SECTION 4A - PROPELLER SHAFT

Service Precaution

Main Data and Specifications

Rear Propell er Shaft

Front Pr opeller Shaf t

Torque Specifications

Rear Propeller Shaft

General Description

Removal

Installation

Universal Joi nt Disassembly

Inspection and Repair

Universal Joint Reassembly

Rear Propeller Shaft Assembly

Disassembly

Reassembly

Front Propeller Shaft (4JH1-TC)

Removal and Installation

Universal Joint Disassembly and Reassembly

DOJ Disassembly and Reassembly

Front Propeller Shaft (6VE1)

Removal and Installation

Disassembly

Universal Joint Disassembly and Reassembly

Reassembly

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN ORDER TO DETERMINE WHETHER YOU A RE PERFORMING

SERVICE ON OR NEAR THE SRS COMPONENTS OR THE SRS WIRING. WHEN YOU ARE PEREFORMING

SERVICE ON OR NEAR THE SRS COMPONENTS OR THE SRS WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNING COULD RESULT IN POSSIBLE AIR BAG DEPLOYMENT,

PERSONAL INJURY, OR OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the proper location. When you replace a fastener, use ONLY the

exact part number for that application. HOLDEN will call out those fasteners that require a replacement after

removal. HOLDEN will also call out the fasteners that require thread lockers or thread sealant. UNLESS

OTHERWISE SPECIFIED, do not use supplemental coatings (Paints, greases, or other corrosion inhibitors) on

threaded fasteners or fastener joint interfaces. Generally, such coatings adversely affect the fastener torque

and the joint clamping force, and may damage the fastener. When you install fasteners, use the correct

tightening sequence and specifications. Following these instructions can help you avoid damage to parts and

systems.

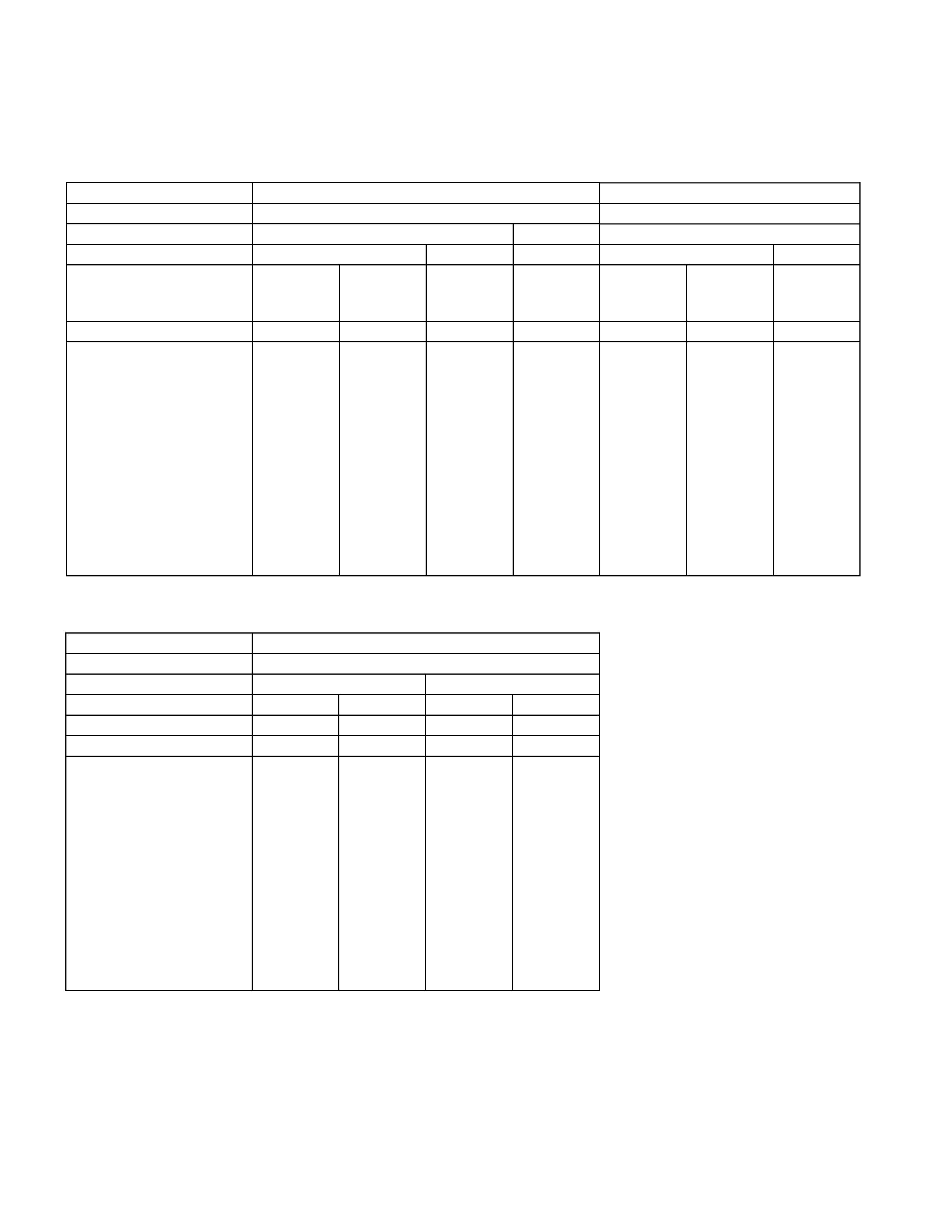

Main Data and Specifications

Rear Propeller Shafts

mm(in)

4×2 Model 4×2 Model

Engine Model 4JH1-TC HEC

Transmission Type 5M/T (MUA) 4A/T 5M/T (MUA)

Wheel Base Long Extra Long Long Long Extra Long

Front Suspension High Ride

Suspension Except High

Ride

Suspension High Ride

Suspension

Except High

Ride

Suspension

Rear Axle 220mm ← ← ← ← ← ←

Type OBS ← ← ← ← ← ←

Outside Diameter mm 68.9 68.9 68.9 63.5 75 75 75

(in) (2.71) (2.71) (2.71) (2.50) (2.95) (2.95) (2.95)

Inside Diameter mm 64.9 64.9 64.9 60.3 71.8 71.8 71.8

(in) (2.63) (2.63) (2.63) (2.44) (2.89) (2.89) (2.89)

Length 1st(L1) mm 798.5 801.5 946.5 720.5 823.5 820.5 970.5

(in) (31.44) (31.56) (37.26) (28.37) (32.42) (32.30) (38.21)

2nd(L2) mm 801 796 801 801 801 796 796

(in) (31.54) (31.34) (31.54) (31.54) (31.54) (31.34) (31.34)

Spline Major mm 29.89 29.89 29.89 29.89 29.89 29.89 29.89

Diameter (in) (1.18) (1.18) (1.18) (1.18) (1.18) (1.18) (1.18)

Fix Bolt Size M10 M10 M10 M10 M10 M10 M10

* OBS - Outboard Slip (Spline Engagement To T/M)

mm(in)

4×2 Model

Engine Model 6VE1

Transmission Type 5M/T (MUA) 4A/T

Wheel Base Long Extra Long Long Extra Long

Front Suspension

Rear Axle 220mm ← ← ←

Type OBS ← ← ←

Outside Diameter mm 68.9 68.9 75 75

(in) (2.71) (2.71) (2.95) (2.95)

Inside Diameter mm 64.9 64.9 71.8 71.8

(in) (2.63) (2.63) (2.89) (2.89)

Length 1st(L1) mm 823.5 971.5 778.5 928.5

(in) (32.42) (38.25) (30.65) (36.56)

2nd(L2) mm 801 801 801 801

(in) (31.54) (31.54) (31.54) (31.54)

Spline Major mm 29.89 29.89 30.48 30.48

Diameter (in) (1.18) (1.18) (1.20) (1.20)

Fix Bolt Size M10 M10 M10 M10

* OBS - Outboard Slip (Spline Engagement To T/M)

mm(in)

4×4 Model 4×4 Model

Engine Model 4JH1-TC 6VE1

Transmission Type 5M/T (MUA) 4A/T 5M/T (MUA) 4A/T

Wheel Base Long Extra Long Long Long Extra Long Long

Front Suspension

Rear Axle 220mm ← ← ← ← ←

Type OBS ← ← ← ← ←

Outside Diameter mm 68.9 68.9 63.5 68.9 68.9 75

(in) (2.71) (2.71) (2.50) (2.71) (2.71) (2.95)

Inside Diameter mm 64.9 64.9 60.3 64.9 64.9 71.8

(in) (2.63) (2.63) (2.44) (2.63) (2.63) (2.89)

Length 1st(L1) mm 468.5 616.5 402.5 492.5 641.5 484.5

(in) (18.44) (24.27) (15.85) (19.39) (25.26) (19.07)

2nd(L2) mm 801 801 801 801 801 801

(in) (31.54) (31.54) (31.65) (31.54) (31.54) (31.54)

Spline Major mm 29.89 29.89 29.89 29.89 29.89 29.89

Diameter (in) (1.18) (1.18) (1.18) (1.18) (1.18) (1.18)

Fix Bolt Size M10 M10 M10 M10 M10 M10

* OBS - Outboard Slip (Spline Engagement To T/M)

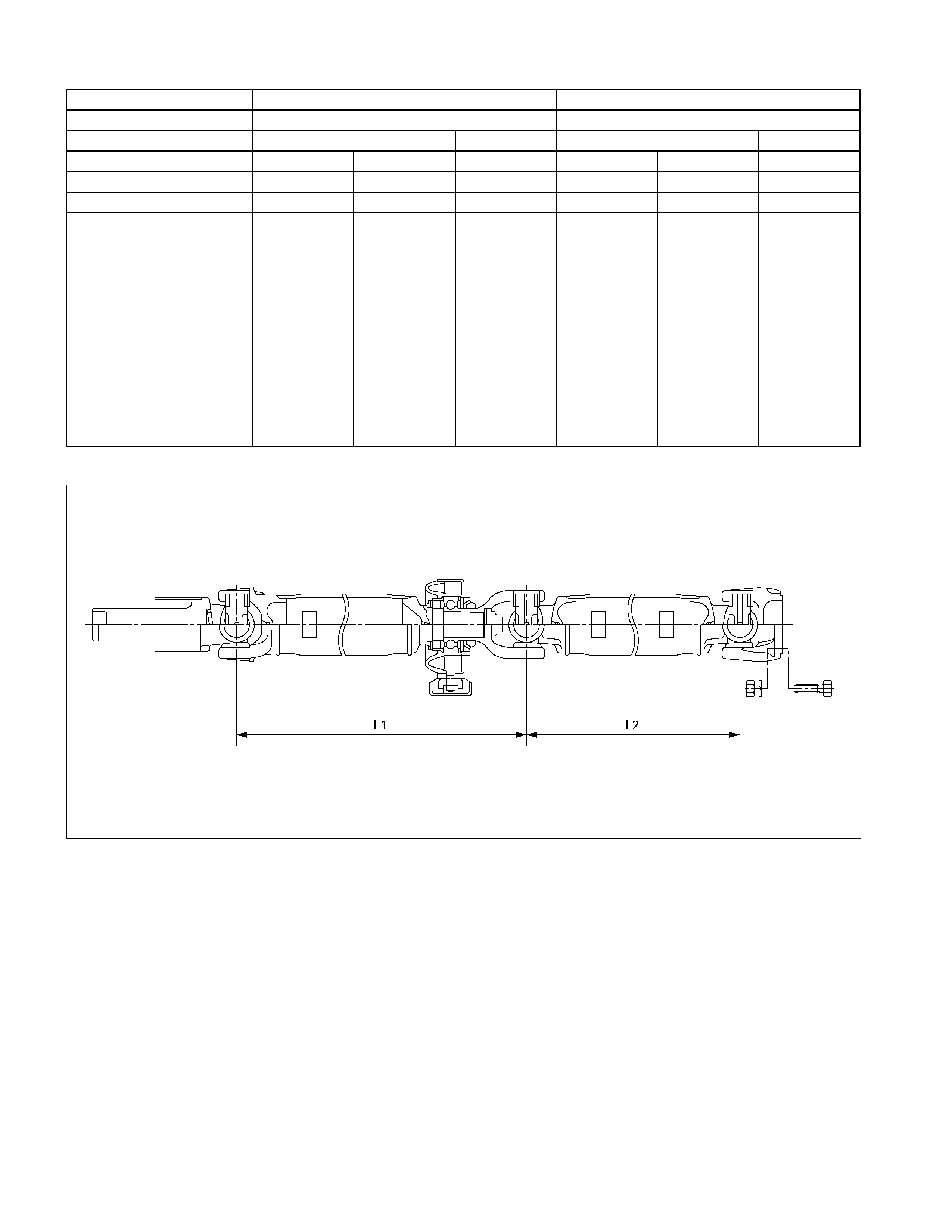

401R300006

Torque Specifications N⋅m (kgf⋅m/lb⋅ft)

RTW34ASF000301

Front Propeller Shaft

mm(in)

4×4 Model

Engine Model 4JH1-TC 6VE1

Transmission Type 5M/T (MUA) 4A/T 5M/T (MUA) 4A/T

Wheel Base Long Long Long Long

Outside Diameter mm 40 40 40 40

(in) (1.57) (1.57) (1.57) (1.57)

Inside Diameter mm 36 36 36 36

(in) (1.42) (1.42) (1.42) (1.42)

Length (L) mm 645 712 586 607

(in) (25.39) (28.03) (23.07) (23.90)

Fix Bolt Size T/F M8 M8 M10 M10

Axle M10 M10 M10 M10

4JH1-TC

401R300026

6VE1

RTW34ASF000101

Torque Specifications

4JH1-TC

RTW34AMF000101

6VE1

RTW34ASF000201

Rear Propeller Shaft

General Description

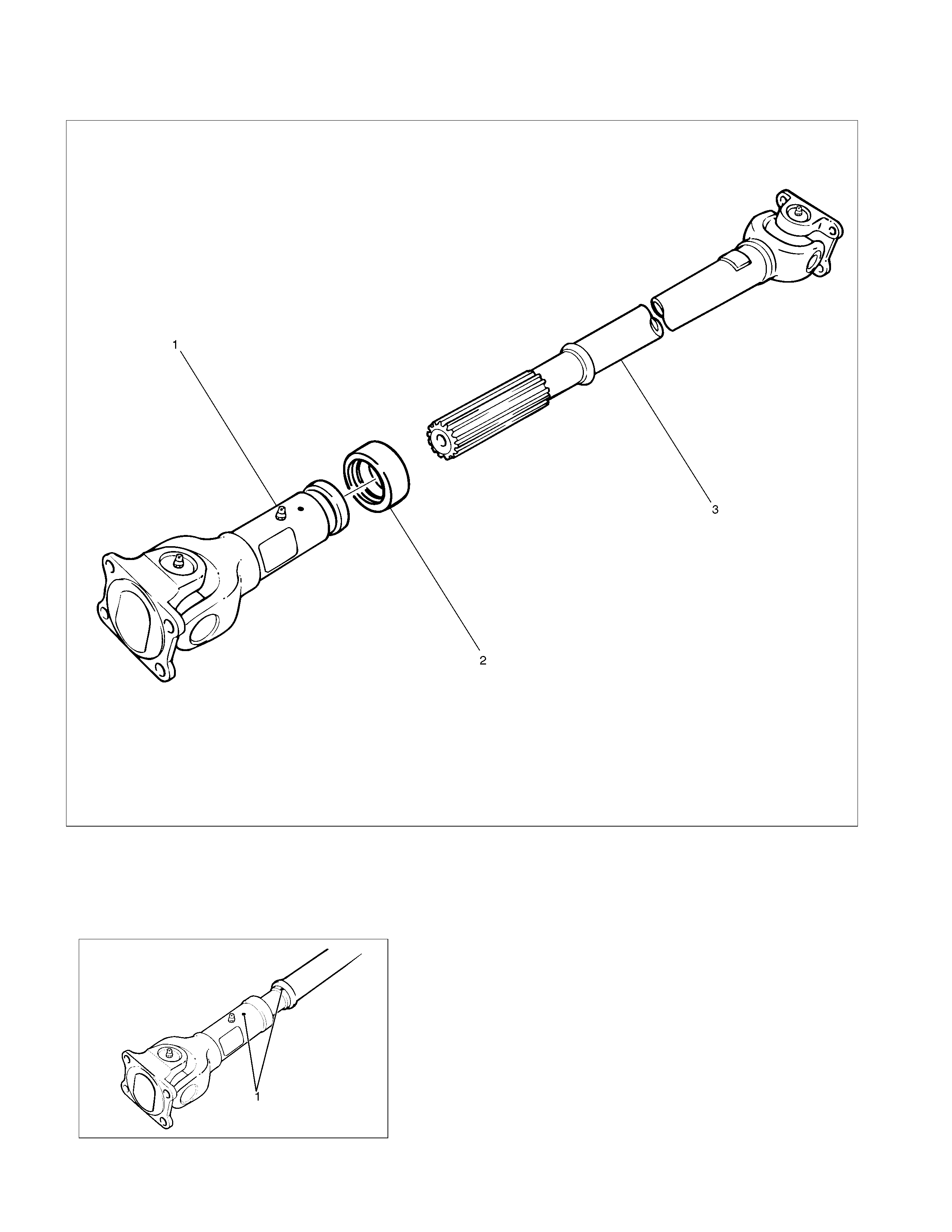

4×2 (Except High Ride Suspension) Model

F04R300001

4×2 (High Ride Suspension), 4×4 Model

401R300007

Torque is transmitted from the transmission to the

axle through propeller shaft and universal joint

assembles. All propeller shafts are the balanced

tubular type. A splined slip joint is provided in some

drivelines.

