Main Data And Specifications

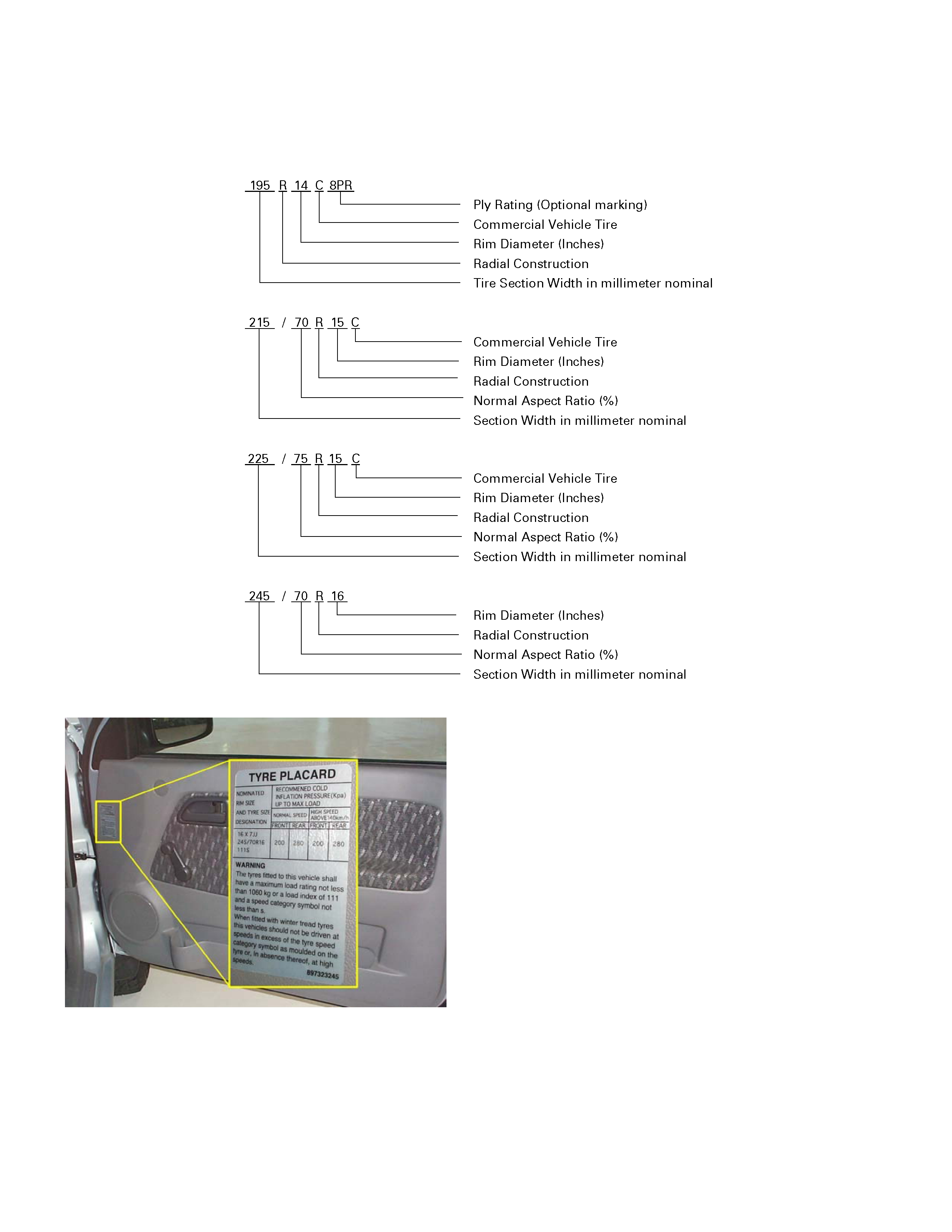

Tire Size and Pressure

Item 4×2 Model 4×4 Model

EXC HIGH RIDE SUS HIGH RIDE SUSPENSION

Tyre Size

Wheel Size

Tyre Pressure

Front (kPa)

