SECTION 8A

ELECTRICAL-BODY AND CHASSIS

General Information

Notes for Working on Electrical Items

Symbols and Abbreviations

Symbols

Abbreviations

Parts for Electrical Circuit

Wiring

Fuse

Fusible Link

Relay

Diode

Connector

Battery

Reading the Circuit Diagram

Parts Location

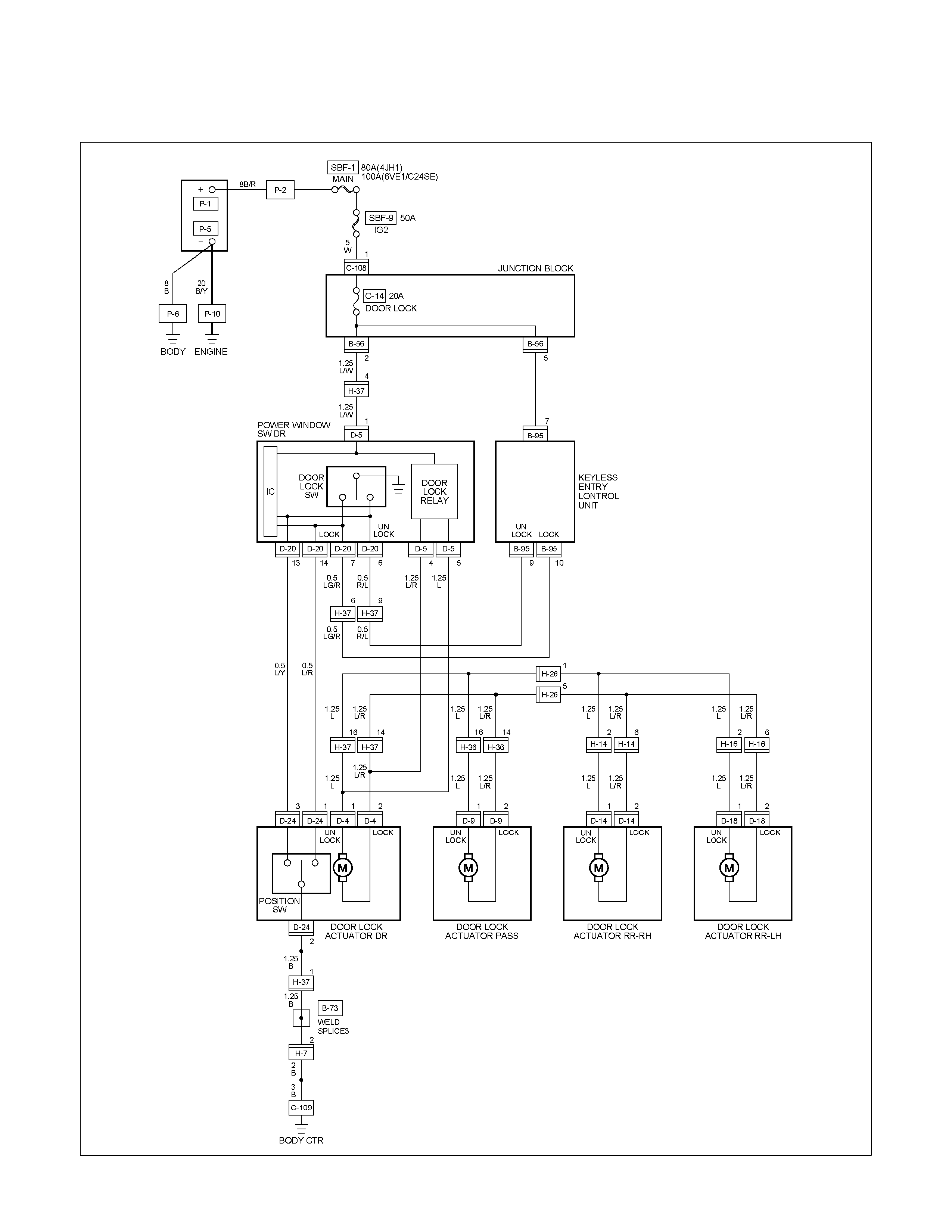

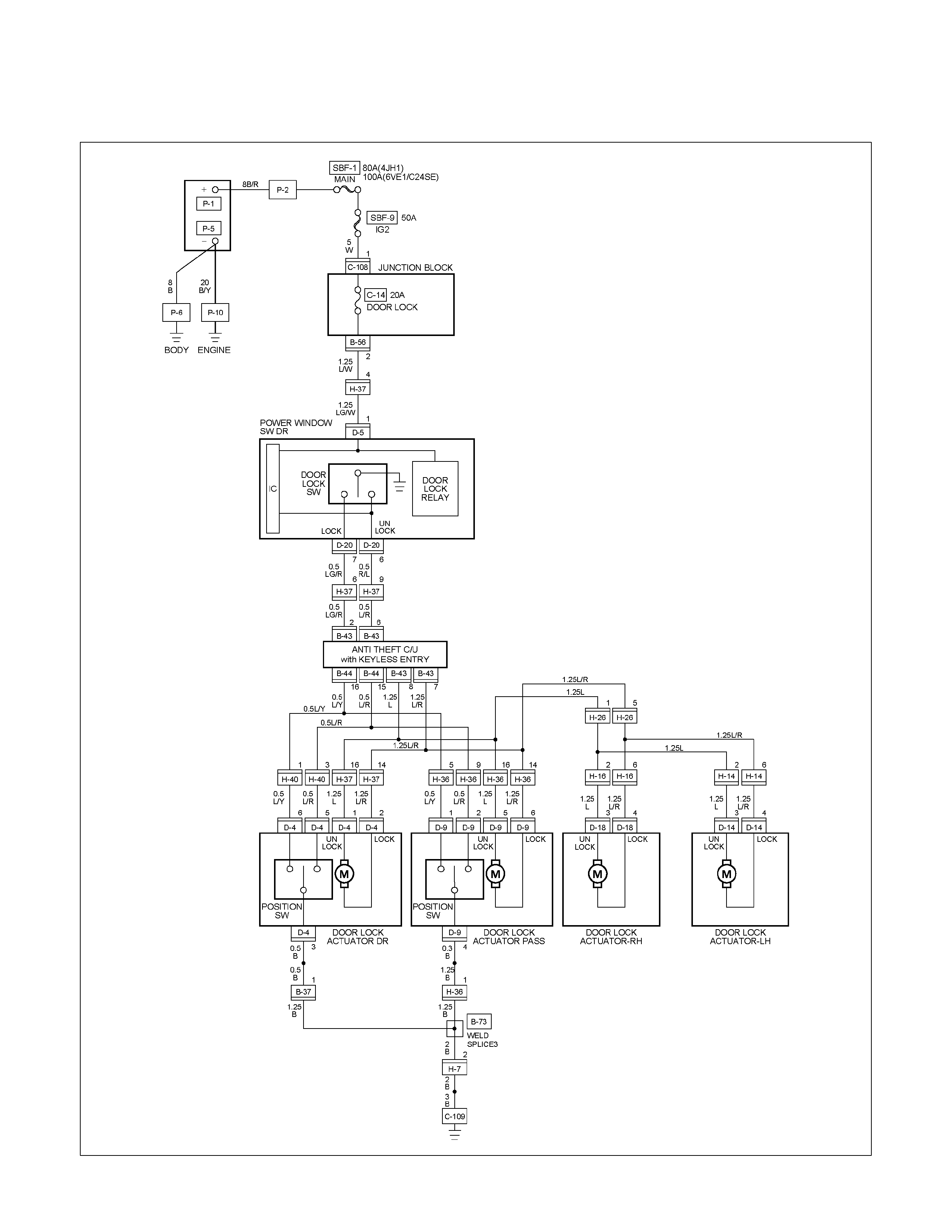

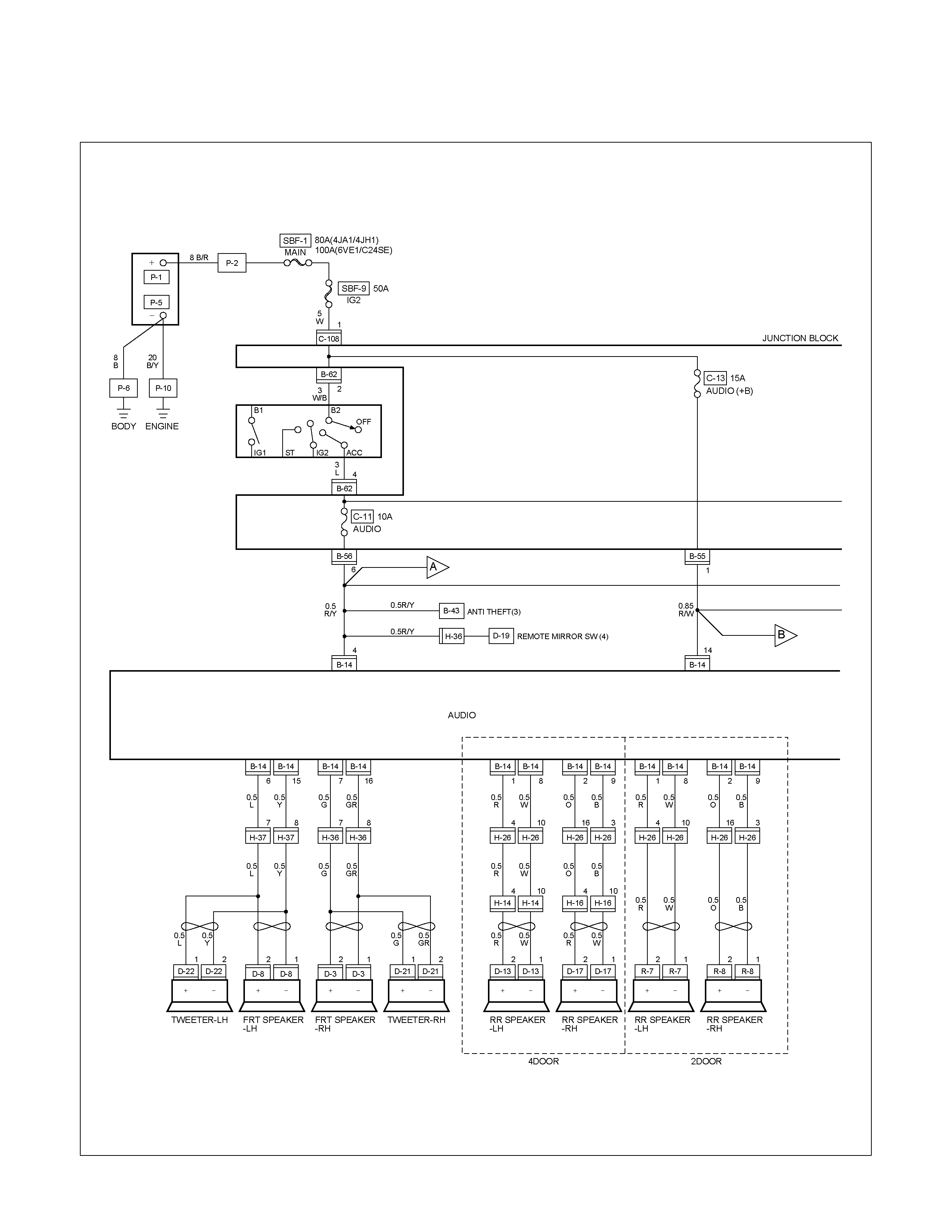

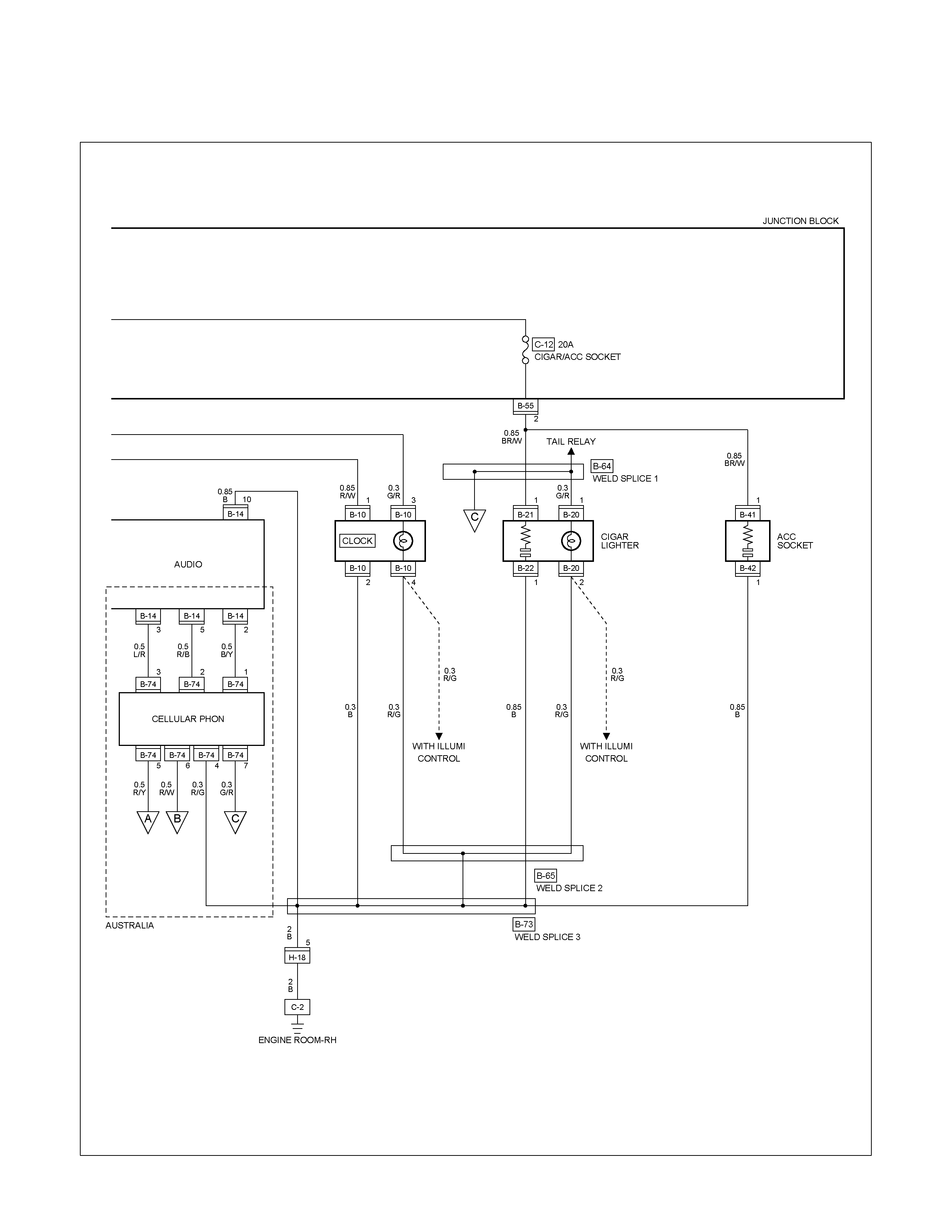

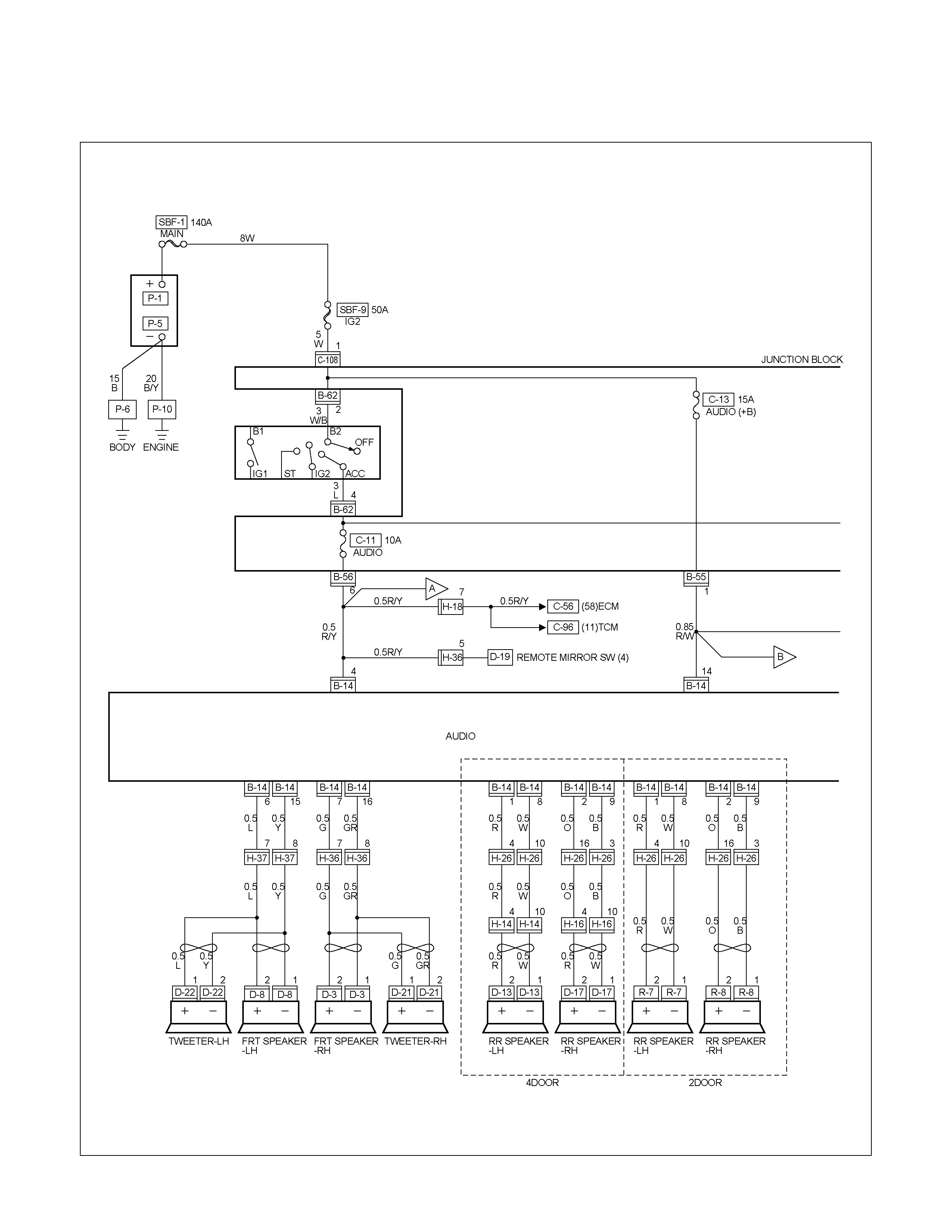

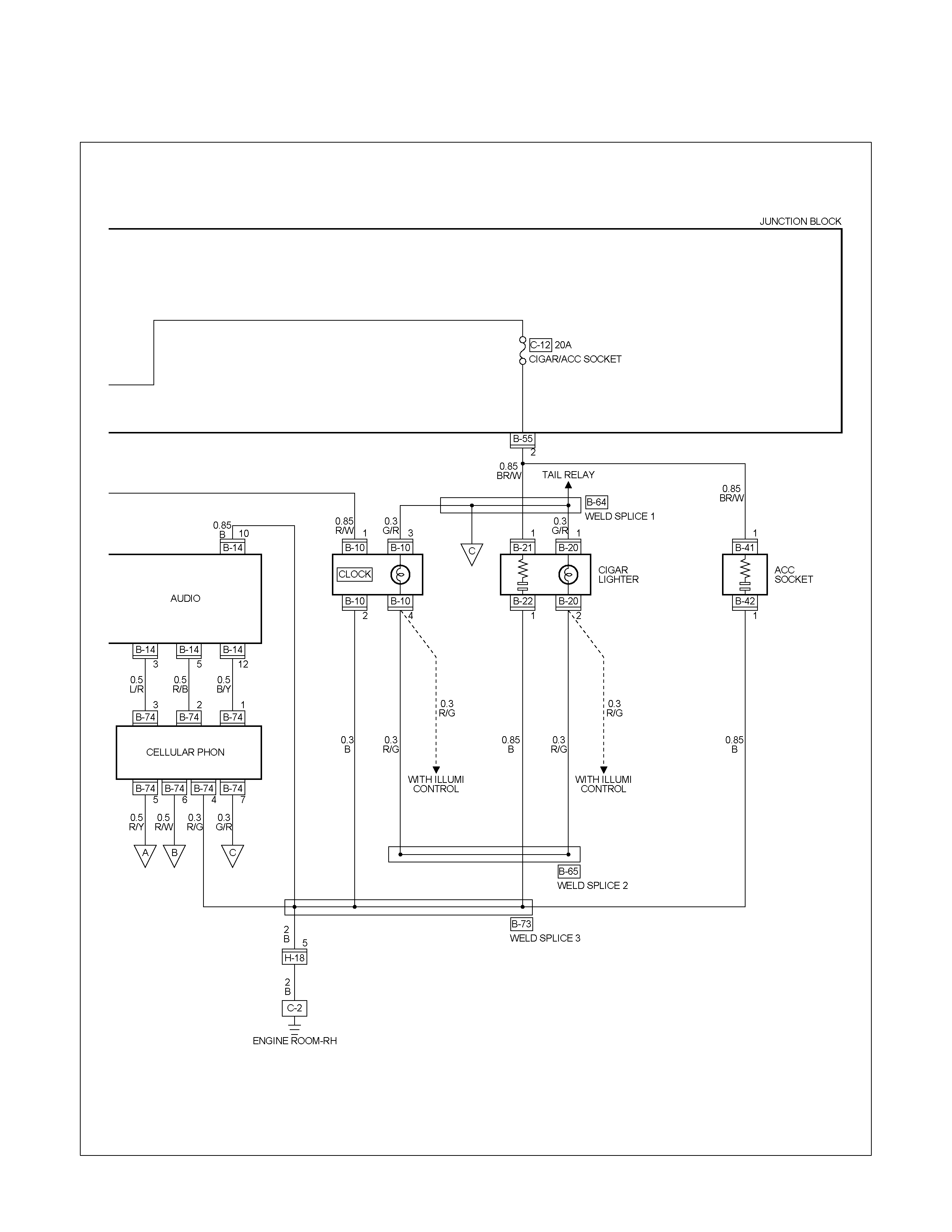

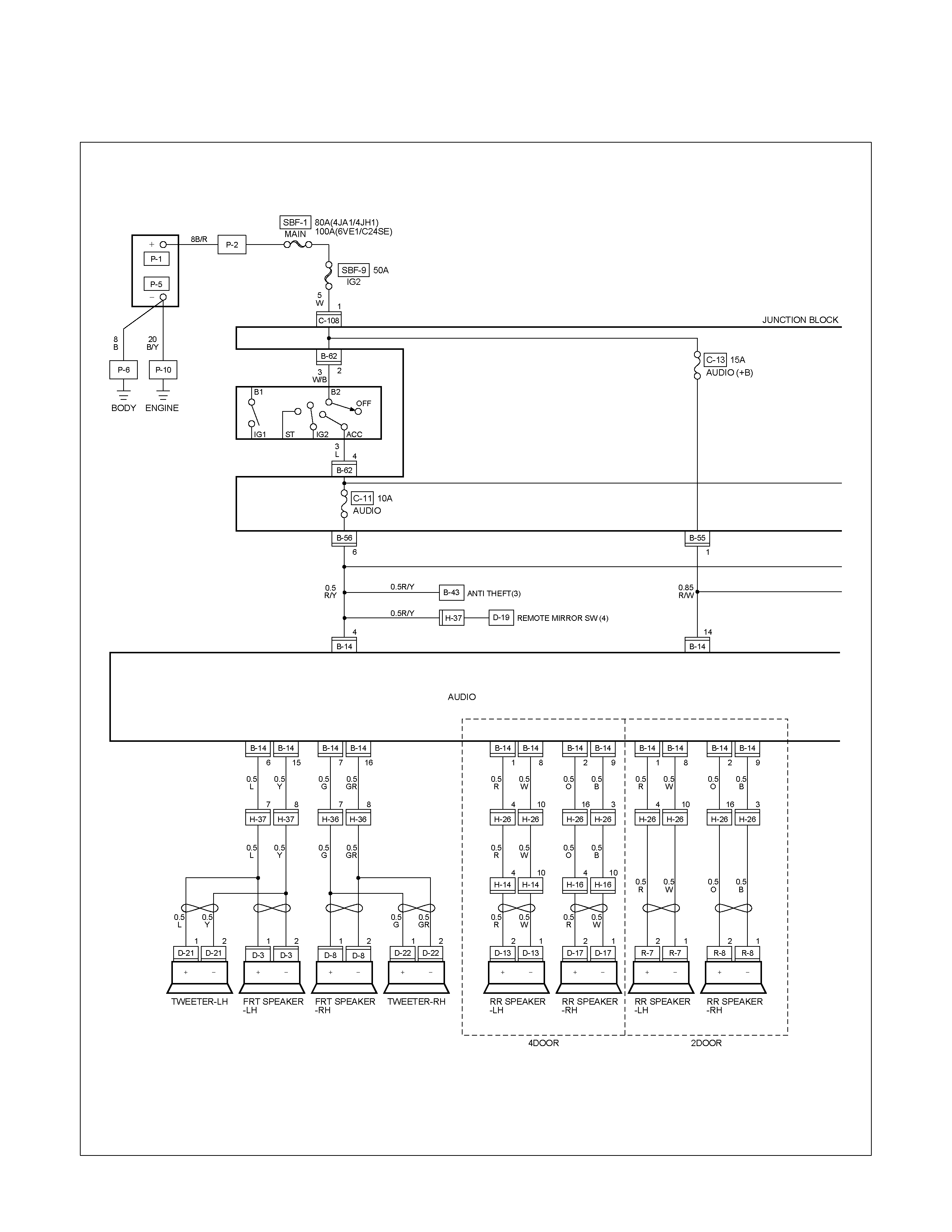

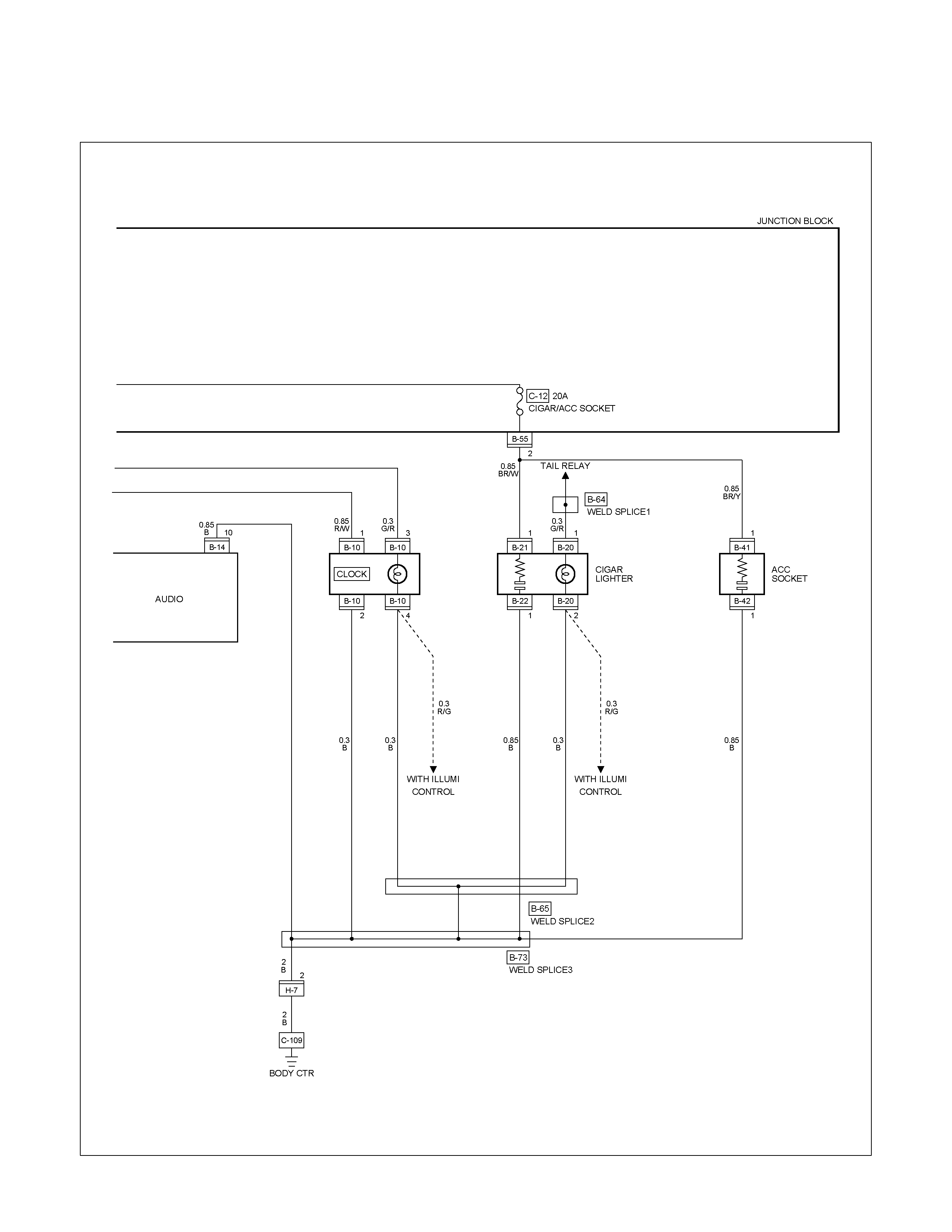

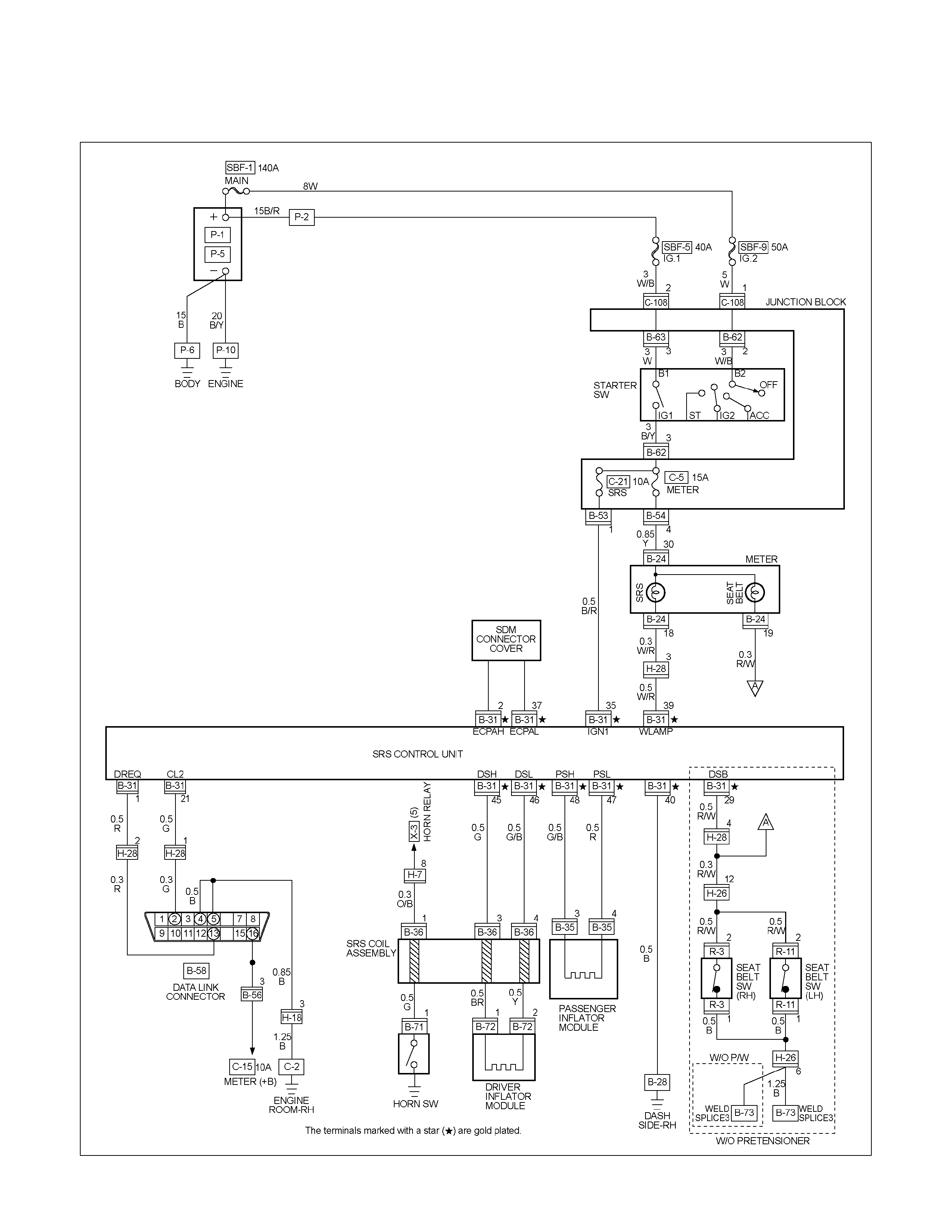

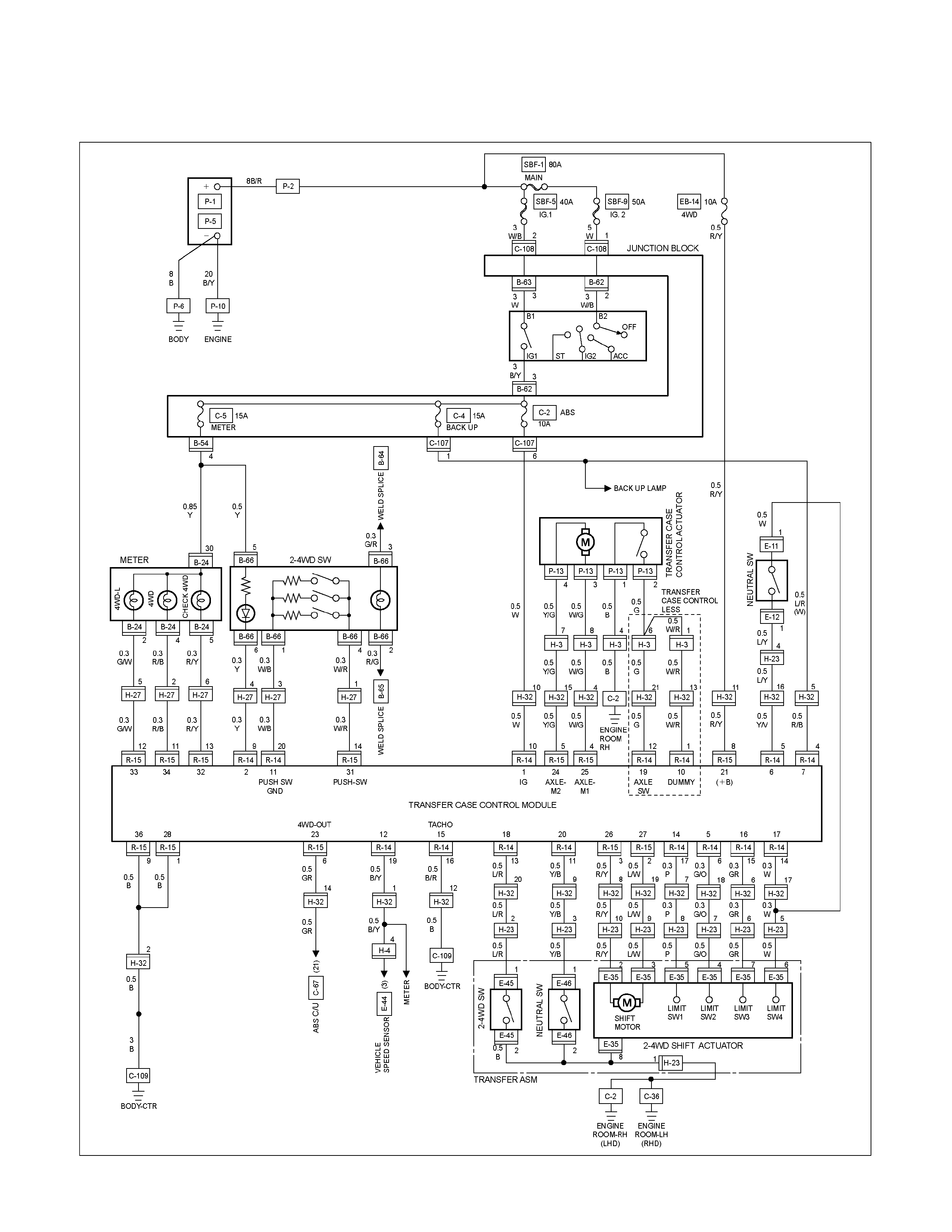

Circuit Diagram

Connector List

Main Data and Specifications

Bulb Specifications

Relay and Fuse

Relay and Fuse Box Location

Relay Location

Fuse and Slow Blow Fuse Location

Fuse Location

Diode Location

Fuse Block Circuit

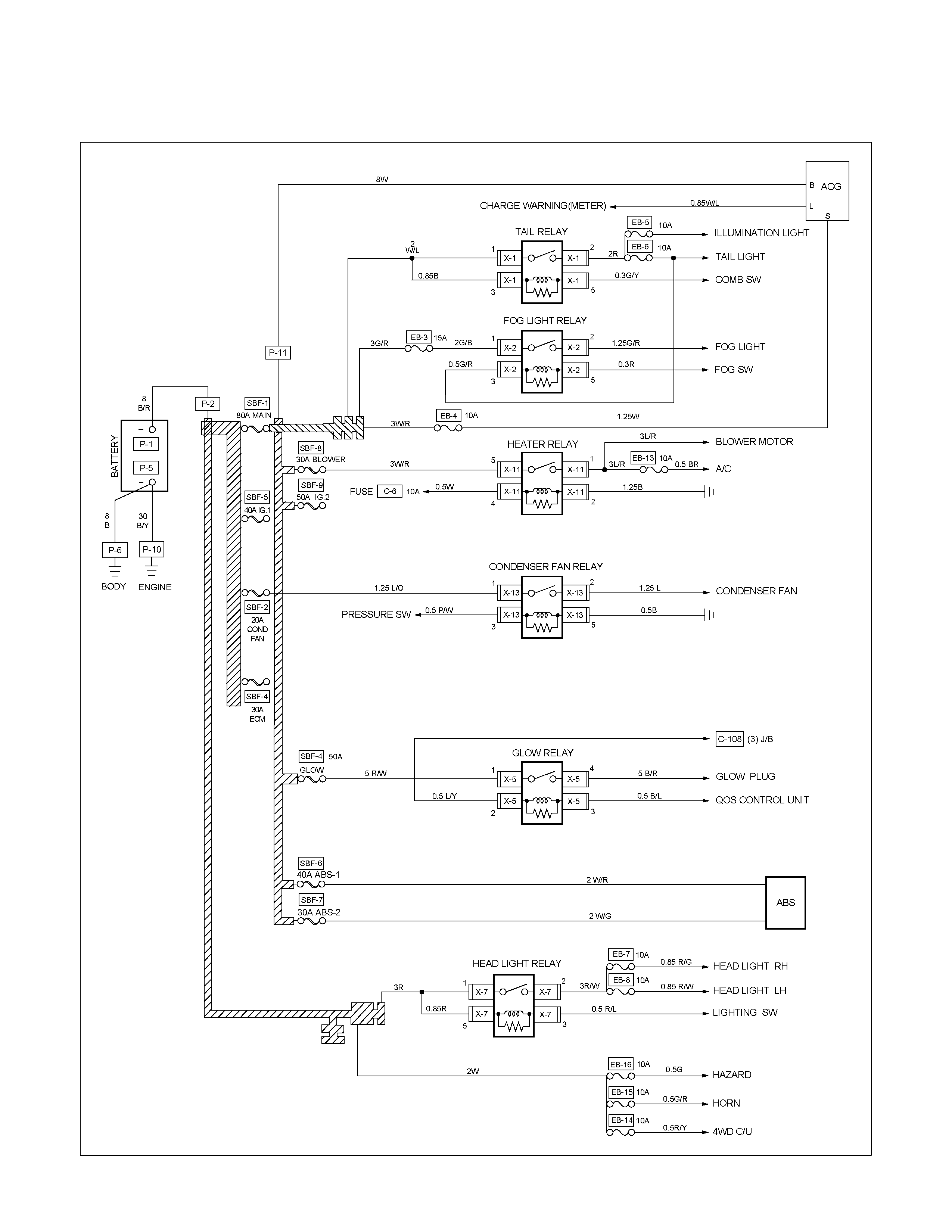

Fuse Block Circuit (C24SE)

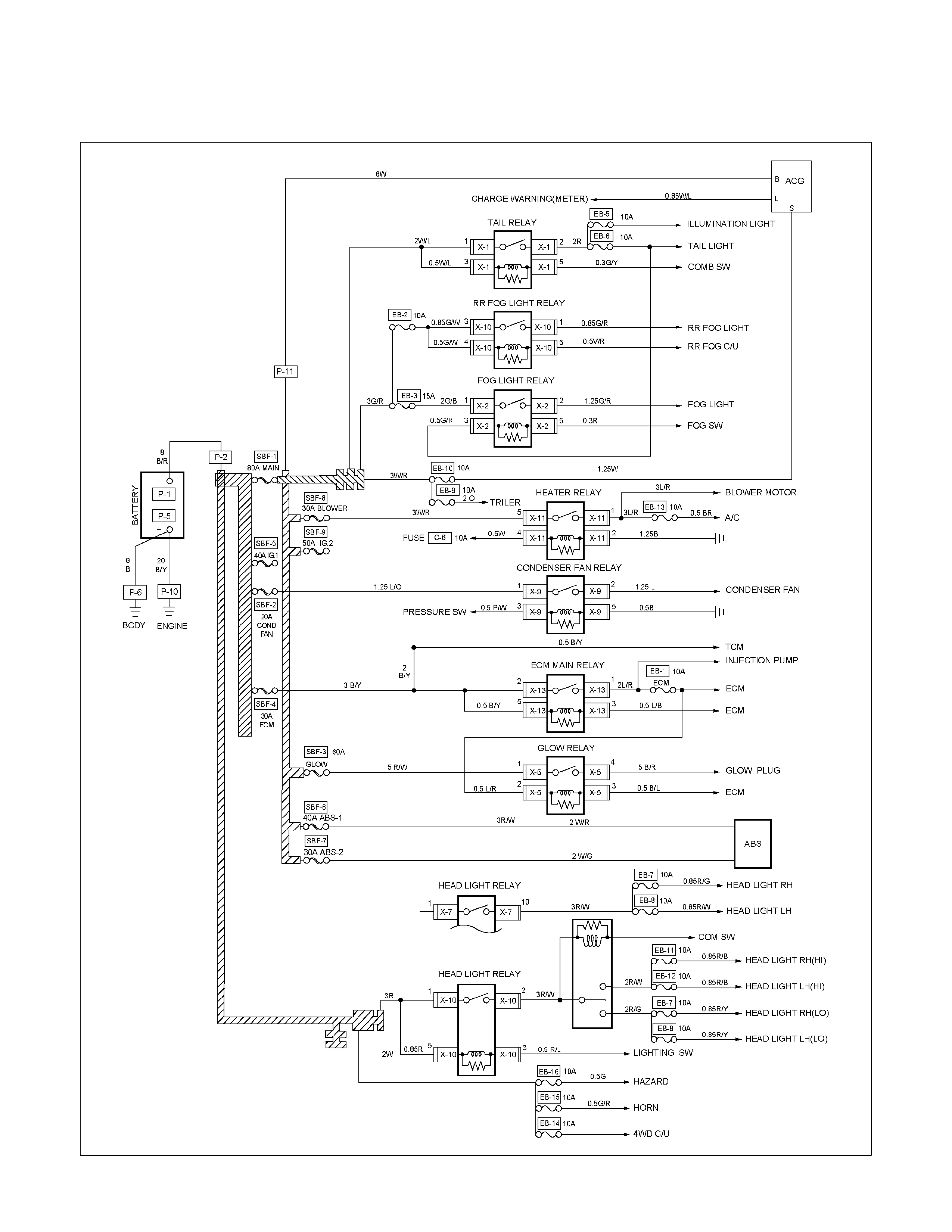

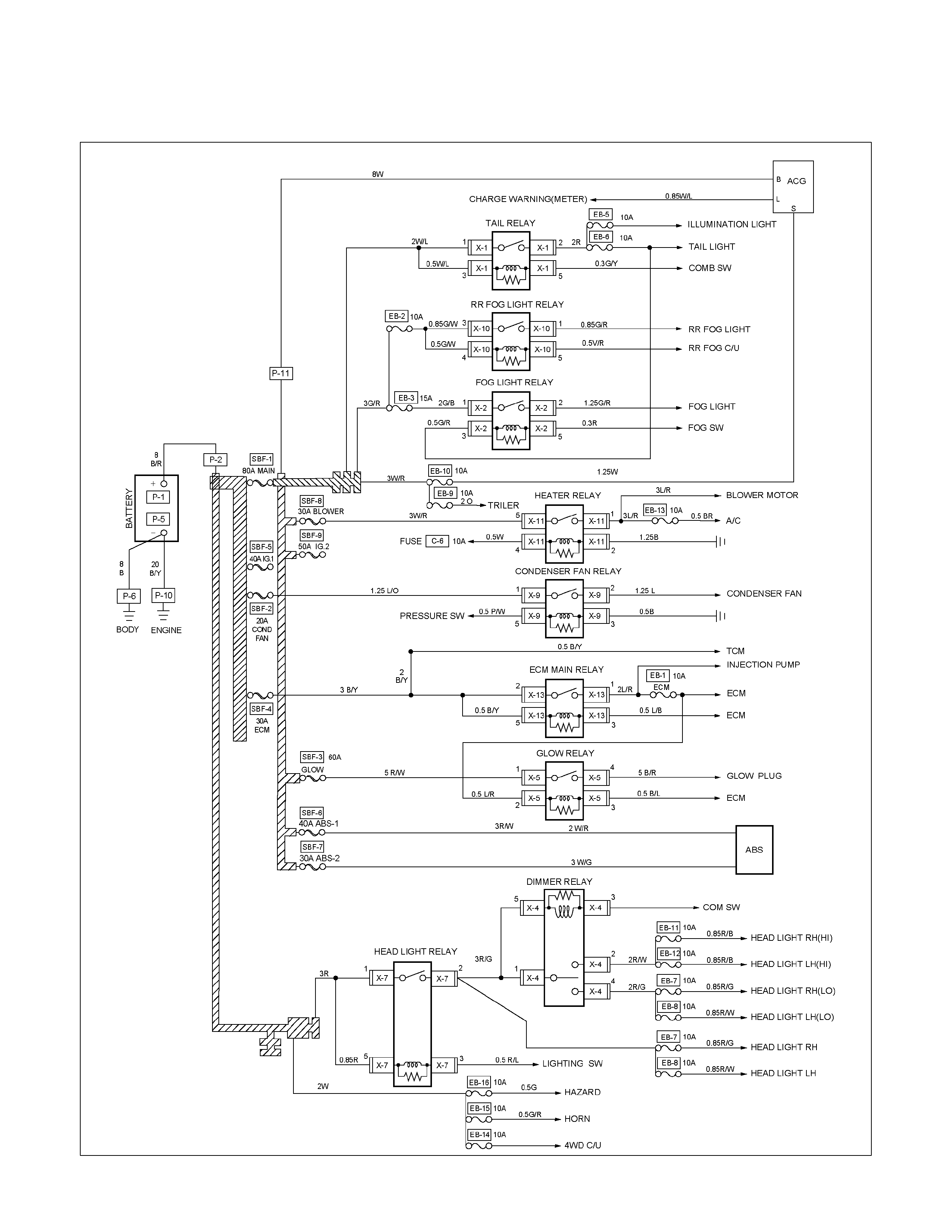

Fuse Block Circuit (6VE1)

Fuse Block Circuit (HFV6)

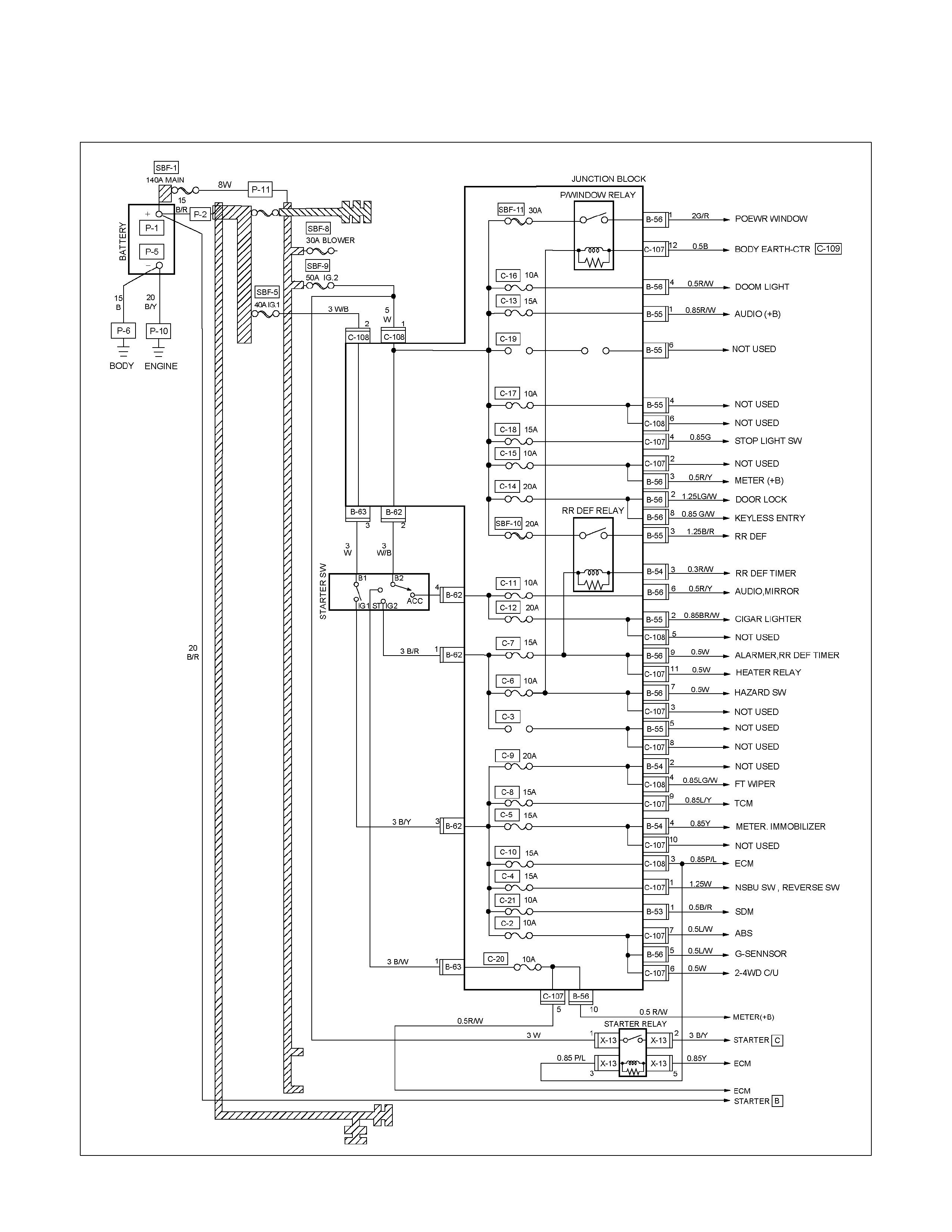

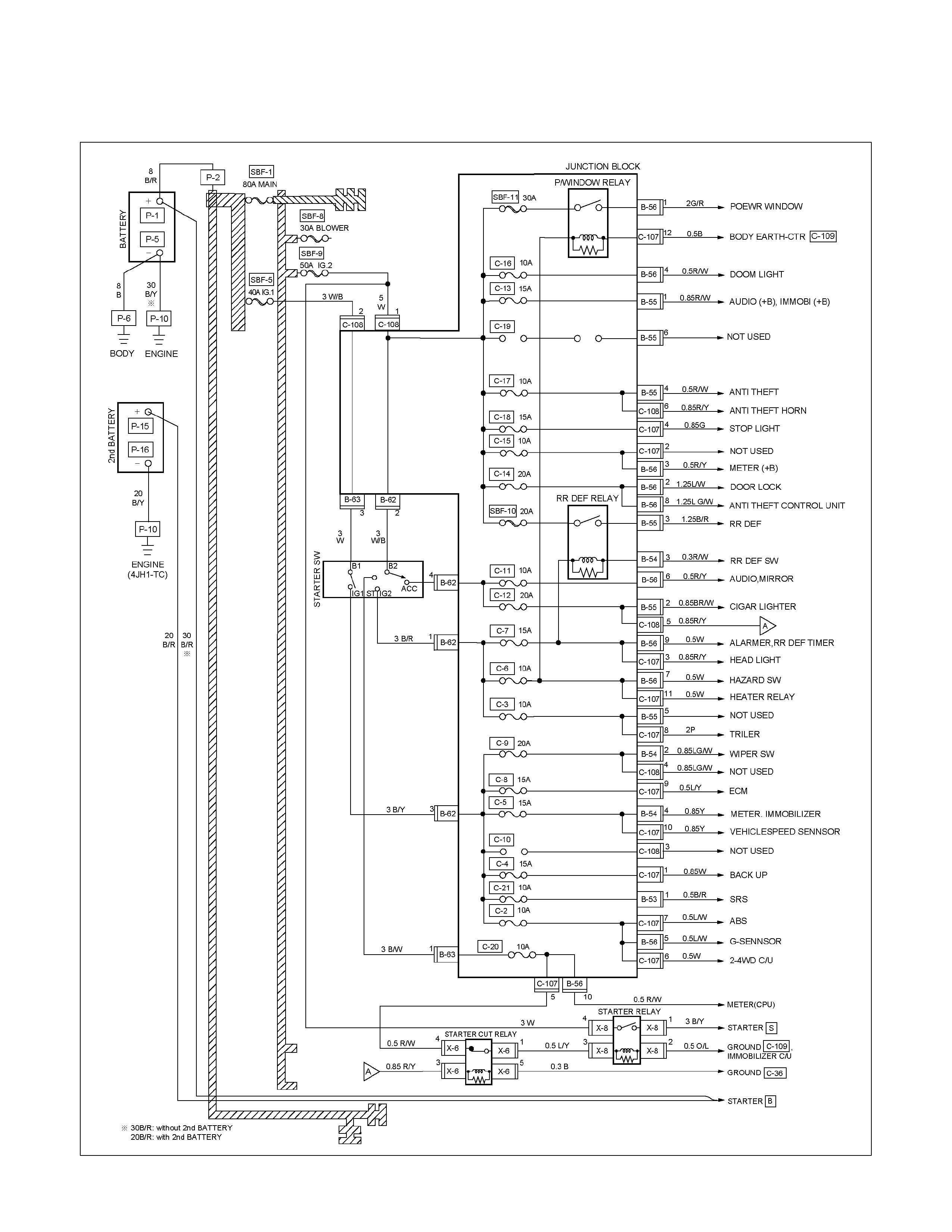

Fuse Block Circuit (4JA1-TC/4JH1-TC)

