Manual Transmission – V6 Page 7B1–1

Page 7B1–1

Section 7B1

Manual Transmission – HFV6

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to General

Information Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or

property damage.

1 General Information ...............................................................................................................................2

1.1 General Description............................................................................................................................................... 2

Synchroniser Assemblies.....................................................................................................................................2

Synchroniser Action ........................................................................................................................................... 2

Lubrication ............................................................................................................................................................. 2

Selector Mechanism .............................................................................................................................................. 2

1.2 Transmission Cross-section................................................................................................................................. 3

Shift Pattern............................................................................................................................................................ 3

1.3 Transmission Identification .................................................................................................................................. 4

1.4 WARNINGS, CAUTIONS and NOTES.................................................................................................................... 5

Definition of WARNING, CAUTION and NOTE Statements................................................................................. 5

WARNING Defined............................................................................................................................................. 5

CAUTION Defined.............................................................................................................................................. 5

NOTE Defined.................................................................................................................................................... 5

1.5 Diagnosis................................................................................................................................................................ 6

2 Servicing Information ............................................................................................................................7

2.1 Recommended Lubricant and Quantity............................................................................................................... 7

2.2 Checking Transmission Lubricant Level............................................................................................................. 8

2.3 Draining and Refilling Transmission.................................................................................................................... 9

3 Minor Service Operations....................................................................................................................10

3.1 Back-Up Lamp Switch ......................................................................................................................................... 10

Remove................................................................................................................................................................. 10

Reinstall................................................................................................................................................................ 10

3.2 Speed Sensor (RWD)........................................................................................................................................... 11

Remove................................................................................................................................................................. 11

Reinstall................................................................................................................................................................ 11

3.3 Transmission Support and Mount...................................................................................................................... 12

Remove................................................................................................................................................................. 12

Reinstall................................................................................................................................................................ 13

3.4 Extension Housing Oil Seal (RWD) .................................................................................................................... 14

Replace................................................................................................................................................................. 14

3.5 Gearshift Lever Knob, Boot Assembly and Lever............................................................................................. 15

Remove................................................................................................................................................................. 15

Reinstall................................................................................................................................................................ 16

3.6 Transmission Assembly...................................................................................................................................... 17

Remove................................................................................................................................................................. 17

Reinstall................................................................................................................................................................ 19

4 Specifications.......................................................................................................................................20

5 Torque Wrench Specifications............................................................................................................21

Manual Transmission – V6 Page 7B1–2

Page 7B1–2

1 General Information

This Section describes the removal and rei nstallation procedures of the Ai sin AR5 five speed manual transmission as

well as the service operations which can be performed with the transmission still fitted to the vehicle.

1.1 General Description

The Aisin AR5 manual shift transmission is a 5-speed assembly, fully synchronised with single overdrive. All gear

positions (including Reverse) are synchronised. The transmission has a reluctor wheel on the output shaft for the vehicle

speed sensor.

Plain roller, tapered roller, and ball bearings are used to support the input shaft, countershaft, and output shaft. All

constant mesh speed gears are supported on needle roller b earings.

Synchroniser Assemblies

The Warner type speed synchronisers are as follows:

• first, second and third gears – triple type synchroniser,

• fourth and fifth gears – single type synchroniser,

• reverse gear – brake type synchroniser.

Synchroniser Action

During synchroniser operation , the synchroniser ring is moved into engagement by the appropriate fork, carrying with it,

three spring loaded synchr oniser inserts and balls, loc ated i n slots in the synchroniser hub.

The outer synchroniser ring, together with the inserts, is moved along the hub, placing a load on the three lugs of the

blocking ring.

This initial force is sufficient to seat the blocking ring and start pre-synchronisation b eca use of the friction between the

cone on the constant mesh gear and the blocking ring/s.

At this stage, gear engagement is prevented as long as there is a difference in spe ed between the mating surfaces of the

blocking ring and cone of the constant mesh gear. As the speeds between the blocking ring and the gear cone become

synchronised, the teeth on the blocking rin g a nd gear cone line up with the internal spli nes of the ring, allowing the outer

synchroniser ring to engage the teeth o n the gear being engaged, completing gear selection.

Lubrication

Lubrication of all internal components is by splash feed, provided by the rotating cou ntershaft gear and constant mesh

gears of reverse, first and second gears. Lubricatio n splash is controlled by an oil separator arou nd the countershaft gear

and the oil distribution channels mounted through out the transmission.

This manual transmission is oil fill ed for life and uses lubricant SAE 75 –90 GL3 or alternatively Mobilube XHP GL4.

Selector Mechanism

The gearshift assembly is mounted to the floor panel and the control lever is directly attached to the top of the

transmission housing. The control lever is linked to a four shift rails mechanism, the control lever mechanism rotates and

connects with one of the four shift rails, as a gear is selected.

Manual Transmission – V6 Page 7B1–3

Page 7B1–3

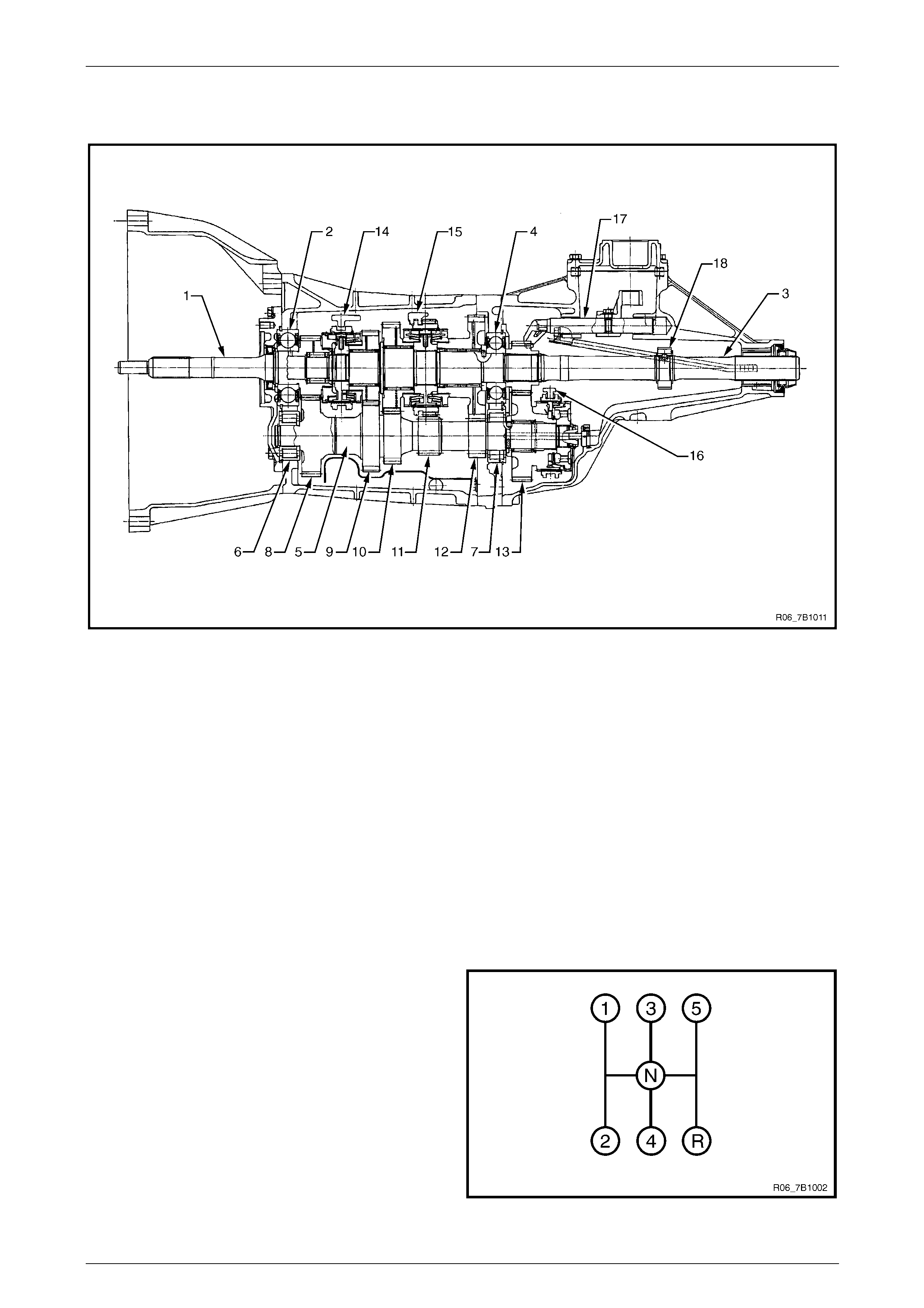

1.2 Transmission Cross-section

Figure 7B1 – 1

Legend

1 Input Shaft

2 Ball Bearing – Input Shaft

3 Output Shaft

4 Ball Bearing – Output Shaft

5 Counter Gear Shaft

6 Front Roller Bearing – Counter

Gear Shaft

7 Centre Roller Bearing – Counter Gear

Shaft

8 Headset Reduction

9 3rd Gear

10 2nd Gear

11 Reverse gear and Idler

12 1st Gear

13 5th Gear

14 3–4 Synchro

15 1–2 Synchro

16 5th Synchro

17 Select Mechanism

18 Reluctor Wheel – Speed Sensor

NOTE

When 4th speed is selected, the input and o utput

shafts are directly coupled (ratio 1:1), there is no

4th gear fitted to the shafts.

