Main Data and Specifications

4×

××

×2 C24SE ENGINE MODEL

Front suspension Type Independent wishbone arms, coil spring

with stabilizer bar.

Coil spring Spring Rate 7.94 kg/mm (77.9 N/mm)

Type Gas-sealed. Hy draulic, double acting

Stroke 116.5 mm (4.59 in)

Compressed length 284.0 mm (11.18 in)

Front shock absorber

Extended length 400.5 mm (15.77 in)

Stabilizer bar Diameter 25.0 mm (0.98 in)

4×

××

×2 6VE1-W and 4JH1-TC ENGINE MODELS (HIGH-RIDE SUSPENSION)

Front suspension Type Independent wishbone arms, torsion bar spring

with stabilizer bar.

Length 1142 mm (44.96 in) Torsion bar spring Diameter 29.0 mm (1.14 in)

Type Gas-sealed. Hy draulic, double acting

Stroke 121.0 mm (4.76 in)

Compressed length 257.0 mm (10.12 in)

Front shock absorber

Extended length 378.0 mm (14.88 in)

Stabilizer bar Diameter 26.0 mm (1.02 in)

4×

××

×4 MODEL

Front suspension Type Independent wishbone arms, torsion bar spring

with stabilizer bar.

Length 1142 mm (44.96 in) Torsion bar spring Diameter 29.0 mm (1.14 in)

Type Gas-sealed. Hy draulic, double acting

Stroke 121.0 mm (4.76 in)

Compressed length 257.0 mm (10.12 in)

Front shock absorber

Extended length 378.0 mm (14.88 in)

Stabilizer bar Diameter 26.0 mm (1.02 in)

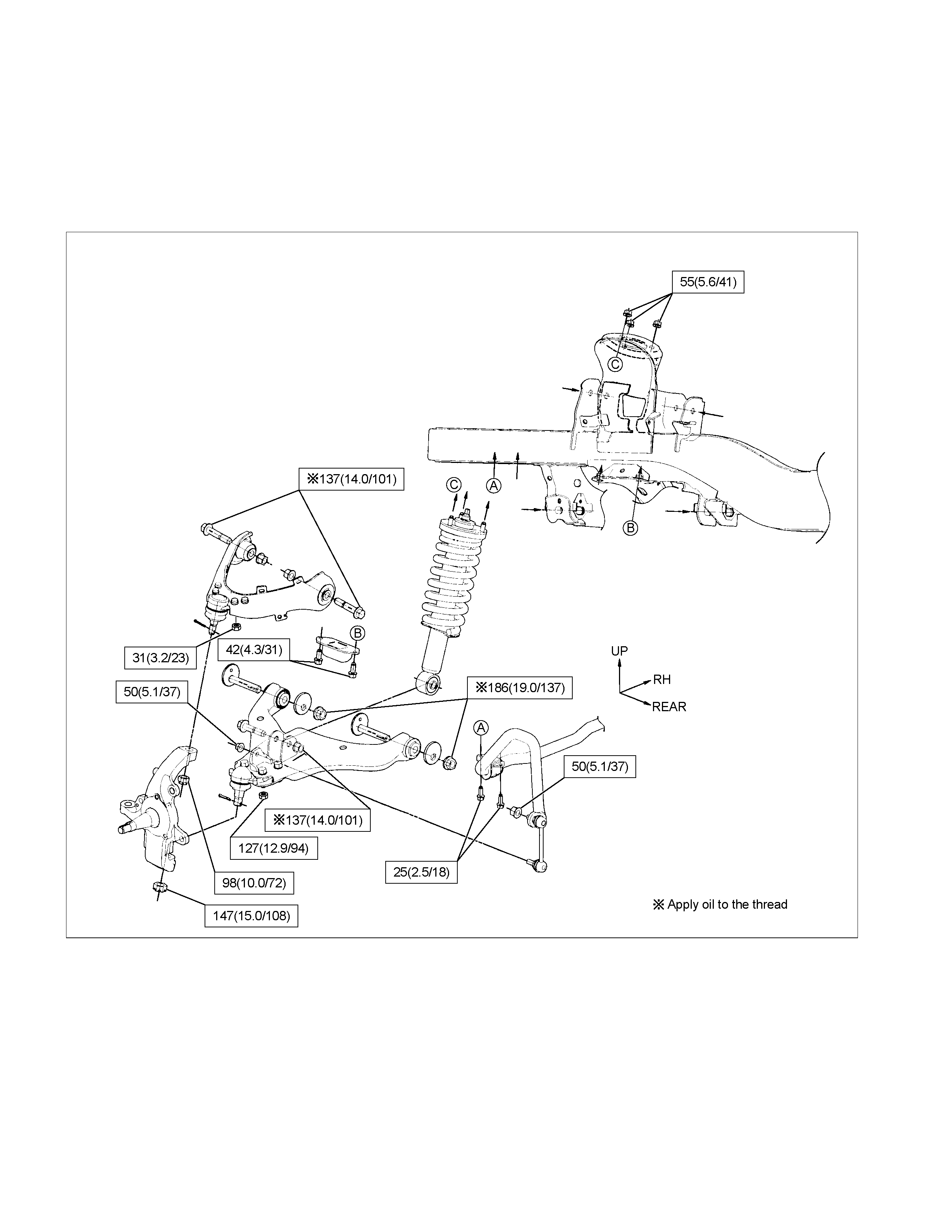

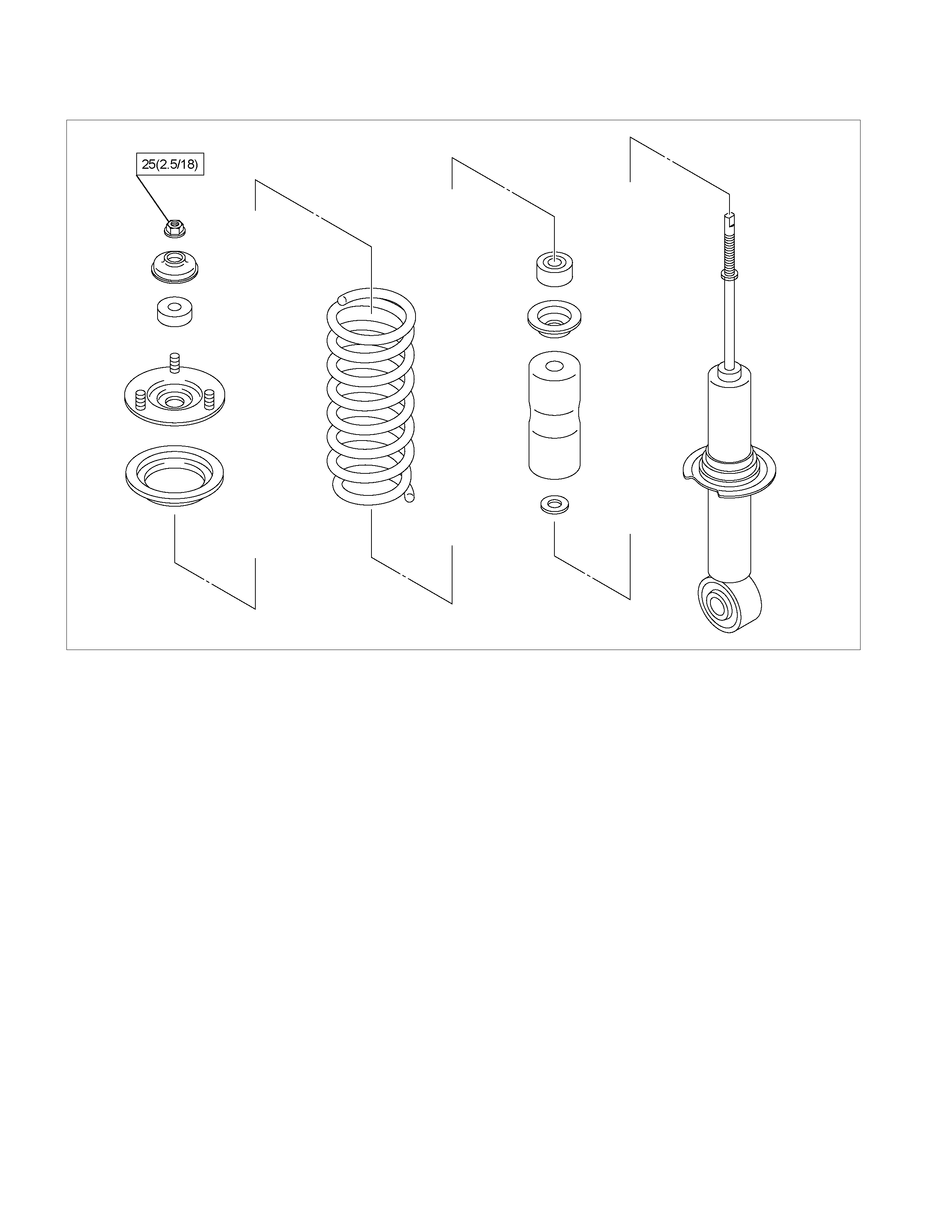

Torque Specifications

Special Parts Fixing Nuts and Bolts

4×

××

×2 C24SE Engine Model

N⋅m (kgf⋅m/lb⋅ft)