- RHD

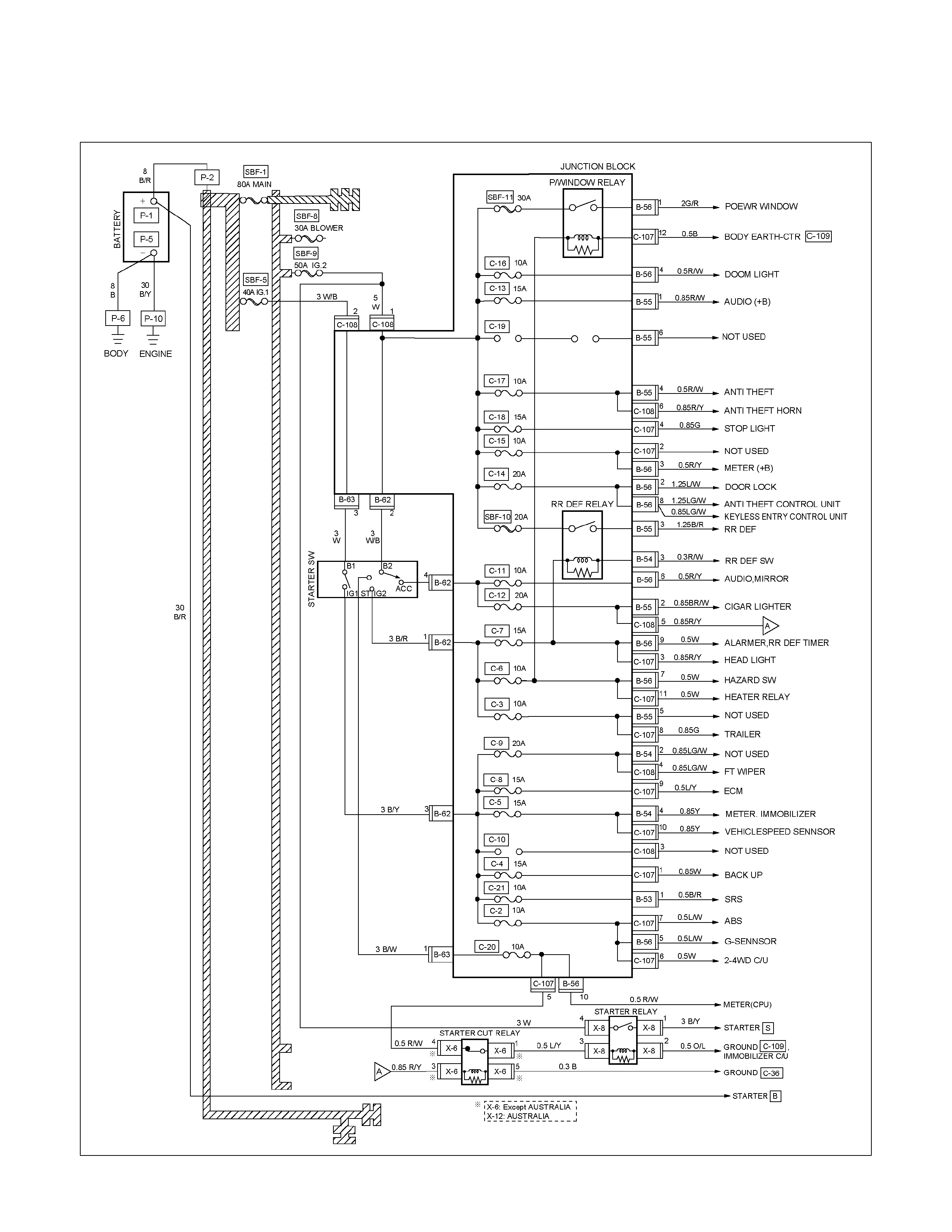

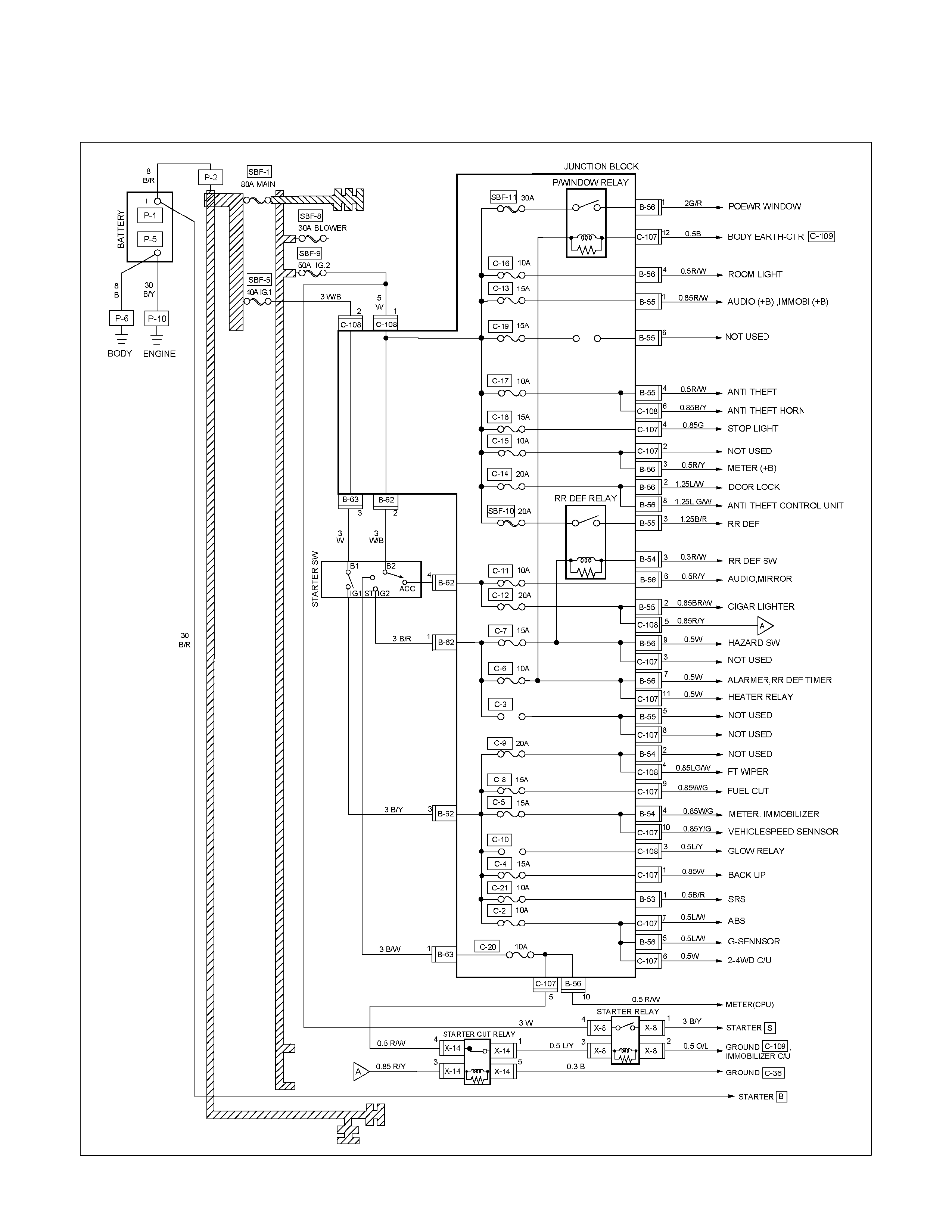

Fuse Block Circuit (4JA1-TC/4JH1-TC)

- LHD

Fuse Block Circuit (4JH1-L)

