SECTION 7A3 - ON-VEHICLE SERVICE (JR405E)

Description

Automatic Transmission Fluid (ATF)

Inspect

ATF Level

Inspect

ATF Change

Inspect

Transmission Control Module (TCM)

Remove and Disconnect

Install or Connect

Throttle Position Sensor

Adjust

Inhibitor Switch

Inspect

Adjust

Remove or Disconnect

Install or Connect

Speed Sensor

Inspect

Turbine Sensor

Inspect

Power and 3rd Start Switch

Inspect

Select Lever

Remove or Disconnect

Install or Connect

Shift Cable

Remove or Disconnect

Install or Connect

Torque Specifications

Solenoids, Oil Pressure Switch and Oil

Temperature Sensor

Remove or Disconnect

Inspect

Install or Connect

Control Valve Assembly

Remove or Disconnect

Install or Connect

Flushing the Transmission Fluid Cooler and Line

Procedures

Transmission Assembly

Remove or Disconnect

Install or Connect

Torque Specifications

Description

Before performing on-vehicle service on the automatic transmission, check that the engine idling speed and general

engine condition are normal.

Automatic Transmission Fluid (ATF)

Inspect

Remove the transmission dipstick to check the condition of the ATF.

Clean the dipstick and look for gum or varnish.

Gum or varnish indicates scorching of the clutch band and other parts.

The transmission control module, the transmission unit, and the vehicle must be carefully checked if gum or varnish is

present.

ATF Level

Inspect

Hot Level

1. W arm up the engine and the transmission by driving

the vehicle on the road so that the temperature

reaches around 80°C (176°F).

Do not turn the engine off.

2. Park the vehicle on a level surface.

3. Apply the parking brake firmly.

4. Let the engine run at idle.

Move the select lever slowly through all the gea

r

ranges.

Stop in each gear range just long enough for the

transmission to engage.

5. Return the select lever to either “P” or “N”.

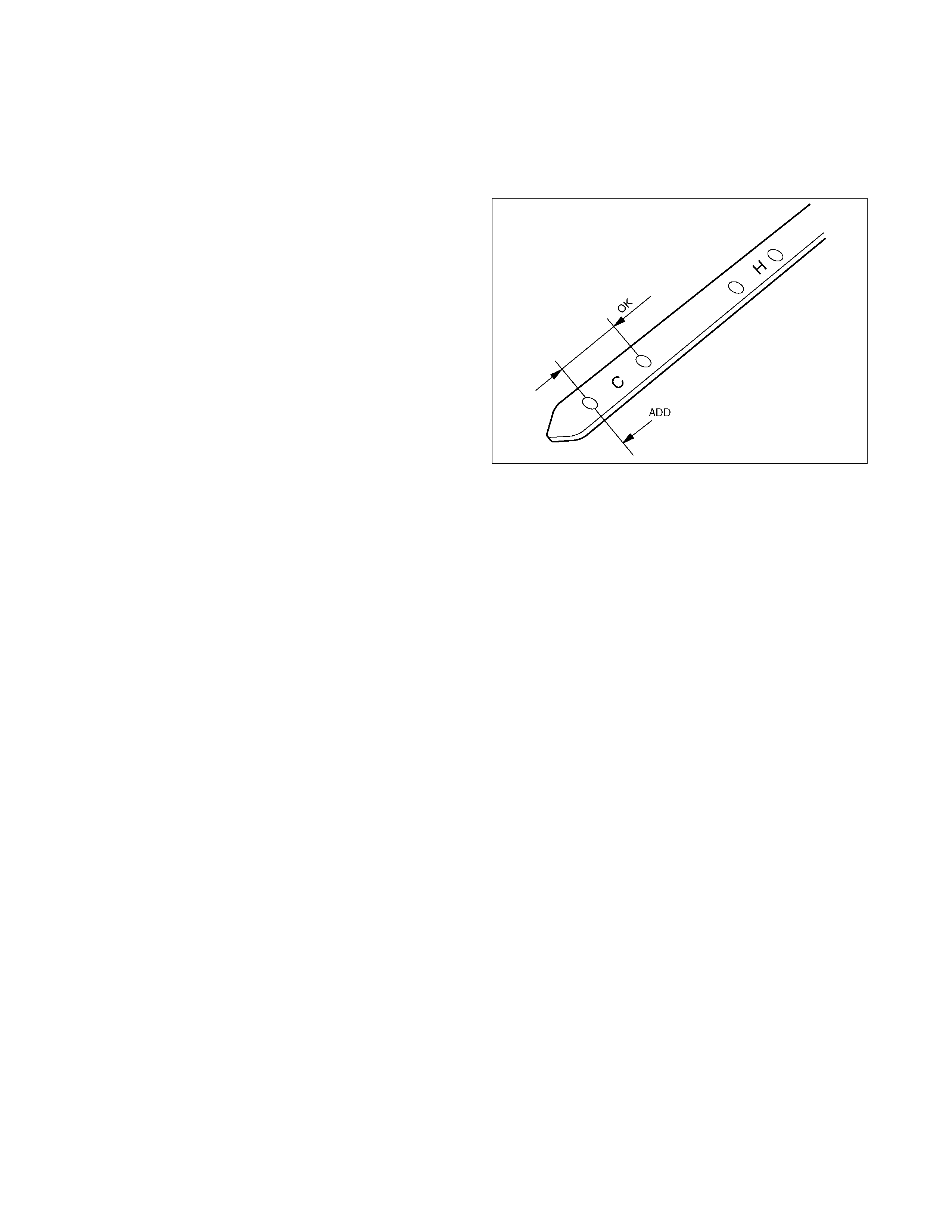

C07RW009

6. Remove the ATF level dipstick.

7. Wipe the dipstick clean with a paper towel.

8. Reinsert the dipstick and wait several seconds.

9. Remove the dipstick.

The AT F level should be inside the “H” range on the

dipstick.

242R300001

If the ATF level is below the “H” range, AT F mus t be

added.

Cold Level

The vehicle must not have been driven so that the

temperature reaches around 20°C (68°F) before the

cold level check is made.

1. Park the vehicle on a level surface.

2. Apply the parking brake firmly.

3. Start the engine and allow it to warm up.

The engine coolant temperature gauge needle

should be midway between the “C” mark and “H”

mark.

4. Let the engine run at idle.

Move the select lever slowly through all the gea

r

ranges.

Stop in each range just long enough for the

transmission to engage.

5. Return the select lever either “P” or “N”.

6. Remove the ATF level dipstick.

7. Wipe the dipstick clean with a paper towel.

8. Reinsert the dipstick and wait several seconds.

9. Remove the dipstick.

The AT F level should be inside the “C” range on the

dipstick.

If the ATF level is below the “C” range, AT F mus t be

added.

242R300002

ATF Change

1. Start the engine and allow it to idle until the ATF

reaches a temperature of 40-50°C

2. Park the vehicle on level ground and block the

wheels.

3. Stop the engine.

4. Raise vehicle and support with suitable safet

y

stands.

5. Remove the drain plug from the oil pan and dr ain the

ATF (approximately 6 liters).

6. Remove the oil pan.

7. Inspect the oil pan (details written below).

8. Install the oil pan.

Note:

Use new gasket. Clean the oil pan and magnet.

Oil pan bolt torque : 8 N⋅m (69 lb⋅in)

9. Replace the gasket and install the drain plug.

Drain plug torque : 35 N⋅m (26 lb⋅ft)

Note:

Do not reuse old washer (gasket).

Clean the drain plug (especially the threaded section).

10. Pour about 5 liters of new AT F. T hen, add m ore AT F

carefully as necessary using the dipstick.

Refer to “ATF LEVEL” previously in this section.

Note:

Keep the engine idle (do not stop it) during the oil level

adjustment.

Inspect

1. Check the drain plug tip for adhesion of foreign

substances.

2. Check the drained ATF f or color, sm ell and inclusion

of foreign substances.

3. Check the oil pan bottom and magnet for adhesion o

f

foreign substances.

If a problem is discovered during those checks, the

Automatic transmission must be overhauled.

Note:

The torque converter and the oil strainer need replaced

with new ones if the drained ATF contains large

amounts of metallic or facing flakes.

In addition, flush the ATF cooler circuit

RTW07ASH000101

11. Remove the safety stands and wheel blocks.

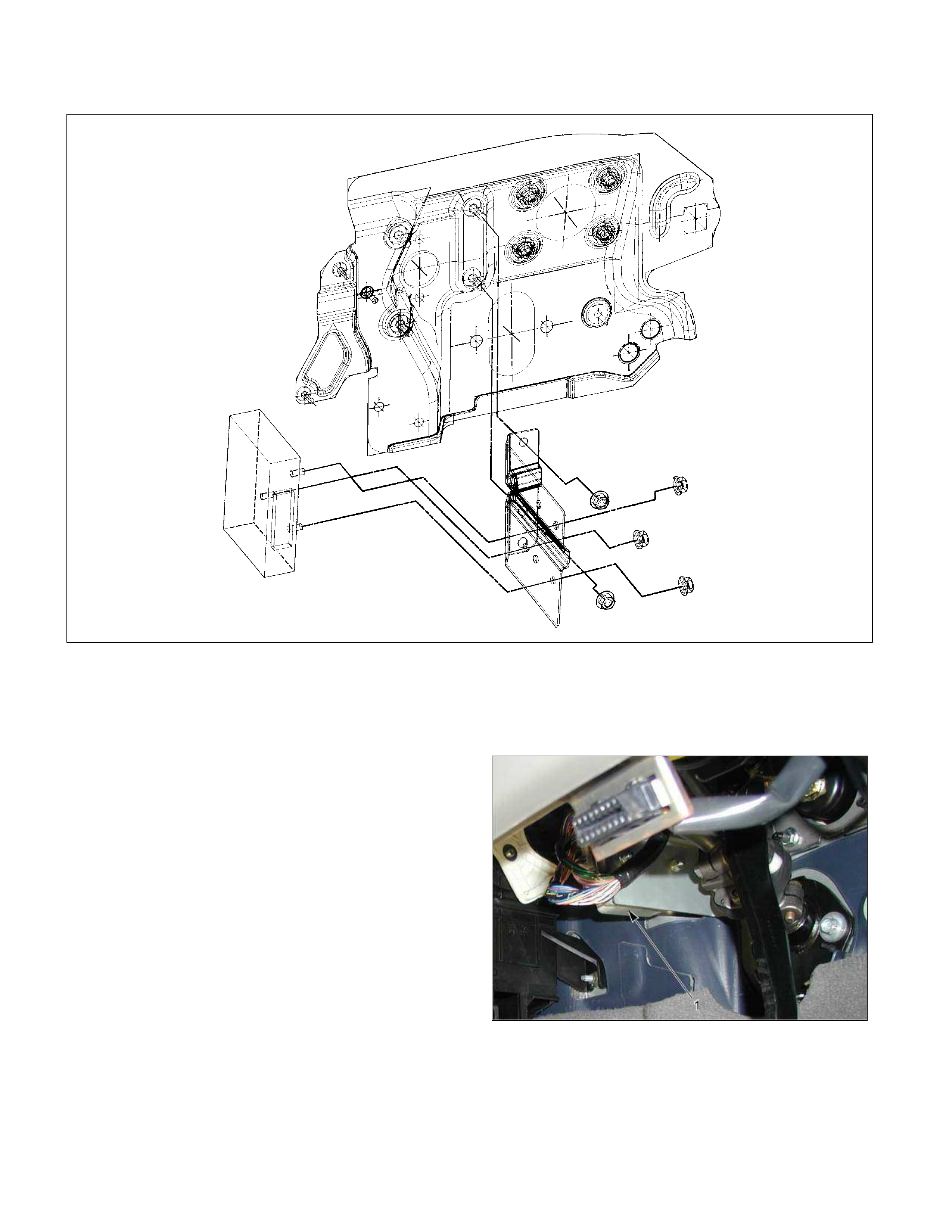

Transmission Control Module (TCM)

RTW37ALF001901

Remove and Disconnect

1. Disconnect the negative battery cable.

2. Remove the connectors.

3. Remove the fixing nuts and remove the TCM (1)

from the bracket.

