SECTION 6D2 - IGNITION SYSTEM (6VE1 3.5L)

Service Precaution

General Description

Diagnosis

Ignition Coil

Removal

Inspection

Installation

Spark Plug

Inspection

Replacement Spark Plugs

Crankshaft Position Sensor

Removal

Installation

Main Data and Specifications

General Specifications

Torque Specifications

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS SYSTEM

REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specifications.

Following these instructions can help you avoid

damage to parts and systems.

General Description

Ignition is done by the electronic ignition (El) that directly fires the spark plugs from ignition coils through spark plug

wires without using a distributor. A pair of ignition coils for the cylinders having different phases by 360° (No. 1 and No.

4, No. 2 and No. 5, No. 3 and No. 6) are fired simultaneously.

Since the cylinder on exhaust stroke requires less energy to fire its ignition plug, energy from the ignition coils can be

utilized to fire the mating cylinder on compression stroke. After additional 360° rotation, respective cylinder strokes are

reversed.

The EI consists of six ignition coils, crankshaft position sensor, engine control module (ECM) and other components.

The ignition coils are connected with the ECM.

The ECM turns on/off the primary circuit of ignition coils, and also it controls the ignition timing.

A notch in the timing disc on the crankshaft activates the crankshaft position sensor which then sends information such

as firing order and starting timing of each ignition coil to the ECM.

Further, the El employs ignition control (IC) to control similar to a distributor system.

