SECTION 3B - POWER-ASSISTED

STEERING SYSTEM

General Description

Power Steering Unit

Hydraulic Pump

Steering Column

Power Steering System Test

Test Procedure

Maintenance

Fluid Level

Bleeding The Power Steering System

Bleeding Procedure

Flushing The Power Steering System

Steering Wheel Free Play Inspection

Front End Alignment Inspection and Adjustment

Torque Specification

Special Tools

Power Steering Unit

Power Steering Unit and Associated Parts

Removal

Installation

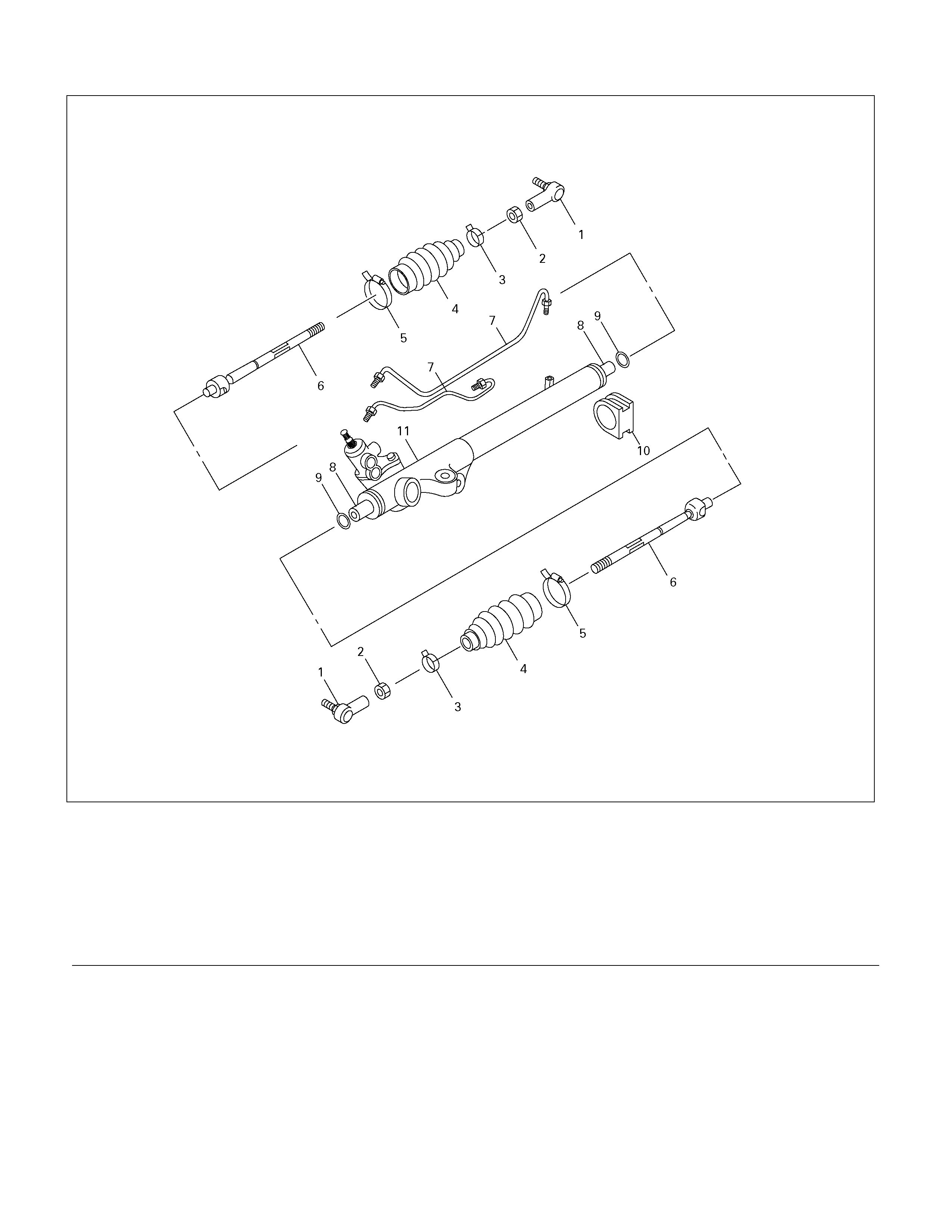

Power Steering Unit Disassembled View

Disassembly

Inspection and Repair

Reassembly

Main Data and Specifications

Special Tools

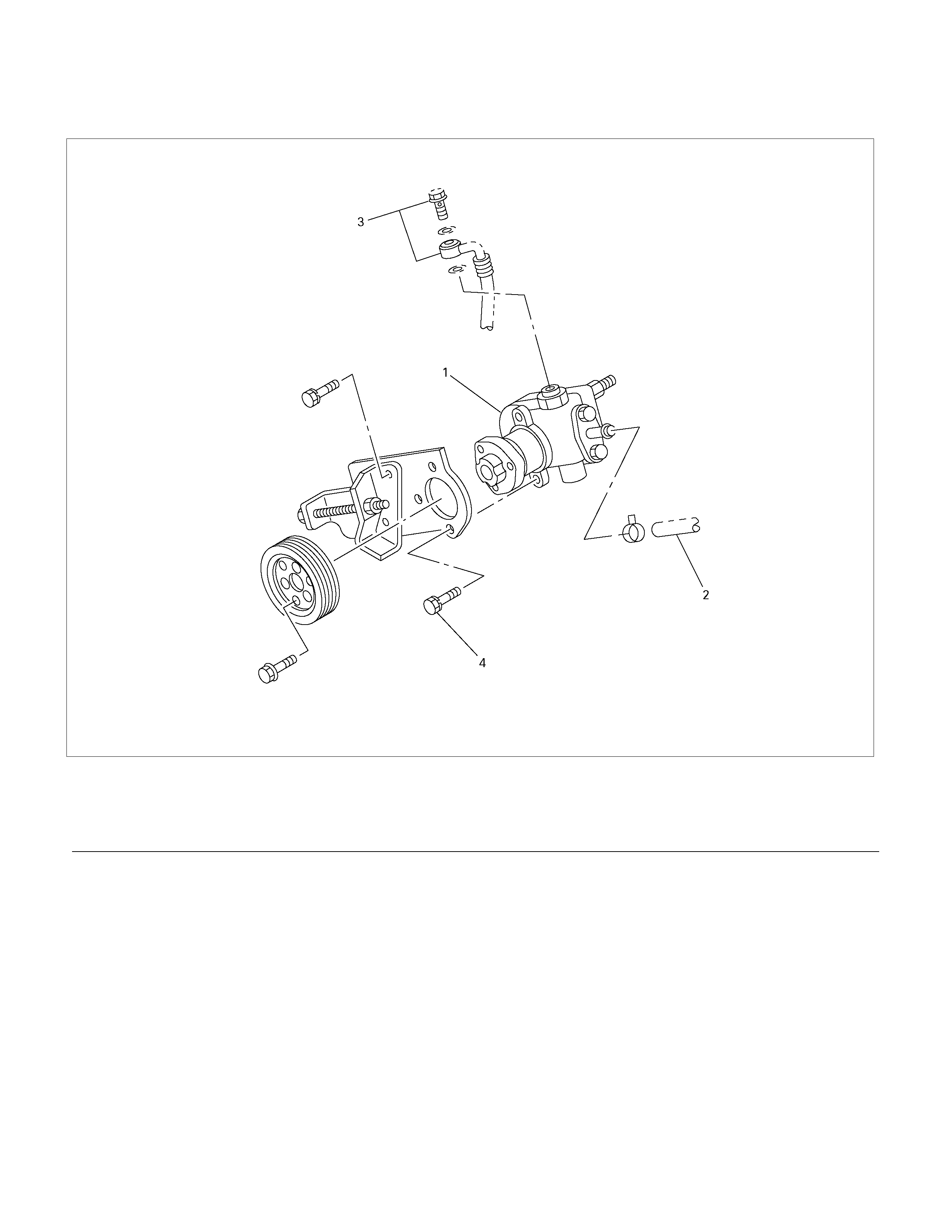

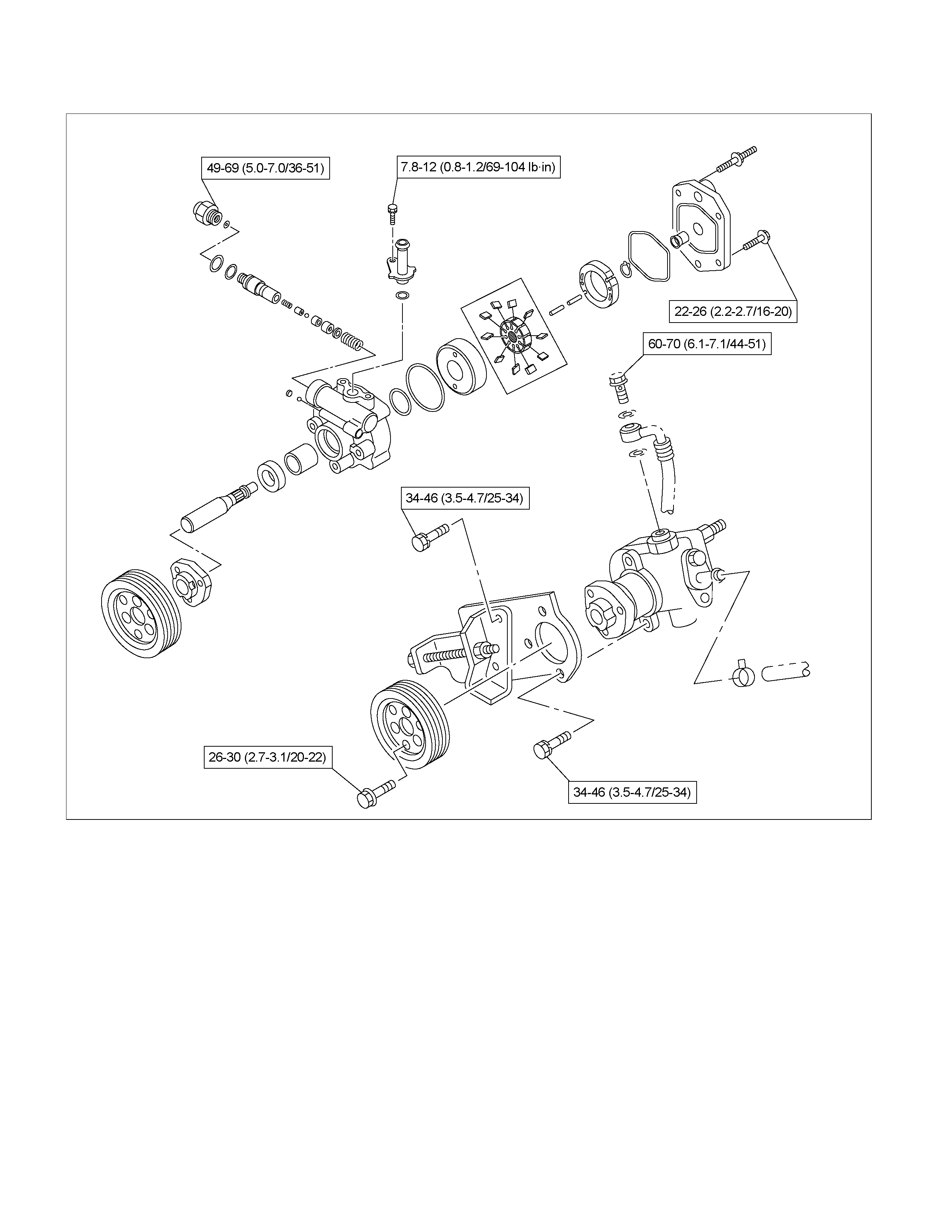

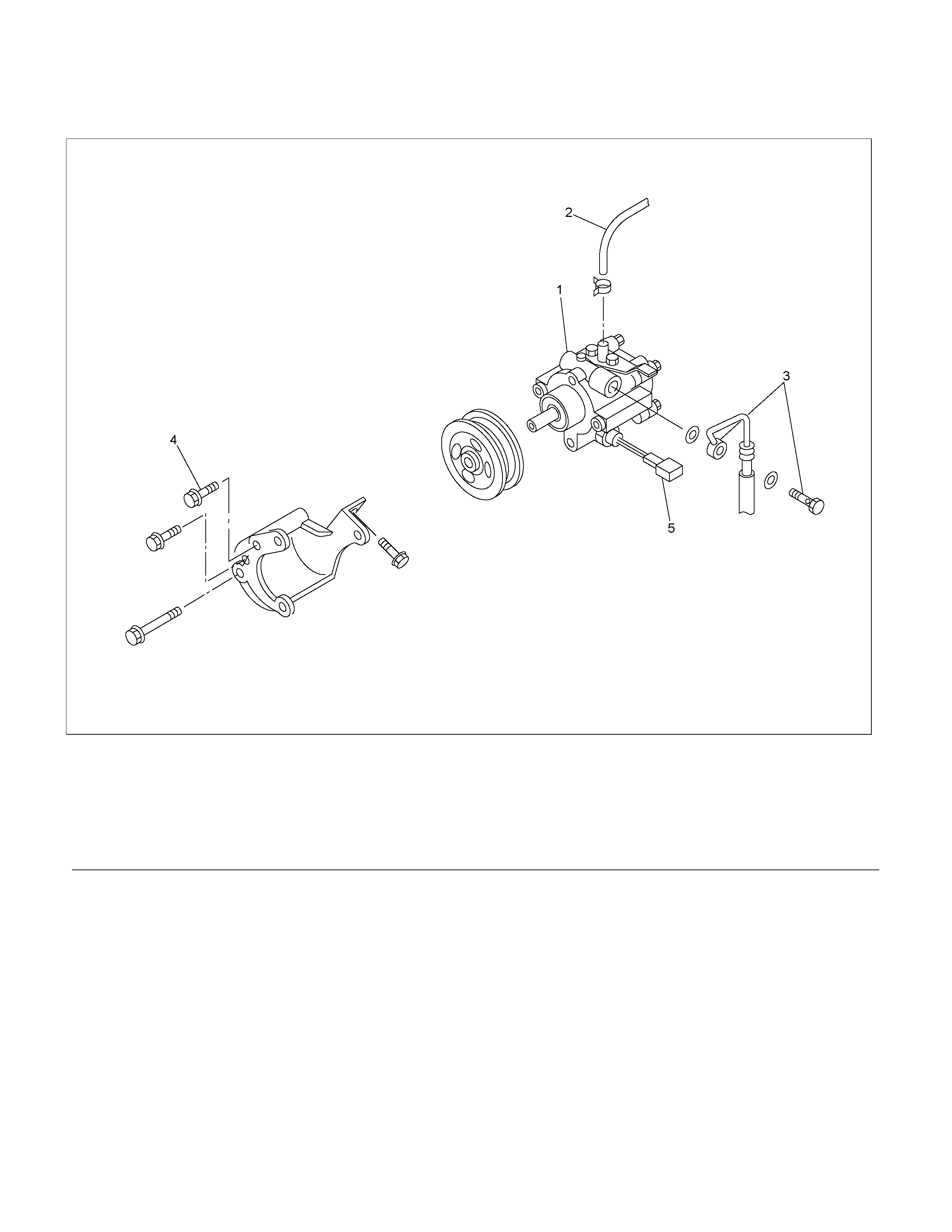

Power Steering Pump (4JH1-TC)

Power Steering Pump and

Associated Parts (4JH1-TC)

Removal

Installation

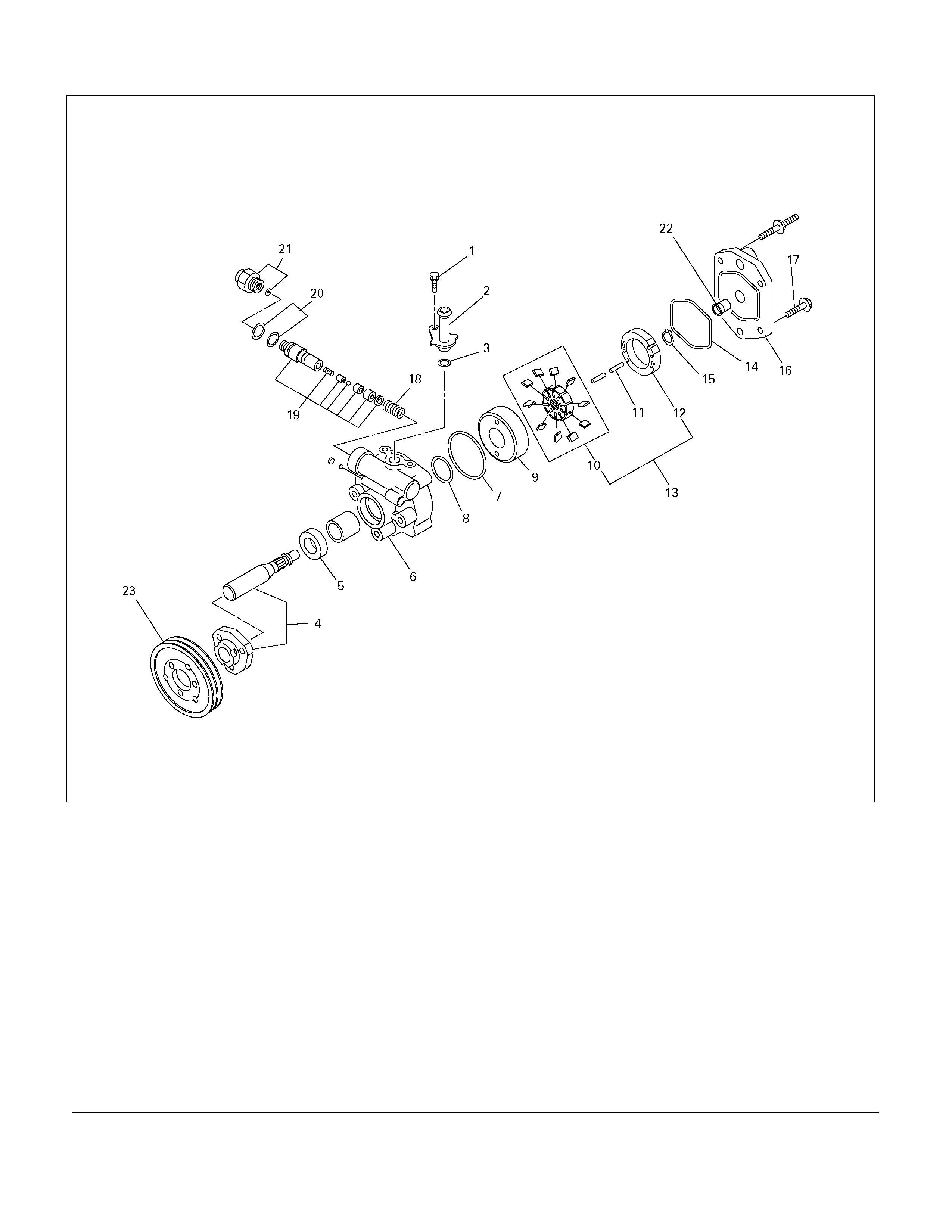

Power Steering Pump Disassembled View

Disassembly

Inspection and Repair

Reassembly

Main Data and Specifications

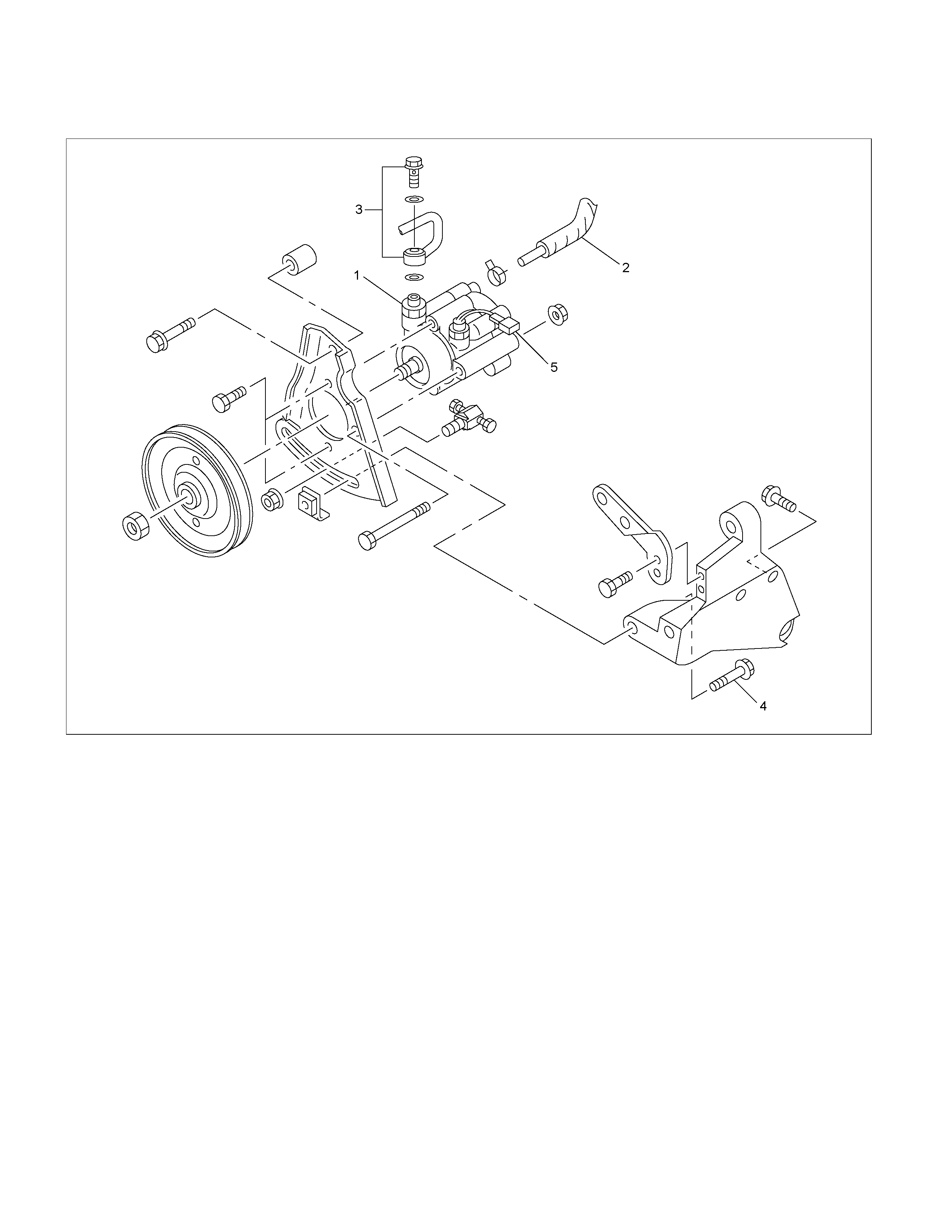

Power Steering Pump (C24SE)

Power Steering Pump and Associated Parts (C24SE)

Removal

Installation

Power Steering Pump Disassembled View

Disassembly

Inspection and Repair

Reassembly

Main Data and Specifications

Power Steering Pump (6VE1)

Power Steering Pump and Associated Parts (6VE1)

Removal

Installation

Power Steering Pump Disassembled View

Disassembly

Inspection and Repair

Reassembly

Main Data and Specifications

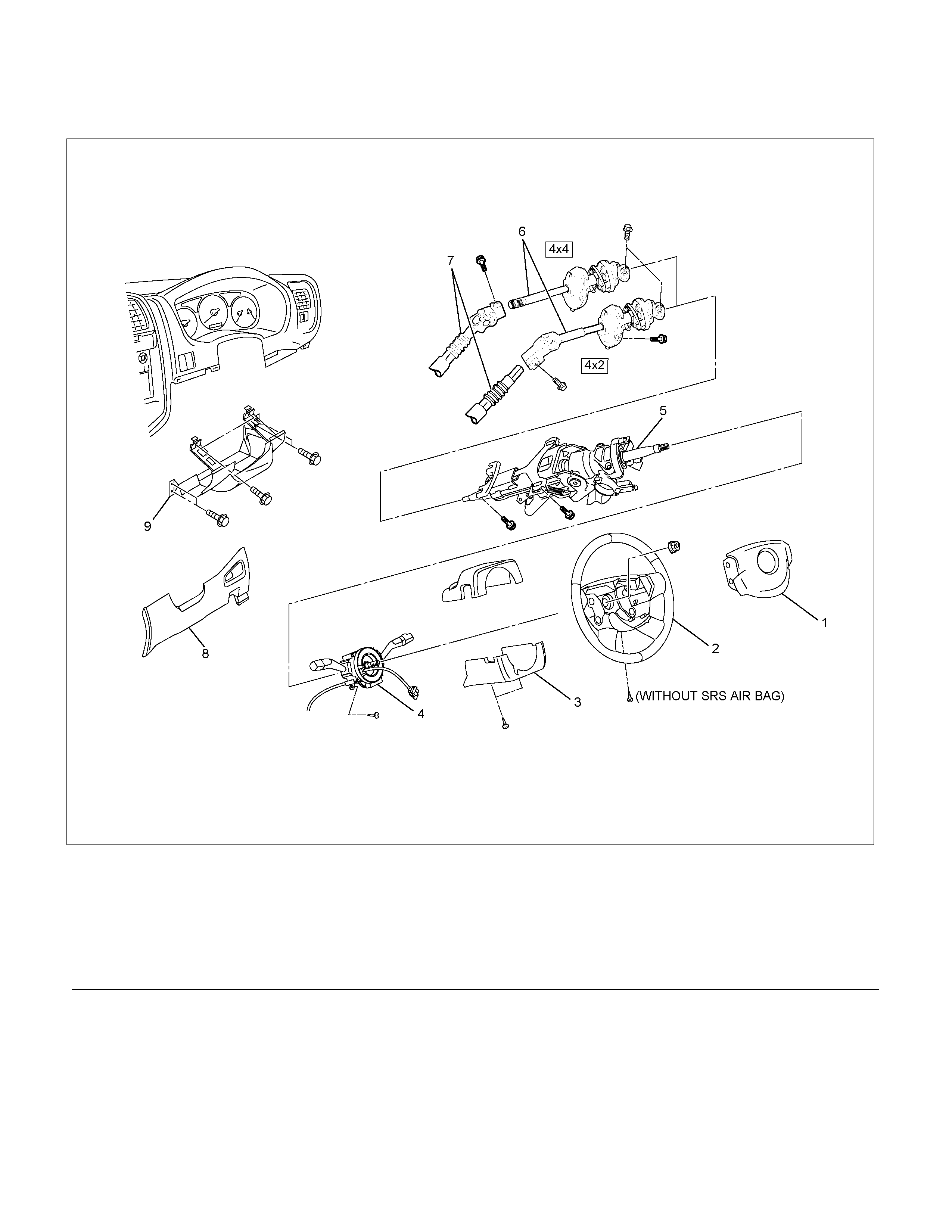

Supplemental Restraint System Steering Wheel &

Column

Service Precaution

SRS Connectors

Inflator Module

Inflator Module and Associated Parts

Removal

Inspection and Repair (with SRS air bag)

Installation

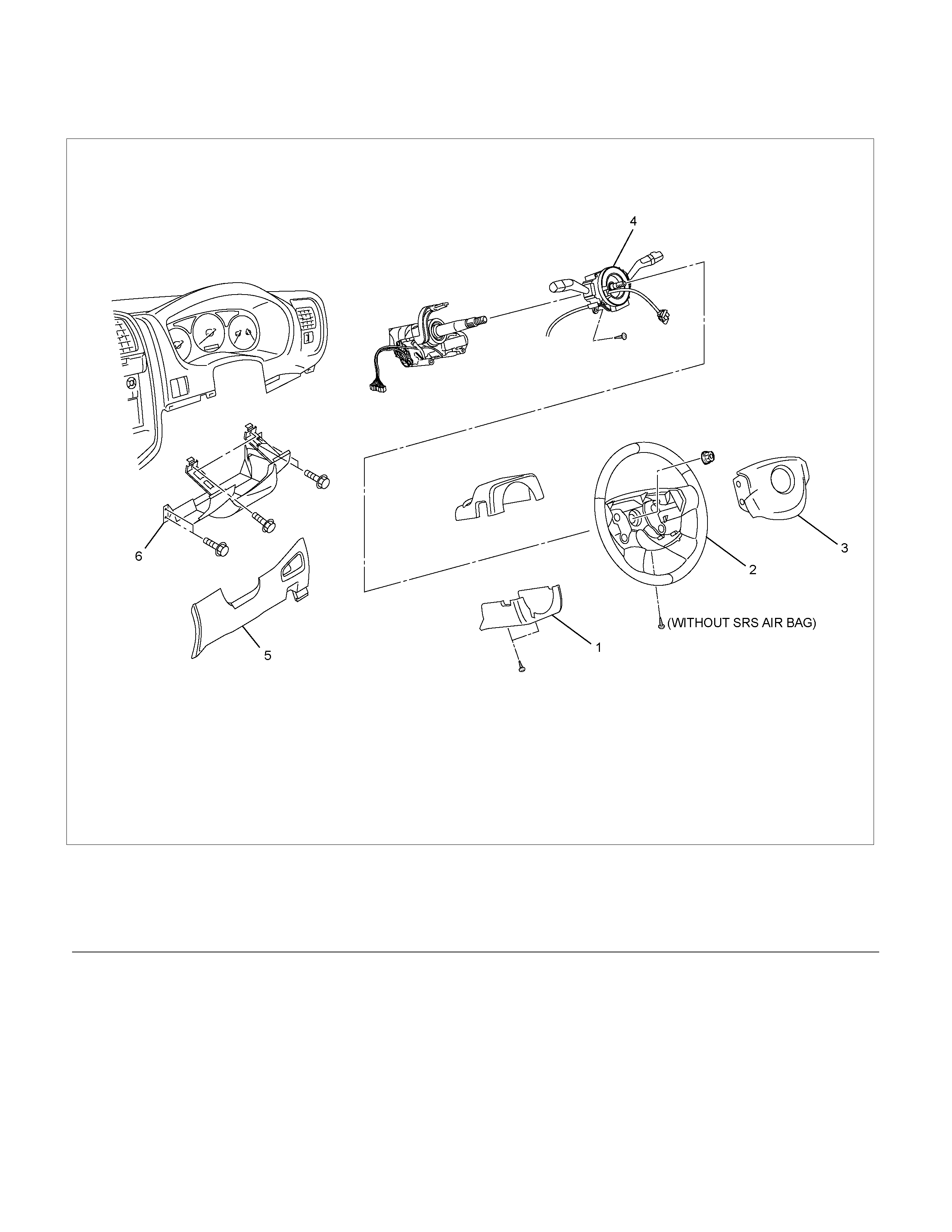

Steering Wheel

Steering Wheel and Associated Parts

Removal

Installation

The adjustment method in case a mark is not

attached

Combination Switch

Combination Switch and Associated Parts

Removal

Installation

Lock Cylinder

Lock Cylinder and Associated Parts

Removal

Installation

System Inspection (with SRS air bag)

Steering Column

Steering Column and Associated Parts

Removal

Inspection

Installation

System Inspection (with SRS air bag)

Supplemental Restraint System Steering Wheel &

Column and Associated Parts

Main Data and Specifications

Special Tools

Techline

General Description

The hydraulic power steering system consists of a pump, an oil reservoir, a steering unit, a pressure hose and a return

hose.

