SECTION 3C-1 - FRONT SUSPENSION

(4×

××

×2 C24SE ENGINE MODELS)

Service Precaution

Shock Absorber

Shock Absorber and Associated Parts

Removal

Installation

Shock Absorber with Coil Spring

Stabilizer Bar

Stabilizer Bar and Associated Parts

Removal

Inspection and Repair

Installation

Knuckle

Knuckle and Associated Parts

Removal

Inspection and Repair

Installation

Upper Control Arm

Upper Control Arm and Asso ci ate d

Parts

Removal

Inspection and Repair

Installation

Lower Control Arm

Lower Control Arm and Associated

Parts

Removal

Inspe cti on an d Repa ir

Installation

Upper Ball Joint

Upper Ball Joint and Associated Parts

Removal

Inspe cti on an d Repa ir

Installation

Low er Ball Joint

Lower Ball Joint and Associated Parts

Removal

Inspe cti on an d Repa ir

Installation

Bump Rubber

Bump Rubber Joint and Associated

Parts

Removal

Inspe cti on an d Repa ir

Installation

Special Tools

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN ORDER TO DETERMINE WHETHER YOU ARE PERFORMING

SERVICE ON OR NEAR THE SRS COMPONENTS OR THE SRS WIRING. WHEN YOU ARE PERFORMING

SERVICE ON OR NEAR THE SRS COMPONENTS OR THE SRS WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS COULD RESULT IN POSSIBLE AIR BAG DEPLOYMENT,

PERSONAL INJURY, OR OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the proper location. When you replace a fastener, use ONLY the

exact part number for that application. HOLDEN will call out those fasteners that require a replacement after

removal. HOLDEN will also call out the fasteners that require thread lockers or thread sealant. UNLESS

OTHERWISE SPECIFIED, do not use supplemental coatings (Paints, greases, or other corrosion inhibitors)

on threaded fasteners or fastener joint interfaces. Generally, such coatings adversely affect the fastener

torque and the joint clamping force, and may damage the fastener. When you install fasteners, use the

correct tightening sequence and specifications. Following these instructions can help you avoid damage to

parts and systems.

Shock Absorber

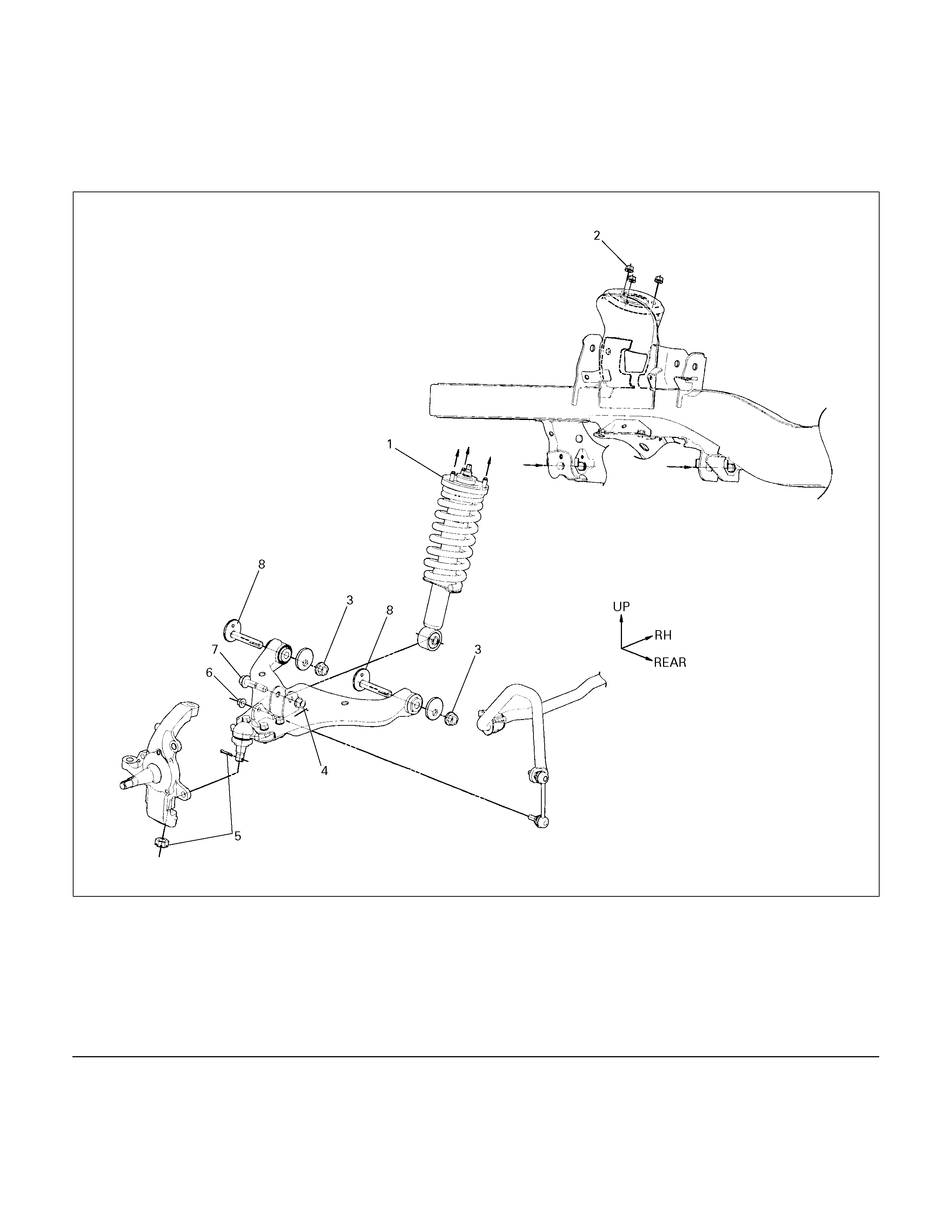

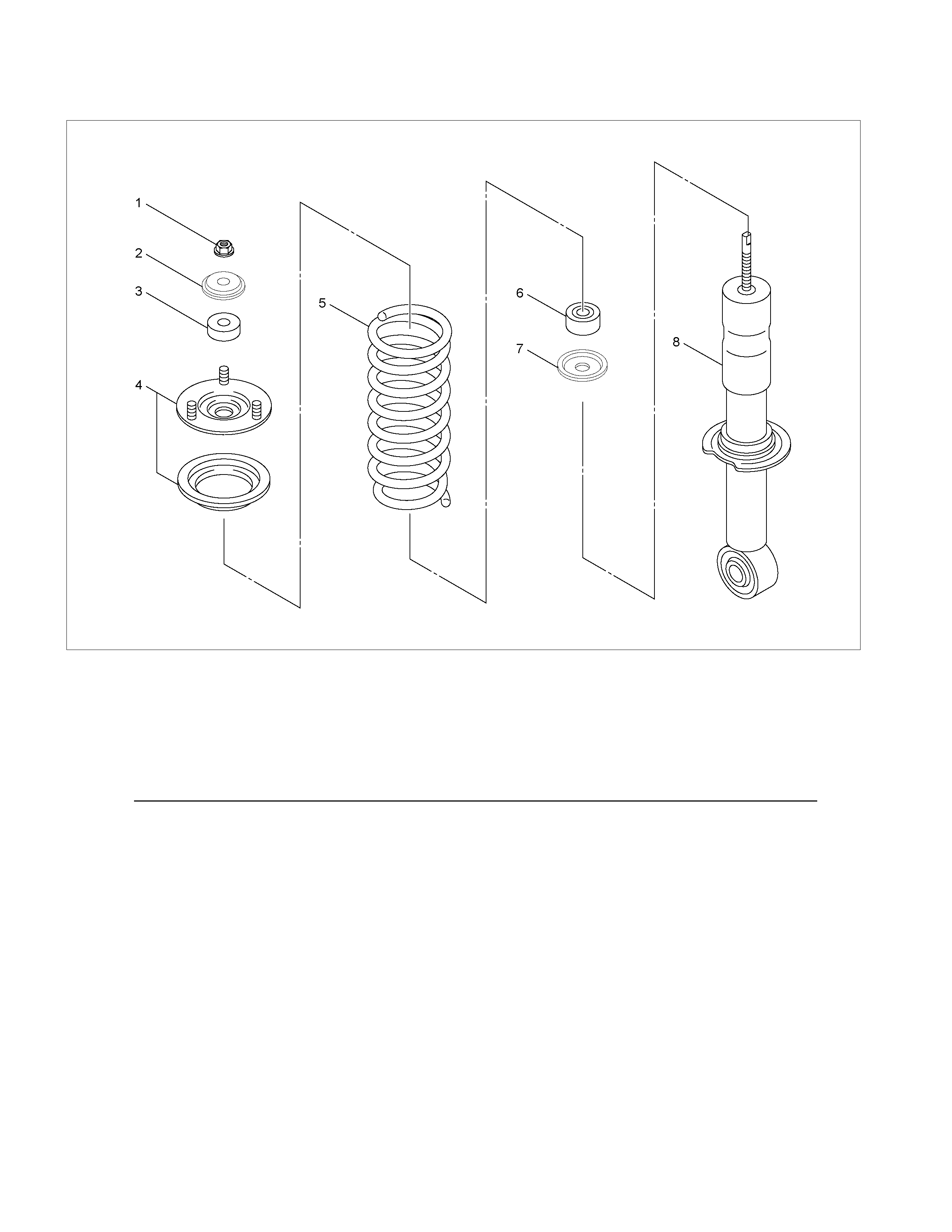

Shock Absorber and Associated Parts

450R300032

Legend

(1) Shock Absorber ASM with coil

(2) Nut

(3) Nut

(4) Nut

(5) Lower ball joint Nut and cot ter pin

(6) Nut

(7) Bolt

(8) Cam bolt

Removal

1. Raise the vehicle and support it with suitable

safety stands.

2. Remove wheel and tire assembly. Refer to

Wheel Replacement in this section.

3. Remove nut (6).

CAUTION: Be careful not o break the ball joint boot.