Ignition Coil

Removal

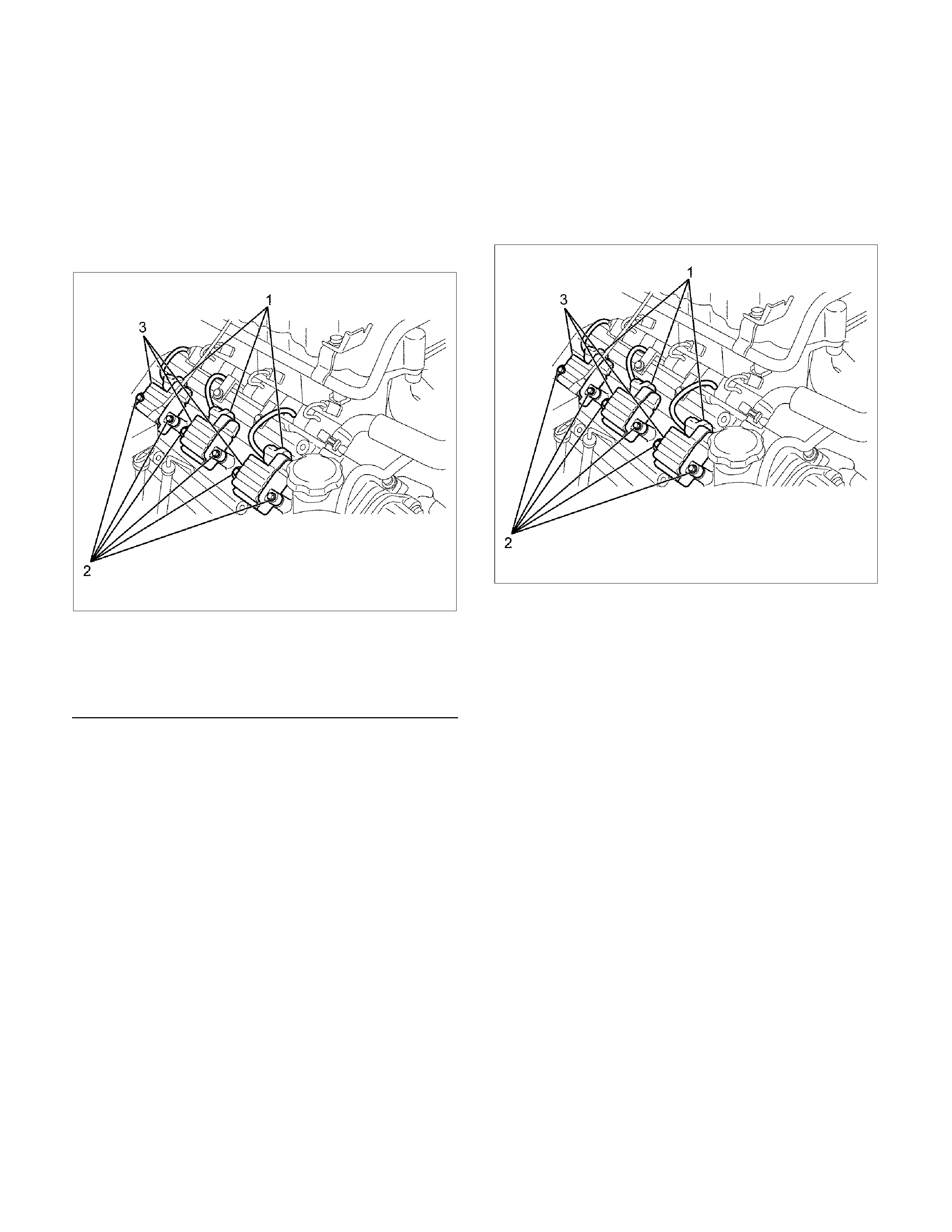

1. Disconnect the battery ground cable.

2. Ignition coil connector and ignition coil.

• Disconnect the connector from the ignition coil.

• Remove harness bracket bolt on the cylinder

head cover.

• Remove fixing bolts on the ignition coil.

RTW4Z0SH000101

Legend

(1) Ignition Coil Connector

(2) Bolt

(3) Ignition Coil Assembly

Inspection

Check the ignition coil assembly for insulation. Check

terminals for corrosion or damage, and replace as

necessary.

NOTE:

Due to the internal construction of the ignition coil unit,

it is impractical to perform primary and secondary

winding resistance tests with a multi-meter. A suspect

ignition coil unit should be substituted with a known

good unit when performing ignition system diagnosis.

Installation

1. Install the ignition coil assembly (3).

Connect the ignition coil connector (1) to the

ignition coil (3), then tighten bolts (2) to the

specified torque.

