Immobiliser System – HFV6 Page 6E1–1

Page 6E1–1

Section 11A-1

Immobiliser System – HFV6

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to 1.1 Warning

Caution and Notes for correct workshop practices with regard to safety and / or property damage.

1 General Information ...............................................................................................................................3

1.1 Warning Caution and Notes.................................................................................................................................. 3

Definition of WARNING, CAUTION and NOTE Statements................................................................................. 3

WARNING defined............................................................................................................................................. 3

CAUTION defined .............................................................................................................................................. 3

NOTE defined..................................................................................................................................................... 3

2 Component Location .............................................................................................................................4

2.1 Engine Compartment............................................................................................................................................. 4

2.2 Interior .................................................................................................................................................................... 5

3 Component Description.........................................................................................................................6

3.1 Immobiliser Control Unit....................................................................................................................................... 6

3.2 Powertrain Interface Module................................................................................................................................. 7

3.3 Engine Control Module.......................................................................................................................................... 8

4 Diagnostics.............................................................................................................................................9

4.1 Diagnostic General Descriptions.......................................................................................................................... 9

Diagnostic Trouble Code (DTC) Tables ............................................................................................................... 9

Multiple DTCs..................................................................................................................................................... 9

Diagnostic Trouble Codes (DTCs)........................................................................................................................ 9

Status of DTCs................................................................................................................................................... 9

Conditions for Clearing DTCs............................................................................................................................. 9

Tech 2 ICU Diagnostic Tests............................................................................................................................... 10

Tech 2 Limitations............................................................................................................................................ 10

Tech 2 Intermittent Fault Tests......................................................................................................................... 10

5 Wiring Diagram and Harness Connector...........................................................................................11

5.1 Wiring Diagram .................................................................................................................................................... 11

5.2 Harness Connector.............................................................................................................................................. 12

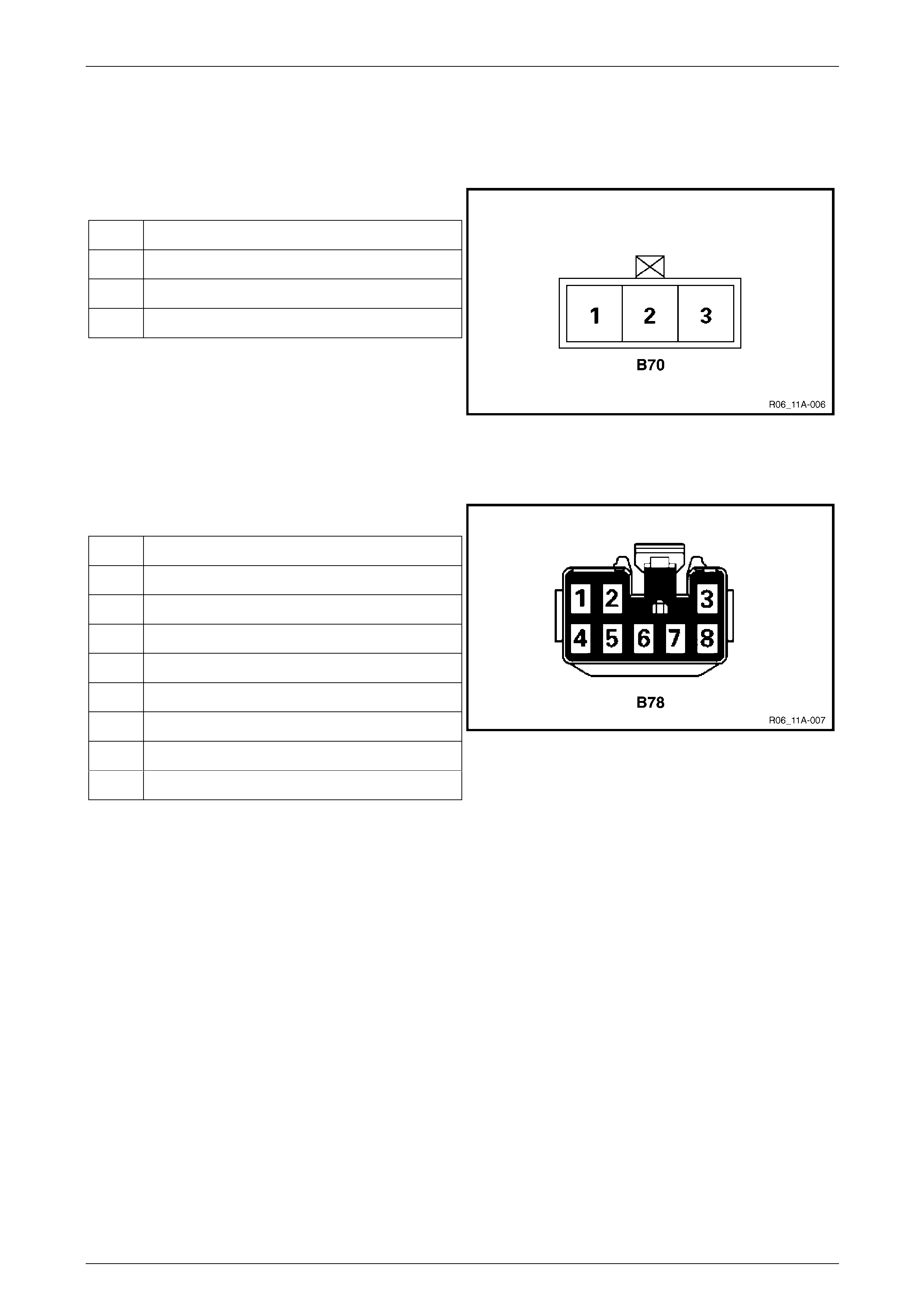

Immobiliser Control Unit Connector – B70........................................................................................................ 12

Pin Description................................................................................................................................................. 12

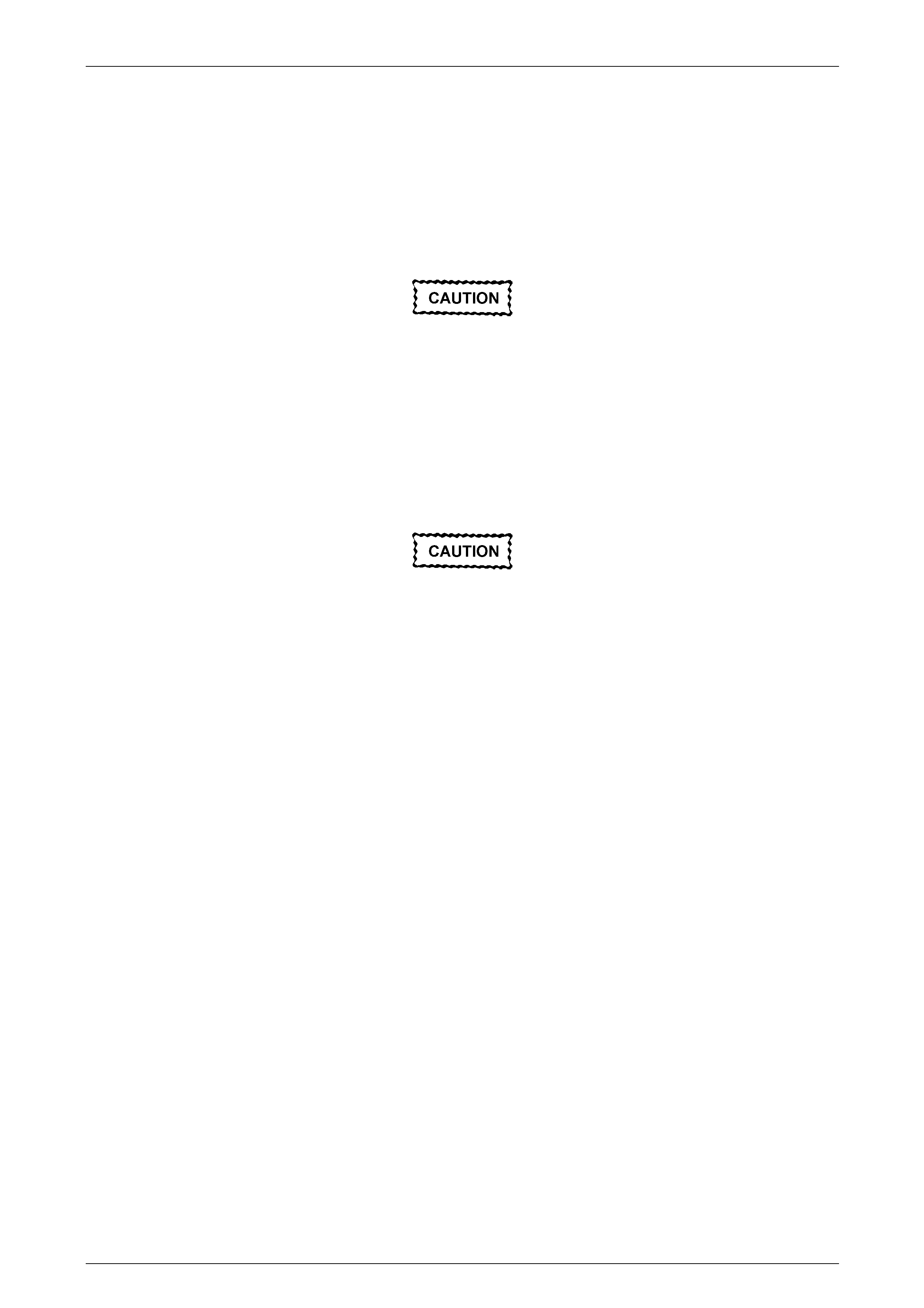

Immobiliser Control Unit Connector – B78........................................................................................................ 12

Pin Description................................................................................................................................................. 12

6 Diagnostics Starting Point ..................................................................................................................13

6.1 Diagnostic Requirements, Precautions and Preliminary Checks.................................................................... 13

Basic Knowledge Required................................................................................................................................. 13

Basic Diagnostic Tools Required....................................................................................................................... 13

Diagnostic Precautions....................................................................................................................................... 13

Preliminary Checks.............................................................................................................................................. 14

Diagnostic Aids.................................................................................................................................................... 14

Check the condition for system parts. .............................................................................................................. 14

Check the Electro Magnetic Interference (EMI)................................................................................................ 14

Immobiliser System – HFV6 Page 6E1–2

Page 6E1–2

Check the other items. ..................................................................................................................................... 14

Check the operation......................................................................................................................................... 14

6.2 Diagnostic Trouble Codes................................................................................................................................... 15

Immobiliser Control Unit (ICU)............................................................................................................................ 15

6.3 Immobiliser System and Warning Lamp Check................................................................................................ 16

Immobiliser System Check ................................................................................................................................. 16

No Immobiliser Warning Lamp........................................................................................................................... 18

Immobiliser Warning Lamp On Steady.............................................................................................................. 19

7 Intermittent Fault Conditions..............................................................................................................20

7.1 Intermittent Conditions Diagnostic Table.......................................................................................................... 20

Description........................................................................................................................................................... 20

Diagnostic Table.................................................................................................................................................. 20

8 DTC Tables............................................................................................................................................22

8.1 B0001 Replace Electronic Control Unit (Immobiliser Fault)............................................................................. 22

8.2 B0002 Immobiliser Not Programmed ................................................................................................................. 23

8.3 B0003 Transponder Key Problem....................................................................................................................... 24

8.4 B0004 Immobiliser Coil Circuit (Antenna Coil Fault) ........................................................................................ 26

8.5 B0005 Communication Line W Voltage Low...................................................................................................... 27

8.6 B0006 Communication Line W Voltage High..................................................................................................... 28

8.7 B0007 No Engine Request Received.................................................................................................................. 29

8.8 B0008 Wrong Transponder Key.......................................................................................................................... 31

8.9 B0009 No Transponder Key Programmed......................................................................................................... 32

8.10 B0010 Unknown Transponder Key..................................................................................................................... 33

8.11 B0055 EEPROM Error.......................................................................................................................................... 34

9 Immobiliser Security and Programming............................................................................................35

9.1 Security and Programming Information ............................................................................................................ 35

Car Pass Card ...................................................................................................................................................... 35

lmportant information on Programming............................................................................................................ 35

Security code ................................................................................................................................................... 35

Entering a code................................................................................................................................................ 35

Transponder (Key) ........................................................................................................................................... 36

9.2 Immobiliser Control Unit Reset Procedure........................................................................................................ 37

9.3 Immobiliser Link to ECM / PIM............................................................................................................................ 38

10 Immobiliser V6 – Tech 2 Functions....................................................................................................39

10.1 Introduction.......................................................................................................................................................... 39

10.2 Tech 2 Functions ................................................................................................................................................. 40

F0: Diagnostic Trouble Codes............................................................................................................................ 40

F1: Data Display................................................................................................................................................... 40

F2: Snapshot Options.......................................................................................................................................... 40

F3: Additional Functions..................................................................................................................................... 40

F4: Programming................................................................................................................................................. 40

10.3 Immobiliser V6 Data List ..................................................................................................................................... 41

Data Display ......................................................................................................................................................... 41

11 Special Tools ........................................................................................................................................42

Immobiliser System – HFV6 Page 6E1–3

Page 6E1–3

1 General Information

For Information not contained in this section, refer to Section 11A Immobiliser.

1.1 Warning Caution and Notes

This Section contains various W A RNINGS, CAUTIONS and NOTE statements that you must observe carefully to reduce

the risk of death or injury during service, repair procedures or vehicle operation. Incorrect service or repair procedures

may damage the vehicle or cause operational faults. WARNINGS, CAUTION and NOTE statements are not exhaustive.

GM HOLDEN LTD can not possibly warn of all the potentially hazardous consequences of failure to follow these

instructions.

Definition of WARNING, CAUTION and NOTE Statements

Diagnosis and repair proce dures in this Section contain both general and specific WARNING, CAUTION and NOTE

statements. GM HOLDEN LTD is dedicated to the presentation of service information that helps the technician to

diagnose and repair the systems necessary for proper operation of the vehicle. C ertain procedures may present a hazard

to the technician if they are not followed in the recommended manner. WA RNING, CAUTION and NOTE statements are

designed to help prevent thes e hazards from occurring, but not all hazards can be foreseen.

WARNING defined

A WARNING statement immediately precedes an operatin g procedure or maintenance practice which, if not correctly

followed, could result in death or injury. A WARNING statement alerts yo u to take necessary action or not to take a

prohibited action. If a WARNING statement is ignored, the following consequences may occur:

• Death or injury to the technician or other personnel working on the vehicle,

• Death or injury to other people in or near the workplace area, and / or

• Death or injury to the driver / or passenger(s) of the vehicle or other people, if the vehicle has been improperly

repaired.

CAUTION defined

A CAUTION statement immediately precedes an operating procedure or maintenance practice which, if not correctly

followed, could result in damage to or destru c tion of equipment, or corruption of data. If a CAUTION statement is

ignored, the following consequences may occur:

• Damage to the vehicle,

• Unnecessary vehicle repairs or component replacement,

• Faulty operation or performance of any system or component being repaired,

• Damage to any system or components which depend on the proper operation of the system or component being

repaired,

• Faulty operation or performance of any systems or components which depend on the pro per operation or

performance of the system or component under repair,

• Damage to fasteners, basic tools or special tools and / or

• Leakage of coolant, lubricant or other vital fluids.

NOTE defined

A NOTE statement immediately precedes or follows an operating procedure, maintenance practice or condition that

requires highlighting. A NOTE statement also emphasises necessary characteristics of a diagnostic or repair procedure.

A NOTE statement is designed to:

• Clarify a procedure,

• Present additional information for accomplishing a procedure,

• Give insight into the reasons for performing a procedure in the recommended manner, and / or

• Present information that gives the technician the ben efit of past experience in accomplishing a procedure with

greater ease.