Rear (kPa)

195R14C

8PR 106/104Q

14 x 5.5J

250 kPa

450 kPa

215/70R15C

106/104S

15 x 6.5JJ

225 kPa

375 kPa

225/75R15C

110/108S

15 x 6.5JJ

225 kPa

325 kPa

245/70R16

111S

16 x 7JJ

200 kPa

280 kPa

245/70R16

111S

16 x 7JJ

200 kPa

280 kPa

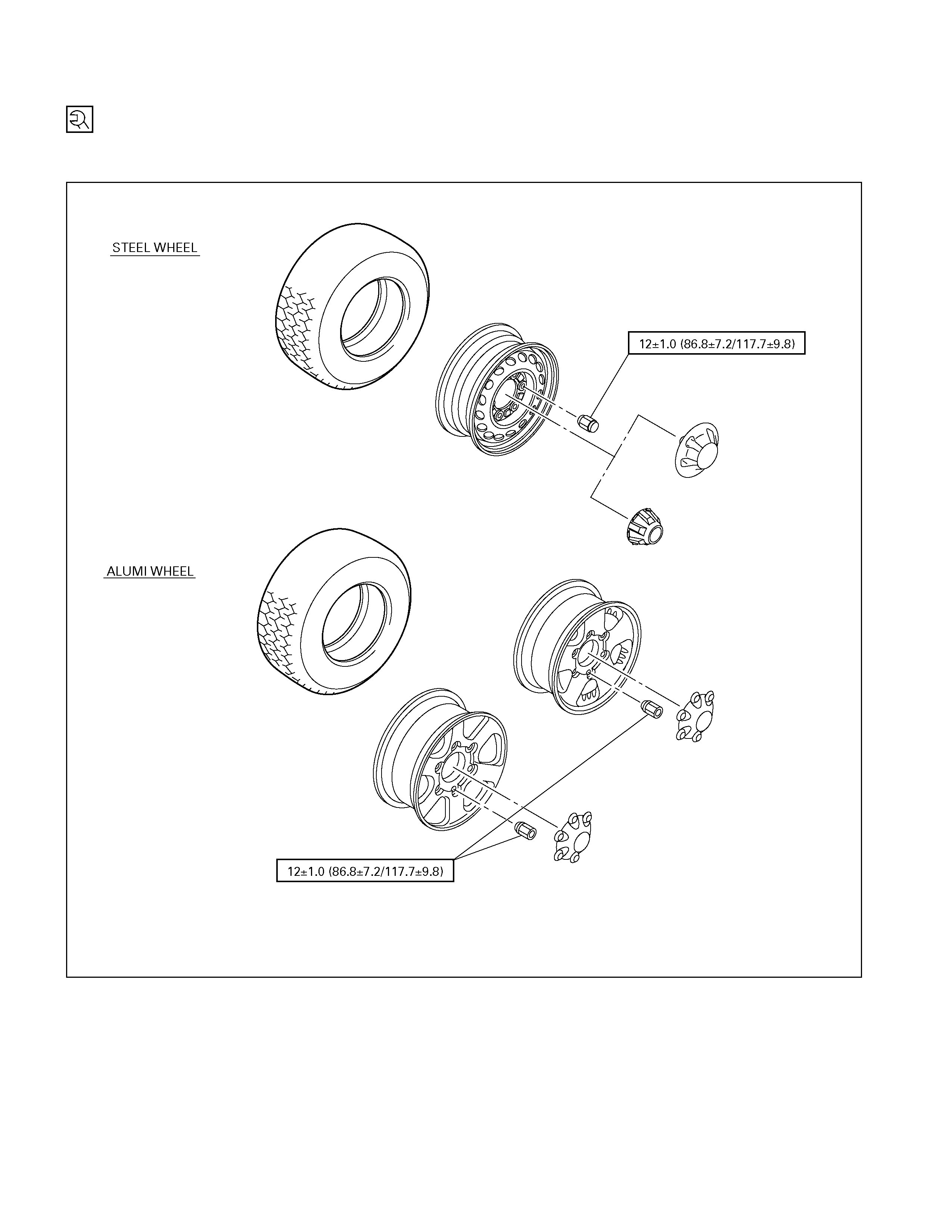

Torque Specifications

Special Parts Fixing Nuts And Bolts

WHEELS AND TIRES kgf⋅m (lb⋅ft/N⋅m)