RTW340LF002401

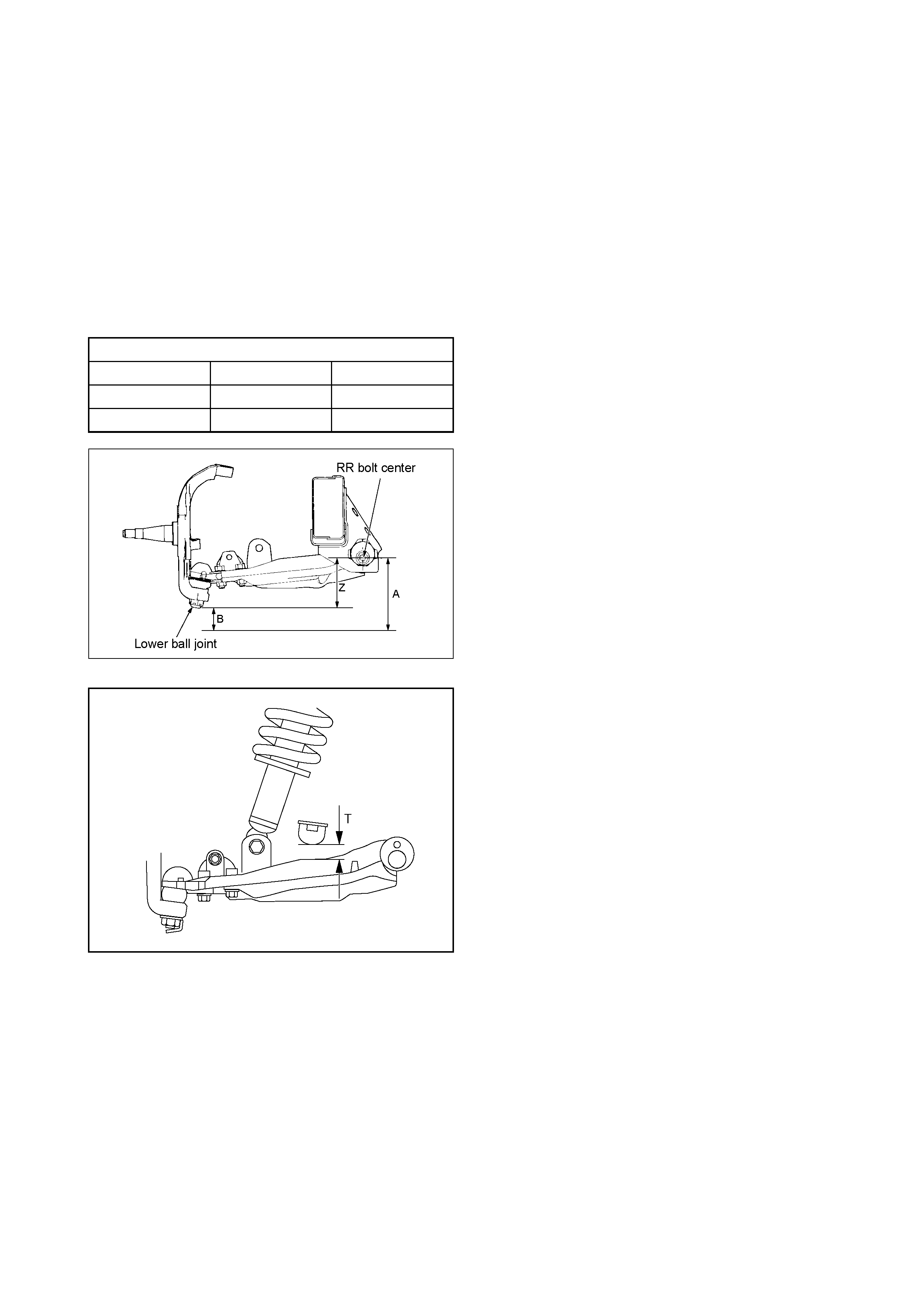

Trim Height Specification – Laden Vehicle

Should excessive spring deflection be reported when the

vehicle is laden, then the procedure detailed here, should

be followed.

Checking Procedure

1 Have the vehicle presented in the laden condition

where the spring deflection occurs.

2 Check that all tyre pressures are as spec ified on the

tyre pressure label.

Gross Vehicle Weight – Axle Loadings (kg)

4x2 Vehicle 4x4 Vehicle

Front Axle 1,120 1,220

Rear Axle 1,680 1,680

Front Trim Height (‘Z’ = A – B)

Front Bump Stop Clearance ‘T ’ (Reference Only)

3 With the vehicle on a weighing platform, check

whether the specified Gross Vehicle Weight (GVW)

axle loadings, are achieved. If not, then adjust (using

sand bags if necessary), to achieve the GVW axle

loading specifications shown.

4 After achieving the recommended front and rear axle

loadings, check and note the dimensions, indicated

in the following diagrams.

Important: Ensure that all measurements are taken with

the vehicle on a flat surface.