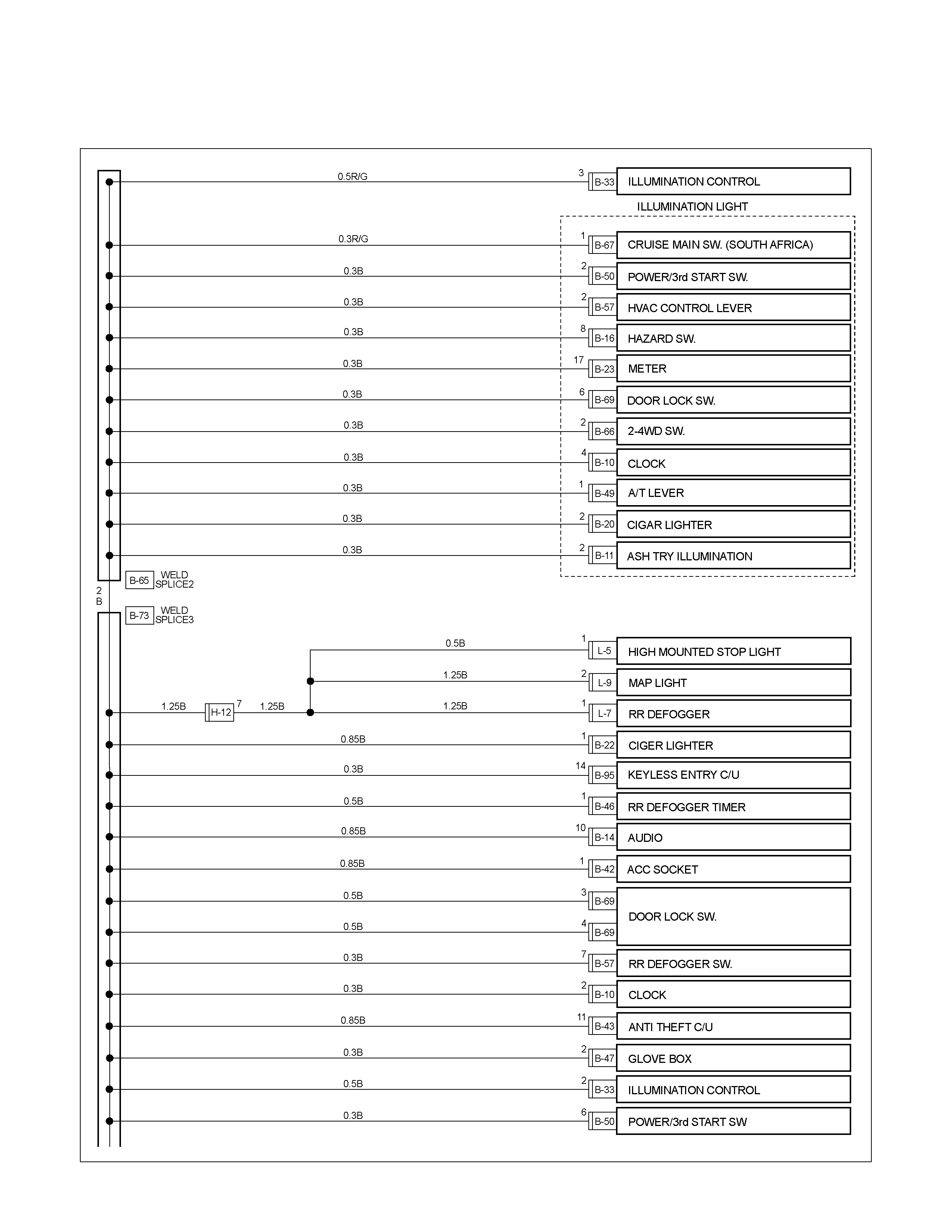

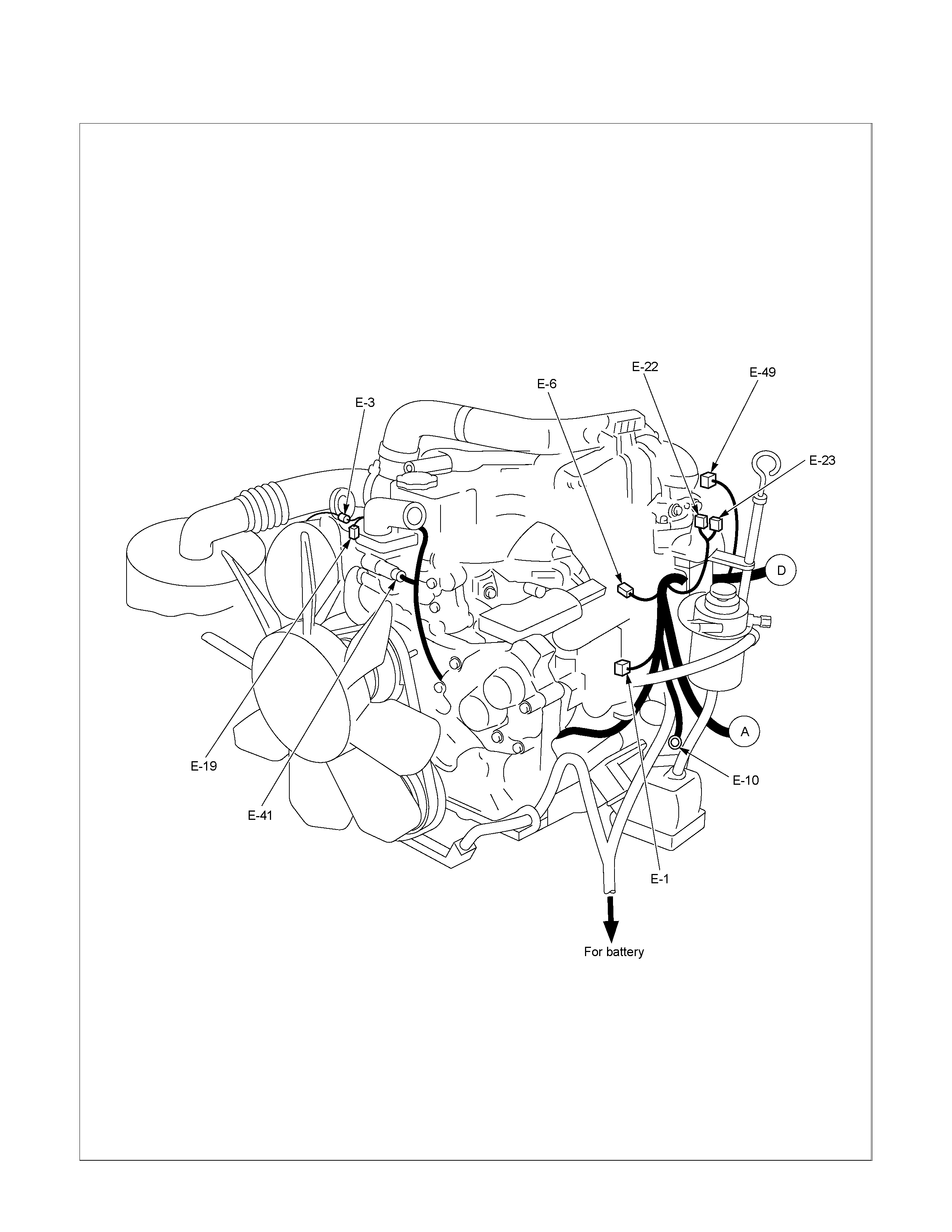

Grounding Point

Ground Point

Ground Point Location

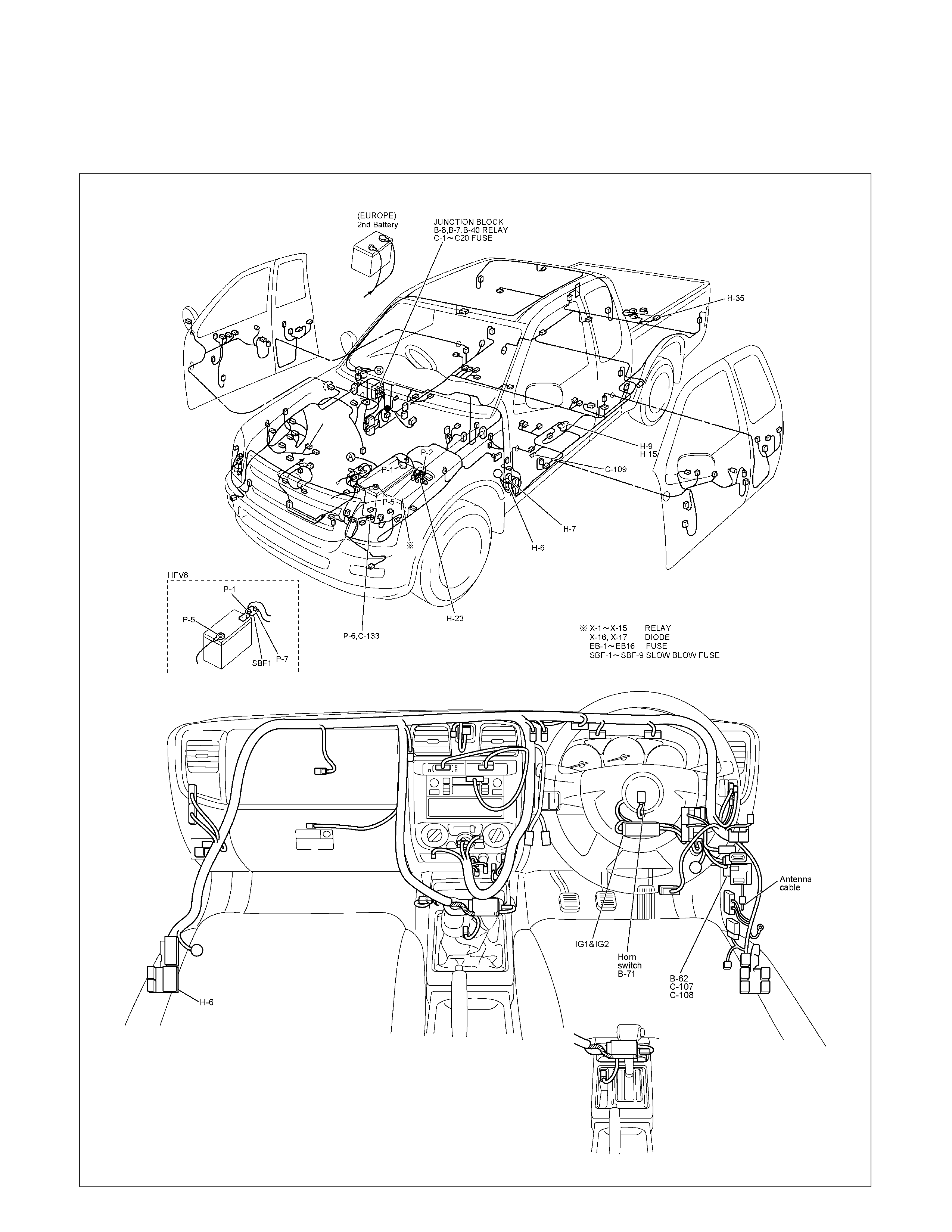

Cable Harness Routing

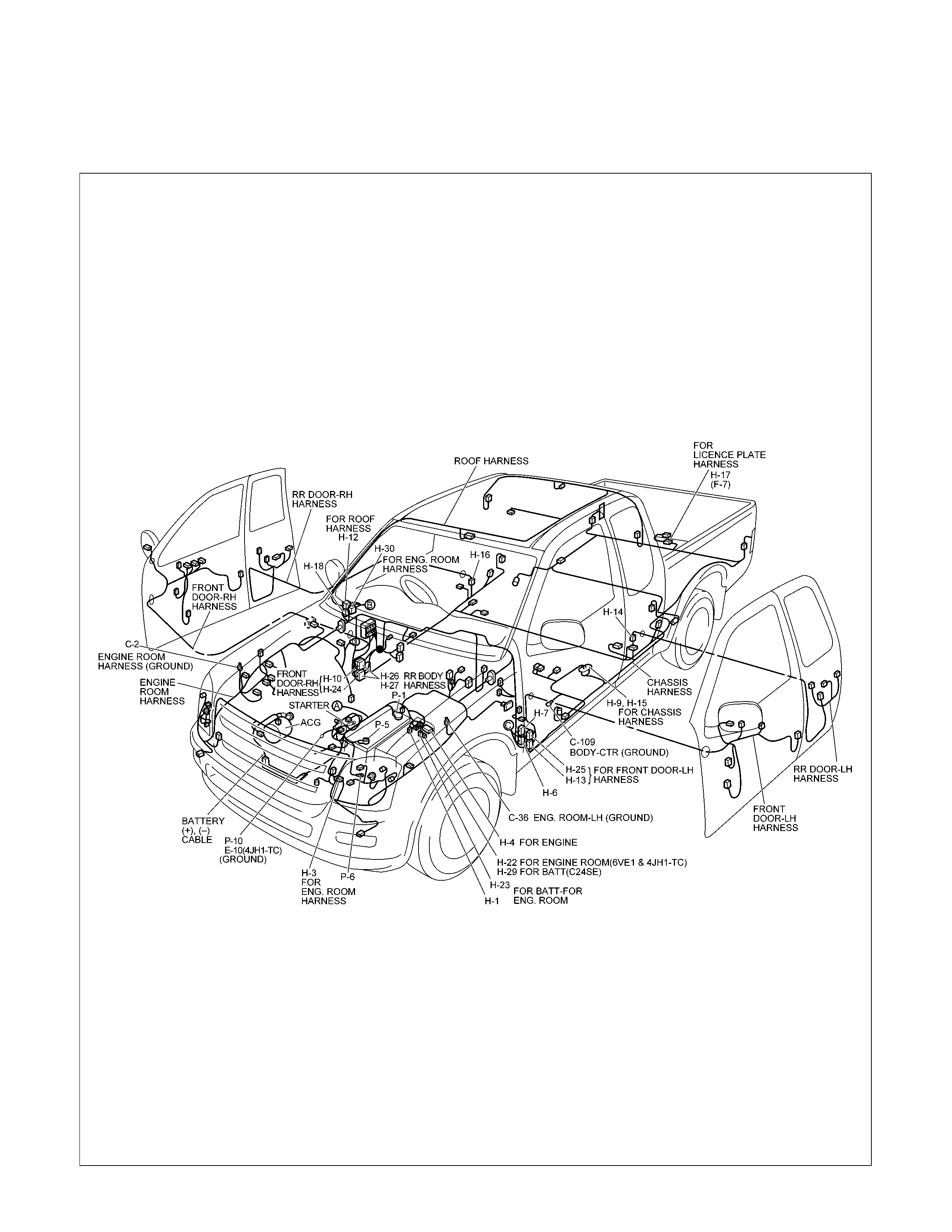

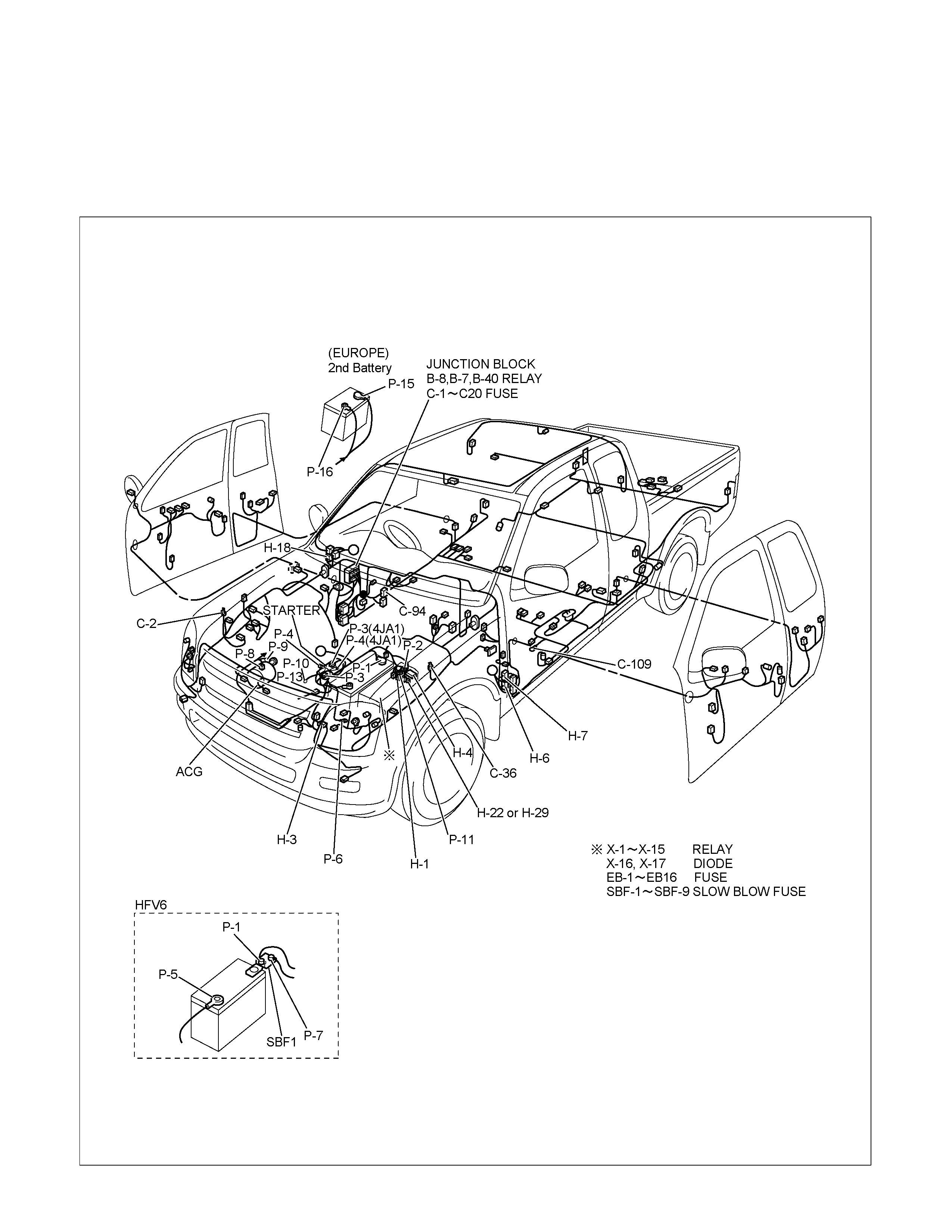

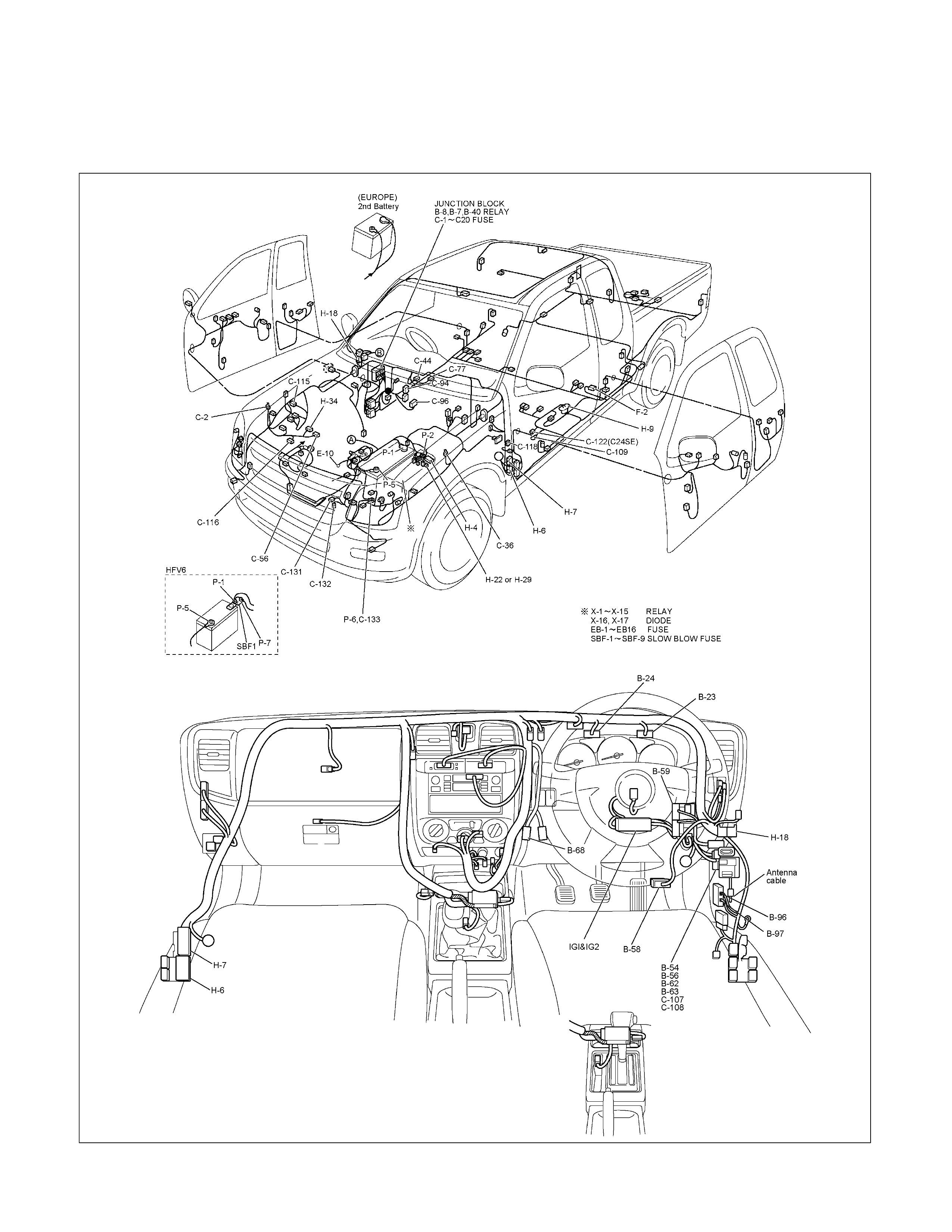

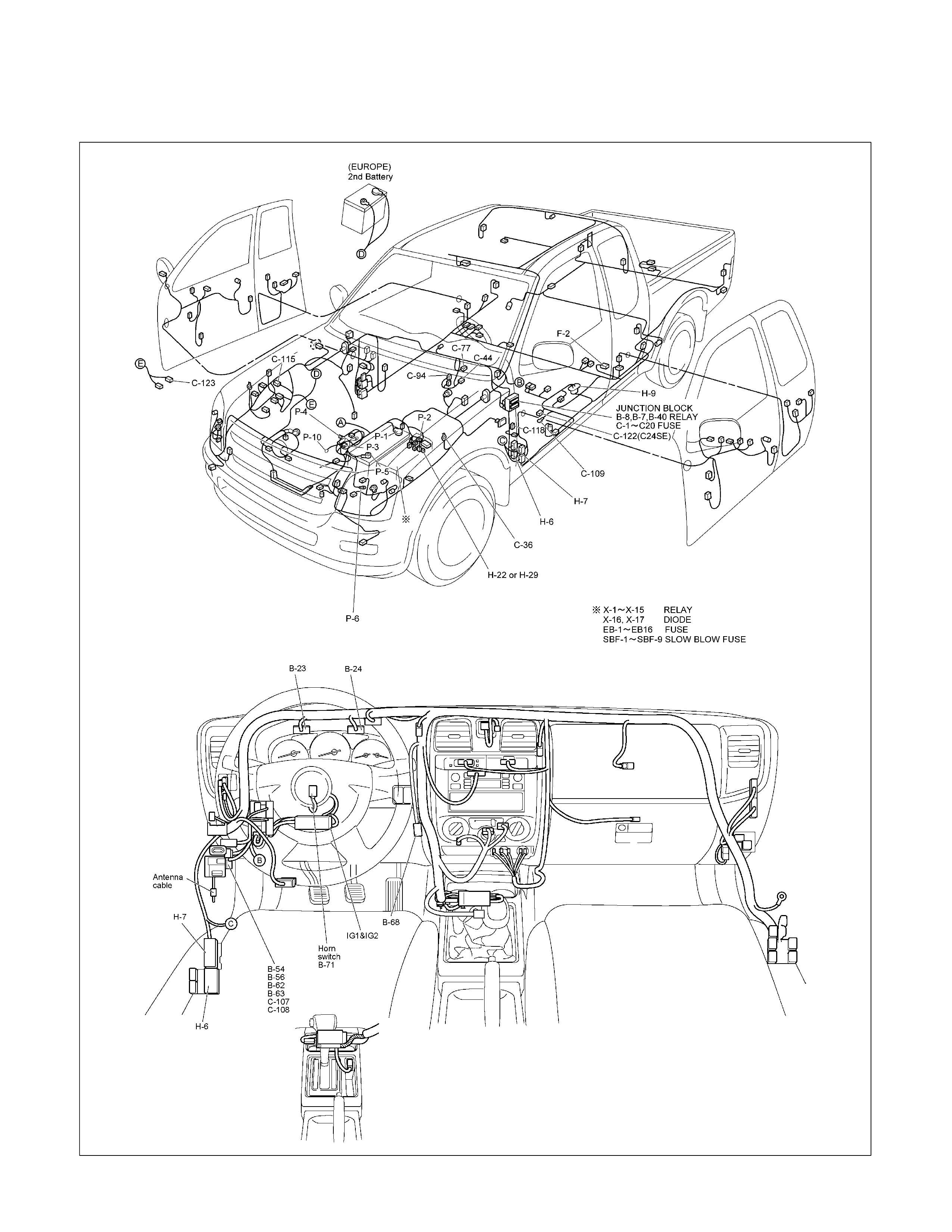

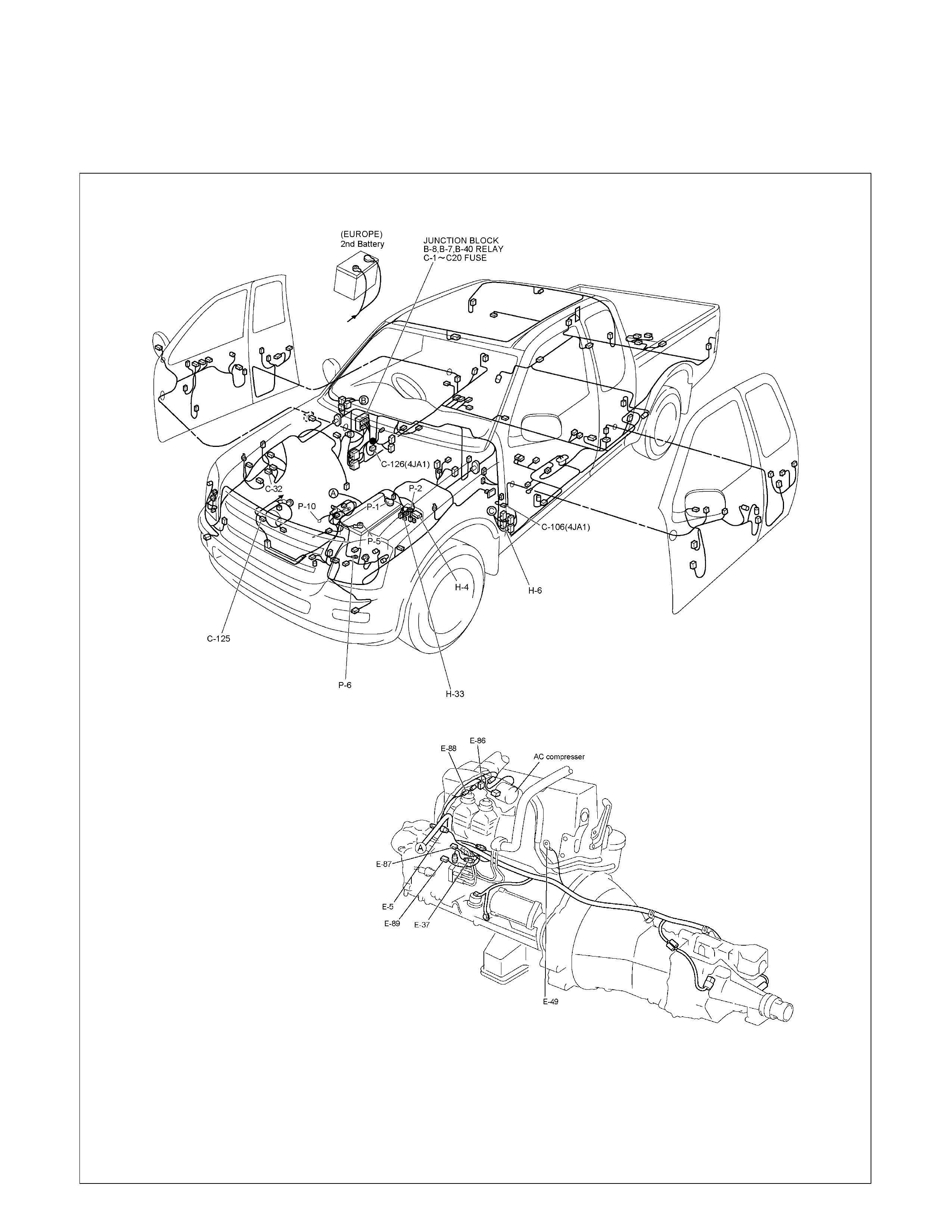

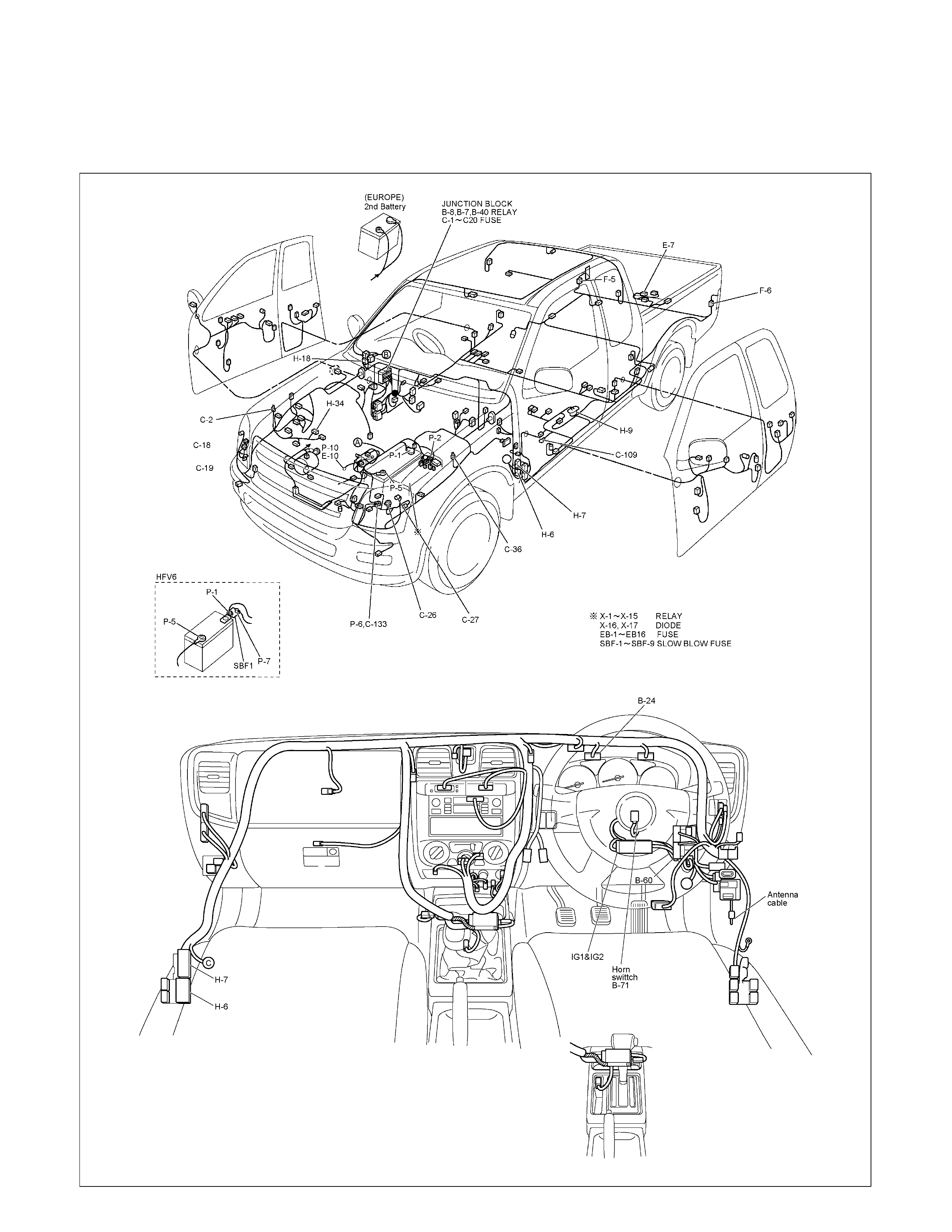

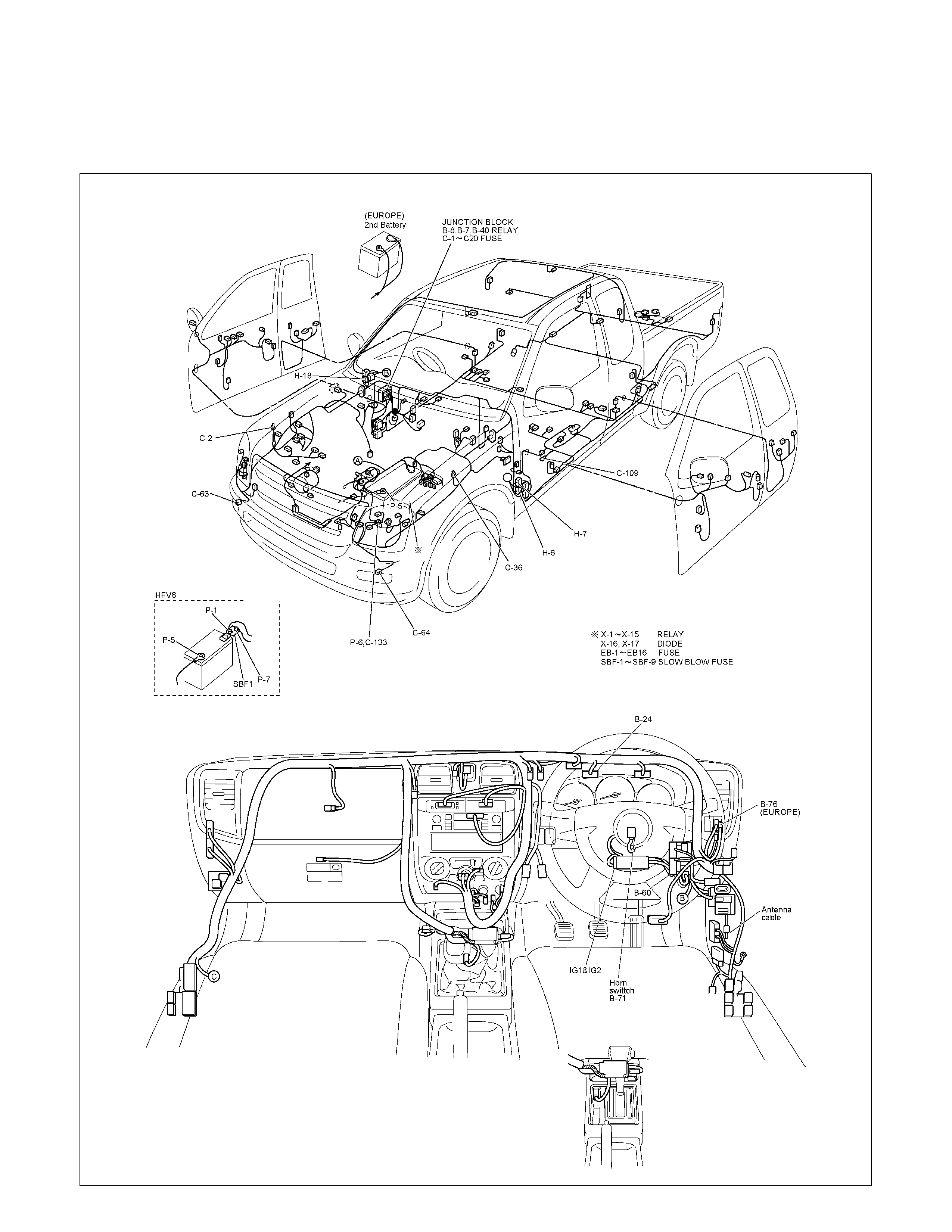

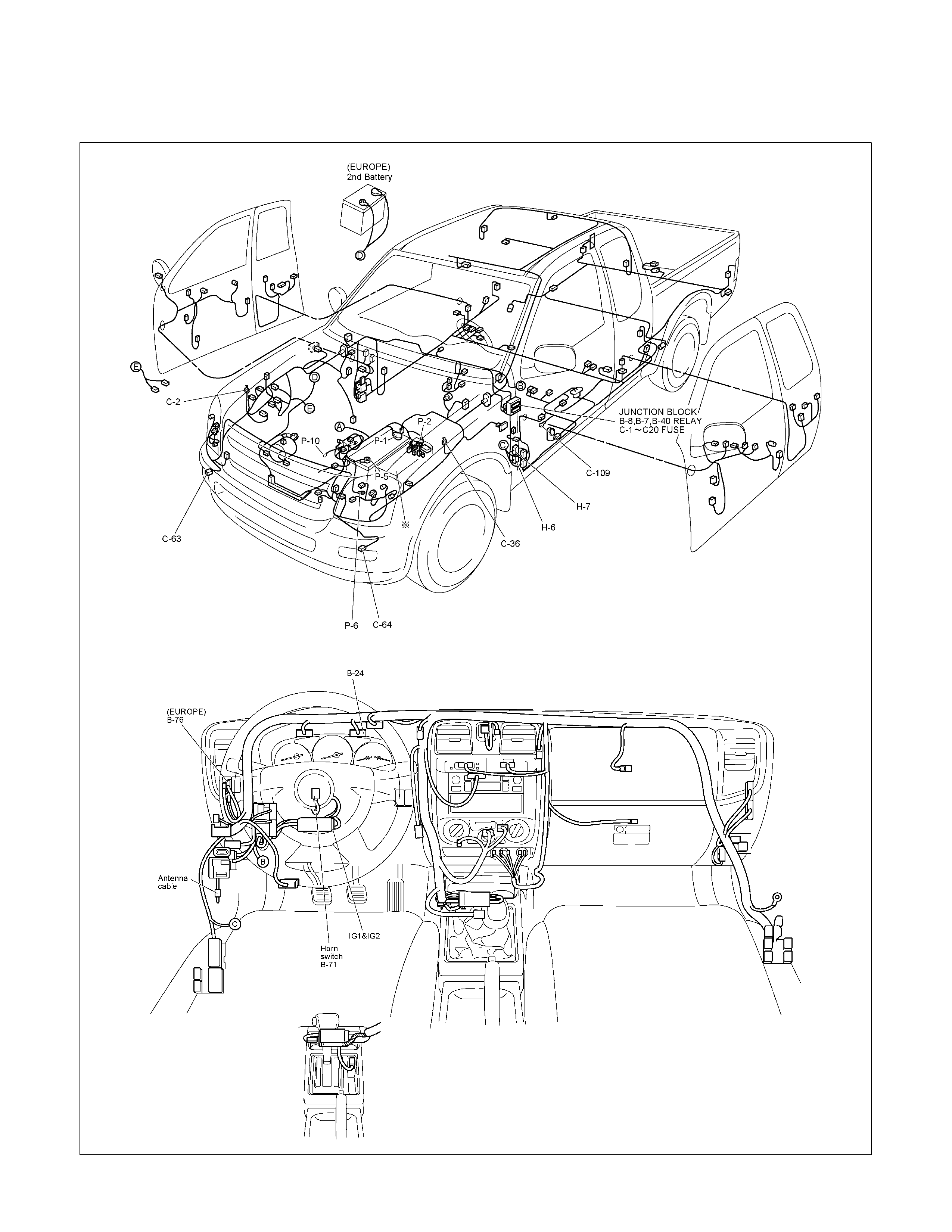

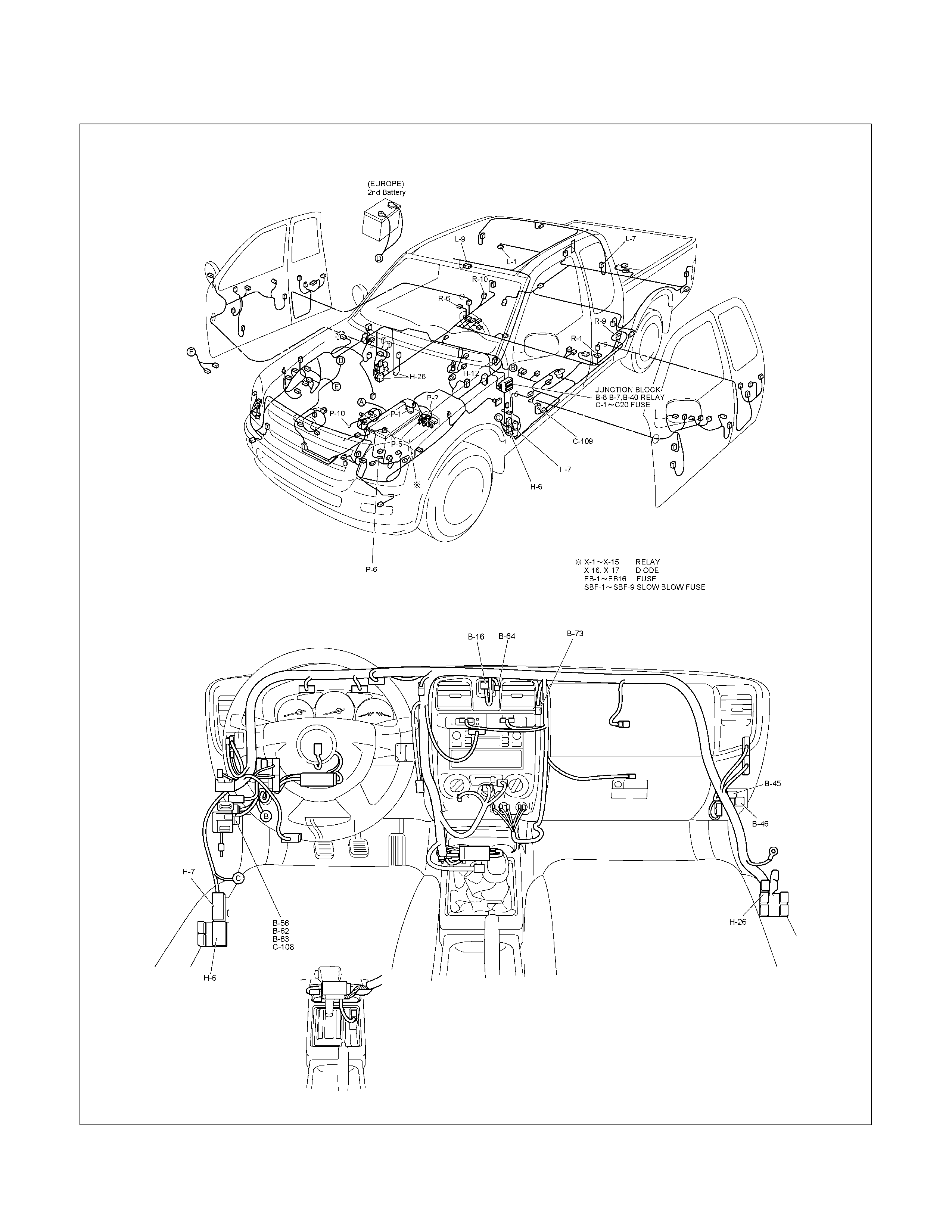

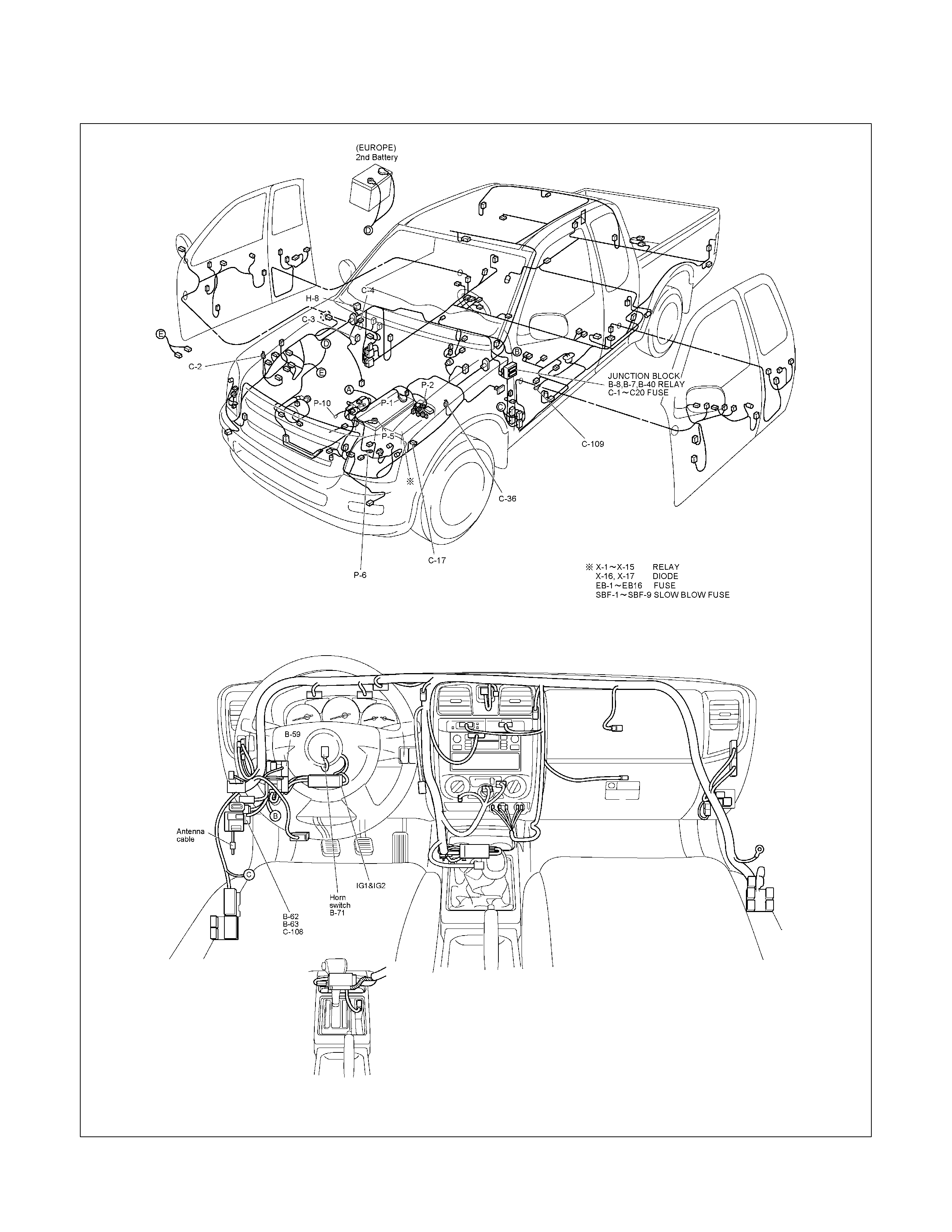

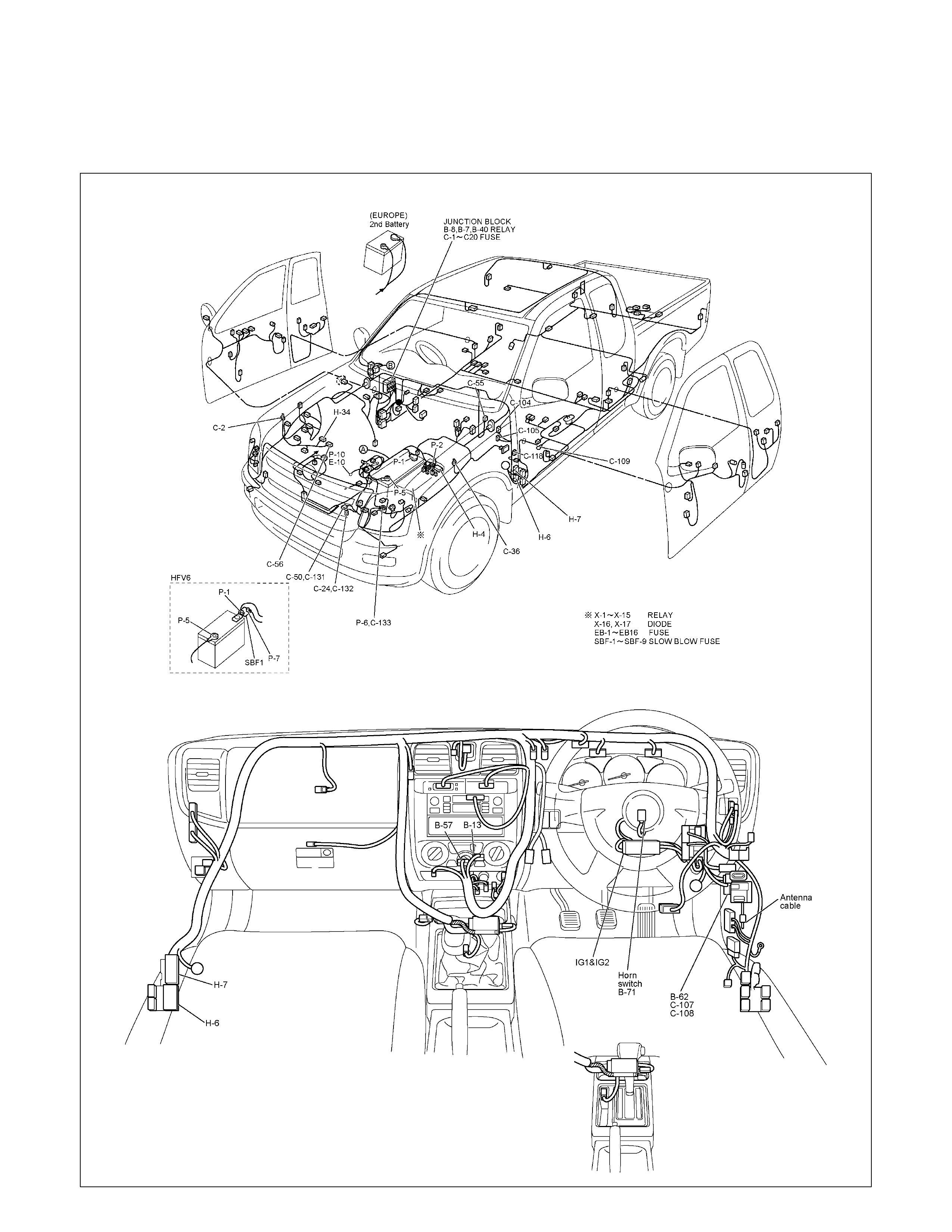

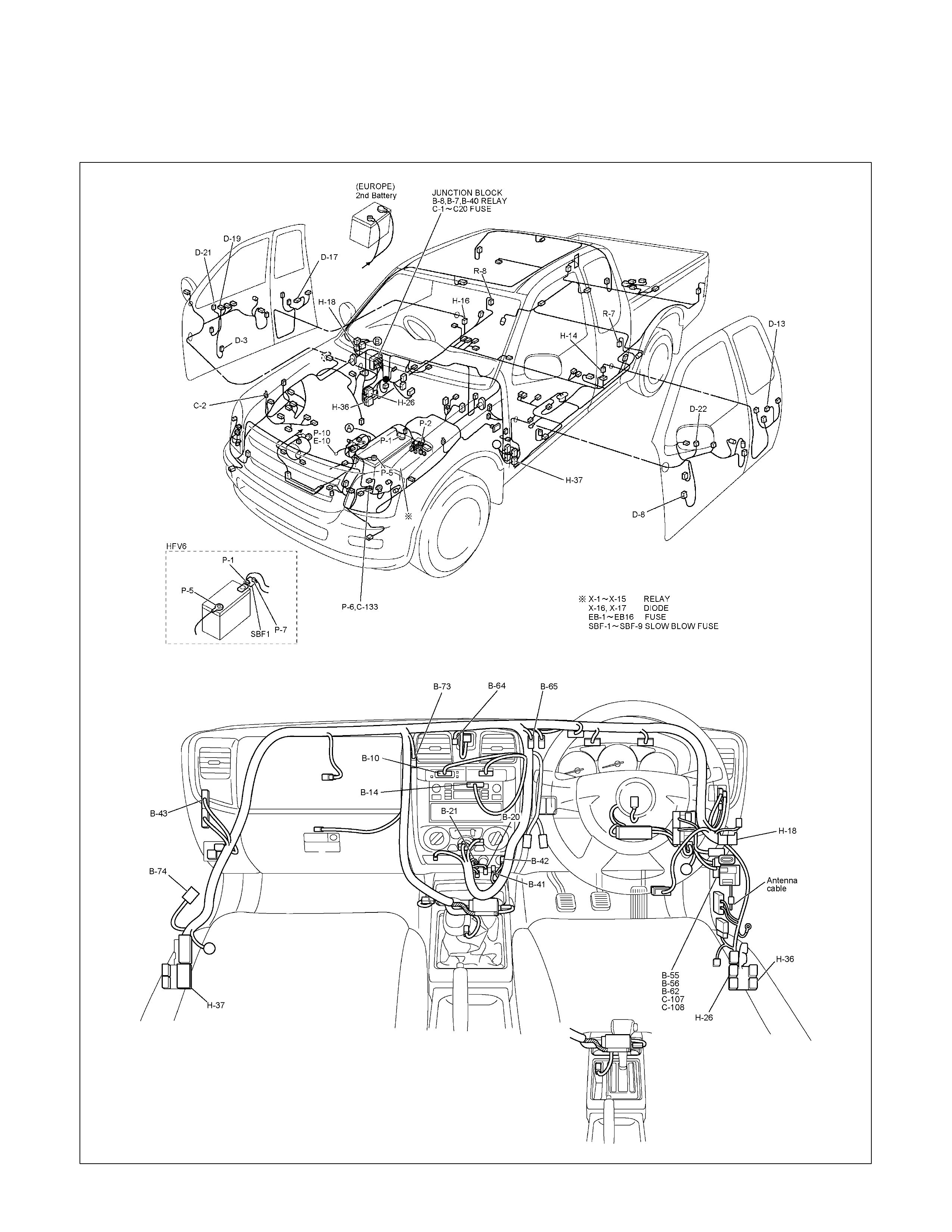

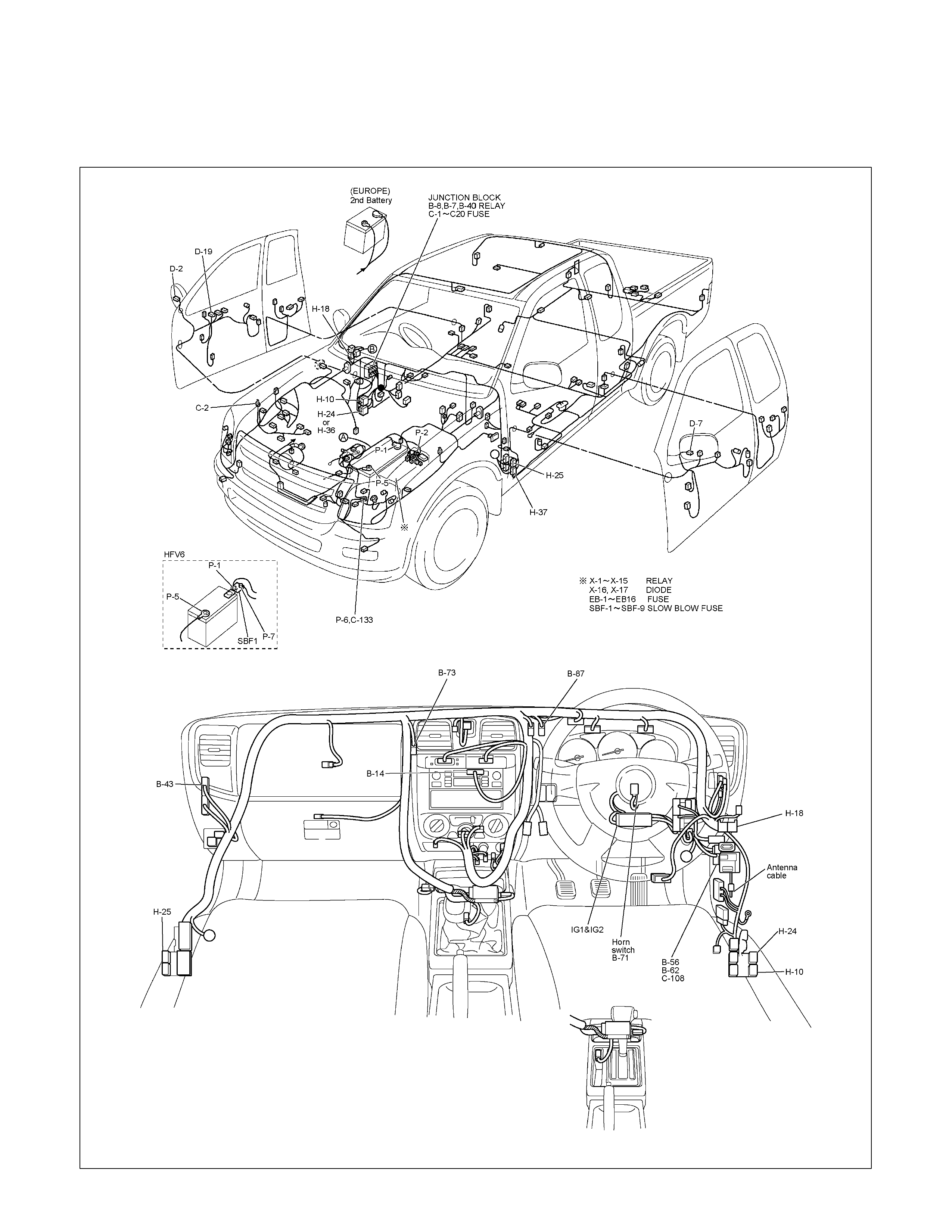

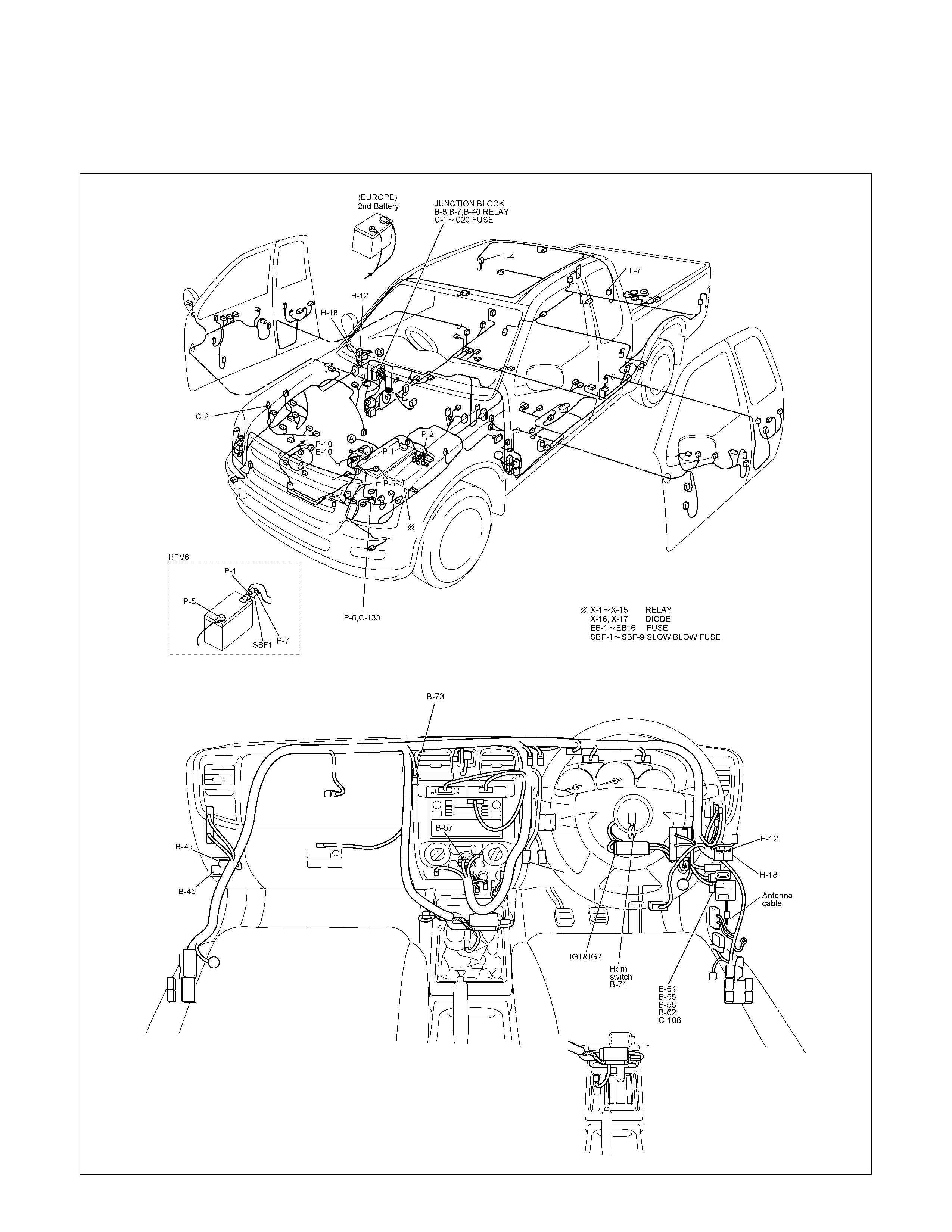

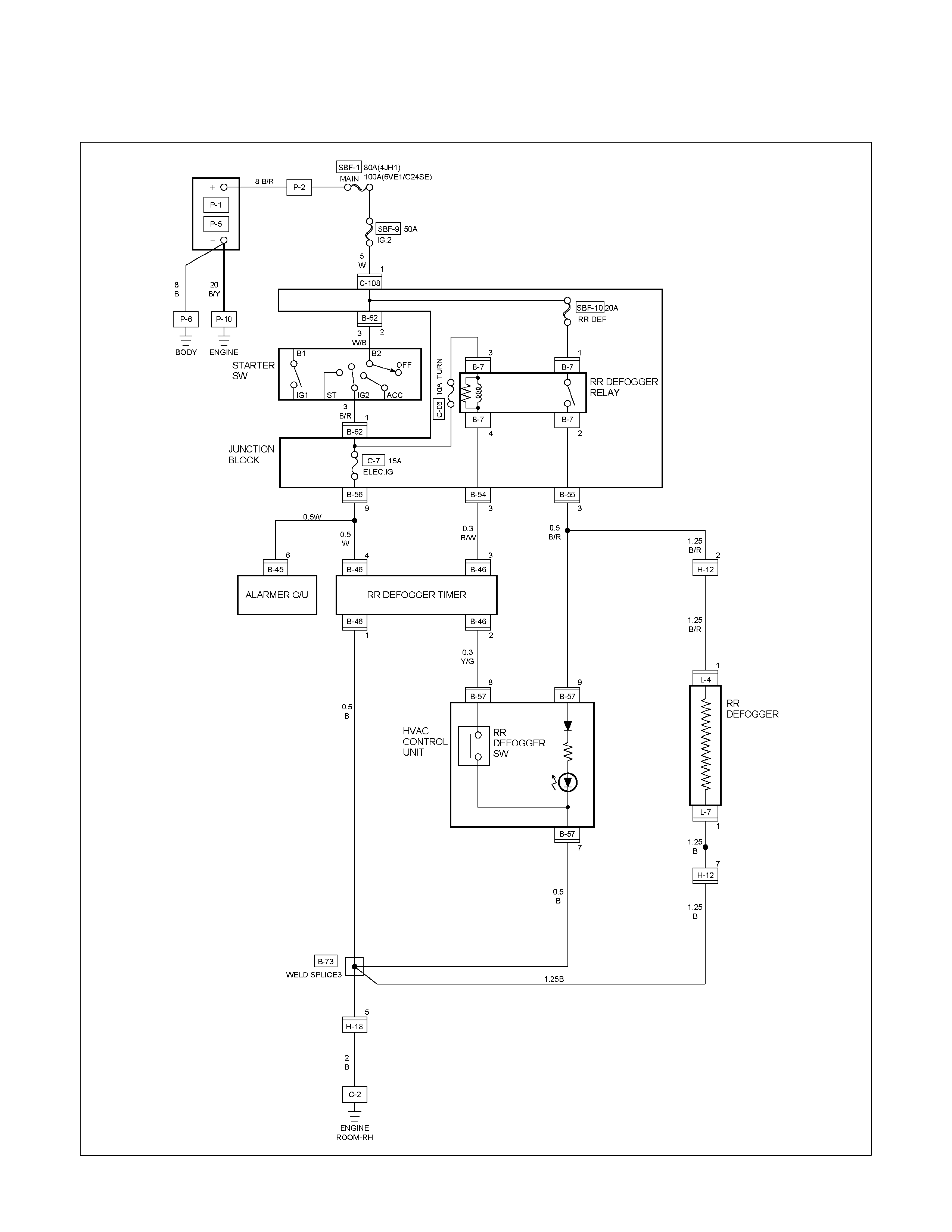

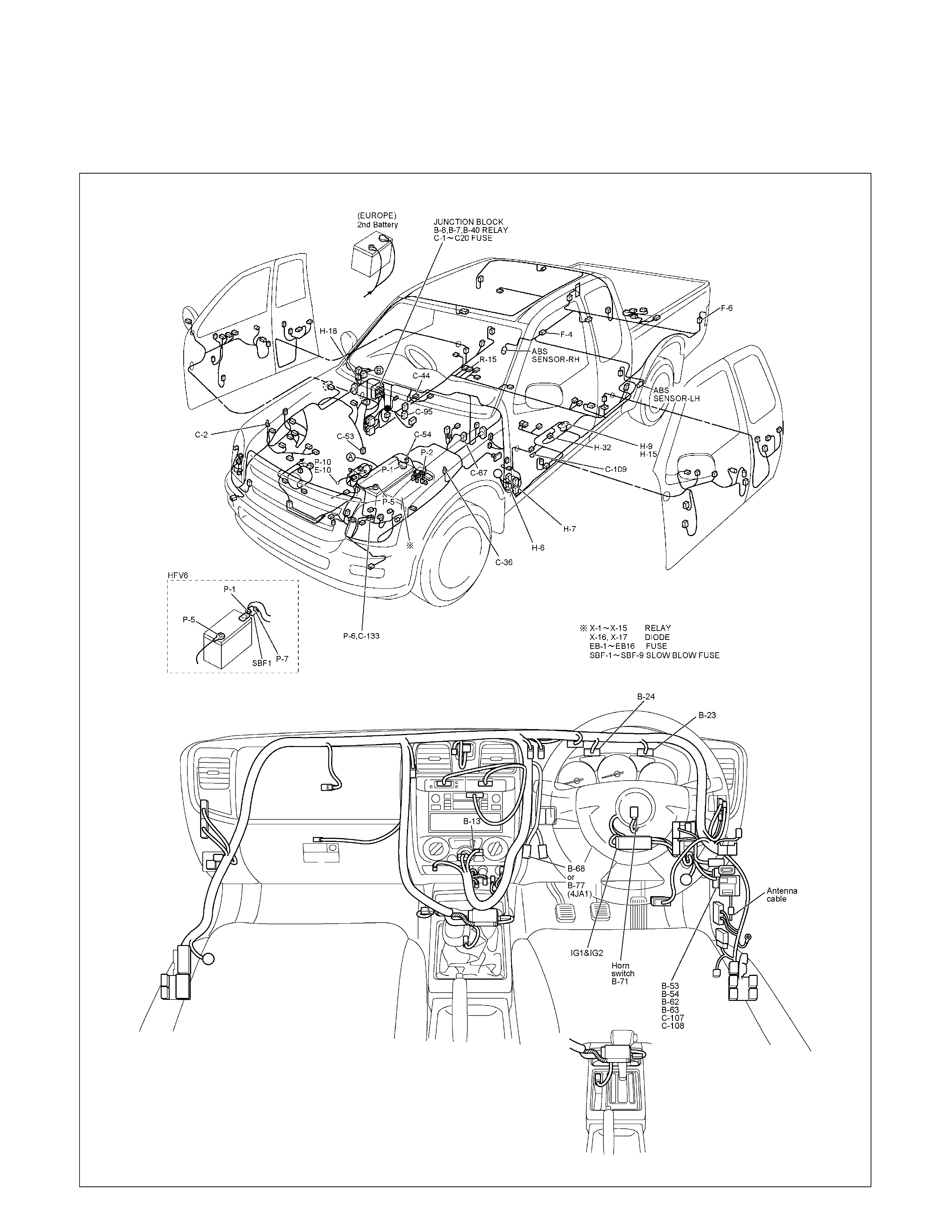

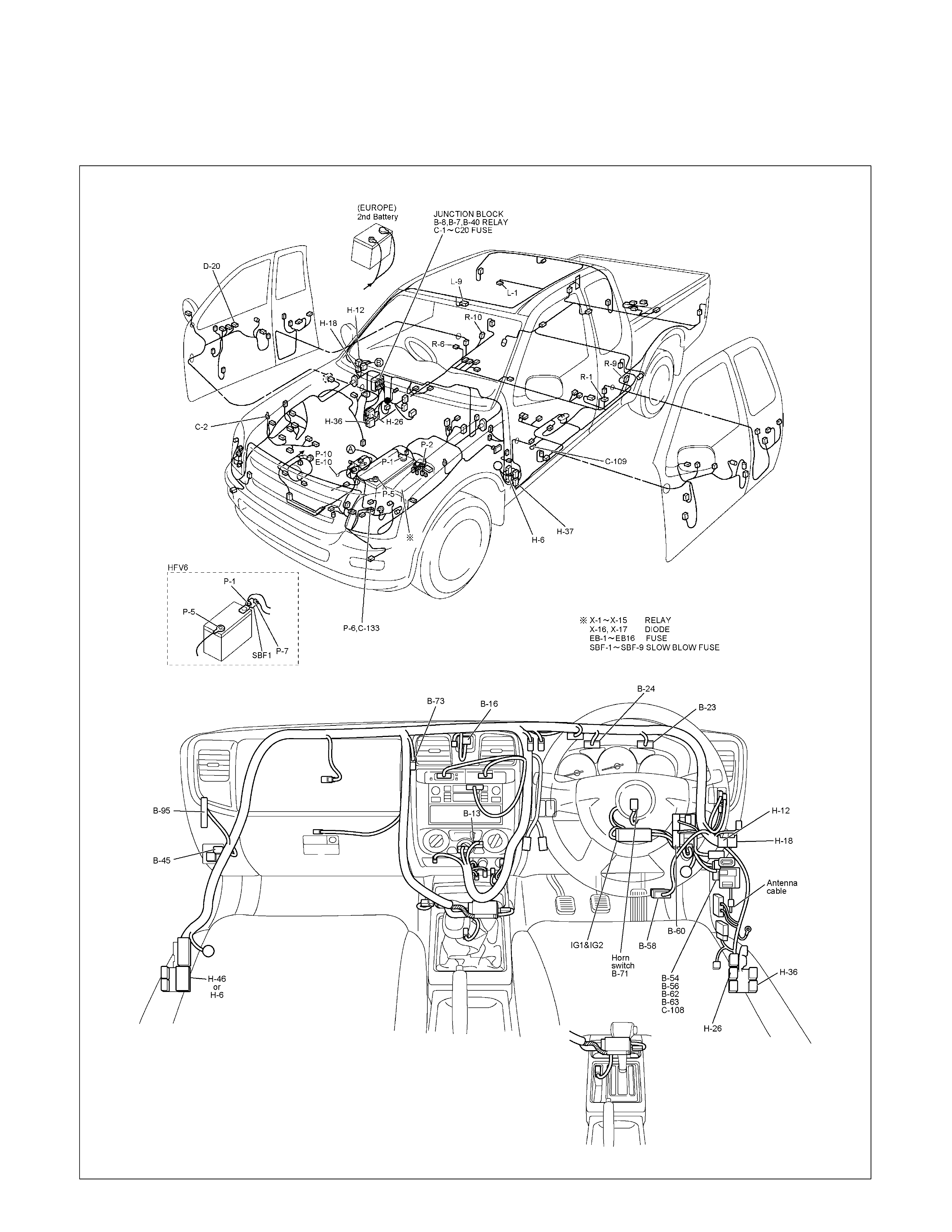

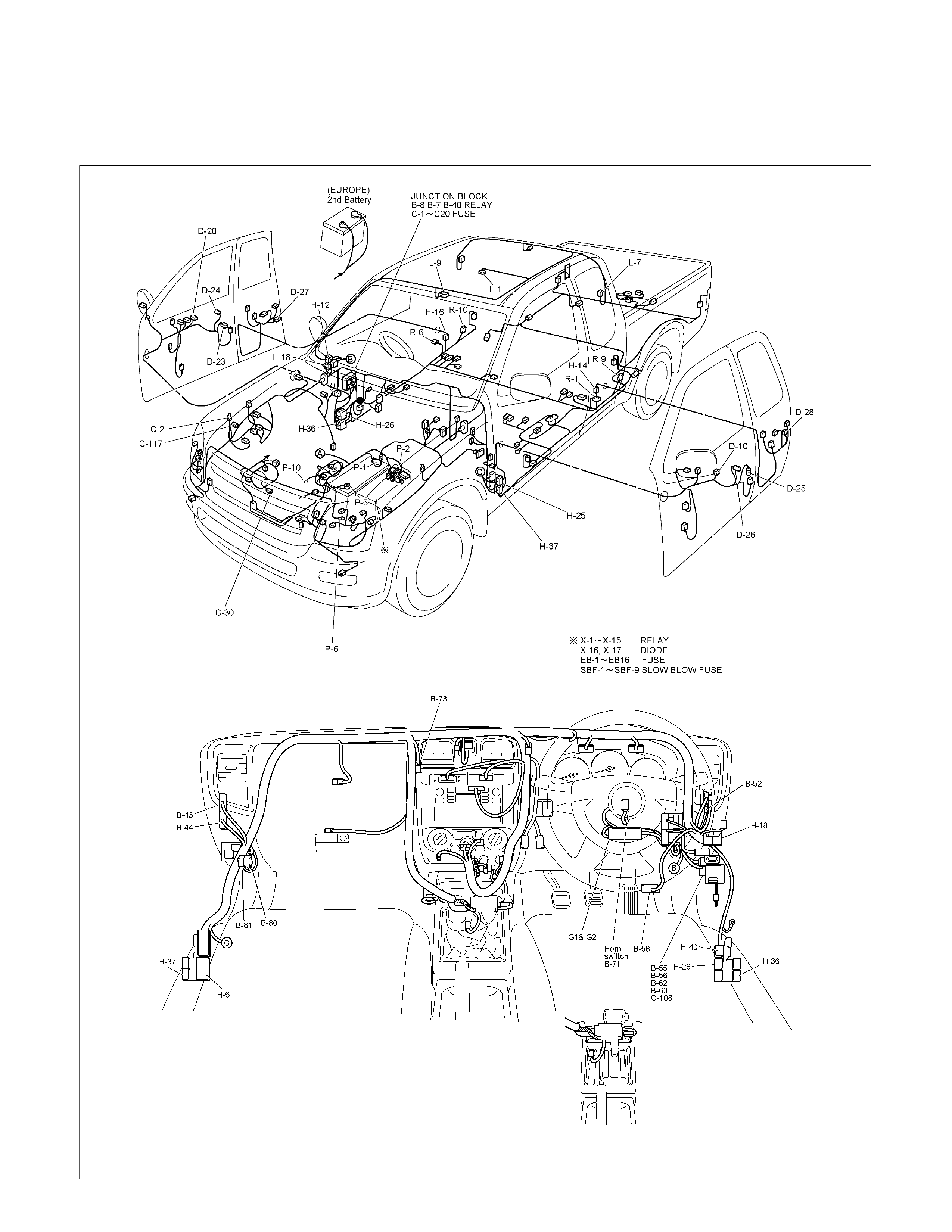

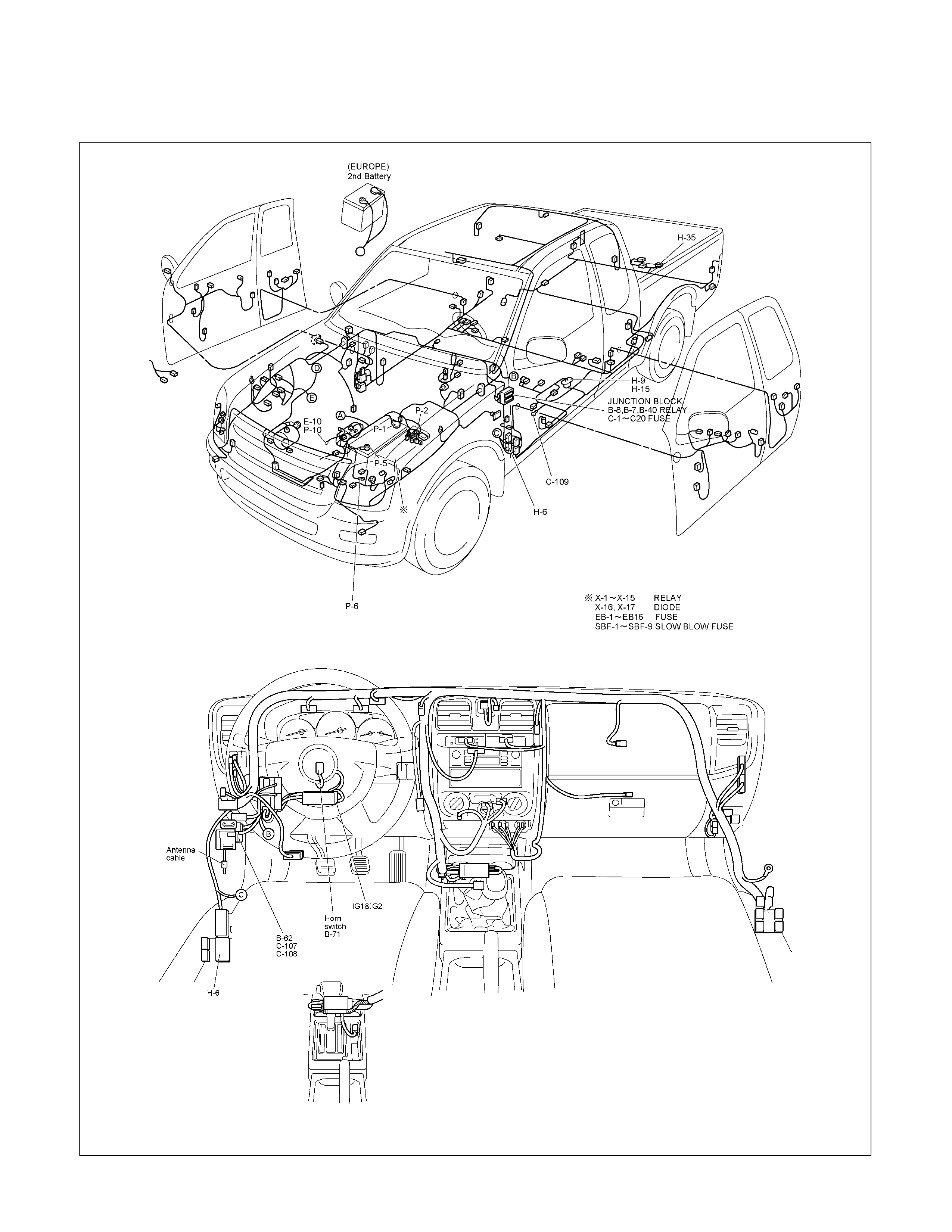

Main Cable Harness (RHD)

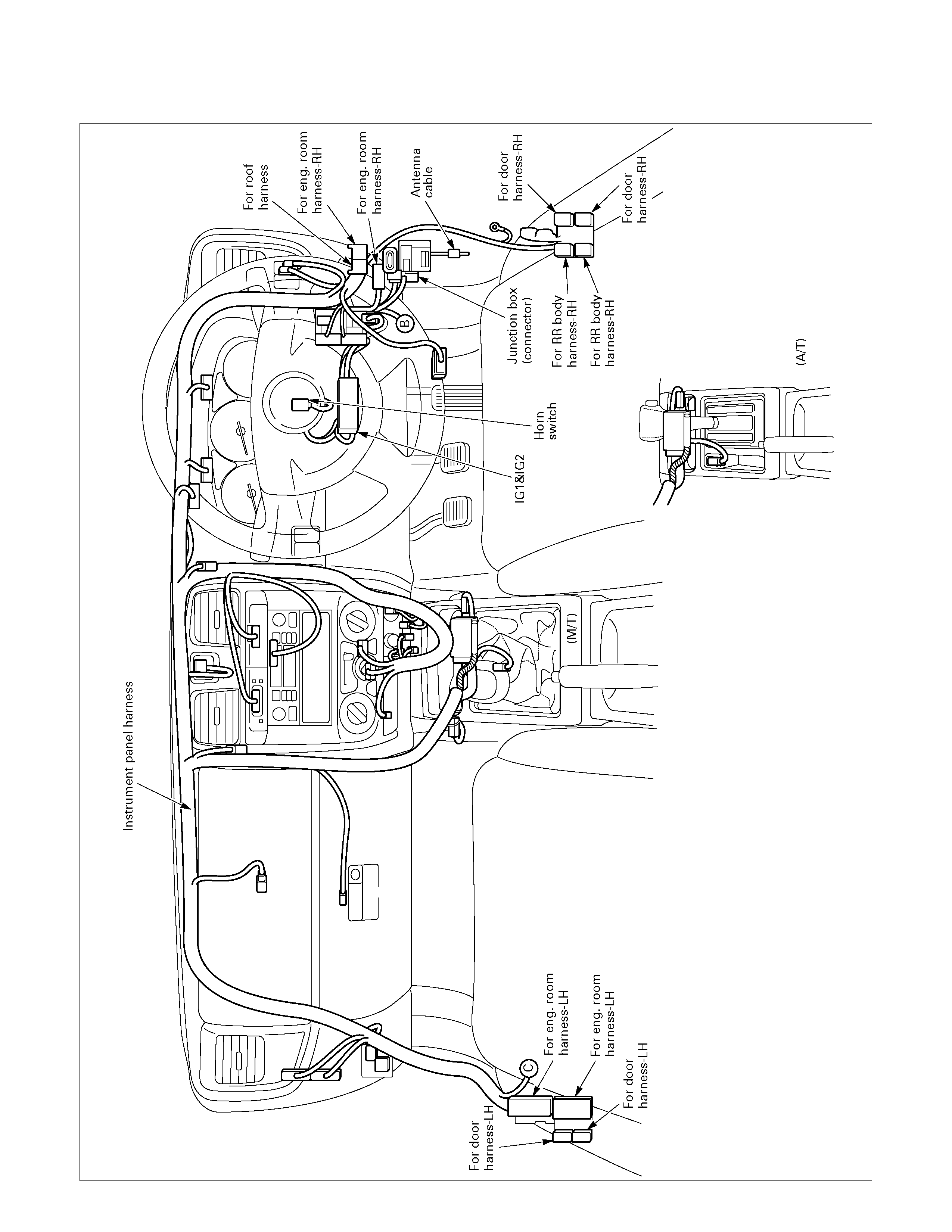

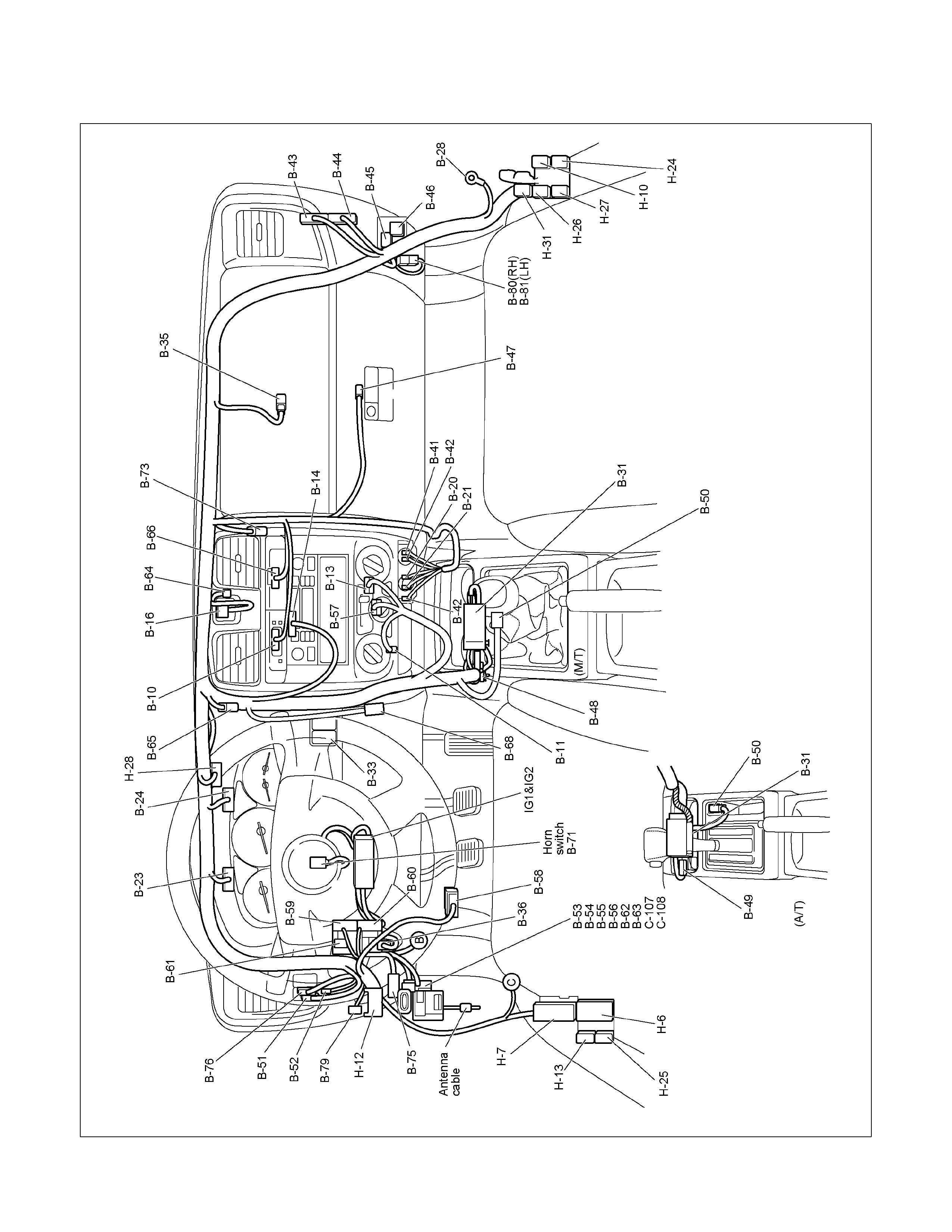

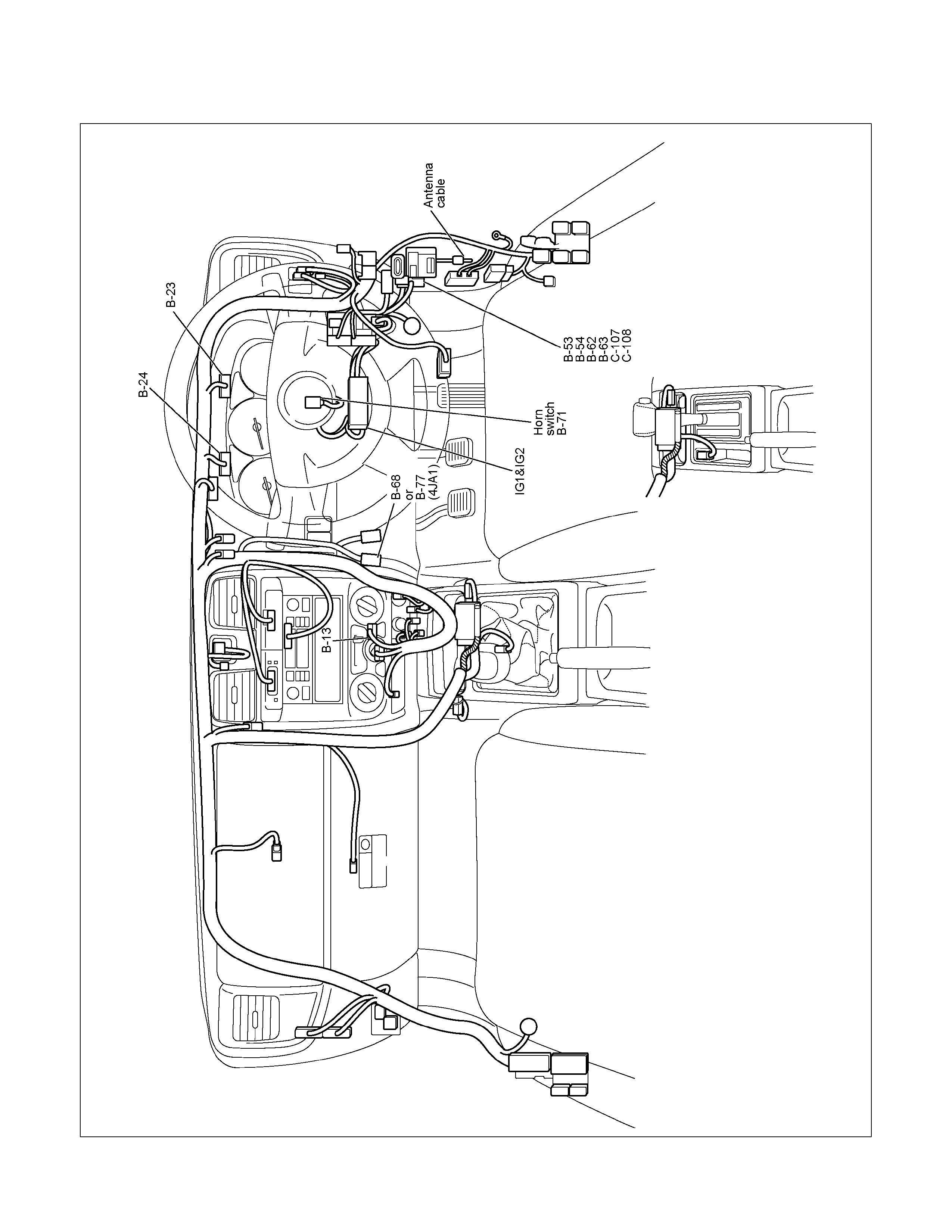

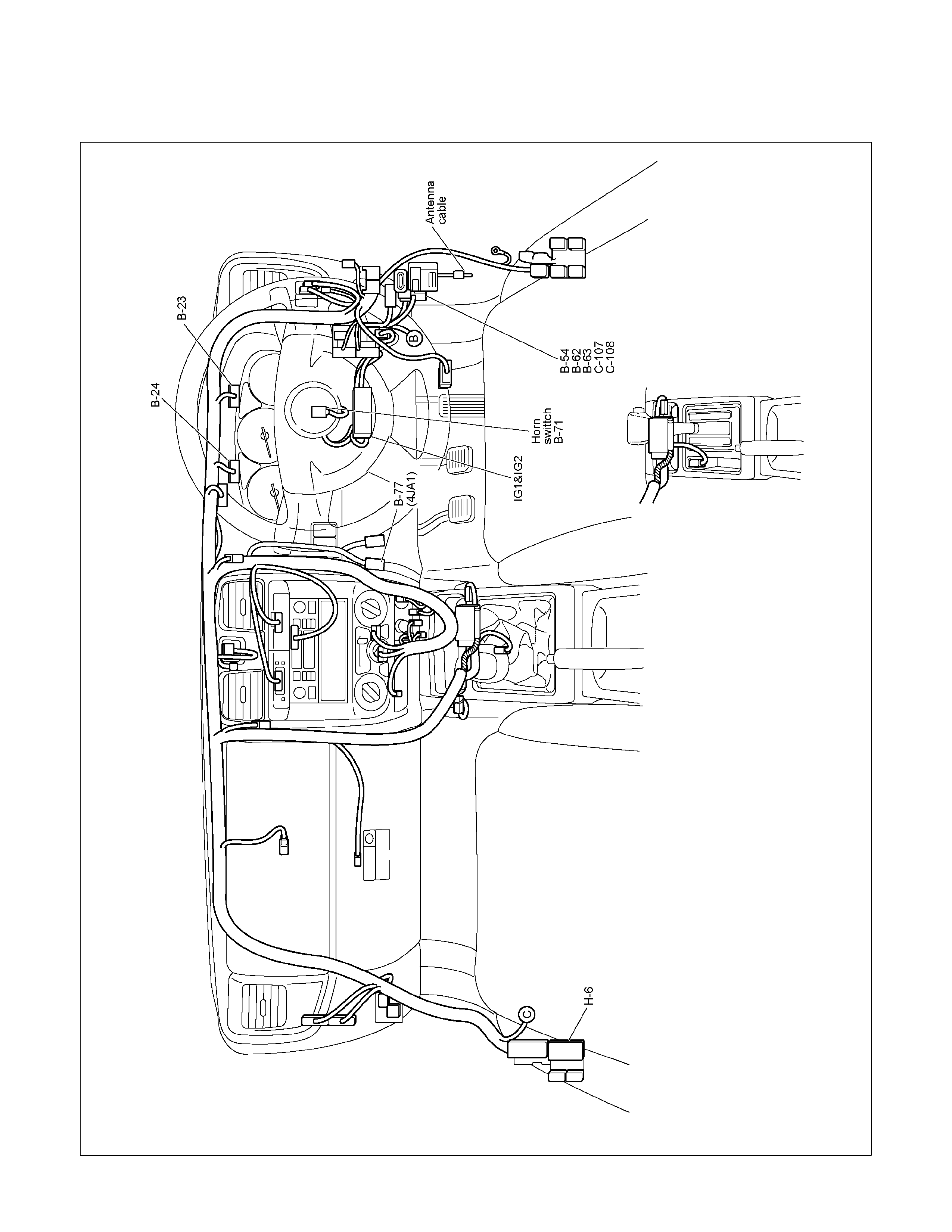

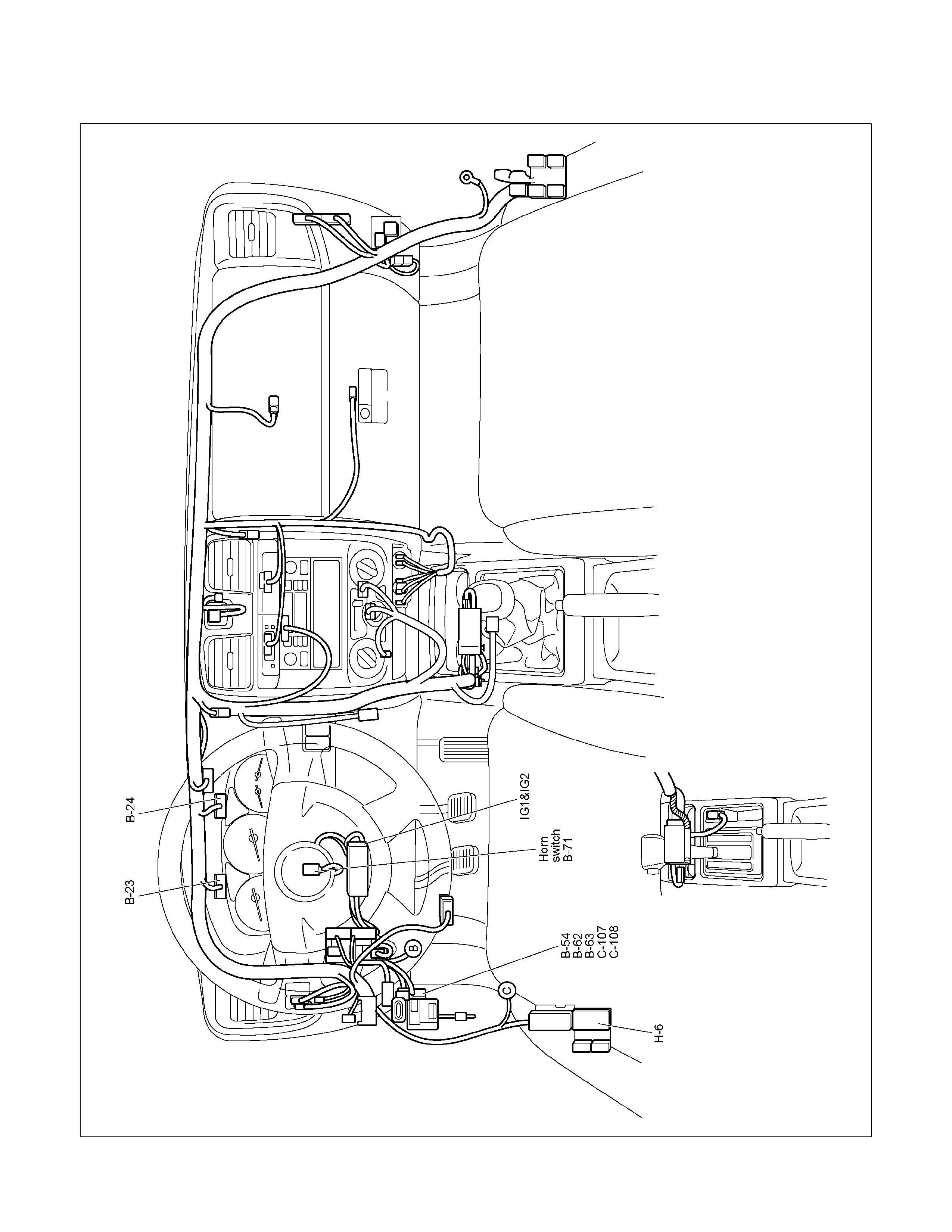

Instrument Harness (RHD)