• Since the propeller shaft is total balanced carefully,

welding or any other modification are not permitted.

• Alignment marks should be applied to each

propeller shaft before removal.

• Be sure vehicle is stopped, engine is not running,

brake is secured and vehicle is secured to prevent

injury.

• Be careful not to grip the propeller shaft tube too

tightly in the bise as this will be cause deformation.

Phasing

The propeller shaft is designer and built with the yoke lugs

(ears) in line with each other. This design produces the

smoothest running shaft possible, called phasing. Vibration can

be caused by an out-of-phase propeller shaft. The propeller

shaft down each time the universal joint goes around. This

vibration would be the same as a person snapping rope and

watching the “wave” reaction flow to the end. A propeller shaft

working in phase would be similar to two persons snapping a

rope at the same time, and watching the “waves” meet and

cancel each other out. In comparison, this would be the same

as the universal joints on a propeller shaft. A total cancellation

of vibration produces a smooth flow of power in the driveline. It

is very important to apply a reference mark to the propeller

shaft before removal, to assure installation alignment.

401RW015

Universal Joint

A universal joint consists of two Y-shaped yokes

connected by a crossmember called a spider.

The spider is shaped like a cross. Universal joints are

designed to handle the effects of various loadings and

front or rear axle windup during acceleration. Within the

designed angle variations, the universal joint will operate

efficiently and safely. When the design angle is changed

or exceeded the operational life of the joint may decrease.

The bearings used in universal joints are of the needle

roller type. The needle rollers are held in place on the

trunnions by round bearing cups. The bearing cups are

held inside the yokes by snap rings.

Diagnosis of Propeller Shaft and Universal Joint

Condition Possible cause Correction

Rough surface on splined yoke;

burred nicked or worn. Replace the seal. Minor burrs can

be Smoothed by careful use of

crocus cloth or fine stone honing.

Replace the yoke if badly burred.

Leak at the Front Slip Yoke (An

Occasional Drop of Lubricant

Leaking from the Splined Yoke is

Normal) Defective transmission rear oil seal. Replace the transmission rear oil

seal and replenish the transmission

oil.

Worn universal joint bearings. Replace.

Improper lubrication. Lubricate as directed.

Universal Joint Noise.

Loose flange bolts. Tighten to specifications.

Loose bushing bolts on the rear

springs or upper and lower control

arms.

Tighten the bolts to specified

torque.

Ping, Snap, or Click in Drive Line

(Usually Heard on Initial Load after

the Transmission is in Forward or

Reverse Gear) Loose or out-of-phase end yoke. Remove end yoke, turn 180

degrees from its original position,

lubricate the splines and reinstall.

Tighten the bolts and pinion nut to

specified torque.

Squeak Lack of lubricant. Lubricate joints and splines. Also

check for worn or brinelled parts.

Loose or missing bolts at the

flanges. Replace or tighten bolts to specified

torque.

Incorrectly set front joint angle. Install shim under the transmission

support mount to change the front

joint angle.

Shudder on Acceleration (Low

Speed)

Worn universal joint. Replace.

Incorrect shaft runout. Replace.

Shaft out of balance. Adjust.

Transmission rear housing bushing,

transfer case housing bushing worn. Replace.

Vibration

Yoke spline jammed. Replace.

Removal

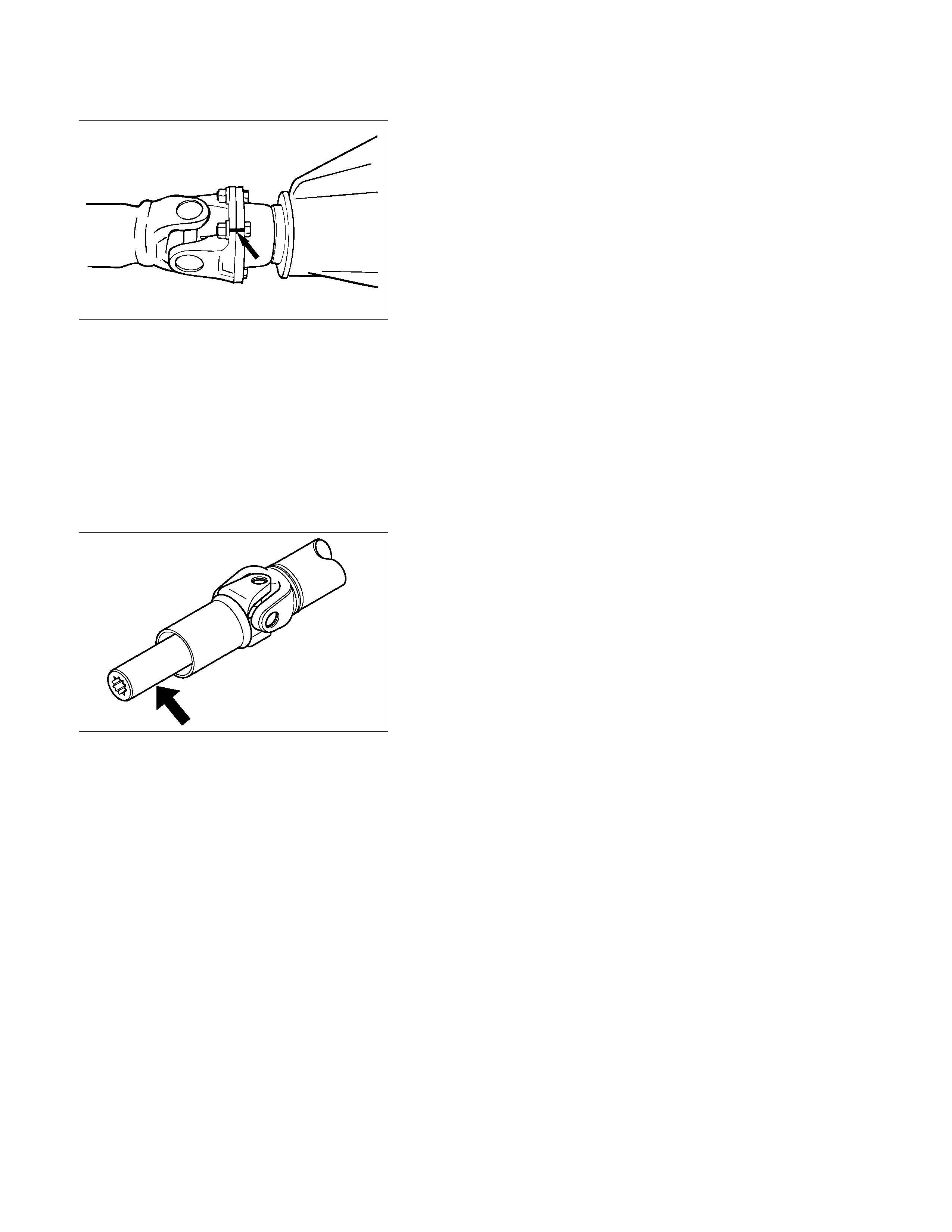

401RS023

1. Raise the vehicle on a hoist.

NOTE:

Apply alignment marks on the flange at the rear

propeller shaft both front and rear side.

2. Remove center bearing fixing bolt.

3. Remove rear axle side bolt, nut and washer.

4. Remove rear propeller shaft.

NOTE:

Plug the hole of the transmission rear end to prevent oil

leakage.

Installation

401L100007

NOTE:

Cover the slip yoke with cloth to avoid damage to the oil seal

contact surface, when removing propeller shaft from

transmission. Do not damage the oil seal contact surface of

slip yoke with other parts at removal and installation.

Completely remove the dust or foreign matter from the

connecting surface of flange coupling on each end of the

propeller shaft.

1. Align the mark which is applied at removal and insert the

propeller shaft in the transmission.

2. Install rear propeller shaft and tighten the bolts to the

specified torque.

Torque: 63 N⋅

⋅⋅⋅m(6.4kg⋅

⋅⋅⋅m/46 lb⋅

⋅⋅⋅ft)

3. Install center bearing and tighten the bolts to the specified

torque.

Torque: 69 N⋅

⋅⋅⋅m(7.0kg⋅

⋅⋅⋅m/51 lb⋅

⋅⋅⋅ft)

