SECTION 7D1 - TRANSFER CONTROL SYSTEM

Service Precaution

General Description

System Components

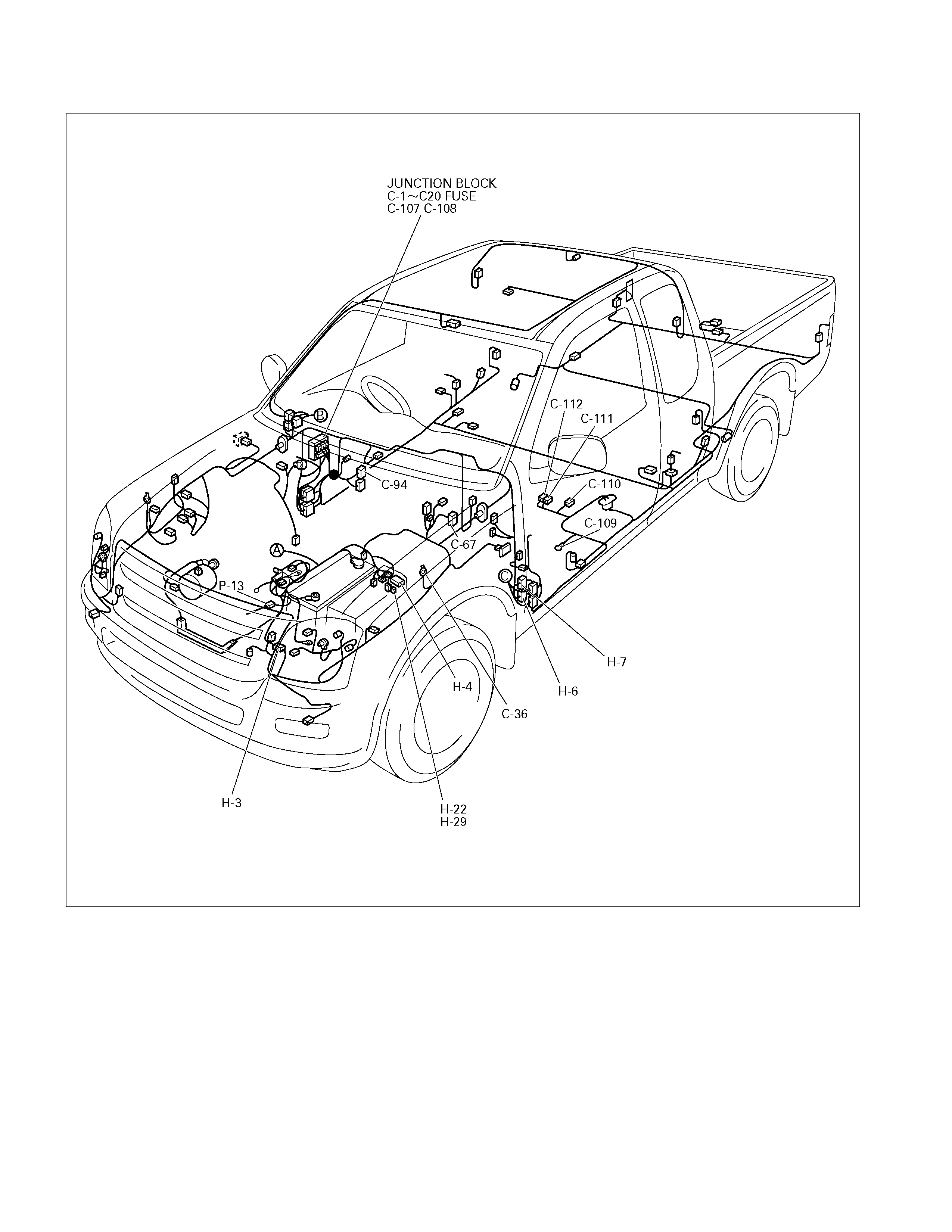

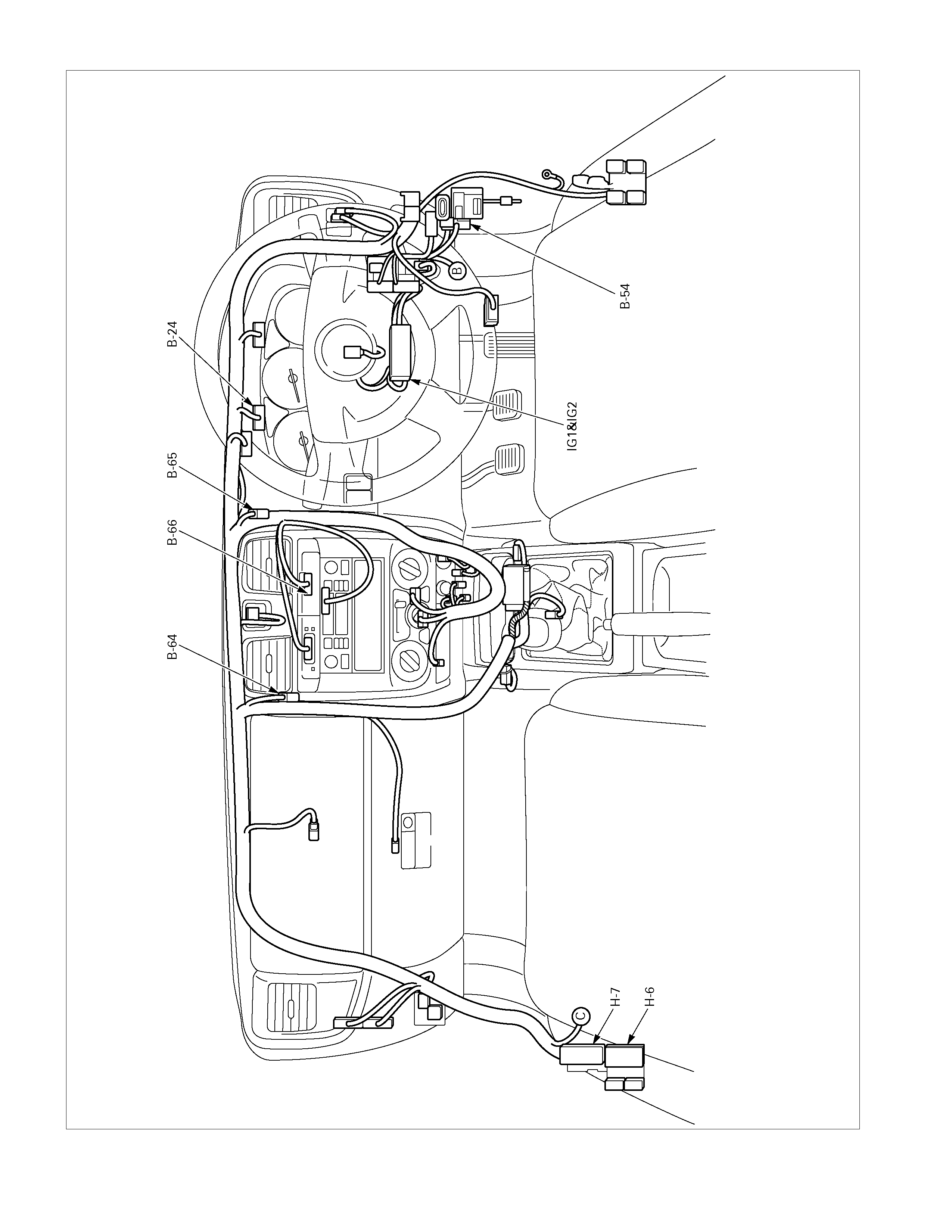

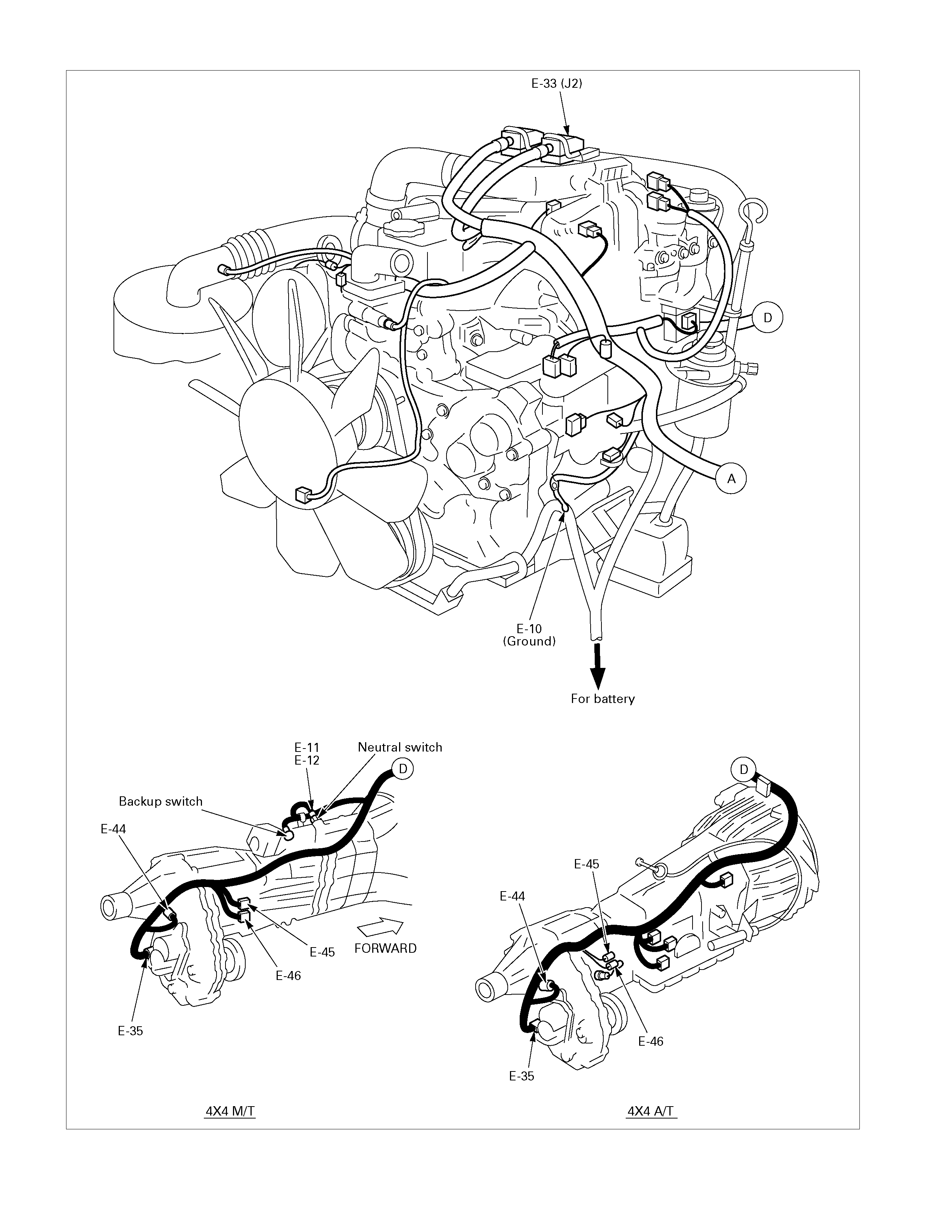

Parts Location

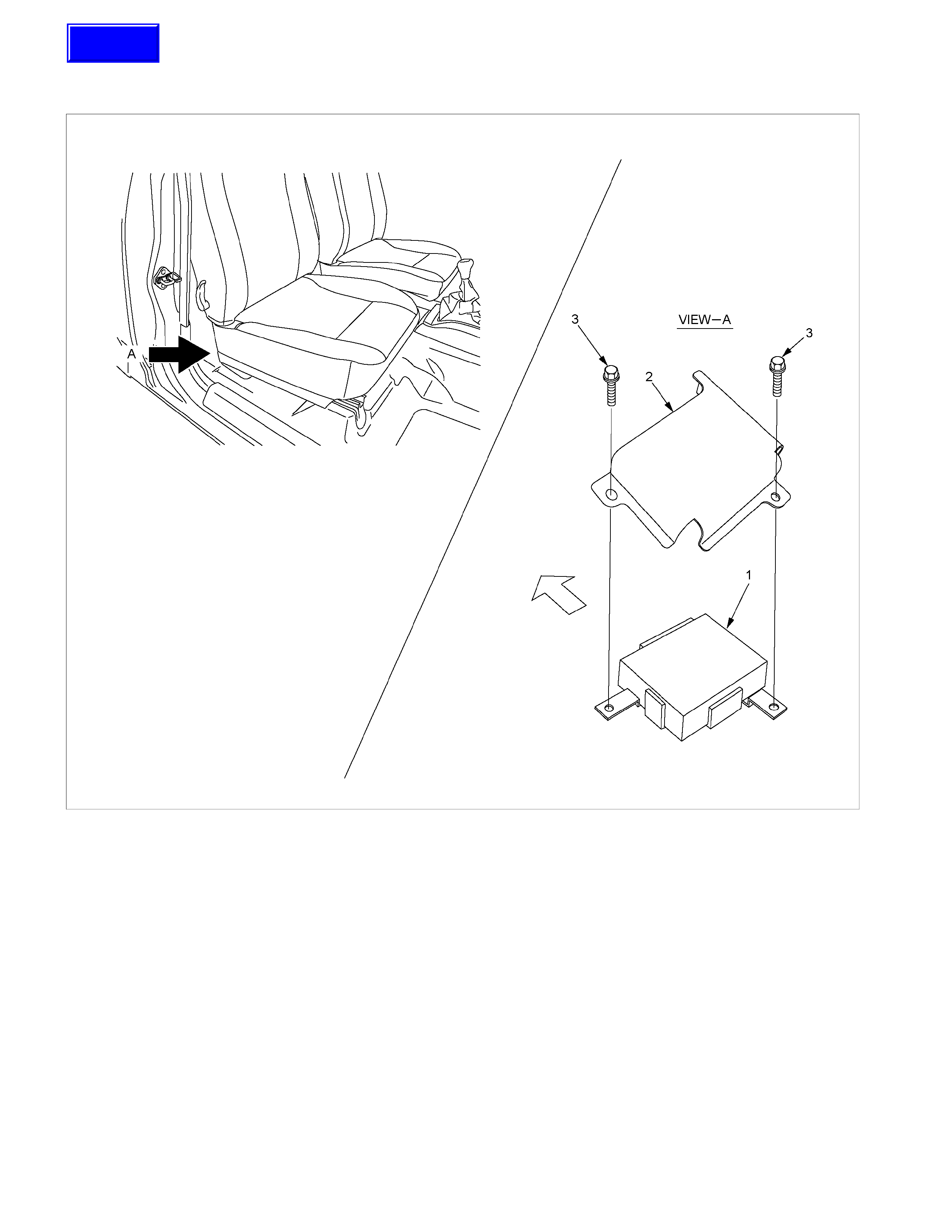

Transfer Case Control Module (TCCM)

