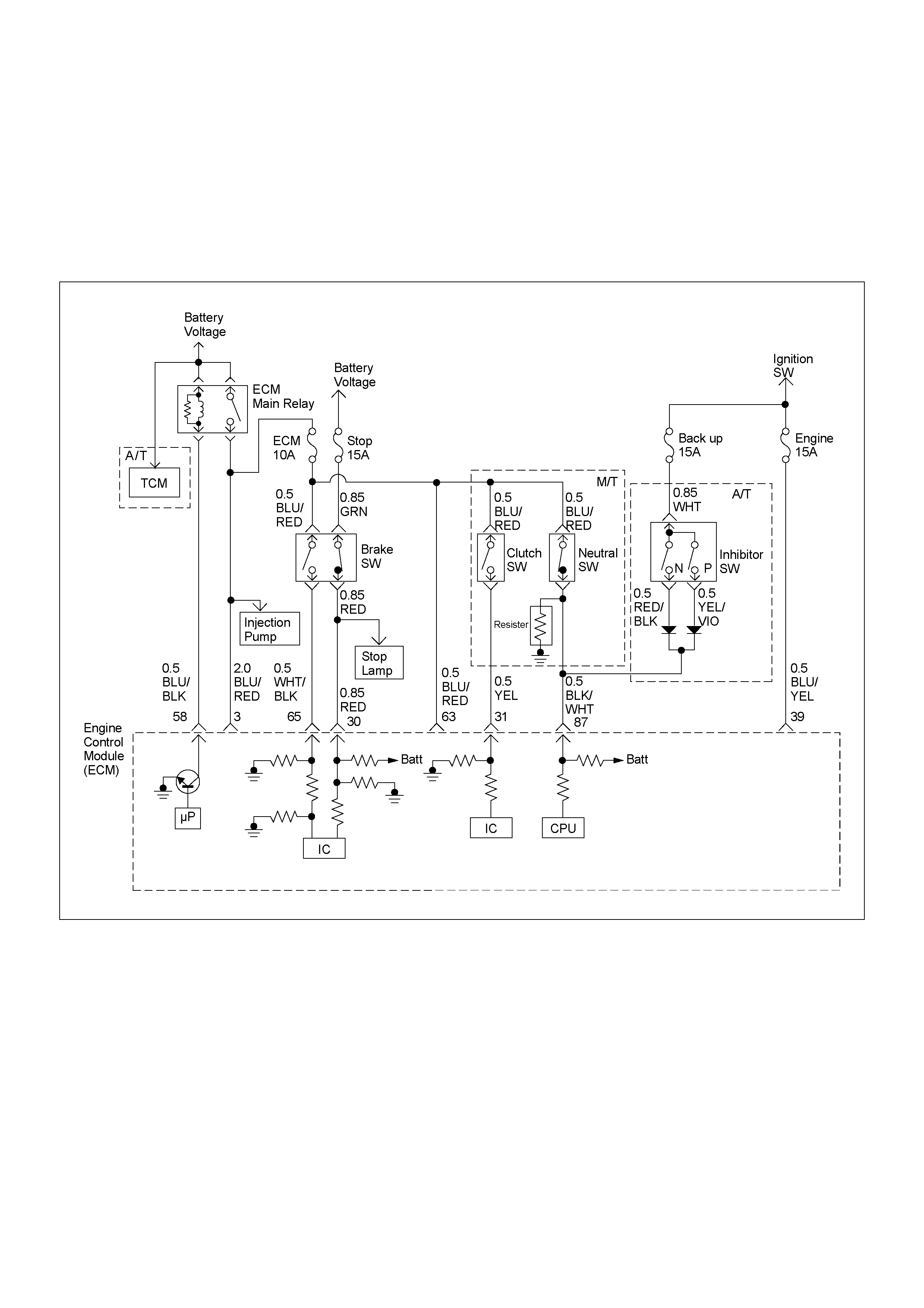

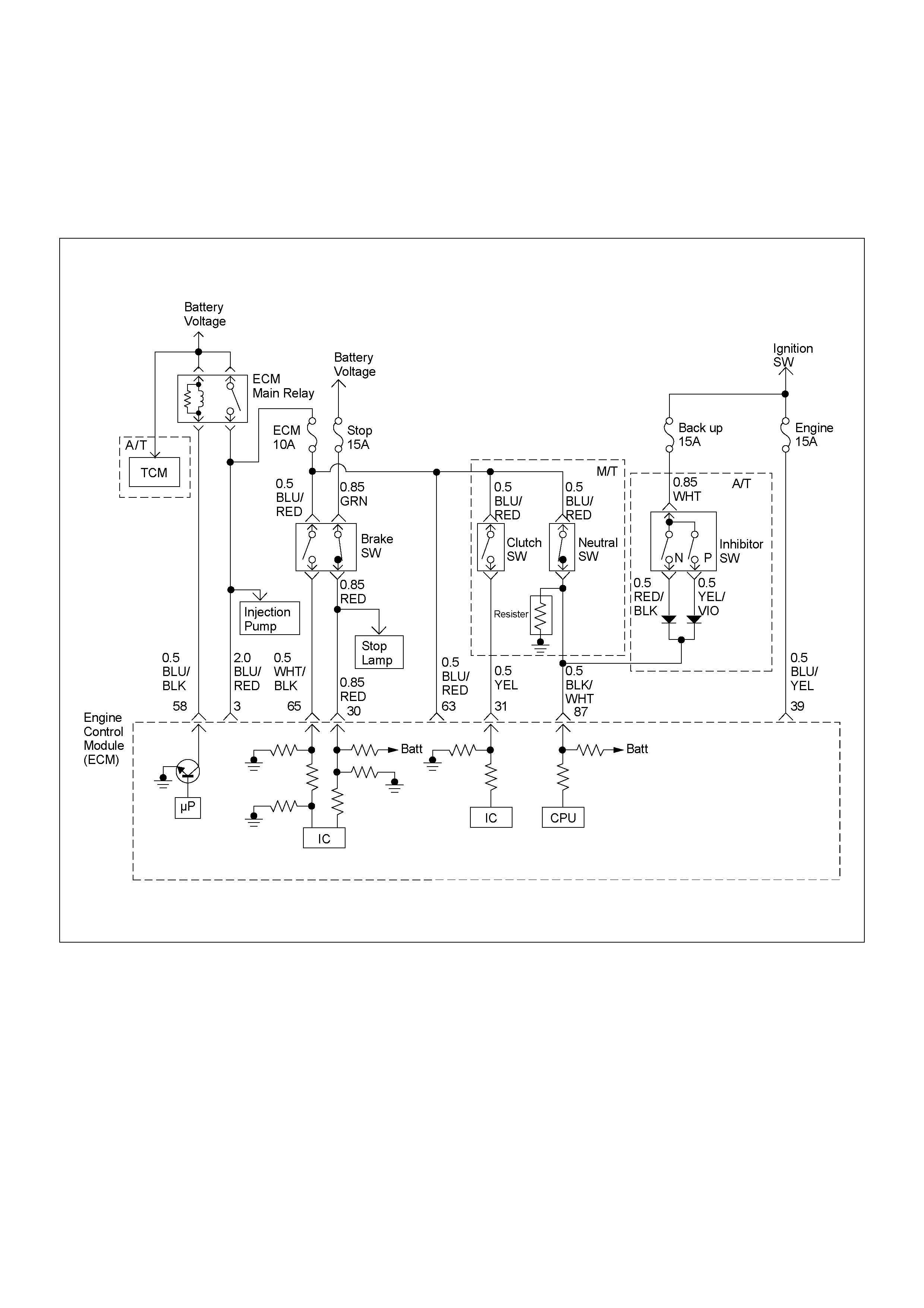

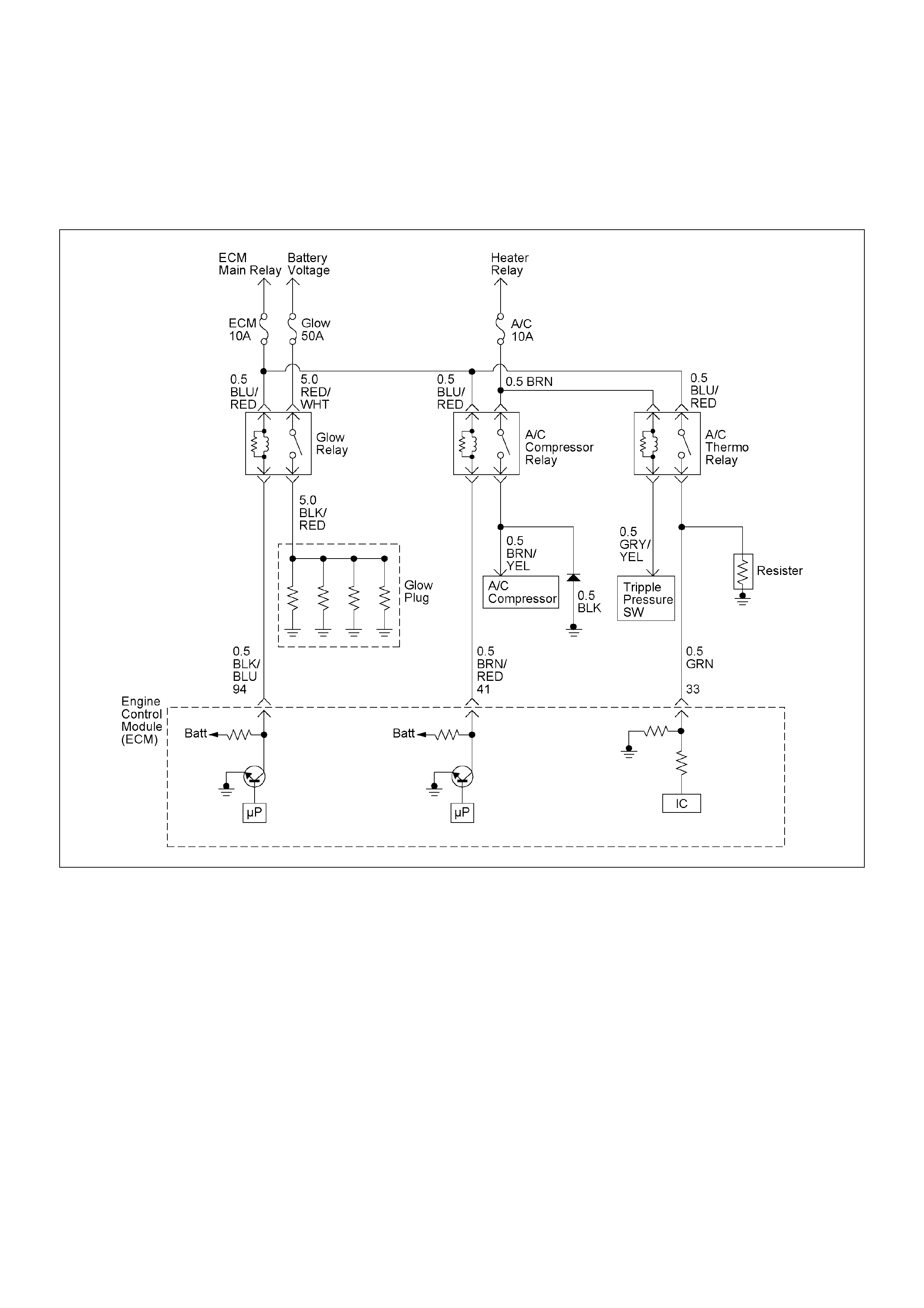

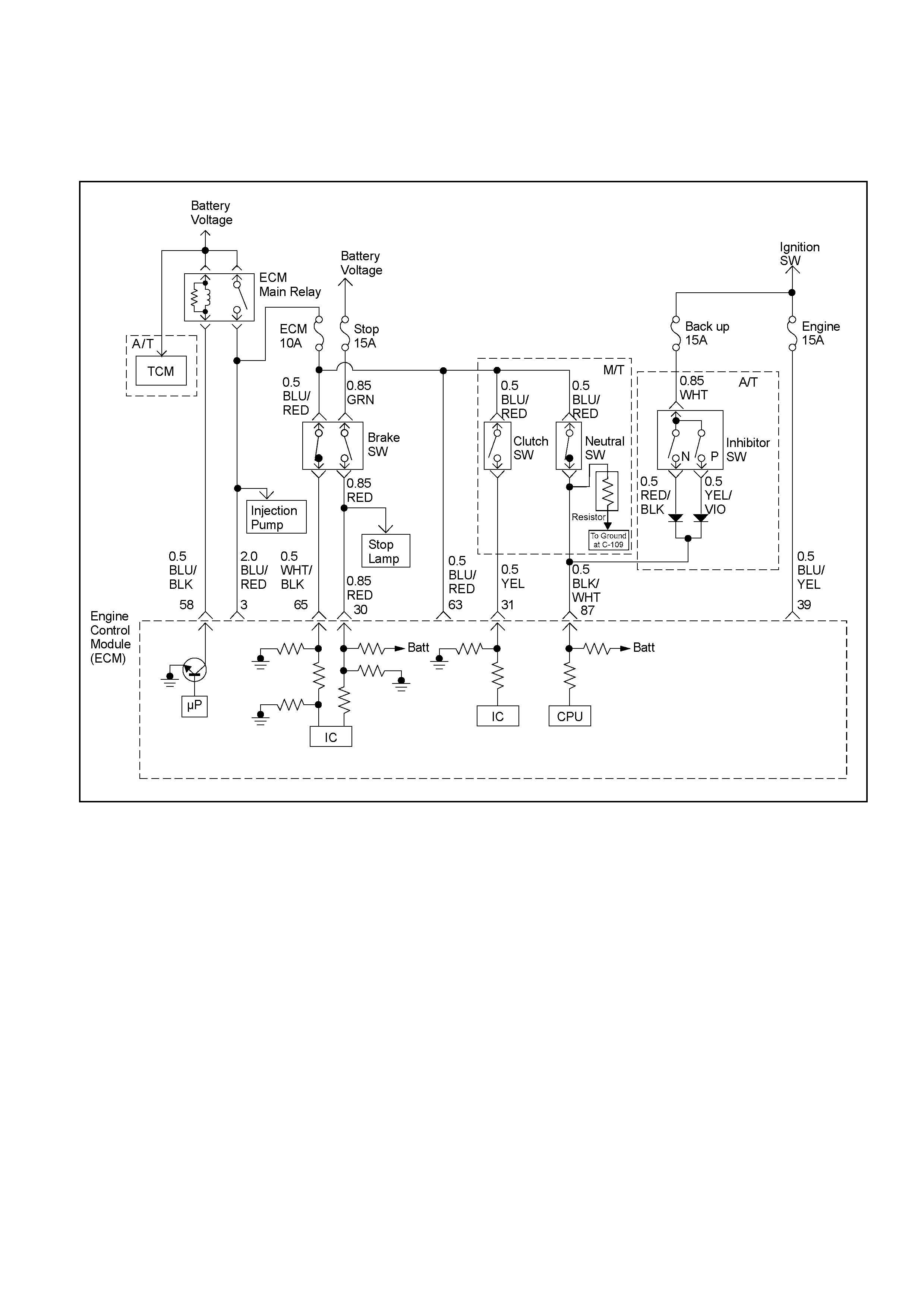

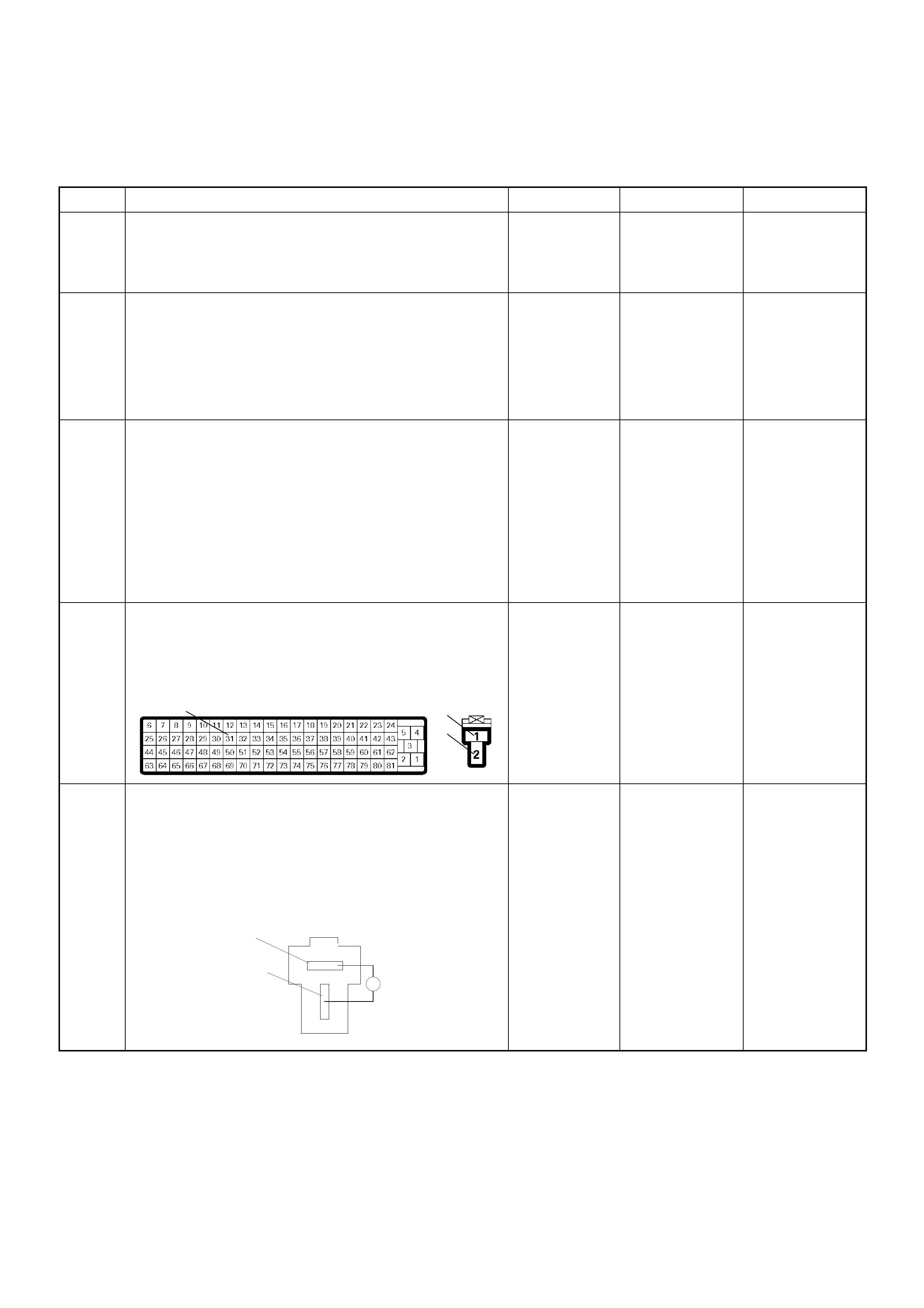

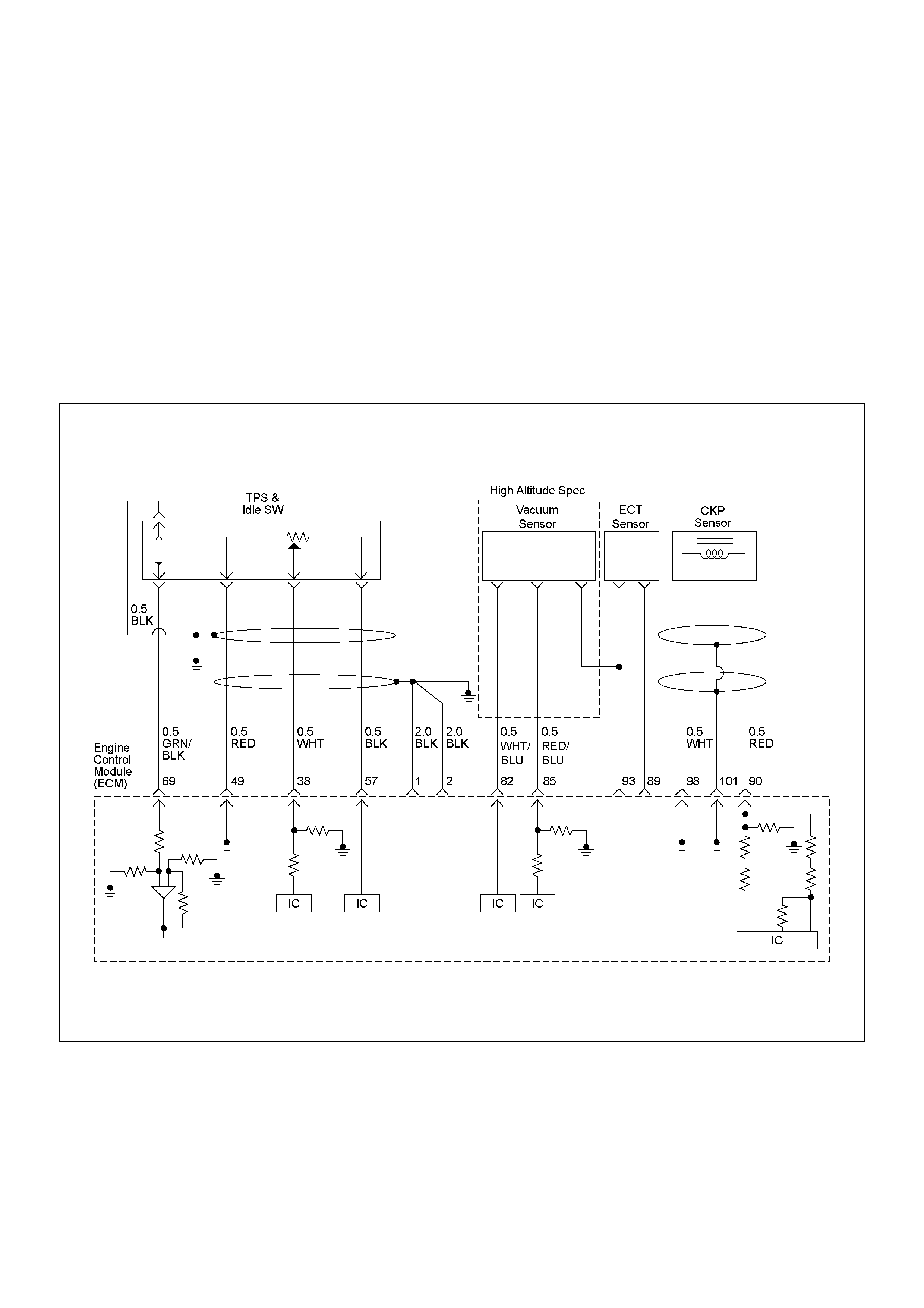

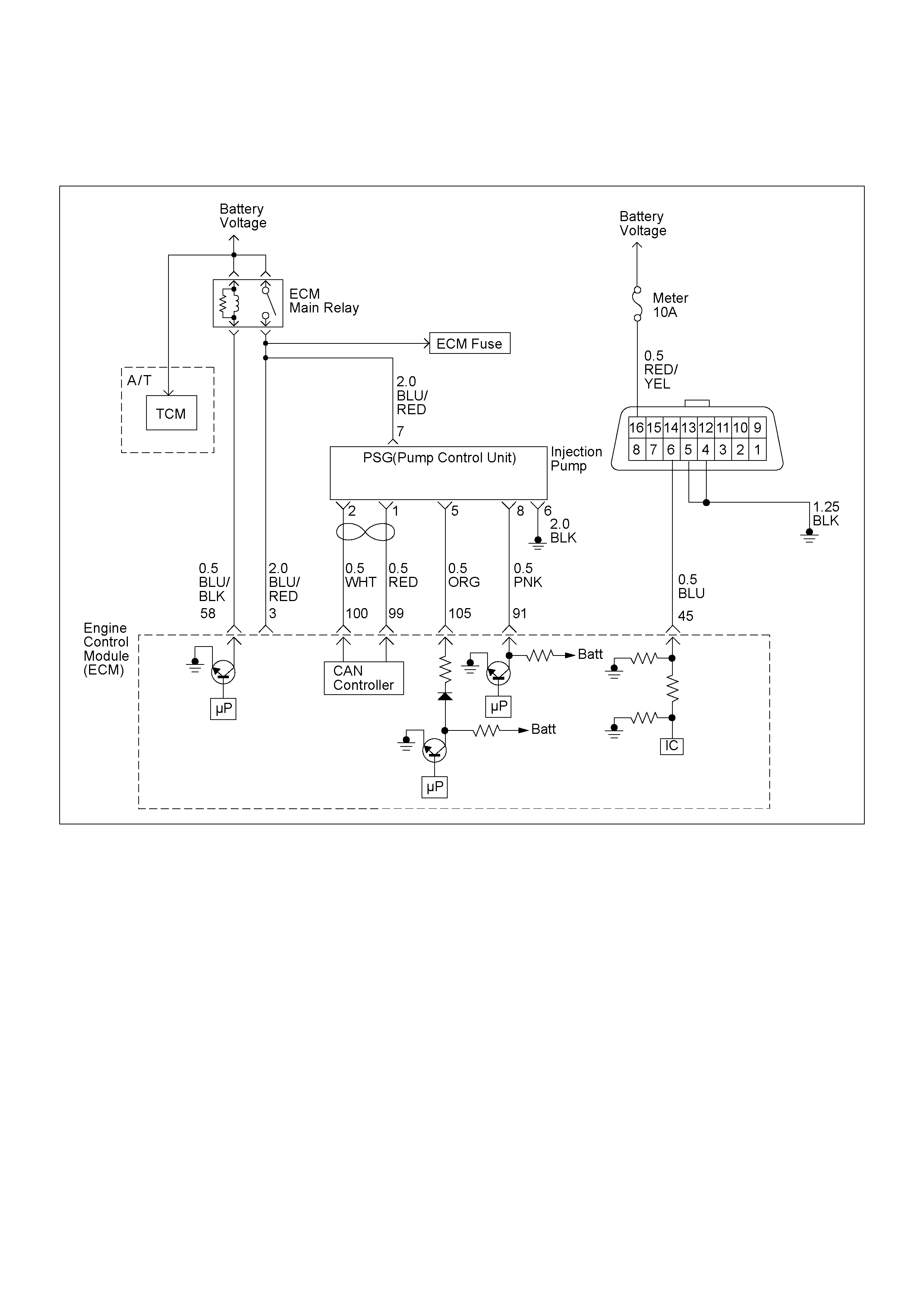

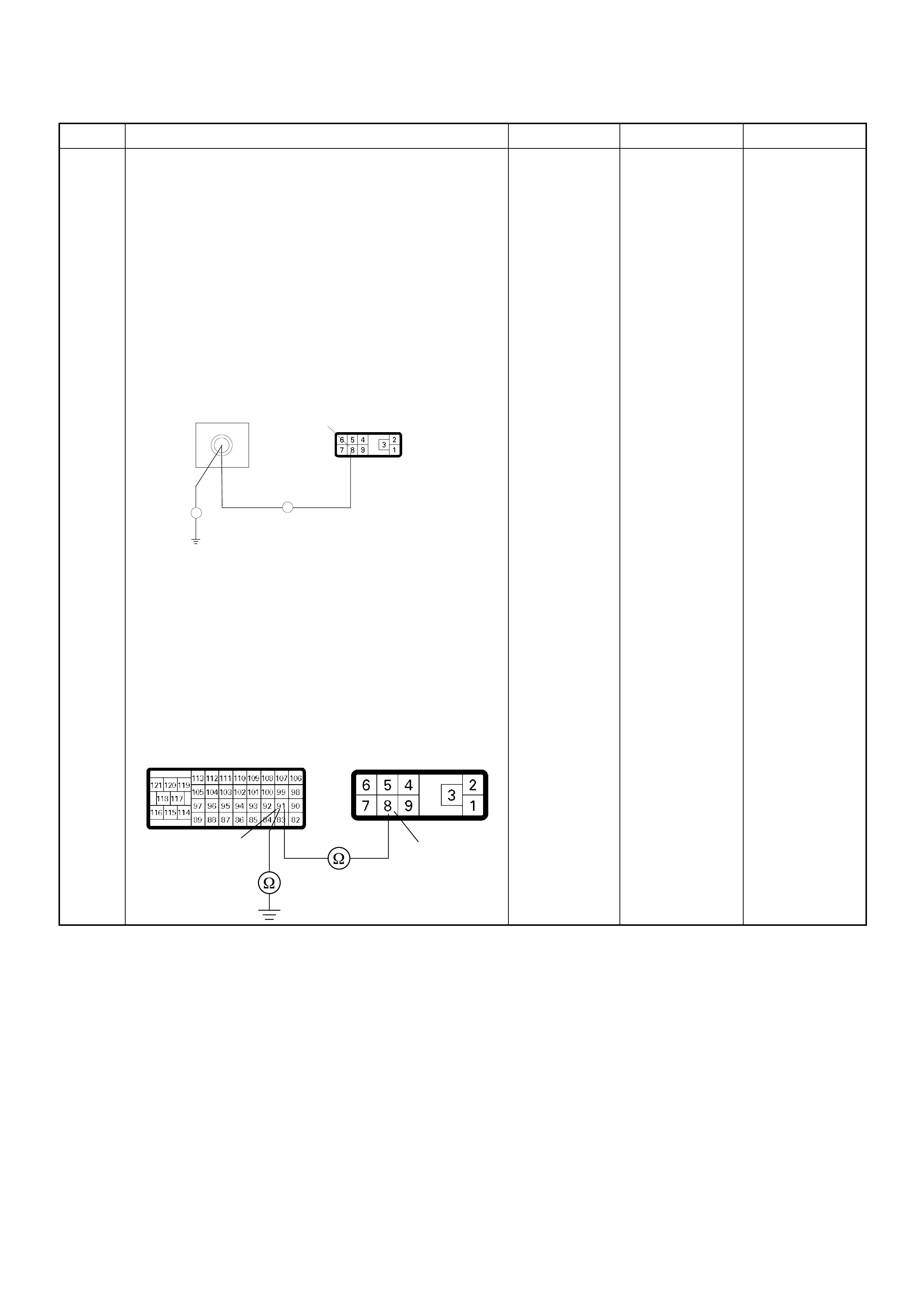

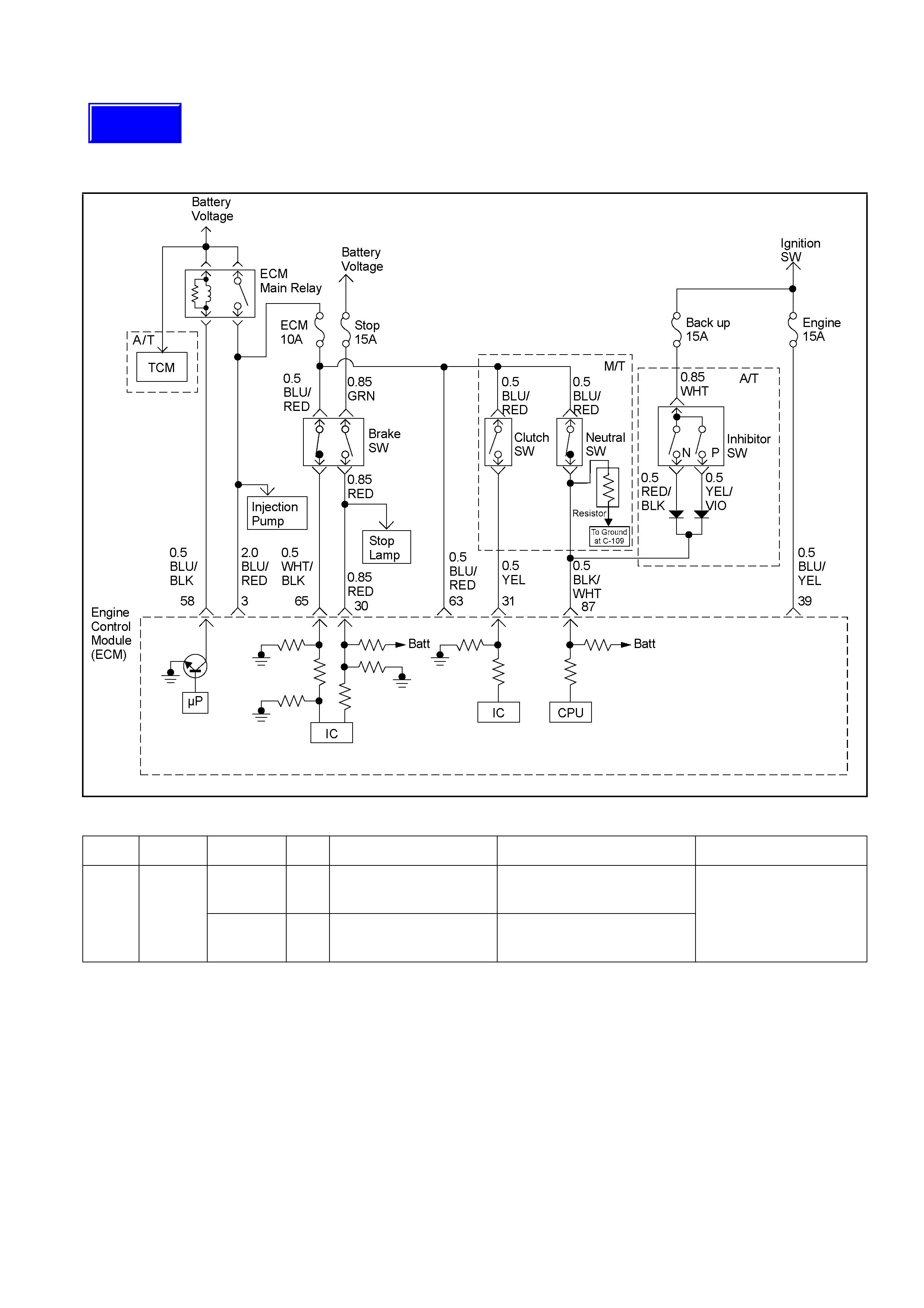

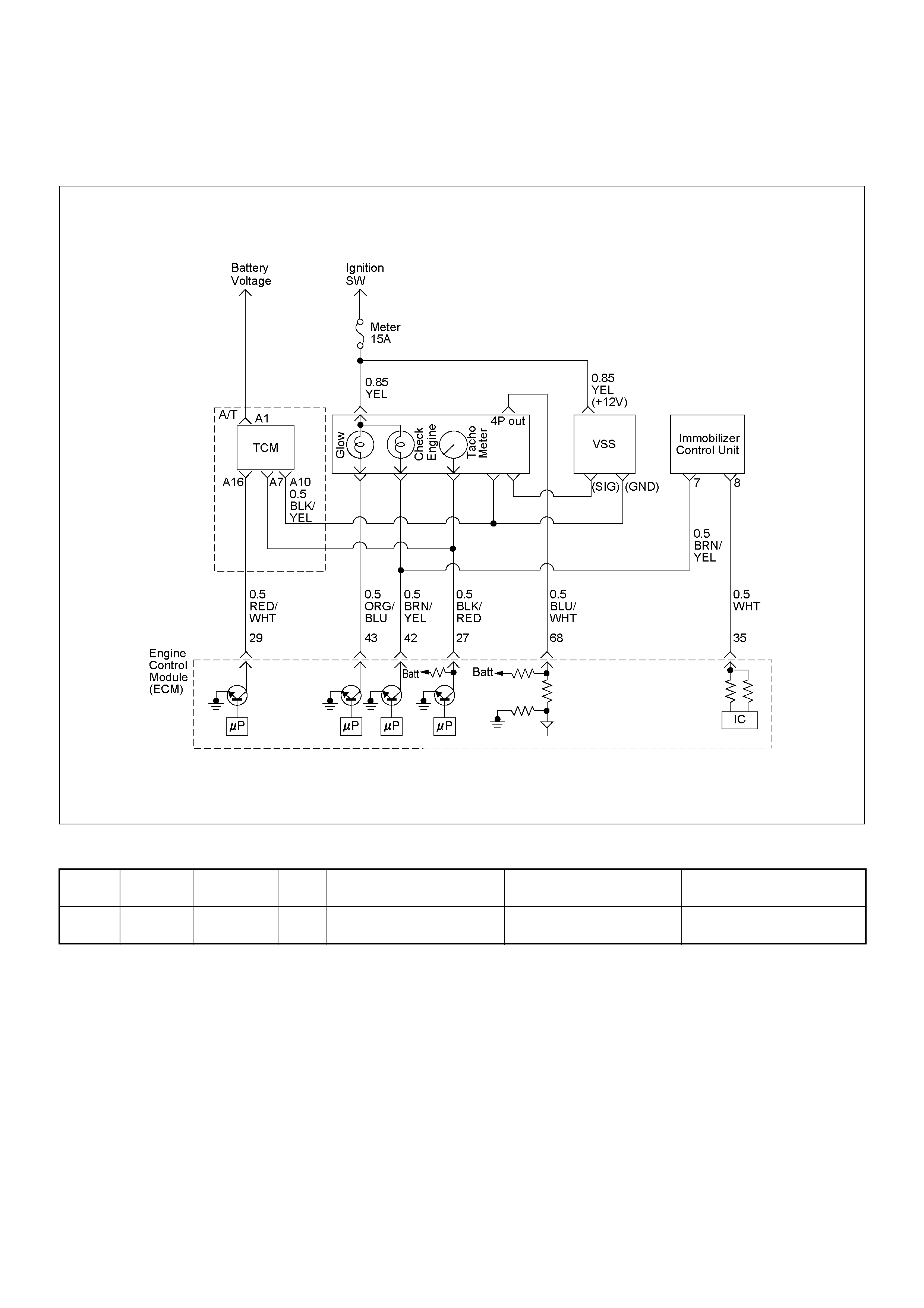

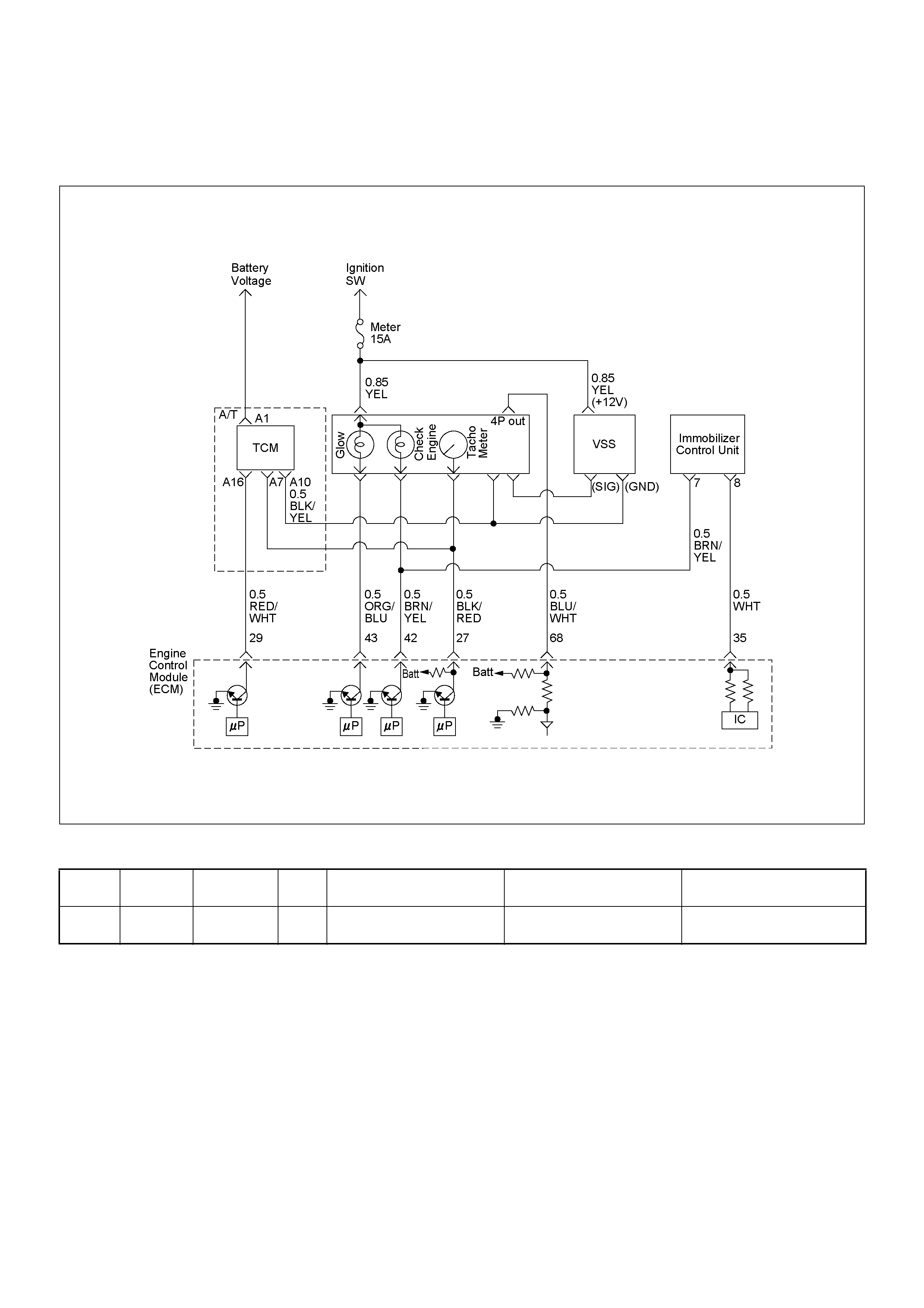

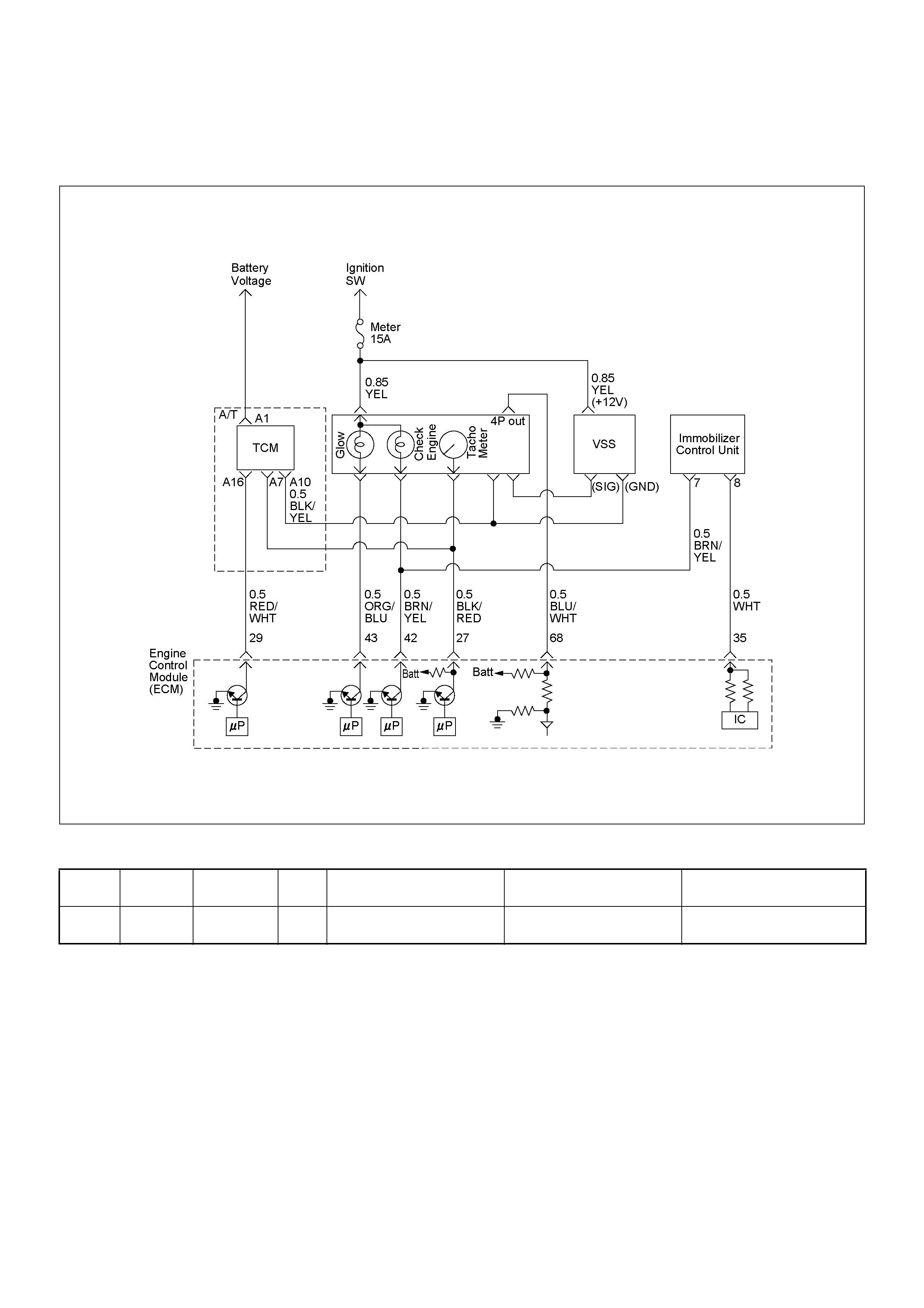

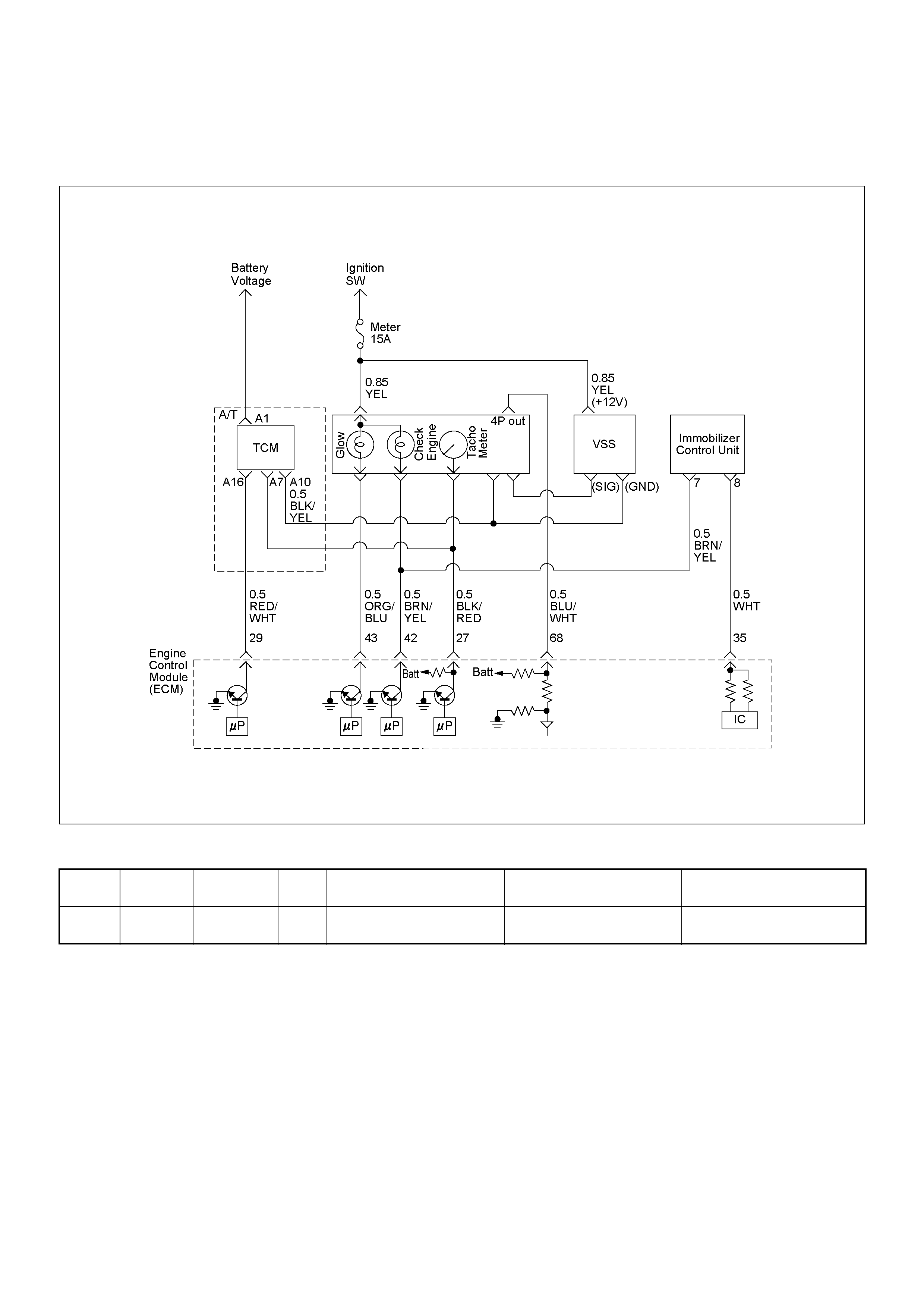

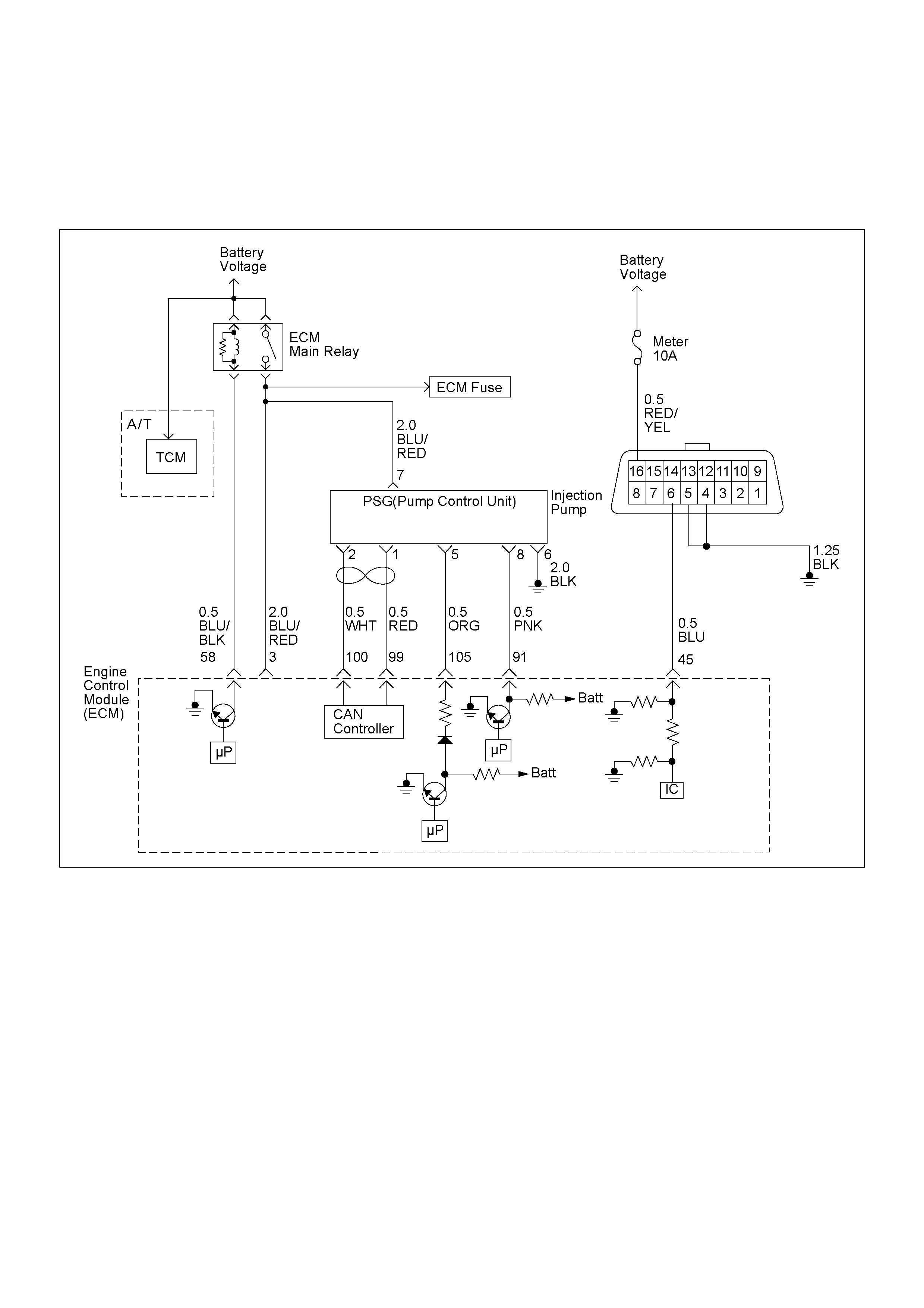

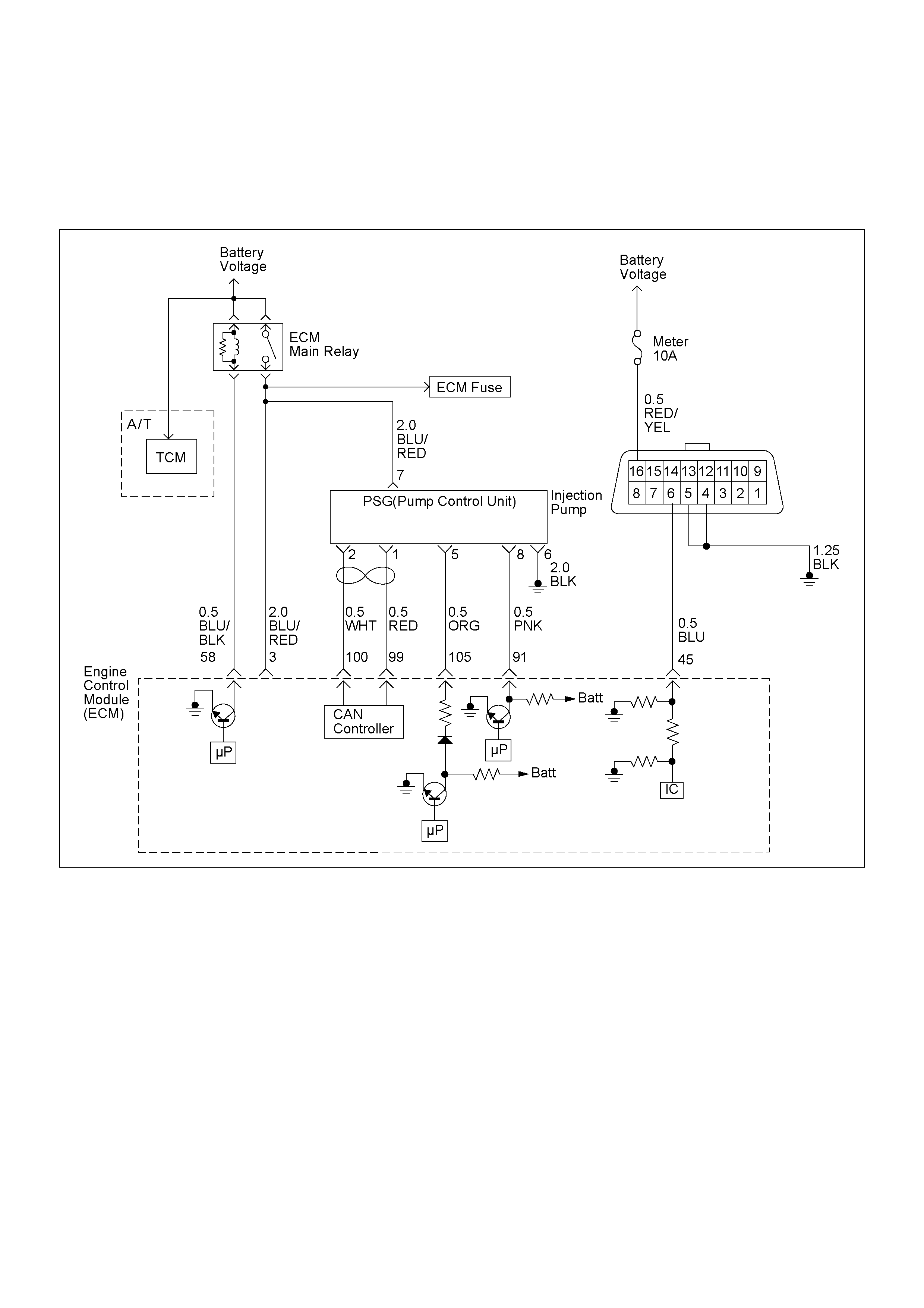

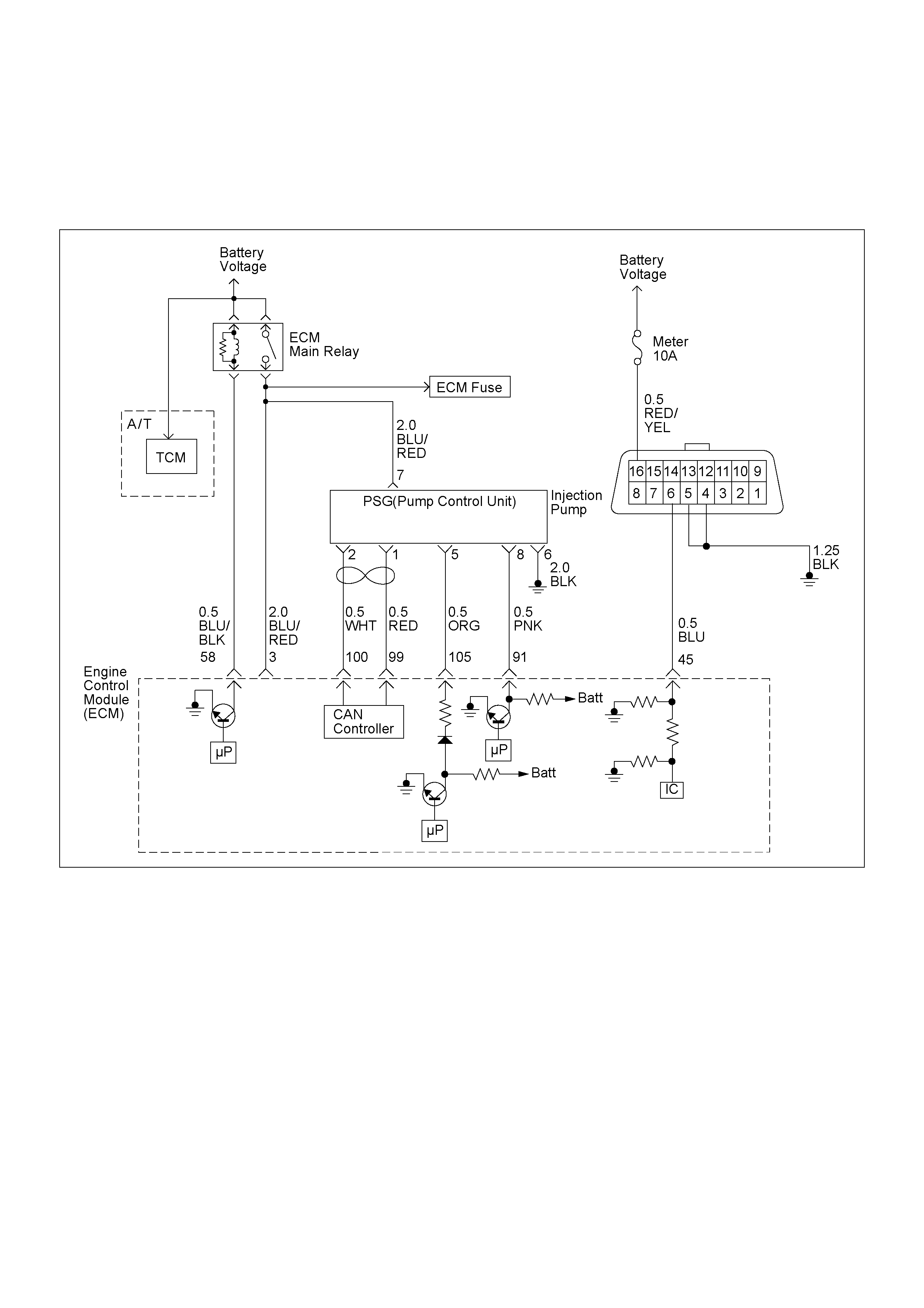

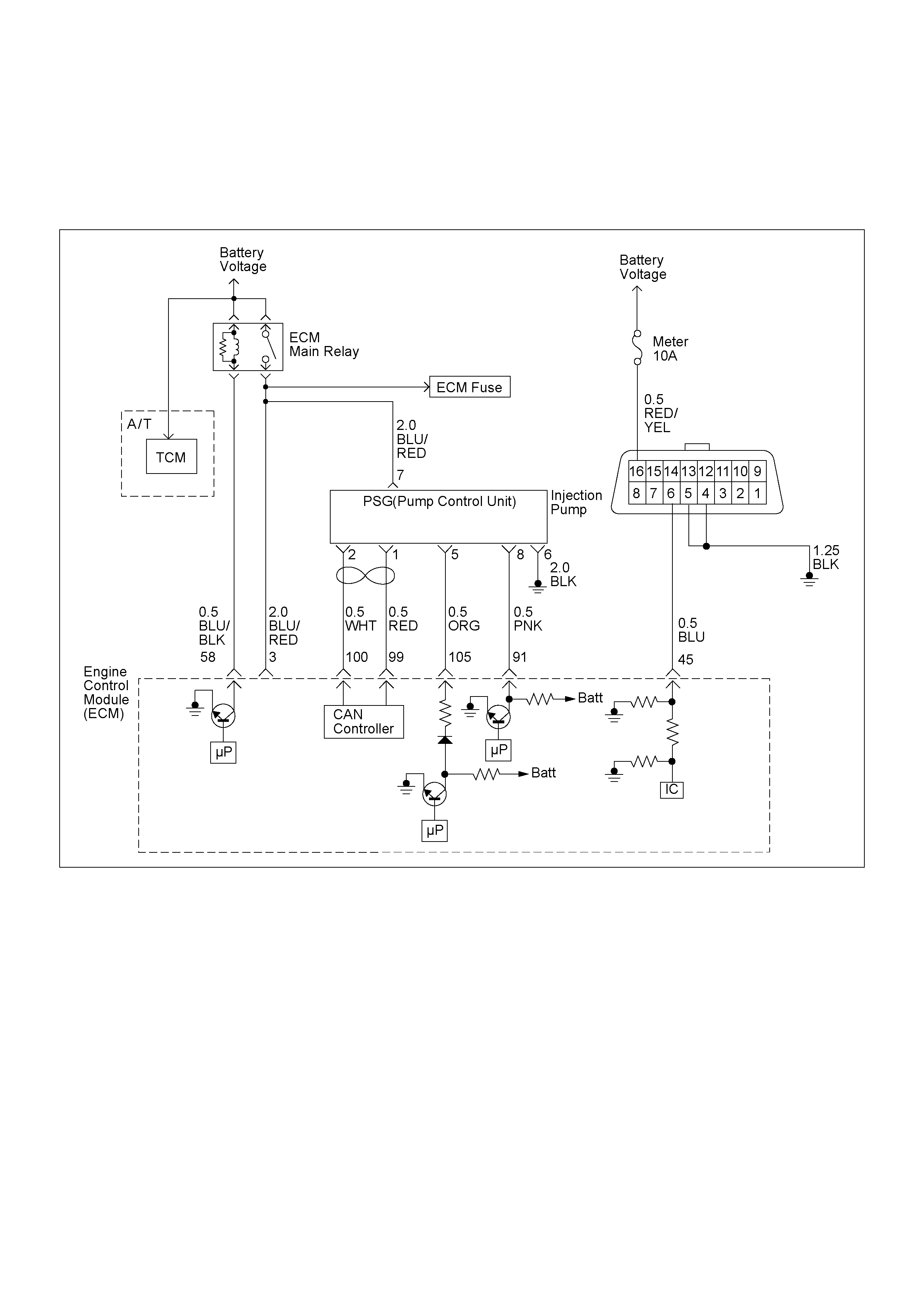

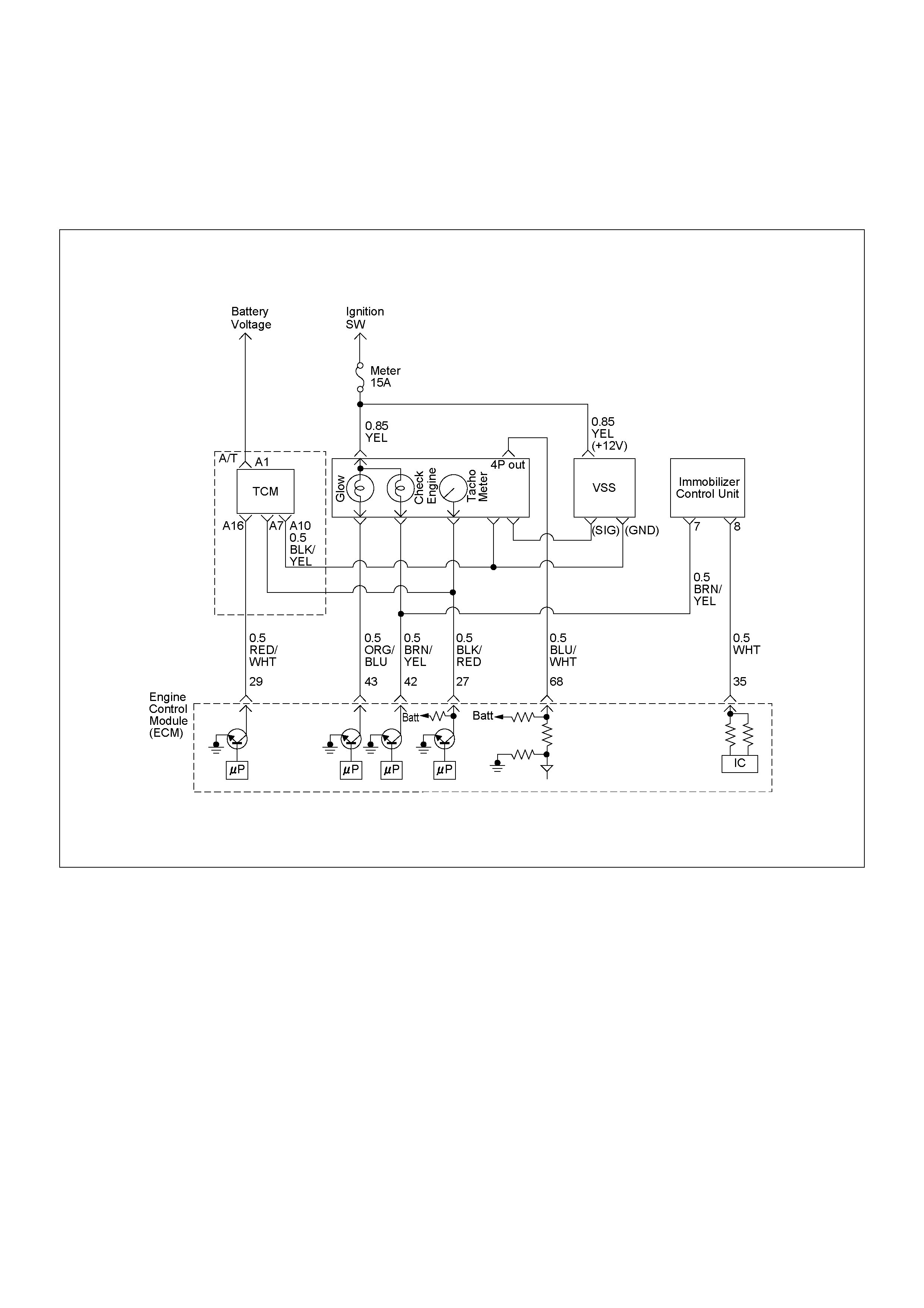

ECM CIRCUIT DIAGRAM

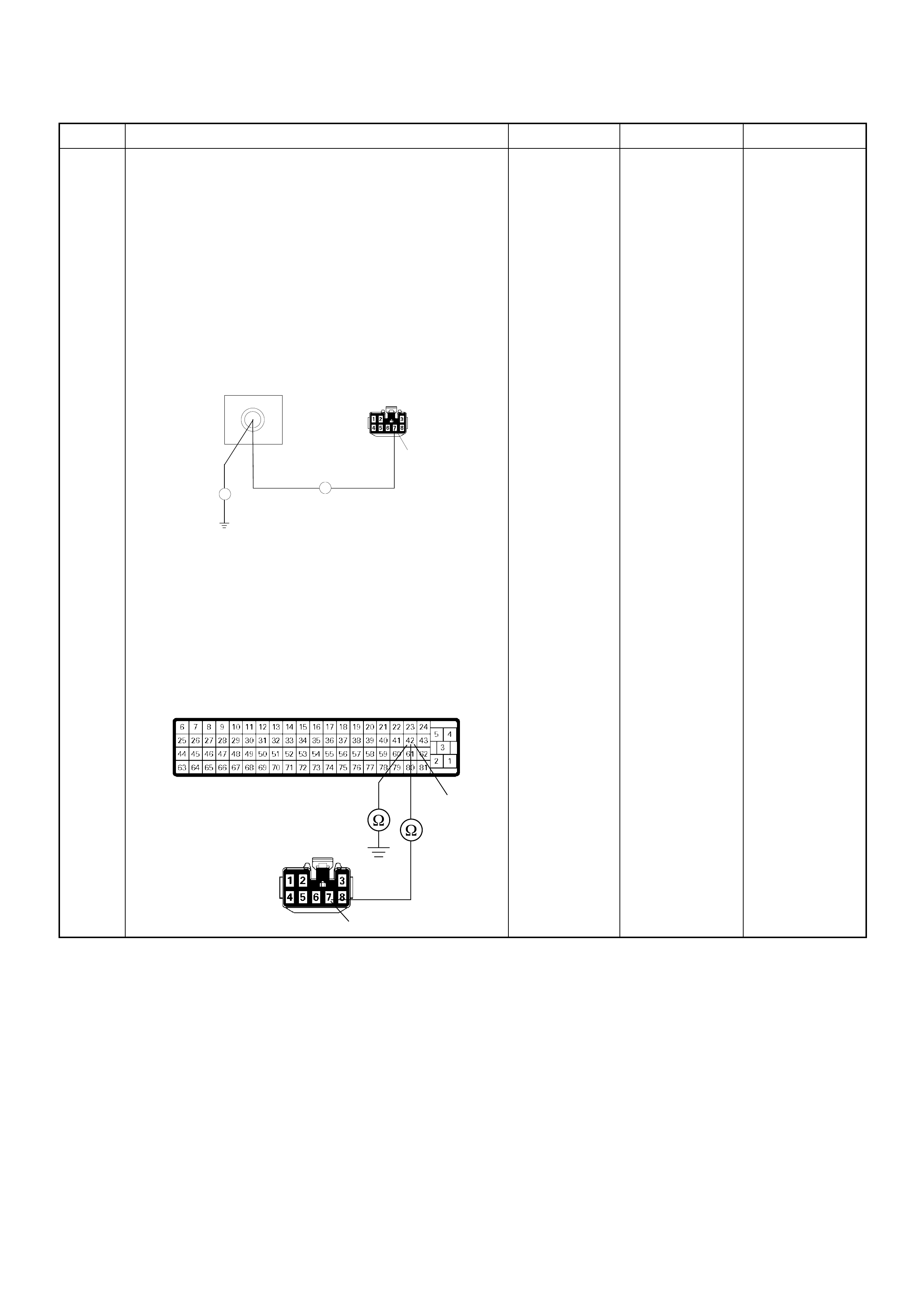

ECM CIRCUIT DIAGRAM (1/2)

ECM CIRCUIT DIAGRAM (2/2)

