SECTION 6A - ENGINE MECHANICAL

General Description

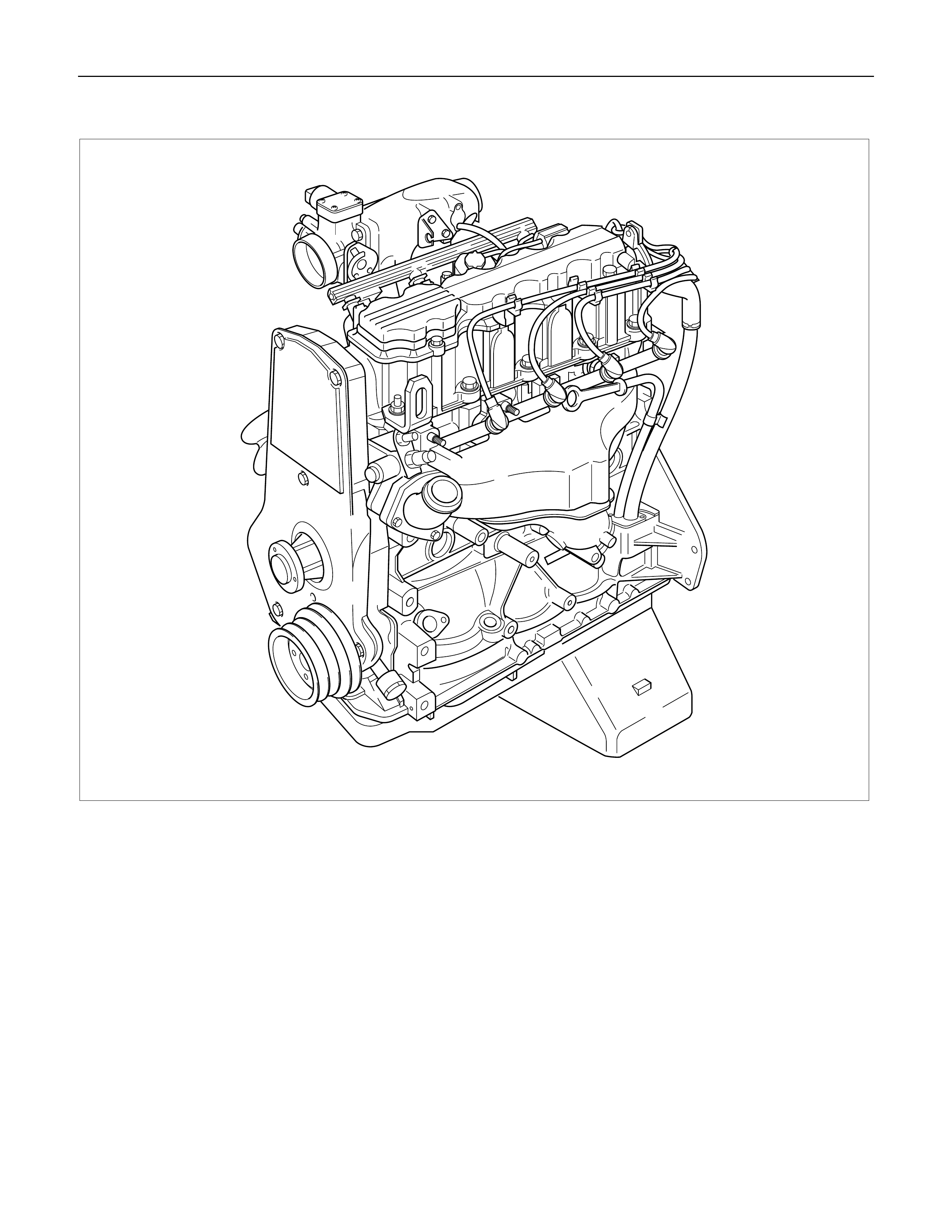

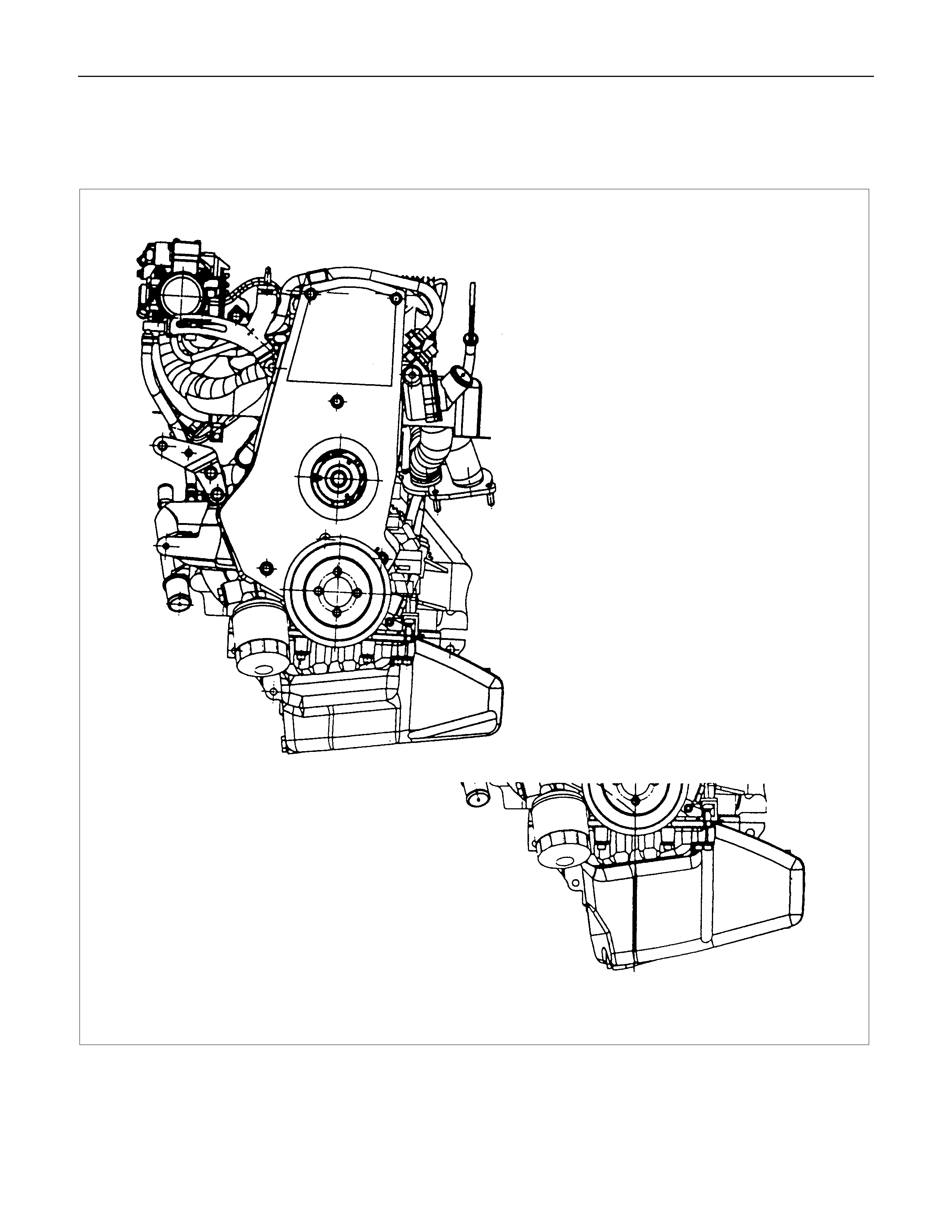

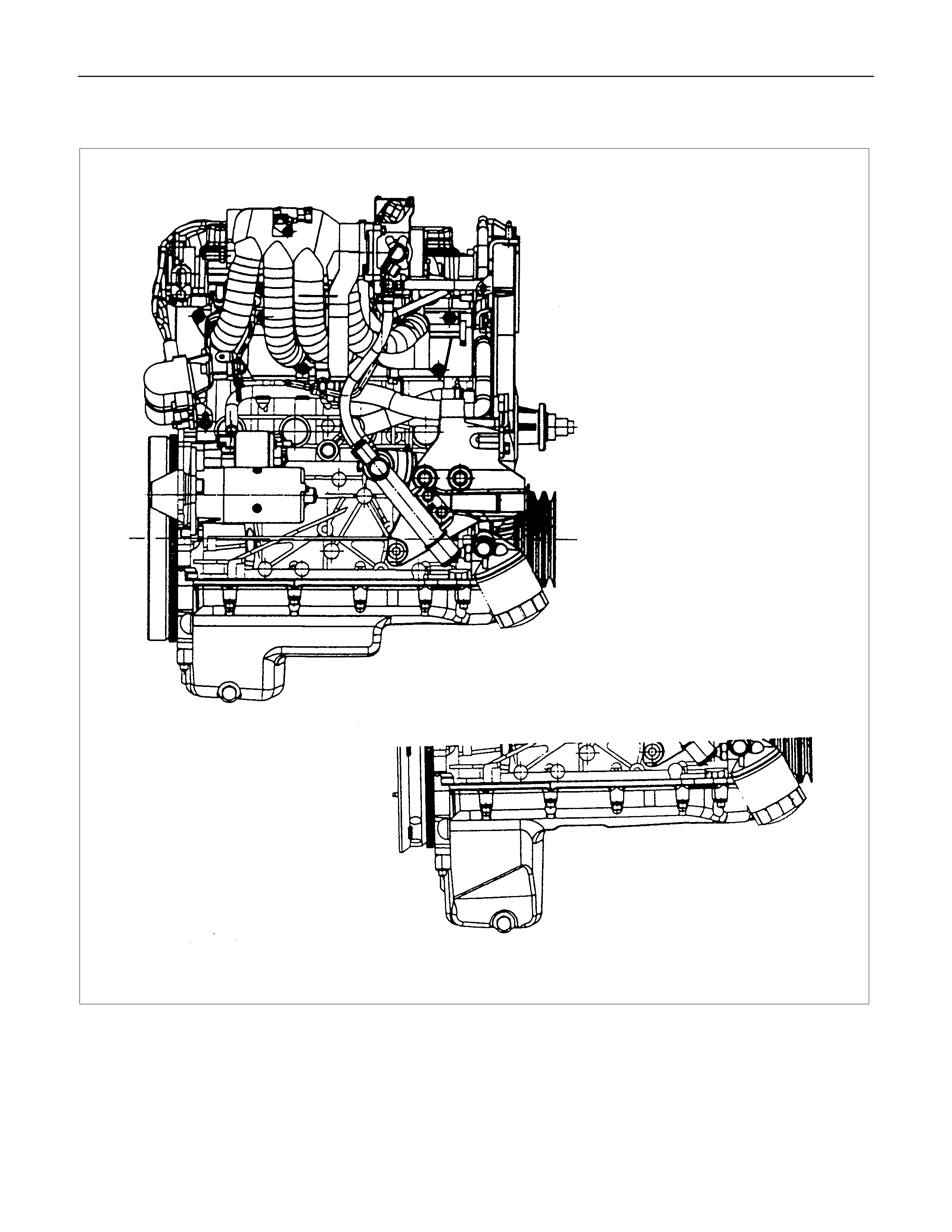

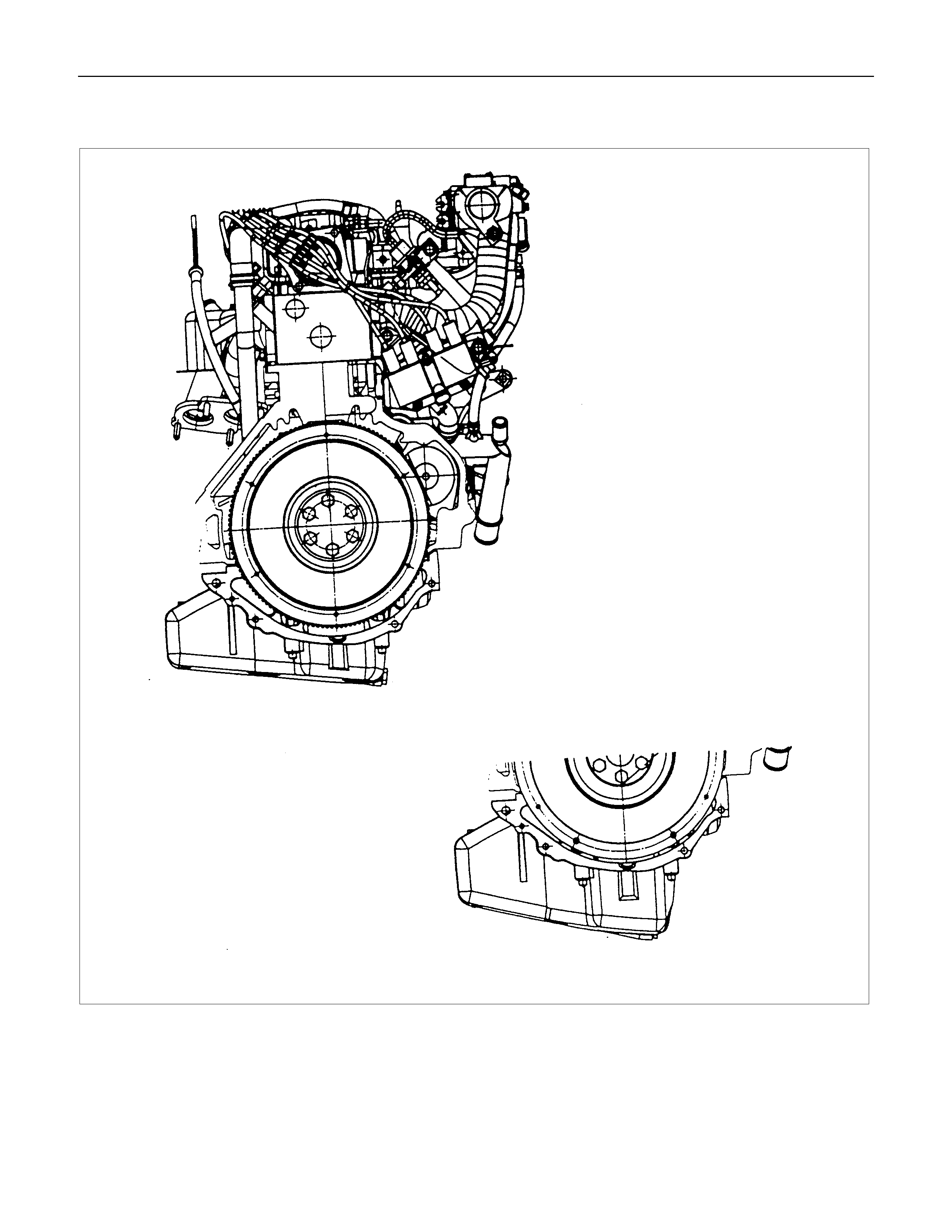

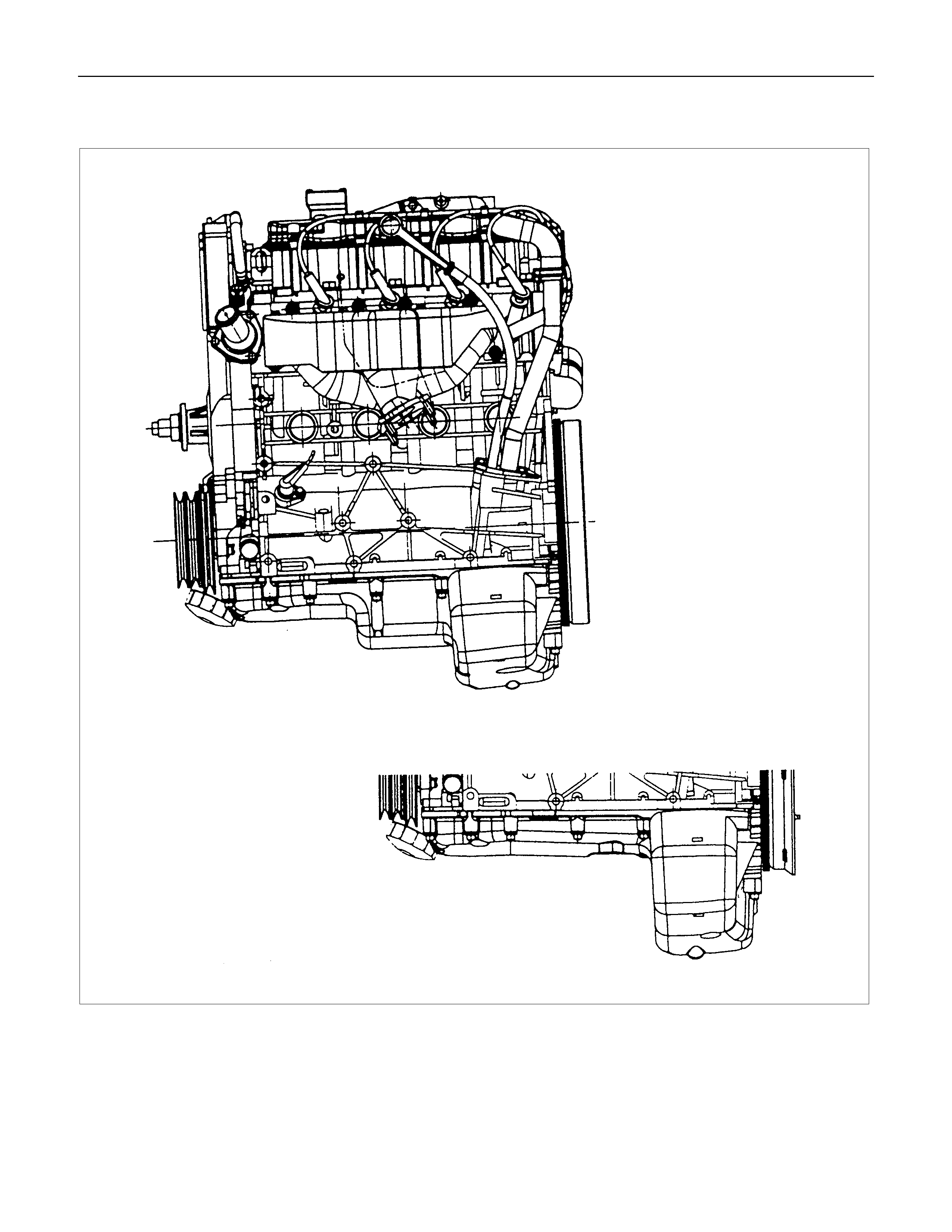

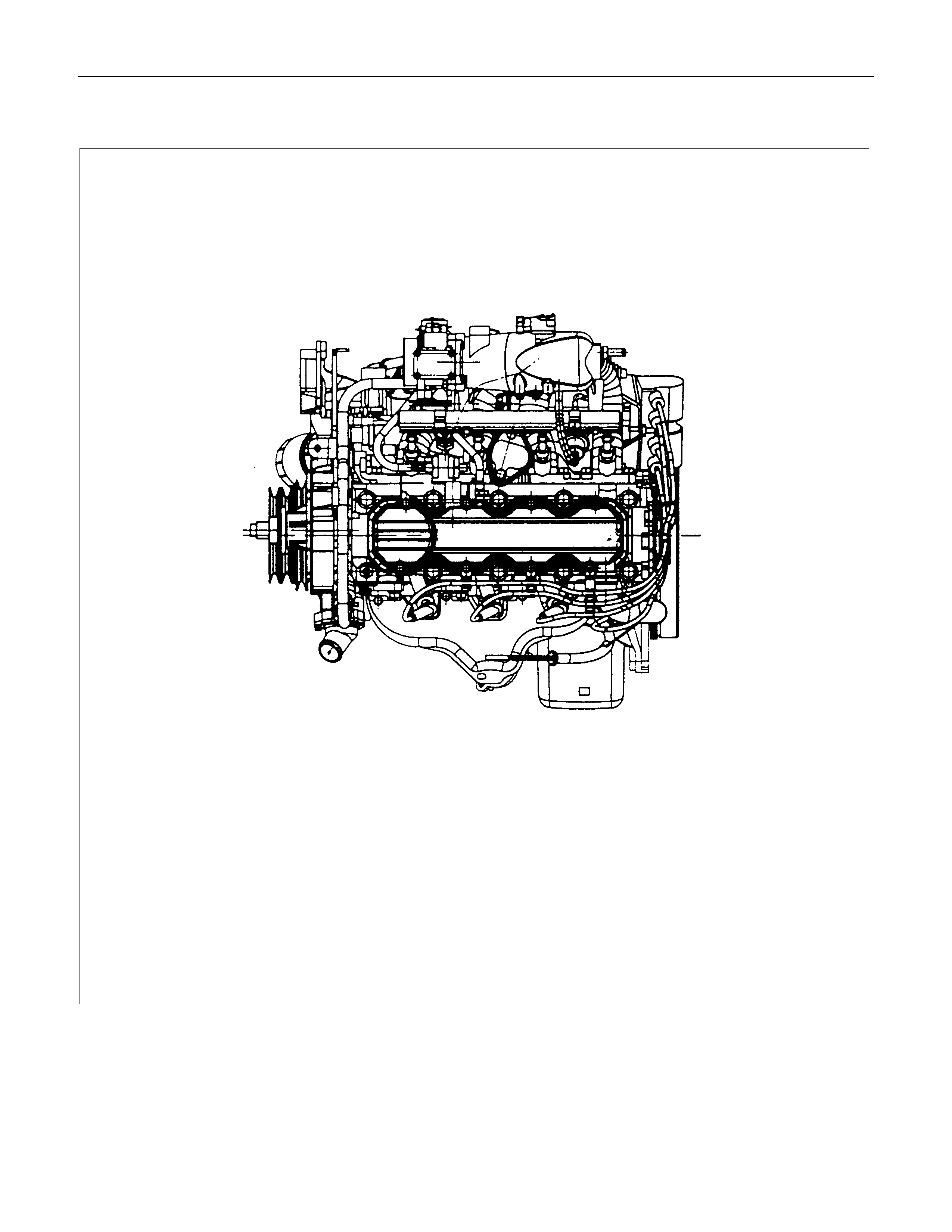

ENGINE PICTORIAL

Main Data and Specification

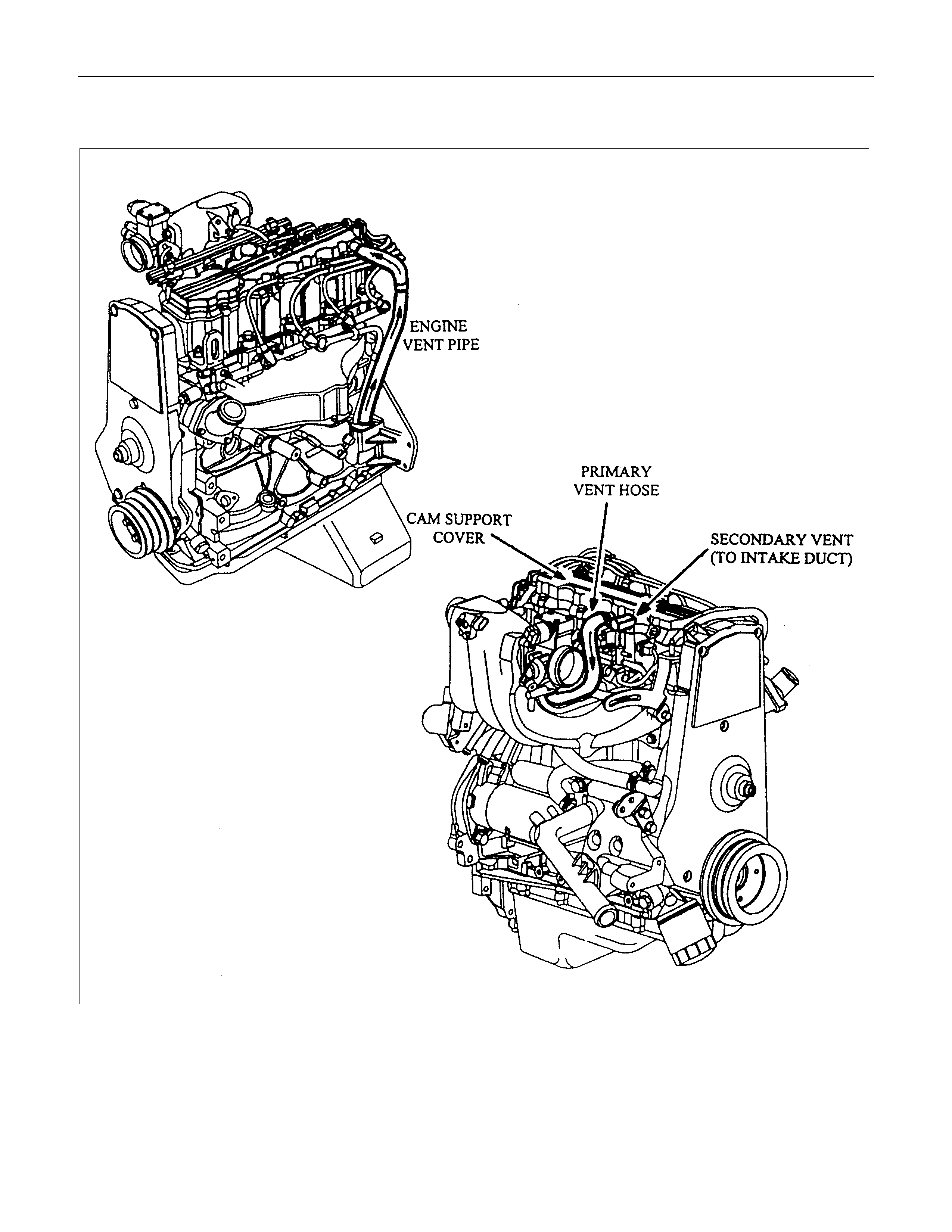

CRANKCASE VENTILATION SYSTEM

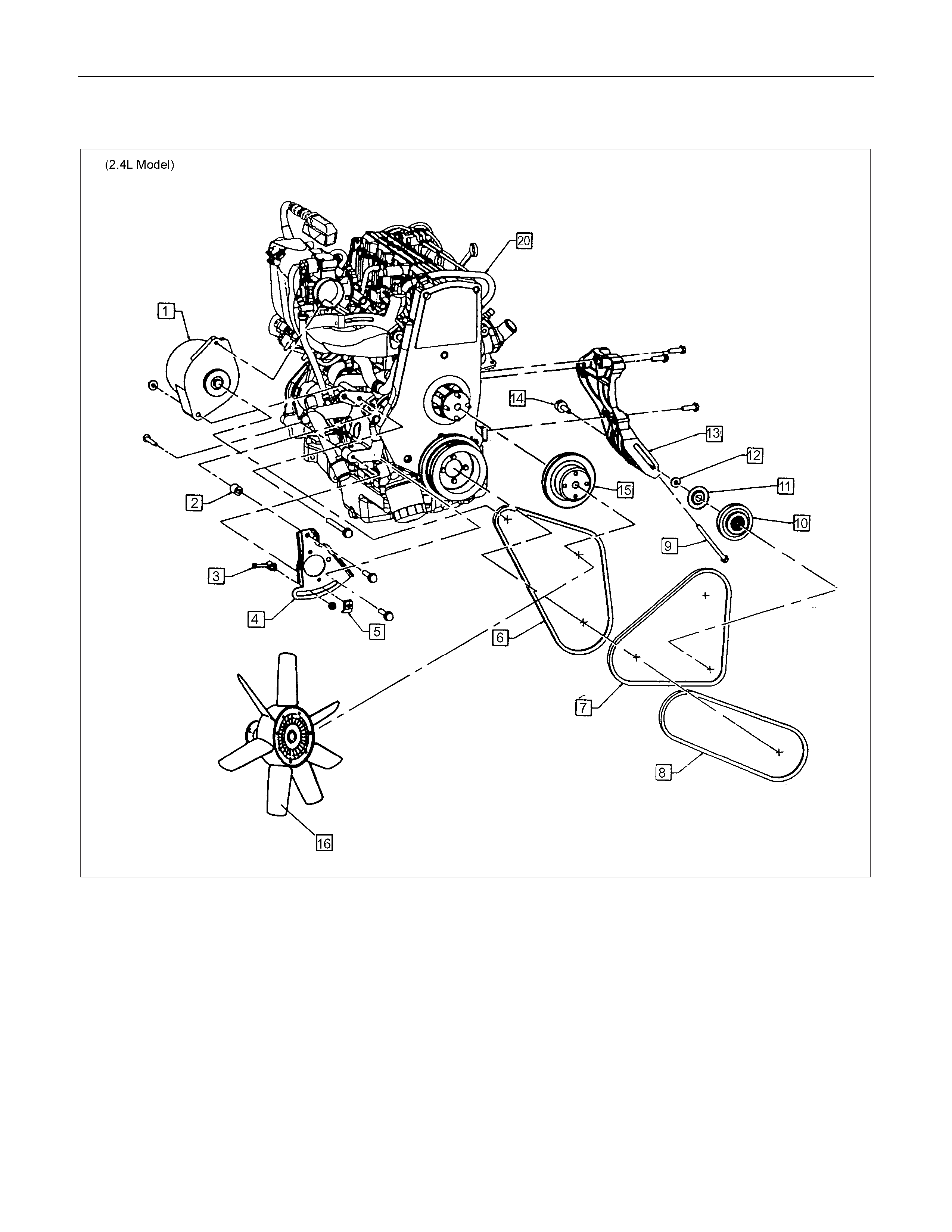

ENGINE ASSEMBLY & LOOSE PARTS

OPERATIONS ON ENGINE AGGREGATES

Engine Damping Blocks(Engine without Transmission)

Toothed Belt Tension, Check

Toothed Belt Tension, Adjust

Toothed Belt, Replace

OPERATIONS ON INSTALLED ENGINE

Gasket, Exhaust Manifold, Cylinder Head

Gasket, Intake Manifold, Clinder Head

Seal Ring, Camshaft Housing, Timing Side

Seal Ring, Thermostat Housing, Cylinder Head

Seal Ring - Front Camshaft Housing, Replace

Toother Belt Rear Cover

Toother Belt Tension Roller

COMPONENT PARTS

Cylinder Head

Hydraulic Valve Lifter

OPERATIONS ON CYLINDER HEAD AND CAMSHAFT HOUSING

Camshaft

Camshaft Housing Removal and Installation

Cylinder Head

Hydraulic Valve Lifers, Replace

Camshaft Housing, Replace

Camshaft Housing, Check for Plance Surface

Cylinder Head, Removal and Installation

Cylinder Head, Disassemble and Assemble

Valve, Grind

Valve Seating, Mill

Cylinder Head, Overhaul

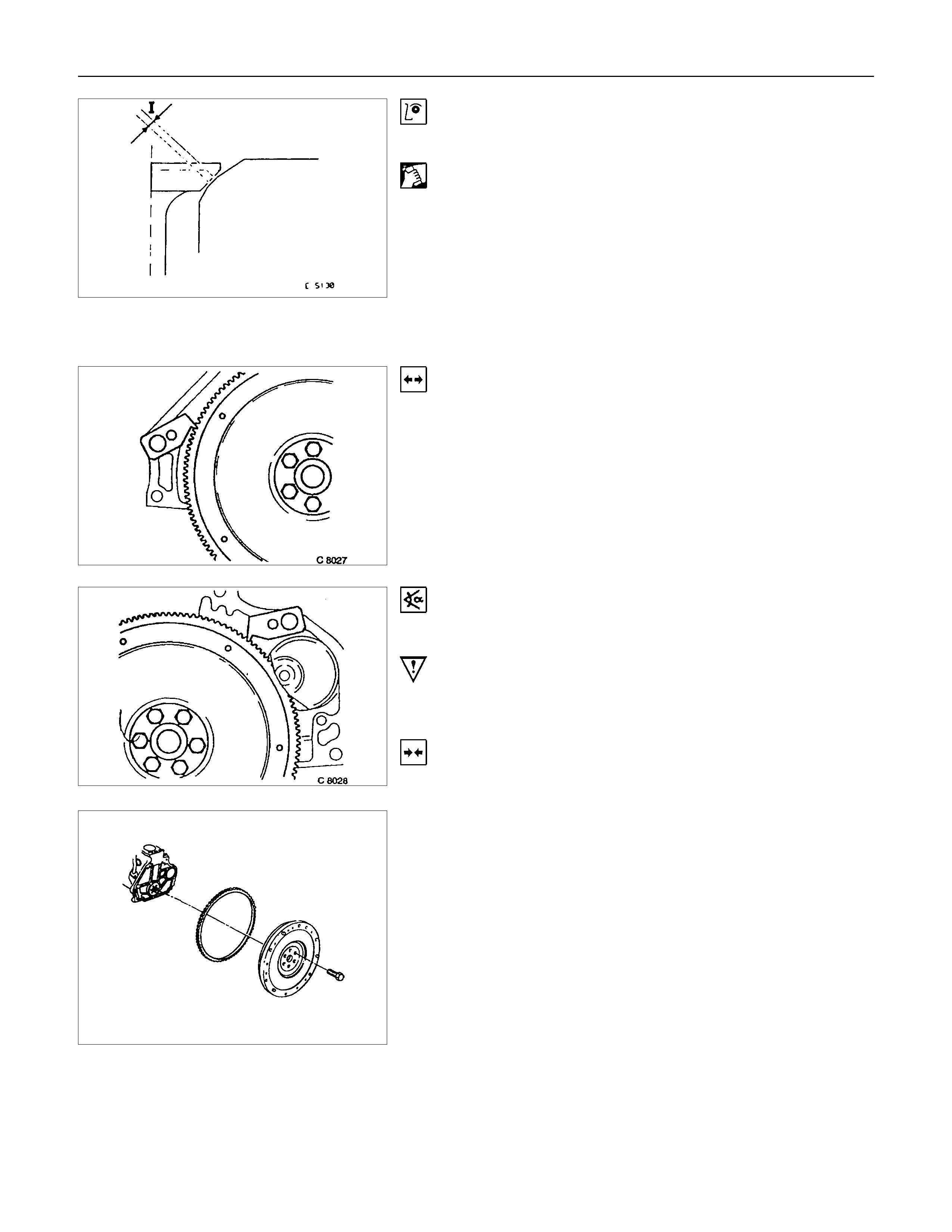

Flywheel

Starter Ring Gear(Manual Transmission)

Seal Ring, Crankshaft

Seal Ring, Crankshaft Rear

Gasket, Oil Pan

OPERATIONS ON CRANKCASE

Con-Rod Bearing

Piston with Con-Rod

Con-Rod

Pistion Rings

OPERATIONS ON REMOVED ENGINE

Crankshaft

Bearing Free Play Measurement

Plastigage Method

Micrometer and gauge method

Bypass Valve

Oil Filter

Oil Pump

Oil Pump Safety Valve

Oil Pump(Overhaul)

OPERATIONS ON OIL CIRCULATION

Cylinder Head Safety Valve

OPERATIONS ON COOLING SYSYTEM

Cooling System, Check for Leakes

Cooling System, Fill Up and Bleed

Refill Coolant

Ignition Timing, Check

ENGINE EXTERNAL PARTS

Radiator

Thermostat

Water Pump

Coating sealing surfaces with Silicone Grease

Alternator

Starter

V-belt Tension of Alternator

FUEL INJECTION SYSTEM

Map Sensor

Pressure Regulator

ECM (Engine Control Module)

ECT

Idle Air Control(IAC) Valve

Ignition Coil

Crank Position Sensor

FUEL INJECTOR

Knock Sensor

Oxygen Sensor

Throttle Valve Position Sensor

Acclelerator Pedal and Cable

Air Cleaner Filter

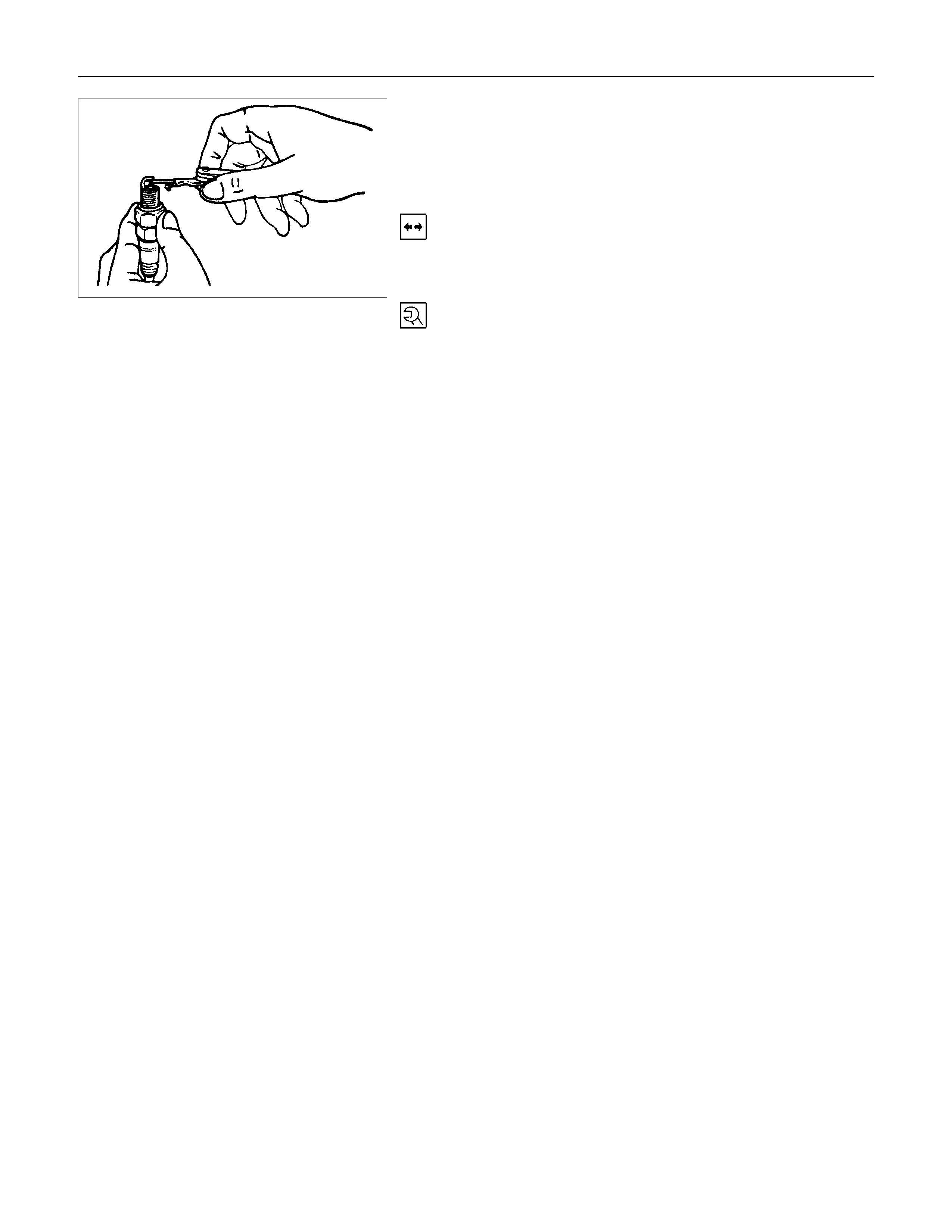

Spark Plug Thread

TECHNICAL DATA

Recommended Torque Values

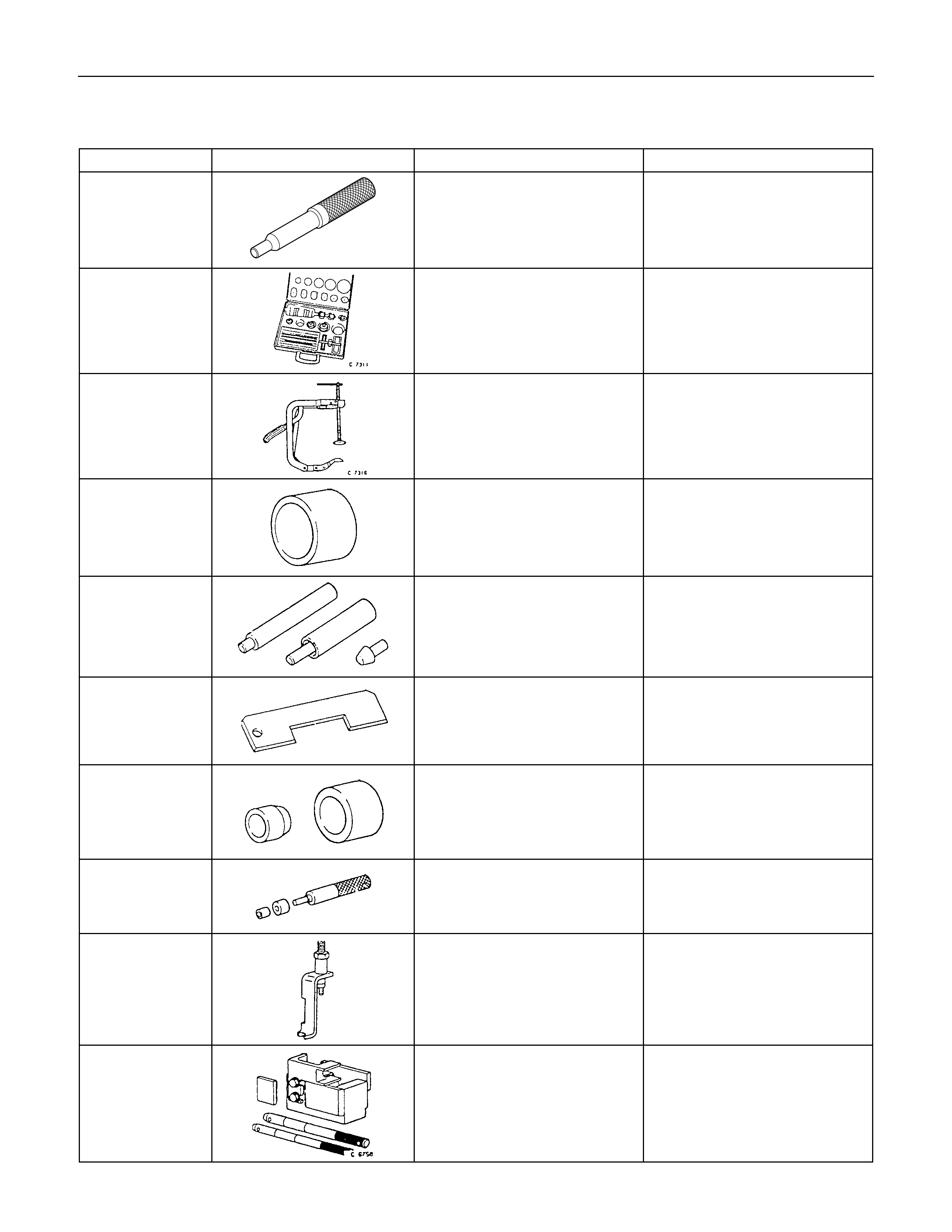

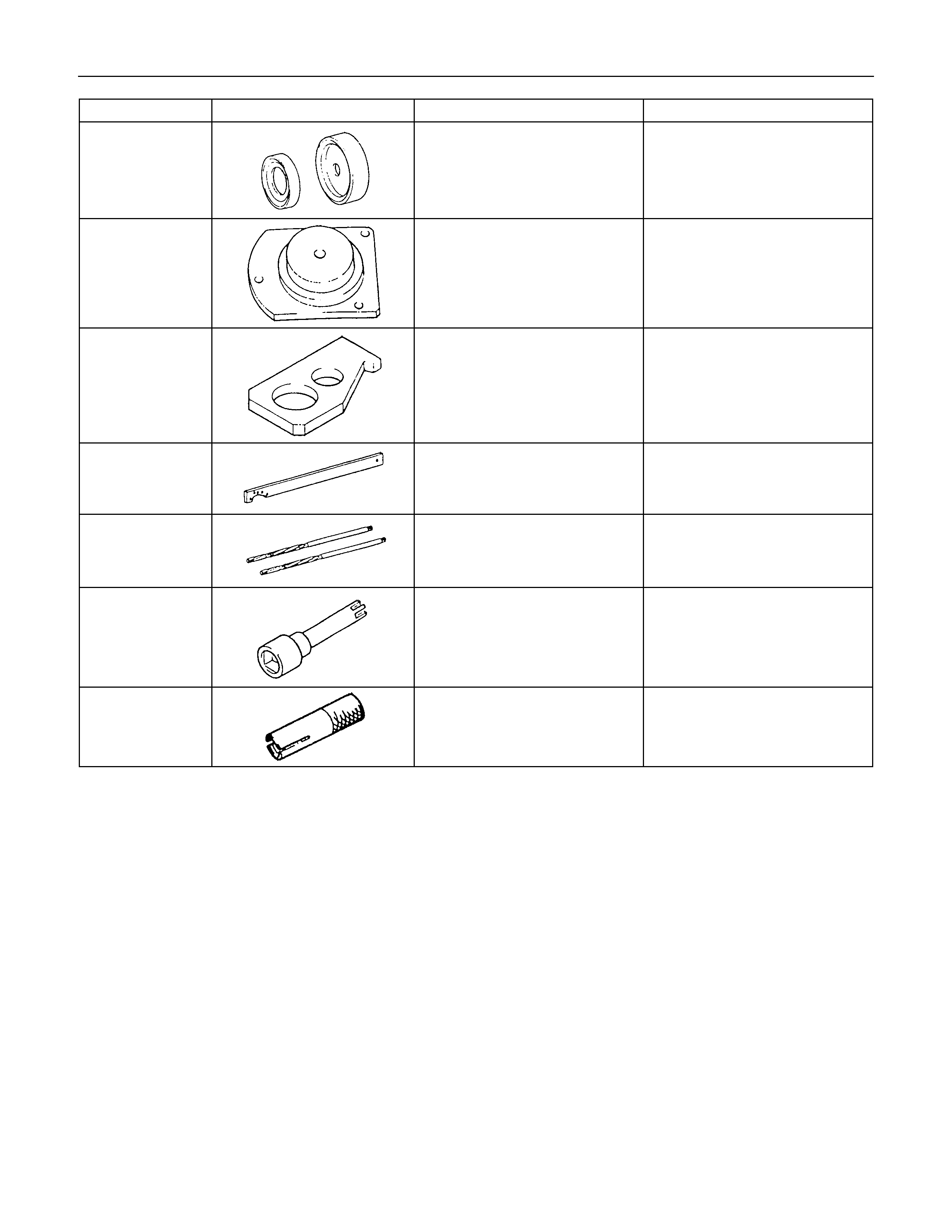

SPECIAL SERVICE TOOL

GENERAL DESCRIPTION

Engine Cleanliness And Care

An automobile engine is a combination of many machined, honed, polished and lapped surfaces with tolerances that

are measured in the thousandths of a millimeter (ten thousandths of an inch). Accordingly, when any internal engine

parts are serviced, care and cleanliness are important. Throughout this section, it should be understood that proper

cleaning and protection of machined surfaces and friction areas is part of the repair procedure. This is considered

standard shop practice even if not specifically stated.