Note:

The TCM is fitted under instrument panel of the driver’s

compartment by means of three stud bolts.

Install or Connect

Follow the removal steps in the reverse order. Be

absolutely sure that the connectors are securely

fastened.

AT CONT

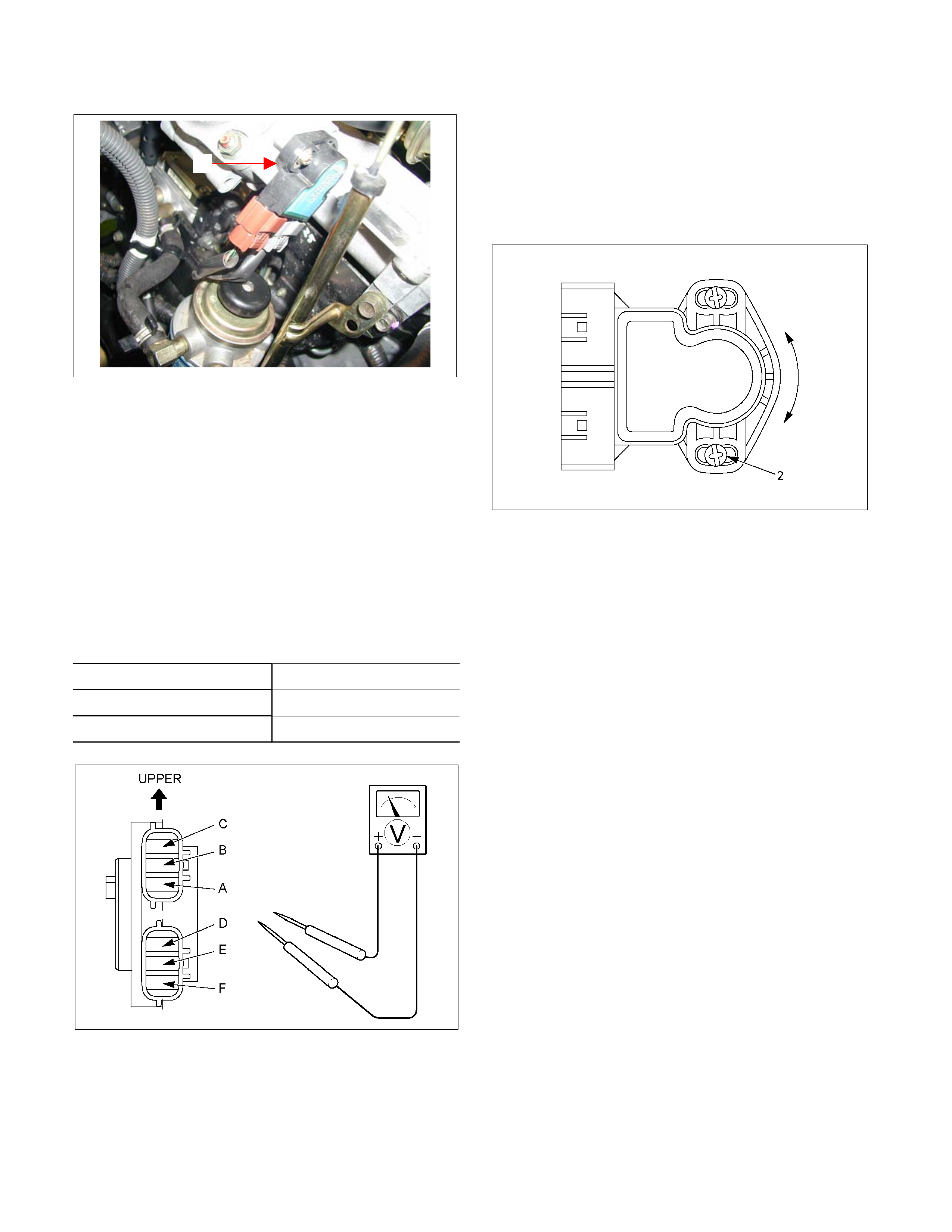

Throttle Position Sensor

1

P1010052

The throttle position sensor (1) is fitted on the throttle

valve body.

Adjust

1. Turn the starter switch to the “ON” position.

2. Measure the voltage between TPS connecto

r

terminals (B) (output) and (A) (ground).

Note:

• Do not remove the sensor connector.

• Make sure that power source (5.0 ± 0.01 V) is

meas ured between TPS c onnector term inals (C ) and

(A) before measurement at step 2.

Standard voltage :

Throttle Angle TPS

Idling (0%) 0.2 - 0.3 V

WOT (100%) 3.4 – 4.1 V

RTW37ASH0013

3. If the reading is beyond the specified value, loosen

the throttle position sensor fixing bolts, and turn it

right or left, so that the specified output voltage be

obtained.

A

fter adjusting, tighten the throttle position sensor

fixing screws (2 ).

