SECTION 7A4 - UNIT REPAIR (JR405E)

Automatic Transmission Disassembly

Cleaning The Automatic Transmission

Automatic Transmission Disassembly Cautions

Disassembly Steps

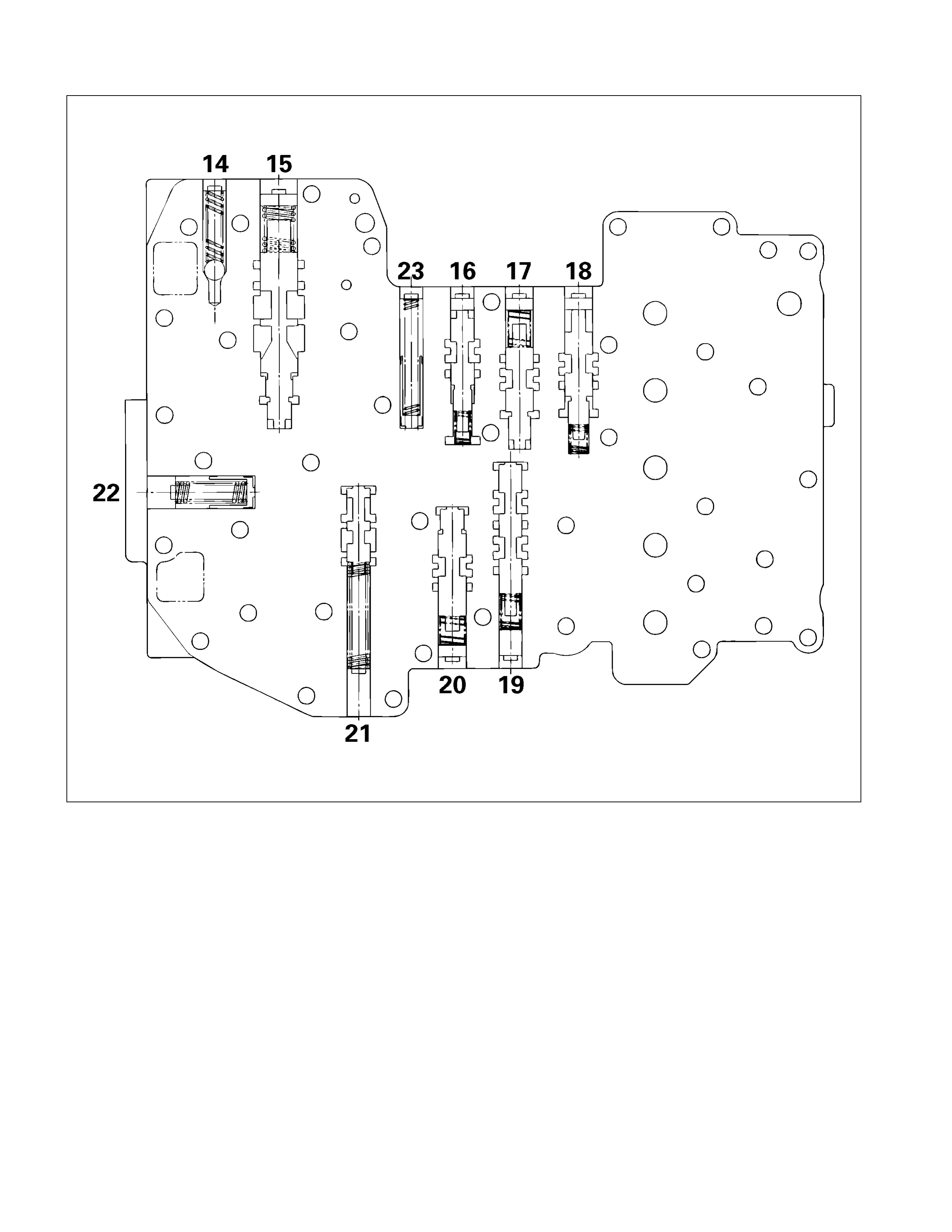

Control Valve Assembly

Disassembly Steps

Inspection

Reassembly Steps

Control Valve Upper Body

Disassembly Steps

Inspection

Valve Specifications

Spring Specifications

Reassembly Steps

Control Valve Lower Body

Disassembly Steps

Inspection

Valve Specifications

Spring Specifications

Oil Pressure Switch

Oil Temperature Sensor (Harness Assembly)

Solenoid

Reassembly Steps

Oil Pump Assembly

Disassembly Steps

Inspection

Reassembly Steps

Clutch Pack (Reverse and High Clutch Assembly)

Disassembly Steps

Inspection

Reassembly Steps

Carrier and Low Clutch Assembly

Disassembly Steps

Inspection

Reassembly Steps

Inspection

Transmission Case

Disassembly Steps

Inspection

Reassembly Steps

Bearing and Bearing Race Installation Position

Automatic Transmission Reassembly

Assembly Cautions

Power Train

Reassembly Steps

Service Standard

Special Service Tool

Automatic Transmission Disassembly

Cleaning The Automatic Transmission

1. Use compressed steam and /or cleaning oil to thoroughly

clean the outside of the transmission before disassembly.

CAUTION:

Steam under high pressure may cause dirt particles

adhering to the transmission to fly through the air at great

speed. These particles can cause serious eye injury. Wear

protective goggles when steam-c leaning the outside of

the transmission.

2. During disassembly, clean the removed parts with cleaning

oil. Dry the parts with compressed air.

Use Compressed air to clean the transmission oil holes

and oil passages.

Automatic Transmission Disassembly Cautions

• Perform the disassembly procedure in a dust-free

environment to prevent the entry of foreign material into

the transmission.

• Inspect each transmission part as you remove it.

• Carefully check the oil pan and the magnet for foreign

material. This is a good way to estimate transmission

condition.

• Use your bare hands or vinyl gloves to disassemble the

transmission. Do not use ordinary work gloves (loose

threads from the gloves may fall into the transmission and

cause problems).

• Use a plastic hammer to loosen the transmission case

and other aluminum parts during disassembly. Strike

around the parts lightly with the hammer. Do not pry

aluminum parts away from each other with a screwdriver

or similar object.

• Arrange the disassembled parts neatly in the order they

were removed. Cover the parts with a plastic sheet or

similar object to protect them from dust.

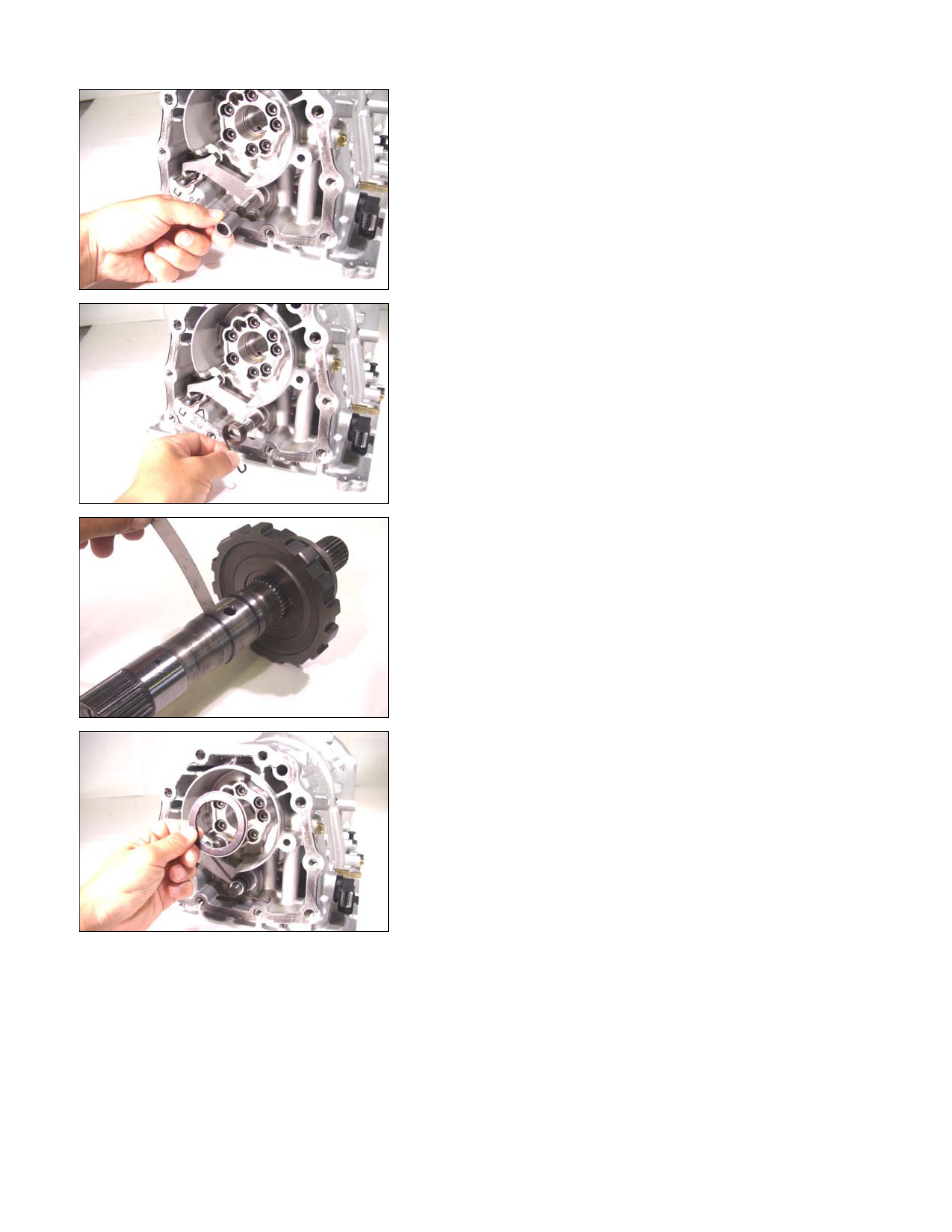

Disassembly Steps

1. Torque converter

• Pull the torque converter free.

NOTE:

Place a pan beneath the torque converter to catch

automatic transmission fluid (ATF) spillage.

• Draining the ATF from the torque converter.

01ASSY101

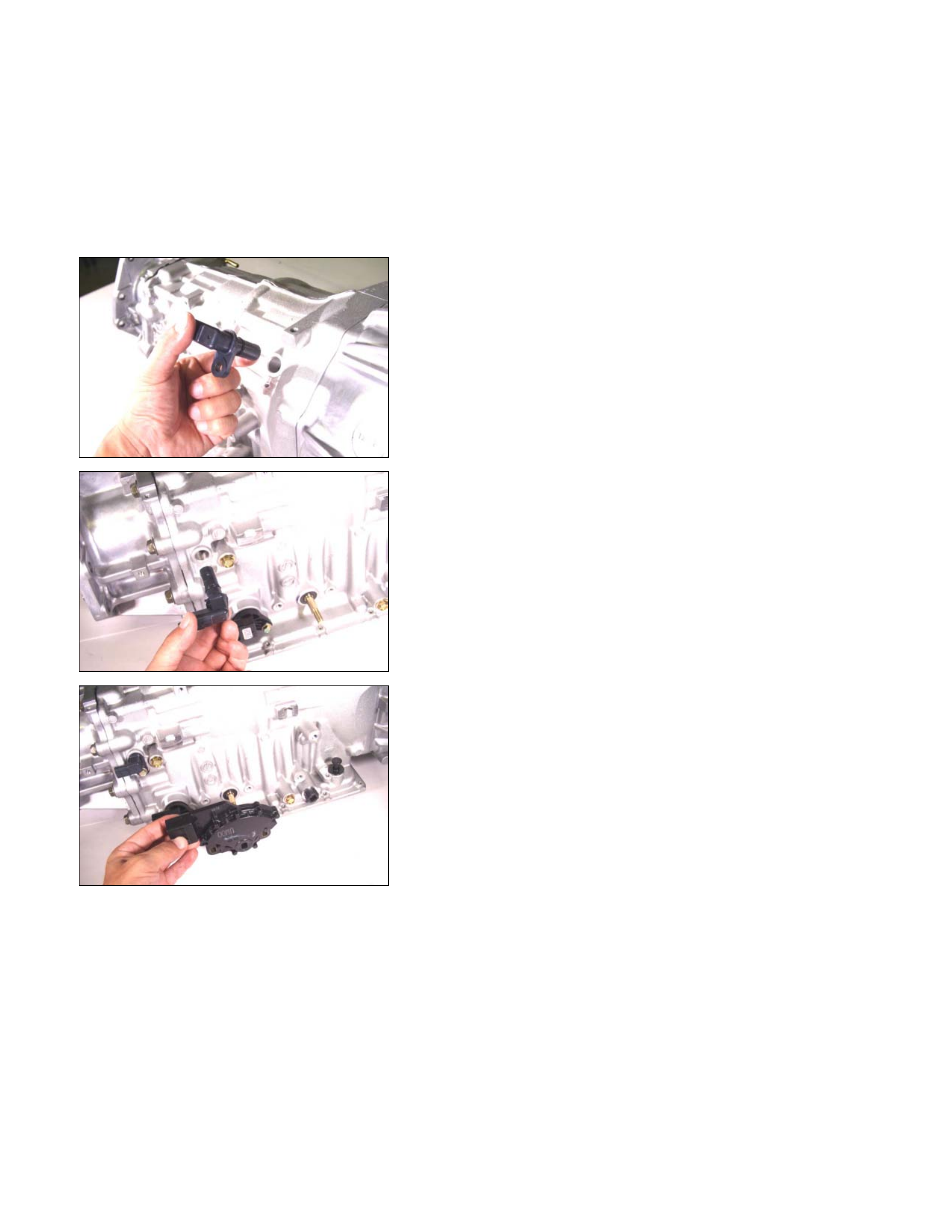

2. Turbine sensor and speed sensor

• Remove the turbine sensor from the transmission case.

02ASSY103

• Remove the speed sensor from the transmission case.

03ASSY106

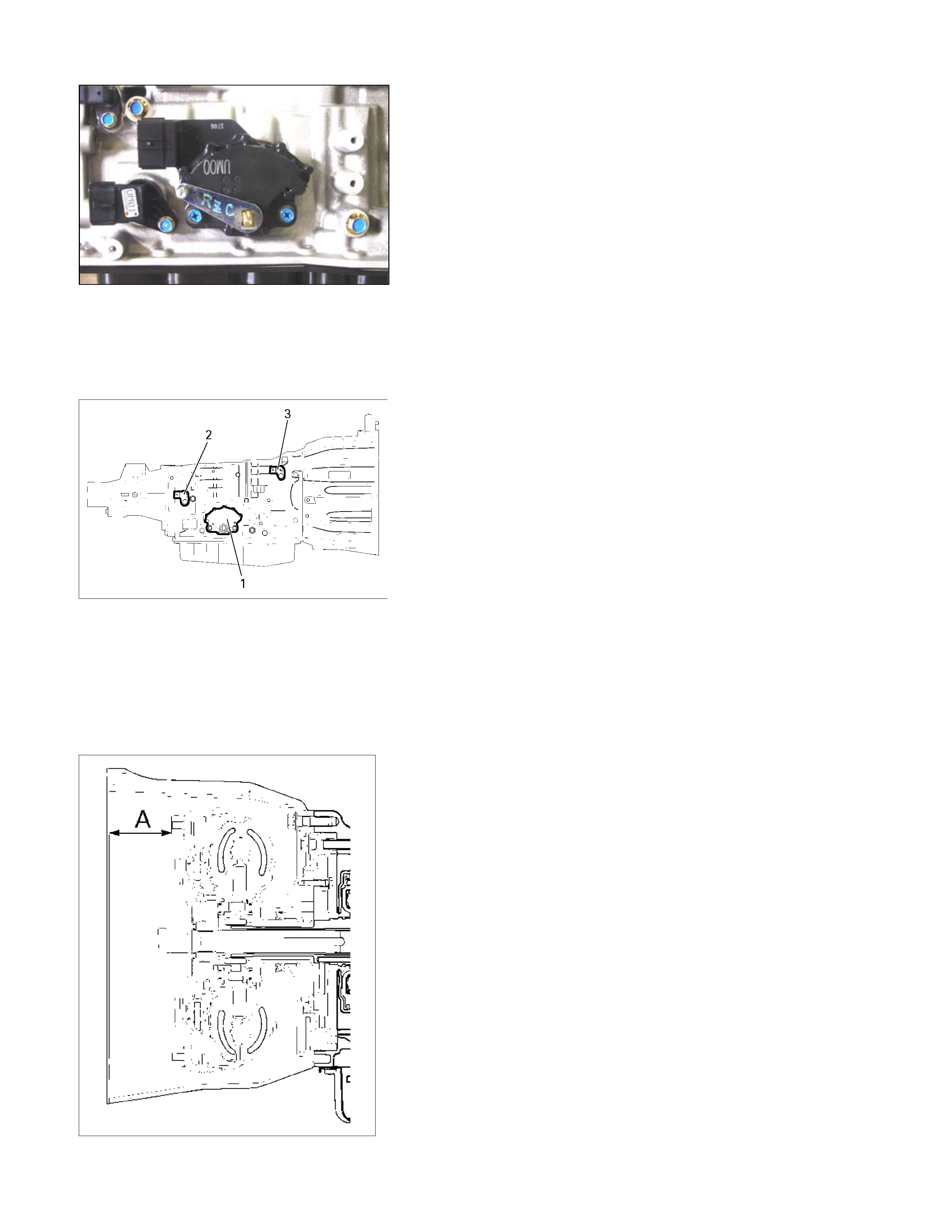

3. Inhibitor switch

Remove the 2 bolts and the inhibitor switch from the

transmission case.

240L300002

4. Oil pan

• Lift and support the transmission with the holding fixture

and holding fixture base.

Holding fixture: 5-8841-0841-0

Holding fixture base: 5-8840-0003-0

• Remove the drain plug from the oil pan and drain the

ATF from the oil pan.

• Rotate the automatic transmission so that the converte

r

housing is facing up and drain the ATF.

• Rotate the automatic transmission so that the oil pan is

facing up.

• Remove the 19 bolts and the oil pan.

04CV37

• Inspect the bottom of the oil pan and strainer netting fo

r

foreign material (clutch facing and metal shavings).

If there is an exc ess ive accum ulation of fo reign m aterial,

the oil strainer must be replaced.

Further inspection is r equired to determ ine the source o

f

the foreign material.

45CV29

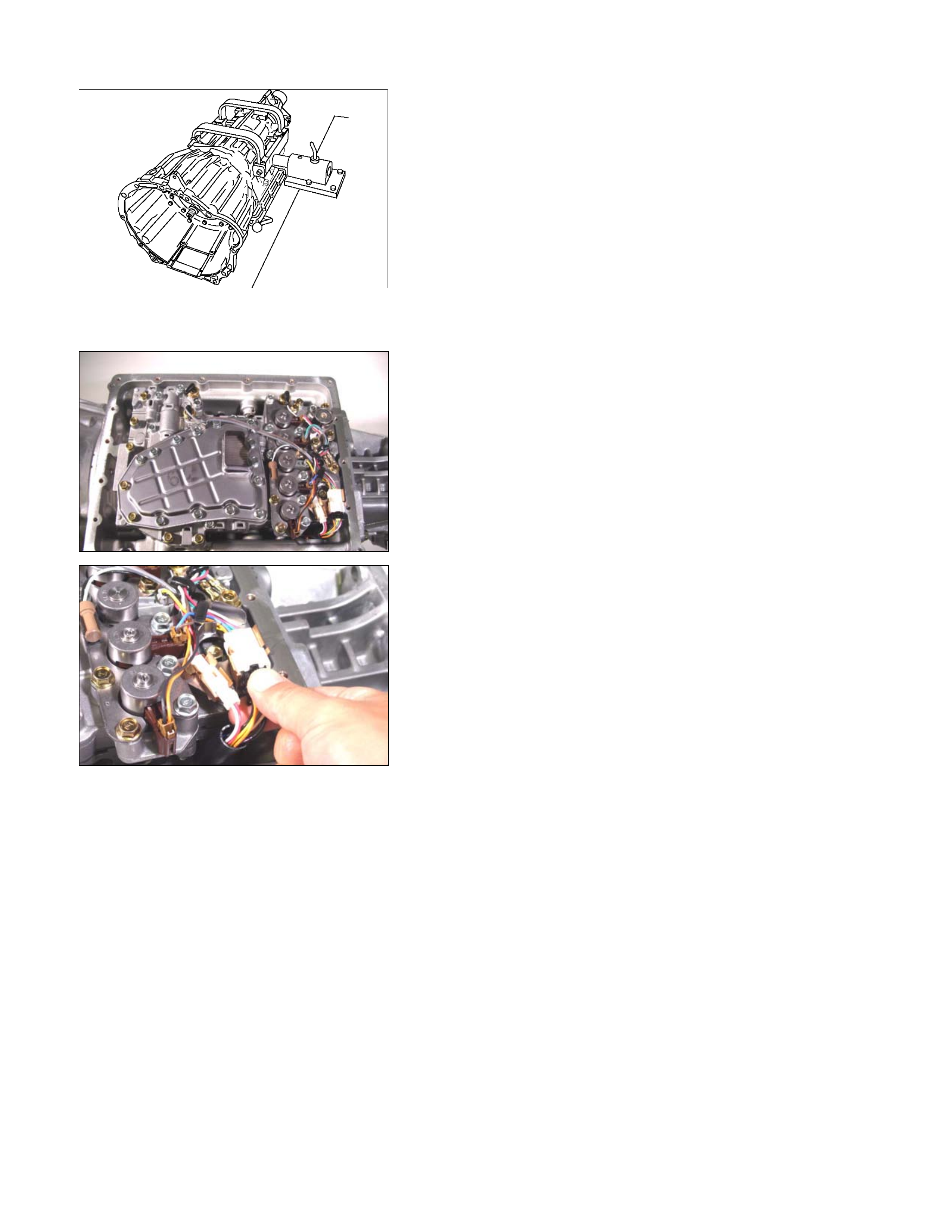

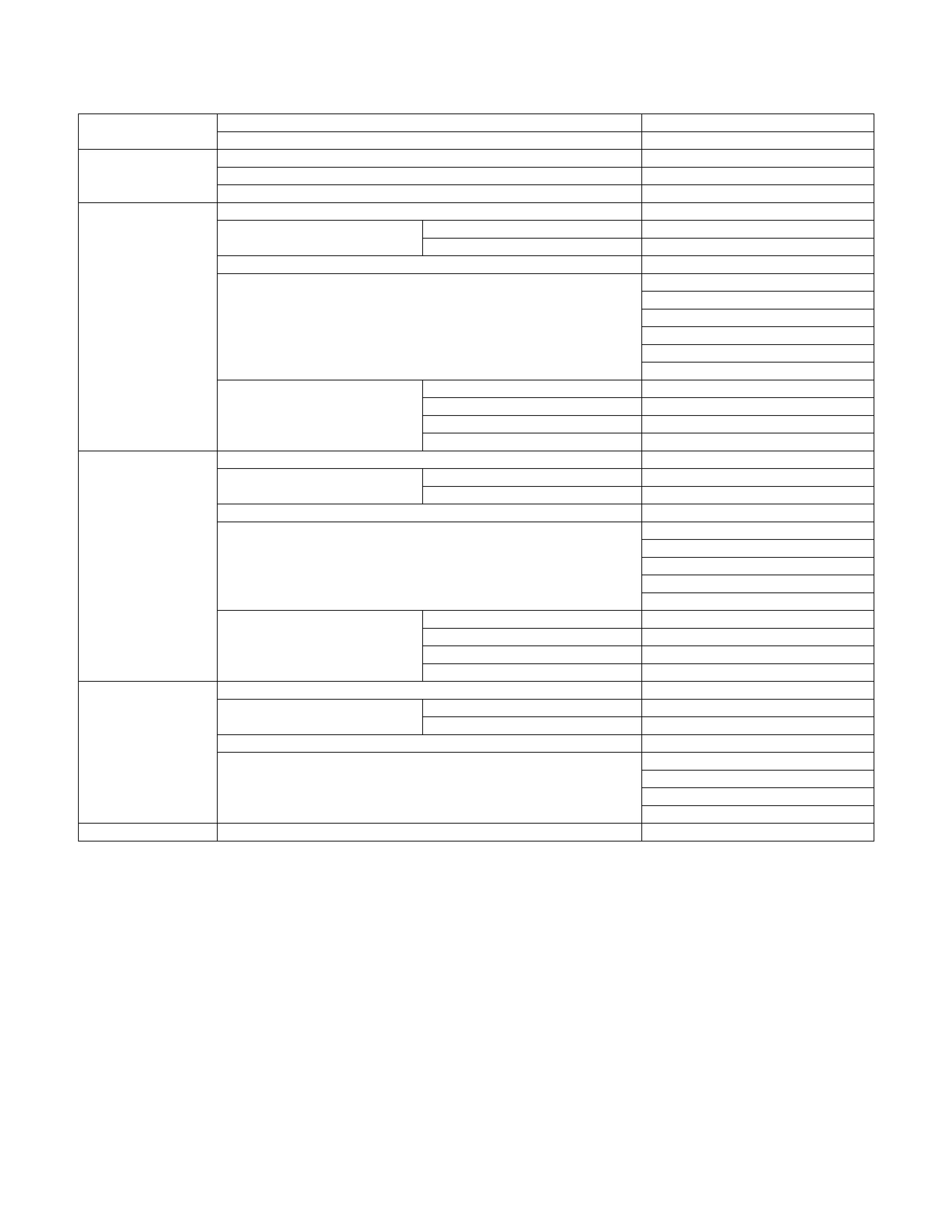

5. Control valve assembly

• Disconnect the 2 harness connectors leading to the

control valve.

244L300001

• Remove the 12 bolts and the control valve assembly.

Number of bolts Length

10 (A)

2 (B) 40 mm (1.57 in)

30 mm (1.18 in)

42ASSY118

NOTE:

Take care not to disturb the manual valve (inside the

control valve assembly).

Do not allow the pin to fall free (the pin prevents the valve

from turning).

10ASSY116

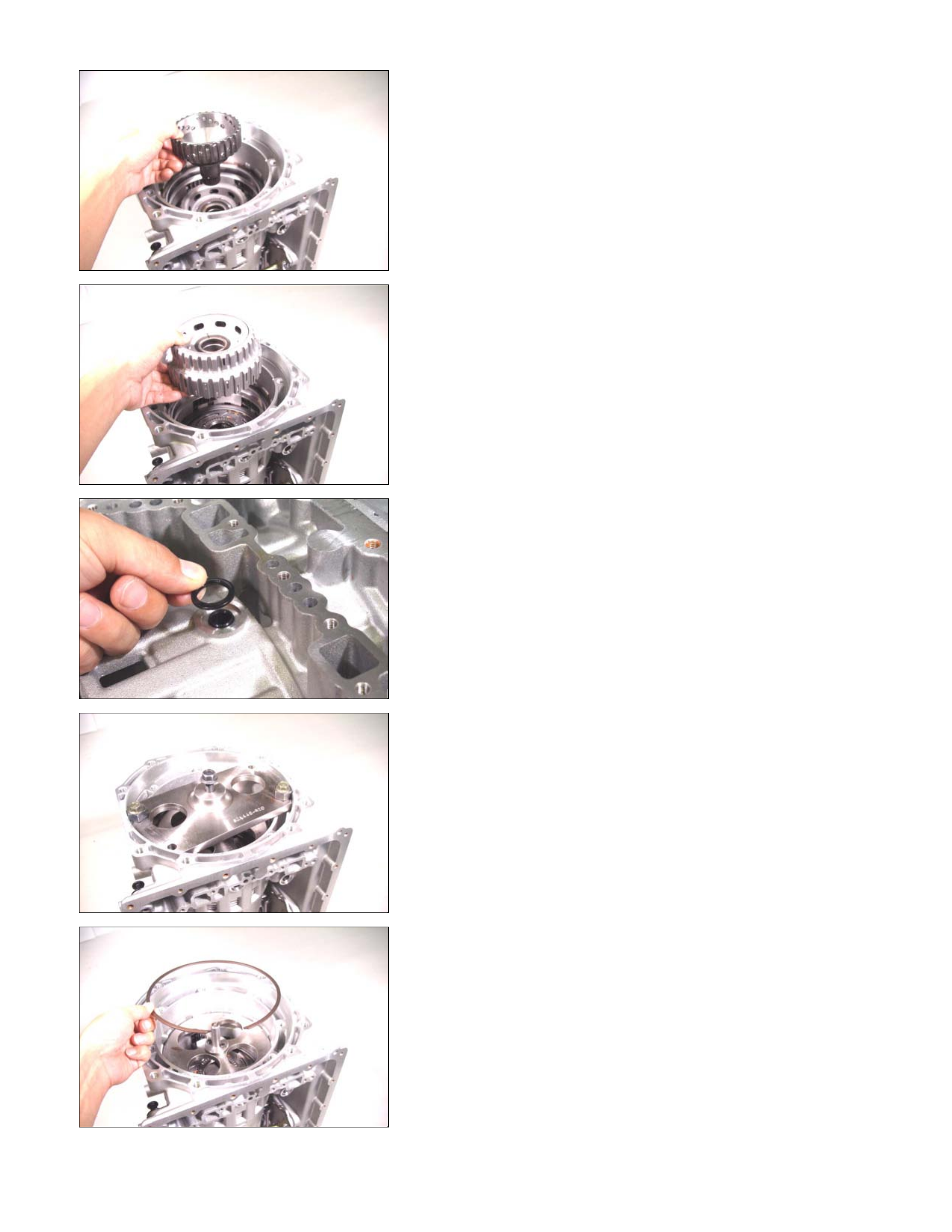

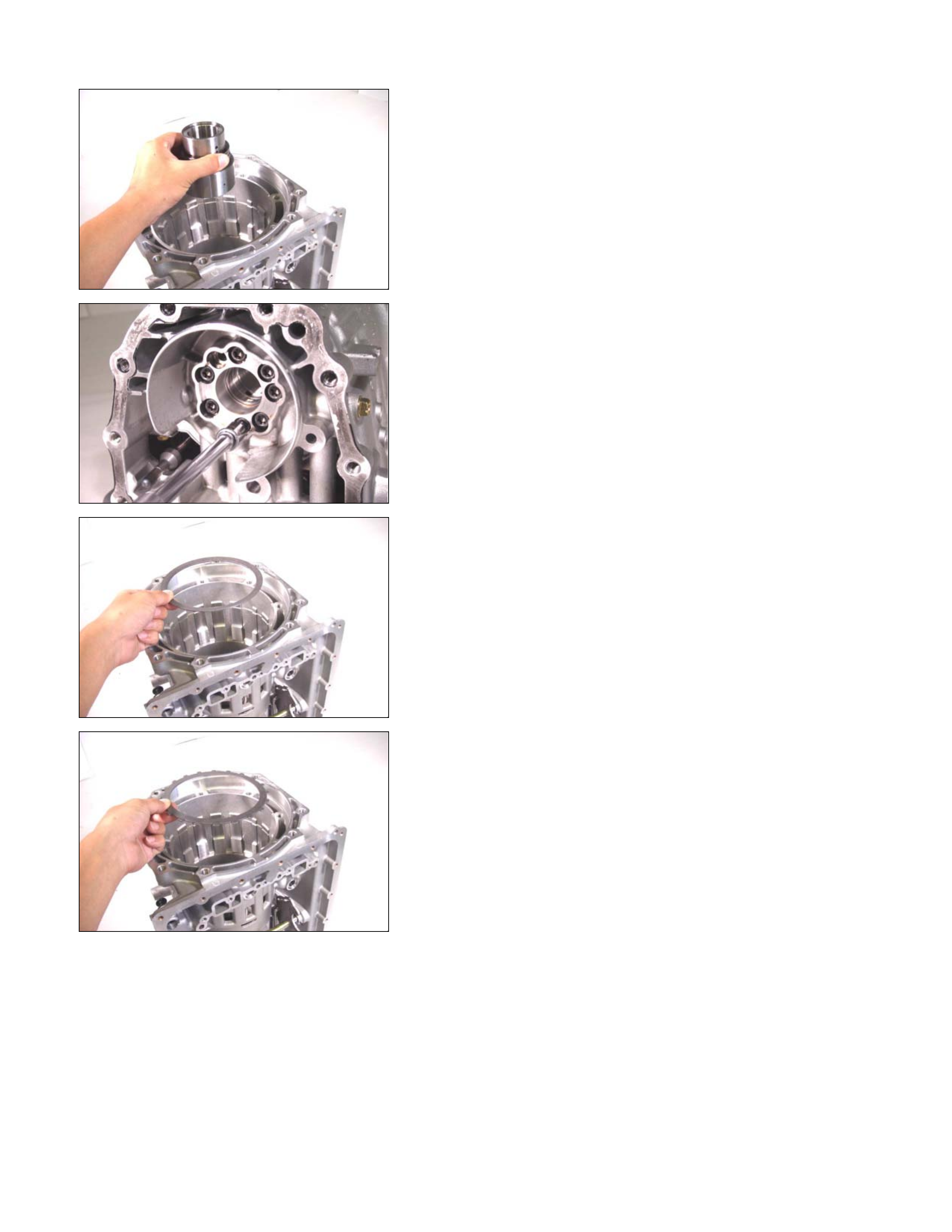

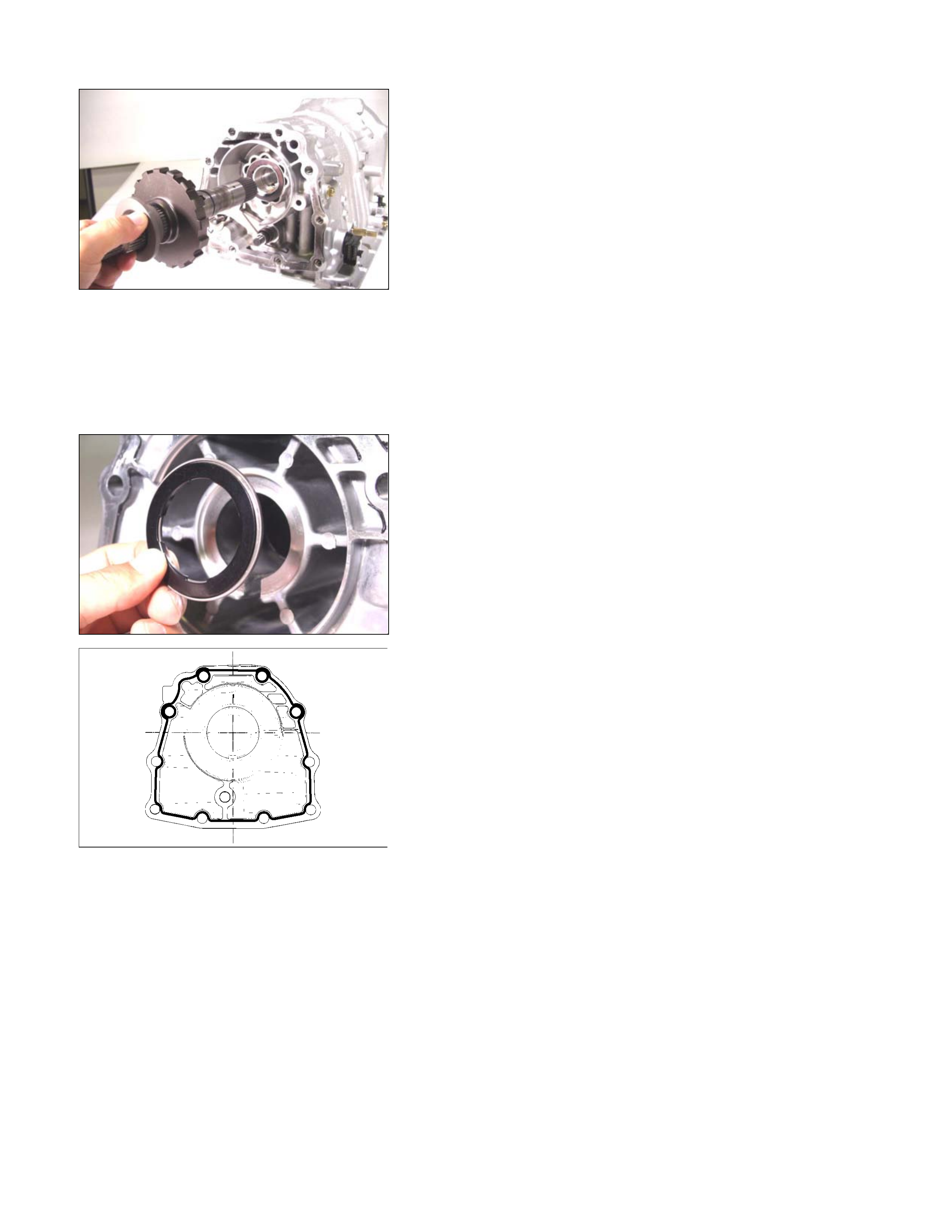

6. Converter housing

• Position the automatic transmission so that the

converter housing is facing up.

• Remove the 8 bolts and the converter housing.

11ASSY068

7. O-ring

Remove the O-ring from the input shaft.

12ASSY067

8. Oil pump assembly and bearing race

• Remove the 8 bolts.

• Use a slide hammer to remove the oil pump assembl

y

from the transmission case.

NOTE:

To prevent damage to the oil pump bolt hole threads,

hand-tighten the slide hammer as far as possible.

• Remove the bearing race from the oil pump assembly.

• Inspect the bearing race surfaces for damage.

14ASSY057

9. Input shaft

Pull the input shaft free.