4. Support lower control arm with a jack.

5. Remove the bolt (7) and nut (4).

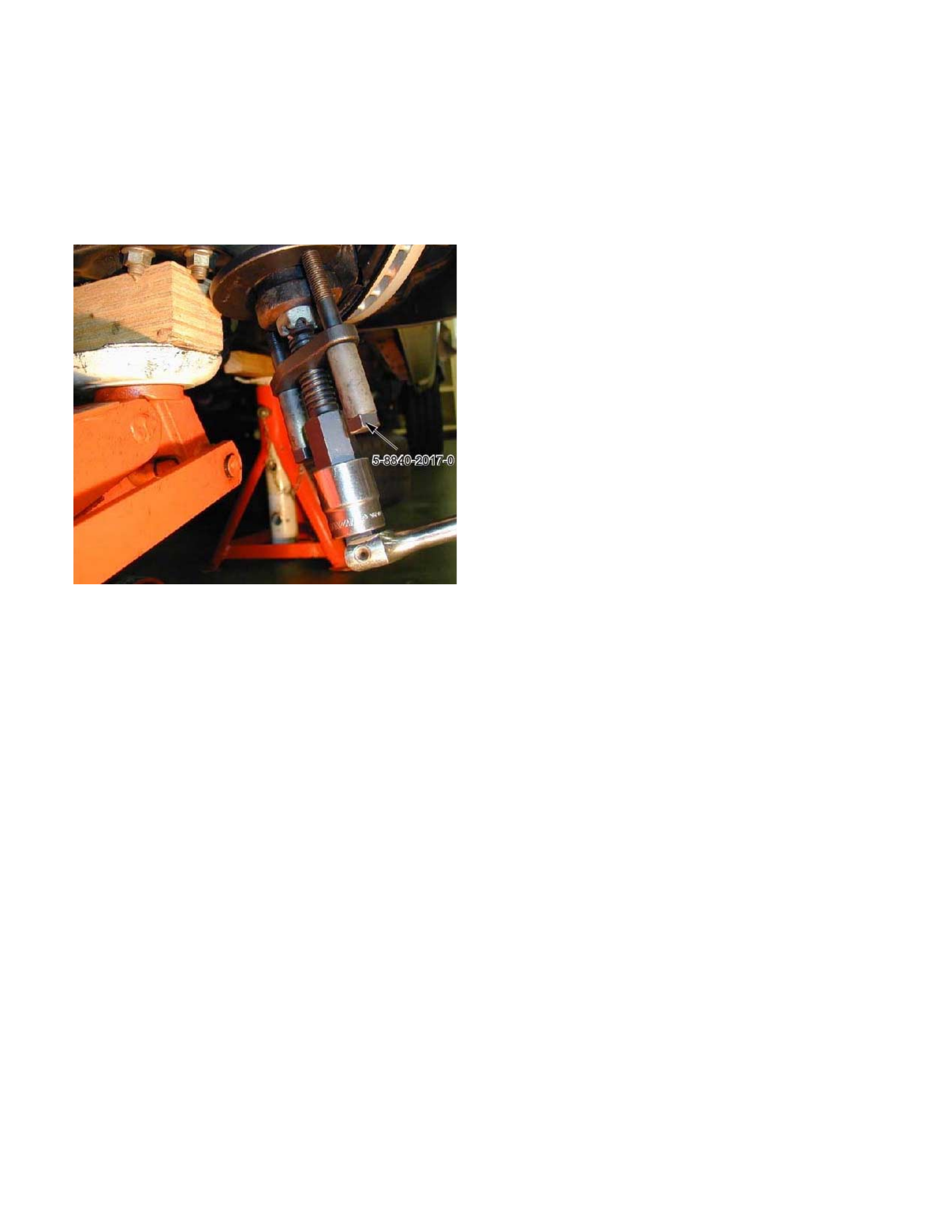

6. Remove lower ball joint nut and cotter pin(5), then

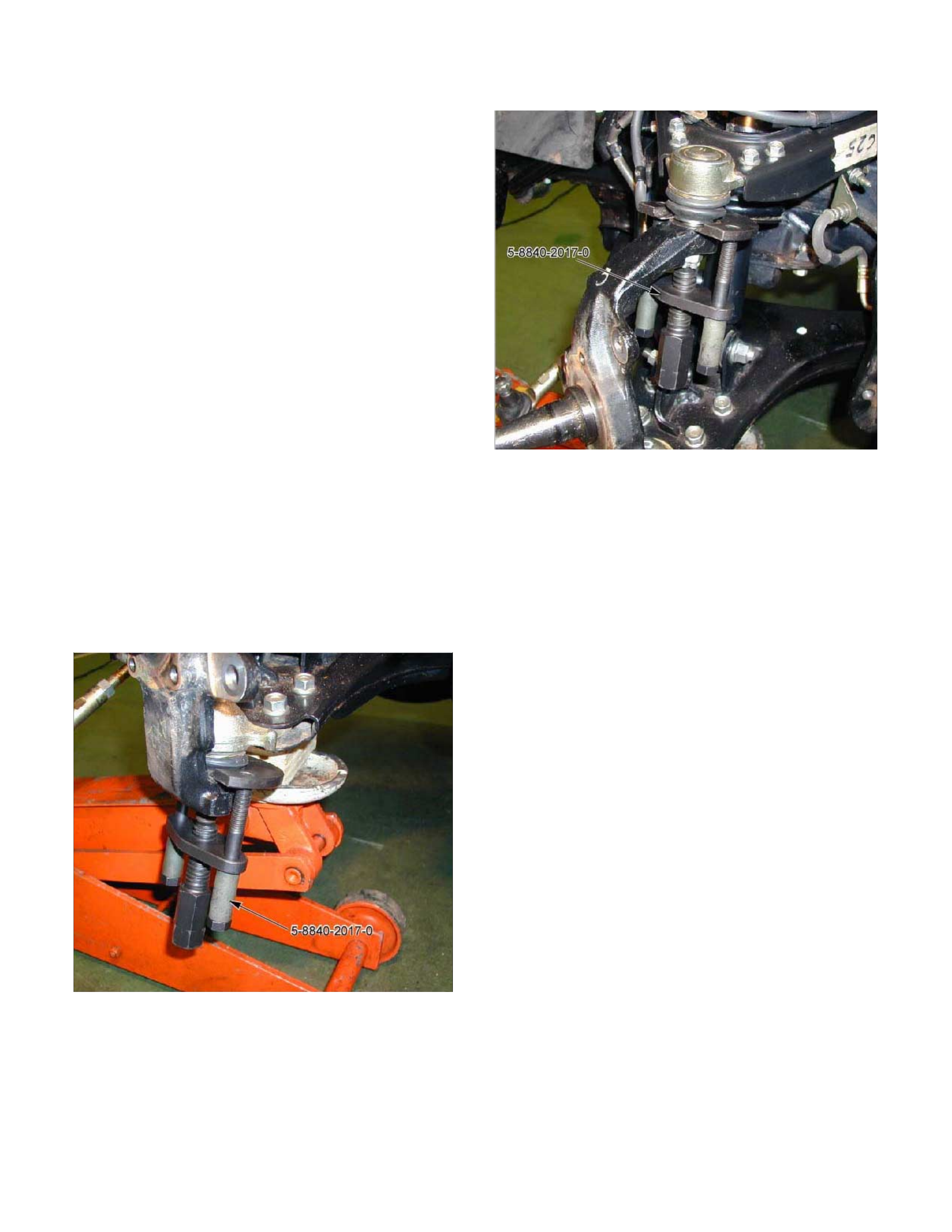

use remover 5-8840-2017-0 to remove the lowe

r

ball joint from the knuckle.

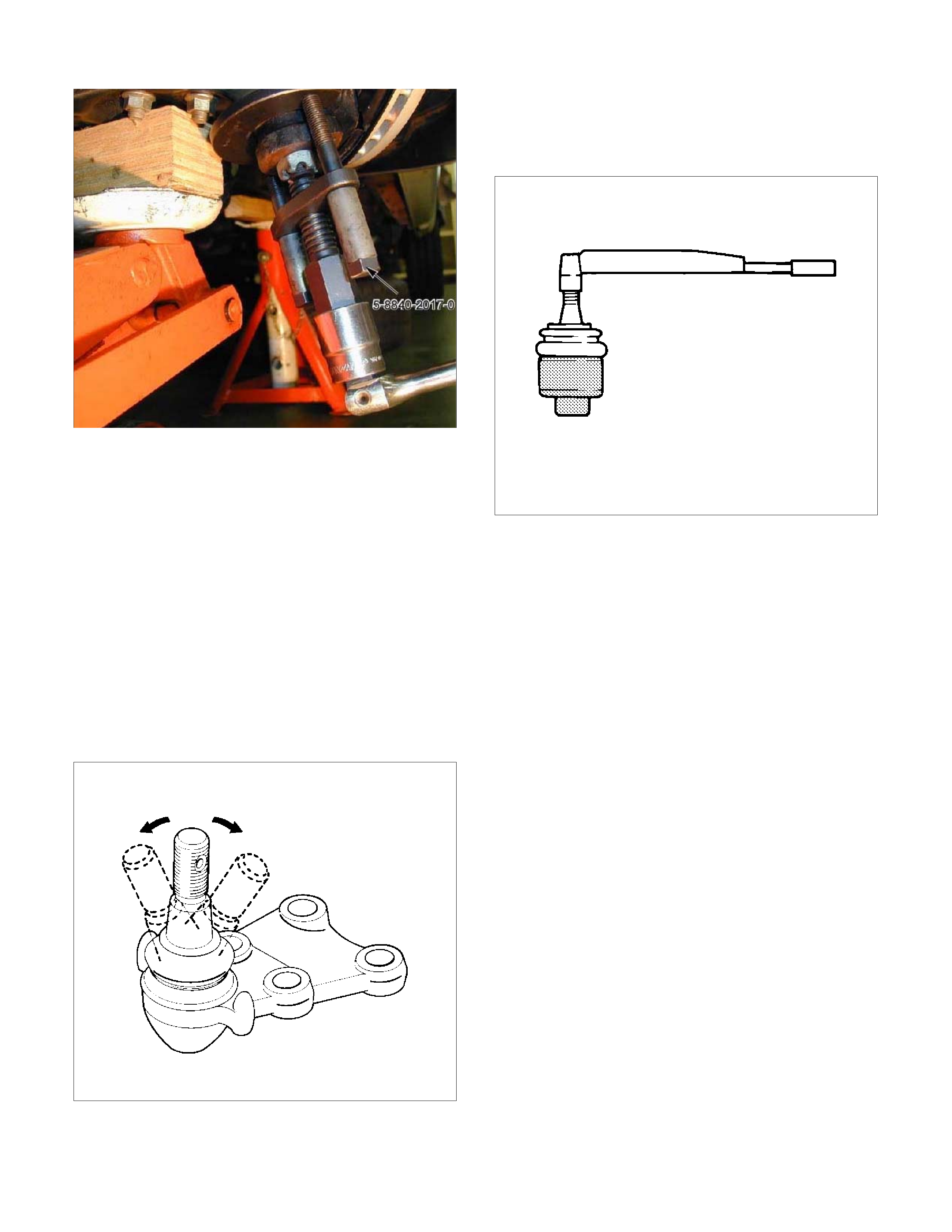

P1010003

7.

A

pply the setting marks to the front and rear cam

bolt and cross mem ber, then loosen nut, and cam

bolt.