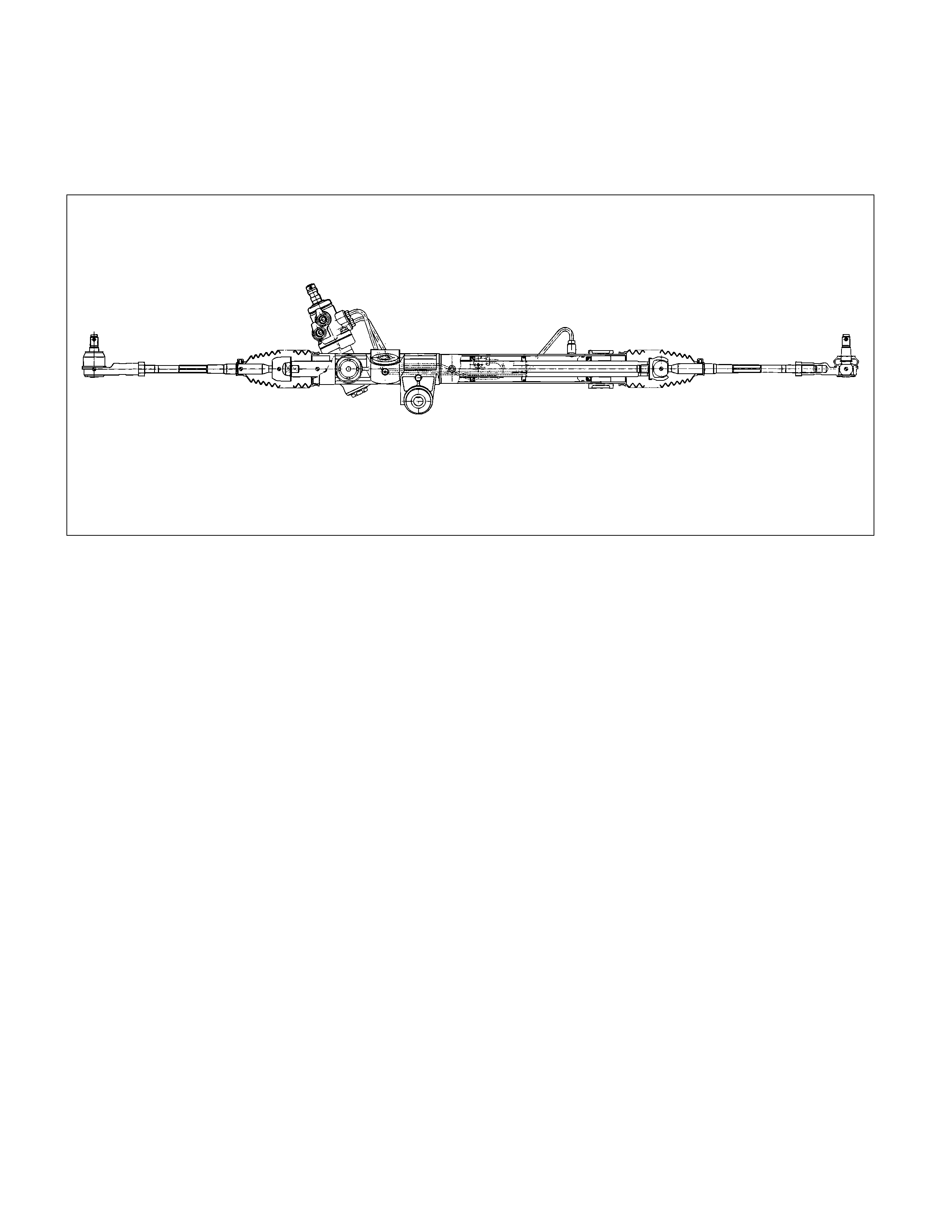

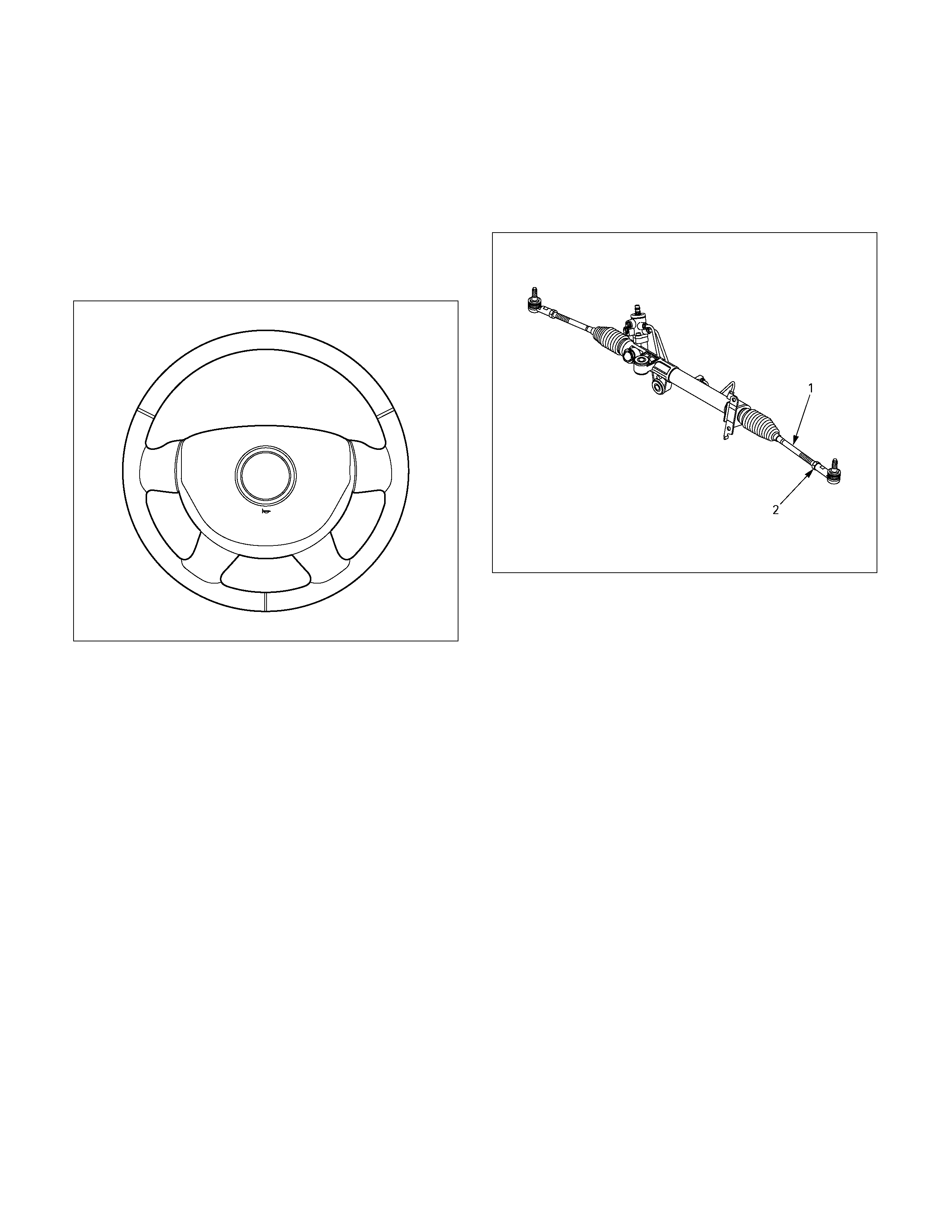

Power Steering Unit

440R300001

The power steering unit is rack and pinion type.

The toe-in angle can be adjusted by turning the rod on each side.

NOTE:

The steering housing cannot be disassembl ed.

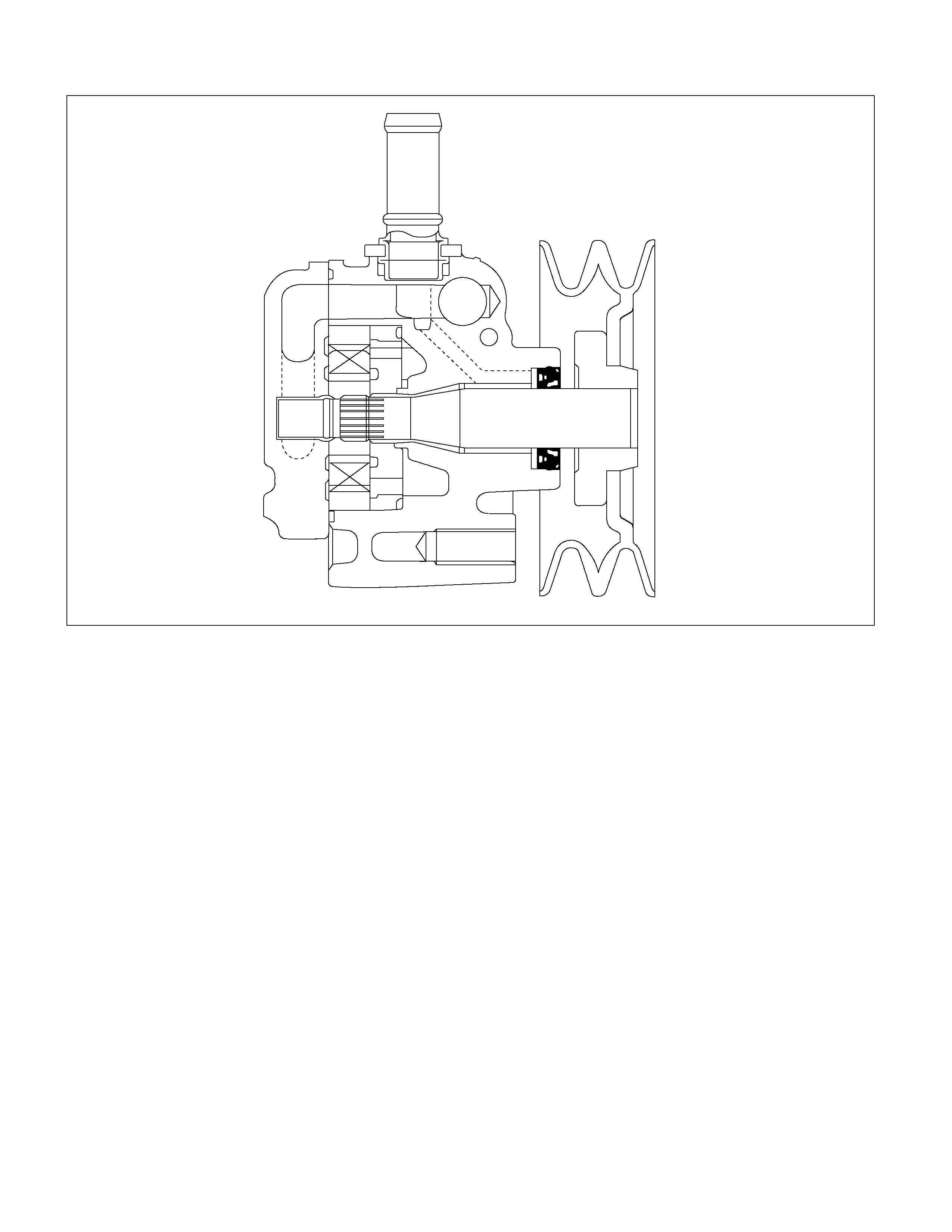

Hydraulic Pump

442R300004

The hydraulic pump is vane-type design. The submerged pump has housing and internal parts that are inside the

reservoir and operate submerged in oil. There are two bore openings at the rear of the pump housing. The larger

opening contains the cam ring, pressure plate, thrust plate, rotor and vane assembly, and end plate. The smaller

opening contains the pressure line union, flow control valve and spring.

The flow control orifice is part of the pressure line union. The pressure relief valve inside the flow control valve limits the

pump pressure.

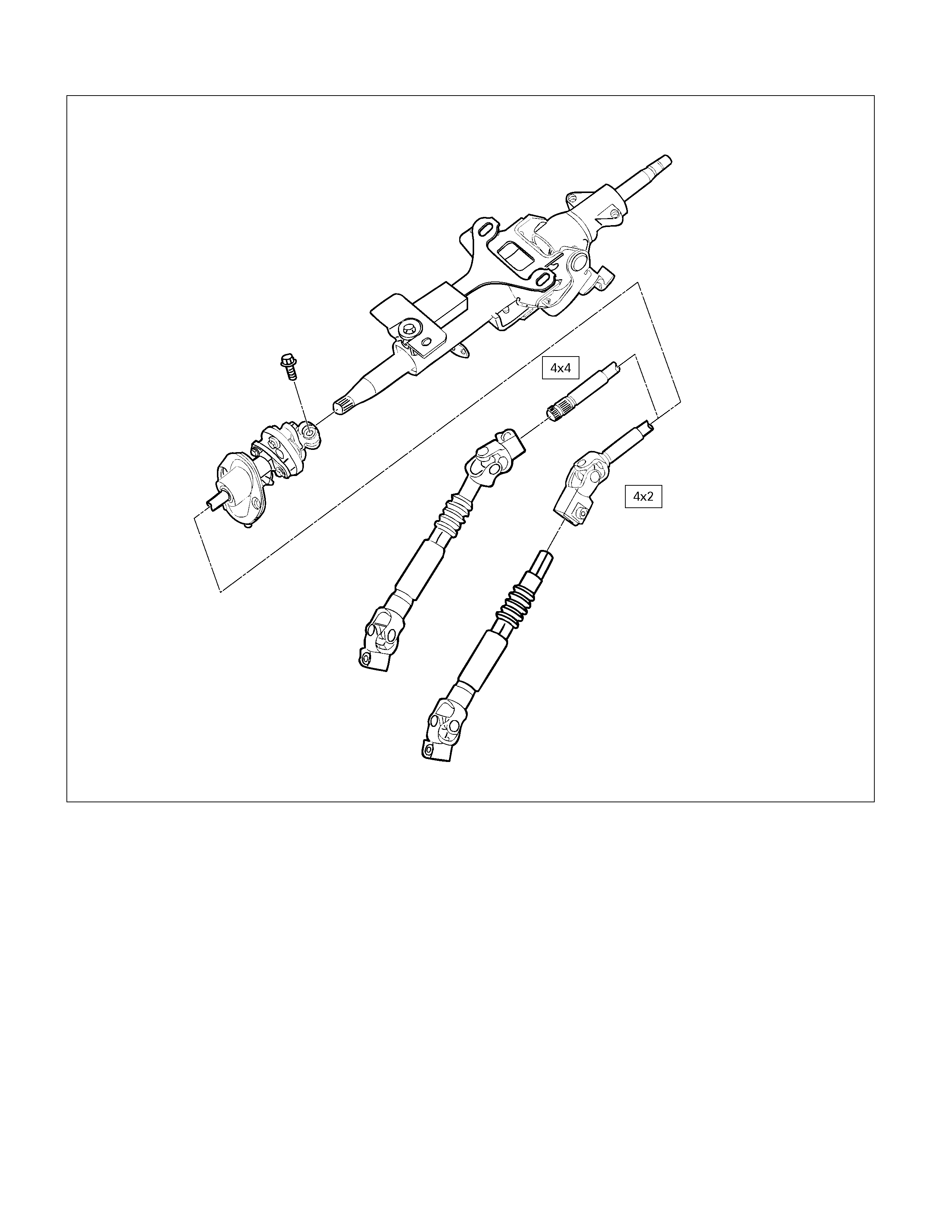

Steering Column

431R300011

WARNING: TO AVOID DEPLOYMENT WHEN TROUBLE-SHOOTING THE SRS SYSTEM, DO NOT USE

ELECTRICAL TEST EQUIPMENT, SUCH AS BATTERY-POWERED OR A/C-POWERED VOLT-METER,

OHMMETER, ETC., OR ANY TYPE OF ELECTRICAL EQUIPMENT OTHER THAN SPECIFIED IN THIS MANUAL.

DO NOT USE A NON-POWERED PROBE-TYPE TESTER. INSTRUCTION IN THIS MANUAL MUST BE FOLLOWED

CAREFULLY, OTHERWISE PERSONAL INJURY MAY RESULT.

When servicing a vehicle equipped with Supplemental Restraint System, pay close attention to all WARNINGS and

CAUTIONS.

For detailed explanation about SRS, refer to Restraints section.

The steering column has three important features in addition to the steering function:

1. The column is energy absorbing, designed to compress in a front-end collision to minimize the possibility of injury to

the driver of the vehicle.

2. The ignition switch and lock are mounted conveniently on the column.

3. With the column mounted lock, the ignition and steering operation can be locked to prevent theft of the vehicle.

The column can be disassembled and reassembled.

NOTE: To insure the energy absorbing action, use only the specified screws, bolts and nuts as designated,

and tighten them to the specified torque.

Handle the column with care when it is removed from the vehicle. A sharp blow on the end of steering shaft or shift

lever, or dropping the assembly could shear or loosen the fasteners that maintain column rigidity.

Power Steering System Test

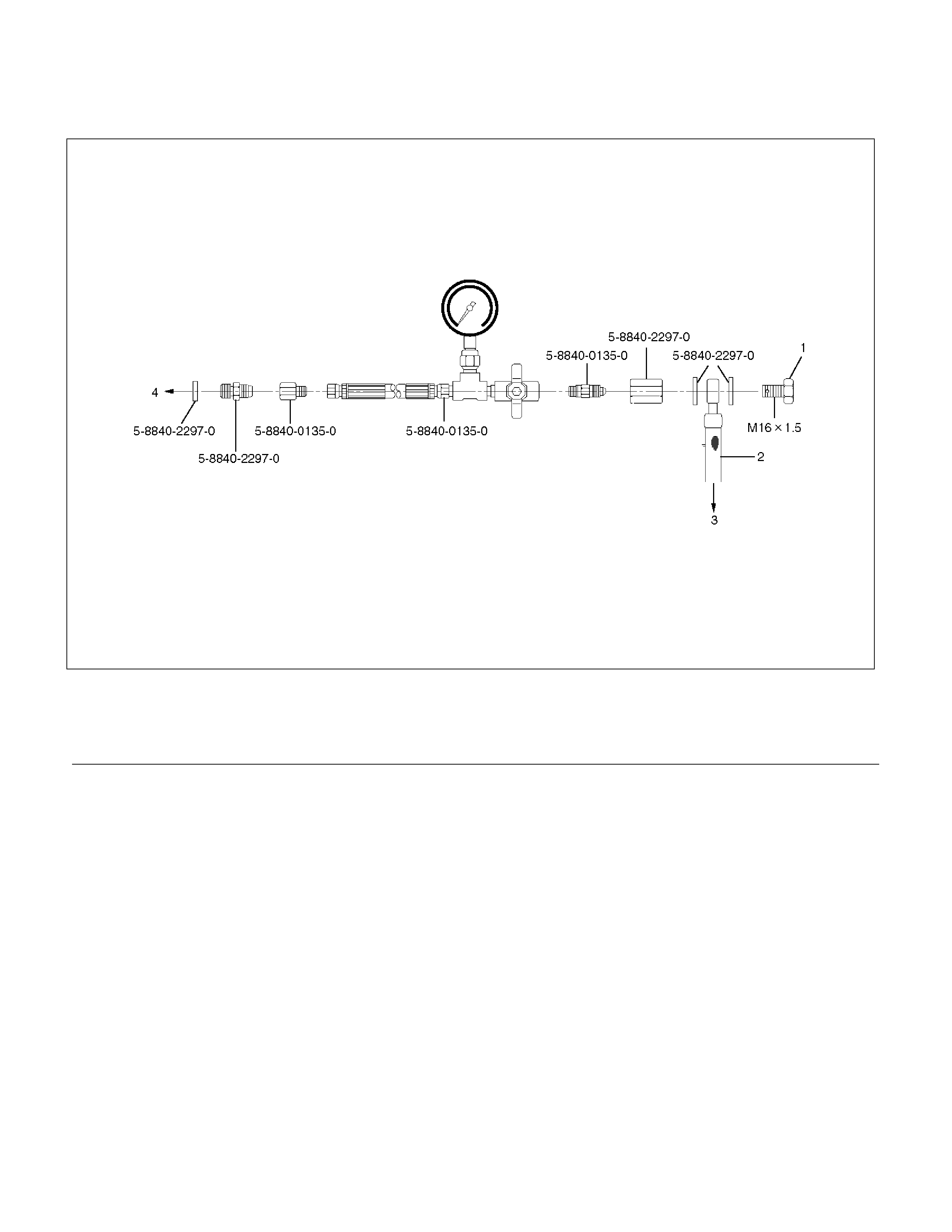

Test Procedure

F02RX002

Legend

(1) Bolt

(2) Hose

(3) Power Steering Unit

(4) Power Steering Pump

Test of fluid pressure in the power steering system is

performed to determine whether or not the oil pump and

power steering unit are functioning normally.

The power steering system test is used to identify and

isolate hydraulic circuit difficulties. Prior to performing

this test, the following inspections and corrections, if

necessary, must be made.

• Inspect pump reservoir for proper fluid level.

• Inspect pump belt for proper tension.

• Inspect pump driver pulley condition.

1. Place a container under the pump to catch the fluid

when disconnecting or connecting the hoses.

2. With the engine NOT running, disconnect the

pressure hose at the power steering pump and

install power steering tester 5-8840-0135-0 as

shown in the illustration. The gage must be between

the shutoff valve and pump. Open the shutoff valve.

3. Check the fluid level. Fill the reservoir with power

steering fluid, to the "Full" mark. Start the engine,

then turn the steering wheel and momentarily hold it

against a stop (right or left). Turn the engine off and

check the connections at tester for leakage.

4. Bleed the system. Refer to Bleeding the Power

Steering System in this section.

5. Start the engine and check the fluid level. Add

power steering fluid if required. When the engine is

at normal operating temperature, increase engine

speed to 1500 rpm.

CAUTION: To prevent internal pump damage, Do

not leave shutoff valve fully closed for more than 5

seconds.

6. Fully close the shutoff valve. Record the highest

pressures.

• If the pressure recorded is within 9300-9800 kPa

(95-100 kg/cm2/1350-1420 psi), the pump is

functioning within its specifications.

• If the pressure recorded is higher than 9800 kPa

(100 kg/cm2/1420 psi), the valve in the pump is

defective.

• If the pressure recorded is lower than 9300 kPa (95

kg/cm2/1350 psi), the valve or the rotating group in

the pump is defective.

7. If the pump pressures are within specifications,

leave the valve open and turn (or have someone

else turn) the steering wheel fully in both directions.

Record the highest pressures and compare with the

maximum pump pressure recorded in step 6. If this

pressure cannot be built in either side of the power

steering unit, the power steering unit is leaking

internally and must be replaced.

8. Shut the engine off, remove the testing gauge.

9. Reconnect the pressure hose, check the fluid level

and make the needed repairs.

10. If the problem still exists, the steering and front

suspension must be thoroughly examined.

Maintenance

The hydraulic system should be kept clean and fluid

level in the reservoir should be checked at regular

intervals and fluid added when required. Refer to

Recommended Fluids and Lubricants in General

Information section for the type of fluid to be used and

the intervals for filling.

If the system contains some dirt, flush it as described in

this section. If it is exceptionally dirty, the pump must be

completely disassembled before further usage. (The

steering unit cannot be disassembled.)

All tubes, hoses, and fittings should be inspected for

leakage at regular intervals. Fittings must be tight. Make

sure the clips, clamps and supporting tubes and hoses

are in place and properly secured.

Power steering hoses and lines must not be twisted,

kinked or tightly bent. Air in the system will cause

spongy action and noisy operation. When a hose is

disconnected or when fluid is lost, for any reason, the

system must be bled after refilling. Refer to Bleeding the

Power Steering System in this section.

• Inspect belt for tightness.

• Inspect pulley for looseness or damage. The pulley

should not wobble with the engine running.

• Inspect hoses so they are not touching any other

parts of the vehicle.

• Inspect fluid level and fill to the proper level.

Fluid Level

1. Run the engine until the power steering fluid

reaches normal operating temperature, about 55°C

(130°F), then shut the engine off.

2. Check the level of fluid in the reservoir.

3. If the fluid level is low, add power steering fluid as

specified in General Information to the proper level

and install the receiver cap.

4. When checking the fluid level after the steering

system has been serviced, air must be bled from

the system. Refer to Bleeding the Power Steering

System in this section.

Bleeding The Power Steering System

When a power steering pump or unit has been installed,

or an oil line has been disconnected, the air that has

entered the system must be bled out before the vehicle

is operated. If air is allowed to remain in the power

steering fluid system, noisy and unsatisfactory operation

of the system may result.

Bleeding Procedure

When bleeding the system, and any time fluid is added

to the power steering system, be sure to use only power

steering fluid as specified in General Information.

1. Fill the pump fluid reservoir to the proper level and

let the fluid settle for at least two minutes.

2. Start the engine and let it run for a few seconds. Do

not turn the steering wheel. Then turn the engine

off.

3. Add fluid if necessary.

4. Repeat the above procedure until the fluid level

remains constant after running the engine.

5. Raise and support the front end of the vehicle so

that the wheels are off the ground.

6. Start the engine. Slowly turn the steering wheel right

and left, lightly contacting the wheel stops.

7. Add power steering fluid if necessary.

8. Lower the vehicle, set the steering wheel at the

straight forward position after turning it to its full

steer positions 2 or 3 times, and stop the engine.

9. Check the fluid level and refill as required.

10. If the fluid is extremely foamy , allow the vehicle to

set a few minutes, then repeat the above procedure.

Flushing The Pow e r Steering System

1. Raise and support the front end of the vehicle off

the ground until the wheels are free to turn.

2. Remove the fluid return line at the pump inlet

connector and plug the connector port on the pump.

Position the line toward a large container to catch

the draining fluid.

3. While running the engine at idle, fill the reservoir

with new power steering fluid. Turn the steering

wheel in both directions. Do not contact or hold the

steering wheel to the wheel stops. This will cause

the pump to go to pressure relief mode, which may

cause a sudden fluid overflow at the reservoir.

4. Install all the lines and hoses. Fill the system with

new power steering fluid and bleed the system as

described in Bleeding The Power Steering System.

Operate the engine for about 15 minutes.

Remove the pump return line at the pump inlet and

plug the connection on the pump. While refilling the

reservoir, check the draining fluid for contamination.

If foreign material is still evident, replace all lines,

disassemble and clean or replace the power

steering system components. Do not re-use any

drained power steering fluid.

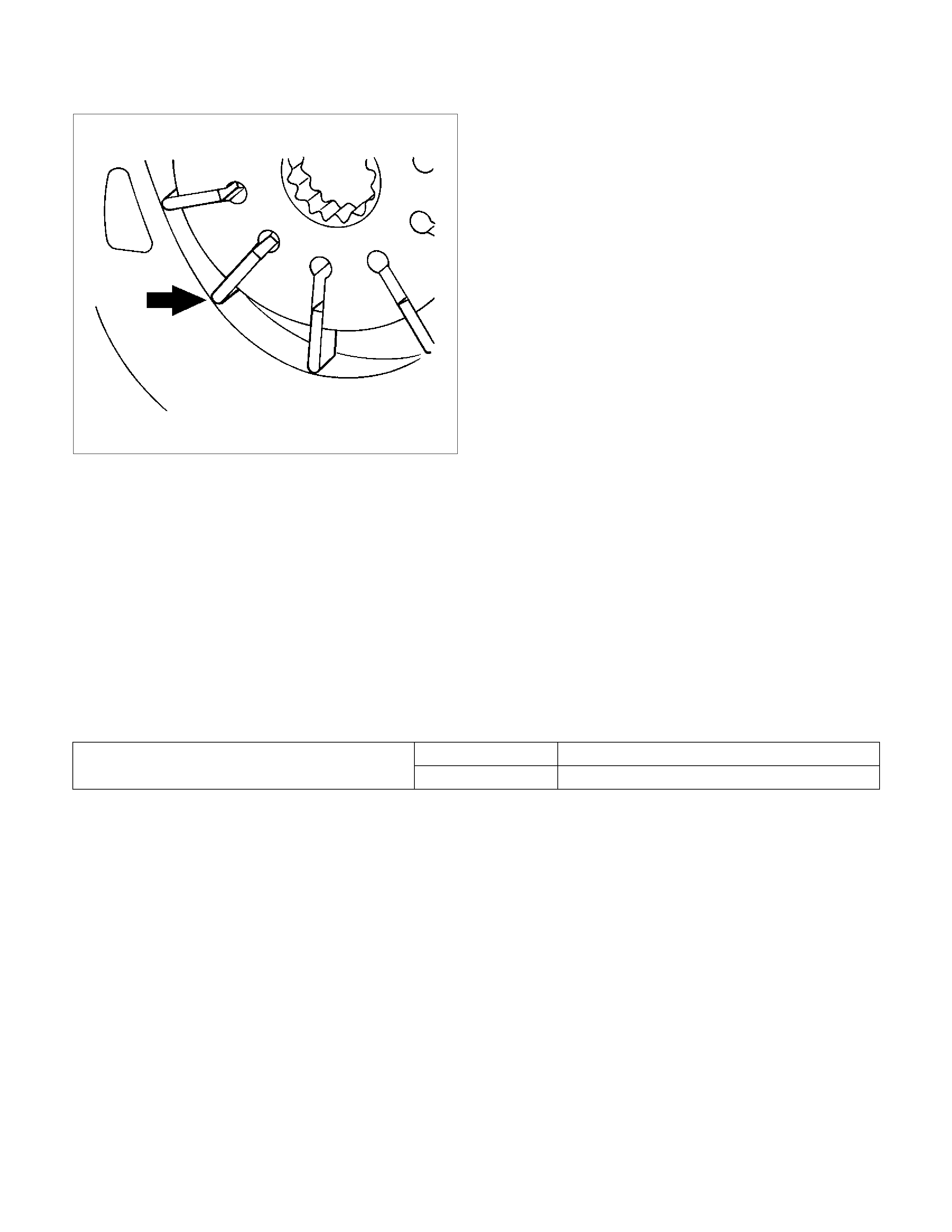

Steering Wheel Free Play Inspection

060R300016

1. With the tires in the straight-ahead position, check

the amount of steering wheel play by turning the

wheel in both directions until the tires begin to move.

NOTE: The wheel free play should be checked with the

engine running.

Free play: 0 - 30 mm (0 - 1.18 in)

2. Also check the steering wheel for play and

looseness in the mount by moving it back and forth

and sideways. When test driving, check for hard

steering, steering shimmy and tendency to pull to

one side.

Front End Alignment Inspection and

Adjustment

Toe-in Adjustment

Toe-in: Refer to Section 3A FRONT ALIGNMENT

1. To adjust the toe-in angle, loosen the lock nuts (2)

on the tie rod (1) and turn the tie rod. Turn both rods

the same amount, to keep the steering wheel

centered .

431R30006

2. Tighten the lock nut to the specified torque.

Torque:

92 - 104 Nm (9.4 - 10.6 kgm/68 - 77 lb ft)

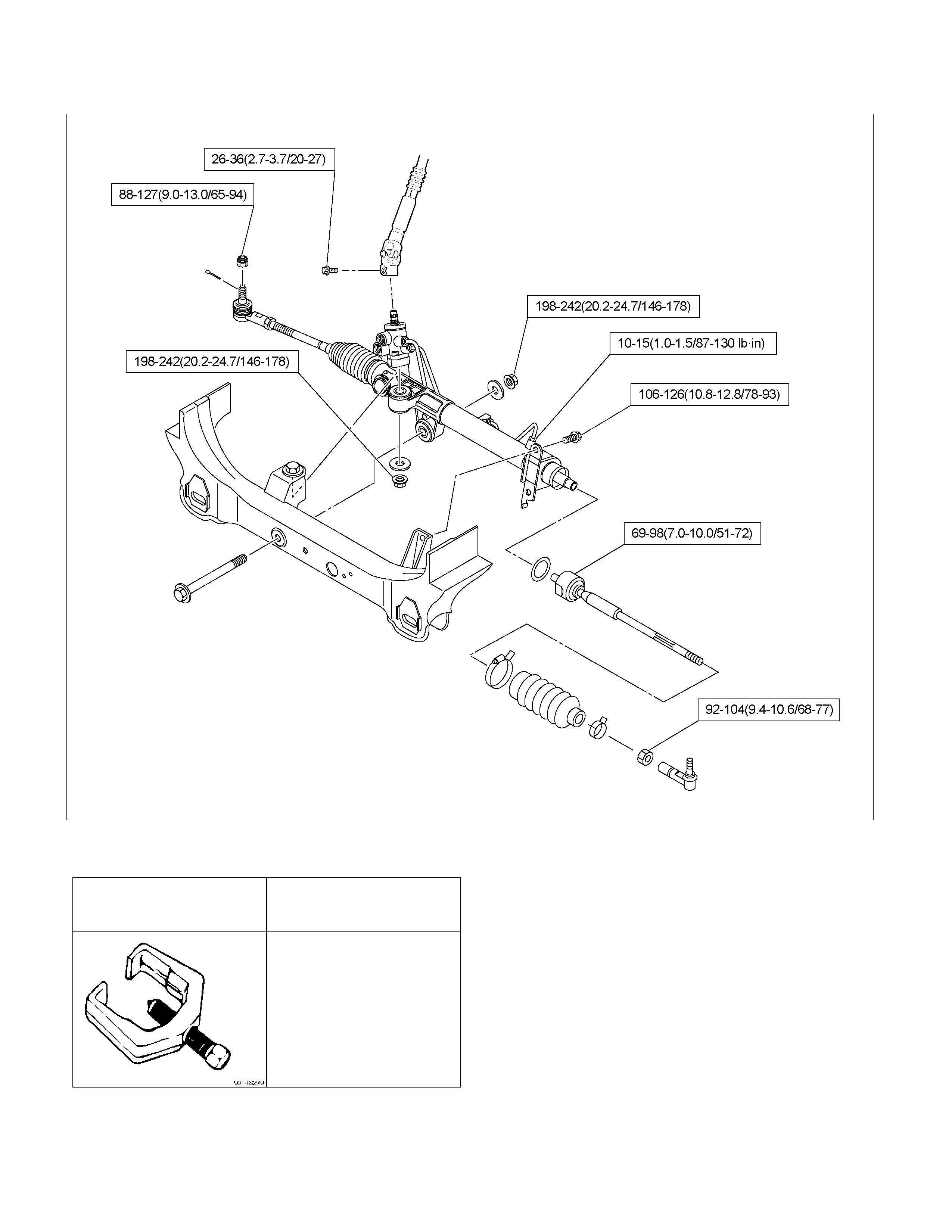

Torque Specification Nm (kgm/Ibft)

RTW33BLF000101

Special Tools

ILLUSTRATION

TOOL NO.

TOOL NAME

ILLUSTRATION

TOOL NO.