Immobiliser System – HFV6 Page 6E1–4

Page 6E1–4

2 Component Location

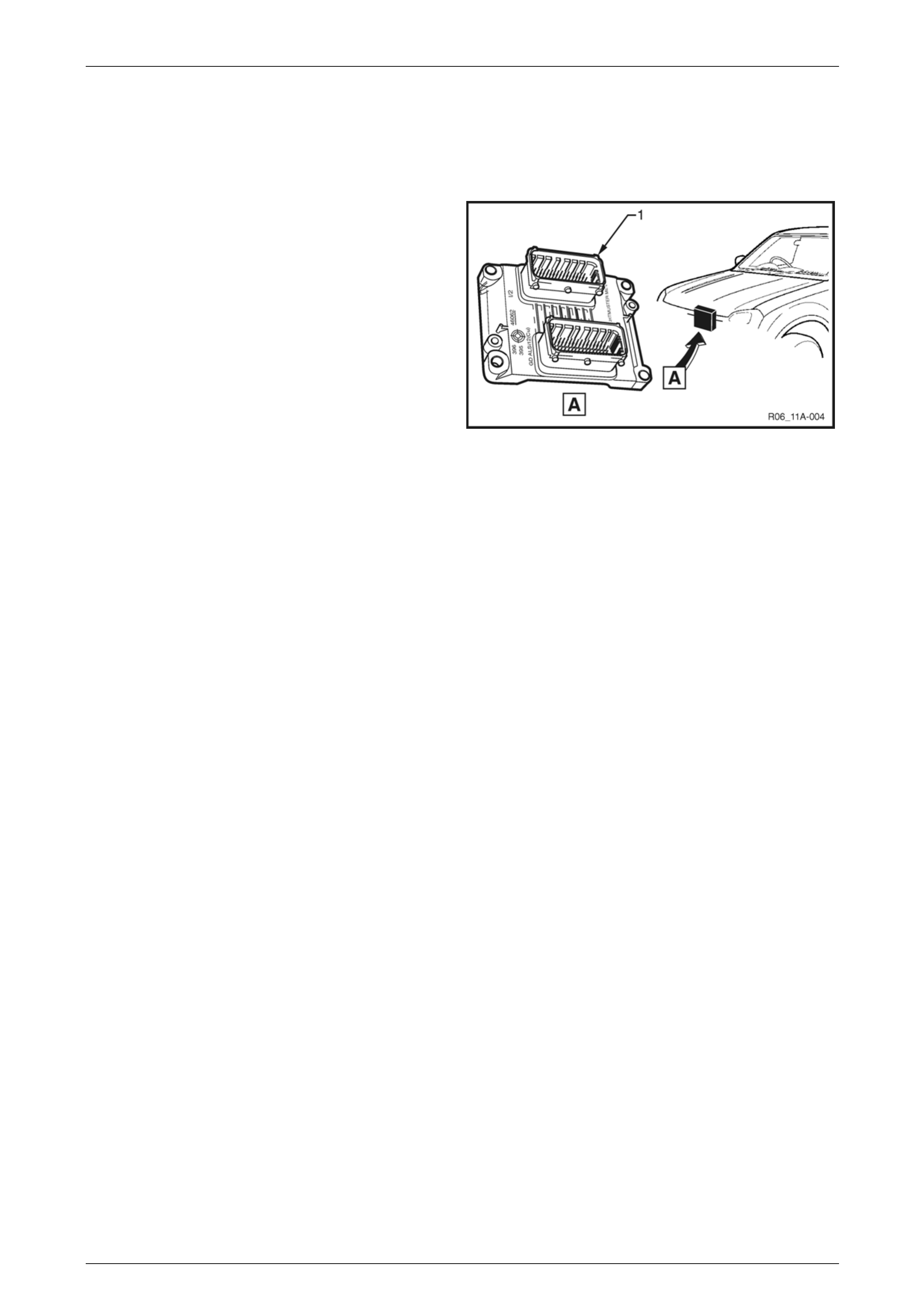

2.1 Engine Compartment

Legend

1 Engine Control Module 2 Powertrain Interface Module

Figure 11A-1 – 1

Immobiliser System – HFV6 Page 6E1–5

Page 6E1–5

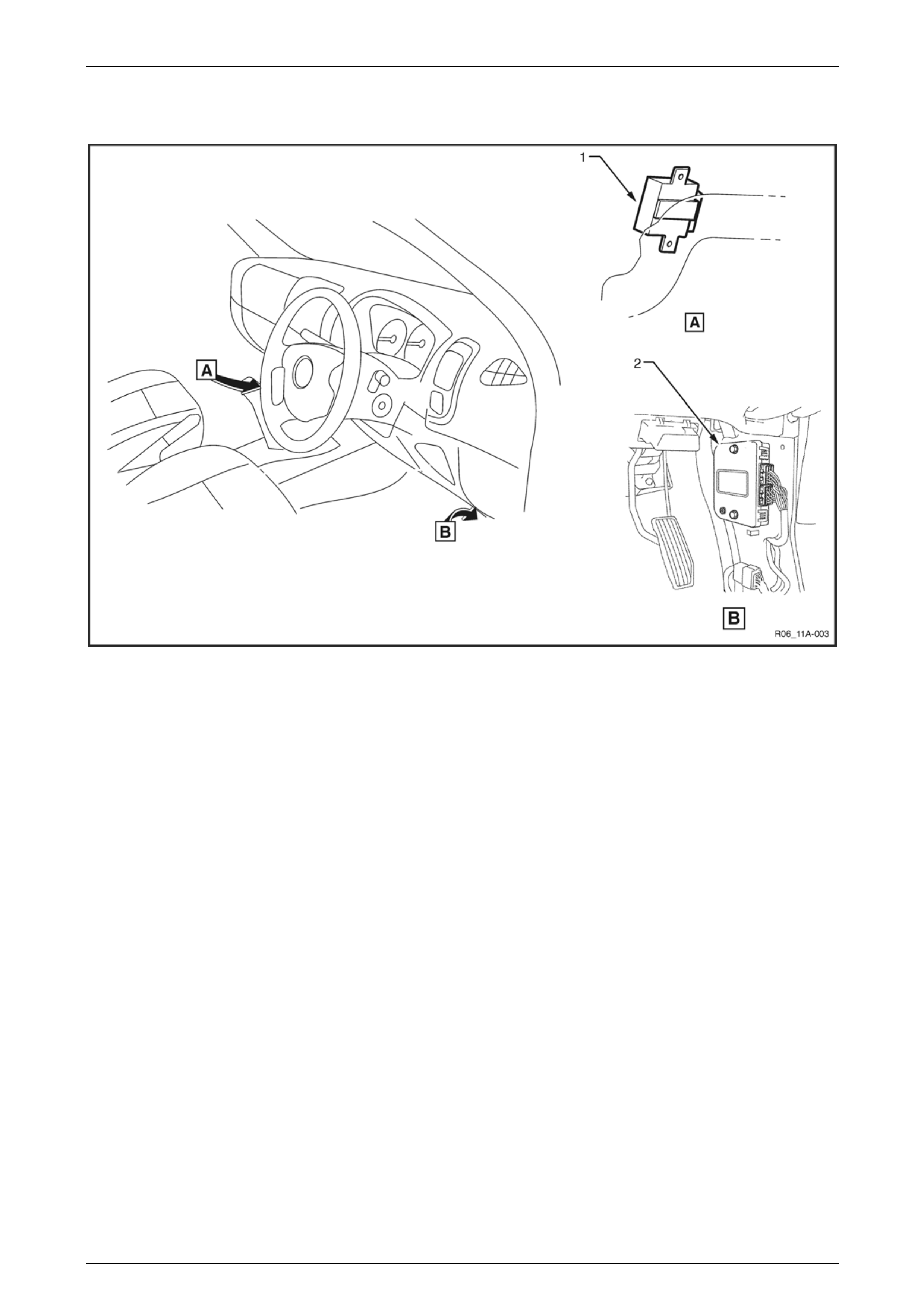

2.2 Interior

Figure 11A-1 – 2

Legend

1 Immobiliser Control Unit 2 Powertrain Interface Module

Immobiliser System – HFV6 Page 6E1–6

Page 6E1–6

3 Component Description

3.1 Immobiliser Control Unit

The immobiliser control unit (ICU) is mounted to the left of

the steering column.

The ICU in conjunction with the po wertrain in terface module

(PIM) and engine control module (ECM) immobilises the

engine. The ICU communicates with the ECM via the PIM.

For further information on immobiliser system operati on,

refer to Section 11A Immobiliser System.

Figure 11A-1 – 3

Immobiliser System – HFV6 Page 6E1–7

Page 6E1–7

3.2 Powertrain Interface Module

The powertrain interface module (PIM) is located behind the

right-hand lower hinge pillar trim.

Figure 11A-1 – 4

The PIM performs the following functions:

• The PIM acts as the communication gateway between the GM LAN communications proto col and keyword 2000

protocol.

• The PIM converts analogue si gnals from the cruise control switches into digital serial data.

• The PIM upon inputs received from the engi ne control module (ECM), transmission control module (TCM) and

immobiliser control unit (ICU) controls the operation of the following instruments and warning lamps. Refer to

Section 6E1-1 Powertrain Interface Module – V6 for further information on the powertrain interface module.

Immobiliser System – HFV6 Page 6E1–8

Page 6E1–8

3.3 Engine Control Module

The ECM is located at the right front of the engine

assembly.

The ECM communicates directly with the transmission

control module (TCM) and PIM via the serial data network.

The ECM is also an integral part of the vehicle security

system.

Figure 11A-1 – 5

Immobiliser System – HFV6 Page 6E1–9

Page 6E1–9

4 Diagnostics

4.1 Diagnostic General Descriptions

The immobiliser control un it (ICU) diagnostic procedure is organised in a logical structure that begins with the Diagnostic

System Check. The Diagnostic System Check directs the diagnostic proce dure to the logical steps or appropriate

diagnostic table required to diagnose an immobiliser fau lt cond ition.

The diagnostic tables locate a faulty circuit or component through a logical based process of elimination. Correct use of

the diagnostic tables is essential to reduce di agnostic time and to prevent misdiagnosis.

In addition, the Diagnostic System Check provides the following information:

• identification of the ICU,

• condition of the diagnostic circuit, and

• identification and status of the DTCs if present.

Diagnostic Trouble Code (DTC) Tables

The diagnostic procedure is directed to a diagnostic trouble code (DTC) table if there are DTCs currently stored in the

ICU.

The diagnostic tables are designed to locate a faulty circuit or component through a logic al based process of elimination.

The diagnostic tables are developed with the following assumptions:

• the vehicle functioned correctly at the time of assembly,

• there are no multiple faults, and

• the problem currently exists.

Multiple DTCs

When performing a DTC check and there are multiple DT Cs, the diag nostic process must begin with the most likely DT C

that may trigger other DTCs.

Knowledge of the ICU and Tech 2 limitations are important to reduce diagn ostic time and to prevent misdiagnosis. Refer

to 6.1 Diagnostic Requirements, Precautions and Preliminary Checks.

Diagnostic Trouble Codes (DTCs)

When the ignition s witch is turned on, the ICU performs an internal integrity check that detects and isolates any interna l

faults. The PIM also monitors the serial data bus for messages from the po wertrain interface module. If a fault is detected

by the PIM, it will log a Diagnostic Trouble Code (DTC) that represents the fault detected. The DTCs stored in the PIM

may be accessed using Tech 2.

Status of DTCs

The ICU designates the DTCs logged into a Current or History DTC.

Current DTCs

If the fault condition that triggers the DTC is present during the last ICU self test, that DT C will be designated as a current

DTC.

History

DTCs

If the fault condition that triggers the DTC is not present during the last ICU self test, that DTC will be designated as a

history DTC.

Conditions for Clearing DTCs

• If there is no DTC logged in the current ICU self test, the current DTC will be cleared.

• If there is no DTC logged after 100 consecutive drive cycles, the history DTC will be cleared.

Immobiliser System – HFV6 Page 6E1–10

Page 6E1–10

Tech 2 ICU Diagnostic Tests

Tech 2 Limitations

Some DTCs trigger other DTCs to set, which causes Tech 2 to display multiple DTCs. In those situations, Tech 2 may

display more DT Cs than is neede d to rectify a fault.

When Tech 2 displays an o utp ut function, it displays only the command given by the ICU. If a connector is disconnected,

that fault will not register in the ICU output function. Tech 2 does not verify the command action.

The service technician must understand t he system being diagnosed as well as the correct use and limitations of Tech 2

to be able to perform diagnostic procedures efficiently and successfully.

Tech 2 Intermittent Fault Tests

The following are lists of Tech 2 diagnostic tests that may be used to diagnose intermittent faults:

• Wiggle test the suspected ICU wiring harne ss and connector while observing Tech 2 operating paramet ers of the

circuit being tested. If Tech 2 read-out fluctuates during this procedure, check the wiring harness circuit for loose

connection.

• Road test the vehicle in conditions that trigger the intermittent fault while an assistant observes the suspected Tech

2 operating parameter data.

• Capture and store data in the Snapshot mode when the fault occurs. The stored data may be repl ayed at a slower

rate to aid in diagnostics. Refer to Tech 2 User Instructions for more infor mation o n the Snapshot function.

• Operate suspected components to test their operation using Tech 2 Output Control Data.

Immobiliser System – HFV6 Page 6E1–11

Page 6E1–11

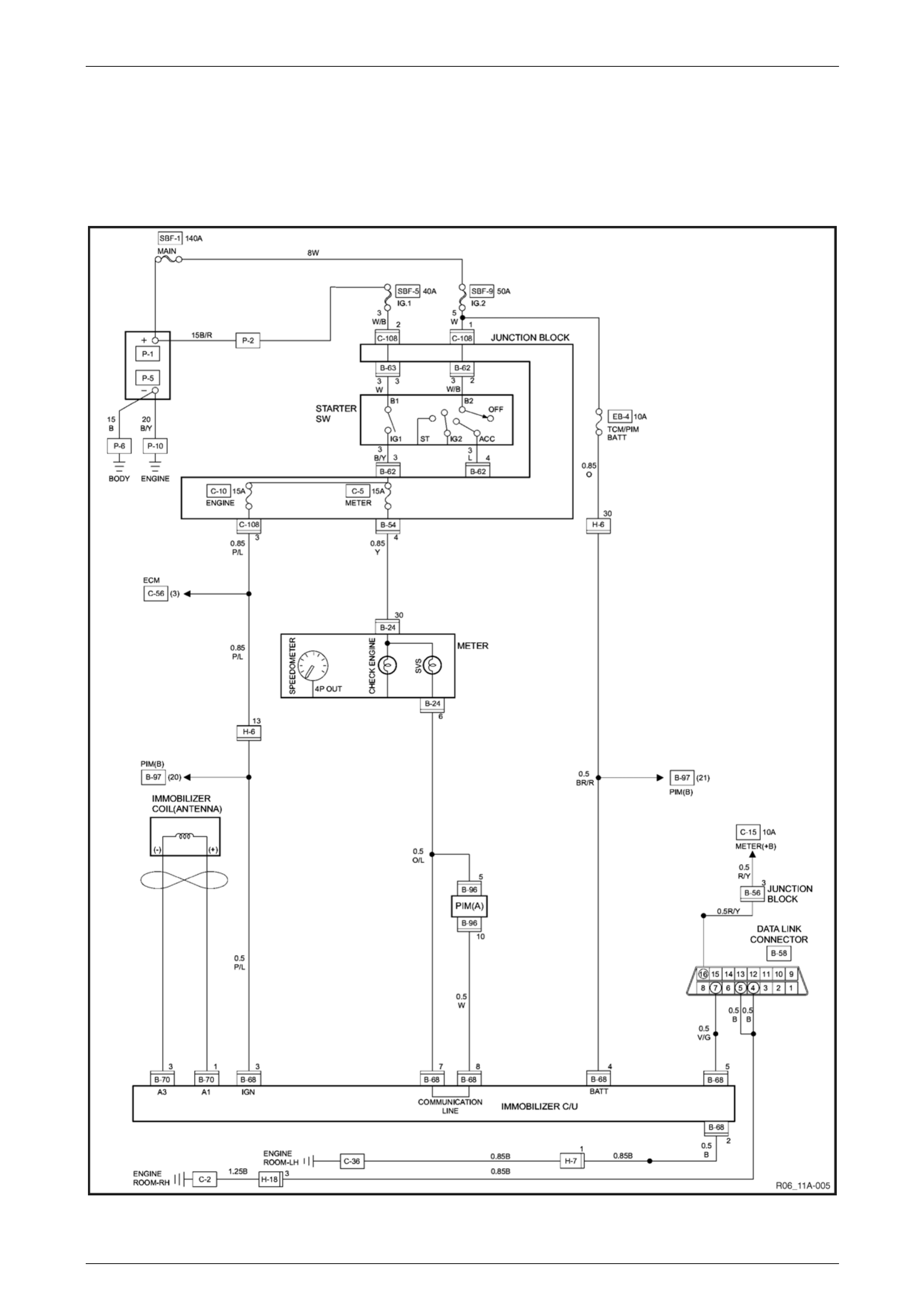

5 Wiring Diagram and Harness

Connector

5.1 Wiring Diagram

Figure 11A-1 – 6

Immobiliser System – HFV6 Page 6E1–12

Page 6E1–12

5.2 Harness Connector

Immobiliser Control Unit Connector – B70

Pin Description

Pin Function

1 Antenna coil positive

2 Not Connected

3 Antenna coil negative

Figure 11A-1 – 7

Immobiliser Control Unit Connector – B78

Pin Description

Pin Function

1 Not Connected

2 Ground

3 Ignition Supply Voltage

4 12 V Uninterrupted Supply Voltage

5 To Tech 2

6 Not Connected

7 Communication

8 Communication

Figure 11A-1 – 8

Immobiliser System – HFV6 Page 6E1–13

Page 6E1–13

6 Diagnostics Starting Point

6.1 Diagnostic Requirements, Precautions

and Preliminary Checks

Basic Knowledge Required

A lack of basic understanding of electronics,

electrical wiring circuits and use of electrical

circuit testing tools when performing the ICU

diagnostic procedures could result in

incorrect diagnostic results or damage to

components.

In addition, understanding of the Engine Management System is essential to prevent misdiagnosis an d component

damage. Refer to Section 6C1-1 Engine Ma nagement – V6 – General Information.

Basic Diagnostic Tools Required

Use of incorrect electrical circuit diagnostic

tools when performing the ICU diagnostic

procedures could result in incorrect

diagnostic results or damage to components.

The following electrical circuit testing tools are required to perform the diagnostic procedu r es detailed in this Section:

• Tech 2.

• Test lamp, refer to Section 8A Electrical - Body and Chassis for further information.

• Digital multimeter with 10 MΩ impedance, refer to Section 8A Electrical - Body and Chass is for further information.

• Connector test adapter kit Tool No. J35616-A.

Diagnostic Precautions

• Use only the test equipment specified in the diagnostic tables. Other test equipment may either give incorrect

results or damage serviceable components.

• Do not clear any DTCs unless instructed.

• The fault must be present when using the DTC Diagnostic T ables. Otherwise, misdiagnosis or replacement of

serviceable parts may occur.

• Always use connector adapters such as those contained in connector test adapter kit Tool No. J35616-A to prevent

connector terminal damage.

• Thorough inspection of the wiring circuits and connectors listed in the diagnostic procedures must be performed,

otherwise misdiagnosis may occur.

• Inspect the electrical circuitry or connector terminals that are suspected to be causing the compl aint for the

following conditions:

• backed-out connector terminals,

• improper wiring connector mating,

• broken wiring connector locks,

• damaged connector terminals, and

• physical damage to the wiring harness.

• Before replacing a component, inspect its connector terminal for corrosion or deformation that may cause the fault

condition.

Immobiliser System – HFV6 Page 6E1–14

Page 6E1–14

Preliminary Checks

The ICU preliminar y check examines easily accessible components which may cause probl ems with the ICU. This visual

and physical inspection proc edure may quickly identify the fault condition and eliminate the need for additional diagnosis.

• Refer to Service Techlines for releva nt information regarding the fault condition.

• Ensure the battery is fully charged.

• Check the battery connections for corrosion or a loose terminal.

• Perform a visual and physical inspection of the following:

• ICU component wiring harness and terminals for proper connections, pinches or cuts, and

• ICU wiring harness routing which may be positioned very close to a high voltage or high current devices such

as aftermarket audio systems.

NOTE

High voltage or high current devices may induce

electrical noise on a circuit, which can interfere

with normal circuit operation.

• The ICU is sensitive to Electro Magnetic Interference (EMI). Check for incorrect aftermarket theft deterrent

devices, lights or mobile phon e installations if an intermittent malfunction is suspected.

Diagnostic Aids

Check the condition for system parts.

• Installation condition, poor connection, damage, system parts malfunction. Harness, Fuse, Relay, Immobiliser coil

(antenna), Key, Meter, immobiliser control unit (ICU), Engine control module (ECM).

NOTE

Breakage of immobiliser fuse does not operate

immobiliser system. SVS flashes at this time.

Check the Electro Magnetic Interference (EMI)

• Location of vehicle check.

Move the vehicle to a new location and p erfo rm the check again.

• Non-OEM Parts.

Switch is "OFF" or remove the Non-OEM parts and perform the check a ga in .

• Other.

Remove the accessory and an other key from key.