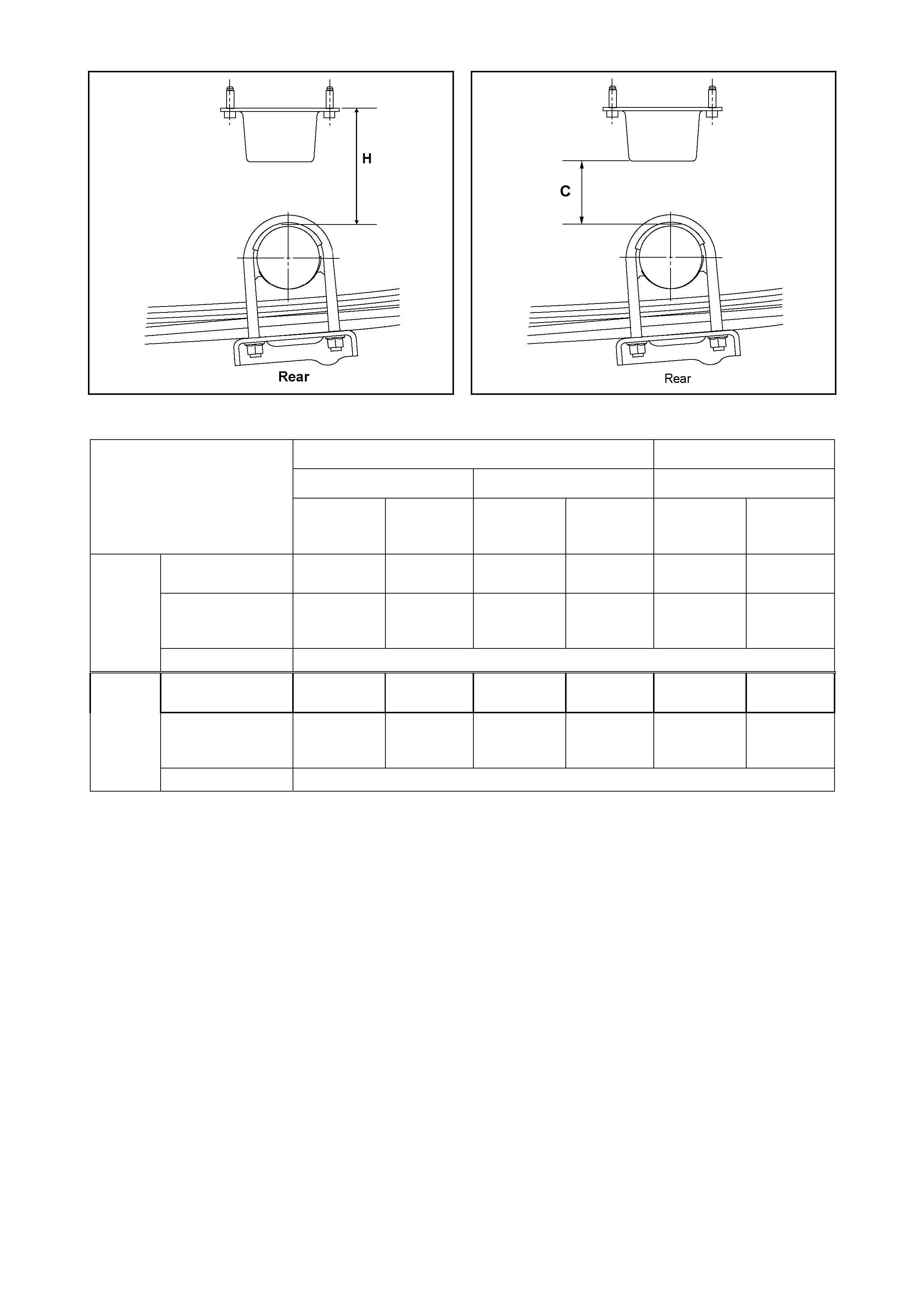

Rear Suspension Heigh t ‘H’

Rear Bump Stop Clearance ‘C’ (Reference Only)

4 x 2 4 x 4

4JH1 & 6VE1 C24SE 4JH1 & 6VE1

RA Rodeo

Vehicle Trim Height

Specifications at GVW

(All Dimensions are in mm) Standard

Rear Springs

(5 leaves)

HD Rear

Springs

(7 leaves)

Standard

Rear Springs

(5 leaves)

HD Rear

Springs

(7 leaves)

Standard

Rear Springs

(5 leaves)

HD Rear

Springs

(7 leaves)

Trim Height

Z 83.2 83.2 60.8 60.8 108.0 108.0

Bump Stop

Clearance ‘T’

(Ref. only) 17.8 17.8 9.4 9.4 17.0 17.0

Front

Tolerance ± 7

Suspension

Height H 75.2 88.3 75.2 88.3 91.9 104.0

Bump Stop

Clearance ‘C’

(Ref. Only) 9.4 22.5 9.4 22.5 9.5 21.6

Rear

Tolerance ± 6

4×

××

×2 C24SE Engine Model

N⋅m (kgf⋅m/lb⋅ft)

RTW340MF000201

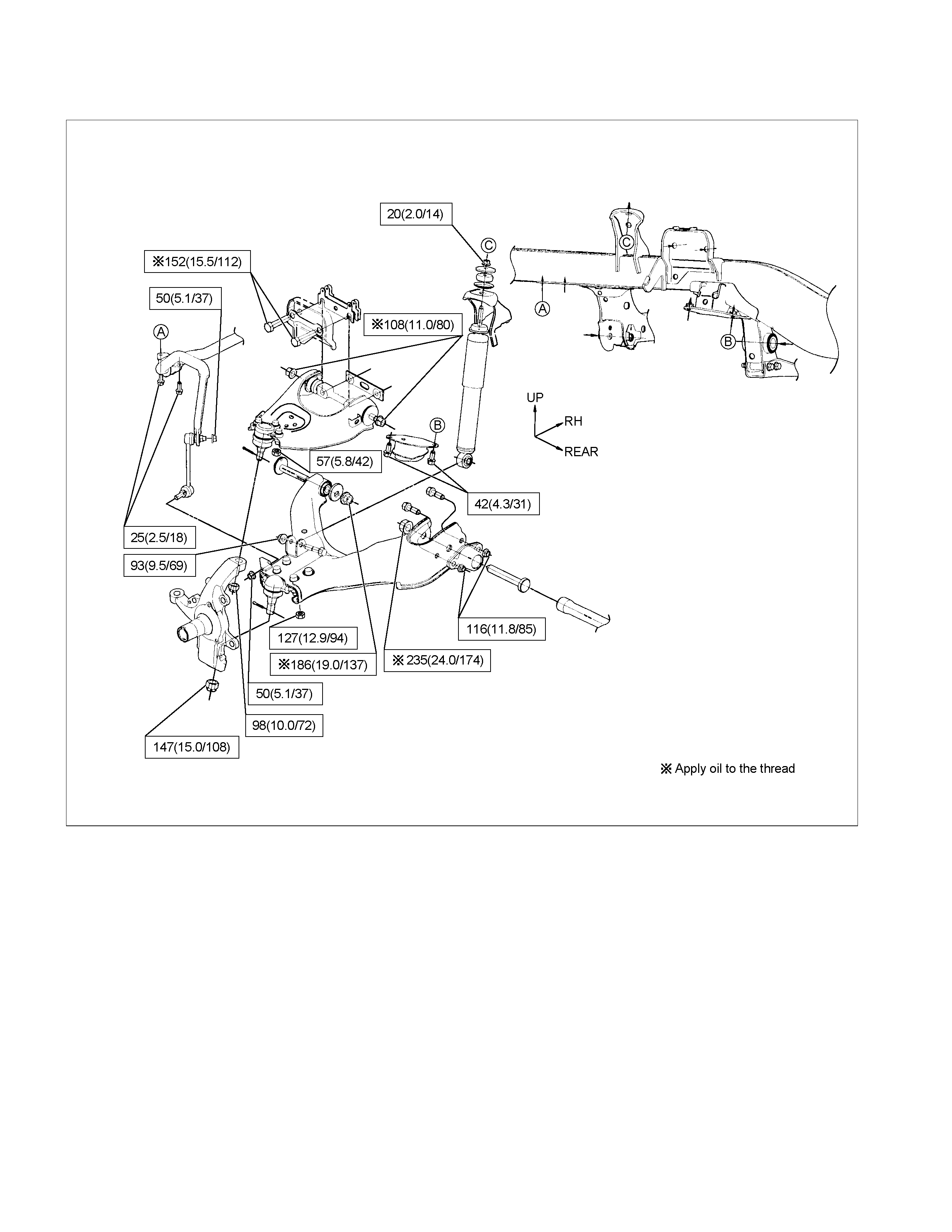

4×

××

×2 (High Ride Suspension) and 4×

××

×4 Model

N⋅m (kgf⋅m/lb⋅ft)

