SECTION 7B1 – MANUAL

TRANSMISSION MUA5G

MUA 5G/5S ( 4×

××

×2)

Service Precaution

Gen era l De scriptio n

Rear Oil Seal (4×

××

×2)

Transmission (4×

××

×2)

Disassembled View

Removal

Installation

Transmission Case

Major Component

Disassembly

Reassembly

Intermediate Plate w ith Gear Assembly, Detent,

Shift A rm, Shift Rod, and Interlock Pin

Disassembled View

Disassembly

Inspection and Repair

Reassembly

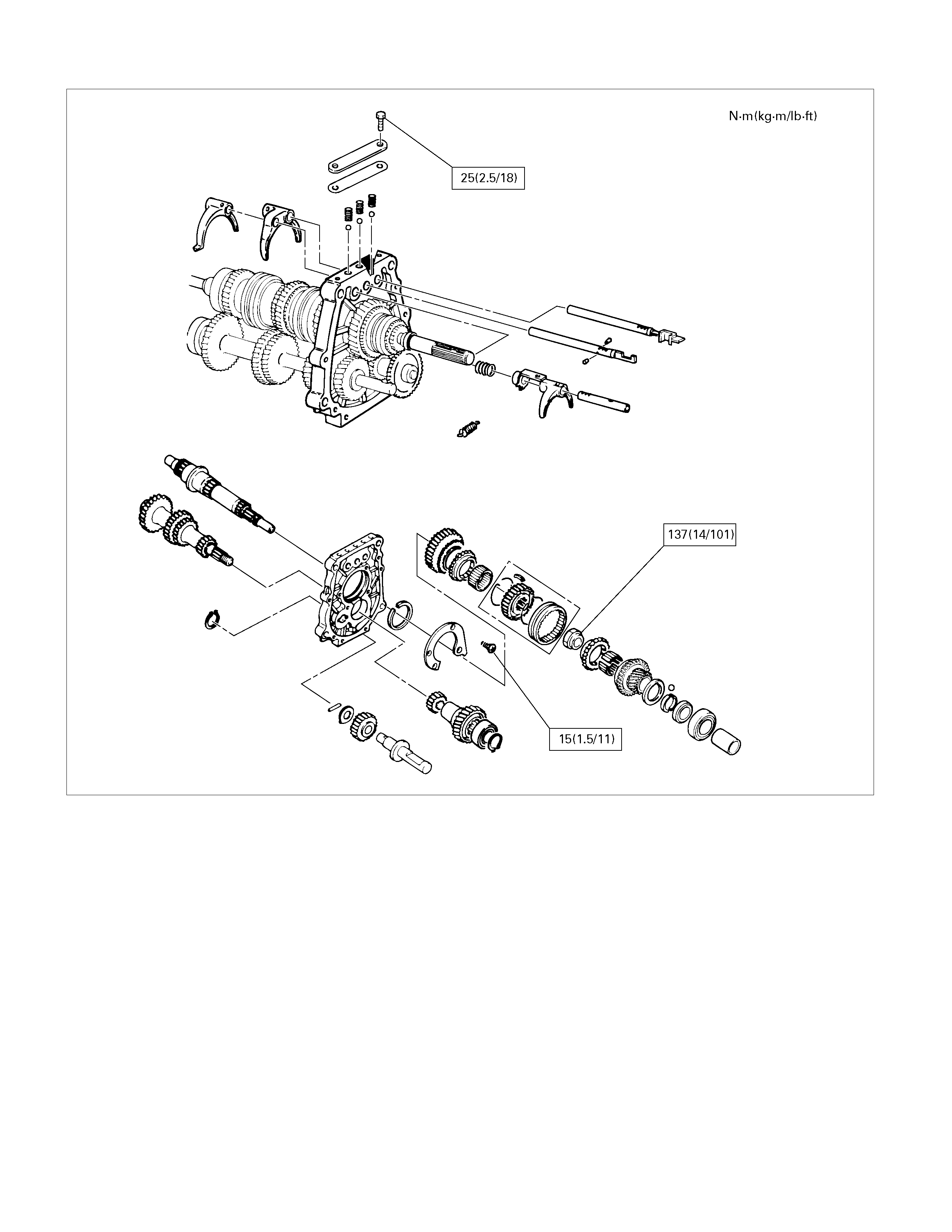

Reverse Gear and 5th Gear

Disassembled View

Disassembly

Inspection and Repair

Reassembly

Top Gear Shaft, Main Gear Shaft,

and Counter Gear Shaft

Disassembled View

Disassembly

Inspection and Repair

Reassembly

Main Data and Specifications

Troubleshooting

Special Tools (MUA)

MUA5G (4×

××

×4)

Service Precaution

General Description

Transmission (4×

××

×4)

Disassembled View

Removal

Installation

Transmission Case

Maj or Compon ent

Disassembly

Reassembly

Intermediate Plate with Gear Assembly, Detent,

Shift A rm, Shift Rod, and Interlock Pin

Disassembled View

Disassembly

Inspection and Repair

Reassembly

Reverse Gear and 5th Gear

Disassembled View

Disassembly

Inspection and Repair

Reassembly

Top Gear Shaft, Main Gear Sh aft,

and Counter Gear Shaft

Disassembled View

Disassembly

Inspection and Repair

Reassembly

Main Data and Specifications

Troubleshooting

Special Tools (MUA)

Techline

Techline

MUA 5G/5S (4×

××

×2)

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener.

When you install fasteners, use the correct

tightening sequence and specifications. Following

these instructions can help you avoid damage to

parts and systems.

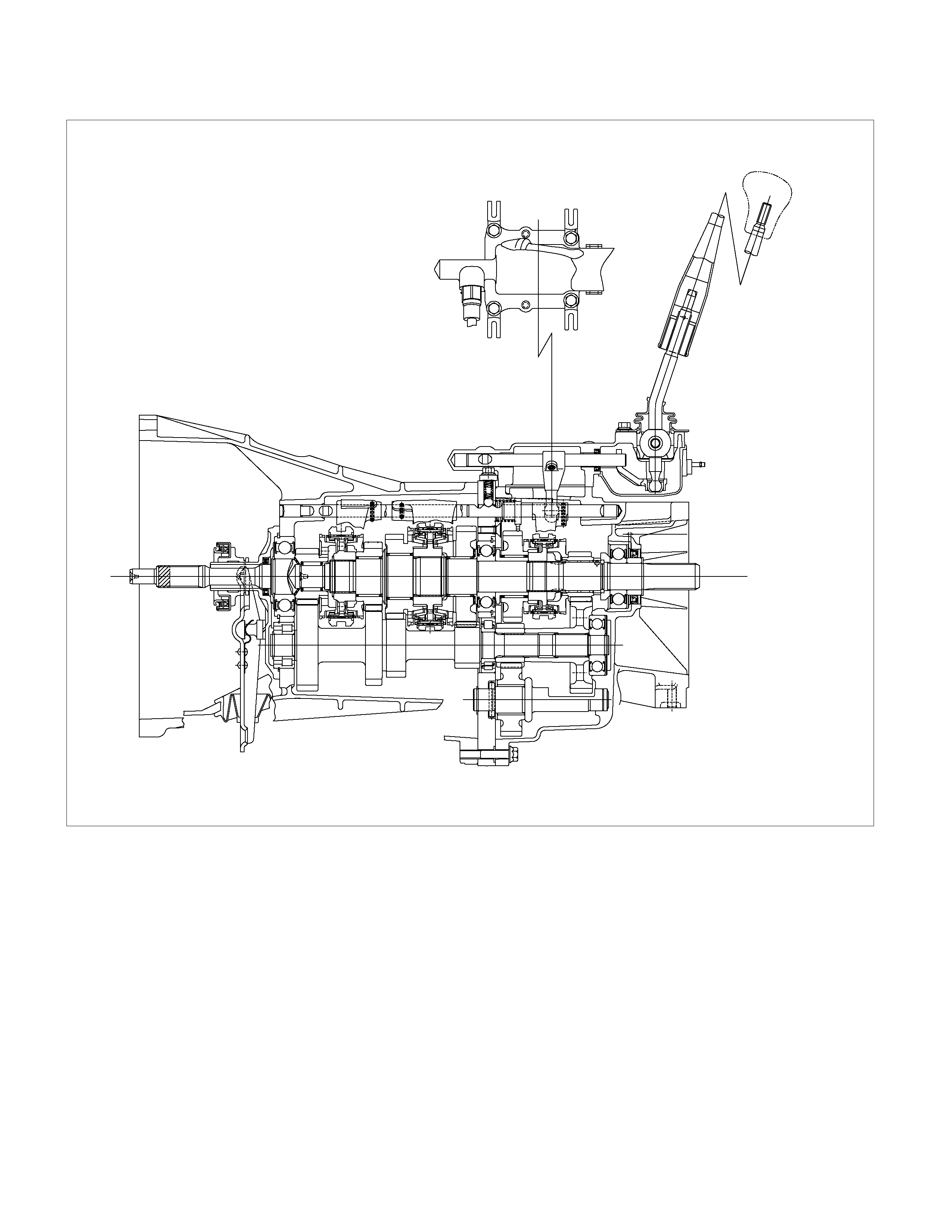

General Description

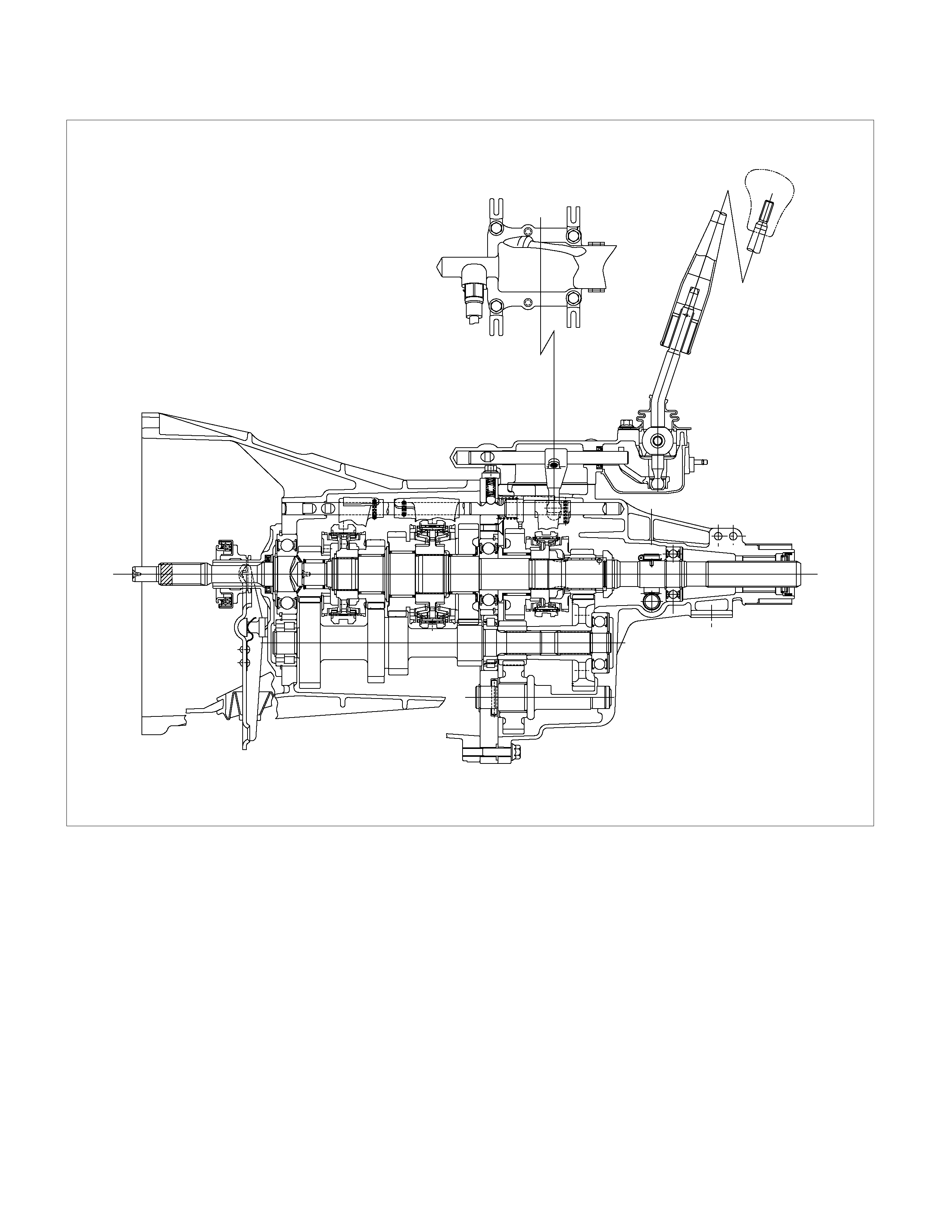

MUA 5G/5S Transmission (4×

××

×2)

A07R300006

The MUA5G is a constant mesh transmission,

synchronised in all speeds. The transmission has been

designed to provide both low shift-effort and low gea

r

noise.

Principle parts of the transmission are the integral clutch

housing, the intermediate plate, the rear cover, and the

gears.

The transmission control box is built into the

transmission.

Rear Oil Seal (4×

××

×2)

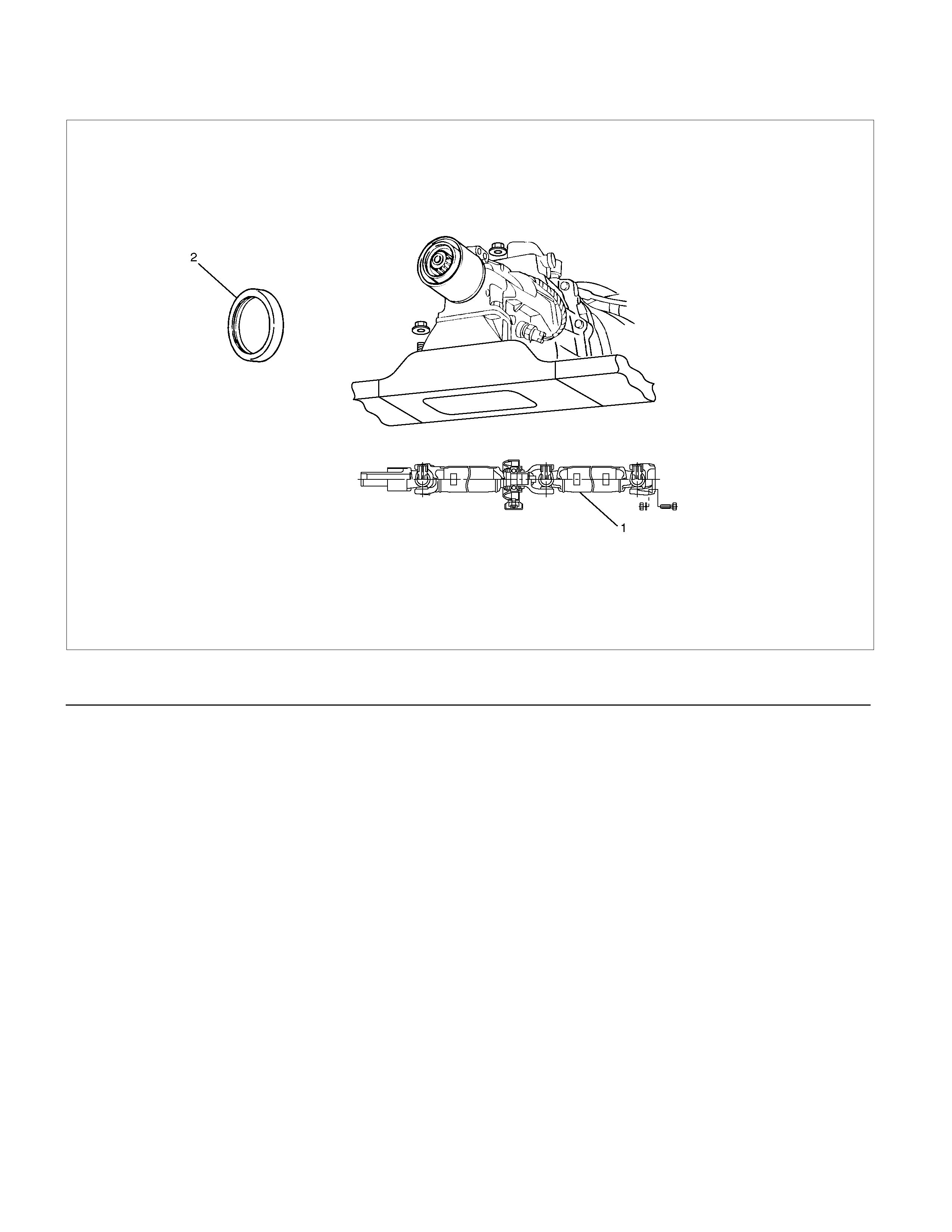

Disassembled View

220R300030

Legend

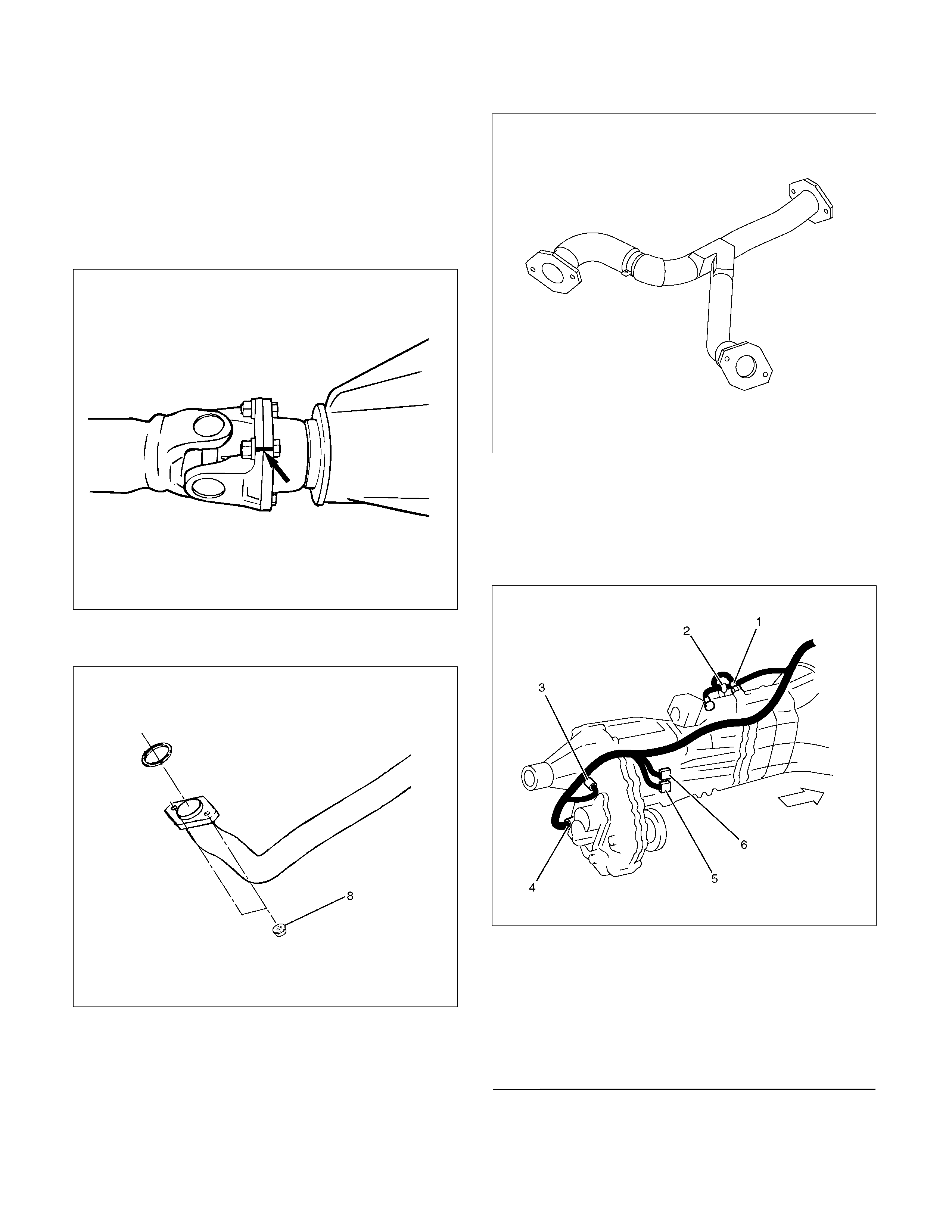

(1) Rear Propeller Shaft (2) Rear Oil Seal

Removal

1. Raise and support vehicle with suitable jack

stands.

2. Remove propeller shaft flange yoke bolts and nuts

at the differential side.

3. Remove center bearing from crossmenber.

4. Remove prepeller shaft from the transmission

main shaft spline.

Refre to the section “Rear Propeller Shaft”.

5. Use a screwdriver to pry the rear oil seal from the

rear cover.

Installation

1. Install a new oil seal (2) using the installer 5-8522-

0050-0.

220RS044

2. Insert the splined yoke into the transimission

mainshaft spline.

3. Install the propeller shaft flange yoke to the drive

pinion flange.

Torque : 63 N·m (6.4 kg·m/46 lb·ft)

4. Install center bearing on crossmember.

Torque : 69 N·m (7.0 kg·m/51 lb·ft)

5. Check transmission fluid level.

6. Lower vehicle.

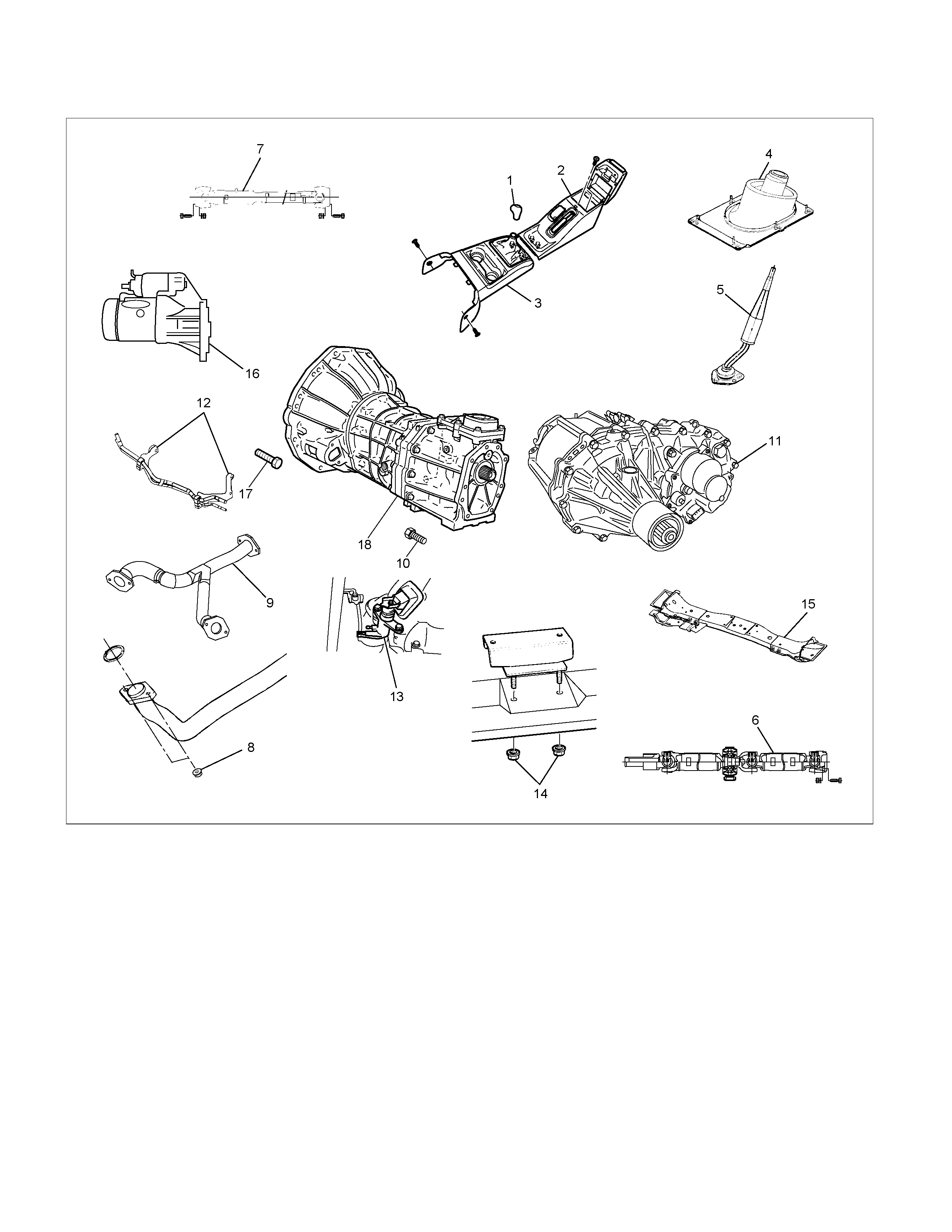

Transmission (4×

××

×2)

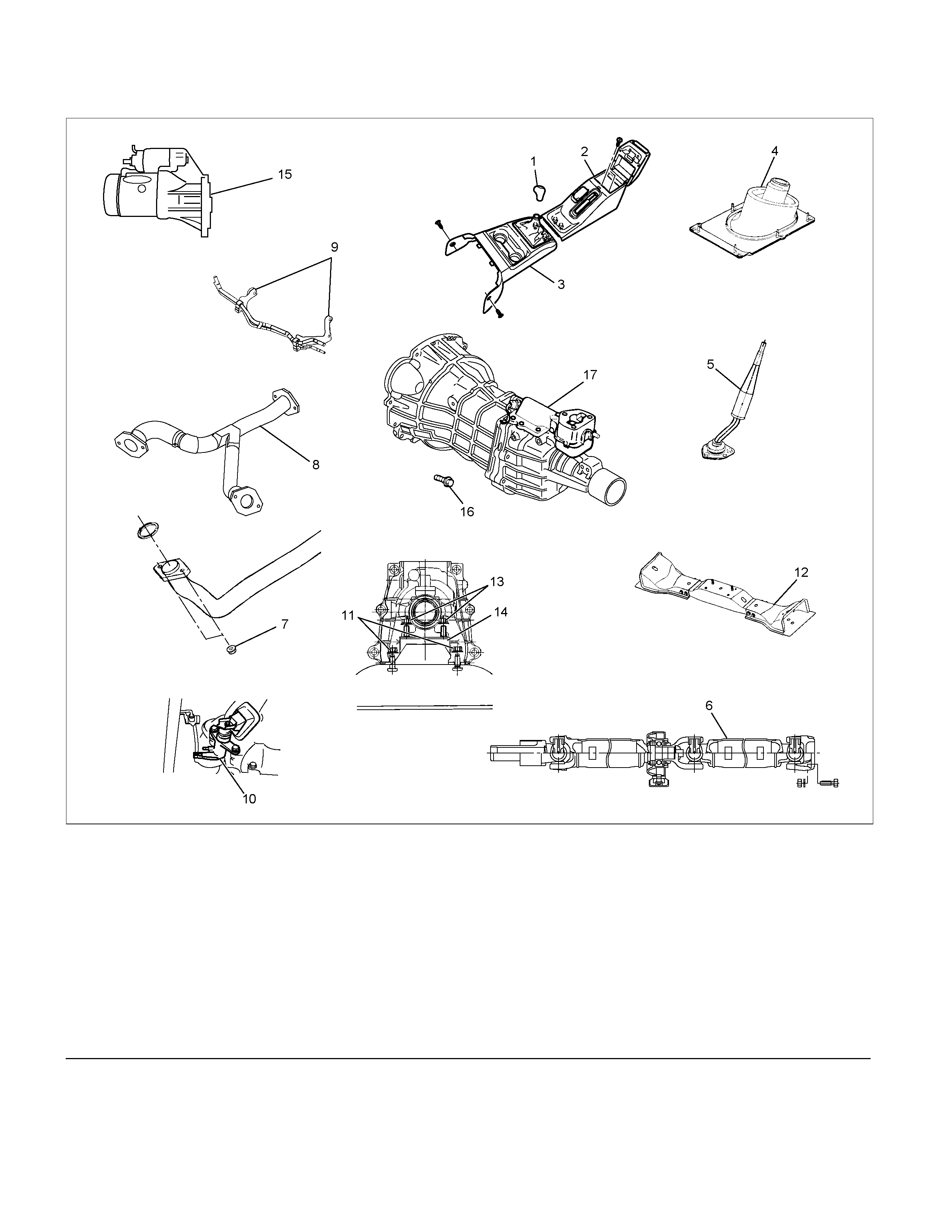

Disassembled View

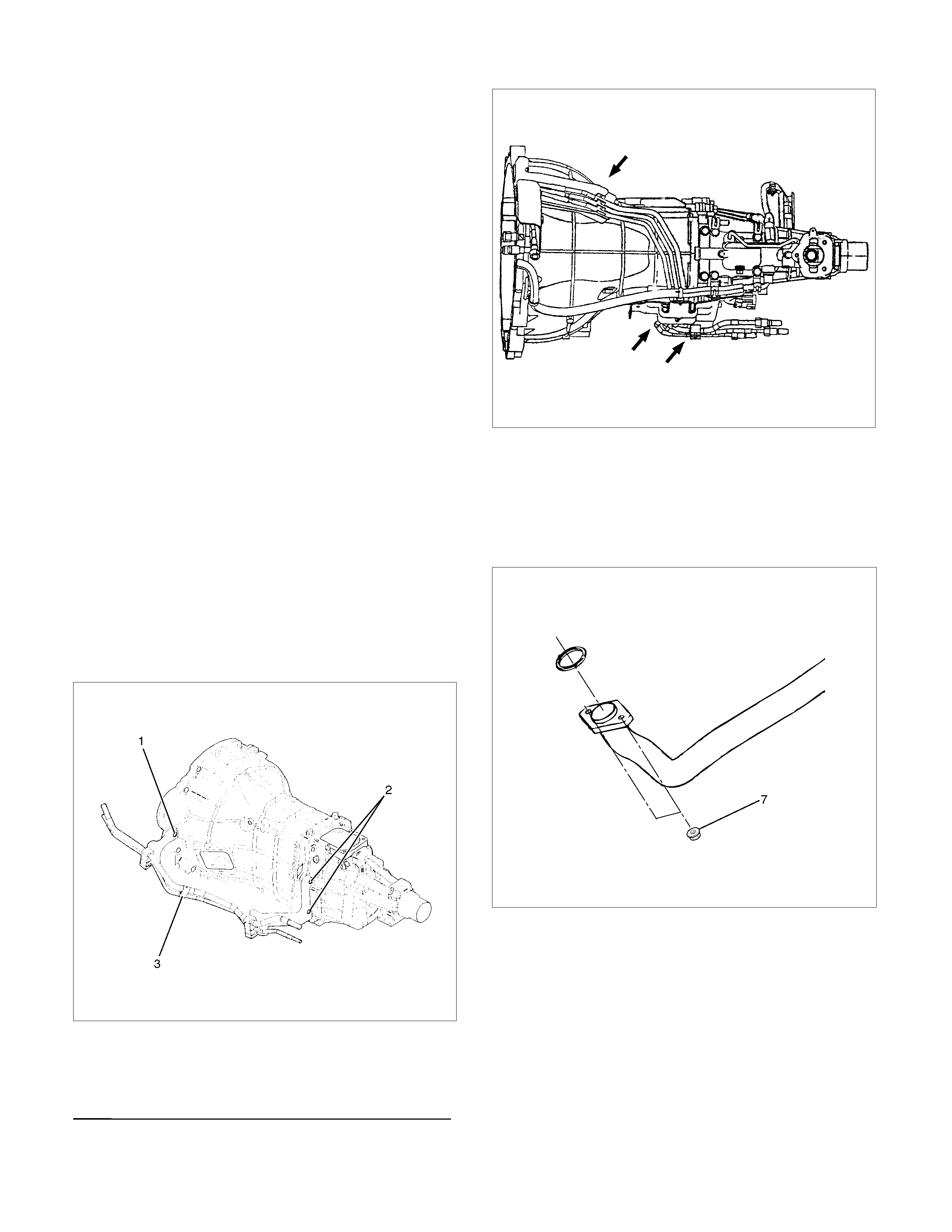

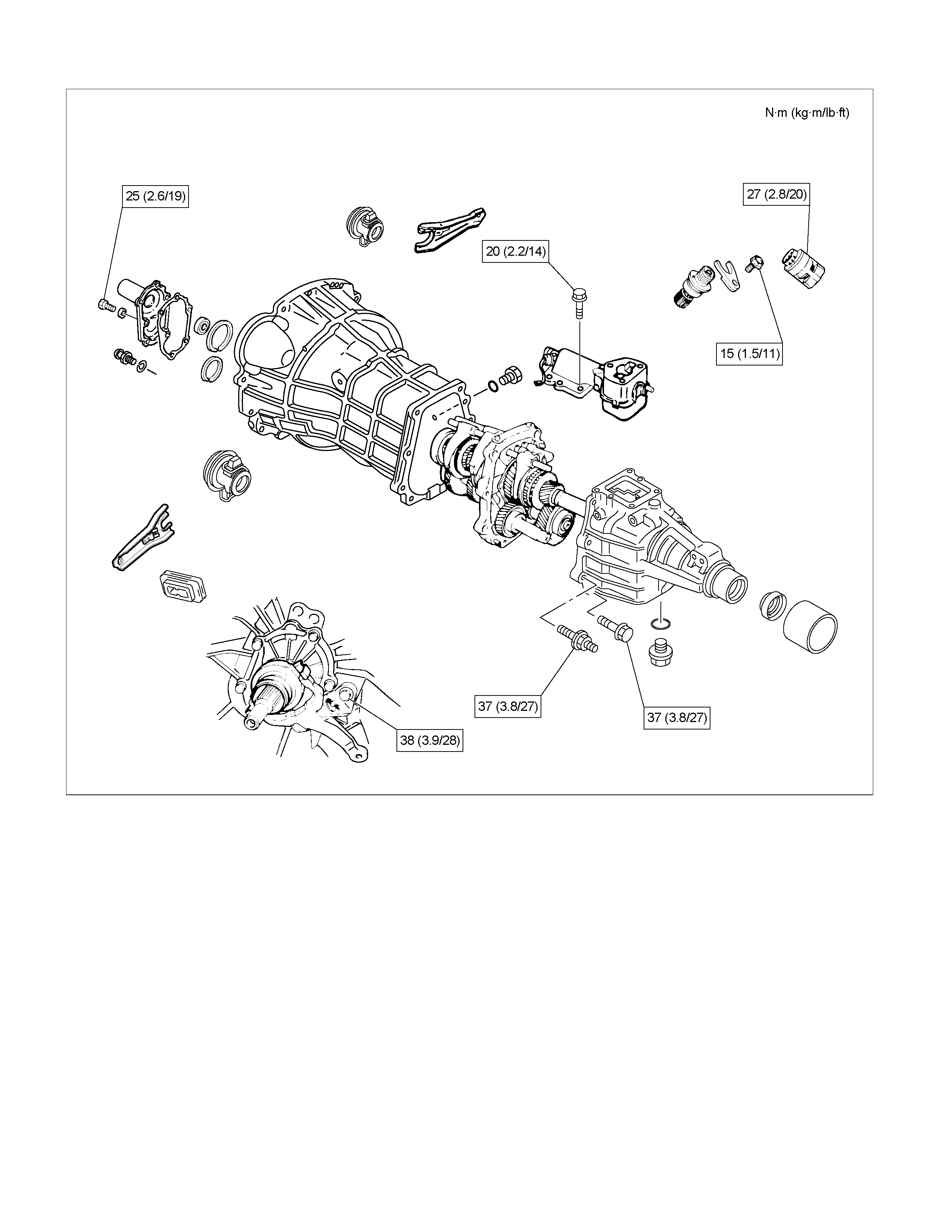

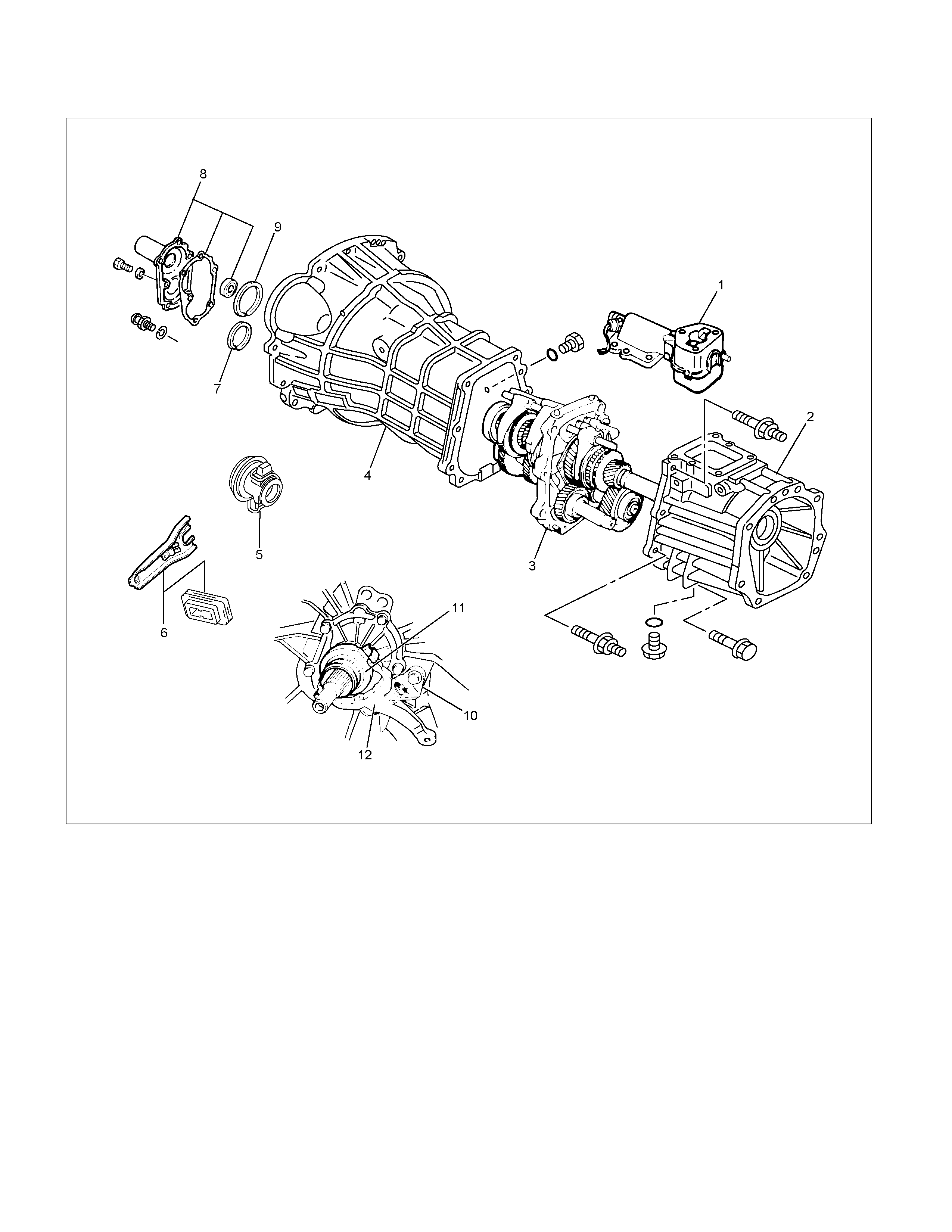

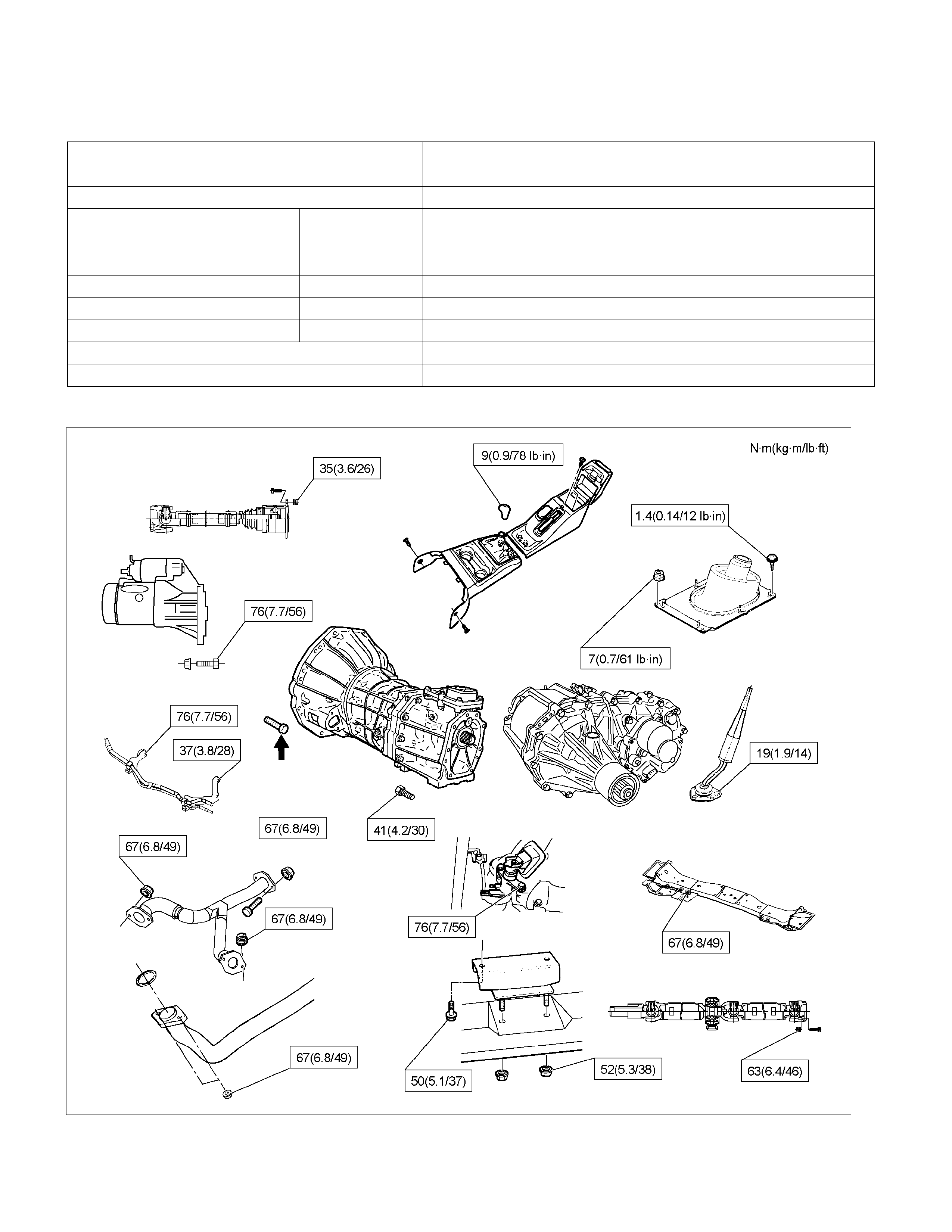

RTW37ALF0001

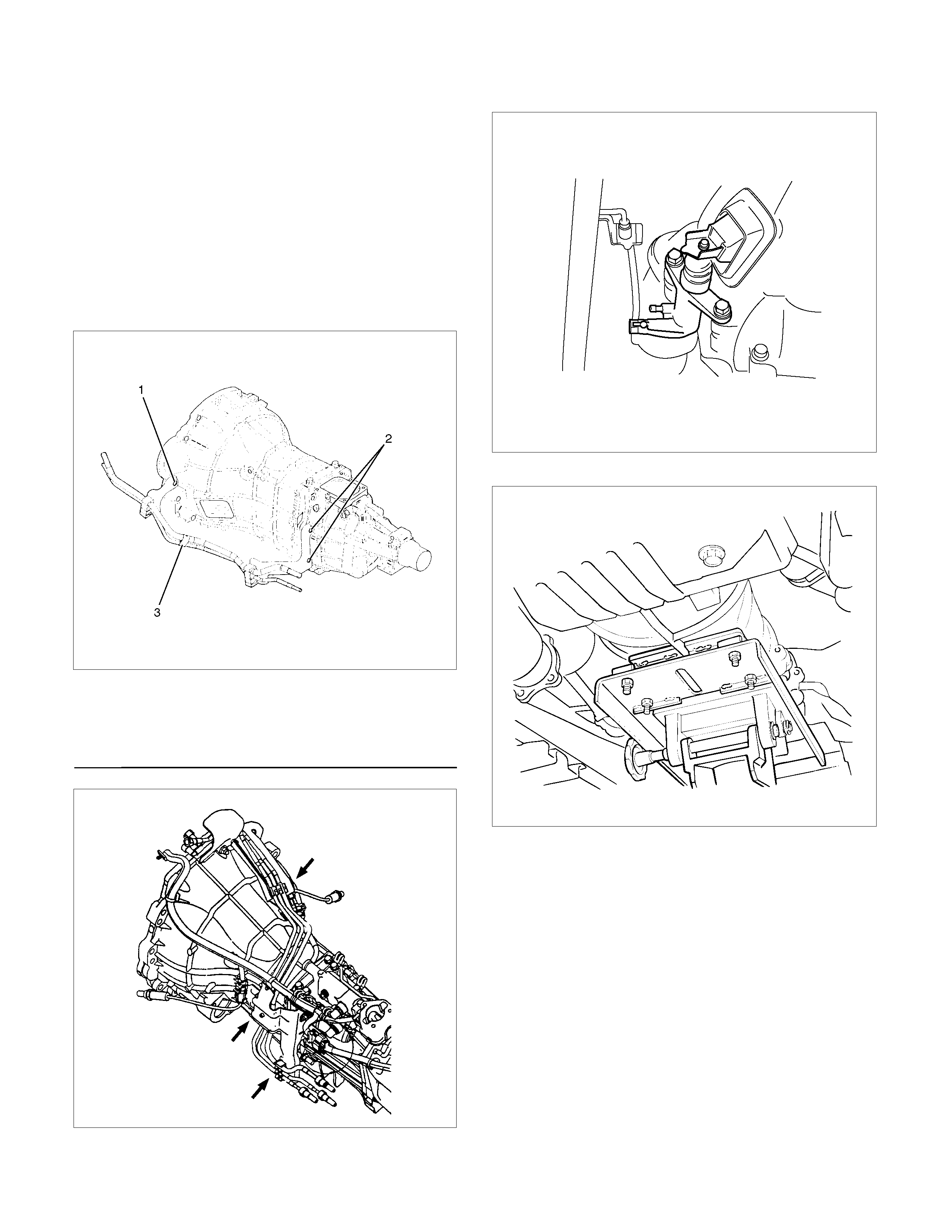

Legend

(1) Gear Control Lever Knob (10) Slave Cylinder

(2) Rear Floor Console (bucket seat) (11) Nut : rear mount to Crossmember

(3) Front Floor Console (12) Transmission Crossmember

(4) Grommet Assembly (13) Nut : rear mount to transmission

(5) Gear Control Lever (14) Rear Mount Rubber

(6) Rear Propeller Shaft (15) Starter (4JH1-TC only)

(7) Exhaust Pipe Nut (4JH1-TC only) (16) Transmission Retaining Nut and Bolt

(8) Exhaust Pipe (6VE1 only) (17) Transmission Assembly

(9) Fuel Pipe Bracket

Removal

1. Disconnect battery ground cable.

2. Remove gear control lever knob (1).

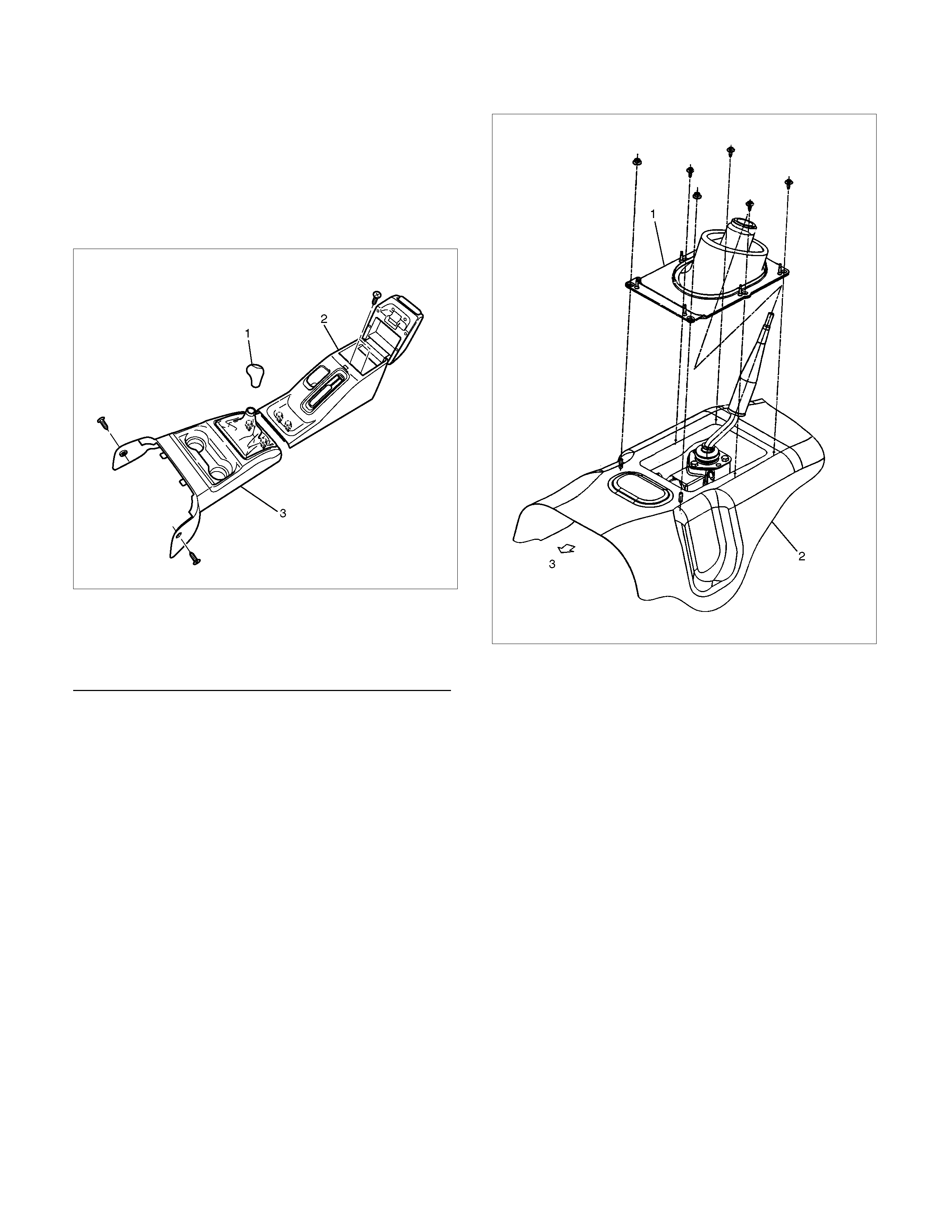

3. Remove rear floor console (2). (Bucket seat)

Refer to the section “Floor Console”.