Check the other items.

• Battery voltage is low.

• Immobiliser programming func tions.

Must be programmed immobiliser system.

• Registration for security code, immobiliser control unit parts number.

• Key switch operation.

Immobiliser system may detect a history DTC by the timing of ON-OFF of a key switch.

• Active the immobiliser system.

• Keyless entry system is malfunction.

• Anti theft system is malfunction.

Check the operation

• Check the operation "Lock / unlock" by using transmitter (key) on the vehicle.

Immobiliser System – HFV6 Page 6E1–15

Page 6E1–15

6.2 Diagnostic Trouble Codes

Immobiliser Control Unit (ICU)

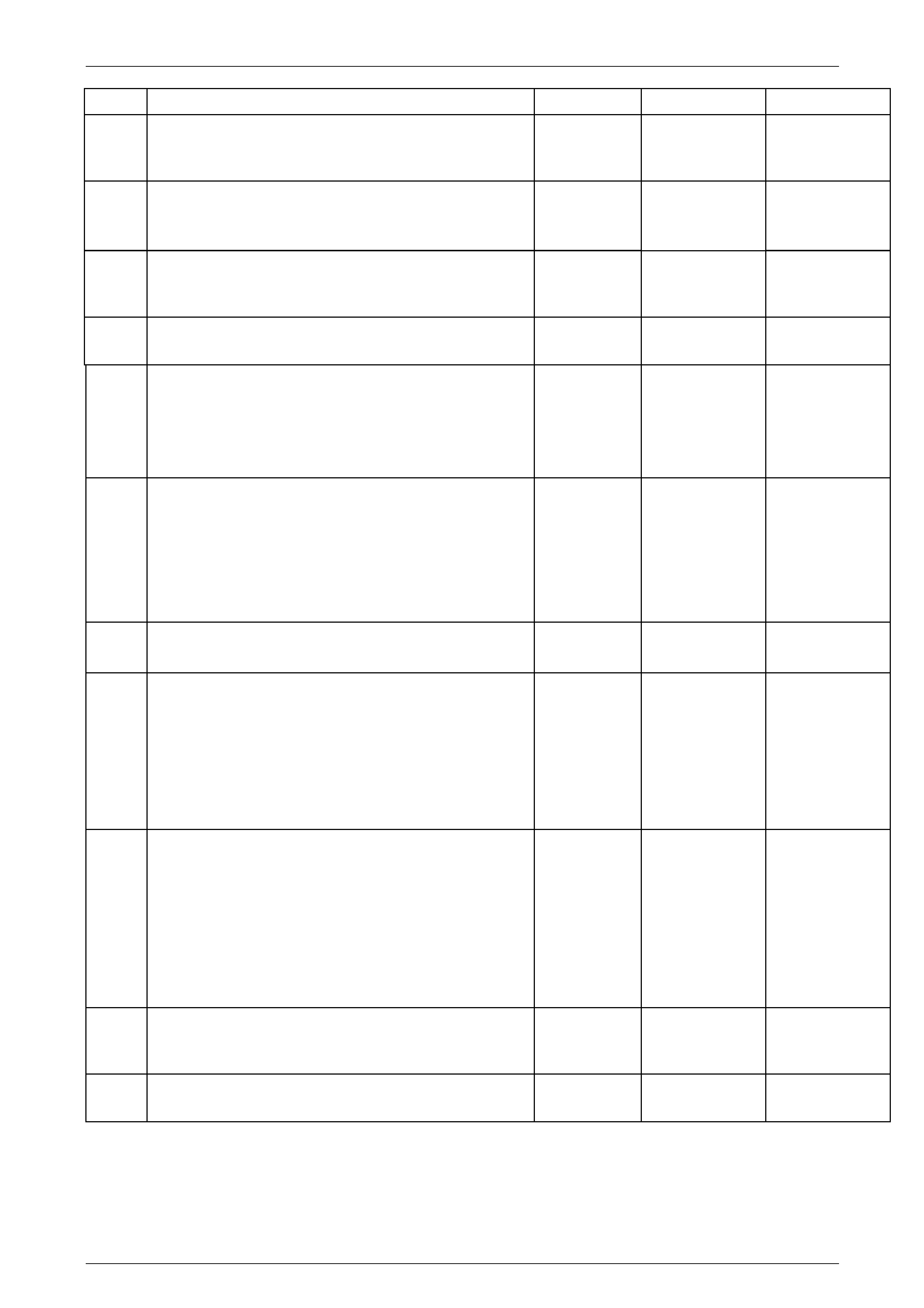

DTC Description Note

B0001 Replace electronic control unit (ECU)

(immobiliser fault) This error code appears if a RAM / ROM Error was

detected or the EEPROM is defect.

B0002 immobiliser not prog rammed Immobiliser control unit is not programm ed.

B0003 Transponder key problem ・Reading of Transponder information failed with ignition

on transponder has a fault.

・Hardware fault in reading circuit.

B0004 Immobiliser coil circuit (antenna coil fault) Immobiliser coil has a fault.

B0005 Communication line w voltage low Short circuit to ground or open circuit.

B0006 Communication line w voltage high Short circuit to 12V.

B0007 No engine request received No PIM Challenge.

B0008 Wrong transponder key Incorrect security code response received.

B0009 No transponder key programmed Transponder security code table empty.

B0010 Unknown transponder key Transponder security code not valid.

Immobiliser System – HFV6 Page 6E1–16

Page 6E1–16

6.3 Immobiliser System and Warning Lamp

Check

Immobiliser System Check

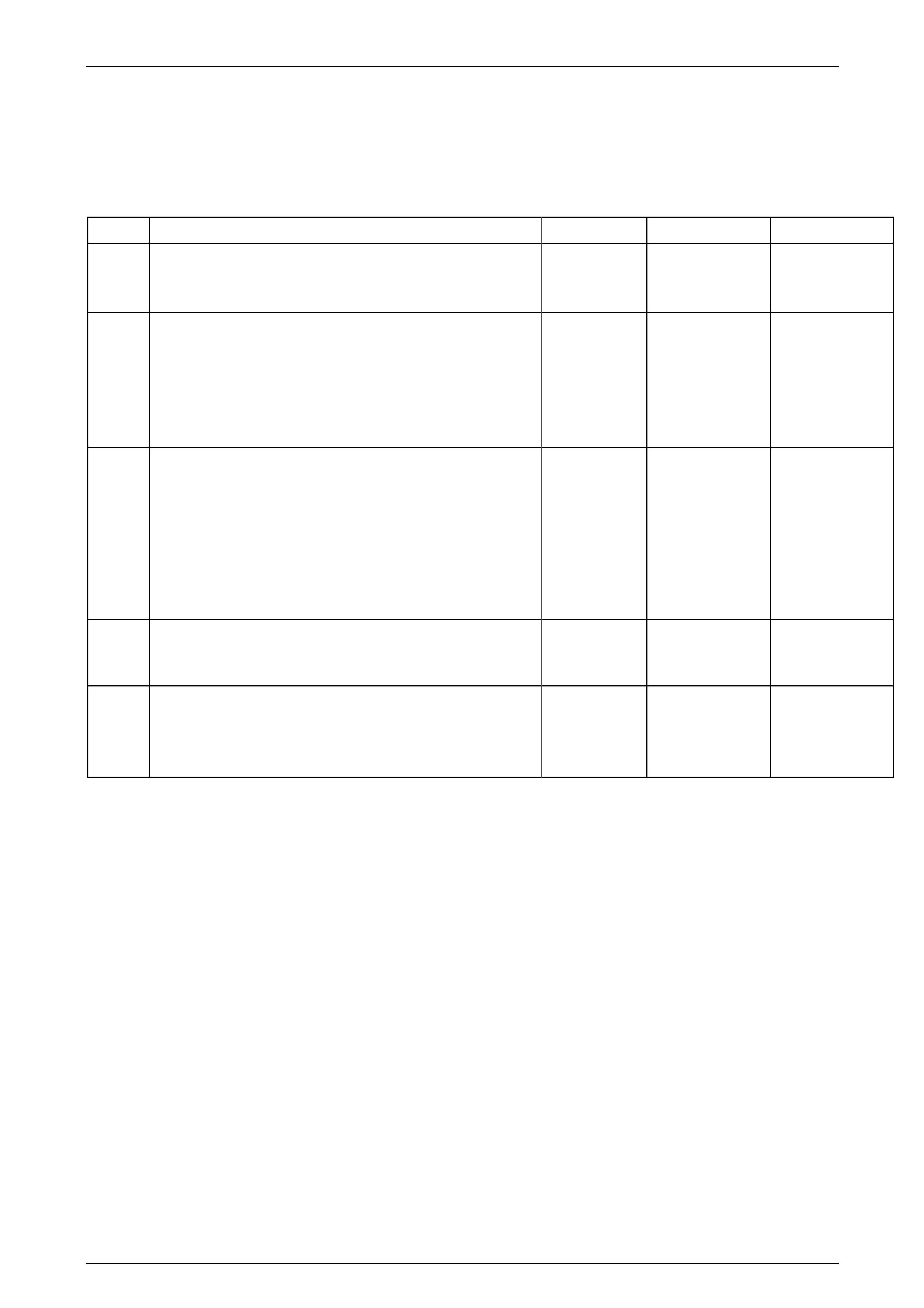

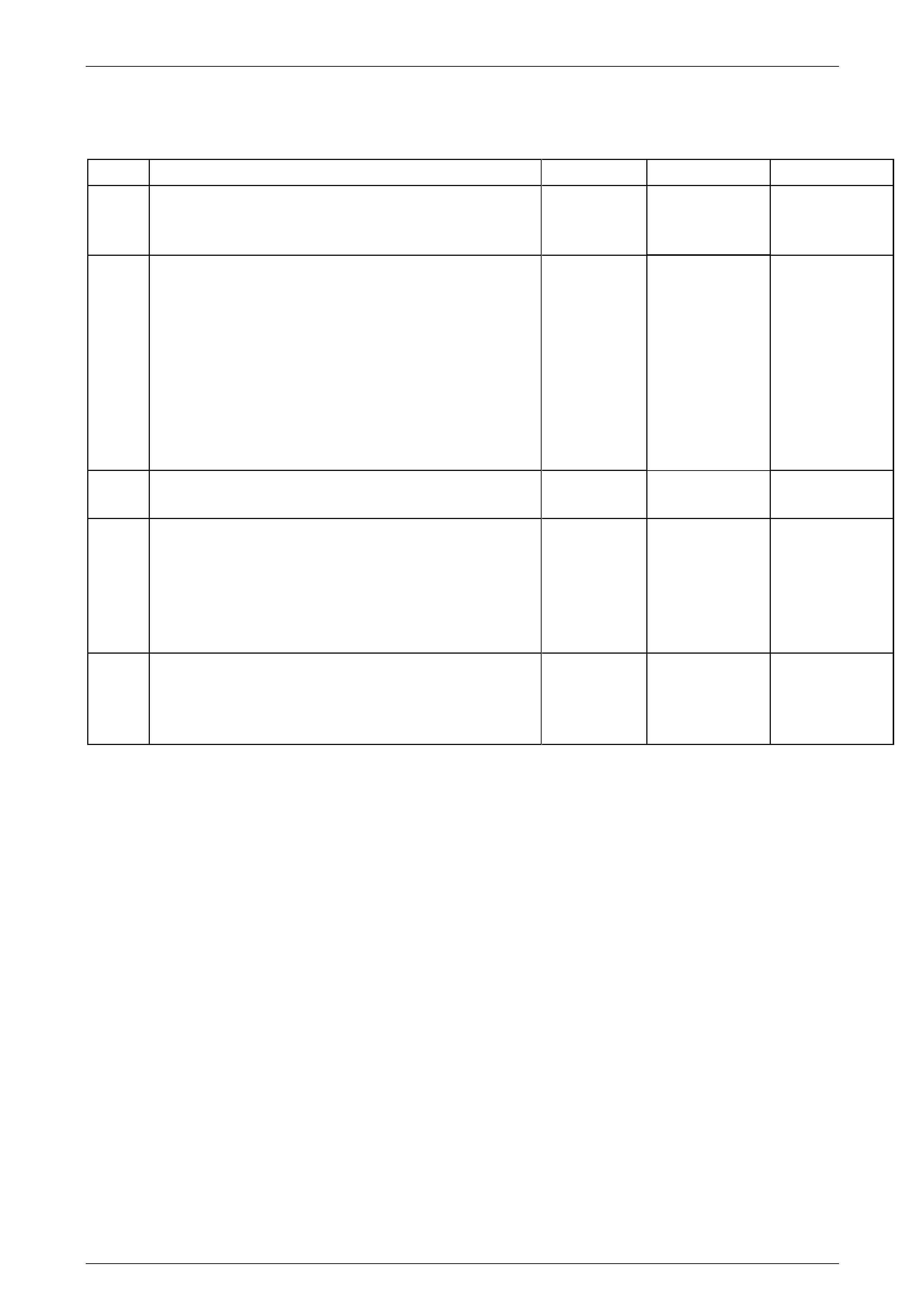

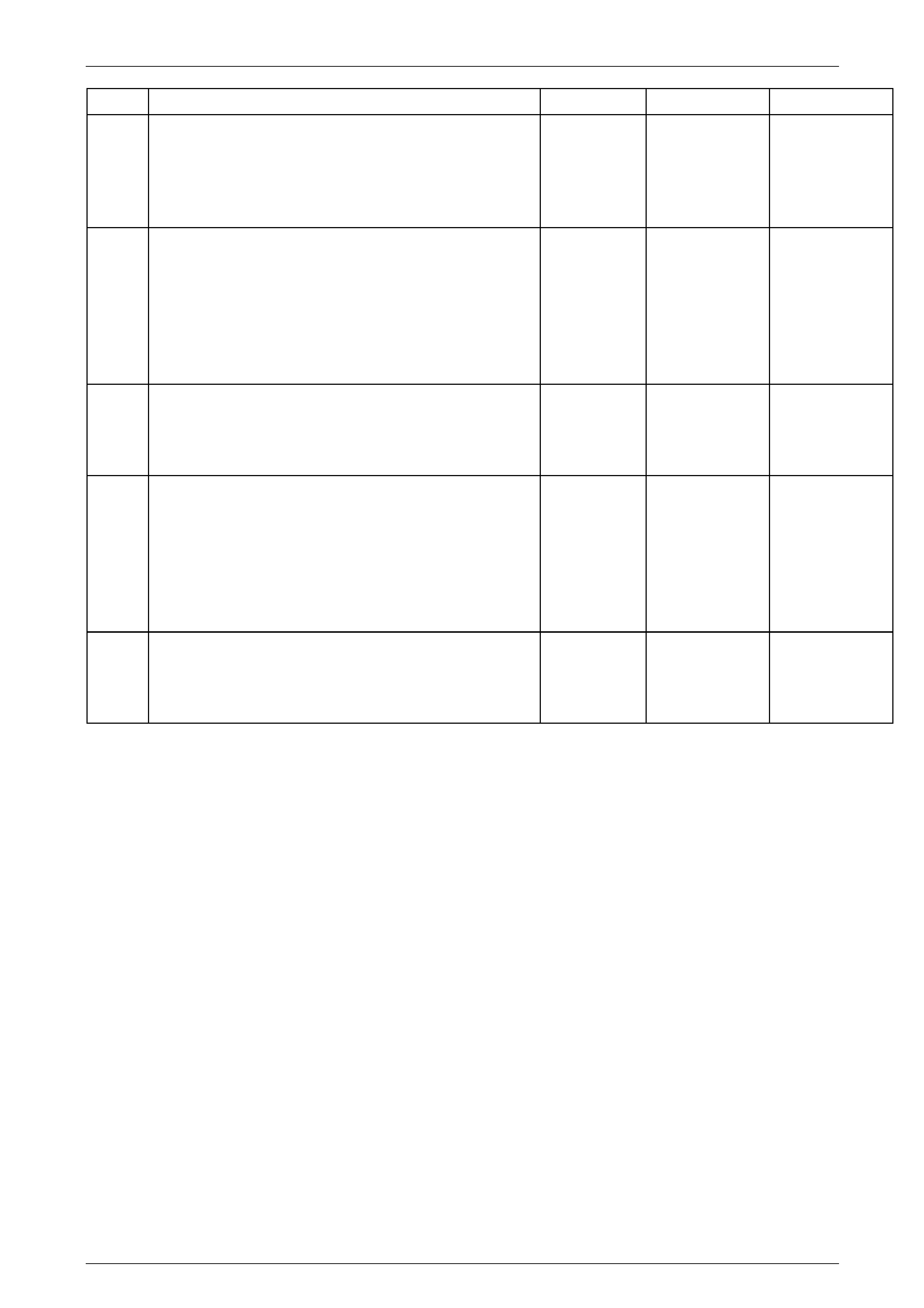

Step Action Value(s) Yes No

1 1. Key position is "ON," engine "OFF."

2. Observe the service vehicle soon (SVS) lamp.

Note: When a key switch is turned ON, SVS lamp will

turn on and a SVS lamp will be turned off after a few

seconds.

Is the SVS "ON"?

⎯ Go to Step 2 Go to

No Immobiliser

Warning Lamp

2 1. Key position is "ON," engine "OFF."

2. Observe the SVS.

Note: When a key switch is turned ON, SVS will turn

on and a SVS will be turned off after a few seco nds.

Is the SVS "OFF"?

( SVS does not flash)

⎯ Go to Step 3 Go to

Immobiliser

Warning Lamp

On Steady

3 1. Key position is "OFF."

2. Install a scan tool.

3. Key position is "ON."

4. Attempt to display immobiliser data with the scan

tool.

Does the scan tool display immobiliser data?

⎯ Go to Step 9 Go to Step 4

4 1. Key position is "OFF," disconnect the immobiliser

control unit (ICU).

2. Check the data link connector (DLC) circuit for an

open, short to ground, or short to voltage.

Also, check the DLC ignition feed circuit for an

open or short to ground and the DLC ground

circuit for an open.

Was a problem found?

⎯ Go to Step 5 Go to Step 6

5 Repair or replace the data link connector (DLC)

circuit.

Was the action complete?

⎯ Go to Step 3 ⎯

6 1. Check the ICU circuit for an open, short to ground,

or short to voltage. Also, check the ICU ignition

feed circuit for an open or short to ground and the

ICU ground circuit for an open.

2. If a problem is found, repair as necessary.

Was a problem found?

⎯ Go to Step 7 Go to Step 8

7 Repair or replace the ICU ignition feed and ground

circuits.

Was the action complete?