Shift Actuator Limit Switch Test

Shift Actuator Harness Test

Function Of Switch And Indicator Lamp

Parts Location

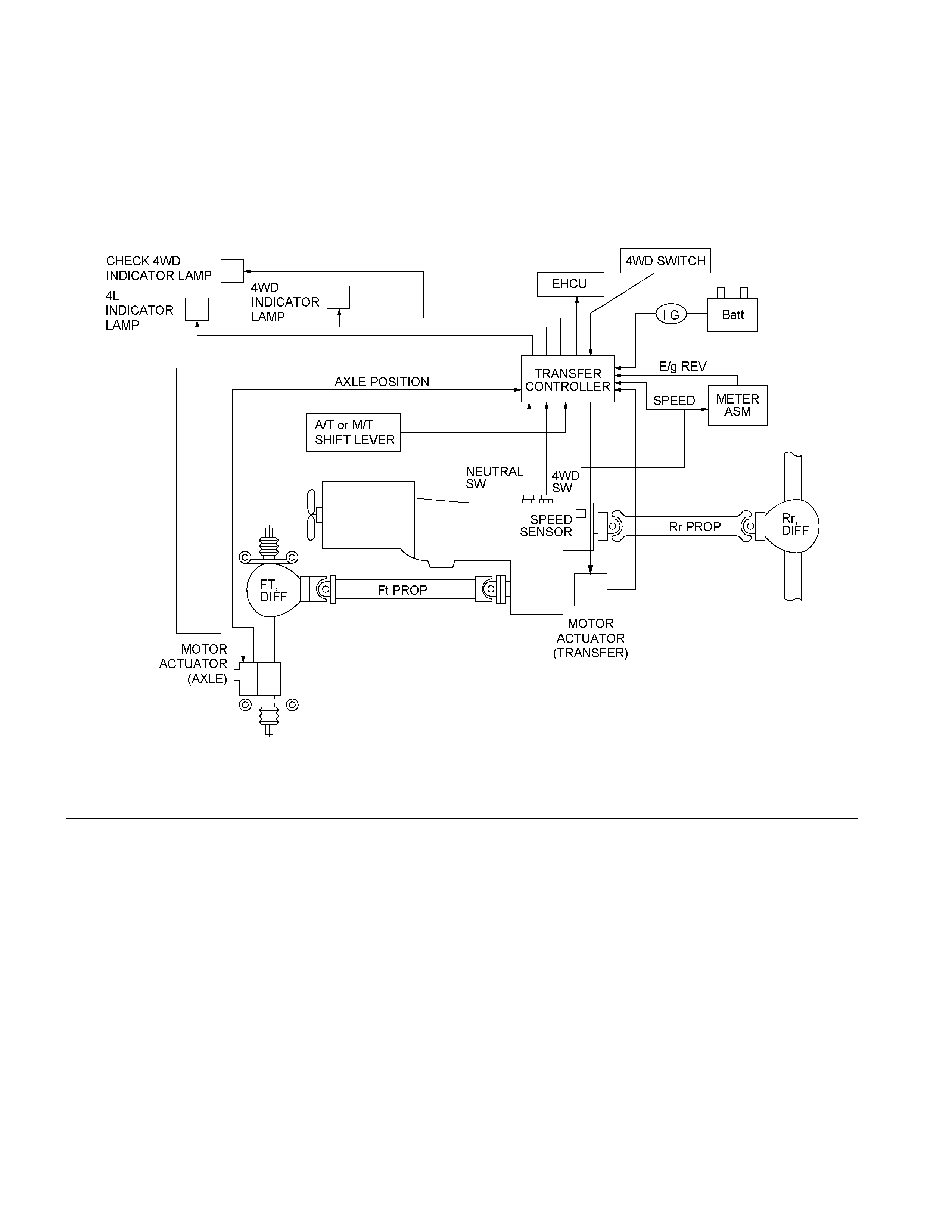

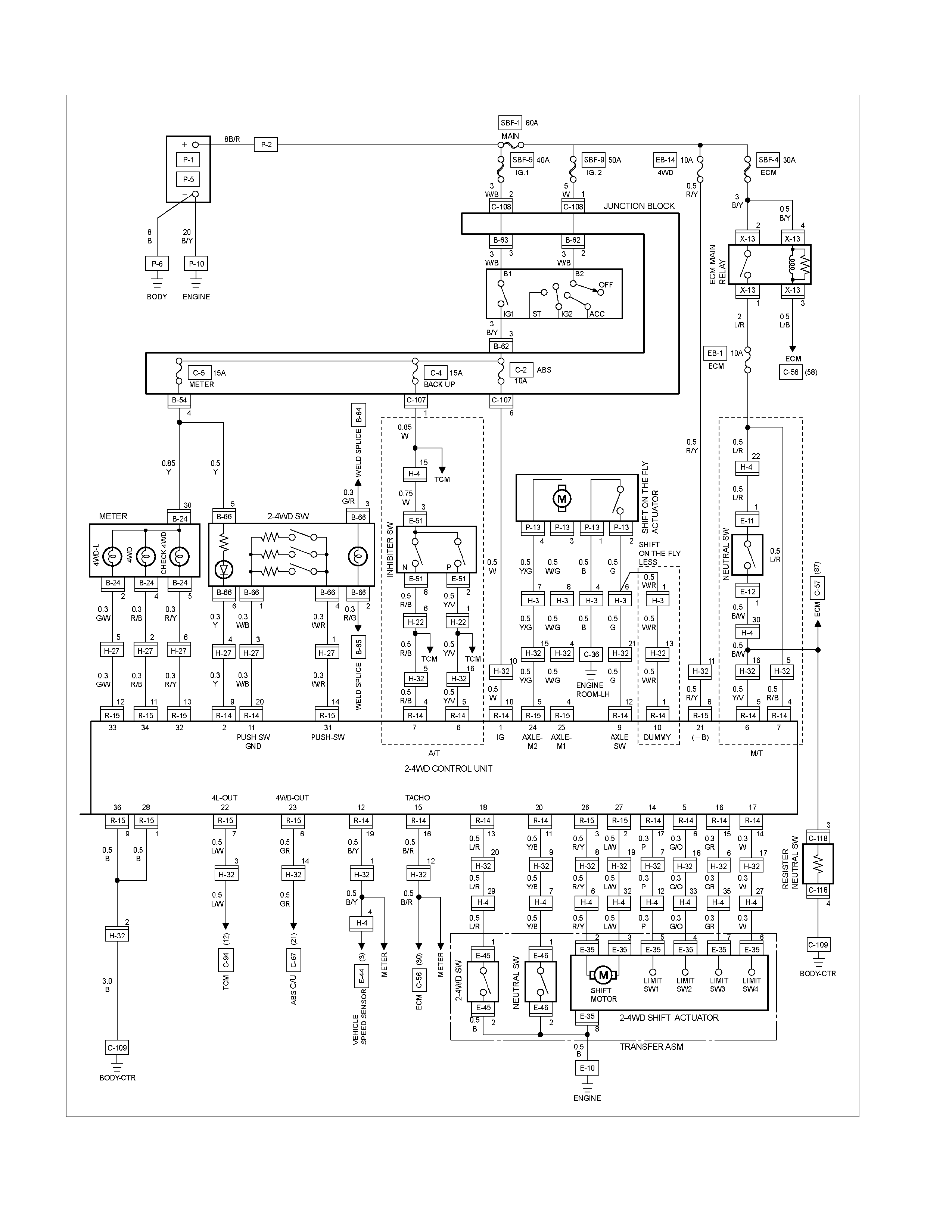

Circuit Diagram

Connector List

Diagnosis

Road Testing Prior To Repair

Shifting From 2H To 4H

Shifting From 4H To 2H

Shifting From 4H To 4L

Shifting From 4L To 4H

Shifting From 4L Or 4H To Neutral

Shifting From Neutral To 2H, 4H Or 4L

4WD Indicator Lamp Flashes When Ignition Is Turned On

‘Check 4WD’ Indicator Lamp On When Ignition Is On

TCCM Memory Erase Procedure

Diagnosis From Symptom

Techline

Techline

Service Precaution

WARNING:

THIS VEHICLE HAS A SUPPLEMENTAL RESTRAINT SYSTEM (SRS). REFER TO THE SRS COMPONENT AND

WIRING LOCATION VIEW IN ORDER TO DETERMINE WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS WIRING. WHEN YOU ARE PERFORMING SERVICE ON OR NEAR

THE SRS COMPONENTS OR THE SRS WIRING, REFER TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION:

Always use the correct fastener in the proper location. When you replace a fastener, use ONLY the exact part

number for that application. HOLDEN will call out those fasteners that require a replacement after removal.

HOLDEN will also call out the fasteners that require thread lockers or thread sealant. UNLESS OTHERWISE

SPECIFIED, do not use supplemental coatings (Paints, greases, or other corrosion inhibitors) on threaded

fasteners or fastener joint interfaces. Generally, such coatings adversely affect the fastener torque and the

joint clamping force, and may damage the fastener. When you install fasteners, use the correct tightening

sequence and specifications. Following these instructions can help you av oid damage to parts and systems.

General Description

RTW34BLF000201

Transfer Position and Drive Mode

Three drive modes can be selected through operation of 4WD switch.

Transfer Position 4WD SWITCH Mode Drive mode

2H RWD Rear wheel drive

HIGH 4H 4WD (HIGH)

High-speed mechanical

lock-up four wheel drive

LOW 4L 4WD (LOW)

Low-speed mechanical

lock-up four wheel drive

NEUTRAL 2H & 4L (10 Sec) NEUTRAL Towed by other vehicle

Summary of transfer control system

The transfer control system switches between the 2-wheel

drive (2H), 4-wheel drive high-speed (4H), 4-wheel drive low-

speed (4L), and neutral positions electrically when the driver

operate the switches.

This system has following functions.

1. Connection or disconnection of drive force distribution to

the front wheel front shaft (axle shaft) (The drive force

distribution to the front propeller is connected o

r

disconnected with the motor actuator.)

2. Try to repeat the connection or disconnection of the front

wheel drive function as described above.

3. Instruction (to the axle controller) of connection o

r

disconnection of the drive force transmission between the

front wheel axle (axle shaft) and front wheel

(The motor actuator connects or disconnects the left front

wheel ad front wheel axle (axle shaft).).

4. Shifting of auxiliary transmission gears, connection o

r

disconnection of wheel and engine drive force (4H, 4L,

neutral).

5. Operation of indicator on the instrument panel.

6. Transmission of position signal to other controllers.

System Components

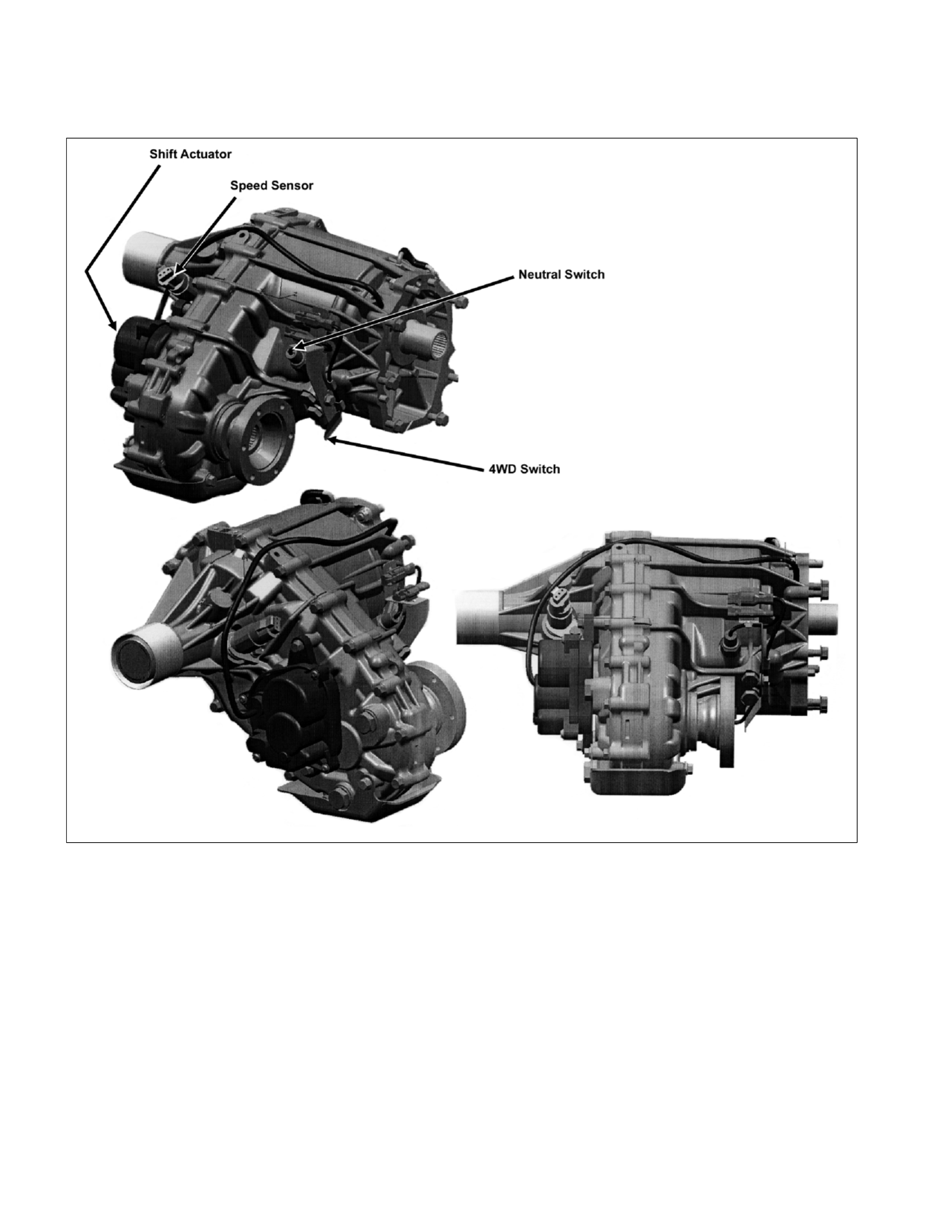

Parts Location

Speed sensor

Revolutions of the rear output shaft are decreased and taken

out by the speed/drive/driven gears installed in the transfer

case and the number of revolutions is detected with a speed

sensor.

About 4/3 pulses per revolution of the shaft is output.

4WD switch

The 4WD switch detects the movement of the shift rod driving

the 4×2 - 4×4 sleeve.

The contact of the switch are open when the shift rod is at the

4×2 position.

4×2 - 4×4 sleeve & Arm

The 4×2 - 4×4 sleeve moves directly in the 4×4 direction with

the 4×2 - 4×4 shift rod, but, when moving in 4×2 direction, a

spring standby mechanism is provided between the rod and

sleeve so that the rod is positioned at the 4×2 position, while

the sleeve is at the 4×4 position in sometime.

This mechanism is provided to protect the shift mechanism

from the force to prevent the movement of the sleeve

(torsional torque etc. of the drive system). By releasing the

preventive force, the sleeve can move to 4×2 state by the

spring force.

Neutral switch

The neutral switch detects the movement of the shift rod

driving the high-low sleeve.

The contacts of the neutral switch are closed when the shift

rod is positioned between the High and the Low, that is, at the

neutral position.

High-Low Sleeve & Arm

The spring standby mechanism is provided for the high-low

sleeve in both directions of the high-low shift rod. For this

reason, the rod position and the actual sleeve position may be

offset in some cases.

This system is provided to protect the shift mechanism from

the damage due to a phase difference between the engaged

splines. When correctly phased, the splines are moved to the

engaged position by the spring force.

Shift actuator

The built-in motor rotates the output shaft and the transfer

range is changed.

Detection (limit) switches to detect the rotating angle of the

output shaft is provided to the actuator at 4 positions, which

are connected to the transfer controller through the vehicle

harness to constantly transmit the actuator operating angle

and changes in its transfer status.

7B4-PDF2

4WD indicator (in meter panel)

This lamp indicates the following items

Valve check

Drive condition (2WD-4WD)

Operating condition (2Hz: Actuator in operation, mechanism

standby)

Restrictions on operation (4Hz, including indication of

interrupted operation due

to excessive load)

7B4-PDF3

4L indicator (in meter panel)

This lamp indicates following items.

Valve check

Driving status (High-Low)

Operating status (2Hz: Actuator in operation, mechanism

standby)

Restrictions on operation (4Hz)

7B4-PDF4

Neutral indicator (in operation switch panel)

This LED indicates following items.

LED check

Driving status (Neutral)

Operating status (2Hz: Actuator in operation, mechanism

standby)

Restrictions on operation (4Hz)

7B4-PDF5

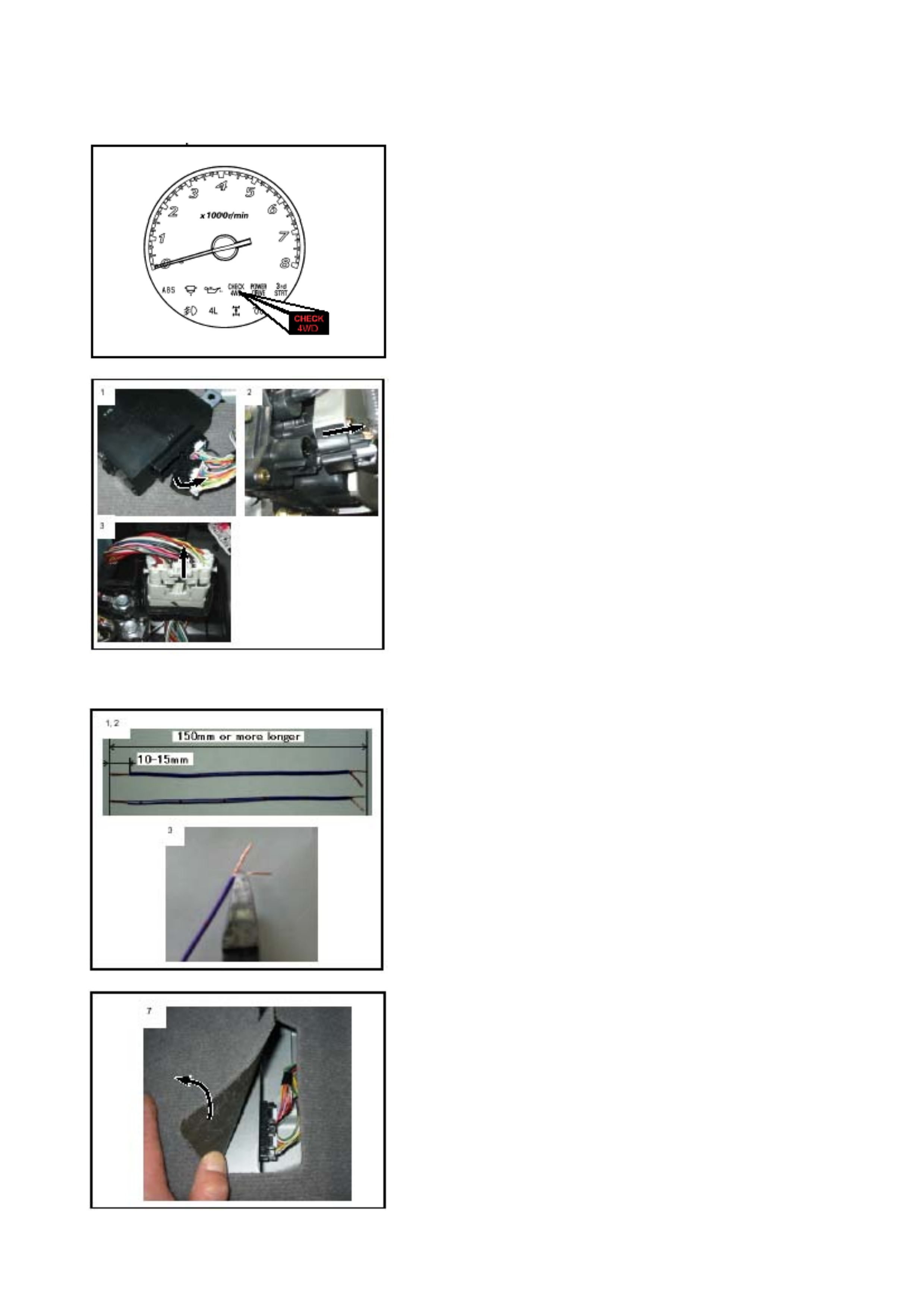

Check 4WD warning light (in meter panel)

This light indicates following items.

Valve check

Faulty actuator limit SW, and fault of circuit related with the

limit switch

825R300018

4WD switch

Switch to transmit a switching command to the 2H, 4H,

Neutral, or 4L position.

It comprises 3 PUSH momentary switches. By keeping to push

the 2H and 4L switches for 10 seconds,

operation is instructed to the neutral position.

To shift from the neutral to other position, other required

switches should be pushed for 10 seconds.