8. Remove the nut (2).

9. Remove to Shock Absorber ASM.

Installation

1. Install shock absorber.

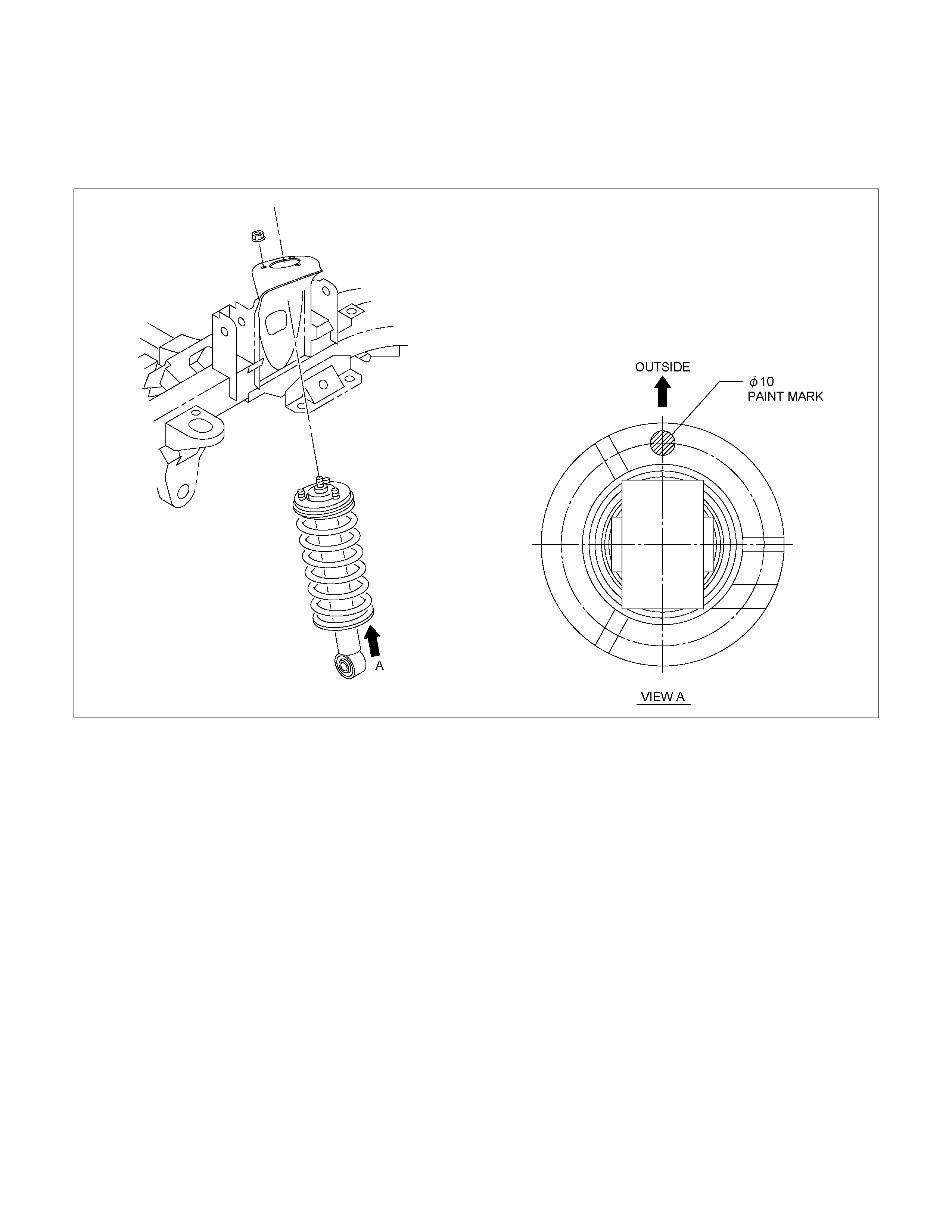

RTW340MF000801

NOTE: Paint mark to be outer side of after assembly to

vehicle.

2. Install nut (2), then tighten it to the specified

torque.

Torque: 55N⋅

⋅⋅⋅m (5.6kg⋅

⋅⋅⋅m/41lb ft)

3. Install bolt (7) and nut (4), then tighten to the

specified torque.

Buffer clearance: 25.9 mm (1.02 in)

Torque: 137N⋅

⋅⋅⋅m (14.0kg⋅

⋅⋅⋅m/101 lb ft)

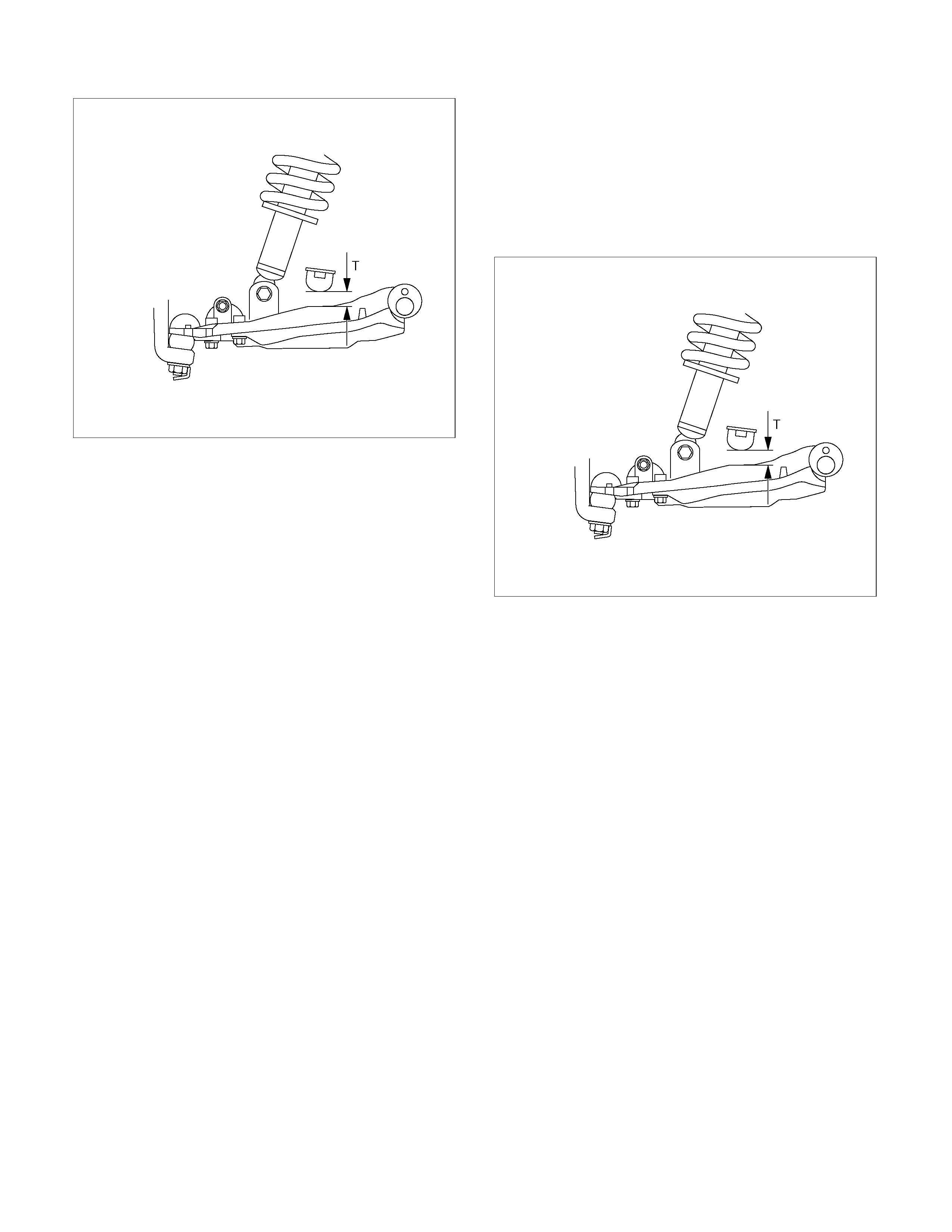

NOTE: Tighten the bolt and nut with the parts in the

position shown in the illustration below. Apply oil to the

thread.

RTW340SH001301

4. Install nut (6), then tighten it to the specified

torque.

Torque: 50N⋅

⋅⋅⋅m (5.1kg⋅

⋅⋅⋅m/37 lb ft)

5. Tighten the cam bolt (8) and nut (3), it to the

interim torque, then turn the cam bolt to the s etting

mark applied during disassembly.

6. Install ball joint nut, then tighten it to the specified

torque with just enough additional torque to align

cotter pin holes. Install new cotter pin (5).

Torque: 147N⋅

⋅⋅⋅m (15.0kg⋅

⋅⋅⋅m/108 lb ft)

NOTE: Check the trim height. Refer to

Front Alignment Inspection and Adjustment.

7. Nut (3) tighten it to the specified torque.

Buffer clearance: 25.9 mm (1.02 in)

Torque: 186N⋅

⋅⋅⋅m (19.0kg⋅

⋅⋅⋅m/137 lb ft)

NOTE: Tighten the bolt and nut with the parts in the

position shown in the illustration below. Apply oil to the

thread.

RTW340SH001301

8. Install wheel and tire assembly. Refer to wheel in

this section.

Shock Absorber with Coil Spring

RTW340LF002101

Legend

1. Nut

2. Washer

3. Bushing ; Rubber

4. Mounting Bracket

5. Coil Spring

6. Bushing ; Rubber

7. Washer

8. Shock Absorber Assembly

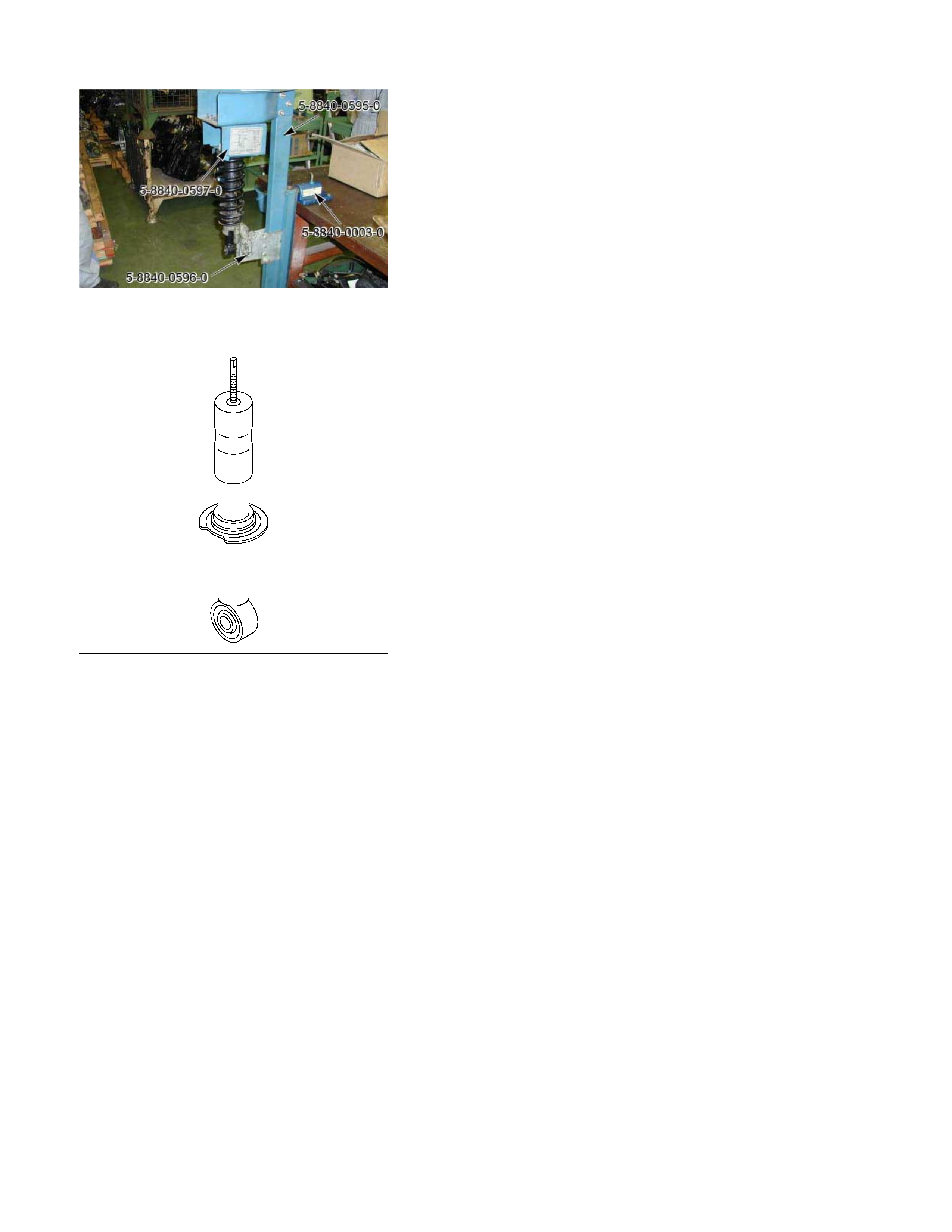

Disassembly

1. Install the support fixture (5-8840-0595-0) to the base (5-

8840-003-0).