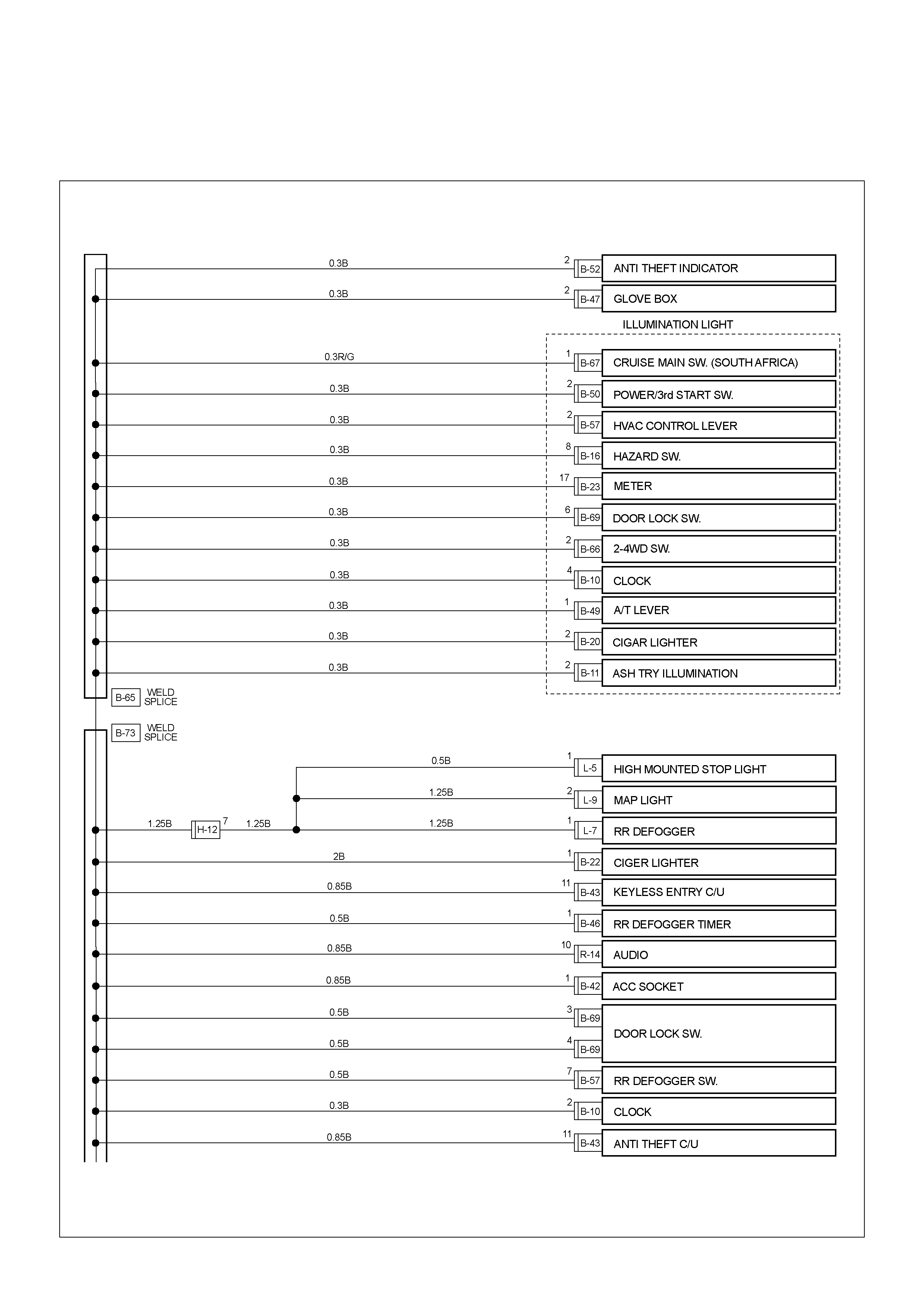

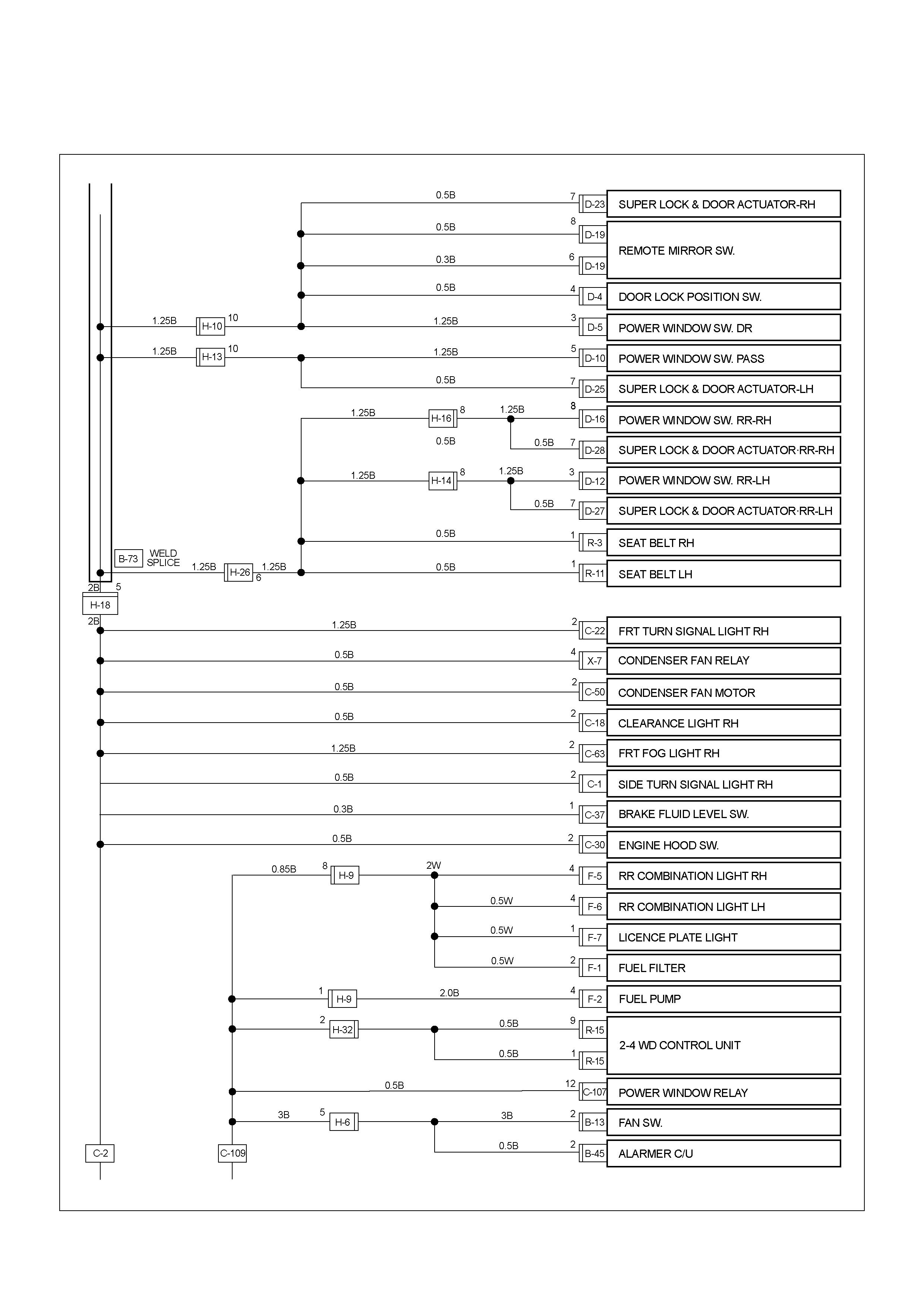

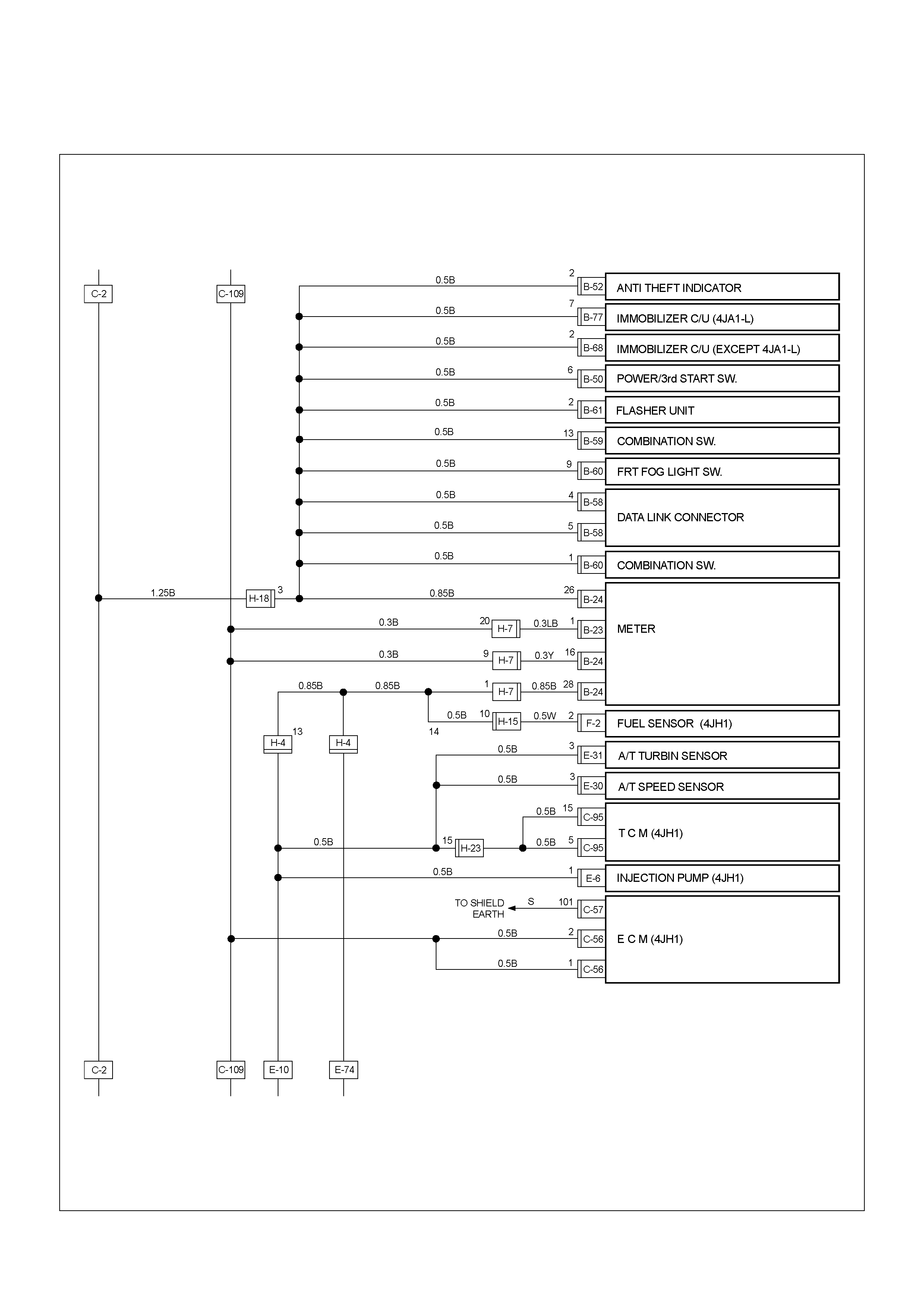

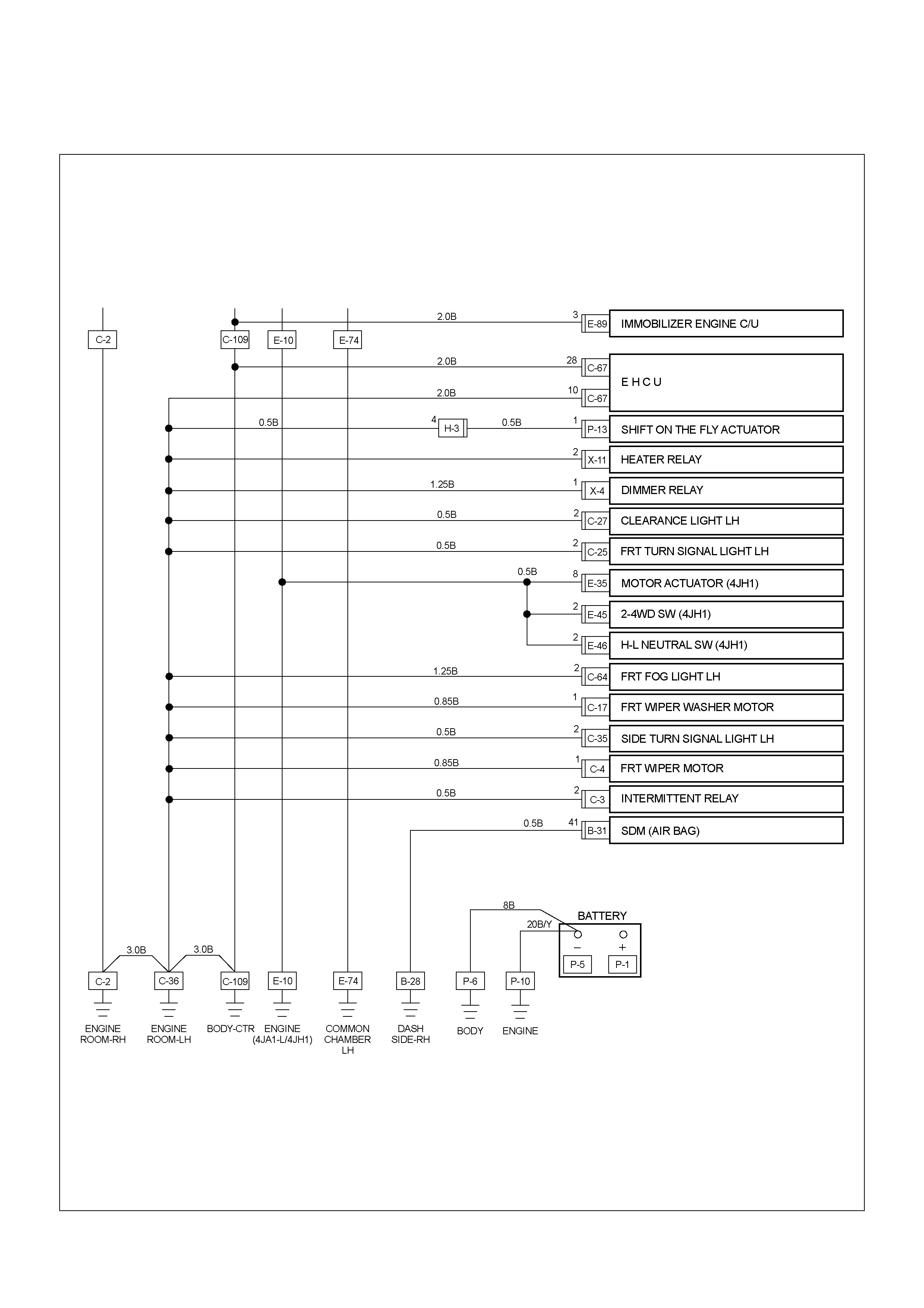

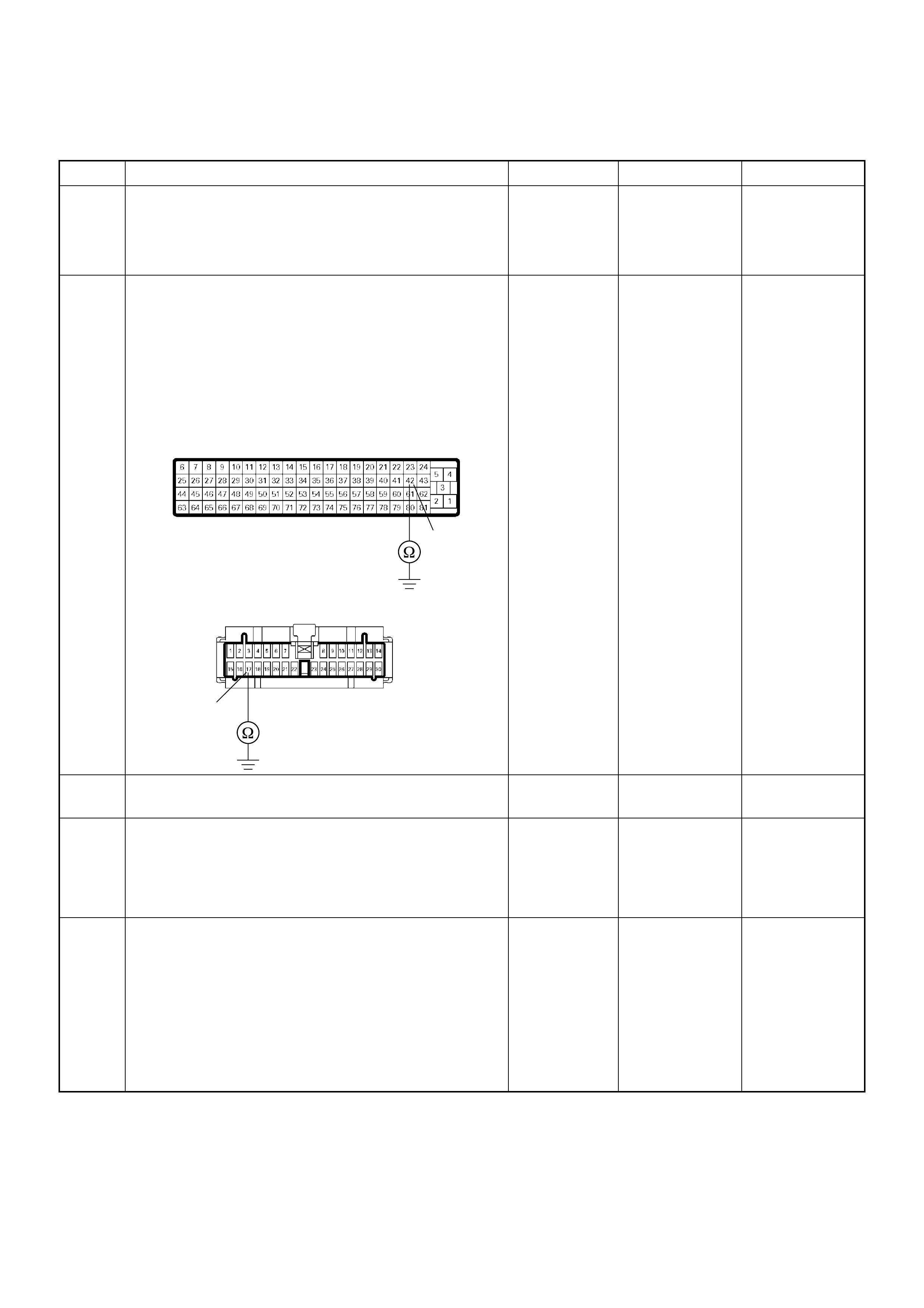

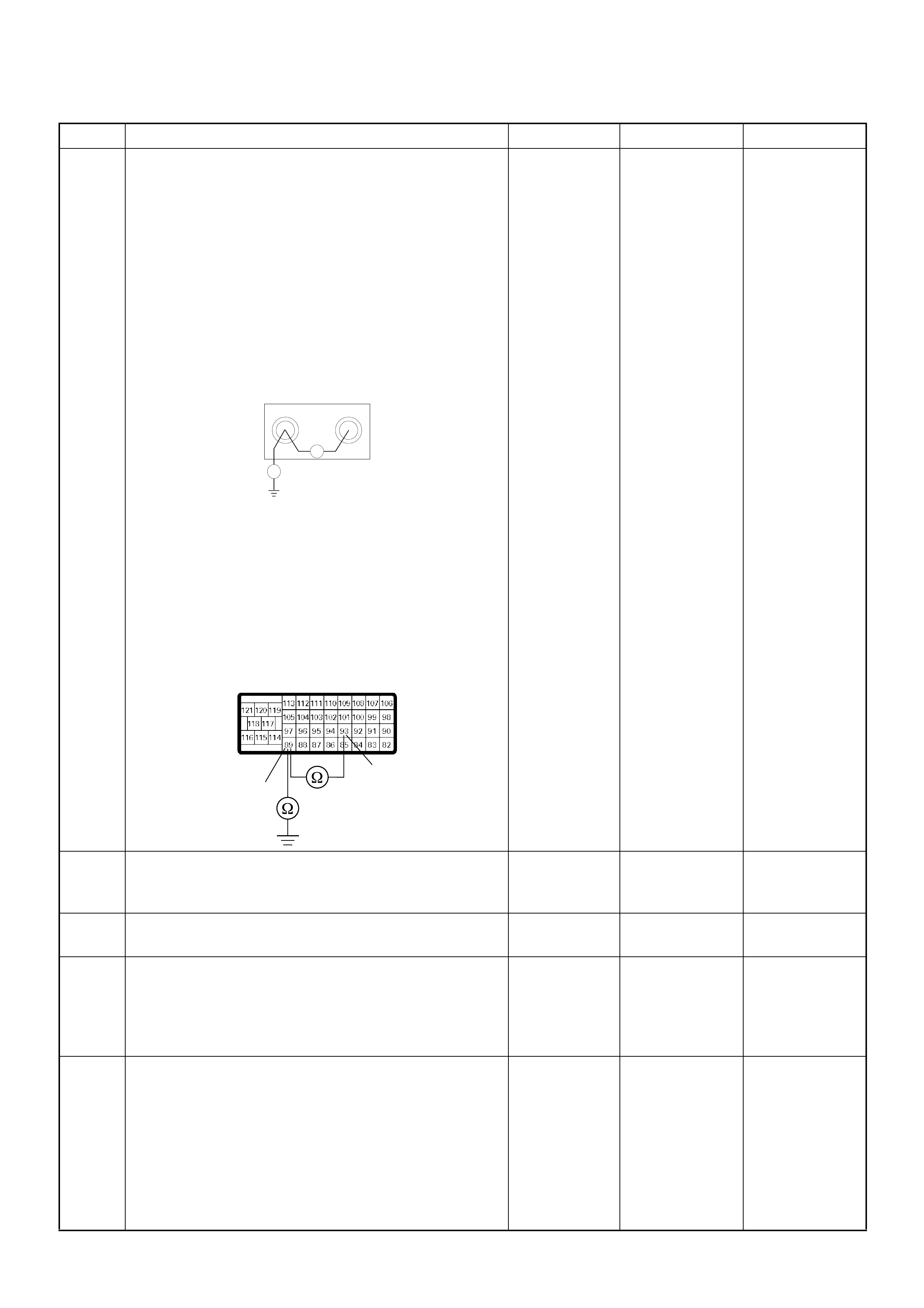

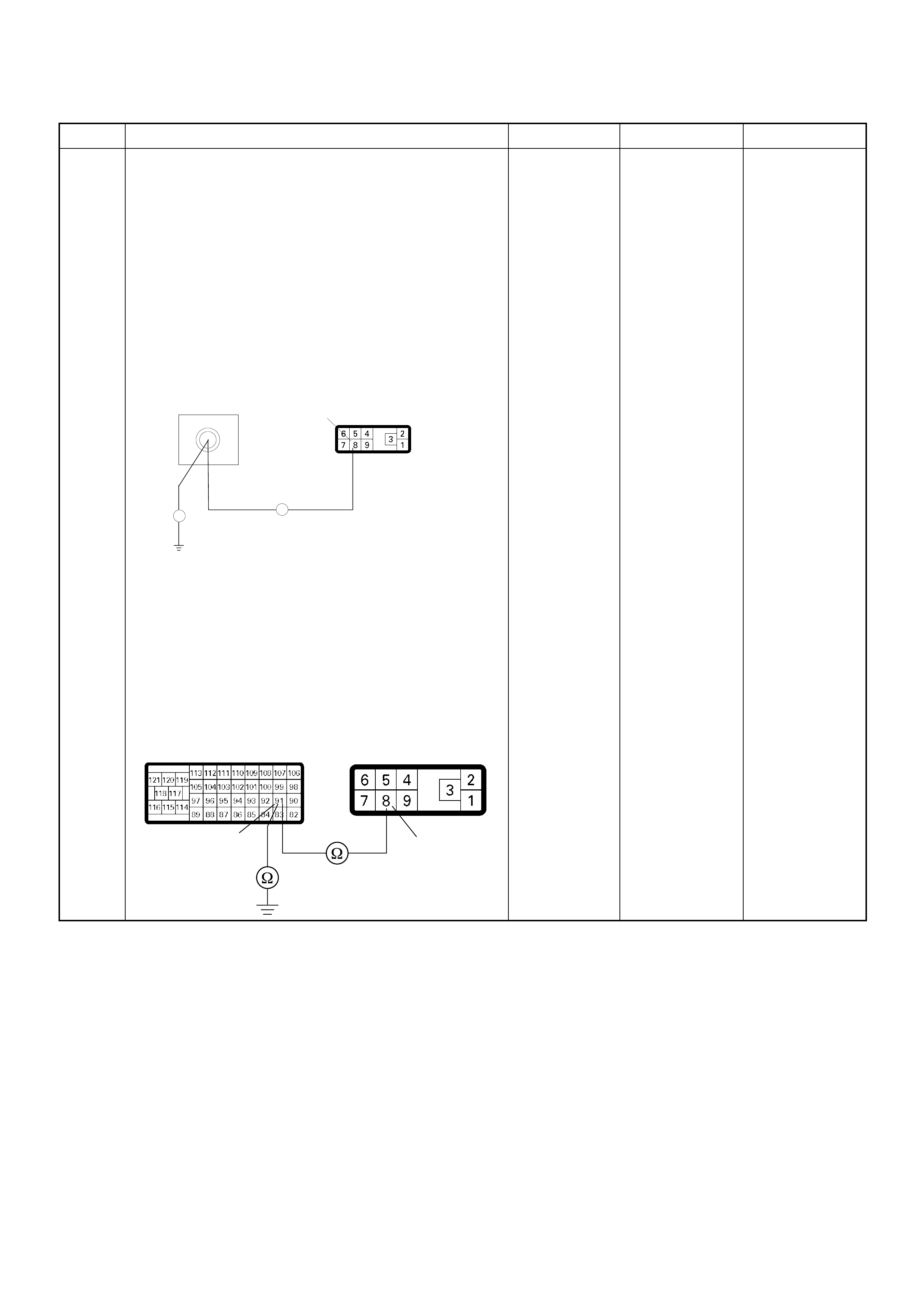

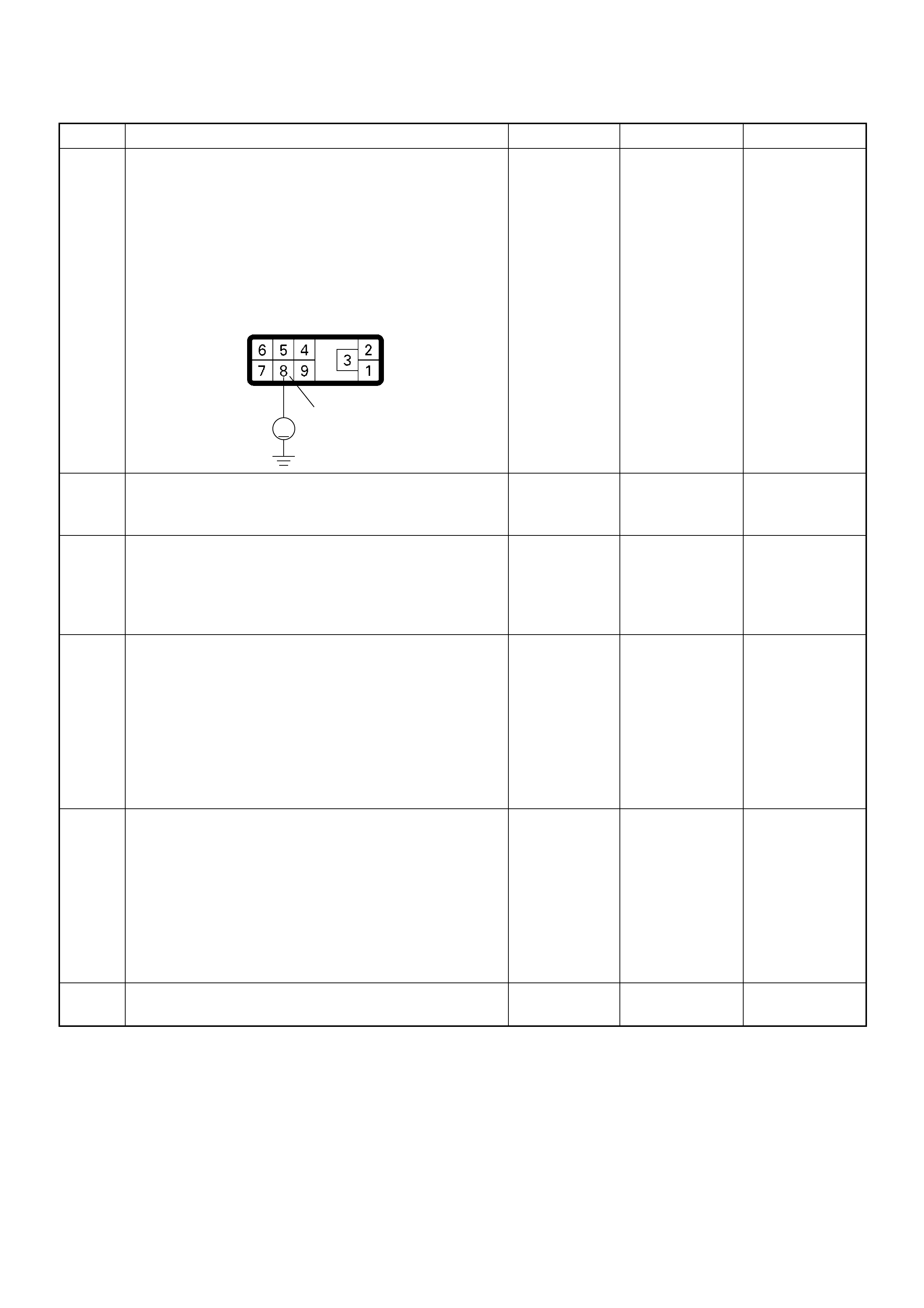

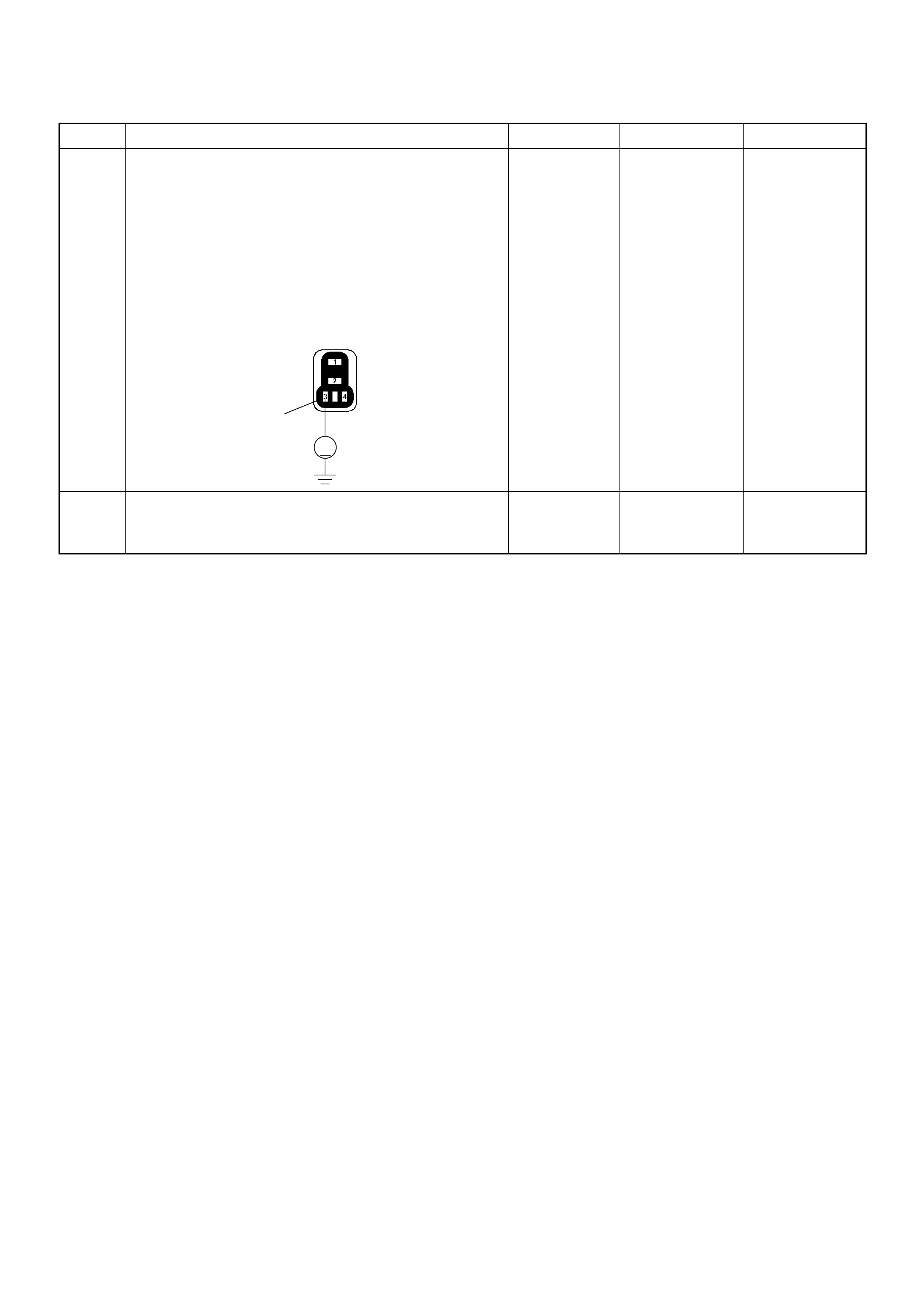

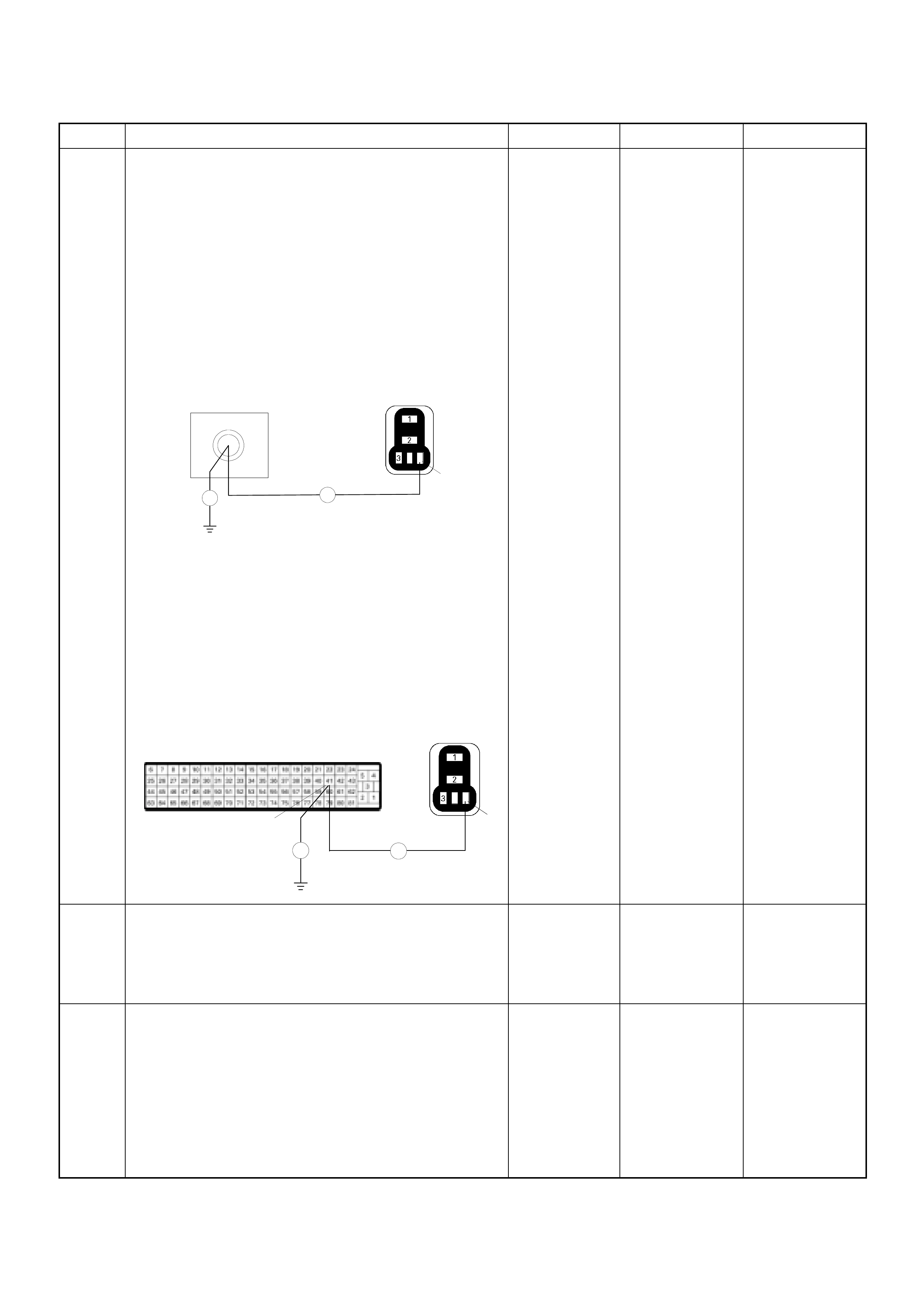

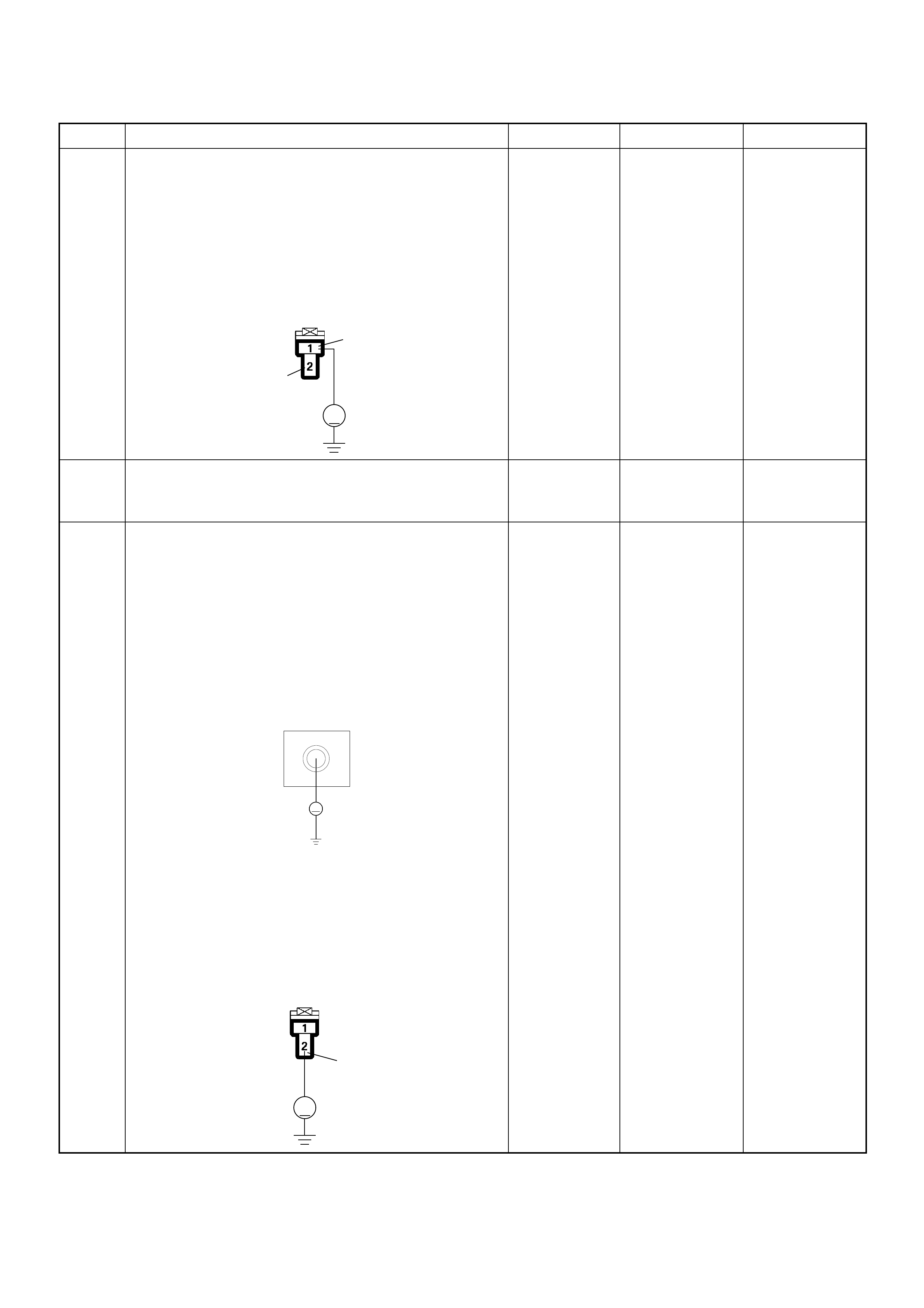

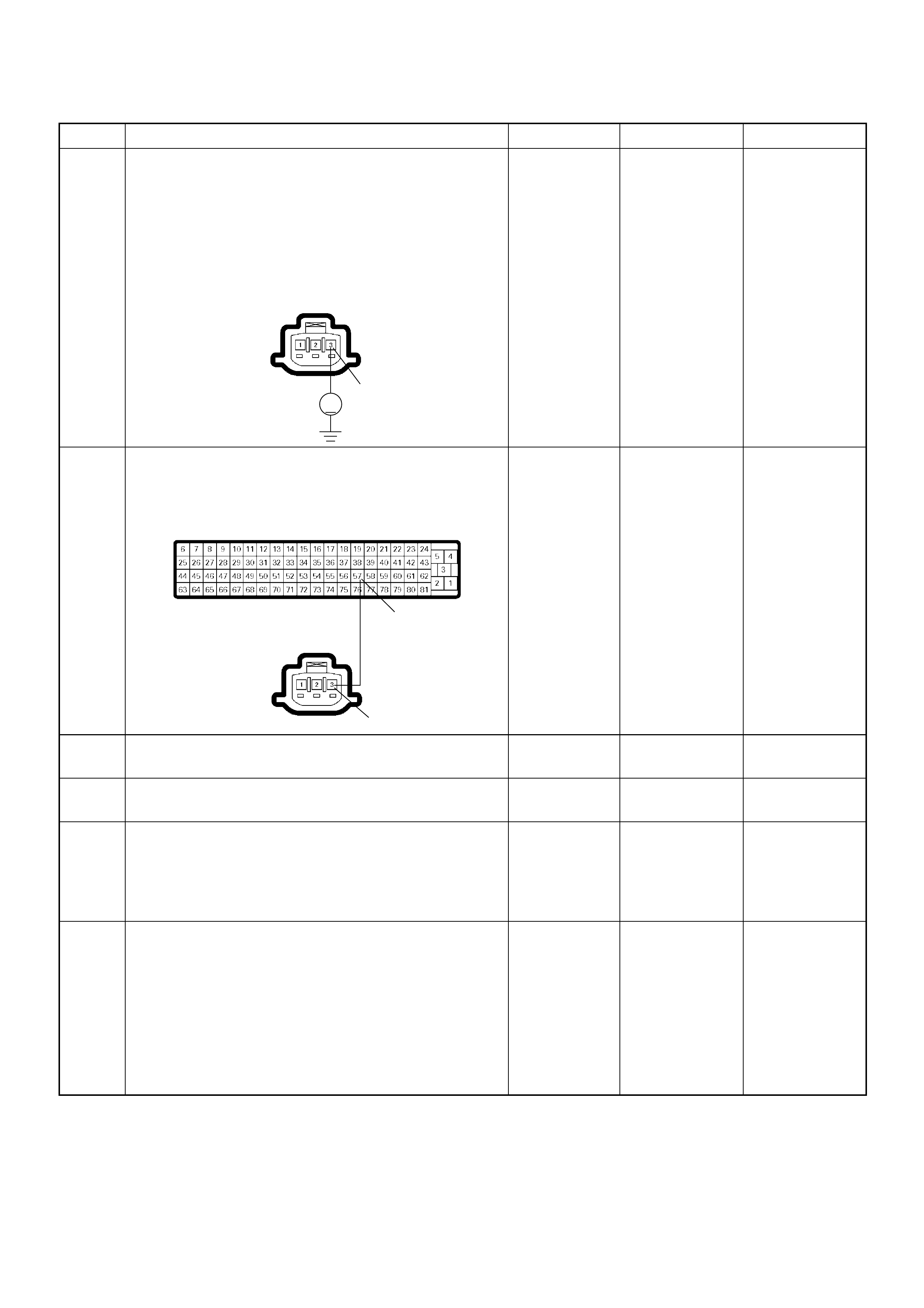

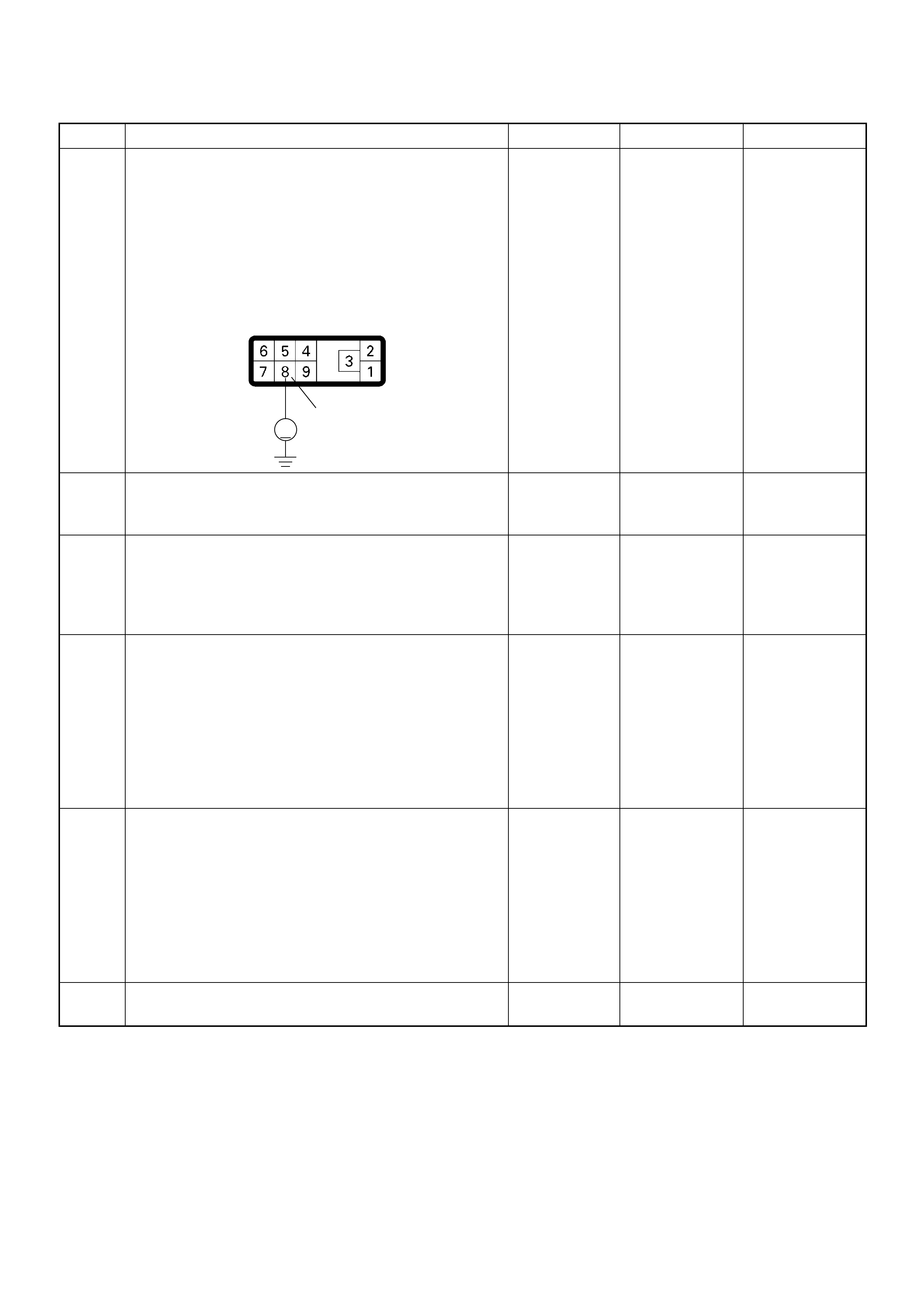

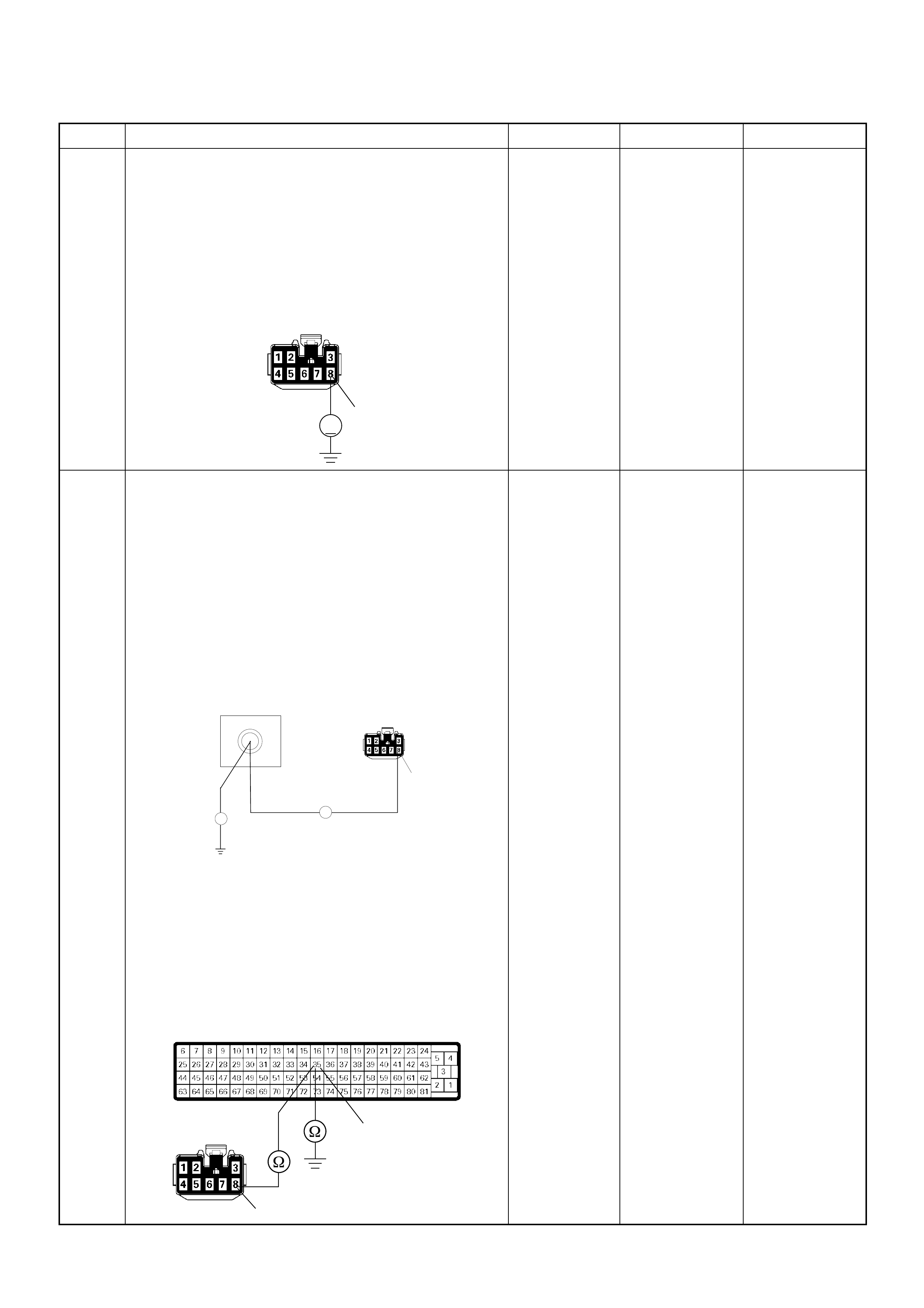

GROUND POINT

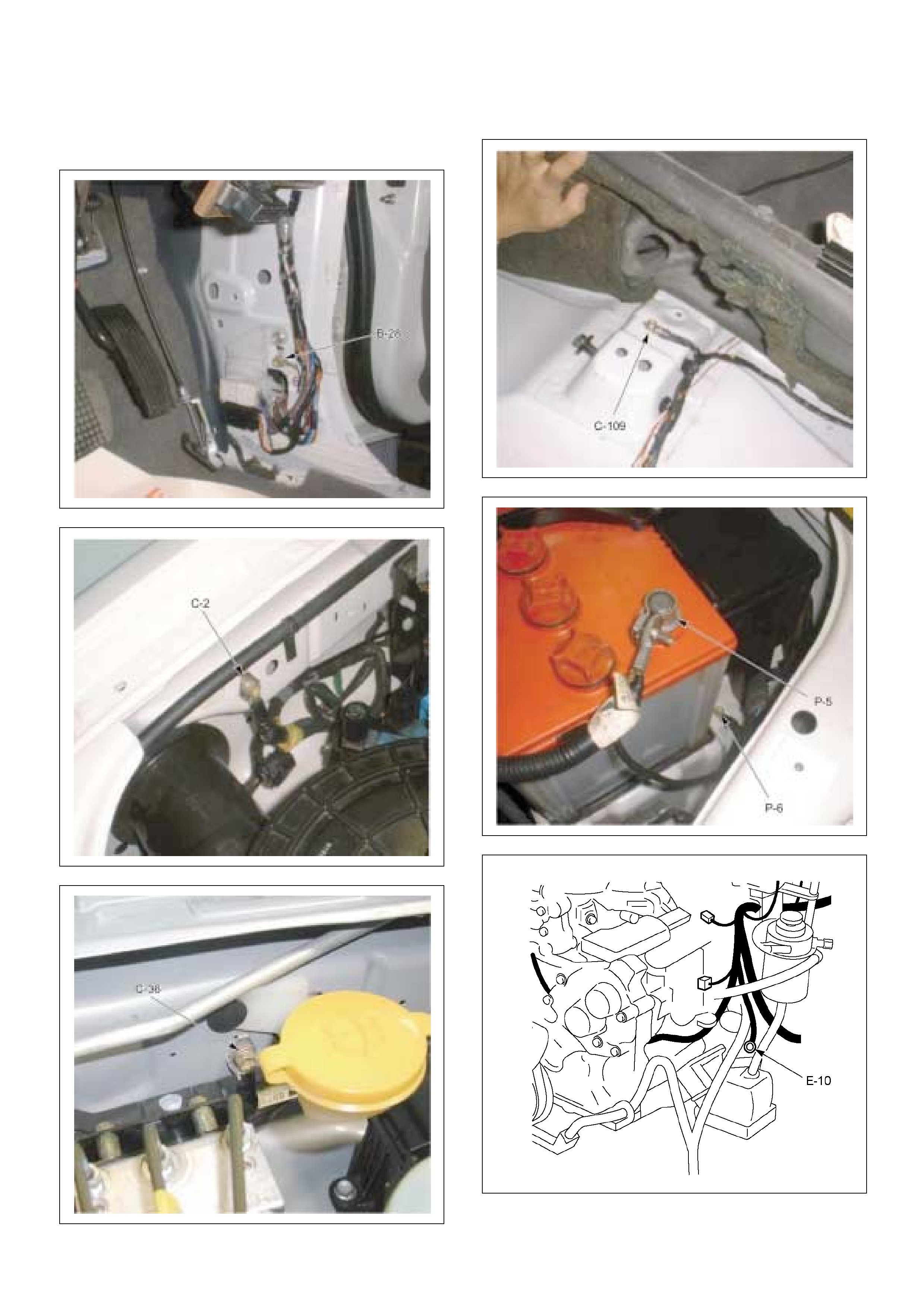

LOCATION

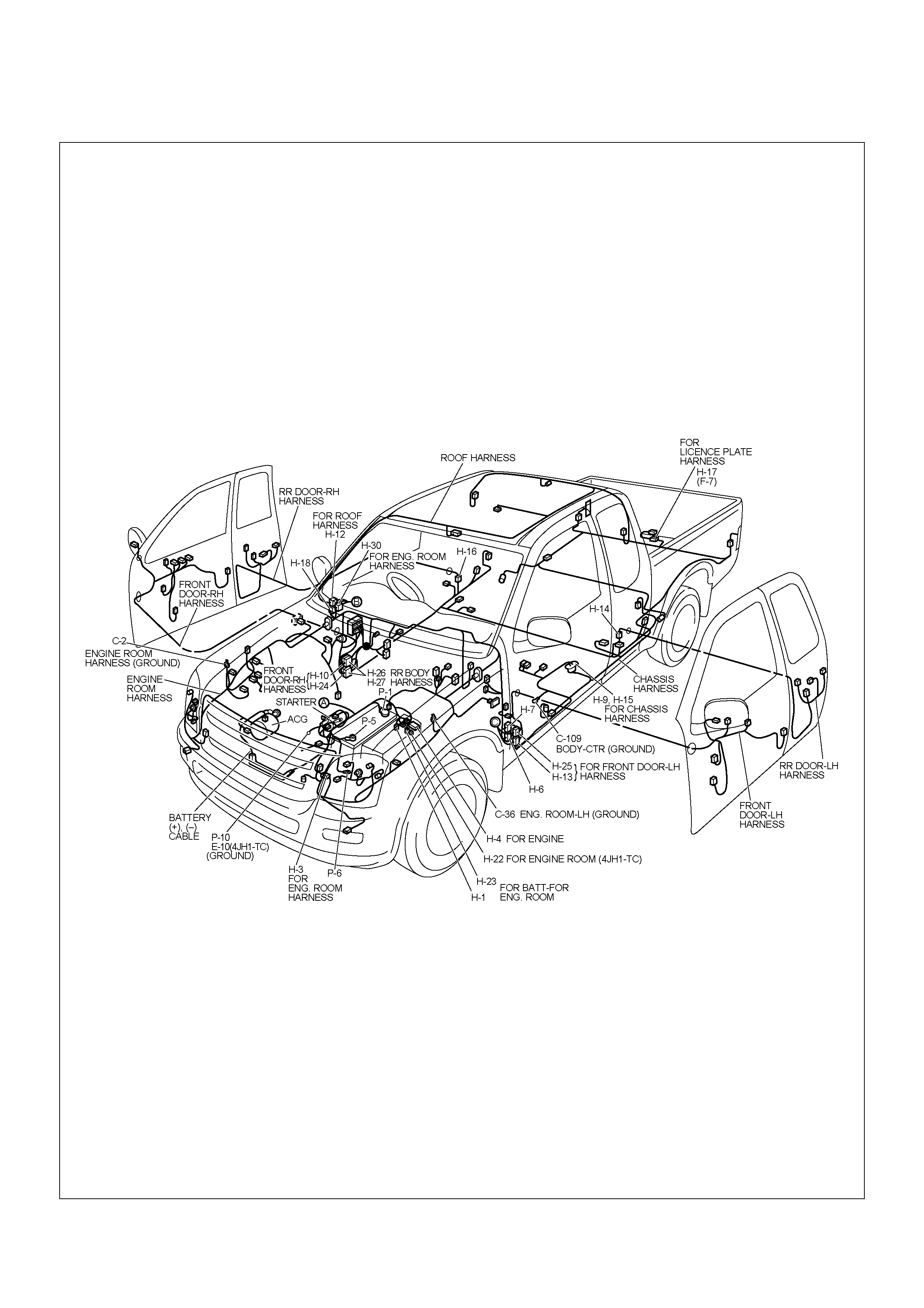

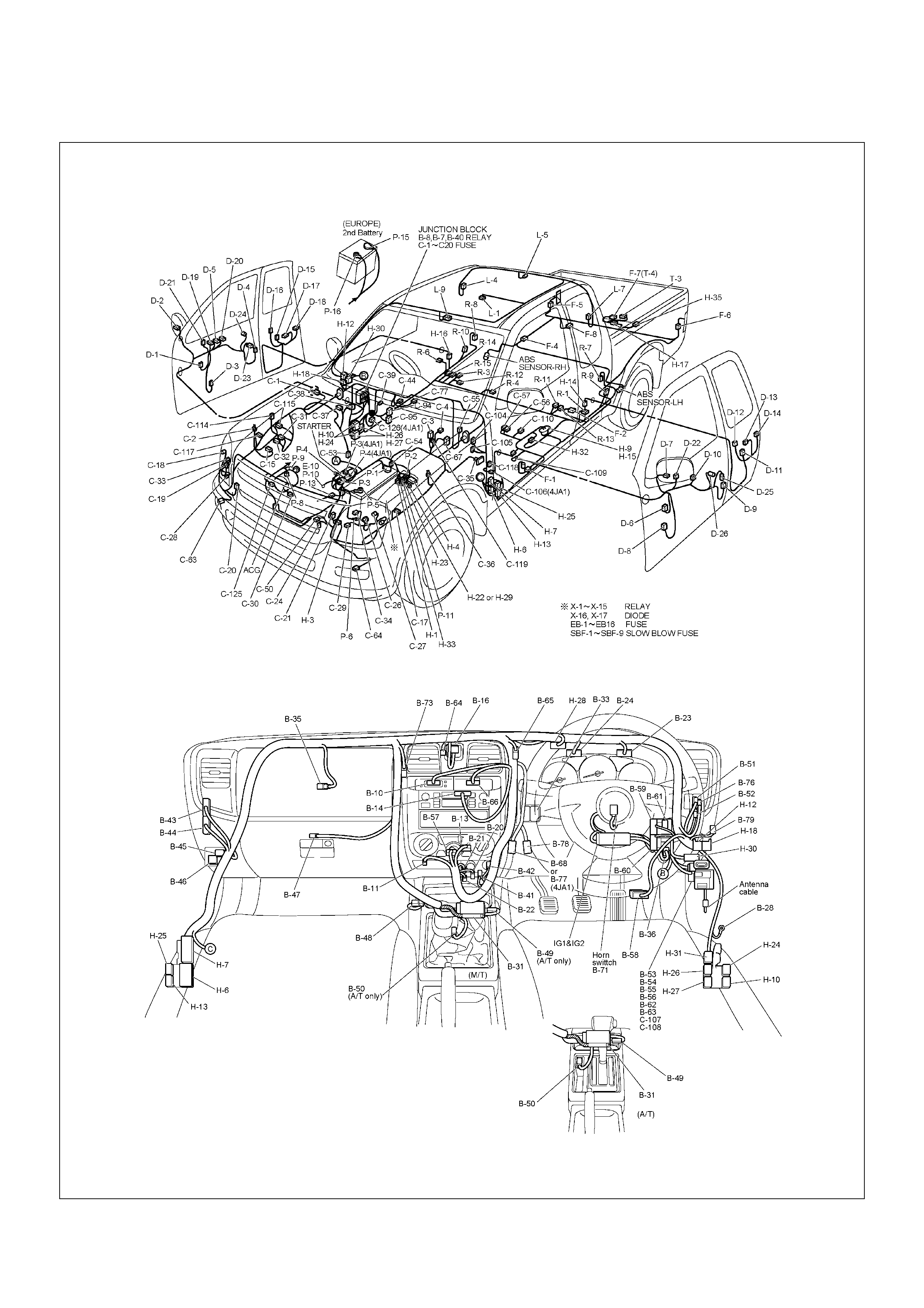

CABLE HARNESS & CONNECTOR LOCATION

PARTS LOCATION

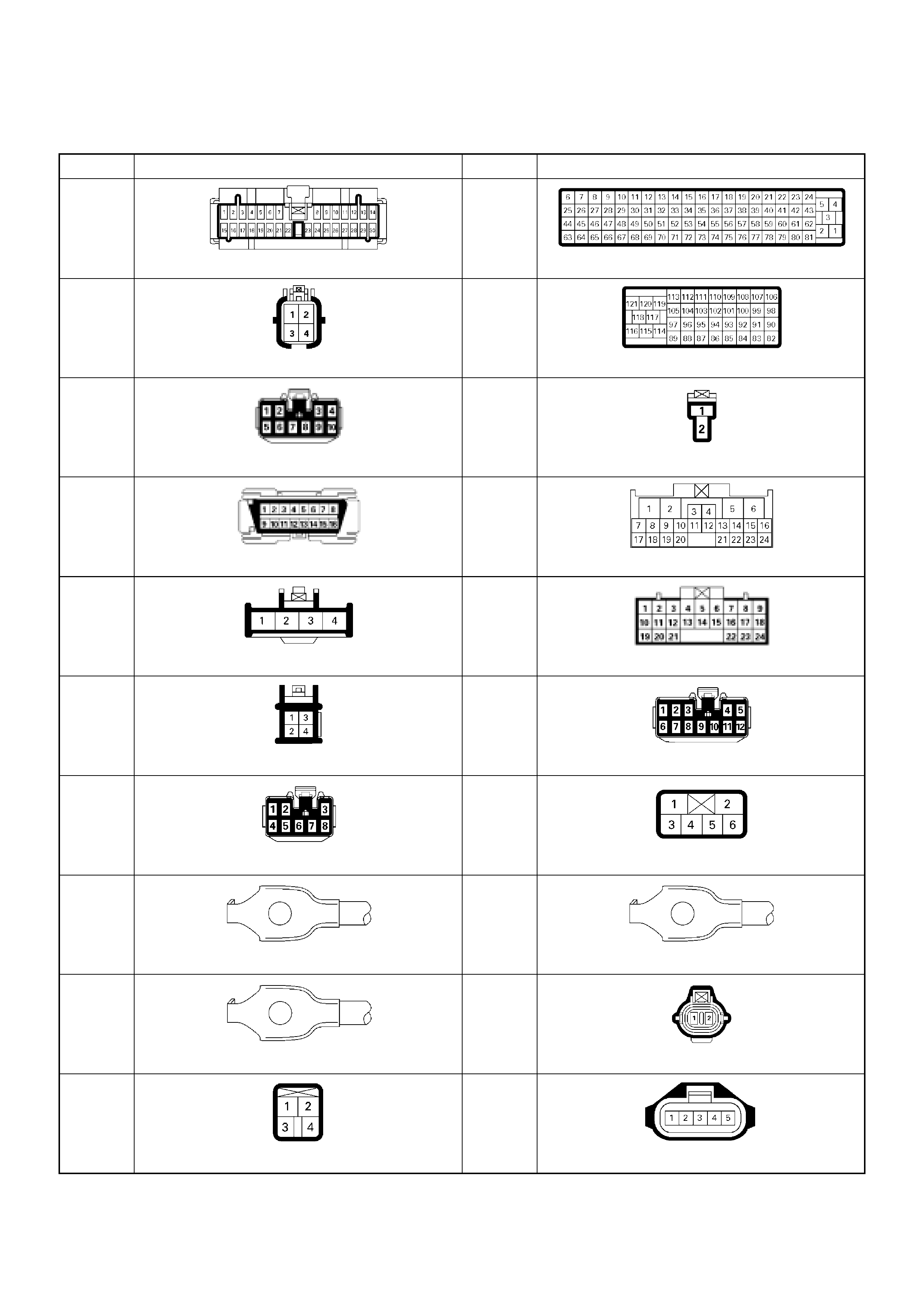

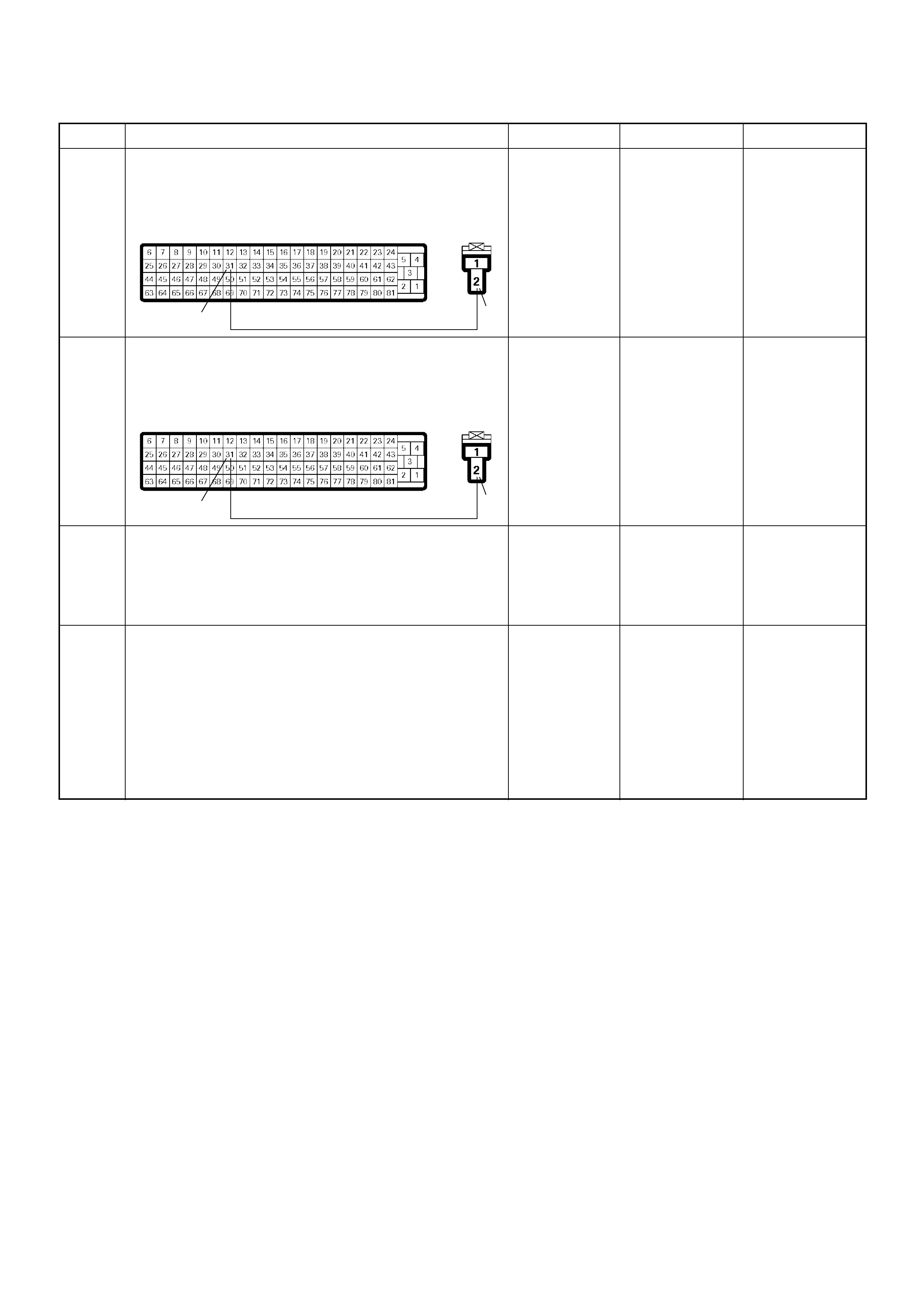

CONNECTOR LIST

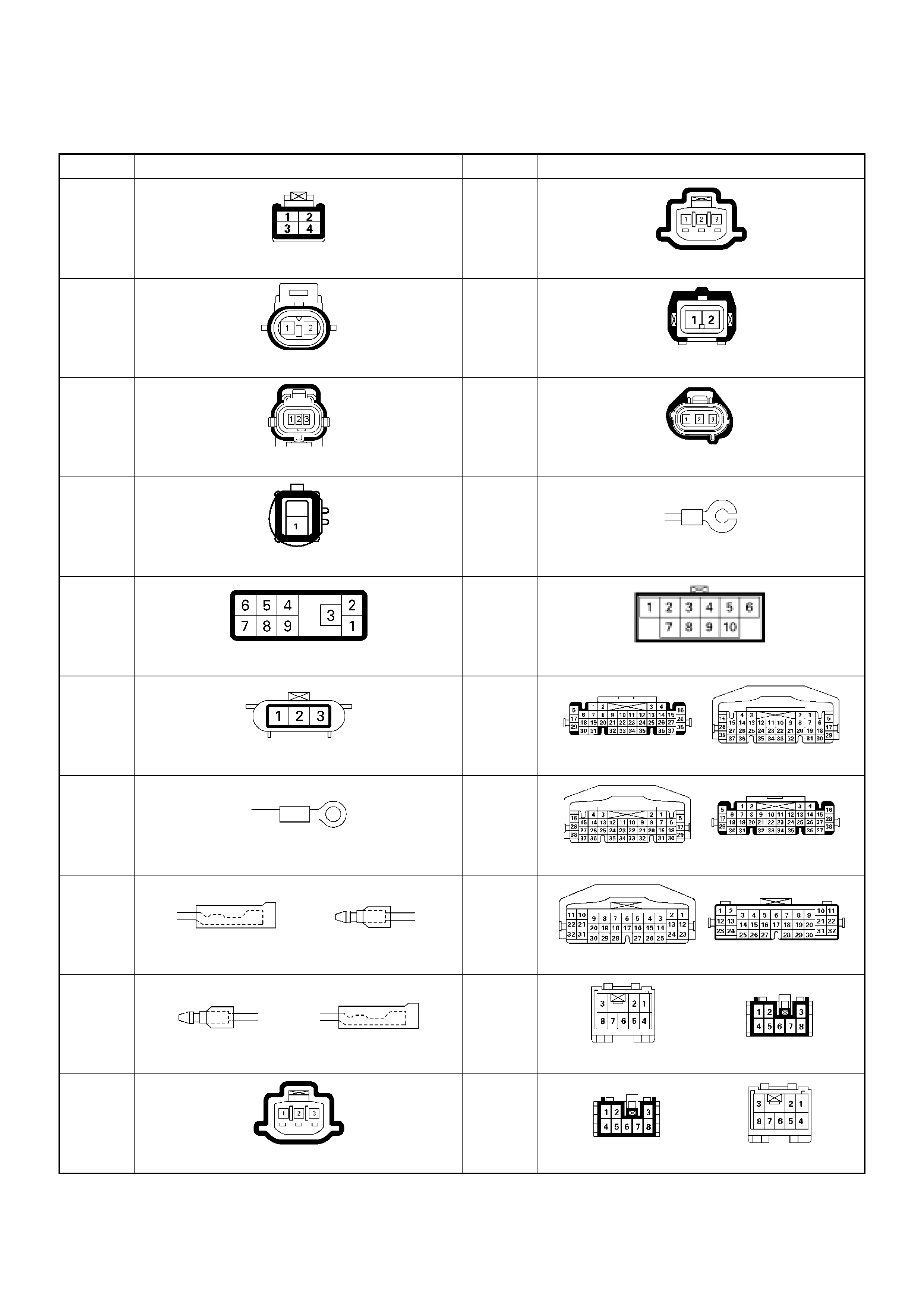

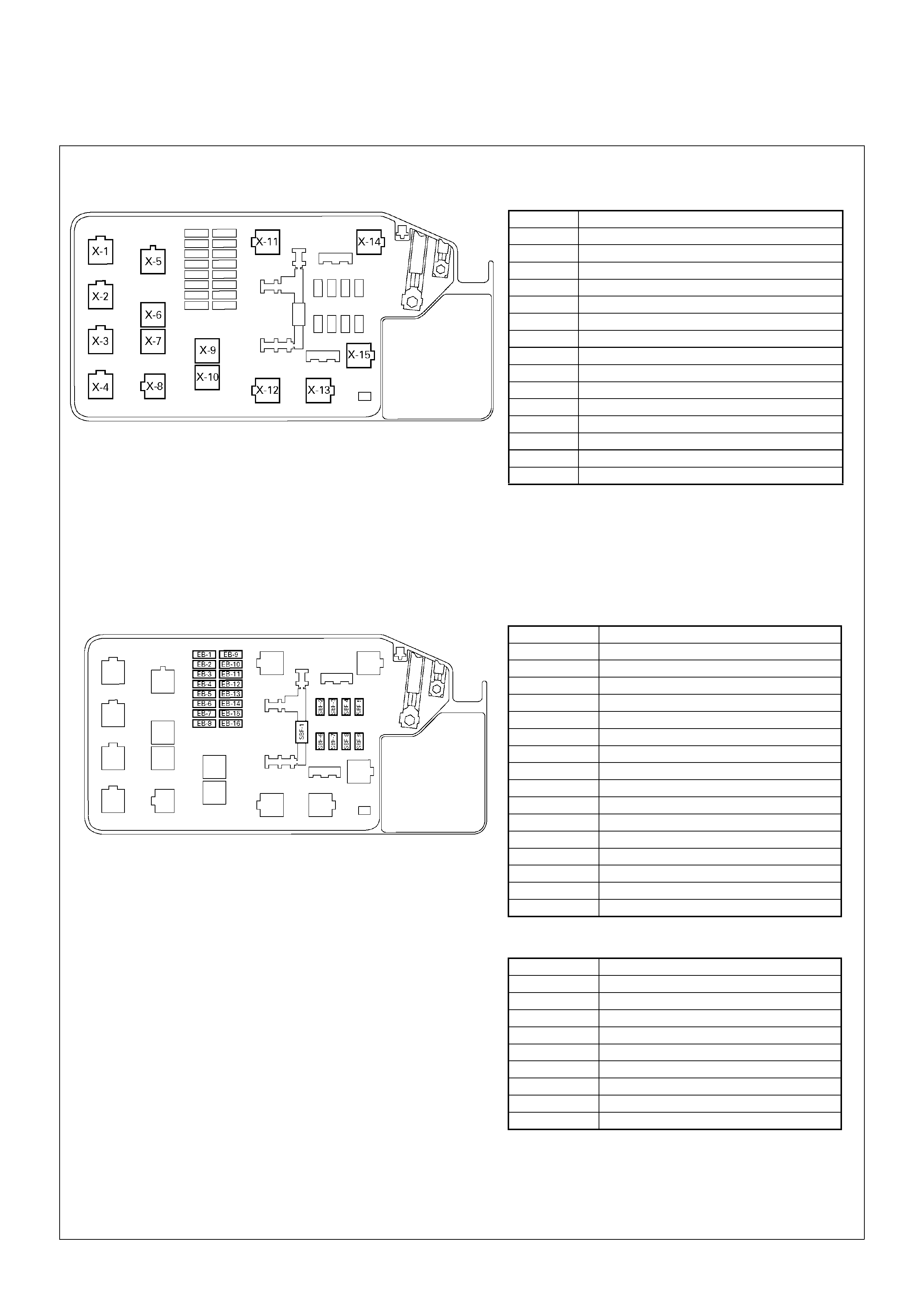

RELAY AND FUSE

RELAY AND FUSE BOX LOCATION

RELAY AND FUSE BOX LOCATION

FUSE AND RELAY LOCATION

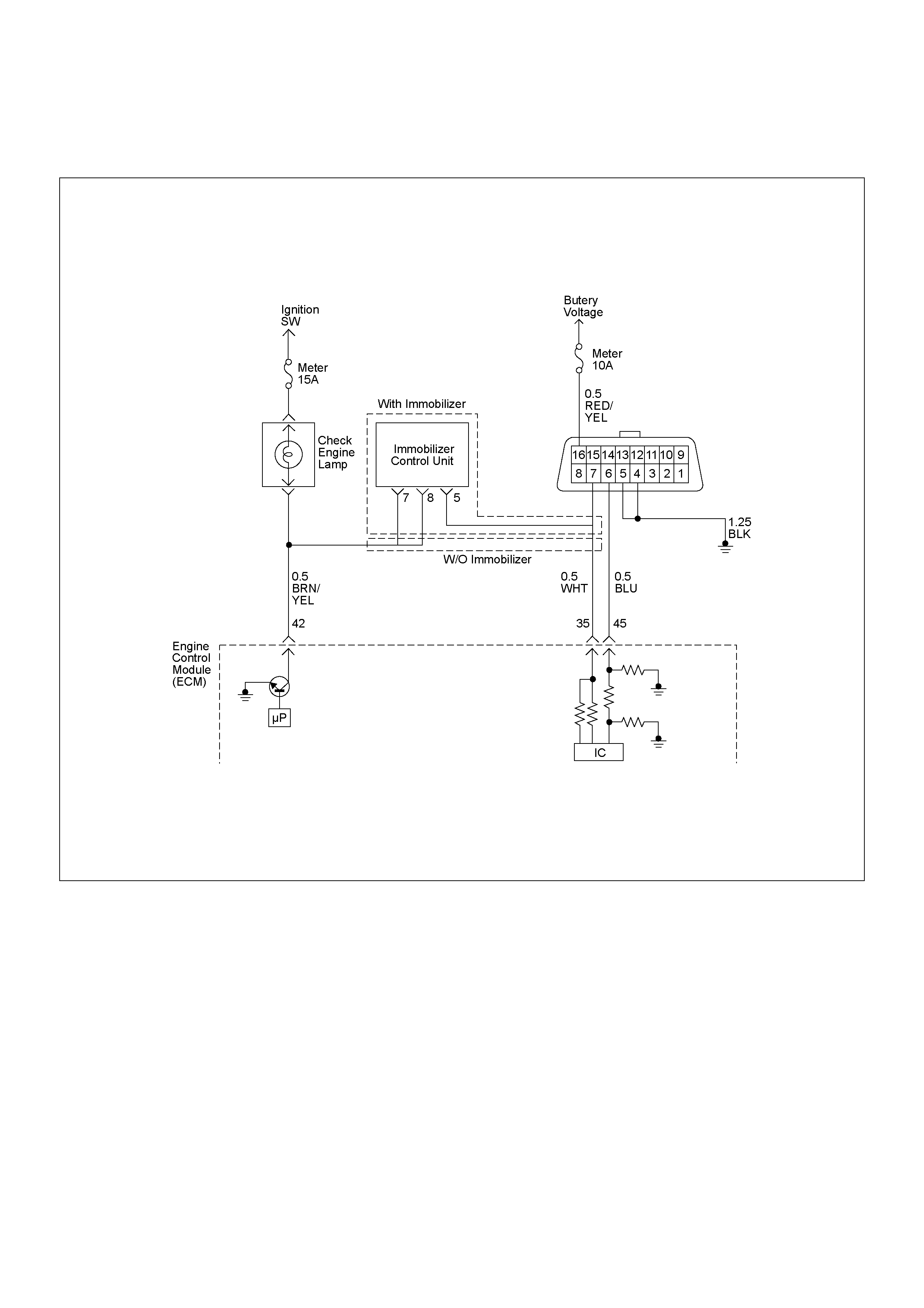

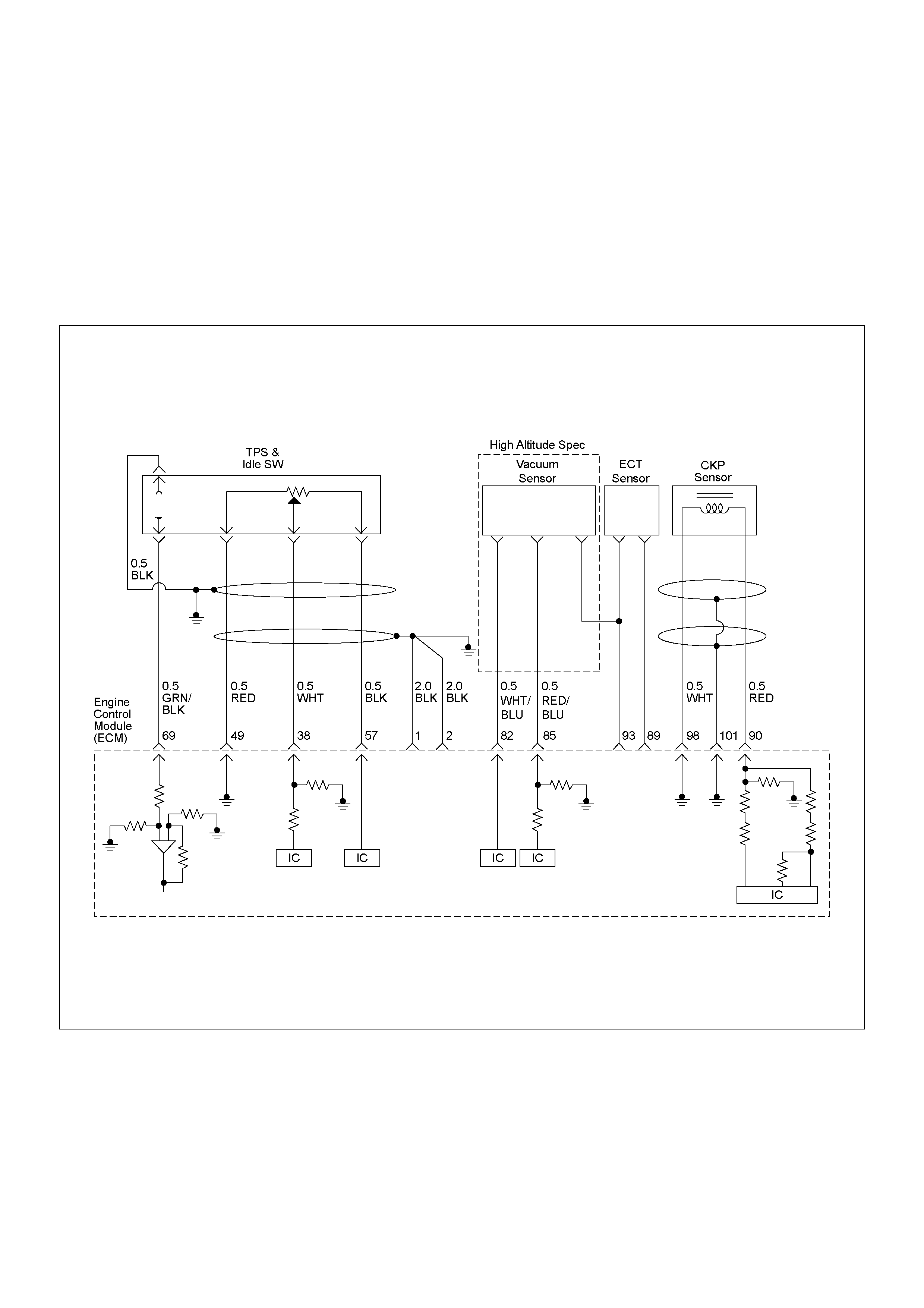

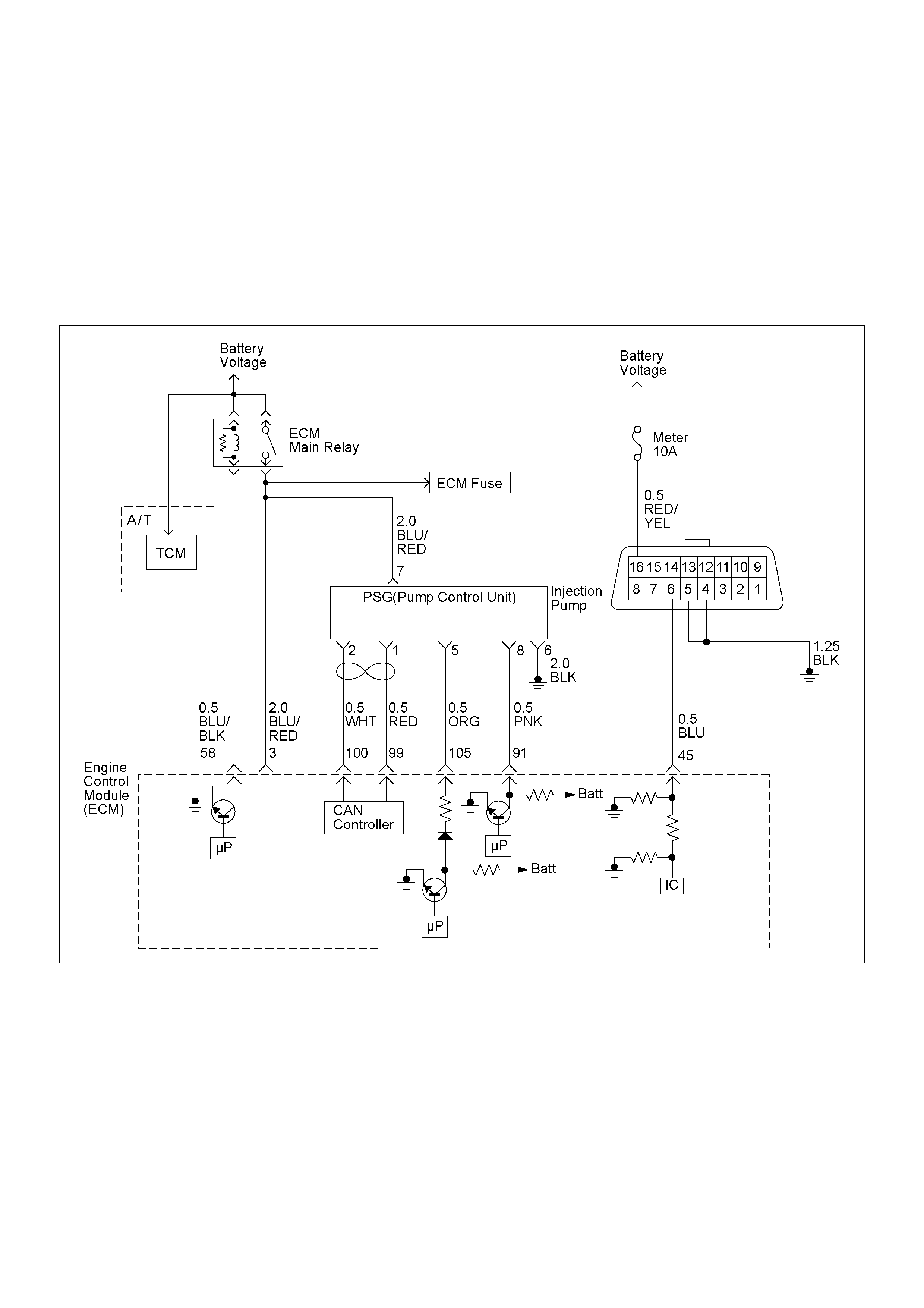

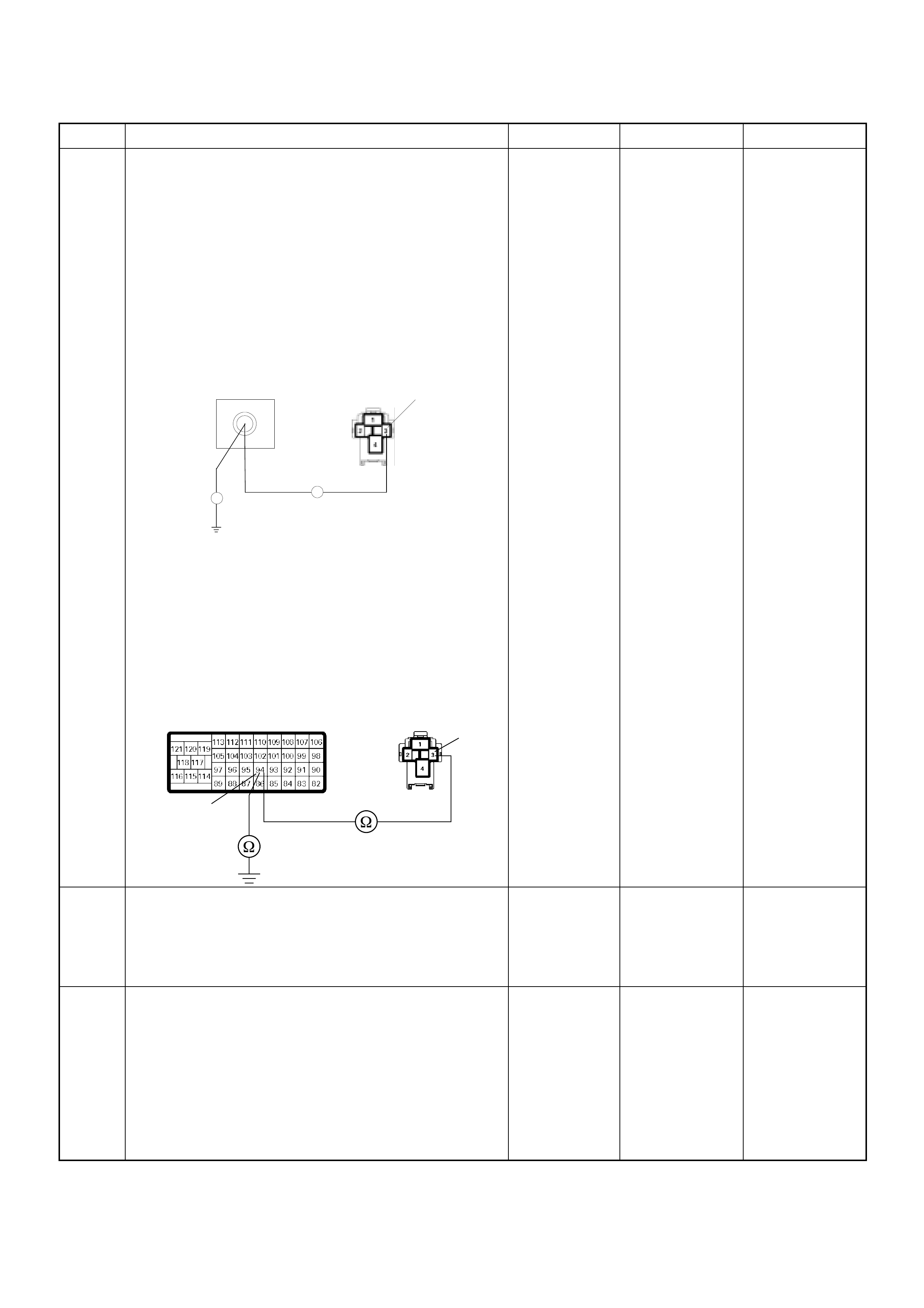

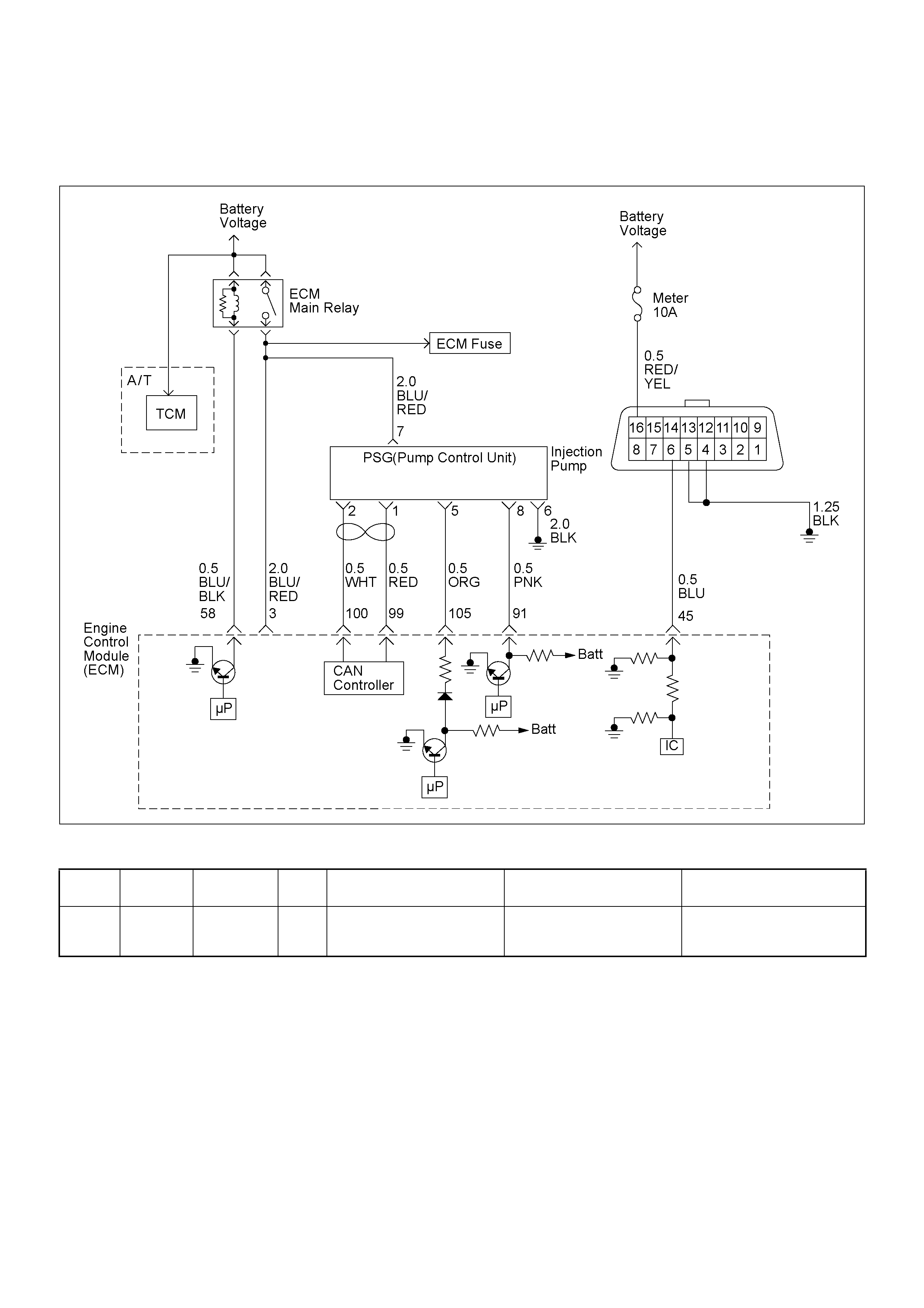

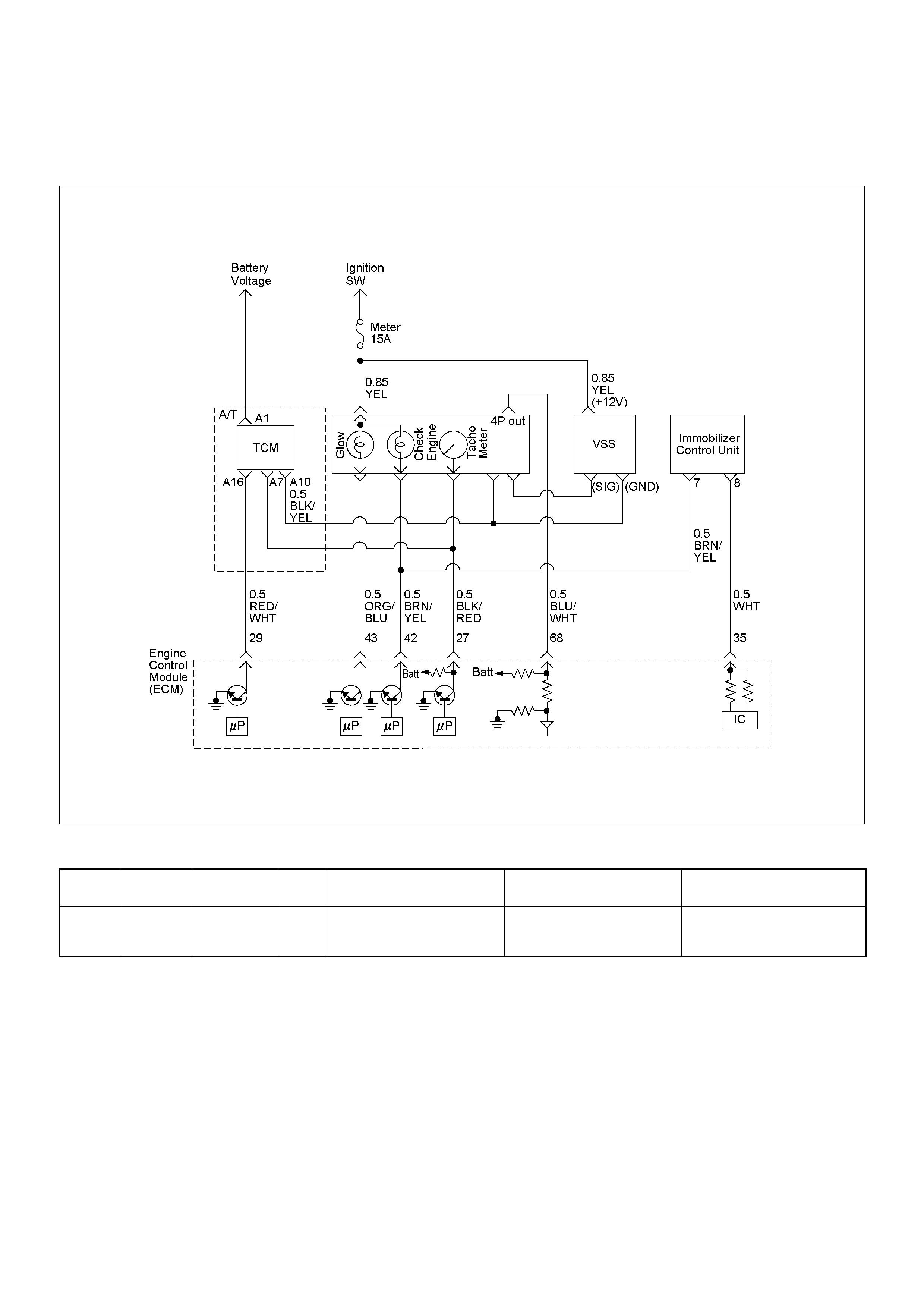

ECM WIRING DIAGRAM

ECM WIRING DIAGRAM (1/7)

ECM WIRING DIAGRAM (2/7)

ECM WIRING DIAGRAM (3/7)

ECM WIRING DIAGRAM (4/7)

ECM WIRING DIAGRAM (5/7)

ECM WIRING DIAGRAM (6/7)

ECM WIRING DIAGRAM (7/7)

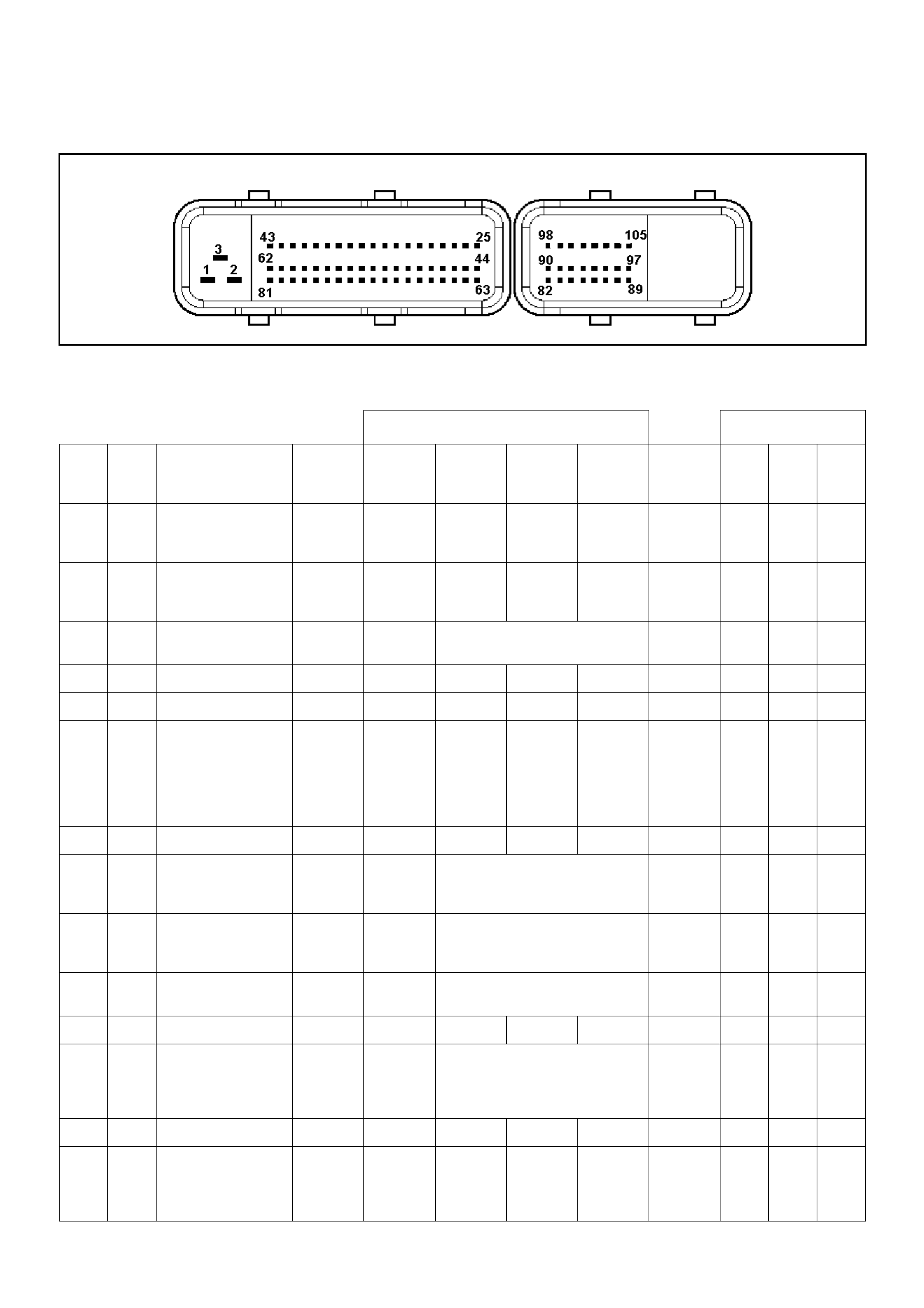

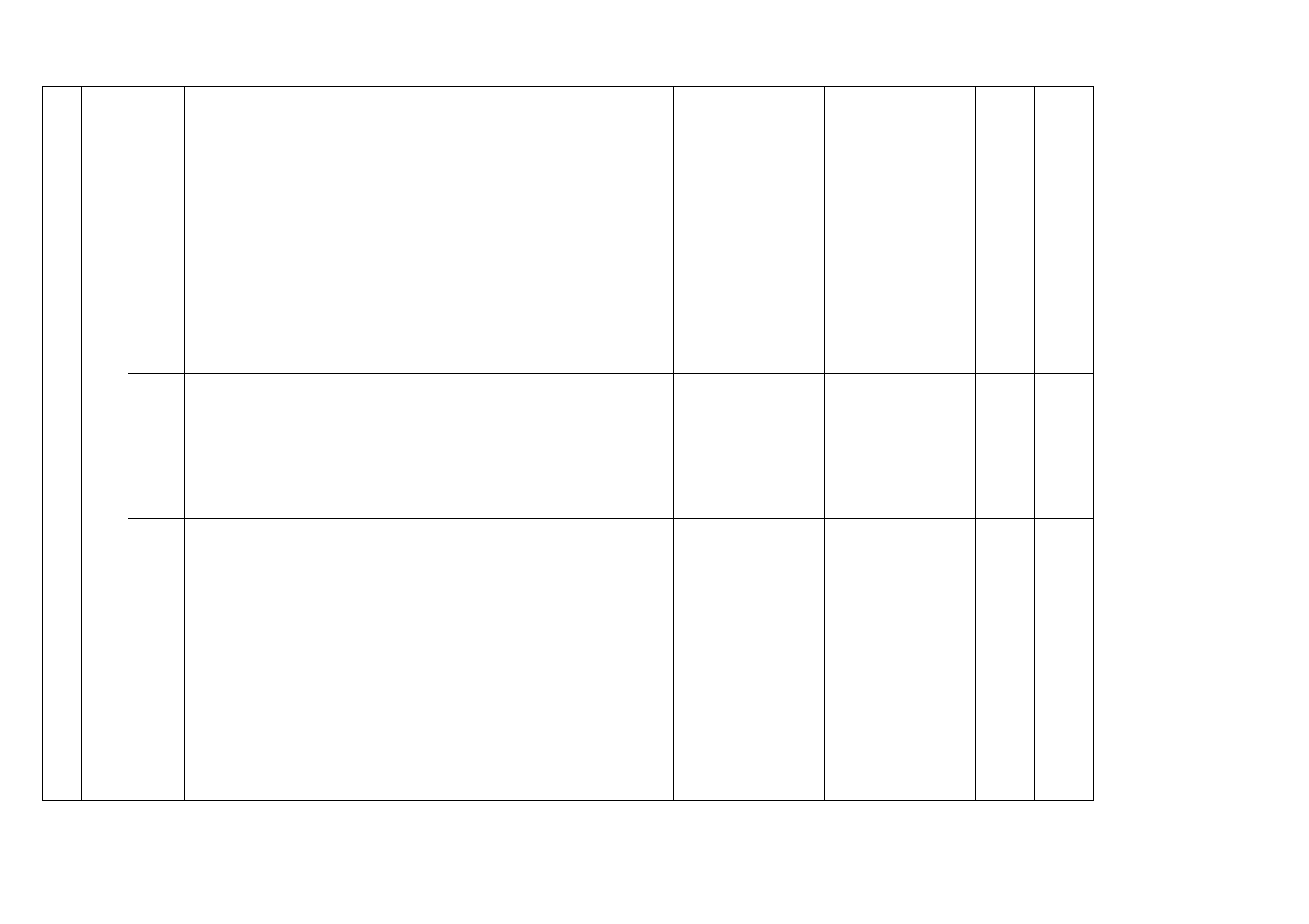

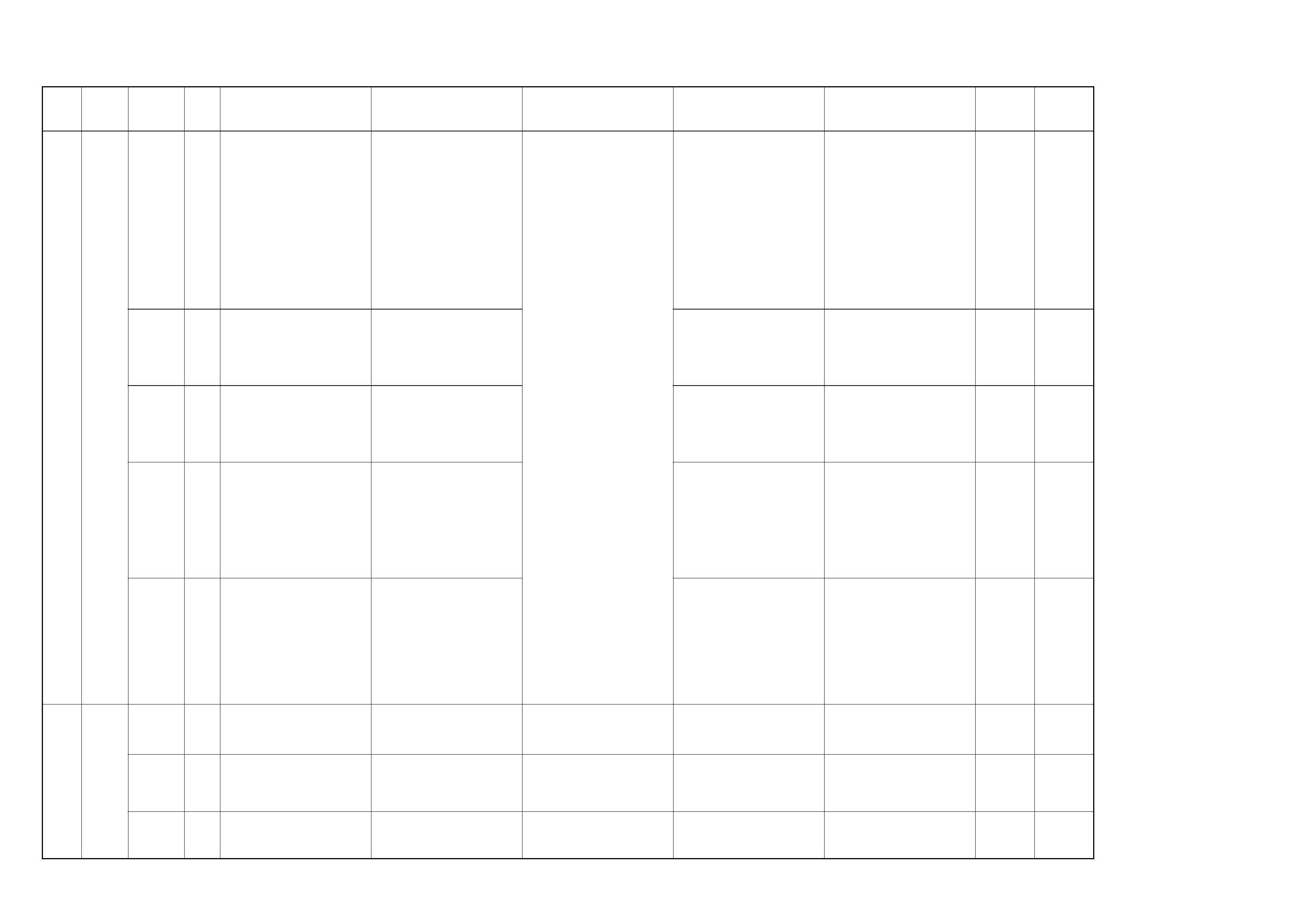

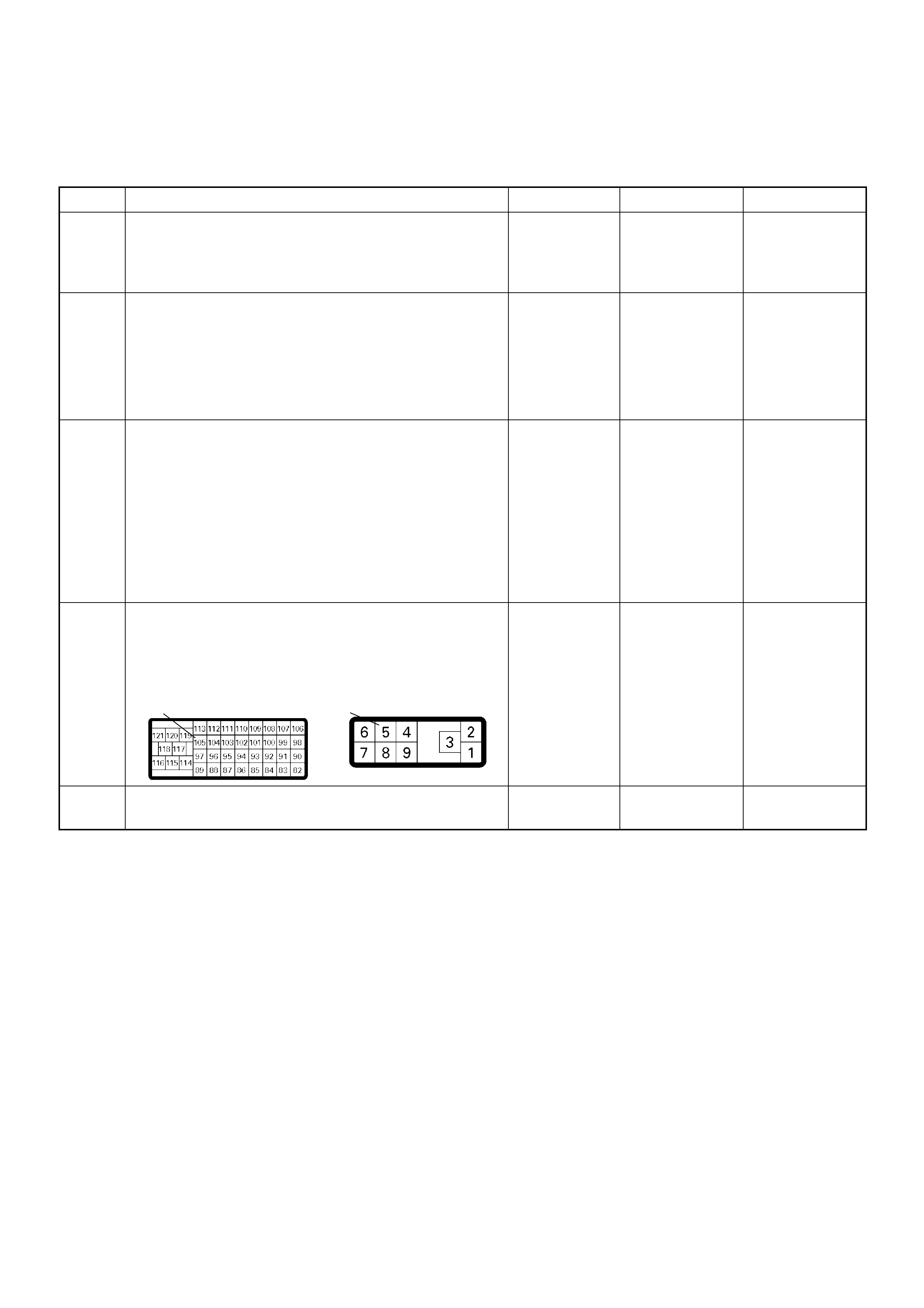

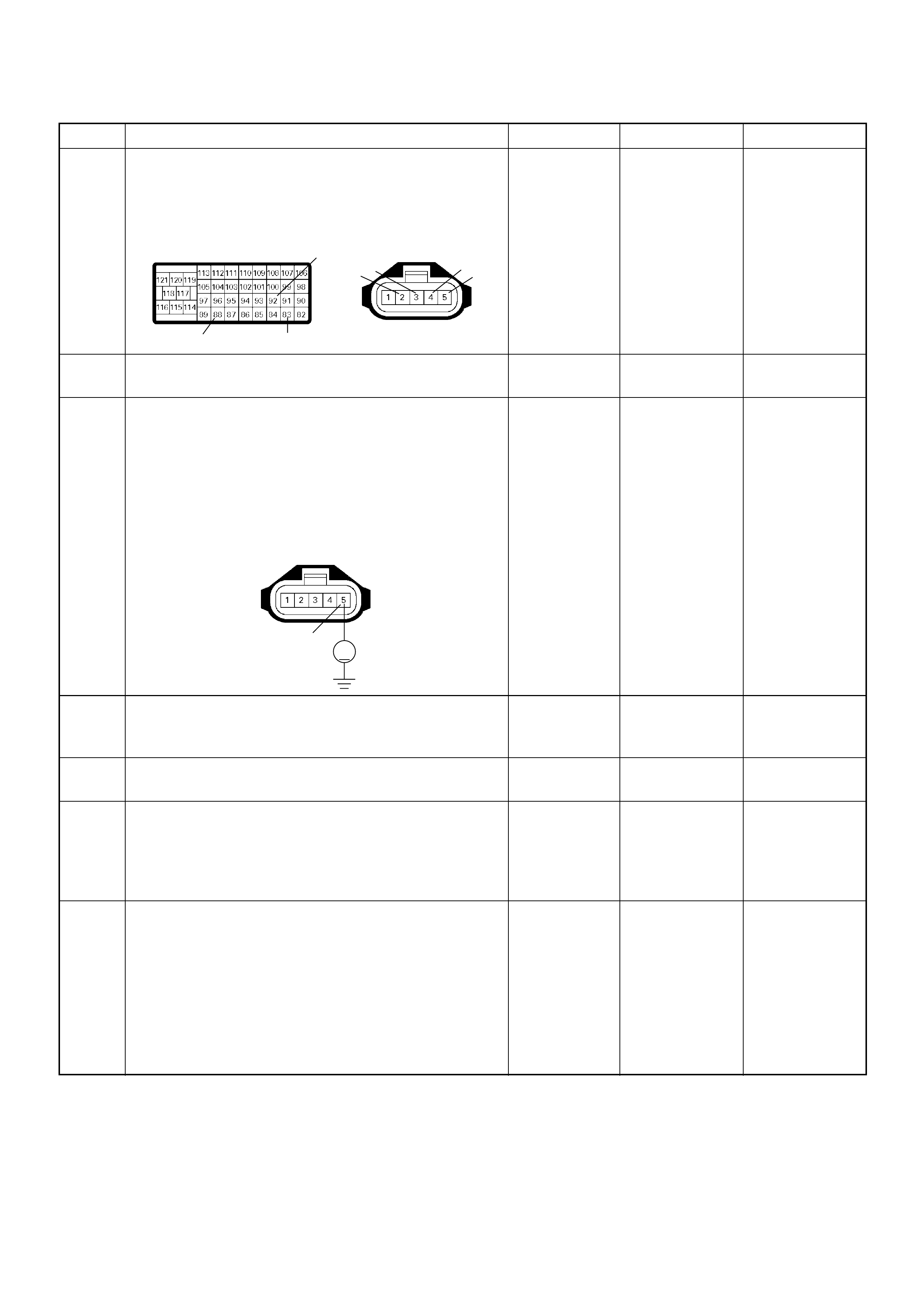

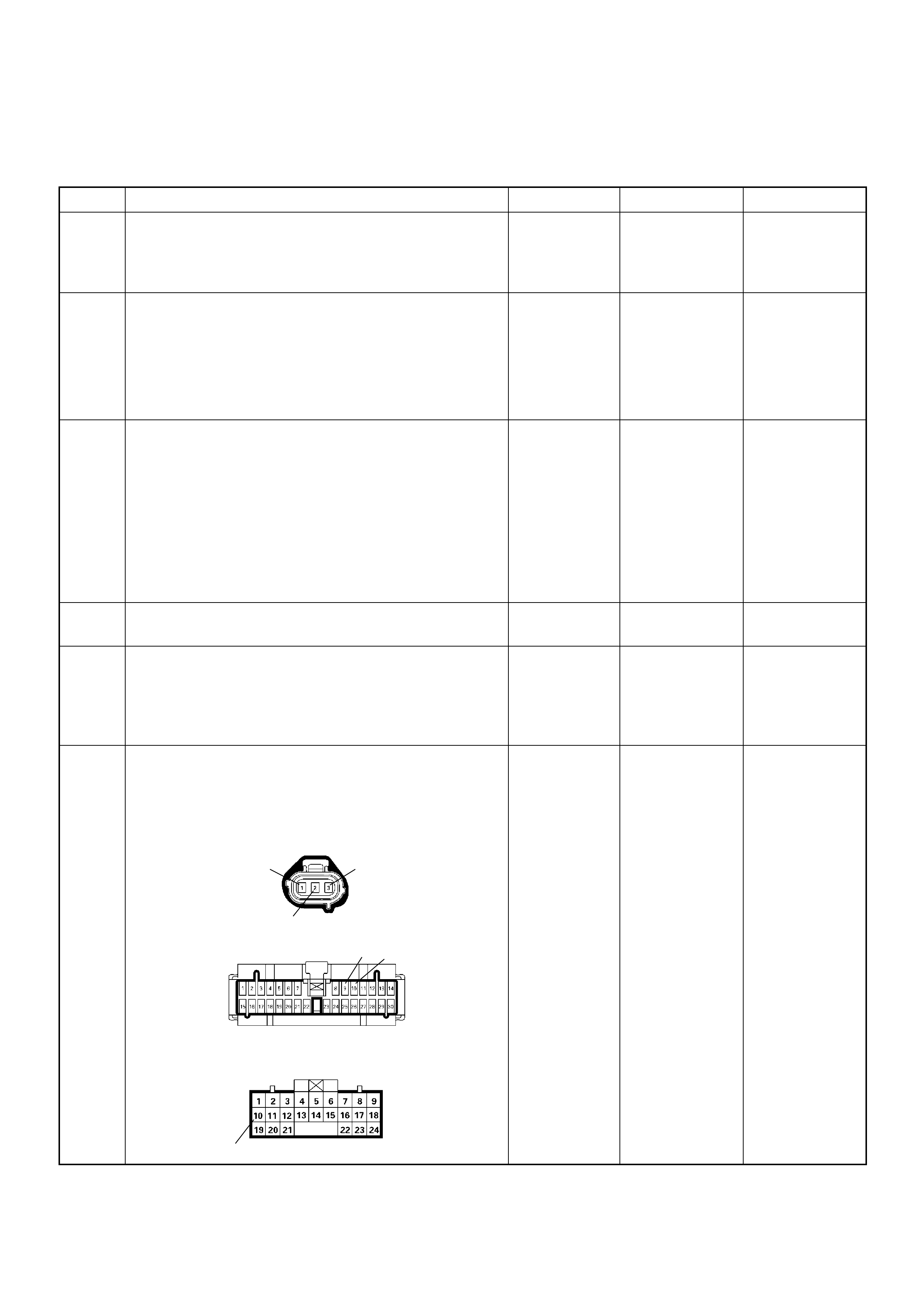

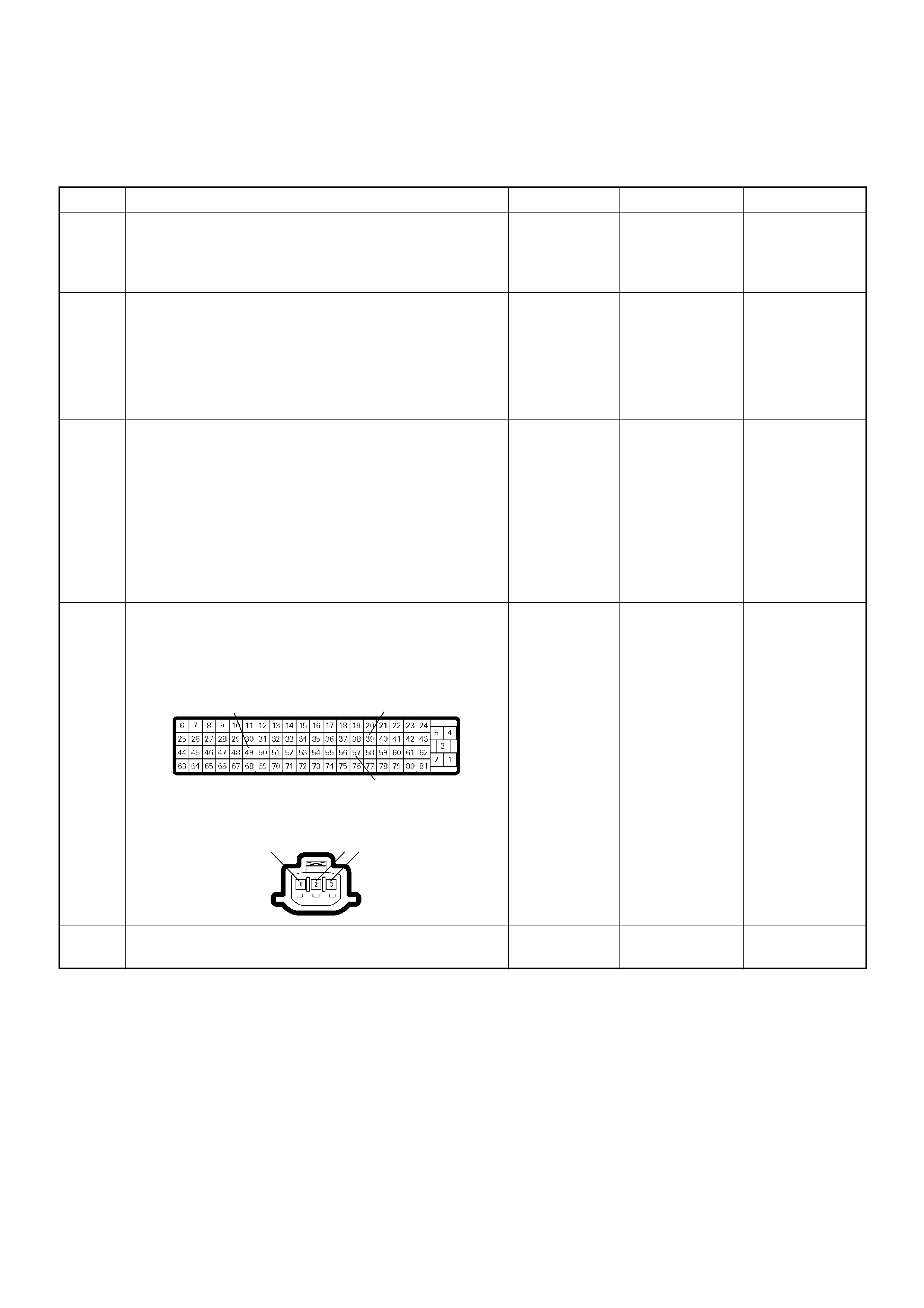

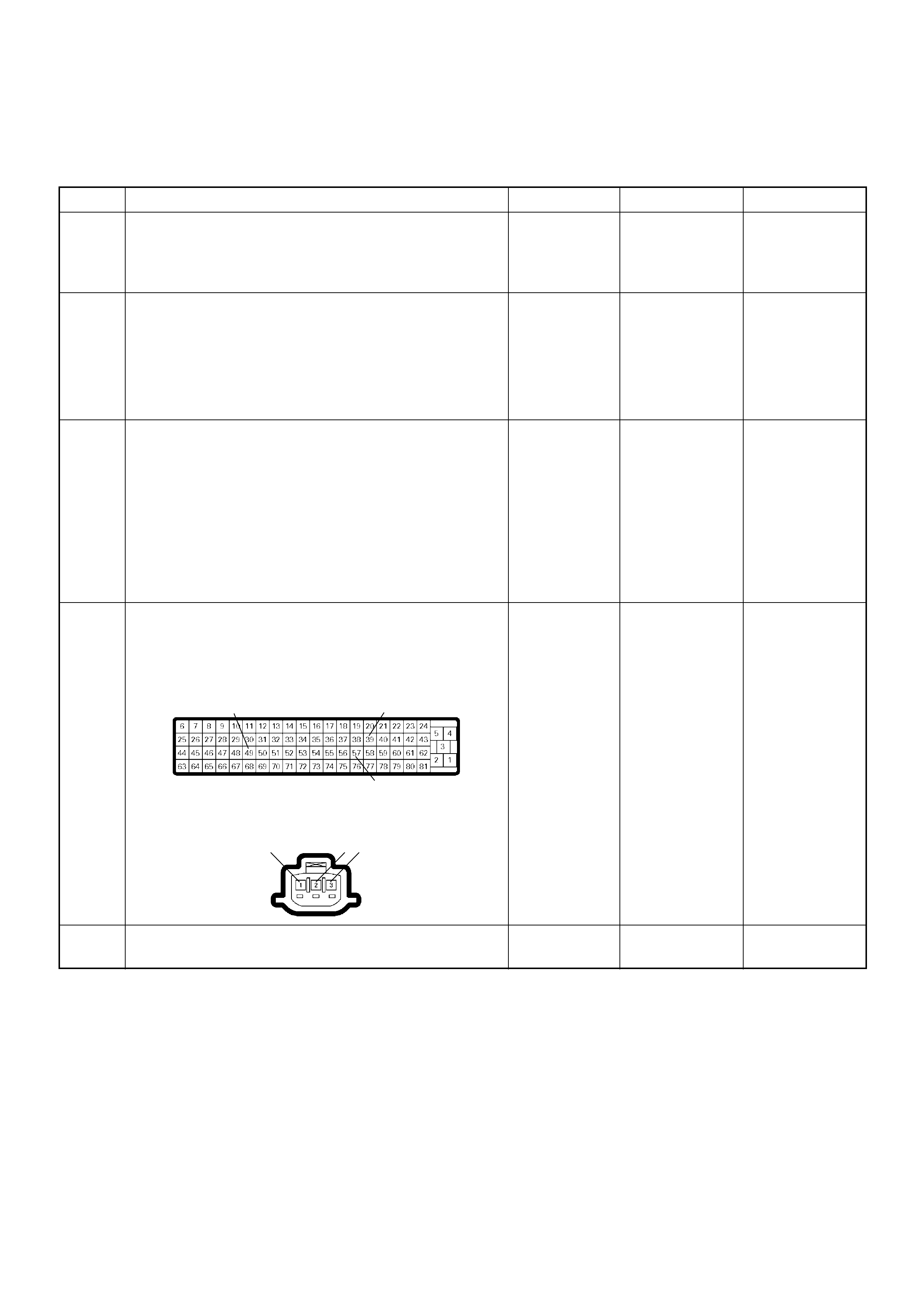

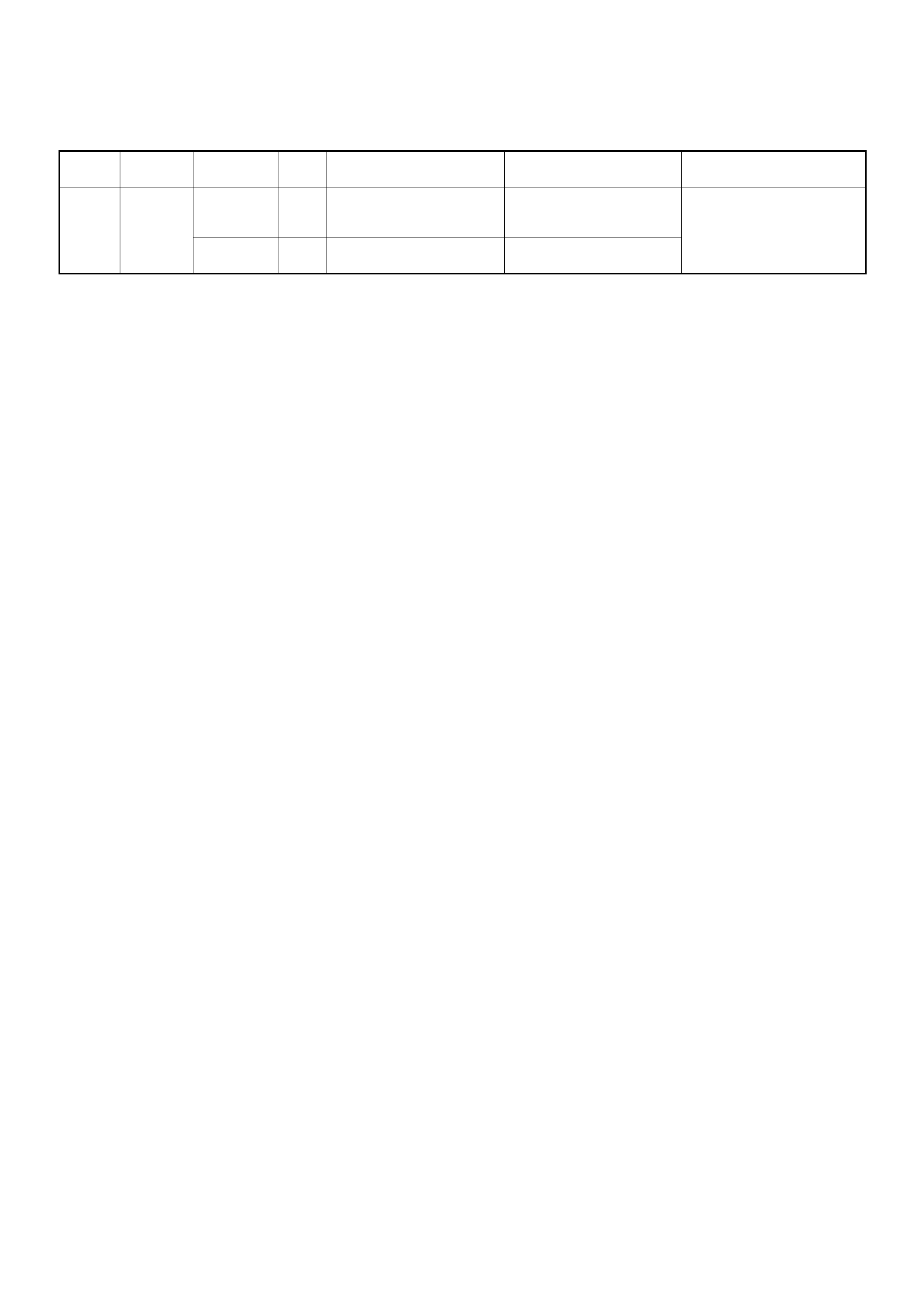

ECM CONNECTOR PIN ASSIGNMENT

& OUTPUT SIGNAL

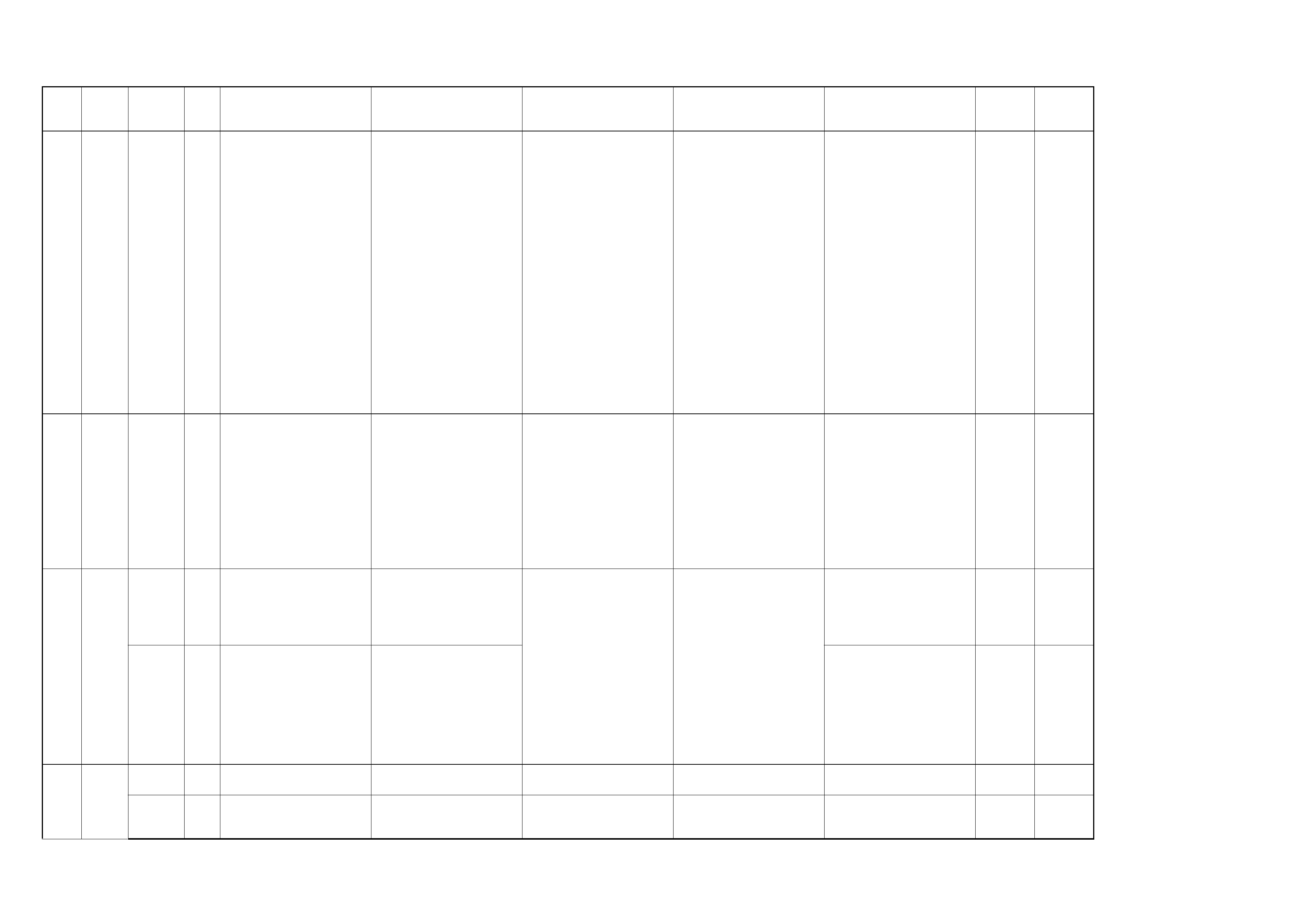

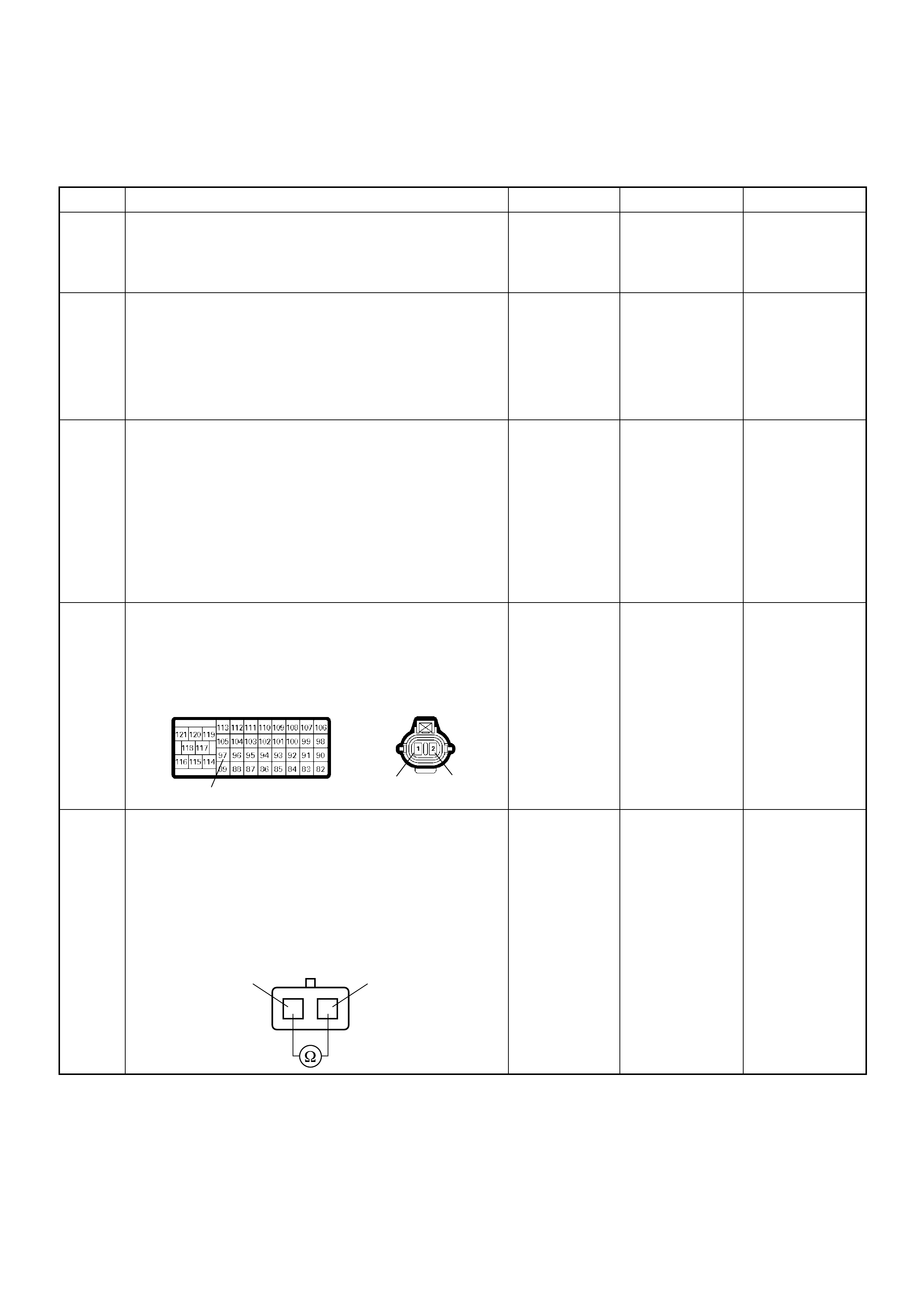

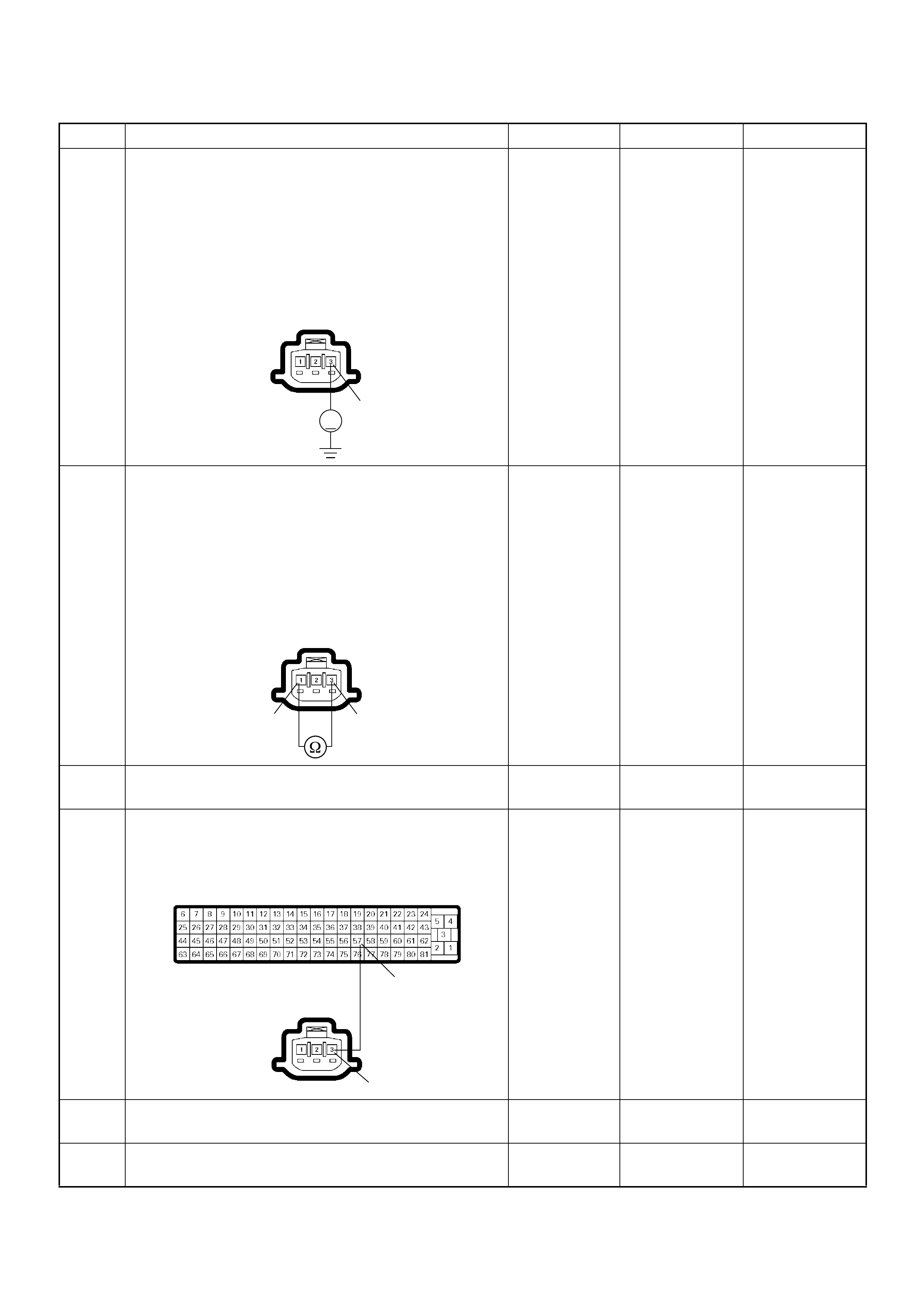

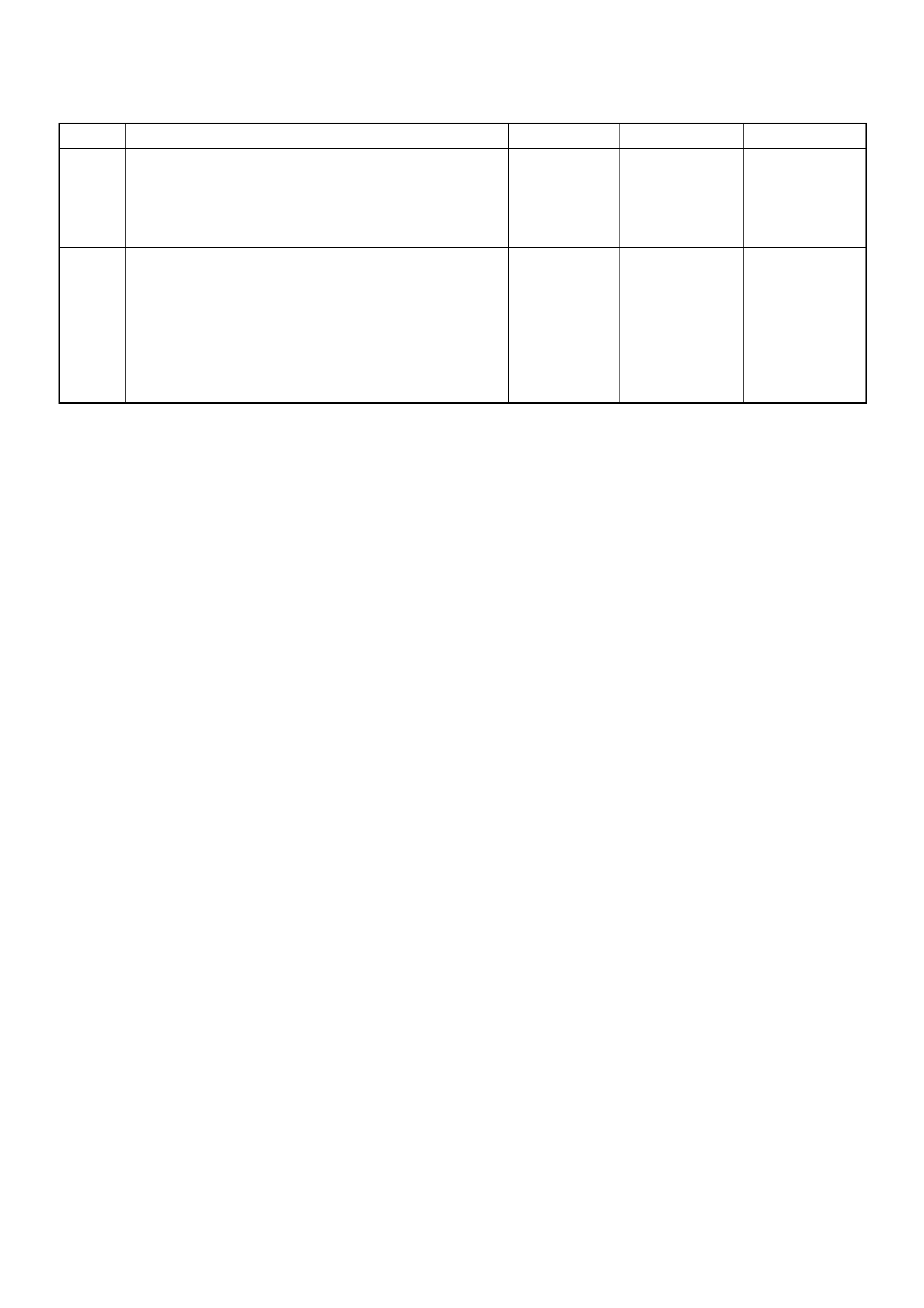

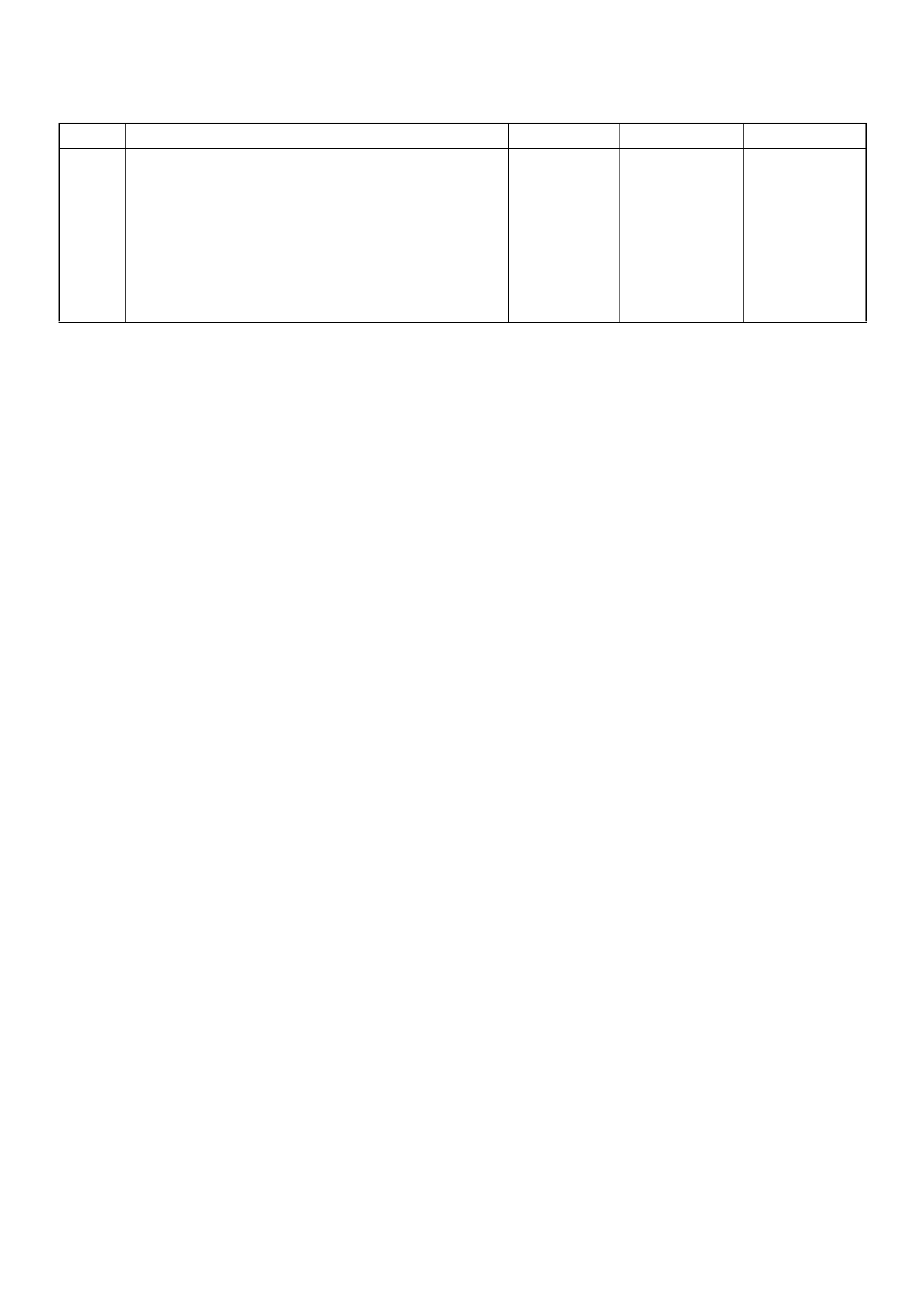

PSG CONNECTOR PIN ASSIGNMENT

& OUTPUT SIGNAL

GENERAL DESCRIPTION FOR ECM AND SENSORS

Engine Control Module (ECM)

Pump Control Unit (PSG) & Data Exchange

Between Control Module

Mass Air Flow (MAF) Sensor & Intake Air

Temperature (IAT) Sensor

Throttle Position Sensor (T PS)

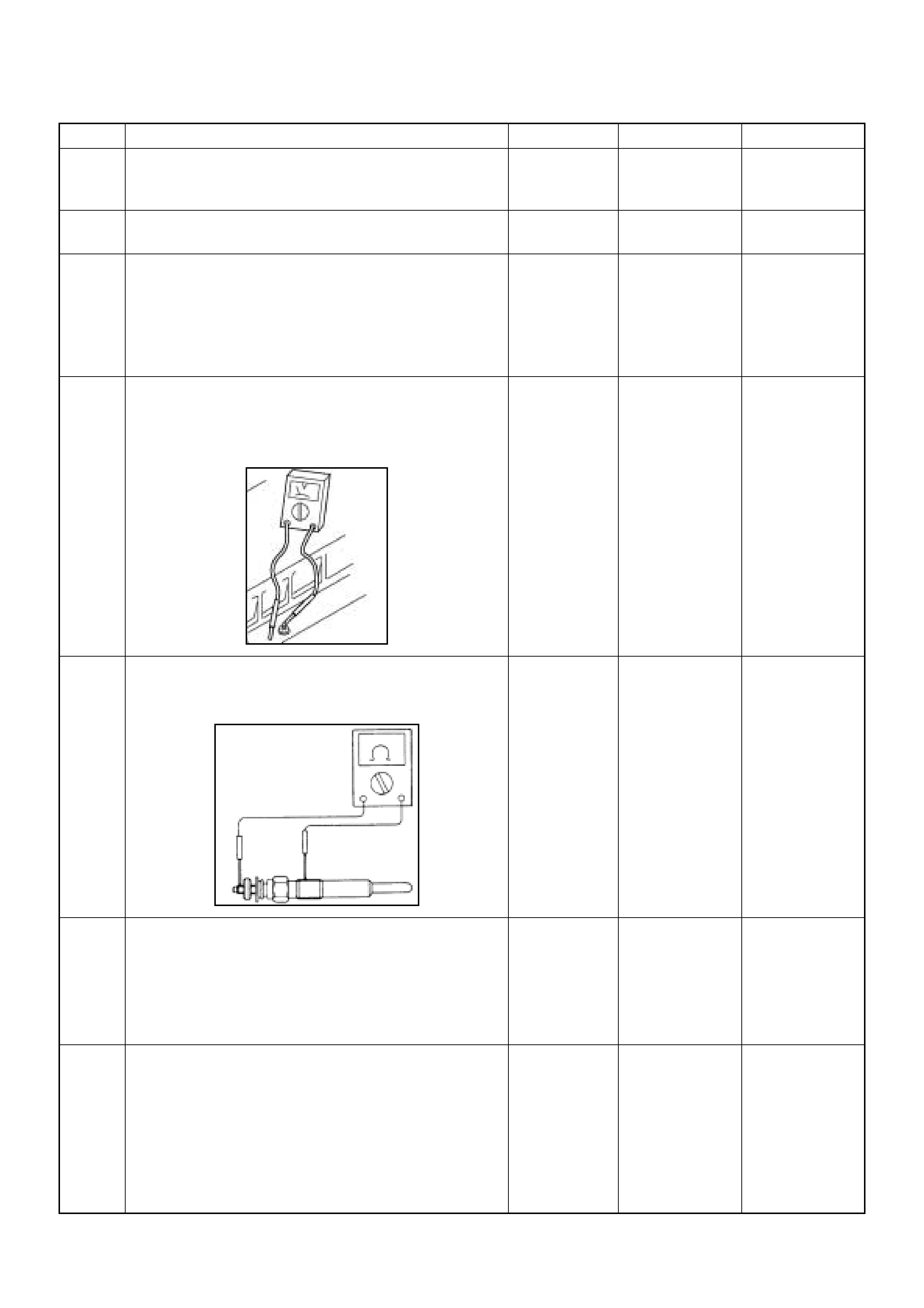

Crankshaft Position (CKP) Sensor

Engine Coolant Temperature (ECT) Sensor

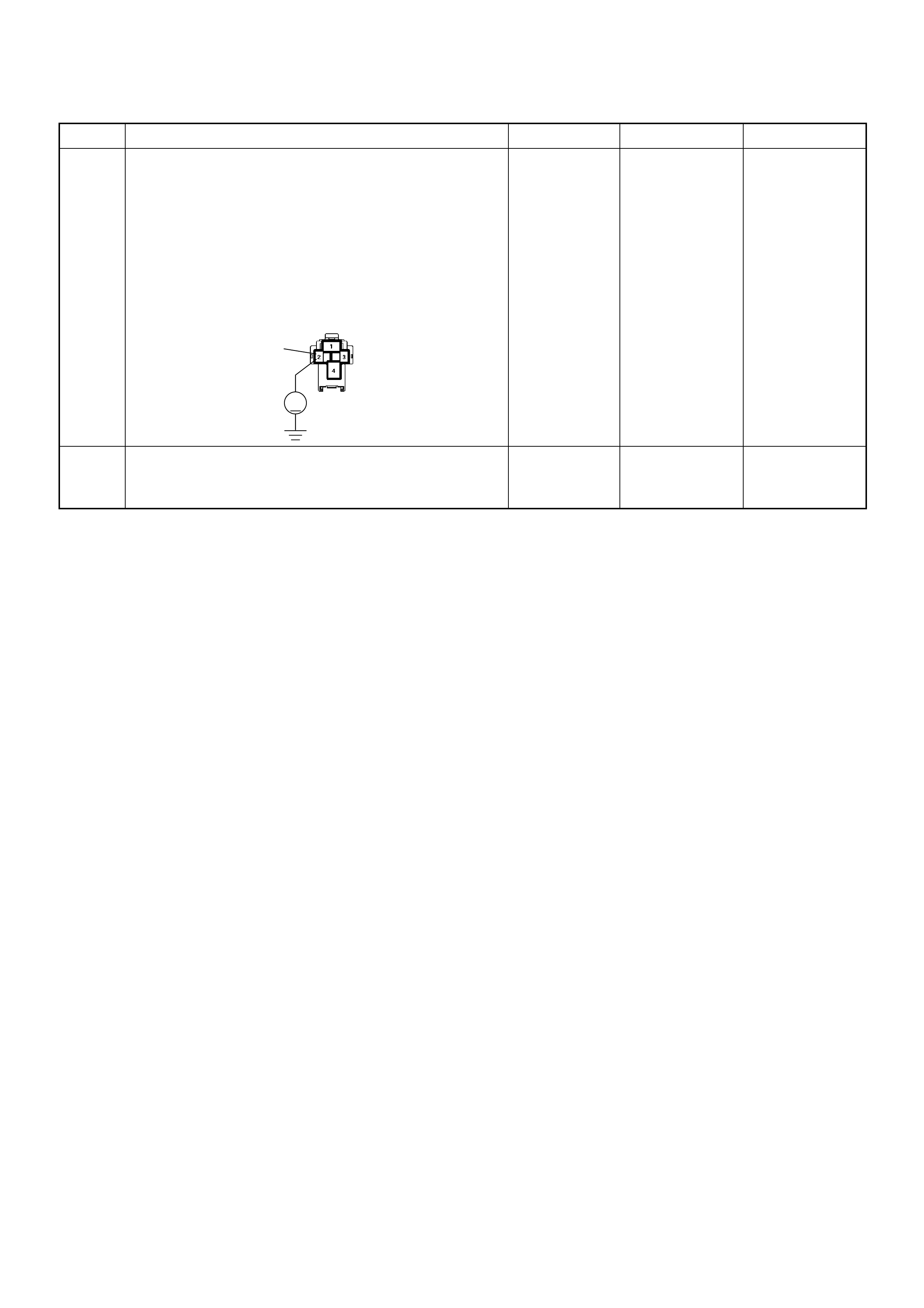

Vehicle Speed Sensor (VSS)

GENERAL DESCRIPTION FOR EGR

(EXHAUST GAS RE-CIRCULATION)

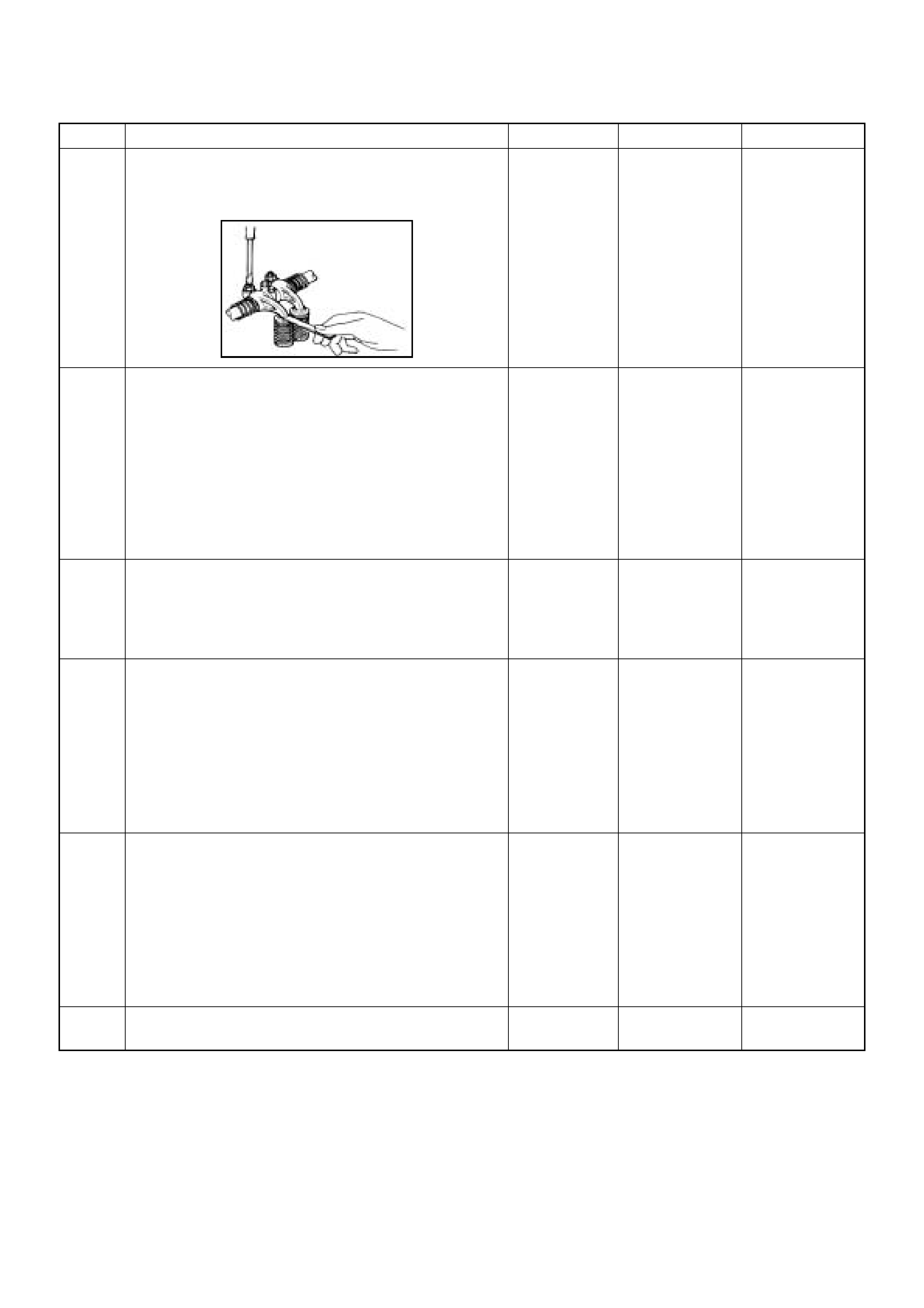

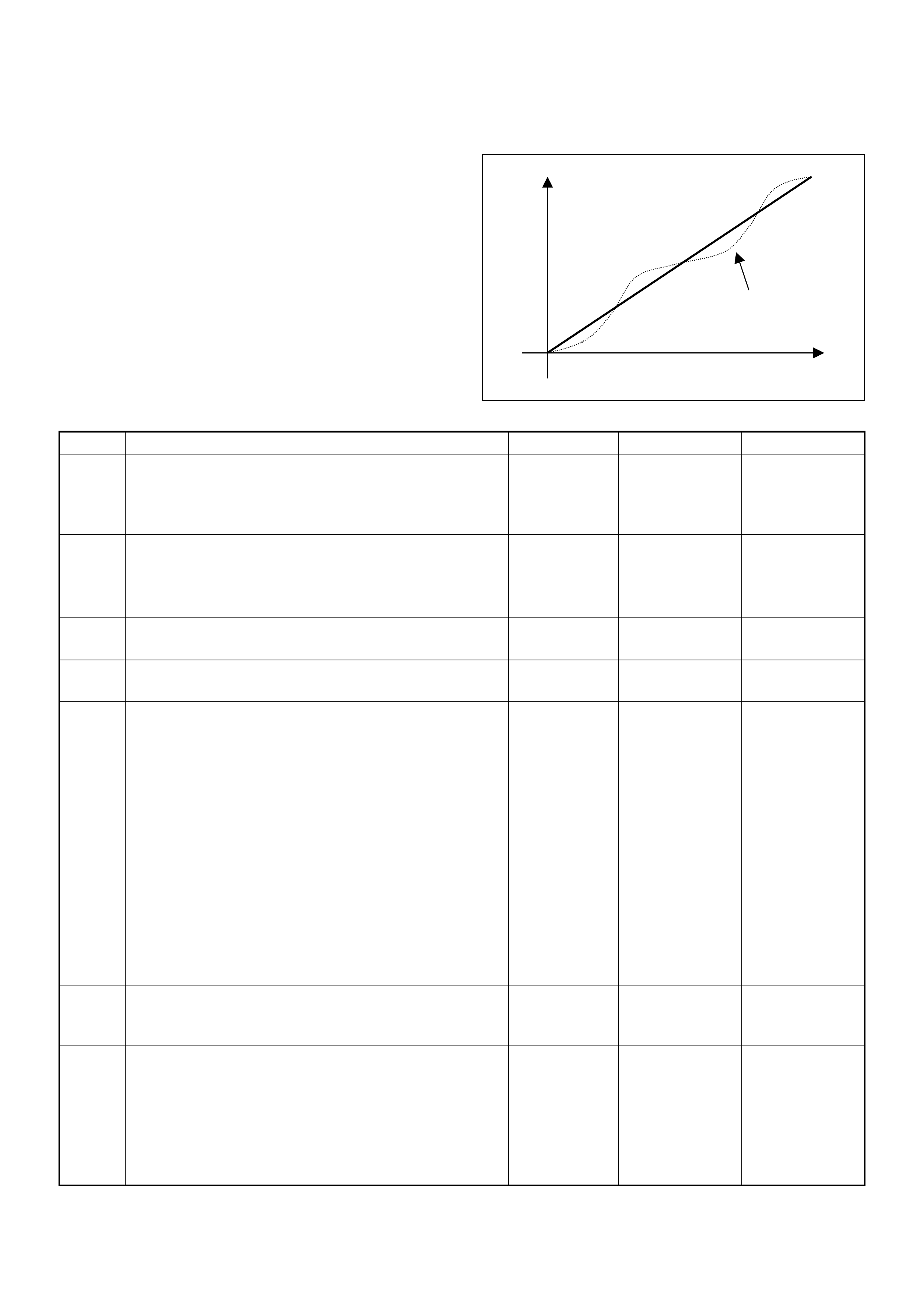

GENERAL DESCRIPTION FOR INJECTION PUMP

Outline

Cross-section View

Low Pressure Fuel Circuit

High Pressure Fuel Circuit

Pump Camshaft Speed Sensor

High Pressure Solenoid Valve

Timing Control Valve (TCV)

STRATEGY BASED DIAGNOSTICS

Overview

Diagnostic Thought Process

1. Verify the Complaint

2. Perform Preliminary Checks

3. Check Bulletins and Troubleshooting Hints

4. Perform Service Manual Diagnostic Checks

5a and 5b. Perform Service Manual

Diag nostic Procedures

5c. Technician Self Diagnoses

5d. Intermittent Diagnosis

5e. Vehicle Operates as Designed

6. Re-examine the complaint

7. Repair and Verify Fix

GENERAL SERVICE INFORMATION

Serviceability Issues

Visual/Physical Engine Compartment Inspection

Basic Knowledge of Tools Required

ON-BOARD DIAGNOSTIC (OBD)

On-Board Diagnostic (Self Diagnosis

System) Tests

The Diagnostic Executive

Verifying Vehicle Repair

Reading Flash Diagnostic Trouble Codes

Reading Diagnostic Trouble Codes

Using a Tech 2

History DTC

Diagnosis With Tech 2

TECH 2 OPERATING FLOW CHART (START UP)

Typical Scan Data & Definitions (Engine Data)

Miscellaneous Test

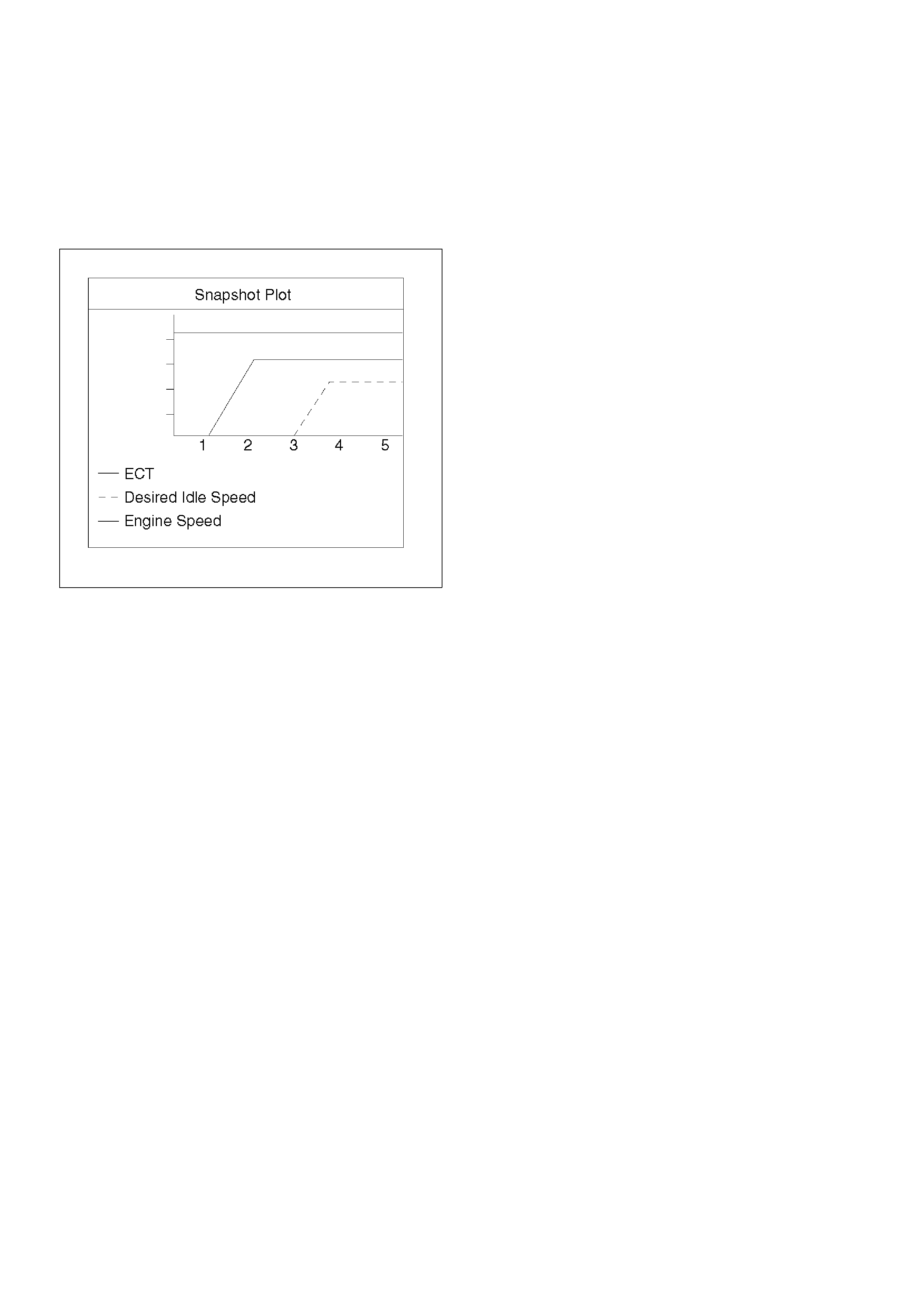

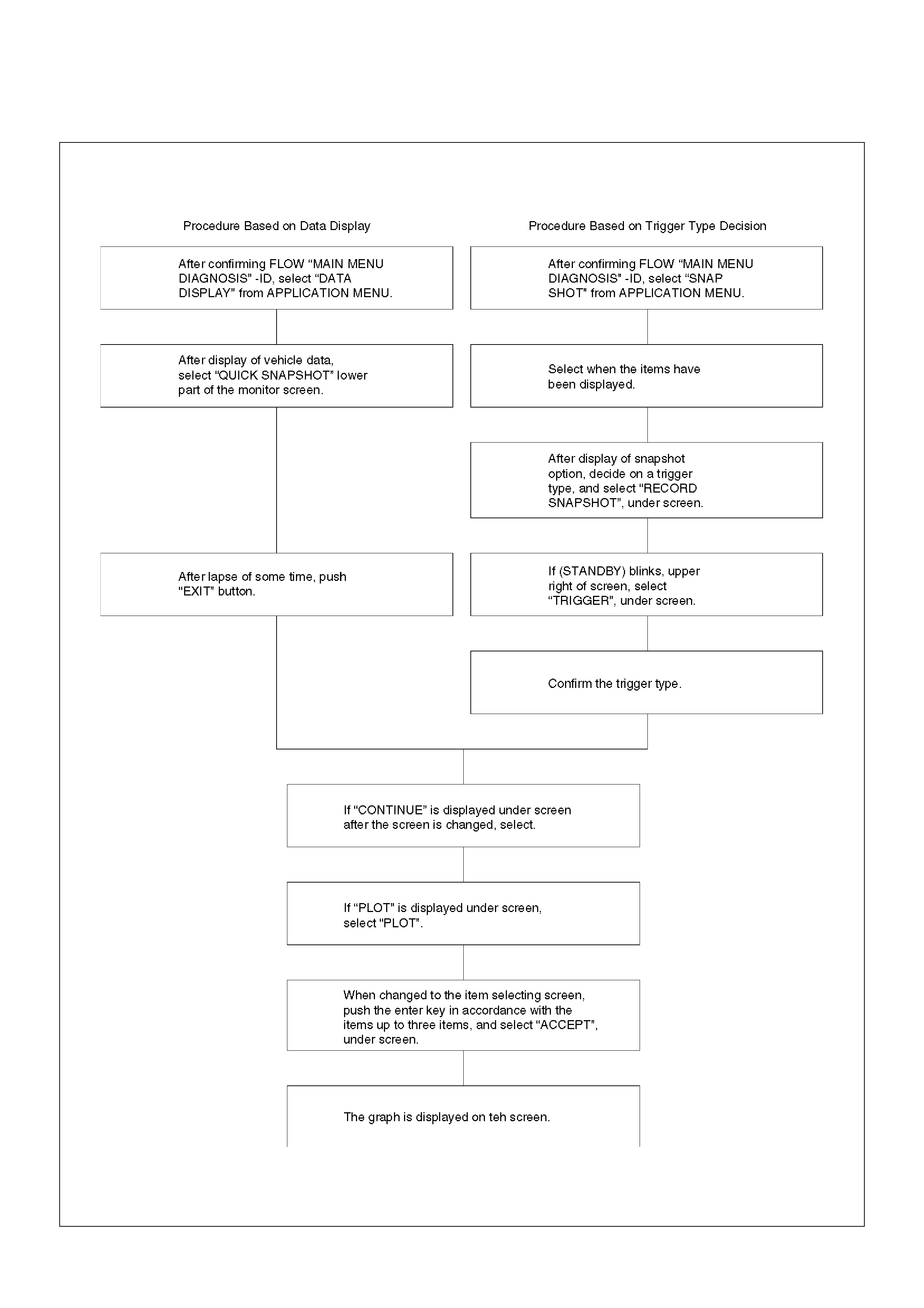

Plotting Snapshot Graph

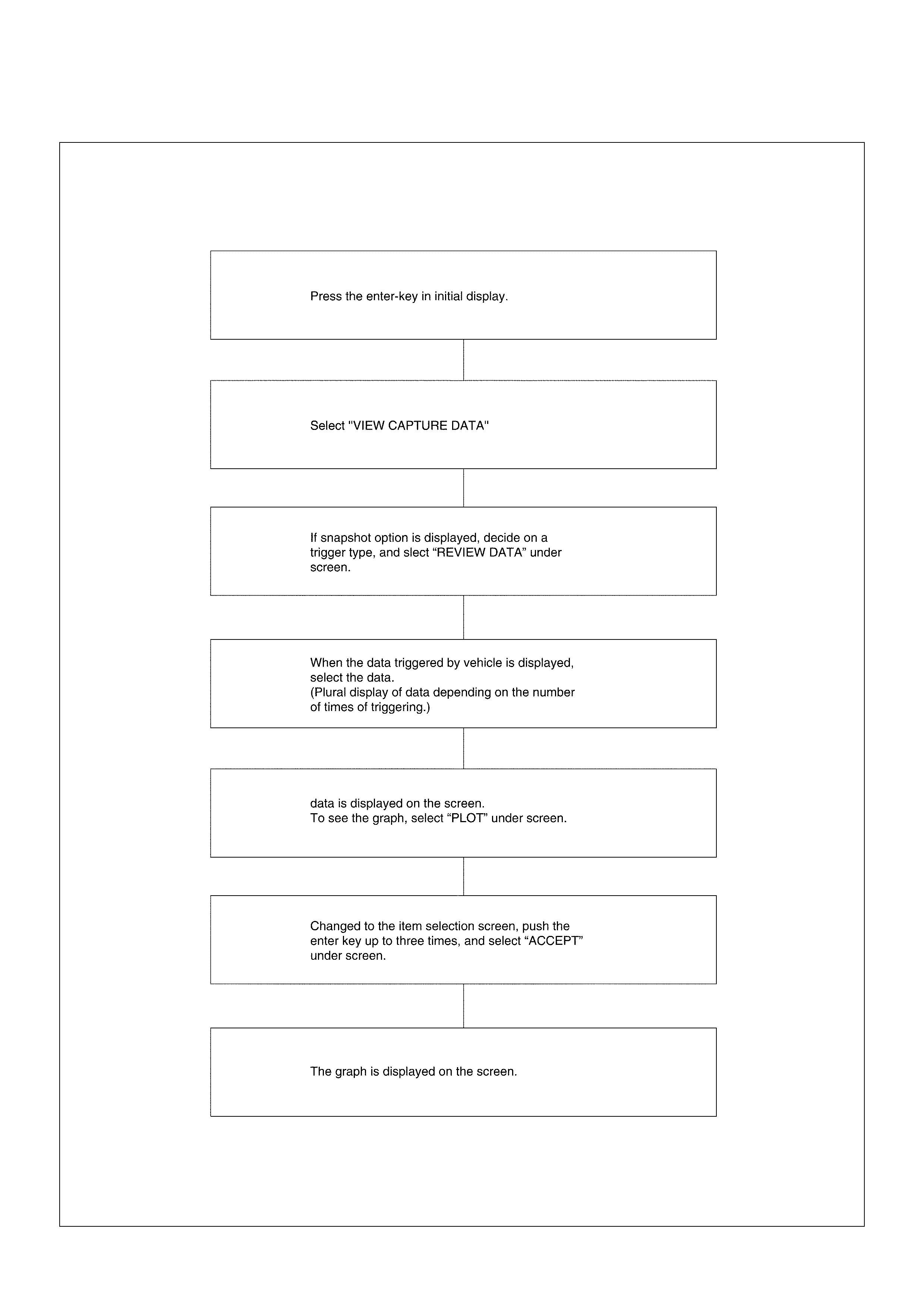

Plotting Graph Flow Chart (Plotting graph

after obtaining vehicle information)

Flow Chart for Snaps hot Replay (Plotting G raph)

