SECTION 6C - ENGINE FUEL (6VE1 3.5L)

Service Precautions

General Information

System Components

Fuel System Depressurizing

Procedure

Fuel Lines and Quick Connector Fittings

Description

Leak Test and Inspection

Removal

Inspection

Installation

Fuel Filter

Removal

Inspection

Installation

In-tank Fuel Filter

Fuel Pump Flow Test

Pressure Test

Fuel Tank

Fuel Tank and Associated Parts

Removal

Installation

Fuel Pump and Sender Assembly

Fuel Pump and Sender Assembly

Associated Parts

Removal

Installation

Fuel Pump Relay

General Description

Fuel Filler Neck

Removal

Installation

Fuel Filler Cap

General Description

Inspection

Main Data and Specifications

Torque Specifications

Special Tools

Service Precautions

Use extreme care when working on the fuel system and follow all safety precautions.

When working on the fuel system, disconnect the ground battery cable except for those tests where battery voltage is

required.

Always keep a dry chemical (Class B) fire extinguisher near the work area.

Replace all fuel lines and fittings with the same type of line and fitting as those removed.

Clean and inspect “O" rings carefully and replace if required.

Always depressurize the fuel line pressure before servicing any fuel system components.

Do not attempt any repairs on the fuel system until, all warnings and instructions, relating to that repair have been read

and ensure all notices and cautions are adhered to.

Do not allow any naked flames or sparks near the work area when working on the fuel system.

If draining of the fuel system is required, this should be done in a well ventilated area.

Protect the fuel lines and associated parts from thermal damage, spattering when welding.

General Information

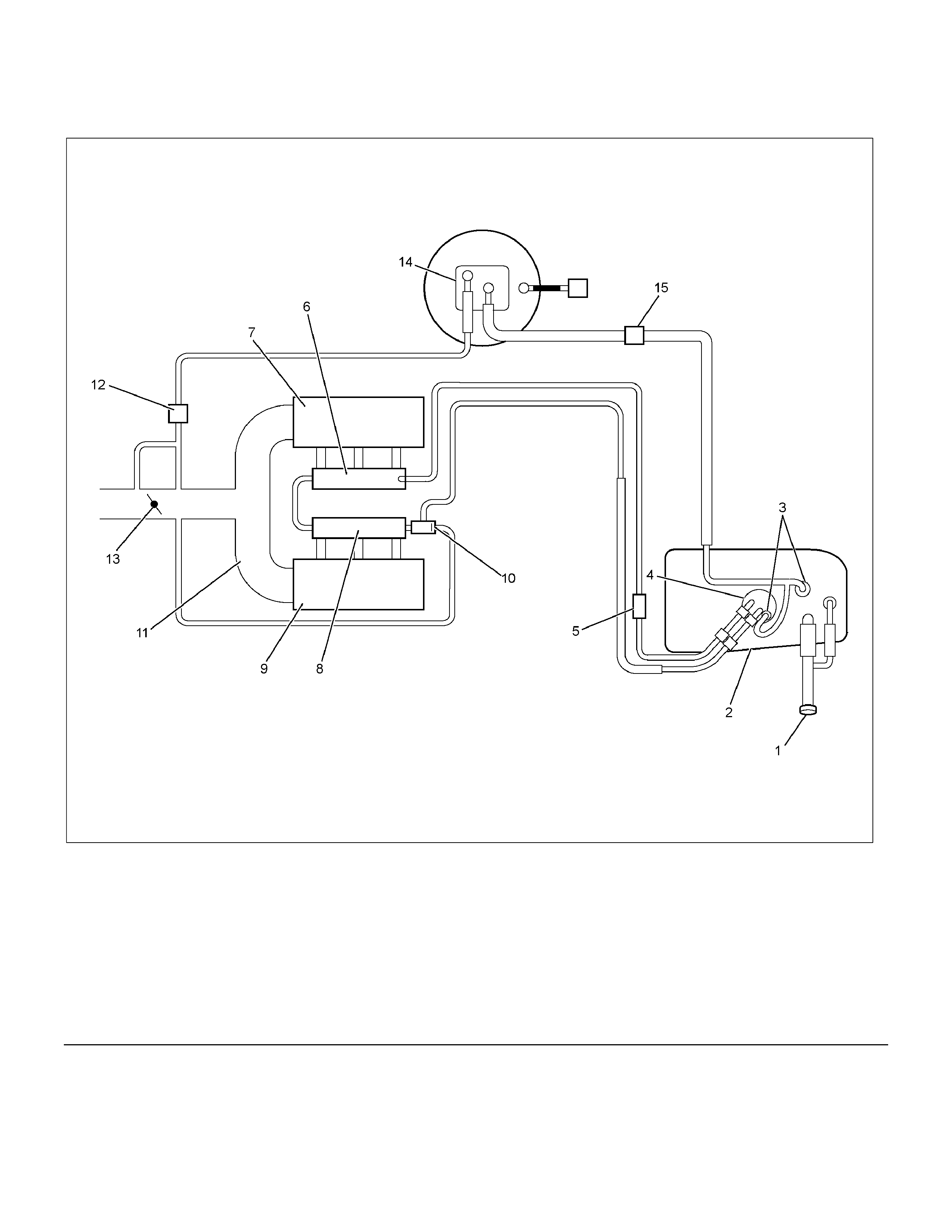

System Components

RTW36CLF000301

Legend (8) Left-hand Fuel Rail

(1) Fuel Filler Cap (9) Intake Air Left Bank

(2) Fuel Tank (10) Fuel Pressure Control Valve

(3) Rollover Valves (11) Common Chamber

(4) Fuel Pump and Sender Assembly (12) Duty Solenoid Valve

(5) Fuel Filter (13) Throttle Valve

(6) Right-hand Fuel Rail (14) Canister

(7) Intake Air Right Bank (15) Evaporative Control Valve

Fuel is injected into the engine by separate fuel injectors that are mounted in the intake manifold (common chamber).

Fuel is supplied to the injectors under pressure from the fuel tank through the fuel lines and a fuel rail, which is

attached to the top of the common chamber.

Fuel is circulated through the fuel rail continually while the engine is running. This removes air and vapours from the

fuel as well as keeping the fuel cool during hot conditions.

A fuel pressure control valve is installed on the fuel rail to maintain fuel line pressure across the injectors under all

operating conditions. Fuel pressure is accomplished by controlling the amount of fuel that is circulated back to the fuel

tank based on the demand of the engine.

See Section 6E Engine Driveability and Emission for more information and diagnosis.

The engine is fitted with a Manifold Atmospheric Pressure (MAP) sensor, which measures changes in the manifold

pressure, resulting from changes to the engine load and speed conditions. The sensor resistance will alter, which then

changes the MAP sensors voltage output.

The changing voltage is transformed into an electric signal and is sent to the Engine Control Module (ECM).

The ECM receives signals from the MAP sensor, intake air temperature sensor engine temperature and other sensors.

The ECM then determines an appropriate fuel injection pulse width (On Time) and sends the signal to the fuel injectors

to allow an appropriate air/fuel ratio.

