Front End Alignment Inspection and Adjustment

General Description

“Front End Alignment” refers to the angular relationship

between the front wheels, the front suspension attaching parts

and the ground.

Proper front end alignment must be maintained in order to

insure efficient steering, good directional stability and to

prevent abnormal tire wear.

The most important factors of front end alignment are wheel

toe-in, wheel camber and axle caster.

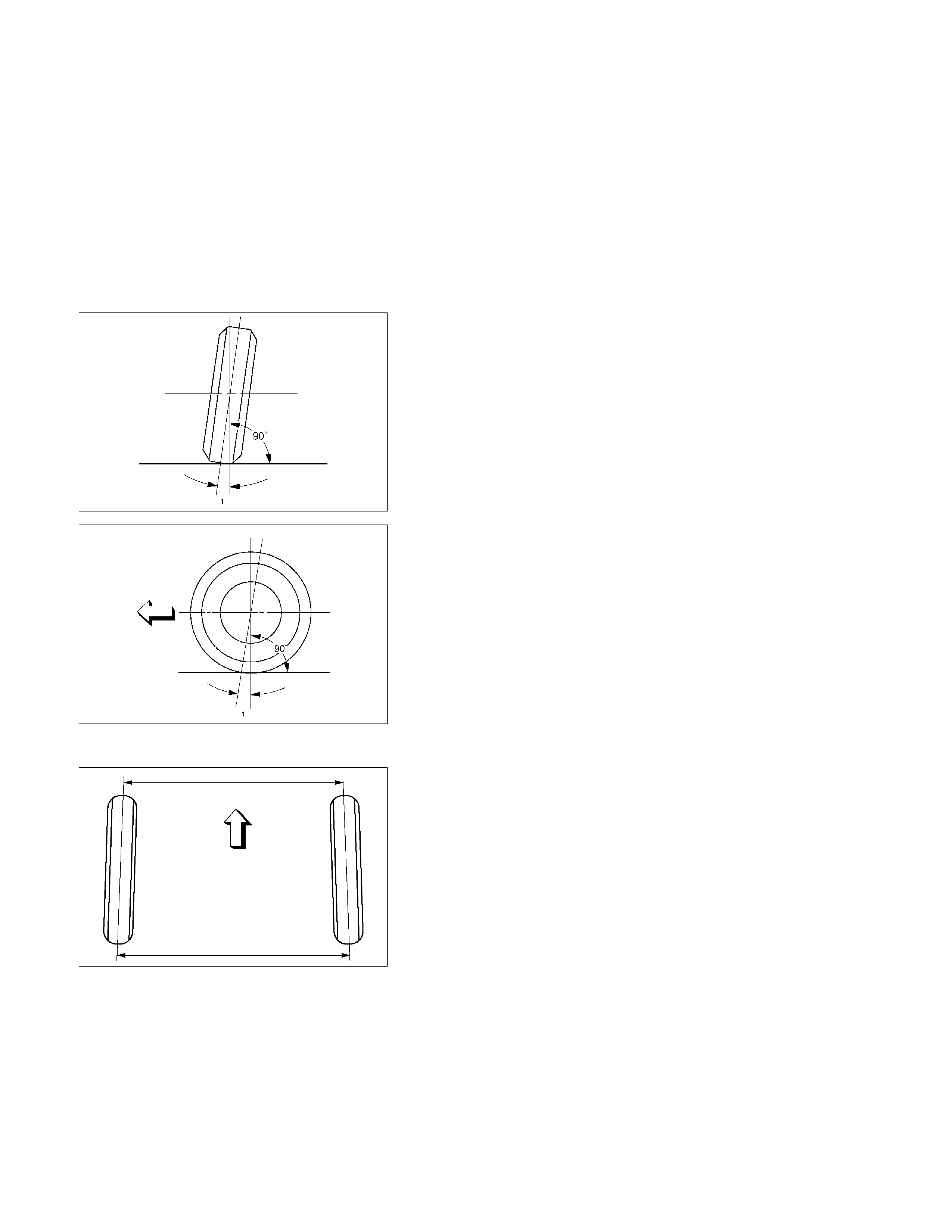

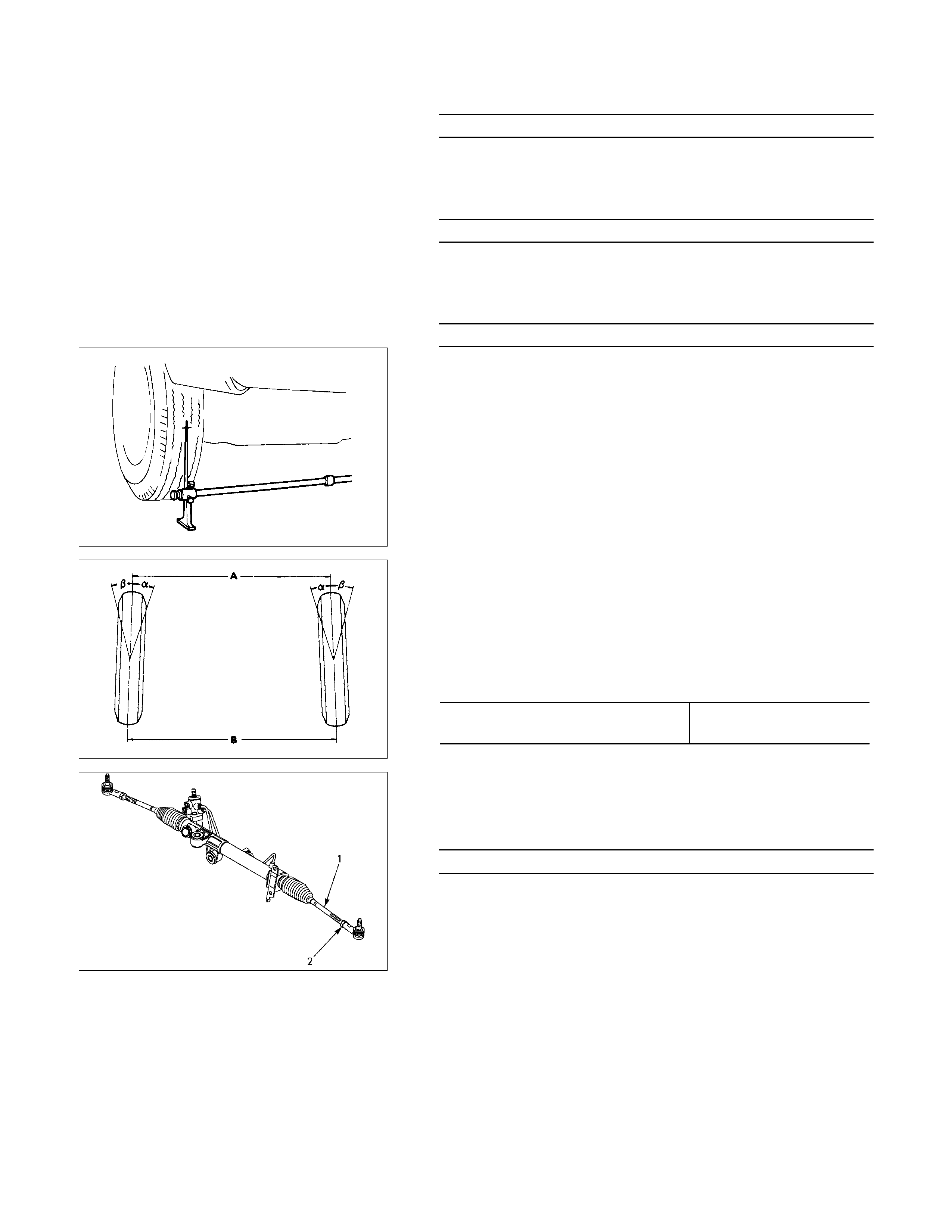

Camber:

This illustration shows the view from the front of the vehicle.

Camber is the vertical tilting inward or outward of the front

wheels. When the wheels tilt outward at the top, the camber is

positive (+). When the wheels tilt inward at the top, the camber

is negative (-). The amount of tilt measured in degrees from

the vertical is called the camber angle (1). If camber is

extreme or unequal between the wheels, improper steering

and excessive tire wear will result. Negative camber causes

wear on the inside of the tire, while positive camber causes

wear to the outside.

Caster:

This illustration shows the view from the side of the vehicle.

Caster (1) is the vertical tilting of the wheel axis either

forward or backward (when viewed from the side of the

vehicle). A backward tilt is positive (+) and a forward tilt is

negative (-). On the short and long arm type suspension

you cannot see a caster angle without a special instrument,

