SECTION 6F - ENGINE EXHAUST

General Description

Service Precaution

Exhaust Pipe

Exhaust pipe and Associated parts

Removal

Installation

Inspection

Front Exhaust Pipe

Front Exhaust Pipe and Associated Parts

Removal

Installation

Mid Pipe

Mid Pipe and associated Parts

Removal

Installation

Catalytic Converter (If applicable)

Catalytic Converter and Associated Parts

Removal

Installation

3 way Catalytic Converter System

Exhaust Silencer

Exhaust Silencer and Associated Parts

Removal & Installation

Main Data and Specifications

Torque Specification

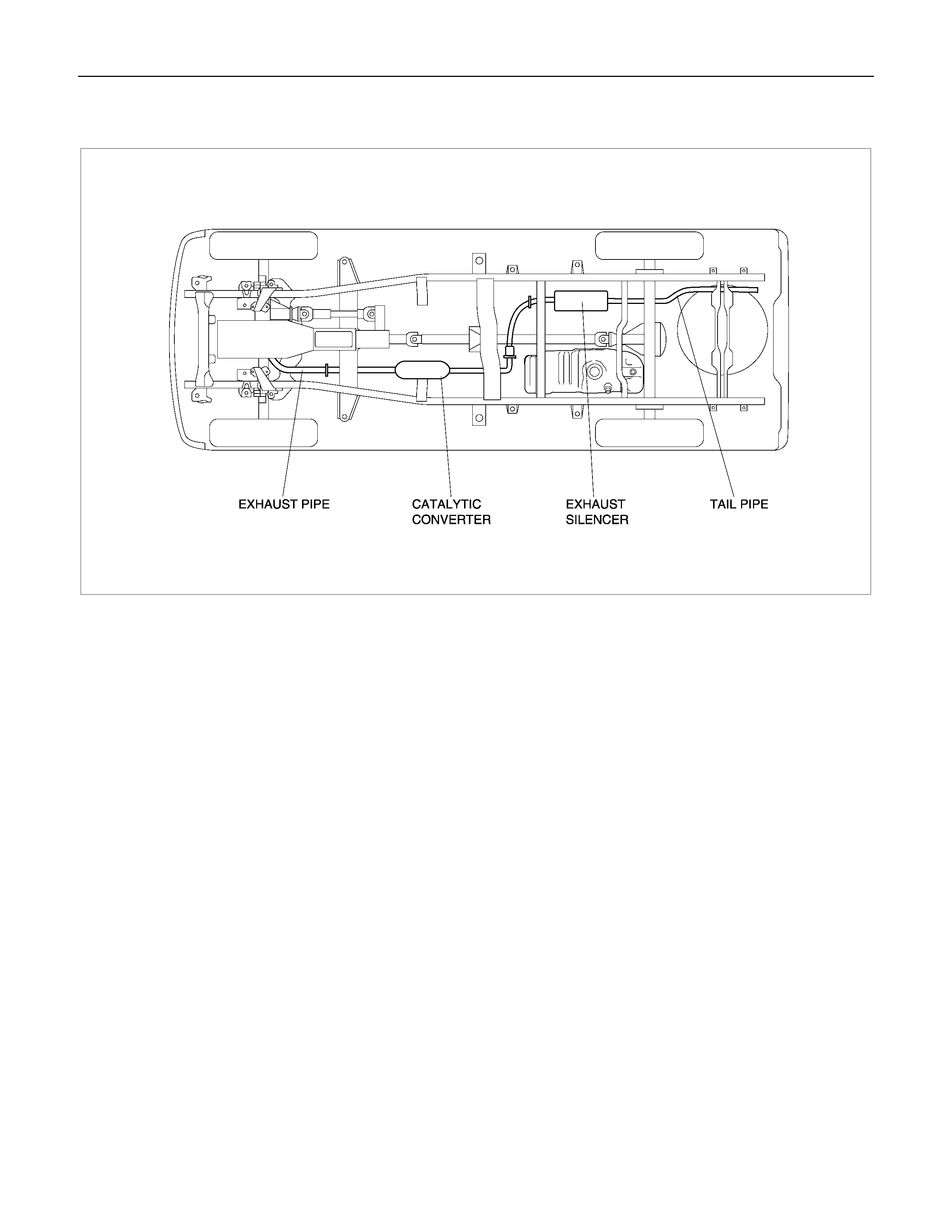

General Description

(2.4L Model)

When inspecting or replacing exhaust system components,

make sure there is adequate clearance from all points on the

underbody to prevent overheating the floor pan and possible

damage to the passenger compartment insulation and trim

materials.

Check complete exhaust system and nearby body areas and

rear compartment lid for broken, damaged, missing or

mispositioned parts, open seams, holes, loose connections or

other deterioration which could permit exhaust fumes to seep

into the rear compartment or passenger compartment. Dust or

water in the rear compartment may be an indication of a

problem in one of these areas. Any faulty areas should be

corrected immediately.

Hangers

Various types of hangers are used to support exhaust

system(s). These include conventional rubber straps, rubber

rings, and rubber blocks.

The installation of exhaust system supports is very important,

as improperly installed supports can cause annoying vibrations

which can be difficult to diagnose.