!A liberal coating of engine oil should be applied to all friction areas during assembly to protect and lubricate

the surfaces on initial operation.

!Whenever valve train components, pistons, piston rings, connecting rods, rod bearings, and crankshaft journal

bearings are removed for service, they should be retained in order.

!At the time of installation, they should be installed in the same locations and with the same mating surfaced as

when removed.

!Battery cables should be disconnected before any major work is performed on the engine. Failure to

disconnect cables may result in damage to wire harness or other electrical parts.

!The four cylinders of this engine are identified by numbers; cylinders 1, 2, 3 and 4, as counted from crankshaft

pulley.

General Information on Engine Service

The following information on engine service should be noted carefully, as it is important in preventing damage and

contributing to reliable engine performance:

!When raising or supporting the engine for any reason, do not use a jack under the oil pan. Due to the small

clearance between the oil pan and the oil pump strainer, jacking against the oil pan may cause damage to the

oil pick up unit.

!The 12-volt electrical system is capable of damaging circuits. When performing any work where electrical

terminals could possible be grounded, the ground cable of the battery should be disconnected at the battery.

!Any time the intake air duct or air cleaner is removed, the intake opening should be covered. This will protect

against accidental entrance of foreign material into the cylinder which could cause extensive damage when

the engine is started.

Cylinder Block

The cylinder block is made of cast iron. The crankshaft is supported by five bearings. The bearing cap is made of

nodular cast iron.

Cylinder Head

The cylinder head is made of aluminum alloy casting with a spark plug in the center.

Valve Train

Valve system is a single over head camshaft.

The valves clearance adjustment are hydraulic.

Hydraulic valve lifter adjustment, no adjustment necessary.

Intake Manifold

The intake manifold is made of aluminum alloy.

Exhaust Manifold

The exhaust manifold is made of high Si-Mo nodular iron.

Pistons and Connecting Rods

Aluminum pistons are used after selecting the grade that meets the cylinder bore diameter. Each piston has two

compression rings and one oil ring. The piston pin is made of cast hardened steel. The connecting rod bearings are

made of modular cast iron. The connecting rod bearings are made of steel backed with tri-metal babbitt metal.

Crankshaft and Bearings

The crank shaft is made of modular cast iron. Pins and journal are graded for correct size selection for their bearing.

ENGINE PICTORIAL

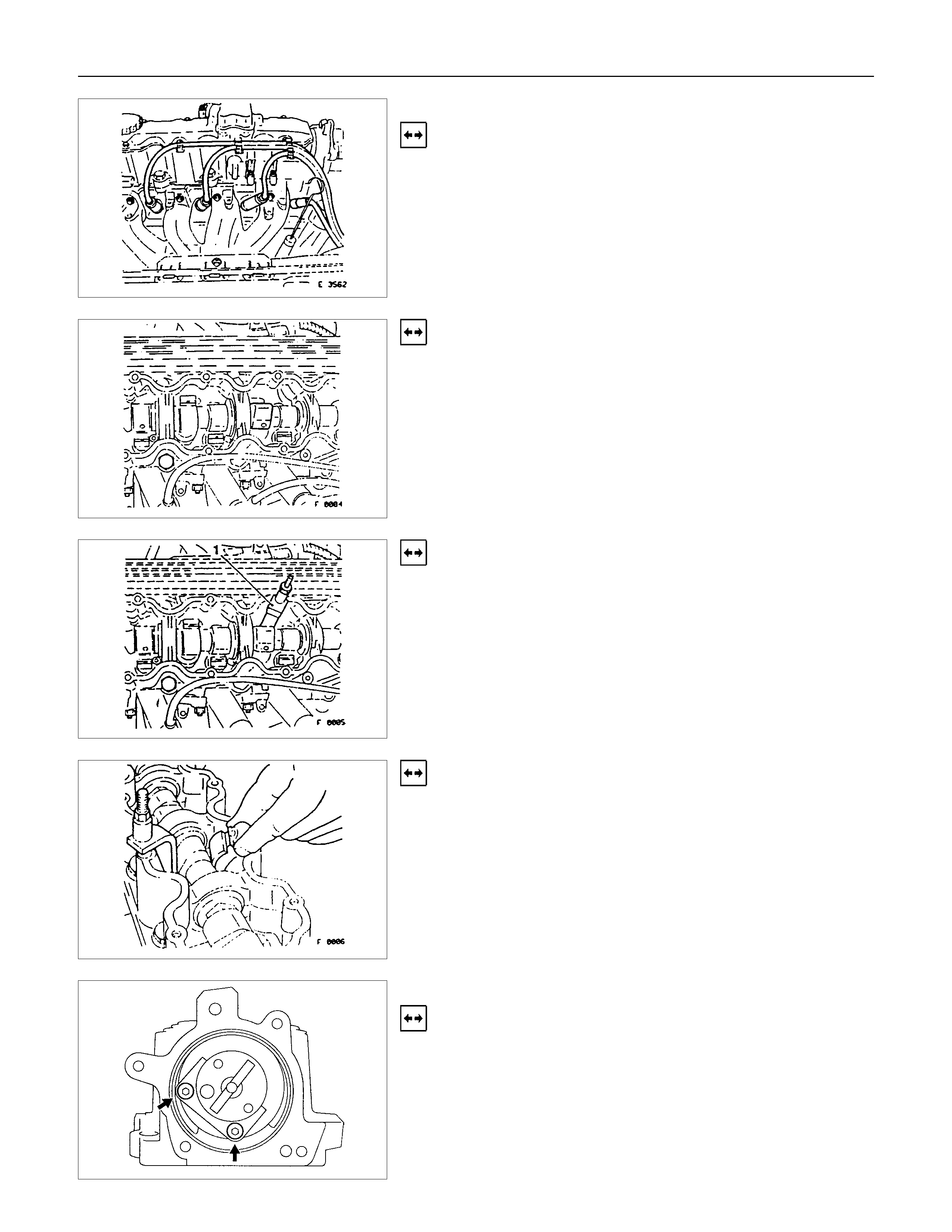

Front View

“4WD OIL PAN”

Inlet Side View

“4WD OIL PAN”

Rear View

“4WD OIL PAN”

Exhaust Side View

“4WD OIL PAN”

Top View

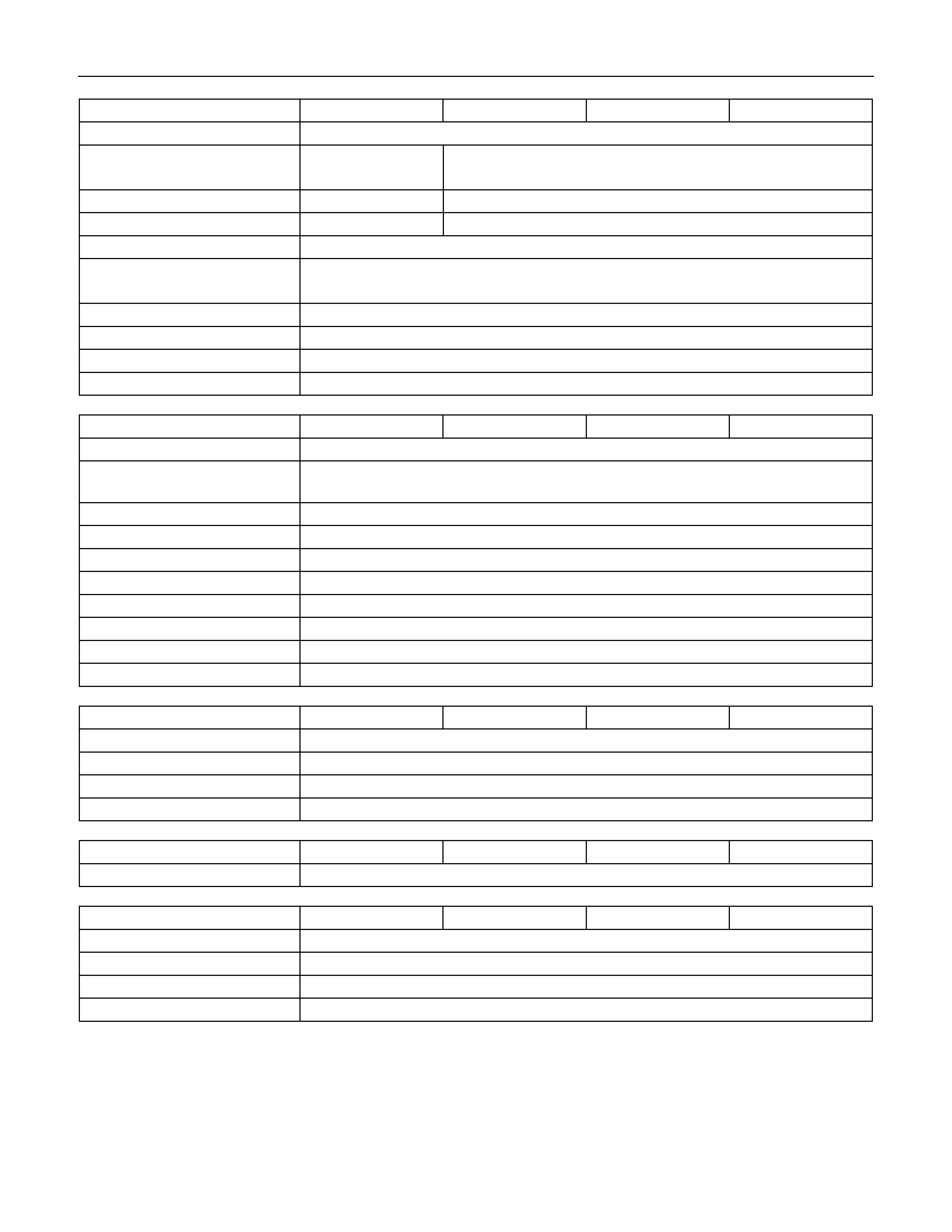

Main Data and Specifications

Engine - General C24SE C22NE 22LE 20LE

Engine type Four-cycle, water cooled cross-flow with single over head camshaft

Micro-computer control, fuel injection

Combustion chamber type

(Volume)

Hemispherical (43.3cm3)

Timing train system Belt drive

No. of cylinders-bore ×

stroke mm (in)

4-87.5×100.0

(3.44×3.93)

4-86.0×94.6 (3.39×3.72)

Bore Spacing(C/L to C/L) 93.0 mm (3.66 in)

Firing Order 1-3-4-2

Bore×Stroke mm (in) 87.5×100.0

(3.44×3.93)

86.0×94.6 (3.39×3.72)

Total piston displacement

cm3 (in3)

2,405(146.80) 2,198 (134.39) 1,998 (122.16)

Combustion Chamber

Volume

43.3cm3

No. of piston ring Compression ring: 2, Oil ring: 1

Compression pressure

kg/cm2 (psi/pa)

12.2-16.3

(174-232/1200-1600)

11.7-15.8 (166.8-224.8/1150-1550)

Ignition timing (BTDC) No adjustment

Idling speed:

rpm(WO/AC,W/AC) A/C off

825

Valve clearances (At cold)

Intake mm (in) 0 (0) (Hydraulic valve lash adjustment)

Exhaust mm (in) 0 (0) ( " )

Open at (BTDC) deg 17°30’ 29

Close at (ABDC) deg 76°30’ 65

Exhaust valves

Open at (BBDC) deg 58°30’ 66

Close at (ATDC) deg 35°30’ 29

Ignition system Fully transistorized battery ignition

Distributor type Not applicable, Electronic Spark Timing control

Distributor advance type Not applicable, Electronic Spark Timing control

Spark plug type RN9YC4

Spark plug gap mm (in) 1.0--1.1 (0.039--0.043)

Lubrication system

Lubricating method Fully flow pressure circulation

Special engine oil (API

grade)

SE, SF, SG or SH grade

Oil pressure kg/cm2 (psi/Pa)

rpm

4-4.6

(56.9-65.4/400-450)

1.5 (21.3/147)

825 (SAE 10W-30/API SE grade) engine oil after warm-up

Oil pump type Gear

Oil filter type Cartridge full flow

Oil capacity lit. (US/UK gal.) 4.25 with Oil Filter change 4.5litres

Engine - General C24SE C22NE 22LE 20LE

Cooling system

Radiator type Corrugated fin with reserve tank

Coolant capacity lit.

(US/UK gal.)

2.3 (0.66/0.55)

Water pump type Centrifugal

Thermostat Wax pellet with jiggle hole

Fuel system Electronically controlled Multi Port Fuel Injection System

Fuel pump type Electric

Fuel pressure kg/cm2

(psi/Pa)

3.4 (48.4/334)

Fuel filter type Cartridge paper element

Air cleaner type Dry paper element

Battery Type/V-Ax No. of

units

34B19L/50D20L 50D20L (STD) 34B19L 46B24L

Alternator

Capacity V-A(W) 12-70 (840)

Starter

Output V-kW 1.4 1.2-1.4

Exhaust system CO

Adjustment

(1) Applicable to Open Loop System (Not equipped H2OS)

(2) Not applicable to Closed Loop System (Equipped H2OS)

Compression Ratio (with

Tolerance)

9.2:1±0.25 9.2:1±0.3 8.6:1±0.3 8.8:1±0.3

Cylinder Head Material Aluminum Alloy (gravity cast)

Cylinder Block Material Cast Iron

No. of Mounting Points

(including trans.)

3

Engine Installation Angles

-Longitudinal

4° 60' 3° 30'

-Lateral 7° 50' (towards exhaust side)

Overall Dimensions

(L ×

××

× W ×

××

×H):

- TF (2.4Litre/2WD) 610×564×708mm

- TF (2.4Litre/4WD) 610×564×746mm

- TF (2.2Litre/2WD) 610×550×744 mm

- TF (2.2Litre/4WD) 610×550×708 mm

- TF (2.0Litre/2WD) 610×550×734 mm

Engine - General C24SE C22NE 22LE 20LE

Engine Weight

Engine Weight

- TF (2.4Liter/Man)

140kg

- TF (2.2Liter/Man) 136kg

- TF (2.0Liter/Man) 134kg

Camshaft Type SOHC

No. of Valves per Cylinder

- Inlet

1

- Exhaust 1

Spark Plug Location Side

Port Arrangement Cross Flow

Working Principle Spark Ignition 4-stroke

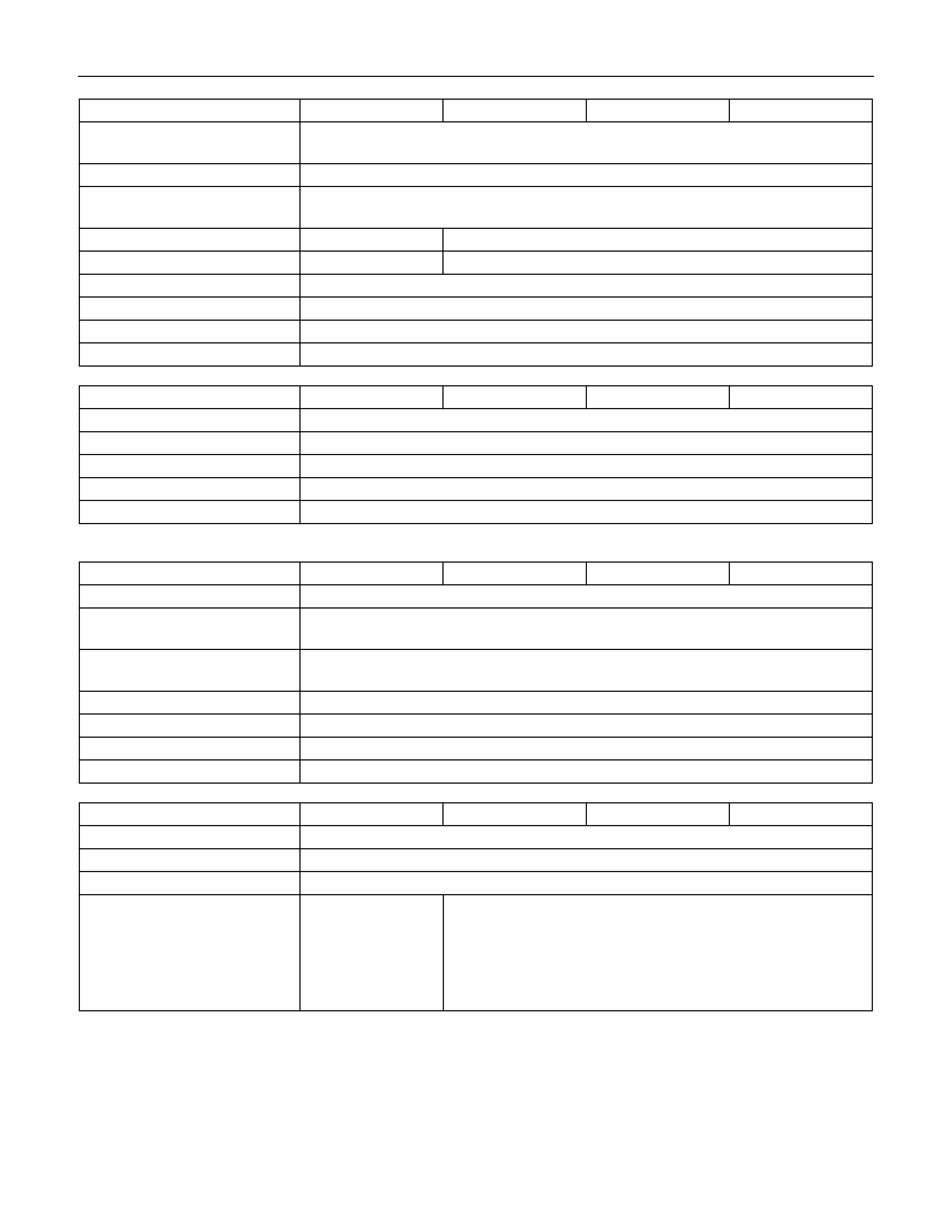

Valve System C24SE C22NE 22LE 20LE

Actuation Type Direct-acting Inverted Bucked Tappet

Valve Clearance

Adjustment

Hydraulic

Valve Rotor Type None

Inlet-Valve Material Chromium Alloyed Steel

-Seat Insert Material Sintered Iron

Exhaust-Valve Material Head: Cr-Mn-Ni Alloyed Shaft: Cr-Si Alloyed &Cr plated

-Seat Insert Material Sintered Iron

Valve Spring Material GME 06 100-C1

Valve Guide Material QS 13 MR 00

Valve Seal Type Lip

Water Pump C24SE C22NE 22LE 20LE

Type Centrifugal

Drive-Material &Type HNBR Toothed-belt

Bearing Type Double Row Ball

Shaft Seal Type Mechanical Ceramic

Thermostat-Coolant C24SE C22NE 22LE 20LE

Type Bypass

Oil Pump & Filter C24SE C22NE 22LE 20LE

Type Gear Pump

Location Front of Engine

Drive Direct Crankshaft Driven

Filter Type Full Flow with Bypass for blocked filter

Oil & Oil Reservoir C24SE C22NE 22LE 20LE

Reservoir-Description &

Location

1-piece below Engine

Reservoir Material Aluminum Alloy (pressure cast)

Replacement Oil Fill

Volume

-With Filter change 4.25liters 4.50liters

-Without Filter change 4.00liters 4.25liters

Recommended Oil-Run-in 10W/30SG

-Service (above-18°C) 10W/40SG

-Service (below-18°C) 5W/30SG

Oil Classification API&CCMC

Ignition Components C24SE C22NE 22LE 20LE

Spark Plugs Conventional

Type Electronic Spark Control

No. of Coils &Type 2 Solid State

Coil Location Engine-mounted

Ignition Lead Type Inductive (hi-resistance)

Crankshaft C24SE C22NE 22LE 20LE

Material Nodular Cast Iron

Bearing subjected to End

Thrust

Guide Bearing NO.3

Main Bearing-Material

&Type

Steel Backed Tri-metal Babbitt

Front Seal-Diameter &Type 35.0mm Lip Seal

Rear seal-Diameter &Type 90.0mm Micro-lip Seal

Crankshaft Balancing Individually Balanced

No. of Counterweights 8

Camshaft C24SE C22NE 22LE 20LE

Location Overhead (Cylinder Head)

Material Grey Cast Iron

Bearing Material Aluminum

No. of Bearings Camshaft

Drive-Material &Type

200-250 HB5/750

(Camshaft drive type:

toothed belt

Camshaft drive

material: rubber

composite GD380)

HNB 5

Pistons C24SE C22NE 22LE 20LE

Material Aluminum Alloy

Finish & Type Tin-coated Strutless

Piston Rings C24SE C22NE 22LE 20LE

Function (top to bottom)

-Ring 1

Compression Ring

-Ring 2 Compression Ring

-Ring 3 Oil Ring

Description -Ring 1 Rectangular

-Ring 2 Taper Face

-Ring 3 3-piece (2 Scrapers&1 Expander)

Material -Ring 1 Molybdenum Inlay Nodular Cast Iron

-Ring 2 Cast Iron (individually cast)

-Ring 3 Steel

Material Case Hardened Steel

Retention Locked in Rod

Bearing Machined in Piston Pin Boss

Connecting Rod C24SE C22NE 22LE 20LE

Material Nodular Cast Iron

Bearing-Material &Type Steel Backed Tri-metal Babbitt

Inlet Manifold C24SE C22NE 22LE 20LE

Material Aluminum Alloy

Exhaust Manifold C24SE C22NE 22LE 20LE

Description Dual Take-down

Material High Si-Mo Nodular Iron

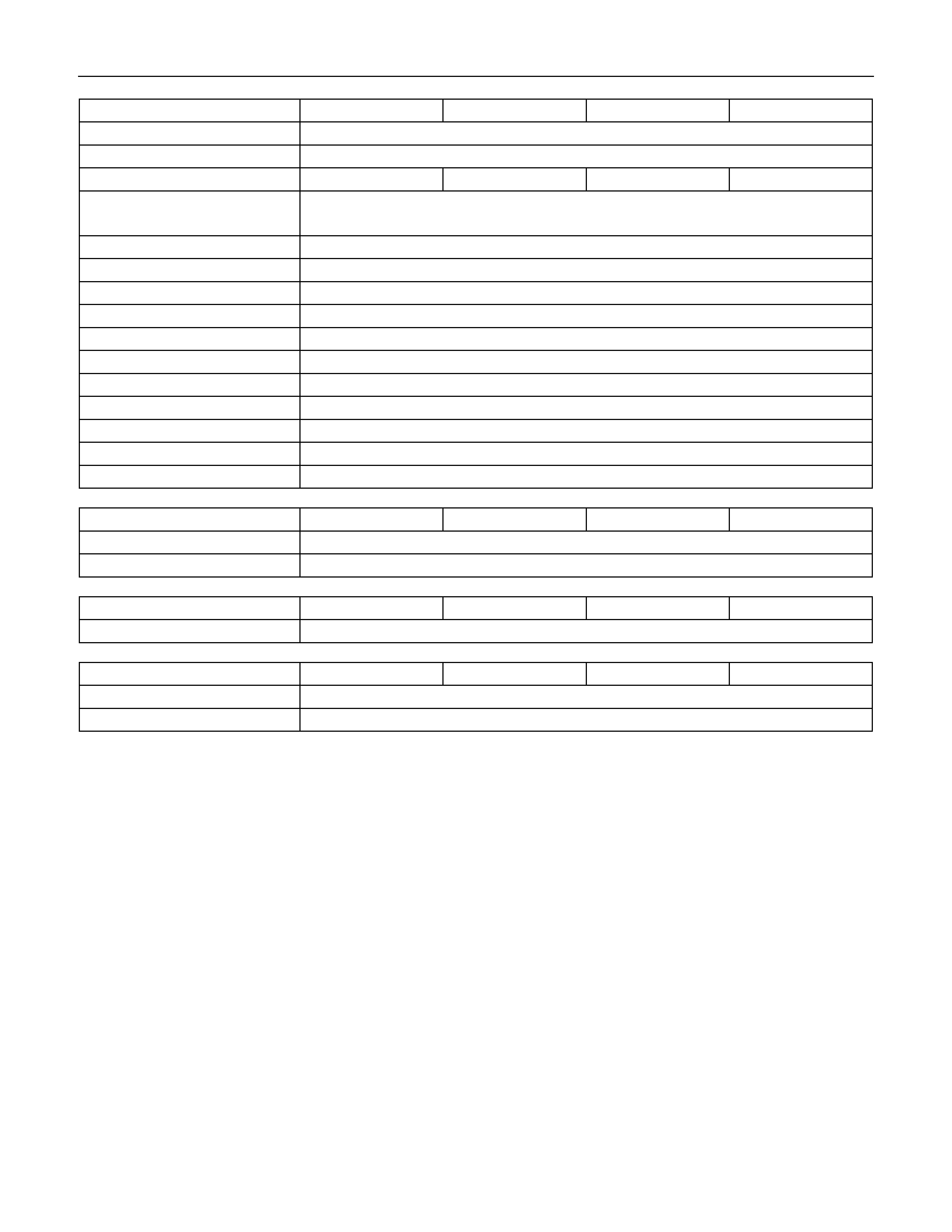

Engine Specification Matrix for destination

03 HEC FOR TF MODEL:

VEHICLE MODEL TFR/S 2.4L

Major Description AUSTRALIA, CHILE,

GULF, NEW ZEALAND,

SAUDI ARABIA,

SOUTH AFRICA

COLOMBIA, COSTA

RICA, EQUADOR,

GUATEMALA

BOLIVIA, GENERAL

EXPORT, PERU,

VENEZUELA

VEHICLE TYPE 4×2 4x4 4×24×44×2

VEHICLE IDENT. CODE TX TY TX TY TX

ENGINE TYPE C22NE <-- <--

FUEL CONTROL SYSYTEM OPEN LOOP CLOSED LOOP CLOSED LOOP

COMPRESSION RATIO 9.6:1 <-- <--

FUEL OCTANE(ROD) 91RON 85RON 80RON

FUEL TYPE UN-LEADED UN-LEADED LEADED

HO2 YES YES YES YES

EVAP CANISTER YES YES YES YES

PURGE CONTROL

SOLENOID

YES YES YES YES

CHECK & RELIEF VALVE YES YES YES YES

ECM YES YES YES YES

EXHAUST SYSTEM

FRONT PIPE

SILENCER

TWC YES YES YES YES

CO ADJUSTMENT NO NO NO NO

Refer to 6A-81 Refer to 6A-81 Refer to 6A-81

CRANKCASE VENTILATION SYSTEM

The Engine Ventilation System passes crankcase vapours, via the Engine Vent Pipe, to the Cam Support Cover,

where separation of oil and exhaust gases occur. The oil drains into the Cylinder Head, via the Camshaft Support.

The gases pass through the Primary and Secondary Vent Hoses to the intake system, and are consumed during

the combustion process.

ENGINE ASSEMBLY & LOOSE PARTS

Legend

1 Alternator

2 P/S Pivot Spacer

3 P/S Adjusting Screw

4 P/S Adjusting Plate

5 P/S Adjusting Nut

6 Alternator & Fan Drive Belt

7 A/C Compressor Drive Belt

8 P/S Pump Drive Belt

9 Tensioner Bolt

10 Tensioner Pulley

11 Pulley Dust Shield Cover

12 Pulley Spacer

13 A/C Compressor Bracket

14 Pulley Bolt

15 Fan Pulley

16 Cooling Fan

Engine Assembly

20C24SE

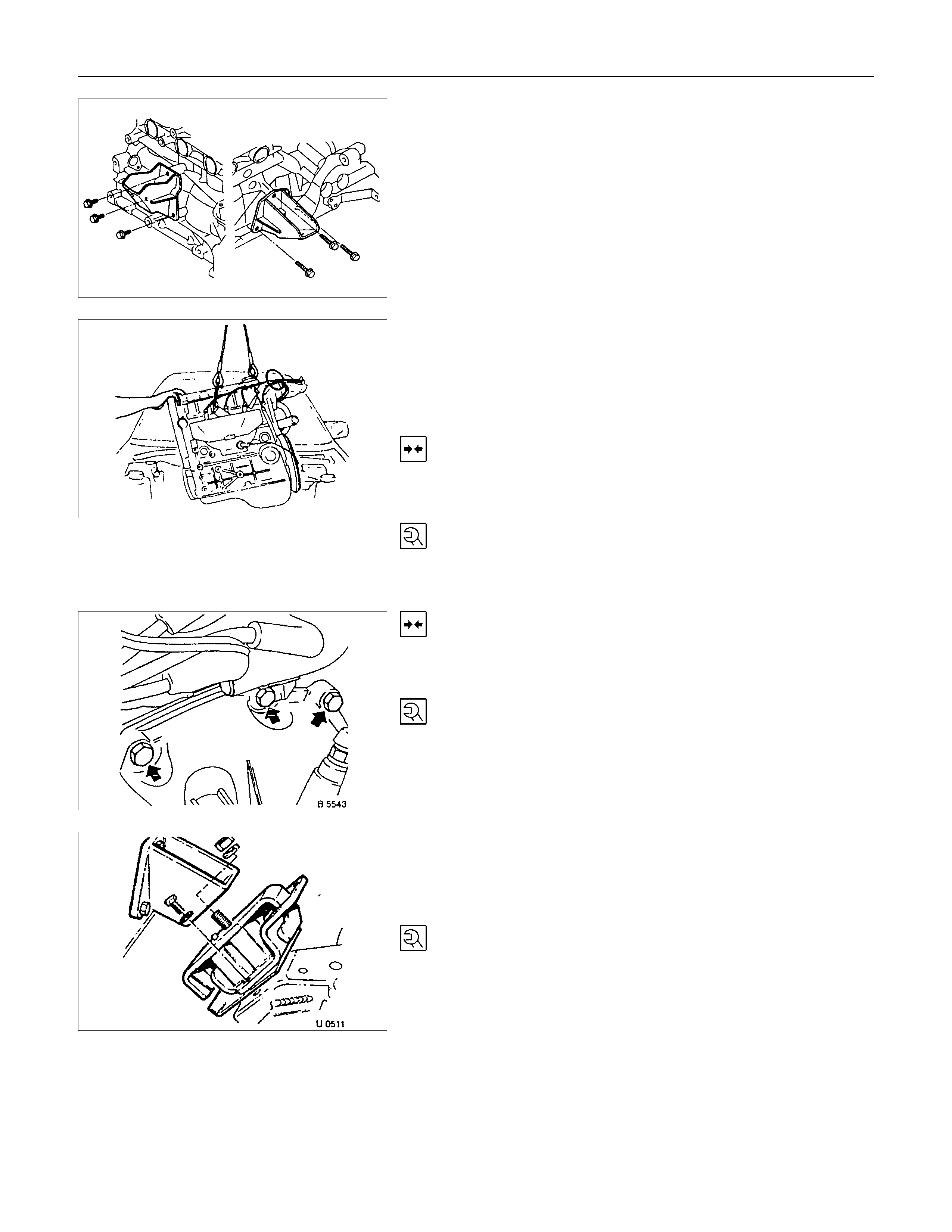

OPERATIONS ON ENGINE AGGREGATES

Engine Damping Blocks (Engine Without

Transmission)

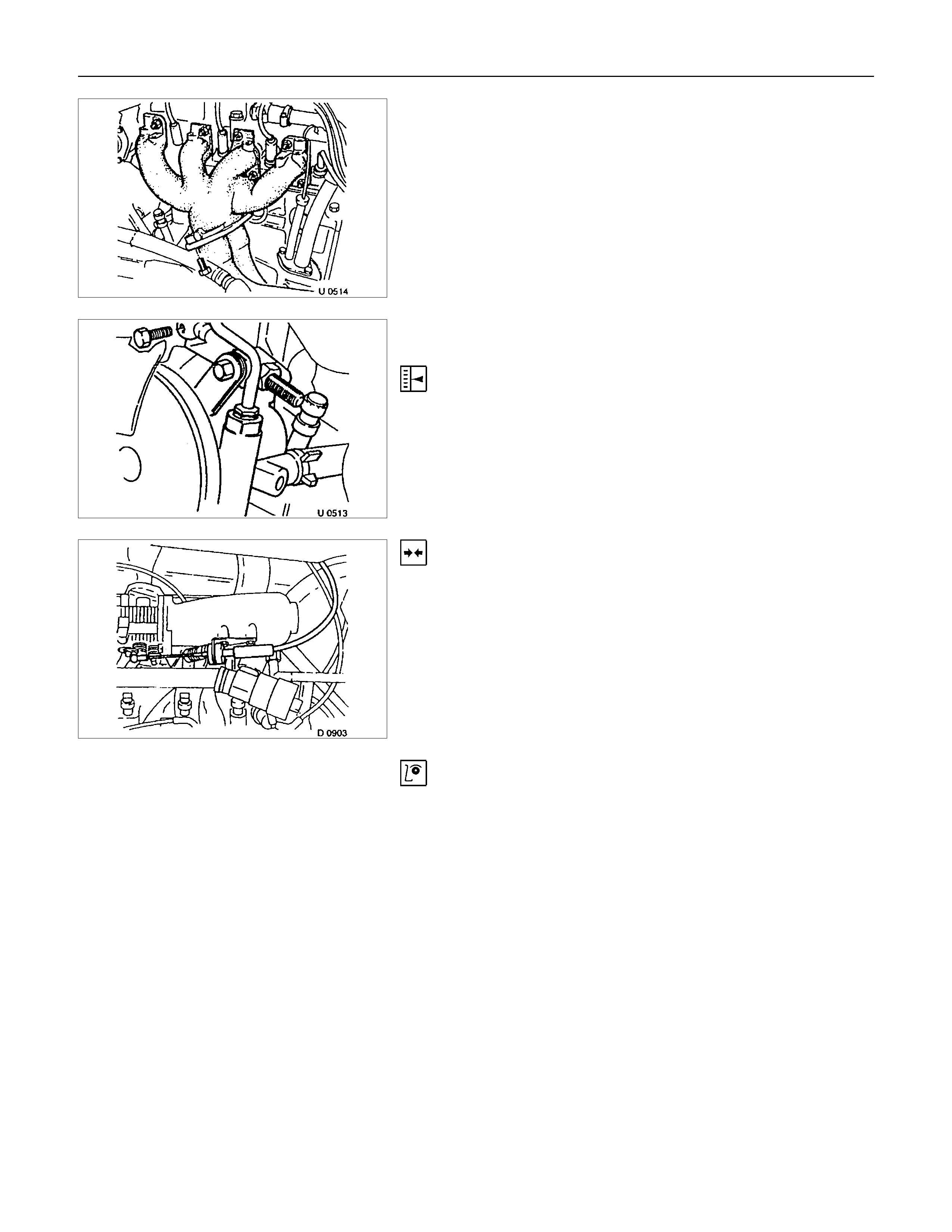

Removal

1. Remove bonnet.

2. Remove radiator.

3. Remove air inlet hose.

4. Remove power steering pump drive belt and power

steering pump from engine.

5. Remove all cable connections, hoses and lines from

engine.

6. Remove accelerator cable from inlet pipe.

7. Remove exhaust pipe from manifold.

8. Remove lower nine bolts and transmission from engine

block.

9. Remove clutch slave cylinder and allow to hang free.

10. Remove starter from engine block.

11. Remove upper bolts of left and right engine mounting

from damping blocks.

12. Raise engine slightly.

13. Remove lower bolts of left and right damping blocks.

14. Remove damping blocks.

Attach engine to cable, support transmission with car jack and

remove upper transmission fastening bolt.

Press off engine from transmission and lift out of engine

compartment.

Installation

Lower engine into engine compartment and insert guide

bushings on cylinder block into transmission.

Tighten (Torque)

Transmission to cylinder block (M10) -45 N⋅m (4.6 kgf⋅m)

Transmission to cylinder block (M12) -60 N⋅m (6.1 kgf⋅m)

Installation

1. Install engine to vehicle and transmission.

2. Install clutch slave cylinder.

Tighten (Torque)

Transmission to engine block bolts - 76 N⋅m (7.6 kgf⋅m)

3. Install left engine damping block to sidemember.

4. Install left and right engine damping blocks to engine

brackets.

Tighten (Torque)

Engine damper block to sidememebr - 52 N⋅m (5.3 kgf⋅m)

Engine damper block to engine bracket - 85 N⋅m (8.6 kgf⋅m)

5. Install exhaust pipe to manifold.

6. Install power steering pump and V-belt.

Adjust

Adjust power steering pump V-belt tension according to the

corresponding operation.

Installation

7. Install radiator according to the corresponding operation.

8. Install air inlet hose.

9. Install all electrical cable connections, hoses and lines to

engine.