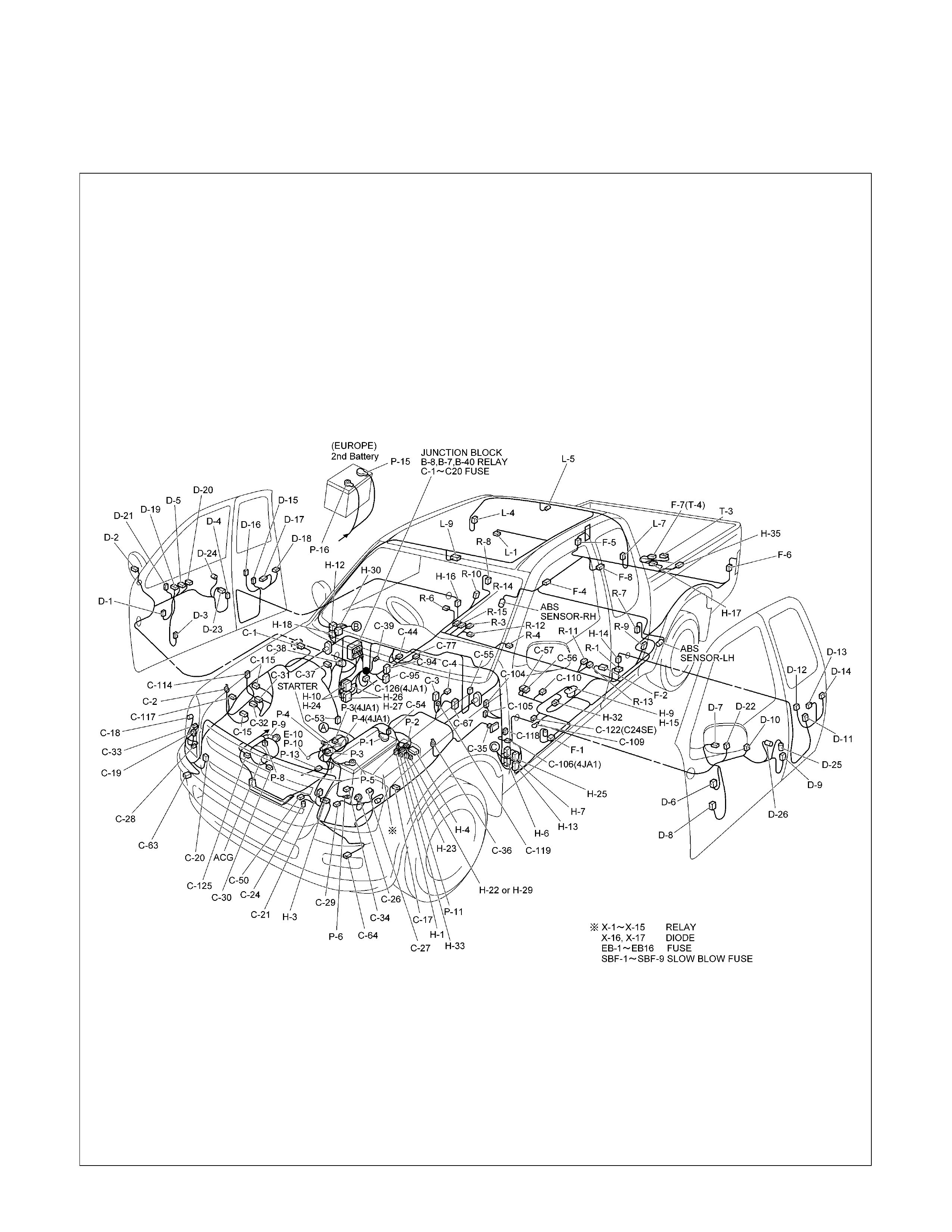

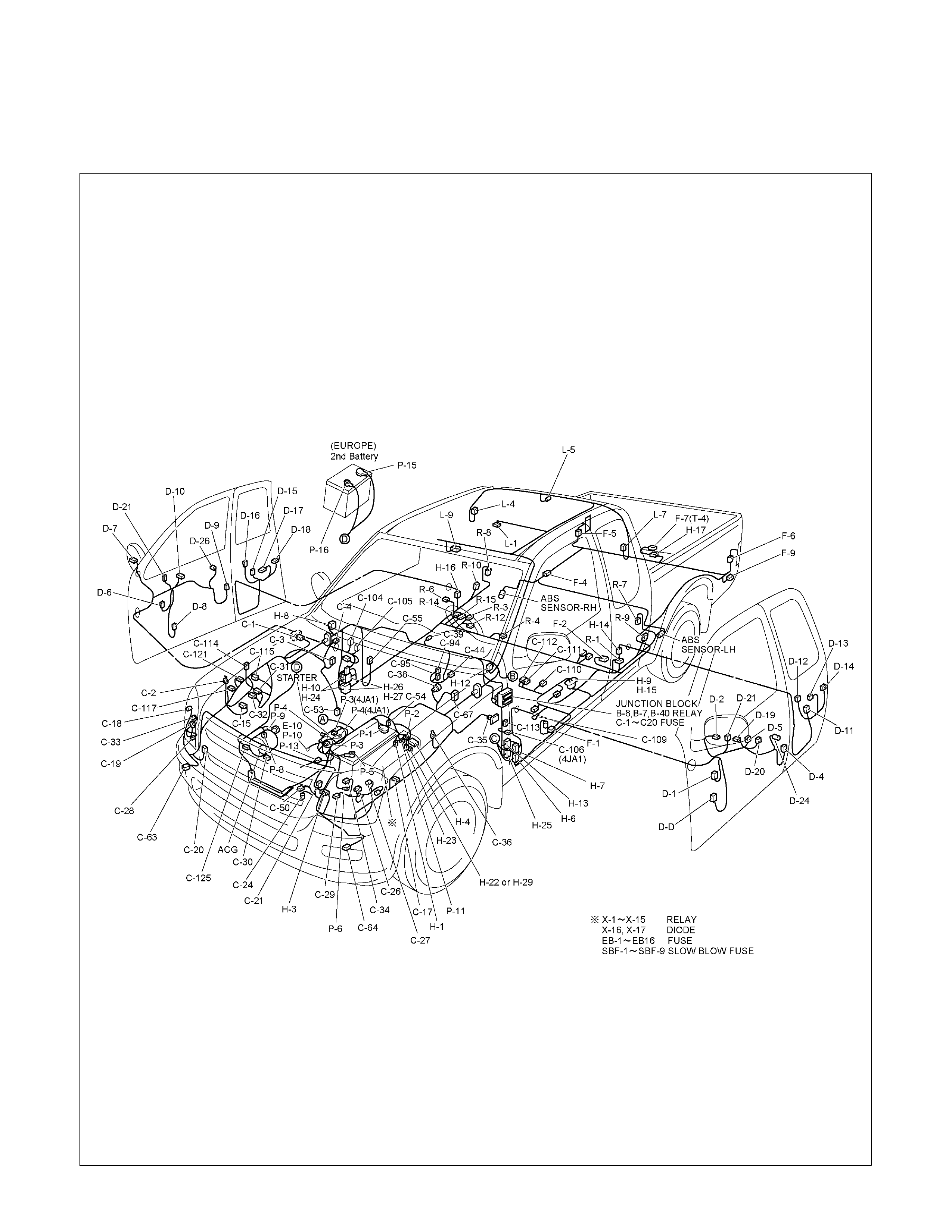

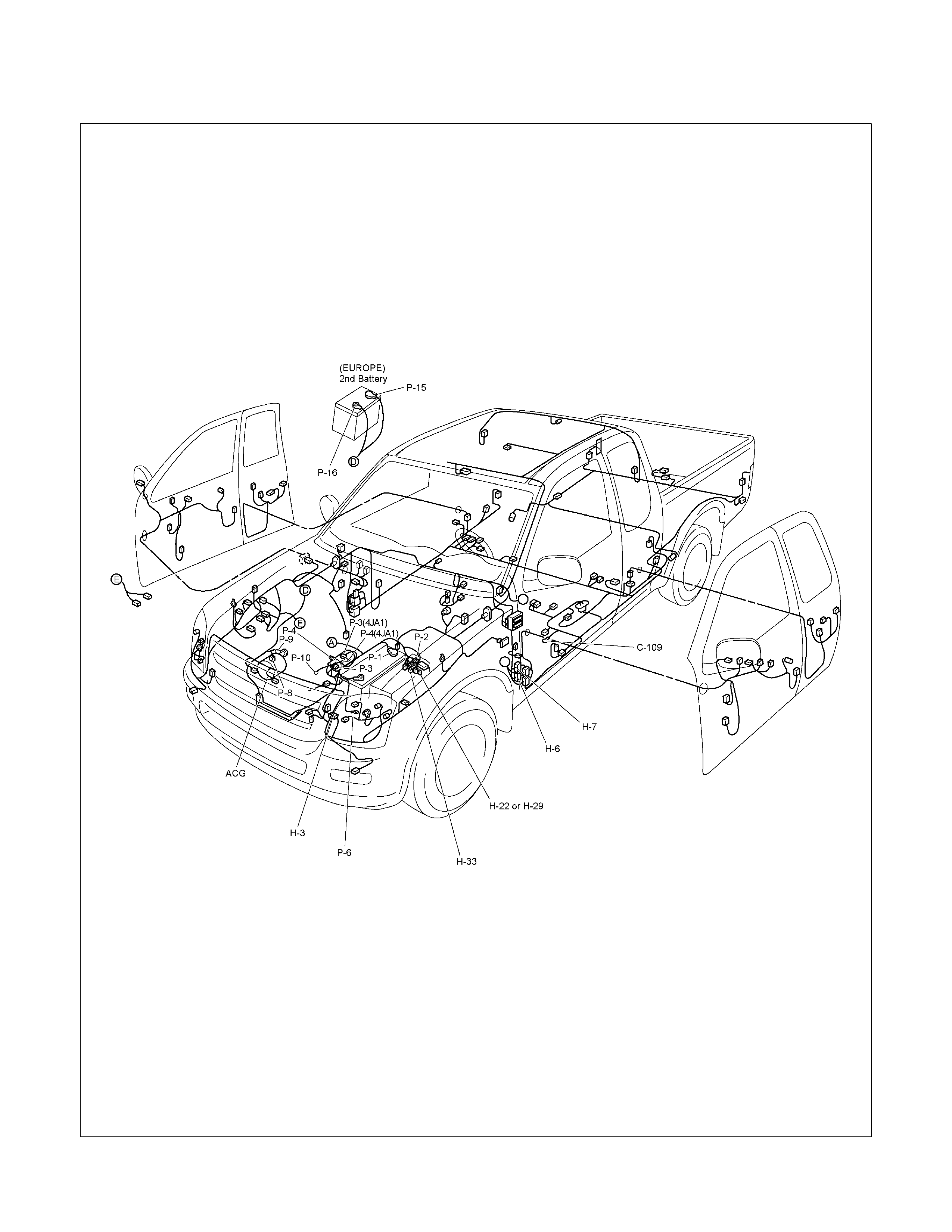

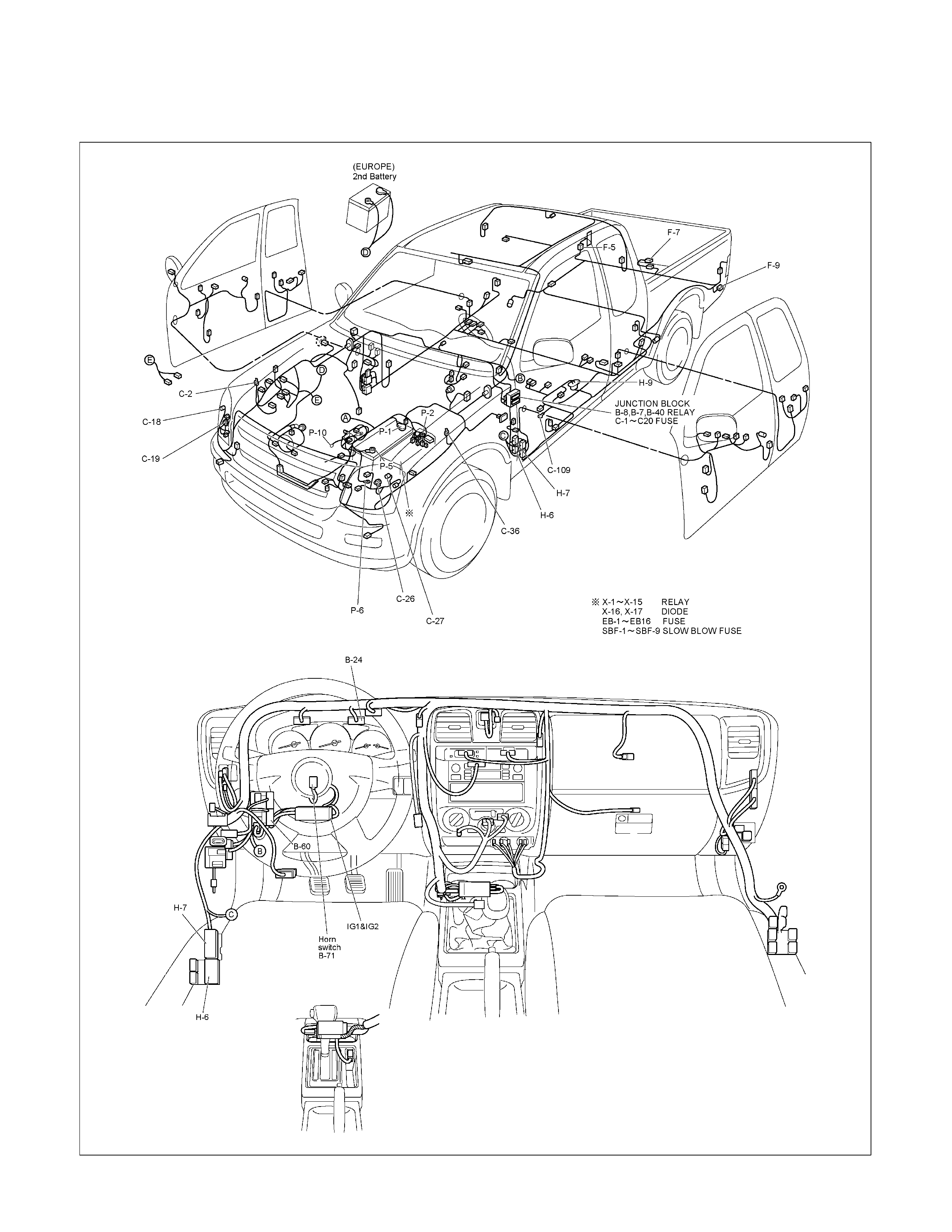

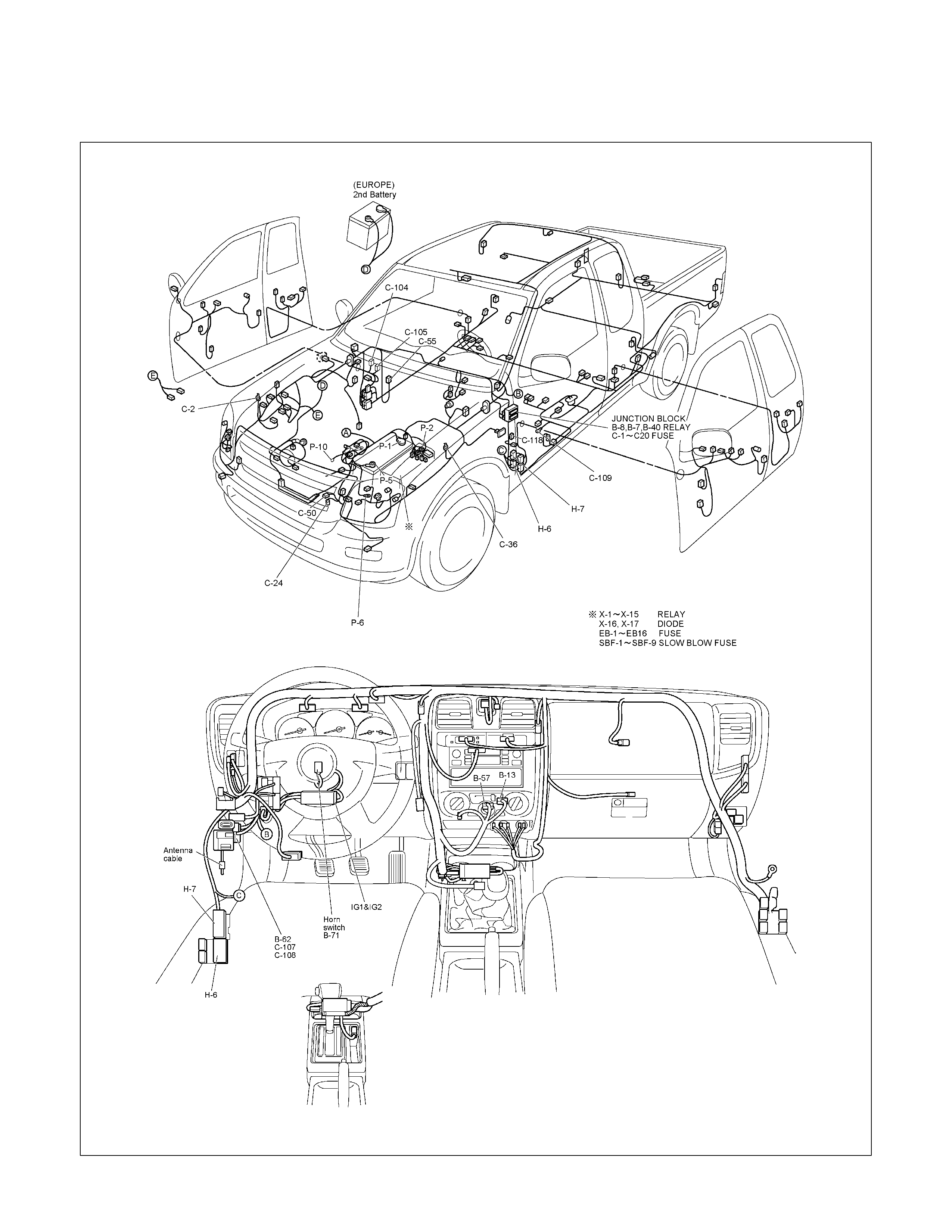

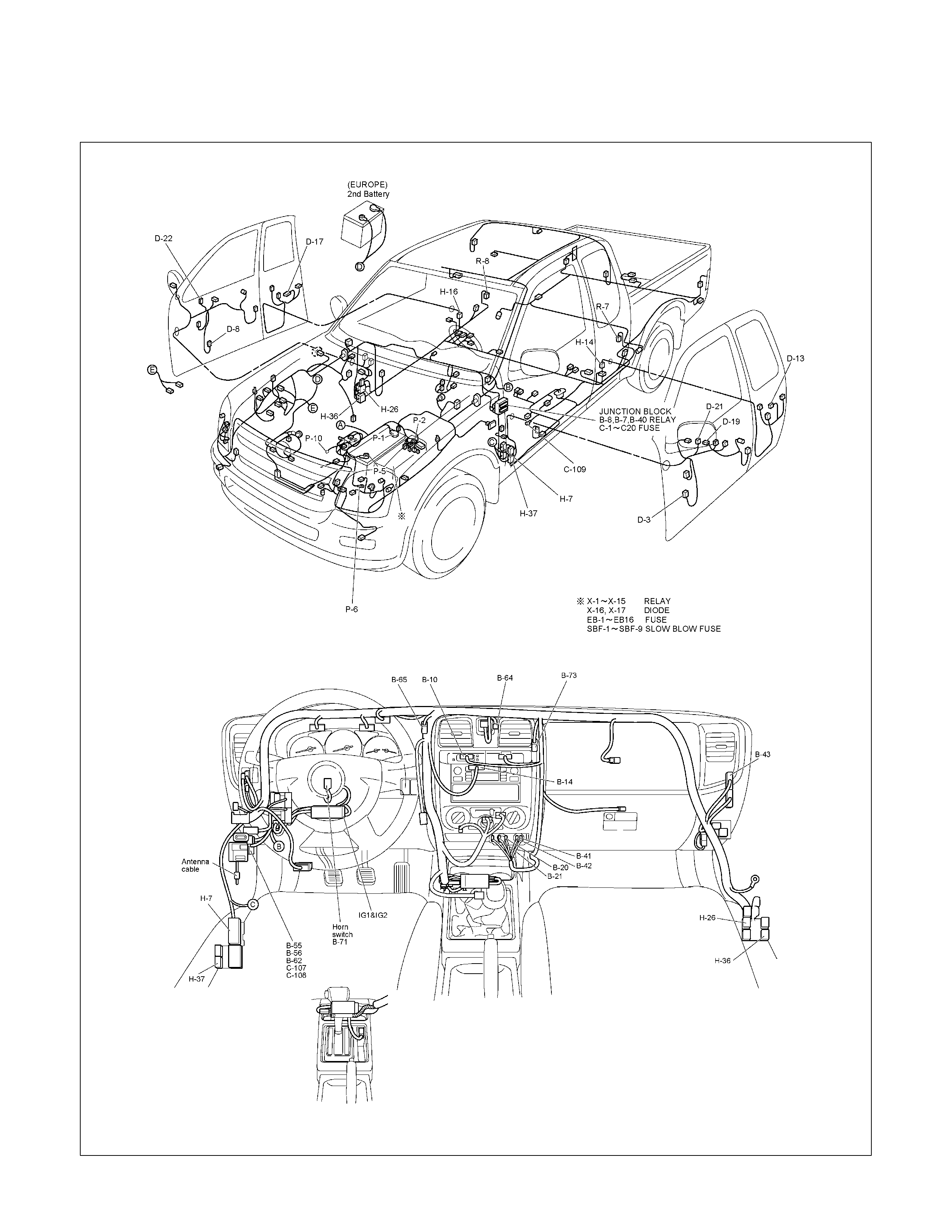

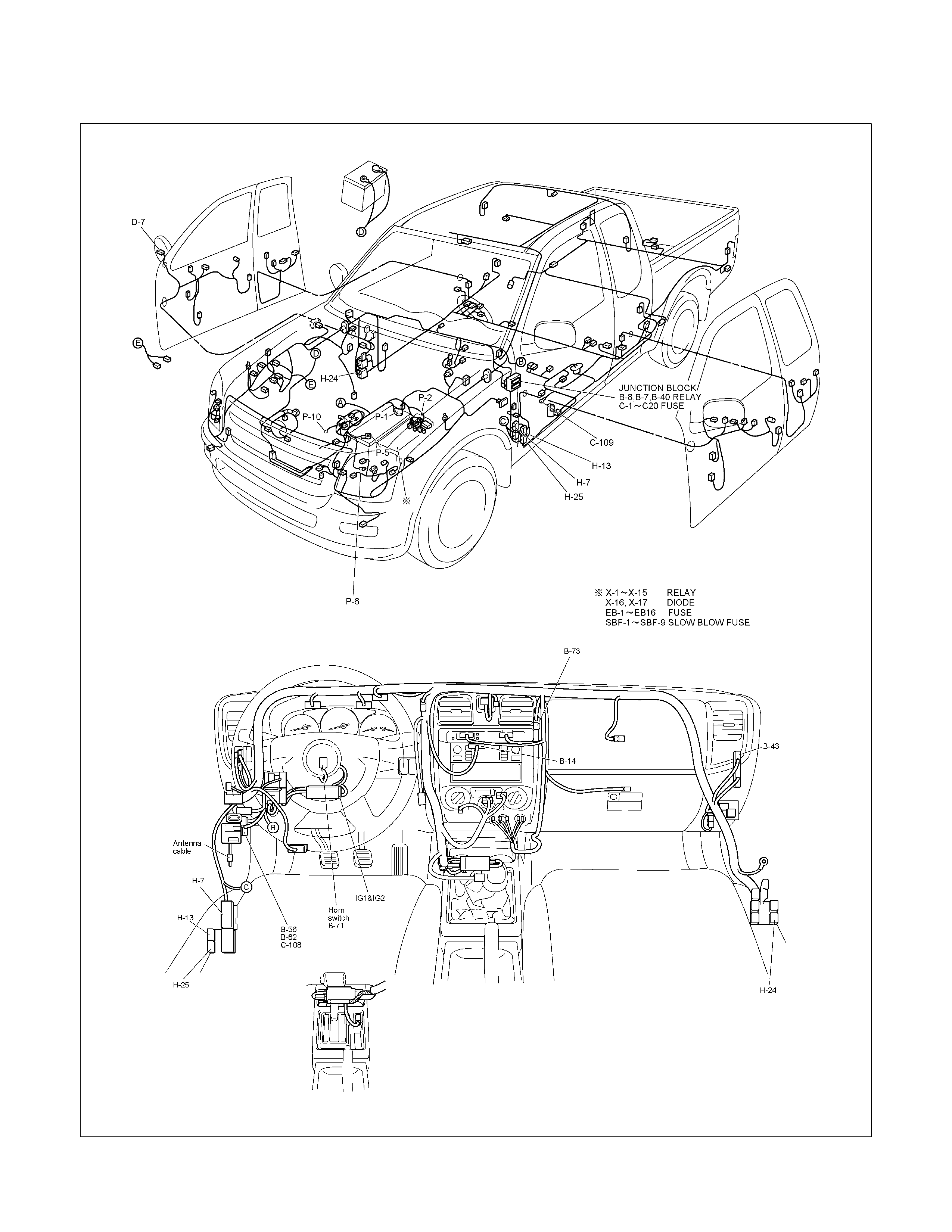

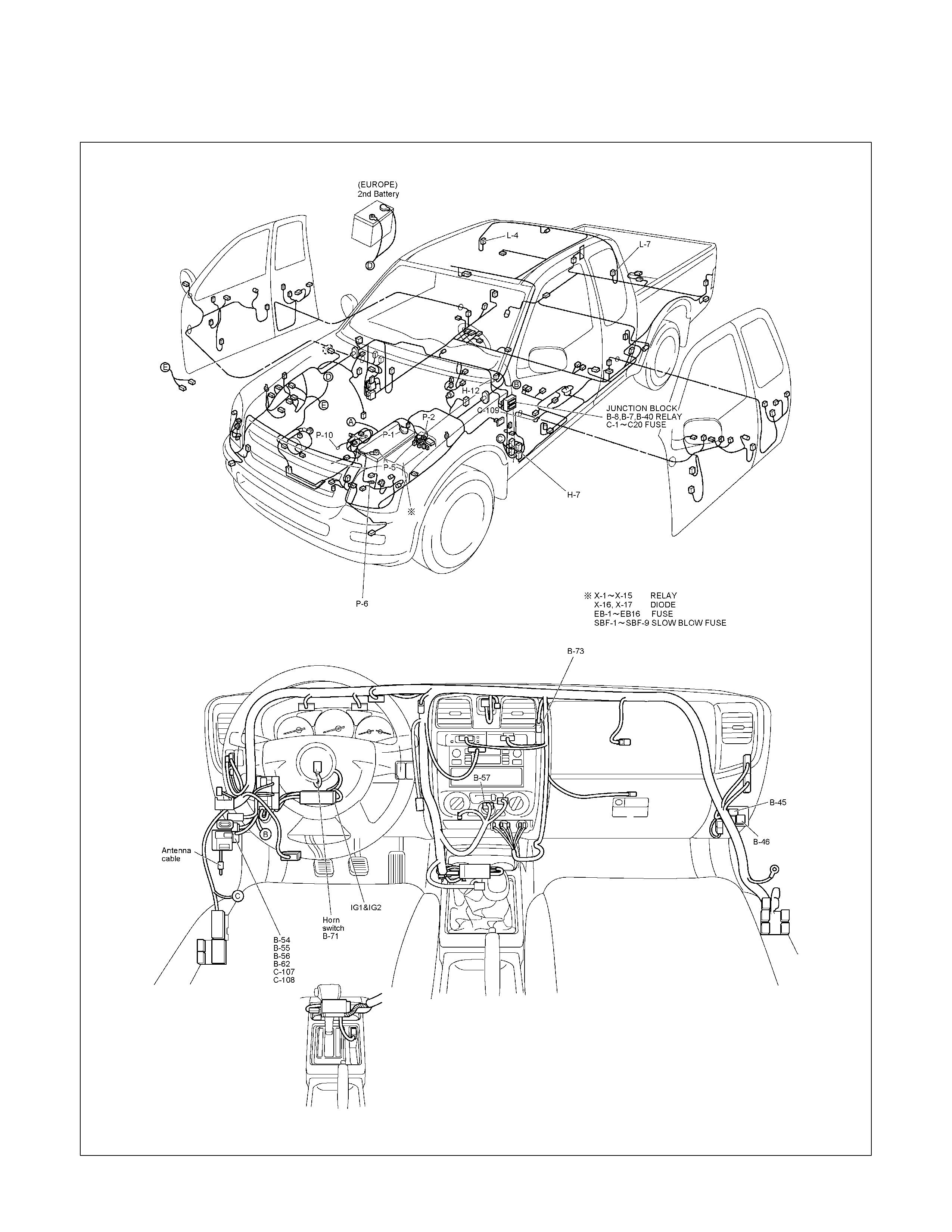

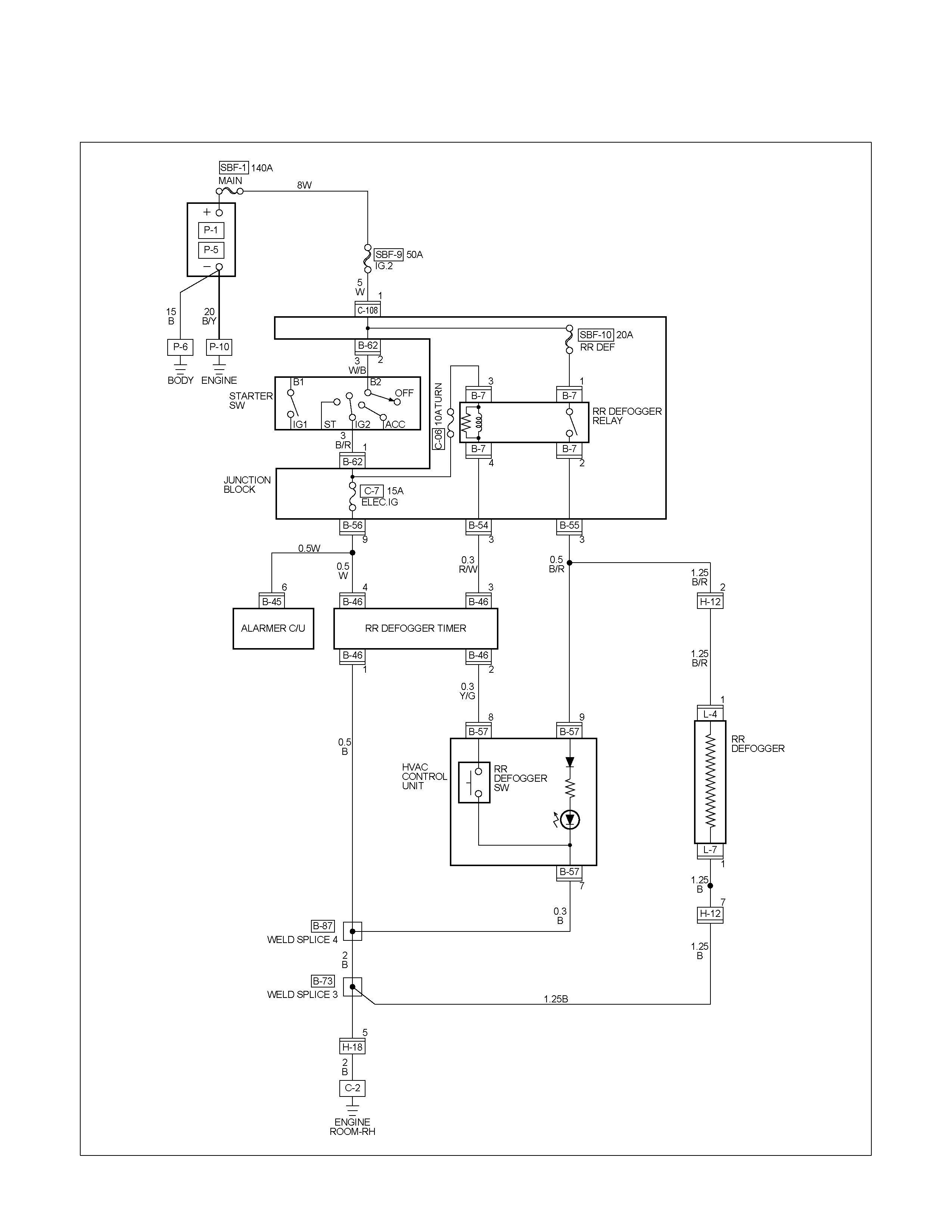

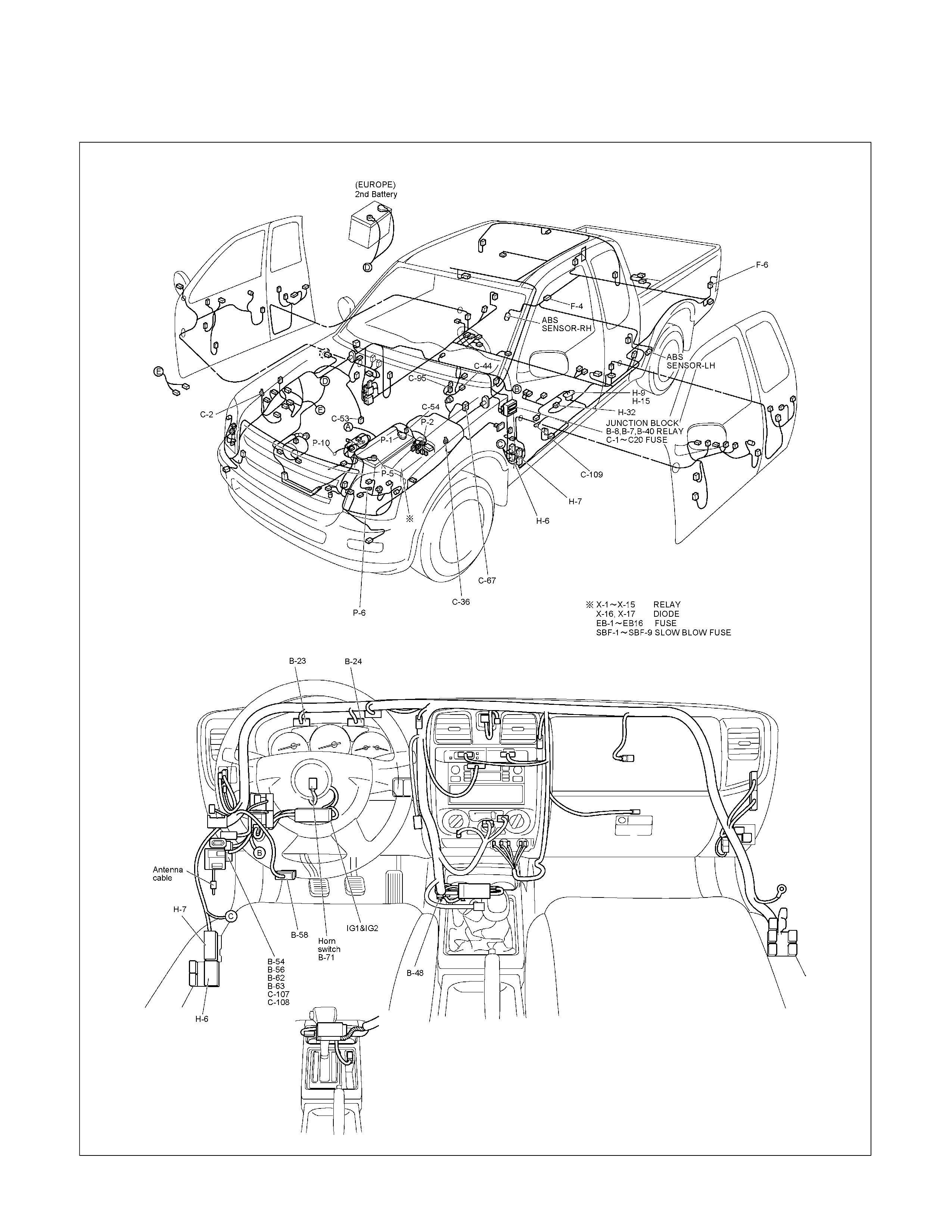

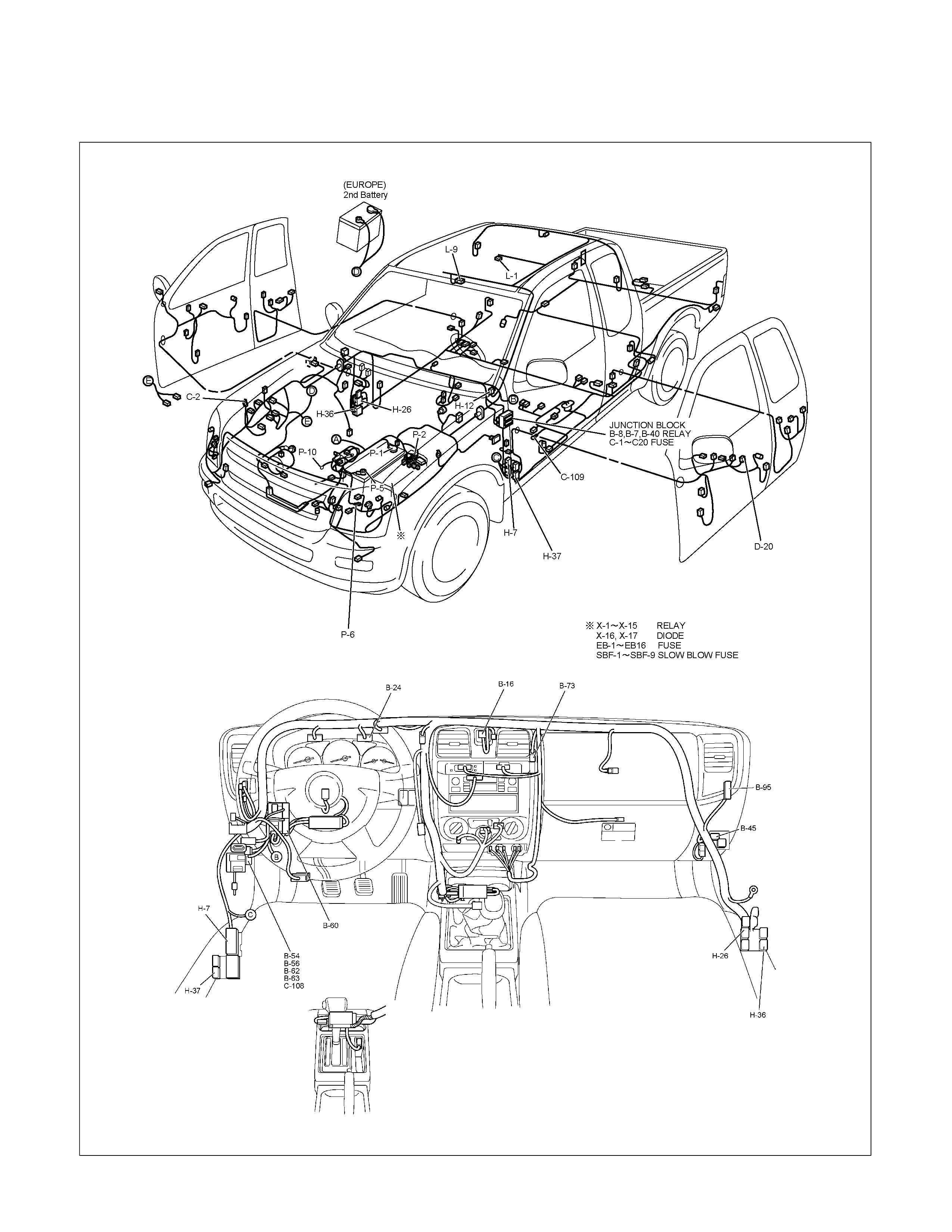

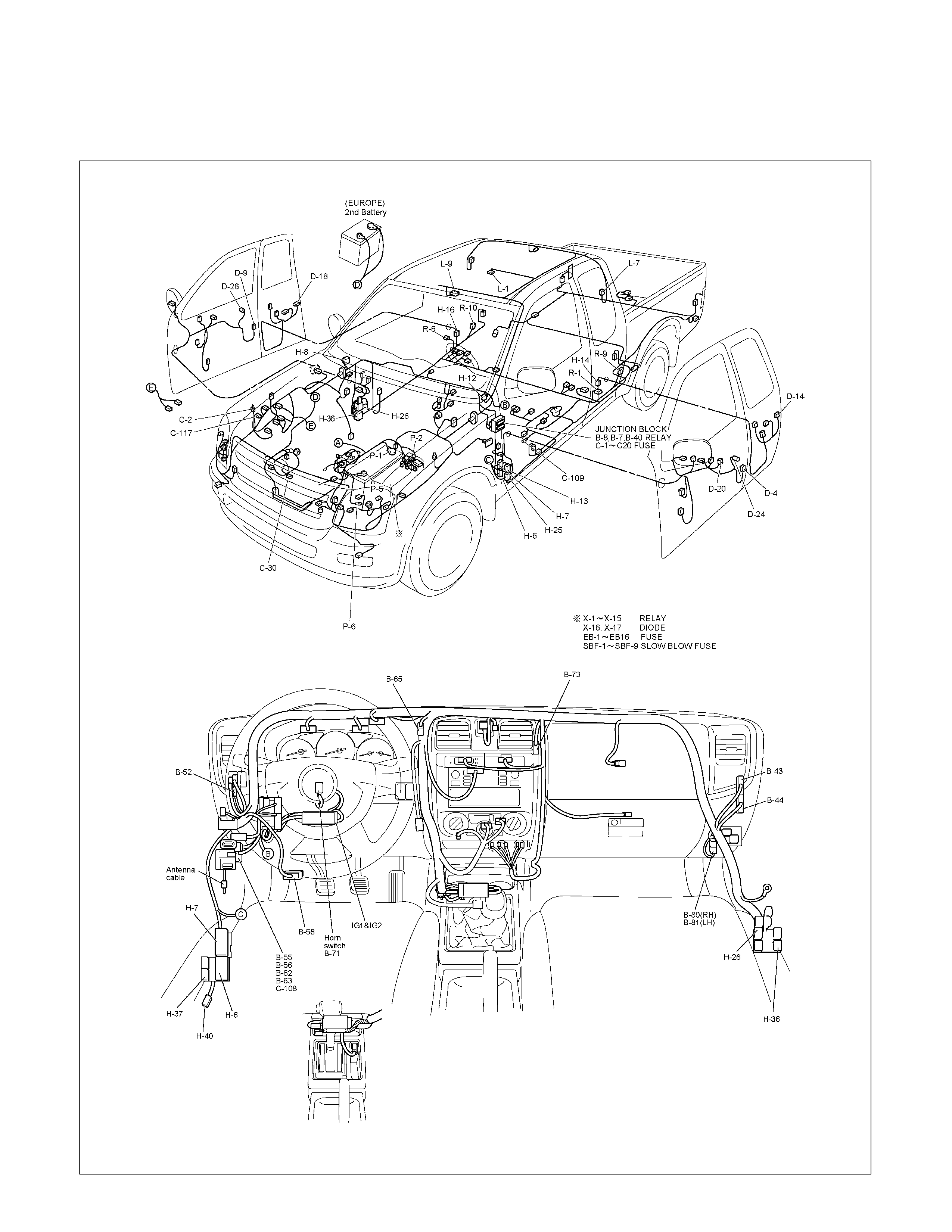

Main Cable Harness (LHD)

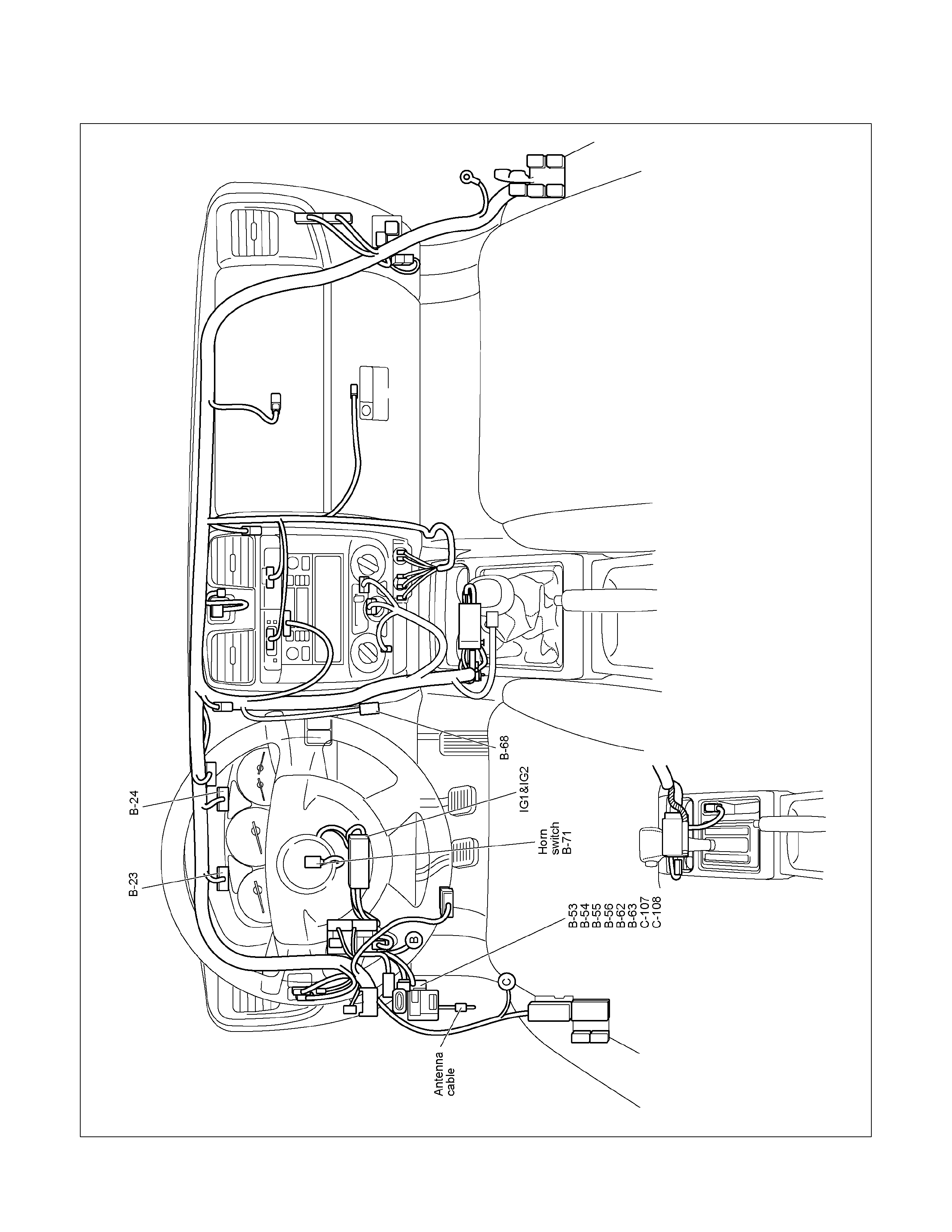

Instrument Harness (LHD)