but if you look straight down from the top of the upper control

arm to the ground, the ball joints do not line up (fore and aft)

when a caster angle other than 0 degree is present. With a

positive angle, the lower ball joint would be slightly ahead

(toward the front of the vehicle) of the upper ball joint center

line.

Toe-in:

This illustration shows the view from the top of the vehicle.

Toe-in is the measured amount the front wheels are turned in.

The actual amount of toe-in is normally a fraction of a degree.

Toe-in is measured from the center of the tire treads or from

the inside of the tires. The purpose of toe-in is to insure

parallel rolling of the front wheels and to offset any small

deflections of the wheel support system, which occurs when

the vehicle is rolling forward. Incorrect toe-in results in

excessive toe-in and

unstable steering. Toe-in is the last alignment to be set in

the front end alignment procedure.

Inspection

Before making any adjustments affecting caster, camber or

toe-in, the following front end inspection should be made.

1. Inspect the tires for proper inflation pressure. Refer to

Main Data and Specifications in Wheel and Tire System

section.

2. Make sure that the vehicle is in an unlade condition

(Without passenger or loading).

3. Make sure that the spare tire is installed at the normal

position.

4. Inspect the front wheel bearings for proper adjustment.

Refer to Front Hub and Disc Overhaul in Suspension

section.