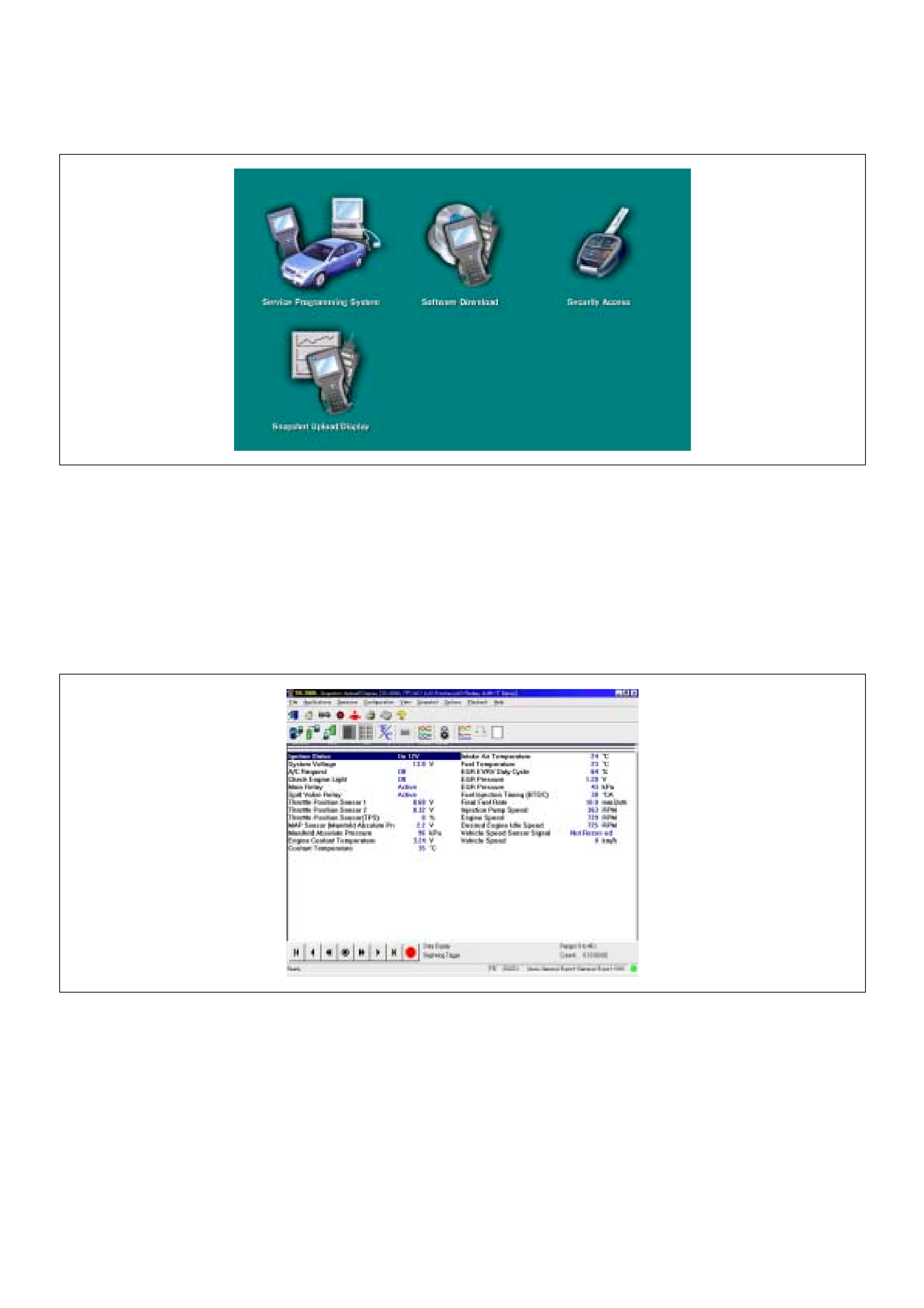

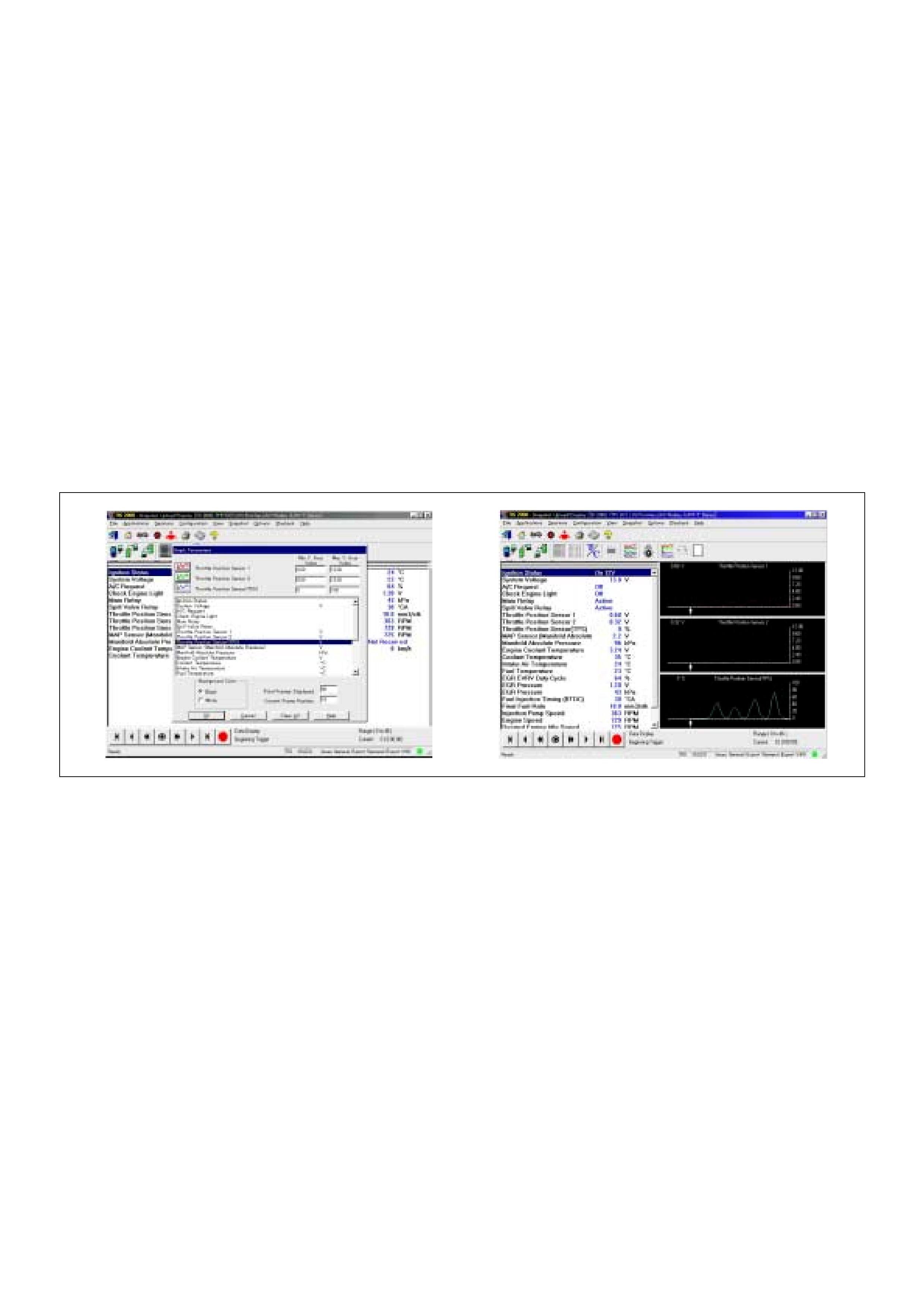

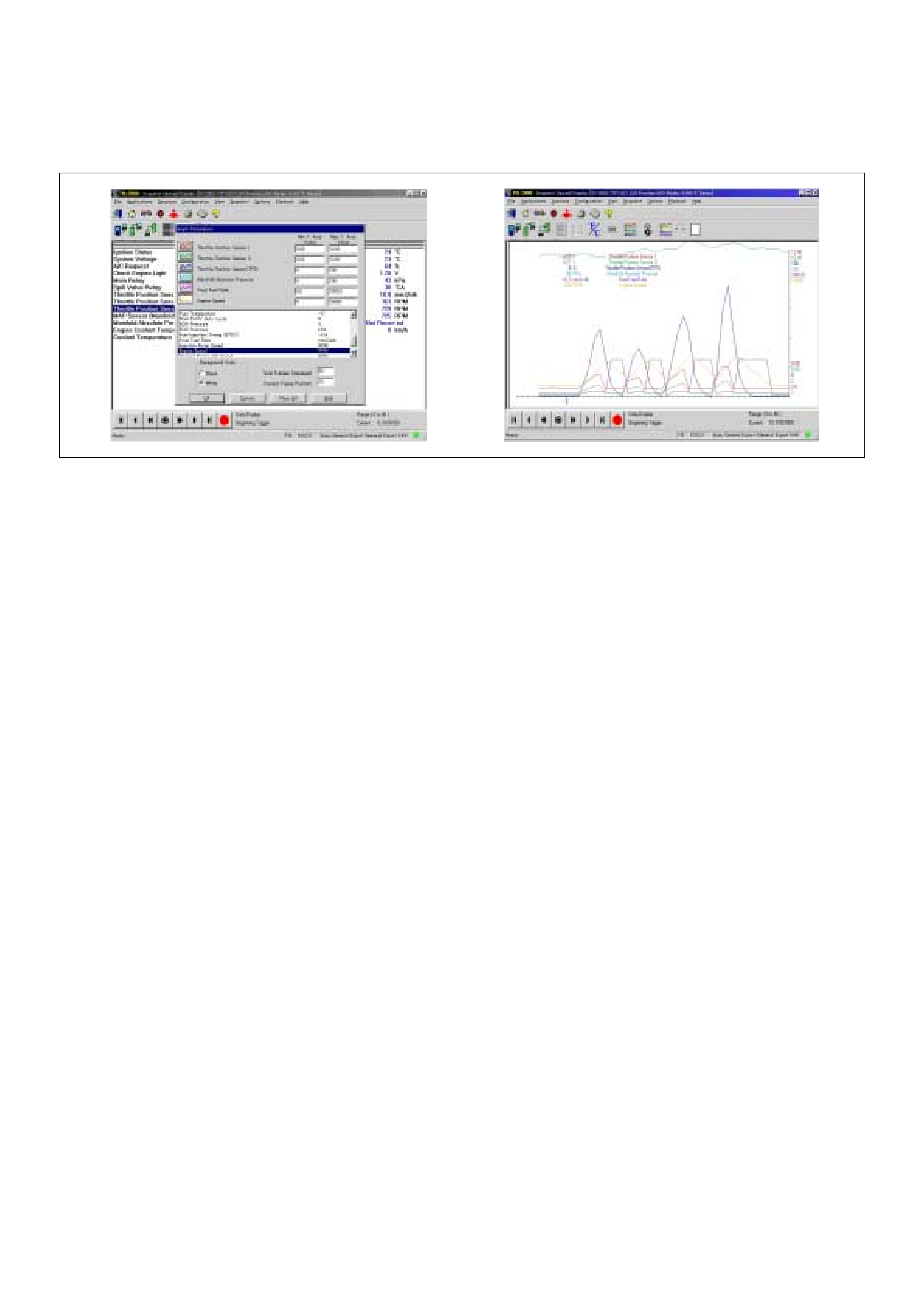

Snapshot Display With TIS2000

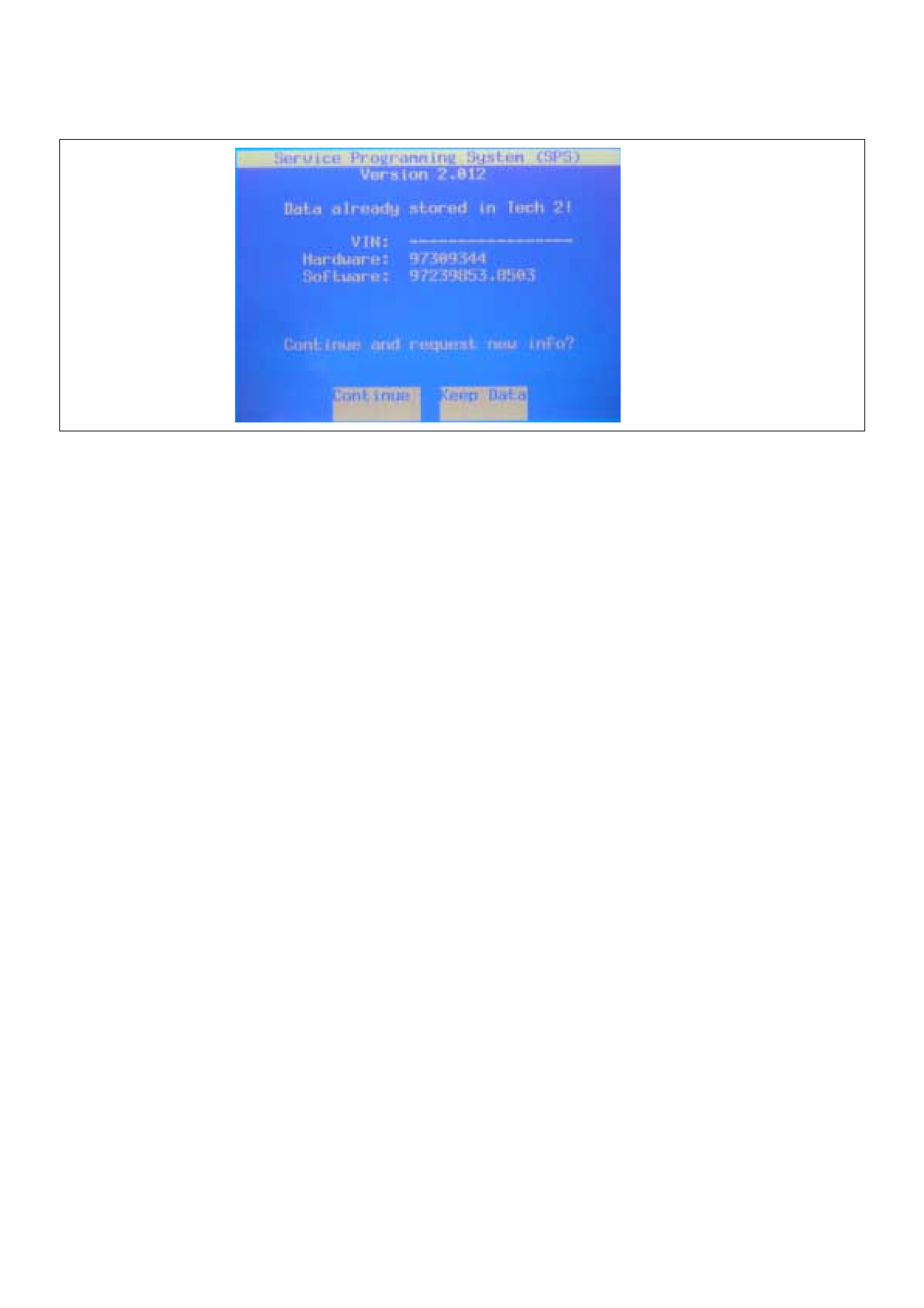

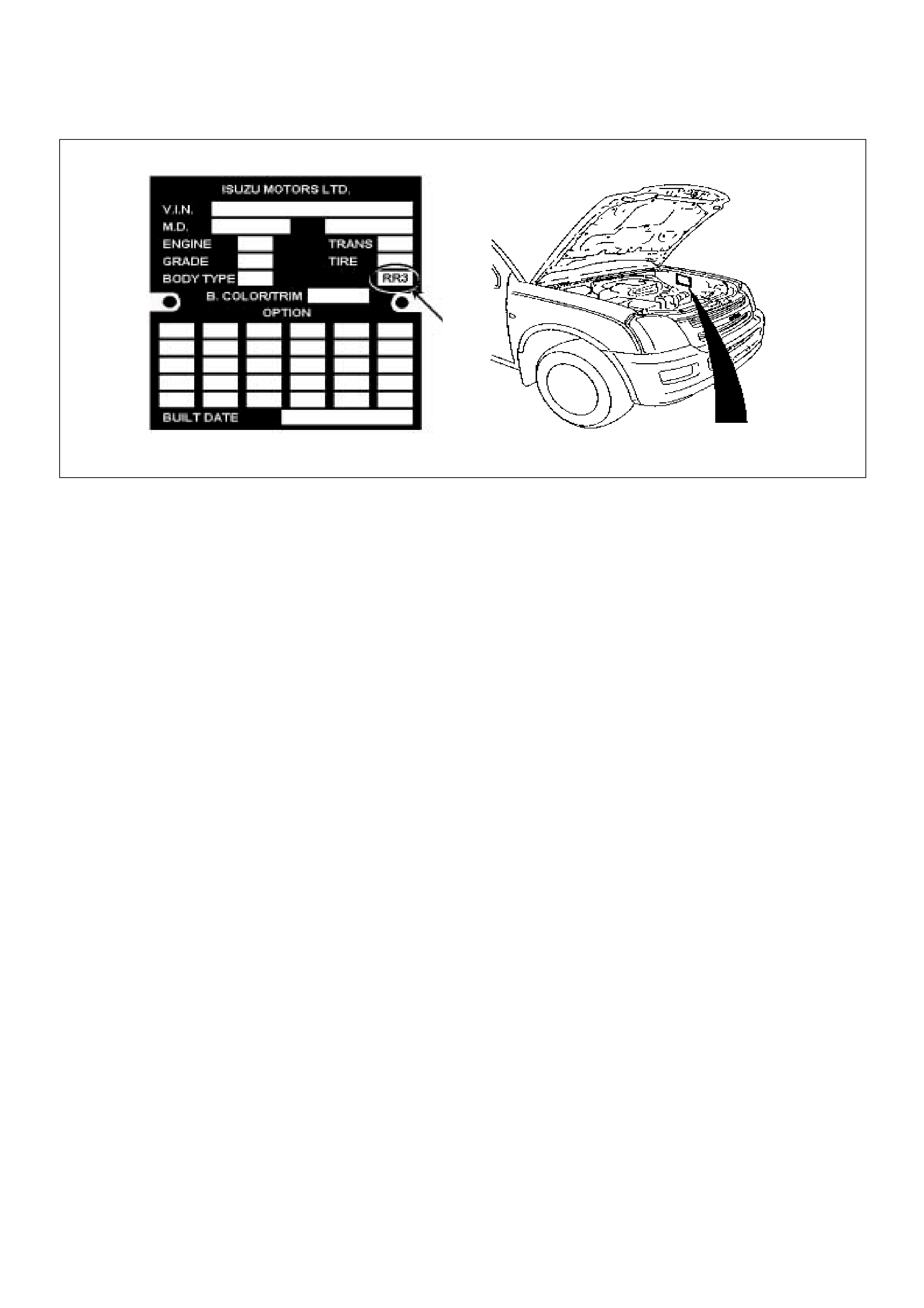

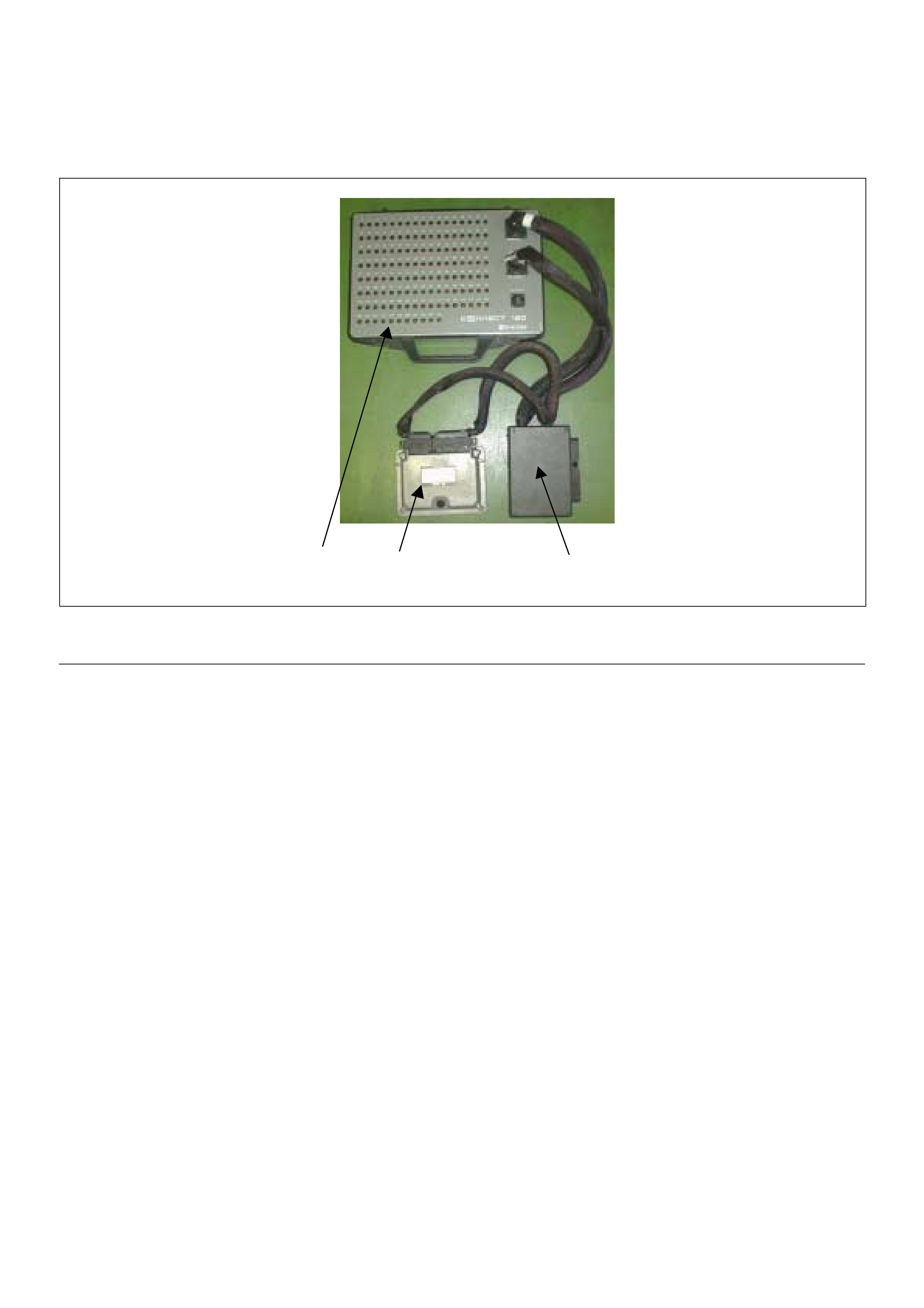

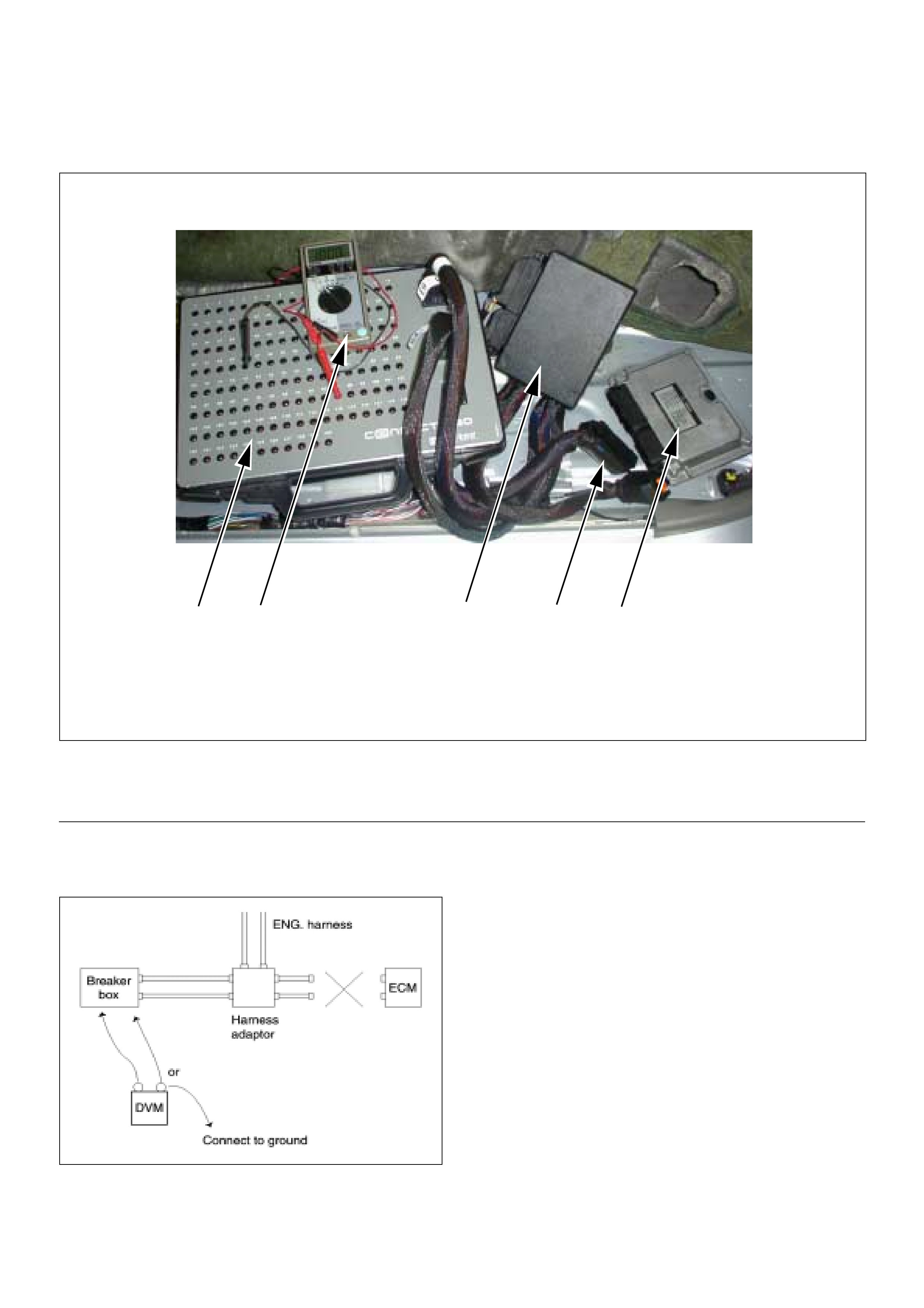

SERVICE PROGRAMMING SYSTEM (SPS)

ON-BOARD DIAGNOSTIC (OBD) SYSTEM CHECK

NO CHECK ENGINE LAMP (MIL)

CHECK ENGINE LAMP (MIL) “ON” STEADY

Techline

Techline

Techline

Techline

Techline

Techline

ECM DIAGNOSTIC TROUBLE CODES

DIAGNOSTIC TROUBLE CODE (DTC) P0100

(SYMPTOM CODE 7) (FLASH CODE 65) MASS

AIR FLOW (MAF) SENSOR VOLTAGE SUPPLY

CIRCUIT HIGH INPUT DIAGNOSTIC TROUBLE

CODE (DTC) P0100 (SYMPTOM CODE 9)

(FLASH CODE 65) MASS AIR FLOW (MAF)

SENSOR VOLTAGE SUPPLY CIRCUIT LOW

INPUT DIAGNOSTIC TROUBLE CODE (DTC)

P0100 (SYMPTOM CODE B) (FLASH CODE 65)

MASS AIR FLOW (MAF) SENSOR OUTPUT

CIRCUIT LOW INPUT DIAGNOSTIC TROUBLE

CODE (DTC) P0100 (SYMPTOM CODE C)

(FLASH CODE 65) MASS AIR FLOW (MAF)

SENSOR OUTPUT CIRCUIT HIGH INPUT

DIAGNOSTIC TROUBLE CODE (DTC) P0105

(SYMPTOM CODE 1) (FLASH CODE 34)

VACUUM PRESSURE SENSOR CIRCUIT HIGH

INPUT DIAGNOSTIC TROUBLE CODE (DTC)

P0105 (SYMPTOM CODE 2) (FLASH CODE 34)

VACUUM PRESSURE SENSOR CIRCUIT LOW

INPUT DIAGNOSTIC TROUBLE CODE (DTC)

P0105 (SYMPTOM CODE 7) (FLASH CODE 34)

VACUUM PRESSURE SENSOR VOLTAGE

SUPPLY CIRCUIT HIGH INPUT DIAGNOSTIC

TROUBLE CODE (DTC) P0105 (SYMPTOM

CODE 9) (FLASH CODE 34) VACUUM

PRESSURE SENSOR VOLTAGE SUPPLY

CIRCUIT LOW INPUT

DIAGNOSTIC TROUBLE CODE (DTC) P0110

(SYMPTOM CODE 1) (FLASH CODE 23)

INTAKE AIR TEMPERATURE (IAT) SENSOR

CIRCUIT HIGH INPUT DIAGNOSTIC TROUBLE

CODE (DTC) P0110 (SYMPTOM CODE 2)

(FLASH CODE 23) INTAKE AIR TEMPERATURE

(IAT) SENSOR CIRCUIT LOW INPUT

DIAGNOSTIC TROUBLE CODE (DTC) P0115

(SYMPTOM CODE 1) (FLASH CODE 14)

ENGINE COOLANT TEMPERATURE SENSOR

CIRCUIT HIGH INPUT DIAGNOSTIC TROUBLE

CODE (DTC) P0115 (SYMPTOM CODE 2)

(FLASH CODE 14) ENGINE COOLANT

TEMPERATURE SENSOR CIRCUIT LOW INPUT

DIAGNOSTIC TROUBLE CODE (DTC) P0180

(SYMPTOM CODE B) (FLASH CODE 15) FUEL

TEMPERATURE SENSOR CIRCUIT RANGE/

PERFORMANCE

DIAGNOSTIC TROUBLE CODE (DTC) P0215

(SYMPTOM CODE A) (FLASH CODE 52) FUEL

CUTOFF SOLENOID VALVE MALFUNCTION

DIAGNOSTIC TROUBLE CODE (DTC) P0215

(SYMPTOM CODE B) (FLASH CODE 52) FUEL

CUTOFF SOLENOID VALVE CIRCUIT HIGH

INPUT DIAGNOSTIC TROUBLE CODE (DTC)

P0215 (SYMPTOM CODE C) (FLASH CODE 52)

FUEL CUTOFF SOLENOID VALVE ALWAYS

ACTIVE DIAGNOSTIC TROUBLE CODE (DTC)

P0215 (SYMPTOM CODE D) (FLASH CODE 52)

FUEL CUTOFF SOLENOID VALVE

MALFUNCTION

DIAGNOSTIC TROUBLE CODE (DTC) P0216

(SYMPTOM CODE A) (FLASH CODE 54)

INJECTION TIMING CONTROL CIRCUIT

MALFUNCTION DIAGNOSTIC TROUBLE CODE

(DTC) P0216 (SYMPTOM CODE B) (FLASH

CODE 54) INJECTION TIMING CONTROL

CIRCUIT MALFUNCTION

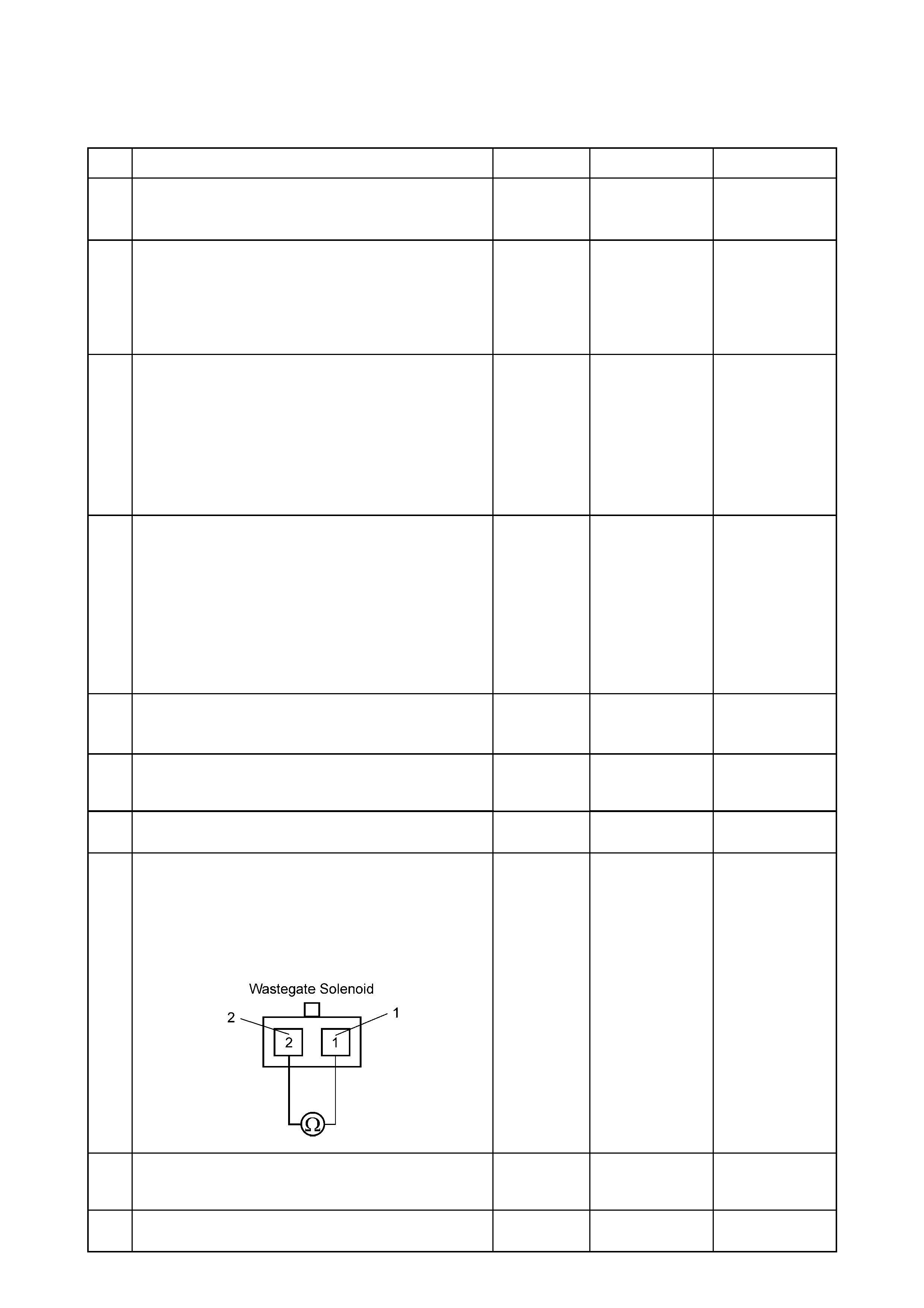

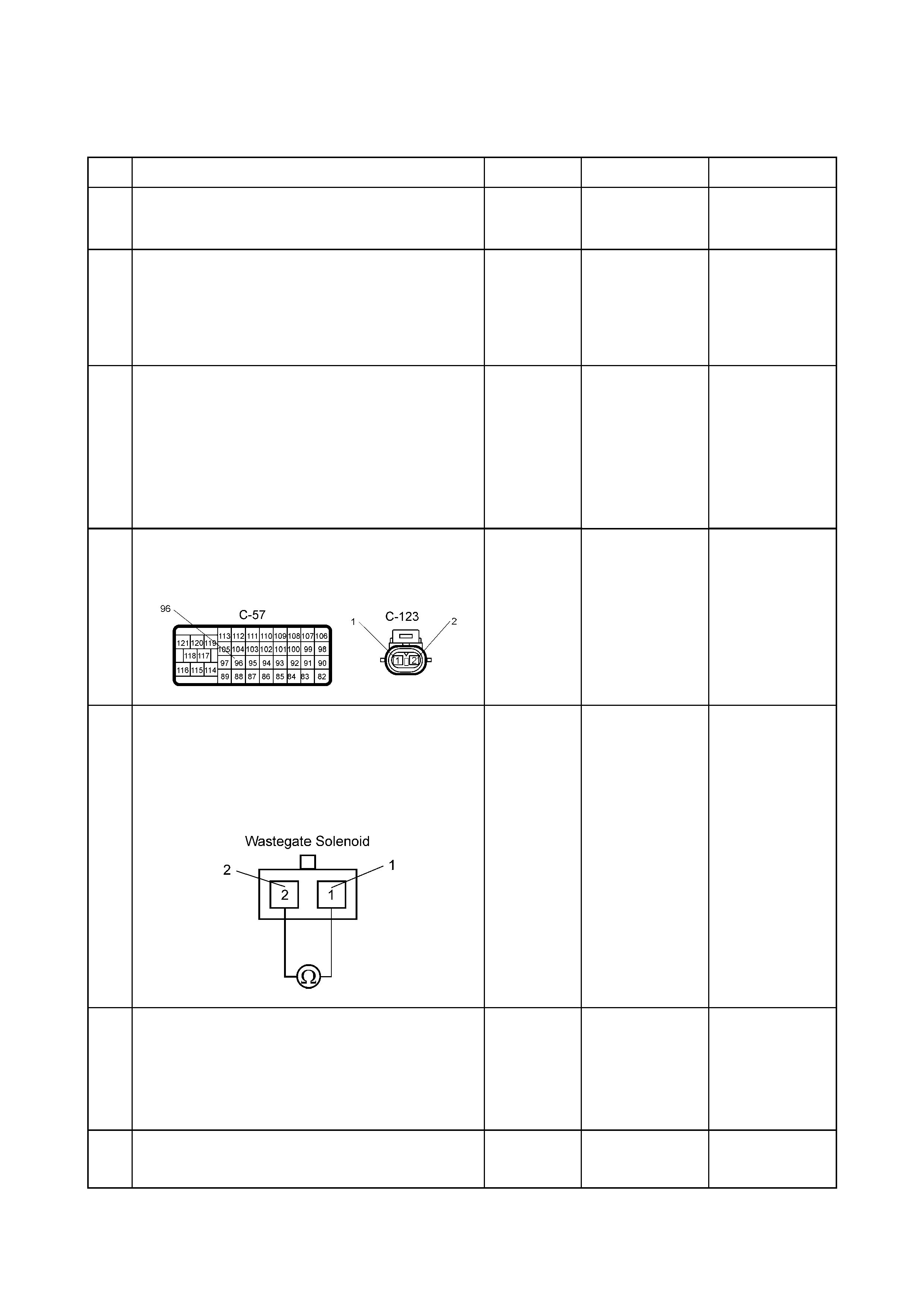

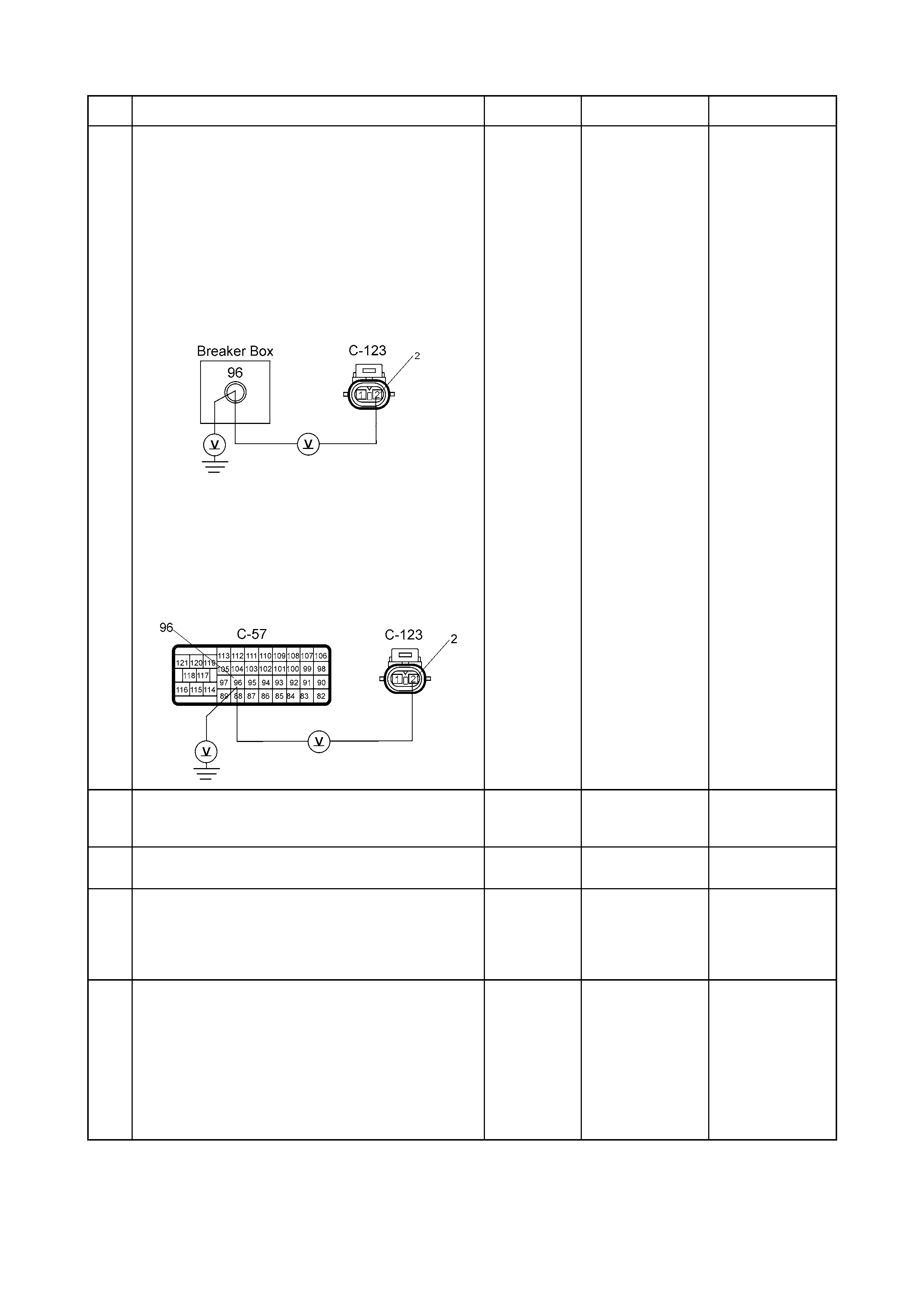

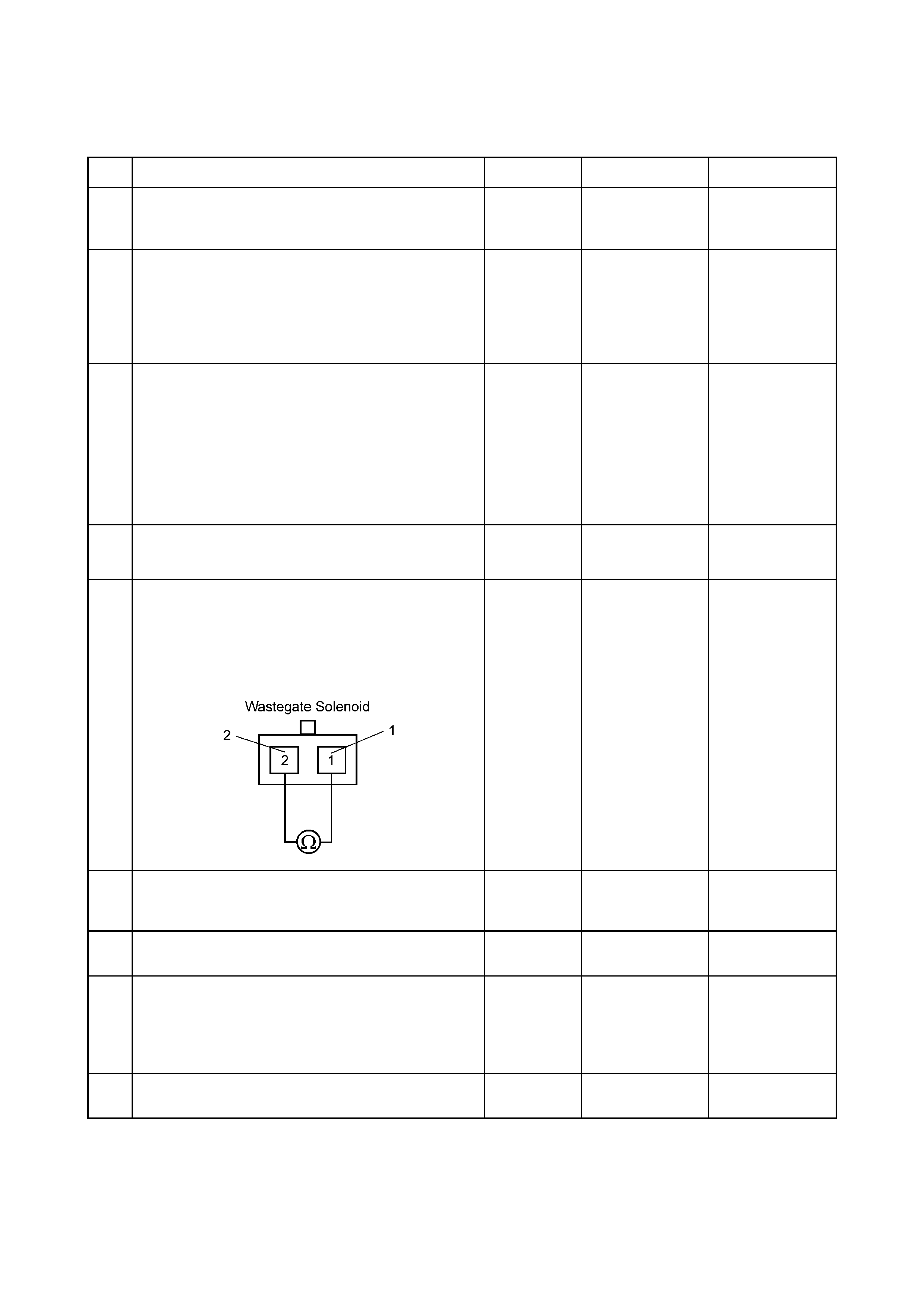

DIAGNOSTIC TROUBLE CODE (DTC) P0243

(SYMPTOM CODE 3) (FLASH CODE 64)

TURBOCHARGER WASTEGATE SOLENOID

"A" RANGE/PERFORMANCE DIAGNOSTIC

TROUBLE CODE (DTC) P0243 (SYMPTOM

CODE 4) (FLASH CODE 64) TURBOCHARGER

WASTEGATE SOLENOID "A" LOW

DIAGNOSTIC TROUBLE CODE (DTC) P0243

(SYMPTOM CODE 5) (FLASH CODE 64)

TURBOCHARGER WASTEGATE SOLENOID

"A" RANGE/PERFORMANCE DIAGNOSTIC

TROUBLE CODE (DTC) P0243 (SYMPTOM

CODE 6) (FLASH CODE 64) TURBOCHARGER

WASTEGATE SOLENOID "A" MALFUNCTION

DIAGNOSTIC TROUBLE CODE (DTC) P0243

(SYMPTOM CODE 8) (FLASH CODE 64)

TURBOCHARGER WASTEGATE SOLENOID

"A" HIGH

DIAGNOSTIC TROUBLE CODE (DTC) P0251

(SYMPTOM CODE 6) (FLASH CODE 53)

INJECTION PUMP MALFUNCTION

DIAGNOSTIC TROUBLE CODE (DTC) P0251

(SYMPTOM CODE 7) (FLASH CODE 53)

INJECTION PUMP MALFUNCTION

DIAGNOSTIC TROUBLE CODE (DTC) P0251

(SYMPTOM CODE 9) (FLASH CODE 53)

INJECTION PUMP MALFUNCTION

DIAGNOSTIC TROUBLE CODE (DTC) P0251

(SYMPTOM CODE A) (FLASH CODE 53)

INJECTION PUMP MALFUNCTION

DIAGNOSTIC TROUBLE CODE (DTC) P0251

(SYMPTOM CODE B) (FLASH CODE 53)

INJECTION PUMP MALFUNCTION

DIAGNOSTIC TROUBLE CODE (DTC) P0251

(SYMPTOM CODE D) (FLASH CODE 53)

INJECTION PUMP MALFUNCTION

DIAGNOSTIC TROUBLE CODE (DTC) P0251

(SYMPTOM CODE E) (FLASH CODE 53)

INJECTION PUMP MALFUNCTION

DIAGNOSTIC TROUBLE CODE (DTC) P0335

(SYMPTOM CODE B) (FLASH CODE

43)CRANKSHAFT POSITION SENSOR CIRCUIT

MALFUNCTION DIAGNOSTIC TROUBLE CODE

(DTC) P0335 (SYMPTOM CODE D) (FLASH

CODE 43) CRANKSHAFT POSITION SENSOR

MALFUNCTION DIAGNOSTIC TROUBLE CODE

(DTC) P0335 (SYMPTOM CODE E) (FLASH

CODE 43) ENGINE SPEED INPUT CIRCUIT

RANGE/PERFORMANCE

DIAGNOSTIC TROUBLE CODE (DTC) P0380

(SYMPTOM CODE 4) (FLASH CODE 66) GLOW

RELAY CIRCUIT VOLTAGE LOW DIAGNOSTIC

TROUBLE CODE (DTC) P0380 (SYMPTOM

CODE 8) (FLASH CODE 66) GLOW RELAY

CIRCUIT VOLTAGE HIGH

DIAGNOSTIC TROUBLE CODE (DTC) P0381

(SUB CODE 4) (FLASH CODE 67) GLOW PLUG

INDICATOR CIRCUIT VOLTAGE LOW

DIAGNOSTIC TROUBLE CODE (DTC) P0381

(SUB CODE 8) (FLASH CODE 67) GLOW PLUG

INDICATOR CIRCUIT VOLTAGE HIGH

DIAGNOSTIC TROUBLE CODE (DTC) P0400

(SYMPTOM CODE 3) (FLASH CODE 32)

EXHAUST GAS RECIRCULATION FLOW

EXCESSIVE DETE CTED DIAGNOSTIC

TROUBLE CODE (DTC) P0400 (SYMPTOM

CODE 4) (FLASH CODE 32) EXHAUST GAS

RECIRCULATION CIRCUIT SHORT TO

GROUND OR OPEN CIRCUIT DIAGNOSTIC

TROUBLE CODE (DTC) P0400 (SYMPTOM

CODE 5) (FLASH CODE 32) EXHAUST GAS

RECIRCULATION FLOW INSUFFICIENT

DETECTED DIAGNOSTIC TROUBLE CODE

(DTC) P0400 (SYMPTOM CODE 8) (FLASH

CODE 32) EXHAUST GAS RECIRCULATION

CIRCUIT SHORT TO BATTERY

DIAGNOSTIC TROUBLE CODE (DTC) P0500

(SYMPTOM CODE 1) (FLASH CODE 24)

VEHICLE SPEED SENSOR CIRCUIT HIGH

INPUT DIAGNOSTIC TROUBLE CODE (DTC)

P0500 (SYMPTOM CODE A) (FLASH CODE 24)

VEHICLE SPEED SENSOR INPUT SIGNAL

FREQUENCY TOO HIGH DIAGNOSTIC

TROUBLE CODE (DTC) P0500 (SYMPTOM

CODE B) (FLASH CODE 24) VEHICLE SPEED

SENSOR INCORRECT SIGNAL

DIAGNOSTIC TROUBLE CODE (DTC) P0560

(SYMPTOM CODE 1) (FLASH CODE 35)

SYSTEM VOLTAGE TOO HIGH DIAGNOSTIC

TROUBLE CODE (DTC) P0560 (SYMPTOM

CODE 2) (FLASH CODE 35) SYSTEM VOLTAGE

TOO LOW DIAGNOSTIC TROUBLE CODE

(DTC) P0560 (SYMPTOM CODE A) (FLASH

CODE 35) SYSTEM VOLTAGE MALFUNCTION

DIAGNOSTIC TROUBLE CODE (DTC) P0561

(SYMPTOM CODE A) (FLASH CODE 18)

IGNITION SWITCH CIRCUIT MALFUNCTION

DIAGNOSTIC TROUBLE CODE (DTC) P0561

(SYMPTOM CODE B) (FLASH CODE 18)

IGNITION SWITCH CIRCUIT MALFUNCTION

DIAGNOSTIC TROUBLE CODE (DTC) P0602

CONTROL MODULE PROGRAMMING ERROR

DIAGNOSTIC TROUBLE CODE (DTC) P0606

(SYMPTOM CODE A) (FLASH CODE 28) ECU

MALFUNCTION DIAGNOSTIC TROUBLE CODE

(DTC) P0606 (SYMPTOM CODE B) (FLASH

CODE 28) ECU MALFUNCTION

DIAGNOSTIC TROUBLE CODE (DTC) P0645

(SYMPTOM CODE 4) (FLASH CODE 46) A/C

COMPRESSOR RELAY CIRCUIT VOLTAGE

LOW DIAGNOSTIC TROUBLE CODE (DTC)

P0645 (SYMPTOM CODE 8) (FLASH CODE 46)

A/C COMPRESSOR RELAY CIRCUIT VOLTAGE

HIGH

DIAGNOSTIC TROUBLE CODE (DTC) P0703

(SYMPTOM CODE A) (FLASH CODE 25)

BRAKE SWITCH CIRCUIT MALFUNCTION

DIAGNOSTIC TROUBLE CODE (DTC) P0703

(SYMPTOM CODE B) (FLASH CODE 25)

BRAKE SWITCH CIRCUIT MALFUNCTION

DIAGNOSTIC TROUBLE CODE (DTC) P0704

(SYMPTOM CODE 6) (FLASH CODE 57)

CLUTCH SWITCH INPUT CIRCUIT

MALFUNCTION

DIAGNOSTIC TROUBLE CODE (DTC) P1105

(SYMPTOM CODE 1) (FLASH CODE 86)

BAROMETRIC PRESSURE SENSOR CIRCUIT

HIGH INPUT DIAGNOSTIC TROUBLE CODE

(DTC) P1105 (SYMPTOM CODE 2) (FLASH

CODE 86) BAROMETRIC PRESSURE SENSOR

CIRCUIT LOW INPUT

DIAGNOSTIC TROUBLE CODE (DTC) P1120

(SYMPTOM CODE 1) (FLASH CODE 21) PEDAL/

THROTTLE POSITION SENSOR CIRCUIT HIGH

INPUT DIAGNOSTIC TROUBLE CODE (DTC)

P1120 (SYMPTOM CODE 7) (FLASH CODE 21)

PEDAL/THROTTLE POSITION SENSOR

VOLTAGE SUPPLY CIRCUIT HIGH INPUT

DIAGNOSTIC TROUBLE CODE (DTC) P1120

(SYMPTOM CODE 9) (FLASH CODE 21) PEDAL/

THROTTLE POSITION SENSOR VOLTAGE

SUPPLY CIRCUIT LOW INPUT DIAGNOSTIC

TROUBLE CODE (DTC) P1120 (SYMPTOM

CODE D) (FLASH CODE 21) PEDAL/THROTTLE

POSITION SENSOR BRAKE SWITCH ERROR

DIAGNOSTIC TROUBLE CODE (DTC) P1120

(SYMPTOM CODE E) (FLASH CODE 21)

PEDAL/THROTTLE POSITION SENSOR IDLE

POSITION SWITCH ERROR

DIAGNOSTIC TROUBLE CODE (DTC) P1173

(SYMPTOM CODE 3) (FLASH CODE 22) FUEL

REDUCTION CAUSED BY HIGH COOLANT

TEMPERATURE DIAGNOSTIC TROUBLE

CODE (DTC) P1173 (SYMPTOM CODE 7)

(FLASH CODE 22) FUEL REDUCTION CAUSED

BY HIGH FUEL TEMPERATURE DIAGNOSTIC

TROUBLE CODE (DTC) P1173 (SYMPTOM

CODE A) (FLASH CODE 22) FUEL REDUCTION

CAUSED BY LOW FUEL TEMPERATURE

DIAGNOSTIC TROUBLE CODE (DTC) P1335

(SYMPTOM CODE A) (FLASH CODE 43)

ENGINE SPEED OUTPUT CIRCUIT

MALFUNCTION

DIAGNOSTIC TROUBLE CODE (DTC) P1345

(SYMPTOM CODE A) (FLASH CODE 45)

CAMSHAFT SPEED MALFUNCTION

DIAGNOSTIC TROUBLE CODE (DTC) P1520

(SYMPTOM CODE A) (FLASH CODE 47)

NEUTRAL SWITCH ON ERROR DIAGNOSTIC

TROUBLE CODE (DTC) P1520 (SYMPTOM

CODE B) (FLASH CODE 47) NEUTRAL SWITCH

OFF ERROR

DIAGNOSTIC TROUBLE CODE (DTC) P1605

(SYMPTOM CODE C) (FLASH CODE 55) SEED

AND KEY FILE DESTROYED DIAGNOSTIC

TROUBLE CODE (DTC) P1605 (SYMPTOM

CODE D) (FLASH CODE 55) EEPROM DEFECT

DIAGNOSTIC TROUBLE CODE (DTC) P1605

(SYMPTOM CODE E) (FLASH CODE 55)

EEPROM DEFECT

DIAGNOSTIC TROUBLE CODE (DTC) P1610

(SYMPTOM CODE A) (FLASH CODE 56)

SECURITY KEY AND SECURITY CODE NOT

PROGRAMMED

DIAGNOSTIC TROUBLE CODE (DTC) P1611

(SYMPTOM CODE A) (FLASH CODE 56)

WRONG SECURITY CODE ENTERED

DIAGNOSTIC TROUBLE CODE (DTC) P1612

(SYMPTOM CODE A) (FLASH CODE 56)

IMMOBILIZER NO OR WRONG SIGNAL

DIAGNOSTIC TROUBLE CODE (DTC) P1613

(SYMPTOM CODE A) (FLASH CODE 56)

IMMOBILIZER NO OR WRONG SIGNAL

DIAGNOSTIC TROUBLE CODE (DTC) P1614

(SYMPTOM CODE A) (FLASH CODE 56)

WRONG TRANSPONDER KEY

DIAGNOSTIC TROUBLE CODE (DTC) P1625

(SYMPTOM CODE A) (FLASH CODE 76) ECM

MAIN RELAY SWITCHED OFF TOO EARLY

DIAGNOSTIC TROUBLE CODE (DTC) P1625

(SYMPTOM CODE B) (FLASH CODE 76) ECM

MAIN RELAY SWITCHED OFF TOO LATE

DIAGNOSTIC TROUBLE CODE (DTC) P1630

(SYMPTOM CODE A) (FLASH CODE 51) FUEL

INJECTION QUANTITY CIRCUIT

MALFUNCTION DIAGNOSTIC TROUBLE CODE

(DTC) P1630 (SYMPTOM CODE B) (FLASH

CODE 51) FUEL INJECTION QUANTITY

CIRCUIT MALFUNCTION

DIAGNOSTIC TROUBLE CODE (DTC) P1650

(SYMPTOM CODE A) (FLASH CODE 44) CAN

DEVICE OFFLINE DIAGNOSTIC TROUBLE

CODE (DTC) P1 650 (SYM PTO M CO DE B)

(FLASH CODE 44) CAN DEVICE HANG-UP

DIAGNOSTIC TROUBLE CODE (DTC) P1651

(SYMPTOM CODE A) (FLASH CODE 45) CAN

MALFUNCTION DIAGNOSTIC TROUBLE CODE

(DTC) P1651 (SYMPTOM CODE B) (FLASH

CODE 45) CAN RECEIVES ERROR

DIAGNOSTIC TROUBLE CODE (DTC) P1690

(SYMPTOM CODE 4) (FLASH CODE 77) CHECK

ENGINE LAMP (MIL) CIRCUIT VOLTAGE LOW

DIAGNOSTIC TROUBLE CODE (DTC) P1690

(SYMPTOM CODE 8) (FLASH CODE 77) CHECK

ENGINE LAMP (MIL) CIRCUIT VOLTAGE HIGH

SYMPTOM DIAGNOSIS

PRELIMINARY CHECKS

VISUAL/PHYSICAL CHECK

INTERMITTENT

ENGINE CRANKS BUT WILL NOT RUN

HARD START SYMPTOM

ROUGH, UNSTABLE, OR INCORRECT IDLE,

STALLING SYMPTOM

SURGES AND/OR CHUGS SYMPTOM

HESITATION, SAG, STUMBLE SYMPTOM

CUTS OUT, MISSES SYMPTOM

LACK OF POWER, SLUGGISH OR

SPONGY SYMPTOM

POOR FUEL ECONOMY S YMPTOM

EXCESSIVE WHITE SMOKE

EXCESSIVE BLACK SMOKE

ON-VEHICLE SERVICE PROC EDURE

ENGINE CONTROL MODULE (ECM)

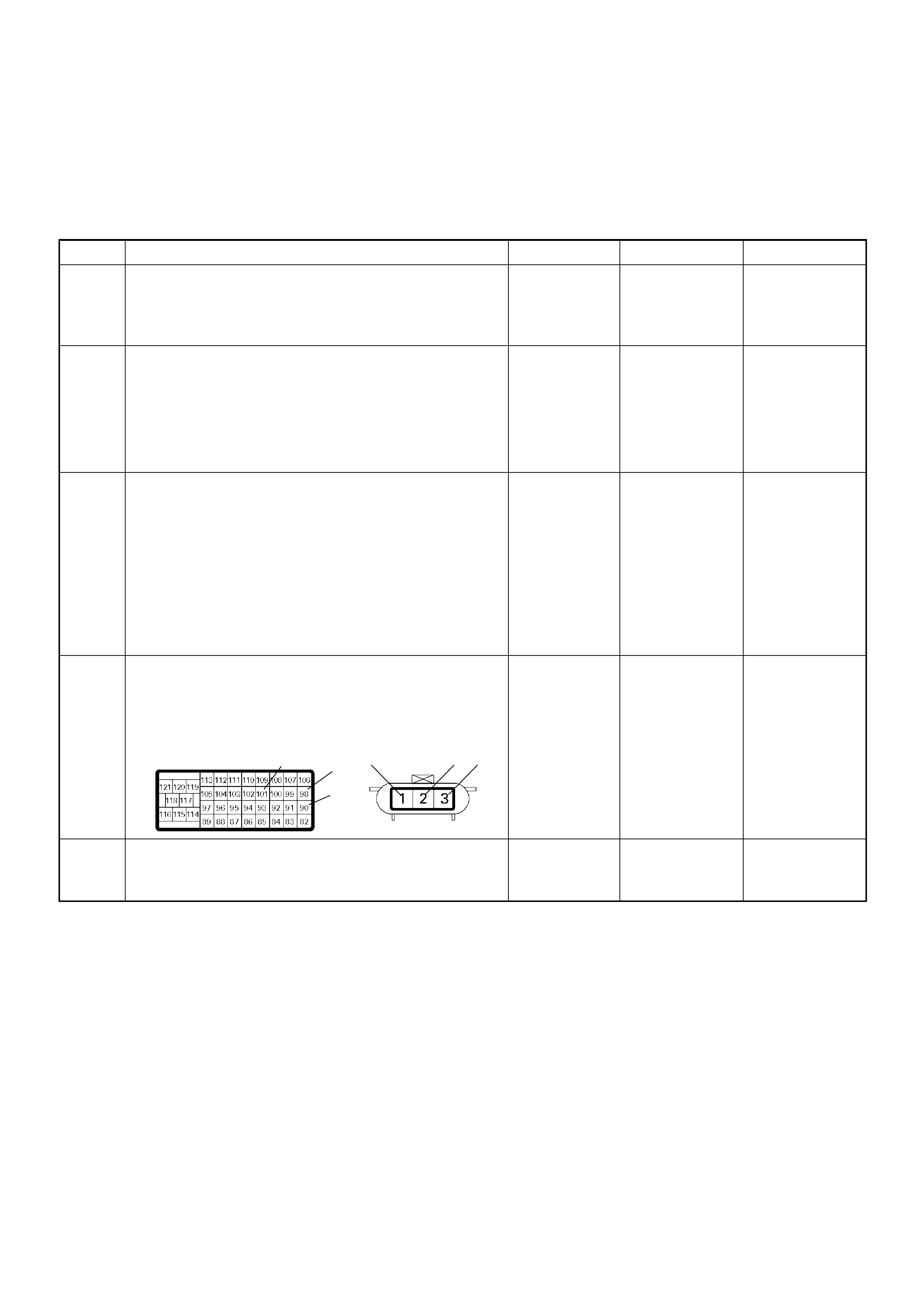

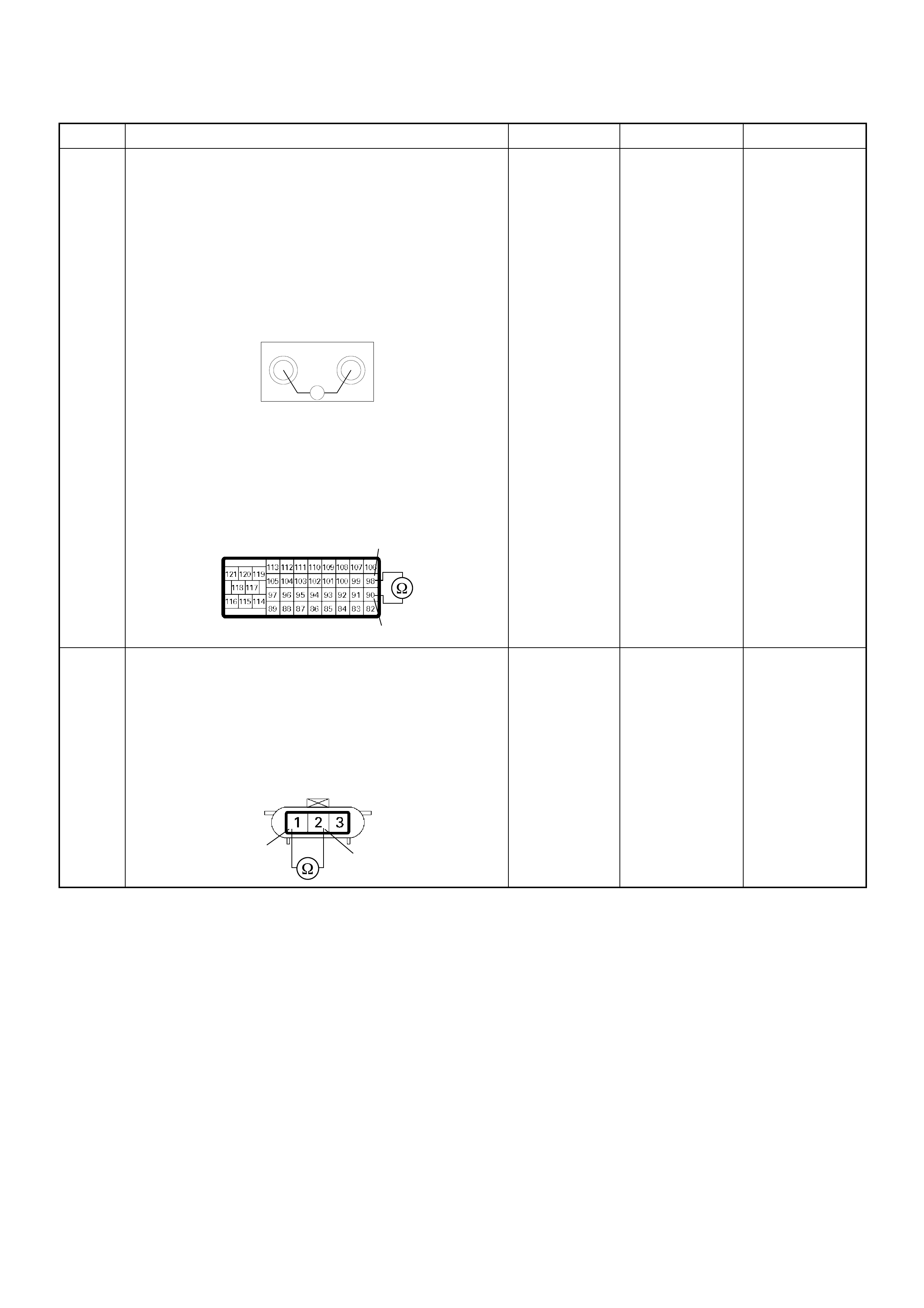

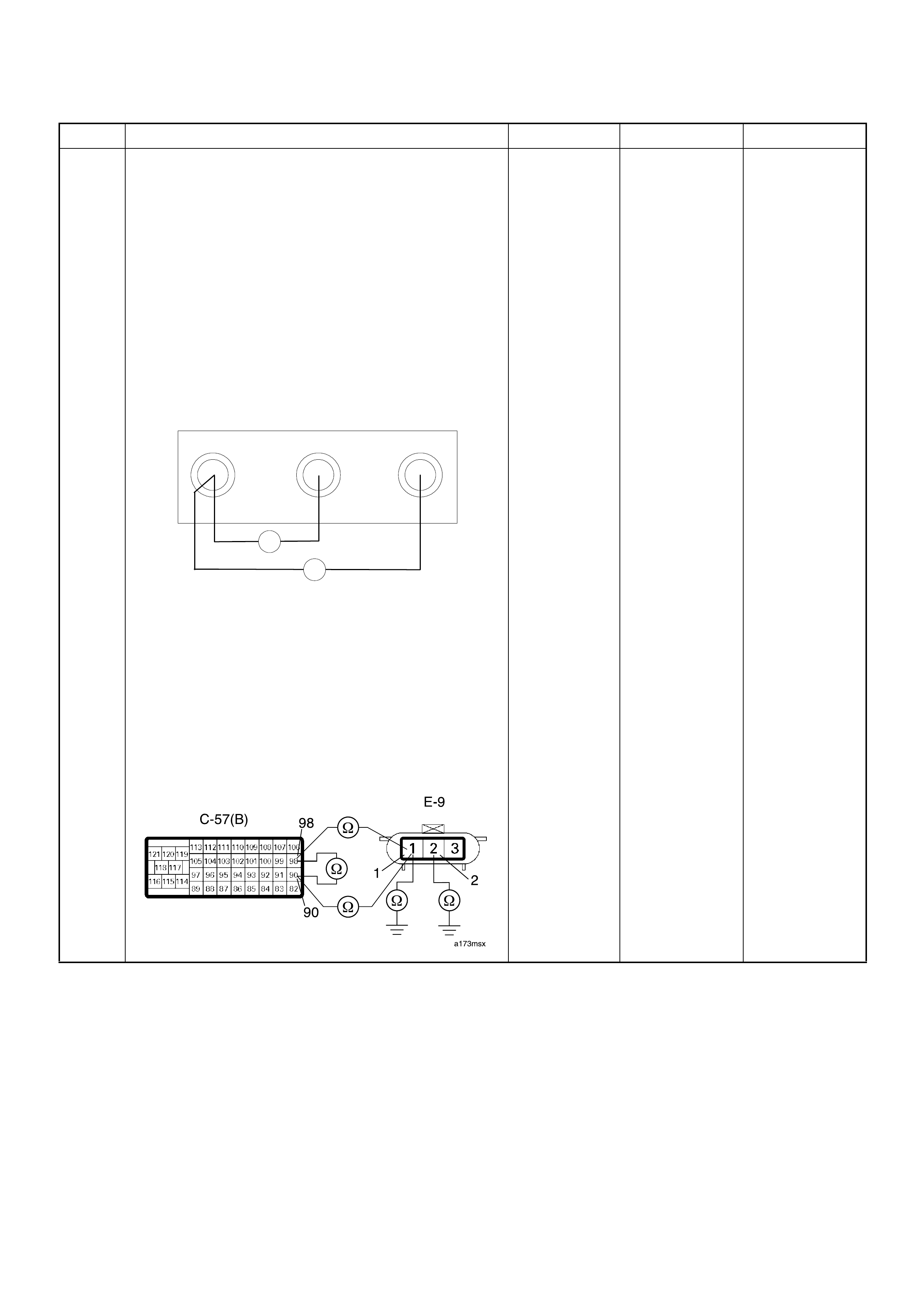

CRANKSHAFT POSITION (CKP) SENSOR

ENGINE COOLANT TEMPERATURE

(ECT) SENSOR

MASS AIR FLOW (MAF) & INTAKE AIR

TEMPERATURE (IAT) SENSOR

THROTTLE POSITION SENSOR (TPS)

EGR EVRV (Electrical Vacuum Regulating Valve)

SPECIAL SERVICE TOOLS

ABBREVIATION CHARTS

Abbreviations Appellation

A/C Air conditioner

A/T Automati c transmi ssio n

ACC Accessory

BLK Black

BLU Blue

BRN Brown

CAN Controller Area Network

CEL Check engine lamp

CKP Crankshaft position sensor

DLC Data link connector

DTC Diagnosis trouble code

DVM Digital voltage meter

ECM Engine co ntr ol module

ECT Engine co olant tempera tur e

EEPROM Electrically erasable & programmable read only memory

EGR Exhaust gas recirculation

EVRV Electric vacuum regulating valve

GND Ground

GRY Gray

IAT Intake air temperature

IG Ignition

M/T Manual transmission

MAB High pressure solenoid valve cutoff (German abbreviation)

MAF Mass air flow

MIL Malfunction indicator lamp

OBD On-board diagnostic

ORN Orange

PNK Pink

RED Red

PSG Pump control unit (German abbreviation)

SW Switch

TCM Transmission control module

TCV Timing control valve

TDC Top dead center

TPS Throttle position sensor

VCC Voltage constunt control

VIO Violet

VSS Vehicle speed sensor

WHT White

YEL Yellow

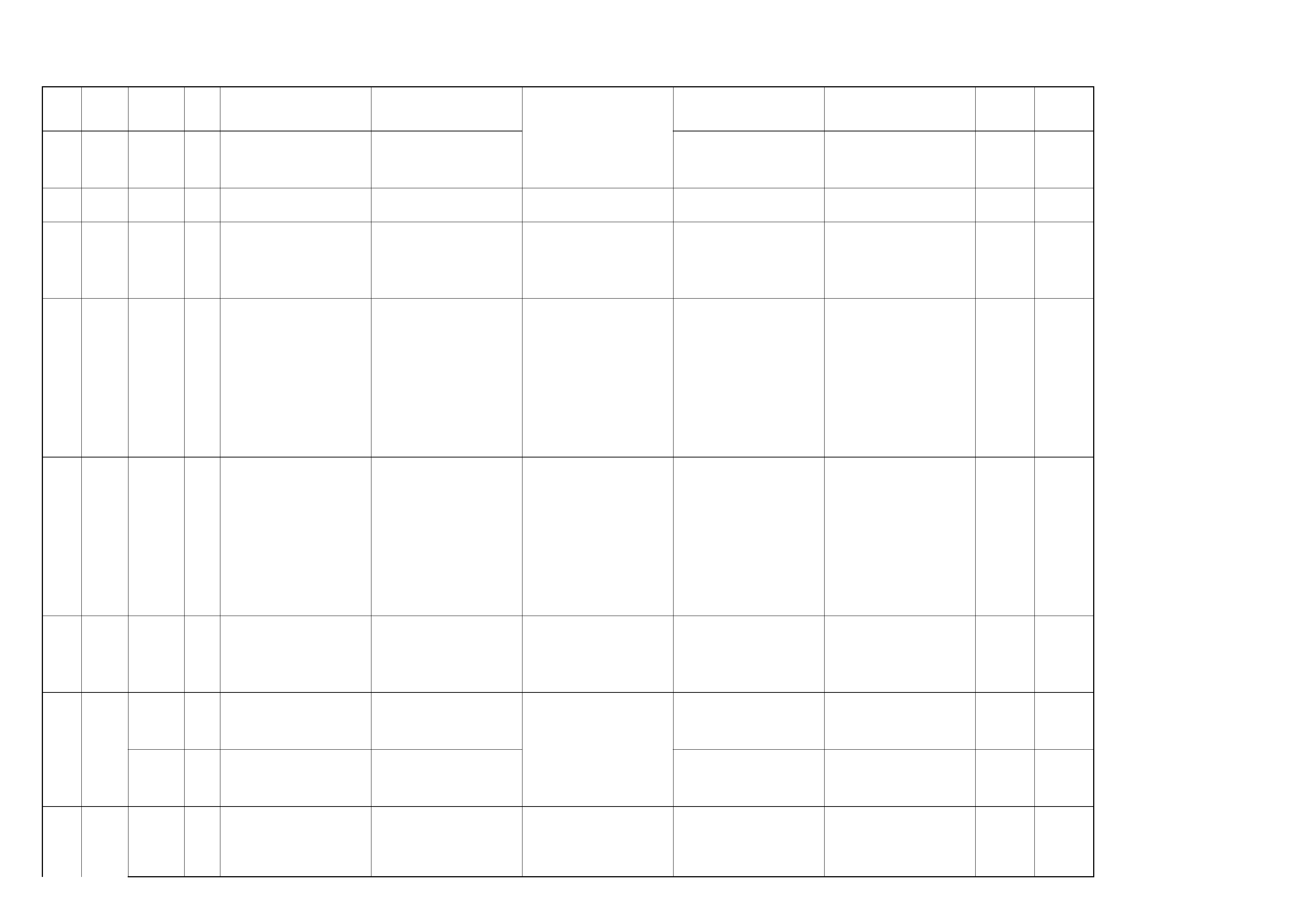

COMPONENT LOCATOR

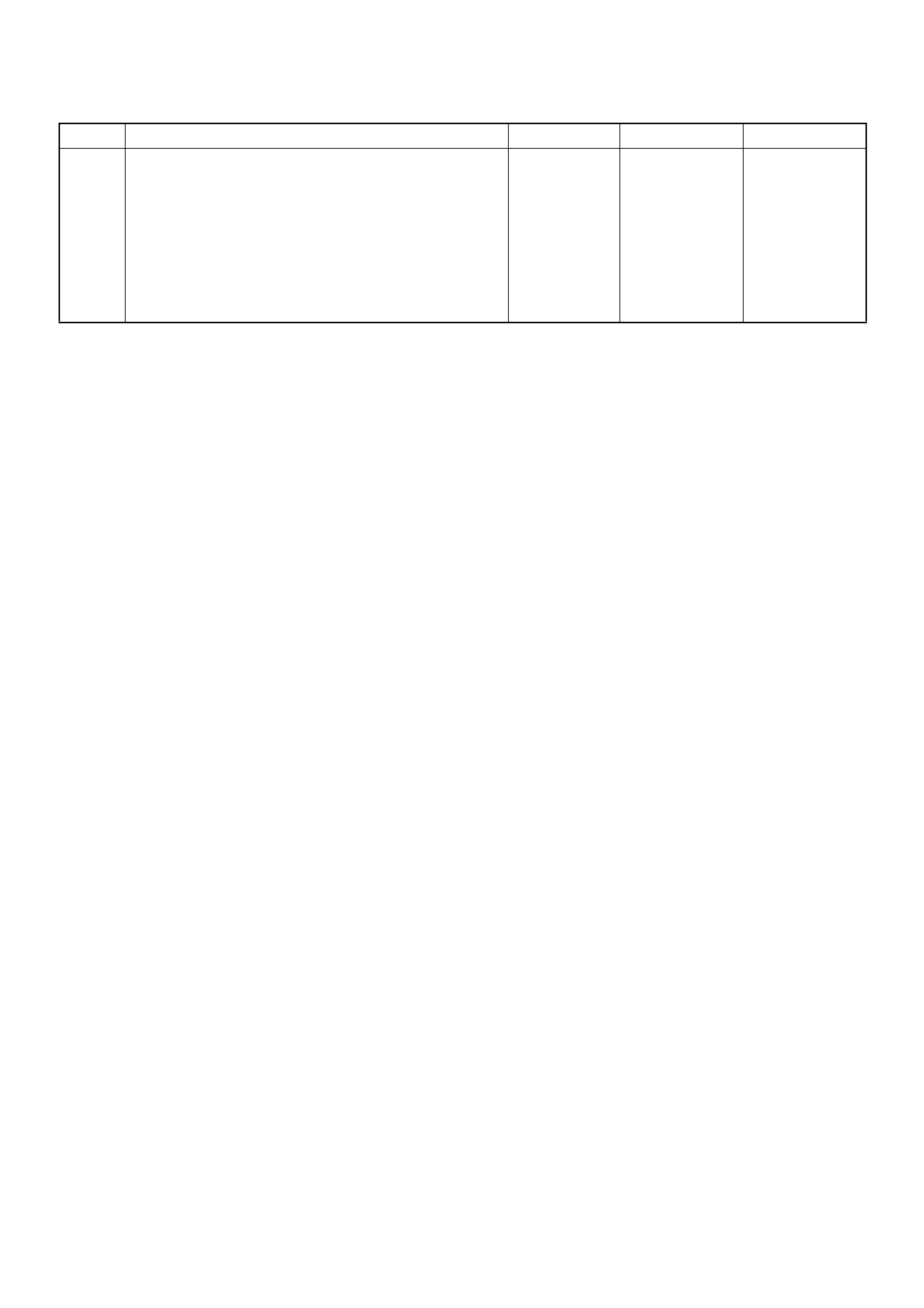

ENGINE COMPONENT LOCATOR TABLE

PNQO

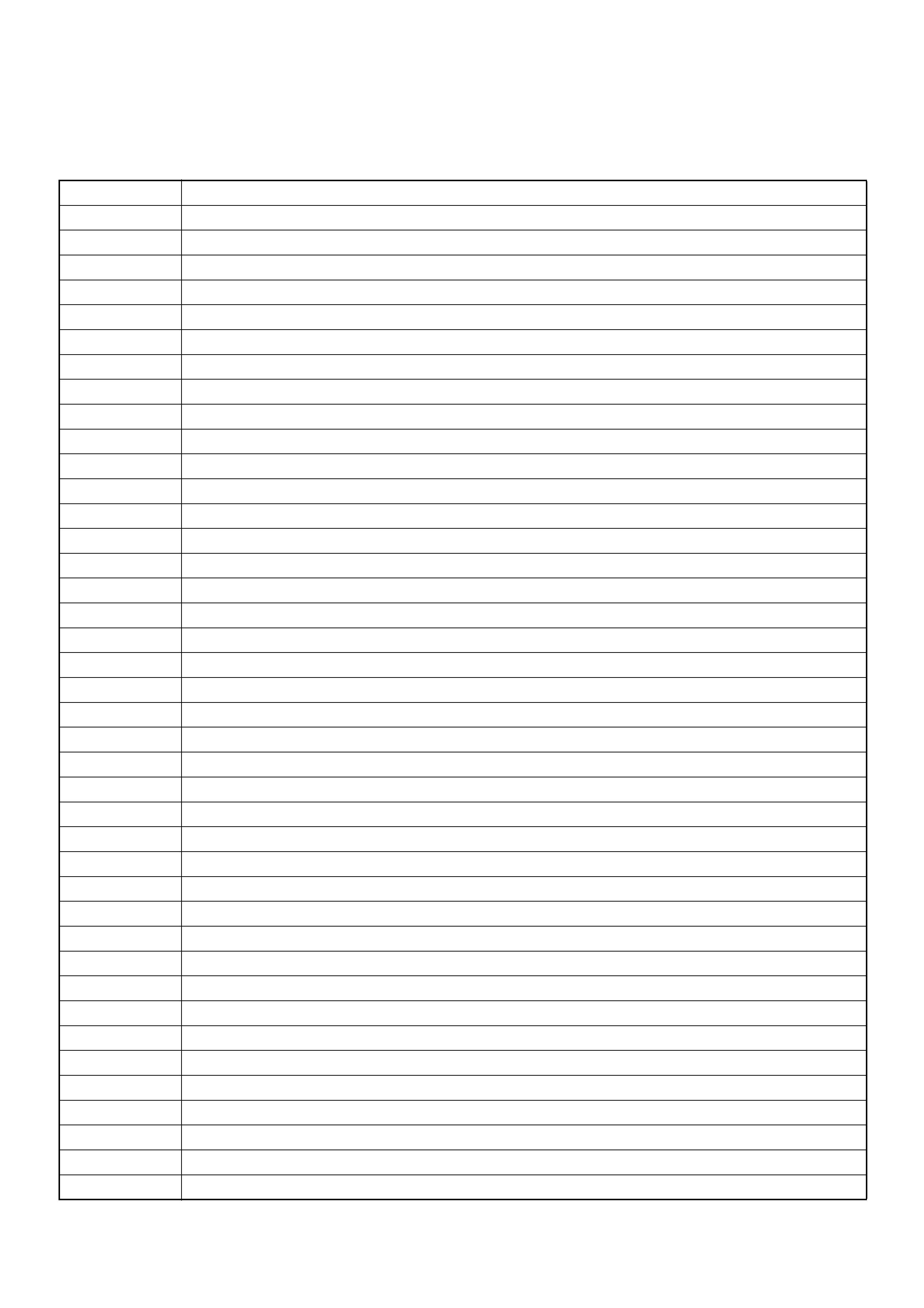

(1) Mass Air Flow (MAF) & Intake Air Temperature

(IAT) Sensor Assembly

(2) Throttle Cable

(3) Air Cleaner Case

(4) EGR Pipe

P O Q

N

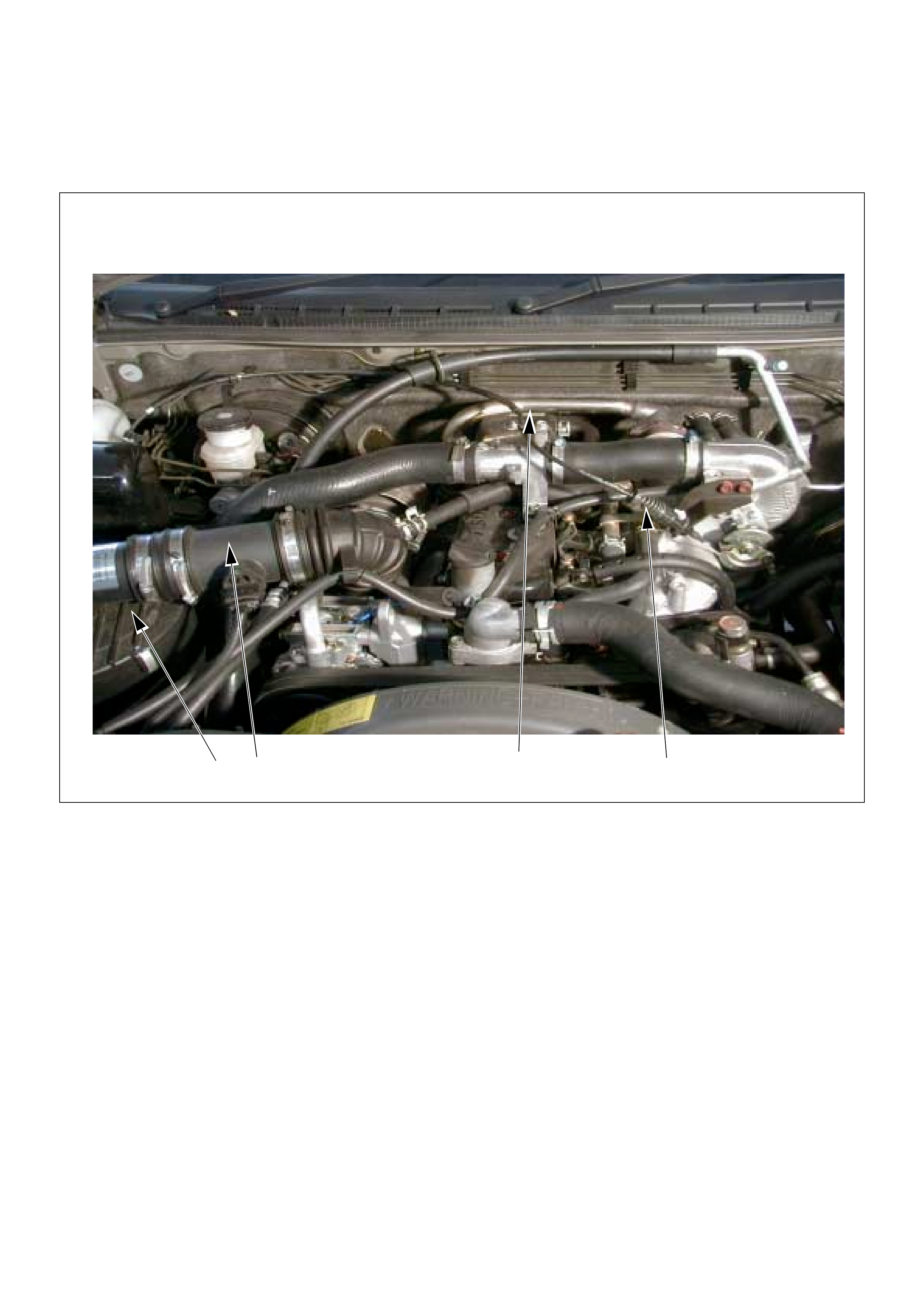

(1) Throttle Position Sensor (TPS)

(2) Pump Control Unit (PSG) (3) Injection Pump Assembly

(4) Fuel Filter

O NP

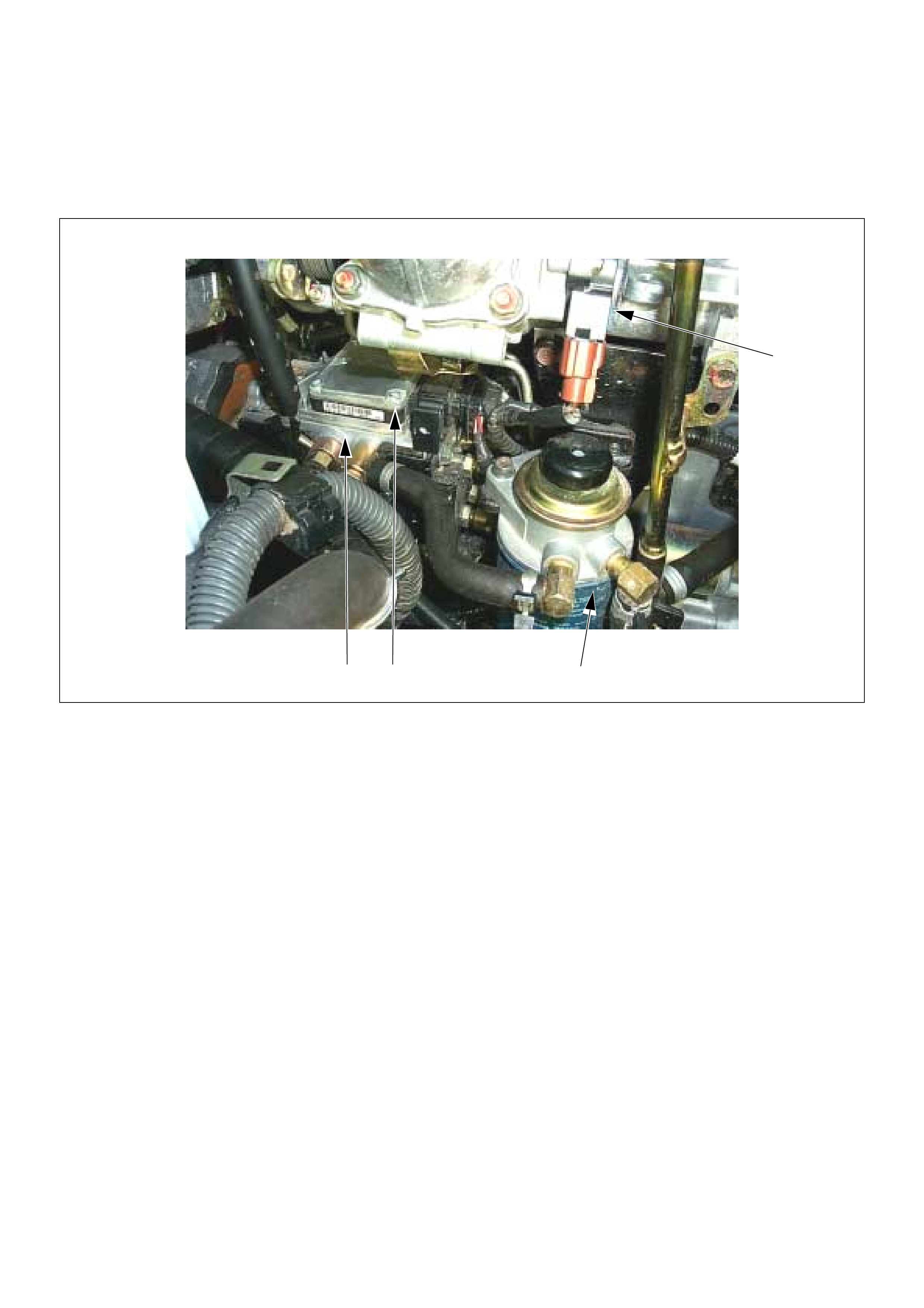

(1) Mass Air Flow (MAF) & Intake Air Temperature

(IAT) Sensor Assembly

(2) EGR EVRV

(3) Air Cleaner Case

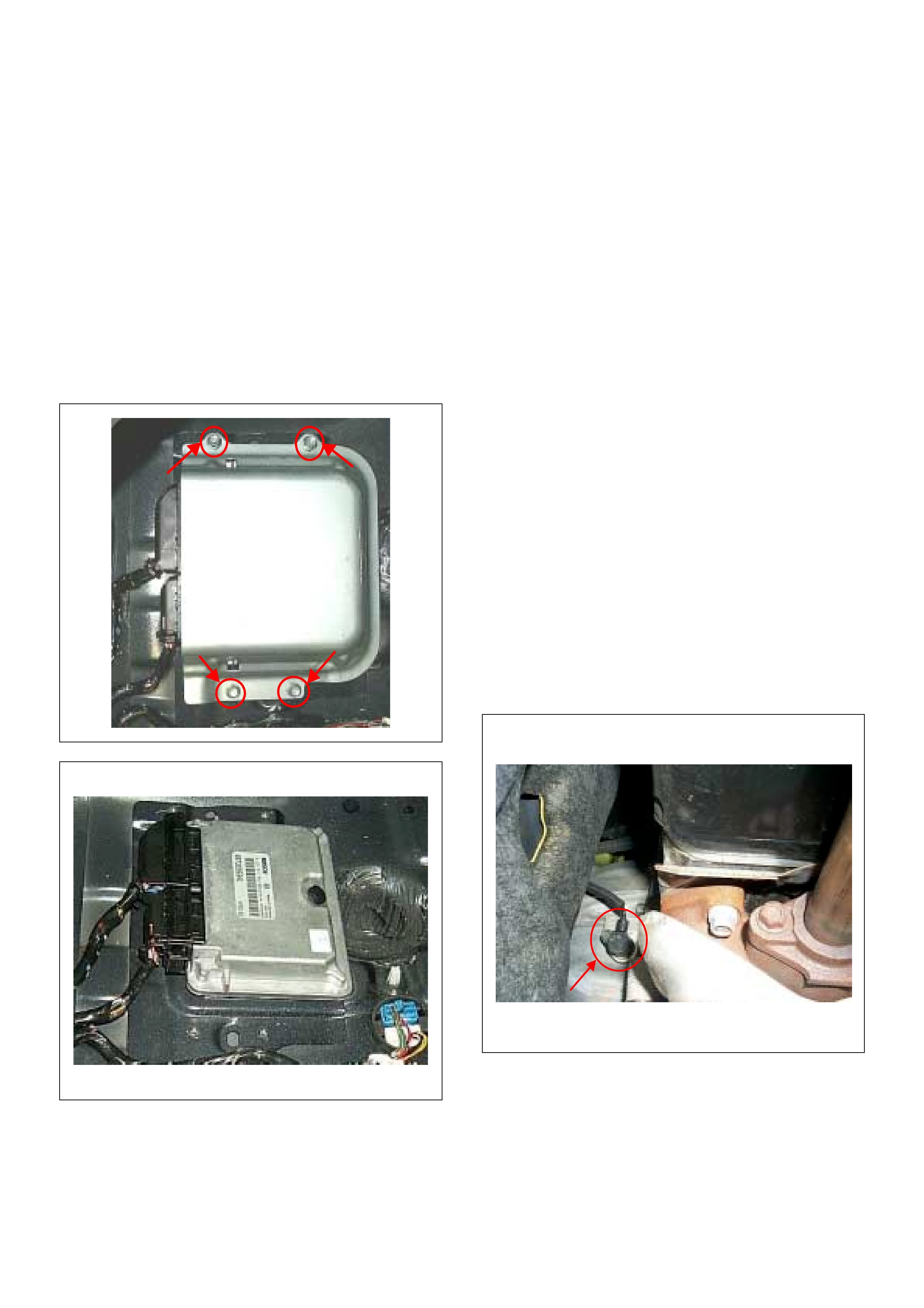

(1) Engine Control Module (ECM) (1) Engine Coolant Temperature (ECT) Sensor

(2) Thermo Unit for Water Temperature Gauge

ON

(1) Vehicle Speed Sensor (VSS)

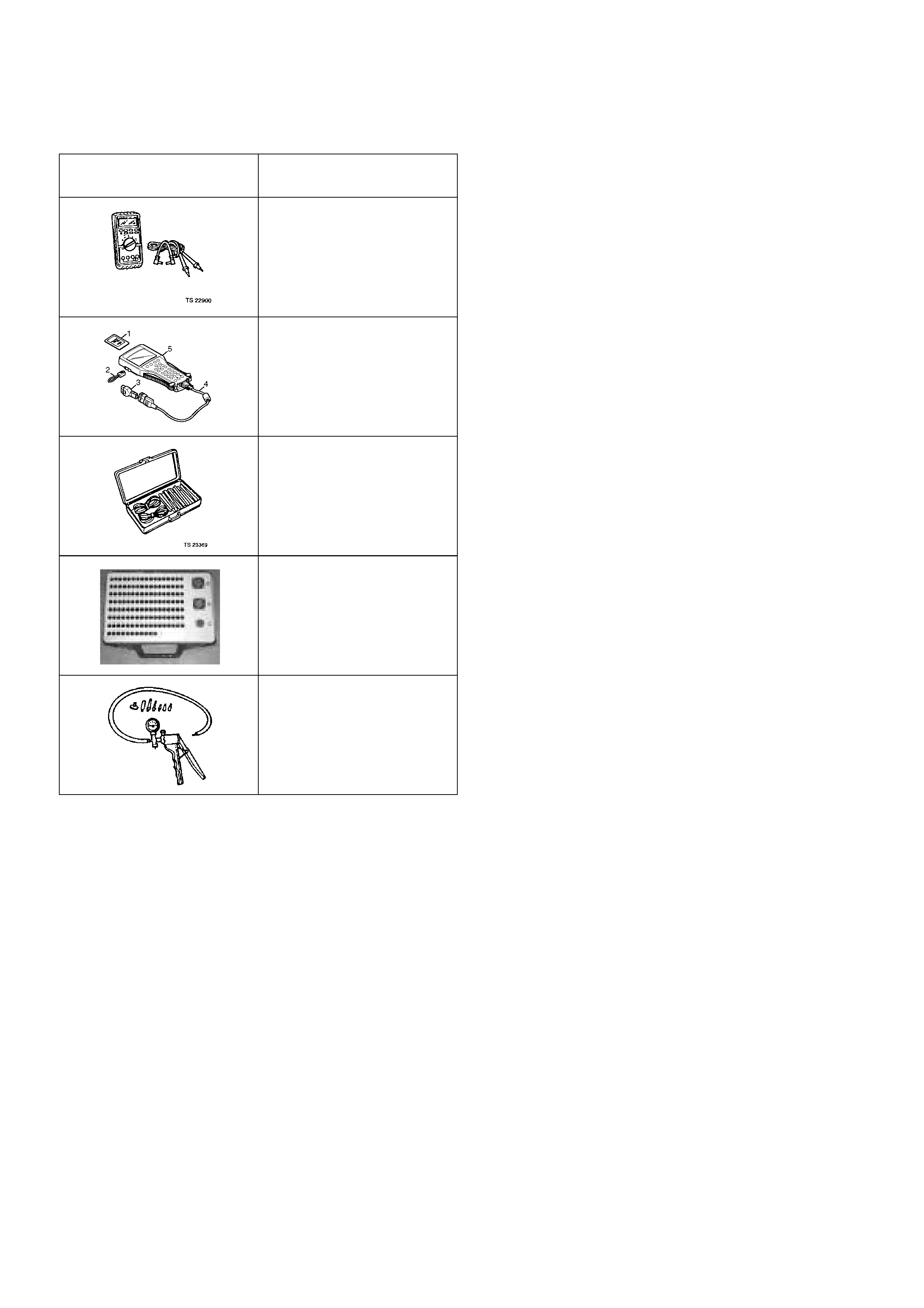

(1) EGR EVRV

(2) To Vacuum Pump

(3) To EGR Valve

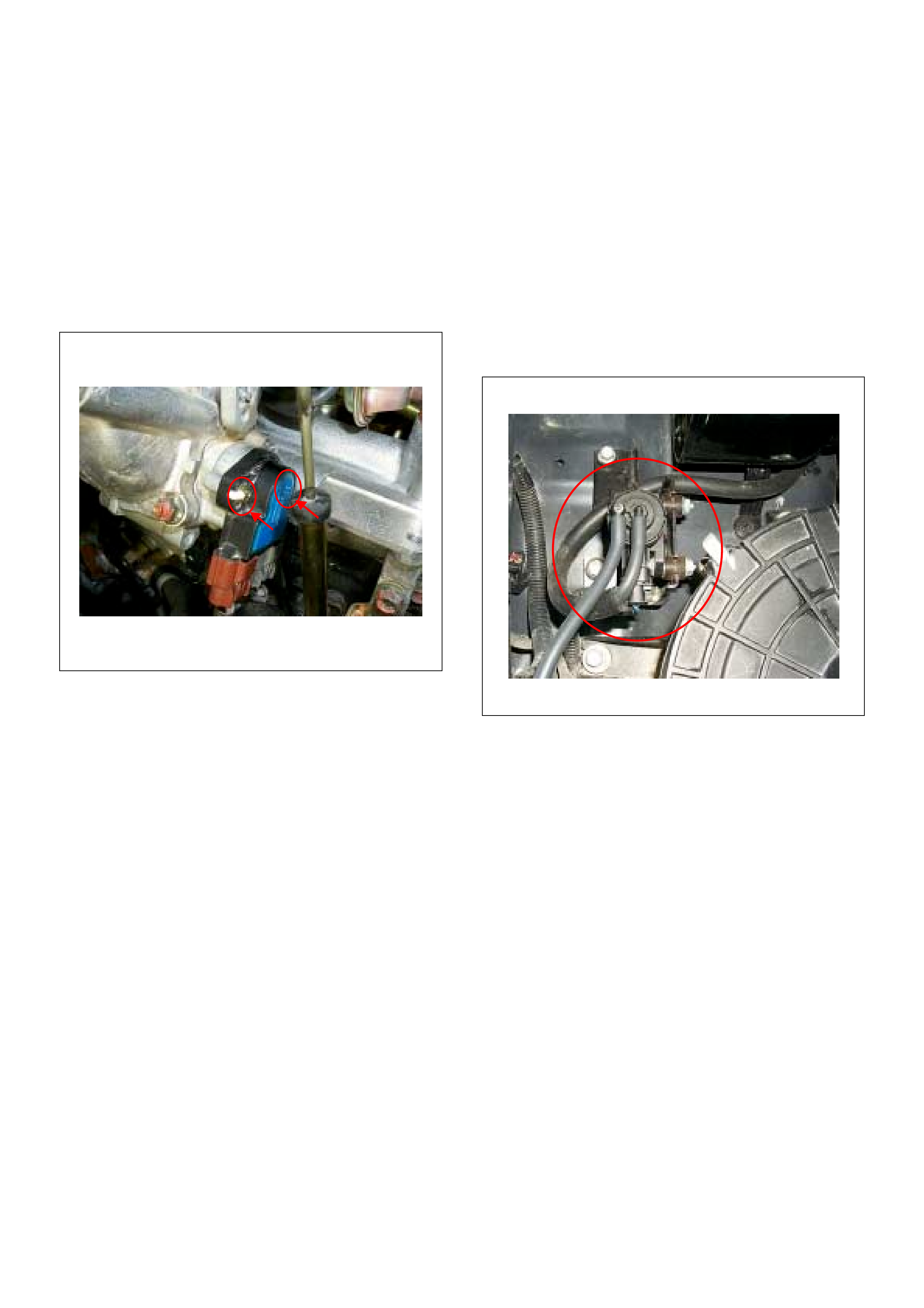

(1) Crankshaft Position (CKP) Sensor

(2) Clutch Housing

P O N

NO

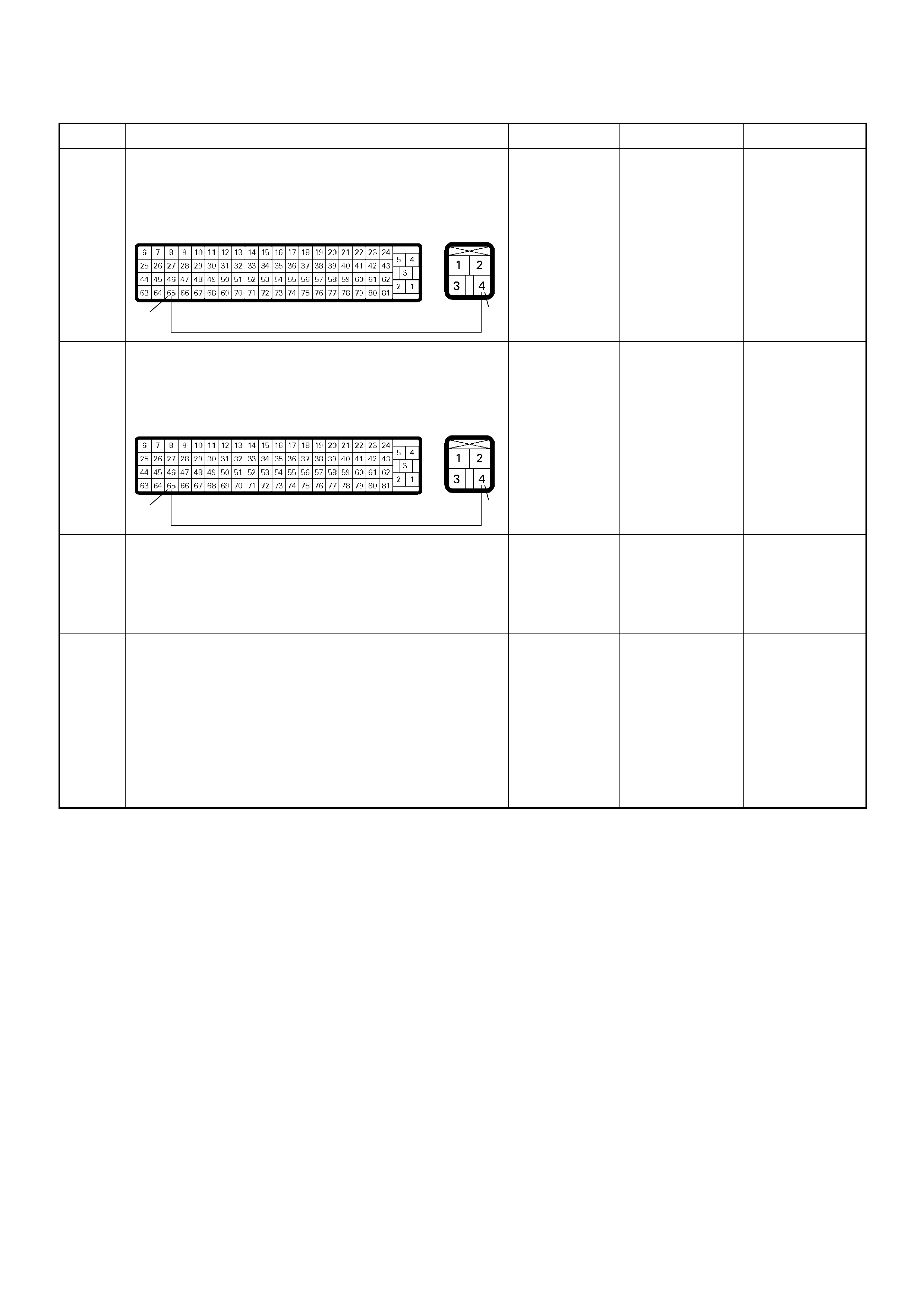

ECM CIRCUIT DIAGRAM

ECM CIRCUIT DIAGRAM (1/2)

ECM CIRCUIT DIAGRAM (2/2)