15ASSY049

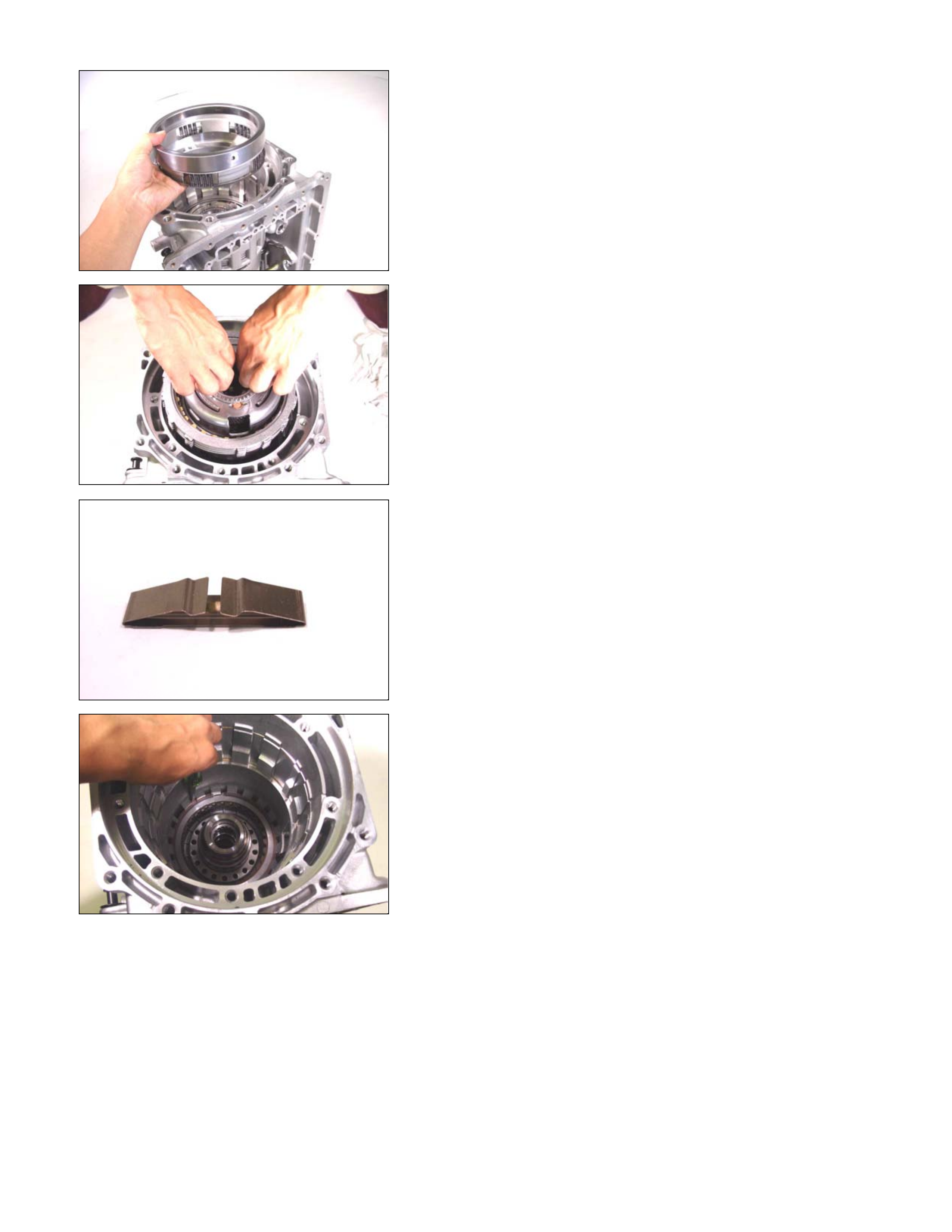

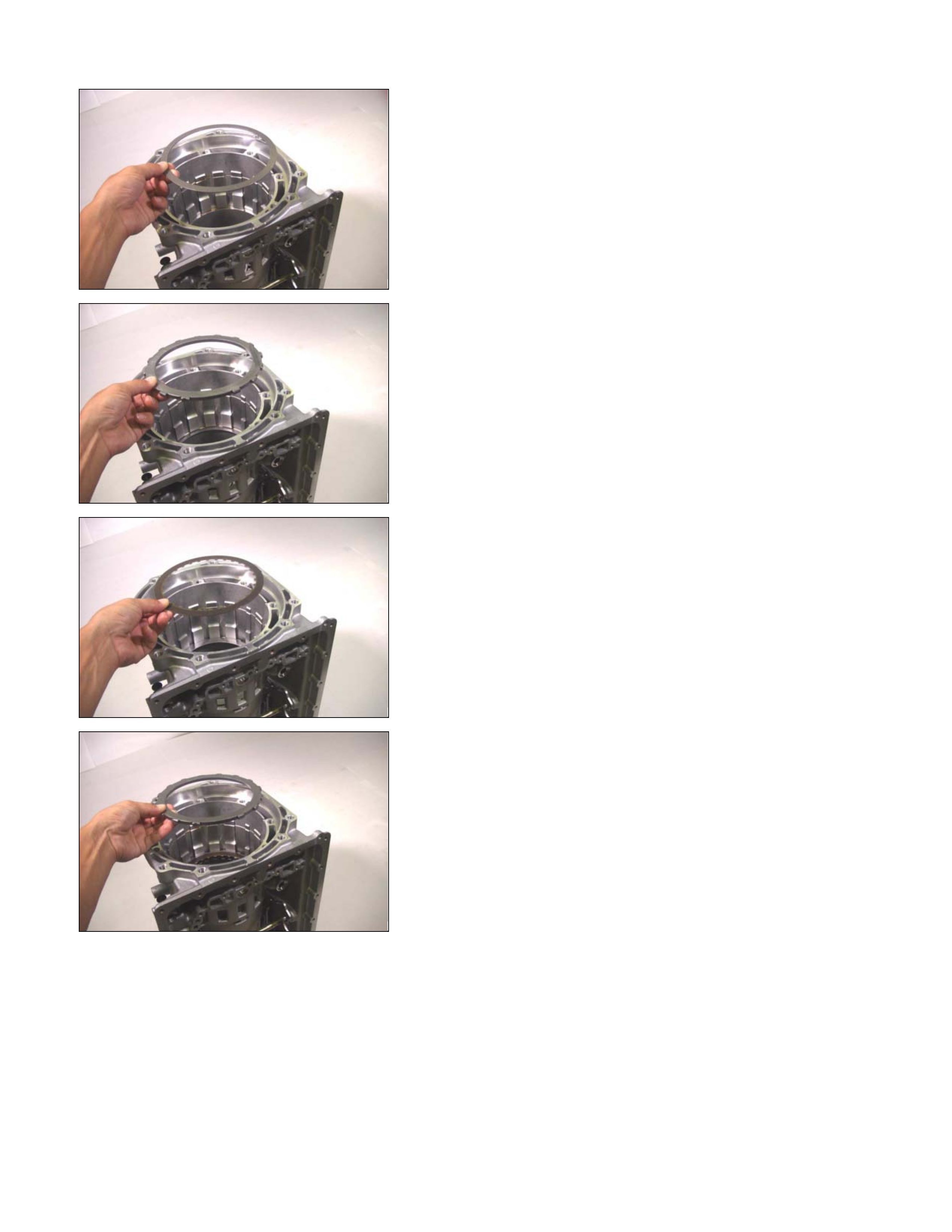

10.Clutch pack (Reverse and high clutch assembly) and

bearing

• Pull the clutch pack free.

• Remove the bearing from the clutch pack.

16ASSY047

11.High clutch hub, bearing, and bearing race

• Rem ove the clutch hub, bearing (with bearing race), and

the bearing race.

• Rem ove the bearing (with bearing race ) and the bearing

race from the high clutch hub.

• Inspect the bearing race surfaces for damage.

17ASSY040

12.Front sun gear, bearing, and bearing race

• Remove the bear ing, the fr ont sun gear, and the bearing

race.

• Rem ove the bearing and the bearing rac e from the f ront

sun gear.

• Inspect the bearing race surfaces for damage.

19ASSY113

13.2-4 brake retainer

• Remove the brake seal ring and the sleeve.

23ASSY030

• Attach the spring compressor to the transmission case.

Spring compressor: 5-8840-2764-0

24ASSY029

• Force out the 2-4 brake retainer and remove the snap

ring.

NOTE:

Overturning the spring compressor will damage the 2-4

brake retainer.

• Remove the spring compressor.

25ASSY019

• Remove the 2-4 brake retainer and return spring.

26ASSY026

14.Carrier assembly (Carrier and low clutch assembly),

bearing, bearing race, and 2 – 4 brake assembly

• Pull the carrier assembly, the bearing, the bearing race

and the 2-4 brake assembly (Dish plate, retaining plate,

drive plate, and driven plate) f rom the transm ission case

at the same time.

• Remove the bearing, the bearing race, and the 2-4

brake assembly from the carrier assembly.

27U-SPG02

• Remove the 3 brake springs from the transmission case.

28L&R06

15.Low and reverse brake

• Remove the snap ring.

• Pull the low and reverse brake free.

16.Rear extension (2WD) or Adapter case (4WD)

• Rotate the transm iss ion case so that the oil pan opening

is facing up.

• Remove the 10 bolts and the rear extension (2WD) o

r

the adapter case (4WD).

29ASSY091

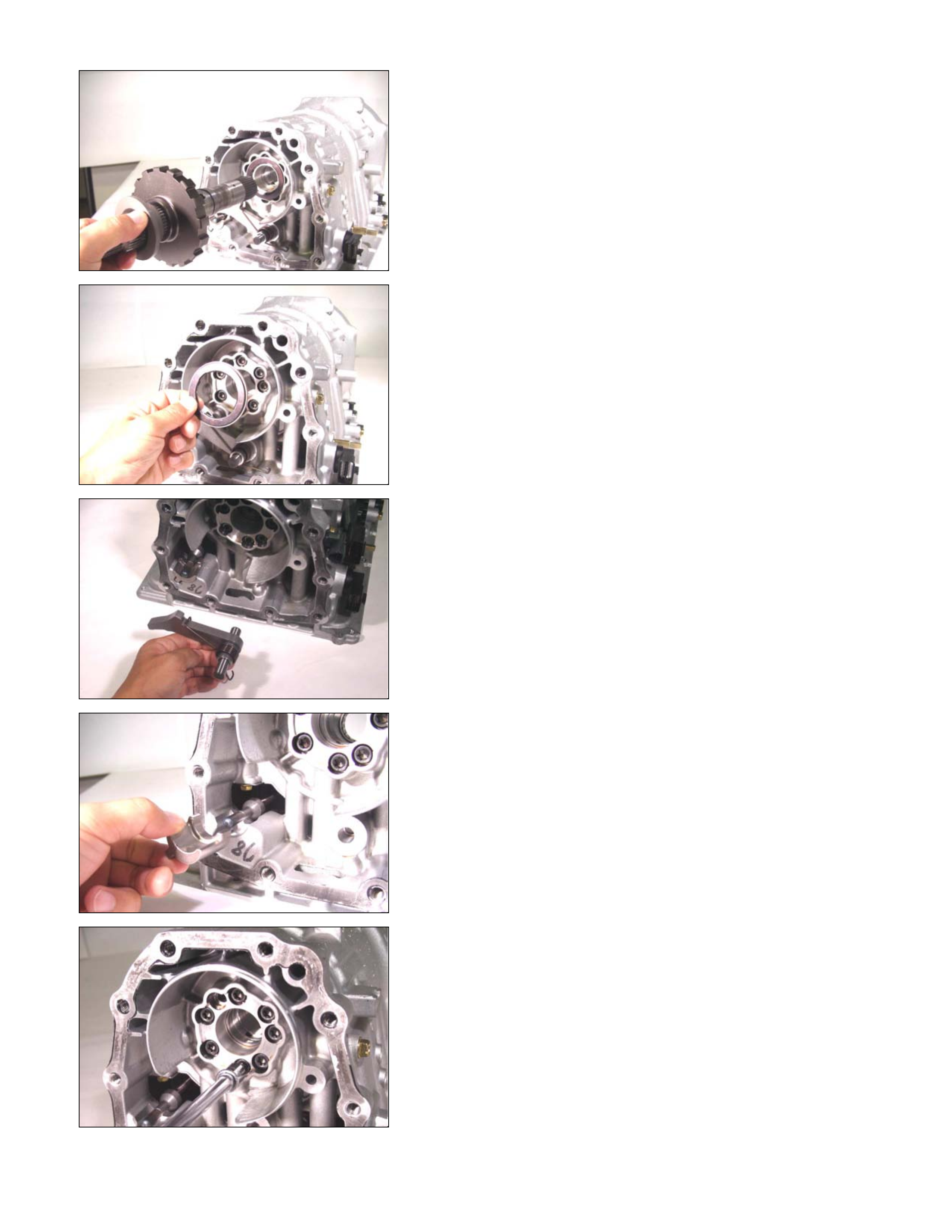

17.Output shaft

• Pull the output shaft from the transmission case.

30ASSY089

• Remove the bearing (with bearing race) from the

transmission case.

31ASSY124

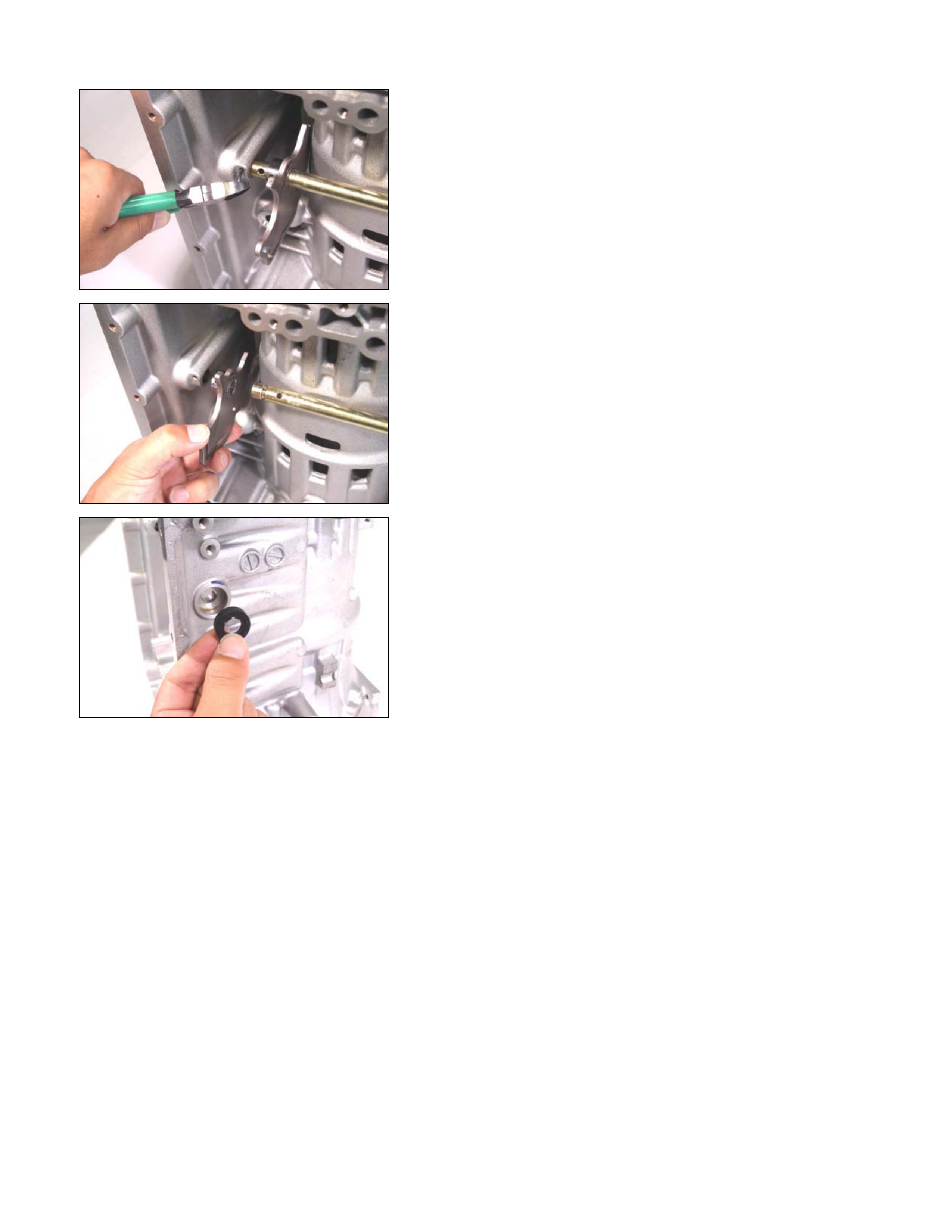

18.Parking pawl, shaft, spring, and spacer

Remove the parking pawl, shaft, spring and spacer from the

transmission case.

36ASSY075

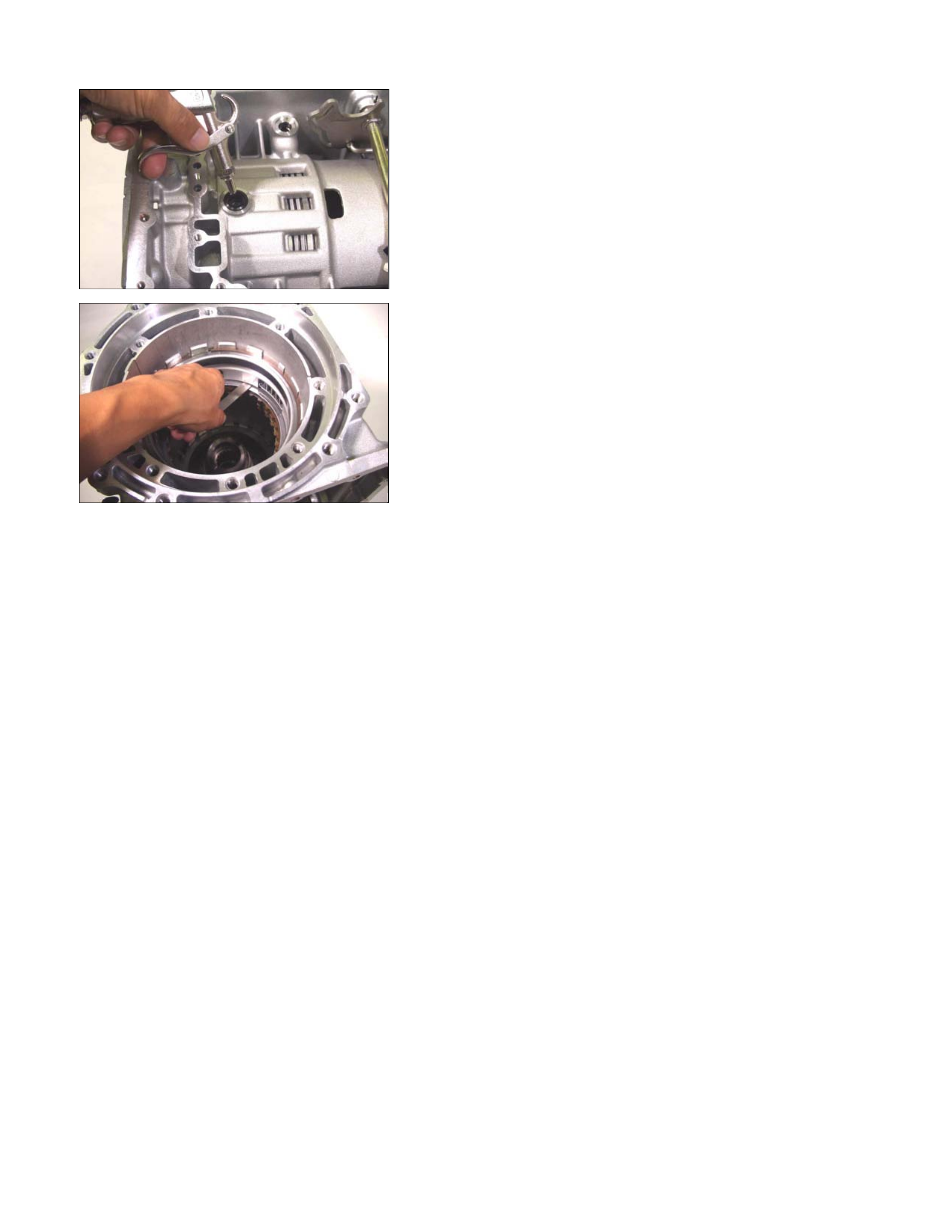

19.Actuator support

Remove the actuator support from the transmission case.

37ASSY074

20.Low one-way clutch inne r race and bearing

• Loosen the 7 bolts securing the low one-way clutch inne

r

race.

NOTE:

Loosen the bolts a little at a time as uniformly as possible

to prevent the inner race from tilting and becoming

jammed.

• Remove the 6 bolts. Support the low one-way clutch

inner race with your hand and remove the final bolt.

39ASSY006

• Remove the bearing and the low one-way clutch inne

r

race from the transmission case.

• Remove the bearing from the low one-way clutch inne

r

race.

40ASSY005

21.Low and reverse brake return spring

Remove the low and reverse brake return spring from the

transmission case.

41L&R02

22.Low and reverse brake piston

• Force compressed air (329kPa/4.0kg/cm2) through the

transmission case oil passages.

42ASSY004

• Remove the low and reverse brake piston from the

transmission case.

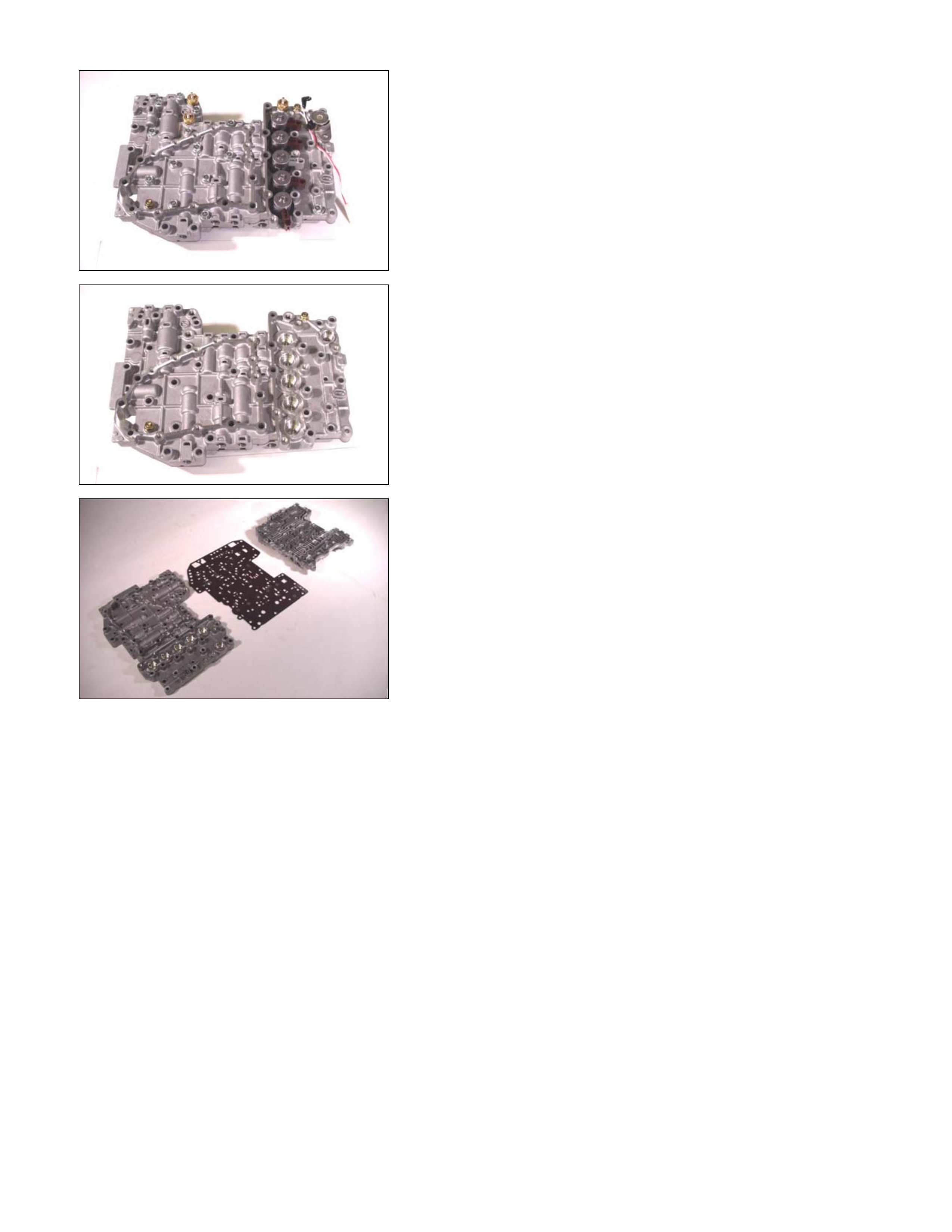

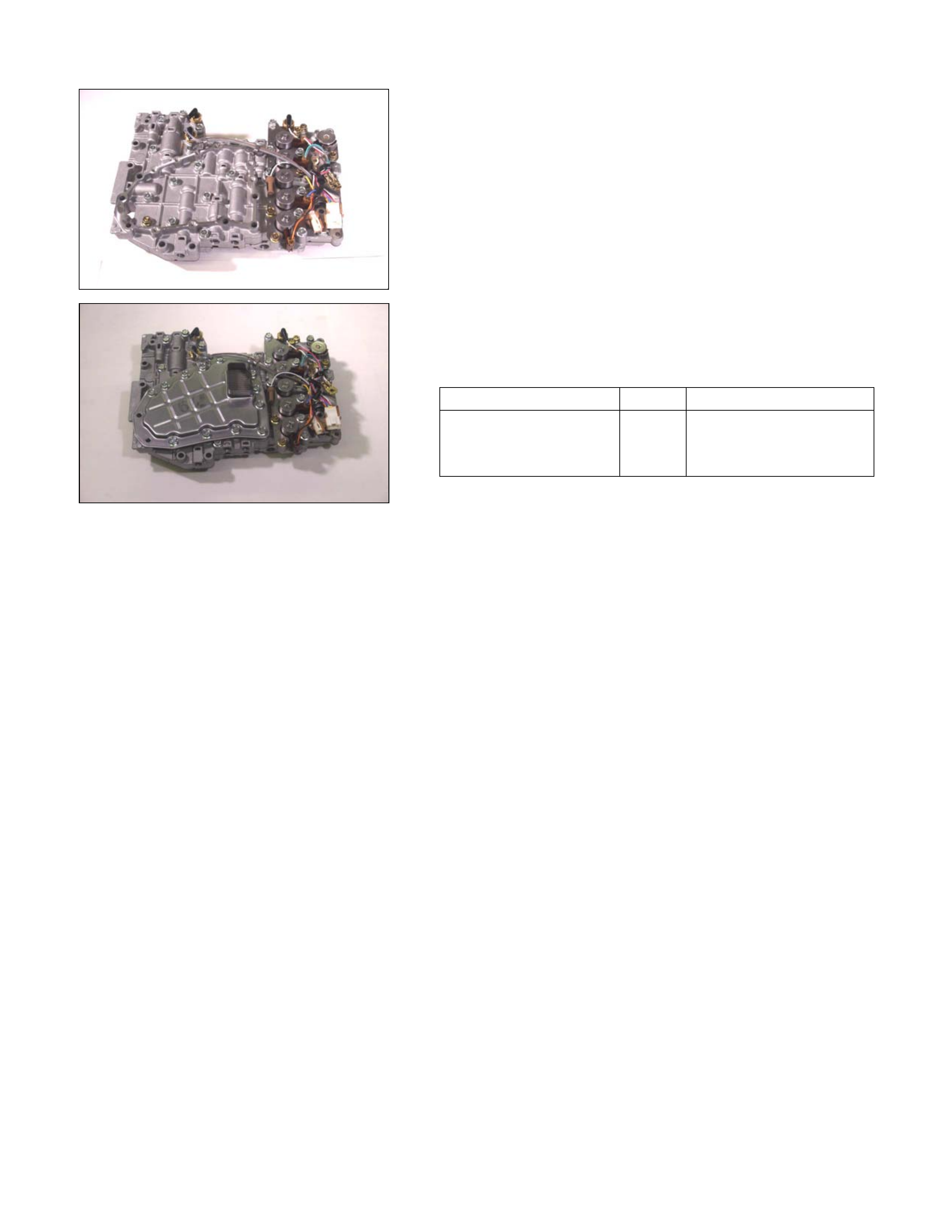

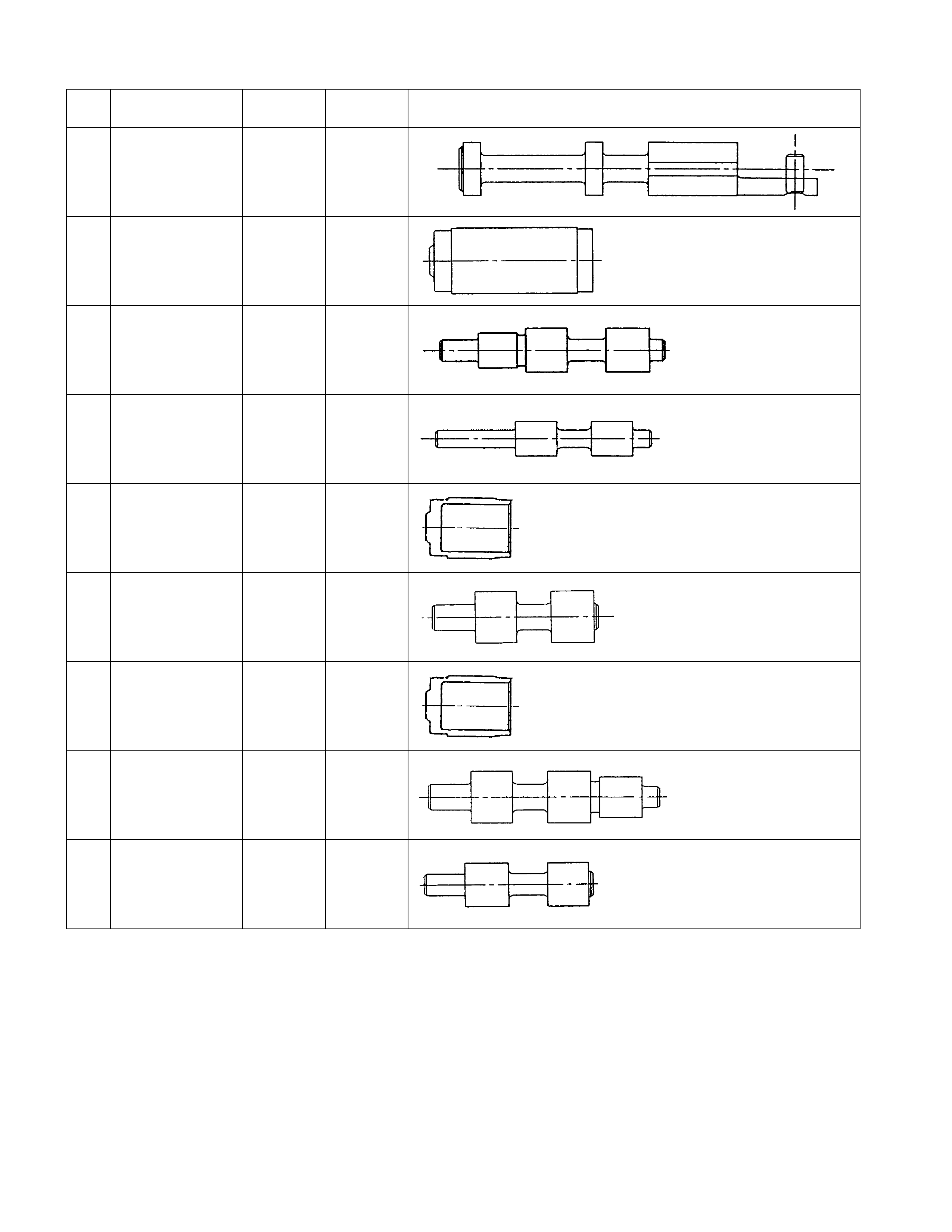

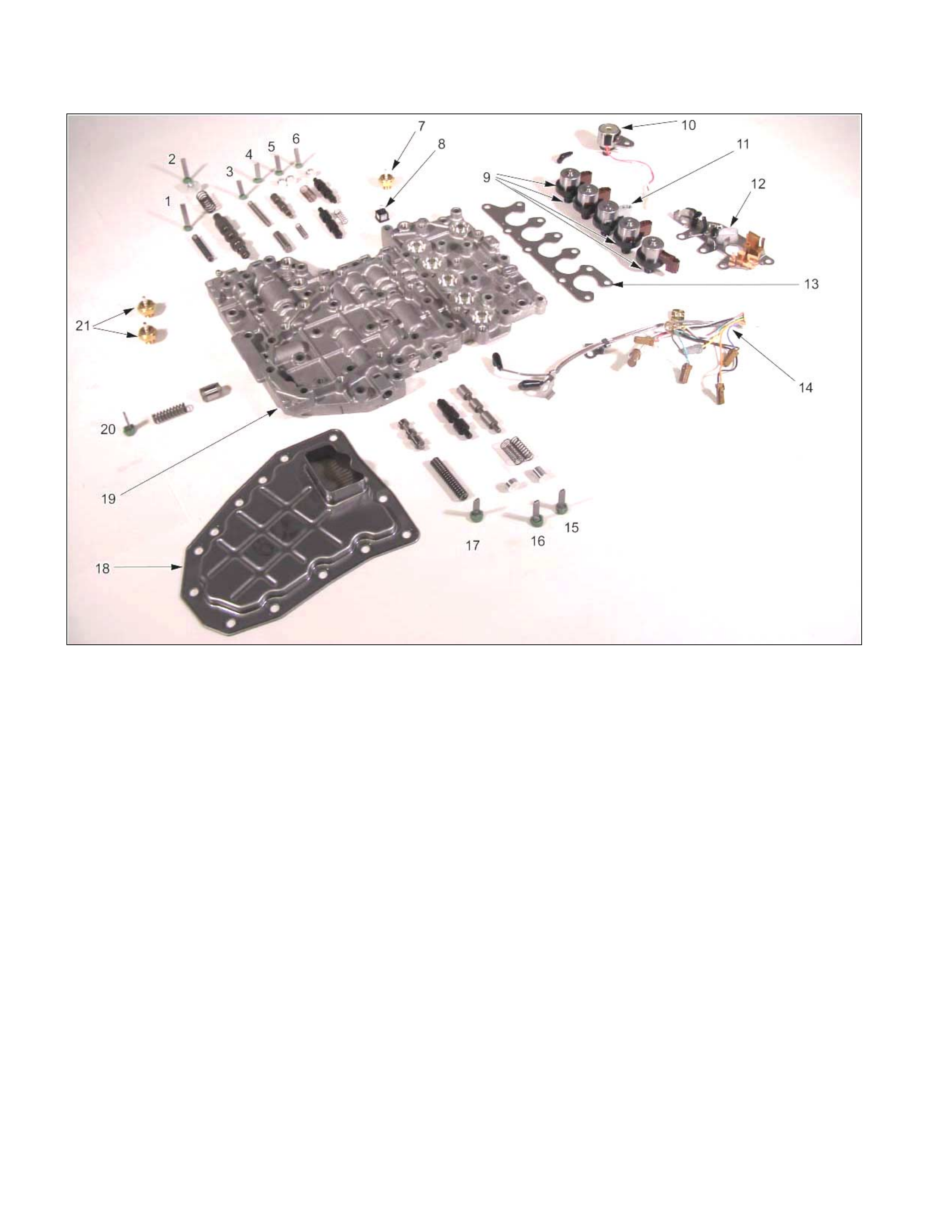

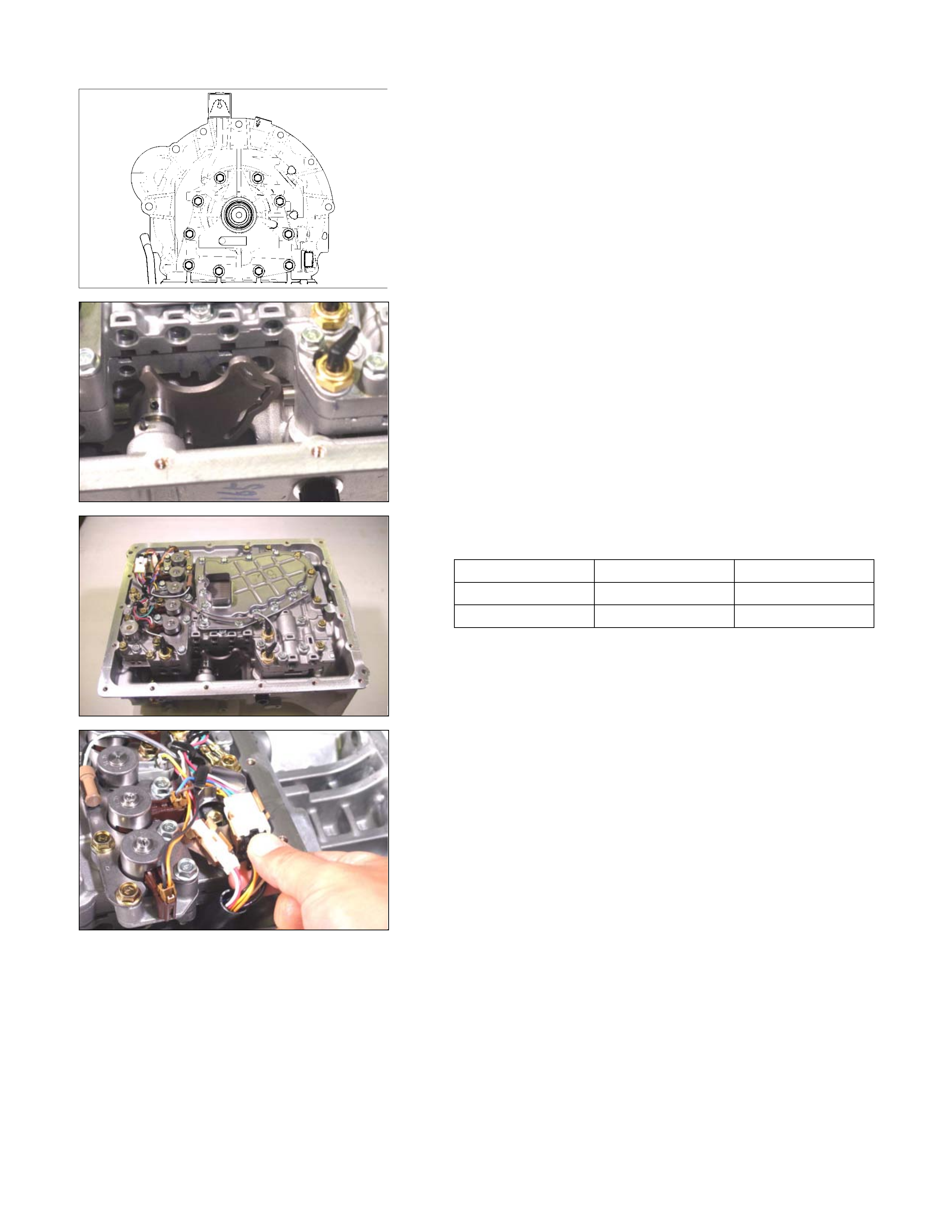

Control Valve Assembly

01CV40

Disassembly Steps

1. Oil strainer

Remove the 13 bolts and the oil strainer from the control

valve assembly.