Wheels And Tires

General Description

TIRE DESIGNATION

TYRE PRESSURE LABEL (LOCATION : DRIVERS DOOR TRIM)

Note :

• The air pressure of the tire should be maintained as indicated in the label instruction on the driver's door or

frame of driver's door.

Lower pressure can cause burst and adverse vehicle handling.

On the other hand, higher pressure can cause shock-burst and reduce gripping effect.

Servicing

Servicing refers to general maintenance procedures to be performed by qualified service personnel.

WHEEL NUT TORQUES

Wheel Nut Torque kgf⋅m(lb⋅ft/N⋅m)

12.0 ± 1.0 (86.8 ± 7.2 / 117.7 ± 9.8)

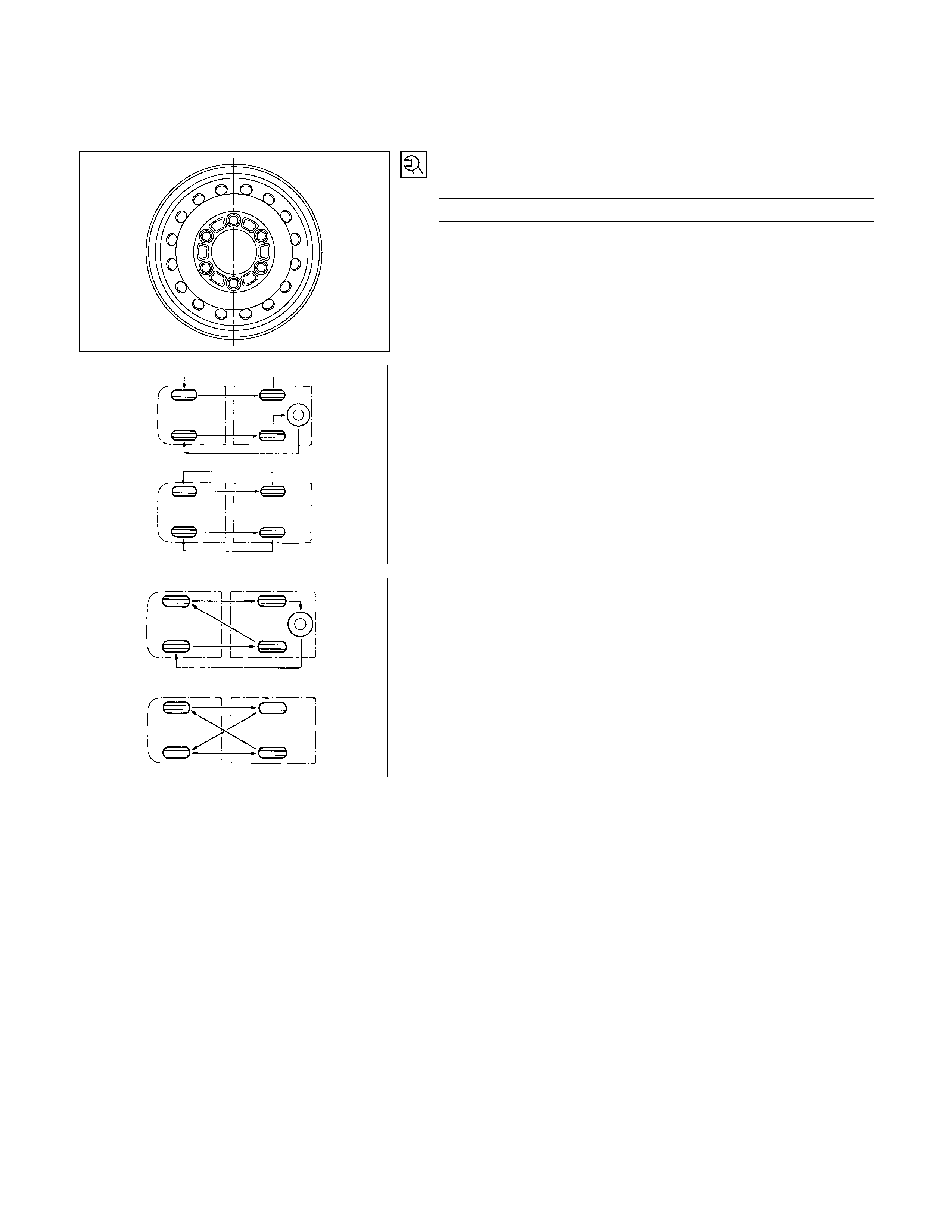

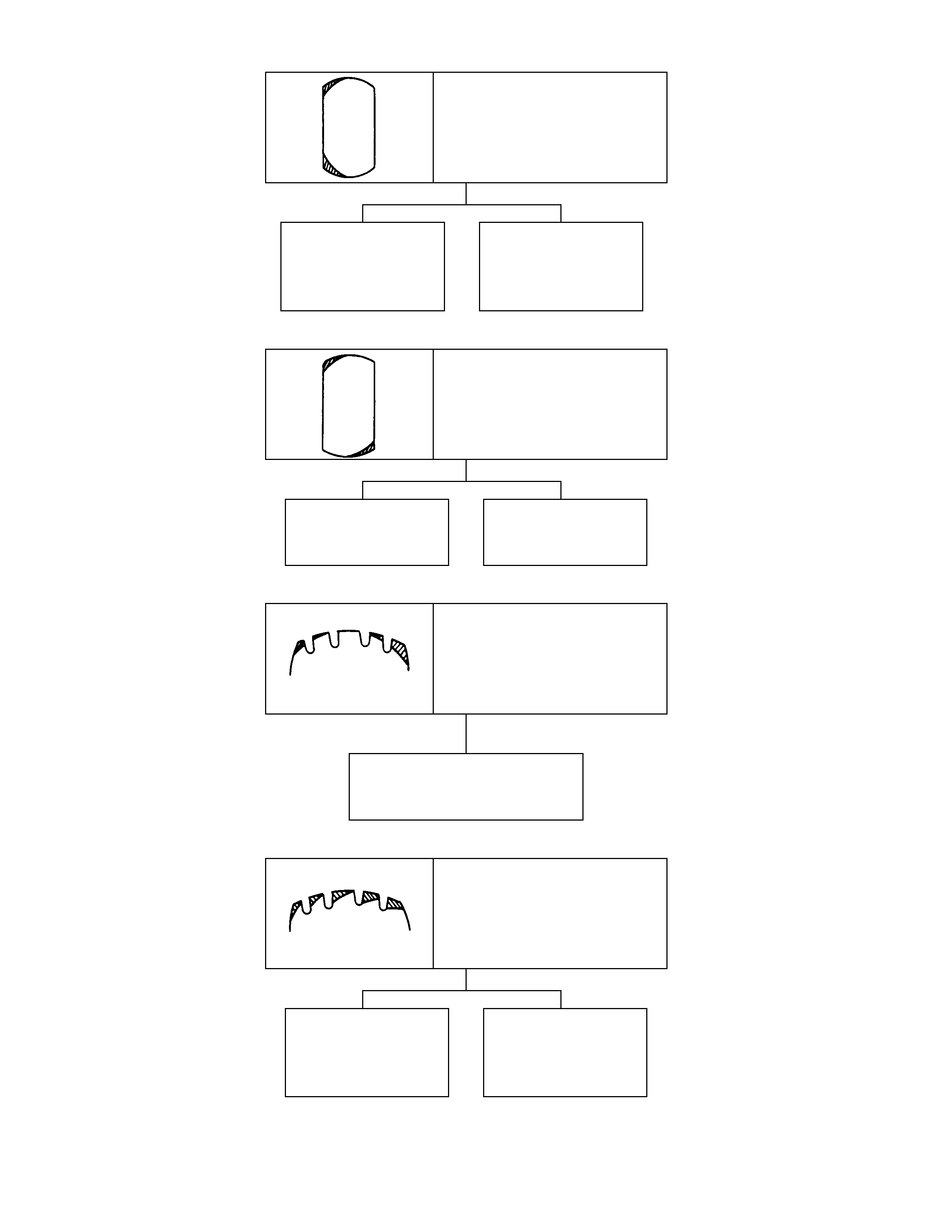

TIRE ROTATION

For rotation of radial tires, interchange the front and the rear

wheels on the same side as shown in the figure.

If one-sided tire wear appears on radial tires, rotate the wheels

as shown in the figure.

Note:

After rotation, adjust the front and rear tire pressure and be sure to check wheel nut tightness.