RTW340LF002501

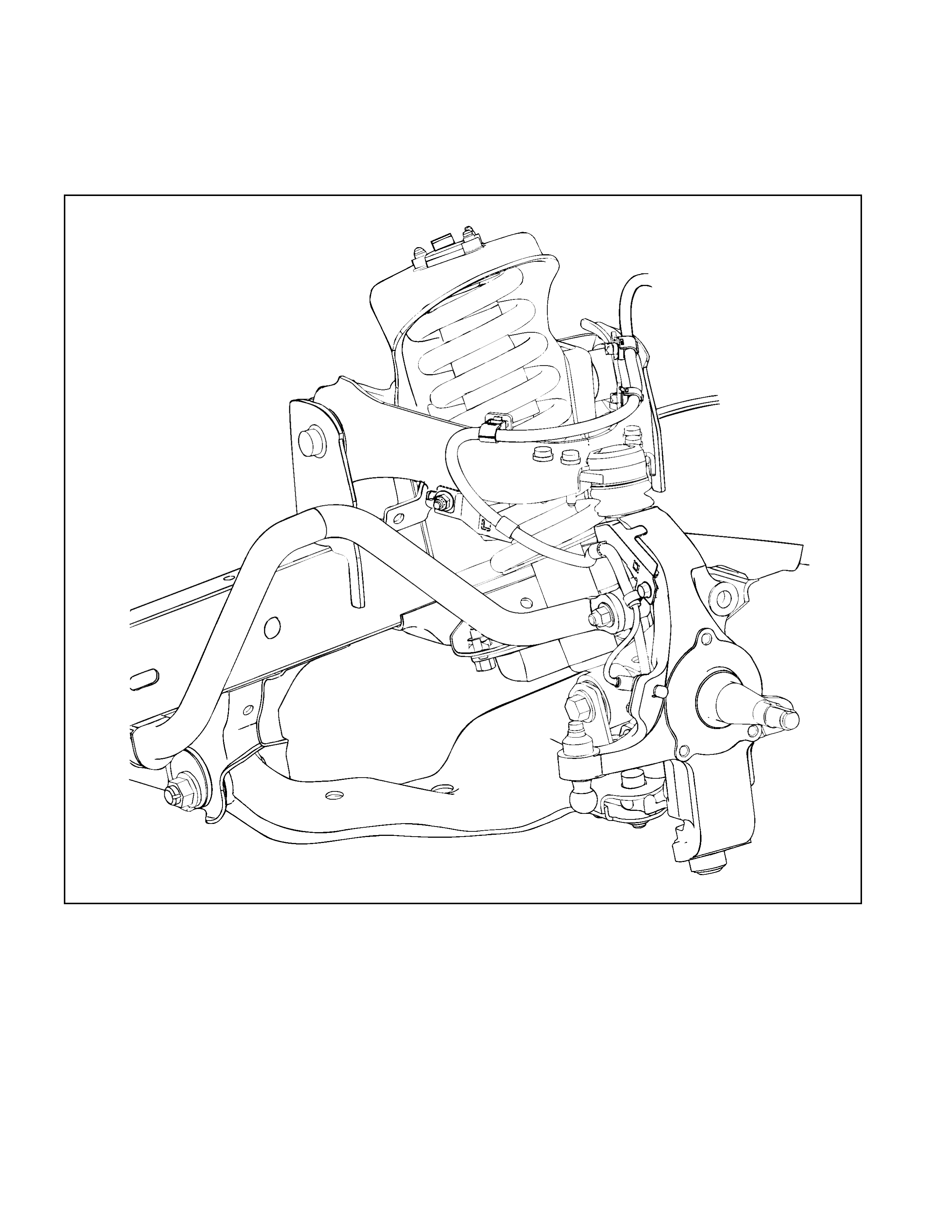

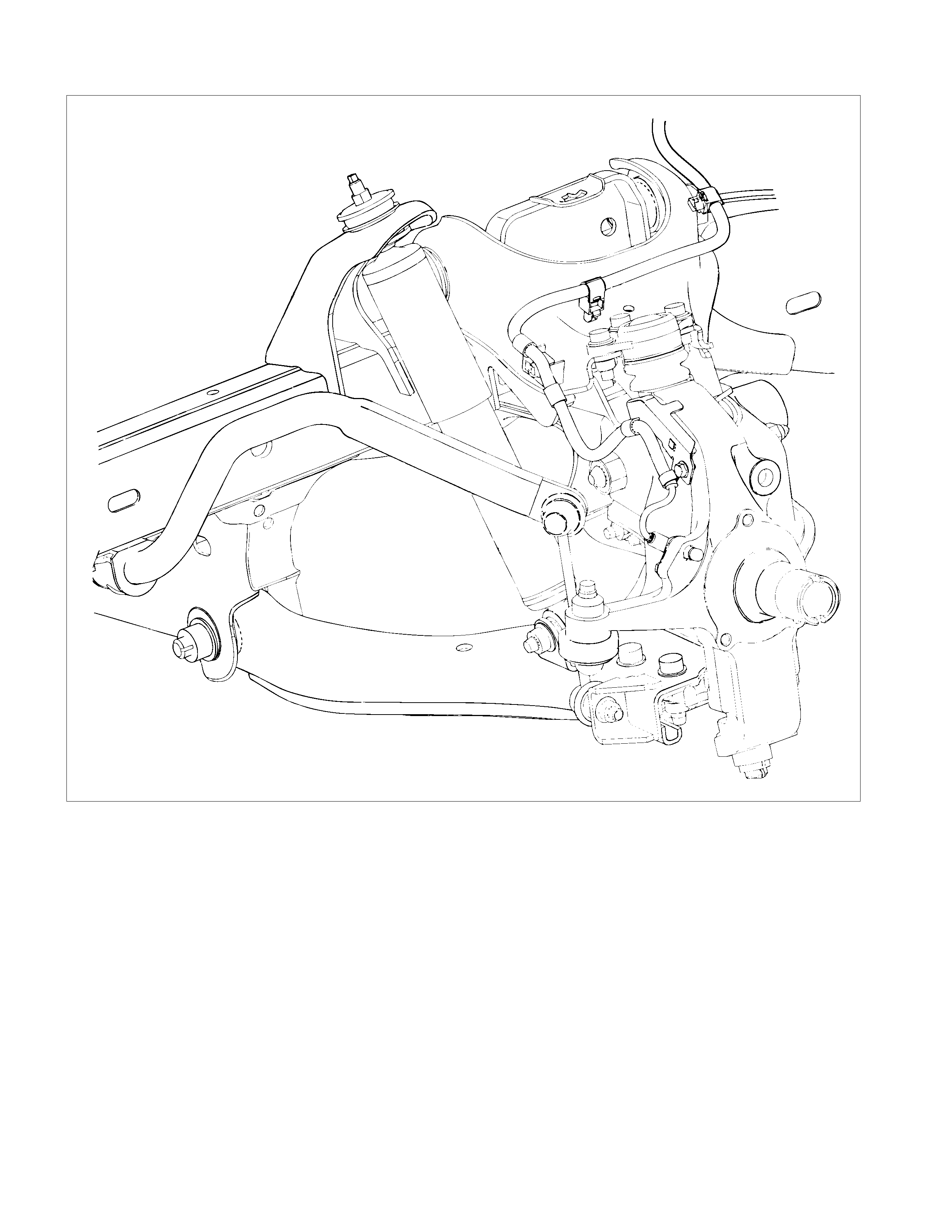

Front Suspension

General Description

4×

××

×2 C24SE Engine Model

4×

××

×2 (High Ride Suspension) and 4×

××

×4 Model

RTW340LF000801

The links attach to the vehicle with bolts and bushings at their inner pivot points and to the steering knuckle, which is

part of the front wheel spindle, at their outer points.

The knuckle is mounted to the upper and lower links each of which has a ball joint to permit pivoting of the knuckle for

steering operations. The hub is supported in position on the knuckle spindle by means of the two bearings and the rotor

is mounted to the hub.

The front suspension is an independent type utilizing torsion bar springs (4×4, 4×2 (High ride suspension)) and coil

springs (4×2 (Except High ride suspension)). The torsion bar spring has splines on each end. Height control is provided

on the third crossmember. Both the upper and lower links are pressed steel and the torsion bar is supported at the ends

by lower link in front and by height control arm in rear.

For more detailed information on the front suspension for 4×2 C24SE engine model and 4×2 High Ride

Suspension, 4×4 please refer to Section 3C-1 FRONT SUSPENSION (4×

××

×2 C24SE ENGINE MODELS) or

Section 3C-2 FRONT SUSPENSION (4×

××

×2 HIGH RIDE SUSPENSION, 4×

××

×4)