4. Remove front floor console (3).

Refer to the section “Floor Console”.

745R300006

Legend

(1) Knob

(2) Rear Floor Console

(3) Front Floor Console

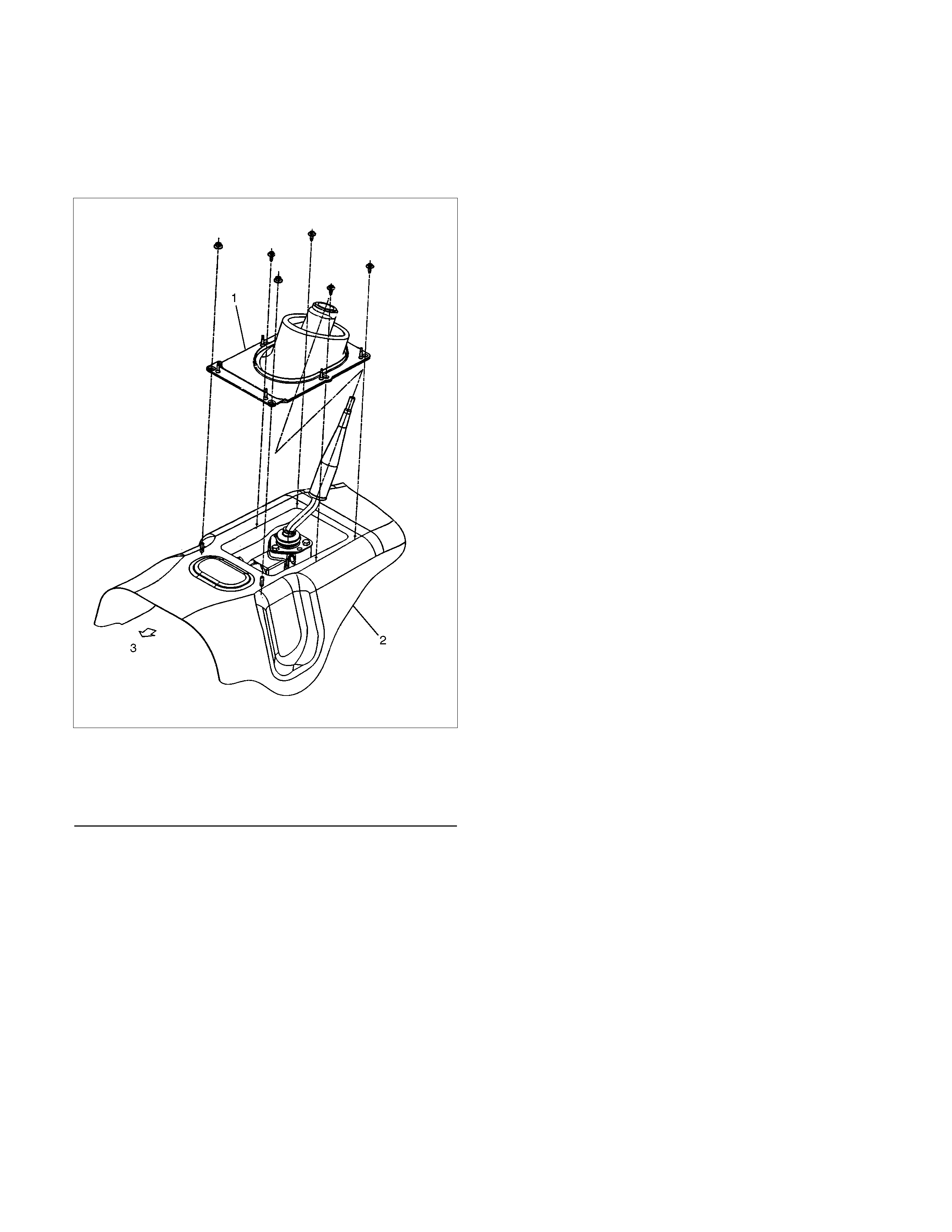

5. Remove grommet assembly (4).

235R300001

6. Remove gear control lever (5).

7. Raise and support vehicle with suitable stands.

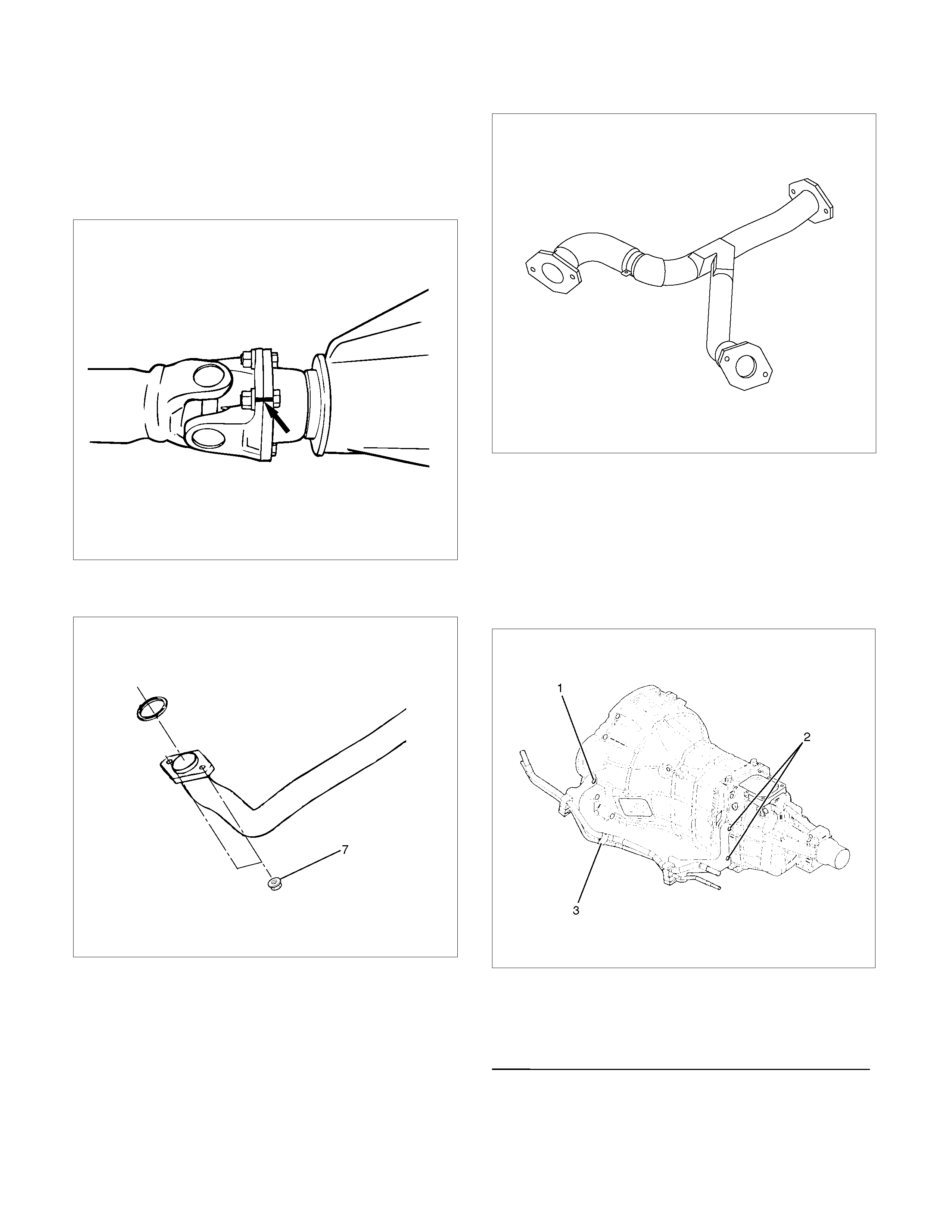

8. Remove rear propeller shaft (6).

NOTE: Apply alignment marks on the flange at the

differential side.

401RS023

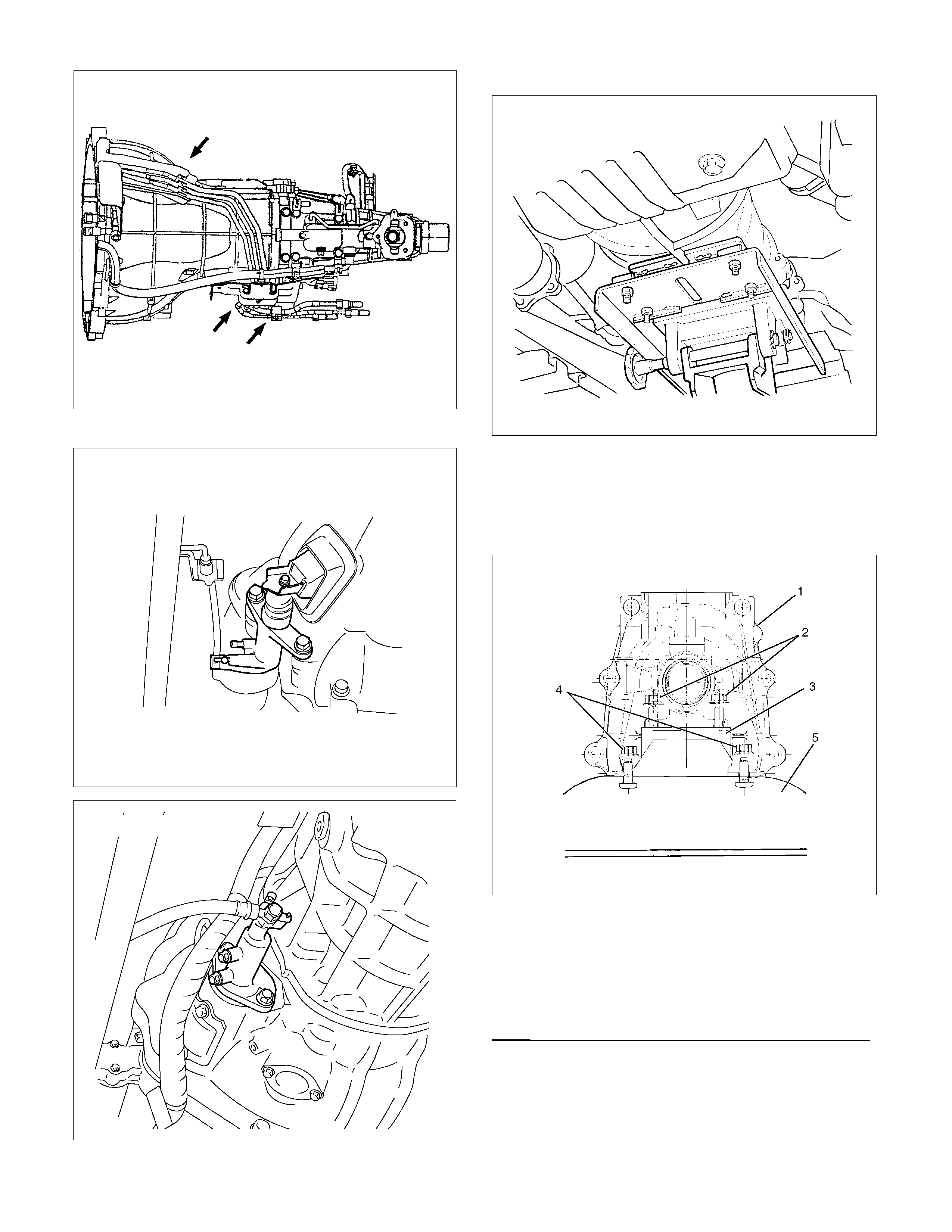

9. Loosen the front exhaust pipe fixing nuts (7) at the

engine side but not remove them. (4JH1-TC only)

150R300003

10. Remove the exhaust pipe (8). (6VE1 only)

RTW37ASH0001

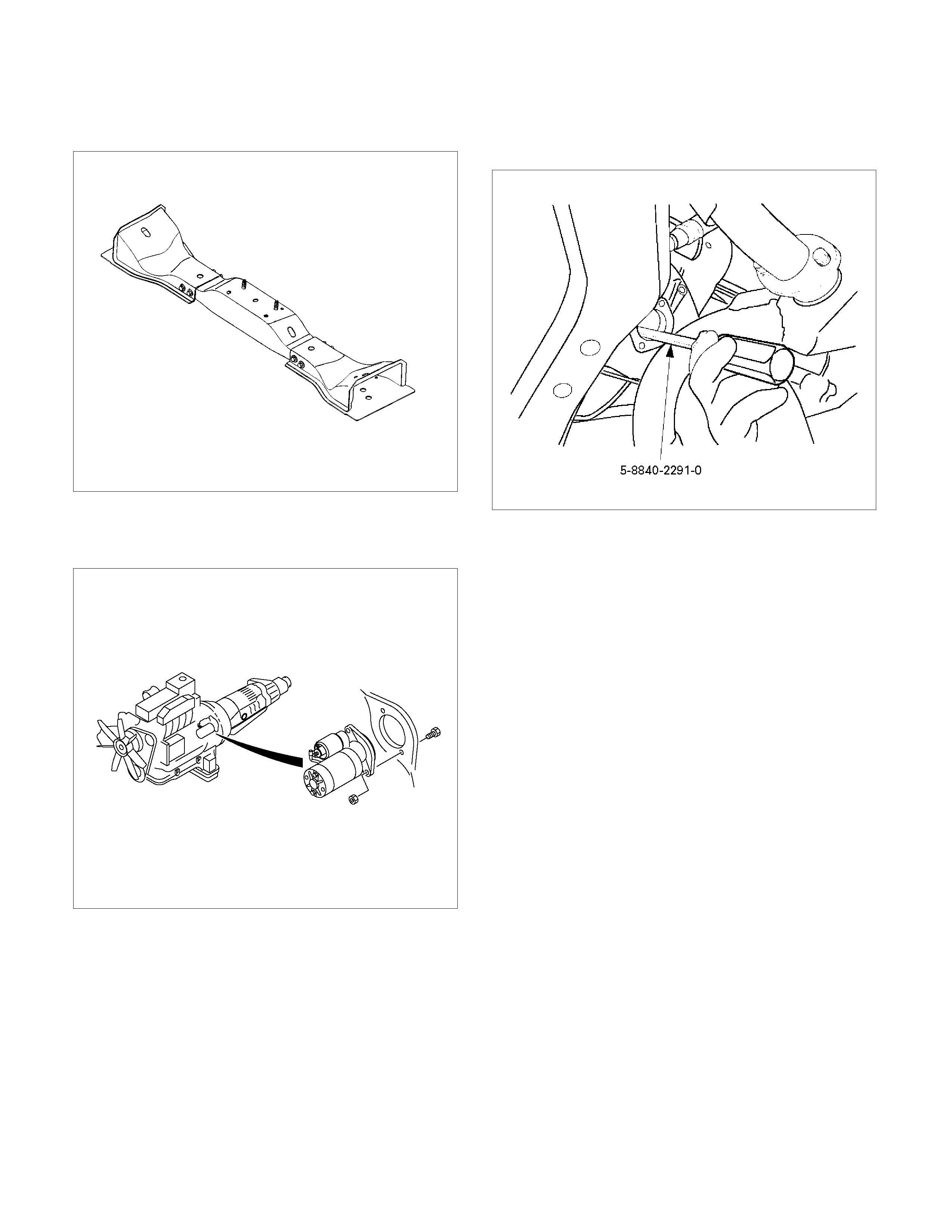

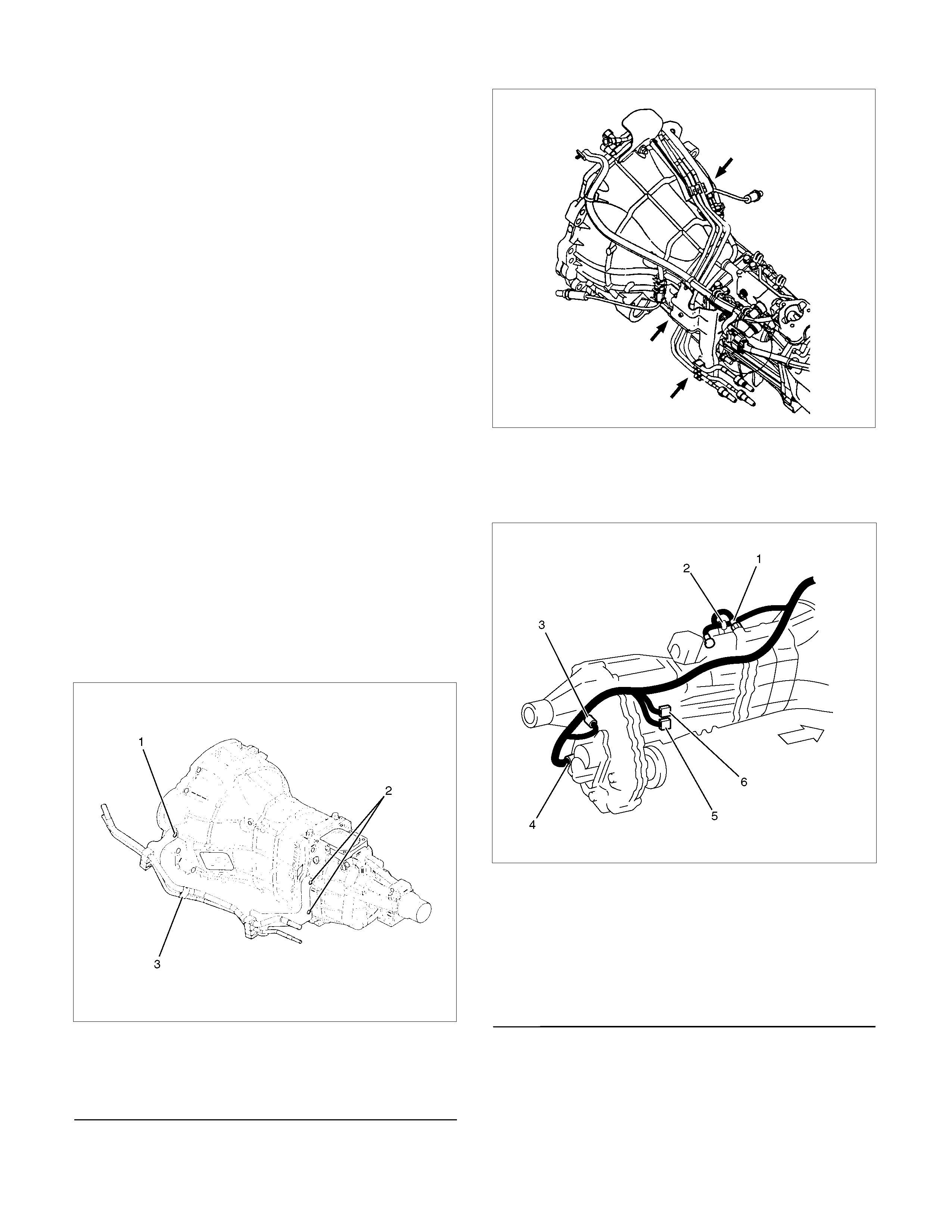

11. Disconnect harness connectors and clips on the

transmission.

• Neutral Switch

• Back up Switch

• Car Speed Sensor

12. Remove the fuel pipe bracket (9) with pipes from

the transmission (17).

4JH1-TC

220R300012

Legend

(1) Bolt

(2) Nut

(3) Fuel Pipe Assembly

6VE1, C24NE

Scan-1

13. Remove slave cylinder (10) and put aside it.

4JH1-TC

220LV019

6VE1

206RW002

14. Support transmission with a transmission jack.

220RS001

15. Remove engine rear mount nuts (11) fixing on

cross member from transmission crossmember

(12).

16. Remove engine rear mount nuts (13) fixing on

transmission.

220R300029

Legend

(1) Transmission

(2) Nut : rear mount to transmission

(3) Rear Mount Rubber

(4) Nut : rear mount to crossmember

(5) Transmission Crossmember

17. Remove the middle part of transmission

crossmember (12) by removing four fixing bolts

and nuts.

501R300008

18. Take out the rear mount rubber (14).

19. Remove starter (15) (4JH1-TC only).

060L100070

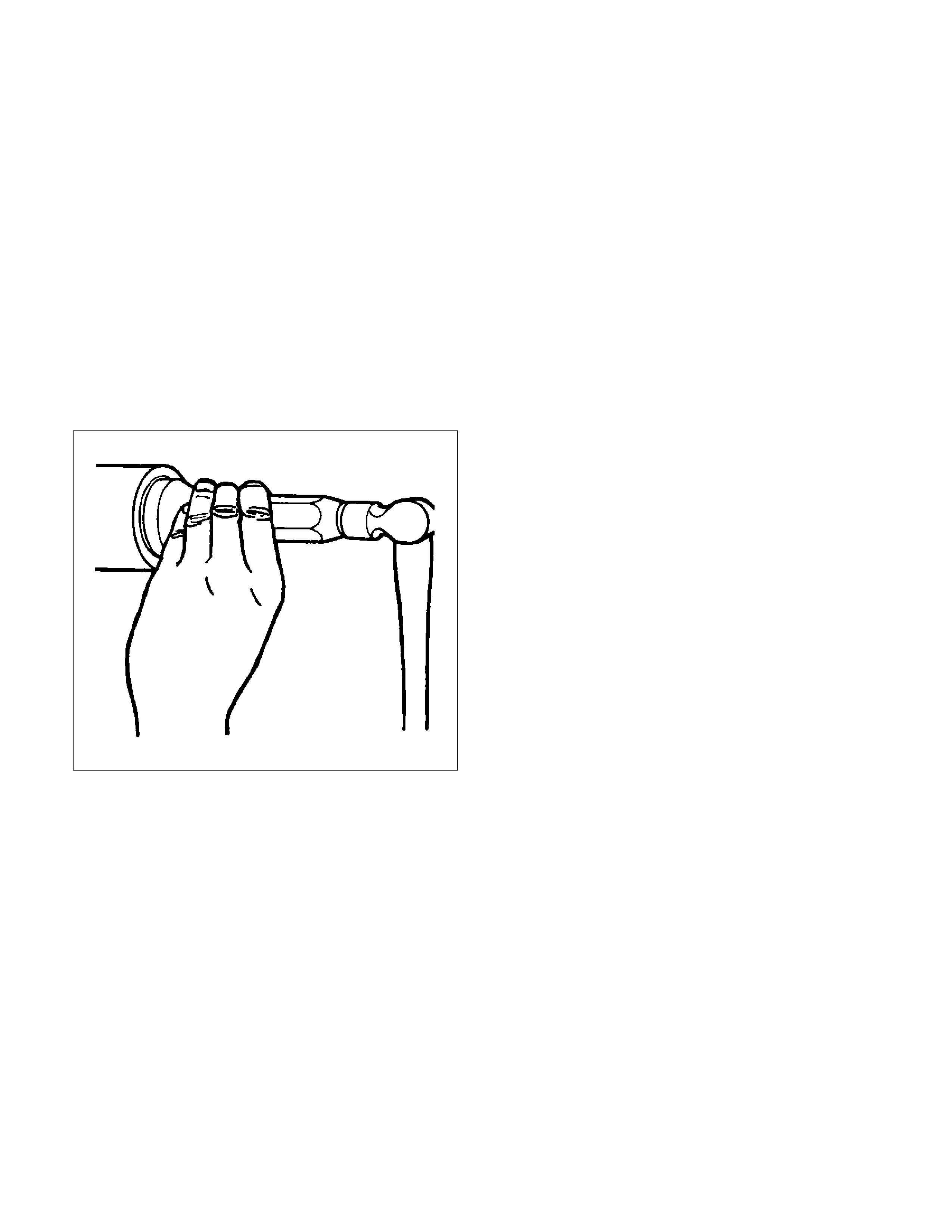

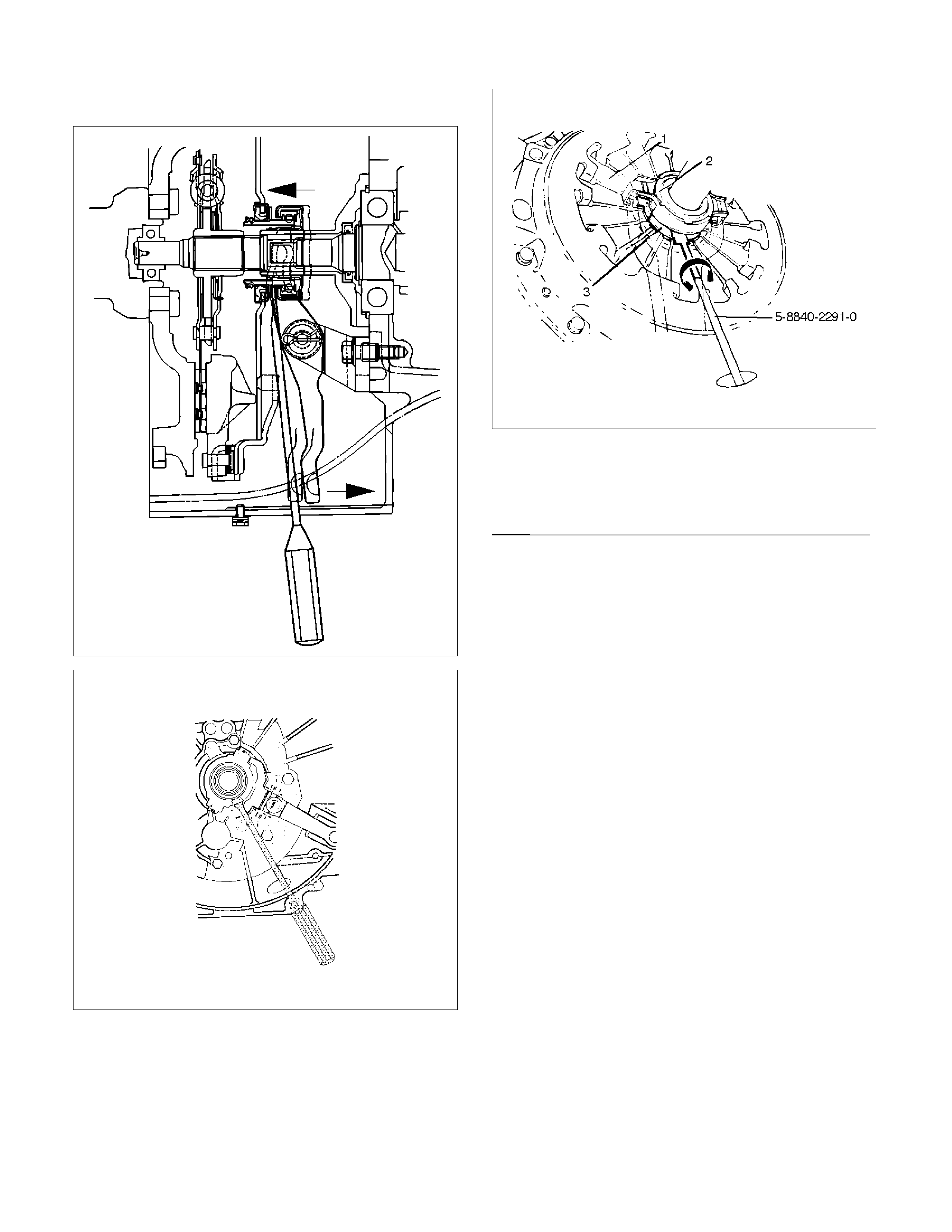

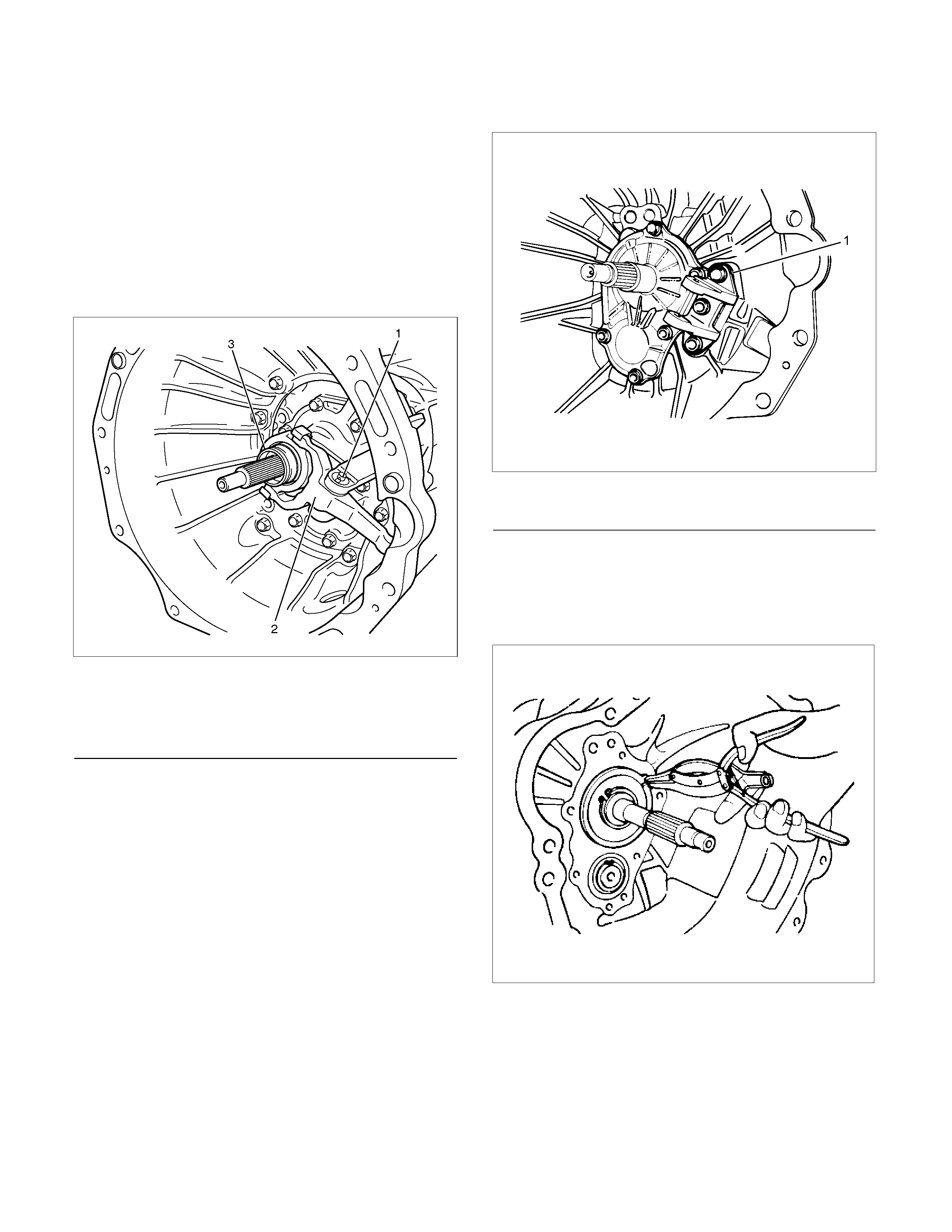

20. Use the clutch release bearing remover 5-8840-

2291-0 (J-39207) to disconnect the clutch release

bearing from the clutch pressure plate. (6VE1

only )

220RW109

Release bearing disconnection

1. Pull the shift fork toward the transmission to

press the clutch release bearing against the

clutch.

2. Insert the clutch release bearing remover

between the wedge collar and the release

bearing.

3. Turn the remover to separate the release

bearing.

NOTE: Be sure not to insert the remover between the

wedge collar and the clutch.

220RW063

220RW064

220RW019

Legend

(1) Pressure Plate Assembly

(2) Release Bearing

(3) Wedge Collar

21. Remove transmission retaining nuts and bolts(16).

Remove transmission assembly (17) from the

vehicle.

Installation

1. Apply a thin coat of molybdenum disulfide grease

to the top gear shaft spline.

2. Slowly operate the transmission jack until the front

of transmission is aligned with the rear of the

engine.

The slope of the engine and the transmission

must be the same.

3. Align the top gear shaft spline with the clutch

driven plate spline.

4. Install the transmission assembly (17) to the

engine.

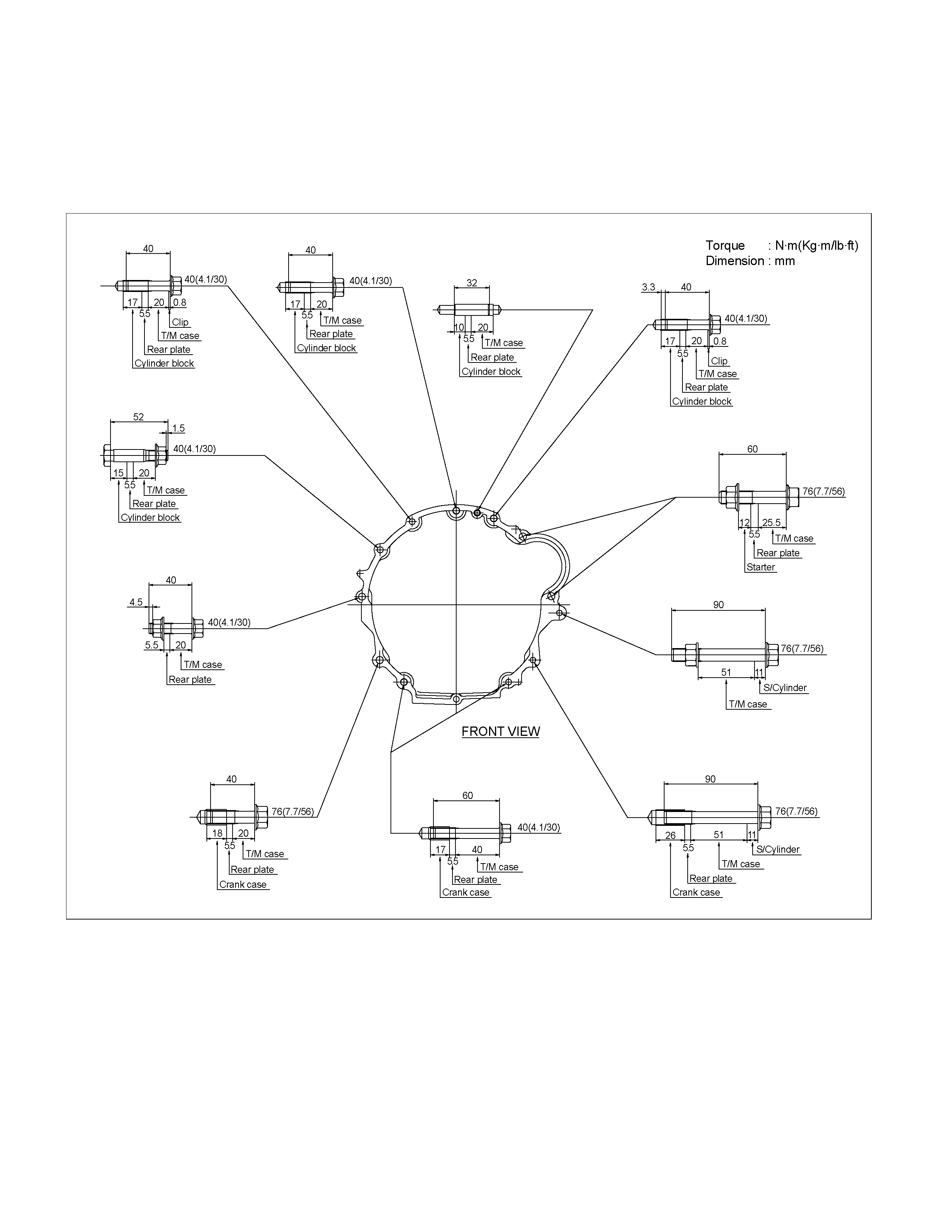

Tighten the transmission nuts and bolts (16) as

shown in the figure.

4JH1-TC

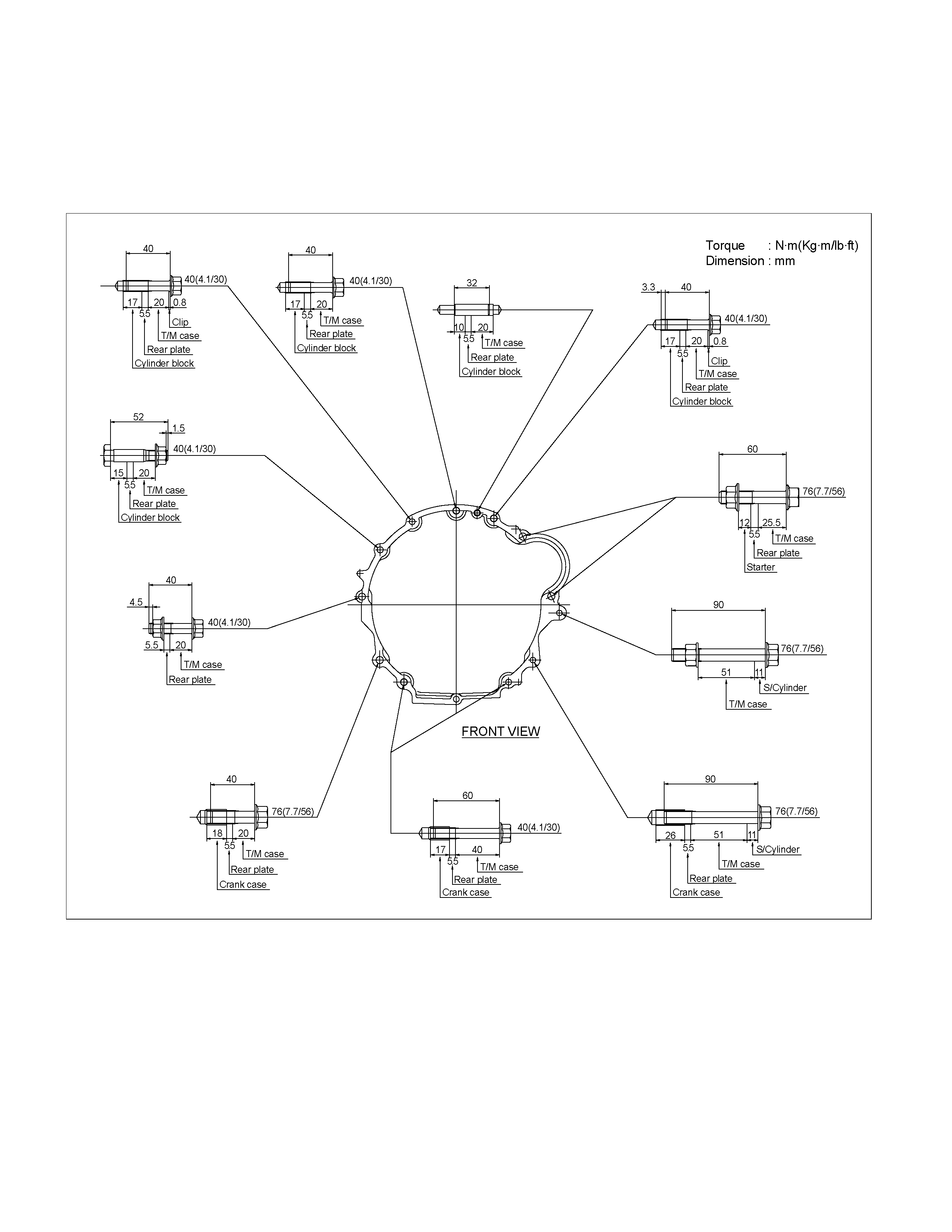

RTW37BLF000901

6VE1

RTW37BLF0001

C24NE

RTW37BLF0002

220RS006

5.

A

pply a force of about 113N (26 Ib) to the tip of the

shift fork in the direction of the transmission to

engage the clutch pressure plate and release

bearing. (6VE1 only)

NOTE: A clicking sound is heard when the release

bearing and the tip of the diaphragm spring engage

each other.

Check to see if they are securely engaged by pushing

the tip of the shift fork toward the engine while applying

a force of about 25 N (5.5 lb). If the shift fork will not

move, then they are securely engaged.

6. Install starter(15). (4JH1-TC only)

NOTE: Tighten the lower bolt temporarily.

After installing the fuel pipe assembly, tighten the bolt to

the specified torque.

Torque: 76 N·m (7.7 kg·m/56 lb·ft)

7. Install the rear support rubber (14) on the

transmission and tighten the nuts to the specified

torque.

Torque: 52 N·m (5.3 kg·m/38 lb·ft)

8. Install the middle part of transmission

crossmember (12) and bolts.

Tighten the nuts to the specified torque.

Torque: 67 N·m (6.8 kg·m/49 lb·ft)

9. Install engine rear mount nuts (11) fixing on

transmission crossmember (12).

Torque: 52 N·m (5.3 kg·m/38 lb·ft)

Remove the transmission jack from transmission

side.

10. Apply grease to top hole portion of the shift fork.

Install slave cylinder (10) and tighten the bolts to the

specified torque.

Torque: 76 N·m (7.7 kg·m/56 lb·ft)

11. Install the fuel pipe brackets (9) on the

transmission.

Install the fuel pipe assembly to the fuel brackets.

Torque: Bolt & Nut 76 N·m (7.7 kg·m/56 lb·ft)

Nut 37 N·m (3.8 kg·m/28 lb·ft)

4JH1-TC

220R300012

Legend

(1) Bolt

(2) Nut

(3) Fuel Pipe Assembly

6VE1, C24NE

Scan-1

12. Connect transmission harness connectors and

clip. Connector: neutral switch, car speed sensor,

and backup switch.

13. Tighten exhaust pipe fixing nuts (7) to the

specified torque. (4JH1-TC)

Torque: 67 N·m (6.8 kg·m/49 lb·ft)

150R300003

14. Install the exhaust pipe (8). (6VE1)

Torque: 67 N·m (6.8 kg·m/49 lb·ft)

RTW37ASH000101

15. Install rear propeller shaft (6).

Torque: 63 N·m (6.4 kg·m/46 lb·ft)

16. Install center bearing on crossmember.

Torque: 69 N·m (7.0 kg·m/51 lb·ft)

17. Install gear control lever (5).

Torque: 19 N·m (1.9 kg·m/14 lb·ft)

18. Install grommet assembly (4).

Torque: Screw 1.4 N·m (0.14 kg·m/12 lb·in)

Nut 7 N·m (0.7 kg·m/61 lb·in)

235R300001

Legend

(1) Grommet Assembly

(2) Floor Panel

(3) Front

19. Install front floor console (3) and rear floor console

(2).

20. Install gear control lever knob (1).

To the female thread portion, adhesive (TB1344 or

LOCTITE 222 or equiv.) of 3 - 4 drops to be

applied and transmission knob tightened.

Torque: 9 N·m (0.9 kg·m/78 lb·in)

After tightening to specified torque, the knob should

be correctly orientated.

21. Connect battery ground cable.

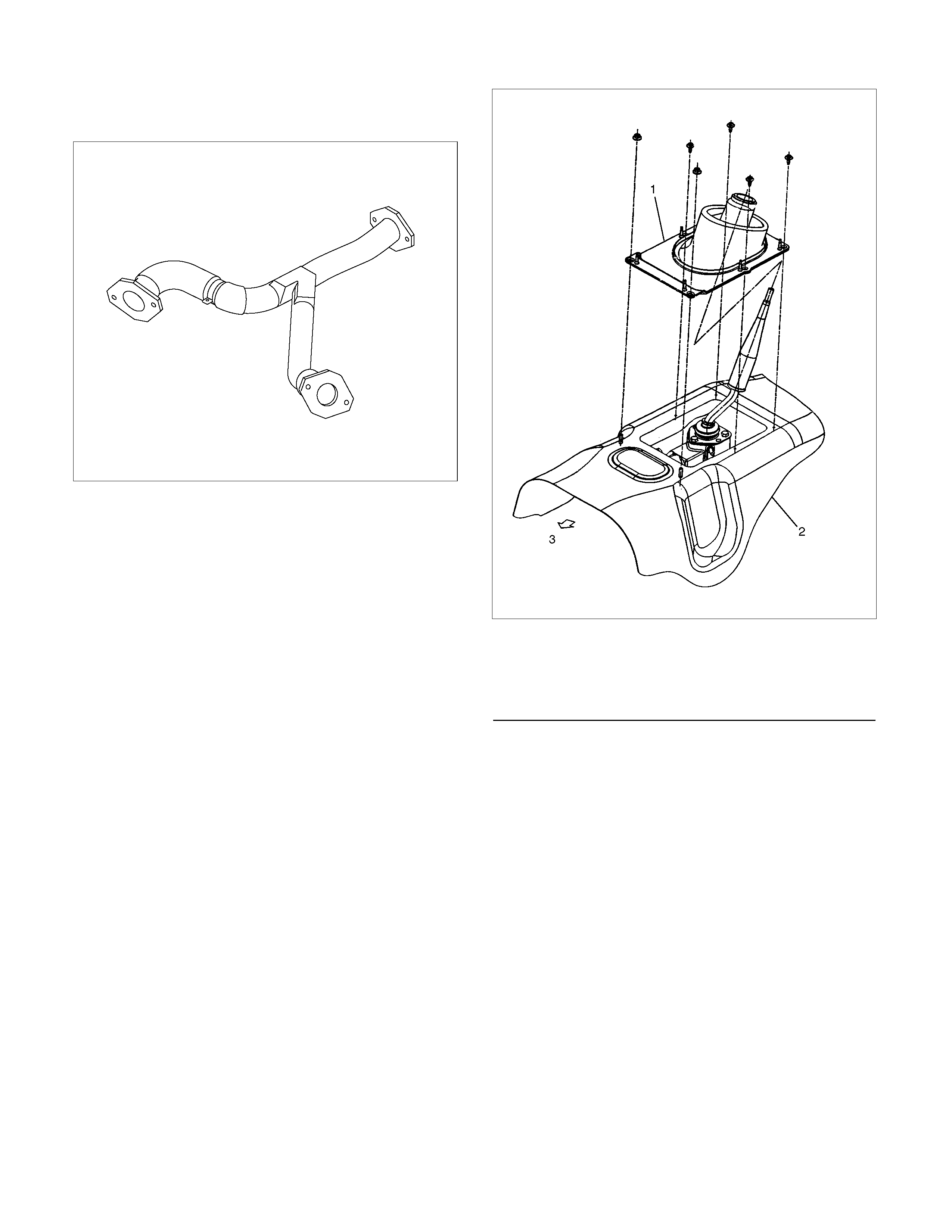

Transmission Case

Major Component

RTW37BLF0005

Legend

(1) Gear Control Box Assembly and Gasket (9) Front Cover (with Oil Seal)

(2) Speedometer Sensor and Driven Gear (10) Top Gear Bearing Snap Ring

(3) Rear Cover Assembly (11) Release Bearing : C24NE

(4) Intermediate Plate with Gear Assembly (12) Shift Fork : C24NE

(5) Transmission Case (13) Fulcrum Bridge : 6VE1

(6) Release Bearing (with Spring) : 4JH1-TC (14) Release Bearing : 6VE1

(7) Shift Fork : 4JH1-TC (15) Shift Fork : 6VE1

(8) Counter Front Bearing Snap Ring

Disassembly

1. Clean the exterior of the unit with solvent.

2. Remove the drain plug from the transmission case

and drain the lubricant.