826R300013

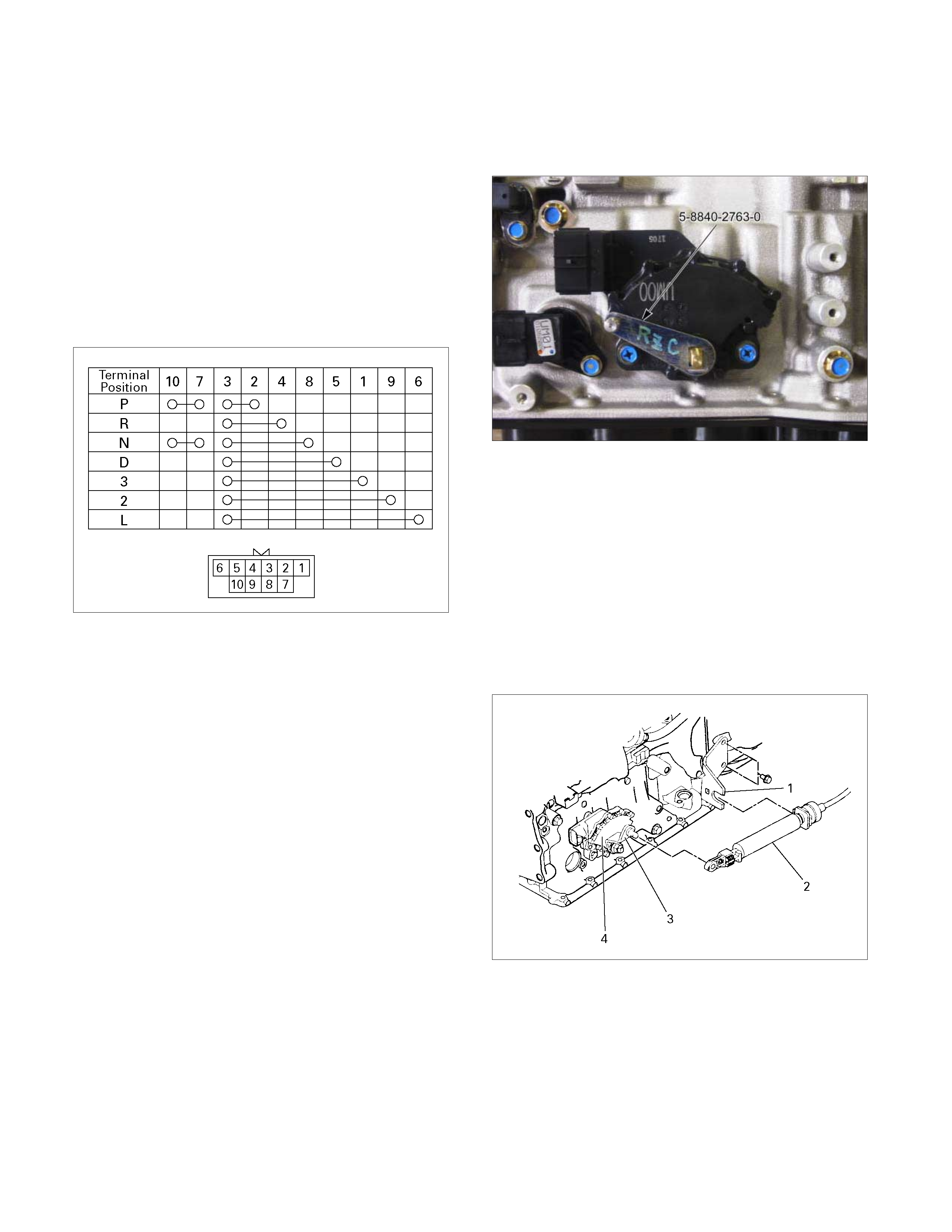

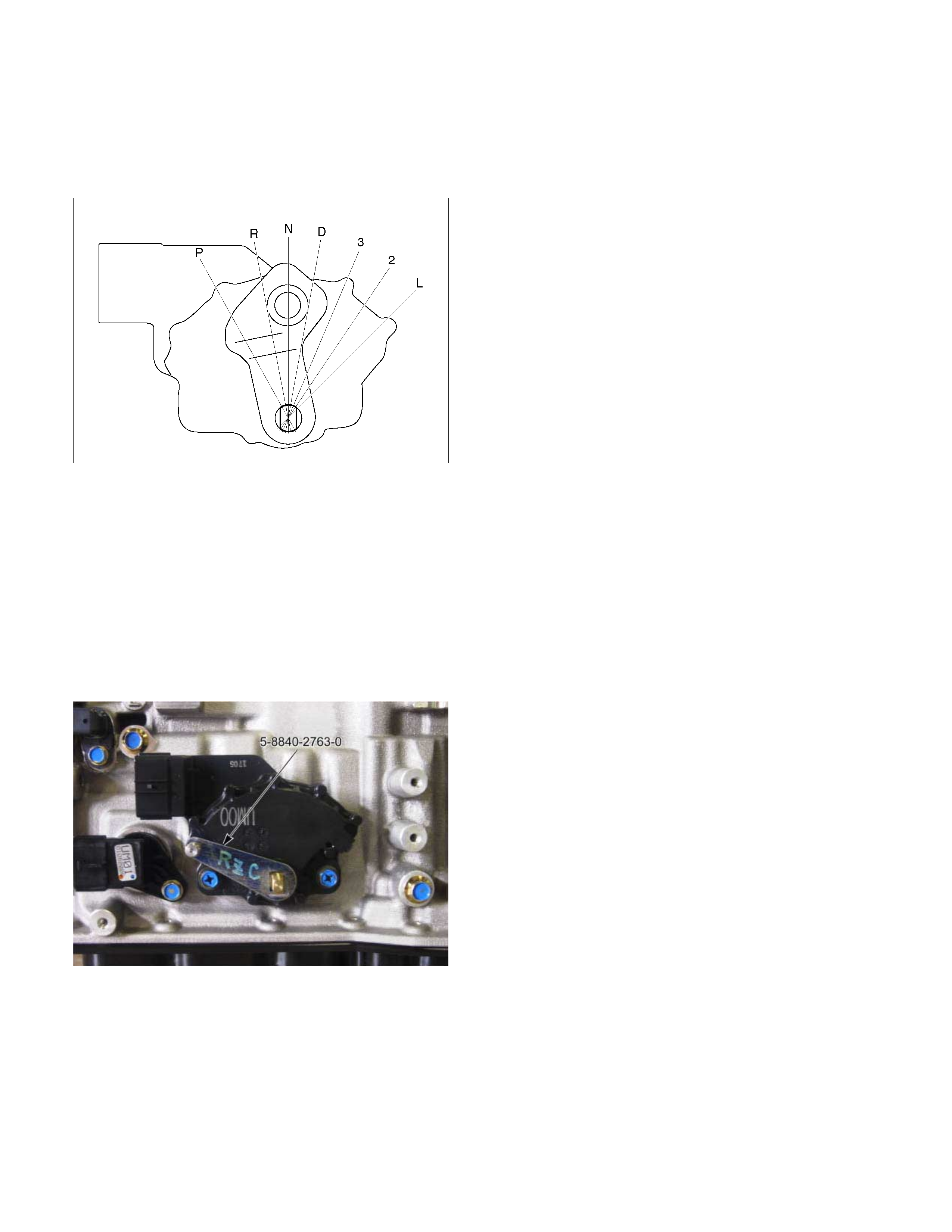

Inhibitor Switch

The inhibitor switch is attached to the right side of the

transmission.

Inspect

1. Block the wheels.

2. Disconnect the negative battery cable.

3. Disconnect the harness connectors.

4. Use an ohmmeter to check the inhibitor switch

continuity between the following terminals as shown

in figure.

5. Place the select lever in the “N” range.

249R300001

6. Move the select lever to either side.

Check the inhibitor switch continuity between the

terminals shown in Step (4).

The continuity readings should remain fairly stead

y

as the select lever is moved.

If there is no continuity or the continuity is

intermittent, the inhibitor switch must be adjusted.

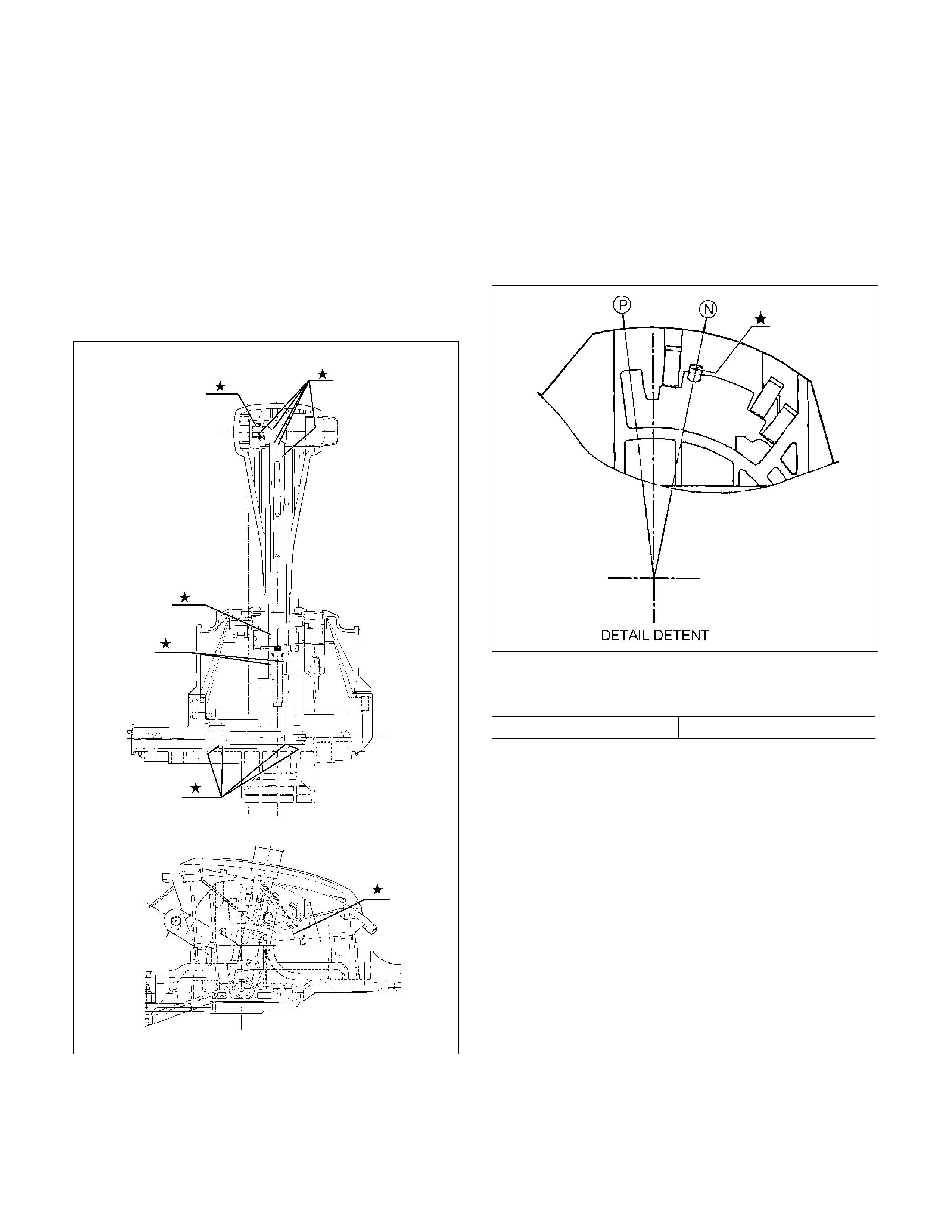

Adjust

1. Disconnect the shift calbe from the lever.

2. Loosen the inhibitor switch bolts.

3. Use the inhibitor switch set plate to align the neutral

holes (manual shaft and inhibitor switch).

Turn the inhibitor switch to adjust it.

Inibitor switch set plate: 5-8840-2763-0

Note:

Inhibitor switch adjustment is very important.

If the inibitor switch is not correctly adjusted, the

automatic transmission will not function normally.

4. Tighten the 2 inhibitor switch bolts to the specified

touque.

Torque: 5.5 N·m (48 lb·in)

47INH-SW01

5. Connect the shift cable to the lever.

6. Connect the harness connector.

Remove or Disconnect

1. Remove the cable bracket (1) from the transmission.

2. Disconnect the shift cable (2) from the lever (3).

3. Disconnect the harness connectors.

4. Remove the inhibitor switch bolts.

5. Remove the inhibitor switch (4) from the

transmission.

238R300001

Install or Connect

1. Install the inhibitor switch (4) to the transmission.

Temporarily tighten the inhibitor switch bolts.

2. Move the manual shaft select lever to the “N” range.

249R300002

3. Use the inhibitor switch set plate to align the neutral

holes (manual shaft and inhibitor switch).

Turn the inhibitor switch to adjust it.

Inhibitor switch set plate: 5-8840-2763-0

Note:

Inhibitor switch adjustment is very important.

If the inhibitor switch is not correctly adjusted, the

automatic transmission will not function normally.

4. Tighten the 2 inhibitor switch bolts to the specified

torque.

Torque: 5.5 N·m (48 lb·in)

47INH-SW01

5. Install the cable bracket (1) to the transmission.

6. Connect the shift cable (2) to the lever (3).

7. Connect the harness connector.

8. Connect the negative battery cable.

9. Remove the wheel blocks.

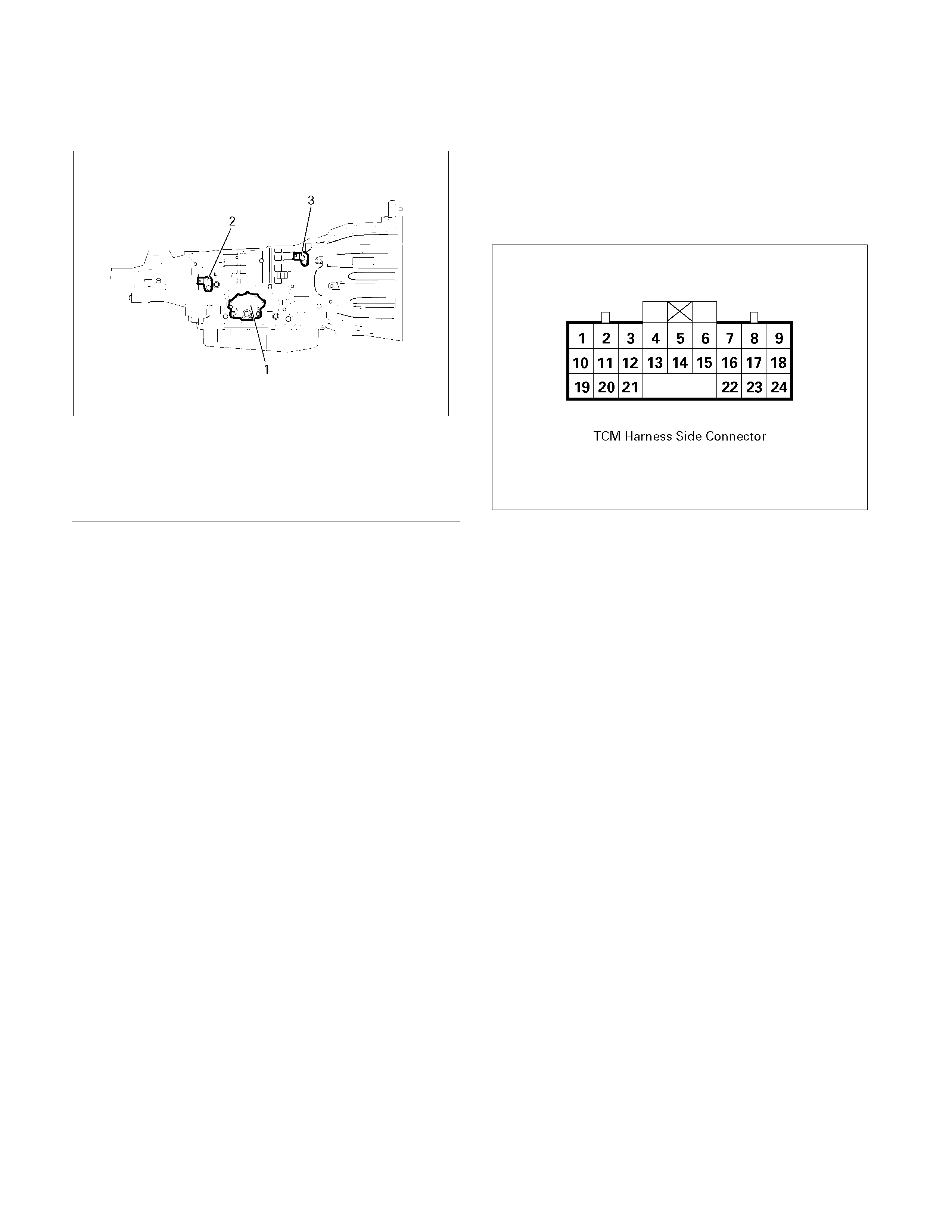

Speed Sensor

The speed sensor is attached to the right side of the

transmission.