TOOL NAME

5-8840-0135-0

Tester;

Power steering

5-8840-2297-0

Adapter;

Power steering tester

Power Steering Unit

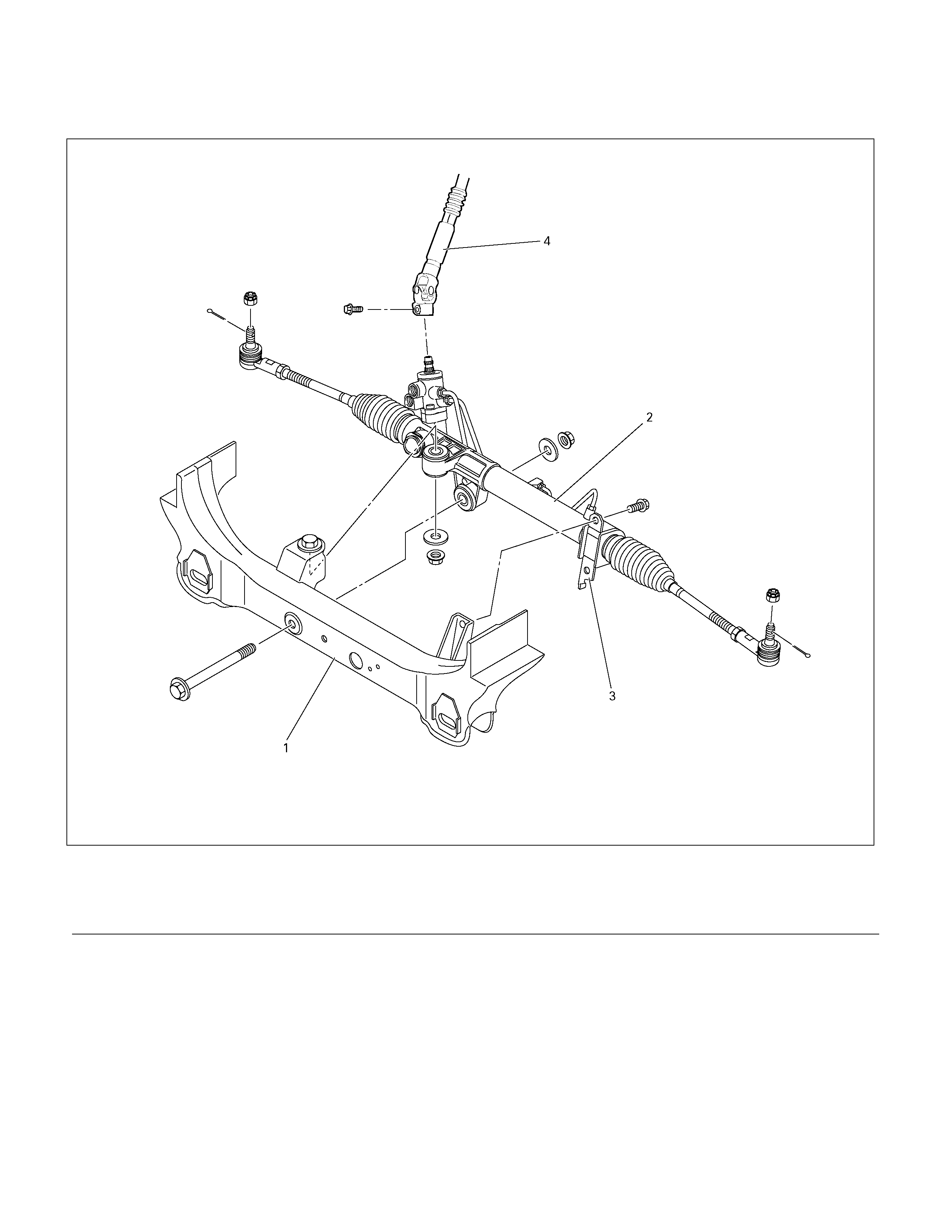

Powe r Steering Unit and Associated Parts

431R300016

Legend

(1) Crossmember

(2) Power Steering Un it Assembly

(3) Bracket

(4) Universal joint (Steering shaft)

Removal

1. Remove the universal joint assembly.

Make a setting mark across the coupling flange and

steering unit to ensure reassembly of the parts in

the original position.

2. Drain power steering fluid.

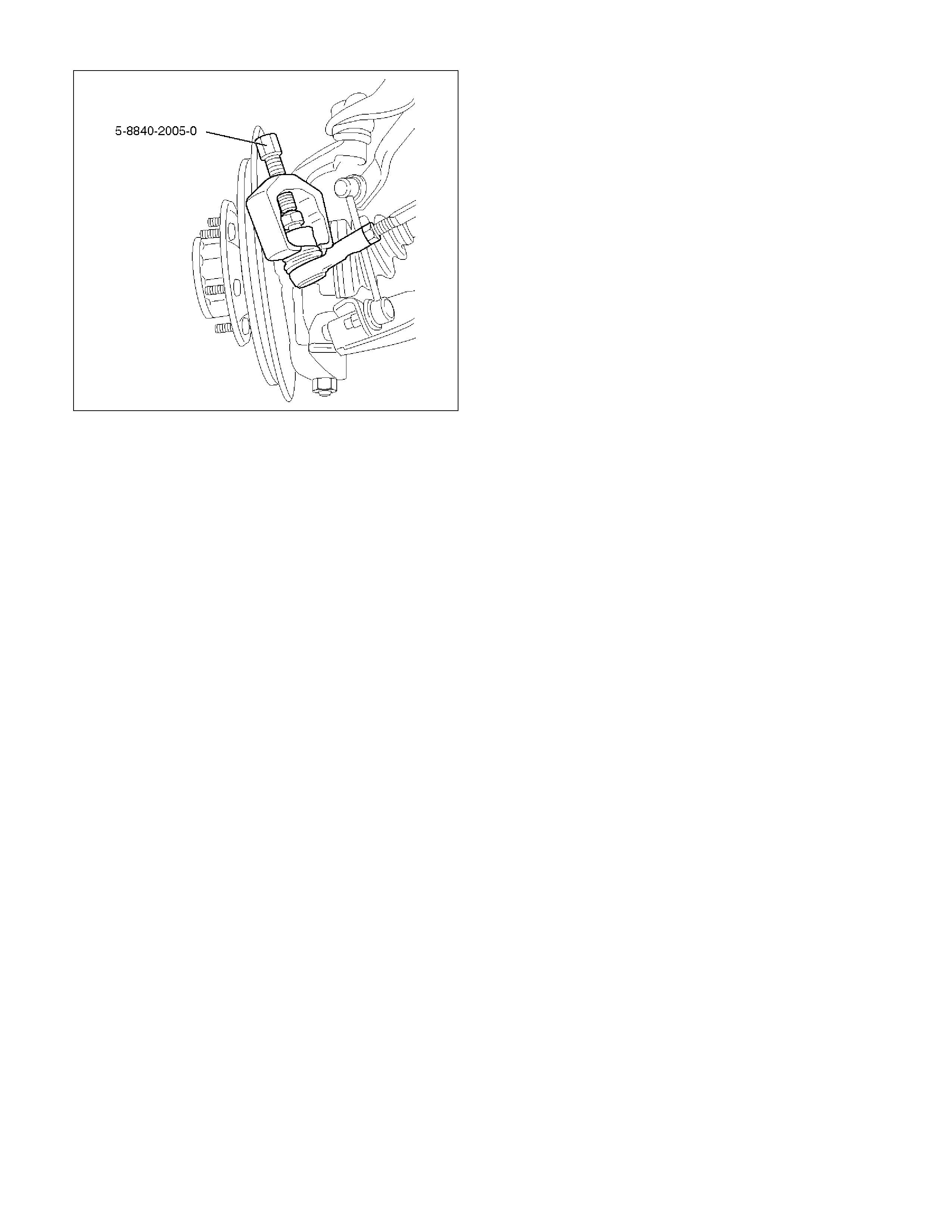

3. Remove the tie rod end assembly from knuckle.

Use tie rod end remover 5-8840-2005-0.

901RW270

4. Disconnect the feed line and return line from

steering unit.

Remove the clips on the crossmember and frame.

Wire the power steering line to frame.

NOTE: Take care to prevent foreign matter from entry

when disconnect the power steering line.

5. Remove the power steering unit from the

crossmember.

Installation

1. Install power steering unit to crossmember.

Tighten fixing bolt and nut to specified torque.

Torque:

106 – 126 Nm (10.8 – 12.8 kgm/78 - 93 lb ft)

Torque:

198 - 242 Nm (20.2 – 24.7 kgm/146 - 178 lb ft)

2. Connect the feed line and return line.

Torque:

20 - 29 Nm (2.0 – 3.0 kgm/14 - 22 lb ft)

3. Install tie-rod end assembly to knuckle.

Torque:

88 – 127 Nm (9.0 – 13.0 kgm/65 - 94 lb ft)

4. Align the setting marks on the universal joint

(applied at disassembly) w ith the setting marks on

the power steering unit. Connect the universal joint

assembly to the power steering unit. Temporarily

tighten the universal joint bolts on the universal joint

assembly side.

5. Tighten the universal joint bolts (bolts at either end

of the joint temporarily tightened in Step 1 and 2) to

the specified torque.

6. Install the stone guard.

7. Bleed the system.

Refer to Bleeding the Power Steering System in

this section.

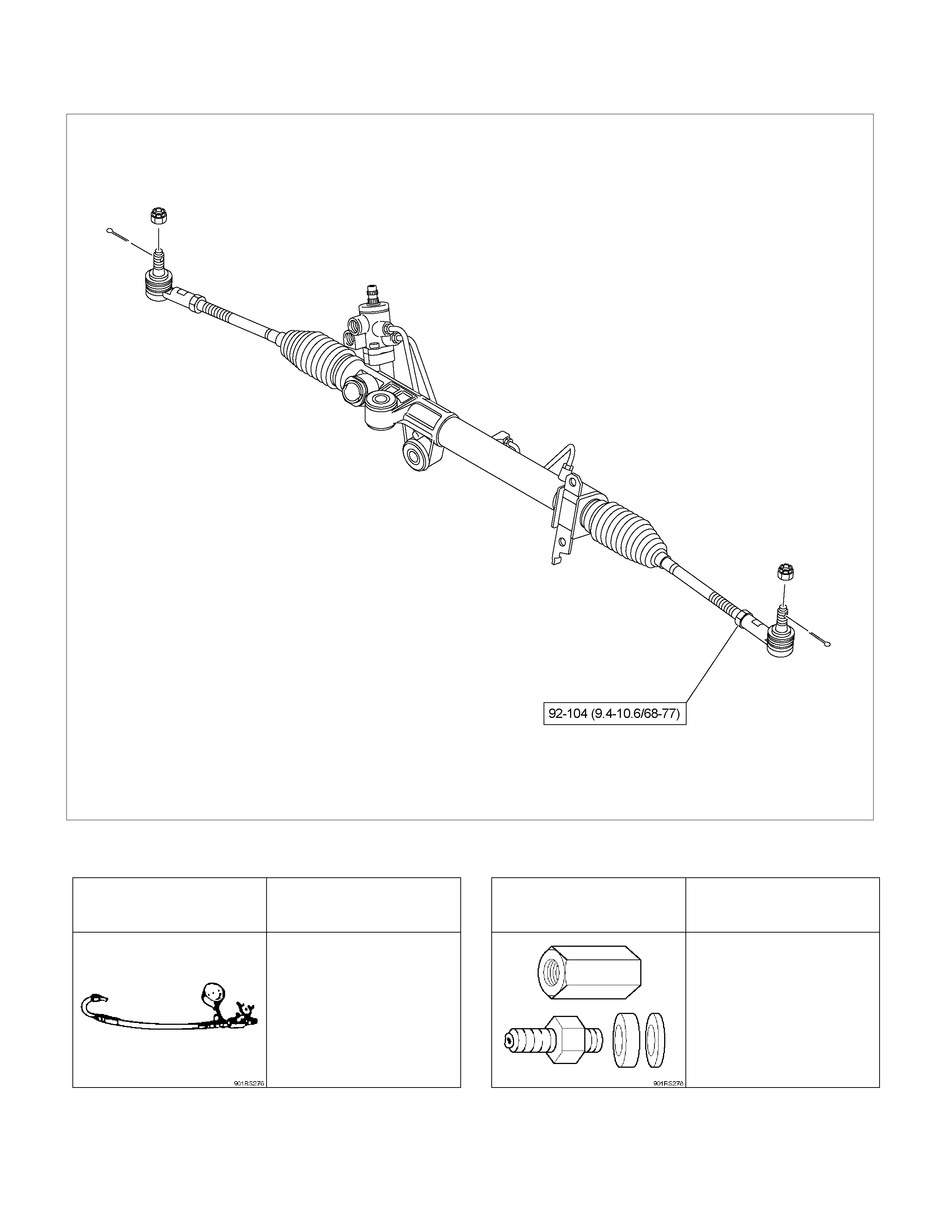

Powe r Steering Unit Disassembled View

440R300003

Legend

(1) Tie-rod End

(2) Lock Nut

(3) Clip

(4) Bellows

(5) Band

(6) Tie-rod Assembly

(7) Oil Line

(8) Inner Ball Joint Assembly

(9) Tab Washer

(10) Mounting Rubber

(11) Housing Assembly

Disassembly

NOTE: The valve housing is made of aluminum and

care should be exercised when clamping in a vise, etc.

to prevent distortion or damage.

1. Loosen lock nut and remove tie-rod end.

2. Remove clip and band, then remove bellows.

3. Remove tie-rod assembly.

To remove, move the boot toward the tie-rod end,

then remove tab washer.

4. Remove oil line, mounting rubber and dust cover.

Inspection and Repair

Inspect the following parts for wear, damage or any

abnormal conditions.

Tie-rod End

If looseness or play is found when checked by moving

the end of ball joint at tie-rod end, replace tie-rod end.

Tie-rod Assembly

If the resistance is insufficient or play is felt when

checked by moving the ball on the tie-rod, replace the

tie-rod assembly.

Rubber Parts

If wear or damage is found through inspection, replace

with new ones.

Reassembly

1. Install mounting rubber and dust cover (If removed).

2. Install oil line.

Torque: 10 - 15 Nm (1.0 – 1.5 kgm/87 - 130 lb in)

3. Install tie-rod assembly w ith tab washer.

Apply grease to ball joint, install tie-rod and tab

washer, then tighten to specified torque.

Torque: 69 - 98 Nm (7.0 – 10.0 kgm/51 - 72 lb ft)

After tightening, bend tab washer against width

across flat of inner ball joint.

4. Apply a thin coat of grease to the shaft for smooth

installation. Then install bellows.

5. Install band and clip.

6. Install tie-rod end and tighten lock nut.

Torque:

92 - 104 Nm (9.4

–

10.6 kgm/68 - 77 lb ft)

Main Data and Specifications

General Specifications 2WD 4WD

Power steering Without With

Type Rack and pinion

Rack stroke mm (in) 138 (5.43) 138 (5.43) 152 (5.98)

Steering unit

Lock to lock 4.84 3.38 3.26

Torque Specifications Nm (kgm/Ibft)

RTW33LF000201

Special Tools

ILLUSTRATION

TOOL NO.

TOOL NAME

5-8840-2005-0

(J-29107)

Tie rod end remover

Power Steering Pump (4JH1-TC)

Powe r Steering Pump and Associated Parts (4JH1-TC)

442R300002

Legend

(1) Pump Assembly

(2) Hose, Suction

(3) Hose, Flexible

(4) Bolt

Removal

1. Remove the drive belt.

2. Remove the pulley

3. Place a drain pan below the pump.

4. Disconnect the suction hose.

5. Disconnect the flexible hose.

6. Remove the power steering fixing bolt and remove

the pump assembly.

Installation

1. Install the pump assembly to the pump braket,

tighten the fixing bolt to the specified torque.

Torque: 34 - 46 N·m (3.5 – 4.7 kg·m/25 - 34 lb ft)

2. Install the flexible hose.

Tighten the eye bolt to specified torque.

Torque: 60 - 70 N·m (6.1 – 7.1 kg·m/44 - 51 lb ft)

3. Install the pulley and tighten the bolt to the specified

torque.

Torque: 26 - 30 N·m (2.7 –3.1 kg·m/20 - 22 lb ft)

4. Install the drive belt.

5. Connect the suction hose, then fill and bleed system.

Refer to Bleeding the Power Steering System in

this section.

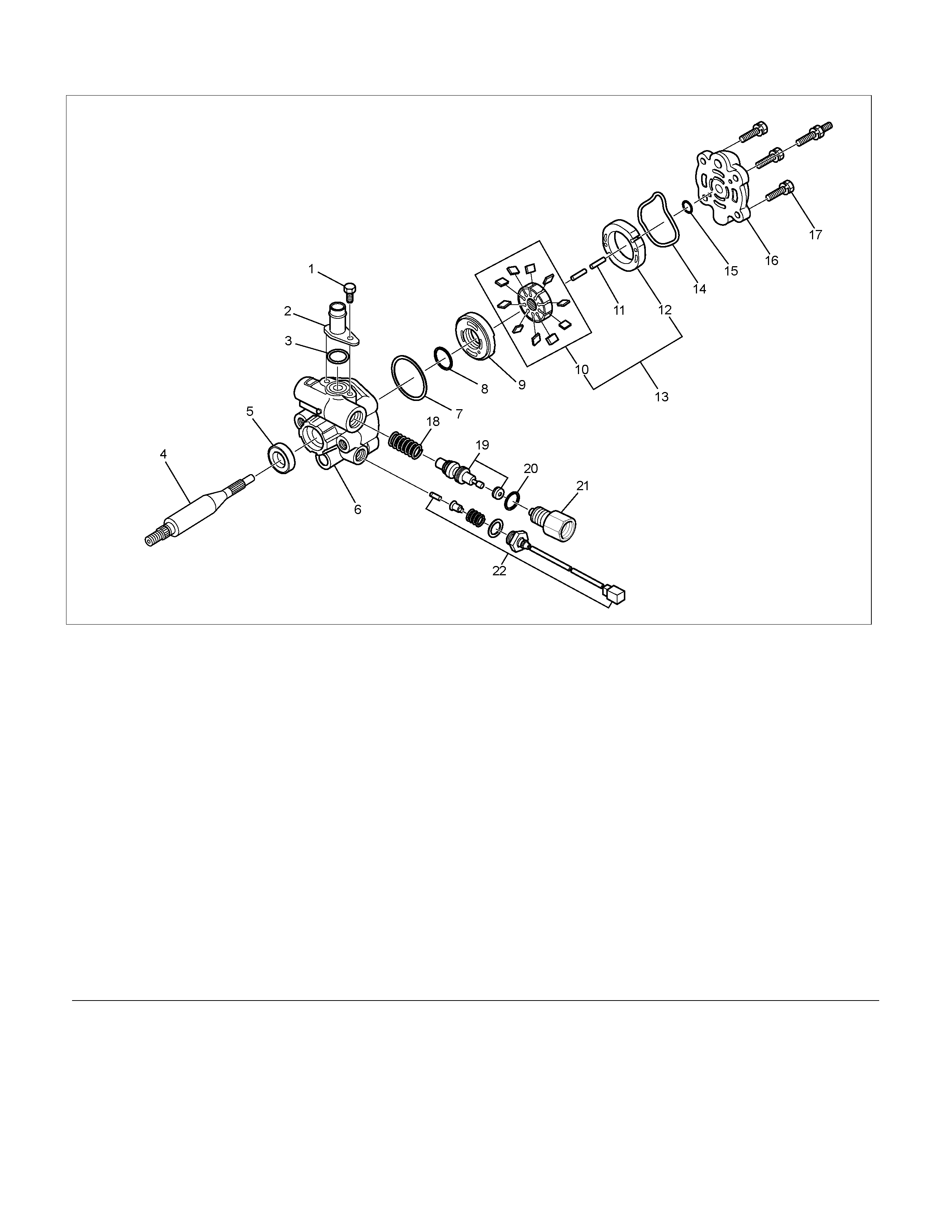

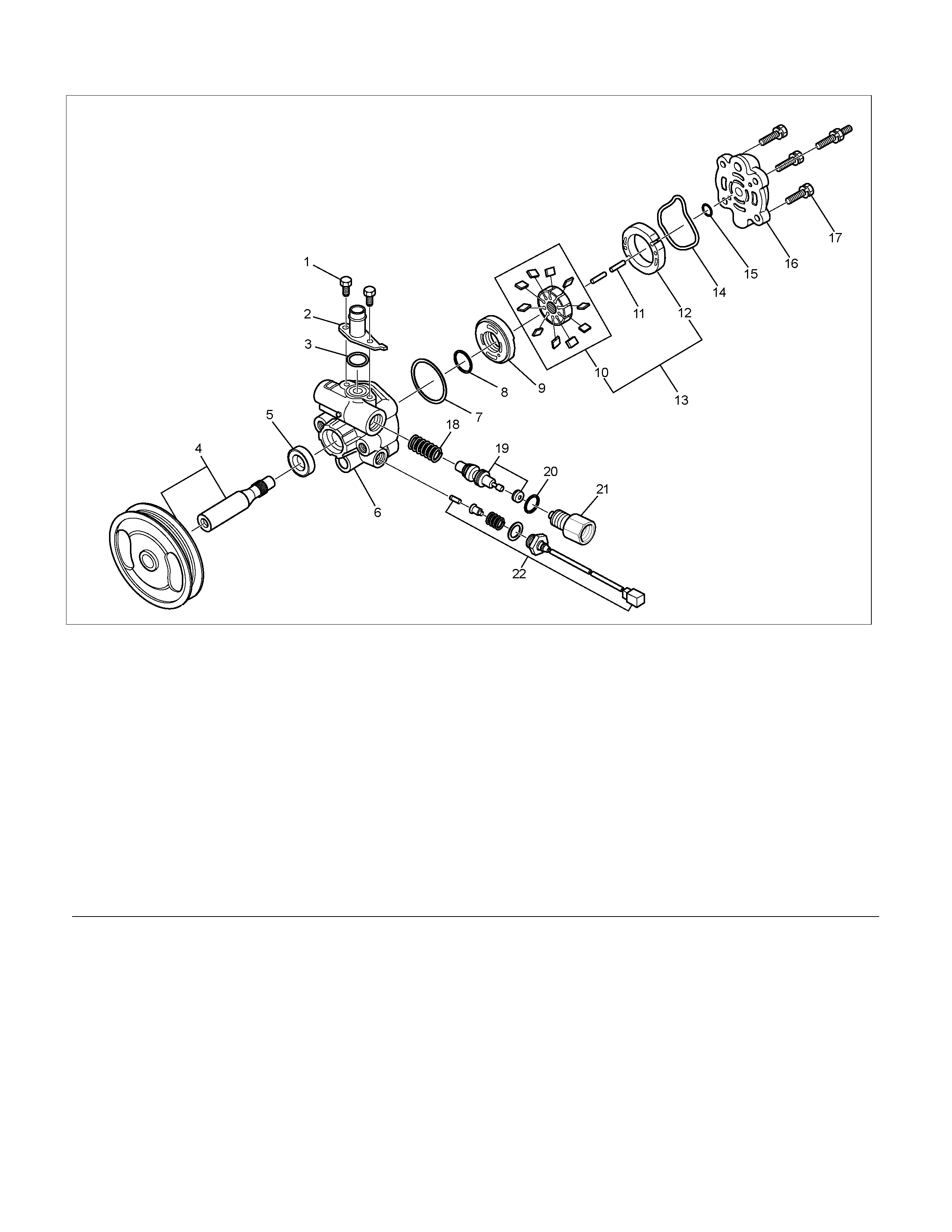

Powe r Steering Pump Disassembled View

442R300001

Legend

(1) Bolt

(2) Suction Pipe

(3) O-ring

(4) Shaft Assembly

(5) Oil Seal

(6) Front Housing

(7) O-ring

(8) O-ring

(9) Side Plate

(10) Rotor and Vane

(11) Pin

(12) Cam

(13) Pump Cartridge Assembly

(14) O-ring

(15) Snap Ring

(16) Rear Housing

(17) Bolt

(18) Spring

(19) Relief Valve

(20) O-ring

(21) Connector

(22) Bush

(23) Plley

Disassembly

1. Clean the oil pump with solvent (plug the discharge

and suction ports to prevent the entry of solvent).

Be careful not to expose the oil seal of shaft

assembly to solvent.

2. Remove the bolt, suction pipe and O-ring.

3. Remove the connector, O-ring, relief valve and

spring.

4. Remove the bolt, rear housing and O-ring.

5. Remove the snap ring.

6. Remove the shaft assembly.

7. Remove the oil seal.

CAUTION: When removing the oil seal, be careful

not to damage the housing.

8. Remove the pump cartridge assembly from the front

housing.

9. Remove two O-rings.

Inspection and Repair

Make all necessary adjustments, repairs, and part

replacements if wear, damage, or other problems are

discovered during inspection.

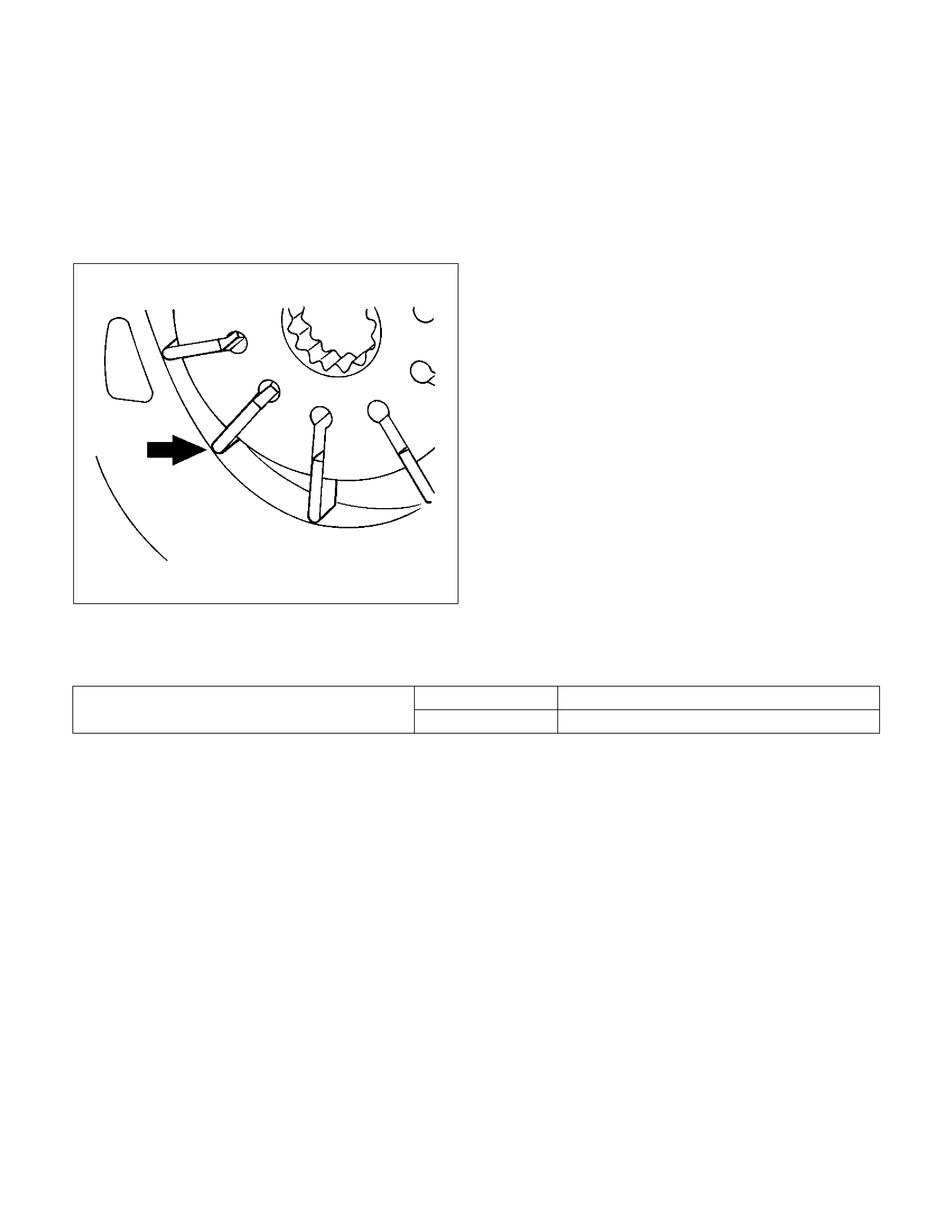

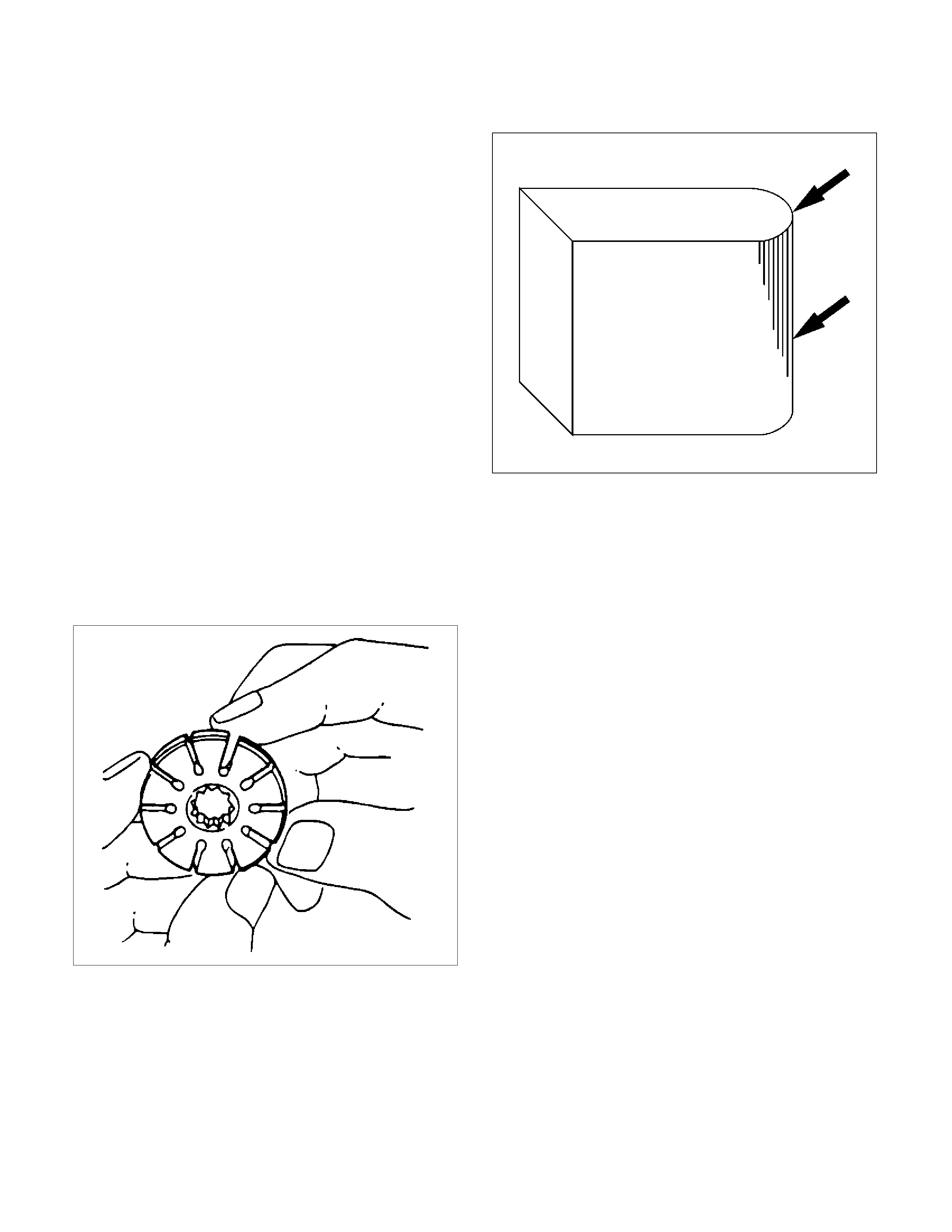

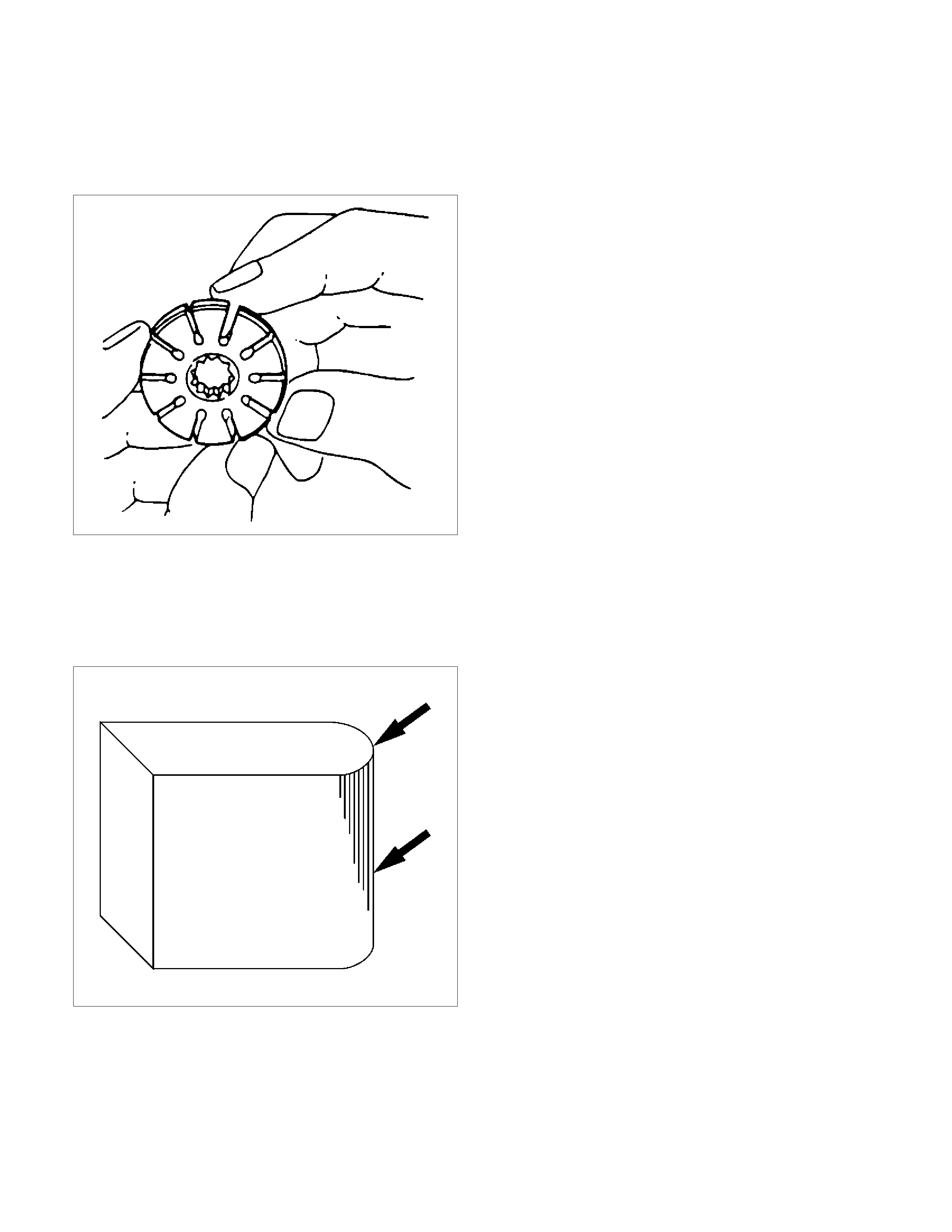

Rotor

442RS002

Check that the groove in the vane is free from excessive

wear and that the vane slides smoothly. When part

replacement becomes necessary, the pump cartridge

should be replaced as a subassembly .