3. Remove the clutch release bearing with spring

(6)(11) from the transmission case.

4. Remove the shift fork (7)(12), and boot. (4JH1-TC,

C24NE)

5. Remove the shift fork snap pin. (6VE1)

6. Remove the shift fork pin and shift fork from the

fulcrum bridge. (6VE1)

220RW088-X

Legend

(1) Shift fork pin

(2) Shift fork

(3) Release bearing

7. Remove the fulcrum bridge from the transmission

case. (6VE1)

RTW37ASH0002

Legend

(1) Fulcrum bridge

8. Remove the front cover (9) and gasket from the

transmission case.

9. Remove snap ring (8) fixing counter front bearing.

10. Use a pair of snap ring pliers to remove the snap

ring (10) fixing top gear bearing.

226RS001

11. Remove the speedometer sensor (2).

Remove the plate (2).

Remove the driven gear bushing and driven gear

(2).

NOTE: Apply a reference mark to the driven gear

bushing before removal.

12. Remove gear control box assembly (1).

13. Remove the rear cover assembly (3) from the

transmission case (5) and intermediate plate (4).

14. Remove intermediate plate with gear assembly (4)

from transmission case (5).

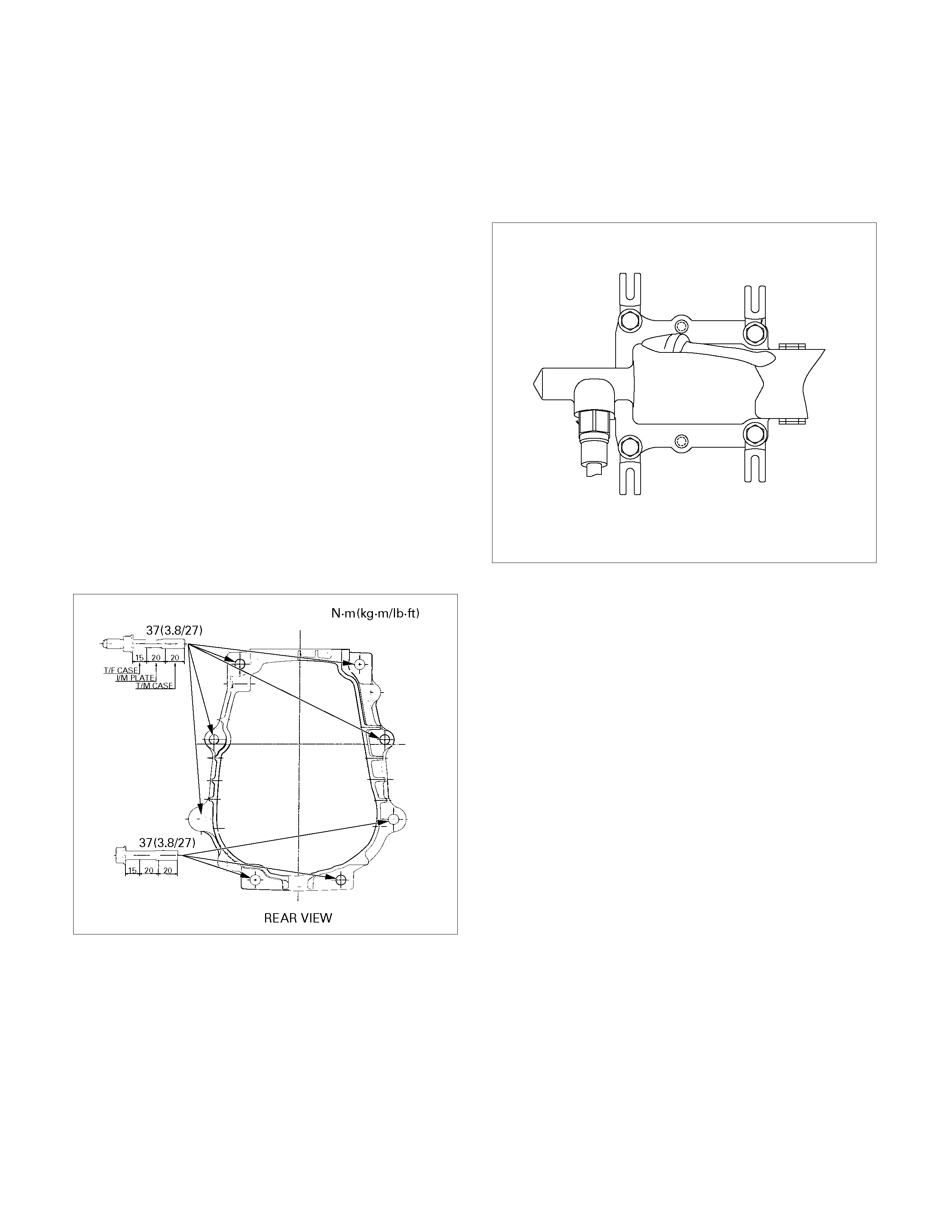

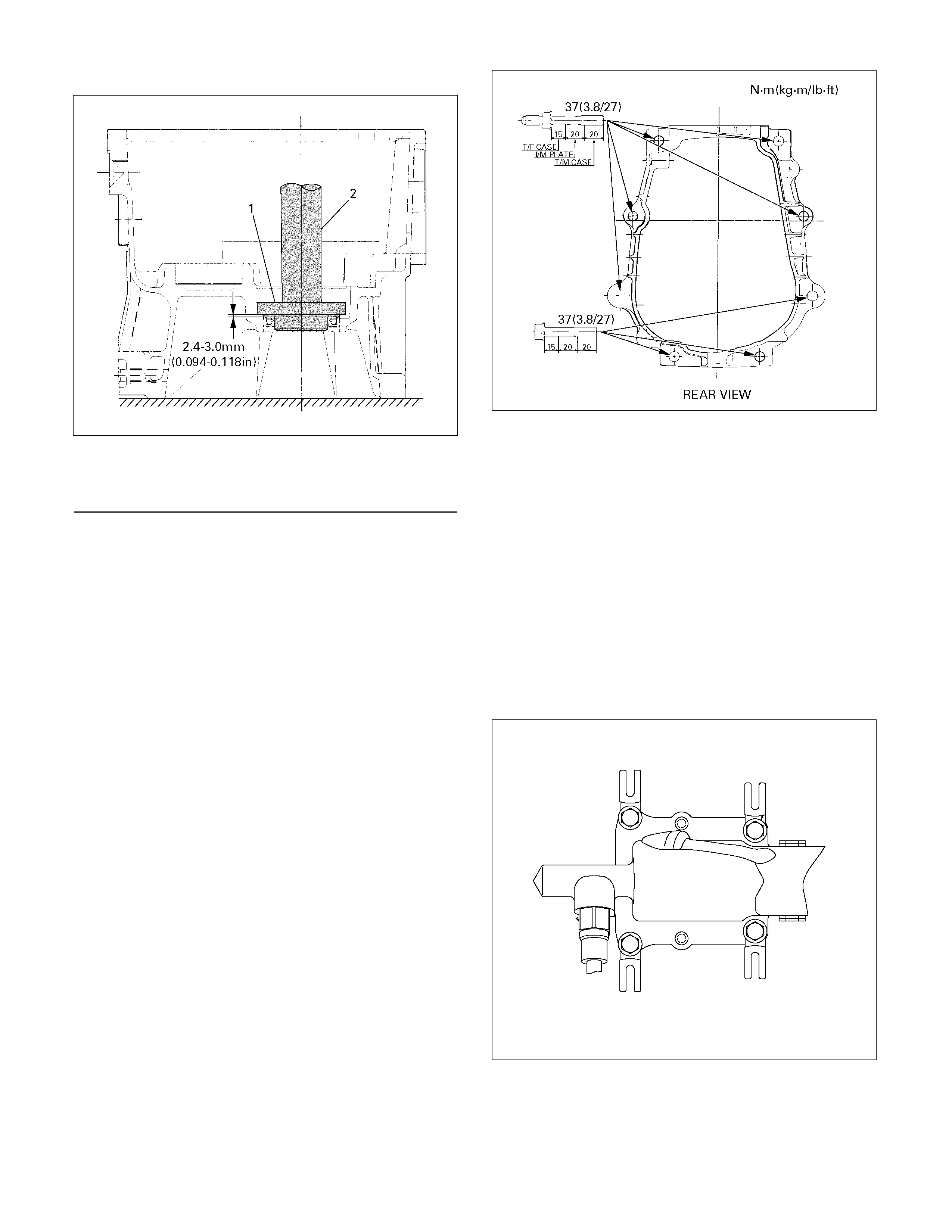

Reassembly

1. Apply recommended liquid gasket (LOCTITE

17430) or its equivalent to the transmission case

(5), intermediate plate (4) and rear cover (3) fitting

surfaces.

2. Install the intermediate plate with gear assembly

(4) to the transmission case (5).

Pull out the top gear shaft until the ball bearing snap

ring groove protrudes from the transmission case

front cover fitting face.

Avoid subjecting the main shaft to sudden shock or

stress.

3. Install the rear cover with oil seal (3) on the

intermediate plate with gear (4) by performing the

following steps.

• Cover the shaft splines with adhesive tape.

This will prevent damage to the oil seal lip.

• Tighten the transmission rear case bolts and

nuts to the specified torque.

Torque: 37 N·m (3.8 kg·m/27 lb·ft)

220R300026

Notes When Tightening the Bolt:

• After cleaning the bolt hole, dry it thoroughly with

air.

• After cleaning the screw face of a removed bolt or

new one, dry it thoroughly. Apply recommended

liquid gasket (LOCTITE 242) or its equivalent on

them before tightening it.

4. Install a new gasket and gear control box

assembly (1).

Install the harness clips and brackets and then

tighten four new gear control box bolts to the

specified torque.

Torque: 20 N·m (2.0 kg·m/14 lb·ft)

261R300004

5. Install the O-ring (4) to the speedometer driven

gear bushing (3).

Install the driven gear to the speedometer driven

gear bushing (3).

6. Install the speedometer driven gear assembly (2)

to the transmission rear cover (3).

Install the plate (1) to the transmission rear cover

(3).

Torque: 15 N·m (1.5 kg·m/11 lb·ft)

7. Install the speedometer sensor (2).

Torque: 27 N·m (2.8 kg·m/20 lb·ft)

225R300001

8. Install top gear bearing snap ring (10) and counter

front bearing snap ring (8).

• Use a pair of snap ring pliers to install the snap

rings to the mainshaft and countershaft.

• The snap rings must be fully inserted into the

bearing snap ring groove.

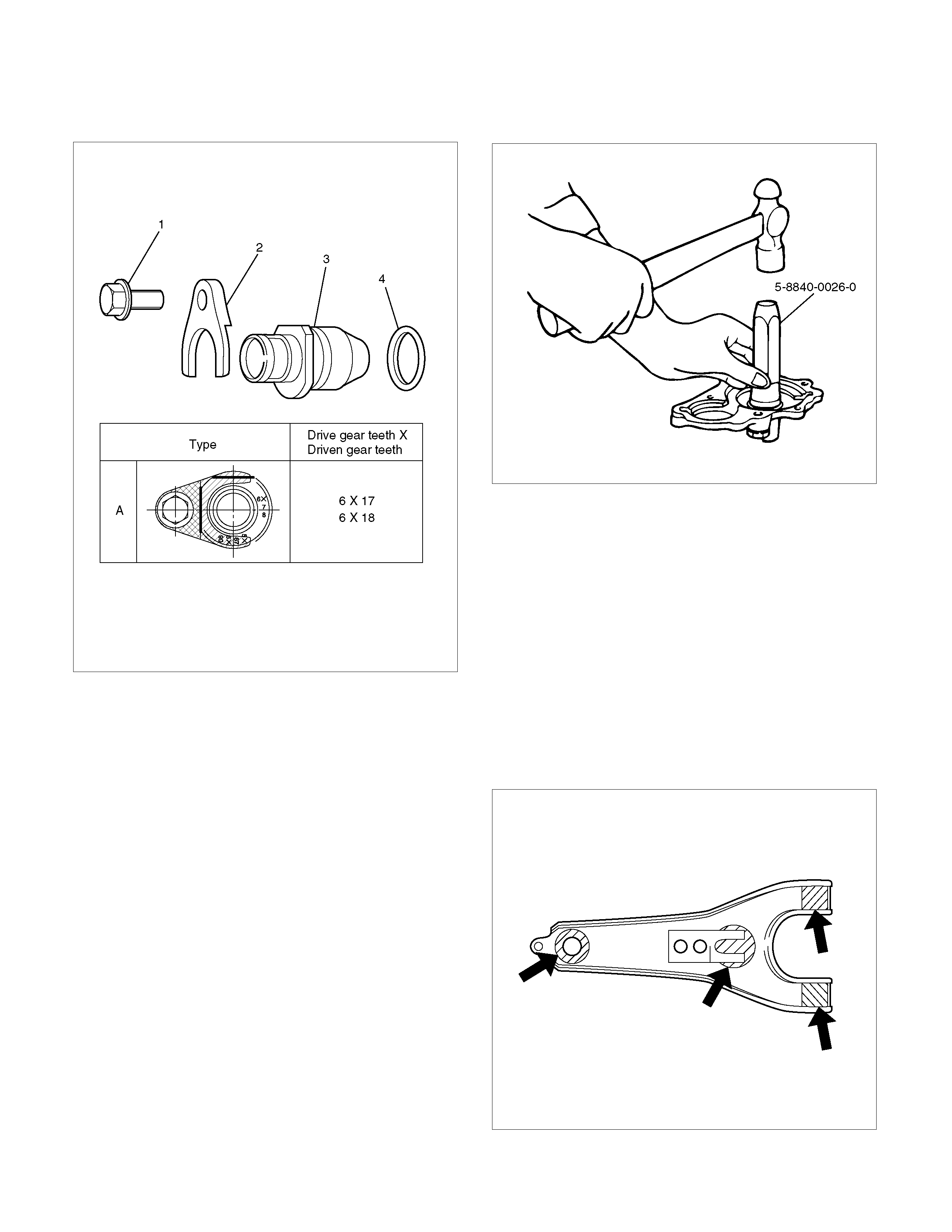

9. Front cover with oil seal (9).

Front Cover Oil Seal Replacement

• Remove the oil seal from the front cover.

• Apply engine oil to a new oil seal outer

circumference.

• Apply recommended grease to the oil seal lip.

• Use the oil seal installer 5-8840-0026-0 to

install the oil seal to the front cover.

220R3000020

10. Install a new gasket and front cover (9) to the

transmission case.

NOTE: Take care not to damage the oil seal.

Notes When Tightening the Bolt:

• After cleaning the bolt hole, dry it thoroughly with

air.

• After cleaning the screw face of a removed bolt or

new one, dry it thoroughly. Apply recommended

liquid gasket (LOCTITE 242) or its equivalent

before tightening it.

Tighten six front cover bolts to the specified torque.

Torque: 25 N·m (2.6 kg·m/19 lb·ft)

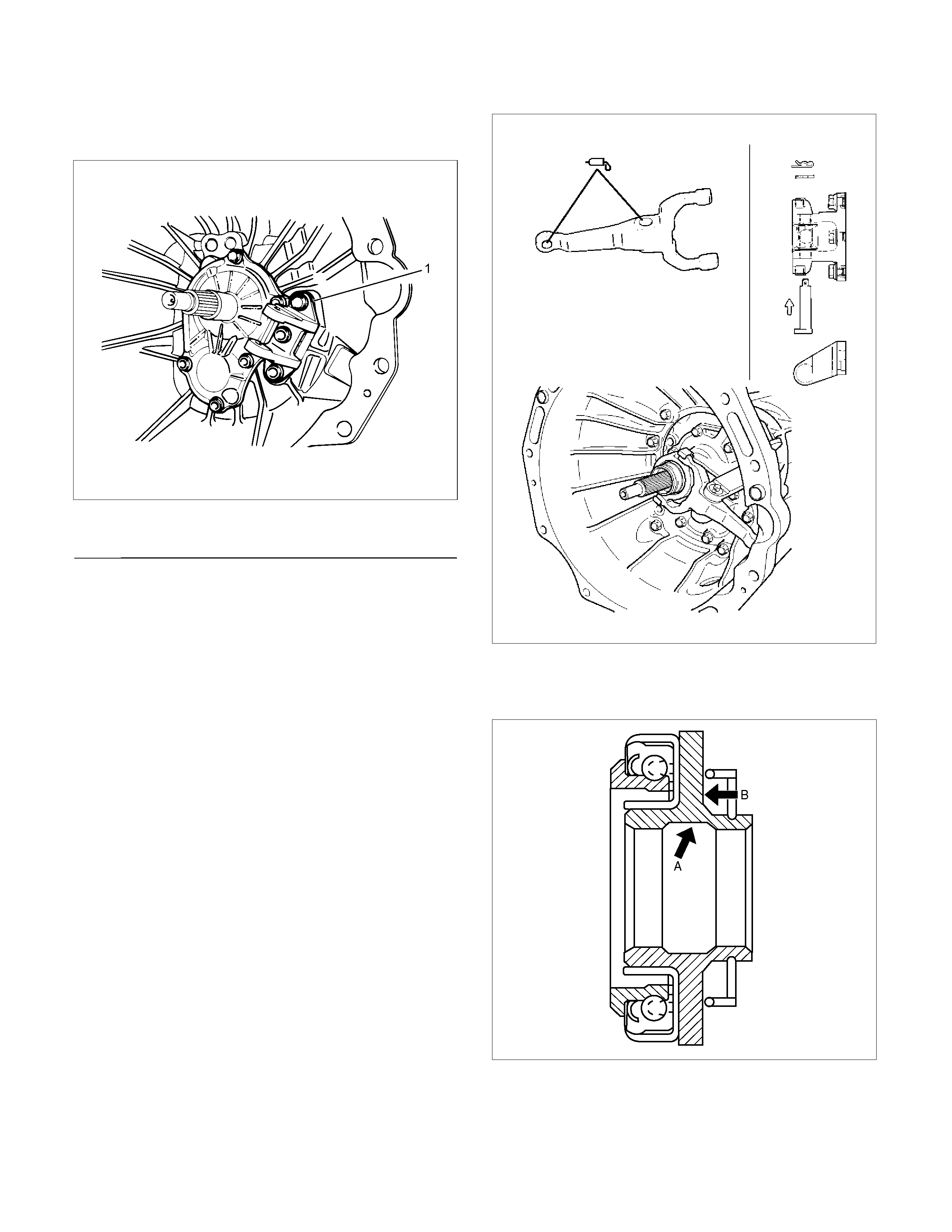

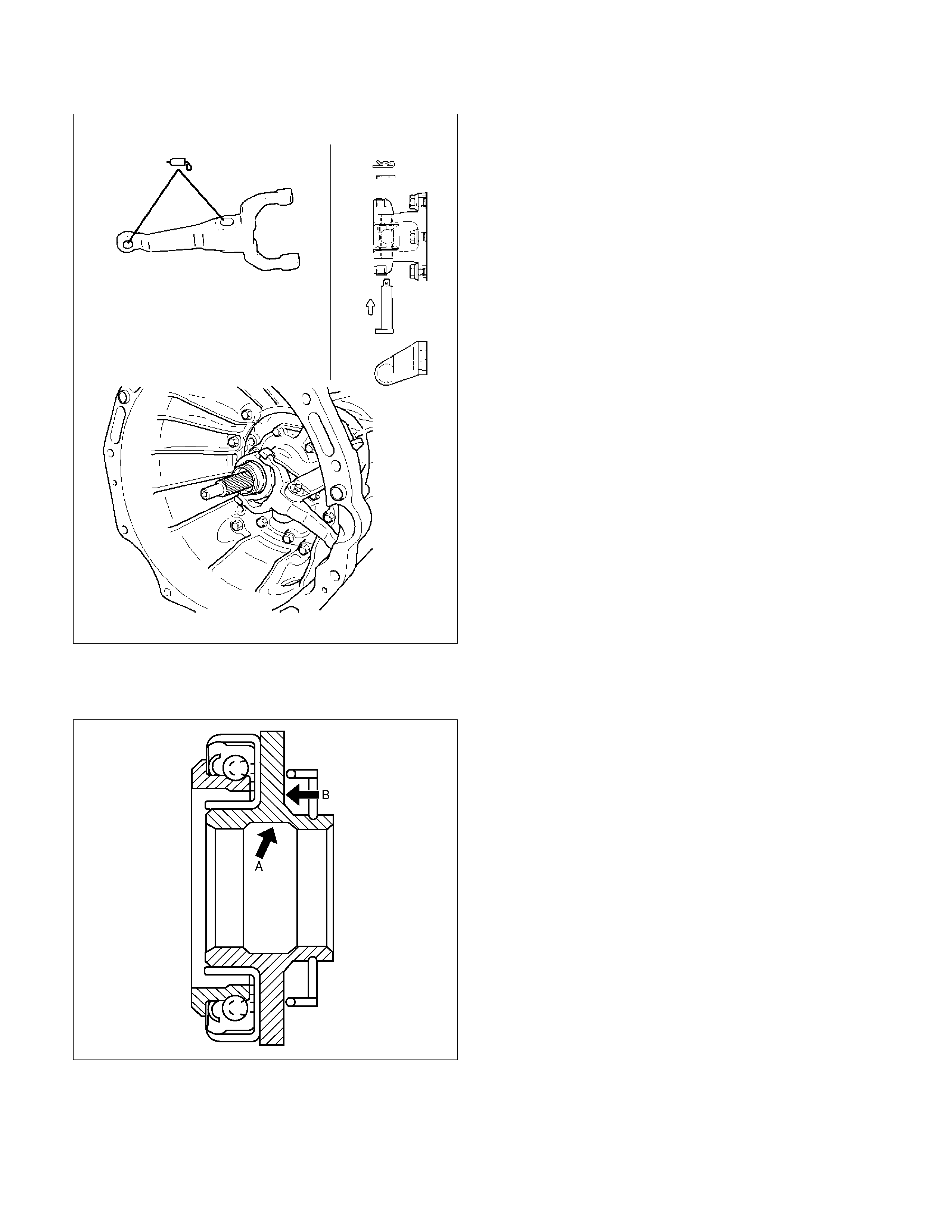

11. Apply molybdenum disulfide type grease to the

areas as shown in the figure and install shift fork

(7). (4JH1-TC, C24NE)

F07L100026

12. Install the fulcrum bridge to the transmission case.

(6VE1)

Torque: 38 N·m (3.9 kg·m/28 lb·ft)

RTW37ASH0002

Legend

(1) Fulcrum bridge

13. Apply molybdenum disulfide type grease to the pin

hole inner circumferences and thrust surfaces.

(6VE1)

14. Attach the shift fork to the fulcrum bridge and

insert the pin from below of the fulcrum bridge.

(6VE1)

15. Install the washer and snap pin. (6VE1)

201RW019

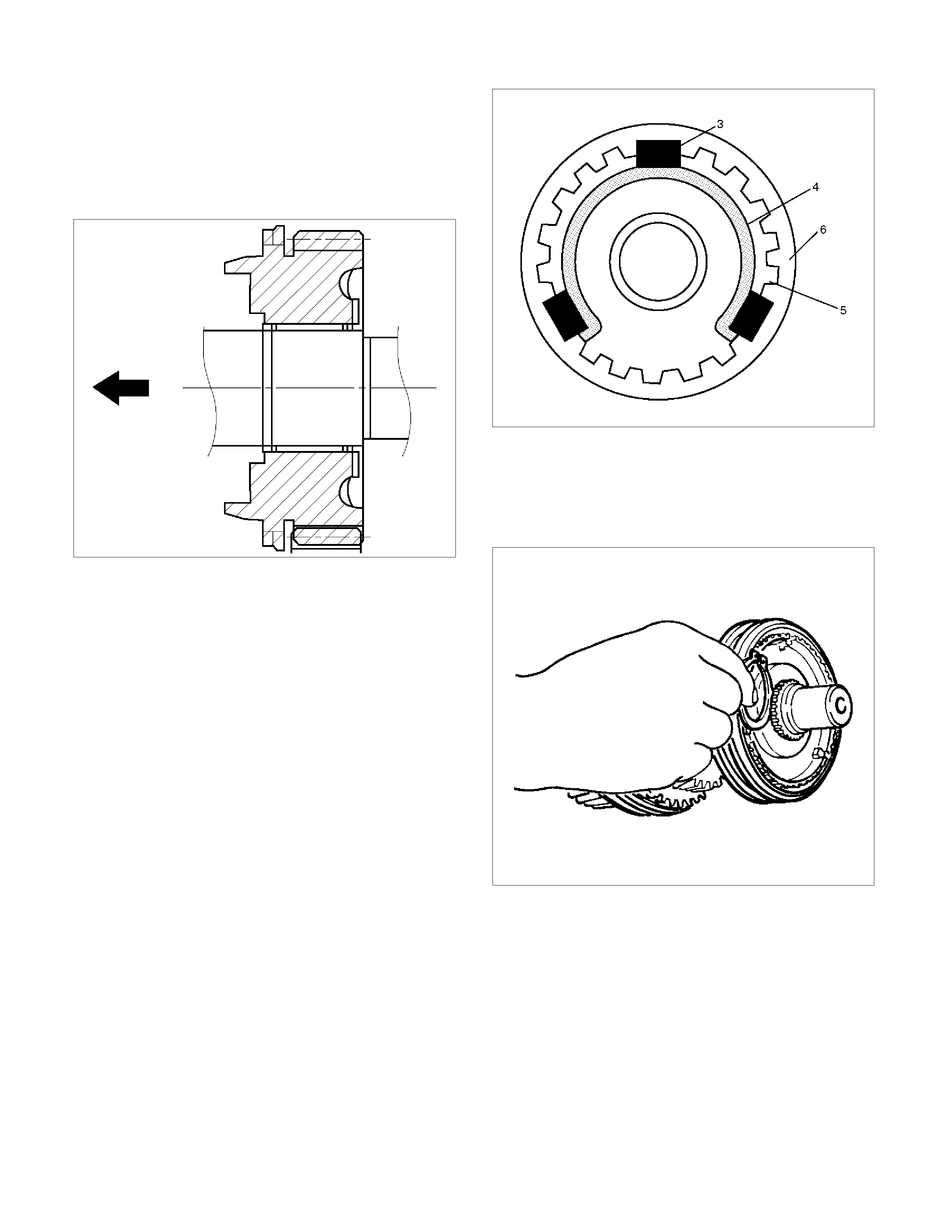

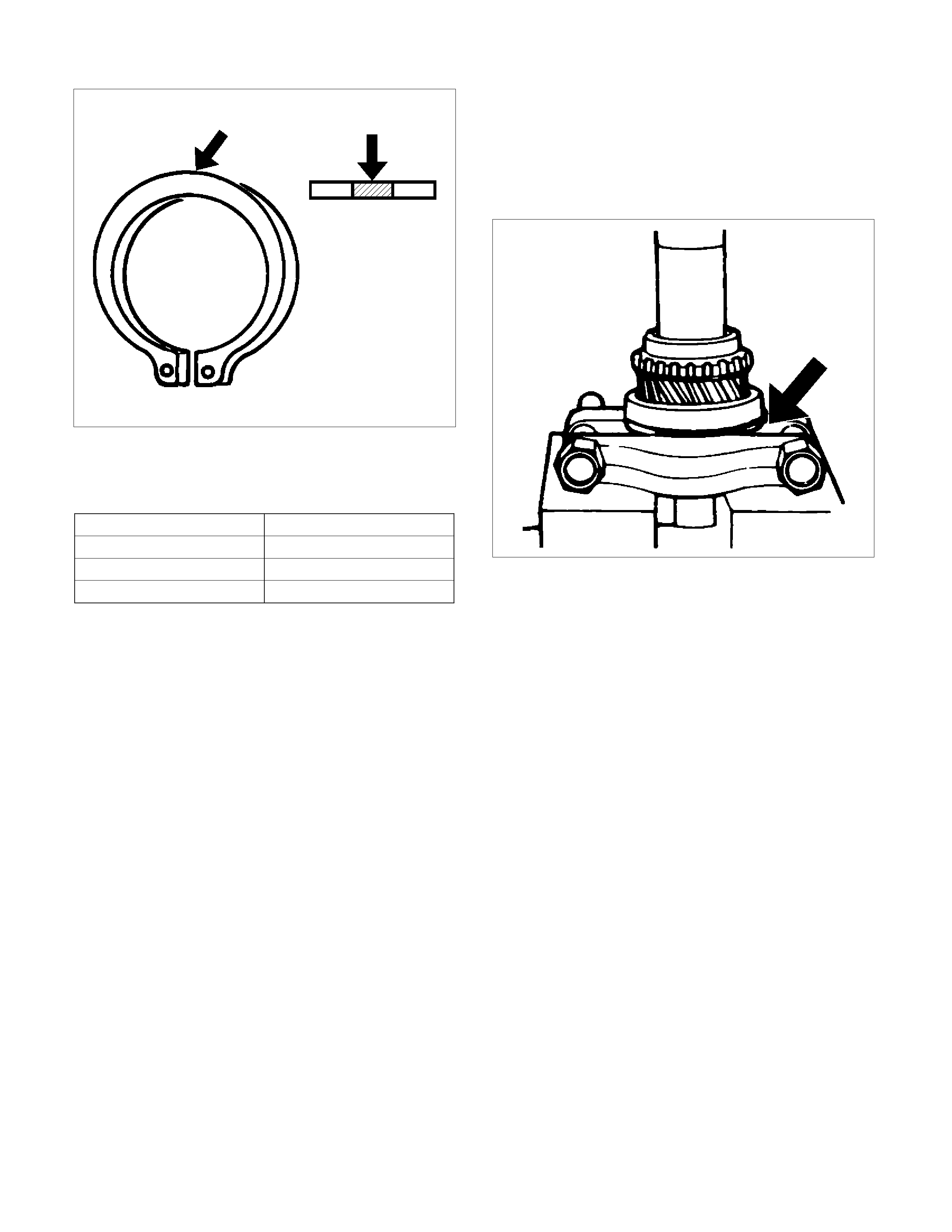

16. Pack the inside recess (A) and coat the back (B)

of the release bearing with molybdenum disulfide

type grease as shown in the figure.

A07RW075

17. Install the release bearing (6) on the front cover,

joining it to the shift fork.

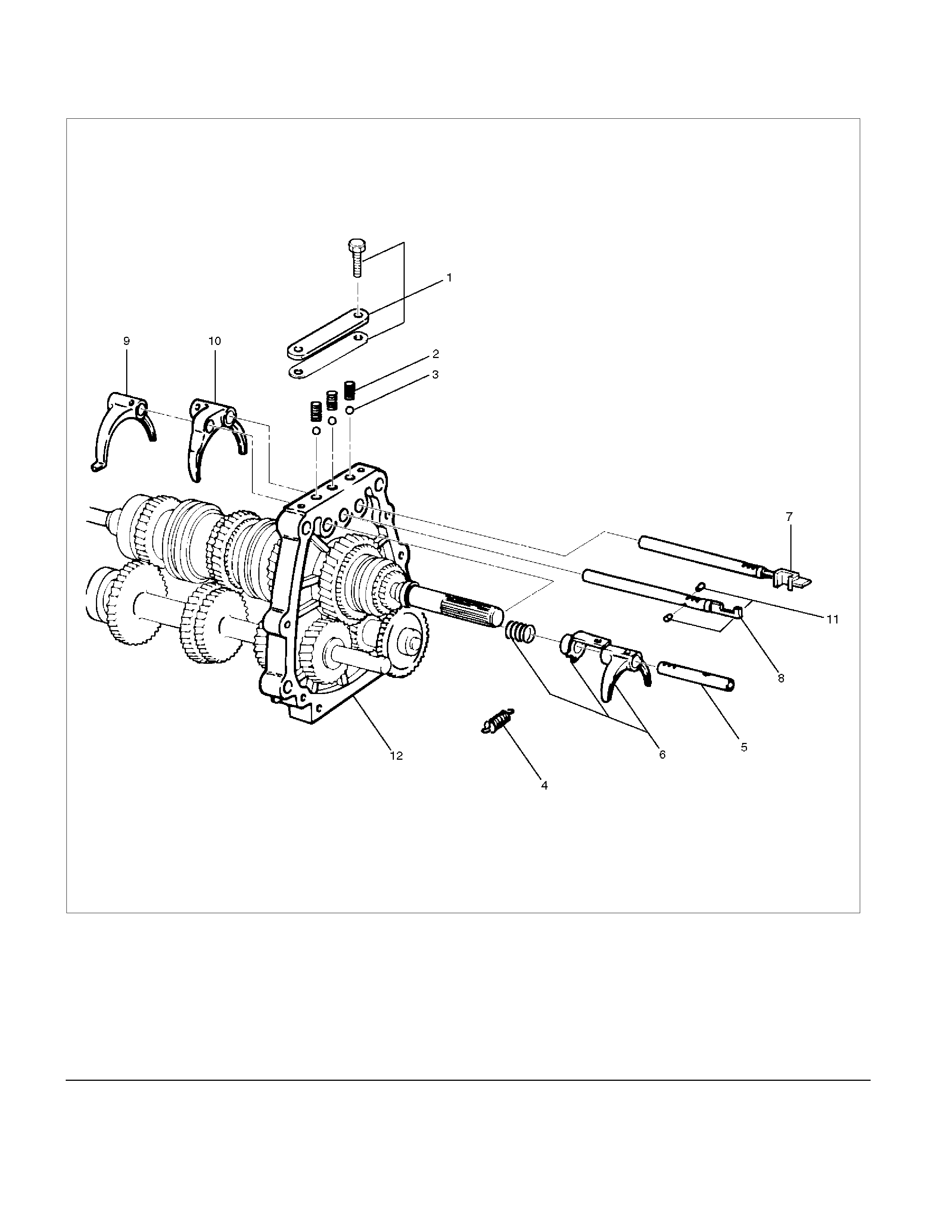

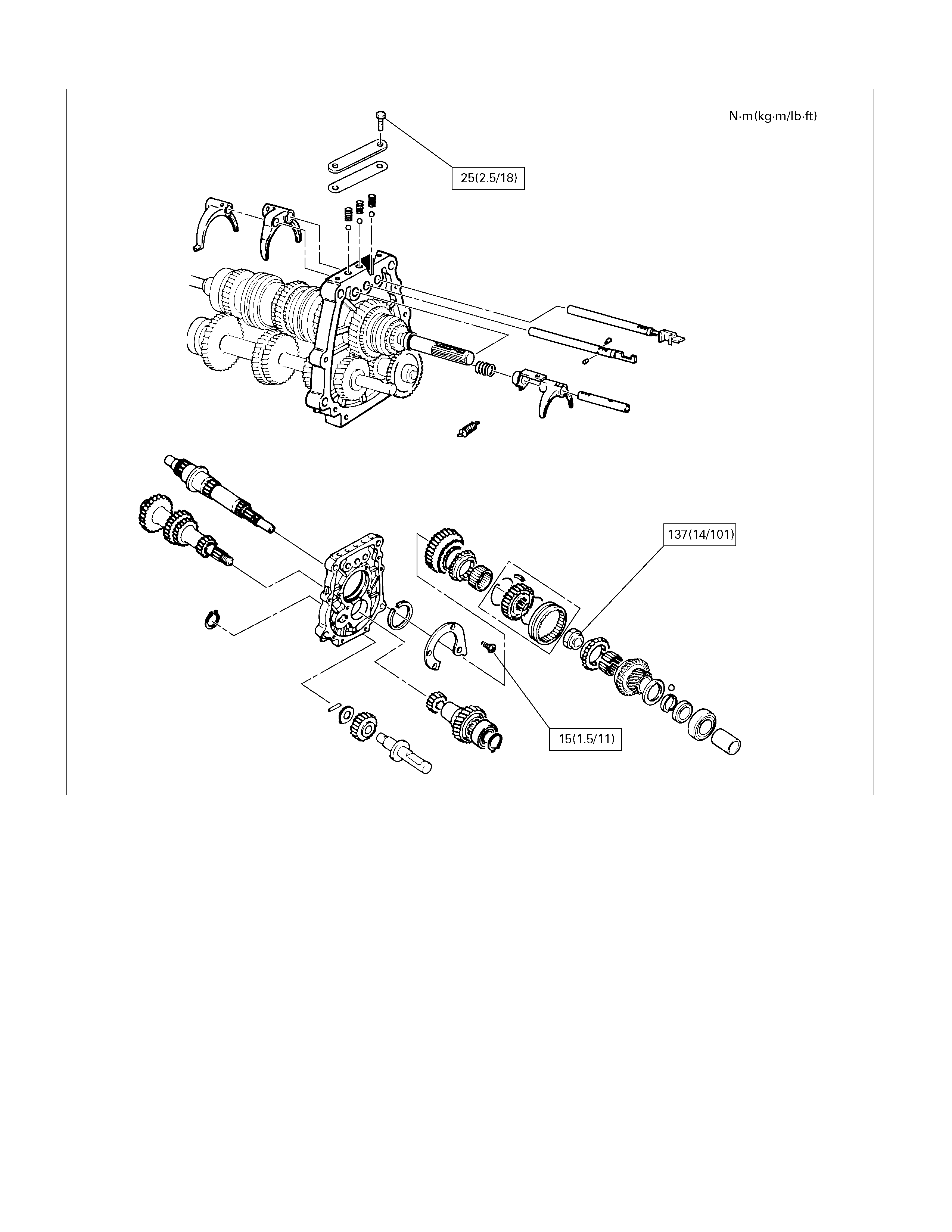

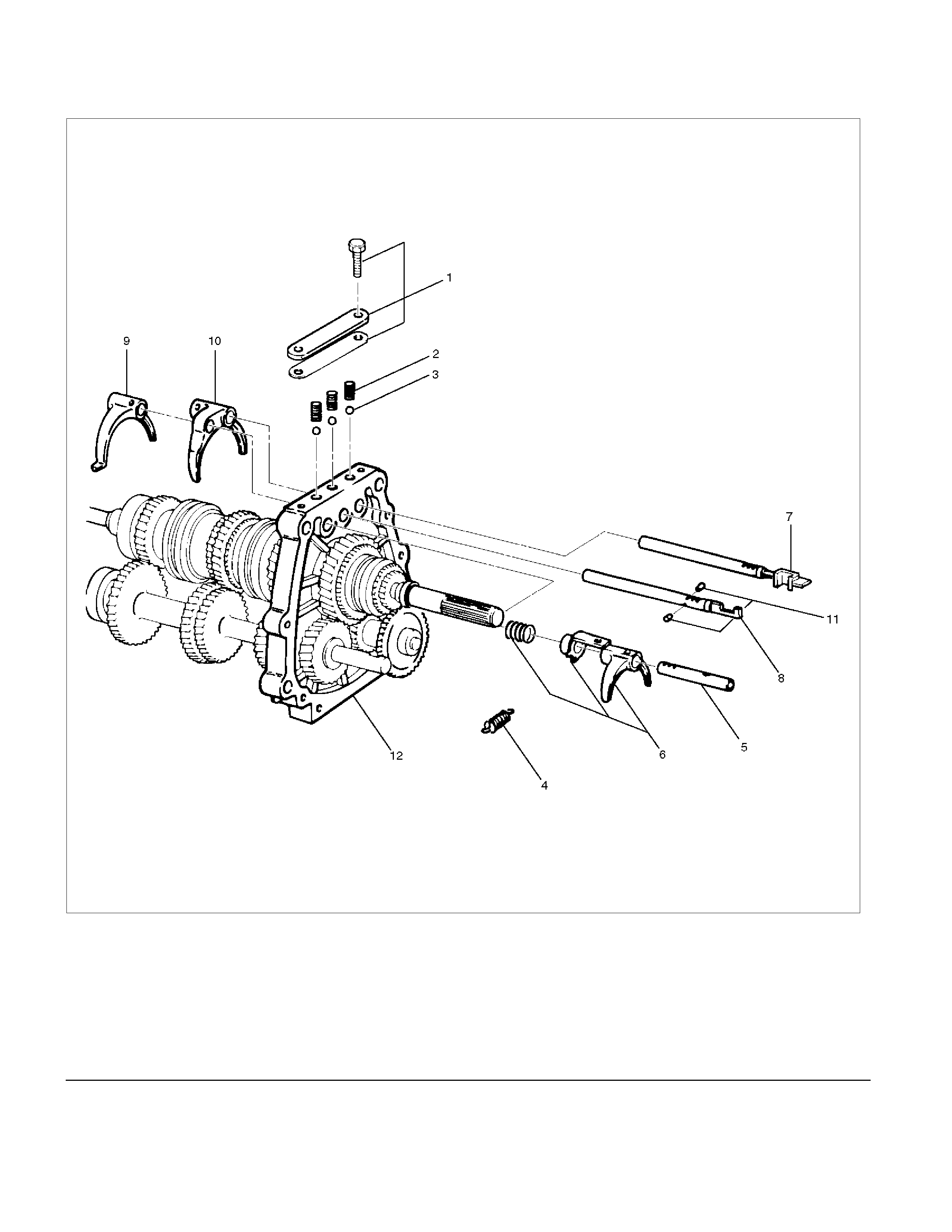

Intermediate Plate with Gear Assembly, Detent, Shift Arm, Shift Rod, and Interlock Pin

Disassembled View

220RS010

Legend

(1) Detent Spring Plate and Gasket (7) 1st-2nd Shift Rod

(2) Detent Spring (8) 3rd-4th Shift Rod

(3) Detent Ball (9) 3rd-4th Shift Arm

(4) Spring (10) 1st-2nd Shift Arm

(5) Rev-5th Shift Rod (11) Interlock Pin

(6) Rev-5th Shift Arm and Reverse Inhibitor (12) Intermediate Plate and Gear Assembly

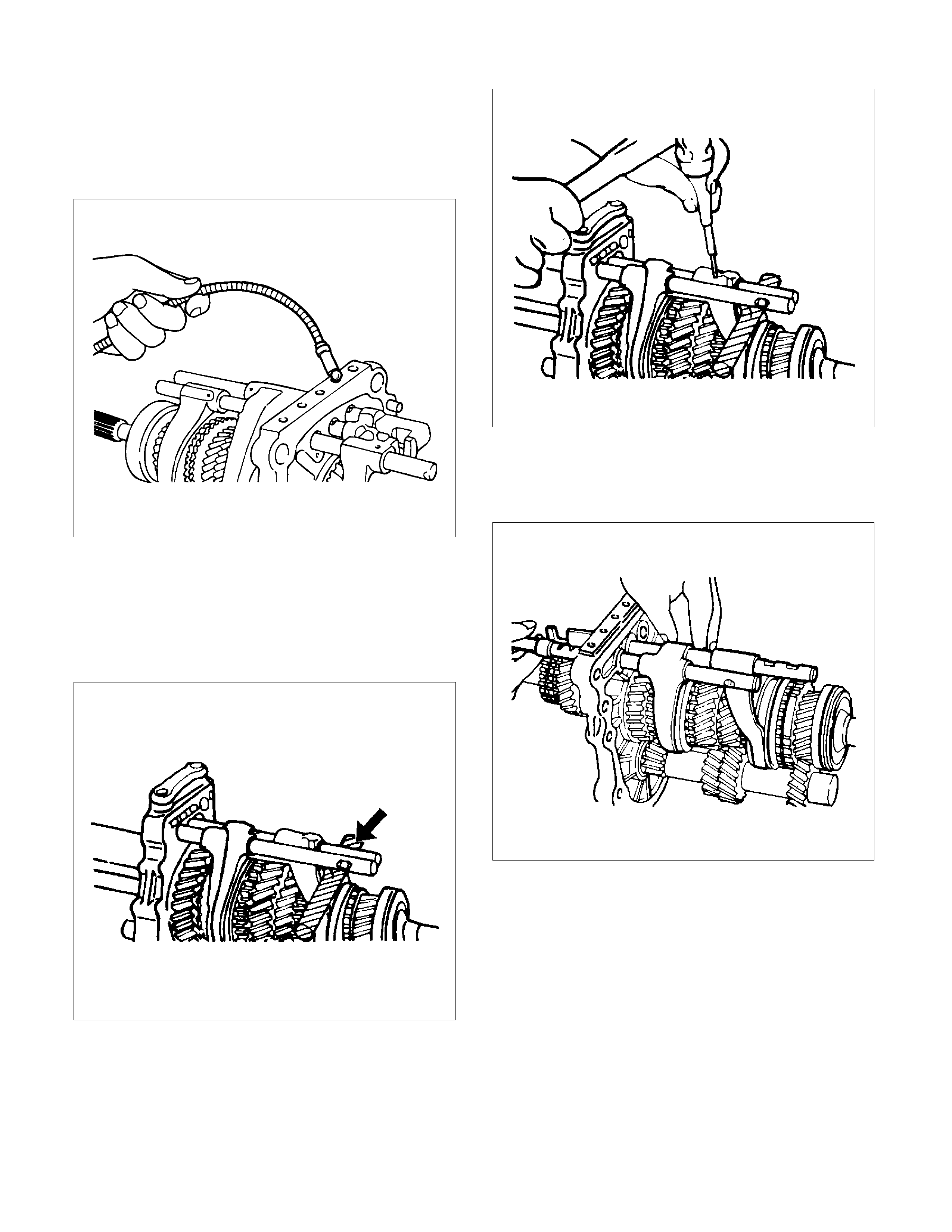

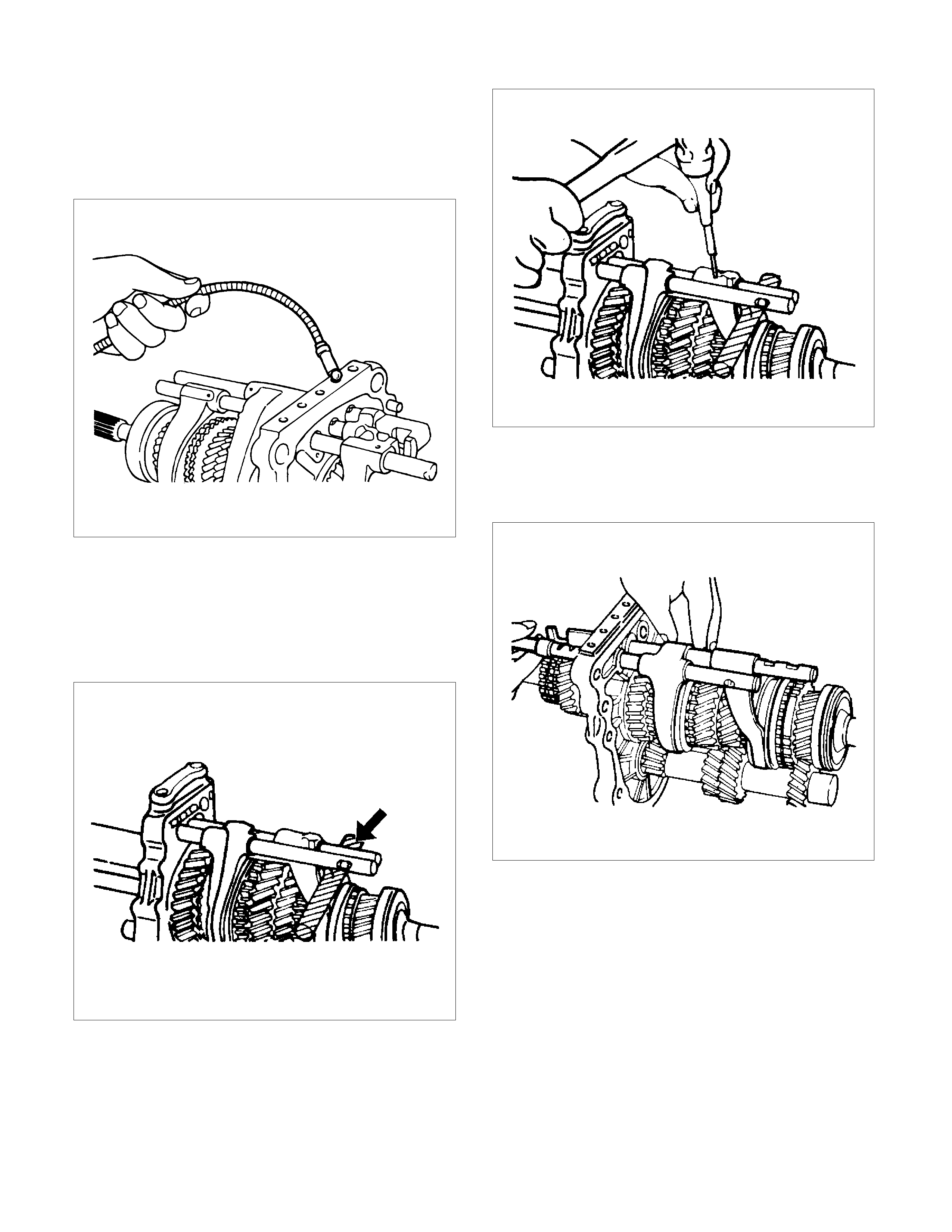

Disassembly

1. Remove detent spring plate and gasket (1), detent

spring (2) and detent ball (3).