Shift Pattern

The shift pattern is as shown, with reverse gear (R) in line

with the fifth gear and neutral (N) in a central position.

Figure 7B1 – 2

Manual Transmission – V6 Page 7B1–4

Page 7B1–4

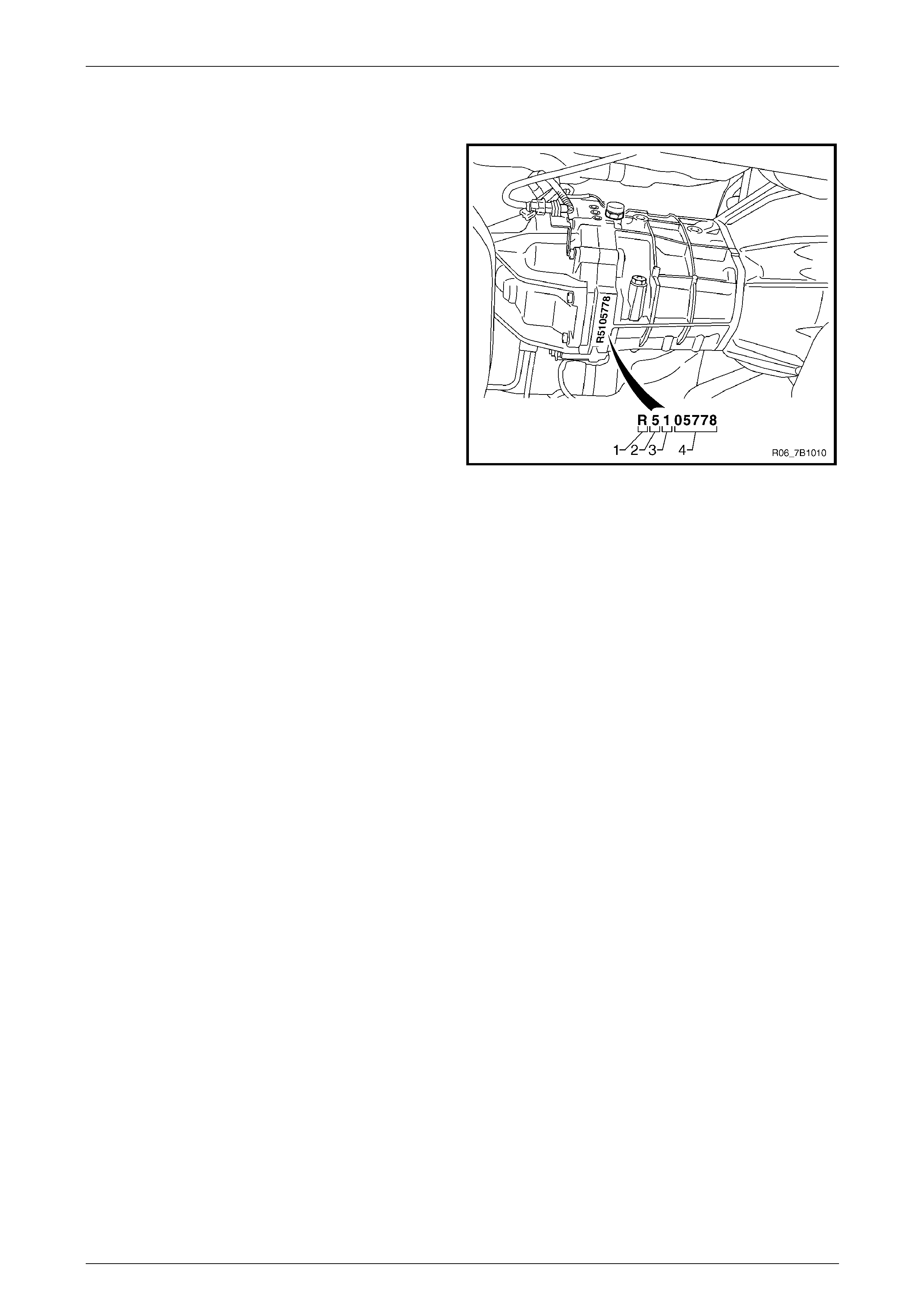

1.3 Transmission Identification

The transmission identificatio n can be determined from the

stamping onto the lower part of the transmission

intermediate case at the interface between the intermediate

case and the transmission rear case.

Legend

1 (R): transmission type (AR5)

2 (5): year of manufacture (2005)

3 (1): month of manufacture (January)

4 (05778): individual transmission S/N built that Month.

NOTE

The first nine months of the year are id entif ied b y

a number 1 to 9, the last three months b y a letter

as follows:

• X for October,

• Y for November, and

• Z for December.

Figure 7B1 – 3

Manual Transmission – V6 Page 7B1–5

Page 7B1–5

1.4 WARNINGS, CAUTIONS and NOTES

This Section contains various W A RNINGS, CAUTIONS and NOTE statements that you must observe carefull y to reduce

the risk of death or injury during service, repair procedures or vehicle op eration. Incorrect service or repair procedures

may damage the vehicle or cause operational faults. WARNINGS, CAUTION and NOTE statements are not exhaustive .

GM HOLDEN LTD can not possibly warn of all the potentially hazardous consequences of failure to follow these

instructions.

Definition of WARNING, CAUTION and NOTE Statements

Diagnosis and repair proce dures in this Section contain both general and specific WARNING, CAUTION and NOT E

statements. GM HOLDEN LTD is dedicated to the presentation of service information that helps the technician to

diagnose and repair the systems necessary for proper operation of the vehicle. Certain procedures may present a hazard

to the technician if they are not followed in the recommended manner. WA RNING, CAUTION and NOTE statements are

designed to help prevent thes e hazards from occurring, but not all hazards can be foresee n.

WARNING Defined

A WARNING statement immediately precedes an operatin g procedure or maintenance practice which, if not correctly

followed, could result in death or injury. A WARNING statement alerts yo u to take necessary action or not to take a

prohibited action. If a WARNING statement is ignored, the following consequences may occur:

• Death or injury to the technician or other personnel working on the vehicle,

• Death or injury to other people in or near the workplace area, and / or

• Death or injury to the driver / or passenger(s) of the vehicle or other people, if the vehicle has been improperly

repaired.

CAUTION Defined

A CAUTION statement immediately precedes an operating procedure or maintenance practice which, if not correctly

followed, could result in damage to or destru c tion of equipment, or corruption of data. If a CAUTION statement is

ignored, the following consequences may occur:

• Damage to the vehicle,

• Unnecessary vehicle repairs or component replacement,

• Faulty operation or performance of any system or component being repaired,

• Damage to any system or components which depend on the proper operation of the system or component being

repaired,

• Faulty operation or performance of any systems or components which depend on the pro per operation or

performance of the system or component under repair,

• Damage to fasteners, basic tools or special tools and / or

• Leakage of coolant, lubricant or other vital fluids.

NOTE Defined

A NOTE statement immediately precedes or follows an operating proc edure, maintenance practice or condition that

requires highlighting. A NOTE statement also emphasises necessary characteristics of a diagnostic or repair procedure.

A NOTE statement is designed to:

• Clarify a procedure,

• Present additional information for accomplishing a procedure,

• Give insight into the reasons for performing a procedure in the recommended manner, and / or

• Present information that gives the technician the ben efit of past experience in accomplishi ng a procedure with

greater ease.

Manual Transmission – V6 Page 7B1–6

Page 7B1–6

1.5 Diagnosis

Condition Probable Cause Corrective Action

Abnormal Noise Flywheel pilot bearing worn

Bearing worn or broken (mainshaft,

counter shaft and transfer shaft)

Gear tooth contact surfaces worn or

scuffed (mainshaft, counter shaft

reverse idler gear and transfer gears)

Splines worn (mainshaft synchronizer

clutch hub)

Gear or bearing thrust face seized

Replace

Repair/replace transmission

Repair/replace transmission

Repair/replace transmission

Repair/replace transmission

Hard Shifting Improper clutch pedal free play

Change lever sliding p ortions worn

Shift block, shift rod and/or control box

sliding faces worn

Shift arm and synchronizer sleeve

groove worn

Thrust washer, collar and/or gear

thrust faces worn (mainshaft and

counter shaft thrust play)

Synchronizer parts worn

Readjust

Repair or replace, regrease

Repair/replace transmission

Repair/replace transmission

Repair/replace transmission

Repair/replace transmission

Walking or Jumping out of Gear Détente ball worn

Détente spring weakened or b r oken

Shift rod and/or control box sli ding

faces worn

Shift arm and synchronizer sleeve

groove worn

Thrust washer, collar and/or gear

thrust faces worn (mainshaft and

counter shaft thrust play)

Bearings worn or broken

Splines worn or broken

Synchronizer spring weakened or

broken

Repair/replace transmission

Repair/replace transmission

Repair/replace transmission

Repair/replace transmission

Repair/replace transmission

Repair/replace transmission

Repair/replace transmission

Repair/replace transmission

Oil Leakage Loose drain plug and/or filler plug

Defective or improperly installed

gasket(s)

Oil seal worn or scratched

Tighten, replenish oil

Repair/replace transmission

Repair/replace transmission

Manual Transmission – V6 Page 7B1–7

Page 7B1–7

2 Servicing Information

2.1 Recommended Lubricant and Quantity

This transmission assembly is oil filled for life (no service interval), with a lubricant capacity as follows:

• RWD vehicles: 2.2 litres

• 4WD vehicles: 2.3 litres.