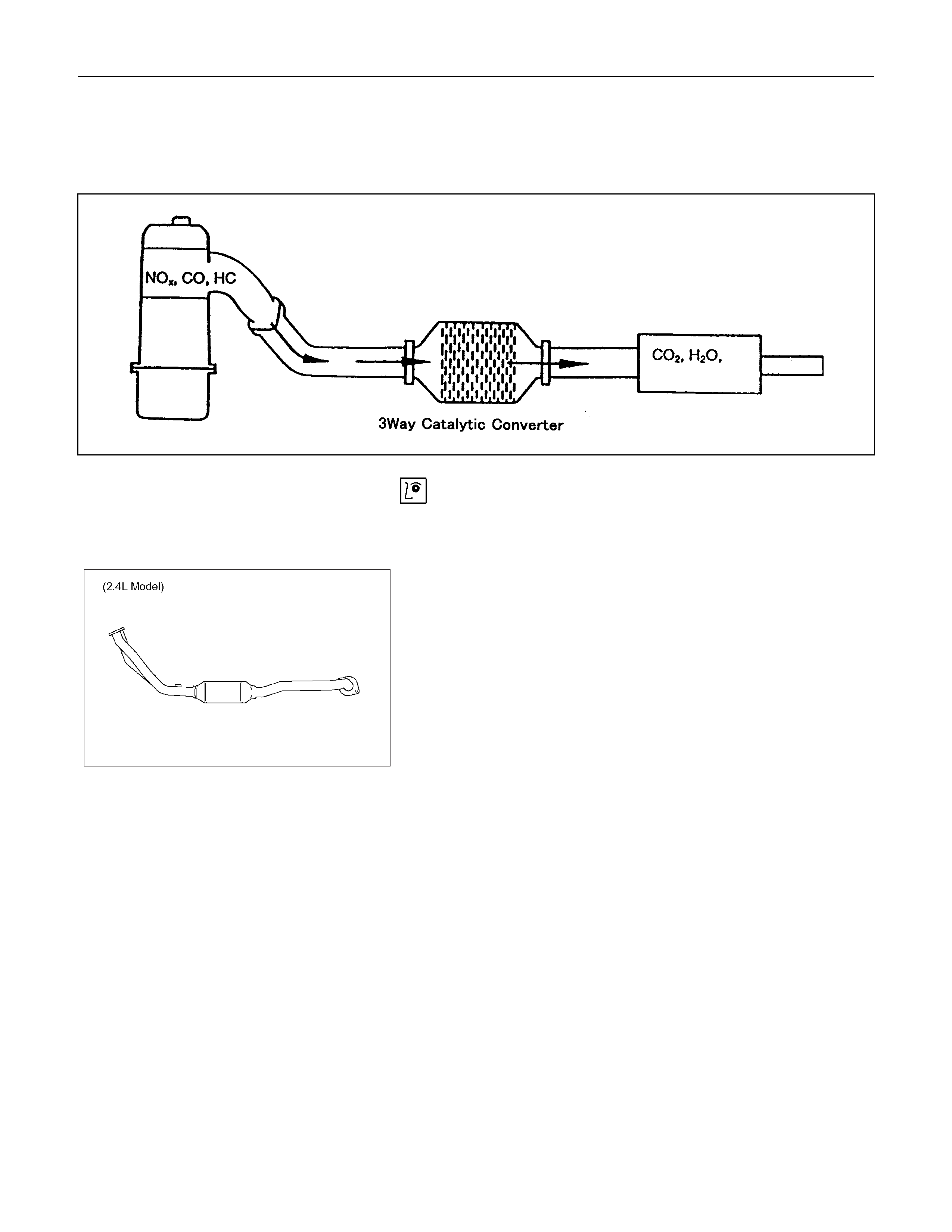

Three Way Catalytic Converter (If applicable)

The three way catalytic converter is an emission control device

added to the exhaust system to reduce pollutants from the

exhaust gas stream.

CAUTION: The catalytic converter requires the use of

unleaded fuel only.

Periodic maintenance of the exhaust system is not required. If

the vehicle is raised for other service, it is advisable to check

the condition of the complete exhaust system.

A dual bed monolith catalytic converter is used in combination

with three way catalytic converter.

Catalytic Types:

Three way (Reduction/Oxidation) catalyst

The catalyst coating on the three way (reduction) converter

contains platinum and rhodium which lowers the levels of

nitrous oxide (NOx) as well as hydrocarbons (HC) and carbon

monoxide (Co).

Gasket

The gasket must be replaced whenever a new exhaust pipe,

muffler or catalytic converter is installed.

Service Precaution

CAUTION:

Always use the correct fastener in the proper location.

When you replace a fastener, use ONLY the exact part

number for that application. Holden will call out those

fasteners that require a replacement after removal.Holden

will also call out the fasteners that require thread lockers

or thread sealant. UNLESS OTHERWISE SPECIFIED, do

not use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or fastener

joint interfaces. Generally, such coatings adversely affect

the fastener torque and the joint clamping force, and may

damage the fastener. When you install fasteners, use the

correct tightening sequence and specifications. Following

these instructions can help you avoid damage to parts and

systems.