2. Install the upper adapter (5-8840-0597-0) and the lower

adapter (5-8840-0596-0) to the base and support fixture

assembly.

3. Install the shock absorber assembly to the support fixture.

4. Remove the nut with spring in place.

CAUTION:

Take care not to apply excessive force to the nut during

removal.

CAUTION :

The shock absorbers have been charged with gas at the

factory. Exposur e to high temperatures or an open flame

can result in a dangerous explosion.

Keep the shock absorbers away from high temperatures

and open flames.

Inspection and Repair

Make all necessary adjustments, repairs, and part replacements if wear, damage, or other problems are discovered

during inspections.

Visual Check

Inspect the following parts for wear, damage or other abnormal

conditions.

• Shock absorber

• Rubber bushing

• Coil spring

Reassembly

1. Reassemble the parts inside the support fixture.

2. When tightening the bolt, compress the spring so that it

does not apply pressure to the spring seat.

3. Install the nut (1), then tighten to the specified torque.

Torque : 25 N⋅

⋅⋅⋅m (2.5 kg⋅

⋅⋅⋅m/19 lb ft)

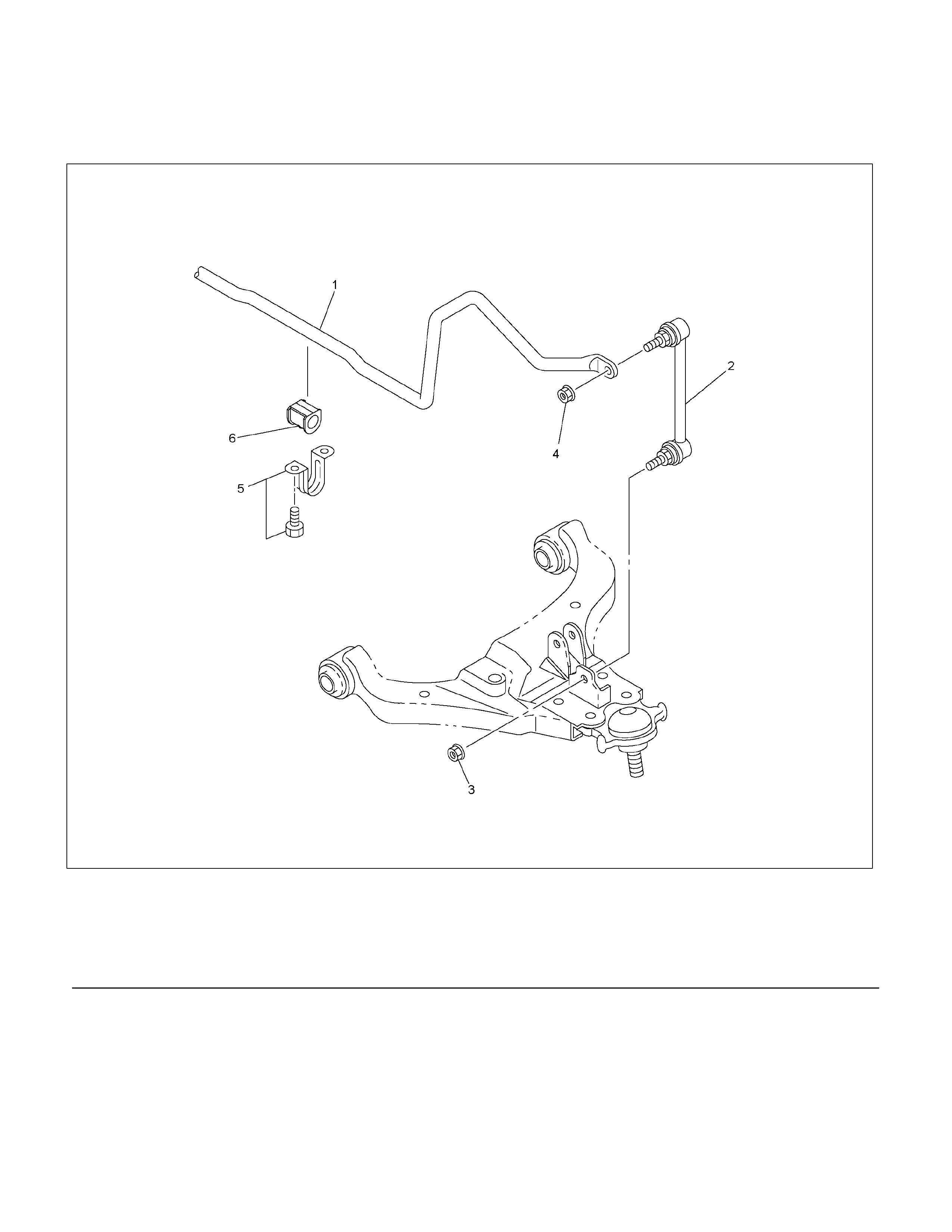

Stabiliser Bar

Stabiliser Bar and Associated Parts

RTW340LF000901

Legend

(1) Stabiliser Bar

(2) Link

(3) Nut

(4) Nut

(5) Bracket and Bolt

(6) Rubber Bushing

Removal

1. Raise the vehicle and support the frame with

suitable safety stands.

2. Remove wheel and tyre assembly. Refer to

Wheel Replacement in this section.

3. Remove nut (3) and (4).

CAUTION: Be careful not to break the ball joint

boot.

4. Remove link.

5. Remove bracket and bolt.

6. Remove Stabiliser bar.

7. Remove rubber bushing.

Inspection and Repair

Make necessary correction or parts replacement if

wear, damage, corrosion or any other abnormal

condition is found through inspection.

Check the following parts :

• Stabiliser bar

• Rubber bushing

• Link ball joint

Installation

1. Install rubber bushing.

2. Install Stabiliser bar.

3. Install bracket and bolt (5), then tighten it to the

specified torque.

Torque: 25 N⋅

⋅⋅⋅m (2.5kg⋅

⋅⋅⋅m/18 lb ft)

4. Install link.

5. Install nut (3), (4), then tighten it to the specified

torque.

Torque: 50 N⋅

⋅⋅⋅m (5.1kg⋅

⋅⋅⋅m/37 lb ft)

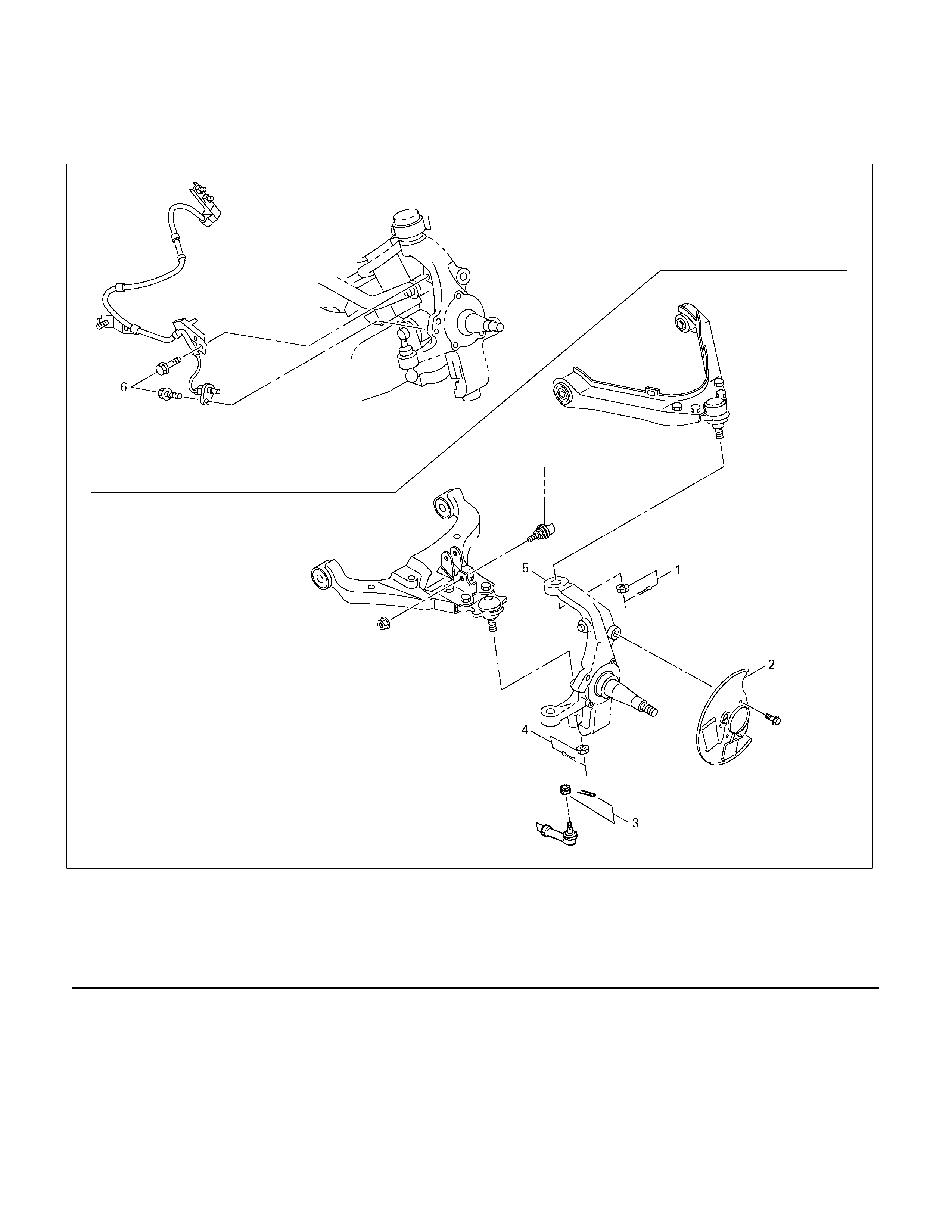

Knuckle

Knuckle and Associated Parts

450R300037

Legend

(1) Nut and Cotter Pin

(2) Back Plate

(3) Nut and Cotter Pin

(4) Nut and Cotter Pin

(5) Knuckle

(6) Bolt

Removal

1. Raise the vehicle and support the frame with

suitable safety stands.

2. Remove wheel and tyre assembly. Refer to

Wheel in this section.

3. Remove the brake caliper. Refer to Disc Brakes

in Brake section.