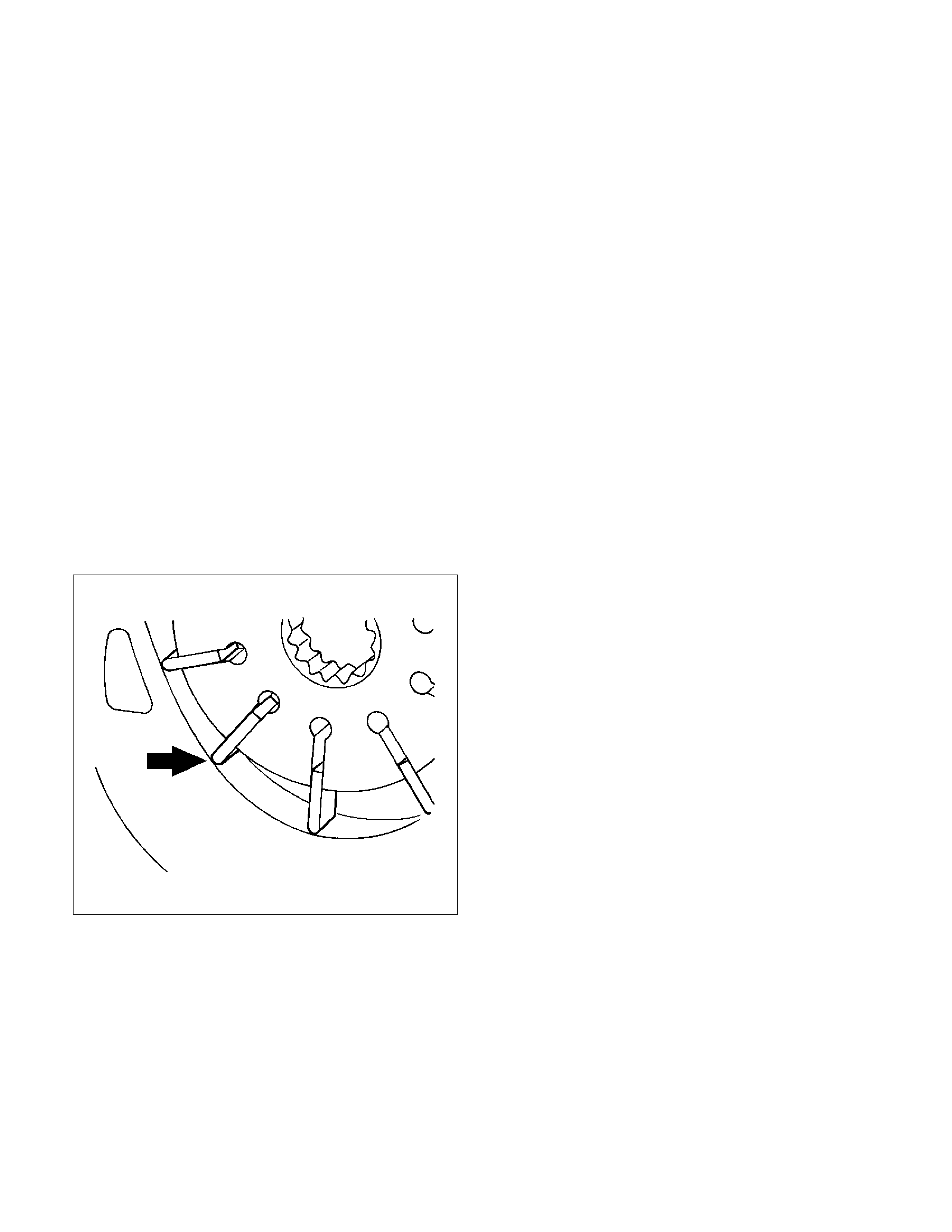

Vane

442RS003

Sliding faces of the vane should be free from wear.

(Particularly the curved face at the tip that contact with

the cam should be free from wear and distortion). When

part replacement becomes necessary, the pump

cartridge should be replaced as a subassembly.

Cam

The inner face of the arm should have a uniform contact

pattern without a sign of step wear. When part

replacement becomes necessary, the pump cartridge

should be replaced as a subassembly .

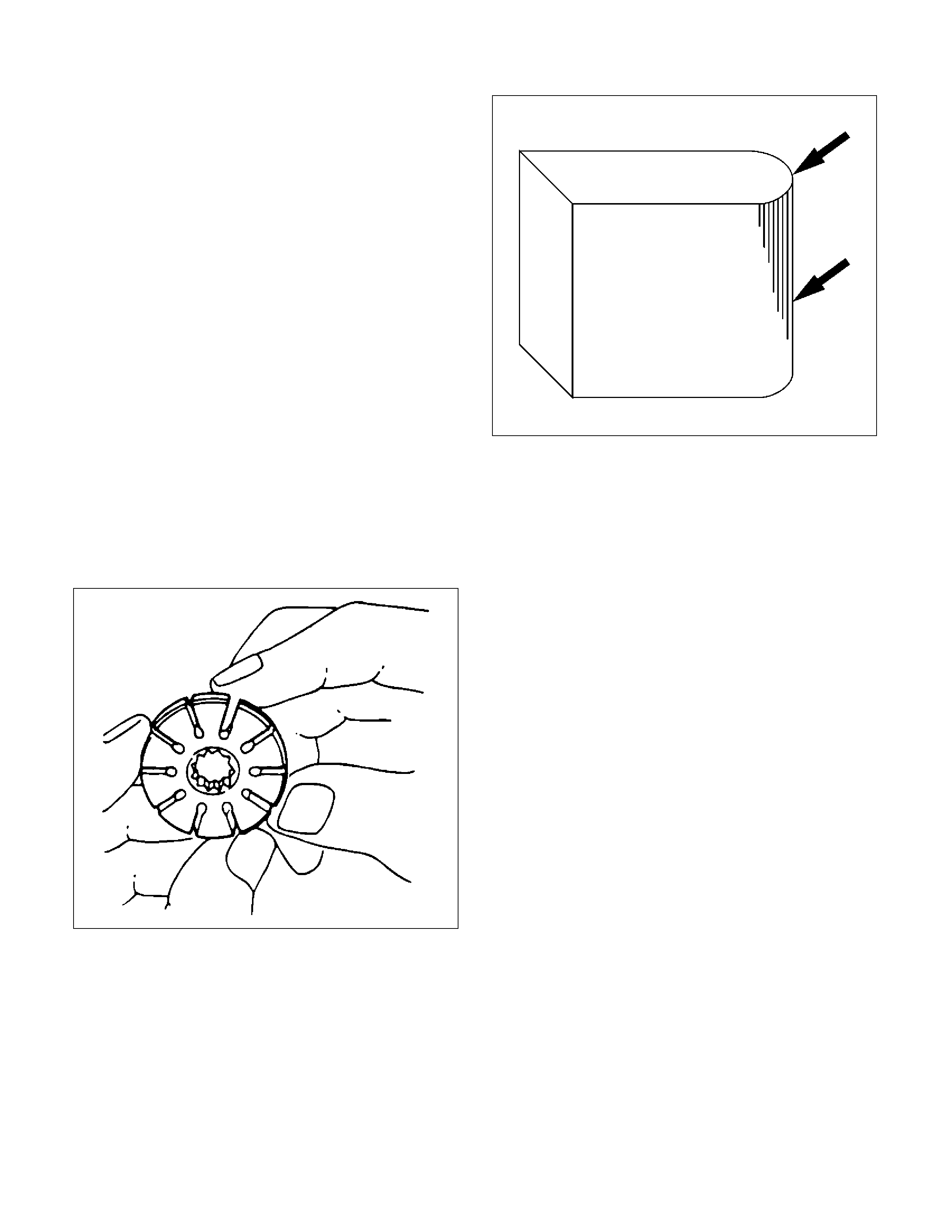

Side Plate

The sliding faces of parts must be free from step wear

(more than 0.01 mm), which can be felt by the finger

nail.

The parts with minor scores may be reused after lapping

the face.

Relief Valve

The sliding face of the valve must be free from burrs

and damage. The parts with minor scores may be

reused after smoothing with emery cloth (#800 or finer).

Shaft

Oil seal sliding faces must be free from a step wear

which can be felt by the finger nail. Bushing fitting face

must be free from damage and wear.

O-ring, Oil Seal, Snap Ring

Be sure to discard used parts, and always use new

parts for installation. Prior to installation, lubricate all

seals and rings with power steering fluid.

Reassembly

1. Install oil seal to front housing. Be sure to discard

used oil seal, and always use new parts for

installation.

CAUTION: When installing the oil seal, be careful

not to damage the oil seal contacting surface of the

housing.

2. Install shaft assembly.

3. Install the vanes to roter with curved face in contact

with the inner wall of cam.

442RS005

4. Install roter and vanes to cam.

5. Install pin to front housing.

6. Install two new O-rings to front housing. Be sure to

discard used O-ring.

7. Install side plate.

CAUTION: When installing side plate, be careful not

to damage its inner surface. Damaged side plate

may cause poor pump performance, pump seizure

or oil leakage.

8. Install pump cartridge assembly to front housing.

9. Install snap ring to shaft end.

10. Install rear housing with a new O-ring. Be sure to

discard used O-ring. Then install bolt and tighten it

to specified torque.

Torque: 22-26 Nm (2.2-2.7kgm/16-20 lb ft)

11. Install suction pipe with a new O-ring. Be sure to

discard used O-ring. Then install bolt and tighten it

to specified torque.

Torque: 7.8-12 Nm (0.8-1.2kgm/69-104 lb in)

12. Install relief valve and spring.

13. Install connector with a new O-ring. Be sure to

discard used O-ring. Tighten the connector to

specified torque.

Torque: 49-69 Nm (5.0-7.0kgm/36-51 lb ft)

Main Data and Specifications

General Specifications

Oil pump Type Vane

Operating fluid ATF DEXRON®III

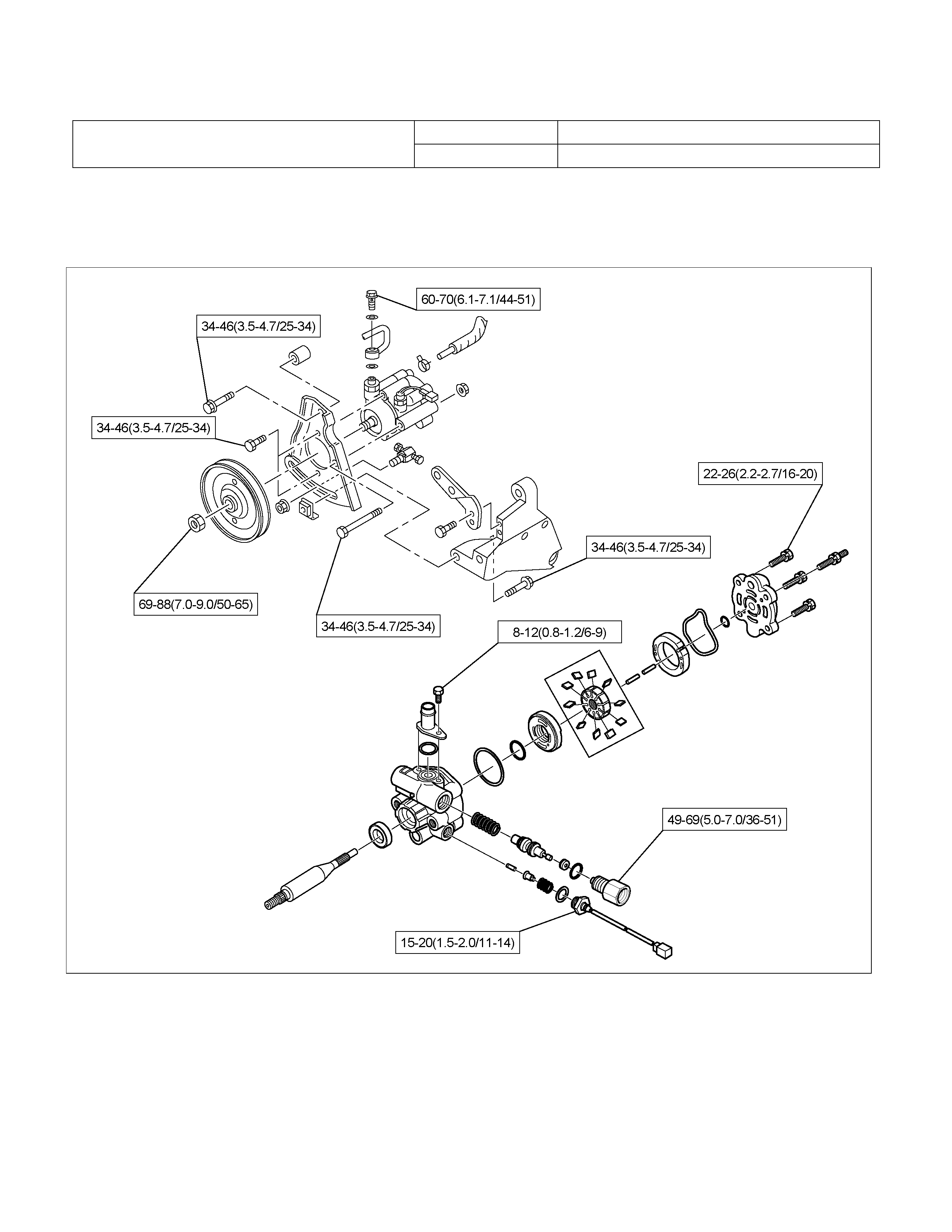

Torque Specifications

4JH1-TC Nm (kgm/Ib ft)

RTW33BLF001001

Power Steering Pump (C24SE)

Powe r Steering Pump and Associated Parts (C24SE)

RTW33BLF000801

Legend

(1) Pump Assembly

(2) Hose, Suction

(3) Hose, Flexible

(4) Bolt

(5) Connector, Pressure switch

Removal

1. Remove the drive belt.

2. Remove the pulley

3. Place a drain pan below the pump.

4. Disconnect the suction hose.

5. Disconnect the flexible hose.

6. Disconnect the oil pressure switch connector.

7. Remove the power steering fixing bolt and remove

the pump assembly.

Installation

1. Install the pump assembly to the pump braket,

tighten the fixing bolt to the specified torque.

Torque: 34-46 N·m (3.5-4.7 kg·m/25-34 lb ft)

2. Connector the oil pressure switch connector.

3. Install the flexible hose.

Tighten the eye bolt to specified torque.

Torque: 60-70 N·m (6.1-7.1 kg·m/44-51 lb ft)

4. Install the pulley and tighten the bolt to the specified

torque.

Torque: 69-88 N·m (7.0-9.0 kg·m/51-65 lb ft)

5. Install the drive belt.

6. Connect the suction hose, then fill and bleed

system. Refer to Bleeding the Power Steering

System in this section.

Powe r Steering Pump Disassembled View

RTW33BMF000301

Legend

(1) Bolt

(2) Suction Pipe

(3) O-ring

(4) Front Housing

(5) Snap Ring

(6) Shaft Assembly

(7) Bearing

(8) Shaft

(9) Retaining Ring

(10) Oil Seal

(11) O-ring

(12) O-ring

(13) Gasket

(14)Rear Housing Assembly and Pump Cartridge

(15) Side Plate

(16) Rotor and Vane

(17) Pin

(18) Cam

(19) Rear Housing

(20) Bolt

(21) Spring

(22) Retaining Ring

(23)Filter

(24) Valve

(25) O-ring

(26) Connector

(27) Pressure Switch

Disassembly

1. Clean the oil pump with solvent (plug the discharge

and suction ports to prevent the entry of s olvent). Be

careful not to expose the oil seal of shaft assembl

y

to solvent.

2. Remove the bolt, suction pipe and O-ring.

Remove the O-ring.

3. Remove the connector, O-ring, relief valve and

spring.

4. Remove the pressure switch assembly.

5. Remove the bolt, rear housing and O-ring.

6. Remove the snap ring.

7. Remove the shaft assembly.

8. Remove the oil seal.

CAUTION: When removing the oil seal, be careful

not to damage the housing.

9. Remove the pump c ar tridge as sembly from the fr ont

housing.

10. Remove two O-rings.

Inspection and Repair

Make all necessary adjustments, repairs, and part

replacements if wear, damage, or other problems are

discovered during inspection.

Rotor

442RS002

Check that the groove in the vane is free from excessive

wear and that the vane slides smoothly. When part

replacement becomes necessary, the pump cartridge

should be replaced as a subassembly .

Vane

442RS003

Sliding faces of the vane should be free from wear.

(Particularly the curved face at the tip that contact with

the cam should be f ree f rom wear and distortion) . When

part replacement becomes necessary, the pump

cartridge should be replaced as a subassembly.

Cam

The inner face of the ar m should have a unif o rm c ontact

pattern without a sign of step wear. When part

replacement becomes necessary, the pump cartridge

should be replaced as a subassembly .

Side Plate

The sliding faces of parts must be free from step wear

(more than 0.01 mm), which can be felt by the finger

nail. The parts with minor scores may be reused after

lapping the face.

Valve

The sliding face of the valve must be free from burrs

and damage. The parts with minor scores may be

reused after smoothing with emery cloth (#800 or finer).

Shaft

Oil seal sliding faces must be free from a step wear

which can be felt by the finger nail. Needle bearing fitting

face must be free from damage and wear.

O-ring, Oil Seal, Retaining Ring

Be sure to discard used parts, and always use new

parts for installation. Prior to installation, lubricate all

seals and rings with power steering fluid.

Pressure Switch

Check the switch operation as follows:

With engine idling and A/C on, turn the steering wheel

fully to the left; compressor should interrupt and engine

idle speed will increase. Shut off A/C and again turn

steering fully to the left; engine idle will increase. I

f

system fails to function properly, disconnect connecto

r

at the pressure switch and repeat system check while

testing continuity across disconnected SW connector.

Reassembly

1. Install oil seal to front housing. Be sure to discard

used oil seal, and always use new parts fo

r

installation.

CAUTION: When installing the oil seal, be careful

not to damage the oil seal contacting surface of the

housing.

2. Install shaft assembly.

3. Ins tall the vanes to roter with curved face in contact

with the inner wall of cam.

442RS005

.

4. Install rotor and vanes to cam

5. Install pin to front housing.

6. Install two new O-rings to front housing. Be sure to

discard used O-ring.

7. Install side plate.

CAUTION: When installing side plate, be careful not

to damage its inner surface. Damaged side plate

may cause poor pump performance, pump seizure

or oil leakage.

8. Install pump cartridge assembly to front housing.

9. Install snap ring to shaft end.

10. Install rear housing with a new O-ring. Be sure to

discard used O-ring. Then install bolt and tighten it

to specified torque.

Torque: 22-26 N⋅

⋅⋅⋅m (2.2-2.7 kg⋅

⋅⋅⋅m/16-20 lb ft)

11. Install suction pipe with a new O-ring. Be sure to

discard used O-ring. Then install bolt and tighten it

to specified torque.

Torque: 7.8-12 N⋅

⋅⋅⋅m (0.8-1.2 kg⋅

⋅⋅⋅m/6-9 lb ft)

12. Install relief valve and spring.

13. Install connector with a new O-ring. Be sure to

discard used O-ring. Tighten the connector to

specified torque.

Torque: 49-69 N⋅

⋅⋅⋅m (5.0-7.0 kg⋅

⋅⋅⋅m/36-51 lb ft)

14. Install pressure switch assembly and tighten it to

specified torque.

Torque: 15-20 N⋅

⋅⋅⋅m (1.5-2.0 kg⋅

⋅⋅⋅m/11-14 lb ft)

Main Data and Specifications

General Specifications

Oil pump Type Vane

Operating fluid

ATF DEXRON®―III

Torque Specifications Nm (kgm/Ib ft)

RTW33BLF000901

Power Steering Pump (6VE1)

Powe r Steering Pump and Associated Parts (6VE1)

RTW33BLF000701

Legend

(1) Pump Assembly

(2) Hose, Suction

(3) Hose, Flexible

(4) Bolt

(5) Connector, Pressure switch

Removal

1. Remove the drive belt.

2. Place a drain pan below the pump.

3. Disconnect the suction hose.

4. Disconnect the flexible hose.

5. Disconnect the oil pressure switch connector.

6. Remove the power steering fixing bolt and remove

the pump assembly.

Installation

1. Install the pump assembly to the pump braket,

tighten the fixing bolt to the specified torque.

Torque: 31-63 N·m (3.2-6.4 kg·m/23-46 lb ft)2.

Connector the oil pressure switch connector.

3. Install the flexible hose.

Tighten the eye bolt to specified torque.

Torque: 60-71 N·m (6.1-7.1 kg·m/44-51 lb ft)

4. Install the drive belt.

5. Connect the suction hose, then fill and bleed

system.

Refer to Bleeding the Power Steering System in

this section.

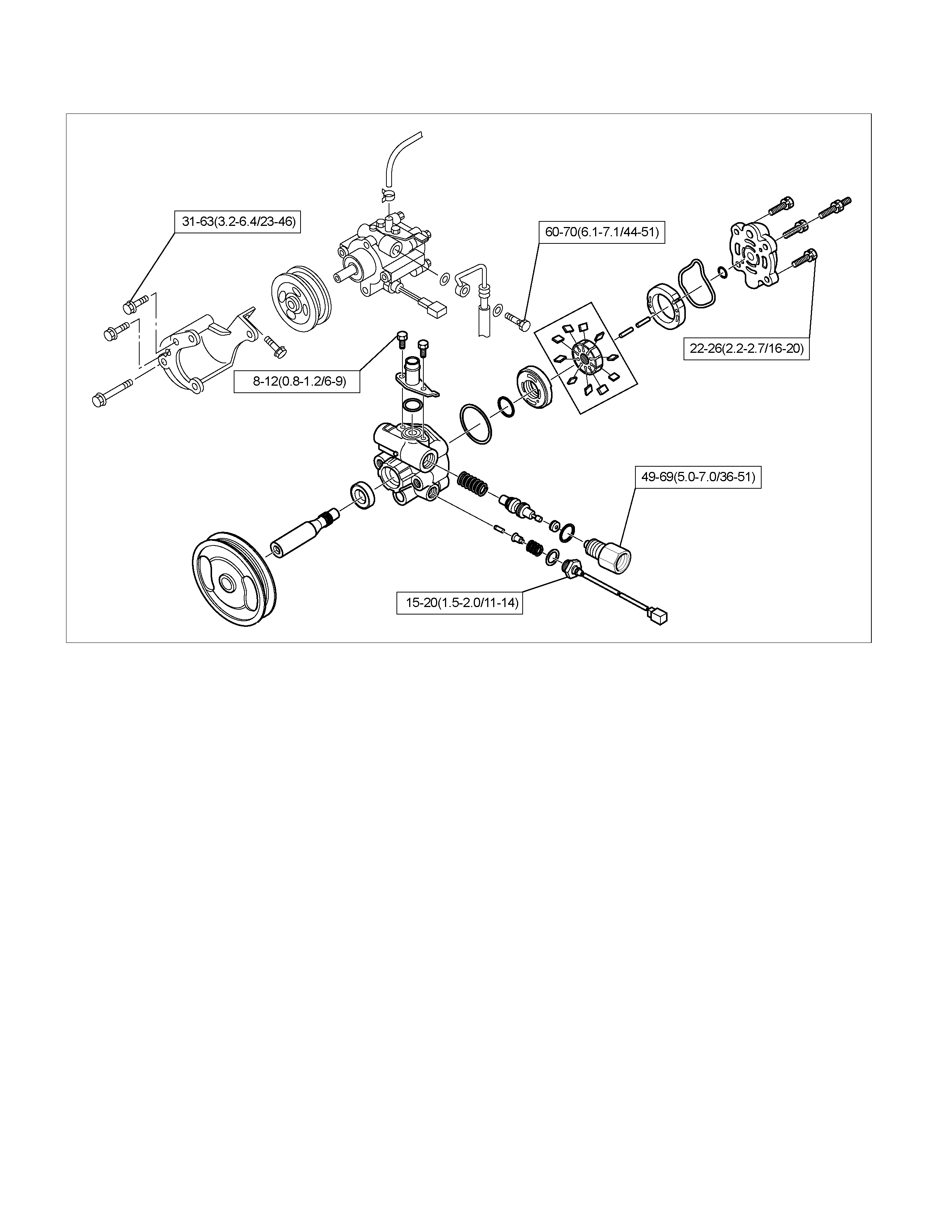

Powe r Steering Pump Disassembled View

RTW33BMF000201

Legend

(1) Bolt

(2) Suction Pipe

(3) O-ring

(4) Shaft Assembly

(5) Oil Seal

(6) Front Housing

(7) O-ring

(8) O-ring

(9) Side Plate

(10) Rotor and Vane

(11) Pin

(12) Cam

(13) Pump Cartridge Assembly

(14) O-ring

(15) Snap Ring

(16) Rear Housing

(17) Bolt

(18) Spring

(19) Relief Valve

(20) O-ring

(21) Connector

(22) P ressure Switch Assembly

Disassembly

1. Clean the oil pump with solvent (plug the discharge

and suction ports to prevent the entry of s olvent). Be

careful not to expose the oil seal of shaft assembl

y

to solvent.

2. Remove the bolt, suction pipe and O-ring.

Remove the O-ring.

3. Remove the connector, O-ring, relief valve and

spring.

4. Remove the pressure switch assembly.

5. Remove the bolt, rear housing and O-ring.

6. Remove the snap ring.

7. Remove the shaft assembly.

8. Remove the oil seal.

CAUTION: When removing the oil seal, be careful

not to damage the housing.

9. Remove the pump c ar tridge as sembly from the fr ont

housing.

10. Remove two O-rings.

Inspection and Repair

Make all necessary adjustments, repairs, and part

replacements if wear, damage, or other problems are

discovered during inspection.

Rotor

442RS002

Check that the groove in the vane is free from excessive

wear and that the vane slides smoothly. When part

replacement becomes necessary, the pump cartridge

should be replaced as a subassembly .

Vane

442RS003

Sliding faces of the vane should be free from wear.

(Particularly the curved face at the tip that contact with

the cam should be free from wear and distortion). When

part replacement becomes necessary, the pump

cartridge should be replaced as a subassembly.

Cam

The inner face of the arm should have a uniform contact

pattern without a sign of step wear. When part

replacement becomes necessary, the pump cartridge

should be replaced as a subassembly .

Side Plate

The sliding faces of parts must be free from step wear

(more than 0.01 mm), which can be felt by the fingernail.

The parts with minor scores may be reused after lapping

the face.

Relief Valve

The sliding face of the valve must be free from burrs

and damage. The parts with minor scores may be

reused after smoothing with emery cloth (#800 or finer).

Shaft

Oil seal sliding faces must be free from a step wear

which can be felt by the finger nail. Bushing fitting face

must be free from damage and wear.

O-ring, Oil Seal, Snap Ring

Be sure to discard used parts, and always use new

parts for installation. Prior to installation, lubricate all

seals and rings with power steering fluid.

Pressure Switch

Check the switch operation as follows:

With engine idling and A/C on, turn the steering wheel

fully to the left; compressor should interrupt and engine

idle speed will increase. Shut off A/C and again turn

steering fully to the left; engine idle will increase. If

system fails to function properly, disconnect connector

at the pressure switch and repeat system check while

testing continuity across disconnected SW connector.

Reassembly

1. Install oil seal to front housing. Be sure to discard

used oil seal, and always use new parts for

installation.

CAUTION: When installing the oil seal, be careful

not to damage the oil seal contacting surface of the

housing.

2. Install shaft assembly.

3. Ins tall the vanes to roter with curved face in contact

with the inner wall of cam.

442RS005

4. Install rotor and vanes to cam.

5. Install pin to front housing.

6. Install two new O-rings to front housing. Be sure to

discard used O-ring.

7. Install side plate.

CAUTION: When installing side plate, be careful not

to damage its inner surface. Damaged side plate

may cause poor pump performance, pump seizure

or oil leakage.

8. Install pump cartridge assembly to front housing.

9. Install snap ring to shaft end.

10. Install rear housing with a new O-ring. Be sure to

discard used O-ring. Then install bolt and tighten it

to specified torque.

Torque: 22-26 N⋅

⋅⋅⋅m (2.2-2.7 kg⋅

⋅⋅⋅m/16-20 lb ft)

11. Install suction pipe with a new O-ring. Be sure to

discard used O-ring. Then install bolt and tighten it

to specified torque.

Torque: 7.8-12 N⋅

⋅⋅⋅m (0.8-1.2 kg⋅

⋅⋅⋅m/6-9 lb ft)

12. Install relief valve and spring.

13. Install connector with a new O-ring. Be sure to

discard used O-ring. Tighten the connector to

specified torque.

Torque: 49-69 N⋅

⋅⋅⋅m (5.0-7.0 kg⋅

⋅⋅⋅m/36-51 lb ft)

14. Install pressure switch assembly and tighten it to

specified torque.

Torque: 15-20 N⋅

⋅⋅⋅m (1.5-2.0 kg⋅

⋅⋅⋅m/11-14 lb ft)

Main Data and Specifications

General Specifications

Oil pump Type Vane

Operating fluid

ATF DEXRON®―III

Torque Specifications Nm (kgm/Ib ft)

RTW33BMF000101

Supplemental Restraint System Steering Wheel & Column

Service Precaution

This steering wheel and column repair section covers

the Supplemental Restraint System (SRS) steering

column. The following repair procedures are specific to

SRS components. When servicing a vehicle equipped

with Supplemental Restraint System, pay close attention

to all WARNINGS and CAUTIONS.

For detailed explanation about SRS, refer to

Restraints section.

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

SAFE HANDLING OF INFLATOR MODULES

REQUIRES FOLLOWING THE PROCEDURES

DESCRIBED BELOW FOR BOTH LIVE AND

DEPLOYED MODULES.