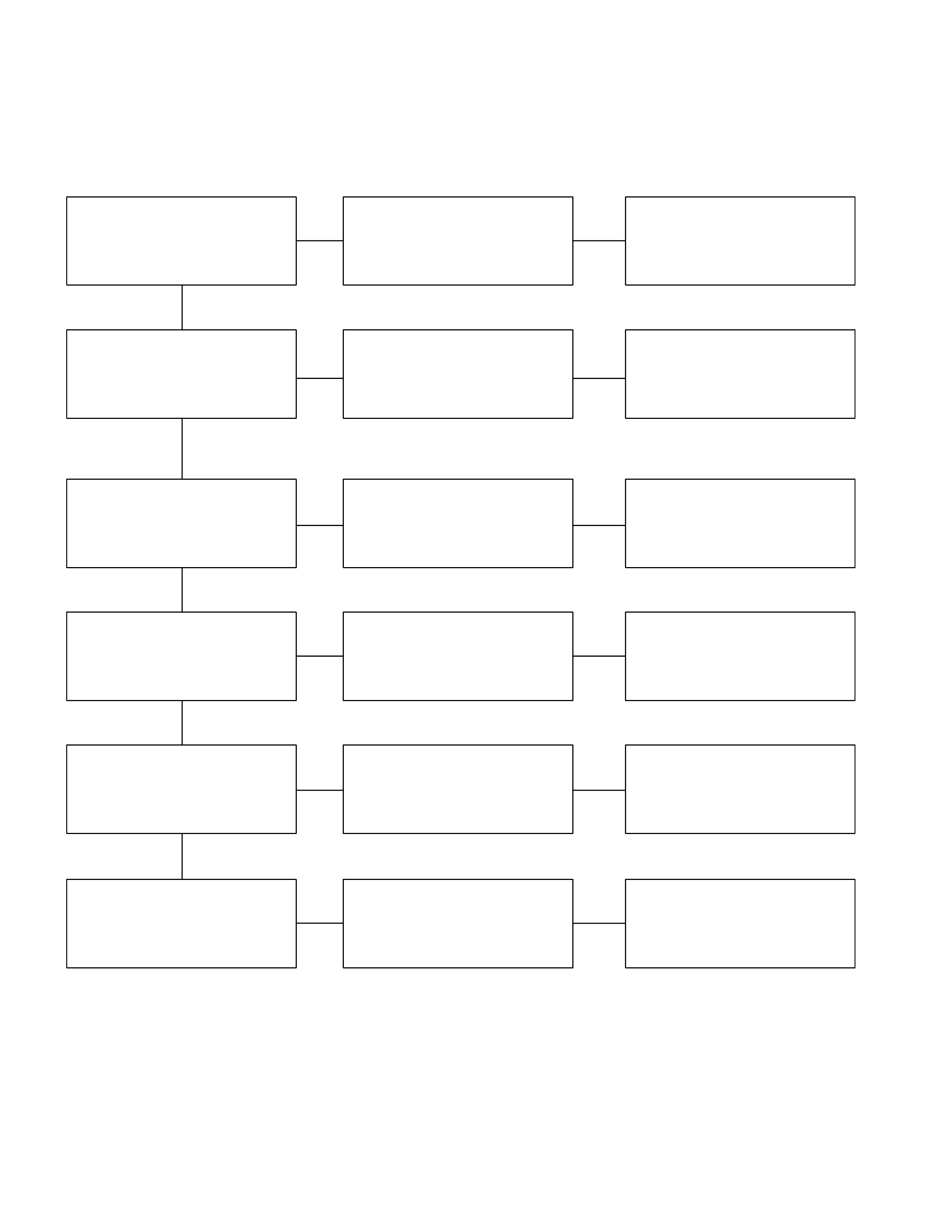

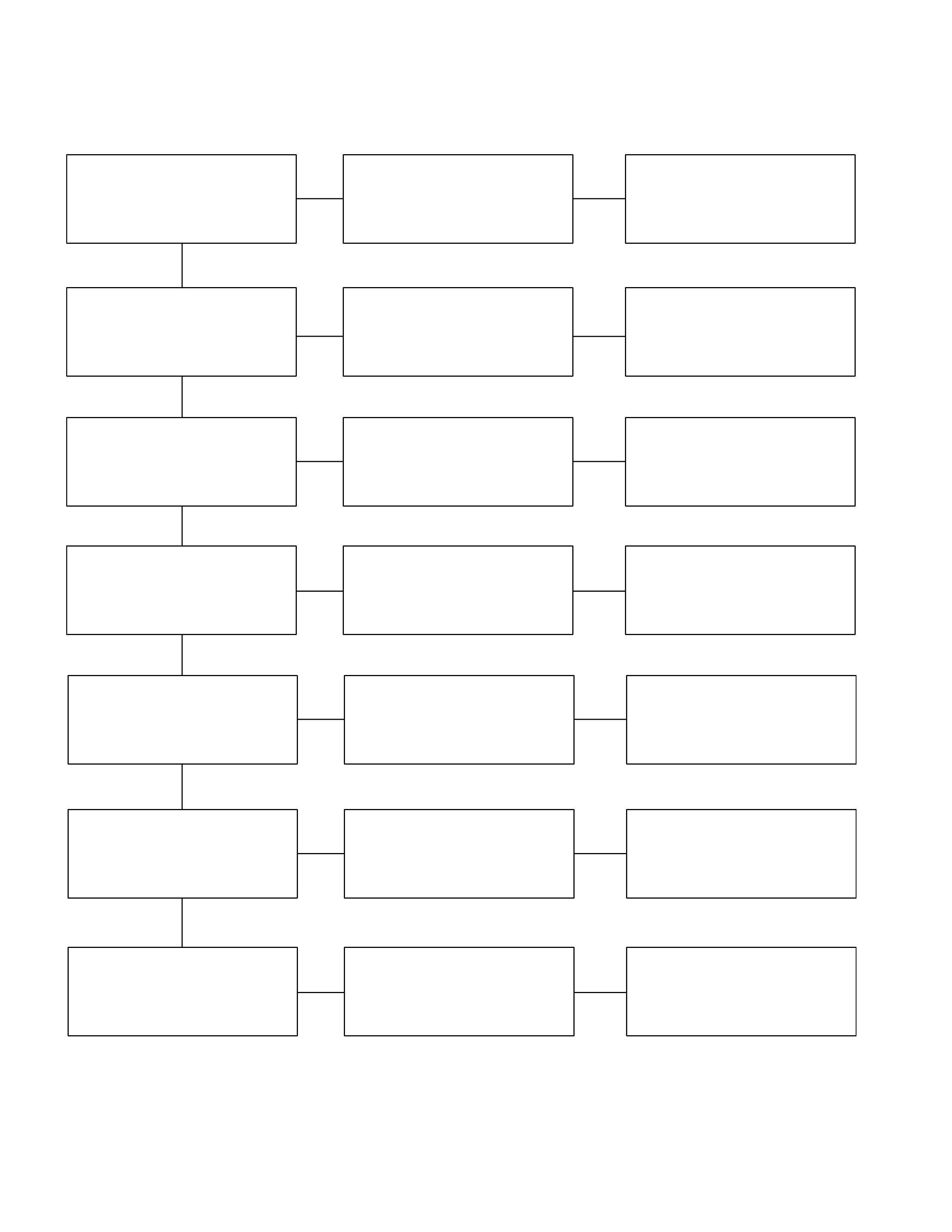

TROUBLESHOOTING

1. VIBRATION, SHOCK, AND SHIMMY OF STEERING WHEEL

Checkpoint Trouble Cause Countermeasure

Check front axle

Check wheel alignment

Check suspension ball joint

Check shock absorber or

attaching nut and bolt

Replace

Adjust

Replace

Replace or retighten

Check steering unit and

linkage

Faulty

Worn

Malfunction or loose

Check upper and lower link

bushings

Replace

Adjust

Worn

Incorrect

OK

OK

OK

NG

NG

NG

NG

NG

NG

OK

OK

Check vehicle trim height

• Improperly adjusted or worn front

wheel bearing.

• Worn or incorrectly adjusted wheel

bearing.

Replace; refer to Section 4C1 Front

Wheel Drive

• Insufficiently tightened steering gea

r

housing.

• Wear of steering linkage.

• Excessive backlash due to imprope

r

adjustment of the steering gear box.

• Worn column bearing weakened

column bearing spring, or loose

clamp.

Replace; refer to Section 3B

Steering

• Improper tire pressure.

• Imbalance and deformation of frond

wheel.

• Unevenly worn tire or insufficient

tightening of wheel nuts.