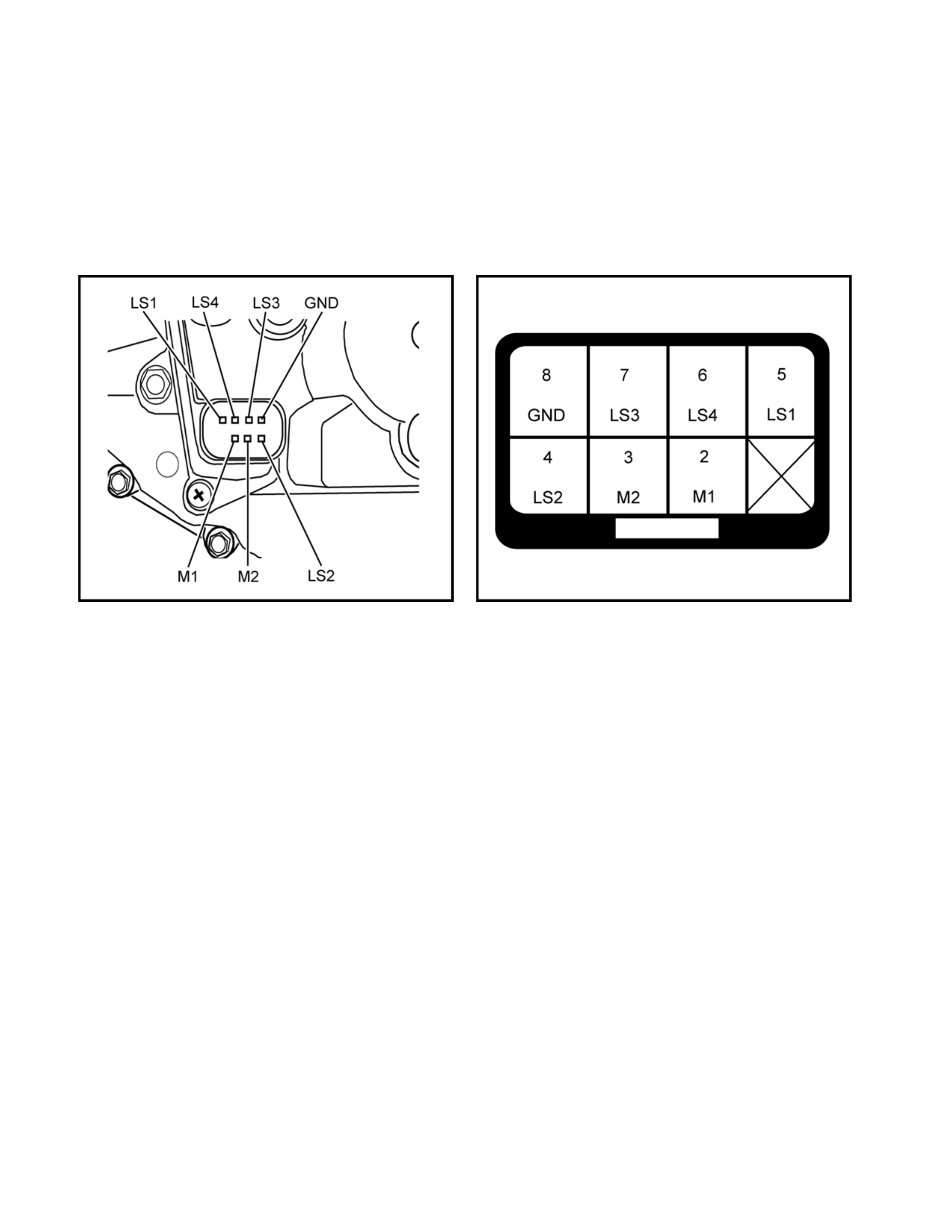

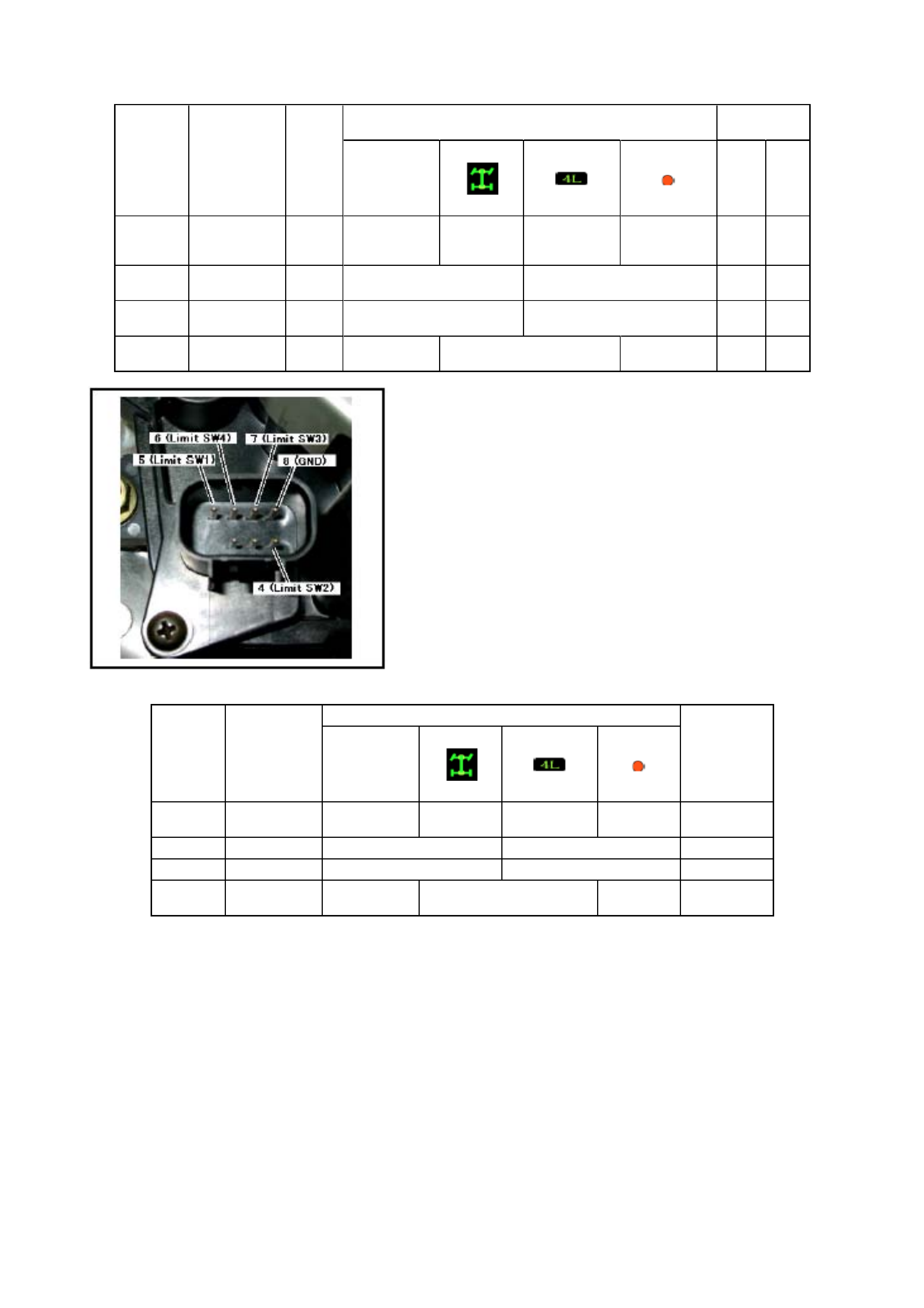

Shift Actuator Limit Switch Test

The initial test is best performed at the TCCM. Refer to the chart for the test conditions and to the TCCM Pin Out

illustration below for the correct harness pin location.

Should the test fail at Step 1, remove the harness connector with the transfer case in each drive range, and conduct

the test on the respective Limit Switch pin.

If the test fails at step 1, but passes at step 2, then a harness/connector fault is the most probable cause of the CHECK

4WD lamp illuminating.

NOTE:

The ignition switch must be in the OFF position whenever removing or replacing the TCCM or Limit Switch harness

connectors.

Under no circumstances should the Transfer Case Actuator harness connector be back-probed. This will damage the

weather-pak seal, leading to possible failure of the system due to contamination of the harness connector and actuator

pins.

2H 4H N 4L

LS1 Closed Open Open Closed

LS2 Open Open Closed Closed

LS3 Closed Closed Open Open

LS4 Open Closed Open Closed

NOTE:

“Closed” indicates continuity between the respective pin and GND pin. (Continuity should also exist between the

“Closed” pins.)

TCCM Pin Locations- Shift Actuator Limit Switch Test

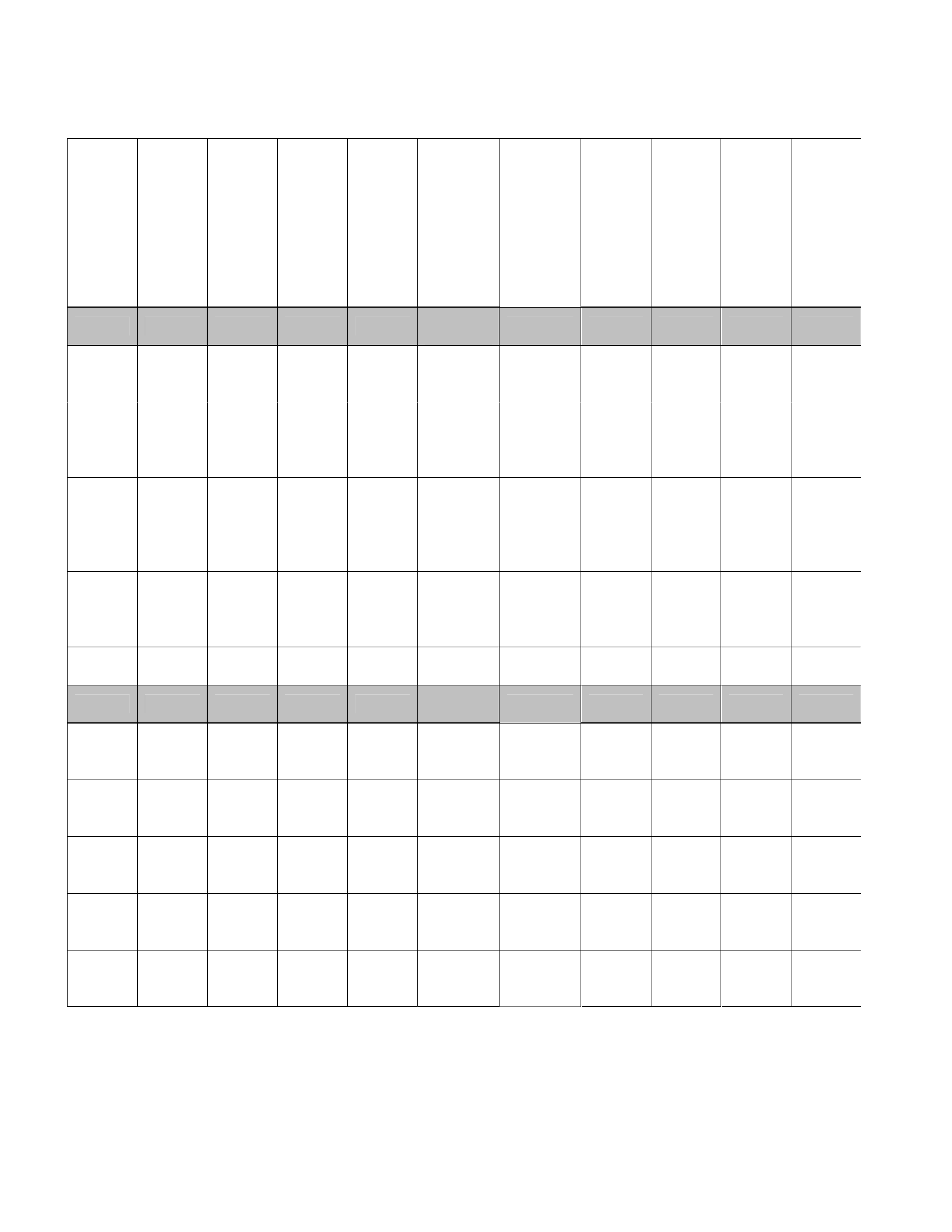

Shift Actuator Harness Test

Disconnect the vehicle harness connector on the transfer controller side and the vehicle harness connector on the

transfer actuator side as shown in the wiring diagram, and check the continuity between the following connector

pins and that there is no continuity between those pins and GND or power source.

Check that there is continuity between the GND pin and vehicle GND on the transfer actuator and pin and power

source.