The lubricant is rated as GL-3 with a viscosity rating of 75W-90 (alternative Mobilube XHP GL4).

Manual Transmission – V6 Page 7B1–8

Page 7B1–8

2.2 Checking Transmission Lubricant Level

1 Raise the vehicle and suppor t in a safe manner,

ensure the vehicle is level, ref er to Section 0A General

Information.

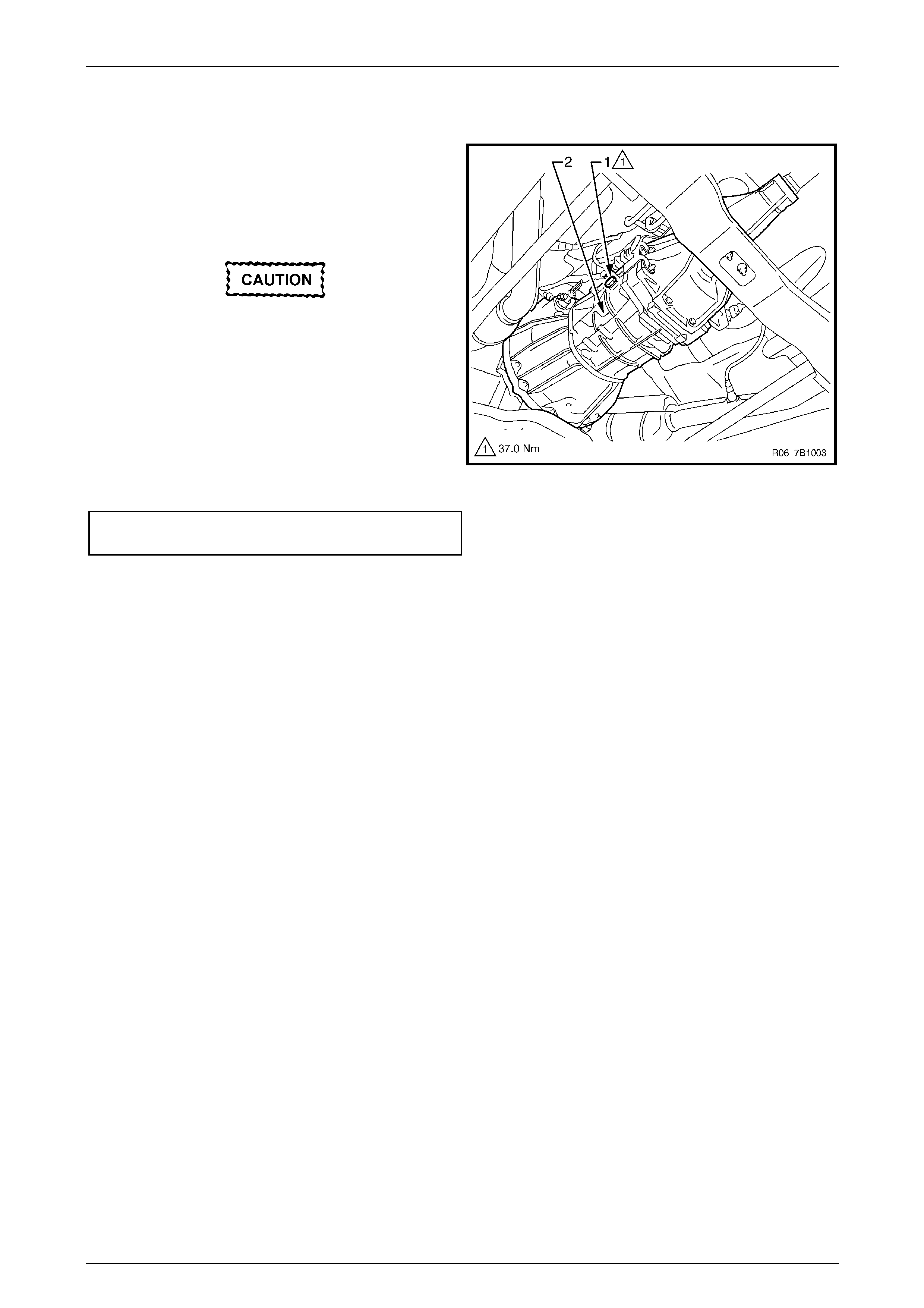

2 Clean the area around the fill er plug (1) on the

transmission case (2).

Ensure the transmission lubricant is at

ambient temperature.

3 Remove the filler plug and gasket using a suitable size

ring spanner.

4 Check if the lubricant level is correct with the lubric ant

just reaching the filler plug threads in the tra nsmissio n

case.

5 Replace the filler plug gasket, then reinstall the filler

plug tightening it to the correct torque specification.

Transmission filler plug

torque specification............................................37.0 Nm

6 If the lubricant level is low, then the reason must be

investigated and corrected. After correction of the

leakage condition, drain and refill the transmi ssion,

refer to 2.3 Draining and Refilling Transmission.

Figure 7B1 – 4

Manual Transmission – V6 Page 7B1–9

Page 7B1–9

2.3 Draining and Refilling Transmission

1 Raise the vehicle and suppor t in a safe manner, ensure the vehicle is level, refer to Section 0A General Information.

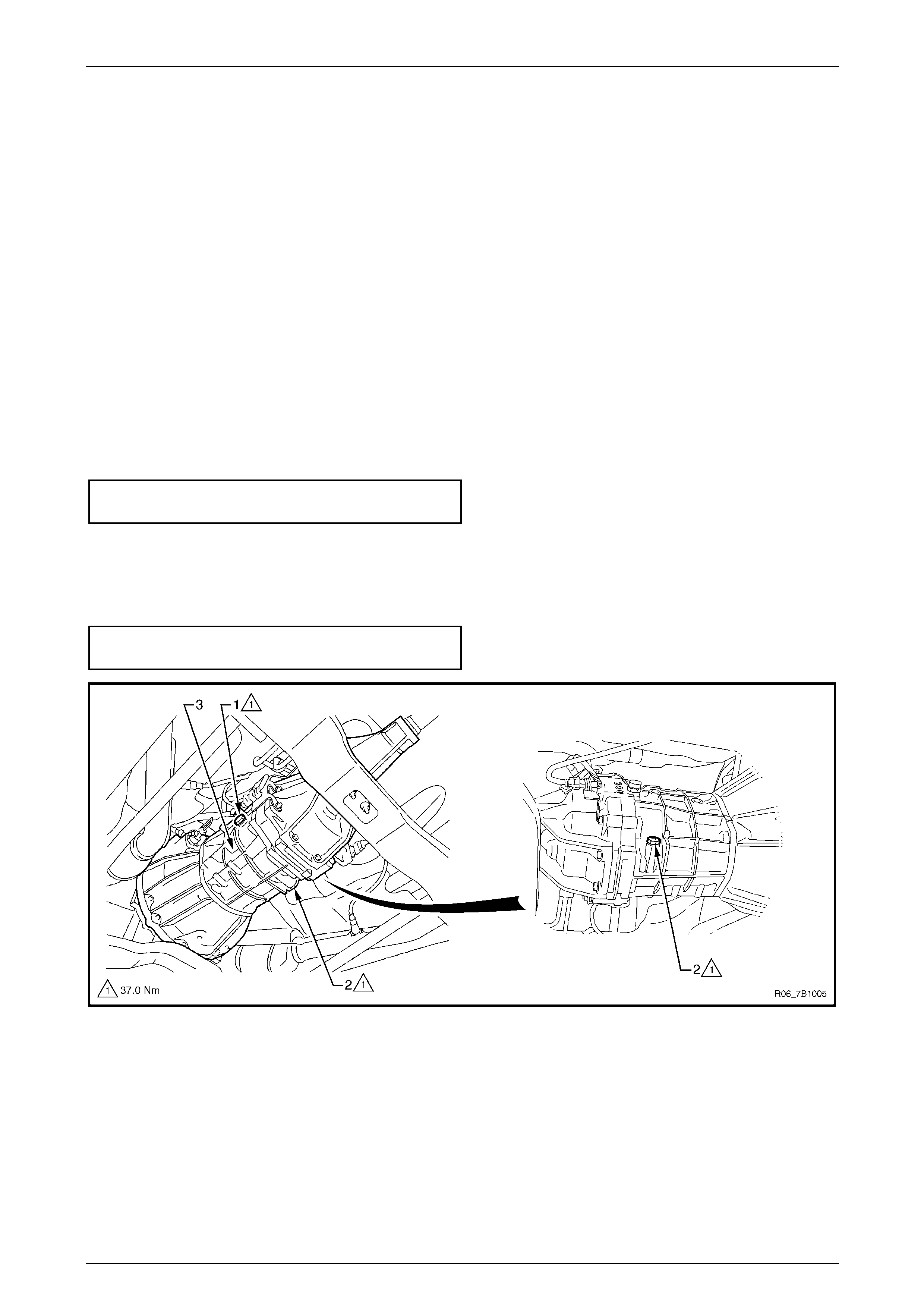

2 Clean the area around the fill er plug (1) and the drain plug (2) on the transmission case (3), refer to

Figure 7B1 – 5.