240L300001

Legend

1. Inhibitor switch

2. Speed sensor

3. Turbine sensor

Inspect

1. During the driving at speed of 20km/h (12mph) with

“L” range in low gear, measure the voltage between

the TCM connector terminals (B13) and (B5) with a

digital voltmeter.

Standard voltage : approx. 7V (AC range)

826R300014

2. If the voltage is out of the standard value, check the

speed sensor pole piece for presence of foreign

meterials and the speeed sensor cable for short or

open circuit.

Res ult of the inspec tion is norm al, replace the speed

sensor.

Torque: 6 N·m (52 lb·in)

Turbine Sensor

The turbine sensor is attached to the right side of the

transmission.

Inspect

1. During the driving at speed of 20km/h (12mph) with

“L” range in low gear, measure the voltage between

the TCM connector terminals (B3) and (B5) with a

digital voltmeter.

Standard voltage : approx. 7V (AC range)

2. If the voltage is out of the standard value, check the

turbine sensor pole piece for presence of foreign

materials and the turbine sensor cable for short o

r

open circuit.

Result of the inspection is normal, replace the

turbine sensor.

Torque: 6 N·m (52 lb·in)

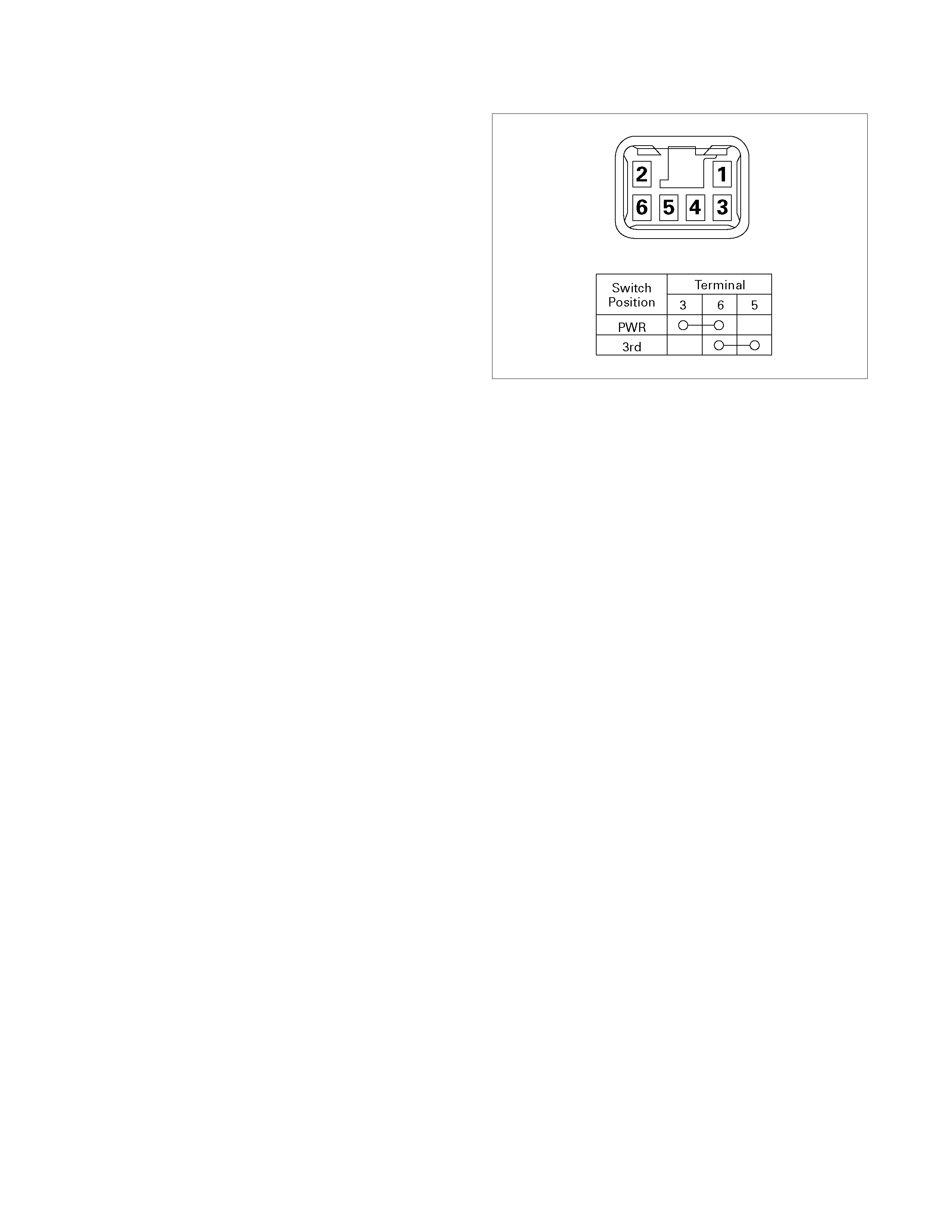

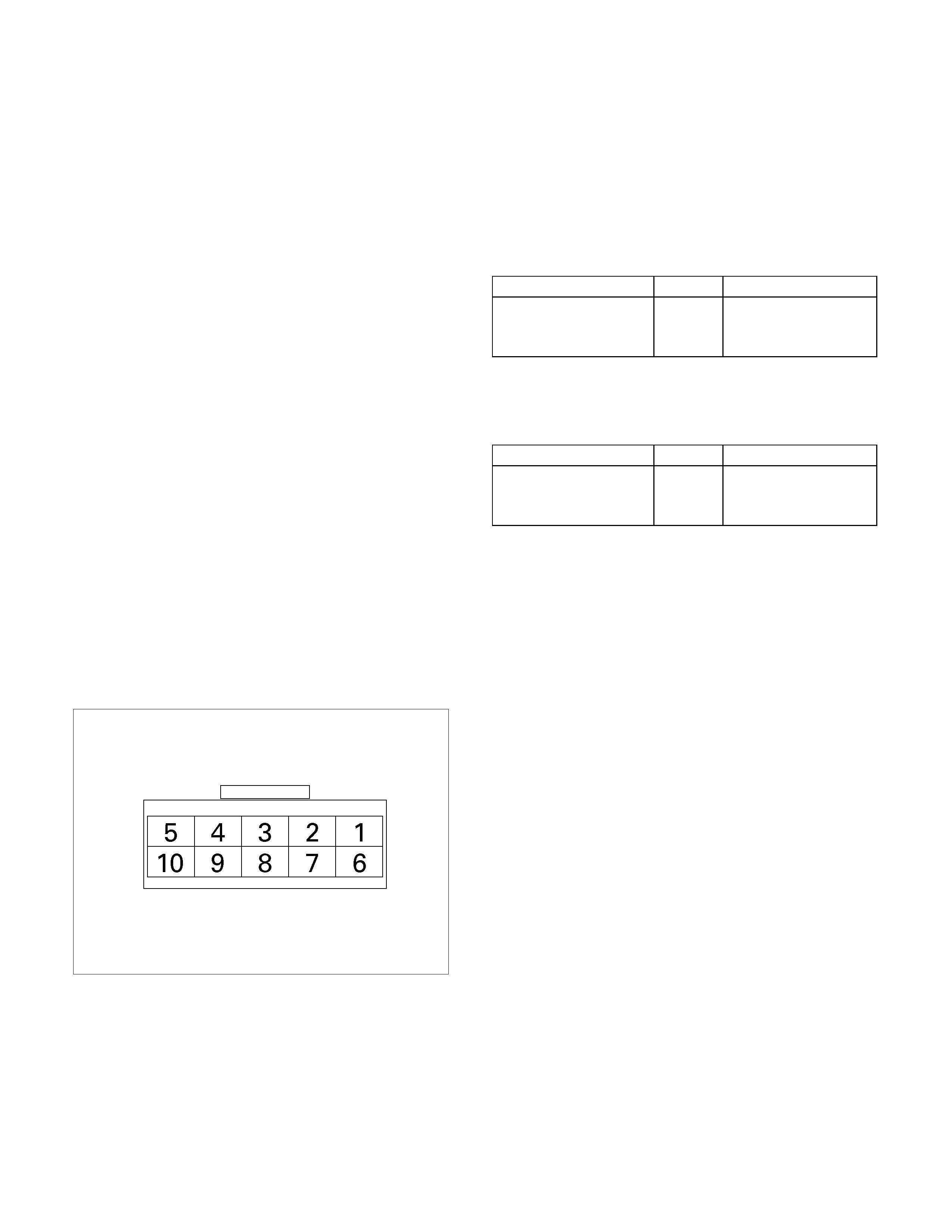

Power And 3rd Start Switch

Inspect

1. Block the wheels.

2. Disconnect the negative battery cable.

3. Pry out the switch from the floor console.

4. Disconnect the harness connector.

5. Check continuity between terminal (5) and ( 6) at thir d

(3rd) position .

6. Check continuity between terminals (3) and (6) at

power (PWR) position.

7. Replace the power and 3rd start switch when the

result of inspection is found abnormal.