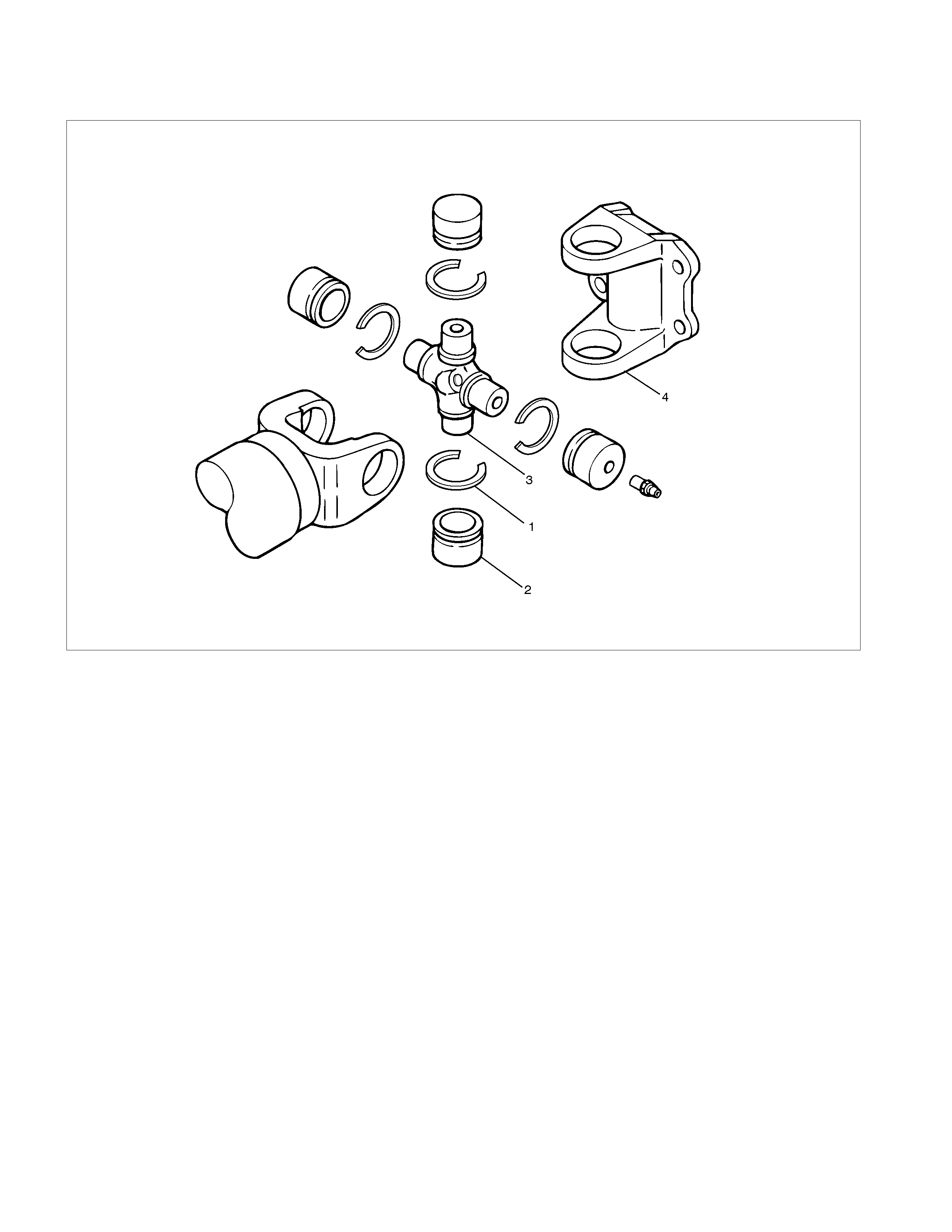

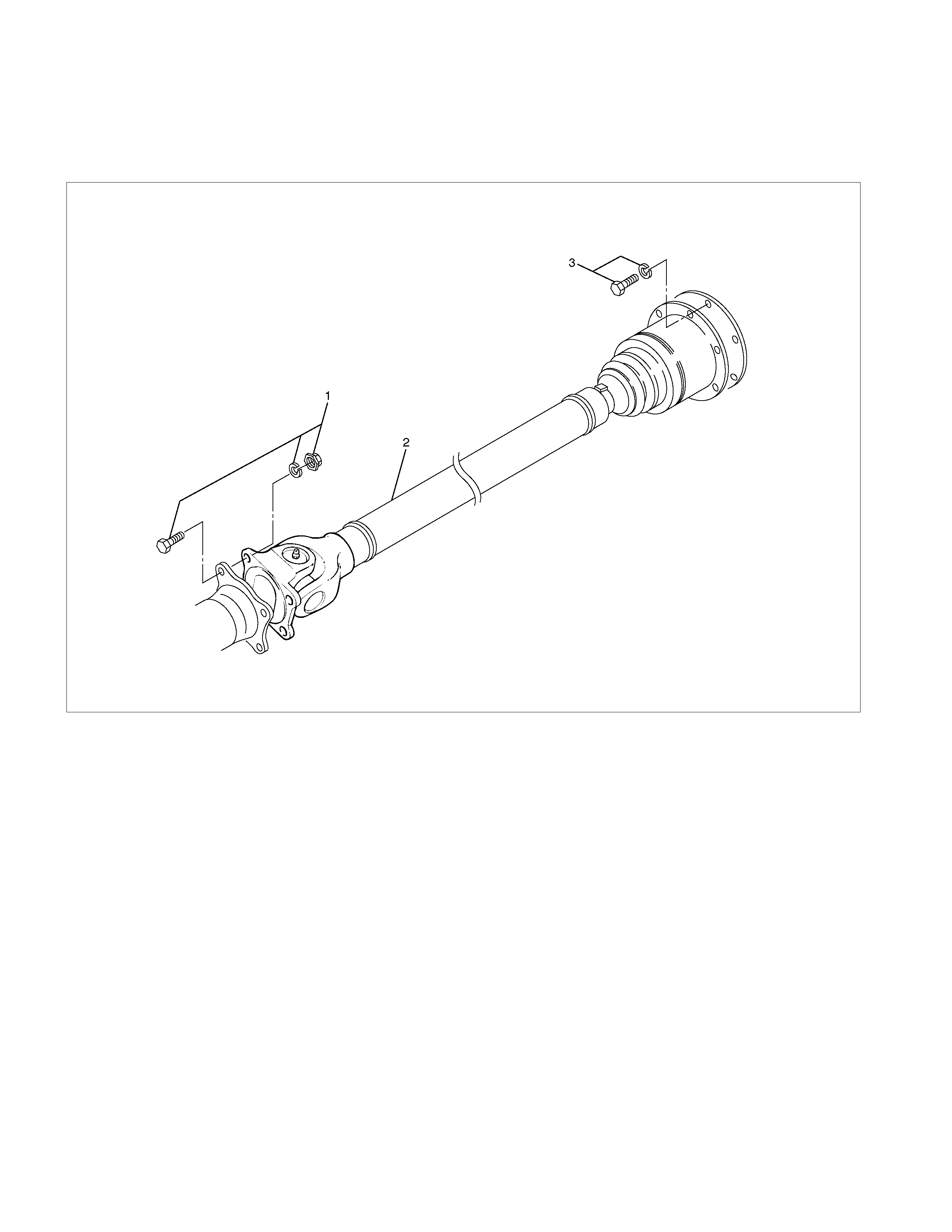

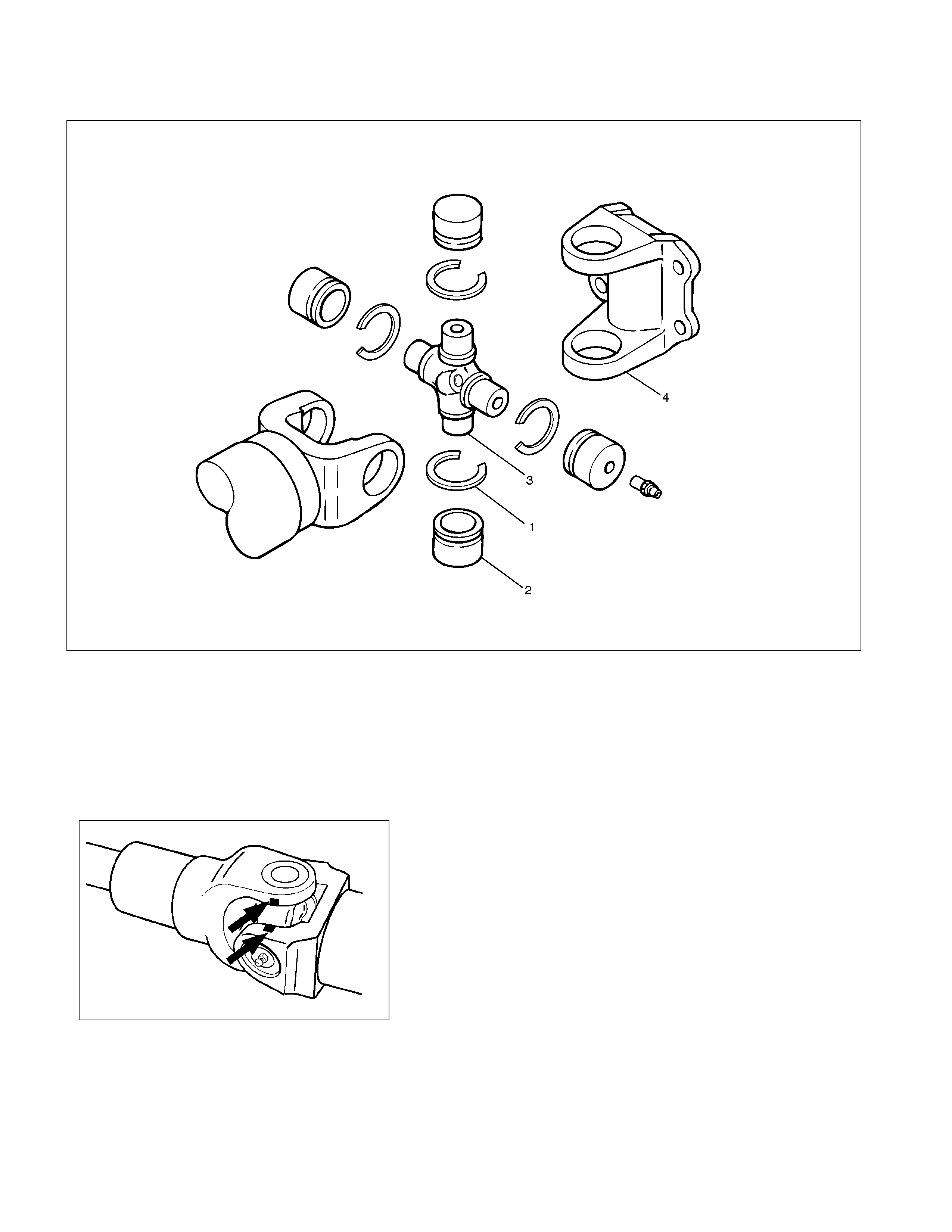

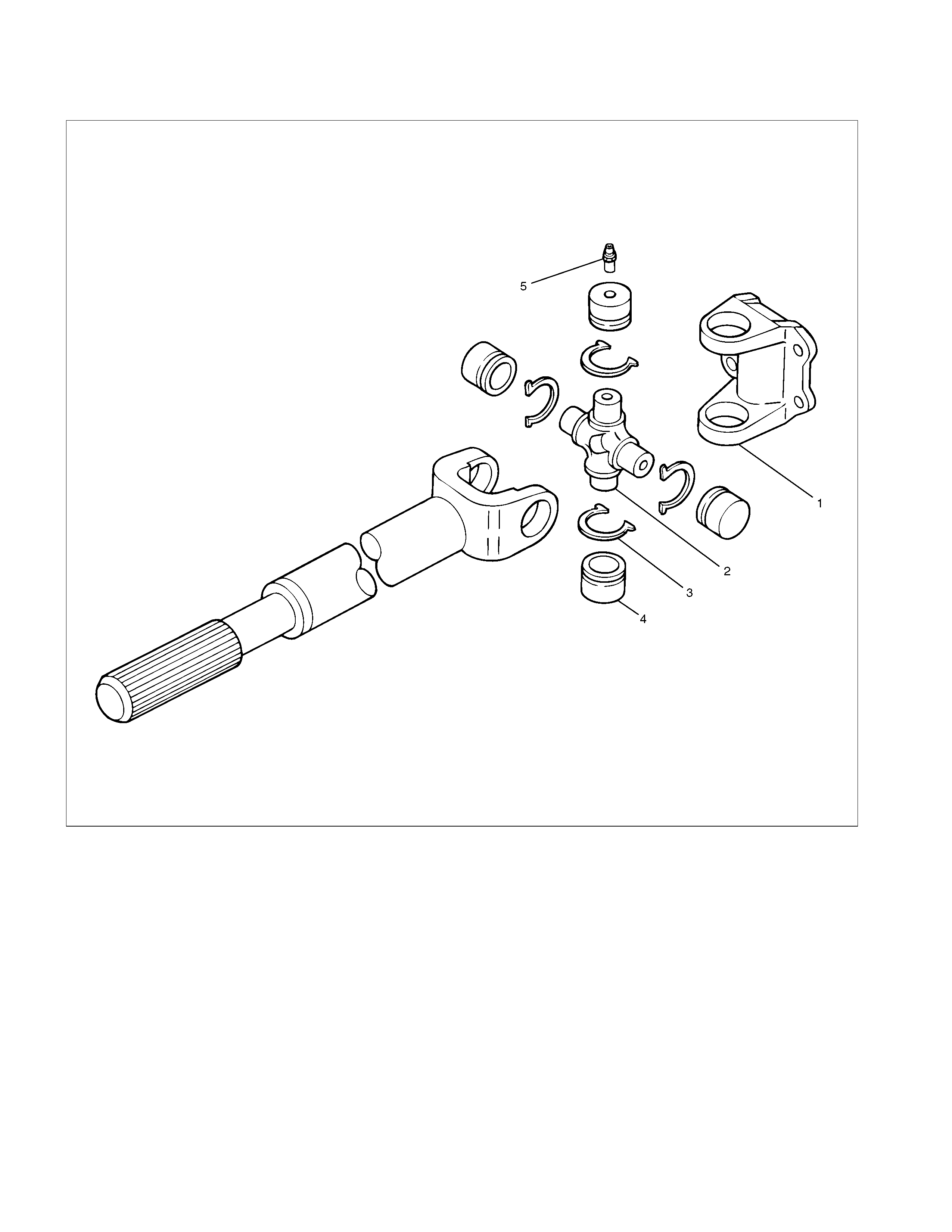

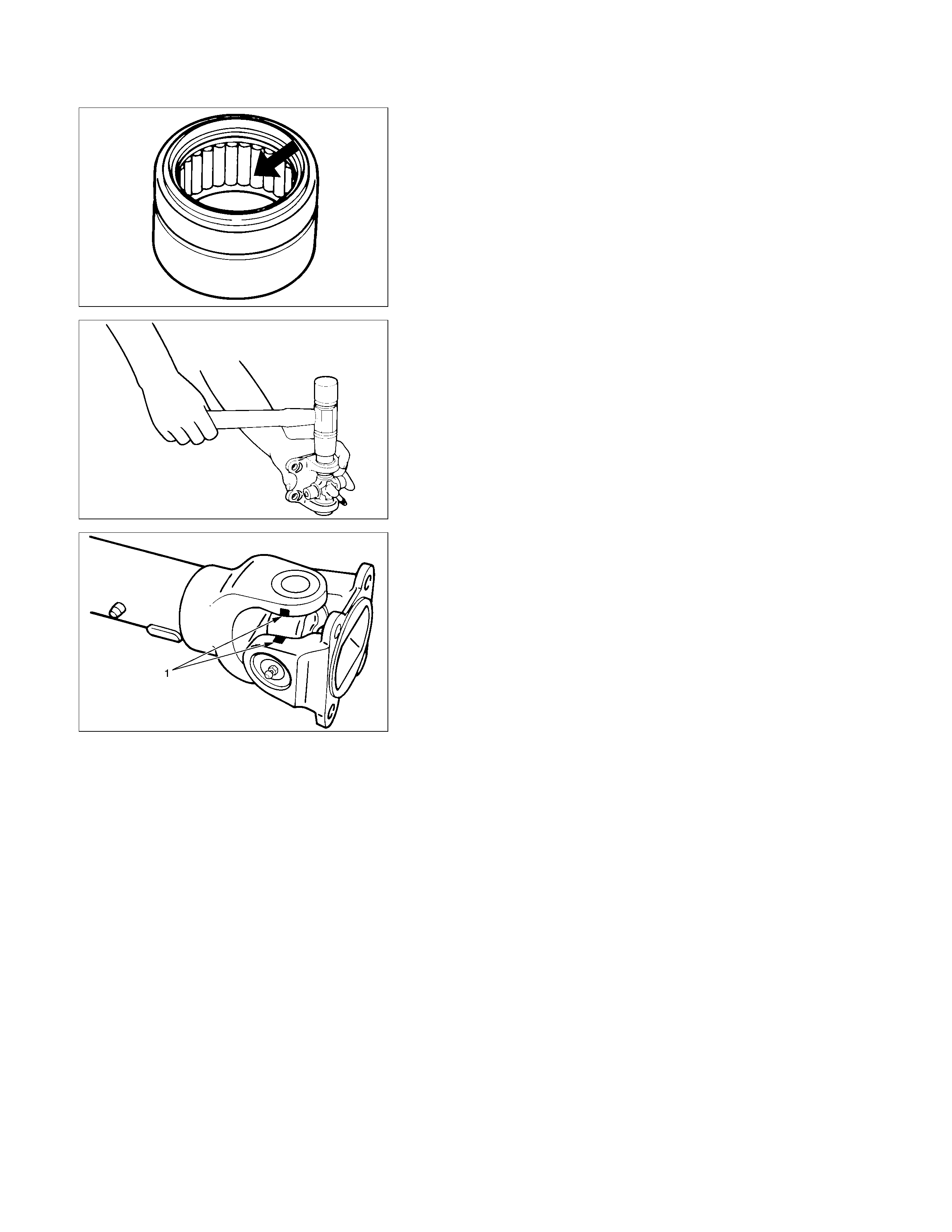

Universal Joint Disassembly

401R300002

Legend

(1). Snap Ring

(2). Needle Roller Bearing

(3). Spider

(4). Propeller Shaft

401R300003

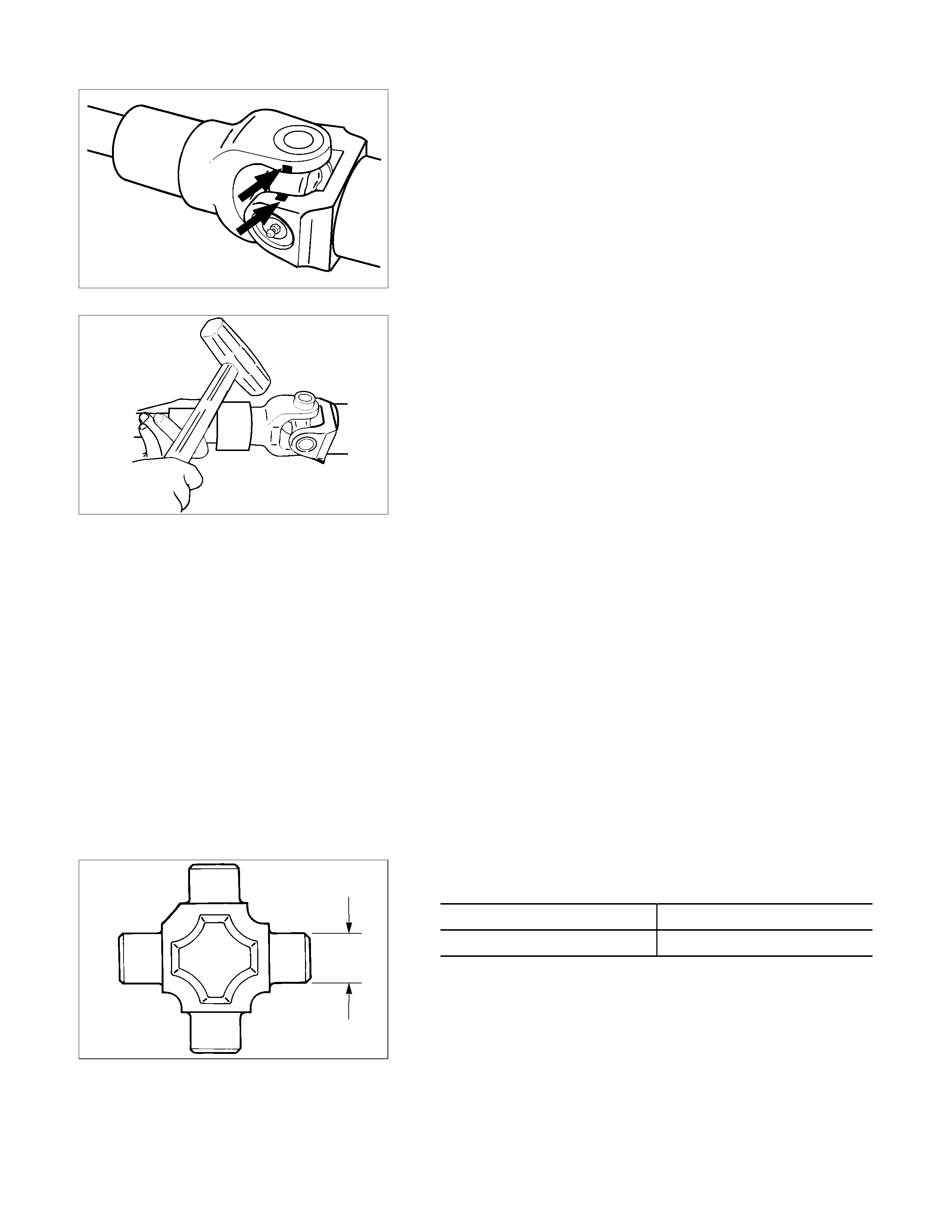

1. Remove the snaprings.

• Apply alignment marks on the yokes of the universal

joint.

401R300004

2. Remove the needle roller bearings.

• Tap out the bearing by gently striking the shoulder of the

yoke, using a mallet or a copper hammer.

3. Remove the spider.

• Make sure of proper position for reinstallation b

y

applying setting marks.

4. Remove the propeller shaft.

Inspection and Repair

Make all necessary adjustment, repairs, and part replacements if wear, damage, or other problems are discovered

during inspection.

Visual Check

Inspect following parts for wear, damage, or other abnormal

conditions.