02CV26

2. Harness assembly

Remove the harness assembly.

04CV21

3. Solenoid fixing plate

4. Harness bracket

• Remove the 11 bolts and the solenoid fixing plate

together with the harness bracket.

05CV20

06CV19

5. Solenoid

6. Oil pressure switch

Remove the 6 solenoids together and the 3 oil pressure

switches.

07CV17

7. Control valve upper body

8. Control valve lower body

9. Separation plate

• Remove the 17 bolts securing the control valve uppe

r

body, the control valve lower body, and the separation

plate.

08CV16

• Separate the upper body, the lower body, and the

separation plate.

NOTE:

Take care not to drop or lose the parts at the inside of the

control valve.

Inspection

• Inspect the separation plate for wear and other damage.

Reassembly Steps

Coat the parts with ATF before installing them.

11CV18

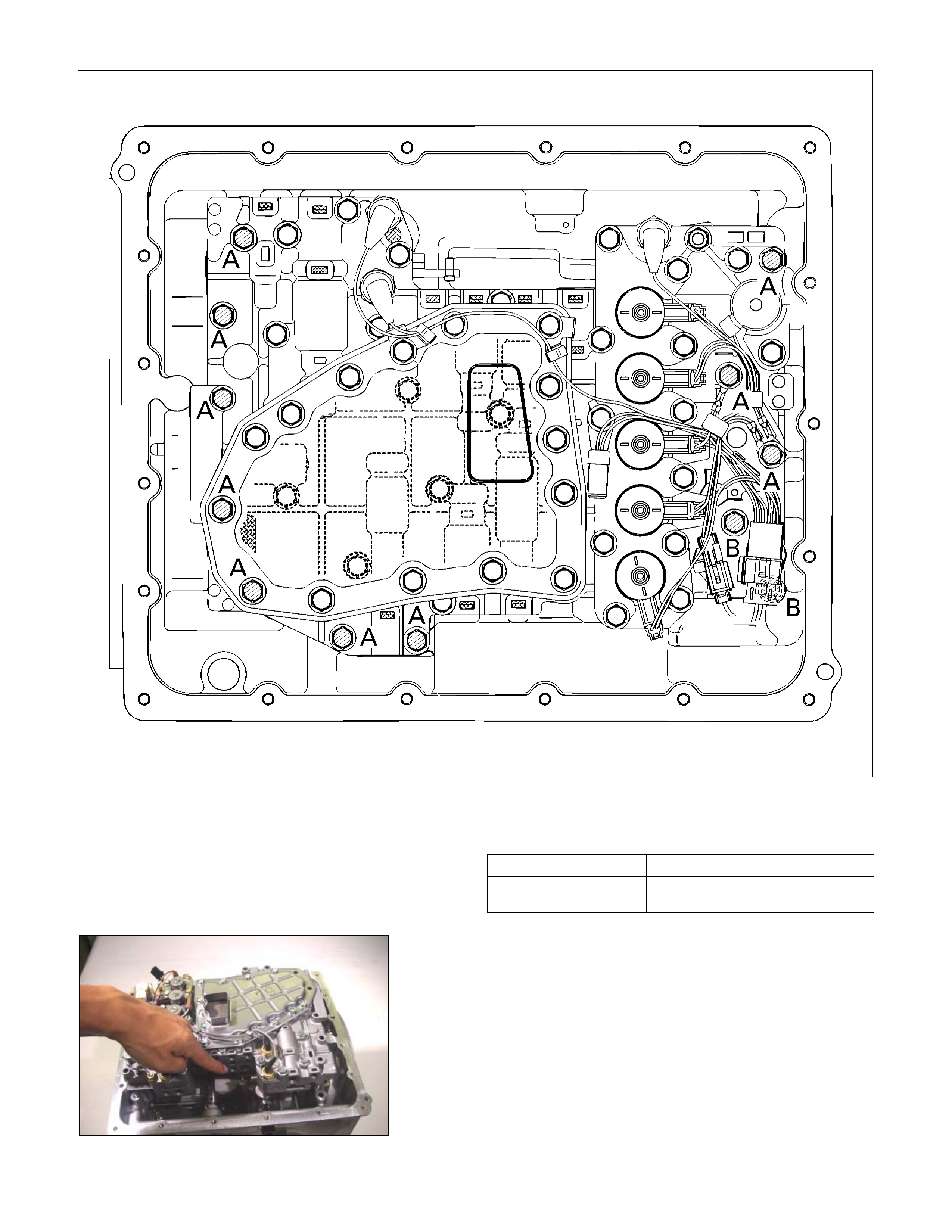

1. Control valve upper body

2. Control valve lower body

3. Separation plate

Assem bly the control valve upper body, the lower body, and

the separation plate.

Tighten the bolts to the specified torque.

244L300002

Number Length (Color)

Control valve rocket

bolts and nuts (A) 2 (Plus 2 nuts) 50 mm (1.97 in) (Gold)

Upper body and

lower body fixing

bolts

(B) 2 45 mm (1.77 in) (Silver)

(C) 13 35 mm (1.38 in) (Silver)

Line pressure

solenoid fixing bolt

(D)

1 16 mm (0.63 in) (Gold)

Torque: 8 N⋅

⋅⋅⋅m (69 Ib⋅

⋅⋅⋅in)

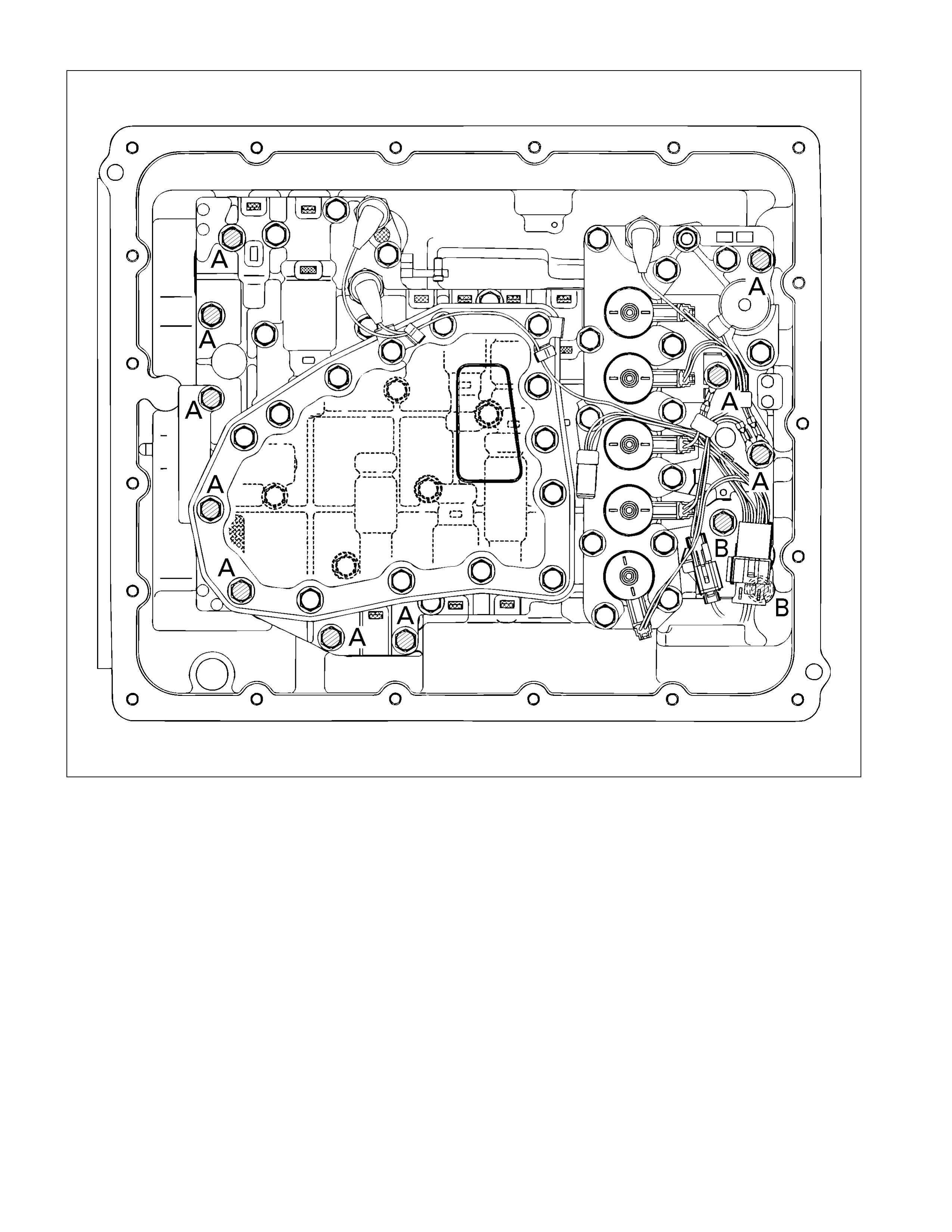

244L300003

Legend

1. High clutch oil pressure switch connector

(wire color: Gray)

2. 2-4 brake oil pressure switch connector

(wire color: Brown)

3. Low and reverse brake oil pressure

switch connector (wire color: White)

4. Low and reverse brake duty solenoid

connector (wire color: Pink and White)

5. High clutch duty solenoid connector

(wire color: Green and Gray)

6. Lock-up duty solenoid connector (wire

color: Yellow and Black)

7. 2-4 brake duty solenoid connector (wire

color: Blue and Brown)

8. Low clutch duty solenoid connector (wire

color: Orange and Black)

9. Line pressure solenoid connector (wire

color: Pink)

12CV19

4. Solenoid

5. Oil pressure switch

• Install the O-rings to each of the solenoids.

• Install the 6 solenoids together and the 3 oil pressure

switches.

NOTE:

Be sure the high clutch oil pressure switch is marked.

• Tighten the bolts to the specified torque.

Torque:

Oil pressure switch bolts – 4.4 N⋅

⋅⋅⋅m (39 Ib⋅

⋅⋅⋅in)

Line pressure solenoid bolt (Single gold-colored bolt 16

mm) – 8 N⋅

⋅⋅⋅m (69 Ib⋅

⋅⋅⋅in)

6. Solenoid fixing plate

7. Harness bracket

Install the solenoid fixing plate together with the harness

bracket.

Tighten the bolts to the specified torque.

Number Length (Color)

Solenoid fixing plate bolt

(A) 4 16 mm (0.63 in) (Gold)

(B) 7 45 mm (1.77 in) (Silver)

13CV20

Torque: 8 N⋅

⋅⋅⋅m (69 Ib⋅

⋅⋅⋅in)

14CV21

15CV26

8. Harness assembly

Install the harness assembly.

9. Oil strainer

Install the oil strainer.

Tighten the bolts to the specified torque.

Number Length (Color)

Oil strainer bolt

(C) 9 13 mm (0.51 in) (Silver)

(D) 4 45 mm (1.77 in) (Silver)

16CV40

Torque: 8 N⋅

⋅⋅⋅m (69 Ib⋅

⋅⋅⋅in)

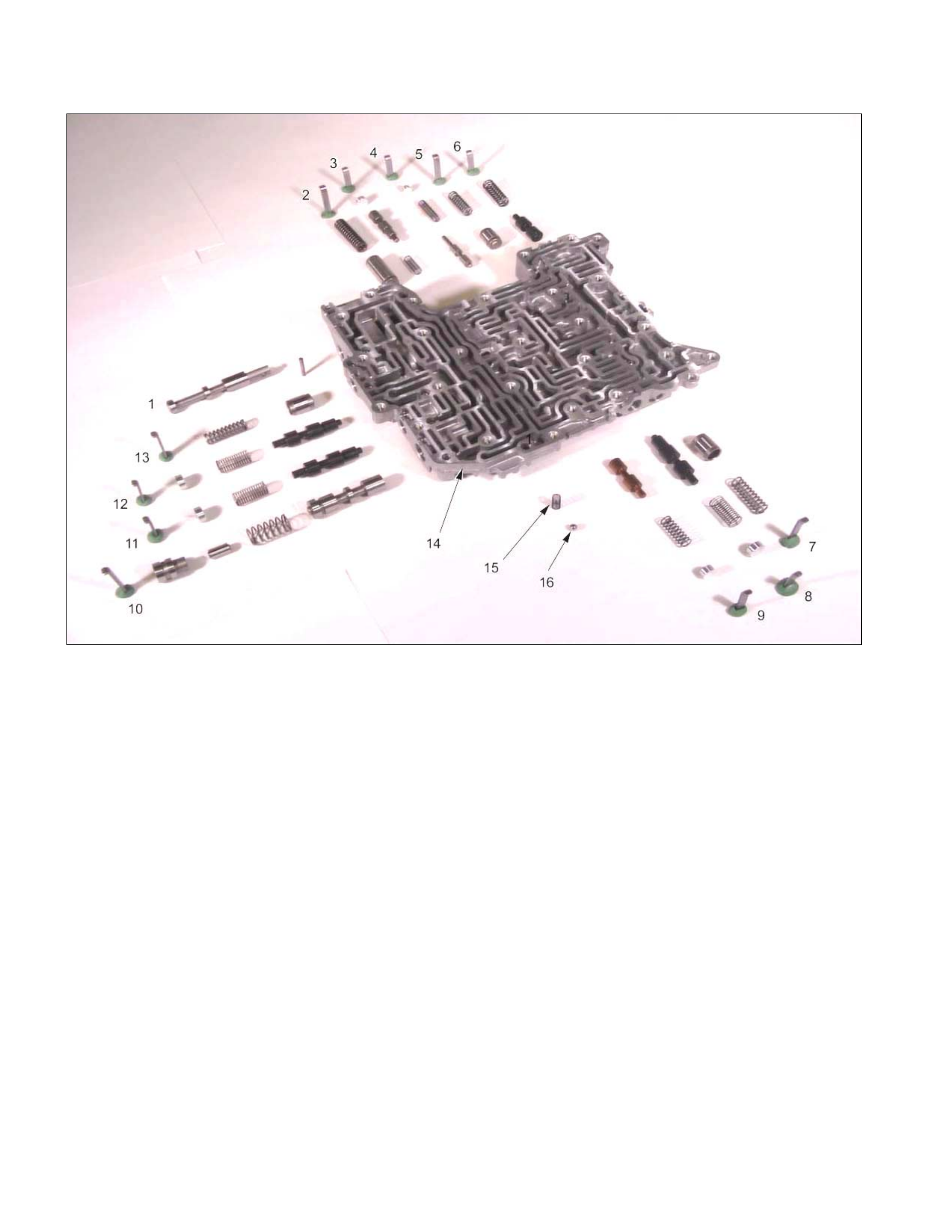

Control Valve Upper Body

09CV02

Legend

1. Manual valve, and pin

2. Retainer plate, spring, and 2-4 brake

accumulator

3. Retainer plate, plug, and low and

reverse brake fail valve B

4. Retainer plate, plug, spring, and reverse

stall valve

5. Retainer plate, spring, and low and

reverse brake solenoid accumulator

6. Retainer plate, spring, and pilot valve

7. Retainer plate, spring, and low clutch

solenoid accumulator

8. Retainer plate, plug, spring, and low

clutch amp valve A

9. Retainer plate, plug, spring, and 2-4

brake fail valve B

10. Retainer plate, sleeve, plug, spring, and

lock-up control valve

11. Retainer plate, plug, spring, and 2-4

brake amp valve

12. Retainer plate, plug, spring, and high

clutch amp valve

13. Retainer plate, spring, and high clutch

solenoid accumulator

14. Control valve upper body

15. Spring

16. Steel ball

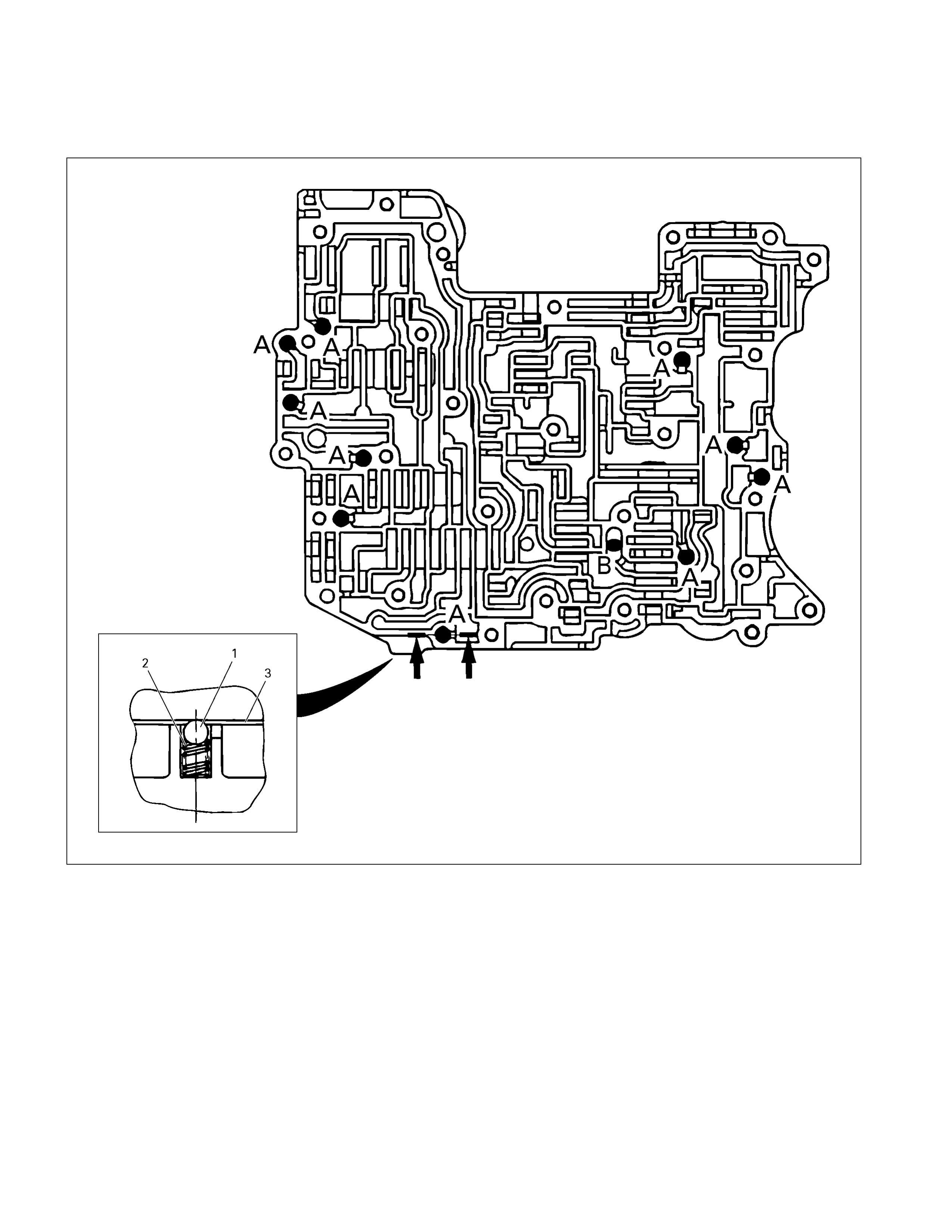

Disassembly Steps

• Remove the 11 steel balls and spring from the control

valve upper body.

244L300005

Legend

1. Steel ball: A – 10 (Silver)

B – 1 (Black)

2. Spring

3. Separation plate

• Remove the control valves from the control valve uppe

r

body.

NOTE:

Place the control valve where it will not get mixed up with

the other parts.

Inspection

Valve

Inspect each of the valves for denting and other damage.

Spring

Inspect each of the springs for wear and fatigue.

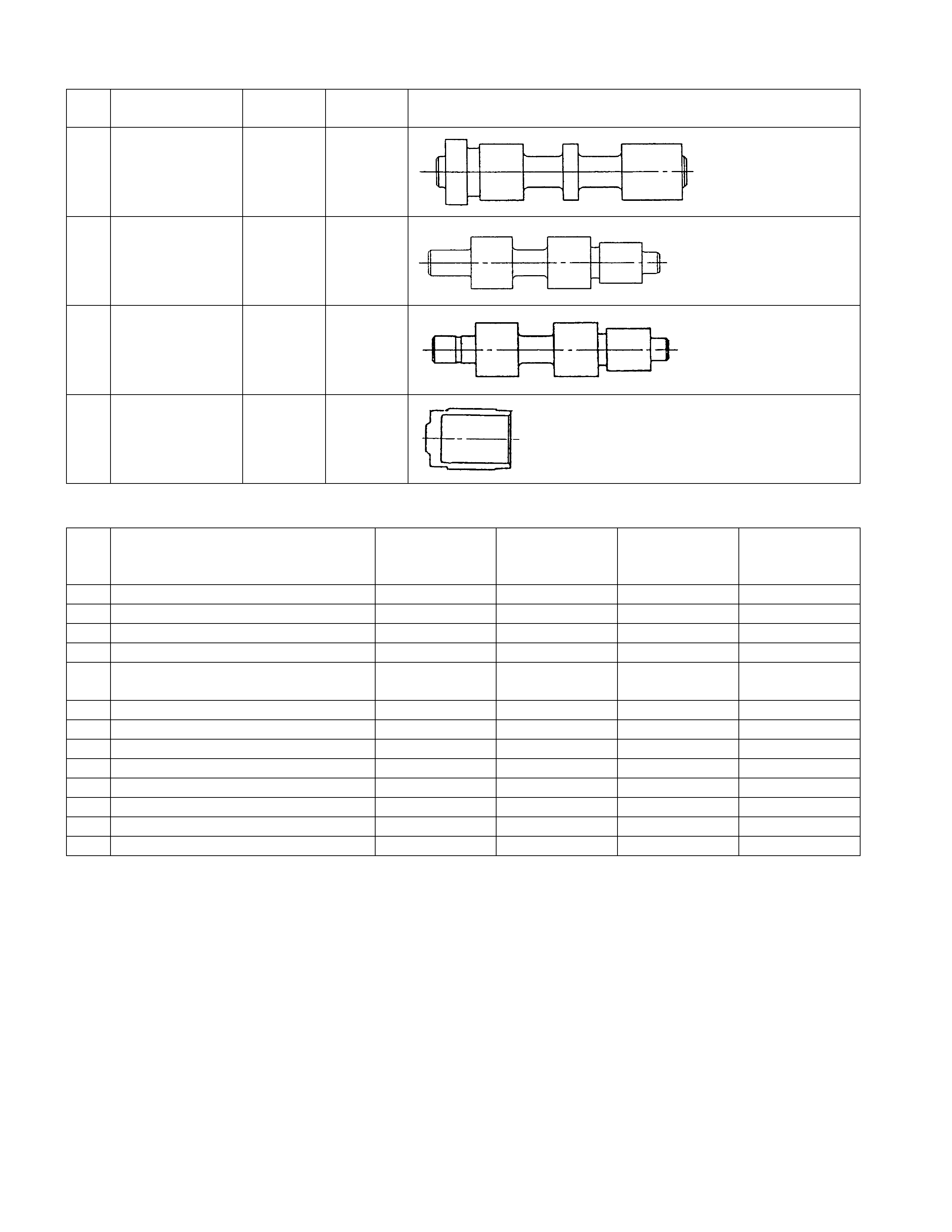

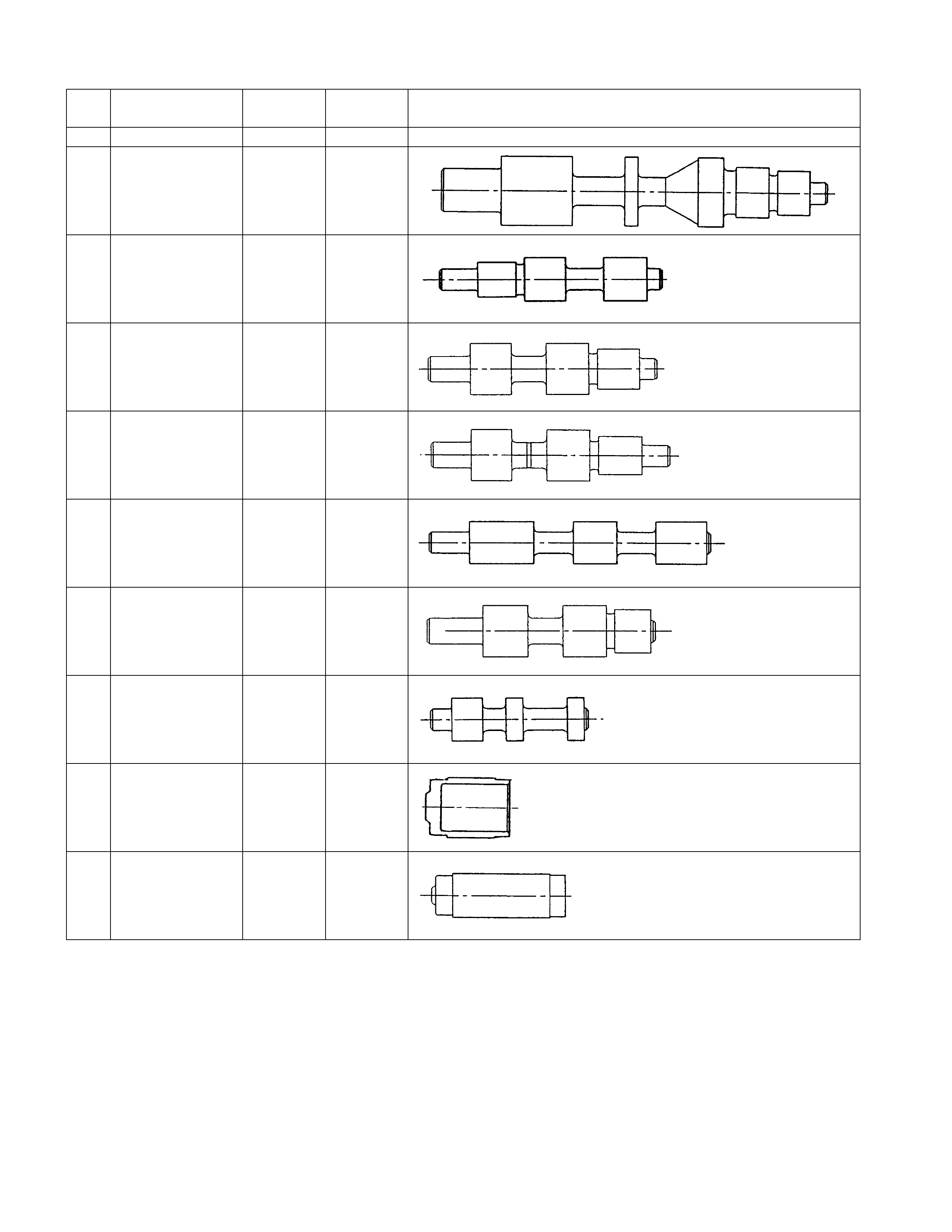

Valve Specifications

244L300006

No. Valve

nomenclature Diameter

(mm / in) Length

(mm / in) Configuration

1 Manual 12.0 /

0.472 82.0 /

3.228

2 2 – 4 brake

accumulator 15.0 /

0.591 37.5 /

1.476

3 Low and reverse

brake fail (B) 10.0 /

0.394 52.0 /

2.047

4 Reverse stall 8.0 /

0.315 50.0 /

1.969

5 Low and reverse

brake solenoid

accumulator

14.0 /

0.551 19.5 /

0.768

6 Pilot 12.0 /

0.472 38.5 /

1.516

7 Low clutch

solenoid

accumulator

14.0 /

0.551 19.5 /

0.768

8 Low clutch amp

(A) 12.0 /

0.472 53.5 /

2.106

9 2 – 4 brake fail

(B) 10.0 /

0.394 39.0 /

1.535

No. Valve

nomenclature Diameter

(mm / in) Length

(mm / in) Configuration

10 Lock-up control 12.9 /

0.508 57.5 /

2.264

11 2 – 4 brake amp 12.0 /

0.472 53.5 /

2.106

12 High clutch amp 12.0 /

0.472 53.5 /

2.106

13 High clutch

solenoid

accumulator

14.0 /

0.551 19.5 /

0.768

Spring Specifications

No. Valve nomenclature Free length

(mm / in)

Outside

diameter (mm

/ in)

Linear

diameter (mm

/ in)

Number of

coils

1 Manual ---- ---- ---- ----

2 2 – 4 brake accumulator 43.9 / 1.728 11.0 / 0.433 2.0 / 0.079 13.1

3 Low and reverse brake fail (B) 22.0 / 0.866 7.0 / 0.276 0.6 / 0.024 10.0

4 Reverse stall 31.5 / 1.240 7.0 / 0.276 1.0 / 0.039 12.8

5 Low and reverse solenoid brake

accumulator 31.4 / 1.236 9.8 / 0.386 1.3 / 0.051 9.3

6 Pilot 32.0 / 1.260 11.0 / 0.433 1.3 / 0.051 9.2

7 Low clutch solenoid accumulator 31.4 / 1.236 9.8 / 0.386 1.3 / 0.051 9.3

8 Low clutch amp (A) 23.0 / 0.906 11.0 / 0.433 0.5 / 0.020 13.2

9 2 – 4 brake fail (B) 24.8 / 0.976 8.5 / 0.335 0.9 / 0.035 7.8

10 Lock-up control 27.0 / 1.063 14.0 / 0.551 1.1 / 0.043 5.7

11 2 – 4 brake amp 23.0 / 0.906 11.0 / 0.433 0.5 / 0.020 13.2

12 High clutch amp 23.0 / 0.906 11.0 / 0.433 0.5 / 0.020 13.2

13 High clutch solenoid accumulator 31.4 / 1.236 9.8 / 0.386 1.3 / 0.051 9.3

Reassembly Steps

• Coat the parts with ATF before installing them.

• Install the control valve to the upper body.

• Install the 11 steel balls and spring to the upper body.

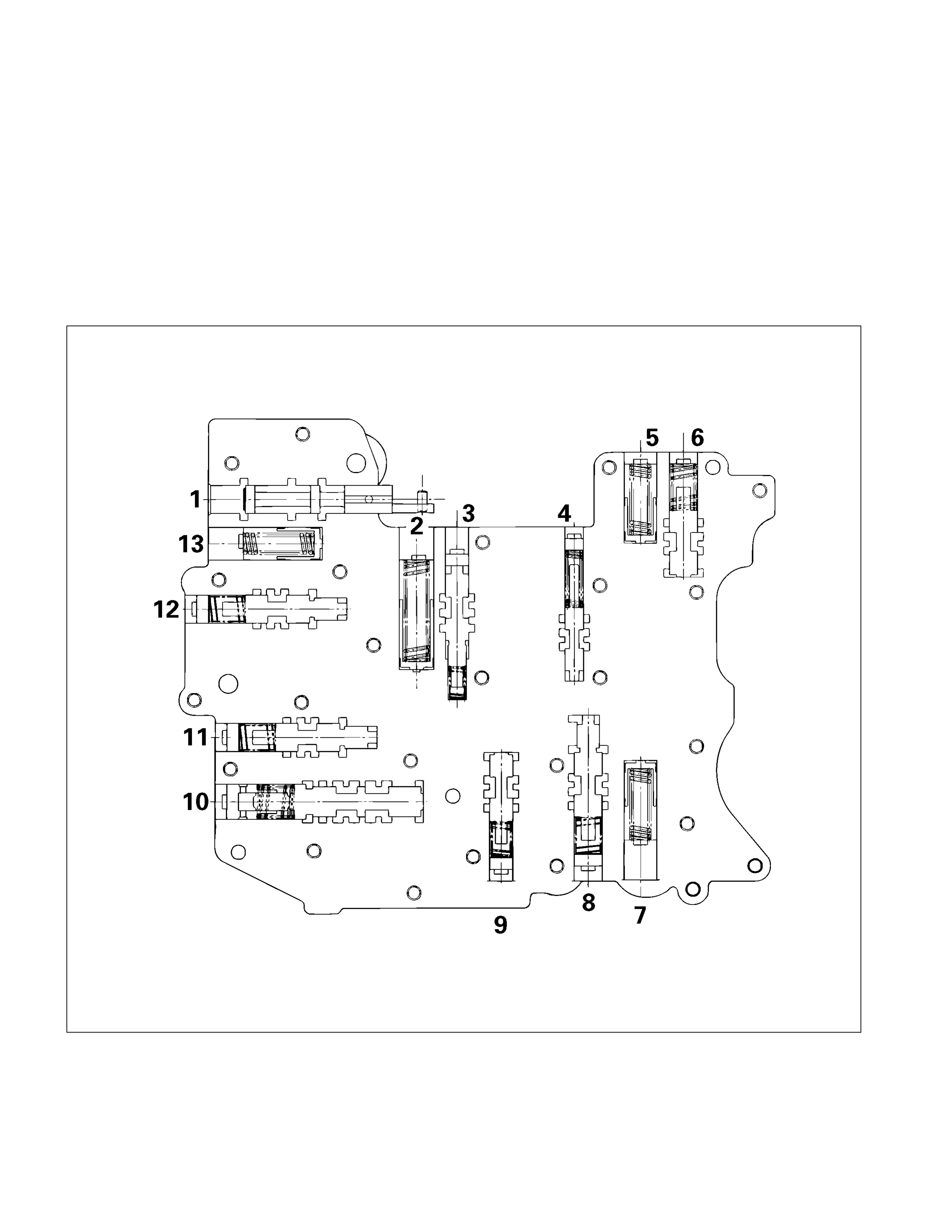

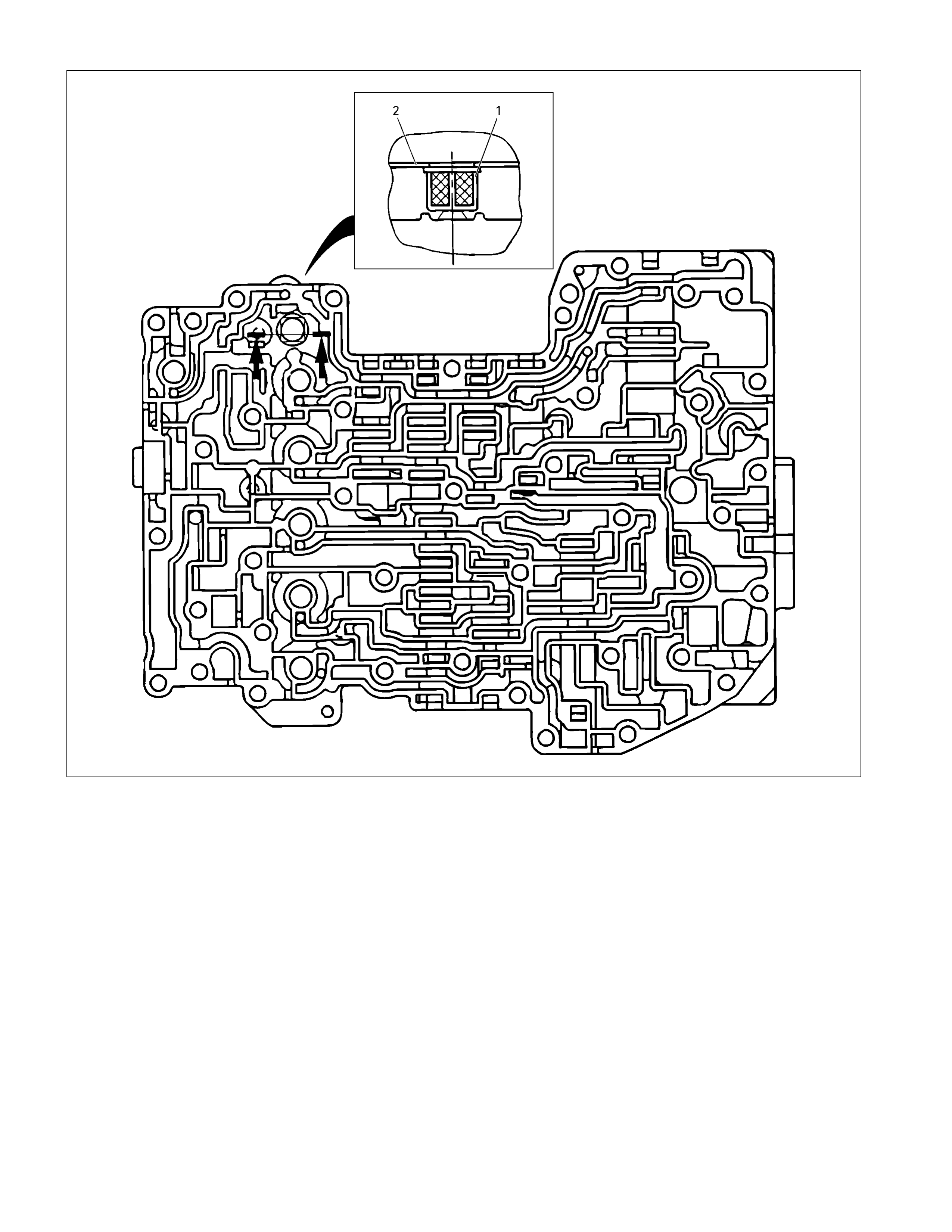

Control Valve Lower Body

10CV11

Legend

1. Retainer plate, spring, and steel ball

2. Retainer plate, plug, spring, and

pressure regulator valve

3. Retainer plate, spring, and high clutch

accumulator

4. Retainer plate, plug, low and reverse

brake fail valve A, and spring

5. Retainer plate, plug, spring, and fail

valve

6. Retainer plate, plug, low and reverse

brake amp valve, and spring

7. Oil pressure swi tch

8. Oil filter

9. Solenoid

10. Line pressure solenoid

11. Lock-up solenoid

12. Harness bracket

13. Solenoid fixing plate

14. Harness assembly

15. Retainer plate, plug, spring, and 2-4

brake fail valve A

16. Retainer plate, plug, spring, and low

clutch amp valve B

17. Retainer plate, spring, and torque

converter relief valve

18. Oil strainer

19. Control valve lower body

20. Retainer plate, spring, and 2-4 brake

solenoid accumulator

21. Oil pressure switch

Disassembly Steps

• Remove the oil filter from the control valve lower body.