4. Remove the hub assembly. Refer to

Front Hub and Disk in this section.

5. Remove tie-rod end from the knuckle. Refer to

Power Steering Unit in Steering section.

P1010011

11. Remove knuckle.

6. Remove the Stabiliser link nut. Right and left.

7. Remove the wheel speed sensor from the knuckle.

8. Remove back plate.

9. Remove lower ball joint by using remover 5-8840-

2017-0.

CAUTION: Be careful not to damage the ball joint

boot.

P1010009

10. Rem ove upper ball joint by using remover 5-8840-

2017-0.

CAUTION: Be careful not to damage the ball joint

boot.

Inspection and Repair

Make necessary correction or parts replacement if

wear, damage, corrosion or any other abnormal

condition is found through inspection.

Check the following parts:

• Knuckle

• Knuckle arm

Installation

1. Install knuckle assembly.

2. Install upper ball joint and tighten the nut to the

specif ied tor que, with just enough additional tor que

to align cotter pin holes. Install new cotter pin (1).

Torque: 98 N⋅

⋅⋅⋅m (10.0kg⋅

⋅⋅⋅m/72 lb ft)

3. Install lower ball joint and tighten the nut to the

specif ied tor que, with just enough additional tor que

to align cotter pin holes. Install new cotter pin (4).

Torque: 147N⋅

⋅⋅⋅m (15.0kg⋅

⋅⋅⋅m/108 lb ft)

4. Install back plate.

5. Install wheel speed sensor.

6. Install Stabiliser link nut. Right and left.

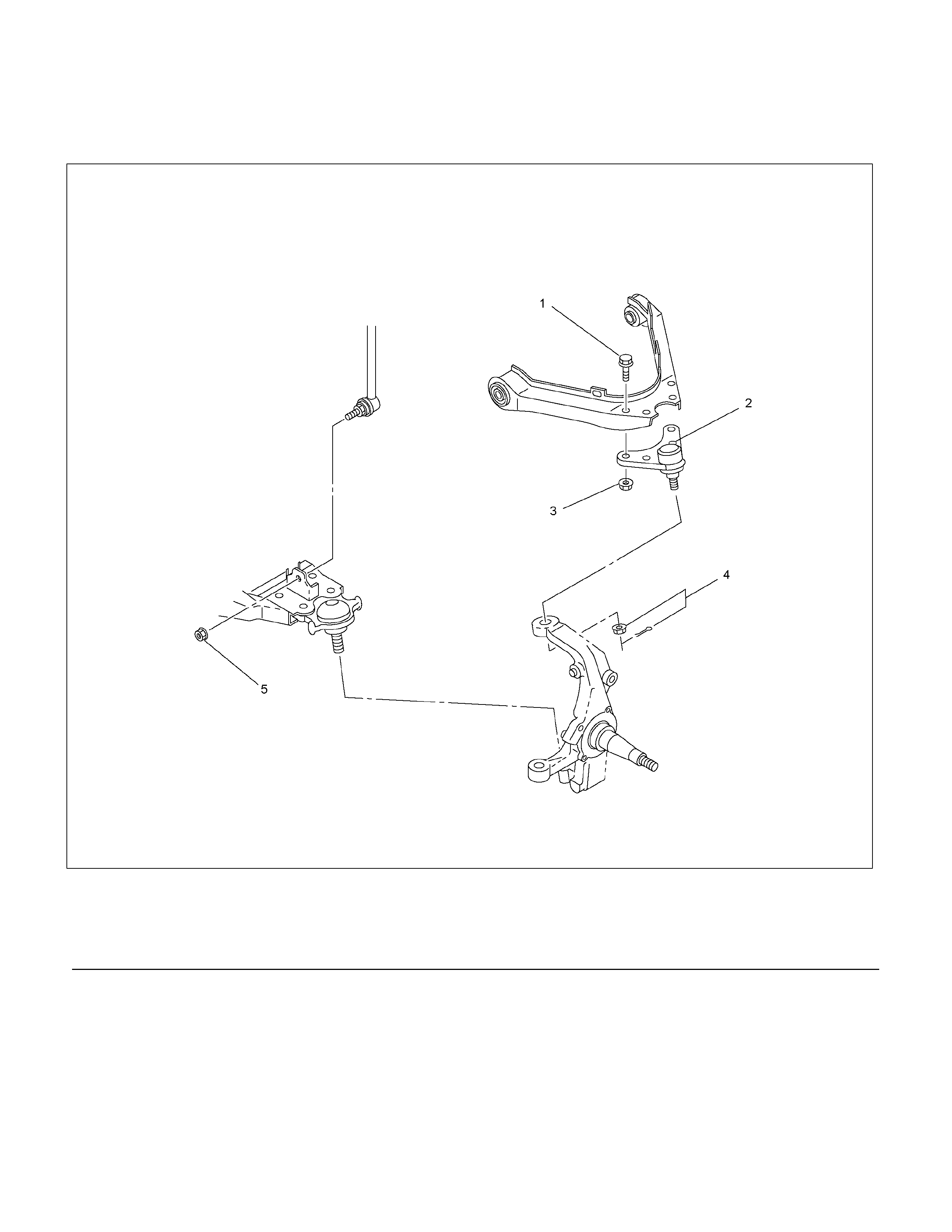

Upper Control Arm

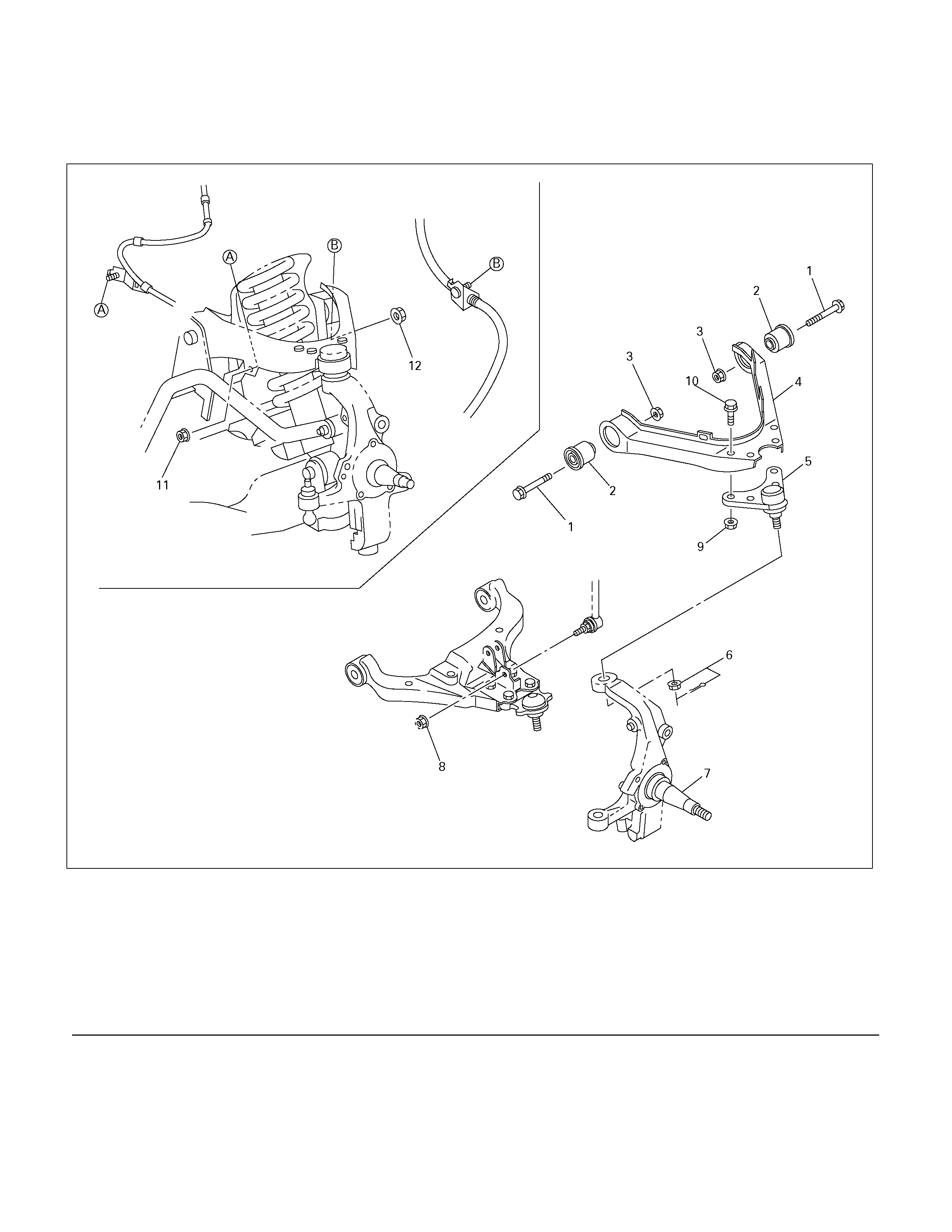

Upper Control Arm and Associated Parts

450R300038

Legend

(1) Bolt

(2) Bushing

(3) Nut

(4) Upper Control Arm Assembly

(5) Upper Ball Joint

(6) Nut and Cotter Pin

(7) Knuckle

(8) Nut

(9) Nut

(10) Bolt

(11) Nut

(12) Nut

Removal

1. Raise the vehicle and support the frame with

suitable safety stands.

2. Remove wheel and tyre assem bly. Refer to Wheel

in this section.

3. Remove nut (11).

4. Remove nut (12).

5. Remove nut (8).

6. Remove upper ball joint by using remover 5-8840-

2017-0.

CAUTION: Be careful not to damage the ball joint

boot.

P1010005

7. Remove nut (3).

8. Remove bolt (1).

9. Remove bolt (10) and nut (9).

10. Remove upper ball joint.

11. Remove upper control arm assembly.

12. Remove bushing.

Inspection and Repair

Make necessary parts replacement if wear, damage,

corrosion or any other abnormal conditions are found

through inspection.