10. Install accelerator cable from inlet pipe.

11. Install bonnet.

Inspection

1. Check engine oil level.

2. Fill up cooling system and bleed according to the

corresponding operation.

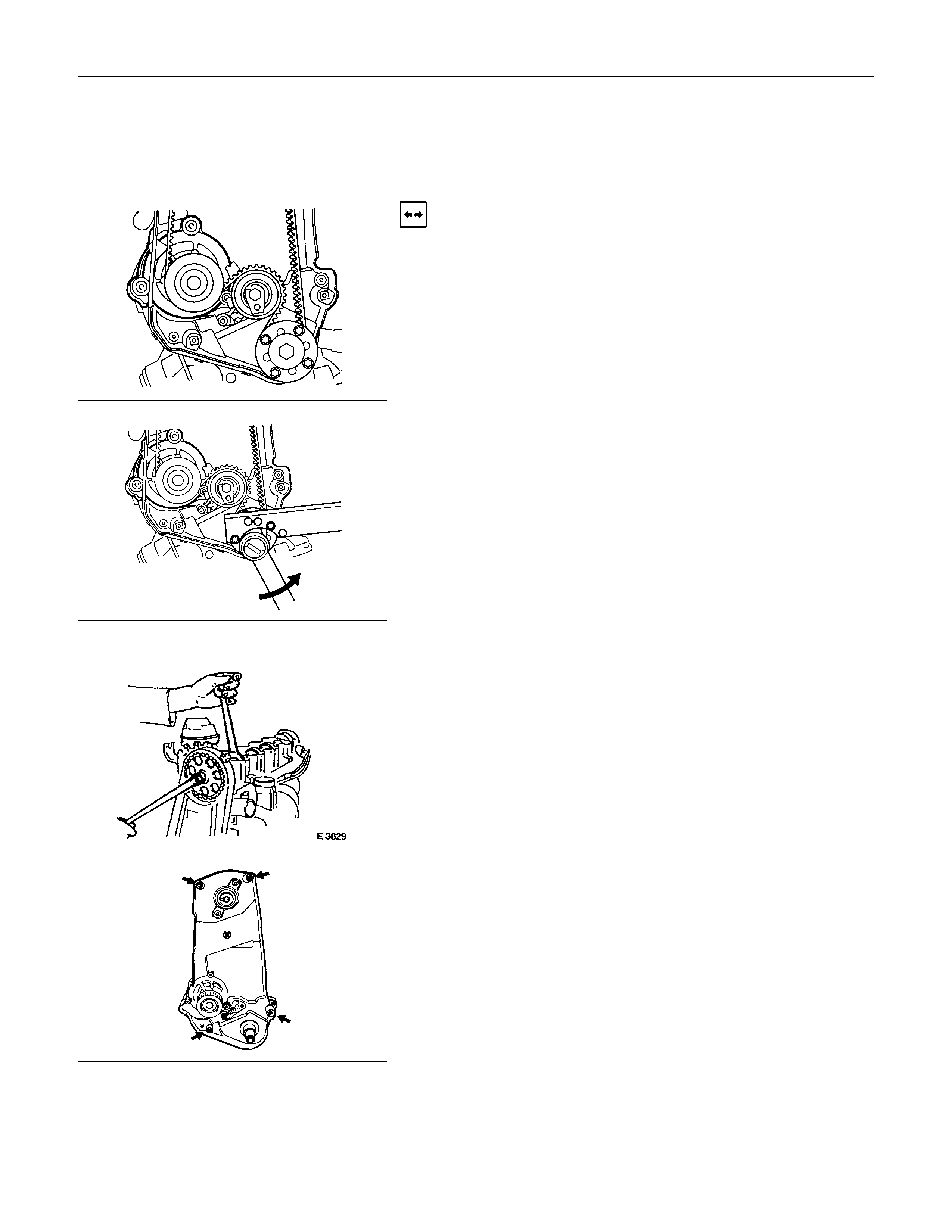

Toothed Belt and Timing Check

Removal

1. Remove the belts on the bracket for alternator.

2. Remove the fan.

3. Remove the V-belt for power steering.

4. Remove the V-belt for A/C.

5. Remove the fan belt.

6. Remove the fan shroud.

7. Remove the crankshaft pulley while counterholding on

the fastening bolt of toothed belt drive gear.

8. Remove the toothed belt from cover.

Inspection

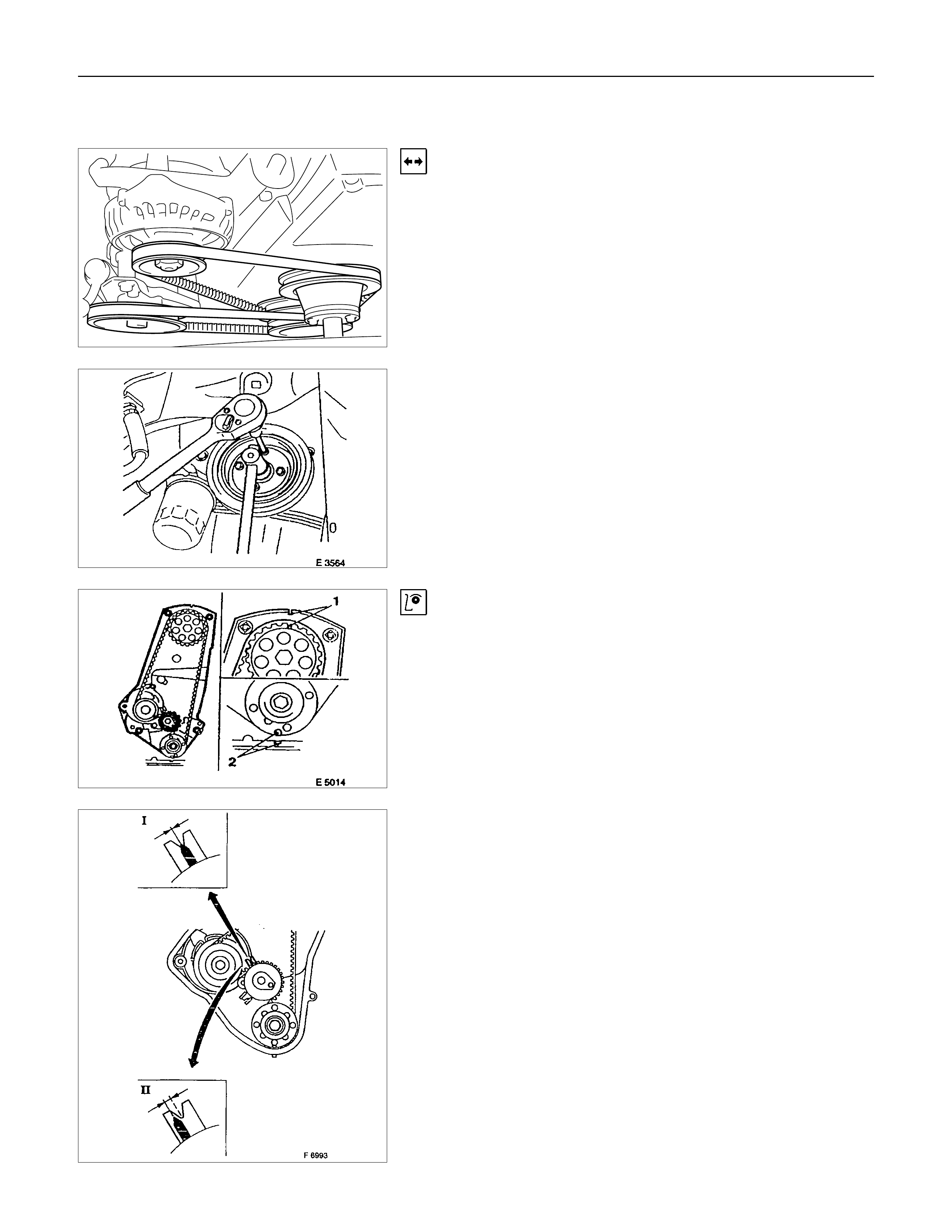

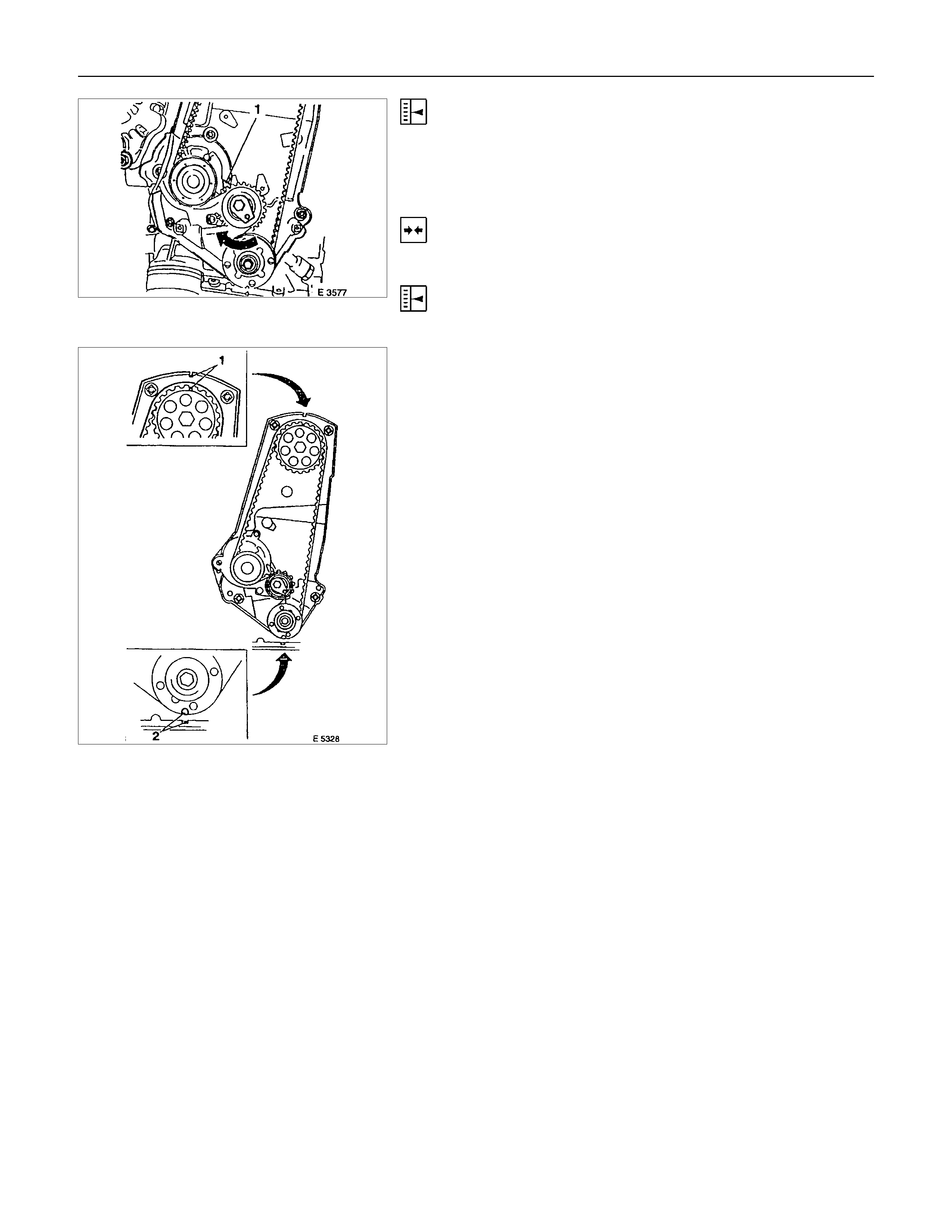

1. Turn the crankshaft in the engine rotational direction

mark(2) so that the notch (1) on the camshaft gear aligns

with the mark on toothed belt rear cover.

2. Check the timing belt for worn, cracks or oil adhesion.

3. Check that the cast on the water pump aligns with the

counterpart on cylinder block (arrowed).

4. The tension of a toothed belt is correctly adjusted when

the pointer and the center of the notch are aligned(I).

The tension of a run-in toothed belt (regardless of

mileage covered) is correctly adjusted when the pointer is

positioned approx. 4mm (0.16 in.) to the left of the center

of the notch(2).

Check the condition of the run-in toothed belt for

suitability for reuse. Only toothed belts of the toothed belt

tension rollers must be replaced and the source of oil

contamination must be eliminated.

Installation

1. Install the toothed belt to the cover.

2. Install the crankshaft pulley while counterholding on the

fastening bolt of toothed belt drive gear.

3. Install the fan shroud.

Tighten(Torque)

Crankshaft pulley bolts - 20 N⋅m (2.1 kgf⋅m)

4. Install the fan belt

5. Install the V-belt for A/C.

6. Install the V-belt for power steering.

7. Install the fan.

8. Install the belts on the bracket for alternator.

Toothed Belt Tension, Adjust

(Engines with toothed belt tension

roller)

Removal

Refer to 6A-26. Toothed Belt and Timing check and removal

steps.

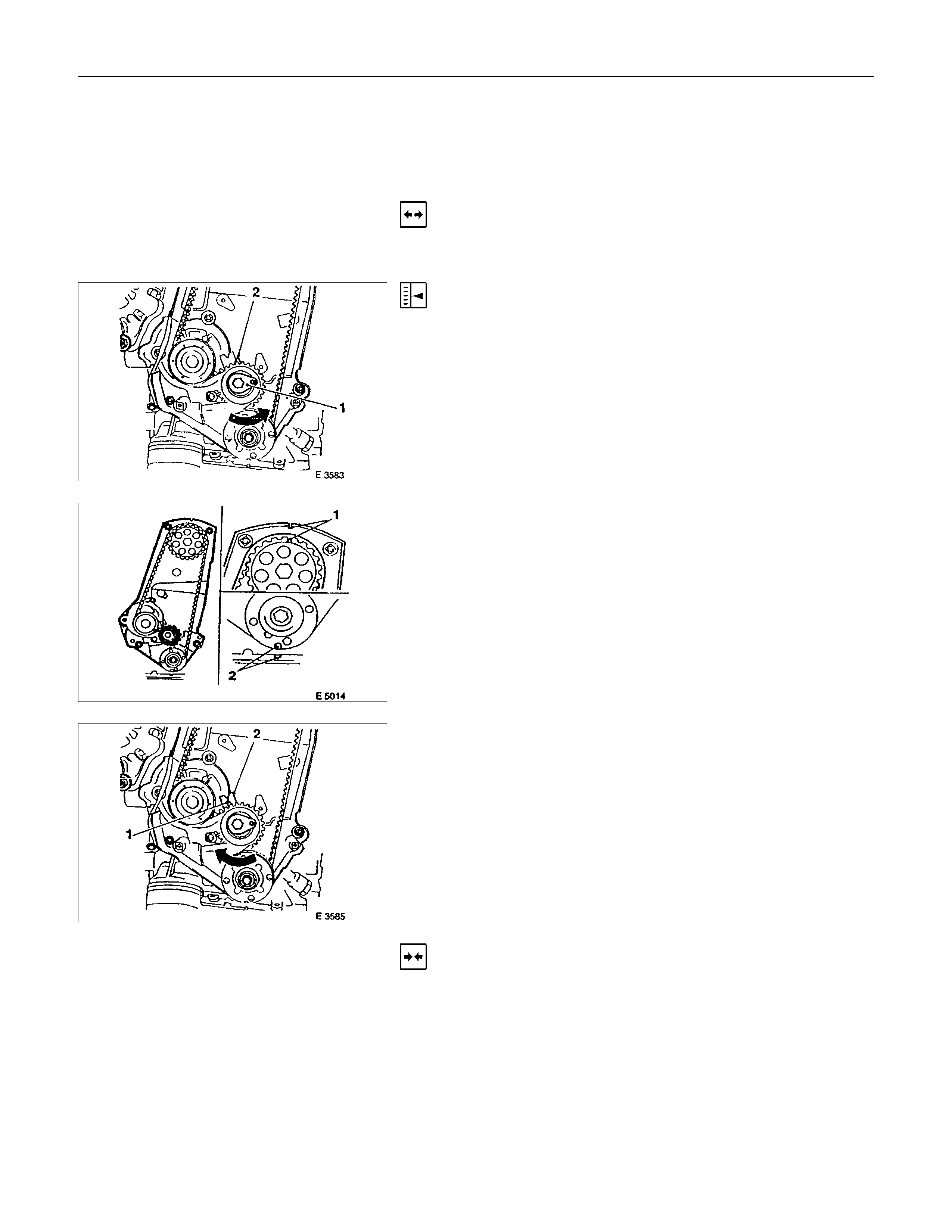

Adjust

1.Loosen the fastening bolt of the toothed belt tension

roller.

2.Turn the toothed belt tension roller at adjustment

eccentric(1) in the direction of arrow (counterclockwise),

until pointer (2) comes to the right stop.

3.If necessary tighten the fastening bolt of toothed belt

tension roller.

4.Rotate the crankshaft twice (720°) in the engine rotational

direction until marks (2) and (1) align again.

5.Turn the eccentric in the direction of arrow (clockwise)

until pointer (1) and notch (2) are positioned to suit age of

toothed belt.

6.Rotate the crankshaft twice (720°) in the engine rotational

direction again and correct adjustment if necessary.

Installation

Refer to 6A-26 Toothed Belt and Timing check and installation

steps.

Toothed Belt, Replace

(Engine with toothed belt tension

roller)

Removal

1. Remove the belts on the bracket for alternator.

2. Remove the fan.

3. Remove the V-belt for power steering.

4. Remove the V-belt for A/C.

5. Remove the fan belt.

6. Remove the fan shroud.

7. Remove the crankshaft pulley while counterholding on

the fastening bolt of toothed belt drive gear.

8. Remove the toothed belt from cover.

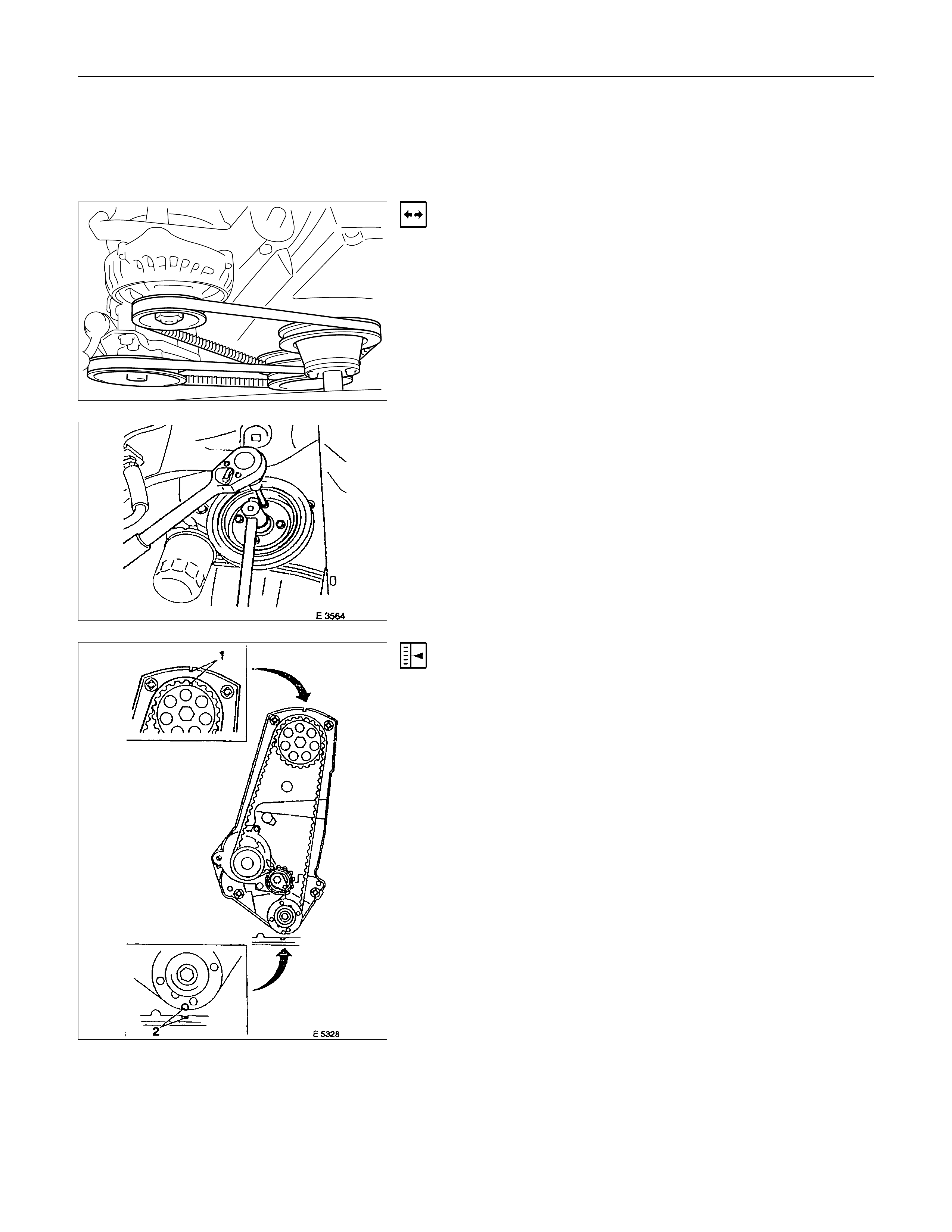

Adjust

Turn the crankshaft in the engine rotational direction to

mark(2).

Align markings on toothed belt and on toothed belt rear cover.

Simultaneously, notch (1) on camshaft gear must align with the

mark on toothed belt rear cover.

Turn the crankshaft slowly and smoothly.

Adjust

Loosen the fastening bolt of the toothed belt tension roller and

turn the adjustment eccentric in the direction of arrow

(clockwise) until pointer (1) comes to the left stop.

Remove the toothed belt.

Installation

1. Install a new toothed belt while keeping tension side taut.

Adjust

Toothed belt tension - see operation " Toothed Belt Tension".

2. Install the toothed belt to the cover.

3. Install the crankshaft pulley while counterholding on the

fastening bolt of toothed belt drive gear.

4. Install the fan shroud.

5. Install the fan belt.

6. Install the V-belt for A/C.

7. Install the V-belt for power steering.

8. Install the fan.

9. Install the belts to the bracket for alternator.

OPERATIONS ON INSTALLED ENGINE

SEALING OPERATIONS

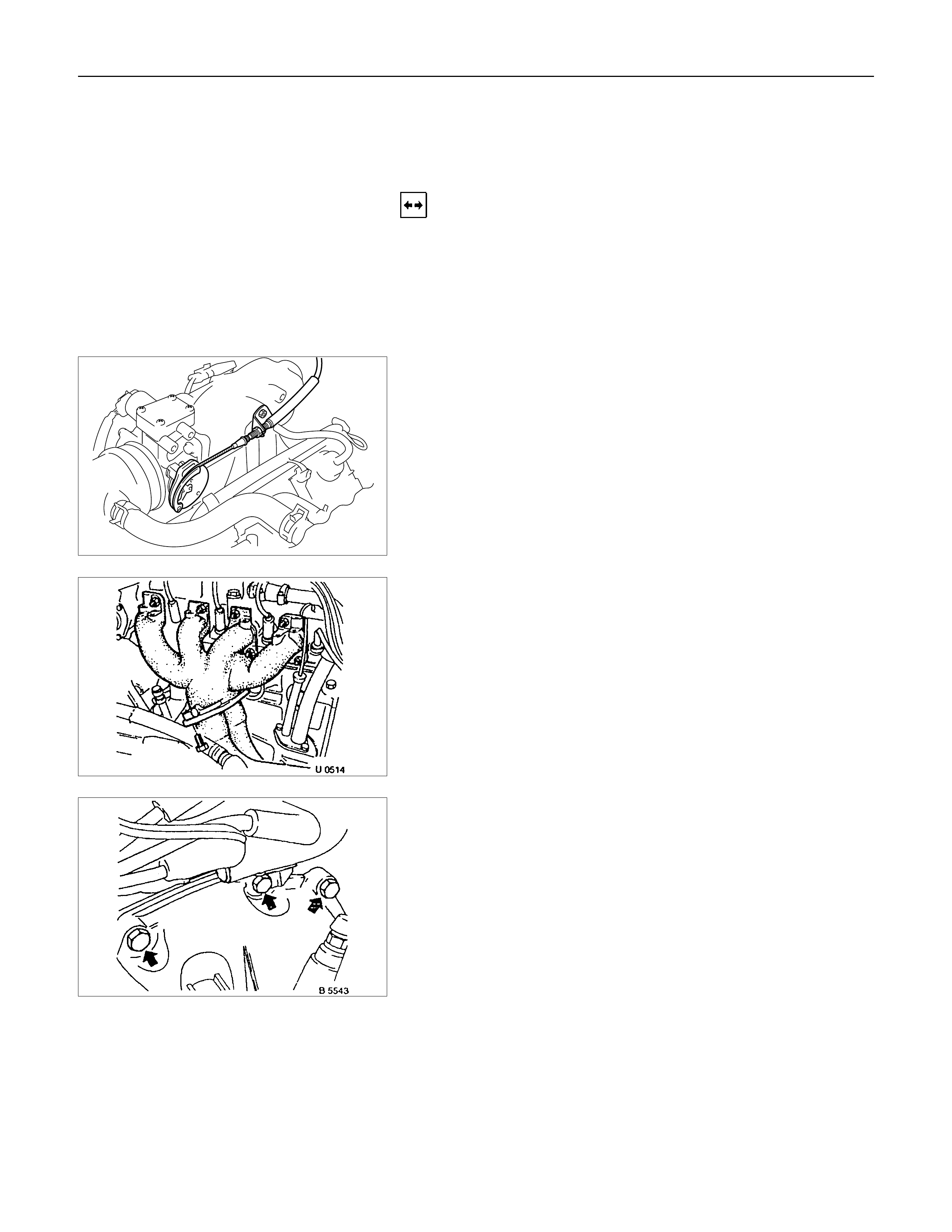

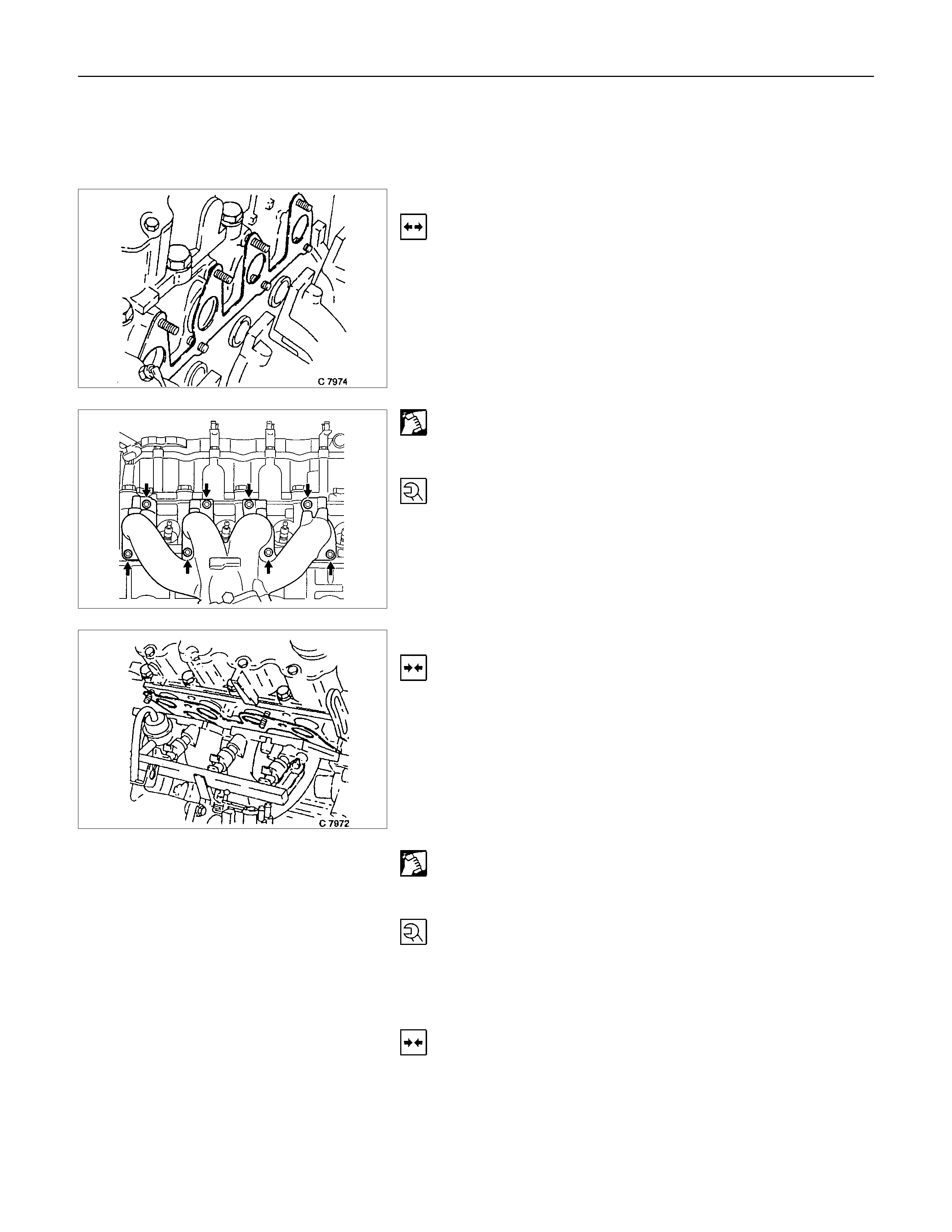

Gasket, Exhaust Manifold, Cylinder Head

Removal

1.Remove front exhaust pipe from exhaust manifold.

2.Remove exhaust manifold heat shield.

3. Remove exhaust manifold retaining nut.

4. Remove exhaust manifold from cylinder head.

Clean

Sealing surfaces.

Tighten (Torque)

Exhaust manifold to cylinder head - 22 N⋅m (2.2 kgf⋅m)

Front exhaust pipe to exhaust manifold - 25 N⋅m (2.6 kgf⋅m)

Gasket, Intake Manifold, Cylinder Head

Removal

1.Remove air intake hose.

2.Remove drive belt for alternator.

3.Remove bolt clamping bracket for alternator from intake

manifold.

4. Remove intake manifold from cylinder head.

Clean

Sealing surfaces

Tighten (Torque)

Intake manifold to cylinder head - 22 N⋅m (2.2 kgf⋅m)

Clamping bracket for alternator to intake manifold - 25 N⋅m (2.5

kgf⋅m)

Installation

1. Install V-belt according to the corresponding operation.

2. Install air intake hose.

Seal Ring, Camshaft Housing, Timing Side

Removal

1.Remove front toothed belt cover toothed belt from

camshaft timing gear according to the corresponding

operation.

2.Remove camshaft housing cover and camshaft timing

gear.

3.Remove sealing ring by making hole in middle of ring,

turning in self-tapping screw and edging out.

Installation

1.Install sealing ring by using 5-8840-0451-0 with camshaft

sprocket bolt and washer.

2.Install coat seal lips of shaft seal ring slightly.

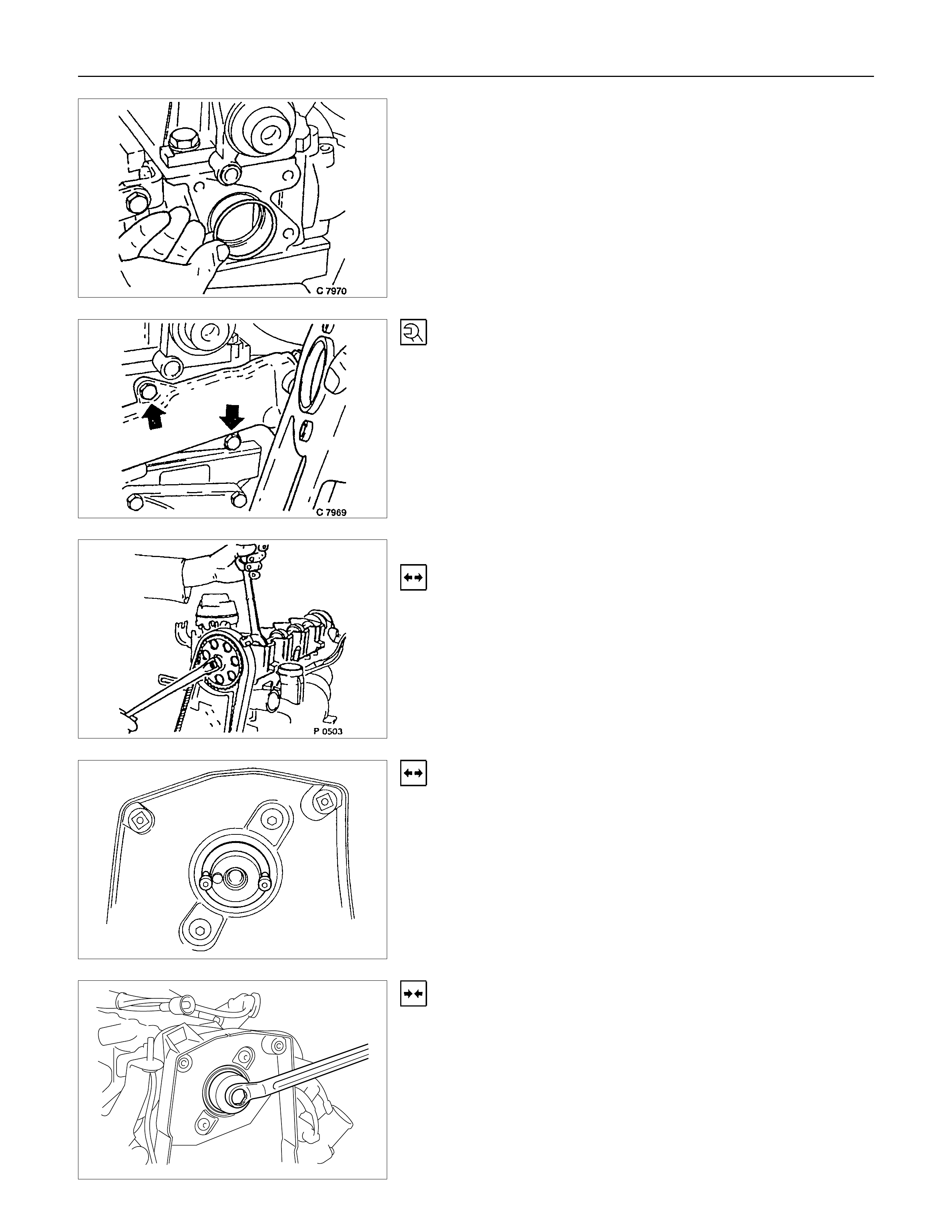

Seal Ring, Thermostat Housing, Cylinder Head

Removal

1. Open radiator drain tap and collect coolant.

2. Remove toothed belt rear cover and toothed belt

according to the corresponding operation.

3. Remove camshaft housing cover.

4. Remove camshaft timing gear by counterholding

camshaft with a flat spanner.

5. Remove cable from temperature sensor.

6. Remove upper inner hex bolts of rear toothed belt cover.

7. Turn rear toothed belt cover to one side.

8. Remove thermostat housing.

9. Remove sealing ring from cylinder head.

Clean

Sealing surfaces in cylinder head and thermostat housing.

Installation

1. Install sealing ring in recess of cylinder head.

2. Install cable to temperature sensor.

3. Install upper bolts of rear toothed belt rear cover.

4. Install camshaft timing gear then check timing according

to the corresponding operation.

5. Install camshaft housing cover.

6. Install toothed belt and front cover.

7. Fill up and bleed cooling system according to the

corresponding operation.

Tighten (Torque)

Thermostat housing to cylinder head - 15 N⋅m/1.5 kgf⋅m.

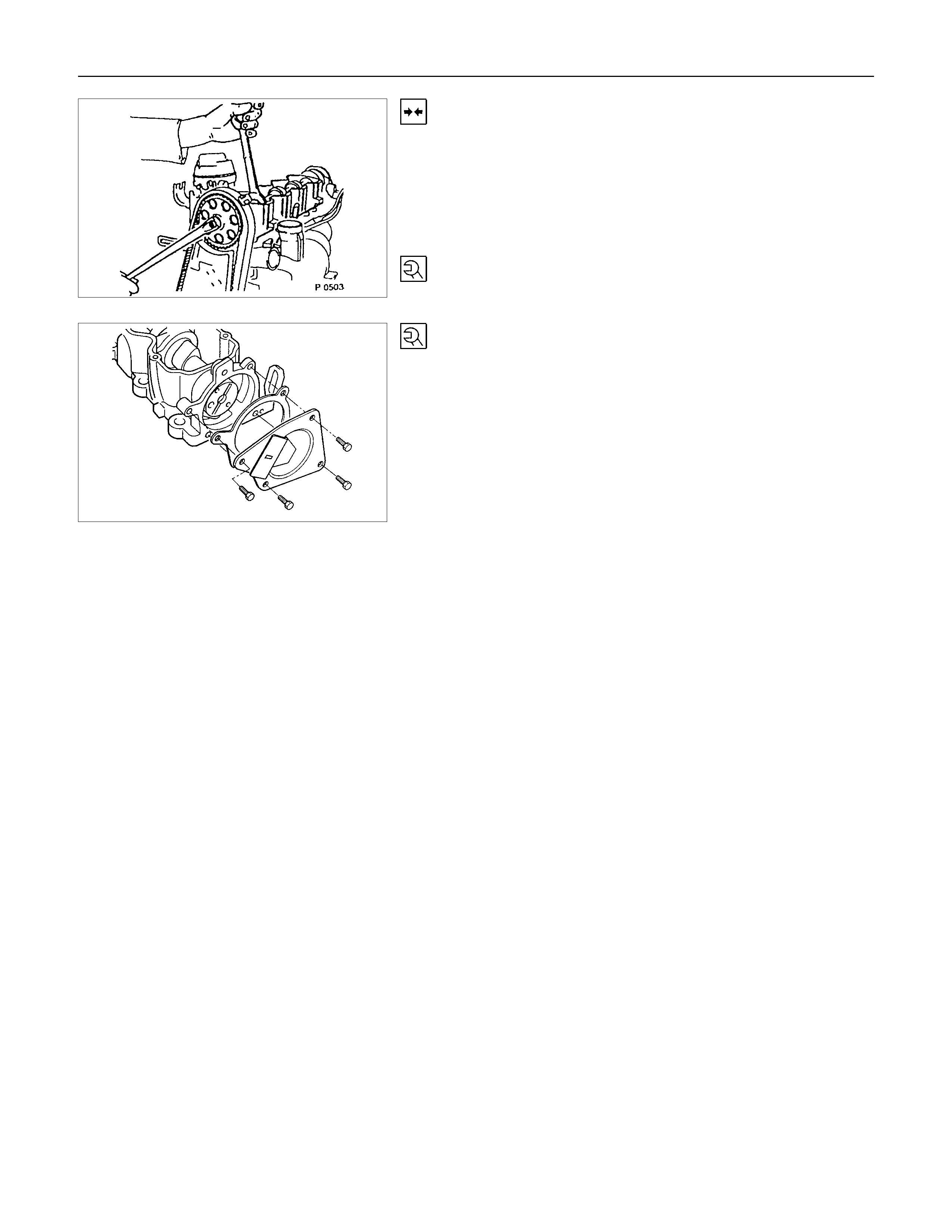

Seal Ring - Front Camshaft Housing, Replace

Removal

Mark running direction of toothed belt.

Remove toothed belt-see operation “Toothed Belt, Replace”.

Camshaft housing cover, camshaft pulley-counterhold on hex

of camshaft.

Removal

Screw self-tapping screw into seal ring.

Edge out seal ring.

Installation

Lightly coat sealing lip of seal ring with protective grease.

Install seal ring with 5-8840-0451-0 into camshaft housing-use

screw and washer of camshaft pulley.

Installation

Camshaft pulley-counterhold at hex head of camshaft,

camshaft housing cover.

Toothed belt-see operation “Toothed Belt, Replace”.

Note operating erection of toothed belt.