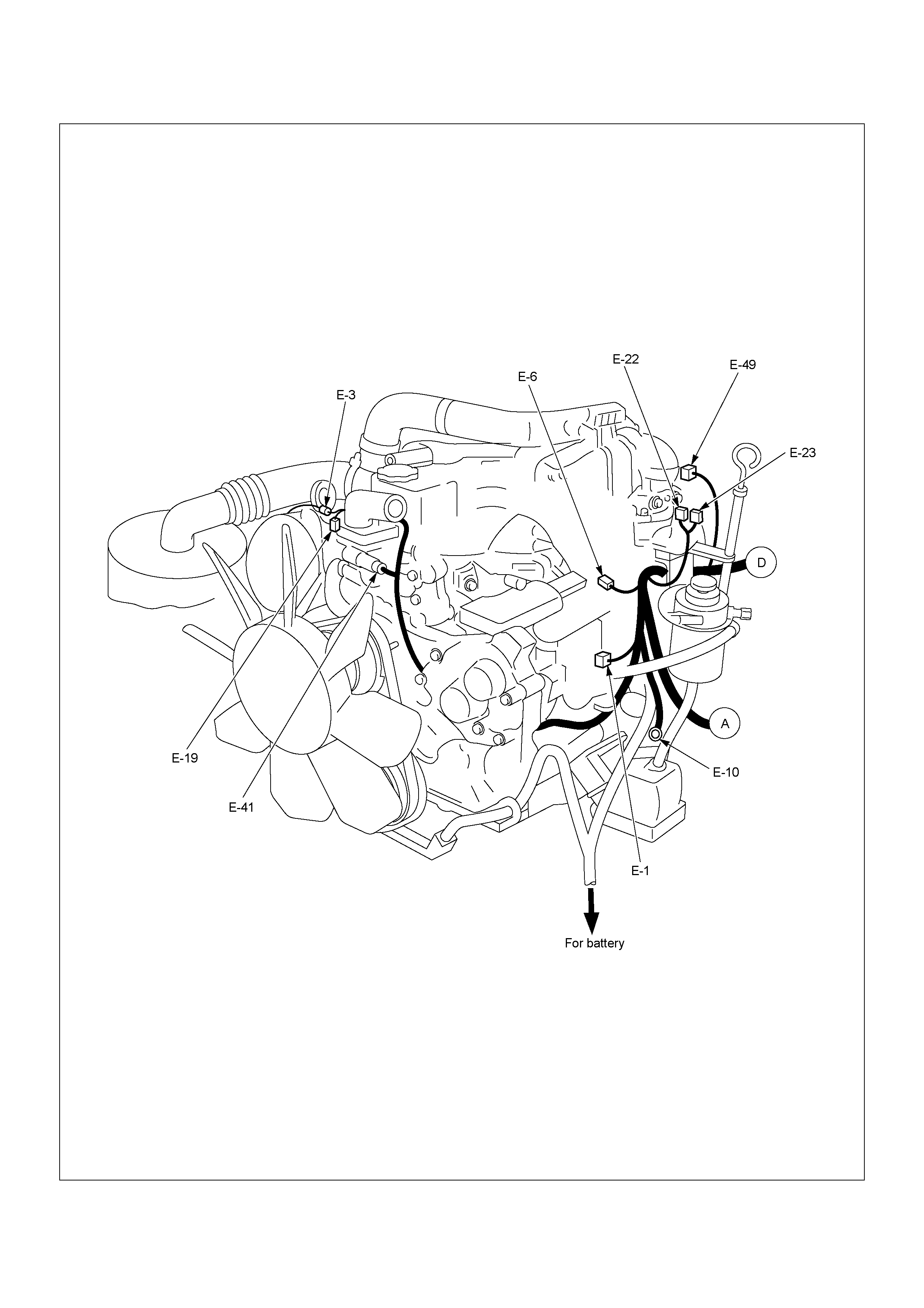

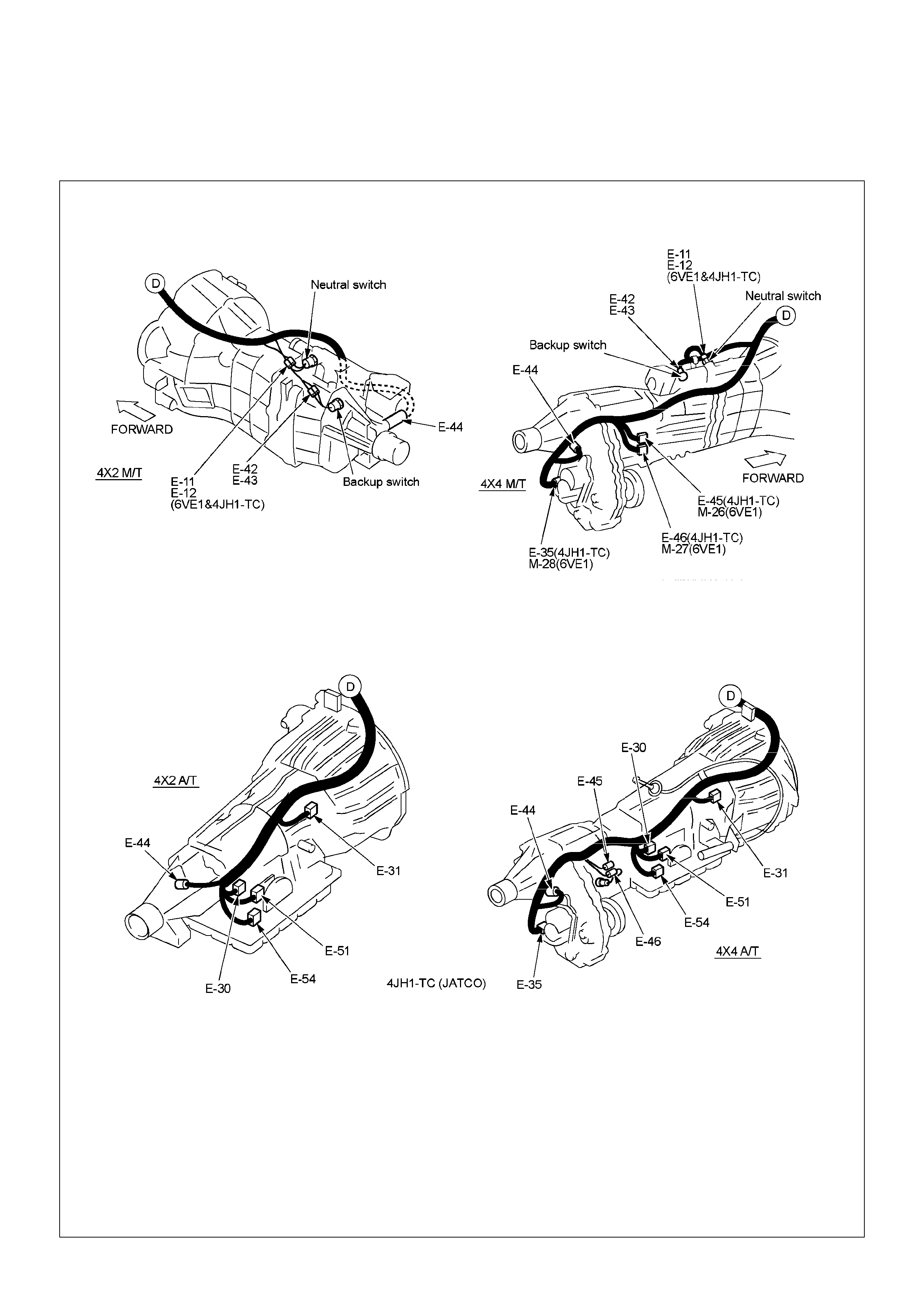

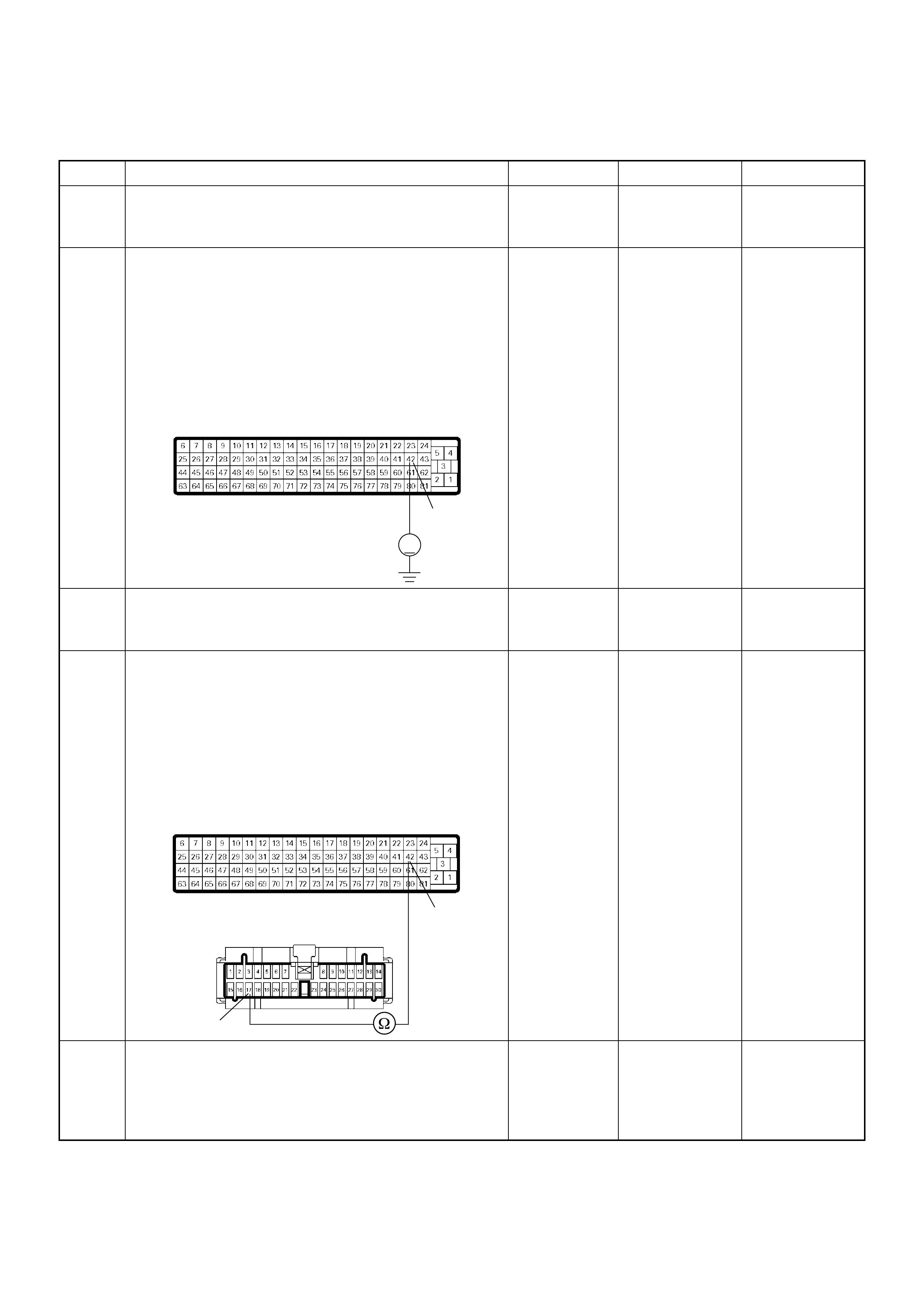

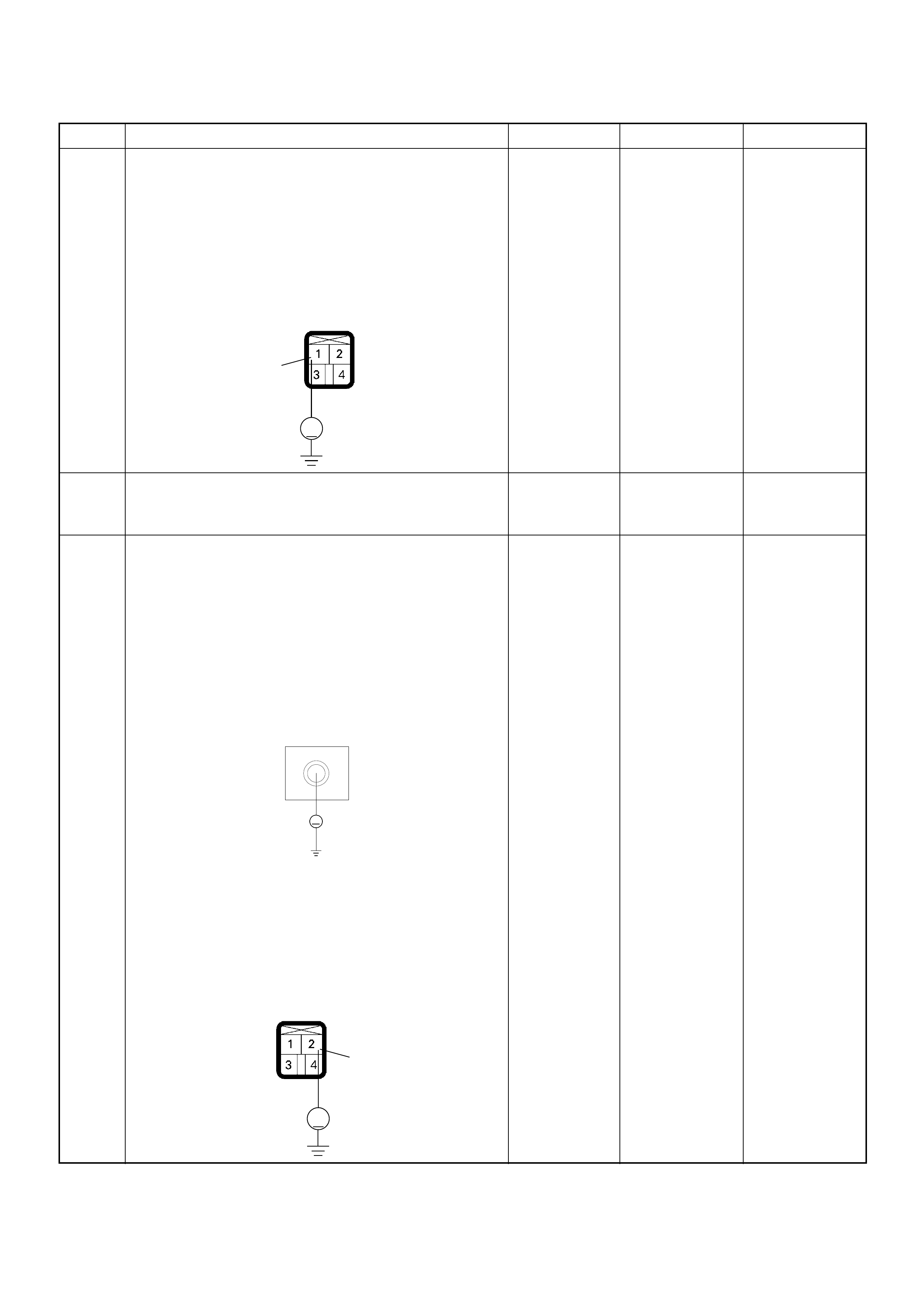

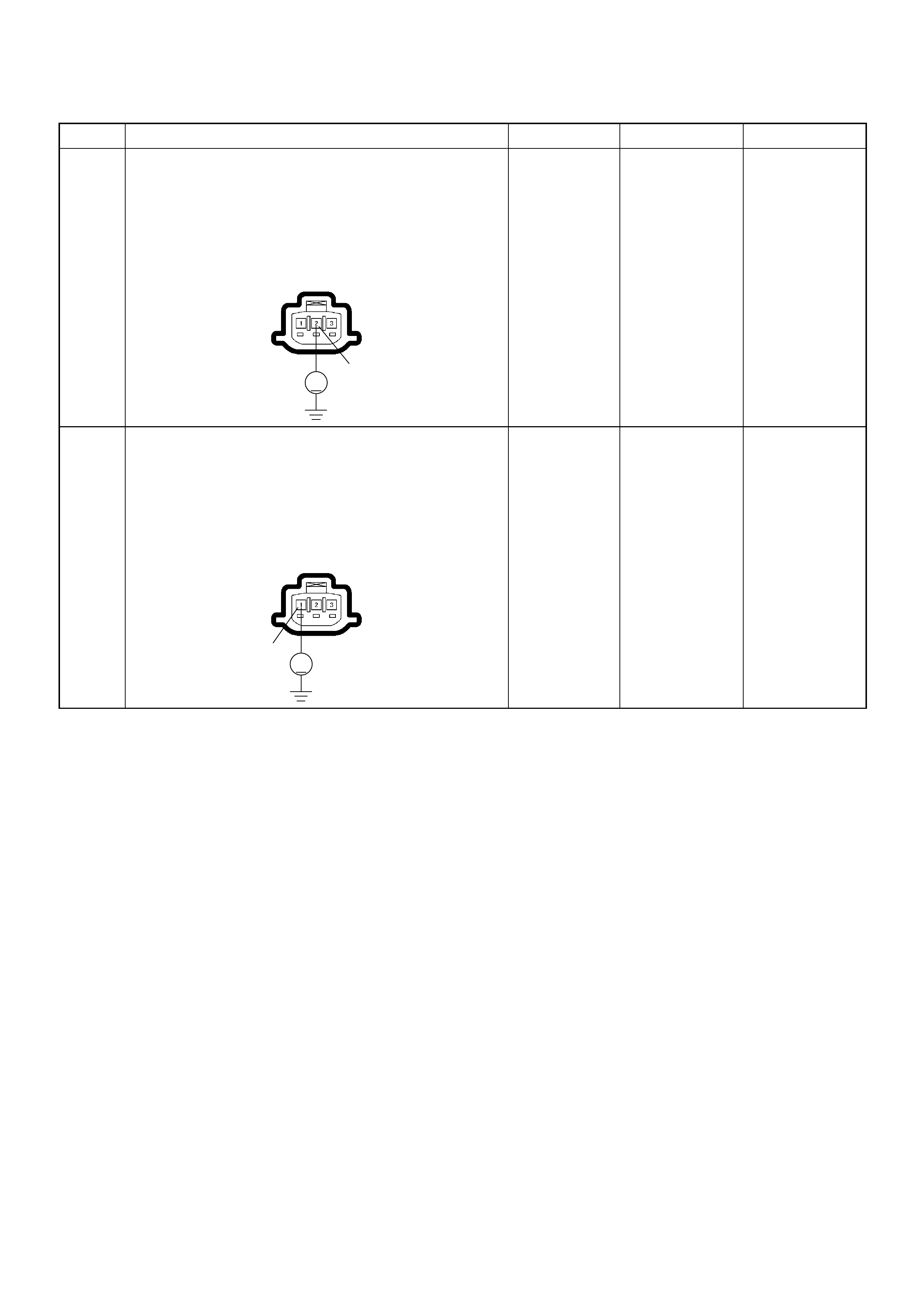

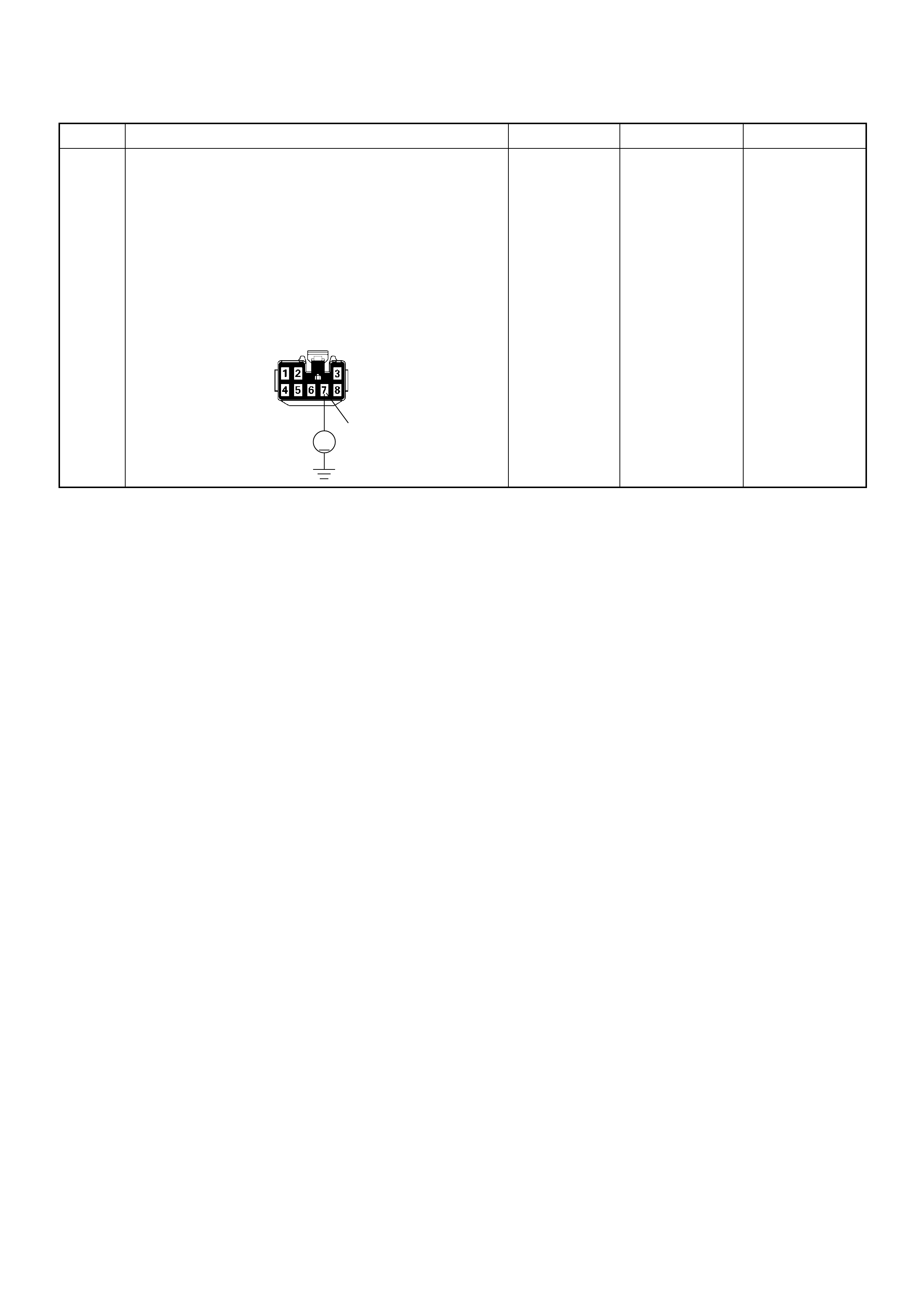

GROUND POINT

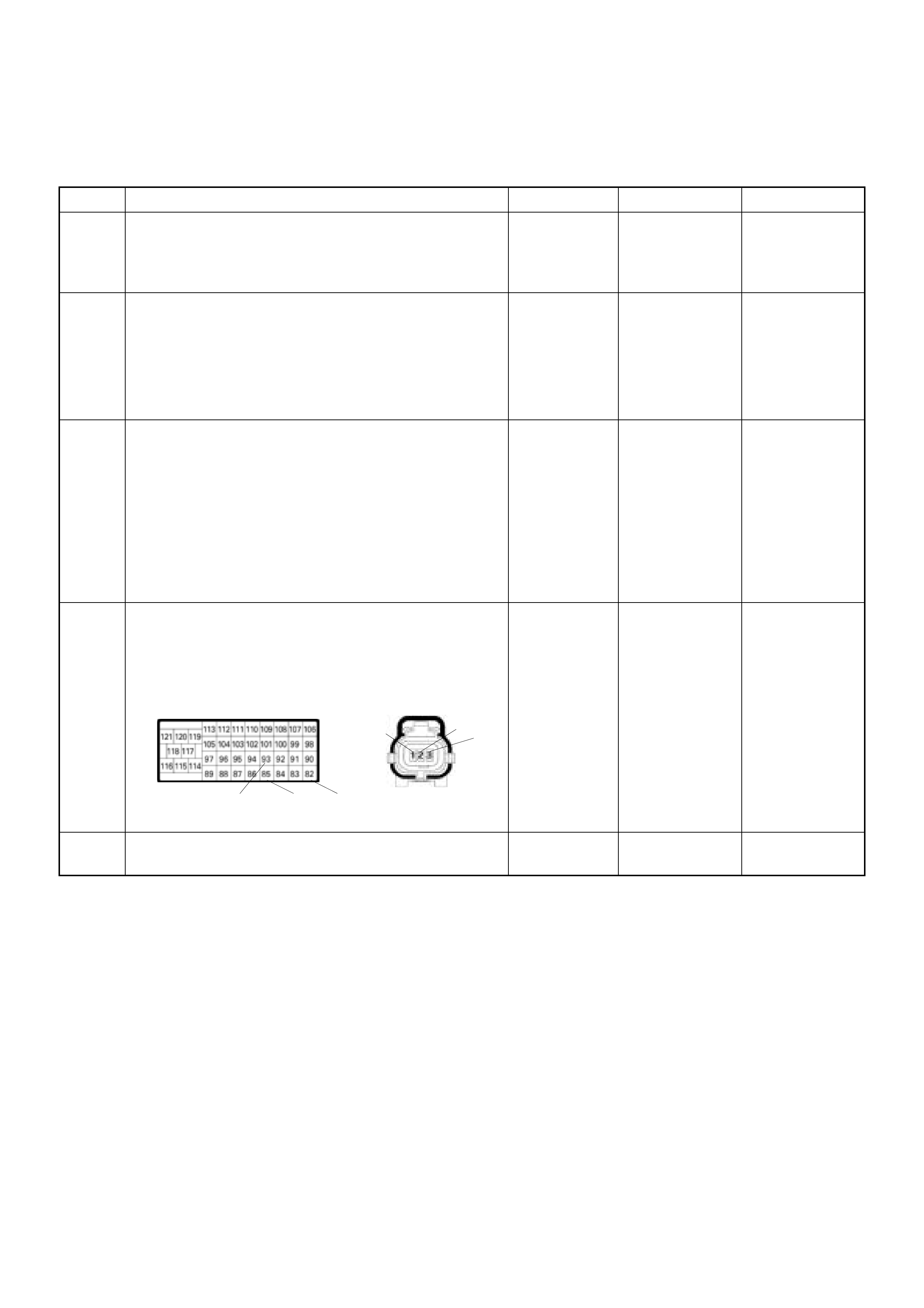

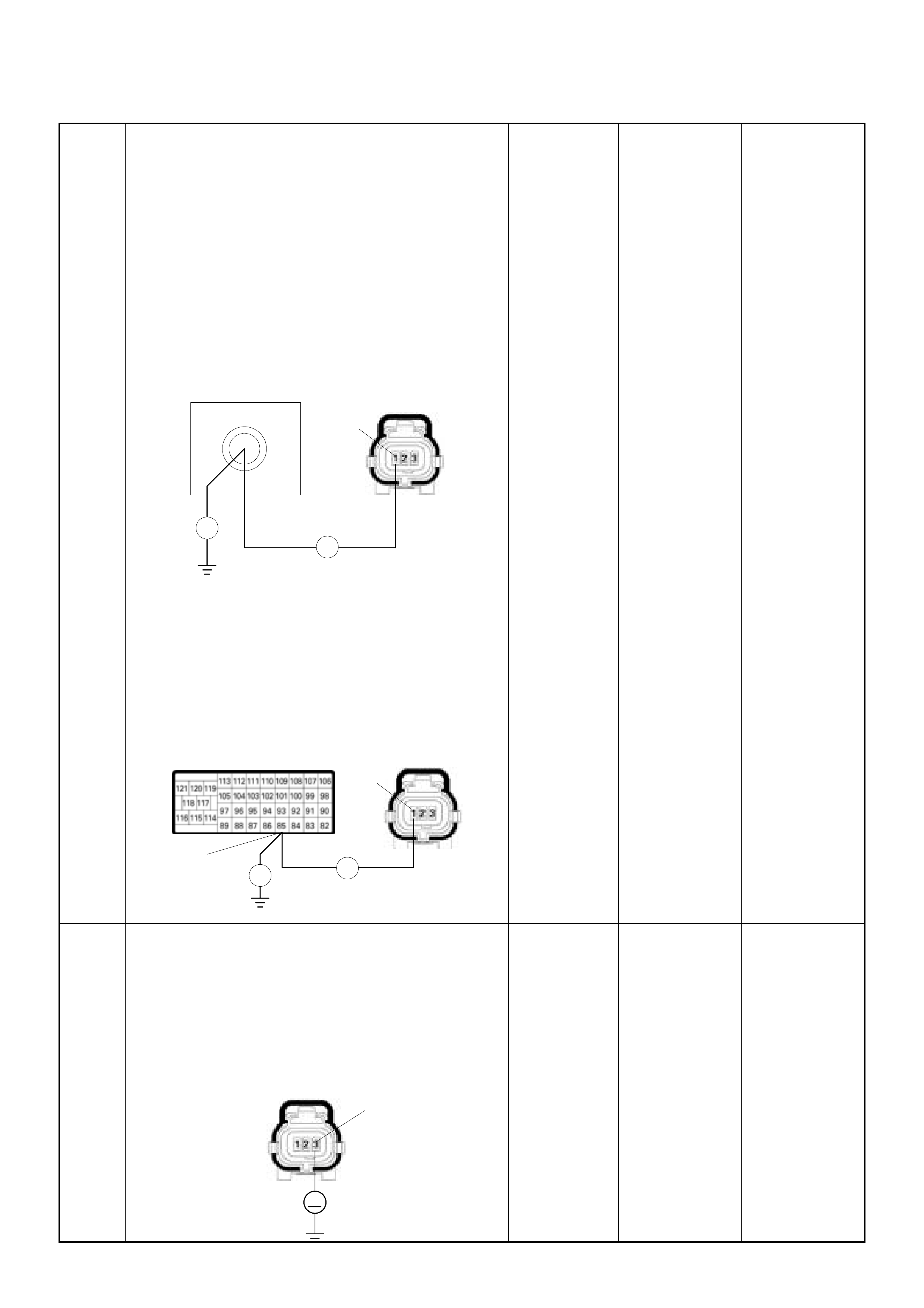

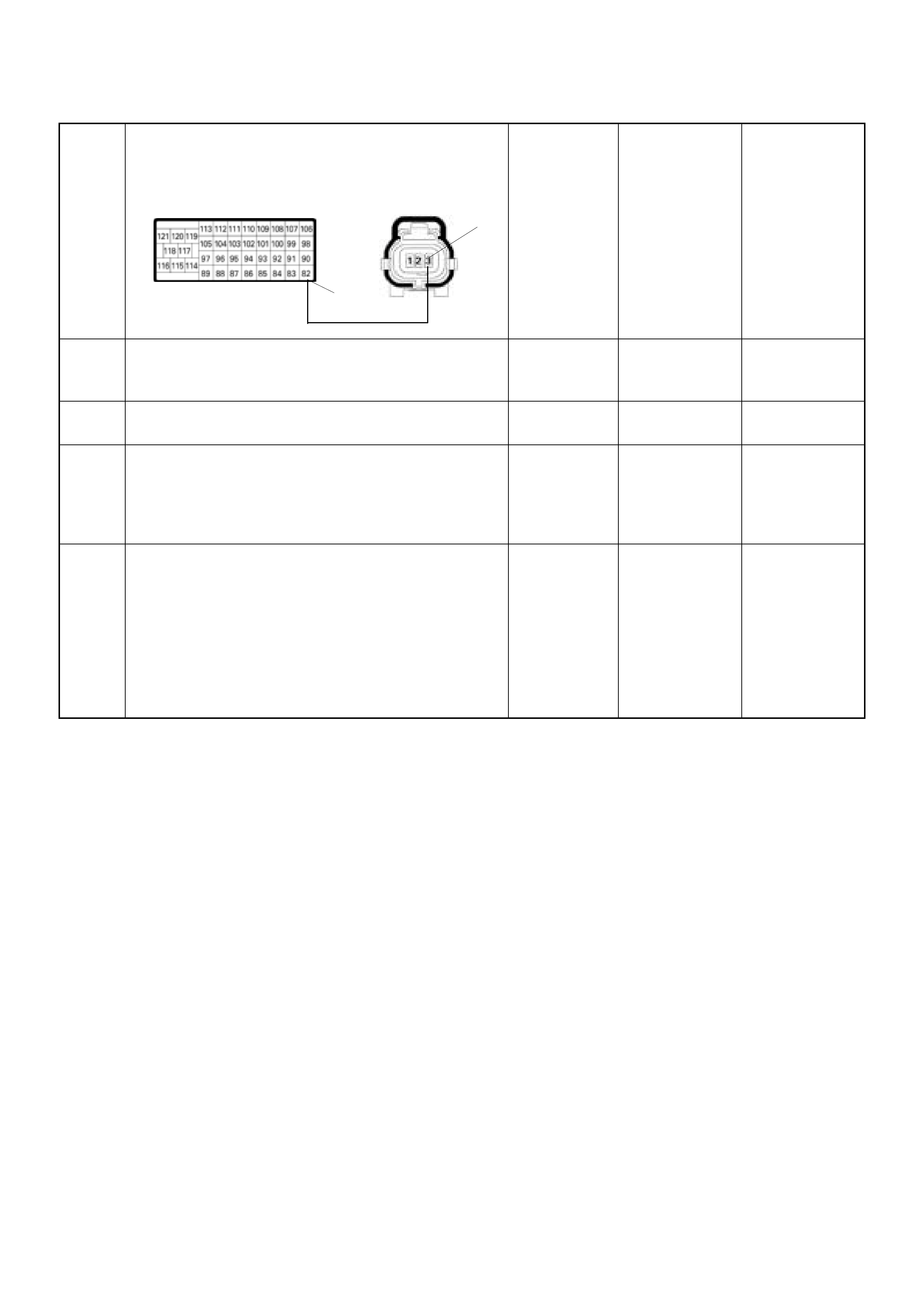

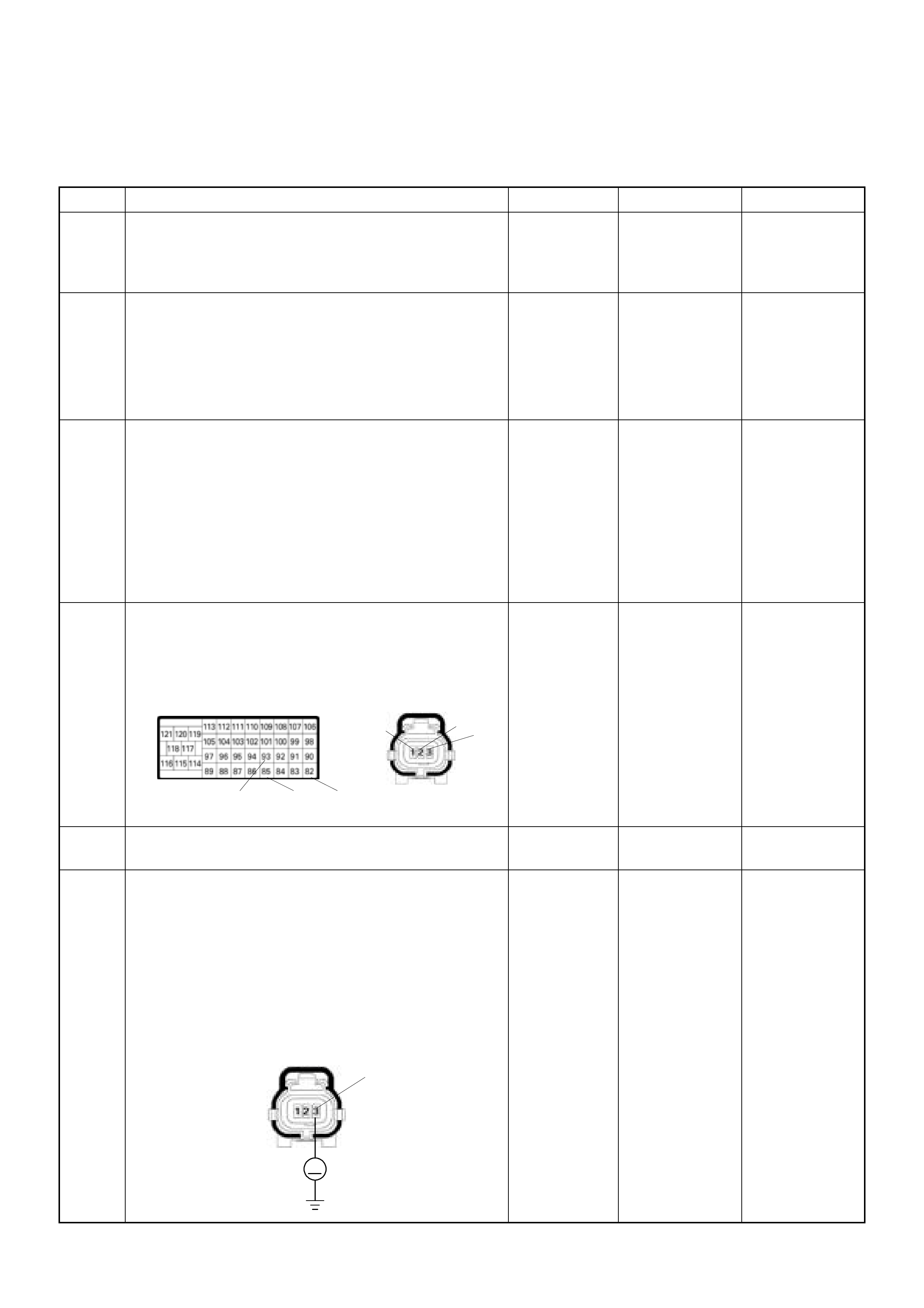

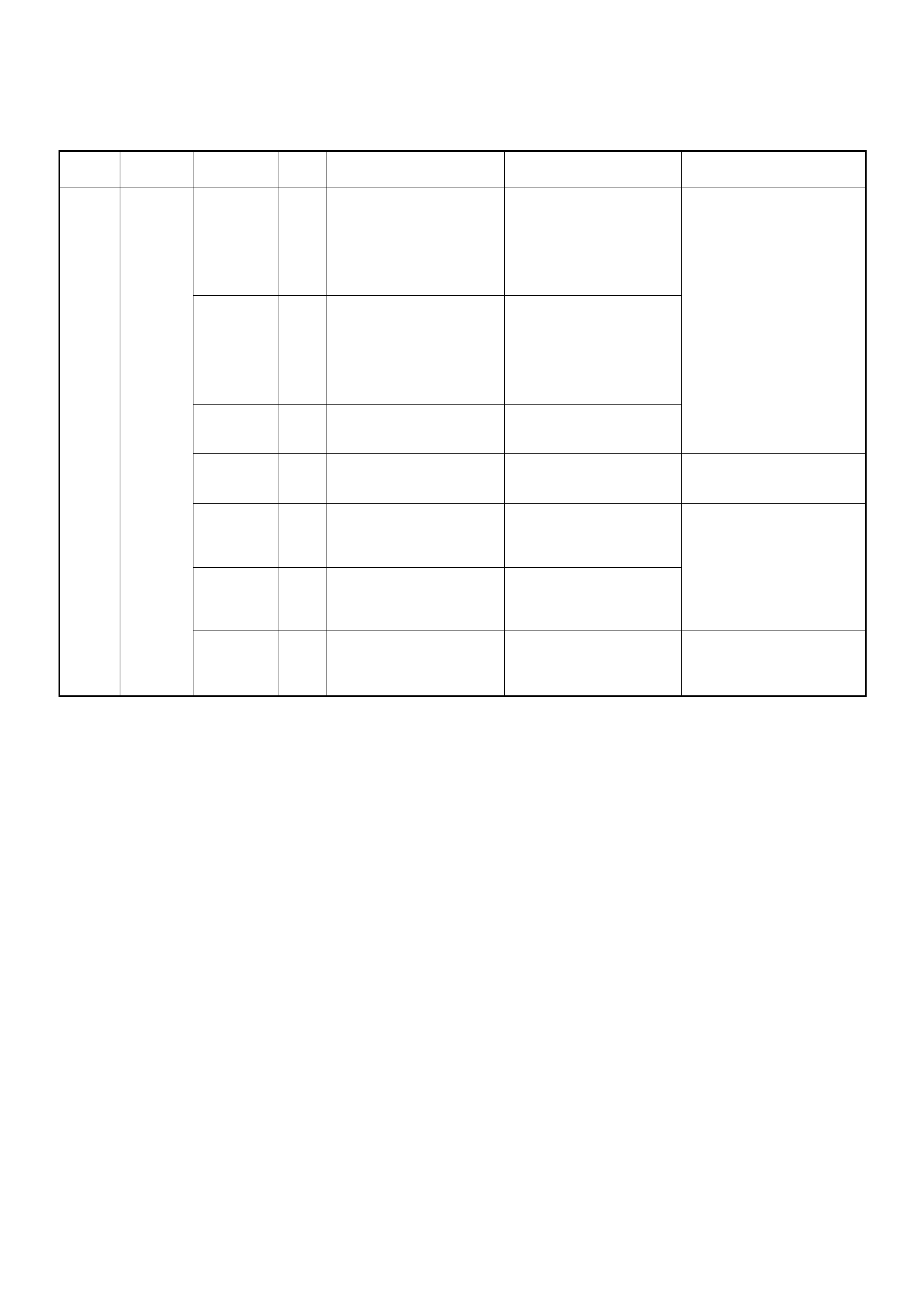

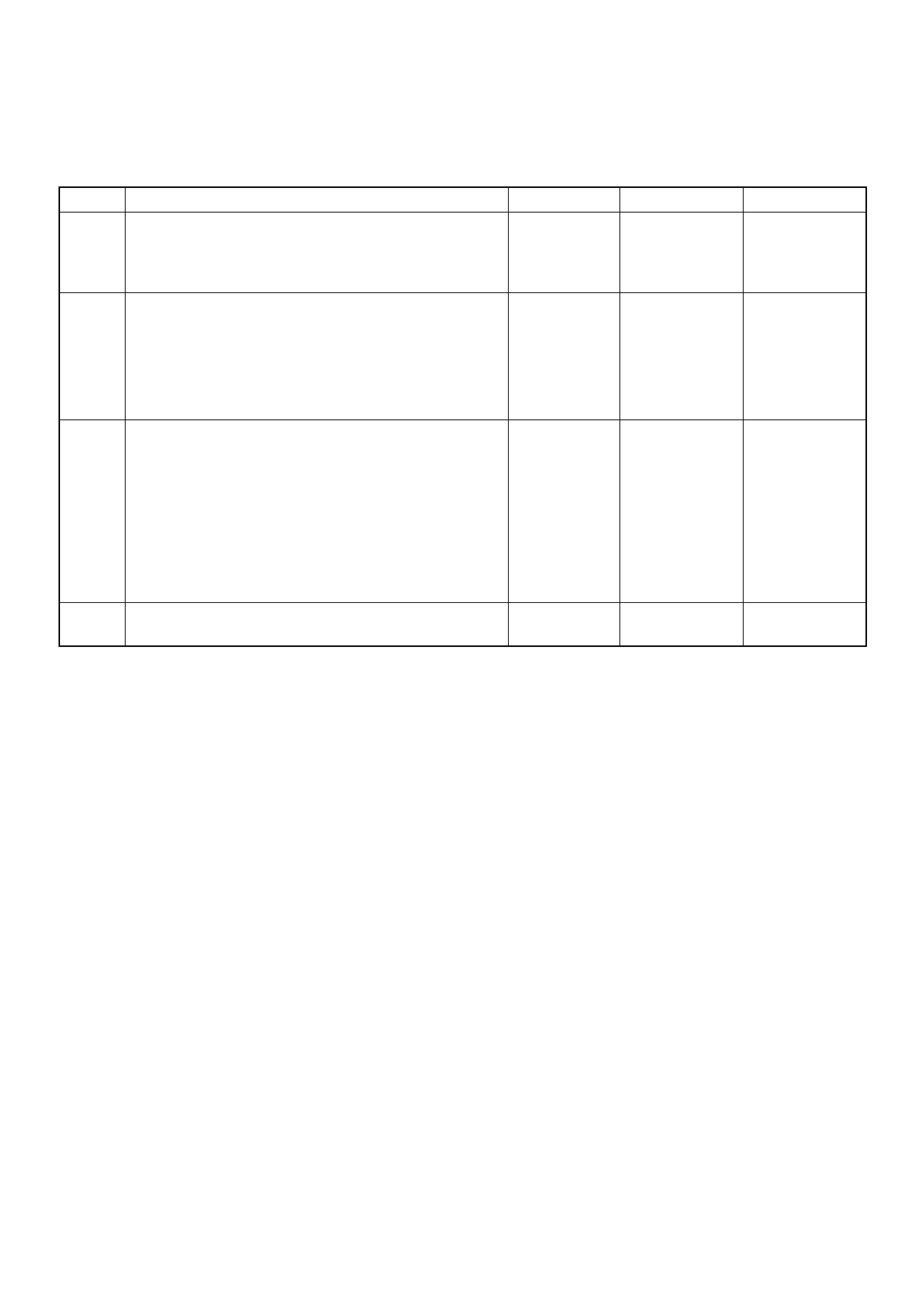

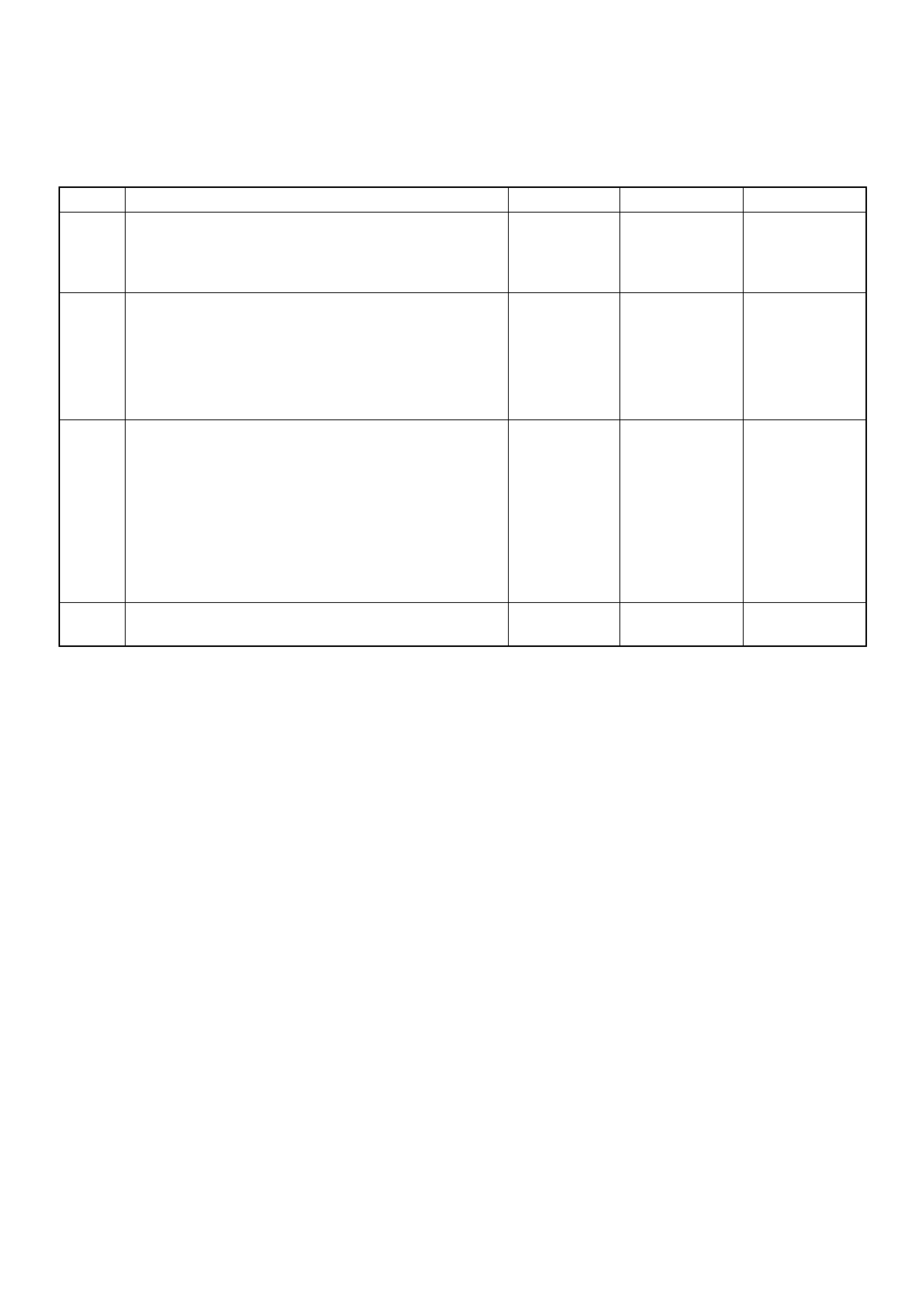

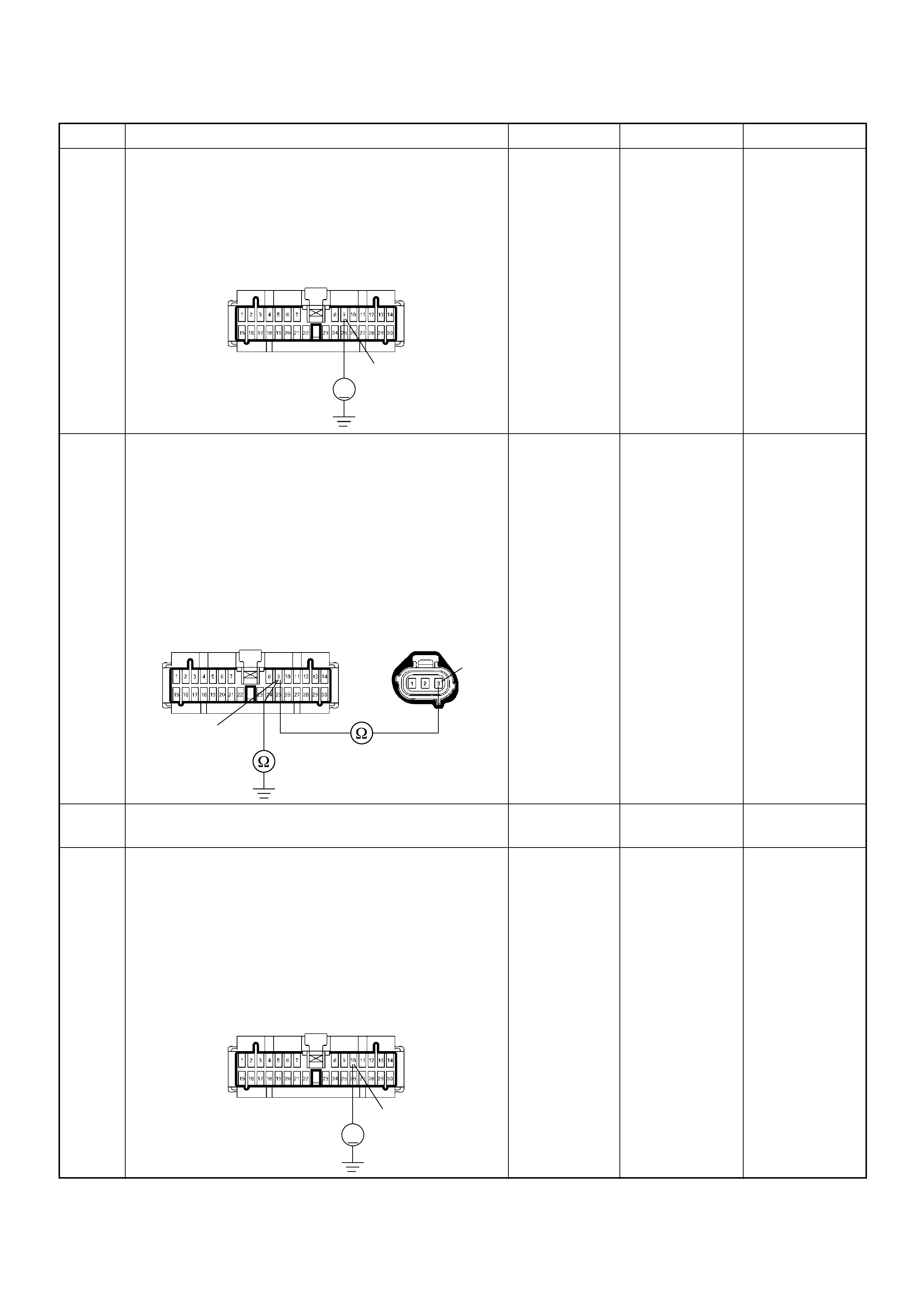

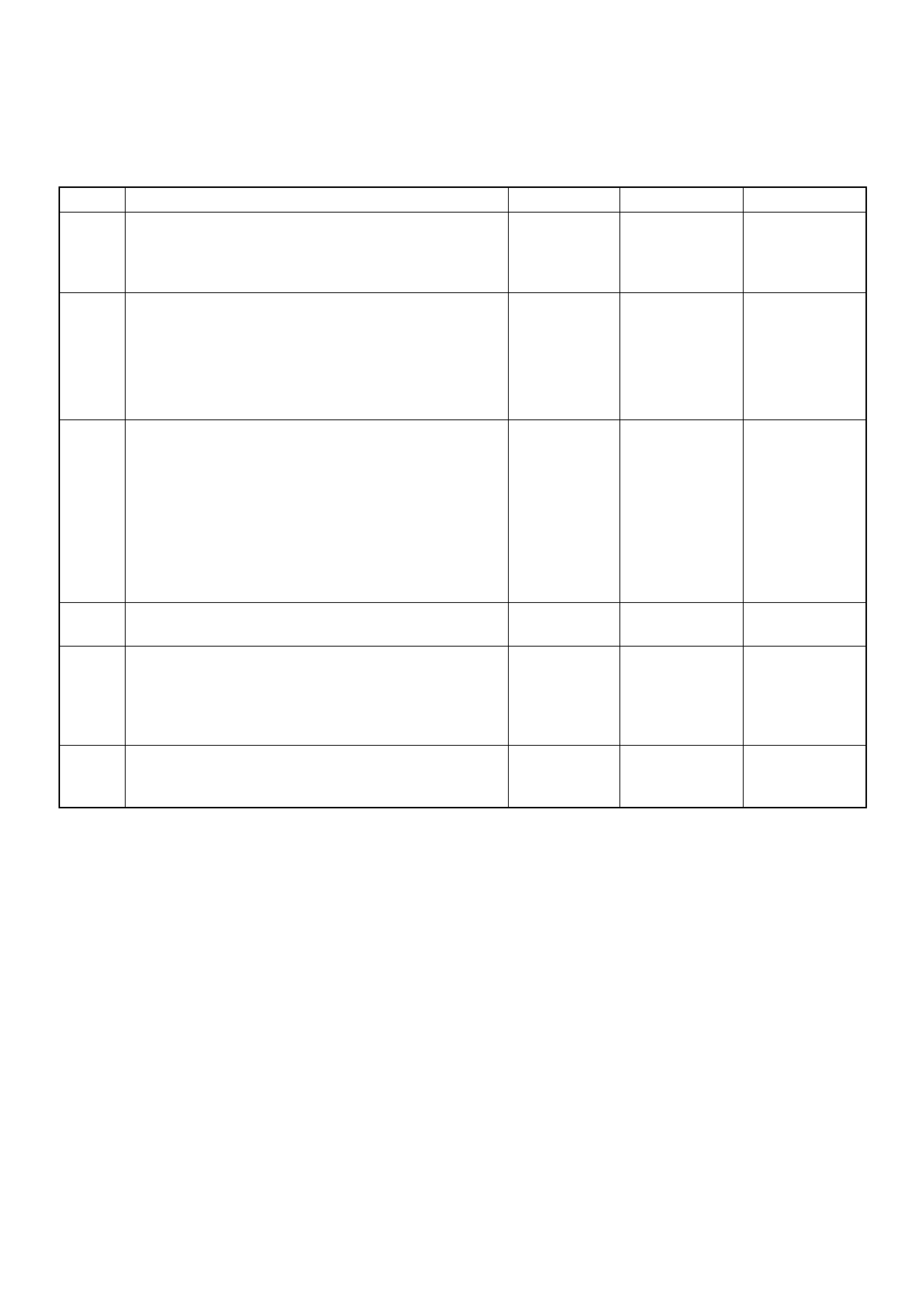

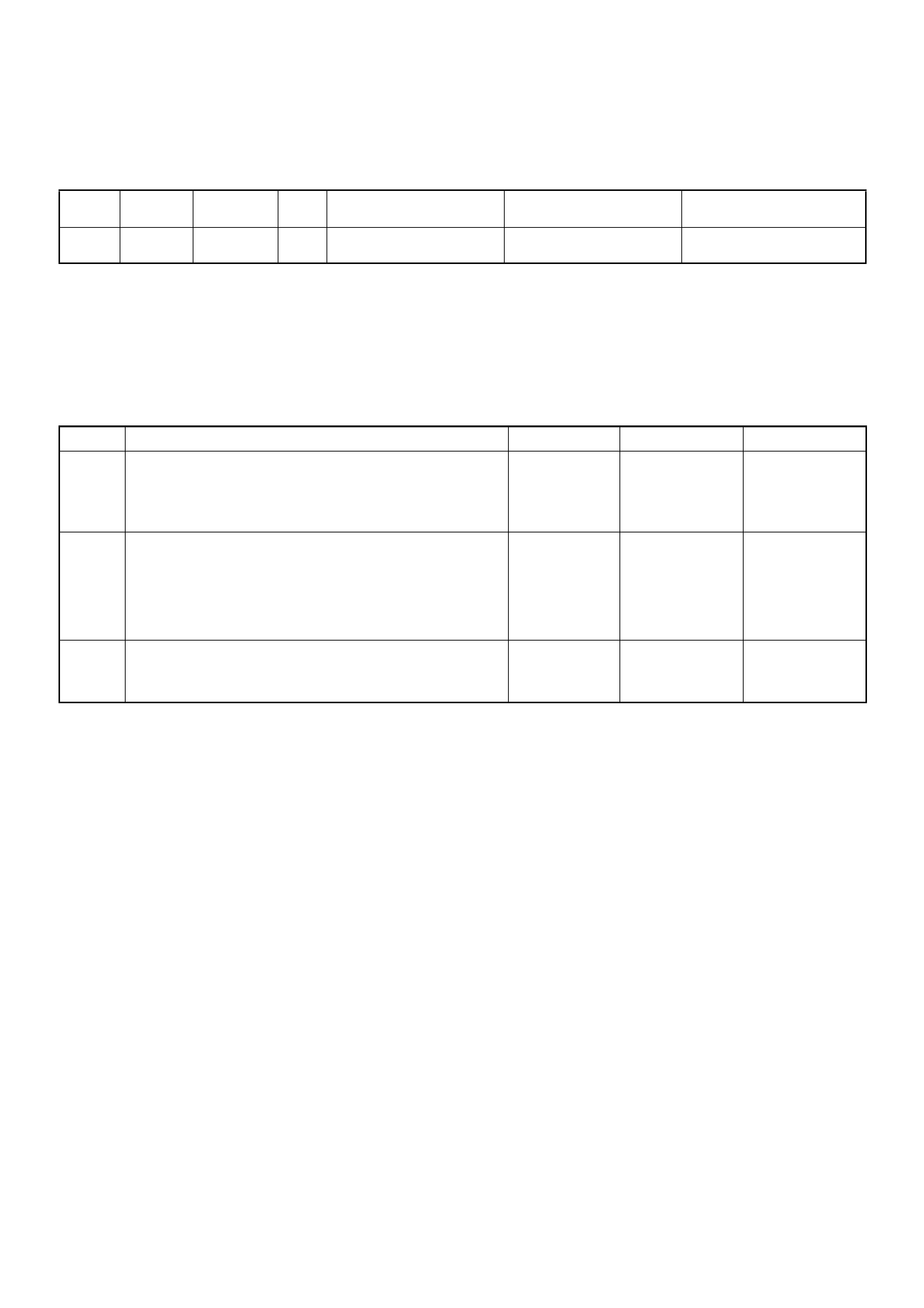

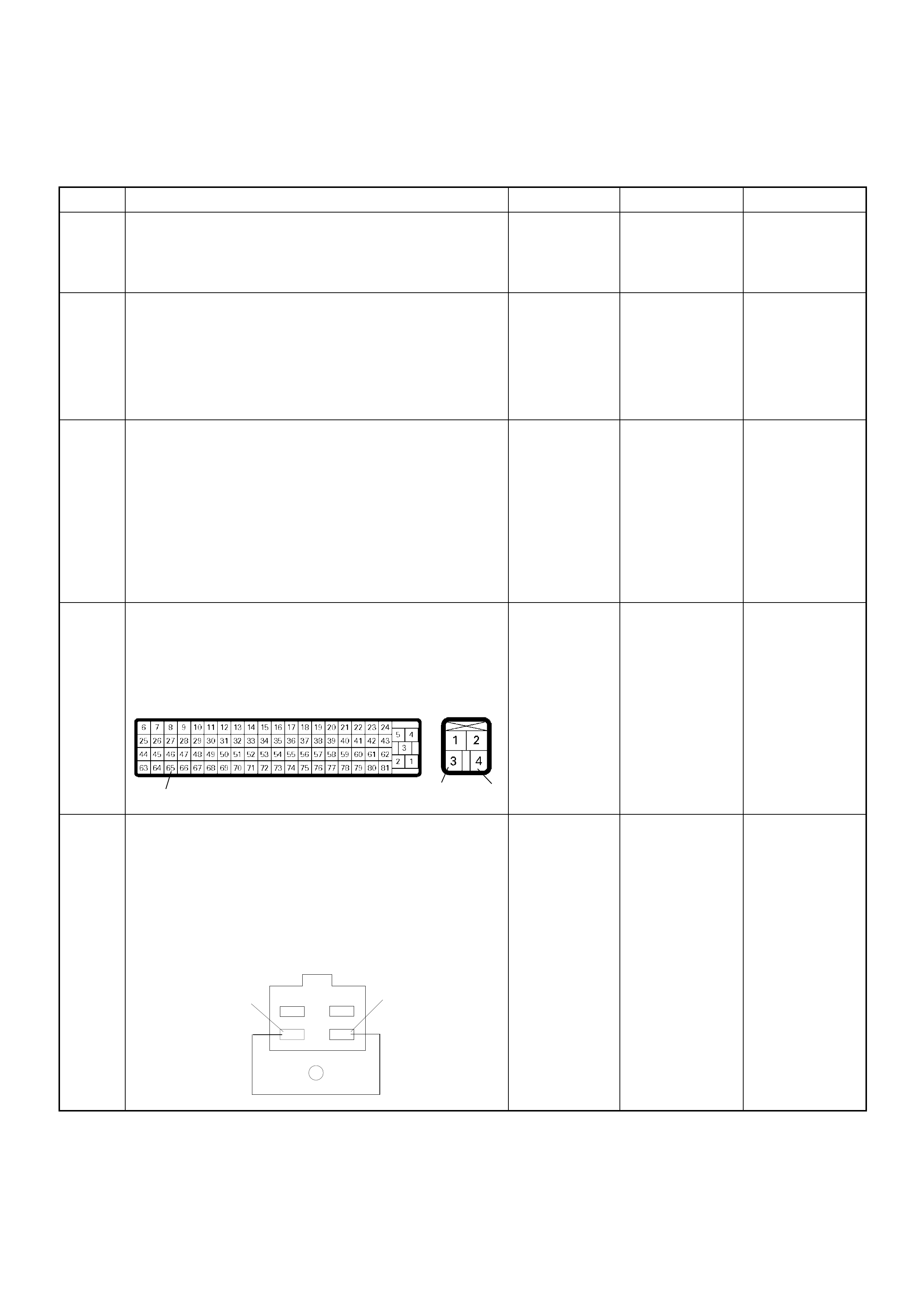

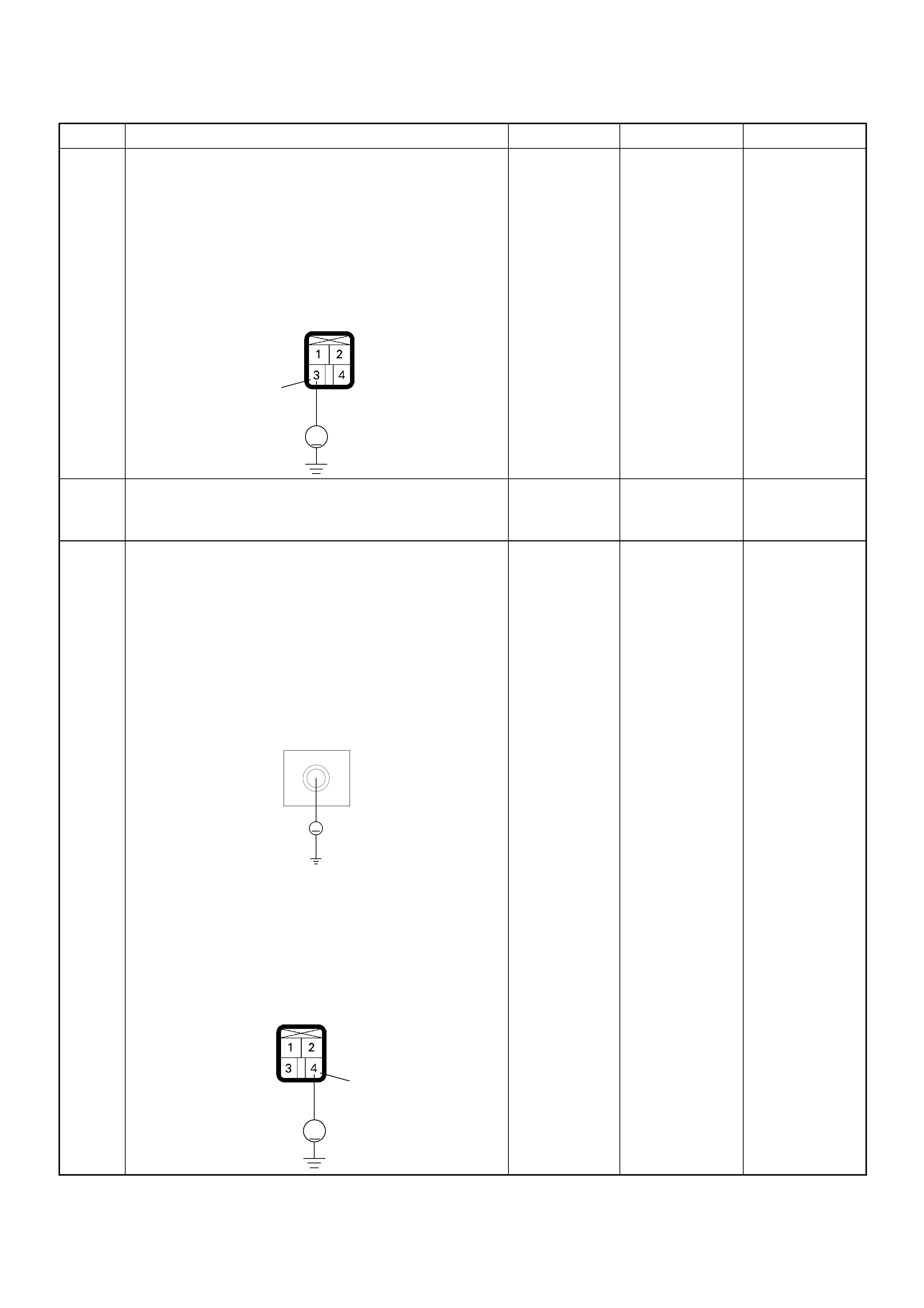

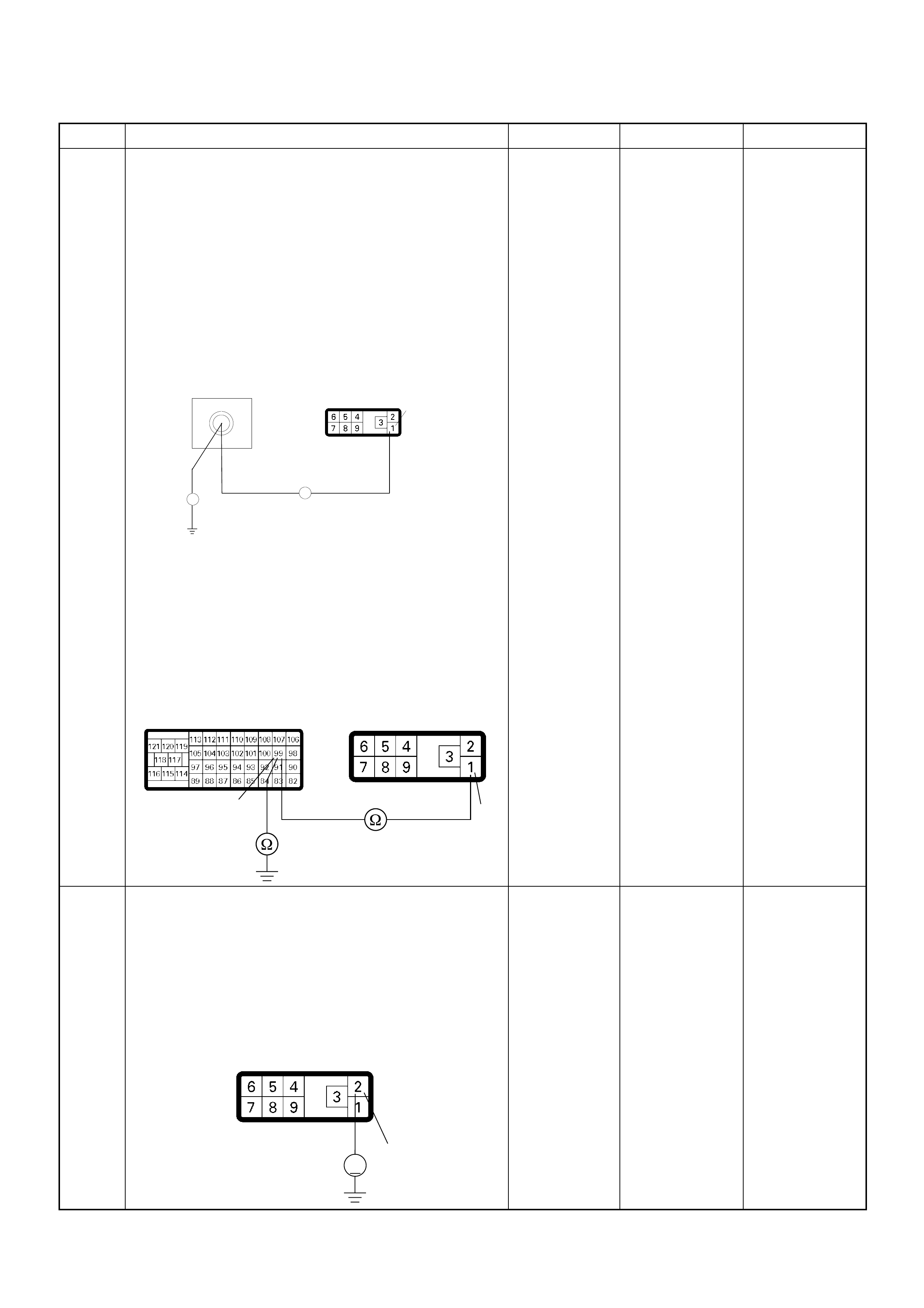

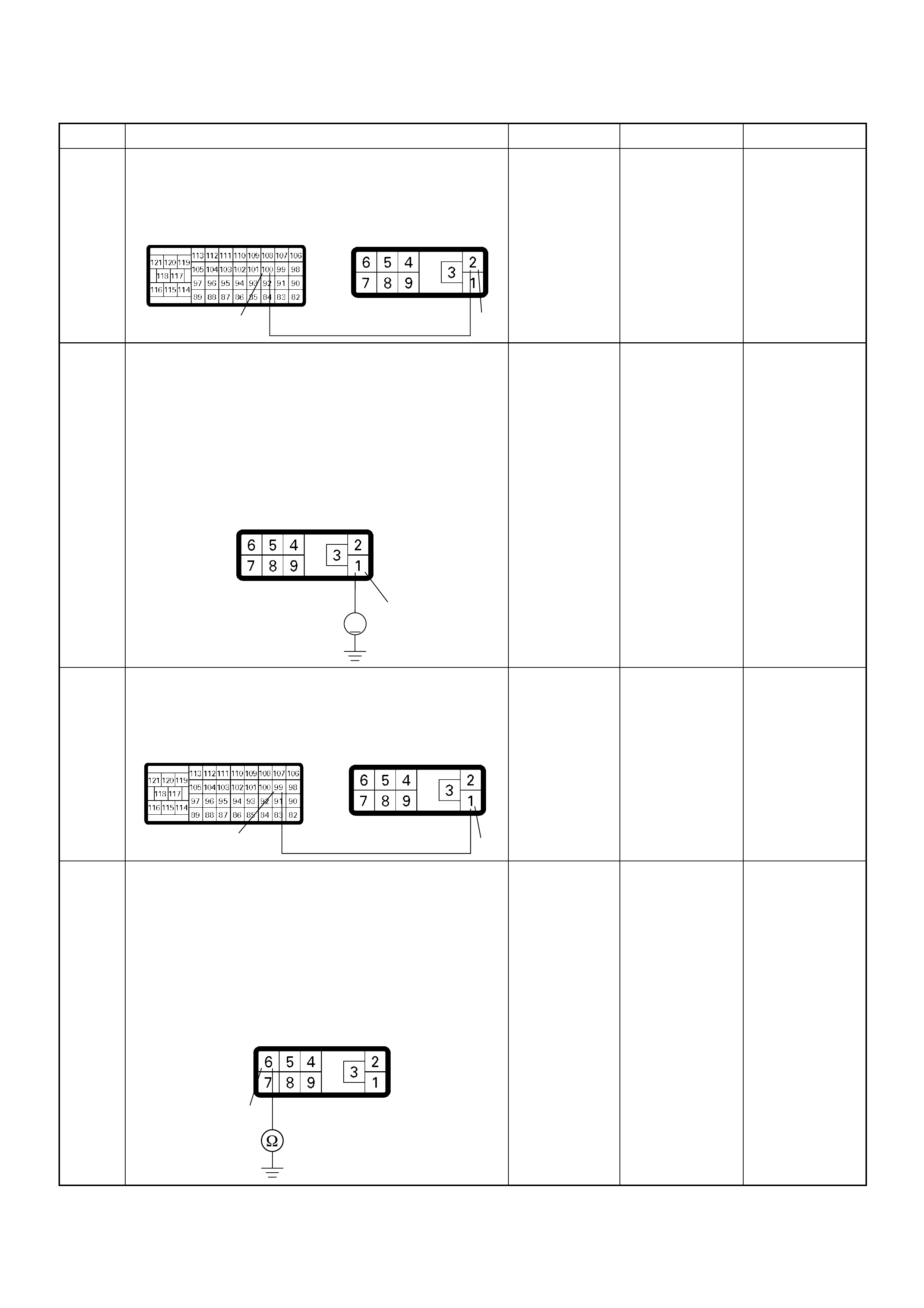

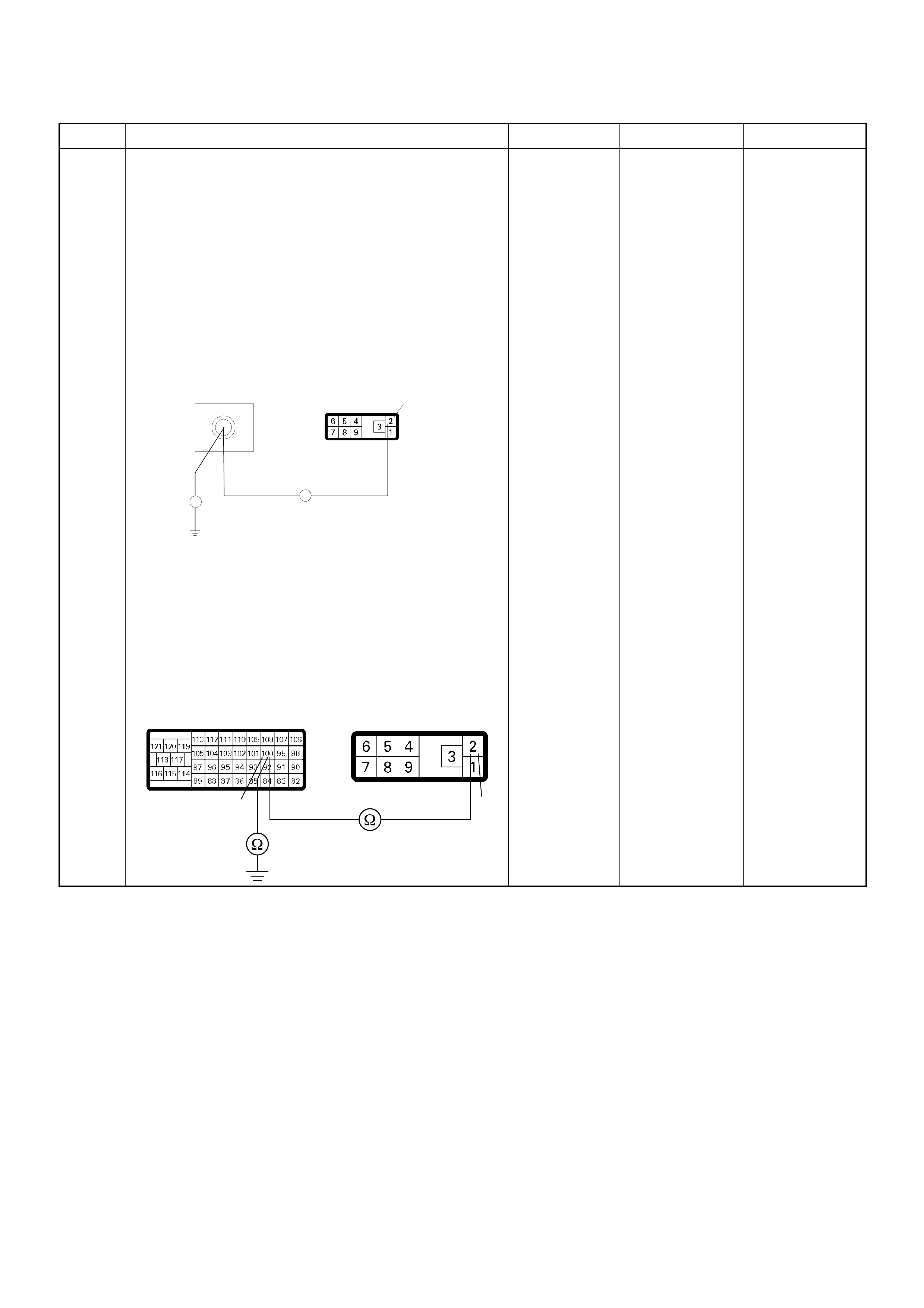

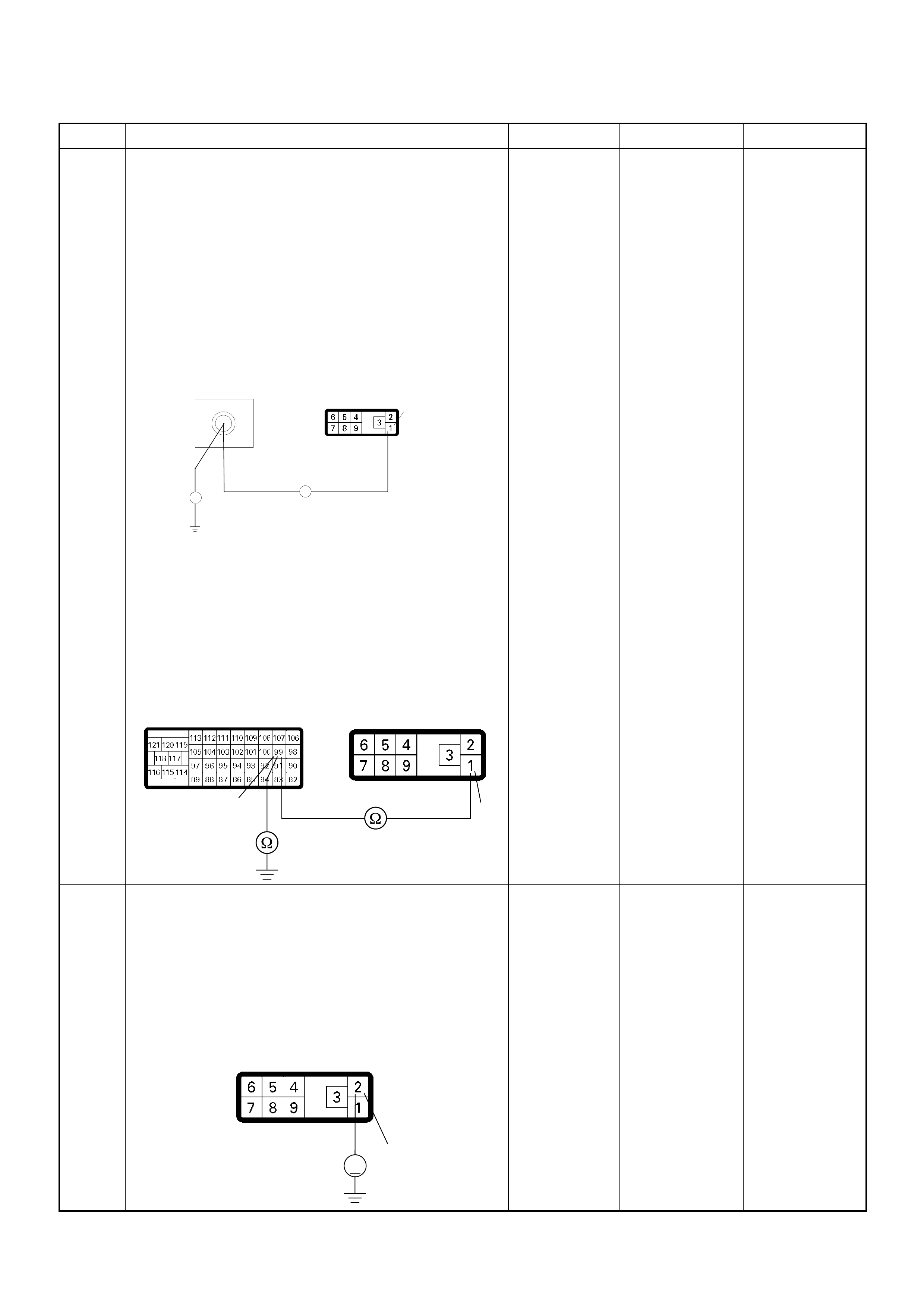

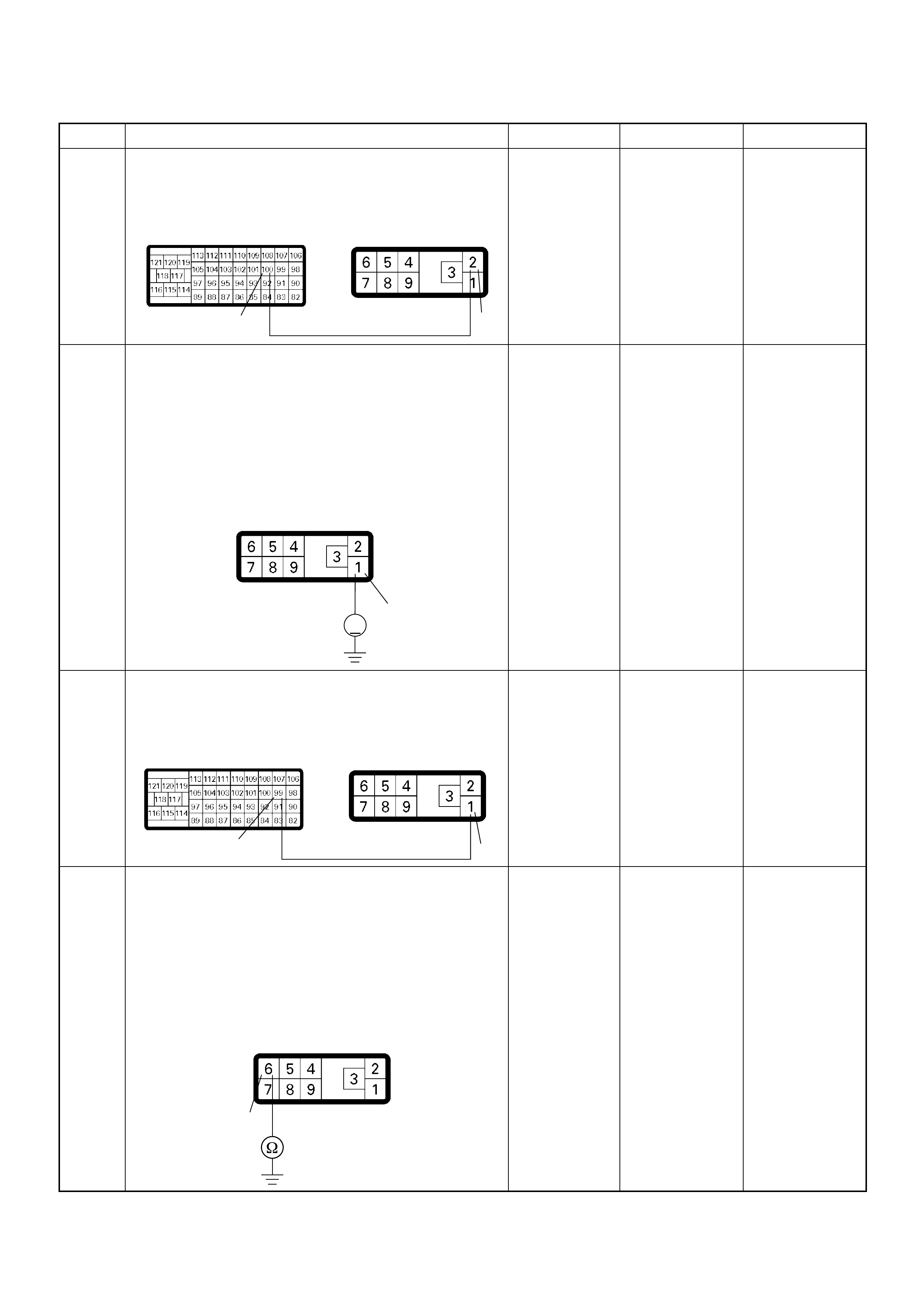

GROUND POINT CHART (1/4)

GROUND POINT CHART (2/4)

GROUND POINT CHART (3/4)

GROUND POINT CHART (4/4)

LOCATION

CABLE HARNESS & CONNECTOR LOCATION

PARTS LOCATION

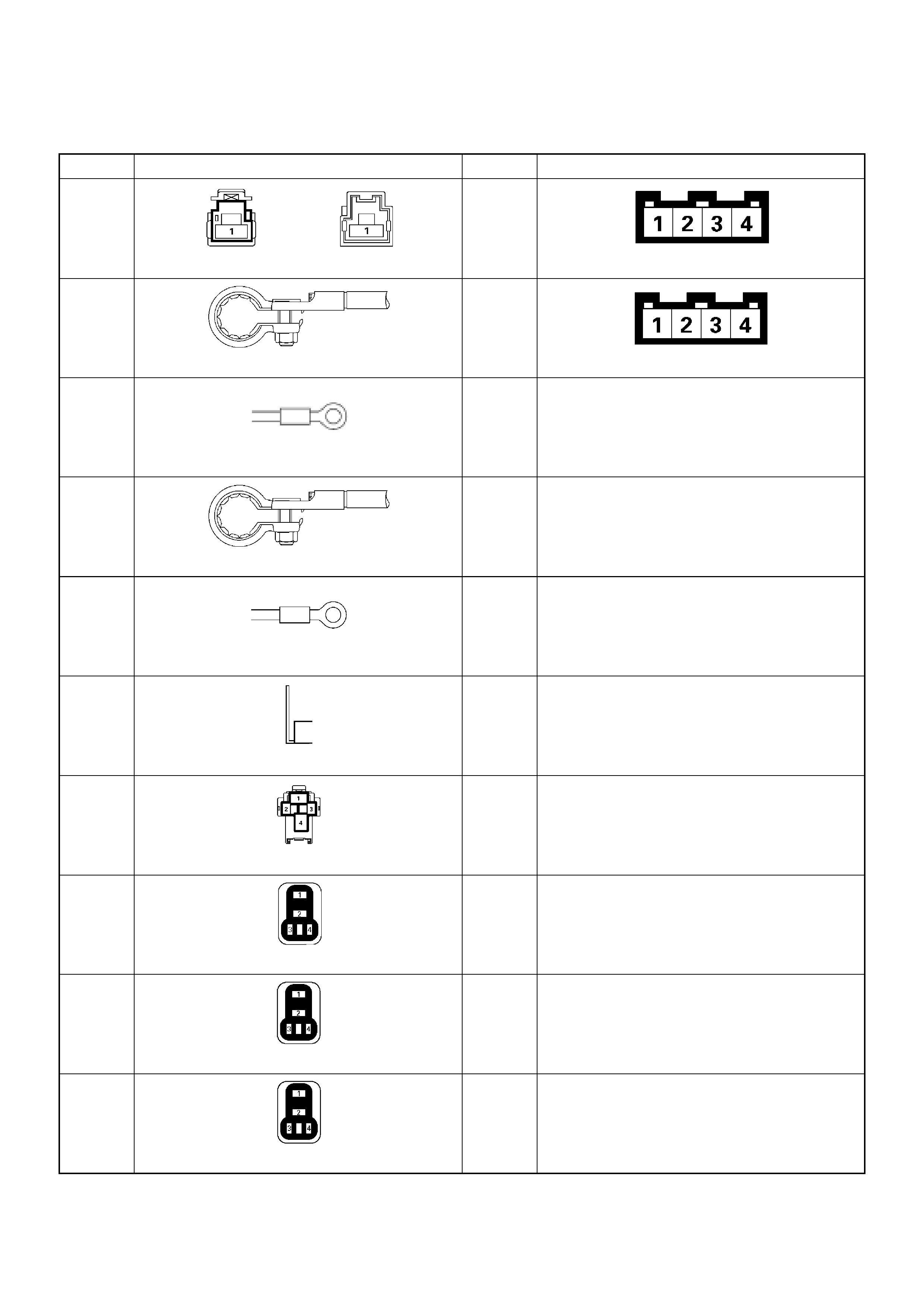

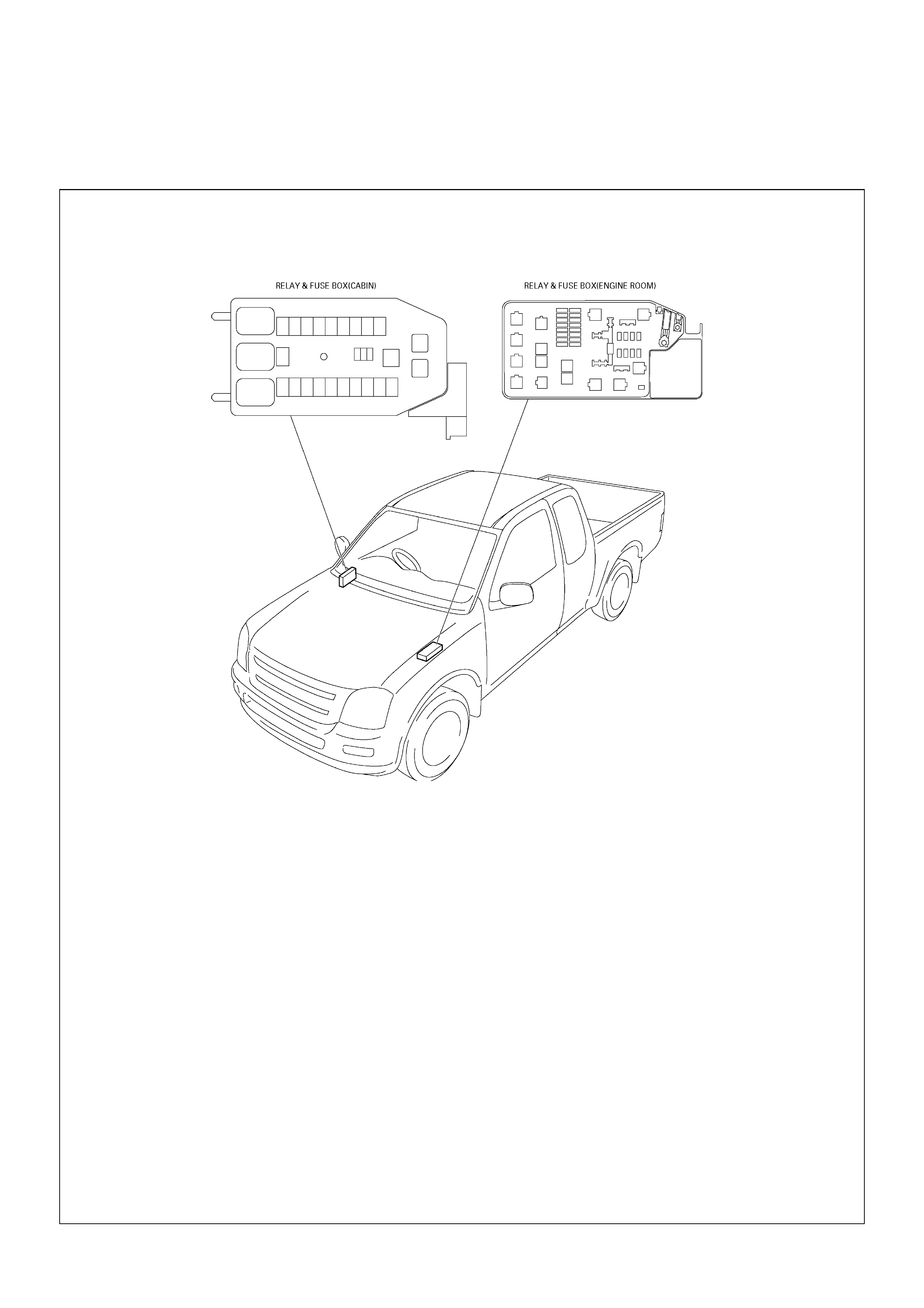

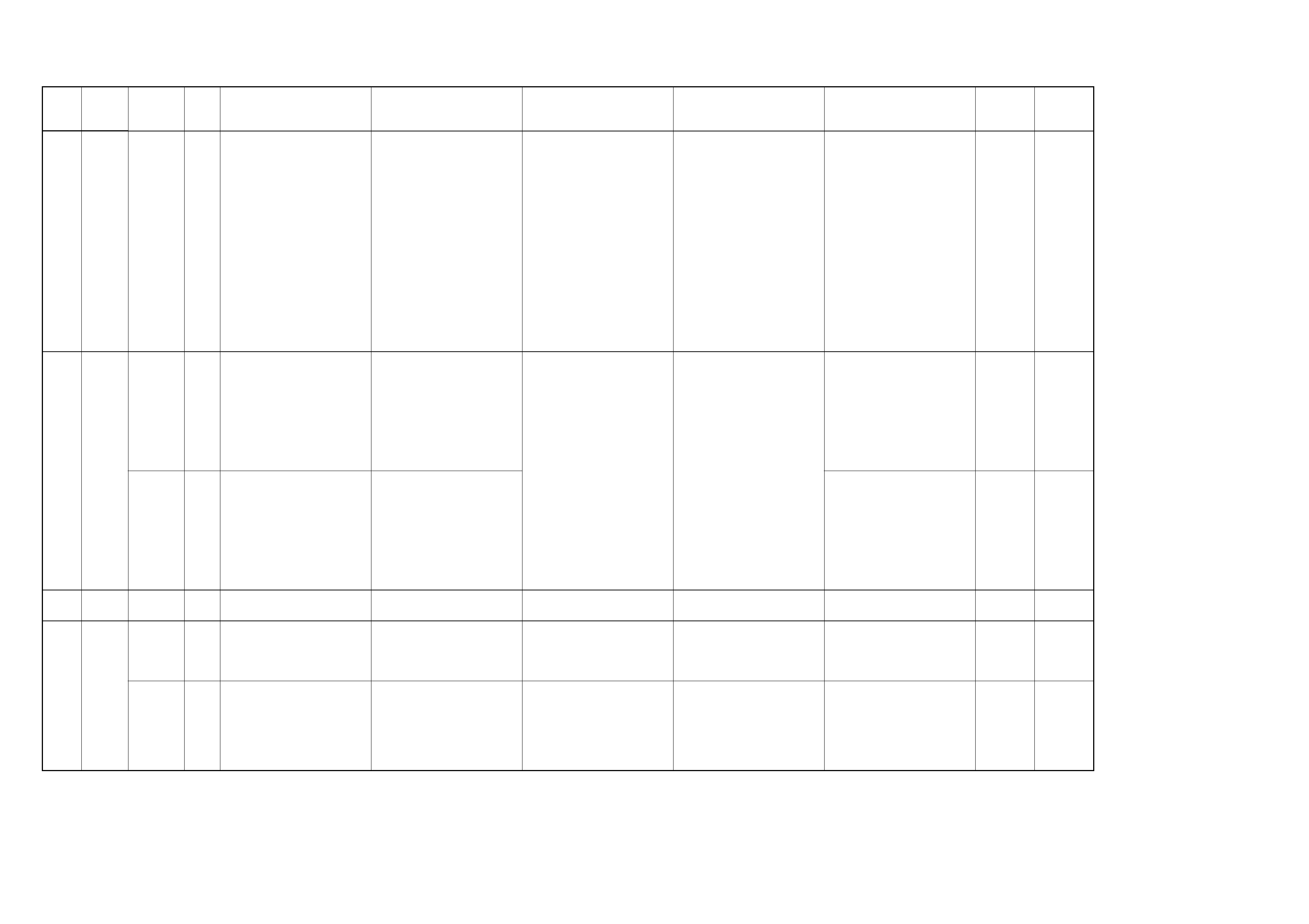

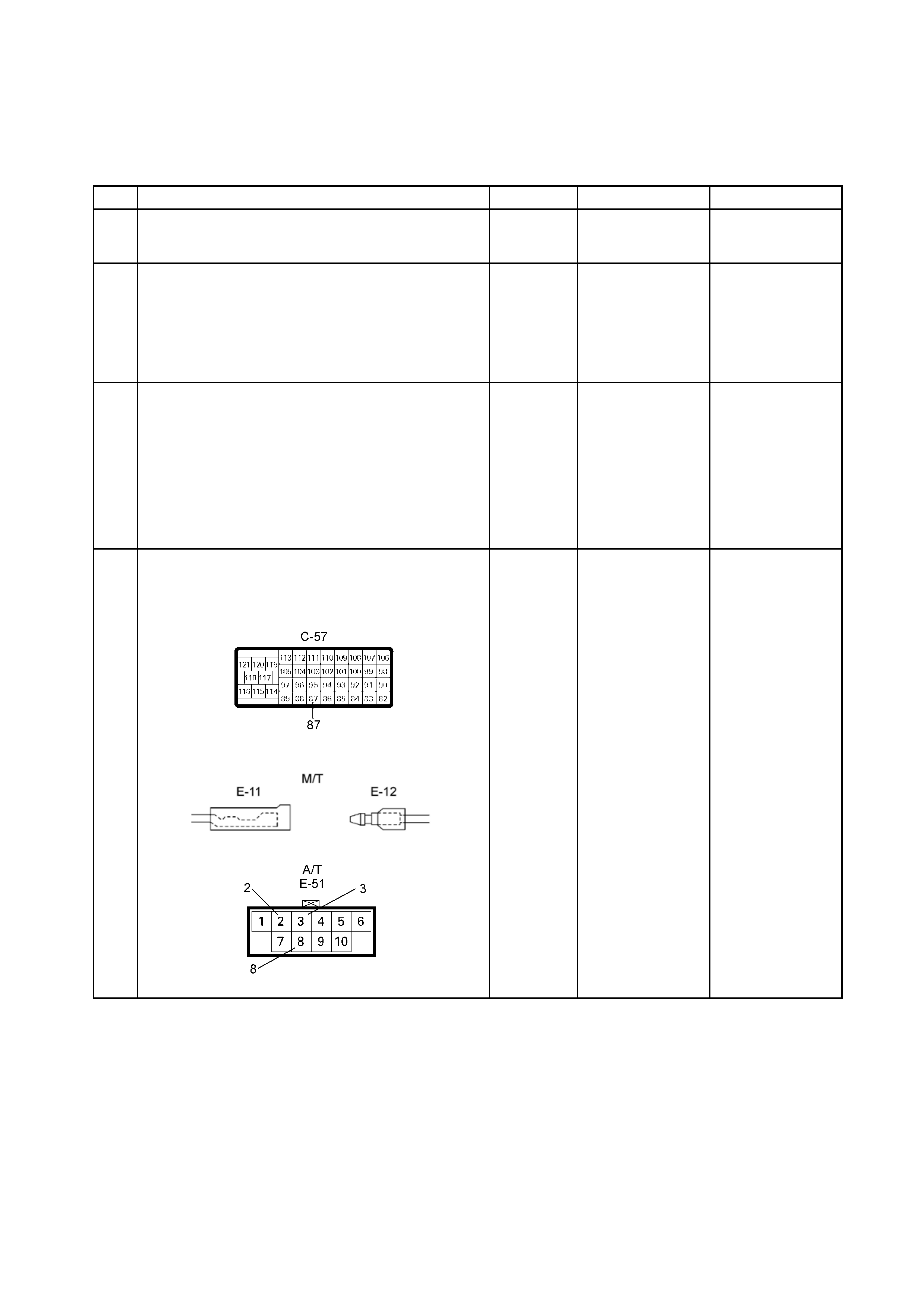

CONNECTOR LIST

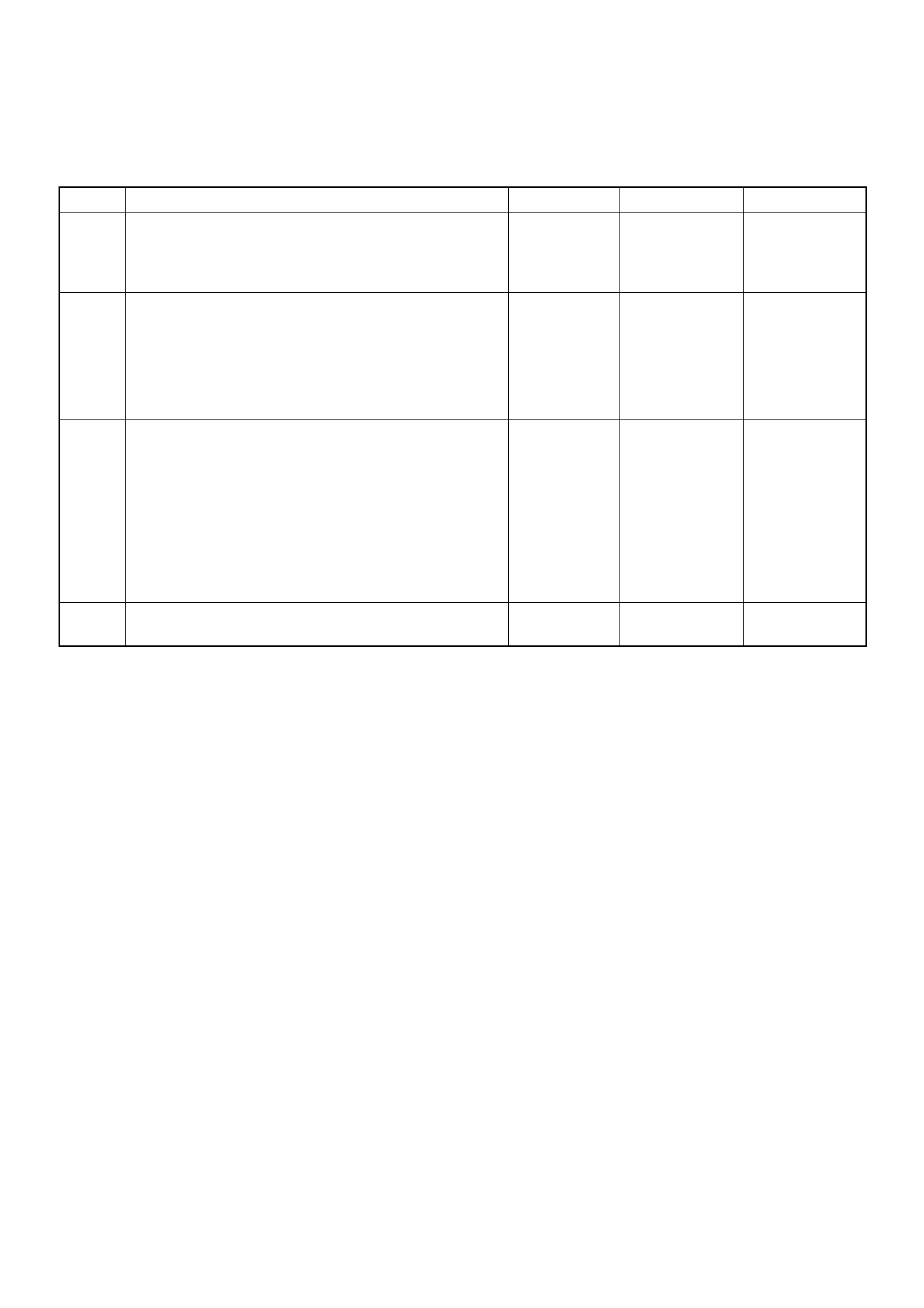

No. Connector face No. Connector face

B-24

Green Meter-B

C-56

ECM-A

B-54

White J/B I2

C-57

ECM-B

B-56

White J/B I4

C-77

Clut ch swi t c h

B-58

Black Check connector

C-94

White TCM

B-62

White Ignition switch (IGSUB : G1)

C-95

White TCM

B-63

White Ignition switch (IGSUB : G2)

C-

White J/B E2

B-68

Immobilizer

C-

White J/B E1

C-2

Silver Engine room-RH ground

C-

Silver Body-LH ; ground

C-36

Silver Engine room-LH ; Ground

C-

Brown EVRV

C-44

White Stop lamp switch

C-

No. Connector face No. Connector face

C-

A/C Resister & Neutral switch

E-23

Gray Idle SW

C- E-41

Black Coolant temp sensor

C- E-44

Gray Vehi cle sp eed sensor

E-3

Black Magnetic clutch AC COMP

E-49

Gray Glow plug

E-6 E-51

Black Inhibiter switch

E-9 H-4

White Engine room ~ Mission

E-10

Silver Engine ground

H-6

White Engine room ~ INST

E-11

Natural

green Neutral switch

H-7

White Engine room ~ INST

E-12

Natural

green Neutral switch

H-18

White Engine room ~ INST

E-22

Brown TPS 1 main

H-22

White Engine ~ Engine room C

No. Connector face No. Connector face

H-33

Engine ~ Engine room

X-16

Black DIODE

P-1

Silver Battery (+)

X-17

Black DIODE

P-2

Silv er Relay & Fuse box

P-5

Silver Battery (-)

P-6

Silver Body earth (Gr oun d)

P-10

Silver Engine ground

X-5

Black Relay ; Glow

X-13

Black Relay ; ECM MAIN

X-14

Black Relay; A/C Compressor

X-15

Black Relay; Thermo

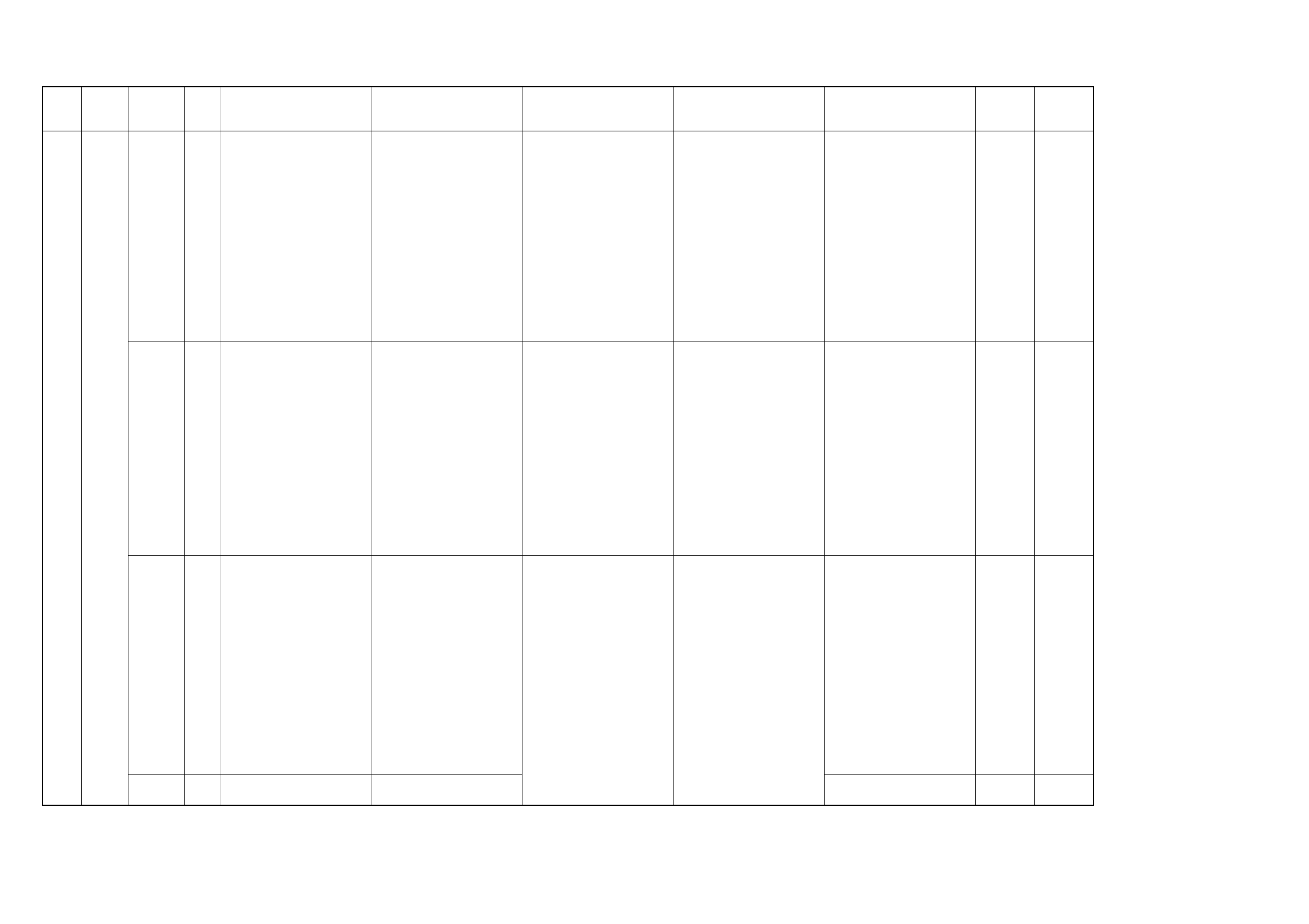

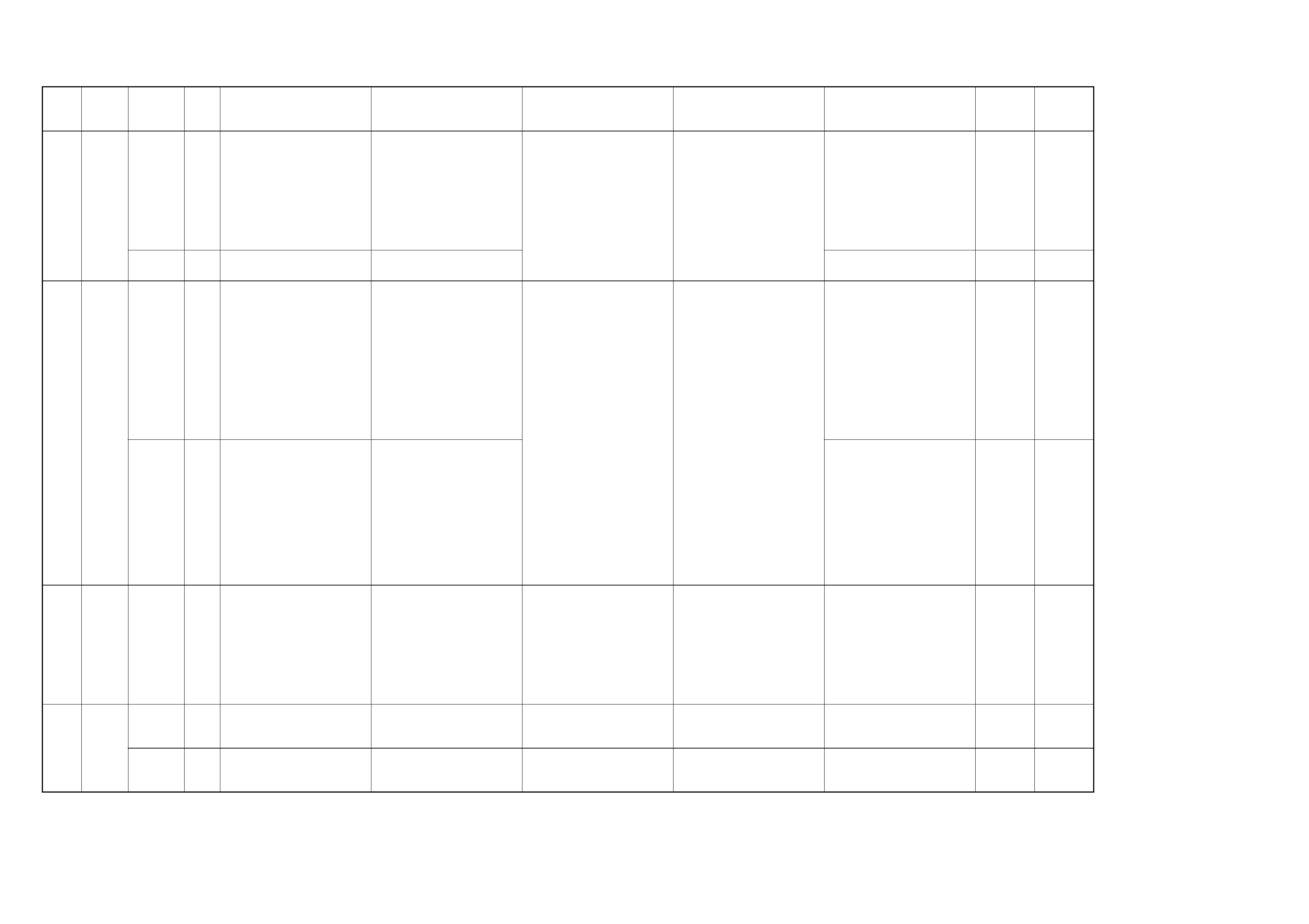

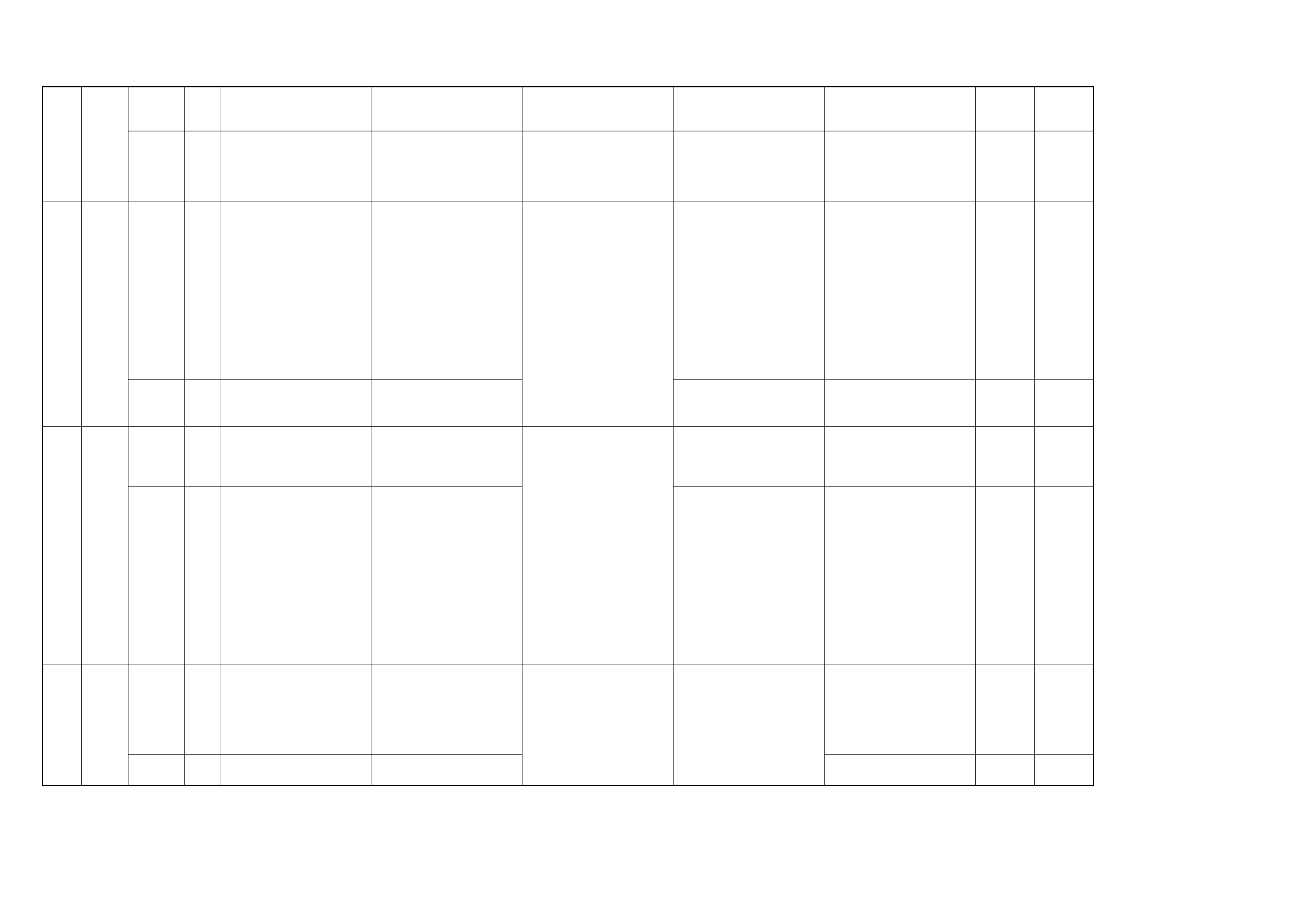

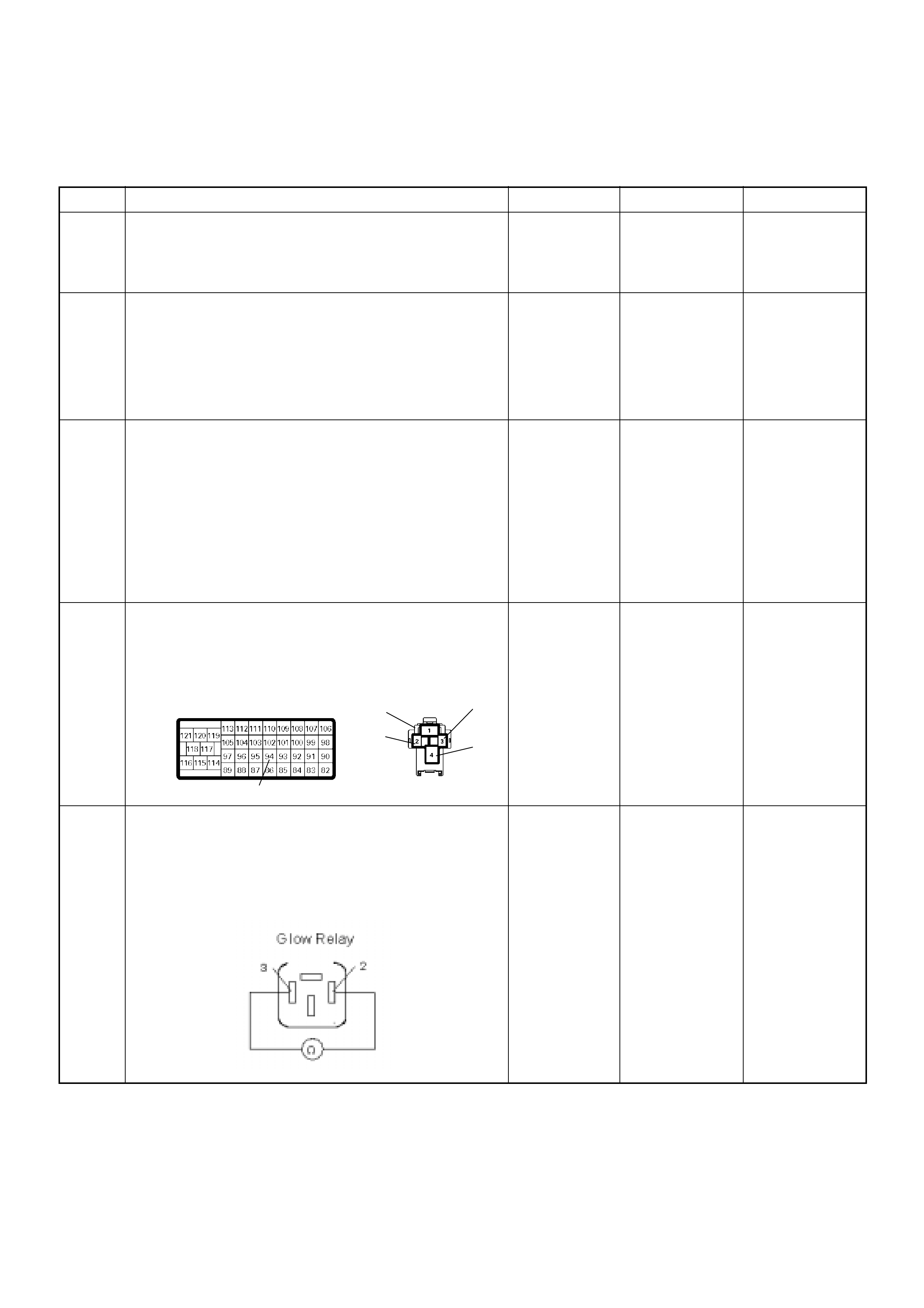

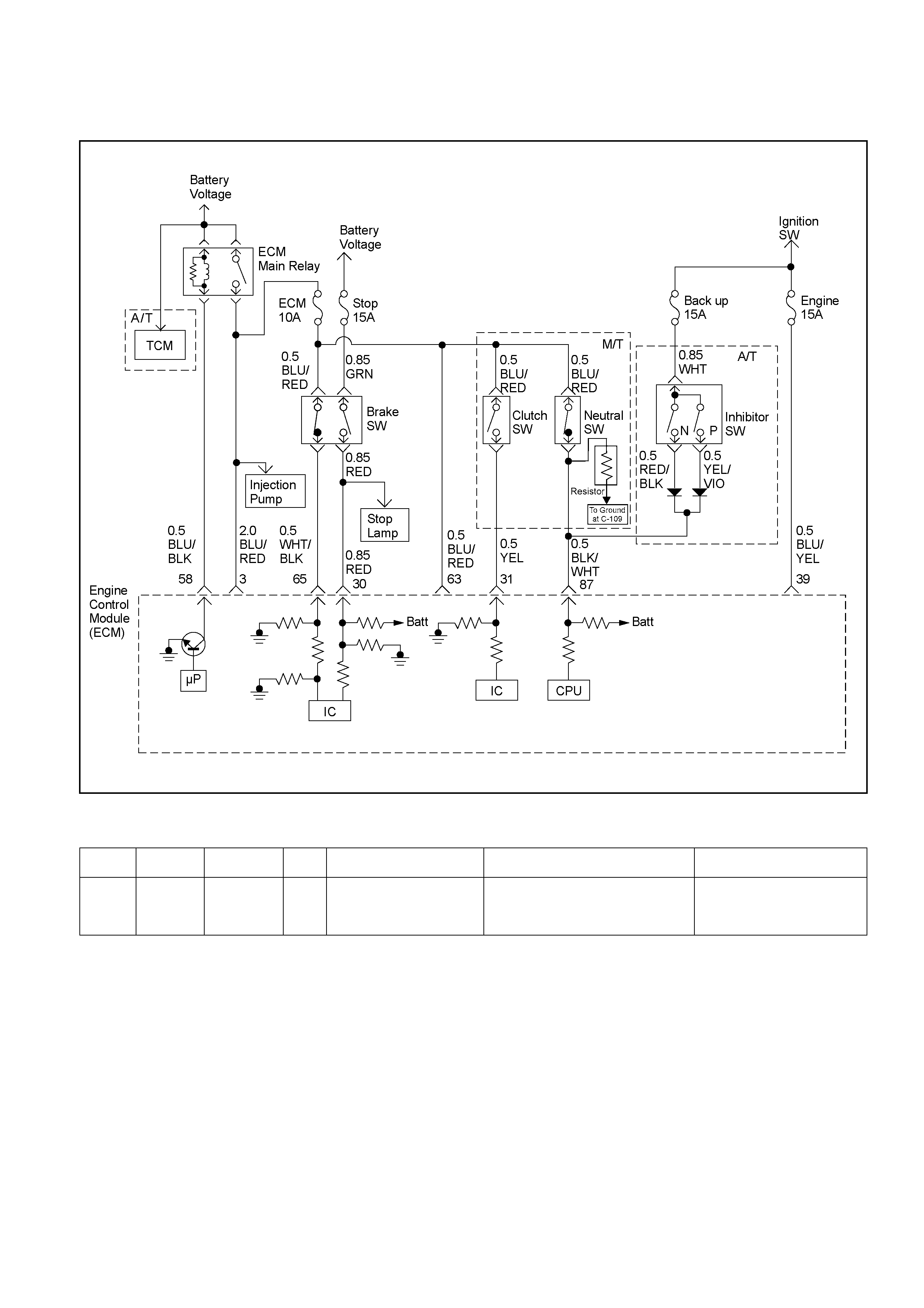

RELAY AND FUSE

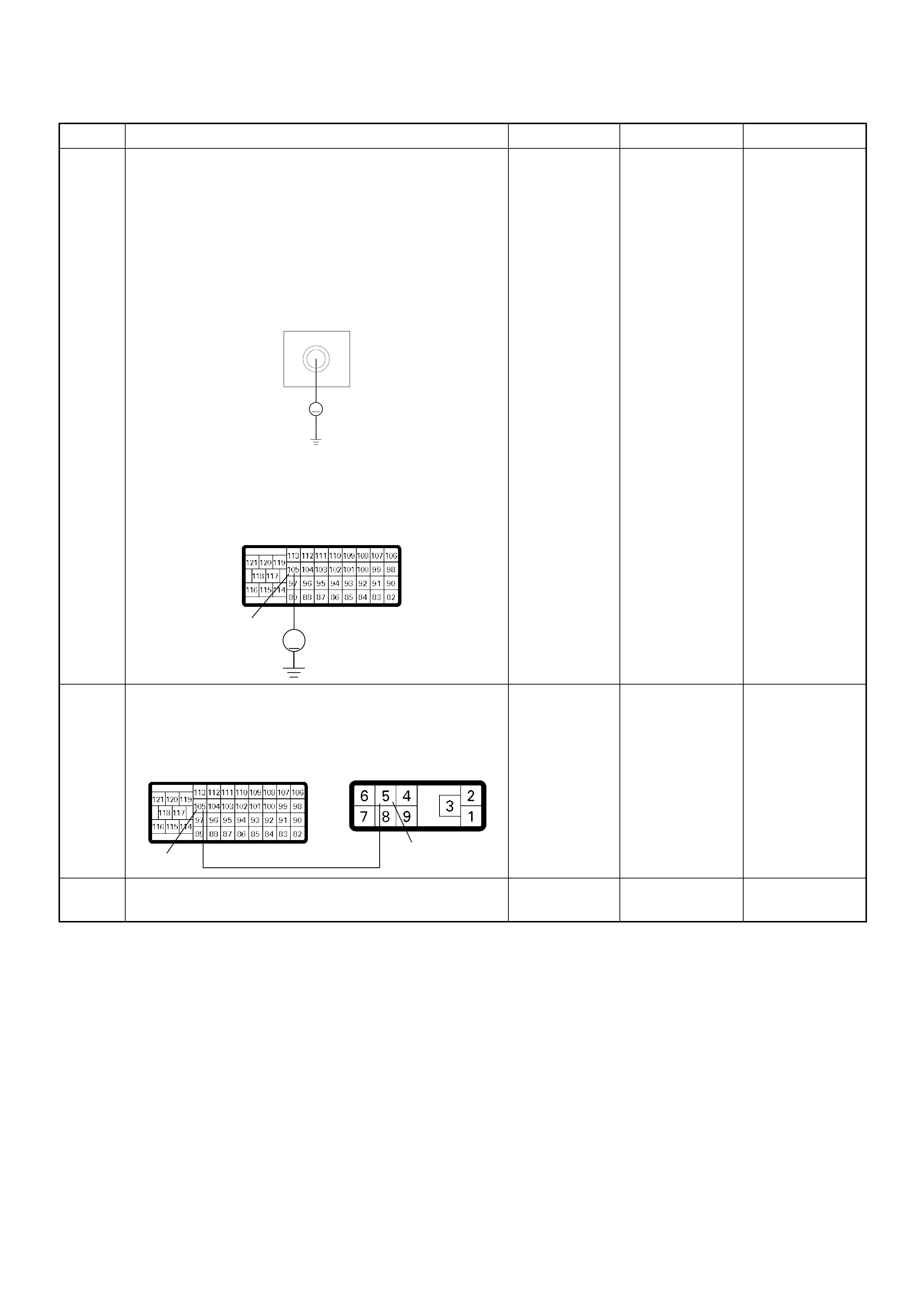

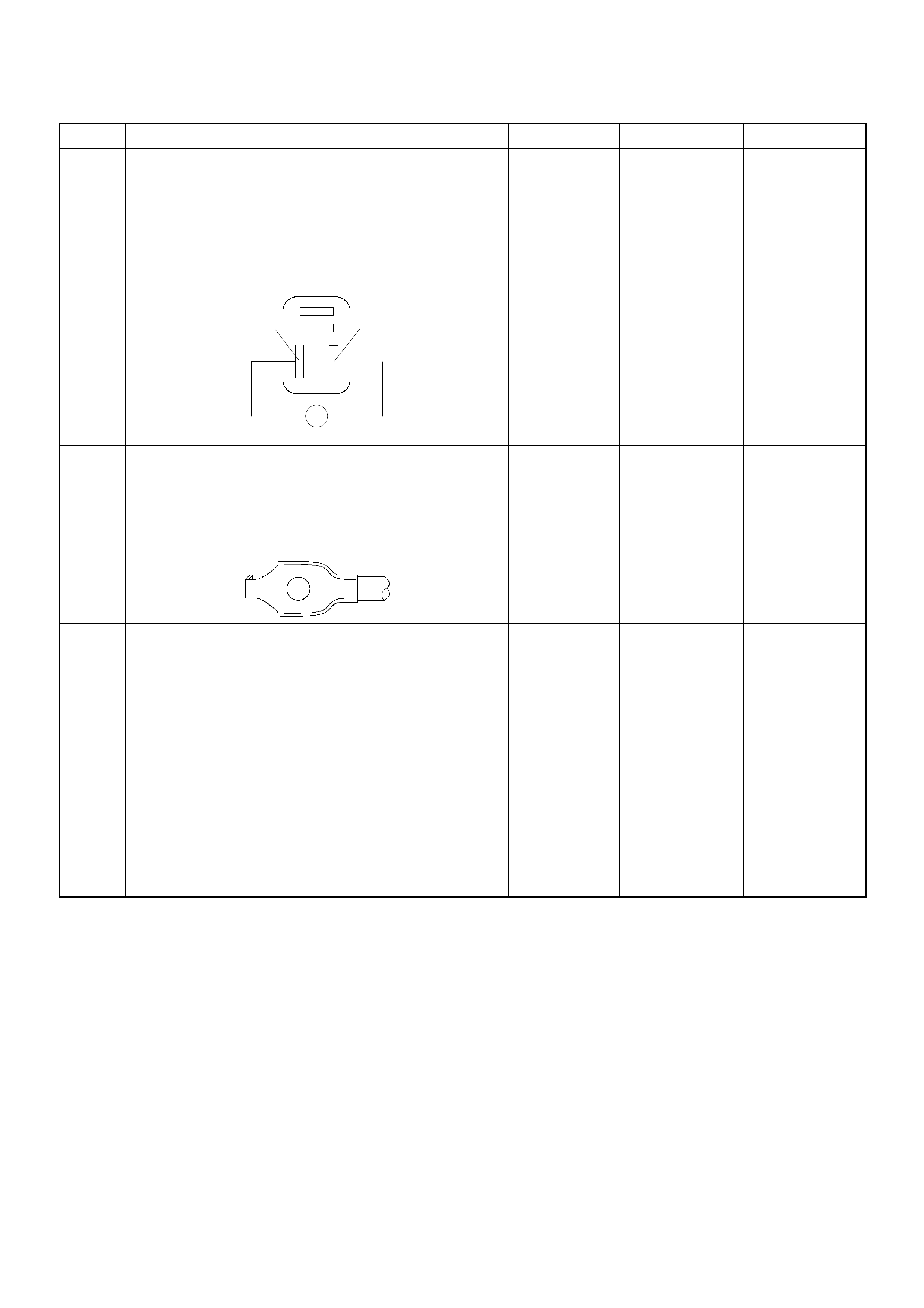

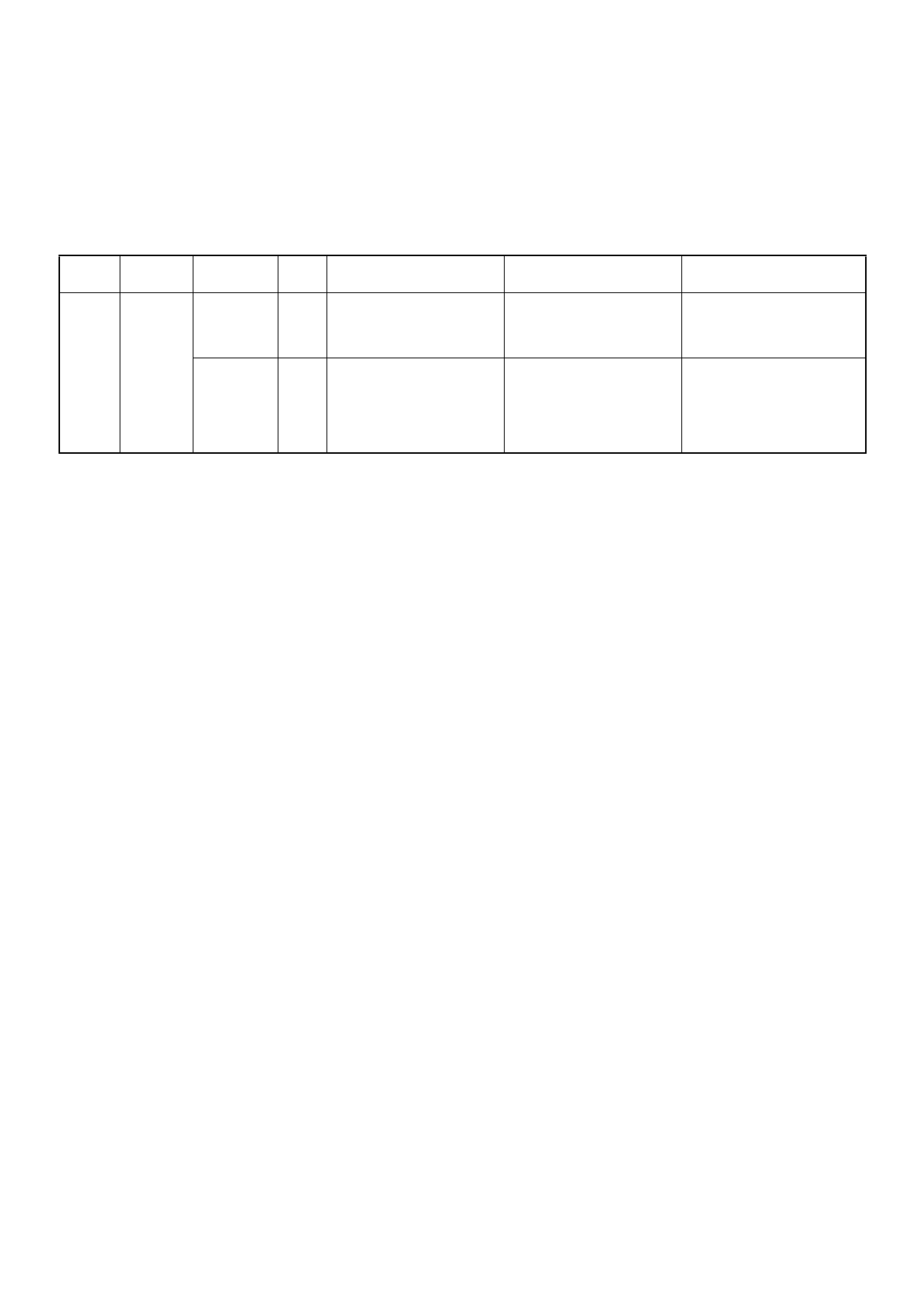

RELAY AND FUSE BOX LOCATION

RELAY AND FUSE BOX LOCATION

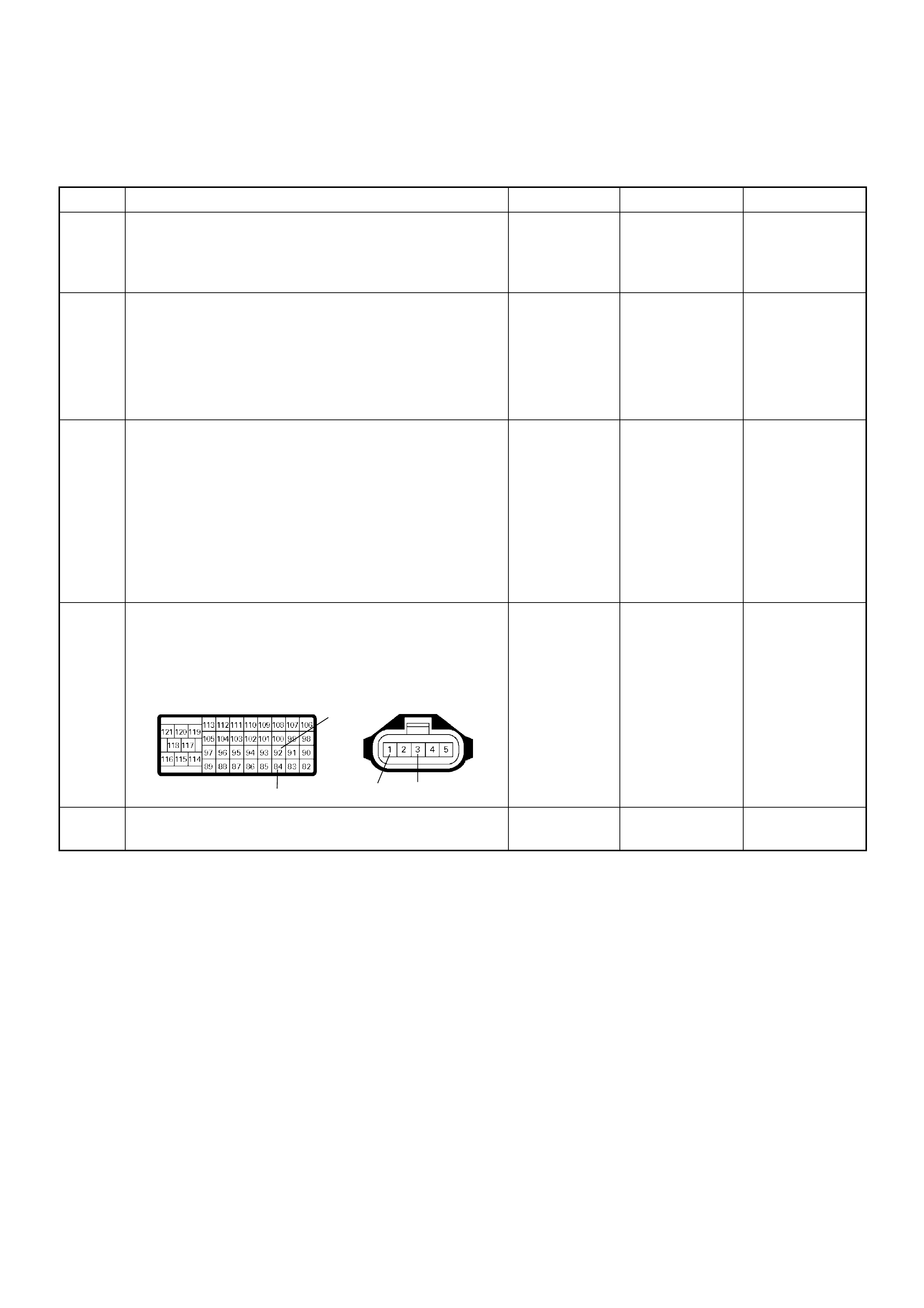

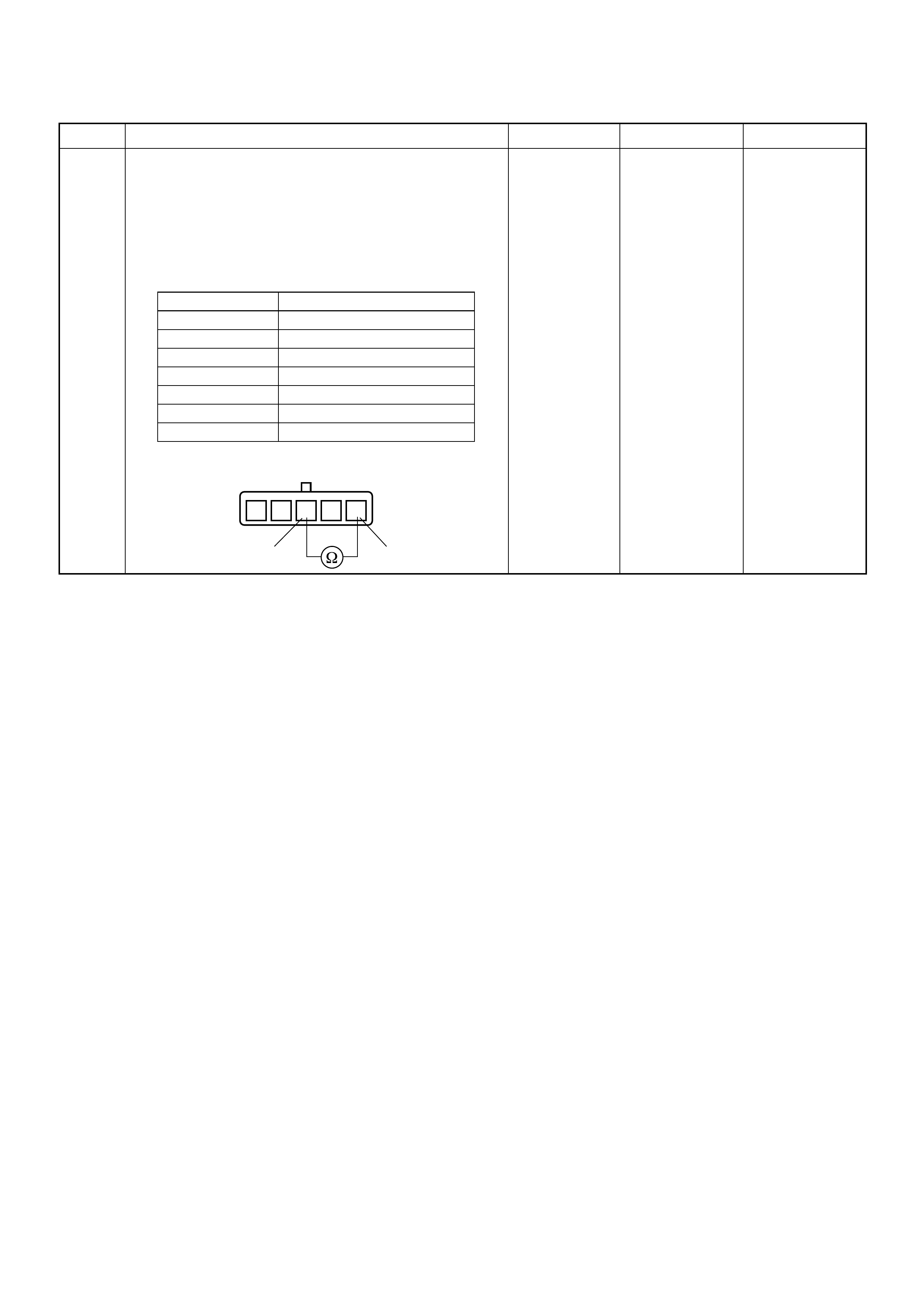

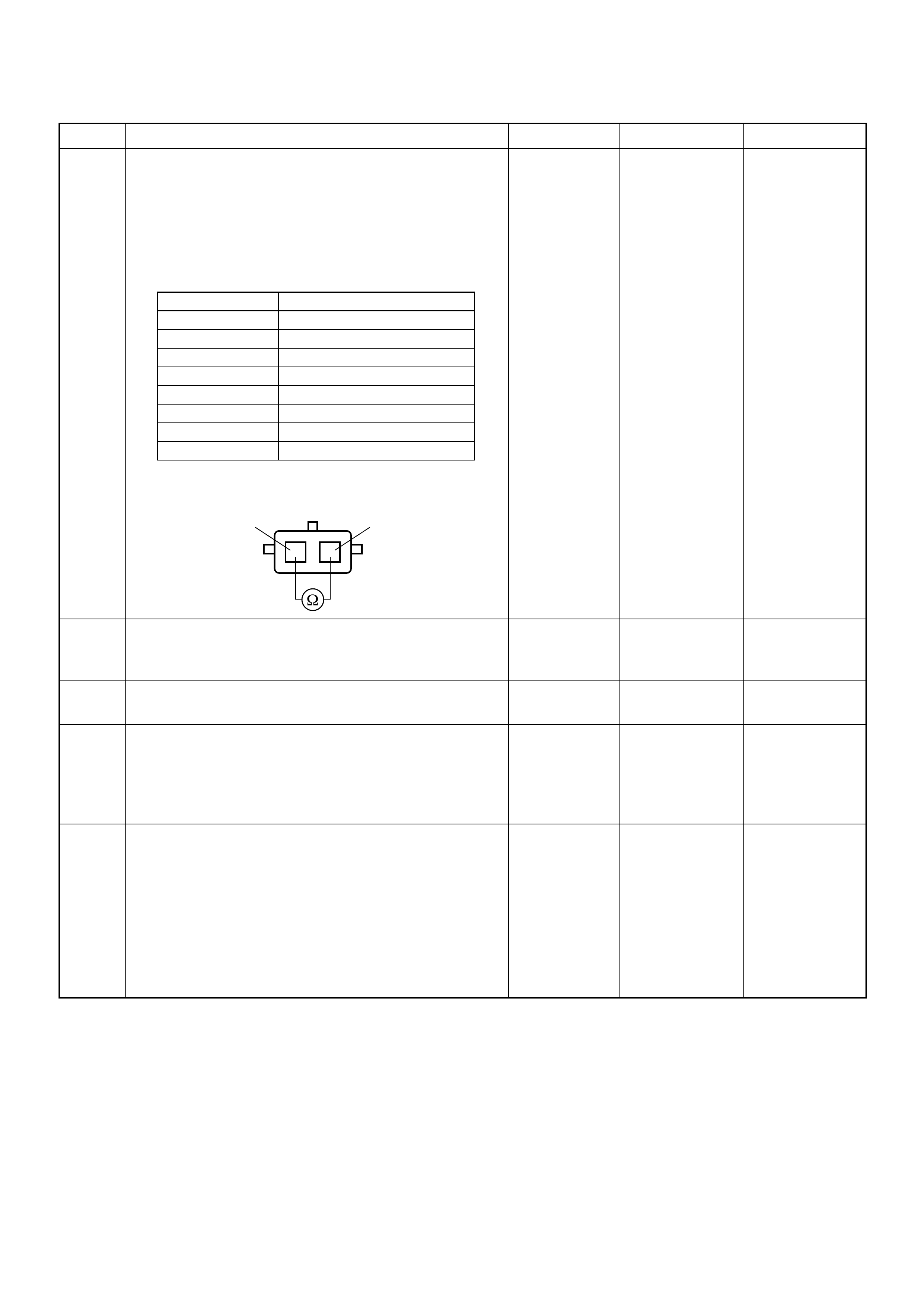

RELAY & FUSE BOX

RELAY

No. RELAY

X-1 RELAY; TAIL LIGHT

X-2 RELAY; FRT FOG LIGHT

X-3 RELAY; HO RN

X-4 RELAY; DI MMER

X-5 RELAY; GLOW

X-6 RELAY; COND, FAN

X-7 R ELAY; RR FO G

X-8 RELAY; STARTER

X-9 RELAY; HAZARD-RH

X-10 RELAY; HAZARD-LH

X-11 RELAY; HEATER

X-12 RELAY; HEAD LIGHT

X-13 RELAY; ECM MAIN

X-14 RELAY; A/C COMP

X-15 RELAY; THERMO

FUSE

SLOW BLOW FUSE

NO. FUSE

EB-1 10A ECM

EB-2 10A RR FOG

EB-3 15A FRT FOG

EB-4 —

EB-5 10A ILLUMI & TAIL-RH

EB-6 10A TAIL-LH

EB-7 10A H/LIGHT RH-LOW

EB-8 10A H/LIGHT LH-LOW

EB-9 10A TRA ILER

EB-10 10A AC G (S)

EB-11 10A H/LIGHT RH-HIGH

EB-12 10A H/LIGHT LH-HIGH

EB-13 10A A/C

EB-14 10A 4WD

EB-15 10A HORN

EB-16 10A HAZARD

NO. SLOW BLOW FUSE

SBF-1 80A MAIN

SBF-2 20A COND, FAN

SBF-3 50A GLOW

SBF-4 30A ECM

SBF-5 40A IG 1

SBF-6 40A ABS-1

SBF-7 30A ABS-2

SBF-8 30A BLOWER

SBF-9 50A IG 2

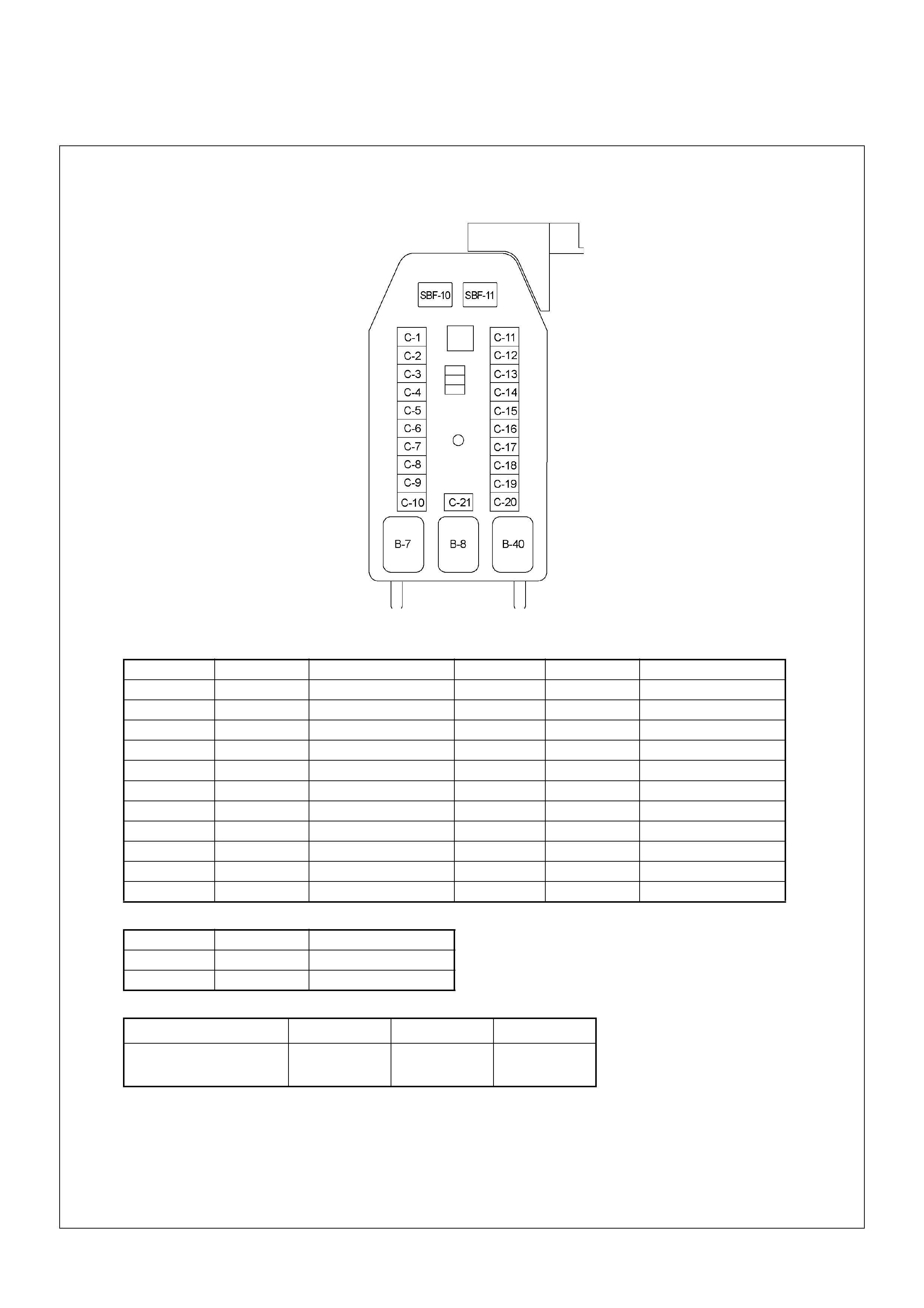

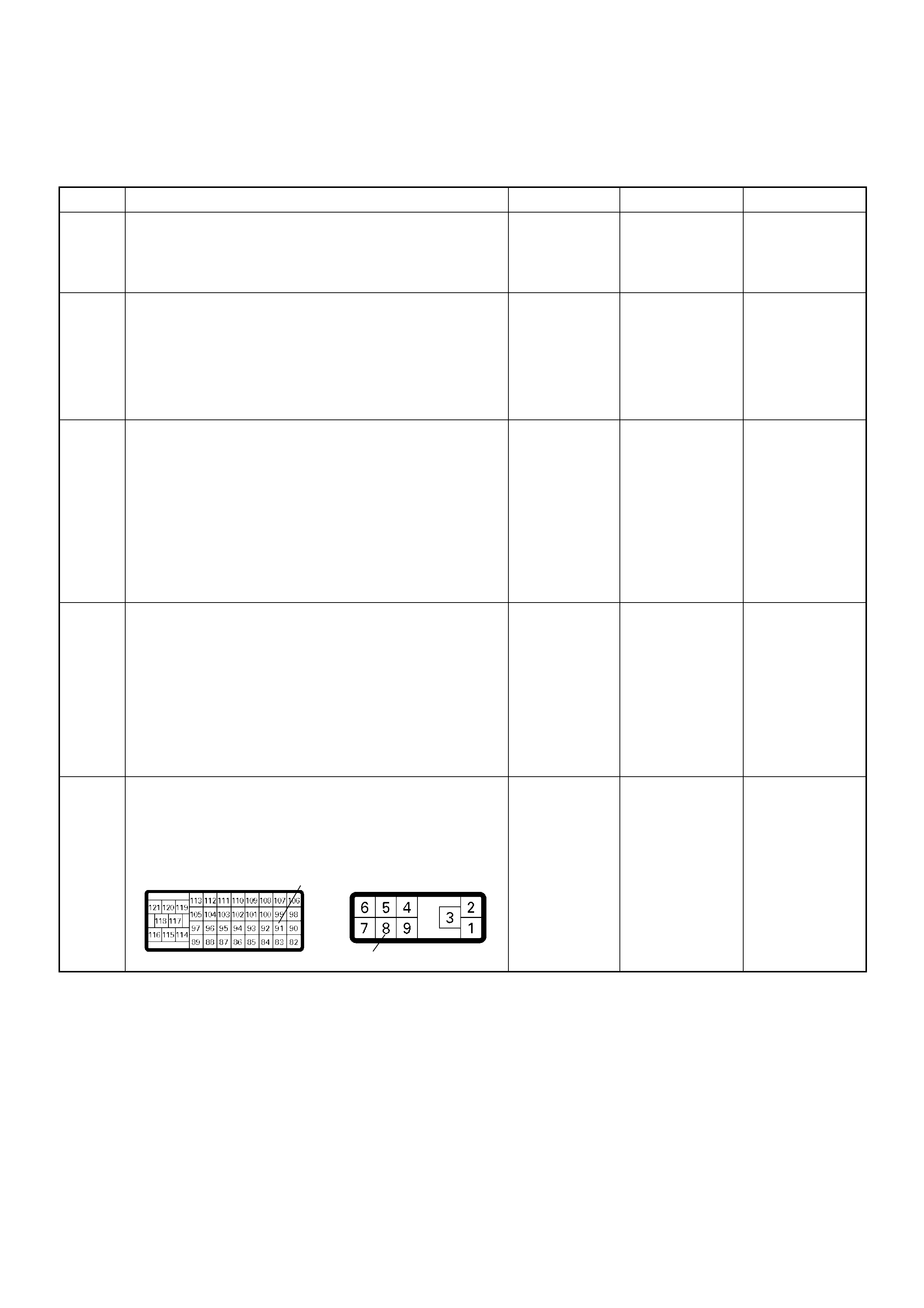

FUSE AND RELAY LOCATION

FUSE

SLOW BLOW FUS E

RELAY

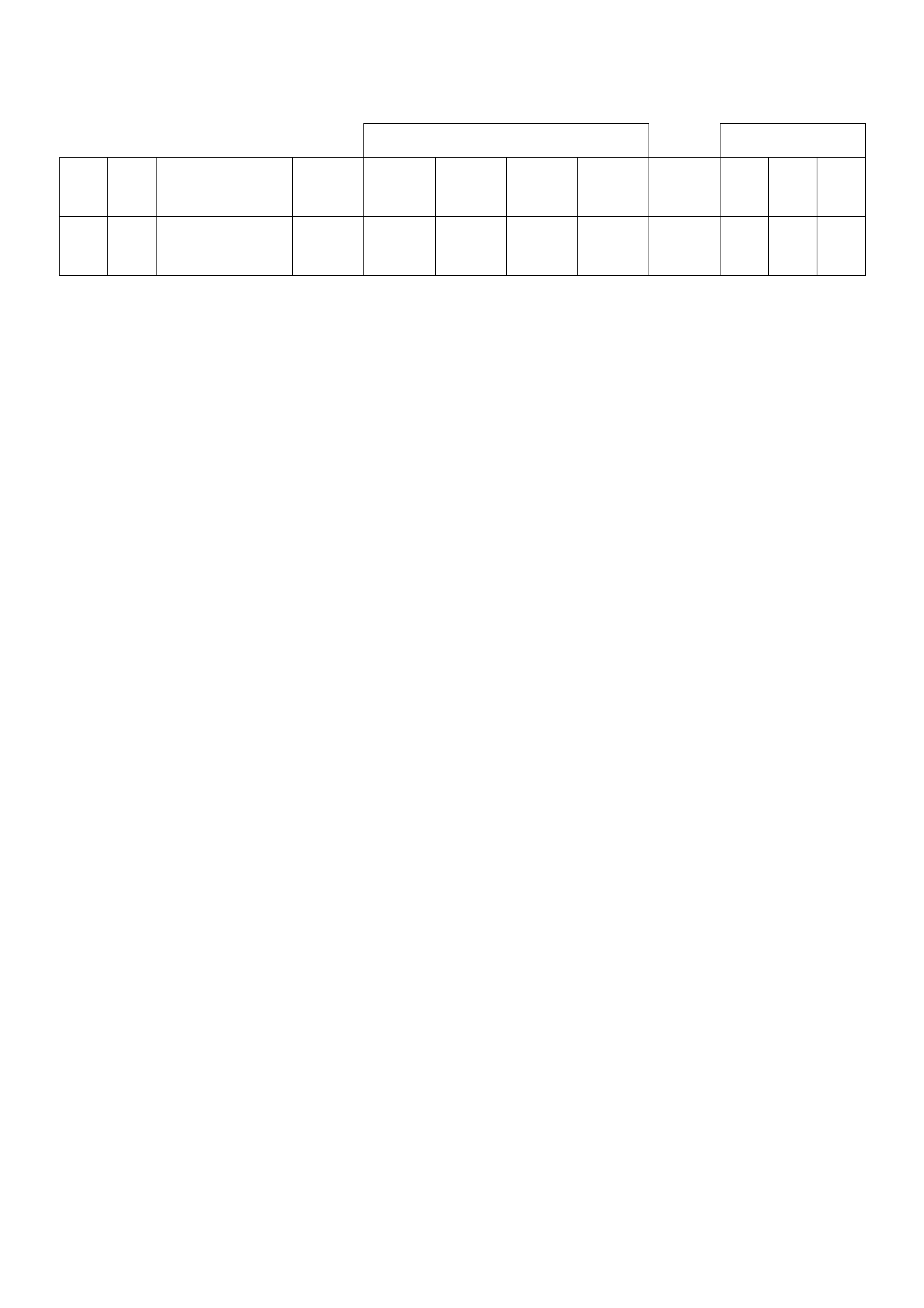

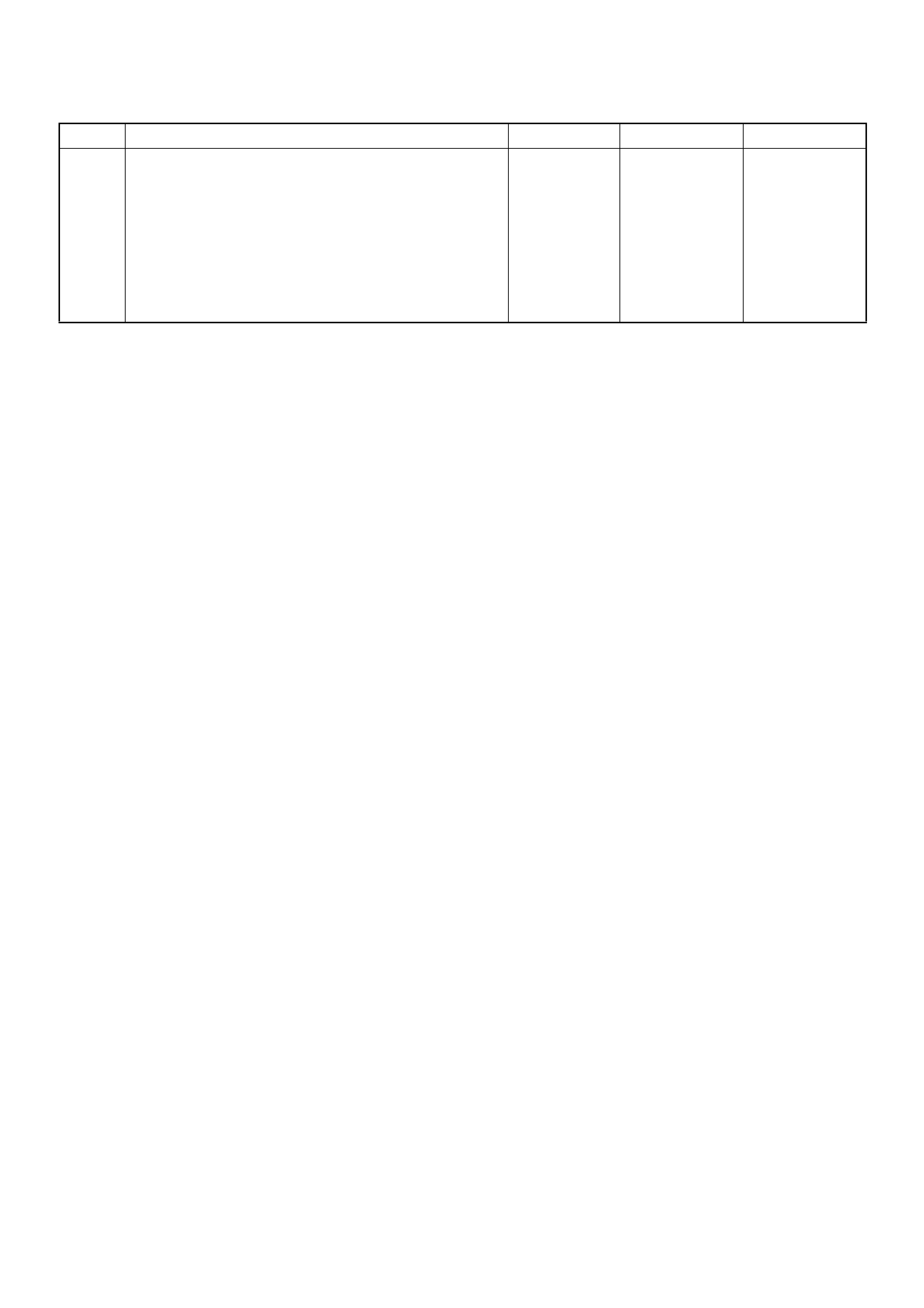

No. Capacity Indication on label No. Capacity Indication on label

1— — 1215ACIGER

2 10A ABS 13 15A AUDIO (+B)