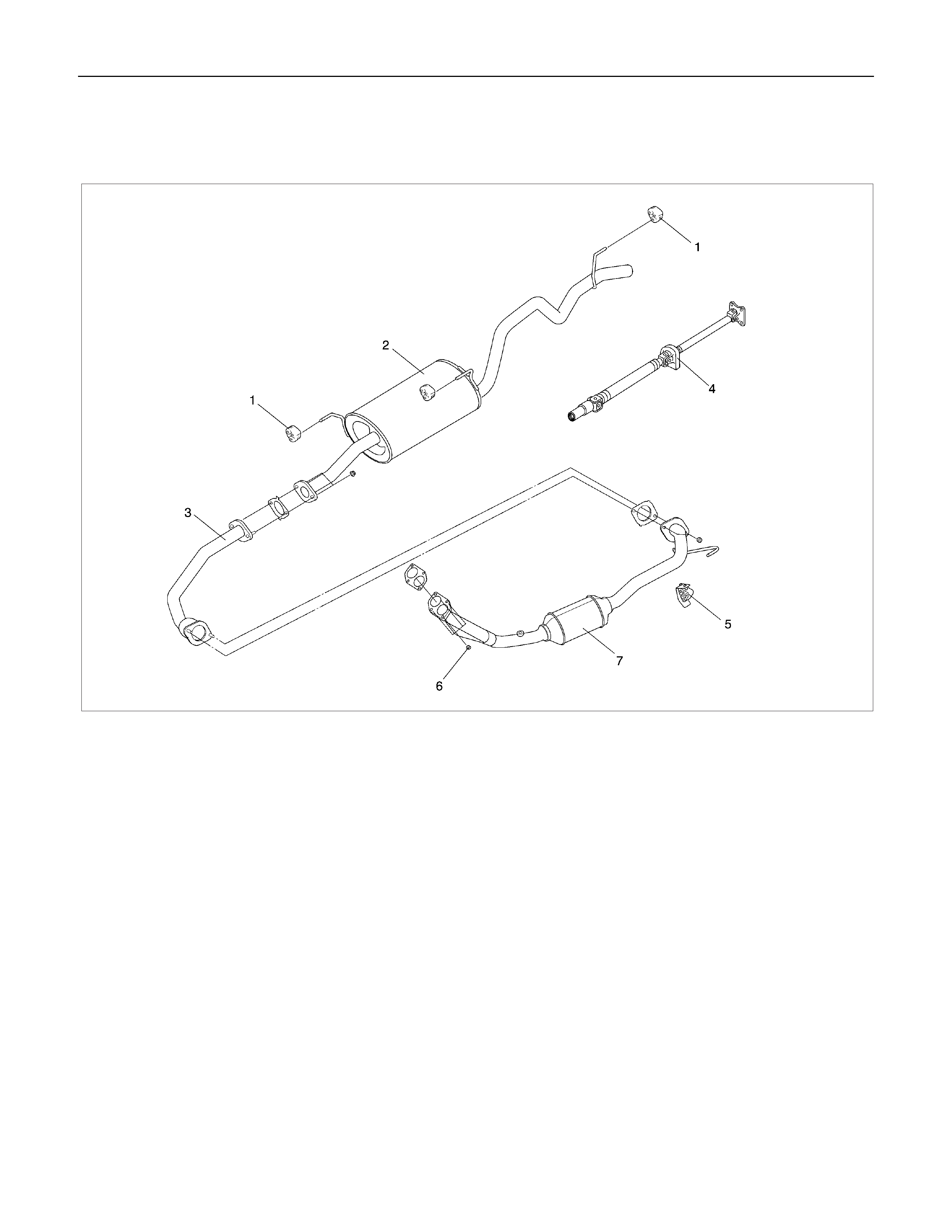

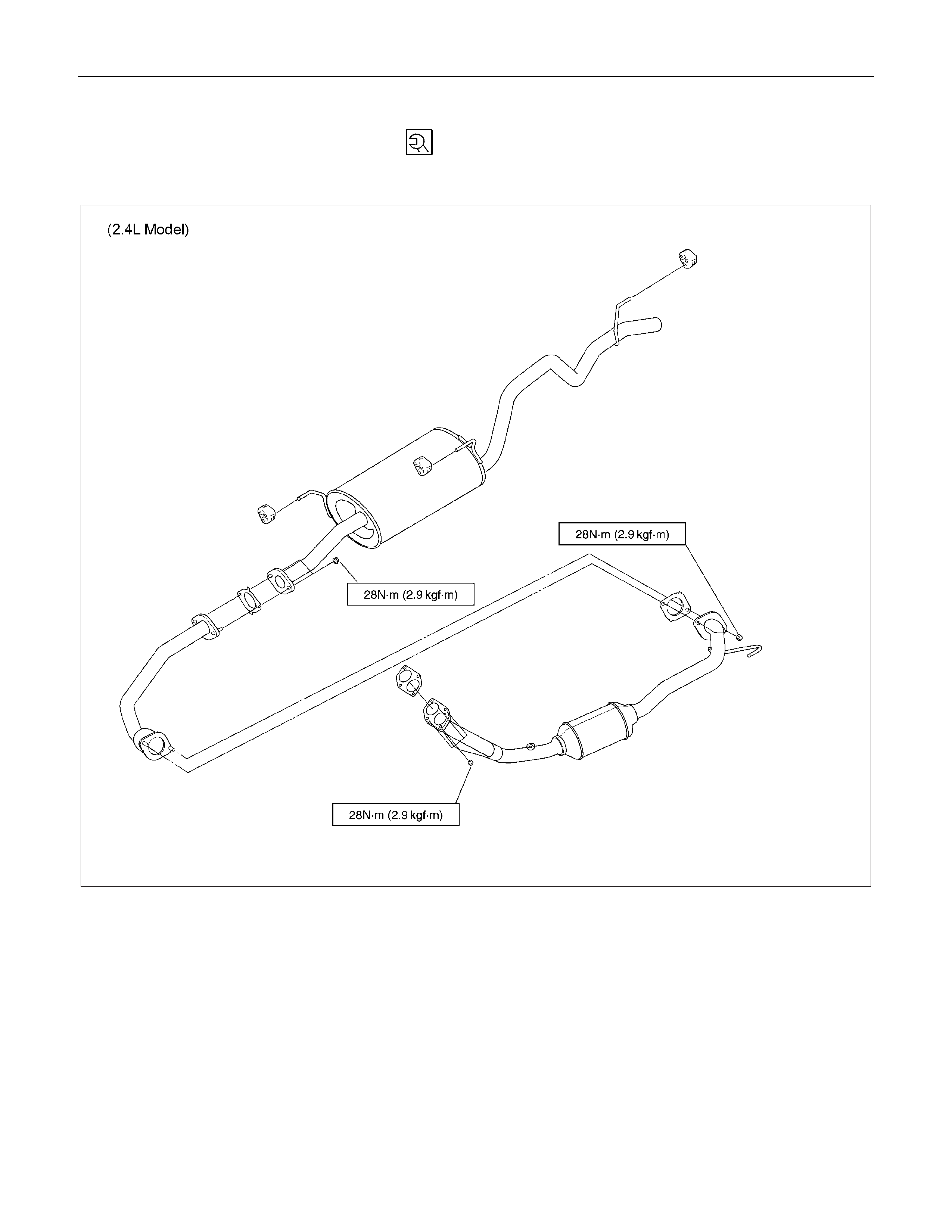

Exhaust Pipe

Exhaust Pipe and Associated parts

(2.4L Model)

Removal

(2.2L & 2.0L)

1.Front exhaust pipe fixing nut

2.Front exhaust pipe

3.Center exhaust pipe damper rubber

4.Catalytic converter (If applicable)

5.Center exhaust pipe

6.Rear exhaust pipe damper rubber

7.Exhaust silencer with rear exhaust pipe

8.Rear exhaust pipe

9.Mid pipe (for 4×4)

9’.Mid pipe (for 4×2)

(2.4L)

CAUTION:

When you remove or install the front exhaust pipe, make

sure not to damage the fuel evaporative pipe.

1.Damper rubber

2.Exhaust silencer

3.Mid pipe

4.Propeller shaft assy

5.Damper rubber

6.Front exhaust pipe fixing nut

7.Catalytic converter (If applicable)

Installation

To install, follow the removal steps in the reverse order.

Important - Installation

1.Front Exhaust Pipe Flange Nut

Connect the exhaust pipe to the exhaust manifold.

Front exhaust pipe to manifold nut.

Torque

N⋅m (kgf⋅m)

28 (2.9)

Inspection

Make the necessary adjustments, and part replacements if

excessive wear or damage is discover during inspection.

1. Front Exhaust Pipe

2. Center Exhaust Pipe and Catalytic Converter Flange Nut

3. Exhaust Pipe Damper Rubber

4. Exhaust Silencer with Rear Exhaust Pipe

Check the pipes for for corrosion, cracking , damage or

misalignment and repair if required.

Check the damper rubber for deterioration or damage and

repair if required.