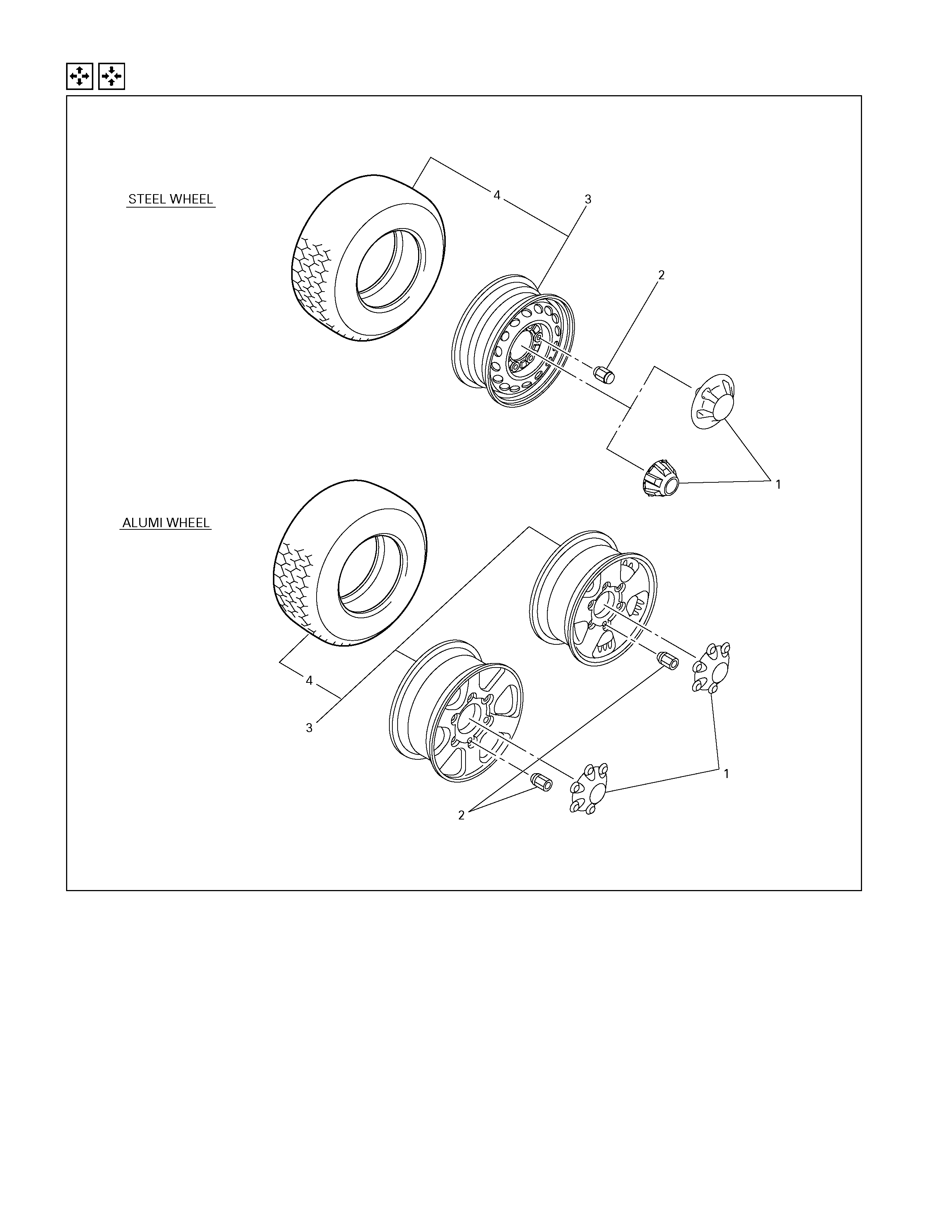

Disassembly And Reassembly

Disassembly Steps

(for Alumi models)

1. Wheel cap

2. Wheel nut

3. Wheel and tire assembly

4. Tire assembly

(for Steel models)

1. Wheel nut

2. Wheel cap

3. Wheel and tire assembly

4. Tire assembly

Reassembly Steps

(for Alumi models)

4. Tire assembly

3. Wheel and tire assembly

2. Wheel nut

1. Wheel cap

(for Steel models)

4 Tire assembly

3. Wheel and tire assembly

2. Wheel cap

1. Wheel nut

Inspection And Repair

Carryout necessary repairs or parts replacement if wear, damage or any other abnormal conditions are found through

inspection.

Visual Check

Inspect all disassembled parts for wear, damage or other

abnormal conditions.