3 — — 14 20A DOOR LOCK

4 15A BACK UP 15 10A METER (+B)

5 15A METER 16 10A ROOM

6 10A TURN 17 10A ANTI THEFT

7 15A ELEC.IG 18 15A STOP

8 15A ENGINE 19 15A ACC SOCKET

9 20A FRT WIPER 20 10A STARTER

10 15A EGR 21 10A SRS

11 10A AUDIO

No. Capacity Indication on label

SBF-10 20A RR DEF

SBF-11 30A POWER WINDOW

Connector No. B-7 B-8 B-40

REAR

DEFOGGER POWER

WINDOW ACC

SOCKET

FUSE BOX

ECM WIRING DIAGRAM

ECM WIRING DIAGRAM (1/7)

ECM WIRING DIAGRAM (2/7)

ECM WIRING DIAGRAM (3/7)

ECM WIRING DIAGRAM (4/7)

ECM WIRING DIAGRAM (5/7)

ECM WIRING DIAGRAM (6/7)

ECM WIRING DIAGRAM (7/7)

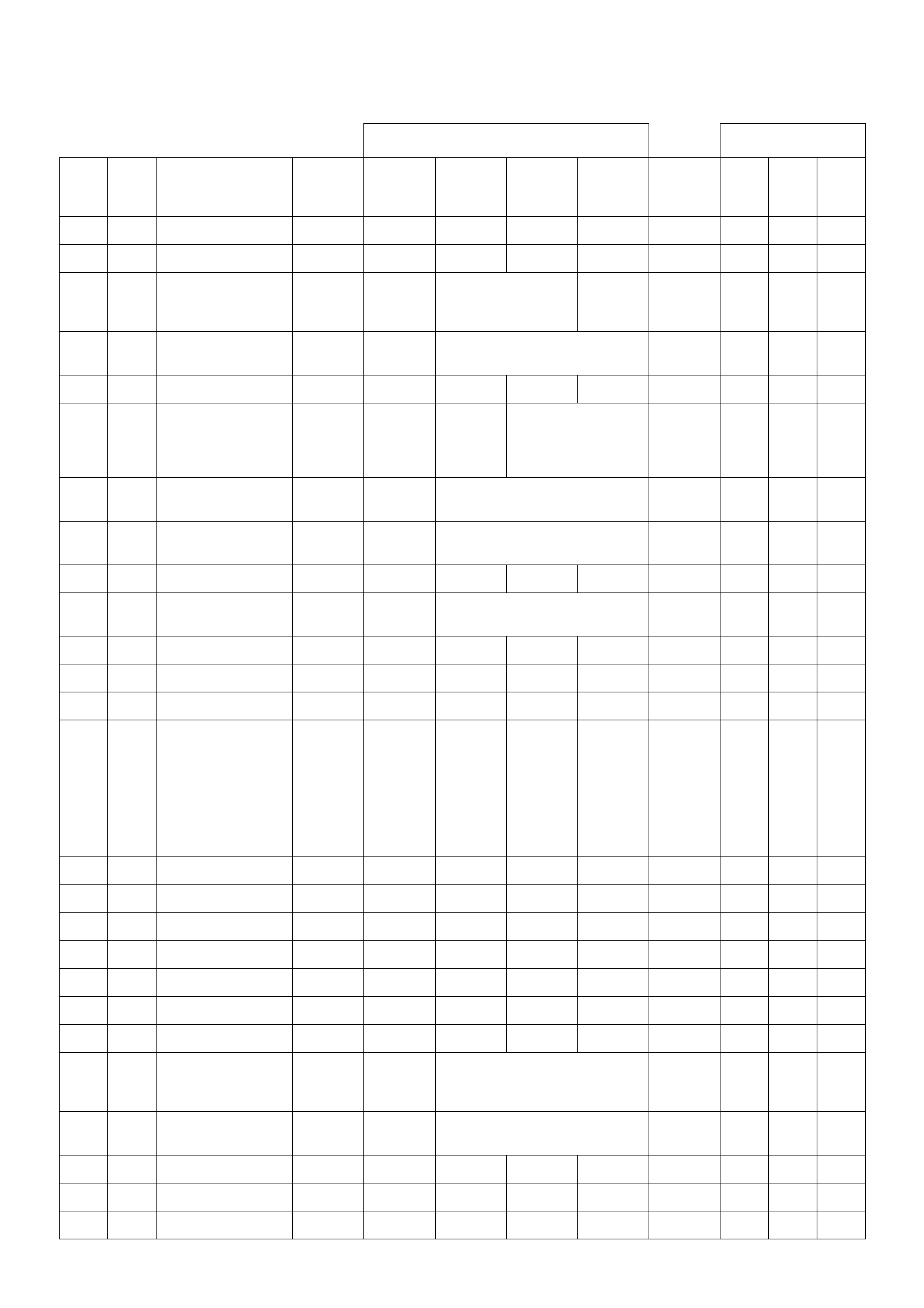

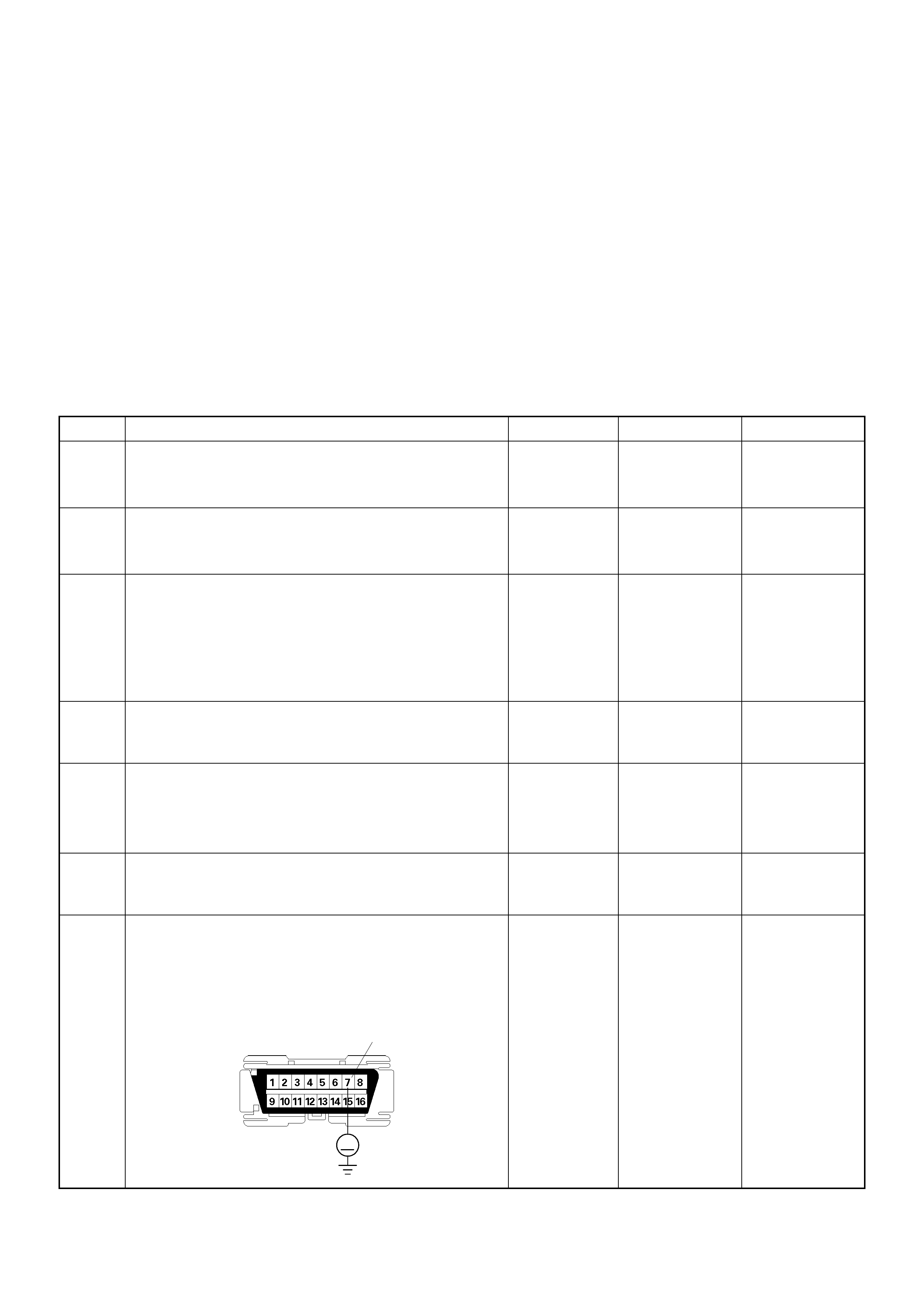

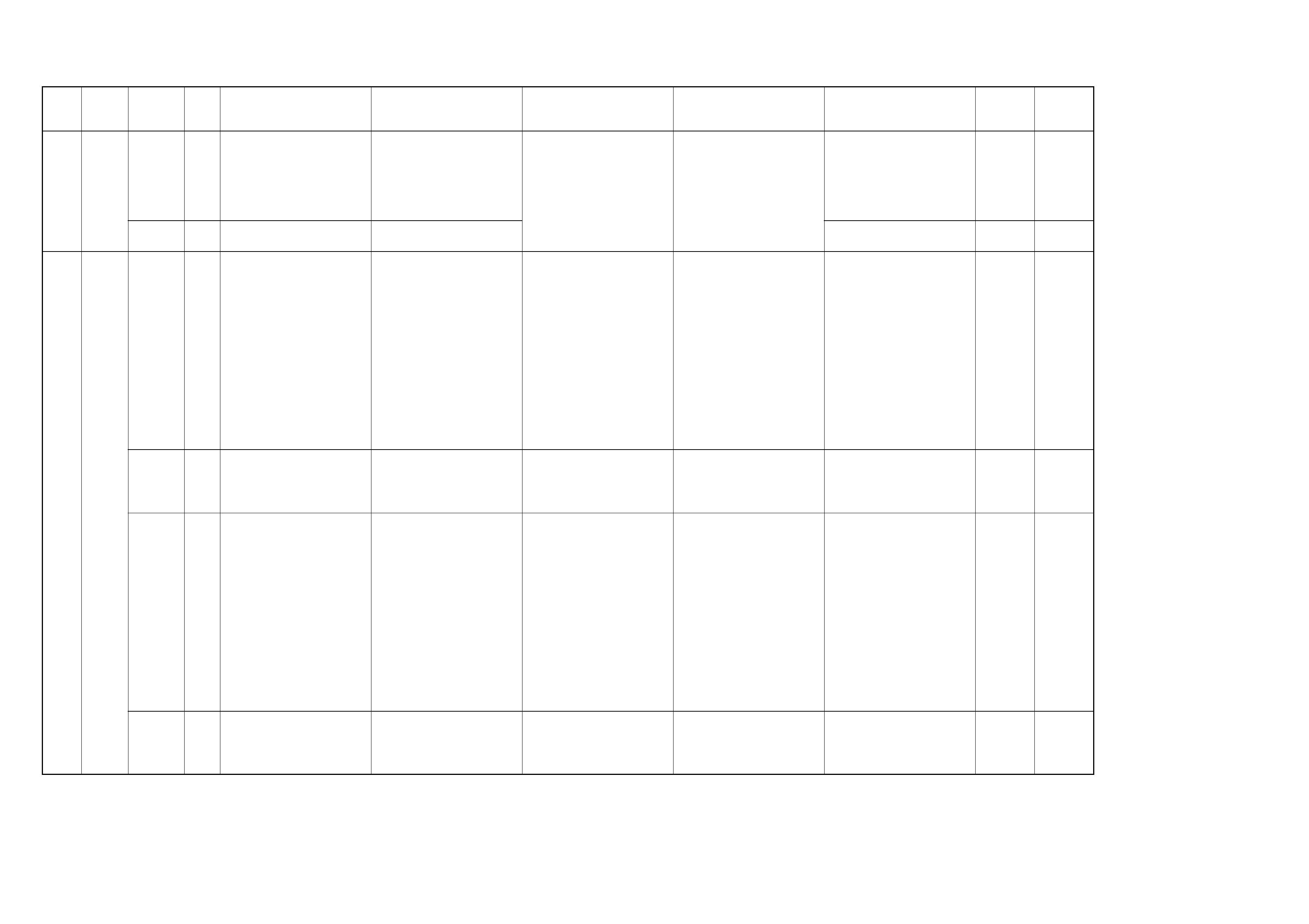

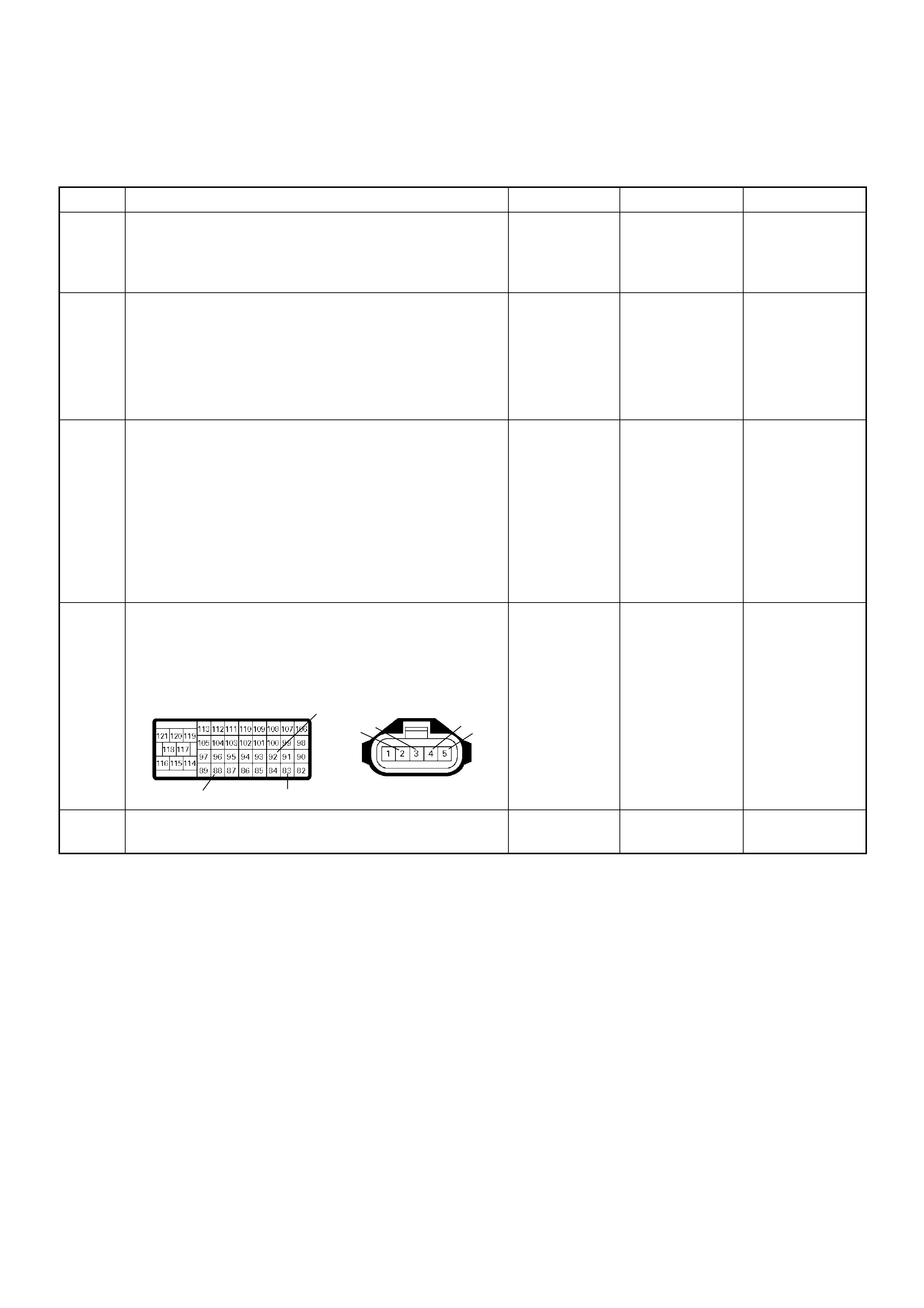

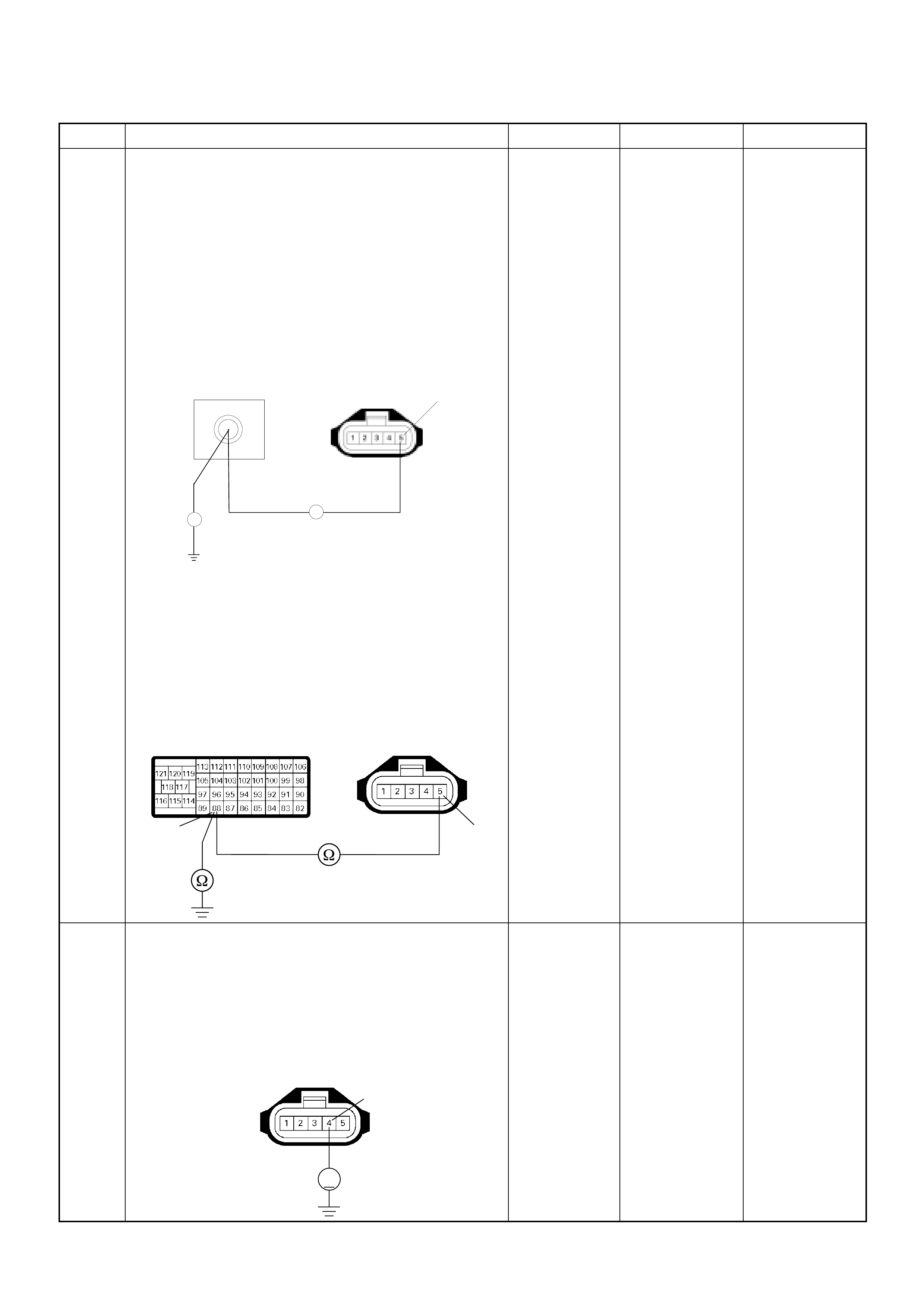

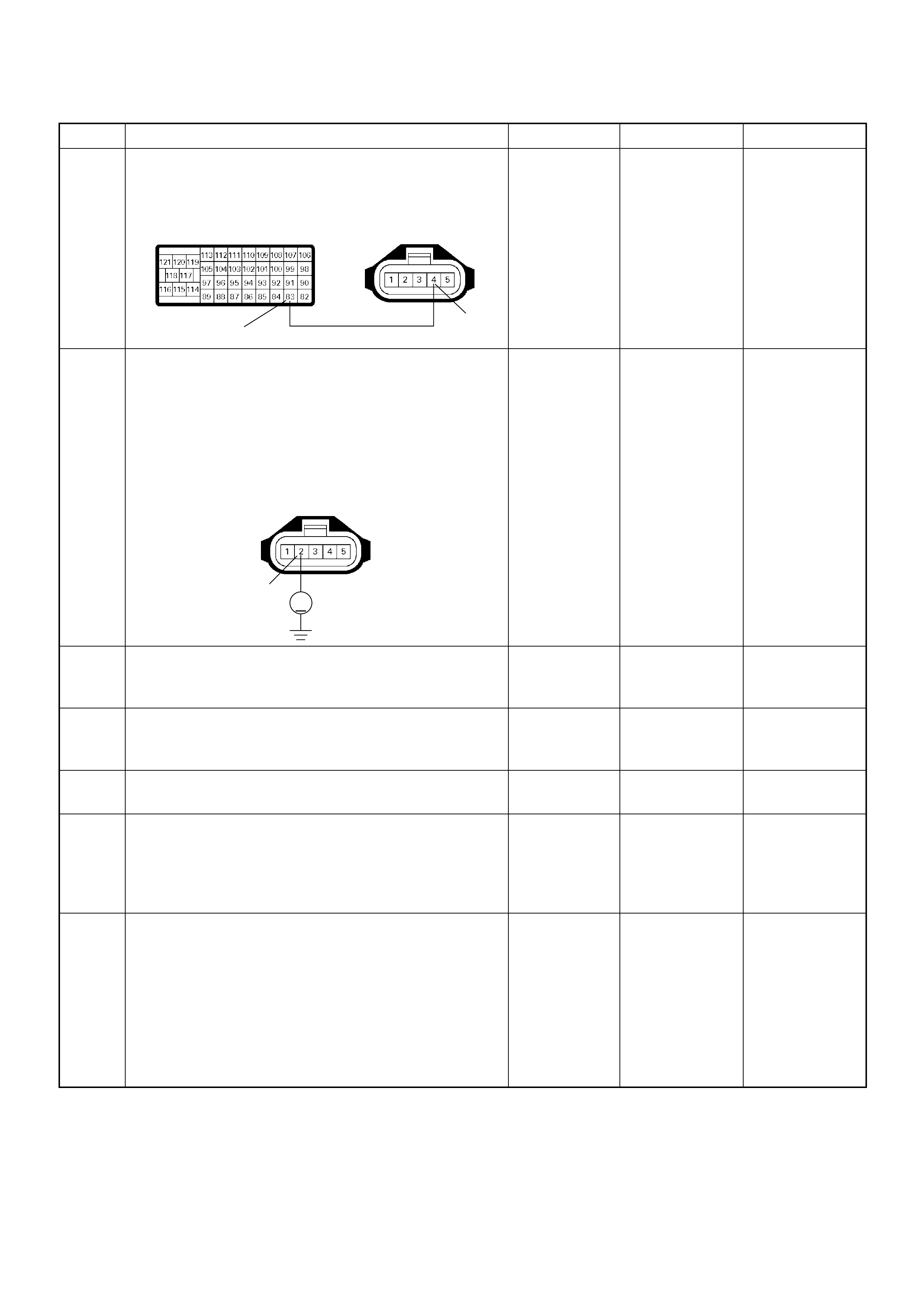

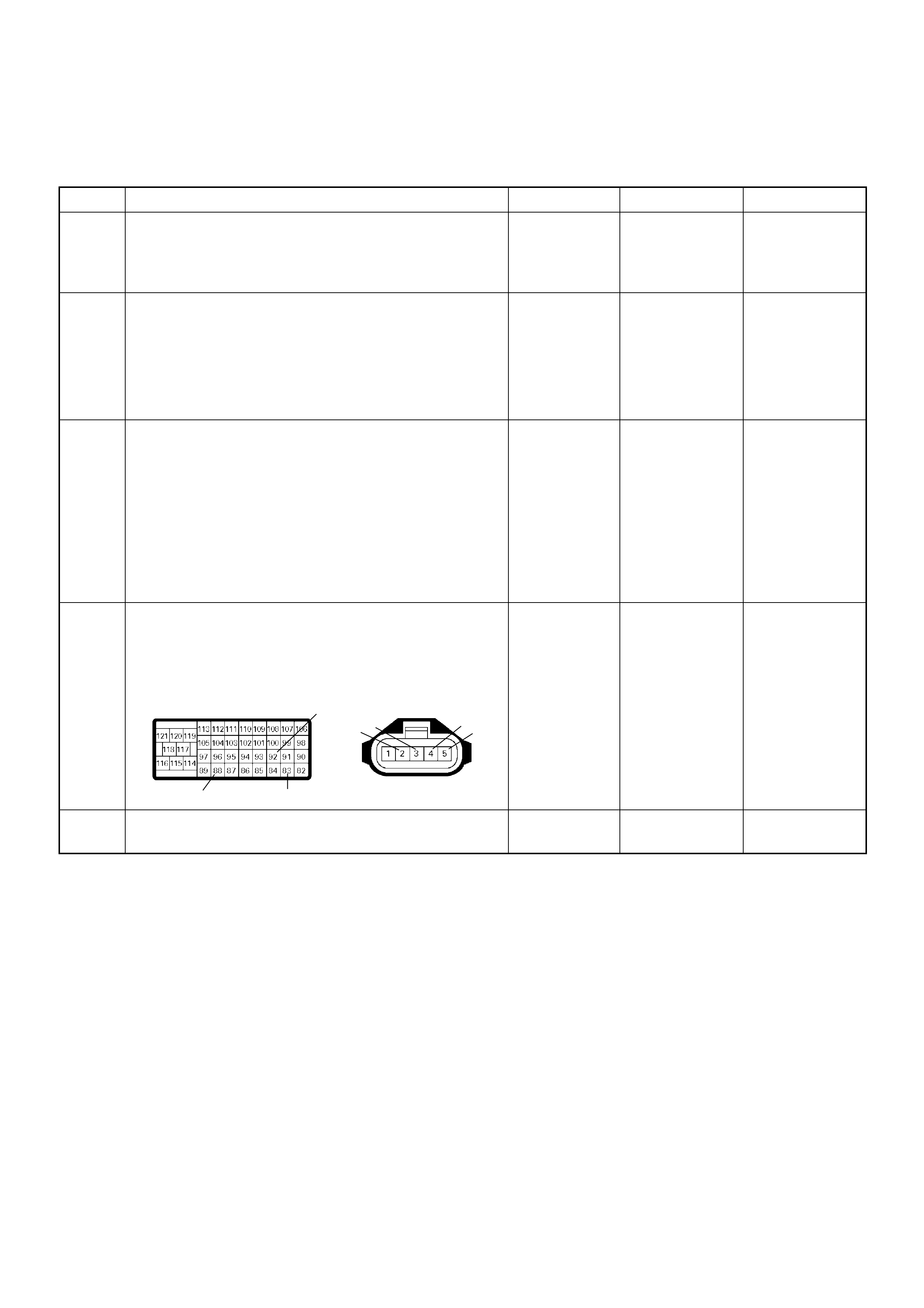

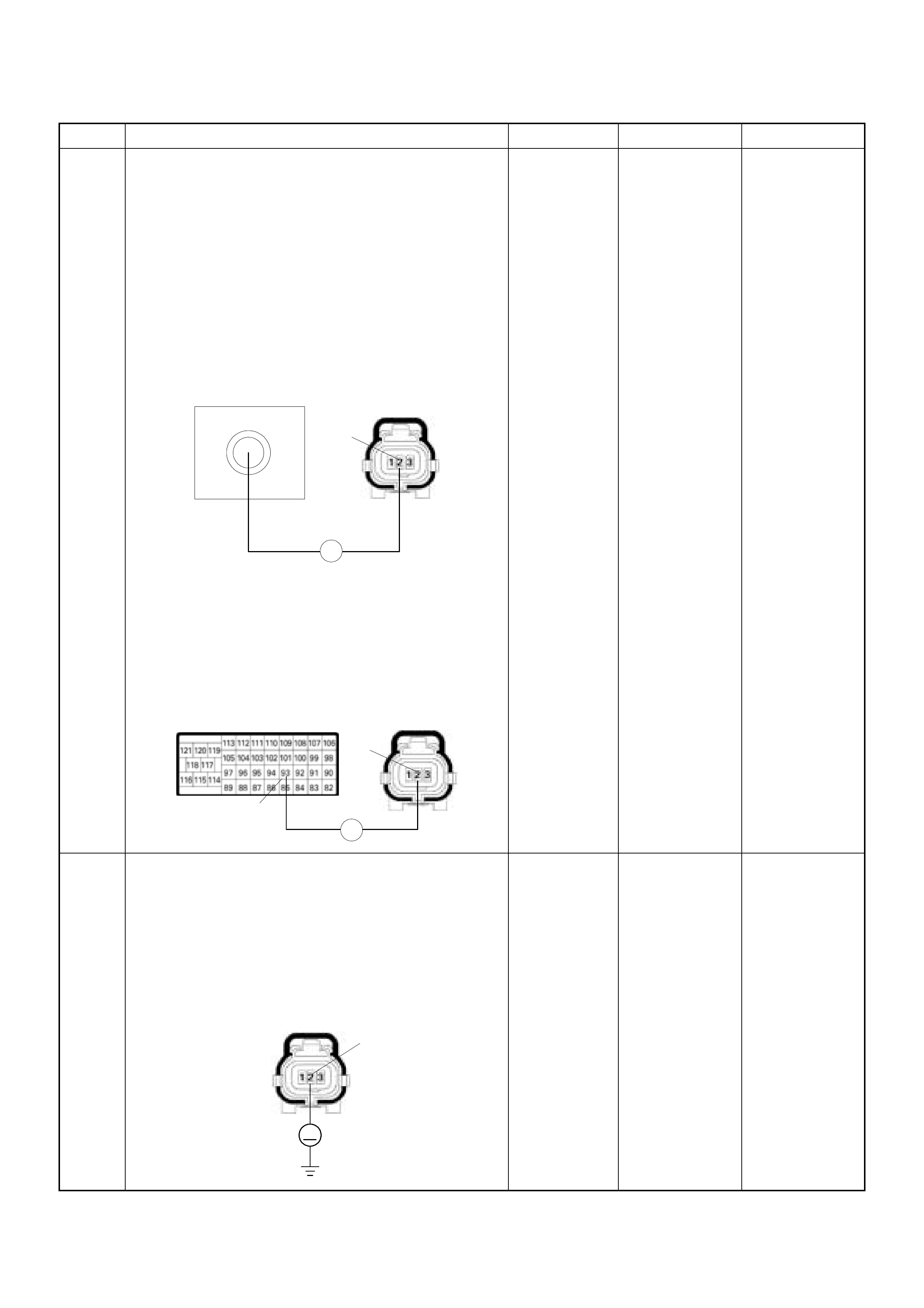

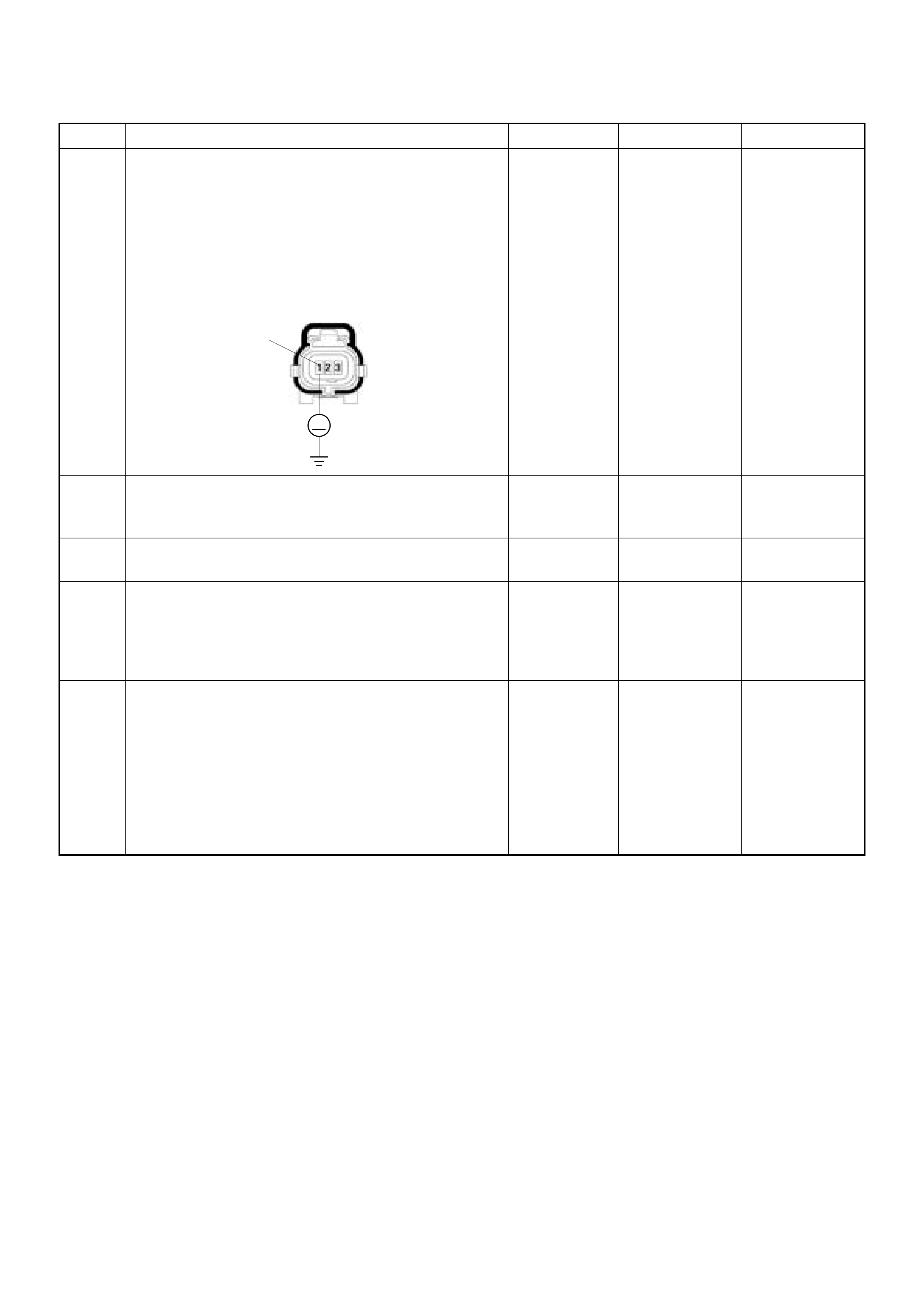

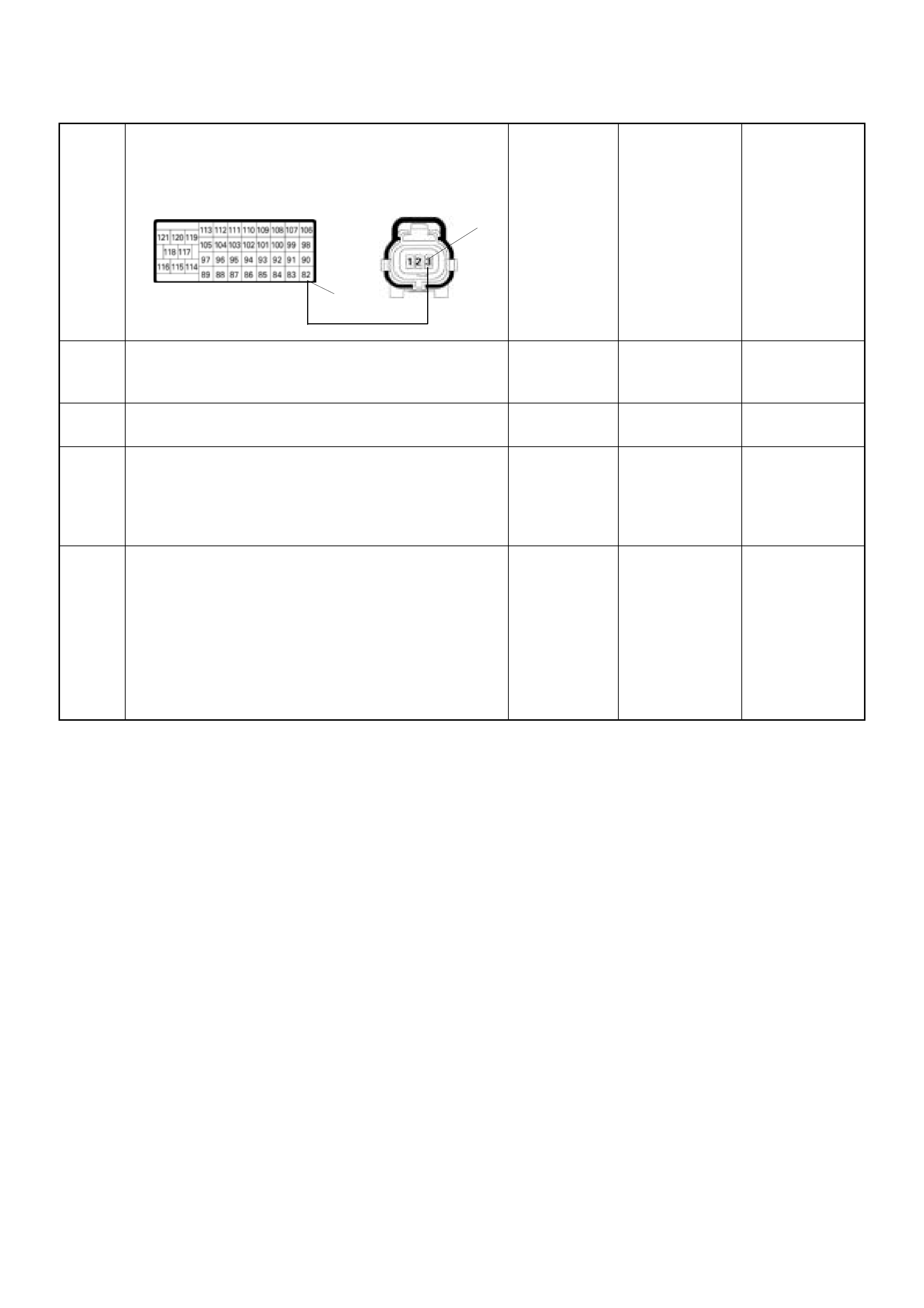

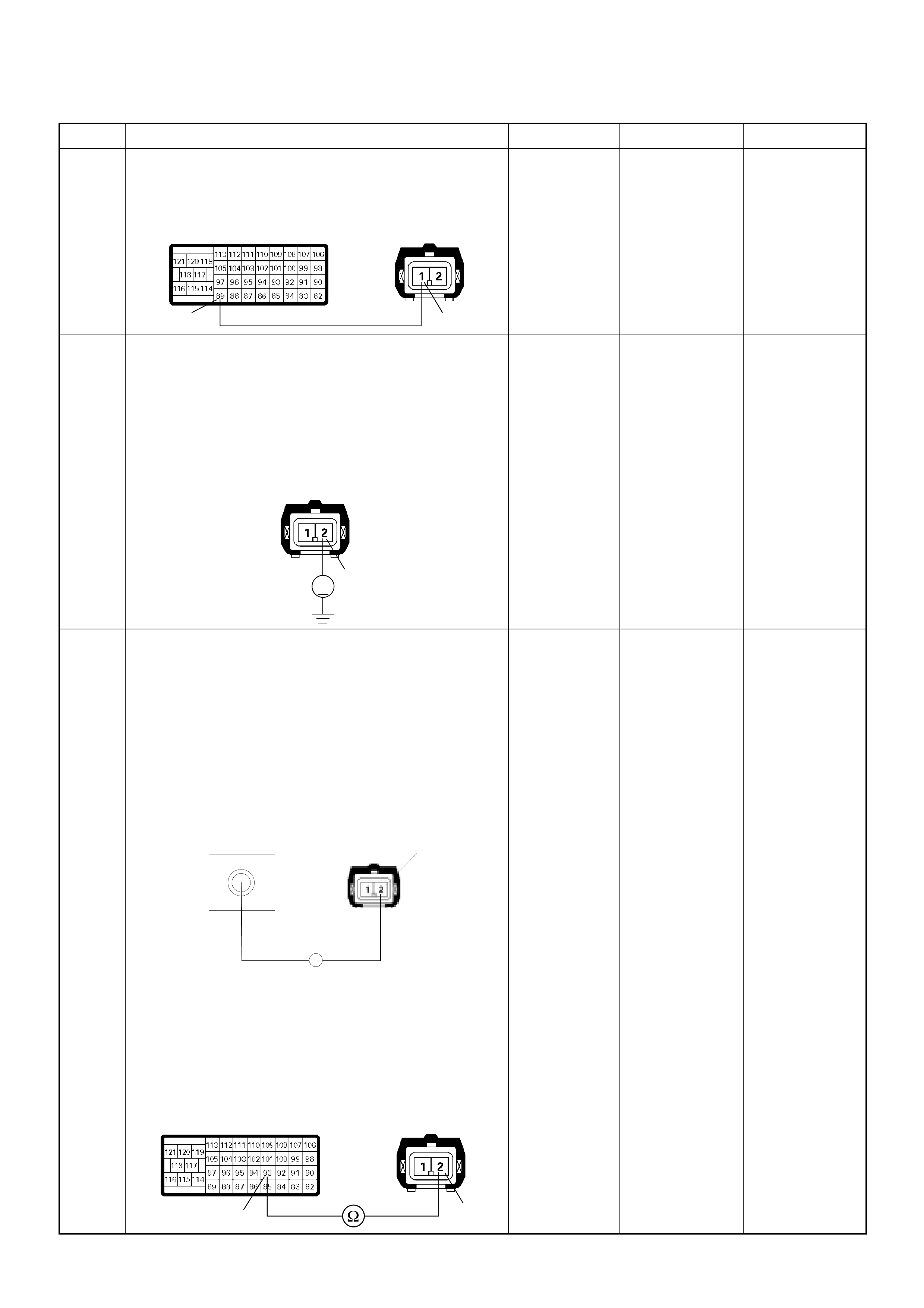

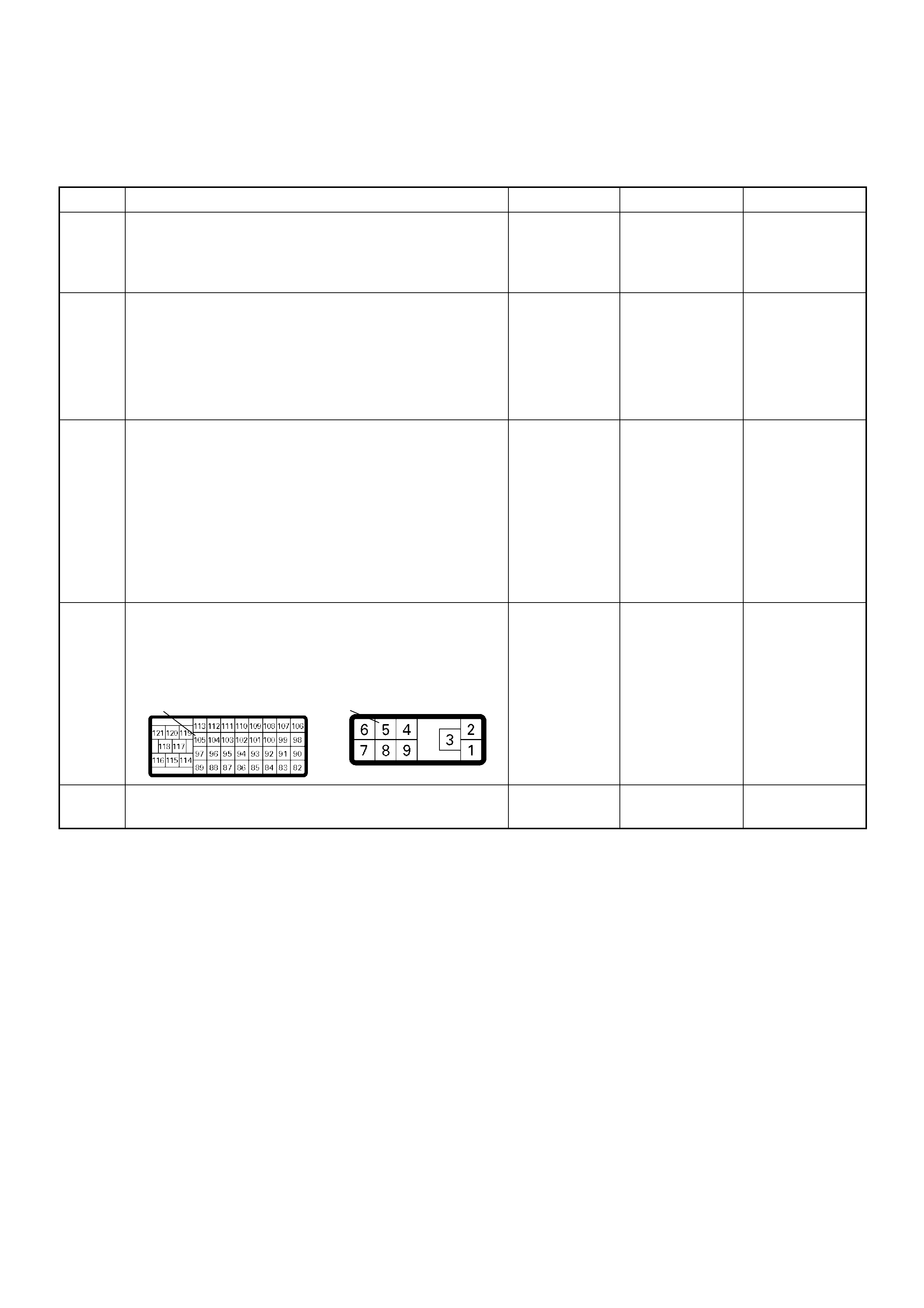

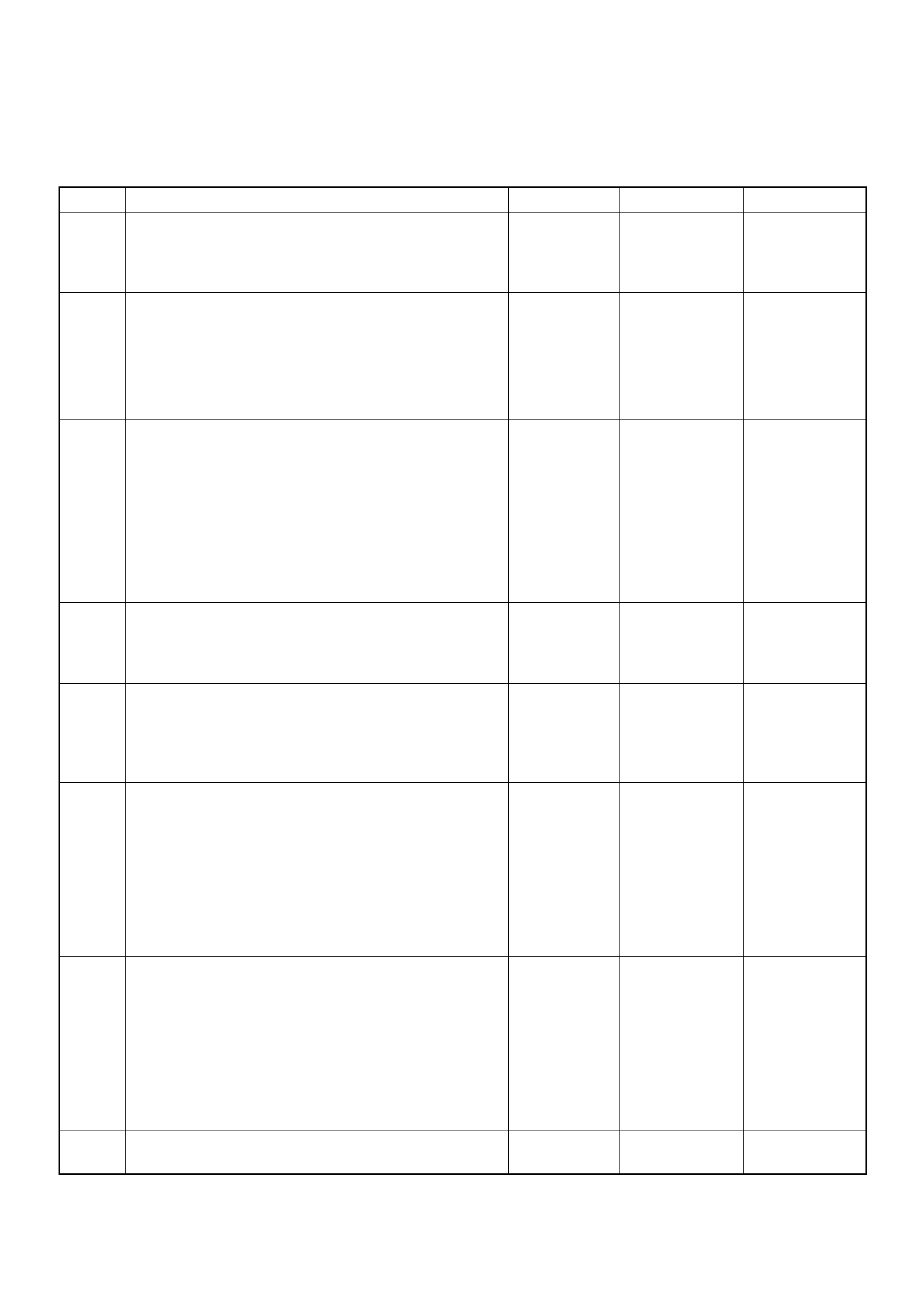

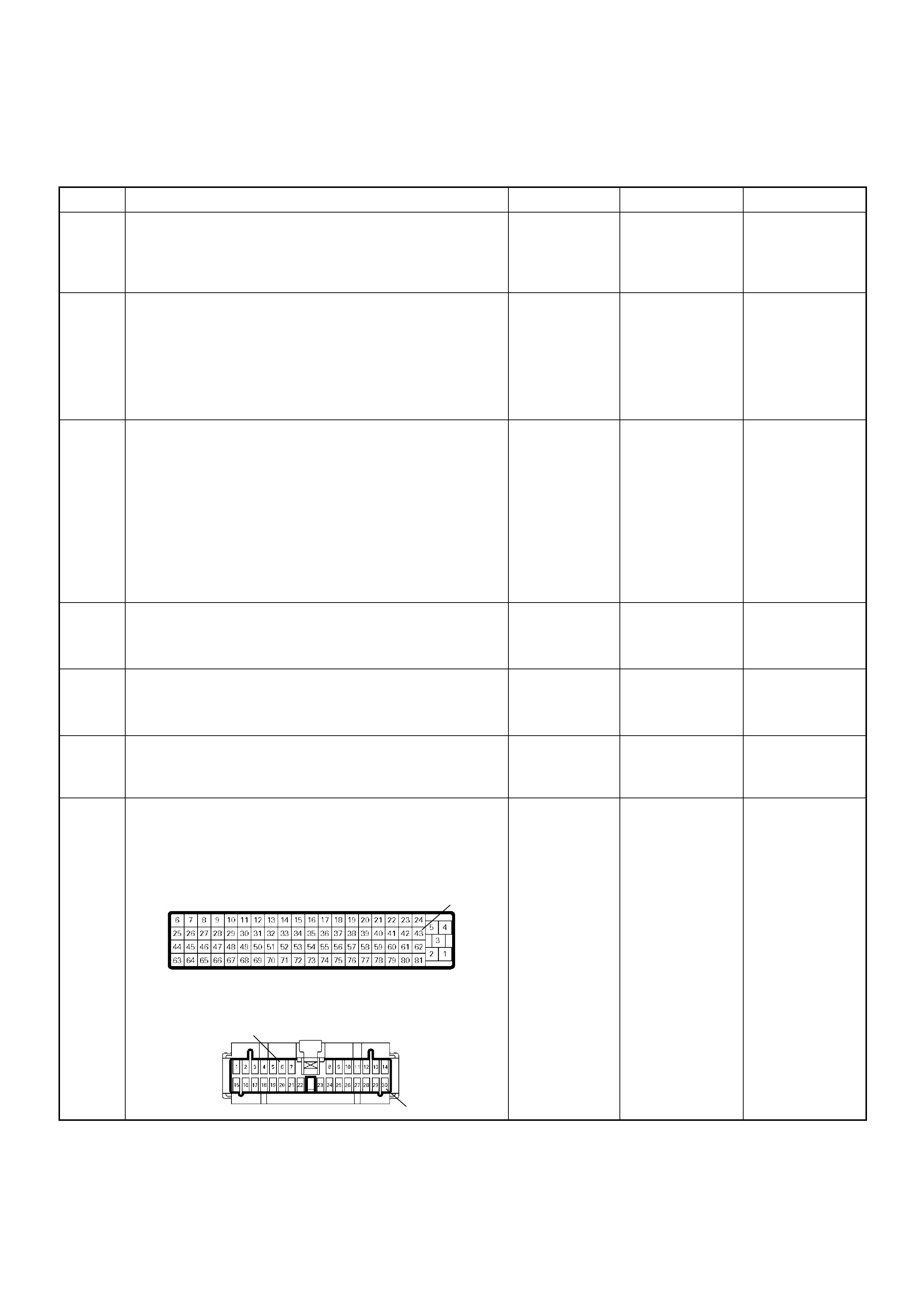

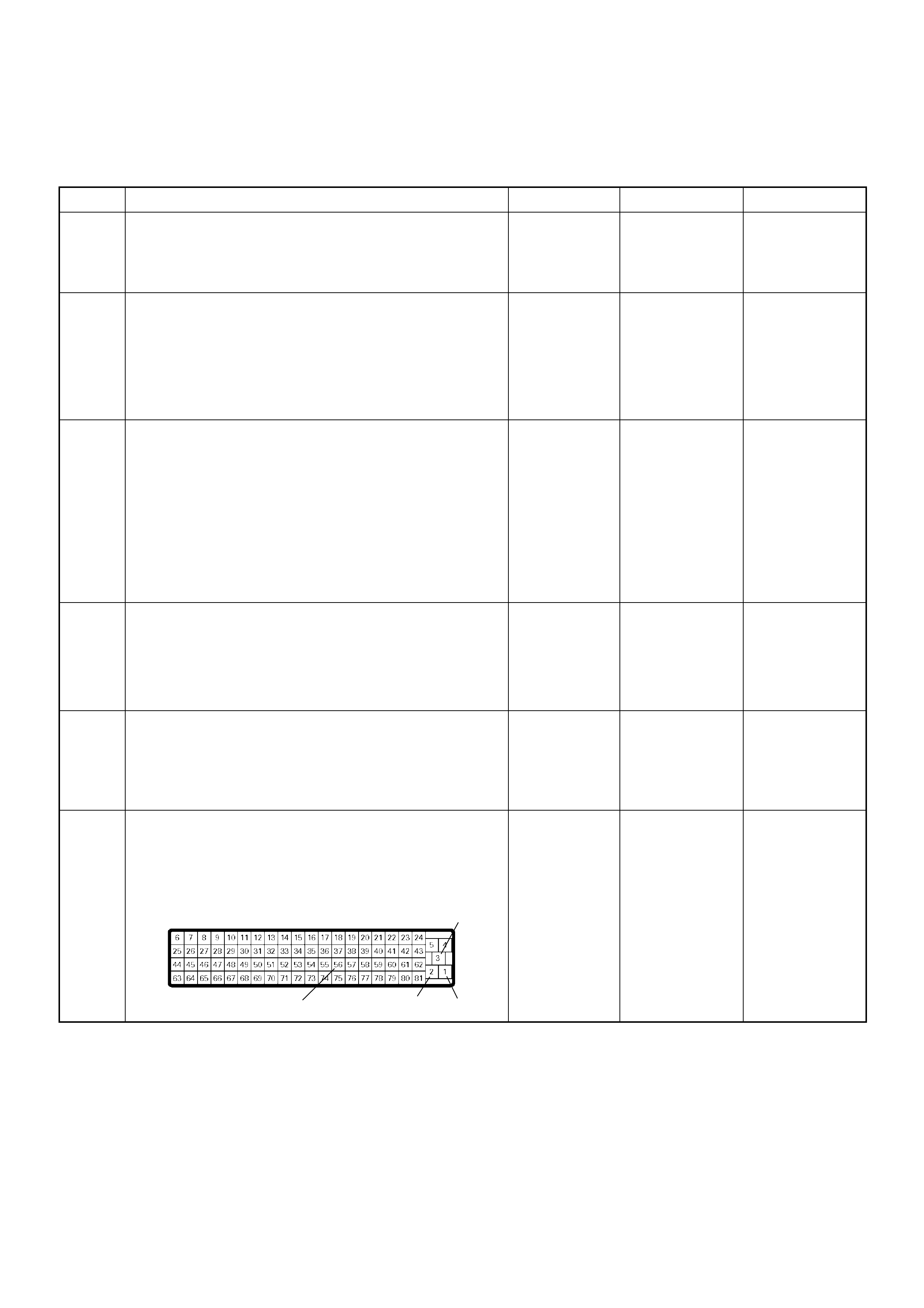

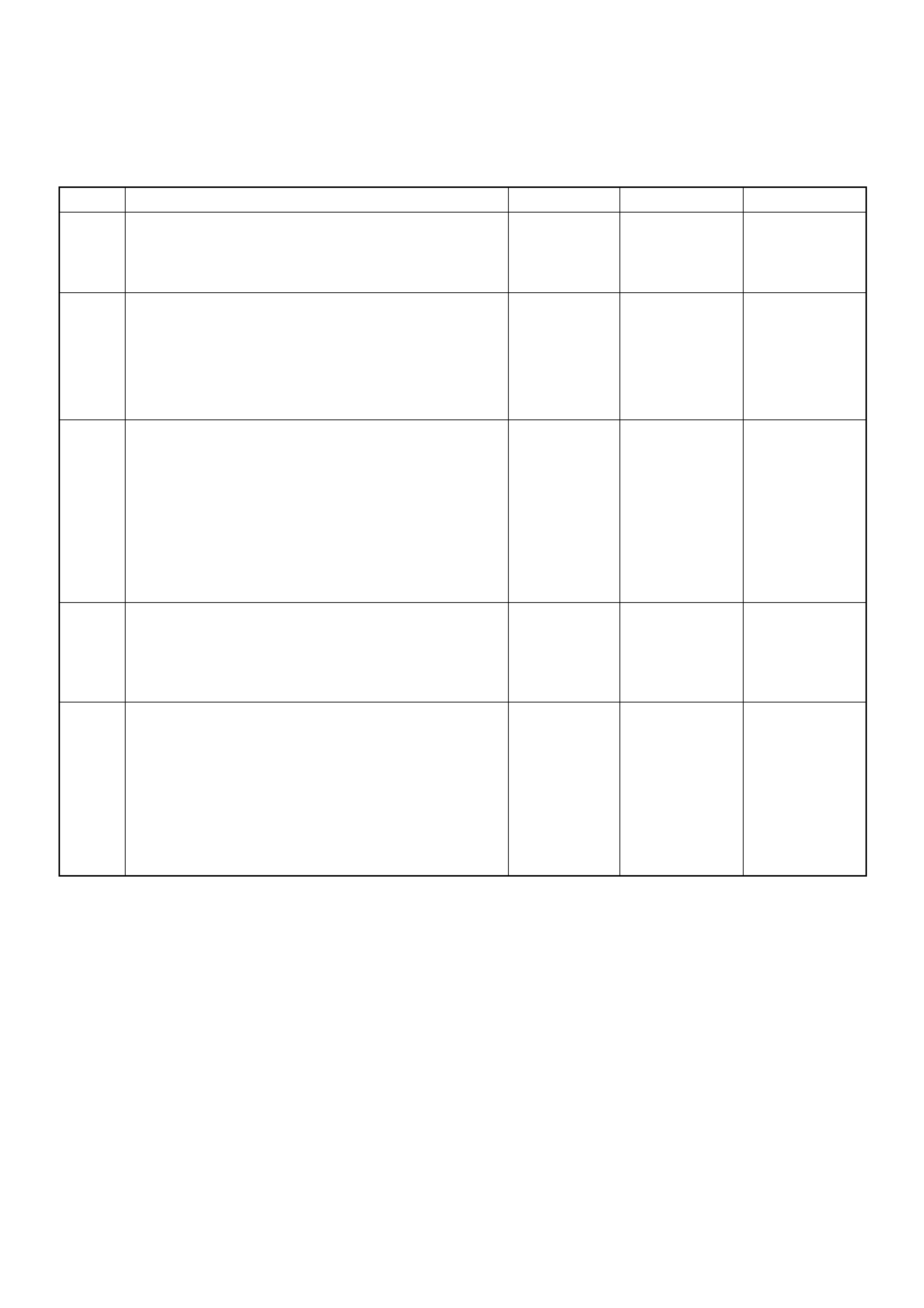

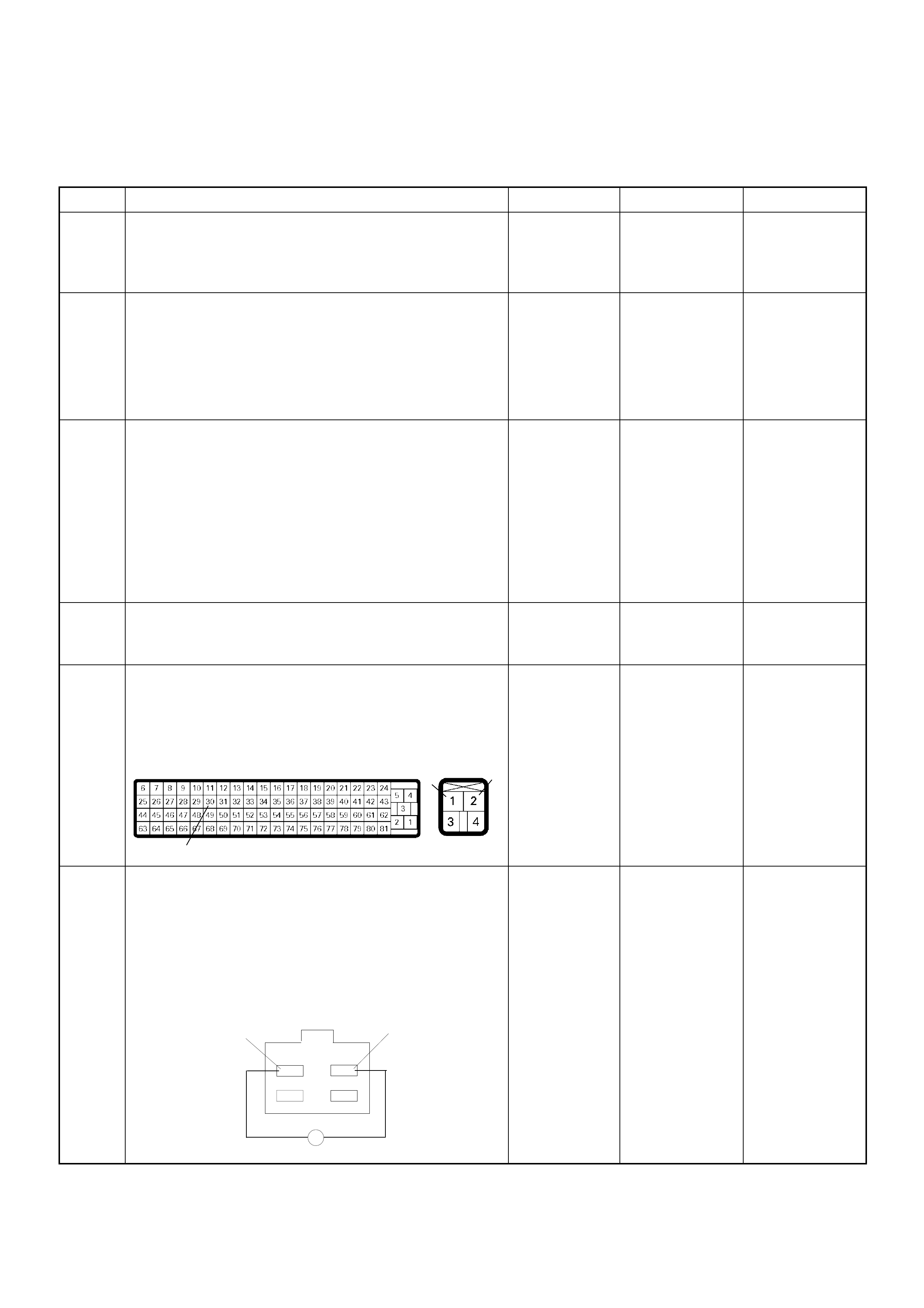

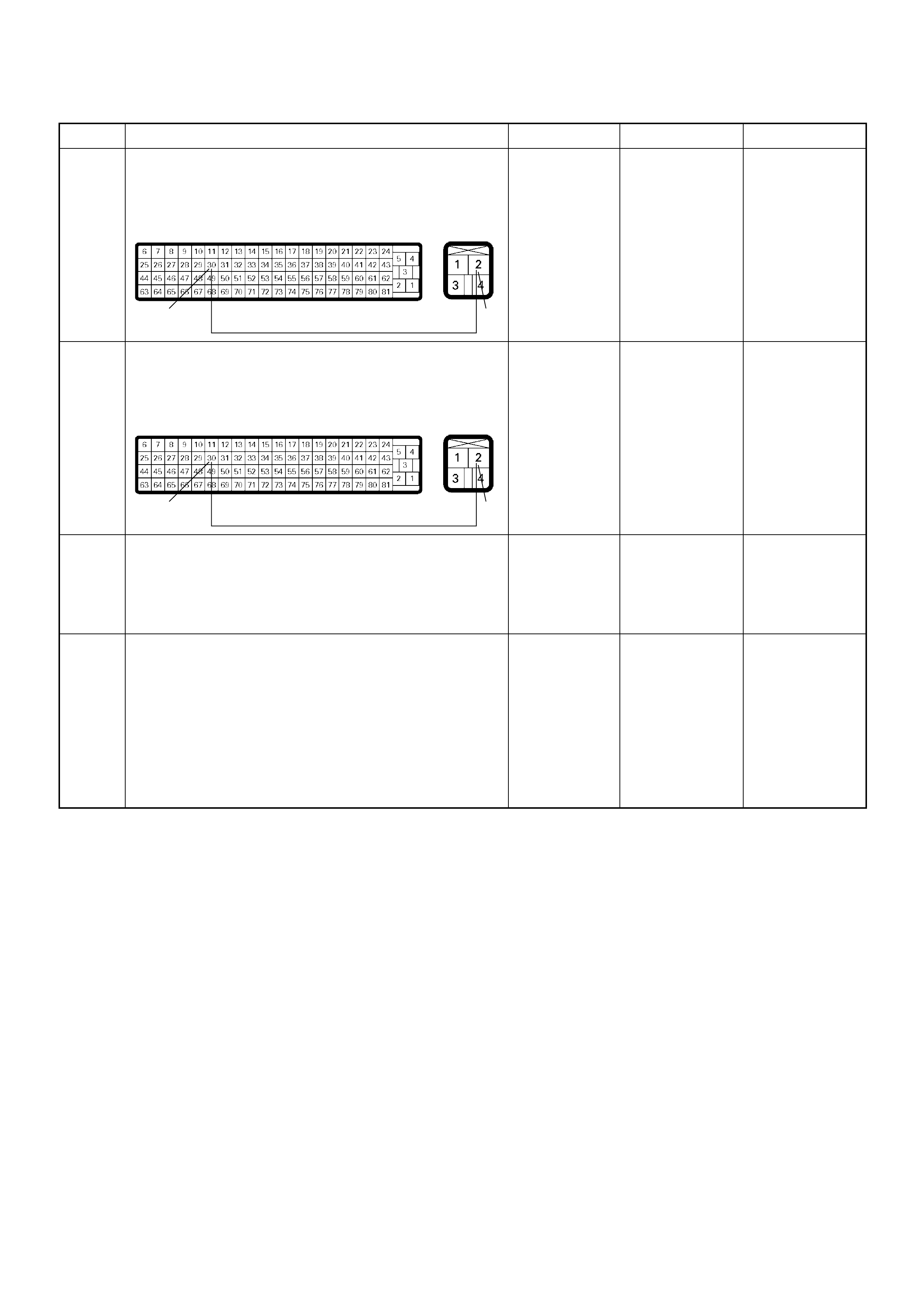

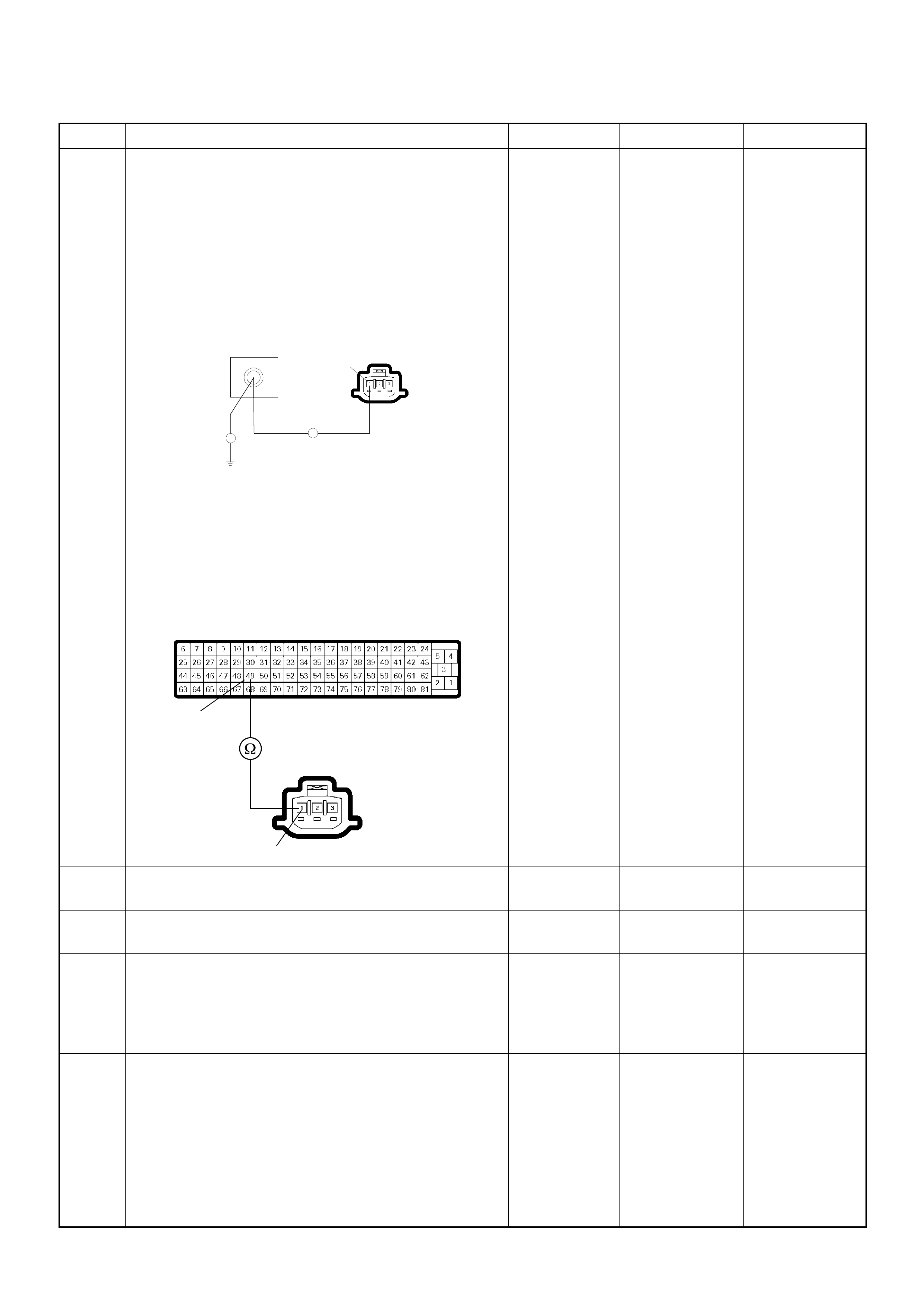

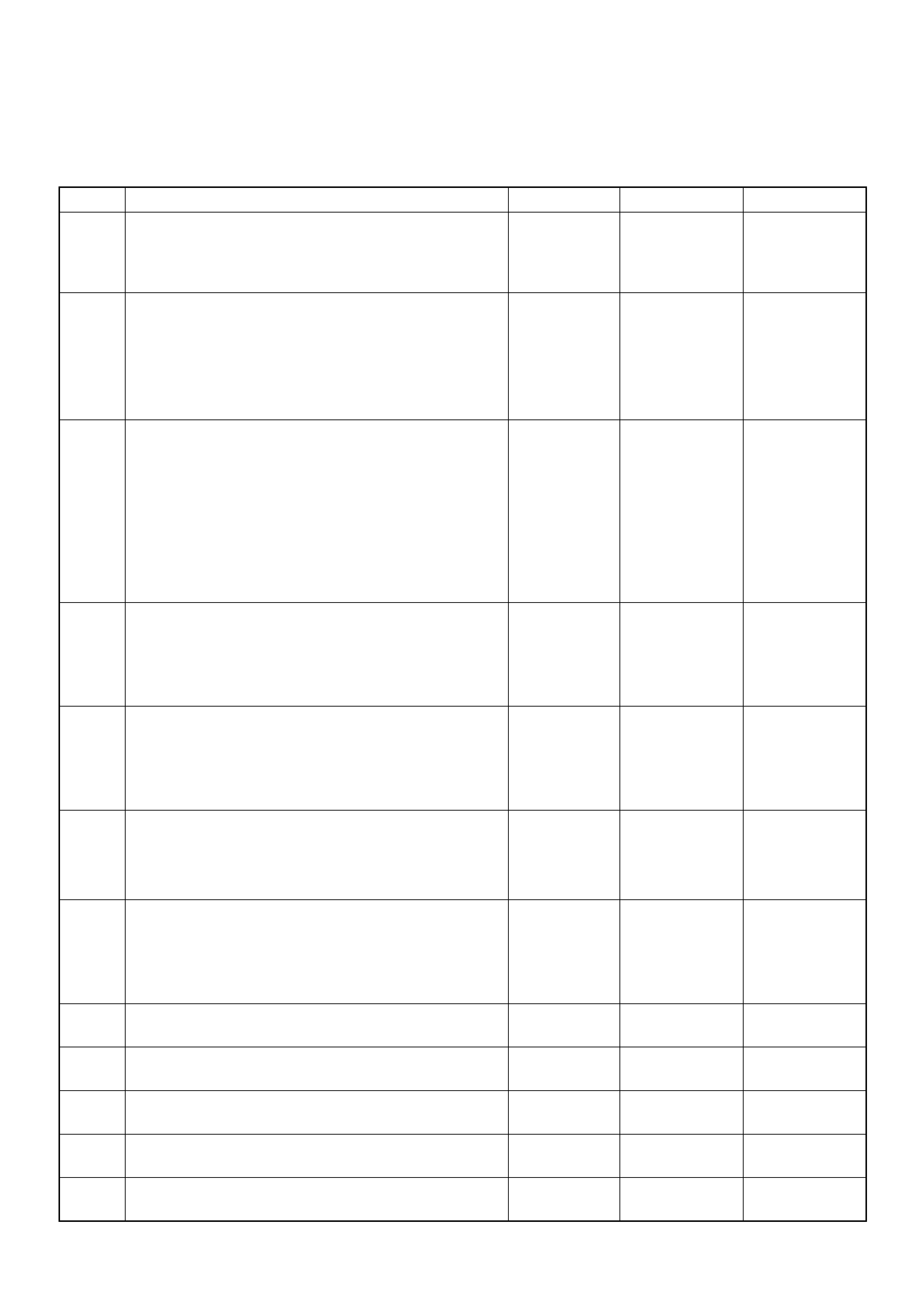

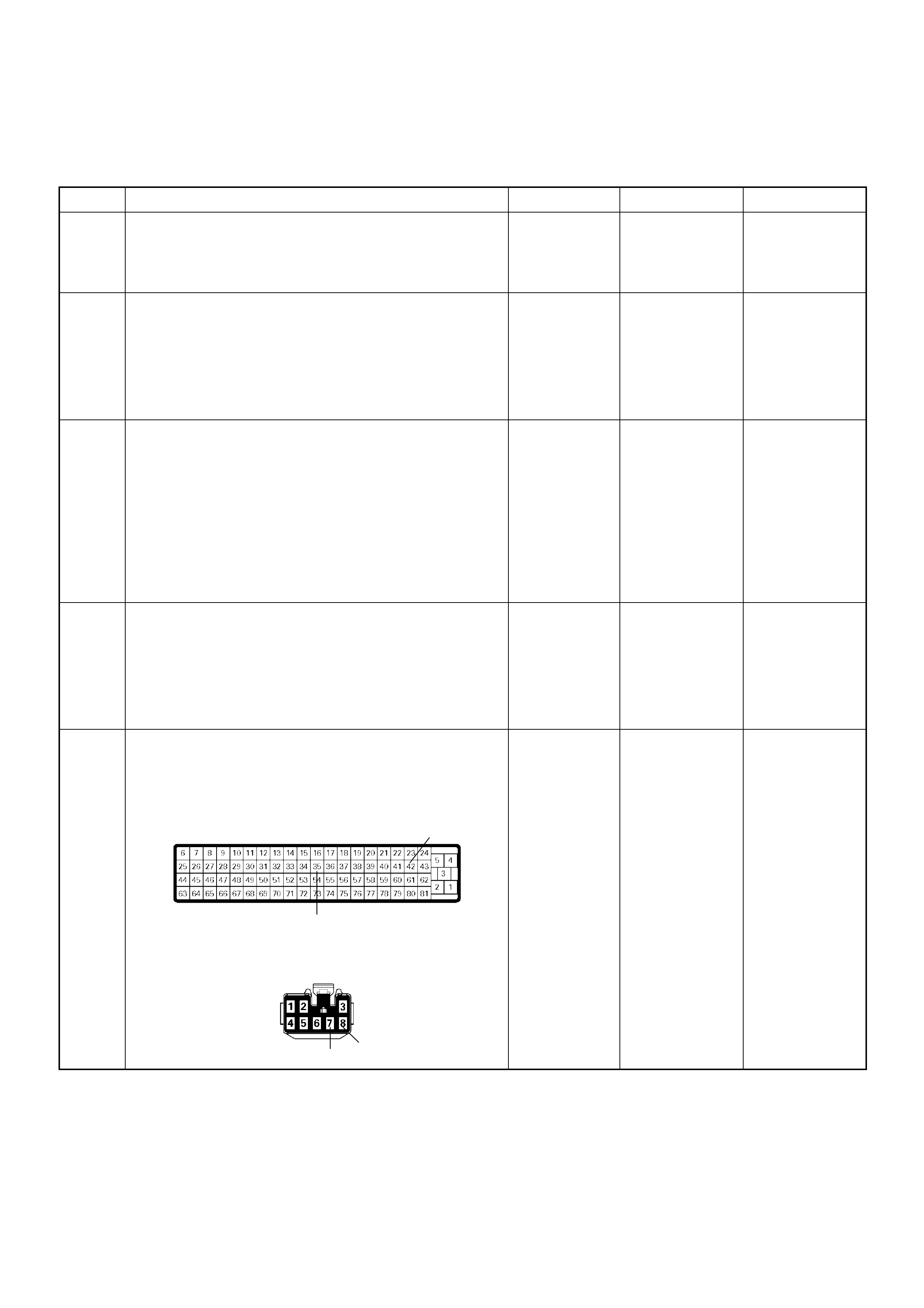

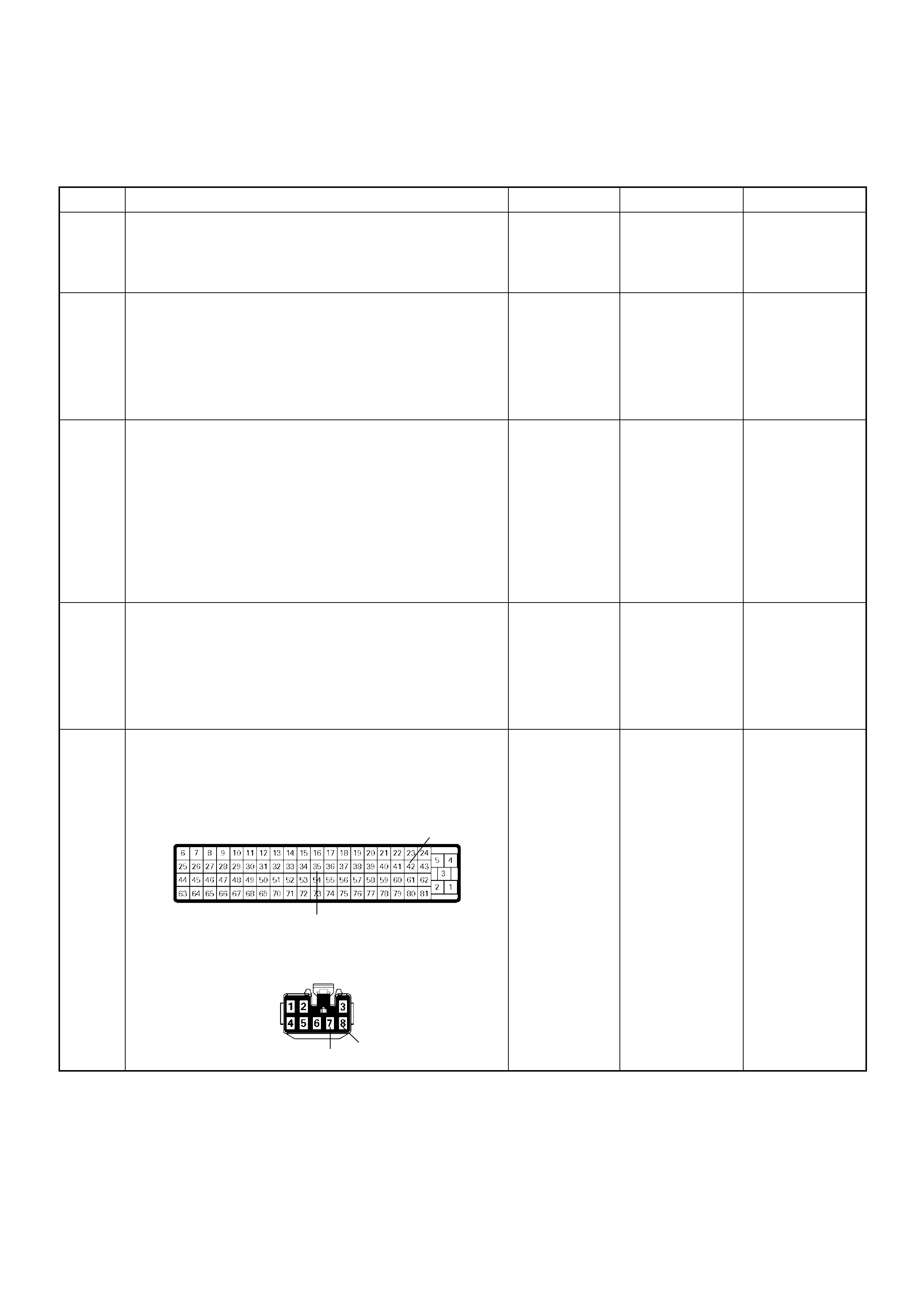

ECM CONNECTOR PIN ASSIGNMENT & OUTPUT SIGNAL

View Looking Into ECM Case

Signal or Continuity Tester Position

Pin

No. B/

Box

No.

Pin Function Wire

Color Key SW

Off Key SW

On Engine

Idle Engine

2000rpm ECM

Connec-

tion

Ran

ge (+) (-)

1 1 ECM Ground BLK Continu-

ity with

ground

- - - Discon-

nect Ohm 1 GND

2 2 ECM Ground BLK Continu-

ity with

ground

- - - Discon-

nect Ohm 2 GND

3 3 Battery Power Sup-

ply BLU/

RED Less

than 1V 10-14V Connect DC V 3 GND

25 25 No Connection - - - - - - - - -

26 26 No Connection - - - - - - - - -

27 27 Engine Speed Output

(To Tacho Me ter) LGN - - Approx.

23Hz by

wave

form o r

approx.

6.3V

Approx.

67Hz by

wave

form or

approx.

6.8V

Connect AC V 27 GND

28 28 No Connection - - - - - - - - -

29 29 Throttle Position Sig-

nal To TCM (A16)

(AT Only)

- Approx. 140Hz by wave form (Idle:

Off dut y 1 0 % / WOT: Off duty 90%) - ---

30 30 Brake Switch 1 Sig-

nal GRN Less

than 1V Pedal is not stepped on: Less than

1V

Pedal is stepped on: 10-14V

Connect DC V 30 GND

31 31 Clutch Switch Signal

(MT Only) YEL Less

than 1V Pedal is not stepped on: 10-14V

Pedal is stepped on: Less than 1V Connect DC V 31 GND

32 32 No Connection - - - - - - - - -

33 33 A/C ON Signal Relay GRN/

YEL Less

than 1V A/C request switch is turned on: 10-

14V

A/C request switch is turned off:

Less than 1V

Connect DC V 33 GND

34 34 No Connection - - - - - - - - -

35 35 To Data Link Con-

nector No. 6 & Immo-

bilizer Control Unit

(ICU B8)

YEL--------

36 36 No Connection - - - - - - - - -

37 37 No Connection - - - - - - - - -

38 38 Throttle Position

Sensor (TPS) Out-

put Signal

GRN/

ORG Less

than 1V Less than 1V Approx.

0.5V Connect DC V 38 49

39 39 Key Switch Input Sig-

nal Via Engine Fuse WHT Less

than 1V 10-14V Connect DC V 39 GND

40 40 No Connection - - - - - - - - -

41 41 A/C Compresso r

Relay WHT/

GRN Less

than 1V 10-14V A/C comp. is oper-

ated: Less than 1V

A/C comp. is not oper-

ated: 10 - 14V

Connect DC V 41 GND

42 42 Check Engine Lamp GRN/

YEL Less

than 1V Lamp is turned on: Less than 1V

Lamp is turned off: 10-14V Connect DC V 42 GND

43 43 Glow Lamp ORG/

BLU Less

than 1V Lamp is turned on: Less than 1V

Lamp is turned off: 10-14V Connect DC V 43 GND

44 44 No Connection - - - - - - - - -

45 45 To Data Link Con-

nector No. 6 BLU Less

than 1V 10-14V Connect DC V 45 GND

46 46 No Connection - - - - - - - - -

47 47 No Connection - - - - - - - - -

48 48 No Connection - - - - - - - - -

49 49 Throttle Position

Sensor (TPS)

Ground

BLK/

GRN Idle:

Approx.

0.4K

ohm /

WOT:

Approx.

4.0K

ohm

- - - Discon-

nect Ohm 38 49

50 50 No Connection - - - - - - - - -

51 51 No Connection - - - - - - - - -

52 52 No Connection - - - - - - - - -

53 53 No Connection - - - - - - - - -

54 54 No Connection - - - - - - - - -

55 55 No Connection - - - - - - - - -

56 56 No Connection - - - - - - - - -

57 57 Throttle Position

Sensor (TPS) Power

Supply

RED/

GRN Less

than 1V Approx. 5V Connect DC V 57 49

58 58 ECM Relay BLU/

BLK 10-14V Less than 1V Connect DC V 58 GND

59 59 No Connection - - - - - - - - -

60 60 No Connection - - - - - - - - -

61 61 No Connection - - - - - - - - -

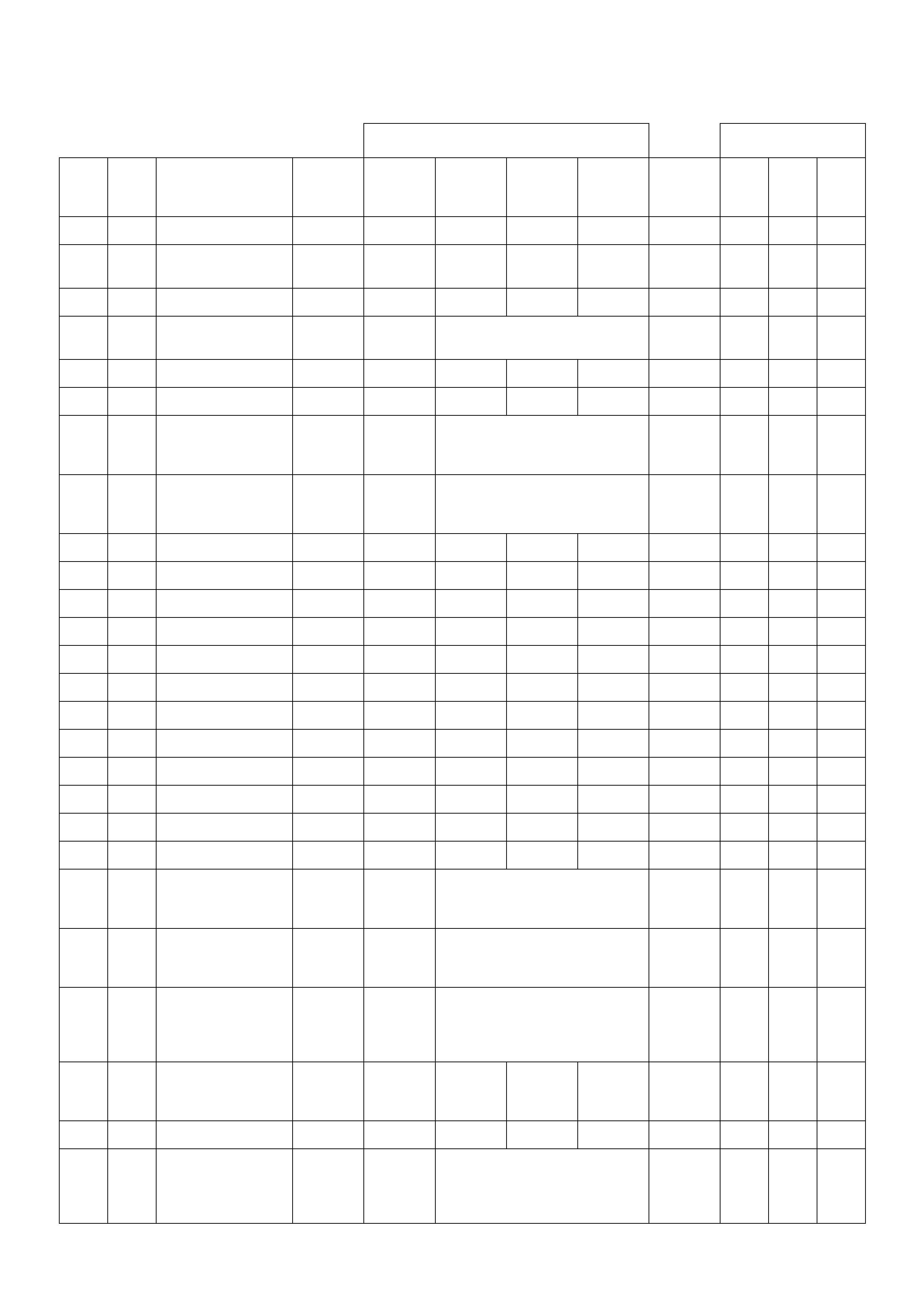

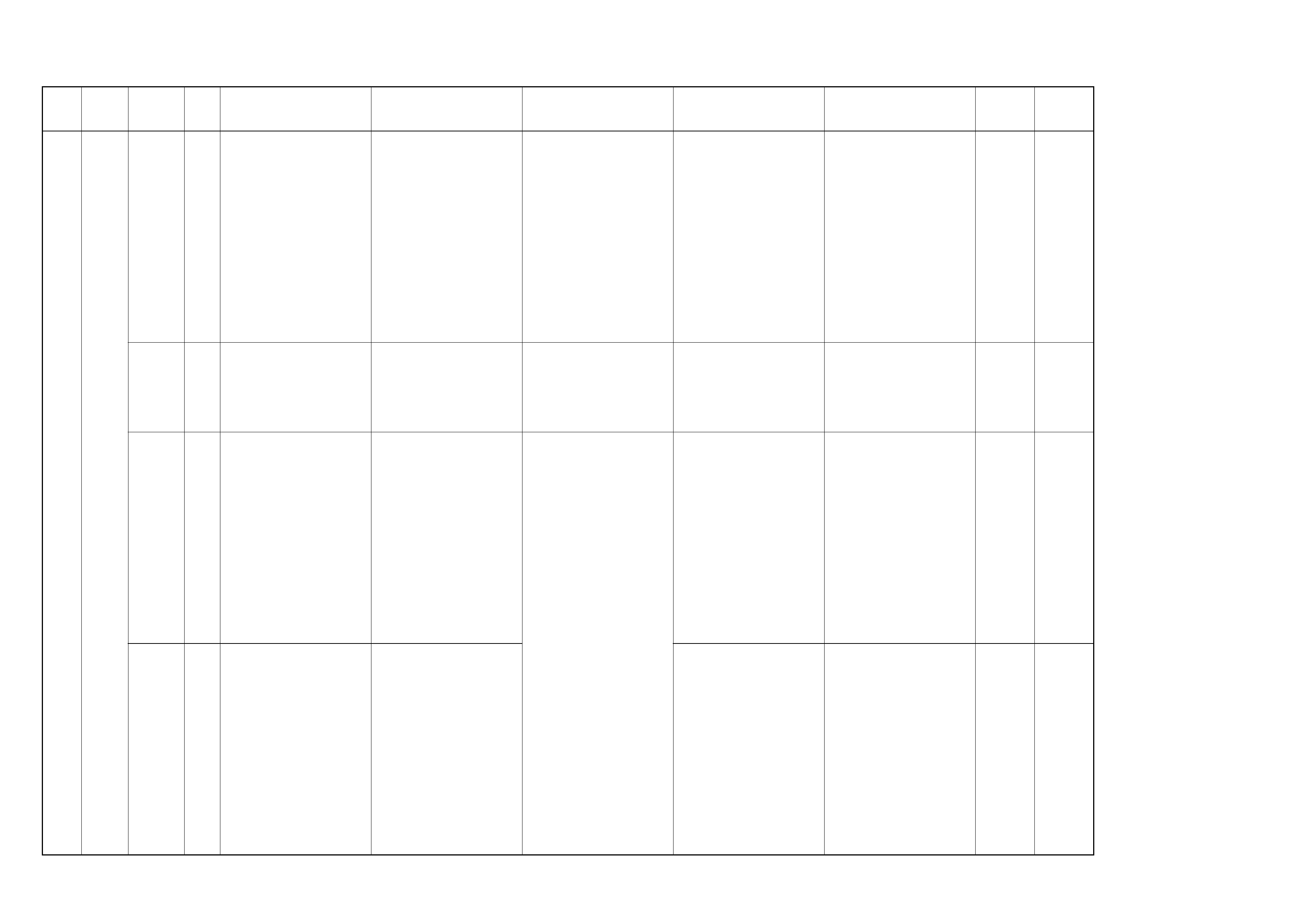

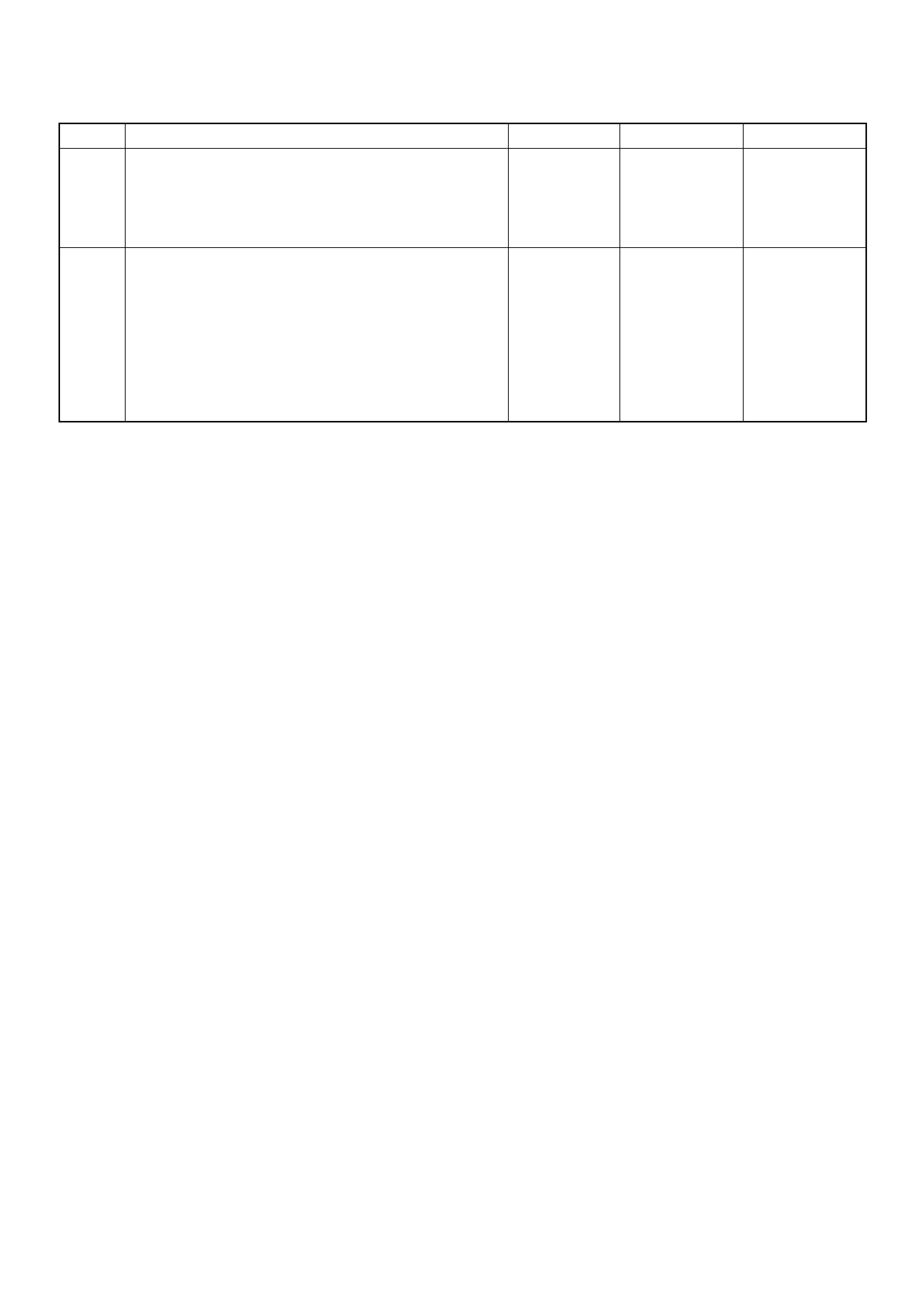

Signal or Continuity Tester Position

Pin

No. B/

Box

No.

Pin Function Wire

Color Key SW

Off Key SW

On Engine

Idle Engine

2000rpm ECM

Connec-

tion

Ran

ge (+) (-)

62 62 No Connection - - - - - - - - -

63 63 ECM Power Supply - Less

than 1V 10-14V - DC V 63 GND

64 64 No Connection - - - - - - - - -

65 65 Brake Switch 2 Sig-

nal WHT/

BLK Less

than 1V Pedal is not stepped on: 10-14V

Pedal is stepped on: Less than 1V Connect DC V 65 GND

66 66 No Connection - - - - - - - - -

67 67 No Connection - - - - - - - - -

68 68 Vehicle Speed Sen-

sor (VSS) YEL/

GRN - Approx. 14.5Hz by wave form or

approx. 6.0V at vehicle speed

20km/h

Connect AC V 68 GND

69 69 Idle Switch GRN/

BLK Less

than 1V Pedal is not stepped on: Less than

1V

Pedal is stepped on: Approx. 5V

Connect DC V 69 GND

70 70 No Connection - - - - - - - - -

71 71 No Connection - - - - - - - - -

72 72 No Connection - - - - - - - - -

73 73 No Connection - - - - - - - - -

74 74 No Connection - - - - - - - - -

75 75 No Connection - - - - - - - - -

76 76 No Connection - - - - - - - - -

77 77 No Connection - - - - - - - - -

78 78 No Connection - - - - - - - - -

79 79 No Connection - - - - - - - - -

80 80 No Connection - - - - - - - - -

81 81 No Connection - - - - - - - - -

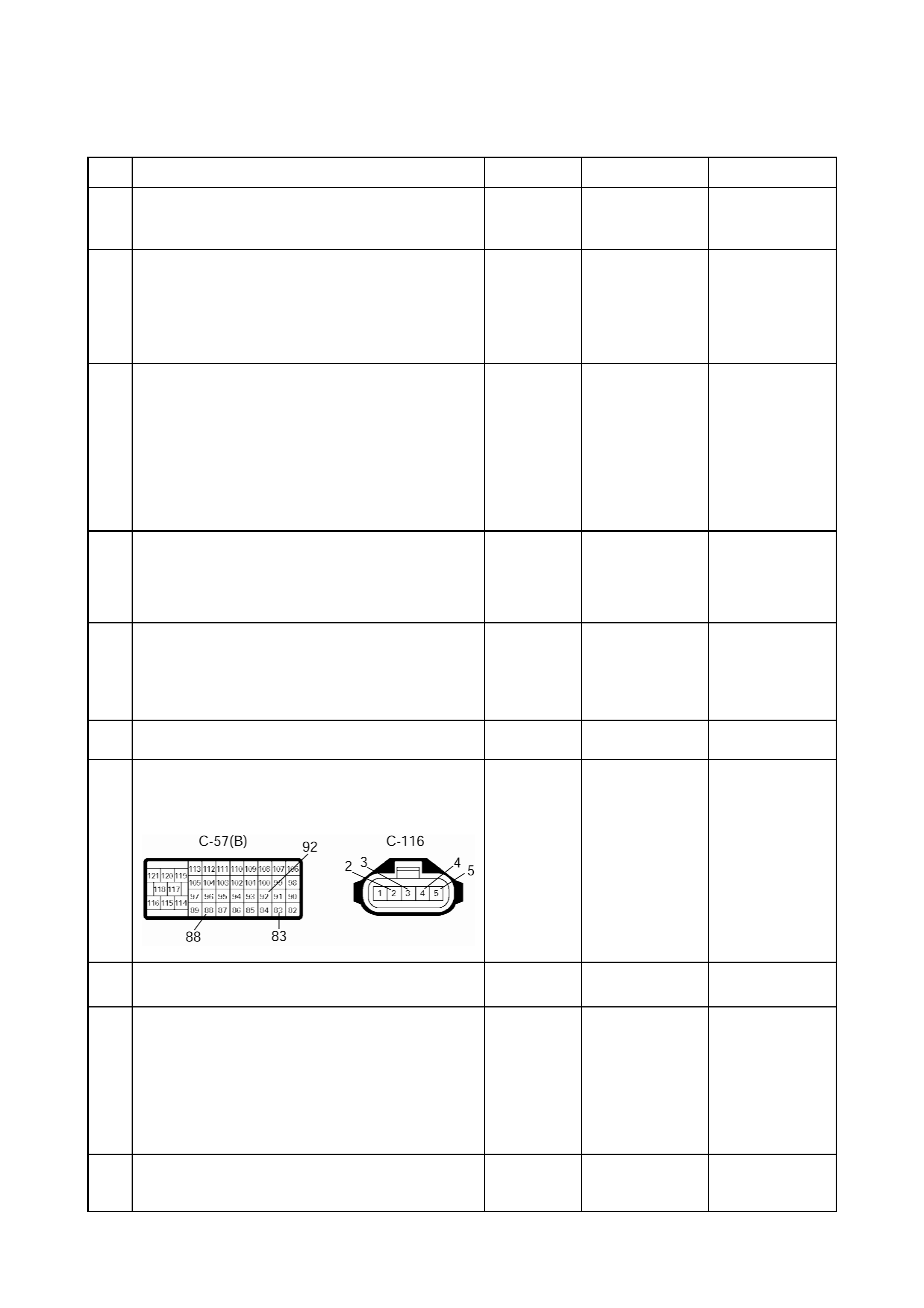

82 82 Boost Pressure Sen-

sor (High Altitude

Spec . Only)

WHT/

BLU Less

than 1V Approx. 5V Connect DC V 82 93

83 83 Mass Air Flow (MAF)

Sensor Power Sup-

ply

WHT/

RED Less

than 1V Approx. 5V Connect DC V 83 92

84 84 Intake Air Tempera-

ture (IAT) Sensor

Signal

BLK/

BLU Less

than 1V 0 deg. C: Approx. 3.6V / 20 deg. C:

Approx. 2.6V / 40 deg. C: Approx.

1.7V / 60 deg. C: 1.1V / 80 deg. C:

0.7V

Connect DC V 84 92

85 85 Manifold Pressure

Sensor (High Altitude

Spec . Only)

RED/

BLU Less

than 1V - - - Connect DC V 85 93

86 86 No Connection - - - - - - - - -

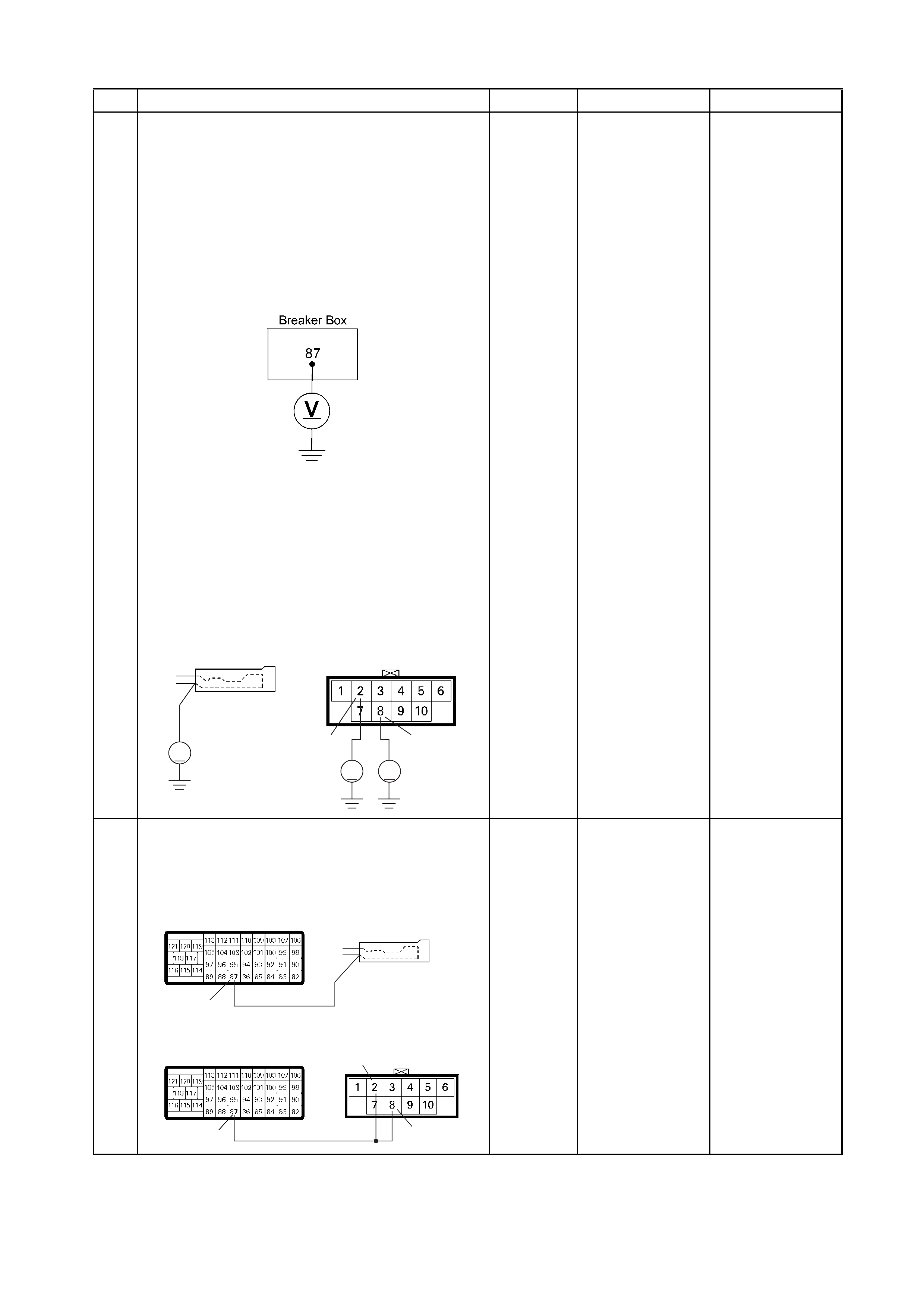

87 87 Neut ral Switch BLK/

WHT Less

than 1V In neutral (A/T: P or N): Less than

1V

Other than neutral (A/T: other than

P or N): 10-14V

Connect DC V 87 GND

Signal or Continuity Tester Position

Pin

No. B/

Box

No.

Pin Function Wire

Color Key SW

Off Key SW

On Engine

Idle Engine

2000rpm ECM

Connec-

tion

Ran

ge (+) (-)

88 88 Mass Air Flow (MAF)

Sensor Signal GRN/

RED Less

than 1V Approx.

1V Approx.

1.8V Approx.

2.5V Connect DC V 88 92

89 89 Engine Coolant Tem-

perature (ECT) Sen-

sor Signal

GRY Less

than 1V 0 deg. C: Approx. 4.4V / 20 deg. C:

Approx. 3.8V / 40 deg. C: Approx.

2.9V / 60 deg. C: 2.1V / 80 deg. C:

1.4V

Connect DC V 89 93

90 90 CKP Sensor Signal RED - - Approx.

47Hz by

wave

form

Approx.

134Hz by

wave

form or

approx.

1.1V

Connect AC V 90 98

91 91 CKP Sensor Output

T o Pump Control Unit

(PSG) No . 8

PNK - - Approx.

47Hz by

wave

form

Approx.

134Hz by

wave

form or

approx.

0.7V

Connect AC V 91 GND

92 92 Mass Air Flow (MAF)

Sensor Ground BLK/

RED Continu-

ity with

ground

- - - Connect Ohm 92 GND

93 93 Engine Coolant Tem-

perature (ECT) Sen-

sor & Manifold

Pressure Sensor

Ground

BLK/

PNK Continu-

ity with

ground

- - - Connect Ohm 93 GND

94 94 Glow Relay BLK/

RED Less

than 1V Glow system is operated: Less than

1V

Glow system is not operated: 10 -

14V

Connect DC V 94 GND

95 95 No Connection - - - - - - - - -

96 96 T urbocharger W aste

gate Control EVRV BRW/

RED - - Wave form - ---

97 97 EGR EVRV BLK/

ORG - - Approx. 140Hz by

wave form when

EVRV is operated

- ---

98 98 CKP Sensor Ground WHT Continu-

ity with

ground

- - - Connect Ohm 98 GND

99 99 CAN (Controller Area

Netwo rk) to PSG

No.1

BLU--------

100 100 CAN (Controller Area

Netwo rk) to PSG

No.2

YEL--------

101 101 CKP Sens or Shield

Line BLK Continu-

ity with

ground

- - - Connect Ohm 101 GND

102 102 No Connection - - - - - - - - -

103 103 No Connection - - - - - - - - -

104 104 No Connection - - - - - - - - -

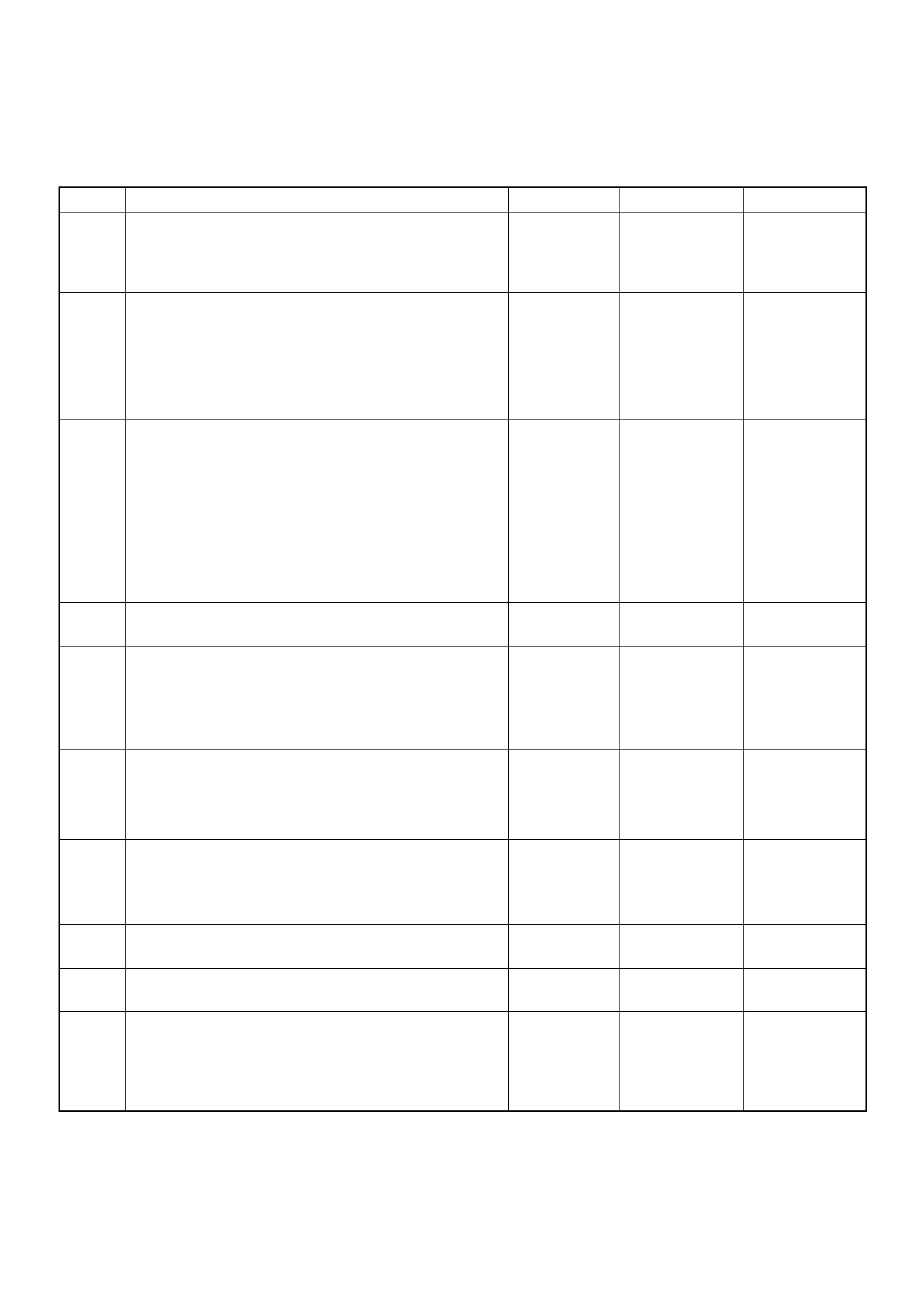

Signal or Continuity Tester Position

Pin

No. B/

Box

No.

Pin Function Wire

Color Key SW

Off Key SW

On Engine

Idle Engine

2000rpm ECM

Connec-

tion

Ran

ge (+) (-)

105 105 Solenoid Valve Shu t

Off (MAB) Output

Signal to PSG No.5

ORG - - - - - - - -

Signal or Continuity Tester Position

Pin

No. B/

Box

No.