244L300009

Legend

1. Oil filter

2. Separation plate

• Remove the control valve from the control valve lowe

r

body.

NOTE:

Place the control valve where it will not get mixed up with

the other parts.

Inspection

Valve

Inspect each of the valves for denting and other damage.

Spring

Inspect each of the springs for wear and fatigue.

Valve Specifications

244L300008

No. Valve

nomenclature Diameter

(mm / in) Length

(mm / in) Configuration

14 Pressure relief ---- ----

15 Pressure

regulator 16.0 /

0.630 89.5 /

3.524

16 Low and reverse

brake fail (A) 10.0 /

0.394 52.0 /

2.047

17 Fail 12.0 /

0.472 53.5 /

2.106

18 Low and reverse

brake amp 12.0 /

0.472 55.5 /

2.185

19 2 – 4 brake fail

(A) 10.0 /

0.394 65.5 /

2.579

20 Low clutch amp

(B) 12.0 /

0.472 53.0 /

2.087

21 Torque

converter relief 10.0 /

0.394 37.4 /

1.472

22 2 – 4 brake

solenoid

accumulator

14.0 /

0.551 19.5 /

0.768

23 High clutch

accumulator 10.0 /

0.394 31.0 /

1.220

Spring Specifications

No. Valve nomenclature Free length

(mm / in)

Outside

diameter (mm

/ in)

Linear

diameter (mm

/ in)

Number of

coils

14 Pressure relief 49.0 / 1.929 7.6 / 0.299 1.1 / 0.043 17.3

15 Pressure regulator 30.5 / 1.201 14.0 / 0.551 1.4 / 0.055 5.7

16 Low and reverse brake fail (A) 22.0 / 0.866 7.0 / 0.276 0.6 / 0.024 10.0

17 Fail 23.0 / 0.906 11.0 / 0.433 0.5 / 0.020 13.2

18 Low and reverse brake amp 19.5 / 0.768 7.9 / 0.311 0.5 / 0.020 6.9

19 2 – 4 brake fail (A) 24.8 / 0.976 8.5 / 0.335 0.9 / 0.035 7.8

20 Low clutch amp (B) 26.0 / 1.024 11.0 / 0.433 0.5 / 0.020 6.9

21 Torque converter relief More than 47.2

/ 1.858 9.2 / 0.362 1.6 / 0.063 20.2

22 2 – 4 brake solenoid accumulator 31.4 / 1.236 9.8 / 0.386 1.3 / 0.051 9.3

23 High clutch accumulator 51.0 / 2.008 6.5 / 0.256 0.8 / 0.031 23.5

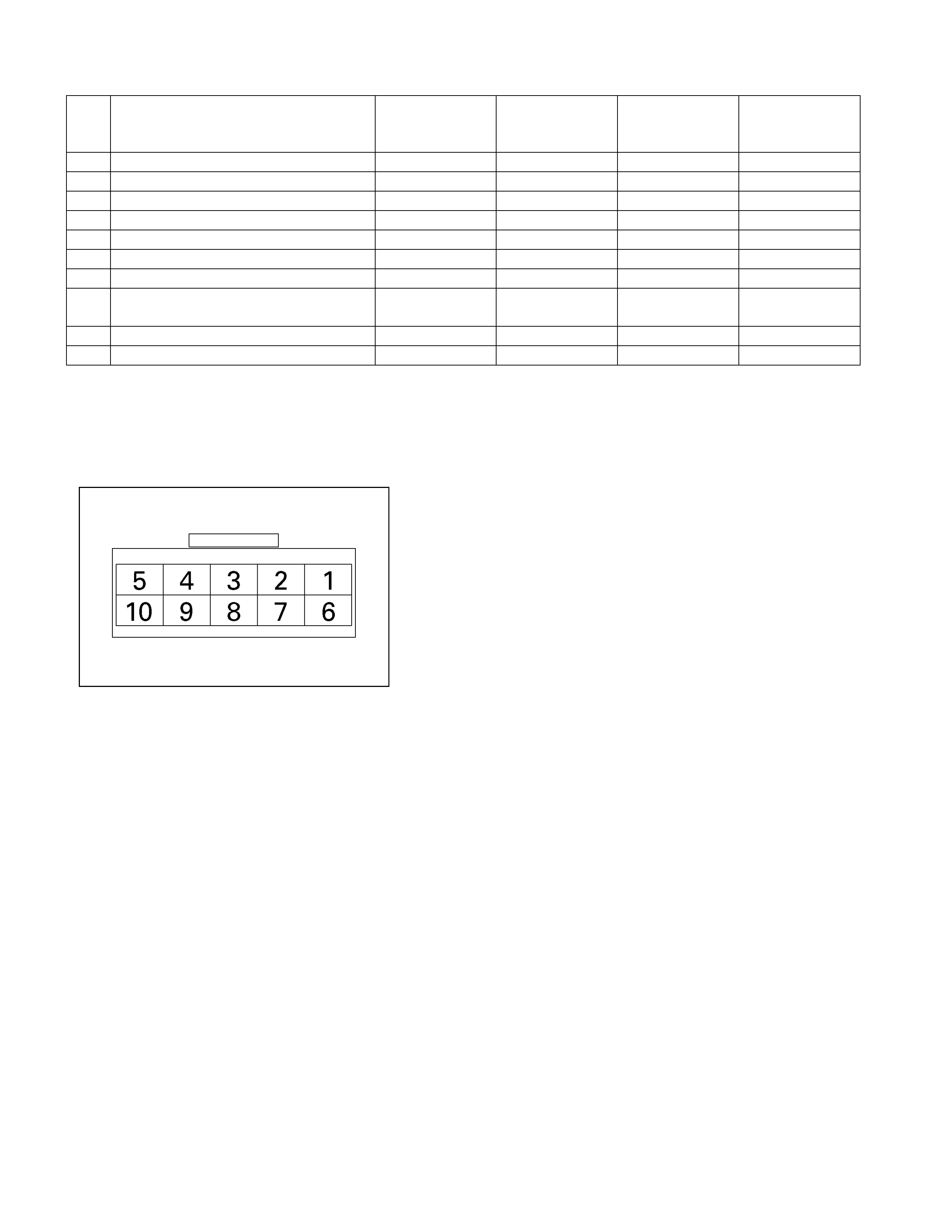

Oil Pressure Switch

Apply compressed air (392 kPa/4.0 kg/cm2) to the oil pressure

switch to check the oil pressure switch continuity between the

connector and screw.

244L300011

Oil Temperature Sensor (Harness Assembly)

Check the oil temperature sensor resistance between harness

terminals 7 and 6 (ground).

Oil temperature sensor resistance: 2,4002,600 ohms

(20)

Solenoid

Measure the resistance of each solenoid.

Resistance:

Brown connector – 3.0∼

∼∼

∼3.4 ohms (20°

°°

°C)

Gray connector – 12.0∼

∼∼

∼13.2 ohms (20°

°°

°C)

White connector – 12.2∼

∼∼

∼13.4 ohms (20°

°°

°C)

Reassembly Steps

• Coat the parts with ATF before installing them.

• Install the control valve to the control valve lower body.

• Install the oil filter to the control valve lower body.

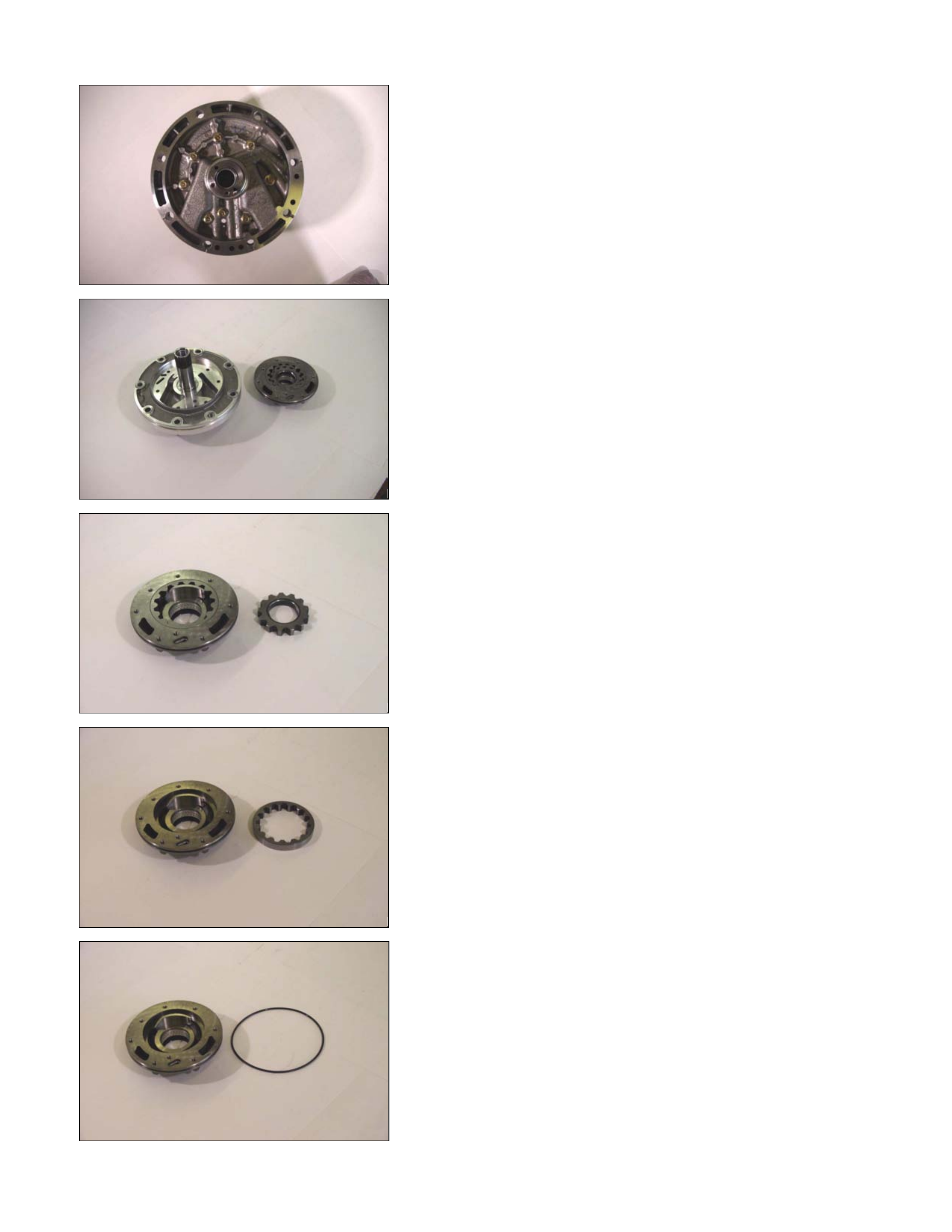

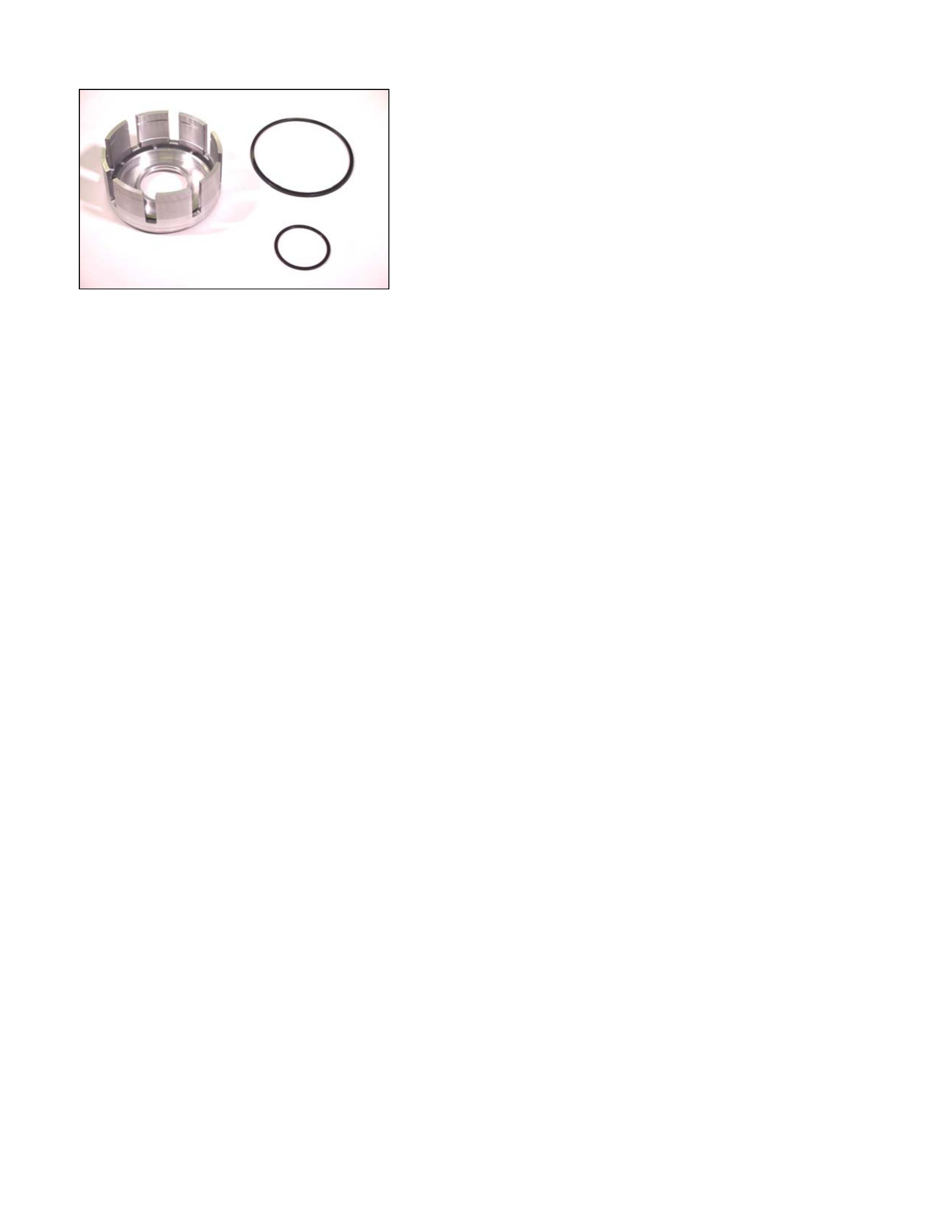

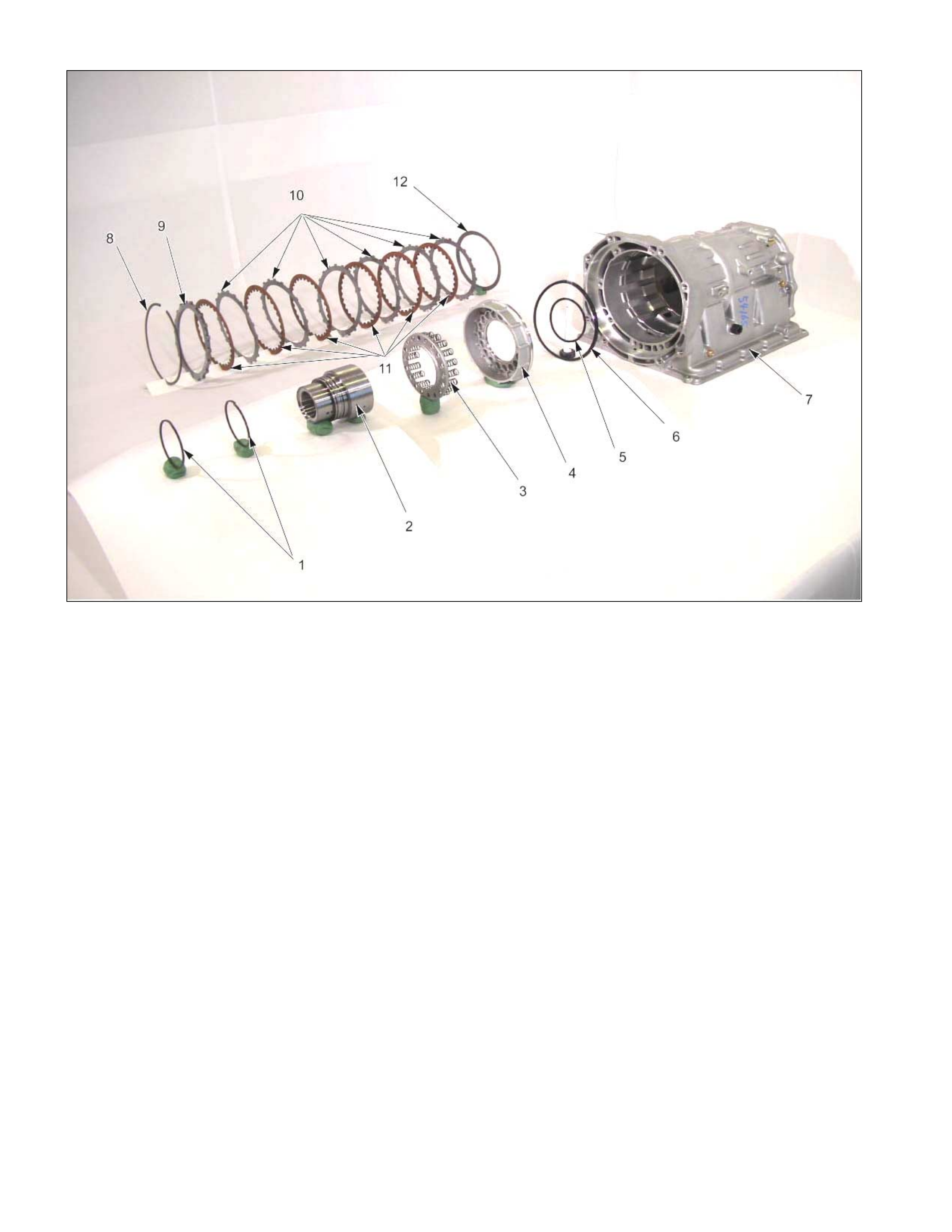

Oil Pump Assembly

01PUMP32

Legend

1. Oil seal

2. O-ring (small)

3. Oil pump housing

4. Inner rotor

5. Outer roto r

6. Oil pump cover

7. O-ring (large)

8. Seal ring (large)

9. Seal ring (small)

10. Bearing race

02PUMP07

Disassembly Steps

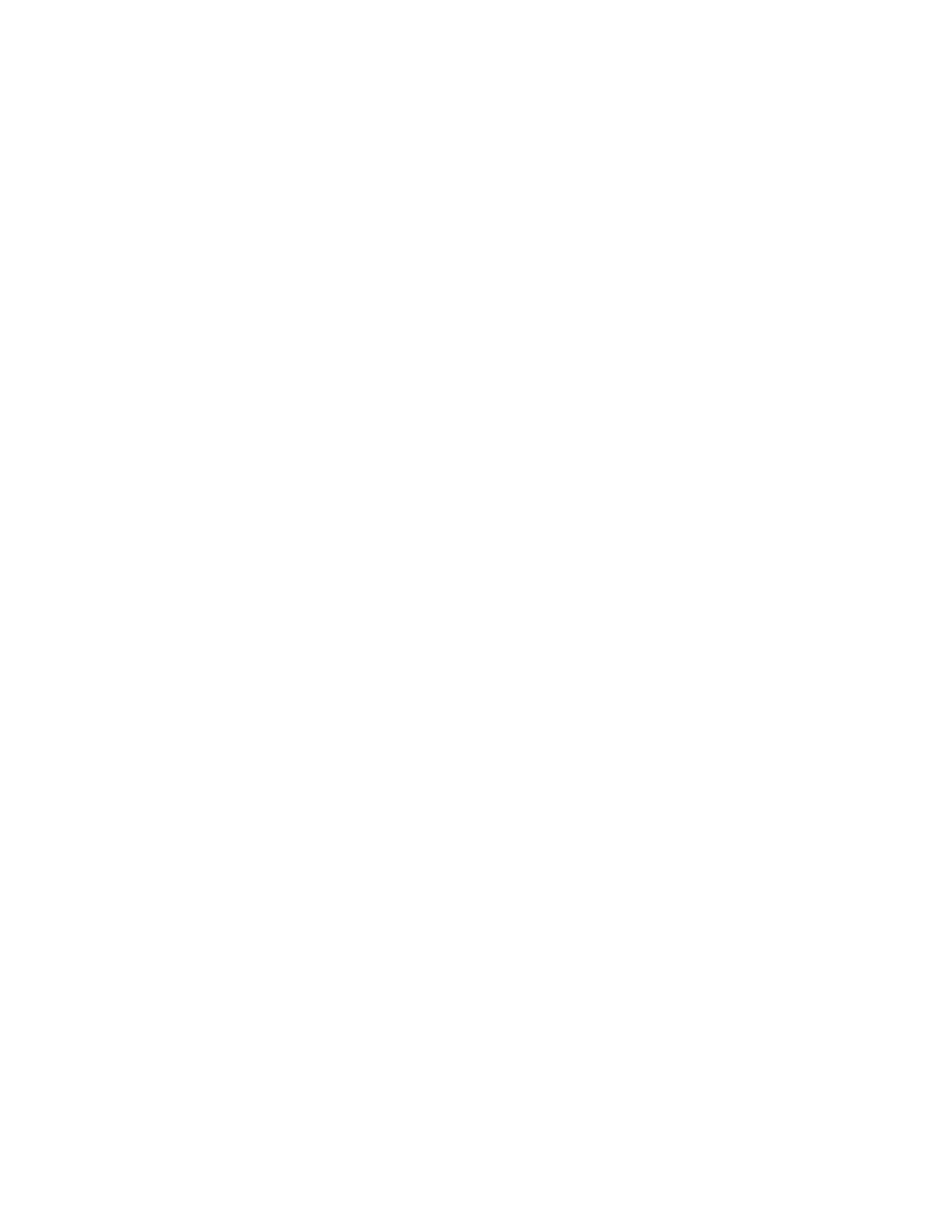

1. Oil pump cover

2. Oil pump housing

• Loosen the 8 bolts evenly a little at a time.

04PUMP10

• Separate the oil pump cover from the oil pump housing

by tapping on each of the bolts with a plastic hammer.

06PUMP13

3. Inner rotor

Remove the inner rotor from the oil pump housing.

07PUMP14

4. Outer rotor

Remove the outer rotor form the oil pump housing.

15PUMP18

5. O-ring (small)

Remove the O-ring (small) from the oil pump housing.

10PUMP19

6. Oil seal

Remove the oil seal from the oil pump housing.

08PUMP09

7. O-ring (large)

Remove the O-ring (large) from the oil pump cover.

09PUMP05

8. Seal ring

Remove the 4 seal rings from the oil pump cover.

11PUMP43

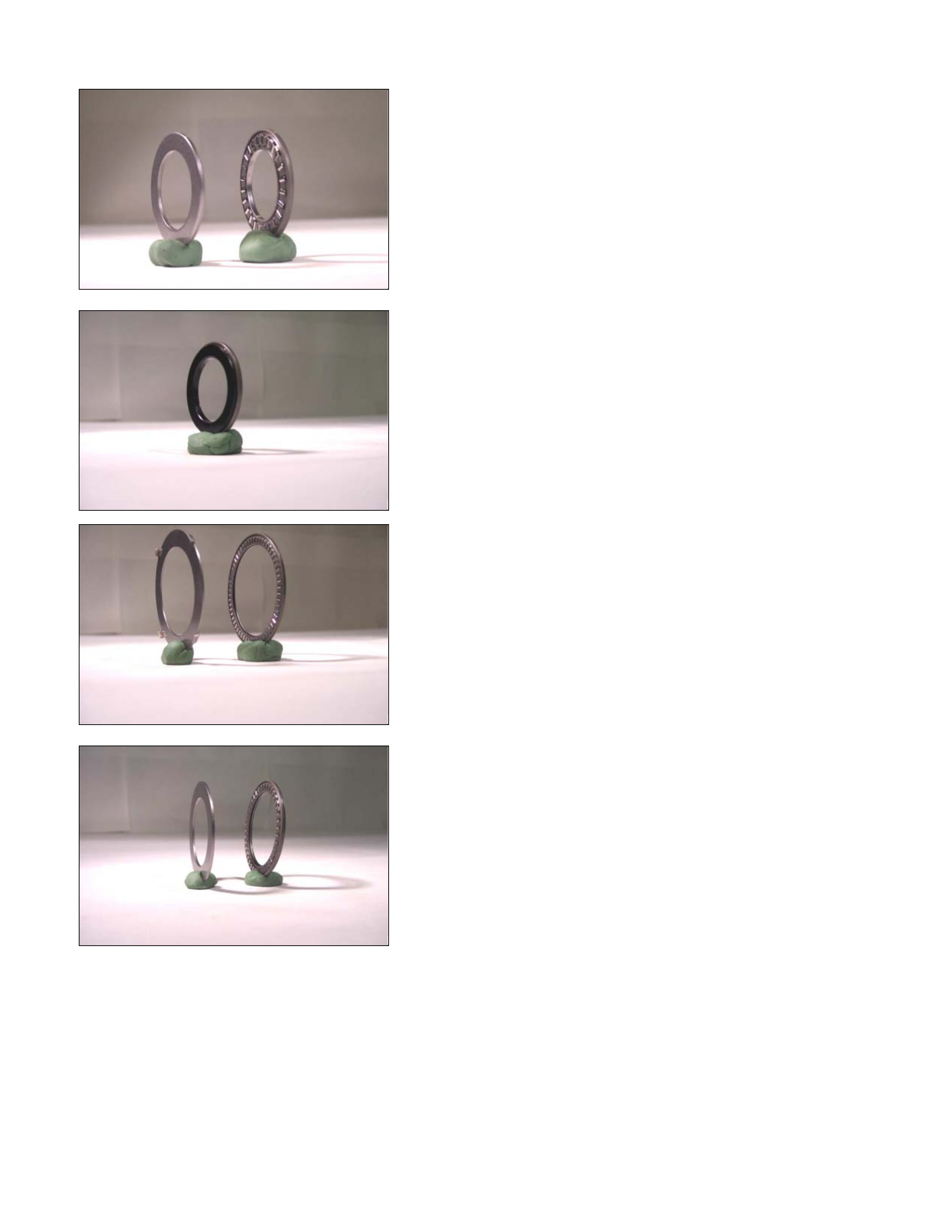

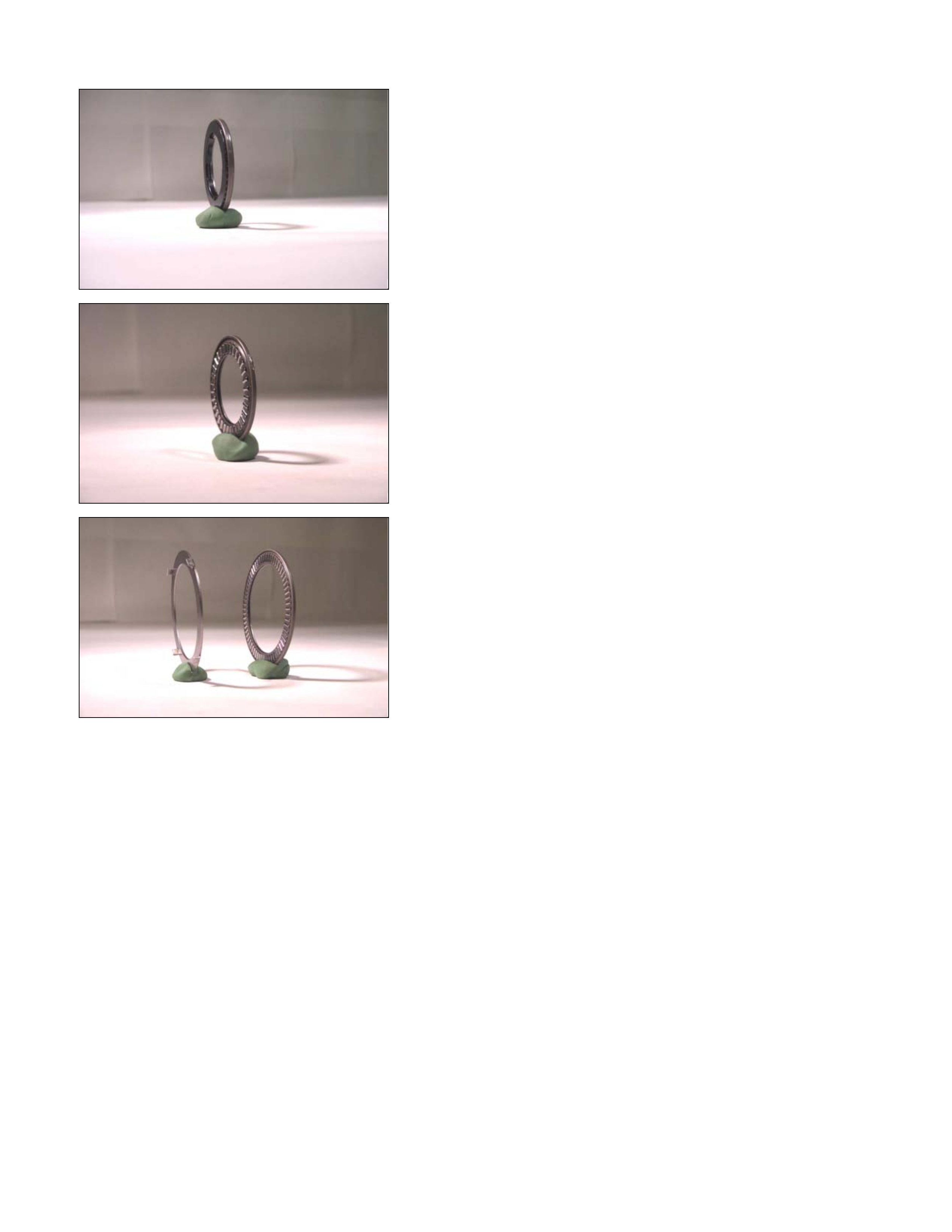

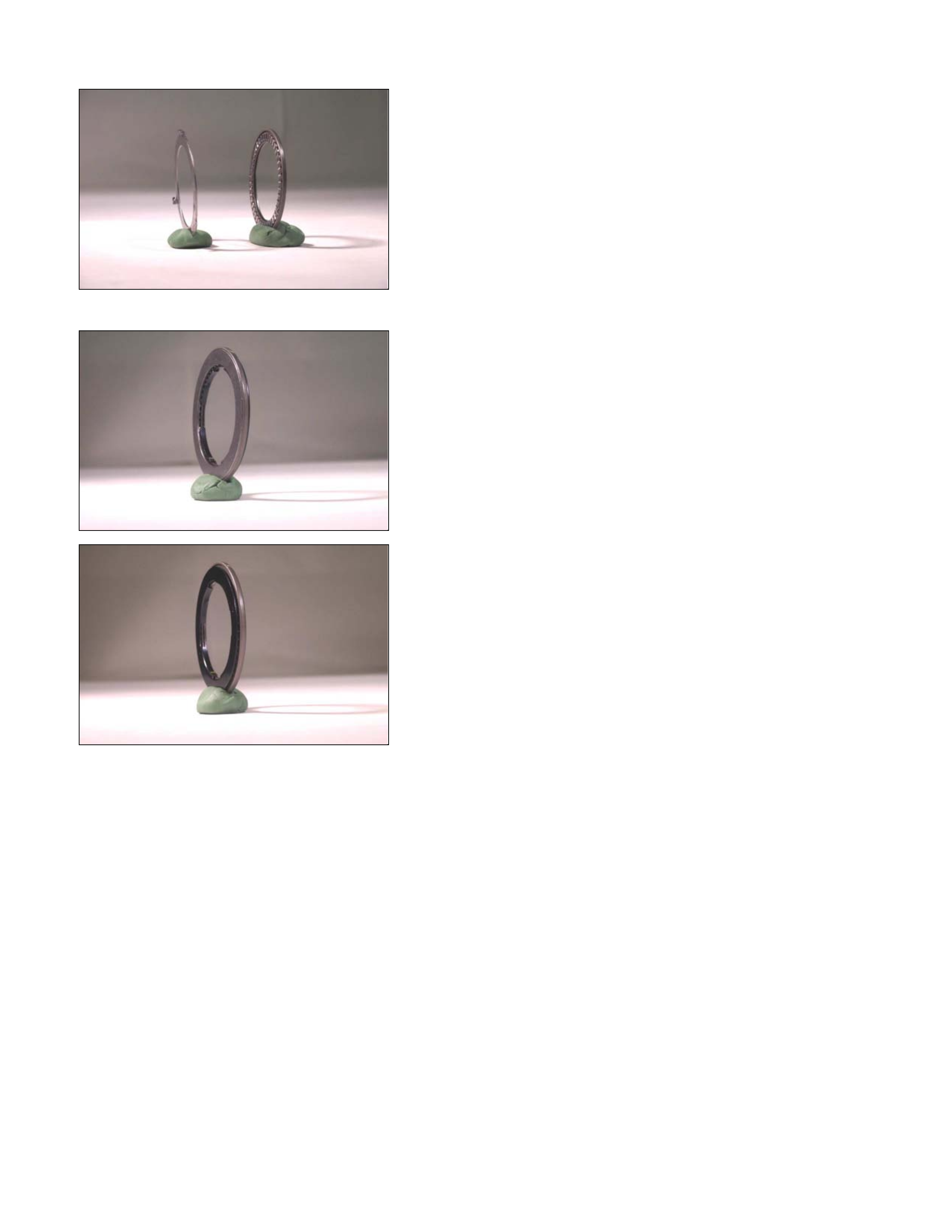

Inspection

Oil pump cover

• Install new seal rings to the oil pump cover.

NOTE:

The seal ring with the large inside diameter fits into the

primary mating surface of the cover.

• Measure the gap between the seal ring and the seal ring

groove.

If the measured gap is outside the specified range, the

oil pump cover must be replaced.

Seal ring and seal ring groove gap: 0.10∼

∼∼

∼0.25 mm

(0.0039∼

∼∼

∼0.0098 in)

12PUMP45

Inner rotor

• Install the inner rotor to the oil pump housing.

• Use a straight edge to measure the side clearance

between the oil pump housing and the inner rotor.

If the measured clearance is outside the specified range,

the inner rotor must be replaced.

Oil pump housing and inner rotor side clea rance:

0.02~0.04 mm (0.0008~0.0016 in)

13PUMP46

Outer rotor

• Install the outer rotor to the oil pump housing.

• Measure the gap between the outer rotor and the

crescent.

If the measured gap is outside the specified range, the

outer rotor must be replaced.

Outer rotor and crescent gap:

0.02~0.15 mm (0.0008~0.0059 in)

14PUMP28

Reassembly Steps

Coat the parts with ATF before installing them.

1. Oil seal

• Use the oil seal installer to install new oil seal to the oil

pump housing.

Oil seal installer: 5-8840-2761-0

15PUMP18

2. O-ring (small)

Install new O-ring (small) to the oil pump housing.

16PUMP29

3. Outer rotor

4. Inner rotor

Install the outer rotor and the inner rotor to the oil pump

housing.

17PUMP42

NOTE:

The identification mark on the inner rotor must be facing

the inside of the oil pump housing.

18PUMP07

5. Oil pump cover

6. Oil pump housing

Install the oil pump cover to the oil pump housing.

Tighten the 8 bolts to the specified torque.

Torque: 9 N⋅

⋅⋅⋅m (78 Ib⋅

⋅⋅⋅in)

7. O-ring (large)

Install the O-ring (large) to the oil pump cover.

8. Seal ring

Install the 4 seal rings to the oil pump cover.