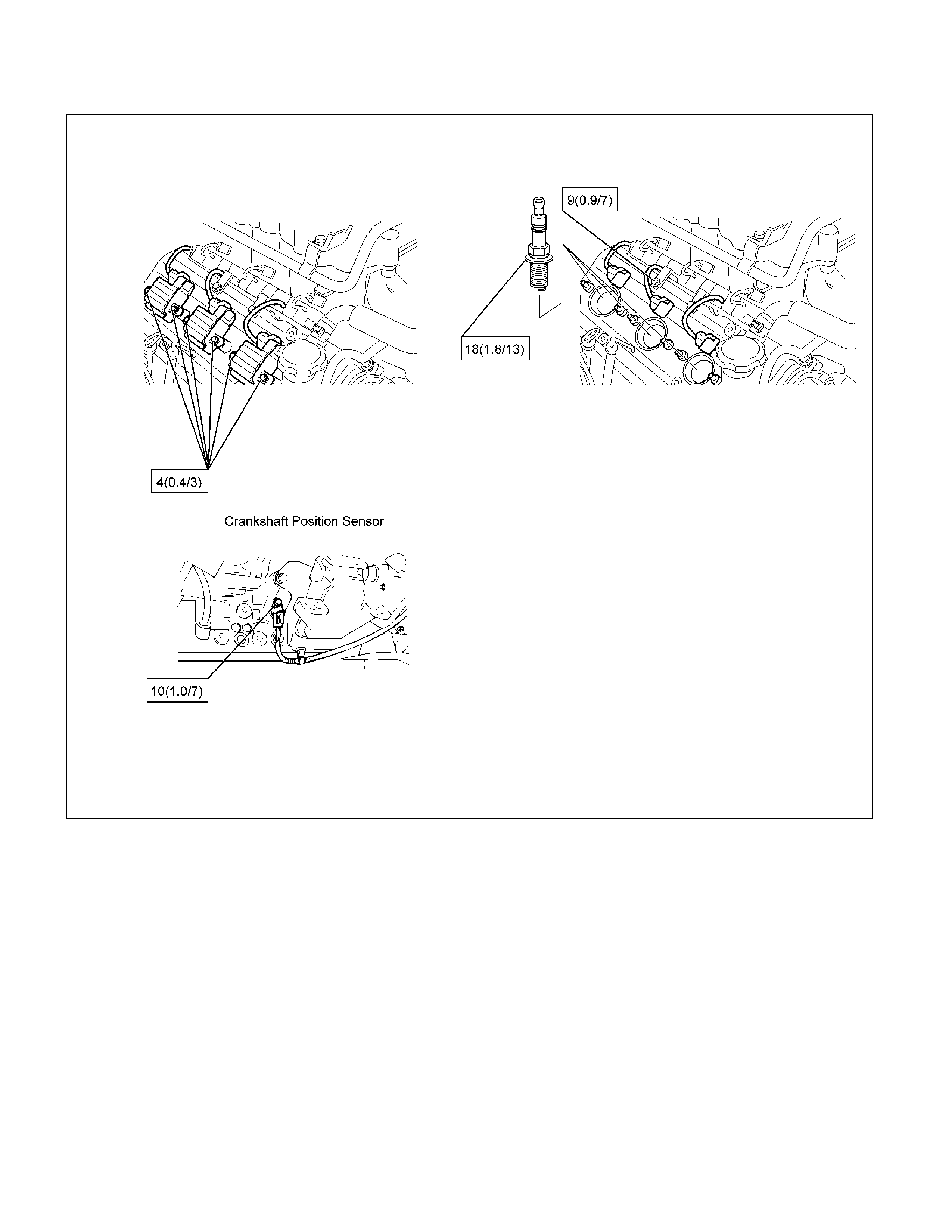

Torque: 4 N⋅m (0.4 kg⋅m/3 lb ft)

RTW4Z0SH000101

2. Connect the battery ground cable.

Spark Plug

Inspection

Poor spark plug condition adversely affects engine

performance. Carefully inspect each spark plug

following the procedure outlined below.