Front Exhaust Pipe

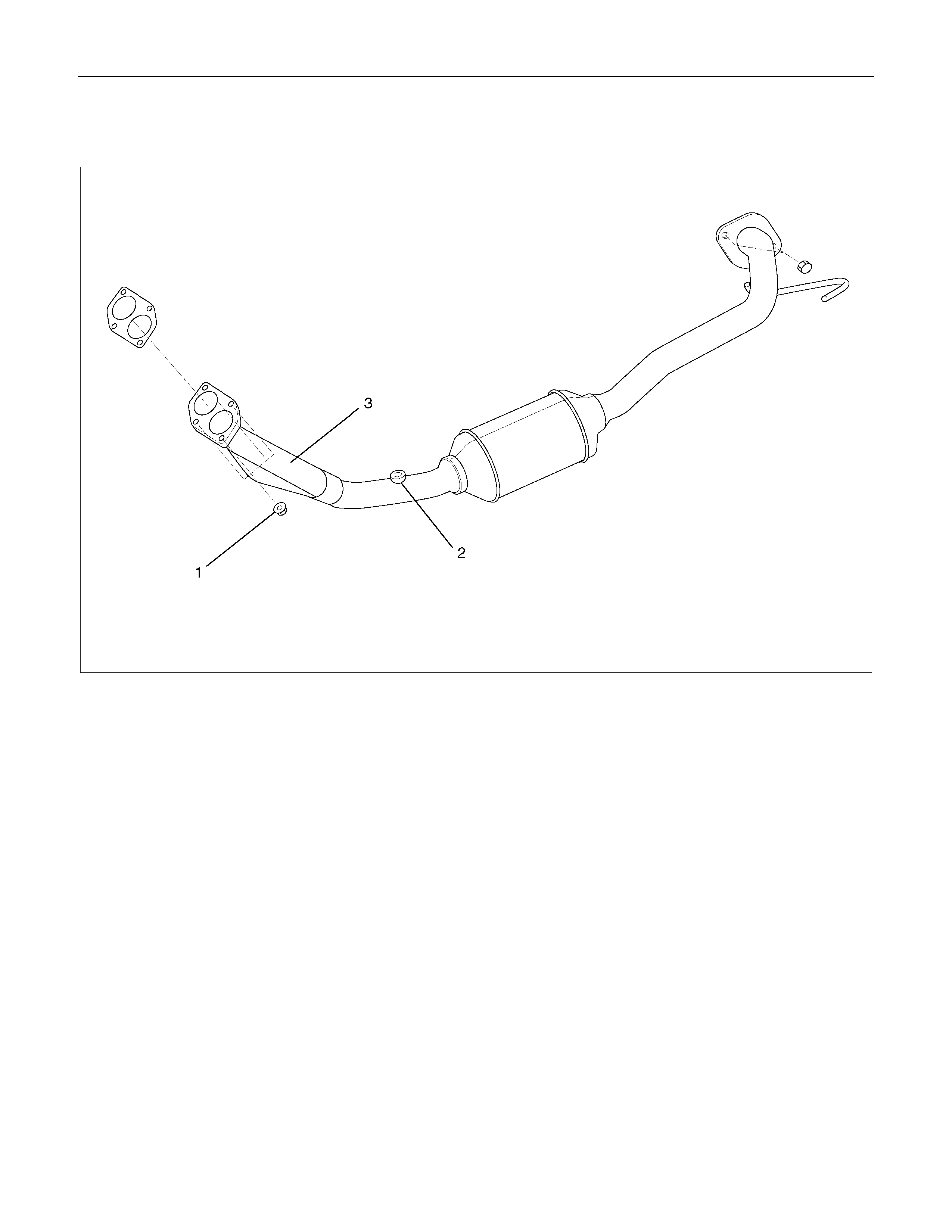

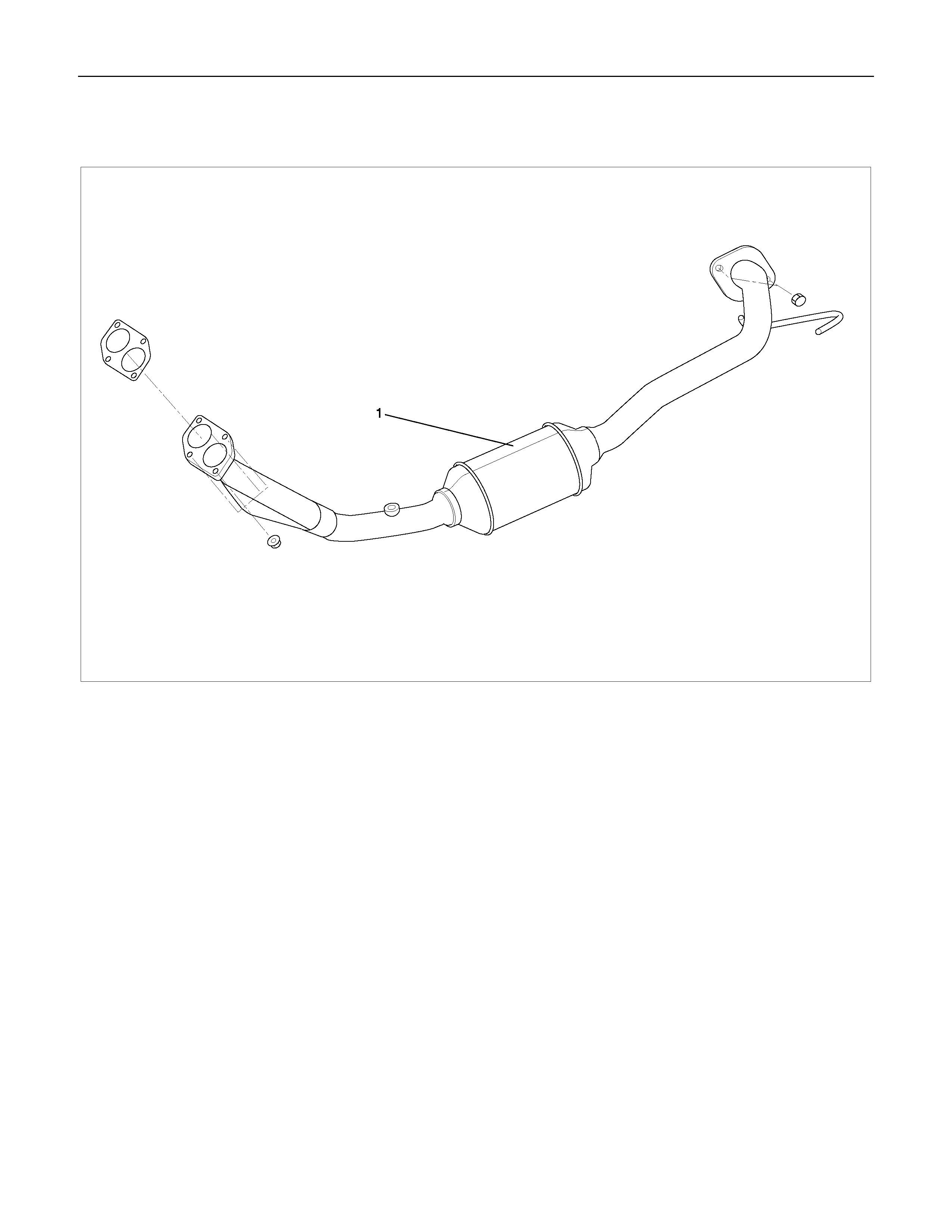

Front Exhaust Pipe and Associated Parts

(2.4L Models)

Legend

1 Front Exhaust Pipe Fixing Nuts

2 O

2

Sensor (If applicable)

3 Front Exhaust Pipe

Removal (2.4L)

1.Disconnect battery ground cable.

