SECTION 5C - BRAKES

General Description

Main Data and Speci fications

Torque Specifications

Servicing

Front Brake Assembly

Removal and Installati on

Removal and installation of Disc Pad

Disassembly

Inspection and Repair

Reassembly

Rear Drum Brake Assembly

Disassembly

Inspection and Repair

Reassembly

Brake Control

Removal and Installation

Master Cylinder

Removal and Installation

Disassembly

Inspection and Repair

Reassembly

Vacuum Booster

Removal and Installation

Adjustment Procedure Of Brake Pedal

Techline

GENERAL DESCRIPTION

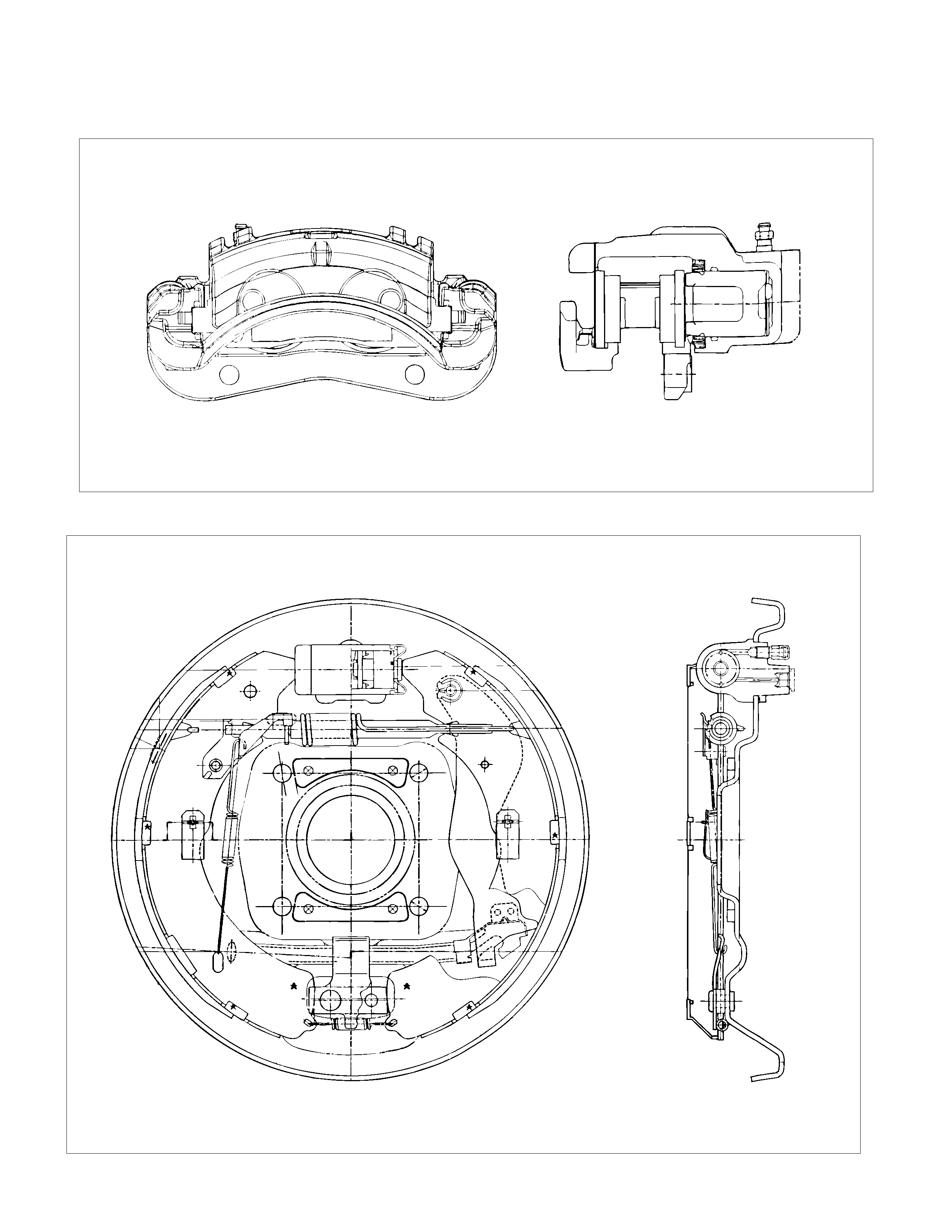

FRONT DISC BRAKE

REAR DRUM BRAKE

REAR WHEEL CYLINDER

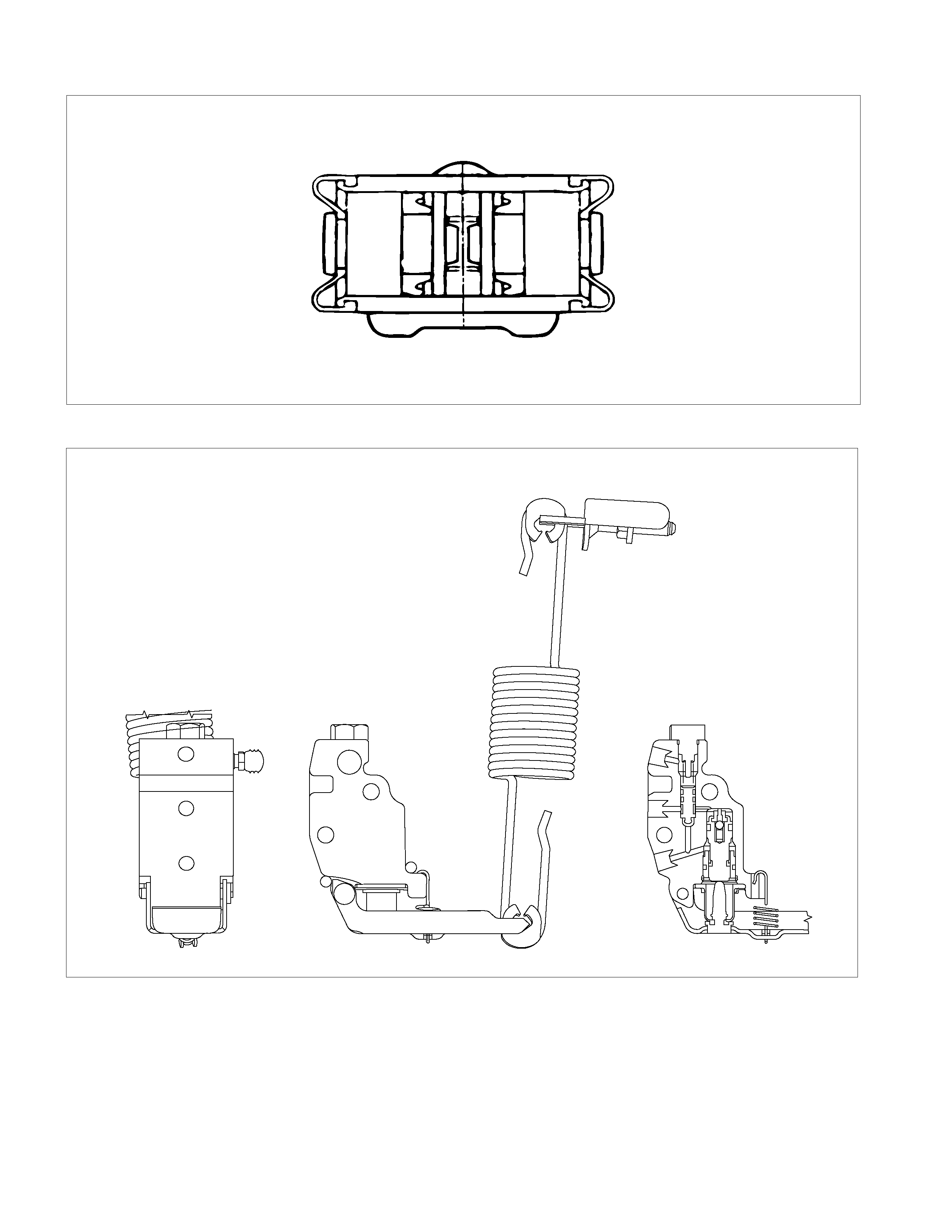

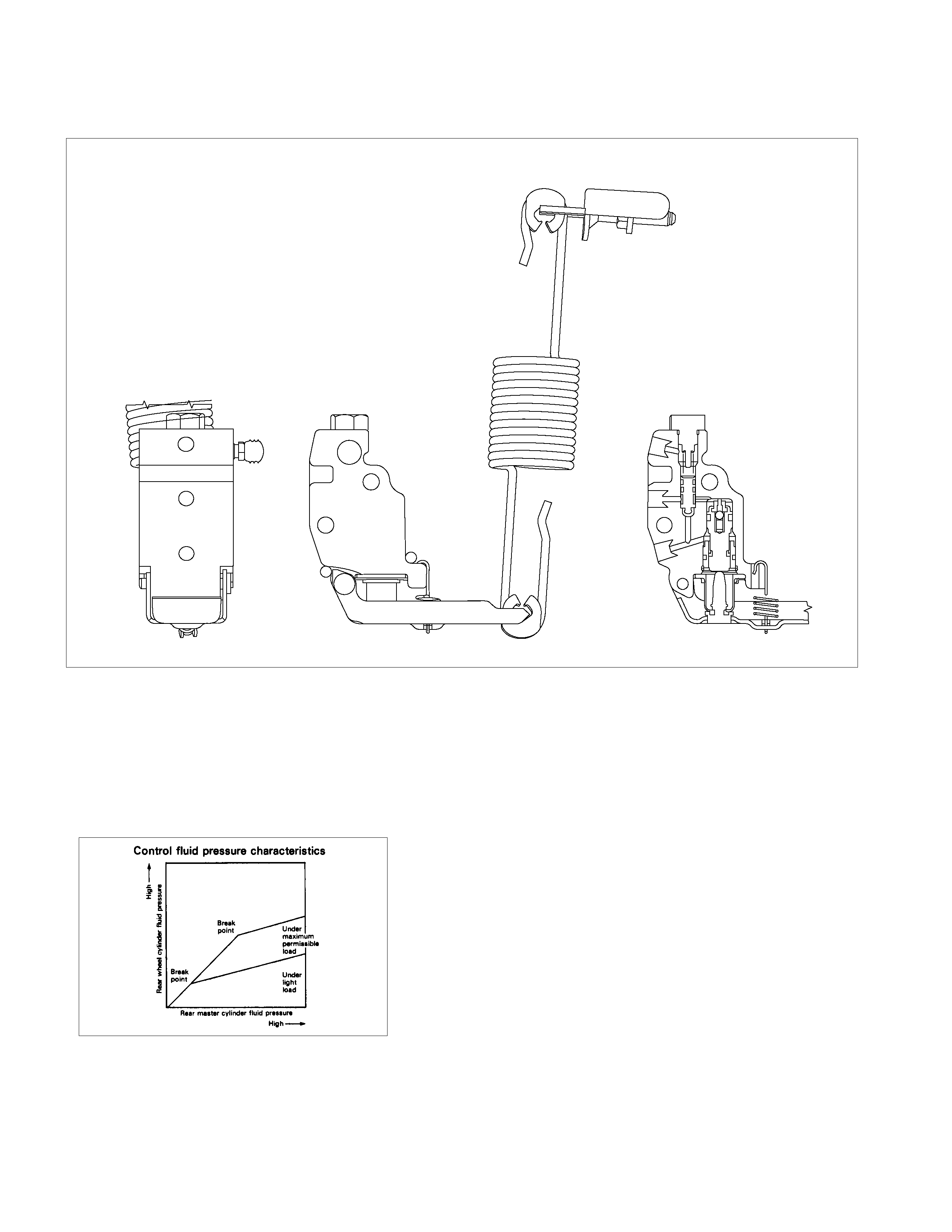

LOAD SENSING PROPORTIONING VALVE (LSPV)

RTW35CMF000101

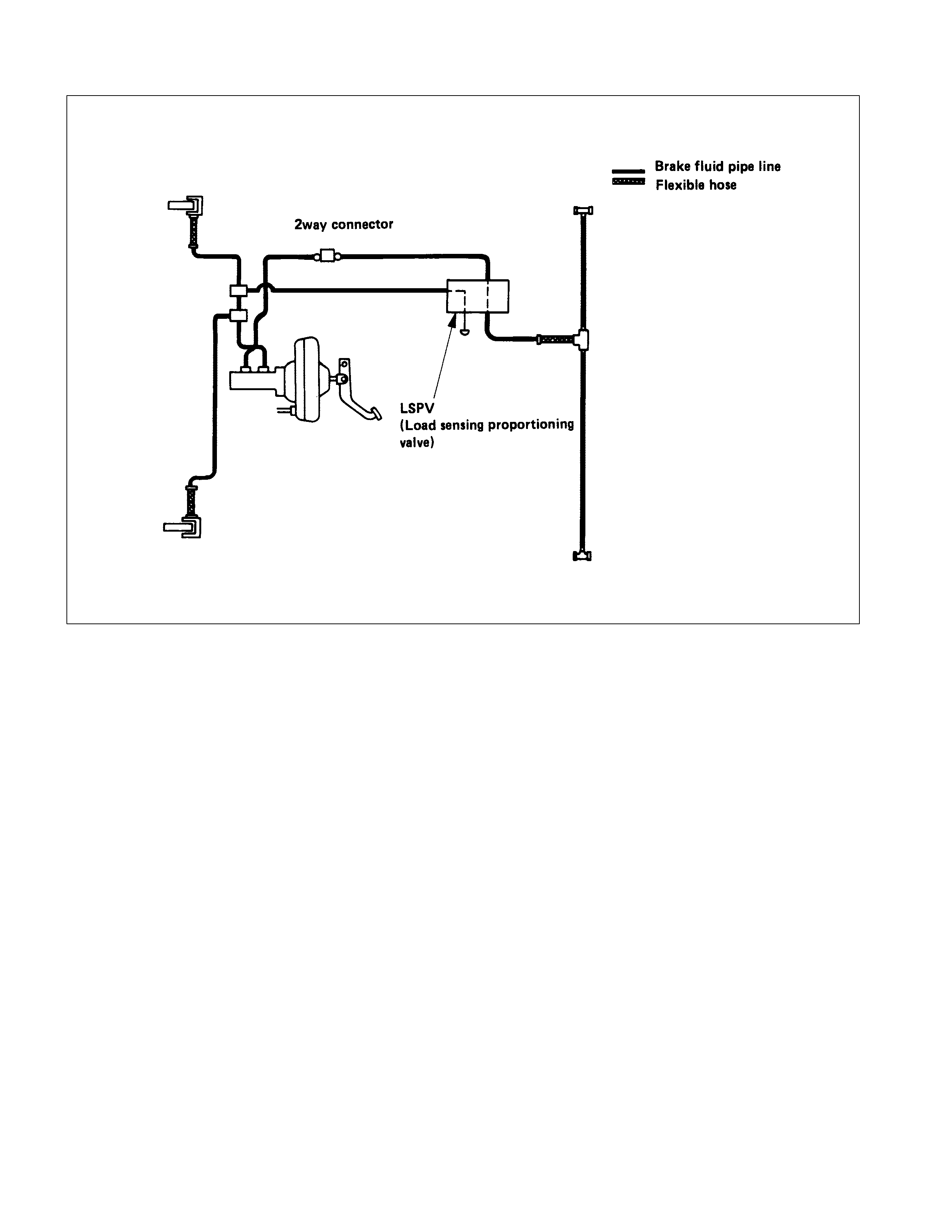

HYDRAULIC LINE DIAGRAM (MODEL WITH LOA D SENSING PROPORTIONING VALVE)

05007-2

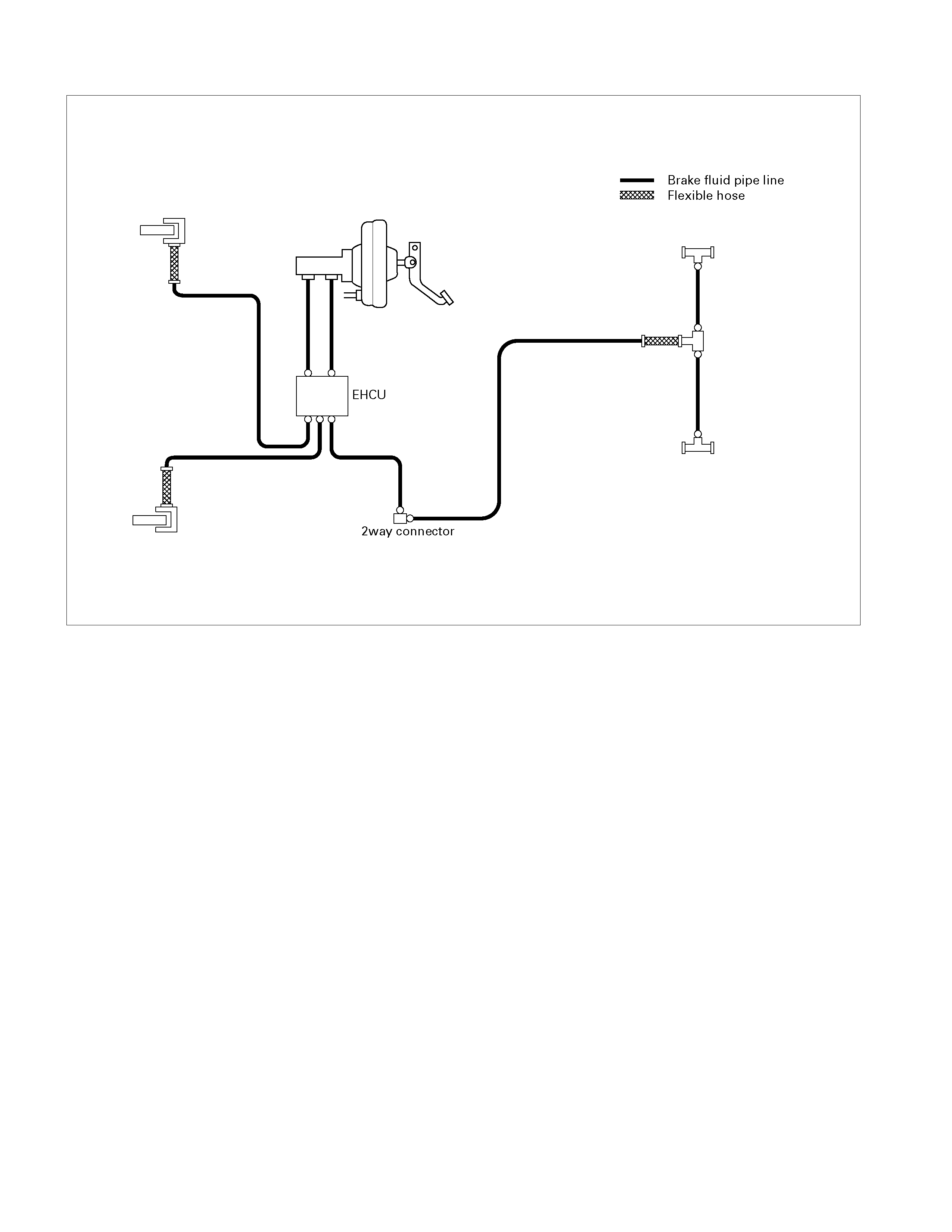

HYDRAULIC LINE DIAGRAM (MODEL WITH A BS)

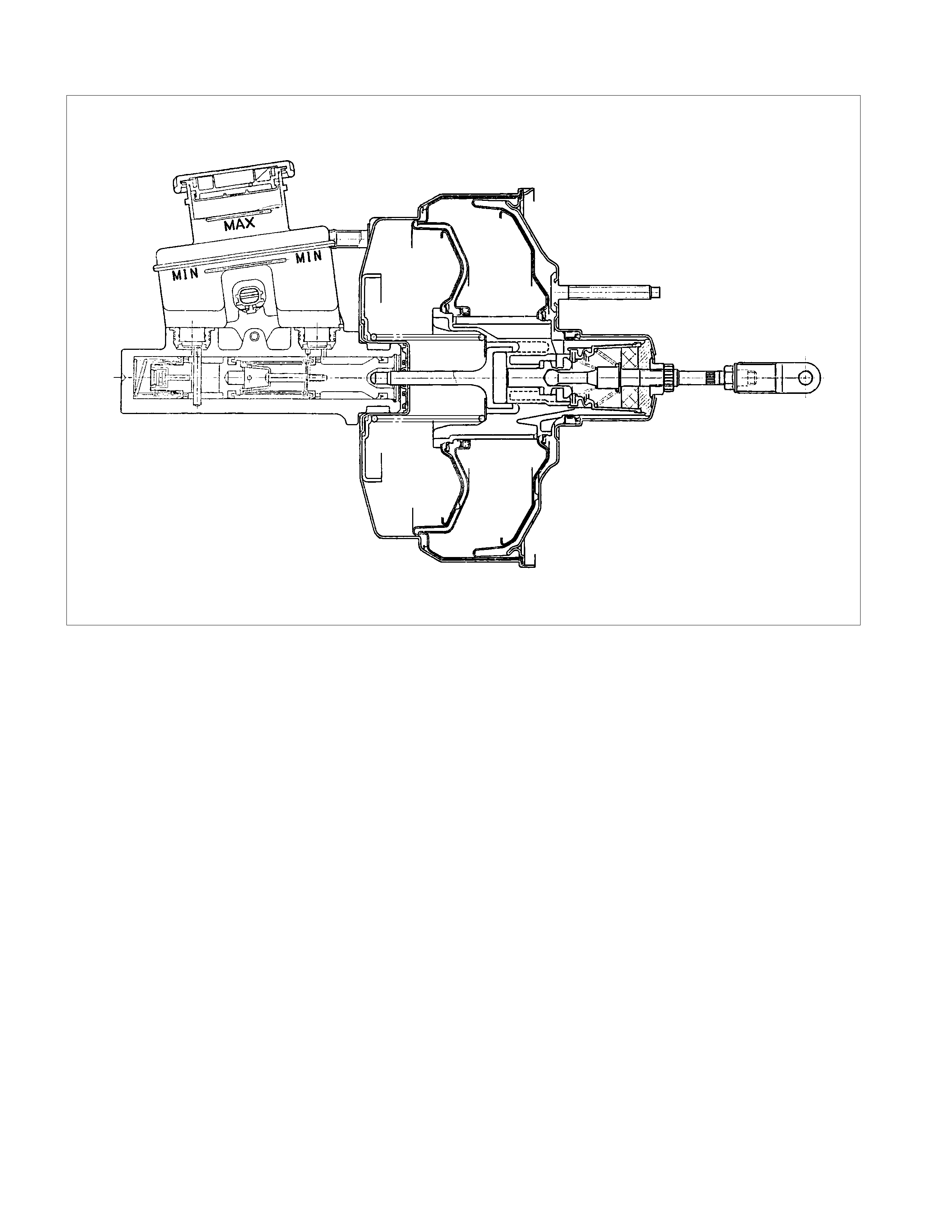

VACUUM SERVO WITH MASTER CYLINDER

MAIN DATA AND SPECIFICATIONS

FRONT DISC BRAKE mm(in.) 4 × 2 4 × 4, 4 × 2 HIGH RIDE

Caliper type Pin slide

Disc outside diameter 256(10.079) 280 (11.023)

Disc thickness 26(1.024) 27 (1.063)

Piston diameter 42.8 (1.685) × 2 45.5 (1.79)

Adjustment method Self-adjusting

REAR DRUM BRAKE mm(in.) 4 × 2 4 × 4

Type Leading and Trailing

Drum inside diameter 254(10.008) 295 (11.614)

Brake lining dimension 244 × 50 × 5 283 × 45 × 5

(Length × Width × Thickness) (9.57 × 1.97 × 0.20) (11.14 × 1.77 × 0.20)

Adjustment method Self-adjusting

WHEEL CYLINDER mm(in.)

Inside diameter : rear 25.4 (1.000) 23.8 (0.937)

MASTER CYLINDER mm(in.)

Type Split

Bore diameter 25.4 (1.000)

Piston stroke (Primary + Secondary) 21.8 + 12 (0.86 + 0.47)

VACUUM SERVO mm(in.) 6VE1/C24NE 4JH1-TC

Diaphragm diameter 205(8.077) + 230(9.055) 180(7.087) + 205(8.077)

Power cylinder stroke 35 (1.378)

PEDAL RATIO 3.7

BALANCE

Type Blend proportioning valve/EBD (with ABS)

TORQUE SPECIFICATIONS

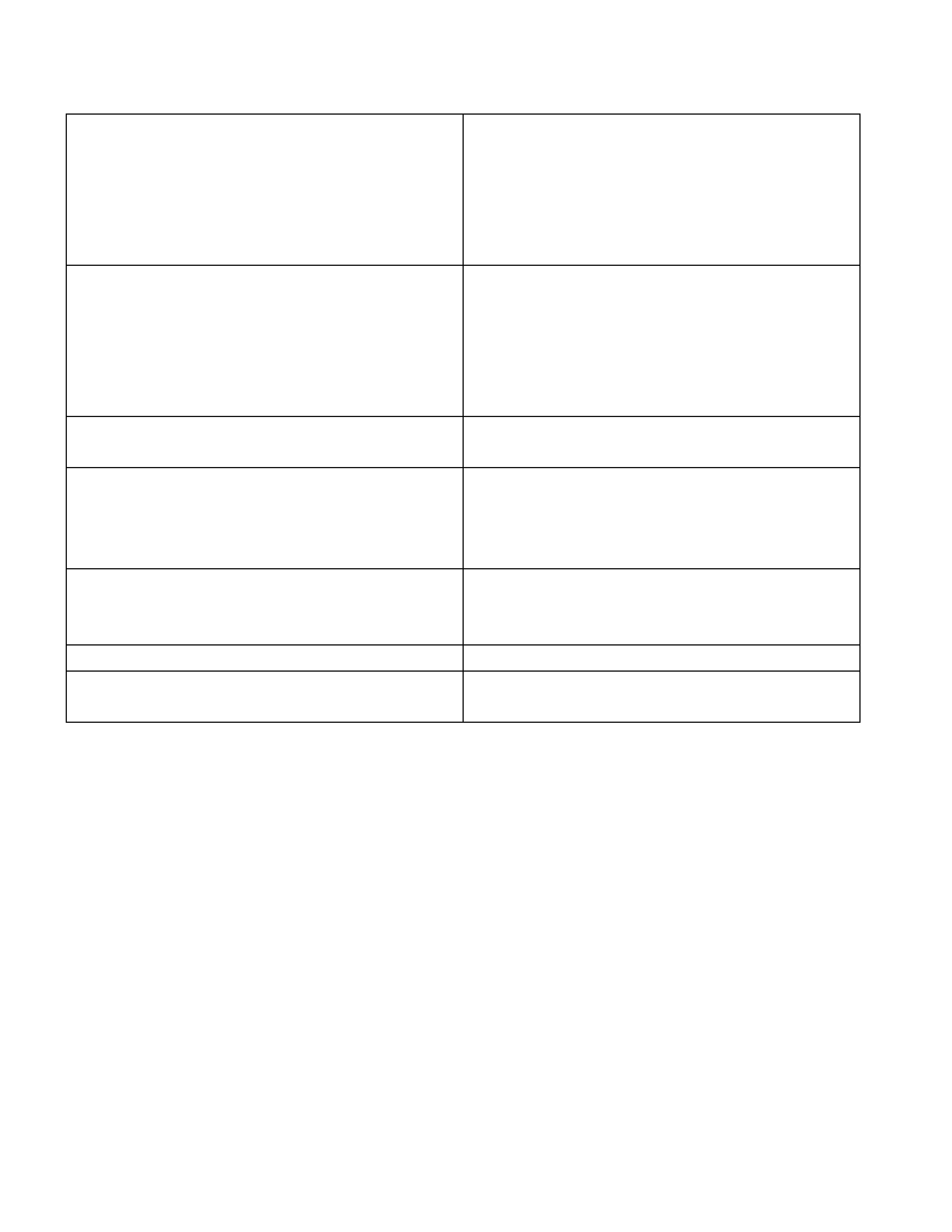

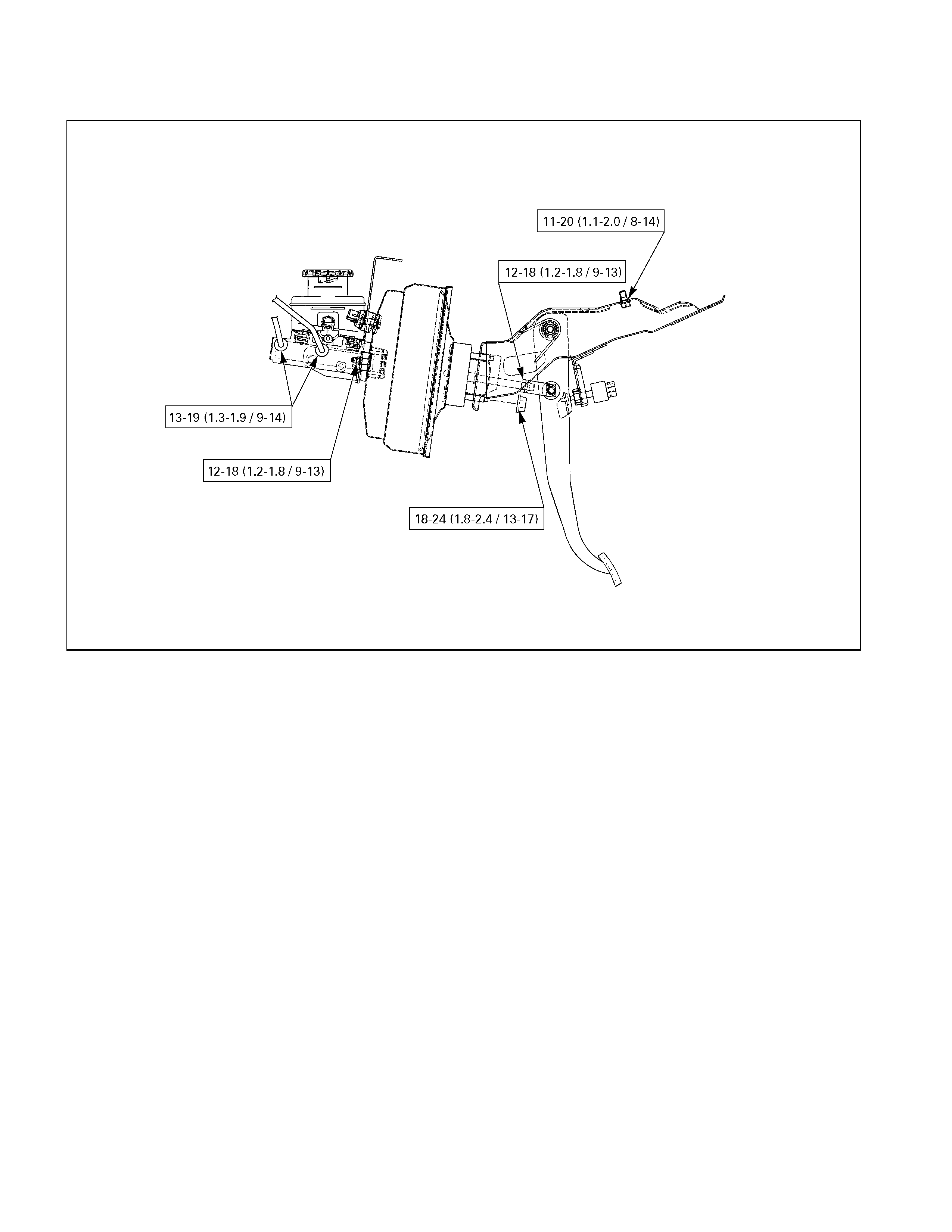

FRONT WHEEL BRAKE

N⋅m(kgf⋅m/lb⋅ft)