⎯ Go to Step 3 ⎯

8 Replace the immobiliser control u nit (ICU).

IMPORTANT: The replacement ICU must be

programmed the immobiliser data by the scan tool.

Was the action complete?

⎯ Go to Step 3 ⎯

9 Select "Display DTCs" with the scan tool.

Are any DTCs stored?

⎯ Go to Step 10 Go to Step 13

Immobiliser System – HFV6 Page 6E1–17

Page 6E1–17

Step Action Value(s) Yes No

10 Review and record for scan tool Failure Records data

and DTCs.

Was the action complete?

⎯ Go to Step 11 ⎯

11 Following the DTC is stored.

Are there DTC B0001 or B0055 stored? Go to applicable

DTC table after

Go to Step 12

Go to Step 12

12 Clear the DTCs by "Clear the Information "with scan

tool.

Did the DTCs Cleared?

⎯ Go to Step 12 ⎯

13 Select "Display DTCs" with the scan tool.

Are any DTCs stored?

⎯ Go to applicable

DTC table Go to Step 14

14 1. Key position is "ON," engine "OFF."

2. Observe the SVS.

Note: If a key switch is turned ON, SVS will turn on

and a SVS will be turned off after a few seconds.

Is the SVS "flash"?

⎯ Go to Step 15 Go to Step 20

15 Check the powertrain interface module and engine

control syst em.

If a problem is found, repair as necessary.

IMPORTANT: The replacement ECM or PIM must be

programmed the immobiliser data by scan tool.

Was the action complete?

⎯ Go to Step 16 ⎯

16 Check the key.

Is a key peculiar to a vehicle?

⎯ Go to Step 18 Go to Step 17

17 Change into a peculiar key.

IMPORTANT: If replace the key, after replace lock

cylinders, perform the following below the items.

• Replace the keys and key cylinders.

• Program the immobiliser system.

(Refer to "Important information on Programming")

Was the action complete?

⎯ Go to Step 18 ⎯

18 Check the immobiliser programming functions.

• Immobiliser control unit (ICU).

• Powertrain Interface Module (PIM).

• Engine control module (ECM).

• Transponder (Key).

If a problem is found, repair as necessary.

(Refer to "Important Information on Programming")

Was the action complete?

⎯ Go to Step 19 ⎯

19 Operate the DTCs by "Clear the Information" with

scan tool.

Was the action complete?

⎯ Go to Step 20 ⎯

20 Attempt to start the engine .

Did the engine start?

⎯ System OK Refer to

Diagnostic Aids

Immobiliser System – HFV6 Page 6E1–18

Page 6E1–18

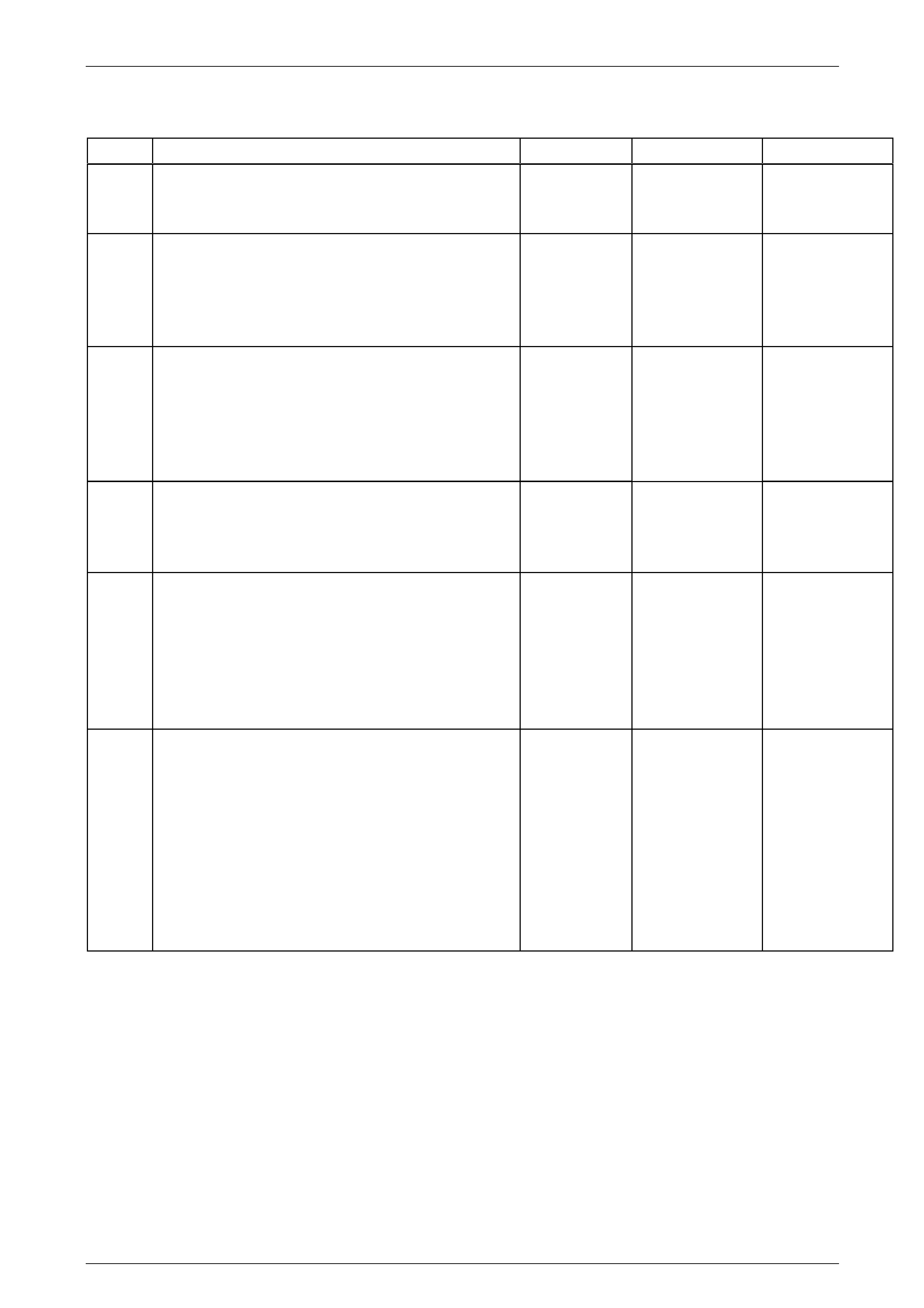

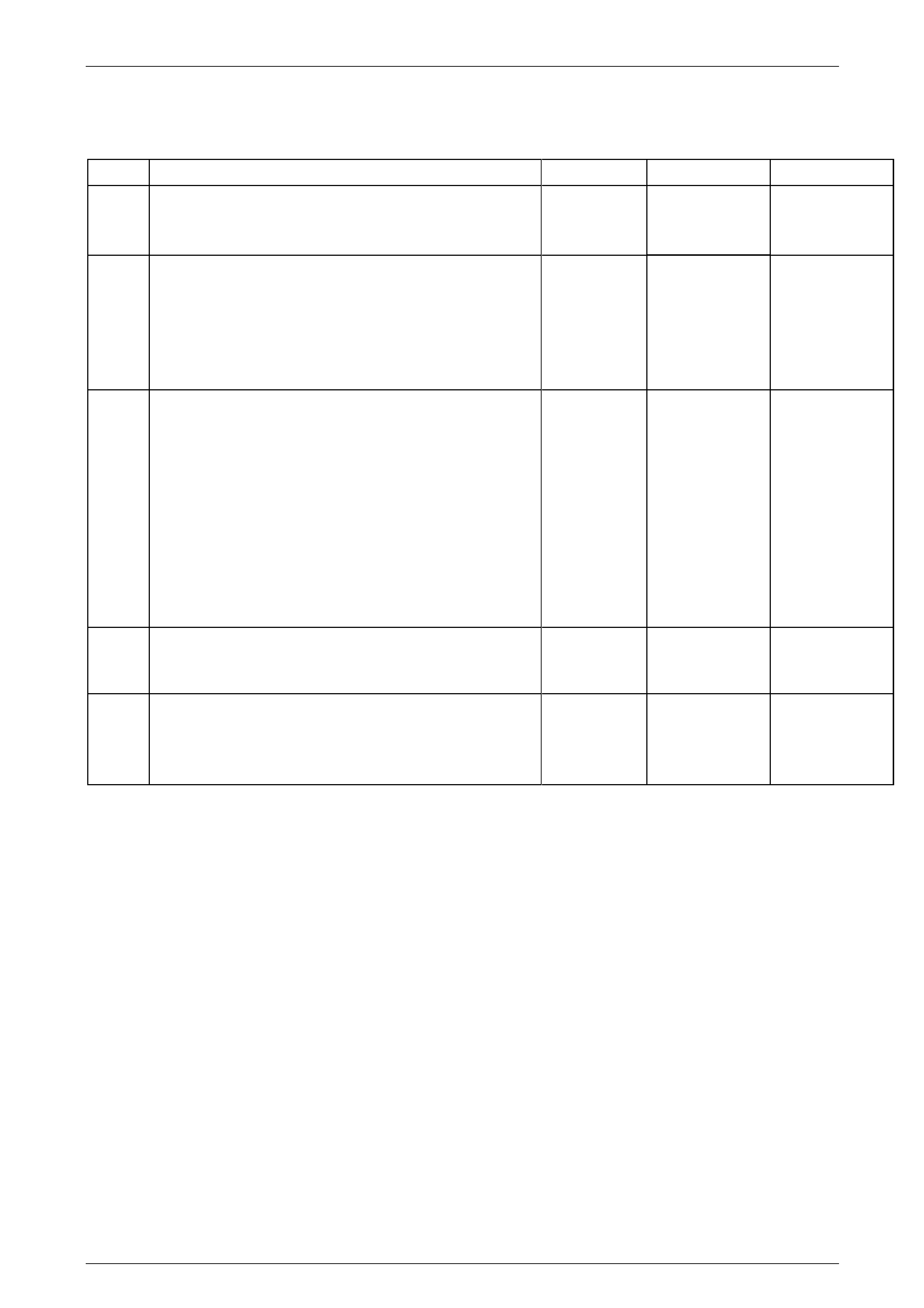

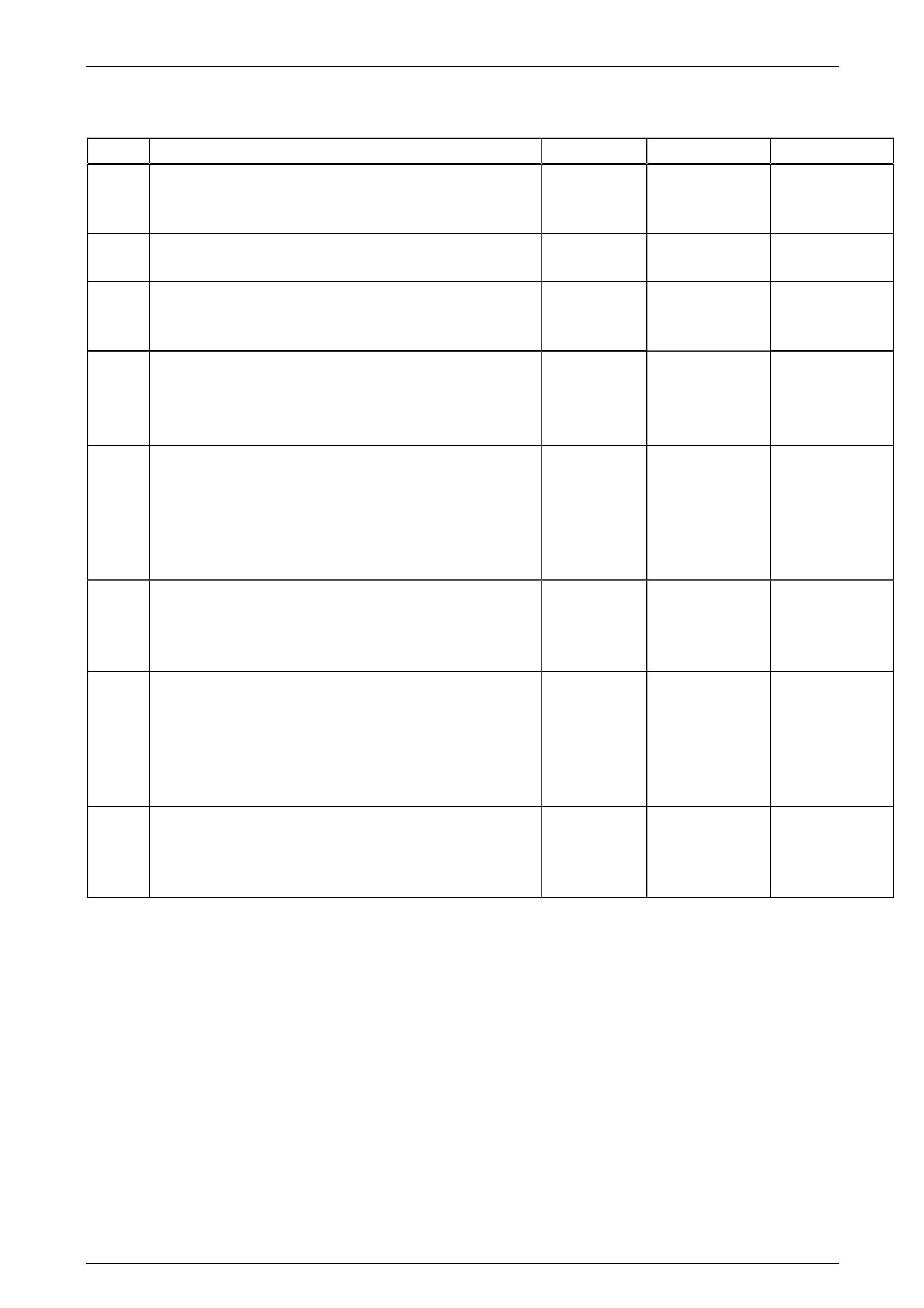

No Immobiliser Warning Lamp

Step Action Value(s) Yes No

1 Check the meter fuse for the instrument cluster

ignition feed circuit.

Is the fuse normal?

⎯ Go to Step 3 Go to Step 2

2 Replace the fuse.

Is the action complete?

⎯ Verify repair

Go to Step 3

⎯

3 1. Key position is "OFF".

2. Disconnect the meter.

3. Disconnect the powertrain interface module (PIM)

and immobiliser control unit.

4. Check the circuit between meter and PIM and

meter and ICU and meter for an open, short to

ground, or short to voltage.

Also, check the meter circuit for an open or short to

ground and the DLC ground circuit for an open.

Was a problem found?

⎯ Go to Step 4 Go to Step 5

4 Repair or replace the m eter circuit.

Was the action complete?

⎯ Go to Step 5 ⎯

5 1. Key position is "ON," engine "OFF."

2. Observe the SVS.

Is the SVS "ON"?

⎯ Go to Step 6 Go to Step 7

6 Repair or replace the m eter.

Was the action complete?

⎯ Go to Step 7 ⎯

7 1. Key position is "OFF".

2. Check the SVS bulb.

Is the SVS bulb normal?

⎯ Go to Step 9 Go to Step 8

8 Replace the SVS bulb.

Is the action complete?

⎯ Verify repair

Go to Step 9

⎯

9 1. Key position is "OFF".

2. Connect the meter.

3. Connect the PIM and ICU).

4. Key position is "ON".

5. Observe the SVS.

Note: If a key switch is turned ON, SVS will turn on

and a SVS will be turned off after a few seconds.

Is the SVS "ON"?

⎯ Verify repair Go to Step 10

10 Replace the powertrain interface modul e (PIM).

IMPORTANT: The replacement PIM must be

programmed the immobiliser data by scan tool.

Was the action complete?

⎯ Verify repair ⎯

Immobiliser System – HFV6 Page 6E1–19

Page 6E1–19

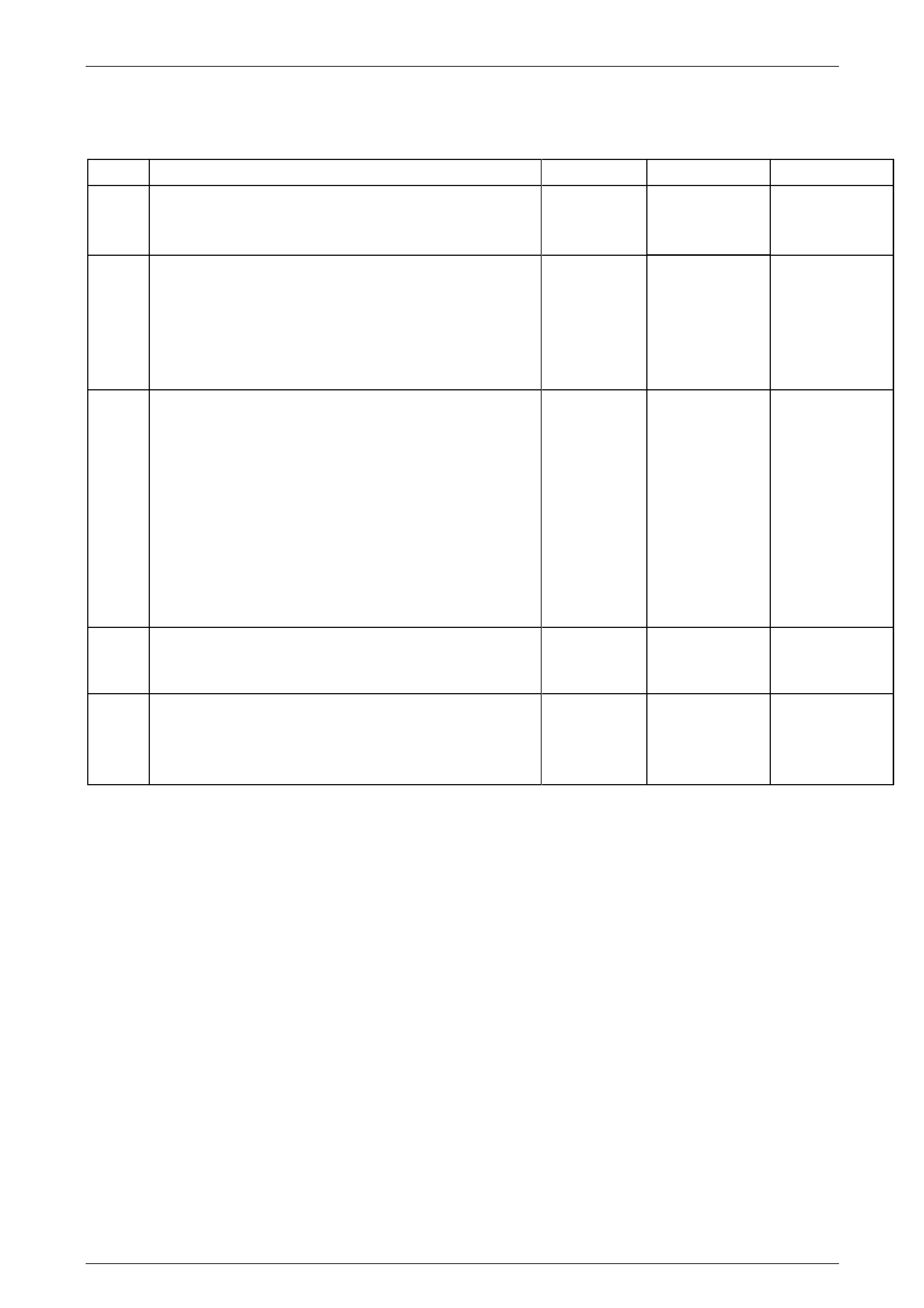

Immobiliser Warning Lamp On Steady

Step Action Value(s) Yes No

1 1. Key position is "OFF".