Two interchangeable “O" rings are used on the fuel injector and must be replaced when the injectors are removed.

The Multiport Fuel Injection system utilizes an injection system where the injectors turn on at every crankshaft

revolution. The ECM controls the injector on time so that the correct amount of fuel is metered depending on driving

conditions.

All petrol engines are designed to use only unleaded petrol.

Unleaded petrol must be used for correct emission control system operation and its use will also minimize spark plug

fouling and extend engine oil life.

Using leaded petrol can damage the emission control system and could void the vehicle warranty.All vehicles are

equipped with an Evaporative Emission Control System. The purpose of the system is to minimize the escape of fuel

vapours to the atmosphere.

Fuel System Depressurizing

CAUTION: Depressurizing of the fuel system is required before any servicing to the fuel system that requires

the fuel lines to be disconnected.

Procedure

1. ,Remove the fuel cap slowly to release any build up of pressure in the fuel tank.

2. Remove the fuel pump fuse from the fuse box. Refer to Section 8A Electrical - Body & Chassis.

3. Crank the engine over for 15 seconds to relieve the pressure in the fuel lines.

NOTE: A small amount of residual pressure may remain in the system after this procedure has been performed. Use

care when servicing the fuel system.

Fuel Lines and Quick Connector Fittings

Description

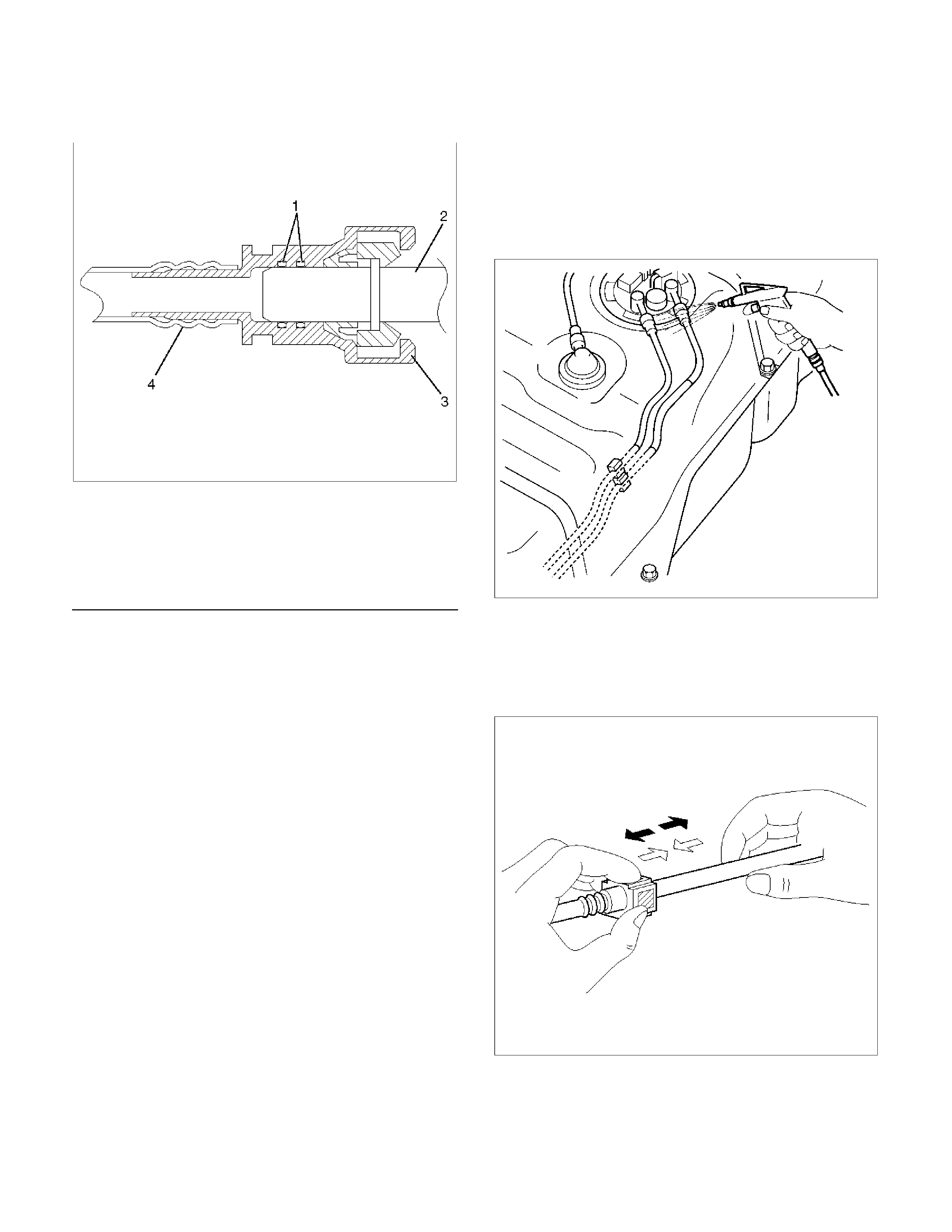

140R100032

Legend

(1) O-ring

(2) Fuel line fuel line/ port

(3) Connector

(4) Plastic fuel line tube

CAUTION: Ensure all service precautions have

been observed prior to removing any connector

fittings.

Leak Test and Inspection

1. Turn the ignition key to the ON position and

ensure the pump runs for a short time by listening

for the pump start-up sound. The fuel pressure will

increase when the fuel pump is actuated.

2. Perform a preliminary check of the system by

inspecting the system for any leaks around the

connections and fittings.

3. Perform steps 2 and 3 several times.

4. If the preliminary check of the system produces no

leaks, start the engine and check the system

again for any signs of leaks around the

connections and lines.

Removal

1. Depressurize the fuel system, refer to

Fuel System Depressurizing in this Section.

2. Use compressed air to remove any dirt around the

fuel line quick connector fittings prior to

disconnecting the fittings.

141R100002

3. Hold the connector in one hand and depress the

square release button on the connector while

gently pulling the quick connector and the fuel

line/port apart with the other hand.

140R100037

4. Cover the quick connectors to prevent dirt o

r

other foreign materials from entering the system.

140R100028

Inspection

1. Check the fuel line/port and quick connector fitting

for any scratches, rust, dents or cracks. Replace

the connector or the fuel line/port if found to be

defective.

2. Inspect the O-rings in the quick connector and

replace the connector or fuel line if found to be

defective.