5. Inspect the ball joints and tie rod ends. If excessive

looseness is noted, correct before adjusting. Refer to

Steering Linkage in this section.

6. Inspect the wheel and tires for run-out. Refer to

Wheel Replacement in Wheel and Tire System section.

7. Inspect the trim height. If not within specifications, the

correction must be made before adjusting caster.

8. Inspect the steering unit for looseness at the frame.

9. Inspect shock absorbers for leaks or any noticeable noise.

Refer to Shock Absorber in Suspension section.

10. Inspect the control arms or stabilizer bar attachment fo

r

looseness. Refer to Suspension section.

11. Inspect the front end alignment using alignment equipment.

Follow the manufacturer’s instructions.

Alignment for 4×2 (Except High Ride Suspension)

Caster and camber Adjustment

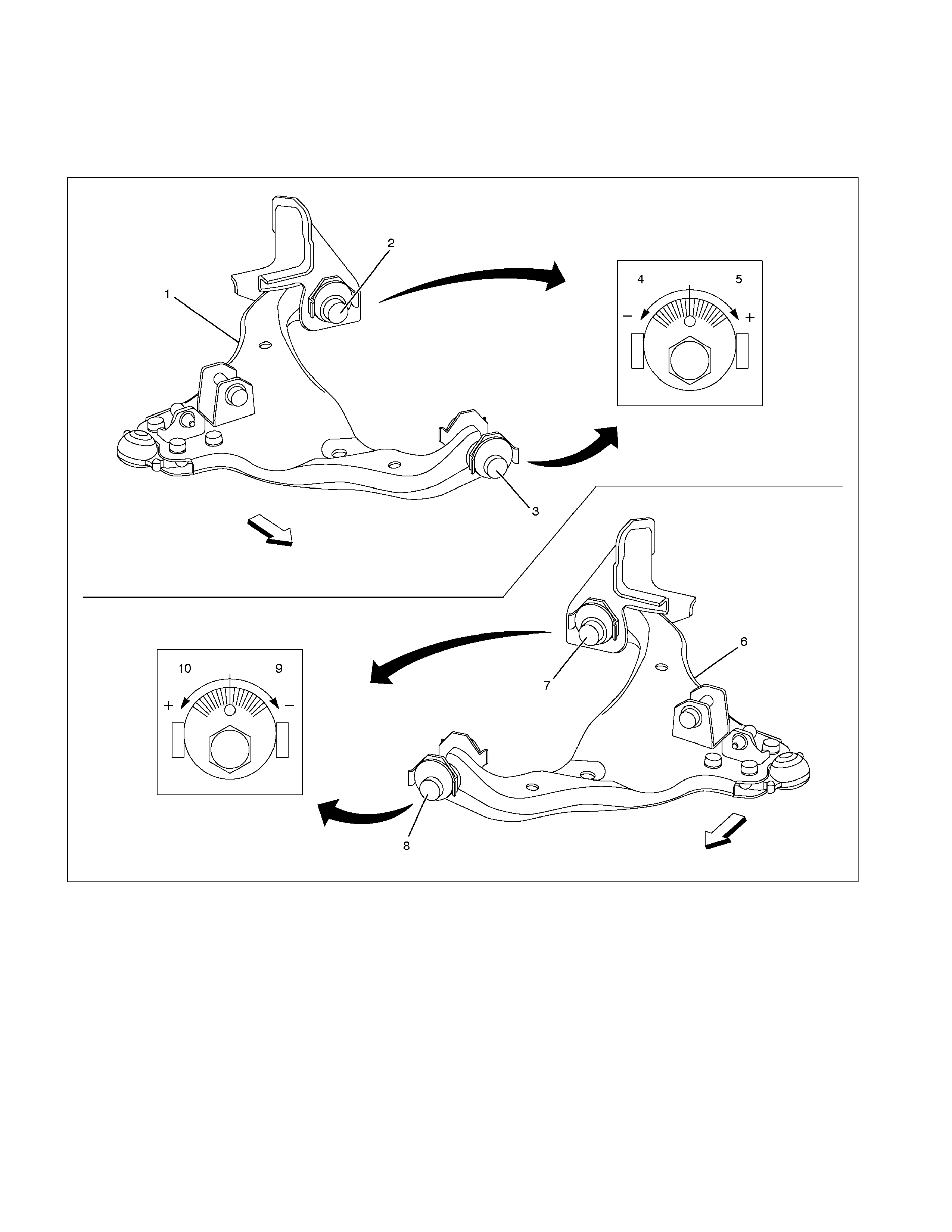

The lower links of the 4X2 vehicle front suspension have an adjusting cam at either end (front and rear). This permits

simultaneous adjustment of camber and caster angle.