2. Disconnect the immobiliser control unit (ICU).

3. Disconnect the powertrain interface module (PIM).

4. Key position is "ON," engine "OFF."

5. Observe the SVS.

Is the SVS "ON"?

⎯ Go to Step 2 Go to Step 5

2 1. Key position is "OFF".

2. Disconnect the meter.

3. Key position is "ON," engine "OFF."

4. Observe the SVS.

Is the SVS "ON"?

⎯ Go to Step 3 Go to Step 4

3 Repair or replace the m eter.

Was the action complete?

⎯ Verify repair

Go to Step 5

⎯

4 Repair or replace the m eter circuit.

(Between meter and ICU/PIM)

Was the action complete?

⎯ Verify repair

Go to Step 5

⎯

5 Check the immobiliser control unit (ICU) circuit.

1. Ignition "OFF," disconnect the ICU.

2. Check the ICU circuit for an open, short to ground,

or short to voltage.

Also, check the ICU ignition feed circuit for an open or

short to ground and the ICU ground circuit for an

open.

Was a problem found?

⎯ Go to Step 6 Go to Step 7

6 Repair or replace the immobiliser control unit (ICU)

circuit.

Was the action complete?

⎯ Verify repair

Go to Step 7

⎯

7 1. Key position is "OFF".

2. Connect the meter.

3. Connect the immobiliser control unit (ICU).

4. Connect the engine control module (PIM).

5. Key position is "ON".

6. Observe the SVS.

Is the SVS "ON"?

⎯ Verify repair Refer to

Diagnostic Aids

Immobiliser System – HFV6 Page 6E1–20

Page 6E1–20

7 Intermittent Fault Conditions

7.1 Intermittent Conditions Diagnostic Table

Description

A fault condition is intermittent if one of the following conditions exists:

• The fault condition is not al ways present.

• The fault condition cannot be presently duplicated.

• There is no current DTC but a History DTC is stored.

Diagnostic Table

Checks Actions

Preliminary • Perform the Preliminary Chec ks, refe r to 6.1 Diagnostic Re quirements,

Precautions and Preliminary Checks.

• Gather information from the customer regarding the conditions that trigger the

intermittent fault such as:

• At what engine or ambient temperature range do es the fault occur?

• Does the fault occur when operating aftermarket electrical equi pment inside

the vehicle?

• Does the fault occur on rough roads or in wet road conditions?

Harness / Connector Install Tech 2 and perform the Tech 2 Intermittent Fault Tests. Refer to

4.1 Diagnostic General Descriptions for information on Tech 2 ECU diagnostic tests.

Warning Indicator The following conditions may cause an intermittent service vehicle soon (SVS) Lamp

fault with no DTC listed:

• Electro Magnetic Interference (EMI) caused b y a faulty relay, ECM controlled

solenoid, switch or other external source.

• Incorrect installation of aftermarket electrical equipment such as the following:

• mobile phones,

• theft deterrent alarms,

• lights, or

• radio equipment.

• Loose ICU or PIM ground connections.

Immobiliser System – HFV6 Page 6E1–21

Page 6E1–21

Checks Actions

Temperature Related The Tech 2 Freeze Frame / Failure Records or Snapshot data may be used if applica ble

to the fault condition. Refer to 4.1 Diagnostic General Descriptions for information on

Tech 2 ECU diagnostic tests.

• If the intermittent fault is heat related, review the Tech 2 data in relationshi p to the

following:

• high ambient temperature,

• underhood / engine generate d heat,

• circuit generated heat due to a poor electrical connection or high electrical

load, and

• higher than normal load conditions (towing, etc.).

• If the intermittent fault is related to cold ambient or engine temperature, review the

Tech 2 data in relationship to the following:

• low ambient temperature, and

• the fault condition that occurs only on a cold start situation.

Additional Tests • Check for incorrect installation of aftermarket electrical equipment such as the

following:

• mobile phones,

• theft deterrent alarms,

• lights, or

• radio equipment.

• Check for Electro Magnetic Interference (EMI) caused b y a faulty relay, ECM

controlled solenoid or switch. The fault is triggered when the relay or solenoid is

activated.

• Check the A/C compressor clutch and some rela ys that contain a clamping diode

or resistor for an open circuit.

• Check the generator for a faulty rectifier bridge that may allow A/C noise into the

ICU or PIM electrical circuit.

When all diagno sis an d repairs are completed, check the engine management system for correct operation.

Immobiliser System – HFV6 Page 6E1–22

Page 6E1–22

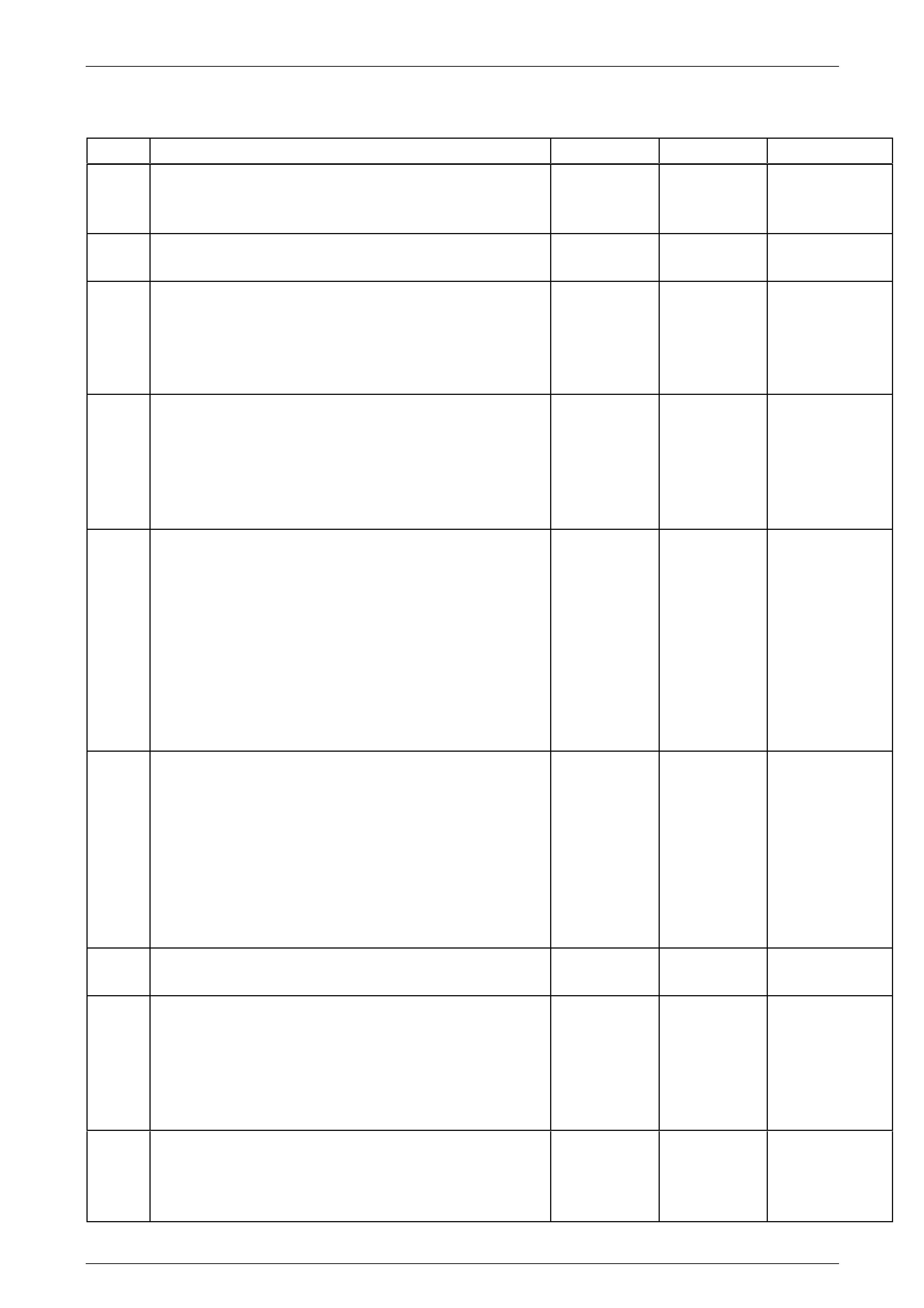

8 DTC Tables

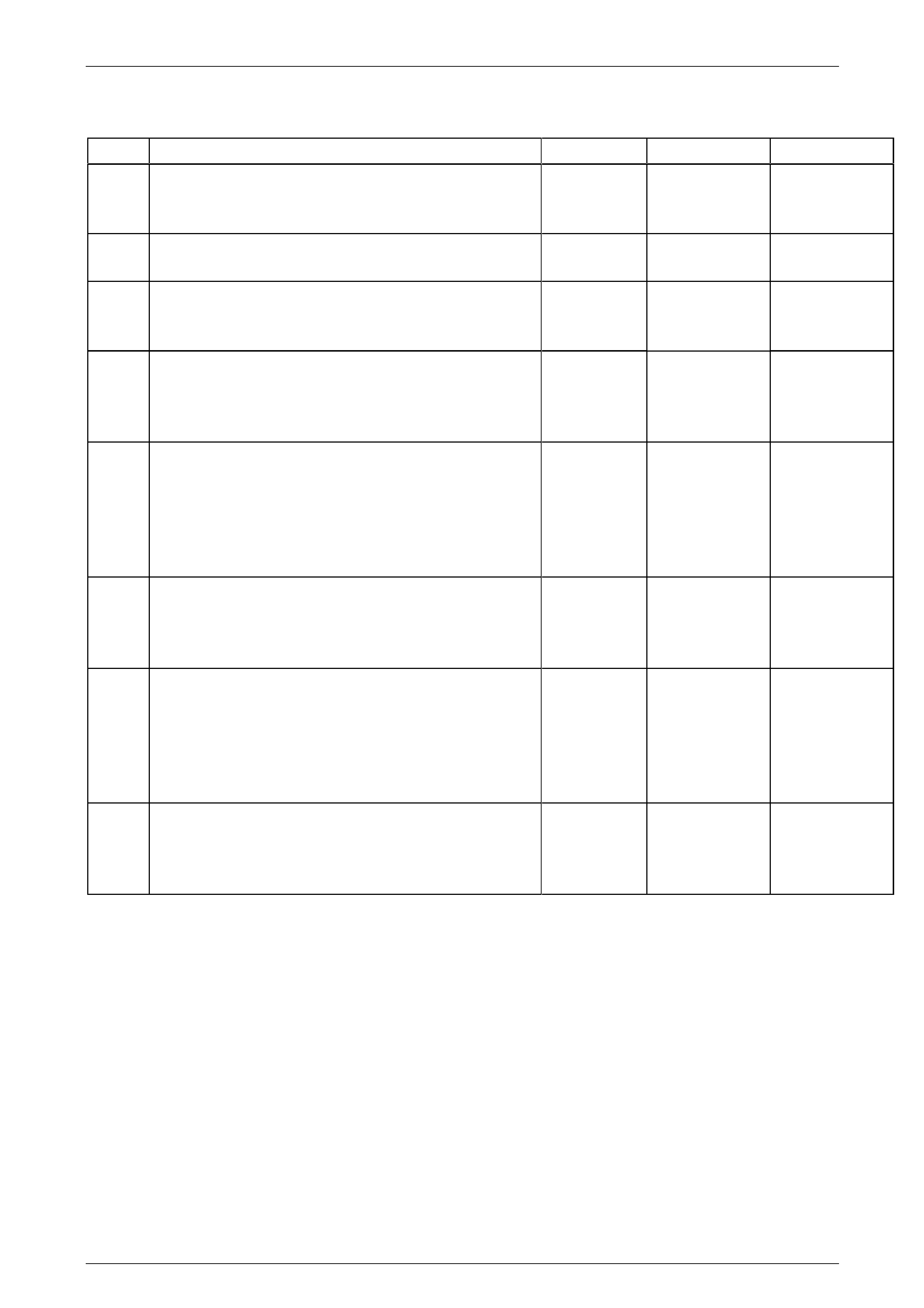

8.1 B0001 Replace Electronic Control Unit

(Immobiliser Fault)

Step Action Value(s) Yes No

1 Was the “Immobiliser System and Warning Lamp

Check” perfor med?

⎯ Go to Step 2 Go to

Immobiliser

System Check

2 Recheck the DT C.

1. Key position is “OFF”.

2. Install the scan tool on vehicle.

3. Key position is “ON”.

4. Check the DTC on scan tool.

Is DTC B0001 stored?

⎯ Go to Step 3 Refer to

Diagnostic Aids

3 Check the immobiliser control unit (ICU) circuit.

1. Ignition "OFF," disconnect the ICU.

2. Check the ICU circuit for an open, short to ground,

or short to voltage.

Also, check the ICU ignition feed circuit for an open or

short to ground and the ICU ground circuit for an

open.

Was a problem found?

⎯ Go to Step 4 Go to Step 5

4 Repair or replace the immobiliser control unit (ICU)

circuit.

Was the action complete?

⎯ Verify repair ⎯

5 Replace the immobiliser c ontrol unit (ICU).

IMPORTANT: The replacement ICU must be

programmed the security data by scan tool.

Was the action complete?

⎯ Verify repair ⎯

Immobiliser System – HFV6 Page 6E1–23

Page 6E1–23

8.2 B0002 Immobiliser Not Programmed

Step Action Value(s) Yes No

1 Was the “Immobiliser System and Warning Lamp

Check” perfor med? ⎯ Go to Step 2 Go to

Immobiliser

System Chec k

2 Check the immobiliser programming functions.

• Immobiliser control unit (ICU).

If a problem is found, repair as necessary.

(Refer to "Important information on Programming")

Was the action complete?

⎯ Go to Step 3 Go to Step 5

3 Recheck the DT C.

1. Key position is “OFF” and keep the position for

more than 30 seconds.

2. Key position is “ON”.

3. Check the DTC on scan tool.

Is DTC B0002 stored?

⎯ Go to Step 4 Verify repair

4 Replace the immobiliser c ontrol unit (ICU).

IMPORTANT: The replacement ICU must be

programmed the security data by scan tool.

Was the action complete?

⎯ Verify repair ⎯

5 Check the immobiliser programming functions.

• Powertrain interface module.

• Engine control module (ECM).

• Immobiliser control unit (ICU).

If a problem is found, repair as necessary.

(Refer to "Important information on Programming")

Was the action complete?

⎯ Verify repair Go to Step 6

6 Replace the key and lock cylinder assembly and

immobiliser system (ICU and ECM).

IMPORTANT:

• ICU, PIM and ECM are not replacing

simultaneously.

• After replace lock cylinders, perform the

following below the items.

• Program the immobiliser system.

(Refer to "Important information on Programming")

Was the action complete?

⎯ Verify repair ⎯

Immobiliser System – HFV6 Page 6E1–24

Page 6E1–24

8.3 B0003 Transponder Key Problem

Step Action Value(s) Yes No

1 Was the “Immobiliser System and Warning Lamp

Check” perfor med?

⎯ Go to Step 2 Go to

Immobiliser

System Chec k

2 Check the key.

Is a key peculiar to a vehicle?

⎯ Go to Step 3 Refer to

Diagnostic Aids

3 Check the immobiliser programming functions.

• All transponder (Key).

If a problem is found, repair as necessary.

(Refer to "Important Information on Programming")

Was the action complete?

⎯ Go to Step 4 Go to Step 5

4 Recheck the DT C.

1. Key position is “OFF” and keep the position for more

than 30 seconds.

2. Key position is “ON”.

3. Check the DTC on scan tool.

Is DTC B0003 stored?

⎯ Go to Step 5 Verify repair

5 Recheck the DT C.

1. Non-OEM parts switch is "OFF" or remove the Non-

OEM parts.

2. Remove the accessory and another key from key.

3. Move the vehicle to a new location.

4. Key position is “OFF” and keep the position for more

than 30 seconds.

5. Key position is “ON”.

6. Check the DTC on scan tool.

Is DTC B0003 stored?