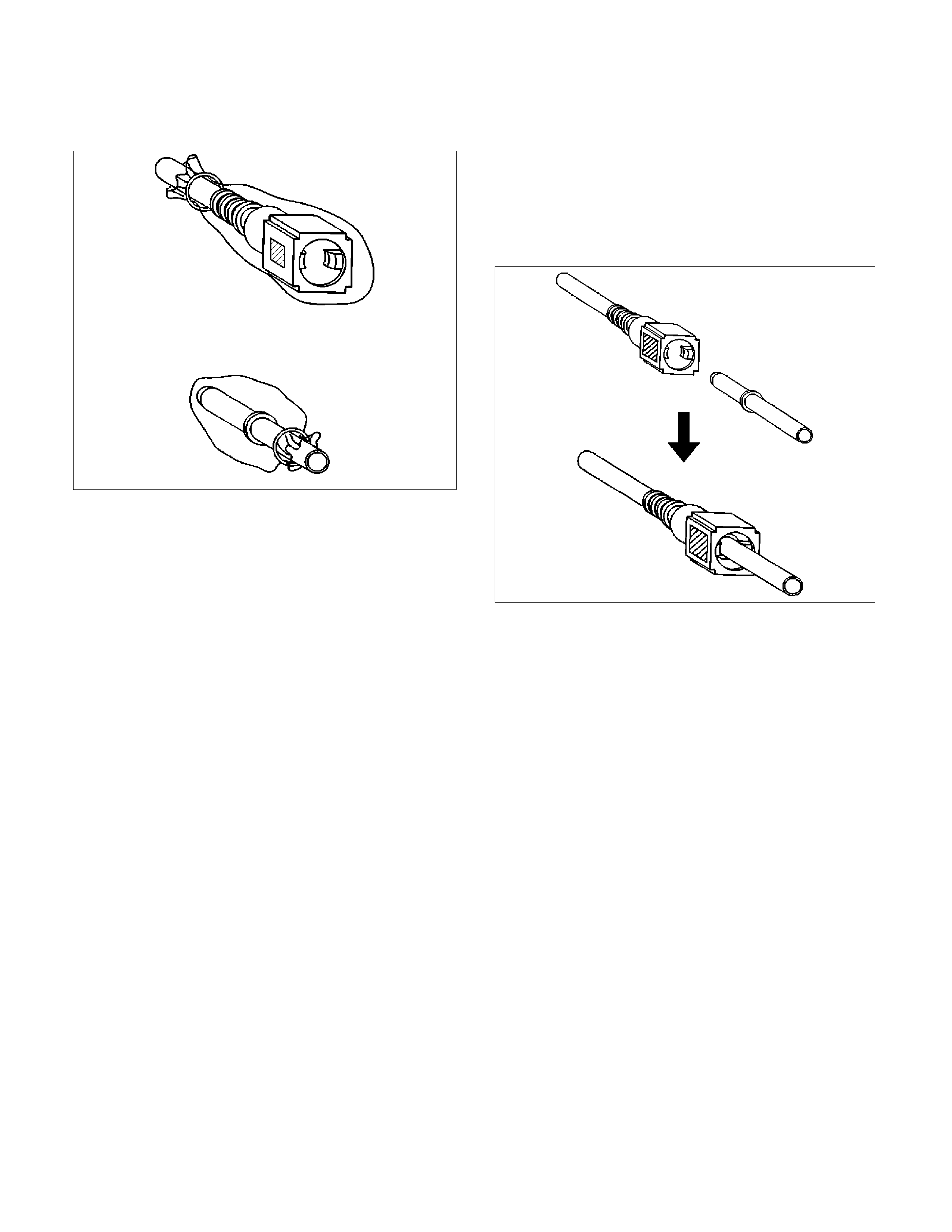

Installation

1.

A

pply a small amount of engine oil or light oil to

the fuel line/port to assist in assembly of the

connector.

NOTE: Assembly of the fuel line/port and quick

connector should take place immediately after applying

the oil to prevent any dust from sticking to the surface,

which may cause the connector to leak.

140R100036

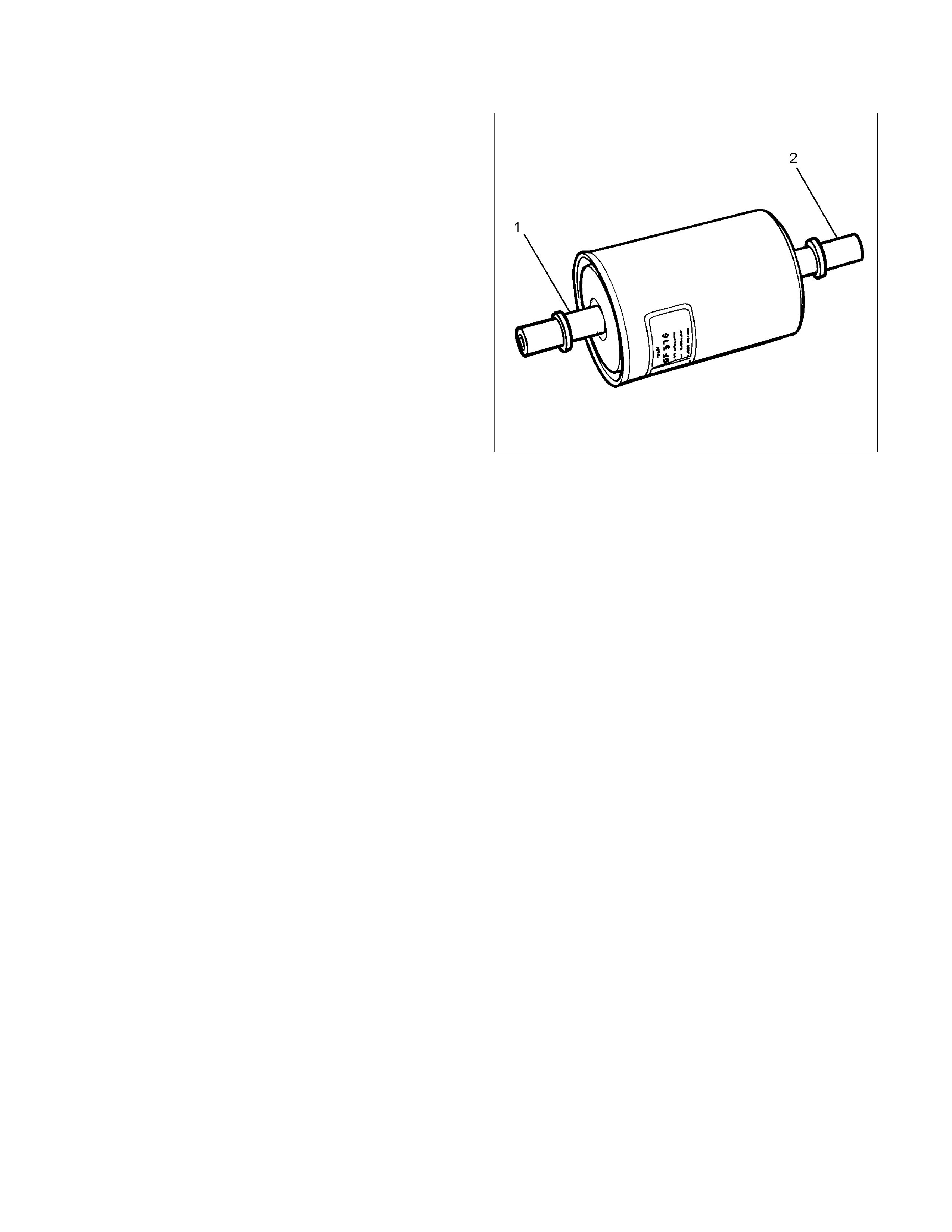

Fuel Filter

Removal

CAUTION: When a repair to the fuel system has

been completed, perform a leak test, refer to

Leak Test and Inspection.