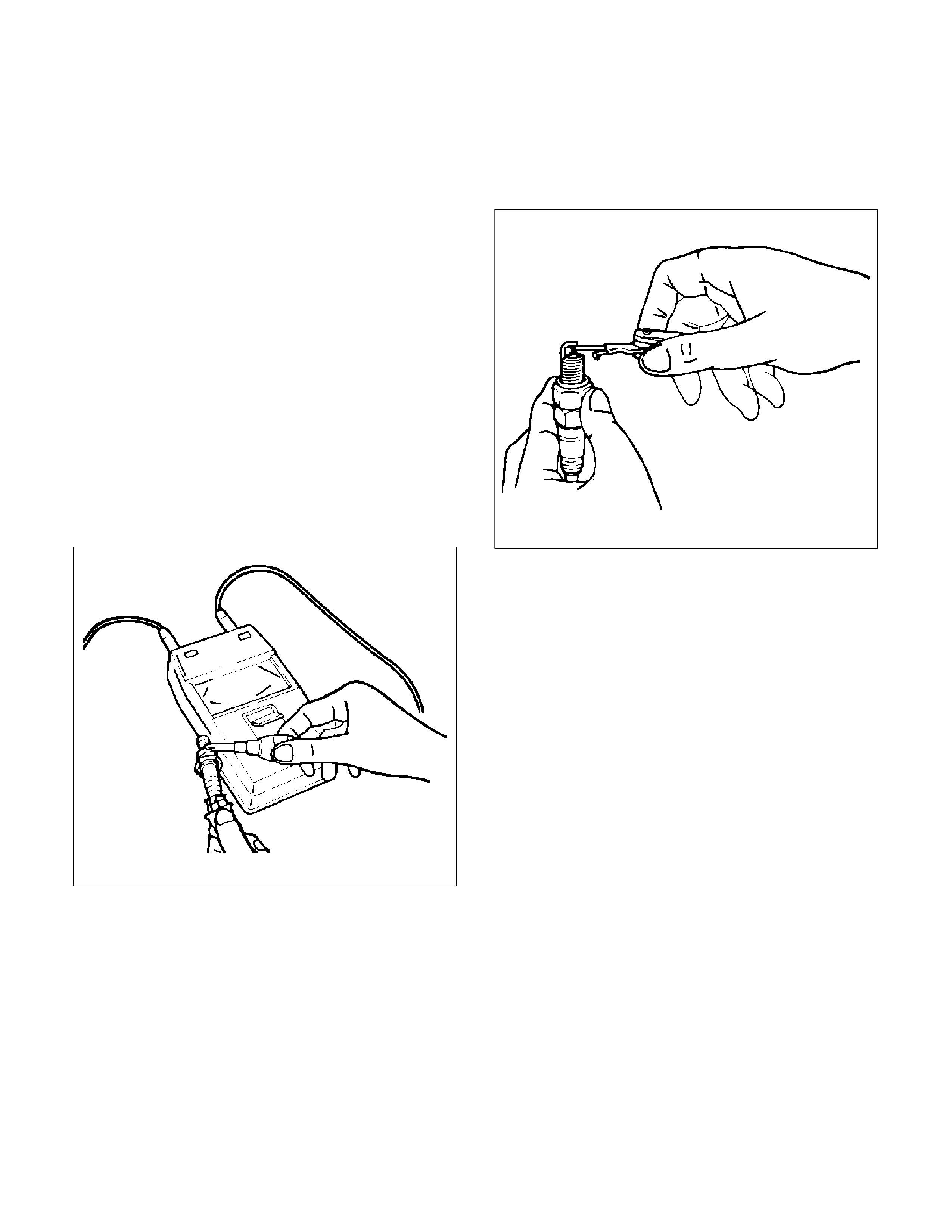

1. Remove the spark plug.

2. Check the plug for dirt and other foreign material.

If the plug is extremely dirty, the fuel and electrical

systems must be checked.

3. If necessary, clean the spark plugs by placing them

in a spark plug cleaning machine for no more than

20 seconds.

4. Check the electrode and insulator for wear and/or

cracking. If there is significant wear or cracking, the

plug must be replaced.

5. Check the gasket for damage. Replace the gasket i

f

necessary.

6. Measure the insulation resistance with a 500-volt

megaohm meter. Replace the plug if the resistance

is less than the specified value.

Insulation resistance: 50 MΩ or more

011RS010

7. Check the spark plug gap. Replace the spark plug

if the gap is not as specified.

Standard: 1.0–1.1 mm (0.04–0.043 in)

Limit: 1.3 mm (0.05 in)

011RS011

• Do not attempt to adjust the gap of an old spark

plug. Replace the plug and adjust the gap of the

new plug if required.

• Take care not to damage the spark plug tip

during handling.

8. Tighten the spark plugs to the specified torque.

Torque: 18 N⋅m (1.8 kg⋅m/13 lb ft)

Replacement spark plugs

• Under normal conditions (no problem with the fuel

and/or electrical systems), use replacement spark

plugs with a low heat value (hot-type plug).

• If insulator and electrode scorching is significant,

use replacement spark plugs with a high heat value

(cold-type plug).