⎯ Go to Step 6 Verify repair

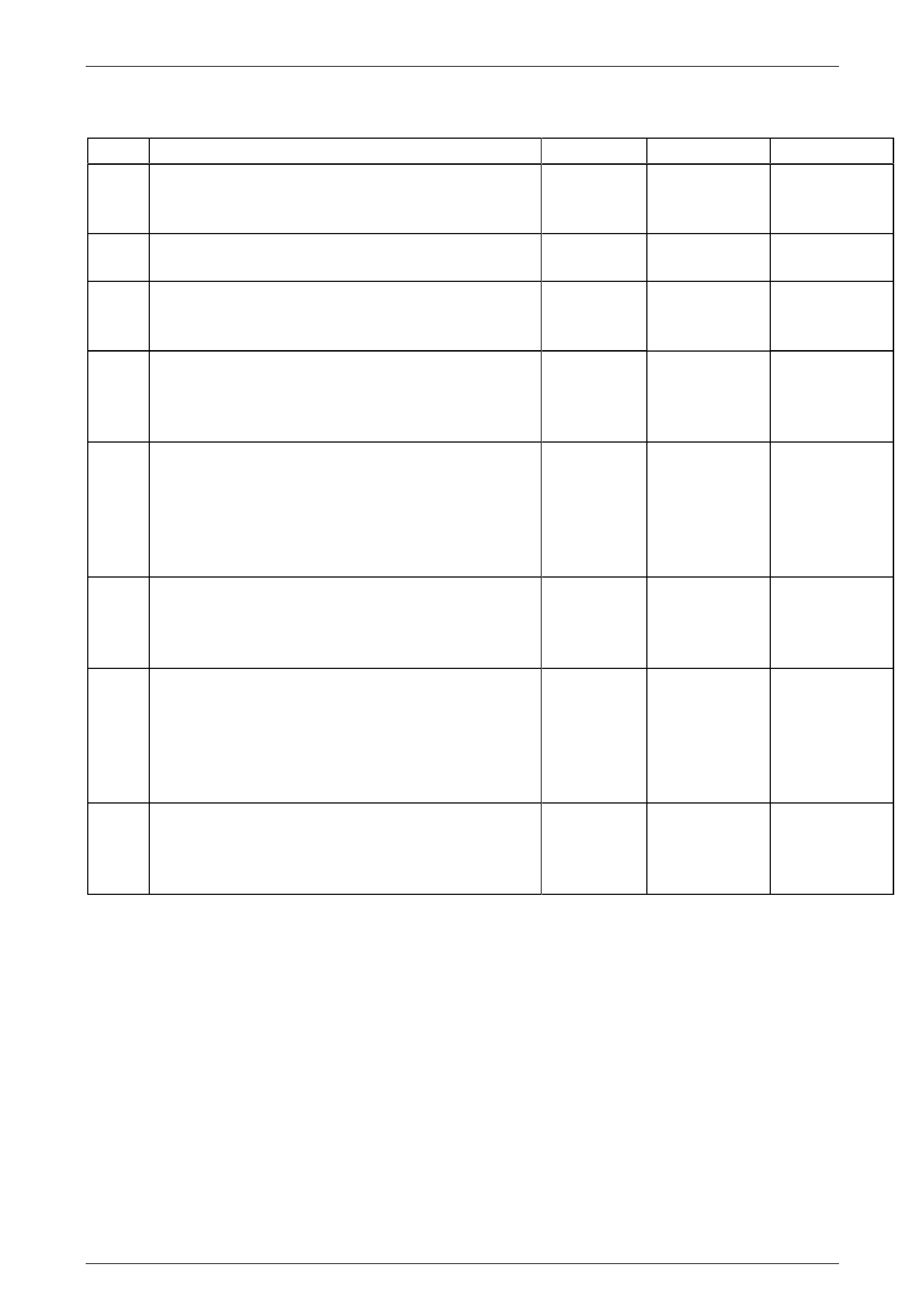

6 Check the immobiliser coil (antenna) circuit.

1. Key position is “OFF”.

2. Disconnect the immobiliser control unit (ICU).

(immobiliser coil circuit : 3 pin connector)

3. Check the immobiliser coil circuit for an open, short

to ground, or short to voltage.

Also, check the ICU ignition feed circuit for an open or

short to ground and the ICU ground circuit for an open.

Was a problem found?

⎯ Go to Step 7 Go to Step 8

7 Repair or replace the immobiliser coil (antenna) circuit.

Was the action complete?

⎯ Verify repair ⎯

8 Recheck the DT C.

1. Key position is “OFF” and keep the position for more

than 30 seconds.

2. Key position is “ON”.

3. Check the DTC on scan tool.

Is DTC B0003 stored?

⎯ Go to Step 9 Verify repair

9 Replace the immobiliser c ontrol unit (ICU).

IMPORTANT: The replacement ICU must be

programmed the security data by scan tool.

Was the action complete?

⎯ Go to Step 10 ⎯

Immobiliser System – HFV6 Page 6E1–25

Page 6E1–25

Step Action Value(s) Yes No

10 Check the immobiliser programming functions.

• Immobiliser control unit (ICU).

• All transponder (Key).

If a problem is found, repair as necessary.

(Refer to "Important information on Programming")

Was the action complete?

⎯ Go to Step 11 ⎯

11 Recheck the DTC.

1. Key position is “OFF” and keep the position for more

than 30 seconds.

2. Key position is “ON”.

3. Check the DTC on scan tool.

Is DTC B0003 stored?

⎯ Go to Step 12 Verify repair

12 Replace the transponder (Key).

IMPORTANT: The replacement transponder (key)

must be programmed the security data b y scan tool.

Was the action complete?

⎯ Verify repair ⎯

Immobiliser System – HFV6 Page 6E1–26

Page 6E1–26

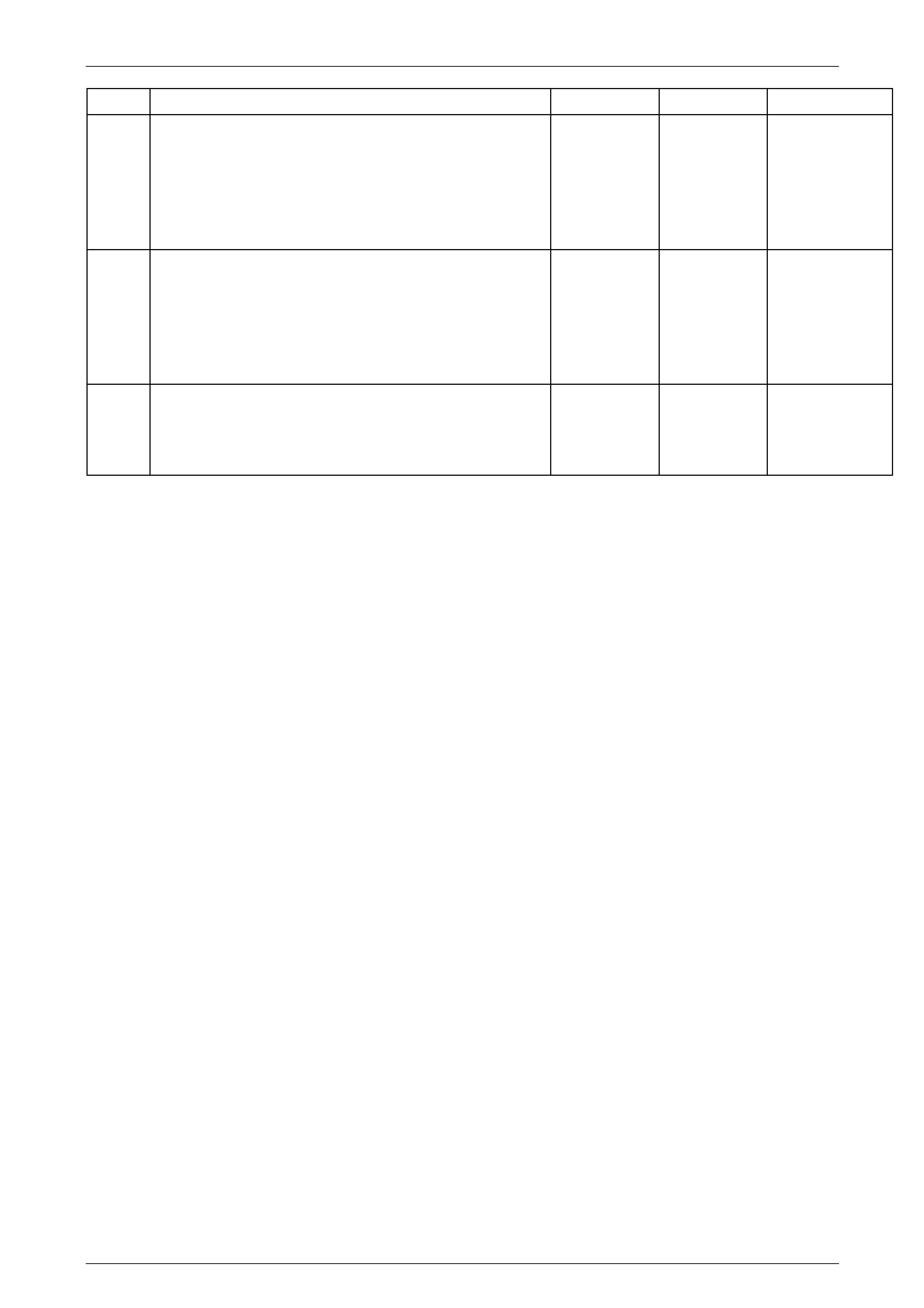

8.4 B0004 Immobiliser Coil Circuit (Antenna

Coil Fault)

Step Action Value(s) Yes No

1 Was the “Immobiliser System and Warning Lamp

Check” perfor med?

⎯ Go to Step 2 Go to

Immobiliser

System Chec k

2 Check the immobiliser coil (antenna) circuit.

1. Key position is “OFF”.

2. Disconnect the immobiliser control unit (ICU).

(immobiliser coil circuit : 3 pin connector)

3. Check the immobiliser coil circuit for an open,

short to ground, or short to voltage.

Also, check the ICU ignition feed circuit for an open or

short to ground and the ICU ground circuit for an

open.

Was a problem found?

⎯ Go to Step 3 Go to Step 4

3 Repair or replace the immobiliser coil (antenna).

Was the action complete?

⎯ Verify repair ⎯

4 Recheck the DT C.

1. Key position is “OFF” and keep the position for

more than 30 seconds.

2. Key position is “ON”.

3. Check the DTC on scan tool.

Is DTC B0004 stored?

⎯ Go to Step 5 Verify repair

5 Replace the immobiliser c ontrol unit (ICU).

IMPORTANT: The replacement ICU must be

programmed the security data by scan tool.

Was the action complete?

⎯ Verify repair ⎯

Immobiliser System – HFV6 Page 6E1–27

Page 6E1–27

8.5 B0005 Communication Line W Voltage

Low

Step Action Value(s) Yes No

1 Was the “Immobiliser System and Warning Lamp

Check” perfor med?

⎯ Go to Step 2 Go to

Immobiliser

System Chec k

2 Recheck the DT C.

1. Key position is “OFF”.

2. Install the scan tool on vehicle.

3. Key position is “ON”.

4. Check the DTC on scan tool.

Is DTC B0005 stored?

⎯ Go to Step 3 Refer to

Diagnostic Aids

3 Check the immobiliser communication W line circuit.

1. Key position is “OFF”.

2. Disconnect the immobiliser control unit (ICU).

3. Disconnect the powertrain interface module (PIM).

4. Check the immobiliser communication W line

circuit for an open, short to ground, or short to

voltage.

Also, check the ICU and PIM ignition feed circuits for

an open or short to ground and the ICU and PIM

ground circuit for an ope n.

Was a problem found?

⎯ Go to Step 4 Go to Step 5

4 Repair or replace the immobiliser communication W

line circuit.

Was the action complete?

⎯ Verify repair ⎯

5 Replace the immobiliser c ontrol unit (ICU).

IMPORTANT: The replacement ICU must be

programmed the security data by scan tool.

Was the action complete?

⎯ Verify repair ⎯

Immobiliser System – HFV6 Page 6E1–28

Page 6E1–28

8.6 B0006 Communication Line W Voltage

High

Step Action Value(s) Yes No

1 Was the “Immobiliser System and Warning Lamp

Check” perfor med?

⎯ Go to Step 2 Go to

Immobiliser

System Chec k

2 Recheck the DT C.

1. Key position is “OFF”.

2. Install the scan tool on vehicle.

3. Key position is “ON”.

4. Check the DTC on scan tool.

Is DTC B0006 stored?

⎯ Go to Step 3 Refer to

Diagnostic Aidss

3 Check the immobiliser communication W line circuit.

1. Key position is “OFF”.

2. Disconnect the immobiliser control unit (ICU).

3. Disconnect the powertrain interface module (PIM).

4. Check the immobiliser communication W line

circuit for an open, short to ground, or short to

voltage.

Also, check the ICU and PIM ignition feed circuits for

an open or short to ground and the ICU and PIM

ground circuit for an ope n.

Was a problem found?

⎯ Go to Step 4 Go to Step 5

4 Repair or replace the immobiliser communication W

line circuit.

Was the action complete?

⎯ Verify repair ⎯

5 Replace the immobiliser c ontrol unit (ICU).

IMPORTANT: The replacement ICU must be

programmed the security data by scan tool.

Was the action complete?

⎯ Verify repair ⎯

Immobiliser System – HFV6 Page 6E1–29

Page 6E1–29

8.7 B0007 No Engine Request Received

Step Action Value(s) Yes No

1 Was the “Immobiliser System and Warning Lamp

Check” perfor med?

⎯ Go to Step 2 Go to

Immobiliser

System Chec k

2 Recheck the DTC on ICU.

1. Key position is “OFF”.

2. Install the scan tool on vehicle.

3. Key position is “ON”.

4. Check the DTC on scan tool.

Is DTC B0007 stored?

⎯ Go to Step 3 Refer to

Diagnostic Aids

3 Check the immobiliser communication line circuit.

1. Key position is “OFF”.

2. Disconnect the immobiliser control unit (ICU).

3. Disconnect the powertrain interface module (PIM).

4. Check the immobiliser communication line circuit

for an open, short to ground, or short to voltage.

Also, check the ICU and PIM ignition feed circuits for

an open or short to ground and the ICU and PIM

ground circuit for an ope n.

Was a problem found?

⎯ Go to Step 4 Go to Step 5

4 Repair or replace the immobiliser communication line

circuit.

Was the action complete?

⎯ Verify repair ⎯

5 Recheck the DTC on ICU.

1. Key position is “OFF” and keep the position for

more than 30 seconds.

2. Key position is “ON”.

3. Check the DTC on scan tool.

Is DTC B0007 stored?

⎯ Go to Step 6 Verify repair

6 Recheck the DTC on PIM.

1. Key position is “OFF” and keep the position for

more than 30 seconds.

2. Key position is “ON”.

3. Check the DTC on scan tool.

Are below DTCs stored?

B3902 or P0633

⎯ Go to Step 7 Go to Step 9

7 Perform the immobiliser programming functions.

(Refer to "Important information on Programming")

• Powertrain Interface Module (PIM).

Was the action complete?

⎯ Go to Step 8 Go to Step 11

8 Recheck the DTC on PIM.

1. Key position is “OFF” and keep the position for

more than 30 seconds.

2. Key position is “ON”.

3. Check the DTC on scan tool.

Are below DTCs stored?

B3902 or P0633

⎯ Go to Step 11 Go to Step 12

Immobiliser System – HFV6 Page 6E1–30

Page 6E1–30

Step Action Value(s) Yes No

9 Check the immobiliser programming functions.

• Powertrain Interface Module (PIM).

If a problem is found, repair as necessary.

(Refer to "Important information on Programming")

Was the action complete?

⎯ Go to Step 10 Go to Step 11

10 Recheck the DTC on PIM.

1. Key position is “OFF” and keep the position for

more than 30 seconds.

2. Key position is “ON”.

3. Check the DTC on scan tool.

Are below DTCs stored?

B3902 or P0633

⎯ Go to Step 11 Go to Step 12

11 Replace the powertrain interface module (PIM).

IMPORTANT: The replacement PIM must be

programmed the security data by scan tool.

Was the action complete?

⎯ Go to Step 12 ⎯

12 Recheck the DTC on PIM.

1. Key position is “OFF” and keep the position for

more than 30 seconds.

2. Key position is “ON”.

3. Check the DTC on scan tool.

Are below DTCs stored?

B3902 or P0633

⎯ Go to Step 13 Go to Step 2

13 Replace the immobiliser c ontrol unit (ICU).

IMPORTANT: The replacement ICU must be

programmed the security data by scan tool.

Was the action complete?

⎯ Verify repair ⎯

Immobiliser System – HFV6 Page 6E1–31

Page 6E1–31

8.8 B0008 Wrong Transponder Key

Step Action Value(s) Yes No

1 Was the “Immobiliser System and Warning Lamp

Check” perfor med?

⎯ Go to Step 2 Go to

Immobiliser

System Chec k

2 Check the key.

Is a key peculiar to a vehicle?

⎯ Go to Step 3 Refer to

Diagnostic Aids

3 Check the immobiliser programming functions.

• Transponder (Key).

Was a problem found?

⎯ Go to Step 4 Go to Step 5

4 Perform the immobiliser programming functions.

• Transponder (Key).

(Refer to "Important information on Programming")

Was the action complete?

⎯ Go to Step 5 ⎯

5 Recheck the DT C.

1. Key position is “OFF” and keep the position for

more than 30 seconds.

2. Key position is “ON”.

3. Check the DTC on scan tool.

Is DTC B0008 stored?

⎯ Go to Step 6 Verify repair

6 Replace the transpond er (Key).

IMPORTANT: The replacement transponder (key)

must be programmed the security data b y scan tool.

Was the action complete?

⎯ Go to Step 7 ⎯

7 Recheck the DT C.

1. Key position is “OFF” and keep the position for

more than 30 seconds.

2. Key position is “ON”.

3. Check the DTC on scan tool.

Is DTC B0008 stored?

⎯ Go to Step 8 Verify repair

8 Replace the immobiliser c ontrol unit (ICU).

IMPORTANT: The replacement ICU must be

programmed the security data by scan tool.

Was the action complete?

⎯ Verify repair ⎯

Immobiliser System – HFV6 Page 6E1–32

Page 6E1–32

8.9 B0009 No Transponder Key Programmed

Step Action Value(s) Yes No

1 Was the “Immobiliser System and Warning Lamp

Check” perfor med?

⎯ Go to Step 2 Go to

Immobiliser

System Chec k

2 Check the key.

Is a key peculiar to a vehicle?

⎯ Go to Step 3 Refer to

Diagnostic Aids

3 Check the immobiliser programming functions.

• Transponder (Key).

Was a problem found?

⎯ Go to Step 4 Go to Step 5

4 Perform the immobiliser programming functions.

• Transponder (Key).

(Refer to "Important information on Programming")

Was the action complete?

⎯ Go to Step 5 ⎯

5 Recheck the DT C.

1. Key position is “OFF” and keep the position for

more than 30 seconds.

2. Key position is “ON”.

3. Check the DTC on scan tool.

Is DTC B0009 stored?

⎯ Go to Step 6 Verify repair

6 Replace the transpond er (Key).

IMPORTANT: The replacement transponder (key)

must be programmed the security data b y scan tool.

Was the action complete?

⎯ Go to Step 7 ⎯

7 Recheck the DT C.

1. Key position is “OFF” and keep the position for

more than 30 seconds.

2. Key position is “ON”.

3. Check the DTC on scan tool.

Is DTC B0009 stored?

⎯ Go to Step 8 Verify repair

8 Replace the immobiliser c ontrol unit (ICU).

IMPORTANT: The replacement ICU must be

programmed the security data by scan tool.

Was the action complete?

⎯ Verify repair ⎯

Immobiliser System – HFV6 Page 6E1–33

Page 6E1–33

8.10 B0010 Unknown Transponder Key

Step Action Value(s) Yes No

1 Was the “Immobiliser System and Warning Lamp

Check” perfor med?