1. Depressurize the fuel system, Refer to

Fuel System Depressurizing in this Section.

2. Disconnect the battery ground cable.

NOTE: Cover the opening of the filler neck to prevent

any dirt from entering.

CAUTION: A small amount of fuel will flow out of

the fuel lines and filter when disconnected.

3. Place a drain tray below the fuel filter and remove

the fuel line quick connectors on the inlet and

outlet side of the fuel filter.

NOTE: Refer to Fuel Lines and Quick Connector

Fittings in this section when performing any repairs.

NOTE: Cover the quick connector to prevent any dirt

from entering the system and any further fuel from

leaking.

4. Remove the fuel filter from the holder attached to

side cross-member.

Inspection

1. Replace the fuel filter if fuel leaks from the fuel

filter body or if the fuel filter body itself is

damaged.

2. Replace the fuel filter if it is clogged with dirt o

r

sediment or the filter shows signs of being

contaminated with water or other foreign

materials.

Installation

1. Install the fuel filter to the holder attached to side

cross-member.

NOTE: Ensure the direction of fuel filter outlet fuel

line/port (1) is facing the engine and the inlet

fuel line/port (2) is facing the fuel tank.

RTW36CSH000301

2. Connect the inlet and outlet fuel line quick

connectors to the fuel filter.

NOTE: Refer to Fuel Lines and Quick Connector

Fittings in this section.

3. Tighten the fuel filler cap until at least one click is

heard.

4. Connect the battery ground cable.

NOTE: After installation, perform a leak test, refer to

Leak Test and Inspection.

In–Tank Fuel Filter

The fuel pump assembly is fitted with a fuel filter, which

is located on the lower end of the fuel pick-up tube in

the fuel tank. This filter helps to prevent dirt from

entering the fuel system and stops water, unless the

filter is completely submerged in the water.

The filter is a self-cleaning type and does not require

scheduled maintenance. However, excess water and

dirt in the fuel tank can restrict the fuel supply to the

engine, resulting in poor engine performance or even

failure to start or run. In such a case, the fuel filter may

become blocked and allow dirt or water to enter the

system. If this occurs, the entire fuel system must be

thoroughly cleaned and the filters replaced.

Fuel Pump Flow Test

If a reduction of the fuel supply is suspected, perform

the following checks.

1. Ensure there is sufficient fuel in the tank.

2. With the engine running, check the fuel lines from

the fuel tank to the injectors for evidence o

f

leakage. Retighten, if the line or the connections

are loose. Also, check the fuel lines for restrictions

such as a squashed pipe or clogging.

3. Depressurize the fuel system, refer to Fuel

System Depressurizing in this Section.

4. Disconnect the fuel line at the fuel rail.

5. Connect a hose from the fuel line and place the

open end into a clean container

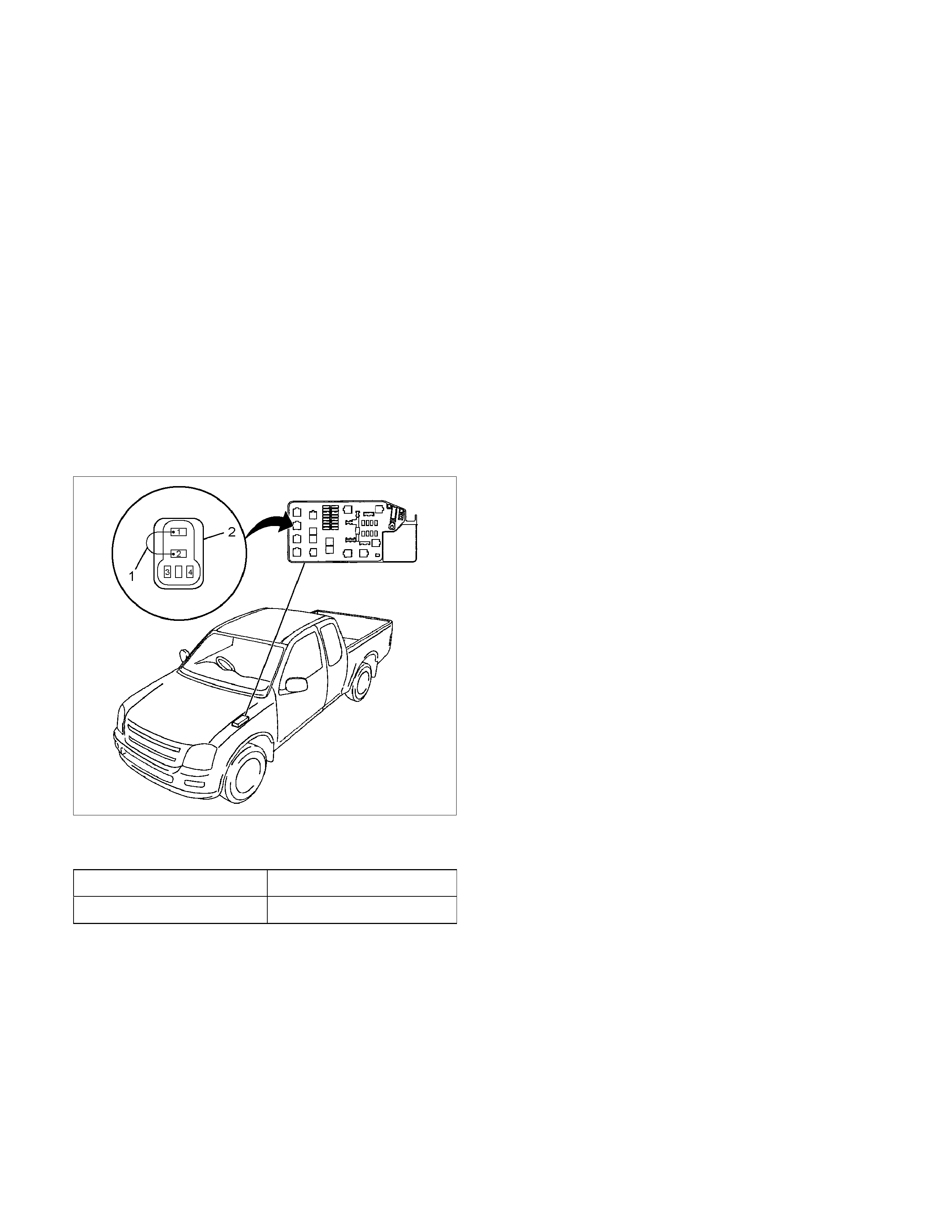

6. Connect the pump relay terminals (2) with a

jumper wire (1) as shown, then turn the ignition

ON to run the fuel pump and then check the fuel

pump flow rate.

RTW36CSH000201

CAUTION: Do not generate any sparks when

connecting the jumper wire.

Delivery Delivery

15 seconds 0.38 liters minimum

NOTE: If the fuel flow rate is below the minimum value,

conduct a pressure test.

Pressure test

To perform a pressure test on the fuel system, refer to

Section 6E Fuel Control System.