Pin Function Wire

Color Key SW

Off Key SW

On Engine

Idle Engine

2000rpm ECM

Connec-

tion

Ran

ge (+) (-)

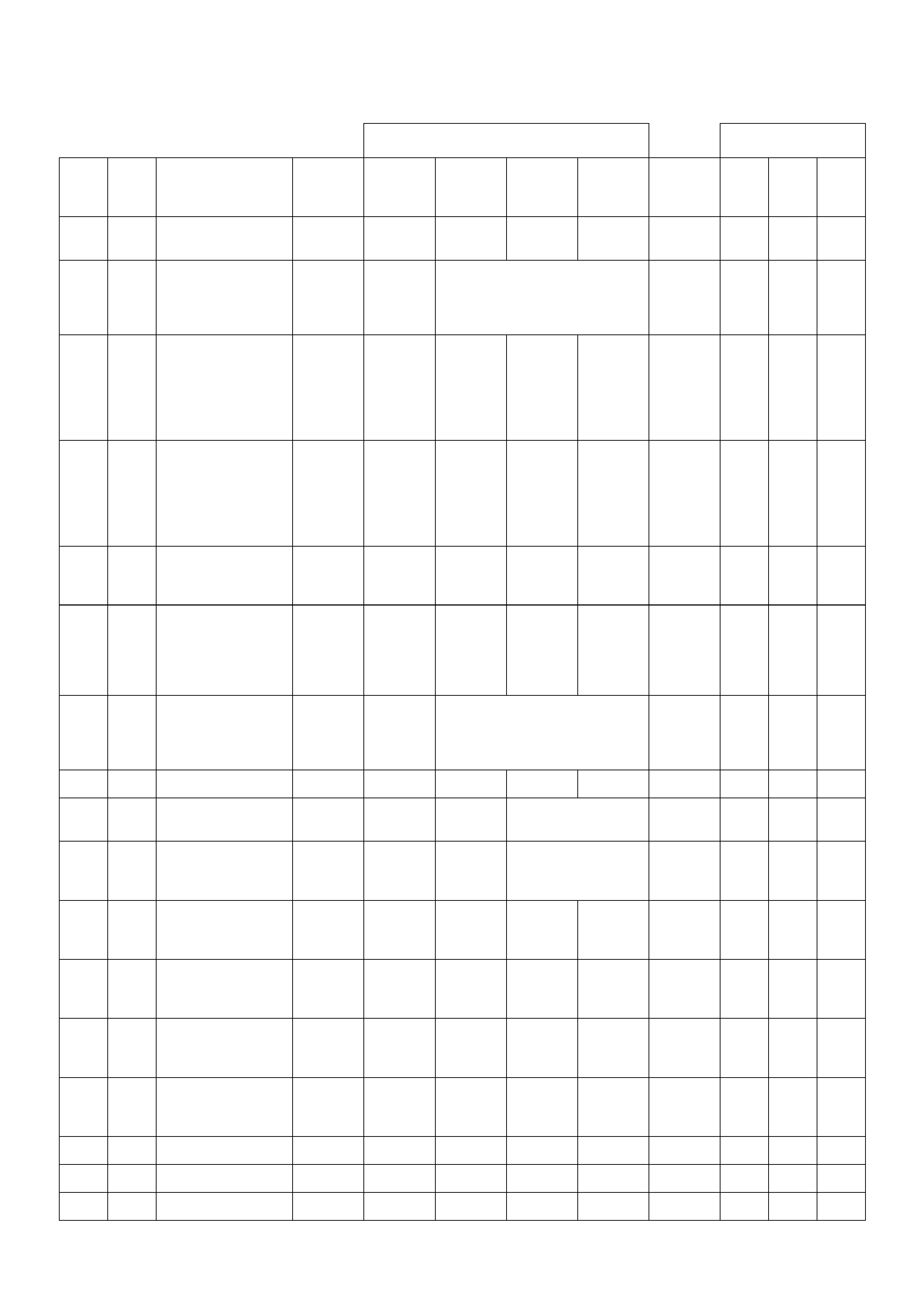

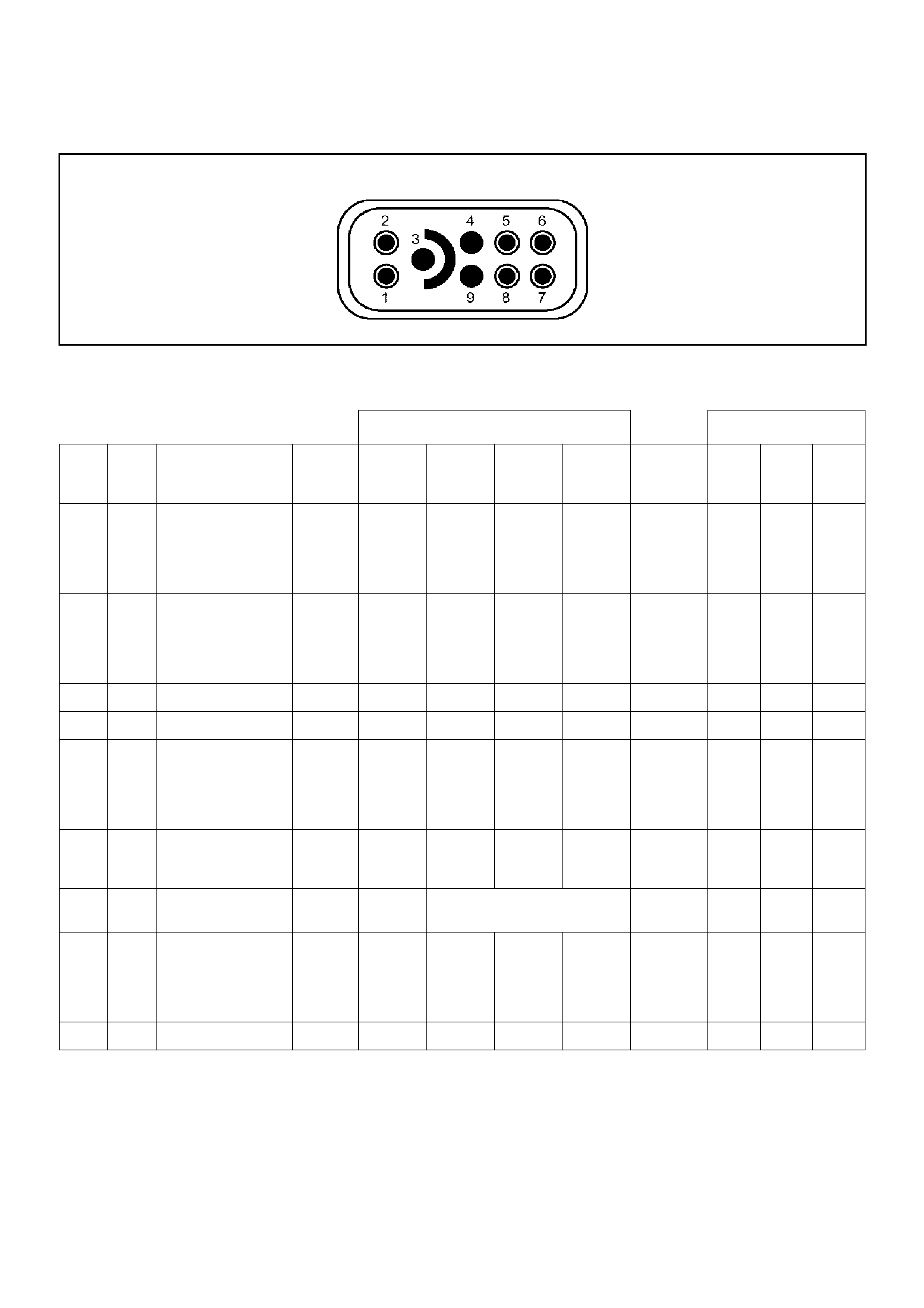

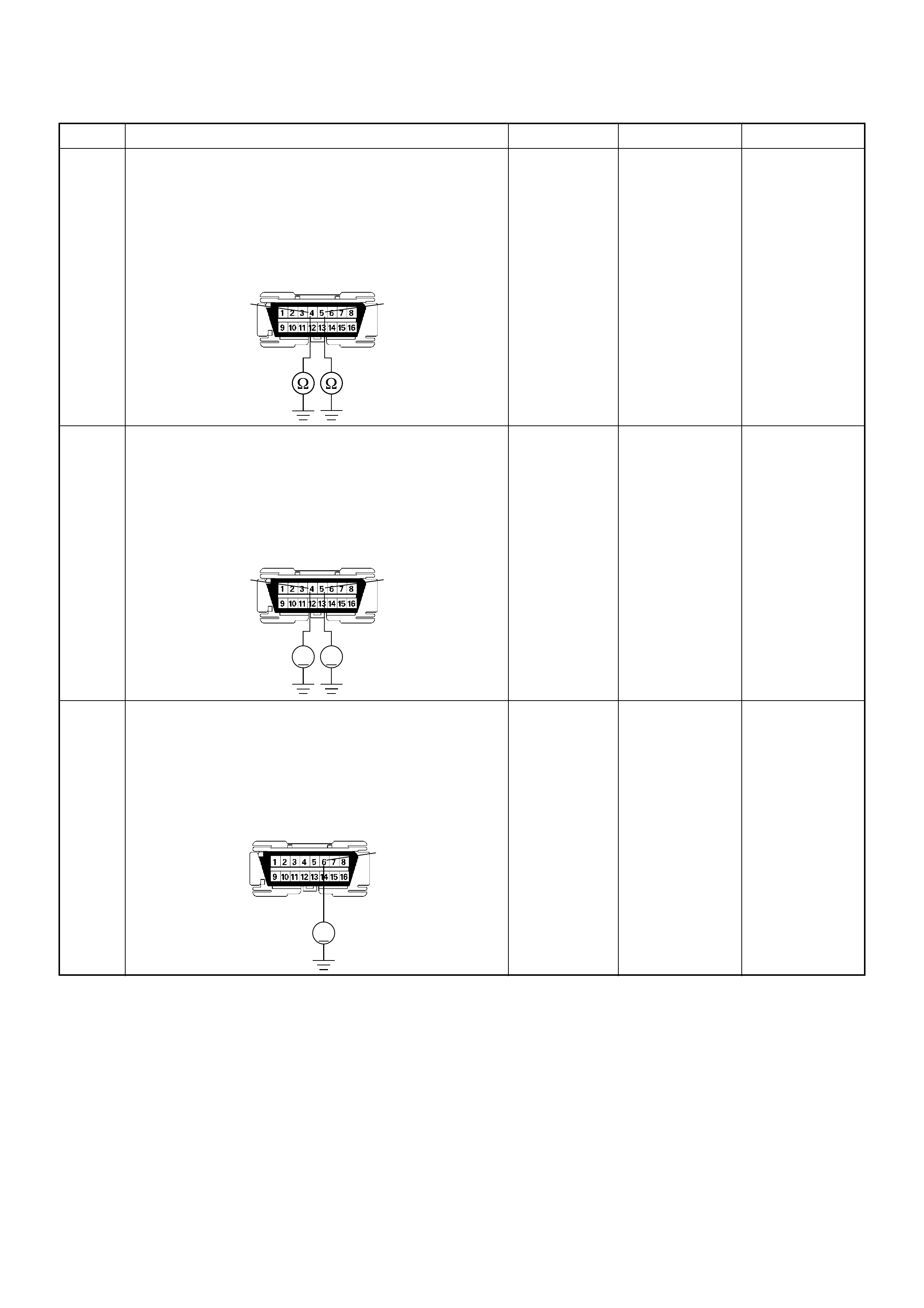

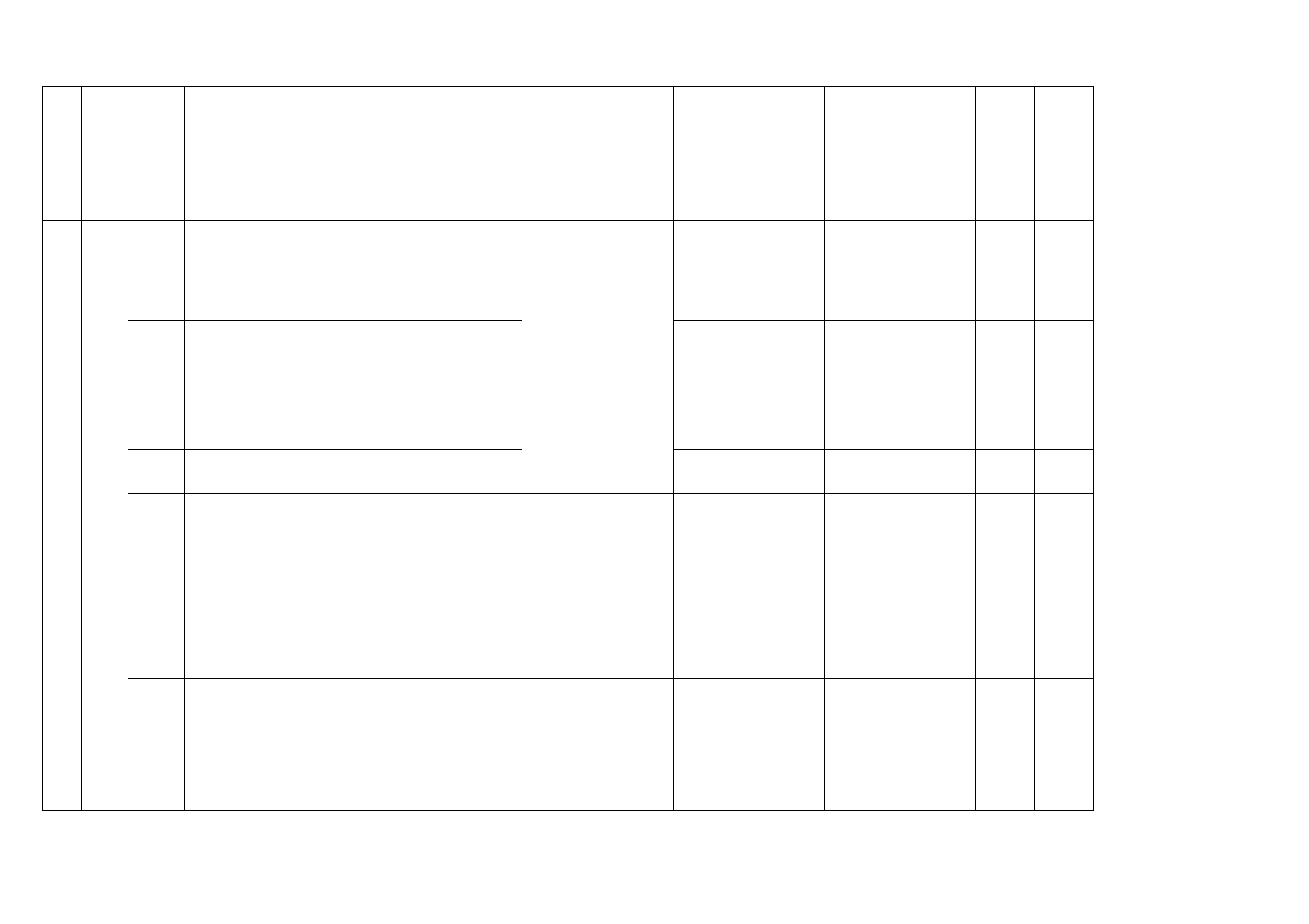

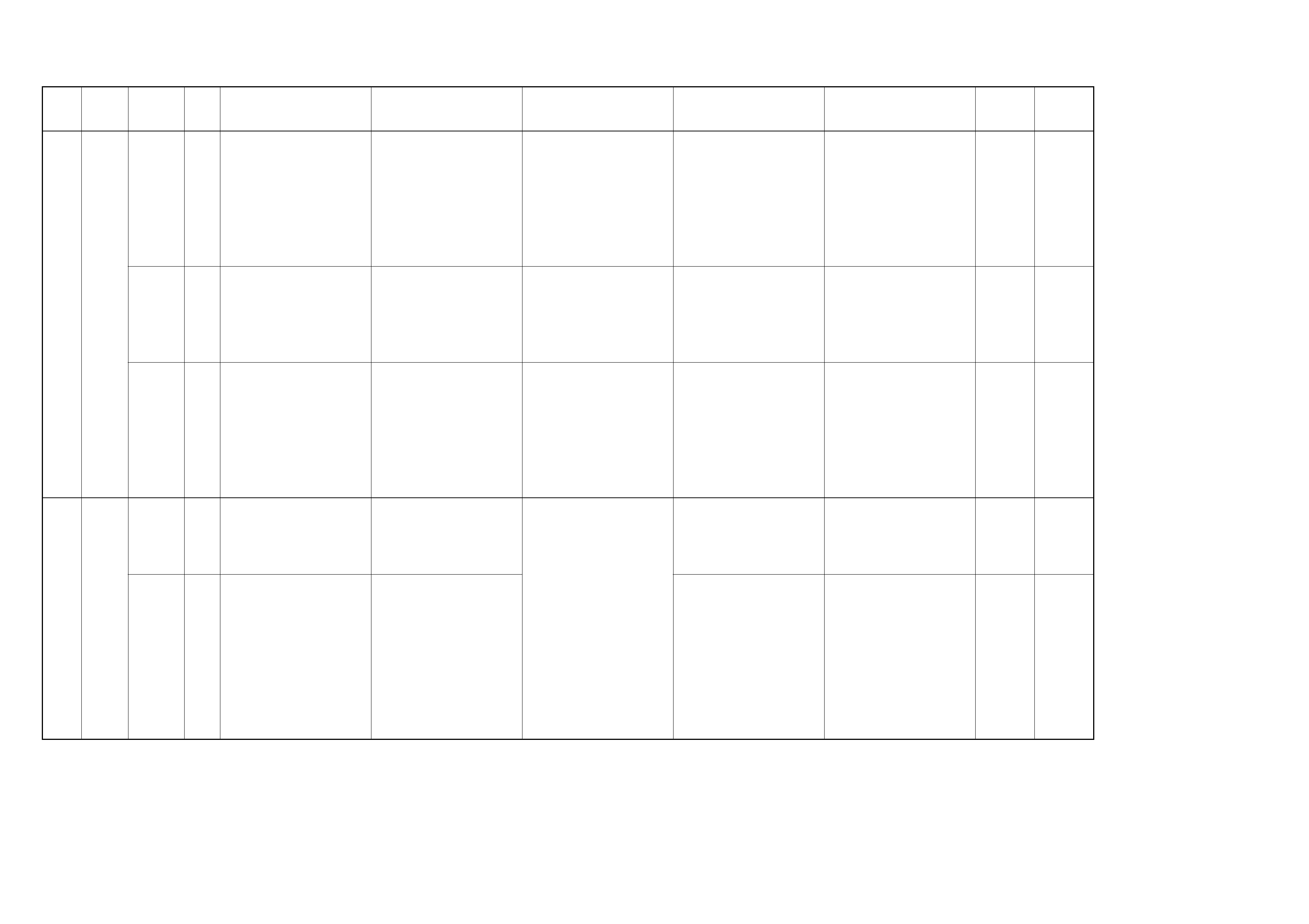

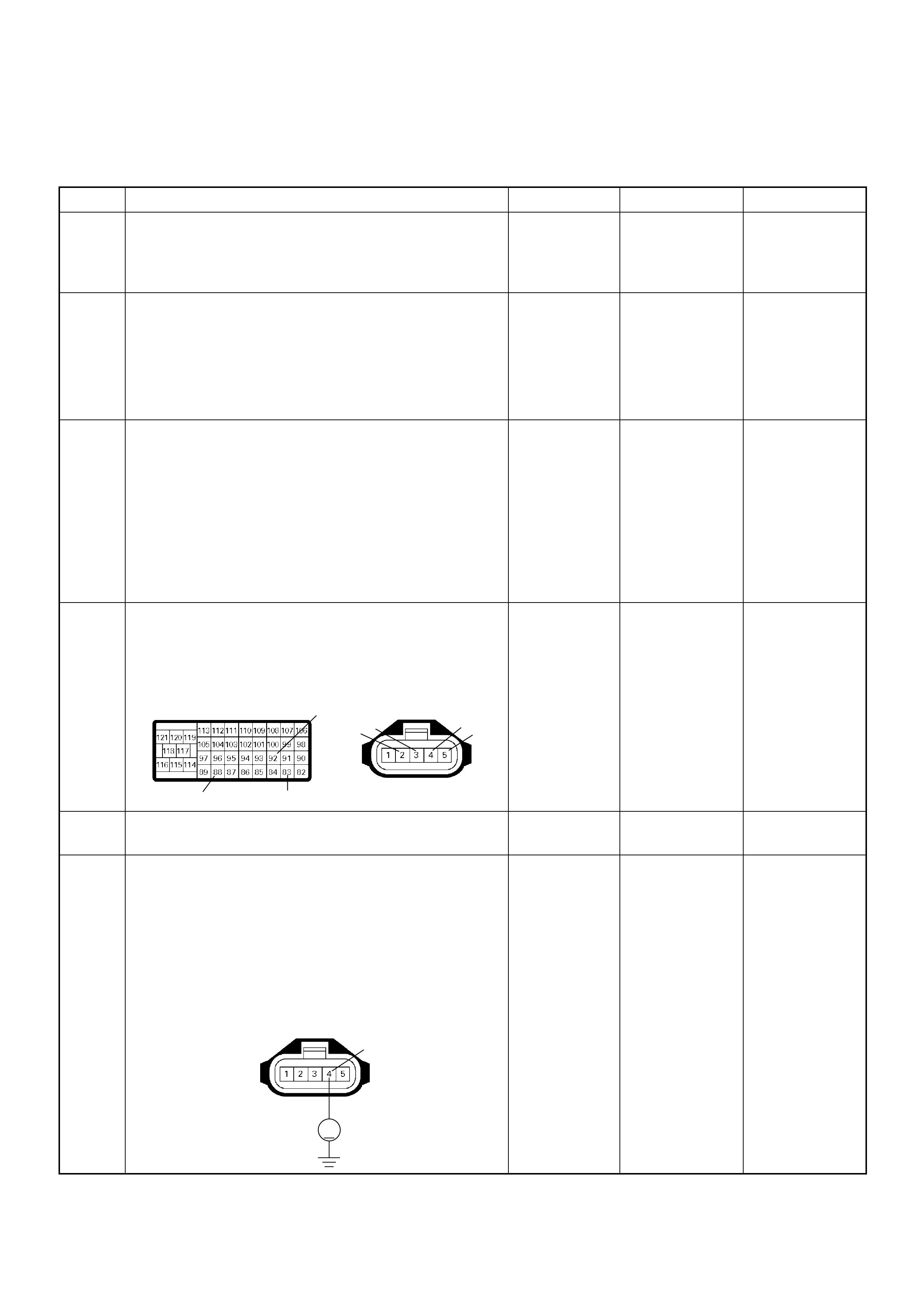

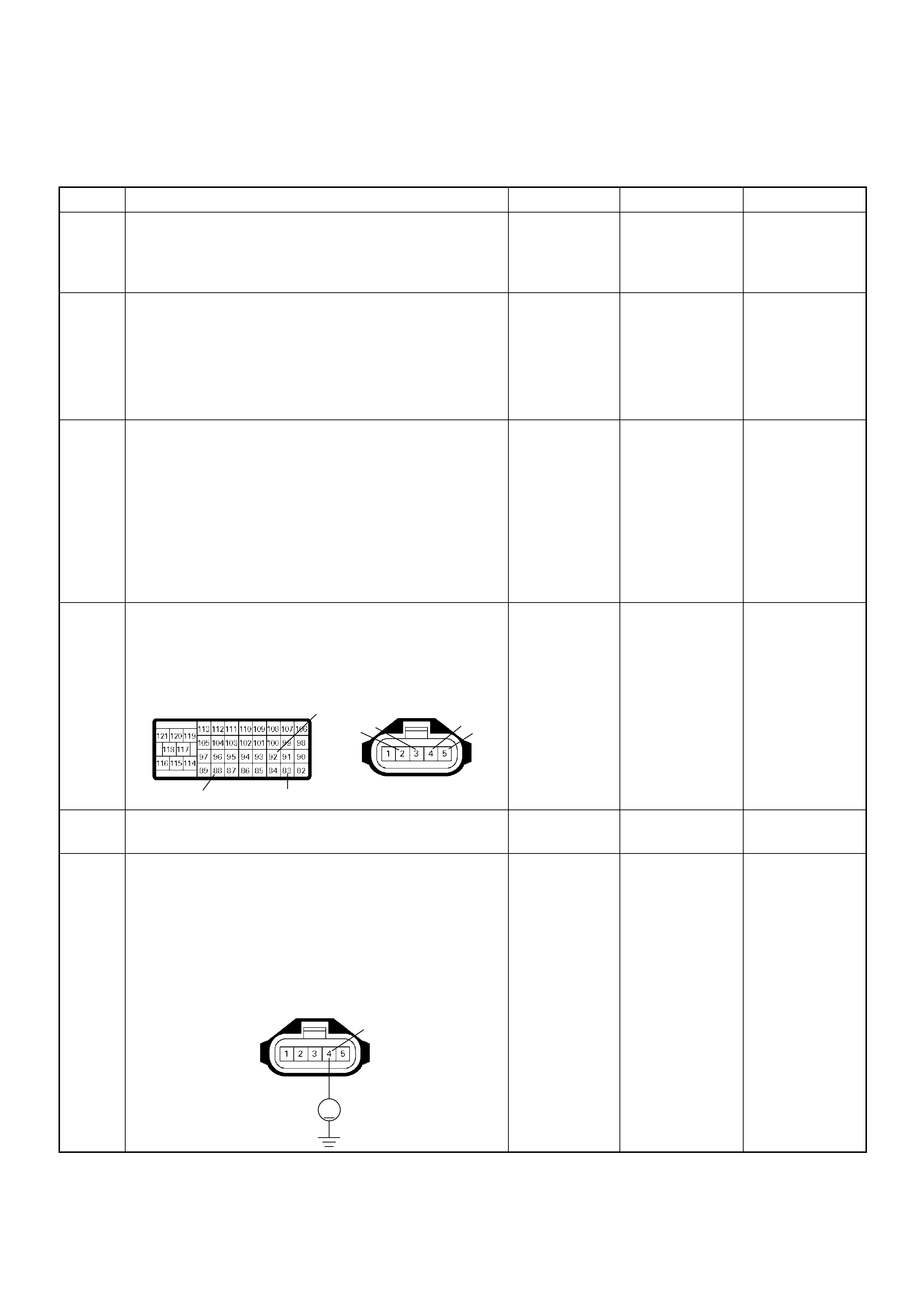

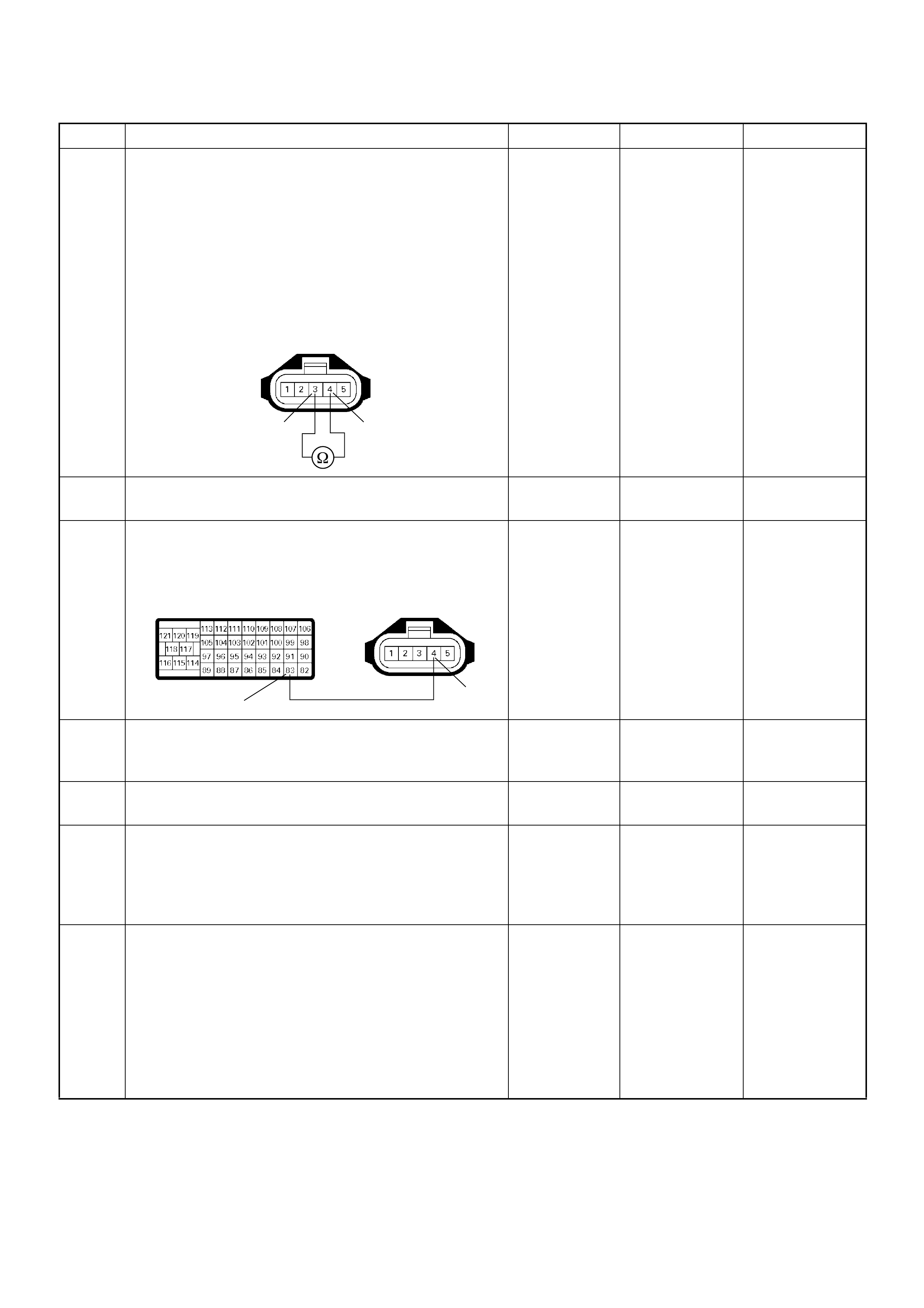

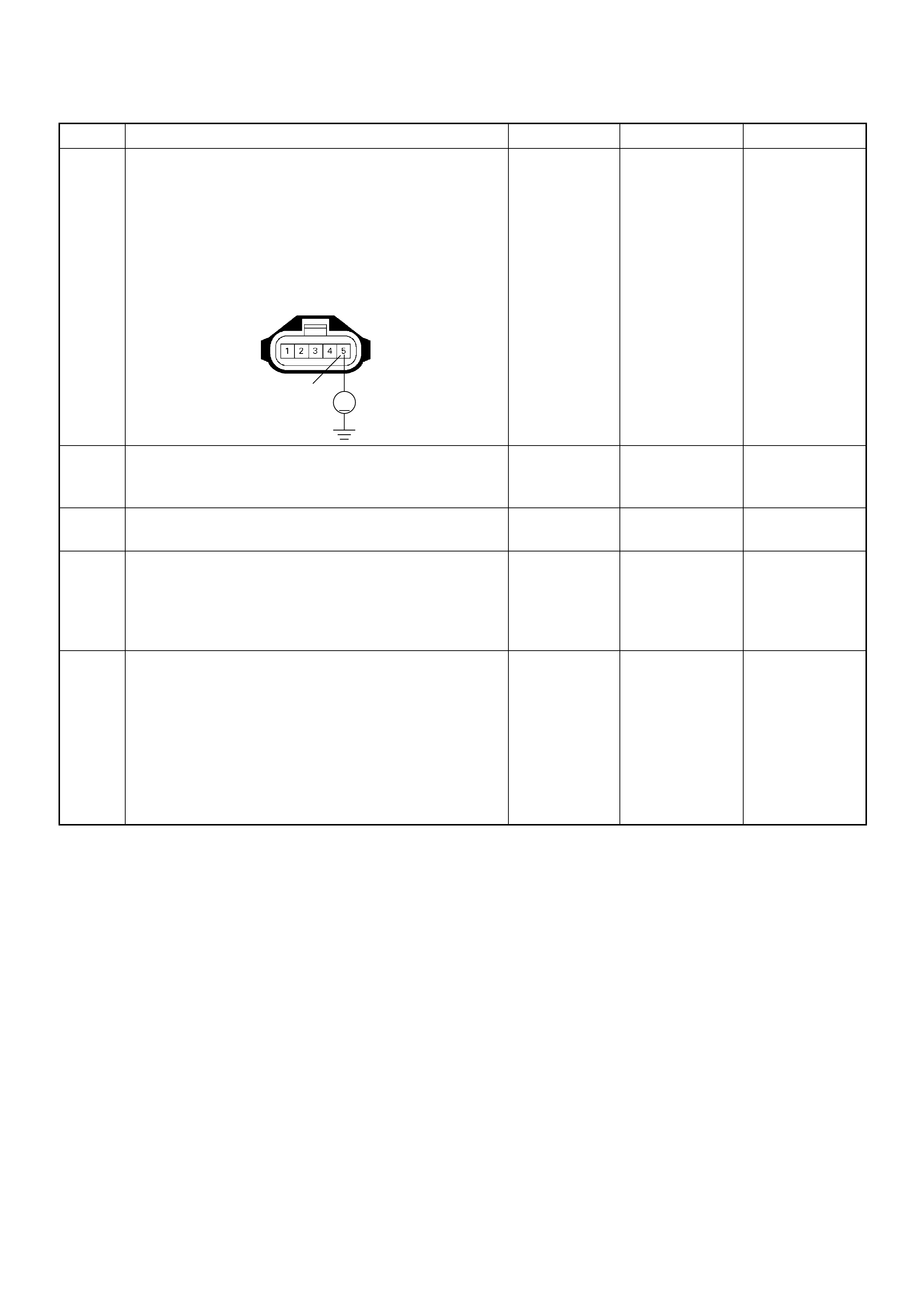

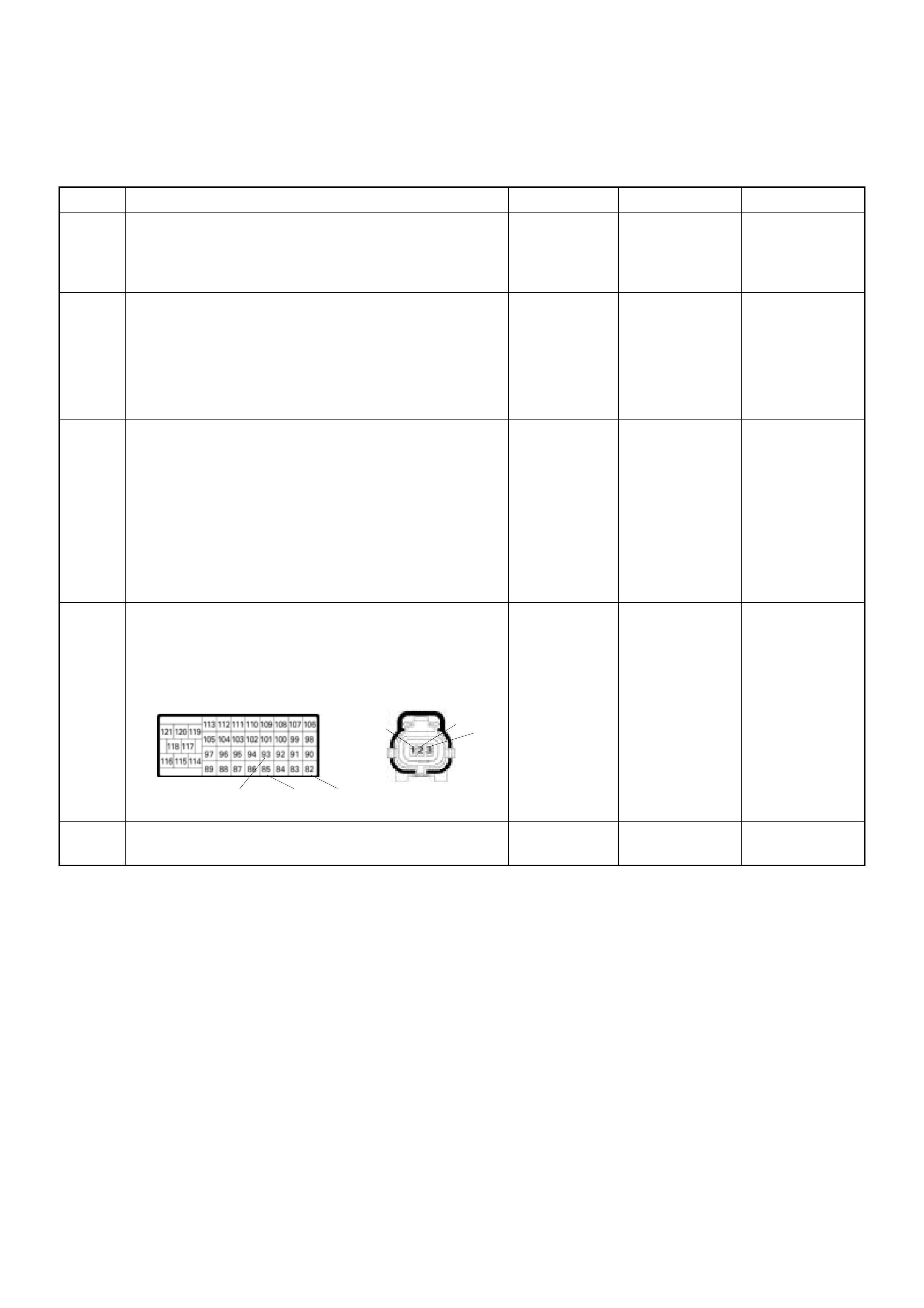

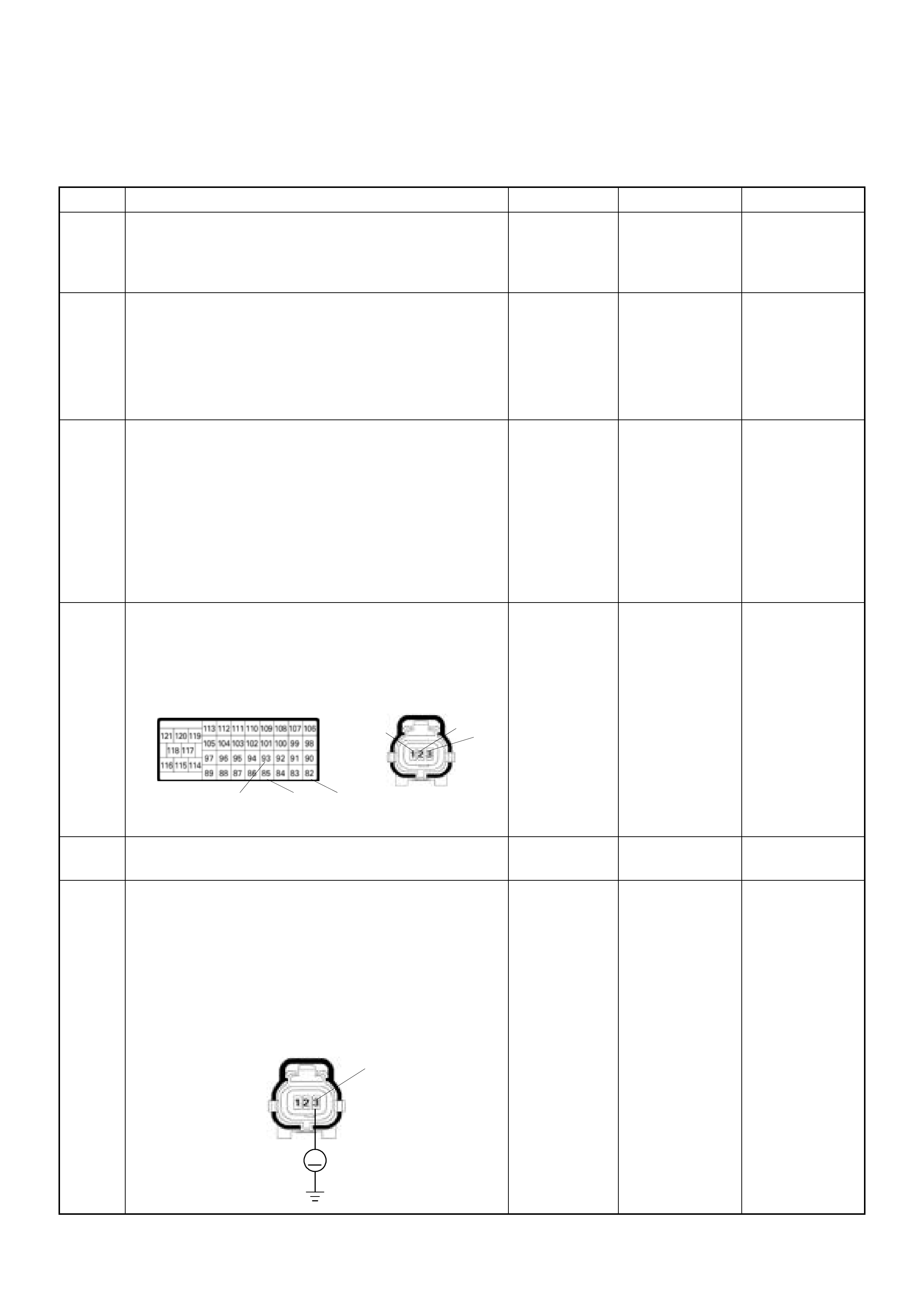

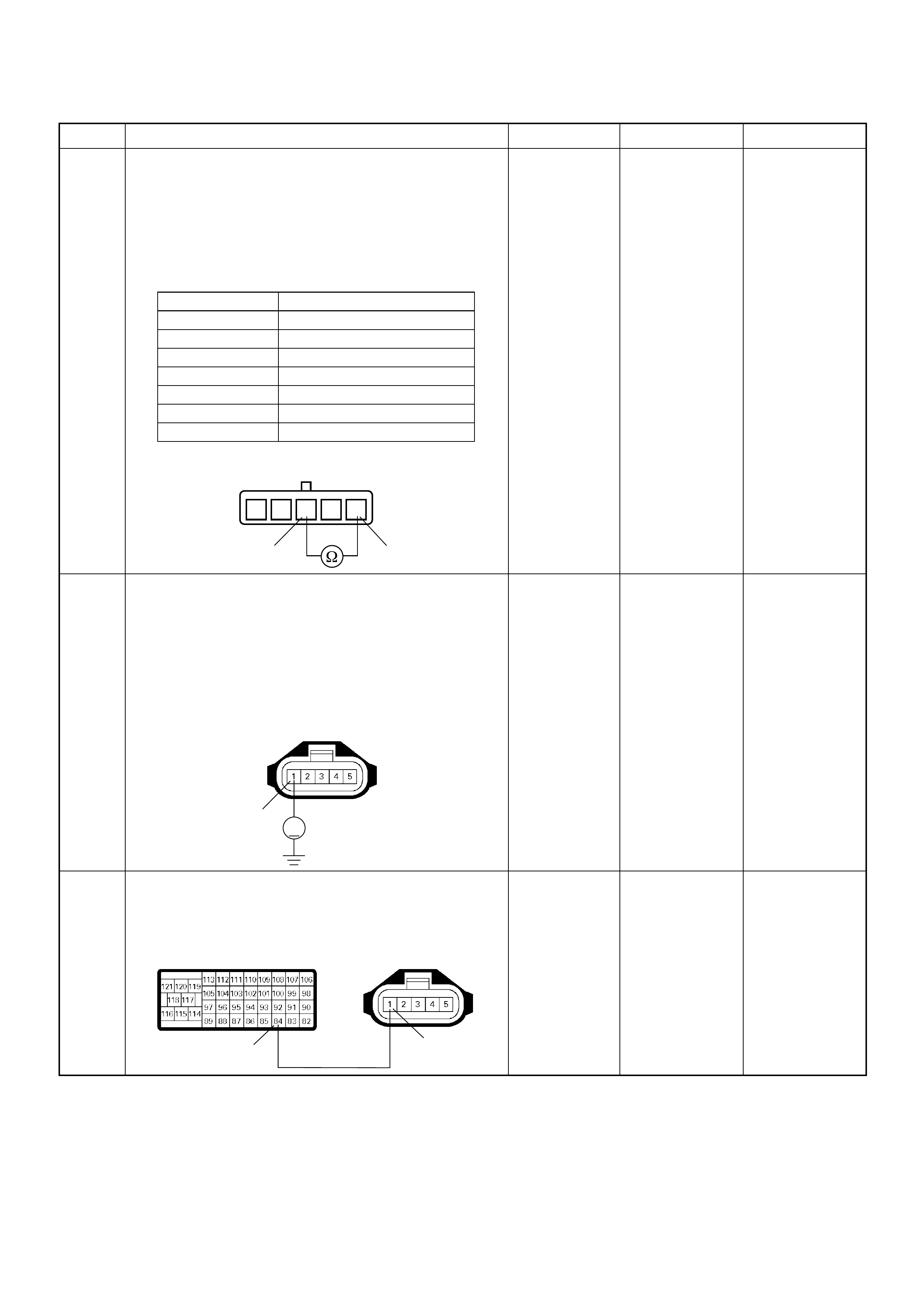

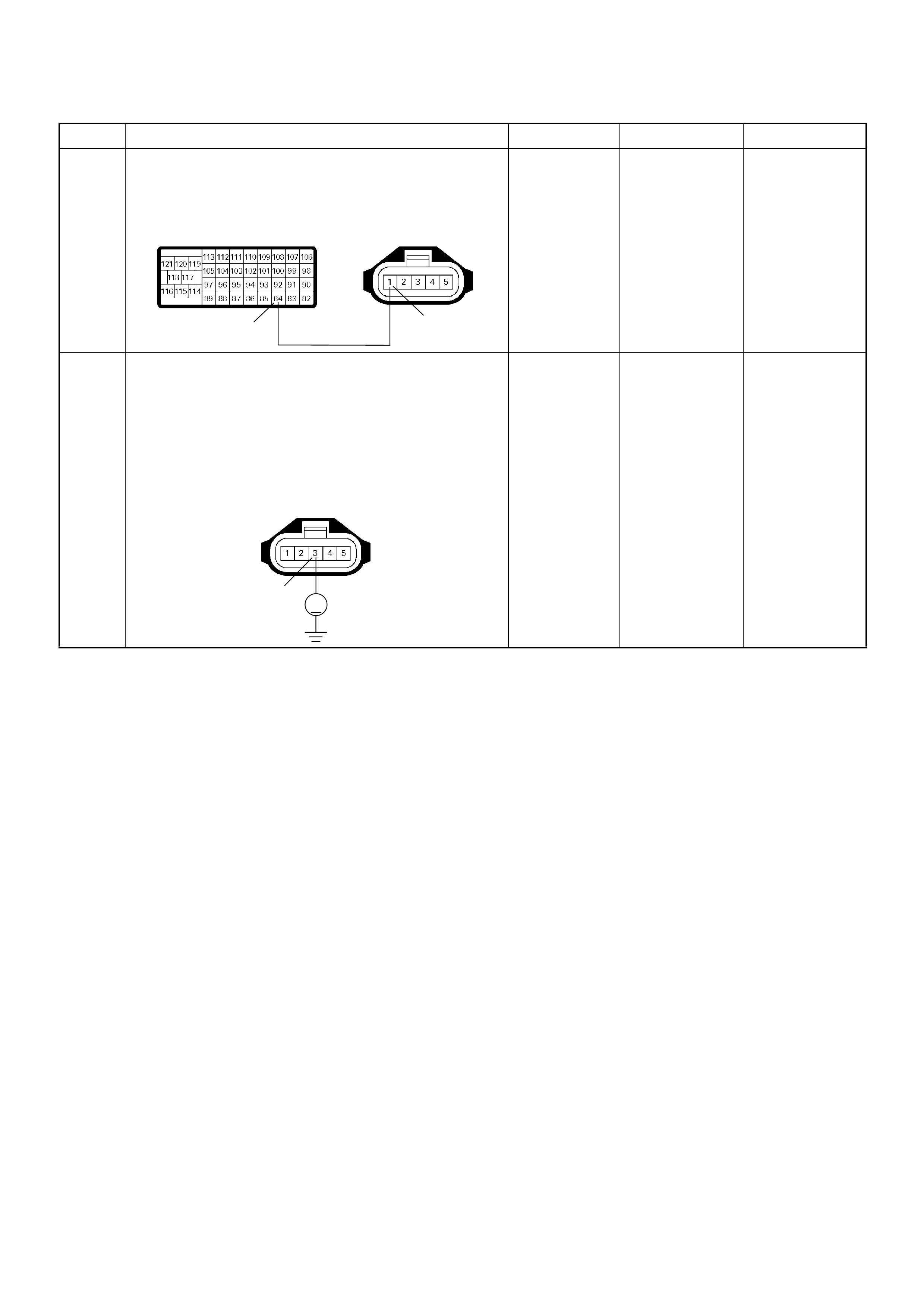

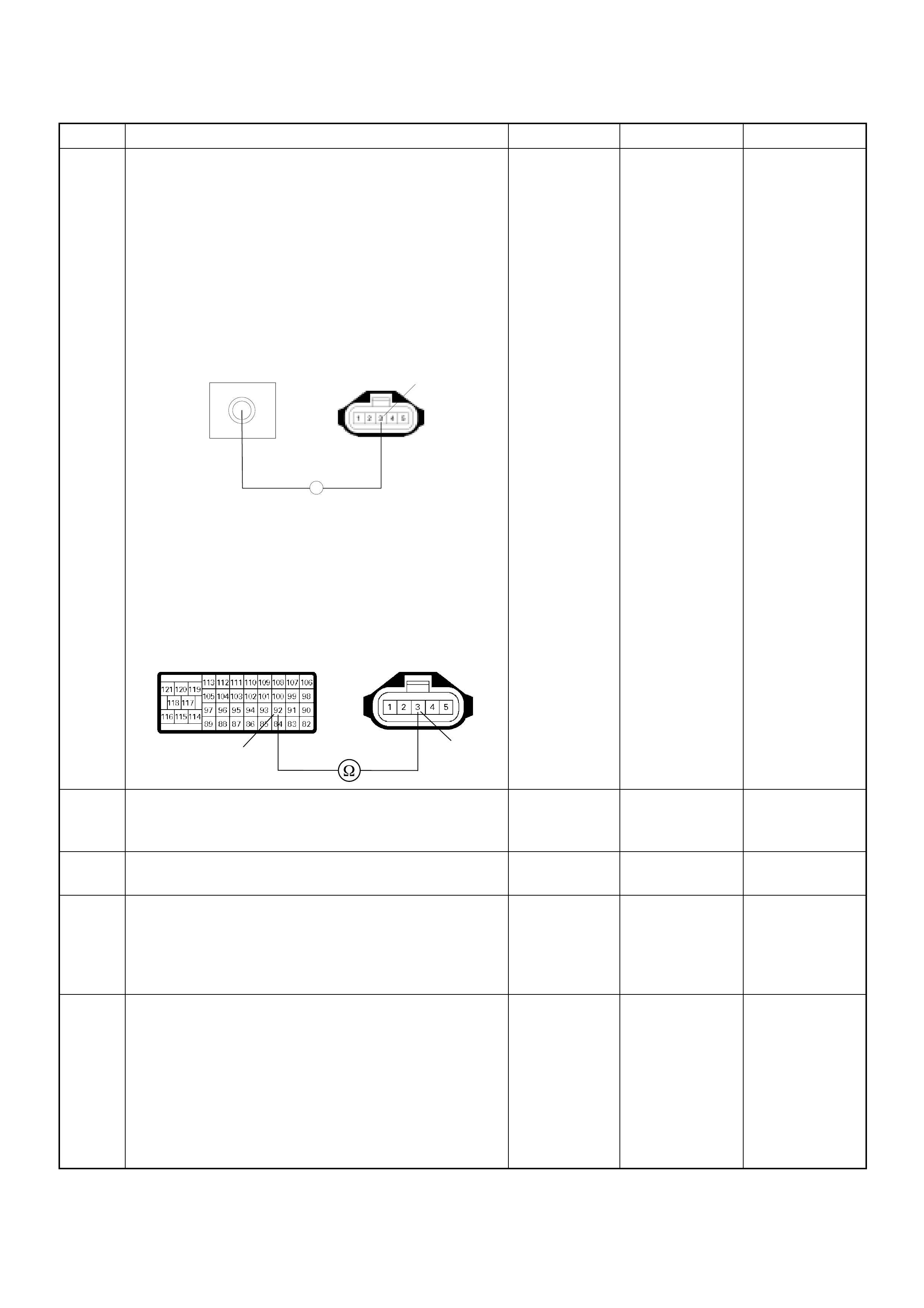

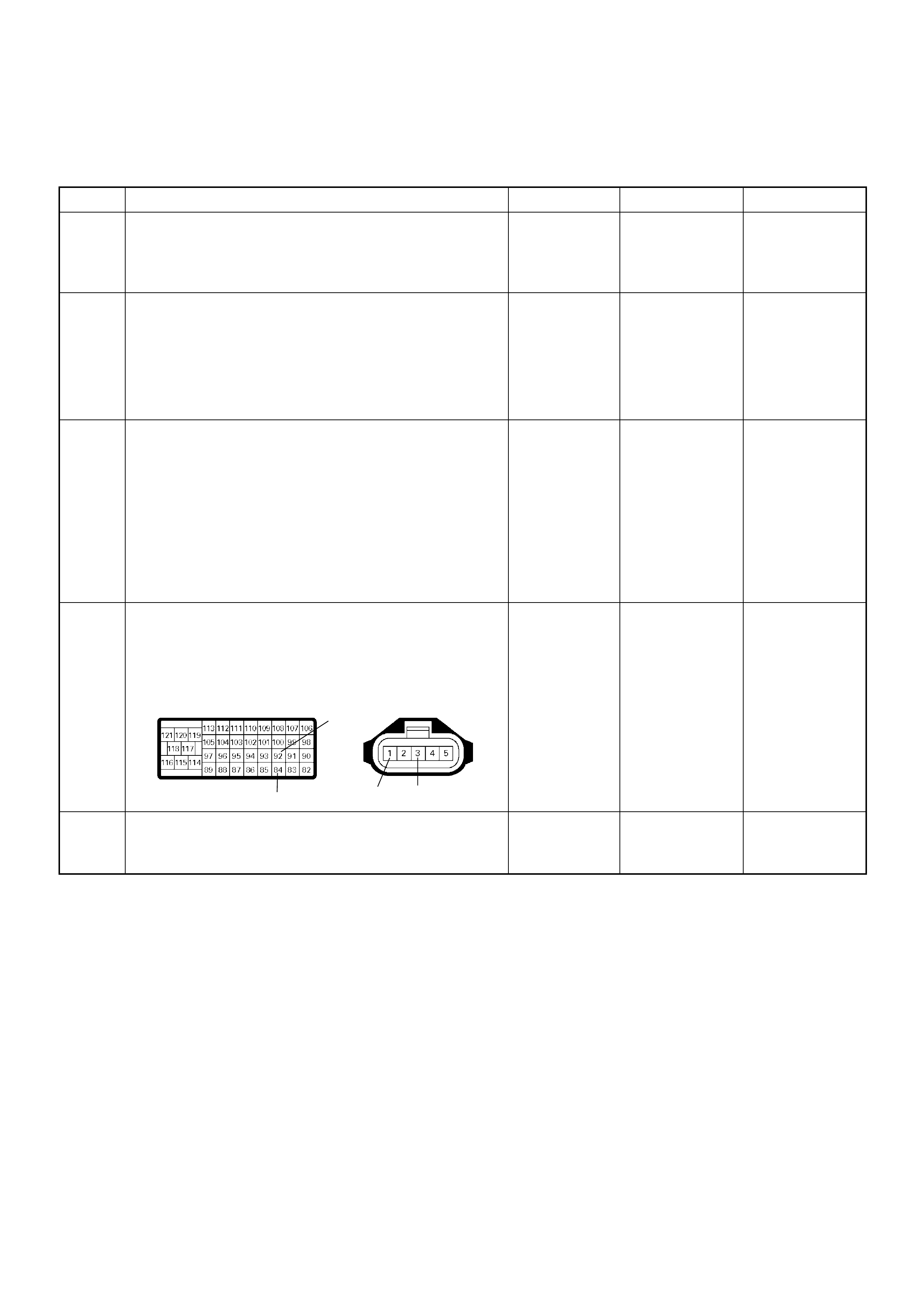

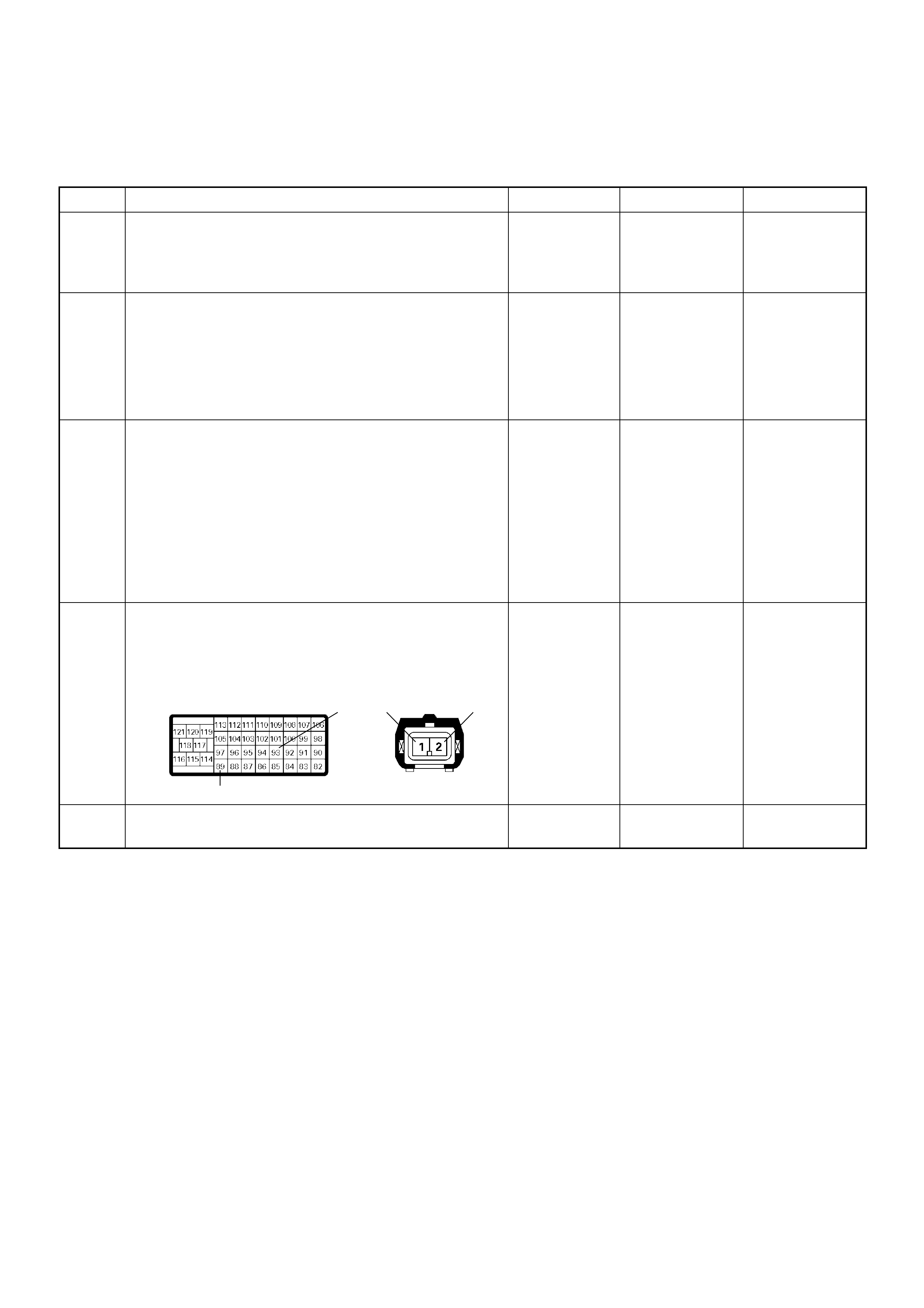

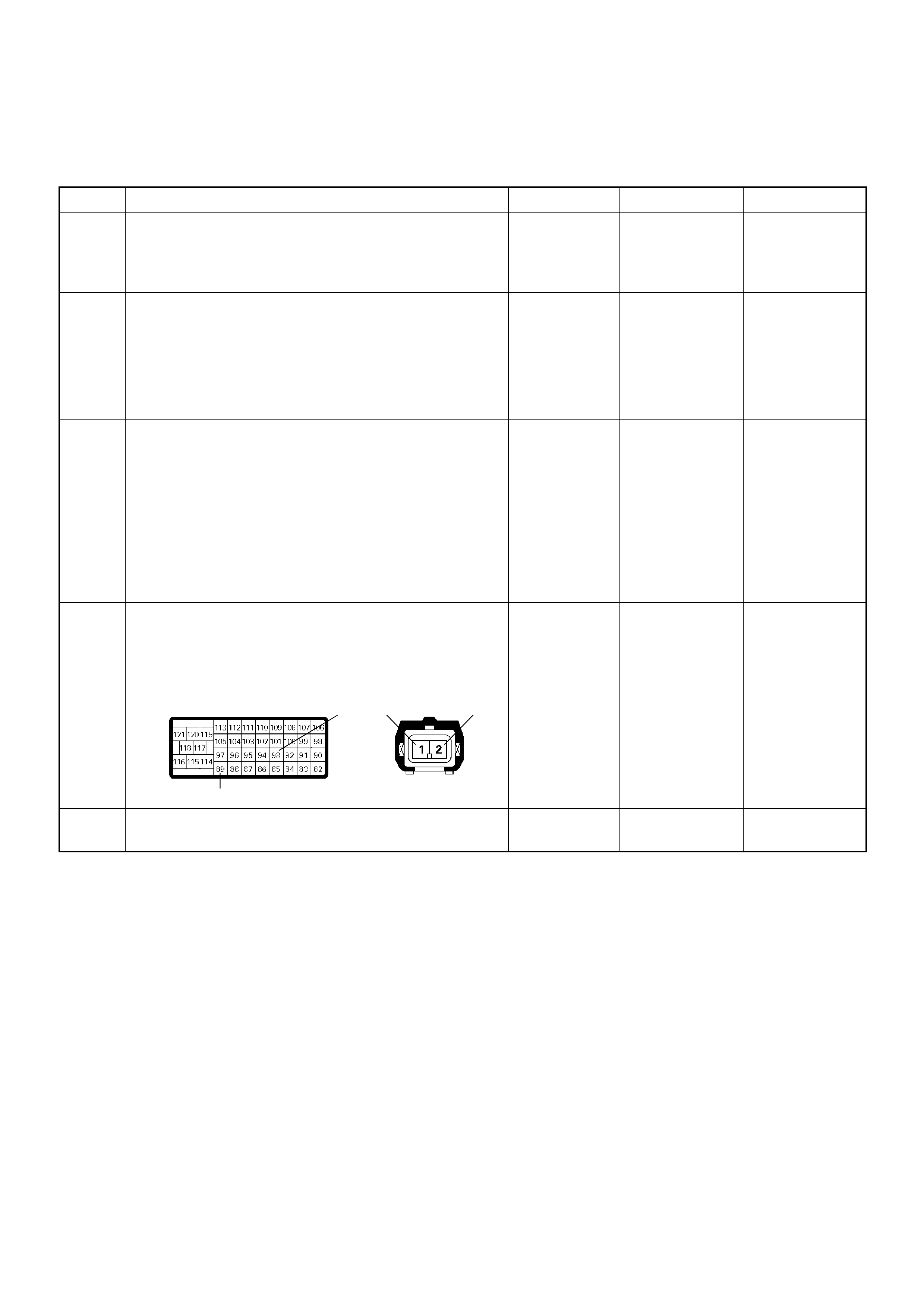

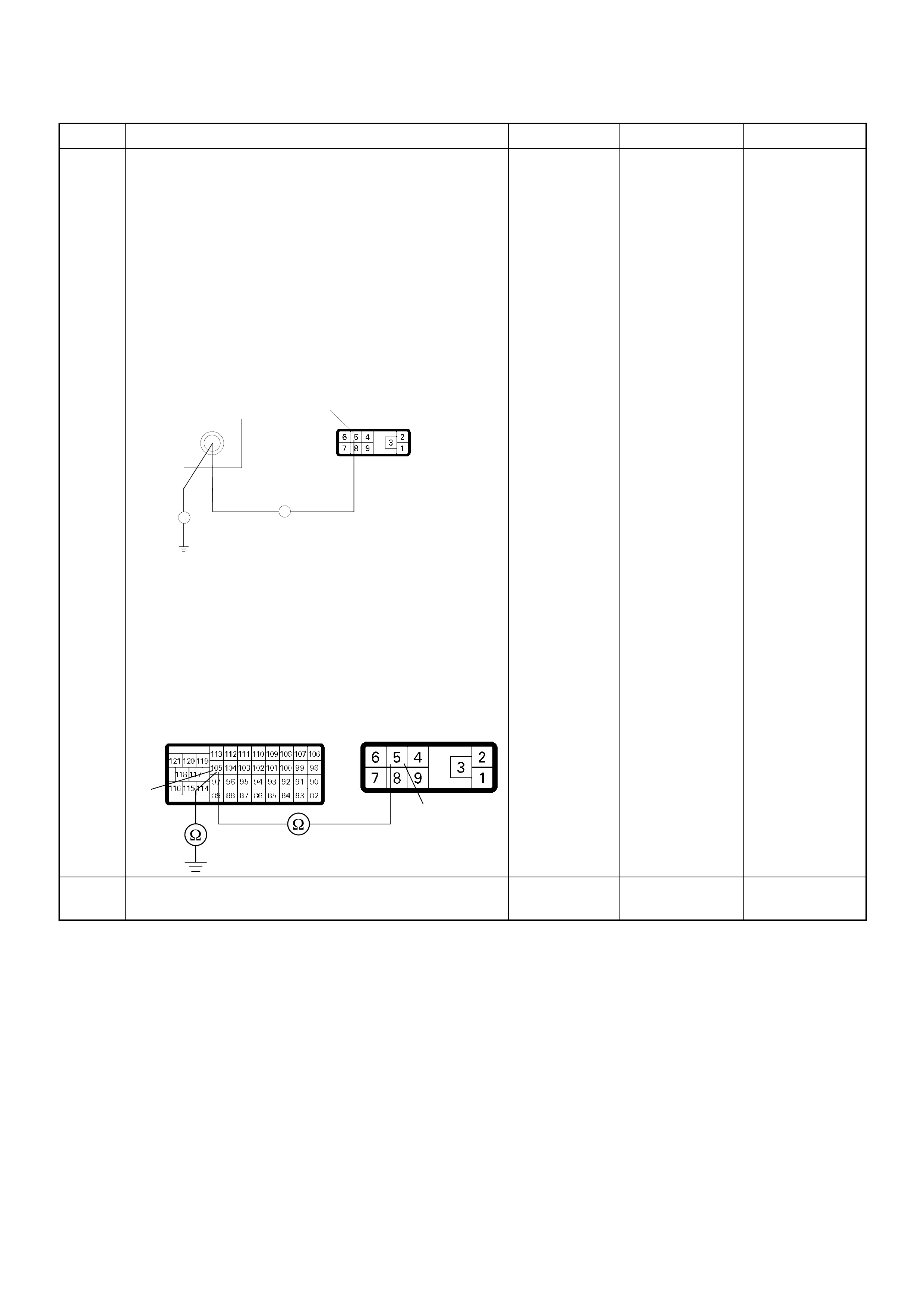

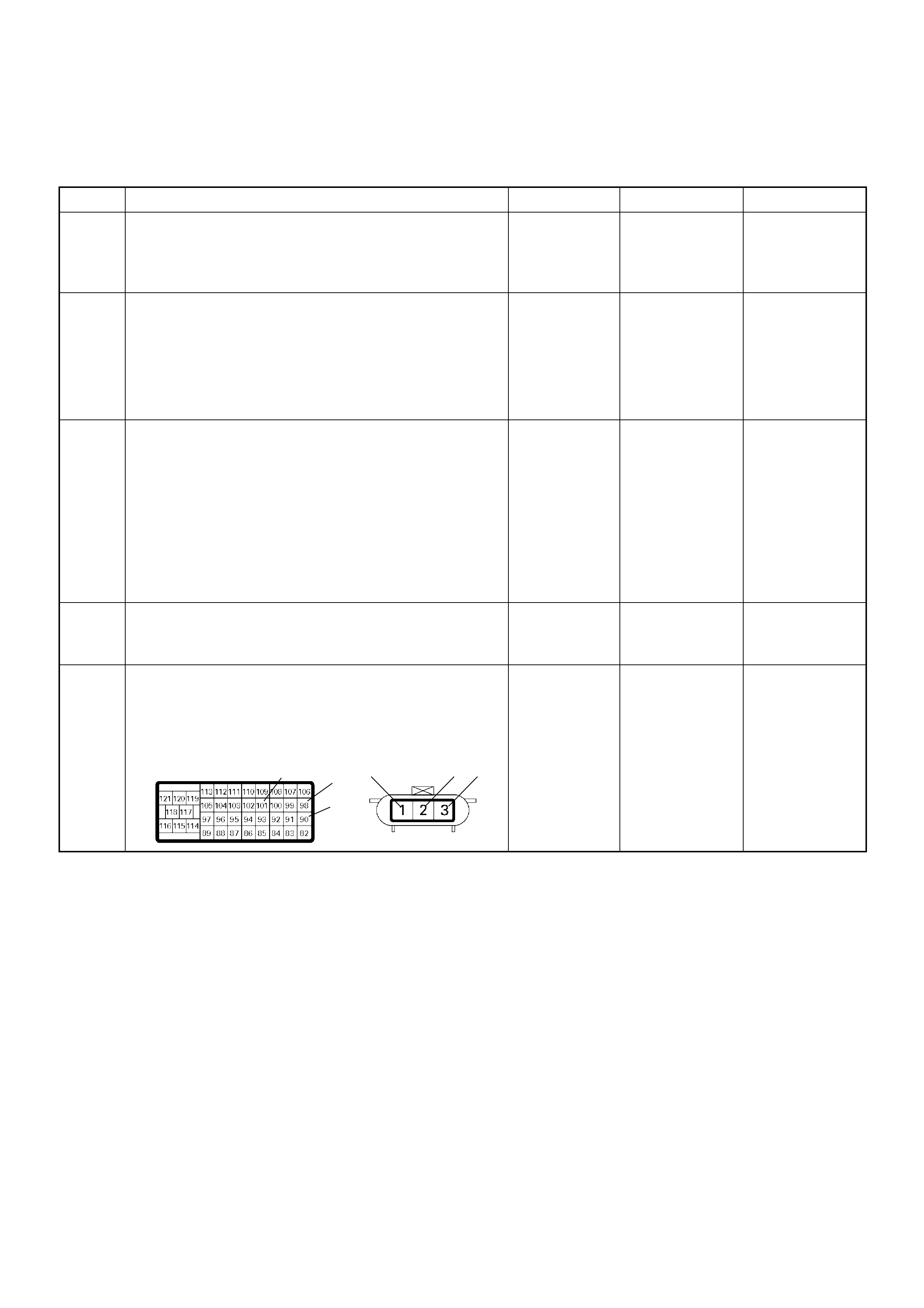

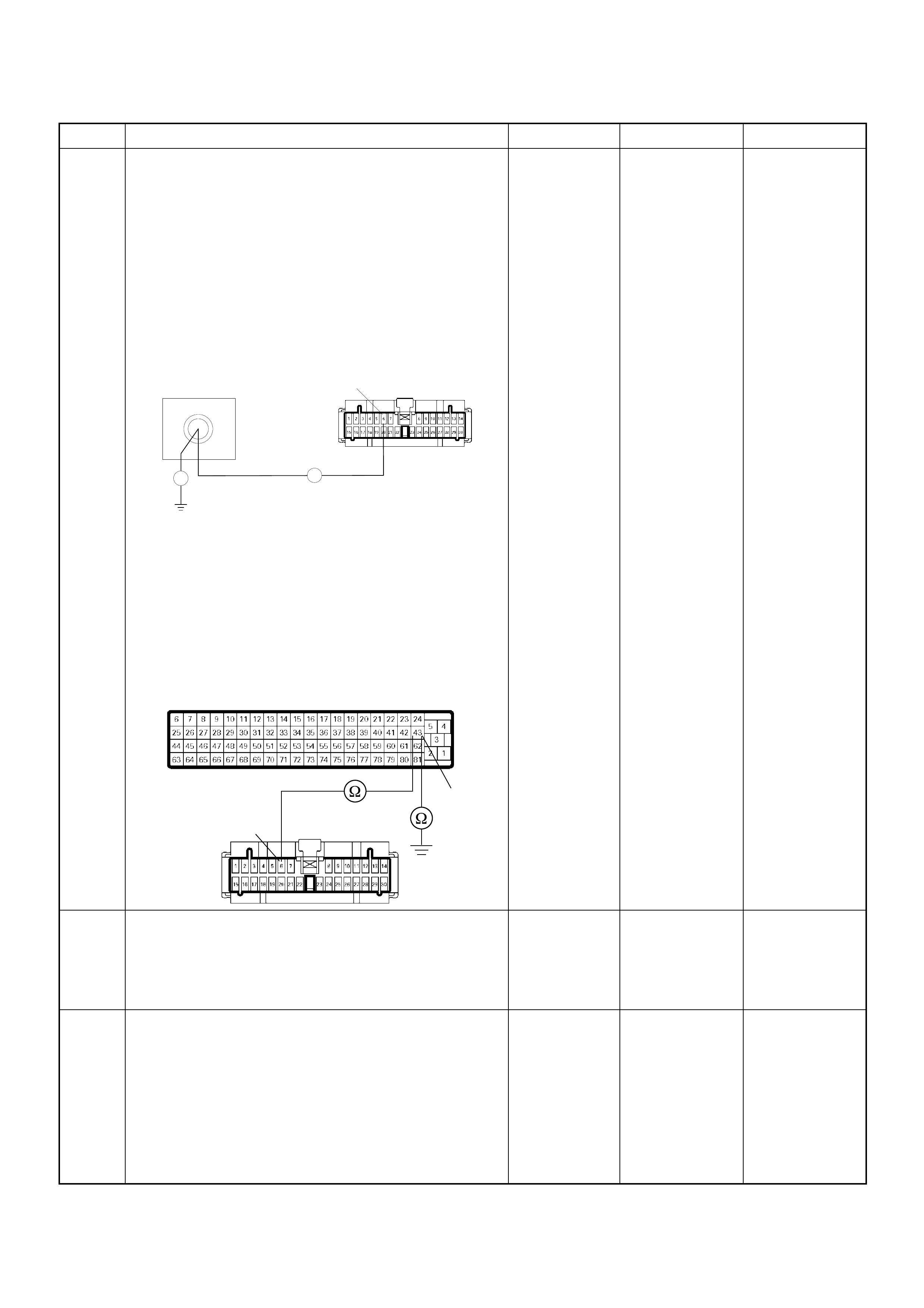

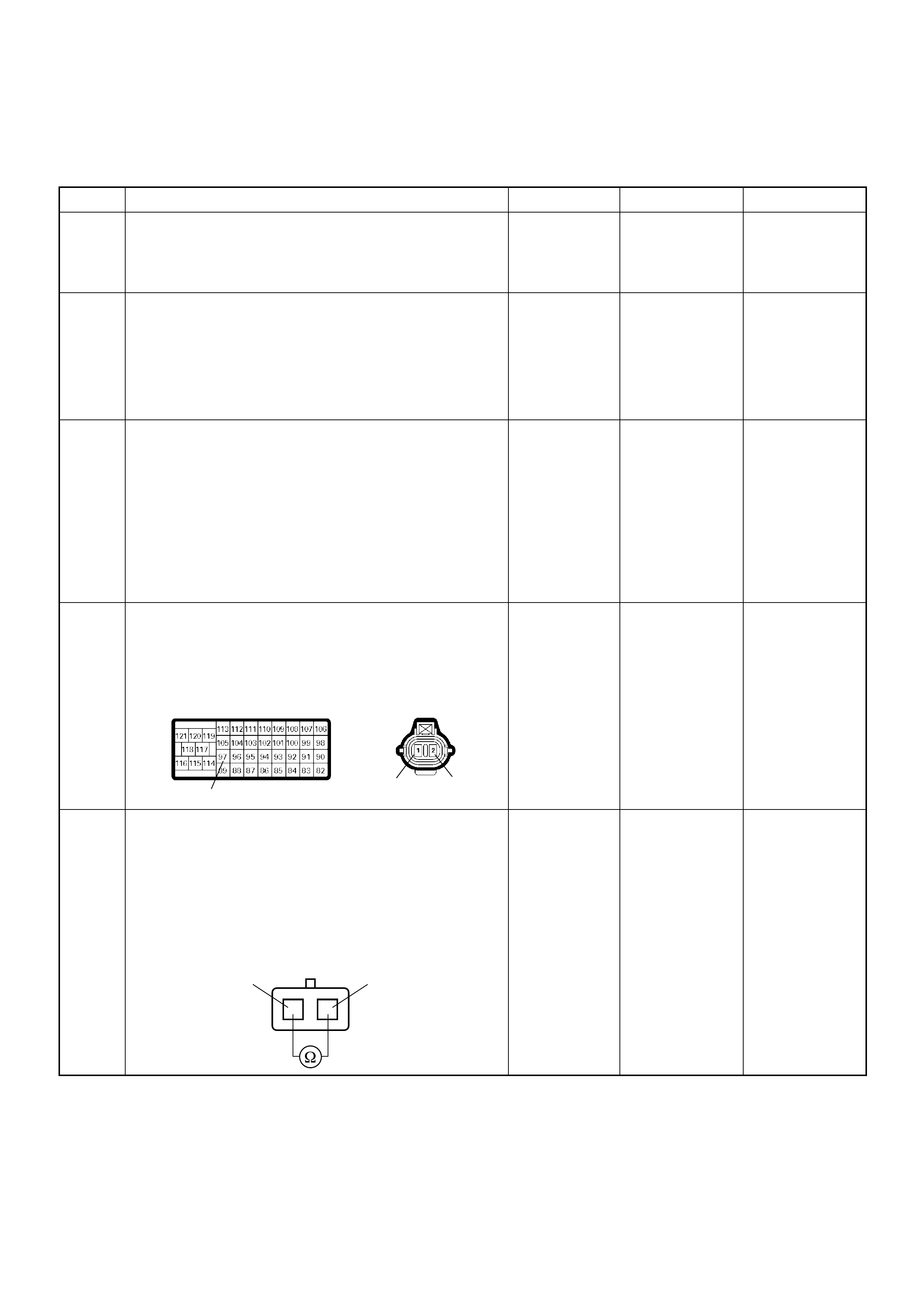

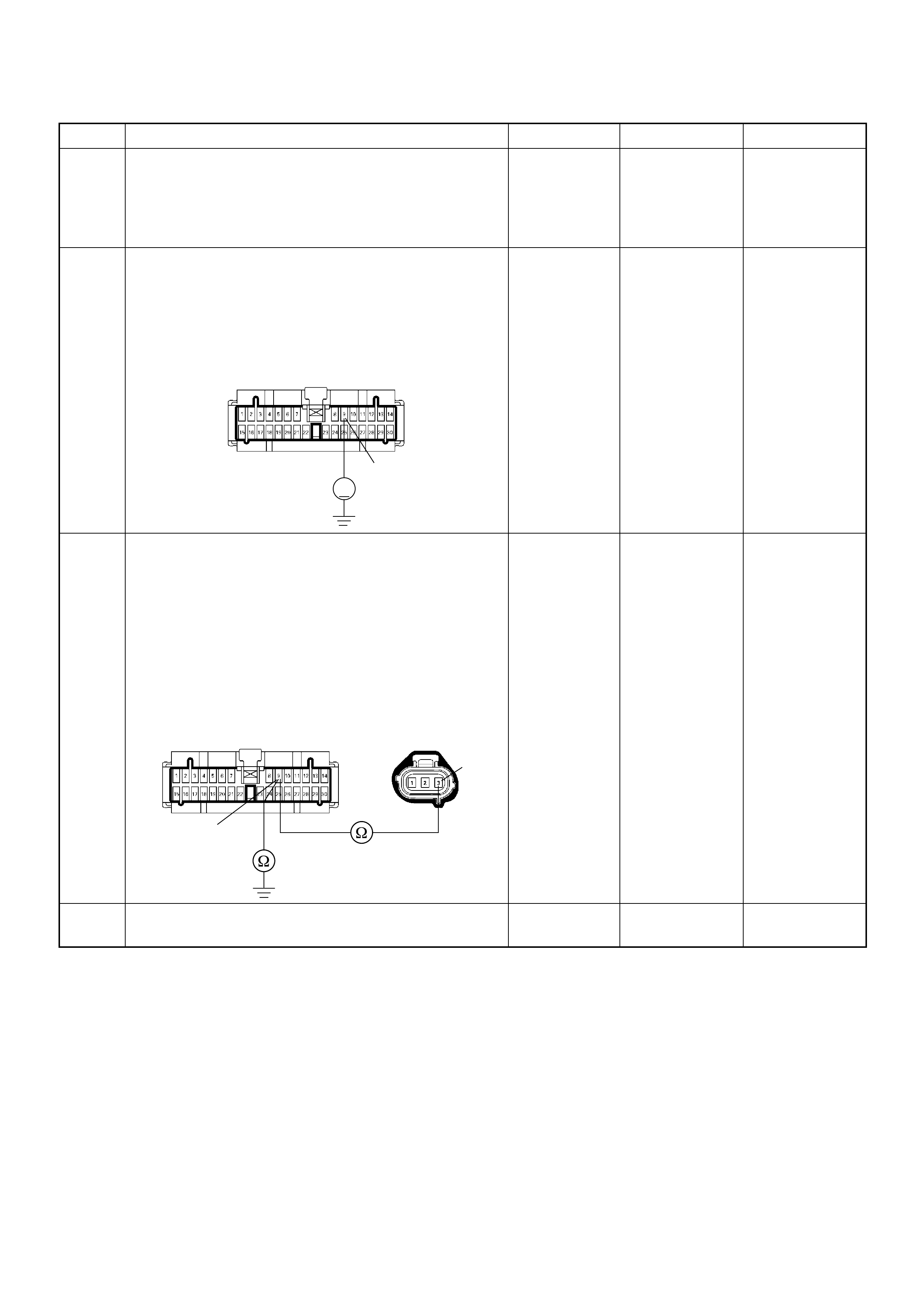

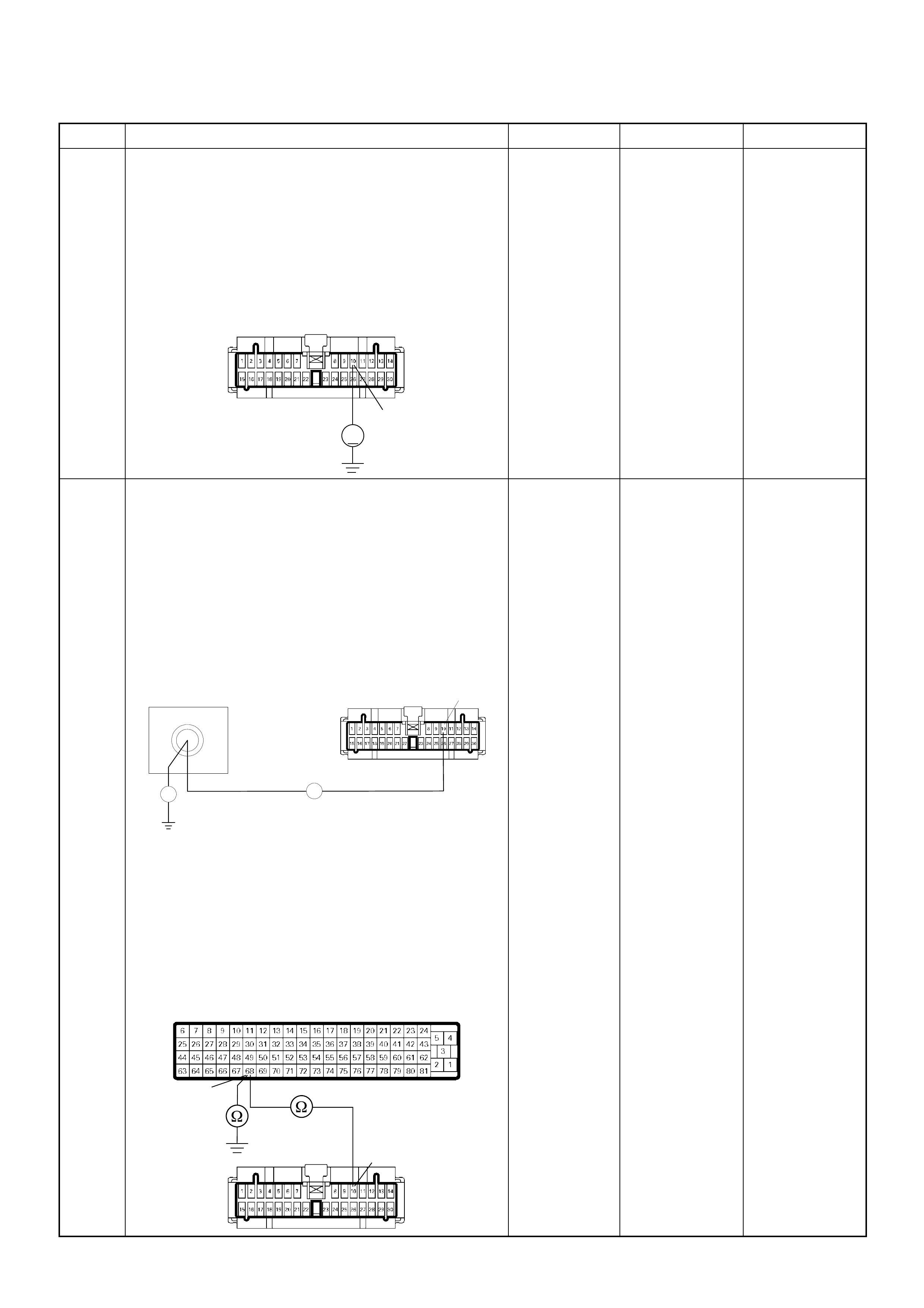

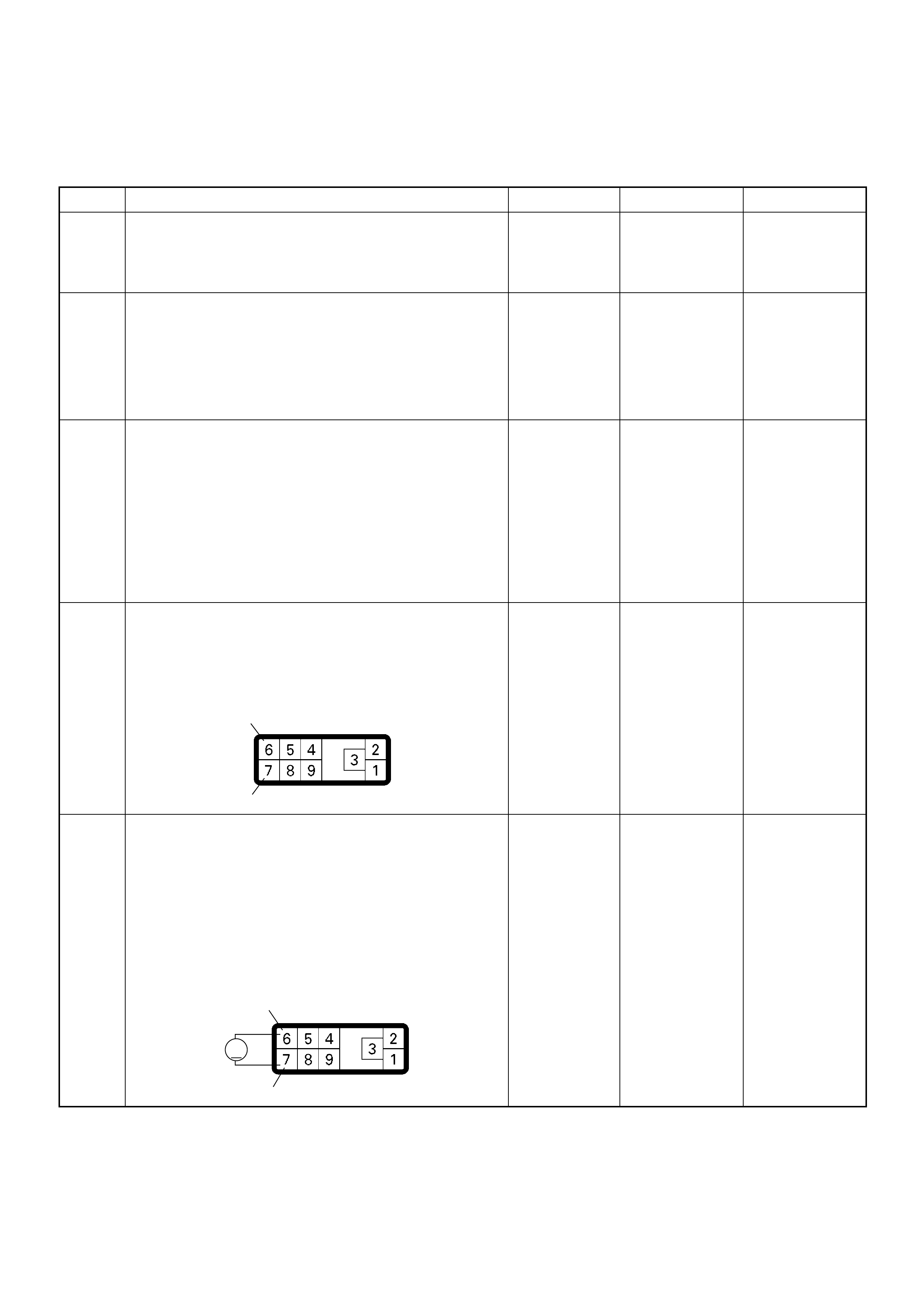

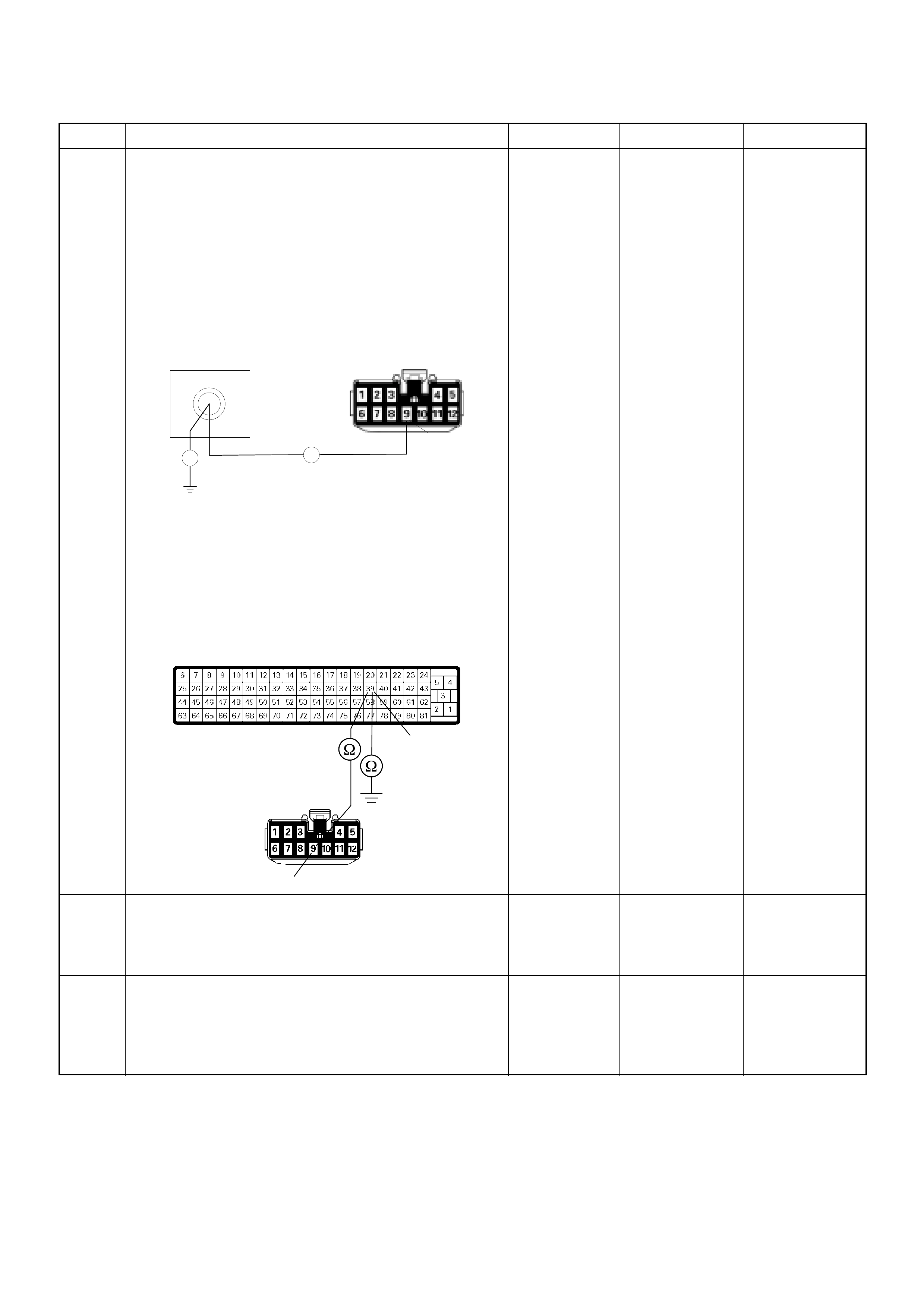

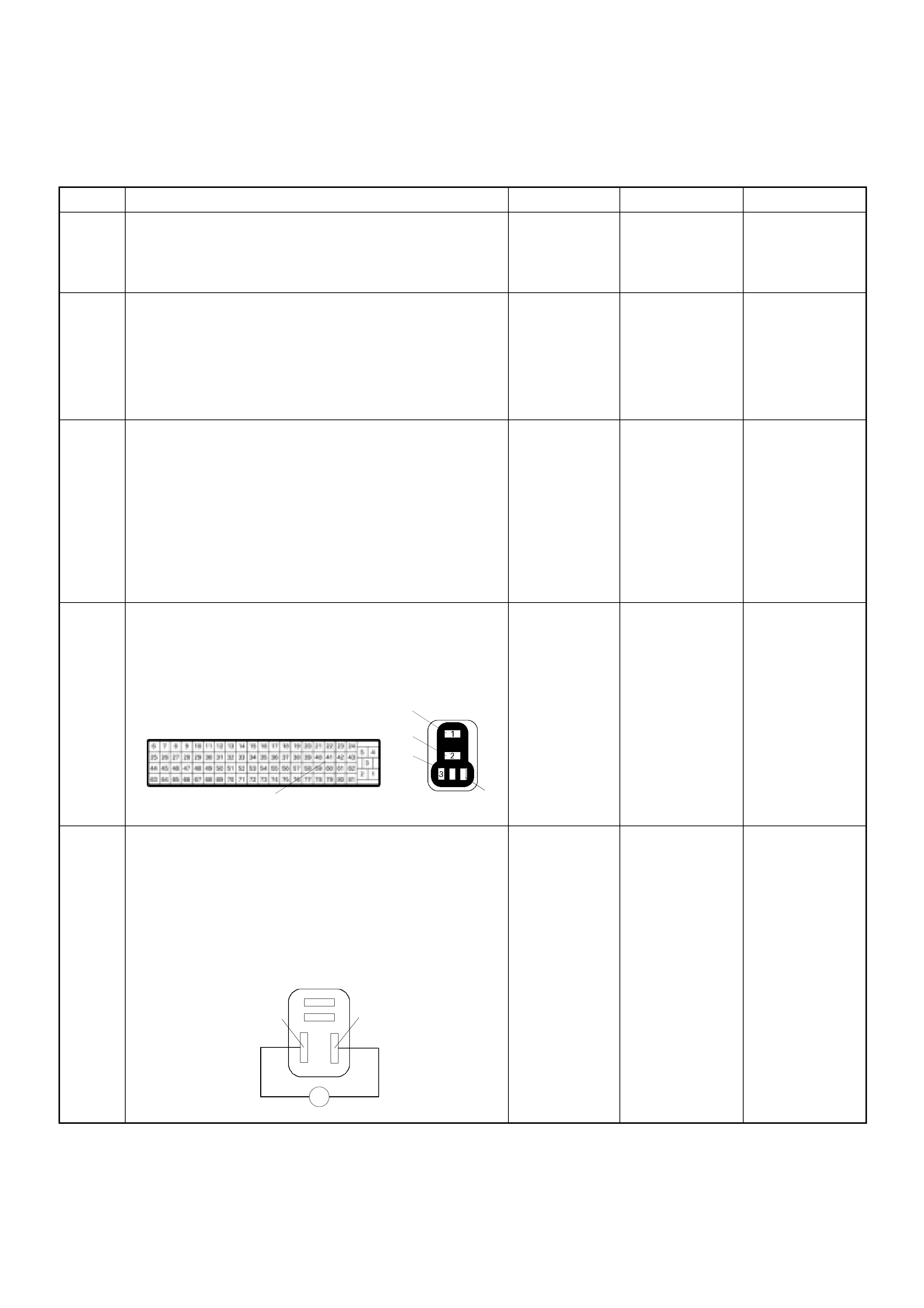

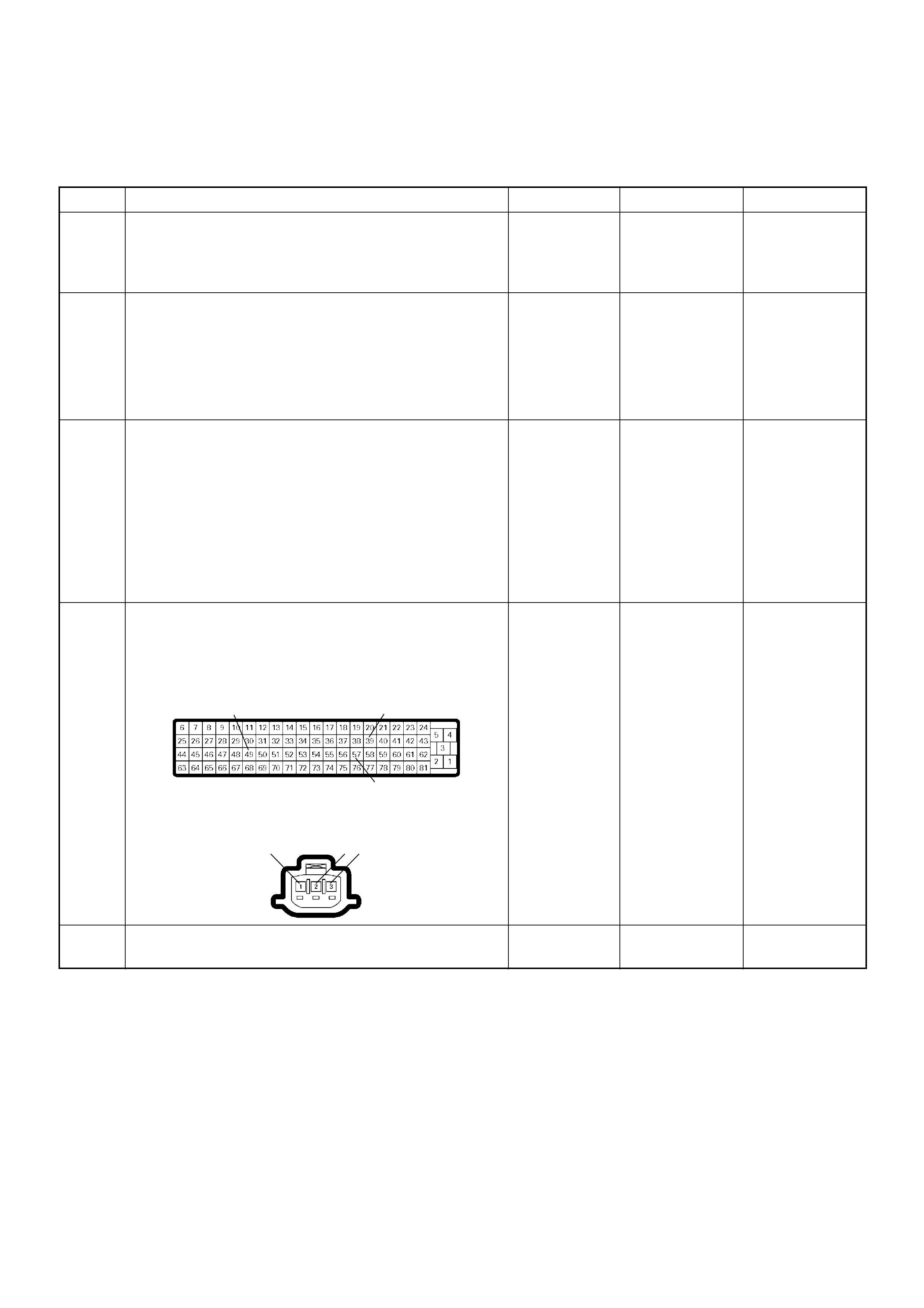

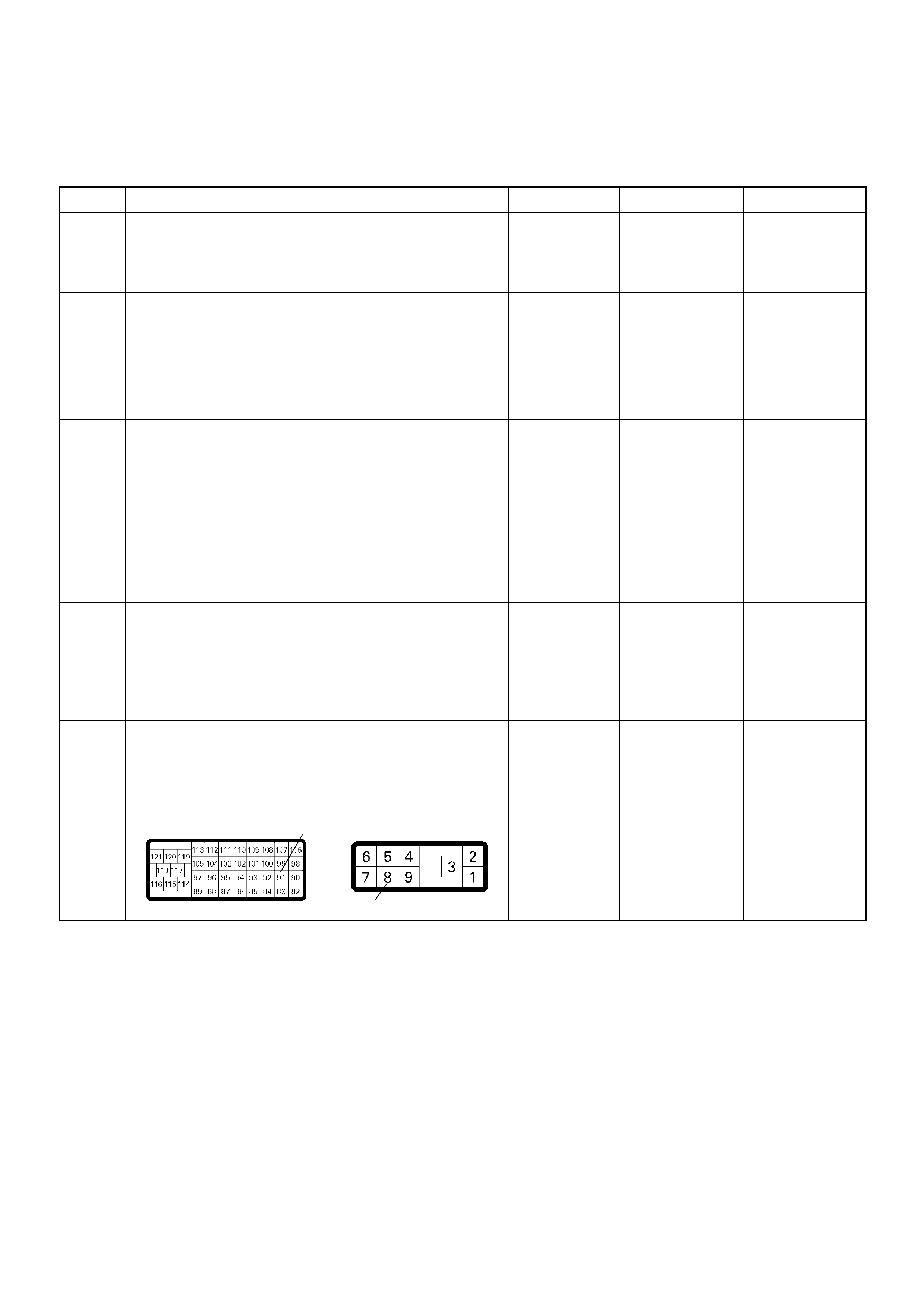

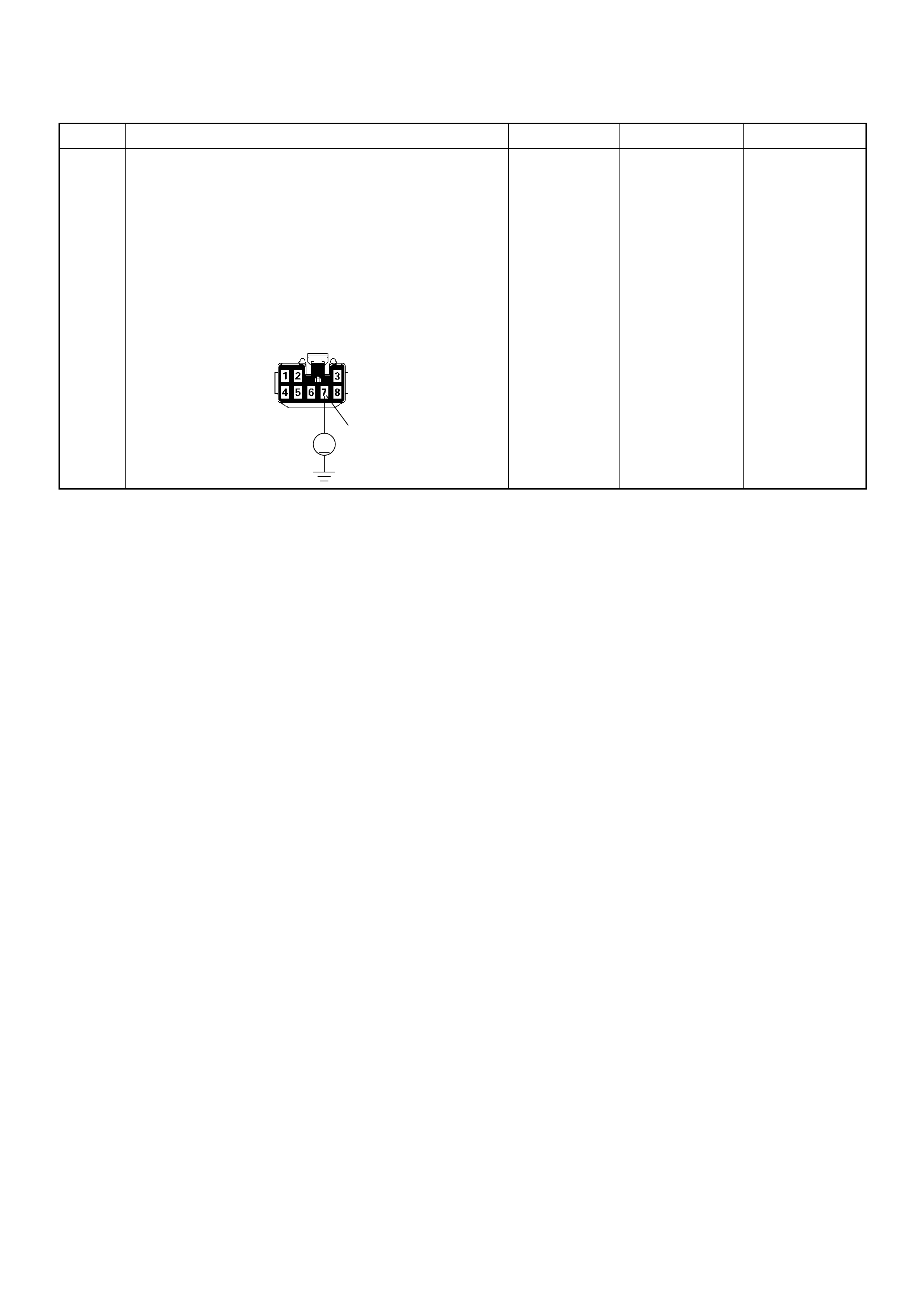

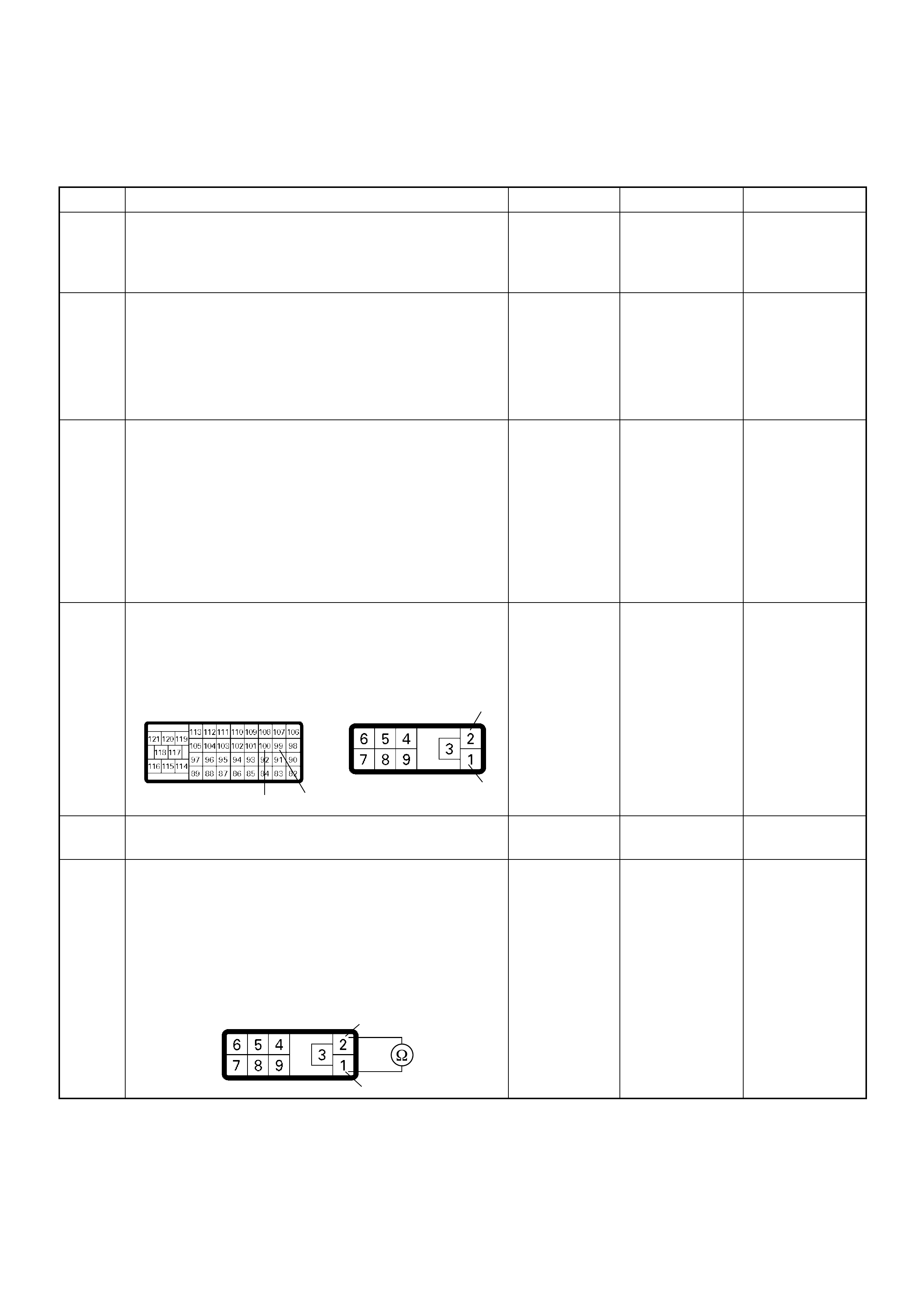

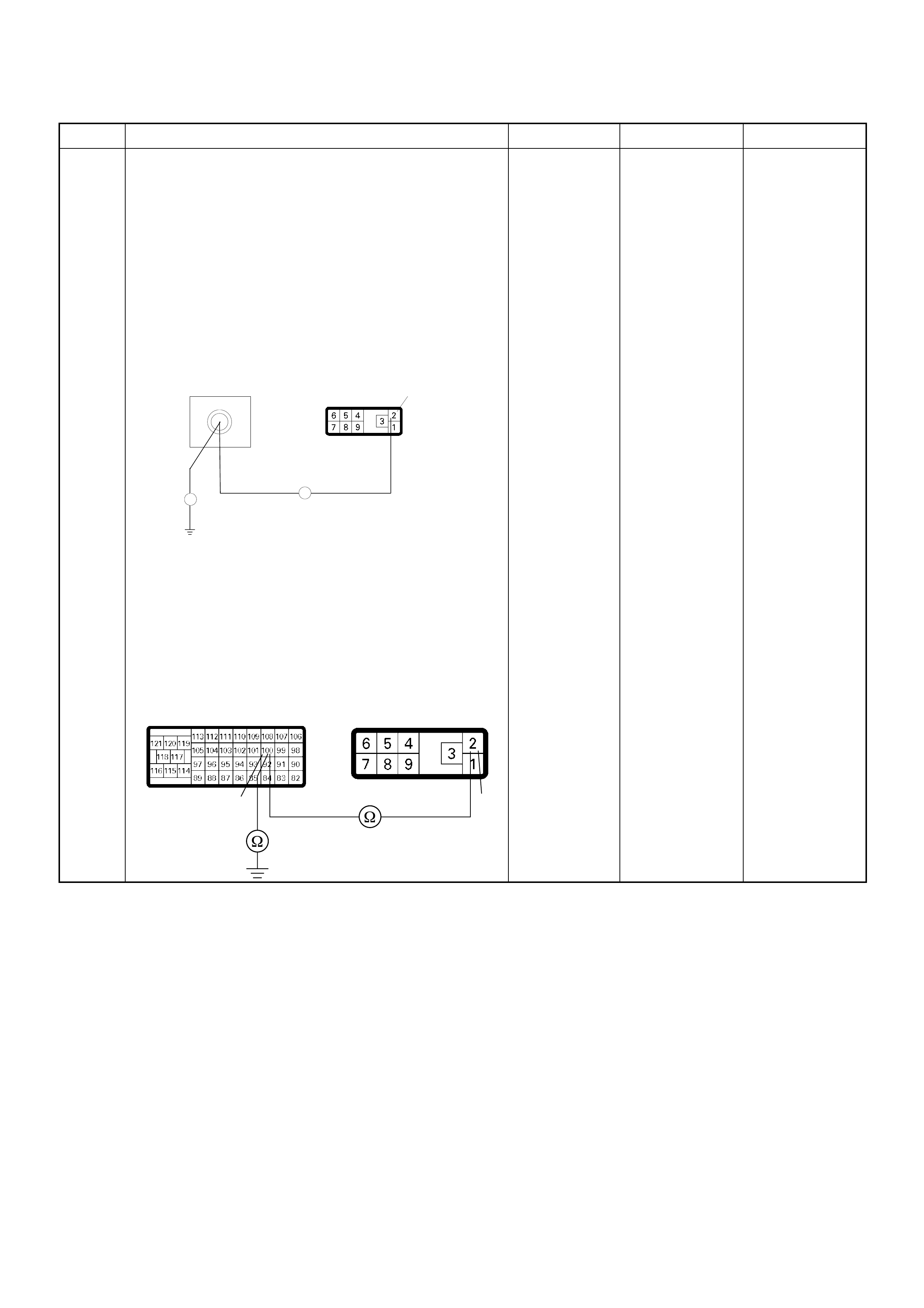

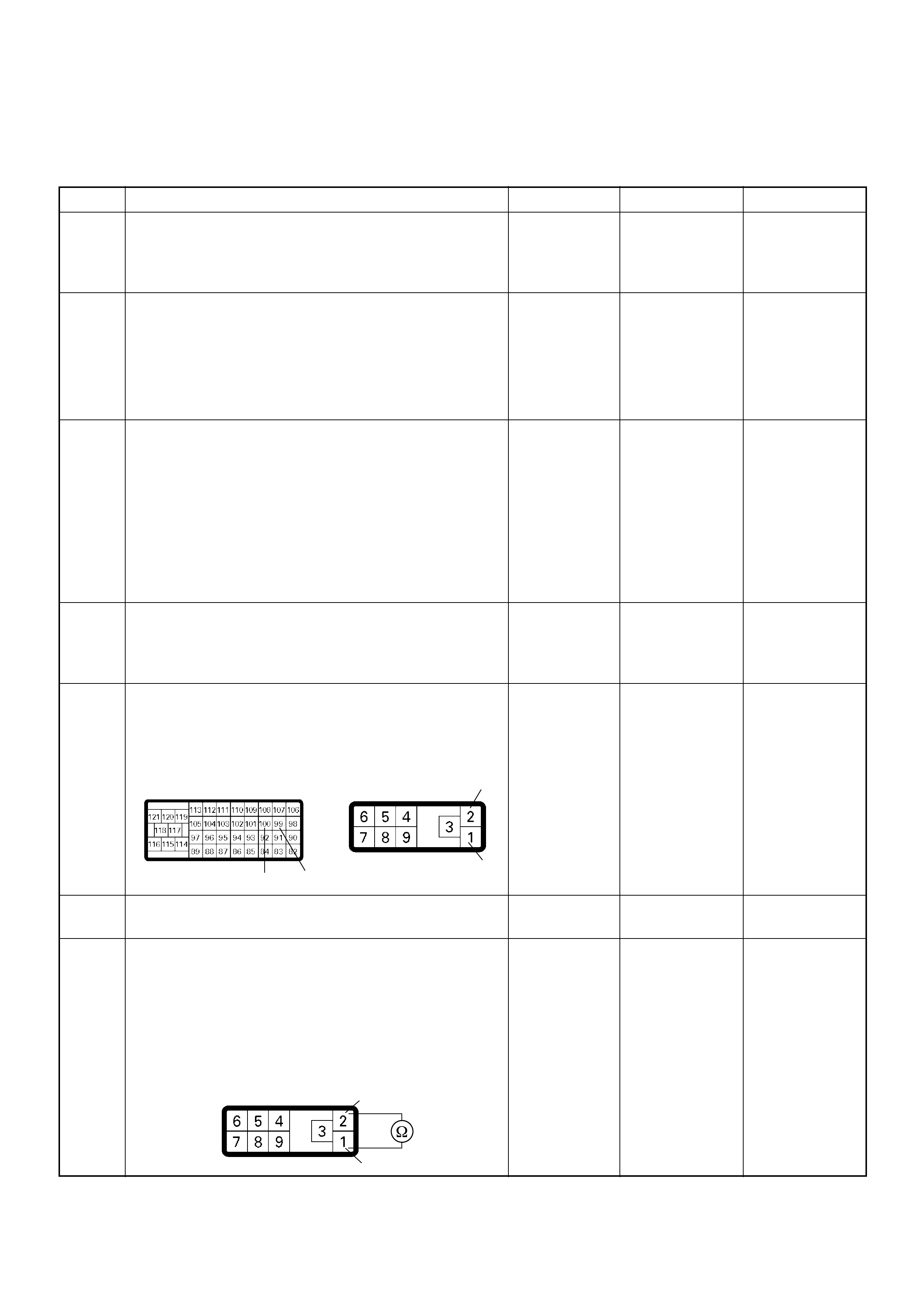

PSG CONNECTOR PIN ASSIGNMENT & OUTPUT SIGNAL

View Looking Into PSG Case

Signal or Continuity Tester Position

Pin

No. B/

Box

No.

Pin Function Wire

Color Key SW

Off Key SW

On Engine

Idle Engine

2000rp

m

ECM &

PSG Con-

nection

Rang

e(+) (-)

1 99 CAN (Controller Area

Network) to ECM

No.99

RED Continu-

ity

between

ECM &

PSG

---Discon-

nect Ohm 1 99

(ECM

)

2 100 CAN (Controller Area

Network) to ECM

No.100

WHT Continu-

ity

between

ECM &

PSG

---Discon-

nect Ohm 2 100

(ECM

)

3 - No Connect ion - ---- ----

4 - No Connect ion - ---- ----

5 105 Solenoid Valve Shut

Off (MAB) Output

Signal to ECM

No.105

ORG Continu-

ity

between

ECM &

PSG

---Discon-

nect Ohm 5 105

(ECM

)

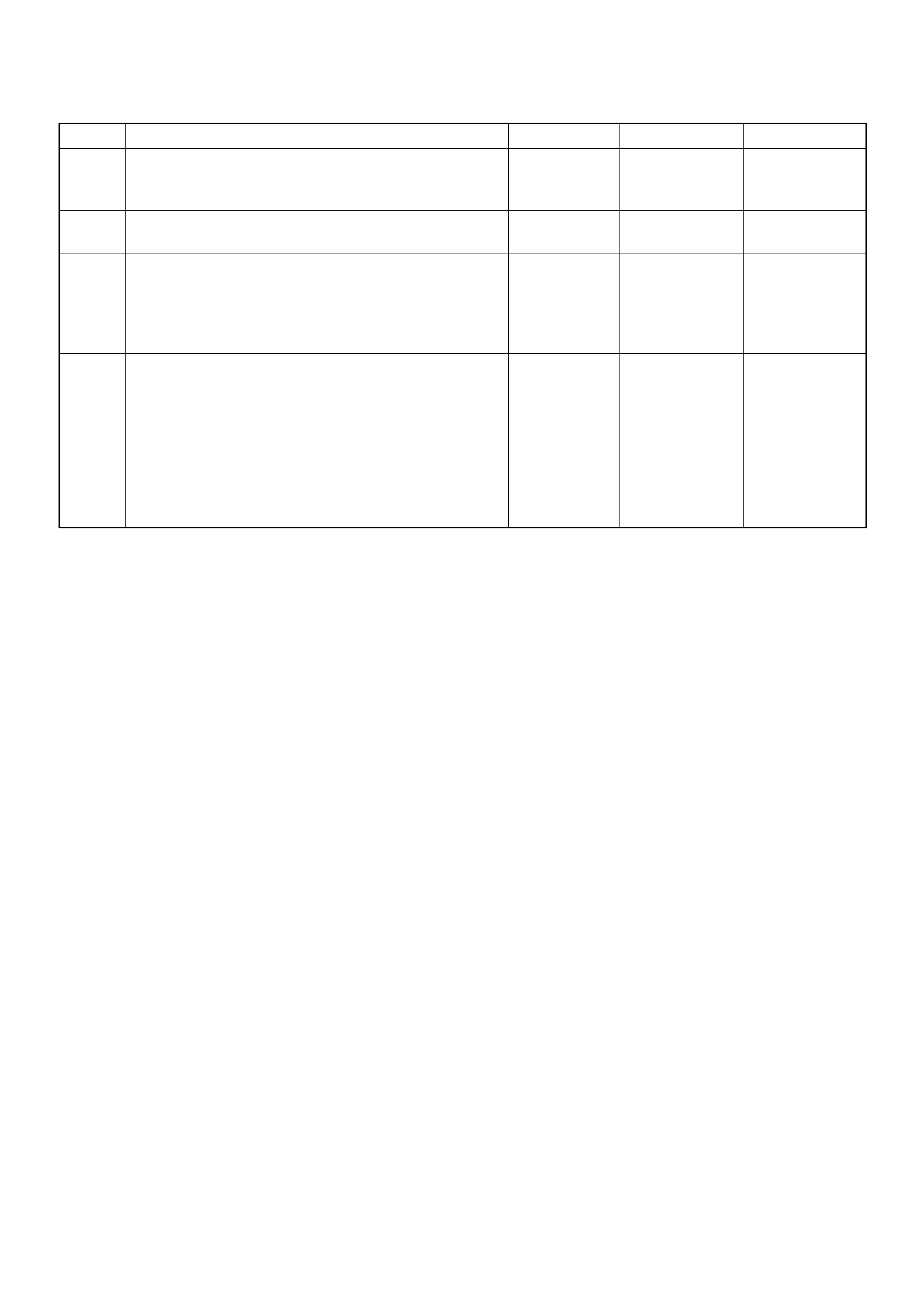

6 - Ground BLK Continu-

ity with

ground

---Discon-

nect Ohm 6 GND

7 - Battery Power Sup-

ply BLU/

RED Less

than 1V 10-14V Discon-

nect Ohm 7 GND

8 91 CKP Sensor Output

ECM No.91 to Pump

Control Unit (PSG)

PNK Continu-

ity

between

ECM &

PSG

---Discon-

nect Ohm 8 91

(ECM

)