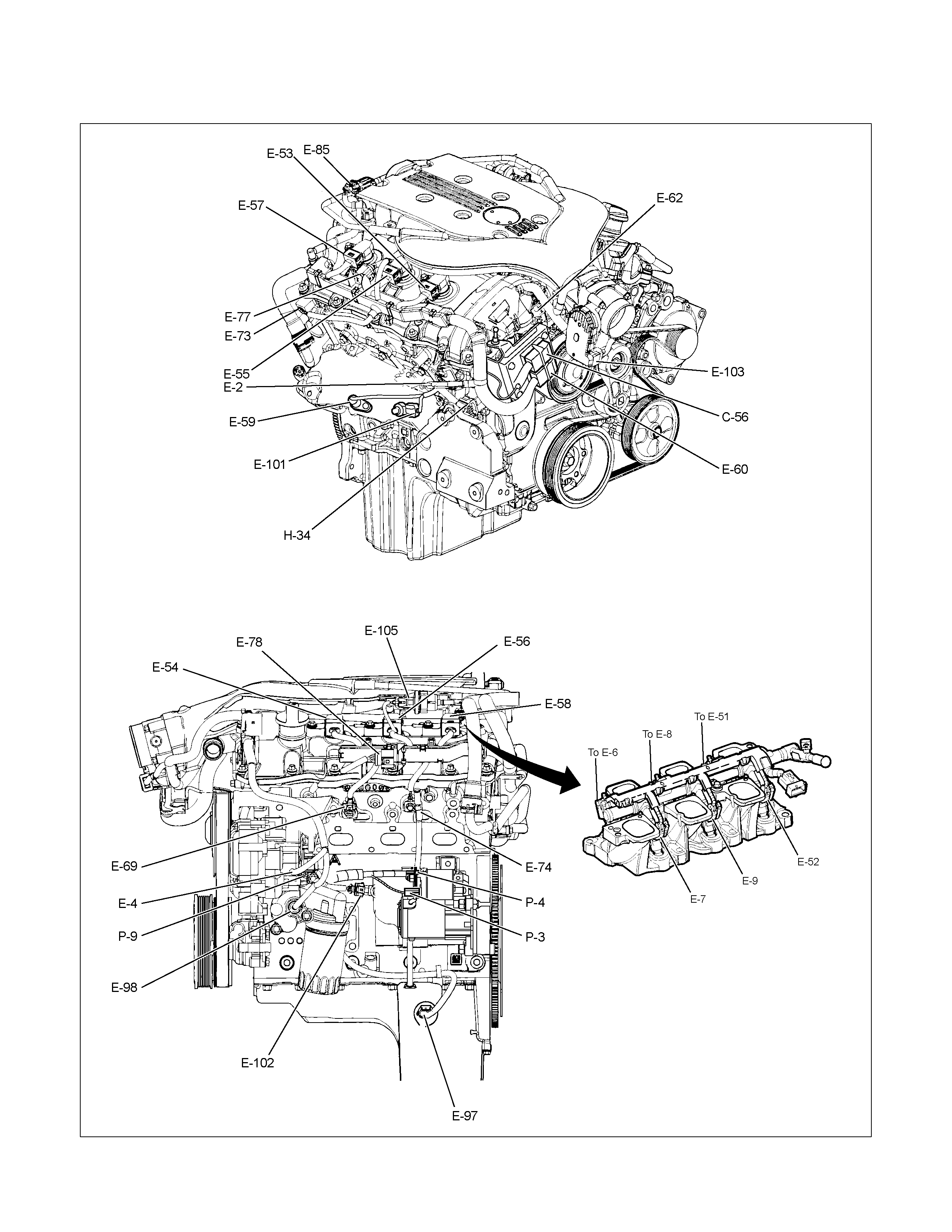

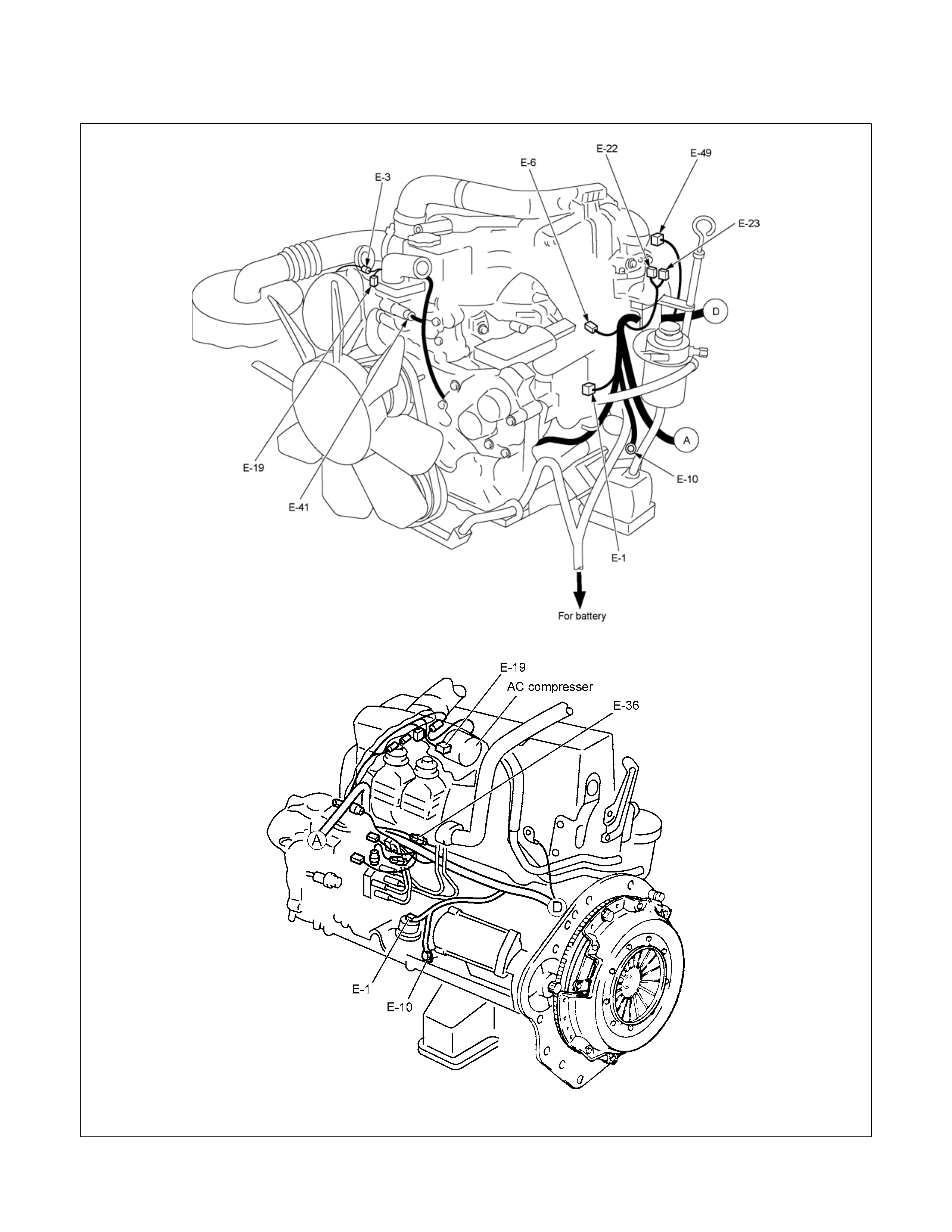

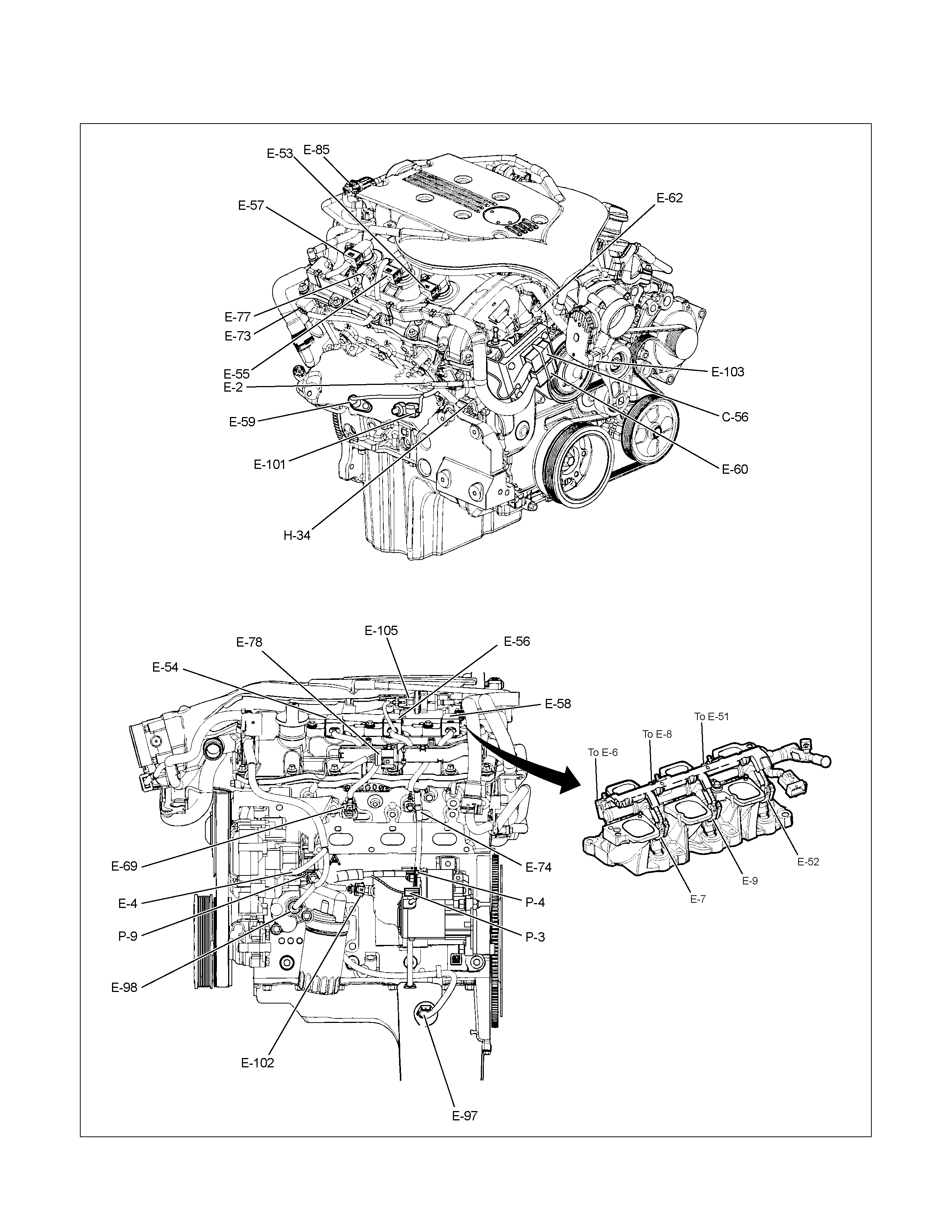

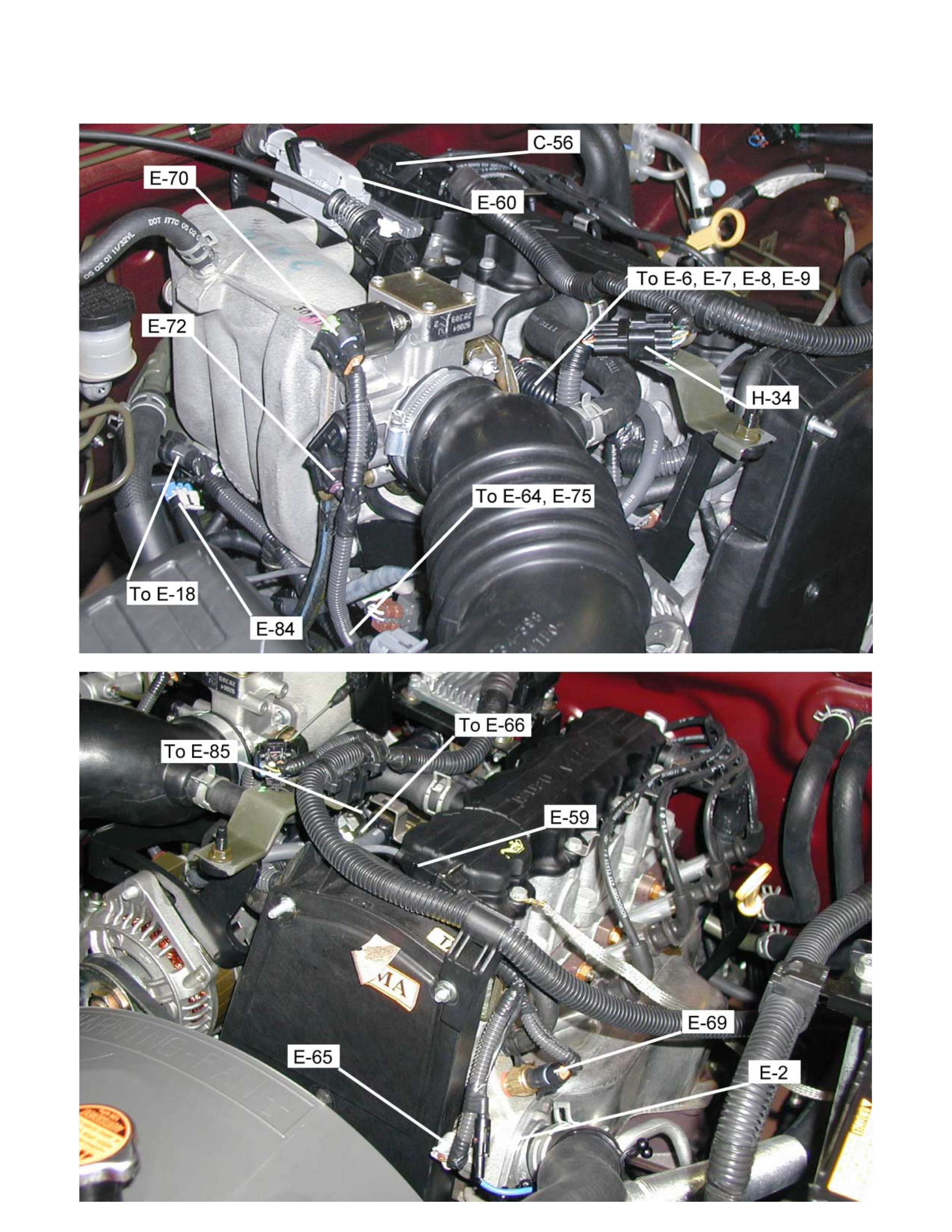

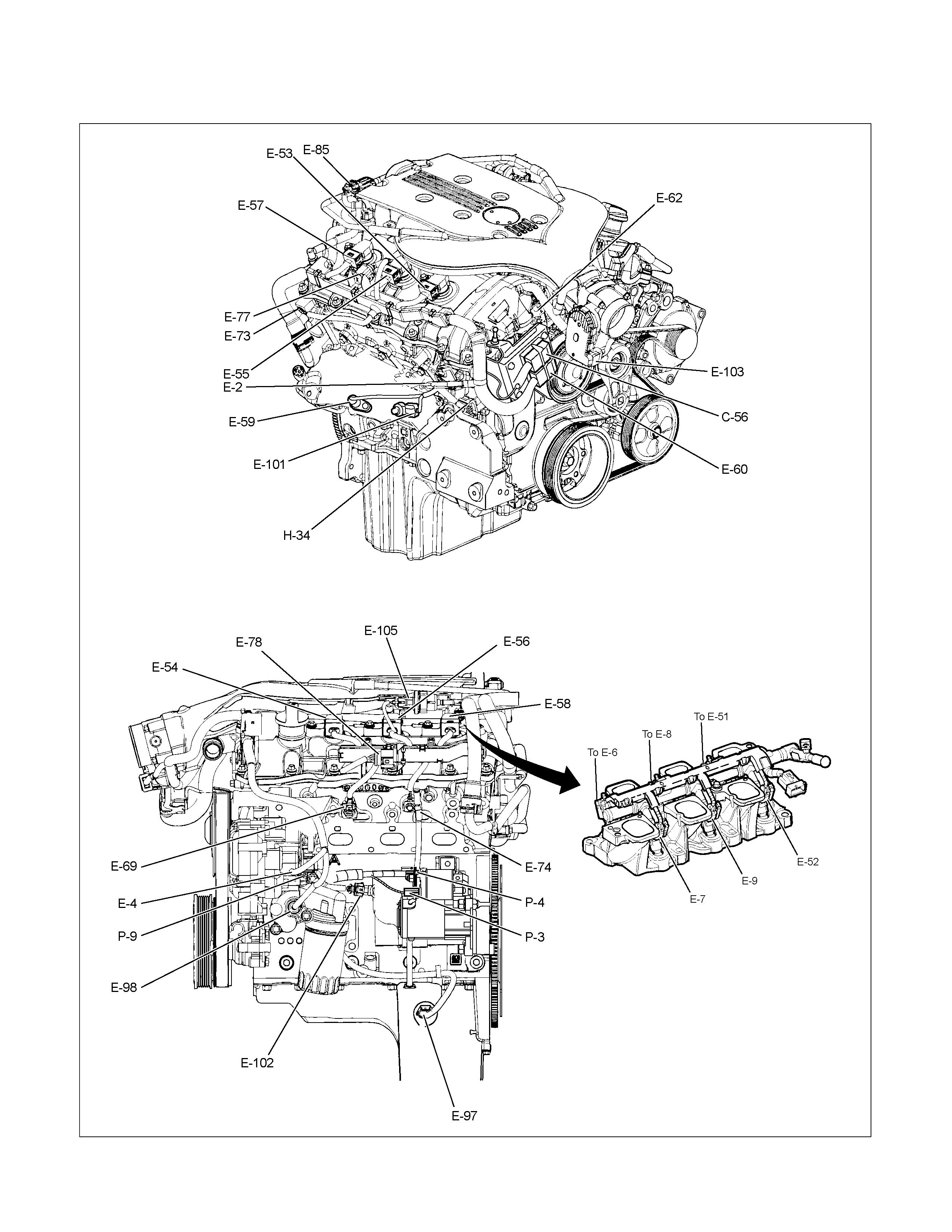

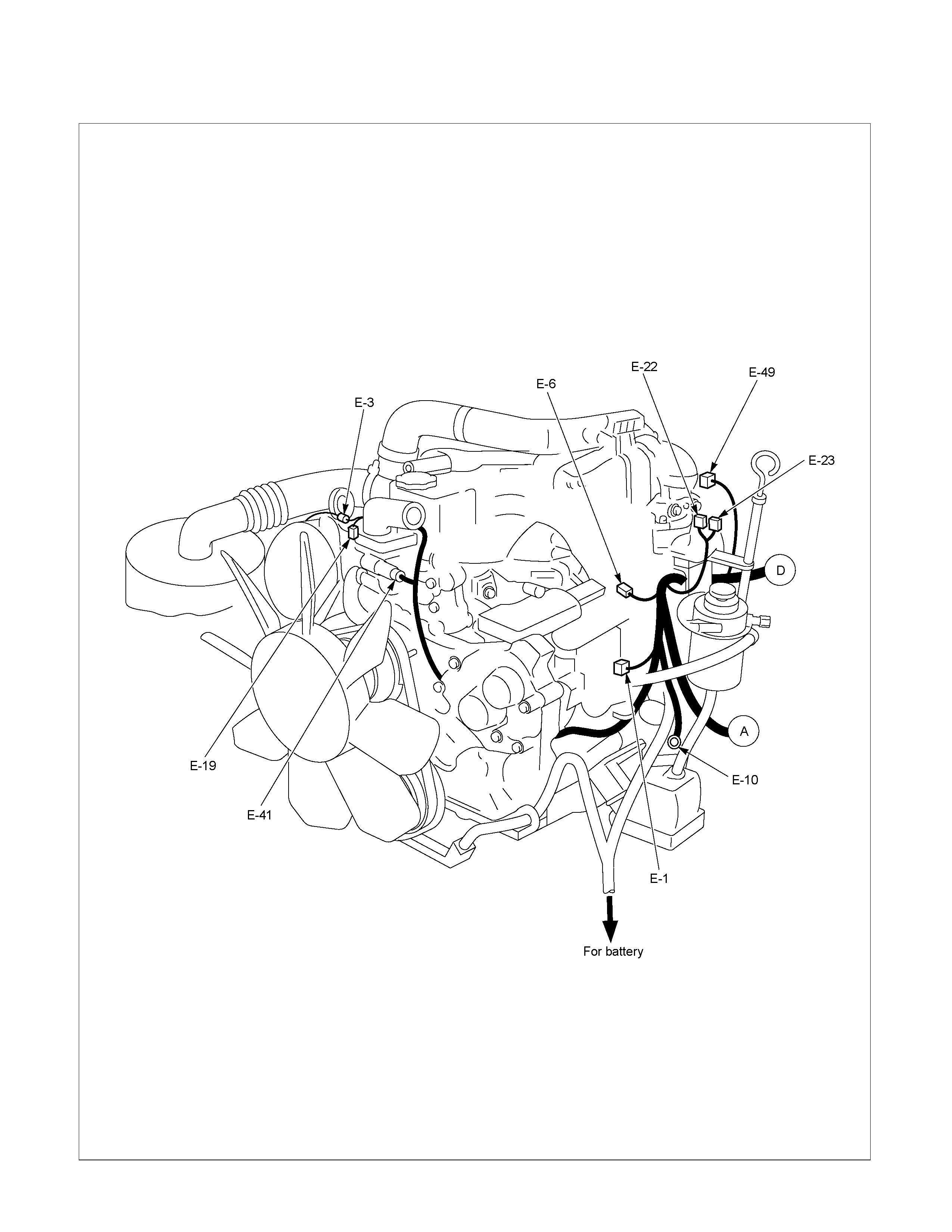

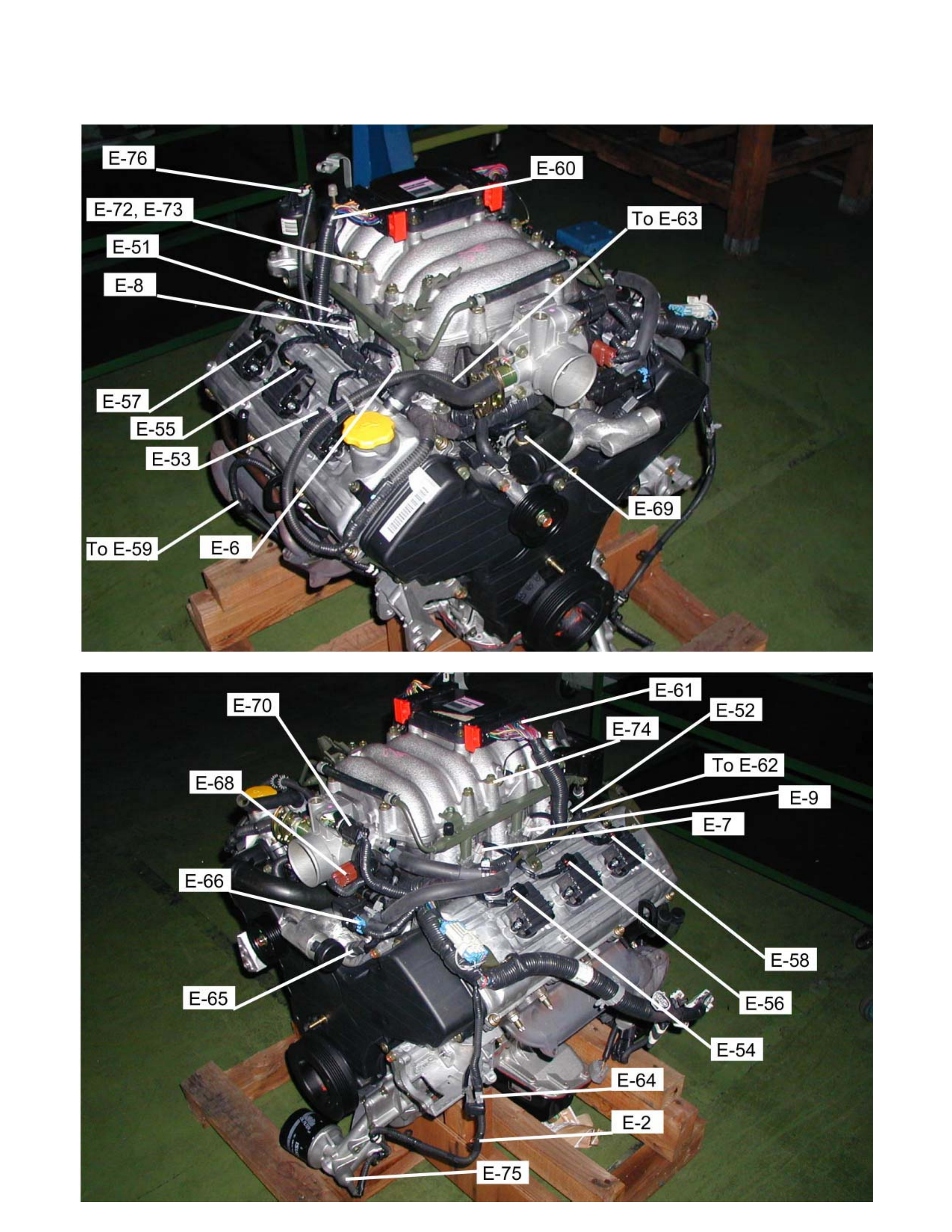

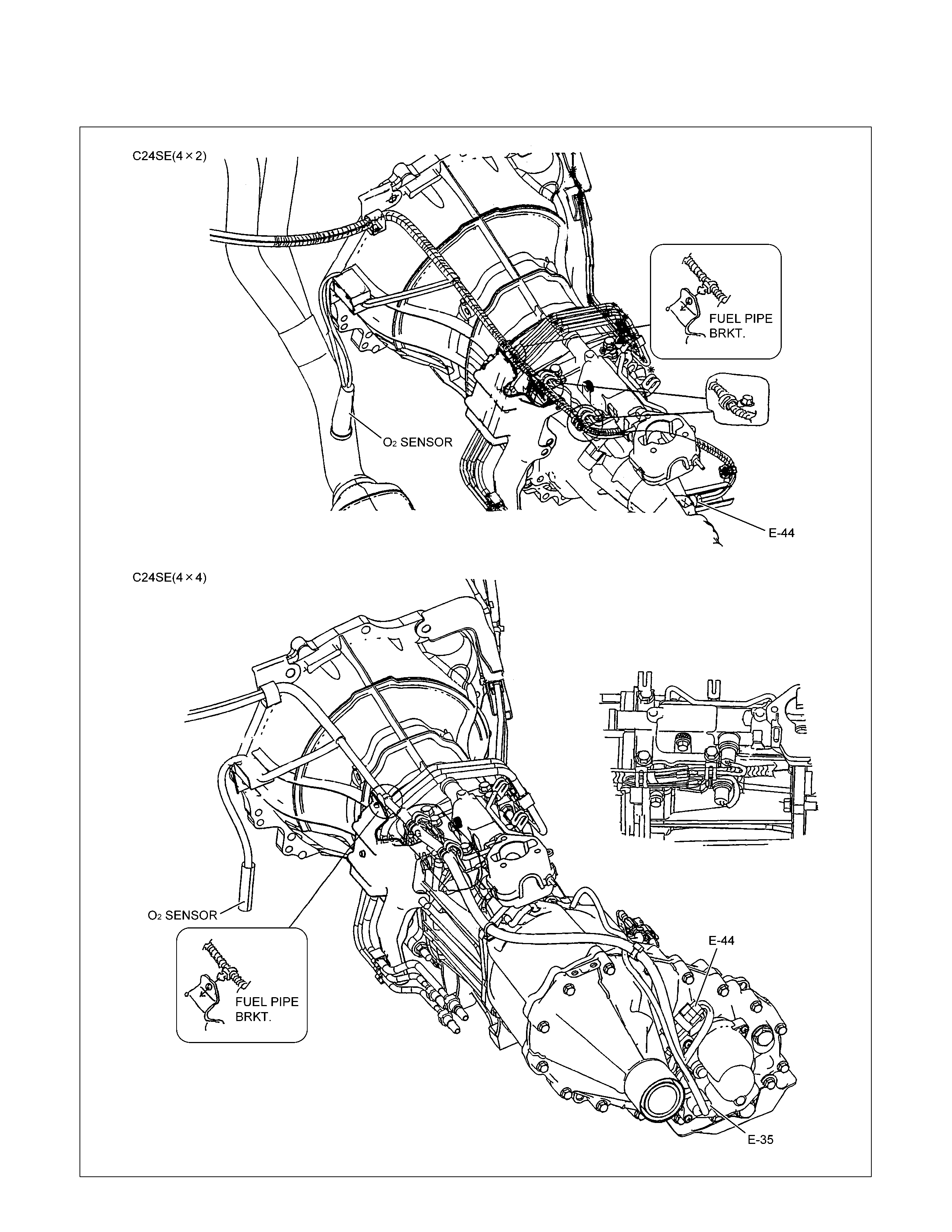

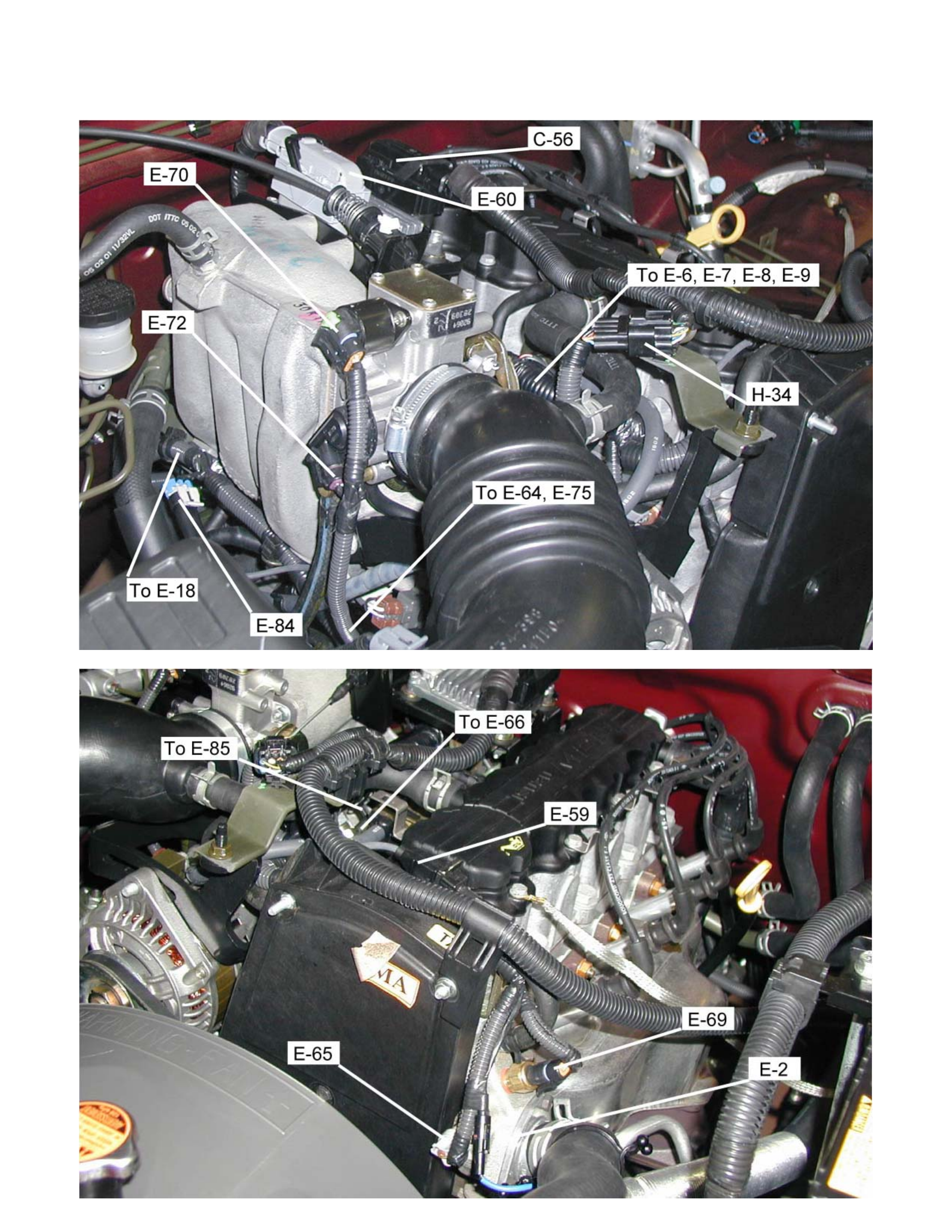

Engine Harness C24SE

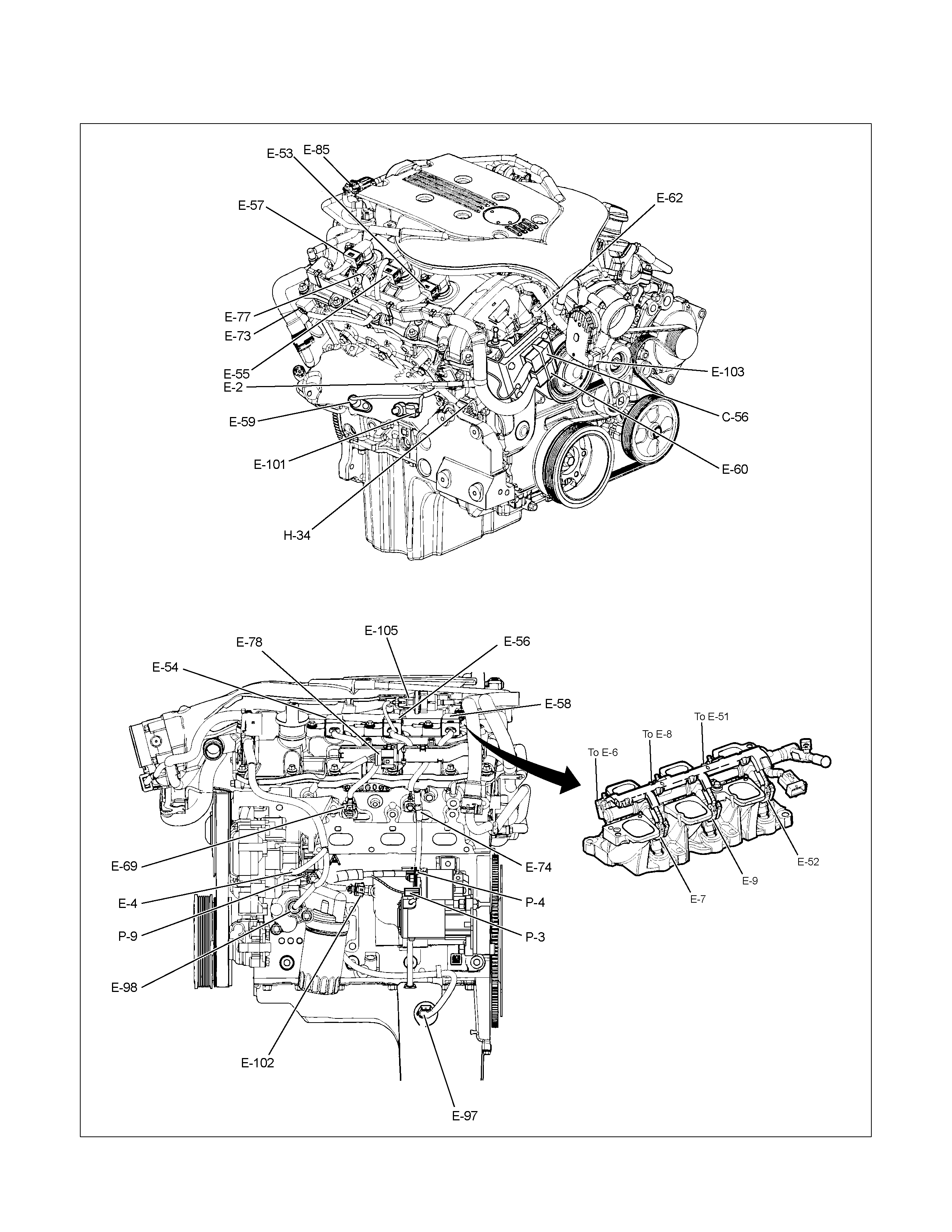

Engine Harness 6EV1

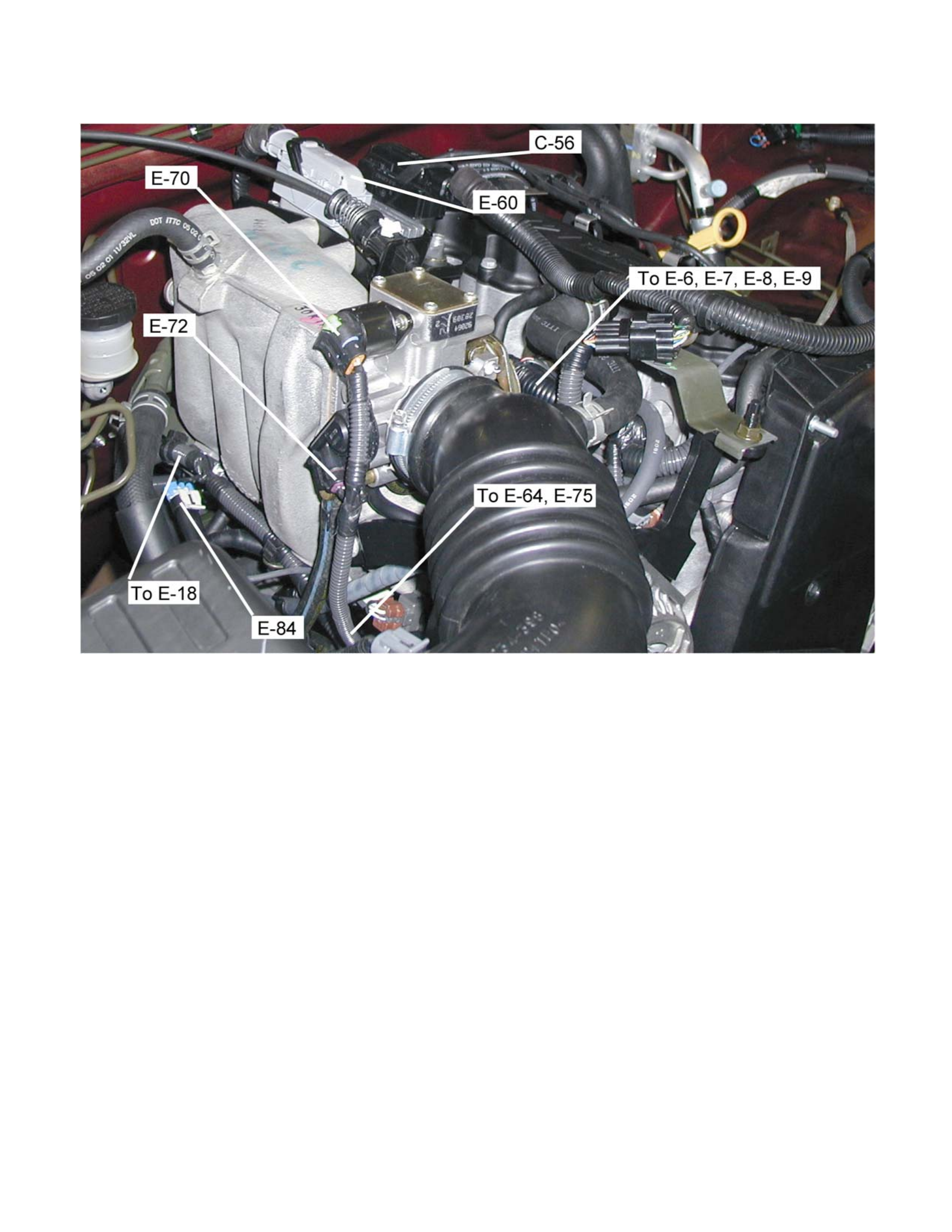

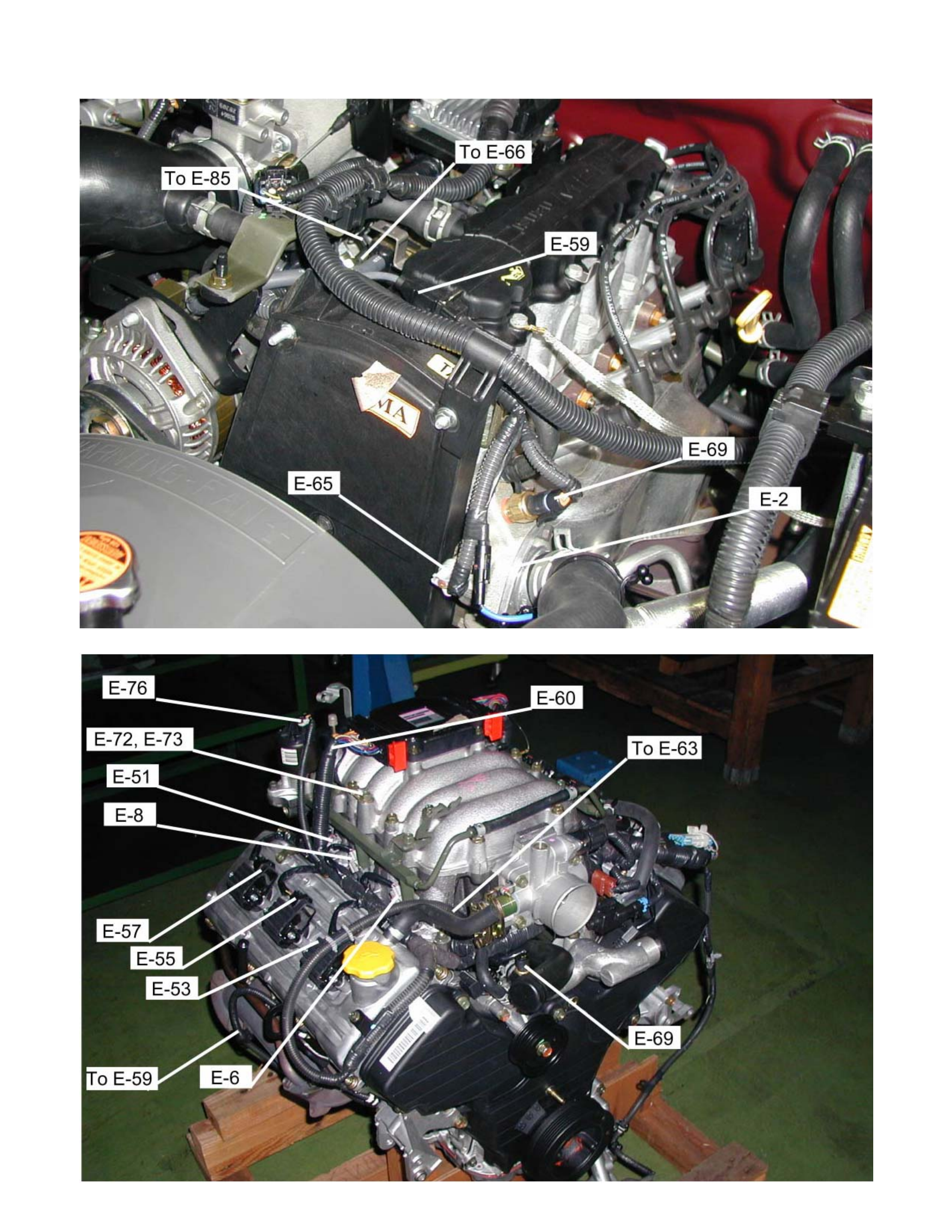

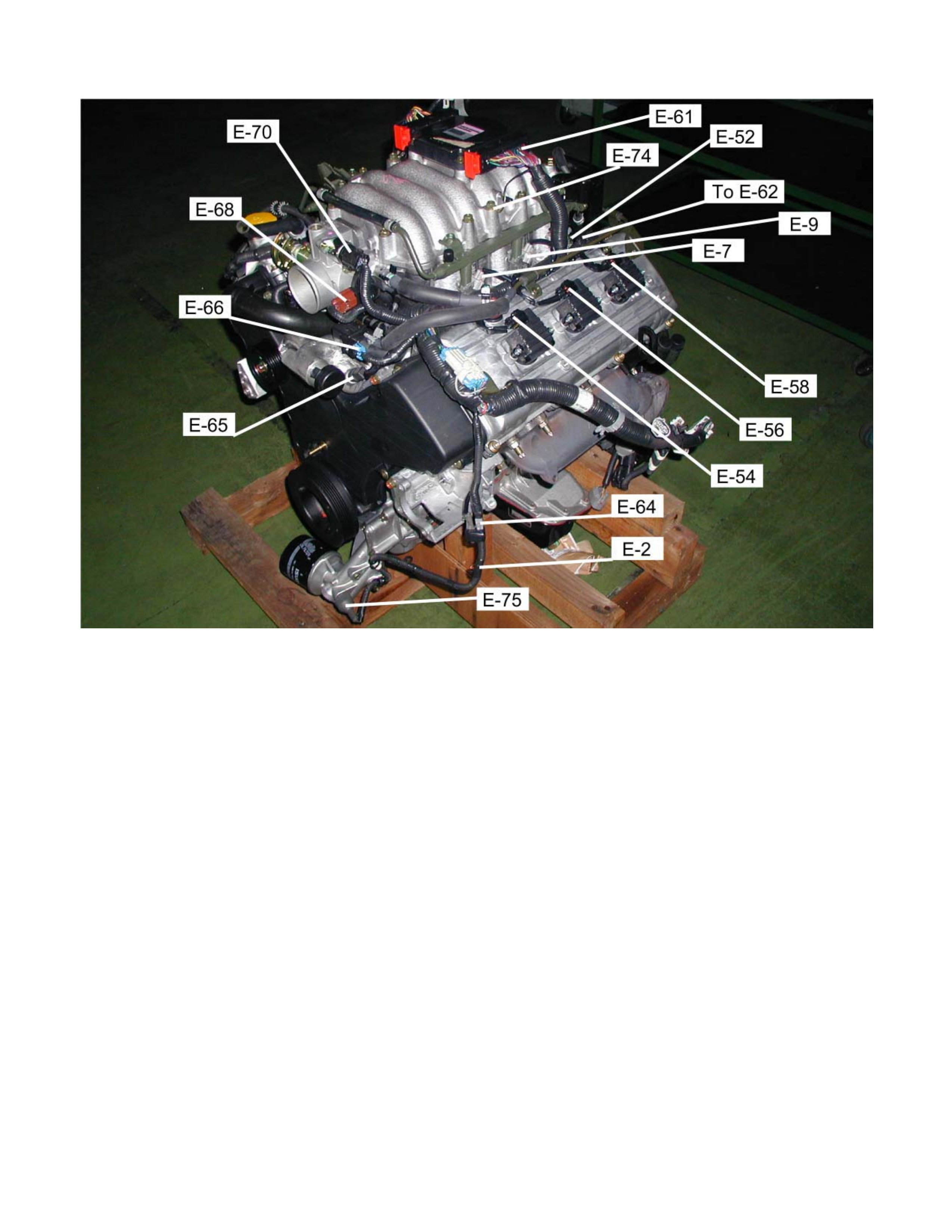

Engine Harness HFV6

Engine Harness 4JA1-TC/4JH1-

TC/4JA1-L

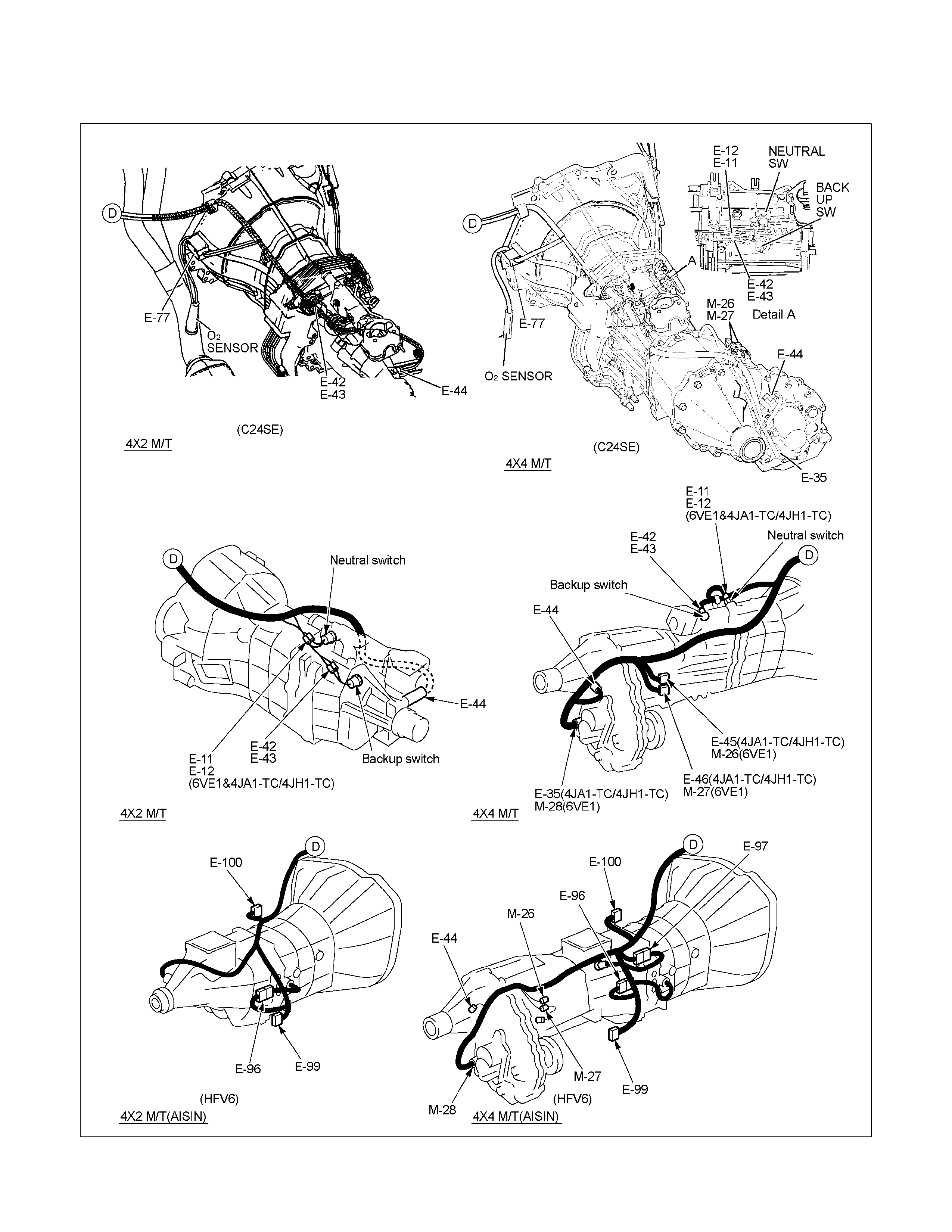

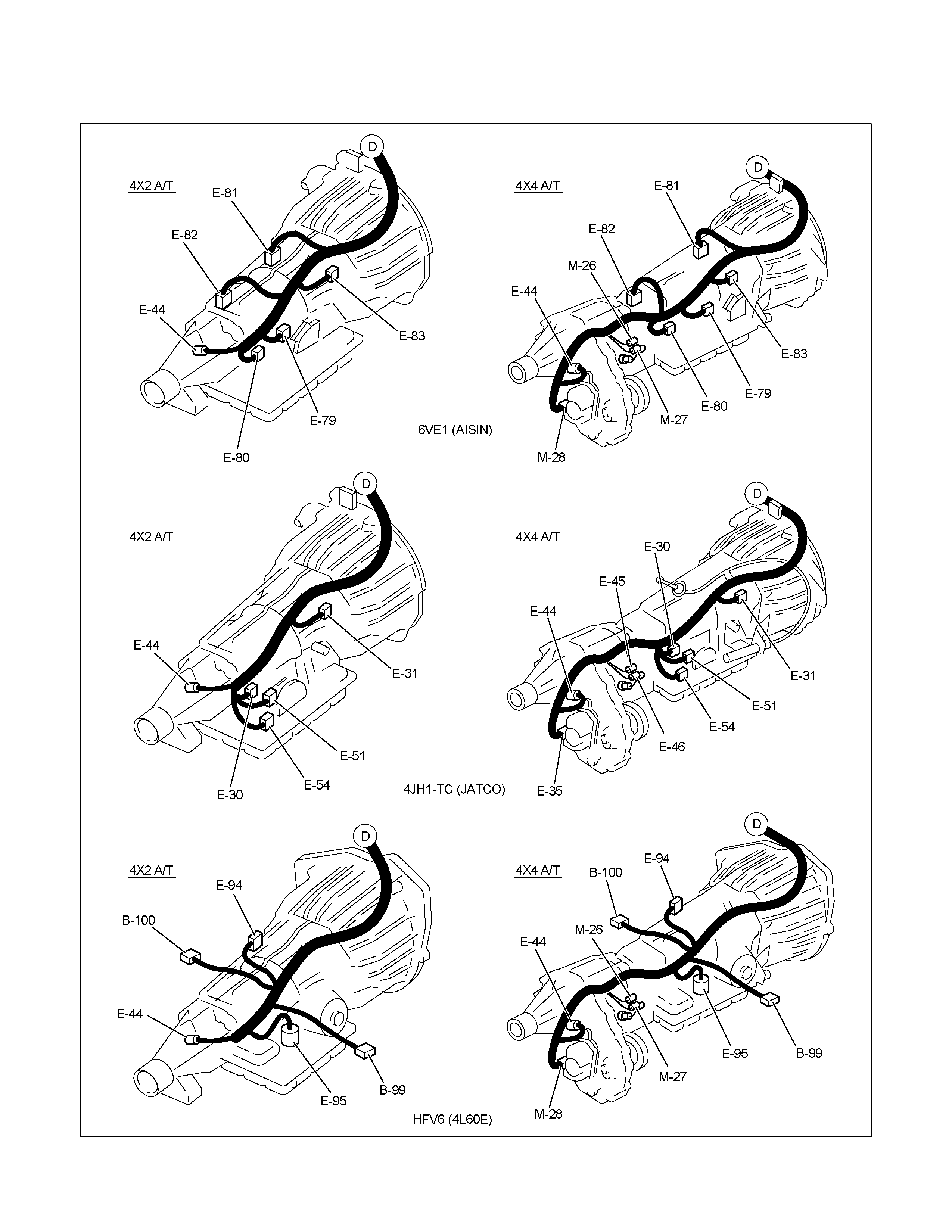