Replace; refer to Section 3E Wheel

and Tires

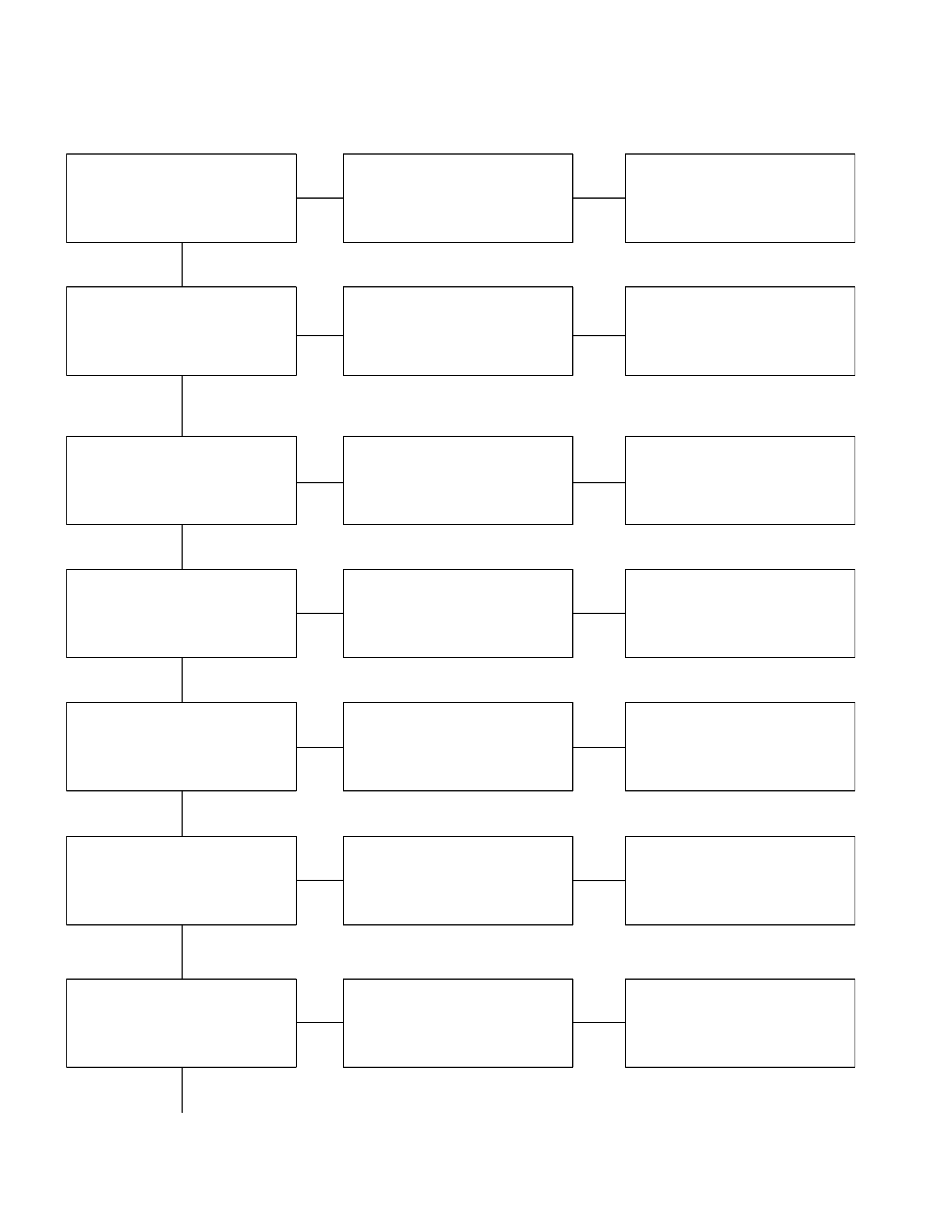

2. VEHICLE PULLS TO RIGHT OR LEFT

Checkpoint Trouble Cause Countermeasure

Steering linkage, and upper

and lower link

Rubber bushing for upper and

lower link

Wheel alignment

Vehicle trim height

Replace

Replace

Adjust

Adjust

Deformed

Worn

Incorrect

Incorrect

Brake adjustment (binding)

Adjust

Replace

Incorrect

Collapsed or break (4×2

Except high ride suspension)

Collapsed or twisted (4×4, 4×2

High ride suspension)

Continued on the next page

OK

OK

OK

OK

NG

NG

NG

NG

NG

NG

OK

OK

Coil spring (4×2 Except high

ride suspension)

Torsion bar (4×4, 4×2 High

ride suspension)

Front wheel bearing

Adjust or replace

Incorrect adjustment or

abrasion

NG

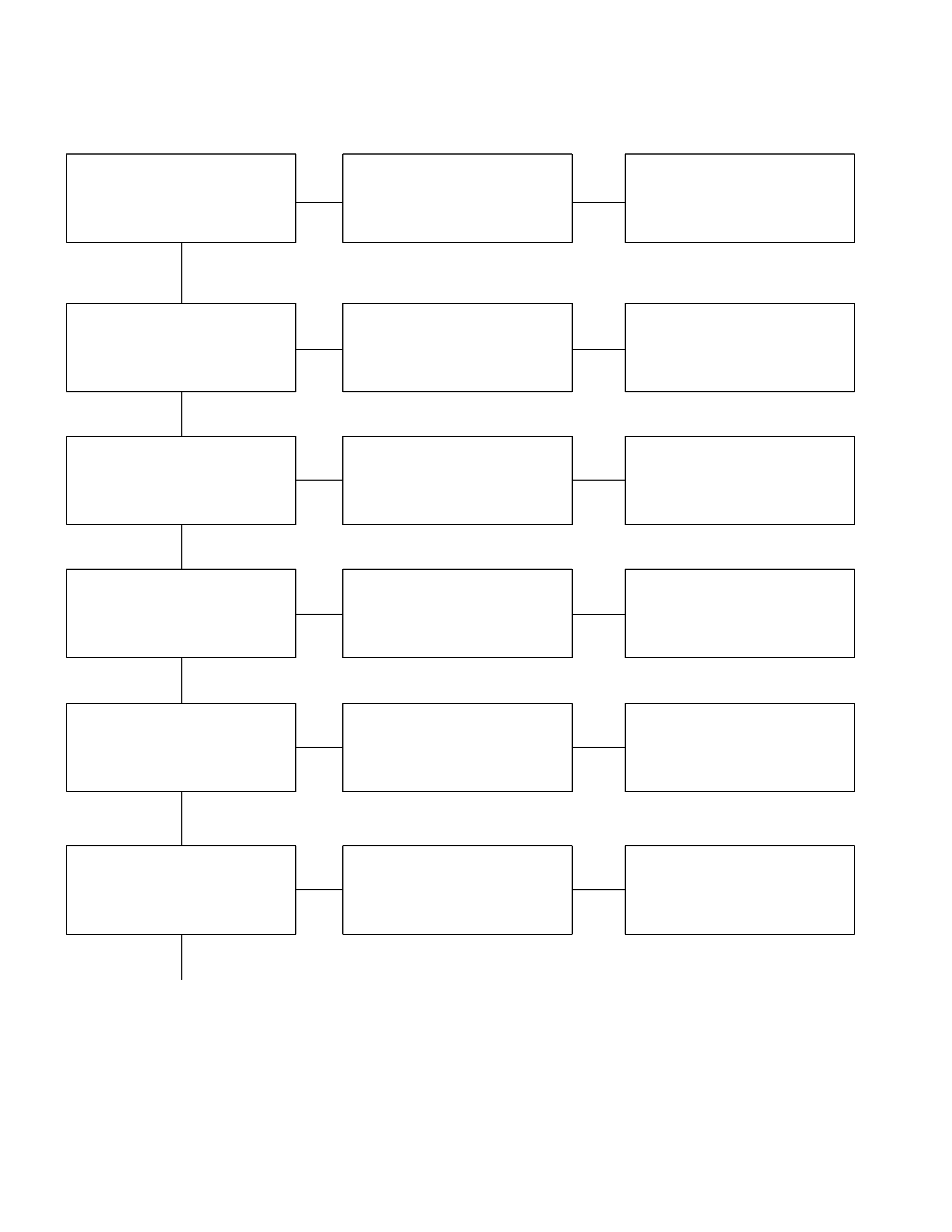

Checkpoint Trouble Cause Countermeasure

Tire tread (right and left)

Replace (tire)

Difference in wear and tear

Adjust or tighten

Improper or instufficient

tightening

NG

NG

OK

Tire pressure or wheel nuts

Continued from the previous page

3. INSTABILITY OF VEHICLE

Checkpoint Trouble Cause Countermeasure

Tire pressure

Wheel alignment

Rubber bushings for upper

and lower links. (4 × 2 Except

high ride suspension)