Use a magnetic hand to remove the detent balls

from the intermediate plate.

220RS011

2. Remove spring (4).

3. Remove rev-5th shift rod (5), and rev-5th shift arm

and reverse inhibitor (6).

Remove 1st-2nd shift rod (7), 3rd-4th shift rod (8),

3rd-4th shift arm (9), and 1st-2nd shift arm (10).

• Hold a round bar against the shift rod end.

230RS003

• Use a spring pin remover to remove the shift

arm spring pins from the shift arms and the

shift rods.

230RS0004

• Be careful not to lose the interlock pins, when

pulling out the shift rod rearward.

Interlock pins are located between the shifter

rods in the intermediate plate.

230RS0005

• Remove the rev-5th, 1st-2nd and 3rd-4th shift

rods carefully.

4. Remove interlock pin (11) from intermediate plate

and gear assembly (12).

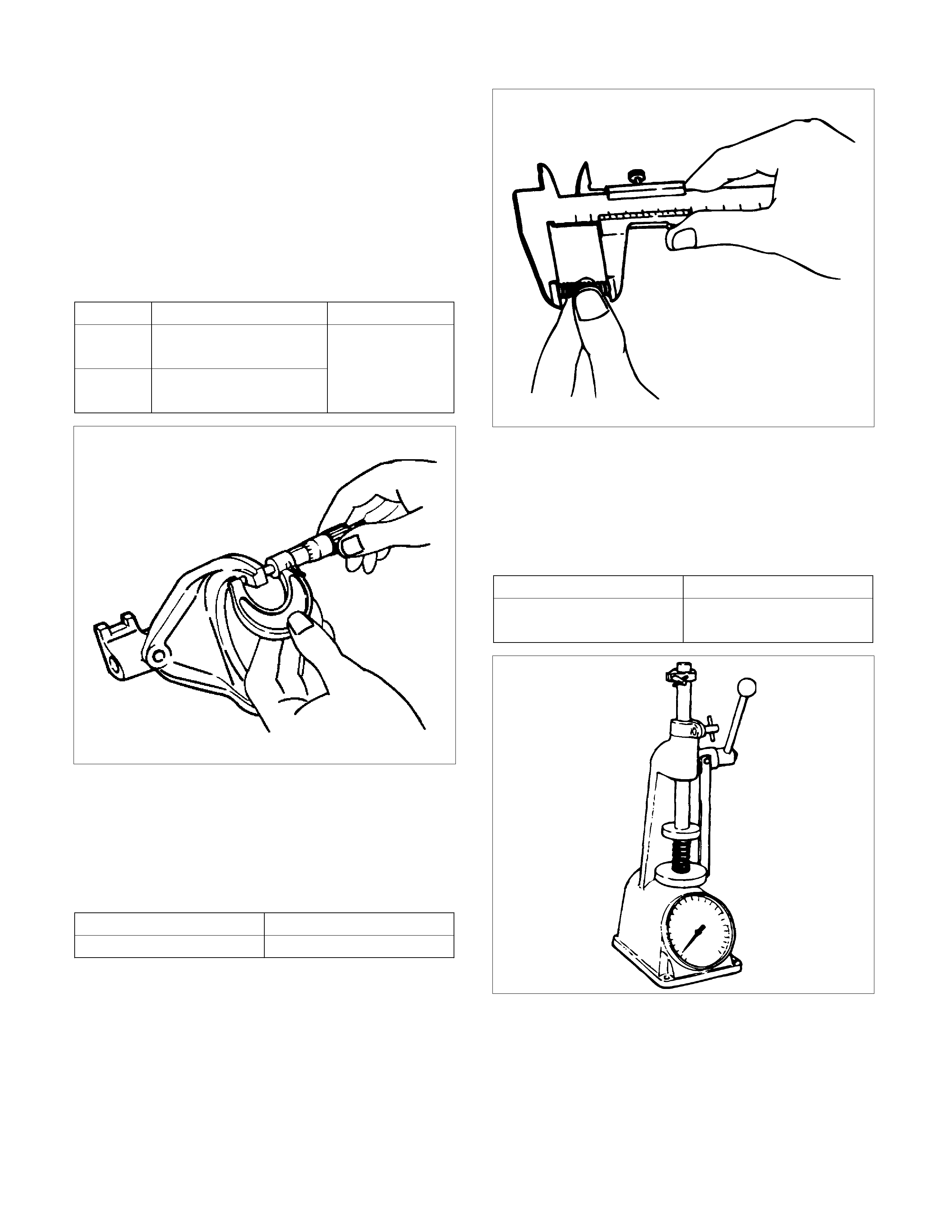

Inspection and Repair

Make the necessary adjustments, and part

replacements if excessive wear or damage is

discovered during inspection.

Shift Arm Thickness

• Use a micrometer to measure the shift arm

thickness.

If the measured value is less than the specified limit,

the shift arm must be replaced.

Shift Arm Thickness

Standard Limit

1st-2nd 9.60 - 9.85 mm

(0.378 - 0.388 in)

3rd-4th

Rev.5th 9.60 - 9.80 mm

(0.378 - 0.386 in)

9.0 mm

(0.354 in)

230RS006

Detent Spring Free Length

• Use a vernier caliper to measure the detent spring

free length.

If the measured value is less than the specified limit,

the detent spring must be replaced.

Detent Spring Free Length

Standard Limit

26.8 mm (1.06 in) 26.2 mm (1.03 in)

220RS012

Detent Spri ng Tension

• Use a spring tester to measure the detent spring

tension.

If the measured value is less than the specified limit,

the detent spring must be replaced.

Detent Spri ng Tension

Compressed height Standard

20 mm (0.787 in) 87.2 - 97.1 N

(19.6 - 21.8 lb)

220RS013

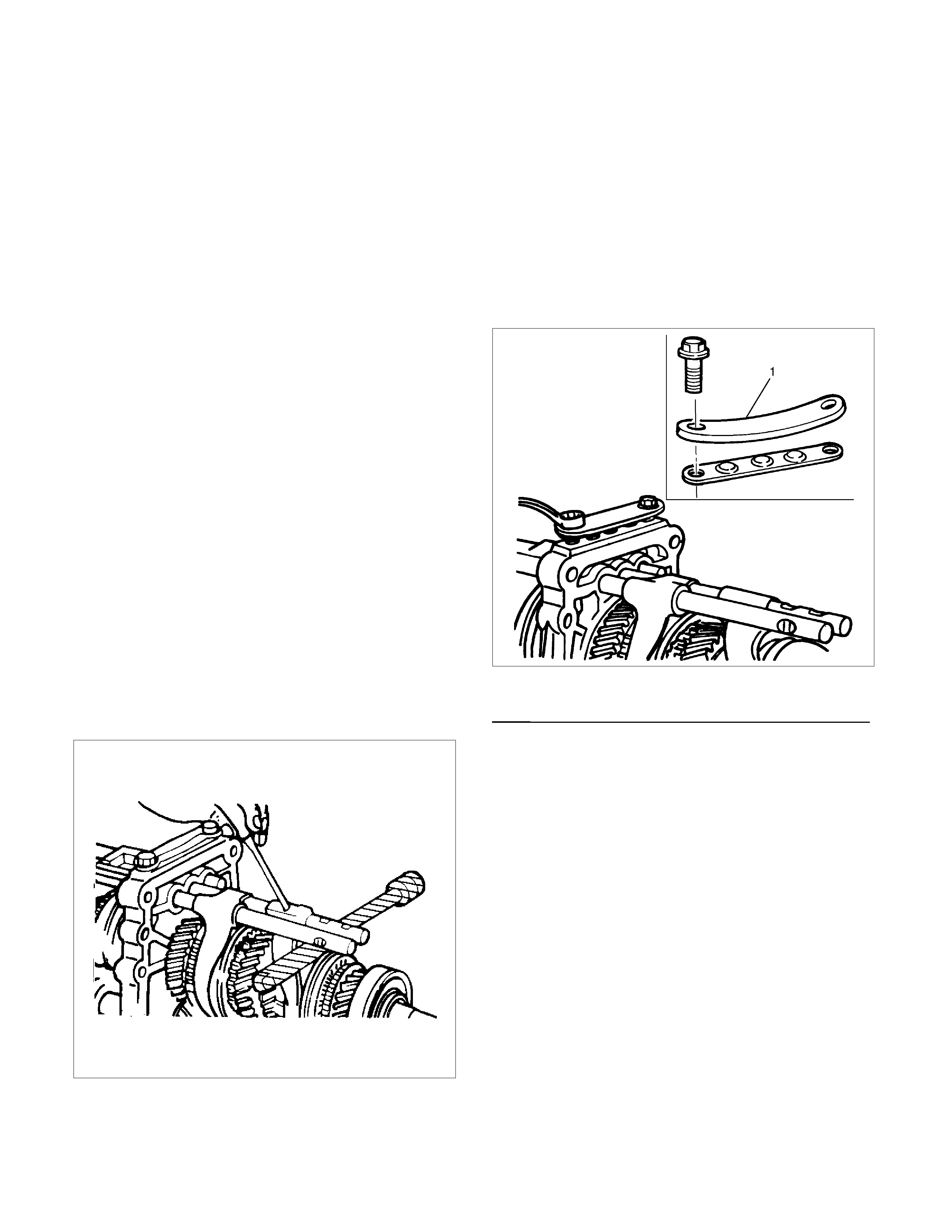

Reassembly

1. Install rev-5th shift arm and reverse inhibitor (6)

and rev-5th shift rod (5).

• Apply oil to the reverse inhibitor inner surface.

• Install the shift rod in the intermediate plate

(12).

• Hold a round bar against the shift rod end

lower face to protect it against damage.

• Install a new spring pin.

Never reinstall the used spring pin.

• Install the interlock pin (11) in the intermediate

plate (12).

Do not allow the interlock pin to fall from the

intermediate plate (12).

2. Install 1st-2nd shift arm (10) and 3rd-4th shift arm

(9) to intermediate plate and gear assembly (12).

3. Install 3rd-4th shift rod (8) and 1st-2nd shift rod

(7).

• Install the interlock pin (11) in the intermediate

plate and gear assembly (12).

• Install the 3rd-4th shift rod (8) in the

intermediate plate (12).

Do not allow the interlock pin to fall from the

intermediate plate.

• Install the interlock pin (11) and then 1st-2nd

shift rod (7) in the intermediate plate (12).

Do not allow the interlock pin to fall from the

intermediate plate.

• Hold a round bar against the shift rod end

lower face to protect it against damage.

• Install a new spring pin.

Never reinstall the used spring pin.

230RS007

4. Install spring (4).

5. Put detent balls (3) in the intermediate plate holes.

• Apply oil to the detent balls.

6. Install detent springs (2) and detent spring plate

and gasket (1).

• Install a new gasket and the detent spring

plate.

• Tighten the detent spring plate bolts to the

specified torque.

Torque: 25 N·m (2.5 kg·m/18 lb·ft)

220RS030

Legend

(1) Warped

Reverse Gear and 5th Gear

Disassembled View

226R300027

Legend

(1) Bearing Snap Ring (11) Reverse Idler Gear Assembly

(2) Ball Bearing (12) Idle Shaft Pin

(3) Bearing Snap Ring (13) Thrust Washer

(4) Speedometer Drive Gear (14) Reverse Idler Gear

(5) Clip (15) Reverse Idler Shaft

(6) Retainer Snap Ring (16) Bearing Snap Ring

(7) Retainer (17) Ball Bearing

(8) Thrust Plate (18) Counter 5th Gear

(9) Thrust Washer and Lock Ball (19) Counter Reverse Gear

(10) Reverse Idler Gear Snap Ring (20) 5th Gear

(21) 5th Block Ring (26) Reverse Gear

(22) Needle Bearing (27) Needle Baring

(23) Mainshaft Nut (28) Bearing Plate and Screw

(24) Rev-5th Synchronizer Assembly (29) Bearing Snap Ring

(25) Reverse Block Ring (30) Intermediate Plate

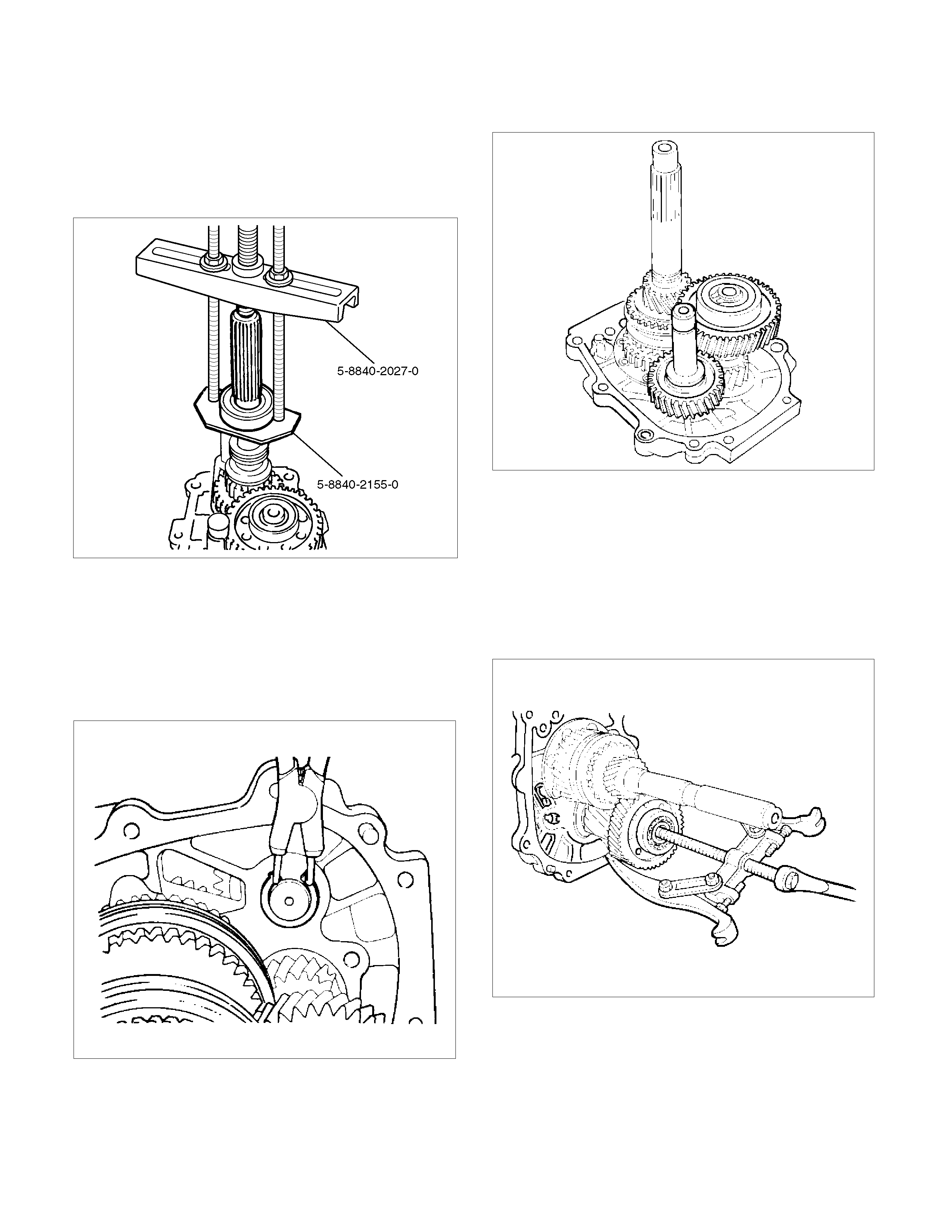

Disassembly

1. Use a pair of snap ring pliers to remove the

bearing snap ring (1).

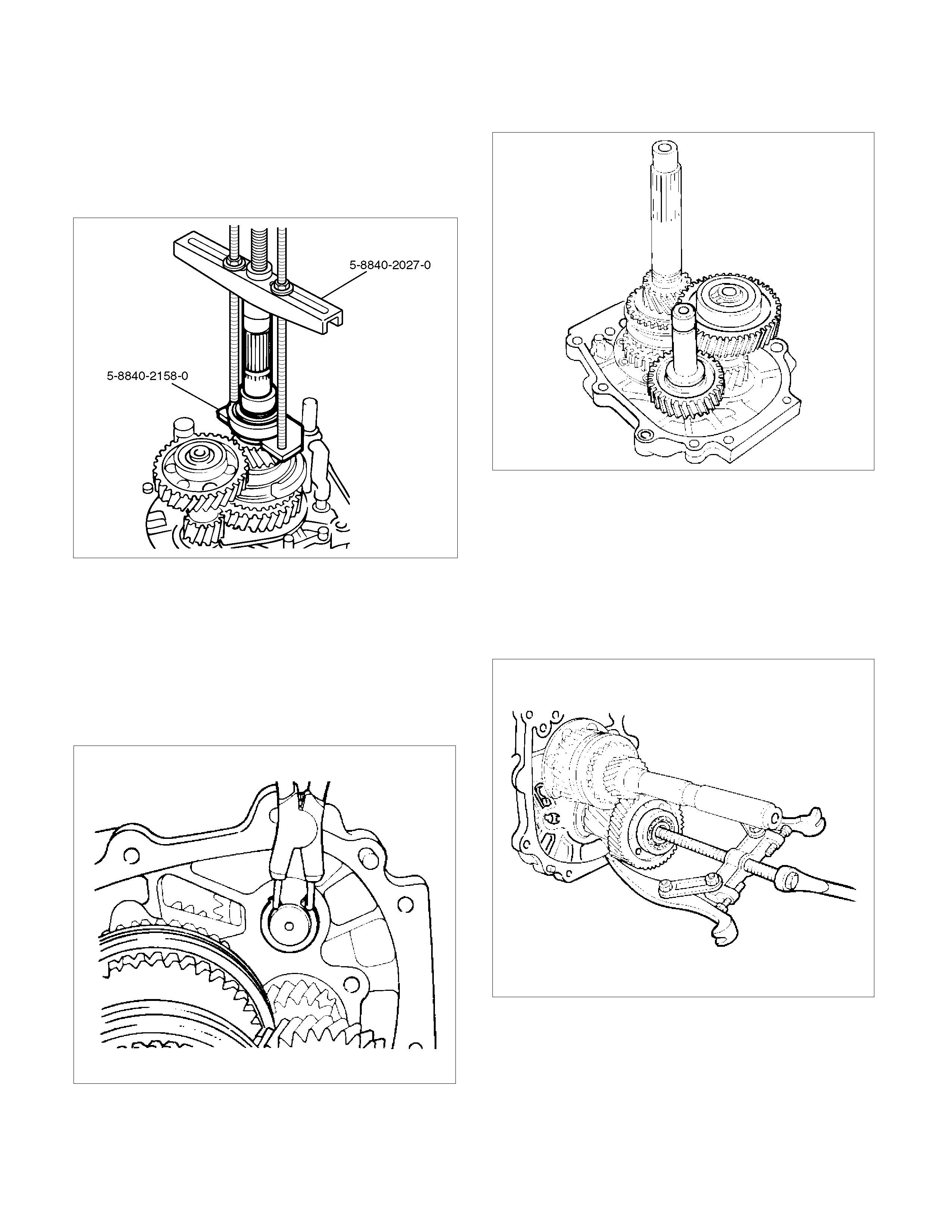

2. Set the bearing remover 5-8840-2155-0 and puller

5-8840-2027-0 to the bearing (2) and the

mainshaft end to remove the ball bearing (2).

262L100001

3. Remove the bearing snap ring (3), clip (5),

speedometer drive gear (4), retainer snap ring (6)

and retainer (7).

4. Remove thrust plate (8) and thrust washer and

lock ball (9).

5. Use a pair of snap ring pliers to remove reverse

idler gear snap ring (10).

226RS004

6. Remove the reverse idler gear assembly (11) from

the intermediate plate (30).

226RS005

7. Remove idle shaft pin (12), thrust washer (13),

reverse idler gear (14), and reverse idler shaft

(15).

8. Use a pair of snap ring pliers to remove the snap

ring (16).

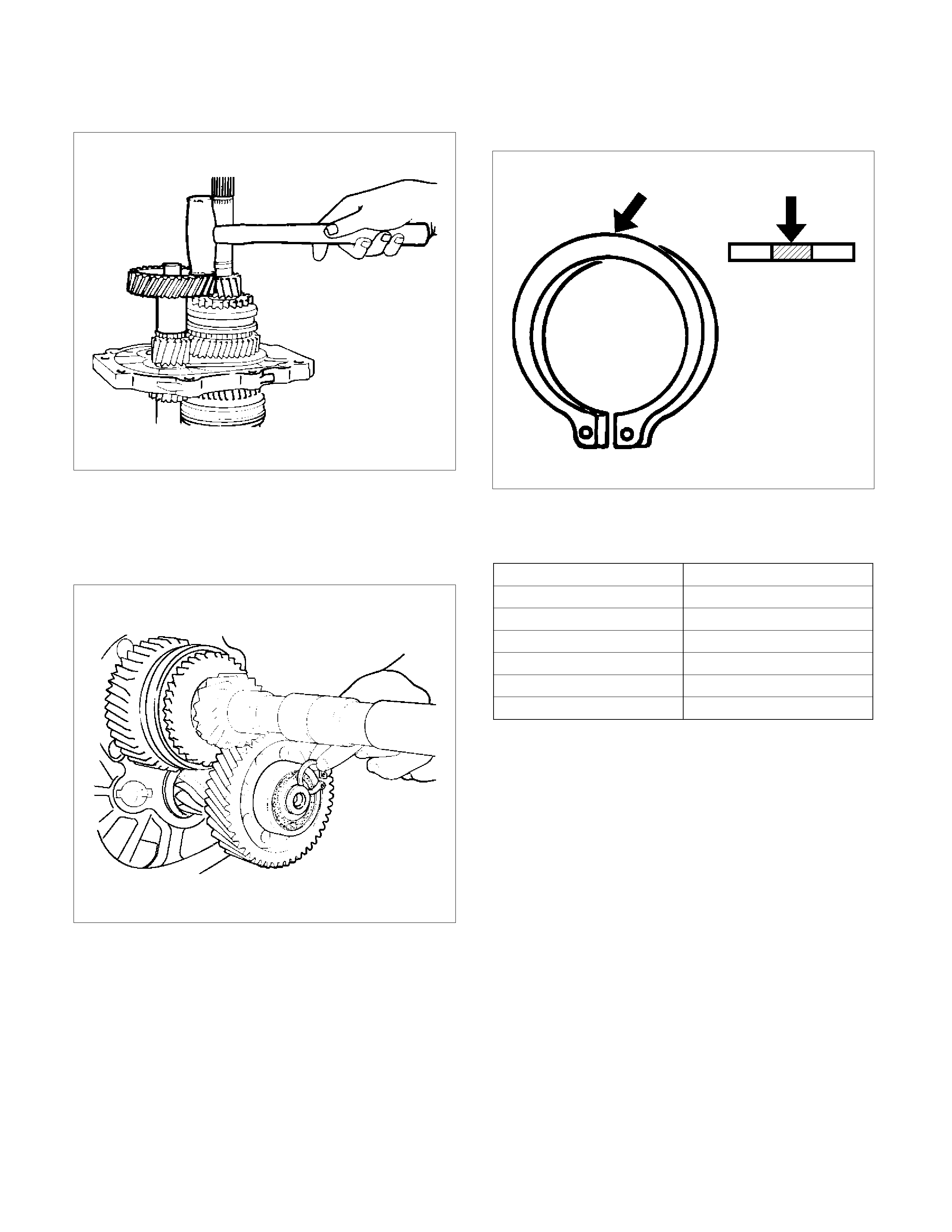

9. Attach a universal puller to the counter gear shaft.

Use a universal puller to remove the ball bearing

(17) and the counter 5th gear (18).

226RS006

10. Remove counter reverse gear (19).

11. Remove 5th gear (20), 5th block ring (21), and

needle bearing (2 piece type) (22).

226RS007

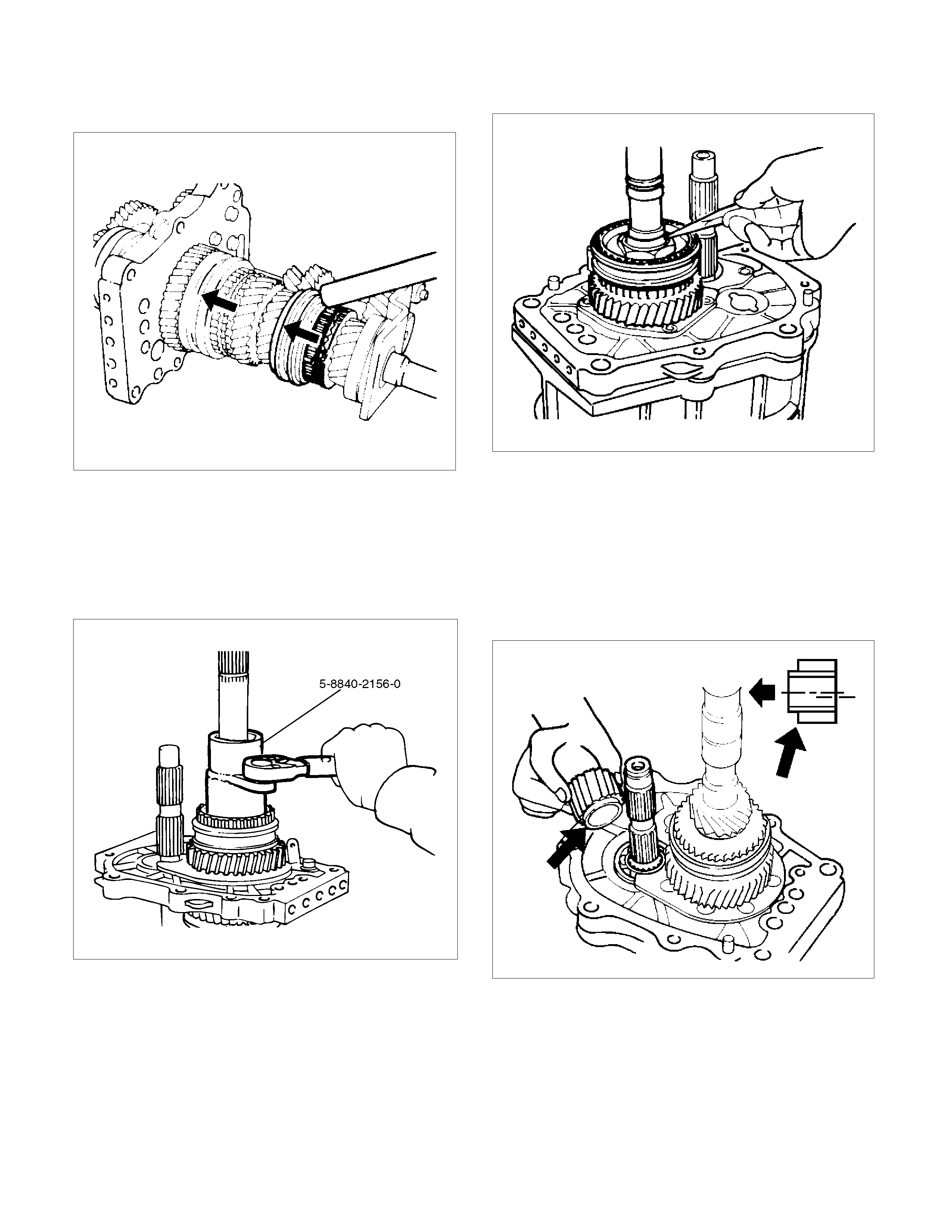

12. Remove the mainshaft nut (23) according to

following steps.

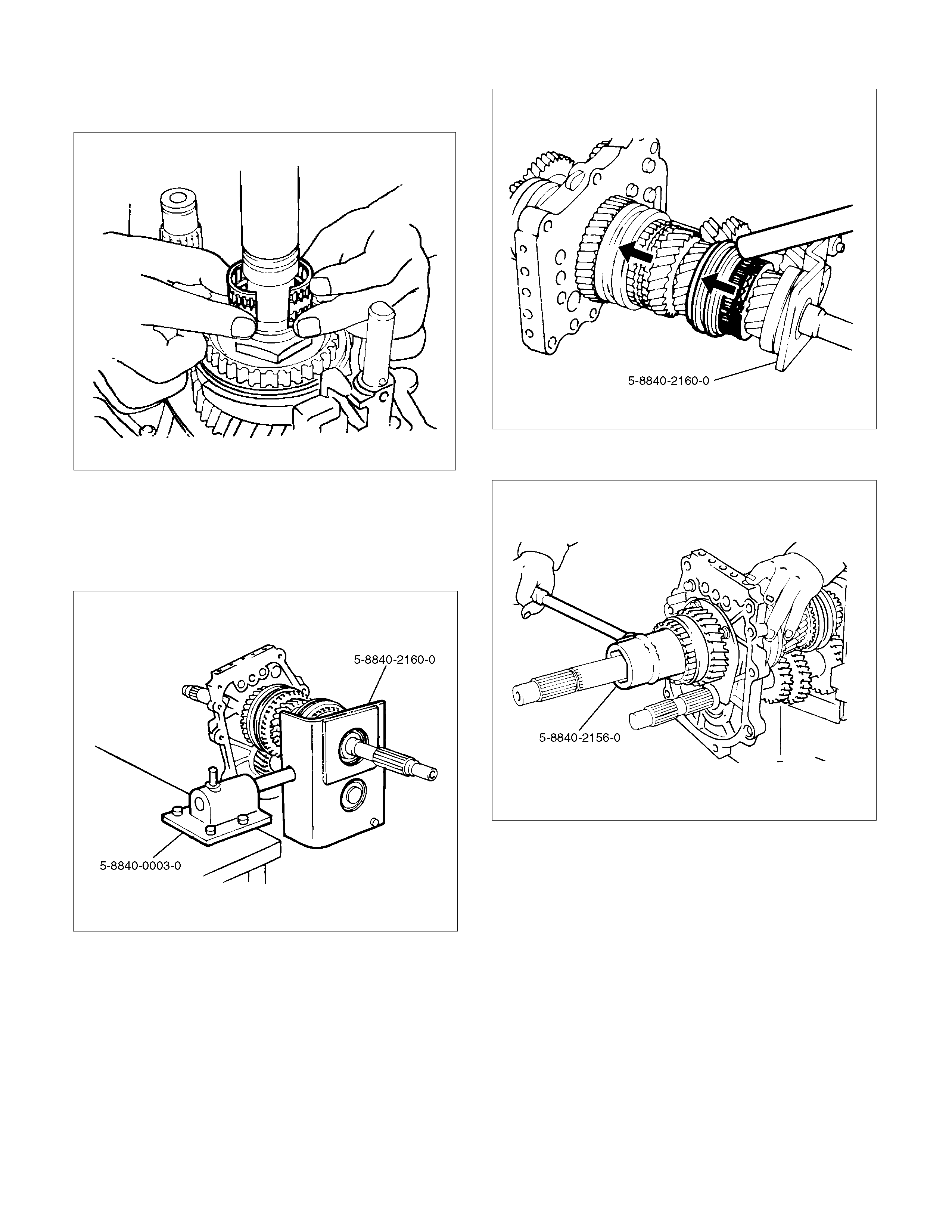

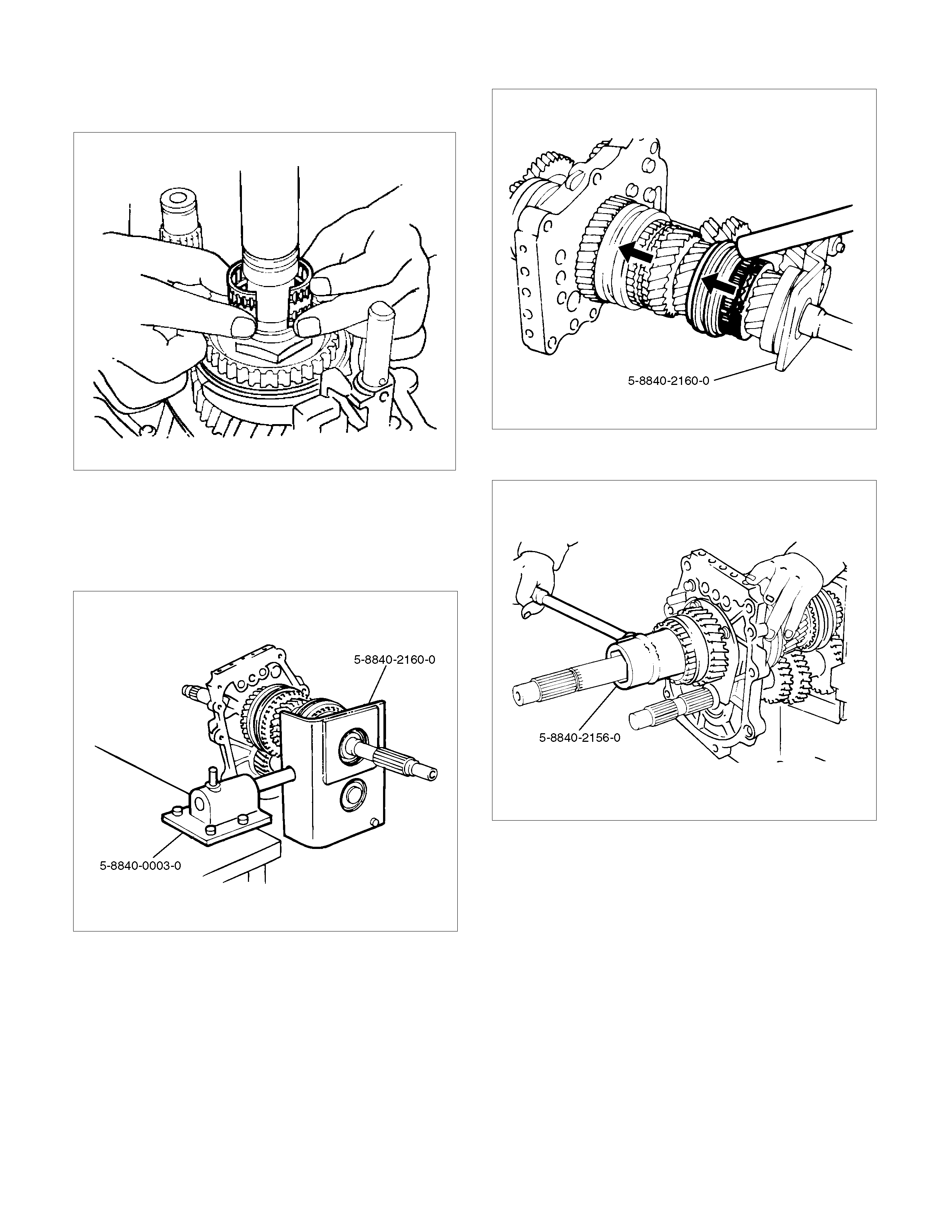

Attach the holding fixture 5-8840-2160-0 and base

5-8840-0003-0 to the mainshaft and the counter

gear.

226RW212

• Engage the 3rd-4th synchronizer with the 3rd

gear.

• Engage the 1st-2nd synchronizer with the 1st

gear.

226RW210

• Use the mainshaft nut wrench 5-8840-2156-0

to remove the mainshaft nut (23).

226RW211

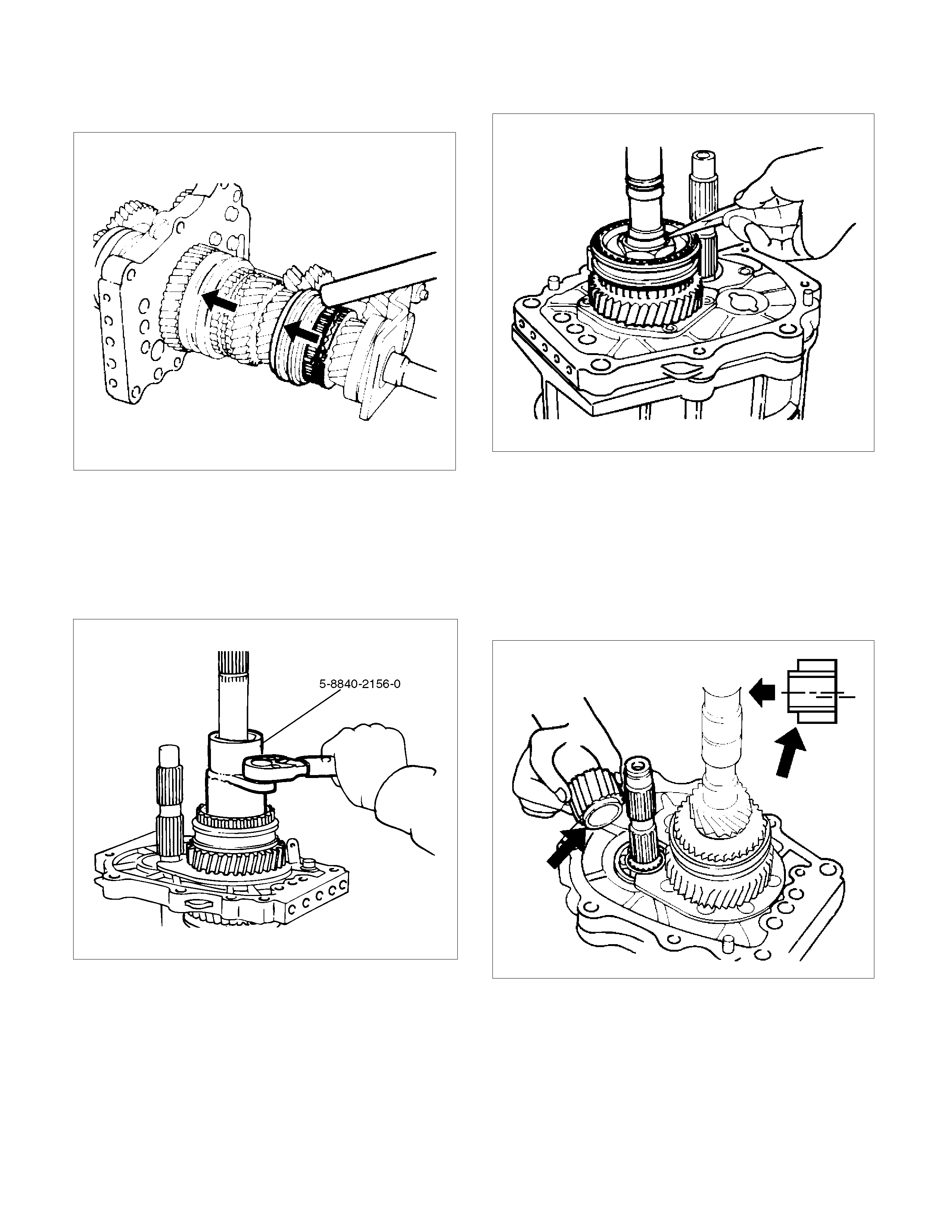

13. Use screw drivers between the reverse gear (26)

and bearing plate (28) to remove the Rev-5th

synchronizer assembly (24) together with reverse

block ring (25) and reverse gear (26).

226RS010

14. Remove needle bearing (27).

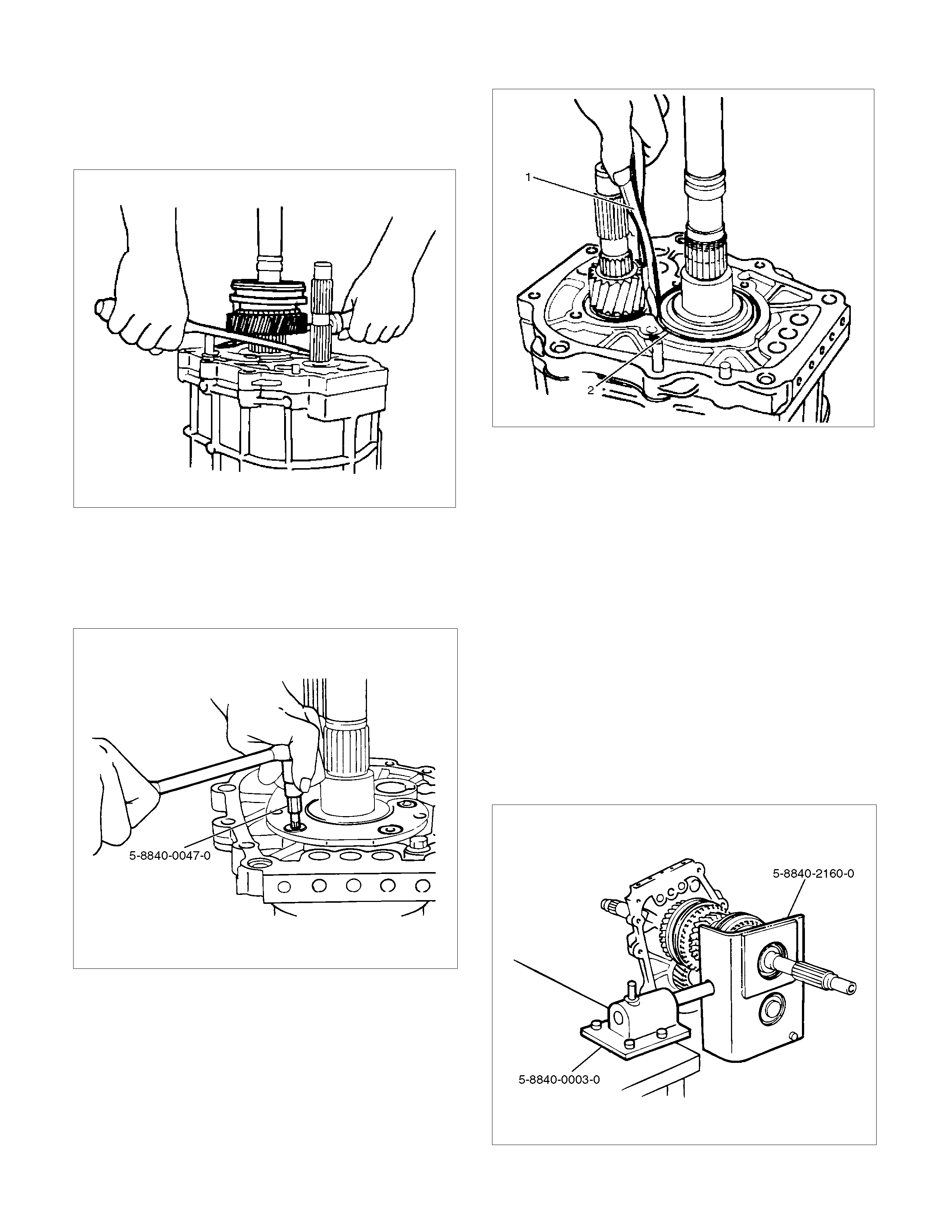

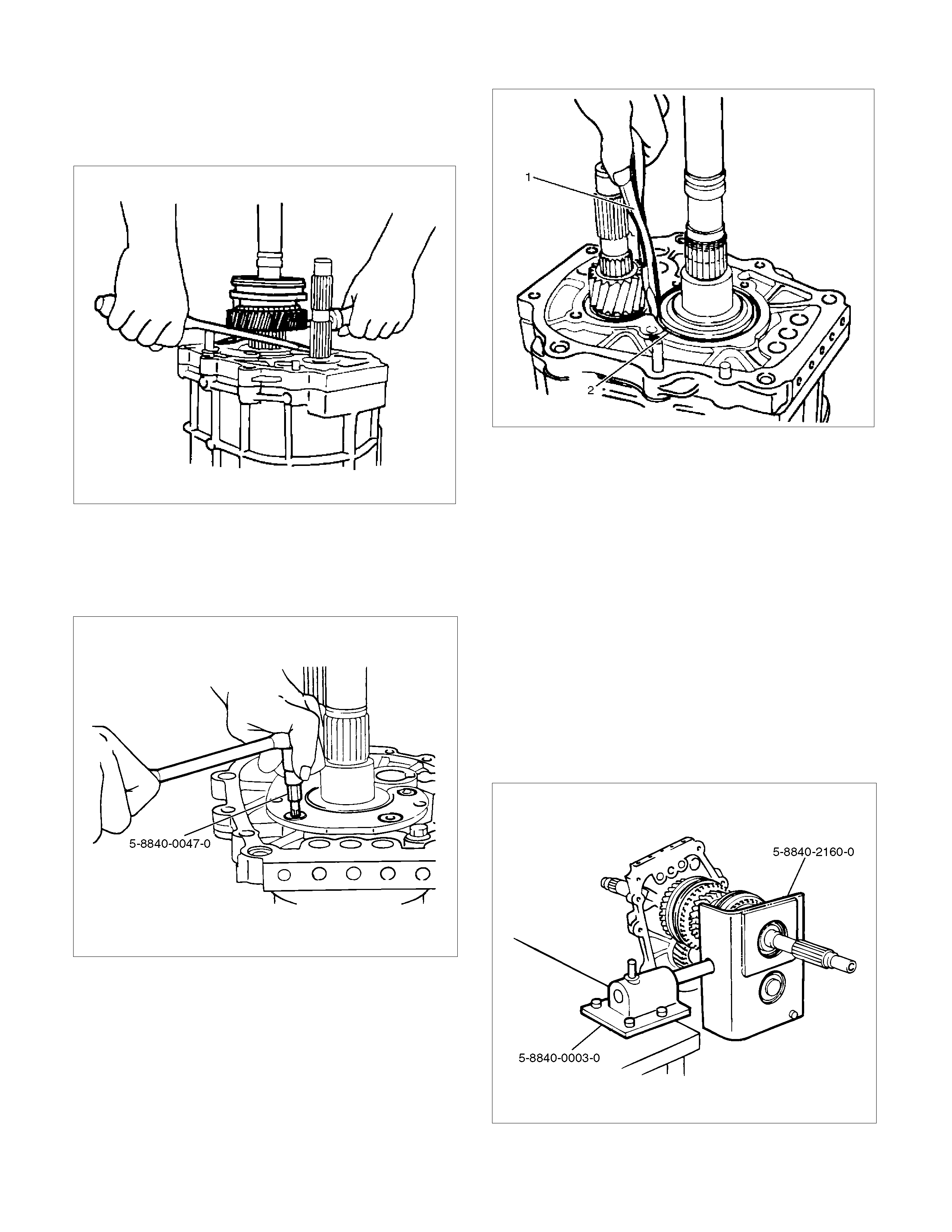

15. Use the torx bit wrench (T45) 5-8840-0047-0 to

remove the bearing plate and screw (28) from the

intermediate plate.