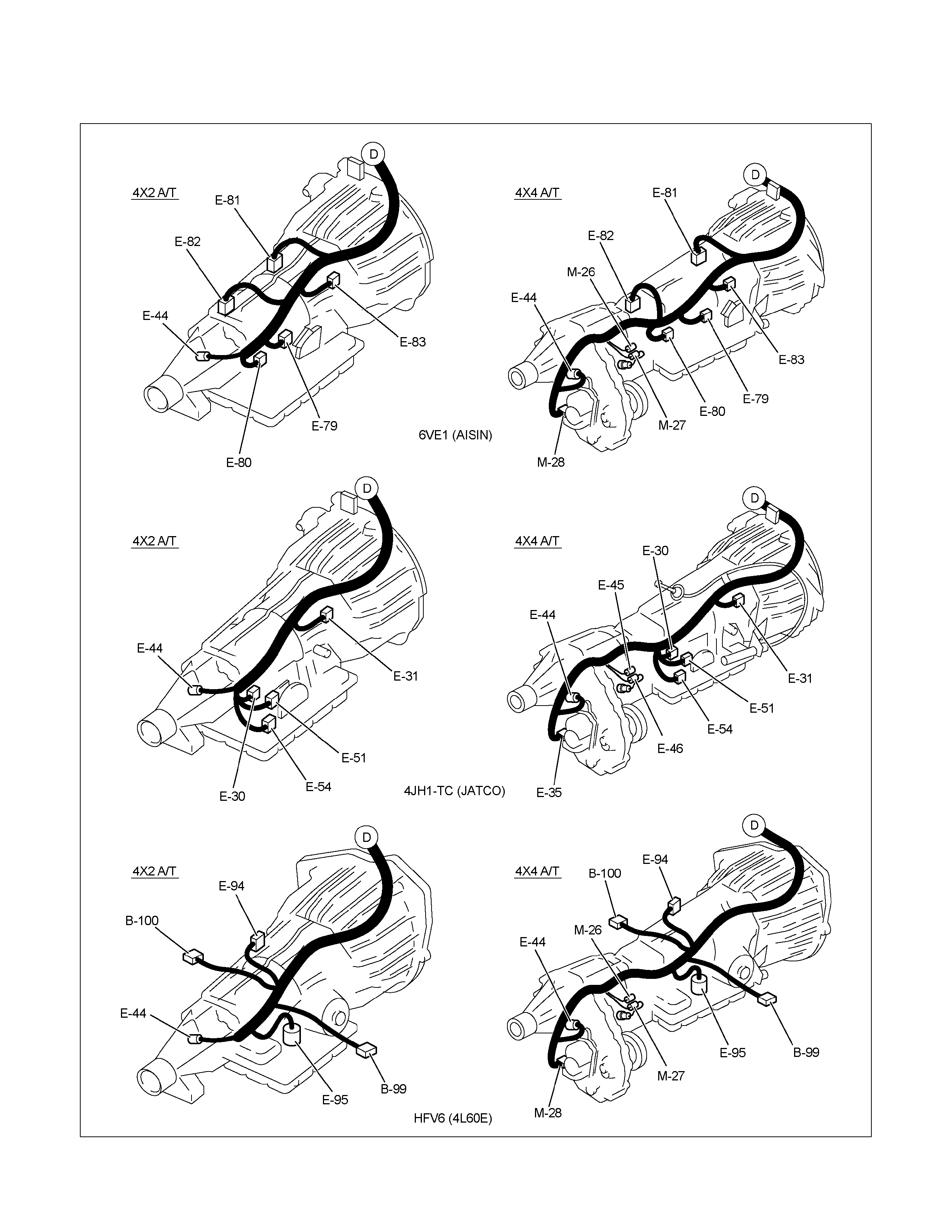

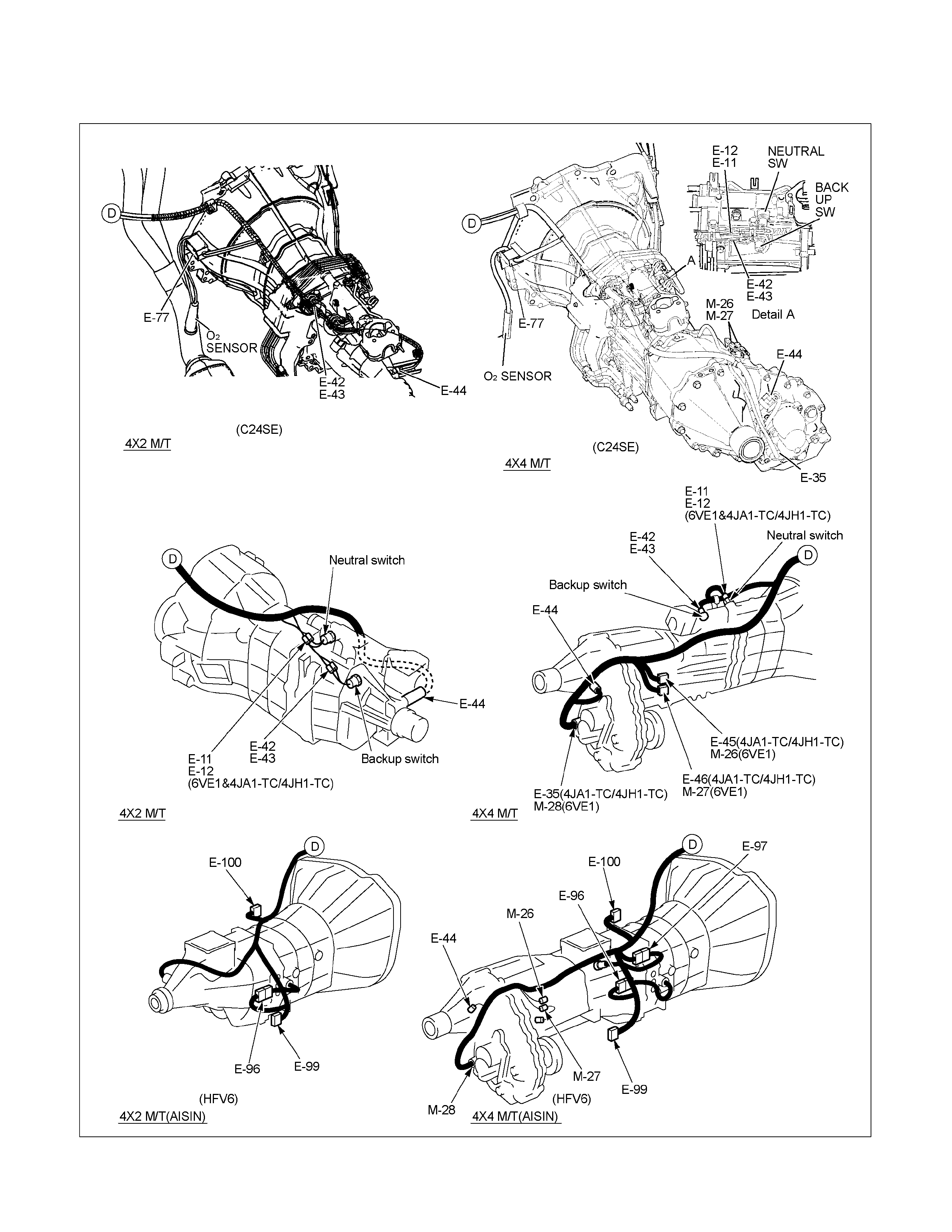

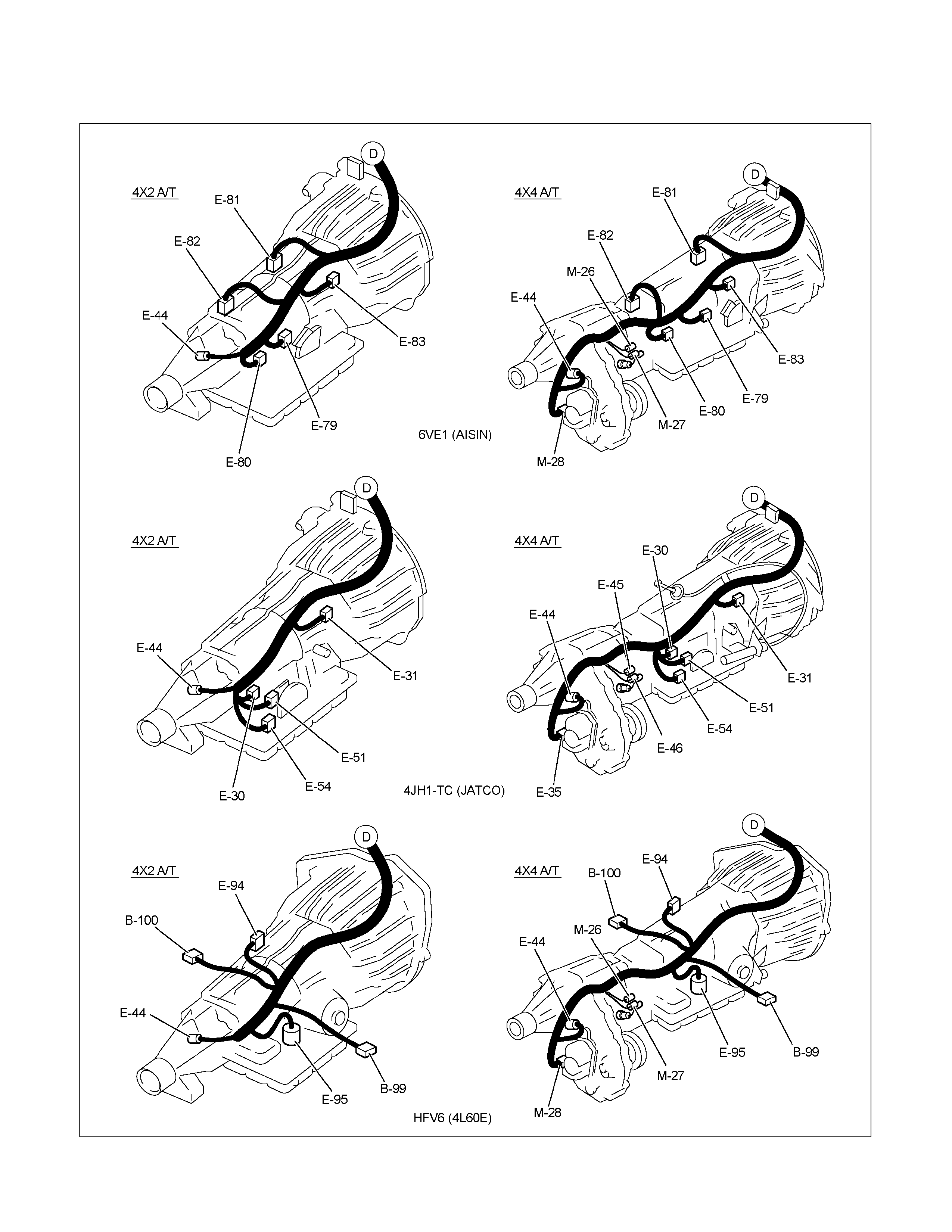

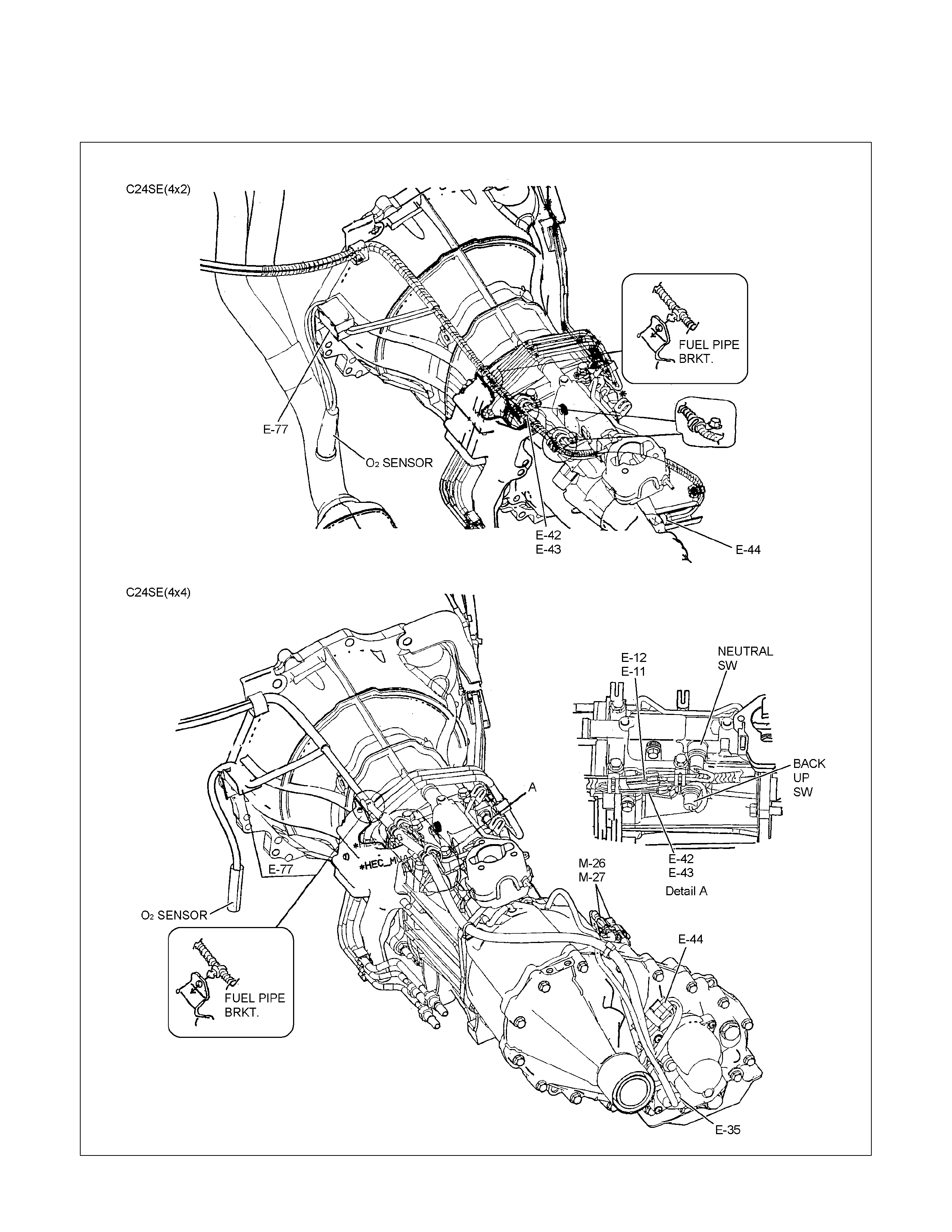

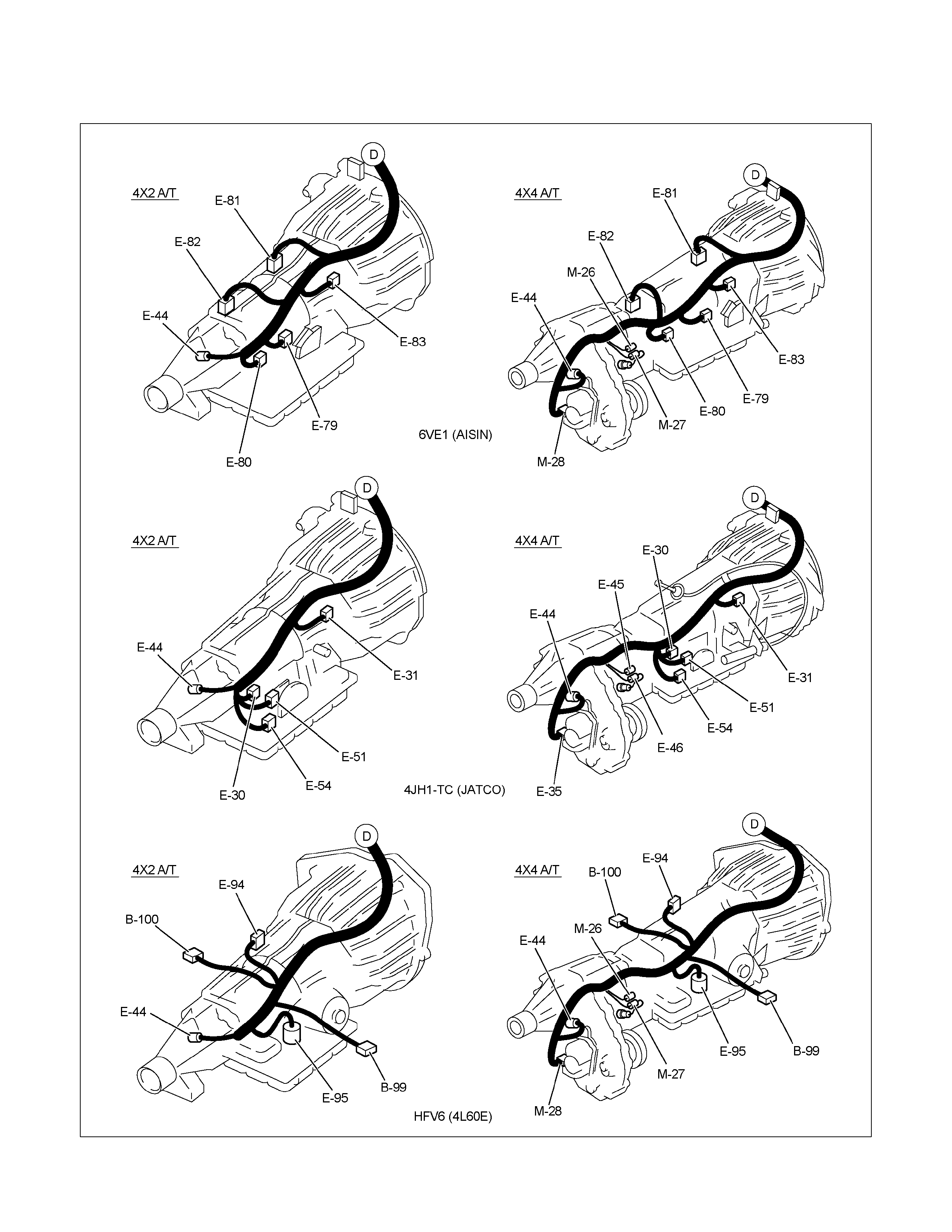

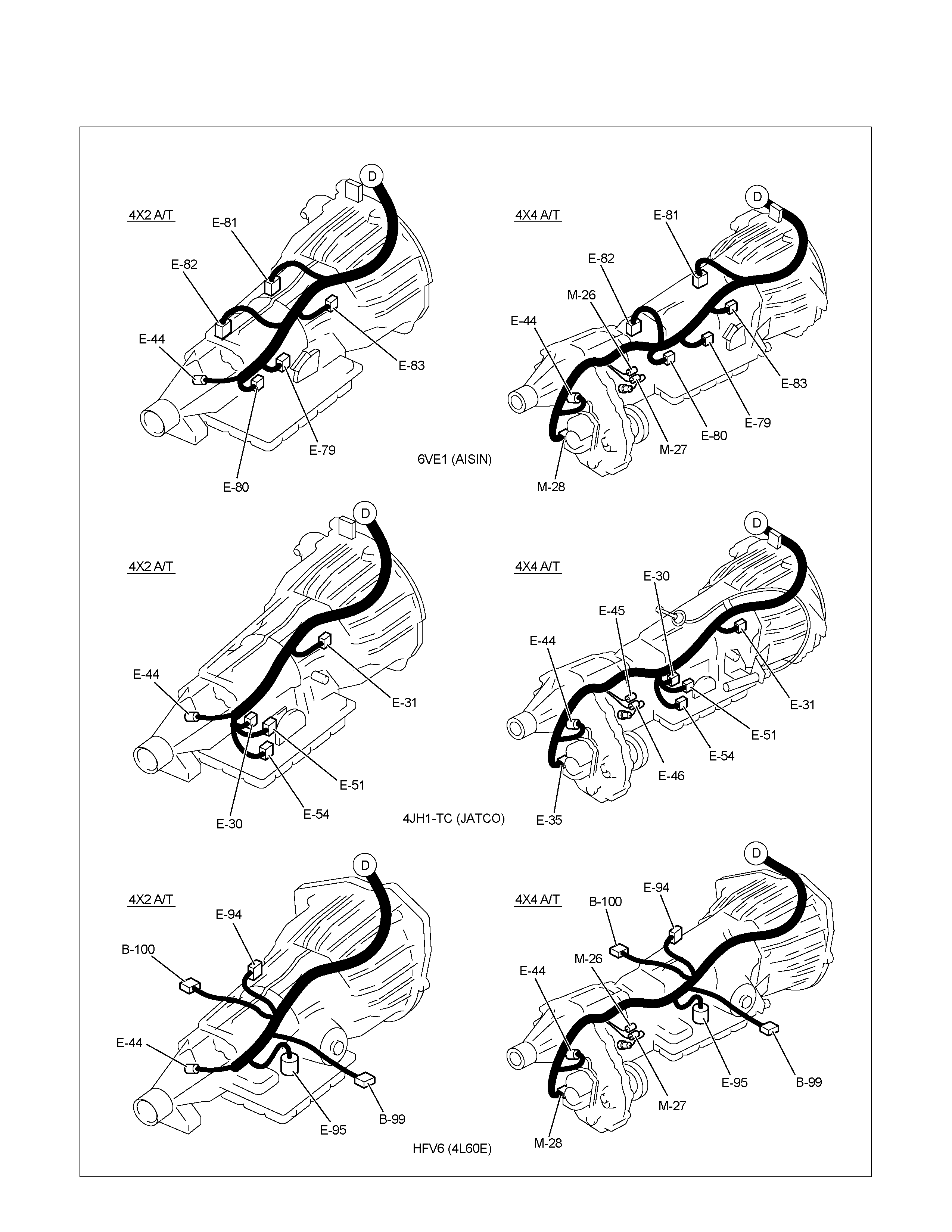

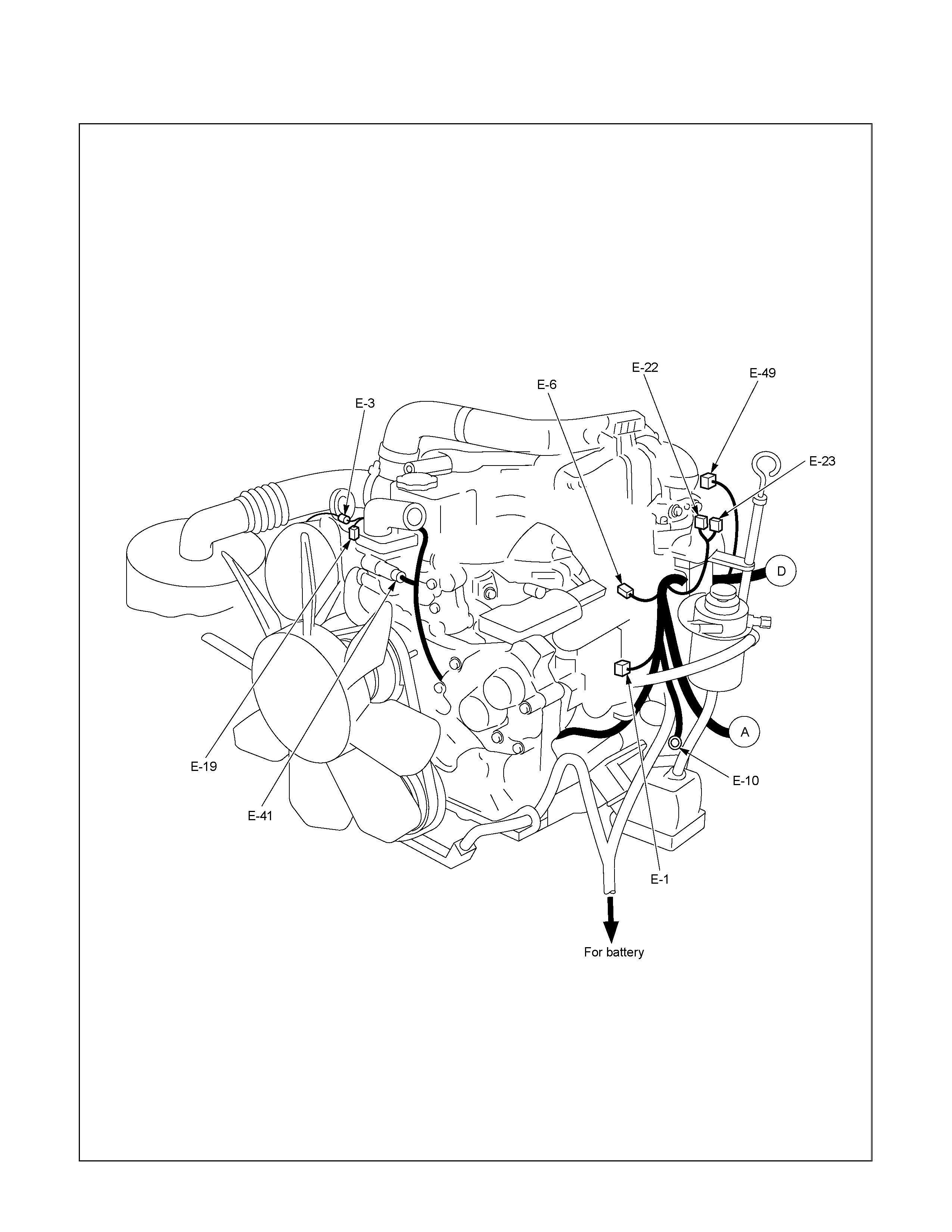

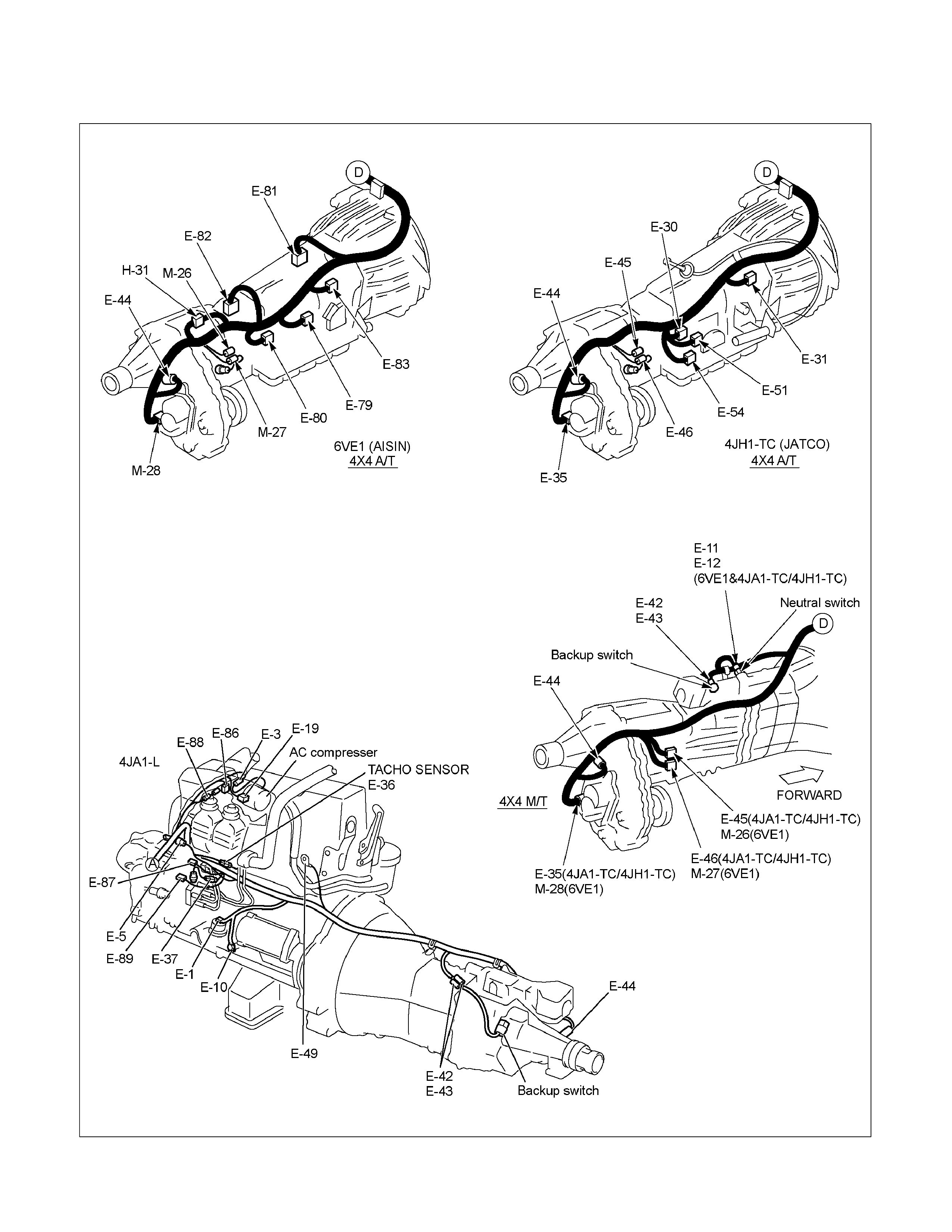

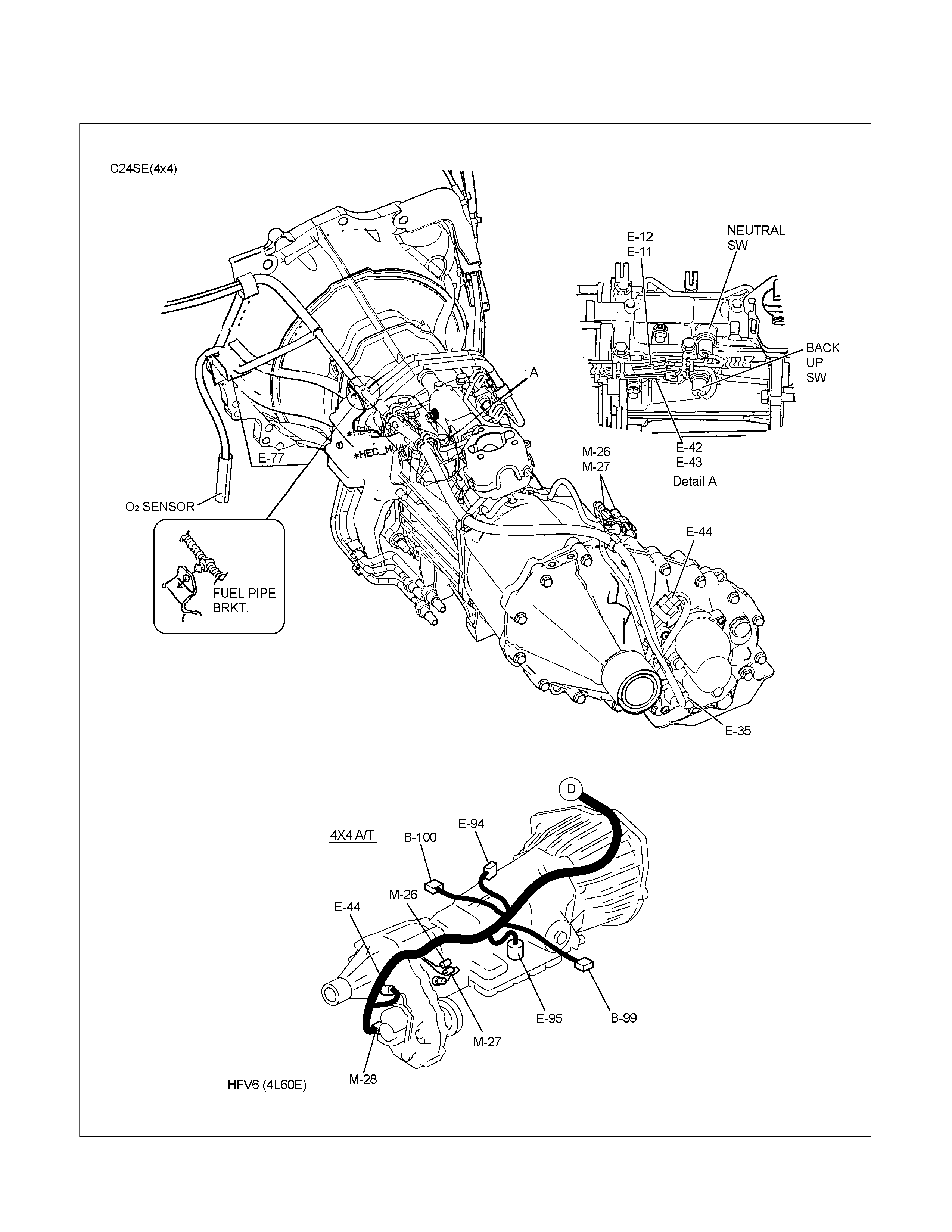

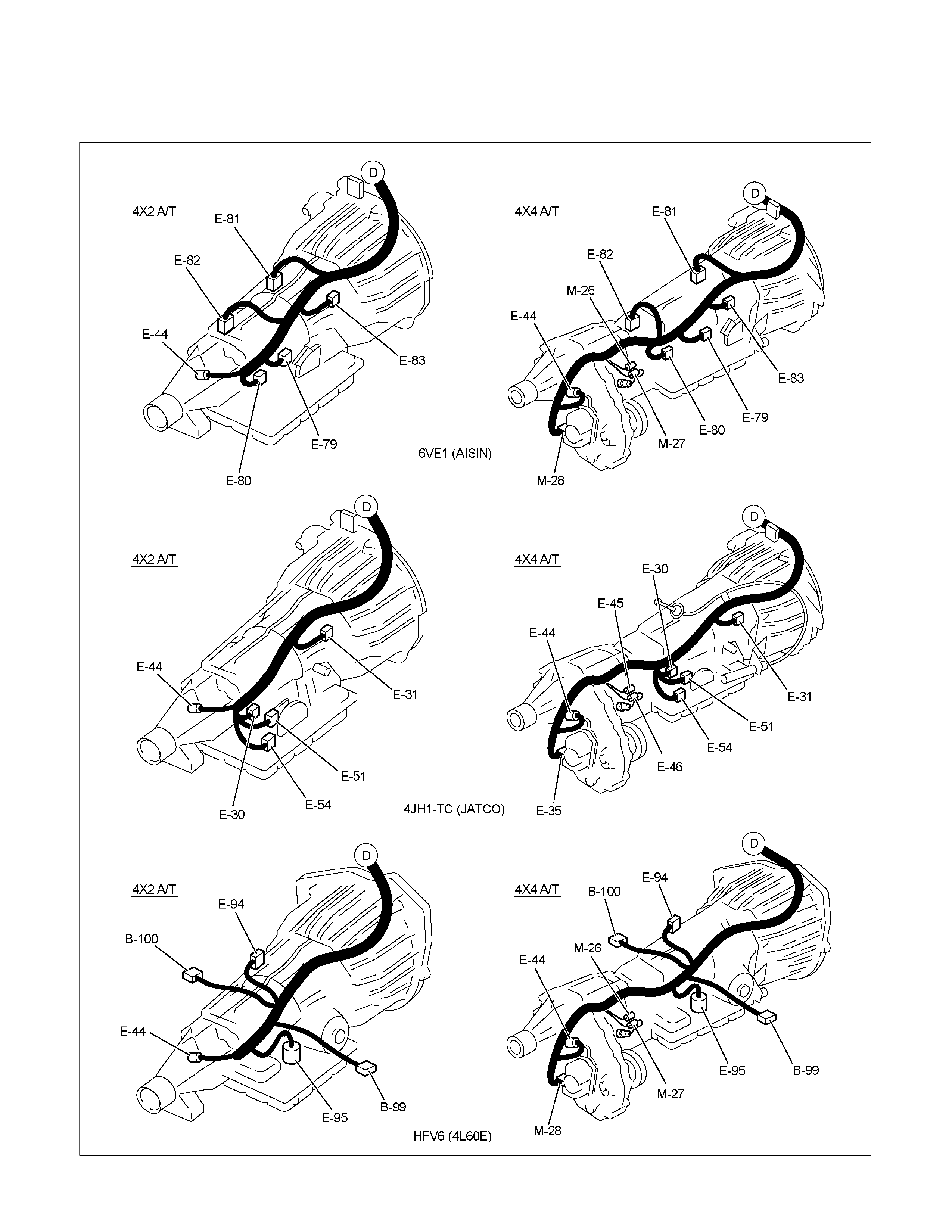

Transmission Harness

System Repair

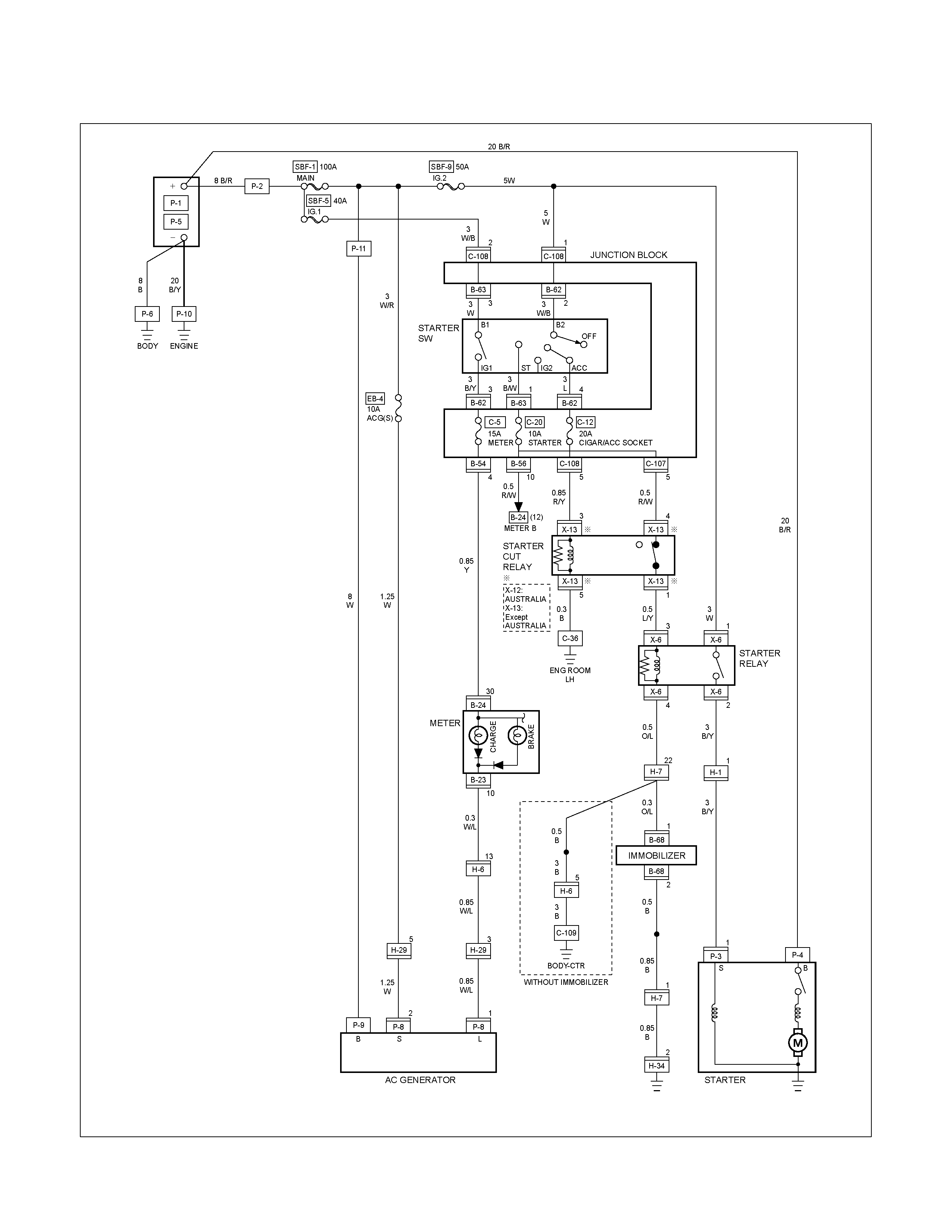

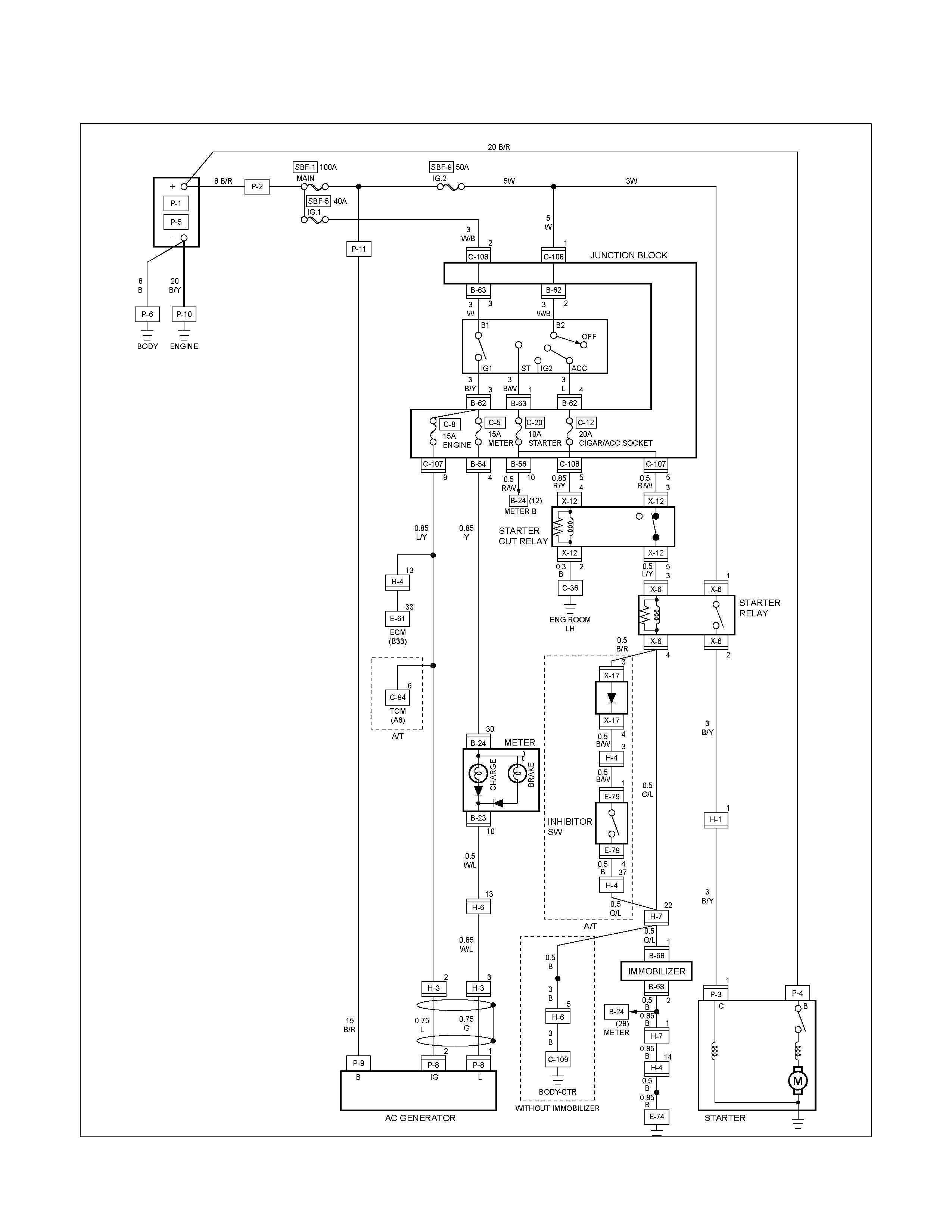

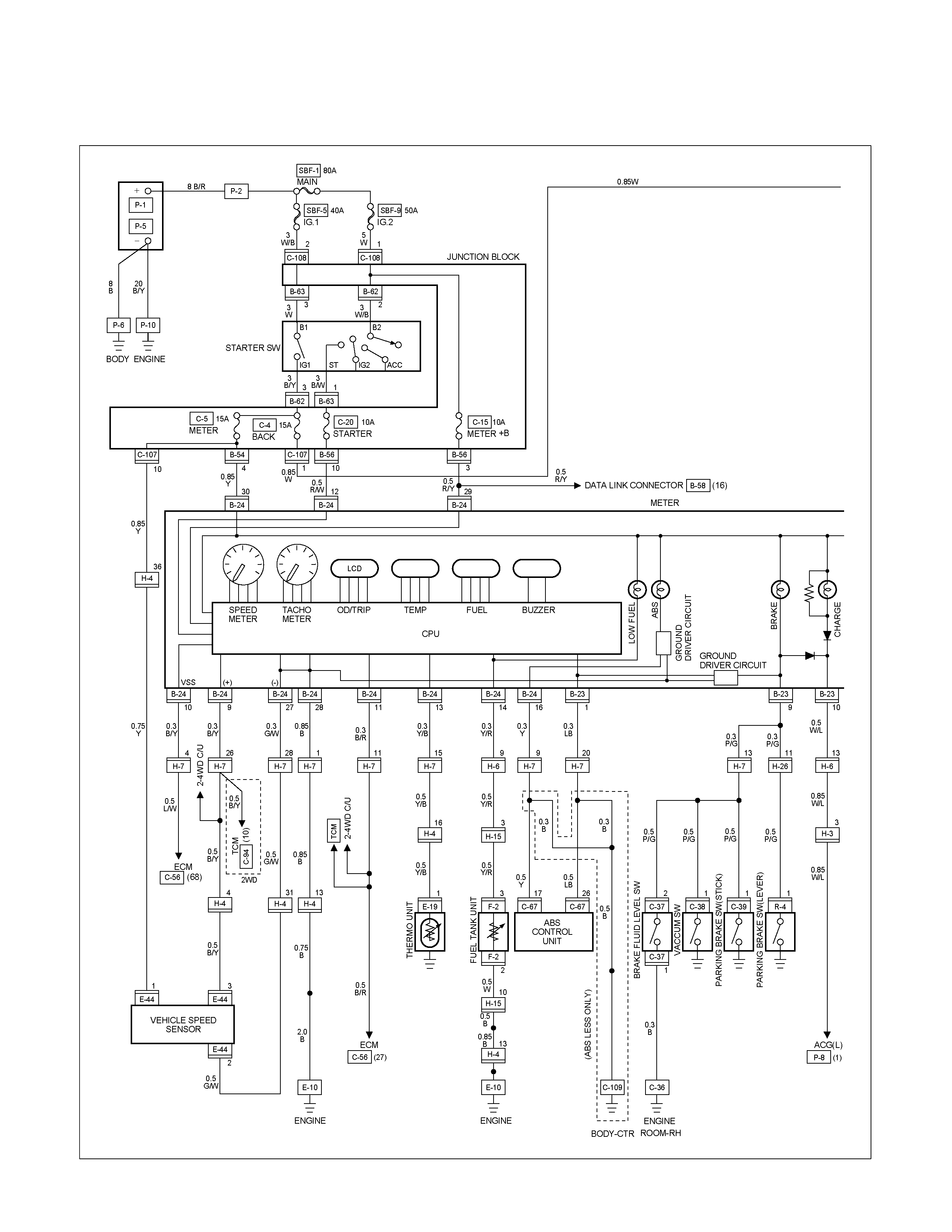

Start and Charging

Engine Control Module (ECM)

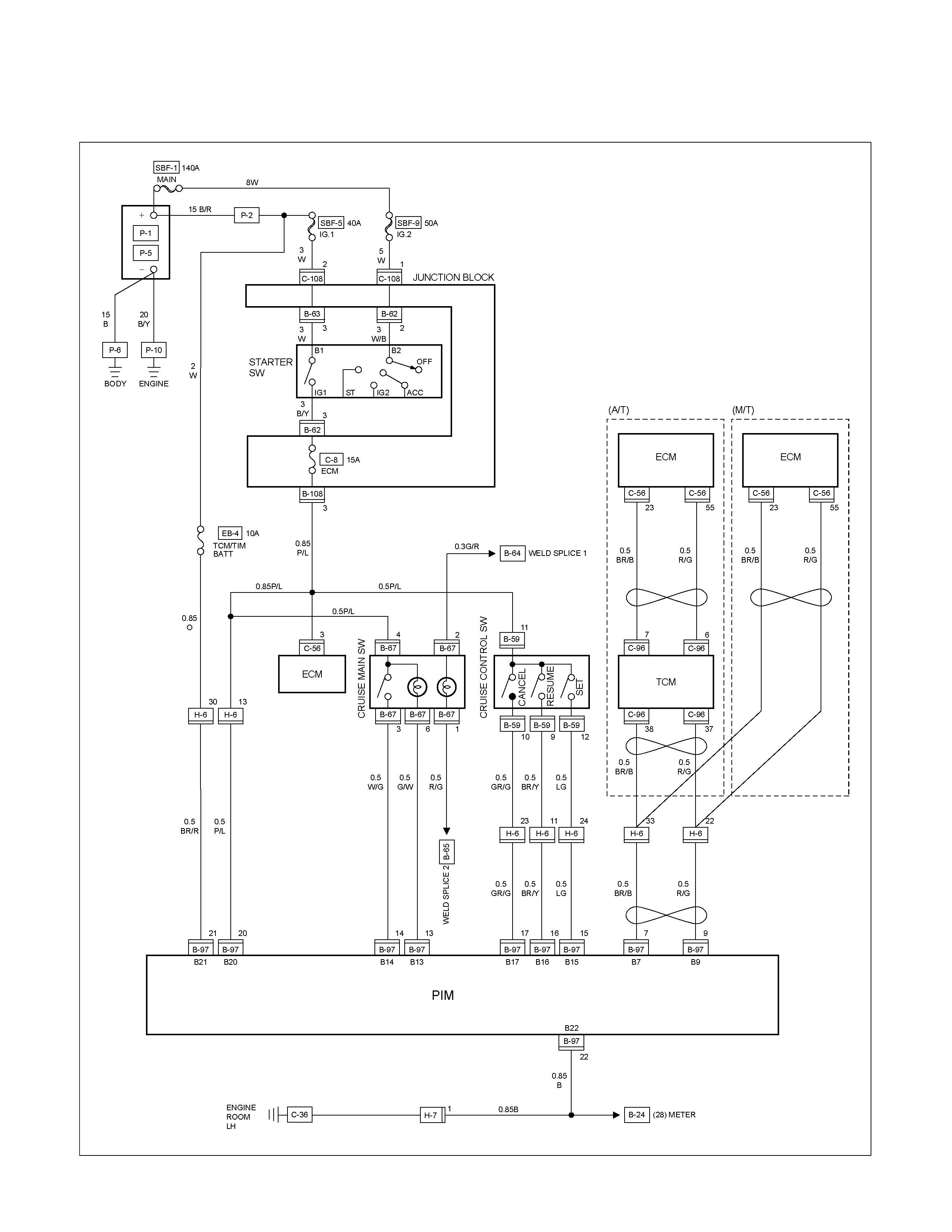

Powertrain Interface Module (PIM):

HFV6 Only

Exhaust Gas Recalculation (EGR):