Front

Front

RTW340LF000301

Legend

1. Lower link ASM RH

2. Adjust cam RR

3. Adjust cam FRT

4. -direction The lower link ASM protrudes

toward the inside

5. +direction The lower link ASM protrudes

toward the outside

6. Lower link ASM LH

7. Adjust cam RR

8. Adjust cam FRT

9. -direction The lower link ASM protrudes

toward the inside

10. +direction The lower link ASM protrudes

toward the outside

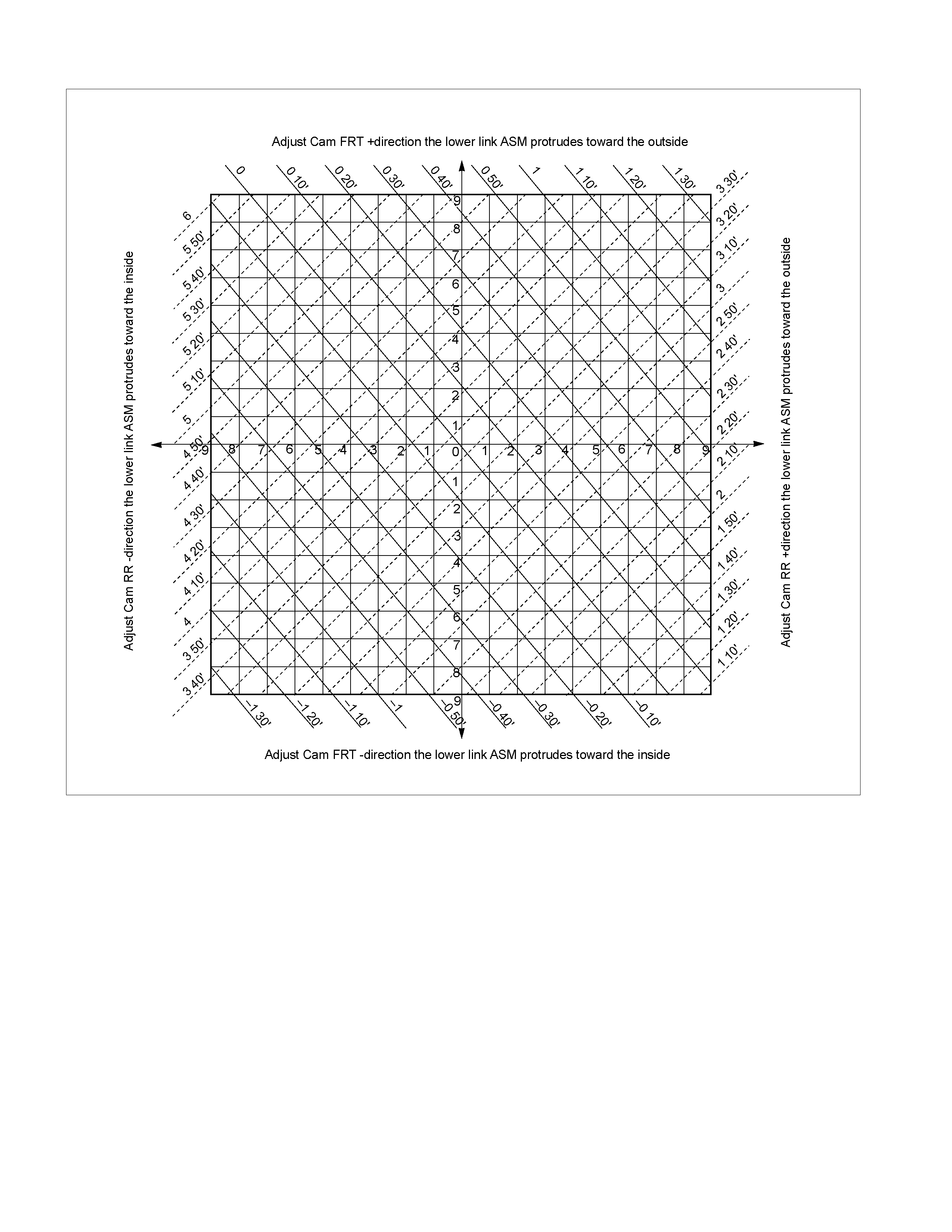

The follow illustration shows the alignment procedure.