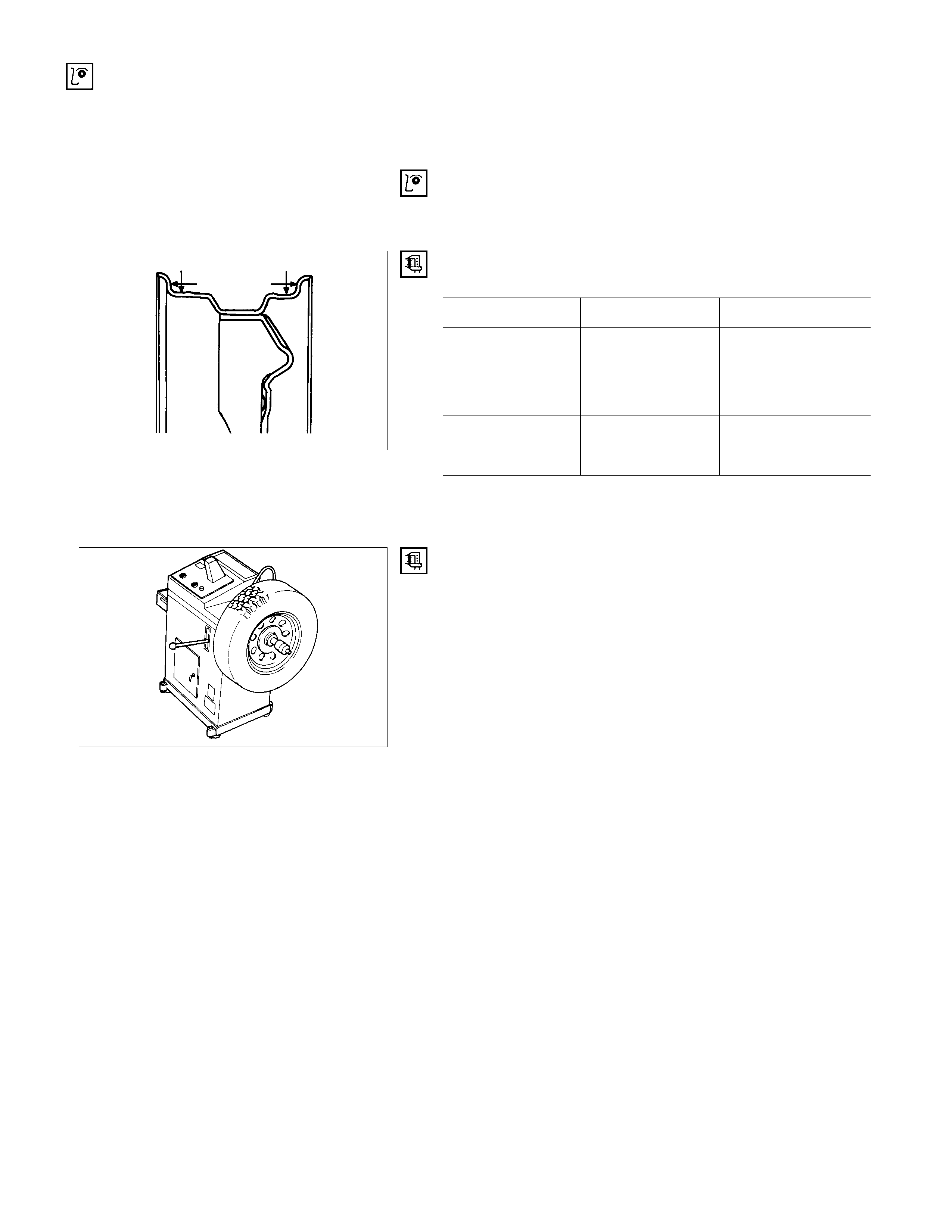

Measure Wheel Runout

mm

Wheel Ty pe Radial Lateral

14 inch St eel

15 inch St eel

16 inch St eel

Less than 1.0 Less than 1.0

15 inch Alumi

16 inch Alumi Less than 0.4 Less than 0.55

If the measured value exceed the specified limit, the wheel

must be replaced.

Balancing Wheel and Tire

On-vehicle Balancing

On-Vehicle balancing methods very with equipment and tool

manufacturers. Be sure to follow each manufacturer’s

instructions during balancing operation.

Off- vehicle Balancing

Most electronic off-vehicle balancers are more accurate than

the on-vehicle spin balancers. They are easy to use and give

a dynamic balance. Although they do not correct for drum or

disc unbalance (as on-vehicle spin balancing does), they are

very accurate.