Clutch Pack (Reverse And High Clutch Assembly)

01R&H17

Legend

1. Reverse and high clutch drum

2. Seal ring (reverse clutch)

3. Lip seal (reverse clutch)

4. Reverse clutch piston

5. Seal ring (small, high clutch)

6. Seal ring (large, high clutch)

7. High clutch piston

8. Return spring

9. High clutch cover

10. Snap ring

11. Dish plate (high clutch)

12. Driven plates (5, high clutch)

13. Drive plates (5, high clutch)

14. Retaining plate (high clutch)

15. Snap ring (high clutch)

16. Dish plate (reverse clutch)

17. Driven plates (2, reverse clutch)

18. Drive plates (2, reverse clutch)

19. Retaining plate (reverse clutch)

20. Snap ring (reverse clutch)

02R&H18

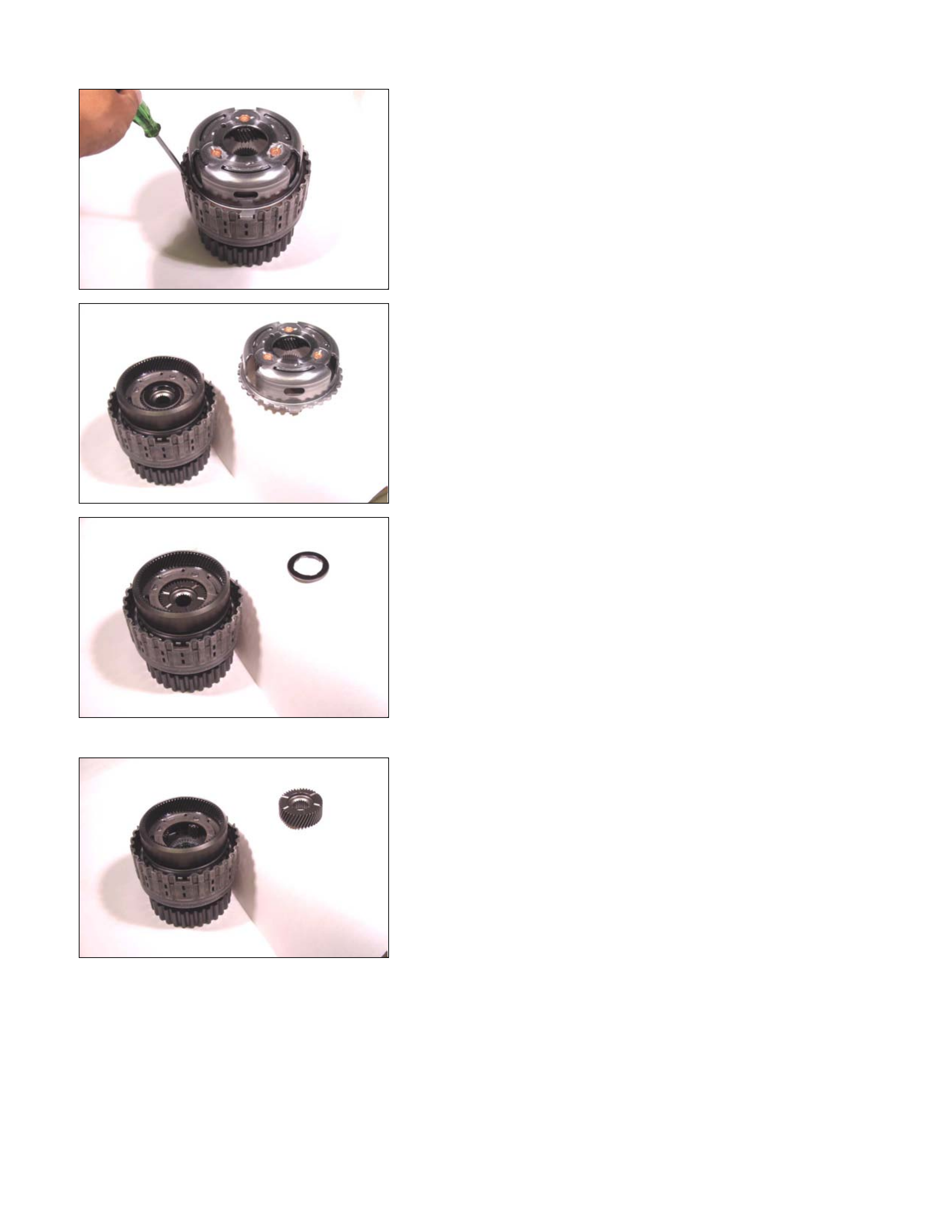

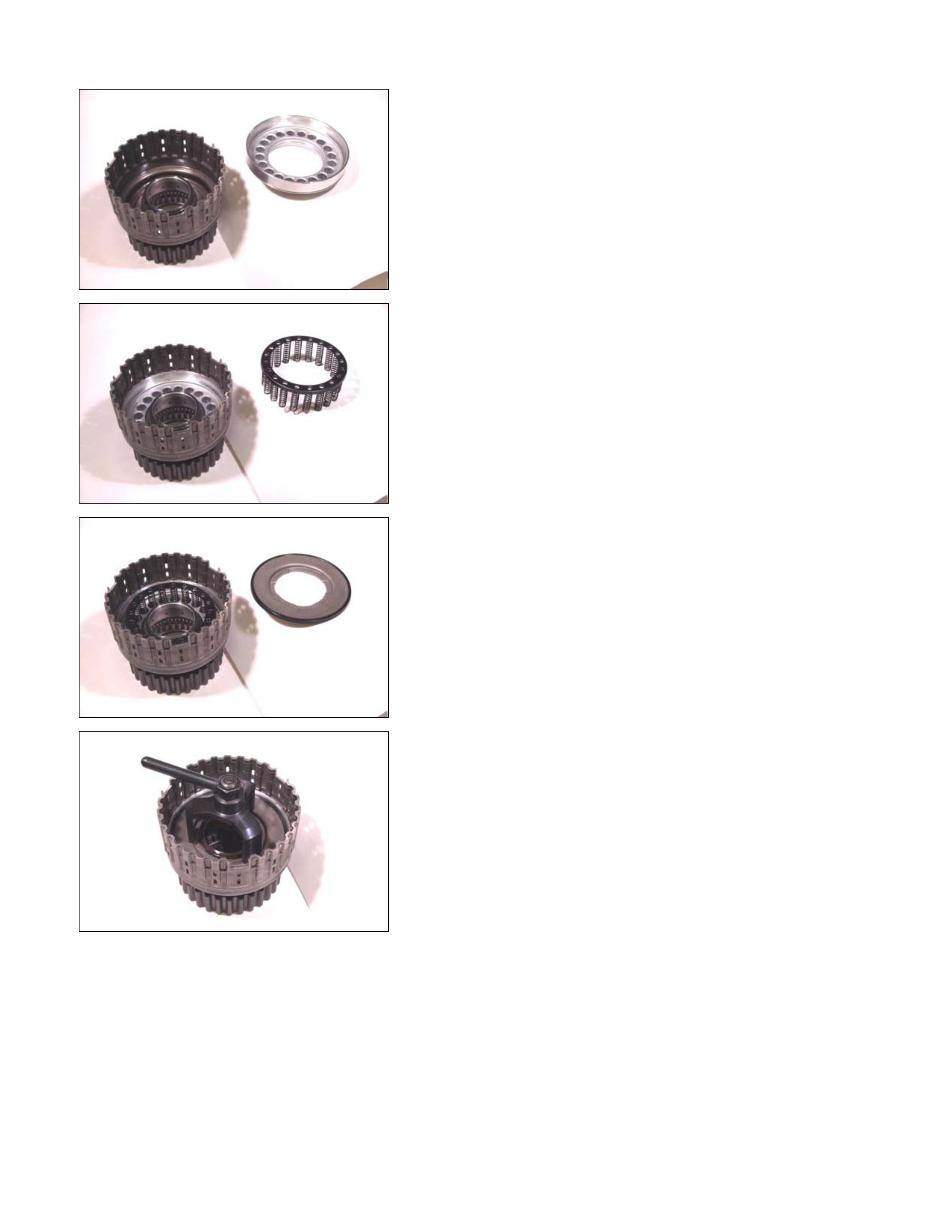

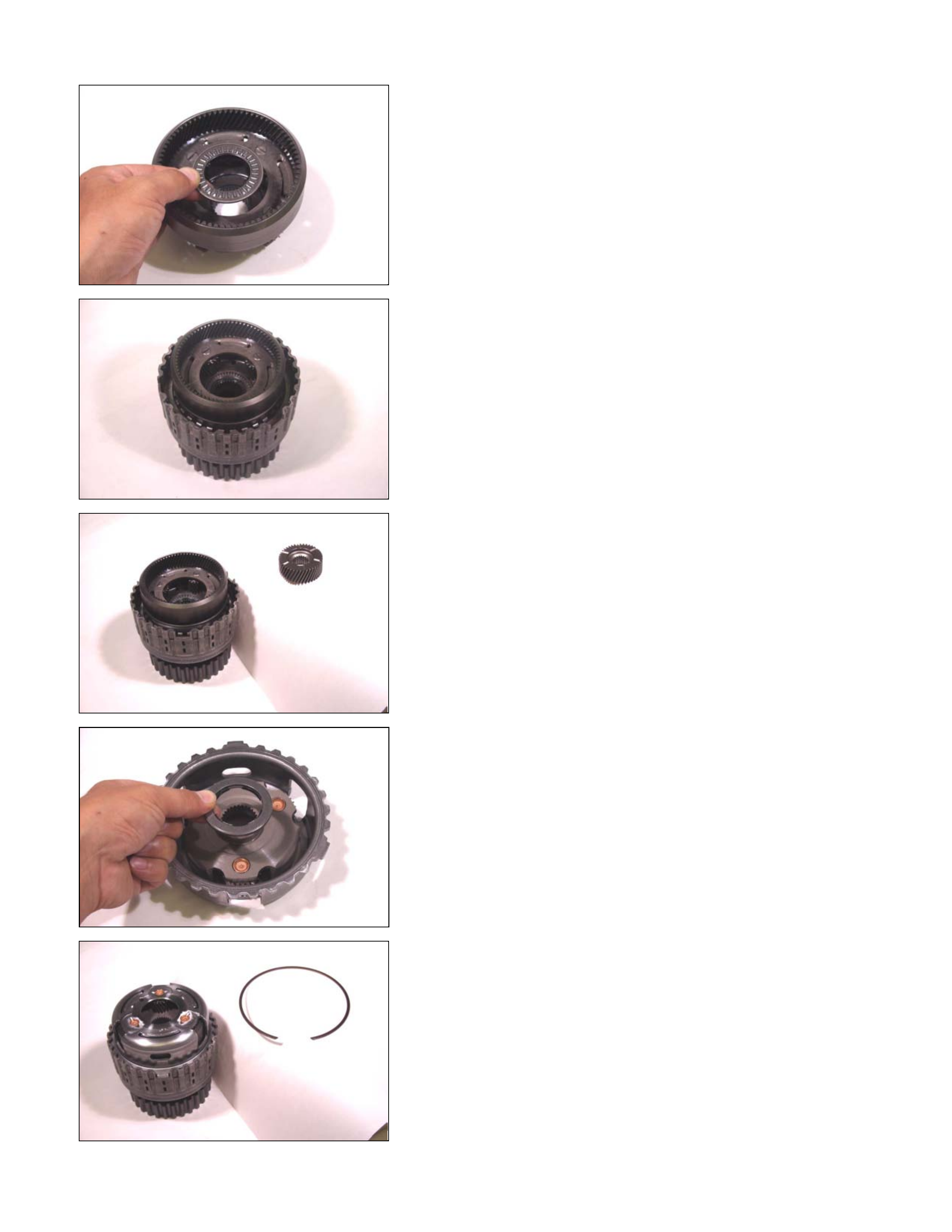

Disassembly Steps

1. Snap ring

Remove the reverse clutch snap ring.

03R&H21

2. Retaining plate, drive plate, driven plate and dish plate

Remove the reverse clutch retaining plate, the 2 drive

plates, the 2 driven plates, and the dish plate.

04R&H22

3. Snap ring

Remove the high clutch snap ring.

05R&H25

4. Retaining plate, drive plate, driven plate and dish plate

Remove the high clutch retaining plate, the 5 drive plates,

the 5 driven plates, and the dish plate.

07R&H28

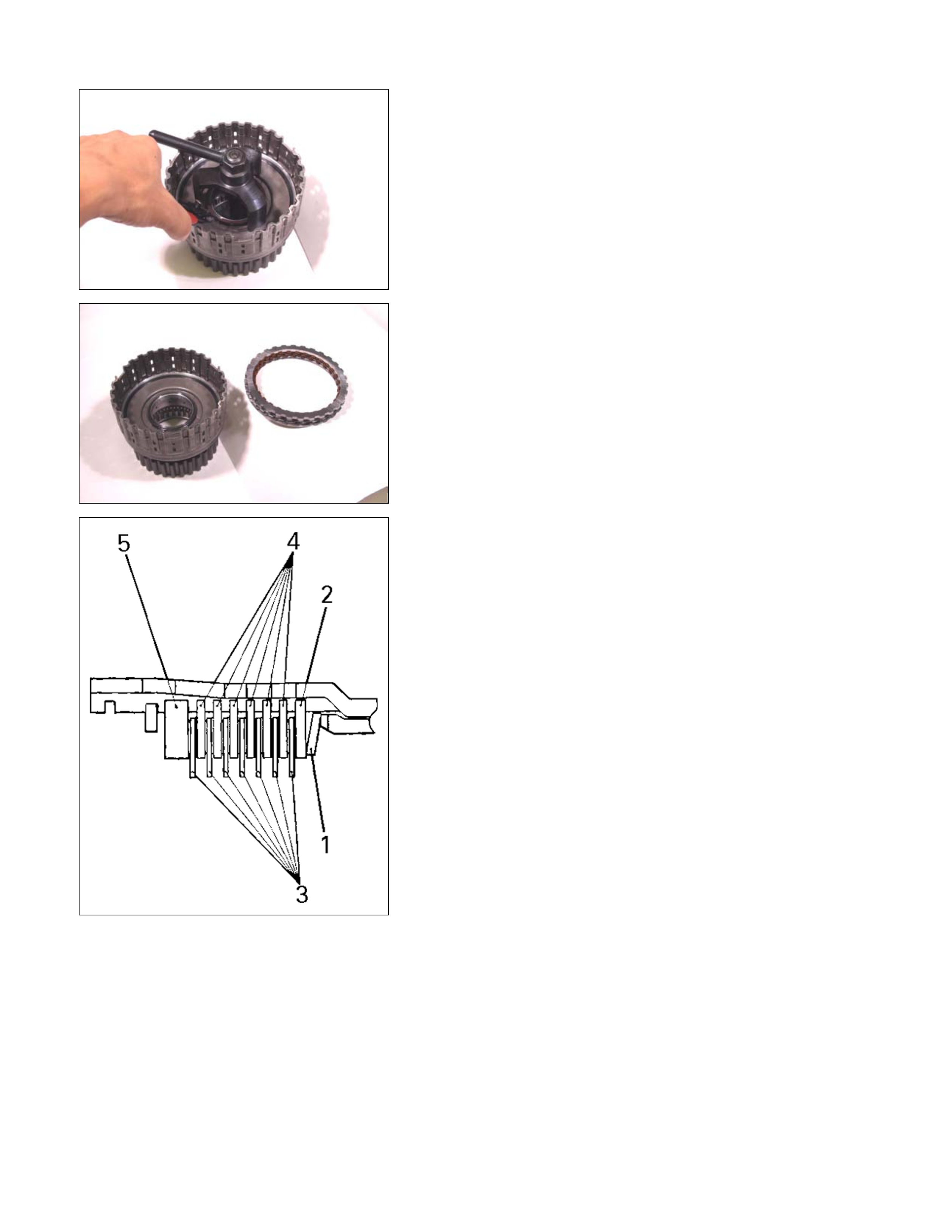

5. Snap ring

6. High clutch cover

7. Return spring

• Install the spring compressor to the reverse and high

clutch drum.

Spring compressor: 5-8840-2767-0

• Carefully press the high clutch cover down.

Take care not to damage the return spring.

• Remove the snap ring.

• Remove the high clutch cover and the return spring.

08R&H36

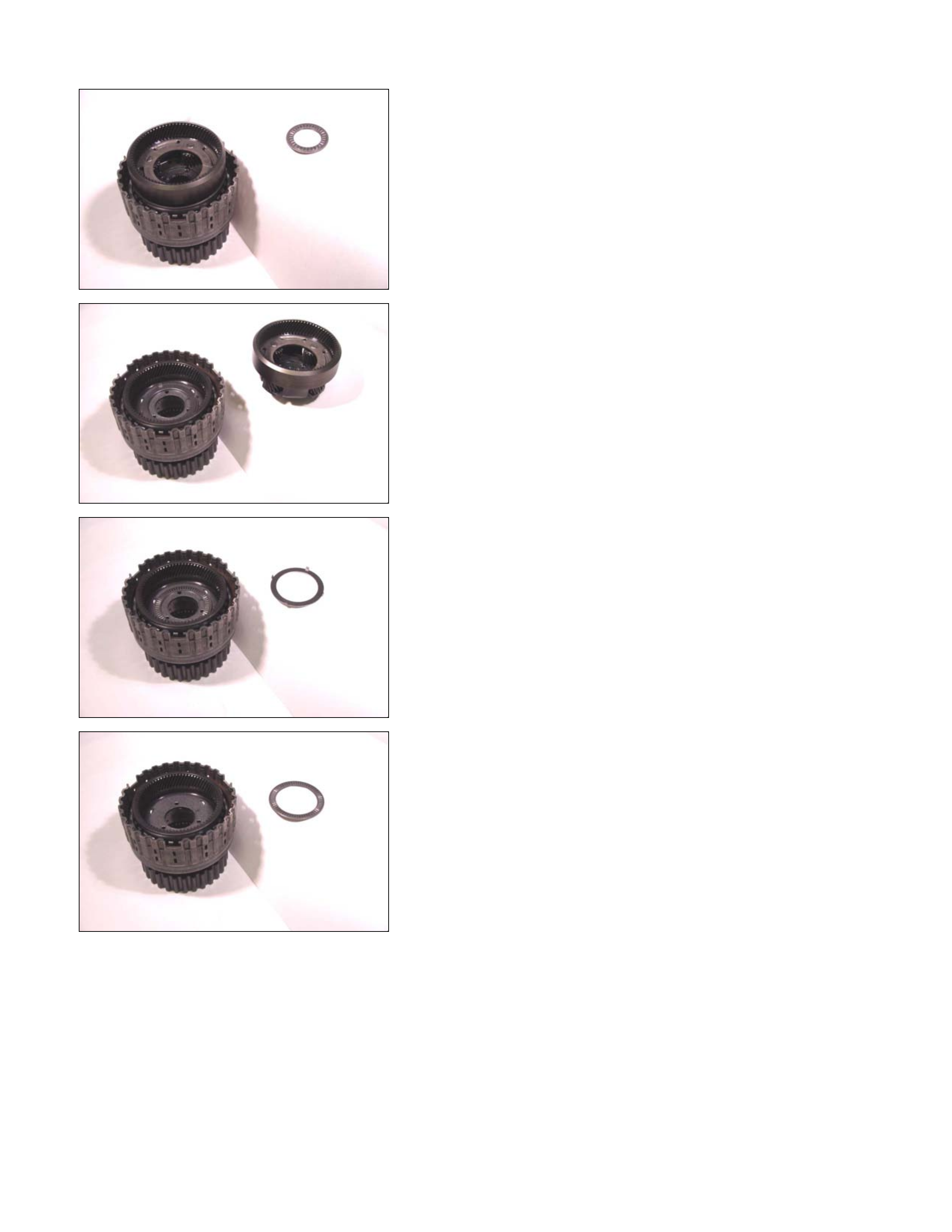

8. High clutch piston

9. Reverse clutch piston

• Install the reverse and high clutch drum to the oil pump.

• Force compressed air into the oil pump oil channels.

• Remove the high clutch piston and the reverse clutch

piston.

09R&H37

12R&H39

10.Seal ring (high clutch)

Remove the 2 seal rings from the high clutch piston.

13R&H38

11.Seal ring (reverse clutch)

Remove the 2 seal rings from the reverse clutch piston.

Inspection

Drive plate

• Measure the drive plate facing thickness at 3 points.

• Calculate the average value.

If the average value is less than the specified limit, the

drive plate must be replaced.

Drive plate facing thickness:

Standard – 2.0 mm (0.079 in)

Limit – 1.8 mm (0.071 in)

Return spring

• Check the number of effective return spring coils.

If the number is less than the specified minimum, the

return spring must be replaced.

Effective return spring coils (standard): 10.2

• Measure the return spring outside diameter, free length,

and linear diameter.

If any of the measur ed values exceed the spec ified lim it,

the return spring must be replaced.

Return spring measurements (standard):

Outside diameter – 8.0 mm (0.315 in)

Free length – 27.1 mm (1.067 in)

Linear diameter – 1.1 mm (0.043 in)

10R&H40

Reverse clutch piston

• Apply compressed air (392 kPa/4.0 kg/cm2) to the

reverse clutch piston from the outside to the inside.

The flow of air should be blocked.

11R&H44

• Apply compressed air (392 kPa/4.0 kg/cm2) to the

reverse clutch piston from inside to the outside.

The flow of air should be unrestricted.

12R&H39

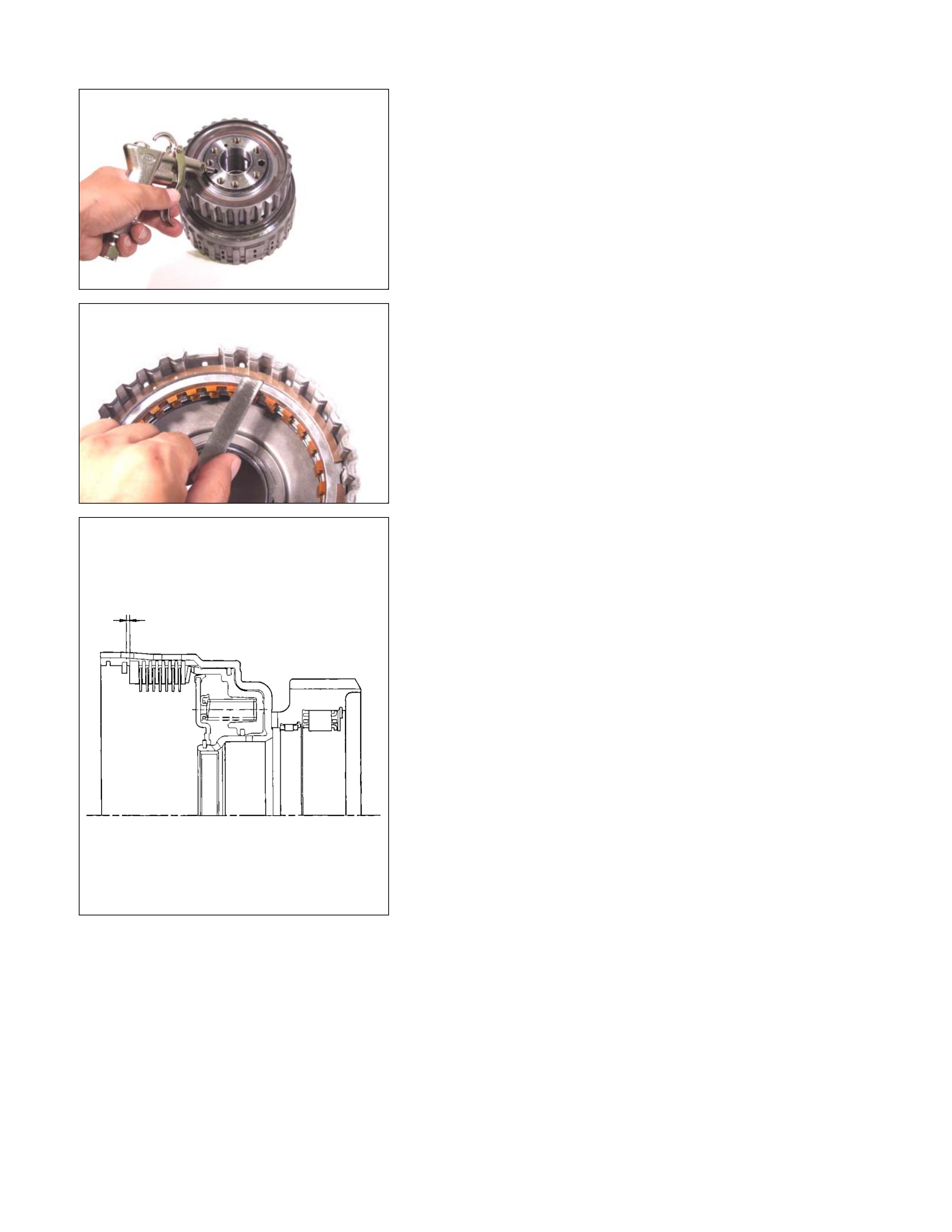

Reassembly Steps

Coat the parts with ATF before installing them.

1. Seal ring (high clutch)

Install new seal rings to the high clutch piston.

13R&H38

2. Seal ring (reverse clutch)

Install new seal rings to the reverse clutch piston.

14R&H32

3. Reverse clutch piston

Install the reverse clutch piston to the reverse and high

clutch drum.

15R&H31

4. High clutch piston

Install the high clutch piston to the reverse clutch piston.

16R&H33

5. Return spring

Install the return spring to the high clutch piston.

17R&H30

6. High clutch cover

• Carefully center the high clutch cover and install it.

NOTE:

If the clutch cover is not centered, the cover outside seal

gum will be forced into the piston area where it will be

damaged.

18R&H27

7. Snap ring

• Install the spring compressor to the reverse and high

clutch drum.

• Use the spring compressor to carefully force the high

clutch cover down.

Spring compressor: 5-8840-2767-0

NOTE:

To avoid damage to return springs, use only as much

force as is required to press the high clutch cover into

place.

19R&H28

• Install the new snap ring to the reverse and high clutch

drum.

20R&H25

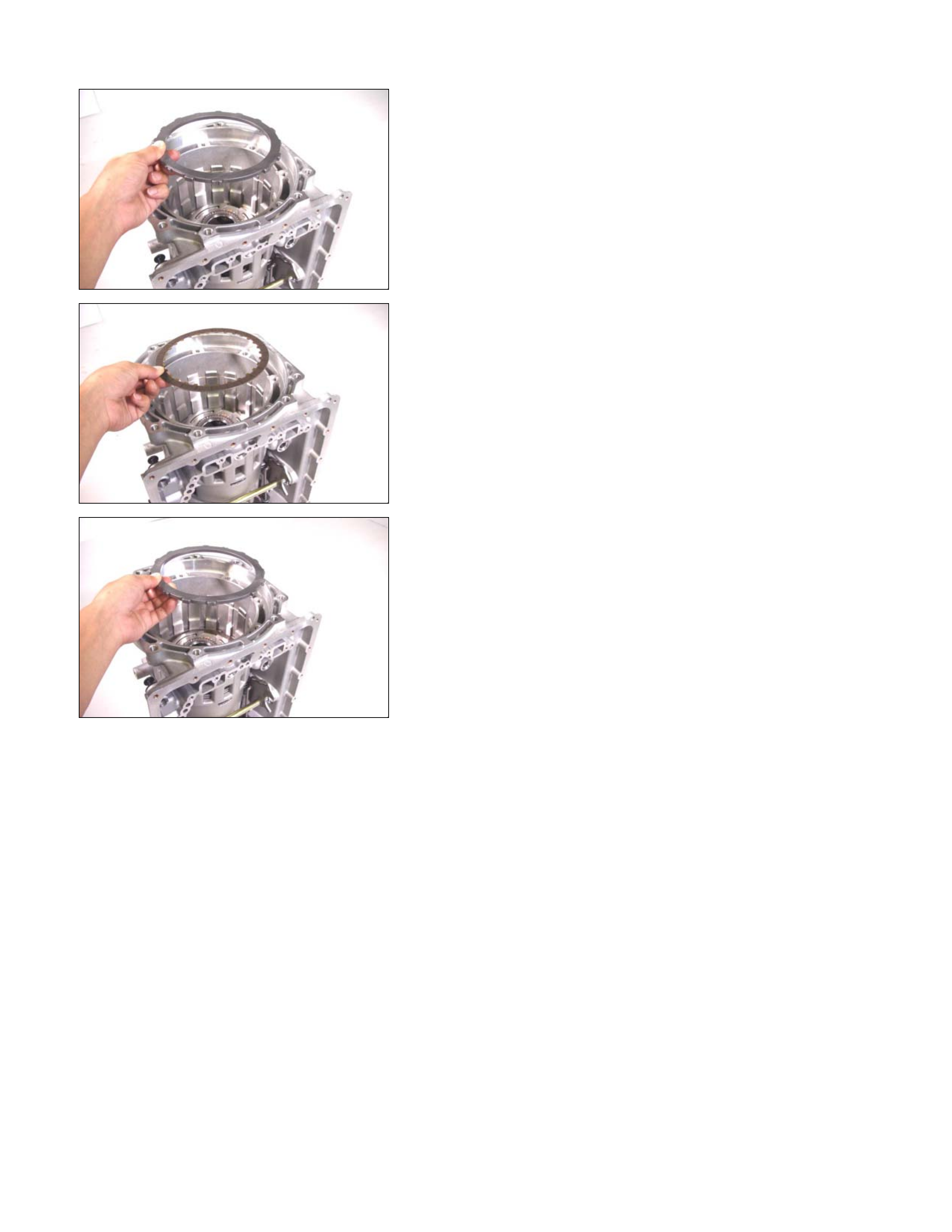

8. Dish plate, drive plates, driven plates, and retaining

plate

Install the high clutch dish plate (1), the 5 driven plates (2),

the 5 drive plates (3), and retaining plate (4).

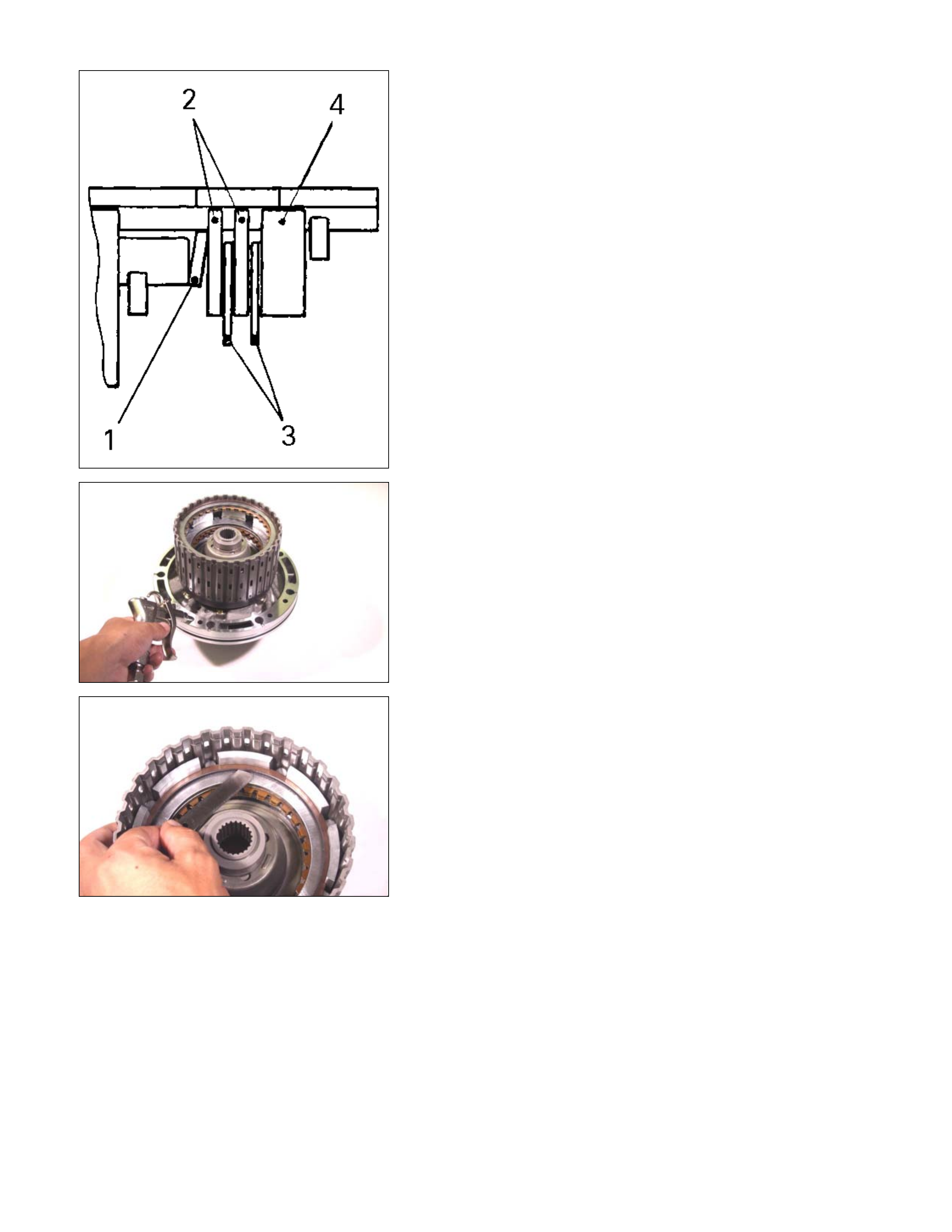

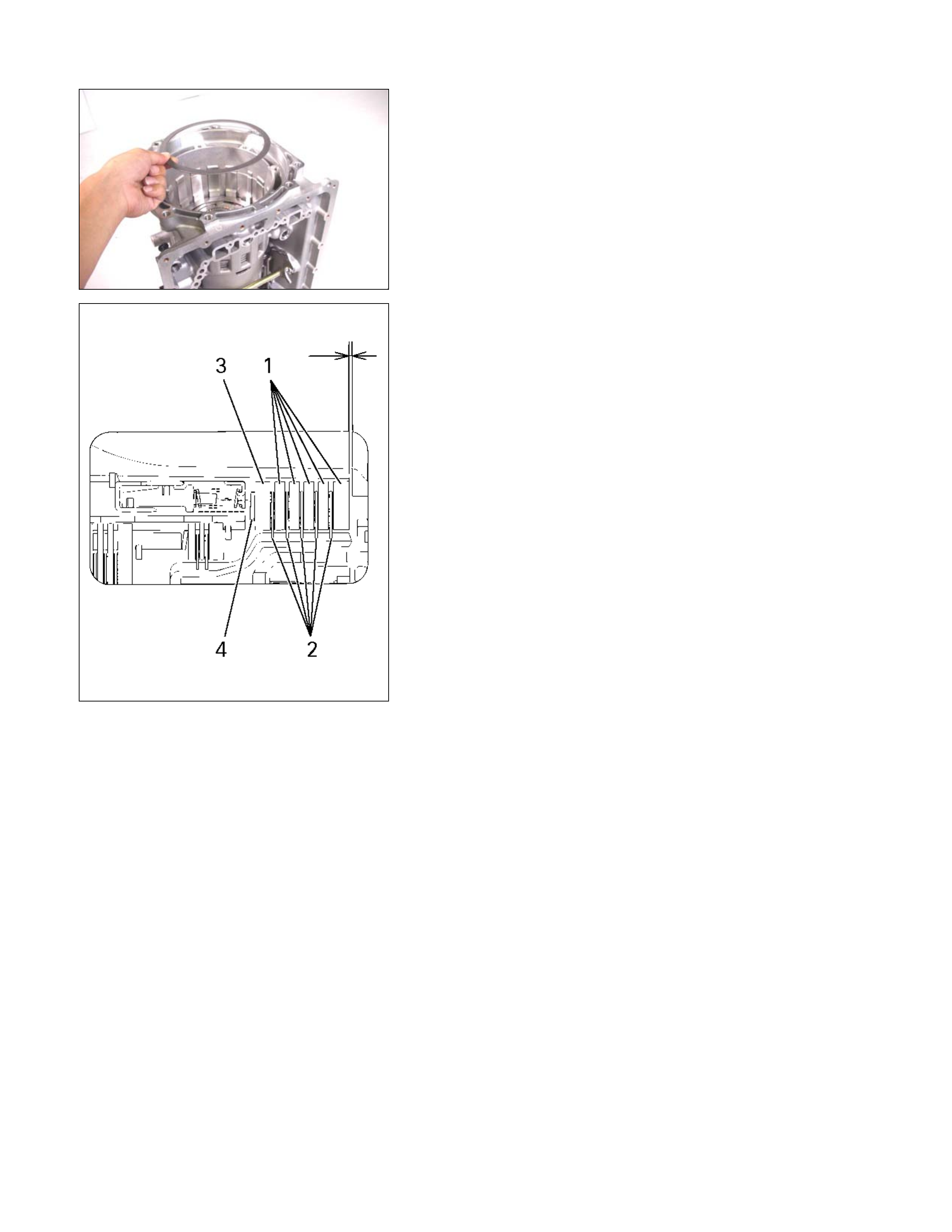

248L300002

9. Snap ring

Install the snap ring.

21R&H21

10.Dish plate, drive plates, driven plates, and retaining

plate

Install the reverse clutch dish plate (1) the 2 driven plates

(2), the 2 drive plates (3), and retaining plate (4).

248L300003

11.Snap ring

Install the snap ring.

22R&H35

• Install the reverse and high clutch drum to the oil pump

assembly.

• Force compressed air (392 kPa/4.0 kg/cm 2) through the

oil pump oil passages to check high clutch operation.

If the clutch does not operate, the seal ring may be

damaged or the parts may have been installed in the

wrong order.

23CLEAR02

• Measur e the c learanc e between the high clutch r etaining

plate and the snap ring.

If the clearance is outside the specified range, replace

the existing retaining plate with a new plate of the prope

r

size (thickness).

High clutch retaining plate and snap ring clearance

(A): 1.2~1.6 mm (0.047~0.063 in)

Available high clutch retaining plate thicknesses

4.6 mm (0.181 in)

248L300004

4.8 mm (0.189 in)

5.0 mm (0.197 in)

5.2 mm (0.205 in)

5.4 mm (0.213 in)

24R&H34

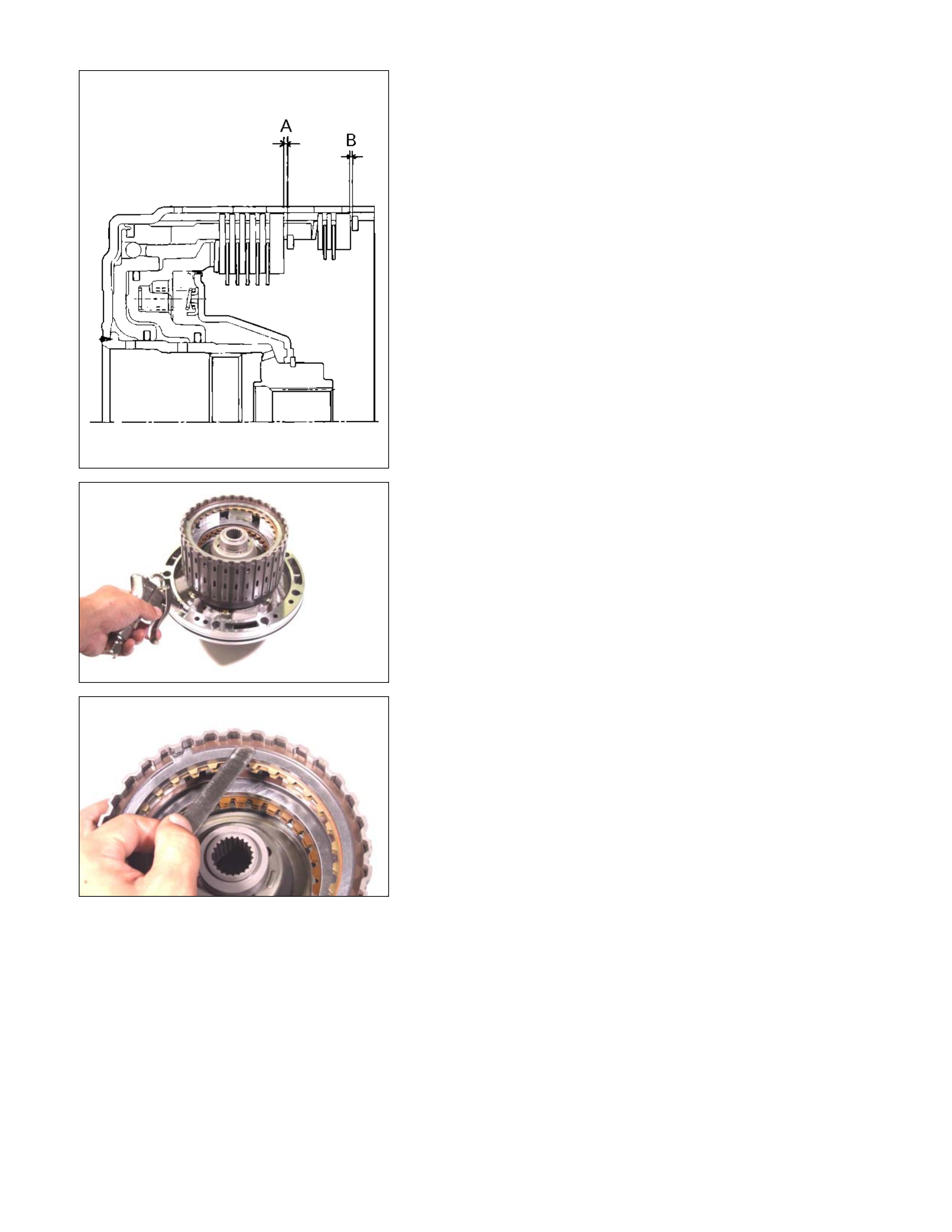

• Force compressed air (392 kPa/4.0 kg/cm 2) through the

oil pump oil passages to check reverse clutch operation.