8. Connect the harness connector.

9. Connect the negative battery cable.

10. Remove the wheel blocks.

238R300003

Select Lever

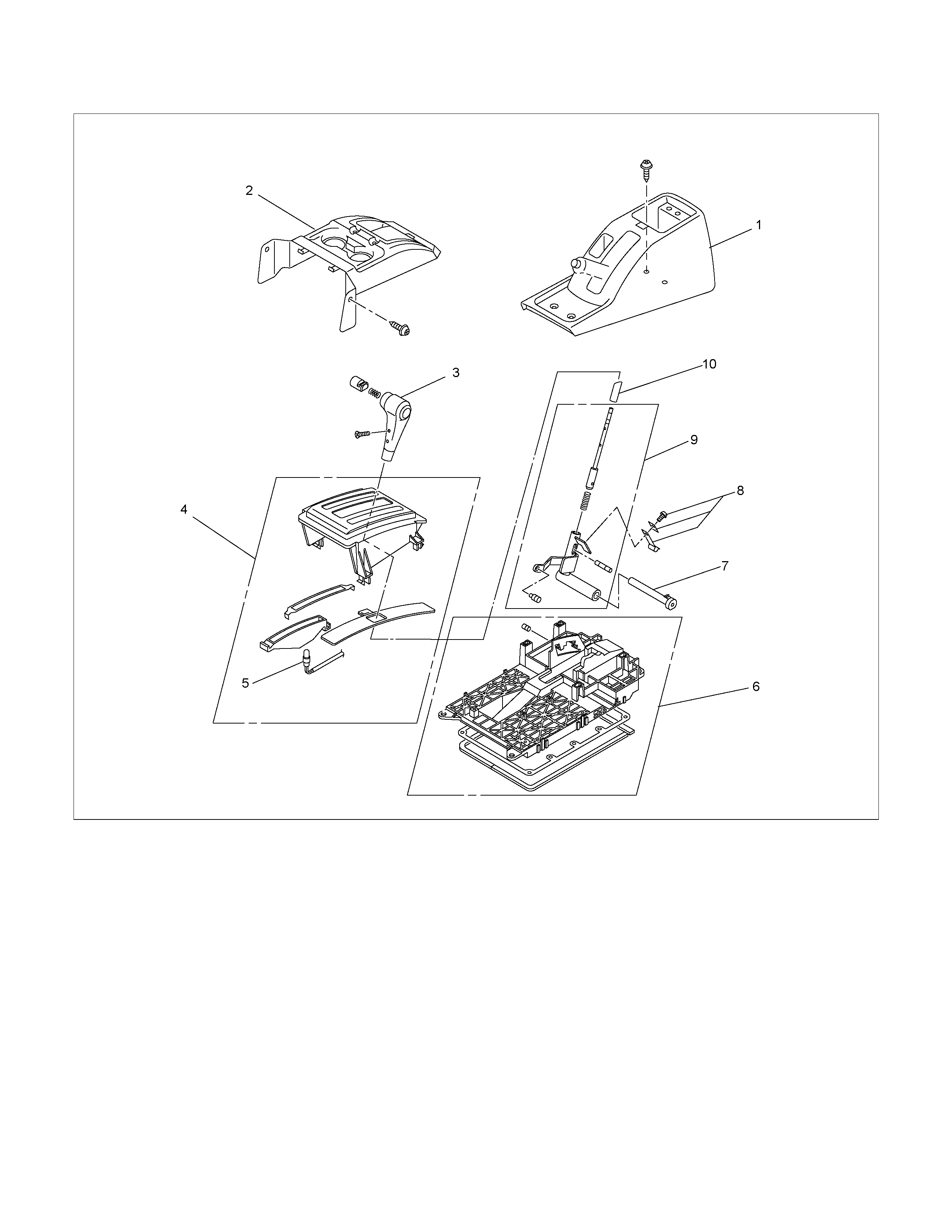

RTW37ALF001101

Legend

1. Rear console

2. Front console

3. Select lever knob

4. Upper housing

5 Lamp assembly

6 Base plate

7 Grooved pin

8 Spring plate

9 Lever assembly

10 Sleeve

Remove or Disconnect

1. Block the wheels.

2. Disconnect the negative battery cable.

3. Remove the rear console and the front console.

4. Remove the 2 screws fixing the select lever knob.

5. Remove the knob together with the knob button and

spring from the lever.

6. T urn the sleeve counterc lockwise to r emove it. Mak e

a note of the number of turns required to free the

sleeve.

7. Remove the harness connectors from the base plate.

8. Remove the upper housing (held in place by 4

latched fasteners).

9. Remove the spring plate.

10. Remove the grooved pin.

11. Remove the lever assembly by pressing the rod

down (lever in N position).

12. If lamp replacement is required, remove the lamp

assembly from the lamp socket (align the socket

grooved portion and the lamp assembly protruding

portion).

Install or Connect

NOTE:

Apply MULTEMP No. 2 grease (or equivalent) to the

select lever. Refer to the illustration.

RTW37ALH000201

1. Install the lever assembly to the base plate.

a. Insert and secure shaft.

b. Insert pawled end of shaft into base plate hole.

c. Insert grooved pin of shaft into detente aperture

(lever assembly in N position).

2.Install the spring plate.

a. Insert the grooved pin into the base plate detente

groove until it touches the front wall (lever

assembly in N position).

RTW37ASH001001

b. Install the short spring plate tighten the screws to

the specified torque.

Screw torque 2 N⋅m (0.2kg⋅m/17 lb ft)

c. Check that the grooved pin moves smoothly in

the detente groove (shift knob temporaril

y

installed).

3. Temporarily install the sleeve.

4. Install the lamp assembly to the lamp socket (i

f

removed at disassembly).

a.

A

lign the recess ed por tion of the lamp socket with

the protruding portion of the lamp assembly.

b. Insert the lamp assembly into the lamp socket

and rotate it 90 degrees clockwise.

5. Attach the harness connectors to the base plate.

6. Move the lever to the “P” position.

7. Install the sleeve (rotate the sleeve clockwise the

same number of turns it was rotated

counterclockwise at disassembly).

8. Install the knob, the knob button, and the knob

spring.

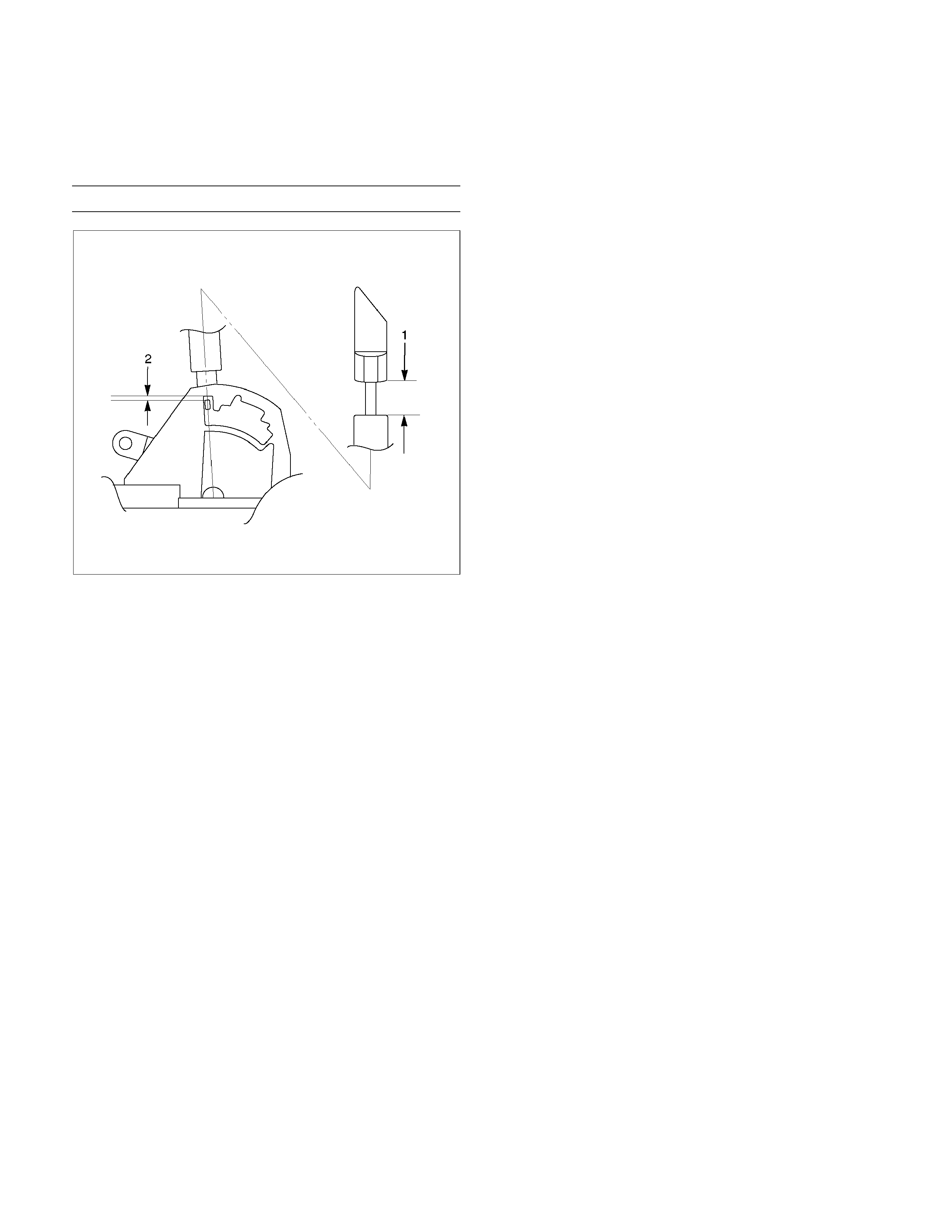

9. Adjust the clearance (2) between the detente plate

and the pin by moving the select lever knob sleeve

(1).

Detente plate and pin clearance mm(in

)

0.2 - 1.0 (0.01 - 0.04)

255R300002

10. Install the 2 screws securing the knob and tighten

them to the specified torque.

Screw torque: 2 N⋅m (0.2kg ⋅m/17 lb in)

11. Install the upper housing. Make sure that the 4

latched fasteners are securely closed.