Fuel Tank

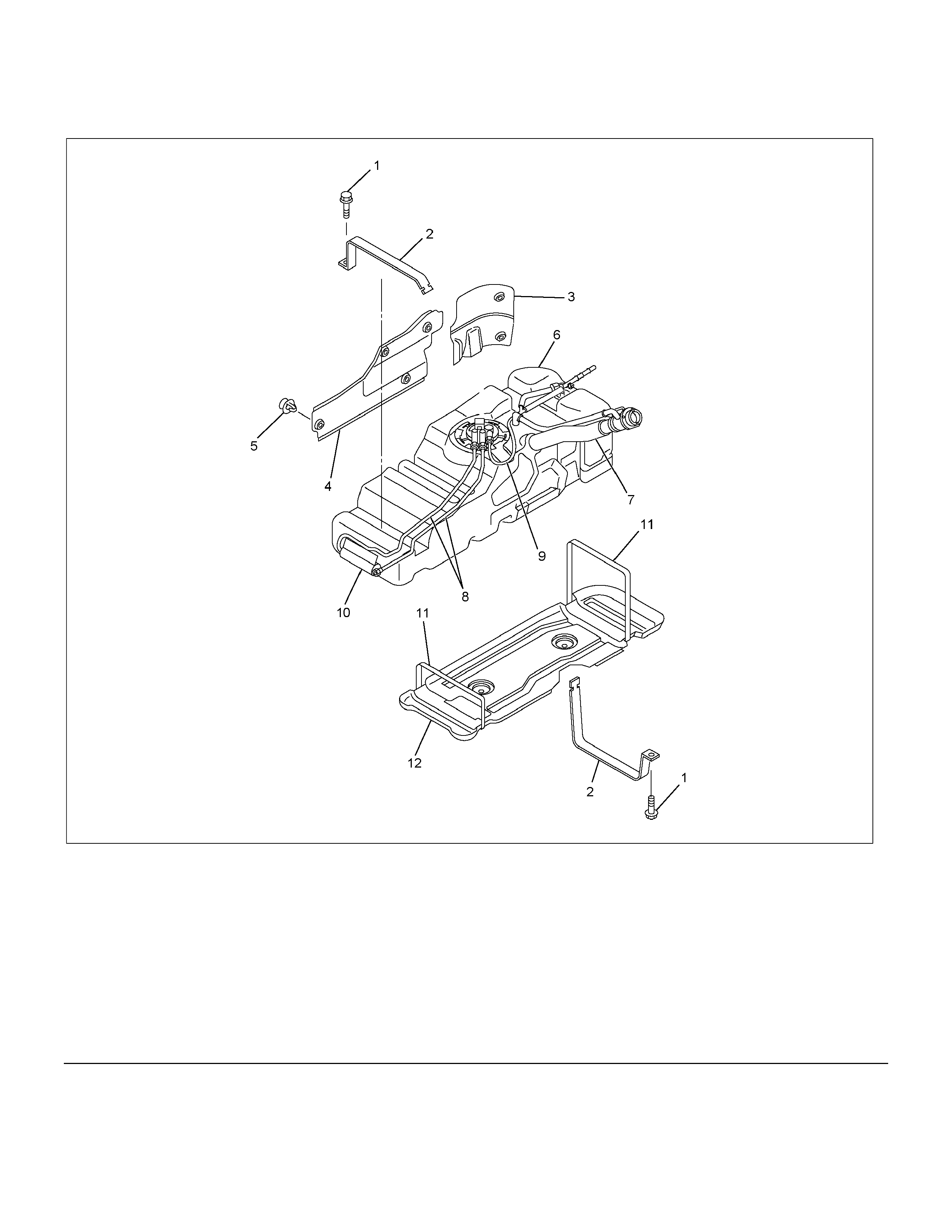

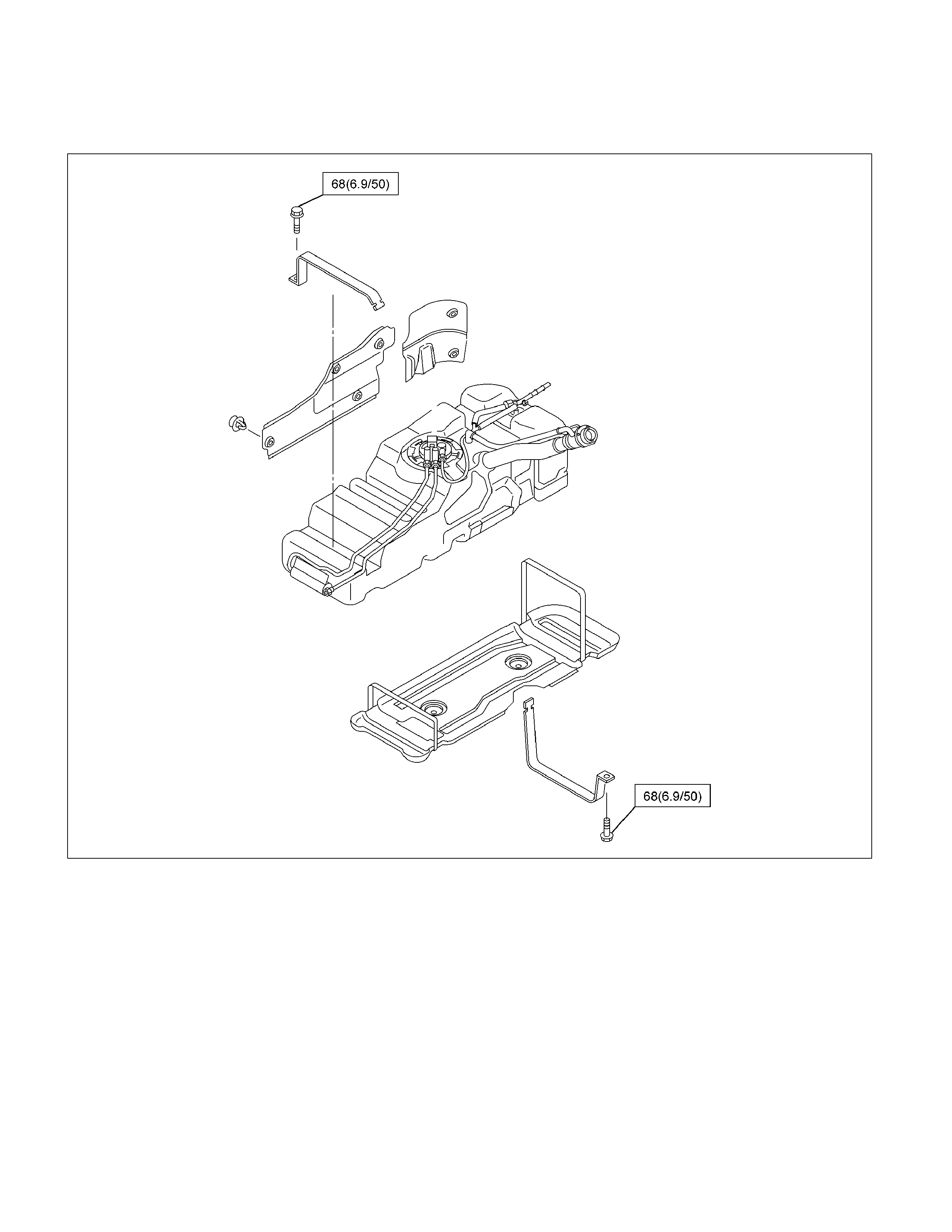

Fuel Tank and Associated Parts

RTW46FLF000301

Legend

(1) Bolt; Fuel Tank Strap (7) Fuel Filler Hose

(2) Fuel Tank Strap (8)

(3)

(4) Rear Side Shield

Side Shield (9)

(10)

Fuel Line and Quick Connector

Evaporative Line and Quick Connector

Fuel Filter

(5) Retainer (11) Strap; Under Shield

(6) Fuel Tank (12) Under Shield

Removal

1. Disconnect the battery ground cable.

2. ,Loosen the fuel filler cap slowly to remove any build up of pressure in the fuel tank.