Shift Actuator Pin Location

Actuator Harness Connector – Face View

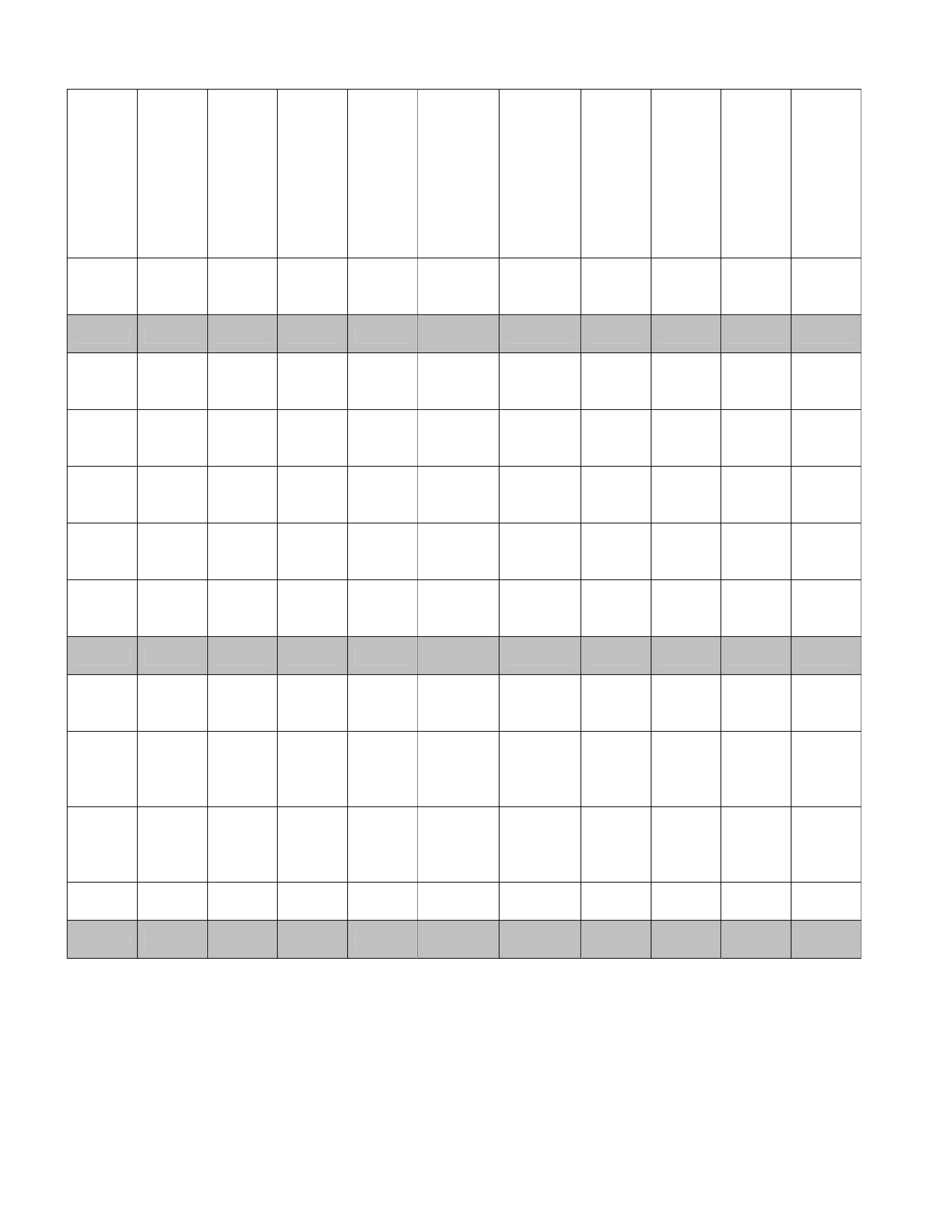

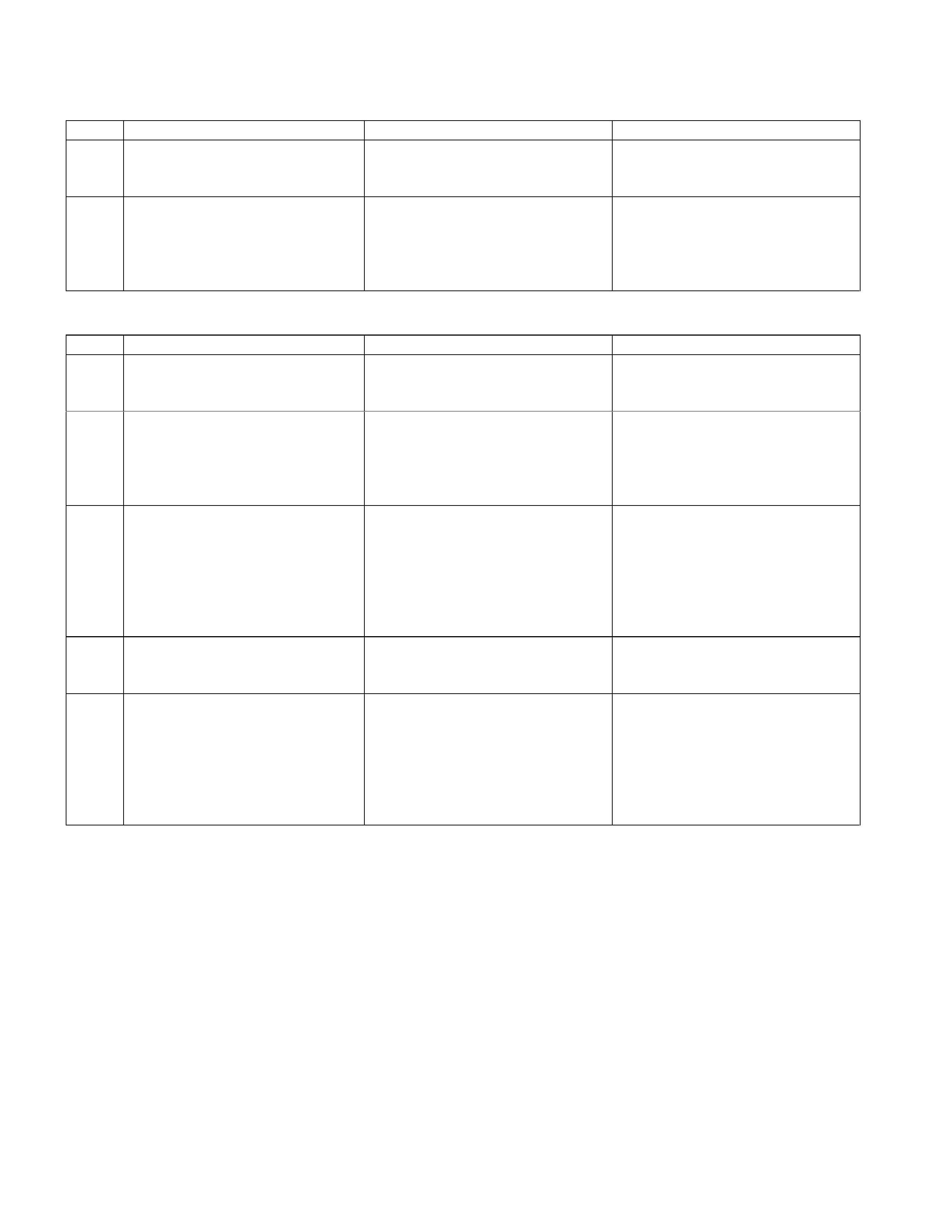

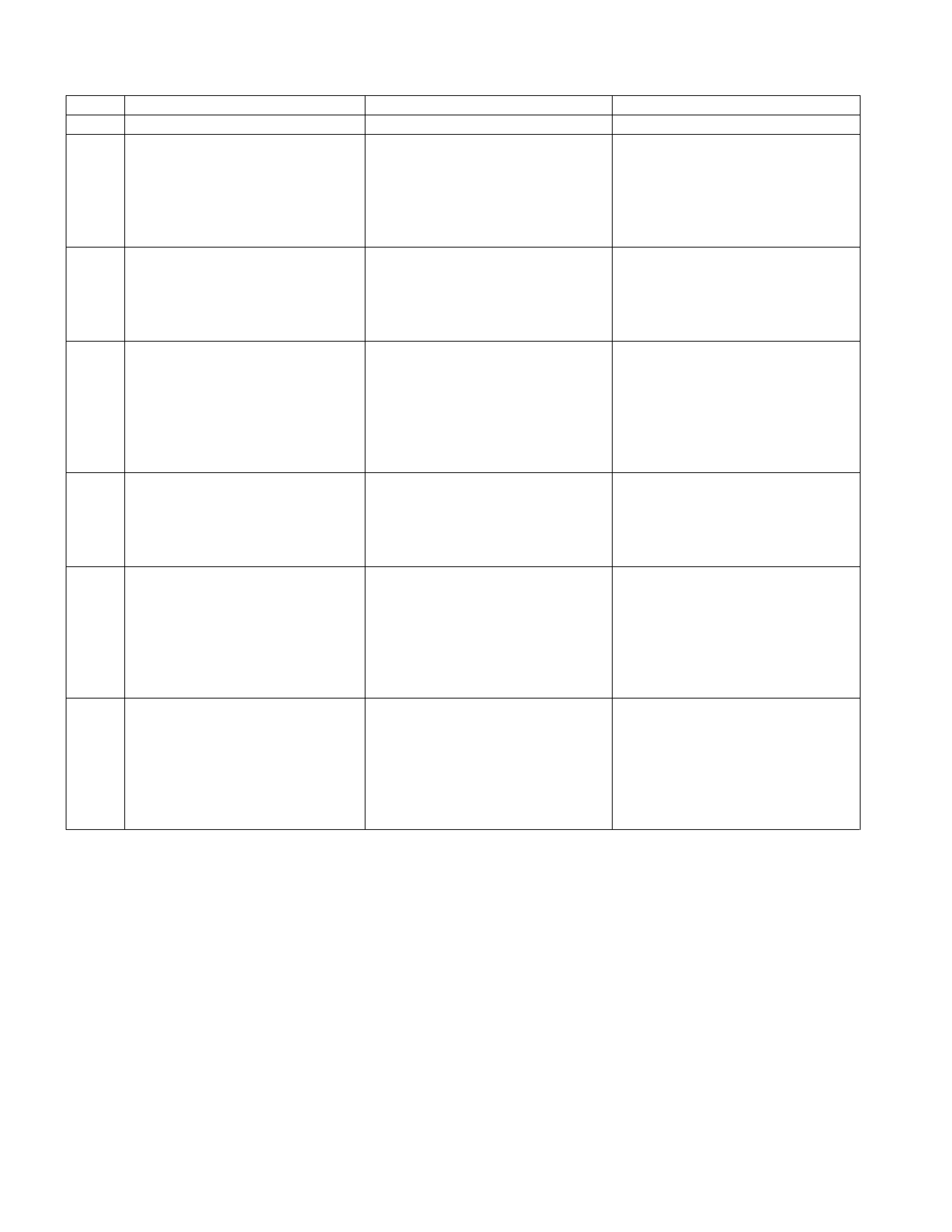

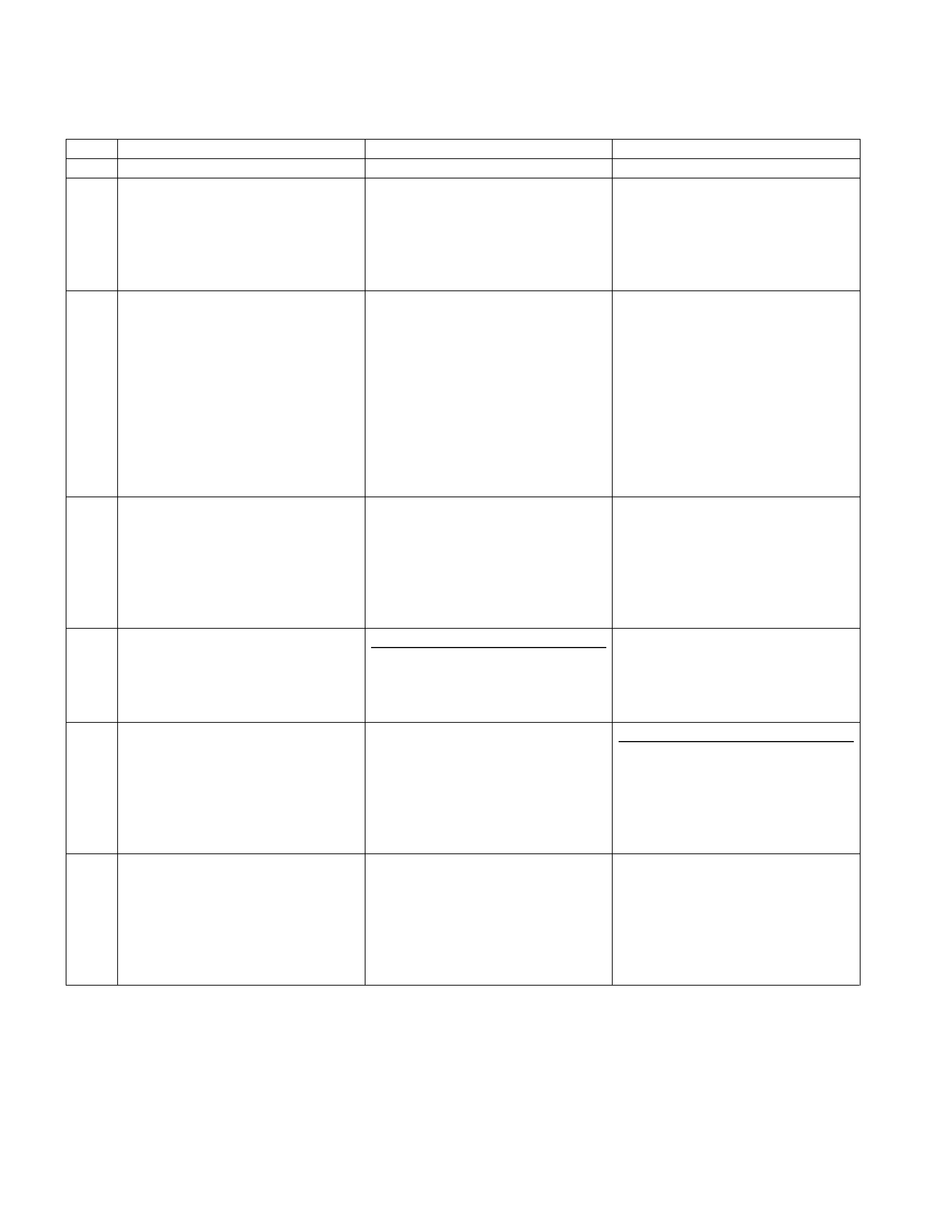

Function of Switch and indicator Lamp

Transfer-related indicator lamp and switch function

Item 4WD

lamp 4L lamp Neutral

lamp

Check

4WD

warning

light

4WD

switch

Actuator

detection

(limit)

switches

LS1, LS2,

and LS3.

and LS4

1 = on

2 = off

Transfer

4WD

switch

Transfer

neutral

switch

SOF

actuator

switch Remarks

2H Off Off Off Off No

operation 1,0,1,0 Open Open Open -----

4H start

of

operation Off Off Off Off 4H position

for 0.1

second 1,0,1,0 Open Open Open Switch

operation

sensor

Start of

operation Blinking

(2HZ) Off Off Off No

operation

1,1,1,0

0,0,1,0

0,1,1,0

0,1,1,1

Open Open Open 2H to 4H

while

driving

During

operation

(Synchro)

Blinking

(2HZ) Off Off Off No

operation

1,1,1,0

0,0,1,0

0,1,1,0

0,1,1,1

Open Open Open

2H to 4H

using

synchro

and

retrial

During

operation

(Axle

drive)

Blinking

(2HZ) Off Off Off No

operation 0,0,1,1 Closed Open Open Axle drive

Axle

waiting Blinking

(2HZ) Off Off Off No

operation 0,0,1,1 Closed Open Open Axle drive

4H On Off Off Off No

operation 0,0,1,1 Closed Open Closed -----

4L start

of

operation On Off Off Off 4L position

for 0.1

second 0,0,1,1 Closed Open Closed

Switch

operation

sensor

Start of

operation On Blinking

(2HZ) Off Off No

operation 0,0,0,1

0,1,0,1 Closed Open Closed 4H to 4L

while

driving

During

operation

(N) Off Blinking

(2HZ) Off Off No

operation 0,0,0,1

0,1,0,1 Closed Closed Closed 4H to 4L

through

neutral

During

operation

(N) Off Blinking

(2HZ) Off Off No

operation 0,1,0,0 Closed Closed Closed 4H to 4L

through

neutral

During

operation

(N) Off Blinking

(2HZ) Off Off No

operation 1,1,0,0 Closed Closed Closed 4H to 4L

through

neutral

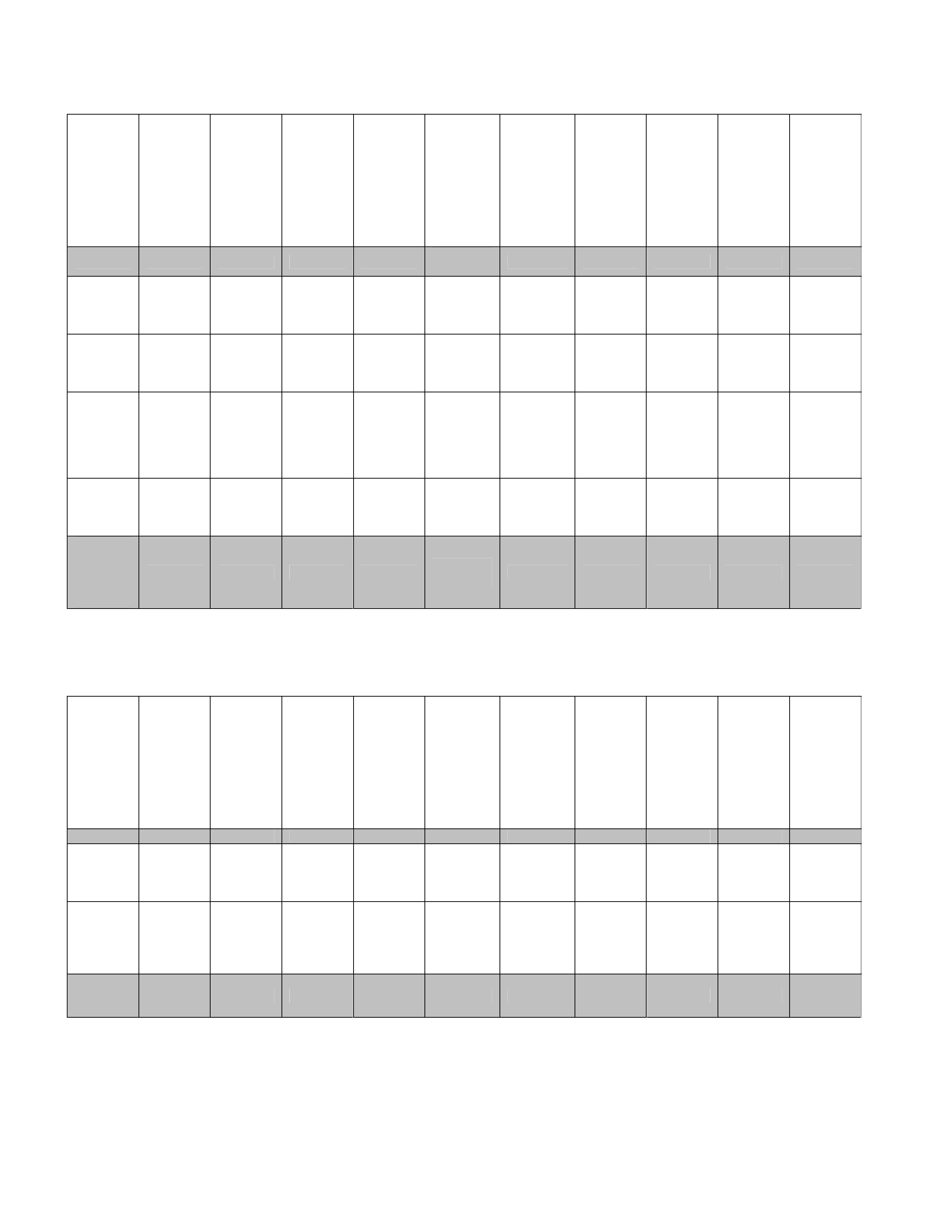

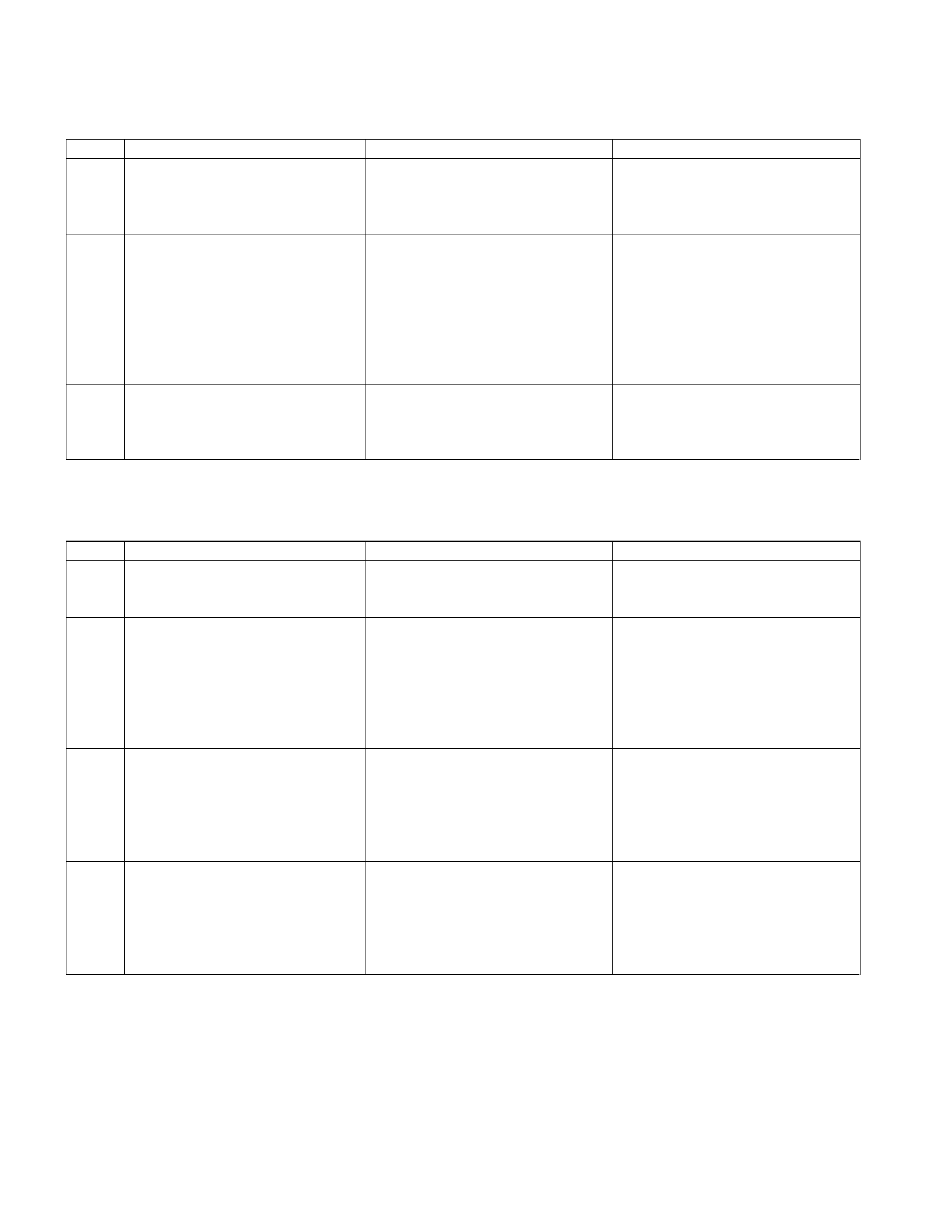

Item 4WD

lamp 4L lamp Neutral

lamp

Check

4WD

warning

light

4WD

switch

Actuator

detection

(limit)

switches

LS1, LS2,

LS3. and

LS4

1 = on

2 = off

Transfer

4WD

switch

Transfer

neutral

switch

SOF

actuator

switch Remarks

4L

waiting On Blinking

(2HZ) Off Off No

operation 1,1,0,1 Closed Closed Closed 4H to 4L

while

waiting

4L On On Off Off No

operation 1,1,0,1 Closed Open Closed -----

4H start

of

operation On Off Off Off 4H position

for 0.1

second 1,1,0,1 Closed Open Closed

Switch

operation

sensor

During

operation On Blinking

(2HZ) Off Off No

operation 1,1,0,1 Closed Open Closed

4L to 4H

while

driving

During

operation

(N) Off Blinking

(2HZ) Off Off No

operation 1,1,0,0 Closed Closed Closed 4L to 4H

through

neutral

During

operation Off Blinking

(2HZ) Off Off No

operation 0,1,0,1

0,0,0,1 Closed Closed Closed 4L to 4H

while

driving

4H

waiting Off Blinking

(2HZ) Off Off No

operation 0,0,1,1 Closed Closed Closed 4L to 4H

while

waiting

4H On Off Off Off No

operation 0,0,1,1 Closed Open Closed -----

2H start

of

operation On Off Off Off 2H position

for 0.1

second 0,0,1,1 Closed Open Closed

Switch

operation

sensor

Start of

operation Blinking

(2HZ) Off Off Off No

operation

0,1,1,1

0,1,1,0

0,0,1,0

1,1,1,0

Closed Open Closed 2H to 4H

while

driving

During

operation

(Axle)

Blinking

(2HZ) Off Off Off No

operation

0,1,1,1

0,1,1,0

0,0,1,0

1,1,1,0

Open Open Closed Axle drive

Axle

waiting Blinking

(2HZ) Off Off Off No

operation 1,0,1,0 Open Open Closed Axle

waiting

2H Off Off Off Off No

operation 1,0,1,0 Open Open Open -----

2H to 4H retrial

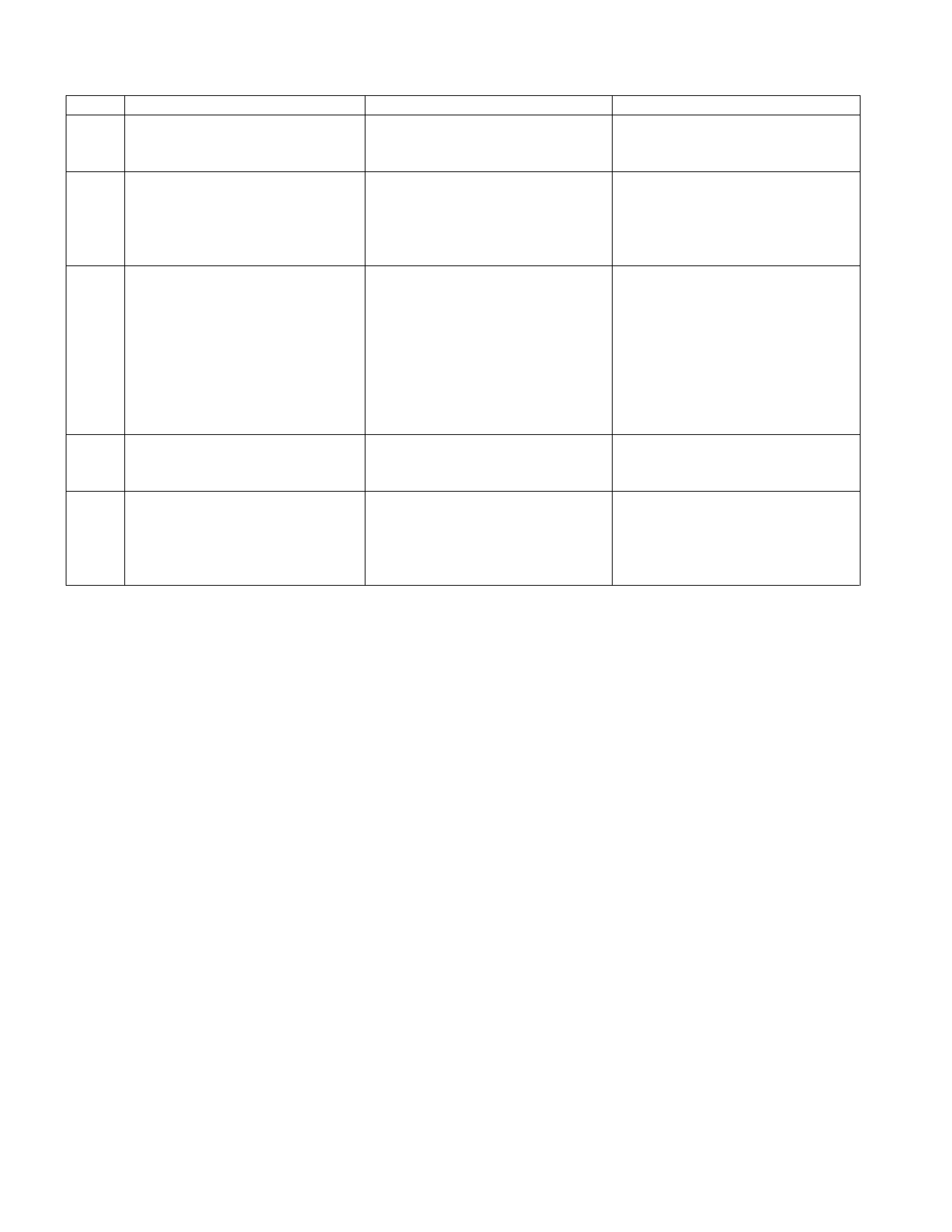

Item 4WD

lamp 4L lamp Neutral

lamp

Check

4WD

warning

light

4WD

switch

Actuator

detection

(limit)

switches

LS1, LS2,

LS3. and

LS4

1 = on

2 = off

Transfer

4WD

switch

Transfer

neutral

switch

SOF

actuator

switch Remarks

2H Off Off Off Off No

operation 1,0,1,0 Open Open Open -----

4H start

of

operation Off Off Off Off

4H

position

for 0.1

second

1,0,1,0 Open Open Open -----

Start of

operation Blinking

(2HZ) Off Off Off No

operation

1,1,1,0

0,0,1,0

0,1,1,0

0,1,1,1

Open Open Open 2H to 4H

while

driving

During

operation

(Synchro)

(Go to 4H

if synchro

complete)

Blinking

(2HZ) Off Off Off No

operation

1,1,1,0

0,0,1,0

0,1,1,0

0,1,1,1

Open Open Open

2H to 4H

using

synchro

and retrial

X 2

Abandon

ed

operation

(2H)

Blinking

(4HZ) Off Off Off No

operation 1,0,1,0 Open Open Open Return to

2H

2H

indication

after

10second

s

Off Off Off Off No

operation 1,0,1,0 Open Open Open -----

• Completion of transfer case H-L area and axle shift timing may cause some variation in 2Hz blinking pattern.