Shift Cable

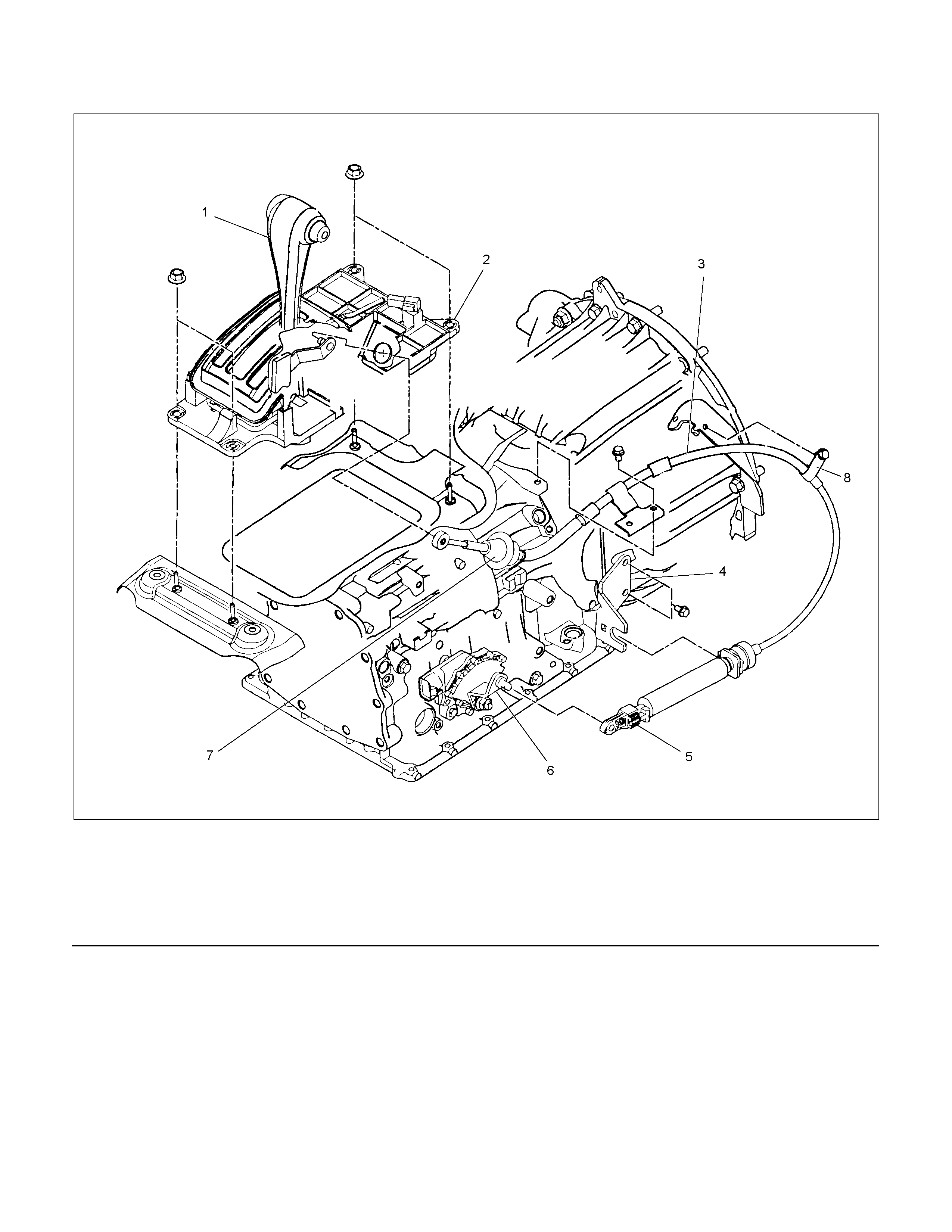

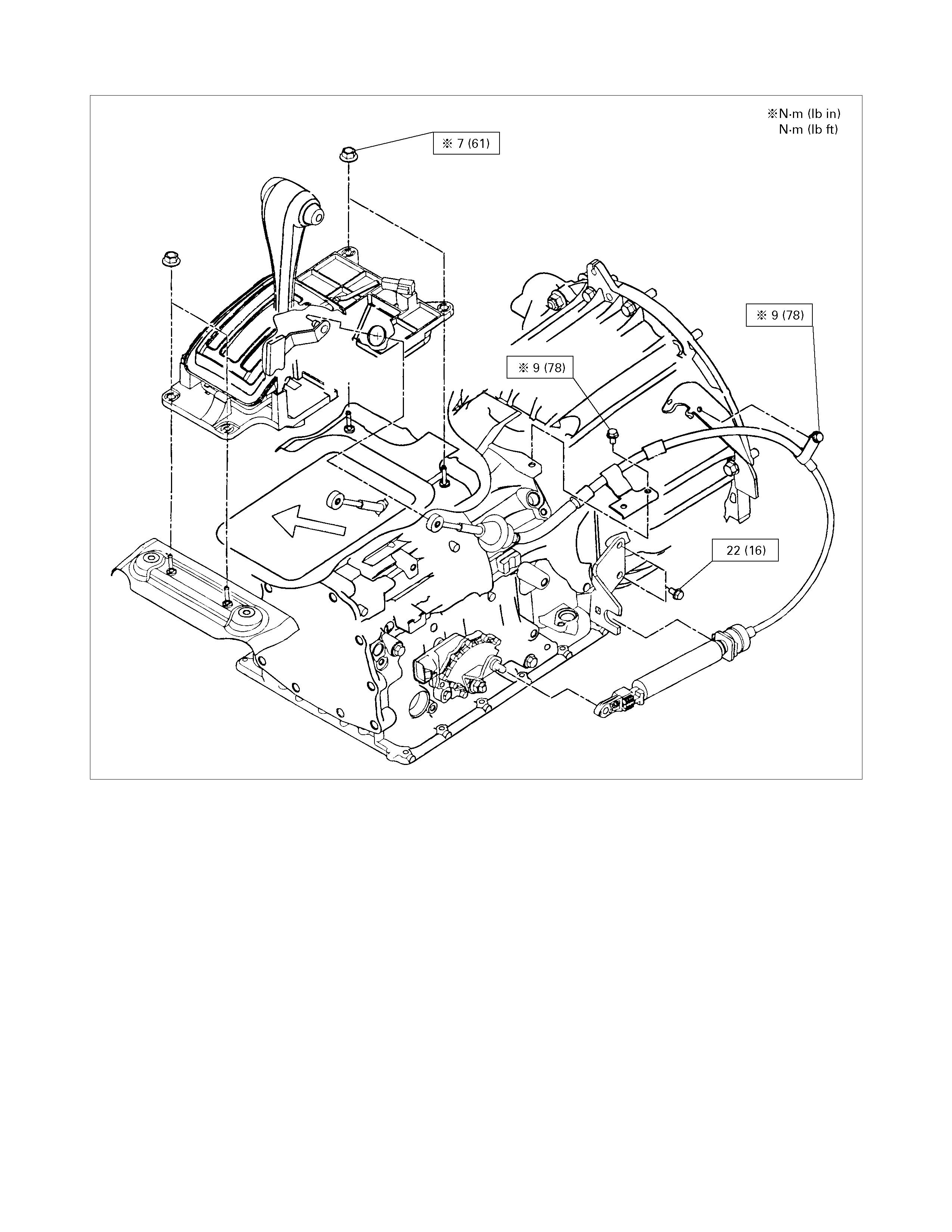

RTW37ALF001201

Legend

1. Select lever

2. Select lever base

3. Shift cable

4. Bracket

5. Adjuster

6. Manual shaft select lever

7. Shift cable retaining pawl

8. Clip

Remove or Disconnect

1. Block the wheels.

2. Disconnect the negative battery cable.

3. Move the select lever to the “N” position.

4. Remove the rear console and front console.

5. Disconnect the shift cable from the select lever.

6. Pr ess on the shif t cable retaining pawl to rem ove the

cable from the select lever base.

7. Disconnect the shift cable from the transmission

side.

8. Remove the shift cable from the bracket.

9. Pull the shift cable free from the bottom of the

vehicle.

Install or Connect

1. Install the shift cable toward the inside of the cabin

from the bottom of the vehicle.

2. Push the shift cable into the select lever base.

3. Connect the shift cable to the select lever.

4. Fix the shift cable to the bracket.

Install the clip on the marking of shift cable.

5. Check that the select lever is in the “N” position.

6. Check that the transmission is in the “N” position.

249R300002

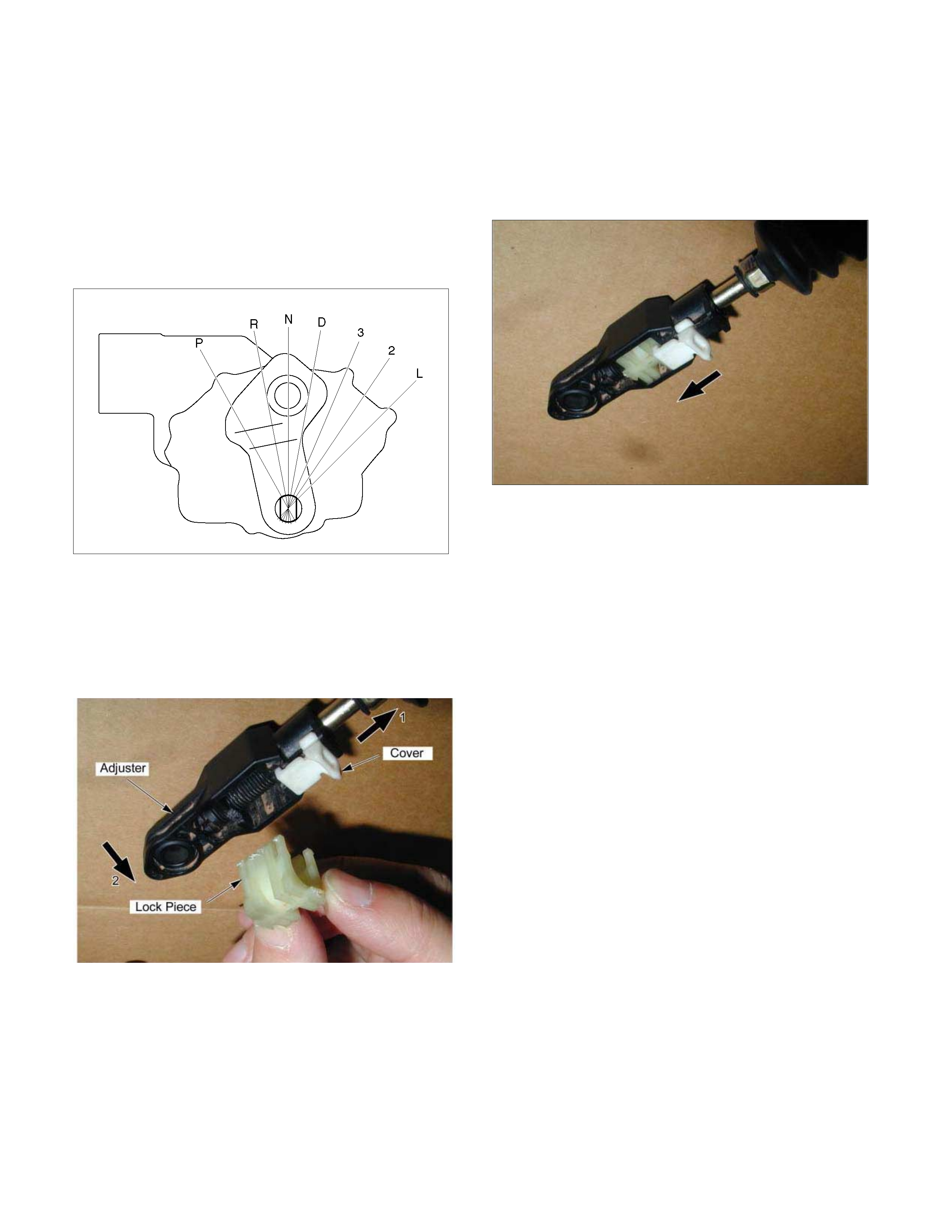

7. Slide the cover in the direction shown by the arro

w

(1).

8. Use an ordinary screwdriver to move the lock piece

from the position indicated by the arrow (2). Continue

to move the lock piece until the adjuster position

begins to change.

P1010012

9. Connect the shift cable to the manual shaft select

lever at the transmission side.

10. Insert the lock piece to the adjuster (cable length

adjustment).

11. Slide the cover on the adjuster and secure lock

piece.

P1010016-2

11. Press the select lever knob button 5 times.

Then check that the select lever moves smoothly to

each of its positions.

13. Check that the shift position indicated by the select

lever and the actual shift position are the same.