E05R300016

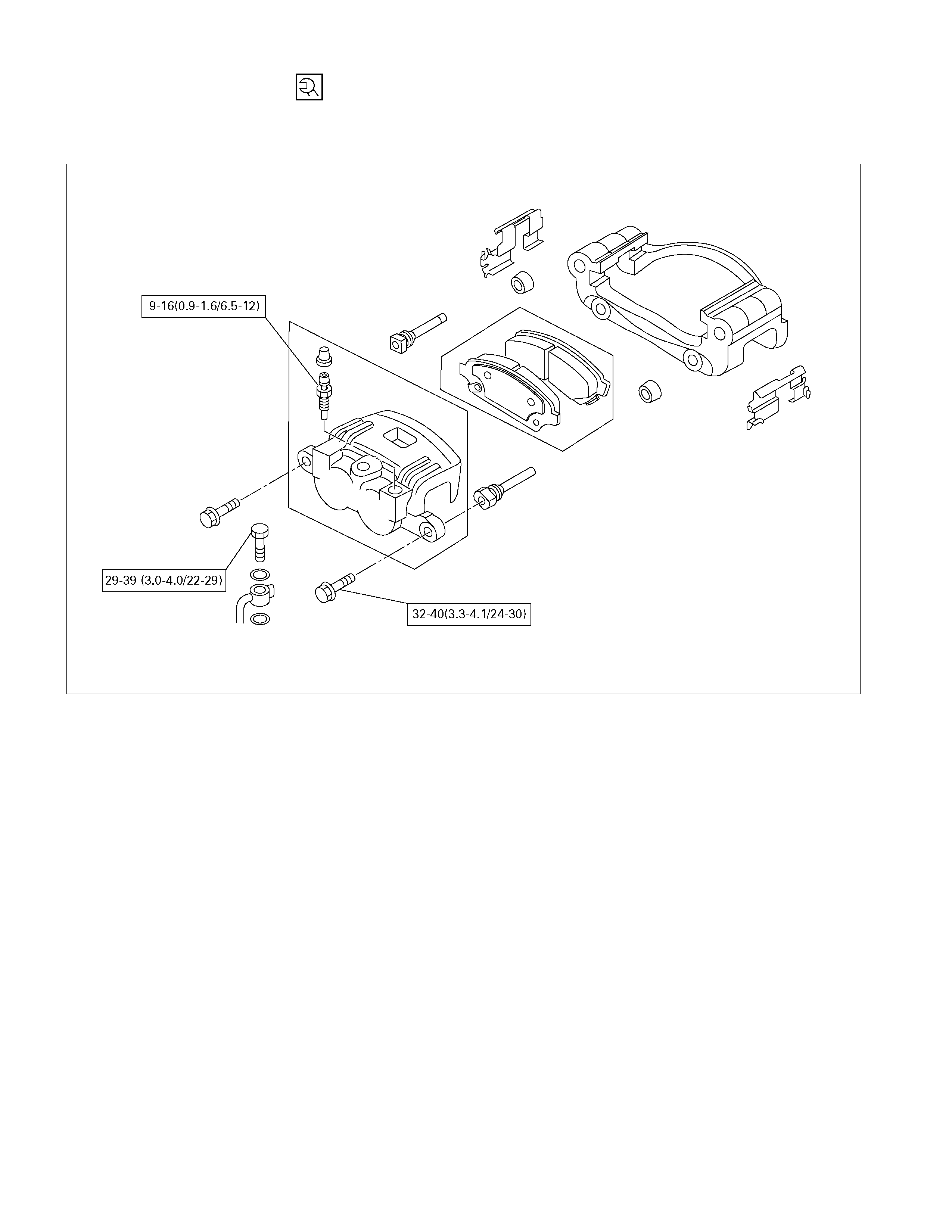

REAR WHEEL DRUM BRAKE

N⋅m(kgf⋅m/lb⋅in)

E05R300014-1

VACUUM SERVO WITH MASTER CYLINDER AND BRAKE PEDAL

N⋅m(kgf⋅m/lb⋅ft)

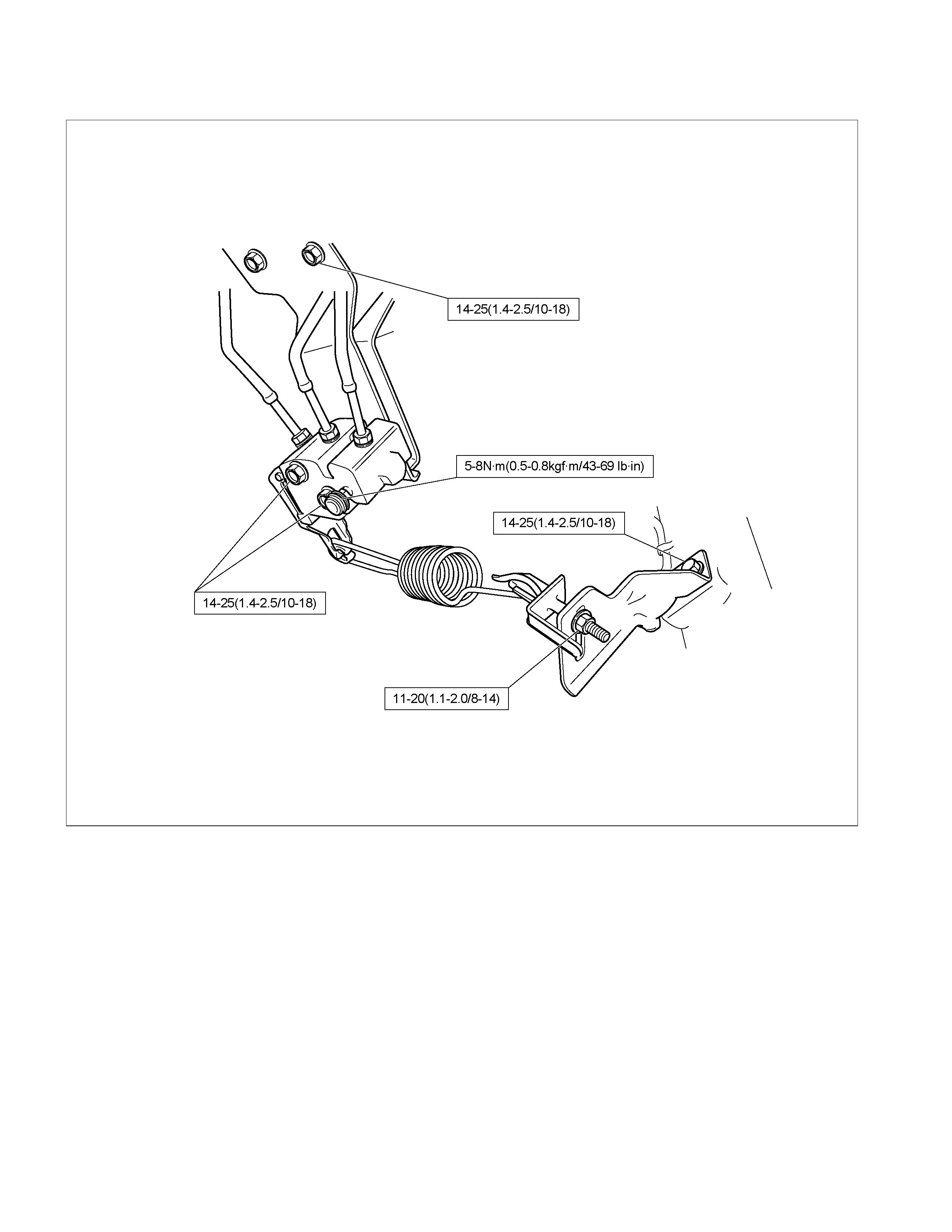

LOAD SENSING PROPORTIONING VALVE (LSPV)

N⋅m(kgf⋅m/lb⋅ft)

RTW5CLF000101

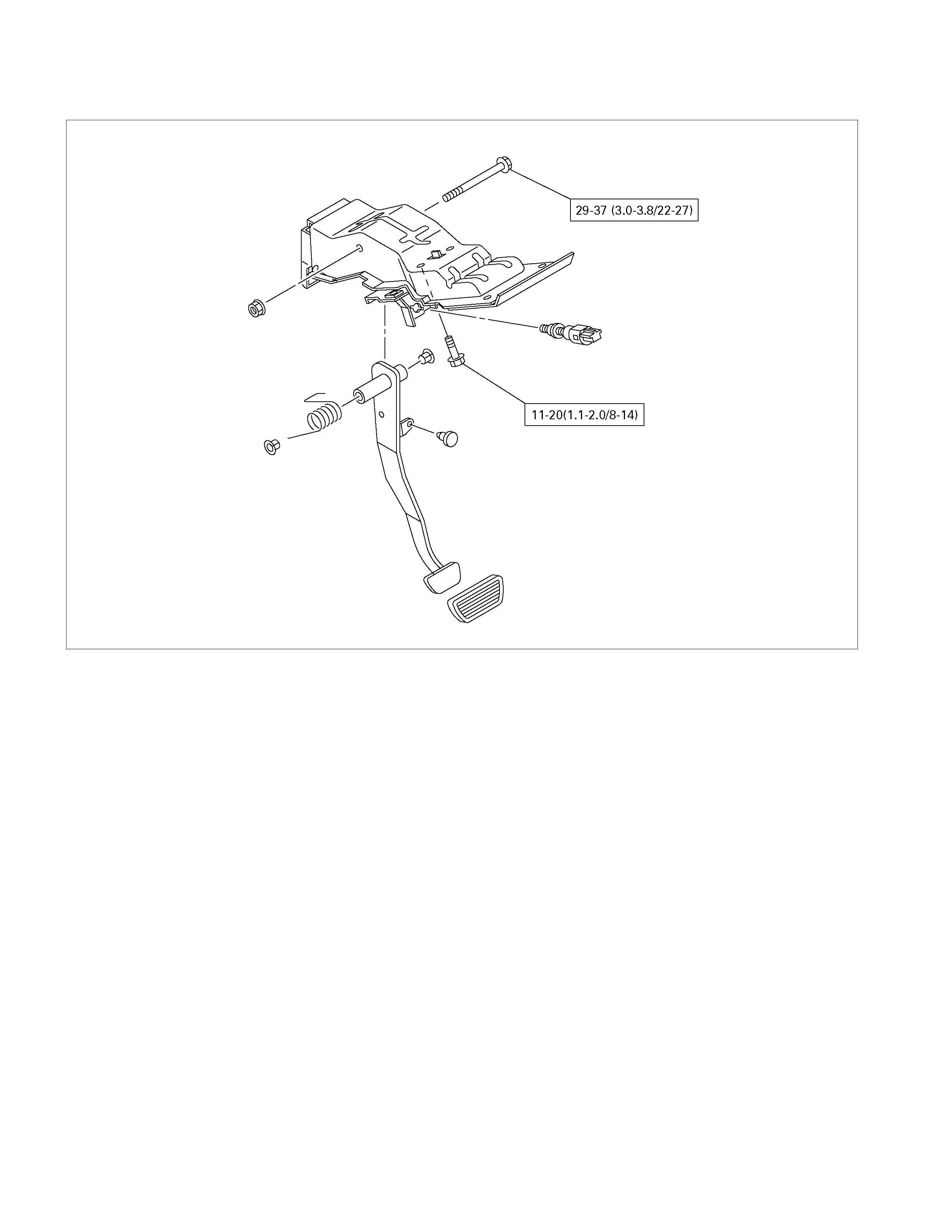

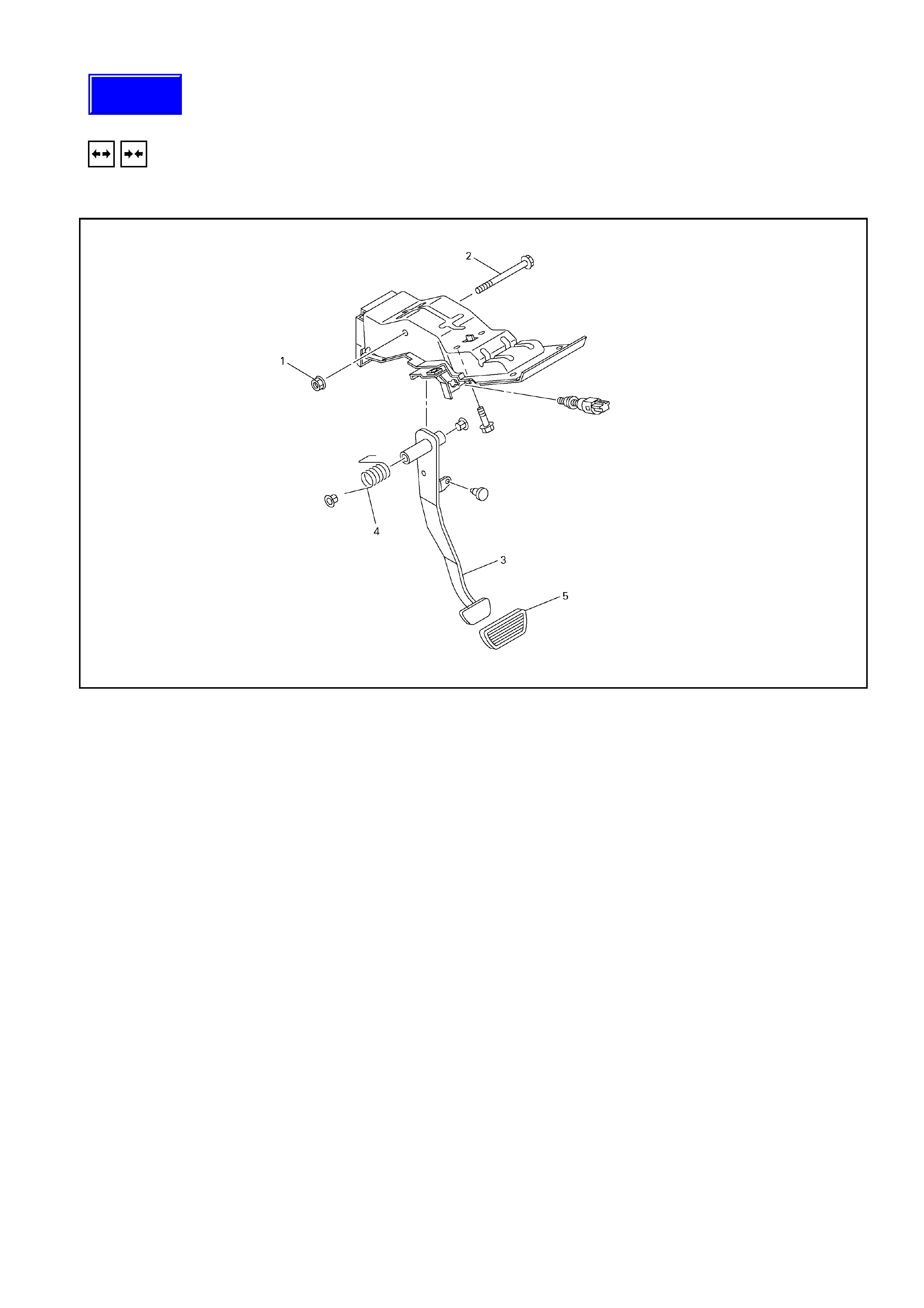

BRAKE PEDAL ASSEMBLY

N⋅m(kgf⋅m/lb⋅ft)

E05R300011-1

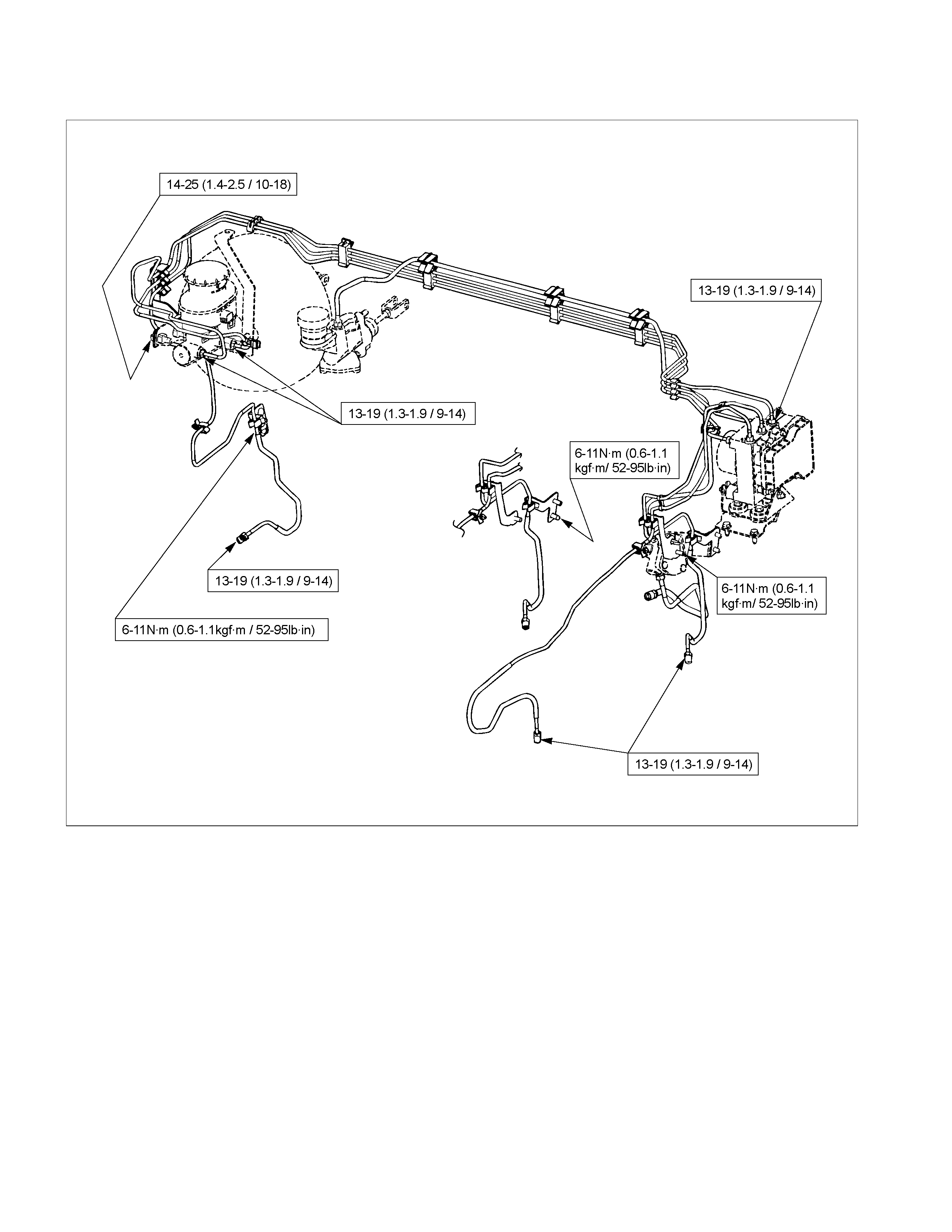

BRAKE LINES (HOSES AND PIPES) (MODEL WITH LOAD SENSING PROPORTIONING VALVE)

N⋅m(kgf⋅m/lb⋅ft)

29-39 (3.0-4.0/22-29)

13-19 (1.3-1.9/9.4-14)

11-20 (1.1-2.0/8-14)

13-19 (1.3-1.9/9.4-14)

7.8-18 (0.8-1.8/5.8-13)

13-19 (1.3-1.9/9.4-14)

Eye Bolt Tightening

05020

BRAKE LINES (HOSES AND PIPES) (MODEL WITH ABS)

N⋅m(kgf⋅m/lb⋅ft)

RTW35CLF0002

SERVICING

LOAD SENSING PROPORTIONING VALVE (LSPV)

RTW35CMF000101

Structure and Operation

The following is an explanation of the structure and operation

of the spring type load sensing device.

This device controls the fluid pressure to the rear brakes in

accordance with changes in rear axle load (vertical

displacements of the rear axle springs).

•

••

• Structure

This device consists of a load sensing spring and a valve.

The valve is mounted through a bracket to the frame.

One end of the load sensing spring is fixed to the valve at

the frame and the other end to the rear axle housing

through a bracket.

RTW35CSH001001

•

••

• Operation

1) Outline

When the LSPV (Load Sensing Proportioning Valve)

detects a change in load weight, the load sensing spring

stretches.

Its reaction force is transmitted to the bottom of the load

sensing valve to secure an optimum rear wheel cylinde

r

fluid pressure break point in proportion to the actual load

weight.

Besides, if the front brake system should fail, the device is

designed to prevent the master cylinder fluid pressure from

decreasing and to apply it directly to the rear wheel cylinde

r

to obtain a sufficient braking performance.