Spider

Needle roller bearing

Yoke

Flange

Center bearing

Cushioning rubber

Bracket

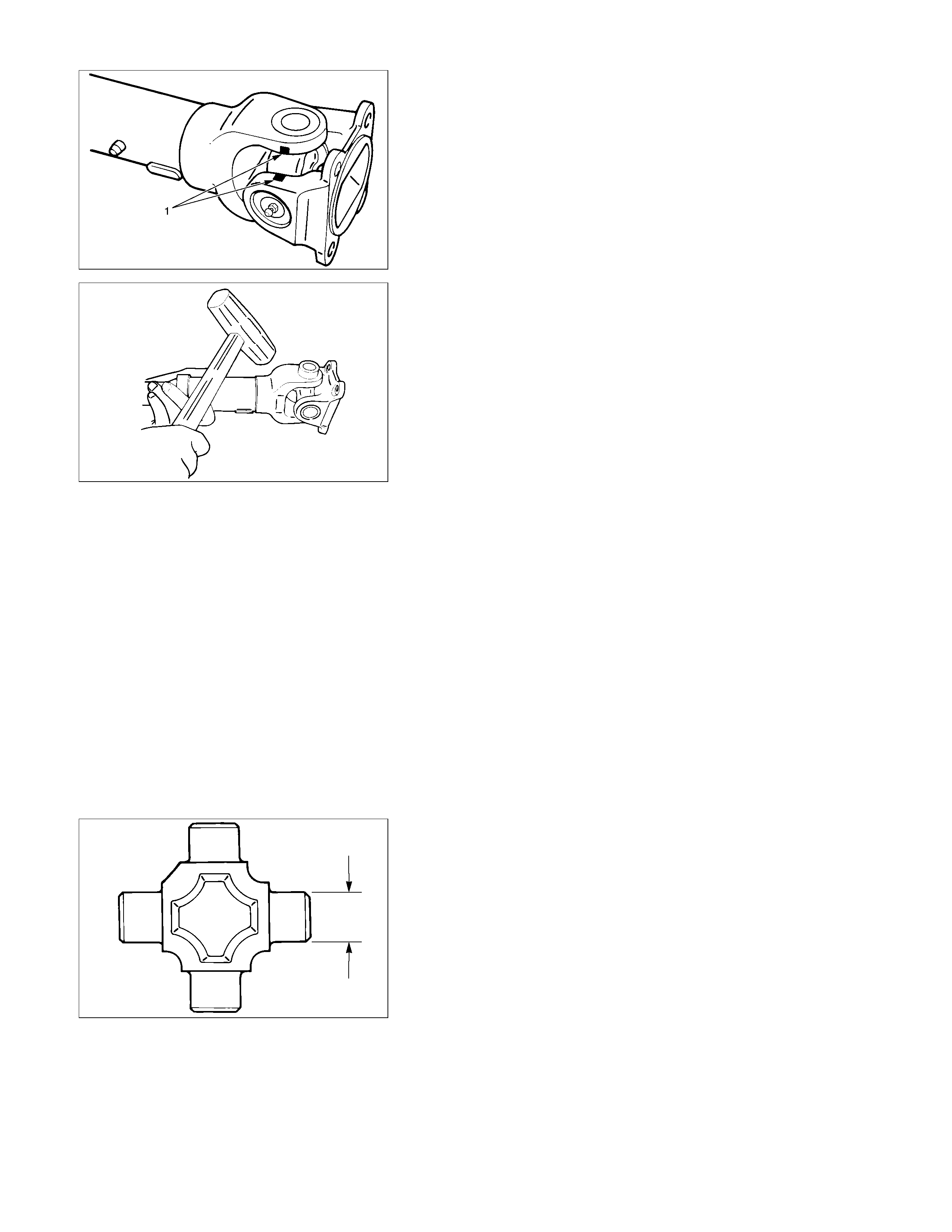

401RS007

Spider Pin Outside Diameter mm(in)

Standard Limit

17 (0.67) 16.99 (0.669)

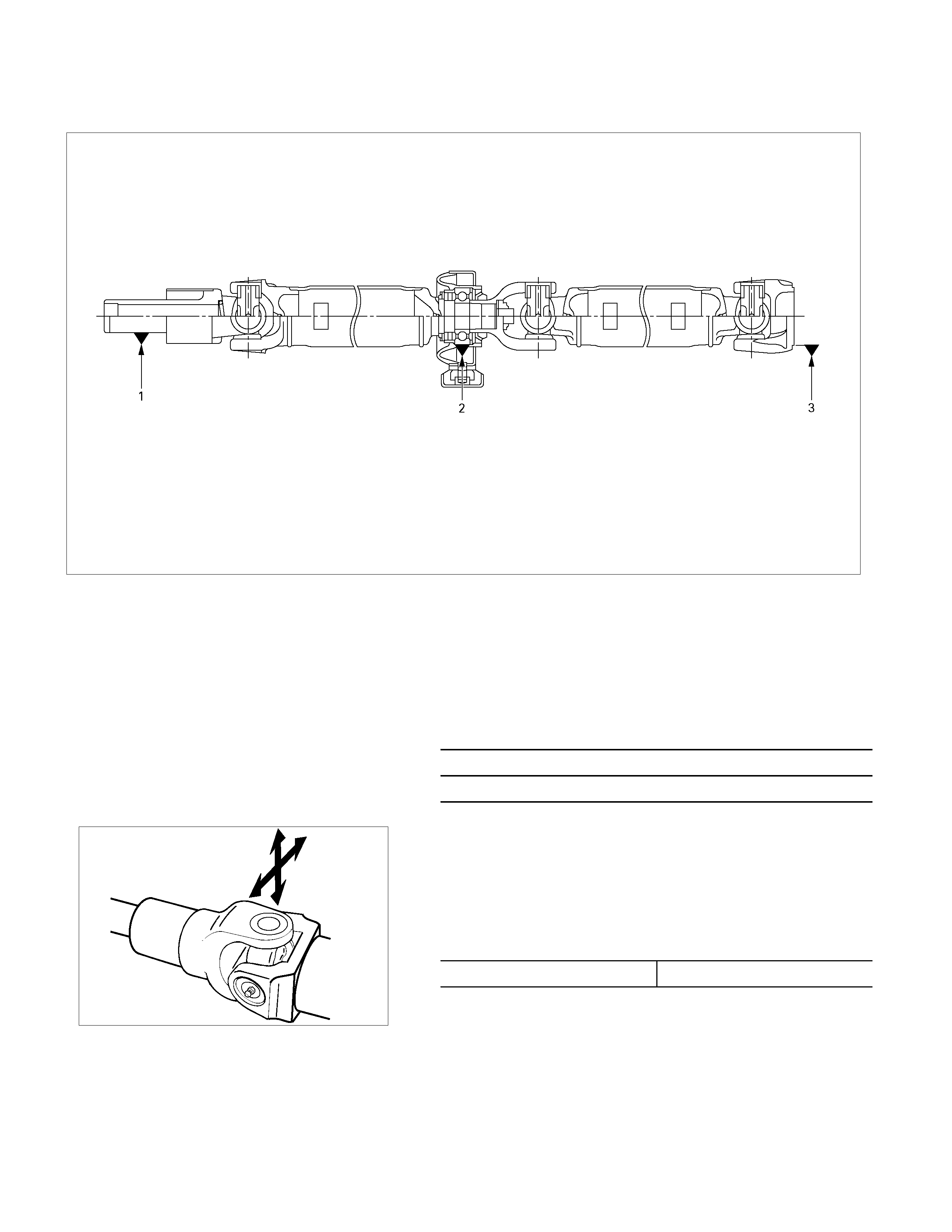

Propeller Shaft Run-Out

401R300005

Support 1 of splined yoke, 2 of center bearing and 3 of flange

yoke and check for static run-out by holding the probe of a dial

indicator in contact with the center part of the shaft and turning

the propeller shaft.

If the amount of run-out is beyond the limit value, correct with a

bench press or replace the shaft with a new one. mm(in)

Limit

1.0 (0.04)

401R300008

Spider Bearing Play

(1) Check the spider bearings for wear or damage.

(2) Check the amount of axial and radial play in spider bearing

by moving the yoke back and forth on the spider axes and

shaft axis. mm(in)

Limit 0.1(0.004)

If the limit is exceeded, replace the shaft assembly.

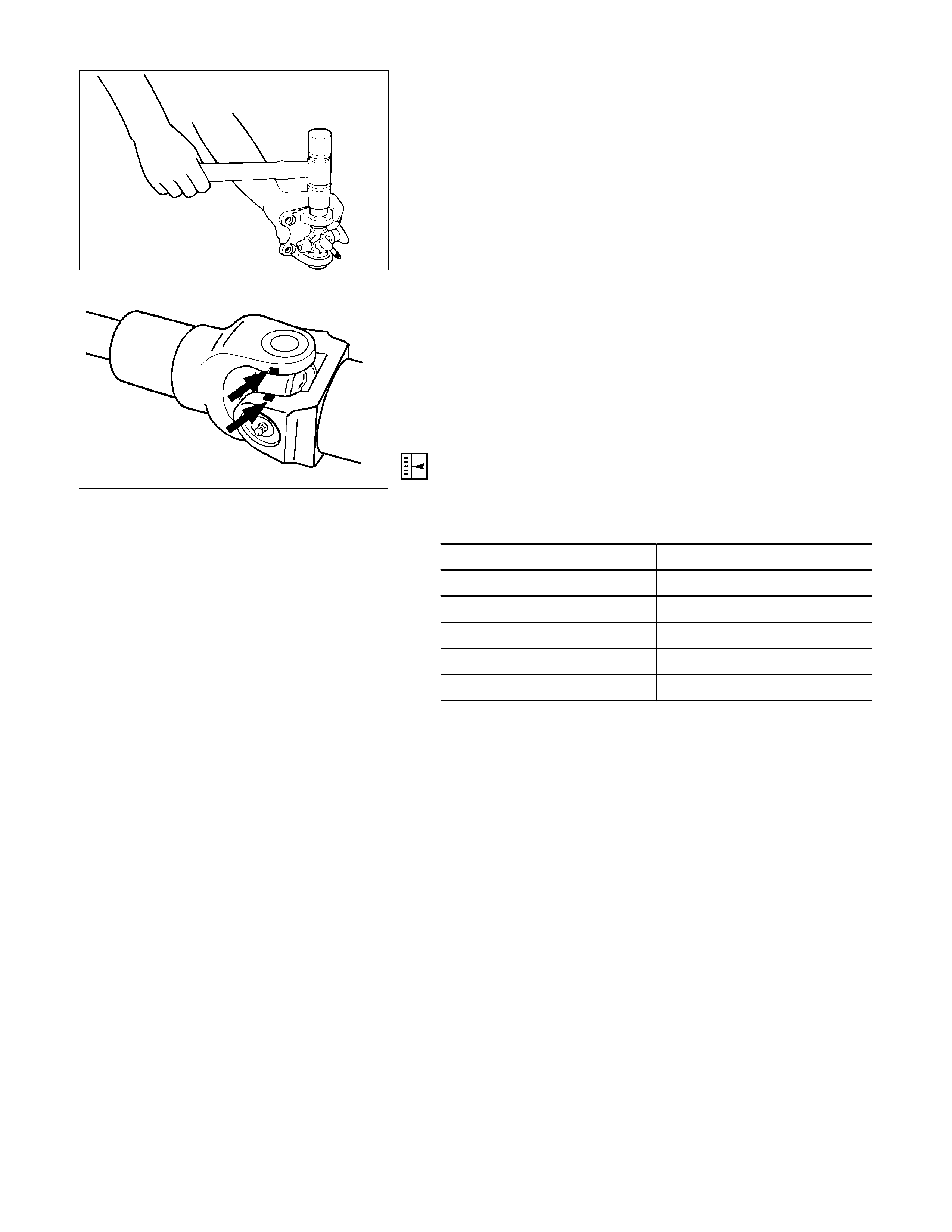

Universal Joint Reassembly

401RS011

1. Set the propeller shafts.

• Be sure to set the propeller shaft yoke by aligning the

setting marks made during dissassembly.

2. Spider

• Be sure to install the spider by aligning the setting marks

made during disassembly.

3. Needle Roller Bearing

1) Apply a molybdenum-disulfide grease or a multi-purpose.

type grease NLGI No.2 to inside of the bearing cap.

Grease Amount g(oz)

Approx. 1.2 (0.042)

401RS012

2) Using either a mallet (or copper hamm er) or a press, ins tall

the needle roller bearing into the yoke s o that snap ring c an

be installed in its groove.

CAUTION:

•

••

• The needle roller bearing cannot be installed smoothly

if it is set at an incorrect angle with the flange.

•

••

• Excessive hammering will damage the needle rolle

r

bearing.

401R300003

3) Align setting marks and join the yokes.

NOTE:

Assemble the spider and spline yoke so that their grease

fittings are arranged on the same side.(4×4)

4. Snap ring

NOTE:

Discard used snap rings and install new ones.

When the bearing cap is in position, select and attach a snap

ring of suitable thickness so that the end play of the spider pin

is held within 0.1mm (0.004in). mm(in)

Snap ring thickness Identification color

1.5 (0.059) Blue

1.545 (0.061) White

1.59 (0.063) Yellow

1.635 (0.064) Green

1.68 (0.066) Not colored

NOTE:

Be sure to use snap rings of the same thickness on both sides.

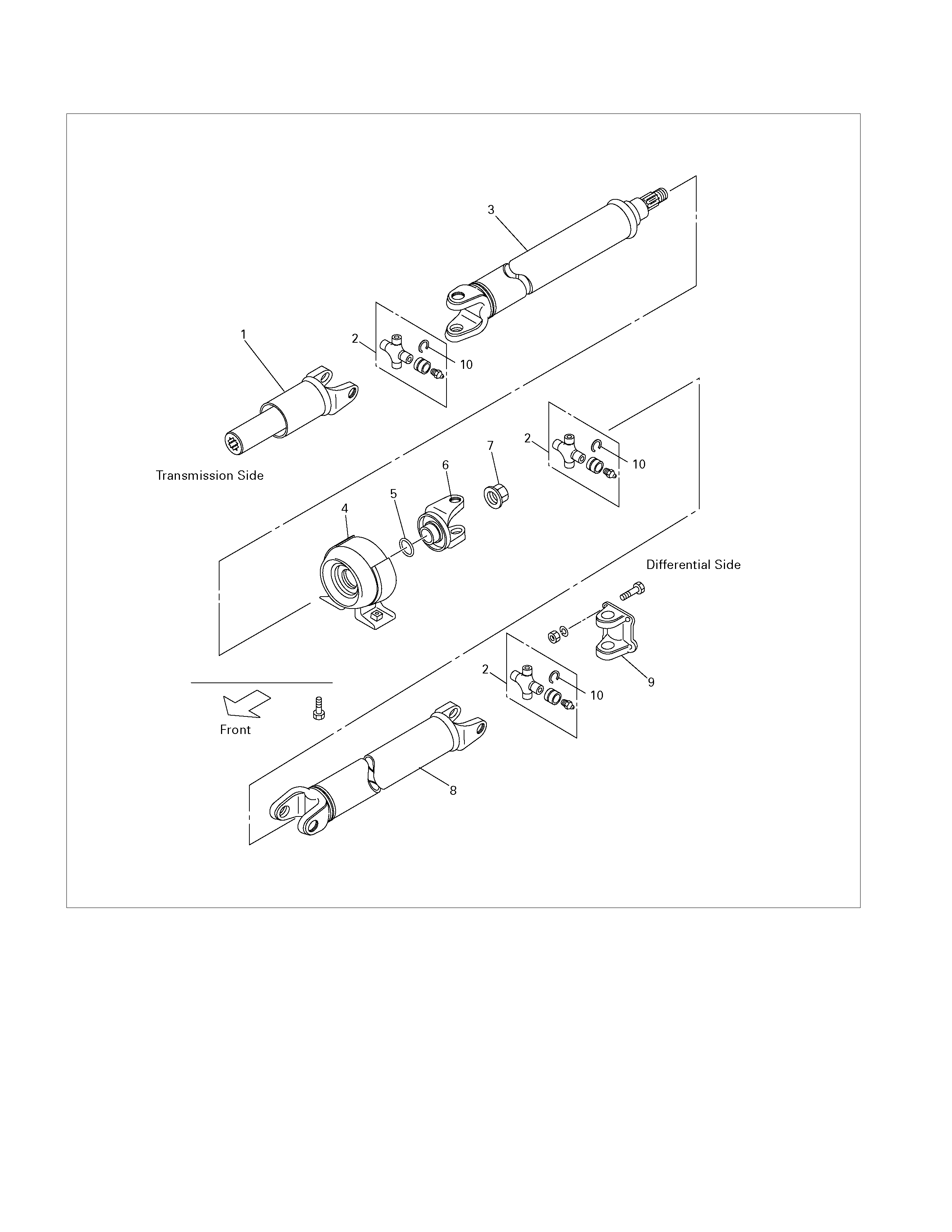

Rear Propeller Shaft Assembly

401R300009

Legend

(1). Splined Yoke

(2). Journal Assembly

(3). 1st Tube Assembly

(4). Center Bearing

(5). Plain Washer

(6). Center Yoke

(7). Lock Nut

(8). 2nd Tube Assembly

(9). Flange Yoke

(10). Snap Ring

Disassembly

1. Disassembly the three portions of the journal assemblies.

2. Remove the s plined yoke, the 1st tube ass em bly with cente

r

bearing, the 2nd tube assembly and the flange yoke.

3. Remove the lock nut.

4. Remove the center yoke, the plain washer the cente

r

bearing and the 1st tube assembly.

Reassembly

1. Install the center bearing on the 1st tube assembly.

Clean the bearing fitting face.

Repack the grease.