Tighten (Torque)

Camshaft pulley to cammshaft-45 N⋅m (3.7 kgf⋅m)

Tighten (Torque)

Camshaft housing cover to cover to housing-8 N⋅m (0.8 kgf⋅m)

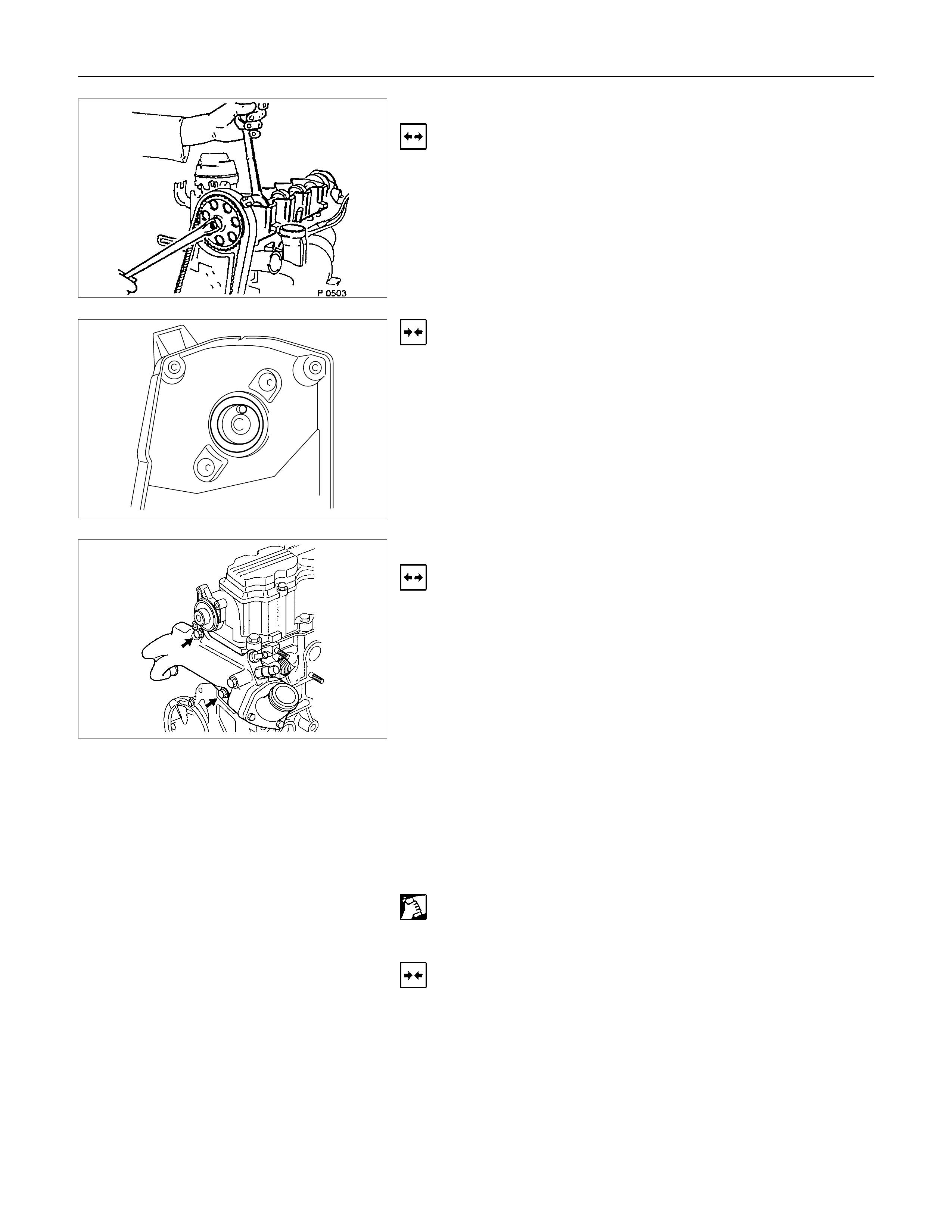

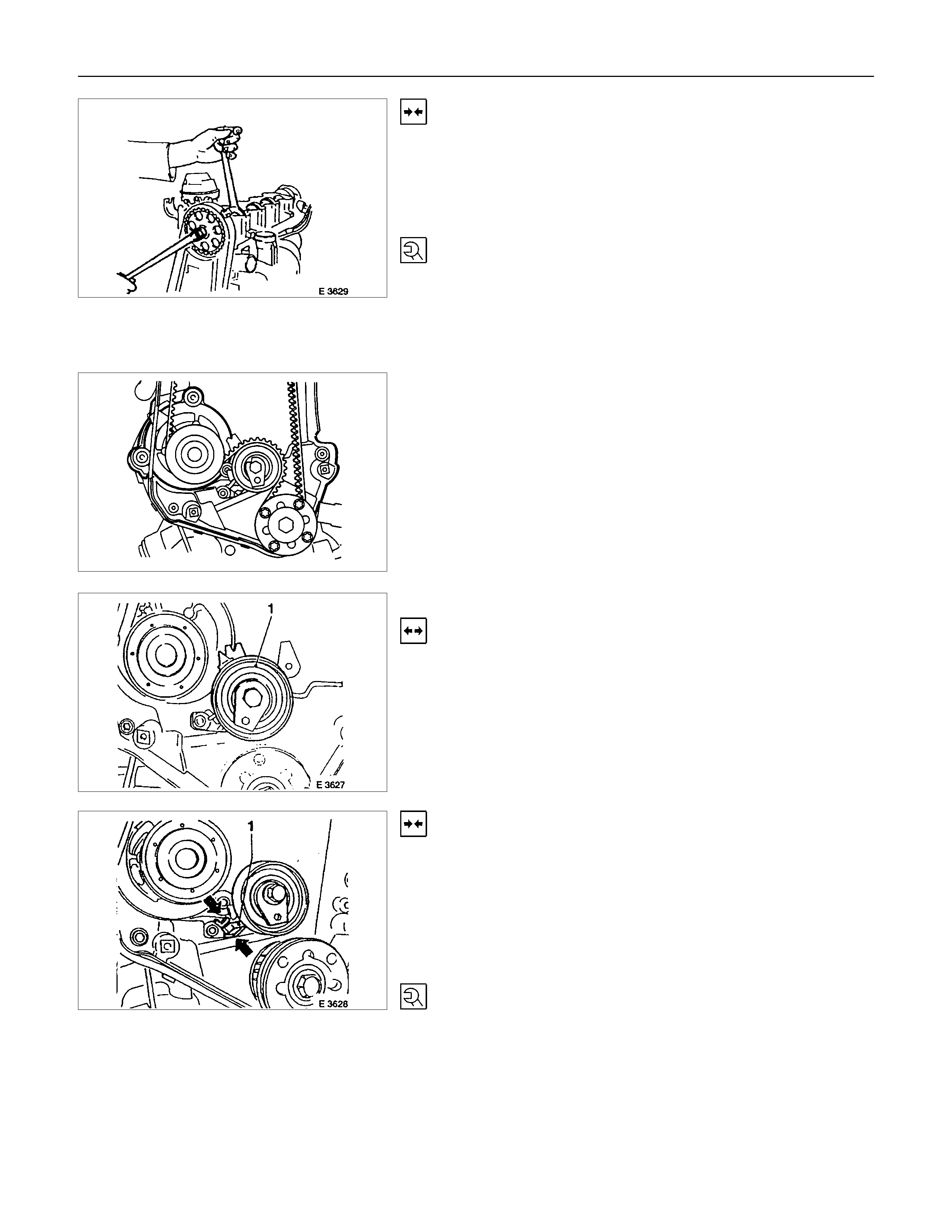

Toothed Belt Rear Cover

(Engine with toothed belt tension

roller)

Removal

1. Mark operating direction of toothed belt.

2. Remove toothed belt according to the operation "Toothed

Belt".

3. Remove toothed belt tension roller according to the

operation "Toothed Belt Tension Roller ".

4. Remove fastening bolt while counterholding with 5-8840-

2598-0 (Holding wrench).

5. Remove toothed belt drive gear while counterholding with

5-8840-2598-0 (Holding wrench).

6. Remove camshaft housing cover.

7. Remove camshaft pulley while counterholding at hex

head of camshaft.

8. Remove toothed belt rear cover (arrows) from oil pump

and camshaft housing.

Installation

1. Install toothed belt rear cover.

2. Install camshaft pulley while counterholding at camshaft

hex head.

3. Install camshaft housing cover.

Tighten (Torque)

Toothed belt rear cover to oil pump and camshaft housing - 6

N⋅m/4 lbf ft.

Camshaft housing cover to housing - 6 N⋅m (0.6 kgf⋅m).

Camshaft pulley to camshaft - 45 N⋅m (4.6 kgf⋅m).

4. Install toothed belt drive gear to crankshaft - 130 N⋅m

(13.3 kgf⋅m).

5. Install toothed belt according to the operation "Toothed

Belt".

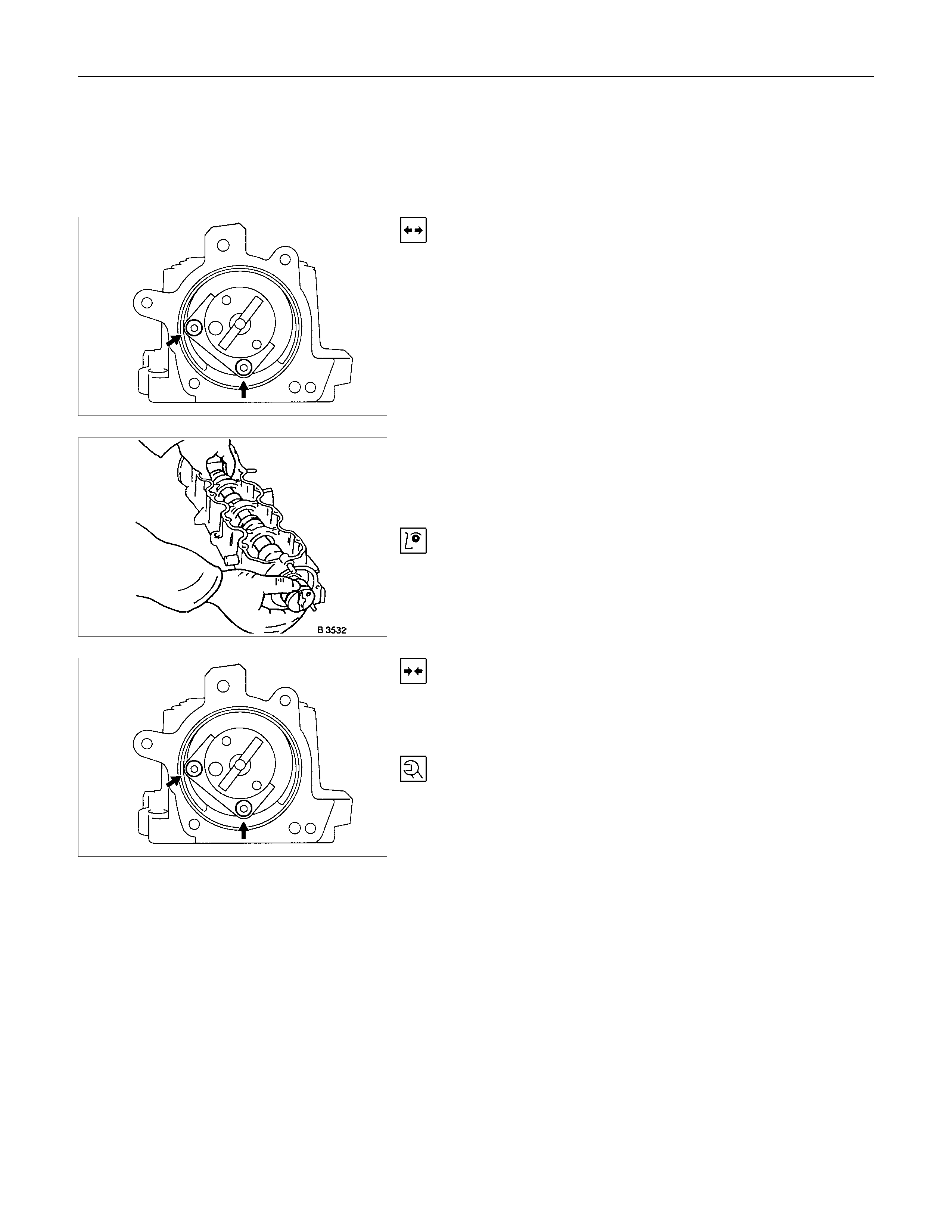

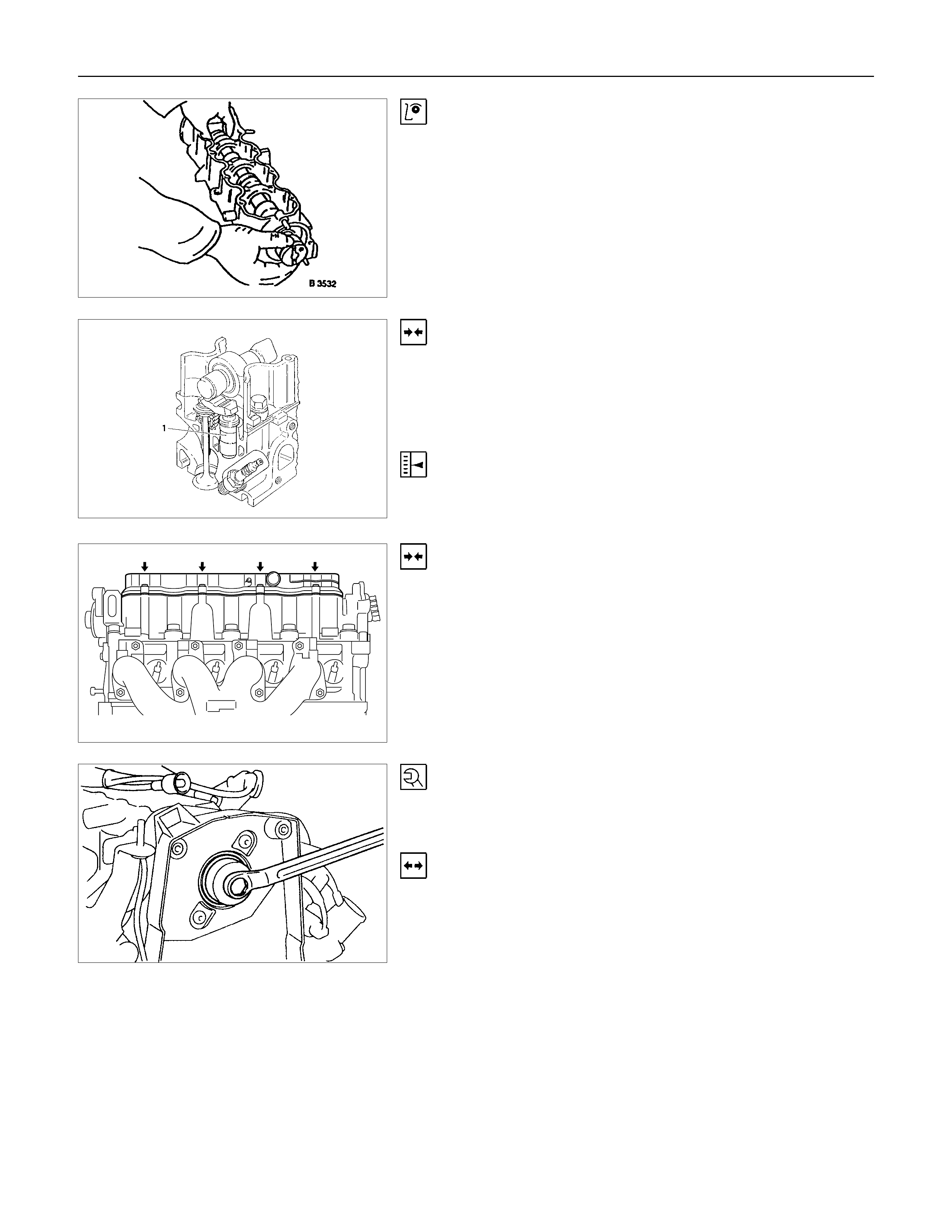

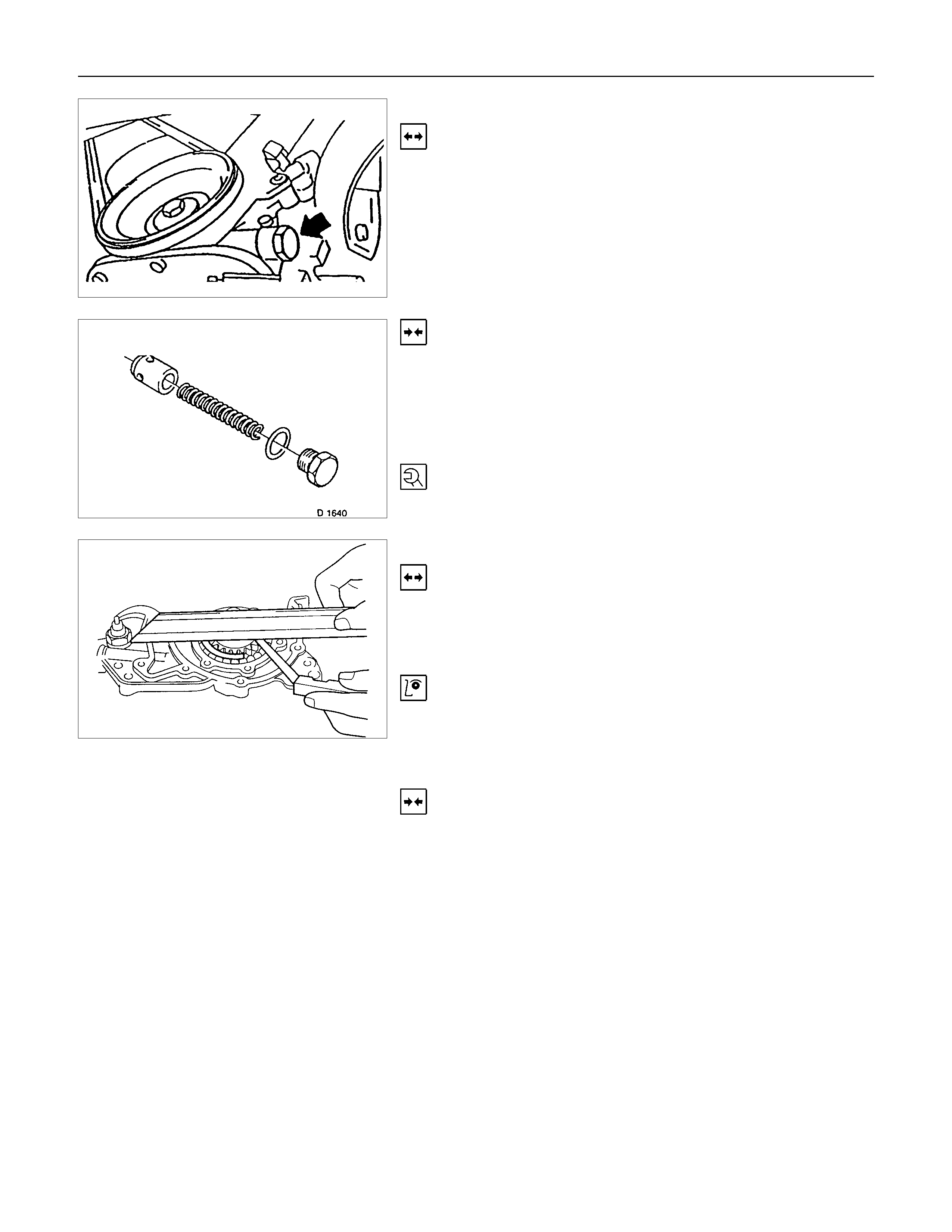

Toothed Belt Tension Roller

Removal

1. Mark operating direction of toothed belt.

2. Remove toothed belt according to the operation "Toothed

Belt”.

3. Remove toothed belt tension roller (1) from oil pump.

Installation

1. Install toothed belt tension roller and make sure that the

locking lever (1) engages in the guide lugs (arrowed) on

the oil pump housing.

2. Install toothed belt according to the operation "Toothed

Belt" with paying attention to the operating direction of

toothed belt.

Tighten (Torque)

Toothed belt tension roller to oil pump - 25 N⋅m (2.5 kgf⋅m)

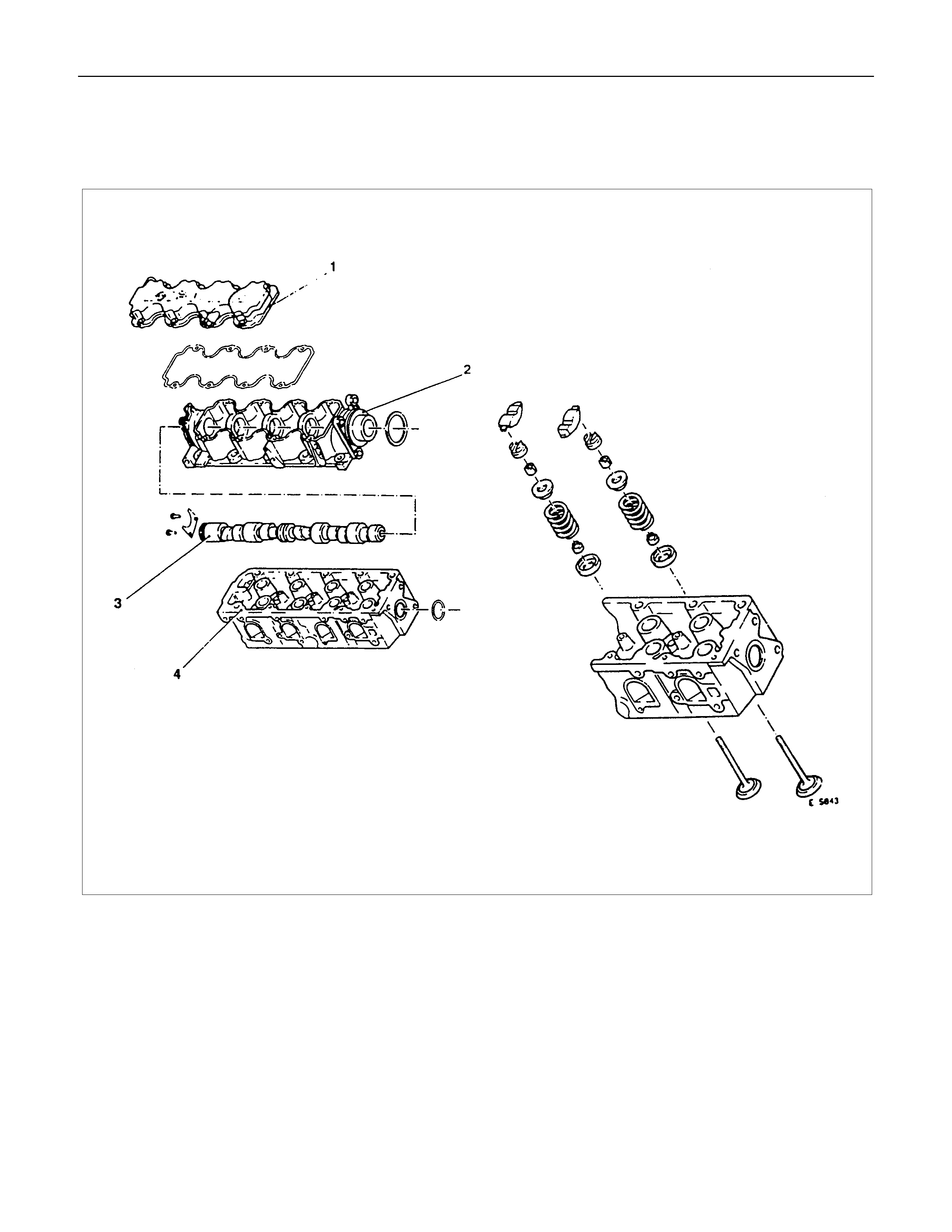

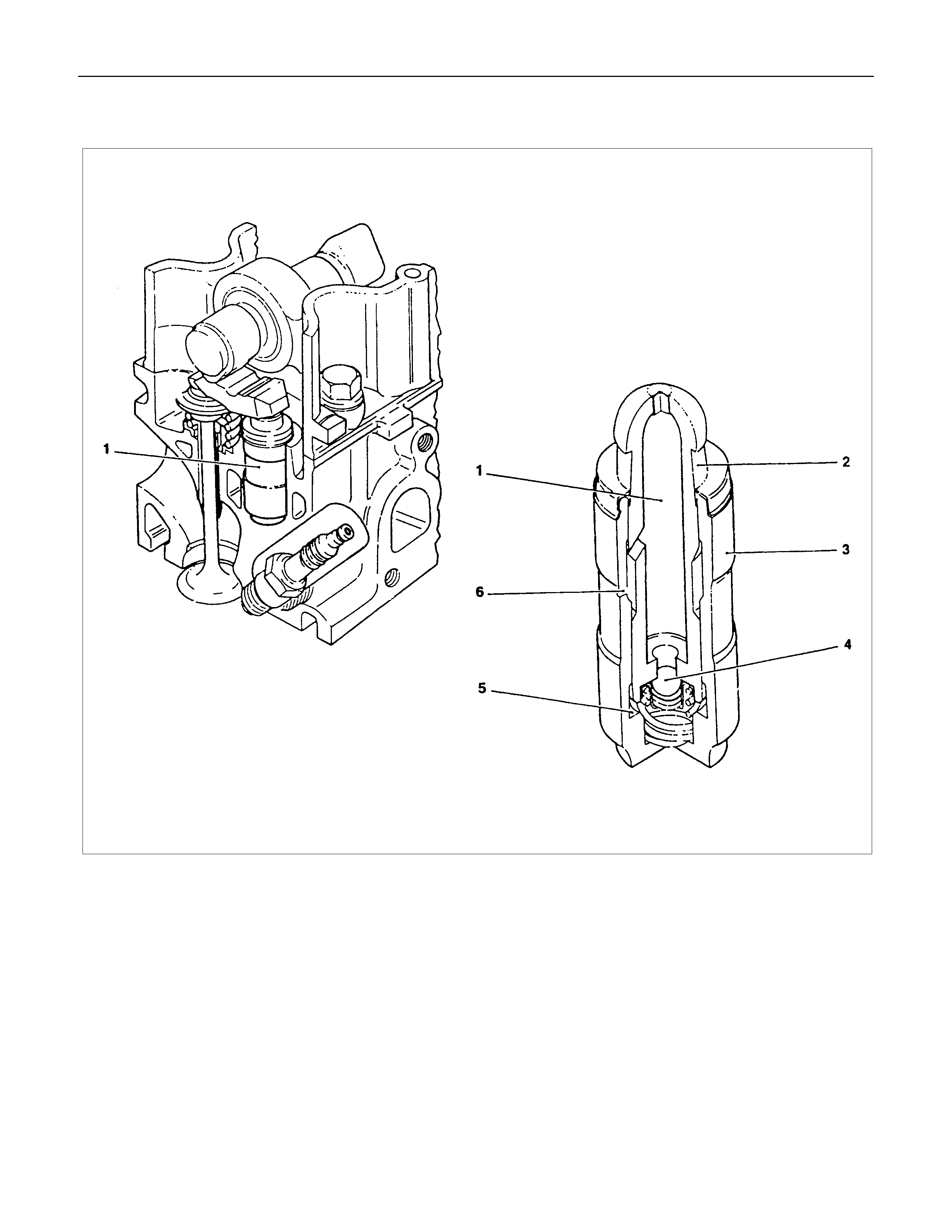

COMPONENT PARTS

CYLINDER HEAD

(A)

1. Camshaft Housing Cover

2. Camshaft Housing

3. Camshaft

4. Cylinder Head

(A) Valve Drive

HYDRAULIC VALVE LIFTER

1. Hydraulic Valve Lifter 1. Oil reservoir

2. Piston with ball head (moving)

3. Pressure cylinder (fixed)

4. Check ball

5. Pressure chamber

6. Oil feed

OPERATIONS ON CYLINDER HEAD AND CAMSHAFT

HOUSING

Camshaft

Removal

1. Remove cylinder head according to the corresponding

operation.

2. Remove camshaft housing from cylinder head and lay

housing on base provided

3. Remove rear sealing gasket and plate camshaft housing

with taking care not to damage housing.

4. Remove thrust plate.

5. Remove camshaft.

6. Remove front sealing gasket and plate from camshaft

housing with taking care not to damage housing.

Inspection

All parts.

Installation

1. Install camshaft.

2. Coat sliding surfaces with molybdenum disulphate paste.

Tighten (Torque)

Thrust plate for camshaft housing - 8 N⋅m (0.8 kgf⋅m)

Camshaft Housing, Removal and

Installation

See operation Camshaft

Cylinder Head

Important!

Remove cylinder head only from cold engine (room

temperature).

Removal

1. Remove ground cable from battery.

2. Open radiator drain tap and collect coolant.

3. Remove air intake hose.

4. Remove all cable connections, hoses and lines to the

cylinder head.

5. Remove accelerator cable on the throttle valve.

6. Remove V-belt for alternator.

7. Remove front toothed belt cover according to the

corresponding operation.

8. Bring piston of 1st cylinder to TDC and mark the position.

9. Remove camshaft housing cover.

10. Remove camshaft timing gear after releasing tension on

toothed belt.

11. Remove upper bolts of rear toothed belt cover.

12. Remove exhaust pipe from exhaust manifold.

13. Remove cylinder head after loosening bolts from outside

inwards (at first quarter turn then half turn) in a spiral

pattern.

14. Remove camshaft housing from cylinder head.

15. Remove rocker arm, pressure parts and hydraulic valve

lifter adjuster.

Clean

All sealing surfaces, drill holes in cylinder head bolts.

Check cylinder block and cylinder head for plane surface

according to the corresponding operations.

Installation

1. Install cylinder head sealing with marking "OBEN/TOP"

facing upwards and to right side of engine.

2. Install cylinder head on cylinder block.

3. Install hydraulic valve lash adjuster, pressure parts and

rocker arm - molybdenum disulphate paste.

4. Install camshaft housing-Sealing Compound TB-1207C

or equivalent.

Important!

Use new cylinder head bolts.

Screw in bolts until they rest on cover.

Torque - Angle Method

Cylinder head to cylinder block - 25 N⋅m (2.5 kgf⋅m)

Further turn angle 90°+90°+ 90°.

Tighten cylinder head bolts from inside outwards. In four

stages in a spiral pattern.

5. Install rear toothed belt cover onto camshaft housing.

6. Install toothed belt and apply tension according to the

corresponding operation.

Tighten (Torque)

Camshaft timing gear to camshaft - 45 N⋅m (4.6 kgf⋅m)

7. Install camshaft housing cover and front toothed belt

cover.

8. Install cable connections, all hoses and lines onto

cylinder head.

9. Adjust accelerator cable for free of play.

10. Install V-belt according to the corresponding operation.

11. Install air intake hose.

12. Install front exhaust pipe.

13. Install ground cable onto battery.

14. Fill up cooling system and bleed according to the

corresponding operation.

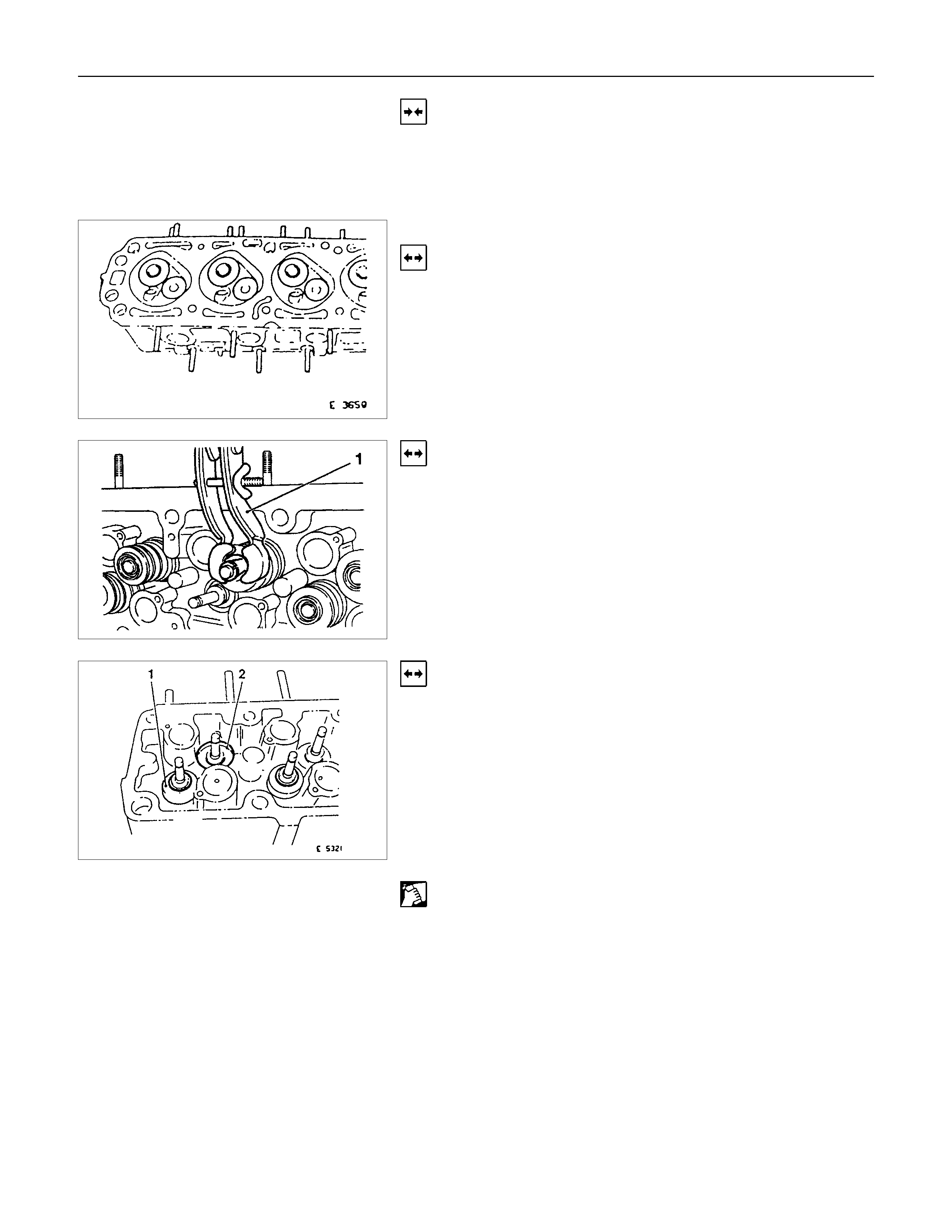

Hydraulic Valve Lifters, Replace

Removal

1.Remove the spark plug connectors and spark plugs.

2.Remove the camshaft housing cover.

Removal

3.Turn the crankshaft at fastening bolt of toothed belt drive

gear in the direction of the engine rotation until the cam

of hydraulic valve lifter being replaced stands vertically.

Removal

4.Apply 5-8840-0457-0 to the camshaft housing, valve

spring cap and tension valve spring.

Removal

5.Remove the cam follower from camshaft housing.

Note thrust pieces.

6.Remove hydraulic valve lifter from camshaft housing.

Camshaft Housing, Replace

Removal

Cylinder head-see operation “Cylinder Head. Remove and

Install”.

Inspection

All parts, if necessary replace.

When replacing camshaft, always replace all cam followers.

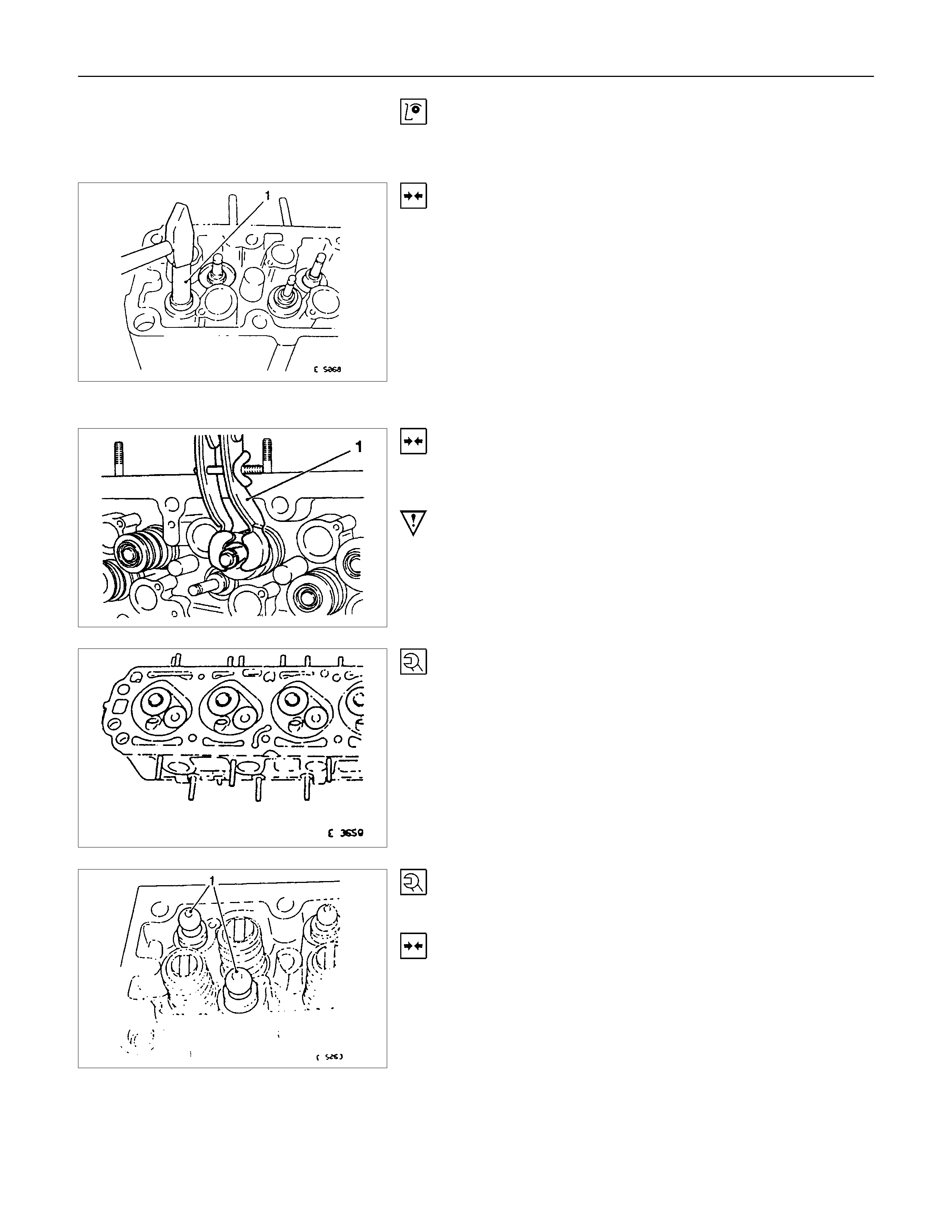

Installation

Insert hydraulic valve lifter (1) in camshaft housing.

Coat sliding surfaces of rocker arm with Mcs, Paste and insert

in camshaft housing.

Adjust

Adjustment of the hydraulic valve liters is not required.

Pretension is provided by the design.

Installation

1. Remove 5-8840-0457-0 and install the camshaft housing

cover.

2. Insert the spark plug connectors.

Tighten (Torque)

Guide plate to camshaft housing.

Insert camshaft with MoS2 paste.

Installation

1. Install the front seal ring in camshaft housing with

5-8840-0451-0.

2. Install the camshaft housing rear cover.

3. Install the cylinder head.

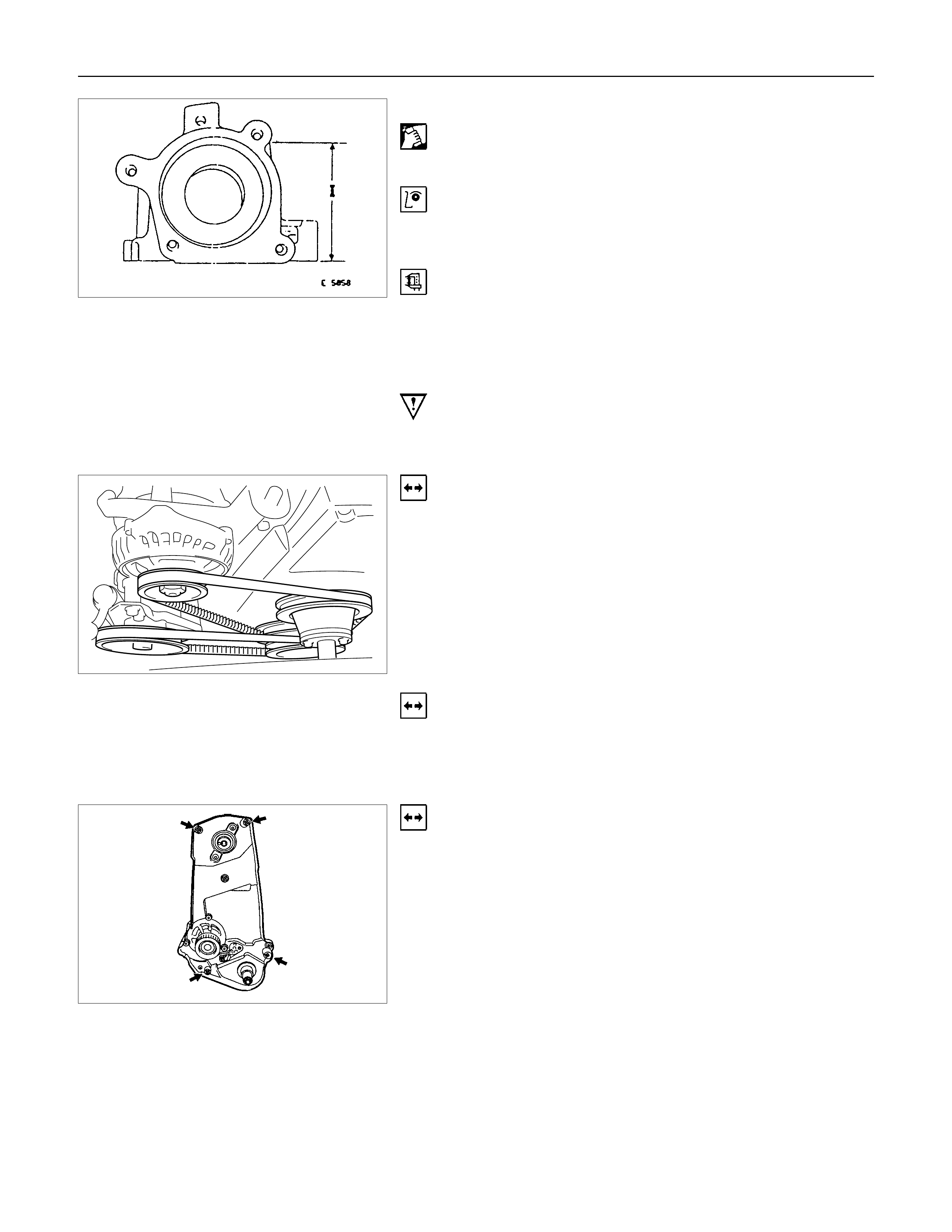

Camshaft Housing, Check for Plane Surface

Clean

Sealing surfaces.

Inspection

Check length and width of sealing surface for deformation and

diagnosis for warpage and use straight edge feeler gauge.