RTW340LF000401

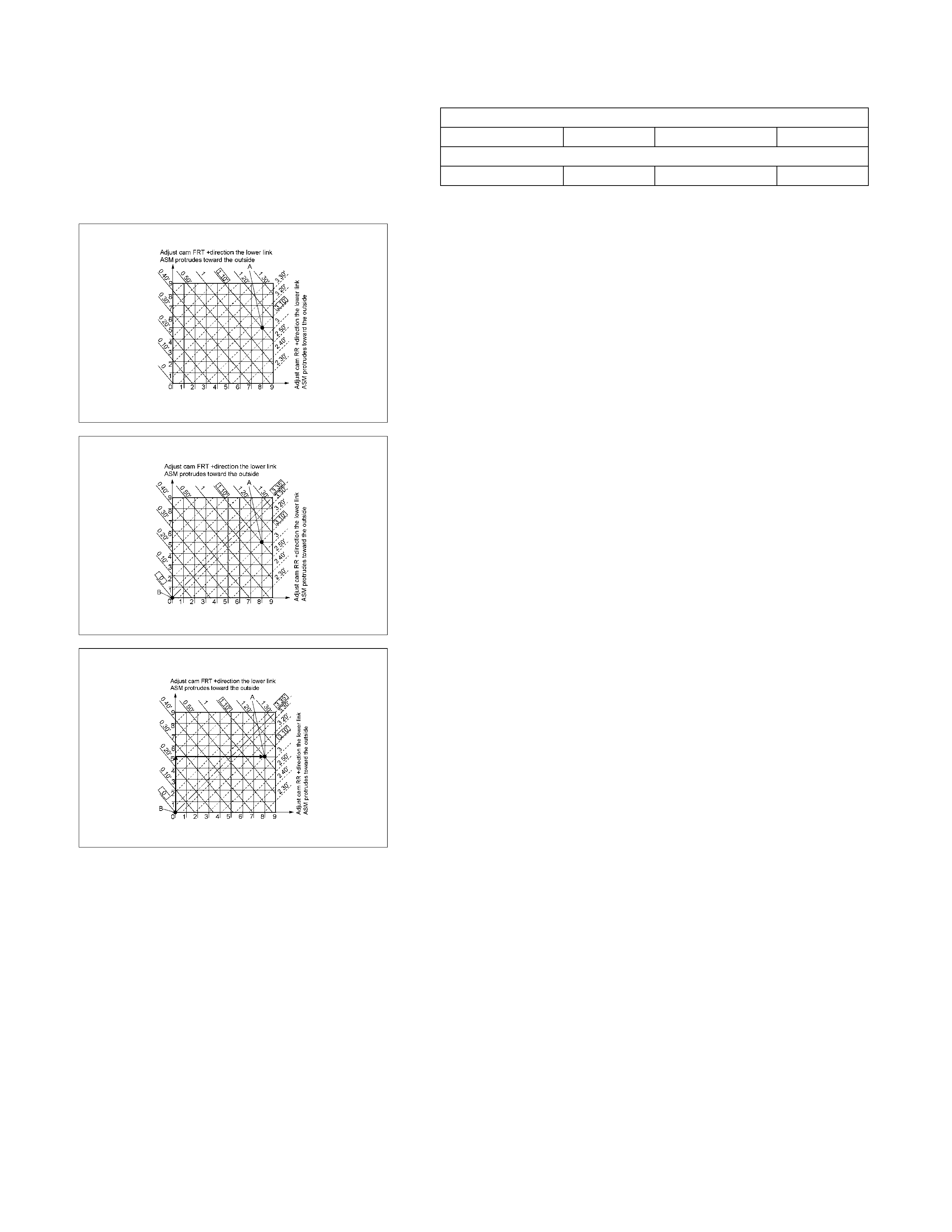

Example

Measured value

Camber angle 1°10' Caster angle 3°10'

Standard value

Camber angle 0°±30' Caster angle 3°35'±45'

RTW340SH001001

1. Mark an ‘A’ at the intersection point of the measured

camber angle value (solid line) and the measured caster

angle value (dotted line).

RTW340SH001101

2. Mark a ‘B’ at the intersection point of the standard camber

angle value (solid line) and the standard caster angle value

(dotted line).

RTW340SH001201

3. The vertical distance between points ‘A’ and ‘B’ represents

the adjustment required at the front cam. The horizontal

distance between points ‘A’ and ‘B’ represents the

adjustment required at the rear cam.

In this example, the front cam would be moved 5 integers

to the positive and the rear cam would be moved 8 integers

to the positive.

CAUTION:

Maximum possible adjustment from the center point of

the cams is 9 integers to either side.

CASTER

3°35'±45'

Note:

Left and right side to be equal within 30'

CAMBER

0°±30'

Note:

Left and right side to be equal within 30'

STEERING AXIS INCLINATION

12°30'±30'

Toe-in Adjustment

Measurement should be taken with the vehicle on a surface

plate.

If a surface plate is not available, toe-in should be checked

with the vehicle parked on a level floor.

1. Set front wheels to straight ahead position.

2. Align the toe-in gauge with center height of each wheel at

front end.

3.

A

pply center marks to each wheel, then take measurement

of distance A between the center marks on each wheel.

4. Slowly move the vehicle rearward until the center marks

reach the rear end position.

5. Take measurement of distance B between the cente

r

marks at rear end.

The toe-in can be calculated with next formula.

Toe-in = B - A

Toe-in mm (in)

4×2

(Except high ride suspension) 0±2 (0±0.08)

To adjust the toe-in angle, loosen the lock nuts (2) on the tie

rod (1) and turn the tie rod. Turn both rods the same amount,

to keep the steering wheel centered.