3 Remove the filler plug, using a suitable size ring spanner.

4 Remove the drain plug using a suitable size ring spanner, draining the lubricant into a suitable container of a

minimum 2.5 litre capac ity.

NOTE

• The lubricant will drain quicker and completely

if it is warm.

• Carefully inspect the drain plug magnet and

the drained lubricant for foreign matter such

as metal particles, etc.

5 Replace the drain plug gasket, then reinstall the drain plug in the transmission case, tightening it to the correct

torque specification.

Transmission drain plug

torque specification............................................37.0 Nm

6 Refill the transmission with the recomme nded lubricant, refer to 2.1 Recommended Lubricant and Quantity, until

the lubricant (cold) just reaches the filler plug threads in th e transmission case.

7 Replace the filler plug gask et, then reinsta ll the filler plug in the transmission case, tightening it to the correct torque

specification.

Transmission filler plug

torque specification............................................37.0 Nm

Figure 7B1 – 5

Manual Transmission – V6 Page 7B1–10

Page 7B1–10

3 Minor Service Operations

3.1 Back-Up Lamp Switch

Remove

Disconnection of the battery affects

certain vehicle electronic systems. Refer

to Sectio n 6D1-3 Battery, before removing the

ground lead.

1 Disconnect the battery ground cable.

2 Raise the vehicle and suppor t in a safe manner, refer to Section 0A General Information.

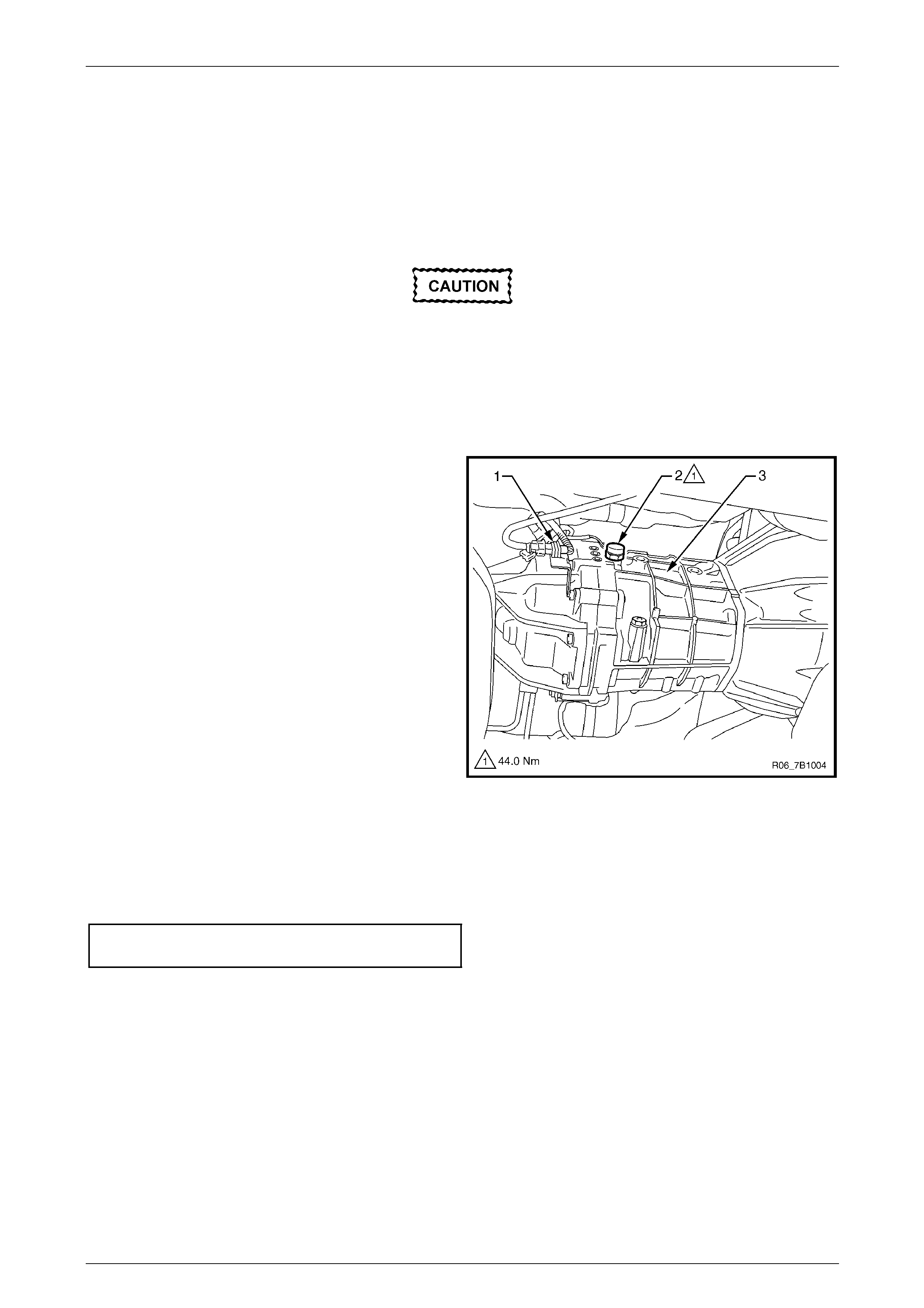

3 Disconnect the back-up lamp s witch harness

connector (1).

4 Using a suitable sized set spanner, remove the back-

up lamp switch (2) and sealing washer from the right

side of the front transmission case (3). Discard the

removed washer.

Figure 7B1 – 6

Reinstall

1 Install the back-up lamp switch, with a new sealing washer fitted.

2 Tighten the back-up lamp switch to the correct torque specification.

Back-up lamp switch

torque specification............................................44.0 Nm

3 Connect the harness connector to the back-up lamp switch.

4 Lower the vehicle to the ground.

5 Reconnect the battery ground cable.

Manual Transmission – V6 Page 7B1–11

Page 7B1–11

3.2 Speed Sensor (RWD)

NOTE

For 4WD vehicle s peed s ensor servic e procedure

refer to Section 7D Transfer Case and Adaptor

Housing.

Remove

Disconnection of the battery affects

certain vehicle electronic systems. Refer to

Section 6D1-3 Battery, before removing the

ground lead.

1 Disconnect the battery ground cable.

2 Raise the vehicle and suppor t in a safe manner, refer to Section 0A General Information.

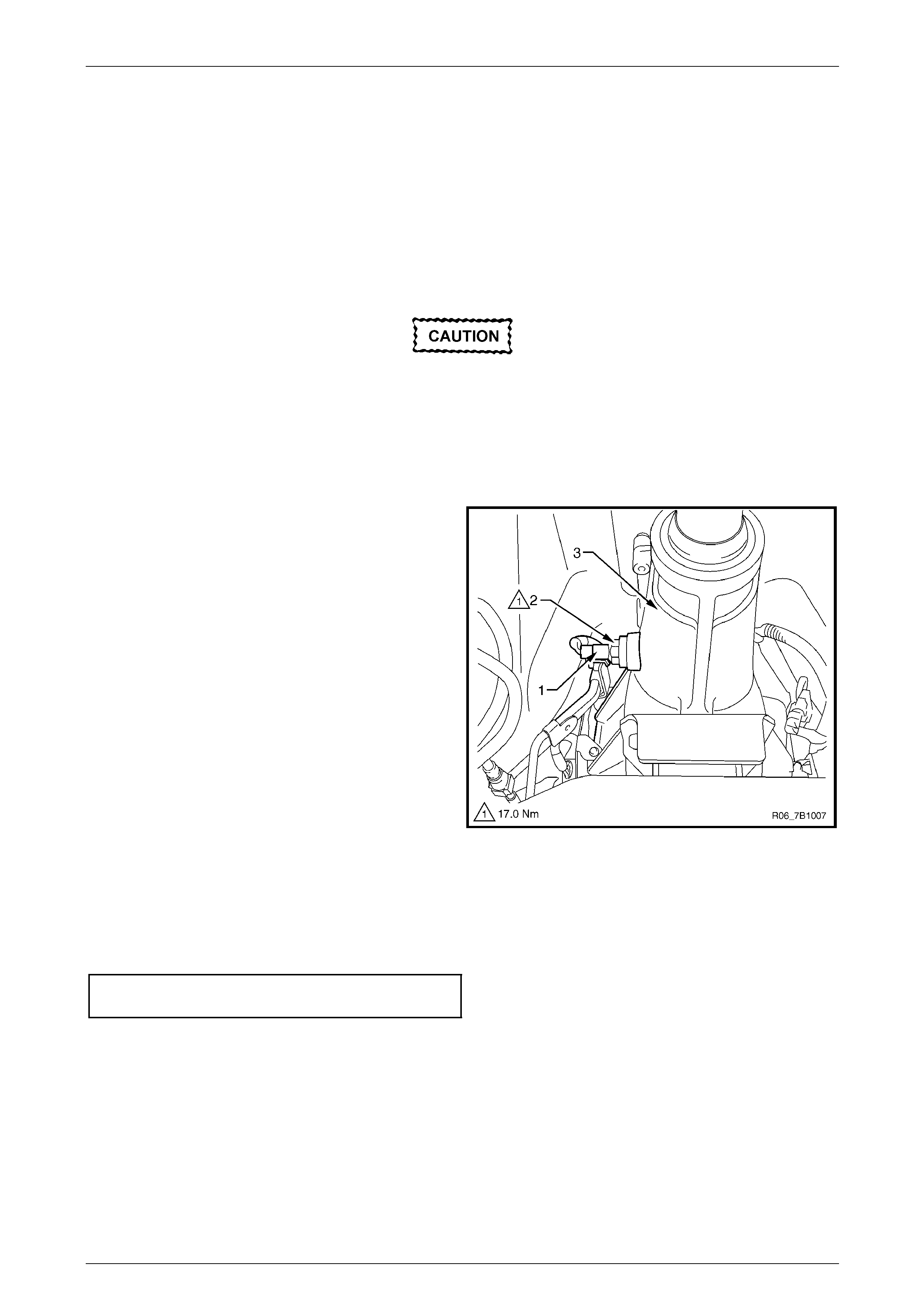

3 Disconnect the speed sensor harness connector (1).

4 Using a suitable sized set spanner, remove the speed

sensor (2) from the extension housing (3).