SAFETY PRECAUTIONS MUST BE FOLLOWED

WHEN HANDLING A DEPLOYED AIR BAG

ASSEMBLY (AIR BAG). AFTER DEPLOYMENT, THE

AIR BAG ASSEMBLY (AIR BAG) SURFACE MAY

CONTAIN A SMALL AMOUNT OF SODIUM

HYDROXIDE, A BY-PRODUCT OF THE

DEPLOYMENT REACTION, THAT IS IRRITATING TO

THE SKIN AND EYES. MOST OF THE POWDER ON

THE AIR BAG ASSEMBLY (AIR BAG) IS HARMLESS.

AS A PRECAUTION, WEAR GLOVES AND SAFETY

GLASSES WHEN HANDLING A DEPLOYED AIR BAG

ASSEMBLY, AND WASH YOUR HANDS WITH MILD

SOAP AND WATER AFTERWARDS.

WHEN CARRYING A LIVE AIR BAG ASSEMBLY,

MAKE SURE THE BAG AND TRIM COVER ARE

POINTED AWAY FROM YOU. NEVER CARRY AN AIR

BAG ASSEMBLY BY THE WIRES OR CONNECTOR

ON THE UNDERSIDE OF MODULE. IN THE CASE OF

AN ACCIDENTAL DEPLOYMENT, THE BAG WILL

THEN DEPLOY WITH MINIMAL CHANCE OF INJURY.

WHEN PLACING A LIVE AIR BAG ASSEMBLY ON A

BENCH OR OTHER SURFACE, ALWAYS FACE THE

BAG A ND TRIM COVER UP, AWAY FROM THE

SURFACE.

NEVER REST A STEERING COLUMN ASSEMBLY

ON THE STEERING WHEEL WITH THE AIR BAG

ASSEMBLY FACE DOWN AND COLUMN VERTICAL.

THIS IS NECESSARY SO THAT A FREE SPACE IS

PROVIDED TO ALLOW THE AIR BAG ASSEMBLY

TO EXPAND IN THE UNLIKELY EVENT OF

ACCIDENTAL DEPLOYMENT. OTHERWISE,

PERSONAL INJURY COULD RESULT.

TO AVOID DEPLOYMENT WHEN

TROUBLESHOOTING THE SRS SYSTEM, DO NOT

USE ELECTRICAL TEST EQUIPMENT, SUCH AS

BATTERY-POWERED OR A/C-POWERED VOLT-

METER, OHMMETER, ETC., OR ANY TYPE OF

ELECTRICAL EQUIPMENT OTHER THAN SPECIFIED

IN THIS MANUAL. DO NOT USE A NON-POWERED

PROBE-TYPE TESTER.

INSTRUCTIONS IN THIS MANUAL MUST BE

FOLLOWED CAREFULLY, OTHERWISE PERSONAL

INJURY MAY RESULT.

SRS Connectors

CAUTION: The special yellow color connectors are

used for supplemental restraint system-air bag

circuit.

When removing the cable harness, do not pull the

cables. Otherwise, cable disconnection may occur.

When connect the SRS connector, insert the

connector completely. Imperfect locking may cause

malfunction of SRS circuit.

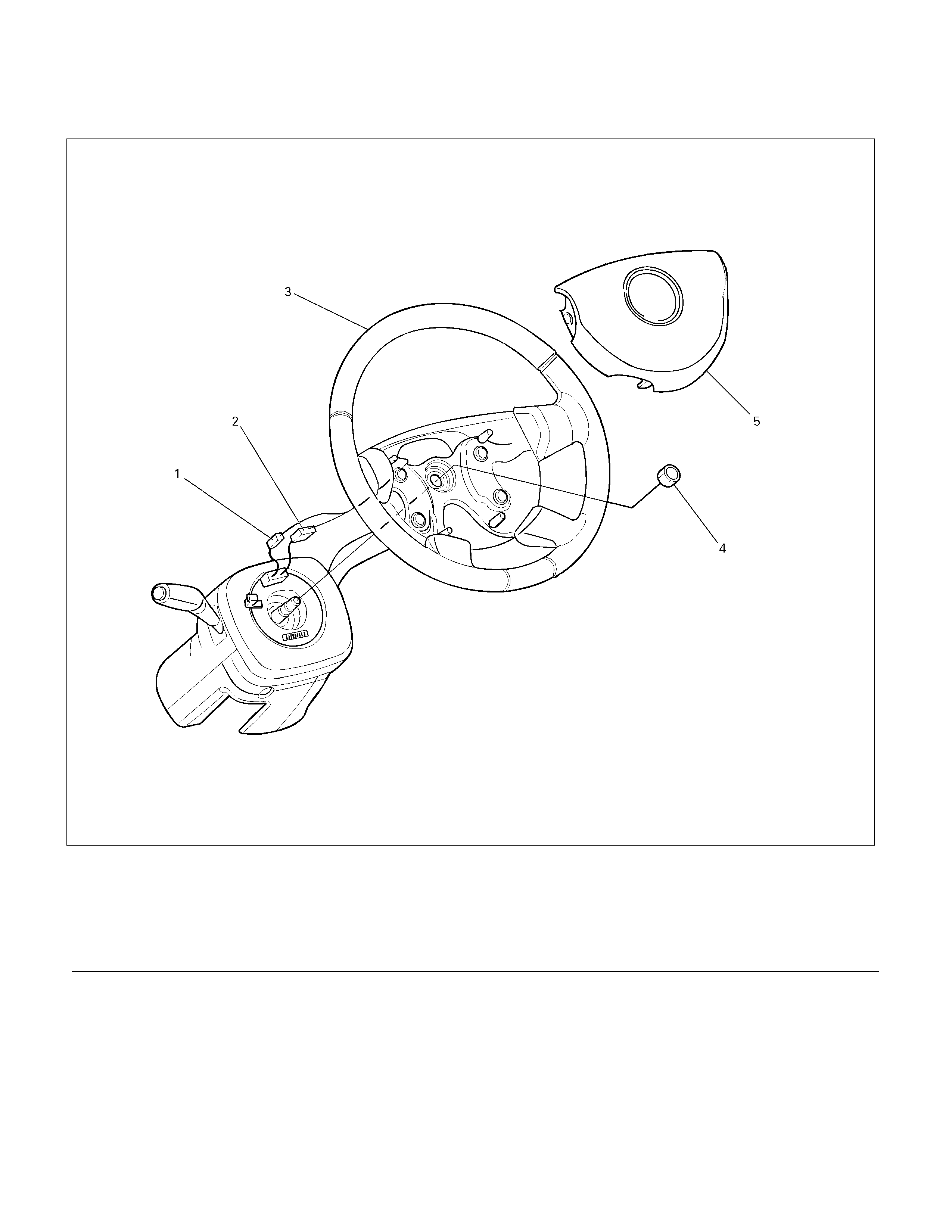

Inflator Module

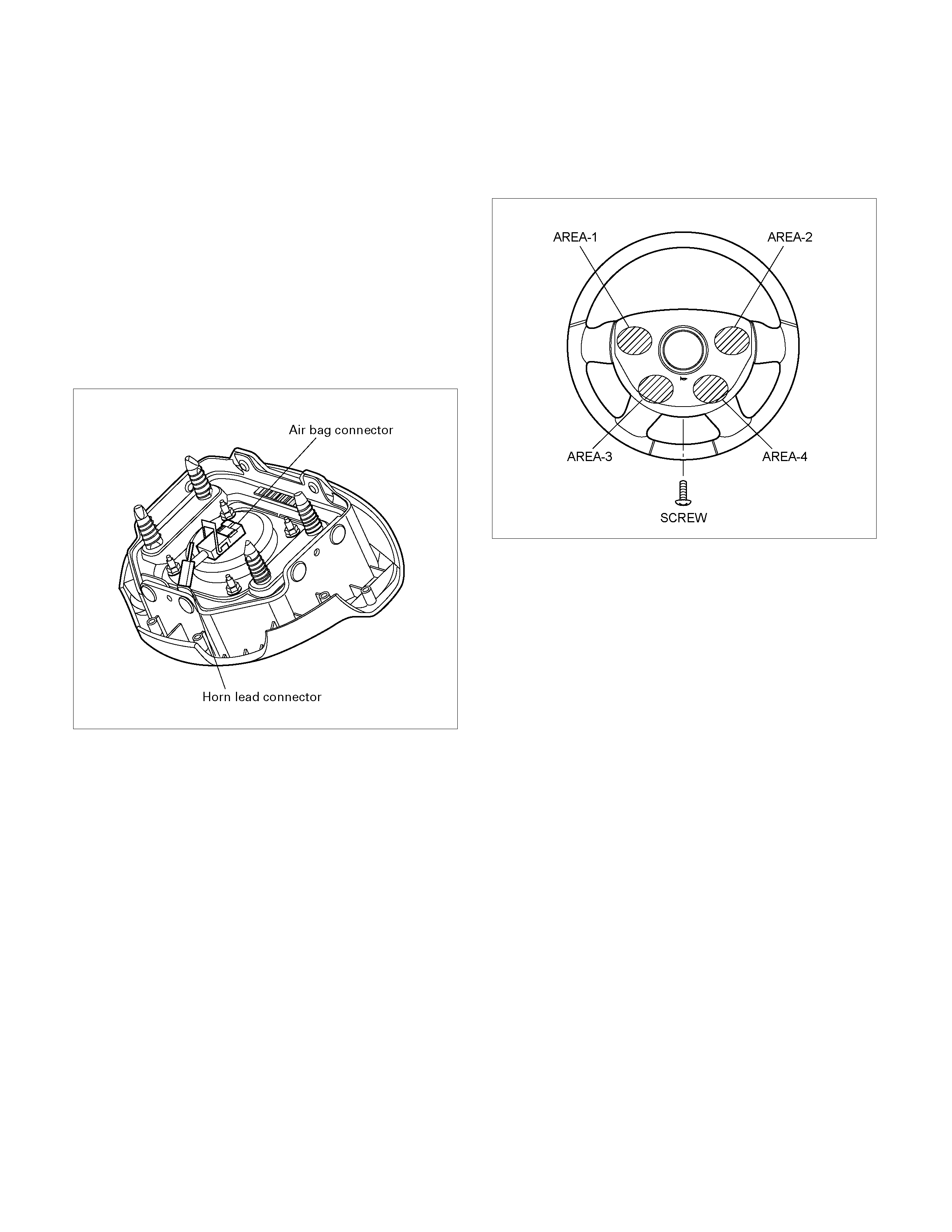

Inflator Module and Associated Parts

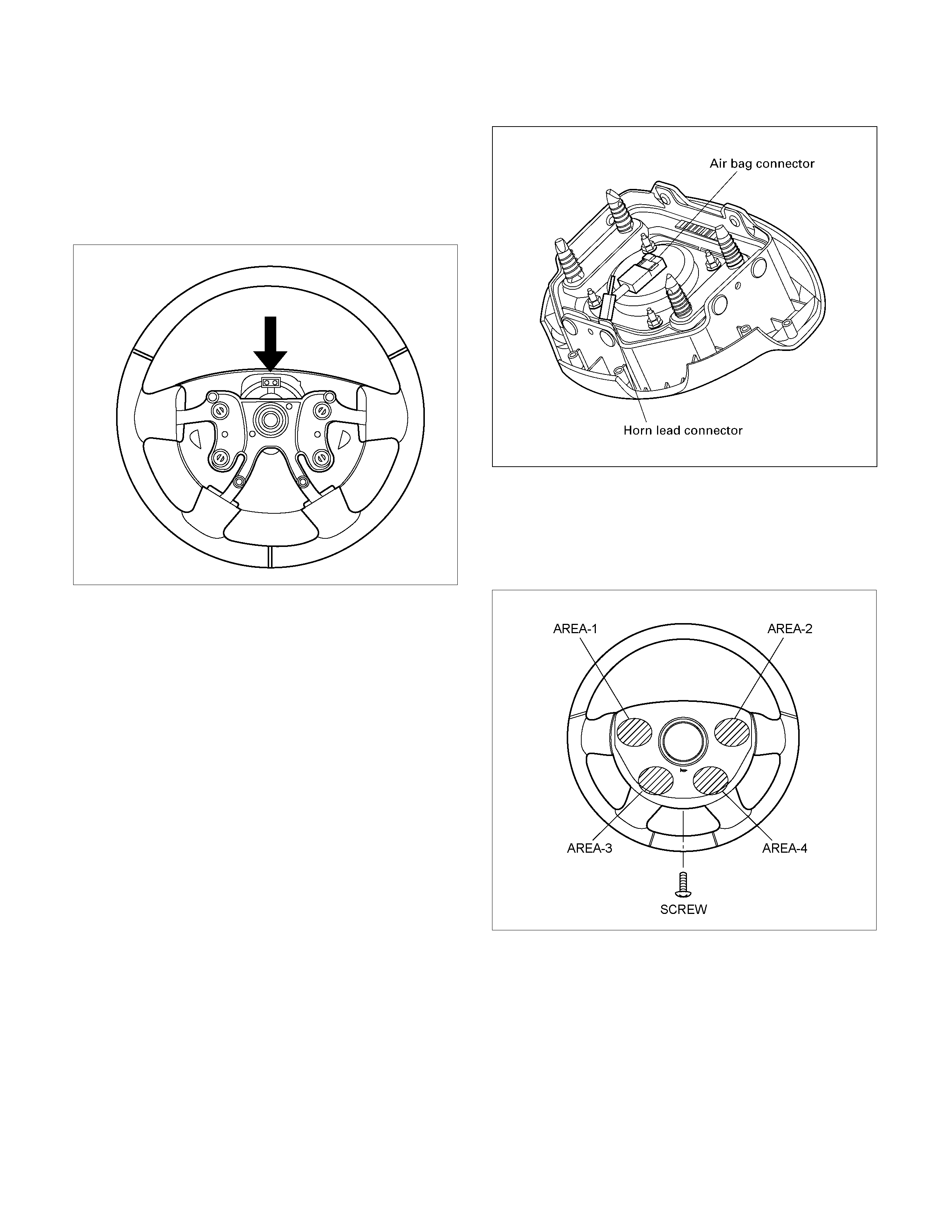

430R300013

Legend

(1) Horn Lead

(2) SRS Connector

(3) Steering Wheel

(4) Steering Wheel Fixing Nut

(5) Inflator Module or Horn Pad

Removal

1. Turn the steering wheel so that the vehicle's wheels

are pointing straight ahead.

2. Turn the ignition switch to "LOCK".

3. Disconnect the battery "-" terminal cable, and wait at

least 5 minutes. (with SRS air bag)

4. Disconnect the yellow 2-way SRS connector located

under the steering column. (with SRS air bag)

CAUTION: The wheels of the vehicle must be

straight ahead and the steering column in the

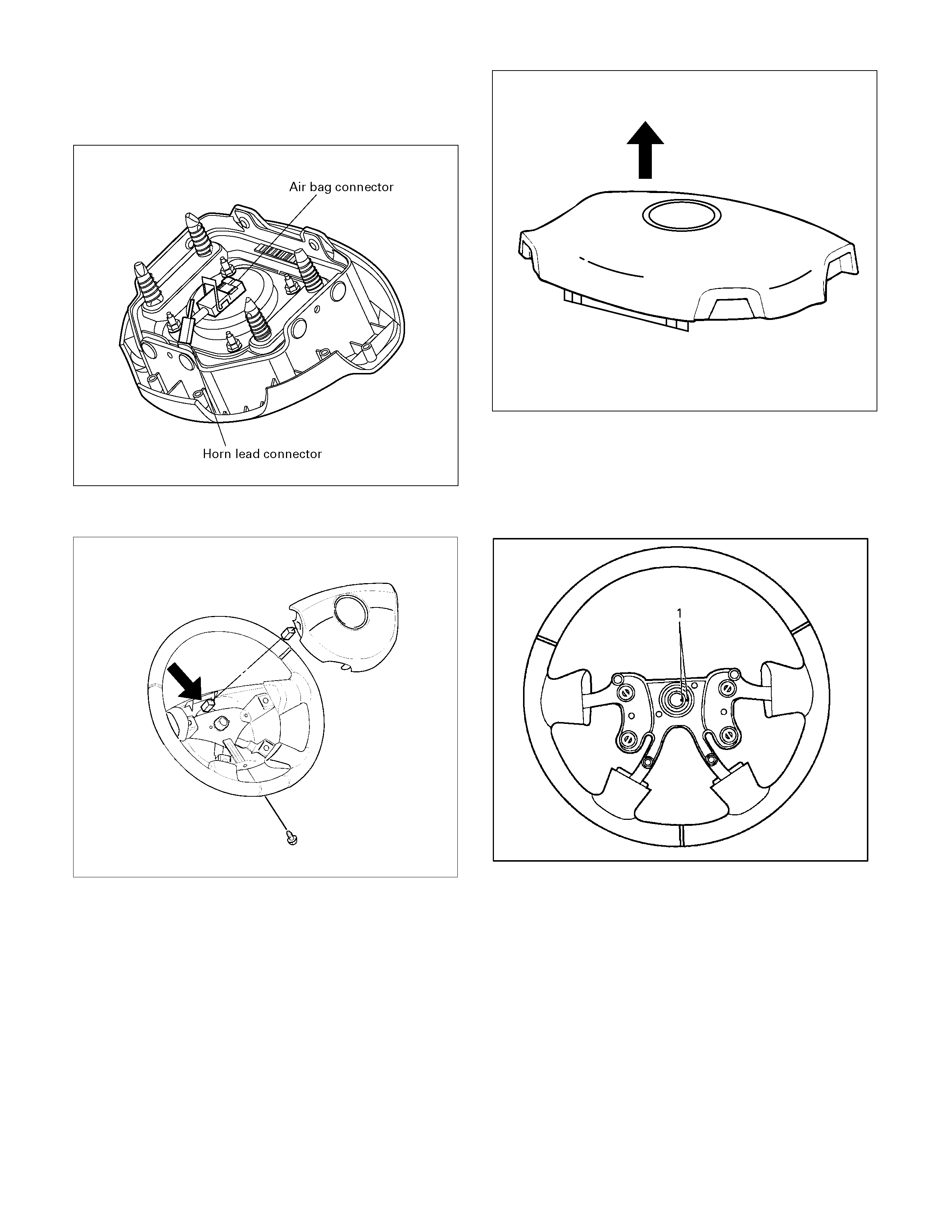

"LOCK" position before disconnecting the steering

wheel. Failure to do so will cause the coil assembly

to become uncentered which will cause damage to

the coil assembly. (with SRS air bag)

5. Disable the SRS (Refer to "Disabling the SRS" in

this section). (with SRS air bag)

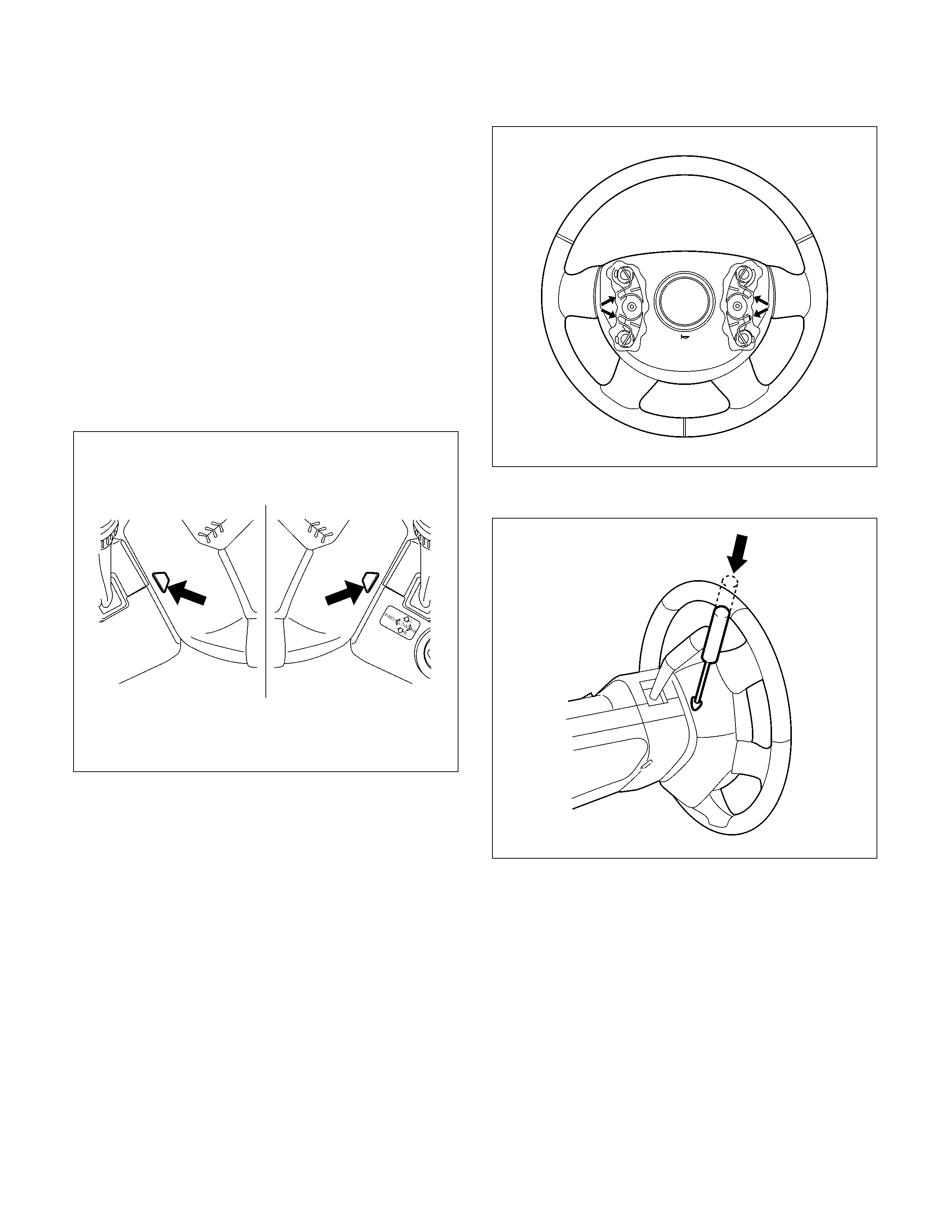

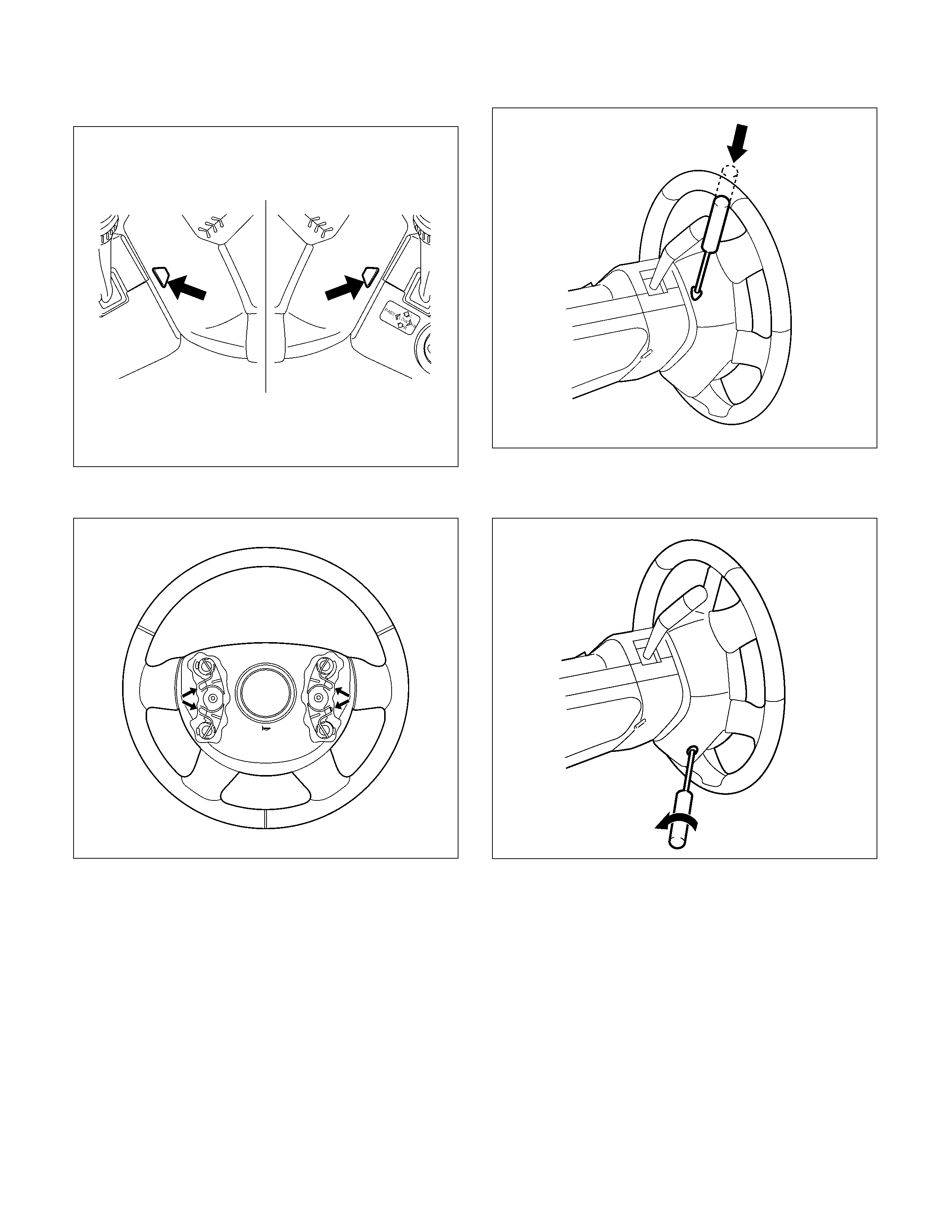

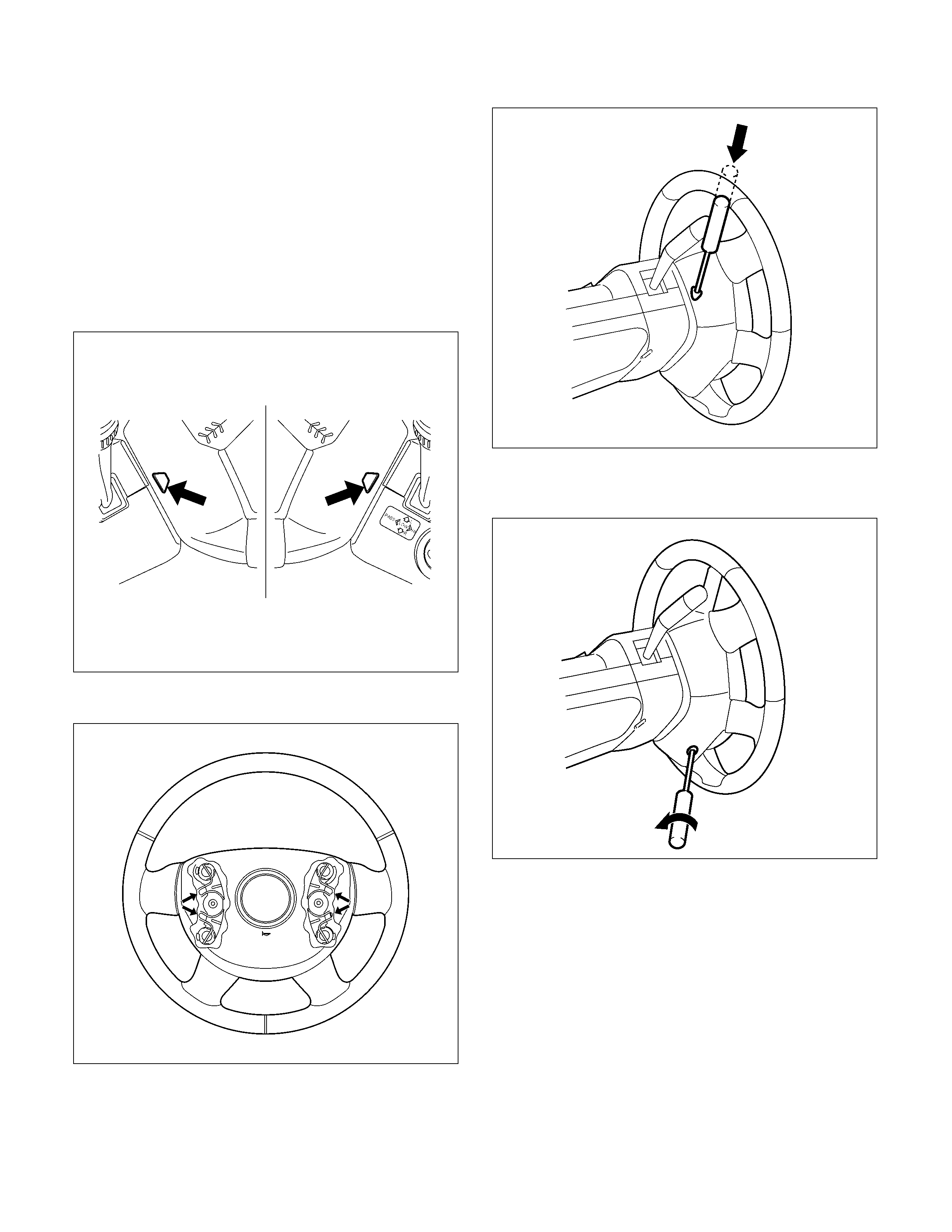

6. Locate the two access holes on the underside of the

steering wheel cover. (with SRS air bag)

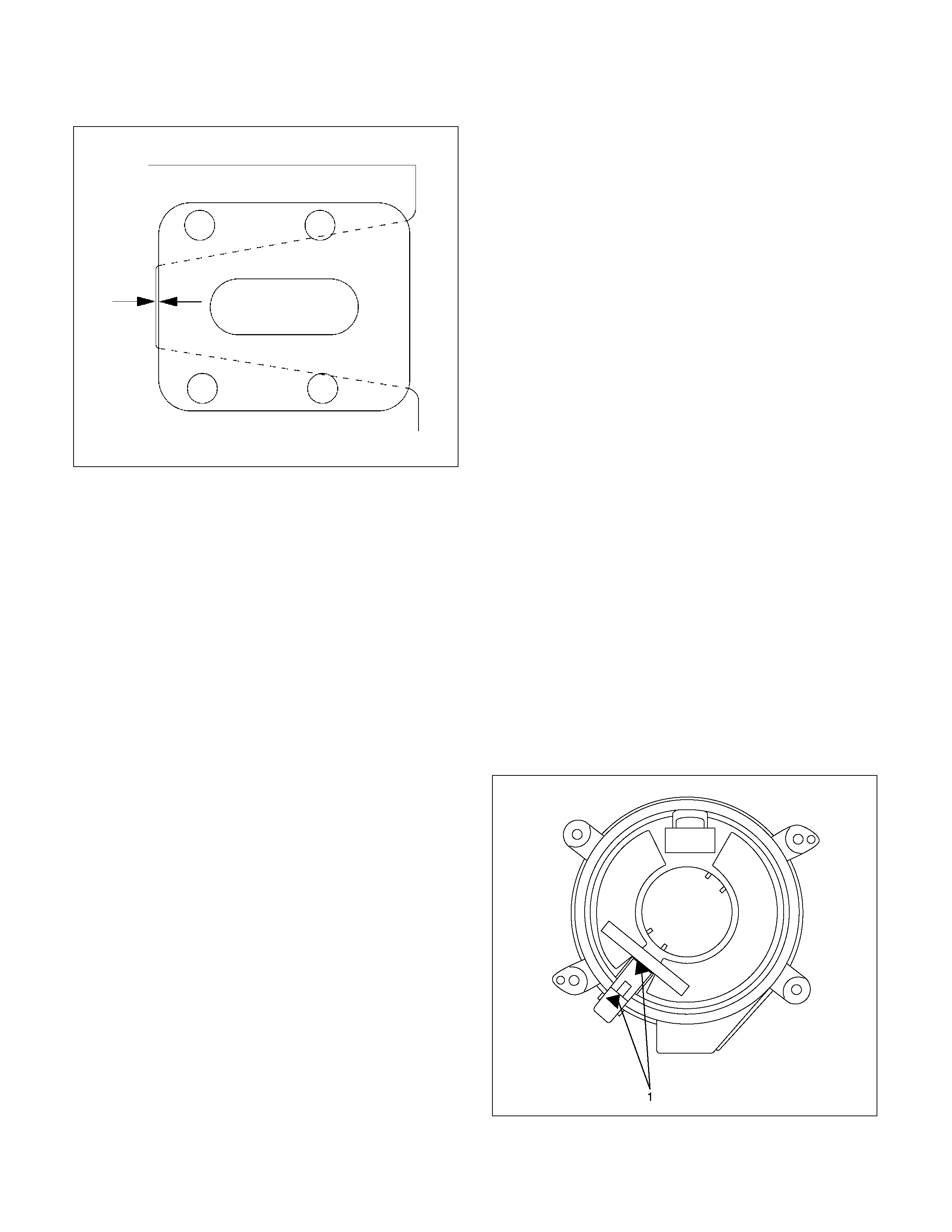

060R300025

7. Check the position of the pins in the holes. Push the

pin in the direction of an arrow. (with SRS air bag)