Lock Nut Torque N⋅m (kgf⋅m/lb⋅ft)

98±6.0 (10.0±0.6 / 72.3±4.3)

RTW330SH000101

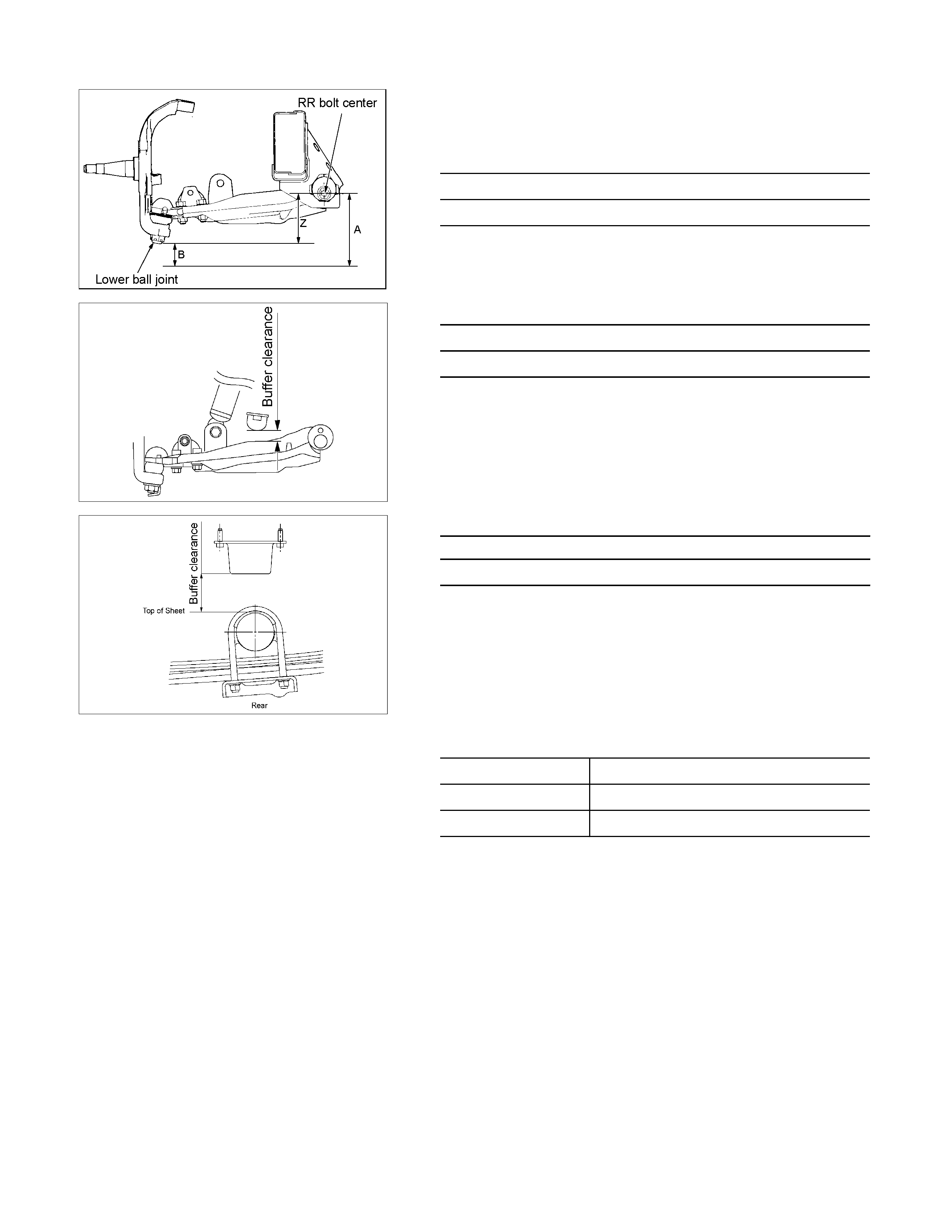

Trim Height

Trim Height : at Curb Weight (Reference Data)

Trim height (Z) = A - B

Front mm (in)

Z

105(4.13)

RTW340SH001301-X

FRT Buffer clearance (Reference Data)

4×2 (Except high ride suspension)

25.9(1.02)

RTW340SH000101-X

RR Buffer clearance (Reference Data) mm(in)

4×2 (Except high ride suspension)

82.1 (3.23)

MAXIMUM STEERING ANGLE

4×2 (Except high ride suspension)

Outside wheel 33.5°

Inside wheel 37.1°

Alignment for 4×2 (High Ride Suspension) and 4×4

Caster and camber Adjustment

The camber angle and caster angle can be adjusted by means of the camber shims and caster shims installed in

position between the chassis frame and fulcrum pins.

RTW340LF001901

Legend

1. Camber shim

2. Caster shim

3. Upper link ASM RH

4. Lower link ASM LH

5. Adjust cam

Adjust Method addition / subtraction of shim

front side rear side move direction

of upper b/j caster angle

alteration camber angle alteration

addition subtraction a decrease decrease (to negative

direction)

subtraction addition b increase increase (to positive

direction)

no change subtraction c decrease no alteration

caster

adjustment

no change addition d increase no alteration

addition e no alteration

decrease (to negative

direction)

camber

adjustment subtraction f no alteration

increase (to positive

direction)

Note:

1. Adjust cam is set at initial position (the hole &

projection are upward as shown in the illustration)

before making a shim adjustment.