Check the following parts:

• Upper control arm

• Bushing

Installation

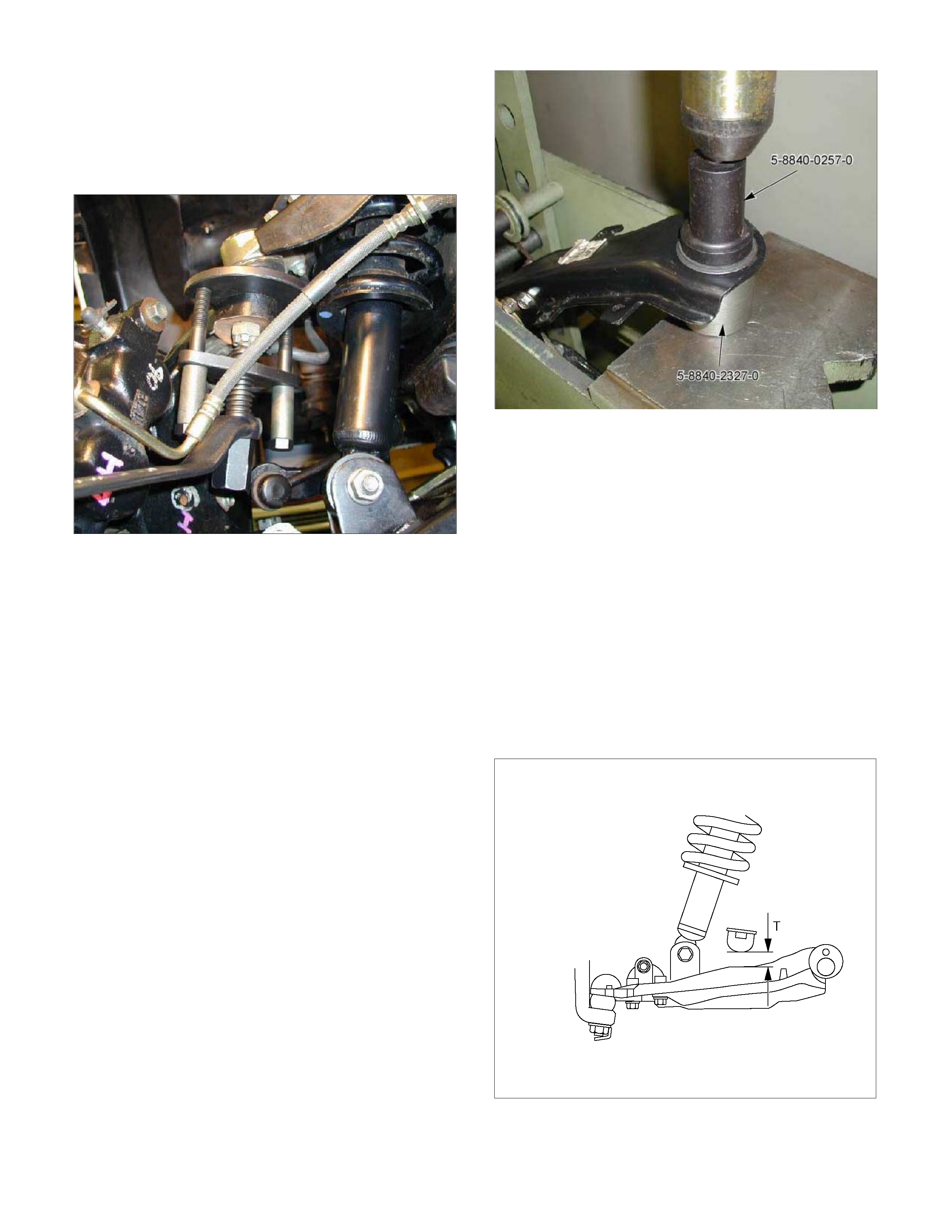

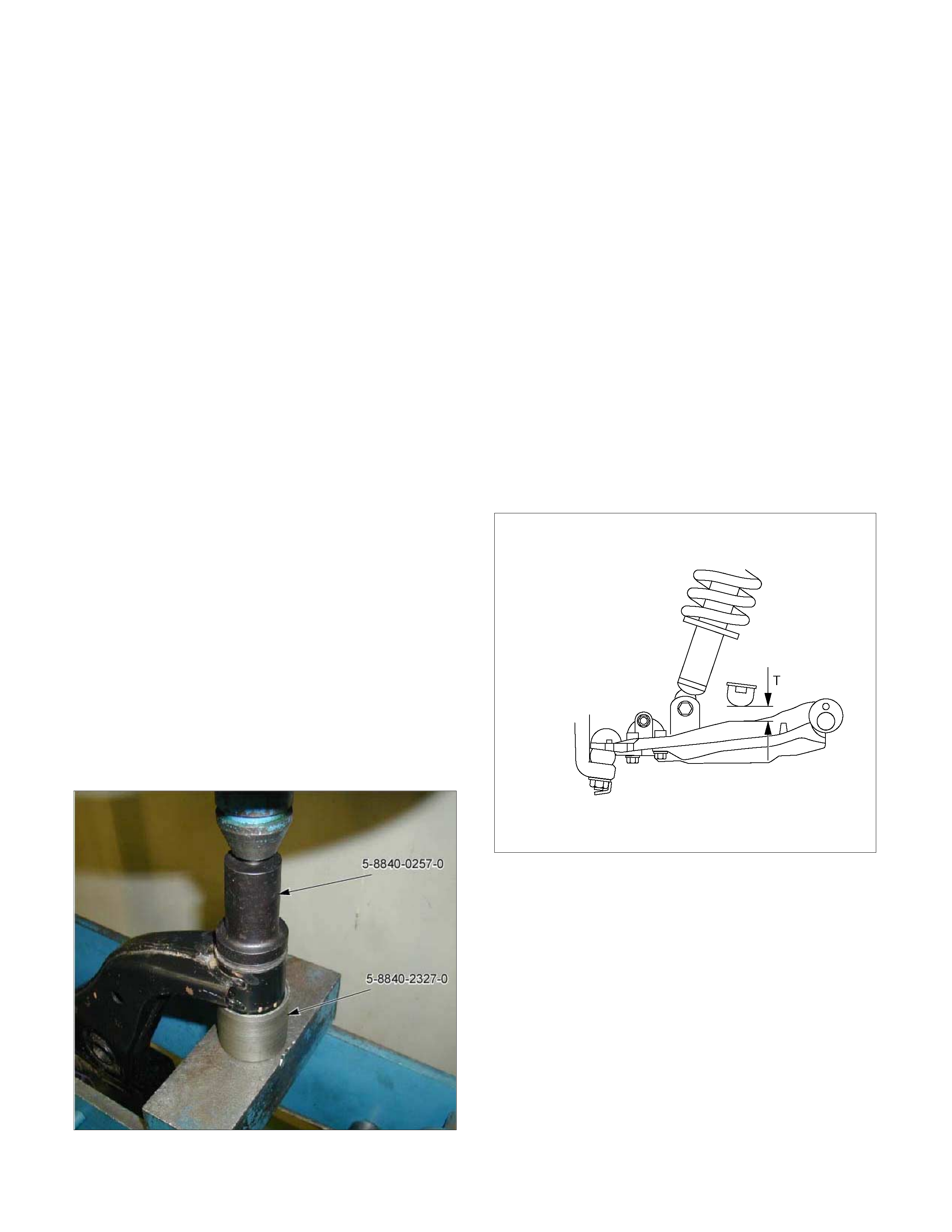

1. Install bushing by using installer 5-8840-0257-0

and 5-8840-2327-0.

P1010062

2. Install upper ball joint and tighten it to the spec ified

torque (9).

Torque: 31 N⋅

⋅⋅⋅m (3.2kg⋅

⋅⋅⋅m/23 lb ft)

3. Ins tall nut (6) and cotter pin then tighten the nut to

the specified torque, with just enough additional

torque to align cotter pin holes. Install new cotter

pin.

Torque: 98 N⋅

⋅⋅⋅m (10.0kg⋅

⋅⋅⋅m/72 lb ft)

4. Install upper control arm assembly.

5. Install bolt (1) and nut (3).

NOTE: Apply oil to the thread.

NOTE: Tighten the bolt (1) with the parts in the position

shown in the illustration below.

Buffer clearance: 25.9 mm (1.02 in)

Torque: 137 N⋅

⋅⋅⋅m (14.0kg⋅

⋅⋅⋅m/101 lb ft)