2.Raise the vehicle and support with suitable safety stands.

3.Remove the exhaust silencer.

4.Remove mid pipe.

5.Remove the propeller shaft assy.

6.Remove the O2 sensor.

7.Remove front exhaust pipe.

Installation

1. Install front exhaust pipe (3) and tighten four stud nuts.

Torque:

Stud Nuts: 28 N⋅

⋅⋅⋅m (2.9 kgf⋅

⋅⋅⋅m)

Nuts: 43 N⋅

⋅⋅⋅m (4.4 kgf⋅

⋅⋅⋅m)

2. Tighten front side O2 sensor and reconnect O2 sensor

harness connector. (If applicable)

Torque:55 N⋅

⋅⋅⋅m (5.6 kgf⋅

⋅⋅⋅m)

Mid Pipe

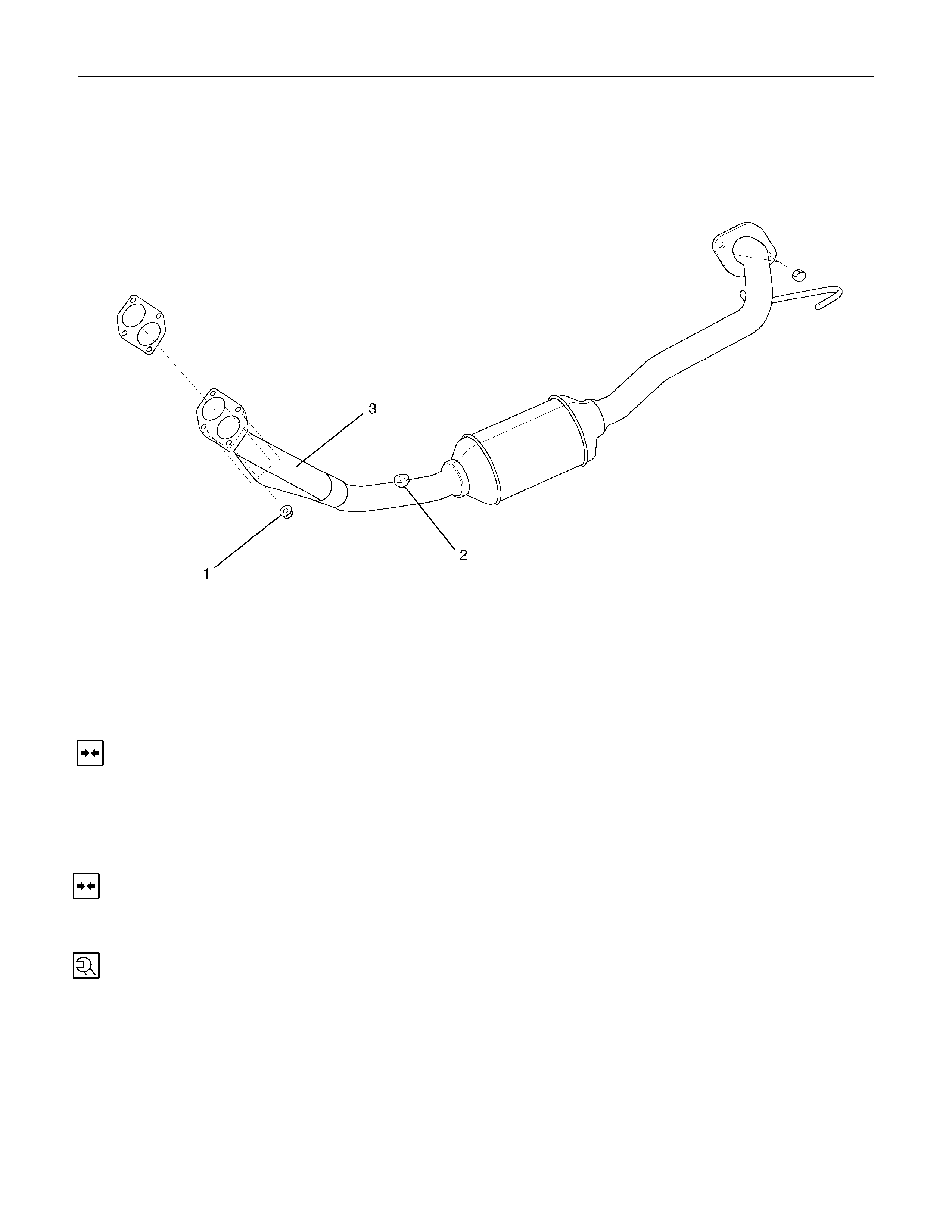

Mid Pipe and Associated Parts

(2.4L Model)

Legend

1. Front Exhaust Pipe Fixing Nuts

2. O

2

Sensor

3. Front Exhaust Pipe

Removal (2.4L)

1.Disconnect battery ground cable.

2.Raise the vehicle and support with suitable safety stands.