2. Difference of caster shim front/rear thickness shall be

3.6mm(0.142in) or less.

Overall thickness of caster shim and camber shim shall

be 10.8mm(0.426in) or less.

3. choose a combination that uses a minimum amount of

shims.

Fulcrum Pin Bolt Torque N⋅m (kgf⋅m/lb⋅ft)

152.0±15 (15.5±1.5 / 112.1±10.8)

CASTER

310’±45’

Note:

Left and right side to be equal within 30’.

CAMBER

0±30’

Note:

Left and right side to be equal within 30’.

STEERING AXIS INCLINATION

1230’±30’

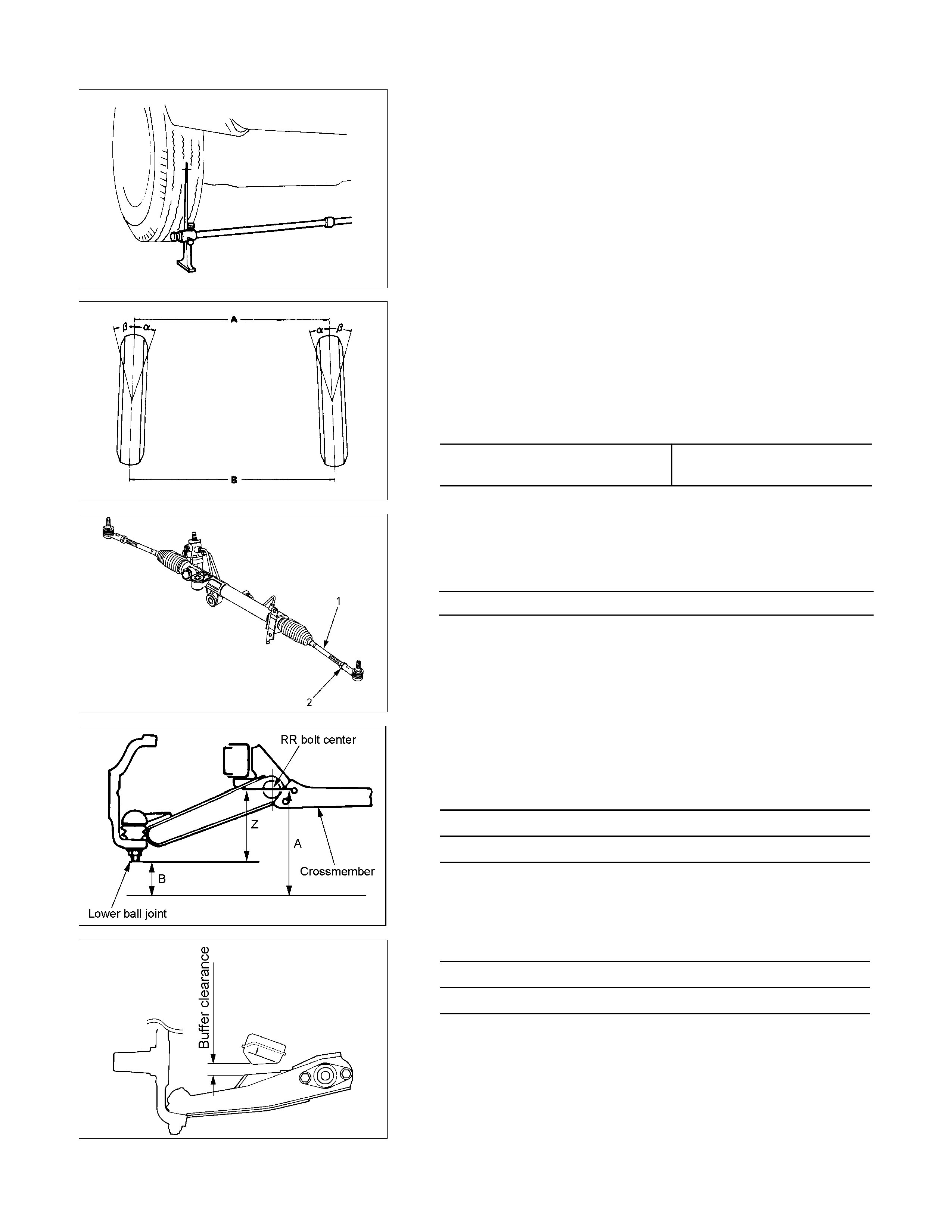

Toe-in Adjustment

Measurement should be taken with the vehicle on a surface

plate.

If a surface plate is not available, toe-in should be checked

with the vehicle parked on a level floor.

1. Set front wheels to straight ahead position.

2. Align the toe-in gauge with center height of each wheel at

front end.

3.

A

pply center marks to each wheel, then take measurement

of distance A between the center marks on each wheel.

4. Slowly move the vehicle rearward until the center marks

reach the rear end position.

5. Take measurement of distance B between the cente

r

marks at rear end.