⎯ Go to Step 2 Go to

Immobiliser

System Chec k

2 Check the key.

Is a key peculiar to a vehicle?

⎯ Go to Step 3 Refer to

Diagnostic Aids

3 Check the immobiliser programming functions.

• Transponder (Key).

Was a problem found?

⎯ Go to Step 4 Go to Step 5

4 Perform the immobiliser programming functions.

• Transponder (Key).

(Refer to "Important Information on Programming")

Was the action complete?

⎯ Go to Step 5 ⎯

5 Recheck the DT C.

1. Key position is “OFF” and keep the position for

more than 30 seconds.

2. Key position is “ON”.

3. Check the DTC on scan tool.

Is DTC B0010 stored?

⎯ Go to Step 6 Verify repair

6 Replace the transpond er (Key).

IMPORTANT: The replacement transponder (key)

must be programmed the security data b y scan tool.

Was the action complete?

⎯ Go to Step 7 ⎯

7 Recheck the DT C.

1. Key position is “OFF” and keep the position for

more than 30 seconds.

2. Key position is “ON”.

3. Check the DTC on scan tool.

Is DTC B0010 stored?

⎯ Go to Step 8 Verify repair

8 Replace the immobiliser c ontrol unit (ICU).

IMPORTANT: The replacement ICU must be

programmed the security data by scan tool.

Was the action complete?

⎯ Verify repair ⎯

Immobiliser System – HFV6 Page 6E1–34

Page 6E1–34

8.11 B0055 EEPROM Error

Step Action Value(s) Yes No

1 Was the “Immobiliser System and Warning Lamp

Check” perfor med?

⎯ Go to Step 2 Go to

Immobiliser

System Chec k

2 Recheck the DT C.

1. Key position is “OFF”.

2. Install the scan tool on vehicle.

3. Key position is “ON”.

4. Check the DTC on scan tool.

Is DTC B0055 stored?

⎯ Go to Step 3 Refer to

Diagnostic Aids

3 Check the immobiliser control unit (ICU) circuit.

1. Ignition "OFF," disconnect the ICU.

2. Check the ICU circuit for an open, short to ground,

or short to voltage.

Also, check the ICU ignition feed circuit for an open or

short to ground and the ICU ground circuit for an

open.

Was a problem found?

⎯ Go to Step 4 Go to Step 5

4 Repair or replace the immobiliser unit (ICU) circuit.

Was the action complete?

⎯ Verify repair ⎯

5 Replace the immobiliser c ontrol unit (ICU).

IMPORTANT: The replacement ICU must be

programmed the security data by scan tool.

Was the action complete?

⎯ Verify repair ⎯

Immobiliser System – HFV6 Page 6E1–35

Page 6E1–35

9 Immobiliser Security and

Programmi ng

9.1 Security and Programming Information

Car Pass Card

When performing certain immobiliser programming functions using Tech 2, you may be prompted to enter a four digit

Security Code. This informati on is found on the vehicle security card issued with the vehicle when new. If the card is

unavailable, contact the GM Holden Technical Assistance (TAS) centre to obtain the relevant Security Code.

lmportant information on Programming

Security code

The security code protects the immobilizer co ntrol unit against unauthorized programming and data access from Tech-2.

The security code consists of a 4 digit code number and is programmed into the immobilizer control unit and engine

control module (ECM).

New control units are not programmed with a security code.

If the control units are replaced, the security code entered on the car pass card, transponder l D etc, must be

programmed into the new control unit with Tech-2.

The security code can only be programmed with Tech-2 once and must therefore be performed with great care.

Once programmed, the security code cannot be overwritten. An already used immobilizer can be reused in a different car

by initializing the immobilizer. After that you can program the security code again. F or initializing command you need the

current security code.

If the immobilizer control unit is returned, al ways enclose the security code that is allocated to that control unit. If this is

not done, we can not process the case and the warranty will not be recognized.

Entering a code

If the Tech-2 display requests that the

• security code,

• mechanical key number, and the

• Vehicle Identification No.

to be entered, process as follo ws;

To input a digit you need to use the up and down buttons of the Tech-2. By using the numeric buttons the accordin g digit

will be displayed at the current position and the cursor will move to the next position.

For letters you need to use the up and do wn buttons of the Tech-2. The up and down key might be used for digits as

well. By using the up and do wn buttons the displa yed digit or letter will be increased or decreased.

To move to the next position you need to use the move-to-right-button.

With the two buttons, move-to-right and move-to-left you can select the position of numb er you want to change.

This will allow you to correct a wrong number.

After the number is completed you need to press the Enter b utton to accept the number. Correction is now no longer

possible.

Use the OKAY soft key to program the number and the NOT OKAY soft key to abort the programming.

NOTE: If an incorrect code is entered, the ICU will go into a security wait time stage. This wait time stage will prevent any

further attempts to enter the security code until the wait time has elapsed.

Should a second incorrect se curity code be entered after the initial wait time has elapsed, the ICU will go into a second

wait time stage. The wait time will increase each time an incorrect code is entered. When the correct code is entered the

wait time will reset back to its original value of 10 seconds. The ignition switch must be in the ON position with the battery

connected during the wait time period.

Immobiliser System – HFV6 Page 6E1–36

Page 6E1–36

The wait time stages are as follows:

• Stage 1 = 10 seconds.

• Stage 2 = 10 seconds.

• Stage 3 = 10 minutes.

• Stage 4 = 20 minutes.

• Stage 5 = 40 minutes.

• Stage 5 = 80 minutes.

Transponder (Key)

If a transponder key is lost:

If a transponder key is lost, all transponder keys in the immobilizer control system must be erased. Transponder keys

can be ordered via the "Your proper organizat ion name such as part and accessory department" as previously by

providing the mechanical key number.

The mechanical key number is provided on the car pass card.

Thereafter, existing and new transponder keys are programmed consecutiv ely using Tech-2. The vehicle can then no

longer be started using lost key.

5 transponder keys can be provided:

Each transponder has different Identifications. If a customer wants more than 2 transponder keys, maximum 5

transponder keys can be prov ided by additional programming b y Tech-2.

If installation of an ignition lock with a different mechanism key number is necessary (an ignition lock which belongs to

the mechanical key number has to be ordered first), all transponder keys must first be erased and the two transponder

keys which belong to the ignition lock that is now installed must be programmed.

The new mechanical key number must be programmed no w into the immobilizer. The mechanical ke y number in the car

pass is to be changed as well.

Important:

After successful programming, the engine control can only be used for vehicles with immobilizer and transponder.

Faults that occur in connection with the immobilizer control unit are recog nized by the engine control unit and as l on g as

"IMMOBILOZER" is not programmed, are indicated by a flashing of the check engin e lamp.

If the immobilizer and engine control u nit are replaced at the same time, the immobilizer control unit must be

programmed first before the "IMMOBILIZ ER" function in the engine control unit can be activated.

Immobiliser System – HFV6 Page 6E1–37

Page 6E1–37

9.2 Immobiliser Control Unit Reset

Procedure

Do not perform the reset procedure within

sixty seconds of turning the ignition switch

on. Failure to comply may result in the PIM

failing to reset.

When an immobiliser control unit (ICU) has been installed into a vehicle, it is security linked to the powertrain interface

module (PIM) and engine control module (ECM). Once this linking has been performed, the ICU cannot be installe d in

any other vehicle, unless the security linking between the PIM and the ECM has been reset using th e following

procedure:

1 Prior to resetting the PIM, obtain the Security Code. For further information, refer to Car Pass Card.

2 Connect Tech 2 to the data link connector (DLC) and turn the ignition switch on.

3 On Tech 2 select: Body / Immobiliser / Additional Functions / Reset Immobiliser.

NOTE

When Tech 2 requests programming approval,

obtain TIS approval.

NOTE

If a Tech 2 screen displ a ying Security Wait Time

Active, Please Wait! appears after selecting the

Reset Immobiliser option, an incorrect security

code has been previously entered. Refer to

9.1 Security and Programming Information for

further information.

4 When Tech 2 displays See Checking Proced ure before Programming, press the Confirm soft key.

5 When Tech 2 displays Enter Security Code, enter the security code, press the Enter key and then the Okay soft

key.

The engine will not start after the ICU has

been reset.

5 When Tech 2 displays Warning: Engine Will Not Start After Reset, press the Confirm soft key.

Do not turn the ignition switch off within 60

seconds of performing the ICU reset

procedure. Failure to co mply may result in th e

ICU failing to reset.

6 When Tech 2 displays Turn Ignition Off, turn the ignition switch off.

7 When Tech 2 displays Turn Ignition On, turn the ignition switch on.

8 When Tech 2 displays Erasing Completed Successfully, press the Confirm soft key.

Immobiliser System – HFV6 Page 6E1–38

Page 6E1–38

9.3 Immobiliser Link to ECM / PIM

Do not perform the Immobiliser Link to ECM /

PIM procedure within sixty seconds of turning

the ignition switch on. Failure to comply may

result in the ICU failing to link.

When the immobiliser control unit (ICU) has been replaced, it is necessary to security link the ICU, powertrain interface

module (PIM) and engine control module (ECM) before the vehicle will start.

NOTE

The following procedure is for an ICU

replacement only. If the ECM, and or PIM has

also been replaced, select the appropriate

options when prompted.

1 Prior to performing the linking proce dure, obtain the security code. For further information, refer to Car Pass Card.

2 Connect Tech 2 to the data link connector (DLC).

3 On Tech 2 select: Body / Immobiliser / Programming / Immobiliser Link to ECM.

4 When Tech 2 displays Immobiliser Replaced, press the Yes soft key.

5 When Tech 2 displays PIM or ECM Replaced?, press the No soft key.

NOTE

When Tech 2 requests programming approval,

obtain TIS approval.

6 When Tech 2 displays Enter Security Code, enter the security code and press the Enter key and then the Okay

soft key.

7 When Tech 2 displays Confirm Security Code, re-enter the security code, press the Enter key and then the Okay

soft key.

8 When Tech 2 displays Enter Vehicle Identification Number (VIN), enter the vehic les VIN and then press the

Enter key

9 When Tech 2 displays Turn Ignition Off, turn the ignition switch off.

10 When Tech 2 displays Insert Non Programmed Transponder-Key, press the Confirm soft key.

11 When Tech 2 displays Turn Ignition On, turn the ignition switch on.

12 When Tech 2 displays Turn Ignition Off, turn the ignition switch off.

NOTE

Using Tech 2, turn the ignition switch on and off

when prompted.

13 When Tech 2 displays Program More Transponder Keys, press the Yes soft key if another transponder key is to

be programmed, or press the No soft key.

14 When Tech 2 displays Turn Ignition On, turn the ignition switch on and press the Confirm soft key to return to the

Tech 2 Immobiliser screen.

Immobiliser System – HFV6 Page 6E1–39

Page 6E1–39

10 Immobiliser V6 – Tech 2

Functions

10.1 Introduction

Do not use a Tech 2 that displays faulty data;

have the Tech 2 repaired. The use of a faulty

Tech 2 can result in misdiagnosis and the

unnecessary repl acement of parts.

From the Main Menu, having selected Diagnostics / 2006 / RA Rodeo / Body / Immobiliser, the Tech 2 functions for

the Immobiliser Interface, include:

F0: Diagnostic Trouble Codes

F1: Data Display

F2: Snapshot

F3: Additional Functions

F4: Programming.

Immobiliser System – HFV6 Page 6E1–40

Page 6E1–40

10.2 Tech 2 Functions

F0: Diagnostic Trouble Codes

When this test mode is initiated, DTCs stored b y the ICU can be displayed or cleared. When entered, there are three

additional modes for selection:

F0: Read DTC Info Ordered By Priority

F1: Read DTC Info As Stored By ECU

F2: Clear DTC Information

F1: Data Display

Use the Tech 2 Data List under the following conditions:

• The Diagnostic System Check – V6 Engine has been completed.

• The On-board Diagnostics are function ing correctly.

• No DTCs are present.

F2: Snapshot Options

In this test mode, Tech 2 captures data before and after a snapshot triggering event that may or may not set a DTC.

Trigger Type : Manual Trigger

F0: Manual Trigger

F1: Any Code

F2: Single Code

Trigger Point : Centre

F4: Beginning

F5: Centre

F6: End

F3: Additional Functions

When this selection is made from the Tech 2 screen, an additional choice is provided:

F0: Read ECU Identification

F1: Reset Immobiliser

F2: Erase Transponder-Keys

F4: Programming

Within this selection, there are two programming selections available:

F0: Immobiliser Link To ECM/PIM

F1: Program Transponder-Keys

Immobiliser System – HFV6 Page 6E1–41

Page 6E1–41

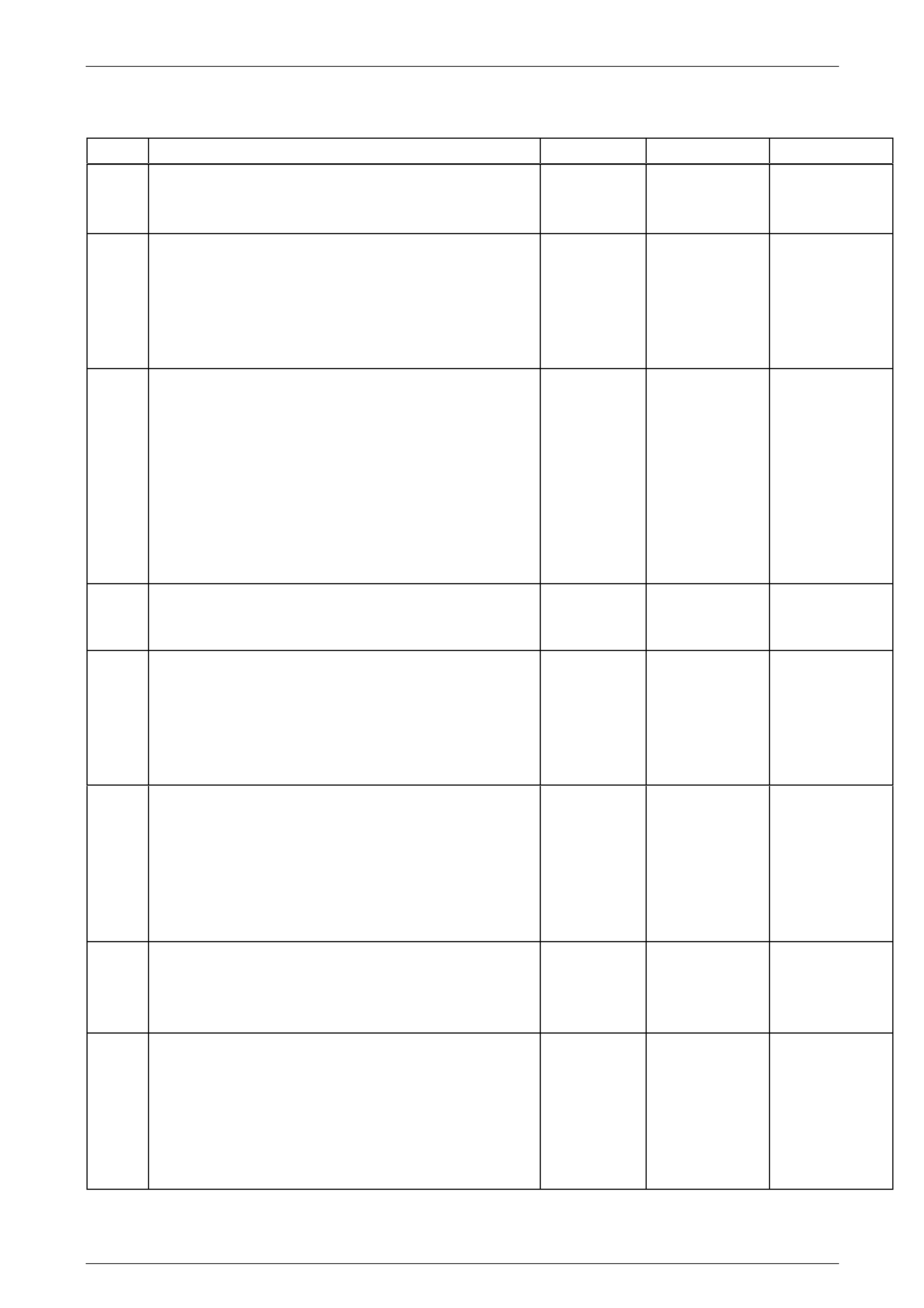

10.3 Immobiliser V6 Data List

Data Display

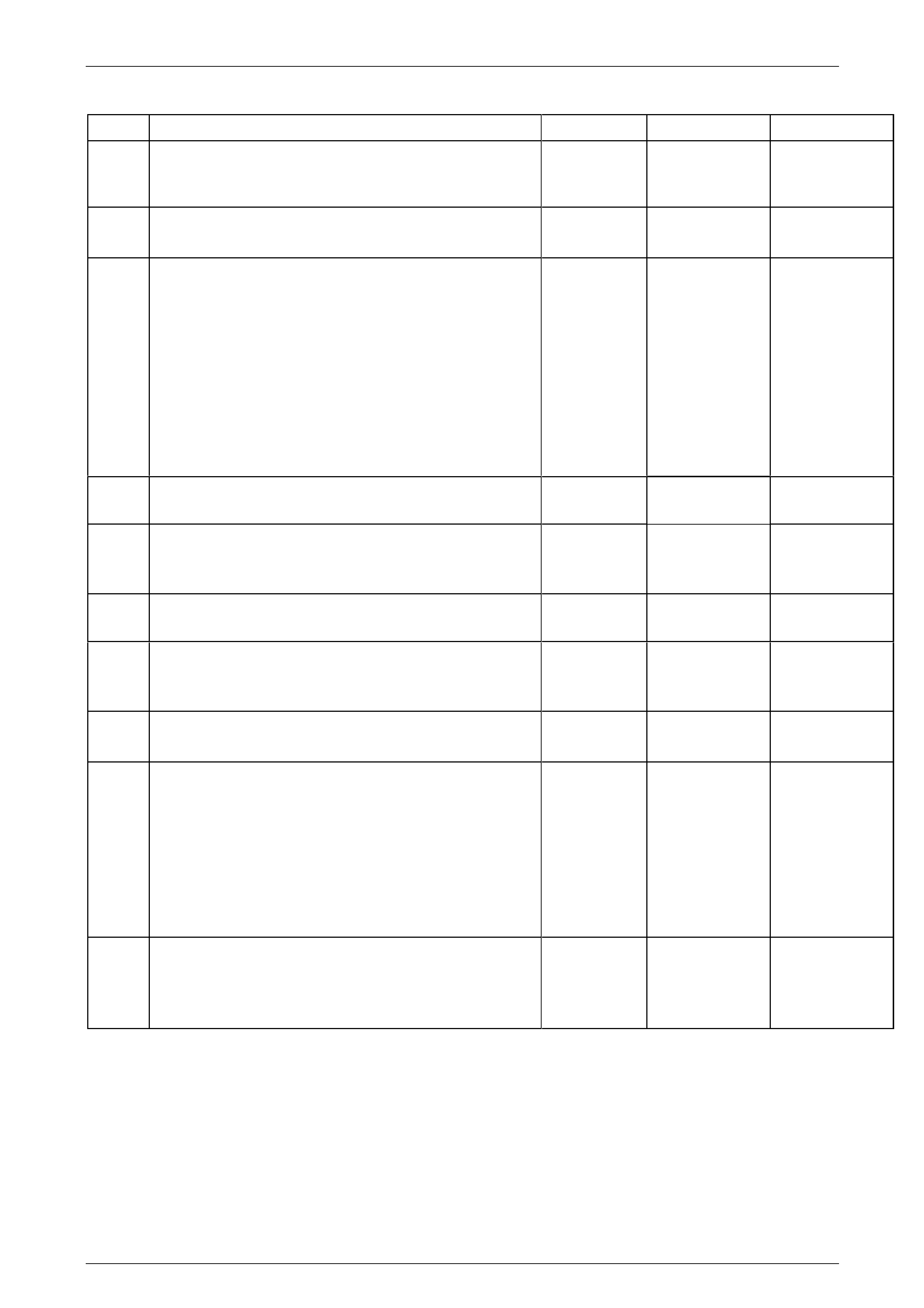

Tech 2 Display Units Displayed Switch On Switch Off

Ignition Status On 12V / Off 0V On 12V Off 0V

Transponder-Key Transp. Key 1 / Invalid Transp. Key 1 Invalid

Transponder Status Correct TP-Key / Invalid Correct TP-Key Invalid

Transponder-Key 1 Status Programmed Programmed Programmed

Transponder-Key 2 Status Not

Programmed Not

Programmed Not

Programmed

Transponder-Key 3 Status Not

Programmed Not

Programmed Not

Programmed

Transponder-Key 4 Status Not

Programmed Not

Programmed Not

Programmed

Transponder-Key 5 Status Not

Programmed Not

Programmed Not

Programmed

Immobiliser Signal Transmitted / Not

Transmitted Transmitted Not

Transmitted

Engine Request Received / Not Received Received Not Received

Vehicle Speed Output Veh.