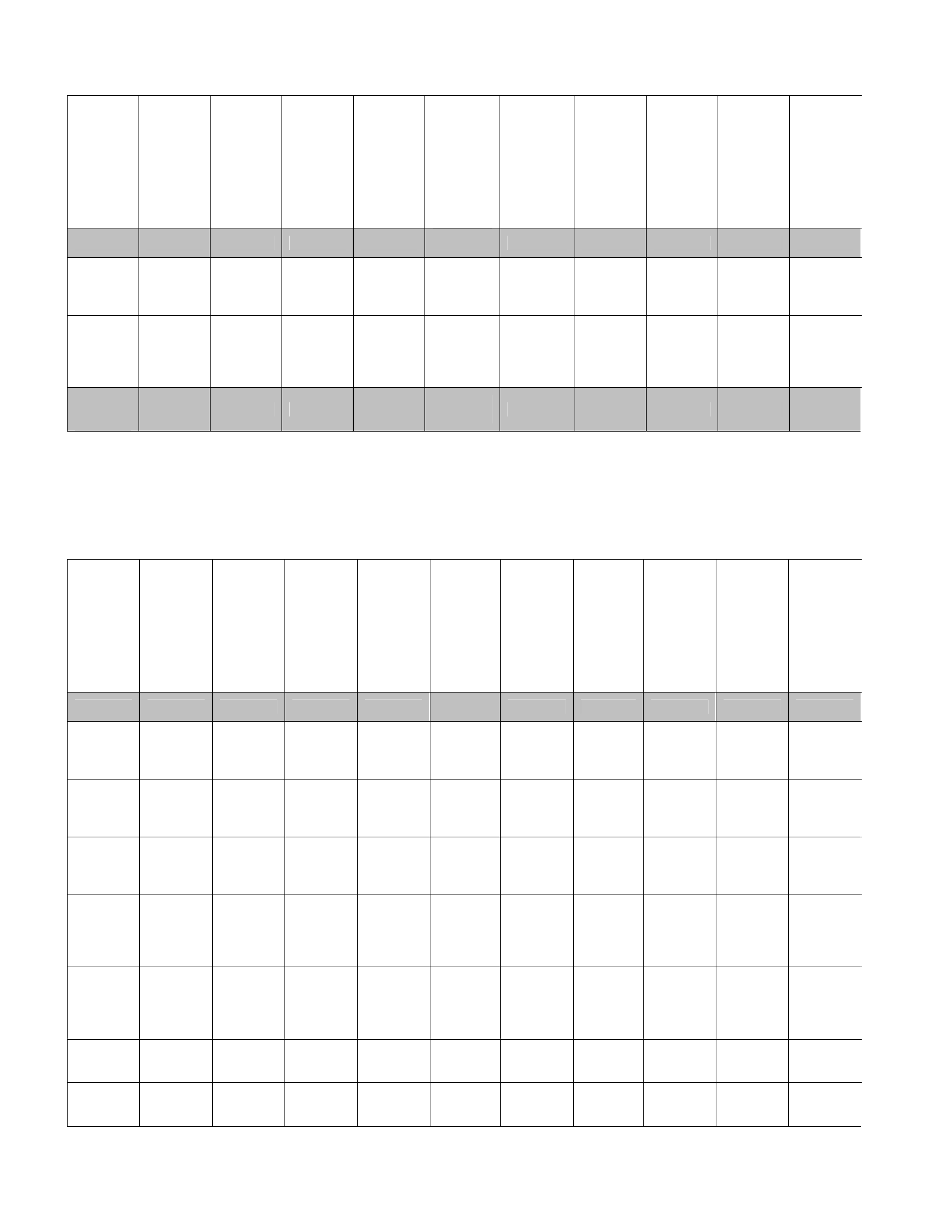

Operational limits (4HÆ4L) (Vehicle speed, engine speed, and transmission position not specified)

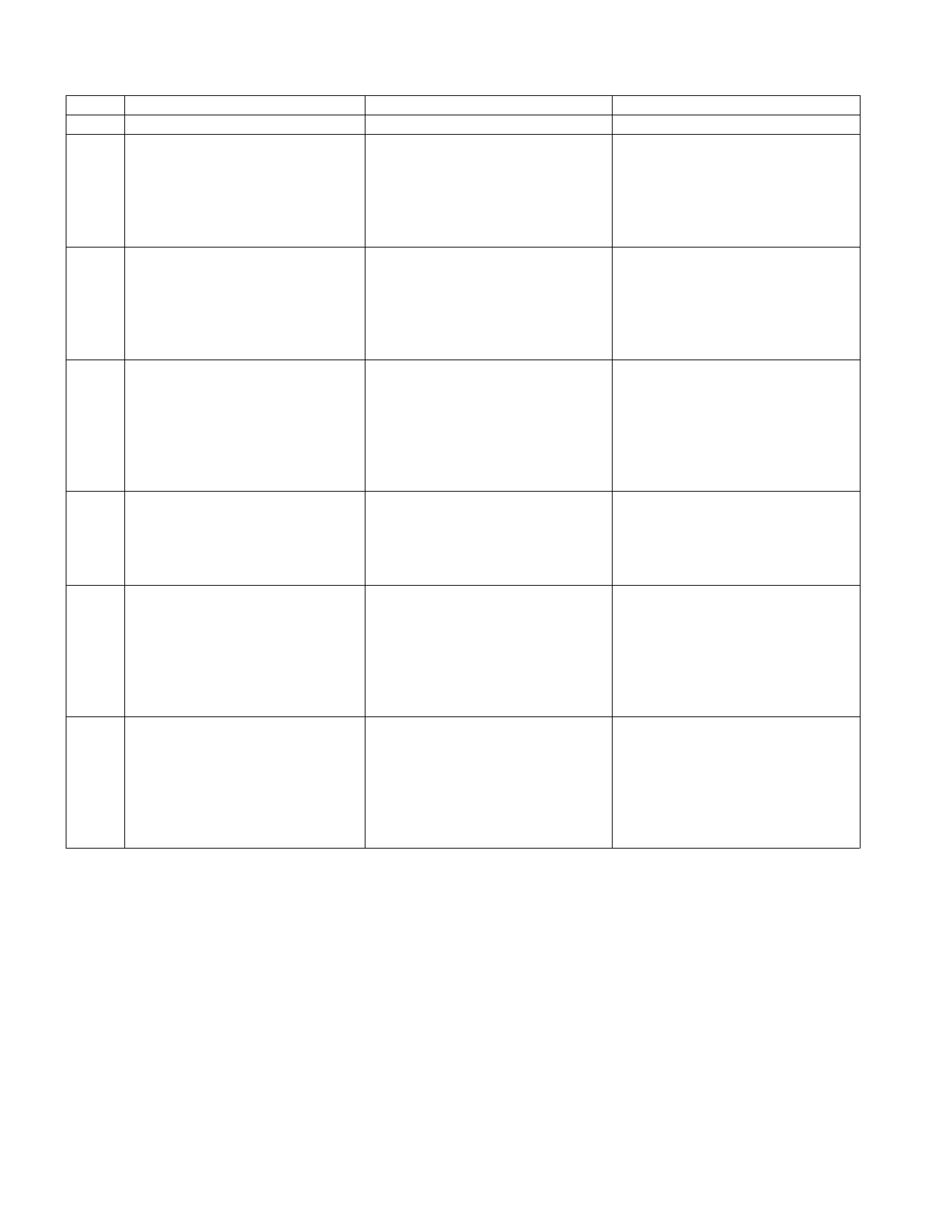

Item 4WD

lamp 4L lamp Neutral

lamp

Check

4WD

warning

light

4WD

switch

Actuator

detection

(limit)

switches

LS1, LS2,

LS3. and

LS4

1 = on

2 = off

Transfer

4WD

switch

Transfer

neutral

switch

SOF

actuator

switch Remarks

4H On Off Off Off Open 0,0,1,1 Closed Open Closed -----

4H start

of

operation On Off Off Off

4L

position

for 0.1

second

0,0,1,1 Closed Open Closed -----

10

second

display

during

limitation

On Blinking

(4HZ) Off Off Open 0,0,1,1 Closed Open Closed

No

operation

during

limitation

Go to 4H

after 10

seconds On Off Off Off Open 0,0,1,1 Closed Open Closed -----

Operational limits (4LÆ4H) (Vehicle speed, engine speed, and transmission position not specified)

Item 4WD

lamp 4L lamp Neutral

lamp

Check

4WD

warning

light

4WD

switch

Actuator

detection

(limit)

switches

LS1, LS2,

LS3. and

LS4

1 = on

2 = off

Transfer

4WD

switch

Transfer

neutral

switch

SOF

actuator

switch Remarks

4L On On Off Off No

operation 1,1,0,1 Closed Open Closed -----

4L start of

operation On On Off Off

4H

position

for 0.1

second

1,1,0,1 Closed Open Closed -----

10

second

display

during

limitation

On Blinking

(4HZ) Off Off Open 1,1,0,1 Closed Open Closed

No

operation

during

limitation

Go to 4L

after 10

seconds On On Off Off No

operation 1,1,0,1 Closed Open Closed -----

• Under some conditions, a secondary operational indication may be received when the 4Hz operational indication is

present.

Transfer-related indicator lamp and switch function

Skip operation

Item 4WD

lamp 4L lamp Neutral

lamp

Check

4WD

warning

light

4WD

switch

Actuator

detection

(limit)

switches

LS1, LS2,

LS3. and

LS4

1 = on

2 = off

Transfer

4WD

switch

Transfer

neutral

switch

SOF

actuator

switch Remarks

2H Off Off Off Off No

operation 1,0,1,0 Open Open Open -----

4L start of

operation Off Off Off Off

4L

position

for 0.1

second

1,0,1,0 Open Open Open Switch

operation

sensor

Start of

operation Blinking

(2HZ) Blinking

(2HZ) Off Off No

operation

1,1,1,0

0,0,1,0

0,1,1,0

0,1,1,1

Open Open Open 2H to 4H

while

driving

During

operation

(Synchro)

Blinking

(2HZ) Blinking

(2HZ) Off Off No

operation

1,1,1,0

0,0,1,0

0,1,1,0

0,1,1,1

Open Open Open

2H to 4H

using

synchro

and retrial

During

operation

(Passing

through

4H)

Off Blinking

(2HZ) Off Off No

operation 0,0,1,1 Closed Open Open -----

During

operation

(Passing

through

4H)

Off Blinking

(2HZ) Off Off No

operation 0,0,1,1

0,1,0,1 Closed Open Open -----

During

operation

(N) On Blinking

(2HZ) Off Off No

operation 0,0,1,1

0,1,0,1 Closed Open Closed -----

During

operation

(N) On Blinking

(2HZ) Off Off No

operation 0,1,0,0 Closed Open Closed Switch

operation

sensor

Item 4WD

lamp 4L lamp Neutral

lamp

Check

4WD

lamp

4WD

switch

Actuator

detection

(limit)

switches

LS1, LS2,

LS3. and

LS4

1 = on

2 = off

Transfer

4WD

switch

Transfer

neutral

switch

SOF

actuator

switch Remarks

During

operation

(N) On Blinking

(2HZ) Off Off No

operation 0,0,1,1 Closed Open Closed 4H to 4L

while

driving

During

operation

(Axle

drive)

Blinking

(2HZ) Blinking

(2HZ) Off Off No

operation 0,0,1,1 Closed Open Open -----

Axle

waiting Blinking

(2HZ) Blinking

(2HZ) Off Off No

operation 0,0,1,1 Closed Open Open -----

4L waiting On Blinking

(2HZ) Off Off No

operation 1,1,0,1 Closed Closed Closed 4H to 4L

while

waiting

4L On On Off Off No

operation 1,1,0,1 Closed Open Closed -----

2H start

of

operation On On Off Off

2H

position

for 0.1

second

1,1,0,1 Closed Open Closed Switch

operation

sensor

During

operation Blinking

(2HZ) Blinking

(2HZ) Off Off No

operation 1,1,0,1 Closed Open Closed 4L to 4H

while

driving

During

operation

(Passing

through

N)

On Blinking

(2HZ) Off Off No

operation 1,1,0,0 Closed Closed Closed 4L to 4H

through

neutral

During

operation

(Passing

through

N)

Off Blinking

(2HZ) Off Off No

operation 0,1,0,0 Closed Closed Closed 4L to 4H

through

neutral

During

operation

(4H

waiting)

Off Blinking

(2HZ) Off Off No

operation 0,0,1,1 Closed Closed Closed 4L to 4H

while

waiting

During

operation

(Axle)

Off while

waiting for

start of H

shift

Blinking

(2HZ)

while

waiting for

start of H

shift

Off Off No

operation

0,1,1,1

0,1,1,0

0,0,1,0

1,1,1,0

Closed Open Closed 2H to 4H

while

driving

During

operation

(Axle)

Blinking

(2HZ) at

end of H

shift

Off at end

of H shift Off Off No

operation

0,1,1,1

0,1,1,0

0,0,1,0

1,1,1,0

Closed Open Closed Axle

driving

Axle

waiting Blinking

(2HZ) Off Off Off No

operation 1,0,1,0 Open Open Closed -----

2H Off Off Off Off No

operation 1,0,1,0 Open Open Open -----

• Completion of transfer case H-L area and axle shift timing may cause some variation in 2Hz blinking pattern.

Skip operation limitations (4LÆ2H) (Vehicle speed, engine speed, and transmission position not specified)

Item 4WD

lamp 4L lamp Neutral

lamp

Check

4WD

warning

light

4WD

switch

Actuator

detection

(limit)

switches

LS1, LS2,

LS3. and

LS4

1 = on

2 = off

Transfer

4WD

switch

Transfer

neutral

switch

SOF

actuator

switch Remarks

4L Off On Off Off Open 1,1,0,1 Closed Open Closed -----

4L start of

operation Off On Off Off

2H

position

for 0.1

second

1,1,0,1 Closed Open Closed -----

10

second

display

during

limitation

Blinking

(4HZ) Off Off Off Open 1,1,0,1 Closed Open Closed

No

operation

during

limitation

Go to 4L

after 10

seconds Off ON Off Off Open 1,1,0,1 Closed Open Closed -----

Skip operation limitations (2HÆ4L) (Vehicle speed, engine speed, and transmission position not specified)

Item 4WD

lamp 4L lamp Neutral

lamp

Check

4WD

warning

light

4WD

switch

Actuator

detection

(limit)

switches

LS1, LS2,

LS3. and

LS4

1 = on

2 = off

Transfer

4WD

switch

Transfer

neutral

switch

SOF

actuator

switch Remarks

2HL Off Off Off Off Open 1,0,1,0 Open Open Open -----

4L start of

operation Off Off Off Off

2H

position

for 0.1

second

1,0,1,0 Open Open Open -----

10

second

display

during

limitation

Blinking

(4HZ) Blinking

(4HZ) Off Off Open 1,0,1,0 Open Open Open

No

operation

during

limitation

Go to 2H

after 10

seconds Off Off Off Off Open 1,0,1,0 Open Open Open -----

Under some conditions, a secondary operational indication may be received when the 4Hz operational indication is

present.