14. Install the front console and rear console.

15. Connect the negative battery cable.

16. Remove the wheel blocks.

Torque Specifications

E07R300015

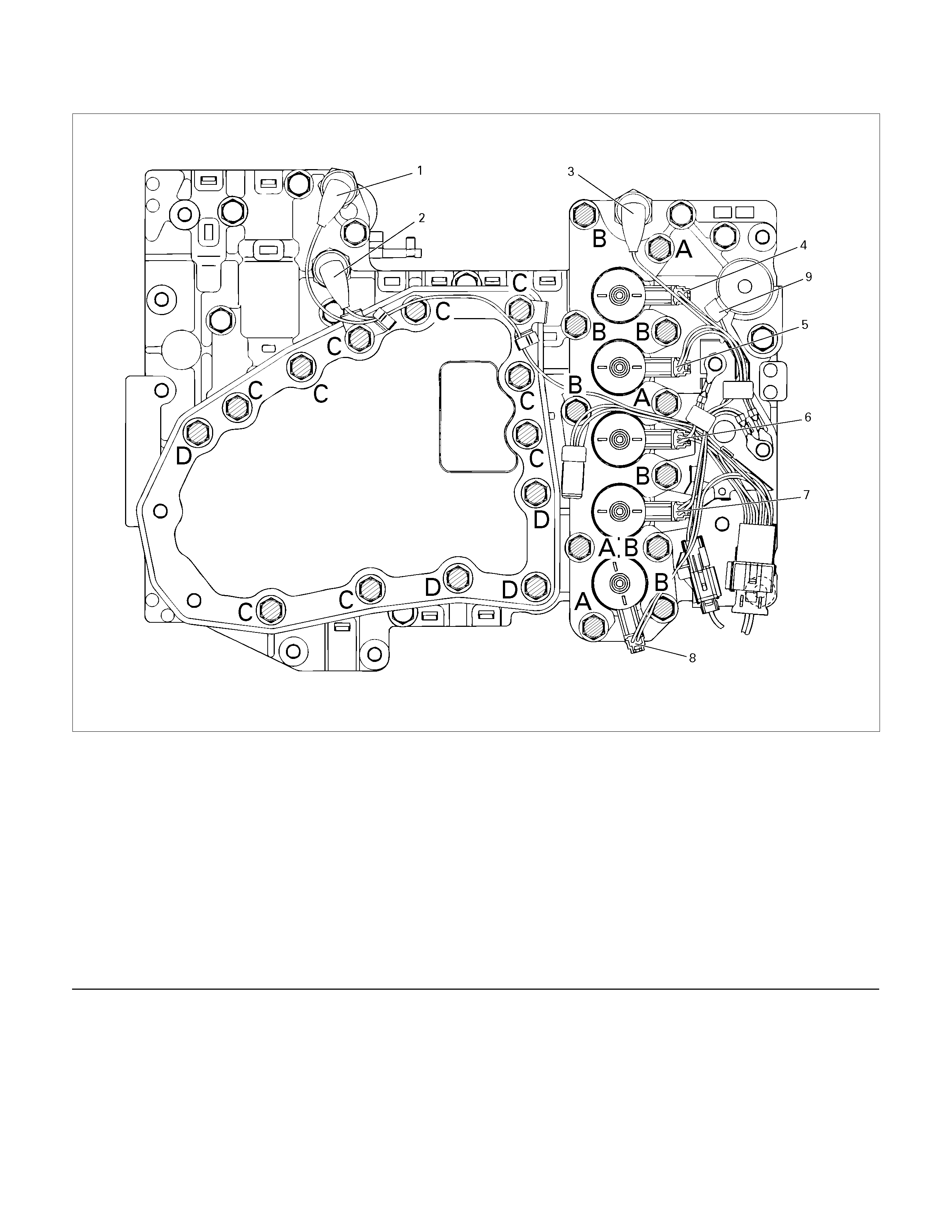

Solenoids, Oil Pressure Switch And Oil Temperature Sensor

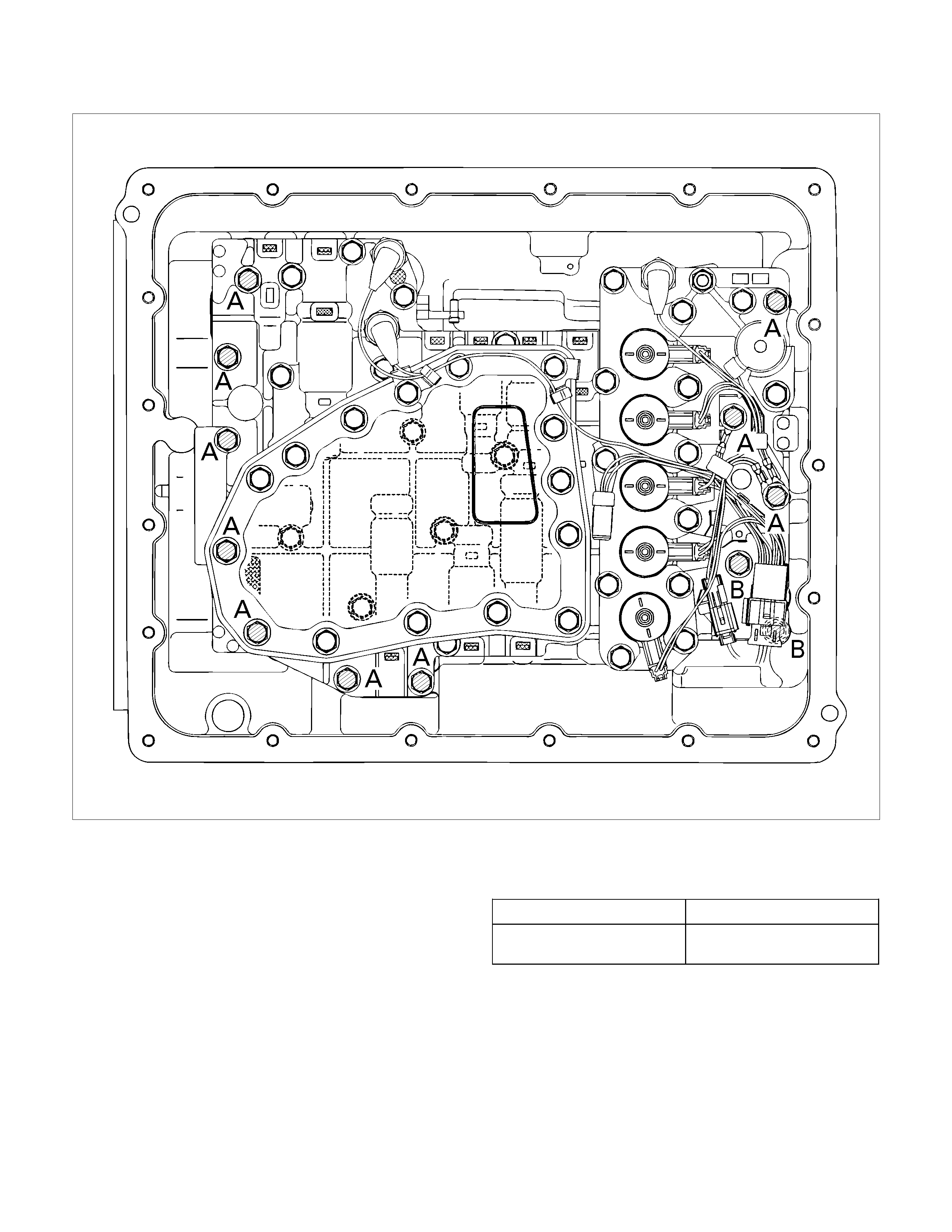

244L300003

Legend

1. High clutch oil pressure switch connector

(wire color: Gray)

2. 2-4 brake oil pressure switch connector

(wire color: Brown)

3. Low and reverse brake oil pressure switch connector

(wire color: White)

4. Low and reverse brake duty solenoid connector

(wire color: Pink and White)

5. High clutch duty solenoid connector

(wire color: Green and Gray)

6. Lock-up duty solenoid connector

(wire color: Yellow and Black)

7. 2-4 brake duty solenoid connector

(wire color: Blue and Brown)

8. Low clutch duty solenoid connector

(wire color: Orange and Black)

9. Line pressure solenoid connector

(wire color: Pink)

Remove or Disconnect

1. Block the wheels.

2. Disconnect the negative battery cable.

3. Drain the fluid.

Refer to “ATF CHANGE” in this section.

4. Remove the 19 bolts and oil pan.

5. Inspect the bottom of the oil pan and strainer netting

for foreign material (clutch facing and metal

shavings).

If there is an excessive accumulation of foreign

material, the oil strainer must be replaced.

Further inspection is required to determine the

source of the foreign material.

6. Remove the harness assembly (including oil

temperature sensor).

7. Remove the 11 bolts and the solenoid fixing plate.

8. Remove the 6 solenoids and 3 oil pressure switches.

Inspect

Oil pressure switch

Apply compressed air (392 kPa/4.0 kg/cm2) to the oil

pressure switch to ch eck the oil pressure swi tch

continuity between the connector and screw.

Oil temperature sensor (harness assembly)

Check the oil temperature sensor resistance between

harness terminals 7 and 6 (ground).

Oil temperature sensor resistance:

2,400~2,600 ohms (20°

°°

°C)

244L300011

Solenoid

Measure the resistance of each solenoid.

Resistance:

Brown connector – 3.0~3.4 ohms (20°

°°

°C)

Gray connector – 12.0~13.2 ohms (20°

°°

°C)

White connector – 12.2~13.4 ohms (20°

°°

°C)

Install or Connect

1. Install the O-rings to each of the solenoids.

2. Install the 6 solenoids and 3 oil pressure switches.

Line pressure solenoid bolt torque:

8 N·m (69 lb·in)

Oil pressure switch bolt torque:

4.4 N·m (39 lb·in)

3. Install the solenoid fixing plate together with the

harness brackets.

Number Length (Color)

Solenoid fixing plate bolt

(A)

(B)

4

7

16 mm (0.63 in) (Gold)

45 mm (1.77 in) (Silver)

Bolt torque : 8 N·m (69 lb·in)

4. Install the harness assembly.

5. If removed, install the oil strainer.

Number Length (Color)

Oil strainer bolt (C)

(D)

9

4

13 mm (0.51 in) (Silver)

45 mm (1.77 in) (Silver)

Bolt torque : 8 N·m (69 lb·in)

6. Install the new gasket and oil pan.

Bolt torque : 8 N·m (69 lb·in)

7. Fill the fluid.

Refer to “ATF CHANGE” in this section.

8. Connect the negative battery cable.

9. Remove the wheel blocks.

Control Valve Assembly

244L300001

Remove or Disconnect

1. Block the wheels.

2. Disconnect the negative battery cable.

3. Drain the fluid.

Refer to “ATF CHANGE” in this section.

4. Remove the 19 bolts and oil pan.

5. Inspect the bottom of the oil pan and strainer netting

for foreign material (clutch facing and metal

shavings).

If there is an excessive accumulation of foreign

material, the oil strainer must be replaced.

Further inspection is required to determine the

source of the foreign material.

6. Disconnect the 2 harness connectors leading to the

control valve.

7. Remove the 12 bolts and the control valve assembly.

Number of bolts Length

10 (A)

2 (B) 40 mm (1.57 in)

30 mm (1.18 in)

Note:

Take care not to disturb the manual valve (inside the

control valve assembly).

Do not allow the pin to fall free (the pin prevents the

valve from turning).