Amount of grease

required g(oz)

Approx. 12 (0.42)

2. Install the plain washer and the center yoke.

3. Install the lock nut and tighten it to the specified torque.

Lock nut Torque : 118 N⋅

⋅⋅⋅m (12.0kg⋅

⋅⋅⋅m/87lb⋅

⋅⋅⋅ft)

(1) Discard the flange nut and install a new one.

(2) Stak e the outer f ace of the flange nut agains t the slot in the

shaft.

4. Install the splined yoke, the 1st tube assembly with cente

r

bearing, the 2nd tube assembly and the flange yoke b

y

assembling the universal joint.

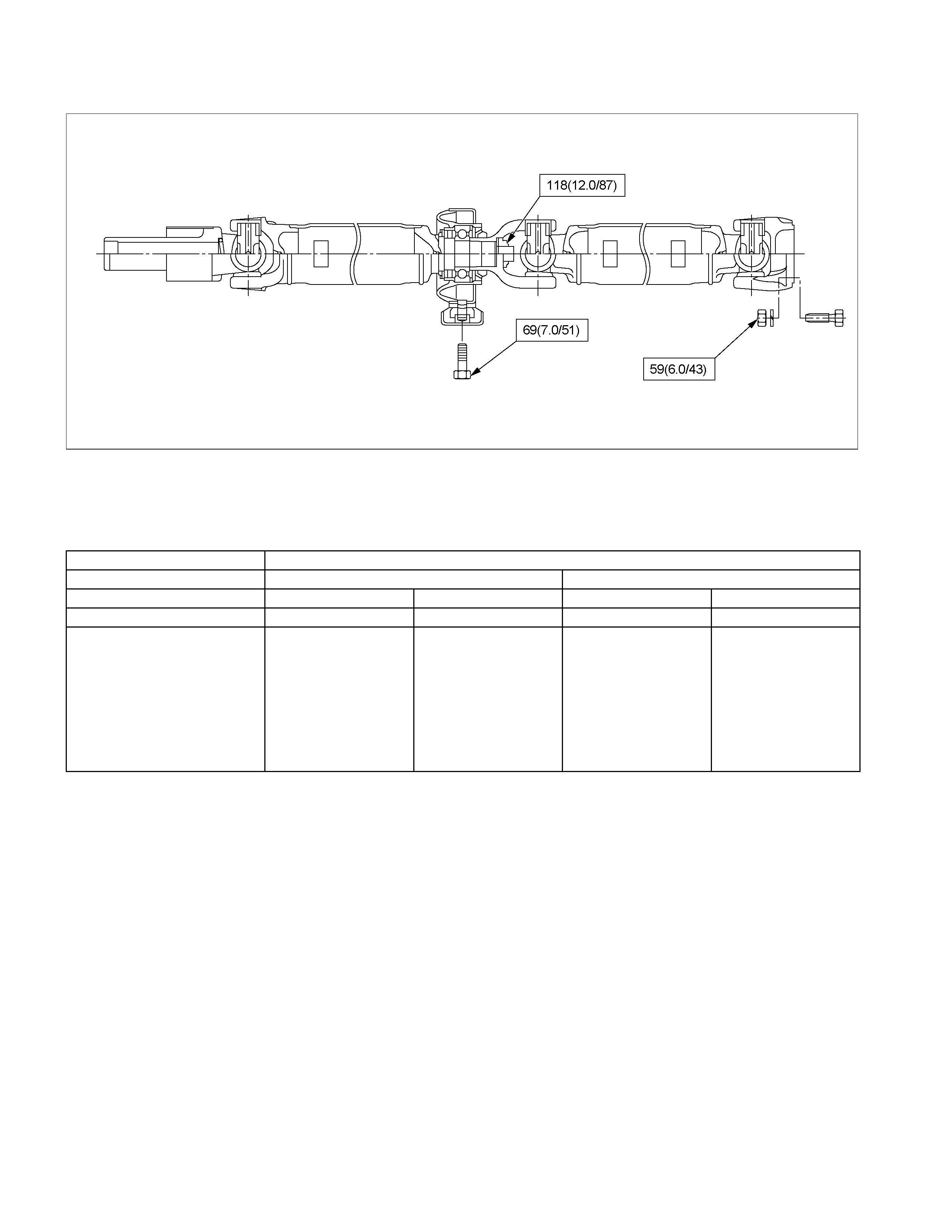

Front Propeller Shaft (4JH1-TC)

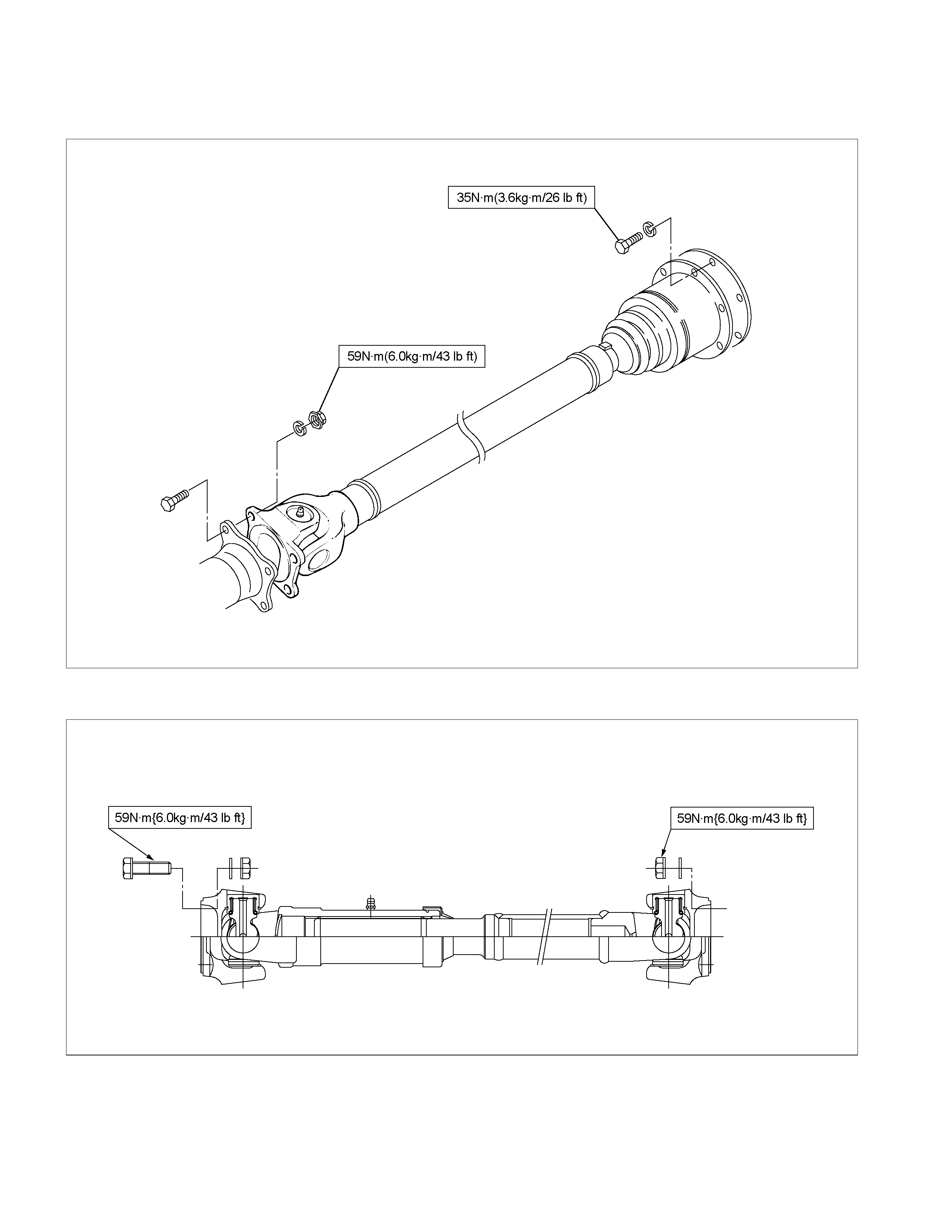

Removal and Installation

401R300014

Legend

(1) Bolt, Nut and Washer (Front Axle Side)

(2) Front Propeller Shaft

(3) Bolt and Washer (Transfer Side)

401RS023

Removal

1. Raise the vehicle on a hoist.

NOTE:

Apply alignment marks on the flange at the rear

propeller shaft both front and rear side.

2. Remove front axle side bolt, nut and washer.

3. Remove transfer side bolt and washer.

4. Remove rear propeller shaft.

401R300017

Inspection and Repair

Propell er Shaft Run-Out

Support the propeller shaft on V-blocks and check for runout

by holding the probe of a dial indicator in contact with the shaft.

If the amount of run-out is beyond the limit value, correct with a

bench press or replace the shaft with a new one. mm(in)

Limit

1.0 (0.04)

401R300008

Spider Bearing Play

(1) Check the spider bearings for wear or damage.

(2) Check the amount of axial and radial play in spider bearing

by moving the yoke back and forth on the spider axes and

shaft axis. mm(in)

Limit 0.1(0.004)

If the limit is exceeded, replace the shaft assembly.

Installation

NOTE:

Completely remove the dust or foreign matter from the

connecting surface of flange coupling on each end of the

propeller shaft.

1. Align the mark which is applied at removal.

Install front propeller shaft and tighten the bolts to the

specified torque.

Transfer Side Bolt Torque: 35N⋅

⋅⋅⋅m (3.6kg⋅

⋅⋅⋅m/26 lb⋅

⋅⋅⋅ft)

Front Axle Bolt Torque: 59N⋅

⋅⋅⋅m (6.0kg⋅

⋅⋅⋅m/43 lb⋅

⋅⋅⋅ft)

Universal Joint Disassembly and Reassembly

401R300002

Legend

(1) Snap Ring

(2) Needle Roller Bearing

(3) Spider

(4) Propeller Shaft

401R300003

Disassembly

1. Remove the snaprings.

•

A

pply alignment marks on the yokes of the universal

joint.

401R300004

2. Remove the needle roller bearings.

• Tap out the bearing by gently s trik ing the shoulder of the

yoke, using a mallet or a copper hammer.

3. Remove the spider.

• Make sure of proper position for reinstallation b

y

applying setting marks.

4. Remove the propeller shaft.

Inspection and Repair

Make all necessary adjustment, repairs, and part replacements

if wear, damage, or other problems are discovered during

inspection.

Visual Check

Inspect following parts for wear, damage, or other abnormal

conditions.

Spider

Needle roller bearing

Yoke

Flange

Center bearing

Cushioning rubber

Bracket

401RS007

Spider Pin Outside Diameter mm(in)

Standard Limit

17 (0.67) 16.99 (0.669)

401RS011

Reassembly

1. Set the propeller shafts.

• Be sure to set the propeller shaft yoke by aligning the

setting marks made during dissassembly.

2. Spider

• Be sur e to ins tall the s pider by aligning the setting mark s

made during disassembly.

3. Needle Roller Bearing

1) Apply a molybdenum-disulfide grease or a multi-

purpose. type grease NLGI No.2 to ins ide of the bearing

cap.

Grease Amount g(oz)

Approx. 1.2 (0.042)

401R5012

2) Using either a mallet (or copper hammer) or a press,

install the needle roller bearing into the yoke so that

snap ring can be installed in its groove.

CAUTION:

•

••

• The needle roller bearing cannot be installed smoothly

if it is set at an incorrect angle with the flange.

•

••

• Excessive hammering will damage the needle rolle

r

bearing.

401R300003

3) Align setting marks and join the yokes.

NOTE:

Assemble the spider and spline yoke so that their grease

fittings are arranged on the same side.(4×4)

4. Snap ring

NOTE:

Discard used snap rings and install new ones.

When the bearing cap is in position, select and attach a snap

ring of suitable thickness so that the end play of the spider pin

is held within 0.1mm (0.004in). mm(in)

Snap ring thickness Identification color

1.5 (0.059) Blue

1.545 (0.061) White

1.59 (0.063) Yellow

1.635 (0.064) Green

1.68 (0.066) Not colored

NOTE:

Be sure to use snap rings of the same thickness on both sides.