4JA1-L Only

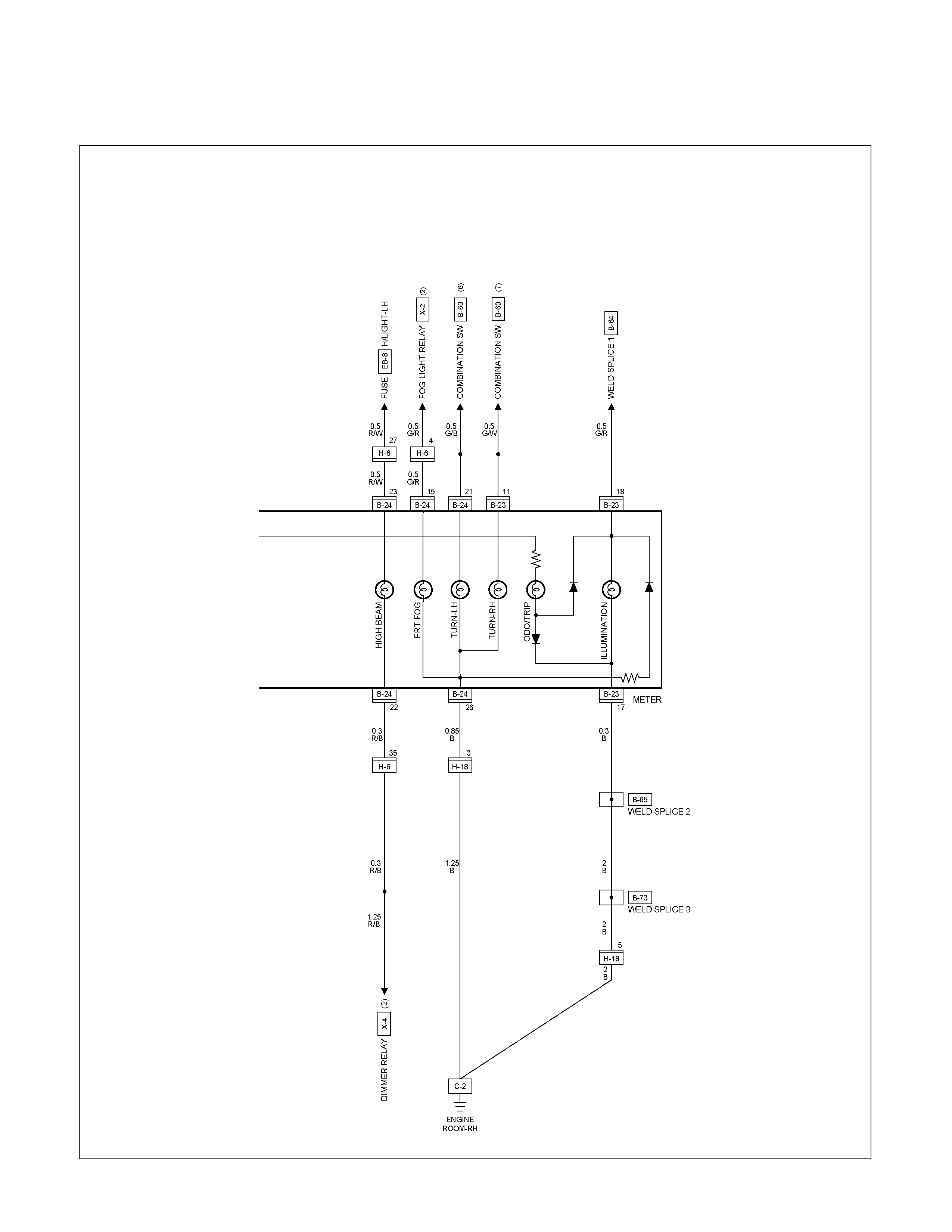

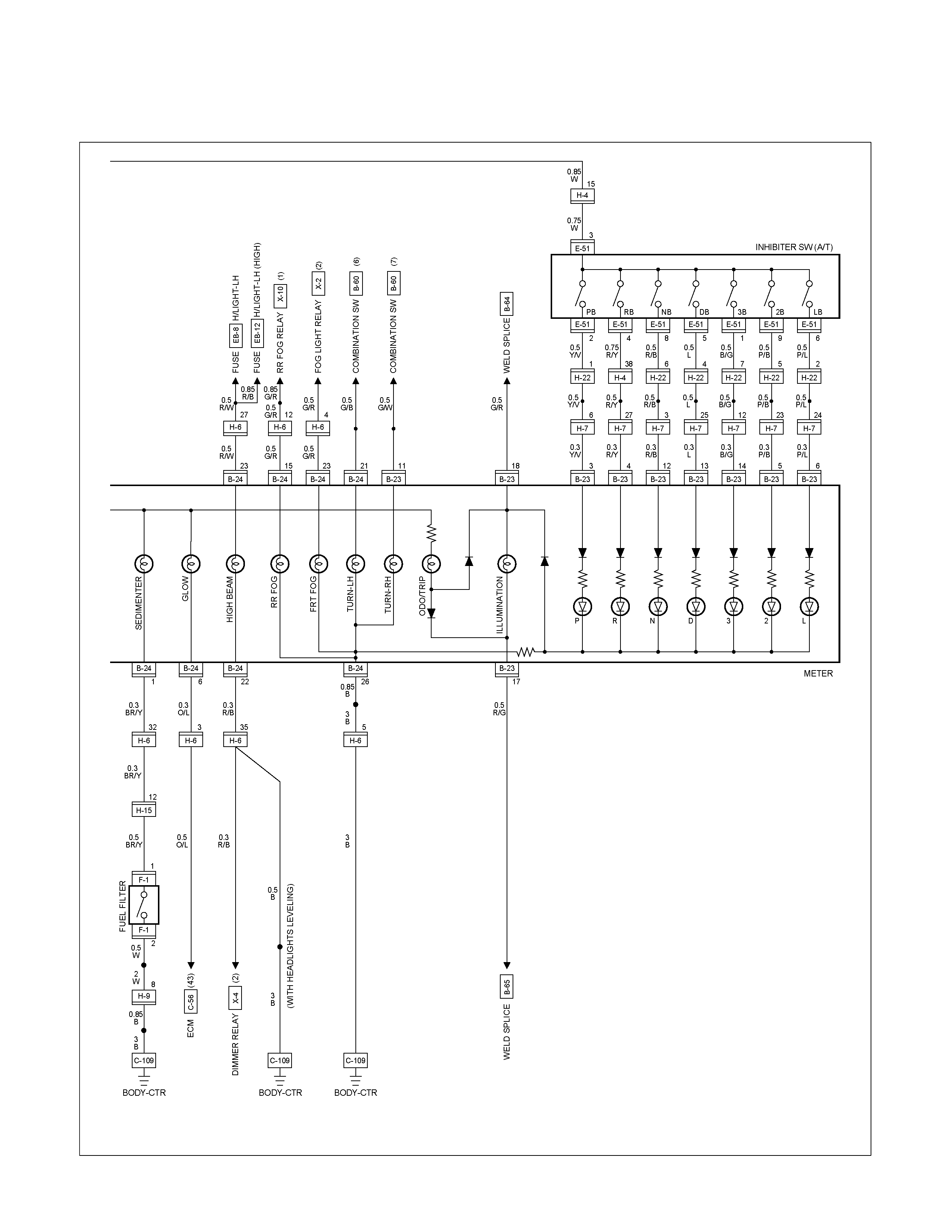

Lighting

Front Fog Light

Rear Fog Light

Head Light Leveling

Illumination

Hazard Warning Flasher, Turn Signal

Light, Back Up Light, Horn and Stop

Light

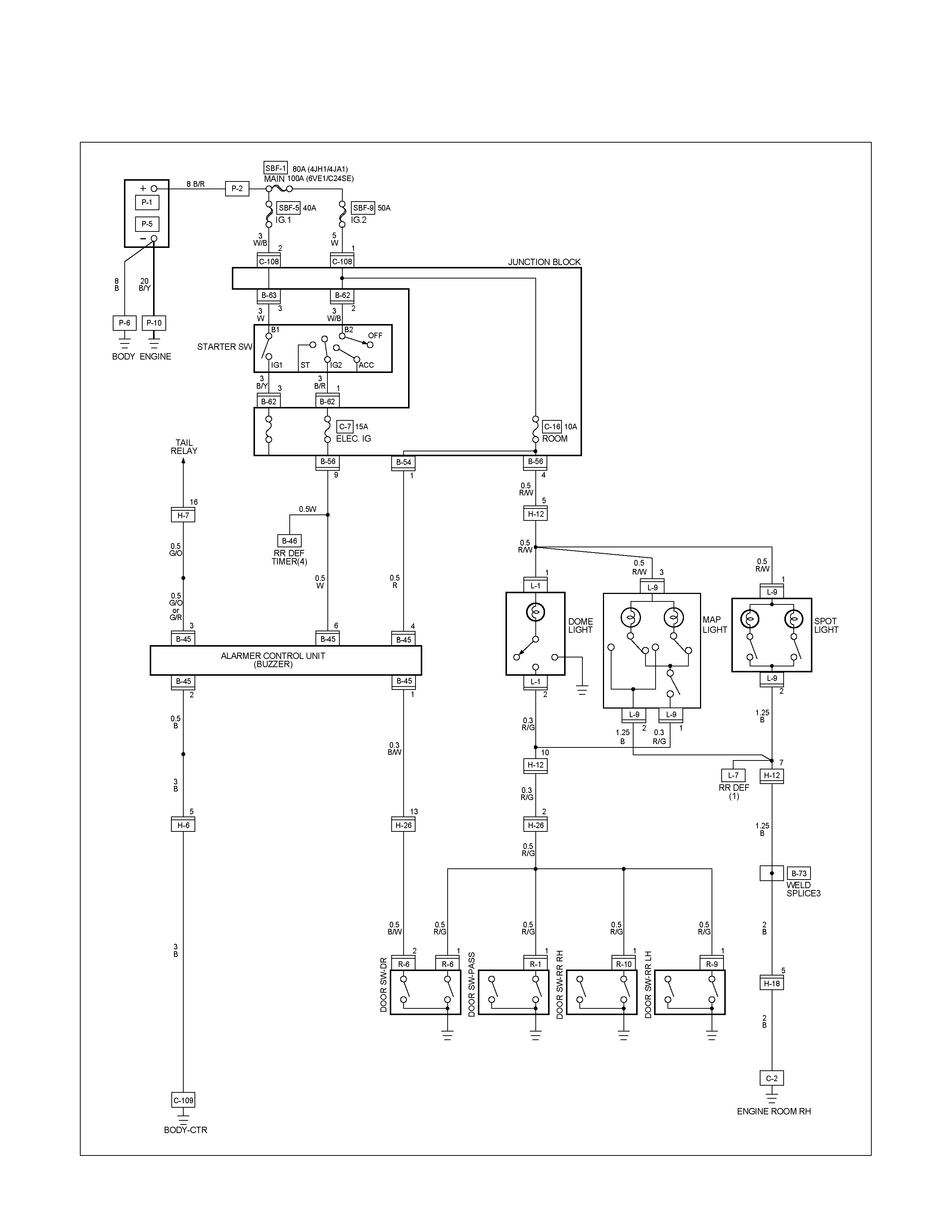

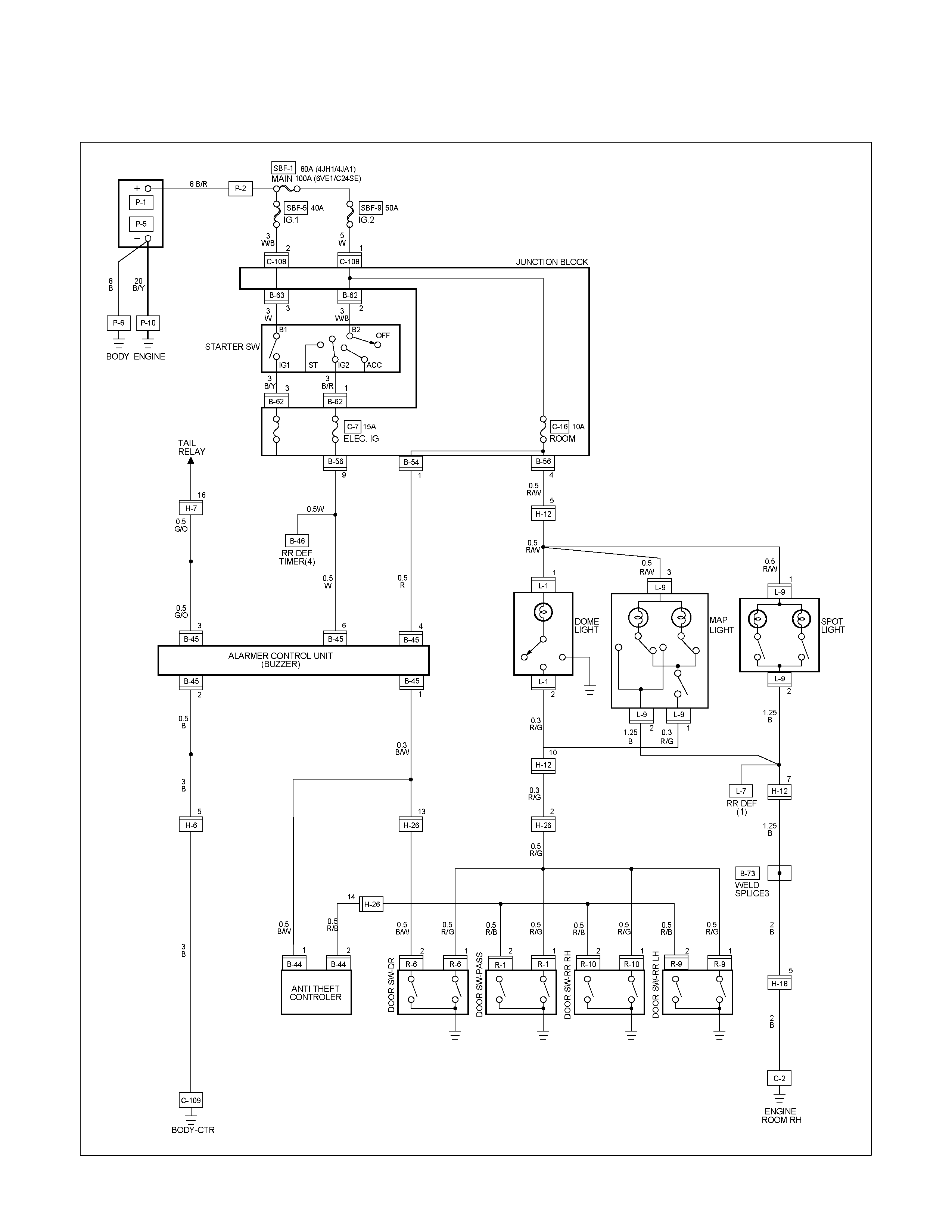

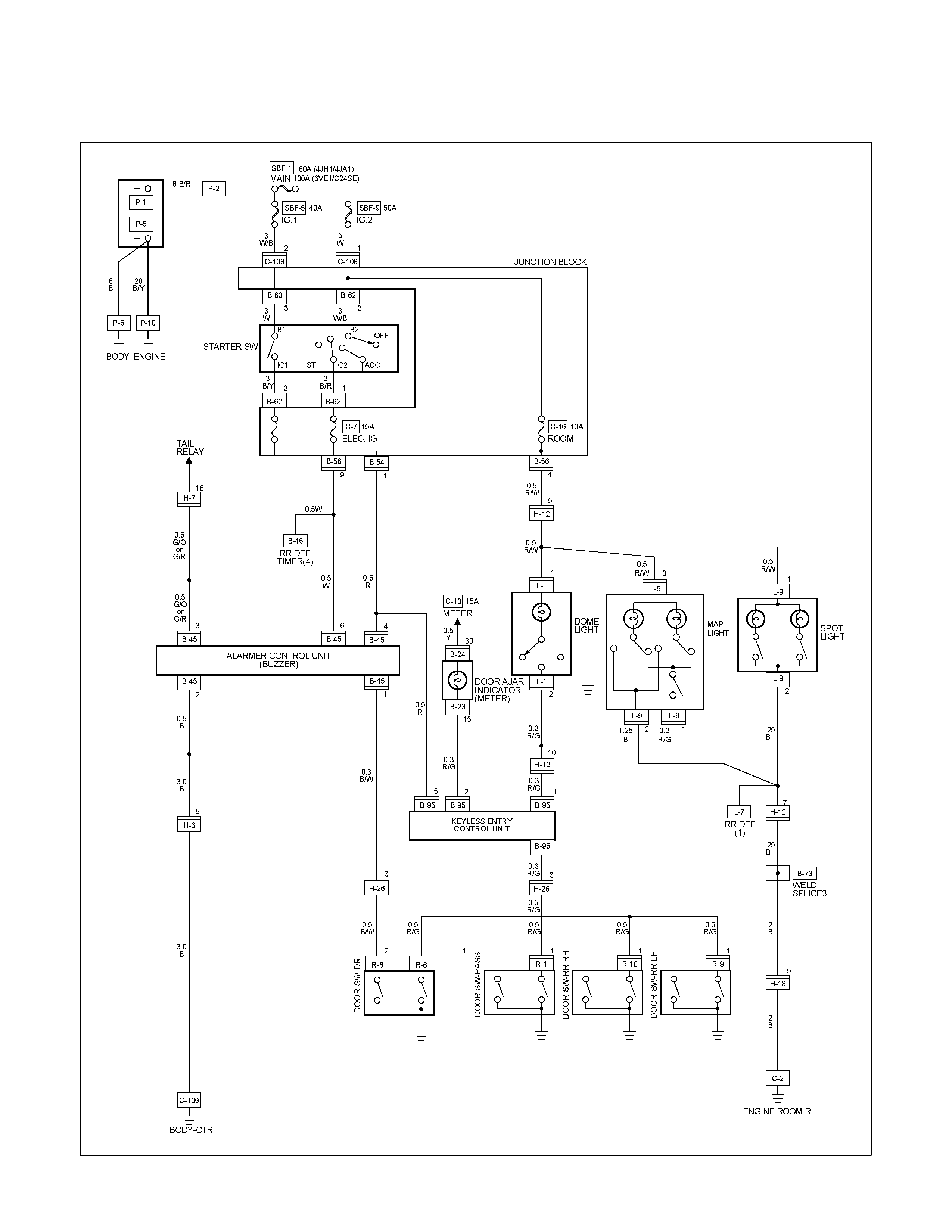

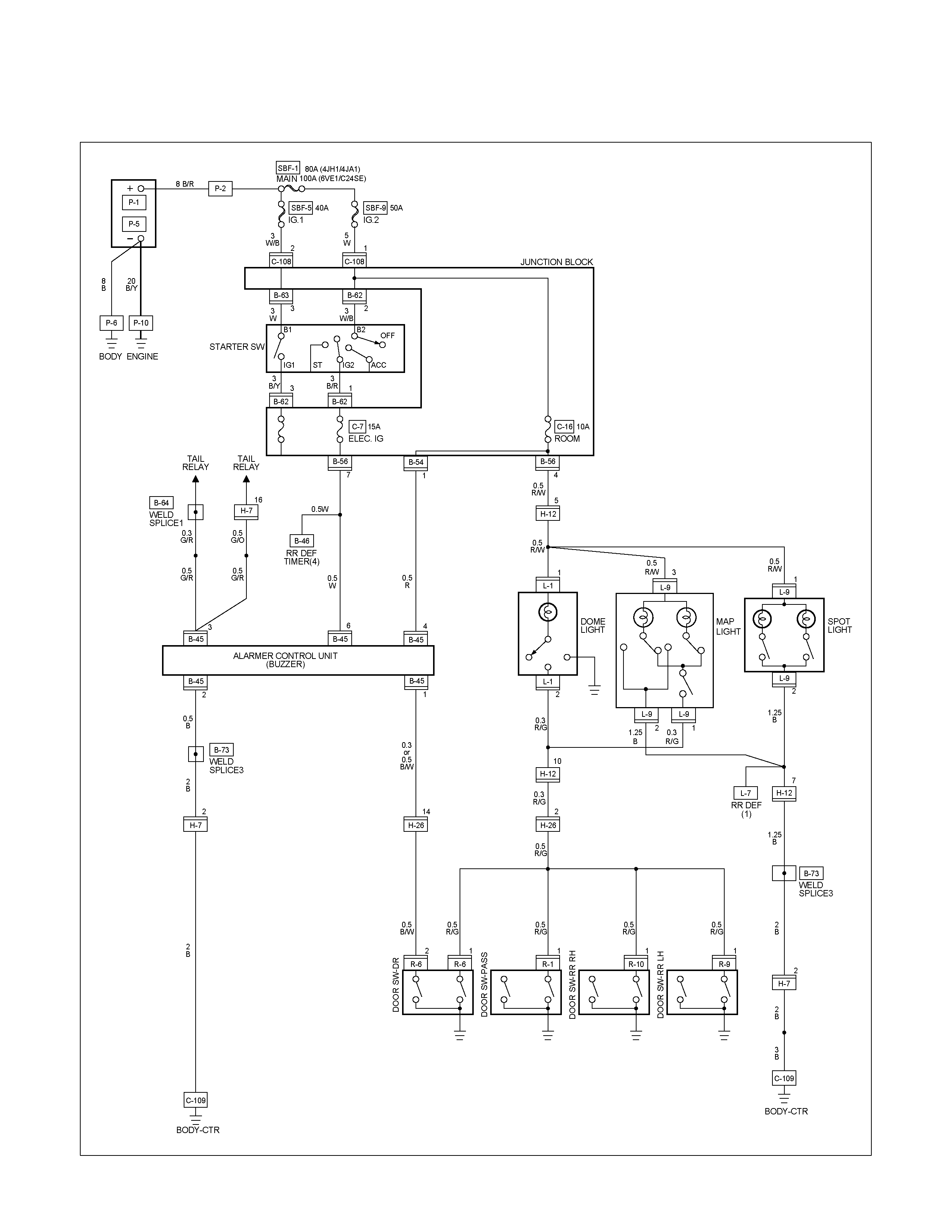

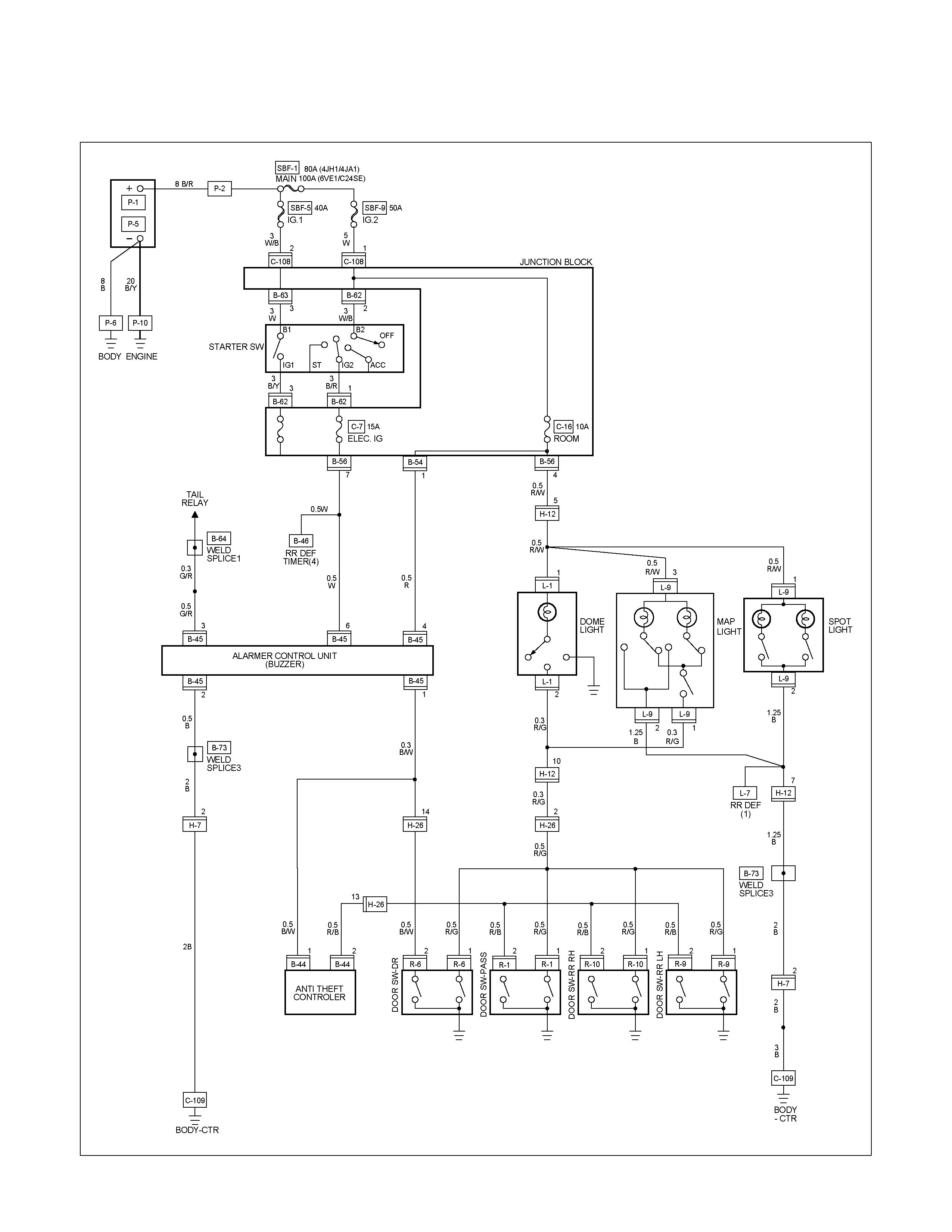

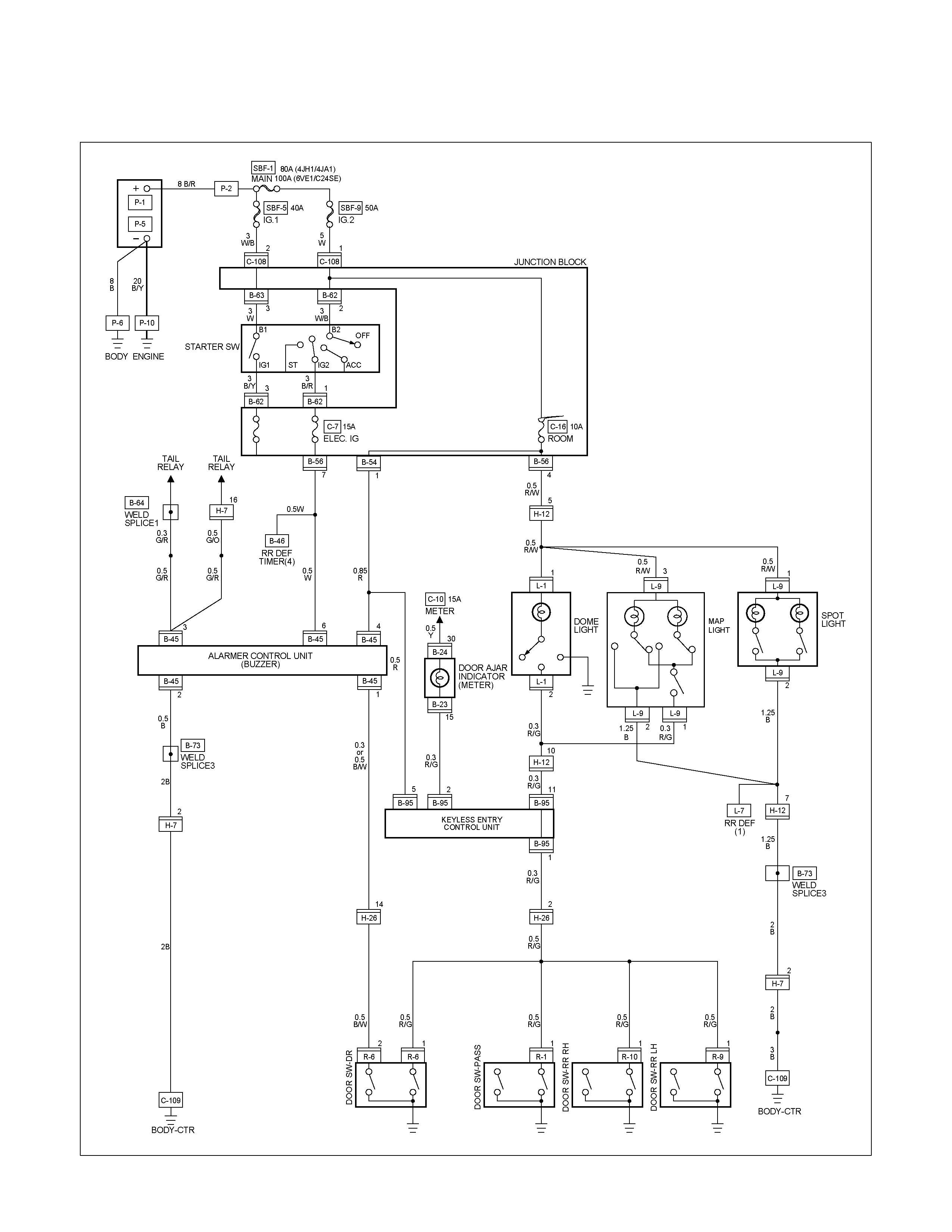

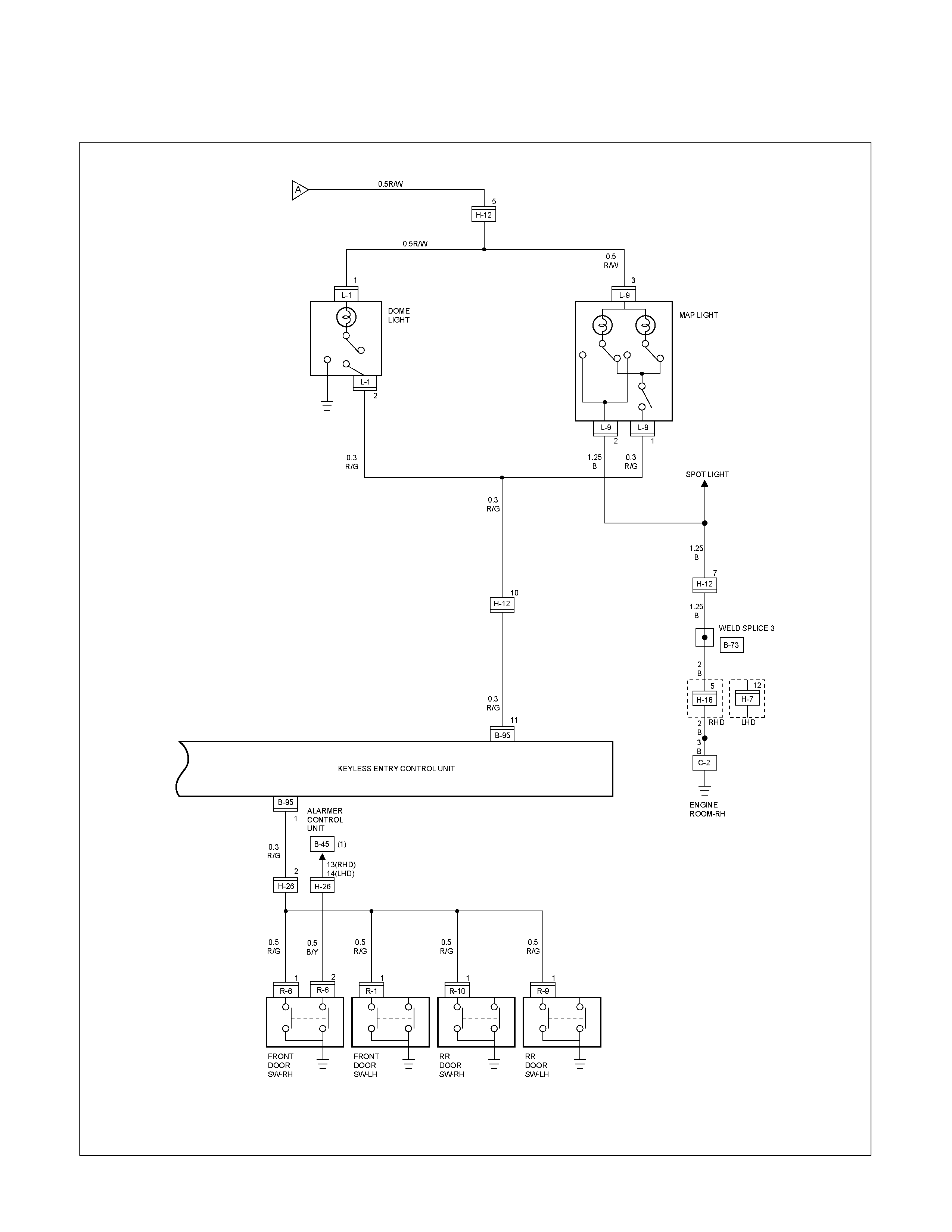

Dome Light, Spot Light, Map Light and

Warning Buzzer

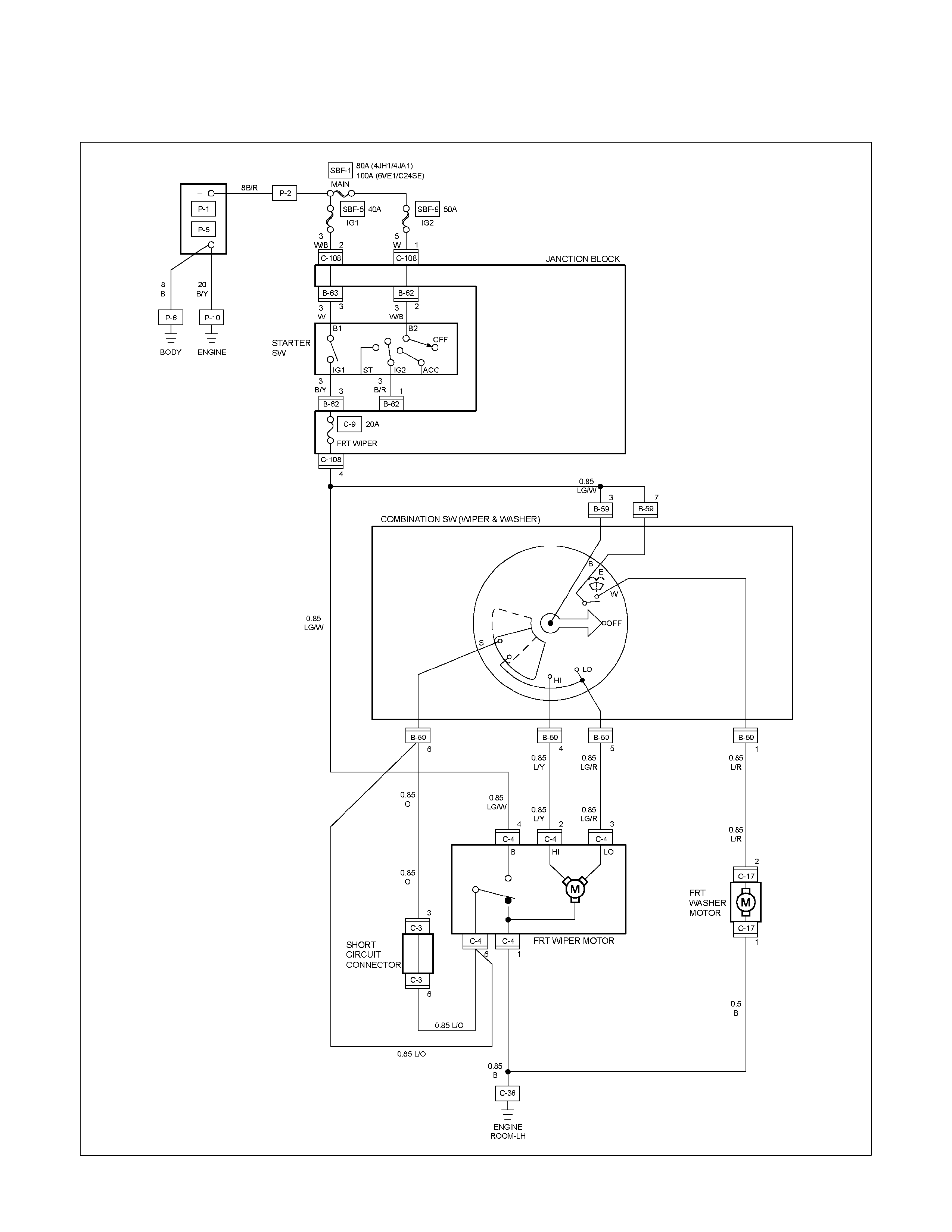

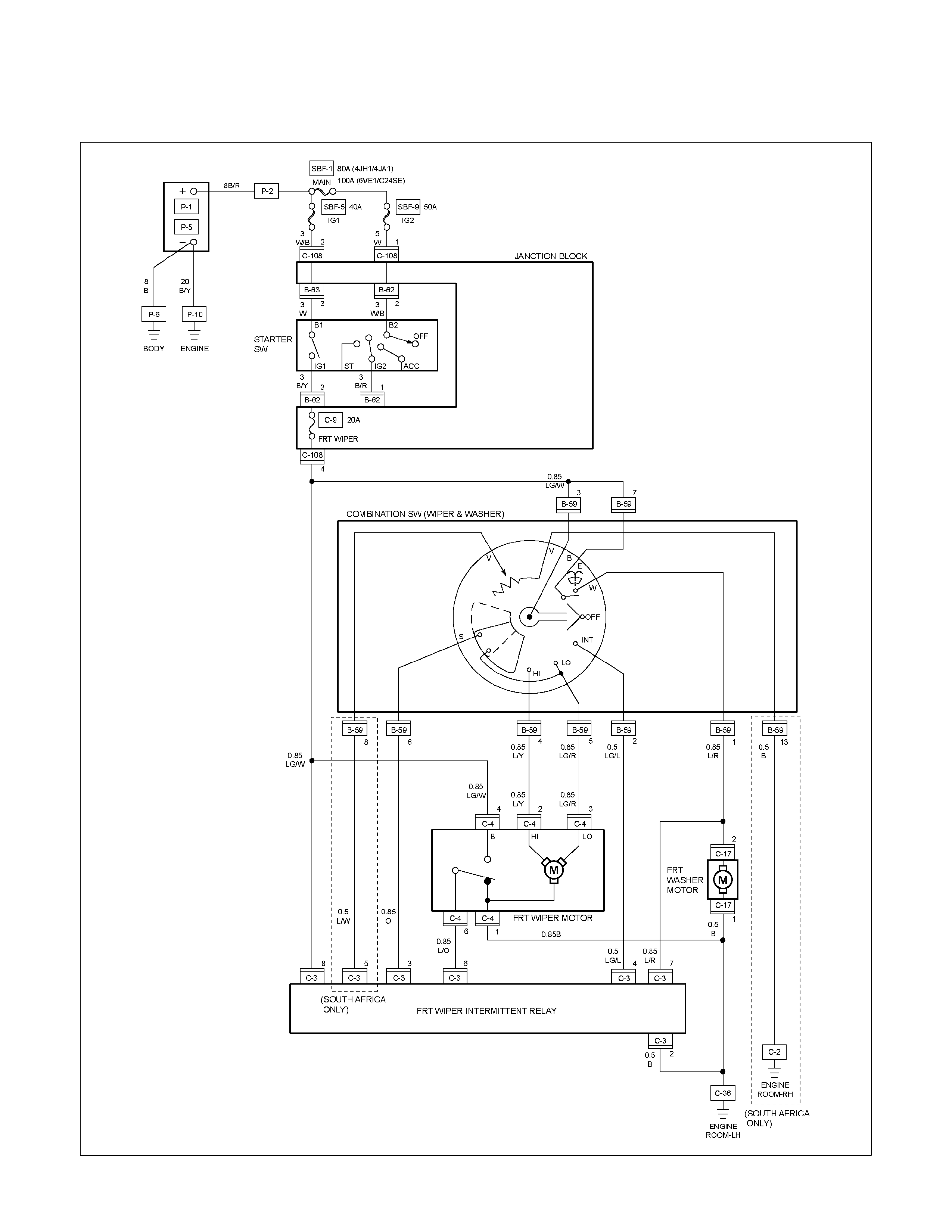

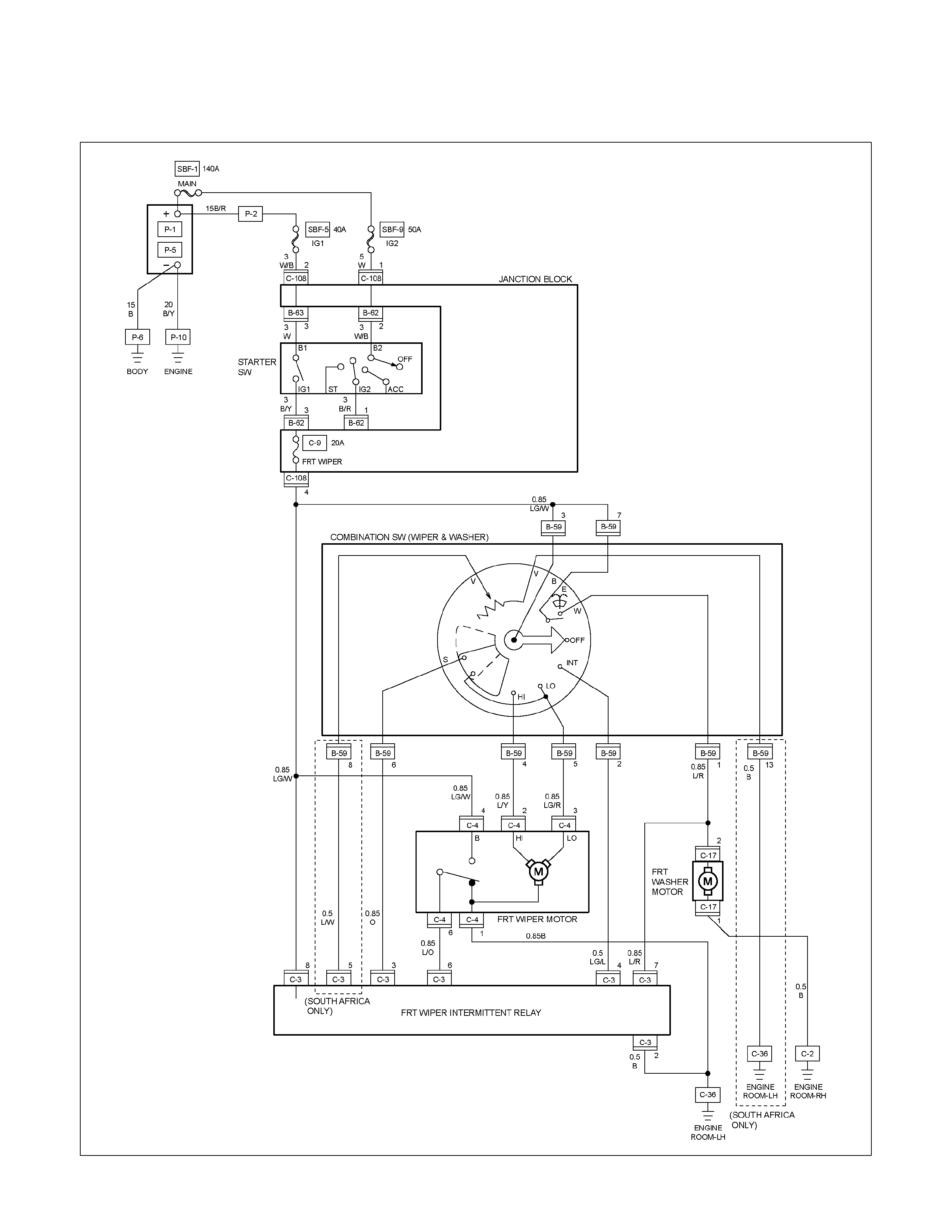

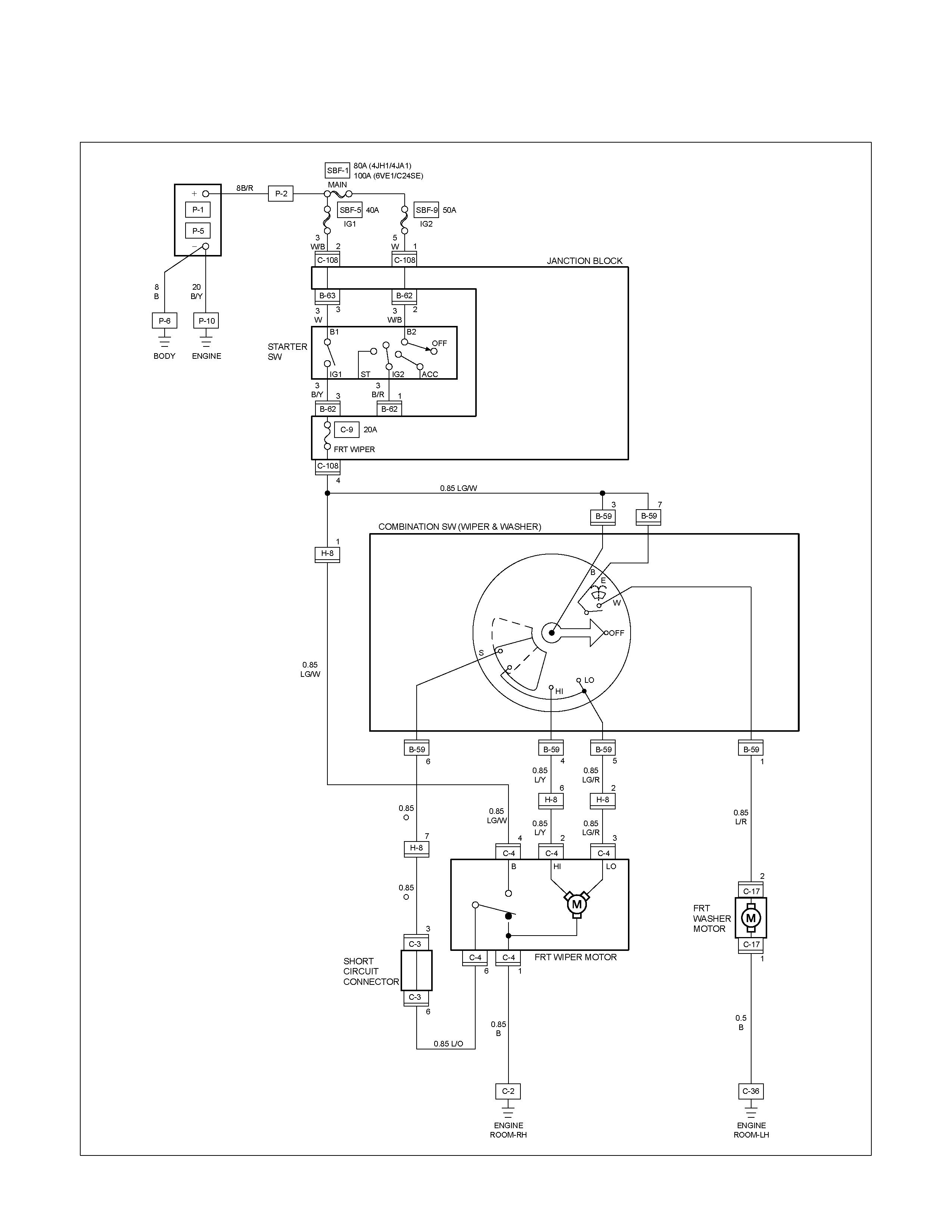

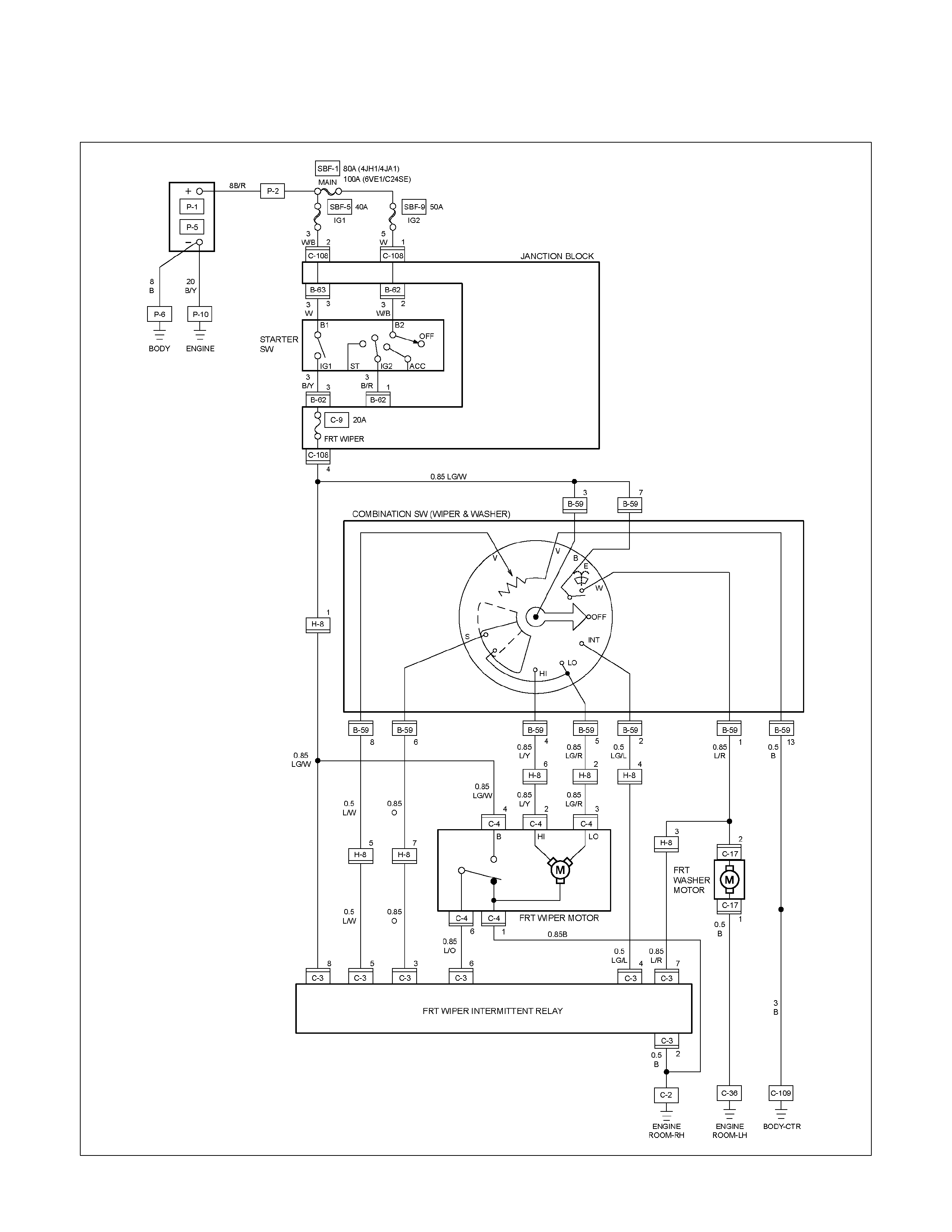

Windshield Wiper and Washer

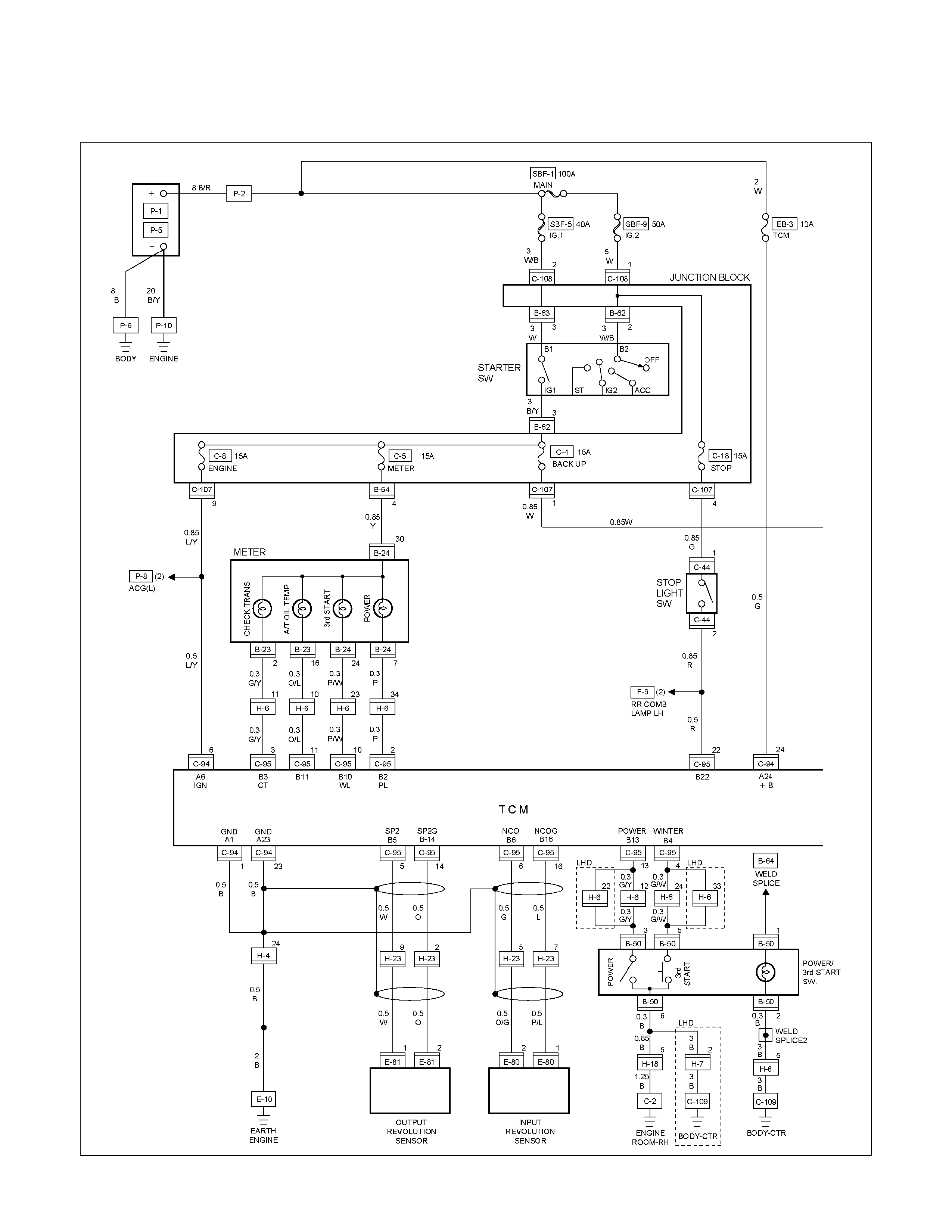

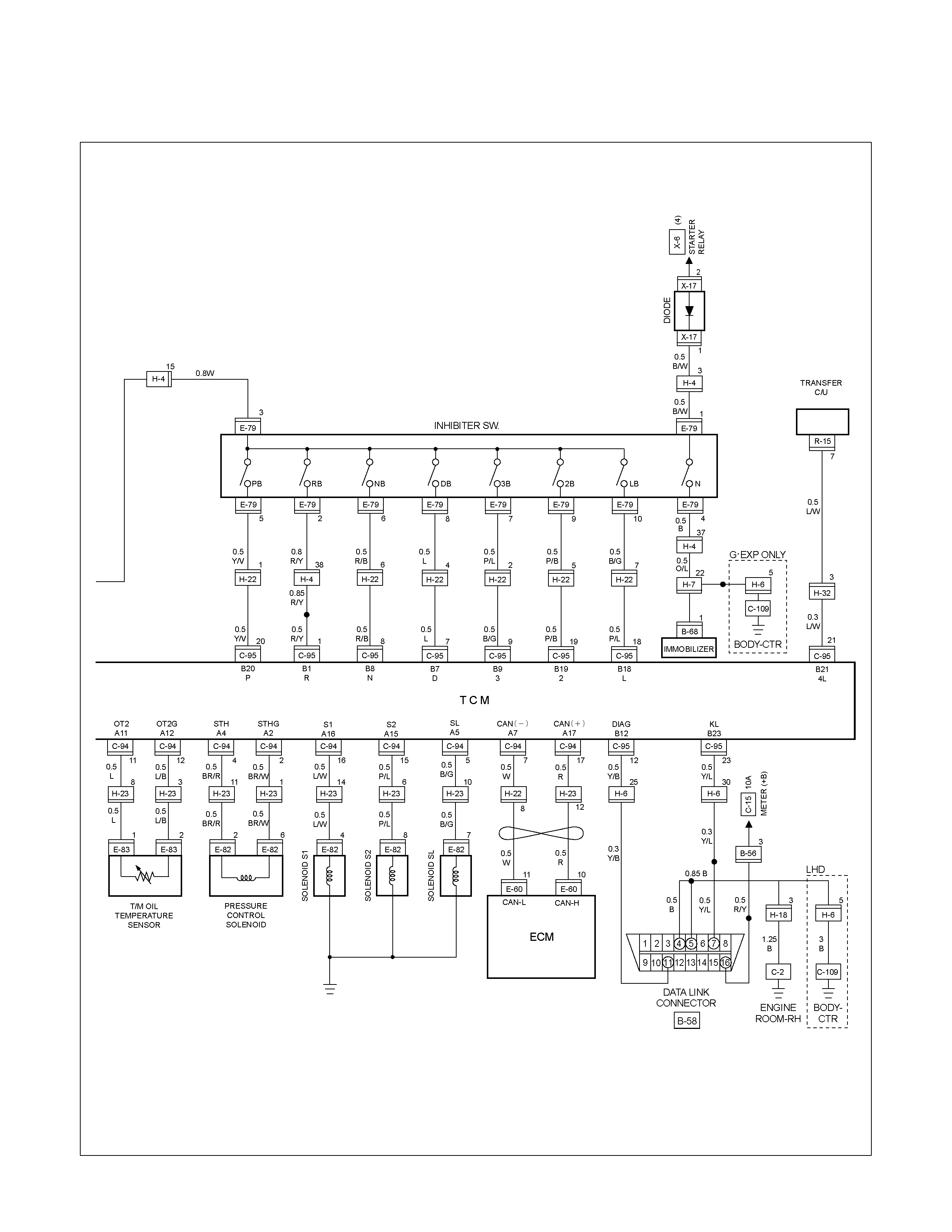

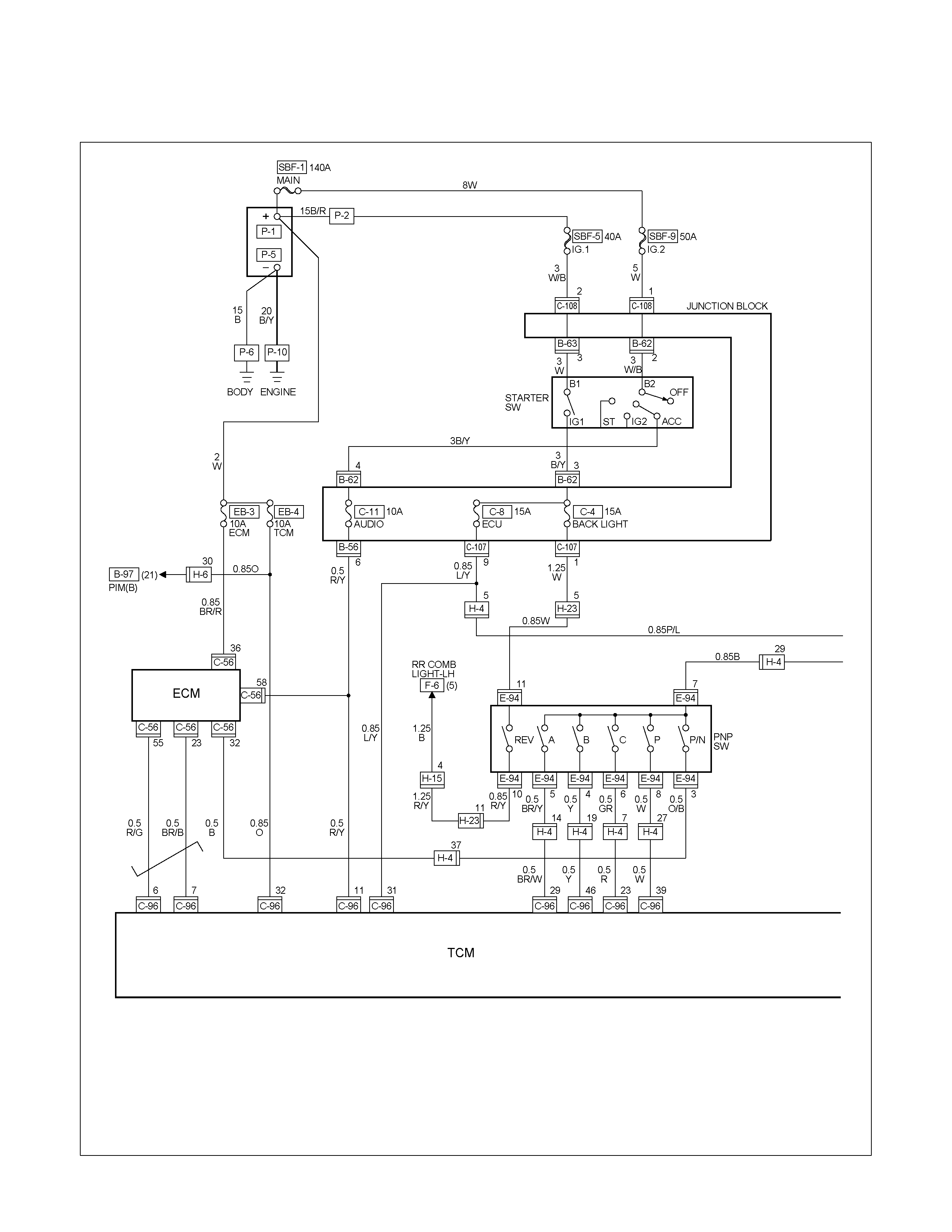

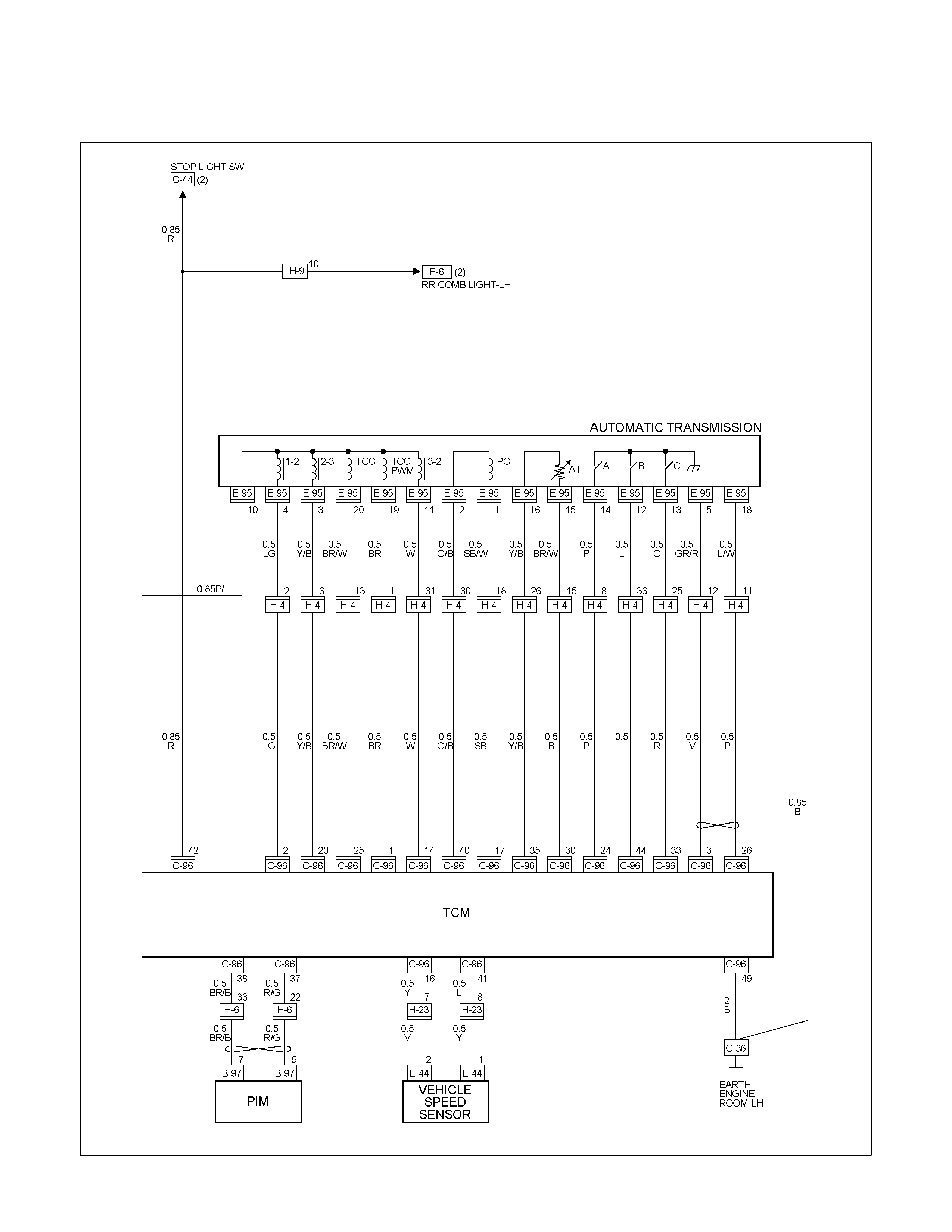

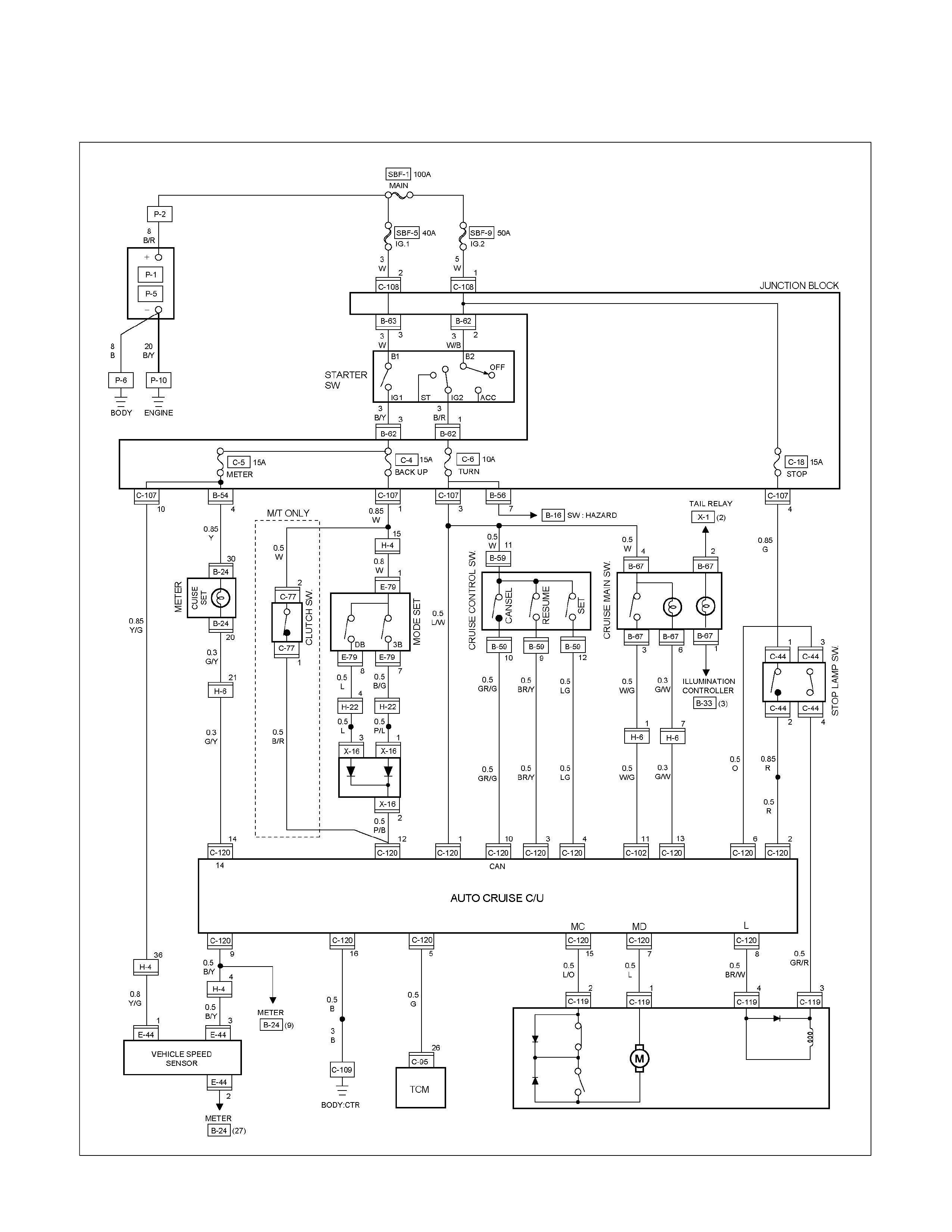

Transmission Control Module (TCM)