Measure

Height of camshaft housing (sealing surface to sealing

surface).

Dimension I: (74.0 mm)

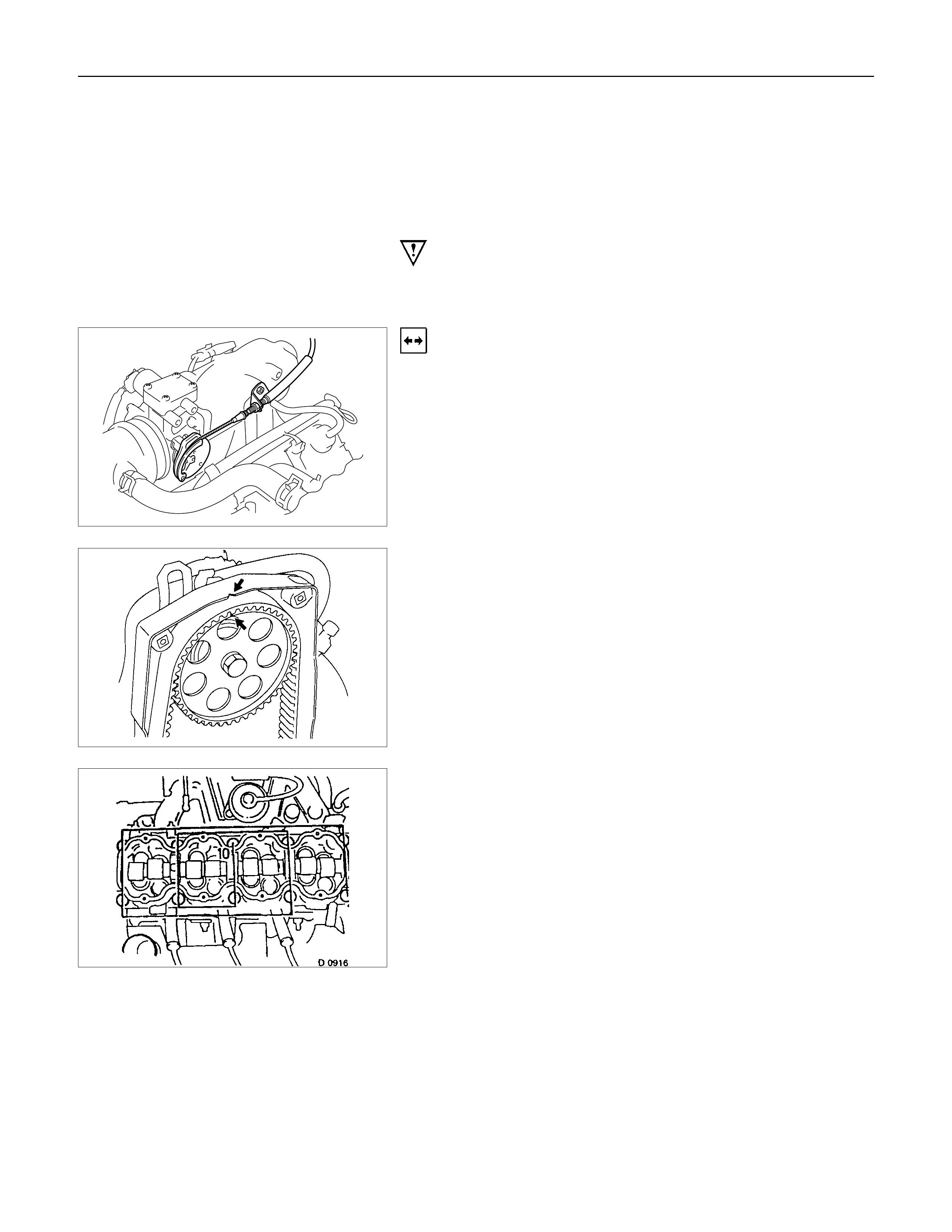

Cylinder Head, Removal and Installation

Important

Only remove cylinder head with engine cold (room

temperature).

Removal

1. Remove the alternator, power steering and V-belts.

Removal

2. Loosen the fastening bolts from alternator.

3. Loosen the lower alternator fastening bolt by swinging the

alternator to the rear.

Removal

4. Remove the front toothed belt cover.

5. Remove the toothed belt from camshaft pulley.

See operation "Timing Check and Adjust".

Removal

6. Remove the camshaft housing cover and camshaft pulley

by counter-holding at the hex head of camshaft.

Removal

7. Remove the fastening bolts from camshaft housing.

Removal

8. Remove the exhaust pipe from exhaust manifold.

9. Loosen the cylinder head bolts spirally from the outside

inwards (first 1/4, then 1/2 revolution).

Removal

1. Remove the camshaft housing from cylinder head.

2. Remove the cam followers, thrust pieces and hydraulic

valve lifters.

Note the allocation.

3. Remove the cylinder head.

Clean

Sealing surfaces, bores and threads of cylinder head bolts.

Inspection

Check cylinder head and cylinder block for plane surfface-see

operations “Cylinder Head, Check for Plane Surface” and

“Cylinder Block, Check for Plane Surface.”

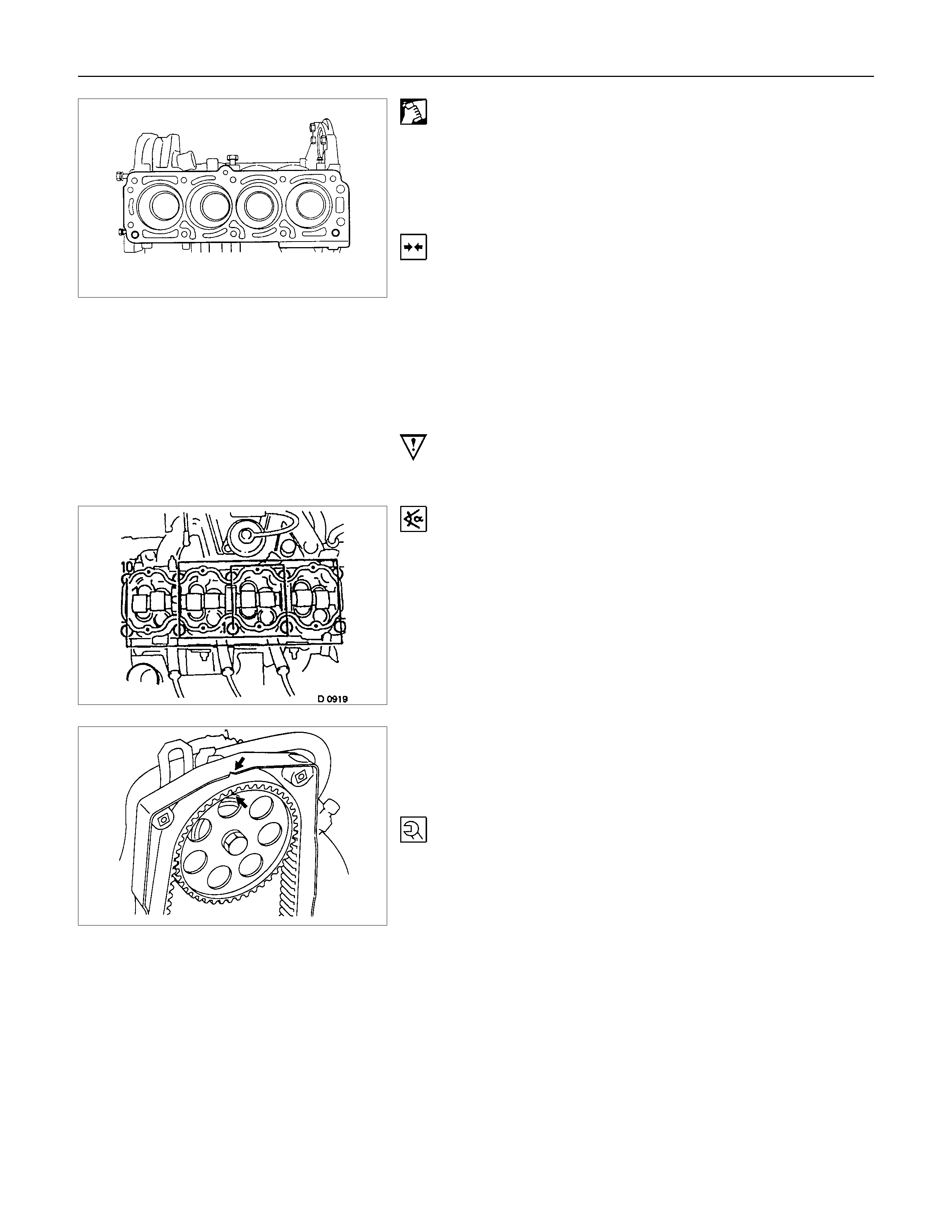

Installation

1. Install the cylinder head gasket.

Mark "OBEN/TOP" on top and turn it towards timing side

of engine.

2. Place cylinder head on cylinder block.

1

2

3

Installation

1. Insert the hydraulic valve lifters (3), thrust pieces (2) and

cam followers (1) with MoS2 paste.

Note allocation.

2. Apply a bead of Sealing Compound TB1207C to sealing

surface of cylinder head.

3. Install the camshaft housing on cylinder head.

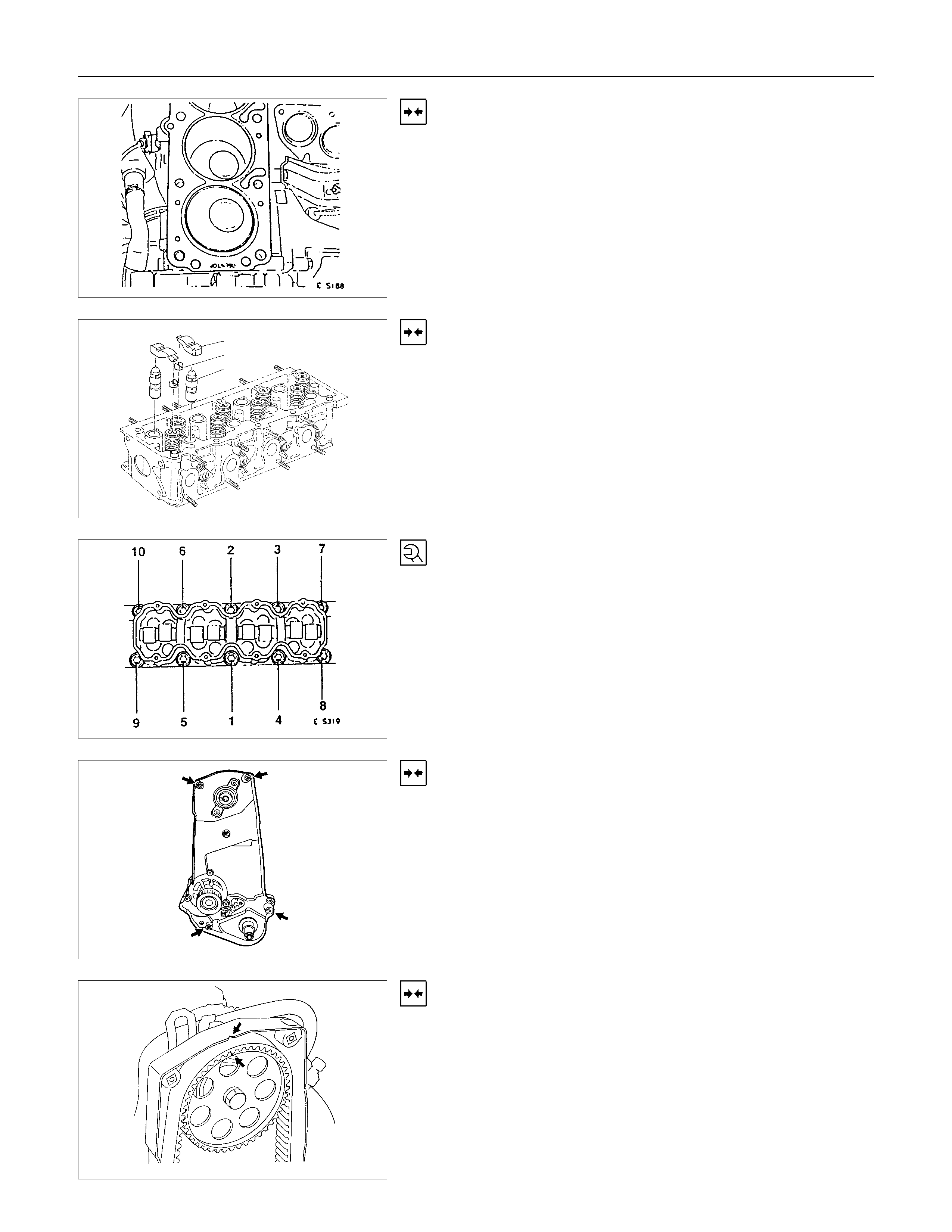

Torque-Angle Method

Cylinder head and camshaft housing with new cylinder head

bolts to cylinder block.

Cylinder head bolts in sequence shown.

Installation

1. Install the rear toothed belt cover to camshaft housing.

2. Install the camshaft pulley to camshaft.

3. Install the camshaft housing cover to housing.

Installation

1. Install the toothed belt on camshaft pulley.

See operation "Timing Adjust".

2. Install the front toothed belt cover.

Installation

1. Install the fastening bolts.

2. Loosen the lower alternator fastening bolt.

3. Install the alternator, power steering and V-belts.

Cylinder Head, Disassemble and Assemble

Removal

1. Remove the hydraulic valve lifters.

Lay aside in installation positions.

2. Remove the spark plugs, exhaust manifold and intake

manifold from cylinder head.

Removal

1. Mark valves.

2. Remove the tension valve springs with 5-8840-2594-0

(1).

3. Remove valve keepers, valve spring cap and valve

spring.

Removal

1. Remove the valve and valve stem seal.

2. Remove the valve spacer ring (1-exhaust) and valve

spring seat (2-intake).

3. Remove valve from cylinder head.

Clean

Sealing surfaces.

Inspection

Sealing surfaces for plane surface, guides, sliding and bearing

points for wear-see operation “Cylinder Head. Overhaul”.

Installation

1. Coat the valves with engine oil and insert in cylinder

head.

2. Install the valve spacer ring or valve rotator(exhaust) and

valve spring seal(intake).

3. Push the accompanying assembly sleeve onto valve

stem and coat with engine oil.

4. Insert a new valve stem seal with 5-8840-2601-0 (1).

5. Drive the valve stem seal carefully in to stop with light

hammer blow.

Installation

1. Install the valve springs and valve spring caps.

2. Install the tension valve springs with 5-8840-2594-0 (1),

valve keeper.

Important!

Note markings made on valves.

Tighten (Torque)

Exhaust manifold and intake manifold with new gaskets to

cylinder head.

Thermostat housing with new seal ring to cylinder head:

Tighten (Torque)

Spark plugs with spark plug wrench to cylinder head.

Installation

1. Coat hydraulic valves lifters (1) with oil.

2. Insert them in cylinder head.

Note installation position.

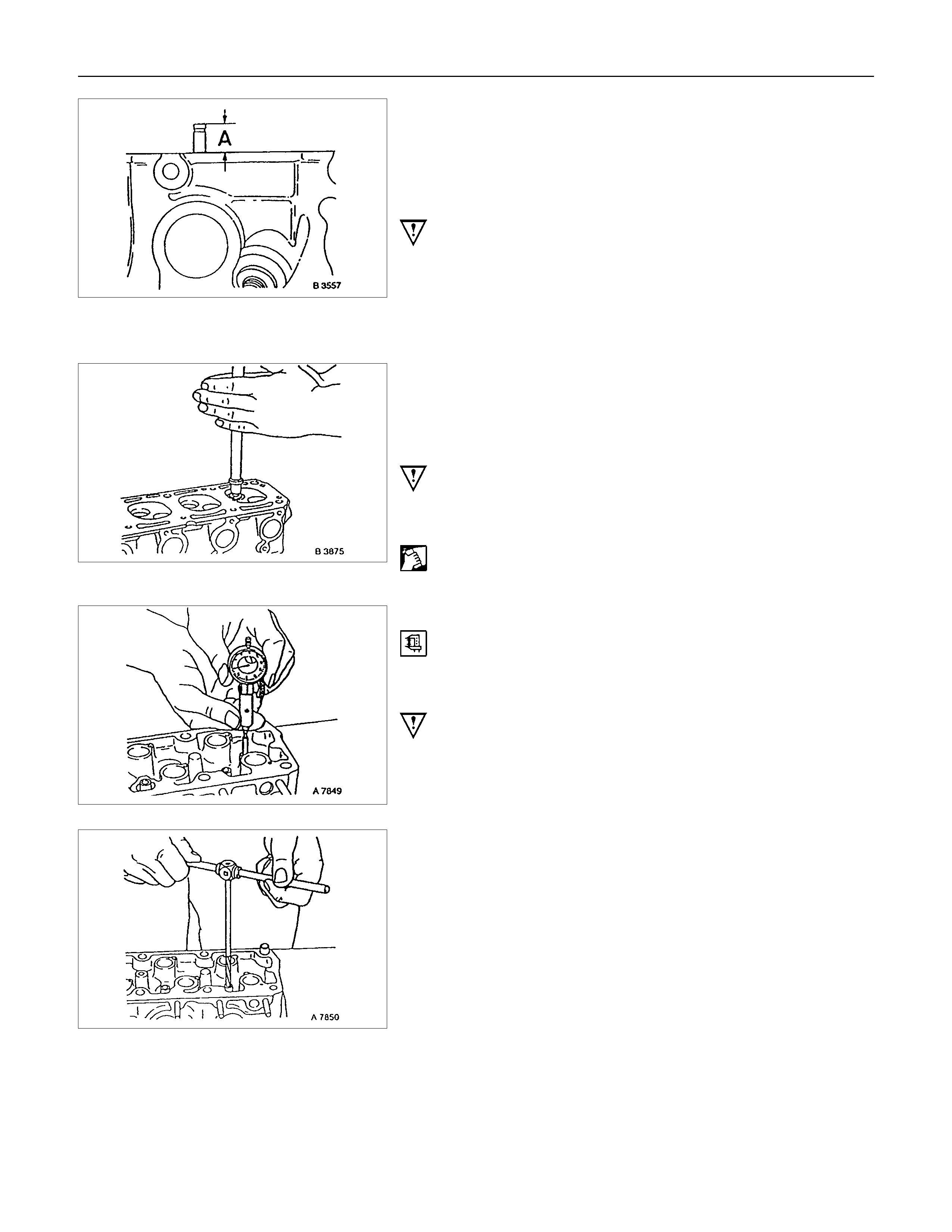

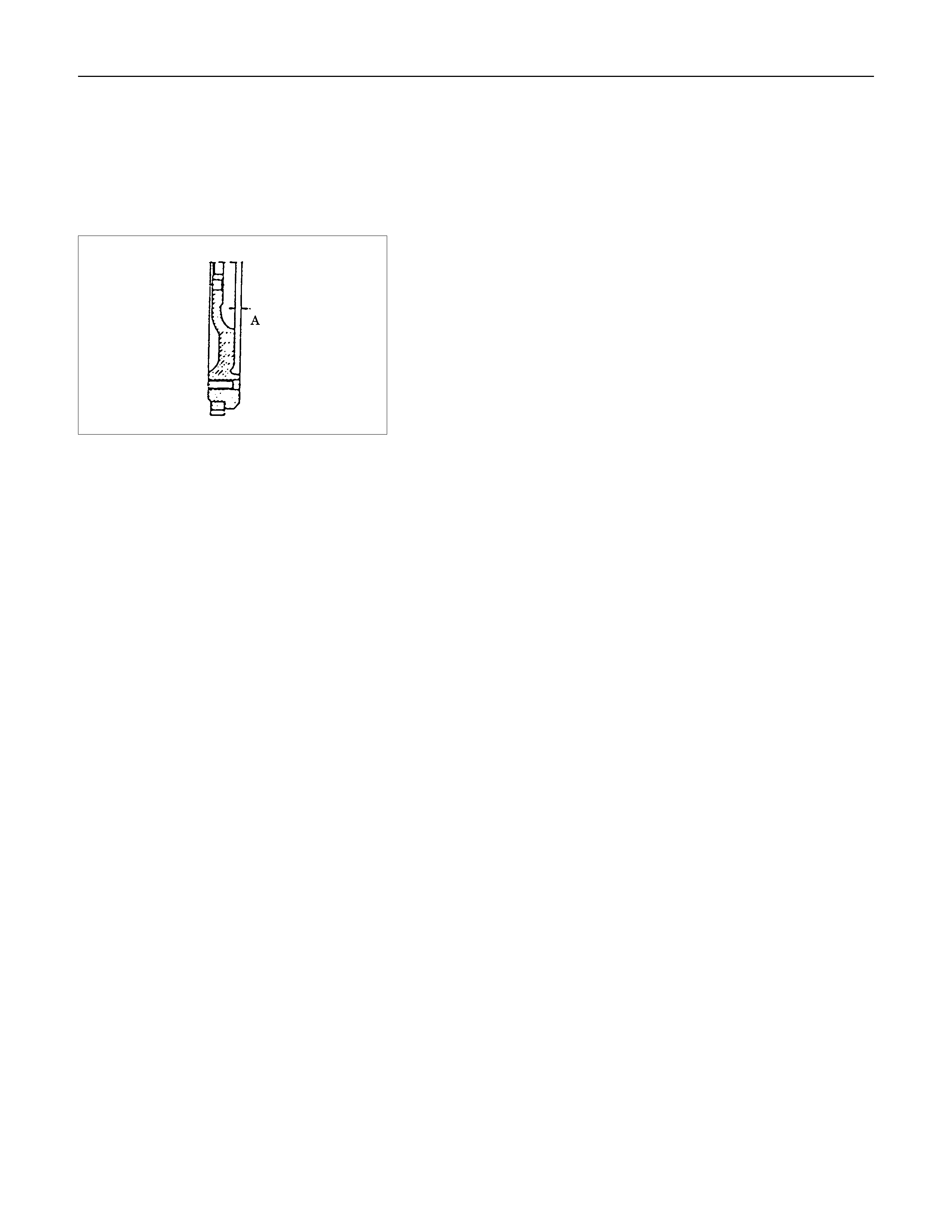

Valve, Grind

Valves can be reused once or twice after regrinding-only if

there are no crater-like burns on the valve cone.

Excessive grinding can cause the upper valve head edge to

become too thin.

Important!

Valve stem protection must not exceed dimension “A”-use 5-

8840-2596-0.

Do not regrind valve stem ends.

For all valve reworking note that angle of valve head is 44° and

the valve seat 45°-see also “Technical Data”.

Valve, Grind In

Grind-In the valve to improve valve seating.

Grind-In by rhythmically lifting valves and turning uniformly.

Use commercially available grinding tool.

Important!

Use only fine-grained pastes for grinding.

Lubricate valve stem before grinding in.

Clean

After grinding, carefully clean valve and valve soat.

Valve Guide, Ream

Measure

Diameter of valve guide-dial gauge and internal measuring

instrument.

Important!

Valve oversizes are available ex-works.

Oversize identification, on the valve guide and on the valve

stem end with the following specified identificaton

flgures/letters-see also “Technical Data”.

Identification Mark

Size Production Customer Service Reamer

Normal none K

0.075 mm 1 K1

0.150mm 2 K2

Ream valve guide from the upper side of the cylinder head to

the next oversize (use 5-8840-2599-0).

After reaming, cross out identification mark and stamp in new

identification mark.

Valve Seating, Mill

Place cylinder head on block of wood.

Inlet and exhaust, Guide Drift and Valve Seat Cutter 5-8840-

2593-0.

Valve seat-45°, side face, upper correction-30°, side face

(arrows on cutter).

Valve seat width:

Inlet-1.0 to 1.5 mm/0.04 to 0.06 in.

Exhaust-1.7 to 2.2 mm/0.072 to 0.088 in.

Inspection

Valve stem projection-use 5-8840-2596-0.

Important!

If dimension “A” is exceeded, use new valves.

Check valve stem projection again. If dimension “A” is

exceeded, replace cylinder head.

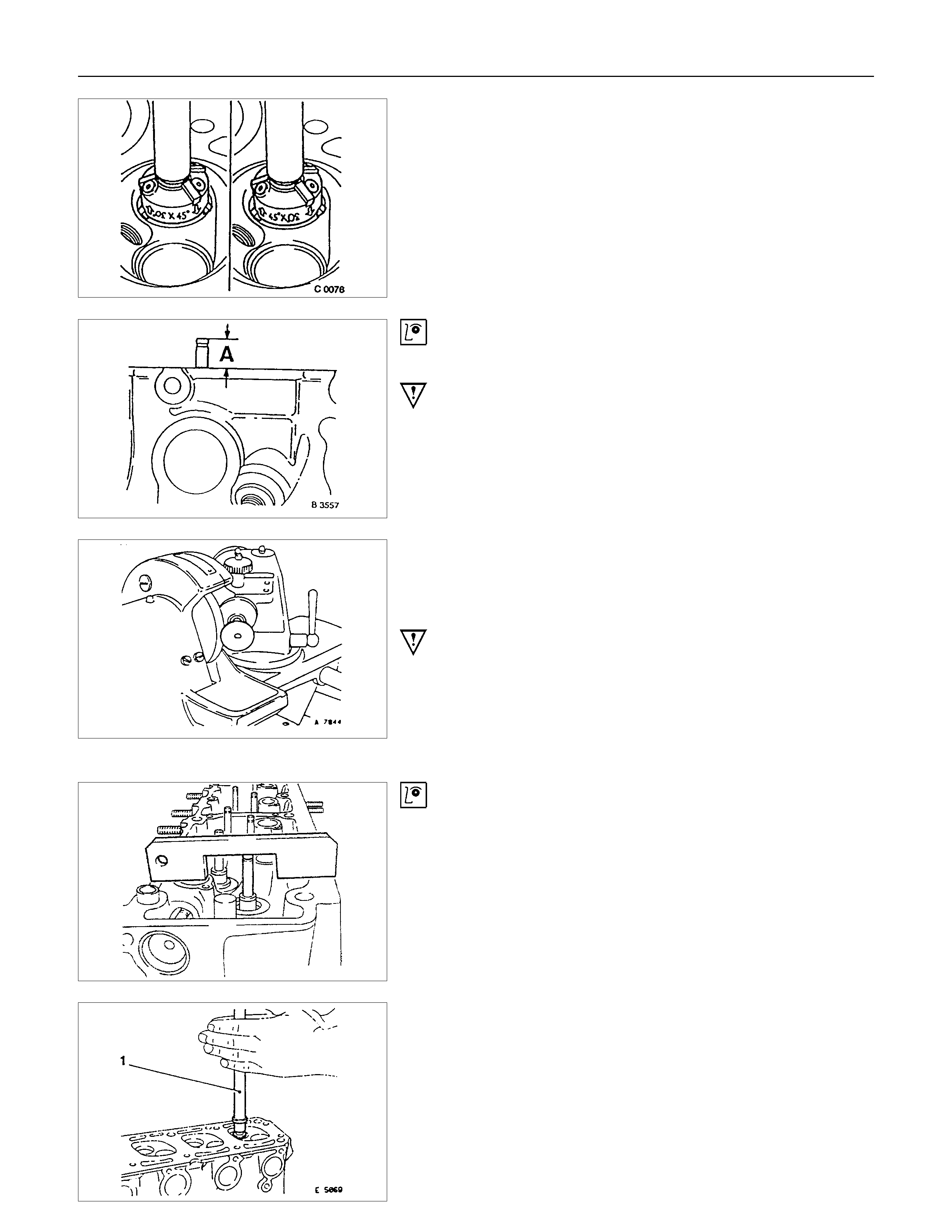

Cylinder Head, Overhaul

Cylinder head disassembled.

Valve, Grind

Important!

Ensure that there are no crater-like burns on the valve cone.

Regrinding possible once or twice.

Grinding of valve stem end is not permitted.

Angle at valve head-44°

Inspection

Check valve stem projection as shown 5-8840-2596-0.

Valve, Grind in

Lubricate valve stem, use fine-graining grinding paste.

Lift up valve from seat rythmically using valve grinding tool (1)

for distribution of grinding paste.

Inspection

Check contact pattern (I) on valve seat and in cylinder head.

Clean

Valves, valve guides, cylinder head.

Flywheel

Removal

1. Remove transmission and clutch.

2. Remove flywheel while locking with 5-88400-446-0.

Torque - Angle Method

Flywheel to crankshaft - 65 Nm/6.5 kgf⋅m.+30° to 45°

Important!

Use new bolts.

Do not apply grease to the thread.

Installation

1. Install clutch and transmission.

Component Parts

Flywheel and Ring gear. (Manual Transmission)

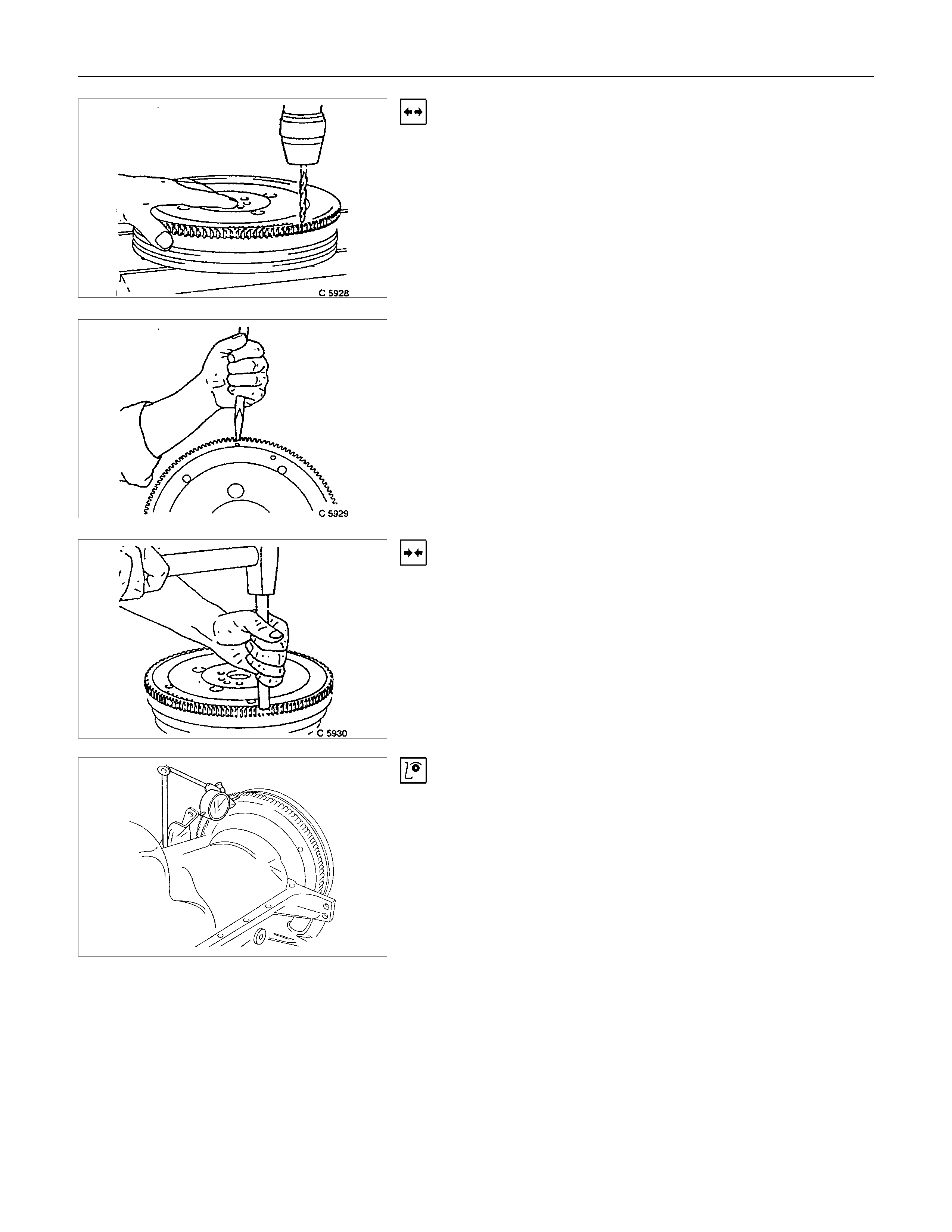

Starter Ring Gear (Manual Transmission)

Removal

1. Remove flywheel according to the corresponding

operation.

2. Drill starter ring gear underneath tooth gap approx.

8mm/0.30in. deep with 8mm/0.25in. diameter drill.

3. Separate starter ring gear with chisel on the drilling point.

Installation

1. Install starter ring gear with inner chamfered edge to

flywheel.

2. Heat starter ring gear evenly to 180°C /356°F to 230°C

/446°F (yellow paint mark)

3. Install flywheel according to the corresponding operation.

Inspection

Lateral run-out of starter ring gear - max. 0.5mm/0.02in.

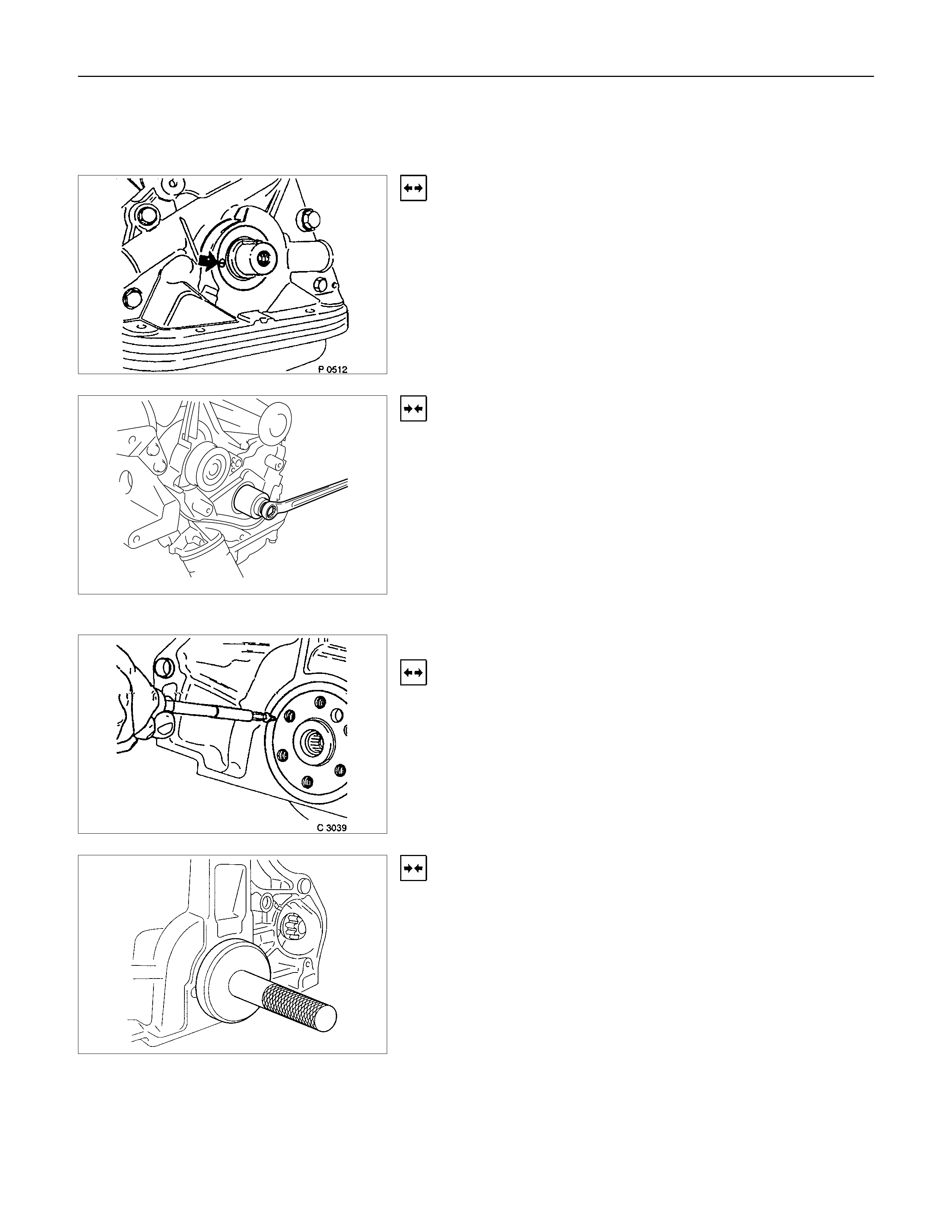

Seal Ring, Crankshaft

(Oil Pump Housing)

Removal

1.Remove toothed belt rear cover according to the

corresponding operation.

2.Remove sealing ring by making hole in middle of ring,

turning in self-tapping screw and edging out.

Installation

1Install the protective sleeve to the crankshaft.

2.Coat the sealing lip with protective grease.

3.Install the sealing ring.

4.Install the sealing ring using 5-8840-0455-0.

5.Install the rear toothed belt cover and toothed belt

according to the corresponding operations.

6.Replace the sealing ring with a new one.

7.Tighten the belt to the crankshaft.

Seal Ring, Crankshaft Rear

Removal

1. Remove transmission and clutch.

2. Remove flywheel or flex plate according to the

corresponding operations.

3. Make hole in middle of sealing ring, turn in self-tapping

screw and edge out.

Installation

1. Install protective sleeve.

2. Coat sealing lip with Protective Grease.

3. Install sealing ring using 5-8840-0459-0 and 5-8840-

2597-0.

4. Install flywheel, clutch and transmission.

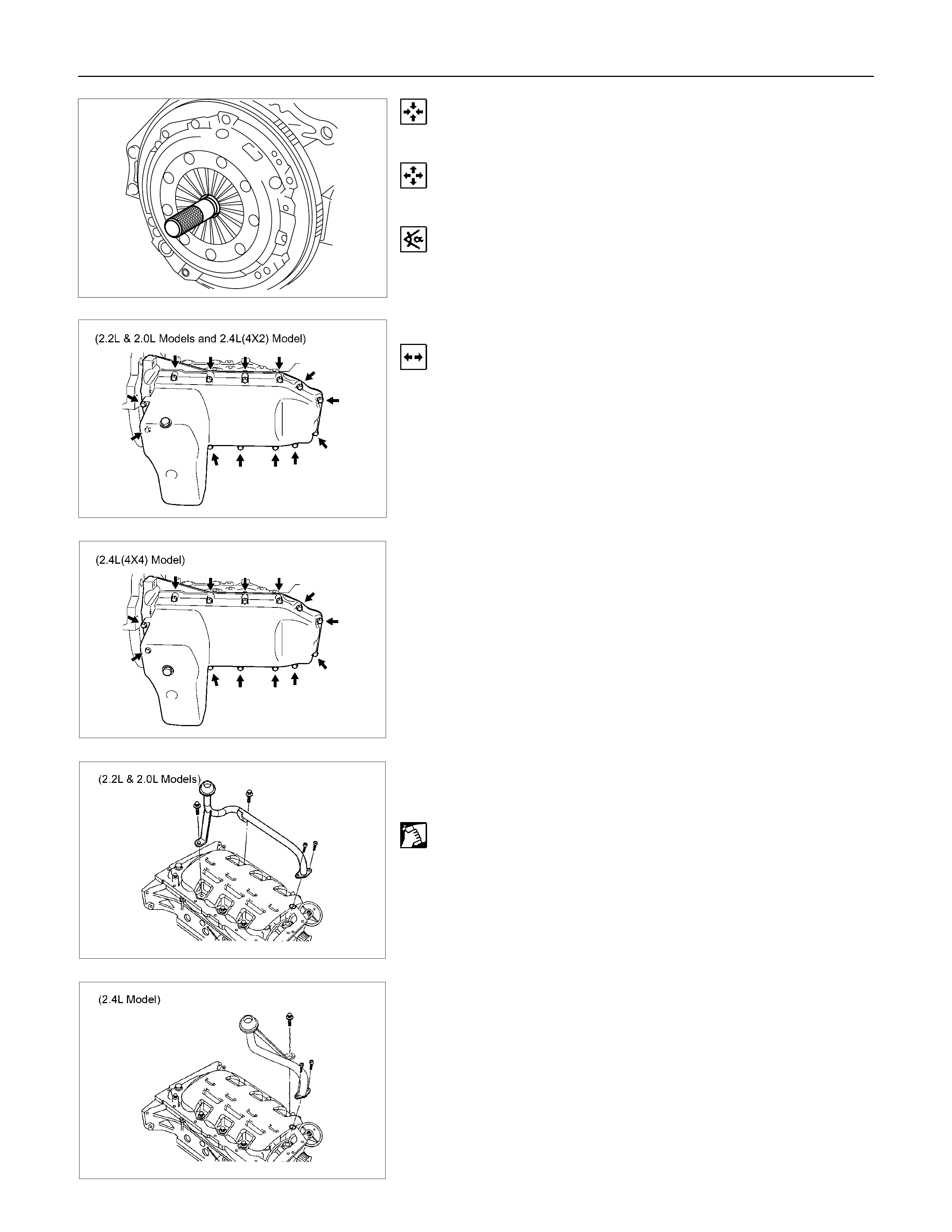

Reassembly

Reassemble clutch assembly.

Disassembly

Disassemble clutch assembly to flywheel using 5-8840-2634-0

Torque Angle-Method

Clutch assembly to flywheel-17.6Nm/1.8 kgf!m.

Gasket, Oil Pan

Removal

1. Loosen fixing bolts.

2. Remove oil pan from oil pump and cylinder block.

3. Remove oil intake pipe, oil intake pipe bracket, and oil

baffle plate.

Clean

Sealing surfaces.

Installation

1.Apply a bead of Sealing Compound, TB120TC or

eguivalent to joint of oil pump.