Speedsignal Veh.

Speedsignal Veh.

Speedsignal

Immobiliser Relay Active 0V / Inactive 12V Active 0V Inactive 12V

Security Wait Time Inactive Inactive Inactive

Immobiliser System – HFV6 Page 6E1–42

Page 6E1–42

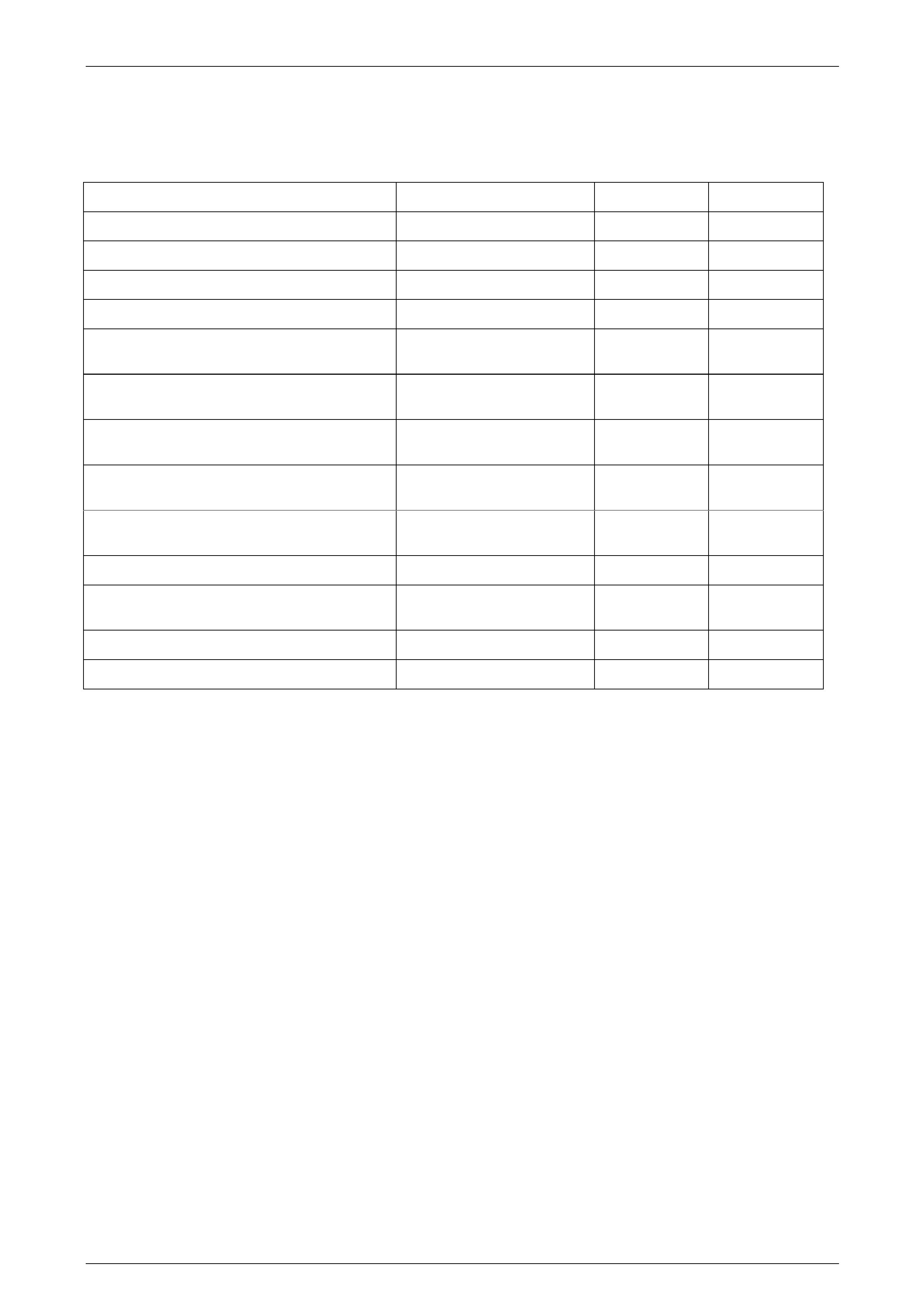

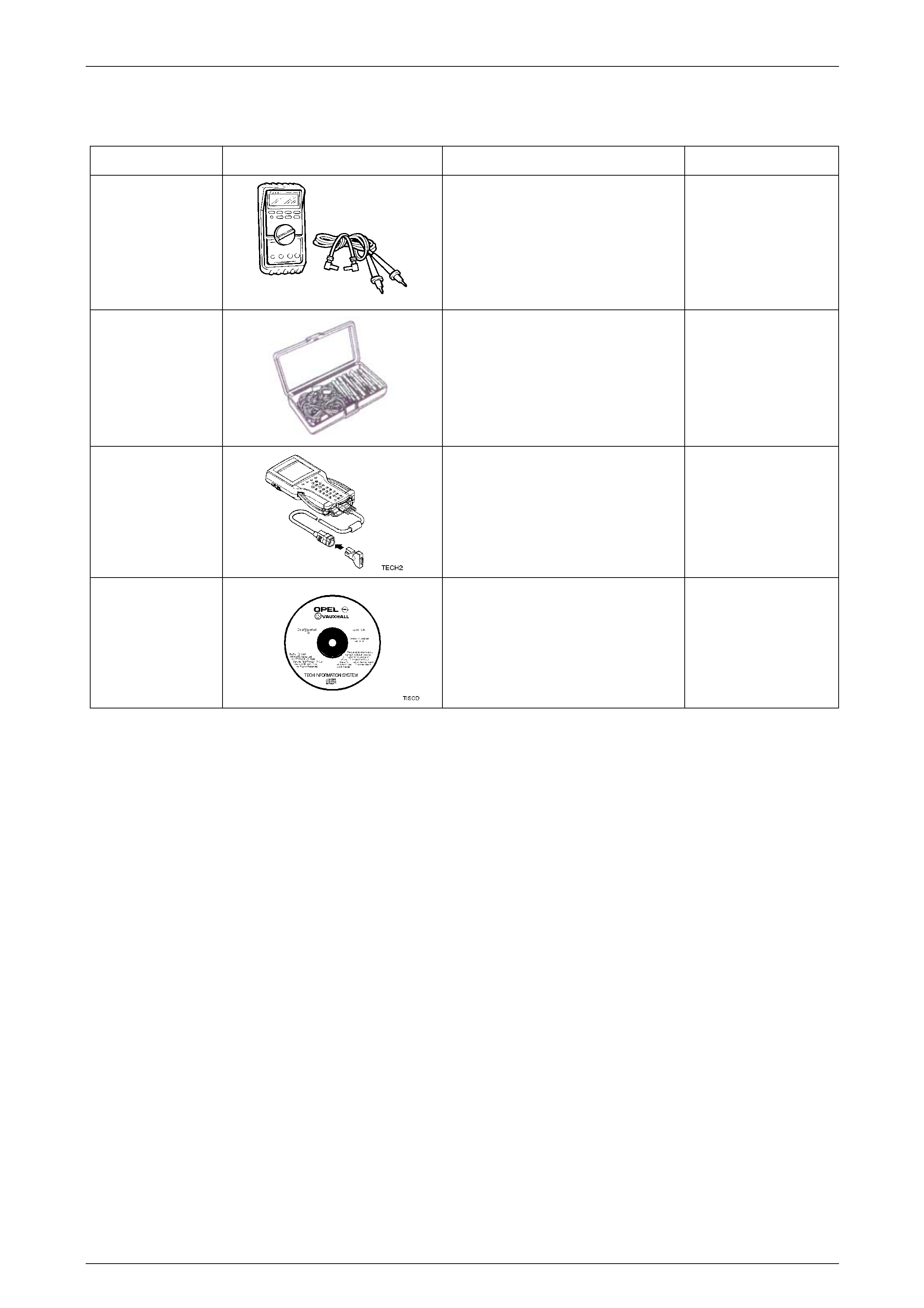

11 Special Tools

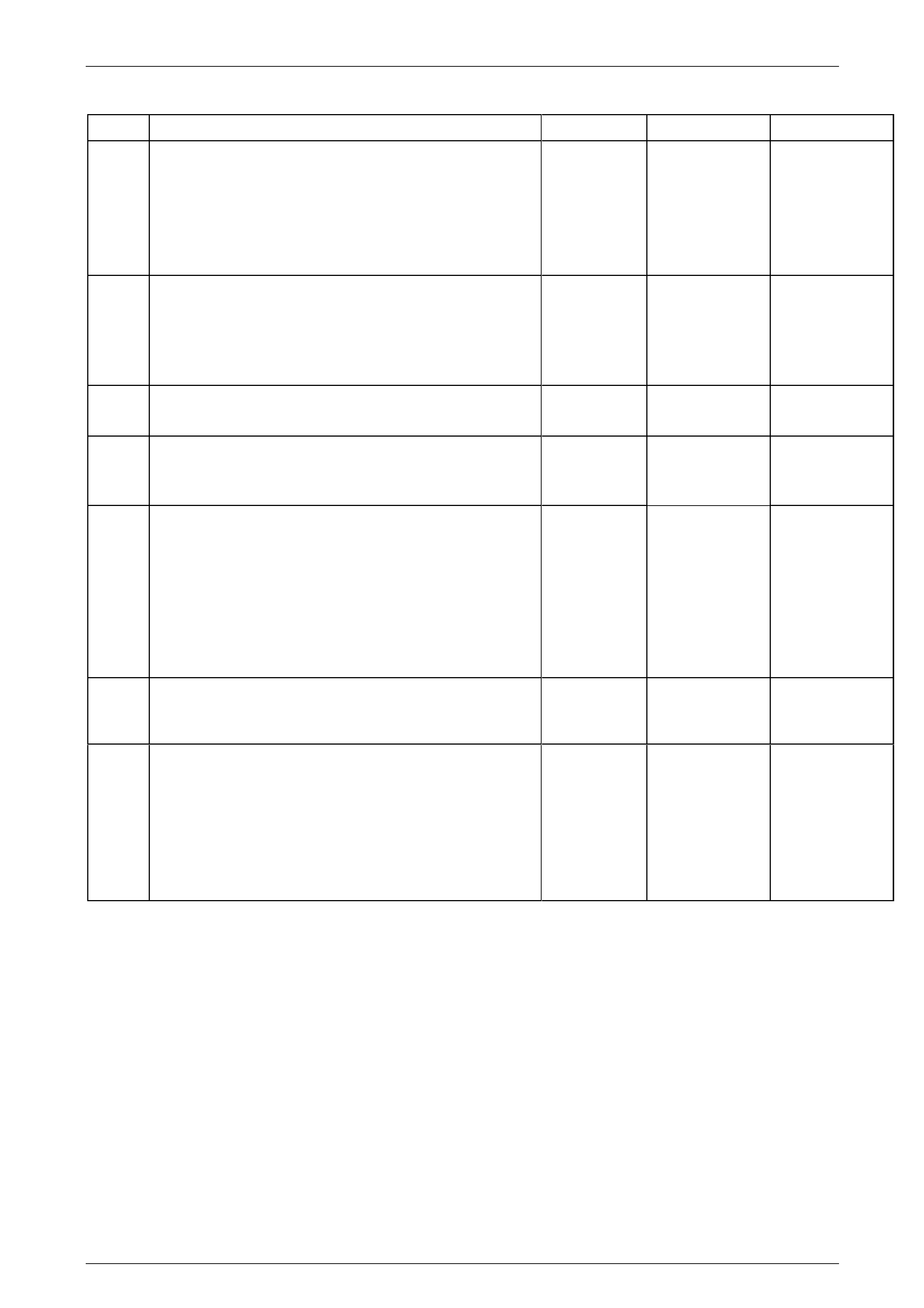

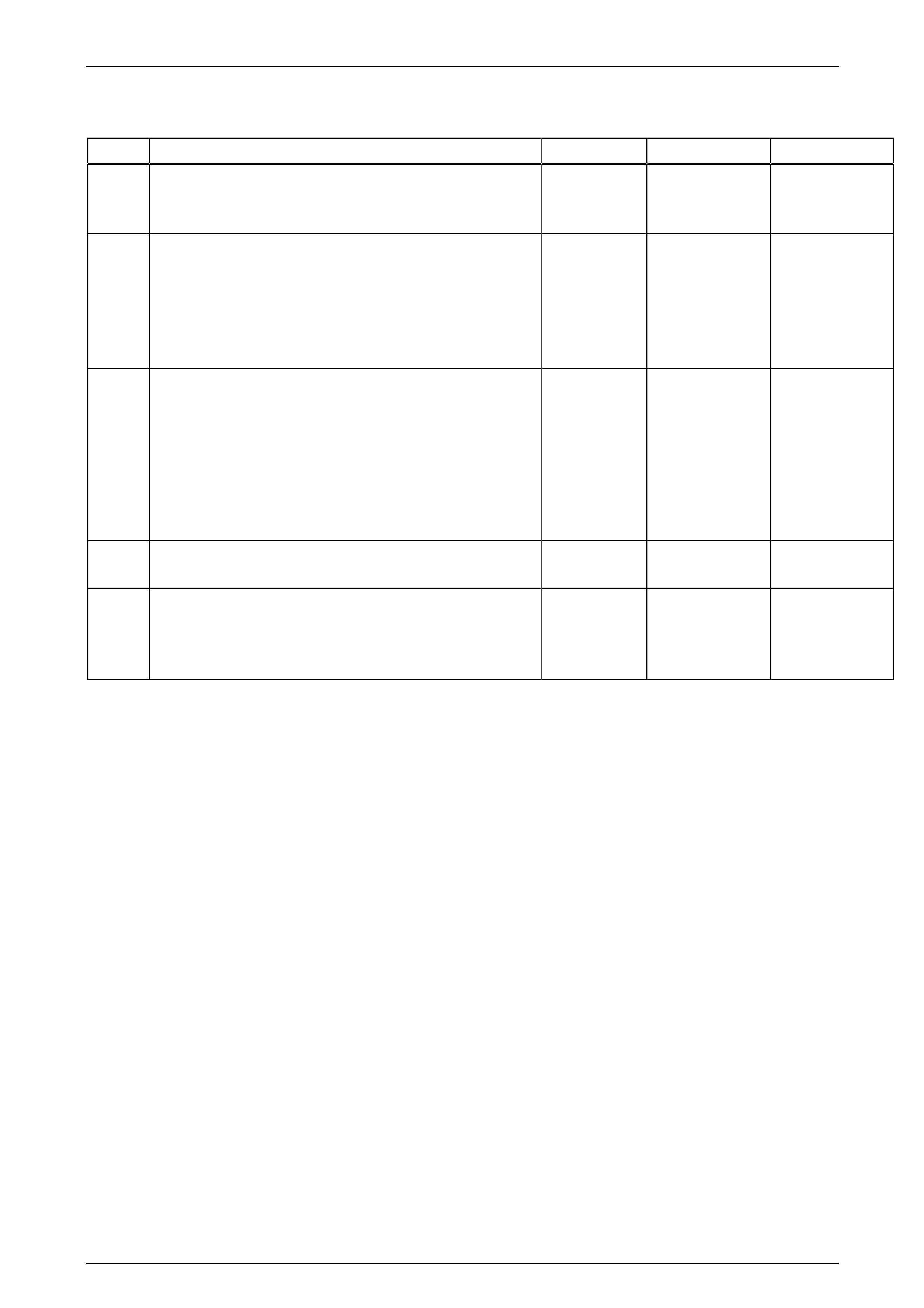

Tool Number Illustration Description Tool Classification

3588

Digital Multimeter

Also Previously released as J 39200 or

equivalent.

NOTE: The instrument must have 10

mega ohms impedanc e and be

capable of reading frequencies.

Mandatory

J35616

Connector Test Adaptor Kit

Used when carrying out electric al

diagnostic circuit checks.

Desirable

70000861

Tech 2 Diagnostic Scan Tool

Previously released.

Mandatory

N/A

Technical Information System (TIS)

CD ROM

Available to Authorised Dealers.

Mandatory