Figure 7B1 – 7

Reinstall

1 Ensure the O-ring is not damaged, replace as required.

2 Install the speed sensor and tighten to the correct torque specification.

Speed sensor

torque specification............................................17.0 Nm

3 Connect the harness connector to the speed sensor.

4 Lower the vehicle to the ground.

5 Reconnect the battery ground cable.

Manual Transmission – V6 Page 7B1–12

Page 7B1–12

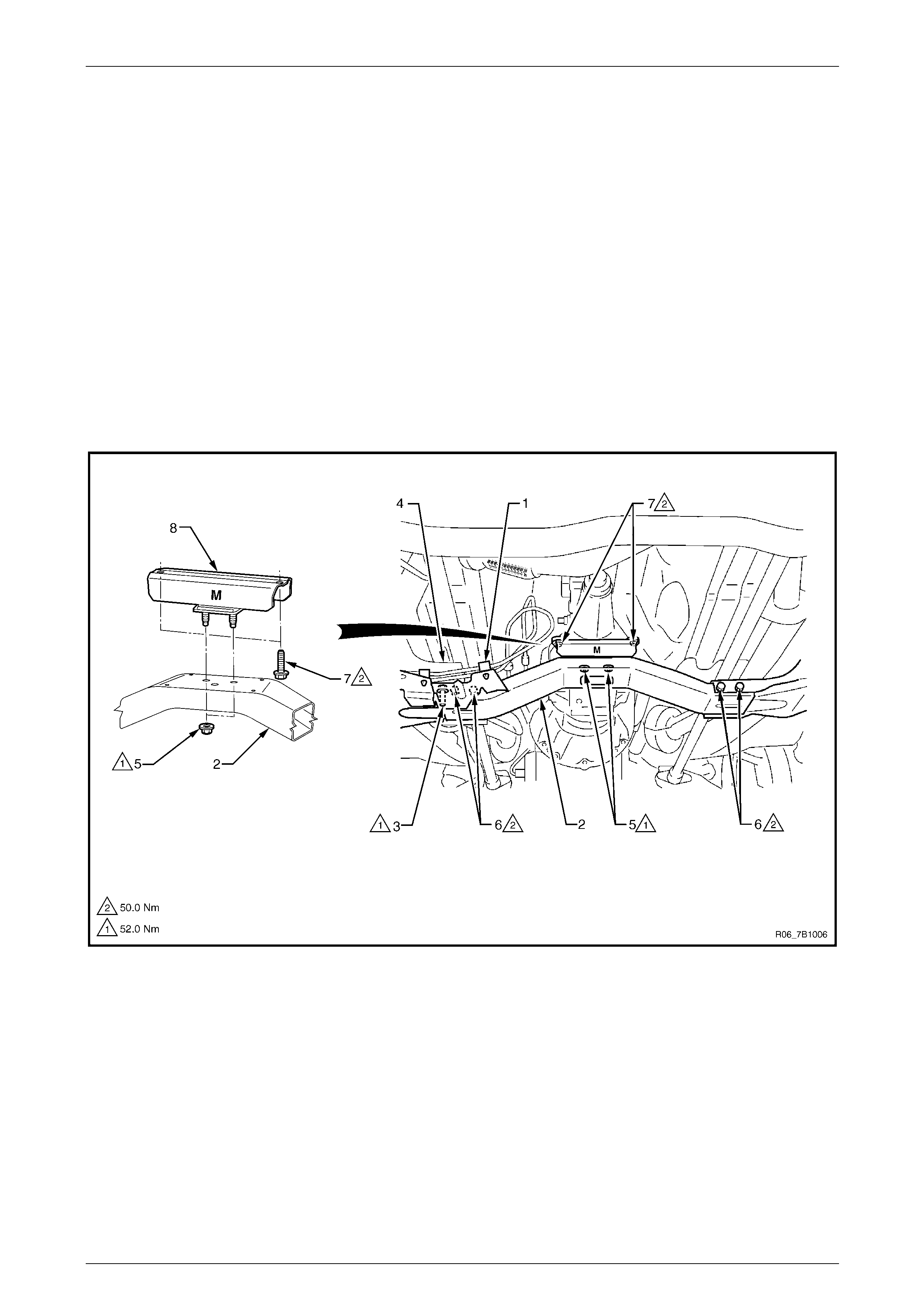

3.3 Transmission Support and Mount

Remove

1 Raise the vehicle and suppor t in a safe manner, refer to Section 0A General Information for the location of support

points.

2 Support the transmission with a Jack, do not plac e the support underneath the e xtensi on housing or the oil pan,

refer to Figure 7B1 – 8.

3 Remove the clip (1) holding the fuel feed and fuel vapour lines on the transmission support (2).

4 Remove the bolt (3) attaching the heat shiel d (4) to the transmission support.

5 Remove the two nuts (5) attaching the transmission mount to the support.

6 Remove the four bolts and nuts (6) attaching the transmission support to the under body side rails and remove the

support.

7 If required, remove the two bolts (7) attaching the transmission mount (8) to the extension housing and remove the

mount.

Figure 7B1 – 8

Legend

1 Fuel Feed and Vapour Lines Clip

2 Transmission Support

3 Heat Shield Bolt

4 Heat Shield

5 Transmission Mount Nuts

6 Transmission Support Bolts

7 Transmission Mount Bolts

8 Transmission Mount

Manual Transmission – V6 Page 7B1–13

Page 7B1–13

Reinstall

1 If required, install the transmission mount (8) onto the extension housing, ti ghten the two attaching bolts (7) to the

correct torque specification, refer to Figure 7B1 – 8.

Transmission mount attaching

bolt torque specification.....................................50.0 Nm

2 Install the transmission suppor t (2) to the under body side rails and tighten the four attaching bolts and nuts (6) to

the correct torque specification.

Transmission support attaching

bolt and nut torque specification ........................50.0 Nm

3 Install and tighten the transmission mount two attaching nuts (5) to the correct torque spe c ification.

Transmission mount attaching

nut torque specification......................................52.0 Nm

4 Install the bolt (3) attaching the heat shield (4) to the transmission supp ort, tighten to the correct torque

specification.