RTW35CSH001101

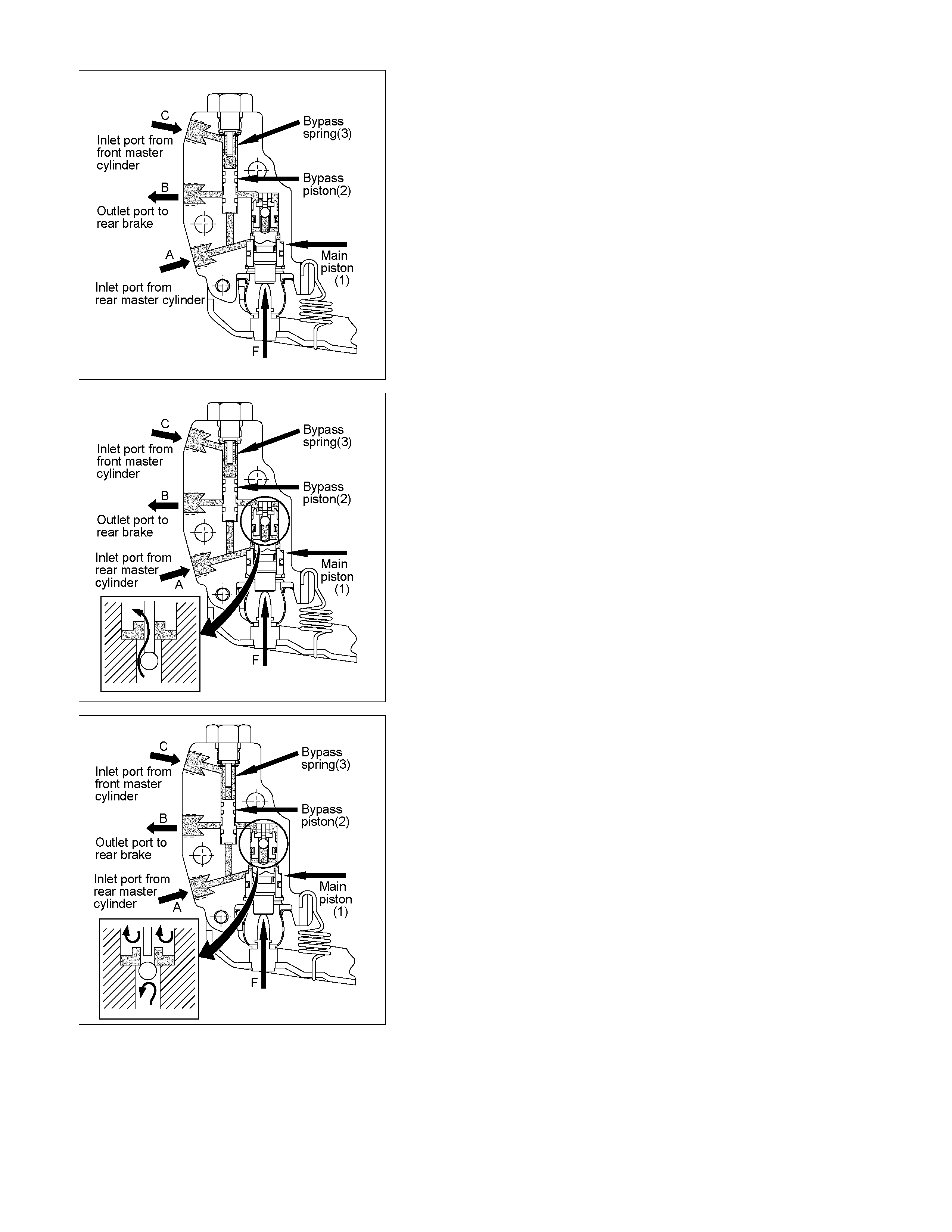

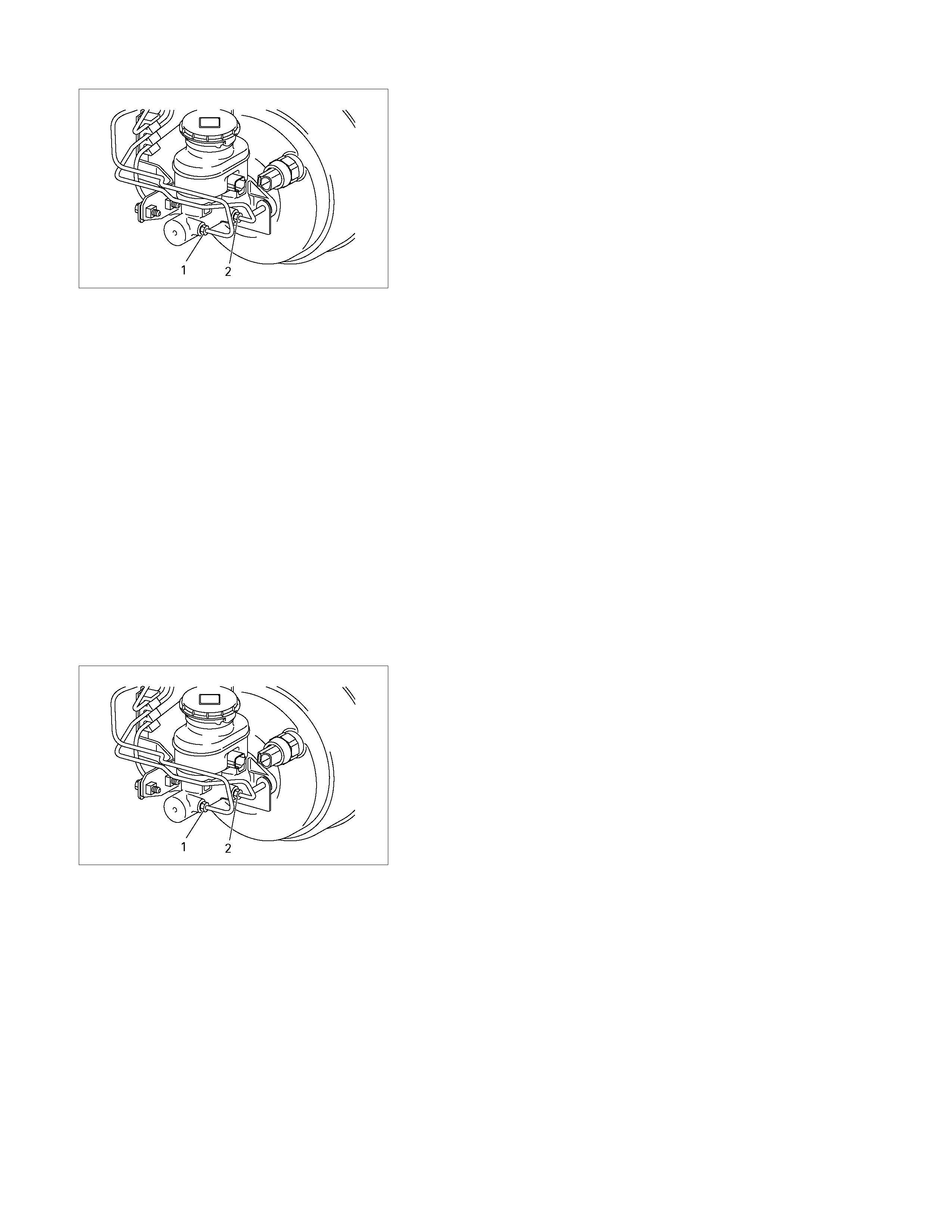

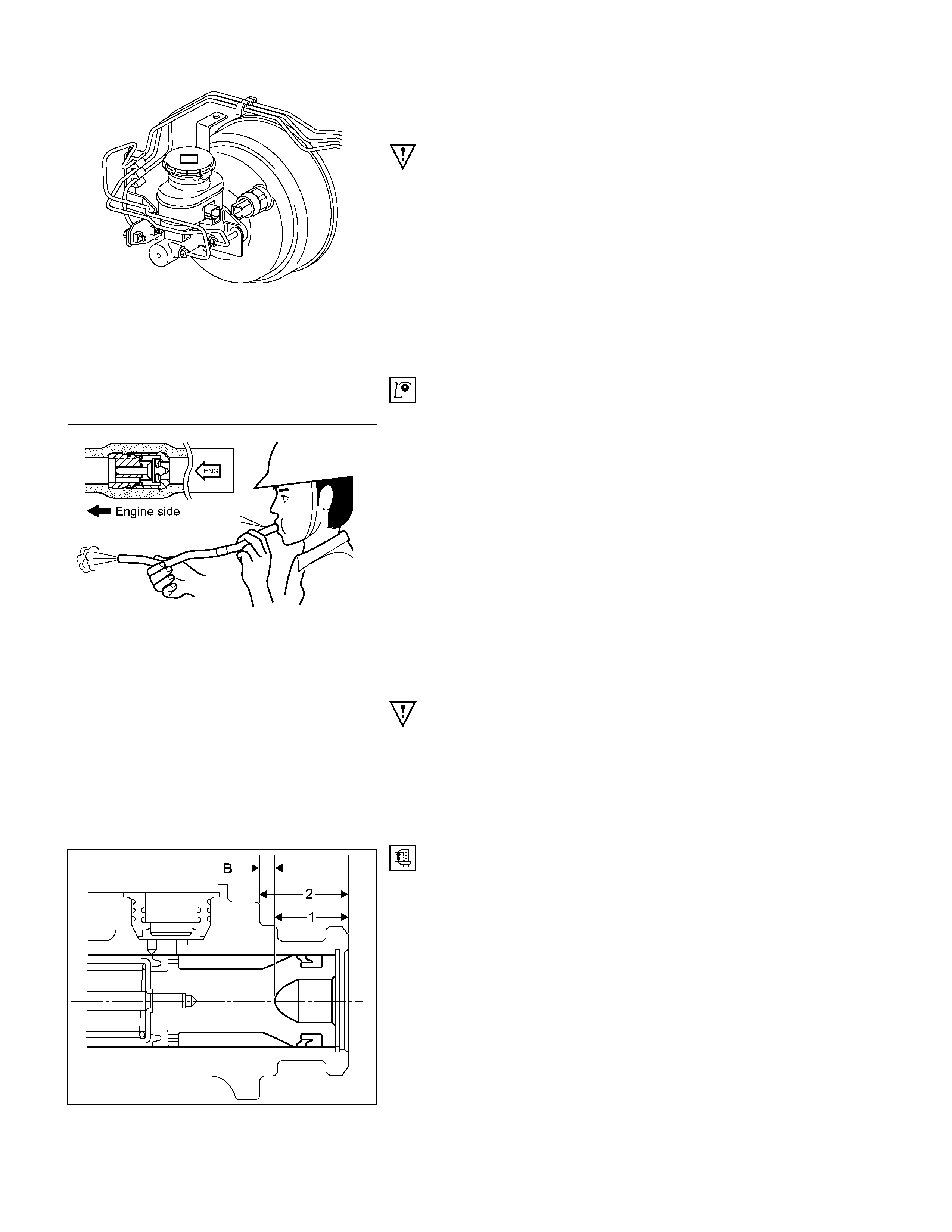

2) Bellow cutting point.

The Force (F) keeps the main piston (1) the rest position.

The inlet pressure ( A) and outlet pressure ( B) are the sam e

as well as the inlet pressure (C) f rom front m aster cylinder.

The bypass piston (2) is k ept on res t pos ition by equilibrium

of the pressures (A) and (C) and the bypass spring load (3).

RTW35CSH001201

3) Cutting point.

The cutting point is given by r elation between force (F ), that

is the load applied by suspension of the vehicle and the

main pis ton ar ea ( 1). The cutting point is achieved when the

force generated by hydraulic pressure is upper than the

forc e ( F) given by the load suspension. T he main piston (1)

moves from the rest position closing the valve. In this

moment the inlet pressure (A) is upper than the outlet

pressure (B). The bypass piston (2) continues on the rest

position by equilibrium of (A) and (C) pressure.

RTW35CSH001301

4) Failure on front master cylinder.

In case of failure on front master cylinder the pressure on

the inlet port (C) drop to zero. The pressure from inlet port

(A) acts on the bypass pist on (2) and m ove it by compr ising

of bypass spring (3). It makes possible the communication

between the inlet port (A) to outlet port (B) through the

bypass system. The outlet pressure (B) reaches the inlet

pressure (A) and the LSPV is bypassed.

Valve Maintenance

In the case to fluid lead or other a abnormalities, faulty valve

should be replaced.

Note:

The load sensing proportioning valve is not repairable and

must be replaced as a completed assembly.

LOAD SENSING PROPORTIONING VALVE (LSPV)

ADJUSTMENT

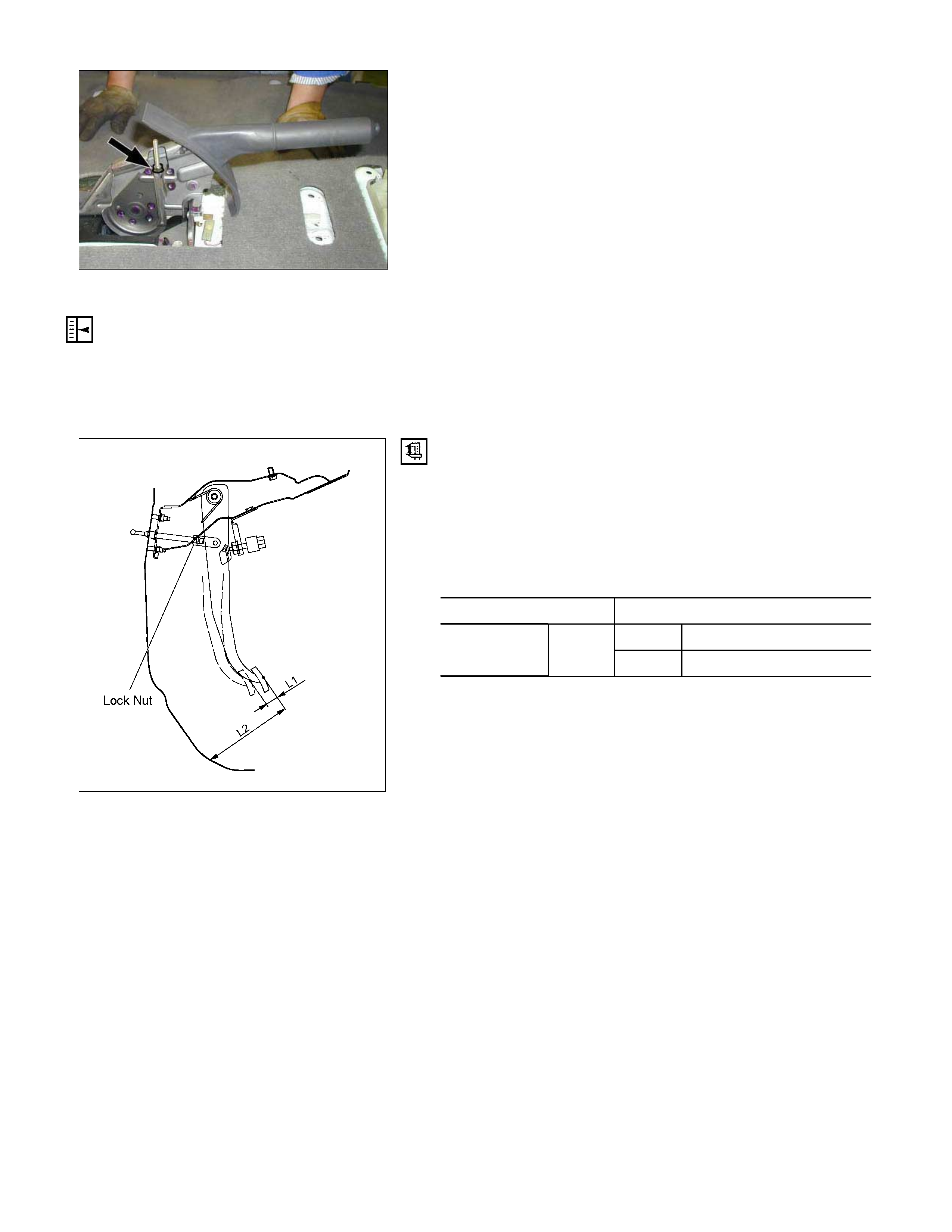

RTW35CSH000301

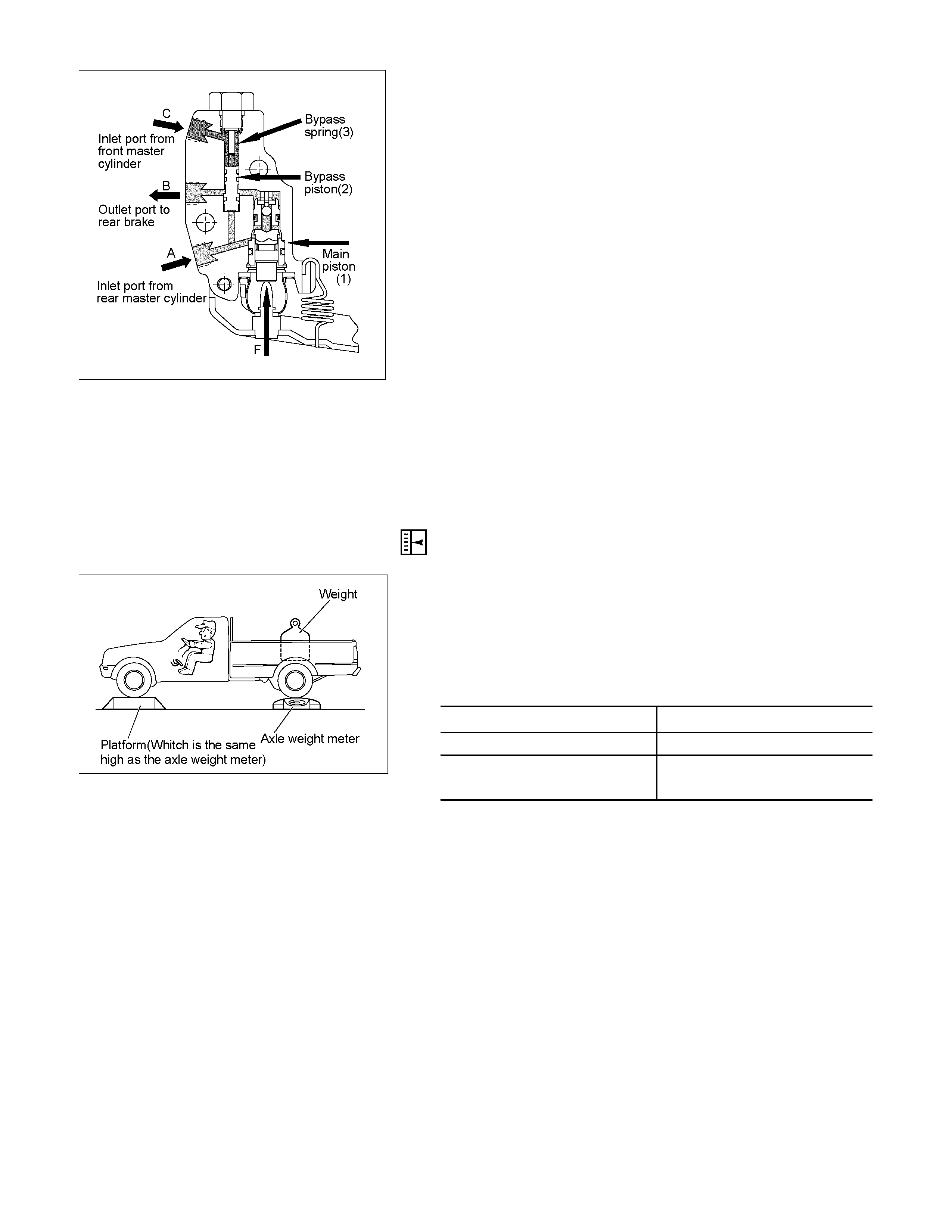

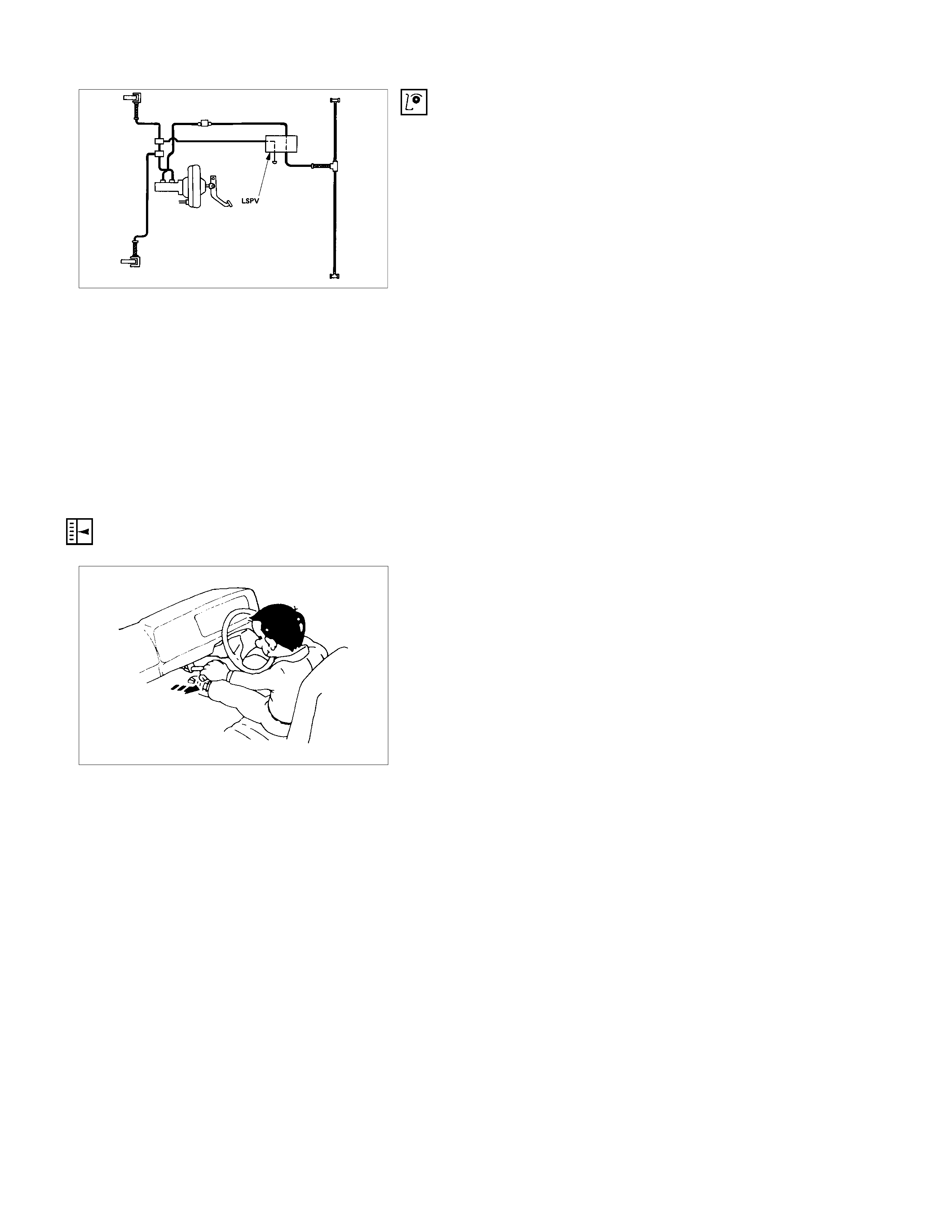

1. Fluid Pressure Measurement

1) Rear axle weight adjustment

With an axle eight meter, adjust the rear axle weight with

a person sitting in the driver’s seat and a weight loaded

in the rear body. N (kg/lb)

MODEL Adjustment value

4 × 2 7845 (800/1764)

4 × 2 HIGH RIDE

4 × 4 9316 (950/2095)

RTW35CSH000101

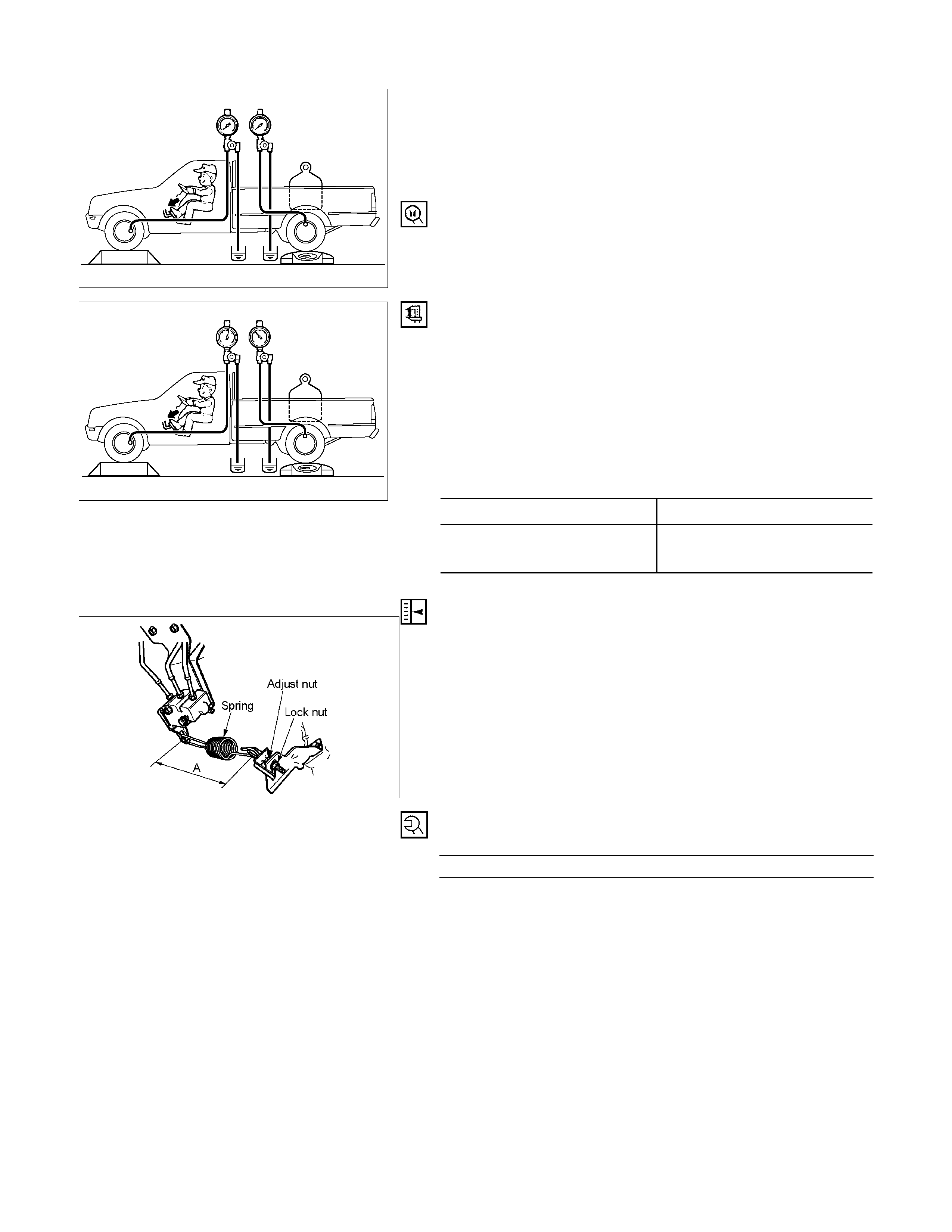

2) Installation of a fluid pressure gauge

Remove the air bleeder of the left hand wheel front and

rear brakes. Bleed air out of the fluid pressure gauge

with the measurement hose of the fluid pressure gauge

installed.

Pressure Tester: Brake oil (Fluid pressure gauge)

5-8840-2190-0

RTW35CSH000201

3) Rear wheel cylinder fluid pressure measurement

Step on the brake pedal until the fluid pressure of the

front wheel cylinder gets to 9.8Mpa (100kg/cm2), and

check the rear wheel cylinder fluid pressure. (Read the

value of the front wheel cylinder fluid pressure 2

seconds after the measurement. When measuring the

L.S.V fluid pressure, keep the brake pedal pressed

down without stepping it down twice or releasing it.)

Rear Wheel Cylinder Fluid Pressure MPa (kg/cm2)

2WD 6.77±0.83 (69.0±8.5)

2WD (With High Ride

Suspension), 4WD 6.77±0.83 (69.0±8.5)

RTW35CSH000401

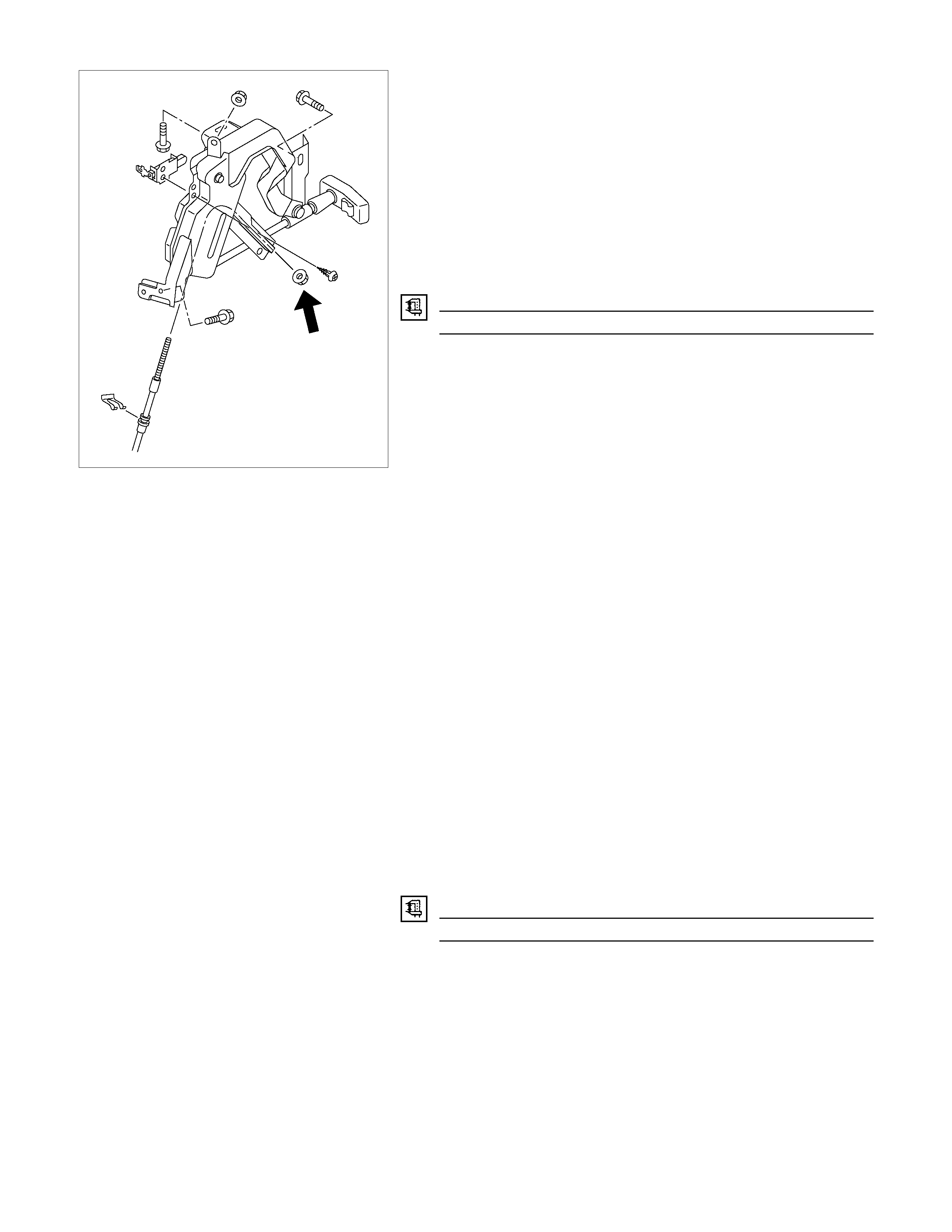

2. Oil Pressure Adjustment

1) LSPV spring length adjustment

Loosen the adjust nut of the LSPV spring joint, and

adjust the length of the LSPV spring.

W hen the oil pressure is insufficient, turn the adjust nut

clock wise to extend the s pan “A”. W hen the oil press ure

is too high, turn the adjust nut counterclockwise to

reduce the span “A”.

2) After adjustment, tighten the lock nut securely.