220RW137

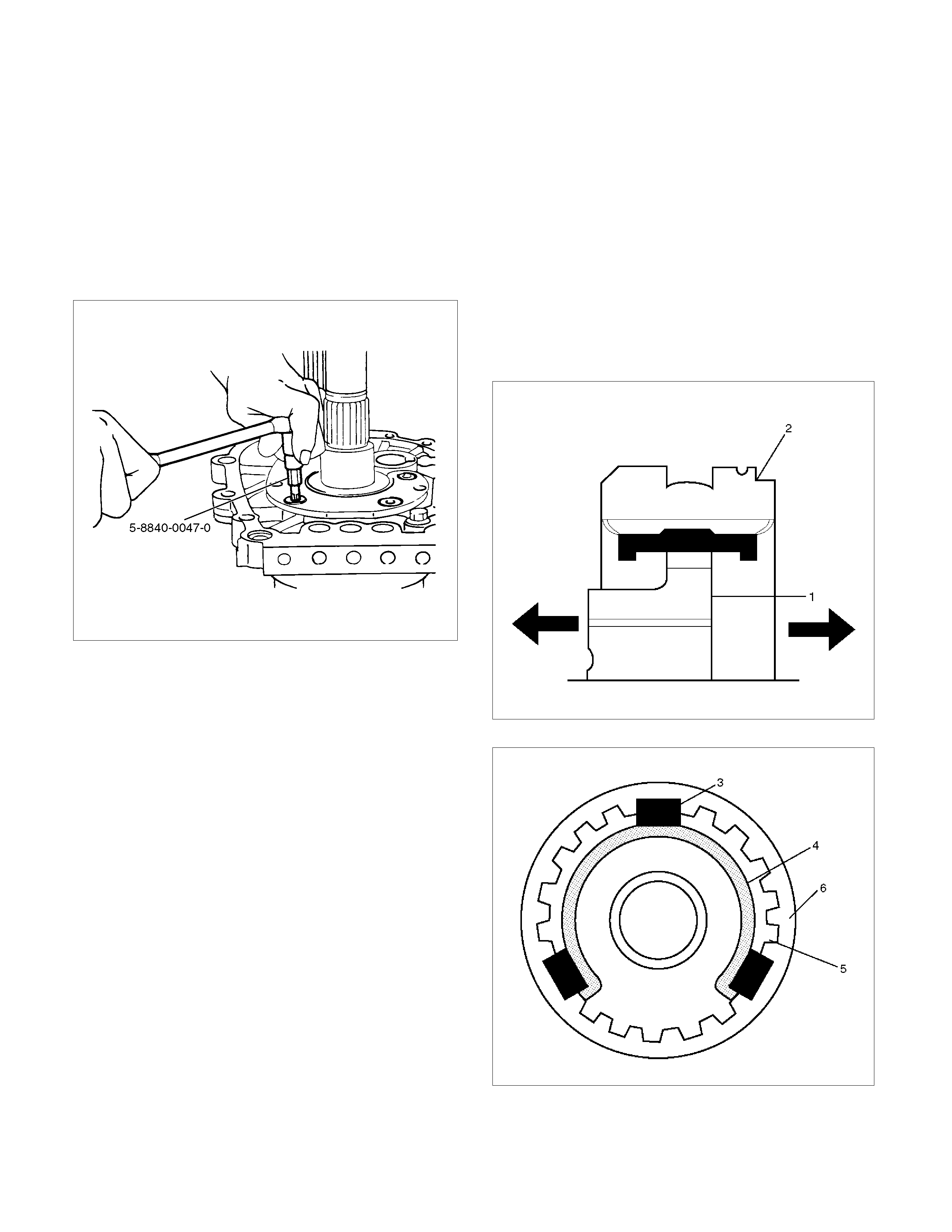

16. Use the snap ring pliers (1) to remove the

mainshaft bearing snap ring (2) (29).

226RS011

17. Hold the snap ring open with the pliers.

Push the intermediate plate (30) toward the rear of

the transmission to remove it.

The bearing snap ring (29) will come free.

Inspection and Repair

Refer to Top Gear Shaft, Main Gear Shaft, and

Counter Gear in this section for inspection and repair.

Reassembly

1. Mesh the counter gear with the mainshaft

assembly.

Set the holding fixture 5-8840-2160-0 to the

mainshaft and the counter gear and then install it on

the base 5-8840-0003-0.

Install the intermediate plate (30) on the gear

assembly.

226RW212

2. Install bearing snap ring (29).

3. Apply recommended thread locking agents

(LOCTITE 242) or its equivalent to each of the

bearing plate screw threads.

Install bearing plate and screw (28).

Tighten the screws to the specified torque by using

torx bit wrench 5-8840-0047-0.

Torque: 15 N·m (1.5 kg·m/11 lb·ft)

220RW137

4. Install needle bearing (27), reverse gear (26), and

reverse block ring (25).

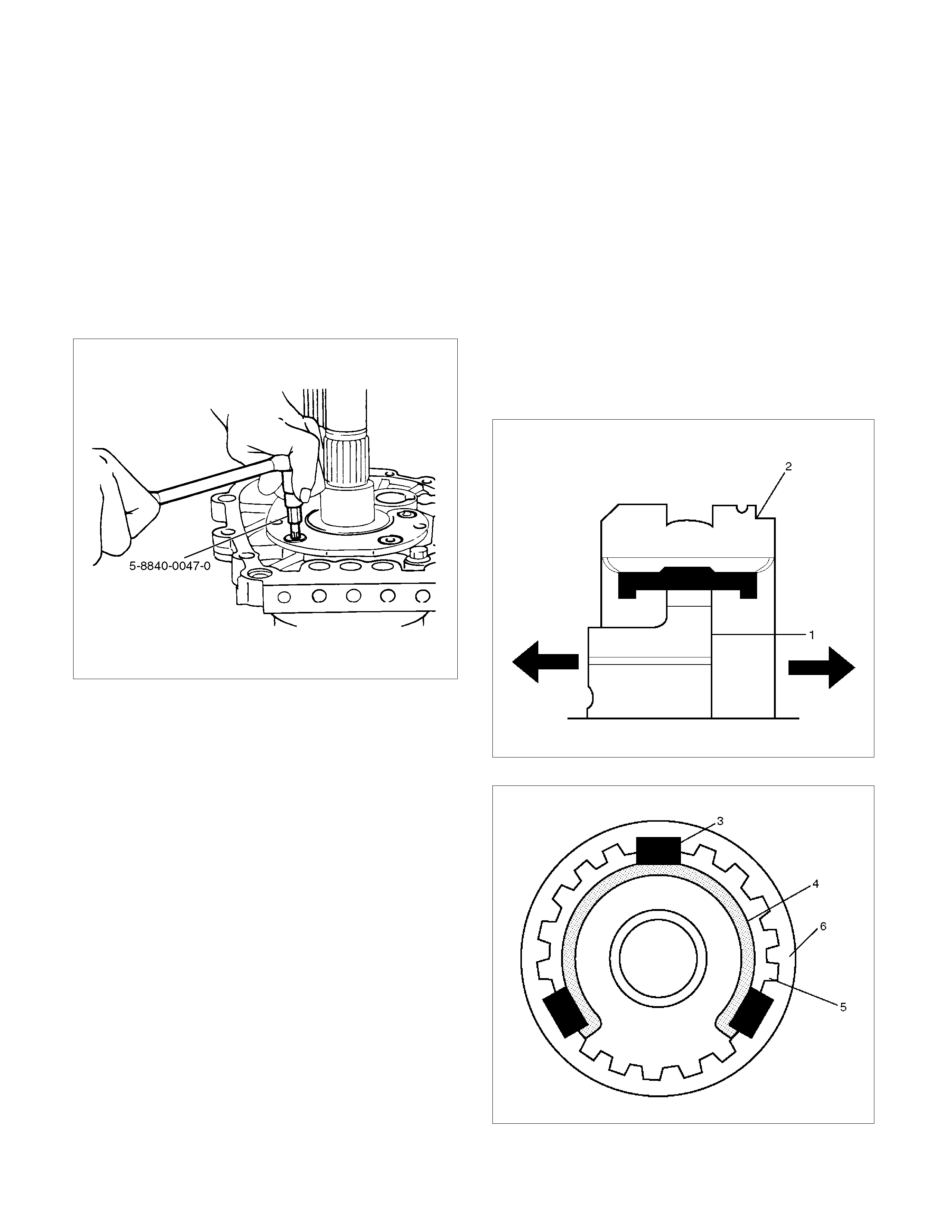

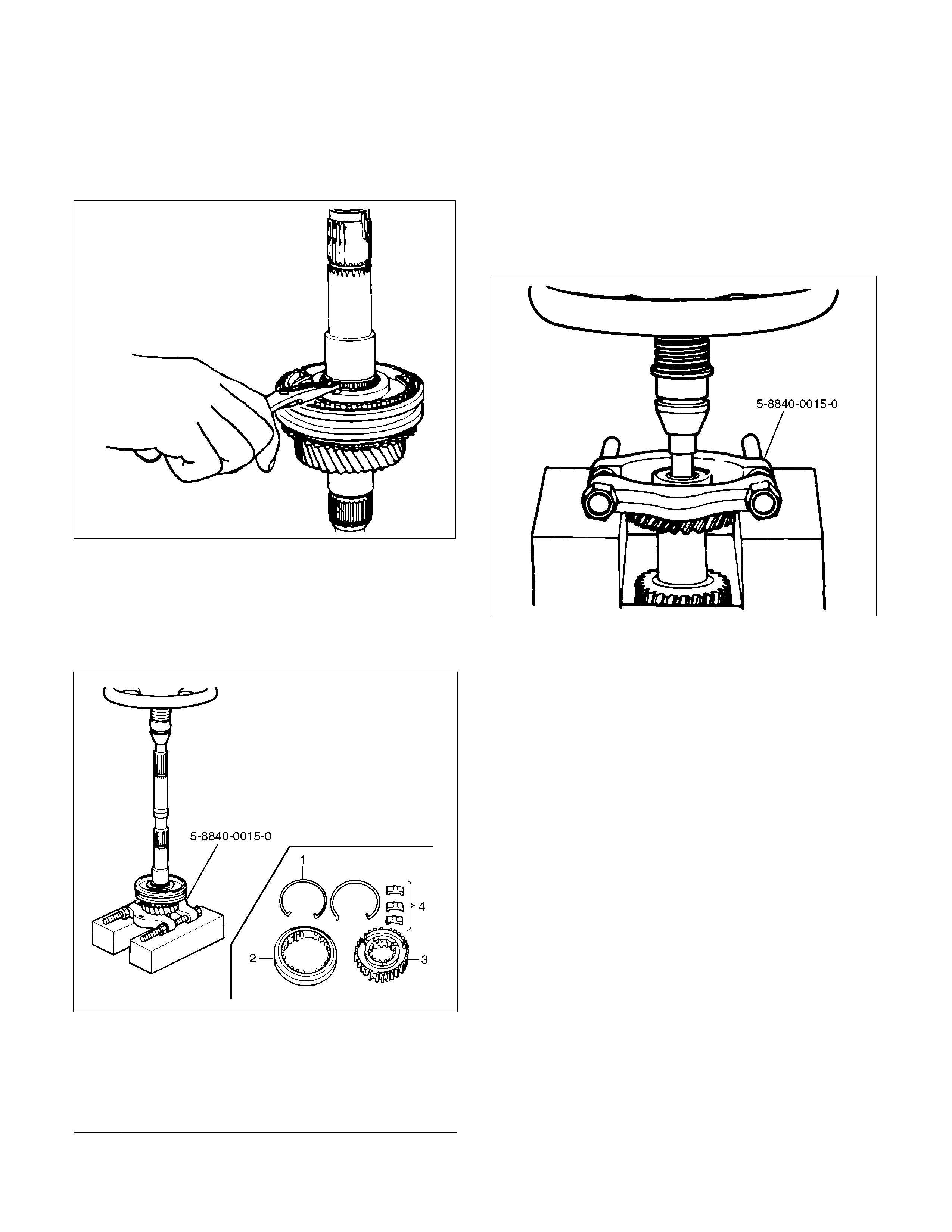

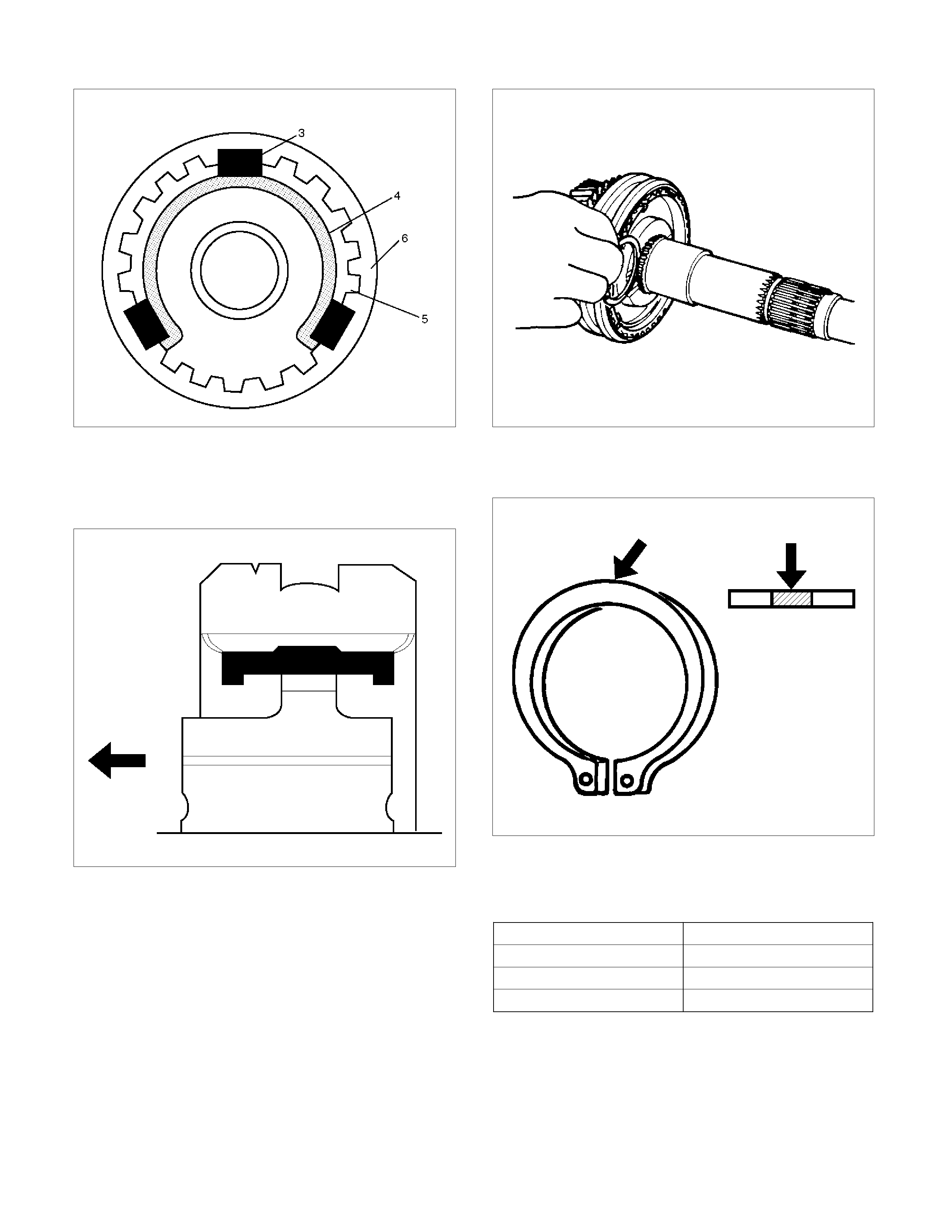

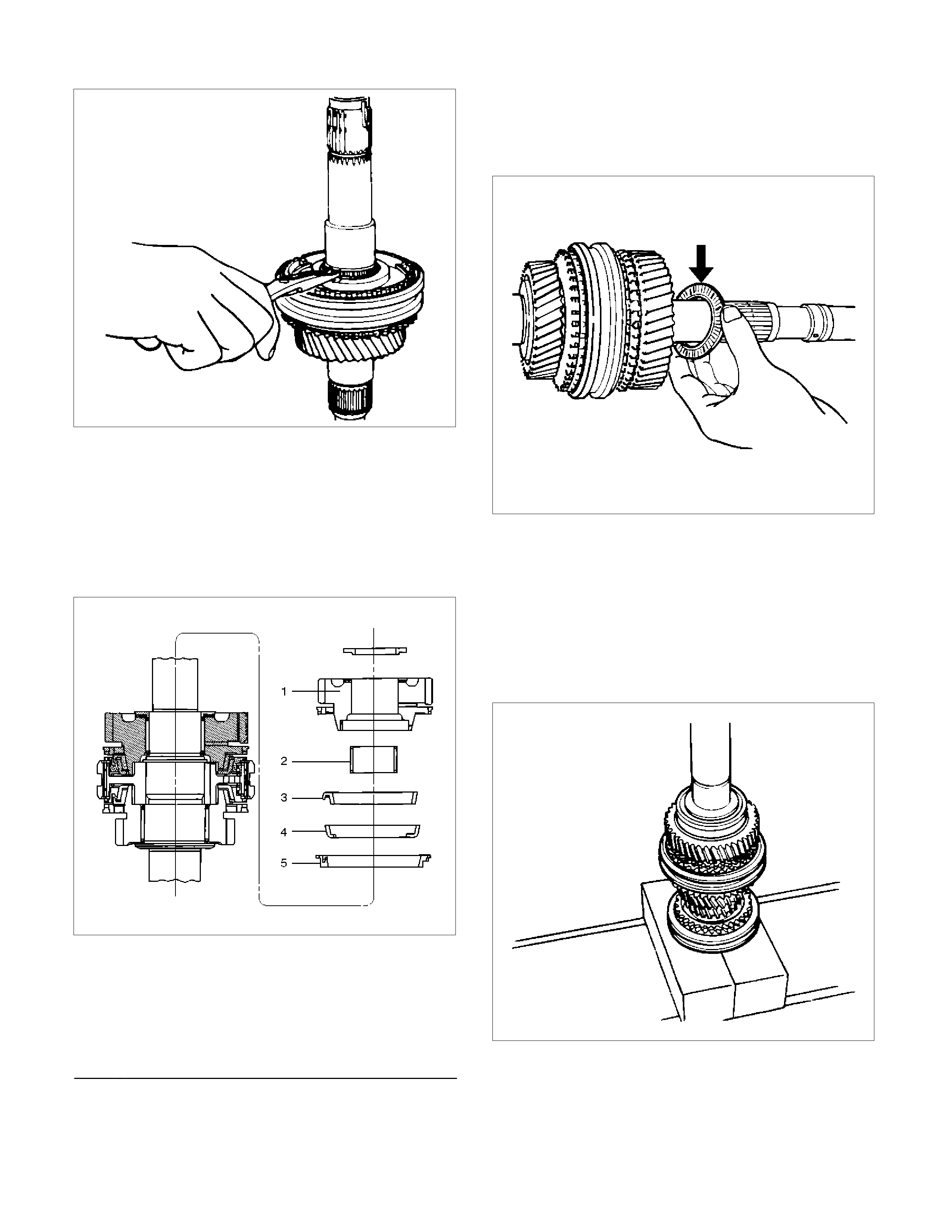

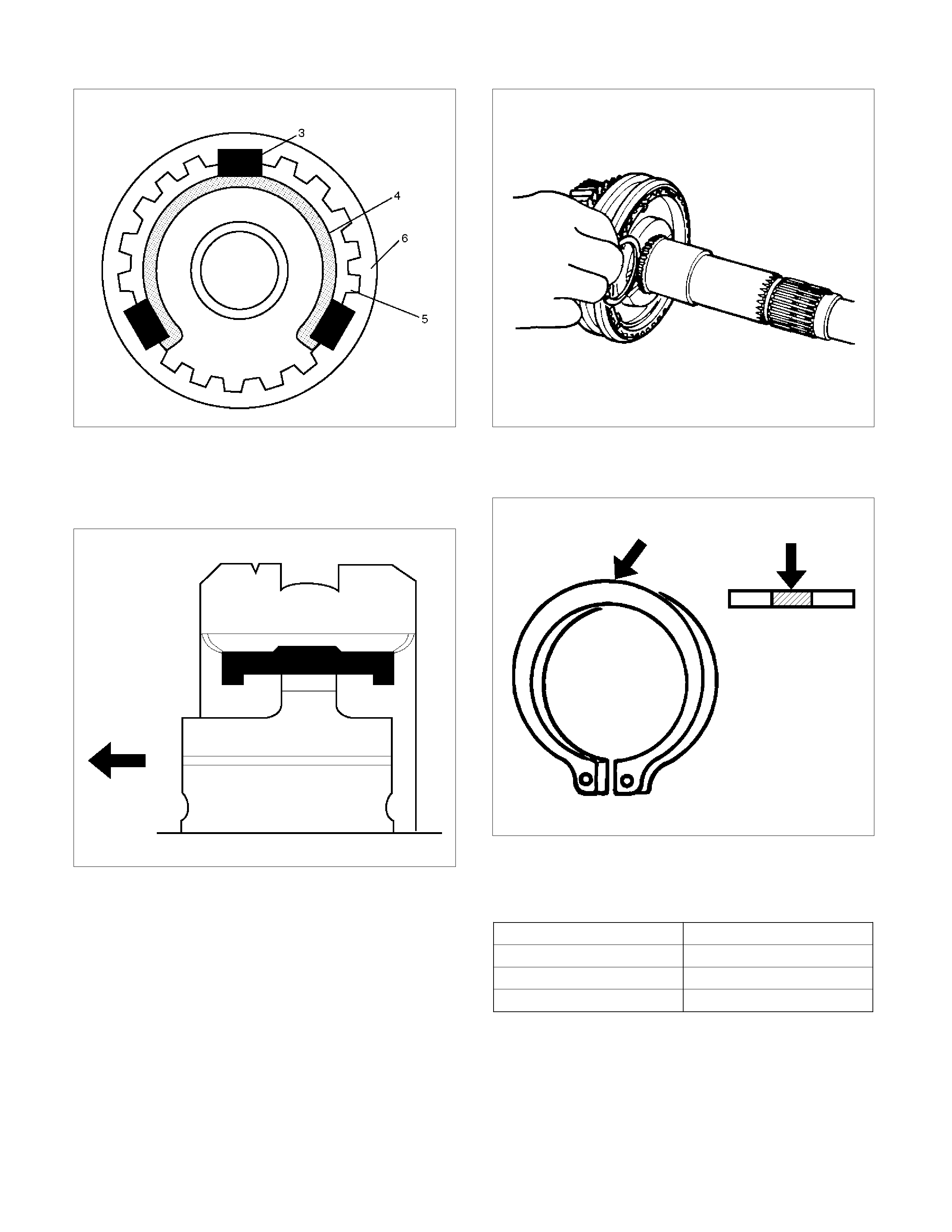

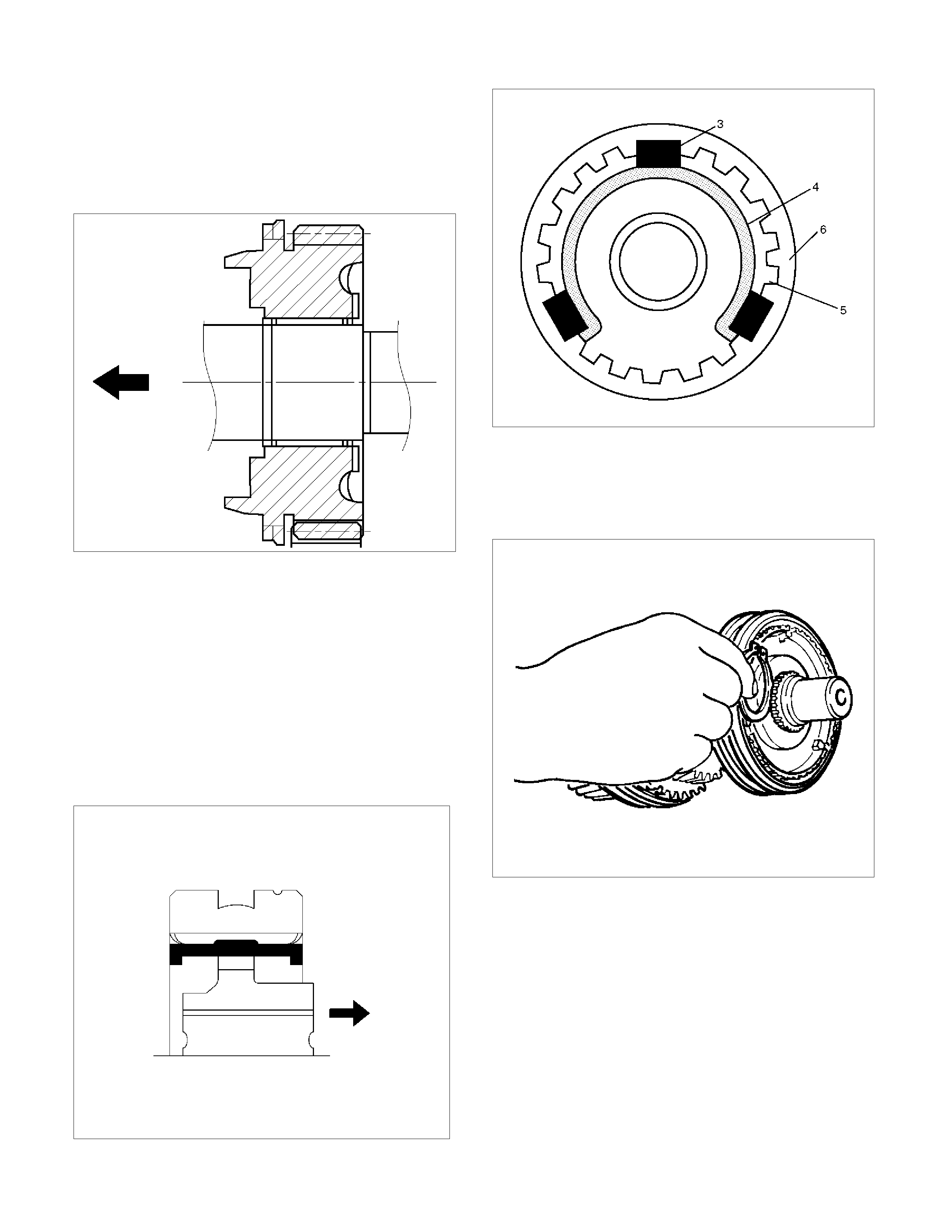

5. Assemble rev-5th synchronizer assembly (24) by

performing the following steps.

1. Turn the clutch hub face (1) toward the sleeve

groove (2) (rear side) on the outer

circumference.

2. Check that the inserts (3) fit snugly into the

clutch hub (5) ring insert grooves.

3. Check that the inserts springs (4) are fitted to

the inserts as shown in the illustration.

4. Check that the clutch hub (5) and the sleeve

(6) slide smoothly.

5. Install the synchronizer assembly (24) to the

mainshaft.

The clutch hub face with the heavy boss must be

facing the reverse gear side.

226RS013

226RS049

6. Mesh the 1st-2nd and 3rd-4th synchronizers with

both the 1st and 3rd gears (double engagement).

226RS015

This will prevent the mainshaft from turning.

7. Install the new mainshaft hub nut.

Use the mainshaft nut wrench 5-8840-2156-0 to

tighten the mainshaft nut (23) to the specified

torque.

Torque: 137 N·m (14 kg·m/101 lb·ft)

226RW214

8. Use a punch to stake the mainshaft nut (23).

226RW153

9. Install needle bearing (22), 5th block ring (21), and

5th gear (20).

10. Apply engine oil to the counter reverse gear (19)

and the reverse gear (26).

Install the counter reverse gear (19) to the counter

shaft.

The reverse gear projection must be facing the

intermediate plate.

226RW151

11. Install the counter 5th gear (18) to the counter

shaft.

226RS019

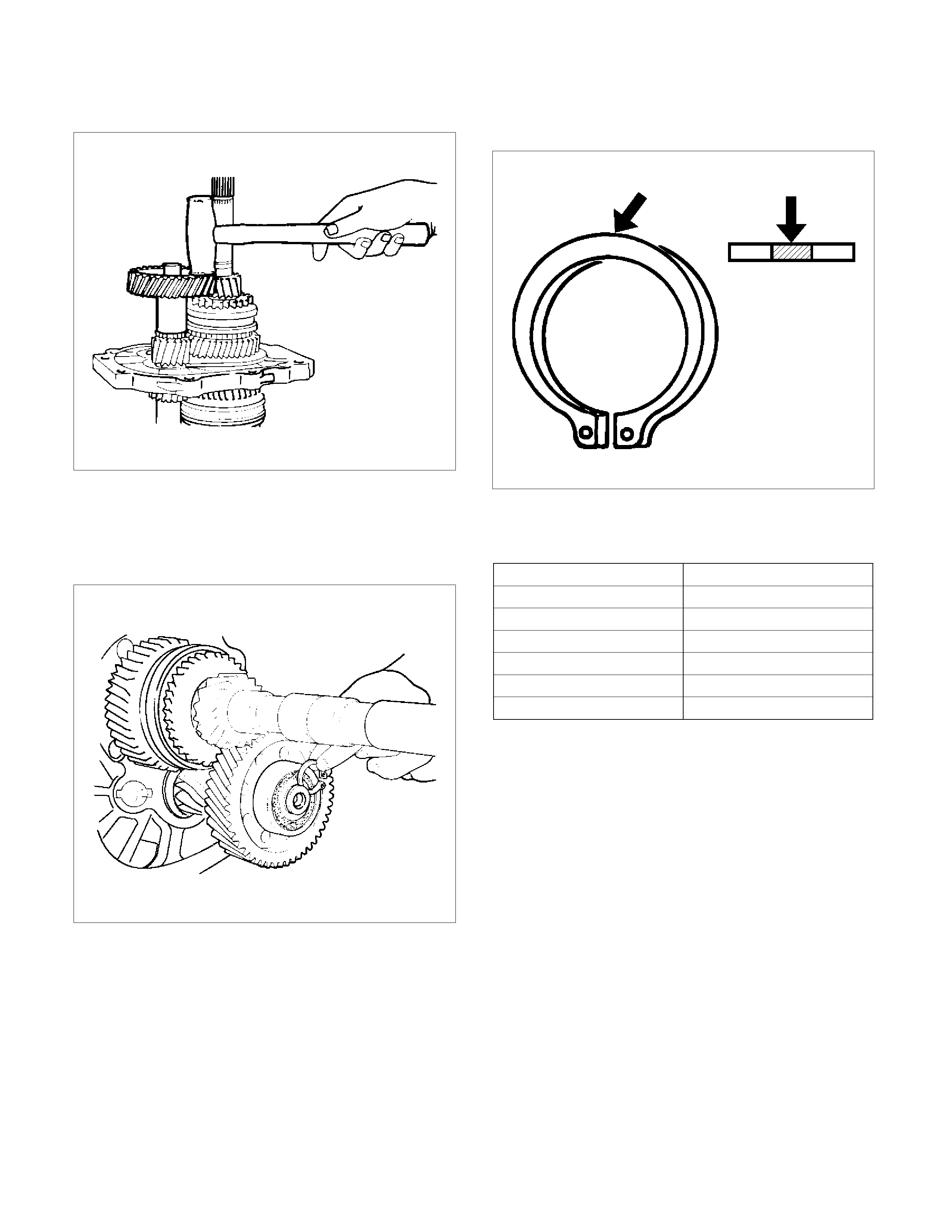

12. Install ball bearing (17) and bearing snap ring (16)

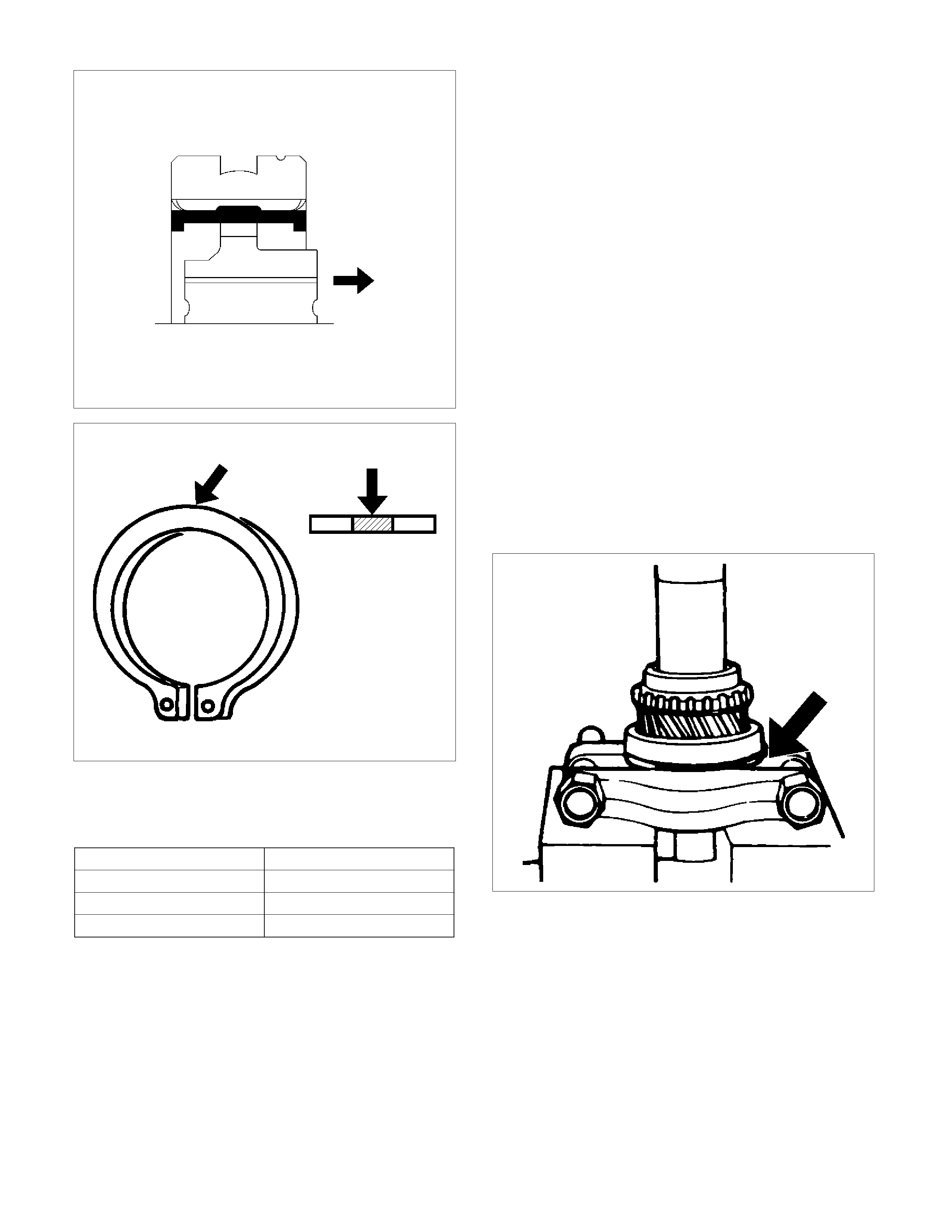

by performing the following steps:

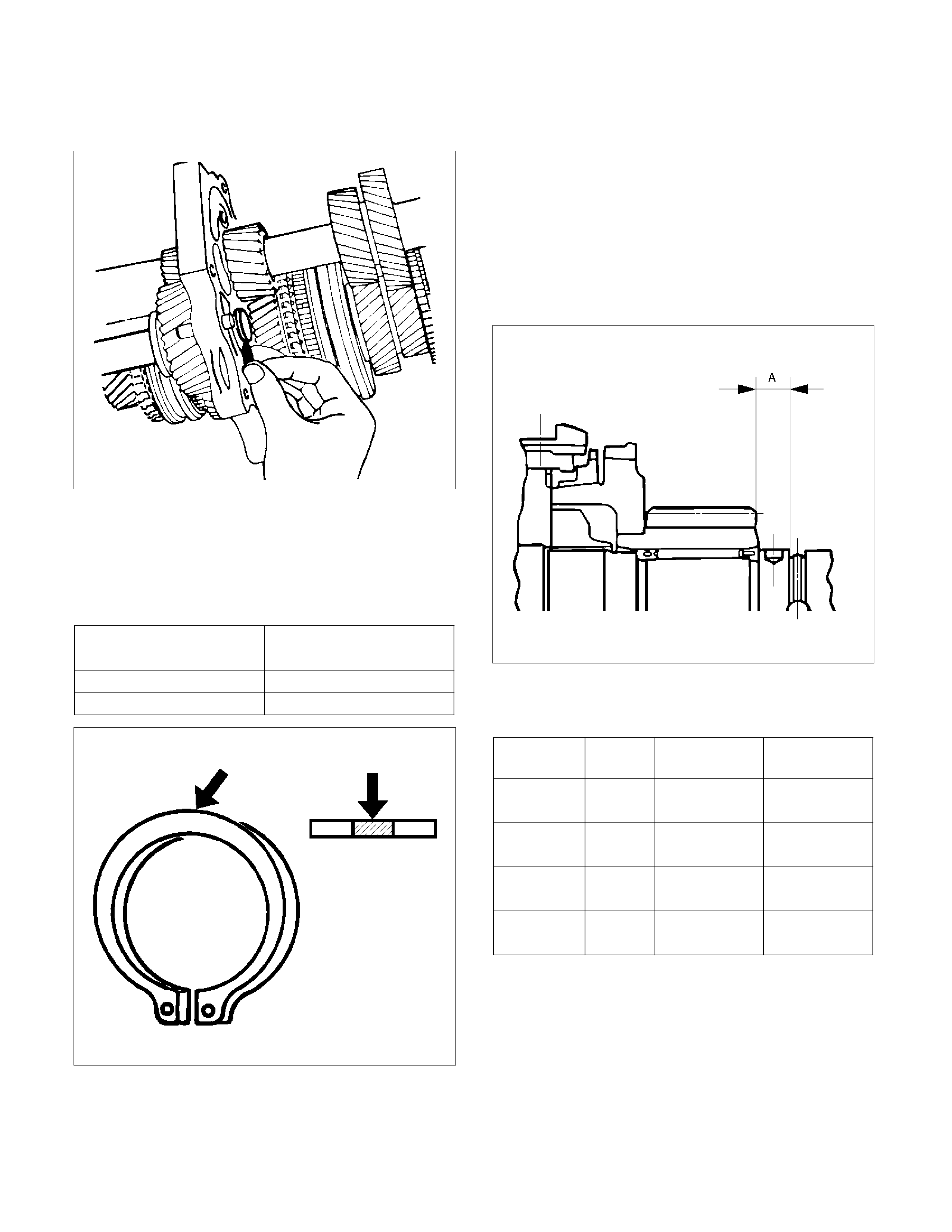

• Select the snap ring, which will provide the

minimum clearance between the ball bearing

and the snap ring.

226RS020

• There are six snap ring sizes available.

The snap rings are color‐coded to indicate

their thickness.

226RS021

Ball Bearing and Snap Ring Clearance

Standard: 0 - 0.15 mm (0 - 0.0059 in)

Snap Ring Availability

Thickness Color Coding

1.1 mm (0.043 in) White

1.2 mm (0.047 in) Yellow

1.3 mm (0.051 in) Blue

1.4 mm (0.055 in) Pink

1.5 mm (0.059 in) Green

1.6 mm (0.063 in) Brow n

• Use a pair of snap ring pliers to install the snap

ring(13) to the counter gear shaft.

The snap ring must be fully inserted into the

counter gear shaft snap ring groove.

13. Assemble reverse idler shaft (15), reverse idler

gear (14), thrust washer (13), and idle shaft pin

(12) into reverse idler gear assembly (11).

The trust washer should be assembled as oil groove

faces to gear side.

14. Select reverse idler gear snap ring (10), which will

provide the minimum clearance between the

intermediate plate (30) and the snap ring (10).

226RS022

• There are three snap ring sizes available.

The snap rings are color-coded to indicate their

thickness.

Intermediate Plate and Snap Ring Clearance

Standard: 0 - 0.15 mm (0 - 0.0059 in)

Snap Ring Availability

Thickness Color Coding

1.2 mm (0.047 in) White

1.3 mm (0.051 in) Yellow

1.4 mm (0.055 in) Blue

226RS021

• Use a pair of snap ring pliers to install the snap

ring to the reverse idler shaft.

The snap ring must be fully inserted into the

reverse idler shaft snap ring groove.

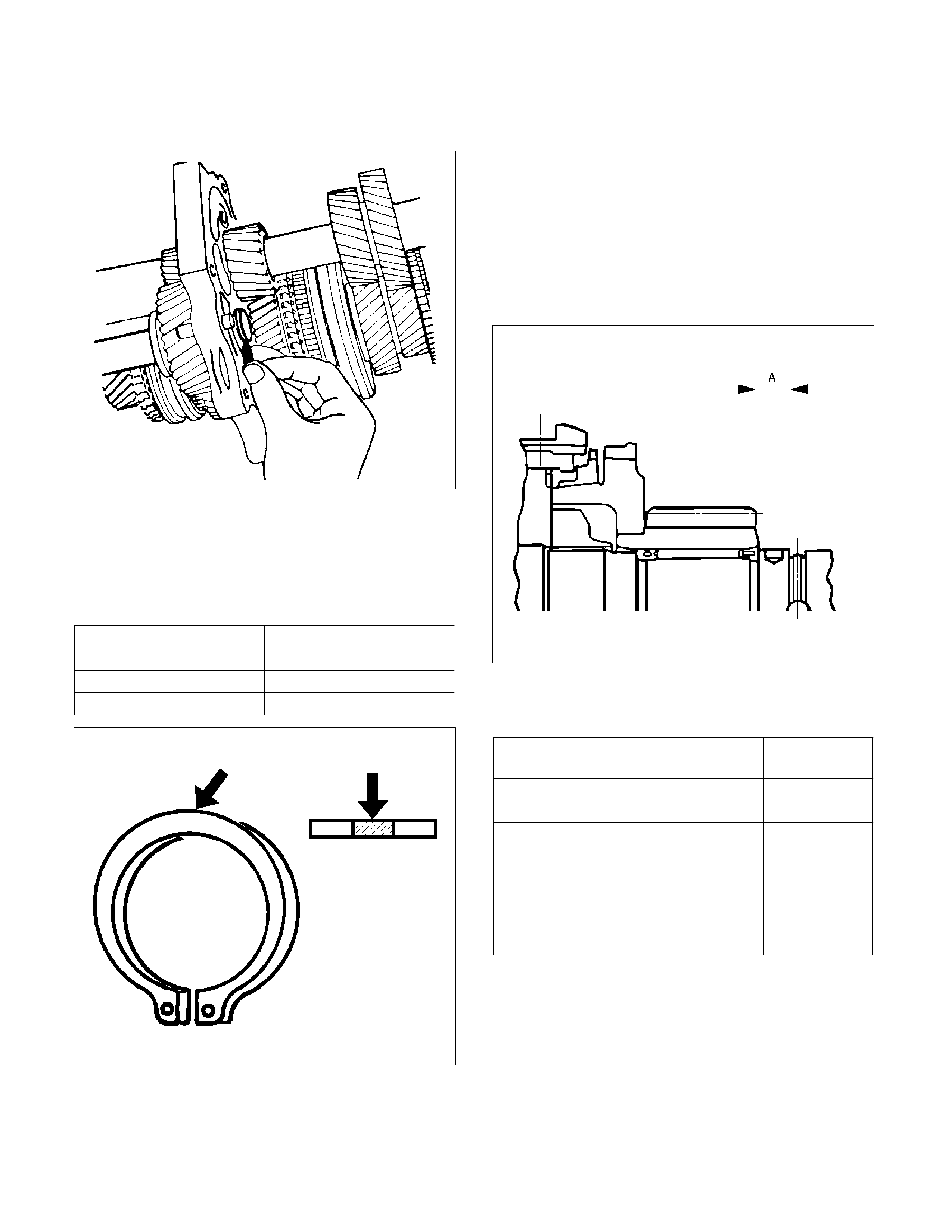

15. Install thrust washer and lock ball (9) by

performing the following steps:

• Use a thickness gauge to measure the

clearance between the 5th gear and the thrust

washer.

5th Gear and Thrust Washer Clearance

Standard: 0.10 - 0.25 mm (0.004 - 0.010 in))

• Measure clearance "A" as shown in the figure.

226RS023

• Select appropriate thrust washer from chart.

• There are four thrust washer sizes available.

Thrust Washer Availability

Thickness

mm (in) Color

Coding A mm (in) Clearance

mm (in)

7.9 (0.311) White 8.05 - 8.1

(0.317-0.319) 0.15 - 0.25

(0.006-0.010)

8.0 (0.315) Yellow 8.1 - 8.2

(0.319-0.323) 0.1 - 0.25

(0.004-0.010)

8.1 (0.319) Green 8.2 - 8.3

(0.323-0.327) 0.1 - 0.25

(0.004-0.010)

8.2 (0.323) Blue 8.3 - 8.36

(0.327-0.329) 0.1 - 0.21

(0.004-0.008)

• The thrust washers are color coded to indicate

their thickness as shown in the figure.

226RS024

• Apply grease to the thrust washer and the lock

ball.

• Install the thrust washer and the lock ball.

16. Install thrust plate (8) and retainer (7).

17. Install the retainer snap ring (6), clip (5),

speedometer drive gear (4) and bearing snap ring

(3).