3.Remove exhaust silencer.

4.Remove mid pipe.

Installation

1. Install center exhaust pipe (4) and tighten four fixing bolts

(2) and two bolts and nuts (1) to the specified torque:

Torque:

Fixing bolts: 43 N⋅

⋅⋅⋅m (4.4 kgf⋅

⋅⋅⋅m)

Bolts: 43 N⋅

⋅⋅⋅m

Catalytic Converter (If applicable)

Catalytic Converter and Associated Parts

(2.4L Model)

Legend

1. Catalytic Converter

Removal (2.4L)

1.Disconnect battery ground cable.

2. Raise the vehicle and support with suitable safety stands.

3. Remove exhaust silencer.

4. Remove mid pipe.

5. Remove the propeller shaft assy.

6. Remove the O2 sensor.

7. Remove the front exhaust pipe with catalytic converter.

Installation

1. Install Catalytic Converter (1) and tighten four exhaust

silencer fixing bolts and center exhaust pipe fixing bolts to

the specified torque:

Torque:

Fixing bolts: 43 N⋅

⋅⋅⋅m (4.4 kgf⋅

⋅⋅⋅m)

3 WAY CATALYTIC CONVERTER

SYSTEM (If applicable)

N2

Inspection

Make the necessary adjustments, and part replacements if

excessive or damage is discovered during inspection.

Exhaust Pipe Assembly

1. Check connections for looseness or damage.

2. Check clamps for weakness, crack, or damage.

Catalytic Converter

Check for dents or damage.

If any part of the converter is damaged or dented, repair or

replace it.

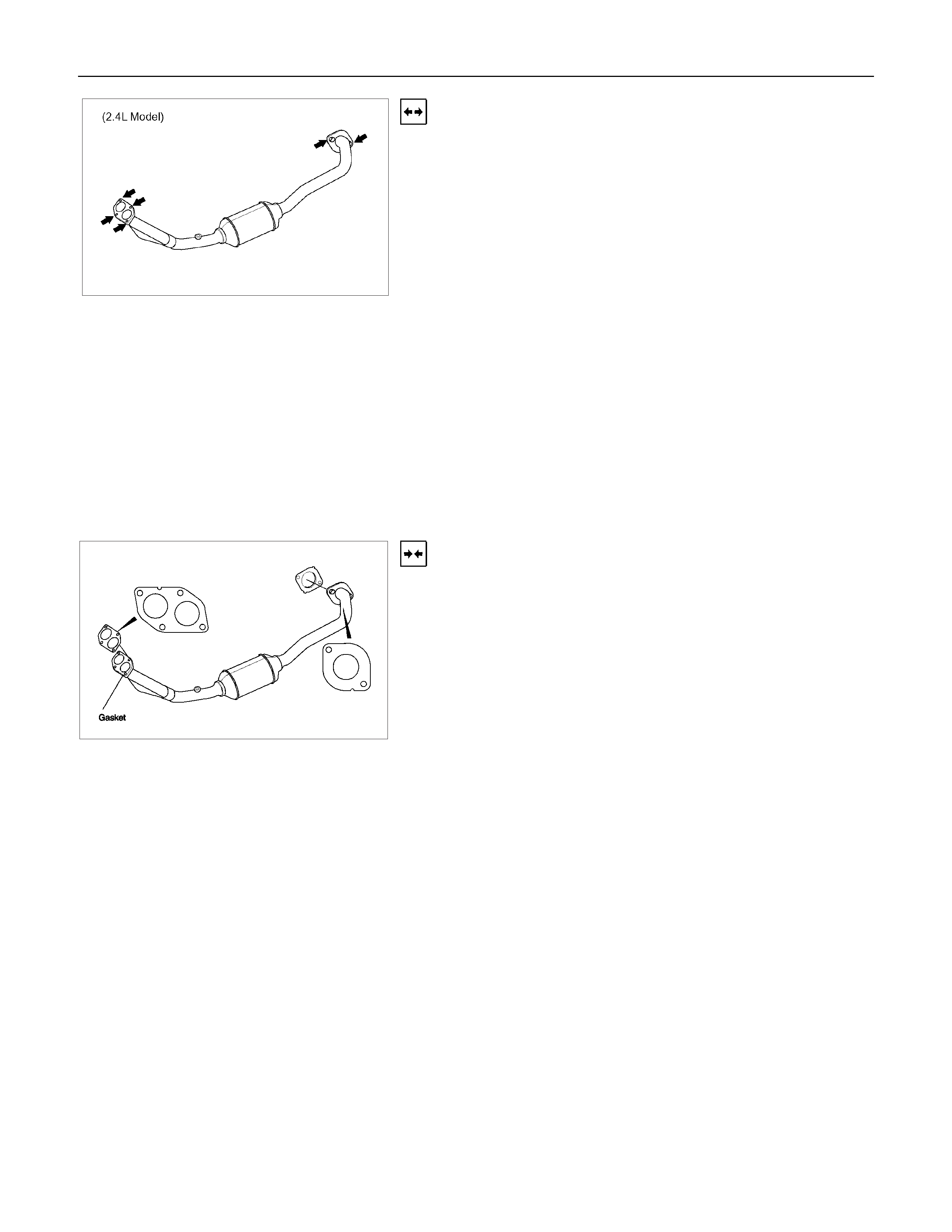

Removal

1. Jack up the vehicle.

2. Check that the converter is cool.

3. Remove the bolts at the front and rear of the converter.

4. Remove the converter and gaskets.

Installation

1. Place new gaskets on the converter front and rear pipes,

and connect the converter to the exhaust pipes.