Heat shield to transmission support

attaching bolt torque specification......................52.0 Nm

5 Reinstall the clip (1) holding the fuel feed and fuel vapour lin es on the transmission support.

6 Lower the vehicle to the ground.

Manual Transmission – V6 Page 7B1–14

Page 7B1–14

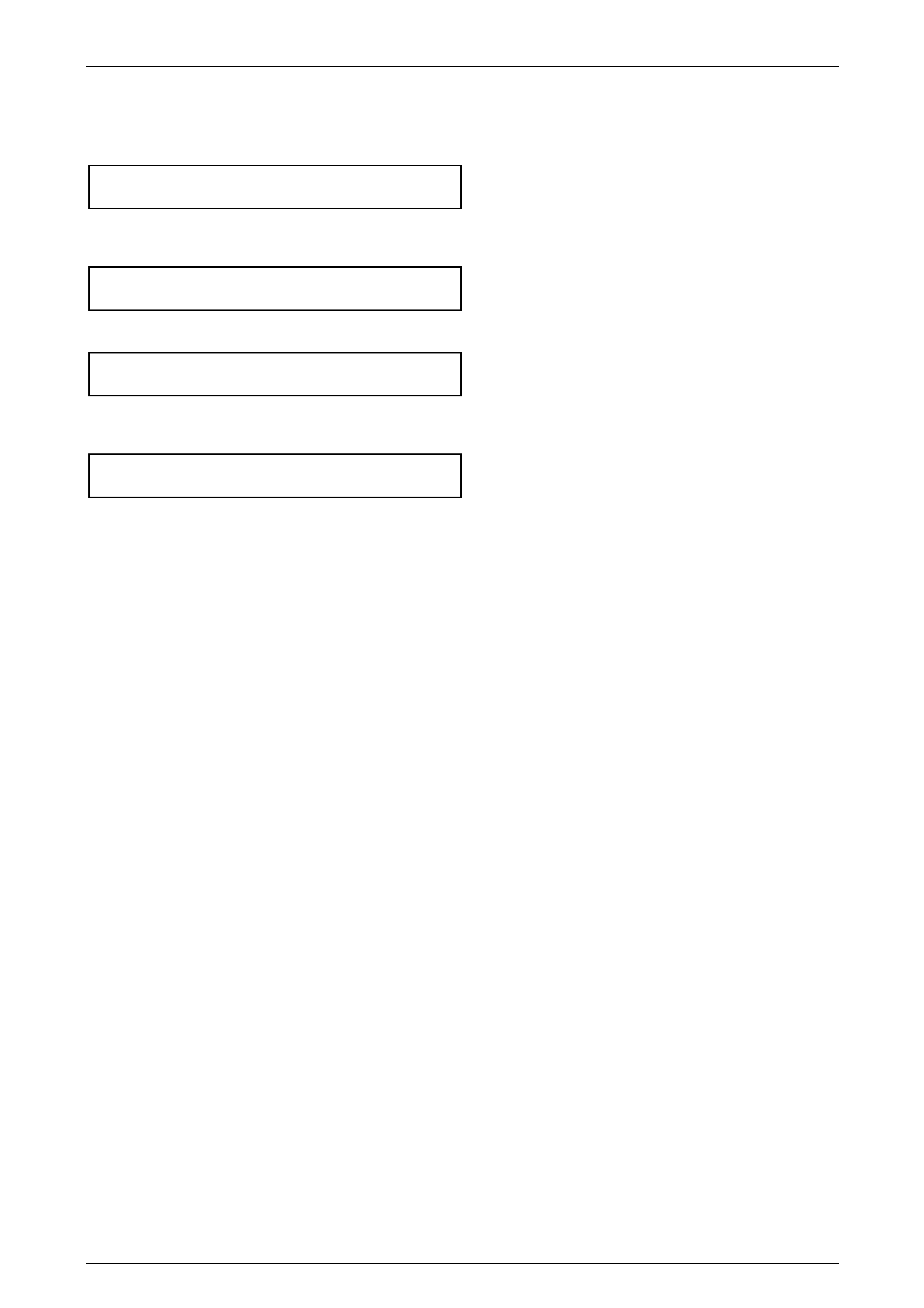

3.4 Extension Housing Oil Seal (RWD)

Replace

1 Raise the vehicle and suppor t in a safe manner, refer to Section 0A General Information for the location of support

points.

2 Remove the rear propeller shaft, refer to Section 4A Propeller Shaft.

3 Place a suitable size drip tray underne ath rear of

transmission.

Take care not to scratch the machined seal

recess in the extension housing as

transmission fluid may weep past the outer

diameter of the installed seal.

4 Using the seal remover, Tool No. E308 (1) or

equivalent, prise the oil seal (2 ) from rear of the

extension hous ing (3) and discard the seal.

5 Thoroughly cle an around the seal bore in the

extension hous ing and ensure there are no burrs.

Figure 7B1 – 9

6 Using a suitable seal installer (1) and a soft faced

hammer, tap a new oil seal (2) into place in the rear of

the extension housing (3).

7 Install the rear propeller shaft, refer to

Section 4A Propeller Shaft.

8 check the fluid level and lower the vehicle to the

ground, refer to 2.2 Checking Transmission Lubricant

Level.

Figure 7B1 – 10

Manual Transmission – V6 Page 7B1–15

Page 7B1–15

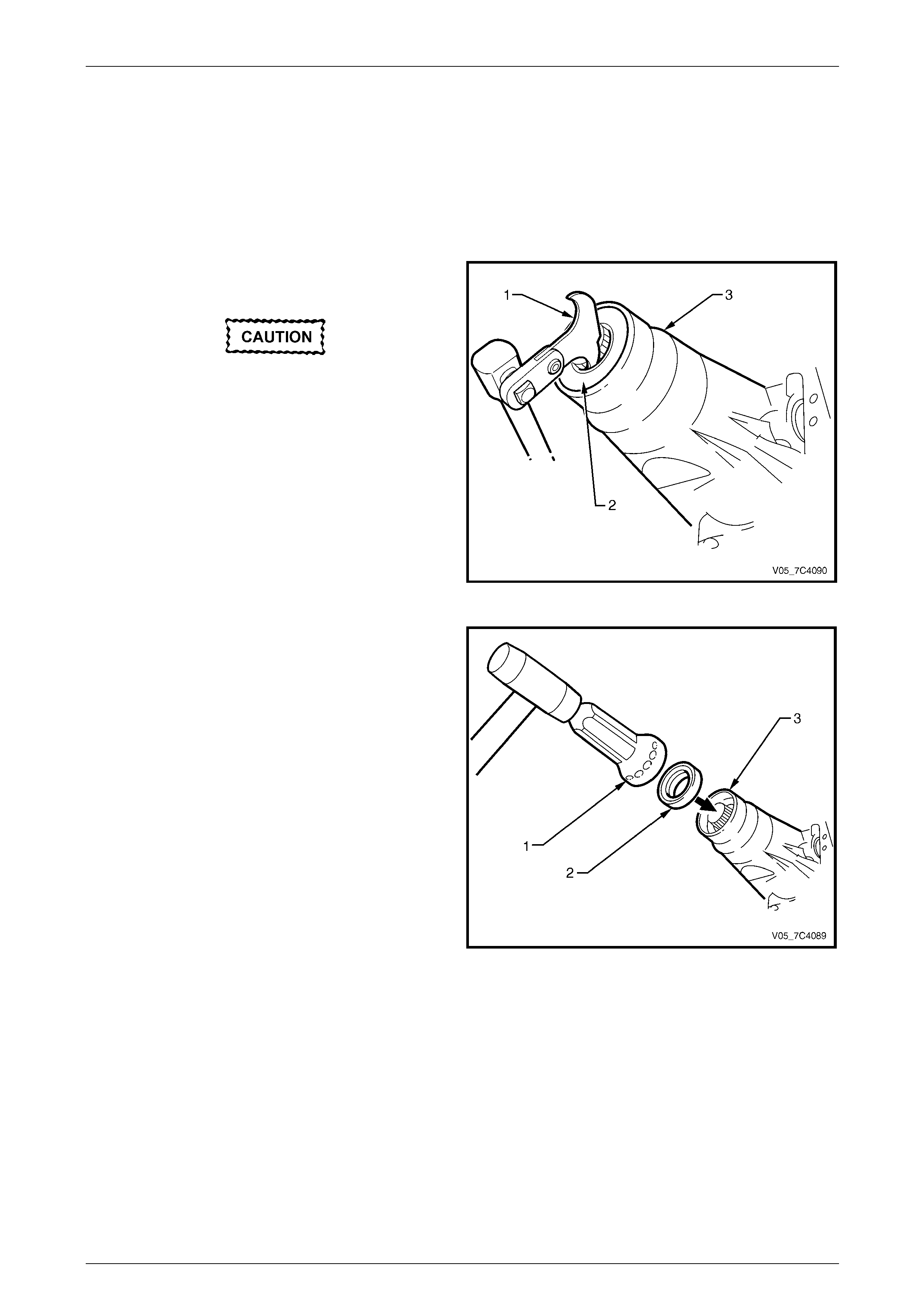

3.5 Gearshift Lever Knob, Boot Assembly

and Lever

Remove

Disconnection of the battery affects

certain vehicle electronic systems. Refer to

Section 6D1-3 Battery, before removing the

ground lead.

1 Disconnect the battery ground cable.

2 Remove the rear centre console from the floor panel, refer to Section 2C Cab and Interior Trim.

3 Loosen the shift lever knob (1) counter clock wise by hand and remove it from the shift lever (2), refer to

Figure 7B1 – 11.

4 Remove the front centre console from the floor panel, refer to Section 2C Cab and Interior Trim.

5 Remove the attaching nut (3), two places, the scre w (4), four places, then remove the boot assembly (5) from the

floor panel.

6 Remove the attaching bolt (6), four places, and the shift lever from the transmission.

Figure 7B1 – 11

Manual Transmission – V6 Page 7B1–16

Page 7B1–16

Reinstall

1 Install the shift lever (2) to the transmission and tighten the attaching bolt (6), four places, to the correct torque

specification, refer to Figure 7B1 – 11.

Shift lever attaching bolt

torque specification............................................18.5 Nm

2 Attach the boot assembly (5) to the floor panel, tighten the attaching nut ( 3), two places, and the screw (4), four

places, to the correct torque specification.

Boot assembly attaching nut

torque specification..............................................6.5 Nm

Boot assembly attaching screw

torque specification..............................................1.4 Nm

3 Install the front centre console to the floor panel, refer to Section 2C C ab and Interior Trim.

4 Secure the shift lever knob (1) rotating it clockwise onto the shift lever.

5 Install the rear centre console to the floor panel, refer to Section 2C Cab and Interior Trim.

6 Reconnect the battery ground cable.

Manual Transmission – V6 Page 7B1–17

Page 7B1–17

3.6 Transmission Assembly

Remove

Disconnection of the battery affects

certain vehicle electronic systems. Refer to

Section 6D1-3 Battery, before removing the

ground lead.

1 Disconnect the battery ground cable.

2 Raise the vehicle and suppor t in a safe manner, refer to Section 0A General Information.

3 Remove the following components:

a Gearshift lever assembly, refer to 3.5 Gearshift Lever Knob, Boot Assembly and Lever.