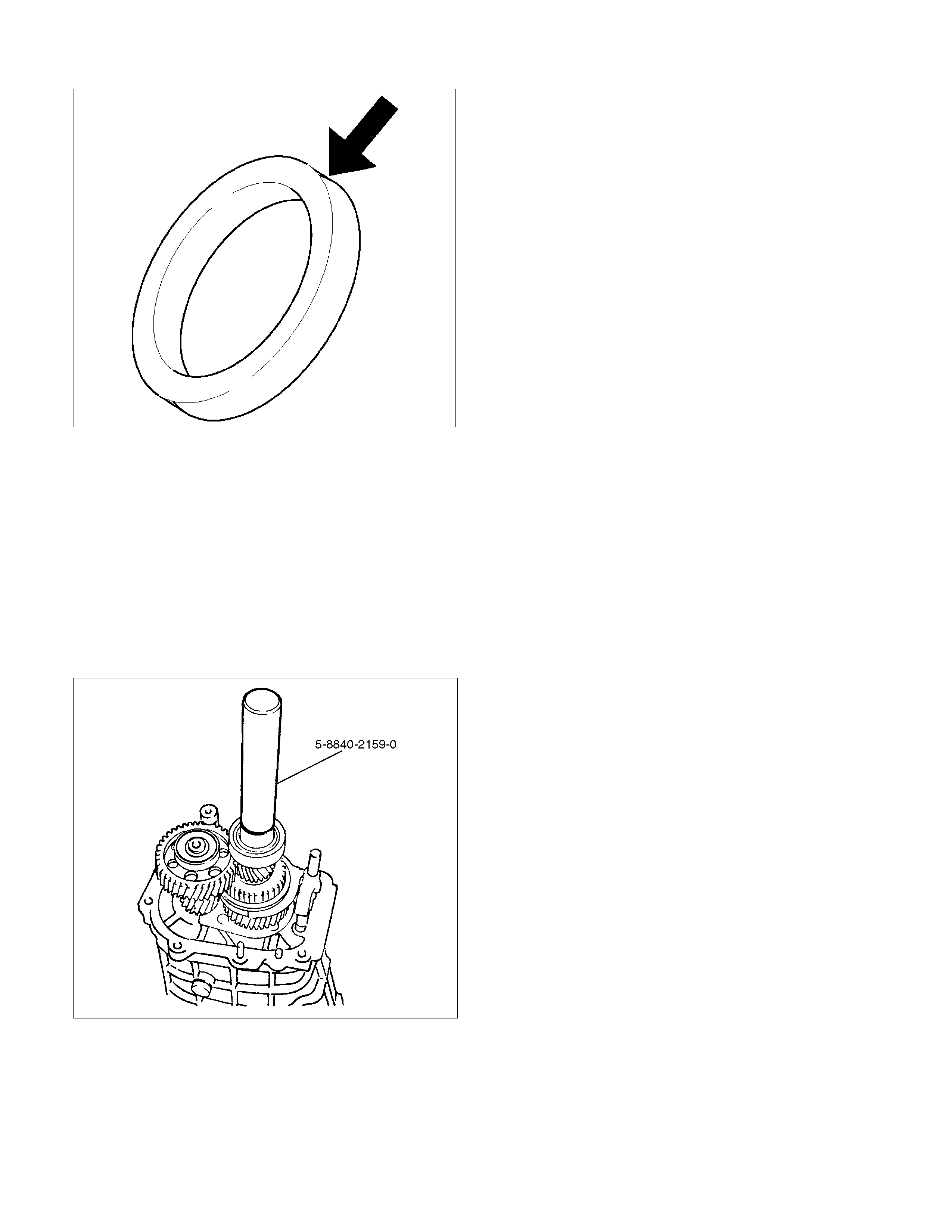

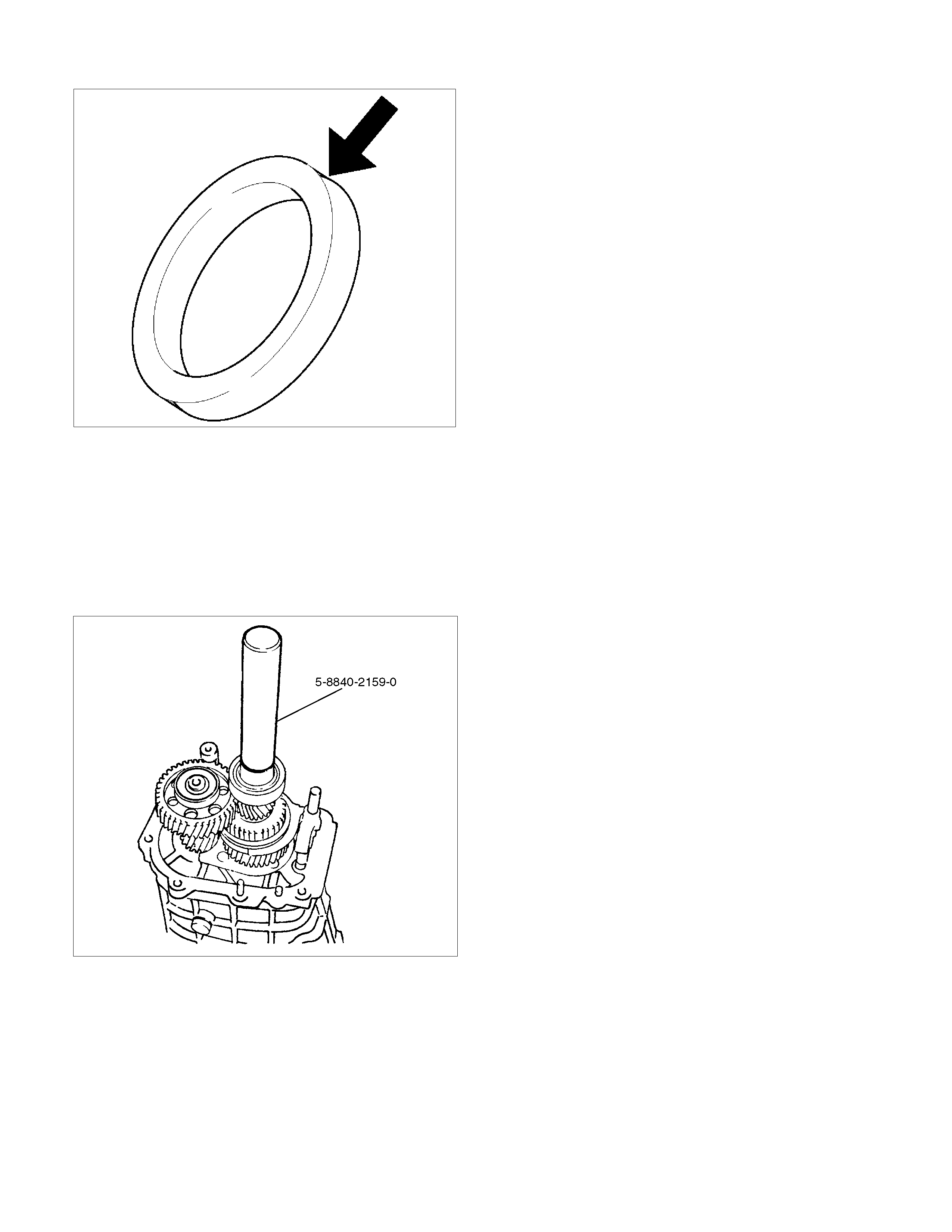

18. Apply engine oil to the bearing (2) inner and outer

circumference.

Use the installer 5-8840-2159-0 to install the ball

bearing (2) to the mainshaft.

226L100002

19. Install the bearing snap ring (1).

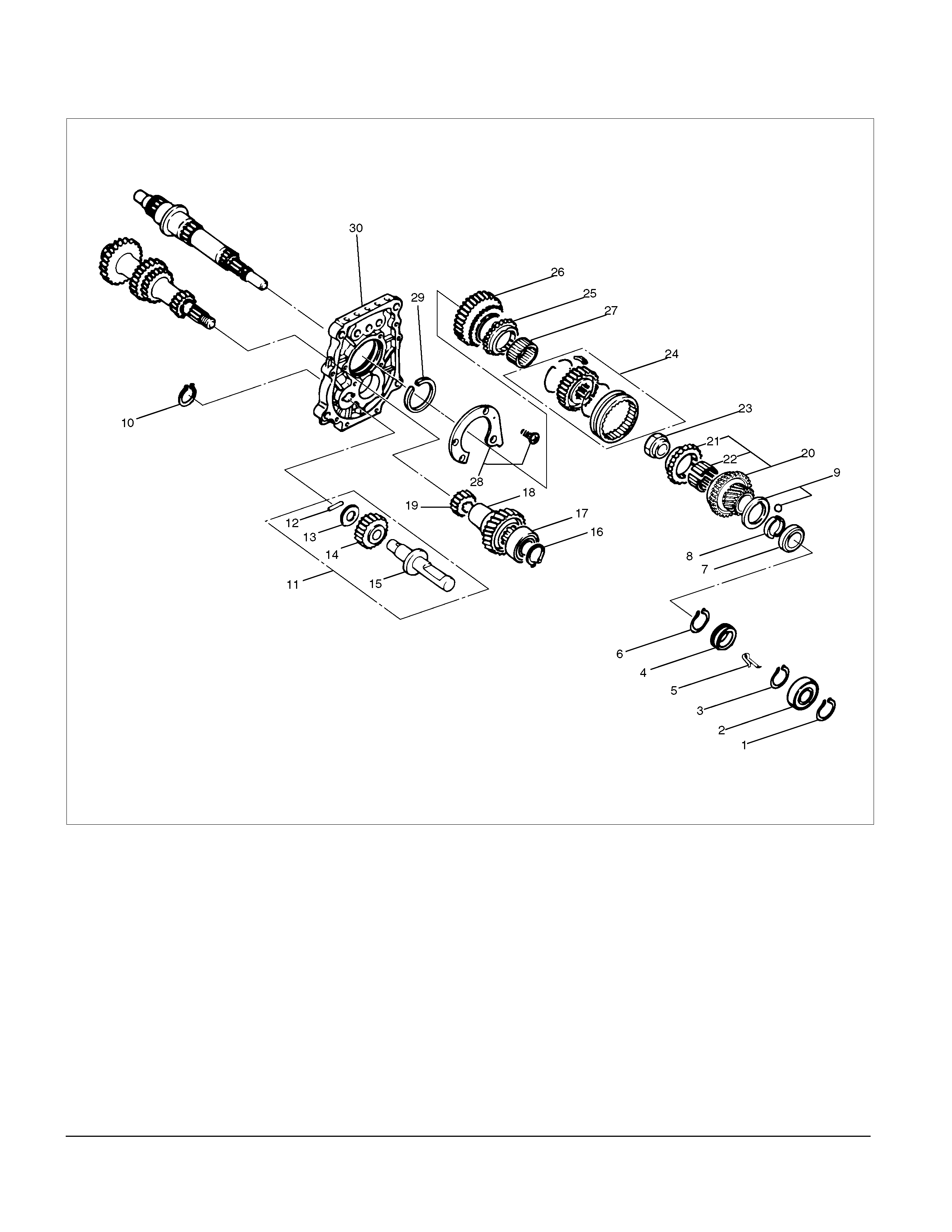

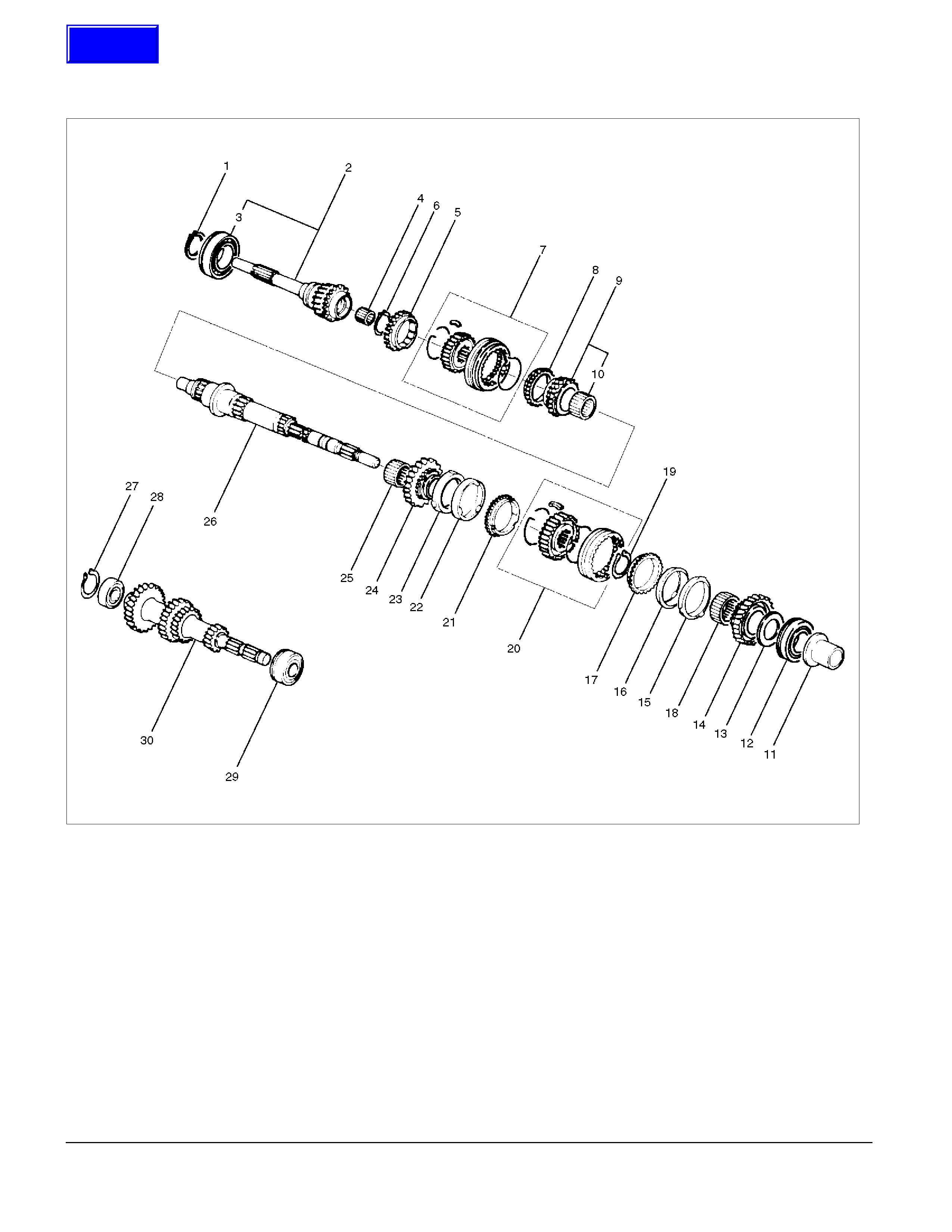

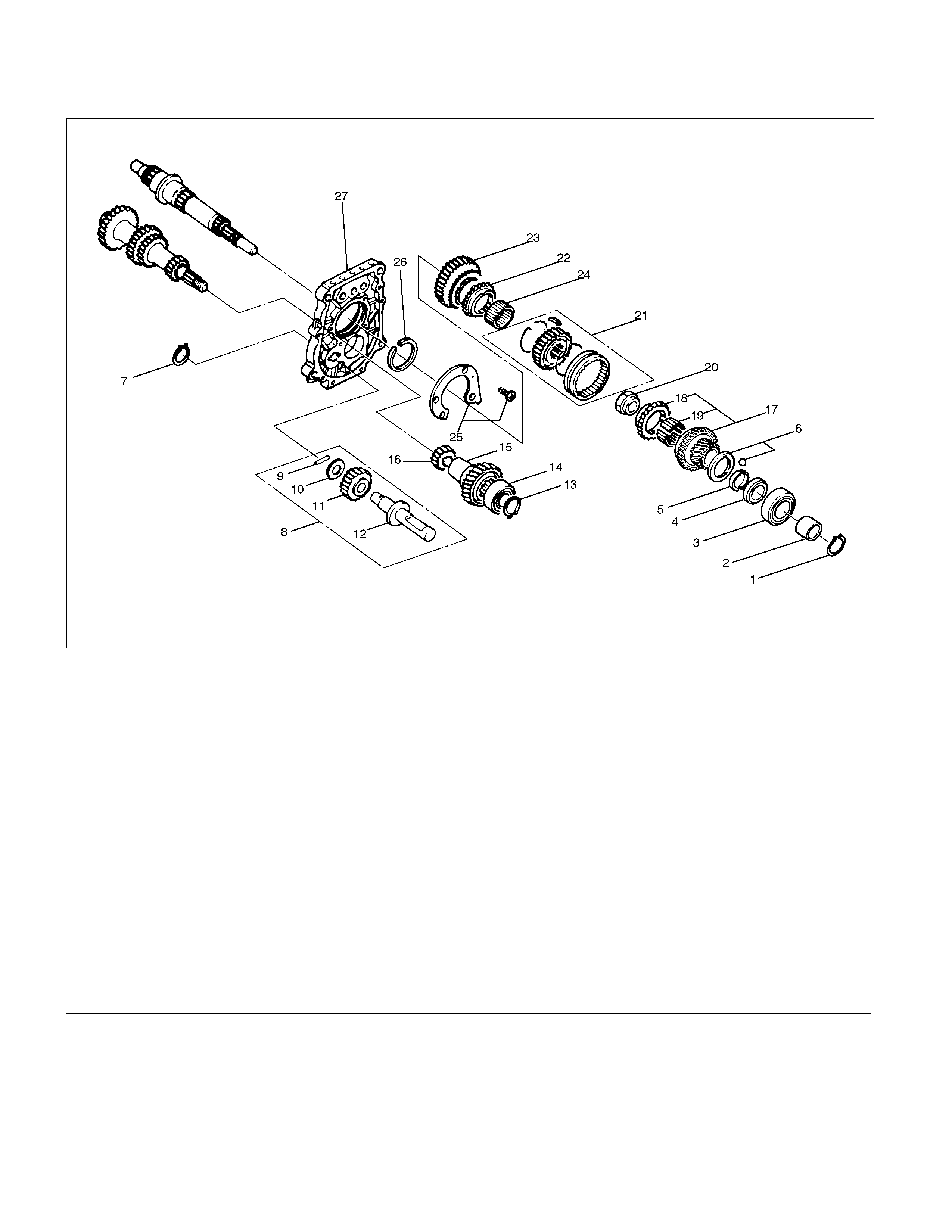

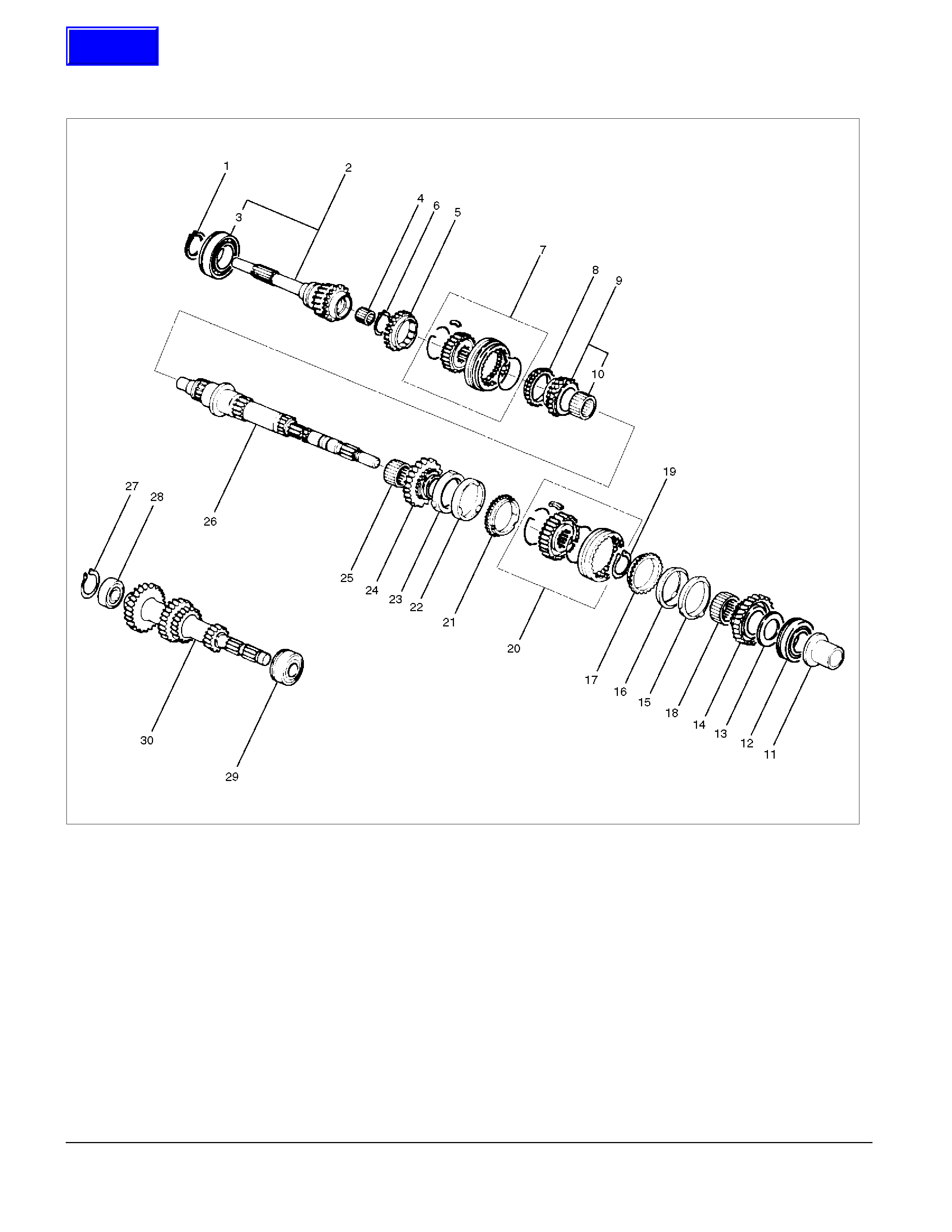

Top Gear Shaft, Main Gear Shaft, and Counter Gear Shaft

Disassembled View

226RS026

Legend

(1) Top Gear Shaft Snap Ring (16) 1st Outside Ring

(2) Top Gear Shaft (17) 1st Block Ring

(3) Ball Bearing (18) Needle Bearing

(4) Needle Bearing (19) Clutch Hub Snap Ring

(5) Top Block Ring (20) 1st-2nd Synchronizer Assembly

(6) Mainshaft Snap Ring (21) 2nd Block Ring

(7) 3rd-4th Synchronizer Assembly (22) 2nd Outside Ring

(8) 3rd Block Ring (23) 2nd Inside Ring

(9) 3rd Gear (24) 2nd Gear

(10) Needle Bearing (25) Needle Bearing

(11) Needle Bearing Collar (26) Mainshaft

(12) Mainshaft Ball Bearing (27) Bearing Snap Ring

(13) 1st Gear Thrust Bearing (28) Front Roller Bearing

(14) 1st Gear (29) Center Roller Bearing

(15) 1st Inside Ring (30) Counter Gear Shaft

Techline

Disassembly

1. Use a pair of snap ring pliers to remove the top

gear shaft snap ring(1).

2. Remove top gear shaft(2) with ball bearing(3).

3. Use a bench press and the bearing remover 5-

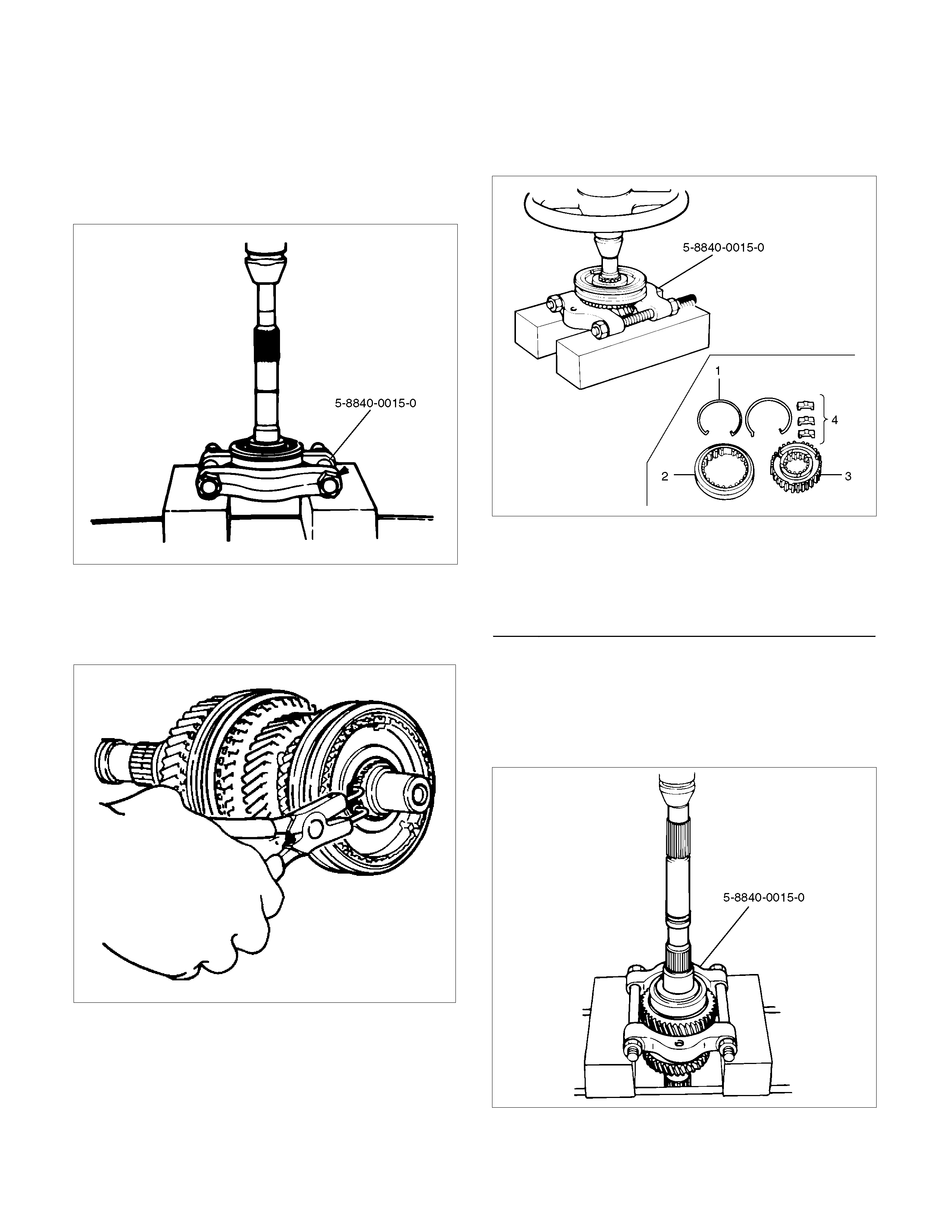

8840-0015-0 to remove the ball bearing(3).

226RW216

4. Remove needle bearing (4) and top block ring (5),

mainshaft snap ring.

5. Use a pair of snap ring pliers to remove the

mainshaft snap ring (6).

226RS008

6. Use a bench press and the bearing remover 5-

8840-0015-0 to remove the 3rd-4th synchronizer

assembly (7) as a set.

Disassemble the synchronizer assembly.

226RW217

Legend

(1) Springs

(2) Sleeve

(3) Clutch Hub

(4) Inserts

7. Remove 3rd block ring (8), 3rd gear (9), and

needle bearing (10).

8. Use a bench press and the bearing remover 5-

8840-0015-0 to remove the 1st gear(14) together

with the mainshaft ball bearing(12), 1st gear thrust

bearing (13), and needle bearing collar (11).

226RW218

9. Disassemble 1st inside ring (15), 1st outside ring

(16), and 1st block ring (17).

10. Remove needle bearing (18).

11. Use a pair of snap ring pliers to remove the clutch

hub snap ring (19).

226RS031

12. Use bench press and the bearing remover 5-8840-

0015-0 to remove the 2nd gear (24) together with

1st-2nd synchronizer assembly (20), 2nd block

ring (21), 2nd outside ring (22), and inside ring

(23).

Disassemble the synchronizer assembly.

226RW220

Legend

(1) Springs

(2) Sleeve

(3) Clutch Hub

(4) Inserts

13. Remove needle bearing (25) from mainshaft (26).

14. Remove bearing snap ring (27).

15. Remove the front roller bearing (28) by performing

the following steps.

• Remove the ring, outer race and bearing

assembly by using a bench press and remover

5-8840-0015-0.

• Remove the inner race by using a bench press

and remover 5-8840-0015-0.

226RW219

16. Remove center roller bearing (29) from counter

gear shaft (30).

Inspection and Repair

Make the necessary adjustments, repairs, and part

replacements if excessive wear or damage is

discovered during inspection.

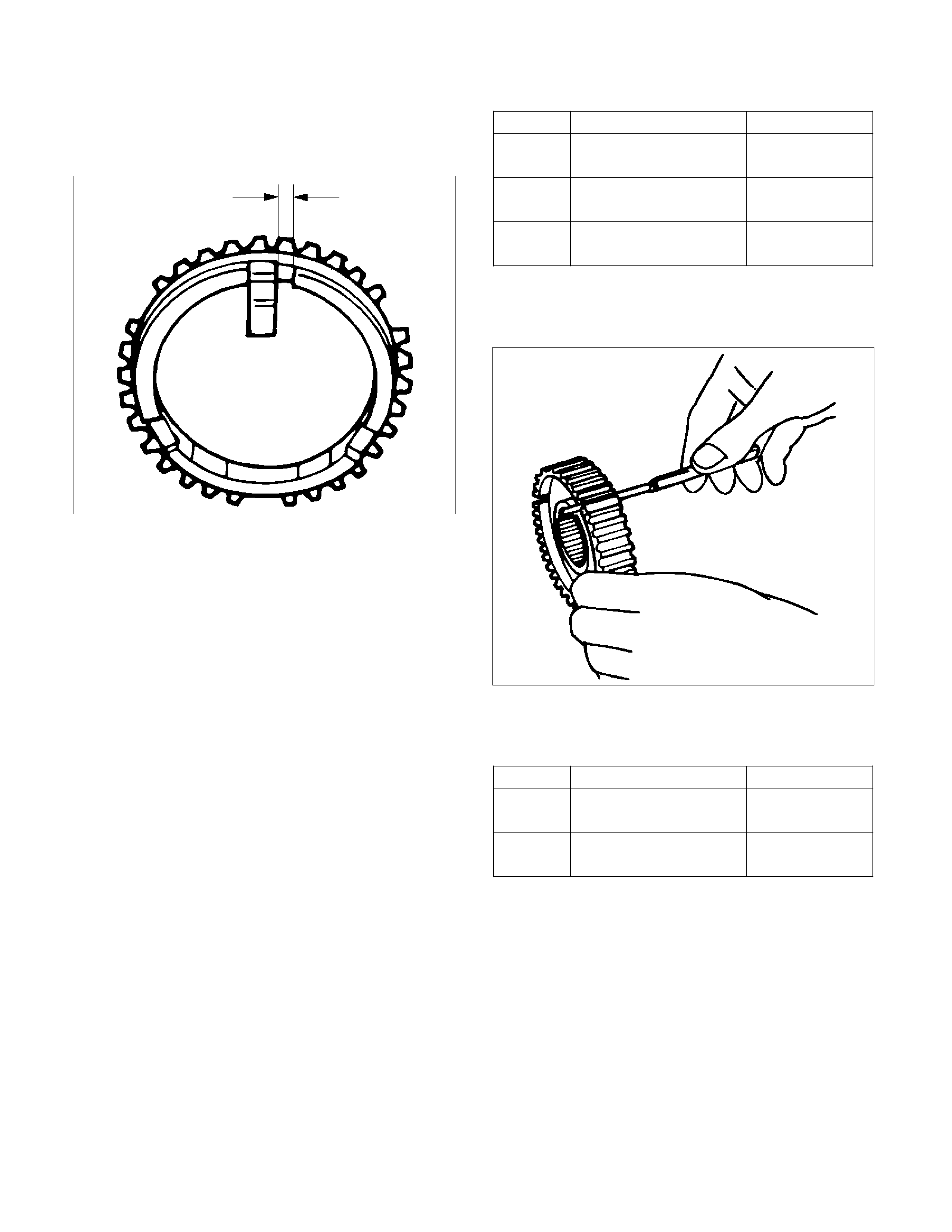

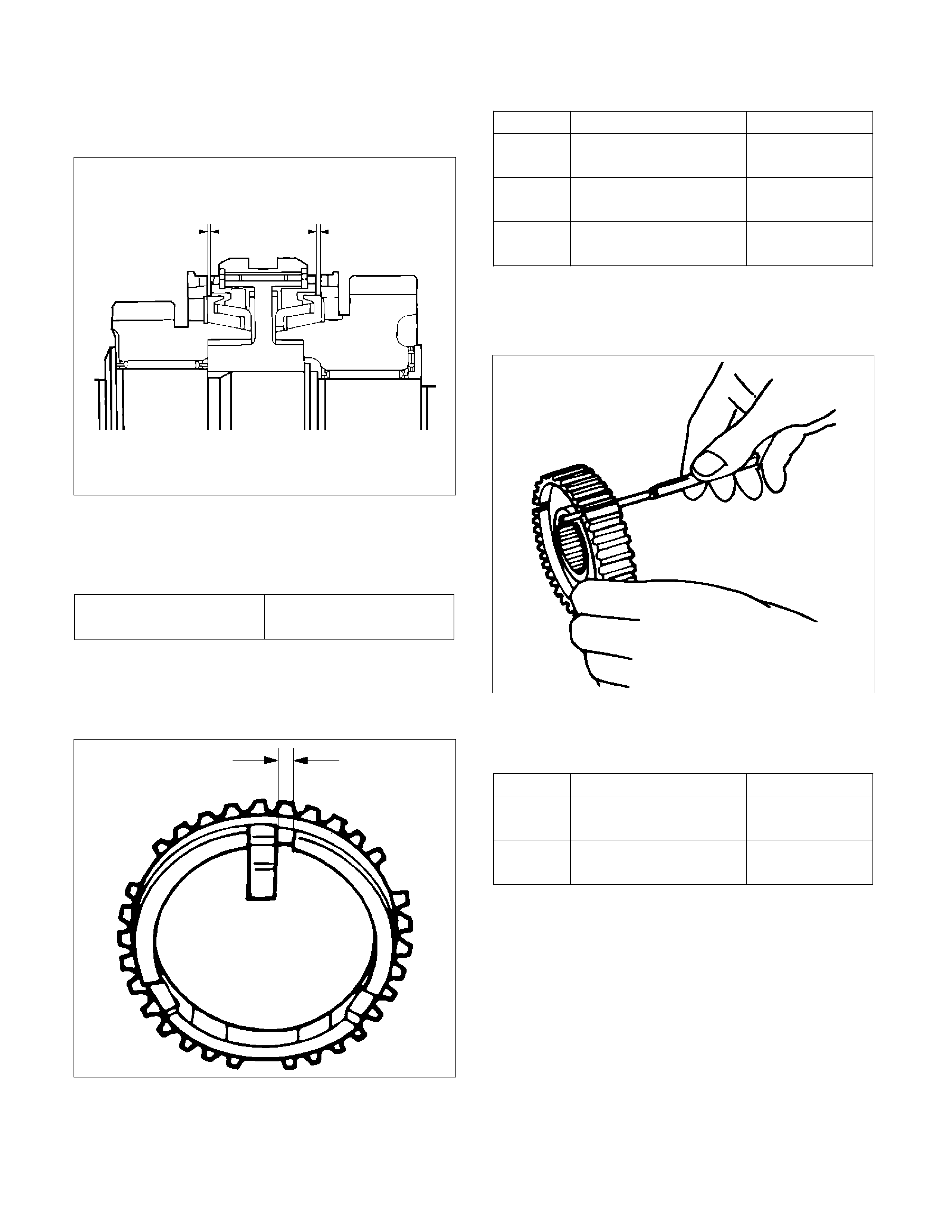

Block Ring and Dog Teeth Clearance

• Use a thickness gauge to measure the clearance

between the block ring and the dog teeth.

226RS035

If the measured value exceeds the specified limit,

the block ring must be replaced.

Block Ring and Dog Teeth Clearance

Standard Limit

1.5 mm (0.059 in) 0.8 mm (0.032 in)

1st-2nd Synchronizer (3-CONE)

• Use a thickness gauge to measure the clearance

between the block ring and the dog teeth.

226RS036

If the measured value exceeds the specified limit,

the 1st-2nd synchronizer assembly must be

replaced.

Block Ring and Dog Teeth Clearance

Standard Limit

1.5 mm (0.059 in) 0.8 mm (0.032 in)

Block Ring and Insert Clearance

• Use a vernier caliper or thickness gauge to

measure the clearance between the block ring and

the insert.

226RS037

If the measured value exceeds the specified limit,

the block ring and the insert must be replaced.

Block and Insert Clearance

Standard Limit

3rd-4th 3.46 - 3.76 mm

(0.136 - 0.148 in) 4.0 mm

(0.158 in)

1st-2nd 3.86 – 4.16 mm

(0.152 - 0.164 in) 4.9 mm

(0.193 in)

Rev.5th 3.59 - 3.91 mm

(0.141 - 0.154 in) 4.1 mm

(0.161 in)

Clutch Hub and Insert Clearance

• Use a thickness gauge to measure the clearance

between the clutch hub and the insert.

226RS038

If the measured value exceeds the specified limit,

the clutch hub and the insert must be replaced.

Clutch Hub and Insert Clearance

Standard Limit

1st-2nd

3rd-4th 0.01 – 0.21 mm

(0.004 - 0.0083 in) 0.3 mm

(0.012 in)

Rev-5th 0.09 – 0.31 mm

(0.0035 - 0.0122 in) 0.4 mm

(0.016 in)

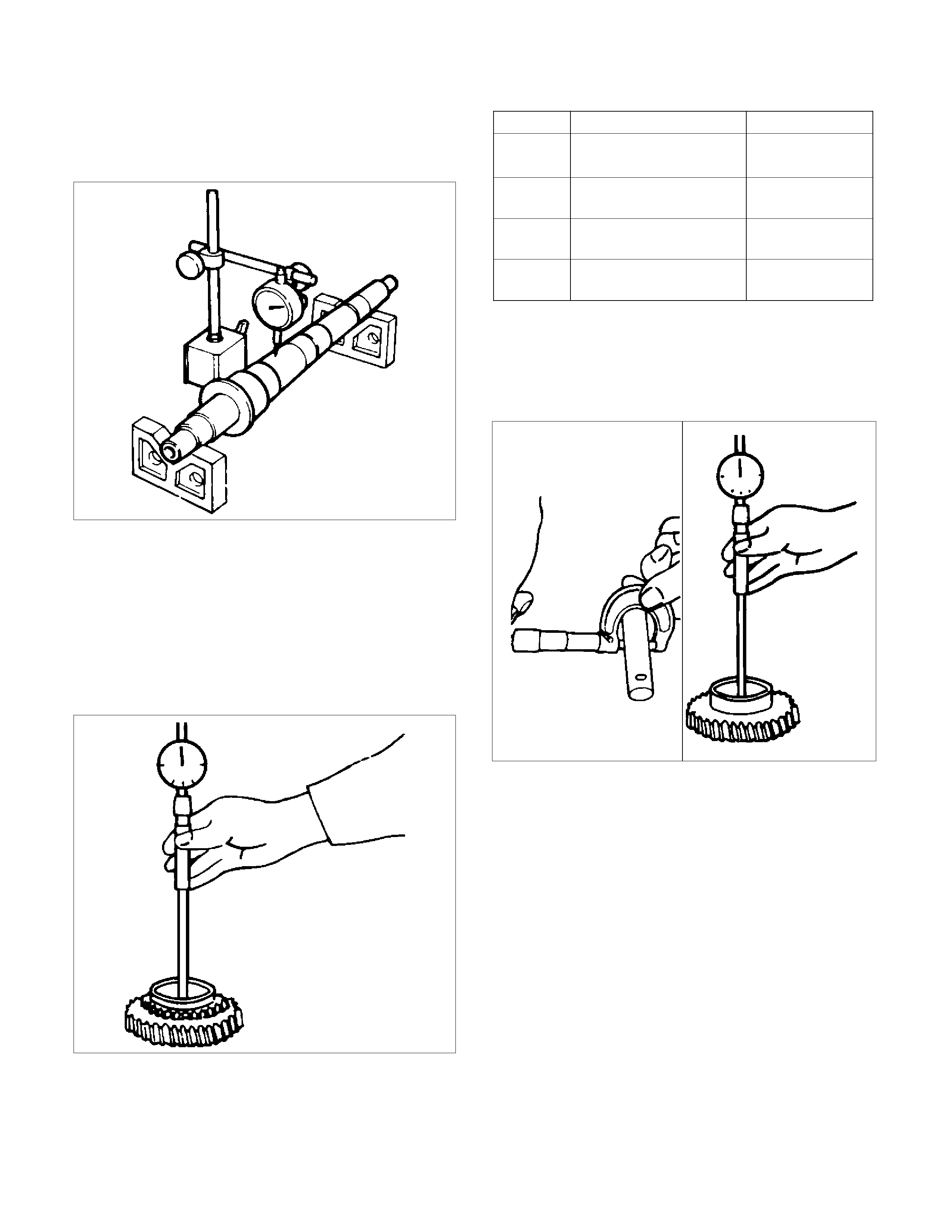

Mainshaft Run-out

• Install the mainshaft to V-blocks.

• Use a dial indicator to measure the mainshaft

central portion run-out.

226RS039

If the measured mainshaft run-out exceeds the

specified limit, the mainshaft must be replaced.

Mainshaft Run-out

Limit: 0.05 mm (0.0020 in)

Gear Inside Diameter

• Use an inside dial indicator to measure the gear

inside diameter.

226RS040

If the measured value is less than the specified limit,

the gear must be replace.

Gear Inside Diameter

Standard Limit

1st

3rd 45.000 - 45.013 mm

(1.771 - 1.772 in) 45.100 mm

(1.776 in)

2nd 52.000 - 52.013 mm

(2.047 - 2.048 in) 52.100 mm

(2.051 in)

Rev. 48.000 - 48.013 mm

(1.889 - 1.890 in) 48.100 mm

(1.894 in)

5th 32.000 - 32.013 mm

(1.259 - 1.260 in) 32.100 mm

(1.246 in)

Reverse Idler Gear and Idler Gear Shaft Clearance

• Use a micrometer to measure the idler gear shaft

diameter.

• Use an inside dial indicator to measure the idler

gear inside diameter.

226RS041

• Calculate the idler gear and idler gear shaft

clearance.

Idler gear inside diameter-idler gear shaft diameter =

idle gear and idler gear shaft clearance.

If the measured value exceeds the specified limit,

the idle gear and/or the idler gear shaft must be

replaced

Idler Gear and Idler Gear Shaft Clearance

Standard: 0.041 - 0.074 mm (0.0016 -0.0029 in)

Limit: 0.150 mm (0.0059 in)

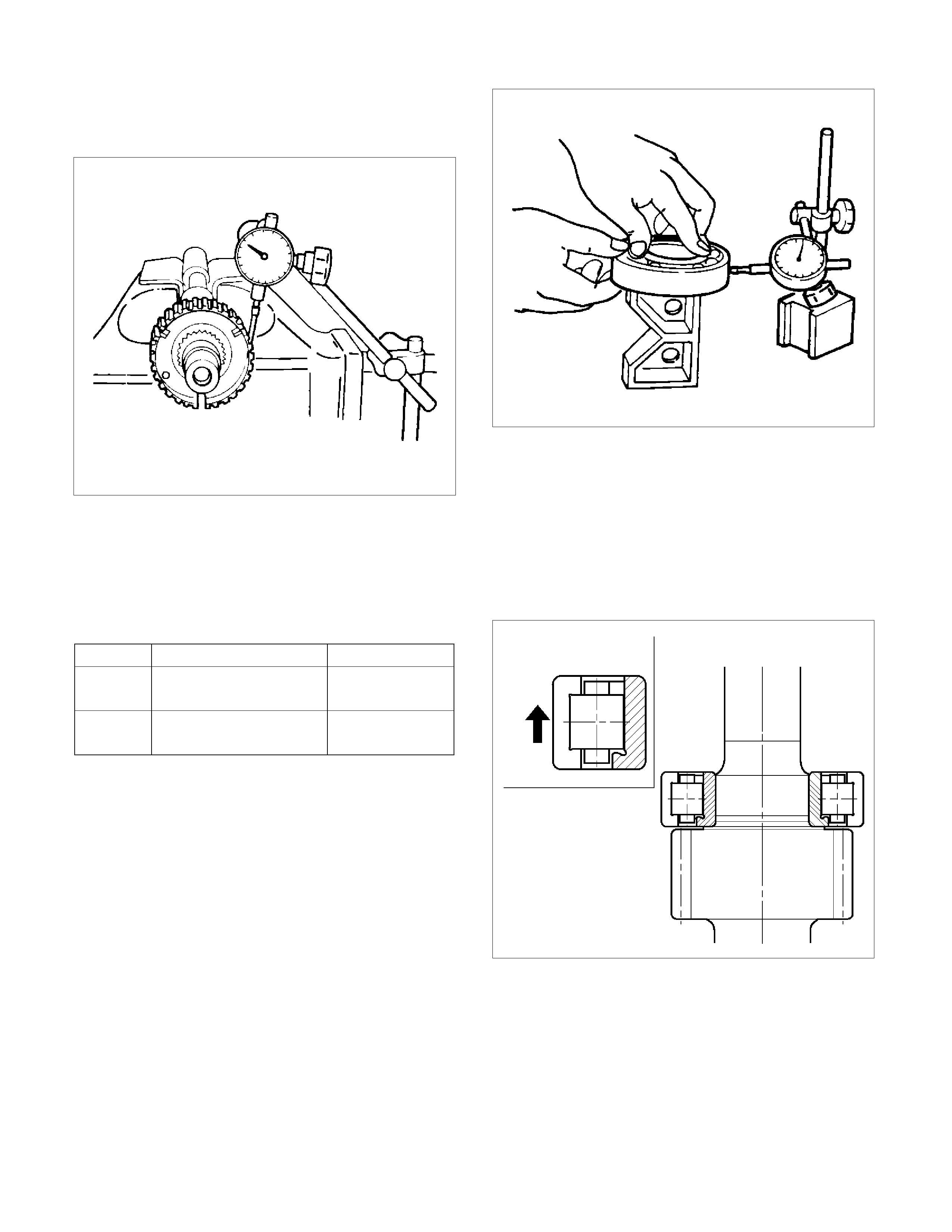

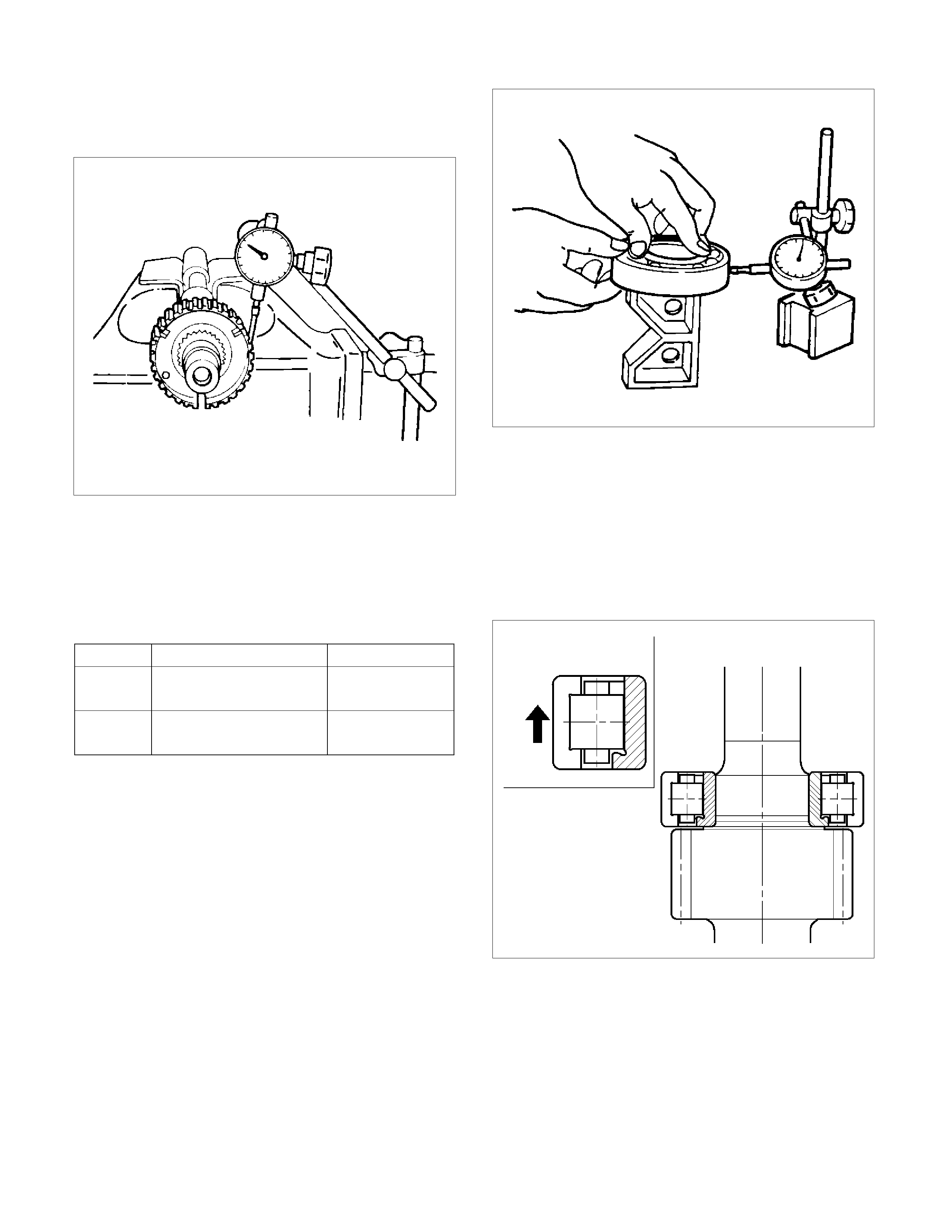

Clutch Hub Spline Play

• Set a dial indicator to the clutch hub to be

measured.

226RS042

• Move the clutch hub as far as possible to both the

right and the left.

Note the dial indicator reading.

If the measured value exceeds the specified limit,

the clutch hub must be replaced.