3. Depressurize the fuel system. Refer to Fuel System Depressurizing.

NOTE: Cover the opening of the filler neck to prevent any dust entering.

4. Jack up the vehicle and support the vehicle on safety stands.

5. Support the fuel tank from underneath the vehicle with a suitable lifter.

6. Remove the left-hand inner wheelhouse liner.

7. Remove the bolt fixing the filler neck to the body.

8. Remove the two side shields (3) and (4).

9. Disconnect the quick connector from the fuel lines (8) quick connector. Refer to Fuel Lines and Quick

Connector Fittings.

NOTE: Cover the quick connector to prevent any dust entering and fuel leaking.

10. Remove the bolt (1) fixing the lower tank strap (2).

11. Disconnect the fuel pump and sender assembly wiring harness connector on the fuel pump and remove the

wiring harness from the clip on the fuel tank.

12. Lower the fuel tank (6) from the vehicle.

NOTE: When lowering the fuel tank from the vehicle, ensure the wiring and fuel lines are free from interference with

the fuel tank.

Installation

Installation of the fuel tank is the reverse of the removal procedure noting the following:

1. Ensure the tank strap fixing bolts are tightened to the specified torque.

Torque: 68 N⋅m (6.9 kg⋅m/50 lb ft)

2. Tighten the filler cap until at least three clicks are heard.

3. Leak test the fuel system, refer to Leak Test and Inspection in this Section.

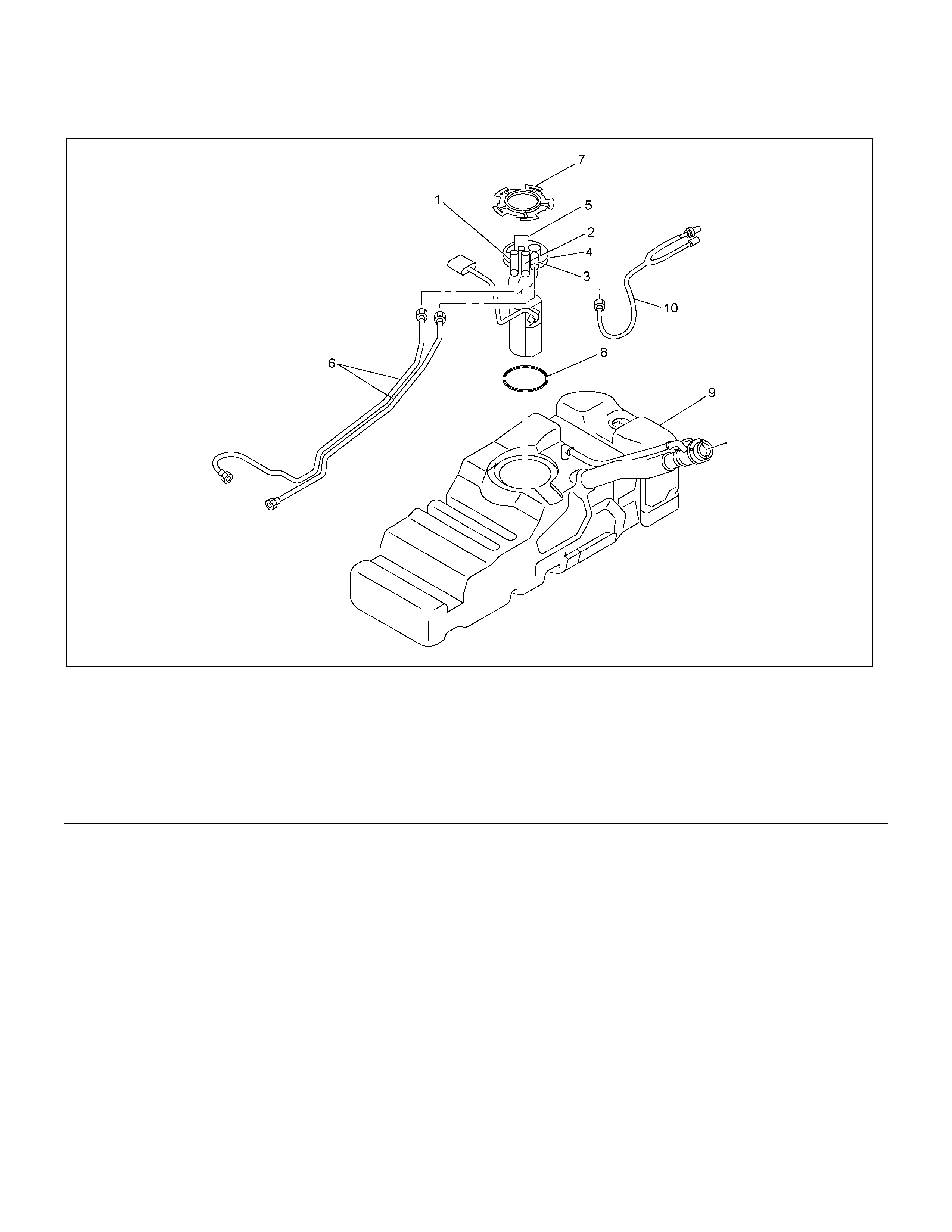

Fuel Pump and Sender Assembly

Fuel Pump and Sender Assembly Associated Parts

RTW46FMF000401

Legend

(1) Fuel Feed Port / Line (6) Fuel Line Quick Connector

(2) Fuel Return Port / Line (7) Retainer Ring (Fuel Pump Lock)

(3) Fuel Emission Port / Line (8) O-ring

(4) Fuel Pump and Sender Assembly (9) Fuel Tank Assembly

(5) Connector; Fuel Feed Pump & Sender (10) Evaporative Line Quick Connector

Removal

1. Remove the fuel tank assembly (9). Refer to

Fuel Tank Removal in this section.

2. Disconnect the fuel line quick connectors (6) and

(10).

3. Disconnect the fuel pump and sender assembly

wiring harness from the fuel pump and sende

r

assembly.

4. Remove the retainer ring (7) from the fuel tank

with the removal tool 5-8840-2602-0.