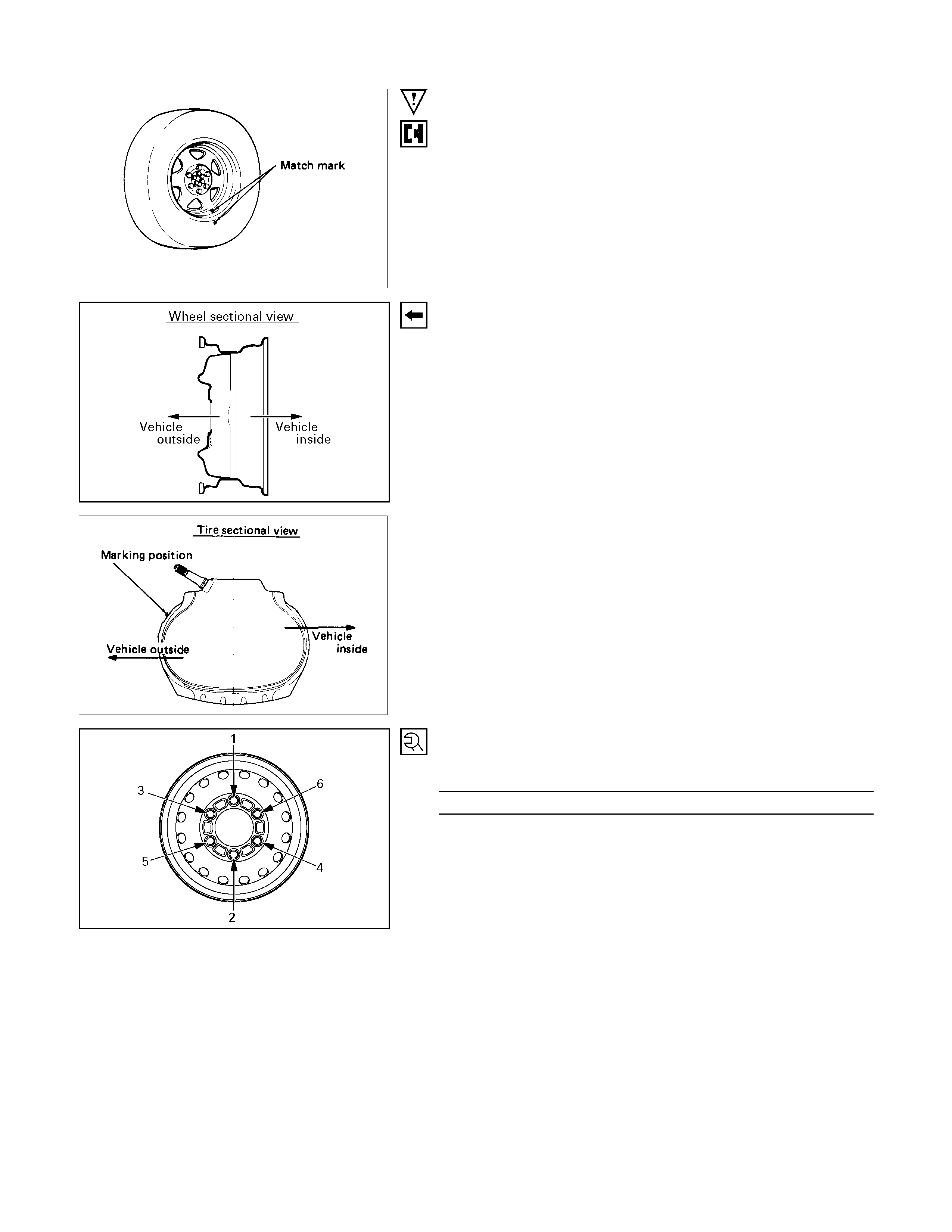

Important Operations

1. Tire Assembly

To assemble align the match mark (approx. 10mm diameter

paint mark) of wheel with the match mark (approx. 8mm

diameter red paint mark) of tire. If the match mark at wheel

has disappeared, align with air valve.

2. Wheel and Tire Assembly

3. Wheel Nut

Tighten wheel nuts in numerical order.

Wheel Nut Torque kgf⋅m (lb⋅ft/N⋅m)

12.0 ± 1.0 (86.8 ± 7.2 / 117.7 ± 9.8)

Troubleshooting

Typical examples of abnormal tire tread wear and major causes :

CAUTION:

Similar wear patterns can be caused by worn suspension parts, misalignment of wheels and tires, and other

suspension related problems.

Spotty wear - wear localized

on shoulder section. In

extreme cases, the tire

becomes polygonal in shape.

Tire or wheel out of

round or distorted. Hub or knuckle out

of round or distorted. Play in hub bearings

or ball joints. Rotating parts out of

balance.

Tread wear one-sided.

Rotating parts out of

balance. Tire or wheel out of

round. Hub or knuckle out

of round or distorted.

Localized tread wear.

Once spotty wear develops in

tread due to hard braking or

abrupt starting, localized wear

tends to be accelerated.

Shoulder wear (generally

wear develops on outer

shoulder).

Camber or toe-in

incorrect. Shoulder wear

caused by repeated

hard-cornering.

Wear on shoulders at points

opposed to each other.

Tire or wheel out of

round or distorted. Play in bearings or

ball joint.

Premature wear on

shoulders.

Flexing of tire excessive due

to under-inflation.

One-sided feather edging.

Wear caused by

repeated hard-

cornering.

Camber or toe-in

incorrect.