Clutch Hub Spline Play

Standard Limit

1st-2nd

3rd-4th 0 - 0.1 mm

(0 - 0.004 in) 0.2 mm

(0.008 in)

Rev. 5th 0 - 0.2 mm

(0 - 0.008 in) 0.3 mm

(0.012 in)

Ball Bearing Play

• Use a dial indicator to measure the ball bearing

play.

Ball Bearing Play

Limit: 0.2 mm (0.008 in)

226RS043

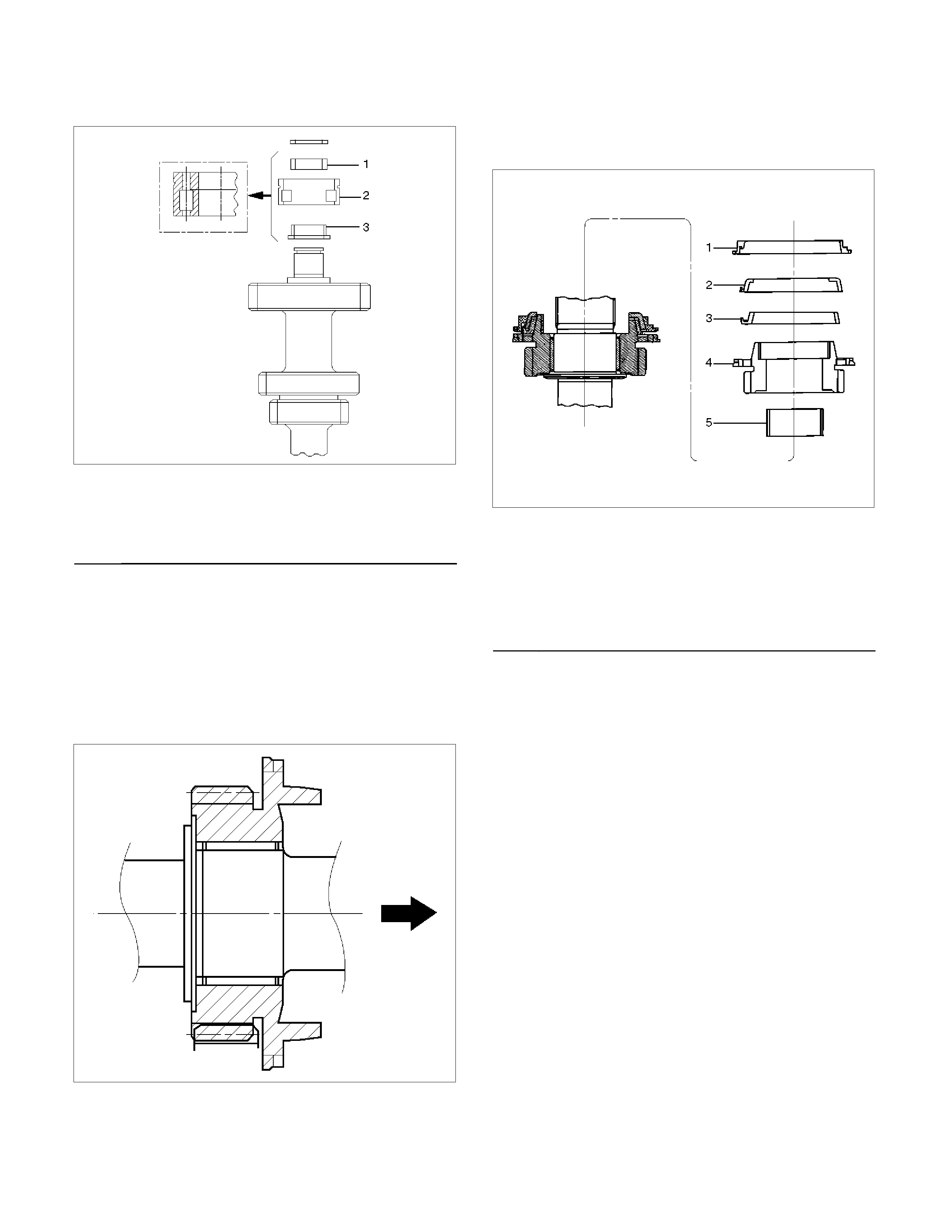

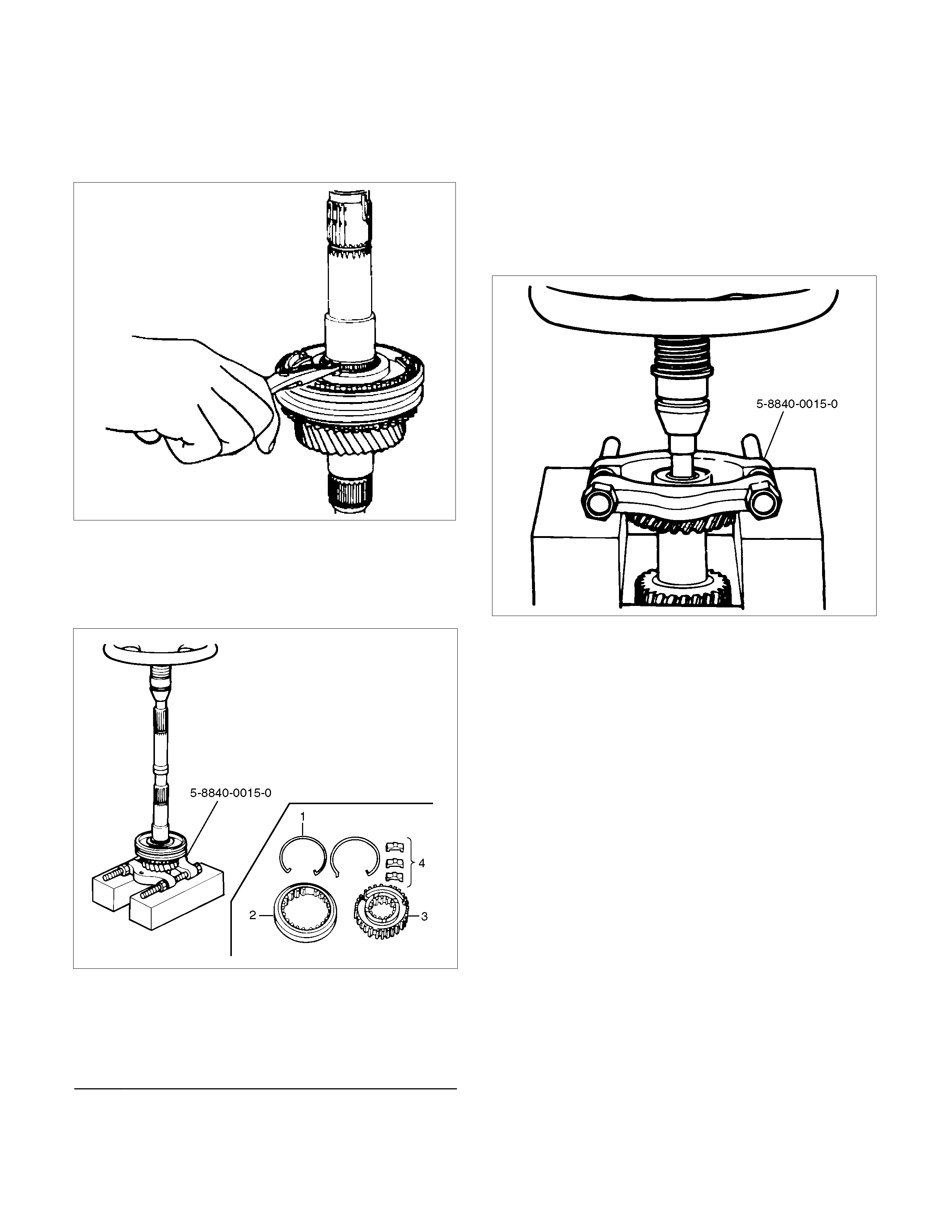

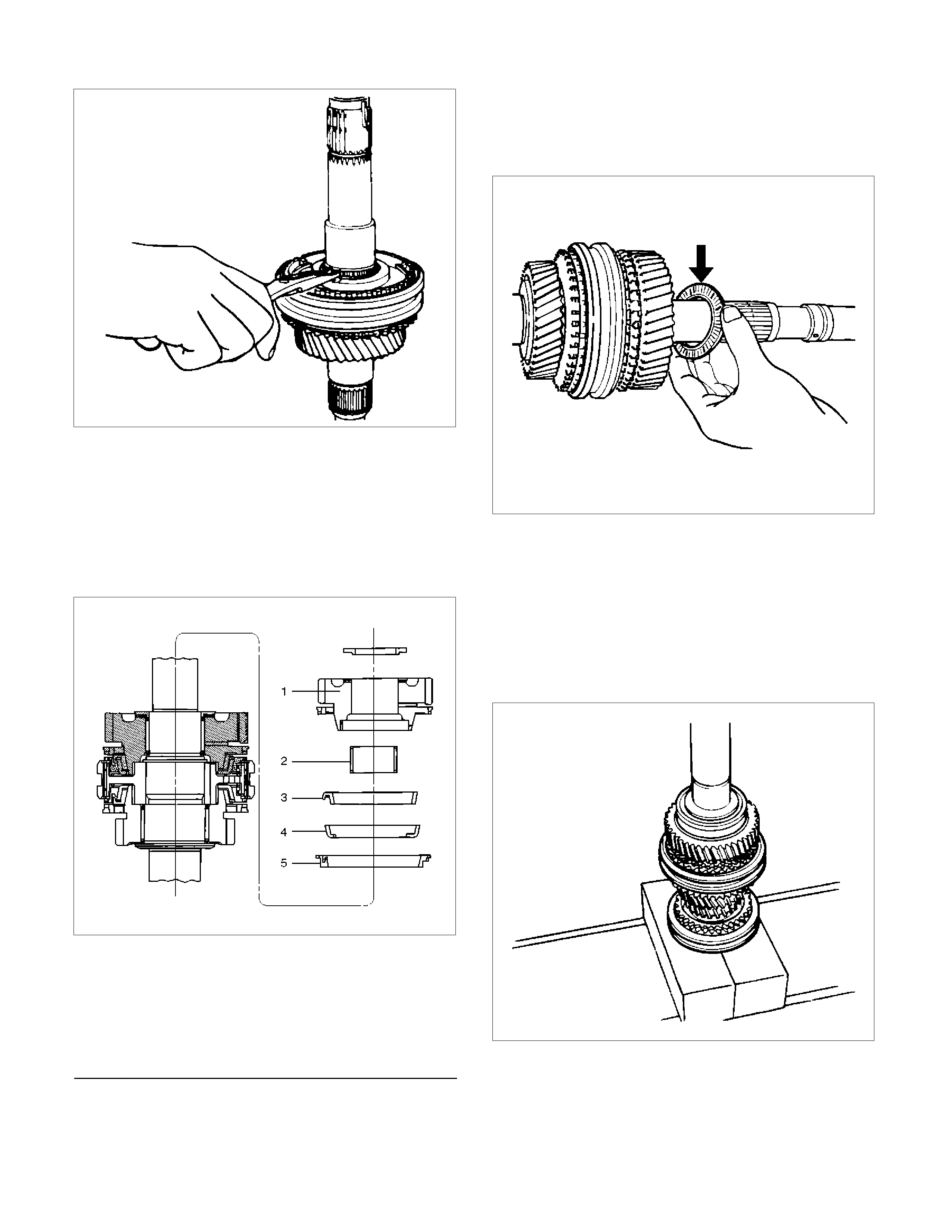

Reassembly

1. Install center roller bearing (29) to counter gear

shaft (30).

• Apply engine oil to the bearing inner and outer

circumferences.

• Install the roller bearing in the proper direction.

NOTE: Check that outer race moves only in the

direction of arrow.

226RS044

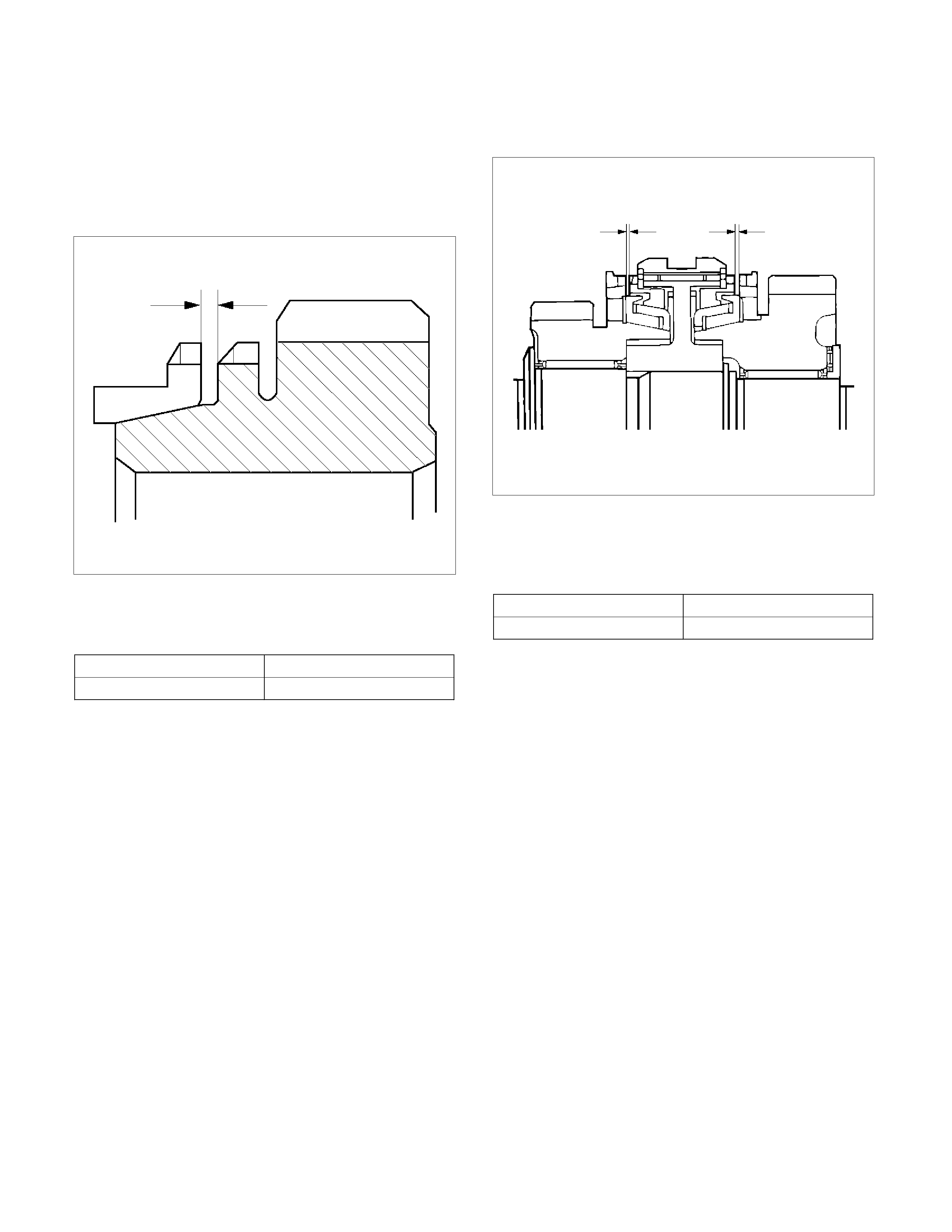

2. Install front roller bearing (28) by performing the

following steps.

• Use bearing installer 5-8840-2194-0 to install

the front roller bearing inner race to the counter

gear shaft (30).

• Install the outer race and roller assembly.

The snap ring groove must be facing the

transmission front side.

• Use bearing installer 5-8840-2194-0 to install

the ring.

226RS045

Legend

(1) Ring

(2) Outer Race and Roller Assembly

(3) Inner Race

3. Install bearing snap ring (27) to counter gear shaft

(30).

4. Apply engine oil to the needle bearing (25) and the

2nd gear (24) thrust surfaces.

Install the needle bearing (25) and the 2nd gear (24)

to the mainshaft (26).

The 2nd gear (24) dog teeth must be facing the

transmission rear side.

226RS046

5. Assemble 2nd inside ring (23), 2nd outside ring

(22), and 2nd block ring (21) on 2nd gear (24).

•

A

pply engine oil to the synchronizer ring friction

surfaces.

226RS047

Legend

(1) Block Ring

(2) Outside Ring

(3) Inside Ring

(4) 2nd Gear

(5) Needle Bearing

6. Assemble 1st-2nd synchronizer assembly (20) by

performing the following steps:

1. Check that the inserts (3) fit snugly into the

clutch hub (5) insert grooves.

2. Check that the inserts springs (4) are fitted to

the inserts as shown in the illustration.

3. Check that the clutch hub (5) and the sleeve

(6) slide smoothly.

266RS049

7. Install the synchronizer assembly (20) to the

mainshaft (26).

The clutch hub face with the heavy boss must be

facing the 2nd gear side.

226RS048

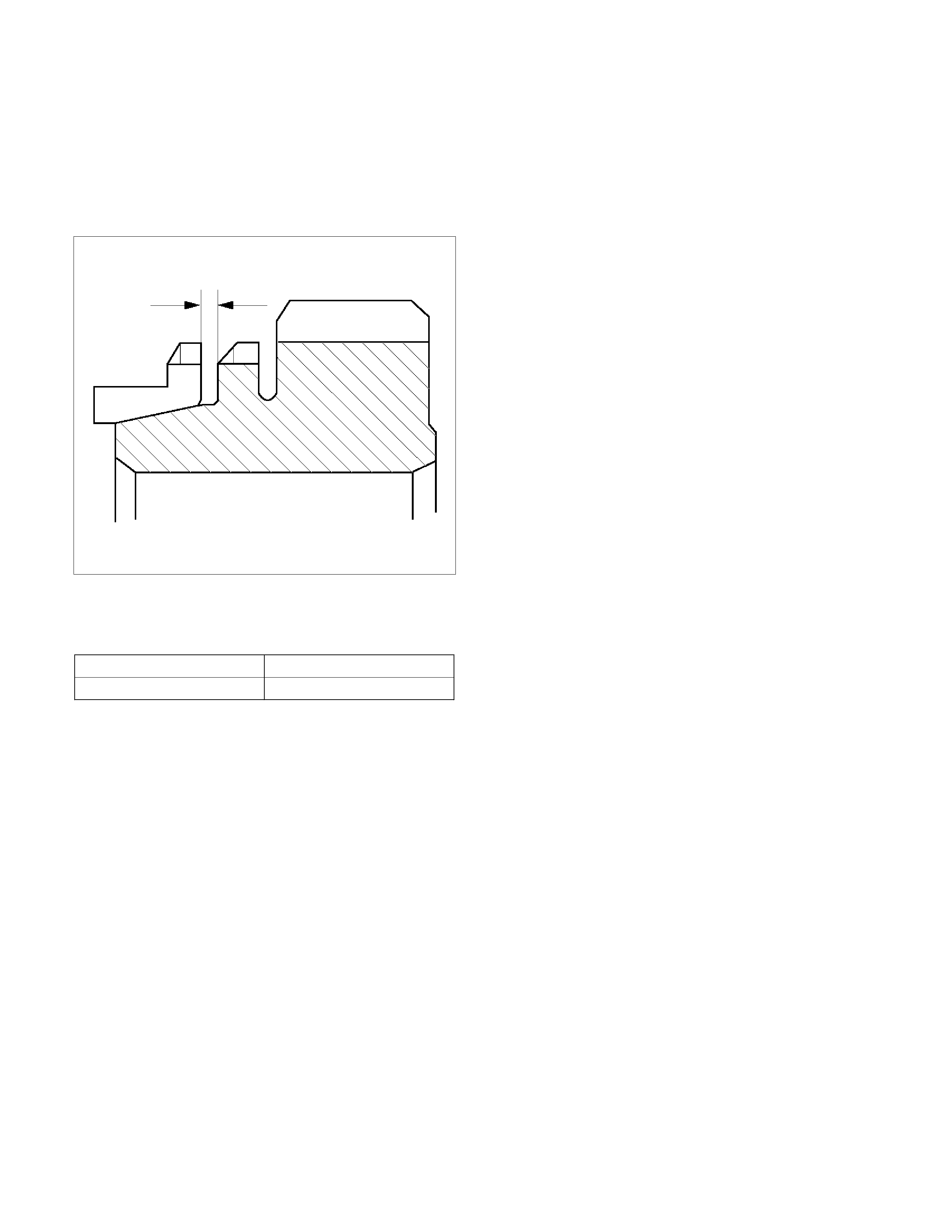

8. Install clutch hub snap ring(19) by performing the

following steps:

• Select the snap ring, which will provide the

minimum clearance between the 1st-2nd clutch

hub and the snap ring.

226RS050

• There are three snap ring sizes available.

• The snap rings are color coded to indicate their

thickness as shown in the figure.

226RS021

Clutch Hub and Snap Ring Clearance

Standard: 0 - 0.1 mm (0 - 0.004 in)

Snap Ring Availability

Thickness Color Coding

1.80 mm (0.071 in) White

1.85 mm (0.073 in) Yellow

1.90 mm (0.075 in) Blue

• Use a pair of snap ring pliers to install the snap

ring (19) to the mainshaft (26).

The snap ring must be fully inserted into the

mainshaft snap ring groove.

226RS031

9. Install needle bearing (18), 1st block ring (17), 1st

outside ring (16), 1st inside ring (15), and 1st gear

(14).

• Apply engine oil to the needle bearing, 1st gear

thrust surfaces and synchronizer ring friction

surfaces.

• The 1st gear dog teeth must be facing the

transmission front side.

226RS053

Legend

(1) 1st Gear

(2) Needle Bearing

(3) Inside Ring

(4) Outside Ring

(5) Block Ring

10. Install the 1st gear thrust bearing and the race(13)

to the main shaft.

The thrust bearing side must be facing the

transmission front side.

226RS054

11. Apply engine oil to the mainshaft ball bearing (12)

and the mainshaft (26).

Install the ball bearing (12) and needle bearing collar

(11) to the mainshaft (26).

The ball bearing snap ring groove must be facing

the transmission rear side.

Use a bench press and installer 9-8522-1165-0 to

slowly force the collar into place.

226RS055

12. Apply engine oil to the needle bearing (10) and the

3rd gear (9) thrust surfaces.

Install the needle bearing (10) and the 3rd gear (9)

to the mainshaft.

The 3rd gear dog teeth must be facing the

transmission front side.

226RS056

13. Install 3rd block ring (8).

14. Check and install 3rd-4th synchronizer assembly

(7) by the following steps:

1. Check that the inserts (3) fit snugly into the

clutch hub insert grooves.

2. Check that the insert springs (4) are fitted to

the inserts as shown in the illustration.

3. Check that the clutch hub (5) and the sleeve

(6) slide smoothly.

4. Install the synchronizer assembly to the

mainshaft.

The clutch hub face with the heavy boss must be

facing the 3rd gear side.

226RS049

15. Select and install mainshaft snap ring(6) in the

following way:

Select the snap ring, which will provide the minimum

clearance between the 3rd-4th clutch hub and the

snap ring.

226RS058

There are three snap ring sizes available.

The snap rings are color coded to indicate their

thickness as shown in the figure.

226RW221

226RS021

Clutch Hub and Snap Ring Clearance

Standard: 0 - 0.1 mm (0 - 0.004 in)

Snap Ring Availability

Thickness Color Coding

1.80 mm (0.071 in) White

1.85 mm (0.073 in) Yellow

1.90 mm (0.075 in) Blue

• Use a pair of snap ring pliers to install the snap

ring to the mainshaft.

The snap ring must be fully inserted into the

mainshaft snap ring groove.

16. Install top block ring (5).

Apply grease to the needle bearing (4) inner and

outer circumferences and install needle bearing (4)

in the top gear shaft (2).

17. Use a bench press to install the top gear shaft ball

bearing (3) to the top gear shaft (2).

226RS059

The snap ring groove of the ball bearing (3) must be

facing the transmission front side.

18. Use a pair of snap ring pliers to install the top gear

shaft snap ring (1) to the top gear shaft (2).

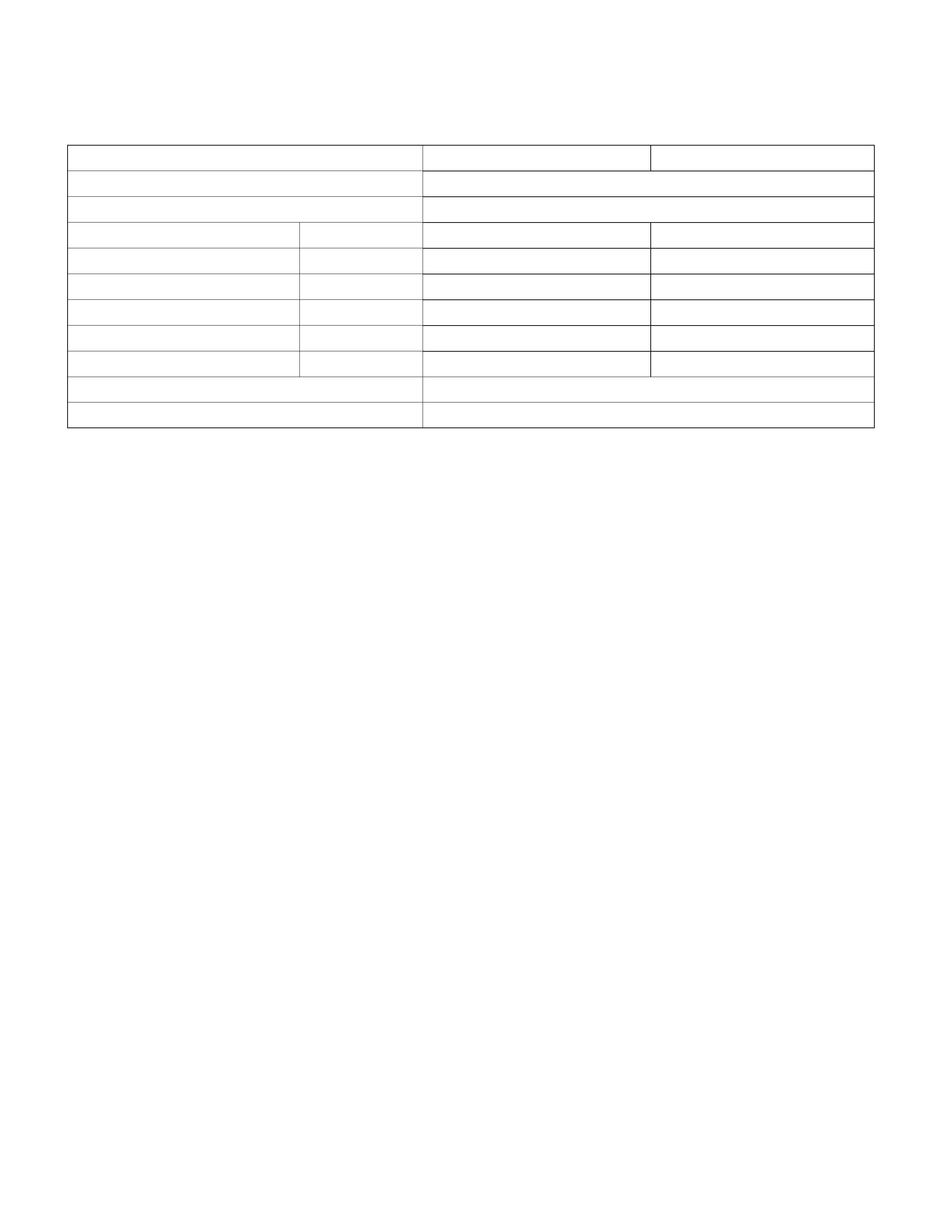

Main Data and Spec ifications

General Specifications

(MUA 5G)

MUA 5G (6VE1, 4JH1-TC) MUA 5S (C24NE)

Transmission type Fully synchronized forward and reverse gears

Control method Remote control with the gear shift lever on the floor.

Gear ratio: Transmission 1st 4.008 4.357

2nd 2.301 2.502

3rd 1.427 1.501

4th 1.000 1.000

5th 0.828 0.809

Rev. 3.651 3.970

Transmission oil capacity 2.95 lit. (3.12 US qt)

Type of lubricant Engine oil: Refer to the chart in "SECTION 0"

RTW37BLF0006

E07R300014

Troubleshooting

1. ABNORMAL NOISE

1) NOISY IN NEUTRAL

Checkpoint Fault Action

Replenish or replace the gear

oil

Insufficient or improper gear

oil

NG

Mainshaft splines

Synchronizer clutch hub

splines

Replace the main shaft and

the synchronizer clutch hub

Replace the gear(s)

Replace the flywheel pilot

Worn splines

Worn or scuffed gear tooth

contact surfaces

Flywheel pilot bearing Worn flywheel pilot bearing

Bearings (Mainshaft,

countershaft, and transfer

shaft)

Gears (Mainshaft,

countershaft, reverse idler

gear and transfer gears)

Replace the bearing(s)Worn or broken bearing(s)

OK

NG

NG

NG

NG

OK

OK

OK

Gear oil

Transmission Realign the transmissionTransmission misalignment

OK

NG

2) NOISY OPERATION

Checkpoint Fault Action

Replenish or replace the gear

oil

Insufficient or improper engine

oil

NG

Replace the gear(s)

Replace the gear(s)

Replace the bearing(s)

Gears (Gear whining) Lack of backlash between

meshing gears

Free running gears seizing on

the thrust face or the inner

face

Bearings (Hissing, thumping

or bumping) Worn or broken bearing(s)

Gears (Squealing at high

speeds)

Replace the gear(s)

Gears (Growling, humming, or

grinding) Worn, chipped, or cracked

gear(s)

NG

NG

NG

NG

OK

OK

OK

OK

Gear oil (Metallic rattling)

2. HARD SHIFTING

Checkpoint Fault Action

Change lever play

Clutch pedal free play

Repair or replace the

applicable parts and regrease

Readjust the clutch pedal free

play

Worn change lever sliding

portions

Improper clutch pedal free

play

Change lever operation Repair or regrease the change

lever assembly

Replenish or replace the

engine oil

Hard operating change lever

caused insufficient grease

Insufficient or improper gear

oil

OK

OK

NG

NG

NG

NG

OK

OK

Gear oil

Continued on the next page

Shift rod and quadrant box

sliding faces, and other parts Replace the shidt rod and/or

the quadrant box

Worn shift rod and/or sliding

faces

Repair or replace the sleeveSleeve movement failure

NG

NG

OK

Shift block sleeve movement

Checkpoint Fault Action

Synchronizer assembly

Shift arm and synchronizer

sleeve

Replace the worn parts

Replace the worn parts

Worn synchronizer parts

Worn shift arm and/or

synchronizer sleeve groove

Mainshaft and countershaft

thrust play Replace the worn parts

Worn thrust washer, collar,

and/or gear thrust faces

OK

NG

NG

NG

OK

OK

Continued from the previous

3. WALKING OR JUMPING OUT OF GEAR

Checkpoint Fault Action

Shift rod and quadrant box

sliding faces

Detent ball

Replace the shift rod and/or

the quadrant box

Replace the detent ball

Worn shift rod and/or sliding

faces

Worn detent ball

Detent spring Repair or replace the detent

spring

Replace the worn parts

Detent spring weak or broken

Insufficient stroke caused by

sliding position wear and

excessive play

OK

OK

NG

NG

NG

NG

OK

OK

Change lever play

Continued on the next page

Mainshaft and countershaft

thrust play Replace the worn parts

Worn thrust washer, collar,

and/or gear thrust faces

Replace the worn parts

Worn shift arm and/or

synchronizer sleeve groove

NG

NG

OK

Shift arm and synchronizer

sleeve

Checkpoint Fault Action

Synchronizer assembly

Bearings (Mainshaft,

countershaft, and individual

gears)

Replace the spring

Replace the bearing(s)

Weak or broken spring

Worn or broken bearings(s)

Mainshaft splines

Synchronizer clutch hub

splines

Replace the main shaft and

the synchronizer clutch hub

Worn splines

OK

NG

NG

NG

OK

OK

Continued from the previous page

4. OIL LEAKAGE

Checkpoint Fault Action

Gear oil Replace the gear oilImproper gear oil

Drain plug and/or filler plug Tighten the plug(s) and

replenish the oil

Drain the oil to the correct

level

Loose plug(s)

Oil level too high

OK

NG

NG

NG

OK

OK

Oil level

Rear cover oil seal

Air breather

Replace the oil seal

Install the air breather

Replace the air breather

Worn or scratched oil seal

Air breather not installed

Air breather clogged

Front cover oil seal Replace the oil seal

Replace the gasket(s)

Worn or scratched oil seal

Defective or improperly

installed gasket(s)

OK

NG

NG

NG

NG

OK

OK

Gaskets

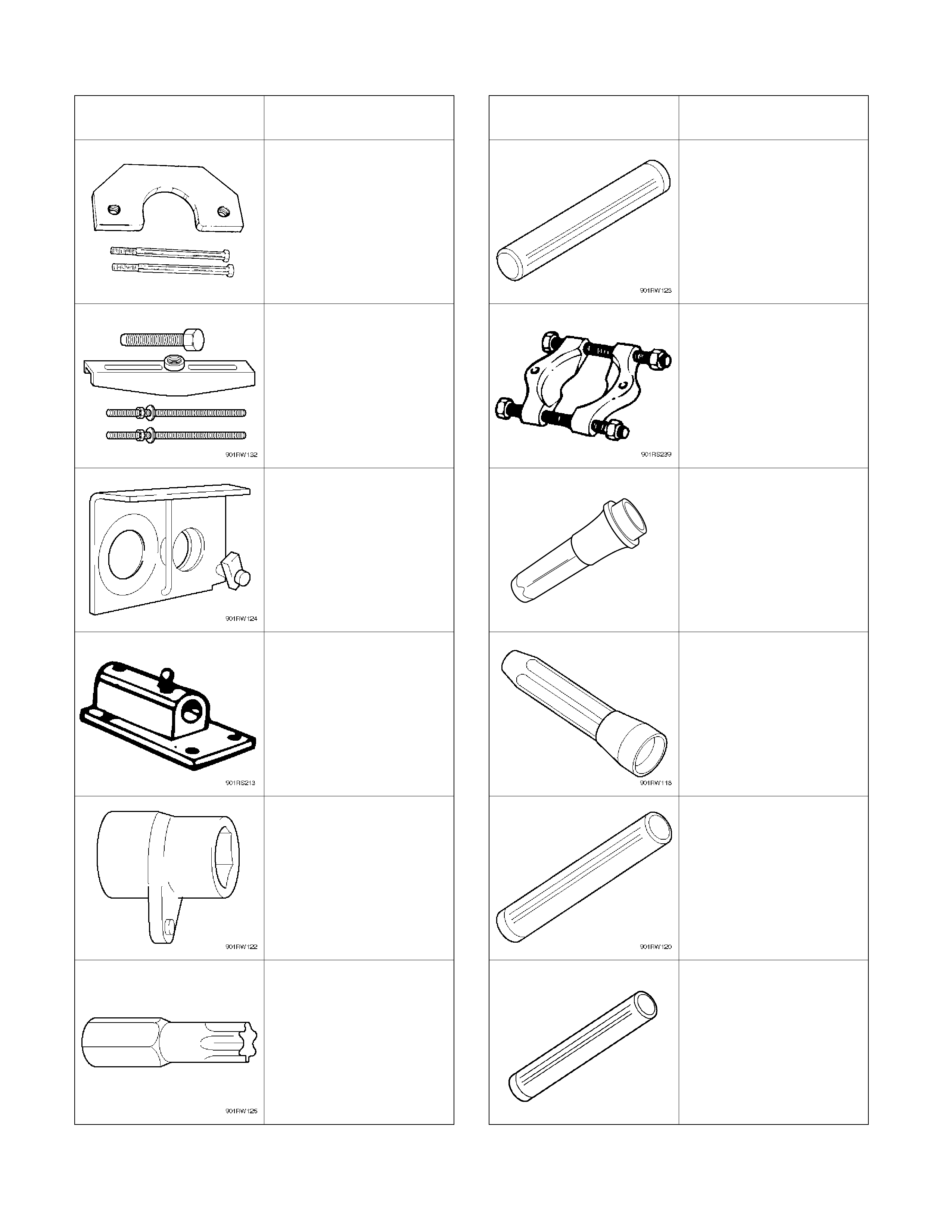

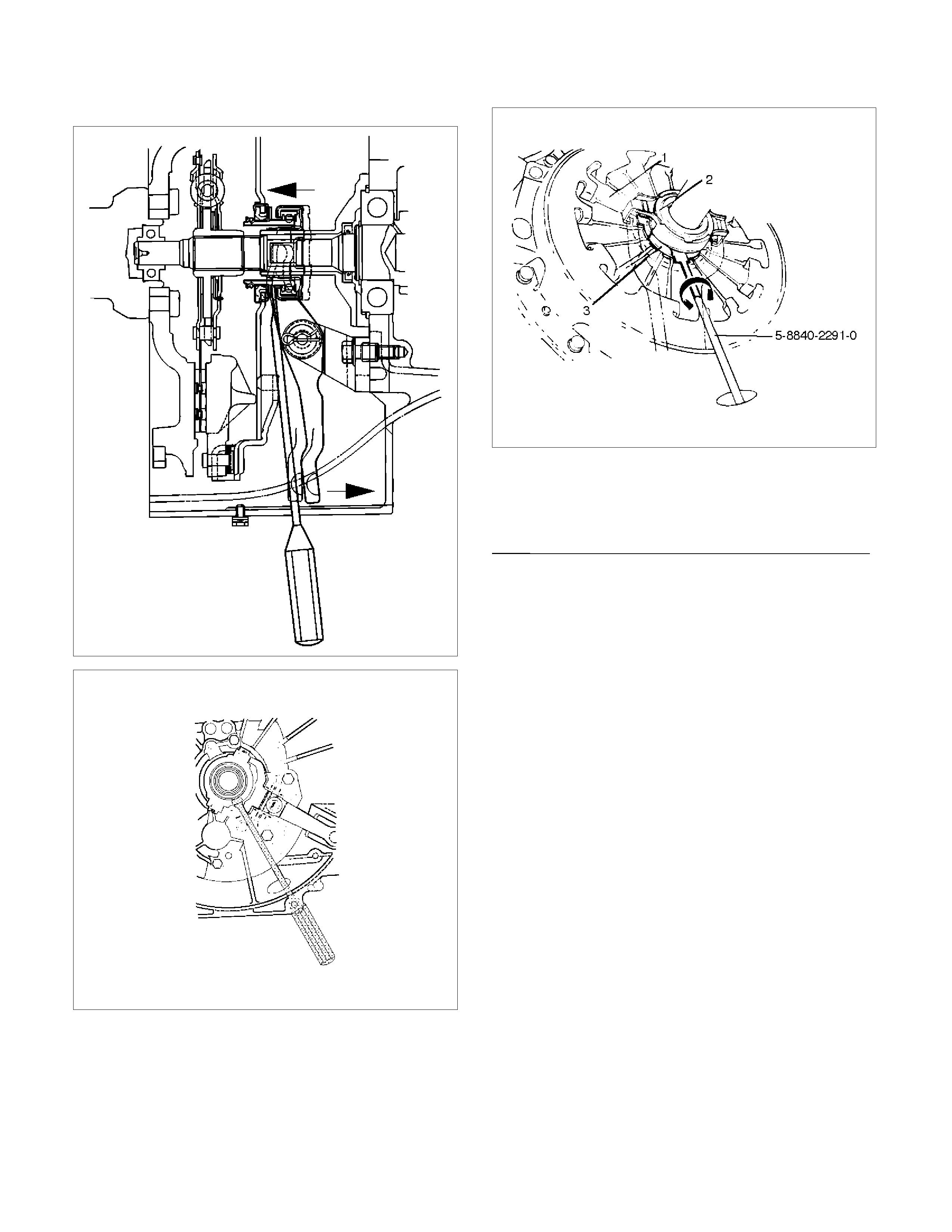

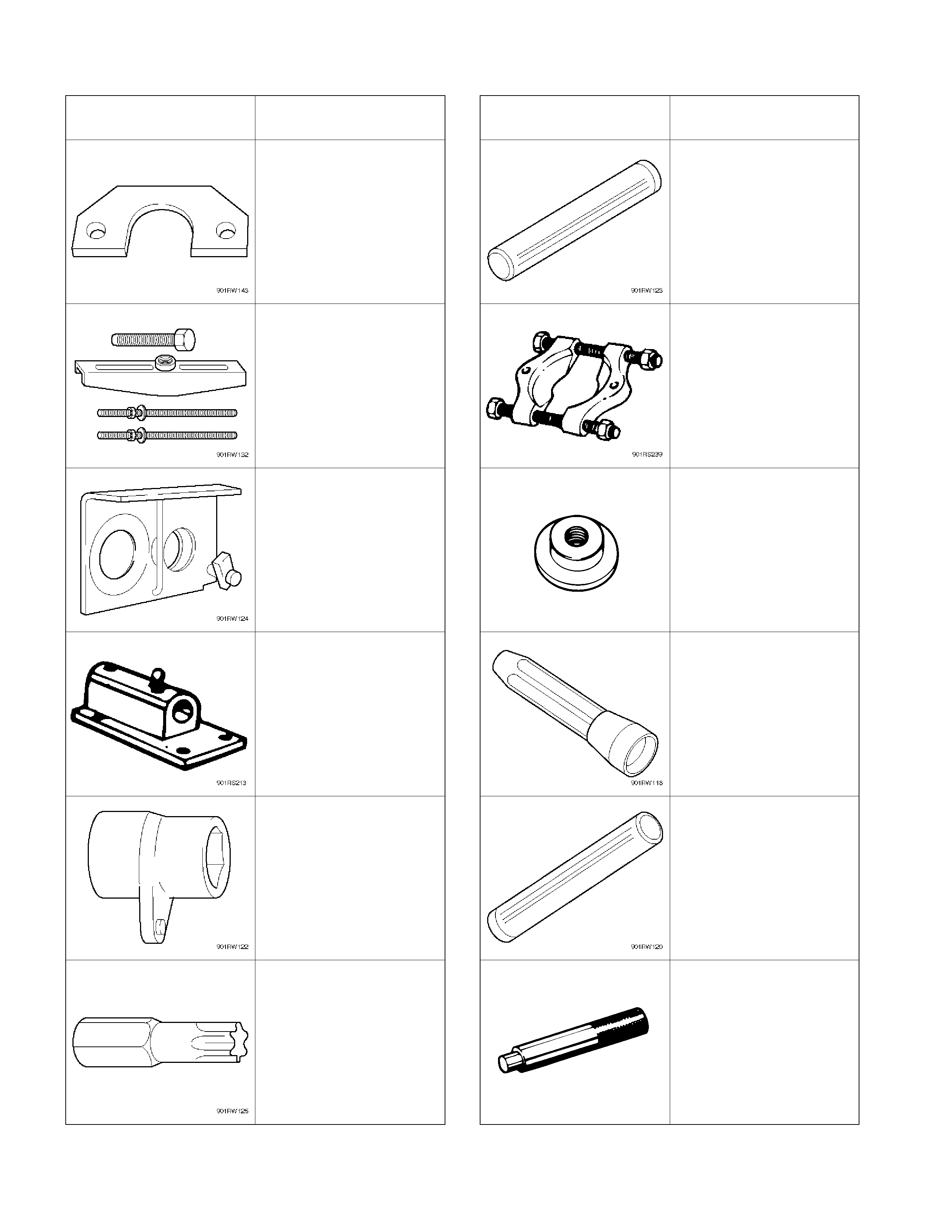

Special Tools (MUA)

ILLUSTRATION TOOL NO.

TOOL NAME ILLUSTRATION TOOL NO.

TOOL NAME

5-8840-2155-0

Bearing remover

5-8840-2159-0

Mainshaft end bearing

installer

5-8840-2027-0

Puller 5-8840-0015-0

Bearing

remover/installer

5-8840-2160-0

Holding fixture

5-8522-0050-0

Rear case oil seal

installer

5-8840-0003-0

Holding fixture base

5-8840-0026-0

Front cover oil seal

installer

5-8840-2156-0

Wrench

9-8522-1165-0

Mainshaft collar remover

5-8840-0047-0

Torx bit wrench

(T–45)

5-8840-2194-0

Bearing installer

MUA5G (4×4)

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

orfastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener.

When you install fasteners, use the correct

tightening sequence and specifications. Following

these instructions can help you avoid damage to

parts and systems.

General Description

MUA5G Transmission (4×

××

×4)

A07R300003

The MUA5C is a constant mesh transmission,

synchronized in all speeds. The transmission is

designed for a great reduction of the shift effort and the

quietest possible operation.

Principle parts of the transmission are the integral clutch

housing, the intermediate plate, the rear case, and the

gears.

The transmission control box is built into the

transmission.