RTW340SH001301

6. Install nut (12).

7. Install nut (11).

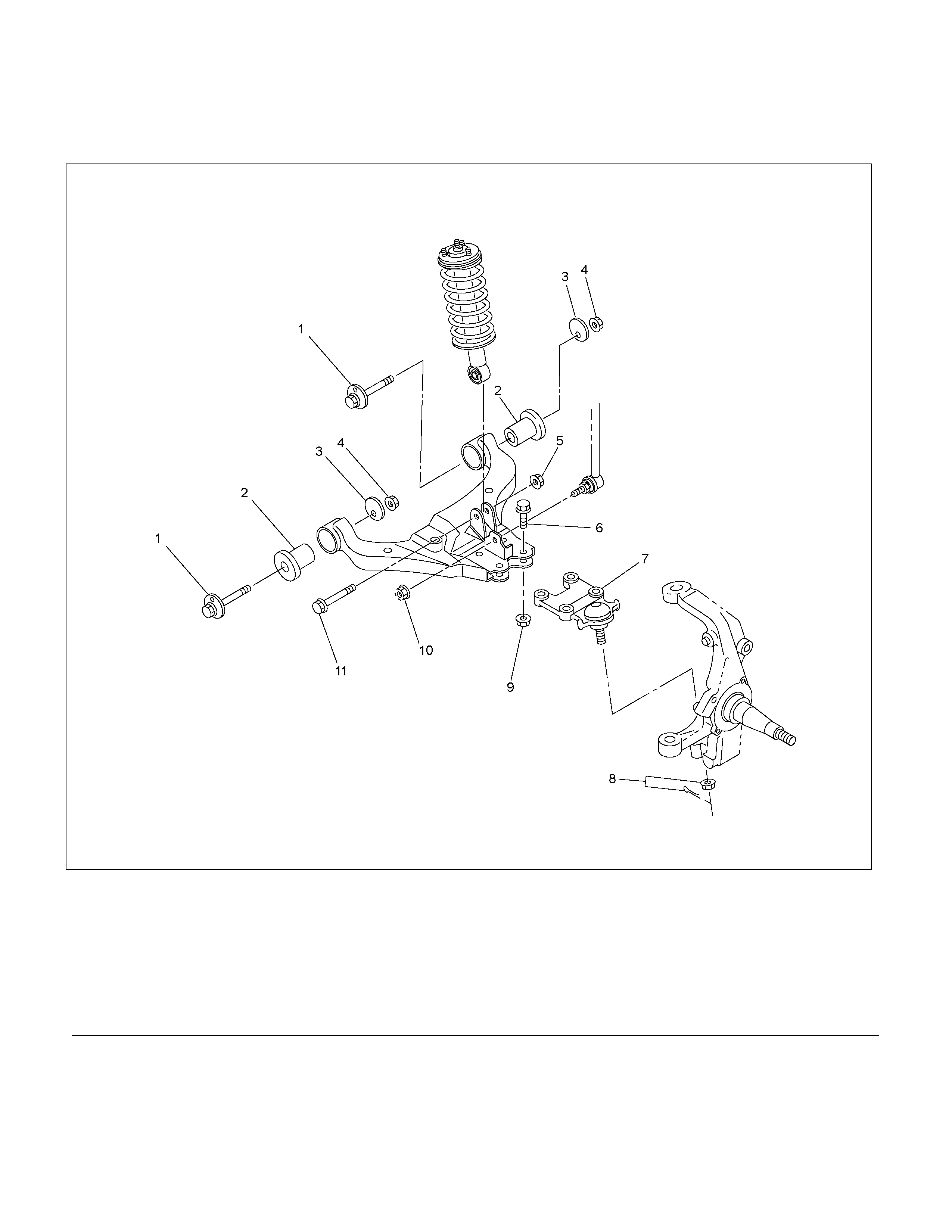

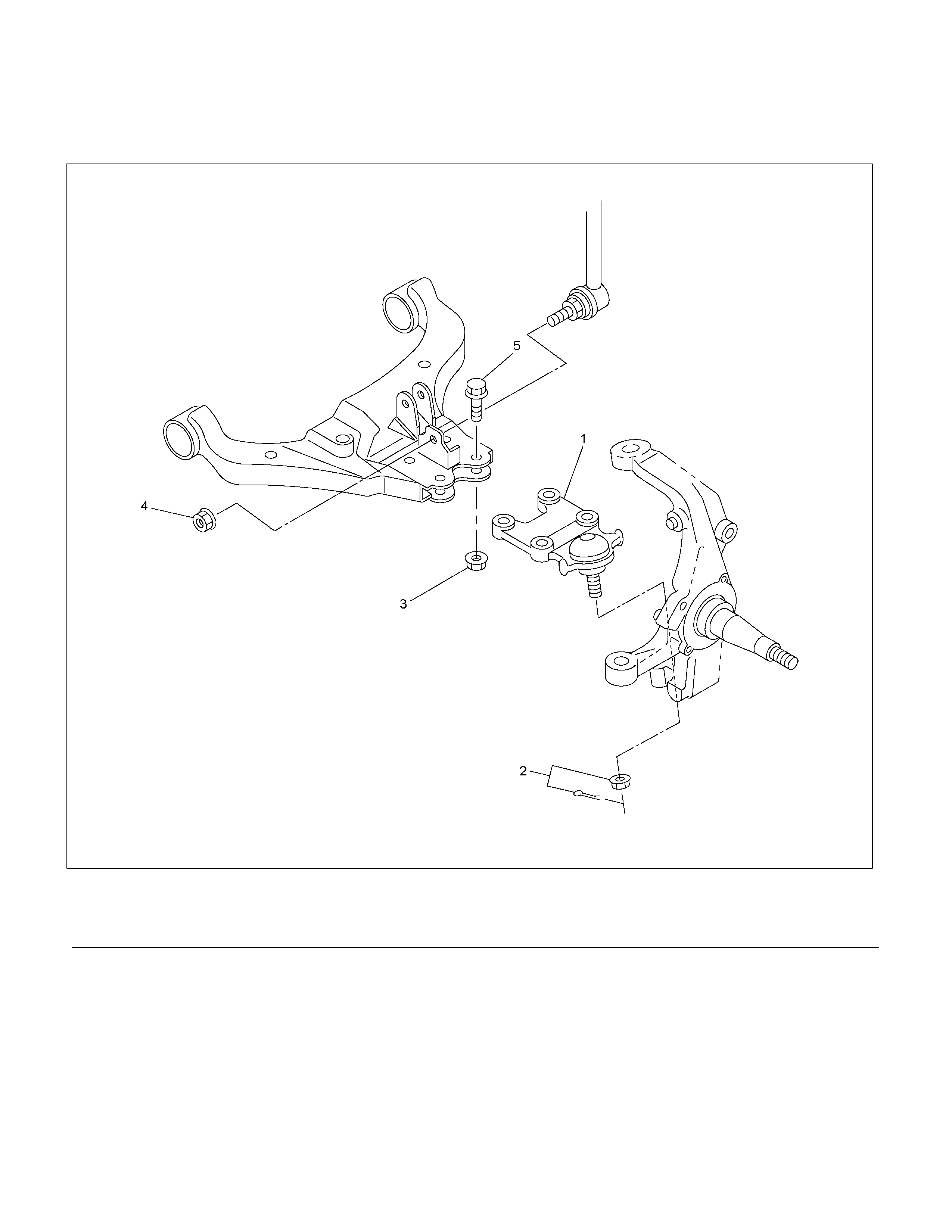

Lower Control Arm

Lower Control Arm and Associated Parts

RTW340LF002301

Legend

(1) Cam bolt

(2) Bush

(3) Cam plate

(4) Nut

(5) Nut

(6) Bolt

(7) Lower Ball Joint

(8) Nut and cotter pin

(9) Nut

(10) Nut

(11) Bolt

Removal

1. Raise the vehicle and support the frame with

suitable safety stands.

2. Remove wheel and tyre assem bly. Refer to Wheel

in this section.

3. Remove the tie- rod end from the k nuckle. Refer to

Power Steering Unit in Steering section.4.

Support lower control arm with a jack.

5. Remove the nut (10).

6. Remove the nut (8).

7. Remove the shock absorber lower end from the

lower control arm.

8. Remove the lower ball joint from the lower control

arm.

9. Remove nut (4) and cam plate.

10. Remove cam bolt.

11. Remove lower control arm.

12. Remove bushing.

Inspection and Repair

Make necessary correction or parts replacement if

wear, damage, corrosion or any other abnormal

condition is found through inspection.

Check the following parts:

• Lower control arm

• Bushing

Installation

1. Install rear bushing by using installer 5-8840-

0257-0 and 5-8840-2327-0.

P1010063

2. Install lower control arm.

3. Install cam bolt.

4. Ins tall lower ball joint and tighten it to the specified

torque (9).

Torque: 127 N⋅

⋅⋅⋅m (12.9kg⋅

⋅⋅⋅m/94 lb ft)

5. Install shock absorber and tighten it to the

specified torque (5).

Torque: 137 N⋅

⋅⋅⋅m (14.0kg⋅

⋅⋅⋅m/101 lb ft)

NOTE: Apply oil to the thread.

6. Install Stabiliser link and tighten it to the specified

torque (10).

Torque: 50 N⋅

⋅⋅⋅m (5.1kg⋅

⋅⋅⋅m/37 lb ft)

7. Install nut (4) and cam plate and tighten lower link

nut finger-tight.

NOTE: Apply oil to the thread.

NOTE: Tighten the nut (4) with the parts in the position

shown in the illustration below.

Buffer clearance: 25.9 mm (1.02 in)

Torque: 186 N⋅

⋅⋅⋅m (19.0kg⋅

⋅⋅⋅m/137 lb ft)

RTW340SH001301

8. Install nut (8) and cotter pin then tighten the nut to

the specified torque, with just enough additional

torque to align cotter pin holes. Install new cotter

pin.

Torque: 147 N⋅

⋅⋅⋅m (15.0kg⋅

⋅⋅⋅m/108 lb ft)

Upper Ball Joint

Upper Ball Joint and Associated Parts

RTW340LF001101

Legend

(1) Bolt

(2) Upper Ball Joint

(3) Nut

(4) Nut and Cotter Pin

(5) Nut

Removal

1. Raise the vehicle and support the frame with

suitable safety stands.

2. Rem ove wheel and tyre assem bly. Refer to wheel

in this section.

3. Remove nut (5).

4. Remove upper ball joint nut and cotter pin, then

use remover 5-8840-2017-0 to remove the upper

ball joint from the knuckle.

CAUTION: Be careful not to damage the ball joint

boot and brake hose.

P1010005

5. Remove bolt (1) and nut (3).

6. Remove upper ball joint.

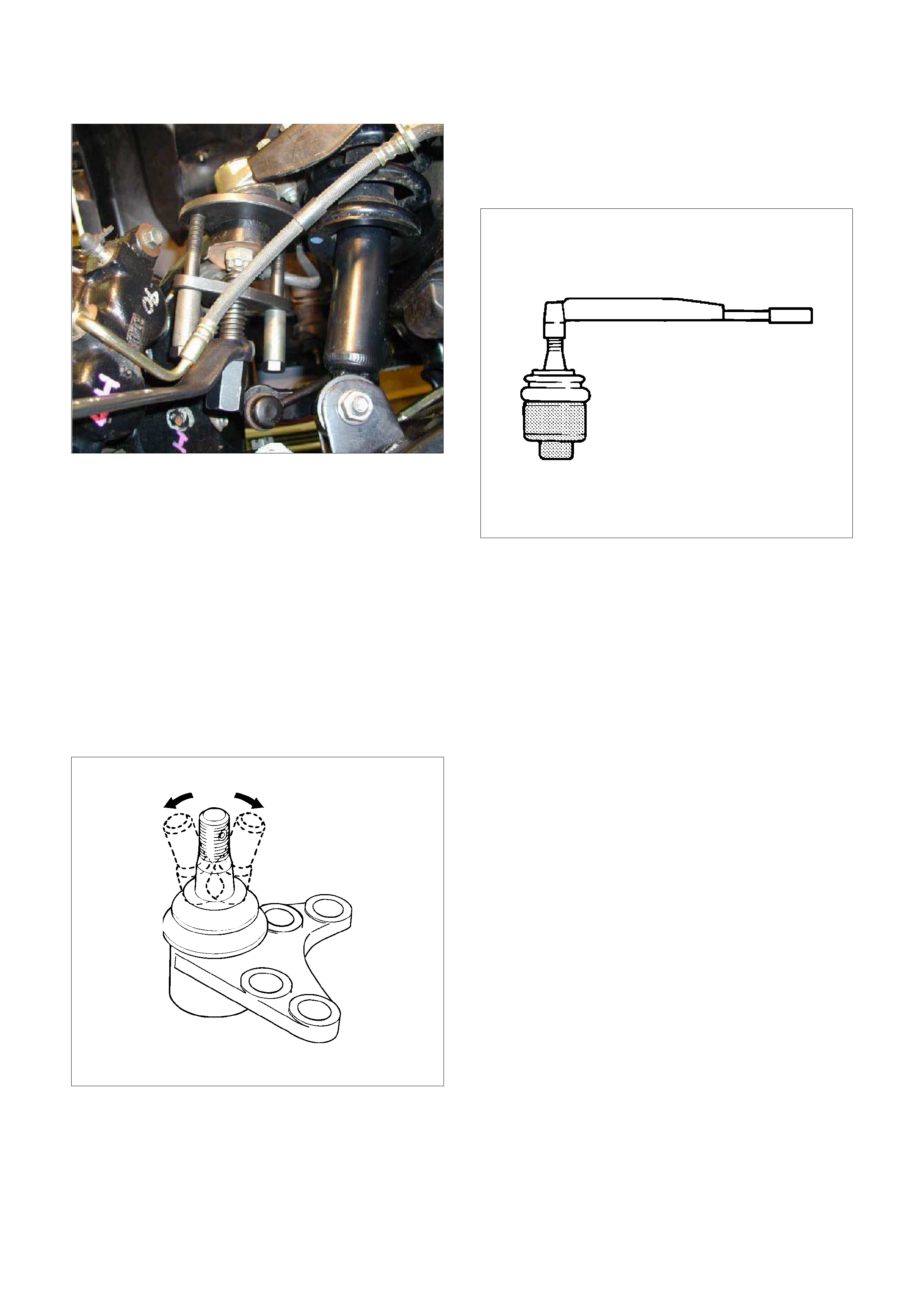

Inspe cti on an d Repa ir

Make necessary parts replacement if wear, damage,

corrosion or any other abnormal conditions are found

through inspection.

• Inspect the lower end boot for damage or grease

leak. Move the ball joint as shown in the figure to

confirm its norm al m ovement.

• Inspect screw/taper area of ball for damage.

• If any defects are found by the above inspections,

replace the ball jo int assembly with new one.

450R300030

• After moving the ball joint 4 or 5 times, attach nut

then measure the preload.

Starting torque: 1.3-3.2 N⋅

⋅⋅⋅m (0.13-0.33kg⋅

⋅⋅⋅

m/0.9-2.4 lb ft)

450RS024

If the above limits specified are exceeded, replace the

ball joint assembly.

Installation

1. Install upper ball joint.

2. Install bolt (1) and nut (3), then tighten them to the

specified torque.