Plug the gear control box opening to prevent foreign matter entry.

b Front and centre exhaust assemblies, refer to Section 6F Exhaust System – V6.

b Rear propeller shaft and for 4WD vehicle front propeller shaft, refer to Section 4A Propeller Shaft.

4 Disconnect the following:

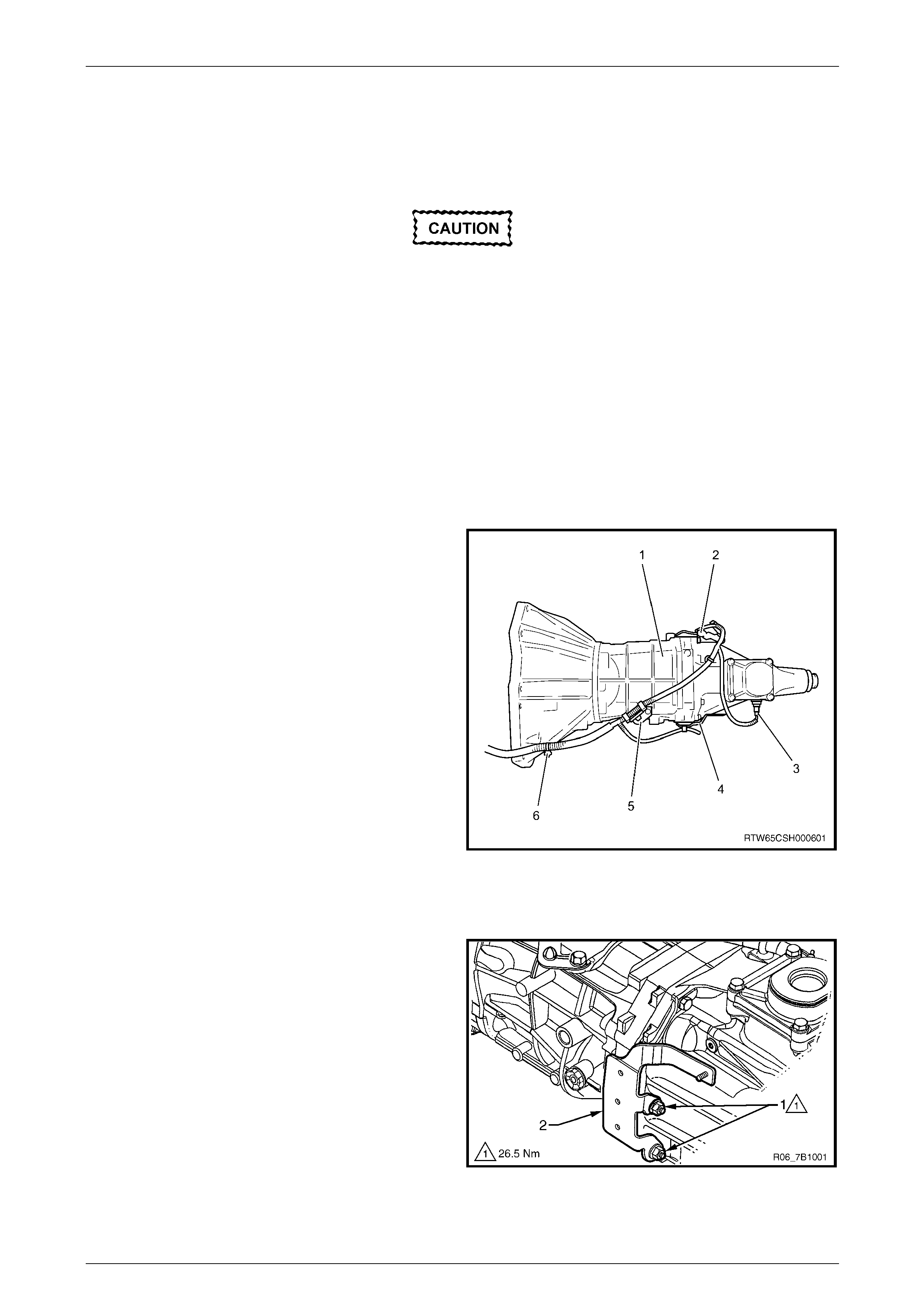

• Oxygen sensor and back up lamp harness

connectors (2) from the bracket by sliding the

connectors upward.

• RWD vehicle only, speed sensor harness

connector (3).

• Oxygen sensor harness from the brack et (4).

• Harness clips (5 and 6) from the brackets on top

of the transmission.

5 For 4WD vehicles only, disconnect the transfer

harness connectors:

• 2–4 switch and neutral s witch,

• transfer actuator, and

• vehicle speed sensor. Figure 7B1 – 12

6 Remove the transmission support, refer to

3.3 Transmission Support and Mount .

7 Disconnect the fuel and EVAP pipes three brackets

and clips, refer to Section 6C Fuel S ystem – V6.

If required, remove the two nuts (1) and the bracket (2)

from the transmission housing.

Figure 7B1 – 13

Manual Transmission – V6 Page 7B1–18

Page 7B1–18

8 Disconnect the clutch flexible hose from the actuatin g cylinder adaptor steel pipe, refer to Section 7A1 Clutch –V6.

Immediately plug both open h ose/pipe ends to minimise fluid loss and prevent the entry of foreign matter.

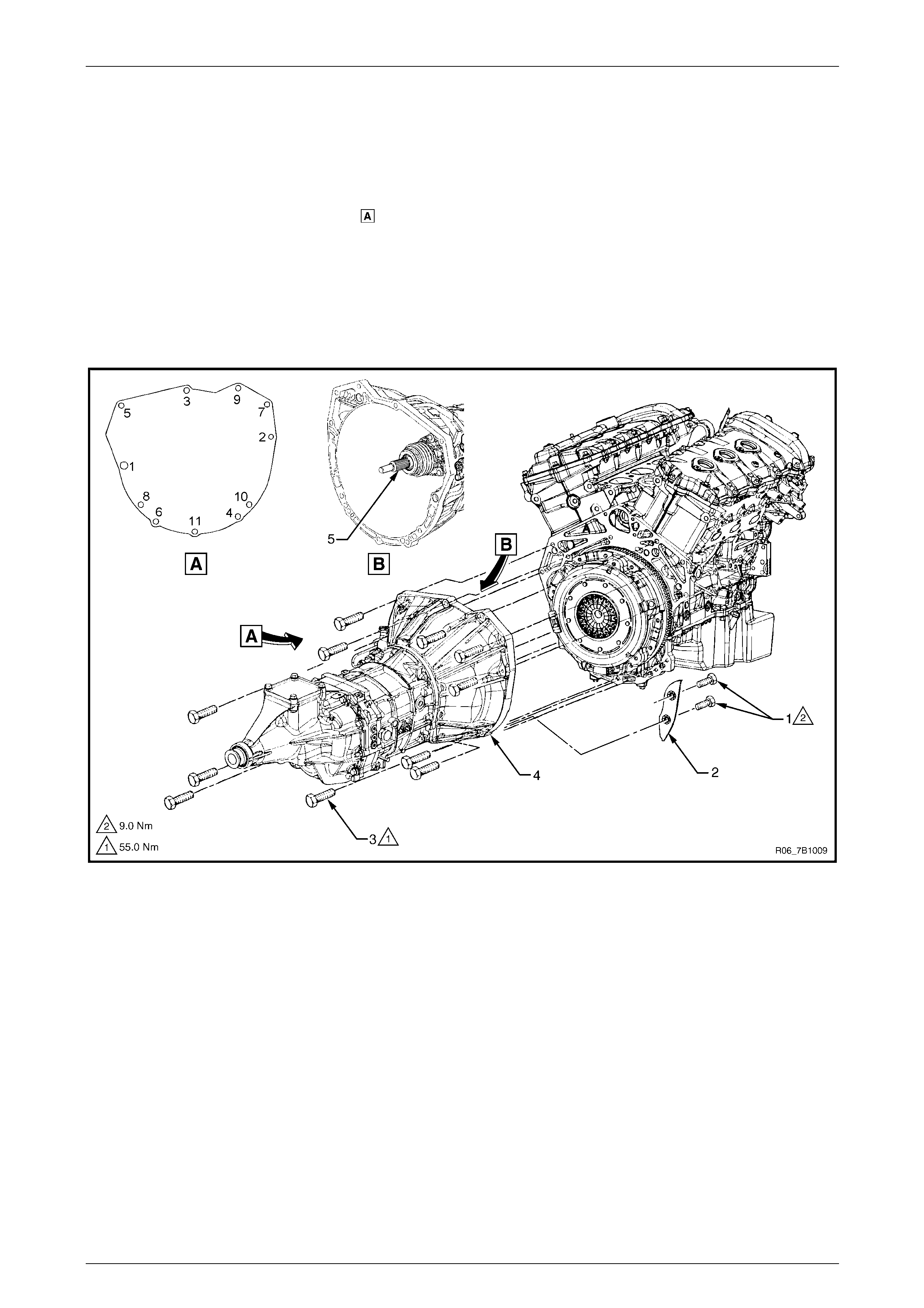

9 Remove the two screws (1) securing the close-out cover (2) to the front of the transmiss ion case, then remove the

cover and set to one side, refer to Figure 7B 1 – 14.

10 With the transmission supported, using a long socket extension, universal joint and suitab le size socket, loosen

then remove the eleven bolts (3) securing the transmission (4) to the rear of the engine block, in the reverse order

of the torque sequence shown in view .