Note:

When placing new gaskets, check that “U” mark on the

gasket is upside.

2. Tighten the bolts with the specified torque.

3. Reinstall the bracket bolts and tighten them.

(2.4L model)

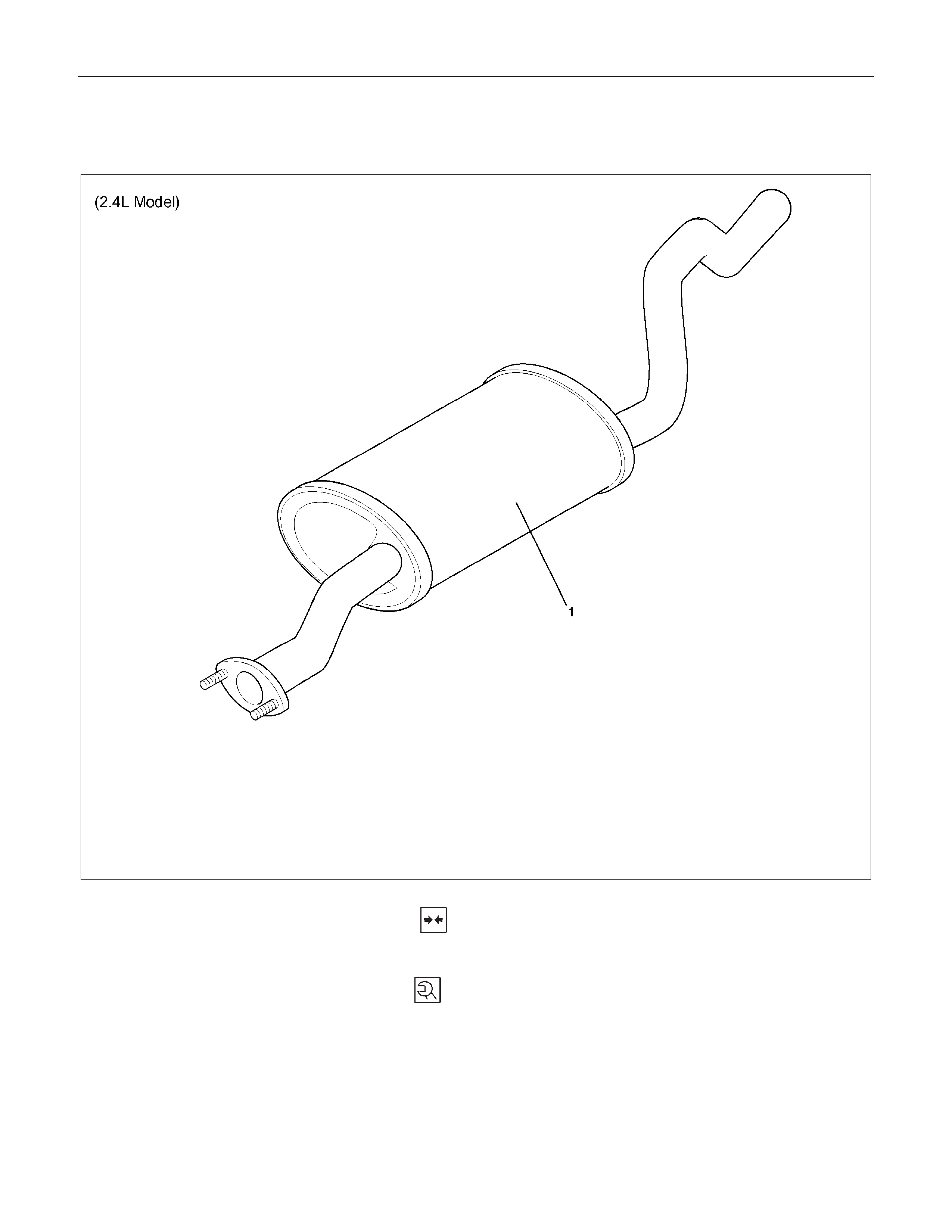

Exhaust Silencer

Exhaust Silencer and Associated Parts

Legend

1. Exhaust Silencer

Removal & Installation (2.4L)

Remove the two nuts and bolts securing the silencer.

For installation reverse the removal procedure.

Torque

Bolts: 43 N m (4.4 kgf m)

.

.

Main Data and Specifications

Exhaust system

Pipe outside diameter ✕ thickness

Front pipe mm(in)

44.5 ✕ 1.5 (1.75✕0.059)

<Flange>

50.8 ✕ 1.5 (2.00 ✕ 0.059)

Middle pipe mm(in)

Rear pipe mm(in)50.8 ✕ 1.5 (2.0 ✕ 0.059)

Silencer

Type Circular section-shell construction

of triple (for 2.4L & 2.0L); double (for 2.4L) skin and

end plates, internal construction of baffles

and perforated tubes.

Inside diameter mm (in) Approximately 180 (7.09)

Length mm (in) Approximately 525 (20.67)

Mounting

Number of suspension points

Type

Catalytic converter type

4

Rubber

Three way Catalytic Converter

Main Data and Specifications

Torque Specification

N!m (kgf!m)