060R300032

8. Push the four pins at 5-6 mm diameter bar. (with

SRS air bag)

060R300031

9. Cancel the lock four pins. (with SRS air bag)

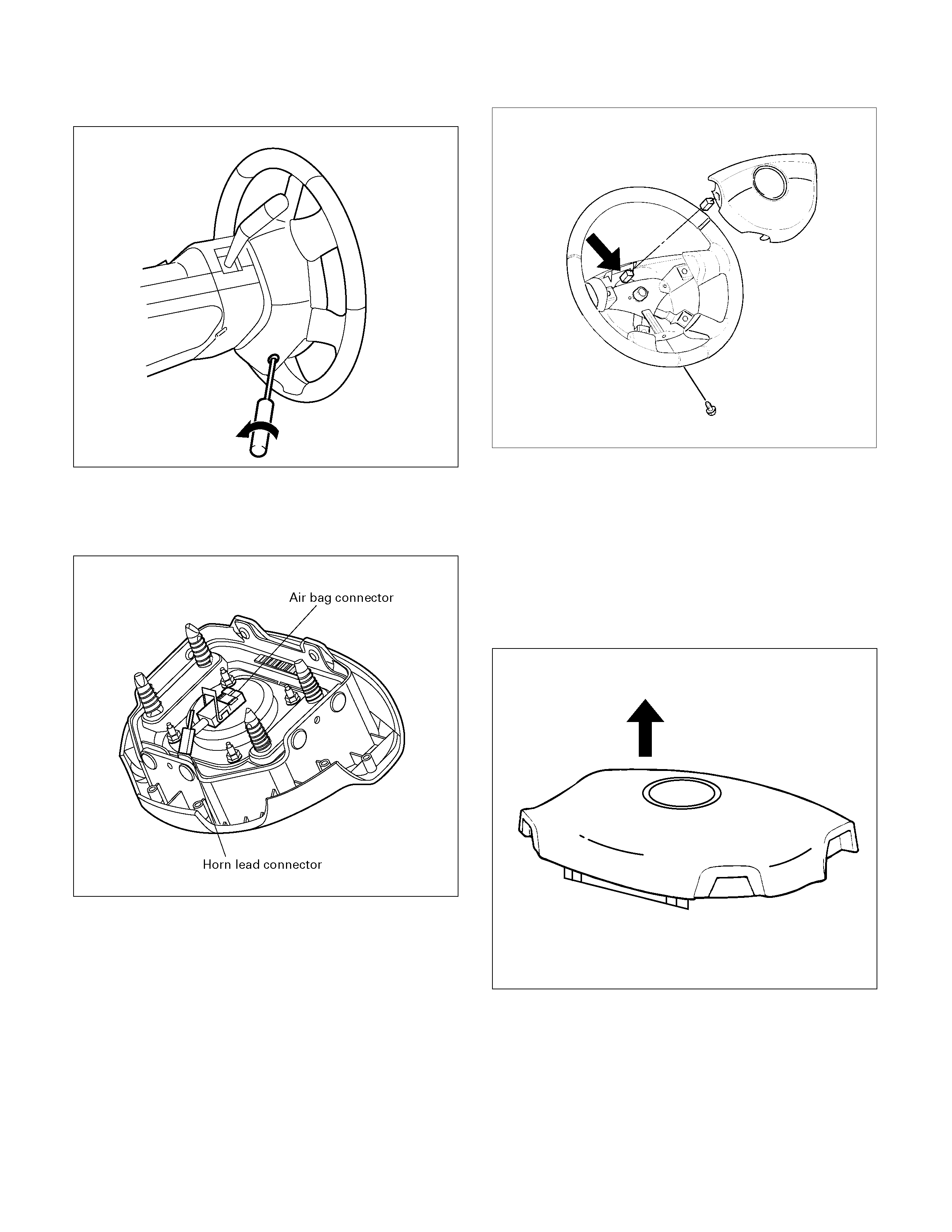

10. NOTE: For those vehicles without SRS Air Bag,

simply loosen the horn pad fixing screw at the rear

of the steering wheel

430R300009

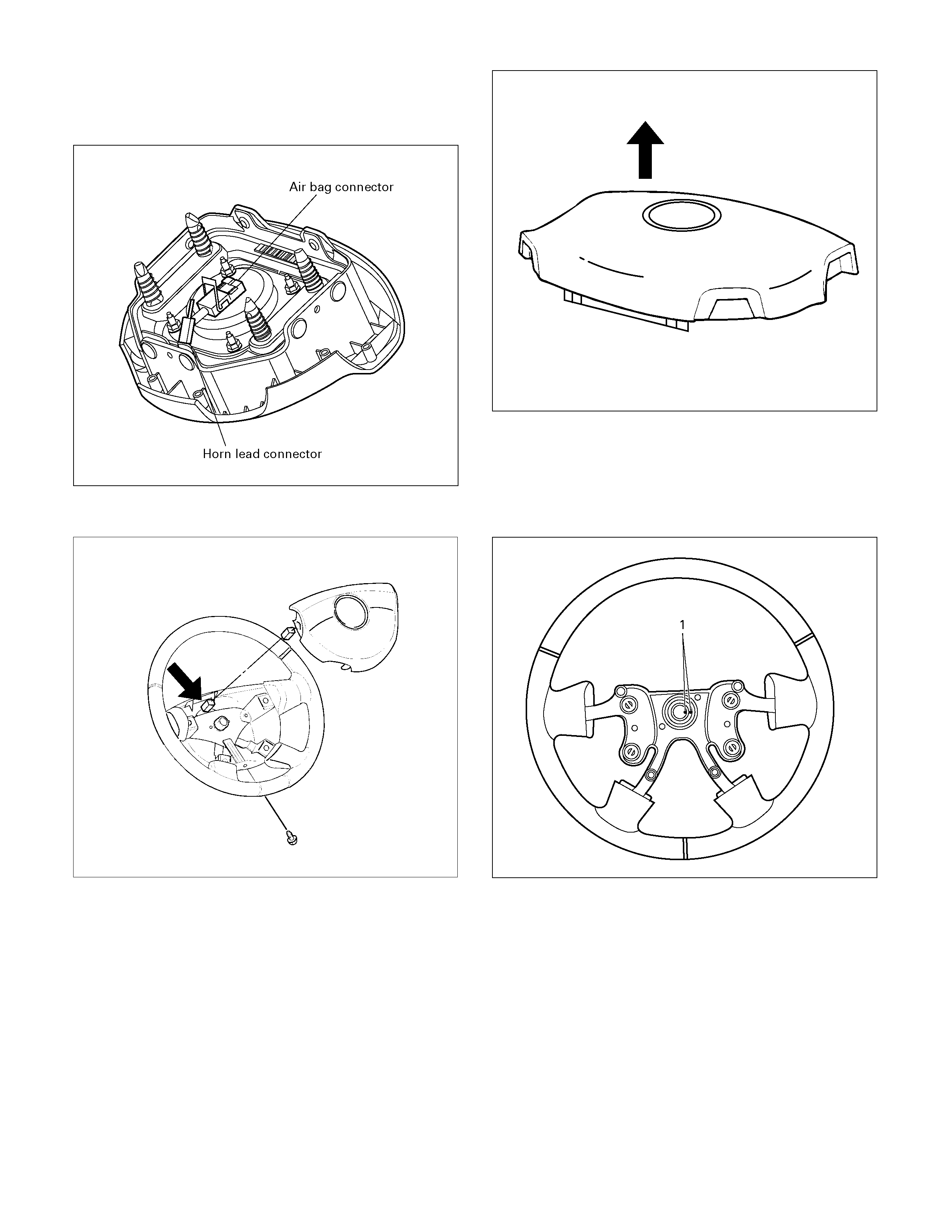

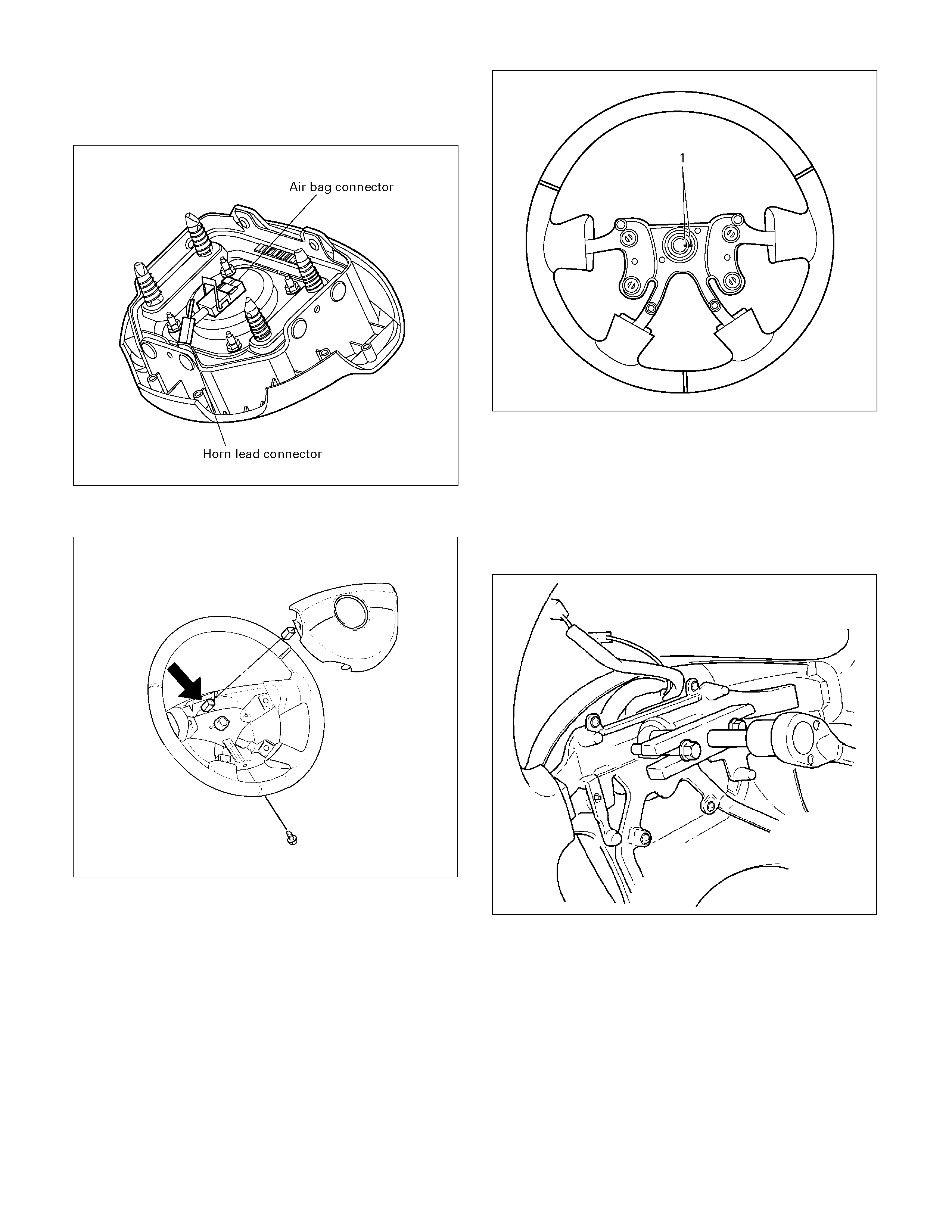

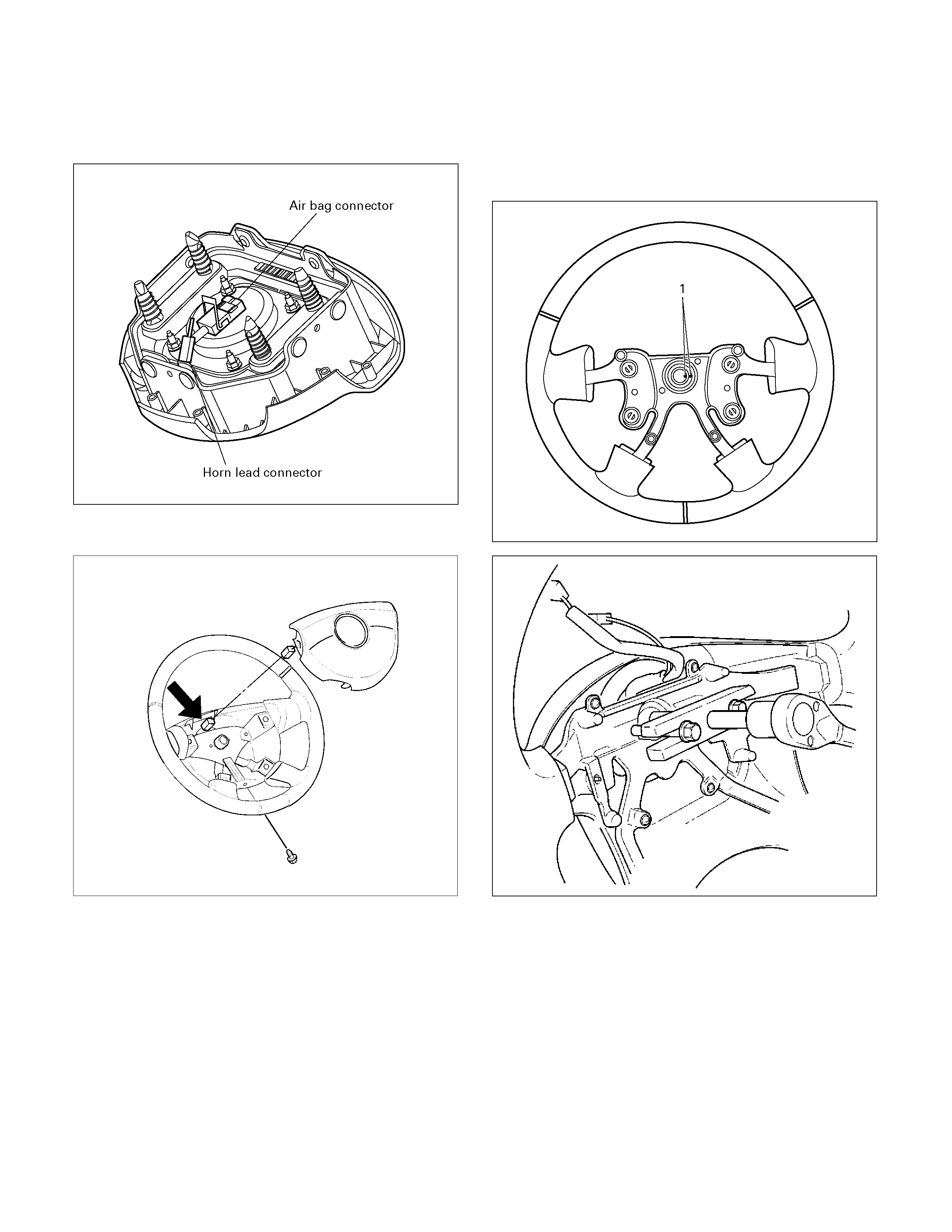

11. Disconnect the SRS air bag connector and horn

lead connector located behind the air bag assembly

and remove the air bag assembly. (with SRS air

bag)

060R300041

12. Remove the horn pad and the horn leads at the

center of the wheel (without SRS air bag).

RTW33BSH000401

WARNING: THE INFLATOR MODULE SHOULD

ALWAYS BE CARRIED WITH THE COVER AWAY

FROM YOUR BODY AND SHOULD ALWAYS BE

LAID ON A FLAT SURFACE WITH THE COVER SIDE

UP. THIS IS NECESSARY BECAUSE A FREE SPACE

IS PROVIDED TO ALLOW THE AIR CUSHION TO

EXPAND IN THE UNLIKELY EVENT OF

ACCIDENTAL DEPLOYMENT. OTHERWISE,

PERSONAL INJURY MAY RESULT. (with SRS air

bag)

430R300007

Inspection and Repair (w ith SRS air bag)

The inflator module consists of a cover, air bag, inflator,

and retainer. Inspect the inflator module mainly for the

following:

• Check for holes, cracks, severe blemishes and

deformation on the cover.

• Check that the retainer is not deformed.

• Check for defects such as damage and breakage in

the lead wire for the igniter.

If an abnormality is found as the result of the inspection,

replace the inflator module with a new one.

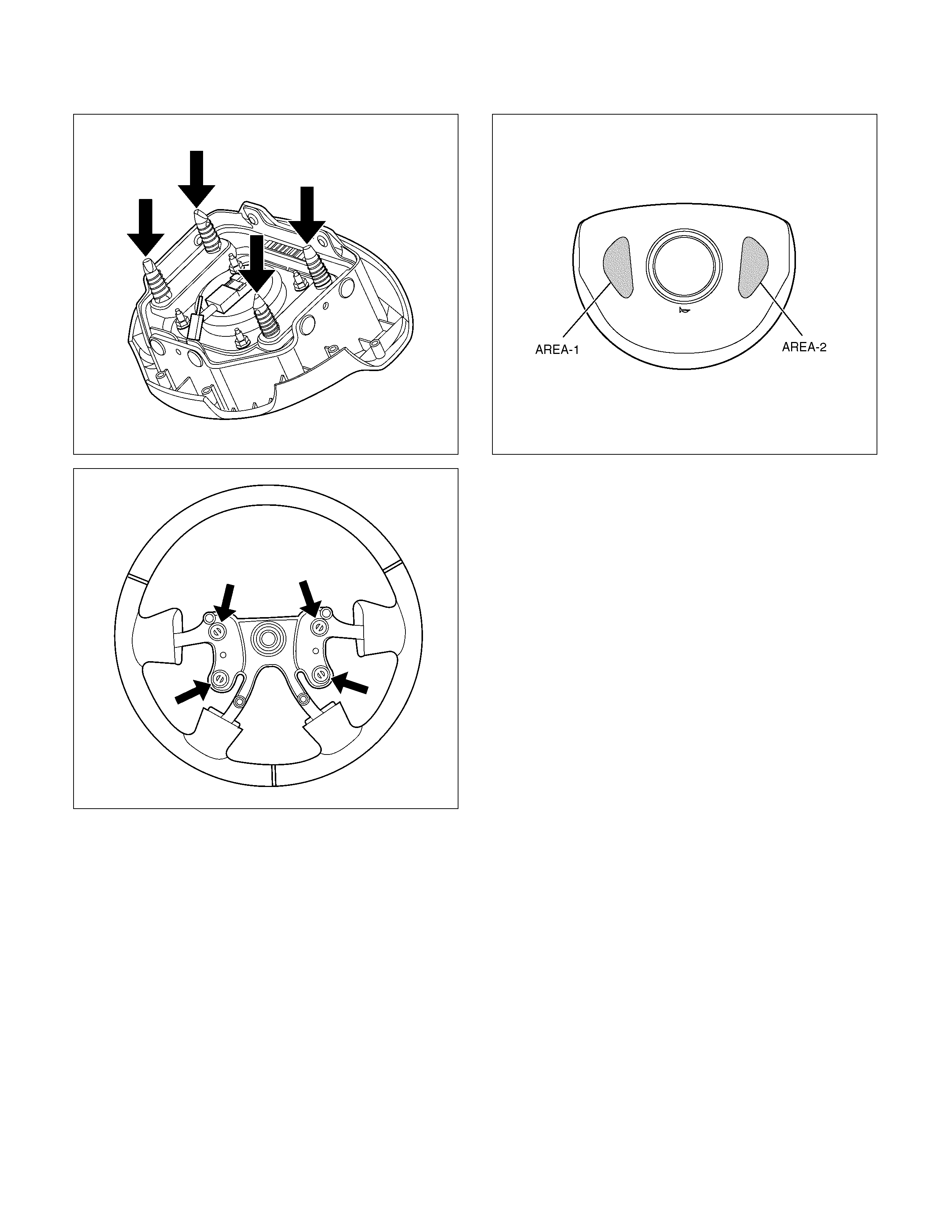

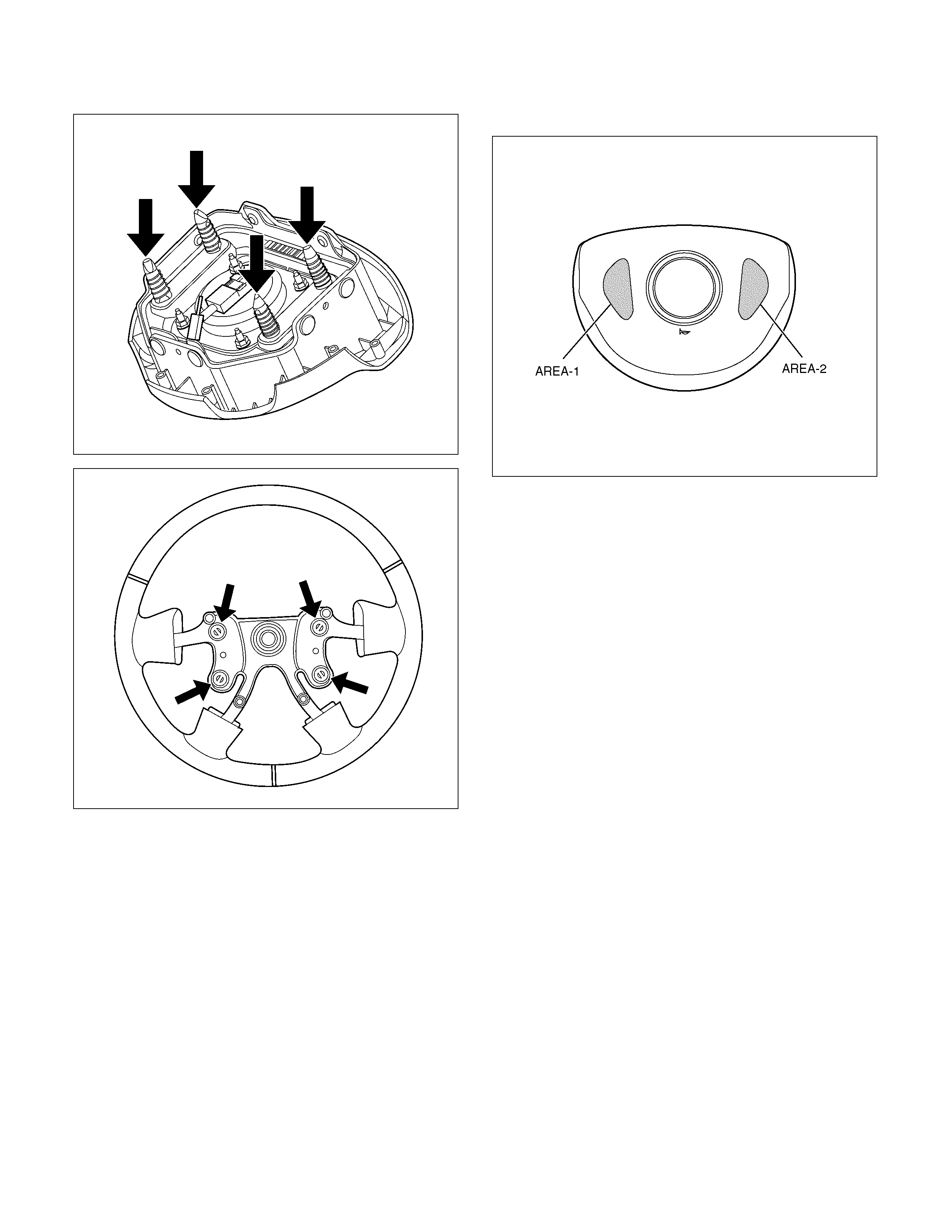

Installation

1. Support the inflator m odule and caref ully connect the

SRS connector and horn lead. (with SRS air bag)

060R300041

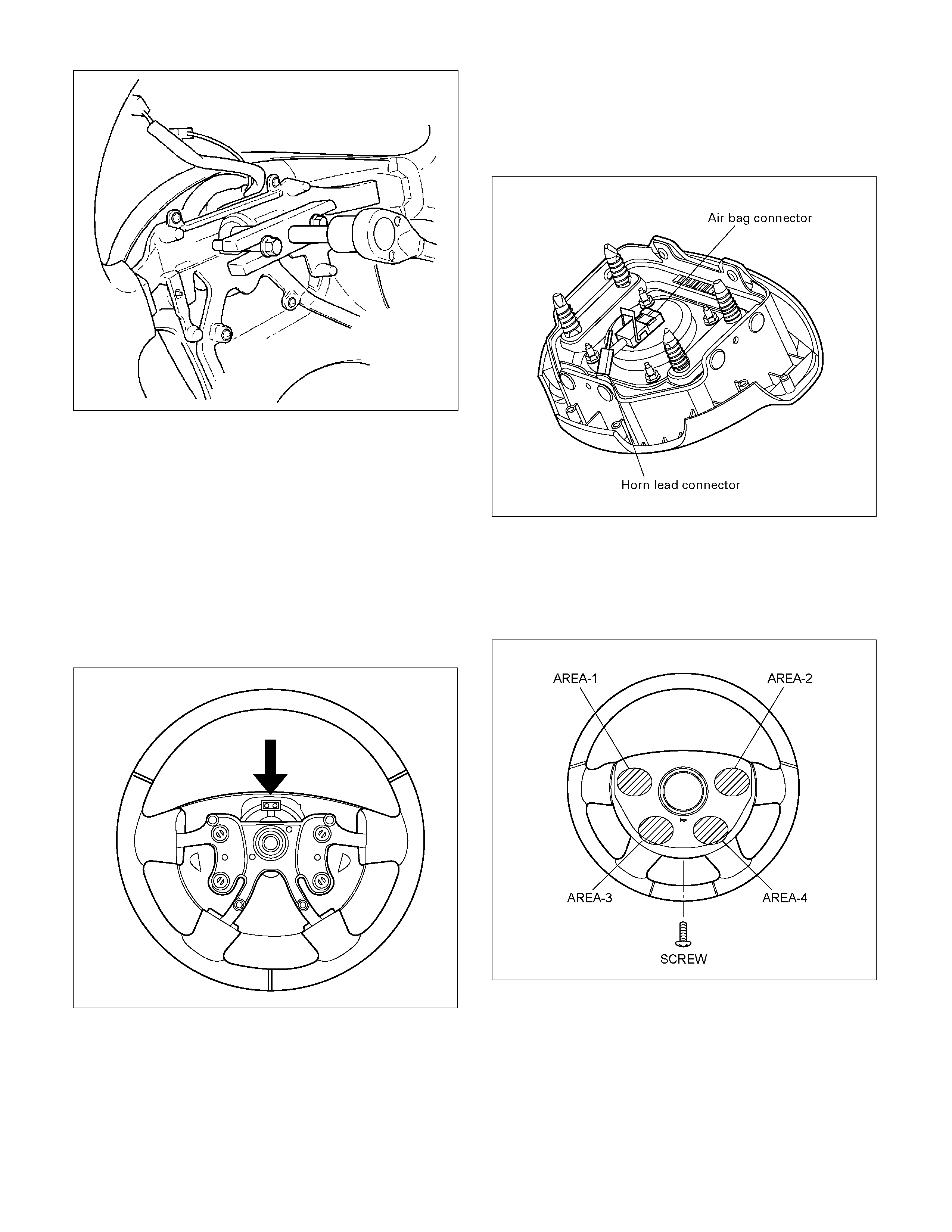

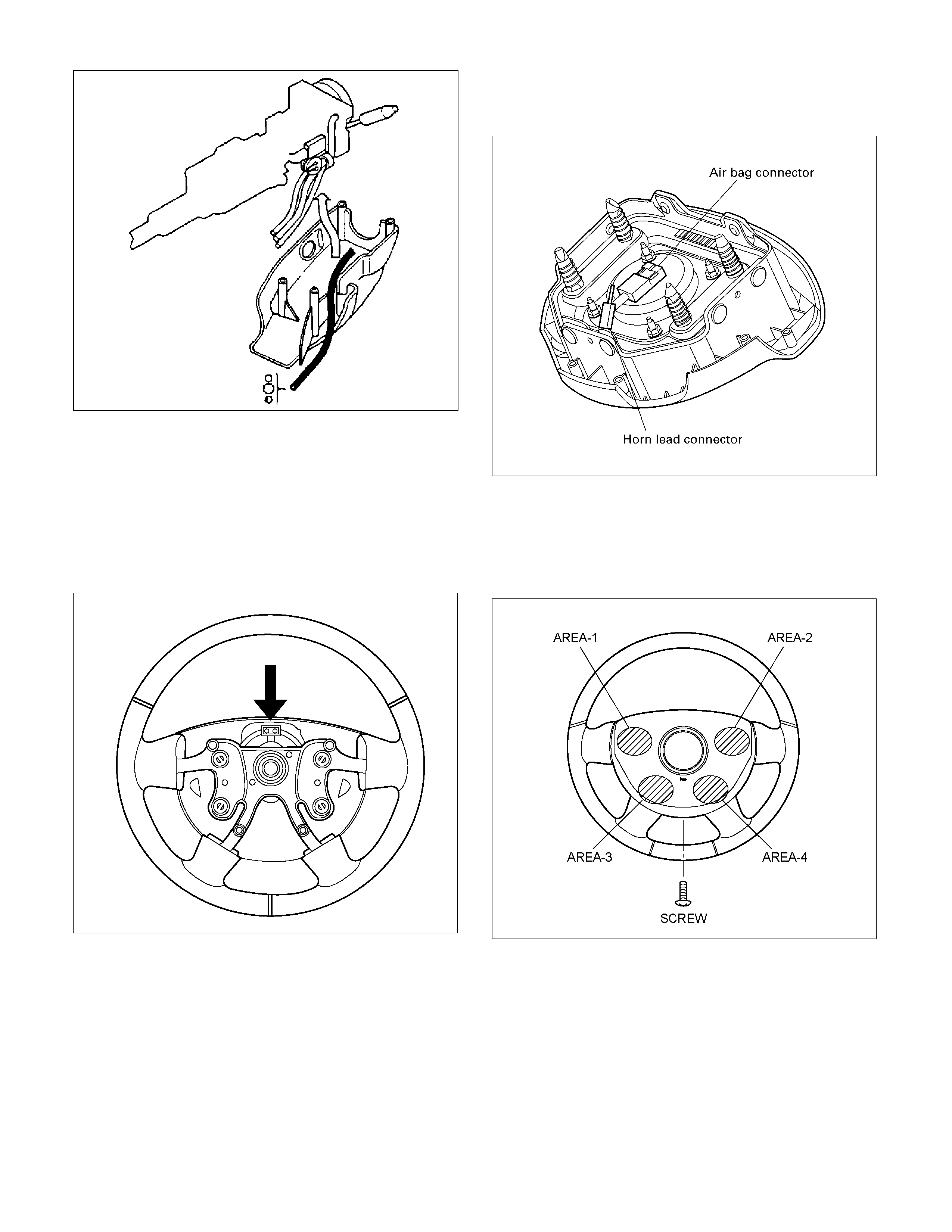

2. Connect the horn leads at center of wheel. Push the

horn pad area 1-4 to check correct horn operation.

Tighten the horn pad fixing screw to the specified

torque (without SRS air bag)

Torque: 2 – 4 Nm (0.2 – 0.4 kgm/17 - 35 lb in)

RTW33BSH000201

3.