Lock Nut Torque N⋅m (kg⋅m/lb in)

11-20 (1.1-2.0/95-174)

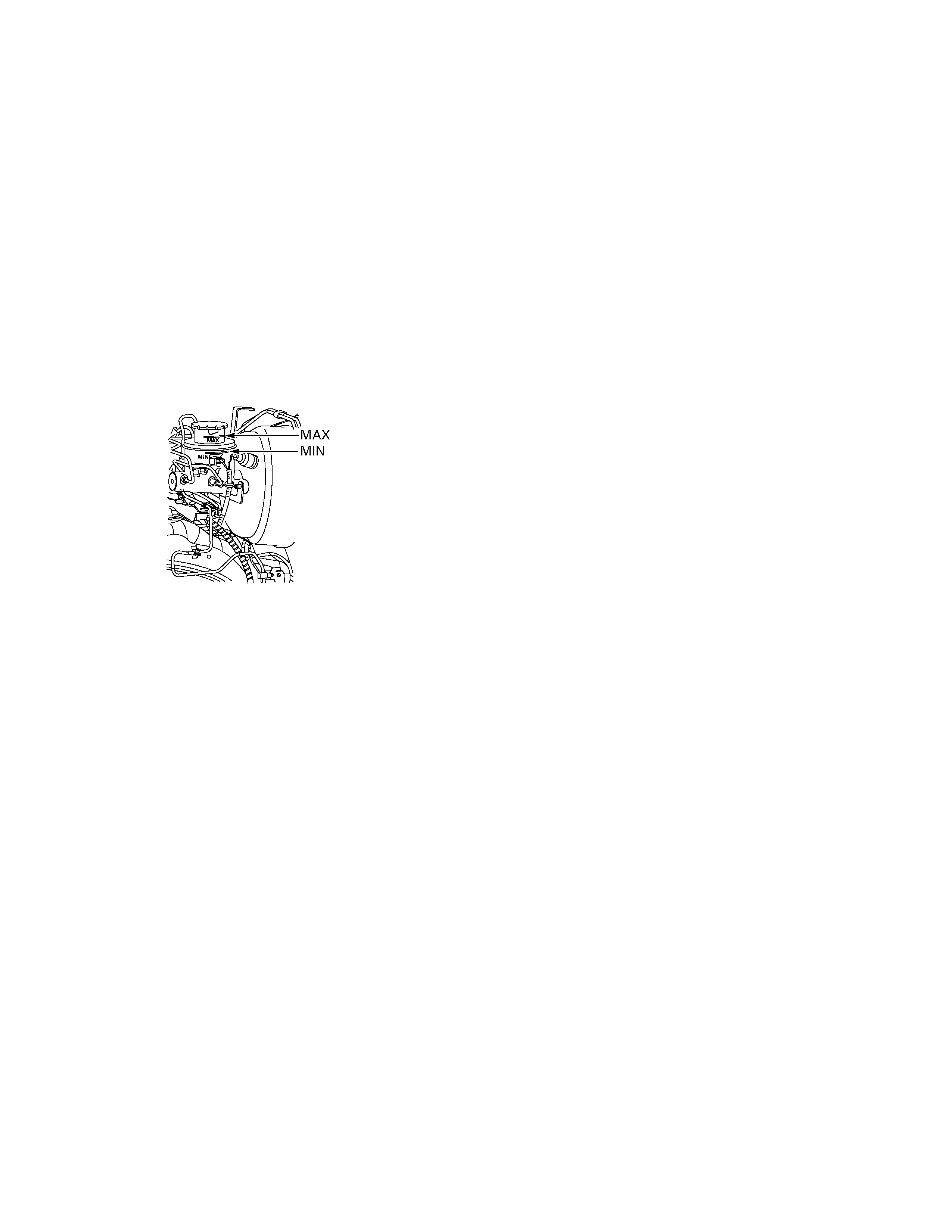

Filling Master Cylinder Reservoir

CAUTION:

Use only specified brake fluid. Do not use any fluid which

contains a petroleum base. Do not use a container which

has been used for petroleum based fluids or a container

which is wet with water. Petroleum based fluid will cause

swelling and distortion of rubber parts in the hydraulic

brake system. Water mixed with brake fluid lowers the

fluid boiling point. Keep all fluid containers capped to

prevent contamination.

Always fill the master cylinder reservoir when the engine

is cold.

Never allow the brake fluid to come in contact with the

painted surfaces.

The master cylinder reservoir must be kept properly filled

to ensure adequate reserve and to prevent air and

moisture from entering the hydraulic system. However,

because of expansion due to heat absorbed from the

brakes and the engine, the reservoir must not be

overfilled. Thoroughly clean reservoir cap before removal

to avoid getting dirt into reservoir. Add fluid as required to

bring level to the “MAX” mark on the reservoir tank. Use

“DOT 3” Hydraulic Brake Fluid.

Leakage of Brake Fluid

With engine idling, set shift lever in the neutral position and

continue to depress brake pedal at a constant pedal

application force.

Should the pedal stroke become deeper gradually, leakage

from the hydraulic pressure system is possible.

Make sure by visual check that there is no leak.

BLEEDING OF THE BRAKE HYDRAULIC CIRCUIT

If air enters the bake lines, it will cause poor brake action.

Therefore, bleeding should be performed if the brakes have

been used with the level of brake fluid in the reservoir

excessively low or if brake pipes have been disconnected in

the course of brake servicing.

Bleeding operation calls for co-operative action of 2 persons.

• Set the parking brake firmly while bleeding.

• Perform bleeding operation with ENGINE RUNNING, to

prevent damage to push rod seal.

Make sure exhaust is suitably ventilated.

• Bleed the hydraulic system with the fluid reservoir filled to

the specified level.

• Bleed the system starting with the rear wheel cylinde

r

farthest from the master cylinder.

A bleeding operation is necessary to remove air from the

hydraulic brake system whenever air is introduced into the

hydraulic system. It may be necessary to bleed the hydraulic

system at all four brakes if air has been introduced through a

low fluid level or by disconnecting brake pipes at the master

cylinder. If a brake pipe is disconnected at one wheel, only that

wheel cylinder/caliper needs to be bled. If the pipes are

disconnected at any fitting located between the master cylinder

and brakes, then the brake system served by the disconnected

pipe must be bled.

1. Set the parking brake completely, then start the engine.

NOTE:

The vacuum booster will be damaged if the bleeding operation

is performed with the engine off.

2. Remove the master cylinder reservoir cap.

3. Fill the master cylinder reservoir with brake fluid. Keep the

reservoir at least half full during the air bleeding operation

4. Always use new brake fluid for replenishment.

5. In replenishing rake fluid, take care that air bubbles do not

enter the brake fluid.

When the master cylinder is replaced or overhauled, first

bleed the air from the master cylinder, then from each

wheel cylinder and caliper following the procedures

described below.

Bleeding the Master Cylinder

6. Disconnect the rear wheel brake pipe (1) from the maste

r

cylinder.

Check the fluid level and replenish as necessary. If

replenished, leave the system for at least one minute.

7. Depress the brake pedal slowly once and hold it depressed.

8. Completely seal the delivery port of the m as ter cylinder with

your finger, where the pipe was disconnected then release

the brake pedal slowly.

9. Release your finger from the delivery port when the brake

pedal returns completely.

10. Repeat steps 7 through 9 until the brake fluid comes out o

f

the delivery port during step 7.

NOTE: Do not allow the fluid level in the reservoir to go below

the half-way mark.

11. Reconnect the brake pipe (1) to the master cylinder and

tighten the pipe.

12. Depress the brake pedal slowly once and hold it depressed.

13. Loosen the rear wheel brake pipe (1) at the master cylinder.

14. Retighten the brake pipe, then release the brake pedal

slowly.

15. Repeat steps 12 through 14 until no air comes out of the

port when the brake pipe is loosened

NOTE: Be very careful not to allow the brake fluid to come in

contact with painted surfaces.

16. Bleed the air from the fr ont wheel brake pipe c onnection (2)

by repeating steps 6 through 15.

Bleeding the Caliper

17. Bleed the air from each wheel in the order listed below:

• Right rear wheel cylinder

• Left rear wheel cylinder

• Left front caliper

• Right front caliper

Conduct air bleeding from the wheels in the above order. I

f

no brake f luid com es out, it s uggests that air is m ixed in the

master cylinder. In this case, bleed air from the maste

r

cylinder. In this case, bleed air from the master cylinder in

accordance with steps 6 through 16, and then bleed ai

r

from the caliper or wheel cylinder.

RTW35CSH000501

18. Place the proper size box end wrench over the bleede

r

screw.

19. Cover the bleeder screw with a transparent tube, and

submerge the free end of the transparent tube in a

transparent container containing brake fluid.

5042

20. Pump the brake pedal slowly three (3) times (once/sec),

then hold it depressed.

21. Loosen the bleeder screw until fluid flows through the tube.

22. Retighten the bleeder screw.

23. Release the brake pedal slowly.

24. Repeat steps 21 through 24 until the air is completel

y

removed.

It may be necessar y to repeat the bleeding pr ocedure 10 o

r

more times for front wheels and 15 or more times for rea

r

wheels.

25. Go to the next wheel in the sequence after each wheel is

bled.

Be sure to monitor reservoir fluid level.

26. Depress the brake pedal to check if you feel “sponginess"

after the air has been rem oved fr om all wheel cylinders and

calipers.

If the pedal feels “spongy", the entire bleeding procedure

must be repeated.

27.

A

fter the bleeding operation is completed on the each

individual wheel, check the level of the brake fluid in the

reservoir and replenish up to the “MAX" level as necessary.

28. Attach the reservoir cap.

29. Stop the engine.

05007-1

BRAKE LINE (HOSES AND PIPES)

• Inspect all hoses and pipes for wear, bending, chafing,

cracks, dents, or any other damage.

Make necessary correction or parts replacement if these

abnormal conditions are found through inspection.

• All hoses, pipes and joints can be damaged easily.

Do not allow the hose to become excessively twisted and

bent when working with then, and pay special attention to all

the brake lines not to damage them when repairing o

r

replacing other parts (axle, suspension, etc).

• Inspection for leakage should be performed by depressing

the brake pedal fully.

If leakage is apparent at the circumference of joints,

retighten or replace these parts.

This procedure must be performed whenever brake lines

are installed.

•

A

fter disconnecting the hoses and pipes, cap or tape the

openings to prevent entry of foreign material.

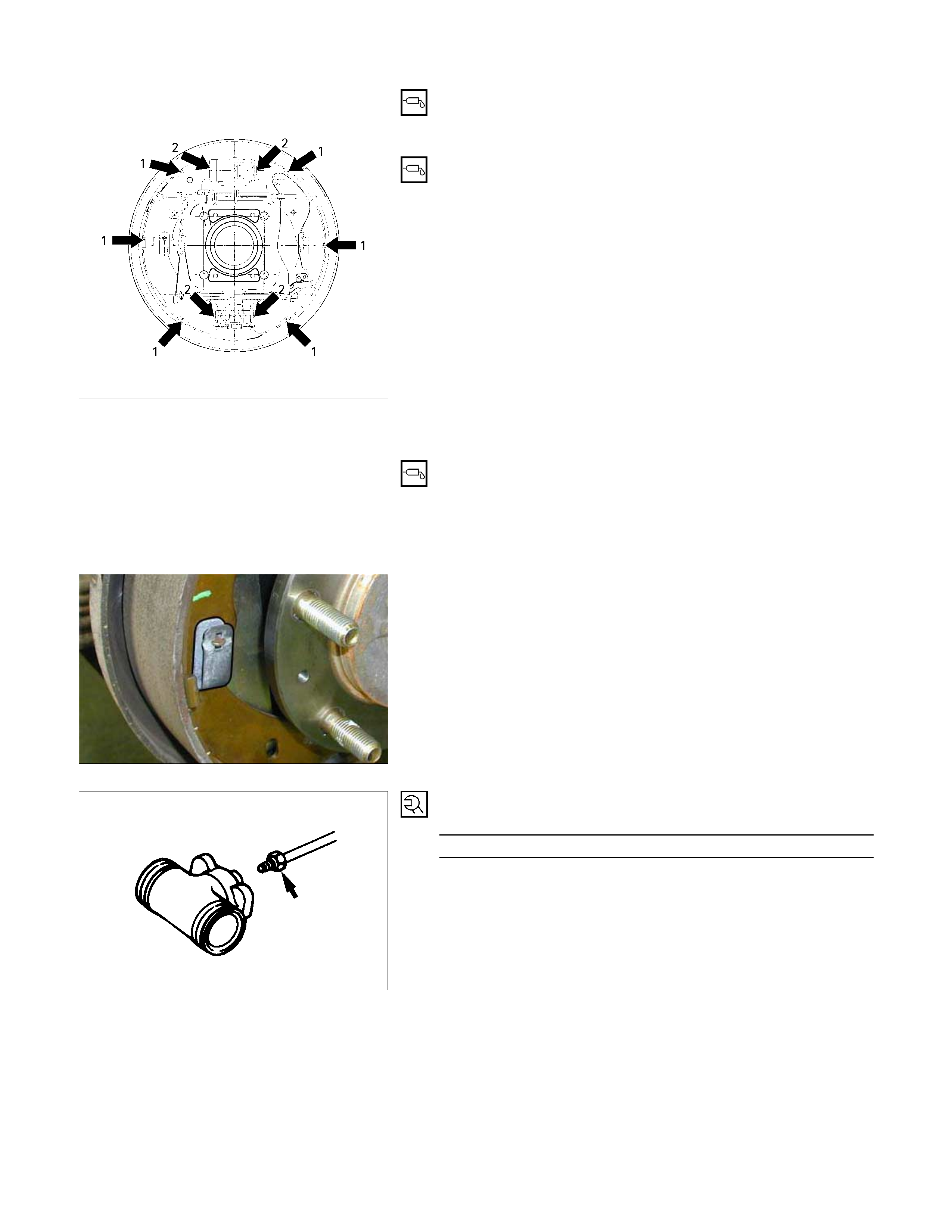

ADJUSTMENT PROCEDURE OF SERVICE AND PARKING BRAKE

Stem type

All brakes are self-adjusting.

Brakes are adjusted by repeated stepping on the brake pedal.

(After stepping on the pedal and releasing it, the rear auto-

adjuster, in the rear brake, produces a clicking sound.

the same operation should be repeated until the sound

disappears.)

Take the following steps after overhauling the rear brake

assembly.

1. Move the parking brake lever to its fully released position.

311R300007

2. Parking cable must be loosened sufficiently.

(Loosen the adjust nut and the lock nut.)

3. Repeat stepping on the brake pedal firmly, and releasing it

until the clicking sound can no longer be heard.

If the dif ference between the brak e drum ins ide diameter o

f

the brake shoes is adjusted to be 0.5 mm, the number o

f

times for depressing the brake pedal can be reduced.

4. Remove the drum.

Measure the brake drum inside diameter and diameter o

f

the brake shoes.

Shoe Clearance mm(in)

0.25 - 0.40 (0.0098 - 0.0157)

If incorrect, check the brake auto-adjusting system.

5. T urn the adjuster nut s o that the parking brak e lever travels

8 to 14 notches when pulled up with a force 30 kg (66 lbs.).

6. Make sure there is not brake dragging.

Floor mount type

All brakes are self-adjusting.

Brakes are adjusted by repeated stepping on the brake pedal.

(After stepping on the pedal and releasing it, the rear auto-

adjuster, in the rear brake, produces a clicking sound.

the same operation should be repeated until the sound

disappears.)

Take the following steps after overhauling the rear brake

assembly.

1. Move the parking brake lever to its fully released position.

2. Parking cable must be loosened sufficiently.

(Loosen the adjust nut and the lock nut.)

3. Repeat stepping on the brake pedal firmly, and releasing it

until the clicking sound can no longer be heard.

If the dif ference between the brak e drum ins ide diameter o

f

the brake shoes is adjusted to be 0.5 mm, the number o

f

times for depressing the brake pedal can be reduced.

4. Remove the drum.

Measure the brake drum inside diameter and diameter o

f

the brake shoes.

Shoe Clearance mm(in)

0.25 - 0.40 (0.0098 - 0.0157)

If incorrect, check the brake auto-adjusting system.

5. T urn the adjuster nut s o that the parking brak e lever travels

6 to 8 notches when pulled up with a force 30 kg (66 lbs.).

6. Make sure there is not brake dragging.

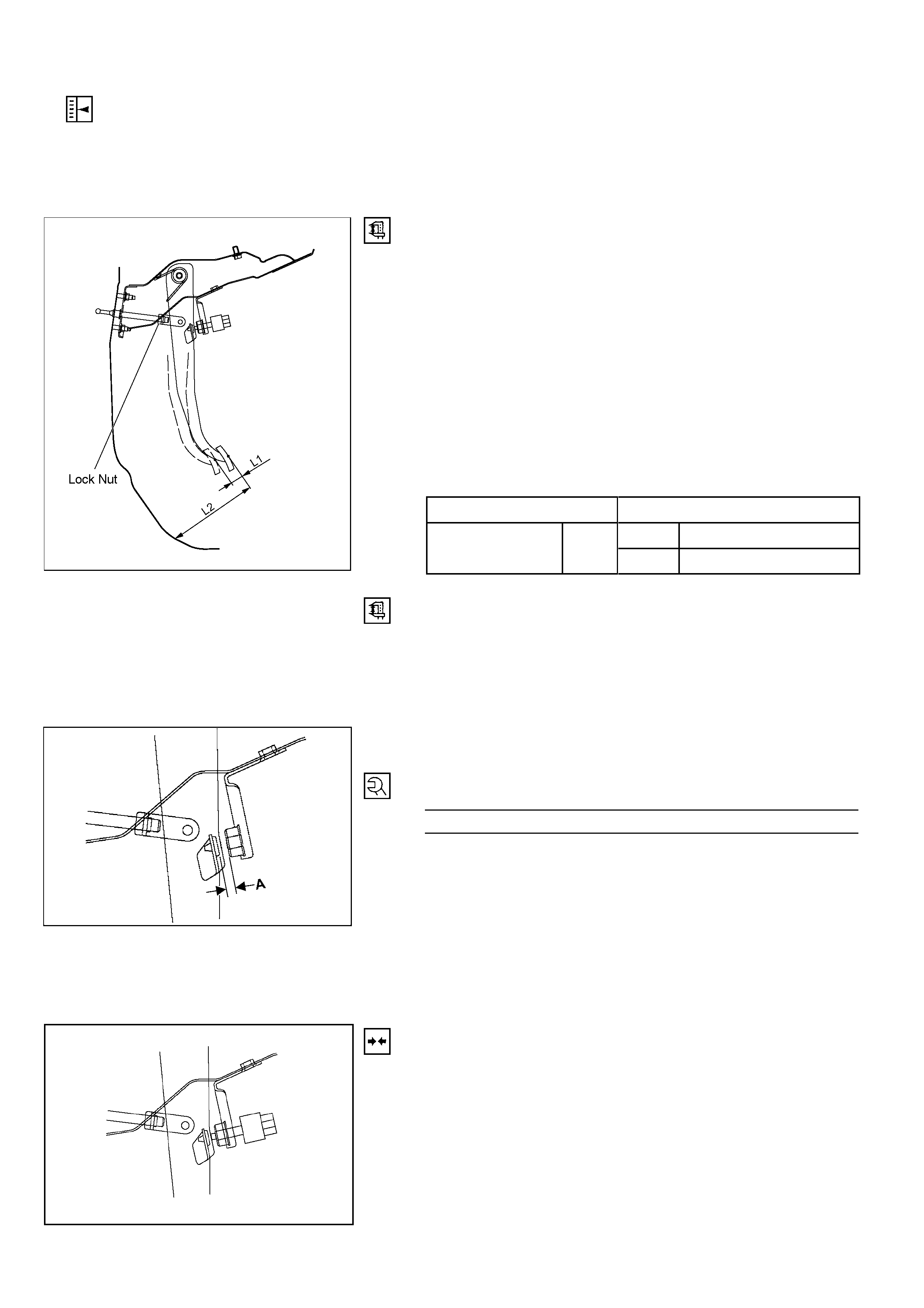

ADJUSTMENT PROCEDURE OF BRAKE PEDAL

The push rod serves as the brake pedal stopper when the

pedal is fully released.

Brake pedal height adjustment should be performed as follows.

RTW35CSH000601

Brake Pedal - Height

Measure the brake pedal height after making sure the pedal is

fully returned by the pedal return spring.

Note:

Pedal height (L2) must be measured after starting the

engine and increasing the revolution several times by

stepping on the accelerator pedal. mm(in)

Pedal free play (L1) 6-10 (0.23 - 0.39)

M/T 174-186 (6.85-7.32)

RHD A/T 176-188 (6.93-7.40)

Height (L2)

Note:

Pedal free play must be measured after turning off the

engine and stepping on the brake pedal firmly five times

or more.

If the measured value deviates from the above range, adjust

the brake pedal as follows:

a) Disconnect the stop lamp switch.

b) Loosen the lock nut on the push rod.

c)

A

djust the brake pedal to the specified height by rotating the

push rod in the appropriate direction.

Lock Nut Torque N⋅m(kgf⋅m/lb⋅

⋅⋅⋅ft)

12 - 18 (1.2 – 1.8 / 9 - 13)

d) Install the stop lamp switch.

Note:

Pedal height (L2) must be 80 mm (3.14 in.) or more when

applying about 50 kg (110.25 lbs.) of stepping force.

331R300005

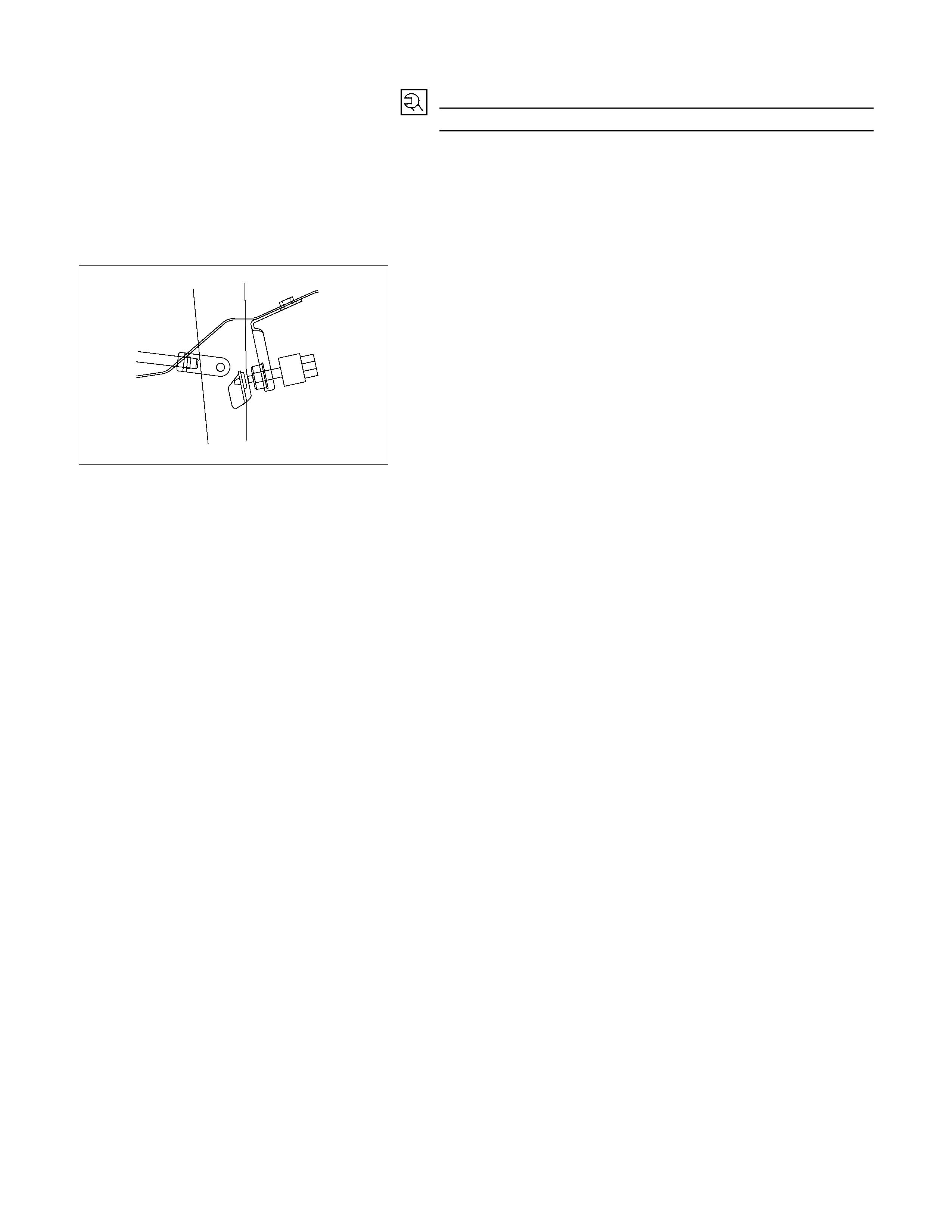

How to connect the CLEVICE of BOOSTER ROD with PEDAL

ARM. and how to adjust the PEDAL SW.

After connecting the CLEVIS of BOOSTER ROD with PEDAL

ARM, adjust the PEDAL SW mounted (PDA) to PEDAL

BRACKET by the procedure explained still more bellow.

1. Set the hole of the CLEVIS of BOOSTER&M/CYL ROD

with the hole of the PEDAL ARM.

2. Enter the PIN; PUSH ROD to PEDAL to these holes

from left side of the PEDAL.

3. Enter and fix the PIN; SANP PIN FIX to the DITCH o

f

the PIN; PUSH ROD to PEDAL from right side of the

PEDAL.

4. Release the LOCK by turning the SWITCH counter-

clock-wise.

5. After doing so, pull PEDAL ARM to yourself a little so

that PEDAL ARM is not pushed in.

6. Making PEDAL ARM not movable with one hand, push

in the whole SWITCH with the other hand until the

PLUNGER of SWTCH is pushed in and SWITCH itself

hits the RUBBER of PEDAL ARM.

In the condition, turn SWITCH clock-wise until “click”

sound is made and lock it.

By doing this the SWITCH is adjusted at 0.7±0.5mm

clearance.