If the clutch does not operate, the seal ring may be

damaged or the parts may have been installed in the

wrong order.

25CLEAR04

• Measure the clearance between the reverse clutch

retaining plate and the snap ring.

If the clearance is outside the specified range, replace

the existing retaining plate with a new plate of the prope

r

size (thickness).

Reverse clutch retaining plate and snap ring

clearance (B):

0.6~0.9 mm (0.024~0.035 in)

Available reverse clutch retaining plate thicknesses

4.8 mm (0.189 in)

5.0 mm (0.197 in)

5.2 mm (0.205 in)

5.4 mm (0.213 in)

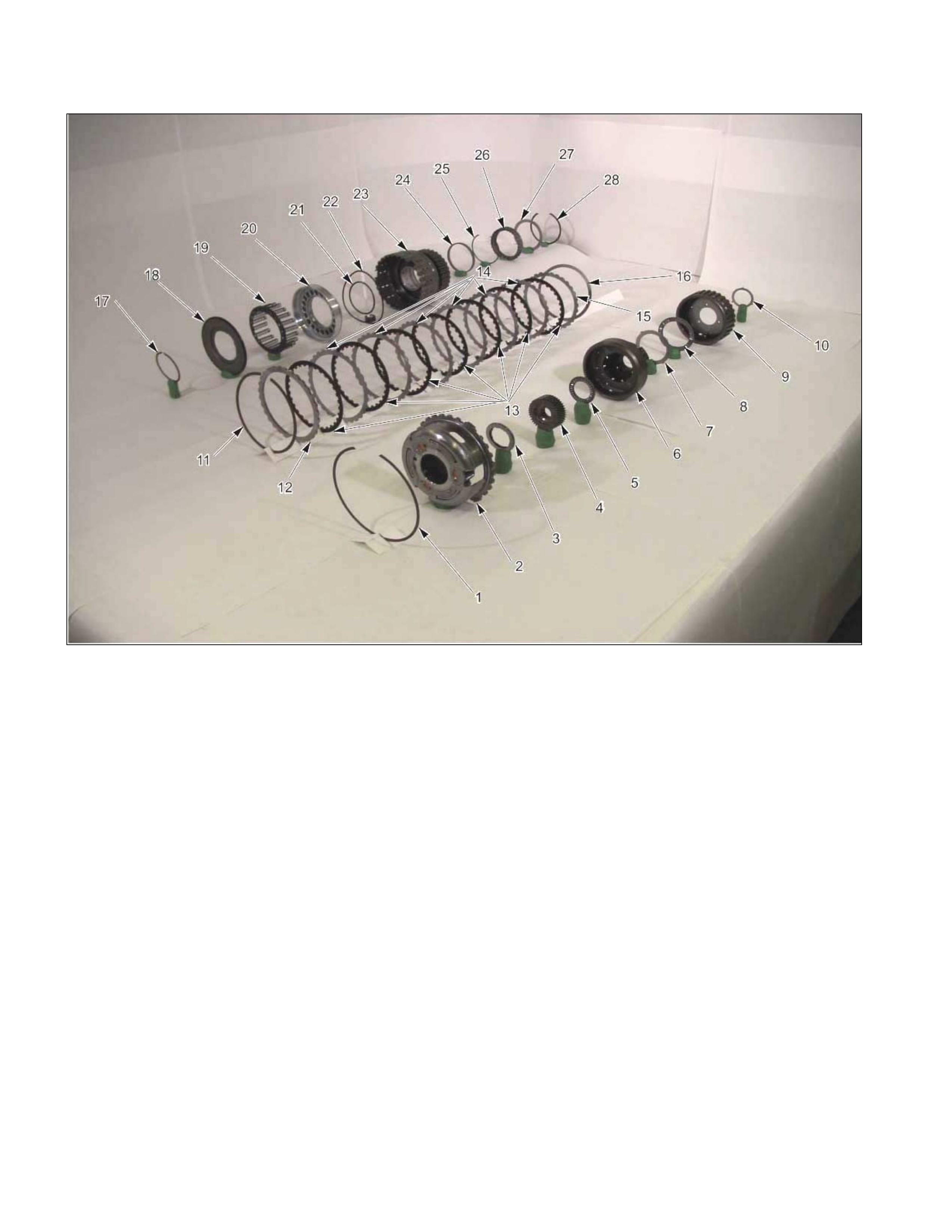

Carrier And Low Clutch Assembly

01C&L12

Legend

1. Snap ring

2. Front carrier

3. Bearing (with bearing race)

4. Rear sun gear

5. Bearing

6. Rear carrier

7. Bearing race

8. Bearing

9. Rear internal gear

10. Bearing race

11. Snap ring

12. Retaining plate

13. Drive plates (7, low clutch)

14. Driven plates (6, low clutch)

15. Driven plate (1, 2 mm thick, low clutch)

16. Dish plate

17. Snap ring

18. Cancel cover

19. Return spring

20. Low clutch piston

21. Seal ring (small)

22. Seal ring (large)

23. Low clutch drum

24. Bearing

25. Snap ring

26. Low one-way clutch

27. Side plate

28. Snap ring

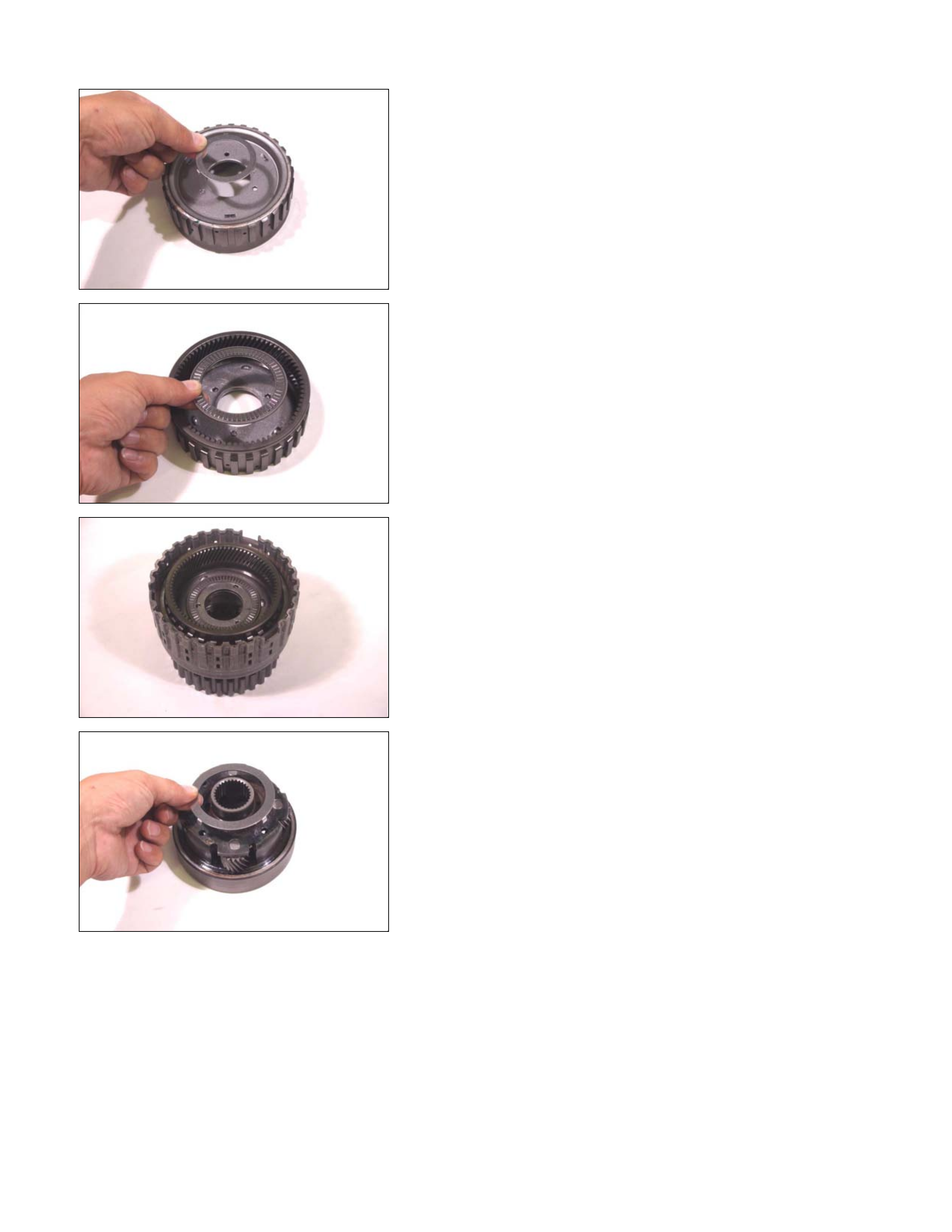

02C&L-SUB03

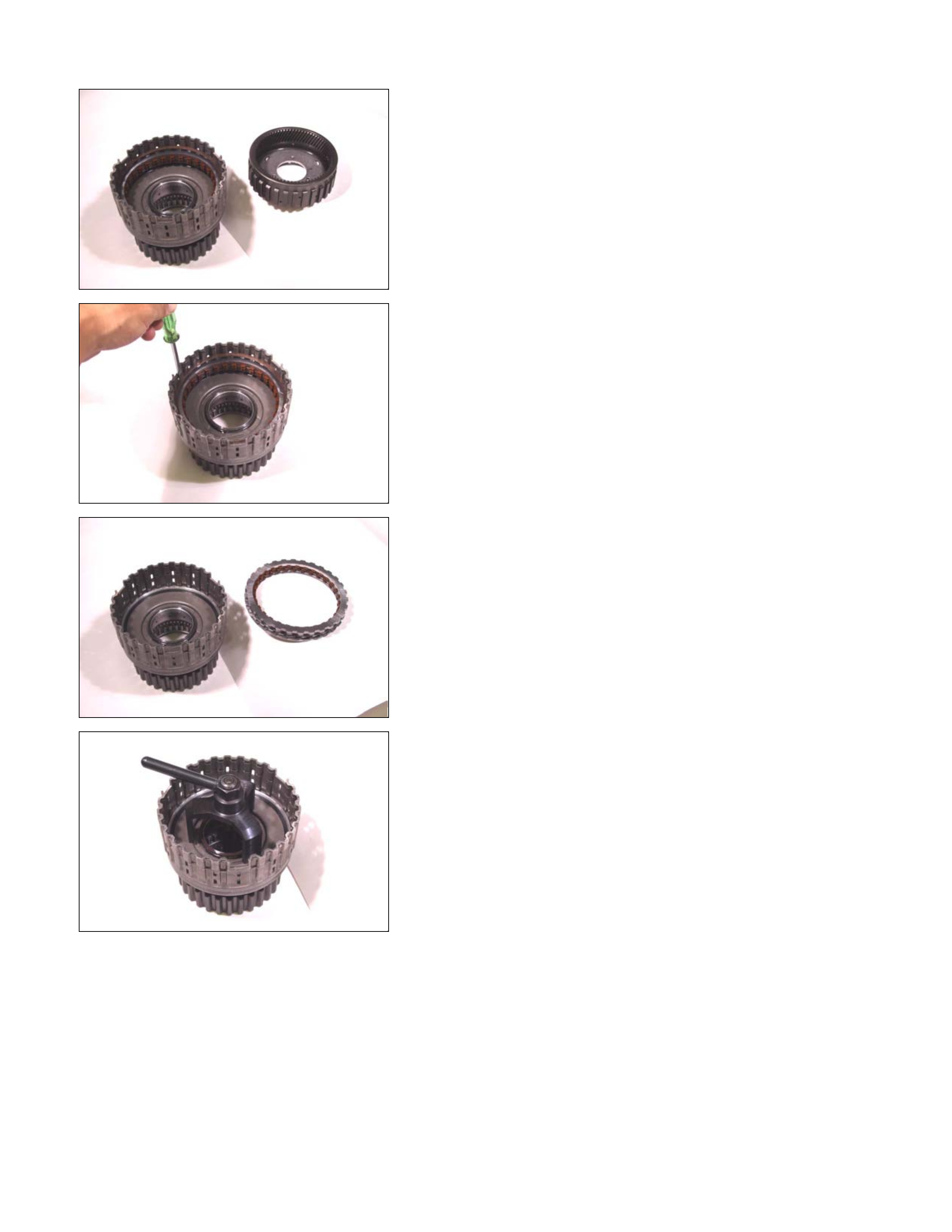

Disassembly Steps

1. Snap ring

Remove the snap ring from the low clutch drum.

03C&L-SUB05

2. Front carrier

Remove the front carrier from the low clutch assembly.

04C&L-SUB06

3. Bearing (with bearing race)

4. Rear sun gear

5. Bearing

6. Rear carrier

7. Bearing race

8. Bearing

9. Rear internal gear

10.Bearing race

Remove the bearing (with bearing race), the rear sun gear,

the bearing, the rear carrier, the bearing race, the bearing,

and rear internal gear.

05C&L-SUB07

06C&L-SUB08

07C&L-SUB09

08C&L-SUB10

09C&L-SUB11

10C&L-SUB12

• Remove the bearing race from the rear internal gear.

11C&L-SUB13

11.Snap ring

Remove the low clutch snap ring.

12C&L-SUB15

12.Retaining plate, drive plate, driven plate, and dish plate

Remove the low clutch retaining plate, the 7 drive plates,

the 7 driven plates, and the dish plate.

13C&L-SUB18

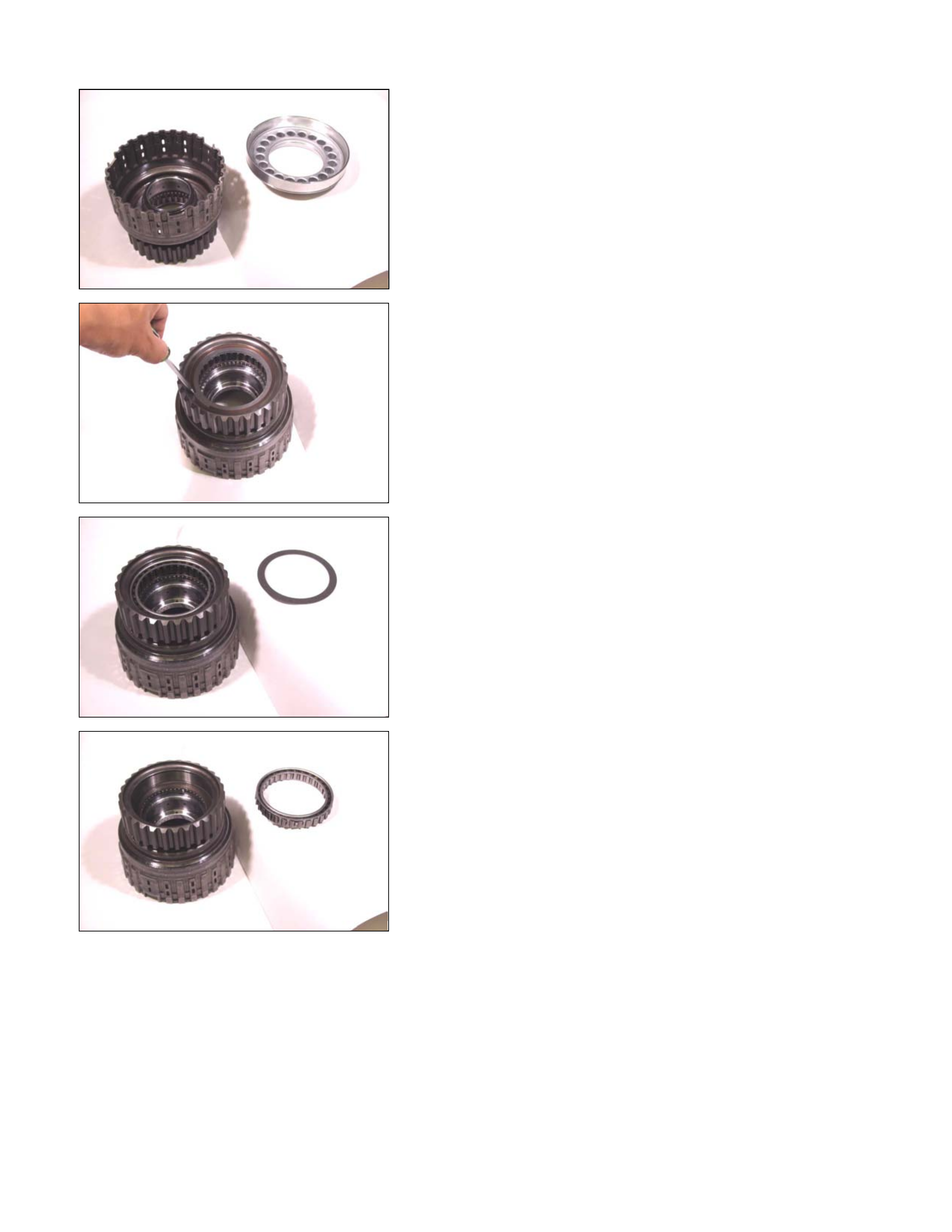

13.Snap ring

• Install the spring compressor to the low clutch drum.

Spring compressor: 5-8840-2759-0

• Carefully press the cancel cover down.

Take care not to damage the return spring.

14C&L-SUB19

• Remove the snap ring.

31C&L-SUB20

14.Cancel cover

Remove the cancel cover.

30C&L-SUB21

15.Return spring

Remove the return spring.

15C&L-SUB38

16.Low clutch piston

• Inser t the low one-way clutch inner race to the low clutc h

drum.

• Force compressed air through the oil passages of the

low one-way clutch inner race to remove the low clutch

piston.

29C&L-SUB22

16C&L-SUB25

17.Snap ring

• Raise the low one-way clutch side.

• Remove the low one-way clutch snap ring.

17C&L-SUB27

18.Side plate

Remove the side plate.

18C&L-SUB28

19.Low one-way clutch

Remove the low one-way clutch.

19C&L-SUB29

20.Snap ring

Remove the snap ring from the low clutch drum.

20C&L-SUB31

21.Bearing

Remove the bearing.

Inspection

Drive plate

• Measure the drive plate facing thickness at 3 points.

• Calculate the average value.

If the average value is less than the specified limit, the

drive plate must be replaced.

Drive plate facing thickness:

Standard – 2.0 mm (0.079 in)

Limit – 1.8 mm (0.071 in)

Return spring

• Check the number of effective return spring coils.

If the number is less than the specified minimum, the

return spring must be replaced.

Effective return spring coils (standard): 9.9

• Measure the return spring outside diameter, free length,

and linear diameter.

If any of the measur ed values exceed the spec ified lim it,

the return spring must be replaced.

Return spring measurements (standard):

Outside diameter – 9.7 mm (0.382 in)

Free length – 36.4 mm (1.433 in)

Linear diameter – 1.2 mm (0.047 in)

21C&L-SUB31

Reassembly Steps

Coat the parts with ATF before installing them.

1. Bearing

Install the bearing into the low clutch drum.

22C&L-SUB30

2. Snap ring

Install the snap ring to the low clutch drum.

23C&L-SUB28

3. Low one-way clutch

Install the low one-way clutch to the low clutch drum.

24C&L-SUB33

NOTE:

The flanged side of the low one-way clutch must face the

outside.

25C&L-SUB27

4. Side plate

Install the side plate.

26C&L-SUB26

5. Snap ring

Install the snap ring to the low clutch drum.

27C&L-SUB58

• Attach the low one-way clutch inner race to the lo

w

clutch drum in the opposite direction of normal position.

• Rotate the one-way clutch inner race clockwise. It

should turn smoothly w ith little resistance.

• Rotate the low one-way clutch inner race

counterclockwise.

It should immediately lock (rotation is impossible).

If it does not, check the low one-way clutch installation

direction.

Inspect and replace the low one-way clutch if required.

• Remove the low one-way clutch inner race.

• Reverse the low clutch drum.

28C&L-SUB32

6. Low clutch piston

• Install new seal rings to the low clutch piston.

29C&L-SUB22

• Install the low clutch piston to the low clutch drum.

30C&L-SUB21

7. Return spring

Install the return spring to the low clutch piston.

31C&L-SUB20

8. Cancel cover

• Carefully center the cancel cover and install it.

NOTE:

If the cancel cover is not centered, the cover outside seal

ring gum will be forced into the low clutch piston area

where it will be damaged.

32C&L-SUB18

• Install the spring compressor to the low clutch.

Spring compressor: 5-8840-2759-0

33C&L-SUB19

9. Snap ring

• Use the spring compressor to carefully force the cancel

cover down.

NOTE:

To avoid damage to the return spring, use only as much

force as is required to press the cancel cover into place.

• Install new snap ring to the low clutch drum.

34C&L-SUB15

10.Dish plate, drive plate, driven plate, and retaining plate

Install the low clutch dish plate (1), the 2 mm thick driven

plate (2), the 7 drive plate (3), the other 6 driven plates (4),

and the retaining plate (5).

NOTE:

Dish plate side with the identification mark must face the

driven plate.

248L300006

11.Snap ring

Install the snap ring to the low clutch drum.

35C&L-SUB38

36CLEAR06

248L300007

Inspection

• Inser t the low one-way clutch inner race to the low clutch

drum.

• Force compressed air (392 kPa/4.0 kg/cm 2) through the

oil passages of the low one-way clutch inner race to

check low clutch operation.

If the low clutch does not oper ate, the seal rings m ay be

damaged or the parts may have been installed in the

wrong order.

• Measure the clearance between the low clutch retaining

plate and the snap ring.

If the clearance is outside the specified range, replace

the existing plate with a new plate of the proper size

(thickness).

Low clutch retaining plate and snap ring clearance:

0.9~1.3 mm (0.035~0.051 in)

Available low clutch retaining plate thicknesses

3.8 mm (0.150 in)

4.0 mm (0.157 in)

4.2 mm (0.165 in)

4.4 mm (0.173 in)

4.6 mm (0.181 in)

4.8 mm (0.189 in)

37C&L-SUB40

12.Bearing race

13.Rear internal gear

14.Bearing

Install the bearing race and the bearing to the rear internal

gear.

NOTE:

Apply Vaseline to the fitting surfaces of the rear internal

gear to prevent the bearing race and the bearing from

falling during the installation process.

38C&L-SUB43

39C&L-SUB60

• Install the rear internal gear to the low clutch drum.

40C&L-SUB46

15.Bearing race

16.Rear carrier

17.Bearing

Install the bearing race and the bearing to the rear carrier.

NOTE:

Apply Vaseline to the fitting surfaces of the rear carrier to

prevent the bearing race and the bearing from falling

during the installation process.

41C&L-SUB49

42C&L-SUB61

• Install the rear carrier to the low clutch drum.

43C&L-SUB07

18.Rear sun gear

Install the rear sun gear to the low clutch drum.

44C&L-SUB52

19.Bearing (with bearing race)

20.Front carrier

Install the bearing (with bearing race) to the front carrier.

NOTE:

Apply Vaseline to the fitting surfaces of the front carrier to

prevent the bearing from falling during the installation

process.

45C&L-SUB04

21.Snap ring

• Install the front carrier to the low clutch drum.

• Install the snap ring to the low clutch drum.

Transmission Case

02CASE-BK06

Legend

1. Transmission case

2. Spring pin (slender)

3. Spring pin (fat)

4. Manual plate

5. Detent spring

6. Parking rod

7. Manual shaft

8. Oil seal

9. Inhibitor switch

01L&R-CS05

Legend

1. Seal ring

2. Low one-way clutch inner race

3. Return spring

4. Low and reverse brake piston

5. Seal ring

6. Lip seal

7. Transmission case

8. Snap ring

9. Retaining plate

10. Driven plate

11. Drive plate

12. Dish plate

04CASE-AY52

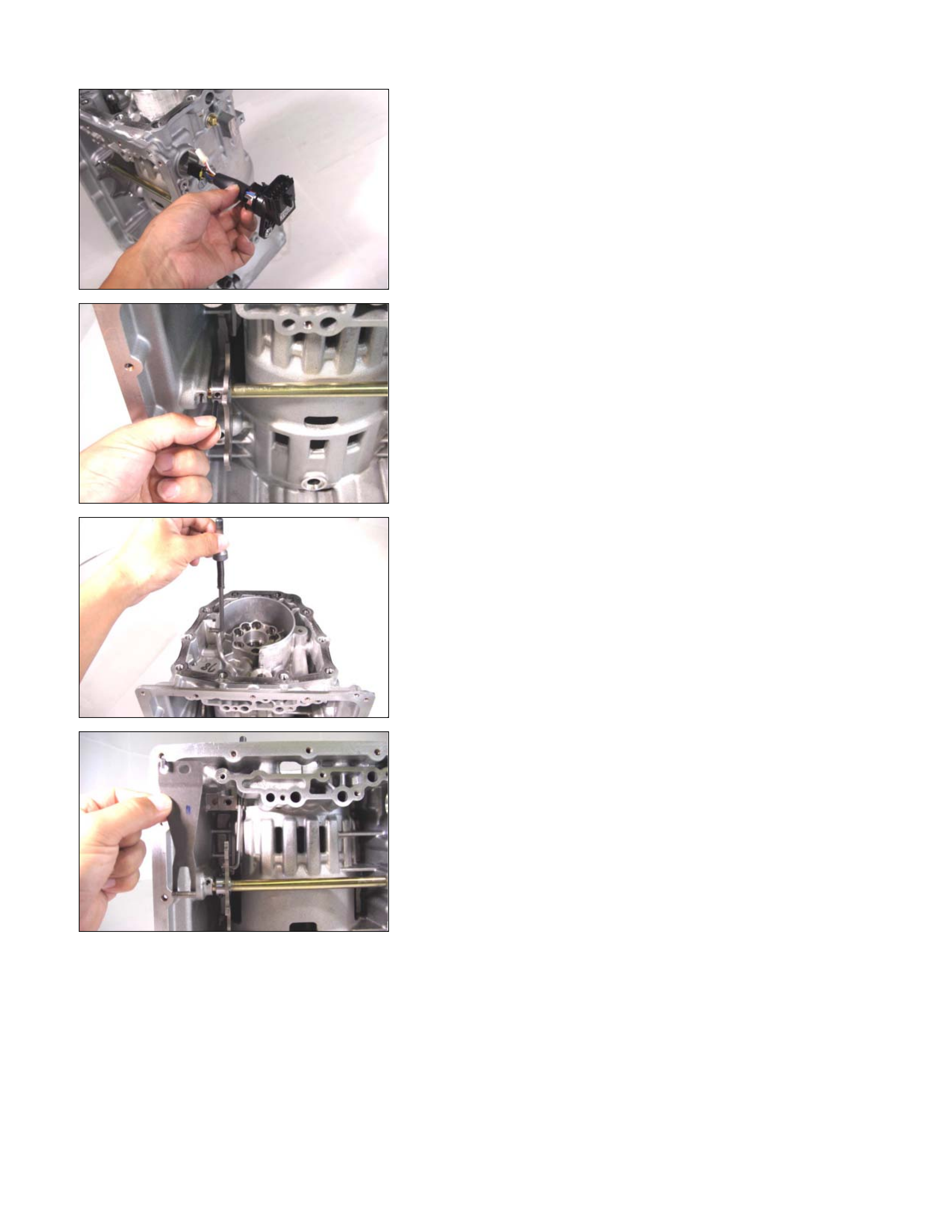

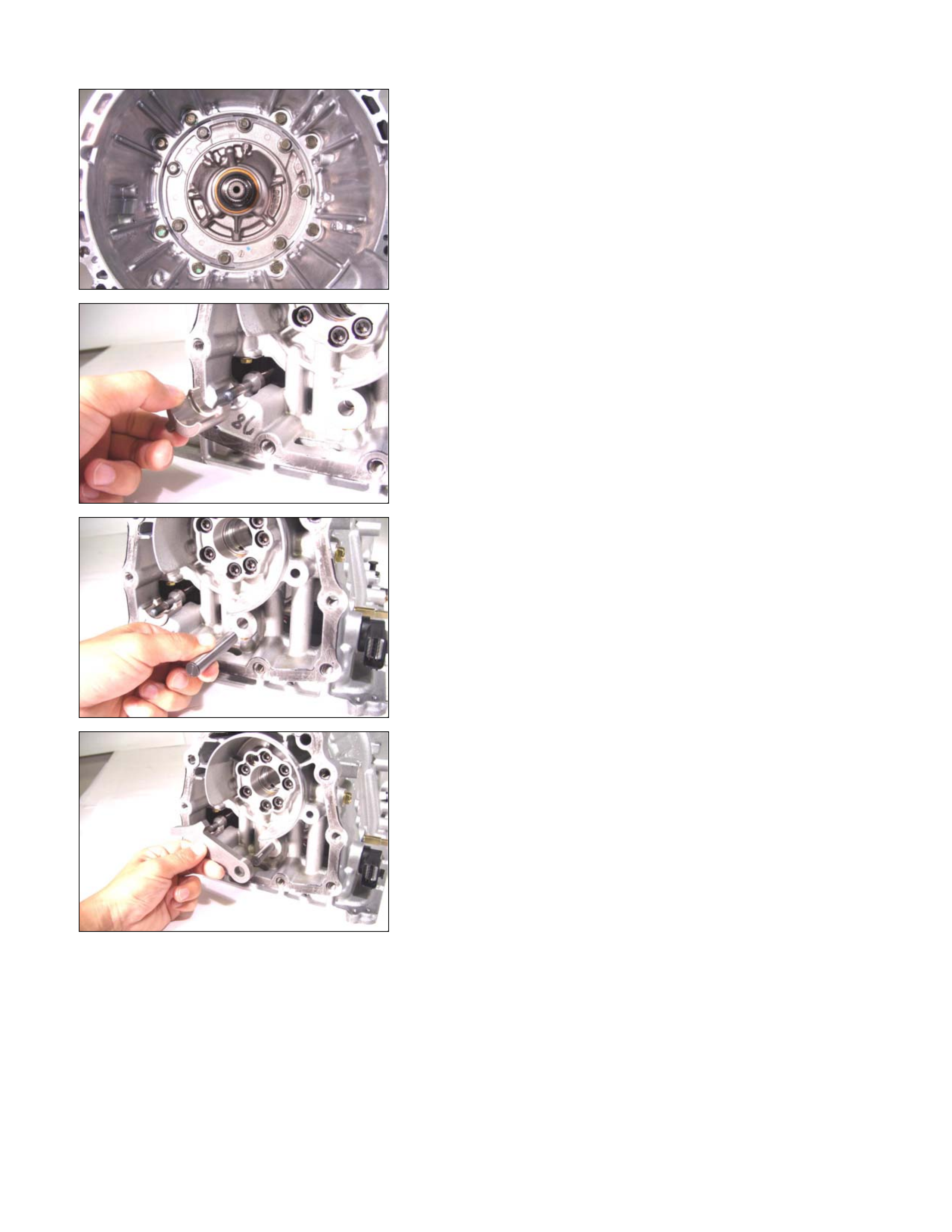

Disassembly Steps

1. Harness assembly

Remove the fixing bolt and the harness assembly.

05CASE-AY30

2. Parking rod

• Use a pin punch to force out the parking rod spring pin.

06CASE-AY37

• Rotate the manual plate as you pull the parking rod free.

08CASE-AY45

3. Detent spring

Remove the fixing bolt and the detent spring.

09CASE-AY28

4. Manual shaft and manual plate

• Remove the manual shaft spring pin.

10CASE-AY21

• Remove the manual shaft together with the manual

plate.

11CASE-AY01

5. Oil seal

Using a screwdriver, remove the oil seal from the

transmission case.

Inspection

2 – 4 brake drive plate

Measure the 2-4 brake drive plate facing thickness at 3

points and calculate the average value.

If the average value is less than the specified limit, the 2-4

brake drive plate must be replaced.

2 – 4 brake drive plate facing thickness:

Standard = 2.0 mm (0.079 in)

Limit = 1.8 mm (0.071 in)

Low and reverse brake drive plate

Measure the low and reverse brake drive plate facing

thickness at 3 points and calculate the average value.

If the average value is less than the specified limit, the lo

w

and reverse drive plate must be replaced.

Low and reverse brake drive plate facing thickness:

Standard = 2.0 mm (0.079 in)

Limit = 1.8 mm (0.071 in)

2 – 4 brake return spring

• Check the number of effective 2-4 brake return spring

coils.

Effective return spring coils (Standard): 10.2

• Measure the 2-4 brake return spring outside diameter,

free length, and linear diameter.

If any of the measur ed values exceed the spec ified lim it,

the 2-4 brake return spring must be replaced.

2 – 4 brake return spring measurements (Standard):

Outside diameter = 6.9 mm (0.272 in)

Free length = 22.5 mm (0.886 in)

Linear diameter = 1.1 mm (0.043 in)

Low and reverse brake return spring

• Check the number of effective low and reverse brake

return spring coils.

Effective return spring coils (standard): 4.8

• Measur e the low and reverse br ake return spr ing outside

diameter, free length, and linear diameter.

If any of the measur ed values exceed the spec ified lim it,

the low and reverse return spring must be replaced.

Low and reverse brake return spring measurements

(Standard):

Outside diameter = 11.2 mm (0.441 in)

Free length = 22.3 mm (0.878 in)

Linear diameter = 1.1 mm (0.043 in)

12CASE-AY06

Reassembly Steps

1. Oil seal, manual shaft, and manual plate

• Use the oil seal installer to force the manual plate oil

seal into place.

Oil seal installer: 5-8840-2758-0

14CASE-AY21

• Install the manual shaft together with the manual plate.

15CASE-AY26

• Drive the spring pin into the transmission case.

16CASE-AY37

2. Parking rod

• Rotate the manual plate while installing the parking rod.

18CASE-AY43

• Use a pin punch to drive the m anual plate spr ing pin into

place.

21CASE-AY48

3. Detent spring

• Install the detent spring and tighten the fixing bolt to the

specified torque.

Torque: 7 N⋅

⋅⋅⋅m (61 Ib⋅

⋅⋅⋅in)

23CASE-AY53

4. Harness assembly

• Apply automatic trans mission f luid to the new O -r ing and

install them to the harness assembly.

• Install the harness assembly to the transmission case.

Tighten the fixing bolt to the specified torque.

Torque: 6 N⋅

⋅⋅⋅m (52 Ib⋅

⋅⋅⋅in)

24ASSY003

5. Low one-way clutch inner race

• Install new seal rings to the low one-way clutch inne

r

race.

25ASSY126

• Measure the gap between the seal ring and the ring

groove.

If the measured valve is outside the specified range the

low one-way clutch inner race must be replaced.

Sealing ring and ring groove gap:

0.10~0.25 mm (0.0004~0.001 in)

26L&R01

6. Low and reverse brake piston

• Install new seal rings to the low and reverse piston.

27ASSY004

• Install the low and reverse brake piston to the

transmission case.

28ASSY005

7. Return spring

• Install the return spring to the low and reverse brake

piston.

29ASSY006

8. Low one-way clutch inner race

• Install the low one-way clutch inner race to the

transmission case.

• Temporarily tighten the 7 fixing bolts.

31ASSY074

• T ighten each of the bolts a little at a tim e to the s pec if ied

torque.

Be sure that the return spring and the low one-wa

y

clutch inner race installation position do not change as

you tighten the bolts.