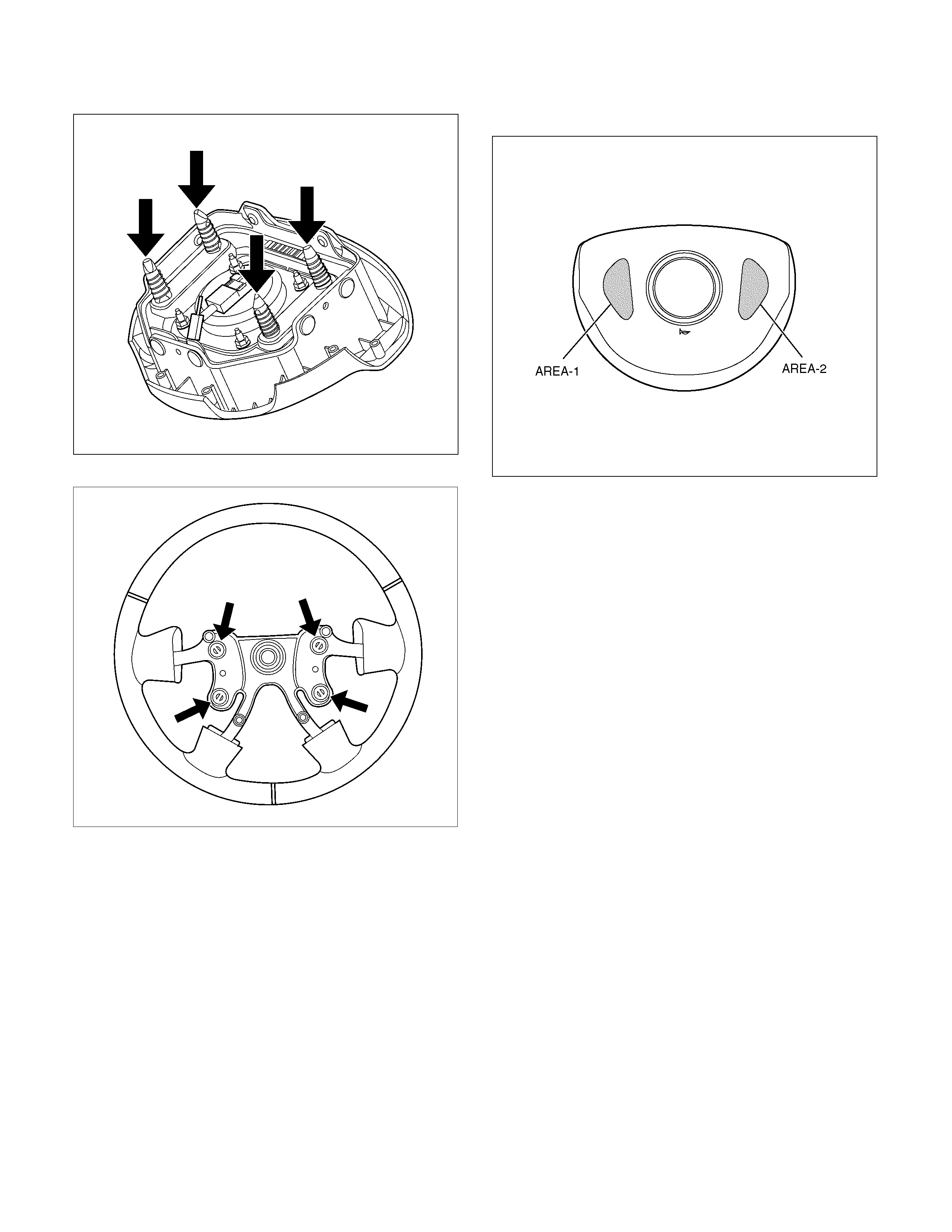

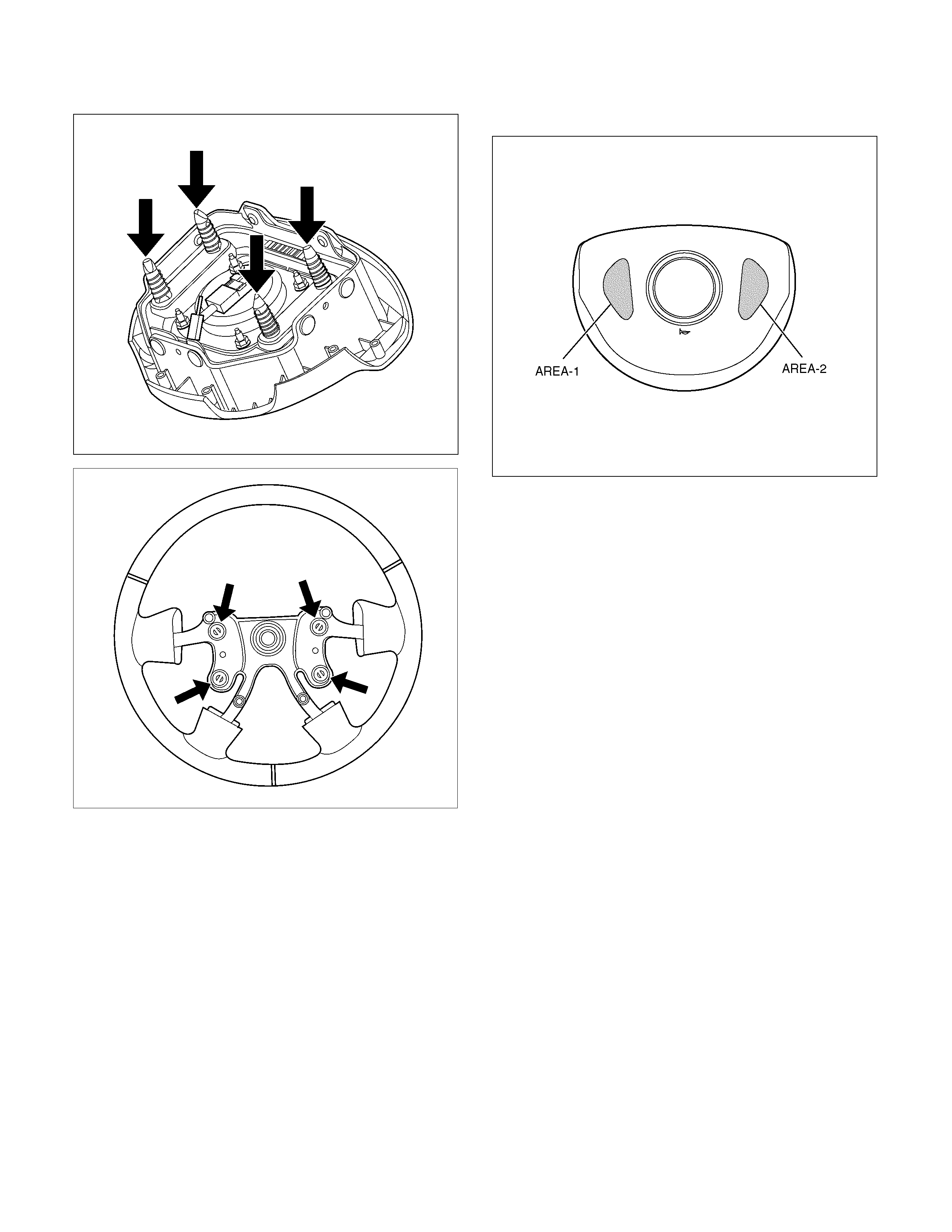

A

lign the each s nap stud of driver air bag to the hole

of steering wheel. (with SRS air bag)

060R300030

060R300020

4. Push the SRS air bag area1 and area2. At that tim e

confirm the audible noise of each stud.

060R300036

5. Enable the SRS (Refer to "Enabling t he SRS" in this

section). (with SRS air bag)

6. Connect the SRS connector. (with SRS air bag)

7. Connect the battery "-" terminal cable. (with SRS air

bag)

8. Turn the ignition switch to "ON" while watching

warning light and check the light should f lash 7 tim es

and then go off. If lamp does not operate correctly,

refer to Restraints section.

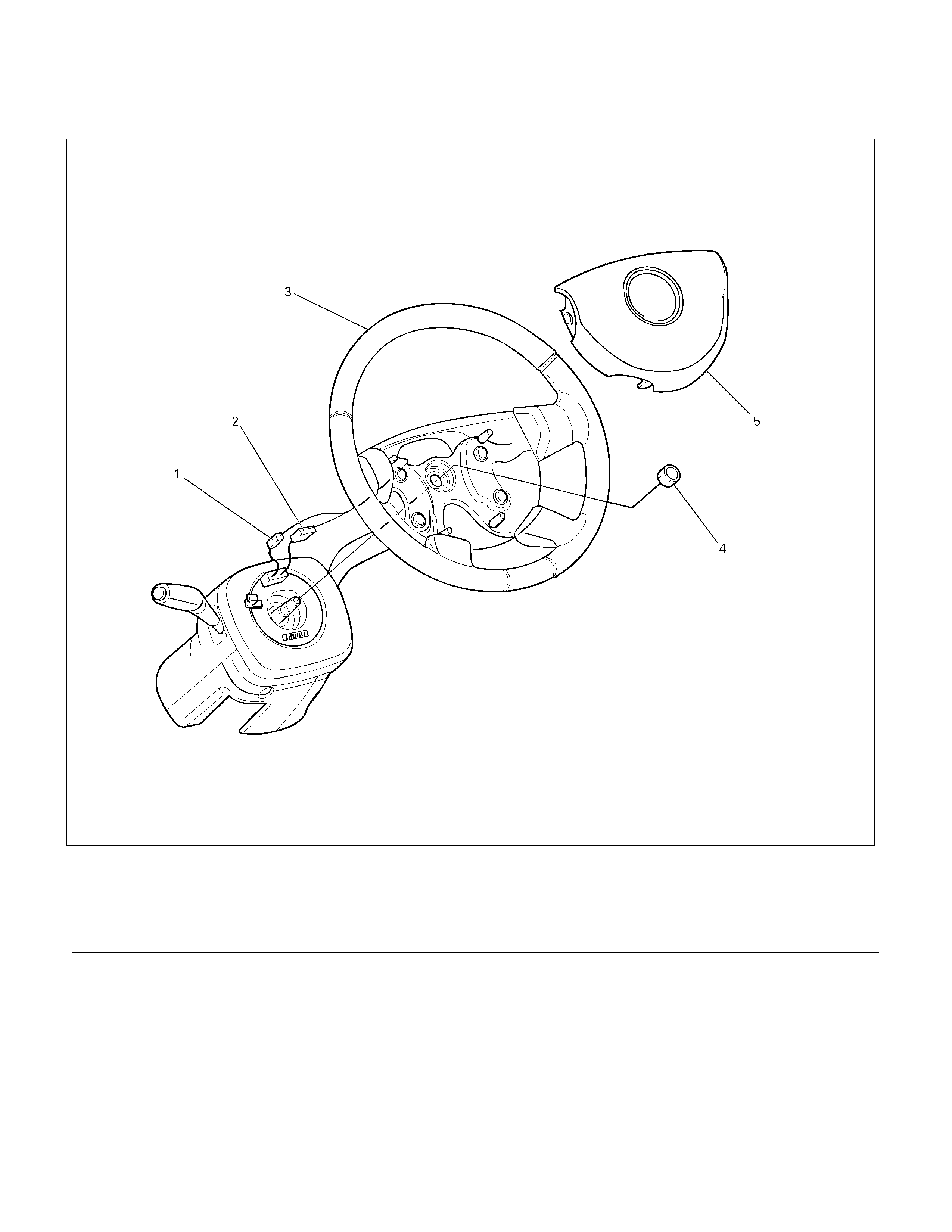

Steering Wheel

Steering Wheel and Associated Parts

430R300013

Legend

(1) Horn Lead

(2) SRS Connector

(3) Steering Wheel

(4) Steering Wheel Fixing Nut

(5) Inflator Module or Horn Pad

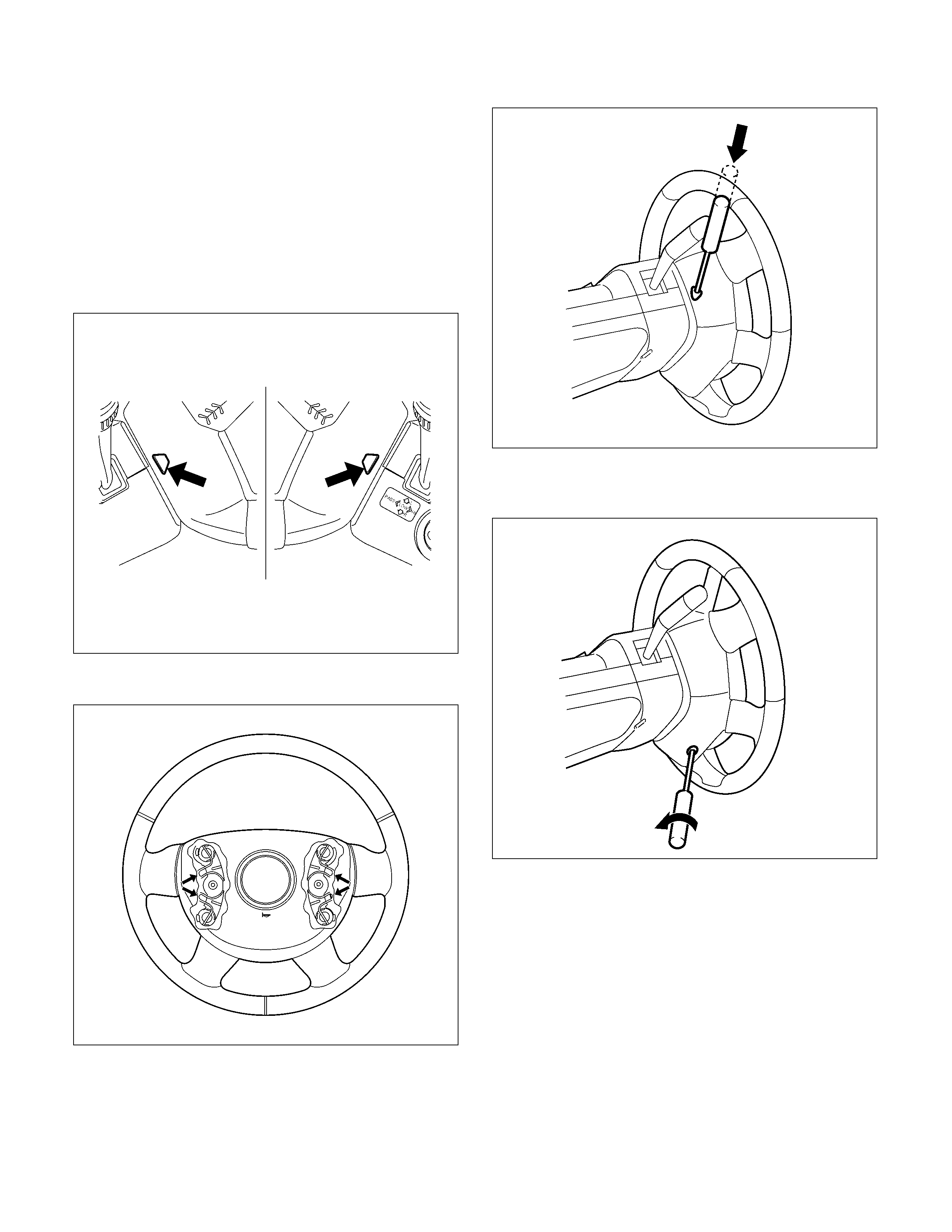

Removal

1. Turn the steering wheel so that the vehicle's wheels

are pointing straight ahead.

2. Turn the ignition switch to "LOCK".

3. Disconnect the battery "-" terminal cable, and wait at

least 5 minutes. (with SRS air bag)

4. Disconnect the yellow 2-way SRS connector located

under the steering column. (with SRS air bag)

CAUTION: The wheels of the vehicle must be

straight ahead and the steering column in the

"LOCK" position before disconnecting the steering

wheel. Failure to do so will cause the coil assembly

to become uncentered which will cause damage to

the coil assembly. (with SRS air bag)

5. Disable the SRS (Refer to "Disabling the SRS" in

this section). (with SRS air bag)

6. Check the both side hole of the steering cover. (with

SRS air bag)

060R300025

7. Check the position of the pins in a hole. Push the

pin in the direction of an arrow. (with SRS air bag)

060R300032

8. Push the four pins at 5-6 mm diameter bar. (with

SRS air bag)

060R300031

9. Cancel the lock four pins. (with SRS air bag)

10. Loosen the horn pad fixing screw at the rear of the

steering wheel (without SRS air bag).

430R300009

11. Disconnect the SRS air bag connector and horn

lead connector located behind the air bag assembly

and remove the air bag assembly. (with SRS air

bag)

060R300041

12. Remove the horn pad and the horn leads at the

center of the wheel (without SRS air bag).

RTW33BSH000401

WARNING: THE INFLATOR MODULE SHOULD

ALWAYS BE CARRIED WITH THE COVER AWAY

FROM YOUR BODY AND SHOULD ALWAYS BE

LAID ON A FLAT SURFACE WITH THE COVER SIDE

UP. THIS IS NECESSARY BECAUSE A FREE SPACE

IS PROVIDED TO ALLOW THE AIR CUSHION TO

EXPAND IN THE UNLIKELY EVENT OF

ACCIDENTAL DEPLOYMENT. OTHERWISE,

PERSONAL INJURY MAY RESULT. (with SRS air

bag)

430R300007

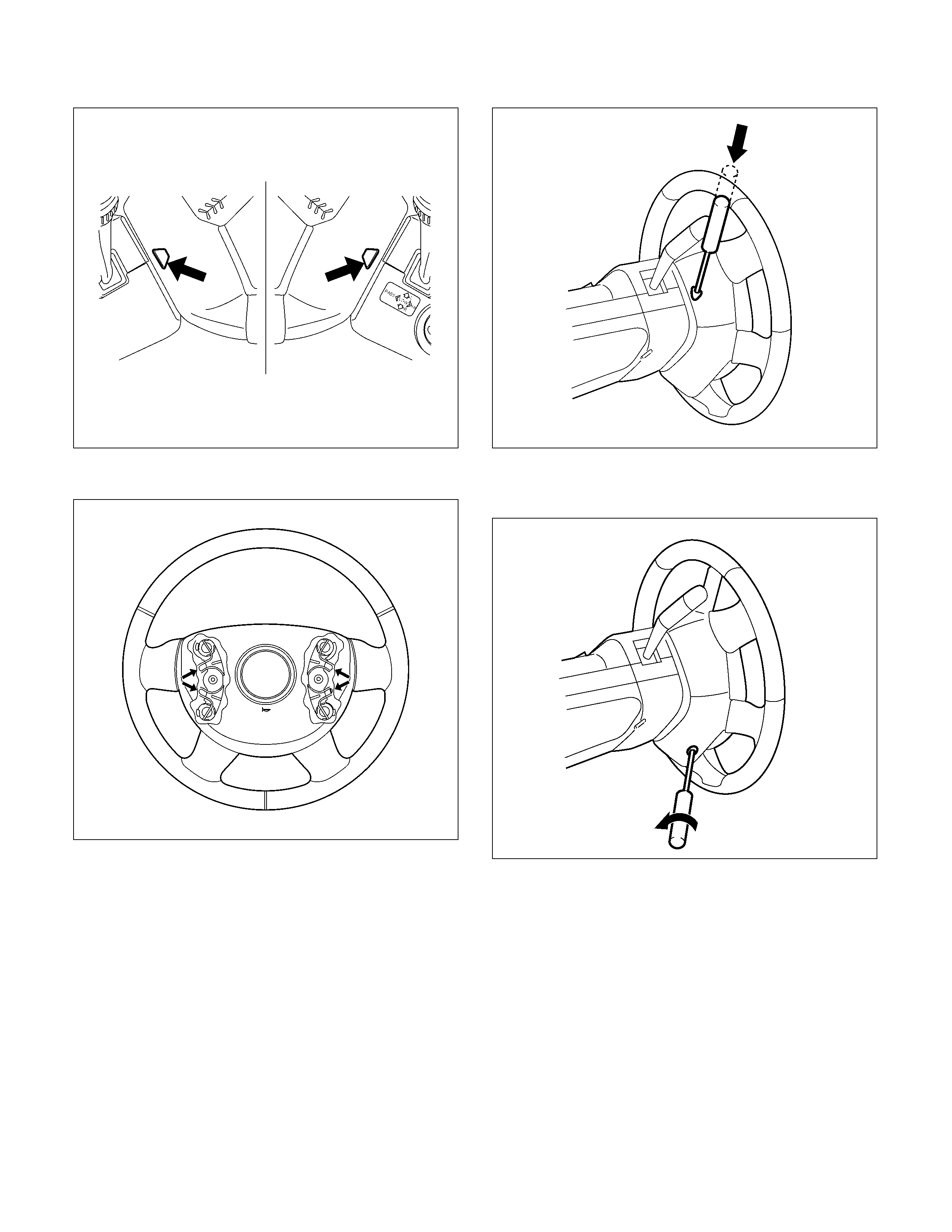

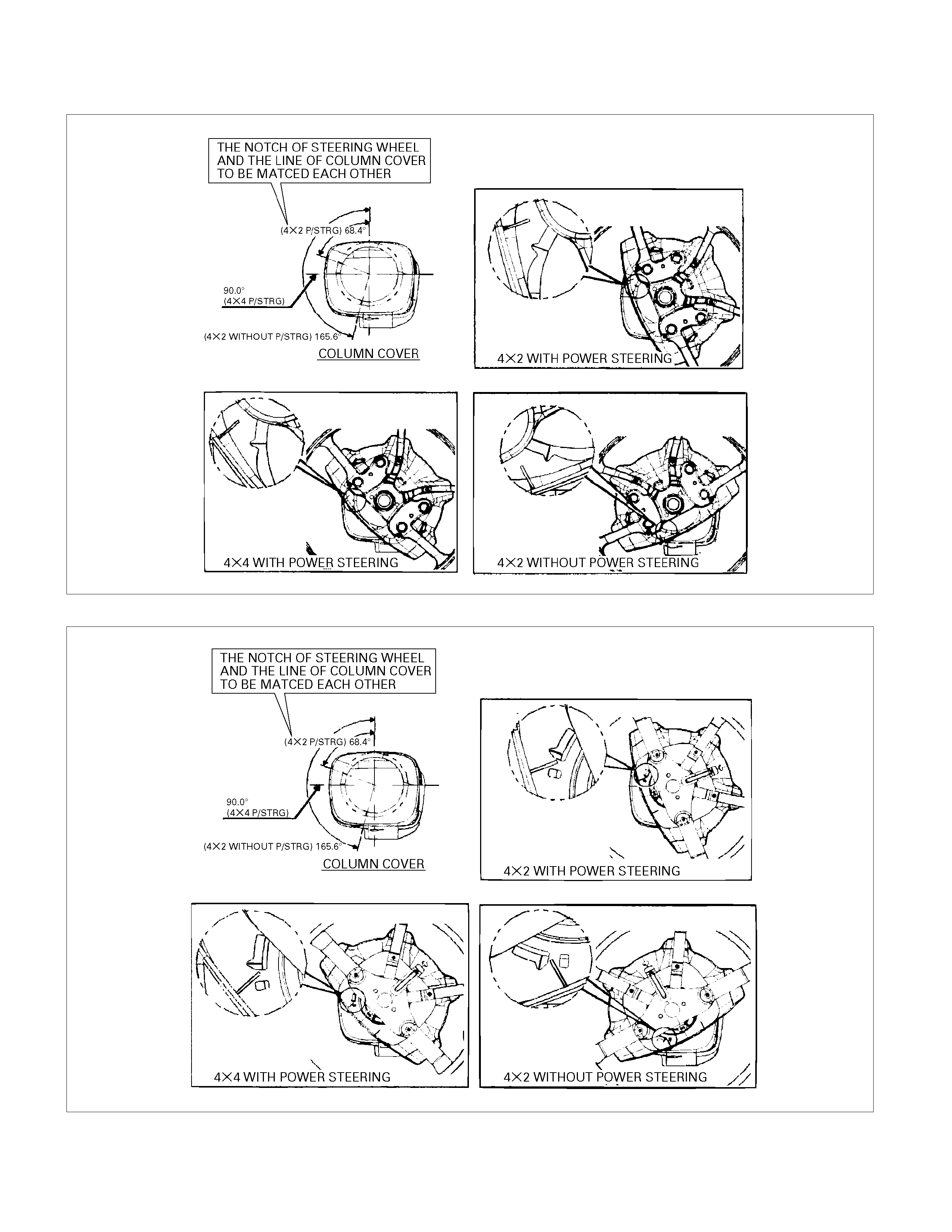

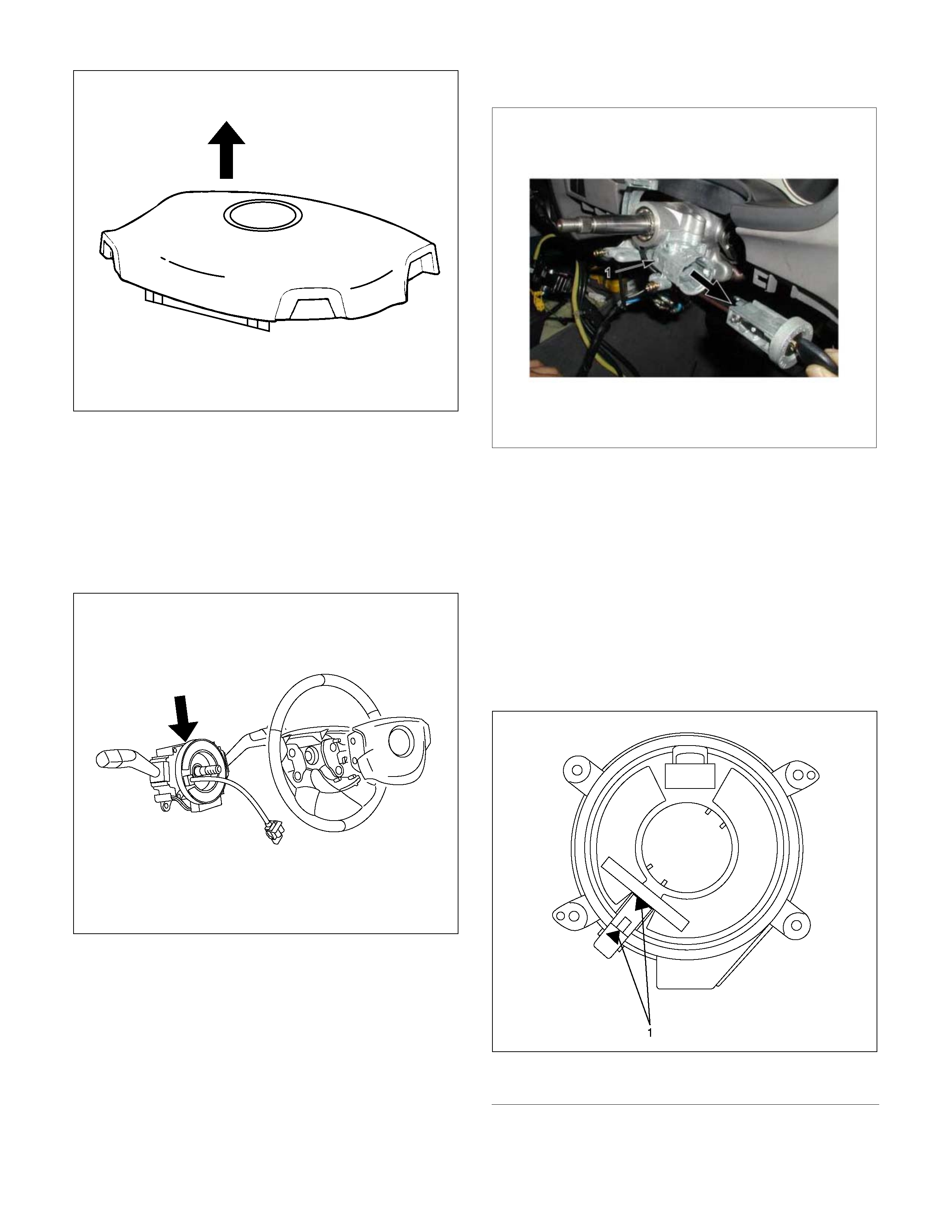

13. Apply a setting mark (1) across the steering wheel

and shaft so parts can be reassembled in their

original position. Move the front wheels to the

straight ahead position, then use steering wheel

remover 5-8521-0016-0 to remove the steering

wheel.

430R300008

CAUTION: Never apply force to the steering wheel in

direction of the shaft by using a hammer or other

impact tools in an attempt to remove the steering

wheel. The steering shaft is designed as an energy

absorbing unit.

430RX005

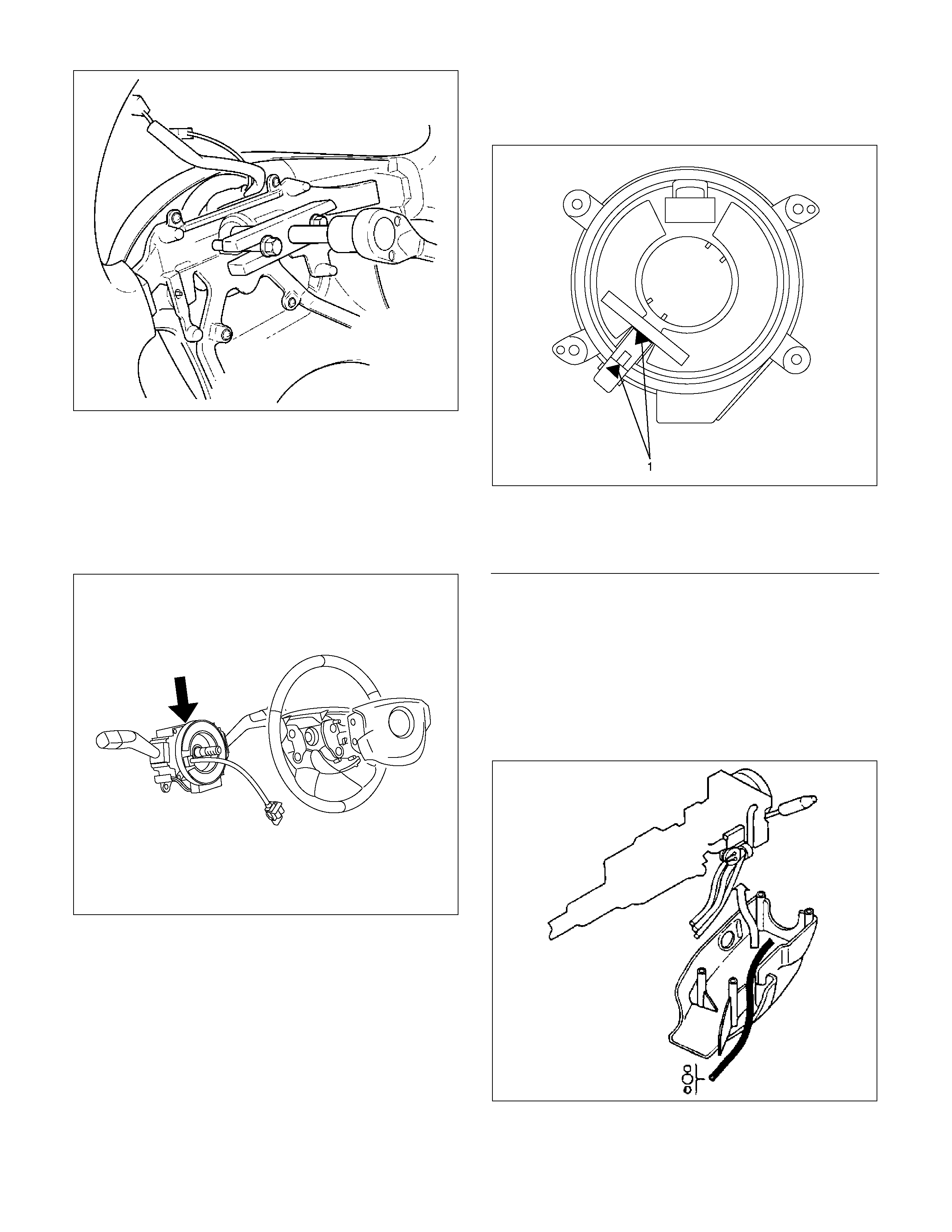

14. Remove steering column cover.

15. Disconnect the wiring harness connectors located

under the steering column then remove combination

switch and SRS coil assembly.

Installation

1.

A

lign the setting marks made when removing then

install steering wheel.

Refer to the adjustment method in case a mark is

not attached in this section.

NOTE: Confirm SRS and Horn harness connector is

fixed by the steering wheel.

RTW33BSH000601

CAUTION: Never apply force to the steering wheel in

direction of the shaft by using a hammer or other

impact tools in an attempt to remove the steering

wheel. The steering shaft is designed as an energy

absorbing unit.

2. Tighten the steering wheel fixing nut to the specified

torque.

Torque: 31 - 39 Nm (3.2 – 4.0 kgm/23 - 29 lb ft)

3. Support the inflator m odule and caref ully connect the

SRS connector and horn lead. (with SRS air bag)

060R300041

4. Connect the horn leads at center of wheel. Push the

horn pad area 1-4.

Tighten the horn pad fixing screw to the specified

torque (without SRS air bag)

Torque: 2 – 4 Nm (0.2 – 0.4 kgm/17 - 35 lb in)

RTW33BSH000201

5.

A

lign the each s nap stud of driver air bag to the hole

of steering wheel. (with SRS air bag)

060R300030

060R300020

6. Push the SRS air bag area1 and area2. At that tim e

confir m the audible nois e of each st ud. ( with SRS air

bag)

060R300036

7. Enable the SRS (Refer to "Enabling t he SRS" in this

section). (with SRS air bag)

8. Connect the SRS connector. (with SRS air bag)

9. Connect the battery "-" terminal cable. (with SRS air

bag)

10. Turn the ignition switch to "ON" while watching

warning light and check the light should f lash 7 tim es

and then go off. If lamp does not operate correctly,

refer to Restraints section.