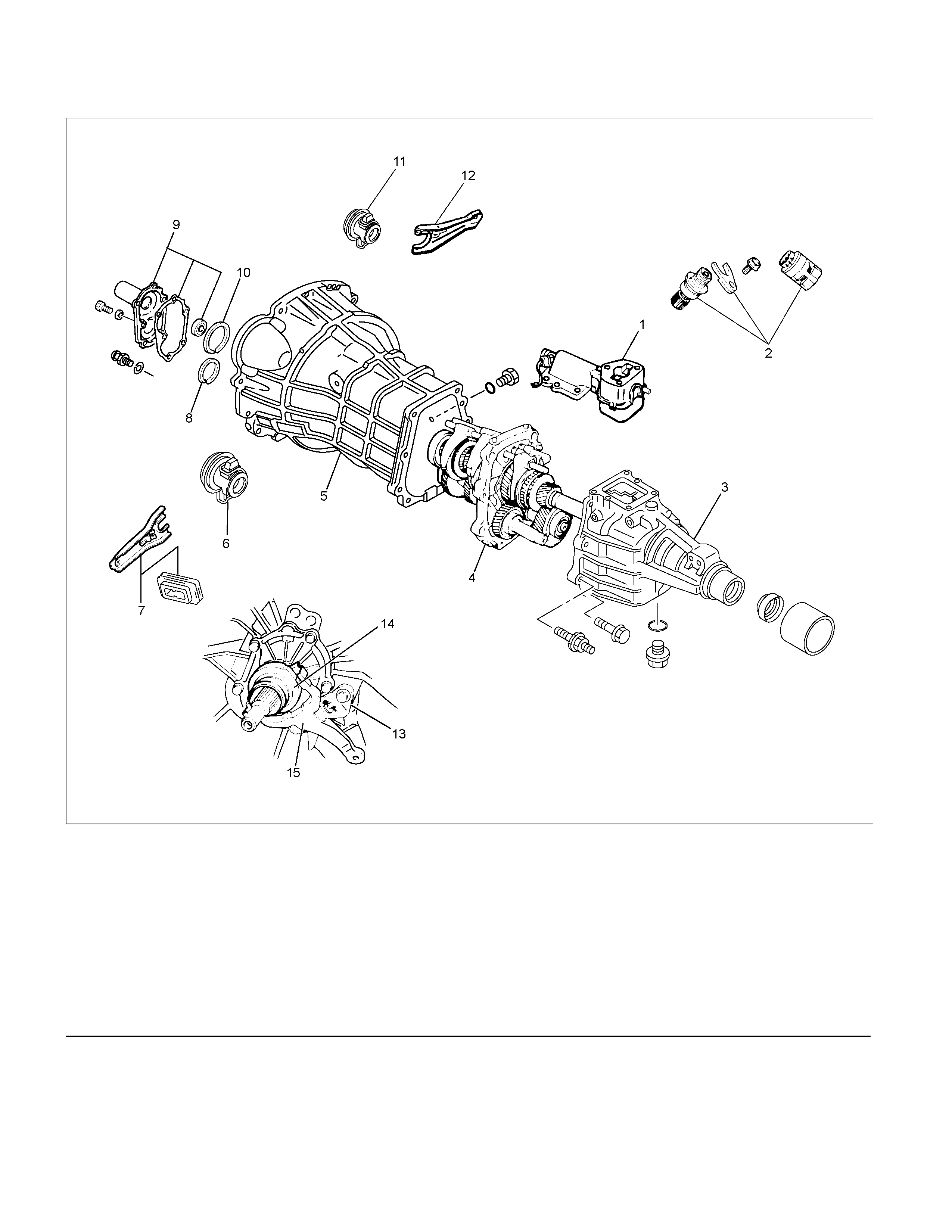

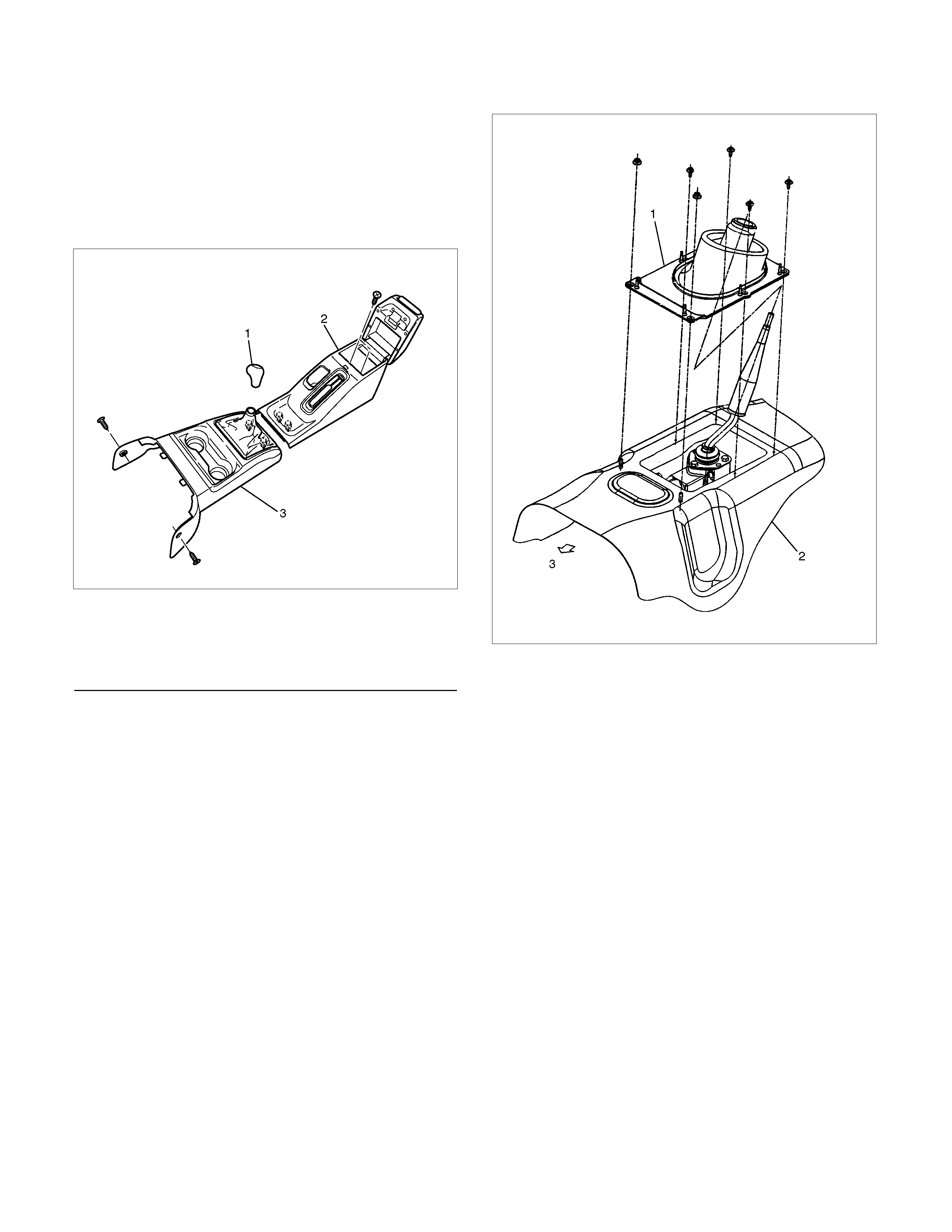

Transmission (4×

××

×4)

Disassembled View

RTW37ALF000201

Legend

(1) Gear Control Lever Knob (10) Transmission-Transfer Fixing Bolt

(2) Rear Floor Console (bucket) (11) Transfer Assembly

(3) Front Floor Console (12) Fuel Pipe Bracket

(4) Grommet Assembly (13) Slave Cylinder

(5) Gear Control Lever (14) Rear Mount Nut

(6) Rear Propeller Shaft (15) Transmission Crossmember

(7) Front Propeller Shaft (16) Starter (4JH1-TC only)

(8) Exhaust Pipe Nut (4JH1-TC) (17) Transmission Retaining Nut and Bolt

(9) Exhaust Pipe Assembly (6VE1) (18) Transmission Assembly

Removal

1. Disconnect battery ground cable.

2. Remove gear control lever knob (1).

3. Remove rear floor console (2). (Bucket seat)

Refer to the section “Floor Console”.

4. Remove front floor console (3).

Refer to the section “Floor Console”.

745R300006

Legend

(1) Knob

(2) Rear Floor Console

(3) Front Floor Console

5. Remove grommet assembly (4).

235R300001

6. Remove gear control lever (5).

7. Raise and support vehicle with suitable stands.

8. Remove rear propeller shaft (6).

NOTE: Apply alignment marks on the flange at the

differential side.

9. Remove front propeller shaft (7).

NOTE: Apply alignment marks on the flange at both

front and rear sides.

401RS023

10. Loosen the front exhaust pipe fixing nuts (8) at the

engine side but not remove them. (4JH1-TC only)

150R300004

11. Remove the exhaust pipe (9). (6VE1 only)

RTW37ASH000101

12. Disconnect harness connectors and clips on the

transfer.

• Actuator connector

• Car Speed Sensor

810R300069

Legend

(1) Neutral Switch Connector: Transmission

(2) Back up Switch Connector

(3) Speed Sensor Connector

(4) Actuator Connector

(5) 2W - 4W Switch Connector

(6) Neutral Switch Connector: Transfer

13. Remove transmission-transfer fixing bolts (10),

and remove the transfer assembly (11) from the

transmission.

14. Disconnect harness connectors and clips on the

transmission.

• Neutral switch; Transmission

• Back up Switch

• 2W-4W Switch

• Neutral Switch; Transfer

15. Remove the fuel pipe brackets (12) with pipes

from the transmission (18).

4JH1-TC

220R300012

Legend

(1) Bolt

(2) Nut

(3) Fuel Pipe Assembly

6VE1

Scan-2

16. Remove slave cylinder (13) and put aside it.

220LV019

17. Support transmission with a transmission jack.

220RS0001

18. Remove engine rear mount nuts (14) from

transmission crossmember (15).

19. Remove engine rear mount bolts fixing

transmission.

220R300009

20. Remove the middle part of transmission

crossmember (15) by removing four fixing bolts

and nuts.

501R30007

21. Take out the rear support rubber.

22. Remove starter (16). (4JH1-TC only)

060L100070

23. Use the clutch release bearing remover 5-8840-

2291-0 (J-39207) to disconnect the clutch release

bearing from the clutch pressure plate. (6VE1

only )

220RW109

Release bearing disconnection

1. Pull the shift fork toward the transmission to

press the clutch release bearing against the

clutch.

2. Insert the clutch release bearing remover

between the wedge collar and the release

bearing.

3. Turn the remover to separate the release

bearing.

NOTE: Be sure not to insert the remover between the

wedge collar and the clutch.

220RW063

220RW064

220RW019

Legend

(1) Pressure Plate Assembly

(2) Release Bearing

(3) Wedge Collar

24. Remove transmission retaining nuts and bolts(17).

Remove transmission assembly (18) from the

vehicle.

Installation

1. Apply a thin coat of molybdenum disulfide grease

to the top gear shaft spline.

2. Slowly operate the transmission jack until the front

of transmission is aligned with the rear of the

engine.

The slope of the engine and the transmission

must be the same.

3.

A

lign the top gear shaft with the clutch driven plate

spline.

4. Install the transmission assembly (18) to the

engine.

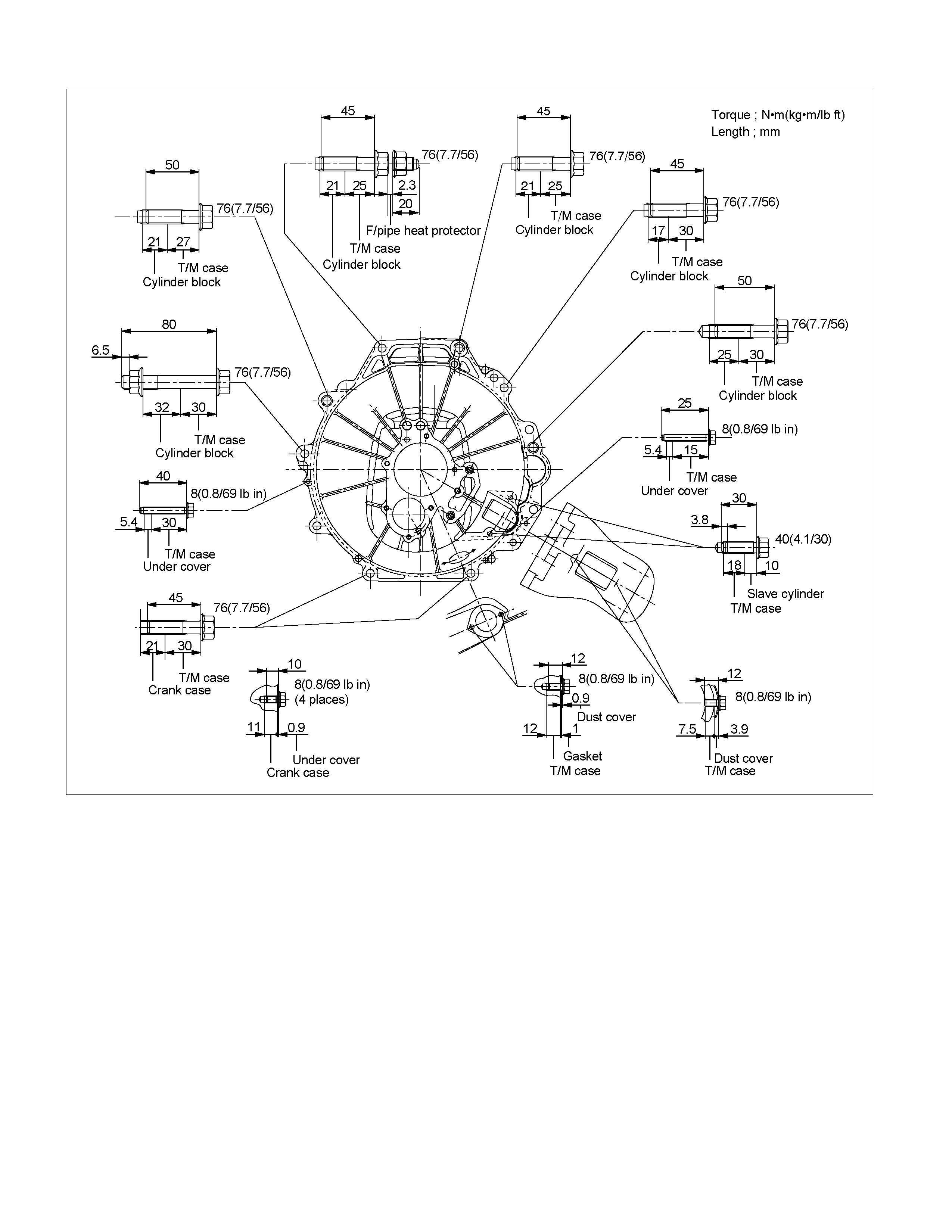

Tighten the transmission nuts and bolts as shown in

the figure.

4JH1-TC

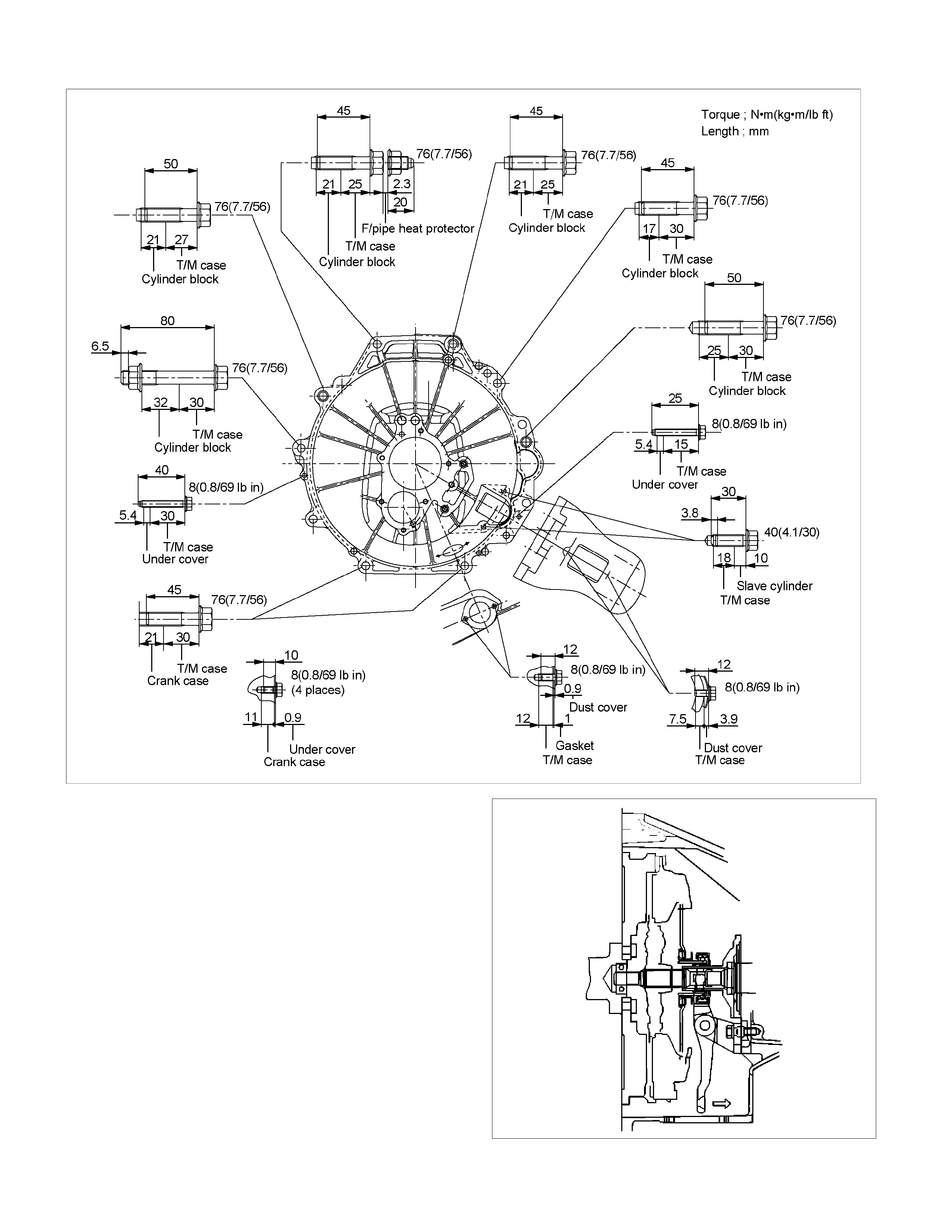

RTW37BLF000901

6VE1

RTW37BLF0001

5. Apply a force of about 113N (26 Ib) to the tip of the

shift fork in the direction of the transmission to

engage the clutch pressure plate and release

bearing. (6VE1 only)

NOTE: A clicking sound is heard when the release

bearing and the tip of the diaphragm spring engage

each other.

Check to see if they are securely engaged by pushing

the tip of the shift fork toward the engine while applying

a force of about 25 N (5.5 lb). If the shift fork will not

move, then they are securely engaged.

220RS006

6. Install starter(16).(4JH1-TC)

NOTE: Tighten the lower bolt temporarily.

After installing the fuel pipe assembly, tighten the bolt to

the specified torque.

Torque: 76 N·m (7.7 kg·m/56 lb·ft)

7. Install the rear support rubber on the transmission

and tighten the bolts to the specified torque.

Torque: 50 N·m (5.1 kg·m/37 lb·ft)

8. Install the middle part of transmission

crossmember (15) and bolts.

Tighten the nuts to the specified torque.

Torque: 67 N·m (6.8 kg·m/49 lb·ft)

9. Install engine rear mount nuts (14).

Torque: 52 N·m (5.3 kg·m/38 lb·ft)

Remove the transmission jack from transmission

side.

10. Apply grease to top hole portion of the shift fork.

Install slave cylinder (13) and tighten the bolts to the

specified torque.

Torque: 76 N·m (7.7 kg·m/56 lb·ft)

11. Install the fuel pipe brackets on the transmission.

Install the fuel pipe assembly to the fuel pipe

brackets

Torque: Bolt & Nut 76 N·m (7.7 kg·m/56 lb·ft)

Nut 37 N·m (3.8 kg·m/28 lb·ft)

4JH1-TC

220R300012

Legend

(1) Bolt

(2) Nut

(3) Fuel Pipe Assembly

6VE1

Scan-2

12. Connect transmission harness connectors and

clips. Connector: transfer neutral switch, 2W - 4W

switch, backup switch, and transmission neutral

switch.

810R300069

Legend

(1) Neutral Switch Connector: Transmission

(2) Backup Switch Connector

(3) Speed Sensor Connector

(4) Actuator Connector

(5) 2W - 4W Switch connector

(6) Neutral Switch Connector: Transfer

13. Apply grease (BESCO L2 or equivalent) on the

splined portion of the output shaft.

14. Connect the transfer to the transmission.

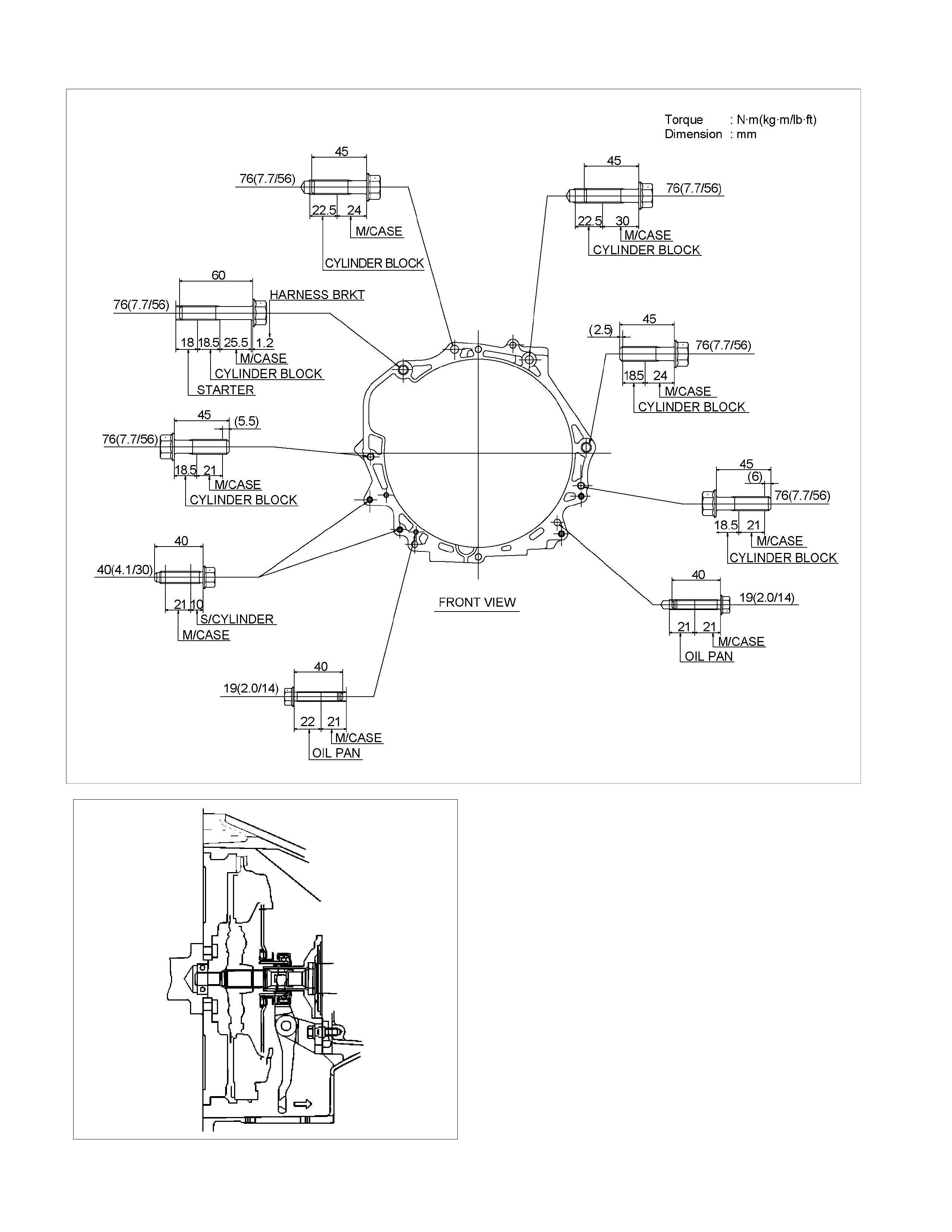

15. Install the transmission-transfer bolts and nut and

tighten them to the specified torque.

Torque: 41 N·m (4.2 kg·m/30 lb·ft)

261R300005

16. Connect transfer harness connectors and clips.

Connector: actuator, car speed sensor.

17. Tighten exhaust pipe fixing nuts (8) to the

specified torque. (4JH1-TC)

Torque: 67 N·m (6.8 kg·m/49 lb·ft)

150R300004

18. Install the exhaust pipe (9). (6VE1)

Torque: 67 N·m (6.8 kg·m/49 lb·ft)

RTW37ASH000101

19. Install front propeller shaft (7).

Refer to the section “Front Propeller Shaft”.

20. Install rear propeller shaft (6).

Torque: 63 N·m (6.4 kg·m/46 lb·ft)

21. Install the centre bearing on crossmember.

Torque: 69 N·m (7.0 kg·m/51 lb·ft)

22. Install gear control lever (5).

Torque: 19 N·m (1.9 kg·m/14 lb·ft)

21. Install grommet assembly (4).

Torque: Screw 1.4 N·m (0.14 kg·m/12 lb·in)

Nut 7 N·m (0.7 kg·m/61 lb·in)

235R300001

Legend

(1) Grommet Assembly

(2) Floor Panel

(3) Front

24. Install front floor console (3) and rear floor console

(2).

25. Install gear control lever knob (1).

To the female thread portion, adhesive (TB1344 or

LOCTITE 222 or equiv.) of 3 - 4 drops to be applied

and transmission knob tightened.

Torque: 9 N·m (0.9 kg·m/78 lb·in)

After tightening to specified torque, ensure shift

knob is correctly aligned.

26. Connect battery ground cable.

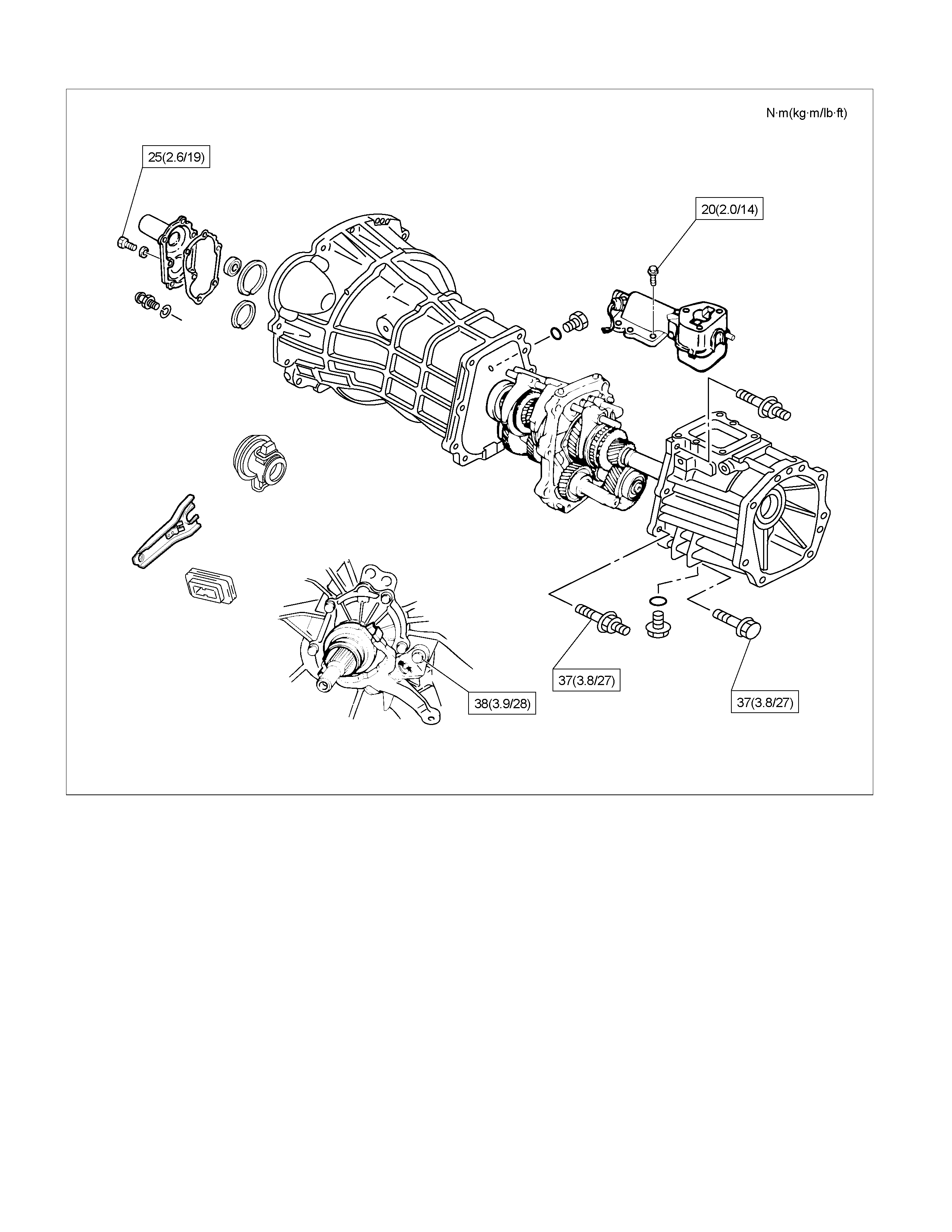

Transmission Case

Major Component

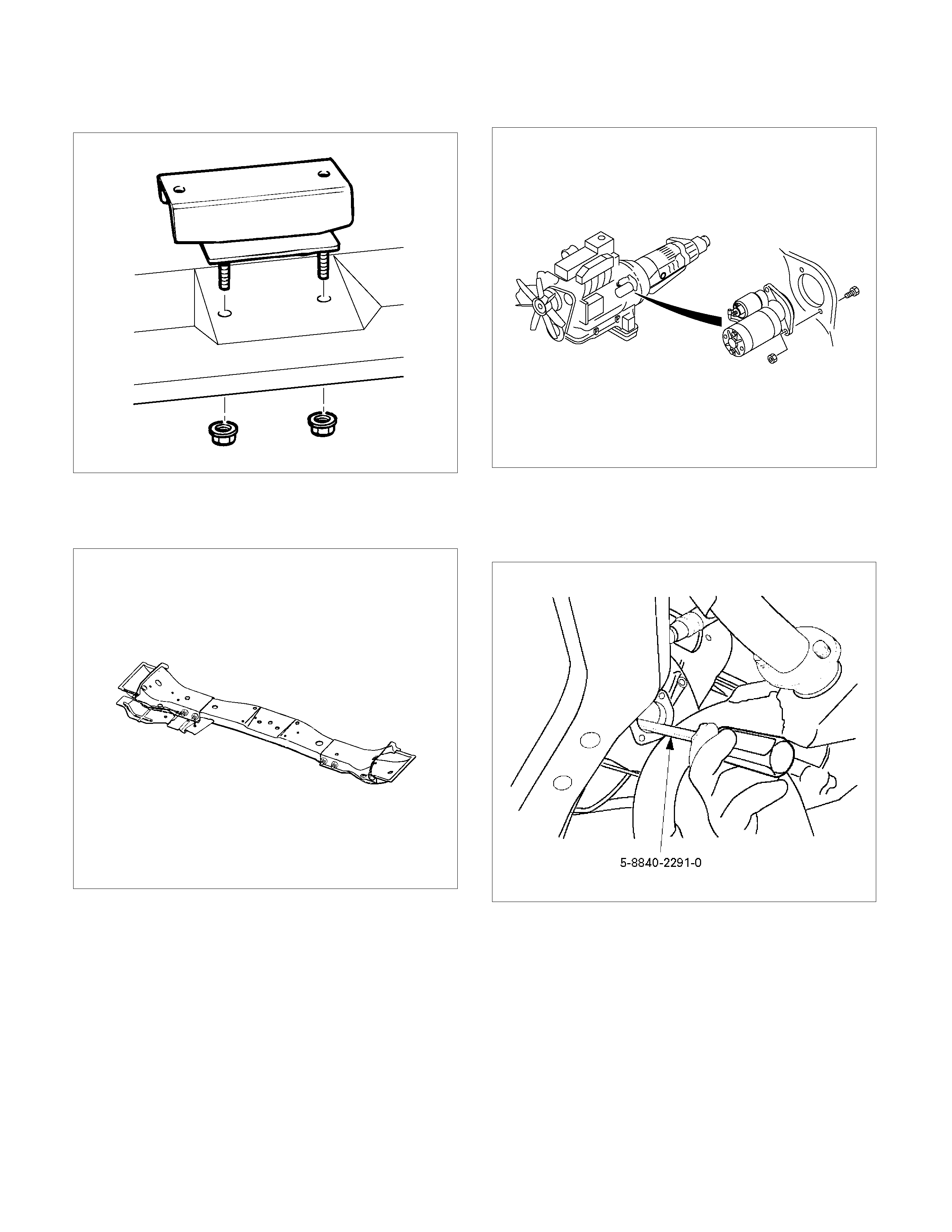

RTW37BLF0007

Legend

(1) Gear Control Box Assembly and Gasket (7) Counter Front Bearing Snap Ring

(2) Re ar Case Assembly (8) Front Cover (with Oil Seal)

(3) Intermediate Plate with Gear Assembly (9) Top Gear Bearing Snap Ring

(4) Transmission Case (10) Fulcrum Bridge : 6VE1

(5) Release Bearing (with Spring): 4JH1-TC (11) Release Bearing : 6VE1

(6) S hift Fork: 4JH1-TC (12) Shift Fork : 6VE1

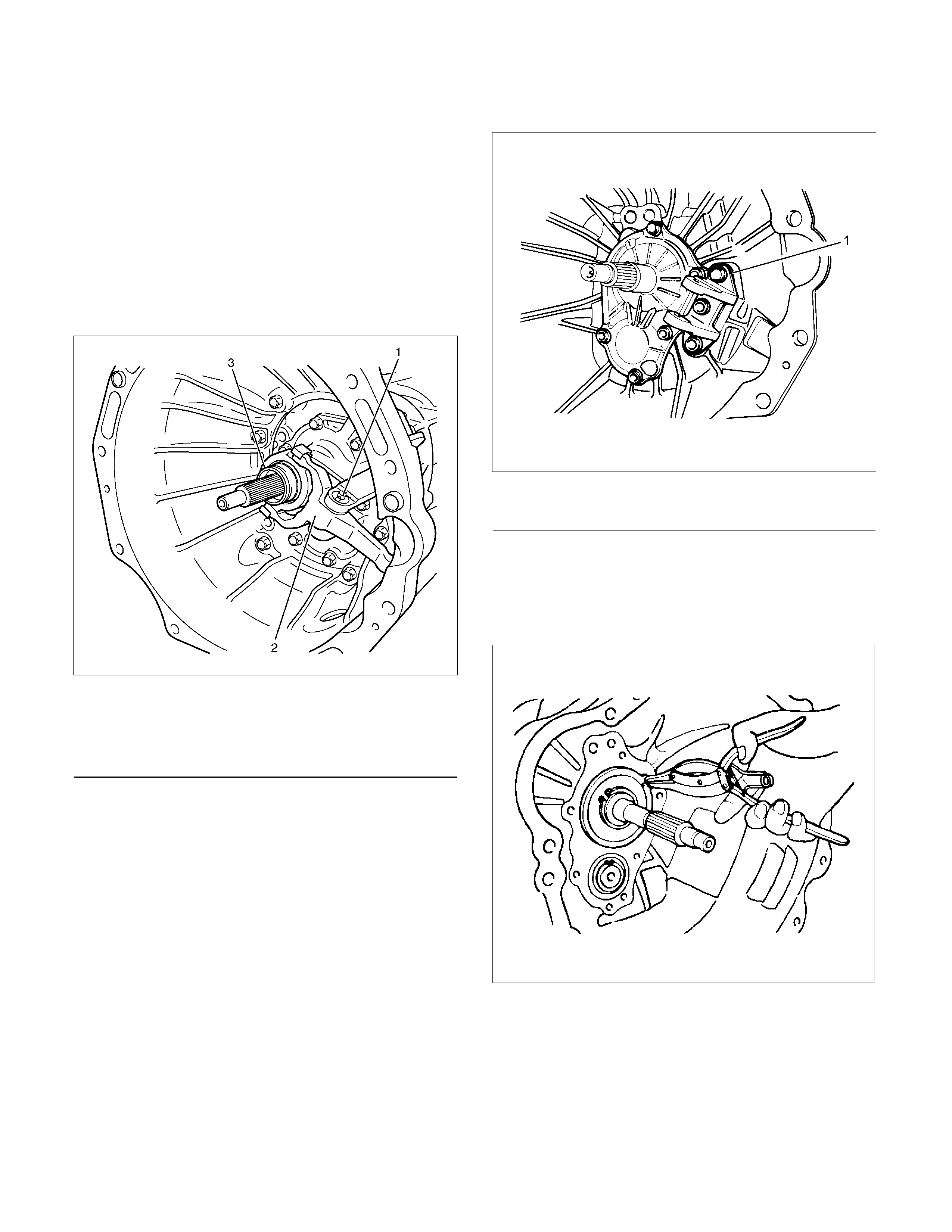

Disassembly

1. Clean the exterior of the unit with solvent.

2. Remove the drain plug from the transmission case

and drain the lubricant.

3. Remove the clutch release bearing with spring (5)

from the transmission case.

4. Remove the shift fork, and boot. (4JH1-TC)

5. Remove the shift fork snap pin. (6VE1)

6. Remove the shift fork pin and shift fork from the

fulcrum bridge. (6VE1)

220RW088-X

Legend

(1) Shift fork pin

(2) Shift fork

(3) Release bearing

7. Remove the fulcrum bridge from the transmission

case. (6VE1)

RTW37ASH0002

Legend

(1) Fulcrum bridge

8. Remove the front cover (8) and gasket from the

transmission case.

9. Remove snap ring (7) fixing counter front bearing.

10. Use a pair of snap ring pliers to remove the snap

ring (9) fixing top gear bearing.

226RS001

11. Remove gear control box assembly (1).

12. Remove the rear case assembly (2) from the

transmission case (4) and intermediate plate (3).

13. Remove intermediate plate with gear assembly (3)

from transmission case (4).

Rear Oil Seal Replacement

220R300025

Legend

(1) Installer 5-8840-2797-0

(2) Grip 5-8840-0007-0

1. Remove the oil seal from the rear case and

discard the used oil seal.

2. Apply engine oil to new oil seal outer surfaces.

3. Apply recommended grease (BESCO L2) or

equivalent to the oil seal lip.

4. Use the oil seal installer 5-8840-2797-0 and grip 5-

8840-0007-0 to install the oil seal to the rear case.

Reassembly

1. Apply recommended liquid gasket (LOCTITE

17430) or its equivalent to the transmission case

(4), intermediate plate (3) and rear case (2) fitting

surfaces.

2. Install the intermediate plate with gear assembly

(3) to the transmission case (4).

Pull out the top gear shaft until the ball bearing snap

ring groove protrudes from the transmission case

front cover fitting face.

Avoid subjecting the mainshaft to sudden shock or

stress.

3. Install the rear case with oil seal (2) on the

intermediate plate with gear (3) by performing the

following steps.

• Cover the shaft splines with adhesive tape.

This will prevent damage to the oil seal lip.

• Tighten the transmission rear case bolts and

nuts to the specified torque.

Torque: 37 N·m (3.8 kg·m/27 lb·ft)

220R300026

Notes When Tightening the Bolt:

• After cleaning the bolt hole, dry it thoroughly with

air.

• After cleaning the screw face of a removed bolt or

new one, dry it thoroughly. Apply recommended

liquid gasket (LOCTITE 242) or its equivalent on

them before tightening it.

4. Install a new gasket and gear control box

assembly (1).

Install the harness clips and brackets and then

tighten four new gear control box bolts to the

specified torque.

Torque: 20 N·m (2.0 kg·m/14 lb·ft)

261R300004

5. Install top gear bearing snap ring (9) and counter

front bearing snap ring (7).

• Use a pair of snap ring pliers to install the snap

rings to the mainshaft and countershaft.

• The snap rings must be fully inserted into the

bearing snap ring groove.

6. Front cover with oil seal (8).

Front Cover Oil Seal Replacement

• Remove the oil seal from the front cover.

• Apply engine oil to a new oil seal outer

circumference.

• Apply recommended grease to the oil seal lip.

• Use the oil seal installer 5-8840-0026-0 to

install the oil seal to the front cover.

220R3000020

7. Install a new gasket and front cover (8) to the

transmission case.

NOTE: Take care not to damage the oil seal.

Notes When Tightening the Bolt:

• After cleaning the bolt hole, dry it thoroughly with

air.

• After cleaning the screw face of a removed bolt or

new one, dry it thoroughly. Apply recommended

liquid gasket (LOCTITE 242) or its equivalent

before tightening it.

Tighten six front cover bolts to the specified torque.

Torque: 25 N·m (2.6 kg·m/19 lb·ft)

8. Apply molybdenum disulfide type grease to the

areas as shown in the figure and install shift fork

(6). (4JH1-TC)

F07L100026

9. Install the fulcrum bridge to the transmission case.

(6VE1)

Torque: 38 N·m (3.9 kg·m/28 lb·ft)

RTW37ASH0002

Legend

(1) Fulcrum bridge

10. Apply molybdenum disulfide type grease to the pin

hole inner circumferences and thrust surfaces.

(6VE1)

11. Attach the shift fork to the fulcrum bridge and

insert the pin from below of the fulcrum bridge.

(6VE1)

12. Install the washer and snap pin. (6VE1)

201RW019

13. Pack the inside recess (A) and coat the back (B)

of the release bearing with molybdenum disulfide

type grease as shown in the figure.

A07RW075

14. Install the release bearing (5) on the front cover,

joining it to the shift fork.

Intermediate Plate with Gear Assembly, Detent, Shift Arm, Shift Rod, and Interlock Pin

Disassembled View

220RS010

Legend

(1) Detent Spring Plate and Gasket (7) 1st-2nd Shift Rod

(2) Detent Spring (8) 3rd-4th Shift Rod

(3) Detent Ball (9) 3rd-4th Shift Arm

(4) Spring (10) 1st-2nd Shift Arm

(5) Rev-5th Shift Rod (11) Interlock Pin

(6) Rev-5th Shift Arm and Reverse Inhibitor (12) Intermediate Plate and Gear Assembly

Disassembly

1. Remove detent spring plate and gasket (1), detent

spring (2) and detent ball (3).

Use a magnetic hand to remove the detent balls

from the intermediate plate.

220RS011

2. Remove spring (4).

3. Remove rev-5th shift rod (5), and rev-5th shift arm

and reverse inhibitor (6).

Remove 1st-2nd shift rod (7), 3rd-4th shift rod (8),

3rd-4th shift arm (9), and 1st-2nd shift arm (10).

• Hold a round bar against the shift rod end.

230RS003

• Use a spring pin remover to remove the shift

arm spring pins from the shift arms and the

shift rods.

230RS0004

• Be careful not to lose the interlock pins, when

pulling out the shift rod rearward.

Interlock pins are located between the shifter

rods in the intermediate plate.

230RS0005

• Remove the rev-5th, 1st-2nd and 3rd-4th shift

rods carefully.

4. Remove interlock pin (11) from intermediate plate

and gear assembly (12).

Inspection and Repair

Make the necessary adjustments, and part

replacements if excessive wear or damage is

discovered during inspection.

Shift Arm Thickness

• Use a micrometer to measure the shift arm

thickness.

If the measured value is less than the specified limit,

the shift arm must be replaced.

Shift Arm Thickness

Standard Limit

1st-2nd 9.60 - 9.85 mm

(0.378 - 0.388 in)

3rd-4th

Rev.5th 9.60 - 9.80 mm

(0.378 - 0.386 in)

9.0 mm

(0.354 in)

230RS006

Detent Spring Free Length

• Use a vernier caliper to measure the detent spring

free length.

If the measured value is less than the specified limit,

the detent spring must be replaced.

Detent Spring Free Length

Standard Limit

26.8 mm (1.06 in) 26.2 mm (1.03 in)

220RS012

Detent Spri ng Tension

• Use a spring tester to measure the detent spring

tension.

If the measured value is less than the specified limit,

the detent spring must be replaced.

Detent Spri ng Tension

Compressed height Standard

20 mm (0.787 in) 87.2 - 97.1 N

(19.6 - 21.8 lb)

220RS013

Reassembly

1. Install rev-5th shift arm and reverse inhibitor (6)

and rev-5th shift rod (5).

• Apply oil to the reverse inhibitor inner surface.

• Install the shift rod in the intermediate plate

(12).

• Hold a round bar against the shift rod end

lower face to protect it against damage.

• Install a new spring pin.

Never reinstall the used spring pin.

• Install the interlock pin (11) in the intermediate

plate (12).

Do not allow the interlock pin to fall from the

intermediate plate (12).

2. Install 1st-2nd shift arm (10) and 3rd-4th shift

arm(9) to intermediate plate and gear assembly

(12).

3. Install 3rd-4th shift rod (8) and 1st-2nd shift rod

(7).

• Install the interlock pin (11) in the intermediate

plate and gear assembly (12).

• Install the 3rd-4th shift rod (8) in the

intermediate plate (12).

Do not allow the interlock pin to fall from the

intermediate plate.

• Install the interlock pin (11) and then 1st-2nd

shift rod (7) in the intermediate plate (12).

Do not allow the interlock pin to fall from the

intermediate plate.

• Hold a round bar against the shift rod end

lower face to protect it against damage.

• Install a new spring pin.

Never reinstall the used spring pin.

230RS007

4. Install spring (4).

5. Put detent balls (3) in the intermediate plate holes.

• Apply oil to the detent balls.

6. Install detent springs (2) and detent spring plate

and gasket (1).

• Install a new gasket and the detent spring

plate.

• Tighten the detent spring plate bolts to the

specified torque.

Torque: 25 N·m (2.5 kg·m/18 lb·ft)

220RS030

Legend

(1) Warped

Reverse Gear and 5th Gear

Disassembled View

226R300024

Legend

(1) Collar Snap Ring (15) Counter 5th Gear

(2) Oil Seal Collar (16) Counter Reverse Gear

(3) Ball Bearing (17) 5th Gear

(4) Retainer (18) 5th Block Ring

(5) Thrust Plate (19) Needle Bearing

(6) Thrust Washer and Lock Ball (20) Mainshaft Nut

(7) Reverse Idler Gear Snap Ring (21) Rev-5th Synchronizer Assembly

(8) Reverse Idler Gear Assembly (22) Reverse Block Ring

(9) Idle Shaft Pin (23) Reverse Gear

(10) Thrust Washer (24) Needle Baring

(11) Reverse Idler Gear (25) Bearing Plate and Screw

(12) Reverse Idler Shaft (26) Bearing Snap Ring

(13) Bearing Snap Ring (27) Intermediate Plate

(14) Ball Bearing

Disassembly

1. Use a pair of snap ring pliers to remove the collar

snap ring (1).

2. Set the retaining ring remover 5-8840-2158-0 and

puller 5-8840-2027-0 to the retainer (4) and the

mainshaft end.

262RW079

3. Remove the retainer (4) together with the bearing

(3) and the oil seal collar (2).

The universal puller may be used in place of the

retaining ring remover.

4. Remove thrust plate (5) and thrust washer and

lock ball (6).

5. Use a pair of snap ring pliers to remove reverse

idler gear snap ring (7).

226RS004

6. Remove the reverse idler gear assembly (8) from

the intermediate plate (27).

226RS005

7. Remove idle shaft pin (9), thrust washer (10),

reverse idler gear (11), and reverse idler shaft

(12).

8. Use a pair of snap ring pliers to remove the snap

ring (13).

9. Attach a universal puller to the counter gear shaft.

Use a universal puller to remove the ball bearing

(14) and the counter 5th gear (15).

226RS006

10. Remove counter reverse gear (16).

11. Remove 5th gear (17), 5th block ring (18), and

needle bearing (2 piece type) (19).

226RS007

12. Remove the mainshaft nut (20) according to

following steps.

Attach the holding fixture 5-8840-2160-0 and base

5-8840-0003-0 to the mainshaft and the counter

gear.

226RW212

• Engage the 3rd-4th synchronizer with the 3rd

gear.

• Engage the 1st-2nd synchronizer with the 1st

gear.

226RW210

• Use the mainshaft nut wrench 5-8840-2156-0

to remove the mainshaft nut (20).

226RW211

13. Use screw drivers between the reverse gear (23)

and bearing plate (25) to remove the Rev-5th

synchronizer assembly (21) together with reverse

block ring (22) and reverse gear (23).

226RS010

14. Remove needle bearing (24).

15. Use the torx bit wrench (T45) 5-8840-0047-0 to

remove the bearing plate and screw(25) from the

intermediate plate.

220RW137

16. Use the snap ring pliers (1) to remove the

mainshaft bearing snap ring (2) (26).

226RS011

17. Hold the snap ring open with the pliers.

Push the intermediate plate (27) toward the rear of

the transmission to remove it.

The bearing snap ring will come free.

Inspection and Repair

Refer to Top Gear Shaft, Main Gear Shaft, and

Counter Gear in this section for inspection and repair.

Reassembly

1. Mesh the counter gear with the mainshaft

assembly.

Set the holding fixture 5-8840-2160-0 to the

mainshaft and the counter gear and then install it on

the base 5-8840-0003-0.

Install the intermediate plate (27) on the gear

assembly.

226RW212

2. Install bearing snap ring (26).

3. Apply recommended thread locking agents

(LOCTITE 242) or its equivalent to each of the

bearing plate screw threads.

Install bearing plate and screw (25).

Tighten the screws to the specified torque by using

torx bit wrench 5-8840-0047-0.

Torque: 15 N·m (1.5 kg·m/11 lb·ft)

220RW137

4. Install needle bearing (24), reverse gear (23), and

reverse block ring (22).

5. Assemble rev-5th synchronizer assembly (21) by

performing the following steps.

1. Turn the clutch hub face (1) toward the sleeve

groove (2) (rear side) on the outer

circumference.

2. Check that the inserts (3) fit snugly into the

clutch hub (5) ring insert grooves.

3. Check that the inserts springs (4) are fitted to

the inserts as shown in the illustration.

4. Check that the clutch hub (5) and the sleeve

(6) slide smoothly.

5. Install the synchronizer assembly (21) to the

mainshaft.

The clutch hub face with the heavy boss must be

facing the reverse gear side.

226RS013

226RS049

6. Mesh the 1st-2nd and 3rd-4th synchronizers with

both the 1st and 3rd gears (double engagement).

226RS015

This will prevent the mainshaft from turning.

7. Install the new mainshaft hub nut.

Use the mainshaft nut wrench 5-8840-2156-0 to

tighten the mainshaft nut (20) to the specified

torque.

Torque: 137 N·m (14 kg·m/101 lb·ft)

226RW214

8. Use a punch to stake the mainshaft nut (20).

226RW153

9. Install needle bearing (19), 5th block ring (18), and

5th gear (17).

10. Apply engine oil to the counter reverse gear (16)

and the reverse gear (23).

Install the counter reverse gear (16) to the counter

shaft.

The reverse gear projection must be facing the

intermediate plate.

226RW151

11. Install the counter 5th gear (15) to the counter

shaft.

226RS019

12. Install ball bearing (14) and bearing snap ring (13)