2.Install baffle plate, or reuse baffle plate with valcanized

gasket.

Caution

Baffle plates with valcanized gasket can be retrofitted without

difficulty - replace baffle plate with gasket.

3. Install oil intake pipe to oil pump and oil intake pipe

bracket to cylinder block.

4. Install oil pan and new gasket to cylinder block and insert

bolts with Locking Compound 15 10 177 (90 167 347).

Maximum assembly time including torque check is 10

min.

Tighten (Torque)

Oil intake pipe to oil pump -8N⋅m (0.8 kgf⋅m)

Oil intake pipe bracket to cylinder block - 6 N⋅m (0.6 kgf⋅m)

Oil pan to cylinder block - 8 N⋅m (0.8 kgf⋅m) with vulcanized

gasket - 15 N⋅m (1.5 kgf⋅m)

OPERATIONS ON CRANK CASE

Con-Rod Bearing

Removal

1.Remove oil pan according to the corresponding

operation.

2.Remove con-rod bearing cap and con-rod bearing after

marking both sides.

Clean

Con-rod journal, con-rod bearing cap

Installation

1.Install new bearing shafts lightly coated with engine oil.

2.Install con-rod bearing cap.

Torque-Angle Method

Con-rod bearing cap to con-rod - 35N⋅m (3.5 kgf⋅m) +45° to

60°

Important!

Use new bolts.

3.Install oil pan according to the corresponding operation.

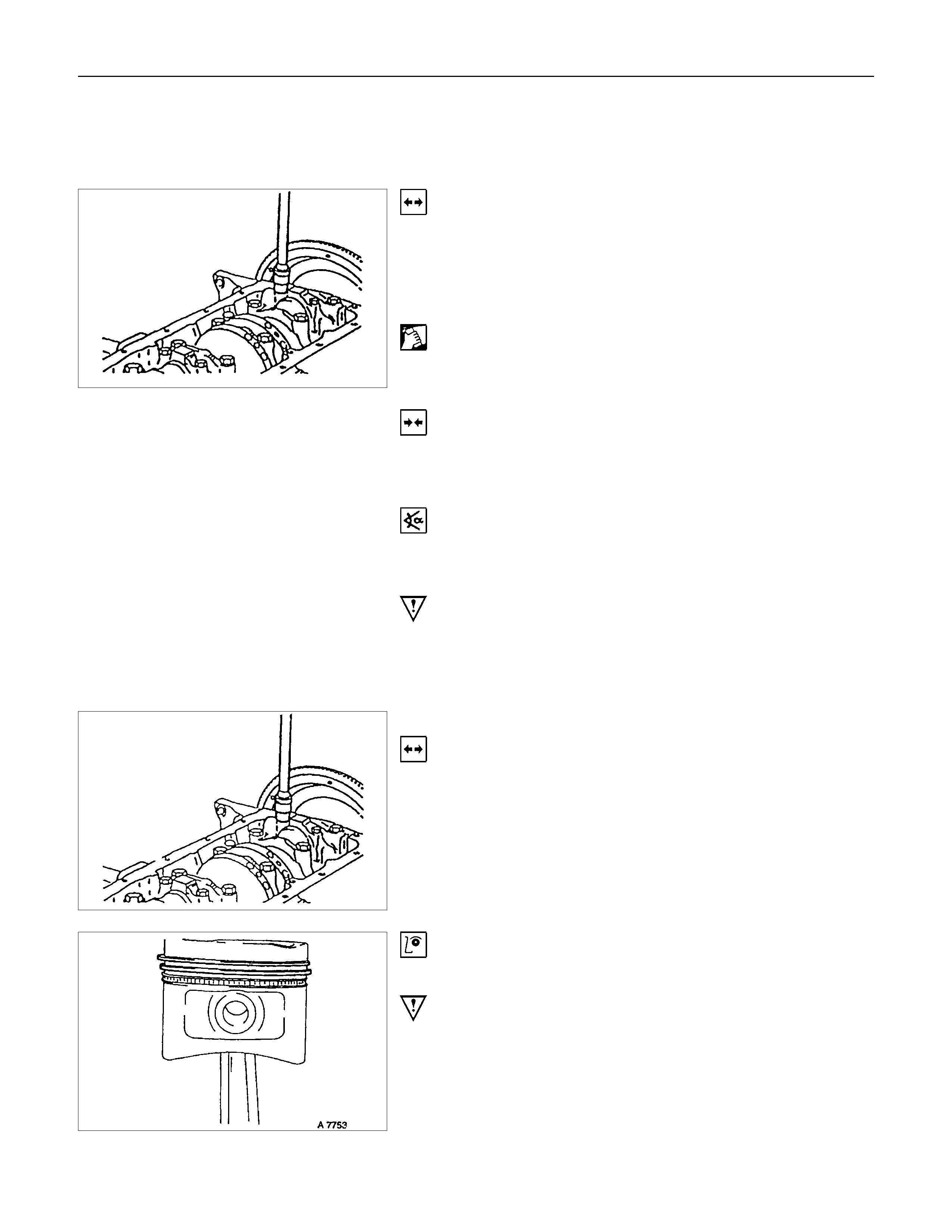

Piston with Con-Rod

Removal

1. Remove cylinder head and oil pan according to the

corresponding operations.

2. Remove piston with con-rod after marking con-rod

bearing cap.

Inspection

Remove and install all parts, if applicable.

Important!

Ring gap offset:

Piston rings - 180°.

Oil scraper rings - 25 to 50 mm/1 to 2 in. from gap of

intermediate ring to the left and to the right.

Installation

1. Install piston with con-rod by inserting with engine oil.

2. Coat piston rings with engine oil and compress with

piston ring compressor.

Important!

Installation position:

Arrow / notch on piston head on timing side of engine

Beads on con-rod on clutch side

Torque-Angle Method

Piston to cylinder block.

Con-rod bearing cap to con-rod-35N⋅m (3.5 kgf⋅m) +45° to 60°

Important!

Use new bolts.

Installation

1. Install oil pan and cylinder head according to the

corresponding operations.

2. Install sealing Gasket or replace if damaged.

3. Install camshaft housing to cylinder head.

4. Install cylinder head according to the corresponding

operation.

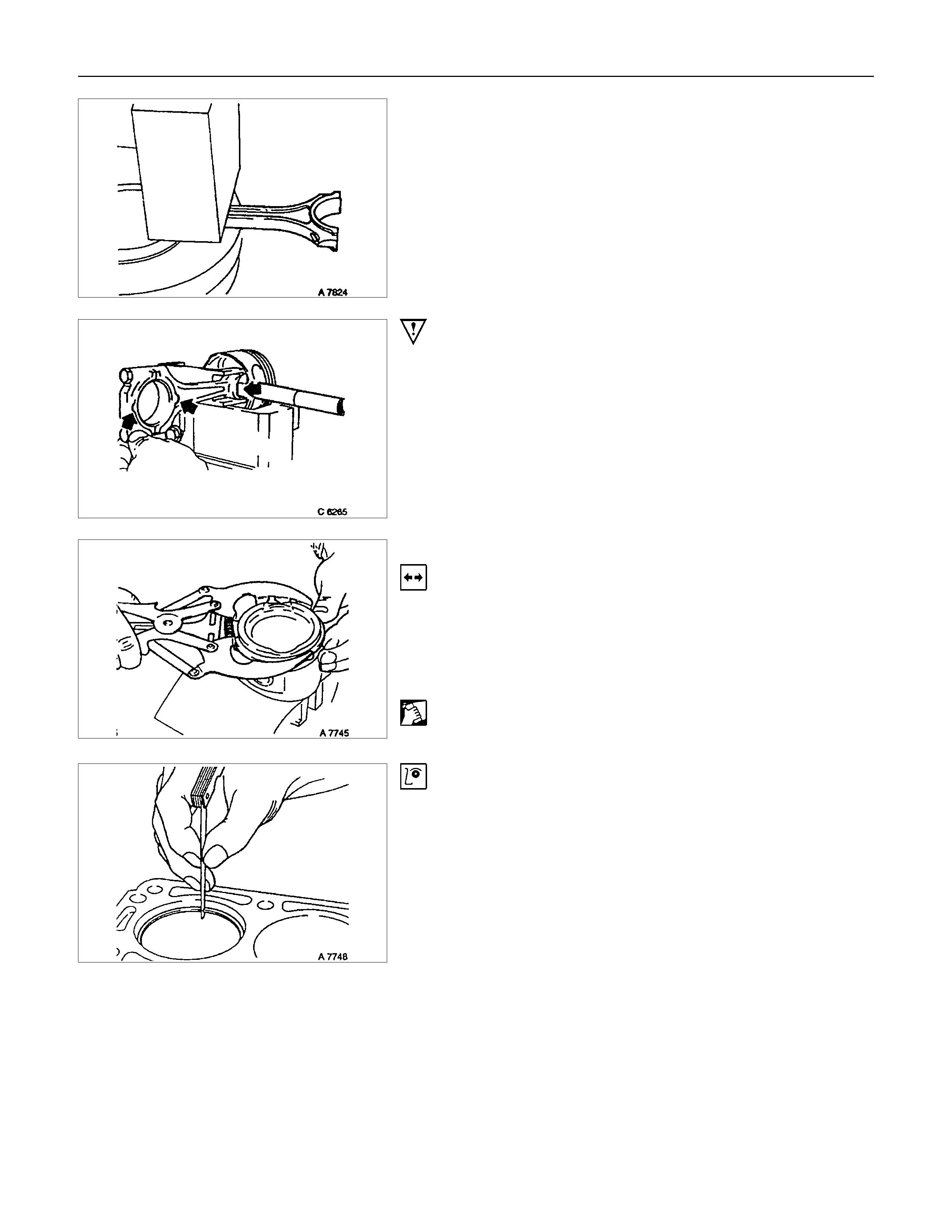

Con-Rod

Removal

1. Remove piston with con-rod according to the

corresponding operation.

2. Disassemble con-rod piston assembly by pressing out

piston pin, using 5-8840-0468-0.

Installation

1. Slide guide drift (5-8840-0468-0) in horizontal position

through piston and con-rod as far as side plate stops.

2. Tighten bolts evenly so that the piston rests flush on the

rear plate.

3. Remove centre piece from guide drift and insert piston

bolts (lubricated) into guide drift.

4. Heat a new con-rod to 280°C in the oil bath.

5. Install the con-rod to the piston and insert the piston pin.

Important!

Since the con-rods have no weight balancing studs, re-working

is not possible.

Exchange con-rods in sets only.

Installation position, beads on con-rod point to the flattening on

the piston pin eye.

Firmly seated piston pin cannot be pushed in. Carry out

installation quickly.

Piston Rings

Removal

1. Remove piston with con-rod according to the

corresponding operation.

2. Remove piston rings using commercially available ring

installer or piston ring clamp pliers.

Clean

Piston ring grooves - ground piece of old piston ring

Inspection

Piston ring gap

For piston ring sizes, permissible piston ring gaps - see

"Technical Data"

Installation

1. Install oil scraper ring.

2. Offset ring gaps of steel band rings each 25 to 50 mm/1

to 2in. to the left or right of the intermediate ring gap.

3. Install piston rings.

4. Offset ring gaps by approx. 180°.

5. Install second piston ring with identification mark "TOP"

facing upwards.

6. Install piston with con-rod according to the corresponding

operation.

OPERATIONS ON REMOVED ENGINE

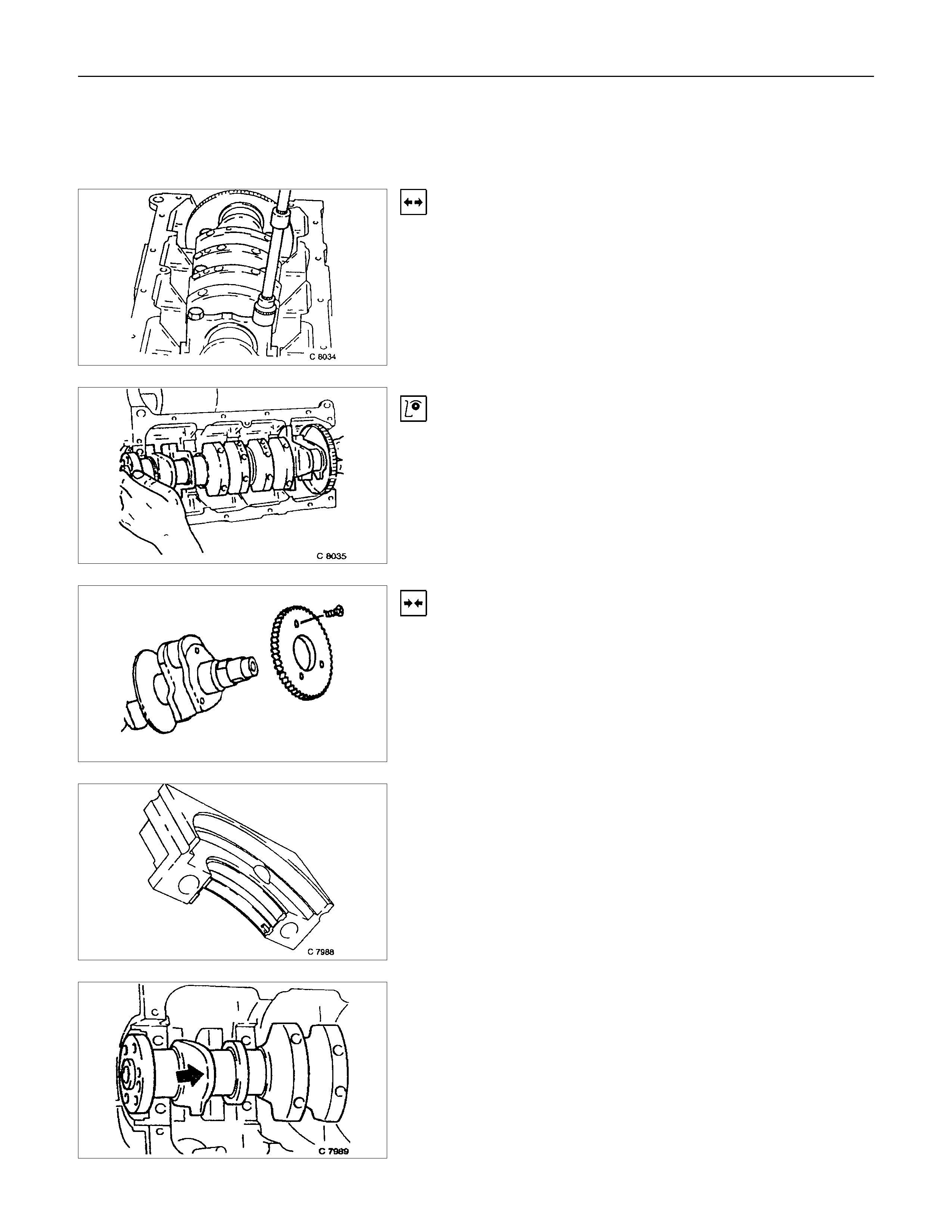

Crankshaft

Removal

1. Mount the engine on an engine overhaul stand with

appropriate adapters.

2. Remove the aggregates, flywheel/drive disc, oil pan, and

oil pump according to the corresponding operation.

3. Mark the con-rod bearing cover.

4. Remove the crankshaft bearing cover.

5. Remove the crankshaft from cylinder block.

Inspection

Remove and install all parts if necessary.

Crankshaft pulse pickup sensor rotor inspection and repair.

Inspect the crankshaft pulse pickup sensor rotor for excessive

wear and damage.

Replace the crankshaft pulse pickup rotor if the inspection

results exceed wear and damage limits.

Installation

1. Install the crankshaft pulse pickup sensor.

Torque: 13N!

!!

!m (1.3 kgf!

!!

!m)

2. Install new bearing shells into the cylinder block and

bearing cover.

3. Coat the bearing shafts with engine oil.

For oversizes-see “Technical Data”

4. Install a new crankshaft into the cylinder block.

Note

The sealing of the crankshaft can be corrected with light

blows with a rubber hammer on the crank arm (arrowed).

5.Apply a bead of sealant (TB-1207C or equivalent) in the

grooves of both bearing shells.

Important!

After installation of bearing cover, press in sealing compound

again from above, until compound emerges at the joints.

Torque - Angle Method

Bearing cover to cylinder block - 50 N⋅m (5.1 kgf⋅m) +40° to 50°

Con-rod bearing cover to con-rod - 35 N⋅m (3.5 kgf⋅m) +45° to

60°.

Use new bolts.

6.Install oil pump, oil pan, rear crankshaft sealing,

flywheel/drive plate, and aggregates according to the

corresponding operations.

Inspection

Bearing play - bearing cover removed

Measure

With "Plastigage" (ductile plastic threads)

Cut threads to length of bearing width and lay axiaity between

crankshaft journal and bearing shell (arrowed).

Install bearing cover with correct torque.

Important!

Grease crankshaft journal and lubricate bearing shell slightly so

that the thread does not tear when the bearing cover is moved.

Crankshaft

Inspection

End play when bearing shells are installed.

Front end contact surfaces of flywheel/flexible plate.

Permissible end play - see "Technical Data "

Inspection

Out-of-round (run-out)-middle bearing shell removed when

mounting on front and rear bearing.

Permissible out-of-round - see "Technical Data"

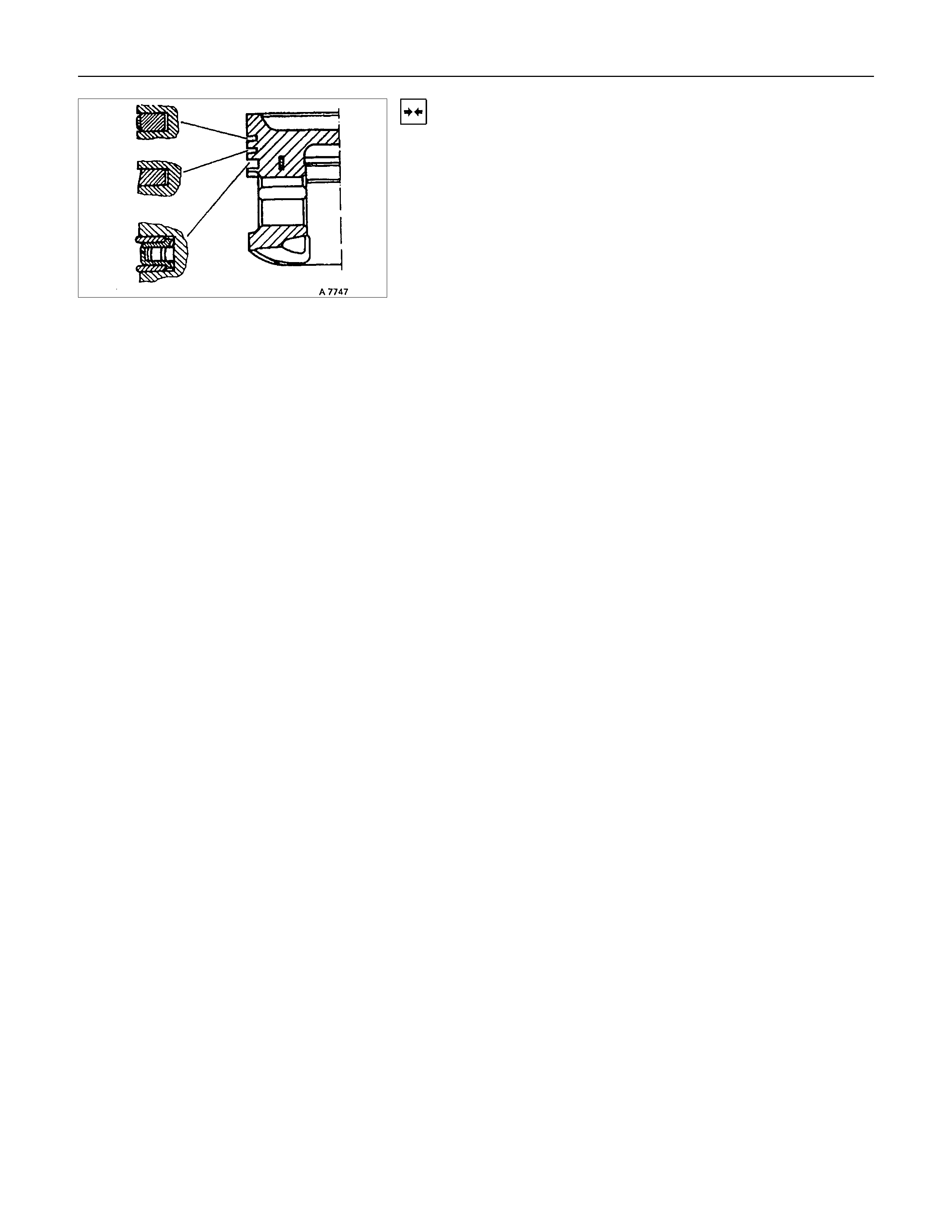

Bearing Free Play Measurement

Two methods for measuring bearing free play are described -

1. Plastigage method and 2. micrometer and gauge method.

The two procedures are suitable for measuring both con-rod

and main bearing free play.

For both methods ensure con-rod and main bearing caps are

identified (1) prior to removal as they are machine matched.

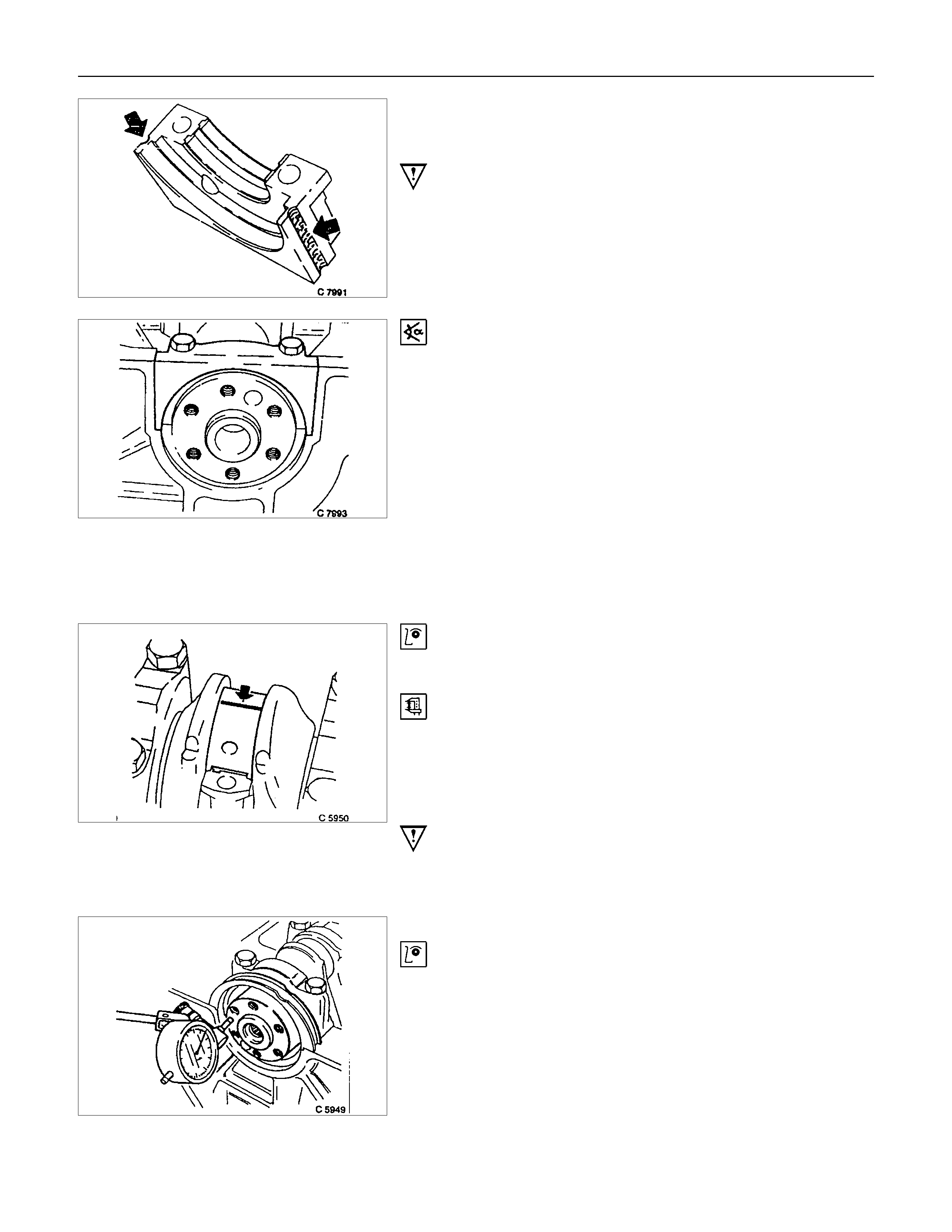

1.Plastigage Method

Removal

1. Remove bearing cap and shell.

2. Lightly coat journals and bearings with engine oil to

prevent Plastigage from tearing when cap is removed.

Installation

1. Lay a length of Plastigage across width of crank pin and

fit bearing cap and shell using old bolts at this stage.

Important!

Do not allow crankshaft to rotate.

Torque - Angle Method

Main bearing cap bolt - 60 N⋅m (6.1 kgf⋅m) +40° + to 50°.

Con-rod bearing cap bolts - 35 N⋅m (3.6 kgf⋅m) +45°.

Removal

1. Remove bearing cap and shell.

Measure

Width of Plastigage -use scale supplied with Plastigage.

If con-rod bearing clearance exceeds 0.031mm/0.001in or

main journal bearing clearance exceeds 0.04mm/0.02in. -

check crankshaft journal diameters - see corresponding

operation.

Replace bearing if crankshaft is within specification - see

"Technical Data"

Clean

Plastigage from journals.

Lightly coat journals and bearings with engine oil.

Installation

Install bearing cap and shell using new bolts.

Torque - Angle Method

Main bearing cap bolt - 60 N⋅m (6.1 kgf⋅m) +40° to 50°.

Con-rod bearing cap bolts - 35 N⋅m (3.9 kgf⋅m) +45°.

2.Micrometer and gauge method.

Crankshaft removed.

Installation

1. Install caps and bearing shells to con-rods and cylinder

block.

Measure

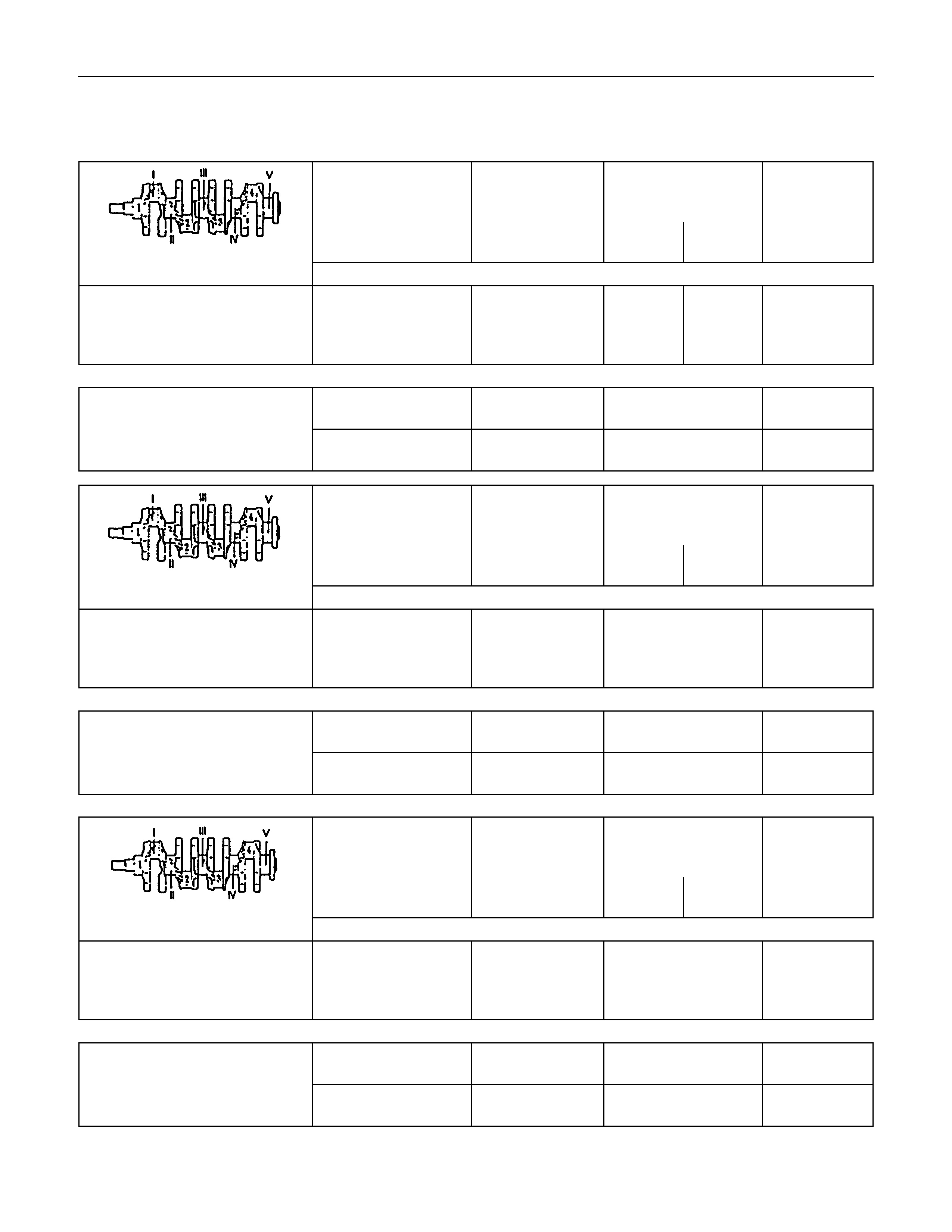

Con-rod and main bearing diameters at three points I, II, III

(arrowed).

Divide the sum of the three measurements by three to obtain a

mean diameter.

The top illustration shows con-rod measuring points.

The second illustration shows main bearing measuring points.

Measure

Crankshaft main and con-rod bearing journals at points I and II.

Divide the sum of both measurements to obtain a mean

diameter.

Crankshaft must be replaced if mean diameter of main or con-

rod journals is below specified limit - see "Technical Data".

If crankshaft is serviceable subtract crankshaft mean journal

diameters from corresponding shell bearing mean diameters to

determine bearing clearance.

Permissible main bearing clearance - 0.015 to 0.04mm/0.0006

to 0.002in.

Permissible con-rod bearing clearance - 0.006 to

0.031mm/0.002 to 0.001in.

Bypass Valve

Removal

1.Remove oil filter.

2.Remove bypass valve by cutting thread in locking disc

with M 10 tap (3rd stage), turning in M 10 bolt and taking

out bypass valve from seating.

Installation

1.Install bypass valve using drift (diameter approx.

15mm/0.6in.).

Oil Filter

Removal

1.Remove oil filter using commercially available tool.

Installation

1.Install oil filter by hand and oil seal ring.

2.Fill up engine oil while preventing overflow.

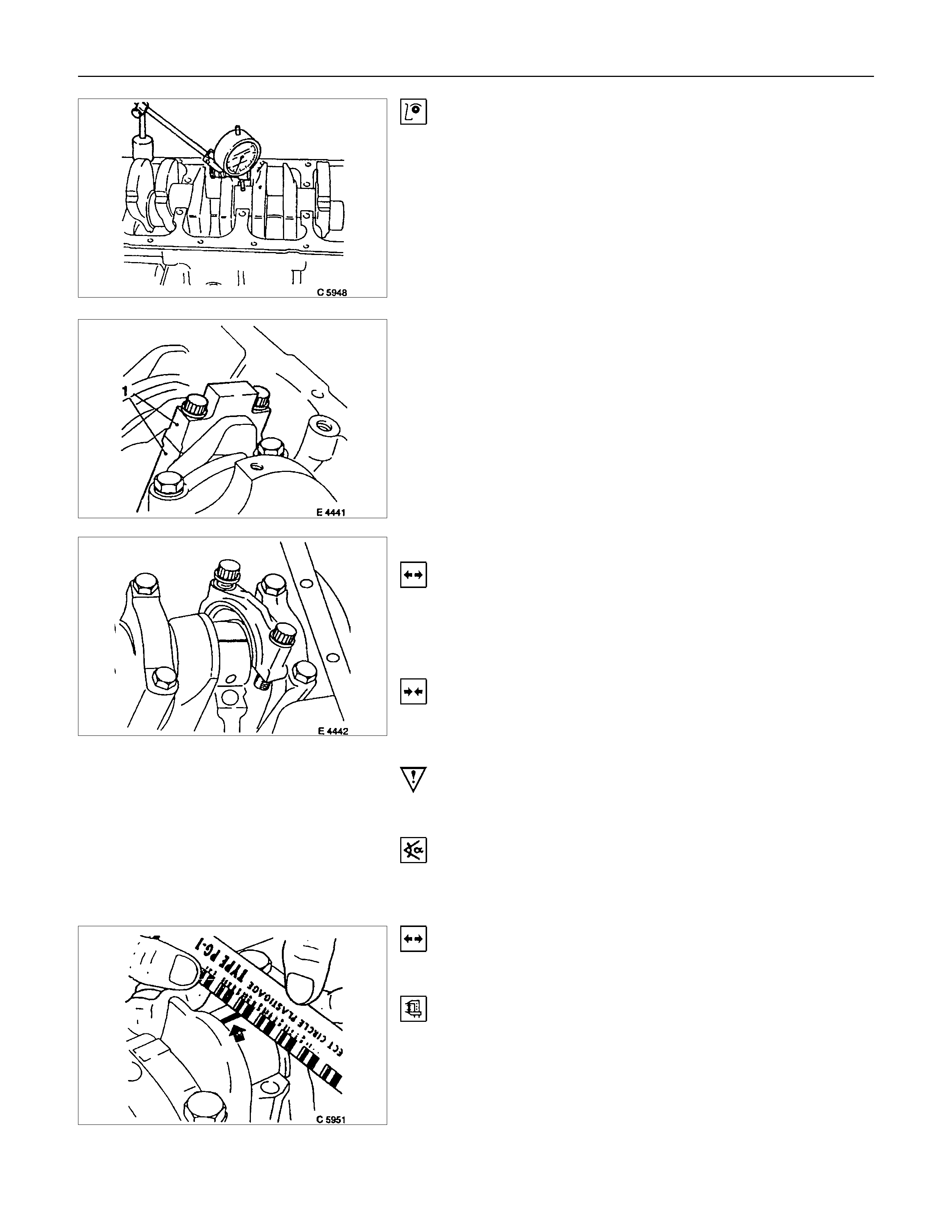

Oil Pump

Removal

1.Remove rear toothed belt cover, and oil pan according to

the corresponding operations.

2.Remove oil filter, wiring plug from oil pressure switch, oil

pump from cylinder block, and oil pressure switch from oil

pump.

Clean

Sealing surfaces

Installation

1.Install oil pressure switch to oil pump, oil pump to cylinder

block, oil pan, wiring plug, oil filter and toothed belt cover.

Tighten (Torque)

Oil pressure switch to oil pump - 30 N⋅m (3.2 kgf⋅m)

Oil pump to cylinder block - 6 N⋅m (0.6 kgf⋅m)

Oil intake pipe to oil pump - 8 N⋅m (0.8 kgf⋅m)

Intake pipe bracket to cylinder block - 8 N⋅m (0.8 kgf⋅m)

*Insert bolts with Locktite (Refer to General Description

Recommended Liguid Gasket)

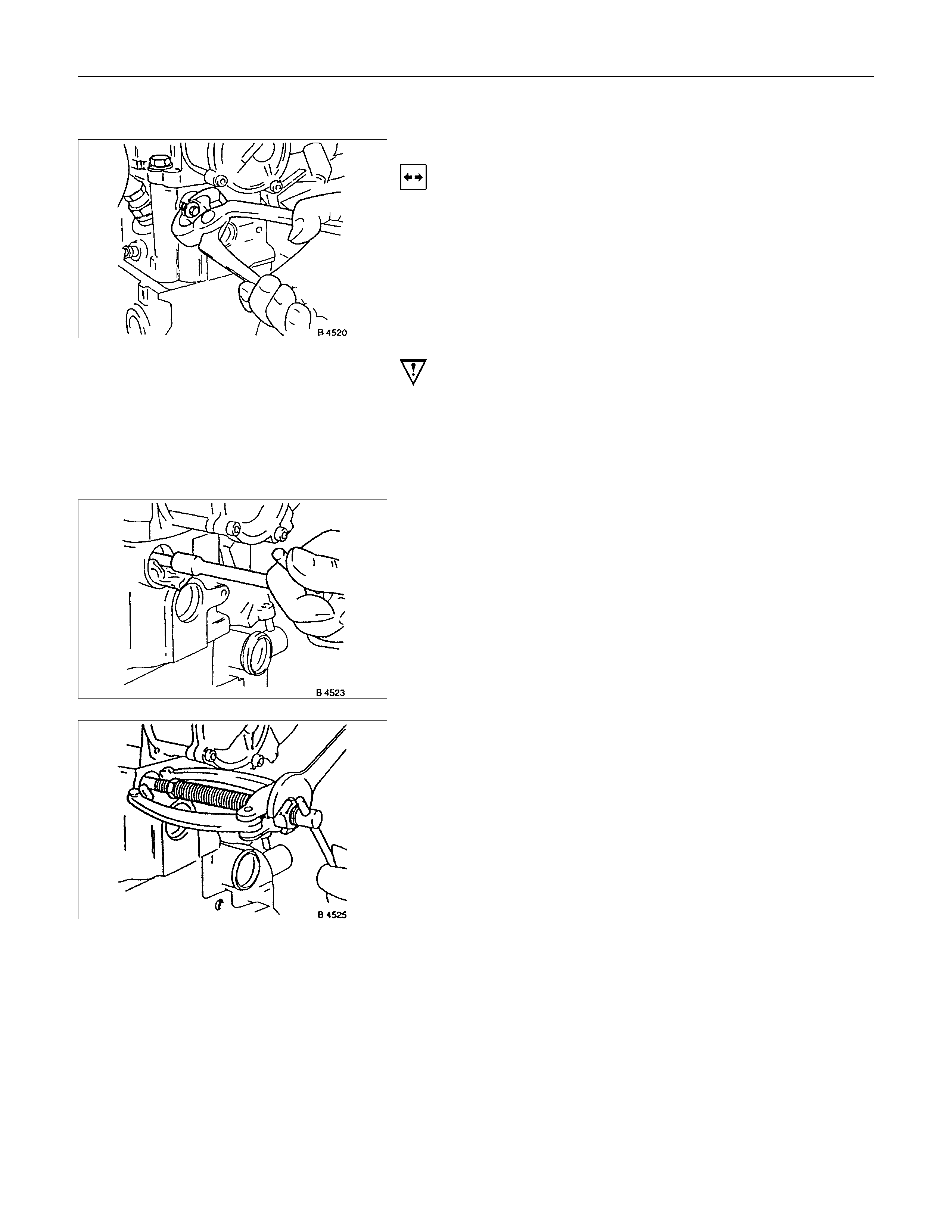

Oil Pump Safety Valve

Removal

1.Remove closure plug.

2.Remove seal ring.

3.Remove spring.

4.Remove piston.

Installation

1.Install piston (observe installation position).

2.Install spring.

3.Install seal ring.

4.Install closure plug.

Tighten (Torque)

Closure plug - 30 N⋅m (3.0 kgf⋅m)

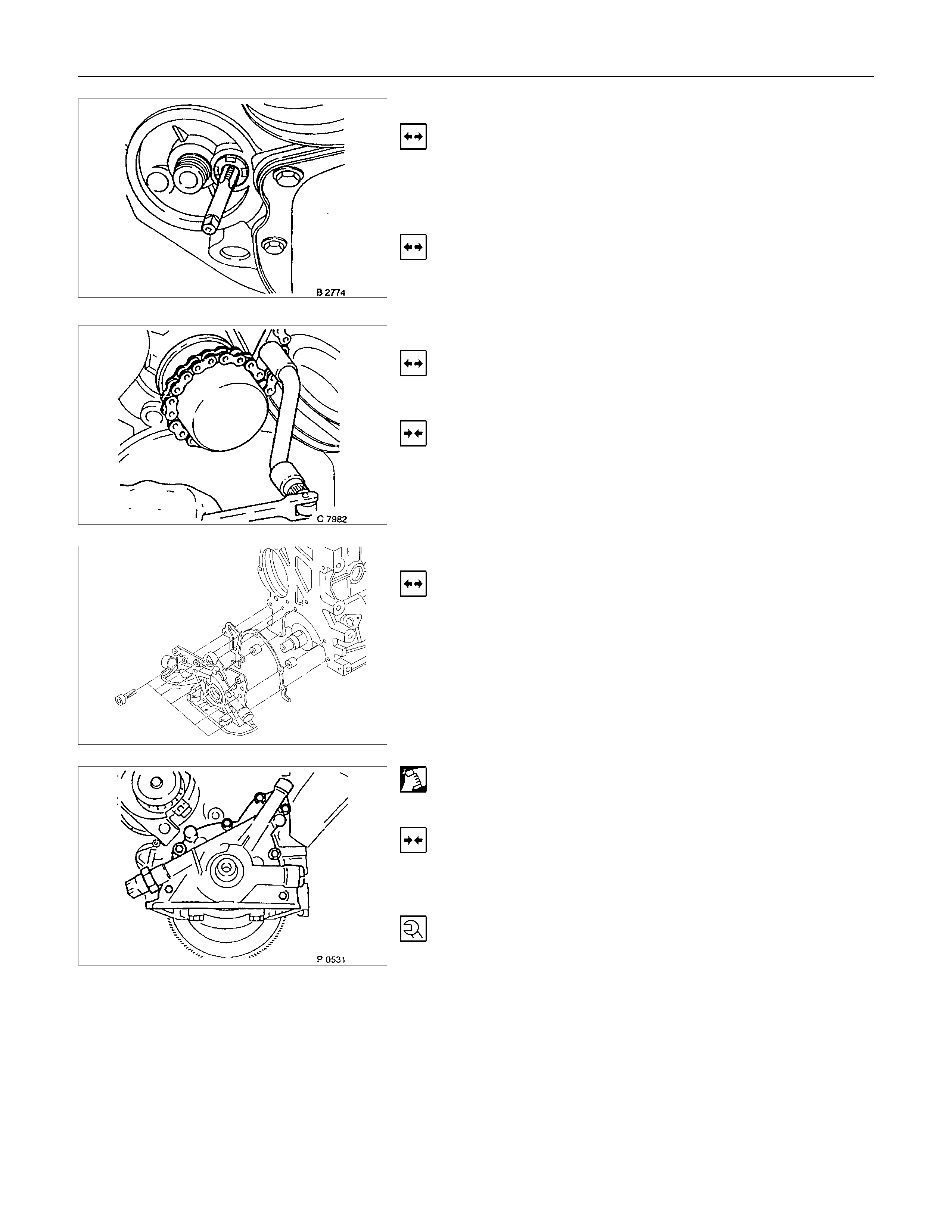

Oil Pump (Overhaul)

Removal

1. Remove oil pump according to the corresponding

operation.