Torque: 31N⋅

⋅⋅⋅m (3.2kg⋅

⋅⋅⋅m/23 lb ft)

3. Install nut and cotter pin, and then tighten the nut

to the specified torque with just enough additional

torque to align cotter pin holes. Install new cotter

pin (4).

Torque: 98 N⋅

⋅⋅⋅m (10.0kg ⋅

⋅⋅⋅m/72 lb ft)

4. Instal l nut (5), then tig hten to the specified torque.

Torque: 50 N⋅

⋅⋅⋅m (5.1kg ⋅

⋅⋅⋅m/37 lb ft)

Lower Ball Joint

Lower Ball Joint and Associated Parts

RTW340LF002201

Legend

(1) Lower Ball Joint

(2) Nut and Cotter Pin

(3) Nut

(4) Nut

(5) Bolt

Removal

1. Raise the vehicle and support the frame with

suitable safety stands.

2. Remove wheel and tyre assem bly. Refer to Wheel

in this section.

3. Remove the nut (4).

4. Support lower control arm with a jack.

5. Remove lower ball joint nut and cotter pin, then

use remover 5-8840-2017-0 to remove the lower

ball joint from the knuckle.

P1010003

6. Remove nut (3).

7. Remove bolt (5).

8. Remove lower ball joint.

Inspection and Repair

Make necessary parts replacement if wear, damage,

corrosion or any other abnormal condition are found

through inspection.

• Inspect the lower end boot for damage or grease

leak. Move the ball joint as shown in the figure to

confirm its normal movement.

• Inspect screw/taper area of ball for damage.

• If any defects are found by the above inspections,

replace the ball joint assembly with new one.

450RS026

•

A

fter moving the ball joint 4 or 5 times, attach nut

then measure the preload.

Starting torque: 2.5-6.4 N⋅

⋅⋅⋅m (0.26-0.65kg⋅

⋅⋅⋅m/1.9-

4.7 lb ft)

450RS024

• If the above lim its specif ied are exc eeded, replace

the ball joint assembly.

Installation

1. Install lower ball joint.

2. Install bolt (5).

3. Install nut (3) and tighten it to the specified torque.

Torque: 127 N⋅

⋅⋅⋅m (12.9kg⋅

⋅⋅⋅m/94 lb ft)

4. Install ball joint nut, then tighten it to the specified

torque with just enough additional torque to align

cotter pin holes. Install new cotter pin (2).

Torque: 147 N⋅

⋅⋅⋅m (15.0kg⋅

⋅⋅⋅m/108 lb ft)

5. Install nut (4), then tighten to the specified torque.

Torque: 50 N⋅

⋅⋅⋅m (5.1kg⋅

⋅⋅⋅m/37 lb ft)

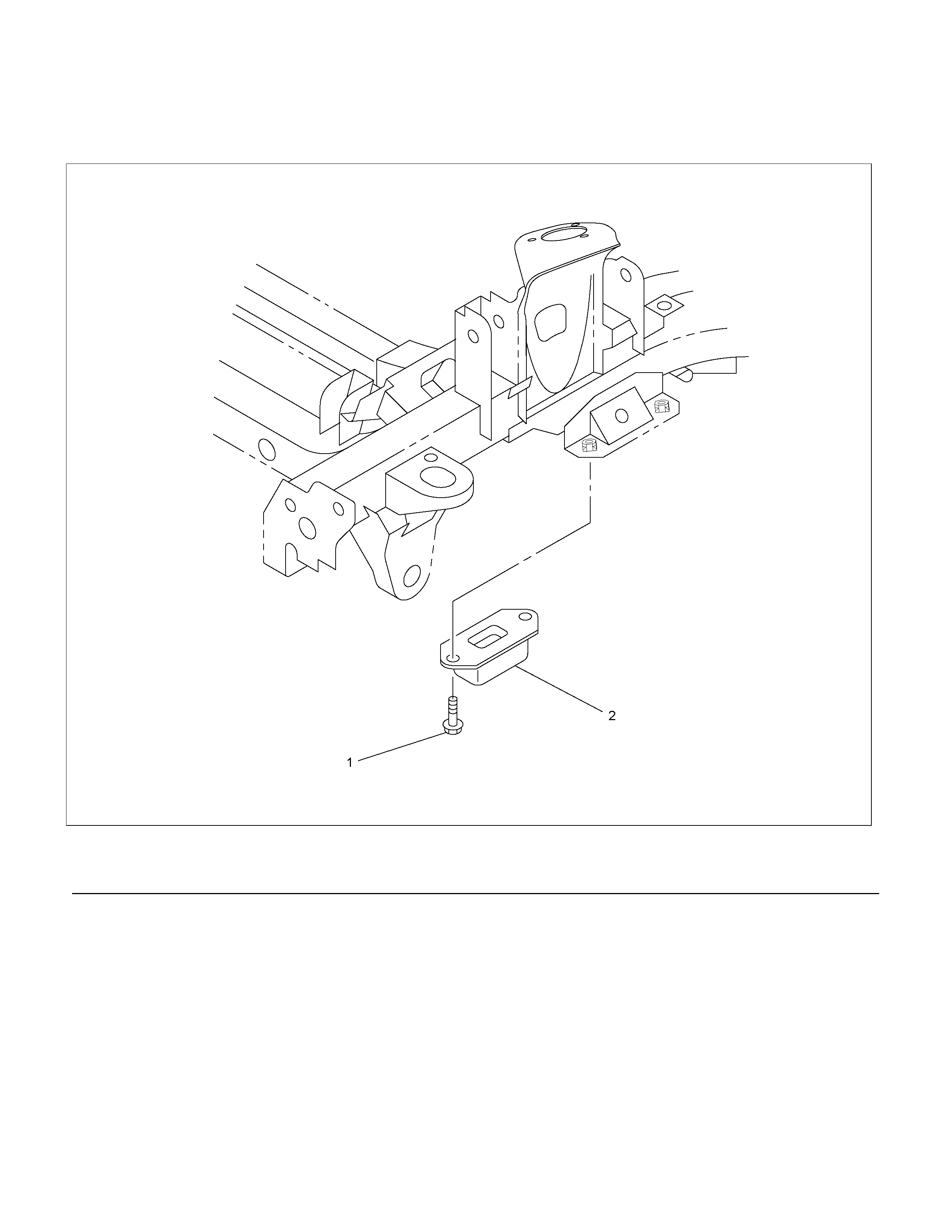

Bump Rubber

Bump Rubber and Associated Parts

RTW340LF002601

Legend

(1) Bolt

(2) Bump Rubber

Removal

1. Raise the vehicle and support the frame with

suitable safety stands.

2. Remove bolt.

3. Remove bump rubber.

Inspection and Repair

Make necessary correction or parts replacement if

wear, damage, corrosion or any other abnormal

condition are found through inspection.

Check the following parts :

• Bump Rubber

Installation

1. Install bump rubber.

2. Install bolt (1), then tighten it to the specified

torque.

Torque: 42 N⋅

⋅⋅⋅m (4.3kg⋅

⋅⋅⋅m/31 lb ft)

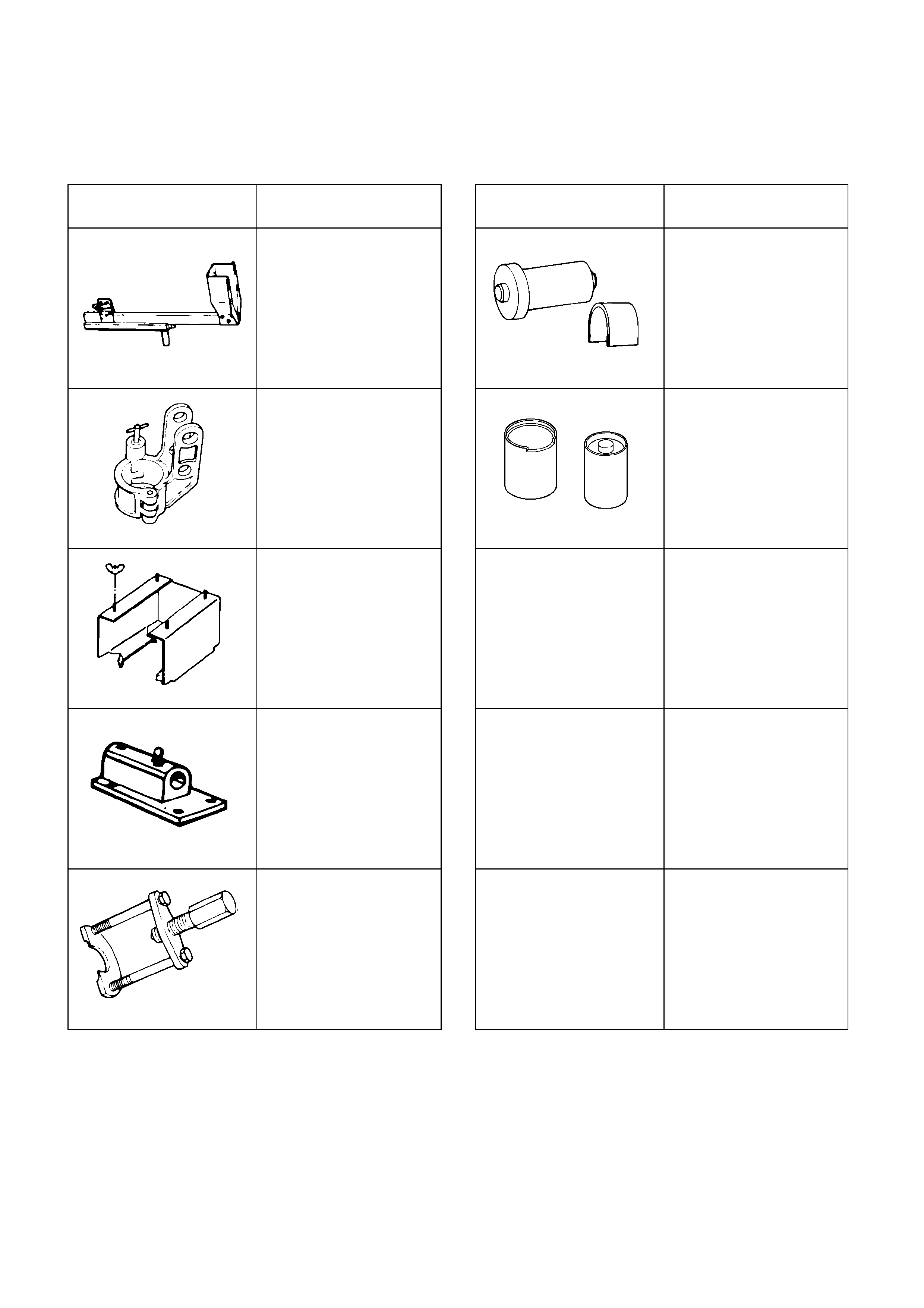

Special Tools

ILLUSTRATION PART NO.

PART NAME ILLUSTRATION PAR T NO.

PA RT NAME

5-8840-0595-0

Support; fixture

5-8840-0257-0

Installer; Upper and

lower arm bushing

5-8840-2828-0

Adapter; lower

5-8840-2327-0

Installer; Upper and

lower arm bushing

5-8840-2829-0

Adapter; Upper

5-8840-0003-0

Base

5-8840-2017-0

Ball joint remover