Crankshaft Position Sensor

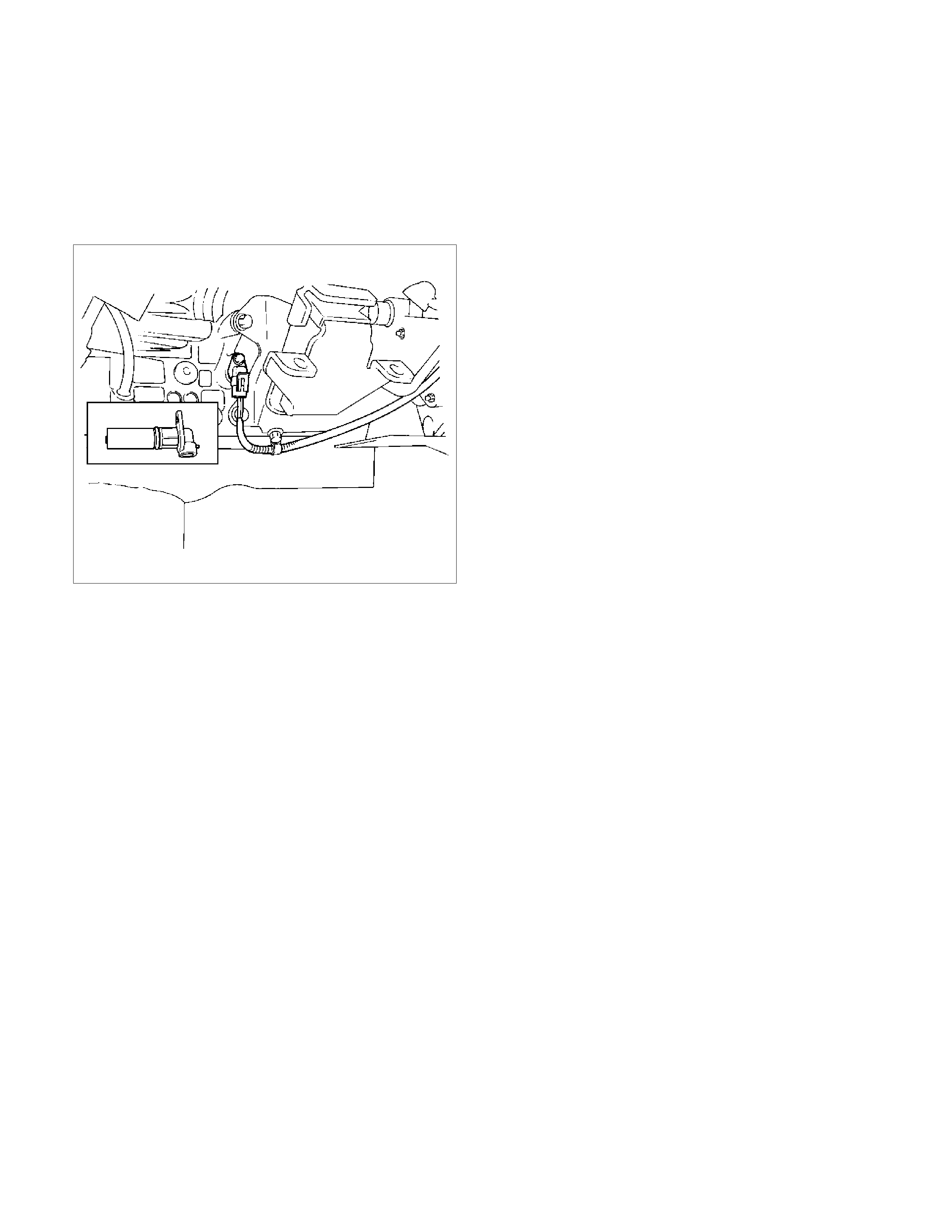

Removal

1. Disconnect the battery ground cable

2. Disconnect the wiring connector from the

crankshaft position sensor.

3. Remove the crankshaft position sensor from the

cylinder block.

012RS008

Installation

1. Install the crankshaft position sensor into the

cylinder block.

Before installation, apply small amount of engine

oil to the O–ring.

Torque: 10 N⋅m (1.0 kg⋅m/7 lb ft)

2. Reconnect the wiring connector to the crankshaft

position sensor.

Main Data and Specifications

General Specifications

Ignition System

Ignition Form Electronic Ignition System (El system) with Crankshaft Position Sensor

Spark Plug

Type K16PR-P11

RC10PYP4

RK16PR11

Plug gap 1.0 mm (0.04 in) – 1.1 mm (0.043 in)

Torque 18 N⋅m (13 lb ft)

Torque Specifications N⋅m (kg⋅m/lb ft)

RTW460LF000101