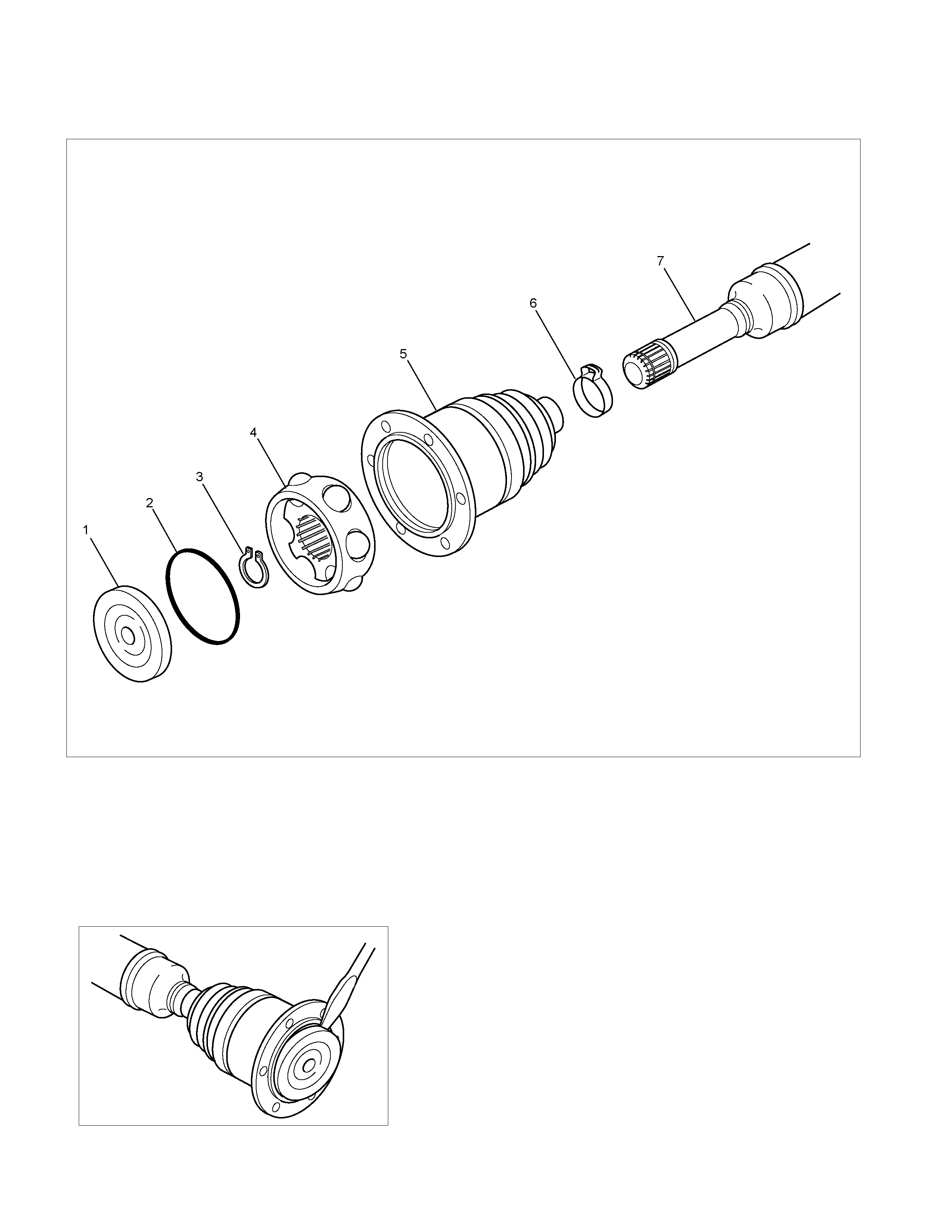

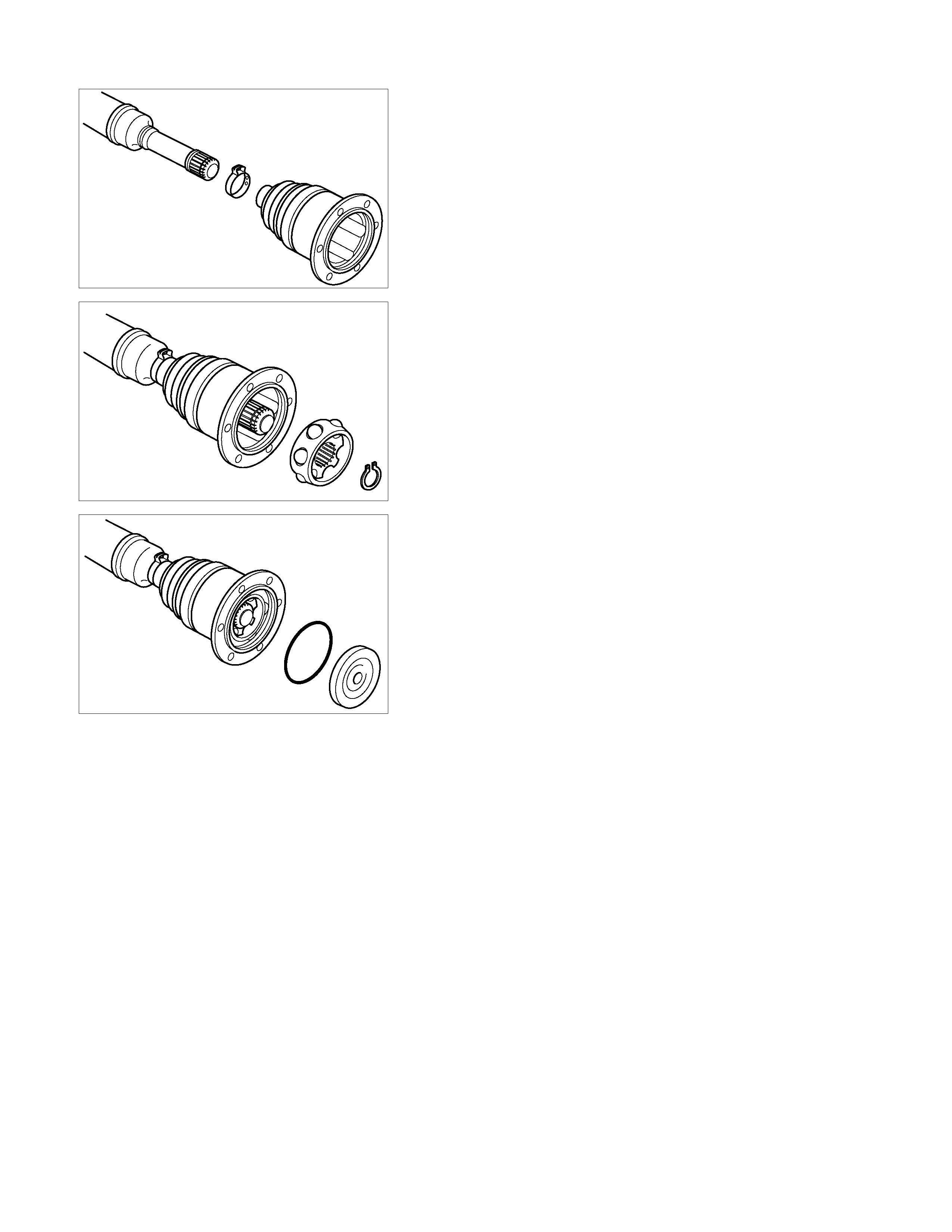

DOJ Disassembly and Reassembly

RTW34MF000201

Legend

(1) Seal Plate

(2) O-ring

(3) Snap Ring

(4) Ball, Ball Retainer, Ball Guide

(5) DOJ Case and Bellows ASM

(6) Band

(7) Shaft

RTW34ASH000101

Disassembly

1. Pry off the seal plate

2. Remove the O-ring.

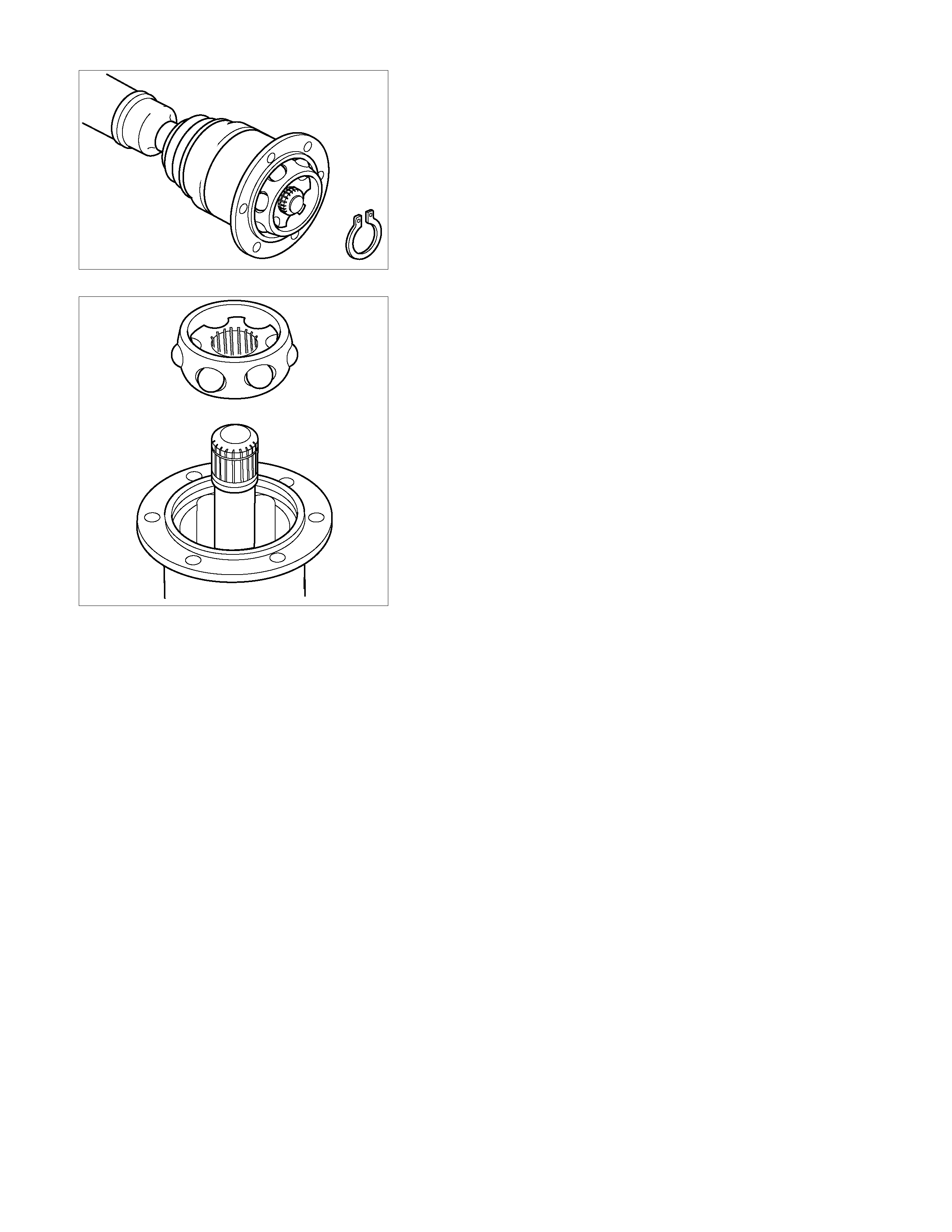

RTW34ASH000201

3. Remove the snap ring.

RTW34ASH000701

4. Remove the ball, ball retainer and ball guide.

5. Remove the band.

6. Remove DOJ case bellows ASM.

Inspection And Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition are found

through inspection.

RTW34ASH000401

Reassembly

1. Install a new band.

2. Pack 75g of specified grease in bellows.

The specified grease is included in the DOJ kit.

3. Apply a thin coat of grease to the shaft for smooth

installation then install DOJ case and bellows ASM.

RTW34ASH000501

4. Install the ball, ball retainer and ball guide with the small

diameter side ahead onto the shaft.

5. Use snap ring pliers, install a new snap ring securing the

ball retainer to the shaft.

NOTE:

• Do not extend the snap ring too much.

Snap ring stretching will result in reduce snap ring tension.

• Use only new snap rings. Do not install the old ones.

RTW34ASH000601

6. Pack 45g of specified grease in DOJ case.

The specified grease is included in the DOJ kit.

7. Install a new O-ring into the DOJ case groove.

8. Install a new seal plate.

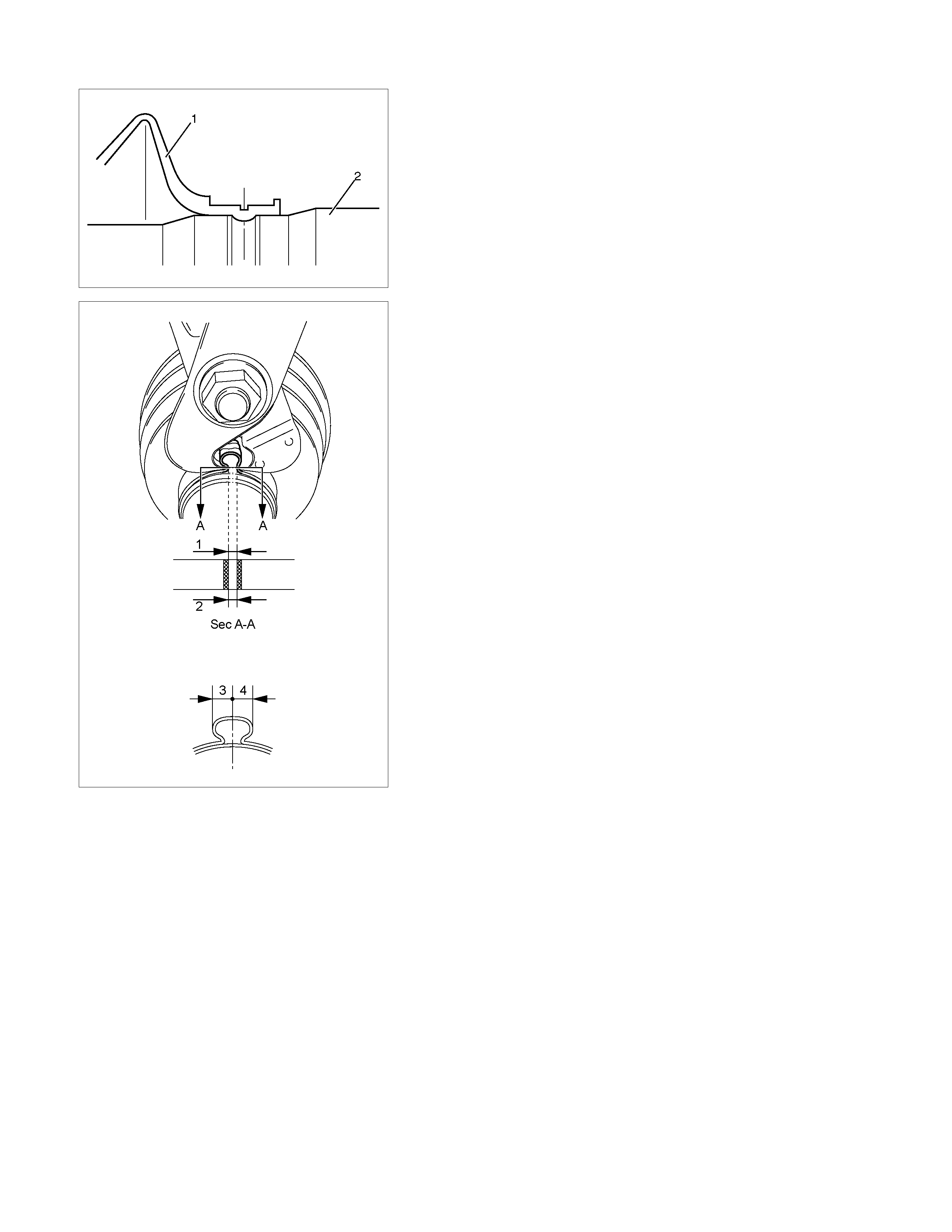

412R100007

9. During bellows assem bly, be sure to insert sm all end of the

bellows (1) into the shaft (2) groove.

RTW24AMH000101

10. Use the special tool pliers 5-8840-2745-0 to caulk the

bands to the specified value.

After installation, check Standard Caulk Measure.

Standard Caulk Measure

• 1.2mm (0.05in) <= (1) and (2) <= 4.0mm (0.16in)

• (1) − (2) or (2) − (1) <= 0.4mm (0.016in)

• (3) ≈ (4)