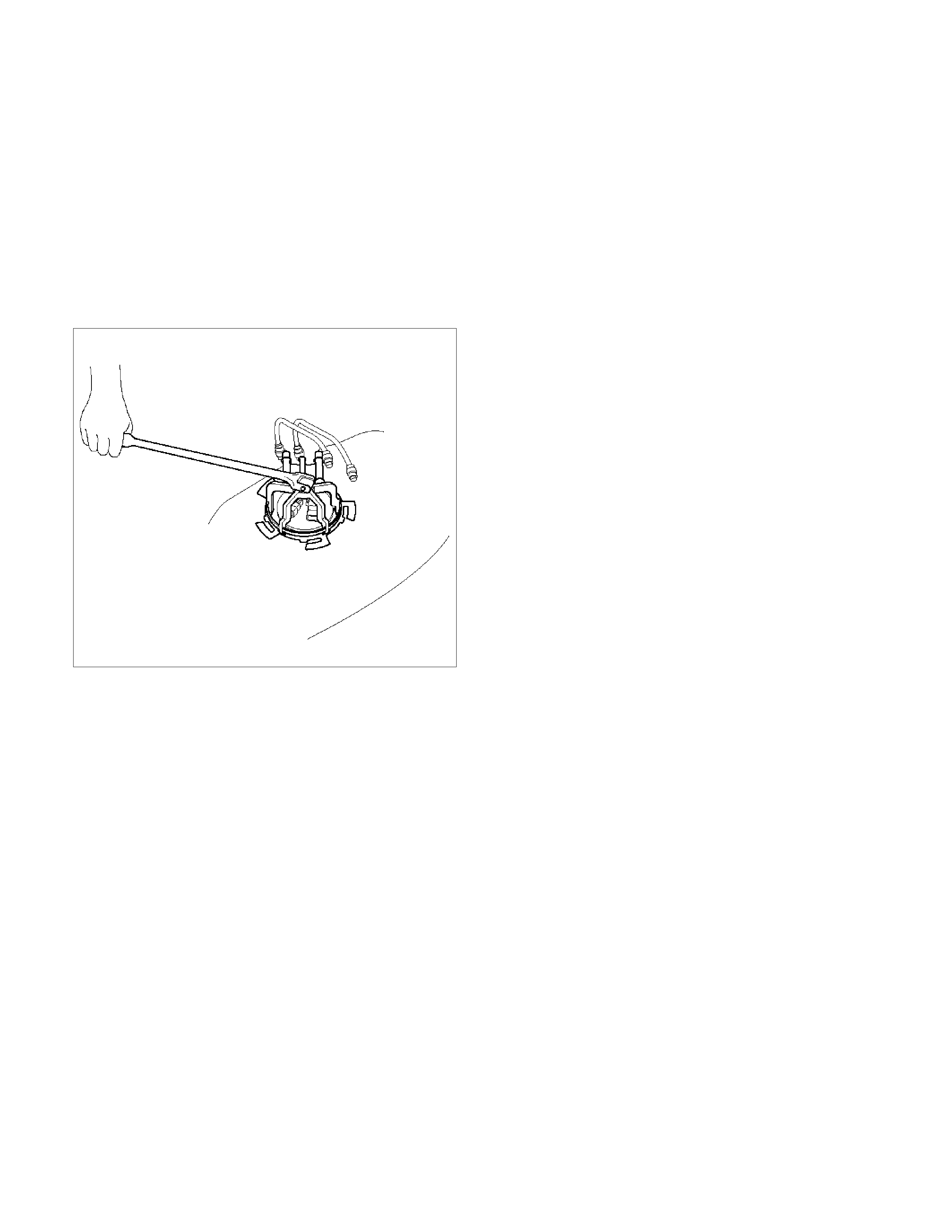

140R100035

5. Slowly, remove the fuel pump assembly from the

fuel tank taking care not to damage the float arm

for the fuel gauge.

NOTE: Cover the opening of the fuel tank to prevent

any dust entering the tank.

Installation

1. Clean the O-ring surface of the fuel tank and the

fuel pump.

2. Install a new fuel pump O-ring (8) over the flange

on the fuel pump.

NOTE: If the fuel pump O-ring comes into contact with

petrol, it will swell and cannot be installed.

3. Carefully, install the fuel pump (4) into the fuel

tank taking care not to damage the float arm fo

r

the fuel gauge sender.

4. Position the flange of the fuel pump to the mating

surface of the fuel tank and hold in position.

5. Slowly lock the retainer ring (7) to the fuel tank

with tool 5-8840-2602-0.

6. Install the fuel line quick connectors (6) and (10).

7. Install the fuel tank, refer to Fuel tank in this

Section.

8. Leak test the fuel system, refer to Leak Test and

Inspection in this Section.

Fuel Pump Relay

General Description

The fuel pump and sender assembly (FPSA) operation is controlled by the FPSA relay. When the ignition switch is

turned to the ON position, the FPSA relay operates the fuel pump for approximately 2 seconds.

When the ignition switch is turned to the START position, the Engine Control Module (ECM) receives the reference

pulse from the Ignition Control Module. The ECM will then operate the FPSA relay, supplying power to the FPSA.

Fuel Filler Neck

Removal

1. Remove the fuel tank. Refer to Fuel Tank in this section.

2. Using a marker pen or similar, place a reference mark at each joint of the fuel filler neck and hose to assist in the

reassembly process.

NOTE: Mark the joints of the fuel filler neck in the axial direction as well as the insertion depth of the joint.

3. Remove the clamps attaching the fuel tank breather hose to the filler neck and the fuel tank and remove the hose.

4. Remove the clamps attaching the fuel filler neck hose to the fuel tank and filler neck.

5. Remove the filler neck and hose by gently twisting and pulling them apart.

NOTE: Cover end of each hose and pipe to prevent any dust entering.

Installation

1. Installation of the fuel filler neck and hose is the reverse of the removal process noting the following:

• Align the marks made in step 2 of the removal process.

• Tighten all clamps to the specified torque.

Torque: 2.5 Nm (0.25 kgm/2 lb ft)

• Install the fuel tank. Refer to Fuel Tank in this section.