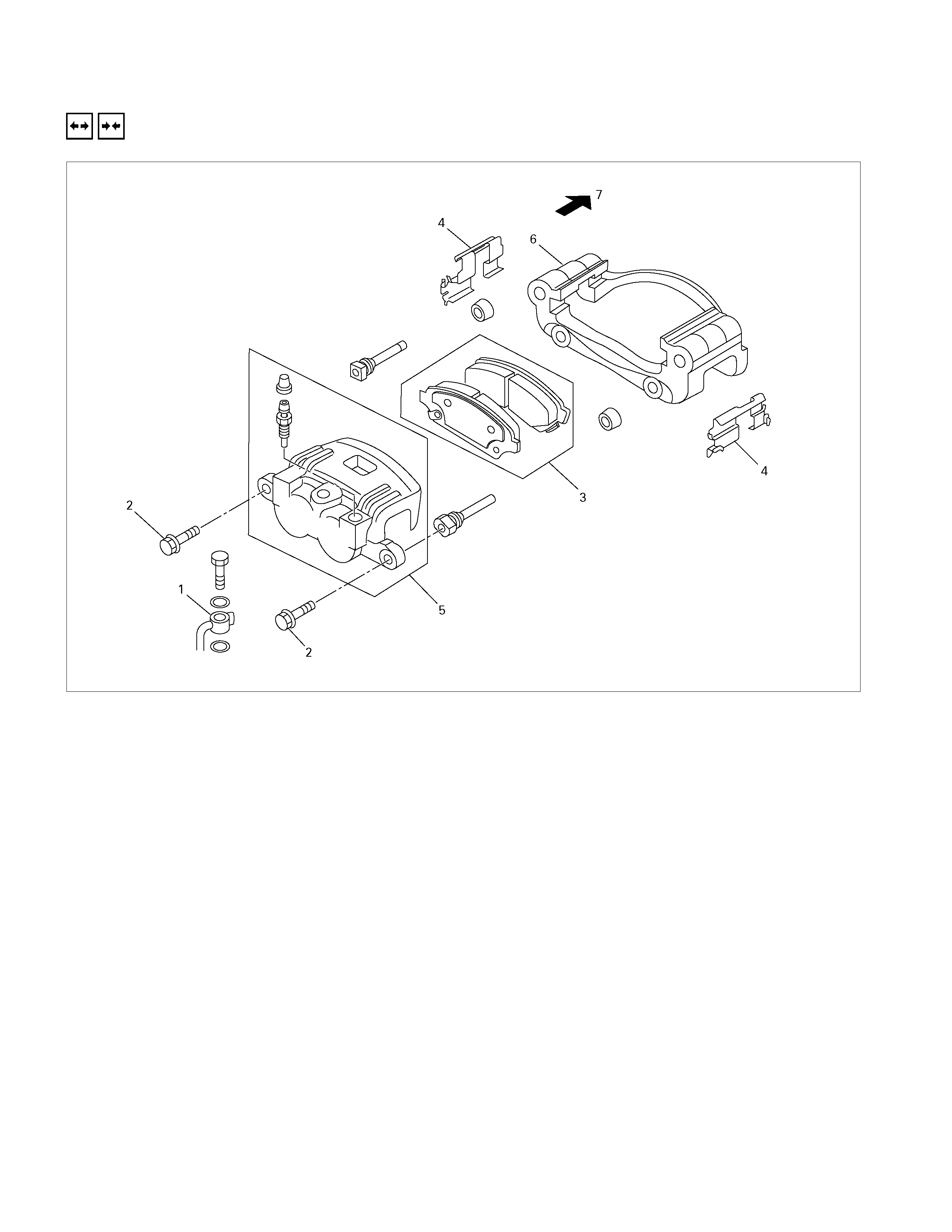

FRONT BRAKE ASSEMBLY

REMOVAL AND INSTALLATION

Removal Steps

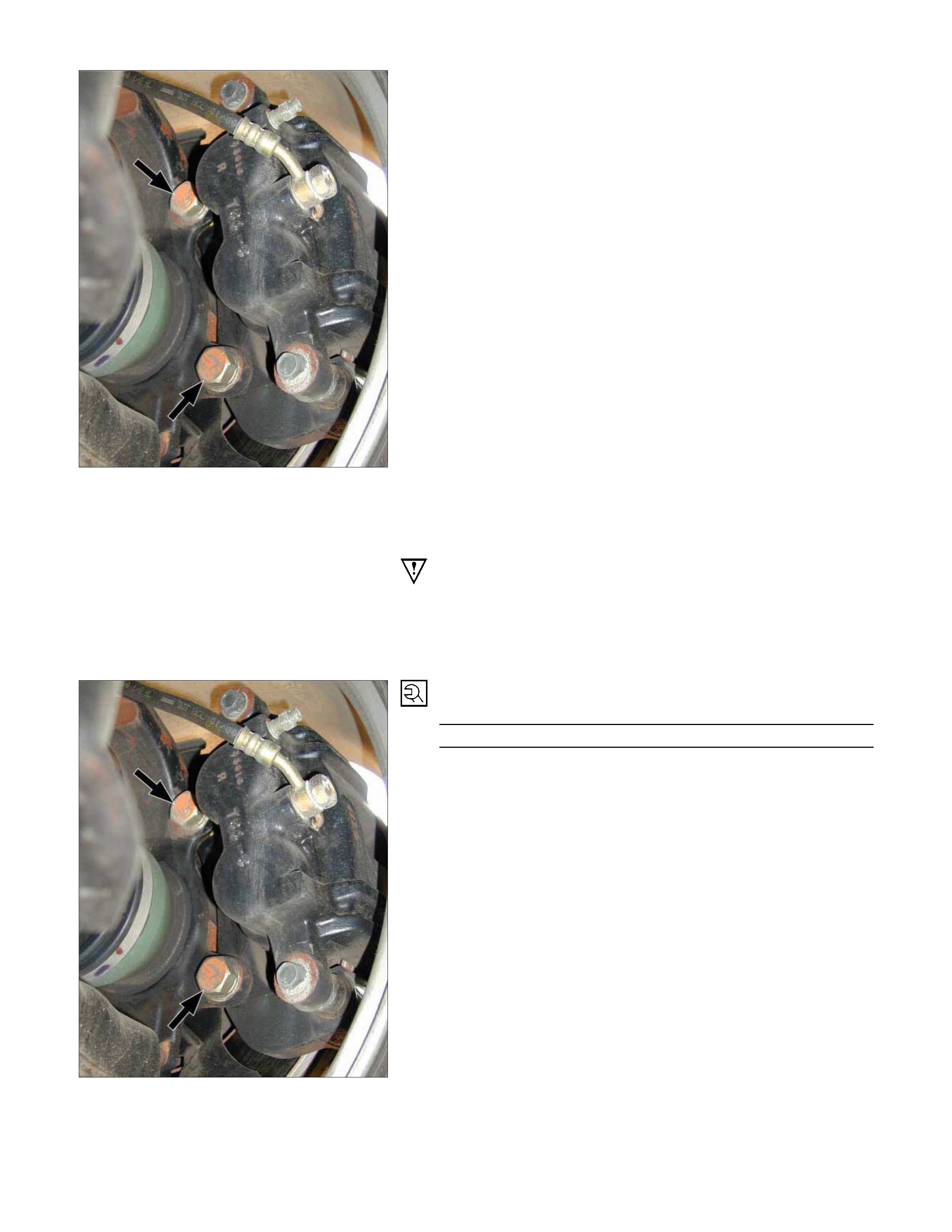

▲ 1. Brake flexible hose

▲ 2. Lock bolt

▲ 3. Pad assembly

4. Clip; pad

5. Caliper assembly

▲ 6. Support bracket

▲ 7. Front hub and disc assembly

Installation Steps

▲ 7. Front hub and disc assembly

▲ 6. Support bracket

5. Caliper assembly

▲ 4. Clip; pad

3. Pad assembly with shim

▲ 2. Lock bolt

▲ 1. Brake flexible hose

Important Operations - Removal

1. Brake Flexible hose

Remove the bolt and gasket and disconnect the brake flexible

hose from the caliper.

After disconnecting the flexible hose, cap or tape the openings

to prevent entry of foreign material.

2. Lock Bolt

Remove the lock bolt from the caliper.

3. Pad Assembly with Shim

Rotate the caliper upward.

Mark the lining locations if they are to be reinstalled.

6. Support Bracket

Take care not to damage the flexible brake hose when

removing the support bracket.

7. Front Hub and Disc Assembly

For the removal procedure, refer to

Section 4C "FRONT WHEEL DRIVE".

Important Operations - Installation

7. Front Hub and Disc Assembly

For the installation procedure, refer to the front hub and disc

reassembly procedure in

Section 4C "FRONT WHEEL DRIVE".

6. Support Bracket

Torque N⋅m(kgf⋅m/lb⋅ft)

196 - 235 (20.0 – 24.0 / 145 - 174)

Set up the clip and pad before installation of the support

racket.

4. Clip ; Pad

Install new parts if necessary.

2. Lock Bolt

Torque N⋅m(kgf⋅m/lb⋅ft)

32 - 40 (3.3 – 4.1 / 24 - 30)

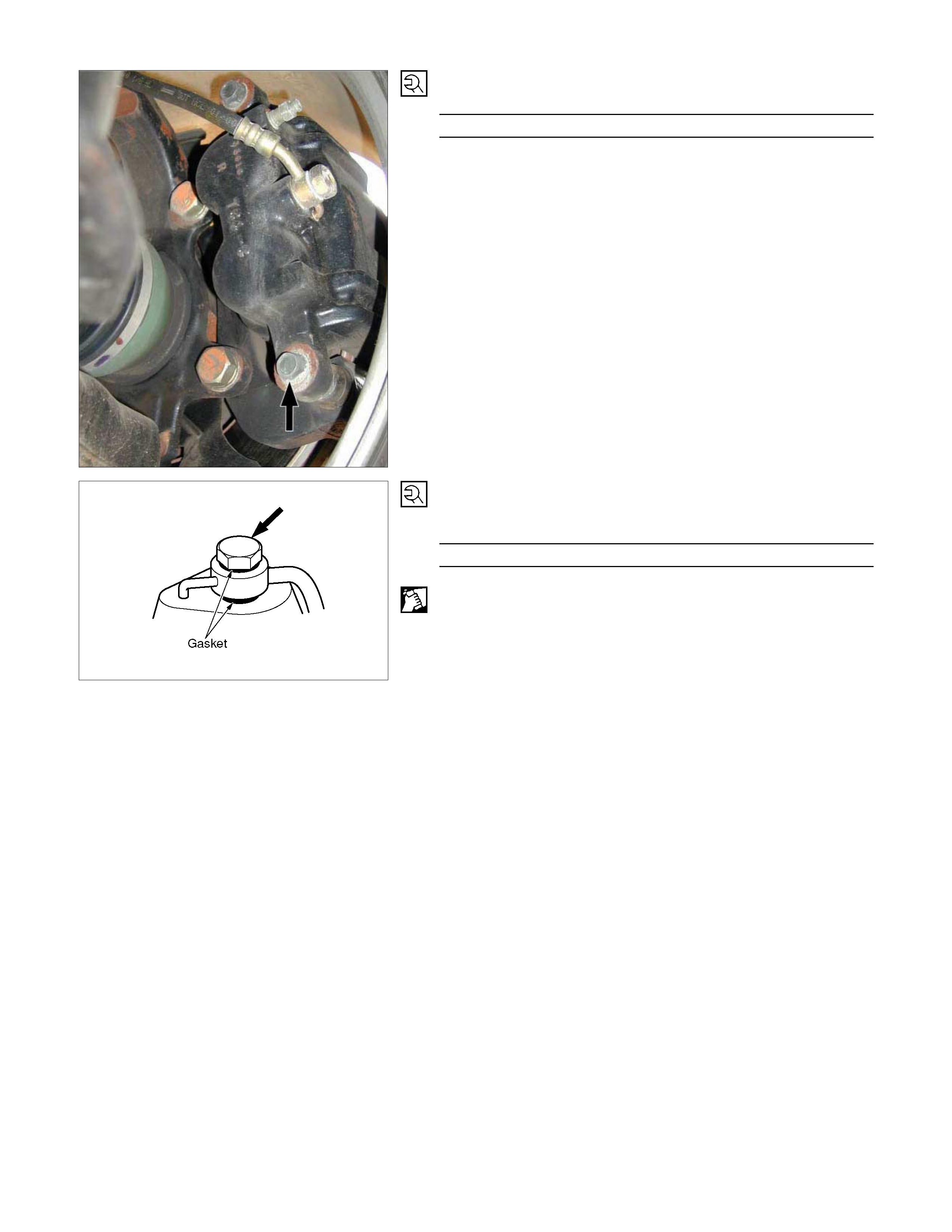

1. Brake Flexible Hose

Attach the bolt and new gasket

Torque N⋅m(kgf⋅m/lb⋅ft)

29 -39 (3.0 - 4.0 / 22 - 29)

After installation, bleeding and replenishing procedure must be

performed.

Wipe the circumference of the hose clean.

Note:

•

••

• Always use new gaskets.

• Be sure to put the hooked edge of the flexible hose end into

the anti-rotation cavity.

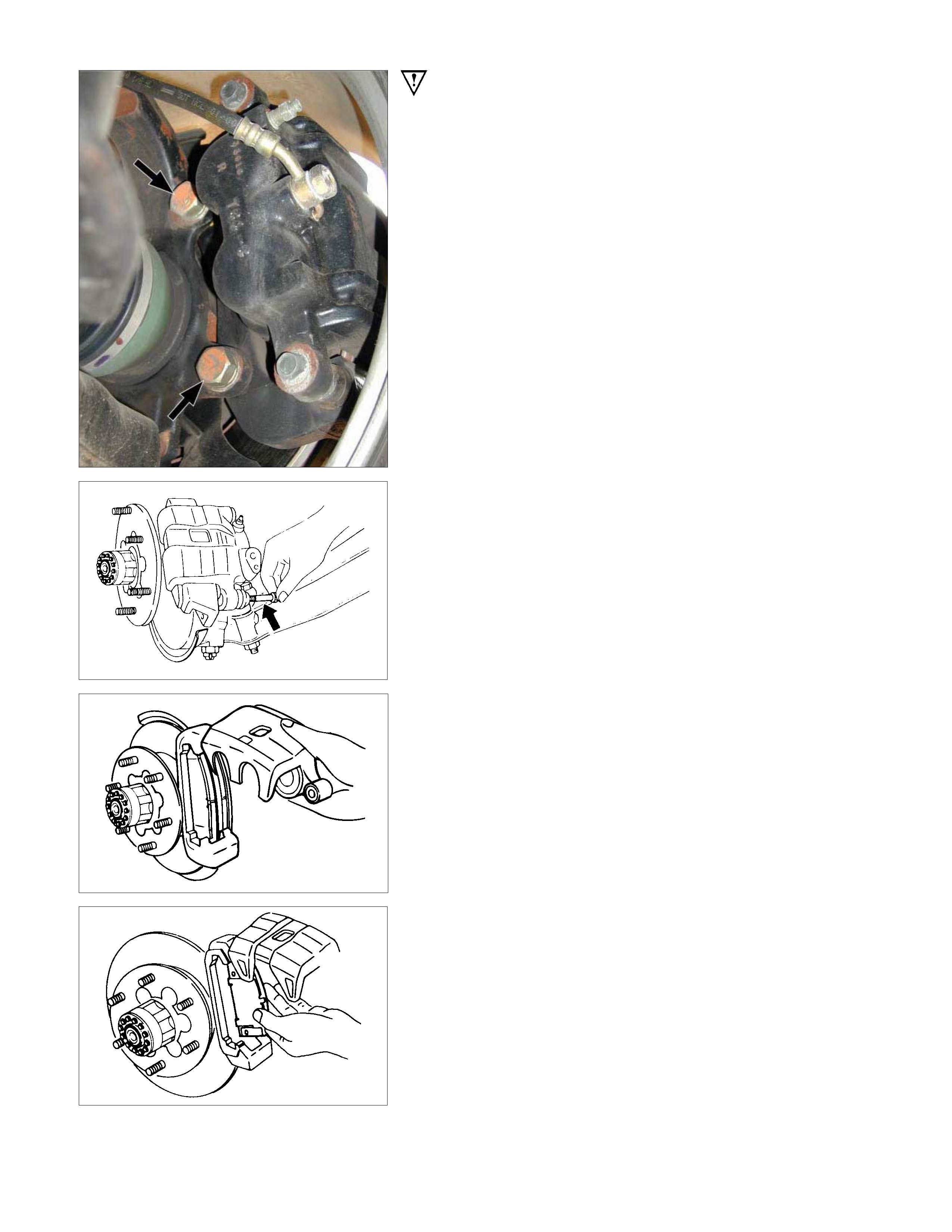

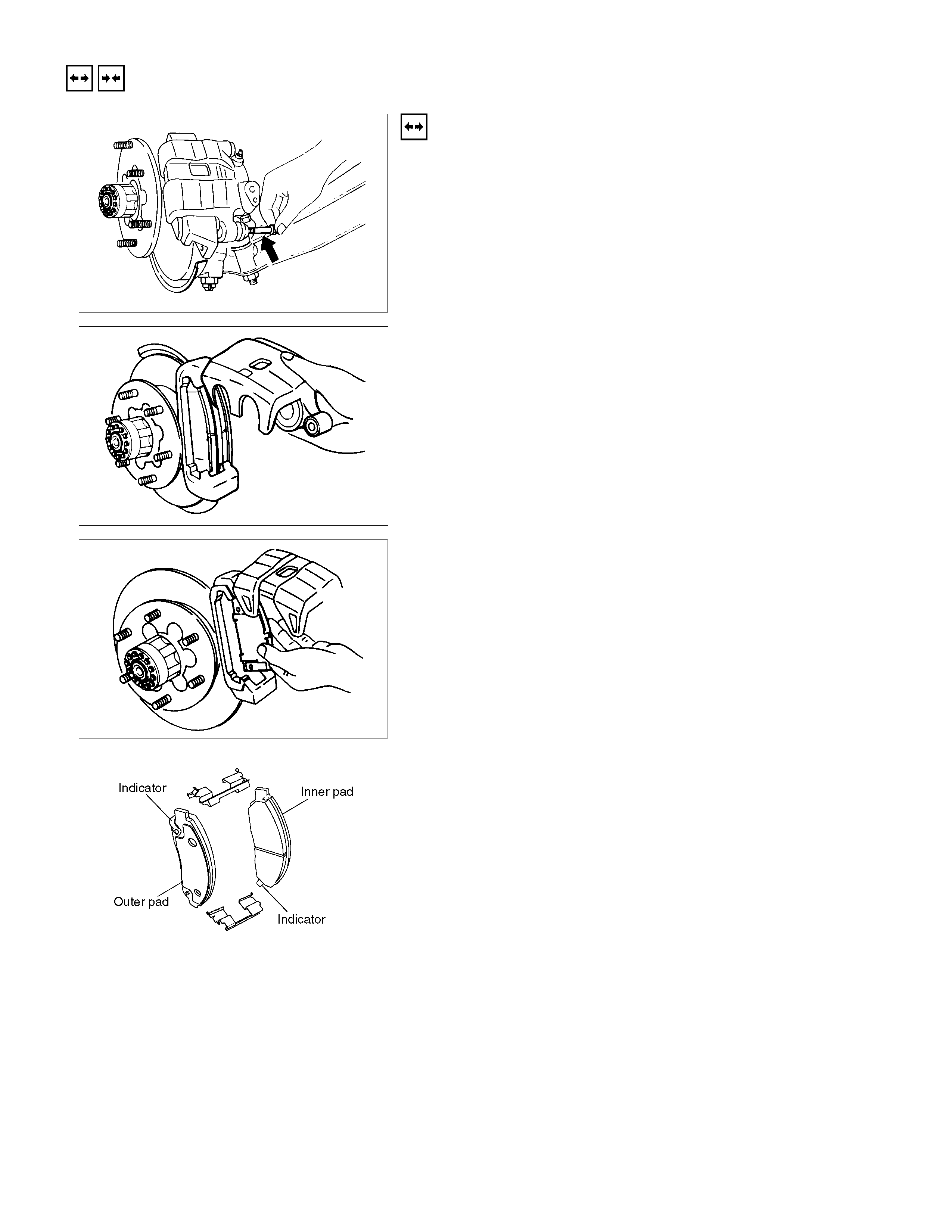

REMOVAL AND INSTALLATION OF DISC PAD

Removal Steps

1. Lock Bolt

Remove the lock bolt from the caliper.

Note:

Don't remove the brake hose from caliper when replacing

pads.

2. Rotate the Caliper Upward

Remove the caliper from the support bracket and ire the

caliper to the upper link or the frame.

Note:

While caliper is removed from support bracket, never step

on the brake pedal or the piston will protrude rapidly.

3. Pad Assembly with Shim

Remove the pad assembly with the shim.

Mark the pad locations if they are to be reinstalled.

4. Clip ; Pad

Discard the used clip and install a new one.

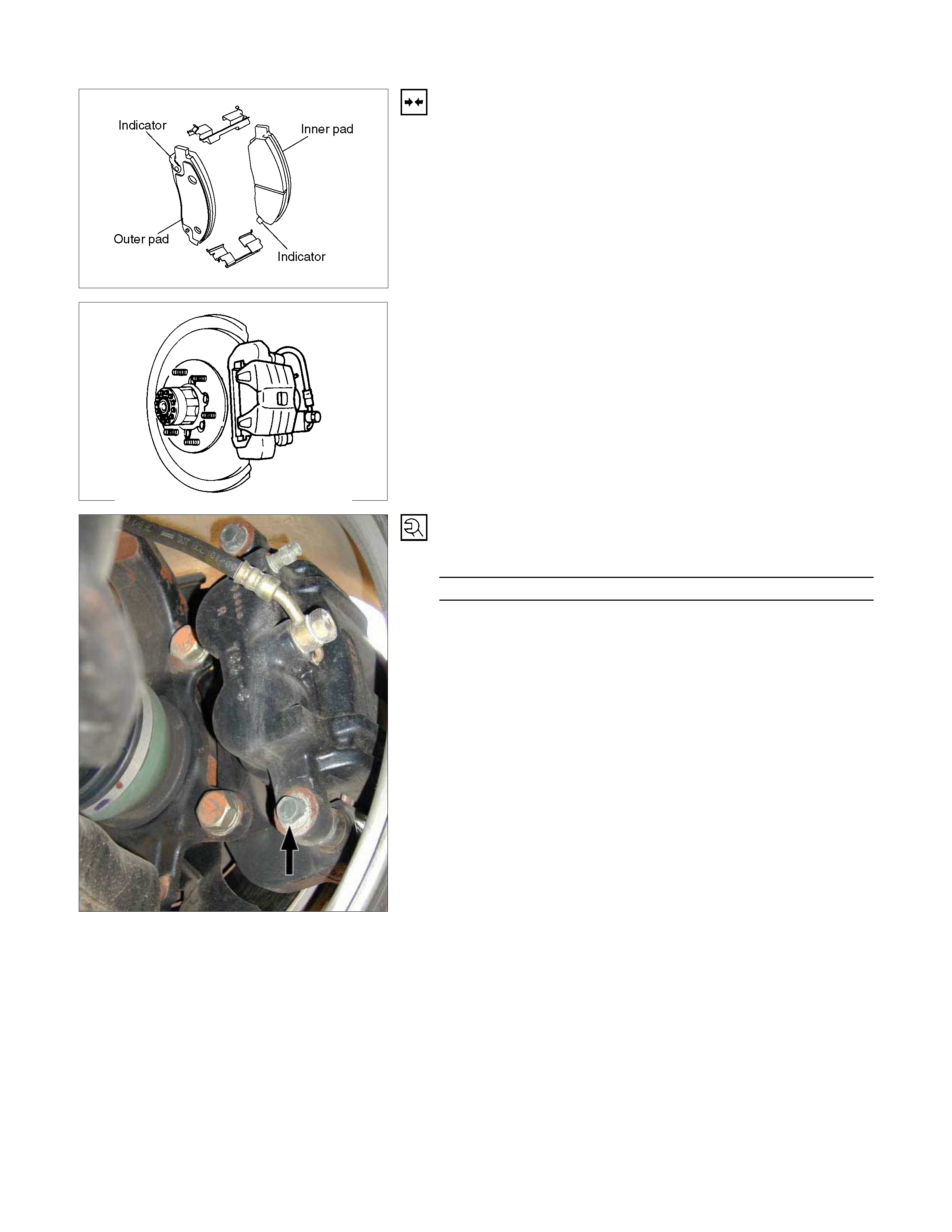

Installation Steps

1. Clip ; Pad

2. Pad Assembly with Shim

After attaching the pad assembly with the shim to the support

bracket, position the wear indicator to the lower side of the

inner pad and position the wear indicator to the upper side of

the outer pad.

3. Caliper Assembly

Lower the caliper into its original position.

Do not damage the flexible hose by twisting or pulling it.

4. Lock Bolt

Attach the lock bolt to the caliper.

Torque N⋅m(kgf⋅m/lb⋅ft)

32 - 40 (3.3 – 4.1 / 24 - 30)