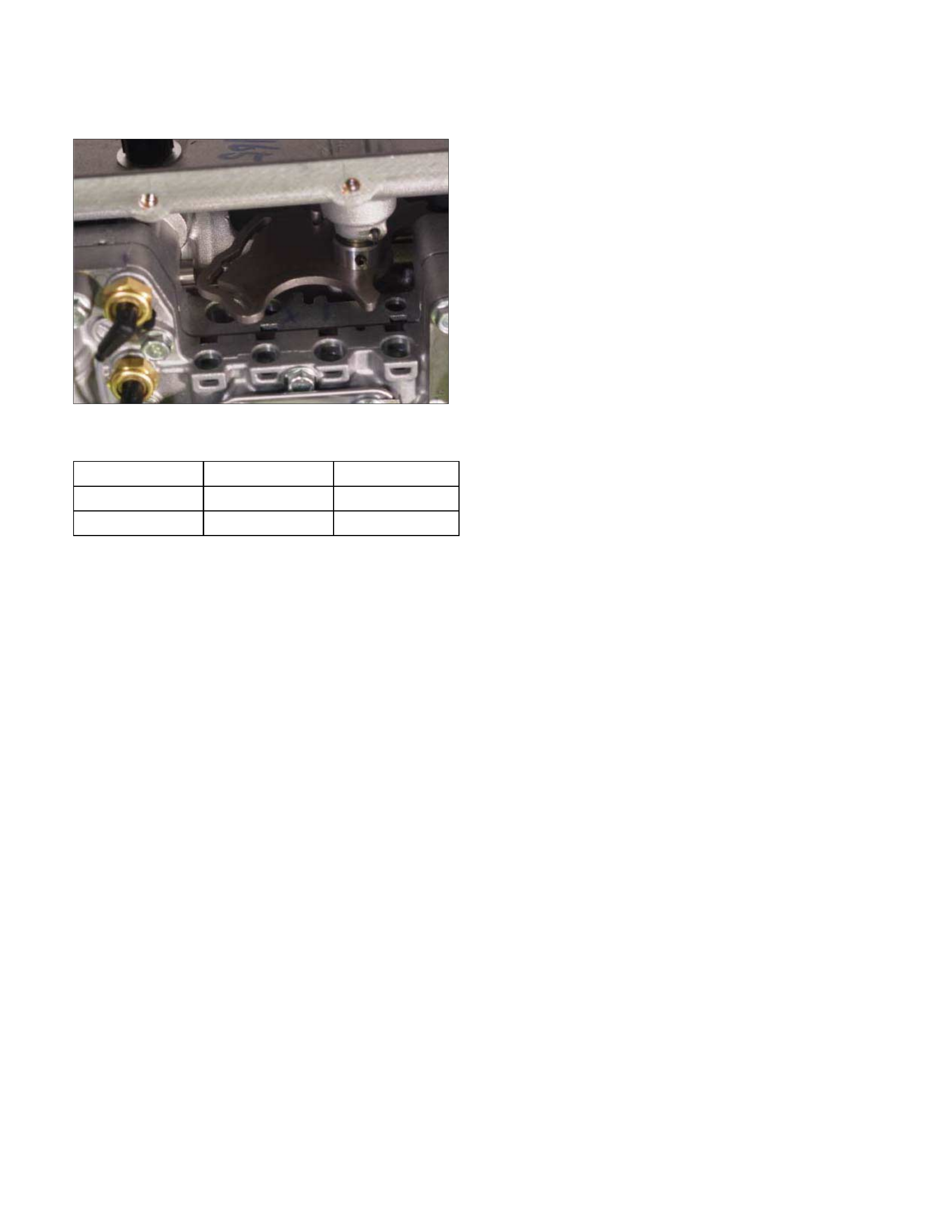

Install or Connect

1.

A

lign the manual valve and the manual plate of the

transmission case.

43ASSY119

2. Install the control valve assembly and tighten the 12

fixing bolts to the specified torque.

Number of bolts Length Color

10 (A) 40 mm (1.57 in) Gold

2 (B) 30 mm (1.18 in ) Gold

Bolt torque : 8 N·m (69 lb·in)

3. Connect the 2 harness connectors.

4. If removed, install the oil strainer.

Refer to “Solenoids, Oil Pressure Switch and Oil

Temperature Sensor” previously in this section.

5. Install the new gasket and oil pan.

Bolt torque : 8 N·m (69 lb·in)

6. Fill the fluid.

Refer to “ATF CHANGE” in this section.

7. Connect the negative battery cable.

8. Remove the wheel blocks.

Flushing The Transmission Fluid Cooler And Line

The fluid cooler and lines may be flushed under the

following condition. This will help prevent more trouble

after the transmission is repaired.

1. When the abnormal amount of debris are found.

2. When the abnormal wear or chips on gears and

shafts are found while overhauling.

3. When the abnormal clutch facing wear and oil

contamination are found.

Procedures

1. Block the wheels.

2. Disconnect negative battery cable.

3. Raise vehicle and support with suitable safet

y

stands.

4. Disconnect fluid cooler lines at transmission case

and fluid cooler.

5. Flush and back-flush the fluid cooler and lines using

solvent and compressed air.

Note:

DO NOT exceed 197 kPa (29 psi) air pressure or

damage may result to oil cooler.

6. Remove all remaining solvent from the system with

compressed air.

7. Flush the cooling system again with Automatic

Transmission Fluid (ATF).

After the final flush, connect all lines.

Cooler line joint connector torque :

44 N·m (33 lb·ft)

8. Replenish ATF

9. Start engine to test the system for the free flow o

f

fluid. If the f low is restricted, the cooler assembly or

lines must be replaced.

Repeated cleaning and flushing may not remove all

debris from the fluid cooler circuit.

Move the select lever through the various ranges and

return to neutral.

Check for fluid level.

If the fluid level is below the specified range, ATF

must be added.

10. Connect negative battery cable.

11. Remove safety stands.

12. Remove wheel blocks.

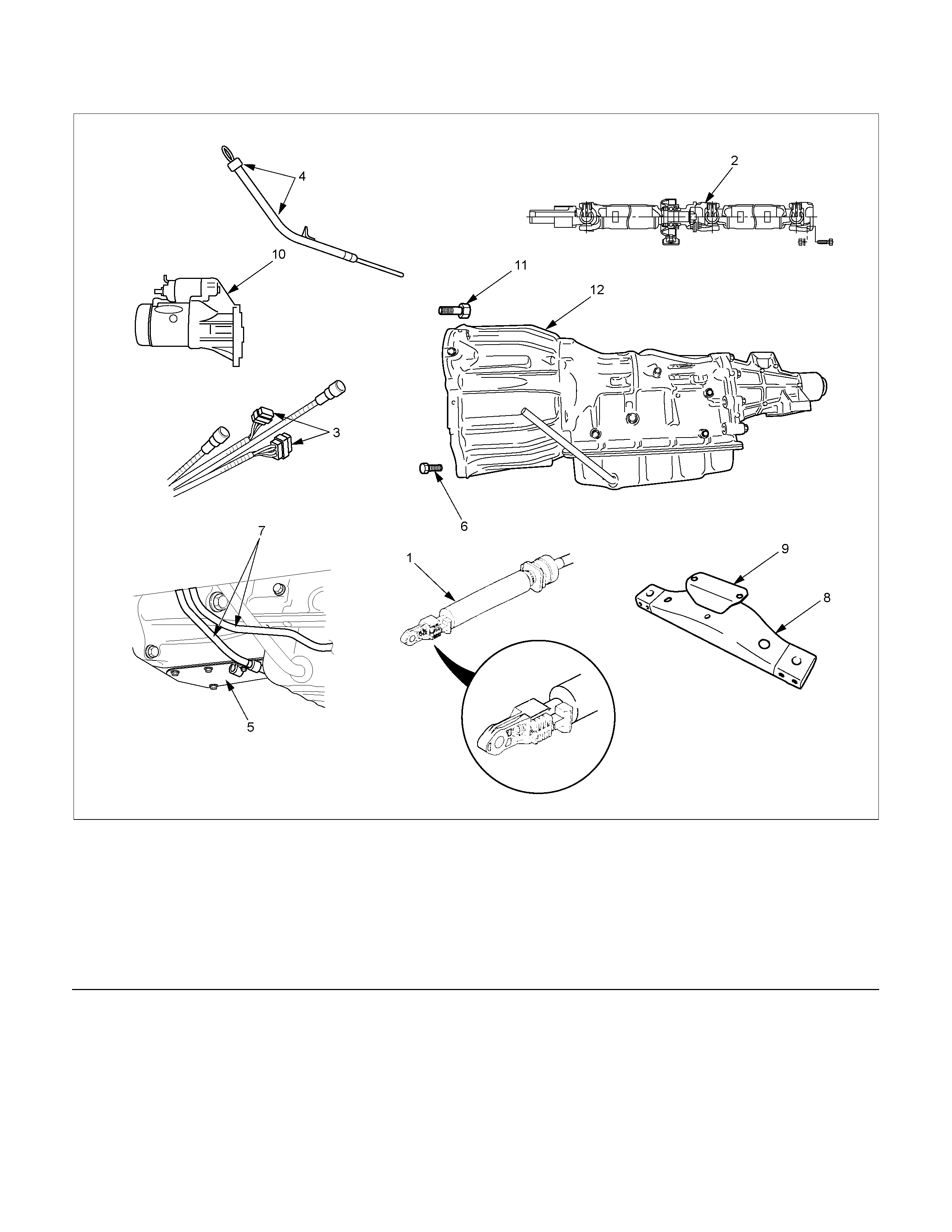

Transmission Assembly

RTW37ALF001401

Legend

1. Shift Cable

2. Propeller Shaft

3. Engine Harness

4. ATF Level Dipstick

5. Under Cover

6. Bolt

7. ATF Pipe

8. Crossmember

9. Bracket

10. Starter Motor

11. Bolt

12. Automatic Transmission

Remove or Disconnect

1. Block the wheels.

2. Disconnect the negative battery cable.

3. Raise the vehicle and suppor t with the suitable saf et

y

stands.

4. Remove the shift cable from the transmission.

P1010068

5. Remove the rear propeller shaft assembly .

6. Loosen (do not remove) the nuts securing the

exhaust manifold and the exhaust pipe.

7. Disconnect the harness connectors from the

transmission.

8. Remove the fuel pipe bracket.

P1010013

P1010014

9. Remove the ATF level dipstick and tube.

10. Remove the undercover.

11. Rotate the ring gear and remove the 6 torque

converter bolts.

P1010016

12. Remove the automatic transmission fluid cooling

pipe.

P1010060

13. Place a jack beneath the engine to support it.

14. Remove the 3rd crossmember.

15. Remove the transmission mount.

16. Lower the jack beneath the engine slightly to tilt the

engine and transmission. Do not allow the radiator

and air conditioner hoses to stretch.

17. Remove the bolts attaching the transmission to the

engine.

18. Lower the transmission from beneath the vehicle.

Take care not to damage the breathers.

Install or Connect

1. Install the transm ission to the engine and tighten the

bolts.

Bolt torque : M10 40 N·m (30 lb·ft)

M12 76 N·m (56 lb·ft)

2. Install the cable bracket to the transmission.

3. Connect the engine harness connectors.

4. Install the 3rd crossmember.

Bolt and Nut torque : 67 N·m (49 lb·ft)

Bolt torque : 50 N·m (37 lb·ft)

5. Install the automatic transmission fluid cooling pipe.

6. Install the torque converter bolts.

Bolt torque : 29 N·m (22 lb·ft)

7. Install the undercover.

Bolt torque : 9 N·m (78 lb·in)

8. Install the ATF level dipstick and tube.

9. Install the fuel hose bracket.

Bolt torque : 6 N·m (52 lb·in)

10. Tighten the nuts securing the exhaust manifold and

the exhaust pipe.

Bolt torque : 43 N·m (32 lb·ft)

11. Install the rear propeller shaft assembly.

Flange bolt torque : 63 N·m (46 lb·ft)

Center bearing bracket bolt torque :

69 N·m (51 lb·ft)

12. Install the shift cable.

13. Connect the negative battery cable.

14. Remove the safety stands.

15. Remove the wheels blocks.

Torque Specifications

RTW37ALF001501