9 - No Connect ion - ---- ----

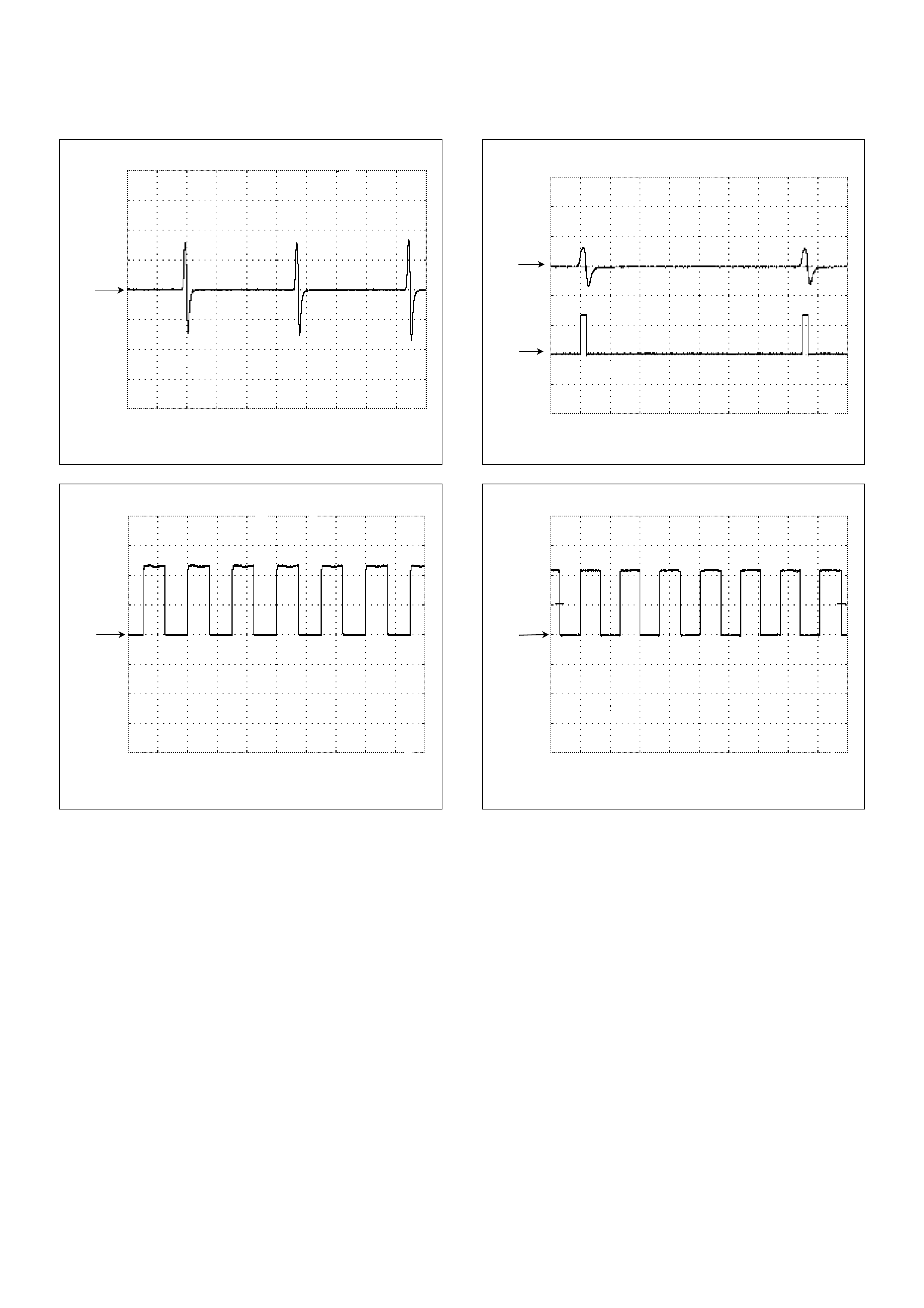

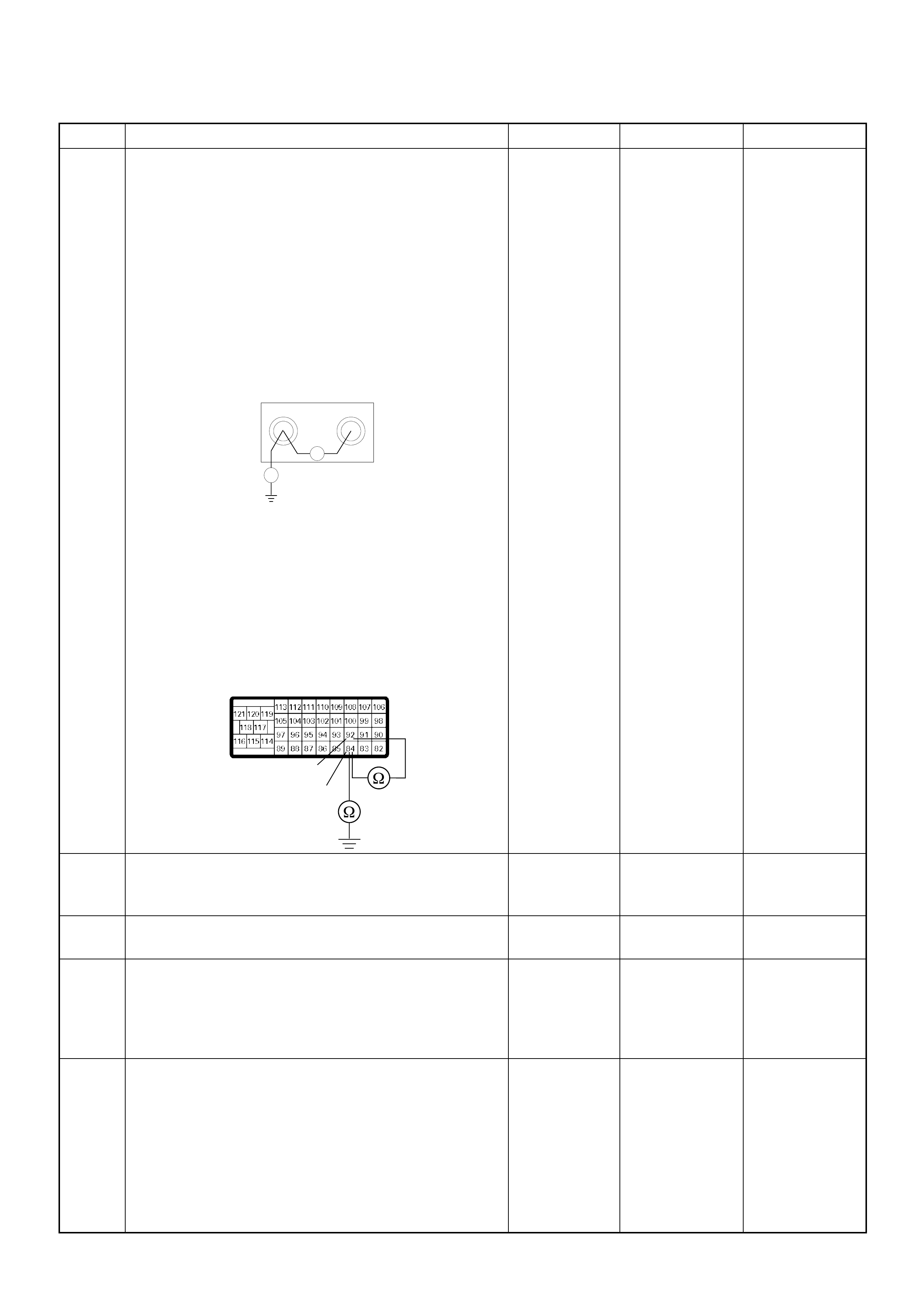

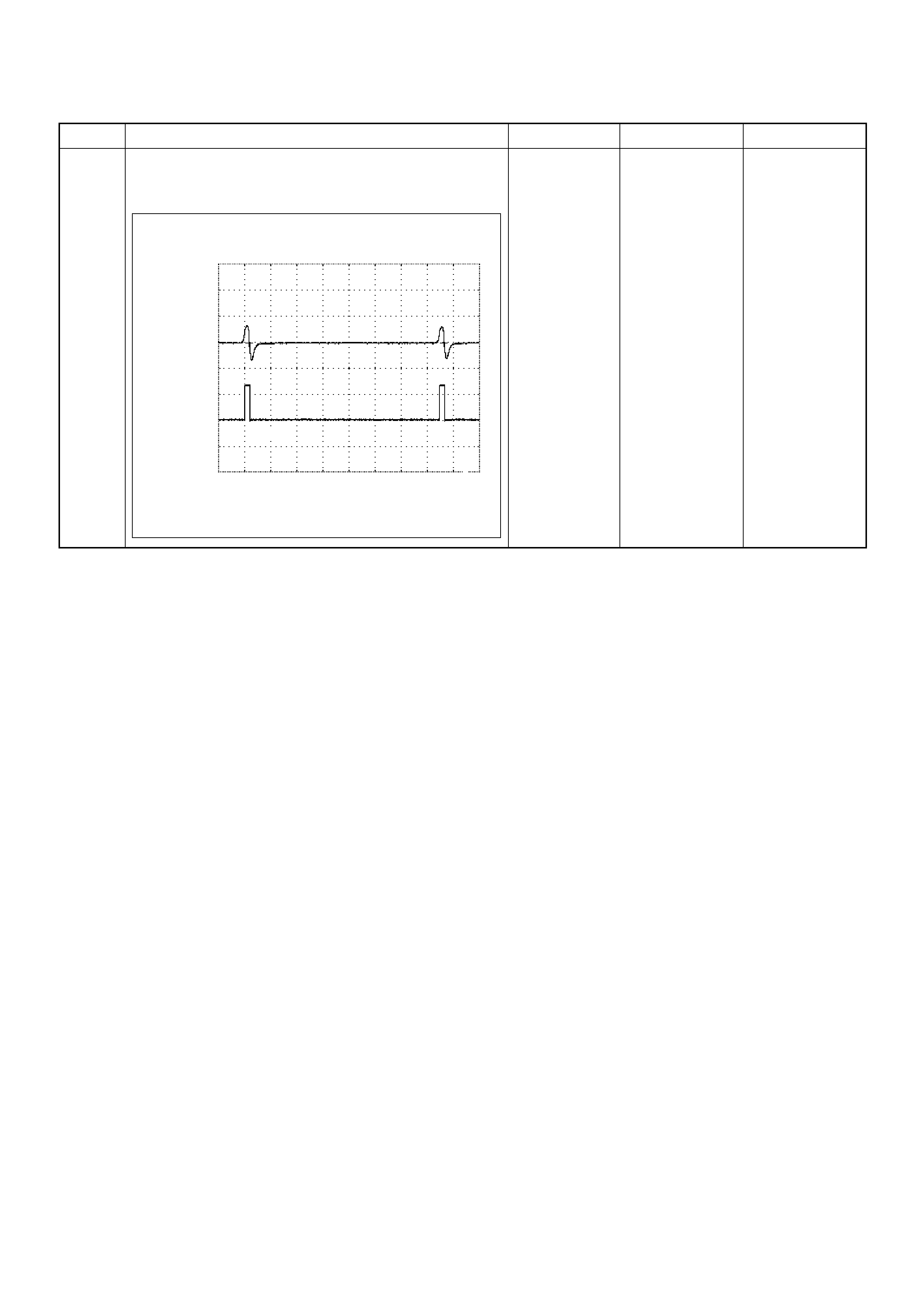

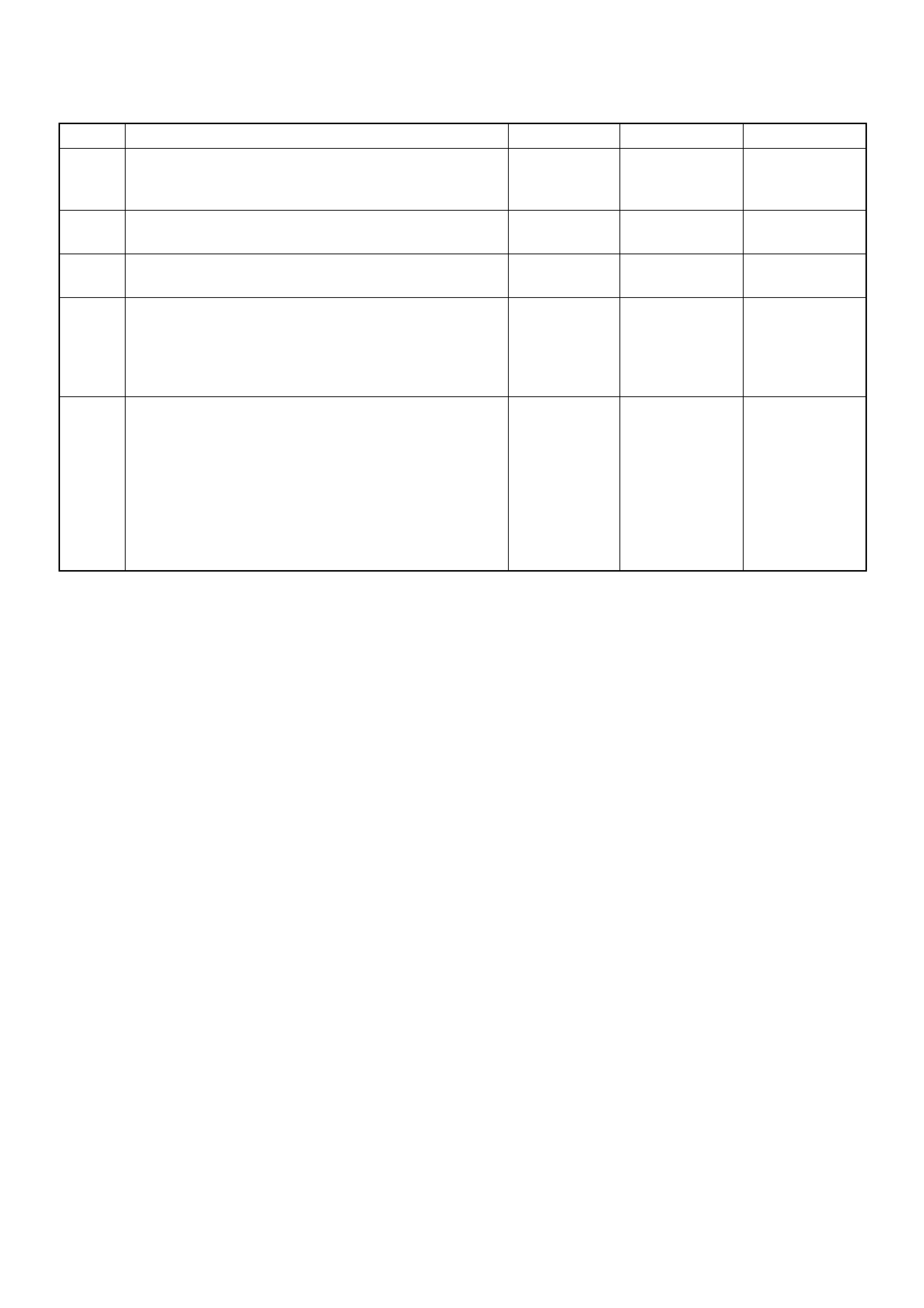

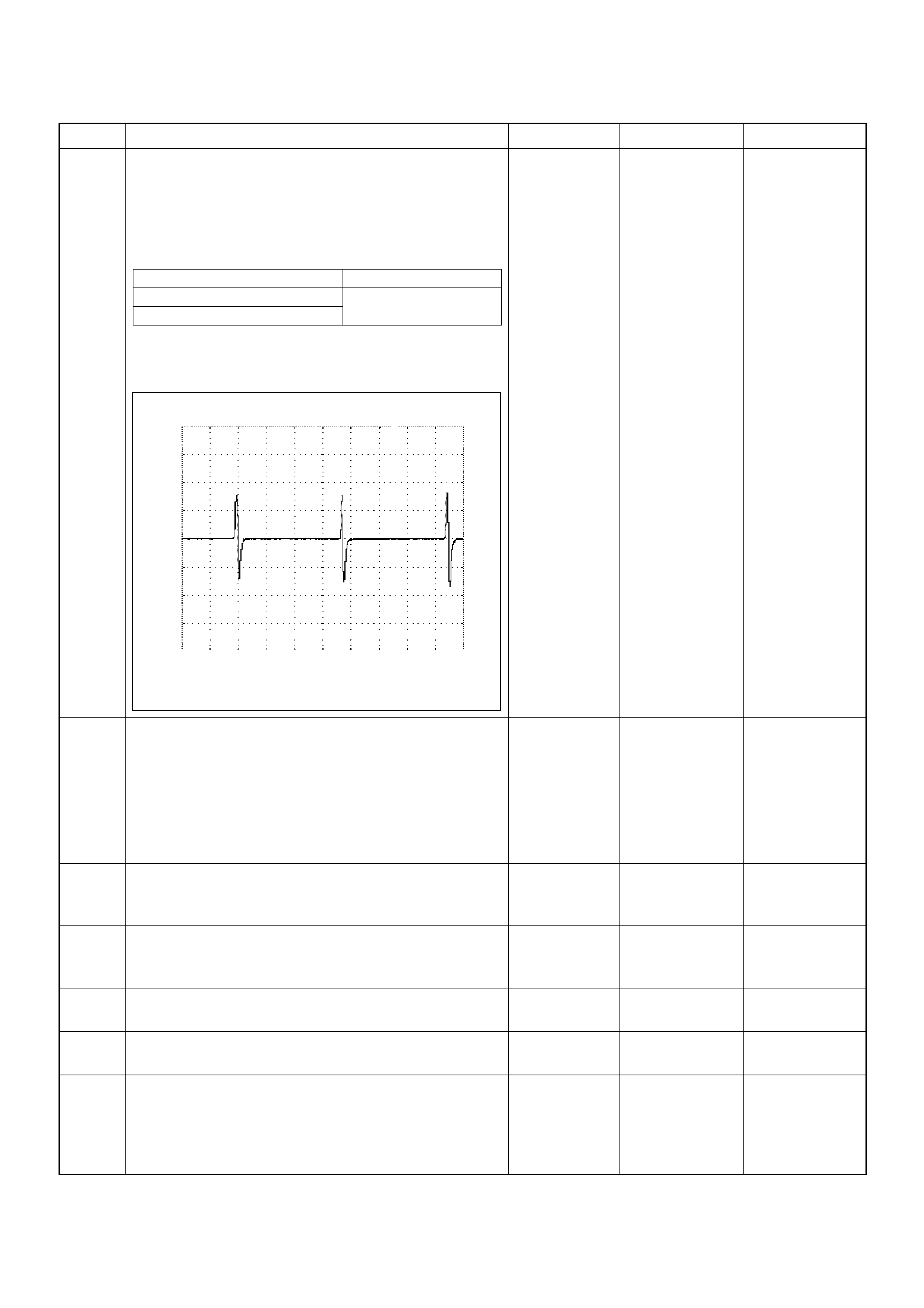

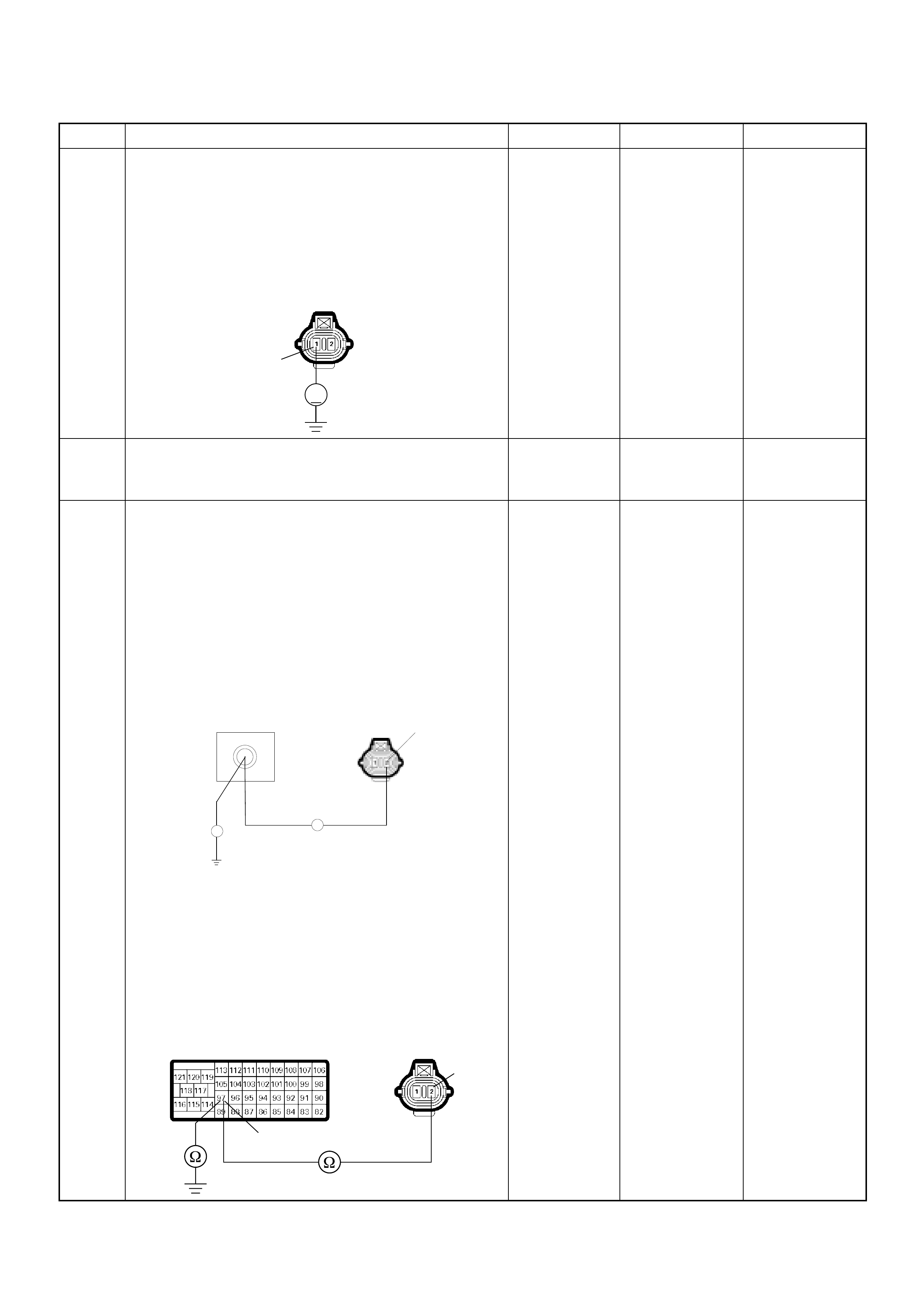

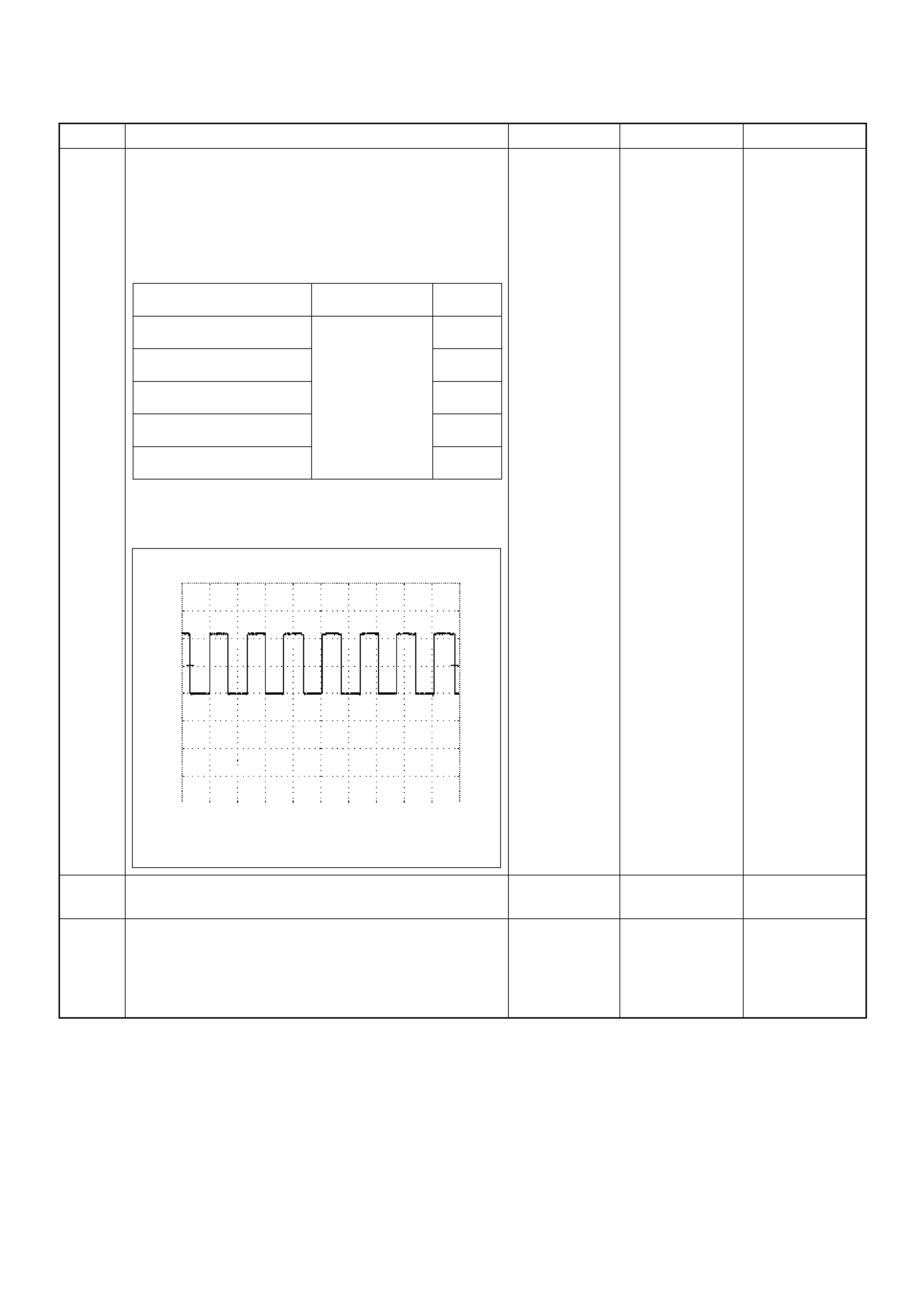

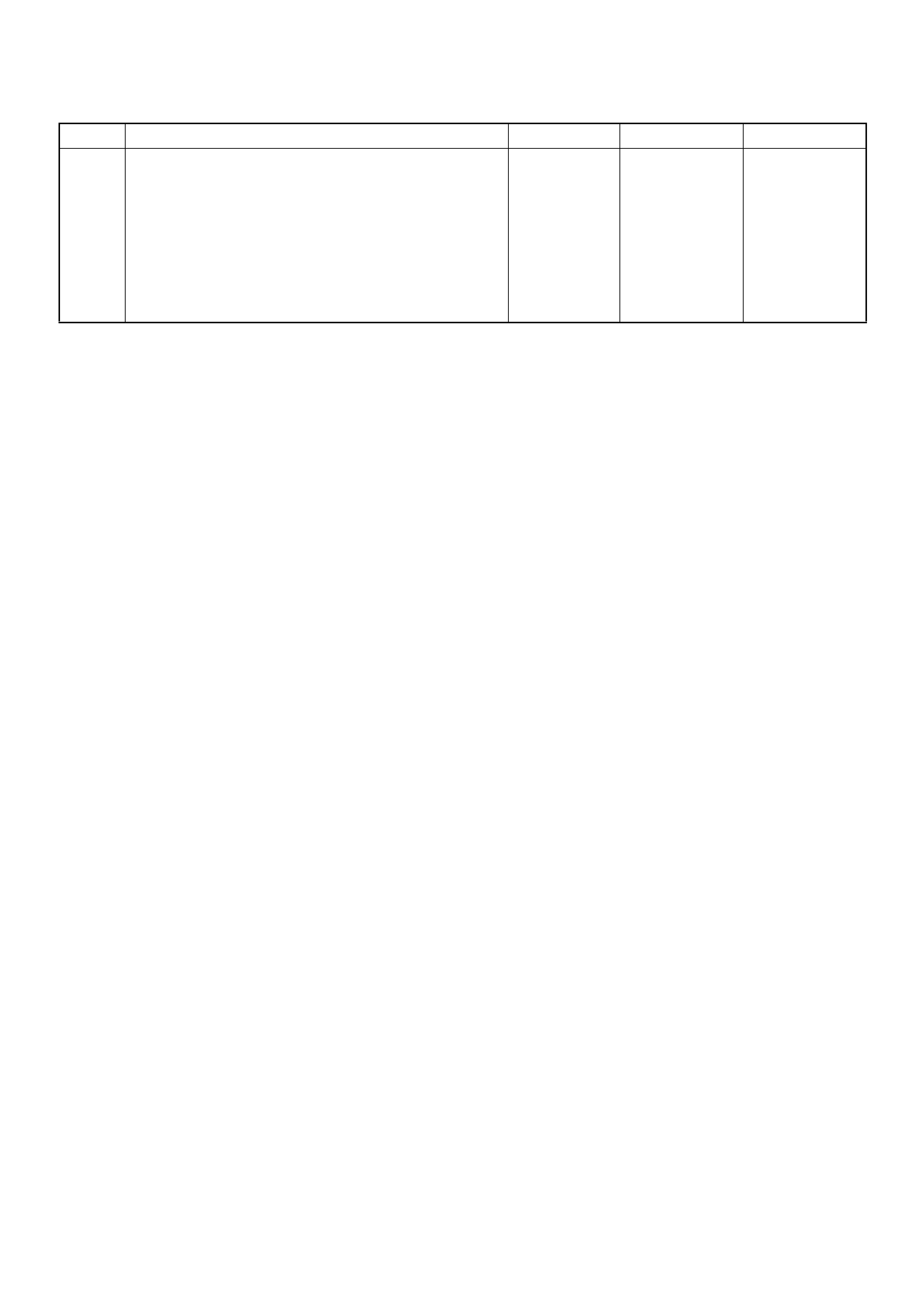

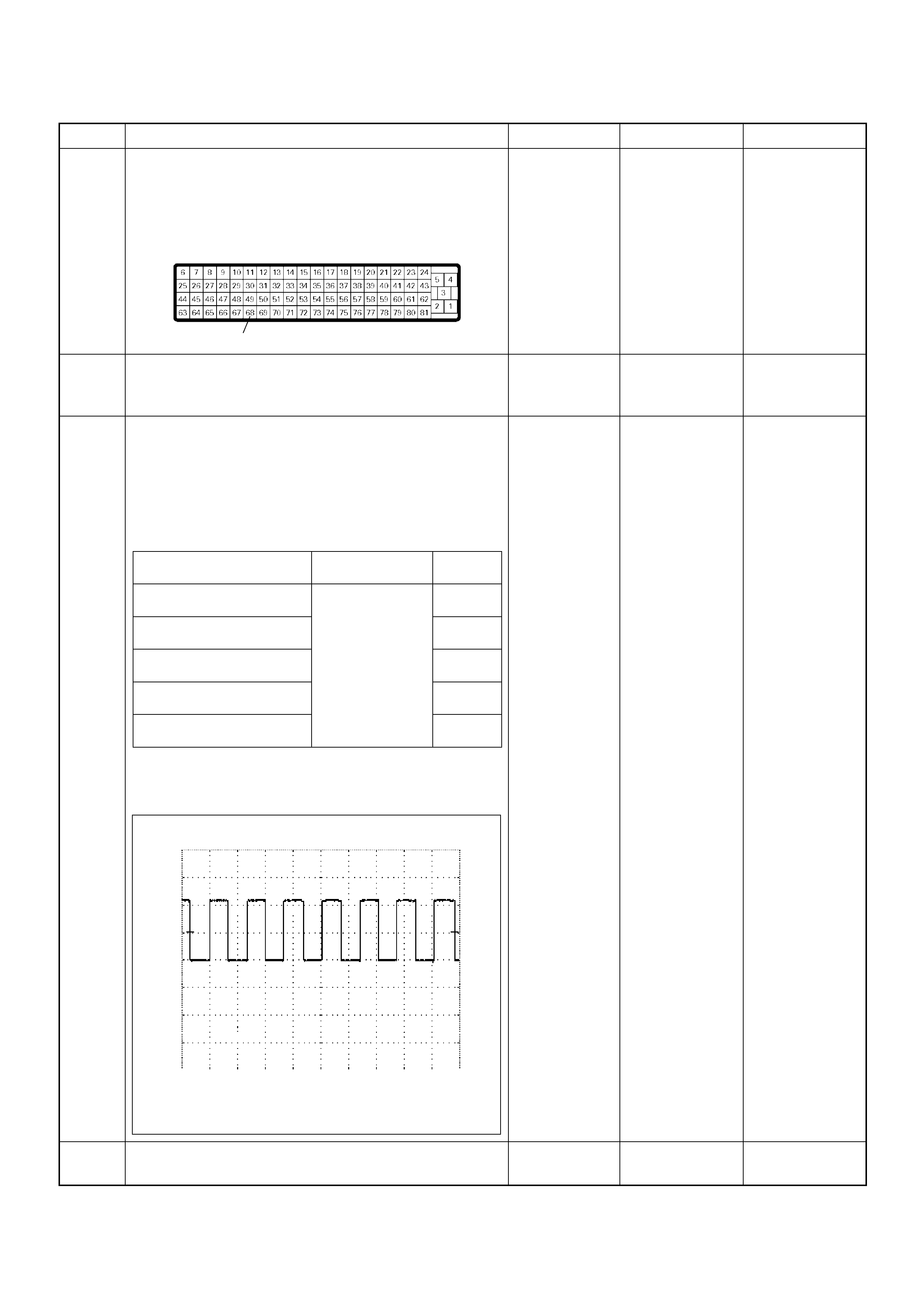

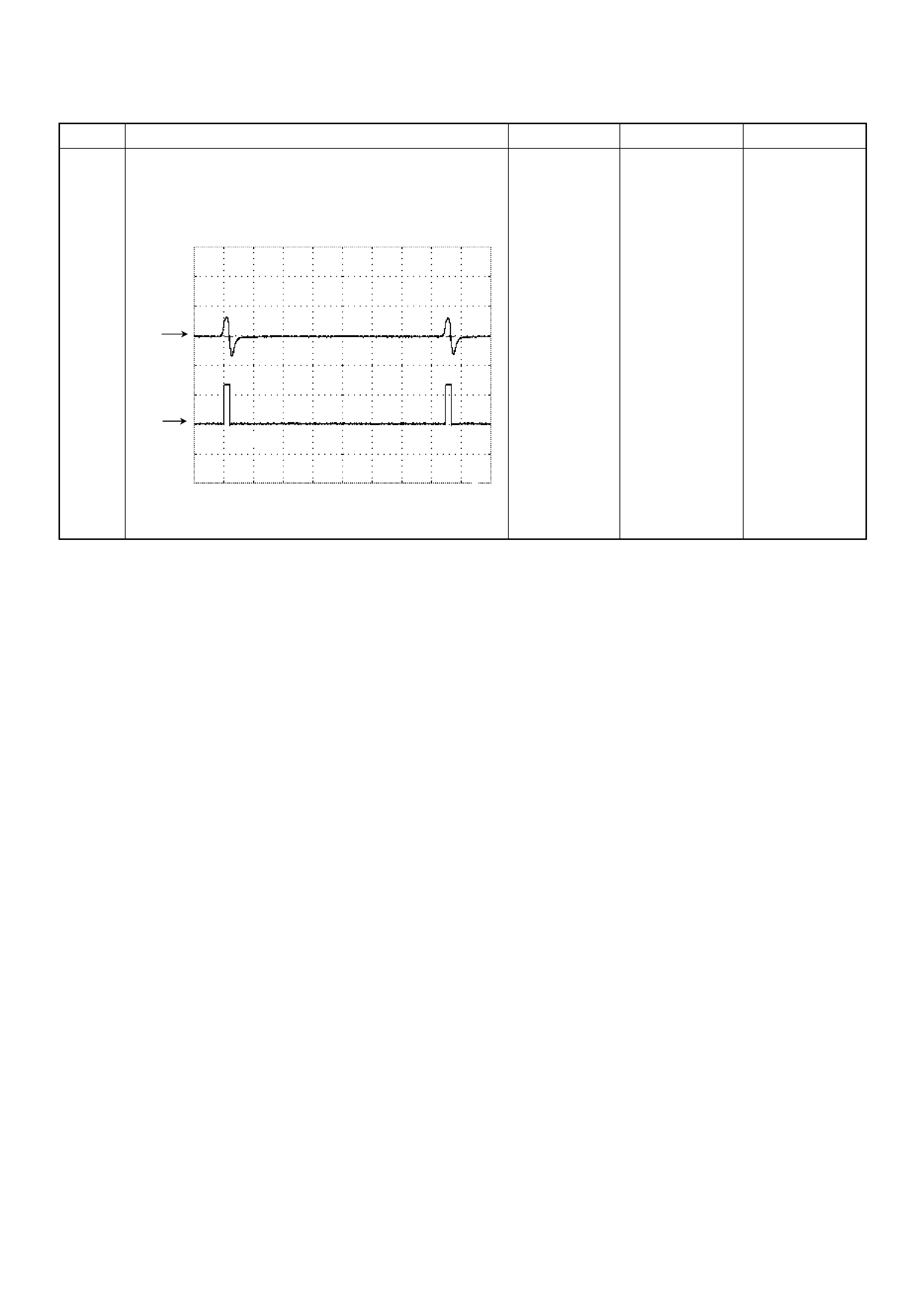

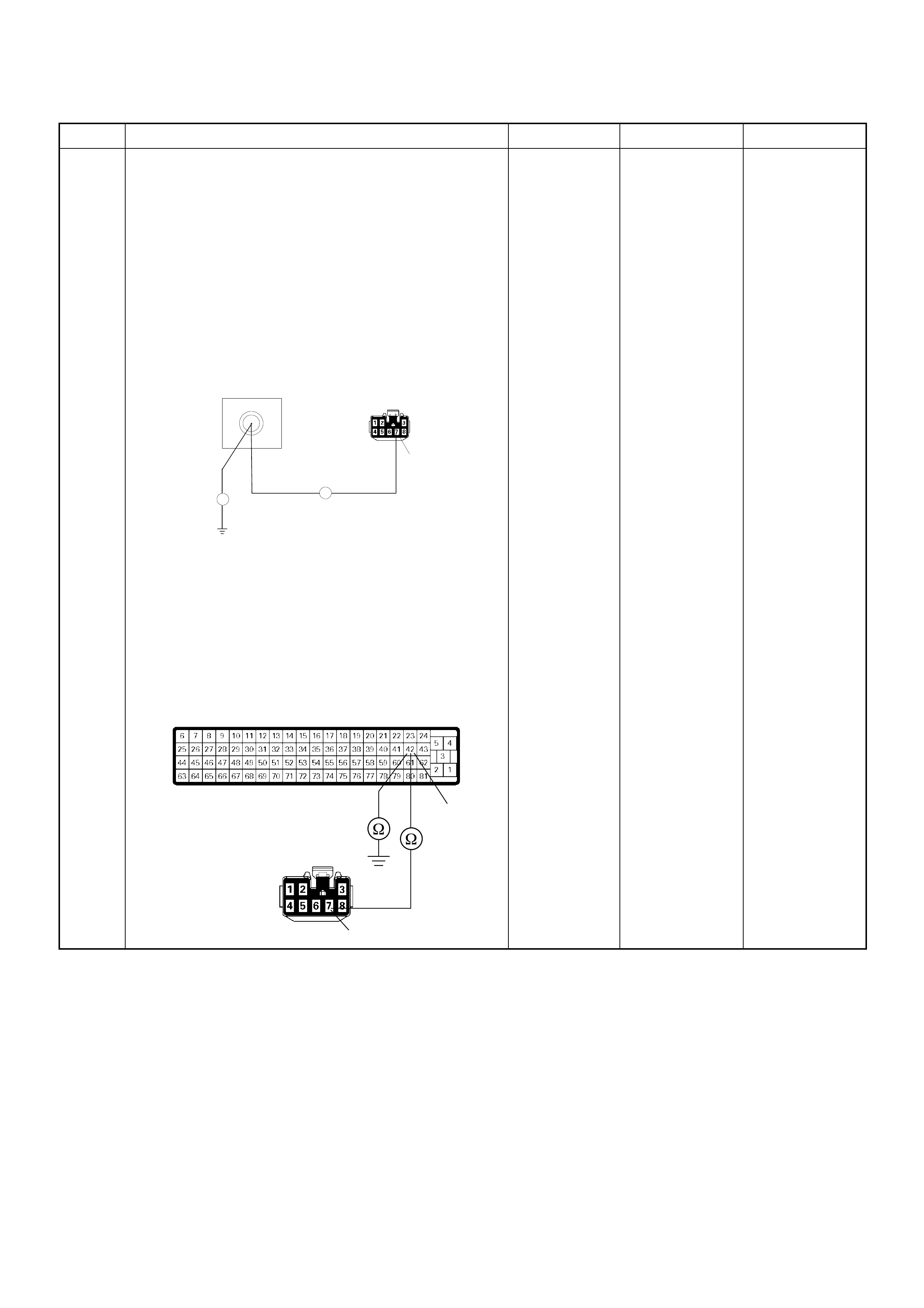

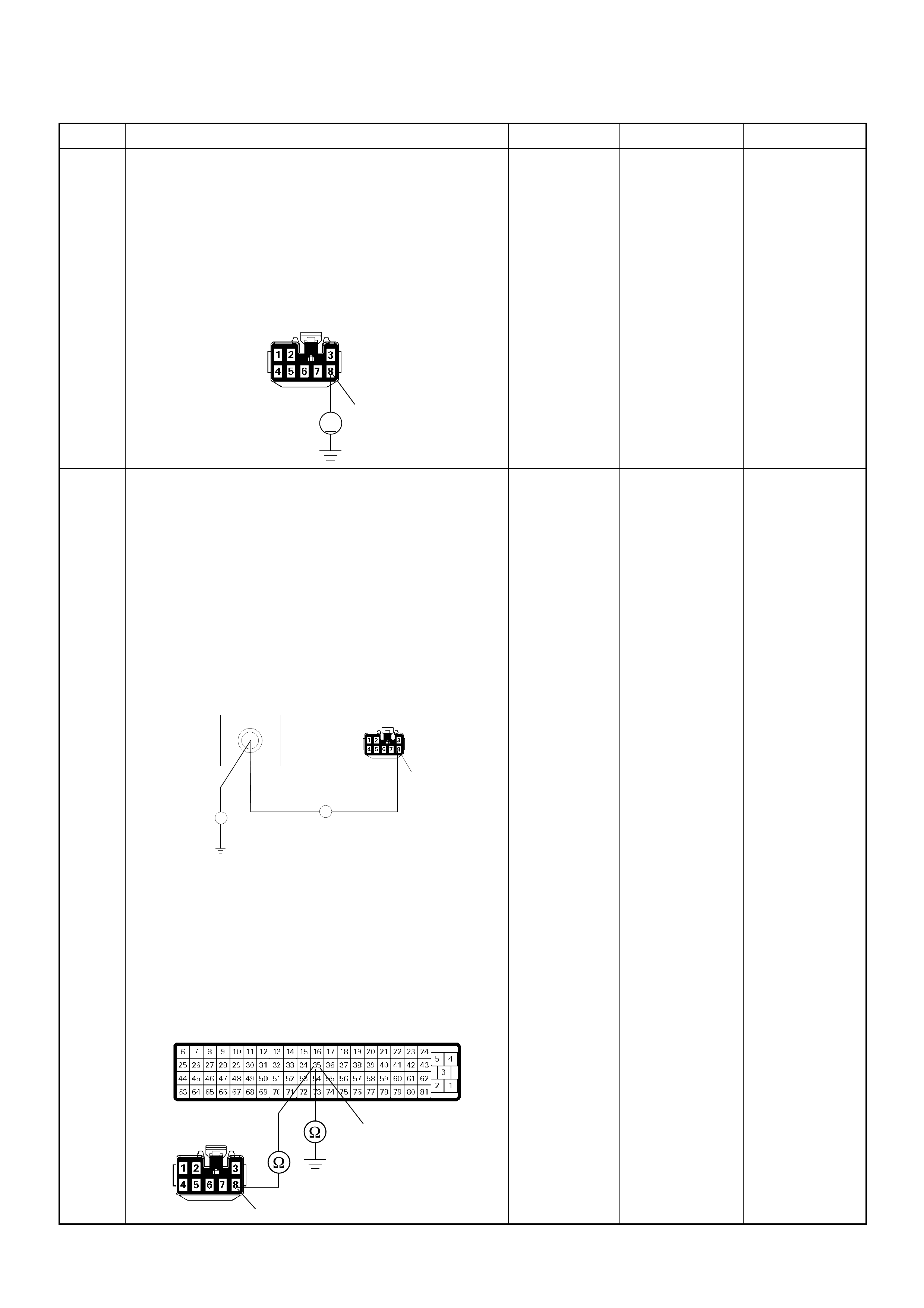

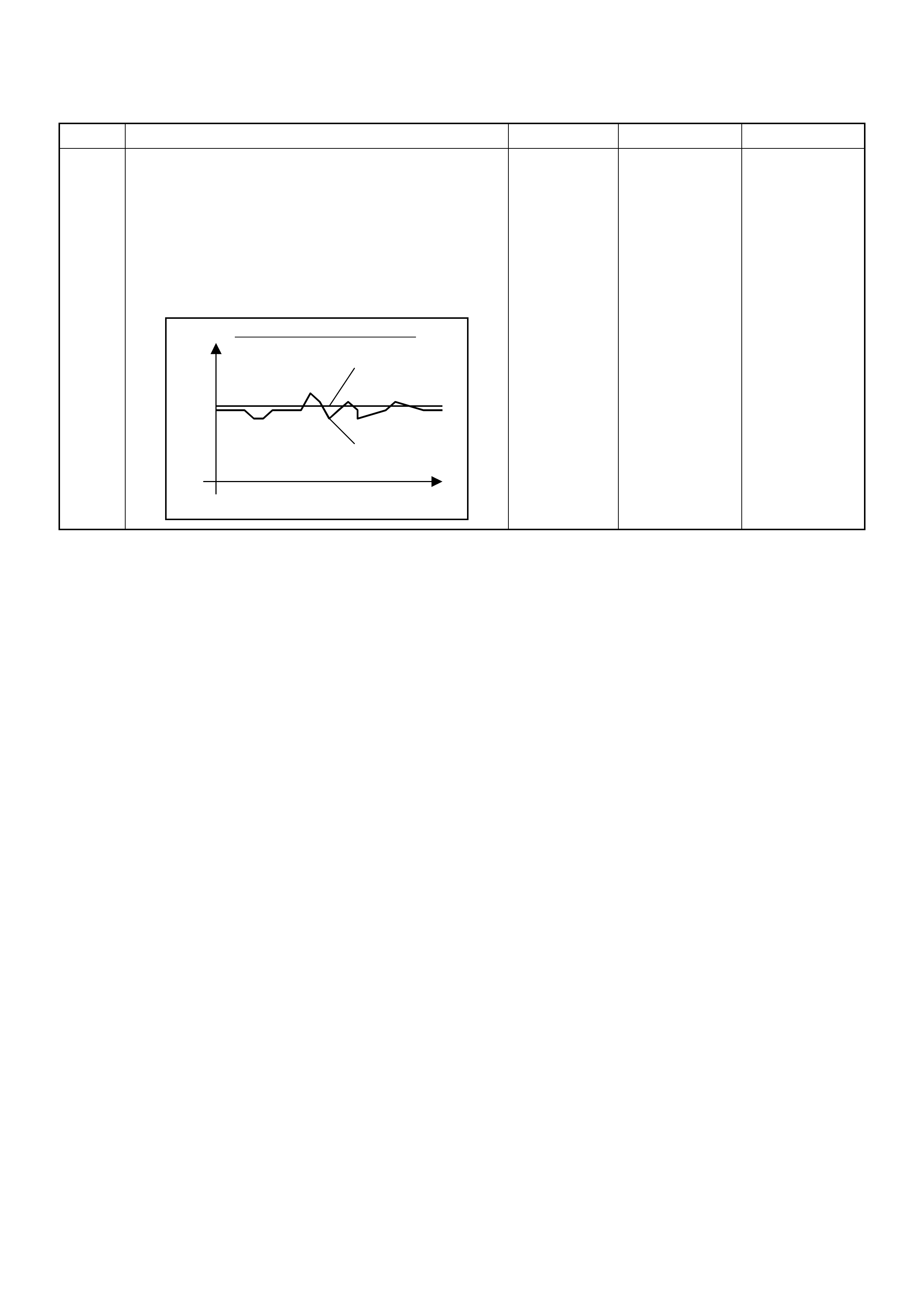

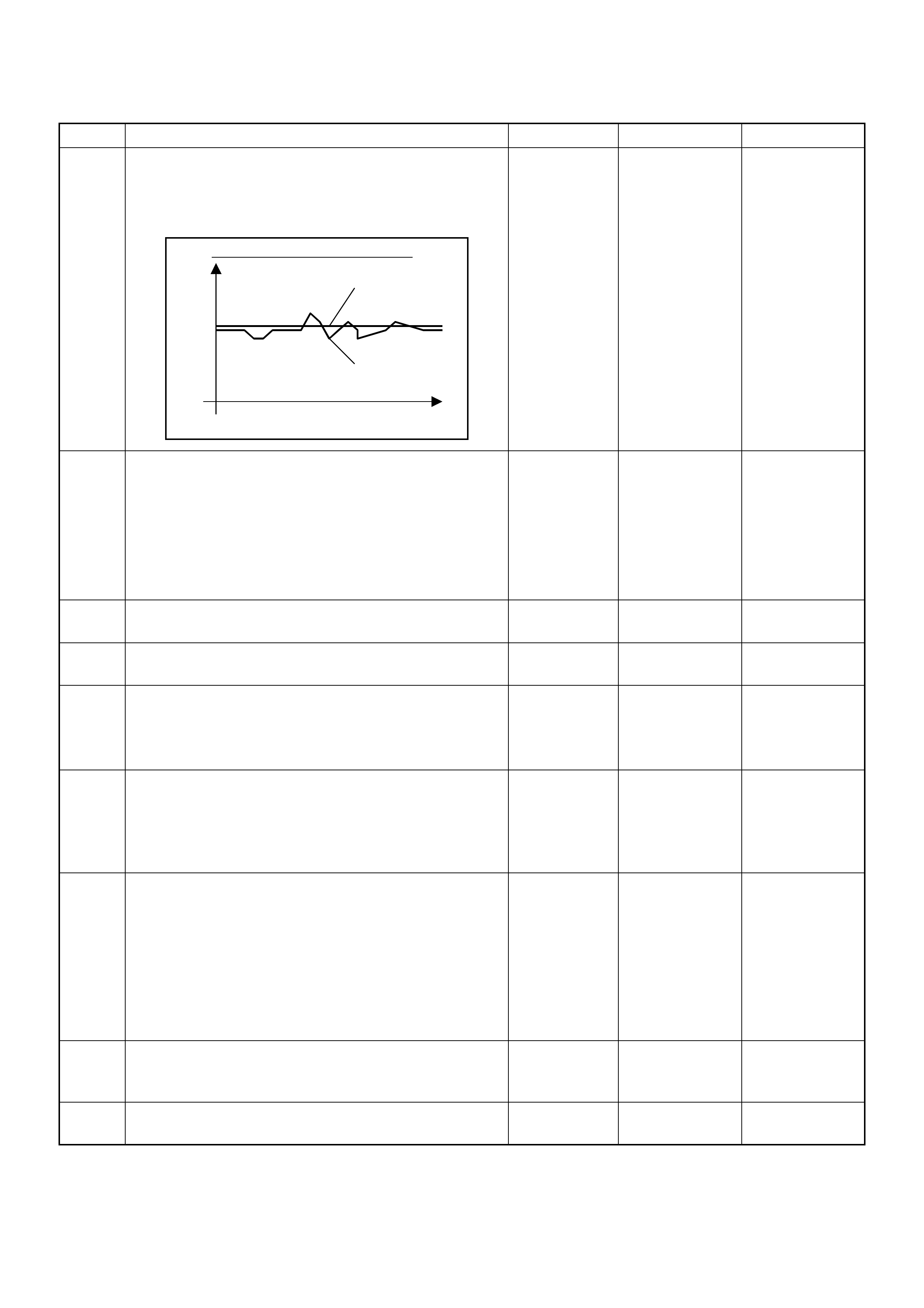

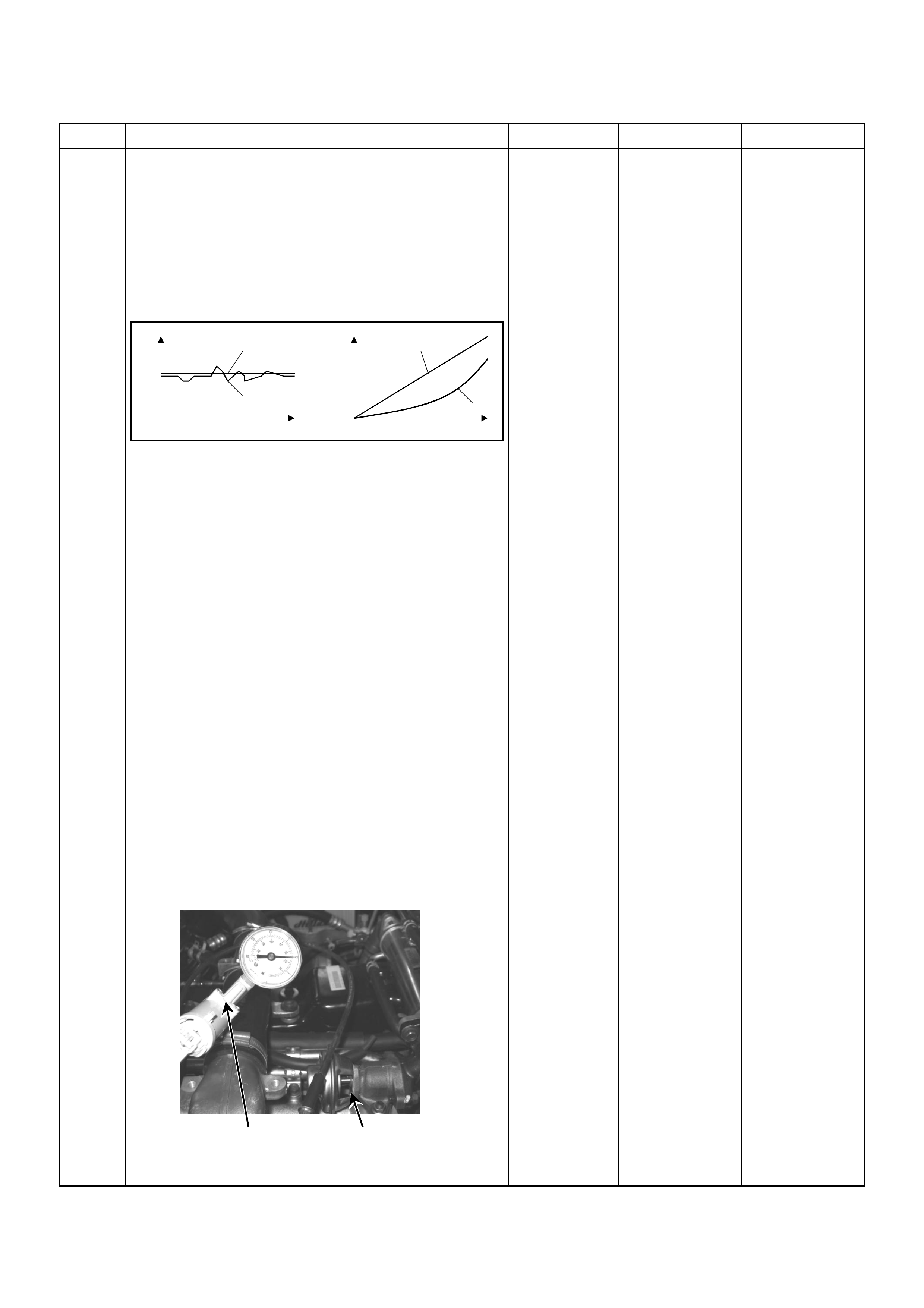

Crankshaft Position (CKP) Sensor Reference Wave Form

0V

Measurement Terminal: 90(+) 98(-)

Measurement Scale: 20V/div 2ms/div

Measurement Condition: Approximately 2000rpm

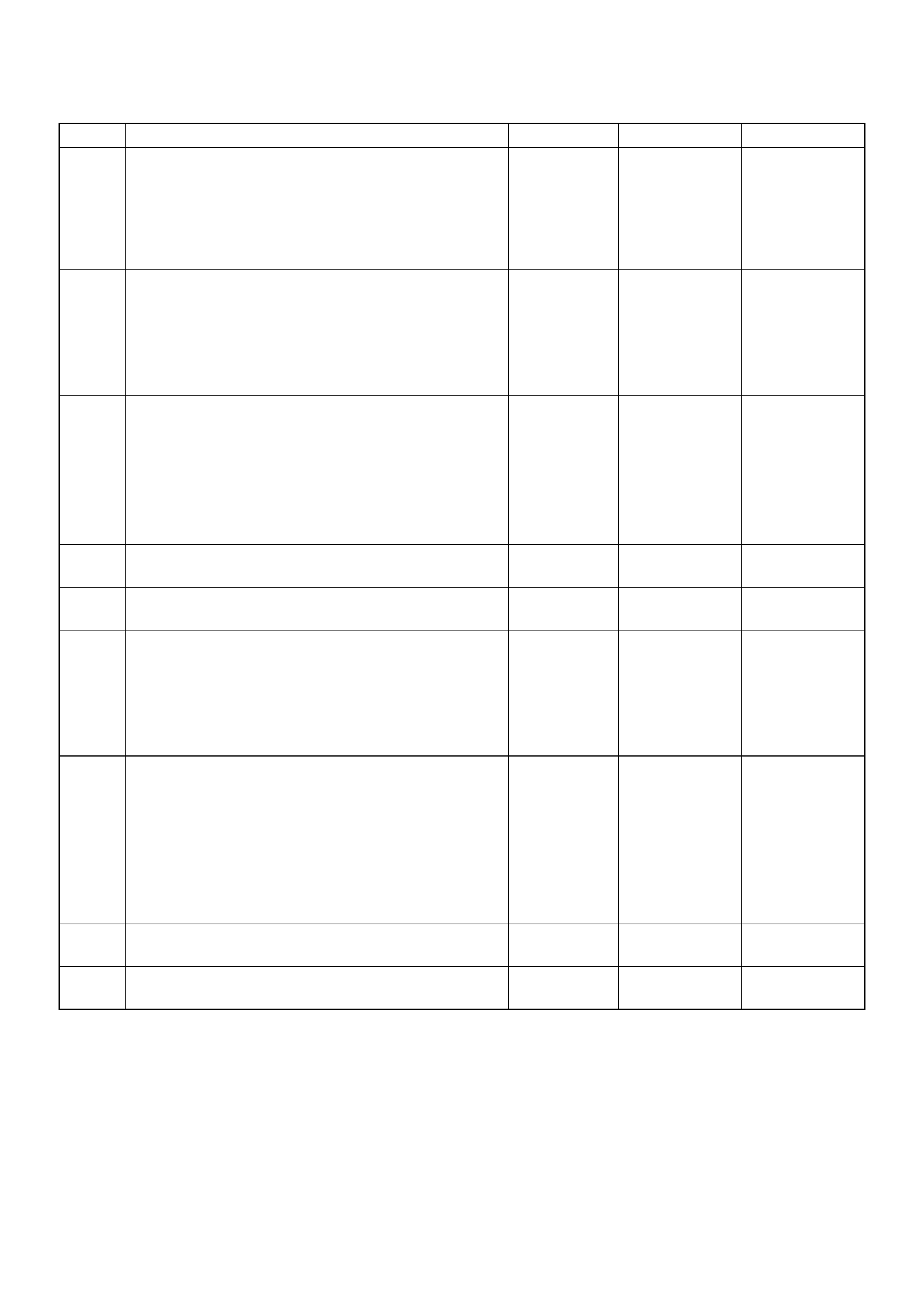

Engine Speed Output Signal Reference Wave Form

0V

Measurement Terminal: 27(+) GND(-)

Measurement Scale: 5V/div 10ms/div

M eas ur em ent C ond iti on: Approximately 2000r pm

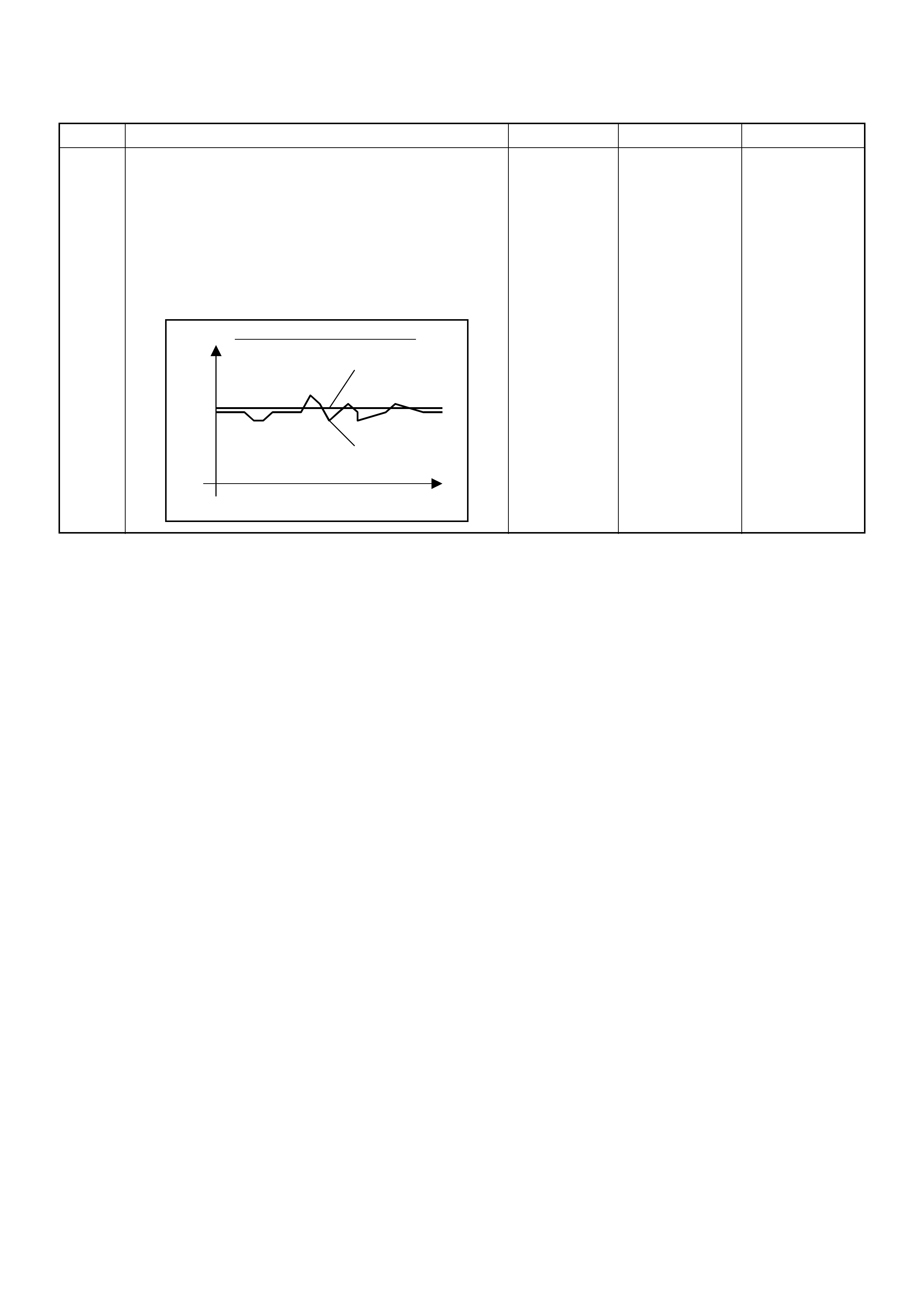

Crank shaft Posit i on (CKP) Sens or & TDC Outpu t Signal

Reference Wave Form

CH1

0V

CH2

0V

Measurement Terminal: CH1: 90(+) / CH2: 91(+) GND(-)

Measurement Scale: CH1: 50V/div / CH2: 10V/div 1ms/div

Measurement Condition: Approximately 2000rpm

Vehicle Speed Sensor (VSS) Reference Wave Form

0V

Measurement Terminal: 68(+) GND(-)

Measurement Scale: 5V/div 50ms/div

M eas ur em ent C ond iti on: Approximately 20km/h

GENERAL DESCRIPTION FOR ECM AND SENSORS

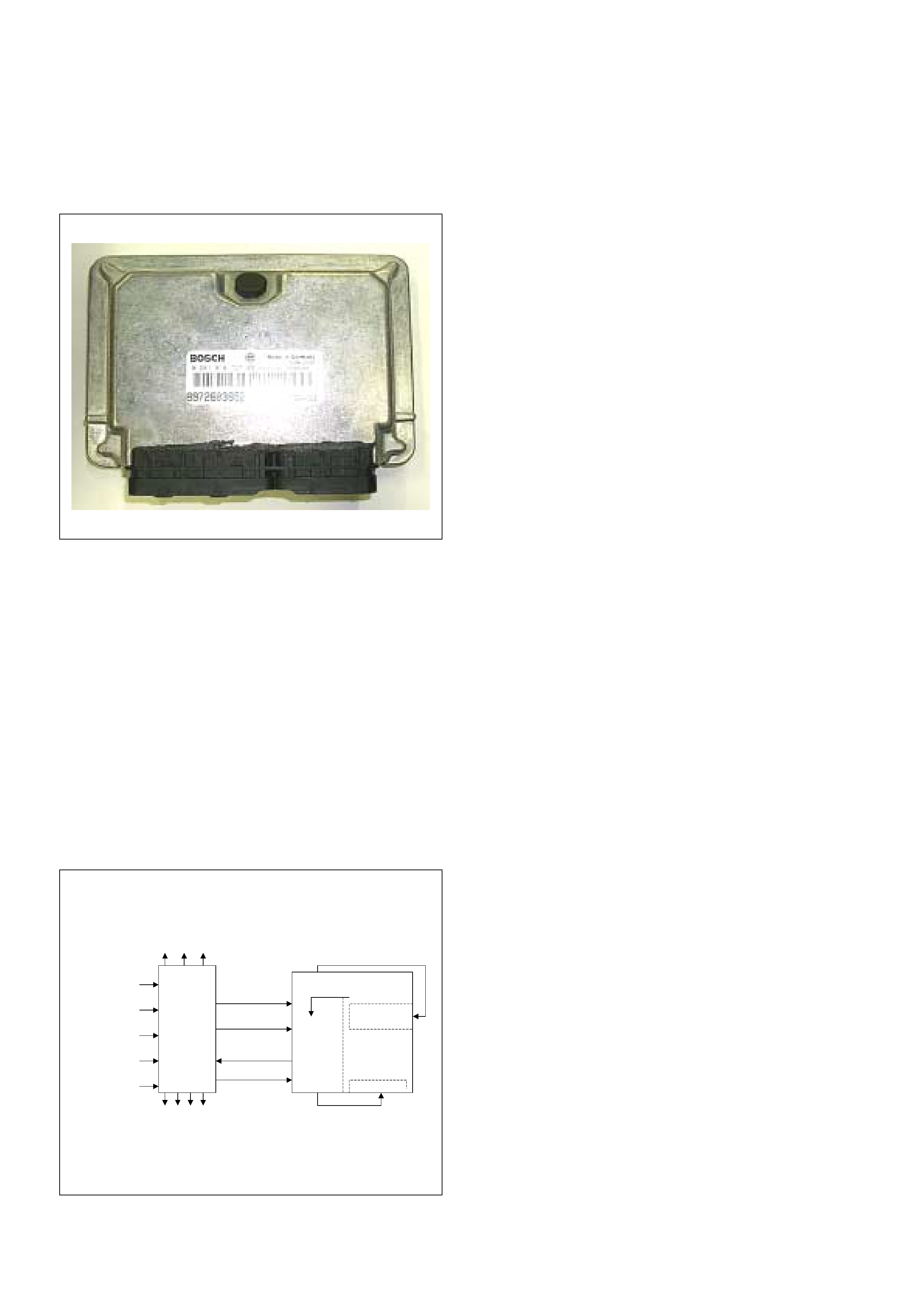

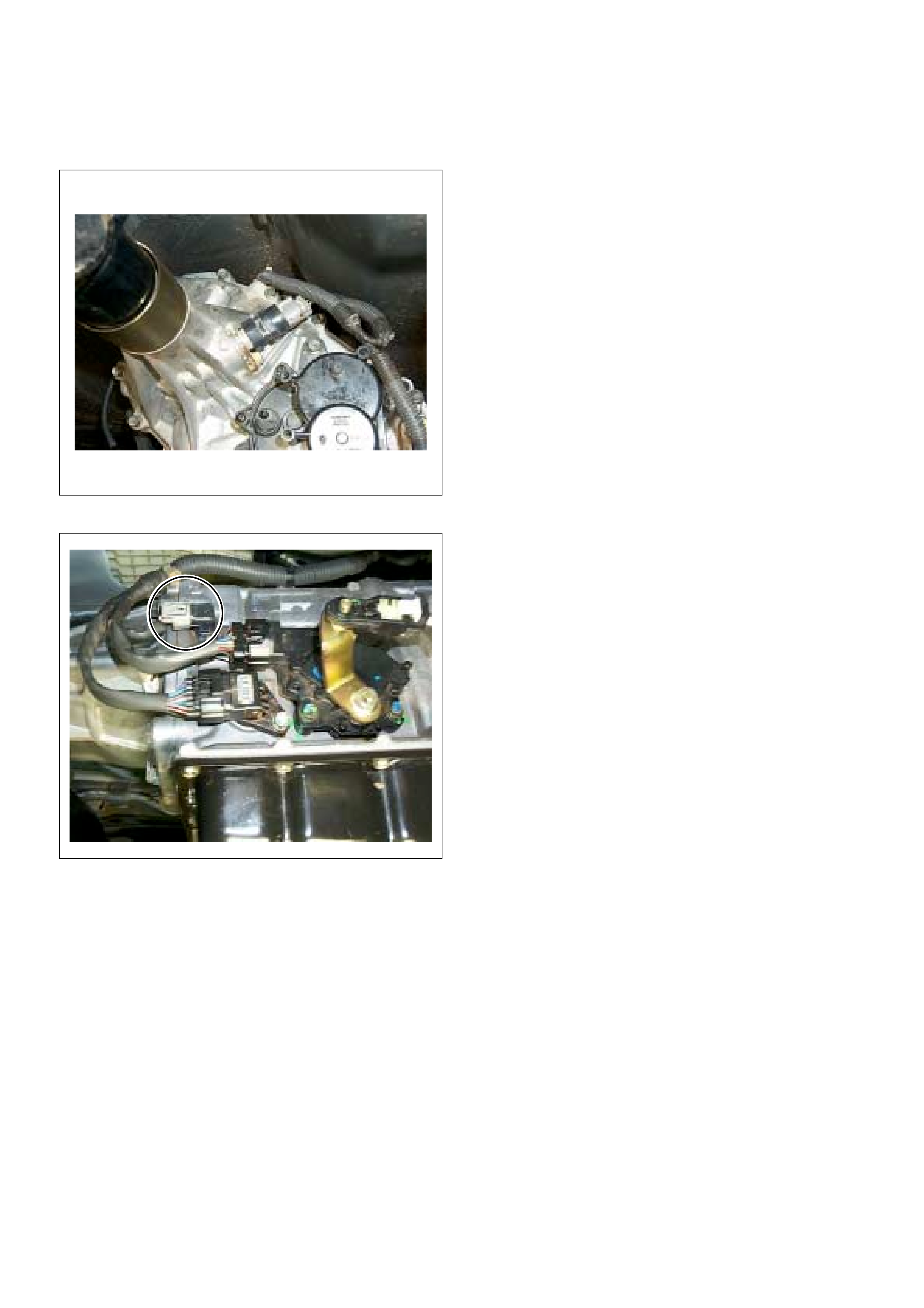

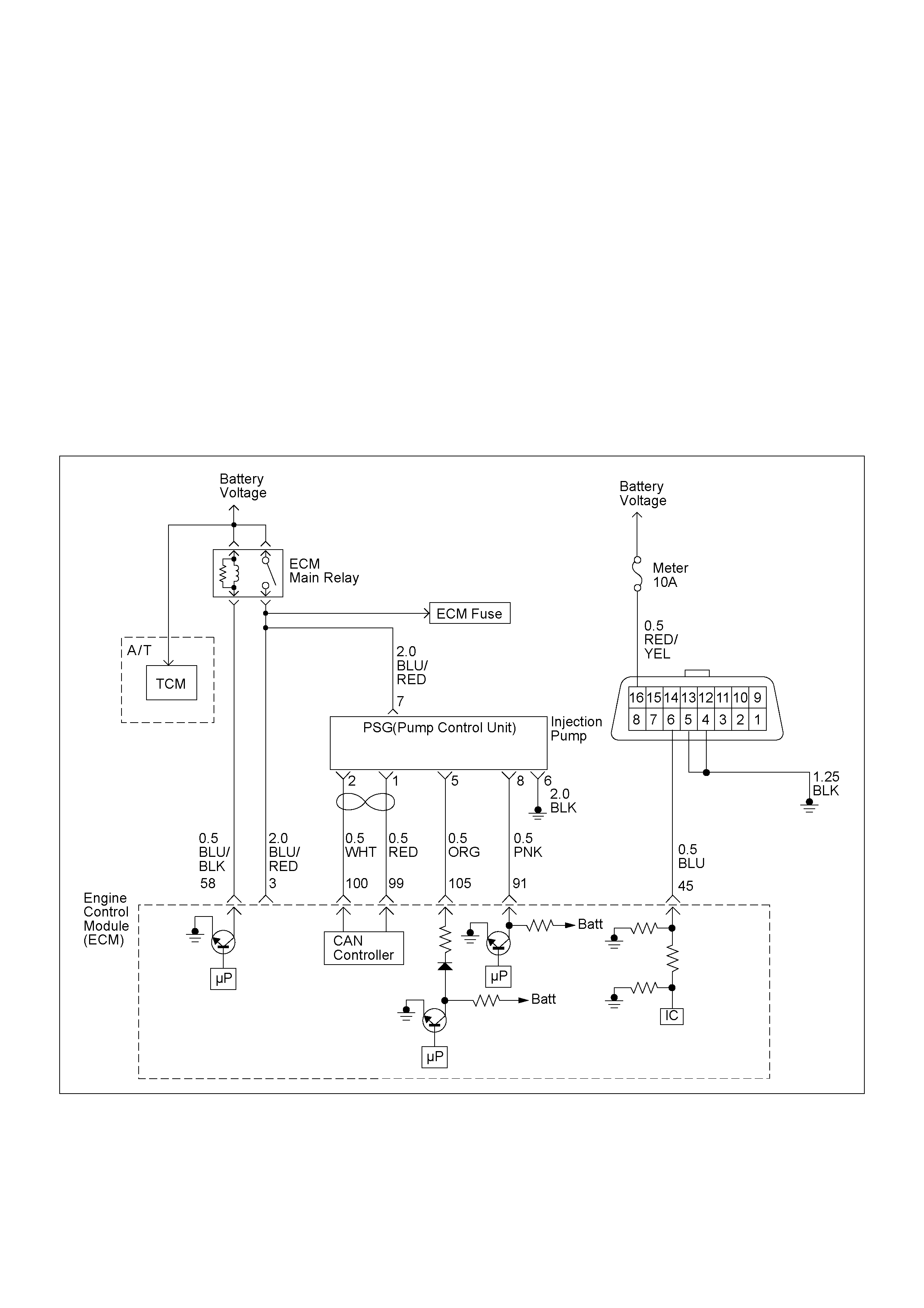

Engine Control Module (ECM)

The engine control module (ECM) is located lower panel

just under the passenger's seat.

The fuel quantity and injection timing related functions

are controlled by the pump control unit (PSG).

The engine control module (ECM) performs the

following functions.

• Control of the exhaust gas re-circulation (EGR)

• Control of the quick on start (QOS) glow control

system

• Control of the A/C compressor

• Execution of the immobilizer function

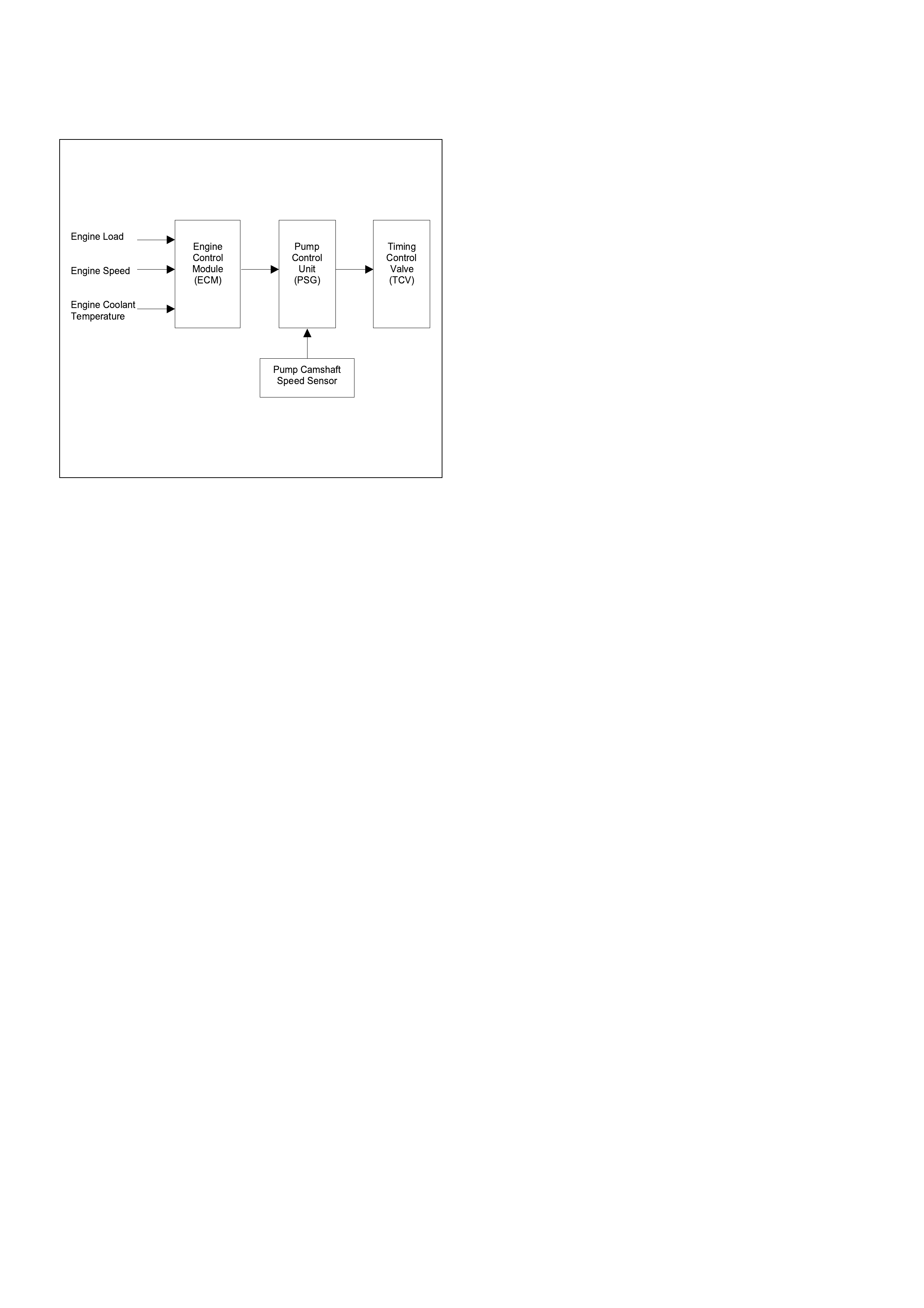

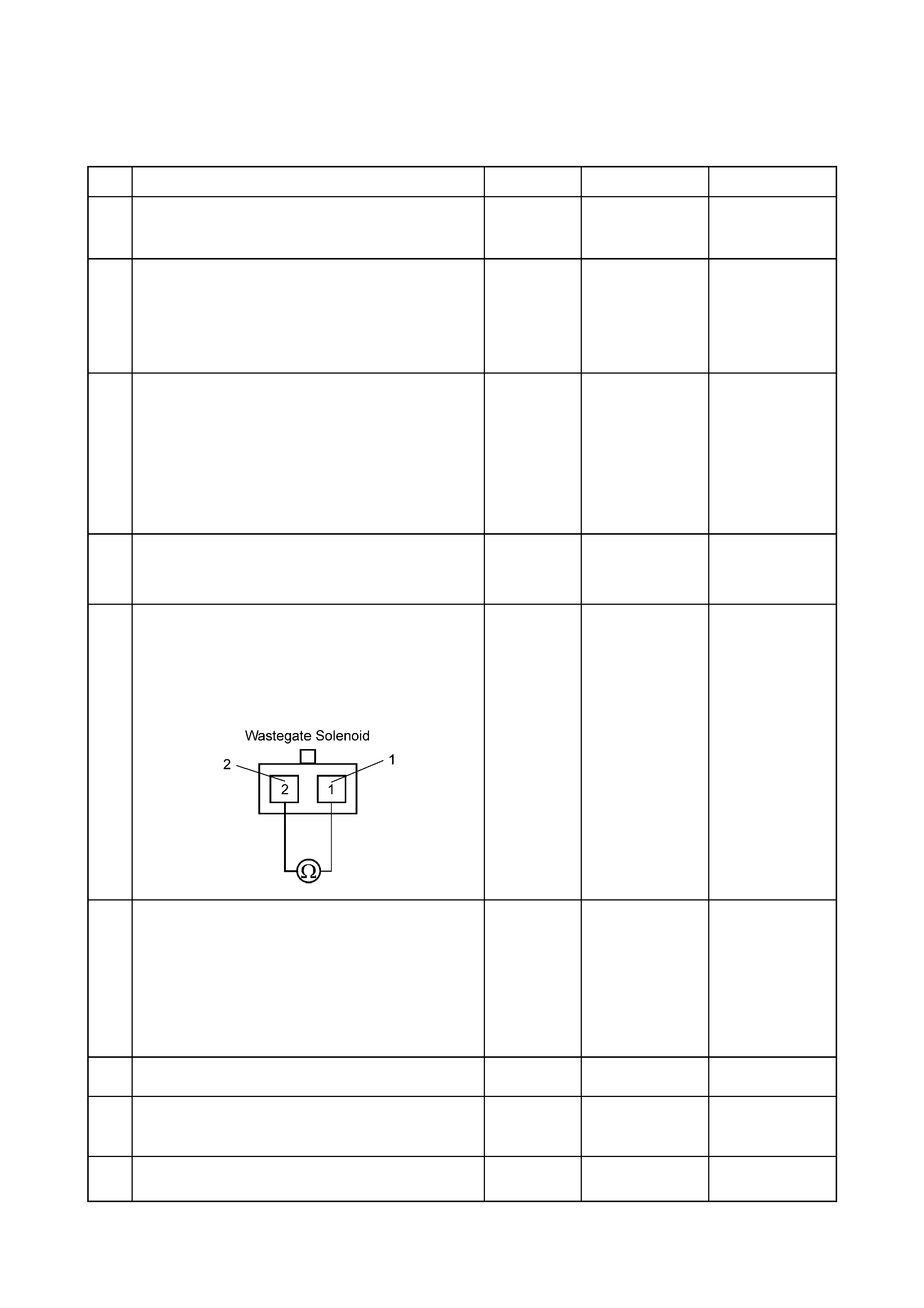

Pump Control Unit (PSG) & Data Exchange

Between Control Module

The radial plunger distributor type injection pump uses

two control modules to execute full control of the engine

management system.

• Engine Control Module (ECM)

• Pump Control Unit (PSG) = Pumpen Steuer Great

(German)

The pump control unit (PSG) receives signals from the

sensors inside the pump to determine the cam ring

rotation angle, the pump speed and the fuel

temper atur e .

These values are then compared to the desired values

sent by the engine control module (ECM) such as the

desired injection timing and the desired fuel injection

quantity.

The engi ne control module ( ECM) processes al l engine

data and data regarding the surrounding environment

received from external sensors to perform any engine

side adjustments.

Maps for both are encoded in both control units. The

control units input circuit process sensor data.

A Microprocessor then determines the operating

conditions and calculates set values for optimum

running.

The interchange of data between the engine control

module (ECM) and the pump control unit (PSG) is

performed via a CAN-bus system. The abbreviation

CAN stands for Controller Area Network. Having two

separate control modules for the high pressure solenoid

valve prevents the discharge of any disturbing signals.

The information exchange between the two control

modules takes place via two means.

• Via analogue signal leads

• Via the CAN-bus

The analogue signal leads are used to exchange the

followi ng inf or mati on .

• Engine speed signal (ECM terminal 91)

• Pump Sp eed (ECM ter minal 105)

• Fuel Cutoff solenoid v alve signal ( MAB signa l) (ECM

terminal 105)

The engine speed signal is sent from the ECM to PSG

based on the input from the crank shaft position (CKP)

sensor.

The analogue CKP sensor signal is converted by the

ECM into a square wave signal.

The fuel cutoff solenoid valve signal is also referred to

as MAB signal.

MAB in this case, refers to the German abbreviation

Magnet ventil ABschaltung that stands for high pressure

solenoid valve cut off.

The MAB signal wire is used for two purposes.

-As a reference for the engine control module (ECM) for

the pump speed (back up for the CKP sensor).

-To turn Off the engine.

Self Diagnosis / Interface / Signal

To High Pressure Solenoid

Engine Speed

Injection Timing

Accelerator Pedal

Injection Quantity

Intake Air Tem perature

Response Signal

Mass Air Flow

Additional Signal

Others

Additional Operations To Timing Control Valve (TCV)

Engine

Control

Module

(ECM)

Cam Ring Rotational Angle

Fuel Temperature

High Pressure

Solenoid Valve

Pump

Control Fuel Injection

Unit (Mechanical)

(PSG)

Timing Device

The following signals are exchanged via the CAN-bus:

From ECM to PSG

• Desired injection quantity

• Desired injection timing

• Engi ne sp eed

From PSG to ECM

• Fuel temperature

• Pump speed

• Cylinder identifier

• Control pulse (actual injection quantity + actual

injection timing)

•PSG status

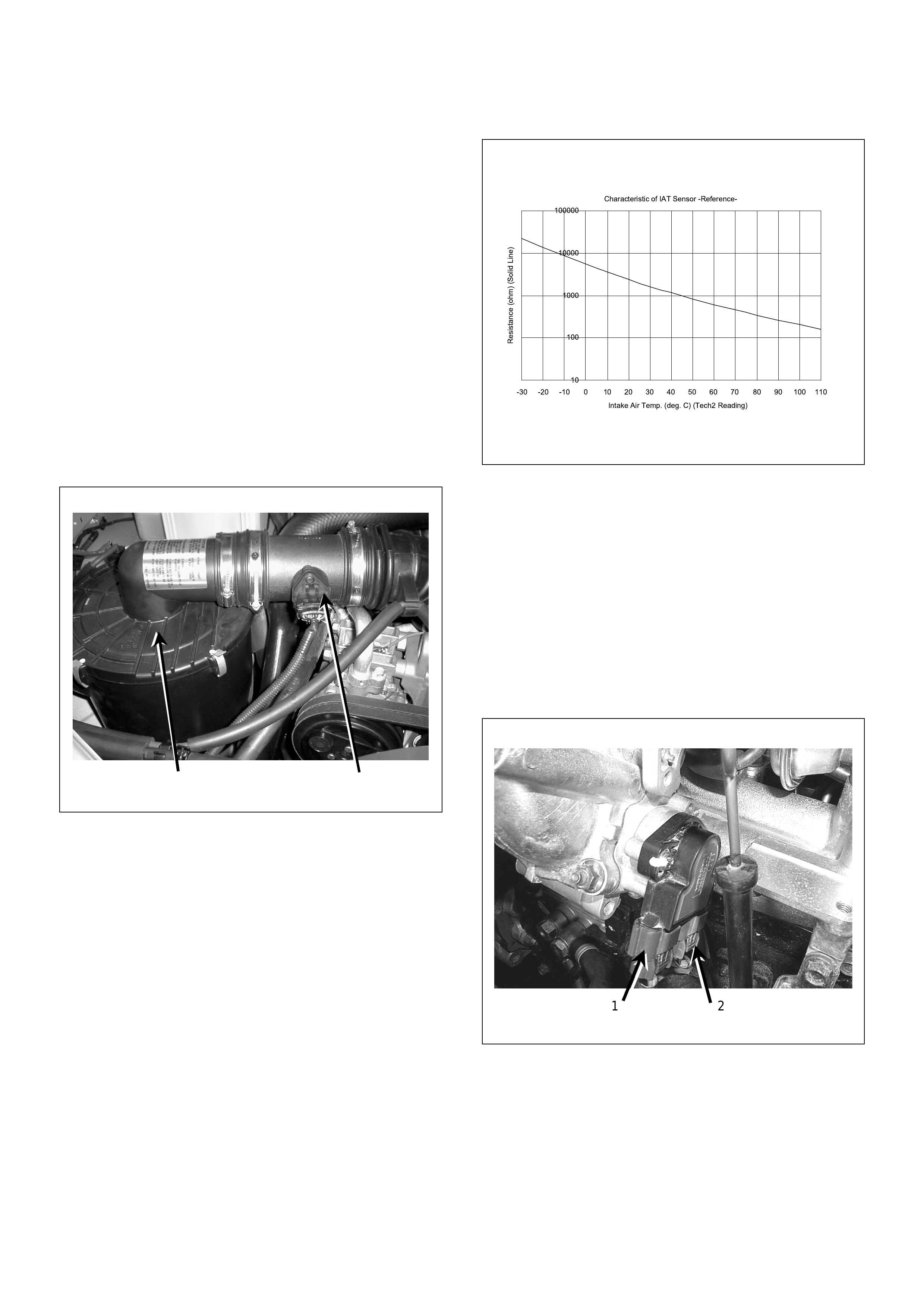

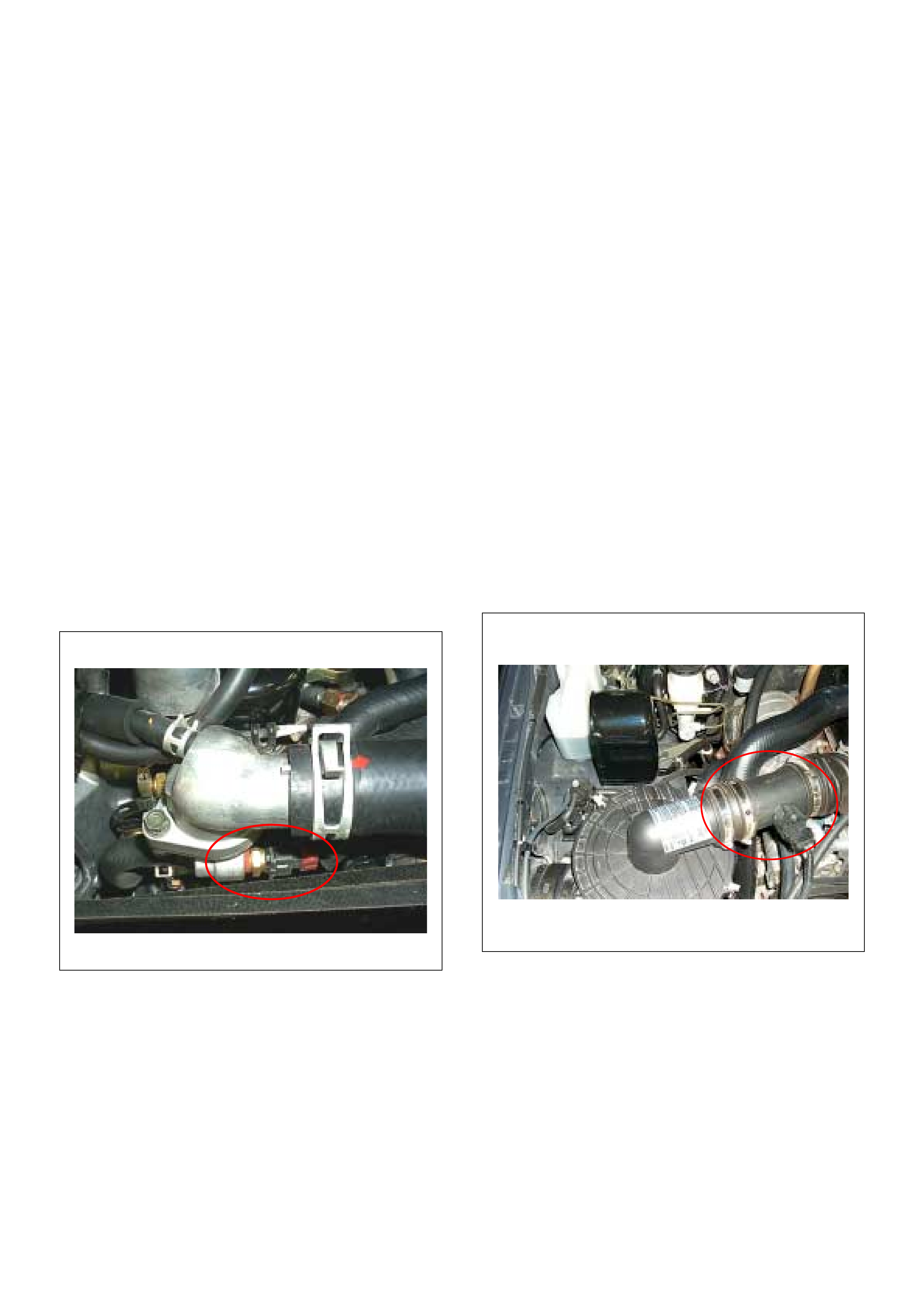

Mass Air Flow (MAF) Sensor & Intake Air

Temperature (IAT) Sensor

The mas s air flo w (MAF) sensor is part of the intake air

system.

It is fitted betw een the air clea ner and turb ocharge r and

measure the mass air flowing into the engine .

The mass air flow (MAF) sensor uses a hot film element

to determine the amount of air flowing into the engine.

The mass air flow (MAF) sensor assembly consist of a

mass air flow (MAF) sensor element and an intake air

temperature sensor that are both exposed to the air flow

to be measured.

The mass air flow (MAF) sensor element measures the

partial air mass through a measurement duct on the

sensor housing.

Using calibration, there is an extrapolation to t he entire

mass air flow to the engine.

The IAT sensor is a thermistor. A temperat ure changes

the resistance value. And it changes voltage. In other

words it measures a temperature value. Low air

temperature produces a high resistance.

The ECM supplies 5 volts signal to the IAT sensor

through resisters in the ECM and measures the voltage.

The signal voltage will be high when the air temperature

is cold, and it will be low when the air temperature is

hot.

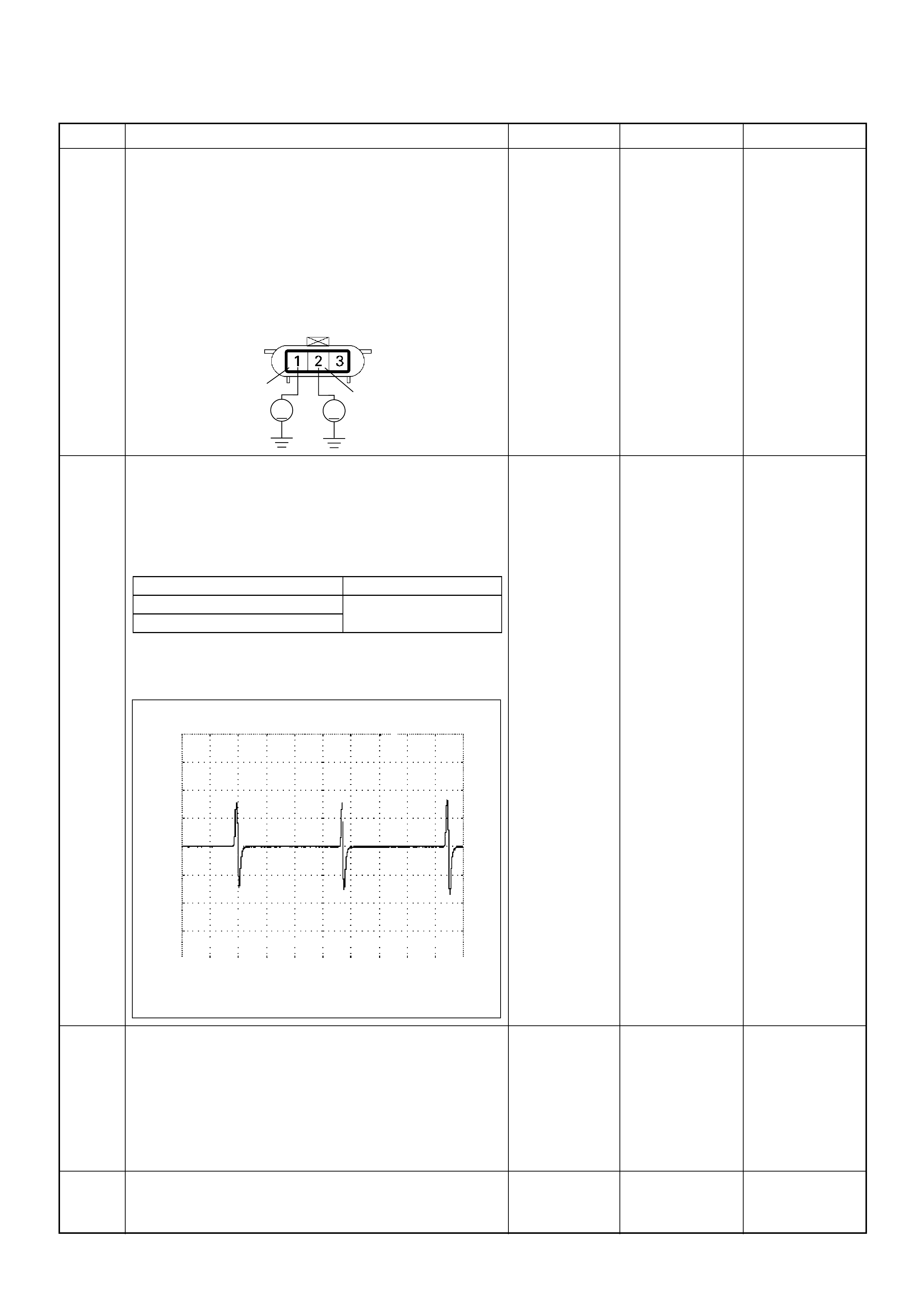

Throttle Position Sensor (TPS)

(1) Air Cleaner Case

(2) Mass Air Flow (MAF) & Intake Air Temperature

(IAT) Sensor

1 2

(1) Throttle Position Sensor (TPS)

(2) Idle Switch

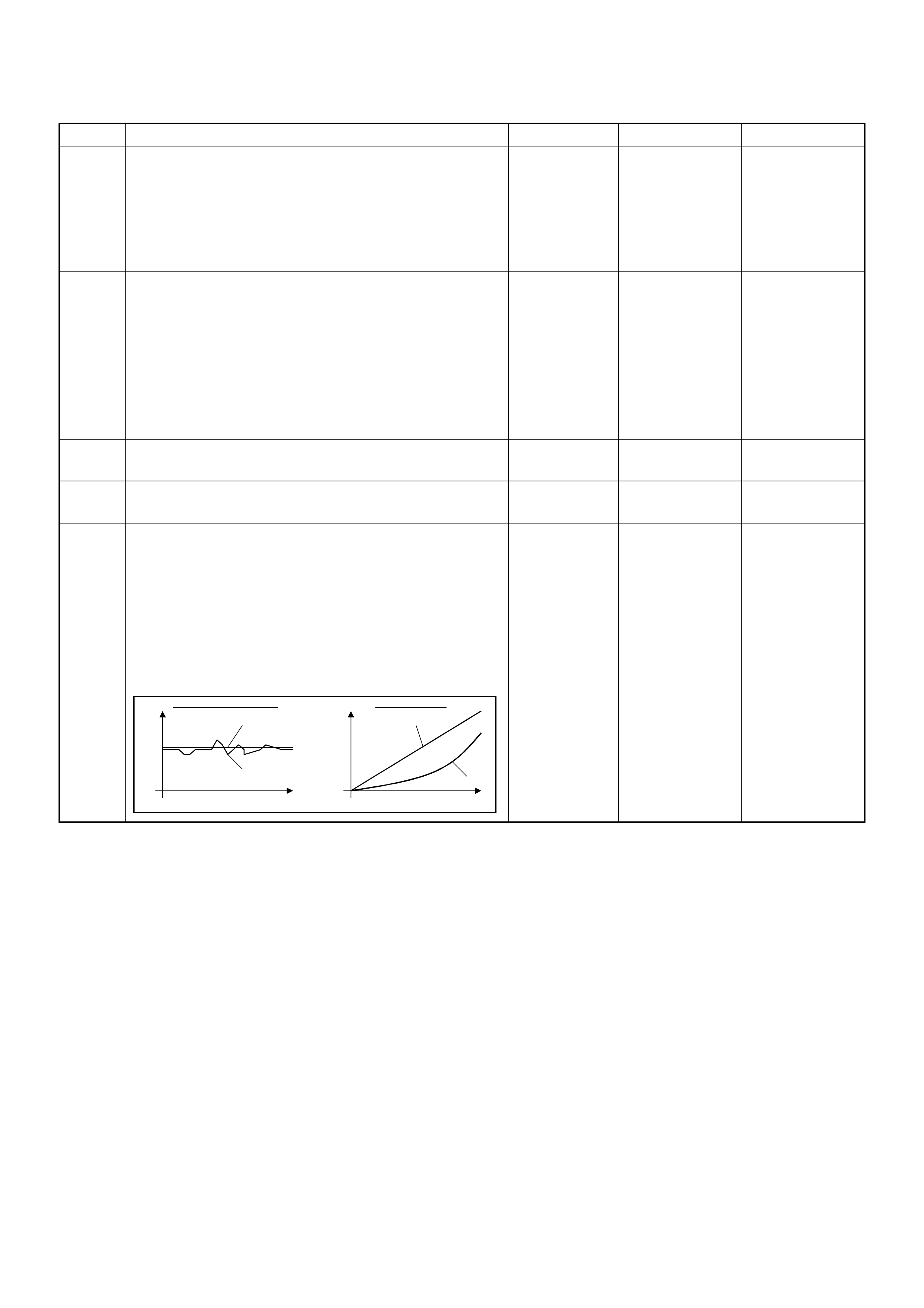

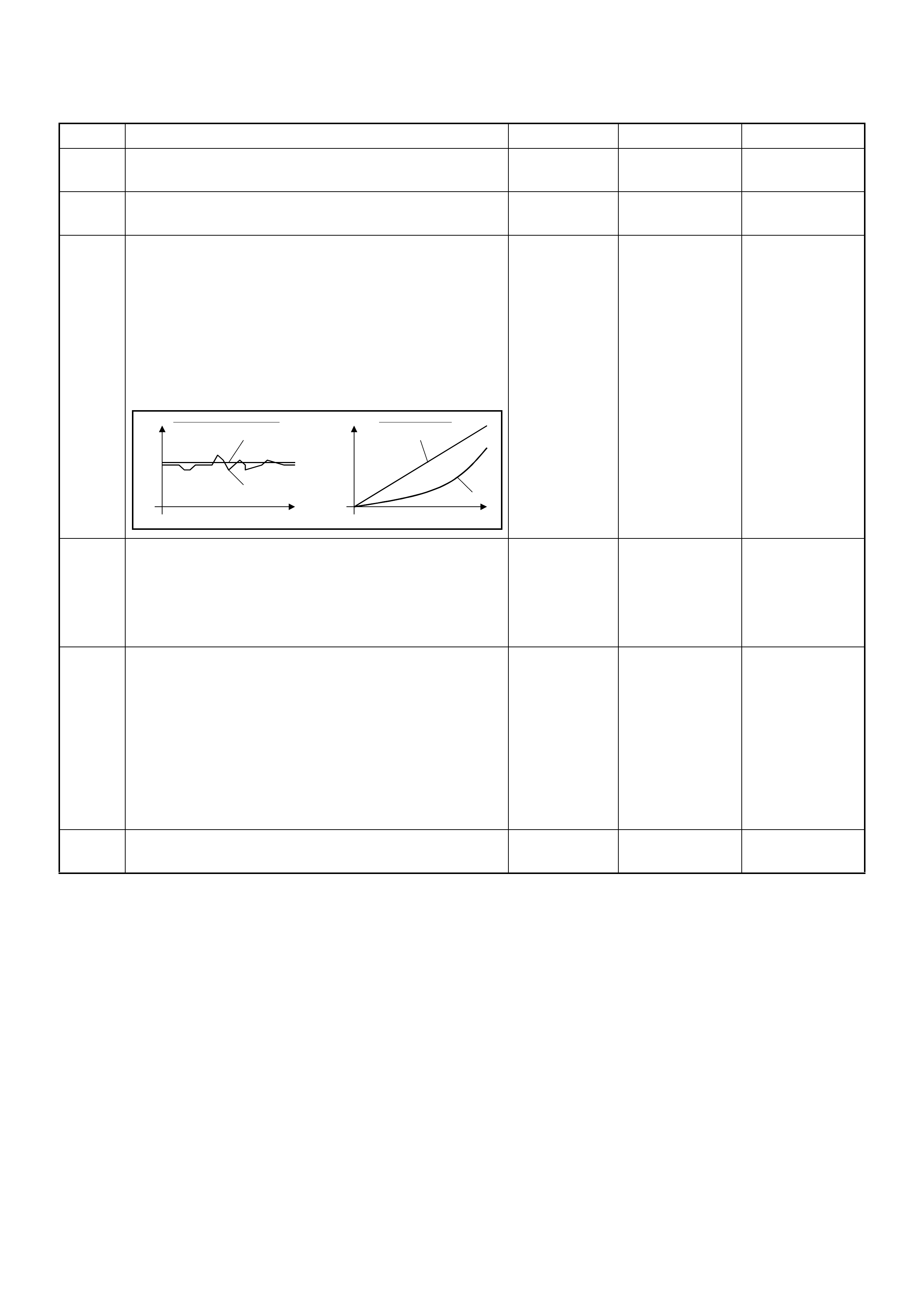

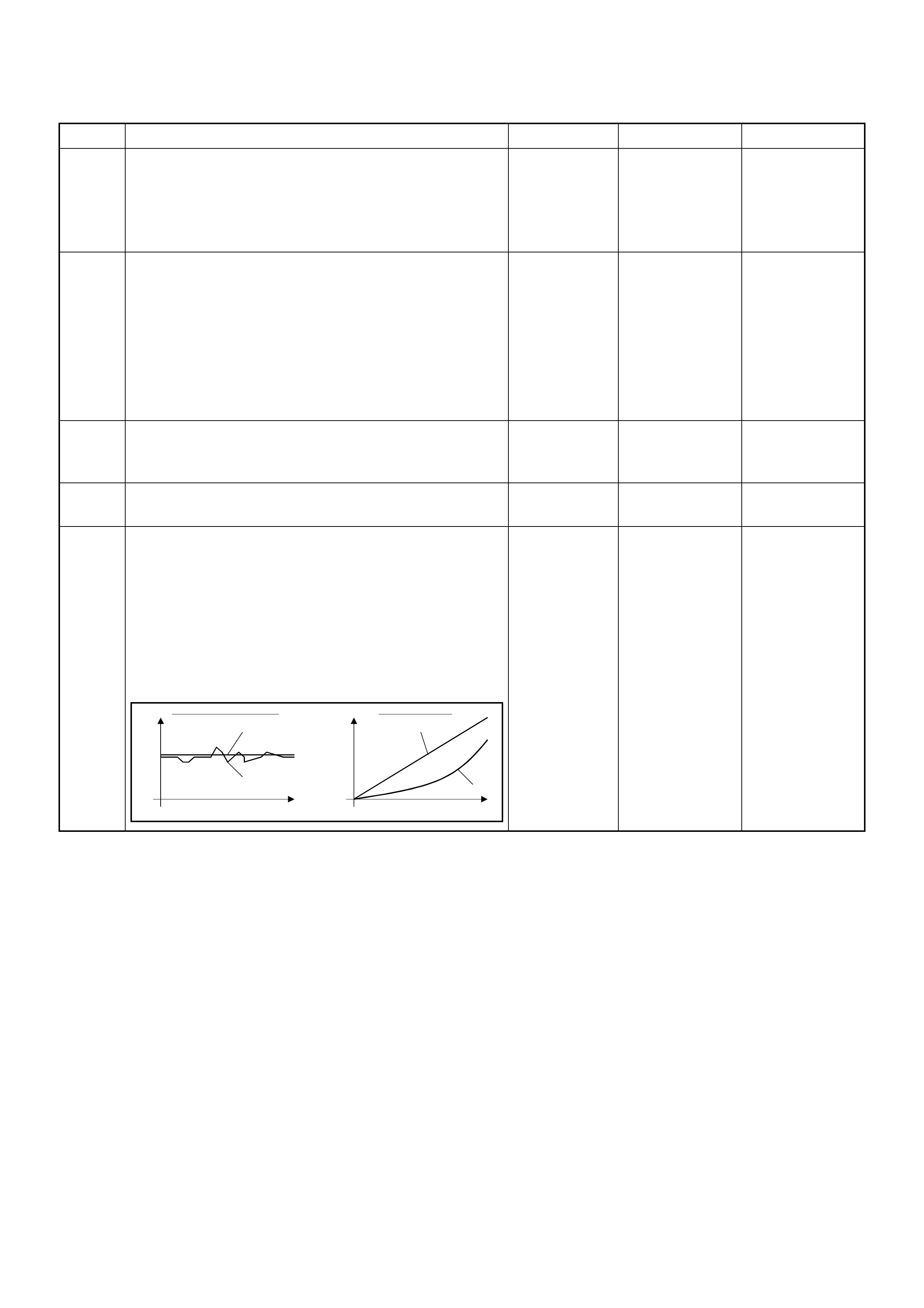

Characteristic of IAT Sensor -Reference-

10

100

1000

10000

100000

-30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110

Intake Air Temp. (deg. C) (Tech2 Reading)

Resistance (ohm) (Solid Line)

1 2

The TPS is a potentiometer connected to throttle shaft

on the throttle body. It is installed to the main TPS and

idle switc h.

The engine control module (ECM) monitors the voltage

on the signal line and calculates throttle position. As the

throttle valve angle is changed when accelerator pedal

moved. The TPS signal also changed at a moved

throttle valve. As the throttle valve opens, the output

increases so that the output voltage should be high.

The engine control module (ECM) calculates fuel

delivery based on throttle valve angle.

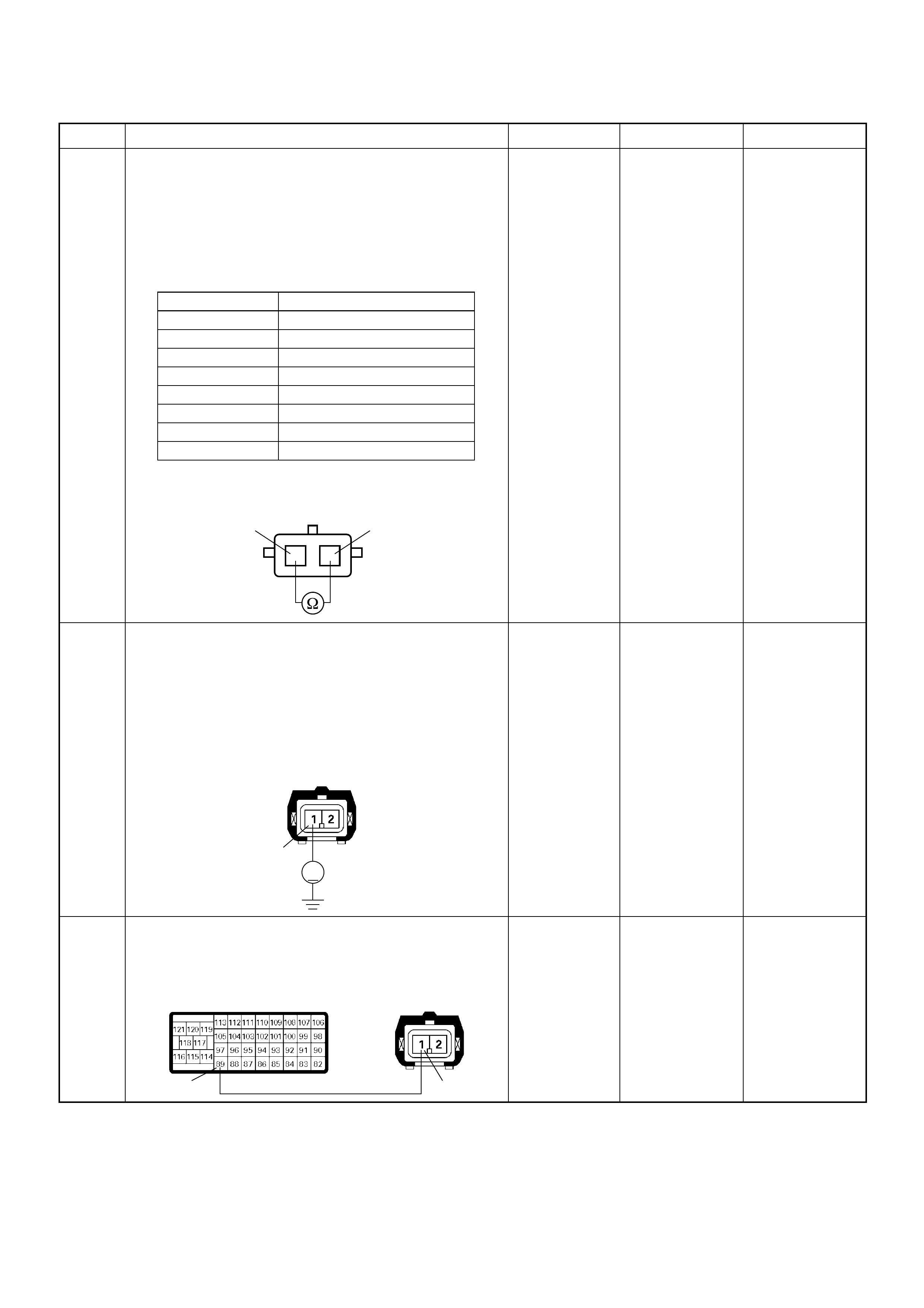

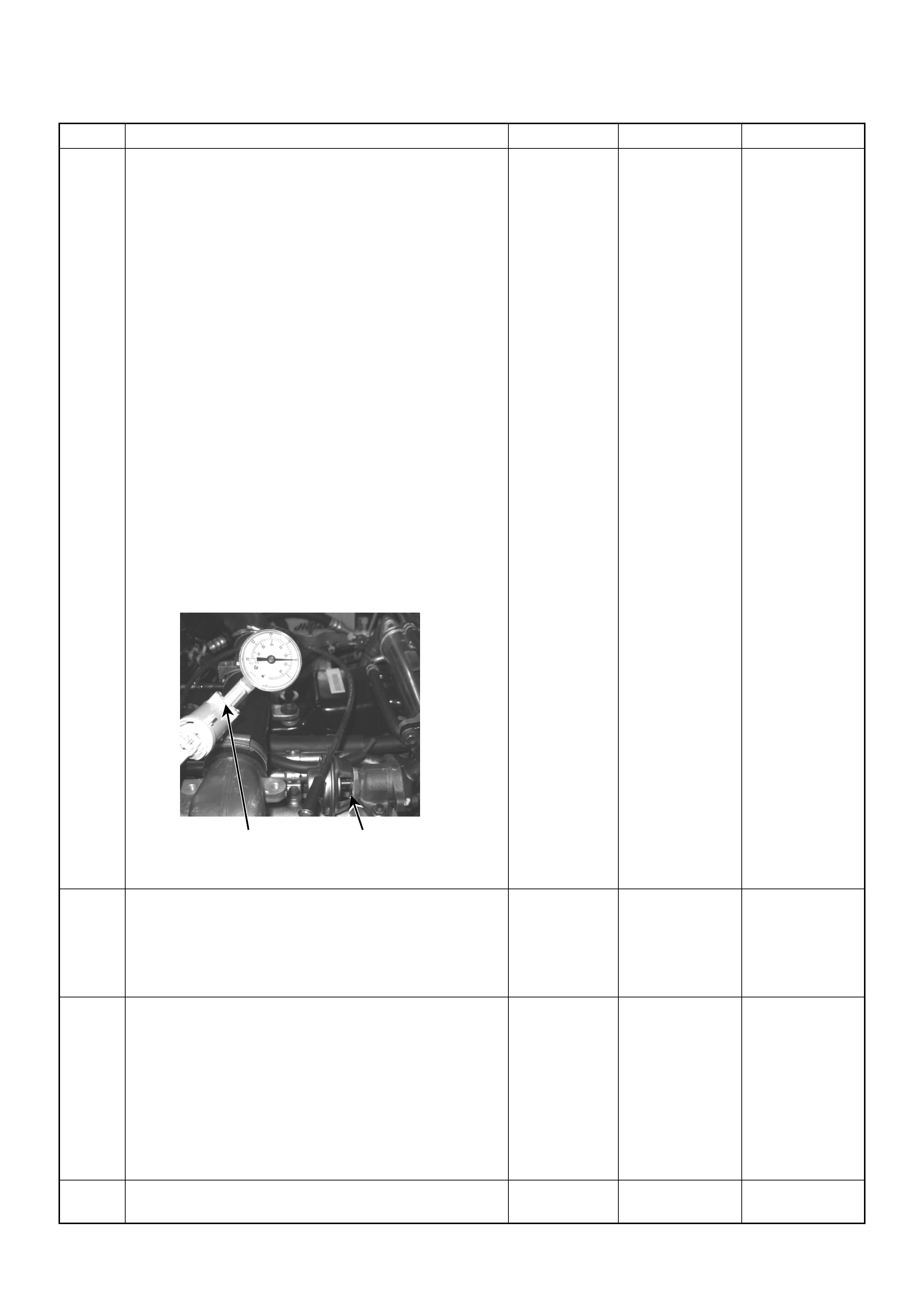

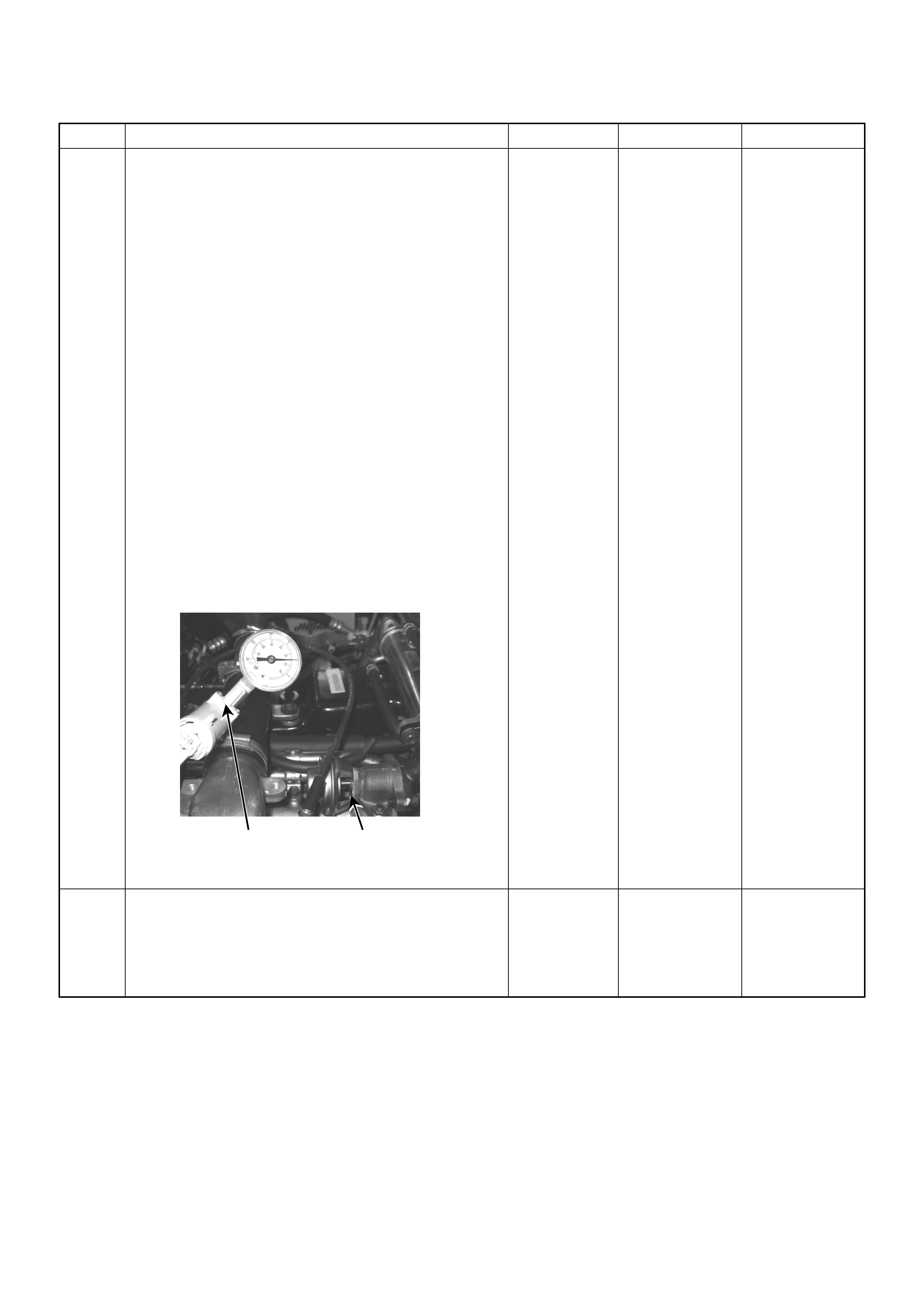

Crankshaft Position (CKP) Sensor

The CKP sensor is located on top of the flywheel

housing of the flywheel and fixed with a bolt.

The CKP sensor is of the magnet coil type. The

inductive pickup sensors four gaps in the flywheel

exciter ring and is used to determine the engine speed

and engine cylinder top dead center (TDC).

Engine Coolant Temperature (ECT) Sensor

The ECT sensor is a thermistor. Temperature changes

it’s resistance value, which therefore changes circuit

voltage. In other words it measures a temperature

value . It is installed on the coolant stream. Lo w coolant

temperature produces a high resistance.

The ECM supplies 5 volts signal to the ECT sensor

through resisters in the ECM and measures the voltage.

The signal voltage will be high when the engine

temperature is cold, and it will be low when the engine

temp eratur e is hot.

(1) Crankshaft Position (CKP) Sensor

(2) Fly wheel with sensor slot

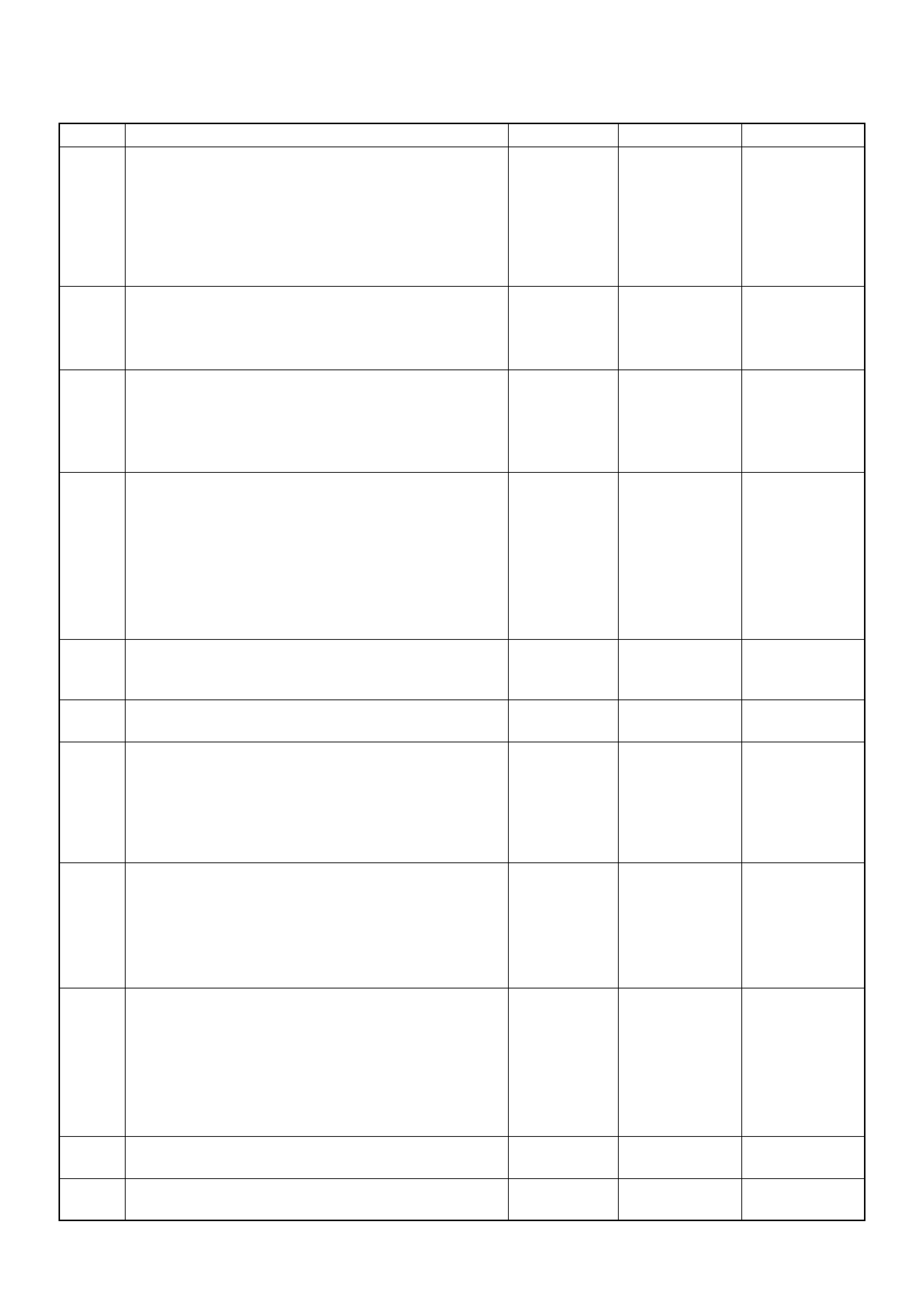

Characteristic of TPS -Reference-

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Pedal Position (%) (Tech2 Readin

g

Output Voltage (V)

1 2

(1) Engine Coolant Temperature (ECT) Sensor

(2) Thermo Unit for Water Temperature Gauge

NO

Characteristic of ECT Sensor -Reference-

10

100

1000

10000

100000

-30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110 120 130

Engine Coolant Temp (deg. C) (Tech2 Reading)

Resistance (ohm) (Solid Line)

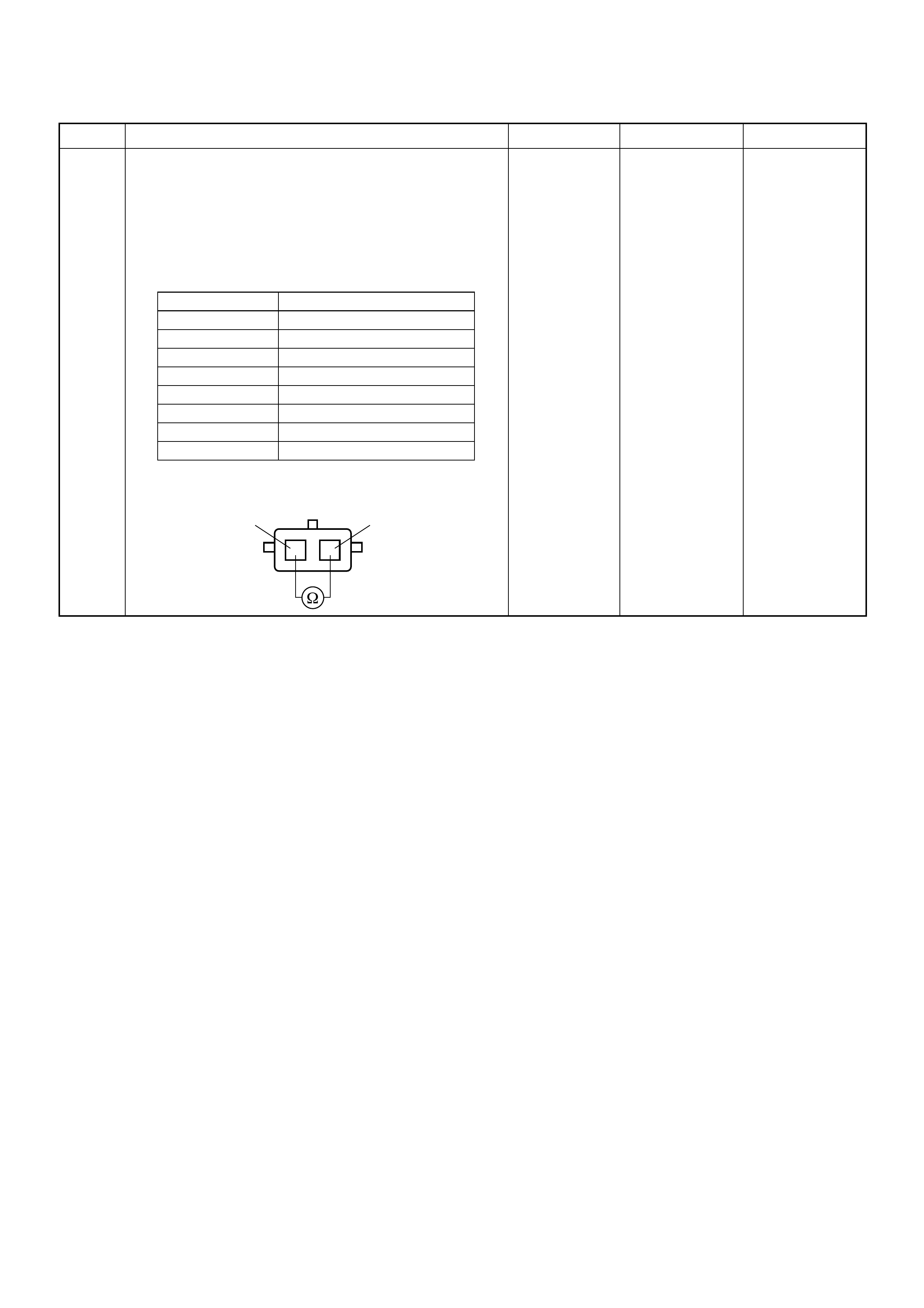

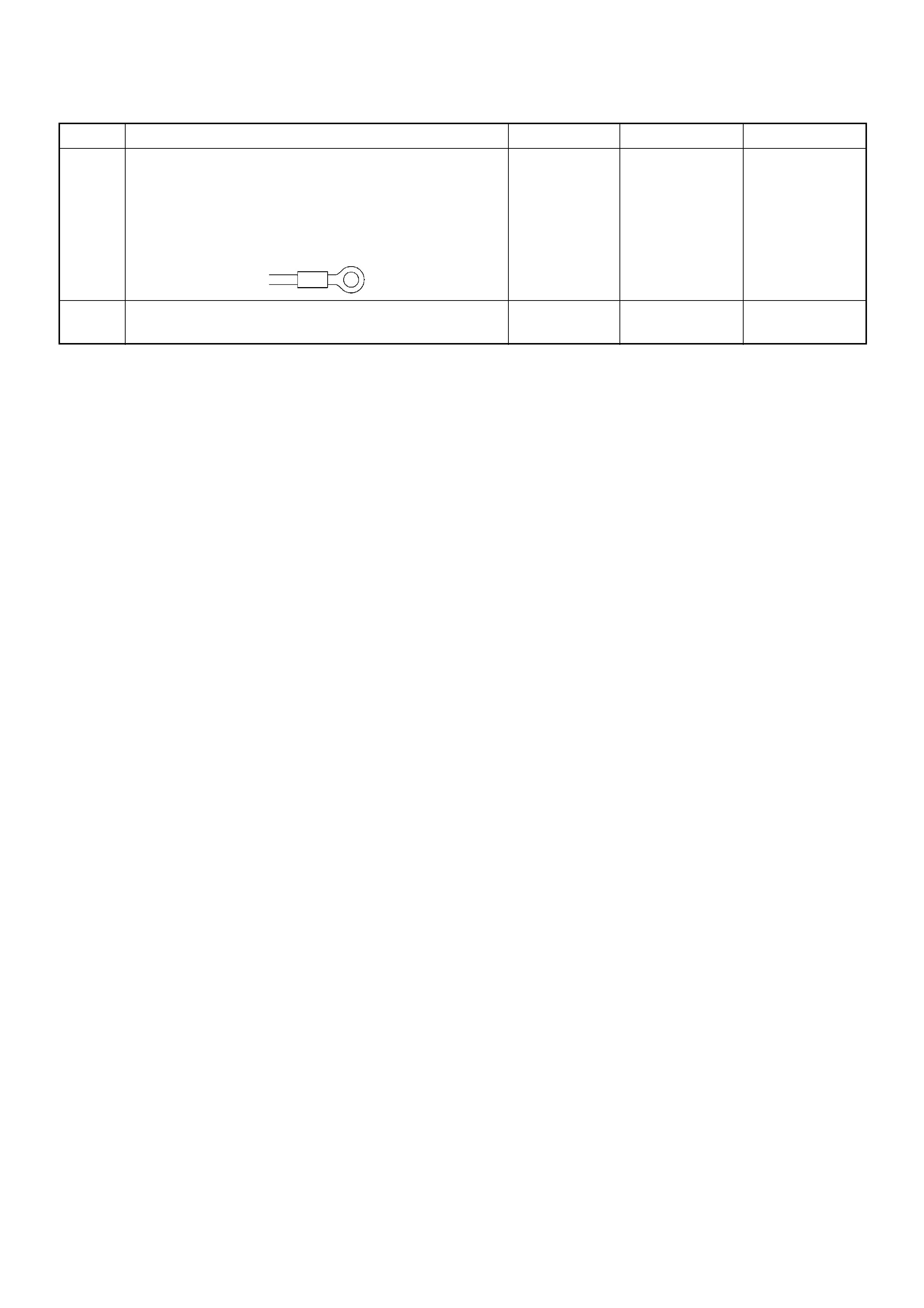

Vehicle Speed Sensor (VSS)

M/T & A/T 4WD

A/T 2WD

The VSS is a magnet rotated by the transmission output

shaft. The VSS uses a hall elemen t. It interac ts with the

magnetic field treated by the r otating magnet. It outputs

a pulse signal. The 12 volts operating supply comes

from the meter fuse.

The engine control module (ECM) calculates the vehicle

speed by VSS.

On 2WD models fitt ed with automatic transmission, the

vehicle speed sensor signal is transmitted from the TCM

to the ECM via vehicle speed meter.

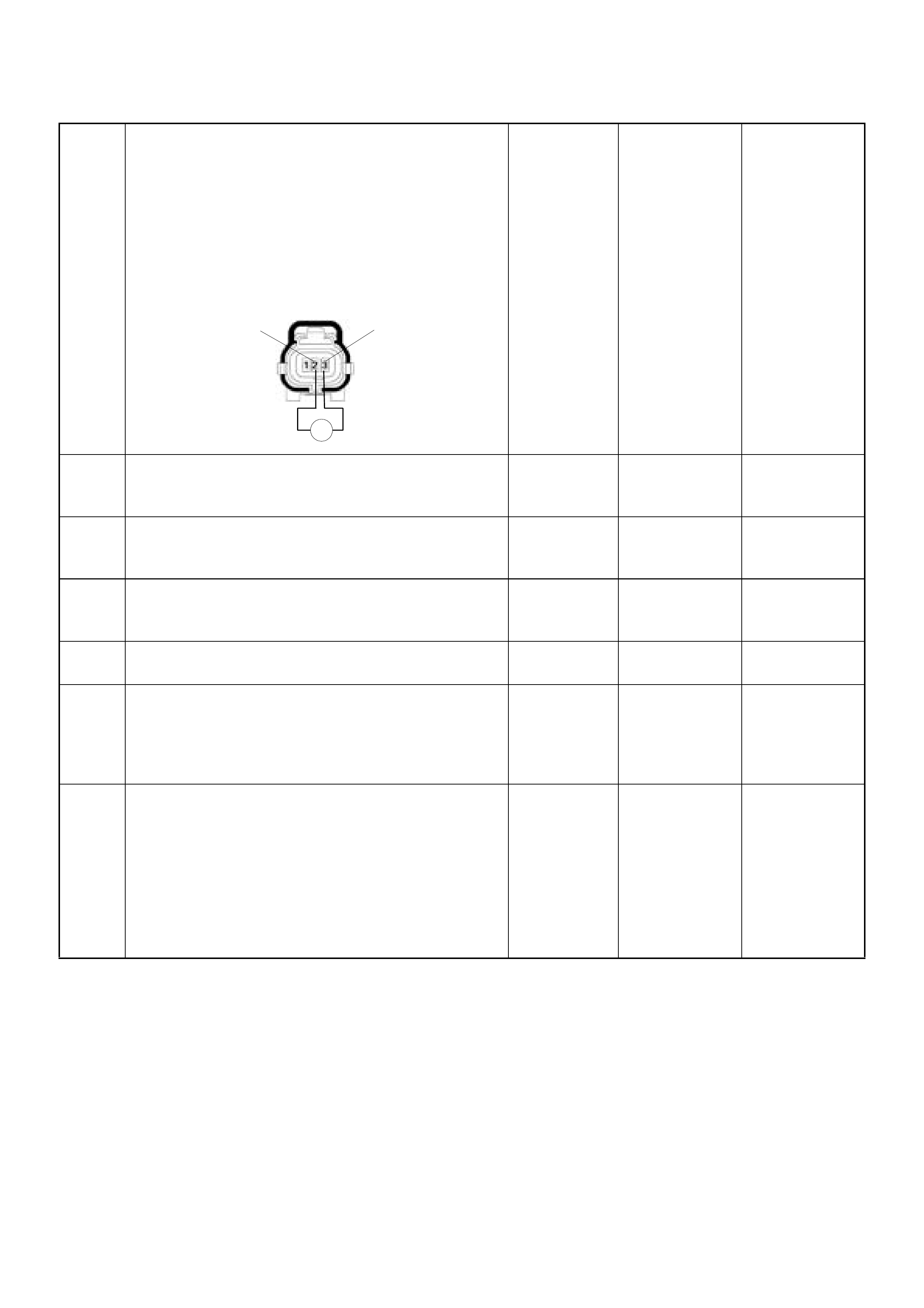

GENERAL DESCRIPTION FOR EGR (EXHAUST GAS RE-CIRCULATION)

The amount of EGR is controlled by EVRV (electrical

vacuu m regulati ng valve) via the engin e control mod ule

(ECM) command signal depends on the following

inputs.

• Engine speed

• Injection quantity

• Mass air flow

• Intake air temperature

• Coolant temperature

• Barometric pressure

(1) EGR Valve

(2) EGR Pipe

(3) Intercooler

(4) Intake Manifold

(5) Exhaust Manifold

(6) Waste Gate

(7) Fresh Ai r

(8) Exhaust Gas

(9) Turbocharger

123

(1) To EGR Valve

(2) From Vacuum Pump

(3) EGR EVRV

(4) EGR Valve

(5) EGR Pipe

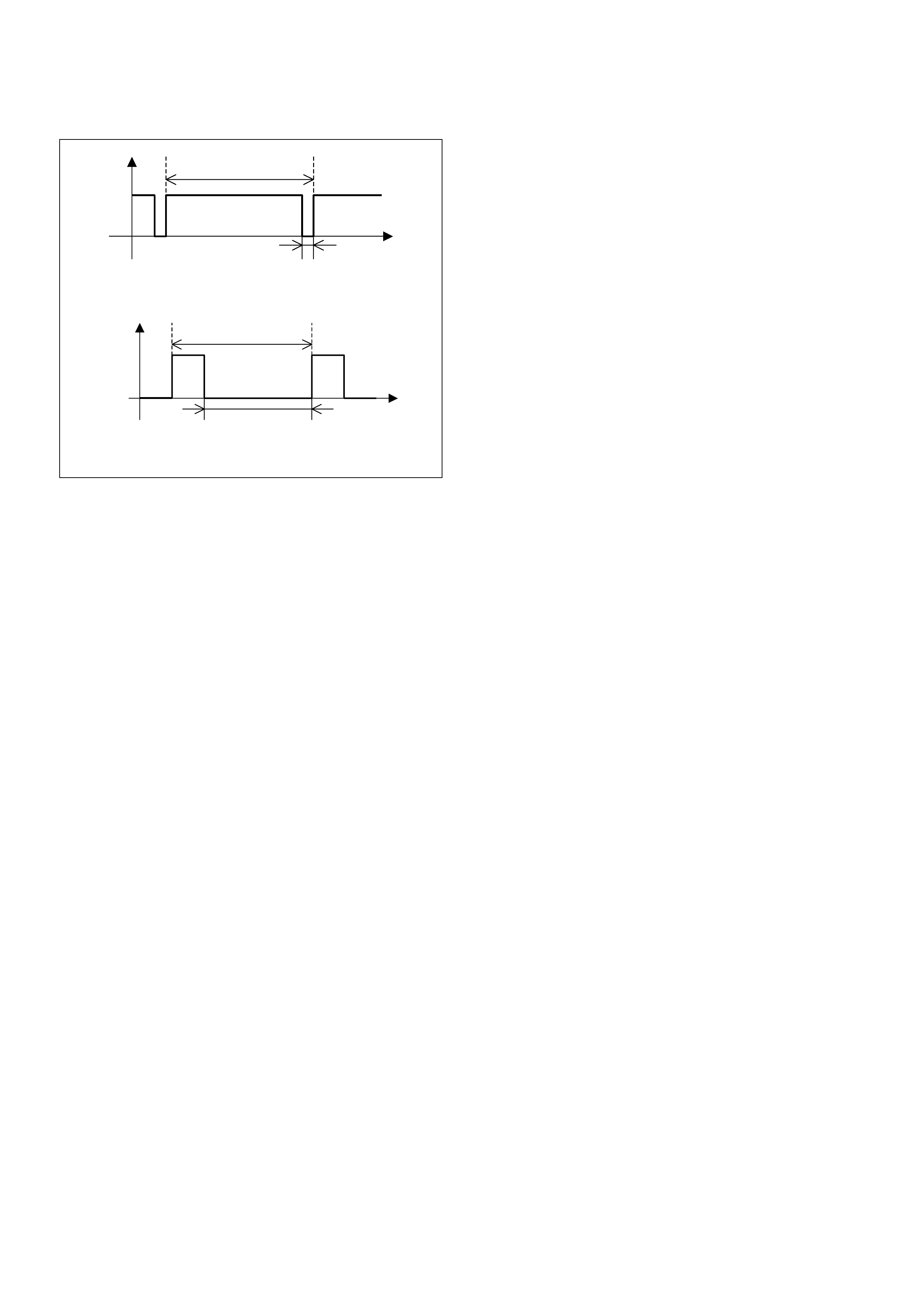

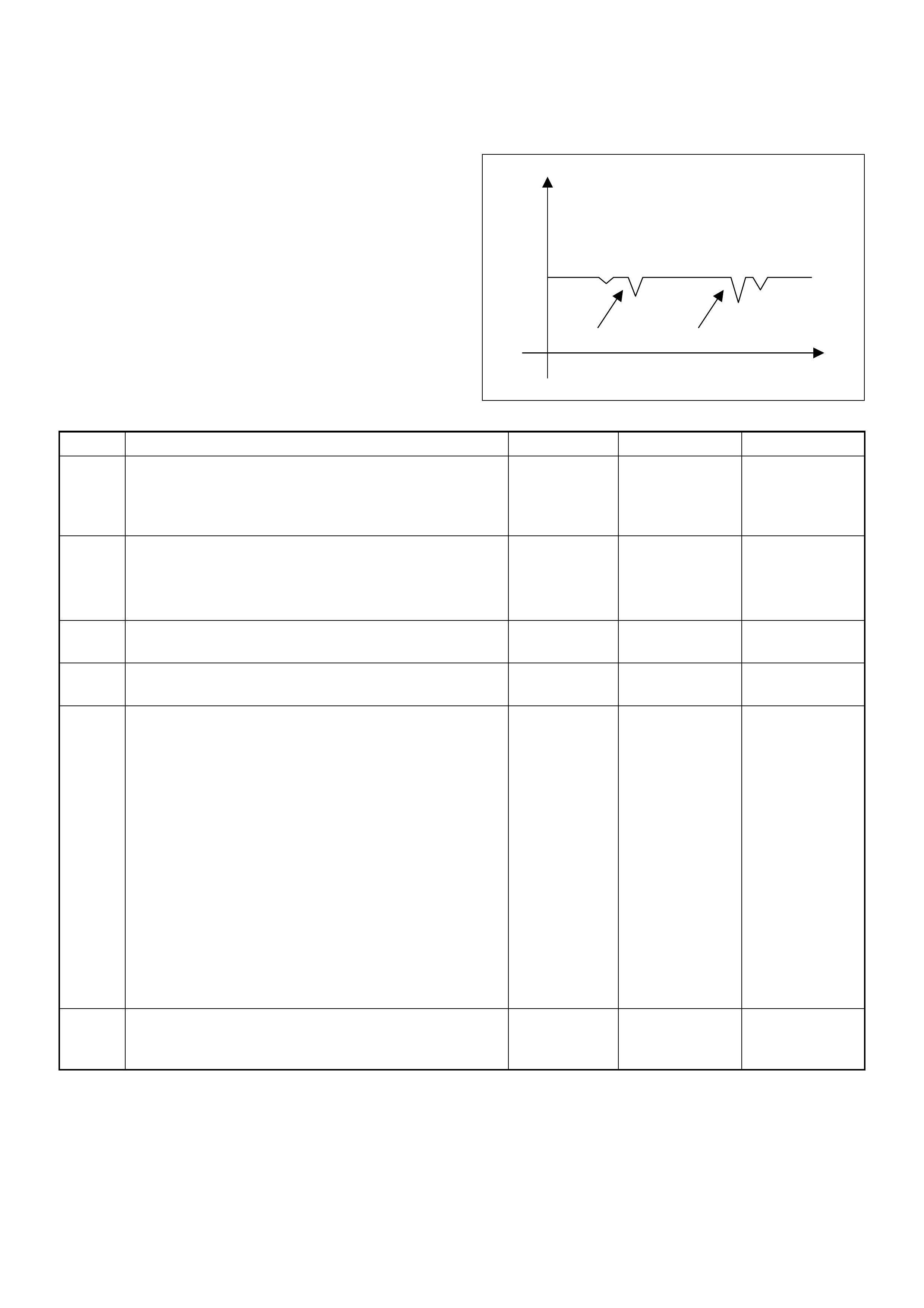

The EVRV is shaped to control vacuum applied to the

diaphragm chamber of the EGR valve based on duty

signal sent from the ECM. The duty ratio is the time that

the EVRV is opened during one EVRV operating cycle.