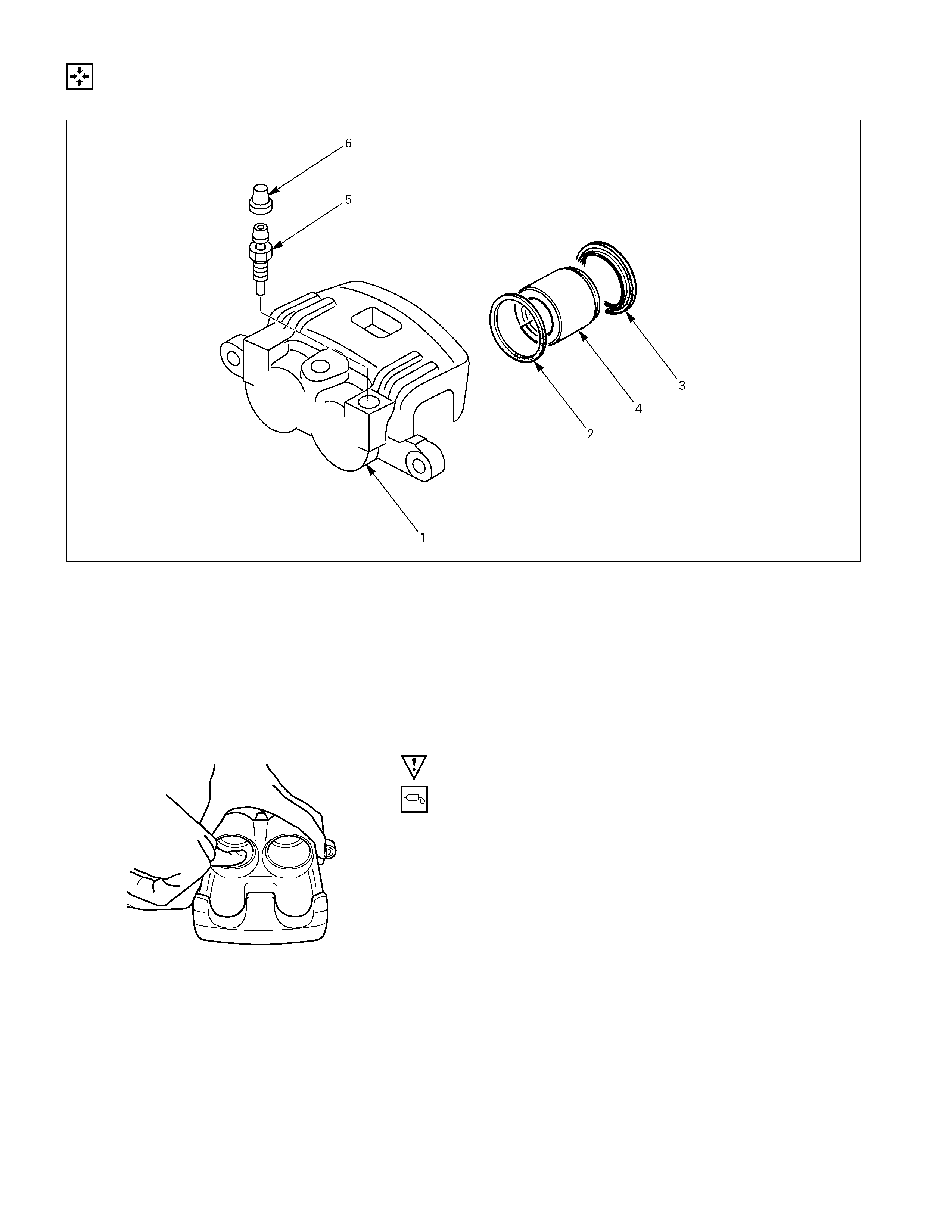

DISASSEMBLY

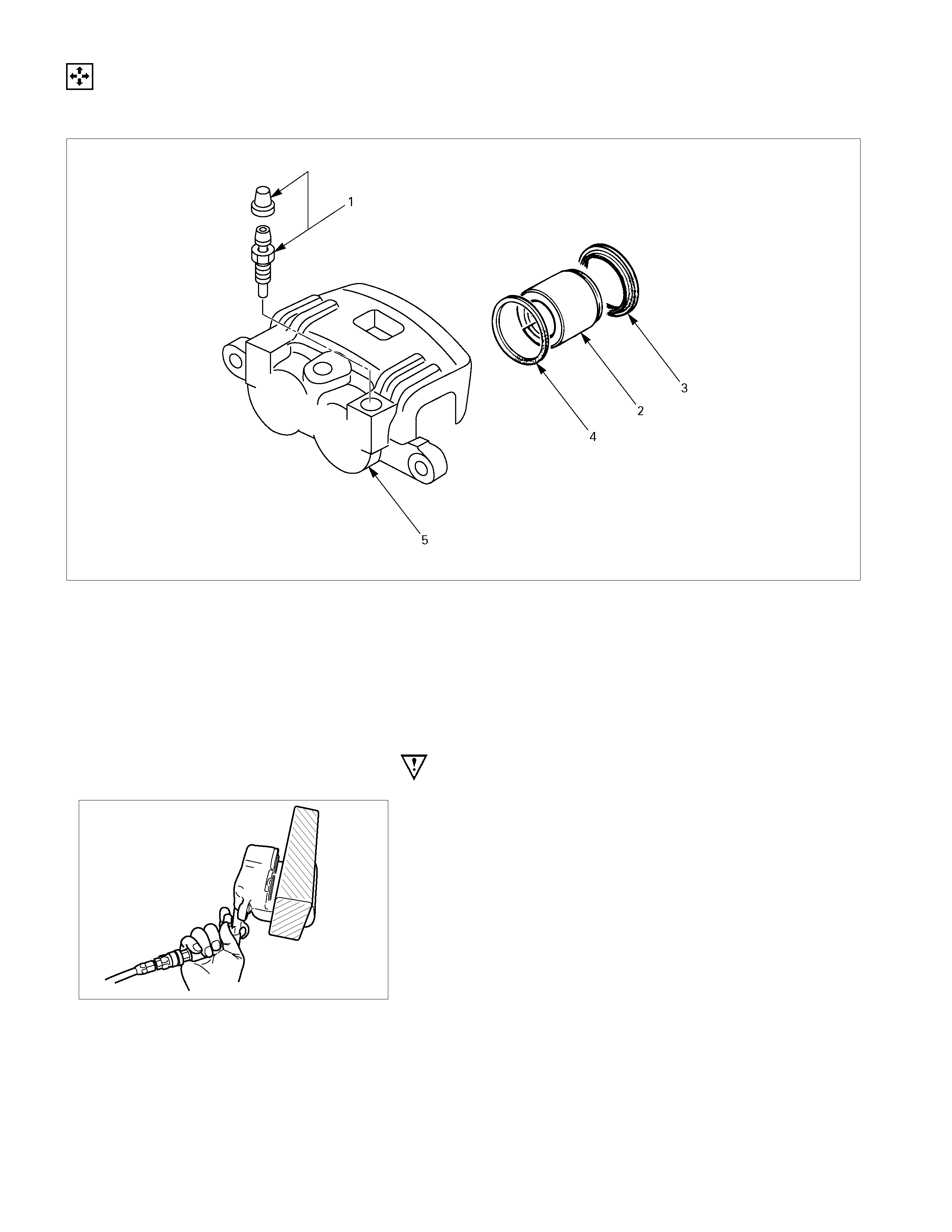

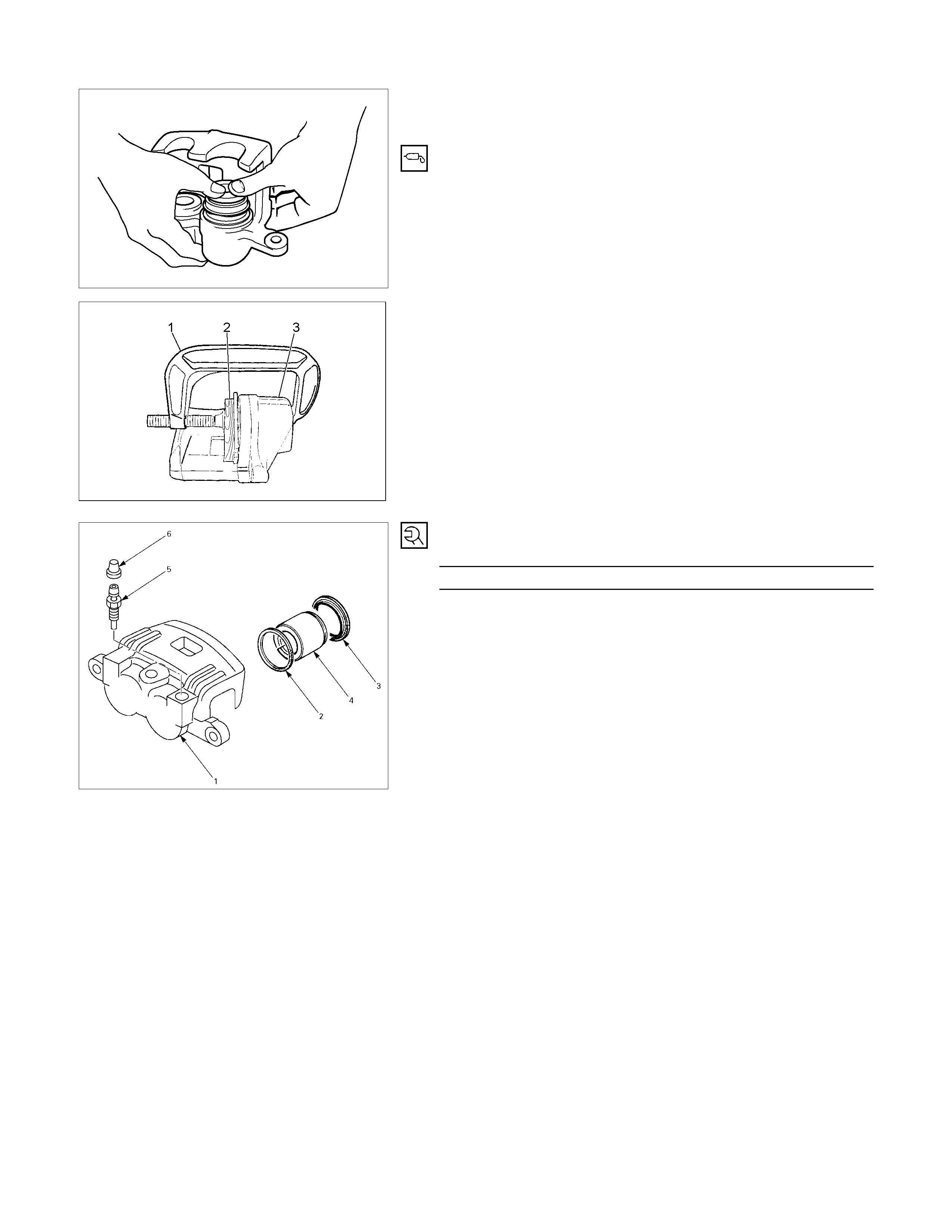

CALIPER ASSEMBLY

Disassembly Steps

1. Bleeder with cap

▲ 2. Piston

3. Dust seal; piston

4. Ring seal

5. Body; caliper

Important Operations

2. Piston (with Ring Seal)

Insert a block of wood into the caliper and force out the piston

by blowing compressed air into the caliper at the flexible hose

attachment.

This procedure must be done prior to removal of dust seal.

CAUTION:

Do not place your fingers in front of the piston in an

attempt to catch or protect it when applying compressed

air.

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear damage or any other abnormal conditions are found through

inspection.

• Rotor

• Caliper body

• Cylinder bore

• Piston

• Support bracket

• Lock bolt

• Guide pin

Visual Check

Inspect the following parts for wear, bending, distortion,

cracking, corrosion, or other abnormal conditions.

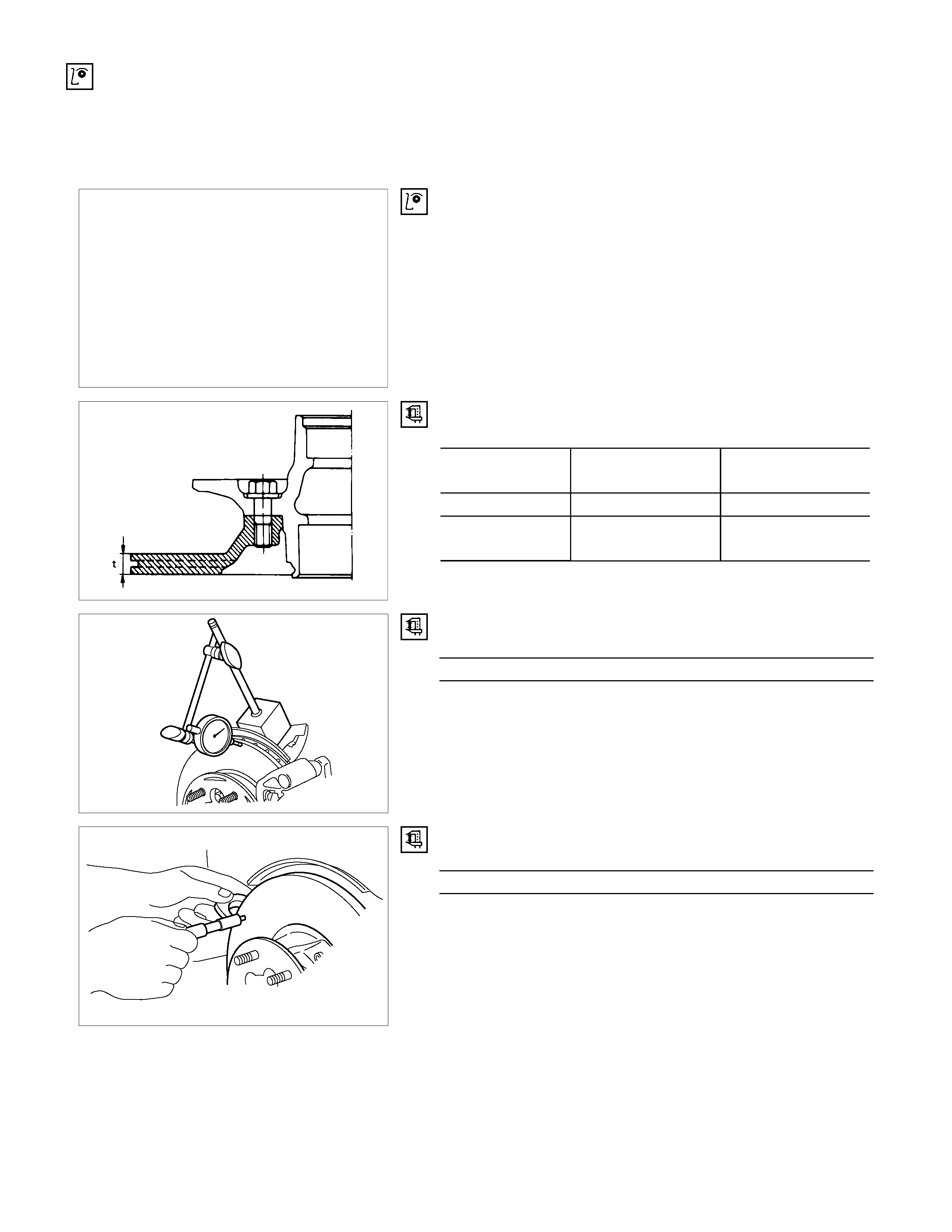

Rotor

• Thickness (t) mm(in)

Standard Replacement

thickness (Discard)

4×2 26.0 (1.024) 24.6 (0.969)

4×2 HIGH RIDE

4×4 27.0 (1.063) 25.6 (1.008)

• Run out

Limit mm(in)

0.075 (0.0029)

Before inspection, adjust the wheel bearing correctly.

Using a dial gauge, measure the run out at the 10mm inside

position from rotor out side edge of disc pad contact surface.

• Parallelism (Total circumferential thickness variation)

Limit mm(in)

0.023 (0.0009)

Contact surface must be within 0.023mm at the 10mm inside

position from rotor out side edge.

(Measurement; shall be measure more than 8 position at

circumferential direction.)

Thickness of Disc Pad

Thickness (t) mm(in)

Standard Limit

10.0 (0.394) 1.8 (0.071)

Replace the front disc pad whenever the pad wear indicator

makes a squeaking noise or when the pad is worn to within 1.8

mm of the shoe table.

All four brake pads should be replaced together.

302R300019

Seal and Boot

The dust seal, dust boot and ring seal are to be replaced each

time the caliper is overhauled.

Discard thee used rubber parts.

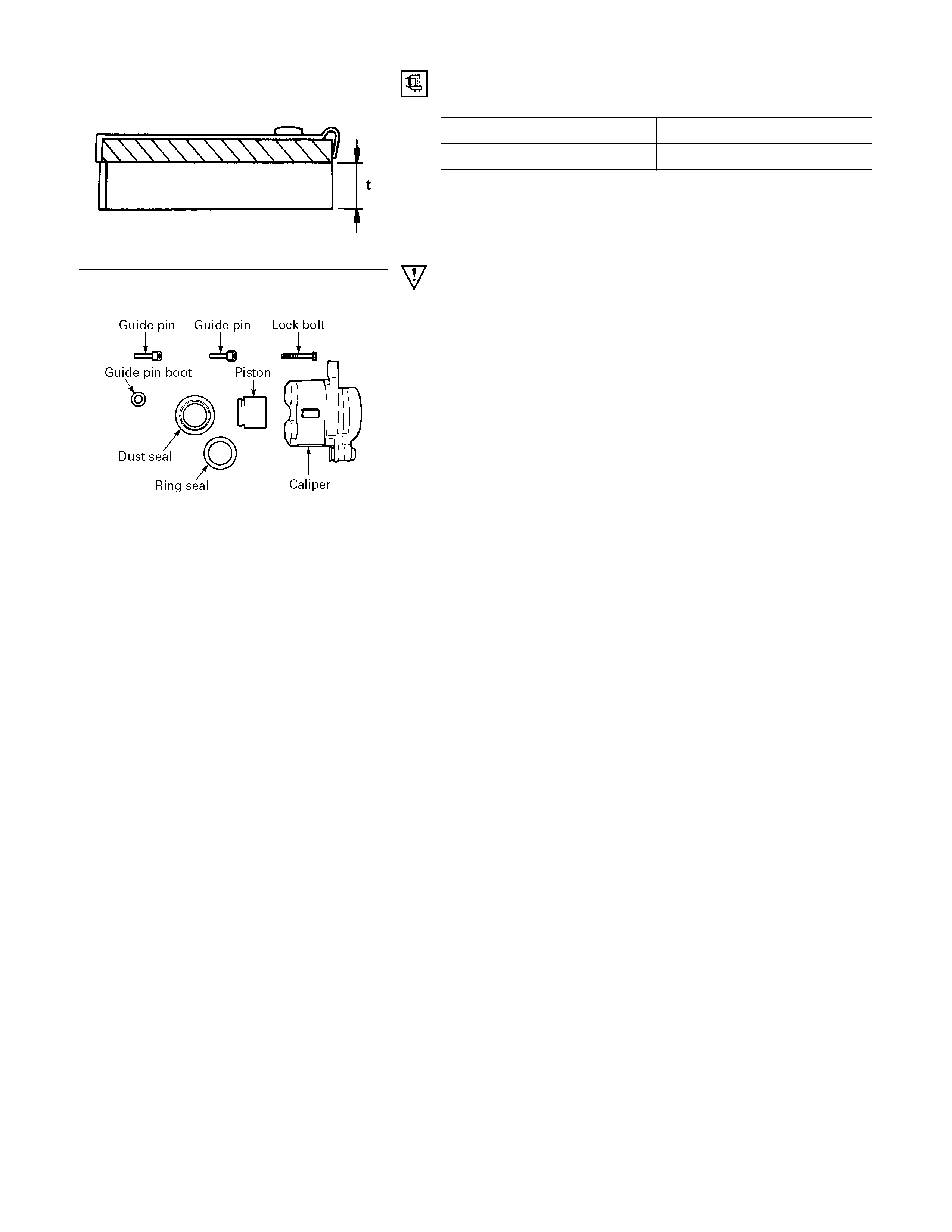

REASSEMBLY

CALIPER ASSEMBLY

Disassembly Steps

1. Body ; caliper

2. Ring seal

3. Dust seal ; piston

4. Piston

5. Bleeder

6. Cap

Important Operations

1. Body ; Caliper

2. Ring Seal

Apply clean brake fluid to the ring seal and cylinder wall, then

insert the ring seal into the cylinder.

Ensure that the piston ring seal are not twisted in the caliper

bore grooves.

3. Dust seal ; Piston

Install the dust seal on the pistons.

4. Piston

Apply clean brake fluid to the piston and attach the dust seal to

the piston and caliper.

When inserting the piston into the cylinder, use finger pressure

only. Do not use a mallet or other impact tools, since damage

to the cylinder wall or ring seal can result.

The movement of a caliper piston into a caliper bore should be

smooth and even. If a caliper piston is frozen or difficult to

bottom, the caliper requires overhaul or replacement.

RTW35CSH000701

For dual piston caliper applications, insert a discarded inner

brake pad (2) or block of wood in front of the pistons. Using 2

large C-clamps (1) installed over the body of the caliper (3) and

against the brake pad or block of wood, slowly bottom the

pistons evenly into the bores.

Insert the dust seal ring into the dust seal.

CAUTION:

Piston made by plastic material.

Don’t must be hit on the piston by hammer etc. and don’t

grasp to face of piston by pliers.

5. Bleeder

Torque N⋅m(kgf⋅m/Ib⋅in)

9 – 16 (0.9 – 1.6 / 78 - 139)

6. Cap

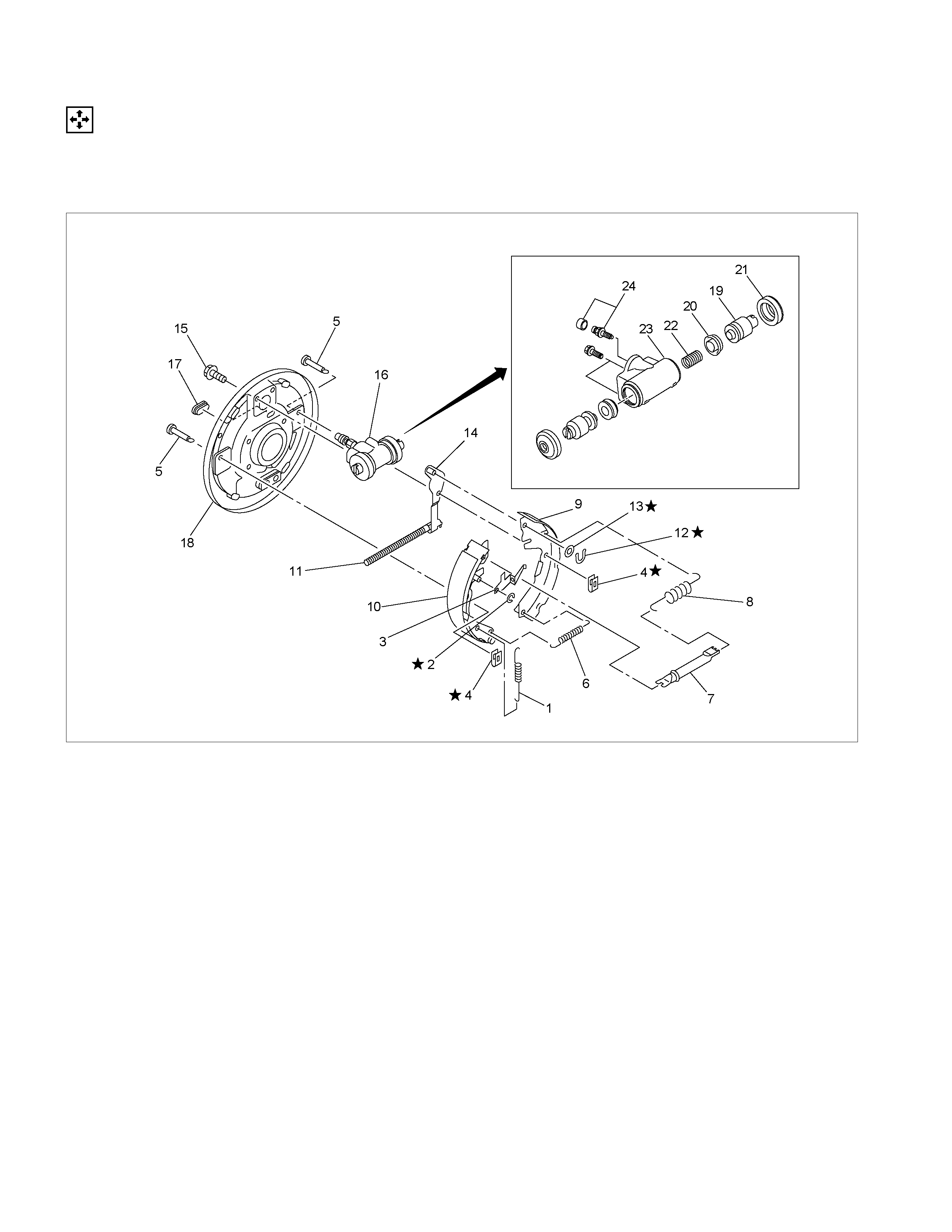

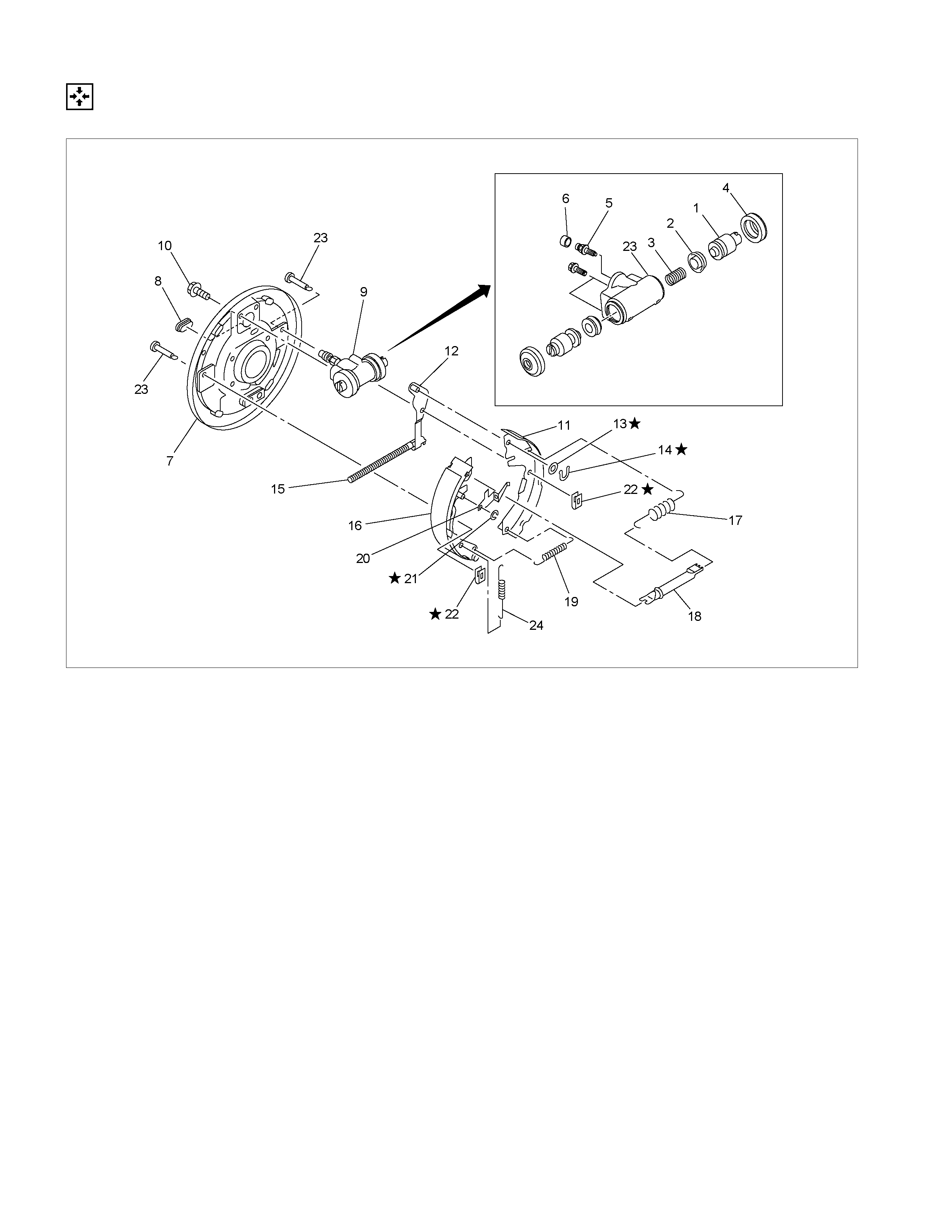

REAR DRUM BRAKE ASSEMBLY

DISASSEMBLY

First, disassemble the brake drum. Then disassemble the rear brake assembly.

Refer to the “REAR AXLE” section for the brake drum disassembly procedure.

RTW35CMF000201

MAJOR COMPONENTS

Disassembly Steps

1. Spring ; adjuster

2. Ring ; Adjuster lever

3. Lever ; adjuster

▲ 4. Spring ; Shoe hold

5. Pin ; Shoe hold

▲ 6. Spring ; Shoe to shoe, lower

7. Adjuster assembly

8. Spring ; shoe to shoe, upper

9. Shoe ; leading

10. Shoe ; trailing

11. Spring ; lever return

12. Retainer

13. Washer ; lever

14. Lever ; parking

15. Bolt ; wheel cylinder

16. Wheel cylinder assembly

17. Cover

18. Back plate

MINOR COMPONENTS

Disassembly Steps

Wheel Cylinder Assembly (14)

19. Piston

20. Cup

21. Boot ; piston

22. Return spring

23. Bleeder

24. Cap ; bleeder

P1010008

Important Operations

4. Spring ; shoe hold

Push the shoe hold spring toward the brake shoe and hold it.

Rotate the spring to remove it from the shoe hold pin.

6. Spring ; shoe to shoe, lower

Slide the brake shoes and lower spring toward the ground.

Remove the lower spring.

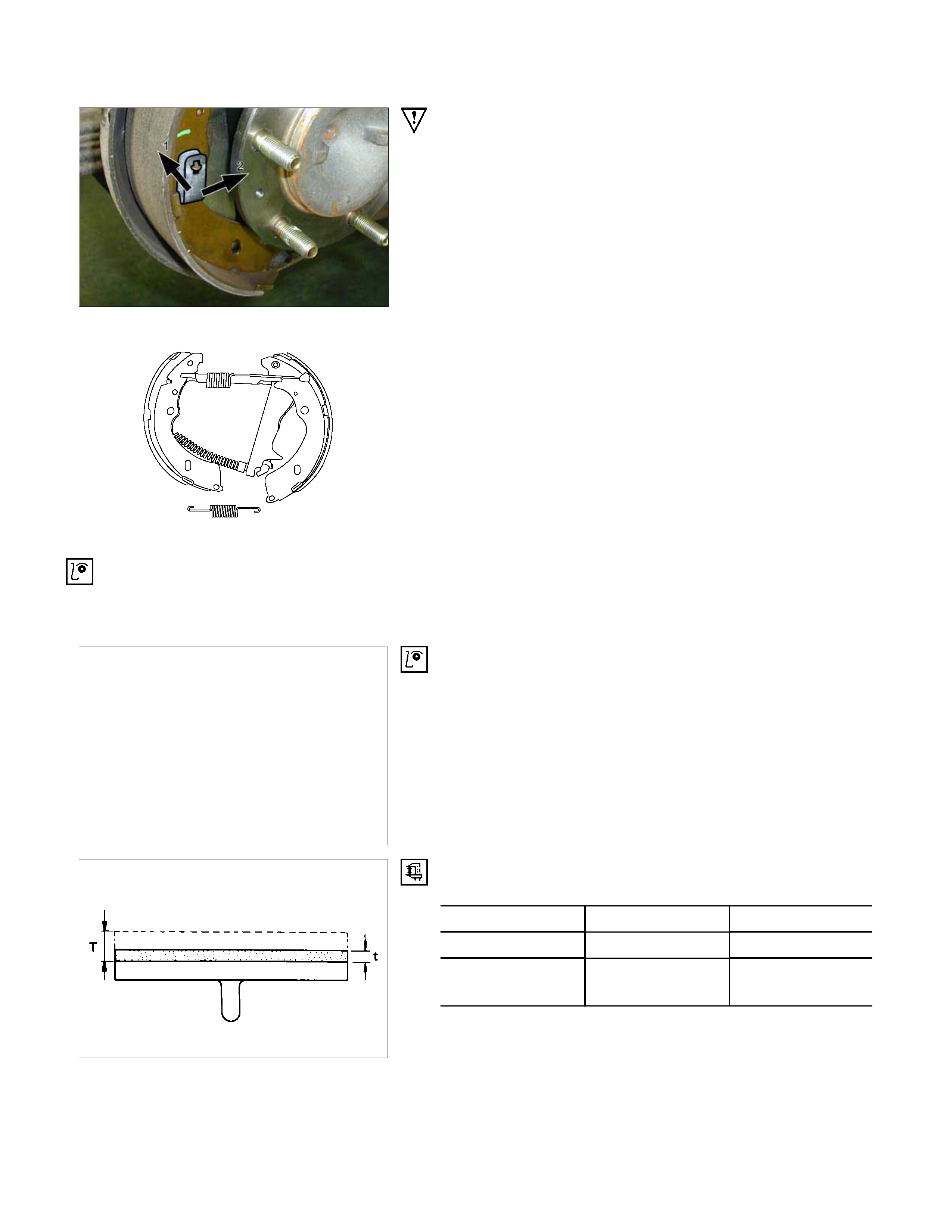

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear damage or any other abnormal conditions are found through

inspection.

• Brake drum

• Back plate

• Brake lining

• Wheel cylinder body

• Piston

• Piston cup

• Return spring

Visual check

Inspect the following parts for wear scuffs, scratches,

corrosion, stains, deterioration, or other abnormal conditions.