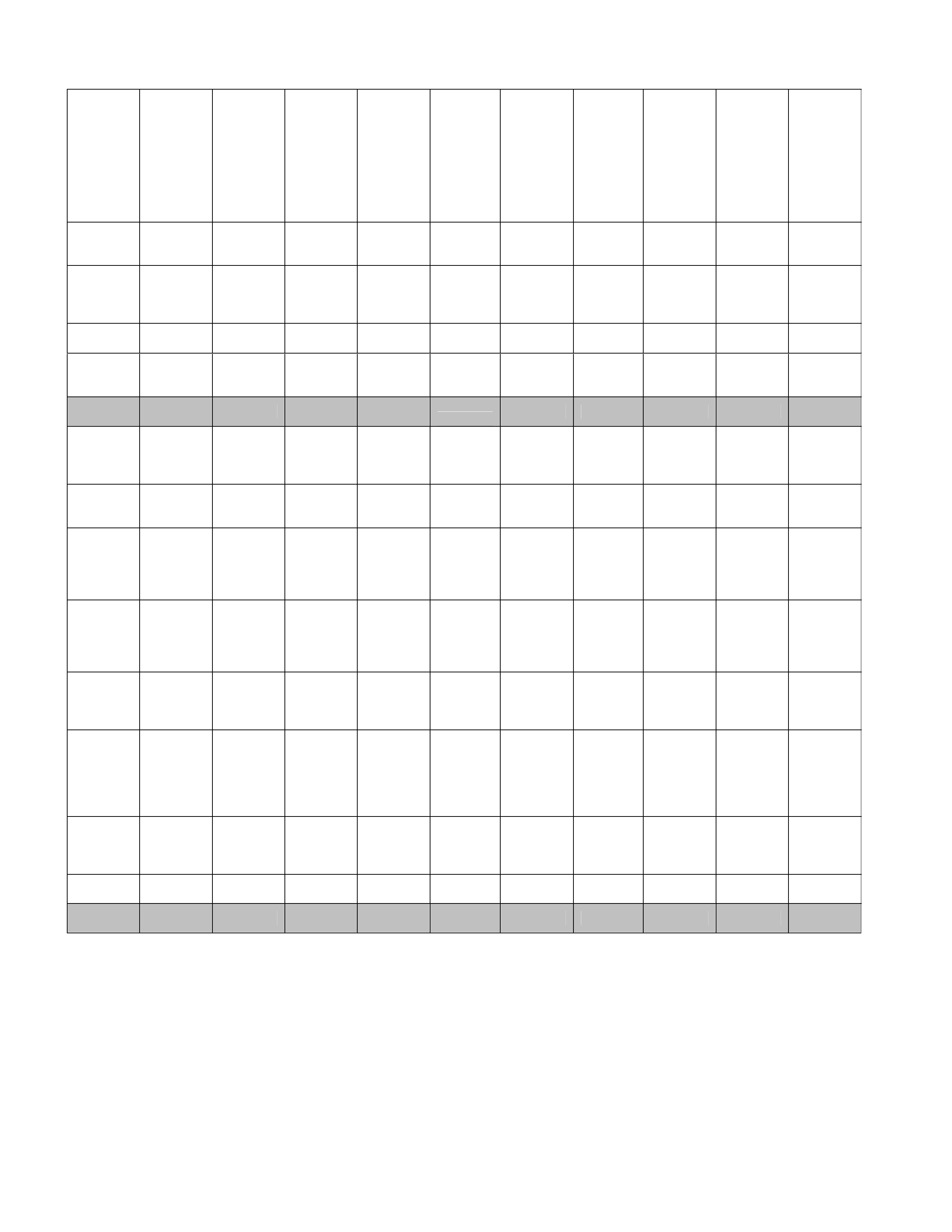

Transfer-related indicator lamp and switch function

2H→Neutral→2H

Item 4WD

lamp 4L lamp Neutral

lamp

Check

4WD

warning

light

4WD

switch

Actuator

detection

(limit)

switches

LS1, LS2,

LS3. and

LS4

1 = on

2 = off

Transfer

4WD

switch

Transfer

neutral

switch

SOF

actuator

switch Remarks

2H Off Off Off Off No

operation 1,0,1,0 Open Open Open -----

Neutral

start of

operation Off Off Off Off

Neutral

position

for 10

seconds

1,0,1,0 Open Open Open Switch

operation

sensor

Start of

operation Off Off Blinking

(2HZ) Off No

operation

1,1,1,0

0,0,1,0

0,1,1,0

0,1,1,1

Open Open Open 2H to 4H

while

driving

During

operation

(Synchro) Off Off Blinking

(2HZ) Off No

operation

1,1,1,0

0,0,1,0

0,1,1,0

0,1,1,1

Open Open Open

2H to 4H

using

synchro

and retrial

During

operation

(Passing

through

4H)

Off Off Blinking

(2HZ) Off No

operation 0,0,1,1 Closed Open Closed -----

During

operation

(Passing

through

4H)

Off Off Blinking

(2HZ) Off No

operation 0,0,0,1

0,1,0,1 Closed Open Closed 4H to 4L

while

driving

During

operation

(N) Off Off Blinking

(2HZ) Off No

operation 0,0,0,1

0,1,0,1 Closed Closed Closed 4H to 4L

through

neutral

During

operation

(N) Off Off Blinking

(2HZ) Off No

operation 0,1,0,0 Closed Closed Closed Switch

operation

sensor

Neutral Off Off On Off No

operation 0,1,0,0 Closed Closed Open -----

2H start

of

operation Off Off On Off

2H

position

for 10

seconds

0,1,0,0 Closed Open Closed Switch

operation

sensor

During

operation

(Passing

through

N)

Off Blinking

(2HZ) Off Off No

operation 0,1,0,0 Closed Closed Closed 4L to 4H

through

neutral

Item 4WD

lamp 4L lamp Neutral

lamp

Check

4WD

warning

light

4WD

switch

Actuator

detection

(limit)

switches

LS1, LS2,

LS3. and

LS4

1 = on

2 = off

Transfer

4WD

switch

Transfer

neutral

switch

SOF

actuator

switch Remarks

During

operation Off Blinking

(2HZ) Off Off No

operation 0,1,0,1

0,0,0,1 Closed Closed Closed 4L to 4H

while

driving

During

operation

(4H

waiting)

Off Blinking

(2HZ) Off Off No

operation 0,0,1,1 Closed Closed Closed 4L to 4H

while

waiting

During

operation

(Axle)

Blinking

(2HZ) Off Off Off No

operation

0,1,1,1

0,1,1,0

0,0,1,0

1,1,1,0

Closed Open Closed 2H to 4H

while

driving

During

operation

(Axle)

Blinking

(2HZ) Off Off Off No

operation

0,1,1,1

0,1,1,0

0,0,1,0

1,1,1,0

Open Open Closed

Axle

driving

Axle

waiting Blinking

(2HZ) Off Off Off No

operation 1,0,1,0 Open Open Closed -----

2H Off Off Off Off No

operation 1,0,1,0 Open Open Open -----

• Operational restrictions (vehicle speed, engine speed, and transmission position) are applicable to transfer shifts in

both directions (H←→Neutral←→L).

4HÆNeutralÆ4H

Item 4WD

lamp 4L lamp Neutral

lamp

Check

4WD

warning

light

4WD

switch

Actuator

detection

(limit)

switches

LS1, LS2,

LS3. and

LS4

1 = on

2 = off

Transfer

4WD

switch

Transfer

neutral

switch

SOF

actuator

switch Remarks

4H On Off Off Off No

operation 0,0,1,1 Closed Open Closed -----

Neutral

start of

operation On On Off Off

Neutral

position

for 10

seconds

1,1,0,1 Closed Open Closed -----

Start of

operation Off Off Blinking

(2HZ) Off No

operation 1,1,0,0 Closed Open Closed

4L to N

while

driving

During

operation

(N) Off Off Blinking

(2HZ) Off No

operation 1,1,0,0 Closed Closed Closed

4L to N

with axle

driving

During

operation

(N) Off Off Blinking

(2HZ) Off No

operation 0,1,0,0 Closed Closed Closed

4L to 4N

with axle

removed

During

operation

(Axle)

Blinking

(2HZ) Off Off Off No

operation

0,1,1,1

0,1,1,0

0,0,1,0

1,1,1,0

Open Open Closed

Axle

driving

Axle

waiting Blinking

(2HZ) Off Off Off No

operation 1,0,1,0 Open Open Closed -----

Neutral Off Off On Off No

operation 0,1,0,0 Closed Closed Open -----

4H start

of

operation Off Off Off Off

2H

position

for 10

seconds

0,1,0,0 Open Open Open Switch

operation

sensor

During

operation

(N) Off Blinking

(2HZ) Off Off No

operation 1,1,0,0 Closed Closed Open 4L to 4H

through

neutral

During

operation

(N) Off Blinking

(2HZ) Off Off No

operation 0,1,0,0 Closed Closed Open 4L to 4H

through

neutral

During

operation Off Blinking

(2HZ) Off Off No

operation 0,1,0,1

0,0,0,1 Closed Closed Open 4L to 4H

while

driving

4H

waiting Blinking

(2HZ) Off) Off Off No

operation 0,0,1,1 Closed Closed Open 4L to 4H

while

waiting

During

operation

(Axle)

Blinking

(2HZ) Off Off Off No

operation 0,0,1,1 Closed Open Open Axle

driving

Axle

waiting Blinking

(2HZ) Off Off Off No

operation 0,0,1,1 Closed Open Open -----

4H On Off Off Off No

operation 0,0,1,1 Closed Open Closed -----

• Operational restrictions (vehicle speed, engine speed, and transmission position) are applicable to transfer shifts in

both directions (H←→Neutral←→L).

4LÆNeutralÆ4L

Item 4WD

lamp 4L lamp Neutral

lamp

Check

4WD

warning

light

4WD

switch

Actuator

detection

(limit)

switches

LS1, LS2,

LS3. and

LS4

1 = on

2 = off

Transfer

4WD

switch

Transfer

neutral

switch

SOF

actuator

switch Remarks

4L On On Off Off No

operation 1,1,0,1 Closed Open Closed -----

Neutral

start of

operation On On Off Off

Neutral

position

for 10

seconds

1,1,0,1 Closed Open Closed -----

Start of

operation Off Off Blinking

(2HZ) Off No

operation 1,1,0,0 Closed Open Closed

4L to N

while

driving

During

operation

(N) Off Off Blinking

(2HZ) Off No

operation 1,1,0,0 Closed Closed Closed

4L to N

with axle

driving

During

operation

(N) Off Off Blinking

(2HZ) Off No

operation 0,1,0,0 Closed Closed Closed

4L to 4N

with axle

removed

During

operation

(Axle)

Blinking

(2HZ) Off Off Off No

operation 0,1,0,0 Closed Closed Closed

Axle

driving

Axle

waiting Blinking

(2HZ) Off Off Off No

operation 0,1,0,0 Closed Closed Closed -----

Neutral Off Off On Off No

operation 0,1,0,0 Closed Closed Open -----

4L start of

operation Off Off On Off

4L

position

for 10

seconds

0,1,0,0 Open Open Open Switch

operation

sensor

During

operation

(N) Off Blinking

(2HZ) Off Off No

operation 1,1,0,0 Closed Closed Open 4H to 4L

through

neutral

During

operation

(N) Off Blinking

(2HZ) Off Off No

operation 1,1,0,0 Closed Closed Open 4H to 4L

through

neutral

During

operation

(N) Off Blinking

(2HZ) Off Off No

operation 1,1,0,0 Closed Closed Open 4H to 4L

through

neutral

4H

waiting On Blinking

(2HZ) Off Off No

operation 1,1,0,1 Closed Closed Open 4L while

waiting

During

operation

(Axle)

Blinking

(2HZ) Off Off Off No

operation 1,1,0,1 Closed Open Open Axle

driving

Axle

waiting Blinking

(2HZ) Off Off Off No

operation 1,1,0,1 Closed Open Open -----

4H On On Off Off No

operation 1,1,0,1 Closed Open Closed -----

• Operational restrictions (vehicle speed, engine speed, and transmission position) are applicable to transfer shifts in

both directions (H←→Neutral←→L).

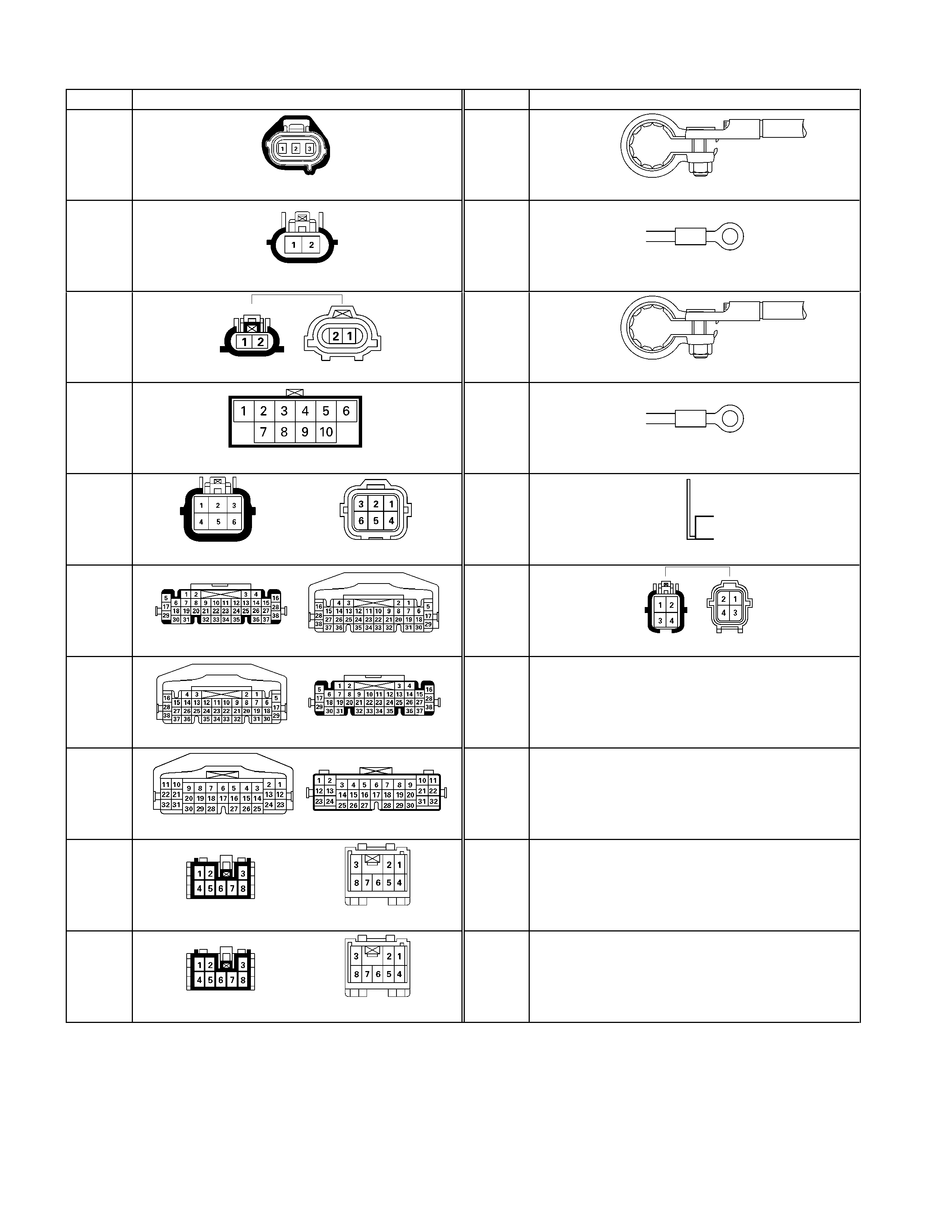

Parts Location

810R300065

810R300066

810R300067

Circuit Diagram

6VE1

RTW38DXF001701

4JH1-TC

RTW38DXF001801

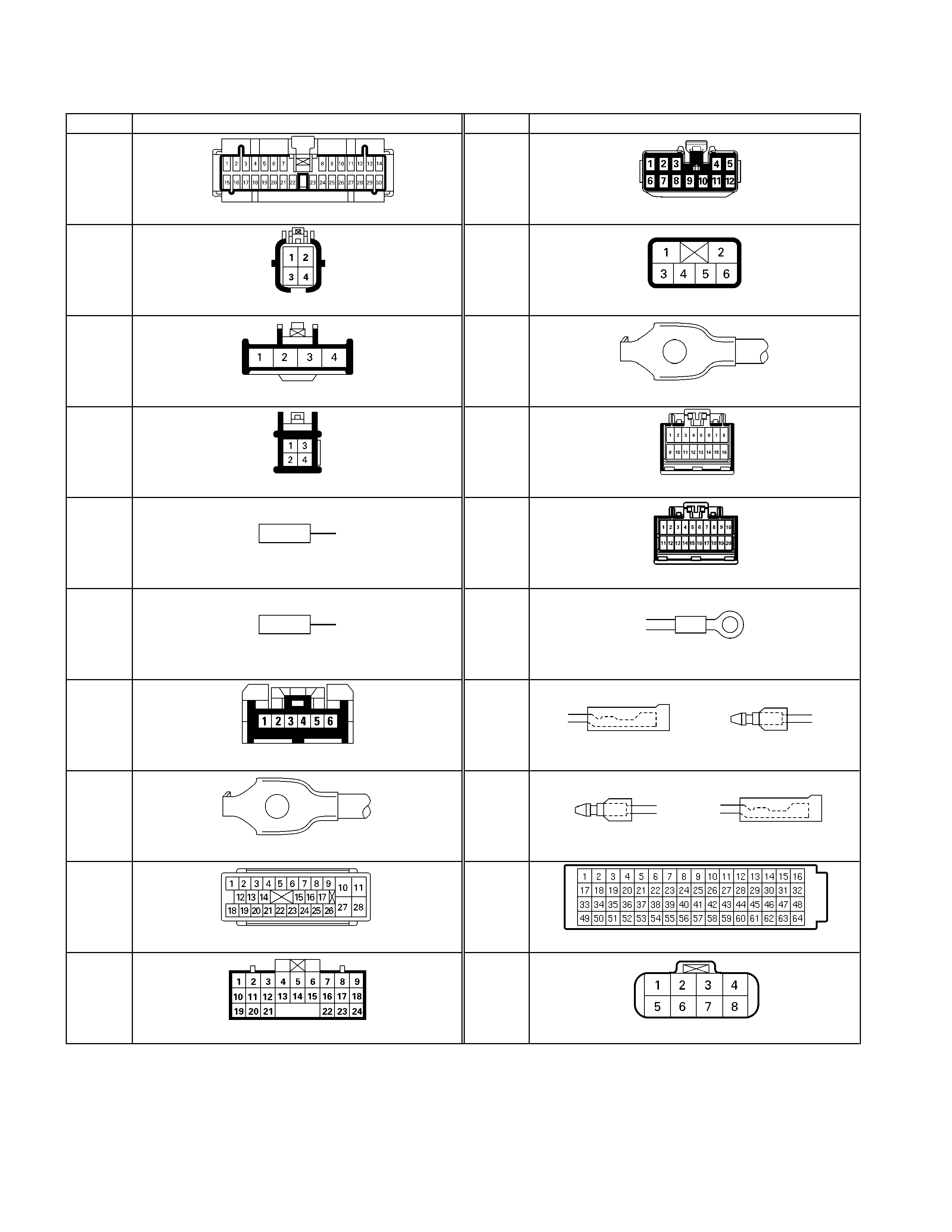

Connector List

No. Connector face No. Connector face

B-24

Green

Meter-B

C-107

White

J/B E2

B-54

White

J/B I2

C-108

White

J/B E1

B-62

White

Ignition switch (IGSUB : G1)

C-109

Silver

Body-LH ; ground

B-63

White

Ignition switch (IGSUB : G2)

R-15

Black

Transfer controller

B-64

Silver

Weld splice 1(Illumination)

R-14

Black

Transfer controller

B-65

Silver

Weld splice 2 (Ground)

E-10

Silver

Engine ground

B-66

White

4WD switch

E-11

(4JH1)

Natural

Green

Neutral switch

C-36

Silver

Engine room-LH ; Ground

E-12

(4JH1)

Natural

Green

Neutral switch

C-67

Black

EHCU

E-33

Black

ECM J2

C-94

Gray

TCM

E-35

Black

Motor actuator

No. Connector face No. Connector face

E44

Gray

Vehicle speed sensor

P-1

Silver

Battery (+)

E-45

White

4WD switch

P-2

Silver

Relay & Fuse box

E-46

Brown

H-L neutral switch

P-5

Silver

Battery (-)

E-51

Black

Inhibiter switch

P-6

Silver

Body earth (Ground)

H-3

(4JH1-

A/T)

White

Battery (+) ∼ Engine room

P-10

Silver

Engine ground

H-4

(4JH1)

White

Engine ∼ Engine room

P-13

(4JH1)

Gray

Shift on the fly actuator

H-6

White

Engine room ∼ INST

H-7

White

Engine room ∼ INST

H-22

(4JA1/H1

-M/T)

Gray

Engine ∼ Engine room C

H-29

(4JH1-

M/T)

White

Battery (+) ∼ Engine room C

Diagnosis

Neither the Transfer Case Control System nor Shift On The Fly (SOF) System can be accessed with the TECH 2 scan

tool. Incorrect diagnosis can be both time-consuming and expensive. Refer to the following for the correct diagnostic

procedures and symptom charts.