A duty ratio change of 90% to 10 % is EGR amount

control range.

7.1ms

Time

0.7ms

Off duty 10% =EGR Pul se Ratio 10%

7.1ms

Time

6.4ms

Off duty 90% =EGR Pu lse Ratio 90%

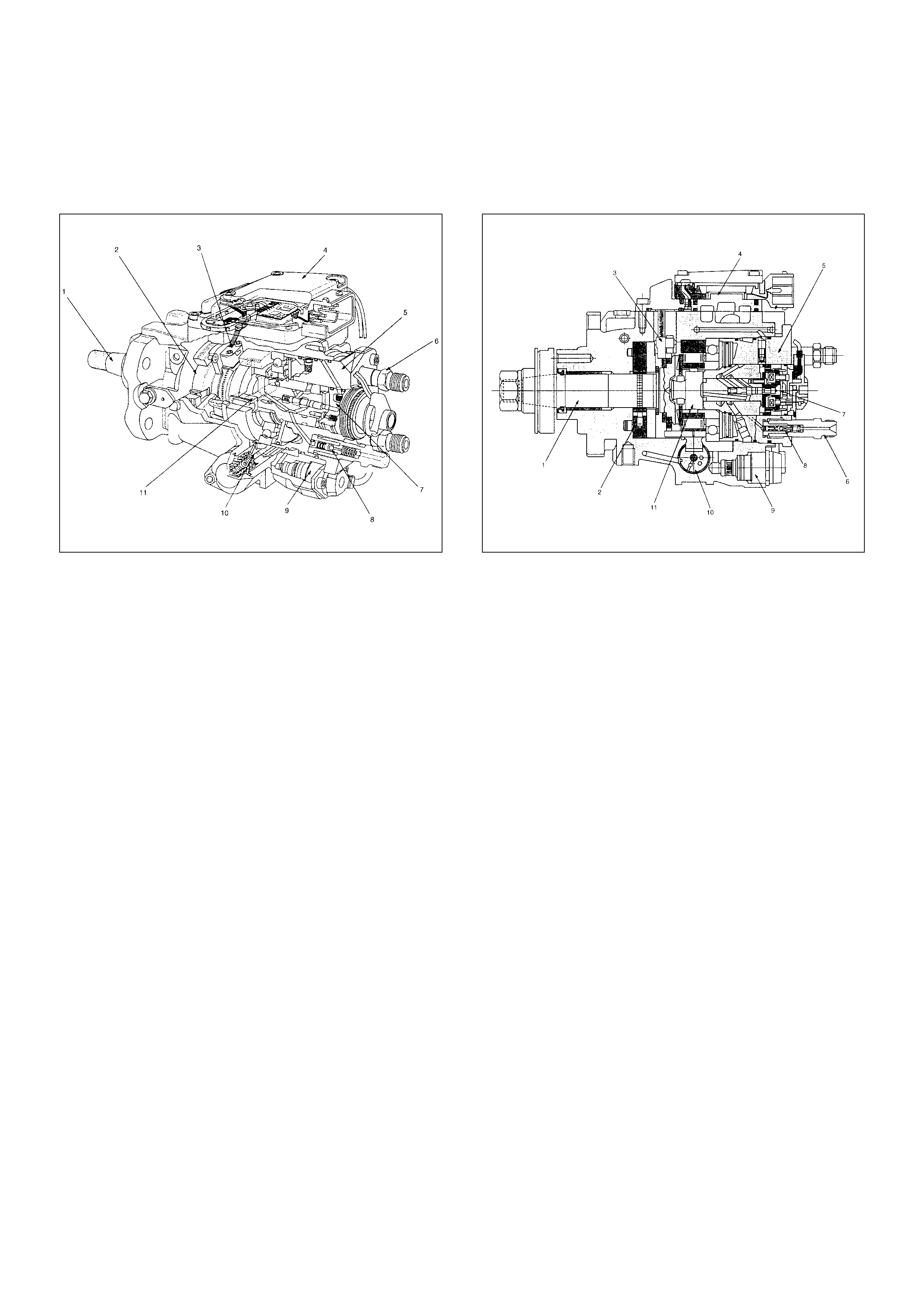

GENERAL DESCRIPTION FOR INJECTION PUMP

Outline

Instead of the previous face cam type, the radial plunger

distributor type injection pump utilizes a cam ring to

enable fuel injection at high-pressures, marking it

suitable for small, high-speed direct injection diesel

engines. T his pump was deve loped to prov ide the most

suitable fuel injection quantity and injection timing to

satisfy the demand for en gine reliabi lity, driveabi lity, lo w

smoke, low noise, high output and clear exhaust

emissions.

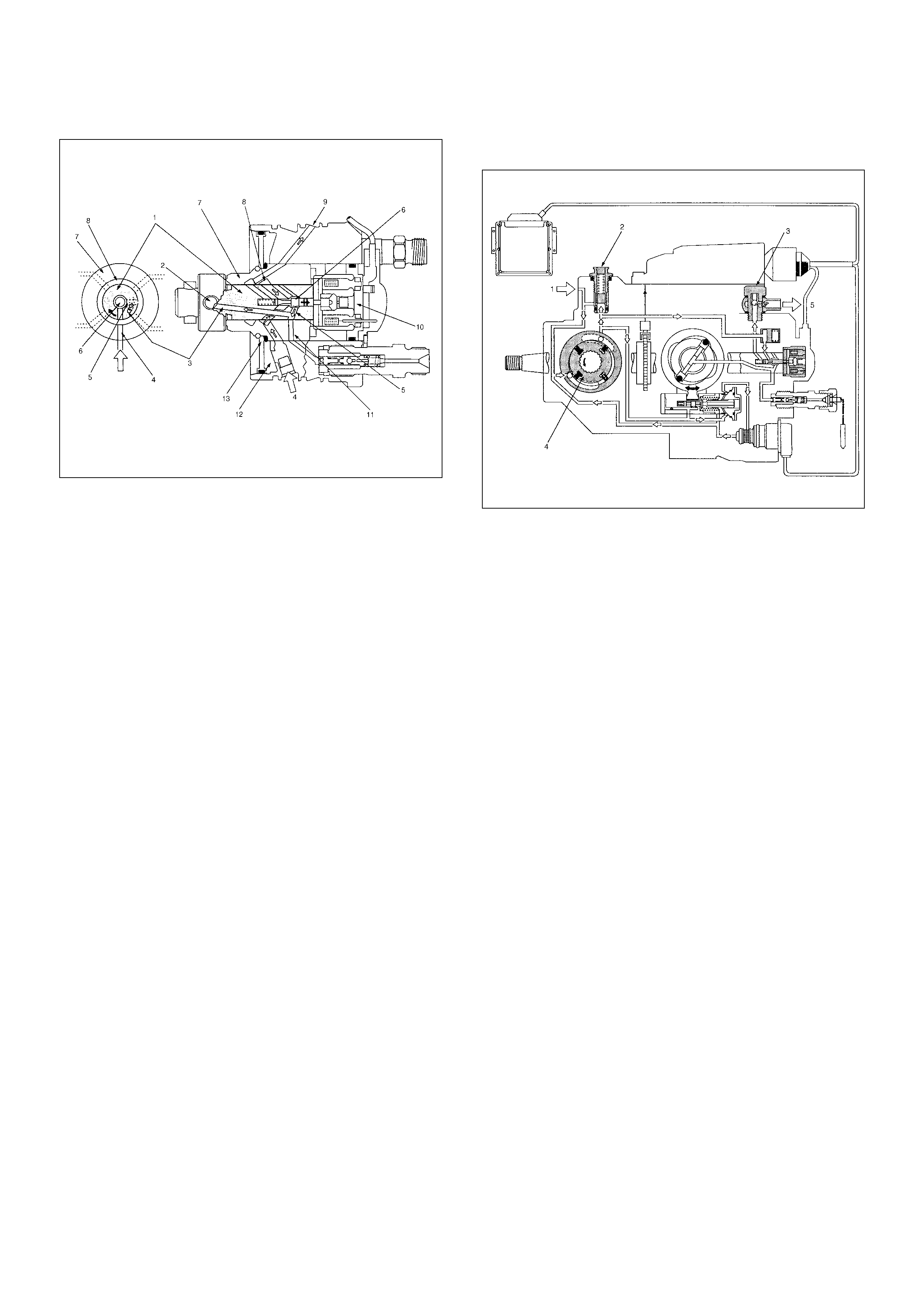

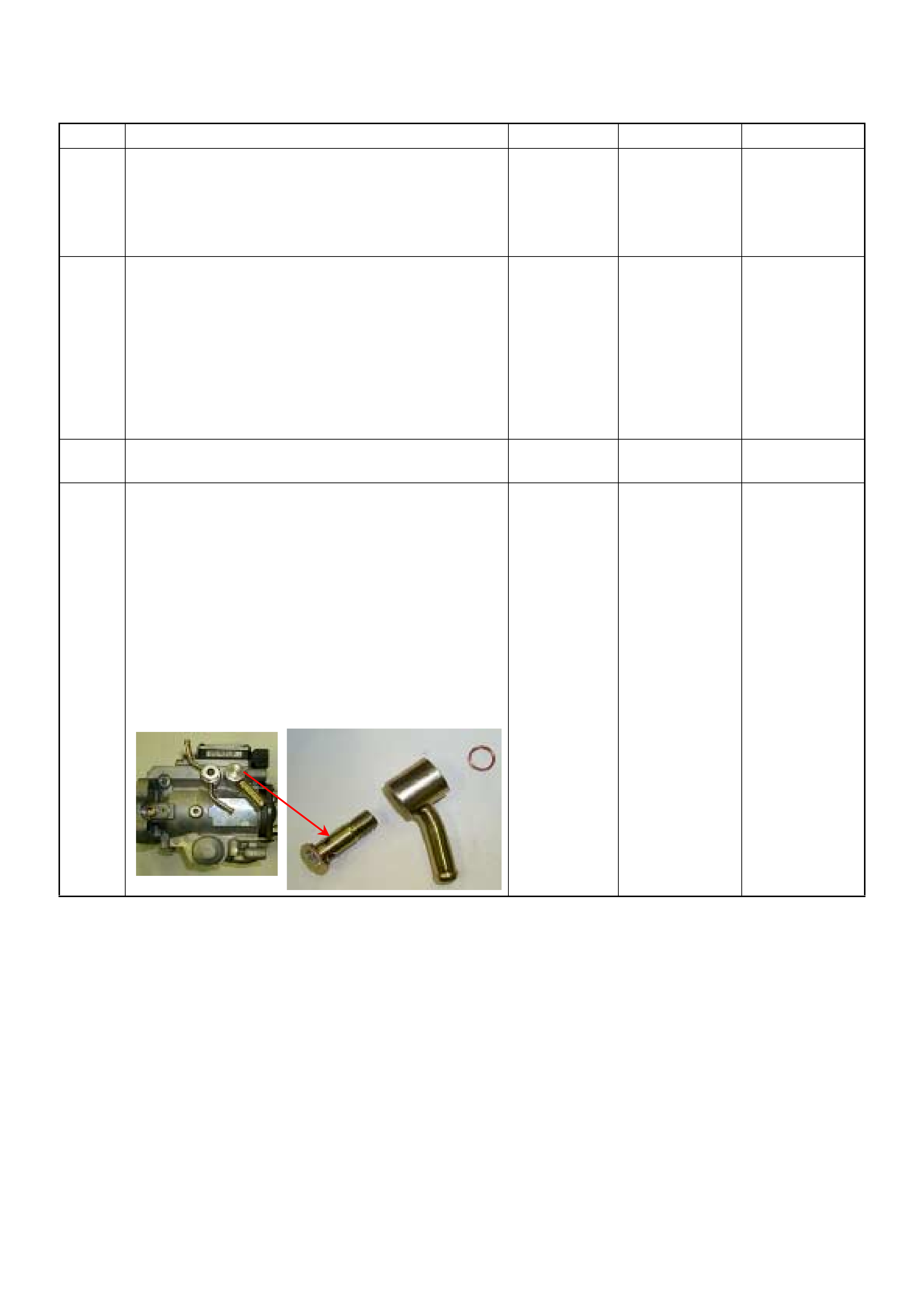

Cross-section View

(1) Drive Shaft

(2) Feed Pump

(3) Pump Camshaft Speed Sensor

(4) Pump Control Unit (PSG)

(5) Distributor Head

(6) Constant Pressure Valve (CPV) Holder

(7) High Pressure Solenoid Valve

(8) Constant Pressure Valve (CPV)

(9) Timing Control Valve (TCV)

(10) Timer

(11) Radial Plunger High Pressure Pump

(1) Dr iv e Sha ft

(2) Feed Pump

(3) Pump Camshaft Speed Sensor

(4) Pump Control Unit (PSG)

(5) Distributor Head

(6) Constant Pressure Valve (CPV) Holder

(7) High Pressure Solenoid Valve

(8) Constant Pressure Valve (CPV)

(9) Timing Control Valve (TCV)

(10) Timer

(11) Radial Plunger High Pressure Pump

Low Pressure Fuel Circuit

The low pressure fuel circuit must supply sufficient fuel

to the high pressure fuel circuit. The main components

are the feed pump, the regulating valve and the

overflow valve.

(1) Rotor Shaft

(2) Radial Plunger

(3) Hi gh Pr ess ur e Passag e

(4) Low Pressure Inlet

(5) Distributor Slit

(6) Valv e Need le

(7) Barrel

(8) Annular Passage

(9) Fuel Return

(10) High Pressure Solenoid Valve

(11) Hi gh Pres s ure Outl et

(12) Diaphram Chamber

(13) Accumulator Diaphram

(1) Fuel Suction

(2) Regulating Valve

(3) Overflow Valve

(4) Feed Pump

(5) To Fuel Tank

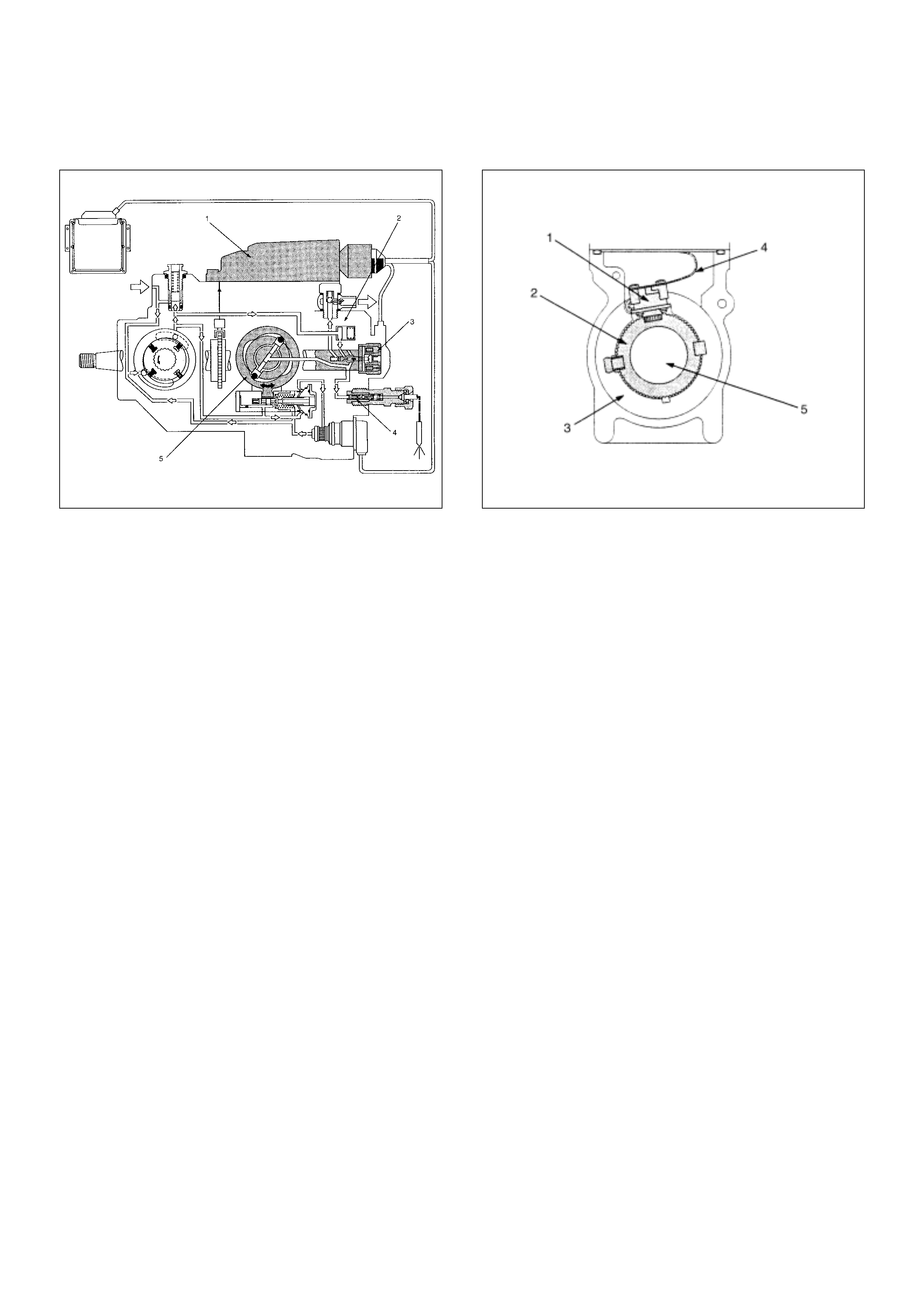

High Pressure Fuel Circuit

In addition to a high pressure generating device, the

high pressure circuit also consists of fuel piping, and

devices to set the beginning of injection and fuel

injection quantity.

The main components are as follows.

• High pressure generation: Radial Plunger High

Pressure Pump

• Fuel distribution: Distributor Head

• Beginning of injection timing: Timing Device

• Prevention of secondary injection: Constant Pressure

Valve (CPV)

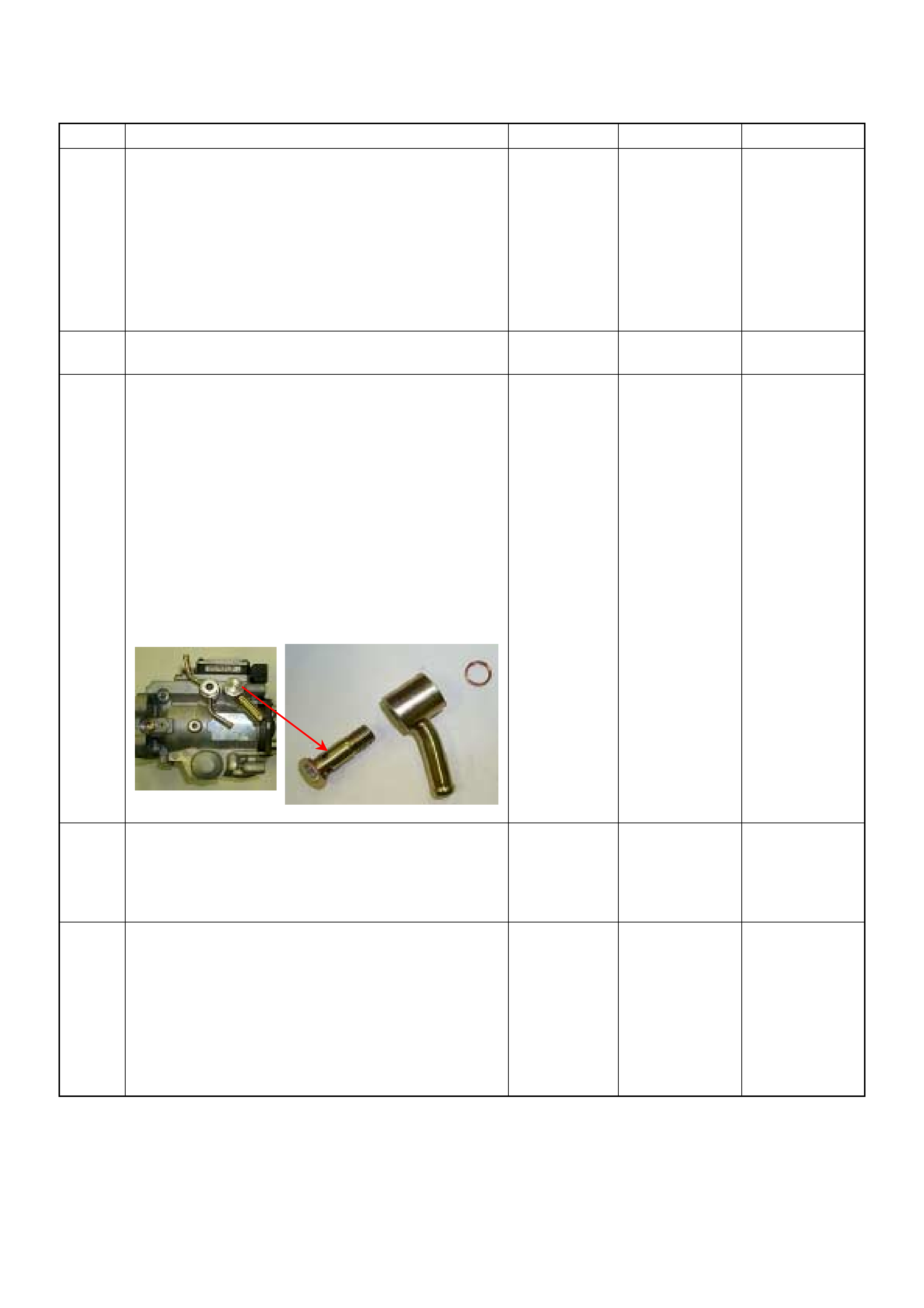

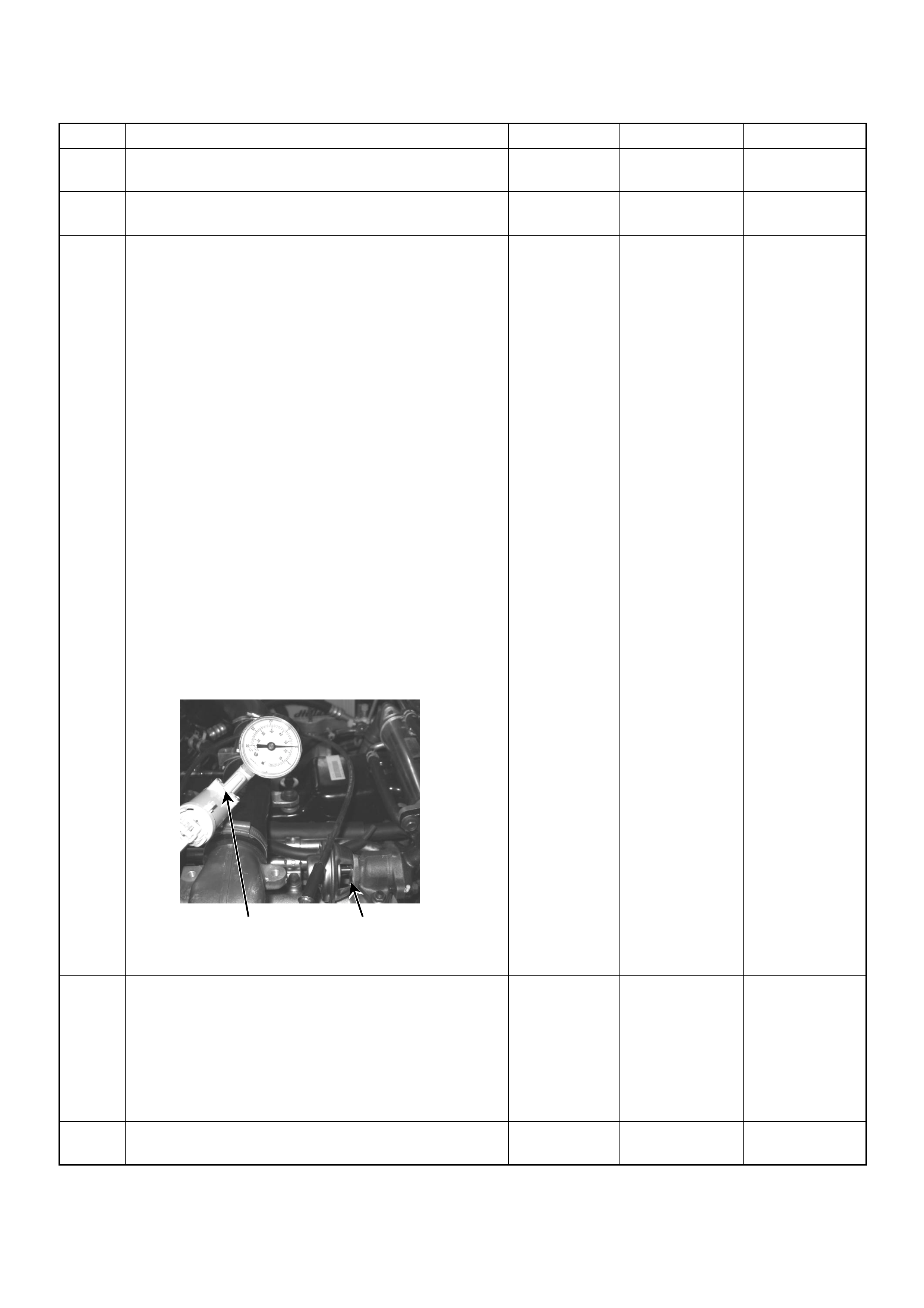

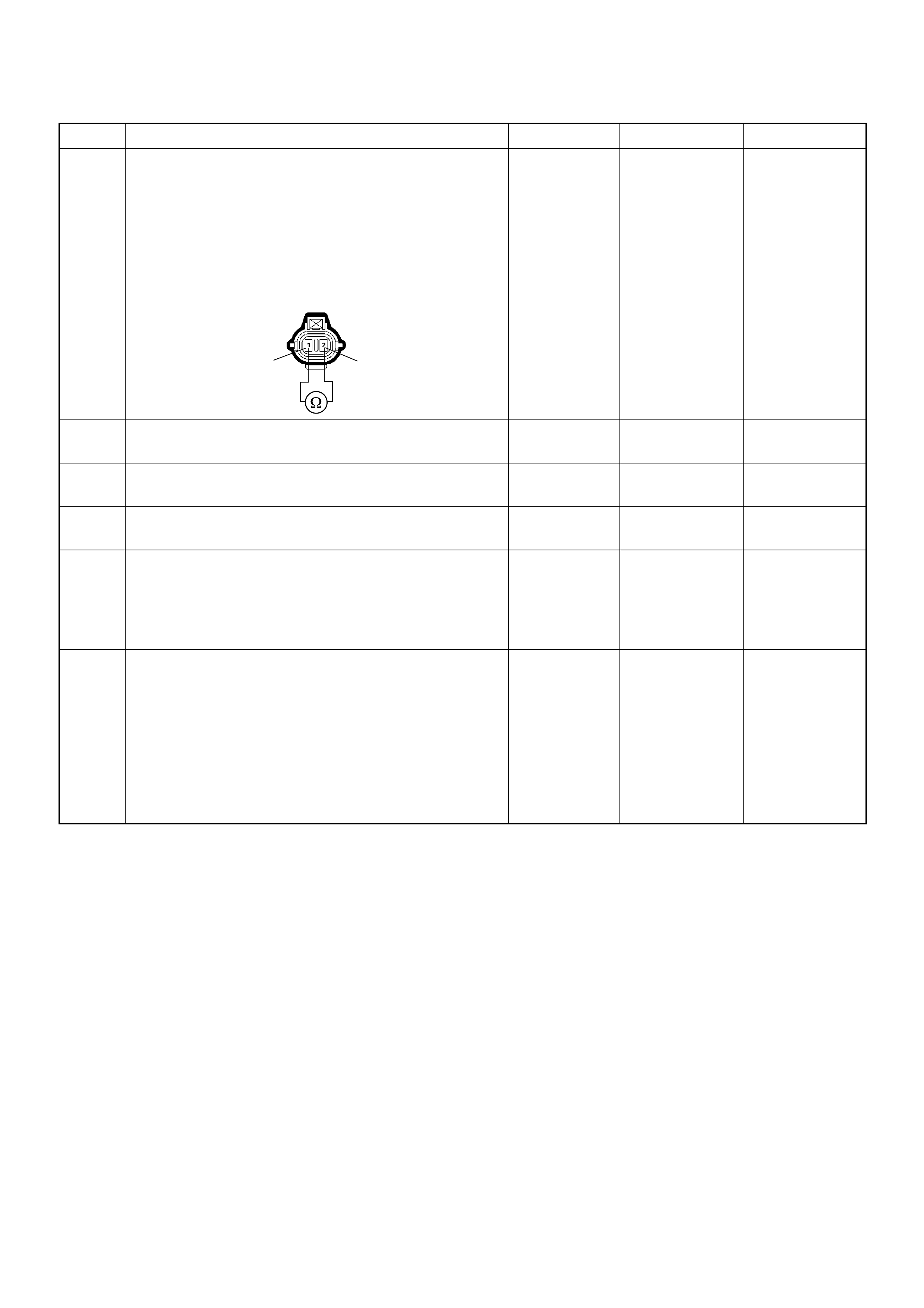

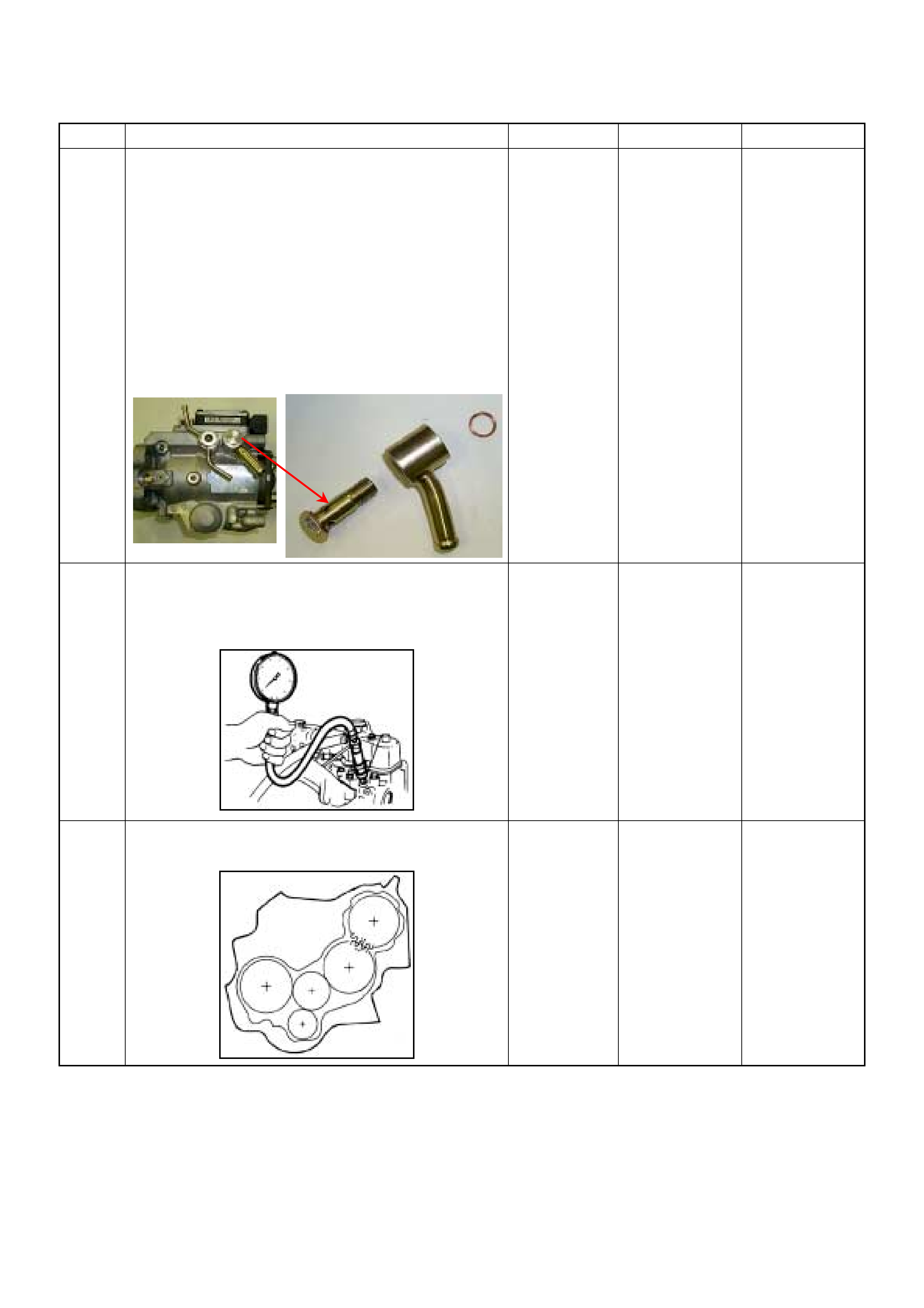

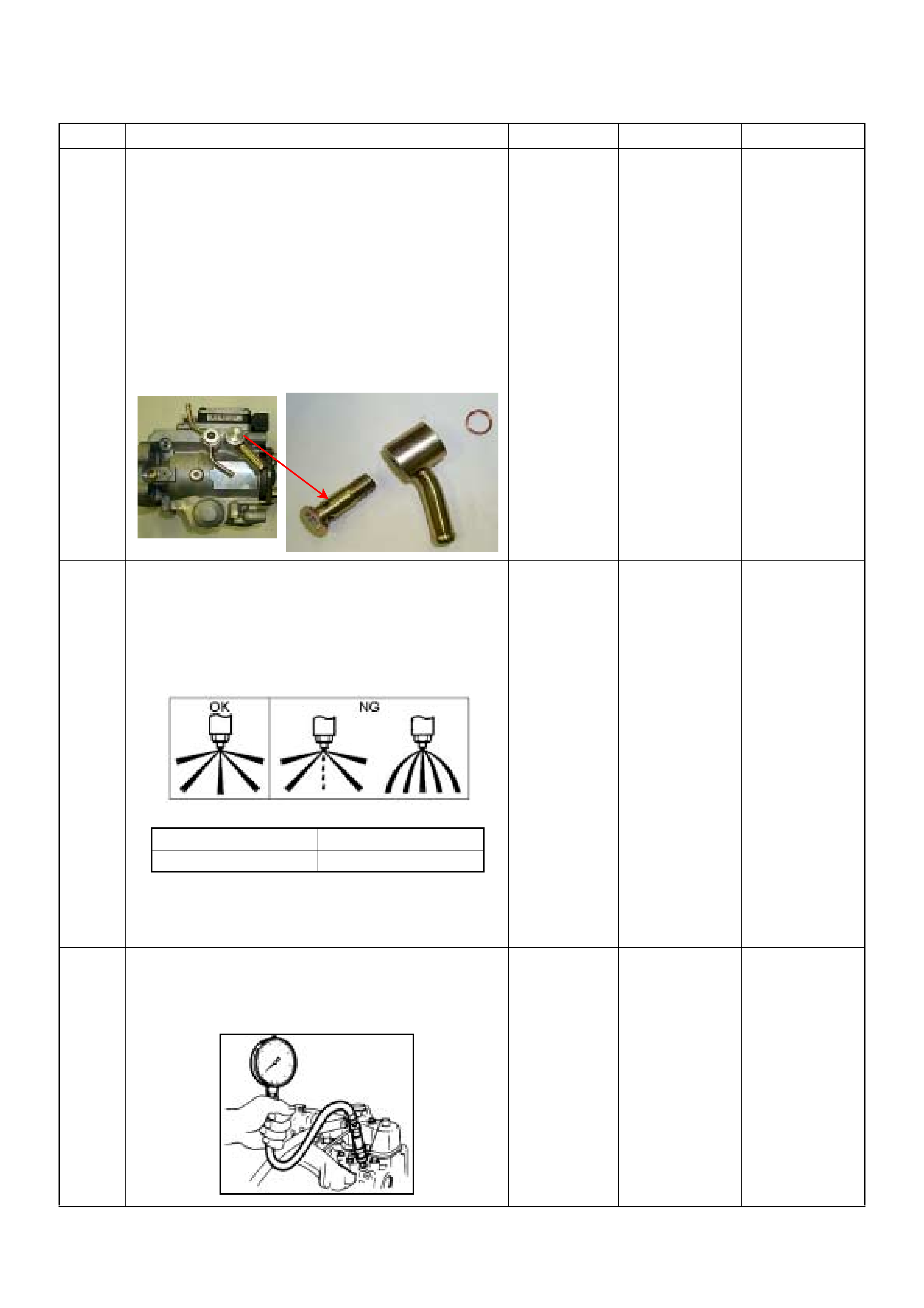

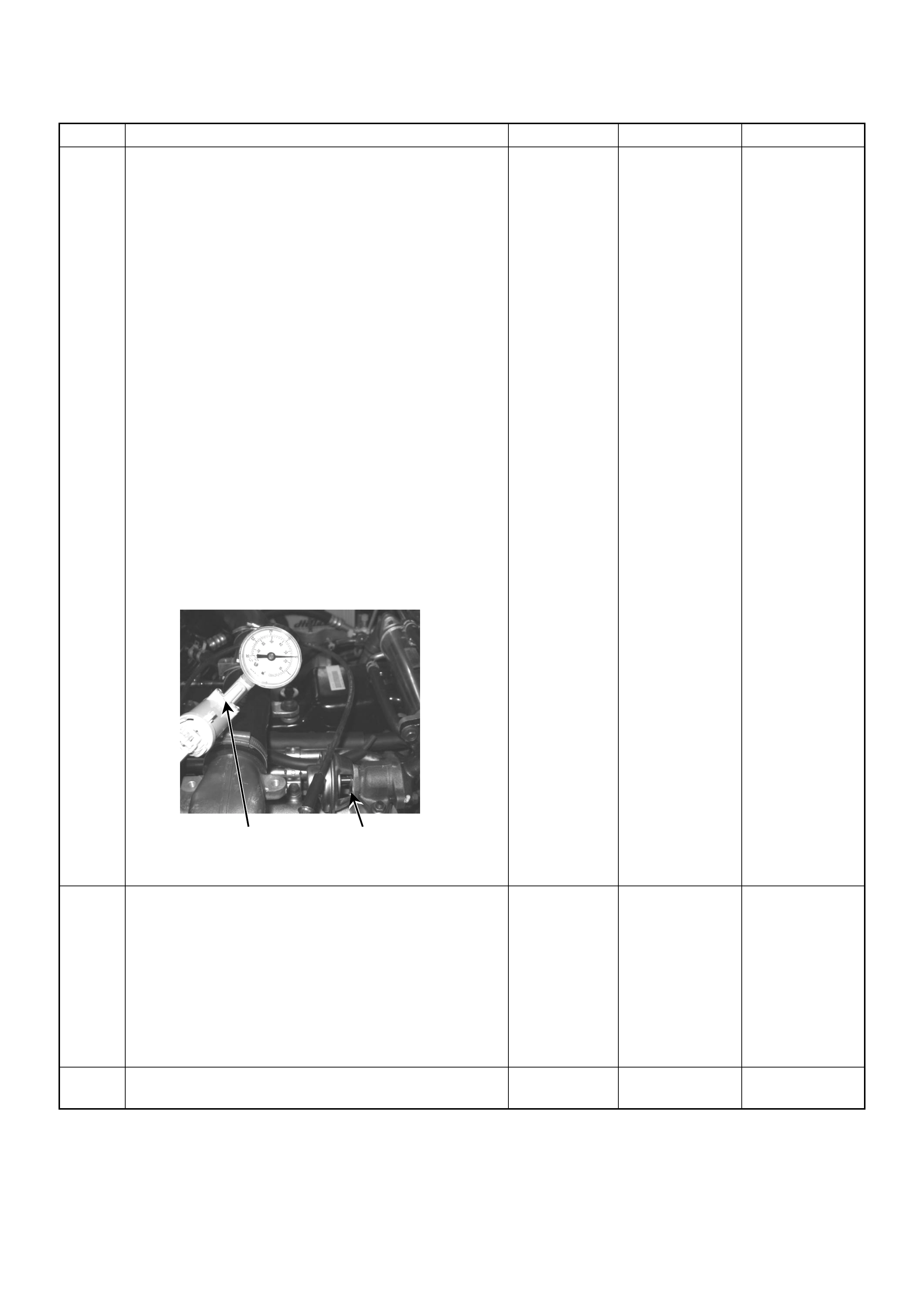

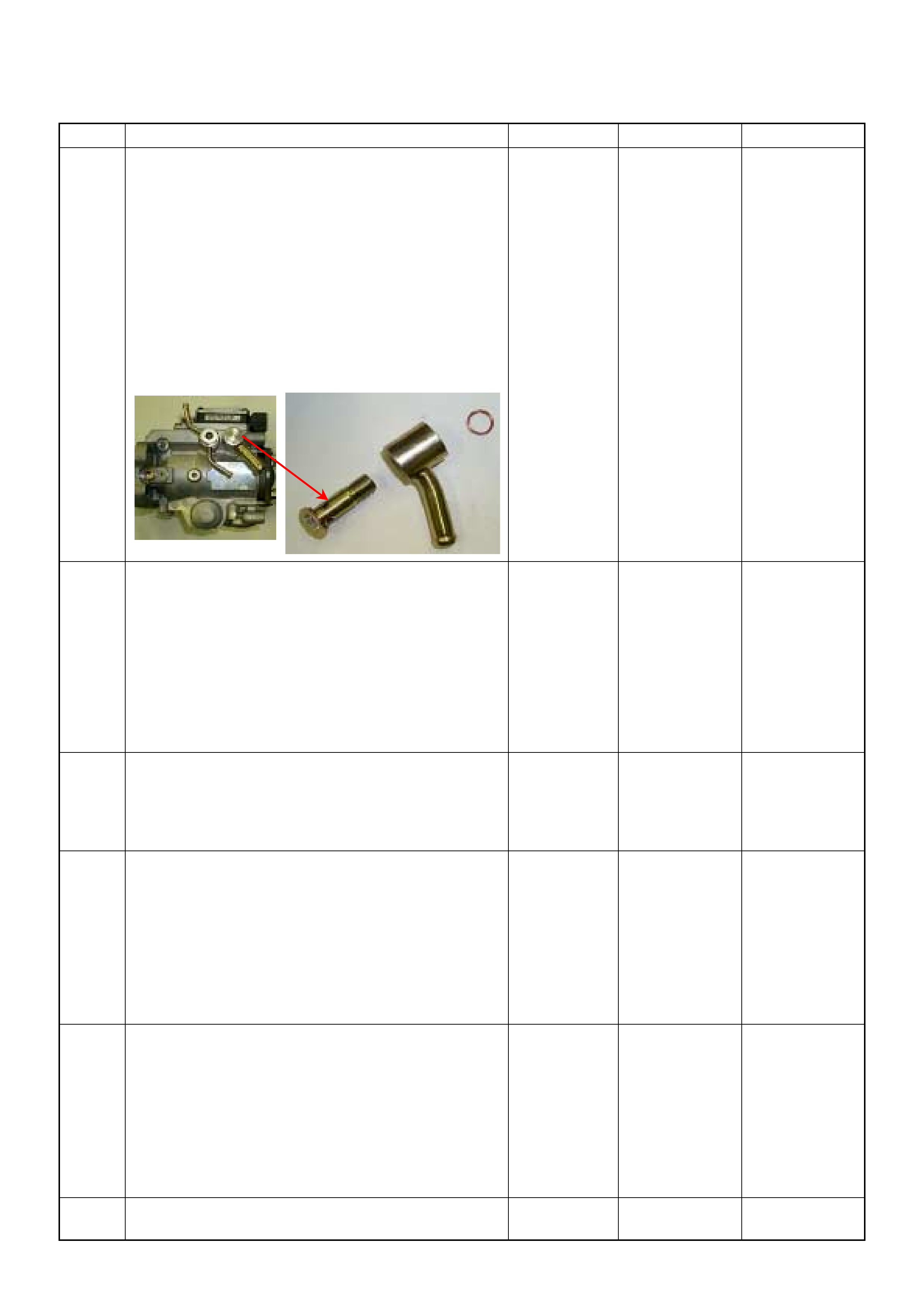

Pump Camshaft Speed Sensor

When the drive shaft rotates, the pump camshaft speed

sensor receives signal form the sensor wheel, and an

electric pulse is sent through the flexible connecting

harness to the pump control unit (PSG).

From these signals the pump control unit (PSG) can

determine the average pump speed and the momentary

pump speed.

The pump camshaft speed sensor is mounted to the

cam ring. Thus, the relationship between the cam ring

and the pump camshaft speed sensor signal is

constant.

The pump camshaft speed sensor signal is utilized for

the following purposes.

To determine the momentary angular position of the

cam ring.

To calculate the actual speed of the fuel injection pump.

To determine the actual timing plunger position.

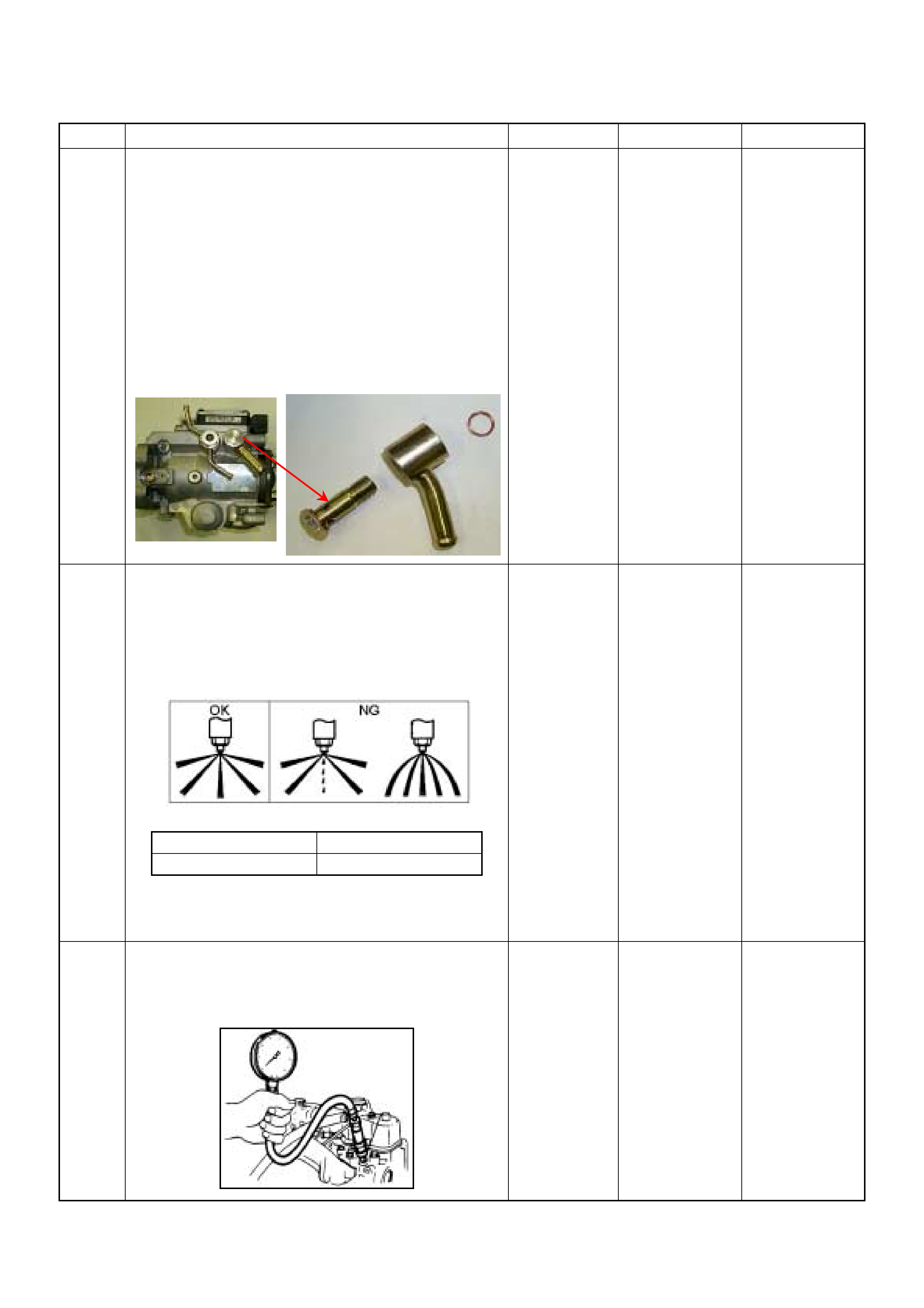

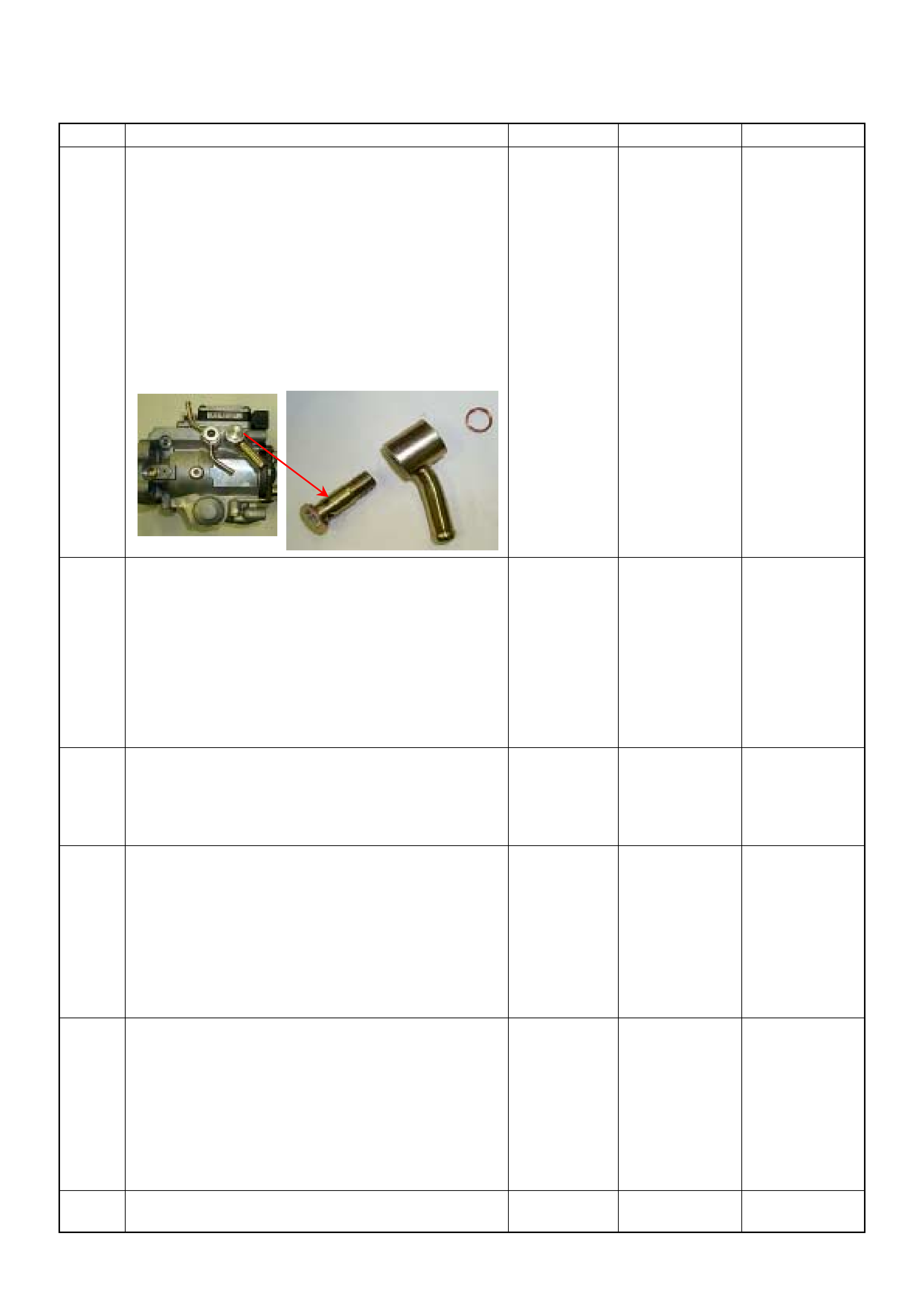

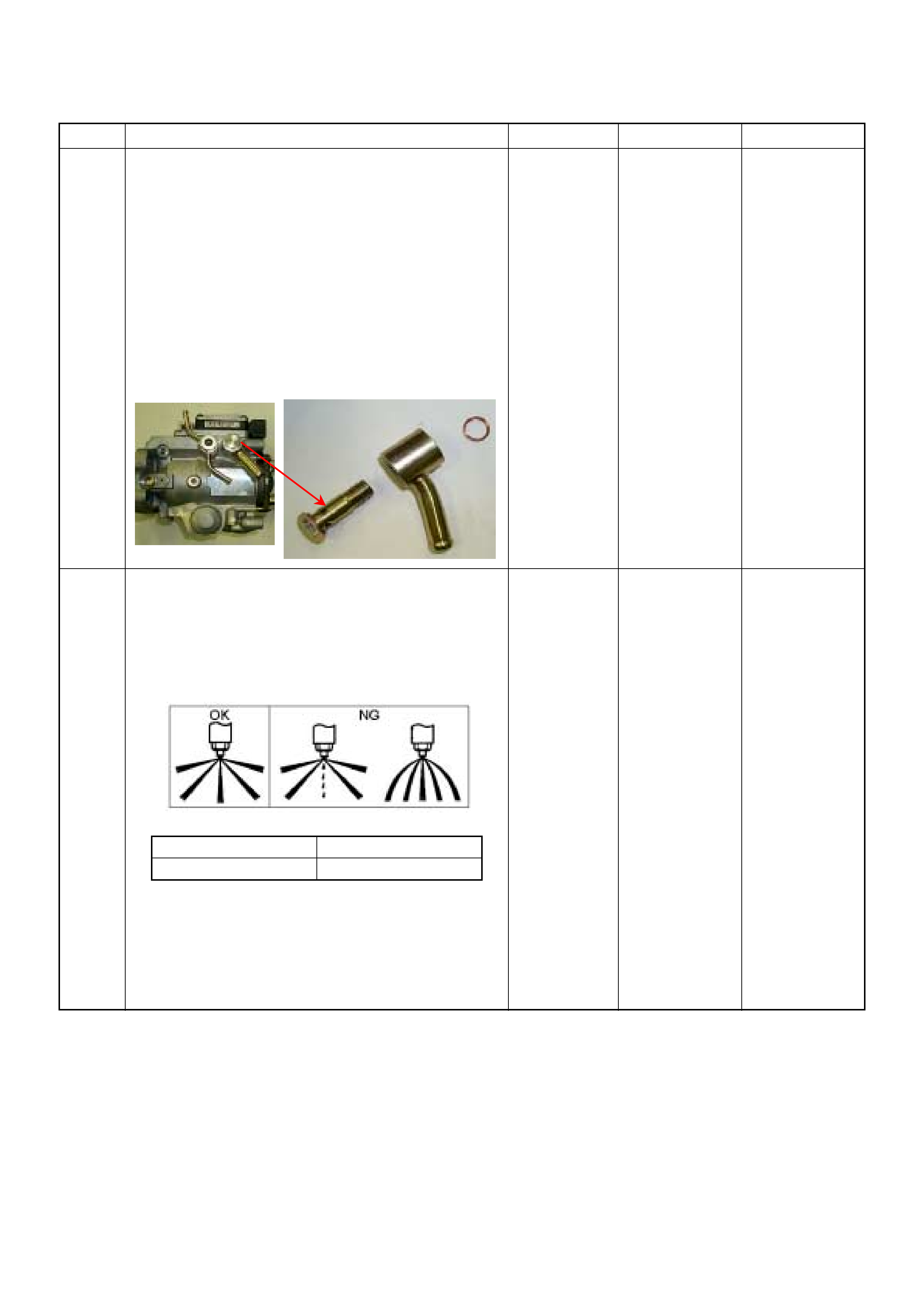

(1) Pump Control Unit (PSG)

(2) Distributor Head

(3) High Pressure Solenoid Valve

(4) Constant Pressure Valve (CPV)

(5) Radial Plun ger High Pressure Pu mp

(1) Pump Camshaft Speed Sensor

(2) Sensor Wheel

(3) Pump Camshaft Speed Sensor Retaining Ring

(4) Flexible Connector Harness

(5) Dr iv e Sha ft

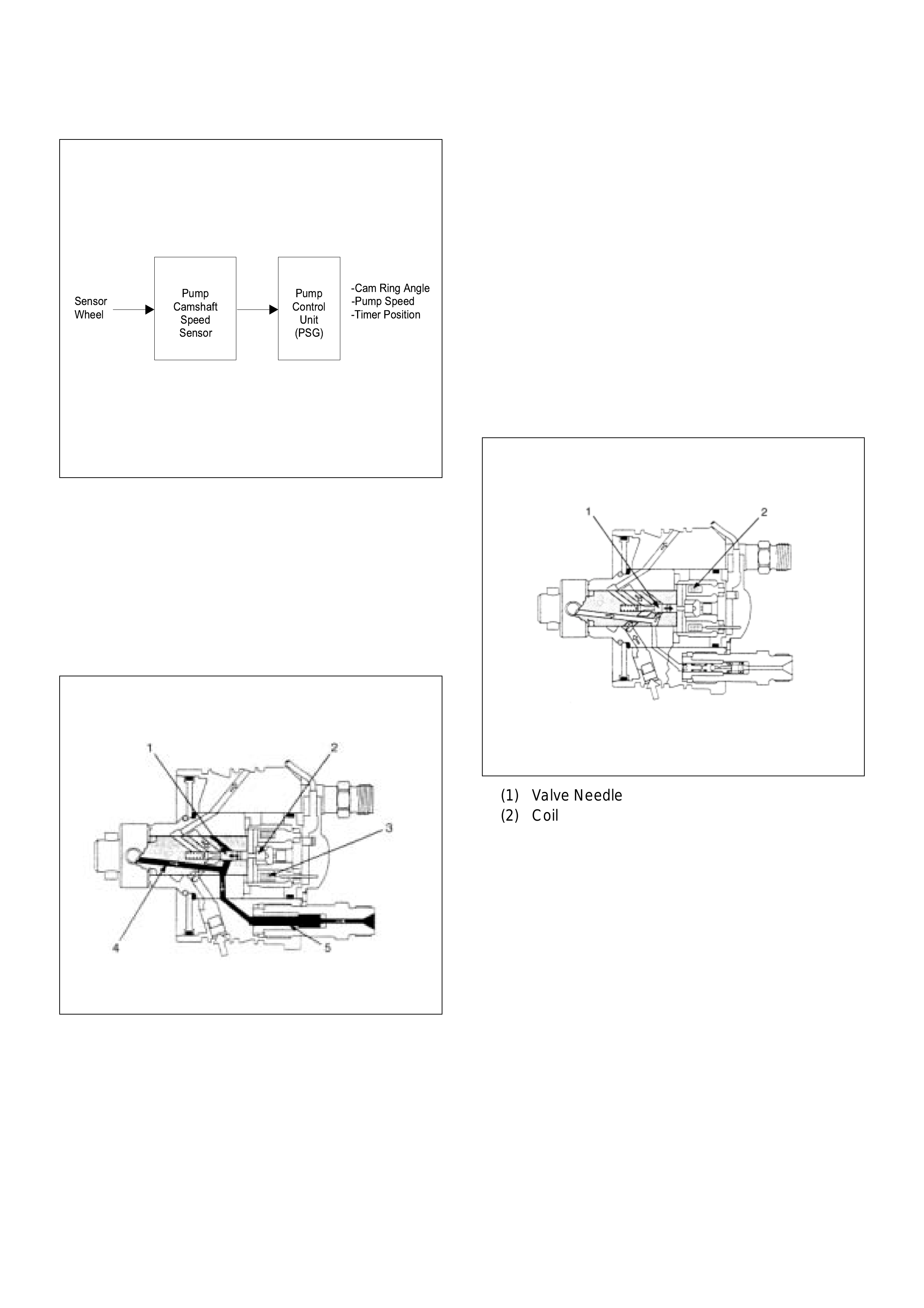

The pump c amshaft sensor signal has a too th gap, and

the crankshaft position (CKP) sensor on the flywheel

housing is used as a reference signal of engine top

dead cente r (TDC ) for the start tim ing of f uel deliv ery or

injection which is to be set.

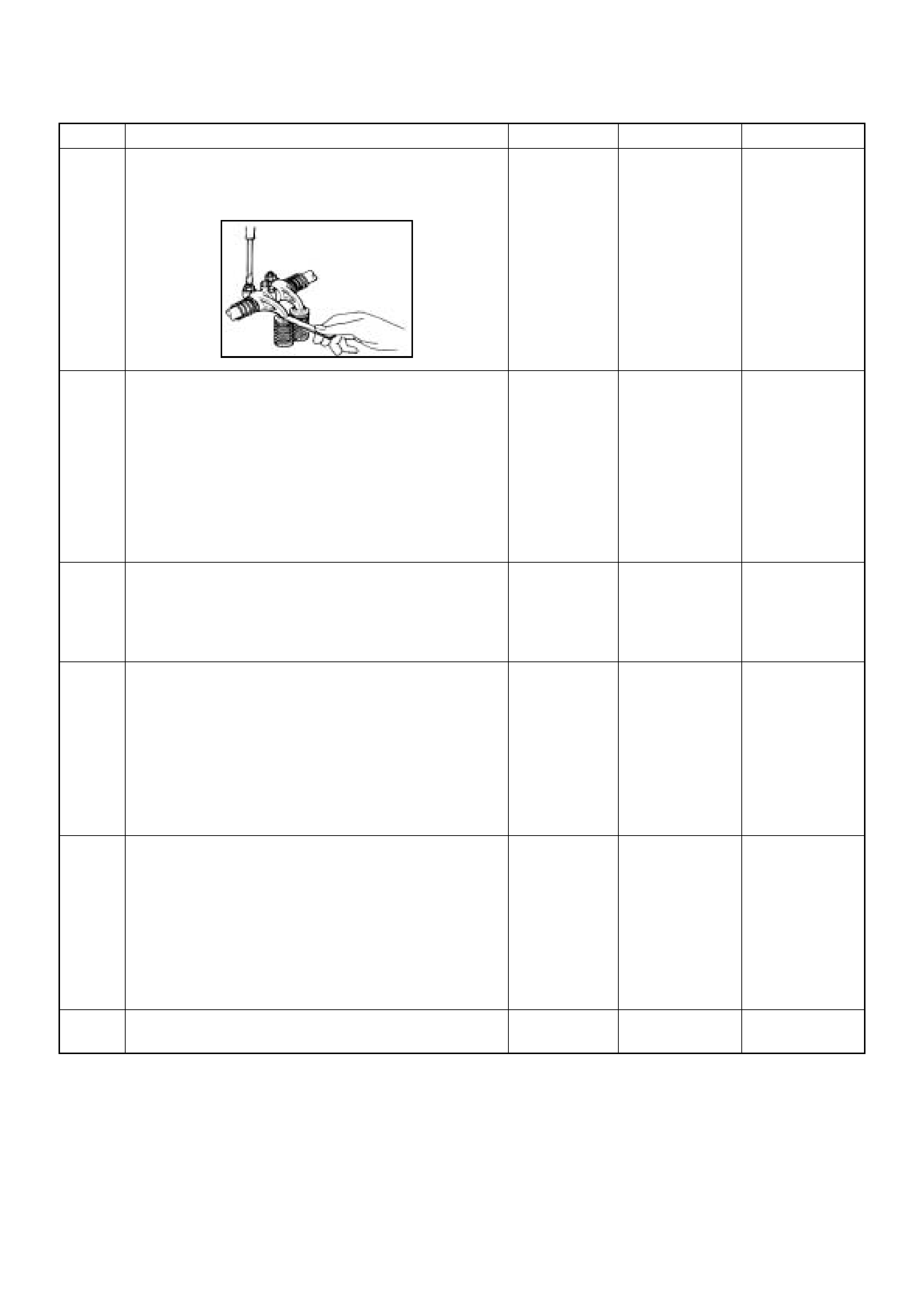

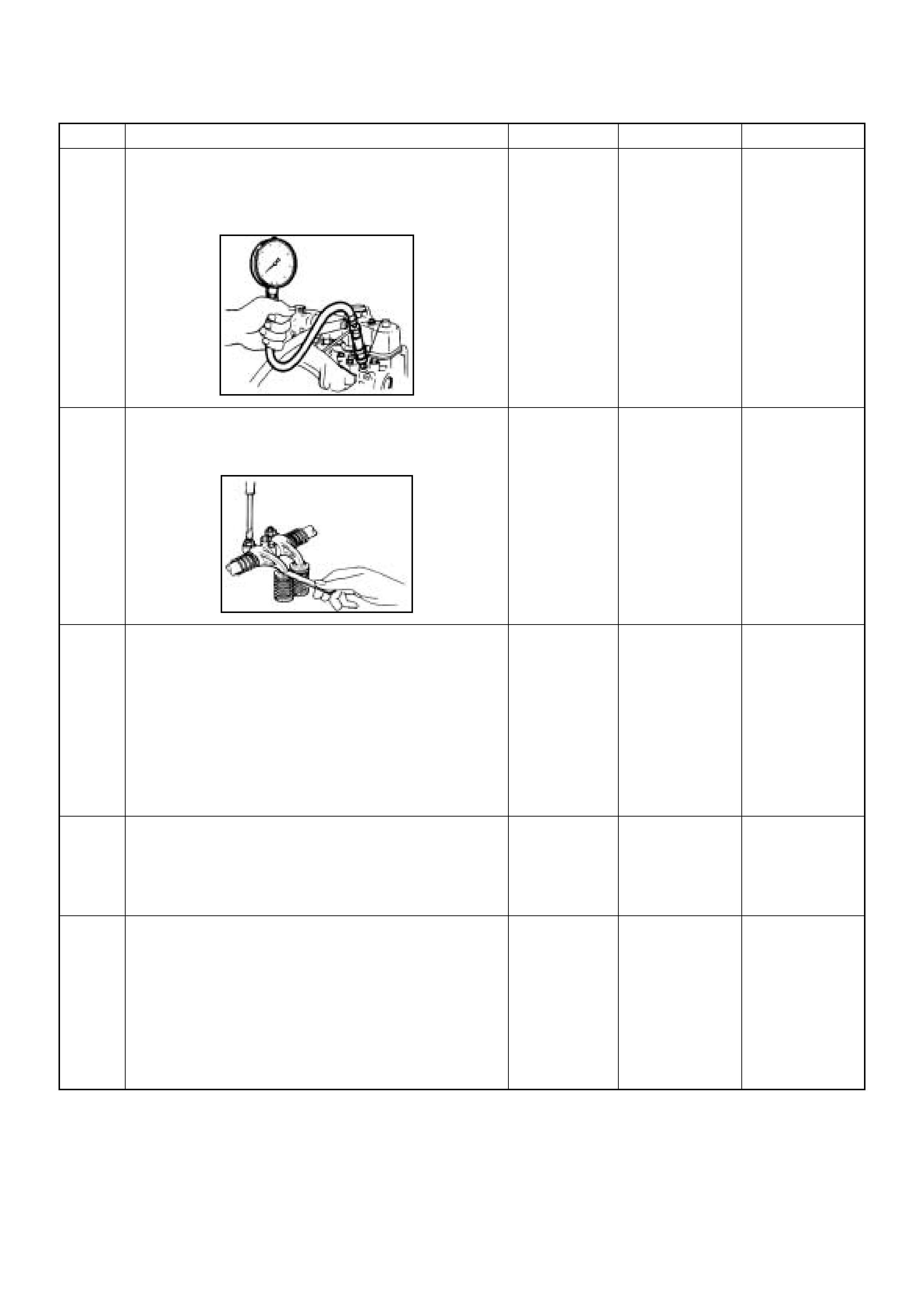

High Pressure Solenoid Valve

Fuel injection quantity control is performed from the

beginning of pressure delivery at the beginning of cam

lift until the high pressure solenoid valve opens at the

end of pressure delivery.

This interval is called the pressure delivery interval.

Accor dingly, the inter val that the high press ure solen oid

valve is closed determines the fuel injection quantity

(high pr es sur e fu el supply end s when the high pr essure

solenoid valve opens).

When cu rren t from the pump cont rol uni t (PS G) flows to

the high pressure solenoid valve coil, the magnet

anchor (a movable iron core) pushes the valve needle,

toward the val ve seat.

When the valve seat is completely closed by the valve

needle, the way, of the fuel in the high pressure

passage to the low pressure circuit is closed.

The pressure of the fuel in the high pressure passage is

rapidly increased by radial plunger lift, and the high

press ure fuel is delivered through the co ns tant pressu re

valve (CPV) to the nozzle holder assembly and is

injected into the engine cylinder.

When the fuel injection quantity demanded by the

engine is reached, the current to the coil is cut and the

valve needle re-opens the valve seat.

As a result of this, a path is opened for the fuel in the

high pressure passage to the low pressure circuit and

the pressure decreases. With a decrease in injection

press ure the nozzl e cl oses and injecti on ends .

(1) Valv e Need le

(2) Magnet Anchor

(3) Coil

(4) Hi gh Pr ess ur e Passag e

-Cam Ring Angle

Sensor -Pump Speed

Wheel -Timer Position

Pump

Control

Unit

(PSG)

Pump

Camshaft

Speed

Sensor

(1) Valve Needle

(2) Coil

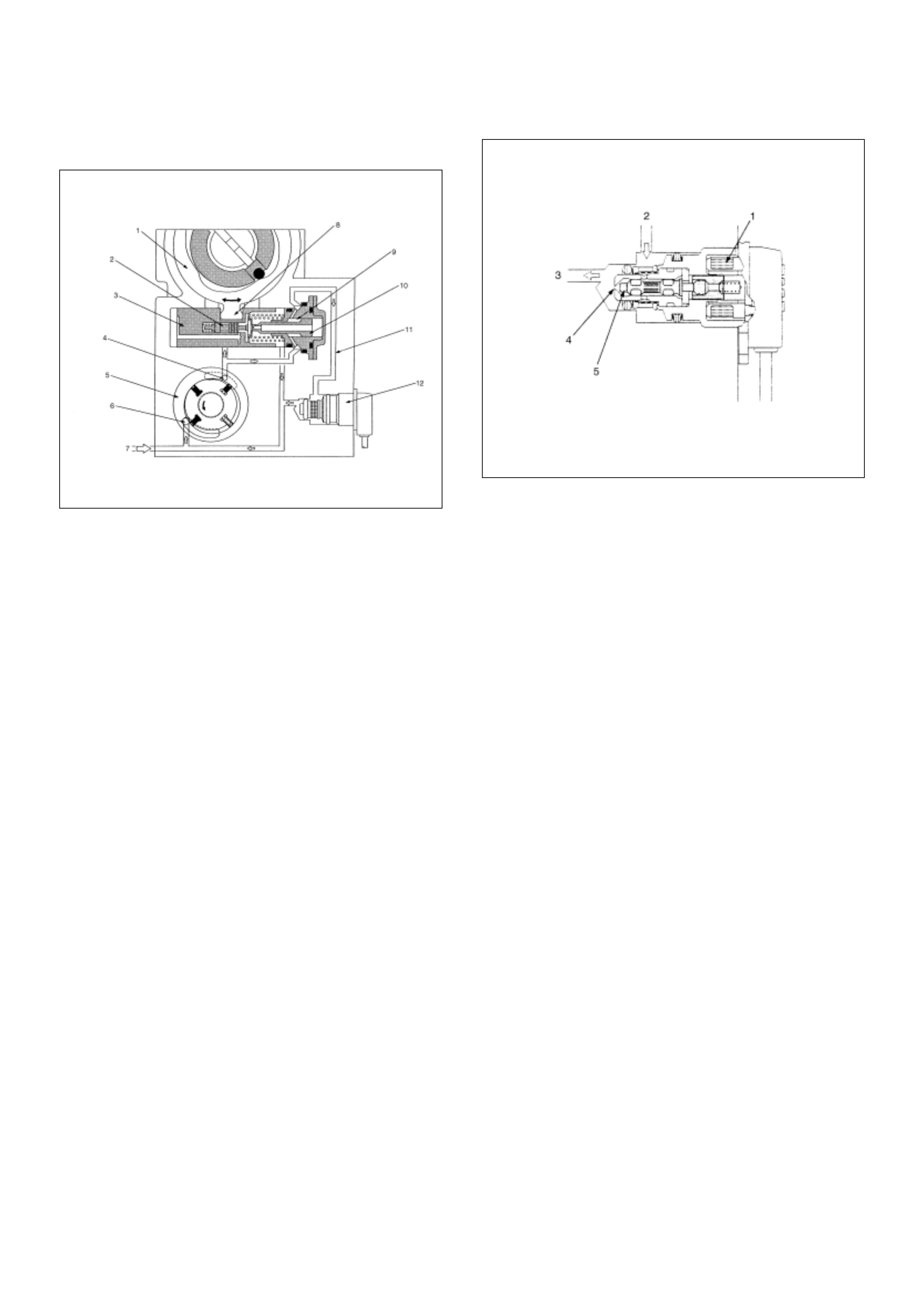

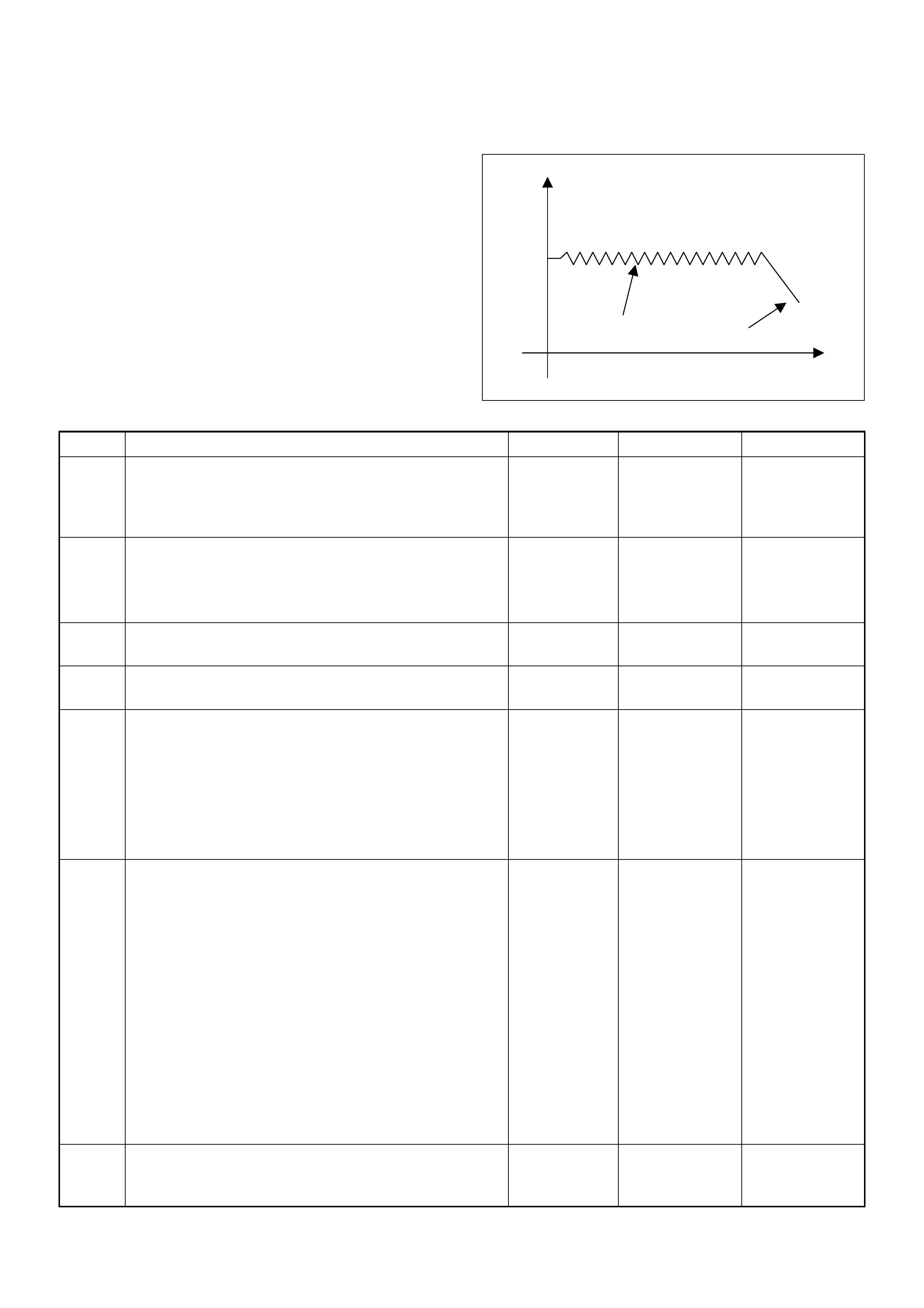

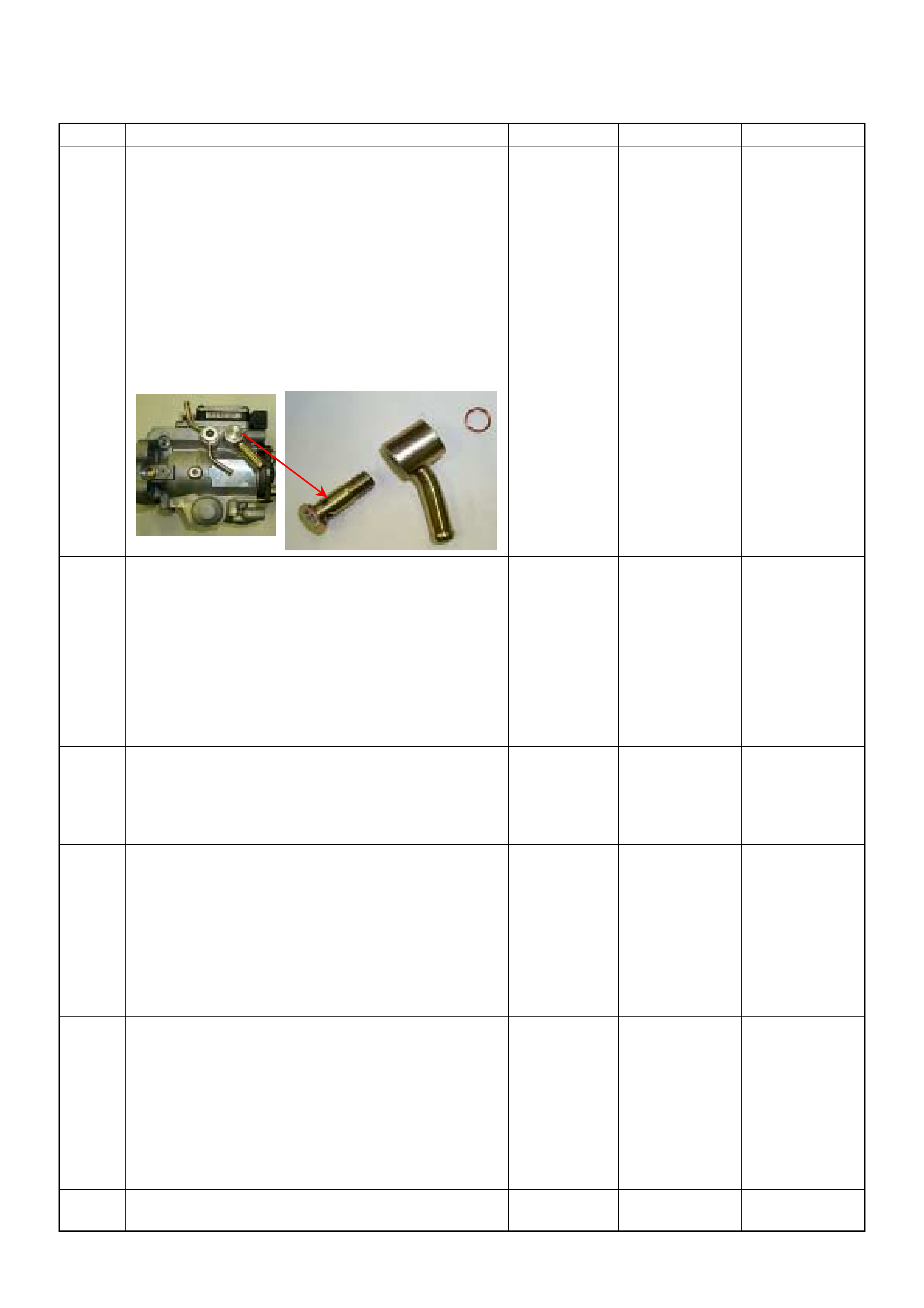

Timing Control Valve (TCV)

The pressure of the fuel fed from the feed pump is

adjusted in accordance with speed by the regulating

valve. This delivery pressure acts on the hydraulic

stopper's annular chamber as control pressure.

The chamber pressure of the annular chamber is

controlled by the timing control valve (TCV).

The timing plunger is connected to the cam ring by a

ball pin. Axial movement of the timing plunger is

transferred to the cam ring in the form of rotational

movement. Movement to th e right of the timing plunger

(to the spring side) advances injection timing.

When control current flows to the timing control valve

(TCV) coil, the valve need le opens and the fuel annul ar

chamber flows through the orifice to the feed pump inlet.

Consequently, the pressure of the annular chamber

decreases and the hydraulic stopper is moved to the

retard side.

The timing control valve (TCV) acts as a variable

throttl e, using the r apid opening and c losing (cyclin g) o f

the valve needle in the timing control valve (TCV).

At normal operation, the TCV controls the pressure

acting on the annular chamber so that the hydraulic

stopper cam move to any position, from the retard

position to the advance position. At this time, the duty

ratio is set by the pump control unit (PSG).

Duty ratio is the ratio of the time that the timing control

valve (TCV) is opened to one complete timing control

valve (TCV) operating cycle. A duty ratio change of

100% to 0% is an advance in injection timing. (The

VP44 displays an ON duty ratio.)

(1) Cam Ring

(2) Servo Valve

(3) Timer Piston

(4) Outlet

(5) Feed Pump

(6) Inlet

(7) Fuel Suction

(8) Ball Pin

(9) Annular Chamber

(10) Hydraulic S topper

(11) Return Passage

(12) Timing Control Valve (TCV)

(1) Coil

(2) From Ann ula r Chamber

(3) To Feed Pump

(4) Orifice

(5) Valve Needle

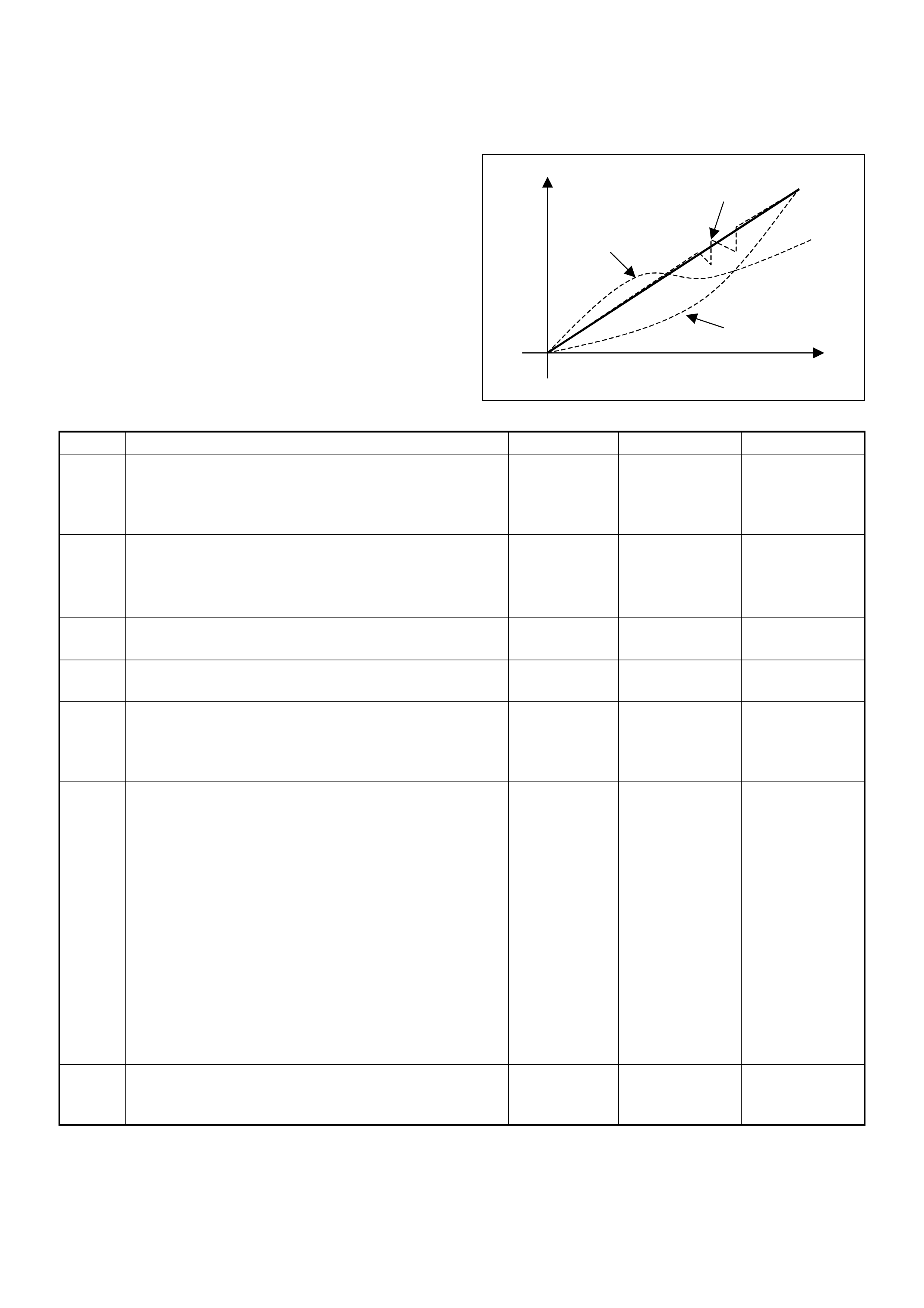

The engine control module (ECM) contains

characteristic maps of the start of injection,

corresponding to engine operating conditions (engine

load, engine speed and engine coolant temperature).

The pump control unit (PSG) is constantly comparing

the set start of injection timing and the actual start of

injection timing. If there is a difference, the timing

control valve (TCV) is controlled by the duty ratio. (The

actual start of injection timing is determined from the

pump camshaft speed sensor).

Engine Load

Engine Speed

Engine Coolant

Temperature

Engine

Control

Module

(ECM)

Pump

Control

Unit

(PSG)

Pump Camshaft

Speed Sensor

Timing

Control

Valve

(TCV)

STRATEGY BASED DIAGNOSTICS

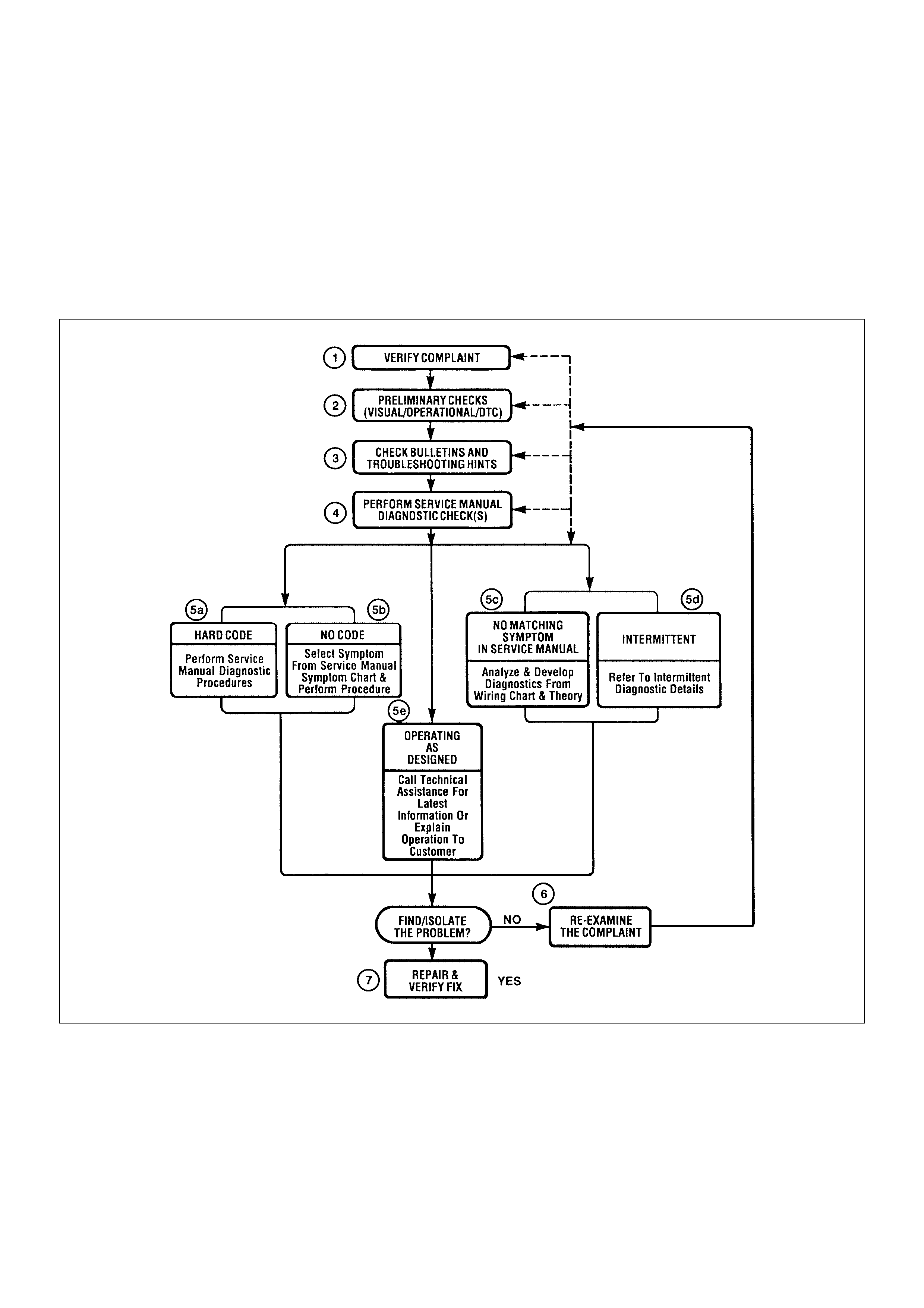

Overview

As a re tail servic e t e ch ni ci an , y ou are part of th e Ho ld en

service team. The team goal is FIX IT RIGHT THE

FIRST TIME for the satisfa ction of every cust omer. You

are a very important member of the team as you

diagnose and repair customer vehicles.

You have maximum efficiency in diagnosis when you

have an effective, organized plan for your work.

St rategy Based Diagnostic s (refer to Figu re 1) provid es

you with guidance as you create and follow a plan of

action for each specific diagnostic situation.

Strategy Based Diagnostics Chart

Diagnostic Thought Process

As you follow a diagnostic plan, every box on the

Strategy Based Diagnostics chart requires you to use

the diagnos tic though t process. Thi s method of think ing

optimize s your diagno si s in the followi ng ways:

• Improves your understanding and definition of the

customer complaint

• Sav es time by a vo iding tes tin g and/or replacing goo d

parts

• Allows you to look at the problem from different

perspectives

• Gui des you to deter mine what lev el of understand ing

about system operation is needed:

– Owner’s manual level

– Service manual level

– In-depth (engineering) level

1. Verify the Complaint

What you should do

To verify the custo mer complai nt, you need to know th e

correct (normal) operating behavior of the system and

verify that the customer complaint is a valid failure of the

system.

The following information will help you verify the

complaint:

• WHAT the vehicle model/options are

• WHAT aftermarket and dealer-installed accessories

exist

• WHAT related system(s) operate properly

• WHEN the problem occurs

• WHERE the problem occurs

• HOW the problem occurs

• HOW LONG the condition has existed (and if the

system ever worked correctly)

• HOW OFTEN the problem occurs

• Whether the severity of the problem has increased,

decreased or stayed the same

What resources you should use

Whenever possible, you should use the following

resources to assist you in verifying the complaint:

• Service manual Theory or Circuit Description

sections

• Service manual “System Performance Check”

• Owner manual operational description

• Technician experience

• Identical vehicle for comparison

• Circuit testing tools

• Vehicle road tests

• Complaint check sheet

• Contact with the customer

2. Perform Preliminary Checks

NOTE: An estimated 10 percent of successful vehicle

repairs are diagnosed with this step!

What you should do

You perform preliminary checks for several reasons:

• To detect if the cause of the complaint is VISUALLY

OBVIOUS

• To identify parts of the system that work correctly

• To accumulate enough data to correctly and

accurately search for a Holden Service Bulletin.

The initial checks may vary depending on the

compl exity of the system and may in clude the follow ing

actions:

• Operate the suspect system

• Make a visual inspection of harness routing and

accessible/visible power and ground circuits

• Check for blown fuses

• Make a visual inspection for separated connectors

• Make a visual inspection of connectors (includes

checking terminals for damage and tightness)

• Check for any DTCs stored by the on-board

computers

• Sense unusual noises, smells, vibrations or

movements

• Investigate the vehicle service history (call other

dealerships, if appropriate)

What resources you should use

Whenever appropriate, you should use the following

resources for assistance in performing preliminary

checks:

• Tech II or other technical equipment for viewing DTCs

• Service manual information:

– Component locations

– Harness routing

– Wiri ng sc hem ati cs

– Procedures for viewing DTCs

• Dealership service history file

• Veh ic le ro ad tes t

• Identical vehicle or system for comparison

3. Check Bulletins and Troub leshooting

Hints

NOTE: An estimated 30 percent of successful vehicle

repairs are diagnosed with this step!

What you should do

You should have enough information gained from

preliminary checks to accurately search for a bulletin

and other related service information. Some service

manual sections provide troubleshooting hints that

match symptoms with specific complaints.

What resources you should use

You should use the following resources for assistance in

checking for bulletins and troubleshooting hints:

• Printed bulletins

• Access Holden Bulletin(s).

• Videotapes

• Service manual

4. Perform Service Manual Diagnostic

Checks

What you should do

The “System Checks” in most service manual sections

and in most cells of section 8A (electrical) provide you

with:

• A systematic approach to narrowing down the

possible causes of a system fault

• Direction to specific diagnostic procedures in the

service manual

• Assistance to identify what systems work correctly

What resources you should use

Whenever possible, you should use the following

resources to perform service manual checks:

• Service manual

• Technical equipment (for viewing DTCs and

analyzing data)

• Digital multimeter and circuit testing tools

• Other tools as needed

5a and 5b. Perform Service Manual

Diagnostic Procedures

NOTE: An estimated 40 percent of successful vehicle

repairs are diagnosed with these steps!

What you should do

When directed by service manual diagnostic checks,

you must then carefully and accurately perform the

steps of diagnostic procedures to locate the fault related

to the customer complaint.

What resources you should use

Whenever appropriate, you should use the following

resources to perform service manual diagnostic

procedures:

• Service manual

• Technical equipment (for analyzing diagnostic data)

• Digital multimeter and circuit testing tools

• Essential and special tools

5c. Technician Self Diagnoses

When there is no DTC stored and no matching

symptom for the condition identified in the service

manual , you must begi n with a thorough understanding

of how the system(s) operates. Efficient use of the

service manual combined with you experience and a

good process of elimination will result in accurate

diagnosis of the condition.

What you should do

Step 1: Identify and understand the suspect

circuit(s)

Having completed steps 1 through 4 of the Strategy

Based Diagnostics chart, you should have enough

information to identify the system(s) or sub-system(s)

involved. Using the service manual, you should

determine and investigate the following circuit

characteristics:

• Electrical:

– How is the circuit powered (power distribution

charts and/or fuse block details)?

– How is the circuit grounded (ground distribution

charts)?

– How is the circuit controlled or sensed (theory of

operation):

– If it is a switched circuit, is it normally open or

normally closed?

– Is the power switched or is the ground

switched?

– Is it a variable resistance circuit (ECT sensor

or TP sensor, for example)?

– Is it a si gnal ge nerating devic e (MAF sens or of

VSS, for example)?

– Does it rely on some mechanical/vacuum

device to operate?

• Physical:

– Where are the circuit components (component

locators and wire harness routing diagrams):

– Are there areas where wires could be chafed

or pinched (brackets or frames)?

– Are there areas subjected to extreme

temperatures?

– Are there areas subjected to vibration or

movement (engine, transmission or

suspension)?

– Are the re areas ex posed to moisture, r oad salt

or other corrosives (battery acid, oil or other

fluids)?

– Are there common mounting areas with other

systems/components?

– Have previous repairs been performed to wiring,

connectors, components or mounting areas

(causing pinched wires between panels and

drivetrain or suspension components without

causing an immediate problem)?

– Does the vehicle have aftermarket or dealer-

installed equipment (radios, telephone, etc.)

Step 2: Isolate the problem

At this point, you should have a good idea of what could

cause th e presen t cond ition, as well a s cou ld not ca use

the condition. Actions to take include the following:

• Divide (and separate, where possible) the system or

circuit into smaller sections

• Confine the problem to a smaller area of the vehicle

(start with main harness connections while removing

panels and trim as necessary in order to eliminate

large vehicle sections from further investigation)

• For two or more circuits that do not share a common

power or ground, concentrate on areas where

harnesses are routed together or connectors are

shared (refer to the following hints)

Hints

Though the symptoms may vary, basic electrical failures

are generally caused by:

• Loose connections:

– Open/high resistance in terminals, splices,

connectors or grounds

• Incorrect connector/harness routing (usually in new

vehicles or after a repair has been made):

– Open/high resistance in terminals, splices,

connectors of grounds

• Corrosion and wire damage:

– Open/high resistance in terminals, splices,

connectors of grounds

• Component failure:

– Opens/short and high resistance in relays,

modules, switches or loads

• Aftermarket equipment affecting normal operation of

other systems

You may isolate circuits by:

• Unplugging connectors or removing a fuse to

separate one part of the circuit from another part

• Operating shared circuits and eliminating those that

function normally from the suspect circuit

• If only one component fails to operate, begin testing

at the component

• If a number of components do no operate, begin tests

at the area of commonality (such as power sources,

ground circuits, switches or major connectors)

What resources you should use

Whenever appropriate, you should use the following

resources to assist in the diagnostic process:

• Service manual

• Technical equipment (for data analysis)

• Experience

• Technical Assistance

• Circuit testing tools

5d. Intermittent Diagnosis

By definition, an intermittent problem is one that does

not occur continuously and will occur when certain

conditions are met. All these conditions, however, may

not be obvious or currently known. Generally,

intermittents are caused by:

• Faulty electrical connections and wiring

• Malfunctioning components (such as sticking relays,

solenoids, etc.)

• EMI/RFI (Electromagnetic/radio frequency

interference)

• Aftermarket equipment

Intermittent diagnosis requires careful analysis of

suspected systems to help prevent replacing good

parts. This m ay i nvolve using cr eativity a nd i ngenui ty to

interpret customer complaints and simulating all

exter nal and internal system conditi ons to duplicat e the

problem.

What you should do

Step 1: Acquire information

A thorough and comprehensive customer check sheet

is critical to intermittent problem diagnosis. You should

acquire this, since it will dictate the diagnostic starting

point. The vehicle service history file is another

source for accumulating information about the

complaint.

Step 2: Analyze the intermittent problem

Analyze the customer check sheet and service history

file to determine conditions relevant to the suspect

system(s).

Using service manual information, you must identify,

trace and locate all electrical circuits related to the

malfunctioning system(s). If there is more than one

system failure, you should identify, trace and locate

areas of commonality shared by the suspect circuits.

Step 3: Simulate the symptom and isolate the

problem

Simulate the symptom and isolate the system by

reprodu cing all possibl e conditions s uggested in Step 1

while monitoring suspected circuits/components/

systems to isolate the problem symptom. Begin with the

most logical circuit/component.

Isolate the circuit by dividing the suspect system into

simpler circuits. Next, confine the problem into a smaller

area of the system. Begin at the most logical point (or

point of easiest access) and thoroughly check the

isolated circuit for the fault, using basic circuit tests.

Hints

You can isolate a circuit by:

• Unplugging connectors or removing a fuse to

separate one part of the circuit from another

• If only component fails to operate, begin testing the

component

• If a number of co mpo nen ts do not operate , begi n tes t

at areas of commonality (such as power sources,

ground circuits, switches, main connectors or major

components)

• Substitute a known good part from the parts

department or the ve hic le syst em

• Try the suspect part in a known good vehicle

See Symptom Simulation Tests on the next page for

problem simulation procedures. Refer to service manual

sections 6E and 8A for information about intermittent

diagnosis. Follow procedures for basic circuit testing in

service manual section 8A.

What resources you should use

Whenever appropriate, you should use the following

resources to assist in the diagnostic process:

• Service manual

• Bulletins

• Digital multimeter (with a MIN/ MAX feature)

• Tech II and Tech II upload function

• Circuit testing tools (including connector kits/

harnes se s and jum per wires )

• Experience

• Intermittent problem solving simulation methods

• Customer complaint check sheet

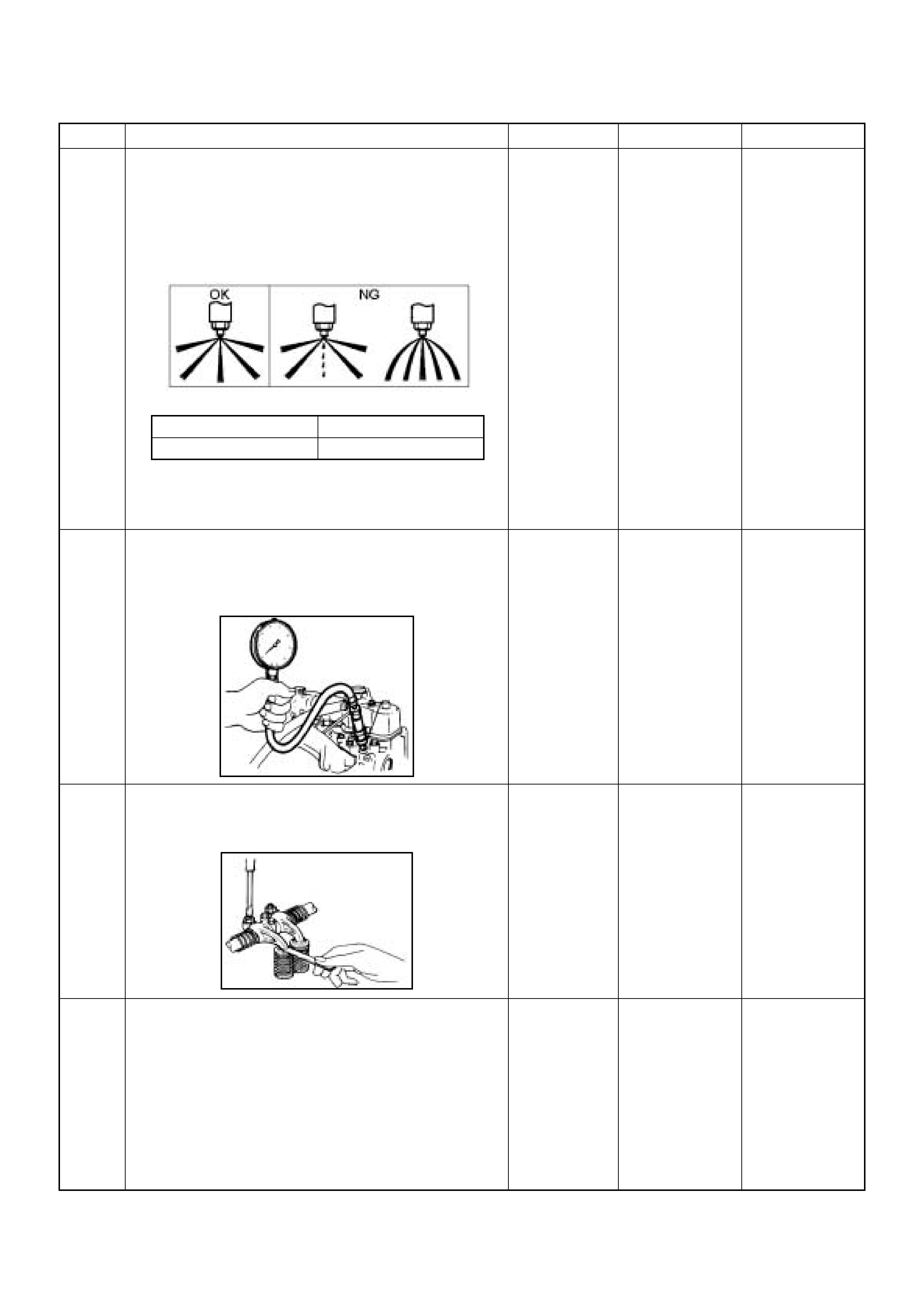

Symptom Simulation Tests

1. Vibration

This method is useful when the customer complaint

analysis indicates that the problem occurs when the

vehicle/system undergoes some form of vibration.

For connectors and wire harness, slightly shake

vertically and horizontally. Inspect the connector joint

and body for damage. Also, tapping lightly along a

suspected circuit may be helpful.

For parts and sensors, apply slight vibration to the part

with a l ig ht tap of the fin ger whi le mo nit or ing the s yst em

for a malfunction.

2. Heat

This method is important when the complaint suggests

that th e problem occur s in a heat ed en vironm ent. App ly

moderate heat to the component with a hair drier or

similar tool while monitoring the system for a

malfunction.

CAUTION: Care must be take to avoid overheating

the compone nt.

3. Water and Moisture

This method may be used when the complaint suggests

that the malfunction occurs on a rainy day or under

conditions of high humidity . In this case, apply water in a

light spray on the vehicle to duplicate the problem.

CAUTION: Care must be take to avoid directly

exposing electrical connections to water.

4. Electrical loads

This method involves turning systems ON (such as the

blower, lights o r rear windo w defogger ) to crea te a load

on the vehicle electrical system at the same time you

are monitoring the suspect circuit/component.

5e. Vehicle Operates as Designed

This condition refers to instances where a system

operat ing as d esigned is perce ived to be unsatis factory

or undesirable. In general, this is due to:

• A lack of understanding by the customer

• A conflict between customer expectations and

vehicle design intent

• A system performance that is unacceptable to the

customer

What you should do

You can verify that a system is operating as designed

by:

• Reviewing service manual functional/diagnostic

checks

• Exa mining bul letins a nd other ser vice informati on for

supplementary information

• Co mpare sys tem oper a tio n to an identic al vehicl e

If the condition is due to a customer misunderstanding

or a con flict betwee n customer expec tation and system

operation, you should explain the system operation to

the custo mer.

If the complaint is due to a case of unsatisfactory

system performance, you should contact Technical

Assistance for the latest information.

What resources you should use

Whenever possible, you should use the following

resour ce s to fa cili tate the dia gno sti c proc es s:

• Vehicle service information (service manual, etc.)

• Holden field support

• Experience

• Identical vehicle or system for comparison

6. Re-examine the complaint

When you do not successfully find/isolate the problem

after executing a diagnostic path, you should re-

examine the com pl ain t.

What you should do

In this case, you will need to backtrack and review

information accumulated from step 1 through 4 of

Strategy Based Diagnostics. You also should repeat any

procedures that require additional attention.

A previous path may be eliminated from consideration

only if you are certain that all steps were executed as

directed. You must then select another diagnostic path

(step 5a, 5b, 5 c or 5d ) . If al l po ss i ble opti ons ha ve been

explored, you may call or seek Holden field support.

What resources you should use

Whenever possible, you should use the following

resour ce s to fa cili tate the dia gno sti c proc es s:

• Service manual

• Accumulated information form a previous diagnostic

path

• Service information and publications

• Holden field support

7. Repair and Verify Fix

What you should do

After you have located the cause of the problem, you

must execute a repair by following recommended

service manual procedures.

When the repair is completed, you should verify the fix

by performing the system checks under the conditions

listed in the customer c omplaint.

If applic able, you should ca rry out preven tive meas ures

to avoid a repeat complaint.

What resources you should use

Whenever possible, you should use the following

resources to facilitate the repair process:

• Electrical repair procedures

• Service manual information and publications

GENERAL SERVICE INFORMATION

Serviceability Issues

Non-OEM Parts

All of the OBD diagnostics have been calibrated to run

with OEM parts. Accordingly, if commercially sold

sensor or switch is installed, it makes a wrong diagnosis

and turns on the check engine lamp.

Aftermarket electronics, such as cellular phones,

stereos, and anti-theft devices, may radiate EMI into the

control system if they are improperly installed. This may

cause a false sensor reading and turn on the check

engine lamp.

Poor Vehicle Maintenance

The sens itivity of OBD dia gnostics will c ause the check

engine lamp to turn on if the vehicle is not maintained

properly. Restricted oil filters, fuel filters, and crankcase

deposits due to lack of oil changes or improper oil

viscosity can trigger actual vehicle faults that were not

previously monitored prior to OBD. Poor vehicle

maintenance can not be classified as a “non-vehicle

fault”, but with the sensitivity of OBD diagnostics,

vehicle maintenance schedules must be more closely

followed.

Related System Faults

Many of the OBD system diagnostics will not run if the

ECM detects a fault on a related system or component.

Visual/Phy sic al Engine Compartment

Inspection

Perform a careful visual and physical engine

compartment inspection when performing any

diagnostic procedure or diagnosing the cause of an

emission te st failure. This can often lea d to repairing a

problem without further steps. Use the following

guidelines when performing a visual/physical

inspection:

• Inspect all vacuum hoses for punches, cuts,

disconnects, and correct routing.

• Inspect hoses that are difficult to see behind other

components.

• Inspect all wires in the engine compartment for

proper connection s, burne d or chafed s pots, pinched

wires, contact with sharp edges or contact with hot

exhaust manifolds or pipes.

Basic Knowledge of Tools Required

NOTE: Lack of basic knowledge of this powertrain

when performing diagnostic procedures could result in

an incorrect diagnosis or damage to powertrain

components. Do not attempt to diagnose a powertrain

problem without this basic knowledge.

A basic understanding of hand tools is necessary to

effectively use this section of the Service Manual.

ON-BOARD DIAGNOSTIC (OBD)

On-Board Diagnostic (Self Diagnosis

System) Tests

A diagno stic test is a serie s of steps, the re sult of whi ch

is a pass or fail reported to the diagnostic executive.

When a diagnostic test reports a pass result, the

diagno sti c ex ec utive re co rd s the foll owi ng data:

• The diagnostic test has been completed since the

last ignition cycle.

• The diagnostic test has passed during the current

ignition cycl e.

• The fault identified by the diagnostic test is not

currently active.

When a diagnostic test reports a fail result, the

diagno sti c ex ec utive re co rd s the foll owi ng data:

• The diagnostic test has been completed since the

last ignition cycle.

• The fault identified by the diagnostic test is currently

active.

• The fault has been active during this ignition cycle.

• The operating conditions at the time of the failure.

The Diagnostic Exec utiv e

The Diagnostic Executive is a unique segment of

software which is designed to coo rdinate and prioritize

the diagn os tic proc edu re s as wel l as define the pro toc ol

for recording and displaying their results. The main

respo ns ib iliti es of the Di agn os tic Ex ecuti ve are li st ed as

follows:

• Commanding the check engine lamp on and off

• DTC logging and clearing

• Current status information on each diagnostic

Diagnostic Information

The diagnostic charts and functional checks are

desig ned to loc ate a faul ty c ircu it or c omp onen t th rough

a proce ss of logica l decis ions . The charts are prepared

with the requirement that the vehicle functioned

correc tly at the ti me of assembl y and that th ere are not

multiple faults present.

There is a continuous self-diagnosis on certain control

functions. This diagnostic capability is complemented

by the diagnostic procedures contained in this manual.

The language of communicating the source of the

malfunction is a system of diagnostic trouble codes.

When a malfunction is detected by the control module, a

diagnostic trouble code is set and the check engine

lamp is illuminated.

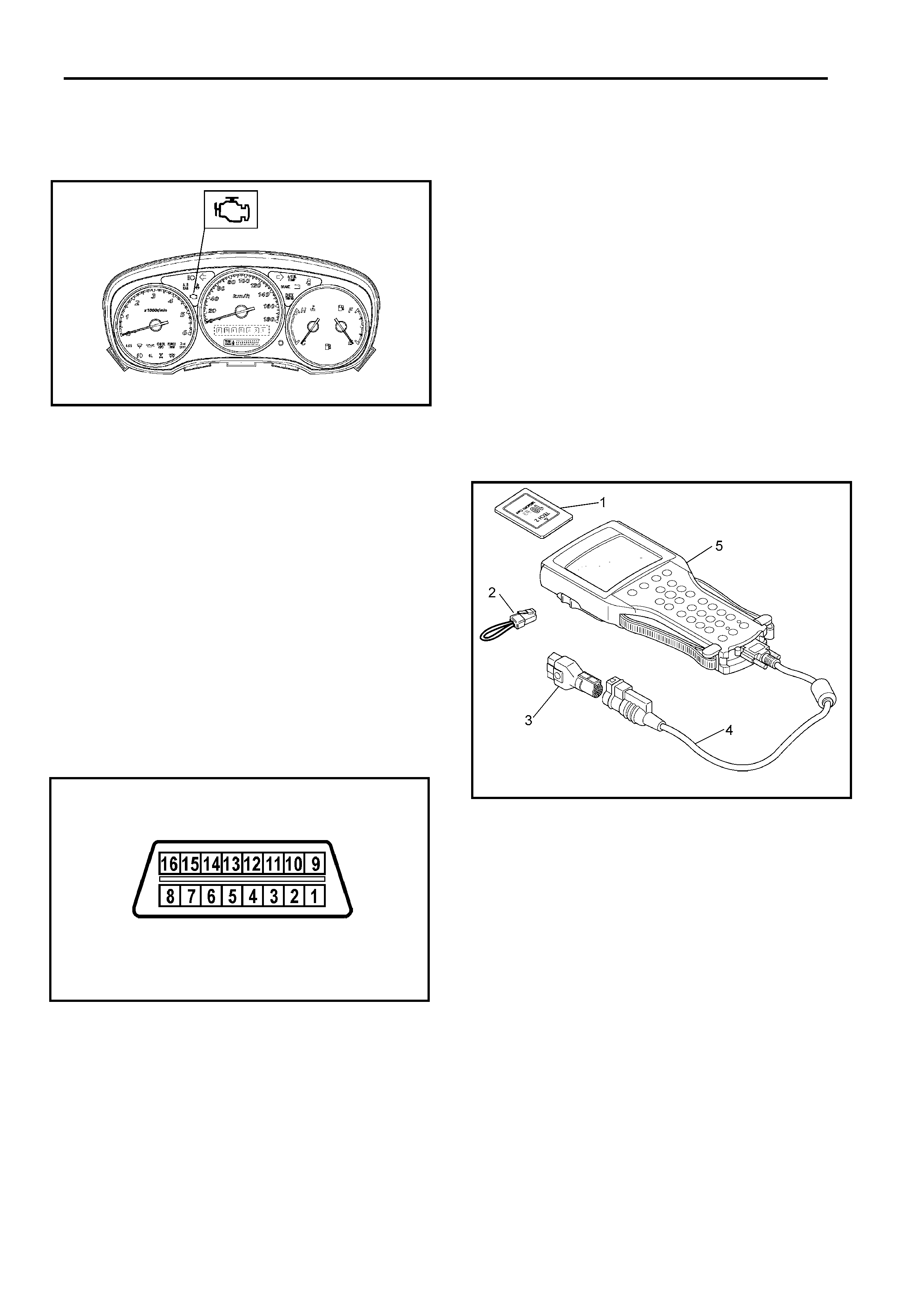

Techline

6E-60 RA – 4JH1-TC

Malfunction Indicator Lamp

The malfunction indicator lamp (MIL) is located in the

instrument pane l cluste r. The MIL will di splay the follow ing

symbol when commanded ‘ON’.

The MIL indicate s that an emissio n relate d faul t ha s occurred

and vehicle service is required. The following is a list of the

modes of operation for the MIL:

• The MIL illuminates for about 2.6 seconds when the

ignition switch is turned ‘ON’, with the engine ‘OFF’. This is

a bulb test to ensu re th a t the MIL is able to illu mi nate .

• The MIL turns ’OFF’ after the engine is started, if a

diagnostic fault is n ot present.

• The MIL remains illuminated after the engine is started, i

f

the engine control module (ECM) detects a fault.

A

diagnostic trouble code (DTC) is stored any time the ECM

illuminate s the MIL due to an emi ssion re lated fau l t.

Data Link Connector (DLC)

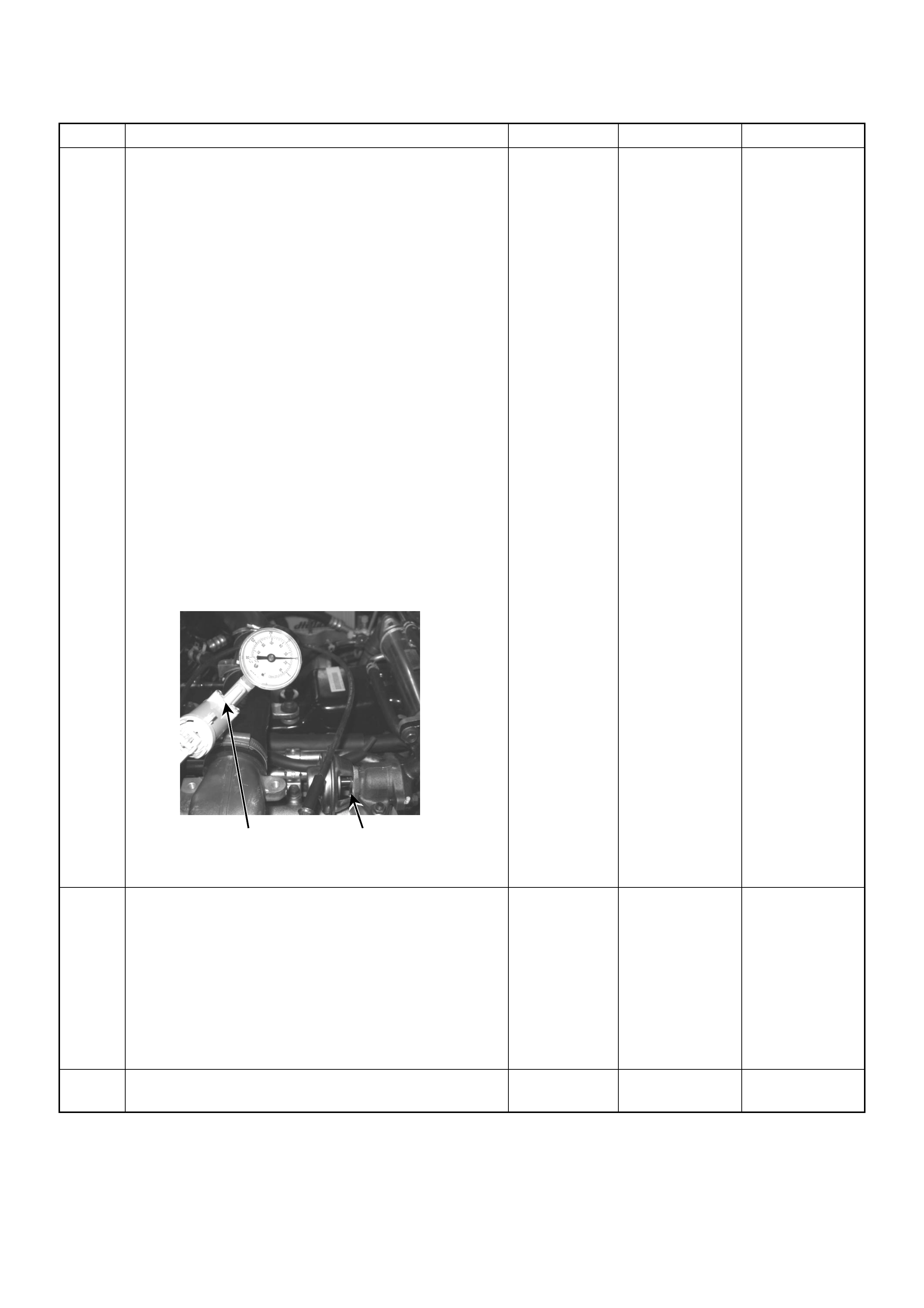

The provision for communication with the control module is the

Data Link Connector (DLC). It is located behind the lower front

instrument pane l. The DLC is used to connect to a Tech2.

Some common uses of the Tech2 are listed below:

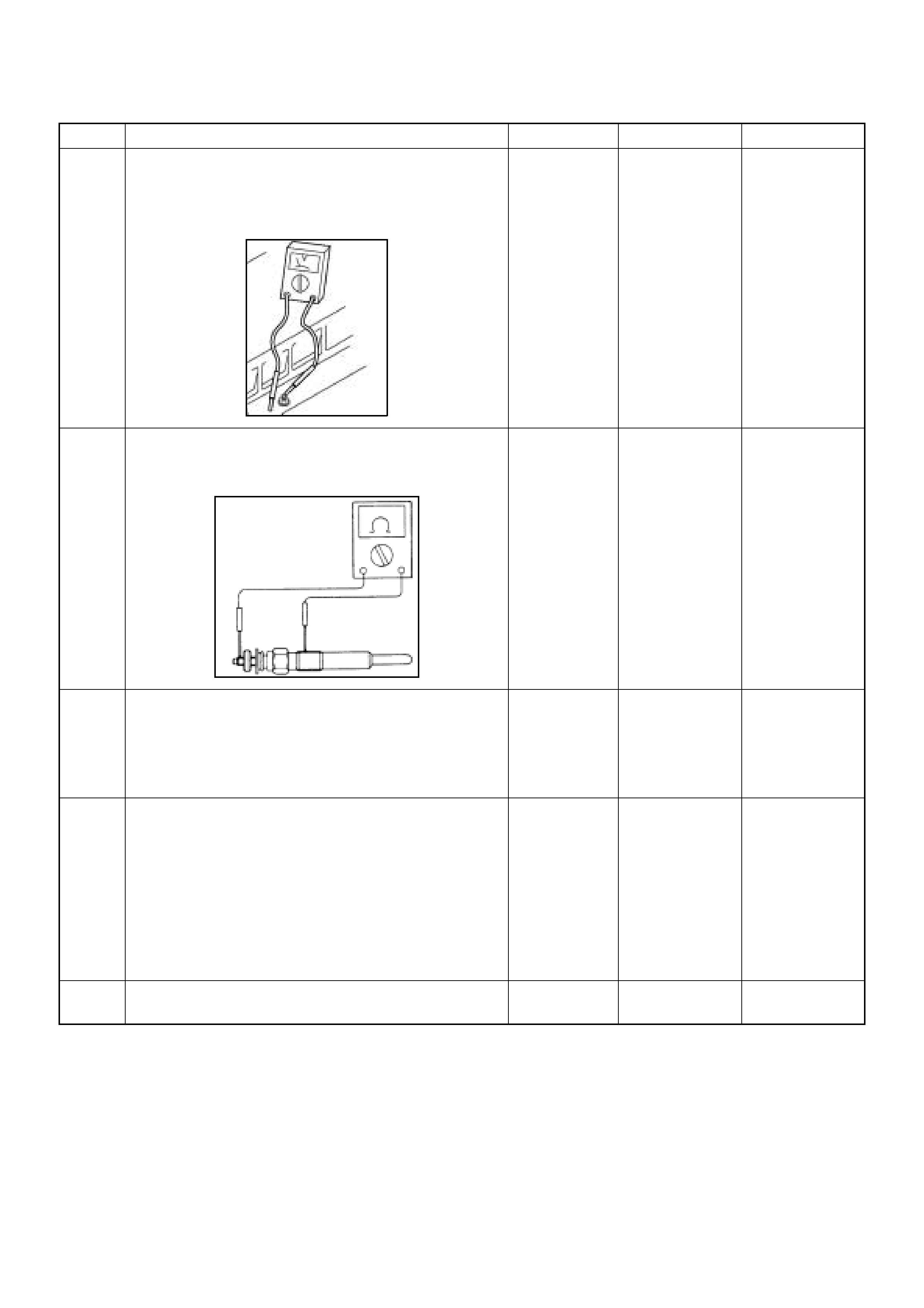

• Identify ing stored Diagno stic Trou ble Code s (D TCs).

• Clearing DTCs.

• Reading serial data.

• Connect the SAE 16/19 adap ter (3 ) to the da ta lin k

connector of the vehicle.

• Connect th e DLC ca ble (4) to th e Tech 2 (5).

• Connect the SAE 16/19 adap ter (3 ) to the da ta lin k

connector (DLC) of the vehicle.

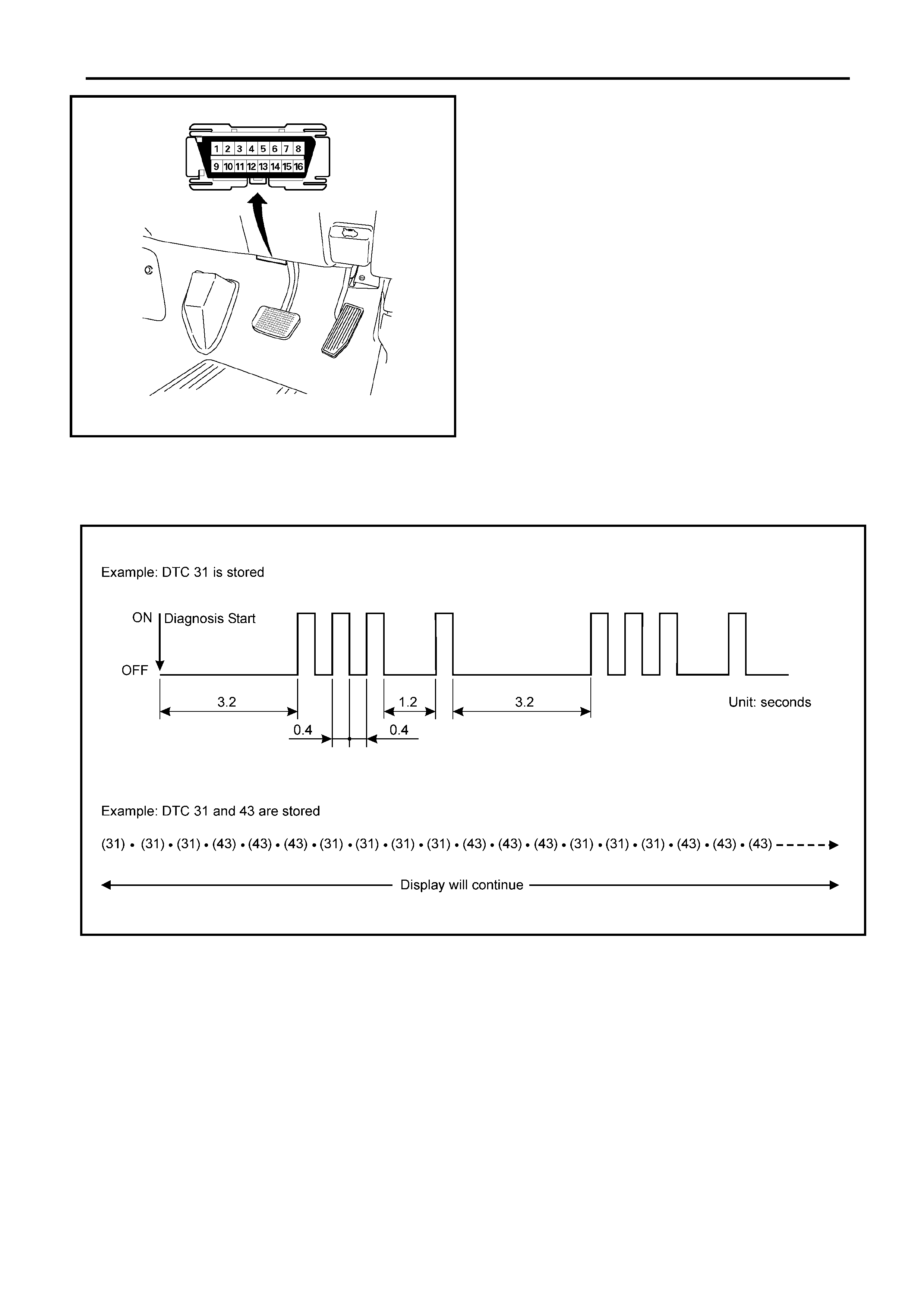

Verifying Vehicle Repair

Verifica tion of ve hi cle rep ai r w ill be mo re comprehensive for

vehicles with OBD system diagnostic. Following a repair, the