Fuel Filler Cap

General Description

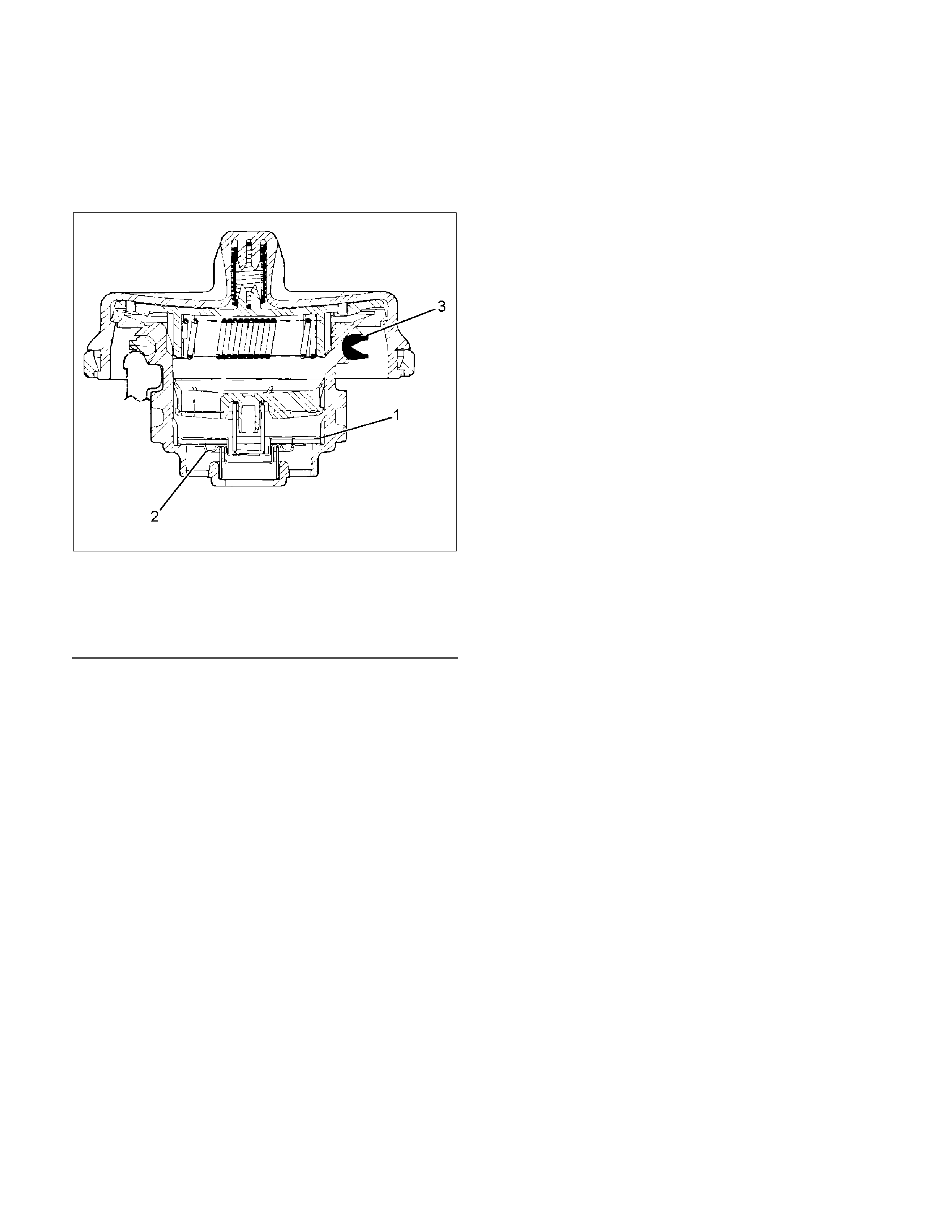

Vacuum and pressure valves are built into the fuel filler

cap which regulate the pressure in the fuel tank and

prevent fuel tank damage.

RTW36CSH000401

Legend

(1) Pressure Valve

(2) Vacuum Valve

(3) Seal Ring

Inspection

Inspect the fuel filer cap and seal for any signs of

damage. Replace the fuel filler cap if found to be

defective.

CAUTION: A replacement fuel filler cap must be the

same type as the original. The fuel filler cap

pressure and vacuum valves are specific to a

particular application and must be replaced with

the same type or fuel system damage may occur.

Main Data and Specifications

Torque Specifications N⋅m (kg⋅m/lb ft)

RTW46FMF000601

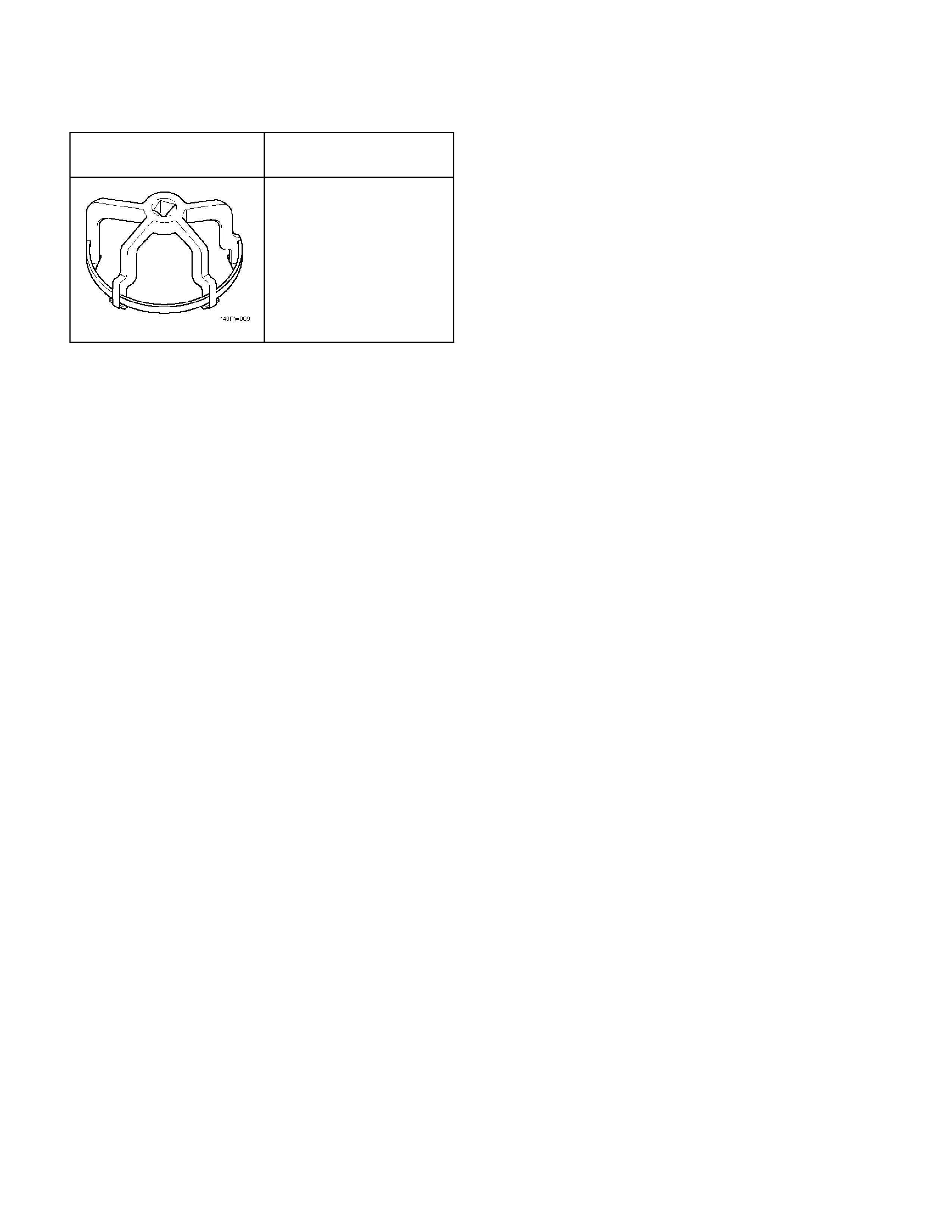

Special Tools

ILLUSTRATION PART NO.

PART NAME

5–8840–2602–0

(J–39765)

Remover; fuel pump

retainer