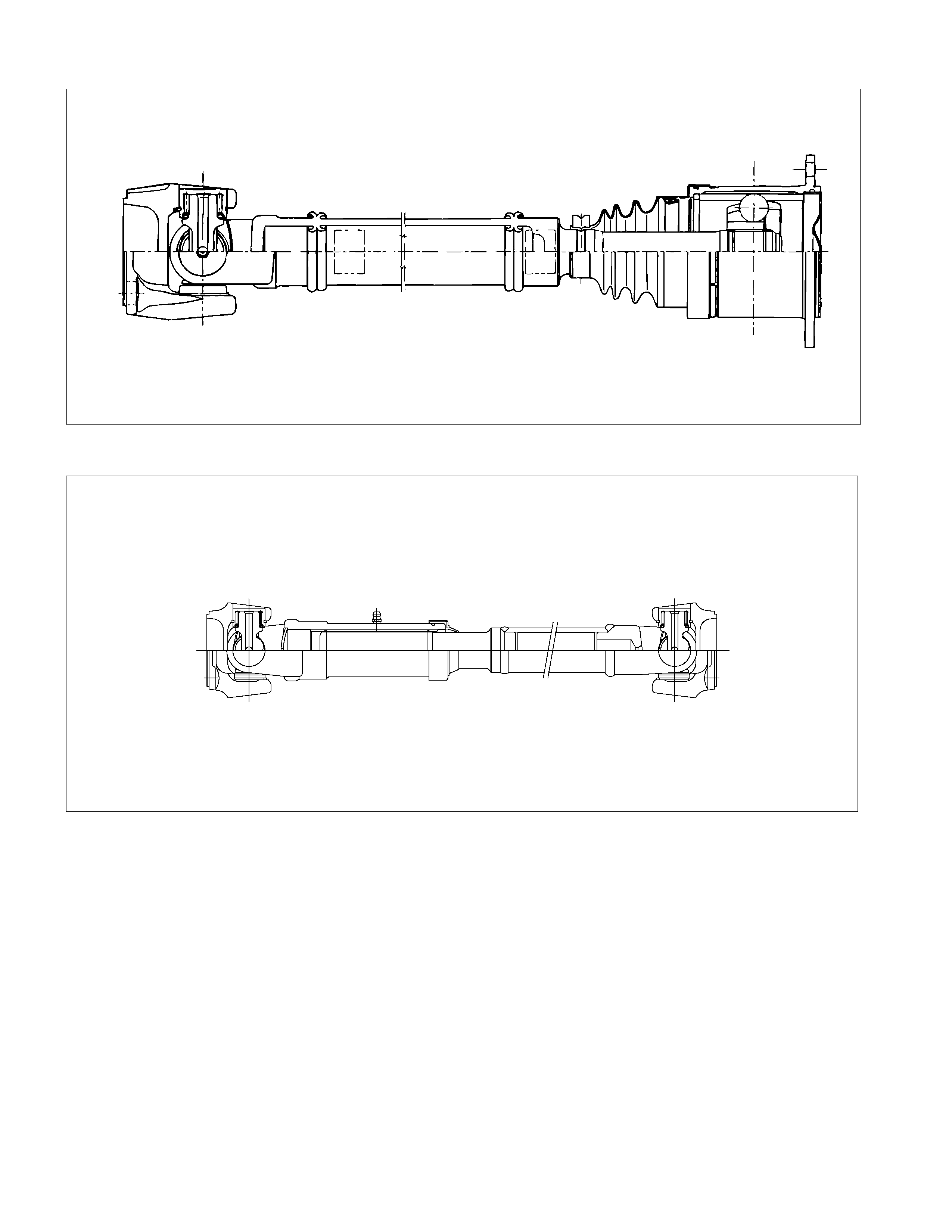

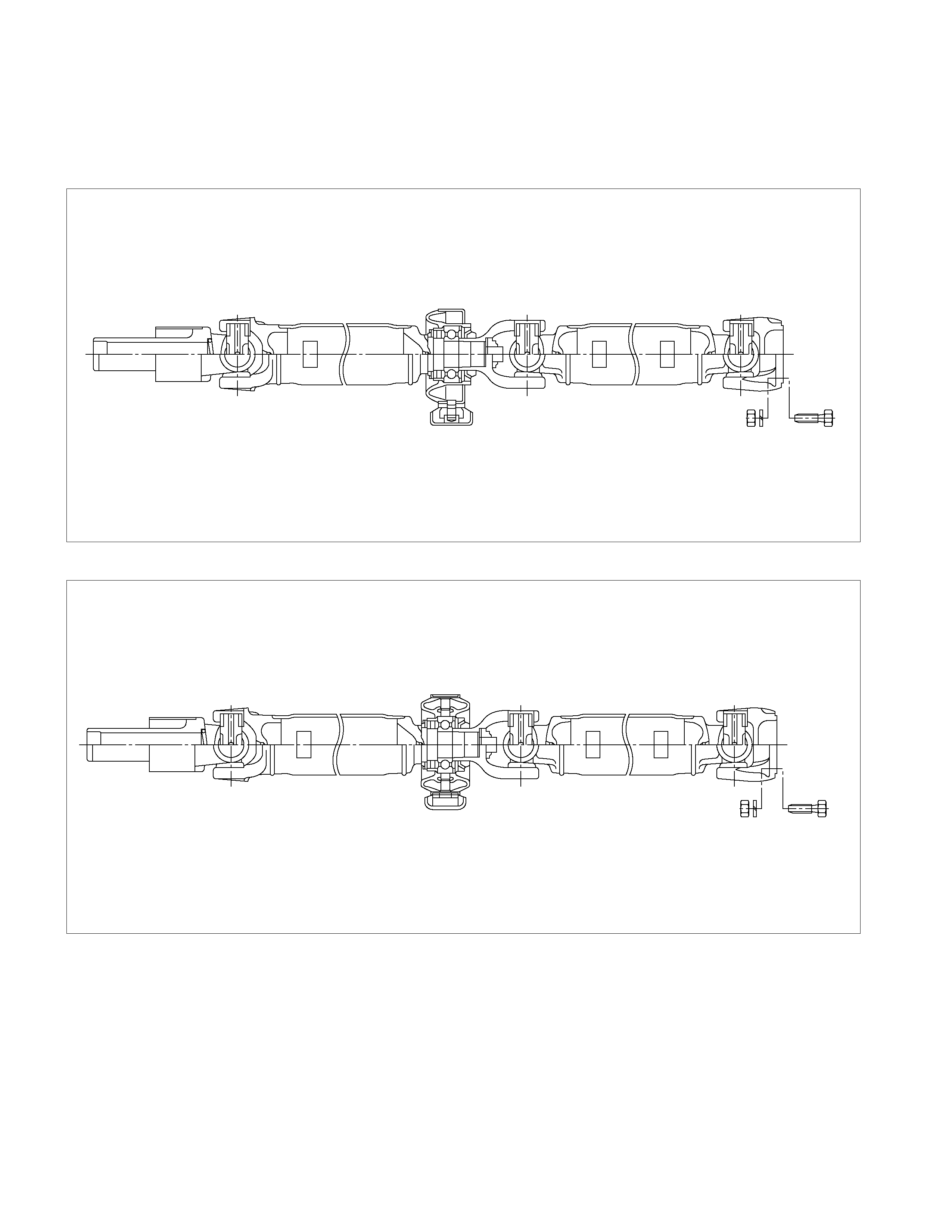

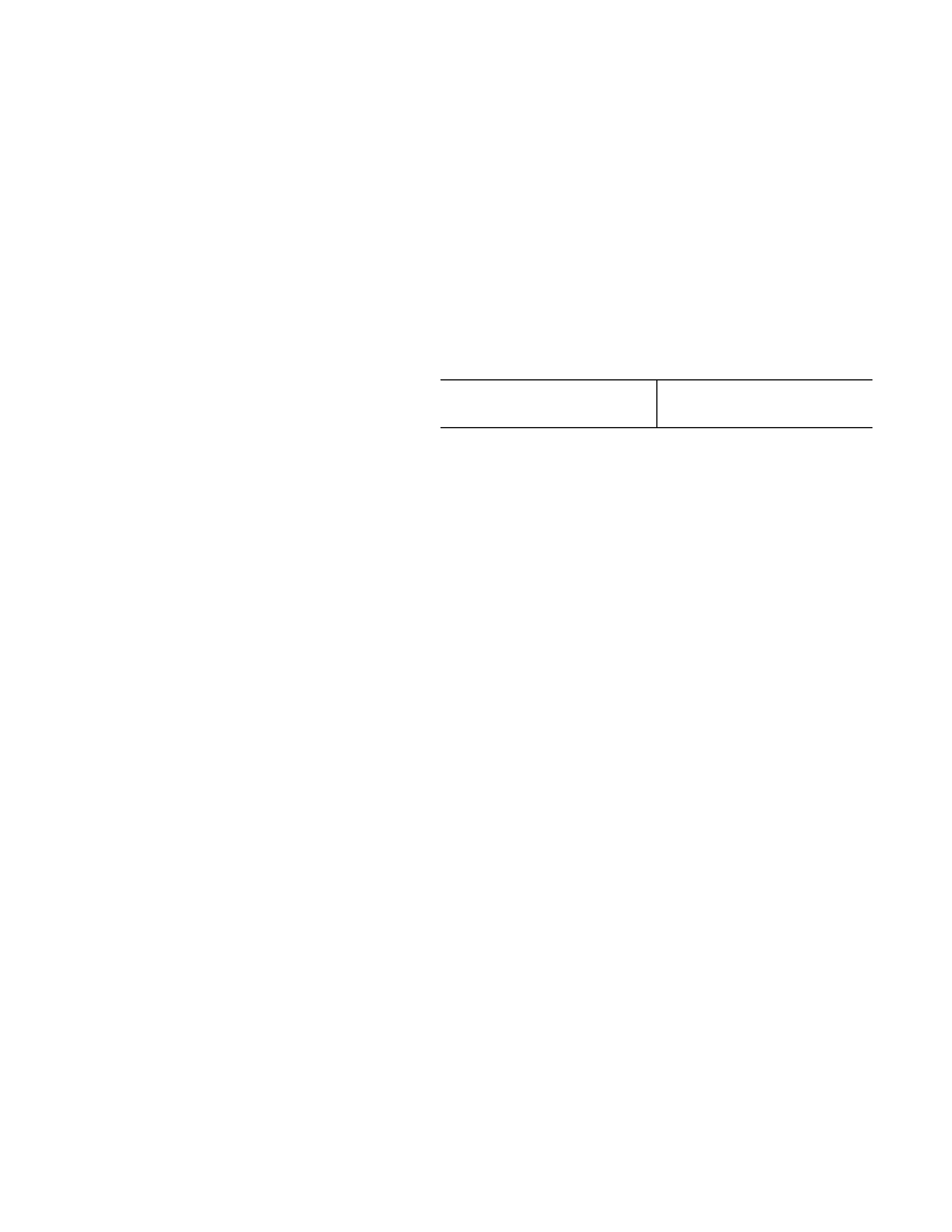

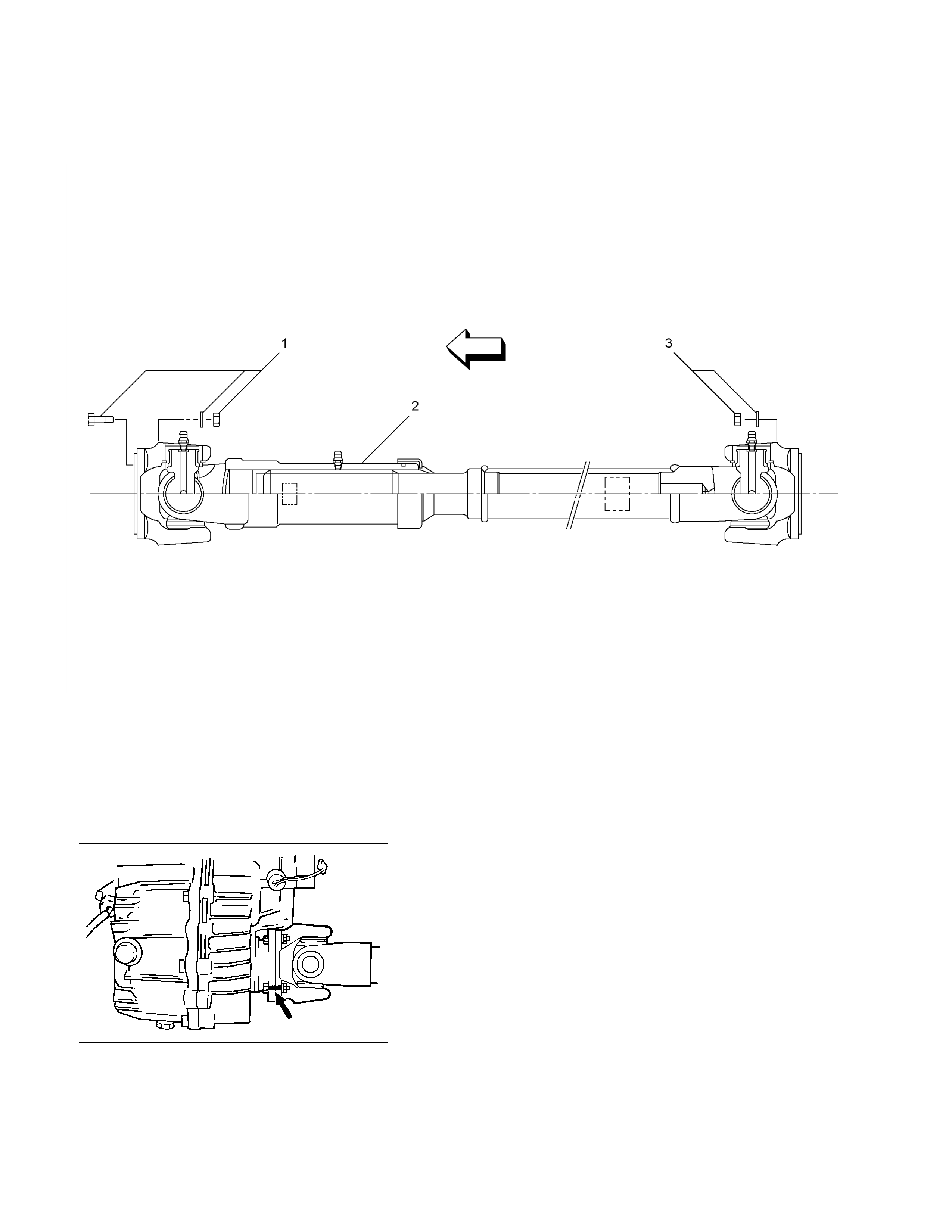

Front Propeller Shaft (6VE1)

Removal and Installation

RTW34AMF000301

Legend

(1) Bolt, Nut and Washer (Front Axle Side)

(2) Front Propeller Shaft

(3) Nut and Washer (Transfer Side)

401RS020

Removal

1. Jack up the vehicle and support it on the chassis stands.

2. Gear shift lever should be placed in neutral position and

parking brake released.

3. Remove the exhaust and transfer protectors.

NOTE:

Apply alignment marks on the flange at the front propeller shaft

both front and rear side.

4. Remove bolt, nut and washer (Front axle side).

5. Remove bolt, nut and washer (Transfer side).

6. Remove front propeller shaft.

Installation

NOTE:

Never install the shaft assembly backwards. Completely

remove the black paint from the connecting surface of flange

coupling on each end of propeller shaft. Clean so that no

foreign matter will be caught in between.

1.

A

lign the mark which was applied at removal. Install front

propeller shaft and tighten the bolts and nuts to the

specified torque.

Torque: 59 N⋅

⋅⋅⋅m (6.0 kg⋅

⋅⋅⋅m/43 lb ft)

2. Install the exhaust and transfer protectors.

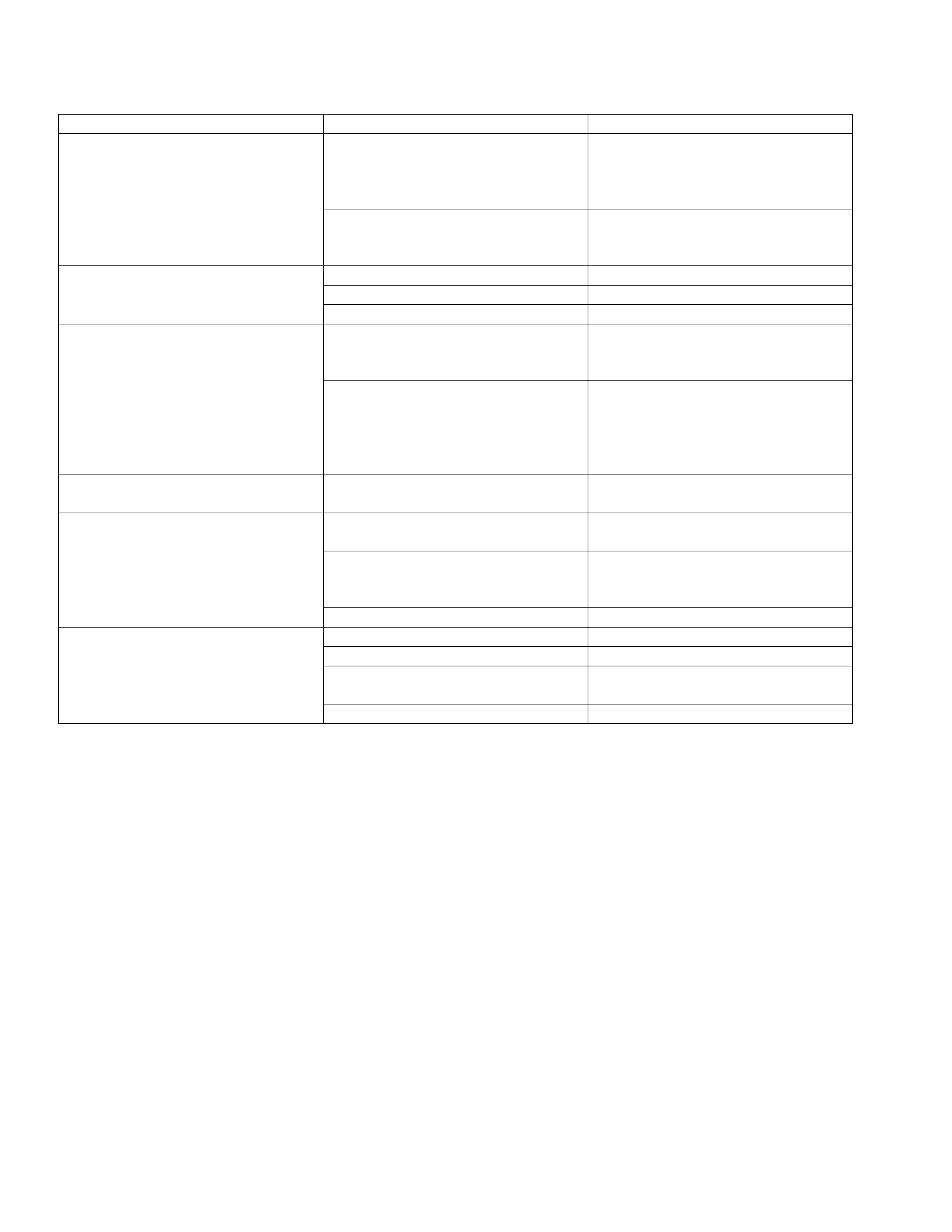

401RS019

3.

A

fter installing the propeller shaft, be sure to apply black

paint (1) to exposed area (other than connec ting surf ace) o

f

the entire surface of flange coupling.