11 Shake the rear of the transmission to separate the front case from the loca ting dowels.

12 Carefully slide the transmission rearward, taking care not to allow the transmission input shaft (5) to drag or hang

on the clutch driven plate.

13 When the input shaft is clear from the clutch pressure plate, lower the transmission and remove it from the vehicle.

14 If required on 4WD vehicle, remove the transfer case, refer to Section 7D Transfer Case and Adaptor Housing.

Figure 7B1 – 14

Manual Transmission – V6 Page 7B1–19

Page 7B1–19

Reinstall

1 If required on 4WD vehicle, reinstall the transfer case, refer to Section 7D Transfer Case and Adaptor Housing.

2 Ensure the transmission and the engine mating surfaces are clean and free of burrs.

3 Apply a thin coat of molybdenum disulfide grease over the full length of the transmission i nput shaft spline (5),

refer to Figure 7B1 – 14.

4 Bring the transmission up to the engine taking care not to allow the input shaft to drag on the clutch driven plate,

and ensuring the locating dowels completely enter the transmission housing.

5 With the transmission supported, install the eleven bolts (3) attaching th e transmission to the engine and tighten to

the correct torque specification following the sequence shown in view .

Transmission housing attach ing

bolt torque specification.....................................55.0 Nm

6 Reinstall the two bolts (1) and the close-out cover (2) to the front of the transmission case, tighten the bolts to the

correct torque specification.

Close-out cover attaching

bolt torque specification.......................................9.0 Nm

7 Reconnect the fuel and EVAP pipes three br ackets and clips, refer to Section 6C Fuel System – V6.

If required, install the fuel and EVAP pipes bracket (2) to the transmission housing, tighten the two nuts (1) to the

correct torque specification, refer to F igure 7B1 – 13.

Fuel and EVAP pipes bracke t

attaching nut torque specification.......................26.5 Nm

8 Reinstall the transmission su pport, refer to 3.3 Transmission Support and Mount.

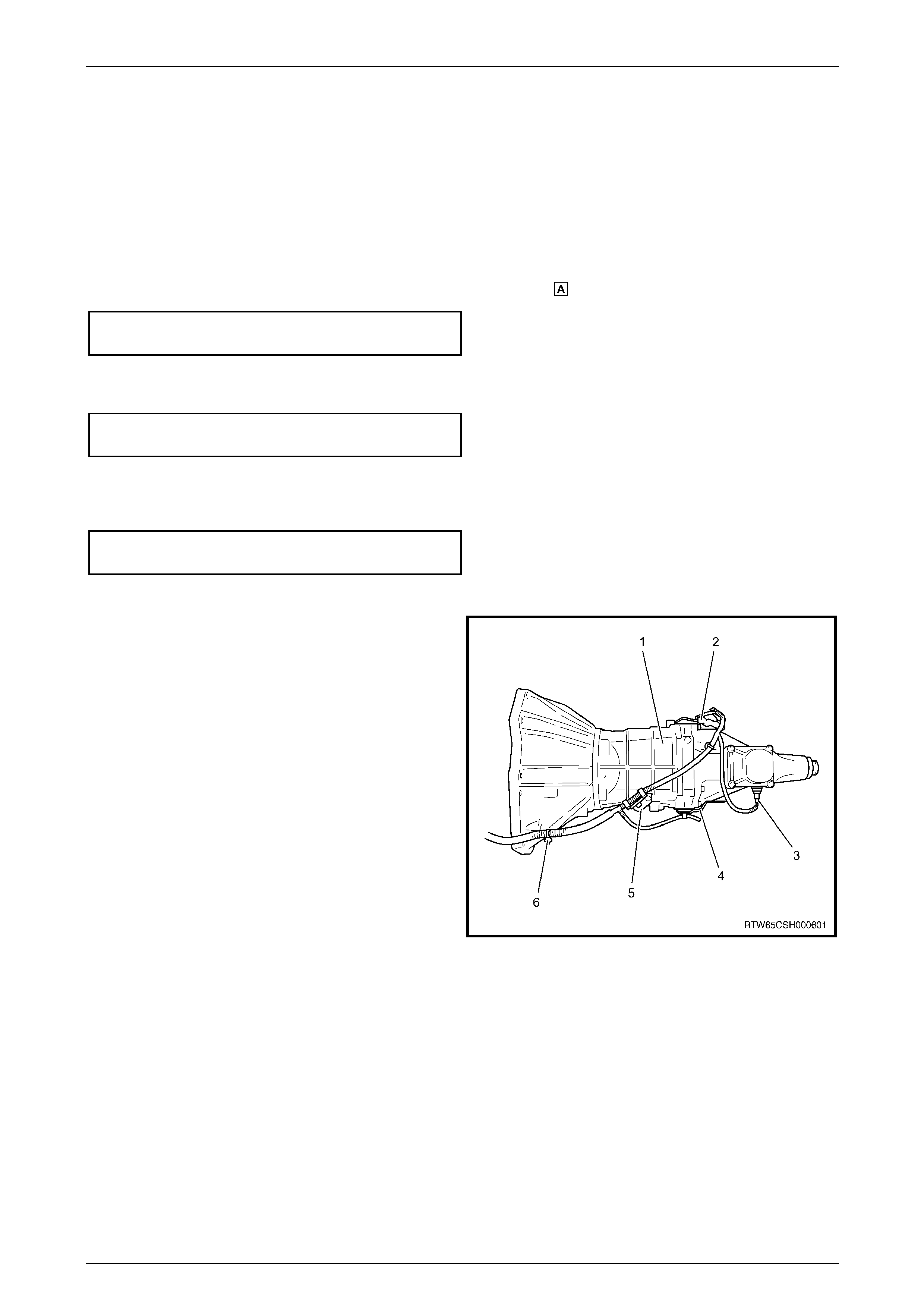

9 Reconnect the following:

• Oxygen sensor and back up lamp harness

connectors (2) to the bracket by sliding the

connectors upward.

• RWD vehicle only, speed sensor harness

connector (3).

• Oxygen sensor harness to the bracket (4).

• Harness clips (5 and 6) to the brackets on top of

the transmission.

10 For 4WD vehicles only, reconnect the transfer harness

connectors:

• 2–4 switch and neutral s witch,

• transfer actuator, and

• vehicle speed sensor. Figure 7B1 – 15

11 Reconnect the clutch flexible hose to the act uating cylinder adaptor steel pipe, refer to Section 7A1 Clutch –V6.

12 Install the following components:

a Gearshift lever assembly, refer to 3.5 Gearshift Lever Knob, Boot Assembly and Lever.

b Front and centre exhaust assemblies, refer to Section 6F Exhaust System – V6.

b Rear propeller shaft and for 4WD vehicle front propeller shaft, refer to Section 4A Propeller Shaft.

13 Bleed the clutch hydraulic system, refer to Section 7A 1 Clutch –V6.

14 Check the lubricant level, top up as requir ed, refer to 2.2 Checking Transmission Lubricant Level.

15 Lower the vehicle to the ground.

16 Reconnect the battery ground cable.

Manual Transmission – V6 Page 7B1–20

Page 7B1–20

4 Specifications

General

Type................................................................Aisin AR5 5 Speed, Synchromesh on all Gears

Production Option............................................................................................................. MA5

Transmission Ratios

1st...................................................................................................................................3.75:1

2nd..................................................................................................................................2.26:1

3rd ..................................................................................................................................1.37:1

4th...................................................................................................................................1.00:1

5th...................................................................................................................................0.73:1

Reverse..........................................................................................................................3.67:1

Mass

RWD............................................................................................................................ 48.4 Kg

4WD............................................................................................................................. 48.7 Kg

Lubricant

Type..............................................................................................................SAE 75 – 90 GL3

...............................................................................................................or Mobilube XHP GL4

Capacity:

RWD................................................................................................................................2.2 Lt

4WD.................................................................................................................................2.3 Lt

Grease ...........................................................NLGI No. 2 lithium soap based EP grease with

.................................................. molybdenum disulphide, such as Shell Retinax HDX2grease

......................................................................... or BP Energrease LMS-EP 23 (or equivalent).

Manual Transmission – V6 Page 7B1–21

Page 7B1–21

5 Torque Wrench Specifications

Transmission Filler Plug.......................................................................37.0 Nm

Transmission Drain Plug ......................................................................37.0 Nm

Back-up Lamp Switch...........................................................................44.0 Nm

Speed Sensor............................................................................13.6 – 20.4 Nm

Transmission Mount Attaching Bolt...........................................43.0 – 57.0 Nm

Transmission Support Attaching Nut....................................................50.0 Nm

Transmission Mount Attaching Nut............................................44.0 – 60.0 Nm

Heat Shield to Transmission Support Attaching Bolt............................52.0 Nm

Shift Lever Attaching Bolt..........................................................15.0 – 22.0 Nm

Boot Assembly Attaching Nut........................................................4.6 – 8.5 Nm

Boot Assembly Attaching Screw....................................................1.3 – 1.5 Nm

Transmission Housing Attaching Bolt........................................50.0 – 60.0 Nm

Close-out Cover Attaching Bolt ...................................................7.5 – 10.0 Nm

Fuel and EVAP Pipes Bracket Attaching Nut ............................26.0 – 27.0 Nm