Torque: 24 N⋅

⋅⋅⋅m (17 Ib⋅

⋅⋅⋅ft)

32ASSY007

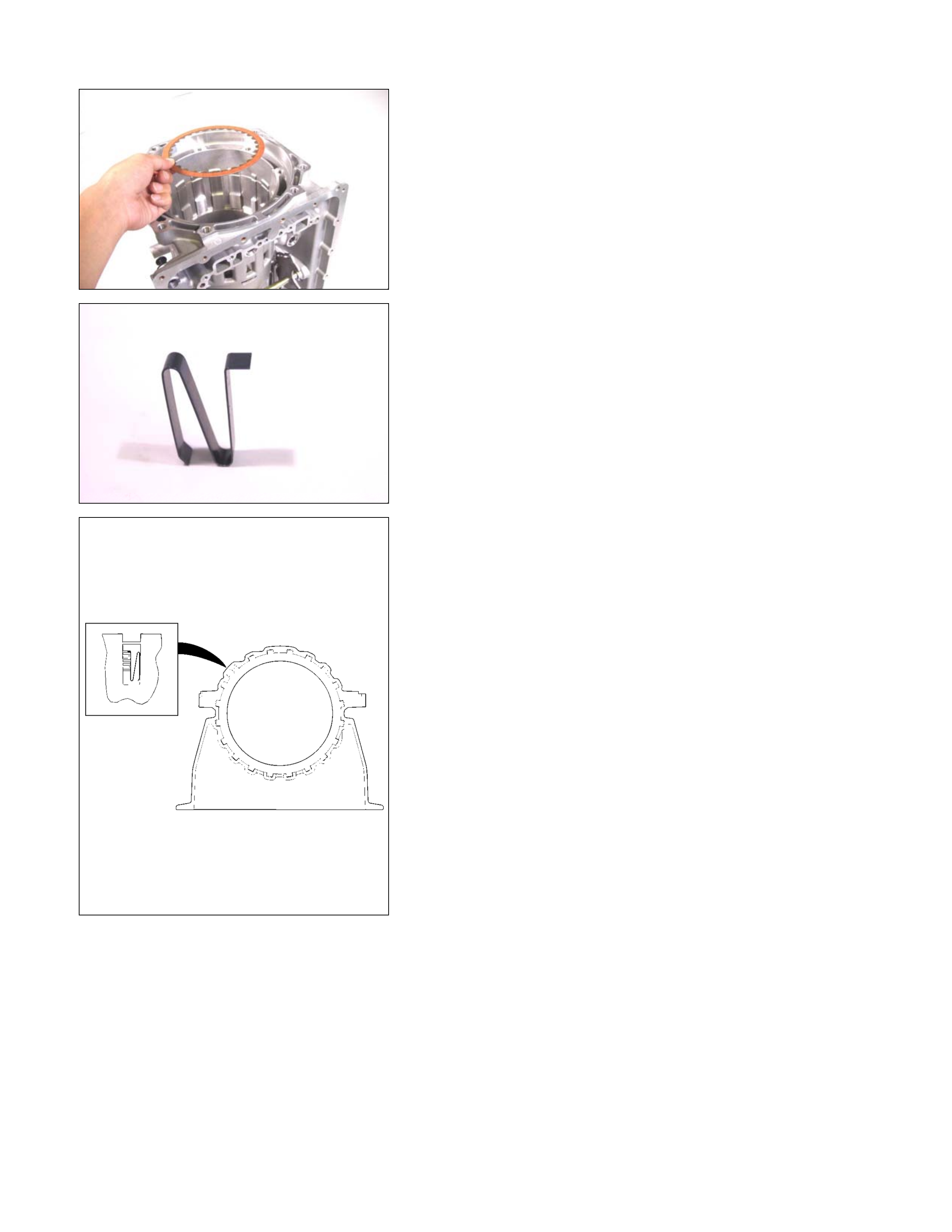

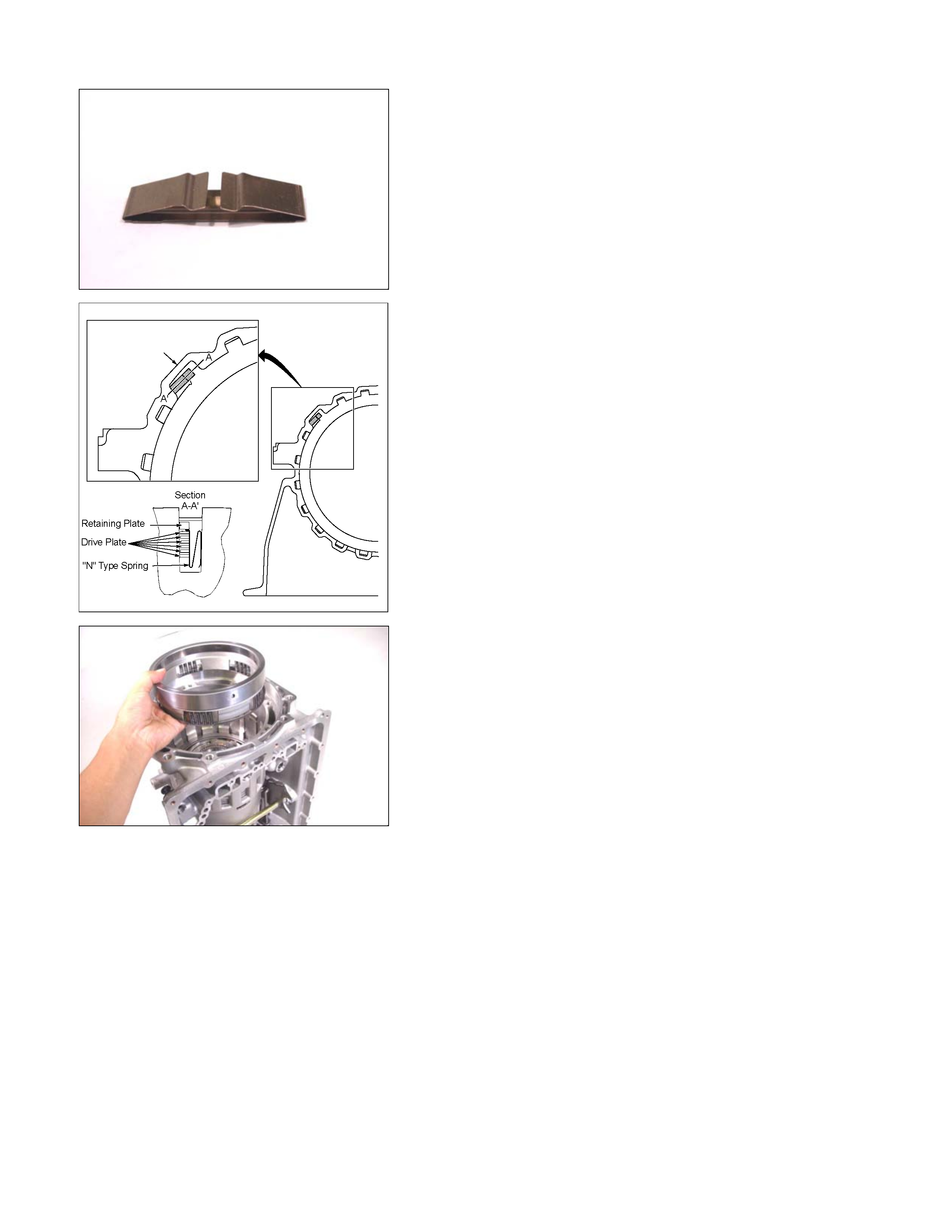

9. Dish plate, driven plate, drive plate, and retaining plate

(low and reverse brake)

• Install the dish plate (1) followed by the 6 driven plates

(2) and drive plates (3) sets.

33ASSY008

34ASSY009

35N-SPG02

• Install the N-type spring.

249L300004

36ASSY10

• Install the retaining plate (4).

37ASSY011

• Install the snap ring.

38L&R03

• Force compressed air (392 kPa/4.0 kg/cm 2) through the

oil passages of the transmission case to check low and

reverse brake operation.

If the low and reverse br ake does not oper ate, c heck the

seal rings for damage and replace if necessary. Also

check that no parts have been installed out of place.

39L&R04

249L300003

• Measure the clearance between the low and reverse

retaining plate and the snap ring.

If the clearance is out side the specified range, replace

the existing retaining plate with a new plate of the prope

r

size (thickness).

Low and reverse retaining and snap ring clearance:

0.7~1.1 mm (0.028~0.043 in)

A

vailable low and reverse brake retaining plate

thicknesses

5.2 mm (0.205 in)

5.4 mm (0.213 in)

5.6 mm (0.220 in)

5.8 mm (0.228 in)

6.0 mm (0.236 in)

10.Dish plate, drive plate, driven plate, and retaining plate

(2-4 brake)

NOTE:

If 2-4 brake clearance measurement is required, it must be

done now.

Brake clearance cannot be measured after the carrier

assembly has been installed.

402-4B08

• Install the 2-4 brake dish plate to the transmission case

(plate contact surface).

412-4B09

• Install the drive plate, driven plate, and the retaining

plate.

422-4B10

432-4B11

442-4B12

11.2 – 4 brake piston and 2 – 4 brake retainer

• Install new seal ring to the 2-4 brake piston.

• Install the 2-4 brake piston to the 2-4 brake retainer.

452-4B15

• Install the 2- 4 brake piston and the 2-4 br ake retainer to

the transmission case.

Pay close attention to the retainer projection from the

case groove.

472-4B17

• Install the spring compressor to the transmission case.

Spring compressor: 5-8840-2764-0

NOTE:

Be sure that the spring compressor is perfectly centered

(an off-center special tool will damage the return spring).

• Use the spring compressor to force the 2-4 brake

retainer.

482-4B18

NOTE:

To avoid damaging the return spring, apply as little force

as possible to the 2-4 brake retainer.

• Install the snap ring.

492-4B22

• Force compressed air (392 kPa/4.0 kg/cm 2) through the

oil passages of the transmission case to operate and

break-in the 2-4 brake.

502-4B19

• Measure the clearance between the 2-4 brake retaine

r

and the retaining plate.

If the clearance is outside the specified range, replace

the existing brake retainer with a new one of the prope

r

size (thickness).

2 – 4 brake retainer and retaining plate clearance:

1.0~1.4 mm (0.039~0.055 in)

Available 2-4 brake retaining plate thicknesses

5.4 mm (0.213 in)

5.6 mm (0.220 in)

5.8 mm (0.228 in)

6.0 mm (0.236 in)

6.2 mm (0.244 in)

6.4 mm (0.252 in)

• Use the spring compressor to release the 2-4 brake.

Bearing And Bearing Race Installation Position

A07L300001

1. Bearing and bearing race

Outside diameter

Bearing – 46 mm (1.811 in)

Bearing race – 45 mm (1.772 in)

01BRG16

2. Bearing (with bearing race)

Outside diameter

Bearing – 46 mm (1.811 in)

02BRG02

Bearing race ( black color) inst allation direction – Fac ing the

front of the transmission.

3. Bearing and bearing race

Outside diameter

Bearing – 65 mm (2.559 in)

Bearing race – 64 mm (2.520 in)

03BRG04

4. Bearing and bearing race

Outside diameter

Bearing – 73 mm (2.874 in)

Bearing race – 72 mm (2.835 in)

04BRG05

5. Bearing (with bearing race)

Outside diameter

Bearing – 53 mm (2.087 in)

05BRG06

Bearing race ( black color) inst allation direction – Fac ing the

front of the transmission.

6. Bearing

Outside diameter

Bearing – 53 mm (2.087 in)

06BRG07

7. Bearing and bearing race

Outside diameter

Bearing – 78 mm (3.071 in)

Bearing race – 76 mm (2.992 in)

07BRG08

8. Bearing and bearing race

Outside diameter

Bearing – 53.4 mm (2.102 in)

Bearing race – 51 mm (2.008 in)

08BRG09

9. Bearing (with bearing race)

Outside diameter

Bearing – 64 mm (2.520 in)

09BRG18

Bearing race ( black color) inst allation direction – Fac ing the

rear of the transmission.

10.Bearing (with bearing race)

Outside diameter

Bearing – 64 mm (2.520 in)

10BRG17

Bearing race ( black color) inst allation direction – Fac ing the

front of the transmission.

Automatic Transmission Reassembly

Assembly Cautions

• Use your bare hands or vinyl gloves to reassemble the

transmission. Do not use ordinary work gloves (loosen

threads from the gloves may fall into the transmission

and cause problems).

• Before installing the drive plates, immerse them in the

recommended automatic transmission fluid (BESCO

ATF II or ATF III). If the drive plate is new, it must be

immers ed f or at least two hours to ens ure oil penetr ation

and saturation of the facing.

•

A

pply ATF to all sliding and contact surfaces before

assembly. Also apply ATF to seal rings and O-rings.

Assemble the parts carefully to avoid damaging them.

• Replace any snap ring that appears worn, bent out o

f

shape, or otherwise damaged.

• If any part contacting the tr ansmission c ase is damaged,

it must be replaced with a new part.

• Be careful not to damage the plates during reassembl

y

(oil leakage from the plate will result).

• If you are reusing a seal, rem ove the old adhesive agent

and clean the surface with cleaning oil before applying

the new adhesive agent.

• Wait at least two hours after installing the oil seals

before installing the plates.

• Do not replace O-rings, snap rings, bearings, and/o

r

bearing races with inferior substitutes.

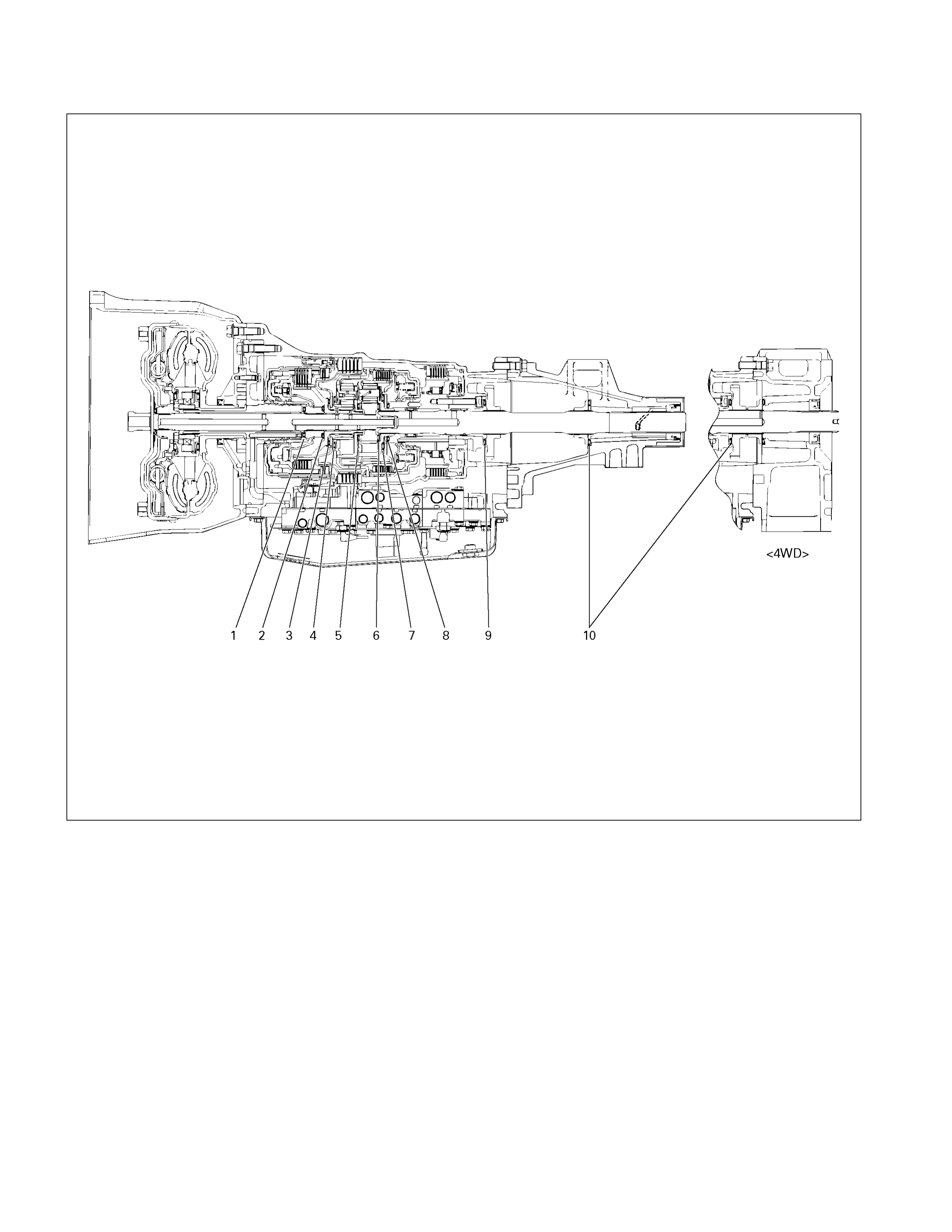

Pow e r Train

01HUB-H04

Legend

1. O-ring

2. Input shaft

3. Bearing

4. Reverse and high clutch assembly

5. Bearing

6. High clutch hub

7. Bearing race

8. Bearing

9. Front sun gear

10. Bearing race

11. Bearing

12. Carrier and low clutch assembly

13. Bearing

14. Transmission case

Reassembly Steps

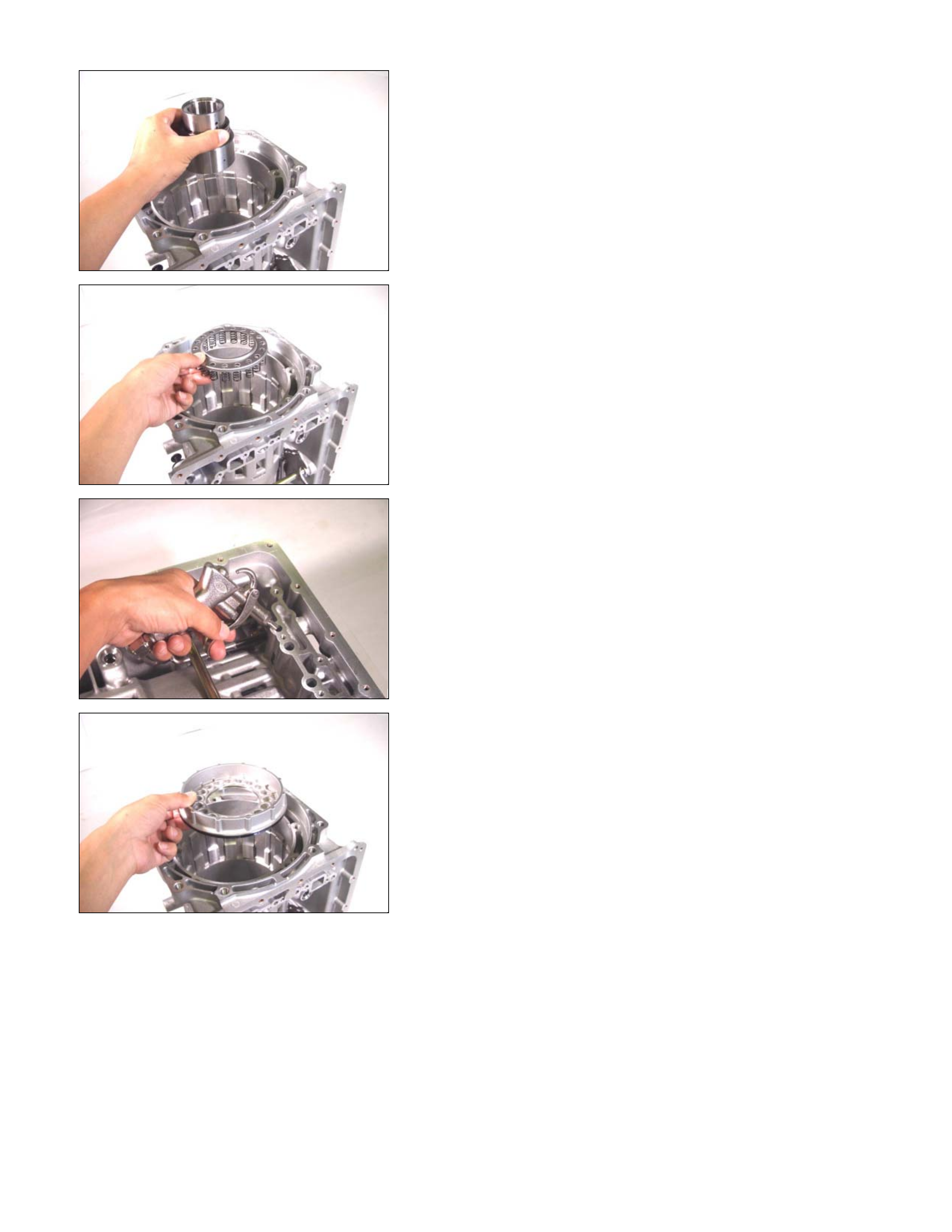

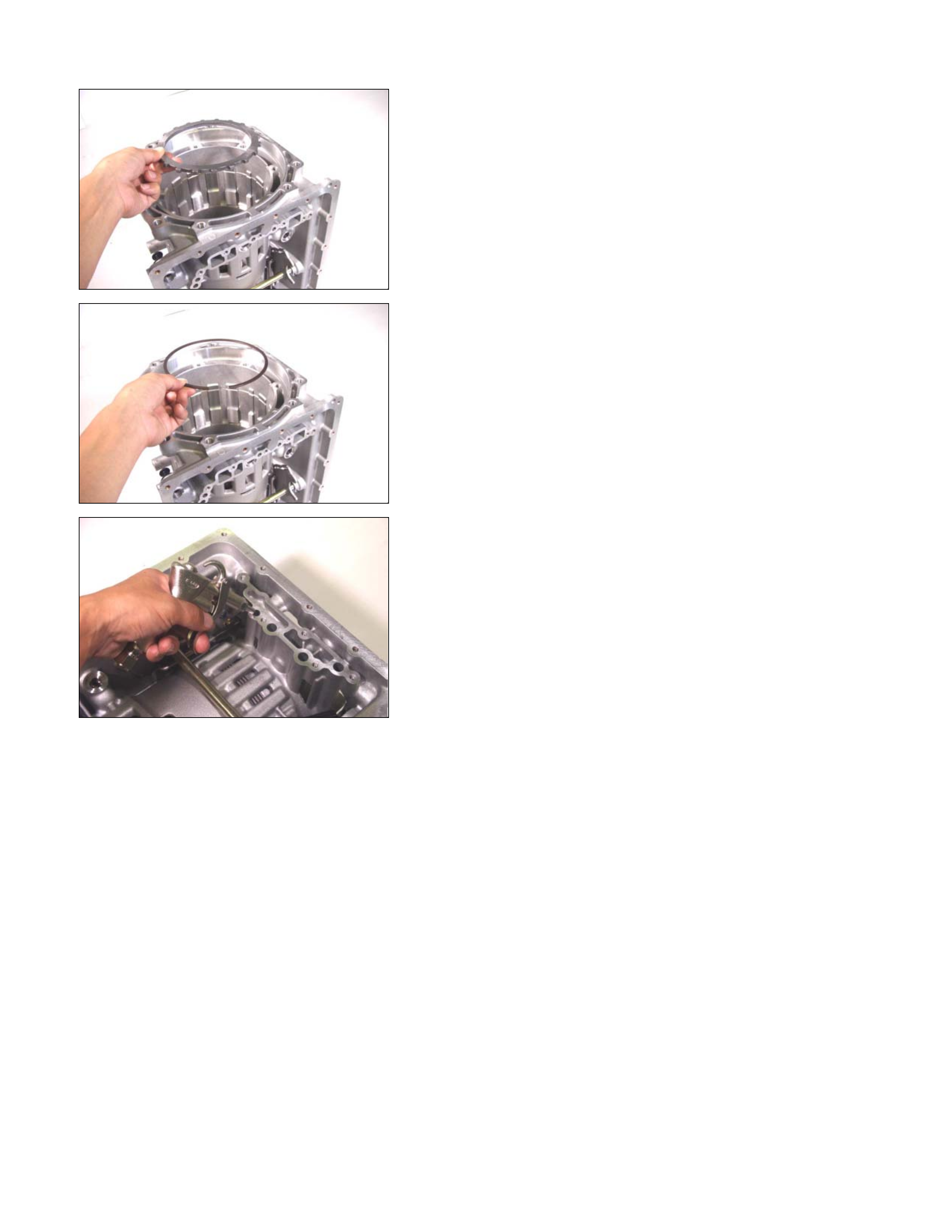

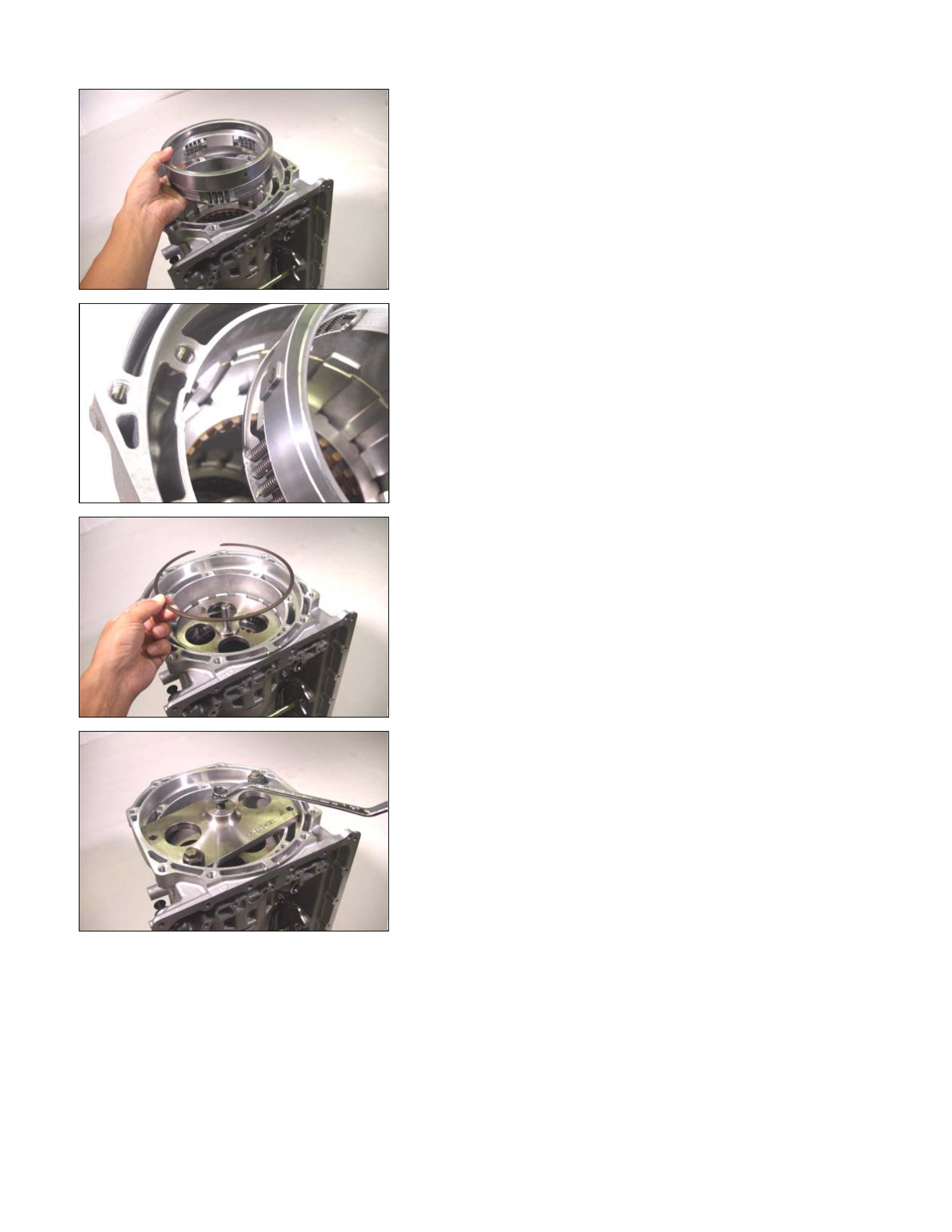

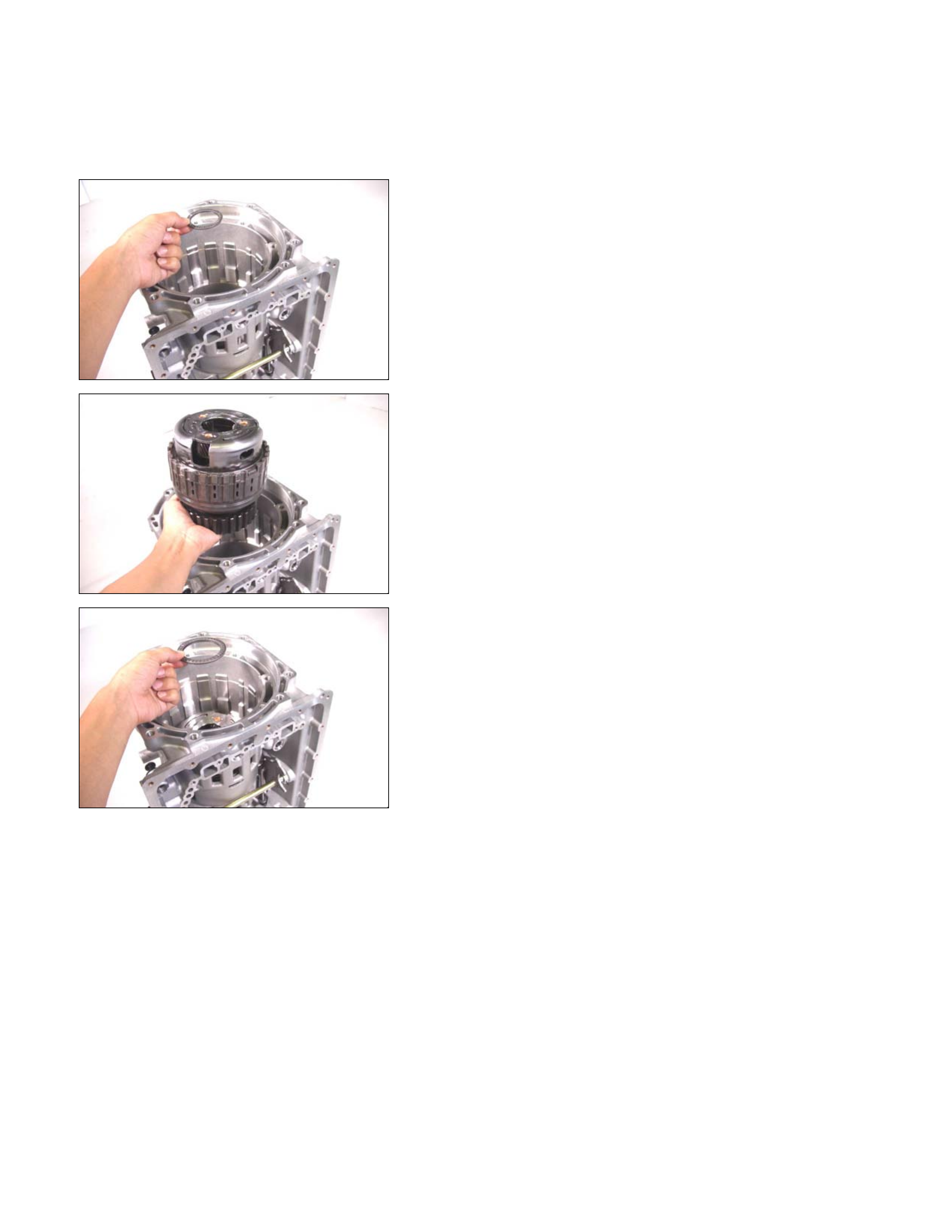

1. Transmission case

Rotate the transmission case so that the converter housing

installation surfaces are facing up.

02ASSY012

2. Bearing

Install the bearing to the low and one-way clutch inner race.

Refer to the item “Transmission Case” for more detailed

information.

NOTE:

Apply Vaseline to the bearing to prevent them from failing

during the installation procedure.

03ASSY013

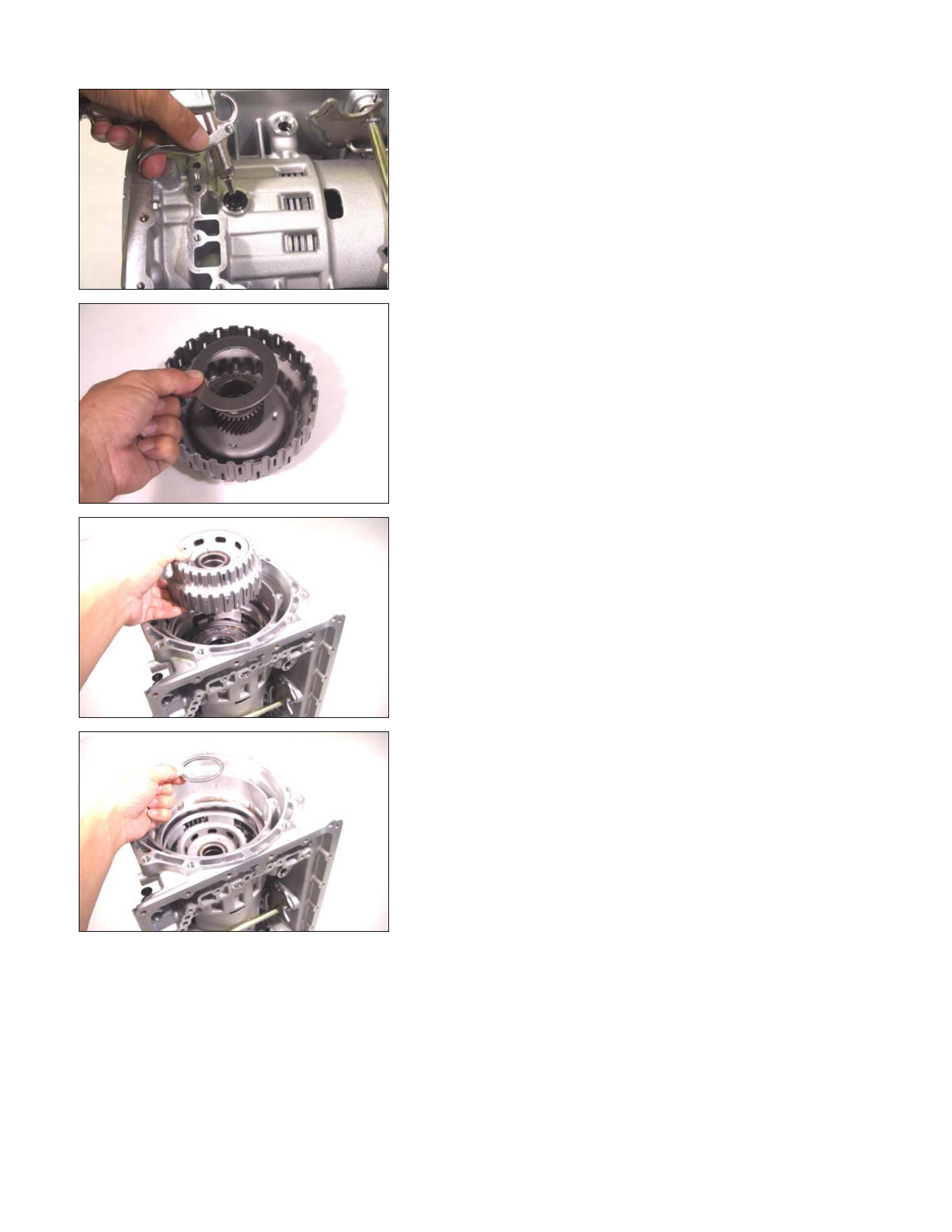

3. Carrier and low clutch assembly

Install the carrier and low clutch assembly to the

transmission case.

NOTE:

Do not allow the low clutch drum end to protrude beyond

the 2-4 brake plate contact surface (transmission case).

04ASSY014

4. Bearing

Install the bearing to the carrier and low clutch assembly.

05ASSY015

5. Driven plate, drive plate, retaining plate, and dish plate

(2 – 4 brake)

Install the 2-4 brake 5 driven plate (1), 5 drive plates (2),

retaining plate (3), and dish plate (4) in that order.

NOTE:

•

••

• The thickest driven plate (5.6 mm) must be installed

at the bottom (transmission case plate surface).

•

••

• Dish plate side with the identification mark must

face the retaining plate.

06ASSY016

07ASSY017

08ASSY018

248L300008

09U-SPG2

6. 2 – 4 brake spring

Install the 2-4 brake springs (3) to the transmission case.

RTW37AMF0001-X

10ASSY019

7. Return spring and 2 – 4 brake retainer

• Align the transmission case groove and the 2-4 brake

retainer projection.

• Install the return spring and the 2-4 brake retainer.

11ASSY028

12ASSY029

• Install the spring compressor to the transmission case.

Spring compressor: 5-8840-2764-0

NOTE:

Carefully center the spring compressor to prevent damage

to the return spring.

• Push the 2-4 brake retainer into place.

NOTE:

Do not push the brake retainer too far.

Damage to the return spring will result.

• Install the snap ring.

14ASSY031

17ASSY113

8. Sleeve and seal ring

• Install the new sleeve and seal ring to the transmission

case.

192-4B22

• Force compressed air (392 kPa/4.0 kg/cm 2) through the

transmission case oil passage to 2-4 brake operation.

If the 2-4 brake does not operate, the seal ring may be

damaged or the parts may have been installed in the

wrong order.

20ASSY037

9. Bearing race, front sun gear, and bearing

• Install the bearing race to the front sun gear.

NOTE:

Apply Vaseline to the bearing race and bearing to prevent

them from falling during the installation procedure.

21ASSY040

• Install the front sun gear to the transmission case.

22ASSY042

• Install the bearing to the front sun gear.

23ASSY045

10.High clutc h hub and bearing race

Install the bearing race to the high clutch hub.

NOTE:

Apply Vaseline to the bearing race.

24ASSY047

• Install the high clutch hub and the bearing race to the

transmission case.