ROAD TESTING PRIOR TO REPAIR

Before attempting diagnosis, the vehicle should be road-tested to determine if a mechanical/electrical fault actually

exists. Many reports of incorrect transfer case or S.O.F. system operation can be attributed to the driving conditions at

the time of “failure”.

Noting the operation of the 4WD, 4 Low, Neutral indicator lamps and the CHECK 4WD warning lamp will provide

valuable information when testing the performance of the four wheel drive system. Observe the operating sequence of

the indicator/warning lamps when operating the transfer case controls, then use the information below to determine

whether or not further diagnosis is required.

SHIFTING FROM 2H TO 4H

4WD Indicator Lamp: Flash rate increases from 2Hz to 4Hz.

Probable Cause: High vehicle speed or extremely low operating temperatures.

Corrective Action: Reduce speed or stop the vehicle and perform the required shift.

At high road speed the relative speed difference between the internal components of the transfer case is too high for

the shift to occur. The TCCM will make four attempts to shift from 2H to 4H. If the shift is not achieved on the fourth

attempt, the 4WD indicator lamp frequency will increase to 4Hz for 10 seconds and then go out. The transfer case will

then remain in 2H.

Similarly, extremely low operating temperature (high transfer case oil viscosity) will give rise to excessive component

speed difference.

4WD Indicator Lamp: Flash rate of 2Hz continues for more than 11.5 seconds.

Probable Cause: Speed or phase difference between LH front wheel and front axle.

Corrective Action: If moving, accelerate and decelerate the vehicle in a straight line.

If stationary, move the vehicle backwards and forwards a few metres.

If there is difference of speed and/or phase between the LH front wheel and axle, the S.O.F. system cannot operate

correctly.

Until the both the transfer case and S.O.F. actions are completed, the 4WD Indicator Lamp flashes at a frequency of

2Hz. The indicator continues flashing at a frequency of 2Hz until the S.O.F. internal switch indicates front axle

engagement.

By correcting the difference in relative speeds or axle phase, the S.O.F. action can be completed.

SHIFTING FROM 4H TO 2H

4WD Indicator Lamp: Flash rate of 2Hz continues for more than 11.5 seconds.

Probable Cause: High torque loading on drivetrain components – possible ‘wind-up’ condition.

Corrective Action: If moving, accelerate and decelerate the vehicle in a straight line.

If stationary, move the vehicle backwards and forwards a few metres.

High torque loading of the drivetrain will usually occur if the vehicle is driven in 4WD on hard ground, particularly if

performing turning manoeuvres. The high torque load will prevent the ‘separation’ of the front axle and transfer case

components and the vehicle will remain in 4WD.

Moving the vehicle with the road wheels in the straight ahead position will usually reduce the torque loading

sufficiently to allow the shift from 4H to 2H to complete.

NOTE: In cases of extreme drivetrain ‘wind-up’, it will be necessary to lift the front wheels of the vehicle from the

ground to remove the torque loading. This operation should be performed with extreme caution due to the rapid wheel

movement that occurs when the torque load is released.

SHIFTING FROM 4H TO 4L

4L Indicator Lamp: Flash rate of 2Hz continues for more than 11.5 seconds.

Probable Cause: Spline phase difference between transfer case components.

Corrective Action: A/T – Select [D] range and then [N] range.

M/T – Select 2nd gear and partially engage the clutch, depress the clutch and select

neutral.

Failure to shift due to spline phase difference may occur if the drivetrain is under load. Selecting [D] or [N] (A/T) or

selecting 2nd gear with a gentle application of the clutch (M/T) will generally allow sufficient component movement for

the transfer case shift to complete.

4L Indicator Lamp: Flash rate of 2Hz for 10 seconds, then remains ‘ON’ continuously (A/T only )

Probable Cause: High torque loading on drivetrain components.

Corrective Action: Apply the footbrake and then Select [N] range.

The transfer case H-L Shift Assembly stand-by mechanism cannot overcome the load applied to the H-L shift

components. This condition will usually occur when a high torque loading has been generated between the drivetrain

and the road surface.

Applying the footbrake and then selecting [N] range will allow the components to dissipate the torque loading.

4L Indicator Lamp: Flash rate of 4Hz

Probable Cause: High engine speed.

Transmission not in [N] or [P] – (A/T)

Transmission not in Neutral – (M/T)

Corrective Action: Reduce engine speed to below 2000rpm.

Select correct transmission range.

Push the 4L Transfer Shift switch.

The TCCM will not allow the transfer case to shift from 4H to 4L or from 4L to 4H if the engine speed is above

2000rpm, the transmission is not in neutral (M/T & A/T) or ‘Park ‘ (A/T). Any of these conditions will cause the TCCM to

enter “Restricted Operation” mode.

NOTE:

‘Restricted Operation’ Mode

The 4H, neutral and 4L shifting mechanism has no synchronisation components. Consequently, attempting to shift

with a high relative component speed difference may lead to component failure. To avoid this incidence, the

TCCM will restrict transfer case and S.O.F. operation if any or all of the following conditions are detected:

Vehicle is moving.

Engine Speed above 2000rpm.

Transmission not in neutral (M/T & A/T) or ‘Park ‘ (A/T).

The programming of the TCCM logic circuit includes a Wait-Time function. When certain conditions are detected via

the input signals to the TCCM, a delay (wait time) will be encountered before the transfer case or S.O.F.

system will operate in response to a driver command.

A/T: If the vehicle has been idling in any drive range for up to three minutes, the wait-time will be between one and

five seconds.

M/T: If the vehicle has been idling, with the transmission in any gear and the clutch disengaged, for up to three

minutes, the wait-time will be between one and five seconds.

Should either of the above conditions be continued for longer than three minutes, the wait-time will increase to a

maximum of three minutes.

Wait-time can be reduced to zero by turning the ignition OFF, then ON or driving the vehicle for 5 metres.

SHIFTING FROM 4L TO 4H

4L Indicator Lamp: Flash rate of 2Hz continues for more than 11.5 seconds.

Probable Cause: Spline phase difference between transfer case components.

Corrective Action: A/T – Select [D] range and then [N] range.

M/T – Select 2nd gear and partially engage the clutch, depress the

clutch and select neutral.

Failure to shift due to spline phase difference may occur if the drivetrain is under load. Selecting [D] or [N] (A/T) or

selecting 2nd gear with a gentle application of the clutch (M/T) will generally allow sufficient component movement for

the transfer case shift to complete.

4L Indicator Lamp: Flash rate of 2Hz for 10 seconds, then remains ‘ON’ continuously (A/T only )

Probable Cause: High torque loading on drivetrain components.

Corrective Action: Apply the footbrake and then Select [N] range.

The transfer case H-L Shift Assembly stand-by mechanism cannot overcome the load applied to the H-L shift

components. This condition will usually occur when a high torque loading has been generated between the drivetrain

and the road surface.

Applying the footbrake and then selecting [N] range will allow the components to dissipate the torque loading.

4L Indicator Lamp: Flash rate of 4Hz

Probable Cause: High engine speed.

Transmission not in [N] or [P] – (A/T)

Transmission not in Neutral – (M/T)

Corrective Action: Reduce engine speed to below 2000rpm.

Select correct transmission range.

Push the 4H Transfer Shift switch.

The TCCM will not allow the transfer case to shift from 4H to 4L or from 4L to 4H if the engine speed is above

2000rpm, the transmission is not in neutral (M/T & A/T) or ‘Park ‘ (A/T). Any of these conditions will cause the TCCM

to enter “Restricted Operation” mode.

SHIFTING FROM 4L OR 4H TO NEUTRAL

Neutral Indicator Lamp: Flash rate of 2Hz continues for more than 11.5 seconds.

Probable Cause: Spline phase difference between transfer case components.

Corrective Action: A/T – Select [D] range and then [N] range.

M/T – Select 2nd gear and partially engage the clutch, depress the

clutch and select neutral.

Failure to shift due to spline phase difference may occur if the drivetrain is under load. Selecting [D] or [N] (A/T) or

selecting 2nd gear with a gentle application of the clutch (M/T) will generally allow sufficient component movement for

the transfer case shift to complete.

Neutral Indicator Lamp: Flash rate of 4Hz

Probable Cause: High engine speed.

Transmission not in [N] or [P] – (A/T)

Transmission not in Neutral – (M/T)

Corrective Action: Reduce engine speed to below 2000rpm.

Select correct transmission range.

Push and hold the 2H and 4L Transfer Shift switches for 10 seconds.

The TCCM will not allow the transfer case to shift fr om 2H, 4H or 4L Neutral if the engine speed is above 2000rpm,

the transmission is not in neutral (M/T & A/T) or ‘Park ‘ (A/T). Any of these conditions will cause the TCCM to enter

“Restricted Operation” mode.

SHIFTING FROM NEUTRAL TO 2H, 4H OR 4L

4L or 4WD Indicator Lamp: Flash rate of 2Hz continues for more than 11.5 seconds.

Probable Cause: Spline phase difference between transfer case components.

Corrective Action: A/T – Select [D] range and then [N] range.

M/T – Select 2nd gear and partially engage the clutch, depress the clutch and select

neutral.

Failure to shift due to spline phase difference may occur if the drivetrain is under load. Selecting [D] or [N] (A/T) or

selecting 2nd gear with a gentle application of the clutch (M/T) will generally allow sufficient component movement

for the transfer case shift to complete.

4WD INDICATOR LAMP FLASHES WHEN IGNITION IS TURNED ON

4WD Indicator Lamp: Flash rate of 2Hz.

Probable Cause: Ignition turned OFF with 4H or 4L selected.

Corrective Action: A/T – Select [D] range and then [N] range.

M/T – Select 2nd gear and partially engage the clutch, depress the

clutch and select neutral.

When the ignition is first turned ON, the TCCM initialises and commands the Shift Actuator motor to the 2WD

position. At the completion of initialisation, the TCCM will the command the Shift Actuator motor to the last selected

position. Failure to shift to that position may be due to spline phase difference if the drivetrain is under load.

Selecting [D] or [N] (A/T) or selecting 2nd gear with a gentle application of the clutch (M/T) will generally allow

sufficient component movement for the transfer case shift to complete.

‘CHECK 4WD’ INDICATOR LAMP ON WHEN IGNITION IS ON

‘CHECK 4WD’ Indicator Lamp: ON when ignition is turned ON

Probable Cause: Failure of Shift Actuator motor or harness

Corrective Action: Conduct the test procedure outlined below, replace failed components.

The initial test is best performed at the TCCM. Refer to the chart below for the test conditions and to the TCCM Pin

Out illustration on 7D1-10 for the correct harness pin location.

Should the test fail at Step 1, remove the harness connector with the transfer case in each drive range, and

conduct the test on the respective Limit Switch pin 7D1-9

If the test fails at step 1, but passes at step 2, then a harness/connector fault is the most probable cause of the

CHECK 4WD lamp illuminating.

NOTE:

The ignition switch must be in the OFF position whenever removing or replacing the TCCM or Limit Switch harness

connectors.

Under no circumstances should the Transfer Case Actuator harness connector be back-probed. This will damage the

weather-pak seal, leading to possible failure of the system due to contamination of the harness connector and actuator

pins.

2H 4H N 4L

LS1 Closed Open Open Closed

LS2 Open Open Closed Closed

LS3 Closed Closed Open Open

LS4 Open Closed Open Closed

NOTE:

“Closed” indicates continuity between the respective pin and GND pin. (Continuity should also exist between the

“Closed” pins.)

Trouble diagnosis based on the operation switch, transfer indicator lamp and operating sound “Check 4WD”

indicator ON (operation guard based on the transfer actuator position detection error)

This condition indicates a faulty circuit related with the detection (limit) switches of the system actuator.

The ECU determines the actuator operating angle based on the combined Detection (limit) switches signals.

The controller monitors transition of the actuator based on the combination of the detection (limit) switch output.

If the transition based on the combinations indicates some trouble, it is memorized, shifting operation is stopped

when the trouble is counted 5 times, and the “Check 4WD” indicator lights up. At this time, the system permits

operation to 2H only.

When such a condition results, inspection of the transfer shift actuator, check of harness related with the detection

(limit) switch, and erasure of the memory of the controller are required.

(Refer to the memory erasure procedure for the erasure of the memory.)

At this time, the position indicator may flash at 4Hz. It means that a detection (limit) switch trouble wad detected in

the operation process shown by that position indicator (example: 4WD indicator when shifting from 2H to 4H).

Caution:

In the course of fault diagnosis and correction, do not turn ON the ignition with the harness connector of the

transfer actuator disconnected. (Do not disconnect the harness connector of the transfer actuator when the

ignition is ON.)

If the controller is connected at this condition, a “Limit SW Failure” is set and the above-described “Check

4WD” condition is brought about.

This can be reset by clearing the memory.

When it is required to disconnect the harness connector of the actuator and turning the ignition ON, remove

the controller at the same time or remove the IG power fuse of the transfer controller.

TCCM Memory Erasing Procedure

Circuit Description

The “CHECK 4WD” indicator lamp is ON when the Transfer Case

Control module (TCCM) detects a faulty circuit related to the limit

switches of the shift-actuator.

The limit switches detect the shift-actuator operating angle based on

their combinations. The TCCM monitors the transition of the shift-

actuators based on the combination of the limit switch outputs.

If the transition based on the combinations indicates some trouble, it

is memorised by the TCCM.

NOTE:

1. Do Not Turn the ignition ON with the TCCM harness connector

disconnected.

2. Do Not Turn the ignition ON with the shift actuator harness

connector disconnected.

3. Do Not Turn the ignition ON with the in-line connector

disconnected.

If any of the above conditions occur, the TCCM will assume a limit

switch problem and will activate the “CHECK 4WD” indicator lamp.

When any connectors need to be disconnected, disconnect the

TCCM harness connector with the ignition key tur ned OFF or remove

the “ABS” fuse in the cabin to disable the TCCM.

The TCCM cannot be disabled by removing the “4WD” fuse in the

engine compartment. It will cause the “CHECK 4WD” to be activated.

Once the “CHECK 4WD” is ON, it cannot be turned OFF until the

erasing procedure is completed, even if the problem has been

corrected. The memory is not erased by key cycles.

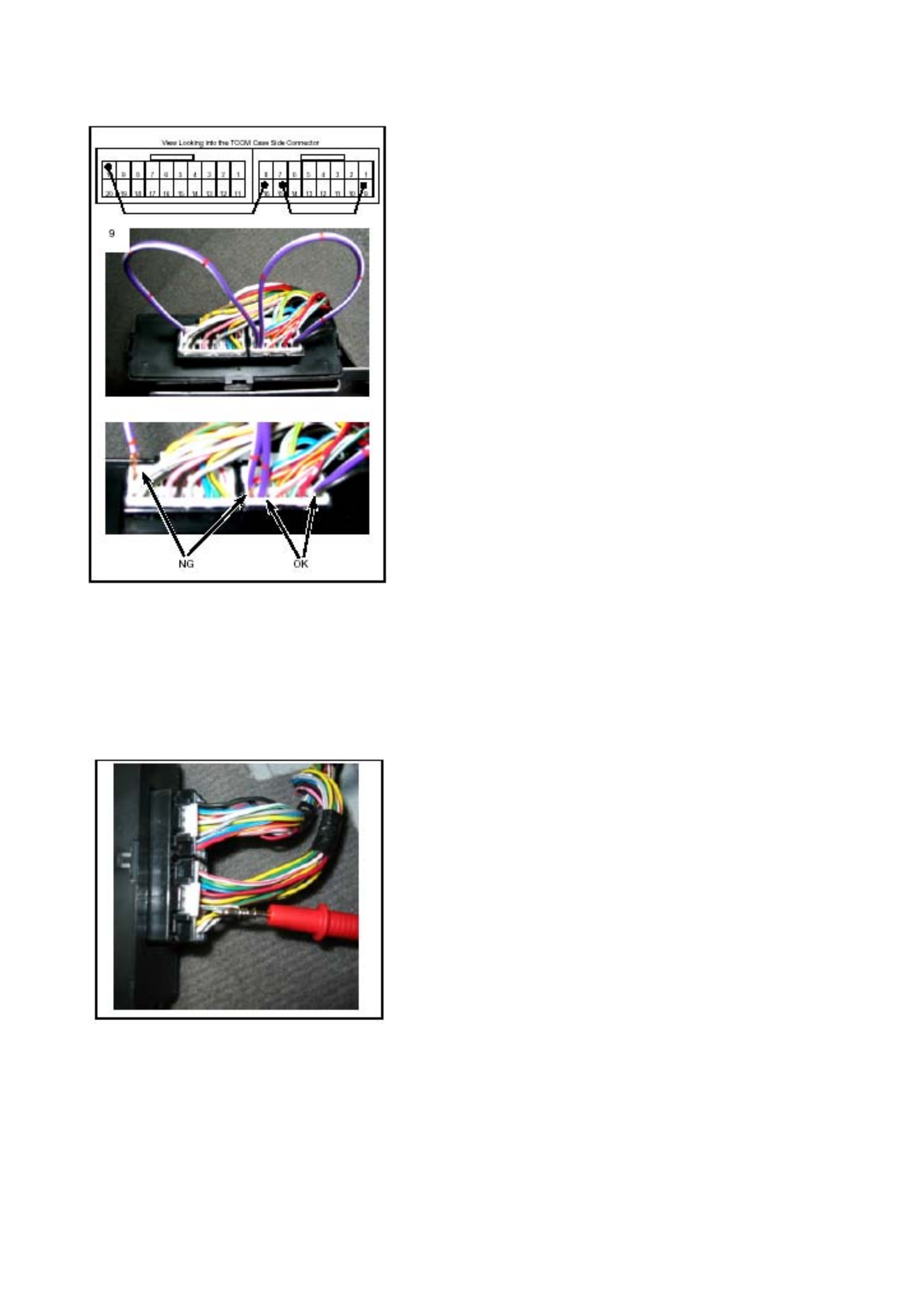

TCCM Memory Erasing Procedure

1. Prepare two pieces of 0.5 mm wiring, approximately 150 mm

long to form two jumper-harnesses.

2. Strip the wire insulation by 10 – 15mm at each end.

3. Cut the stripped wire to reduce the wire size in half, at each , then

twist the exposed wires. Soldering the wires will improve

stiffness.

4. Turn OFF the ignition switch.

5. Disconnect the seat belt s witch and/or SRS pretens ioner harness

connectors, if fitted.

6. Remove the front seat assembly.

7. Spread the cut line of the floor carpet or roll up the floor carpet.

8. Remove two bolts and protective cover. Pull the TCCM out onto

the carpet.

9. With the TCCM harness connector still connected, insert the

jumper-harnesses into the ba ck of the connectors:

One end of jumper wire #1 into cavity 10 of the 20 pin connector

and cavity 16 of the 16 pin connector.

Insert jumper wire #2 into cavities 9 and 15 of the 16 pin

connector.

When fully installed, none of the stripped wire should be visible.

NOTE:

The jumper-harness must be installed in the correct positions as

shown in the picture on the left.

Inadequate installation or installation in the wrong connector cavities

will cause the memory erasing procedure to fail or cause the “ABS”

fuse to fail.

10. Turn the ignition switch ON more than 3 seconds

11. Turn OFF the ignition s witch, then remove the jum per wires from

the TCCM connectors.