2. Remove oil cover and pressure control valve.

Inspect

Clearance between gear pair and housing upper edge - see

“Technical Data”.

Check housing, cover and pressure control valve.

Installation

1. Install pump cover with Sealing Compound 15 03 166 (90

094 714).

2. Install oil pump safety valve according to the

corresponding operation.

3. Install oil pump according to the corresponding operation.

OPERATIONS ON OIL CIRCULATION

Cylinder Head Safety Valve

Removal

1. Remove cylinder head according to the corresponding

operation.

2. Make hole in core plugs with pointed drift, turn in self

tapping screw and edge out.

Important!

Cover oil duct in cylinder head with piece of cloth.

3. Pull out valve retainer, using commercially available tool.

4. Remove ball and spring.

5. Cut three threads in the ball seating with M 10 tap (3rd

stage).

6. Coat tap with grease.

7. Remove ball seating from cylinder head with

commercially available tool.

Do not damage cylinder head.

Installation

1. Install new pressure valve into cylinder head - with

suitable pipe until stop.

2. Install core hole plugs into cylinder head - with suitable

pipe to end of chamfer.

OPERATIONS ON COOLING SYSTEM

Caution!

Before working with the cooling system, be sure to confirm that

the temperature of the engine is cooled down.

Failure to observe this may cause burn.

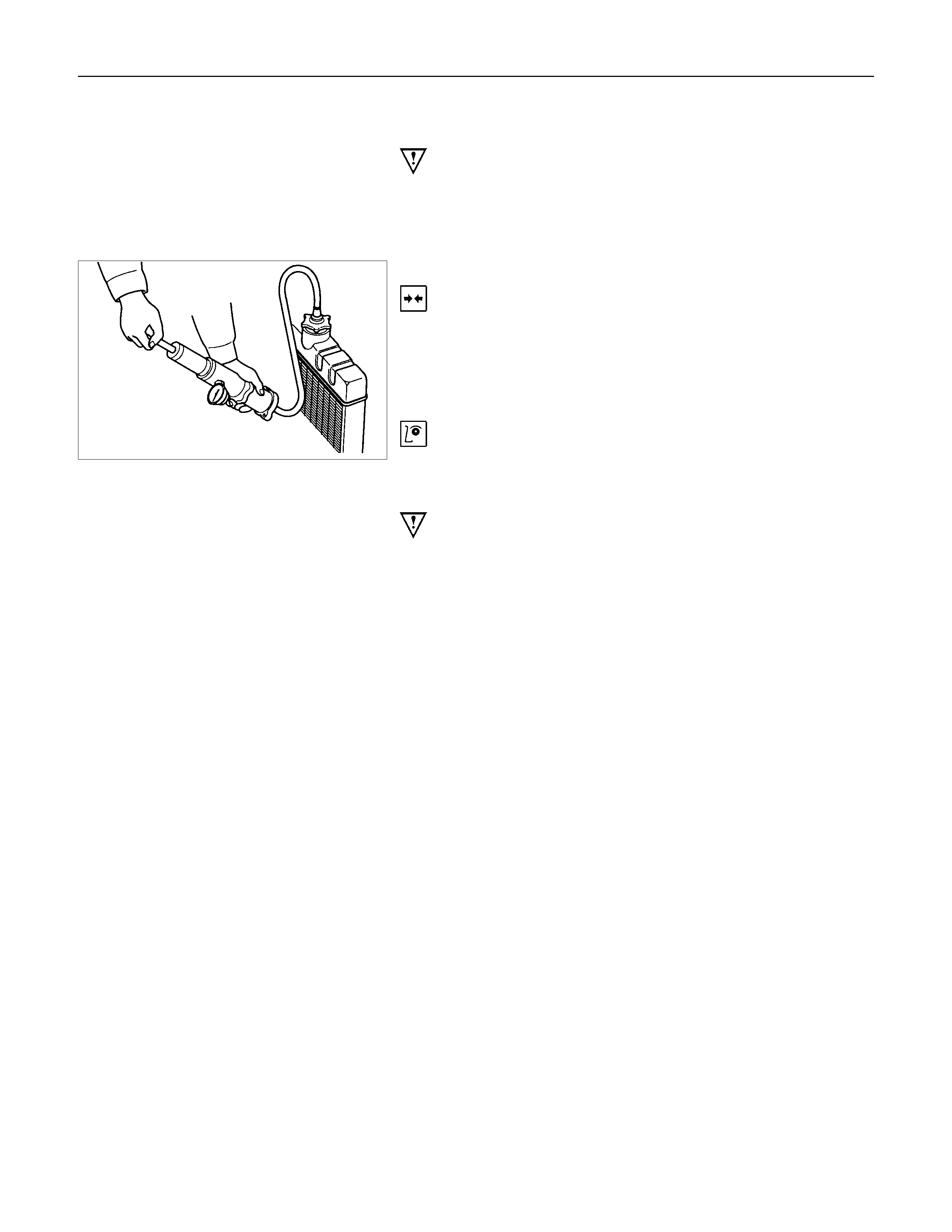

Cooling System, Check for Leaks

Installation

1.Install commercially available coolant checking

instrument onto compensation tank (Refer to section 6B;

Engine cooling).

2.Check coolant level.

Inspection

Use 5-8840-0277-0 tester & 5-8840-2603-0 adaptor.

Cooling System, Fill Up and Bleed

Important!

Radiator and heater core are made from alminium.

To avoid corrosion, use only anti-freeze with corrosion

protection.

Replace Coolant

1. Confirm the engine is cold enough.

2. Open the radiator cap, pour coolant to the filler neck level

and close the cap.

3. Pour coolant into the reservoir until MAX line is reached.

4. Start the engine, run 2 ∼ 3 minutes at idling speed and

switch off the engine.

5. Refill coolant if the coolant level is lowered.

Important!

Do not loosen or open the radiator cap when coolant is hot.

Doing so may cause hot water or steam to splash out, resulting

in burn. When opening the radiator cap, be sure to confirm the

coolant is cold. Cover a thick cloth over the cap and loosen it

slowly to reduce pressure, then open the cap.

6.Close the radiator cap firmly and run the engine at

approx. 2000 rpm. In addition, set the heater temperature

adjuster to the max position to circulate coolant in the

heater conduit system.

7.Confirm that the temperature gauge reads half or more of

full scale and that the thermostat is activated.

Then continue idling 5 minutes more and switch off the

engine, and allow it to cool.

8.After the engine cools down, check the coolant level and

refill it if necessary. When the level is lowered extremely,

check the coolant conduit system and reservoir hose for

leak.

9.Pour coolant into the reservoir to MAX level.

Refill Coolant

Important!

After closing the cooling system, let engine run warm until

thermostat opens (coolant approx. 92°C/197.6F)

Inspection

Coolant level

Allow engine to cool. If necessary, refill coolant.

Check that cooling system self-bleeds during engine warming-

up phase.

Ignition Timing, Check

No Adjustment

ENGINE EXTERNAL PARTS

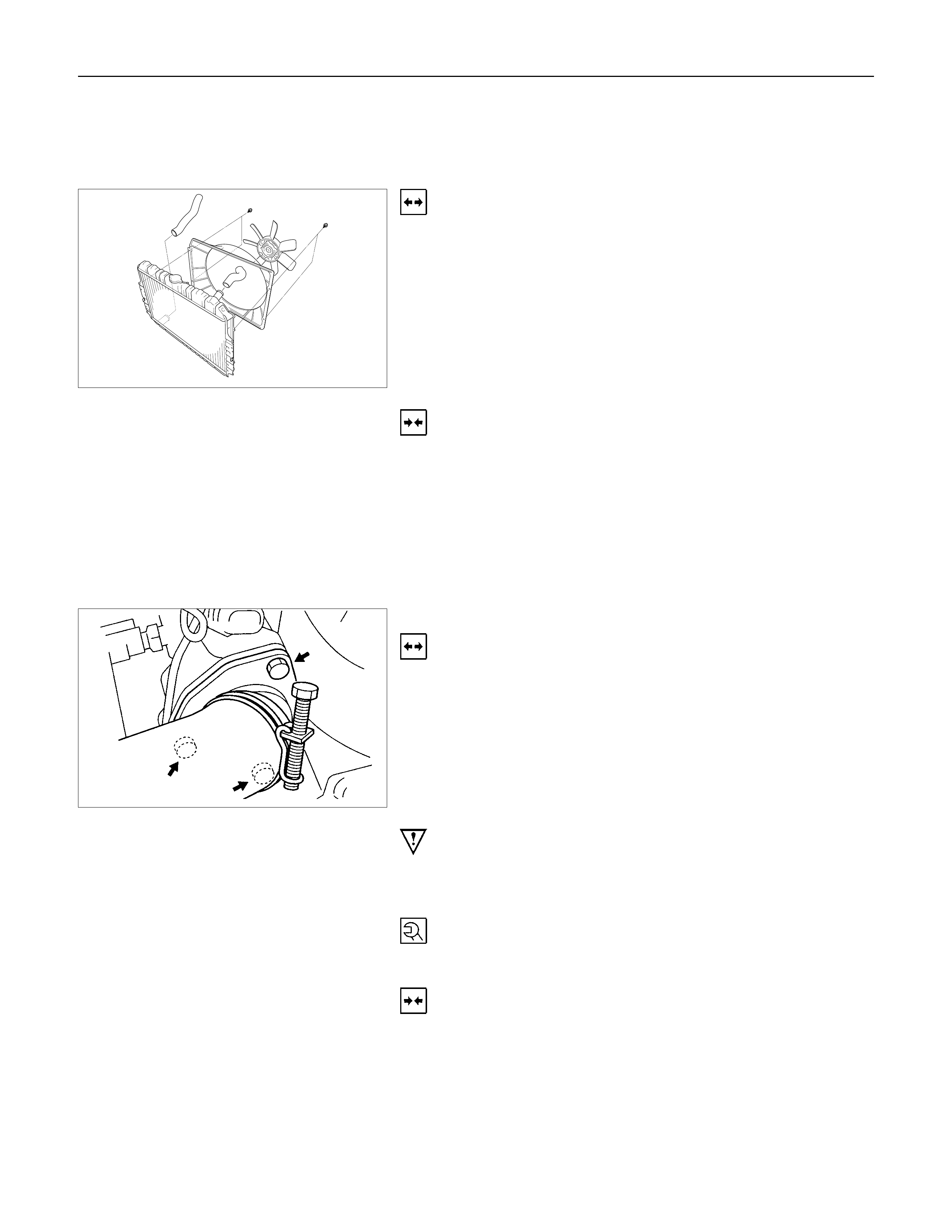

Radiator

Removal

1. Remove the upper hose and lower hose.

2. Remove all V-belts.

3. Remove the cooling fan.

4. Remove the fan guide.

5. Remove the radiator.

Installation

1. Install the radiator.

2. Install the fan guide.

3. Install the cooling fan.

4. Install all V-belts.

5. Install the lower and upper hose.

Thermostat

Removal

1. Remove water outlet nozzles with thermostat from

thermostat housing.

2. Remove coolant hose and collect coolant.

Important!

Remove and Install thermostat only together with water outlet

nozzles.

Tighten (Torque)

Water outlet nozzles to thermostat housing - 8 N⋅m (0.8 kgf⋅m)

Installation

1. Install coolant hose.

2. Fill cooling system and bleed according to the

corresponding operation.

Water Pump

Removal

1.Remove lower hose band from pipe band and collect

coolant.

2.Remove front toothed belt cover according to the

corresponding operation.

3.Remove water pump from cylinder block after releasing

tension on toothed belt.

Clean

Sealing surfaces

Coating sealing surfaces with Silicone Grease

Installation

1.Install water pump to cylinder block with new rubber O-

ring.

2.Apply tension to toothed belt according to the

corresponding operation.

3.Install coolant hoses.

4.Fill cooling system and bleed according to the

corresponding operation.

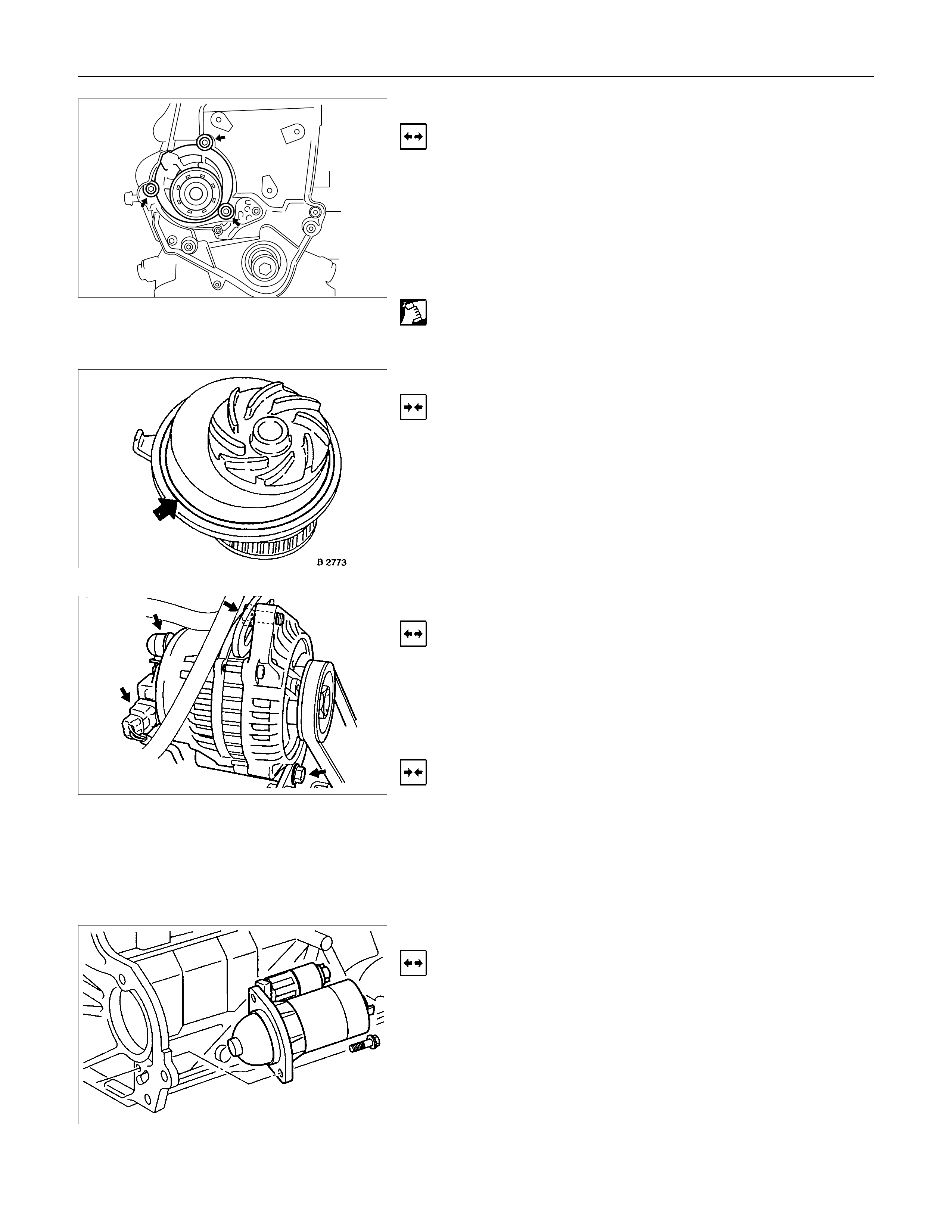

Alternator

Removal

1.Remove ground cable from battery.

2.Remove cable connection from alternator and V-belt.

3.Remove alternator from retaining strap and lower

fastening.

Installation

1.Install alternator by tightening firmly by hand.

2.Install V-belt and apply tension according to the

corresponding operation.

3.Install cable connections to alternator.

4.Install ground cable to battery.

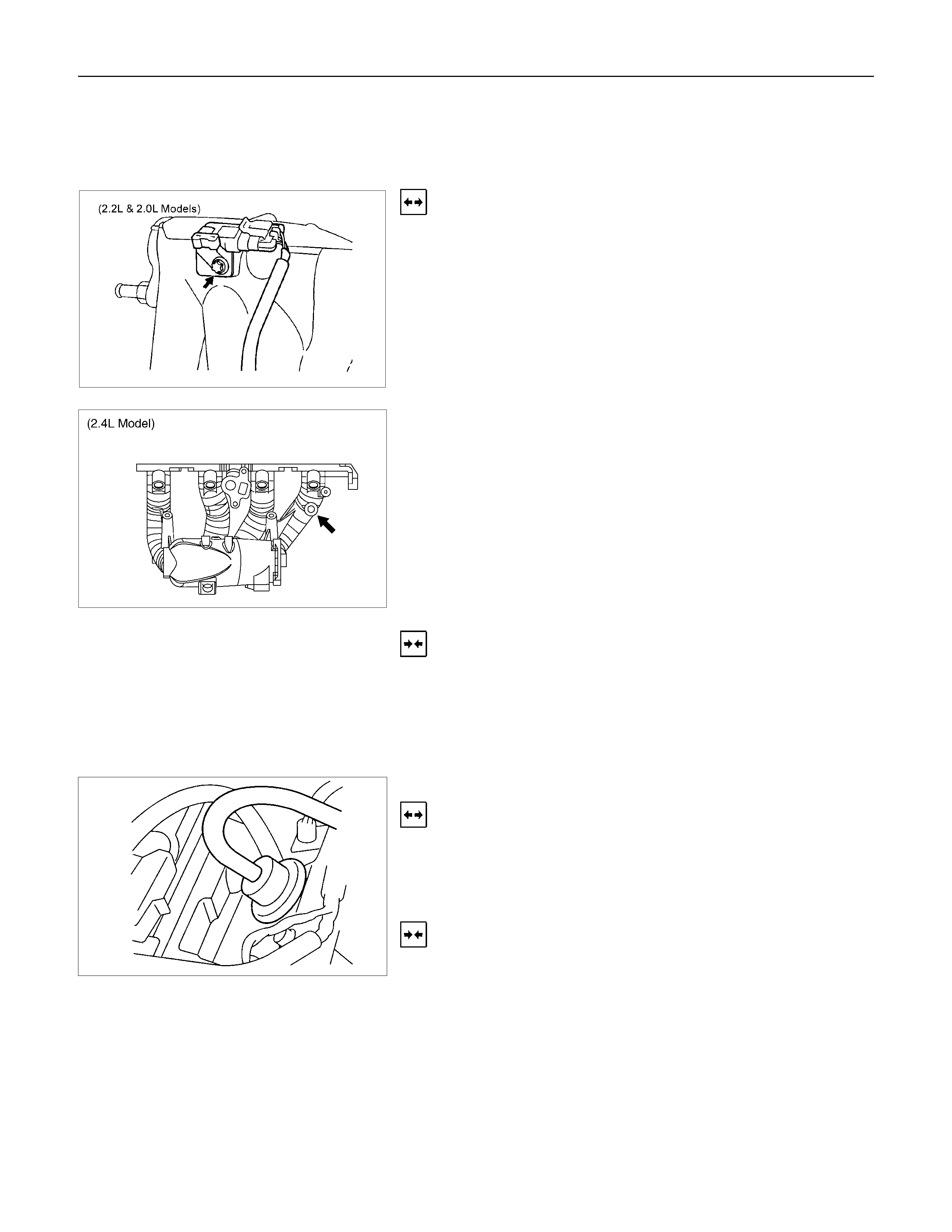

Starter

Removeal

1. Remove cable connections from starter.

2. Remove upper bolt of transmission side.

3. Remove lower bolt of engine side.

Tighten (Torque)

Starter to cylinder block:

Engine side - 45 N⋅m (4.6 kgf⋅m)

Transmission side - 75 N⋅m (7.6 kgf⋅m)

Starter support to cylinder block - 25 N⋅m (2.5 kgf⋅m)

Re-connect cables.

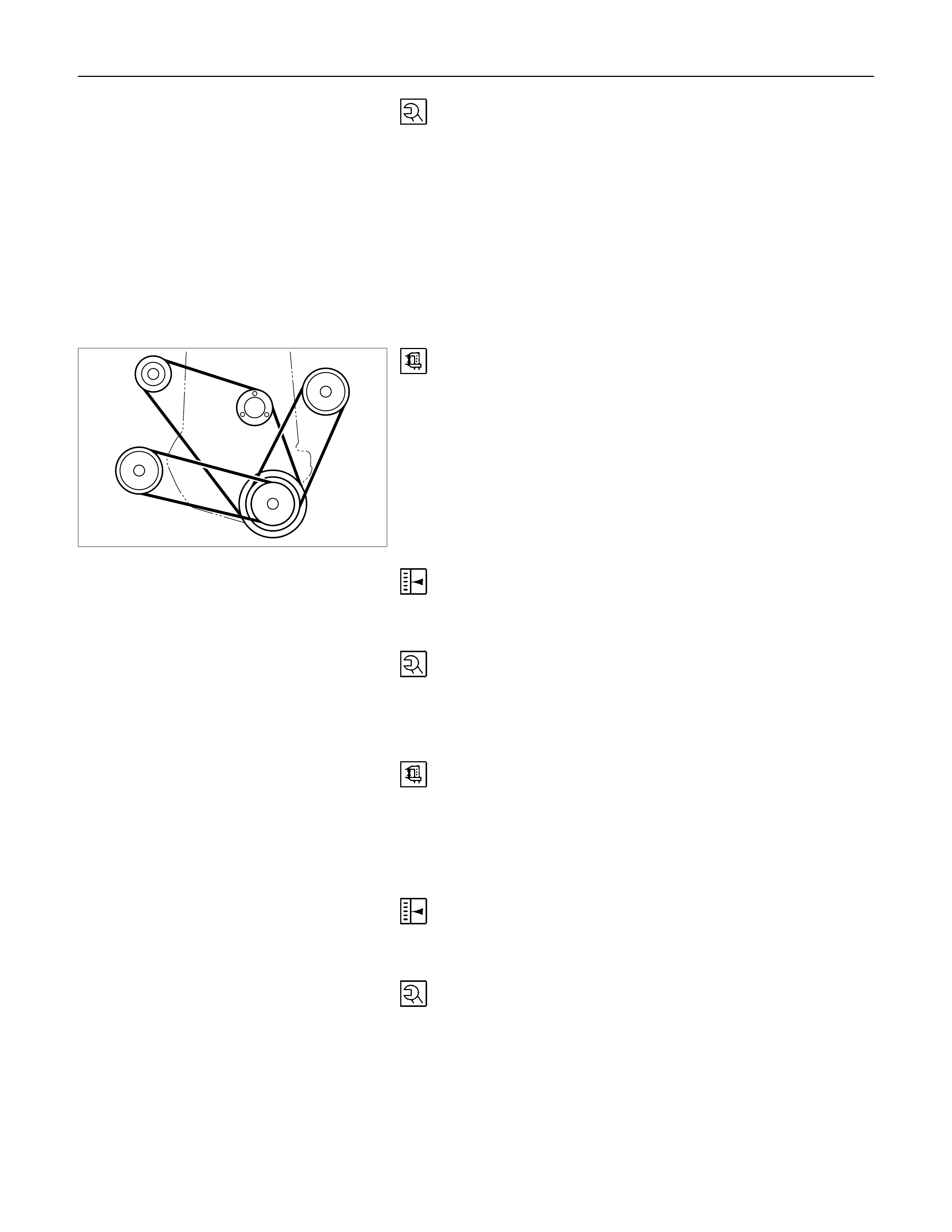

V-belt Tension of Alternator

Measure

Measure V-belt tension of alternator.

Permitted values for new V-belt are approx. 311-489N (31-50

kgf).

Note:

V-belt to deflection as loaded with 10kg : 8-12mm.

Adjust

Adjust V-belt tension by loosening clamping bracket and lower

alternator bracket and moving alternator.

Tighten (Torque)

Clamping bracket to alternator - 25 N⋅m (2.6 kgf⋅m)

Lower alternator bracket - 25 N⋅m (2.6 kgf⋅m)

V-Belt Tension of Power Steering Pump

Measure

Measure V-belt tension of power steering pump. Permitted

values for new belt are approx. 578-712N (59-73 kgf) and 534-

667N (54-68 kgf) for used belt.

Note:

V-belt to deflection as loaded with 10kg : 8-12mm.

Adjust

Adjust V-belt tension by loosening clamping bolt, lower pump

bracket, and adjusting nuts and moving steering pump.

Tighten (Torque)

Adjusting nuts - 18 N⋅m (1.8 kgf⋅m)

Clamping bolt - 25 N⋅m (2.6 kgf⋅m)

Lower pump bracket - 26 N⋅m (2.6 kgf⋅m)

FUEL INJECTION SYSTEM

MAP SENSOR

Removal

1.Disconnect the battery cable.

2.Disconnect the electrical connector from the sensor.

3.Remove the mounting bolts securing the sensor to the

manifold.

4.Remove the sensor from the intake manifold.

Installation

1.Push MAP sensor into the manifold.

2.Install the mounting bolts and tighten them.

3.Connect electrical connector.

4.Connect the battery cable.

Pressure Regulator

Removal

1. Remove vacuum hose.

2. Remove fuel hoses.

3. Remove pressure regulator.

Installation

1. Install pressure regulator.

2. Install fuel hoses.

3. Install vacuum hoses.

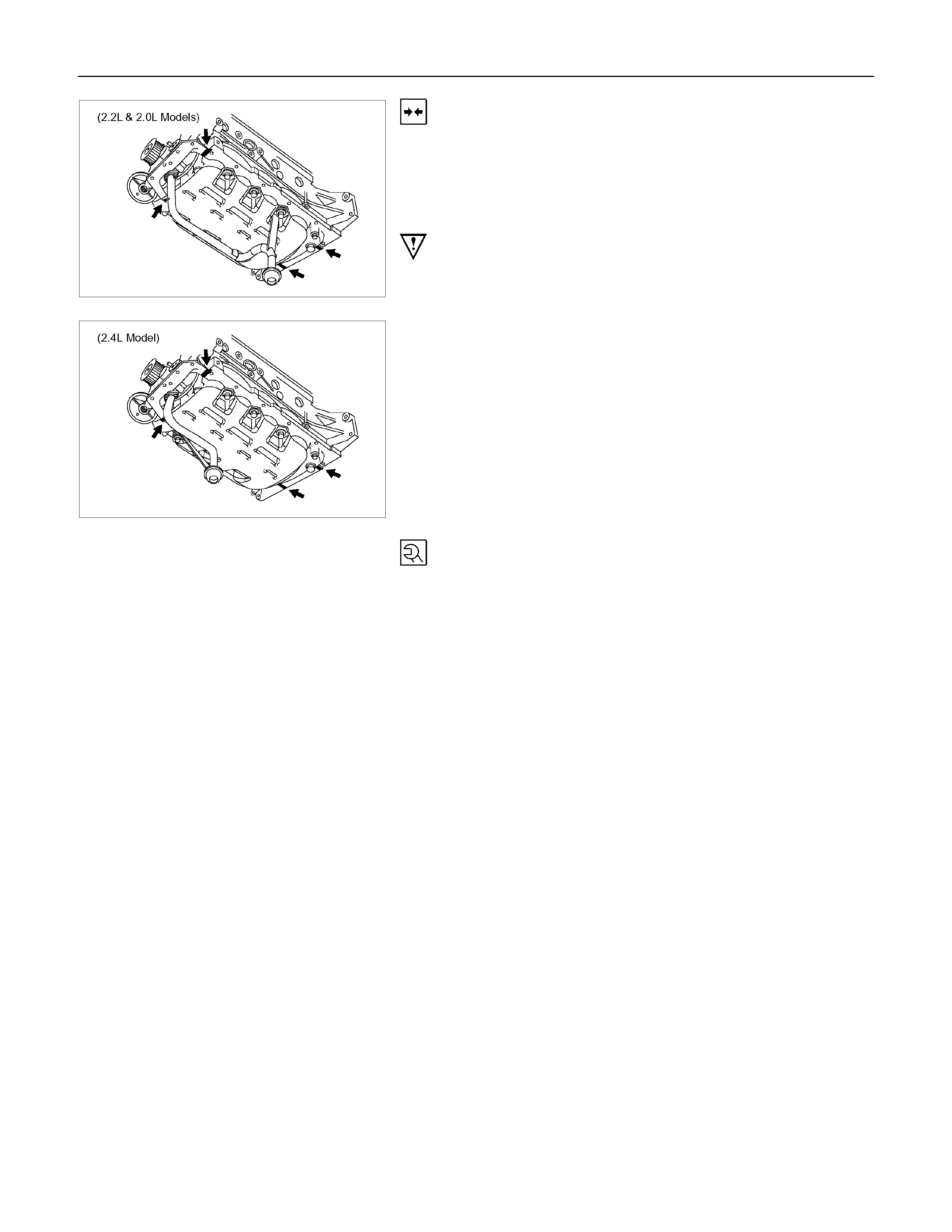

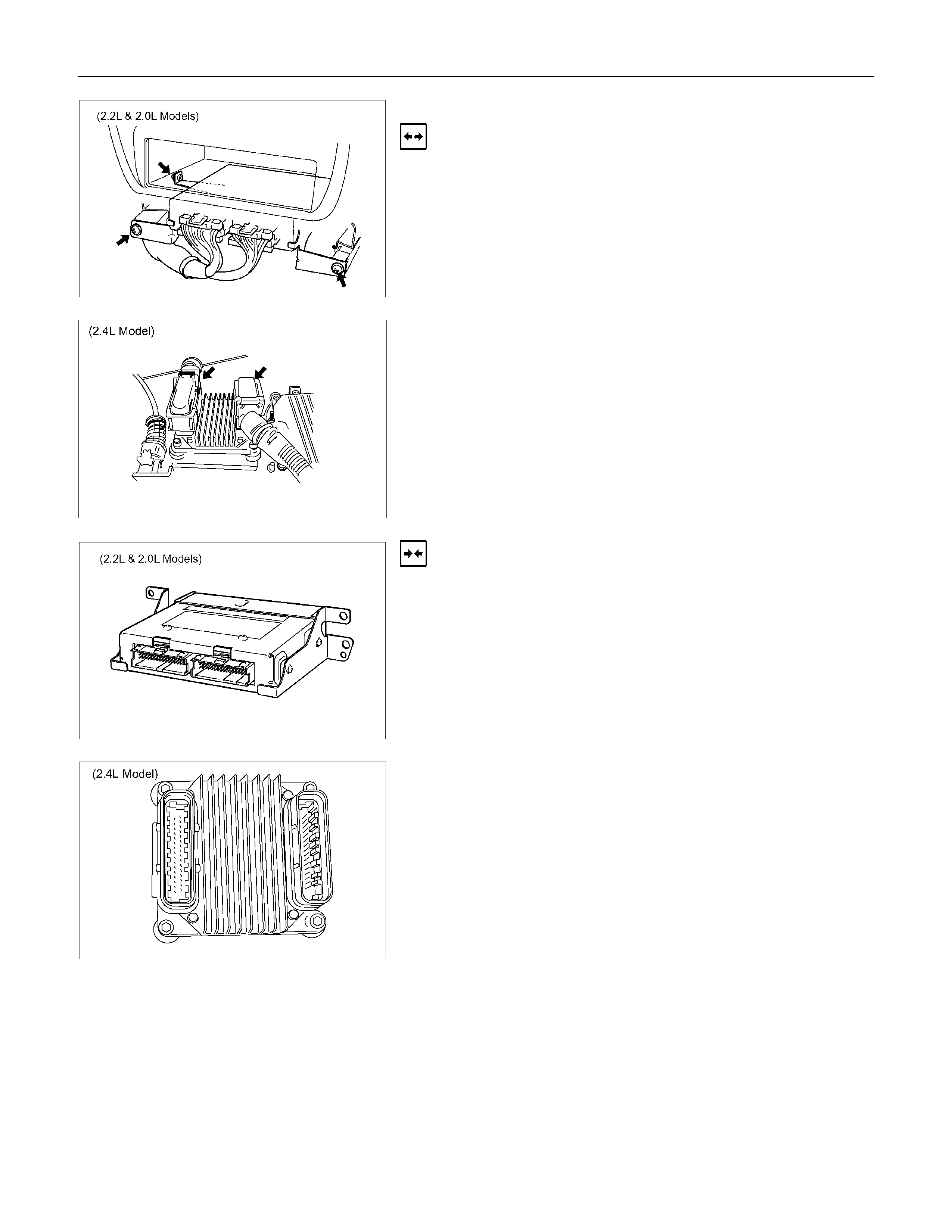

ECM (Engine Control Module)

Removal

(2.2L & 2.0L)

1. Remove the center console assembly.

2. Remove the ECM cover.

3. Remove three screws for the bracket.

4. Pull ECM out.

5. Disconnect the connectors.

(2.4L)

1. Disconnect the ECM connector.

2. Remove the four hex bolts and nuts.

3. Remove the ECM from the ECM bracket on engine.

Installation

(2.2L & 2.0L)

1. Connect the connectors.

2. Install the ECM to to the proper position.

3. Tighten the four screws to the bracket.

4. Install the ECM cover.

5. Install the center console assembly.

(2.4L)

1. Install the ECM to the ECM bracket on engine.

2. Tighten the four screws to the bracket.

3. Connect the connector.

ECT

Removal

1.Remove wiring harness plug and coolant temperature

sensor.

Tighten (Torque)

Temperature sensor to intake pipe - 10 N⋅m (1.0 kgf⋅m)

Wiring harness plug to temperature sensor

Inspection

Coolant level

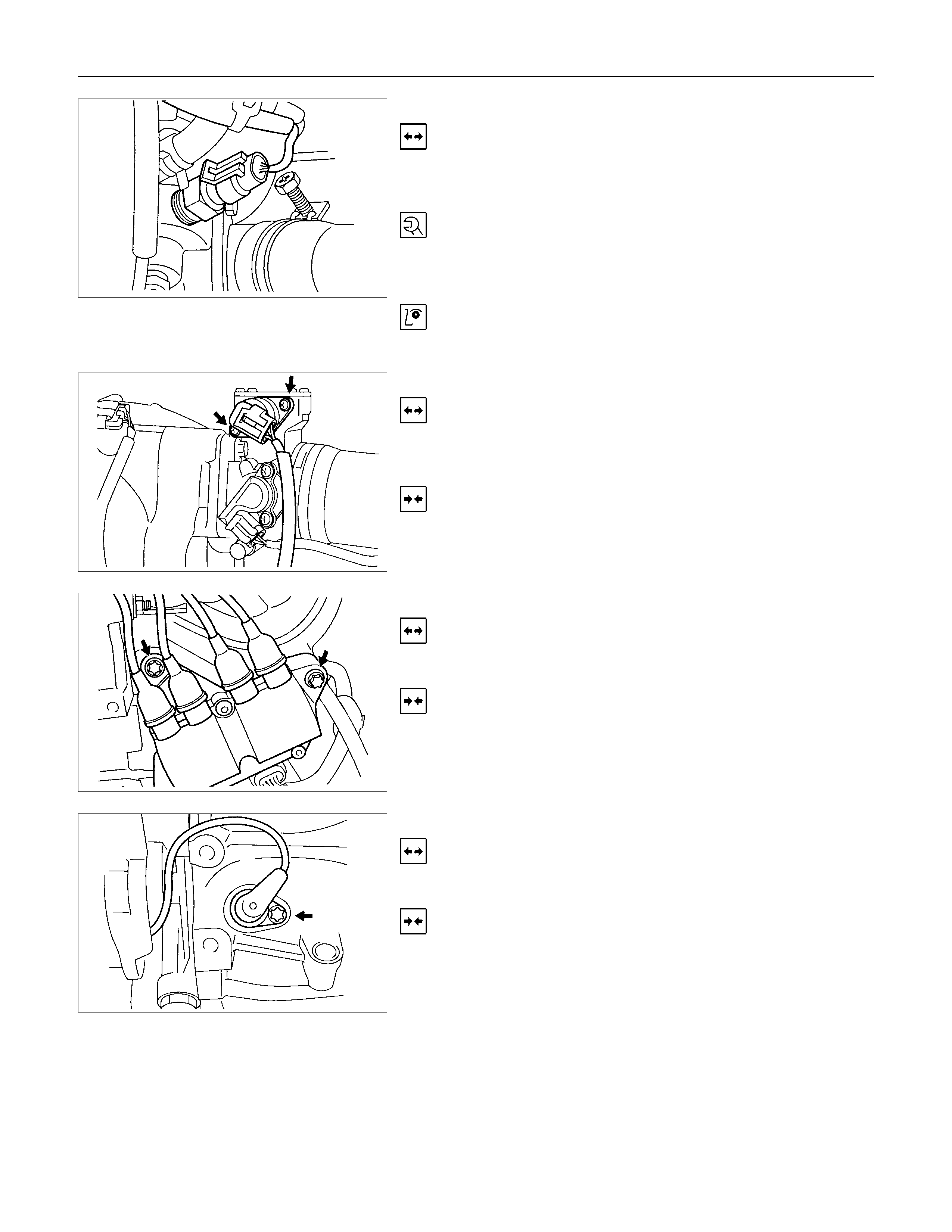

Idle Air Control (IAC) Valve

Removal

1.Remove wiring harness plug, hose clamps and idle

speed adjuster.

Installation

1.Install idle speed adjuster, hose clamps and wiring

harness plug.

Ignition Coil

Removal

1.Remove 2 bolts, plug and ignition coil.

Installation

1.Install ignition coil, plug and bolts.

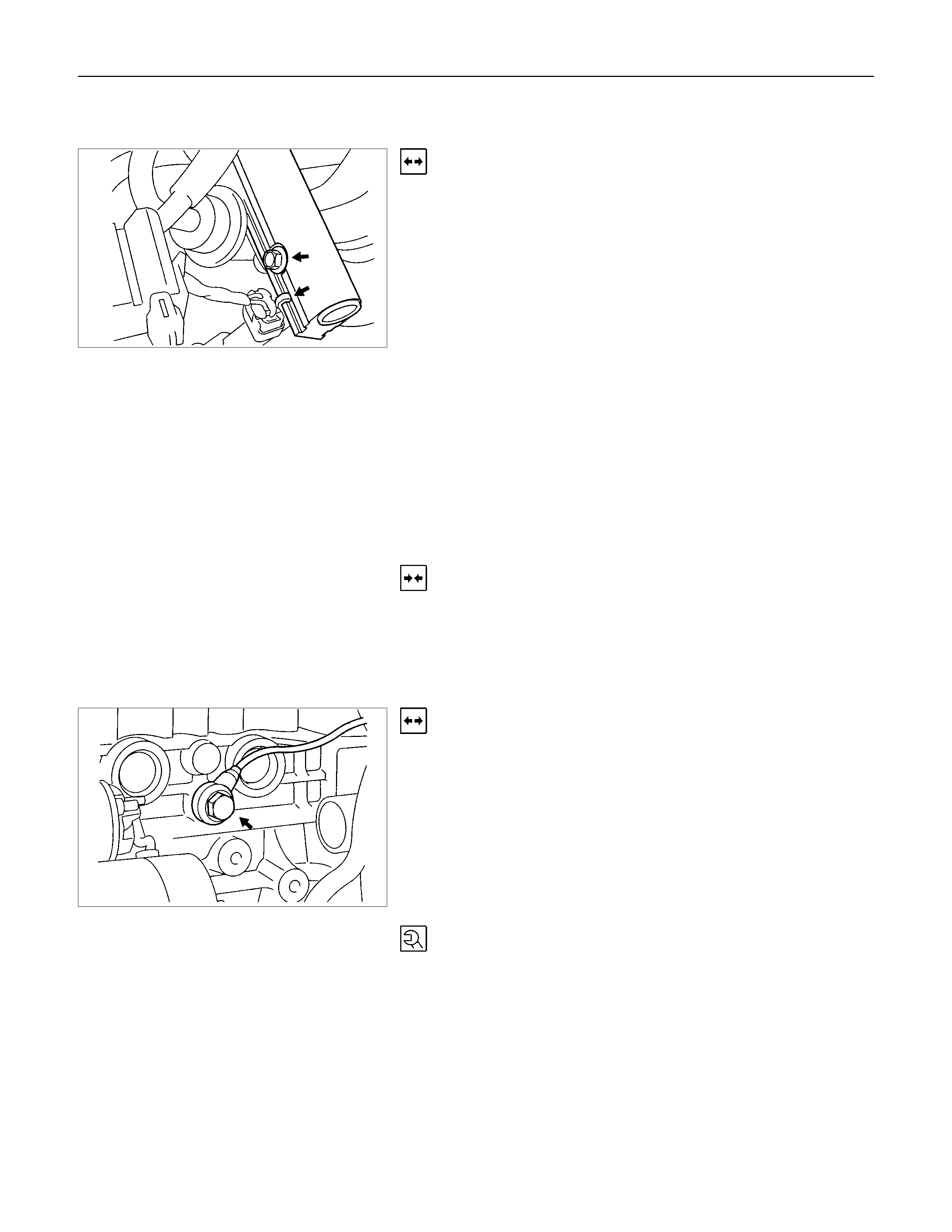

Crank Position Sensor

Removal

1. Remove crank position sensor.

Installation

1. Install crank position sensor.

FUEL INJECTOR

Removal

Caution: To reduce the risk of fire and personal injury, it is

necessary to relieve the fuel system pressure before

servicing the fuel system components.