Adjust

Adjust

Replace

Incorrect

Incorrect

Worn

Steering linkage and upper

and lower links

Replace

Adjust

Worn or deformed

Incorrect

OK

OK

OK

NG

NG

NG

NG

NG

OK

OK

Vehicle trim height

Road wheel

Adjust

Deformed or unbalanced

NG

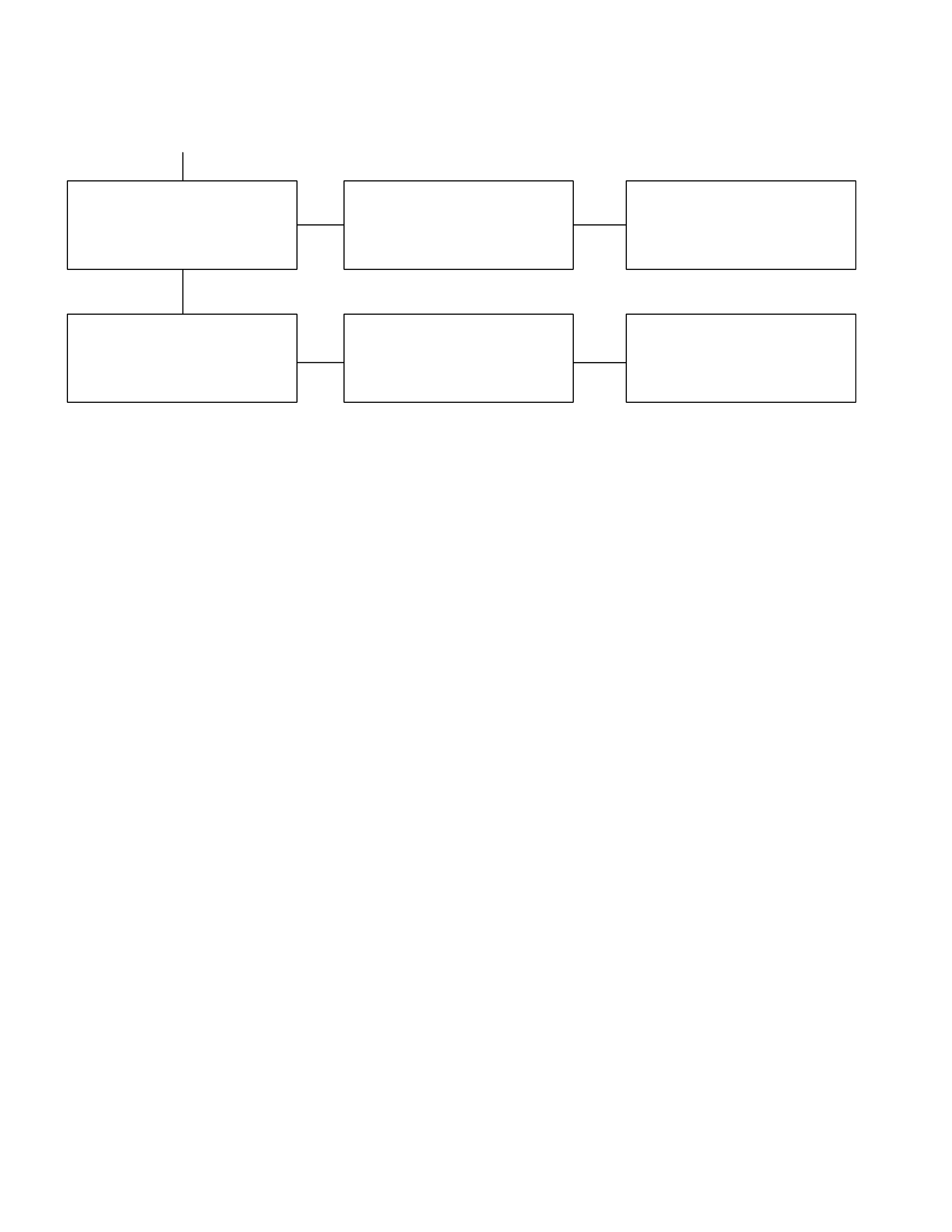

4. STIFF STEERING WHEEL

Checkpoint Trouble Cause Countermeasure

Steering gear box or steering

linkage

Steering linkage

Steering gear

Wheel alignment

Replace the part

Replace

Replace

Adjust

Insufficient lubricants or

impurities present; or

excessively worn

Deformed

Worn or damaged

Incorrect

Replace

Stiff or damaged or lack of

grease

OK

OK

OK

OK

OK

NG

NG

NG

NG

NG

OK

Upper and ball joint

Steering column with turn

signal switch

Replace

Interference abrasion

NG

Tire pressure

Adjust

Improper

NG

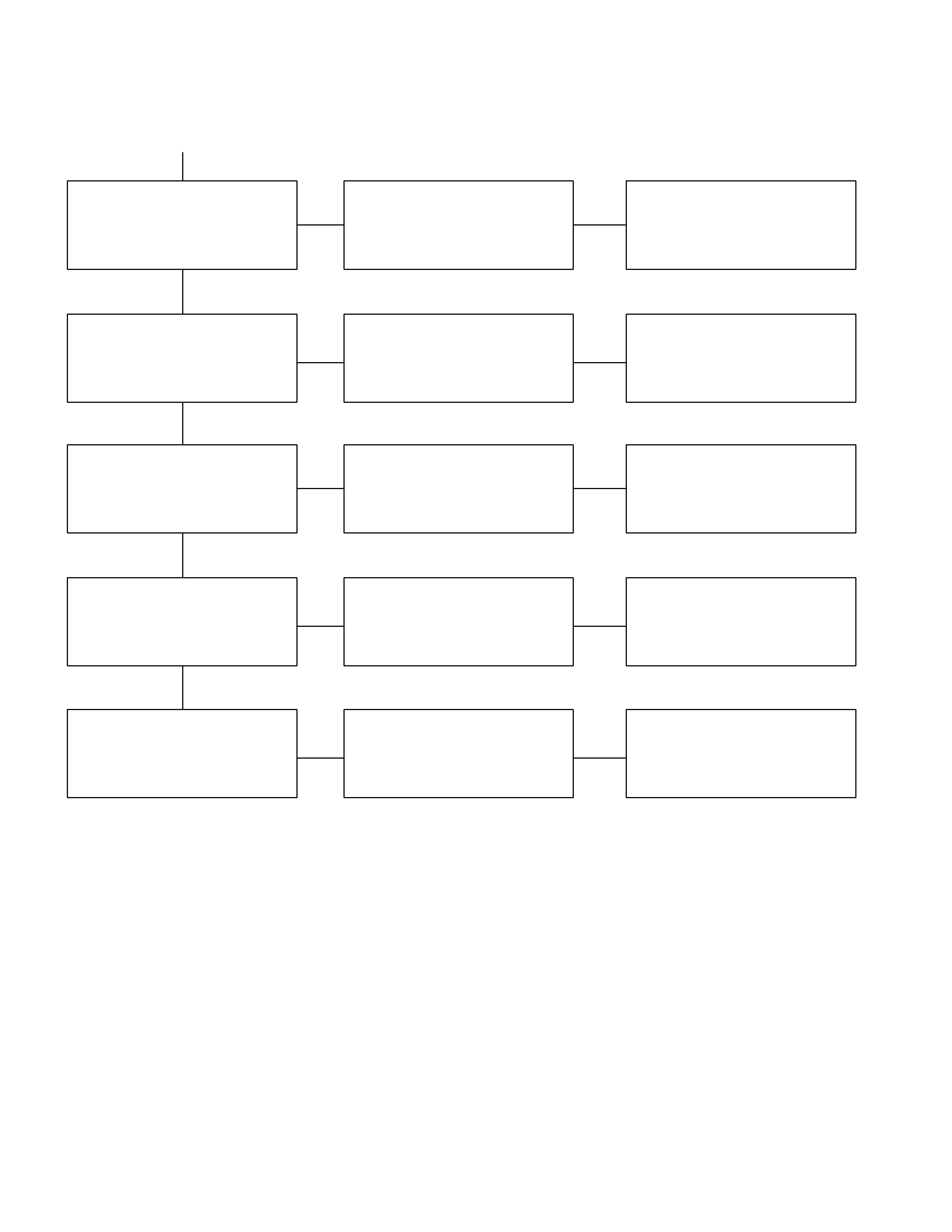

5. NOISES

Checkpoint Trouble Cause Countermeasure

Lubricating oil and grease for

upper and lower ball joint

Shock absorber

Stabilizer fixing nuts and bolts

Upper and lower links

bushings

Replace

Replace

Retighten

Replace

Insufficient

Faulty

Loose

Worn

Shock absorber fixing nut and

bolt

Retighten

Loose

Continued on the next page

OK

OK

OK

OK

NG

NG

NG

NG

NG

OK

Upper and lower ball joint

Replace

Damaged

NG