12. Turn the ignition switch ON then, after the bulb check process,

verify the “CHECK 4WD” indicator lamp is OFF.

If the “CHECK 4WD” indicator lamp stays ON, repeat the TCCM

memory erasing procedure again as described, or perform the

limit switch circuit test.

13. Reinstall all removed parts and reconnect all disconnected

harness connector(s).

Test 1

Check the TCCM output voltage at the harness conn ector, using a

multi-meter.

Test Condition:

1. Ignition switch is ON.

2. Probe the test-lead from the back of the connector as shown in

the picture on the left.

3. Measure the output voltage at each transfer case position.

NOTE:

Use fine wire around the test lead prob es to prevent damage to the

rear of the connector.

The following causes can be considered when the voltage need ed is

ignition voltage (10-14.5V) and output voltage is less than needed.

• There is a circuit short to ground between the TCCM and the

shift-actuator.

• Faulty limit switch in the shift-actuator.

• Faulty TCCM.

The following causes can be considered when the voltage need ed is

less than 1V and output voltage is more than nee ded.

• Circuit is short to battery or ignition voltage between the TCCM

and the shift actuator.

• Faulty limit switch in the shift actuator.

• Faulty TCCM.

Output Voltage Status at Each Transfer Position Measurement

Terminal

Connector

Terminal

No. Pin Function Wire

Colour 2H 4H

4L

Neutral

(+) (–)

14 Limit Switch 1 PNK Less than 1 V Ignition

voltage

(10–14.5 V) Less than 1 V Ignition voltage

(10–14.5 V) 14 GND

5 Limit Switch 1

GRN/

ORG Ignition voltage

(10–14.5 V) Less than 1 V 5 GND

16 Limit Switch 3 GRY Less than 1 V Ignition voltage

(10–14.5 V) 16 GND

17 Limit Switch 4 WHT

Ignition voltage

(10–14.5 V) Less than 1 V Ignition voltage

(10–14.5 V) 17 GND

Test 2

Shift-actuator limit switch continuity testing at the shift-actuator

connector with a multimeter.

Test Condition:

• While the harness connector is disconnected, ignition switch

must be in the OFF position.

• Measure the continuity between the limit switch terminal and

ground terminal at each transfer position.

Test Result:

A faulty limit switch in the shift-actuator is indicated, when continuity

is expected and non-continuity results or when non-continuity is

expected and continuity results.

Output Voltage Status at Each Transfer Position

Connector

Terminal

No. Pin Function 2H 4H

4L

Neutral

Measurement

Terminal

14 Limit Switch 1 Continuity Non

Continuity Continuity Non

Continuity 5 & 8

5 Limit Switch 1 Non Continuity Continuity 4 & 8

16 Limit Switch 3 Continuity Non Continuity 7 & 8

17 Limit Switch 4 Non Continuity Continuity Non

Continuity 6 & 8

Test 3

Test the TCCM and shift-actuator harness continuity at the harness

connectors, using a multi-meter.

Test Condition:

While the harness connector is disconnected, ignition switch must be

OFF.

• Measure the continuity in each circuit, as detaile d in the following

table. Make sure that the correct cavity numbers are tested.

• Measure the non-continuity in each circuit, as detailed in the

following table. Make sure that the correct cavity numbers are

tested.

Test Result:

A wiring harness problem is expected when:

• An open circuit is found, when continuity is required and non-

continuity is the result.

• When non-continuity is needed and continuity is the result, a

short circuit to other limit switch circuits is probable.

Measurement Terminal

Pin Function Wire

Colour Continuity

Status TCCM

Connector Shift Actuator

Connector

Limit Switch 1 PNK Continuity 17 5

Limit Switch 2 GRN/ORG Continuity 6 4

Limit Switch 3 GRY Continuity 15 7

Limit Switch 4 WHT Continuity 14 6

Diagnosis from symptom

Check4WD lighting up

Step Action Yes No

1 Check what was done before

the trouble occurred.

Was the harness between the

transfer controller and actuator

disconnected with the ignition

kept ON for the purpose of

servicing the vehicle, etc.?

Or, was the ignition turned ON

(power supplied to the transfer

controller) with the harness of

the actuator removed?

If the power is supplied with the

actuator not connected, faulty

position detection switch is

considered.

Clear the memory and trace this

chart from the beginning.

Go to step 2.

2 Is the ignition switch ON? Go to step 3. Turn the ignition switch ON and

trace this chart from the

beginning.

3 Does the transfer-related

indicators (4WD, 4Lo, Check

4WD, neutral) light up for 2

seconds when the ignition

switch is turned ON?

Go to step 4. Indicator lamp burnt out.

Disconnected harness wire .

After repairing, trace this chart

from the beginning.

4 Is the harness between the

Check4WD indicator and

transfer controller GND

shorted?

GND (body) short of the indicator

harness.

After repairing, trace this chart

from the beginning.

Go to step 5.

5 Check the continuity of harness

between the transfer controller

and transfer actuator. Check

the power short and GND short.

Check the GND harness of the

transfer actuator.

Is a trouble noticed?

Repair the harness, clear the

memory and trace this chart from

the beginning.

Go to step 6.

6 Check the limit switch of the

actuator.

Is a trouble noticed?

Failed actuator. Replace the

actuator, clear the memory and

trace this chart from the

beginning.

Clear the memory and trace this

chart from the beginning.

Failed controller.

Replace the controller, clear the

memory and trace this chart from

the beginning.

To check the operation after completing the repair and clearing the memory, shift between 2H and 4L at least 5 times.

To judge the condition more quickly, ask the customer the situation when the Check 4WD lamp illuminated.

(Since it indicates the situation immediately before detection of failure whether the vehicle is running or standstill, that

possibility of failure around that point is high.)

Cannot shift from 2WD to 4H or 4L.

When shifting from 2H to other position, the indicator (4WD, 4Lo, Check 4WD, neutral) does not respond.

Step Action Yes No

1 Is the ignition switch ON? Go to step 2. Turn the ignition switch ON and

trace this chart from the

beginning.

2 Does the transfer-related

indicators (4WD, 4Lo, Check

4WD, neutral) light up for 2

seconds when the ignition

switch is turned ON?

Failed operation switch. Only 2H

is stuck at ON condition and 4H-

4L position is internally

disconnected. Or,

Failed controller

Indicator lamp burnt out.

Disconnected harness wire .

After repairing, trace this chart

from the beginning.

Even after correction step 1-1(*), 4WD indicator blinks at 4Hz and changes to 2H after 10 seconds.

Step Action Yes No

1 Is the ignition switch ON? Go to step 2. Turn the ignition switch ON and

trace this chart from the

beginning.

2 Does the transfer-related

indicators (4WD, 4Lo, Check

4WD, neutral) light up for 2

seconds when the ignition

switch is turned ON?

Go to step 3. Indicator lamp burnt out.

Disconnected harness wire.

After repairing, trace this chart

from the beginning.

3 After 2 seconds, check that the

Check4WD lamp is ON or OFF.

Is the Check4WD lamp OFF?

Go to step 4. Failed actuator position detection

switch (LS1, LS2, LS3, LS4,

GND).

Short or disconnection of harness

of this detection switch.

After repairing, trace this chart

from the beginning.

4 Press the 4H button.

Is sound of relay heard from the

transfer control?

Go to step 5. Failed controller.

Replace the controller and trace

this chart from the beginning.

5 Is the sound of running motor

heard? Failed control system of the

transfer mechanism. Check and

repair and trace this chart from

the beginning.

Failed actuator motor.

Disconnected controller motor

drive output circuit, GND short

circuit. +B fuse blown out.

Disconnection of that harness.

After repairing, trace this chart

from the beginning.

*Before determining cause of a failure (No fault mode)

Even after performing step 1-2(*), the 4WD indicator still blinks at 2Hz when shifting from 2H to 4H.

Step Action Yes No

1 Check the air pressure and

wear of all the tires. Is any

trouble apparent?

After adjusting the air pressure

and repairing the tire worn away,

try the correction step 1-2(*).

Go to step 2.

2 Check the 4WD detection switch

on the transfer case, neutral

detection switch and each

harness. Is a fault apparent?

4WD detection switch is open or

the harness failed.

The neutral detection switch is

closed or the harness GND is

shorted.

Replace or repair and then trace

this chart from the beginning.

Go to step 3.

3 Is there continuity in the harness

between the transfer controller

and front axle controller? Isn’t a

body short or disconnection

noticed?

Go to step 4. Body short or disconnection of

the harness between the transfer

controller and front axle

controller.

After repairing, trace this chart

from the beginning.

4 Is there continuity in the harness

between the axle controller and

actuator?

Isn’t short or disconnection

noticed?

Isn’t the connection mistaken?

Go to step 5. Body short, disconnection or

incorrect connection of the

harness between the axle

controller and actuator.

After repairing, trace this chart

from the beginning.

5 Is a fault present in the axle

detection switch harness

between the axle actuator and

transfer controller?

Disconnected harness.

After repairing trace this chart

from the beginning.

GND disconnection of axle

actuator.

Malfunction of axle actuator.

Malfunction of axle controller.

Refer to the paragraph of the

axle disconnect.

After repairing, trace this chart

from the beginning.

*Before determining cause of a failure(No fault mode)

After operation, 4WD indicator blinks for 1.5 sec. at 2Hz, return to 2H condition (4WD indicator going out)

Step Action Yes No

1 Keep to press the 4H button

(about 10 seconds).

Does the 4WD indicator blink at

2Hz for 15 seconds and then

blink at 4Hz?

Failed actuator motor.

Disconnection of controller motor

drive output circuit, or GND short.

+B fuse blown out.

Disconnection of that harness.

After repairing, trace this chart

from the beginning.

Go to step 2.

2 Press the 4H button.

Is the sound of relay heard from

the transfer controller?

Go to step 3. Failed controller.

Replace the controller and trace

this chart from the beginning.

3 Is the sound of running motor

heard? Failed control system of the

transfer mechanism. Check and

repair and trace this chart from

the beginning.

Failed actuator motor.

Disconnection or GND short of

controller motor drive output

circuit.

After repairing, trace this chart

from the beginning.

Transfer cannot shift to a position other than 4H.

When shifting from 4H to other position, indicator (4WD, 4Lo, Check 4WD, neutral) does not respond (4WD

stays illuminated).

Step Action Yes No

1 Is the ignition switch ON? Go to step 2. Failed 4WD indicator and

harness.

After repairing, trace this chart

from the beginning.

2 Do the transfer-related

indicators (4WD, 4Lo, Check

4WD, neutral) light up for 2

seconds when the ignition

switch is turned ON?

Then, only 4H lights up.

Go to step 3. Indicator lamps other than the

4WD indicator are burnt out.

(Check for GND short circuit

between the 4WD indicator and

transfer controller.)

Disconnected harness wire.

After repairing, trace this chart

from the beginning.

3 Press the 2H button.

Is the sound of relay heard from

under the seat, and the sound of

running motor heard?

Failed controller.

After replacing the controller,

trace this chart from the

beginning.

*Failed operation switch. Or

disconnected or shorted of the

harness for the operation switch.

* The operation switch is an analog type switch that reads the internal composite resistance value at the time of

operation. If an abnormal value is detected, it is judged to be an instruction to shift into 4H.

Even after the correction step 2-1(*), the 4WD indicator still blinks at 2Hz when shifting from 4H to 2H.

Step Action Yes No

1 Check all the tires for air

pressure and wear. Is any

trouble noticed?

After adjusting the air pressure

and repairing the tire worn away,

try the correction step 2-1(*).

Go to step 2.

2 Check the 4WD detection switch

on the transfer case and neutral

detection switch and each

harness. Is a fault apparent?

4WD detection switch is closed

or the GND short of harness.

The neutral detection switch is

closed or the harness GND is

shorted.

Replace or repair and then trace

this chart from the beginning.

Go to step 3.

3 Is there continuity in the harness

between the axle controller and

axle actuator?

Isn’t short or disconnection

noticed?

Isn’t the connection mistaken?

Go to step 4. Body short, disconnection or

incorrect connection of the

harness between the axle

controller and actuator.

After repairing, trace this chart

from the beginning.

4 Is a trouble apparent in the axle

detection harness between the

axle actuator and transfer

controller?

GND short of harness Malfunction of axle actuator.

Malfunction of axle controller.

Refer to the paragraph of axle

disconnect.

After repairing, trace this chart

from the beginning.

*Before determining cause of a failure (No fault mode)

Though the indicator responds when shifting from 4H to 2H(or other position), it returns to 4H.

Step Action Yes No

1 Is the ignition switch ON? Go to step 2. Turn the ignition switch ON and

trace this chart from the

beginning.

2 Does the transfer-related

indicators (4WD, 4Lo, Check

4WD, neutral) light up for 2

seconds when the ignition

switch is turned ON?

Go to step 3. Indicator lamp burnt out.

Disconnected harness wire.

After repairing, trace this chart

from the beginning.

3 After 2 seconds, check if the

Check4WD lamp lights up.

Is the Check4WD lamp OFF?

Go to step 4. Failed actuator position detection

(limit) switch (LS1, LS2, LS3,

LS4, GND).

Short or disconnection of

harness of this detection switch.

Refer to paragraph of

Check4WD.

After repairing, trace this chart

from the beginning.

4 Press the 2H button.

Is the sound of relay heard from

the transfer controller?

Go to step 5. Failed controller.

Replace the controller and trace

this chart from the beginning.

5 Is the sound of running motor

heart? Failed control system of the

transfer mechanism. Check and

repair and trace this chart from

the beginning.

Failed actuator motor.

Disconnection of controller motor

drive output circuit or GND short.

After repairing, trace this chart

from the beginning.

If the motor does not or cannot run at all (stuck transfer mechanism, disconnected motor, failed drive circuit), the lamp

blinks at 4Hz when the position is shifted to other position by pressing the button for more 10 seconds (20 seconds in

case of neutral position).

From 4H to 4L; Even after the correction step 3-3(*), 4Lo indicator blinks at 4Hz

Step Action Yes No

1 Is the ignition switch ON? Turn it OFF once. Go to step 2.

2 Turn ON the ignition switch and

check the valve. Do not start

the engine.

Has the valve check for 2

seconds been completed

normally?

Go to step 3. Refer to the paragraph about the

indicator when it does not react

when shifted from 2H to 4H.

After taking the remedy, trace

this chart from the beginning.

3 Shift to 2H.

Can be shifted to 2H and then to

4H?

Go to step 4. Refer to the paragraph about

shifting from 2H to 4H.

In particular, check if not at the

Check4WD condition, return to

this chart and trace it from the

beginning.

4 Set to N or P position in case of

AT and set to the neutral

position in case of MT and

check if the lamp blinks at 4Hz

after operation.

Failed T/M position switch and

harness (failure of TM1 and TM2

harness and their related

switches shown in the figure).

Incorrect wiring.

Repair as required and trace this

chart from the beginning.

Shift back to 4H and go to step 5.

5 Start the engine and travel the

vehicle.

Does the speedometer run at

this time?

Go to step 6. Failure of speed sensor or

disconnection or short of harness

(for the meter).

After repairing, trace this chart

from the beginning.

6 Check the harness between the

transfer controller and speed

sensor.

(Check the engine rotation

detection harness at the same

time.)

Is any trouble noticed?

Failed harness between the

transfer controller and speed

sensor.

After repairing, trace this chart

from the beginning.

(Repair the engine rotation

detection unit, if required.)

Go to step 7.

7 Drive the vehicle several

metres, stop, and meet the

requirements for operation.

Did you wait for several seconds

after the requirements were

met?

Failed controller.

Replace the controller and trace

this chart from the beginning.

You did not wait for enough time.

Optimum waiting time is 1

second or maximum 3 minutes

depending on the previous

conditions.

Refer to the paragraph about

operation without failure.

*Before determining cause of a failure (No fault mode)

From 4L to 4H: After the correction step 4-3(*), 4Lo indicator blinks at 4H.

Step Action Yes No

1 Is the ignition switch ON? Turn it OFF once. Go to step 2.

2 Turn ON the ignition switch and

check the valve. Do not start

the engine.

Has the valve check for 2

seconds been completed

normally?

Go to step 3. Refer to the paragraph about the

indicator when it does not react

when shifted from 2H to 4H.

After taking the remedy, trace

this chart from the beginning.

3 Can be shifted to 2H and then to

4L? Go to step 4.

(Impossible usually.)

Failed controller

In case of Check 4WD, shifting to

2H is possible.

Returning to 4L is impossible.

Refer to the paragraph about

Check4WD.

4 Set to N or P position in case of

AT and set to the neutral

position in case of MT and

check if the lamp blinks at 4Hz

after operation.

Failed T/M position switch and

harness (failure of TM1 and TM2

harness and their related

switches shown in the figure).

Incorrect wiring.

Repair as required and trace this

chart from the beginning.

Press the operation switch of 4L

and go to step 5.

5 Start the engine and travel the

vehicle.

Does the speedometer run at

this time?

Go to step 6. Failure of speed sensor or

disconnection or short of harness

(for the meter).

After repairing, trace this chart

from the beginning.

6 Check the harness between the

transfer controller and speed

sensor.

(Check the engine rotation

detection harness at the same

time.)

Is any trouble noticed?

Failed harness between the

transfer controller and speed

sensor.

After repairing, trace this chart

from the beginning.

(Repair the engine rotation

detection unit, if required.)

Go to step 7.

7 Drive the vehicle several

metres, stop, and meet the

requirements for operation.

Did you wait for several seconds

after the requirements were

met?

Failed transfer controller.

Replace the controller and trace

this chart from the beginning.

You did not wait for enough time.

Optimum waiting time is 1

second or maximum 3 minutes

depending on the previous

conditions.

Refer to the paragraph about

operation without failure.

*Before determining cause of a failure (No fault mode)

To neutral: After the correction step 5-2(*), neutral indicator blinks at 4Hz.

Check the function between H and L according to the chart for 4L to 4H instead of check for the requirements

of neutral.

Step Action Yes No

1 Is the ignition switch ON? Turn it OFF once. Go to step 2.

2 Turn ON the ignition switch and

check the valve. Do not start the

engine.

Has the valve check for 2

seconds been completed

normally?

Go to step 3. Refer to the paragraph about the

indicator when it does not react

when shifted from 2H to 4H

(7D1-37).

After taking the remedy, trace

this chart from the beginning.

3 Can be shifted to 2H and then to

4L? Go to step 4.

(Impossible usually.)

Failed controller

Refer to the paragraph about

shifting from 2H to 4H.

In particular, check if not at the

Check4WD condition, return to

this chart and trace it from the

beginning.

In case of Check4WD, shifting to

2H is possible.

Returning to 4H is impossible.

Refer to the paragraph about

Check4WD.

4 Set to N or P position in case of

AT and set to the neutral position

in case of MT and check if the

lamp blinks at 4Hz after

operation.

Failed T/M position switch and

harness (failure of TM1 and TM2

harness and their related

switches shown in the figure).

Incorrect wiring.

Repair as required and trace this

chart from the beginning.

Shift back to 4H and go to step 5.

5 Start the engine and travel the

vehicle.

Does the speedometer run at this

time?

Go to step 6. Failure of speed sensor or

disconnection or short of harness

(for the meter).

After repairing, trace this chart

from the beginning.

6 Check the harness between the

transfer controller and speed

sensor.

(Check the engine rotation

detection harness at the same

time.)