The toe-in can be calculated with next formula.

Toe-in = B - A

Toe-in mm (in)

4×2 (High ride suspension)

4×4 0±2 (0±0.08)

To adjust the toe-in angle, loosen the lock nuts (2) on the tie

rod (1) and turn the tie rod. Turn both rods the same amount,

to keep the steering wheel centered.

Lock Nut Torque N⋅m (kgf⋅m/lb⋅ft)

98±6.0 (10.0±0.6 / 72.3±4.3)

RTW330SH000201

Trim Height

Trim Height : at Curb Weight

Trim height (Z) = A - B

mm (in)

Z

140±5 (5.51)

450R100002-X

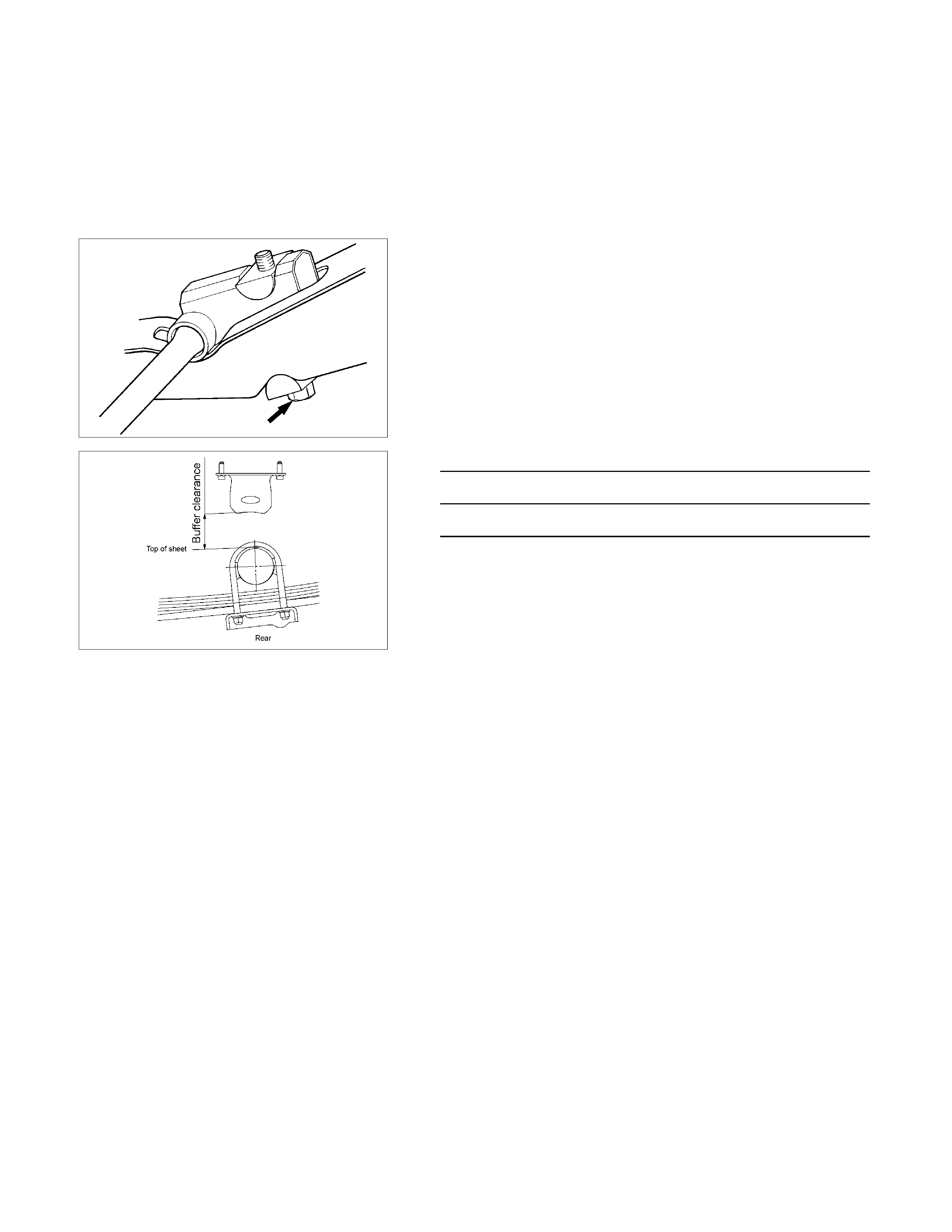

FRT Buffer clearance (Reference Data)

4×2 (High ride suspension), 4×4

29.7(1.17)

Adjustment

Adjust the trim height by means of the adjusting bolt on the

height control arms.

1. Check and adjust the tire inflation pressures.

2. Park the vehicle on a level ground and move the front o

f

the vehicle up and down several times to settle the

suspension.

410RS001

3. Make necessary adjustment with the adjusting bolt on the

height control arms.

RTW340SH000201-X

RR Buffer clearance (Reference Data) mm(in)

4×2 (High ride suspension), 4×4

80.0 (3.15)