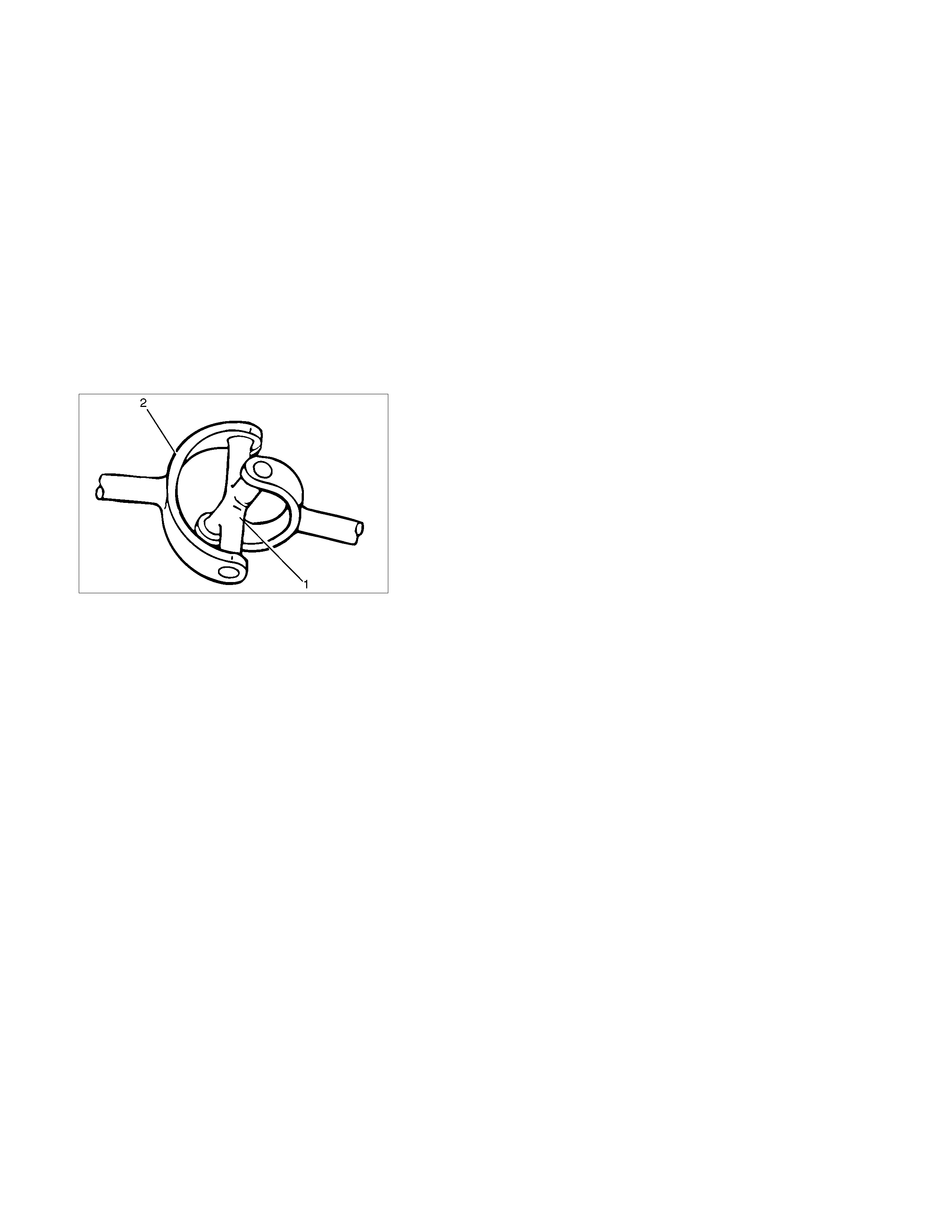

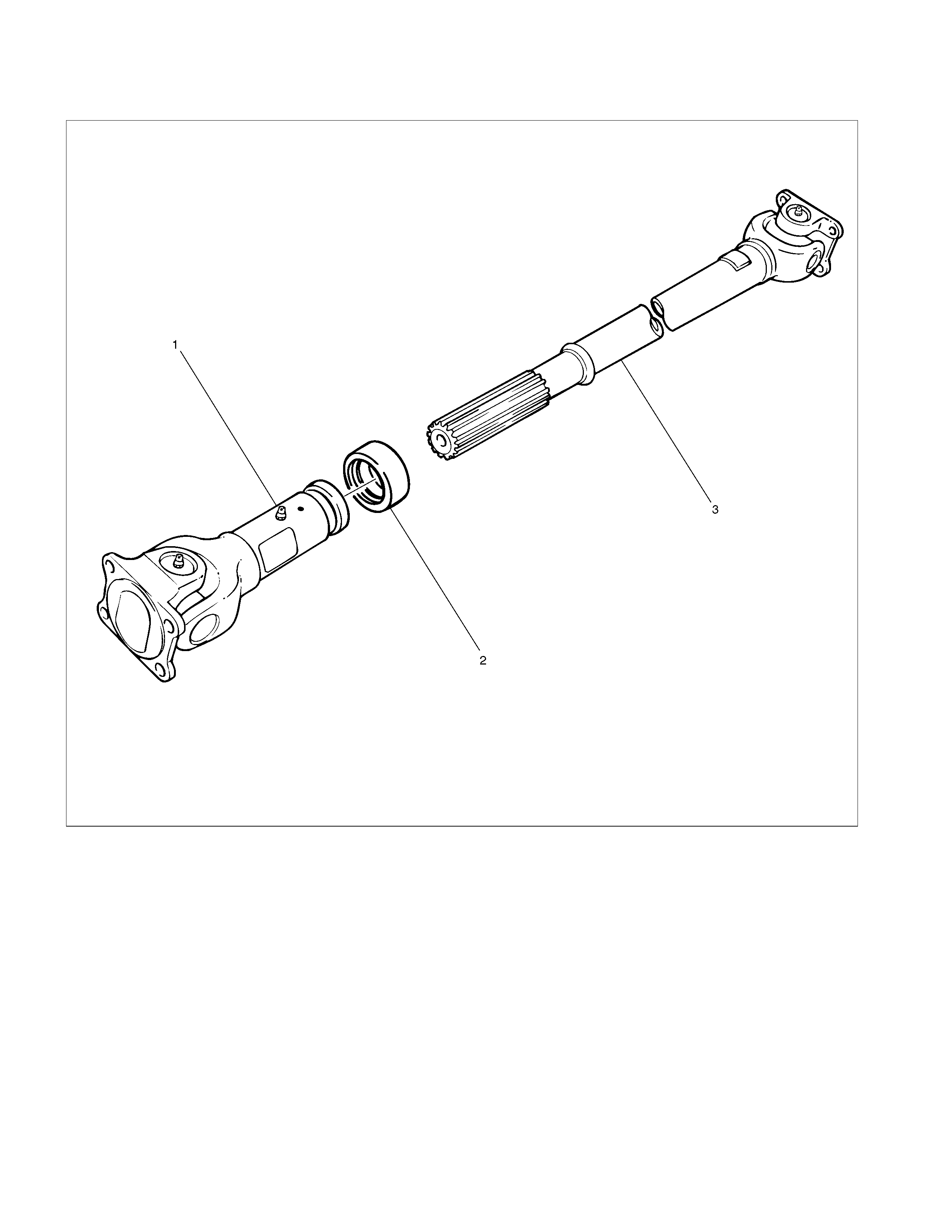

Disassembly

401RW057

Legend

(1) Sleeve Yoke

(2) Seal

(3) Tube Assembly

401RW056

1.

A

pply alignment marks (1) on the sleeve yoke and tube

assembly then remove sleeve yoke.

2. Remove seal.

3. Remove tube assembly.

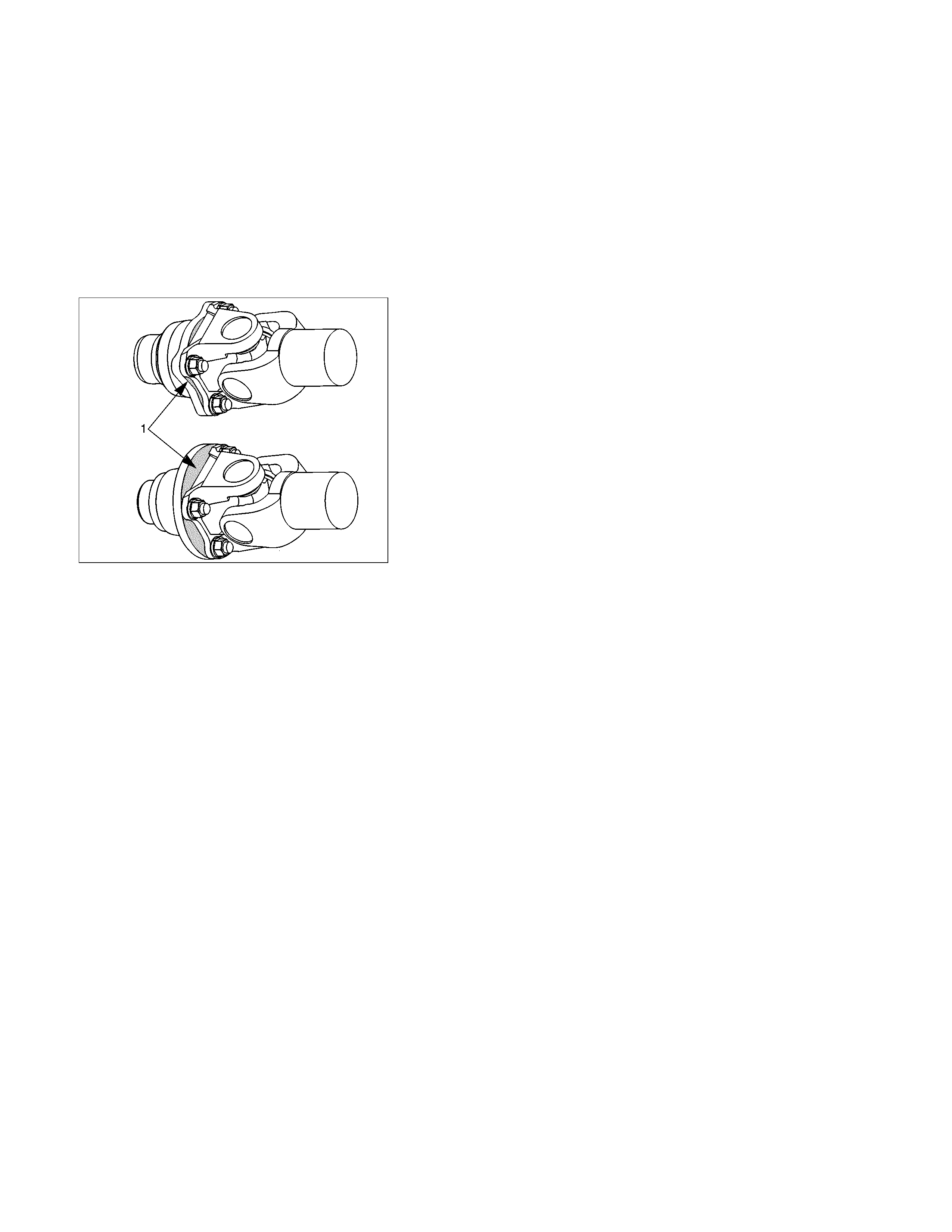

Universal Joint Disassembly and Reassembly

401RW055

Legend

(1) Flange Yoke

(2) Spider

(3) Snap Ring

(4) Needle Roller Bearing

(5) Grease Fitting

401RS028

1.

A

pply alignment marks (1) on the yokes of the universal

joint, then remove snap ring.

401RS006

2. Tap out the needle roller bearing by gently striking the

shoulder of the yoke, using a mallet or a copper hammer.

3. Make sure of proper position for reinstallation by applying

setting marks, then remove spider.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition is found

through inspection.

NOTE:

When any part of the journal assembly (spider, needle roller

bearing) requires replacement, be sure to replace the entire

assembly.

Check the following parts for wear, damage, noise or any other

abnormal conditions:

1. Spider

2. Needle roller bearing

3. Yoke

4. Flange

5. Constant velocity joint

401RS007

Outside Diameter of Spider Pin

Standard: 17.00 mm (0.669 in)

Limit: 16.90 mm (0.665 in)

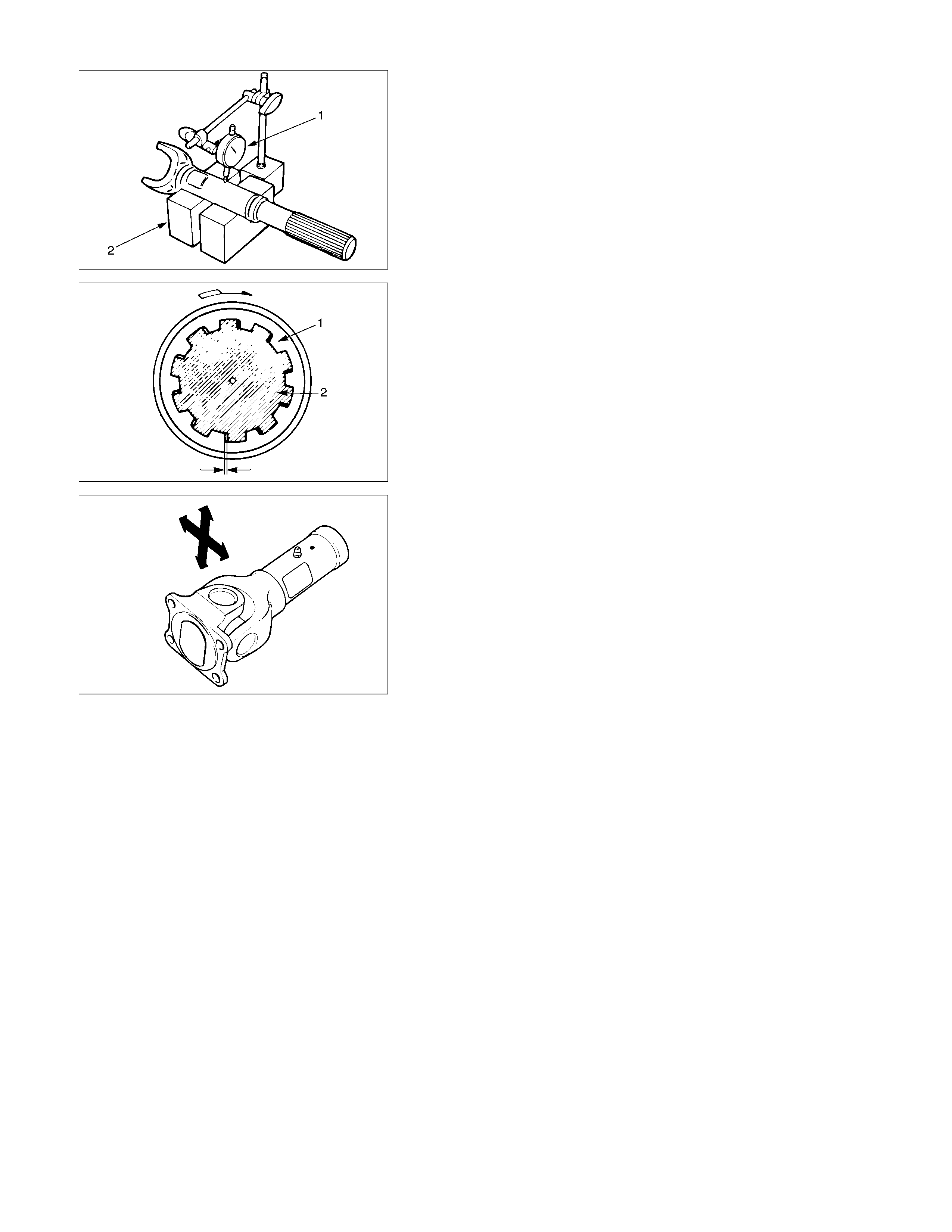

401RS027

Propeller Shaft Runout

Support the ends of the propeller shaft on V-blocks (2) and

check for runout by holding the probe of a dial indicator (1) in

contact with the center part of the shaft. If the amount of run

out is beyond the standard value for assembly, correct with a

bench press or replace the shaft with a new propeller shaft

assembly.

Standard: 0.3 mm (0.012 in)

Limit: 0.5 mm (0.02 in)

401RS009

Play in Splines in Normal Direction of Rotation

Check the amount of play between the sleeve yoke (1) and the

propeller shaft spline (2) in the direction of rotation, using a

pointed feeler gauge.

Standard: 0.073 0.156 mm (0.003 0.006 in)

Limit: 0.3 mm (0.012 in)

401RS010

Play in Universal Joint

Limit: Less than 0.1 mm (0.004 in)

401RS011

Reassembly

1. Install spider to f lange yok e. Be sure to install the spider b

y

aligning the setting marks made during disassembly.

2. Apply a molybdenumdisulfide grease or a multipurpose

type grease NLGI No. 2 to inside of the bearing cap.

Grease Amount: Approx. 1.2 g (0.042 oz)

401RS012

3. Using either a mallet (or c opper hamm er) or a press , install

the needle roller bearing into the yoke so that the snap ring

can be installed in its groove.

CAUTION:

The needle roller bearing cannot be installed smoothly if it

is set at an incorrect angle with the flange and excessive

hammering will damage the needle roller bearing.

401RS028

4. Align setting marks (1) and join the yokes.

5. Install snap ring.

NOTE:

Discard used snap rings and install new ones.

When the bearing cap is in position, select and attach a snap

ring of suitable thickness so that the end play of the spider pin

is held within 0.1 mm (0.004 in).

Snap ring thickness and Identification color

1.5 mm (0.059 in); Blue

1.53 mm (0.060 in); White

1.59 mm (0.063 in); Yellow

1.62 mm (0.064 in); Green

1.68 mm (0.066 in); Not colored

NOTE:

Be sure to use snap rings of the same thickness

on both sides.

Reassembly

401RW057

Legend

(1) Sleeve Yoke

(2) Seal

(3) Tube Assembly

1. Discard used seal and install new one.

2.

A

lign the alignment marks and install tube assembly to

sleeve yoke.