Thickness of the Brake Lining

Thickness mm(in

)

standard (T) Limit (t)

4×2 5.0 (0.197) 1.0 (0.039)

4×2 HIGH RIDE

4×4 5.0 (0.197) 1.0 (0.039)

Clean wheel Cylinder Parts

Always use clean brake fluid to clean wheel cylinder parts.

Note:

Do not use mineral-vase cleaning solvents such as

gasoline, kerosene, acetone, paint thinner, or carbon

tetrachloride.

Piston Cups

Inspect the piston cups for wear, distortion, fatigue, fatigue or

other abnormal conditions.

Measuring the Brake Drum

mm(in)

Standard Limit

Inside diameter 254 (10.000) 255.5 (10.059)

Run out 0.08 (0.003) 0.15 (0.006)

Inside diameter 295 (11.614) 296.5 (11.673)

TFR

(HIGH RIDE)

TFS Run out 0.08 (0.003) 0.15(0.006)

TFR

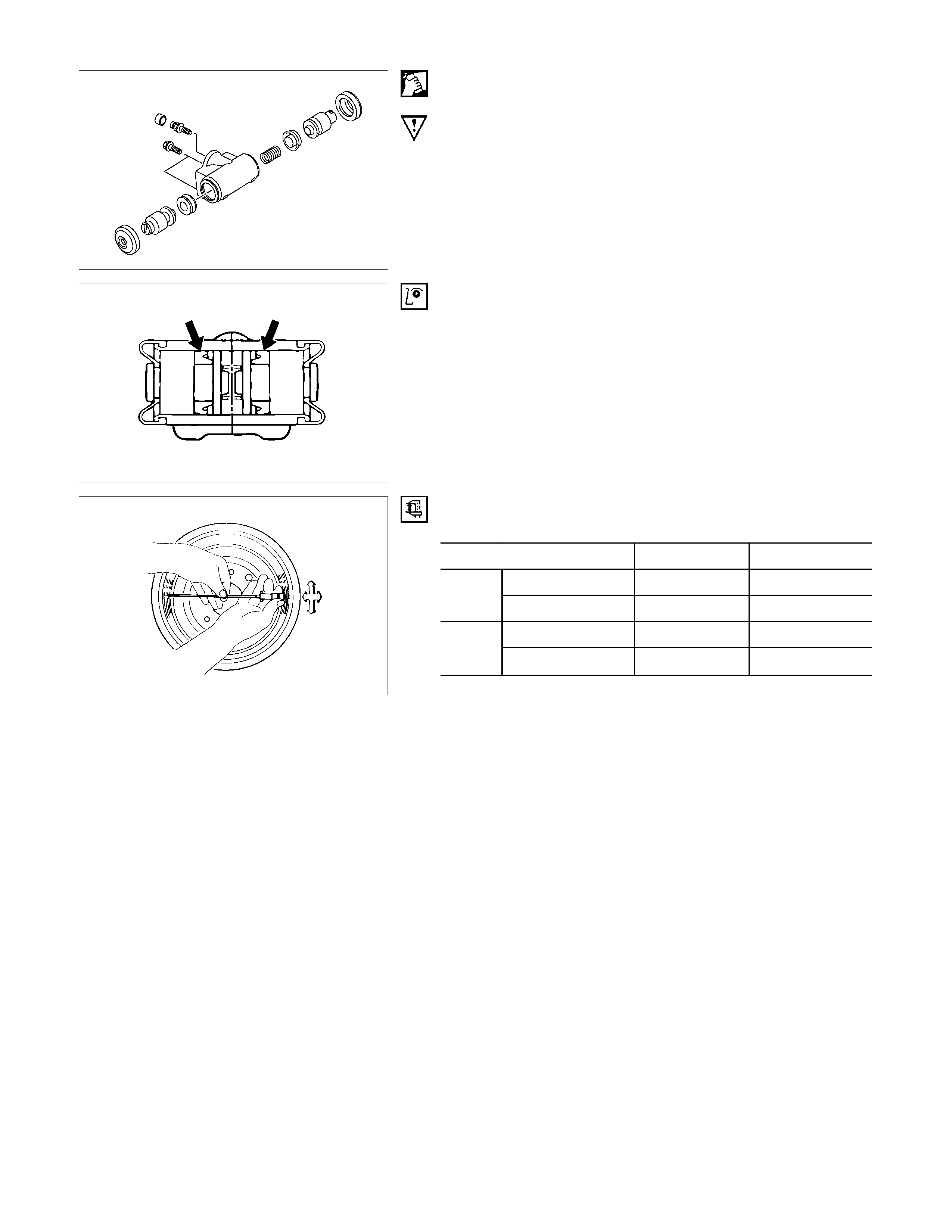

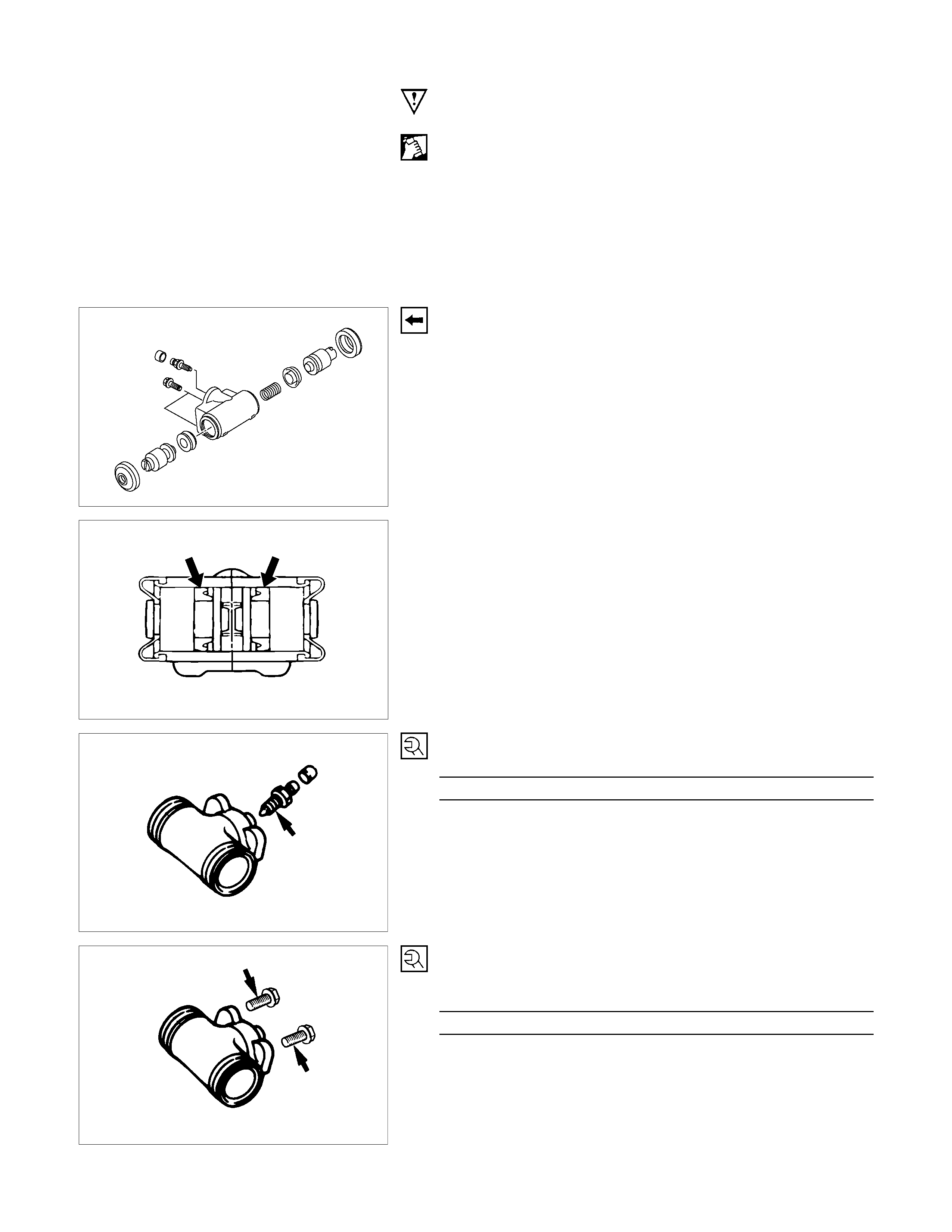

REASSEMBLY

RTW35CMF000301

MINOR COMPONENTS

Reassembly Steps

Wheel cylinder Assembly (7)

1. Piston assembly

2. Cup ; piston

3. Return spring

▲ 4. Boot ; piston

▲ 5. Bleeder

6. Cap ; bleeder

MAJOR COMPONENTS

Reassembly Steps

7. Back plate

8. Cover

▲ 9. Wheel cylinder assembly

▲ 10. Bolt ; wheel cylinder

▲ 11. Shoe ; leading

▲ 12. Lever ; parking

▲ 13. Washer ; lever

▲ 14. Retainer

15. Spring ; lever return

▲ 16. Shoe ; trailing

▲ 17. Spring ; shoe to shoe, upper

▲ 18. Adjust assembly

19. Spring ; shoe to shoe ; lower

▲ 20. Lever ; adjuster

▲ 21. Ring ; Adjuster lever

22. Spring ; shoe hold

▲ 23. Pin ; shoe hold

▲ 24. spring ; adjuster

Important Operations

Note:

• Wash the disassembled parts in clean brake fluid.

• Use compressed air to clean the ports.

• Protect the disassem bled part s urfac es from dust and othe

r

foreign material contamination.

• Before reassembly, check the part surfaces for dust and

other foreign material contamination.

• Be sure to replace the designated parts with new ones.

4. Piston Assembly

Install new piston cups on each piston so that the flared end of

the cups are turned to the inboard side of the pistons.

Attach the return spring and the boot to the piston.

Be sure to use new piston cup and boot.

• Apply brake fluid to the piston and the inner face of the

boots.

• Note the direction of piston cup.

5. Bleeder ; Wheel Cylinder

Torque N⋅m(kgf⋅m/Ib⋅in)

6 - 8 (0.6 – 0.8 / 52 - 69)

9. Wheel Cylinder Assembly

10. Bolt ; Wheel cylinder

Torque N⋅m(kgf⋅m/Ib⋅ft)

14 - 18 (1.4 – 1.8 / 10 - 13)

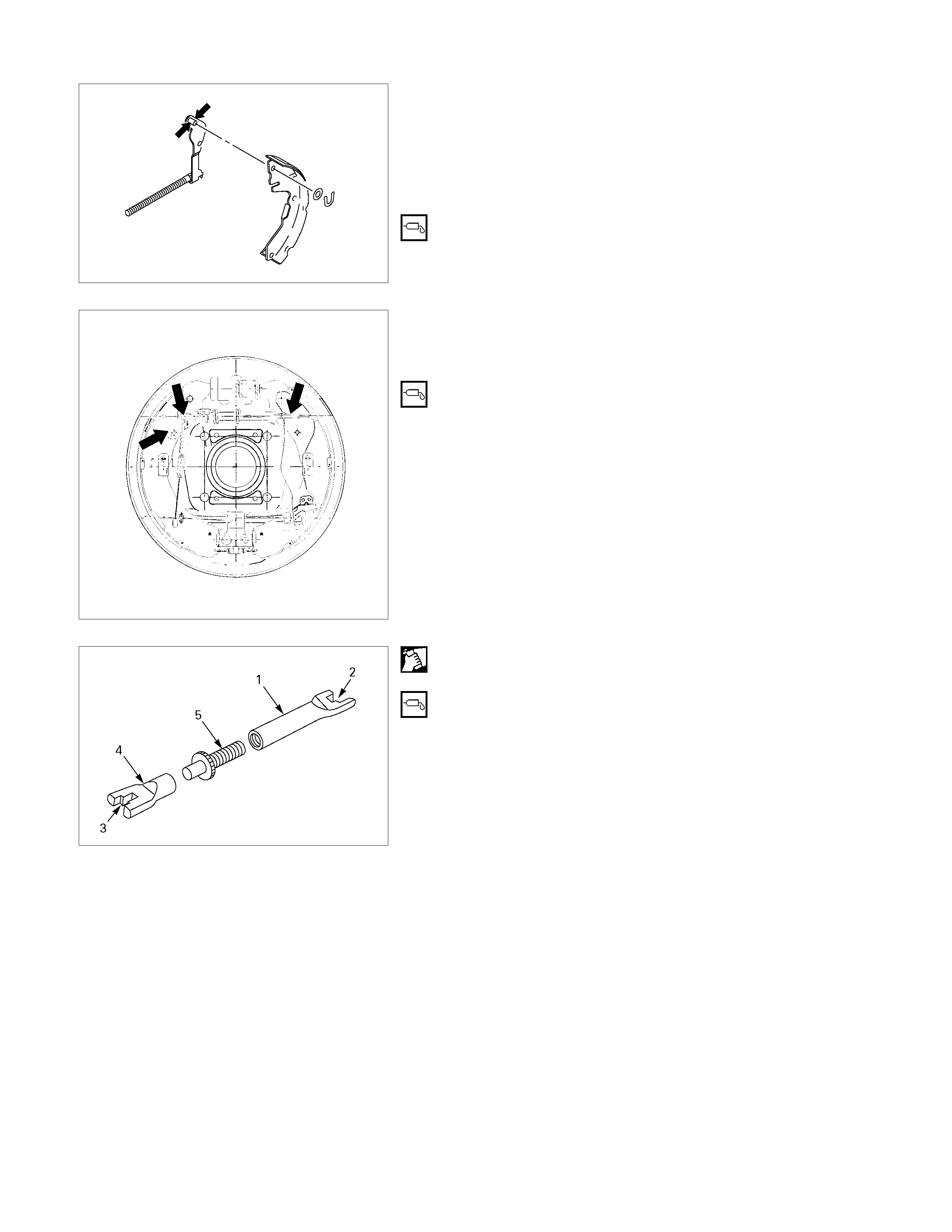

308R300008

11. Shoe ; leading

• Be sure to use new spring; shoe hold.

12. Lever ; parking

13. Washer ; lever

14. Retainer

Install the lever, the washer and the retainer to the leading

brake shoe.

•

A

pply grease to the sliding surfaces of the lever and

brake shoe.

• Be sure to use new retainer and washer.

305R300009

16. Shoe ; trailing

• Be sure to use new spring; shoe hold.

17. Spring ; shoe to shoe, upper

18. Adjuster assembly

1. Apply grease to each of the parts shown in the

illustration before installing the brake shoe.

• Lever; adjuster-shoe

• Adjuster-shoe

2. Clean the adjuster bolt (5) and the adjuster rods (1) (4).

Apply grease to the threaded portion of the adjuster bolt.

3. Install the adjuster rod to the adjuster bolt.

4.

A

pply grease to the adjuster asm ends (2) (3). Set the

spring ; upper to the adjuster asm, then install them to

the brake shoe.

305R300010

5. Before s etting the brake shoes , apply grease to the back

plate portions (1) contacting the brake shoe edge as

shown in the illustration.

6.

A

pply grease to the wheel cylinder parts contacting the

brake shoe (2).

7. Install the brake shoe.

Note:

• Be careful not to damage the wheel cylinder dust cover.

• Do not allow the wheel cylinder piston to fly free.

20. Lever ; adjuster

21. Ring ; Adjuster lever

• Apply grease to the lever ; adjuster sliding surface.

Install the lever ; adjuster and the ring to the shoe ;

trailing.

• Be sure to use new ring.

P1010008B

23. Pin ; shoe hold

24. Spring ; shoe hold

• Install the brake drum.

• Install the rear wheel.

• If the wheel cylinder has been removed, the brake

system must be bled.

• Pump the brake pedal 10 times. Check that there is little

or no stroke length variation as the pedal is pumped.

• Adjust the lining clearance.

• Brake Line

Torque N⋅m(kgf⋅m/Ib⋅ft)

13 - 19 (1.3 - 1.9 / 9 - 14)

BRAKE CONTROL

REMOVAL AND INSTALLATION

BRAKE PEDAL ASSEMBLY

310R300001

Removal Steps

1. Nut ; fulcrum pin

2. Pin ; fulcrum, pedal to bracket

3. Pedal arm

4. Return spring

5. Pedal pad

Installation Steps

Before installation, apply grease to the entire

circumference of the fulcrum pin (2).

Refer to “Adjustment Procedure of Brake Pedal”,

in this Section.

Techline

ADJUSTMENT PROCEDURE OF BRAKE PEDAL

The push rod serves to stop the brake p edal when released.

Brake pedal height adjustment should be performed as

follows:

RTW35CSH000601

Brake Pedal – Height

1. Rotate the brake light swit ch counter-clockwise to release,

then remove from the mounting bracket.

2. Check that the pedal is fully released an d not binding, by

lightly lifting the pedal, assisting the pedal return spring.

3. Measure the brake pedal height (L2) with the pedal in the

fully released position.

Notes:

• Pedal height (L2) must be measured after starting the

engine and providing full vacuum to the booste r.

• Pedal free play (L1) must be measured after turni ng off

the engine, then applying/releasing the brake pedal at

least five times to exhaust stored vacuum. mm(in)

Pedal free play (L1) 6 – 10 (0.23 – 0.39)

M/T 174 – 186 (6.85 – 7.32)

Pedal Height (L2) RHD A/T 176 – 188 (6.93 – 7.40)

331R300005b

4. If the pedal height (L2) is not within the above range,

adjust as follows:

a) Check that the stop lamp switch has been removed.

b) Loosen the lock nut on the push rod clevis yoke.

c) Adjust the brake pedal to the specified height (L2)

by rotating the push rod in the appropriate direction.

d) The gap between the stoplight swit ch mount and the

pedal bracket (A) sh ould then be from 5 – 8 mm.

e) Tighten the push rod lock nut to the specified torque.

Lock Nut Torque N⋅m(kgf⋅m/lb⋅ft)

12 – 18 (1.2 – 1.8 / 9 - 13)

f) Reinstall the stop lamp swit ch, using the following

procedure.

NOTE:

Pedal height (L2) must be 80 mm (3.14 in.) or more when

applying about 50 kg (110.25 lbs. ) of stepping force.

331R300005

Connecting Pedal and Fitting Stop Lamp Switch.

1.

A

lign the hole in the booster & master cylinder rod clevis

yoke with the hole in the brake pedal.

2. Insert the clevis pin into these holes from left side of the

pedal and secure with snap clip.

3. Pull the brake pedal upwards to take up all slack and hold

in this position.

4. With your other hand, install the brake light switch until the

switch plunger is completely depressed.

5. Turn the switch clock-wise until a “click” sound is made,

locking the switch into position.

6. The pedal when released should now have a small

amount of free-play

MASTER CYLINDER

REMOVAL AND INSTALLATION

MASTER CYLINDER ASSEMBLY

Removal Steps

▲ 1. Brake line

2. Nut ; master cylinder to vacuum booster

3. Master cylinder assembly

Installation Steps

3. Master cylinder assembly

▲ 2. Nut ; master cylinder to vacuum booster

▲ 1. Brake line

Important Operation - Removal

1. Brake Line

Be very careful not to spill brake fluid on the painted surface.

Damage to the painted surface will result.

Important Operation - Installation

2. Nut ; Master Cylinder to Vacuum Booster

Torque N⋅m (kg f⋅m/lb⋅ft)

12 – 18 (1.2 – 1.8 / 9 – 13)

1. Brake Line

Torque N⋅m (kg f⋅m/lb⋅ft)

13 – 19 (1.3 – 1.9 / 9 – 14)

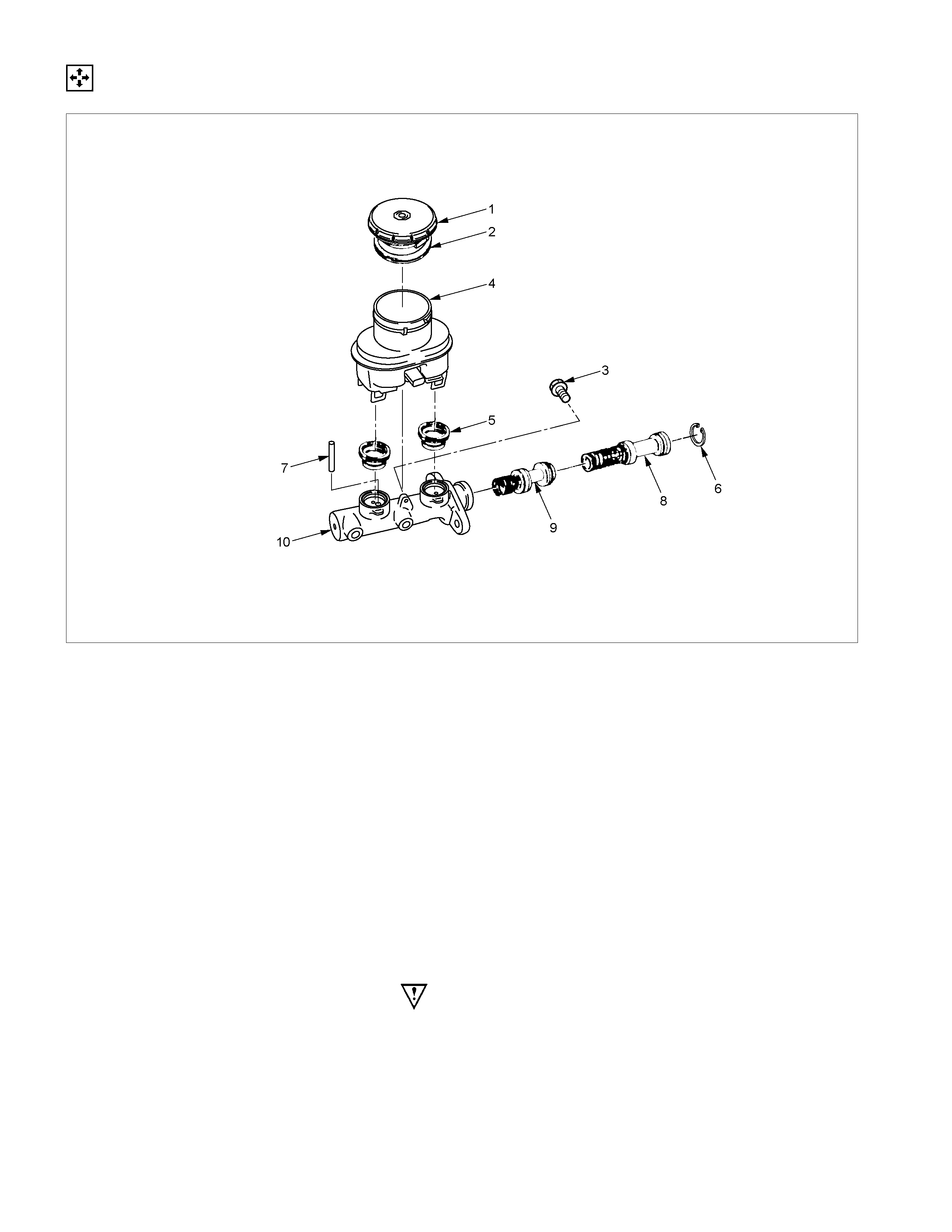

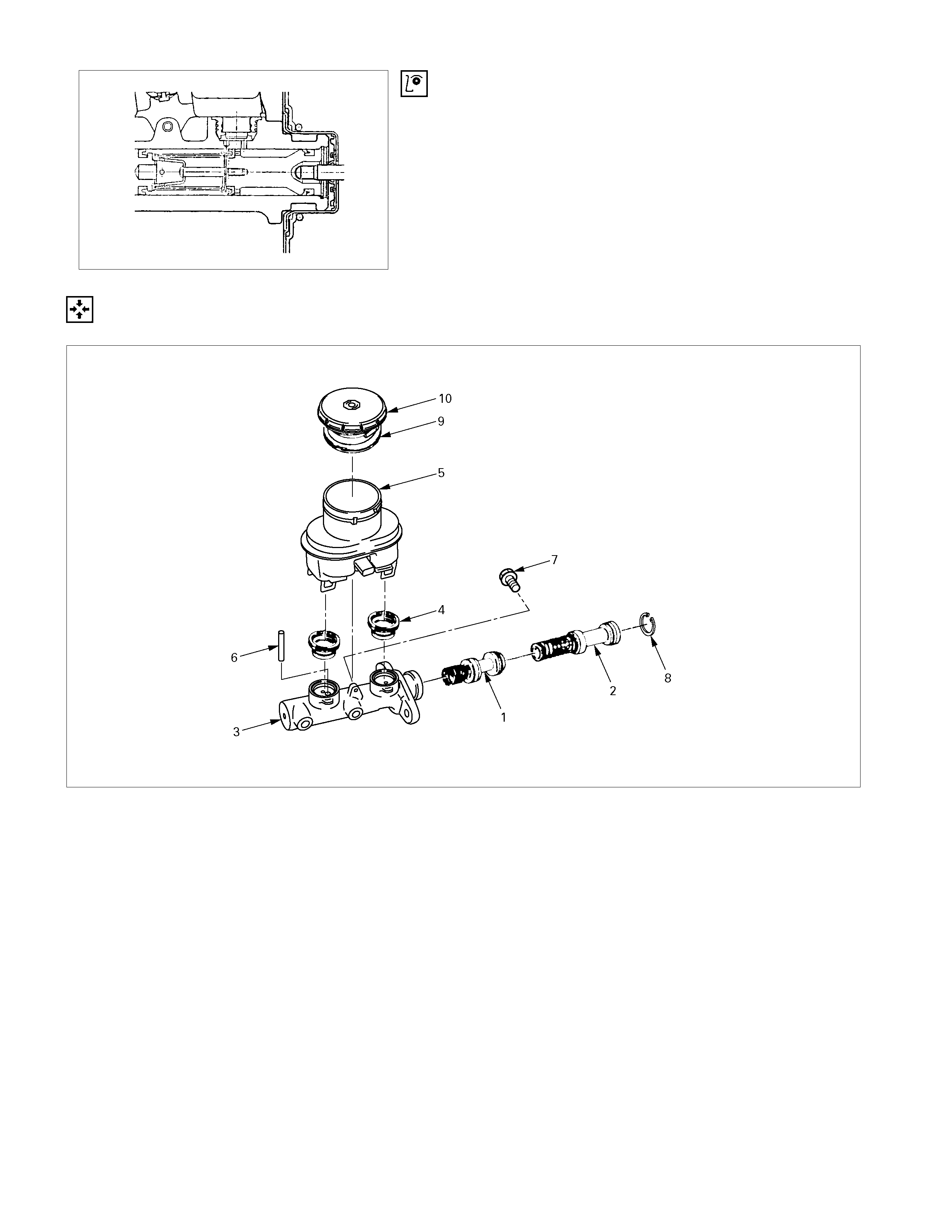

DISASSEMBLY

RTW35CMF000401

Disassembly Steps

1. Cap

2. Diaphragm

3. Bolt

4. Resever tank

5. Grommet

▲ 6. Snap ring

▲ 7. Stop pin

▲ 8. Primary piston

▲ 9. Secondary piston

10. Cylinder body

Note:

• Be sure to replace the designated with new ones.

• Wash the disassembled parts in clean brake fluid.

• Use compressed air to clean the ports.

• Do not allow dirt and dust to contaminate the dis assembled

parts.

Important Operations

When disassembling, inspecting or reassembling the master

cylinder assembly, take care not to bring the parts into contact

with mineral oil or dust. Wash the piston cups only with brake

fluid. Do not use gasoline or other mineral-base cleaning

solvents.