25R&H42

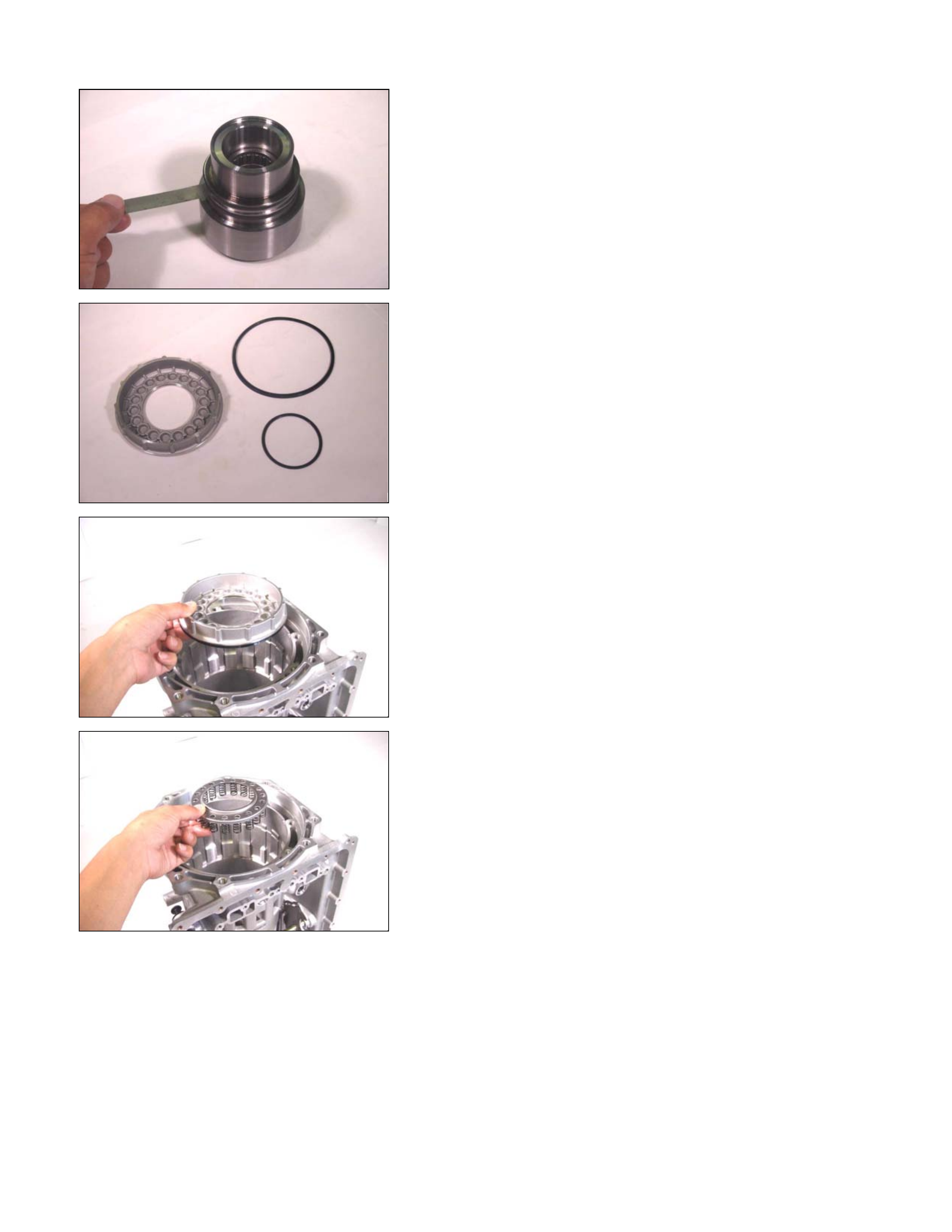

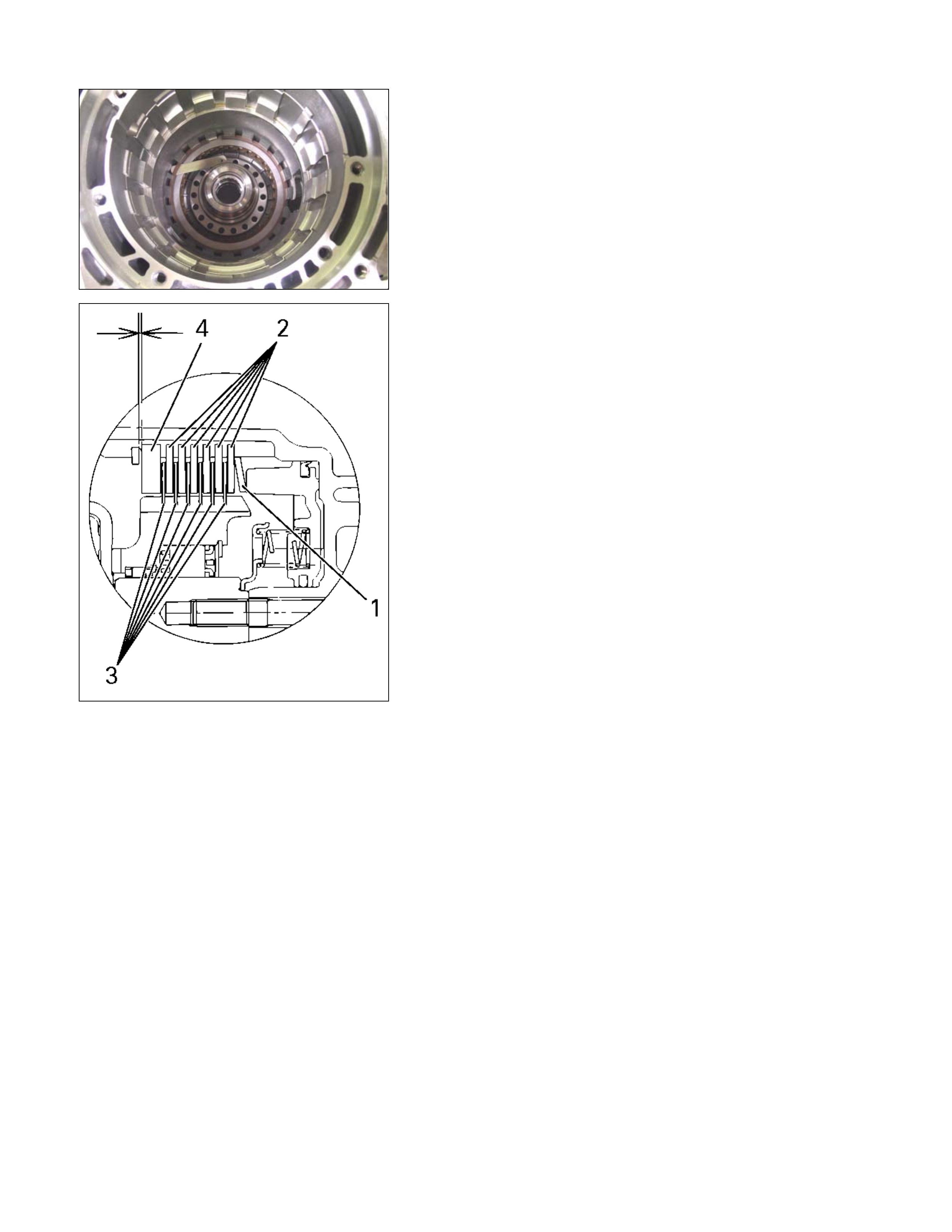

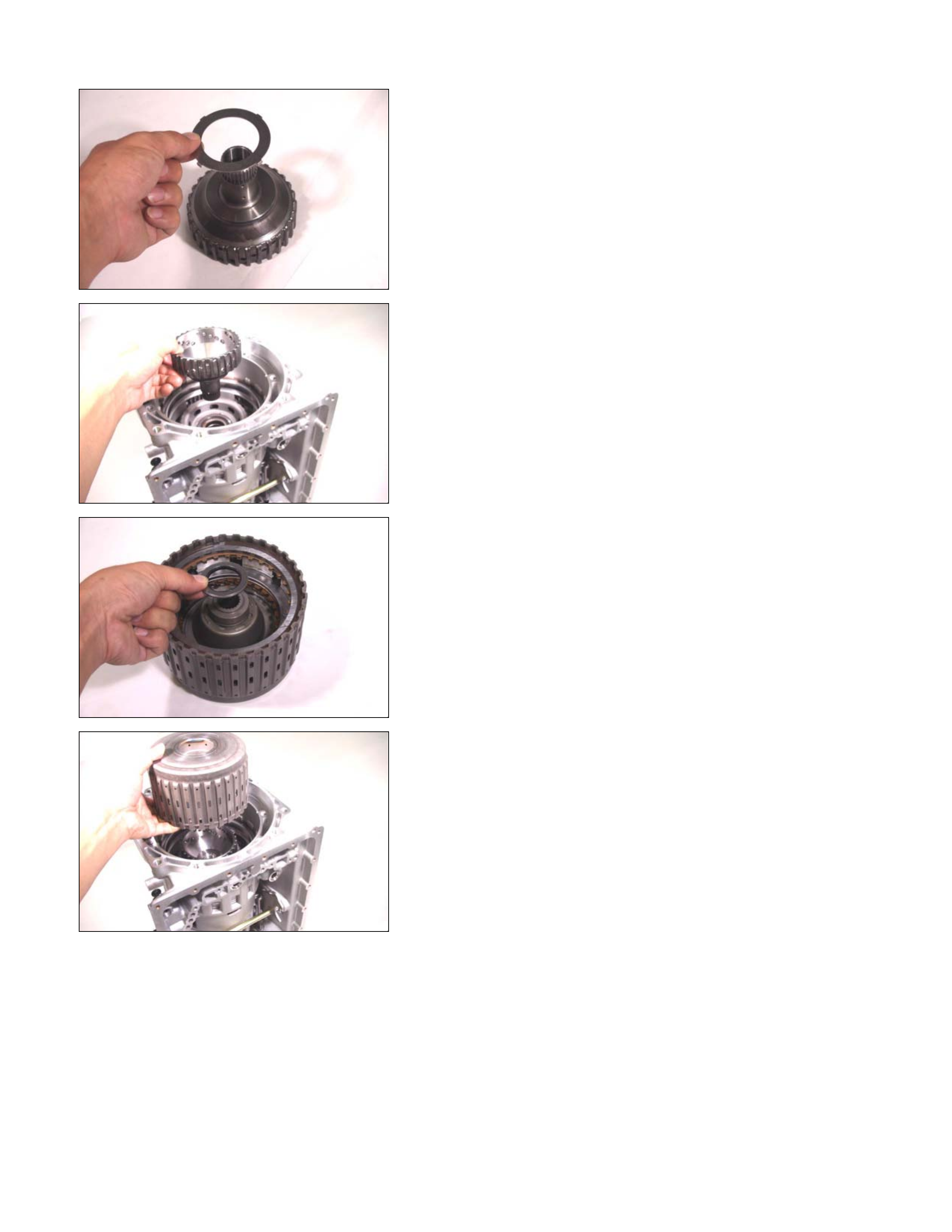

11.Clutch pack (reverse and high clutch assembly)

• Install the bearing (with bearing race) to the clutch pack.

NOTE:

•

••

• The black side (bearing race) of the bearing must

contact the clutch pack.

•

••

• Apply Vaseline to the bearing.

26ASSY049

• Install the clutch pack and bearing to the transmission

case.

27ASSY051

• Install the bearing to the clutch pack.

NOTE:

Apply Vaseline to the bearing.

A07L300002

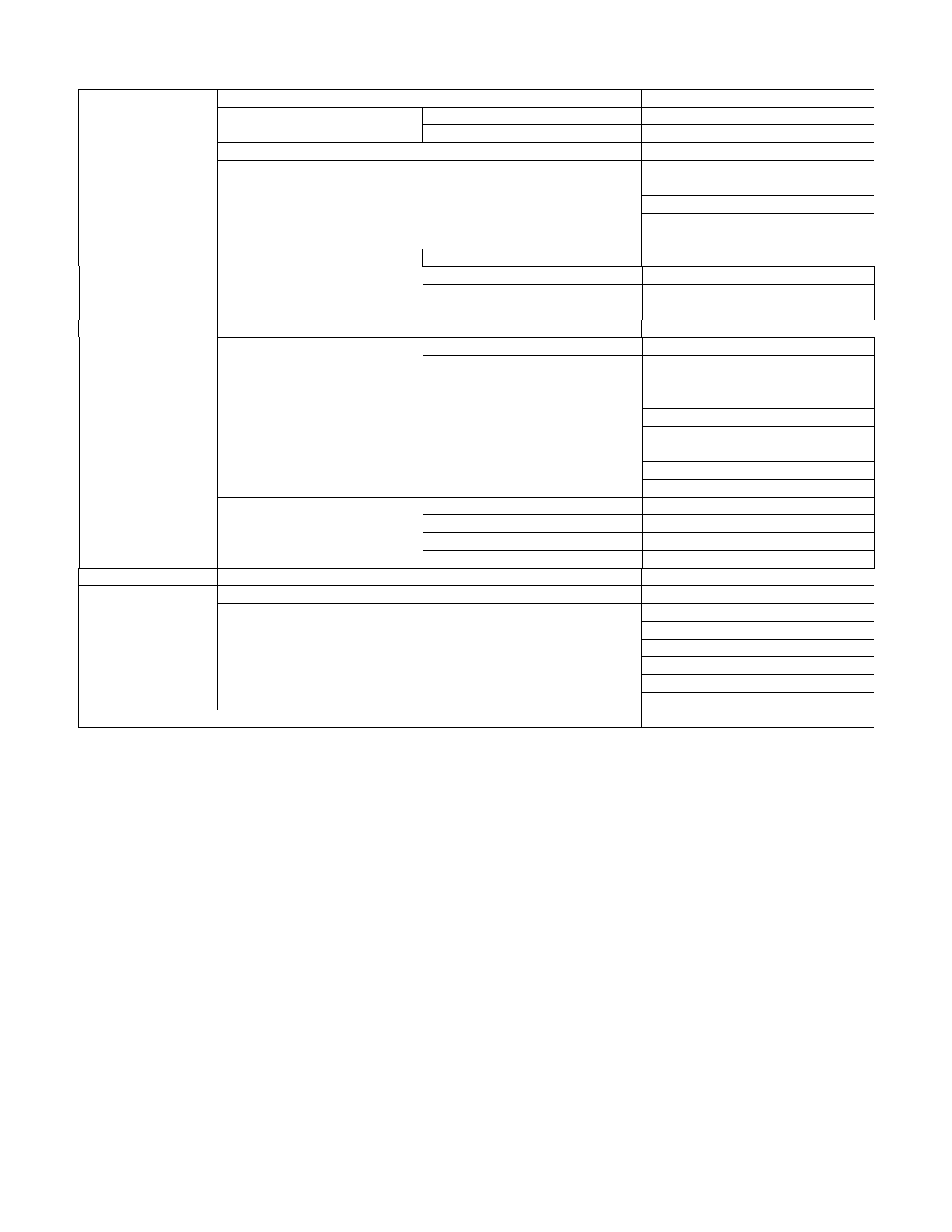

Total end play measurement

• Install the bearing race (oil pump) to the clutch pack.

• Measure the distance (A) between the oil pump

installation surface and the bearing race.

241L300003

• Measure the distance (B) between the bearing race

installation surface and the machined surface.

• Calculate the total end play using the following formula.

Total end play = distance (A) – distance (B)

If the measured and calculated end play is outside the

specified range, replace the existing bearing race with a

bearing race of the proper size (thickness).

Total end play = 0.25~0.55 mm (0.0098~0.0217 in)

Available oil pump bearing race thicknesses

1.4 mm (0.055 in)

1.6 mm (0.063 in)

1.8 mm (0.071 in)

2.0 mm (0.079 in)

2.2 mm (0.087 in)

2.4 mm (0.094 in)

28ASSY058

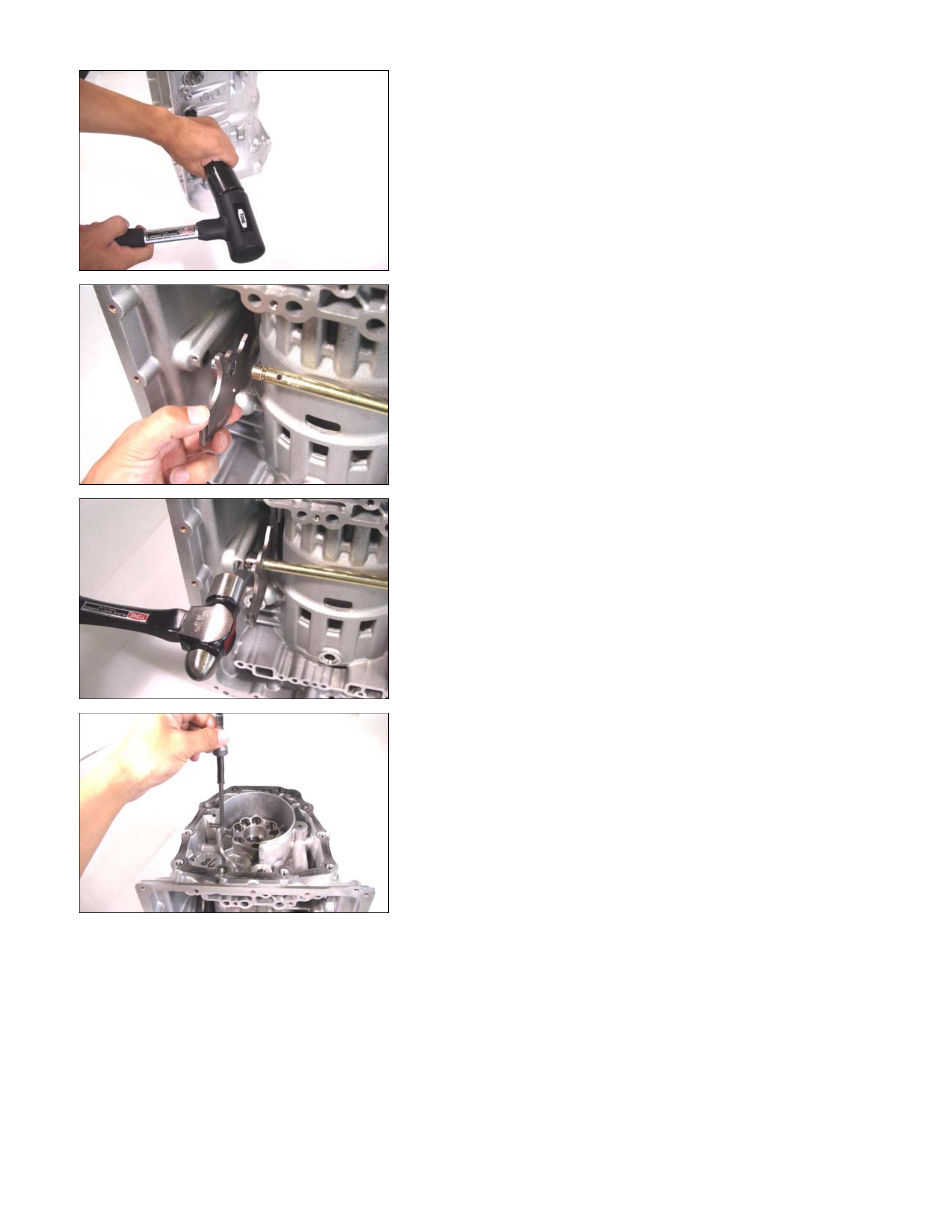

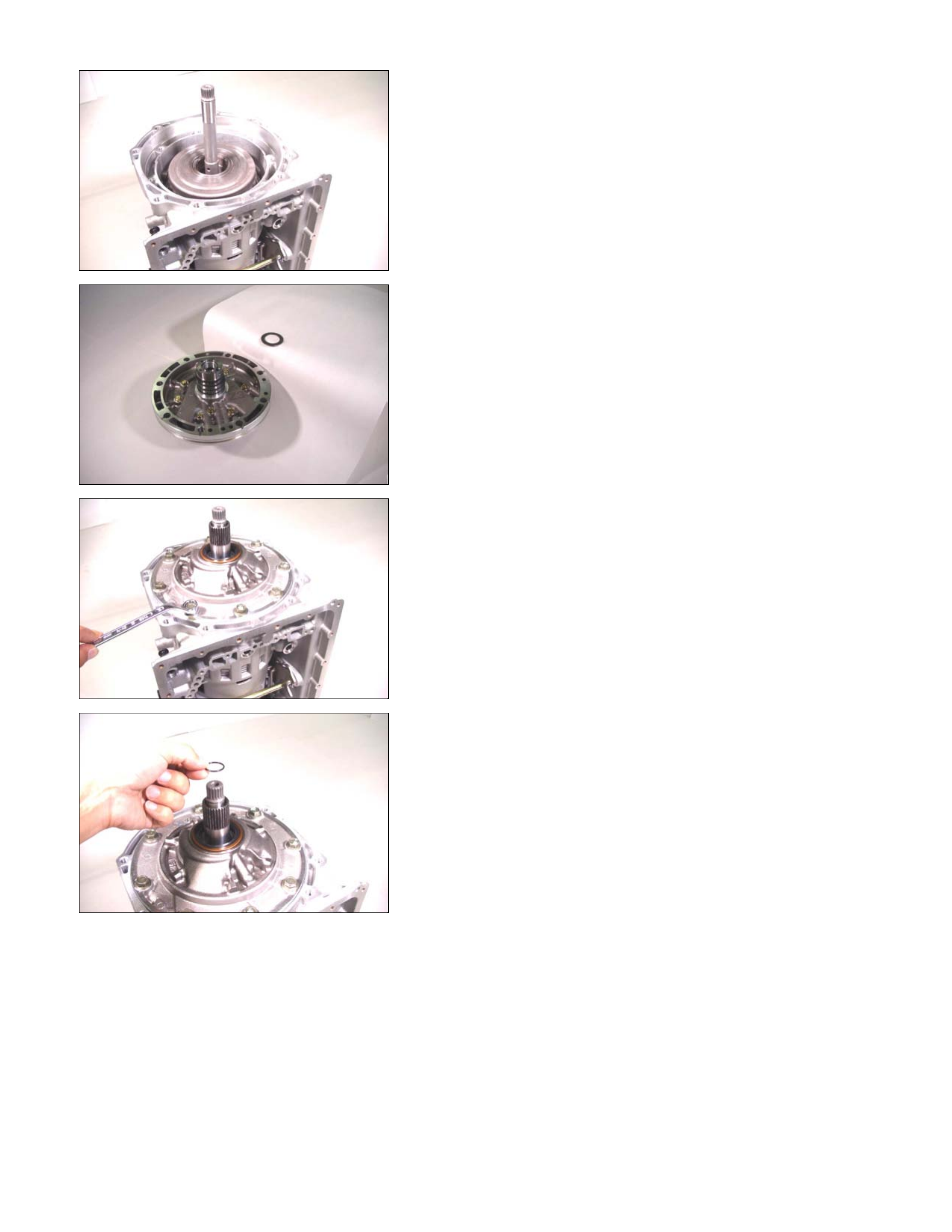

12.Input shaft

Install the input shaft.

29PUMP02

13.Oil pump assembly

• Install a new O-ring to the outside of the oil pump.

• Install the bearing race to the oil pump.

NOTE:

Apply Vaseline to the bearing race.

30ASSY067

• Apply ATF to the O-ring at the outside of the oil pump.

• Install the oil pump assembly to the transmission case.

•

A

pply sealing agent (TB1215) to the threaded surfaces

of the 8 fixing bolts and tighten to the specified torque.

Torque: 58 N⋅

⋅⋅⋅m (43 Ib⋅

⋅⋅⋅ft)

31ASSY068

14.O-ring

Install a new O-ring to the input shaft.

32ASSY116

15.Converter housing

Install the converter housing and tighten the bolts to the

specified torque.

Torque: 53 N⋅

⋅⋅⋅m (39 Ib⋅

⋅⋅⋅ft)

33ASSY075

16.Actuator support

Install the actuator support.

34ASSY077

17.Parking pawl, shaft, spring, and spacer

Install the parking pawl, the shaft, the spring, and the

spacer.

35ASSY082

36ASSY084

37ASSY086

38OUTPUT25

29ASSY089

18.Output shaft

• Install a new seal ring to the output shaft assembly.

• Measure the gap between the seal ring and the ring

groove.

If the gap is outs ide the specif ied r ange, the output shaf t

must be replaced.

Seal ring and ring groove gap:

0.10~0.25 mm (0.0039~0.0098 in)

• Install the bearing to the case.

NOTE:

•

••

• Apply Vaseline to the bearing (with bearing race).

•

••

• T he black side (bearing race) of th e bearin g must be

visible.

40ASSY091

• Push the output shaft into place.

19.Rear extension (2WD) or adapter case (4WD)

• Use the oil seal installer to install the oil seal to the rea

r

extension (2WD) or adapter case (4WD).

Oil seal installer:

5-8840-2769-0 (2WD)

5-8840-2770-0 (4WD)

41ASSY096

• Install the bearing (with bearing race) to the rea

r

extension (2WD) or adapter case (4WD).

NOTE:

•

••

• T he black side (bearing race) of th e bearing must be

visible.

•

••

• Apply Vaseline to the bearing.

249L300005

•

A

pply sealing agent (TB1216B) to the rear extension

(2WD) or adapter case (4WD) contact surfaces.

249L300006

• Install the rear extension (2W D) or adapter case (4W D)

to the transmission case and tighten the 10 bolts to the

specified torque.

Torque: 53 N⋅

⋅⋅⋅m (39 Ib⋅

⋅⋅⋅ft)

43ASSY119

20.Control valve assembly

• Align the manual valve and the manual plate of the

transmission case.

• Install the control valve assembly and tighten the 12

fixing bolts to the specified torque.

Number of bolts Length Color

10 (A) 40 mm (1.57 in) Gold

2 (B) 30 mm (1.18 in) Gold

44ASSY121

Torque: 8 N⋅

⋅⋅⋅m (69 Ib⋅

⋅⋅⋅in)

45CV29

• Connect the harness assembly and control valve

assembly connectors.

244L300001

21.Oil pan

• Install a new gasket and the oil pan.

• Tighten the bolts to the specified torque.

Torque: 8 N⋅

⋅⋅⋅m (69 Ib⋅

⋅⋅⋅in)

47INH-SW01

22.Inhibitor switch

• Secure the inhibitor switch (1) by hand-tightening the 2

bolts.

• Use the inhibitor switch set plate to align the neutral

holes (manual shaft and inhibitor switch).

Turn the inhibitor switch to adjust it.

Inhibitor switch set plate: 5-8840-2763-0

NOTE:

Inhibitor switch adjustment is very important.

If the inhibitor switch is not correctly adjusted, the

automatic transmission will not function normally.

• Tighten the 2 inhibitor switch bolts to the specified

torque.

Torque: 5.5 N⋅

⋅⋅⋅m (48 Ib⋅

⋅⋅⋅in)

• Remove the holding fixture from the transmission case.

240L300001

23.Speed sensor and turbine sensor

• Apply ATF to the new O-rings and install them the speed

sensor (2) and the turbine sensor (3).

• Install the speed sensor and the turbine sensor. Tighten

the bolt to the specified torque.

Torque: 6 N⋅

⋅⋅⋅m (52 Ib⋅

⋅⋅⋅in)

24.Torque converter

• Pour the new ATF into the torque converter.

• Shake the torque converter to thoroughly clean the

inside.

• Drain the ATF from the torque converter.

• Pour the new ATF into the torque converter.

NOTE:

If significant amounts of foreign material (clutch facing,

metallic fragments, etc.) are found in the automatic

transmission at time of disassembly, the existing torque

converter must be replaced with a new one.

A07L300003

• Install the torque converter.

• Measure the torque converter end play (A).

If the measured value is greater than the specified

minimum, the torque converter is correctly installed.

Torque converter end pay (Minimum): 67 mm (2.64

in)

Service Standard

Name ATF DEXRON

ATF Quantity L 9.2 – 9.6

Seal ring clearance mm (in) 0.10 – 0.25 (0.0039 – 0.0098)

Housing and inner rotor side clearance mm (in) 0.02 – 0.04 (0.0008 – 0.0016)

Oil pump

Outer rotor and crescent clearance mm (in) 0.02 – 0.15 (0.0008 – 0.0059)

Number of drive plate / driven plate 7/7

Standard mm (in) 2.0 (0.079) Drive plate facing thickness Limit mm (in) 1.8 (0.071)

Retaining plate and snap ring clearance mm (in) 0.9 – 1.3 (0.035 – 0.051)

3.8 (0.150)

4.0 (0.157)

4.2 (0.165)

4.4 (0.173)

4.6 (0.181)

Available low clutch retaining plate thickness mm (in)

4.8 (0.189)

Number of coil 9.9

Outside diameter mm (in) 9.7 (0.382)

Free length mm (in) 36.4 (1.433)

Low clutch

Return spring

Linear diameter mm (in) 1.2 (0.047)

Number of drive plate / driven plate 5/5

Standard mm (in) 2.0 (0.079) Drive plate facing thickness Limit mm (in) 1.8 (0.071)

Retaining plate and snap ring clearance mm (in) 1.2 – 1.6 (0.047 – 0.063)

4.6 (0.181)

4.8 (0.189)

5.0 (0.197)

5.2 (0.205)

Available high clutch retaining plate thickness mm (in)

5.4 (0.213)

Number of coil 10.2

Outside diameter mm (in) 8.0 (0.315)

Free length mm (in) 27.1 (1.067)

High clutch

Return spring

Linear diameter mm (in) 1.1 (0.043)

Number of drive plate / driven plate 2/2

Standard mm (in) 2.0 (0.079) Drive plate facing thickness Limit mm (in) 1.8 (0.071)

Retaining plate and snap ring clearance mm (in) 0.6 – 0.9 (0.0236 – 0.035)

4.8 (0.189)

5.0 (0.197)

5.2 (0.205)

Reverse clutch

Available reverse clutch retaining plate thickness mm (in)

5.4 (0.213)

Low one-way clutch Seal ring clearance mm (in) 0.10 – 0.25 (0.0039 – 0.0098)

Number of drive plate / driven plate 6/6

Standard mm (in) 2.0 (0.079) Drive plate facing thickness Limit mm (in) 1.8 (0.071)

Retaining plate and snap ring clearance mm (in) 0.7 – 1.1 (0.028 – 0.043)

5.2 (0.205)

5.4 (0.213)

5.6 (0.220)

5.8 (0.228)

Low & reverse brake

Available low & reverse brake retaining plate thickness mm (in)

6.0 (0.236)

Number of coil 4.8

Outside diameter mm (in) 11.2 (0.441)

Free length mm (in) 22.3 (0.878)

Return spring

Linear diameter mm (in) 1.1 (0.043)

Number of drive / driven plate 5/5

Standard mm (in) 2.0 (0.079)Drive plate facing thickness Limit mm (in) 1.8 (0.071)

Retaining plate and retaining plate clearance mm (in) 1.0 – 1.4 (0.039 – 0.055)

5.4 (0.213)

5.6 (0.220)

5.8 (0.228)

6.0 (0.236)

6.2 (0.244)

Available 2-4 brake retaining plate thickness mm (in)

6.4 (0.252)

Number of coil 10.2

Outside diameter mm (in) 6.9 (0.272)

Free length mm (in) 22.5 (0.886)

2-4 brake

Return spring

Linear diameter mm (in) 1.1 (0.043)

Output shaft Seal ring clearance mm (in) 0.10 – 0.25 (0.0039 – 0.0098)

Total end play mm (in) 0.25 – 0.55 (0.0098 – 0.0217)

1.4 (0.055)

1.6 (0.063)

1.8 (0.071)

2.0 (0.079)

2.2 (0.087)

Total end play Available oil pump bearing race thickness mm (in)

2.4 (0.094)

Torque converter end play mm (in) 67.0 (2.638)

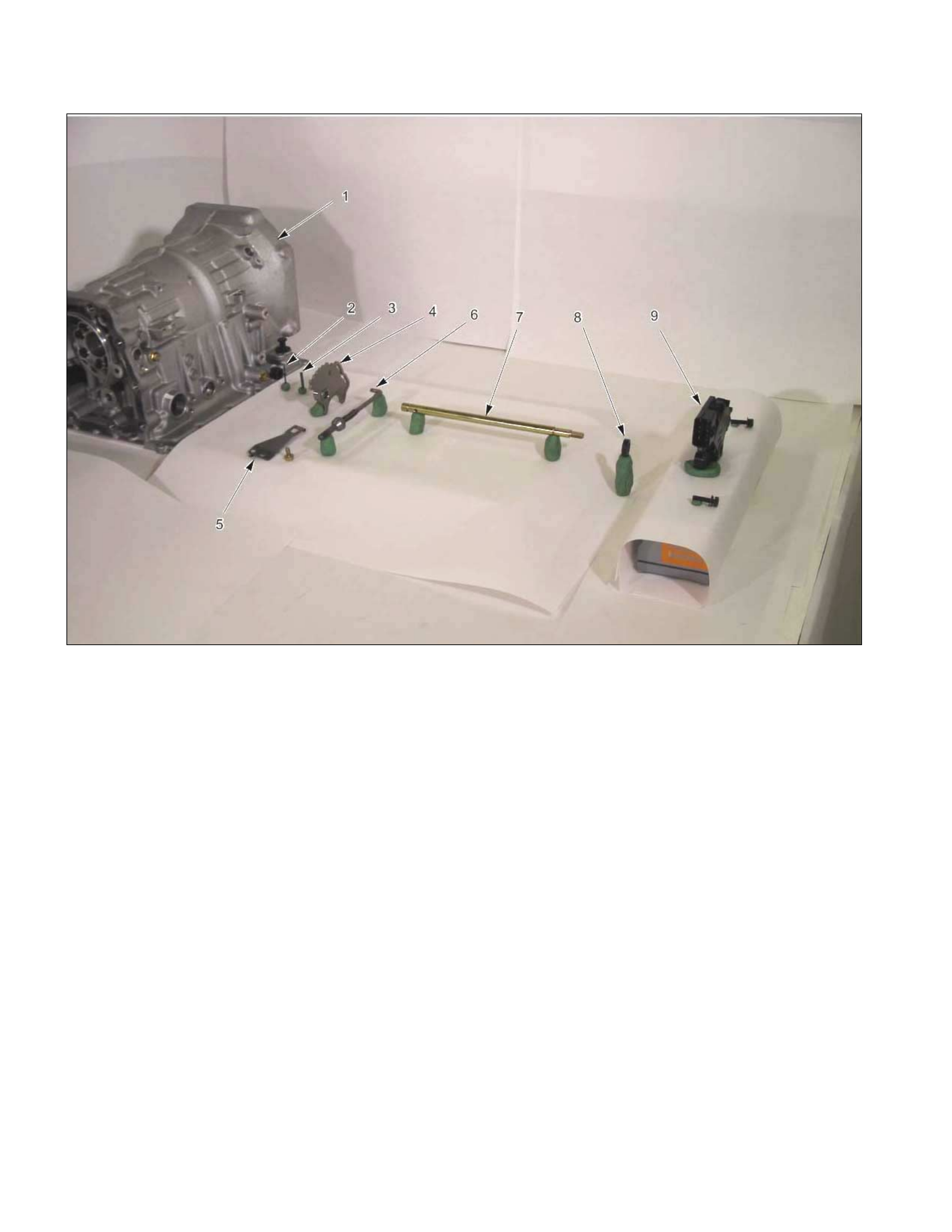

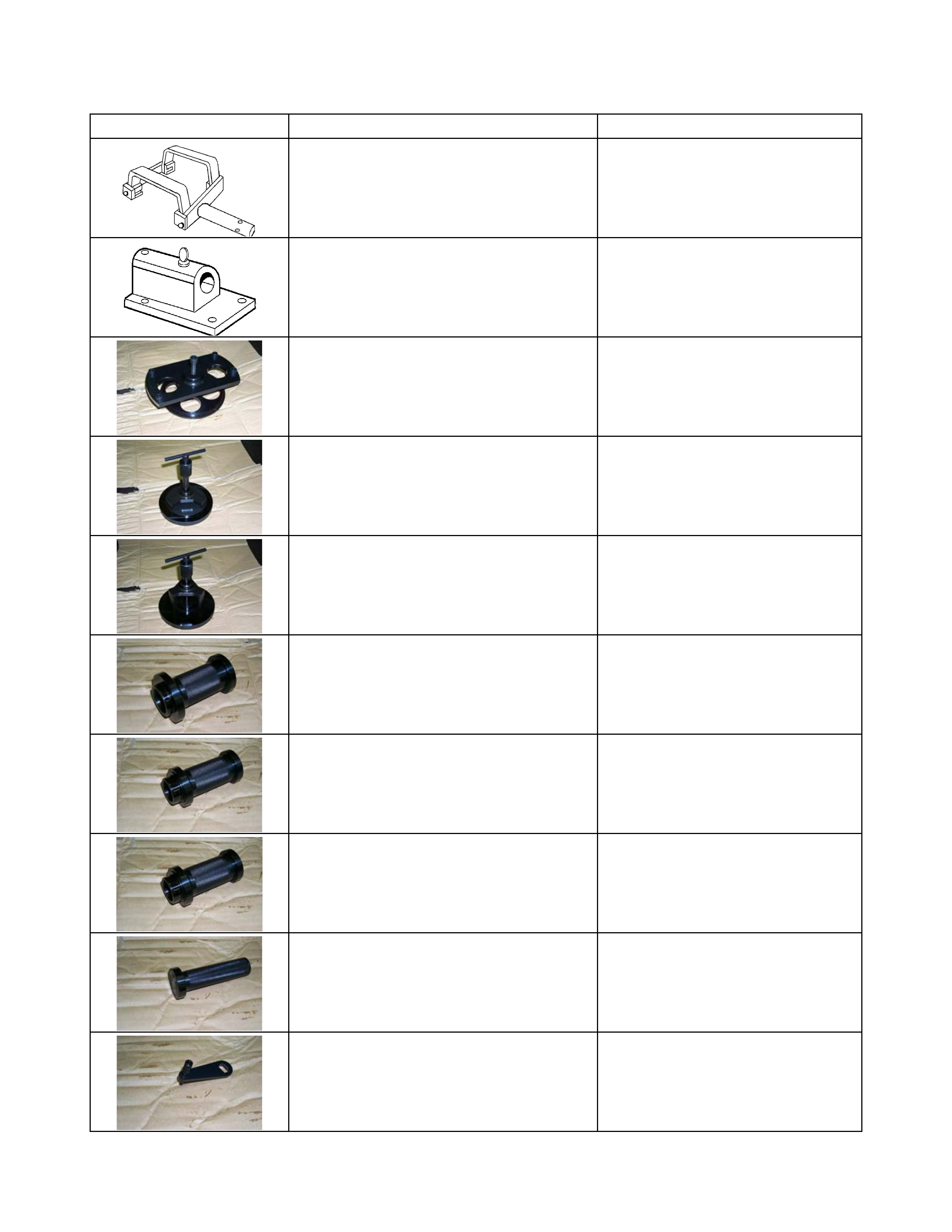

Special Service Tool

ILLUSTRATION PART NO. PART NAME

5-8841-0841-0

Holding Fixture

5-8840-0003-0

Holding Fixture Base

5-8840-2764-0

2-4 Brake Spring Compressor

5-8840-2767-0

High Clutch Spring Compressor

5-8840-2759-0

Low Clutch Spring Compressor

5-8840-2761-0

Oil Pump Oil Seal Installer

5-8840-2769-0

Rear Extension Oil Seal Installer

5-8840-2770-0

Rear Adapter Oil Seal Installer

5-8840-2758-0

Manual Shaft Oil Seal Installer

5-8840-2763-0

Inhibitor Switch Set Plate