Caution: After relieving the fuel system pressure, a small

amount of fuel may be released when servicing fuel lines

or connections. Reduce the chance of personal injury by

covering the fuel line fitting with a shop towel before

disconnecting the fittings. The towel will absorb any fuel

that may leak out. When the disconnect is completed,

place the towel in an approved container.

1.Depressurize the fuel system.

2.Disconnect the fuel inlet.

3.Disconnect the fuel return line.

4.Remove the fuel rail from the intake manifold.

5.Remove the fuel injector from the fuel rail by disengaging

claws.

Installation

1.Install the fuel injector to the fuel rail by engaging claws.

2.Install the fuel rail to the intake manifold.

3.Connect the fuel return line firmly.

4.Connect the fuel supply line firmly.

Knock sensor

Removal

1. Remove fixing bolts.

2. Disconnect the connector at the other side.

Tighten (Torque)

Oxygen sensor in exhaust pipe - 30N⋅m (3.2 kgf⋅m)

When re-using, insert oxygen sensor.

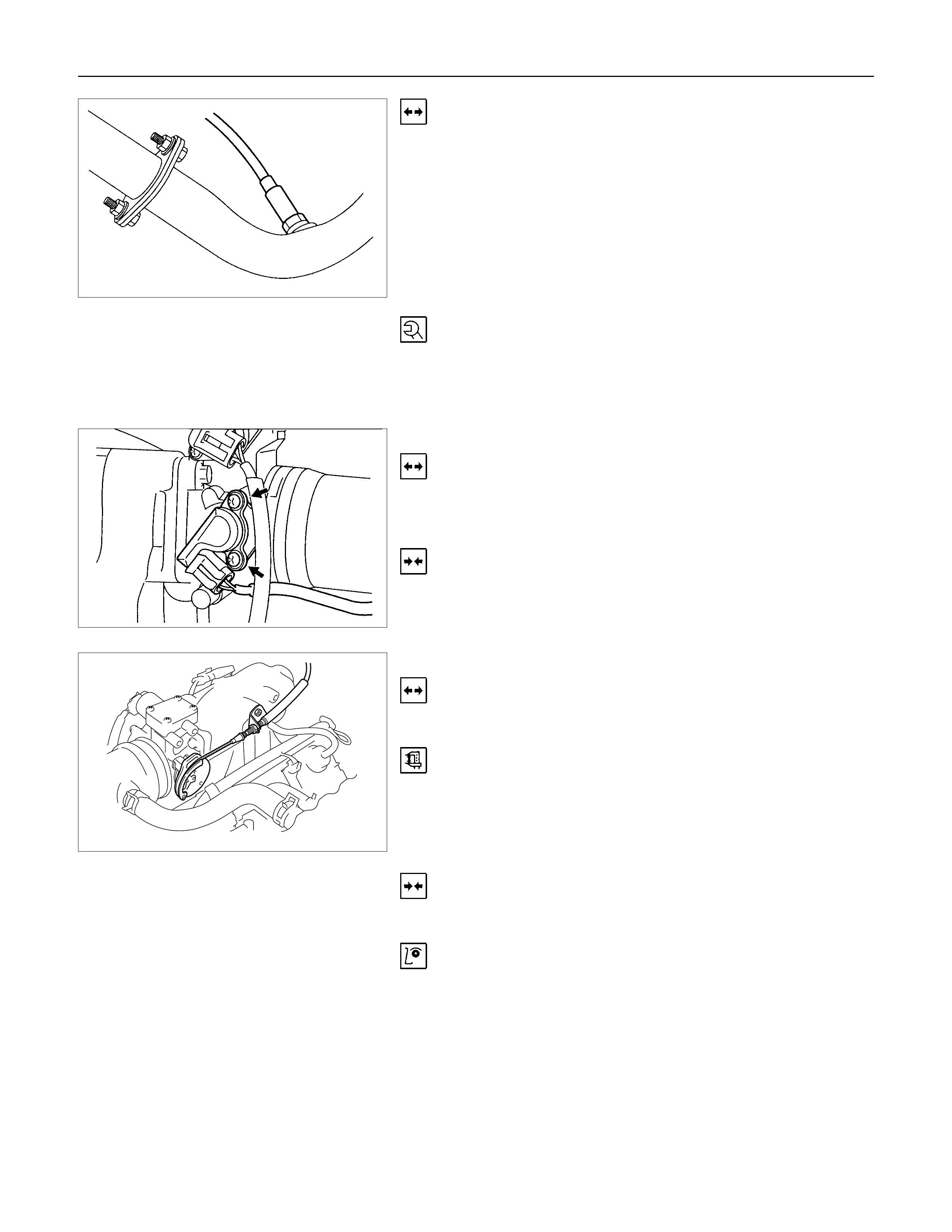

Oxygen Sensor (If applicable)

Removal

1.Remove wiring harness plug.

2. Remove oxygen sensor from the front exhaust pipe.

Tighten (Torque)

Oxygen sensor in exhaust pipe - 30 N⋅m (3.1 kgf⋅m)

Throttle Valve Position Sensor

Removal

1.Remove wiring harness connector.

2. Remove throttle valve position sensor.

Installation

1. Install throttle valve position sensor.

2. Install wiring harness connector.

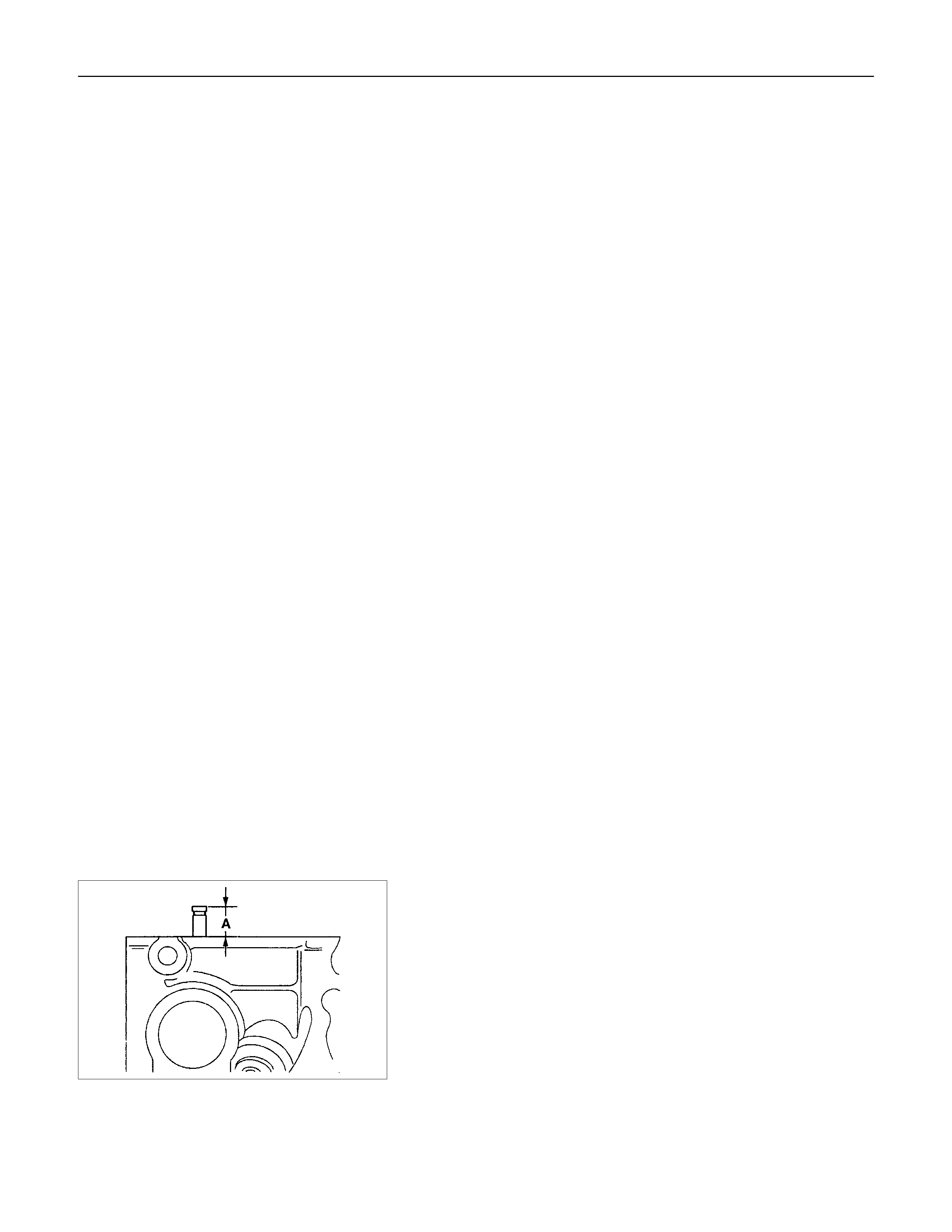

Accelerator Pedal and Cable

Removal

1. Remove pad stopper from pedal stop bolt.

Measure

Dimension "A":

RD=15mm ± 0.5mm/0.59in. ± 0.02in.

LD=14mm ± 0.5mm/0.55in. ± 0.02in.

Installation

1. Install pad stopper.

Inspection

Ensure that accelerator pedal is fully in idle position and

accelerator level at engine is in closed position.

Pull outer sleeve of accelerator cable towards pedal and check

that clip on sleeve is in slot nearest to grommet.

Reposition clip if necessary, and check that full throttle and idle

positions are obtained at engine lever.

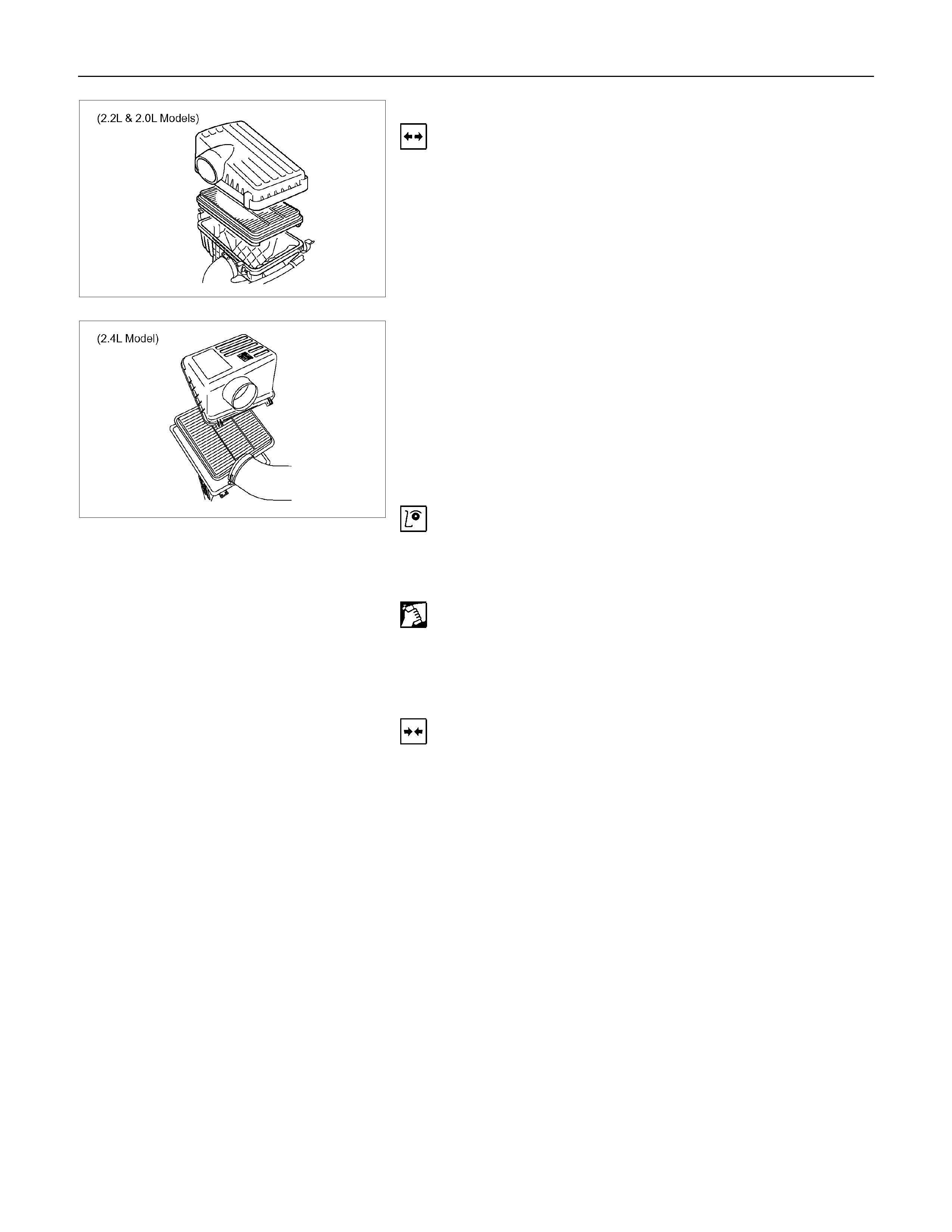

Air Cleaner Filter

Removal

(2.2L & 2.0L)

1. Remove positive ventilation hose connector.

2. Remove intake air temperature sensor.

3. Remove mass air flow sensor.

4. Remove air cleaner duct assembly.

5. Remove air cleaner element.

(2.4L)

1. Remove air cleaner cover and air cleaner element.

2. Remove air intake nose.

3. Remove lower air cleaner.

4. Remove mud guard.

5. Remove front fender cover.

6. Remove outside air intake duct.

Inspection

Check the air cleaner filter for damage or dust clogging.

Replace if it is damaged, or clean if it is clogged.

Cleaning Method

Tap the air cleaner filter gently so as not to damage the paper

filter, or clean the element by blowing with compressed air of

about 490 kPa (71 psi) from the clean side if it is extremely

dirty.

Installation

(2.2L & 2.0L)

1. Install air cleaner element.

2. Attach the air cleaner duct cover to the body completely,

then clamp it with the clip.

3. Install mass air flow sensor.

4. Install mass air temperature sensor.

5. Install positive crankcase ventilation hose connector.

(2.4L)

1. Install outside air intake duct.

2. Install front fender cover.

3. Install mud guard.

4. Install lower air cleaner.

5. Install air intake hose.

6. Install air cleaner element and air cleaner cover.

Spark Plug Thread

Recondition

Ream thread and recut using commercially available spark

plug thread drill (observe manufacturer's instructions).

Removal

Remove thread bush on spark plug. (dimensions (A) =

17mm/0.67in.)

Tighten (Torque)

Spark plug with thread bush into cylinder head - 25N⋅m (2.5

kgf⋅m) - use.

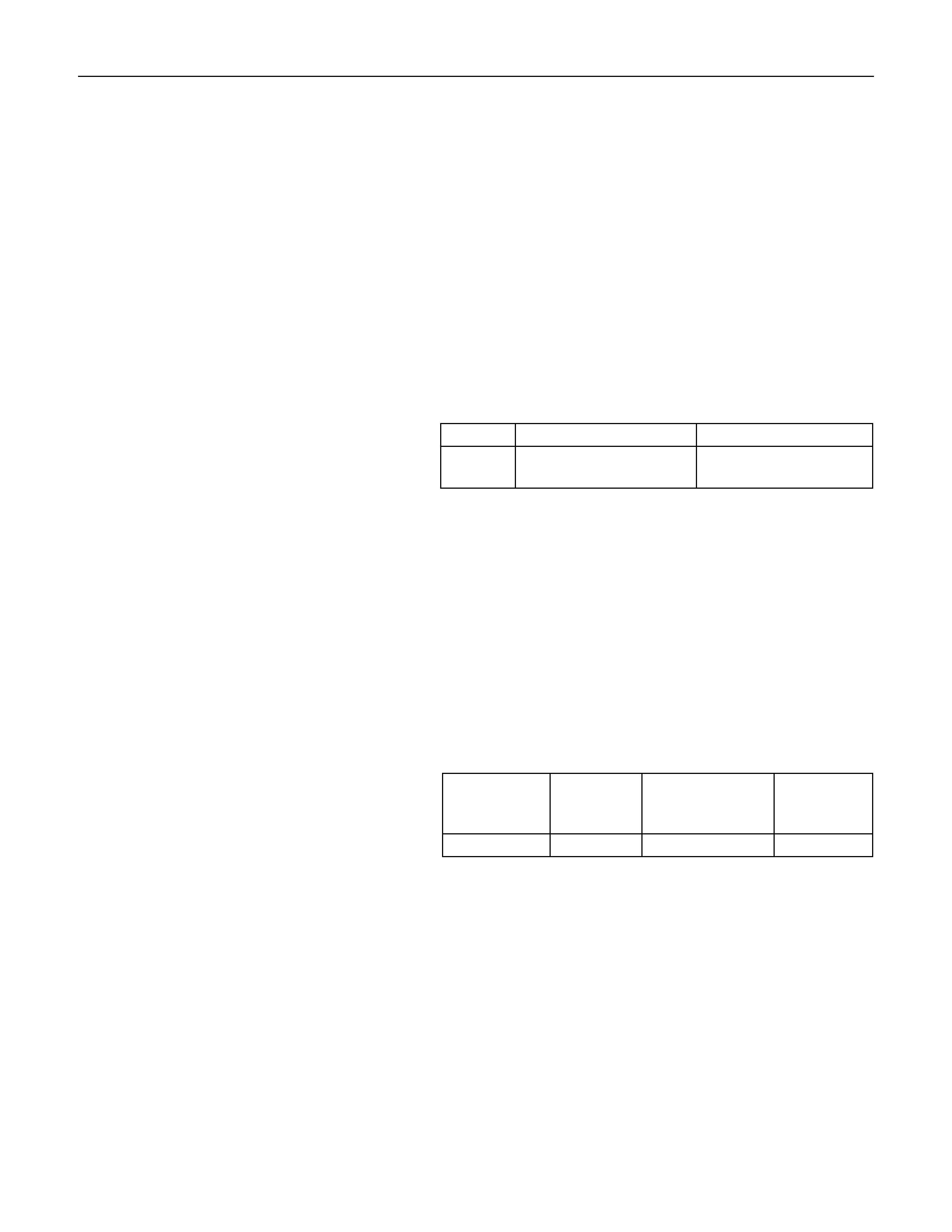

TECHNICAL DATA

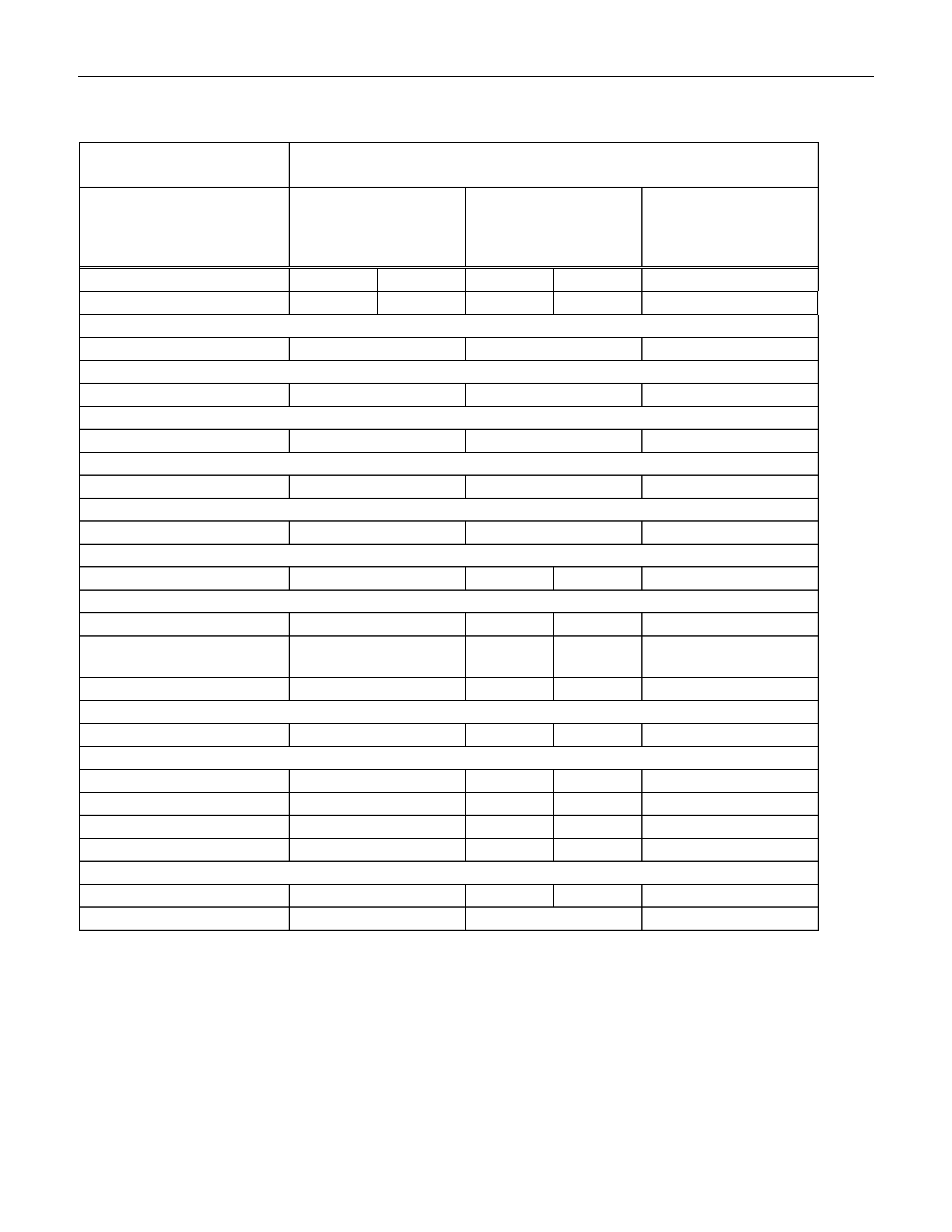

SOHC Gasoline Engine C24SE/C22NE/22LE/20LE

Engine Oil Viscosity

Refer to Section 0B for correct grade and viscosity

Engine Oil Quality

It is important that the oil quality recoomendations in Section 0B

are adhered to. Examples are shown below

EnginesSingle and multigrade oilsEasy run oils

PetrolAPI-SF/CC, SF/CD, SG/CC,

SG/CD, CCMC/G4

API-SF/CC, SF/CD, SG/CD

CCMC-G5/PD2

Important!

CD engine oils designed by manufacturers specially for diesel

engines are not suitable for petrol engines, unless a sufficient

performance class for petrol engines (e.g. API-SF/CCMC-G4)

is also indicated.

Disposal.

Observe the relevant national regulations when disposing of

used oil.

Engine Oil Filling Quantities

Engine Model Initial filling

(litres)

Filling quantity

with filter change*

(litres)

MIN to MAX

(litres)

2.4L 4.80 4.25 1.00

*Up to mark "MAX" on oil dipstick

Oil Pump

Backlash 0.1 to 0.2mm

Gaps in gears opposite housing 0.03 to 0.1mm

Oil pressure at idle speed Engine at operating

temperature (>70°C oil and

approx. 80°C coolant) 150

kPa/1.5 bar

Oil drain plug M14 × 1.5

Cooling System

Radiator

Type:Cross-flow

Radiator core surface in cm2:2000

Cooling system capacity (in litres):7.2

Coolant Specification

Refer to Section 0B - Maintenance and Lubrication

Cooling System (continued)

Fan

TypeVisco Clutch Fan

Number of blades5

Distribution of bladesasymmetric

Diameter mm

Radiator cap

Boiling point123°C

Opening pressure kPa (bar)120 to 135 (1.20 to 1.35)

Thermostat

Start of opening92°C

Fully opened107°C

TypeBypassed

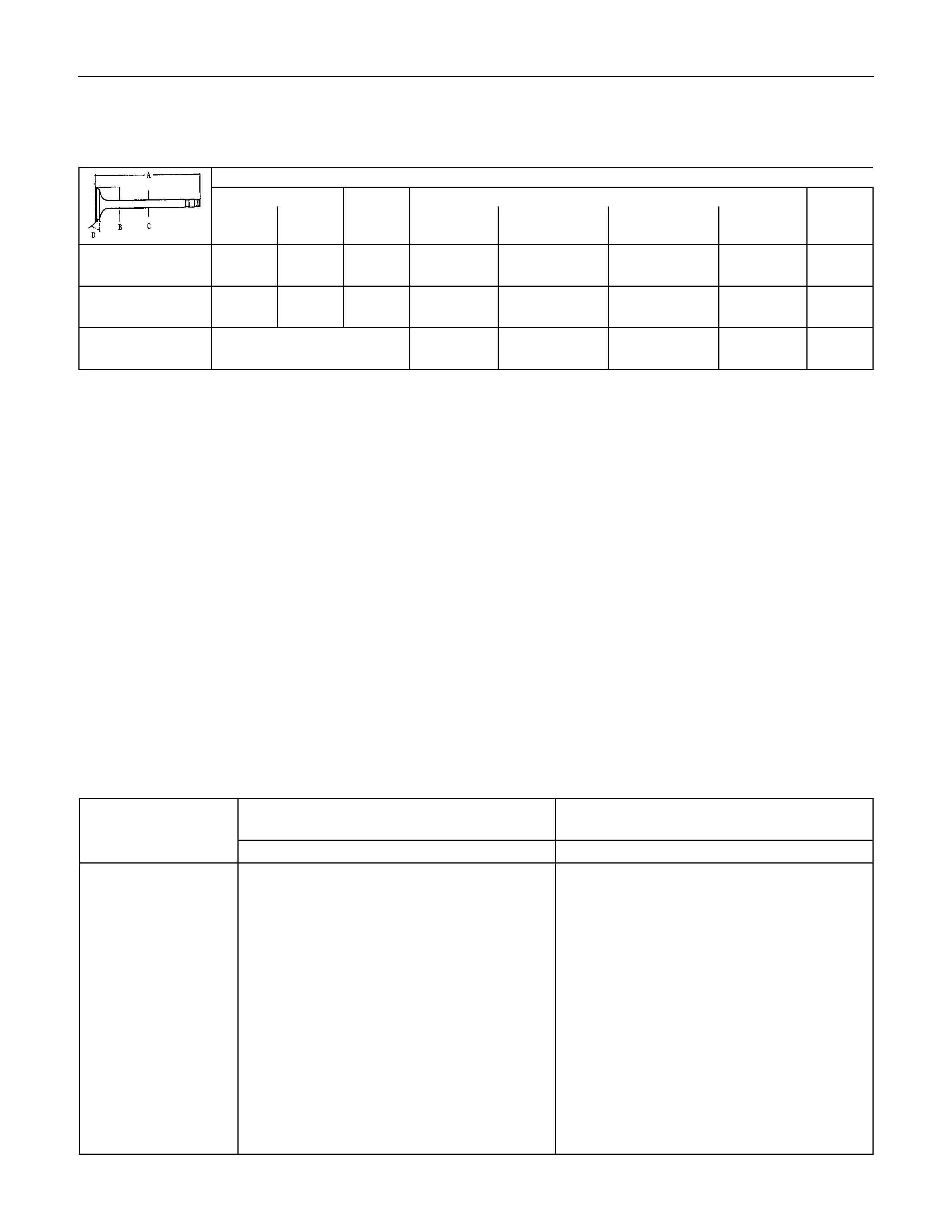

Idle Speeds, CO Content, Ignition

Adjustment

Applicable SystemIdle speed in min-1 (rpm)

Manual

CO content

in vol. %

Ignition timing in CA BTDC (adjustment

ensues at able speed,

ignition marks must align) with TDC

sensor measuring instrument:

Closed Loop System825*<0.4*** 8 to 12

Open Loop System825**1.0+0.2

-0.5*** 8 to 12

Note) * CO content adjustment not applicable.

** CO content adjustment (Except Australia)

*** Ignition timing adjustment not possible.

Adjustment Values/Checking Values

Valve clearance

Inlet Hydraulic valve lash adjustment

Outlet No adjustment necessary

Spark plugs - electrode gap 1.0 ∼ 1.1mm

Compression The difference in compression

between the individual cylinders

in the engine must not exceed

100 kPa (1 bar).

Pressure loss The pressure loss of an engine

in perfect condition per cylinder

is not more than max. 25%

Cylinder Head

Cylinder Head Gasket

Thickness - installed mm 1.15 to 1.30

Valve seat width at cylinder head

inlet mm 1.0 to 1.5

outlet mm 1.7 to 2.2

Valve stem play inlet mm 0.018 to 0.052

outlet mm 0.038 to 0.072

Permissible valve stem to cone runout

inlet mm 0.03

outlet mm 0.33

Overall height of cylinder head

(Sealing surface to sealing surface) mm 96.00 ± 0.25

Installation height

inlet and

outlet valves mm 17.85 to 18.25

dimension "A" Distance Gauge

5-8840-2596-0

Installation height valve guide mm 83.50 to 83.80

Sealing surface peak-to-valley height mm max. 0.025

Cylinder Head (continued)

Valve System

Valve lifter valve play compensator

(hydraulic)

Valve rotators

(inlet or outlet) outlet

Valve play

(warm or cold) inlet mm 0

outlet mm 0

Cylinder head height mm 280.3±0.075

Cylinder head bottom, face parallelism mm 0.05

Cylinder Head (continued)

Valve Dimensions

A in mm B in mm C(diameter in mm) and identification mark D

1) 2) Normal K Oversize K1

0.075

Oversize K2

0.150

Oversize A

0.250

Inlet valve 104.2 103.8 41.8 7.012

6.998

7.087

7.073

7.162

7.148

7.262

7.248

44°

Outlet valve 104.0 103.6 36.5 6.992

6.978

7.087

7.053

7.142

7.128

7.242

7.228

44°

Valve stem

bore

- 7.050

7.030

7.125

7.105

7.200

7.180

7.300

7.280

-

1) Production

2) Customer service

The P and A department only supplies valves with a length of 103.8mm (inlet valve) and 103.6mm (outlet valve)

only

Camshaft

2.4L

Identification letterK

Colour code Normal size -

0.1mm undersize violet

Radial runout mm 0.03

End play mm 0.09 to 0.21

Cam lift Inlet and outlet valve mm 6.67

Grinding Dimension for Camshaft Bearing Position

Bearing Bearing journal

diameter in mm

Diameter

in housing

normal -0.1mm normal -0.1mm

1 42.470

42.455

42.370

42.355

42.525

42.425

42.500

42.400

2 42.720

42.705

42.620

42.605

42.775

42.750

42.675

42.650

3 42.970

42.955

42.870

42.855

43.025

43.000

42.925

42.900

4 43.220

43.205

43.120

43.105

43.275

43.250

43.175

43.150

5 43.470

43.455

43.370

43.355

43.525

43.500

43.425

43.400

Crankshaft, Cylinder Block

Cylinder Grinding and Piston dimensions

Cylinder Grinding and Piston Dimensions

Size Cylinder bore dia. in mm Cylinder to Related piston dia. in mm Piston head

Crankshaft co- efficient

housing

co-efficient

over to over to

Production

(2.4L)

1 87.48

87.49

87.49

87.50

99

00

87.46

87.47

87.47

87.48

99

00

Customer

service

(2.4L)

- 87.99 88.00 0+0.5 87.97 87.98 7+0.5

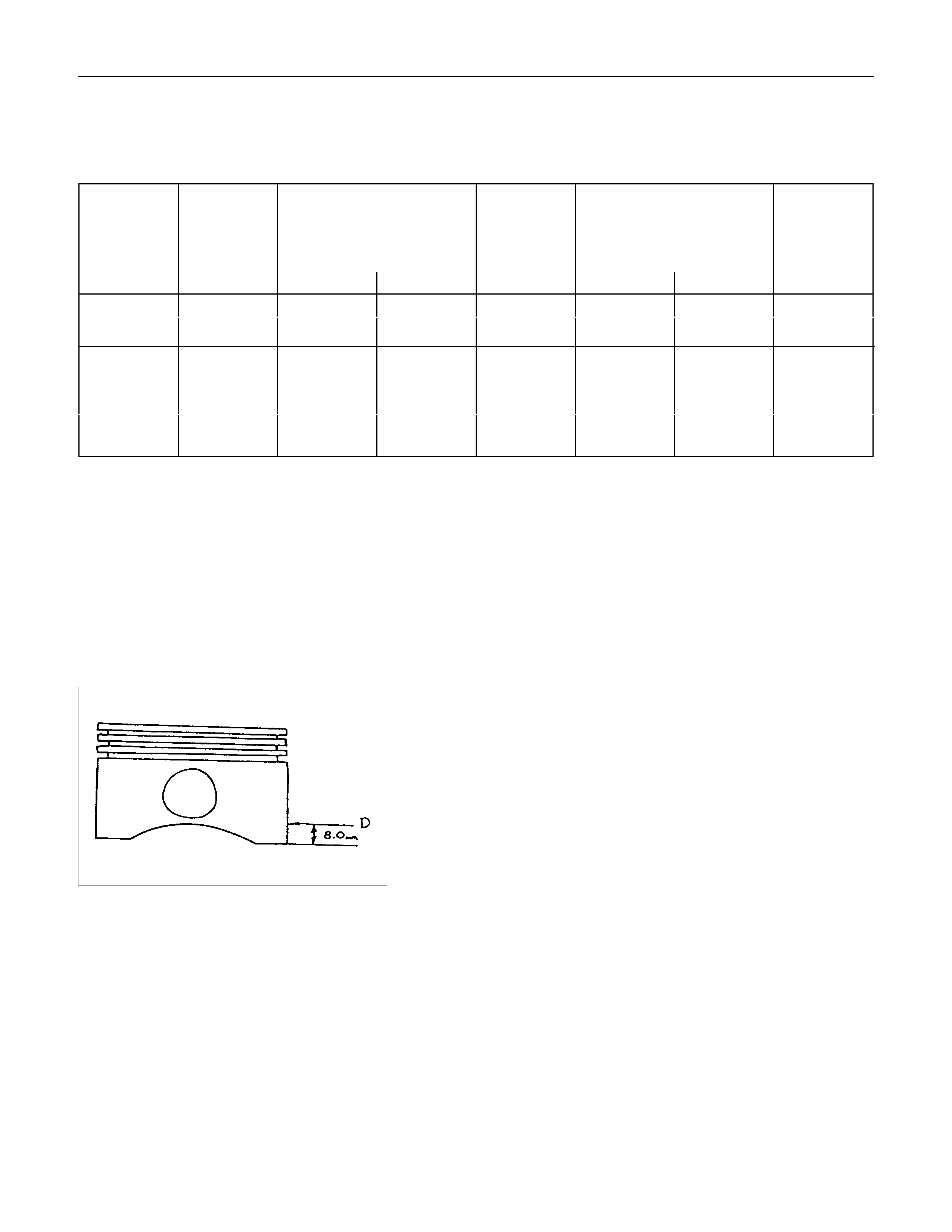

Piston diameter must be measured at the position "D".

*inclusive

Crankshaft, Cylinder Block (continued)

Cylinder Bore

Rebore cylinder Permissible oversize to 0.5mm (see parts

microfiche)

After reboring, invalidate original crankcase

housing coefficient and drive in new oversize

coefficient

Permissible out-of-round: 0.013mm

Permissible taper: 0.013mm

Measure out-of-round in bore at 4 different

heights

Piston projection above upper edge of cylinder block

0.40mm

Piston

Type Recessed pistons

Clearance For short-blocks and cylinder blocks with

complete pistons, the clearance is 0.02 to

0.04mm

For replacement (oversize), depending on

available pistons, a clearance of 0.02 to

0.04mm is permissible

Crankshaft, Cylinder Block (continued)

Piston Rings

2.4L

Square ringHeightmm1.2

Tapered ringHeightmm1.5

Oil scraperHeightmm 2.5

Ring gap offset 180°

Note that the upper steel band ring gap is offset 25 to 50mm to

the left and the lower 25 to 50mm to the right opposite the

intermediate ring gap.

Piston Pin

Length mm 61.5

Diameter mm 21

Type Shrunk into con-rod

Playmm2.4L

in piston0.010-0.015

in con-rod none

Installation When installing piston pins,

heat con-rods to approx.

280°C in oil bath. This

temperature should under no

circumstances be exceeded.

Crankshaft, Cylinder Block (continued)

The permissible weight variation of con-rods without piston and

bearing shell inside an engine is 8 g.

As the con-rods do not have balancing studs, reworking is not

possible.

Con-rods can only be replaced in sets.

Crankshaft, Cylinder Block (continued)

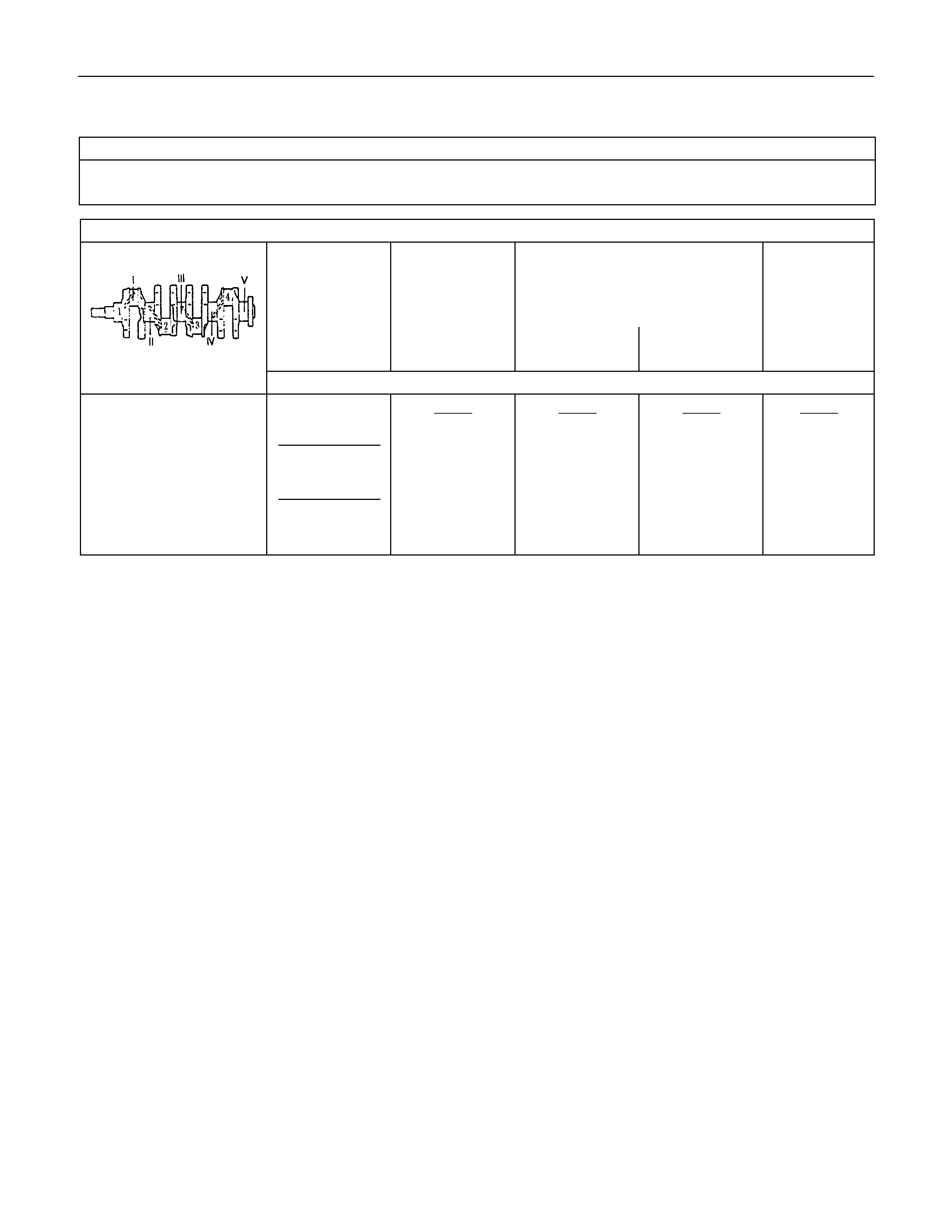

Crankshaft Grinding Dimensions

Crankshaft

jounal

I, II, IV, V

Guide

bearing

III

Con-rod journal

1 to 4

Con-rod width

Diameter

mm

Widtht

mm

Diameter

mm

Width

mm mm

Normal size

Bearing journal and colour code from 57.9820 green

to 57.9885

> 57.9885 brown

to 57.9950

25.900

25.850

48.988

48.970

26.580

26.460

26.390

26.338

Bearing shell identification mark

Colour code and embossed

Crankshaft bearing

I, II, IV, V

Guide bearing

III

Con-rod bearing

1 to 4