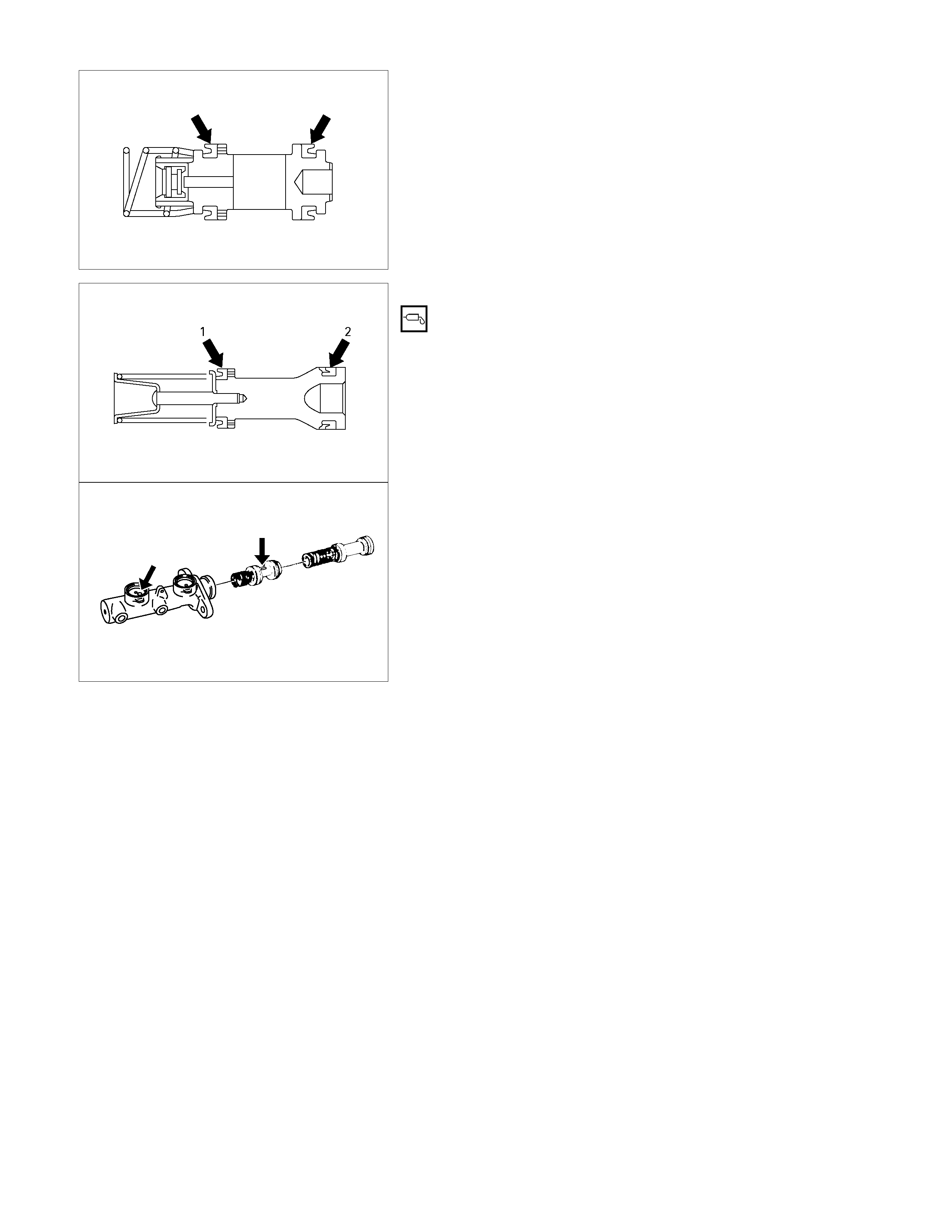

6. Ring ; Snap

Remove the snap ring from the cylinder body with pushing in

the primary and secondary pistons.

7. Stop Pin

Remove the stop pin from the cylinder body with pushing in the

primary and secondary pistons.

8. Piston Assembly ; Primary and Spring

9. Piston Assembly ; Secondary and Spring

Don’t remove the spring from the piston.

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear damage or any other abnormal conditions are found through

inspection.

• Cylinder inside face

• Piston

• Piston cap

• Piston cap spacer

• Return port

• Return spring

Visual Check

Inspect the following parts for wear, distortion, cuts, nicks,

corrosion, or other abnormal conditions.

Return Port

Check the return port for obstructions and if necessary, clean

with a tag wire.

Blow away foreign matter with compressed air.

Primary Piston

A

fter reassembly, push in the primary piston to see that returns

smoothly .

Repeat the test two or three times to see that brake fluid is

forced out from the front and rear outlets.

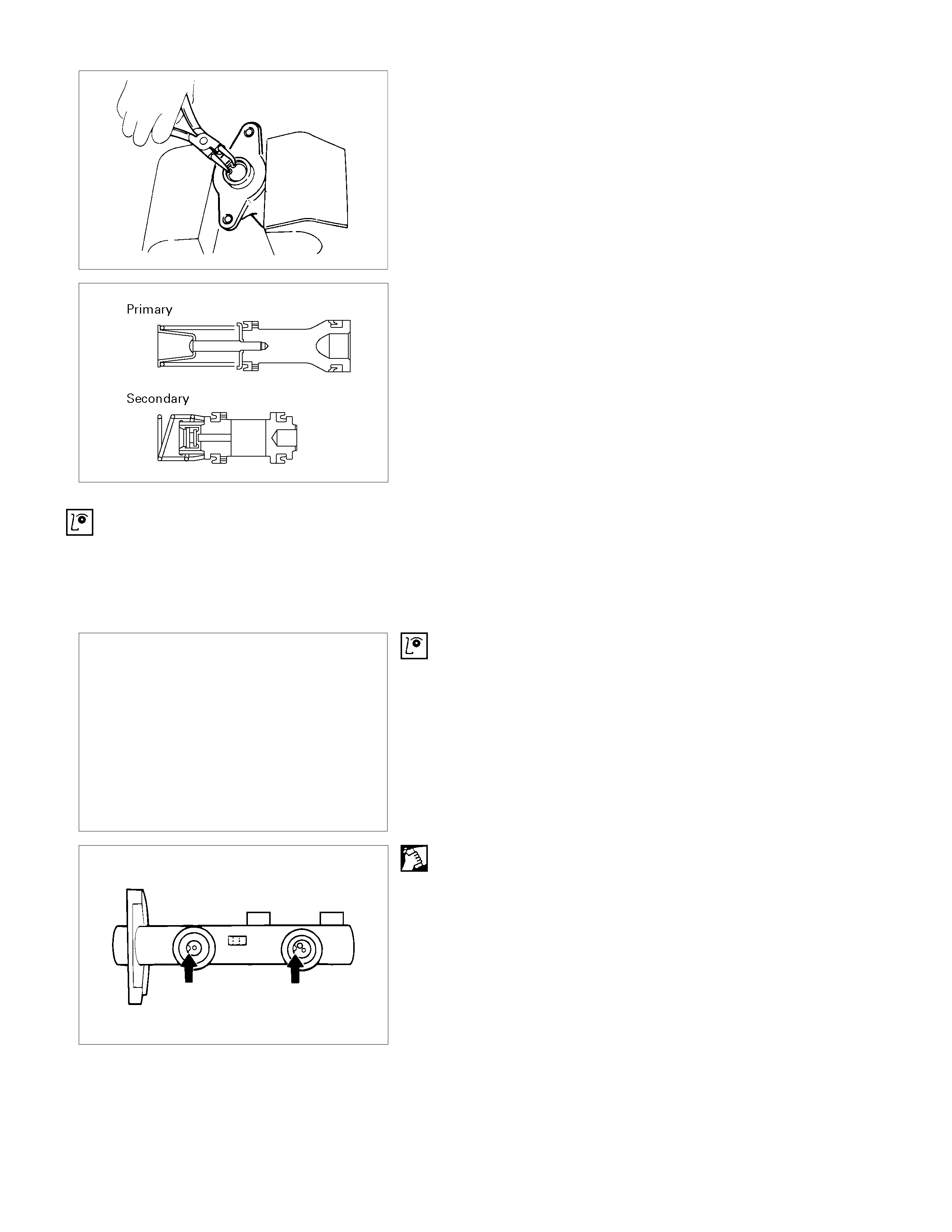

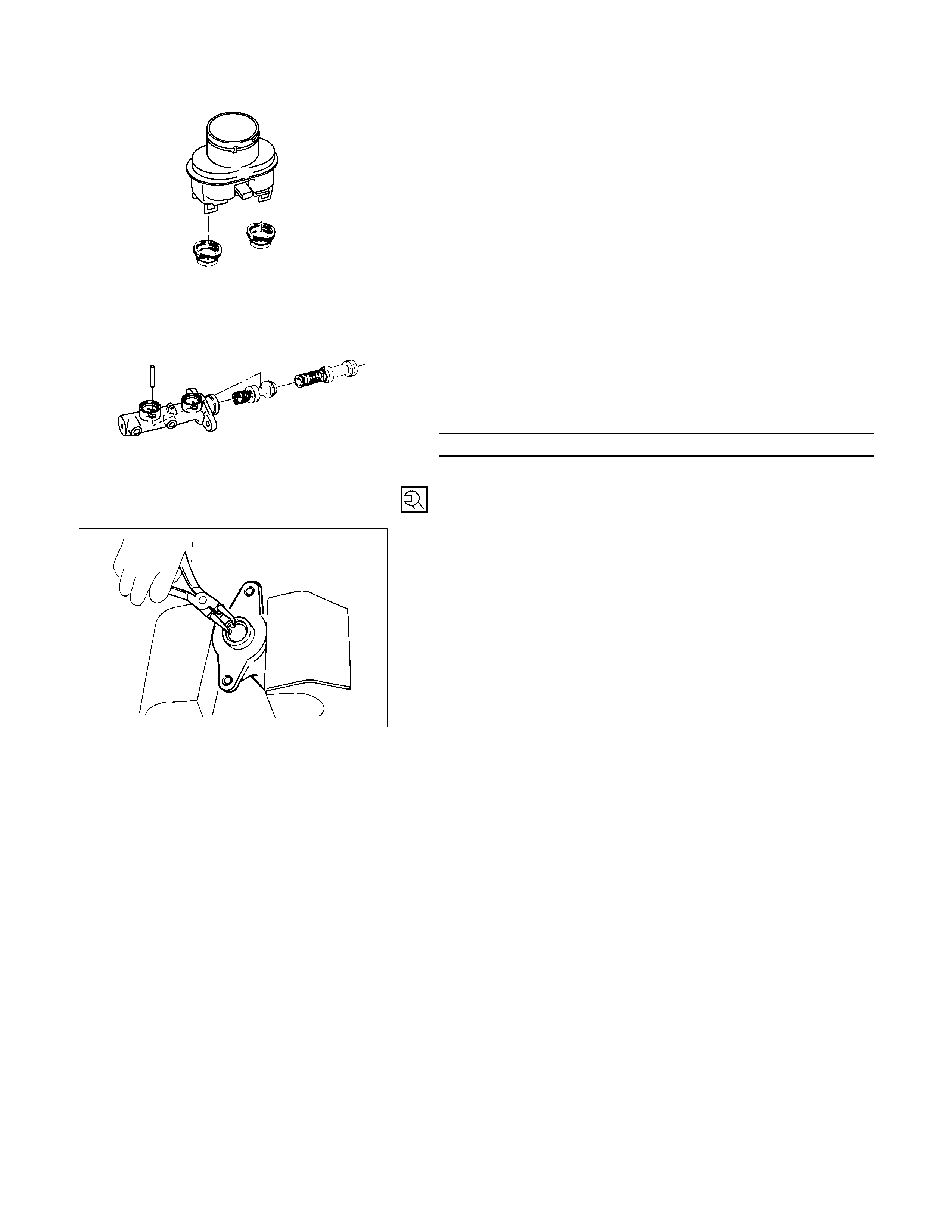

REASSEMBLY

Reassembly Steps

1. Secondary piston

2. Primary piston

3. Cylinder body

4. Grommet

5. Reservoir tank

6. Stop pin

7. Bolt

8. Snap ring

9. Diaphragm

10. Cap

1. Secondary piston

Lubricate the piston cups on the secondary piston assemblies

with brake fluid.

Note:

Be sure to use a new piston.

2. Primary piston

Lubricate the piston cups on the primary piston assemblies

with brake fluid (1) and the rubber grease (2).

Note:

Be sure to use a new piston.

3. Cylinder body

Install the secondary piston and the primary piston to the

cylinder body.

Note:

The secondary piston long hole and the cylinder body stop pin

hole must be aligned at installation.

4. Grommet

5. Reservoir tank

6. Stop pin

7. Bolt

1. Install the grommets to the reservoir tank.

Note:

Be sure to use are new grommets.

330R300018

2. Press down on the prim ar y piston and install the stop pin

to the cylinder body (the piston long hole must be

aligned with the cylinder body installation hole).

3. Install the reservoir tank to the cylinder body.

4. Tighten the bolts to the specified torque.

Torque N⋅m (kg f⋅m/lb⋅in)

2 - 3 (0.2 - 0.3 / 17 - 26)

8. Snap pin

Press down on the primary piston and install the snap ring to

the cylinder body groove.

Note:

Be sure to use new snap ring.

9. Diaphragm

10. Cap

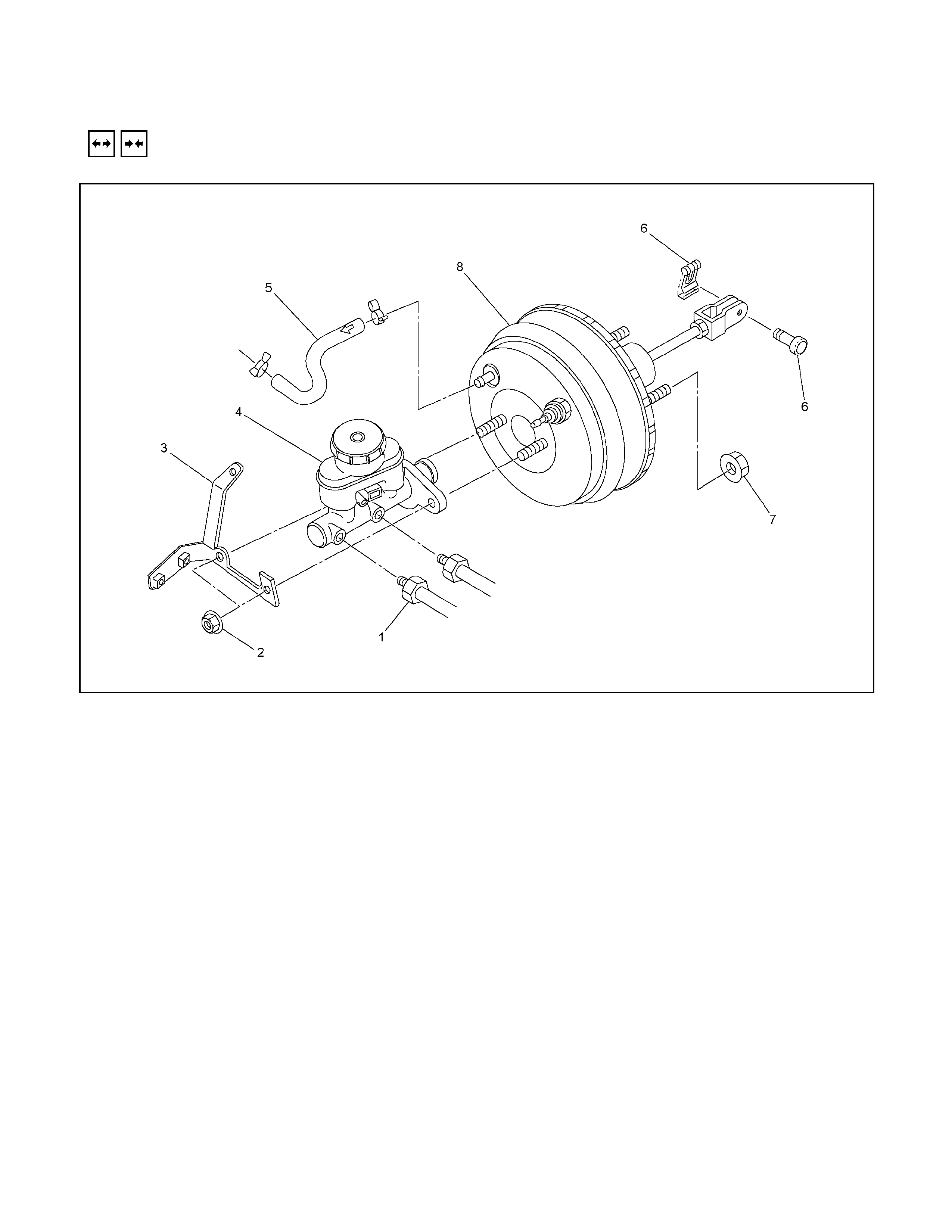

VACUUM BOOSTER

REMOVAL AND INSTALLATION

RTW35CMF000501

Removal Steps

▲ 1. Brake pipe

▲ 2. Master cylinder fixing nut

▲ 3. Bracket (only RHD model)

▲ 4. Master cylinder assembly

▲ 5. Vacuum hose

6. Spring retaining clip and clevis pin

7. Vacuum booster fixing nut

8. Vacuum booster assembly

Installation Steps

▲ 8. Vacuum booster assembly

▲ 7. Vacuum booster fixing nut

▲ 6. Clevis pin and spring retaining clip

▲ 5. Vacuum hose

4. Master cylinder assembly

3. Bracket

2. Master cylinder fixing nut

1. Brake pipe

330R300002

Removal

1. Brake pipe

Important Operation

When removing brake pipes and master cylinder, be careful

not to spill brake fluid over the painted surfaces, as damage to

the paint finish will result.

2. Master Cylinder Fixing Nut

3. Bracket

4. Master Cylinder Assembly

NOTE:

Before removing the master cylinder from the vacuum booster,

depress and release the brake pedal approximately five times

to exhaust any stored vacuum in the booster.

Inspection and Repair

5. Vacuum Hose (The built in check valve)

360R300002

Inspect the check valve, installed inside the vacuum hose, as

follows:

1. Blow air into the hose from the booster side as

shown in the illustration. The air should pass freely

through the hose.

2. Blow air into the hose from the engine side. The

check valve should close to block the passage of air.

The vacuum hose and built-in check valve must be replaced

as an assembly, if either is found to be defective.

Installation

8. Vacuum Booster Assembly

Important Operation

Perform vacuum booster and vacuum booster push rod

adjustment.

NOTE:

When replacing either the master cylinder or vacuum booster,

it is vital that the push rod to piston clearance is measured and

adjusted, as detailed here:

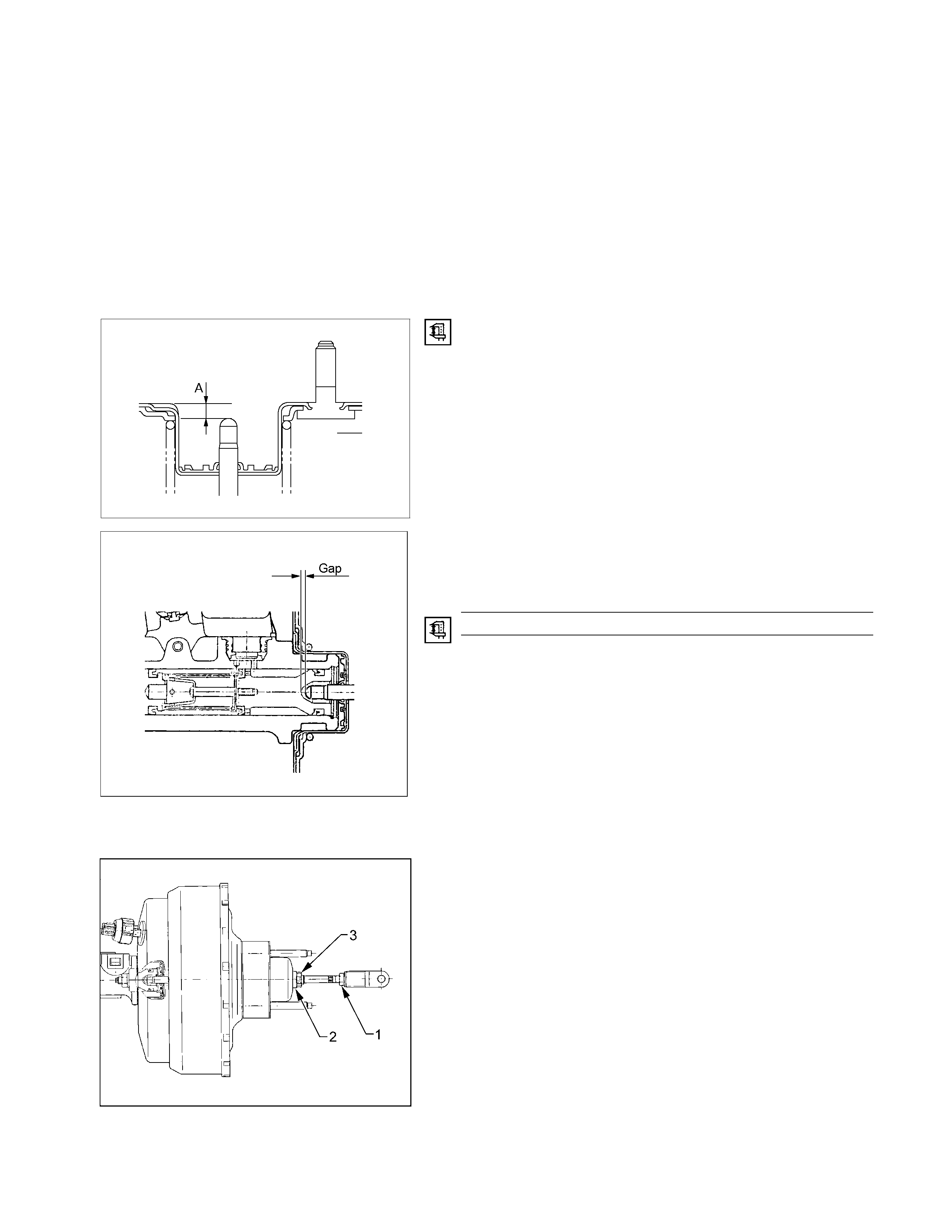

RTW35CSH000901

1. Measure dimension (B) at the master cylinder, as

follows:

a Using a depth micrometer or vernier calipers,

measure the distance from the end of the maste

r

cylinder to the end of the counter-bore in the

piston (1).

b Using the same technique, measure from the end

of the master cylinder to the larger stepped flange

(2).

c Subtract (1) from (2) to achieve dimension ‘B’.

d Record dimension ‘B’.

2.

A

pply a negative pressure (vacuum) to the vacuum

booster to achieve the specified vacuum reading;

Gasoline Engine: 66.7 kPa (500 mm Hg) or Diesel

Engine 93.3 kPa (700 mm Hg).

NOTE:

To achieve the required vacuum reading, it will be

necessary to use the engine as the vacuum source. As it is

recommended that the following booster push rod

measurement is taken with the booster removed from the

vehicle, a suitable length and wall thickness hose will be

needed to connect the engine to the booster.

3. Push the booster push rod inward to ensure that it is

fully seated.

4. With vacuum applied to the booster (refer Step 2),

measure the distance from the booster shell to the

end of the push rod, using a depth micrometer o

r

vernier calipers. Thi s be comes dimension ‘A’.

5. Record the measure d dimension ‘A’.

RTW35CSH000801

6. Calculate the clearance between the end of the

booster push rod and the master cylinder piston by

subtracting dimension ‘A’ from ‘B’.

Gap mm

0 − 0.4 (0 − 0.0157)

7. If the gap dimension (A-B) is not as specified, adjus

t

the push rod as follows:

a Check that the clevis yoke lock nut (1) is tight.

b While holding the 17 mm nut (2) with a se

t

spanner, loosen the push rod lock nut (3) at the

vacuum booster.

NOTE:

A

s lock nut (3) is a double hexagon, the use of a

suitable size pipe spanner will be required to loosen

/ tighten the lock nut.

c Use the adjuster (2) to adjust the length of the

protruding portion of the push rod to achieve the

dimension specified in Step 6.

NOTE:

When repeating Steps 3 to 5 inclusive, ensure that

the specified vacuum is applied to the booste

r

(Applied vacuum should be; Gasoline Engine:– 66.7

kPa (500mm Hg) or Diesel Engine:– 93.3 kPa

(700mm Hg) after adjustment).

7. Vacuum Booster Fixing Nut

1. Install the vacuum booster assembly to the dash panel

and pedal mounting bracket.

2. Install the booster retaining nuts and tighten to the

specified torque.

Torque N⋅m(kgf⋅m/lb⋅f

t

18 – 24 (1.8 – 2.4 / 13 – 17)

6. Clevis Pin and Spring Retaining Clip

1. Reinstall the brake pedal clevis pin through the clevis

yoke and brake pedal, from left to right.

2. Secure the clevis pin, usi ng the spring retaining clip.

3. Check and adjust the brake pedal height, as required.

Refer to “Adjustment Procedure of Brake Pedal”, in

Servicing, in this Section.

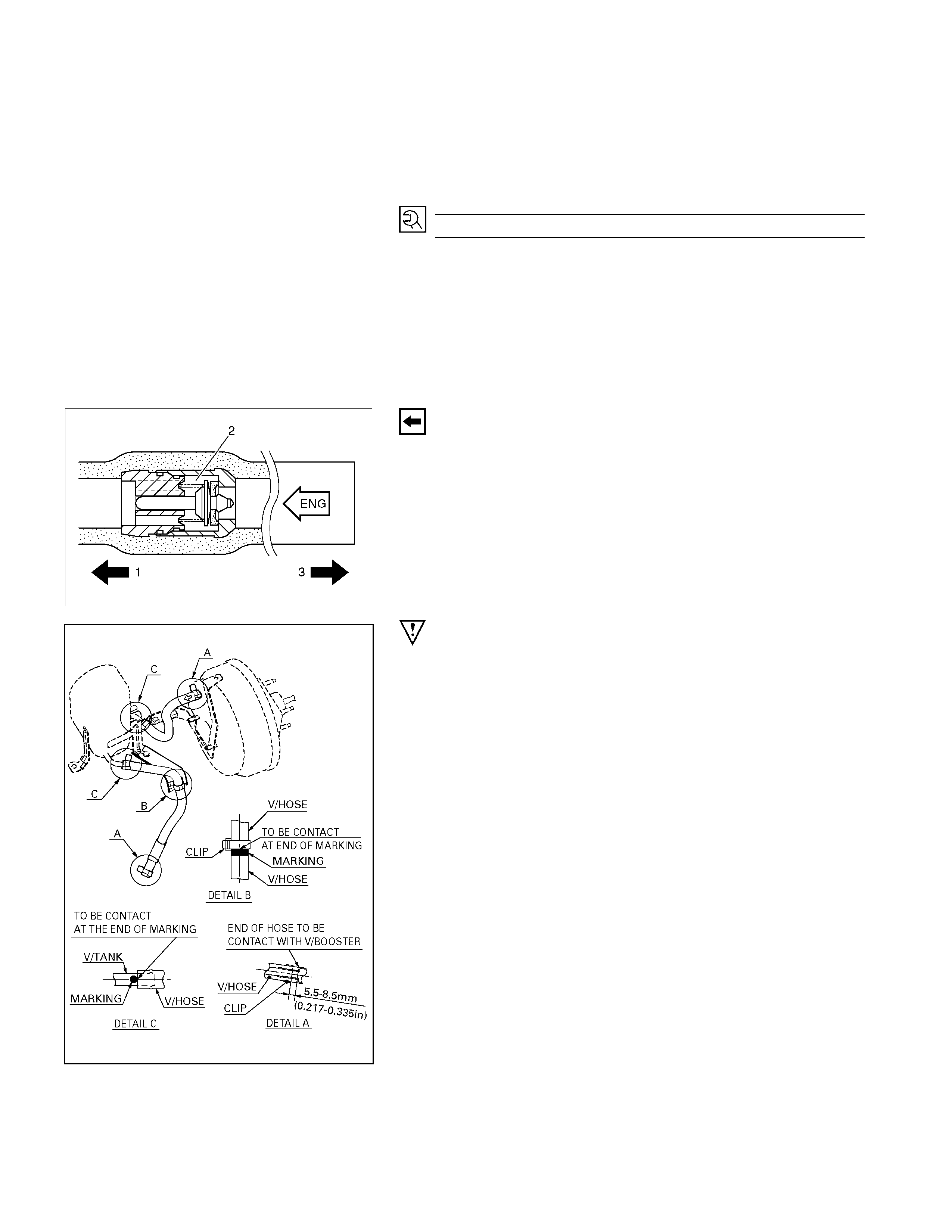

360r300003

5. Vacuum Hose

The check valve (2) is built-in to the vacuum hose.

When installing the vacuum hose make sure that the arrow on

the hose is facing the engine (1 ).

NOTE:

Do not apply oil to the vacuum hose.

331R300008

Important Operation

The vacuum hose installation direction is very important. The

booster will not operate if the vacuum hose is installed in the

wrong direction.