The adjustment method in case a mark is not attached

with SRS air bag

430R300011

without SRS air bag

430R300010

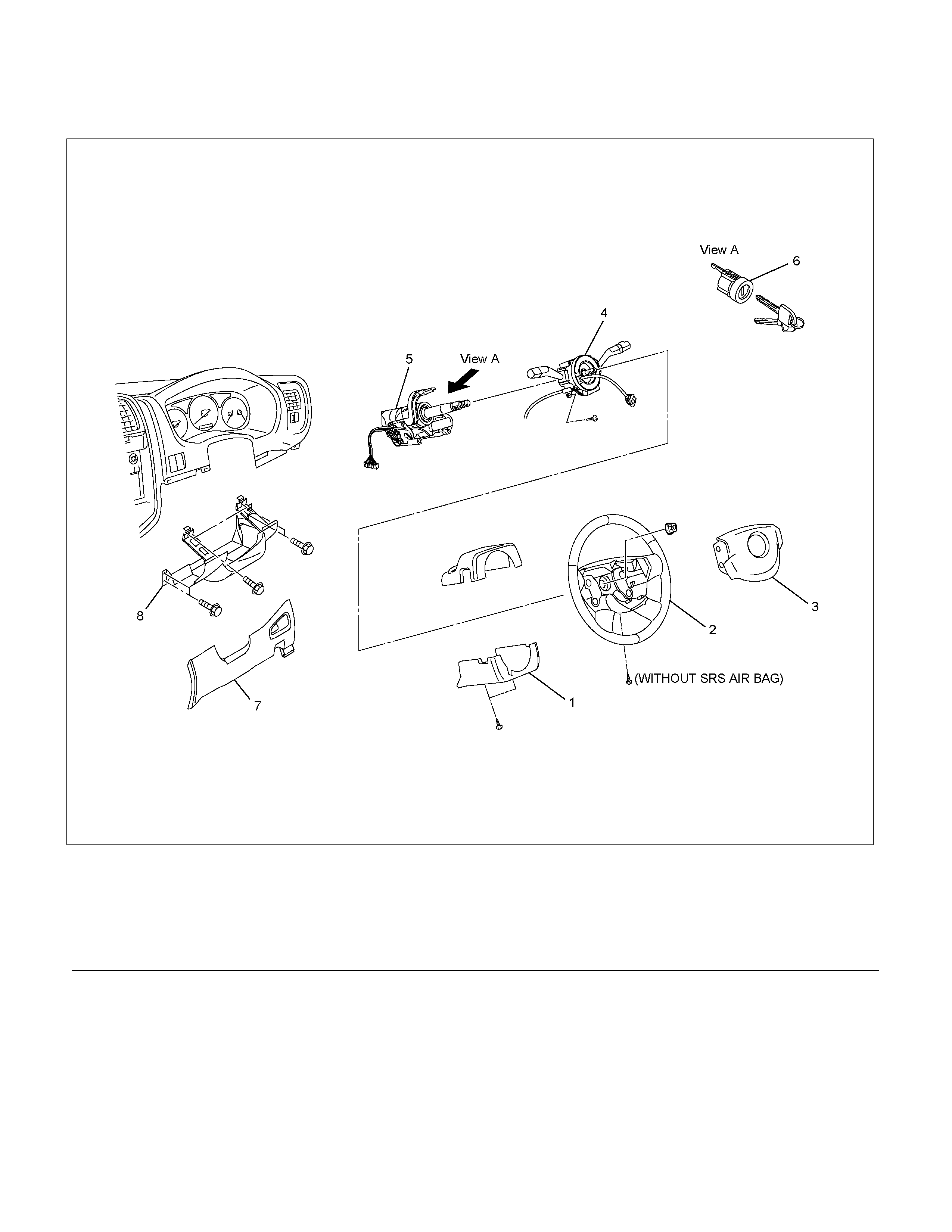

Combination Switch

Combination Switch and Associated Parts

RTW33BLF000601

Legend

(1) Steering Column Cover

(2) Steering Wheel

(3) Inflator Module or Horn Pad

(4) Combination Switch and SRS Coil Assembly

(5) Instrument Panel Lower Cover

(6) Driver Knee Bolster (reinforcement)

Removal

1. Turn the steering wheel so that the vehicle's wheels

are pointing straight ahead.

2. Turn the ignition switch to "LOCK".

3. Disconnect the battery "-" terminal cable, and wait at

least 5 minutes. (with SRS air bag)

4. Disconnect the yellow 2-way SRS connector located

under the steering column. (with SRS air bag)

CAUTION: The wheels of the vehicle must be

straight ahead and the steering column in the

"LOCK" position before disconnecting the steering

wheel. Failure to do so will cause the coil assembly

to become uncentered which will cause damage to

the coil assembly. (with SRS air bag)

5. Remove the engine hood opening lever, then

remove instrument panel lower cover.

6. Remove the driver knee bolster (reinforcement).

7. Disable the SRS (Refer to "Disabling the SRS" in

this section). (with SRS air bag)

8. Check the both side hole of the steering cover.

060R300025

9. Check the position of the pins in a hole. Push the

pin in the direction of an arrow. (with SRS air bag)

060R300032

10. Push the four pins at φ56 mm bar. (with SRS air

bag)

060R300031

11. Cancel the lock four pins. (with SRS air bag)

12. Loosen the horn pad fixing screw at the rear of the

steering wheel (without SRS air bag).

430R300009

13. Disconnect the SRS air bag connector and horn

lead connector located behind the air bag assembly

and remove the air bag assembly. (with SRS air

bag)

060R300041

14. Remove the horn pad and the horn leads at the

center of the wheel (without SRS air bag).

RTW33BSH00401

WARNING: THE INFLATOR MODULE SHOULD

ALWAYS BE CARRIED WITH THE COVER AWAY

FROM YOUR BODY AND SHOULD ALWAYS BE

LAID ON A FLAT SURFACE WITH THE COVER SIDE

UP. THIS IS NECESSARY BECAUSE A FREE SPACE

IS PROVIDED TO ALLOW THE AIR CUSHION TO

EXPAND IN THE UNLIKELY EVENT OF

ACCIDENTAL DEPLOYMENT. OTHERWISE,

PERSONAL INJURY MAY RESULT. (with SRS air

bag)

430R300007

15. Apply a setting mark (1) across the steering wheel

and shaft so parts can be reassembled in their

original position. Move the front wheels to the

straight ahead position, then use steering wheel

remover 5-8521-0016-0 to remove the steering

wheel.

430R300008

CAUTION: Never apply force to the steering wheel in

direction of the shaft by using a hammer or other

impact tools in an attempt to remove the steering

wheel. The steering shaft is designed as an energy

absorbing unit.

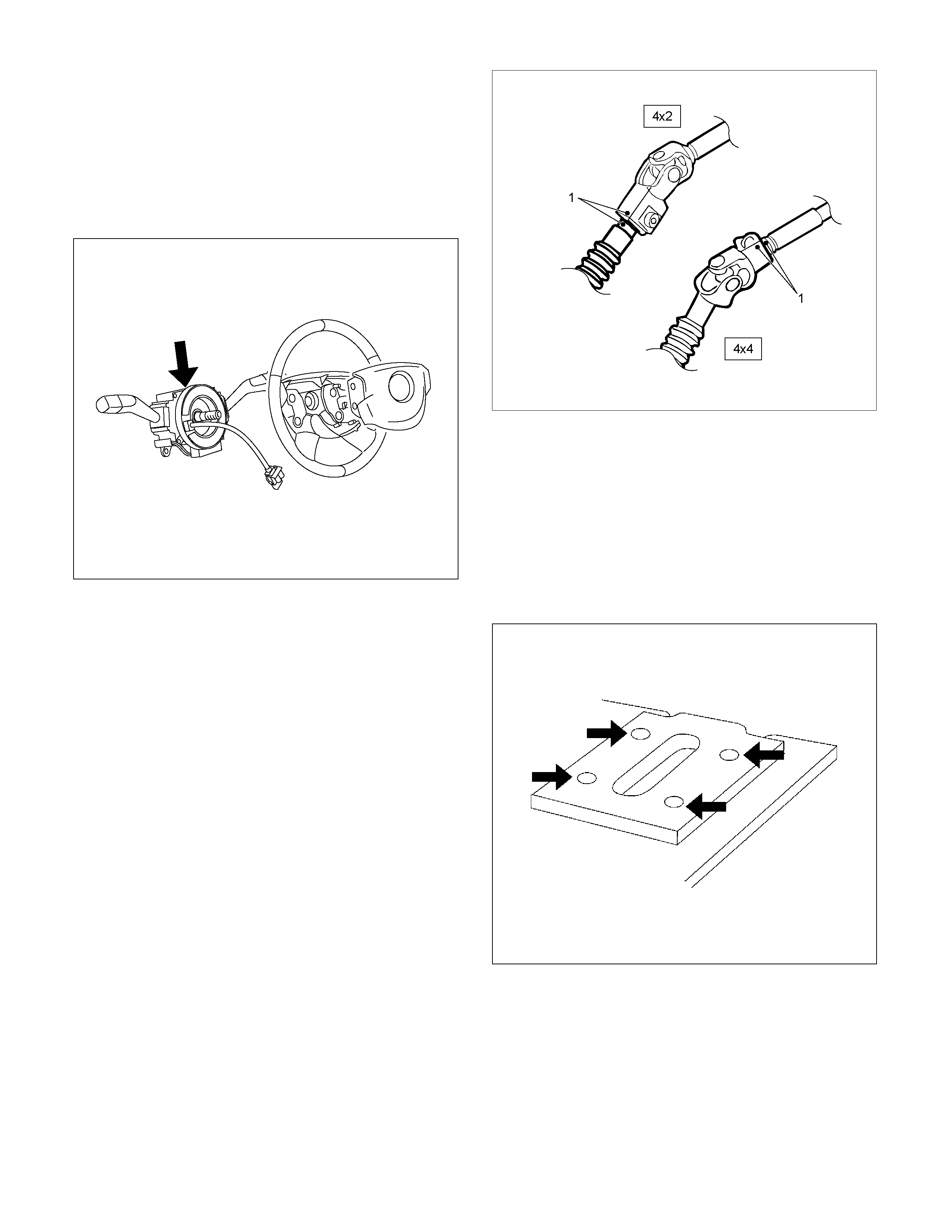

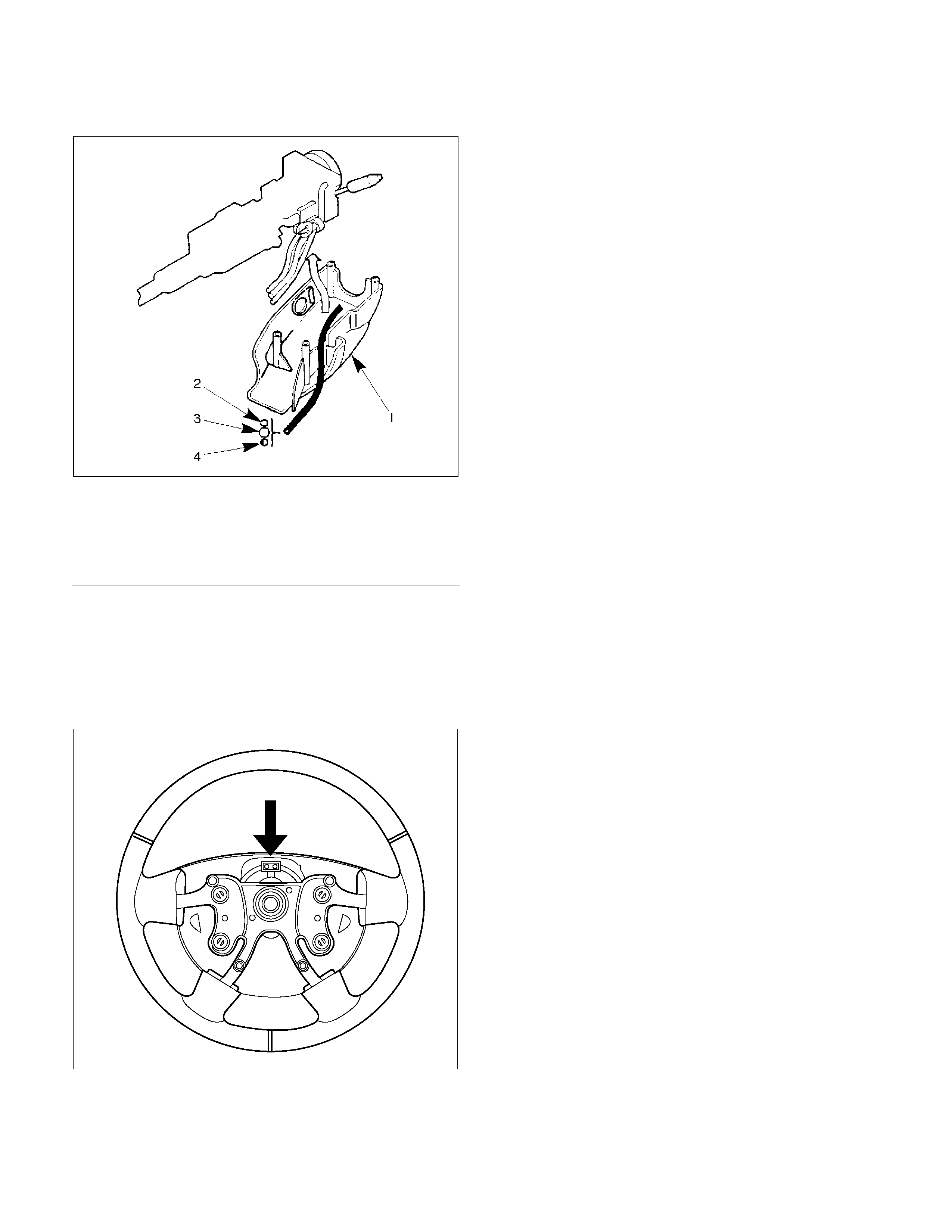

CAUTION: When turning the SRS coil

counterclockwise to full, stop turning if resistance

is felt. Forced further turning may damage the cable

in the SRS coil. (with SRS air bag)

826RW014

Legend

(1) Neutral mark

430RX005

16. Remove steering column cover.

17. Disconnect the wiring harness connectors located

under the steering column then remove combination

switch and SRS coil assembly. (with SRS air bag)

NOTE: The SRS coil is a part of the combination switch

assembly, which can not be replaced separately.

Therefore, be sure not to remove the SRS coil from the

combination switch assembly. (with SRS air bag)

430R300014

Installation

1. Install the combination switch assembly with SRS

coil. (with SRS air bag)

2. Turn the SRS coil counterclockwise to full, return

about 3 turns and align the neutral mark. (with SRS

air bag)

3. Connect the wiring harness connectors located at

the base of steering column.

4. Install the air conditioning lower duct.

5. Install the steering column cover.

CAUTION: When installing the steering column

cover, be sure to wire (through each harness) as

illustrated so that the harness starter switch,

combination switch and SRS coil may not catch

wiring. (with SRS air bag)

825RS048

6. Install the driver knee bolster assembly.

7. Install the steering lower cover and engine hood

opening lever.

8. Install the steering wheel and align the setting

marks.

Refer to the adjustment method in case a mark is

not attached in this section.

NOTE: Confirm SRS and Horn harness connector is

fixed by the steering wheel.

RTW33BSH000601

CAUTION: Never apply force to the steering wheel in

direction of the shaft by using a hammer or other

impact tools in an attempt to remove the steering

wheel. The steering shaft is designed as an energy

absorbing unit.

9. Tighten the steering wheel fixing nut to the specified

torque.

Torque: 31 - 39 Nm (3.2 – 4.0 kg m/23 - 29 lb ft)

10. Support the inflator module and carefully connect

the SRS connector and horn lead. (with SRS air

bag)

060R300010

11. Connect the horn leads at center of wheel. Push the

horn pad area 1-4.

Tighten the horn pad fixing screw to the specified

torque (without SRS air bag)

Torque: 2 – 4 Nm (0.2 – 0.4 kgm/17 - 35 lb in)

RTW33BSH000201

12.

A

lign the each s nap stud of driver air bag to the hole

of steering wheel. (with SRS air bag)

060R300030

060R300020

13. Push the SRS air bag area1 and area2. At that tim e

confir m the audible nois e of each st ud. ( with SRS air

bag)

060R300036

14. Enable the SRS (Refer to "Enabling t he SRS" in this

section). (with SRS air bag)

15. Install driver knee bolster (reinforcement).

16. Install instrument panel lower cover then Install the

engine hood opening lever.

17. Connect the SRS connector. (with SRS air bag)

18. Connect the battery "-" terminal cable. (with SRS air

bag)

19. Turn the ignition switch to "ON" while watching

warning light and check the light should f lash 7 tim es

and then go off. If lamp does not operate correctly,

refer to Restraints section.

Lock Cylinder

Lock Cylinder and Associated Parts

RTW33BLF000401

Legend

(1) Steering Column Cover

(2) Steering Wheel

(3) Inflator Module or Horn pad

(4) Combination Switch and SRS Coil Assembly

(5) Steering Column Assembly

(6) Lock Cylinder Assembly

(7) Instrument Panel Lower Cover

(8) Driver Knee Bolster (reinforcement)

Removal

1. Turn the steering wheel so that the vehicle's wheels

are pointing straight ahead.

2. Turn the ignition switch to "LOCK".

3. Disconnect the battery "-" terminal cable, and wait at

least 5 minutes. (with SRS air bag)

4. Disconnect the yellow 2-way SRS connector located

under the steering column. (with SRS air bag)

CAUTION: The wheels of the vehicle must be

straight ahead and the steering column in the

"LOCK" position before disconnecting the steering

wheel. Failure to do so will cause the coil assembly

to become uncentered which will cause damage to

the coil assembly. (with SRS air bag)

5. Remove the engine hood opening lever and

steering lower cover.

6. Remove driver knee bolster (reinforcement).

7. Disable the SRS (Refer to "Disabling the SRS" in

this section). (with SRS air bag)

8. Check the both side hole of the steering cover. (with

SRS air bag)

060R300025

9. Check the position of the pins in a hole. Push the

pin in the direction of an arrow. (with SRS air bag)

060R300032

10. Push the four pins at φ56 mm bar. (with SRS air

bag)

060R300031

11. Cancel the lock four pins. (with SRS air bag)

12. Loosen the horn pad fixing screw at the rear of the

steering wheel (without SRS air bag).

430R300009

13. Disconnect the SRS air bag connector and horn

lead connector located behind the air bag assembly

and remove the air bag assembly. (with SRS air

bag)

060R300041

14. Remove the horn pad and the horn leads at the

center of the wheel (without SRS air bag).

RTW33BSH00401

15. Apply a setting mark (1) across the steering wheel

and shaft so parts can be reassembled in their

original position.

430R300008

16. Move the front wheels to the straight ahead position,

then use steering wheel remover 5-8521-0016-0 to

remove the steering wheel.

CAUTION: Never apply force to the steering wheel in

direction of the shaft by using a hammer or other

impact tools in an attempt to remove the steering

wheel. The steering shaft is designed as an energy

absorbing unit.

430RX005

WARNING: THE INFLATOR MODULE SHOULD

ALWAYS BE CARRIED WITH THE COVER AWAY

FROM YOUR BODY AND SHOULD ALWAYS BE

LAID ON A FLAT SURFACE WITH THE COVER SIDE

UP. THIS IS NECESSARY BECAUSE A FREE SPACE

IS PROVIDED TO ALLOW THE AIR CUSHION TO

EXPAND IN THE UNLIKELY EVENT OF

ACCIDENTAL DEPLOYMENT. OTHERWISE,

PERSONAL INJURY MAY RESULT. (with SRS air

bag)

430R300007

17. Remove steering column cover.

18. Disconnect the wiring harness connectors located

under the steering column.

19. Remove the combination switch assembly with SRS

coil.

NOTE: The SRS coil is a part of the combination switch

assembly, which can not be replaced separately.

Therefore, be sure not to remove the SRS coil from the

combination switch assembly. (with SRS air bag)

430R300014

20. Turn the ignition switch to the ACC position.

21. Insert a pin (1) into the hole and push on it. Pull the

key cylinder free.

P1010003

Installation

1. Install lock cylinder assembly.

2. Install the combination switch assembly with SRS

coil. (with SRS air bag)

3. Turn the SRS coil counterclockwise to full, return

about 3 turns and align the neutral mark. (with SRS

air bag)

CAUTION: When turning the SRS coil

counterclockwise to full, stop turning if resistance

is felt. Forced further turning may damage the cable

in the SRS coil. (with SRS air bag)

826RW014

Legend

(1) Neutral mark

825RS048

4. Install the driver knee bolster assembly.

5. Install the steering lower cover and engine hood

opening lever.

6. Install the steering wheel and align the setting marks.

Refer to the adjustment method in case a mark is not

attached in this section.

NOTE: Confirm SRS and Horn harness connector is

fixed by the steering wheel.

RTW33BSH000601

CAUTION: Never apply force to the steering wheel in

direction of the shaft by using a hammer or other

impact tools in an attempt to remove the steering

wheel. The steering shaft is designed as an energy

absorbing unit.

7. Tighten the steering wheel fixing nut to the specified

torque.

Torque: 31 - 39 Nm (3.2 – 4.0 kgm/23 - 29 lb ft)

8. Support inflator module and carefully connect the

SRS connector and horn lead, then install inflator

module. (with SRS air bag)

060R300010

9. Connect the horn leads at center of wheel. Push the

horn pad area 1-4.

Tighten the horn pad fixing screw to the specified

torque (without SRS air bag)

Torque: 2 – 4 Nm (0.2 – 0.4 kgm/17 - 35 lb in)

RTW33BSH000201

10.

A

lign the each s nap stud of driver air bag to the hole

of steering wheel. (with SRS air bag)

060R300030

060R300020

11. Push the SRS air bag area1 and area2. At that tim e

confir m the audible nois e of each stud. ( with SRS air

bag)

060R300036

12. Enable the SRS (Refer to "Enabling t he SRS" in this

section). (with SRS air bag)

13. Install driver knee bolster (reinforcement).

14. Install instrument panel lower cover, then install the

engine hood opening lever.

15. Connect the yellow 2-way SRS connector located

under the steering column. (with SRS air bag)

16. Connect the battery "-" terminal cable. (with SRS air

bag)

System Inspection (with SRS air bag)

Turn the ignition switch to "ON" while watching warning

light.

The light should flash 7 times and then go off. If lamp

does not operate correctly, refer to Restraints section.

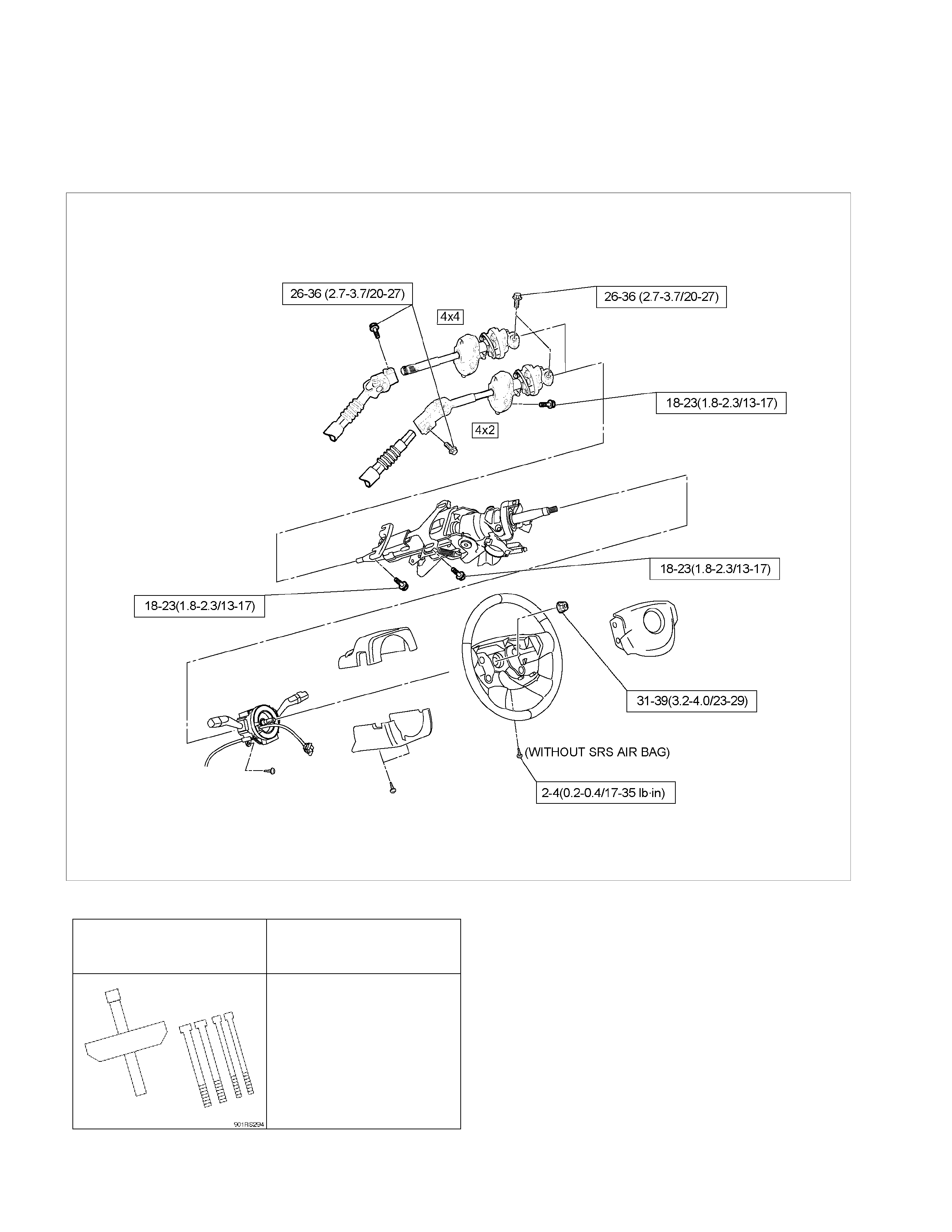

Steering Column

Steering Column and Associated Parts

RTW33BLF000501

Legend

(1) Inflator Module

(2) Steering Wheel

(3) Steering Column Cover

(4) Combination Switch and SRS Coil Assembly

(5) Steering Column Assembly

(6) Second Steering Shaft

(7) Lower Second Steering Shaft

(8) Instrument Panel Lower Cover

(9) Driver Knee Bolster (reinforcement)

Removal

1. Turn the steering wheel so that the vehicle's wheels

are pointing straight ahead.

2. Turn the ignition switch to "LOCK".

3. Disconnect the battery "-" terminal cable, and wait at

least 5 minutes. (with SRS air bag)

4. Disconnect the yellow 2-way SRS connector located

under the steering column. (with SRS air bag)

CAUTION: The wheel of the vehicle must be straight

ahead and the steering column in the "LOCK"

position before disconnecting the steering column

from the steering gear. Failure to do so will cause

the SRS coil assembly to become uncentered which

will cause damage to the SRS coil assembly. (with

SRS air bag)

5. Remove the engine hood opening lever and

steering lower cover.

6. Remove the driver knee bolster (reinforcement).

7. Disable the SRS (Refer to "Disabling the SRS" in

this section). (with SRS air bag)

8. Check the both side hole of the steering cover. (with

SRS air bag)

060R300025

9. Check the position of the pins in a hole. Push the

pin in the direction of an arrow. (with SRS air bag)

060R300032

10. Push the four pins at φ56 mm bar. (with SRS air

bag)

060R300031

11. Cancel the lock four pins. (with SRS air bag)

12. Loosen the horn pad fixing screw at the rear of the

steering wheel (without SRS air bag).

430R300009

13. Disconnect the SRS air bag connector and horn

lead connector located behind the air bag assembly

and remove the air bag assembly. (with SRS air

bag)

060R300041

14. Remove the horn pad and the horn leads at the

center of the wheel (without SRS air bag).

RTW33BSH000401

15. Apply a setting mark (1) across the steering wheel

and shaft so parts can be reassembled in their

original position. Move the front wheels to the

straight ahead position, then use steering wheel

remover 5-8521-0016-0 to remove the steering

wheel.

430R300008

430RX005

16. Remove steering column cover.

17. Disconnect the wiring harness connectors located

under the steering column.

18. Remove the combination switch assembly with SRS

coil.

NOTE: The SRS coil is a part of the combination switch

assembly, which can not be replaced separately.

Therefore, be sure not to remove the SRS coil from the

combination switch assembly.

430R300014

19. Remove snap ring.

20. Remove cushion rubber.

21. Remove shift lock cable (For A/T).

22. Disconnect the starter switch harness connector

located under the steering column, then remove

lock cylinder assembly.

23. Apply a setting mark (1) across the universal joint

and transfer gear to reassemble the parts in their

original position, then remove steering column

assembly and second shaft.

NOTE: A setting mark can be easily made if the shaft is

withdrawn a little by loosening the steering shaft

universal joint.

RTW33BSH000501

Inspection

If the abnormal conditions are found through inspection,

replace the steering column assembly.

Column Capsule

Check capsules on steering column bracket assembly;

all must be securely seated in bracket slots and

checked for any loose conditions when pushed or pulled

by hand.

431RW030

Check clearance between capsule and bracket. If must

be within 1mm (0.039 in).

431RW031

Column Universal Joint (between the power

steering unit and the steering shaft)

If the resistance is felt when checked by rotate the joint,

replace the lower second steering shaft.

Shaft Universal Joint (between the lower second

steering shaft and the second steering shaft)

If the resistance is felt when checked by rotate the joint,

replace the second steering shaft assembly.

Tilt Mechanism

Tilt mechanism should moves smoothly.

While locked the tilt mechanism, be sure the steering

column latch securely by pushing the steering wheel

upward and downward.

Installation

1. Align the setting marks on the second steering shaft

and the steering column assembly (applied at

disassem bly).

2. Connec t the steering colum n ass embly to the second

steering shaft. Tighten the bolts to the specified

torque.

Torque: 26 - 36 Nm (2.7 – 3.7 kgm/20 - 27 lb ft)

3. Thread the steering column assembly through the

hole in the dashpanel. Temporarily tighten the

steering column and the second steering shaft fixing

bolt.

4. Connect the lower second steering shaft and the

second steering shaft. Tighten the universal joint

bolts to the specified torque.

Torque: 26 - 36 Nm (2.7 – 3.7 kgm/20 - 27 lb ft)

5. Tighten the second steering shaft fixing bolt to the

specified torque (This bolt was temporarily tightened

in Step 3)

Torque: 18 -23 Nm (1.8 – 2.3 kgm/13 - 17 lb ft)

6. Tighten the steering column fixing bolt (dashpanel

side) to the specified torque (This bolt was

temporarily tighten in Step 3).

Torque: 18 -23 Nm (1.8 – 2.3 kgm/13 - 17 lb ft)

7. Tighten the steering column fixing bolt (pedal brkt

side) to the specified torque (This bolt was

temporarily tighten in Step 3).

Torque: 18 -23 Nm (1.8 – 2.3 kgm/13 - 17 lb ft)

8. Install combination switch and SRS coil assembly.

A

fter installation of combination switch assembly,

connect the combination switch wiring harness

connector and the SRS 2-way connector located

under the steering column.

9. Turn the SRS coil counter clockwise to full, return

about 3 turns and align the neutral mark. (with SRS

air bag)

CAUTION: When turning the SRS coil counter

clockwise to full, stop turning if resistance is felt.

Forced further turning may damage to the cable in

the SRS coil.

826RW014

10. When installing the steering column cover, be sure to

route each wire harness as illustrated so that the

harnesses do not catch any moving parts.

825RW017

Legend

(1) Steering Column Cover

(2) Starter Switch Harness

(3) Combination Switch Harness

(4) Inflator Module Harness

11. Install steering wheel and align the setting marks

made when removing.

Refer to the adjustment method in case a mark is

not attached in this section.

NOTE: Confirm SRS and Horn harness connector is

fixed by the steering wheel.

RTW33BSH000601

CAUTION: Never apply force to the steering wheel in

direction of the shaft by using a hammer or other

impact tools in an attempt to remove the steering

wheel. The steering shaft is designed as an energy

absorbing unit.

12. Tighten the steering wheel fixing nut to the specified

torque.

Torque: 31 - 39 Nm (3.2 – 4.0 kgm/23 - 29 lb ft)

13. Support the module and carefully connect the

module connector and horn lead, then install inflator

module.

NOTE: Pass the lead wire through the tabs on the

plastic cover (wire protector) of inflator to prevent lead

wire from being pinched.

14. Tighten bolts to specified torque.

Torque: 2 - 4 Nm (0.2 – 0.4 kgm/17 - 35 lb in)

15. Install driver knee bolster (reinforcement).

16. Install instrument panel lower cover.

17. Install the engine hood opening lever.

18. Connect the yellow 2-way SRS connector and horn

lead located under the steering column.

19. Connect the battery "-" terminal cable. (with SRS air

bag)

System Inspection (with SRS air bag)

Turn the ignition switch to "ON" while watching warning

light.

The light should flash 7 times and then go off. If lamp

does not operate correctly, refer to Restraints section.

Supplemental Restraint System Steering Wheel &

Column and Associated Parts

Main Data and Specifications

Torque Specifications N⋅m (kg⋅m/lb ft)

RTW33BLF001101

Special Tools

ILLUSTRATION

TOOL NO.

TOOL NAME

5-8521-0016-0

(J-29752)

Steering wheel remover