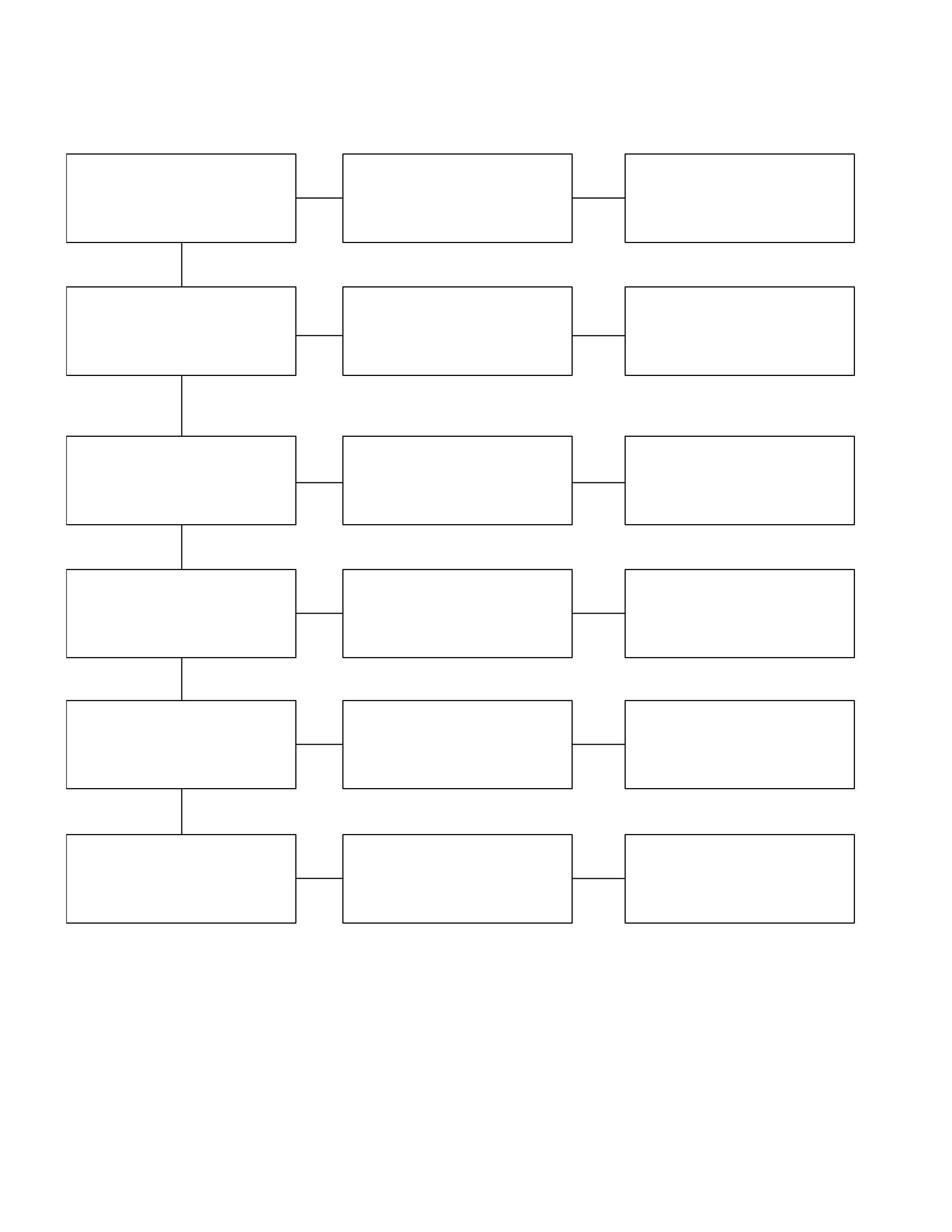

Checkpoint Trouble Cause Countermeasure

Steering linkage and steering

gear ReplaceWorn

AdjustImproper

OK

NG

NG

OK

Tire pressure

Continued from the previous page

Steering unit fixing bolts and

linkage RetightenLoose

Adjust or replace

Incorrect adjustment or

abrasion

OK

NG

NG

OK

Front wheel bearing

Lubricating oil and grease to

steering linkage ReplaceInsufficient

NG

OK

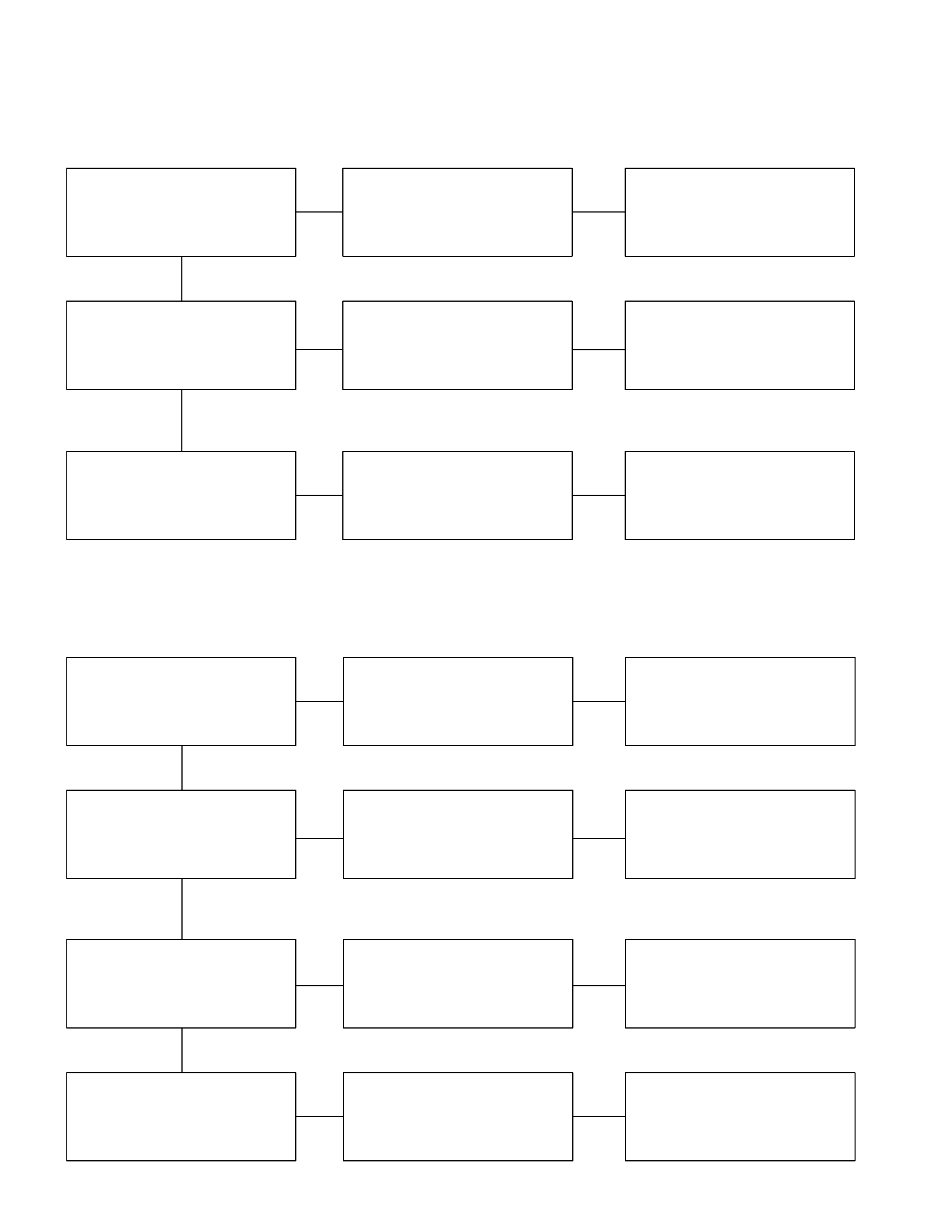

6. EXCESSIVE STEERING WHEEL PLAY

Checkpoint Trouble Cause Countermeasure

Front wheel bearing

Steering linkage

Adjust or replace

Replace

Incorrect adjustment or

abrasion

Worn

Replace

Worn

NG

NG

NG

OK

OK

Upper, and lower links,

bushing (4 × 2 Except high

ride suspension)

7. GRATING TIRE NOISE

Checkpoint Trouble Cause Countermeasure

Tire pressure

Knuckle spindle and steering

linkage

Adjust

Replace

Improper

Deformed

Suspension fixing bolt Replace

Adjust

Loose

Incorrect

OK

NG

NG

NG

NG

OK

OK

Wheel alignment

8. EXCESSIVELY OR PARTIALLY WORN TIRE

Checkpoint Trouble Cause Countermeasure

Brake adjustment

Wheel alignment

Adjust

Adjust

Incorrect

Incorrect

Front wheel bearing Replace

Adjust

Faulty

Improper

OK

NG

NG

NG

NG

OK

OK

Tire pressure

Tire rotation Rotate tires at recomended

intervals

Not rotated

OK

NG