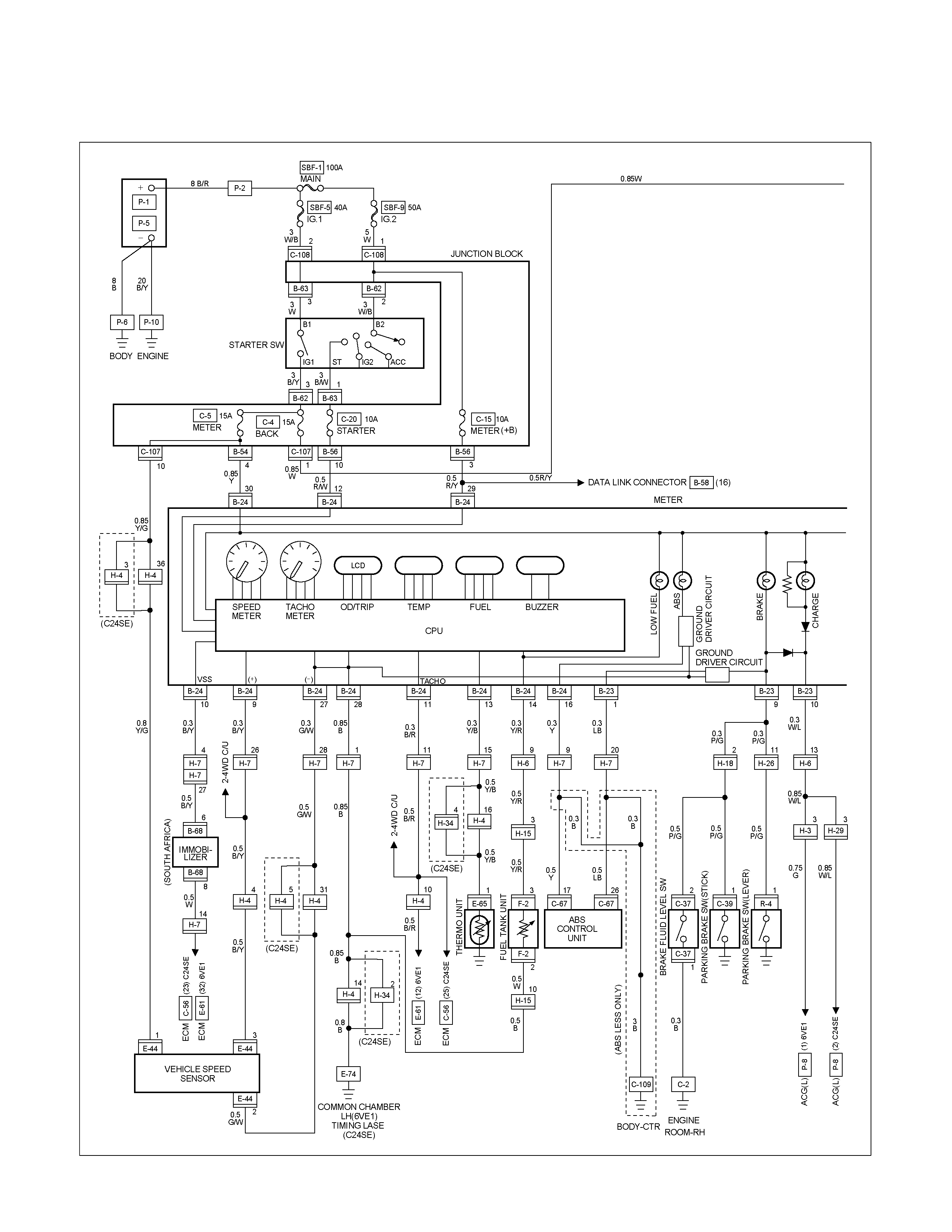

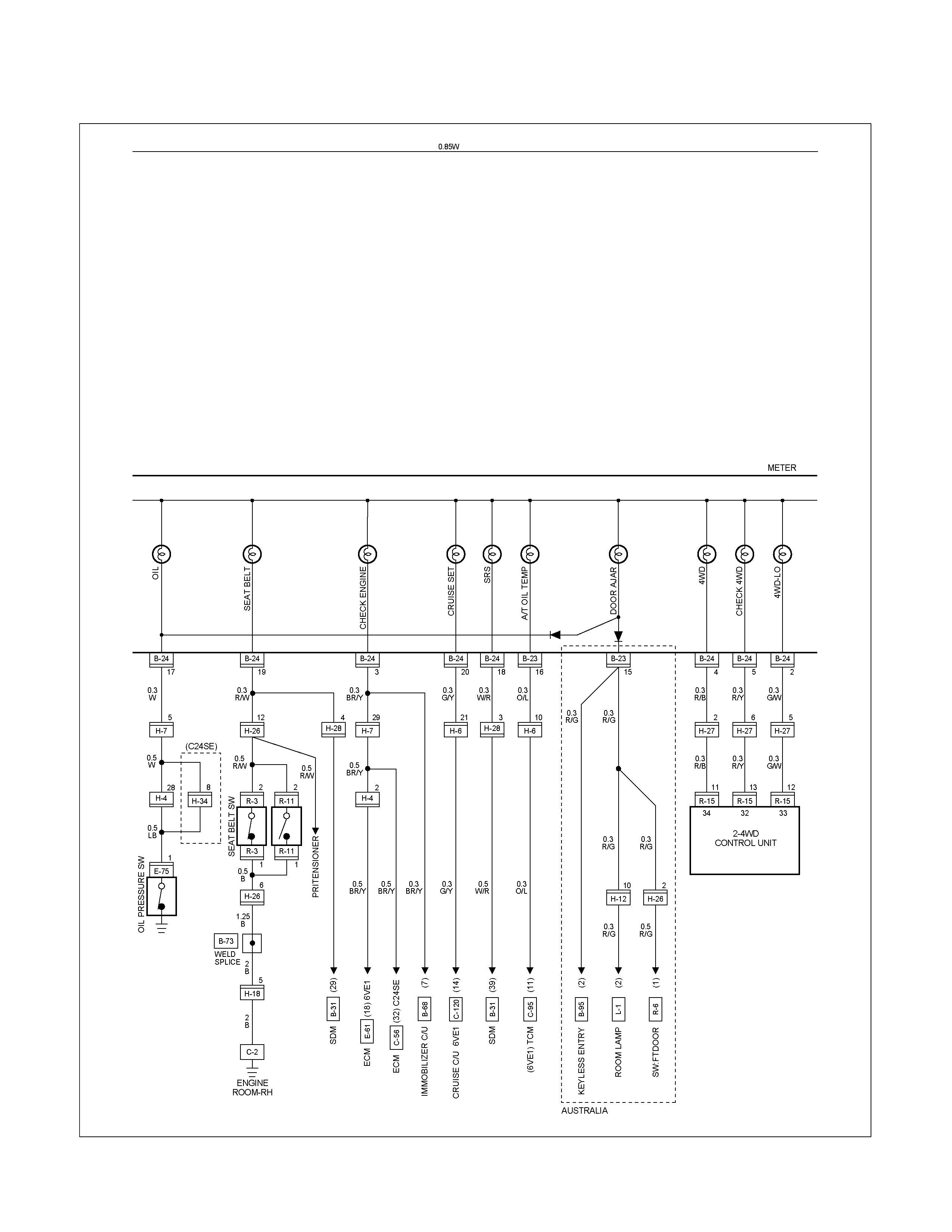

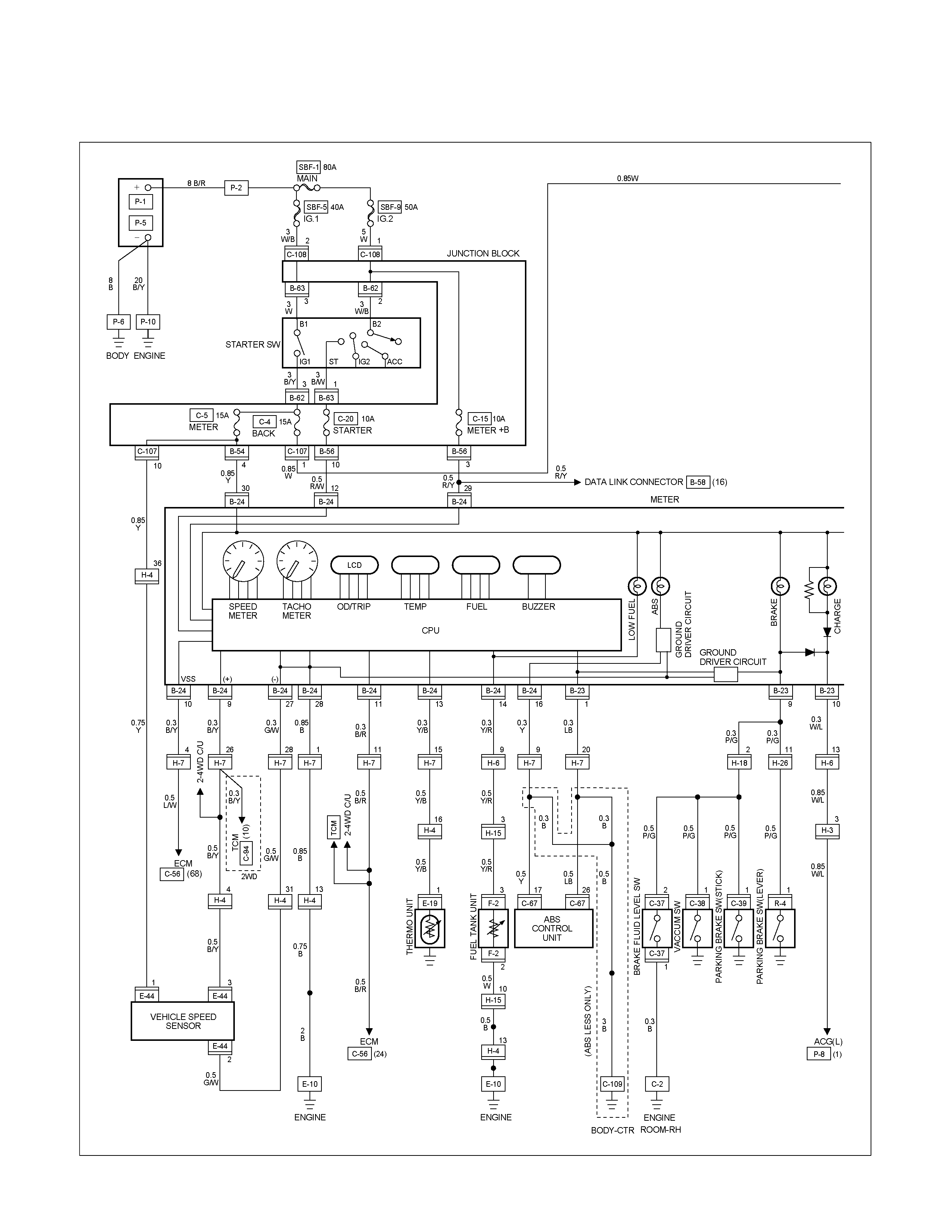

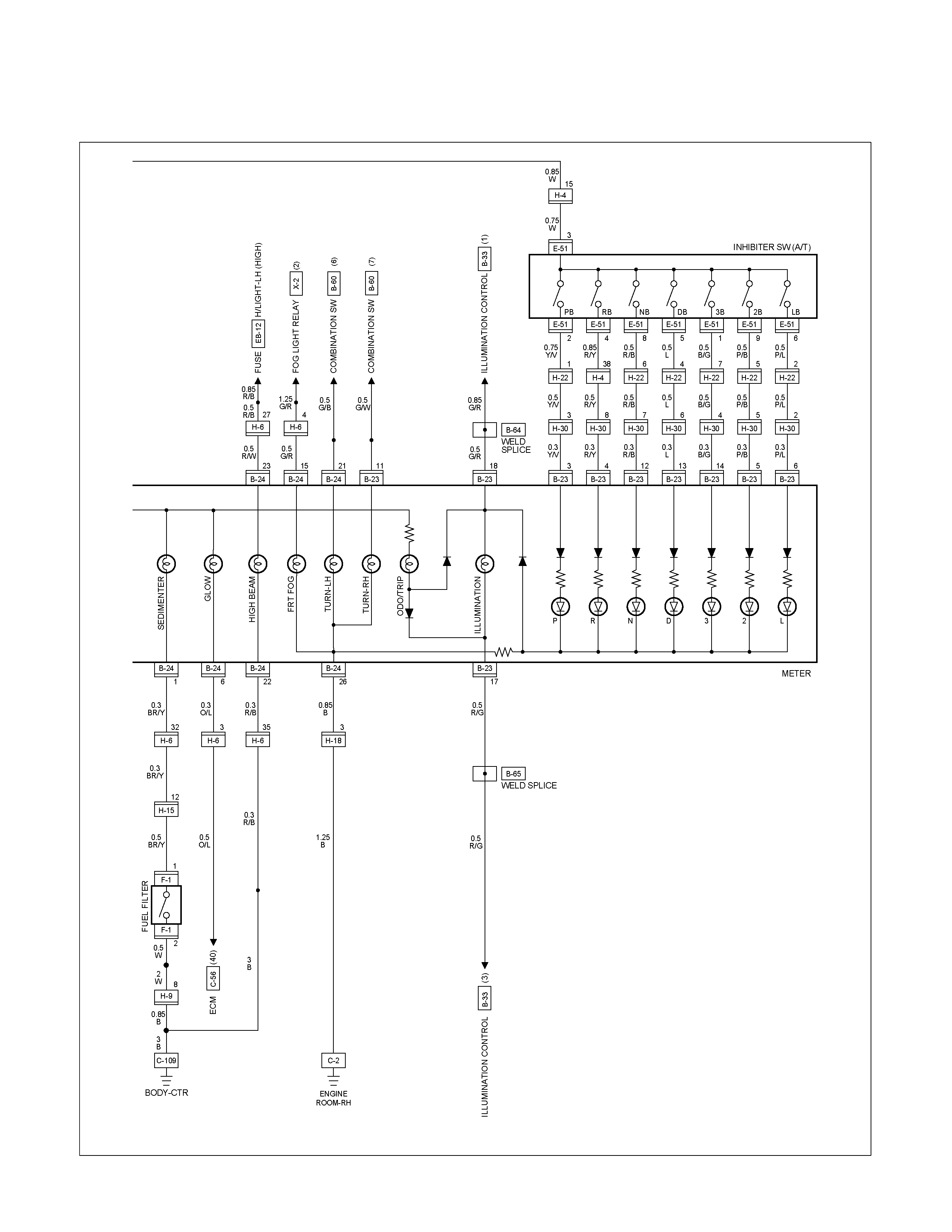

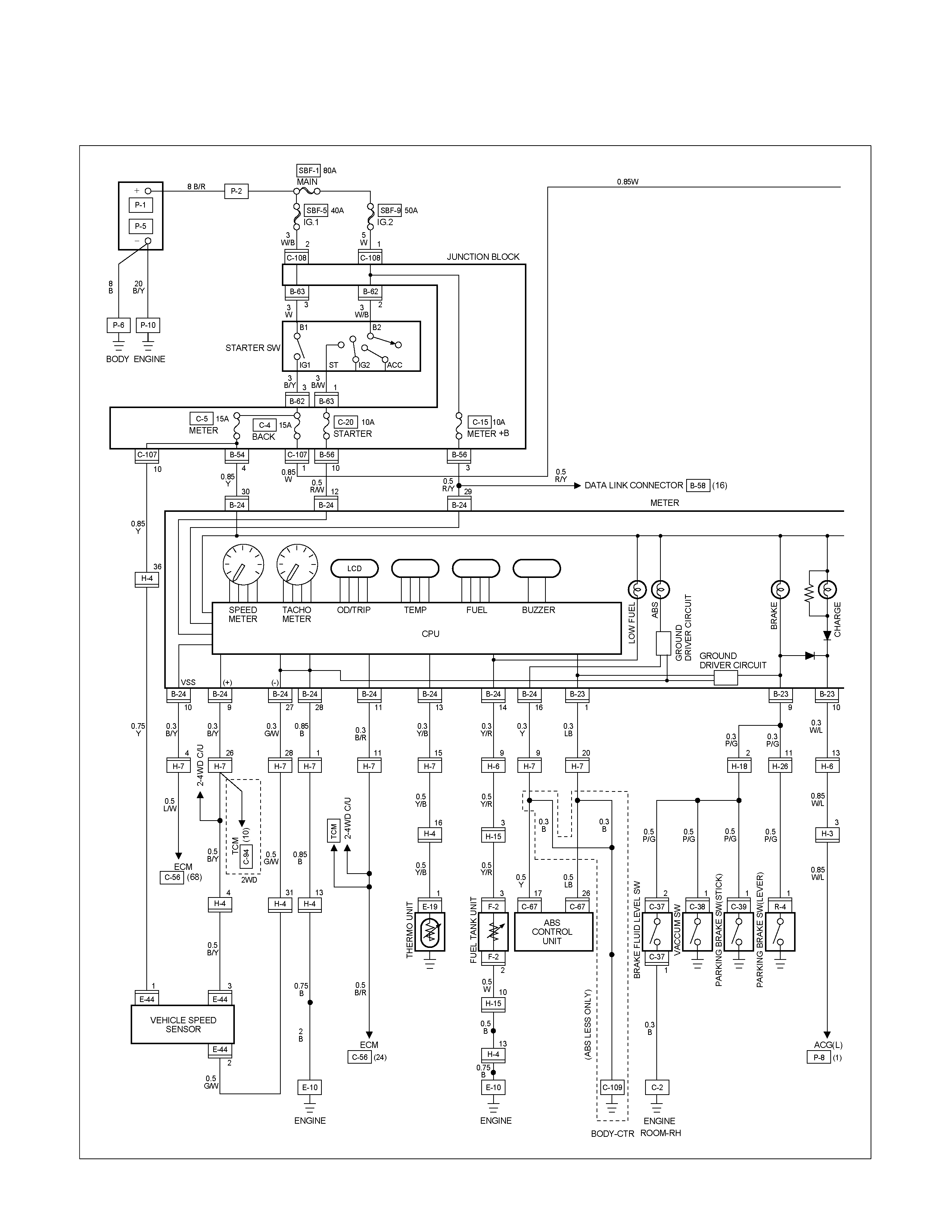

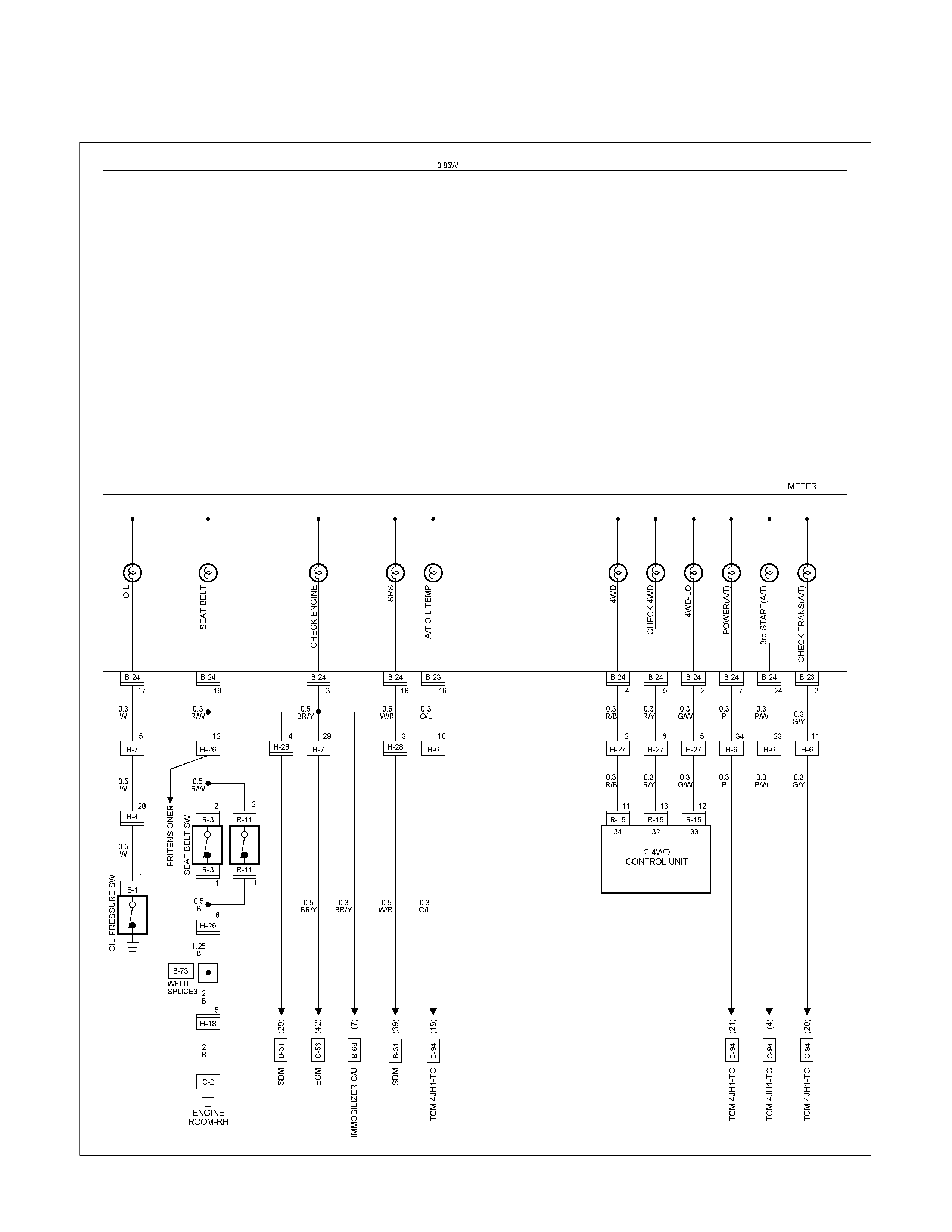

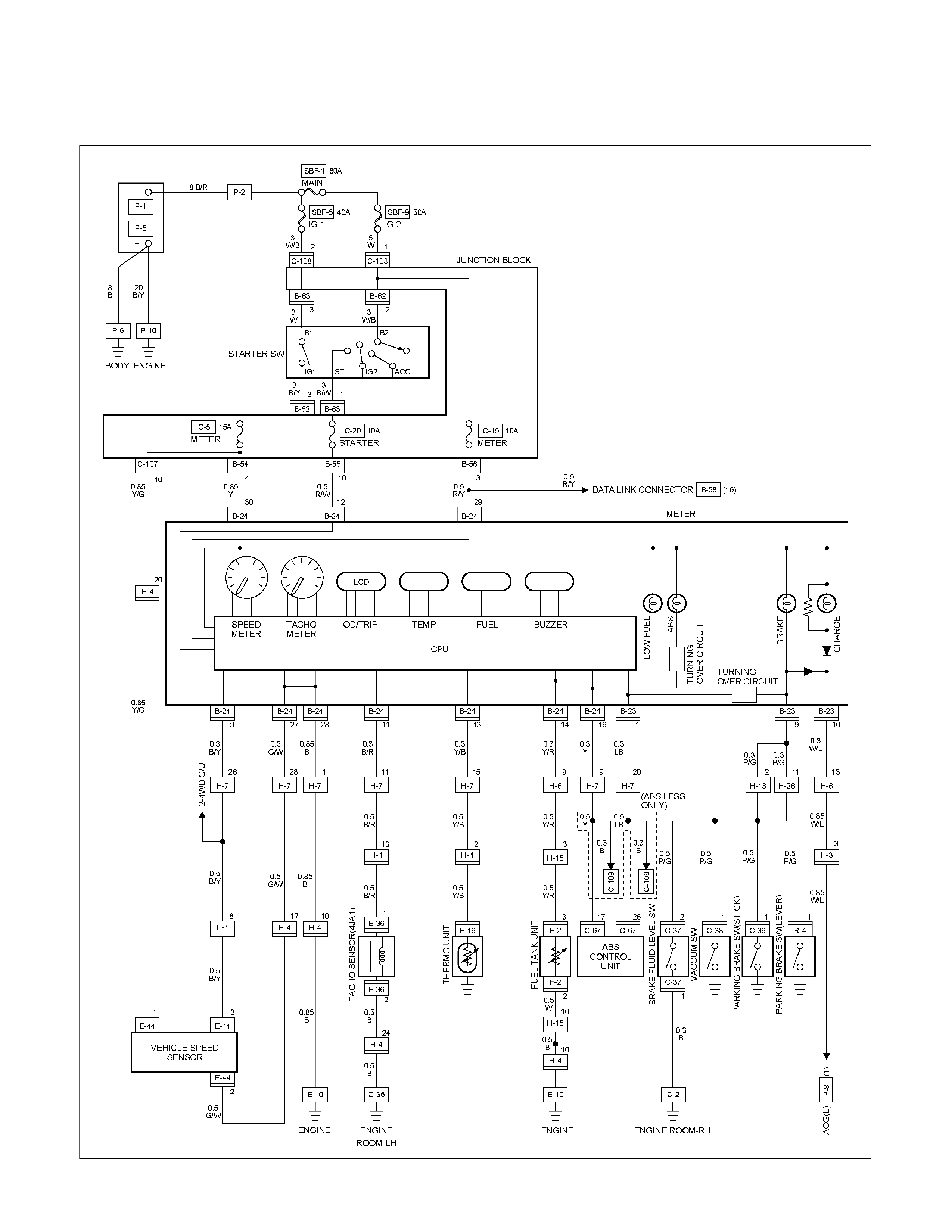

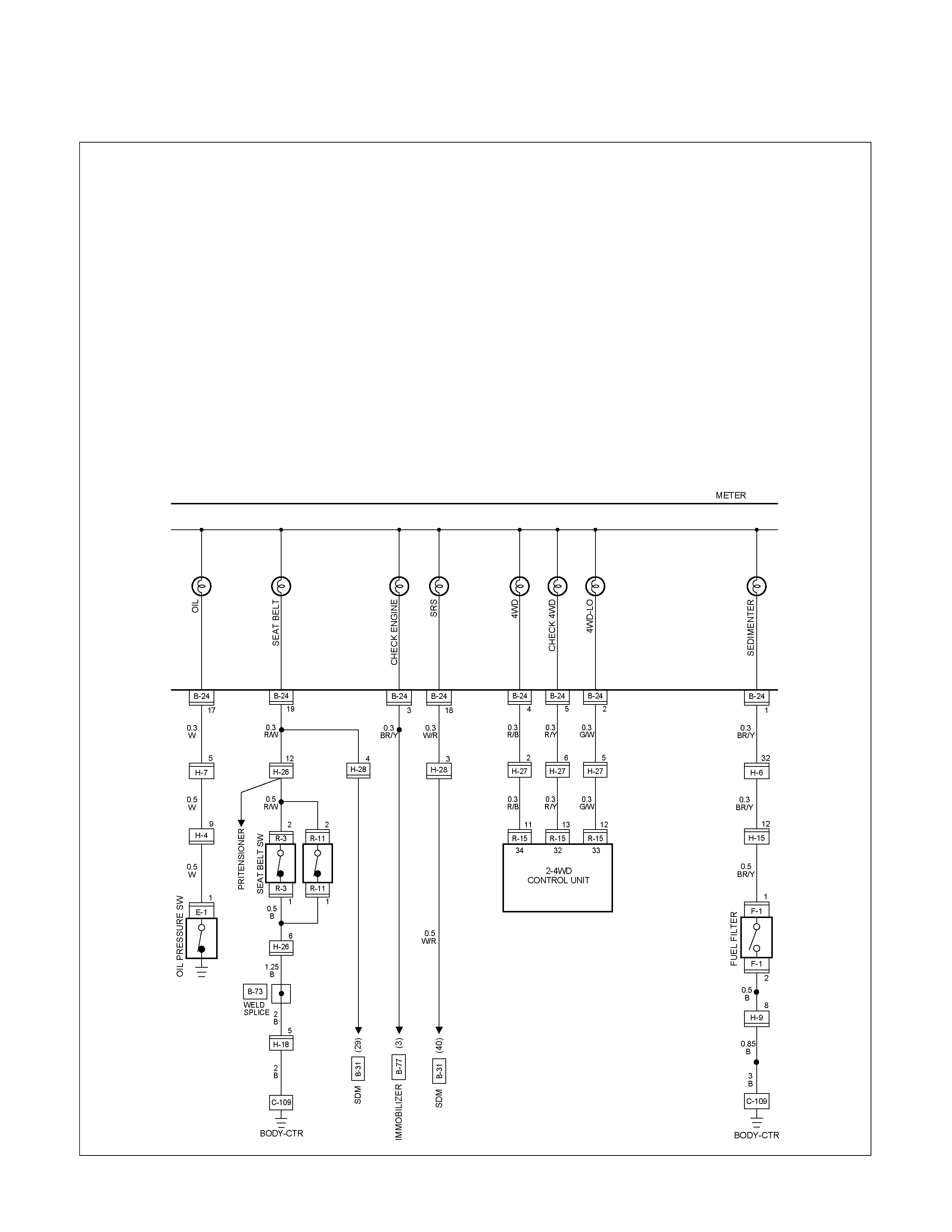

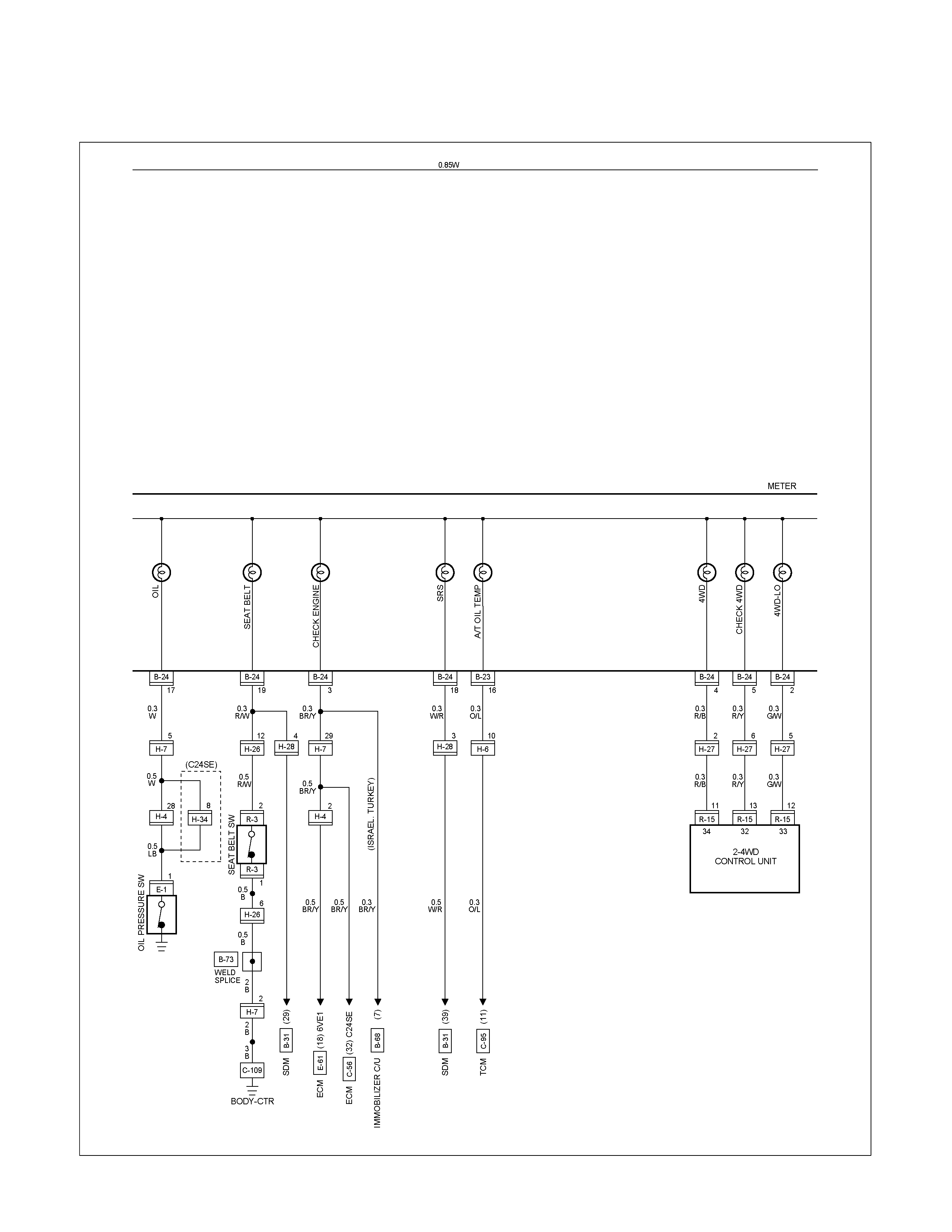

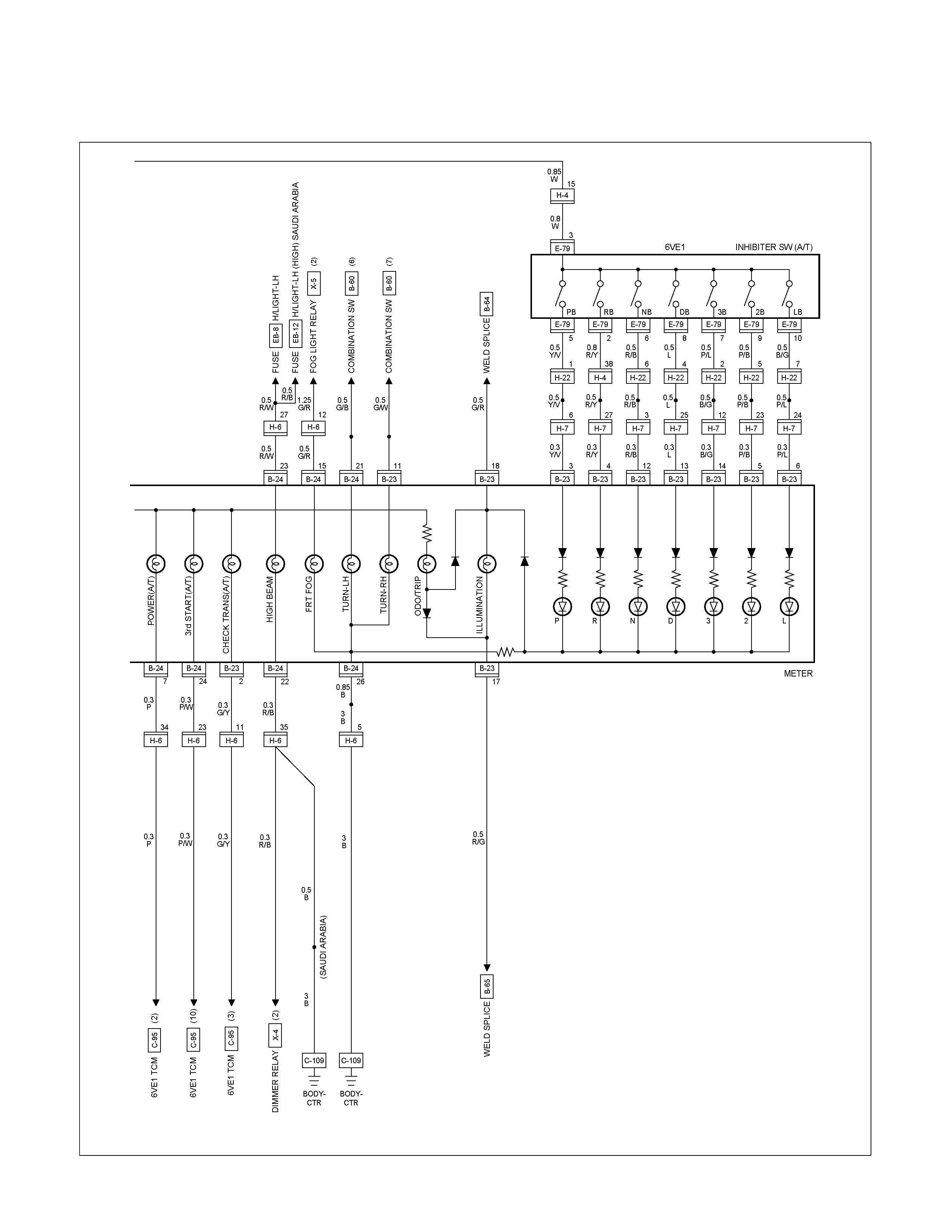

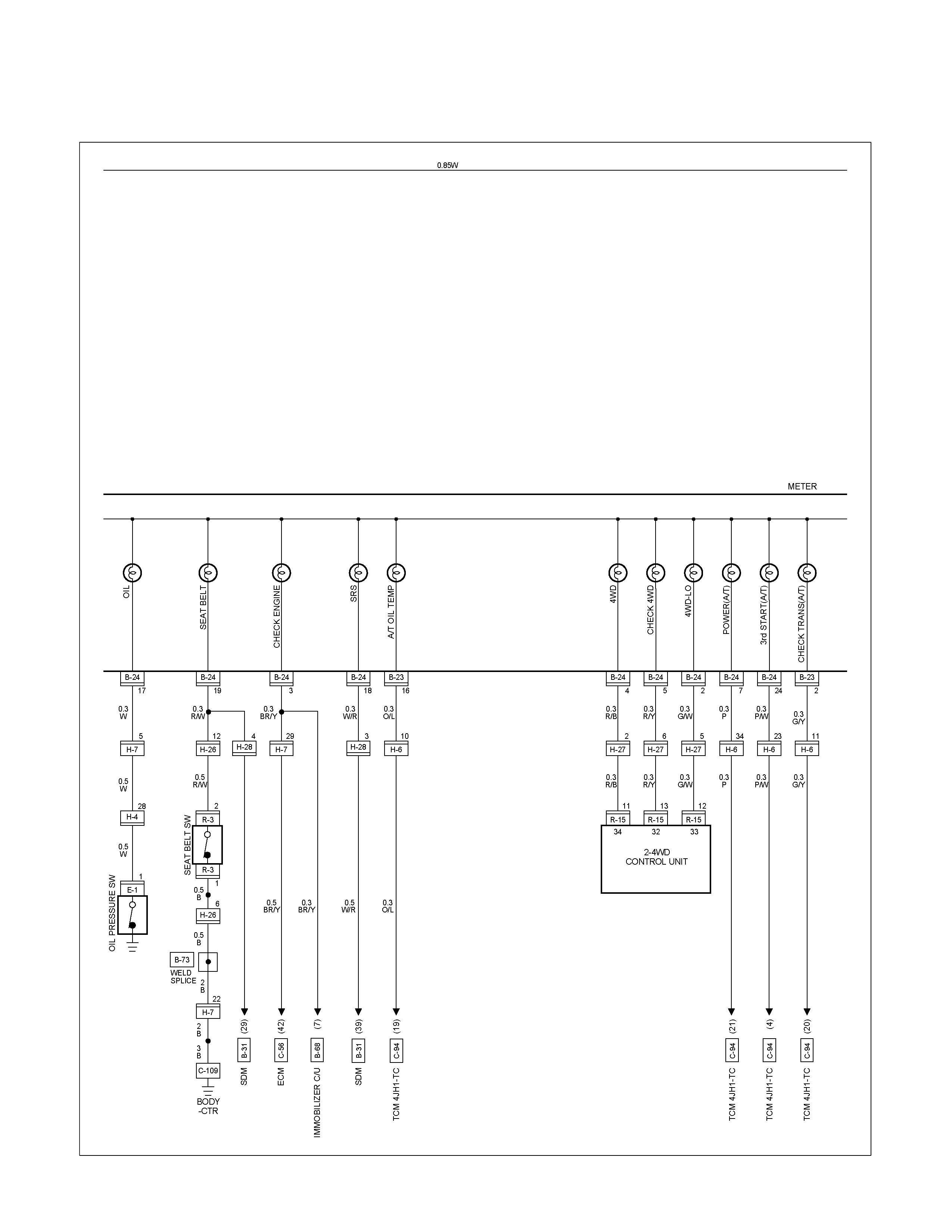

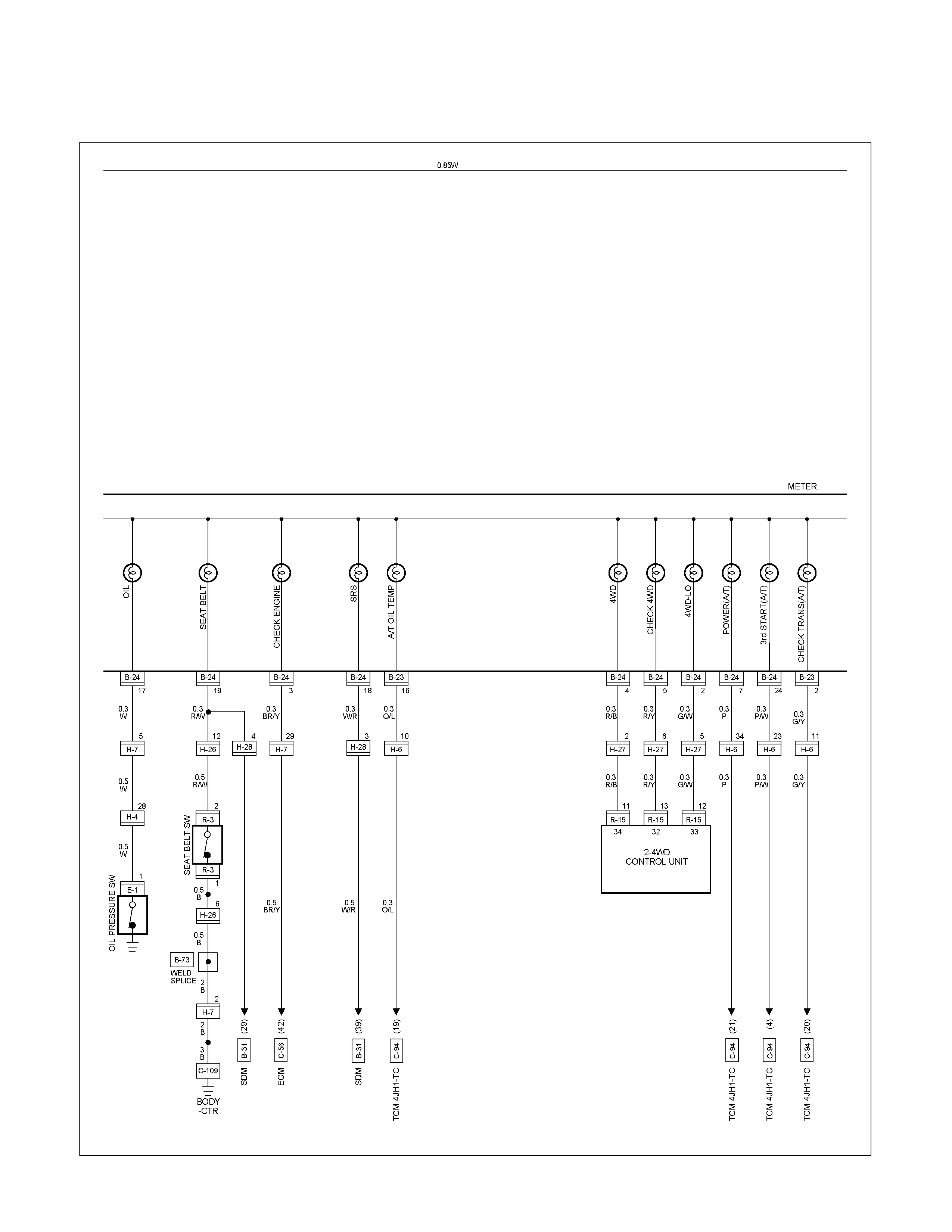

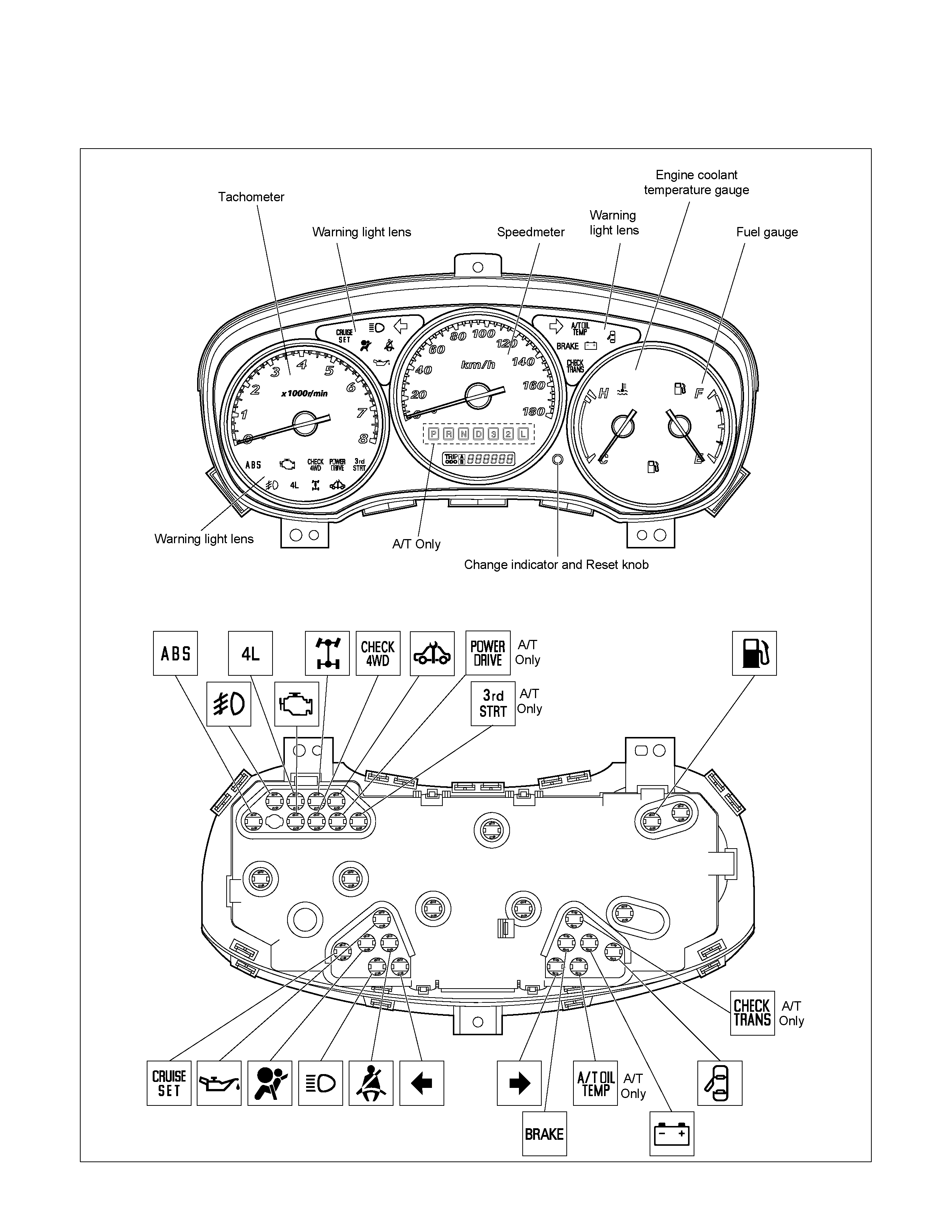

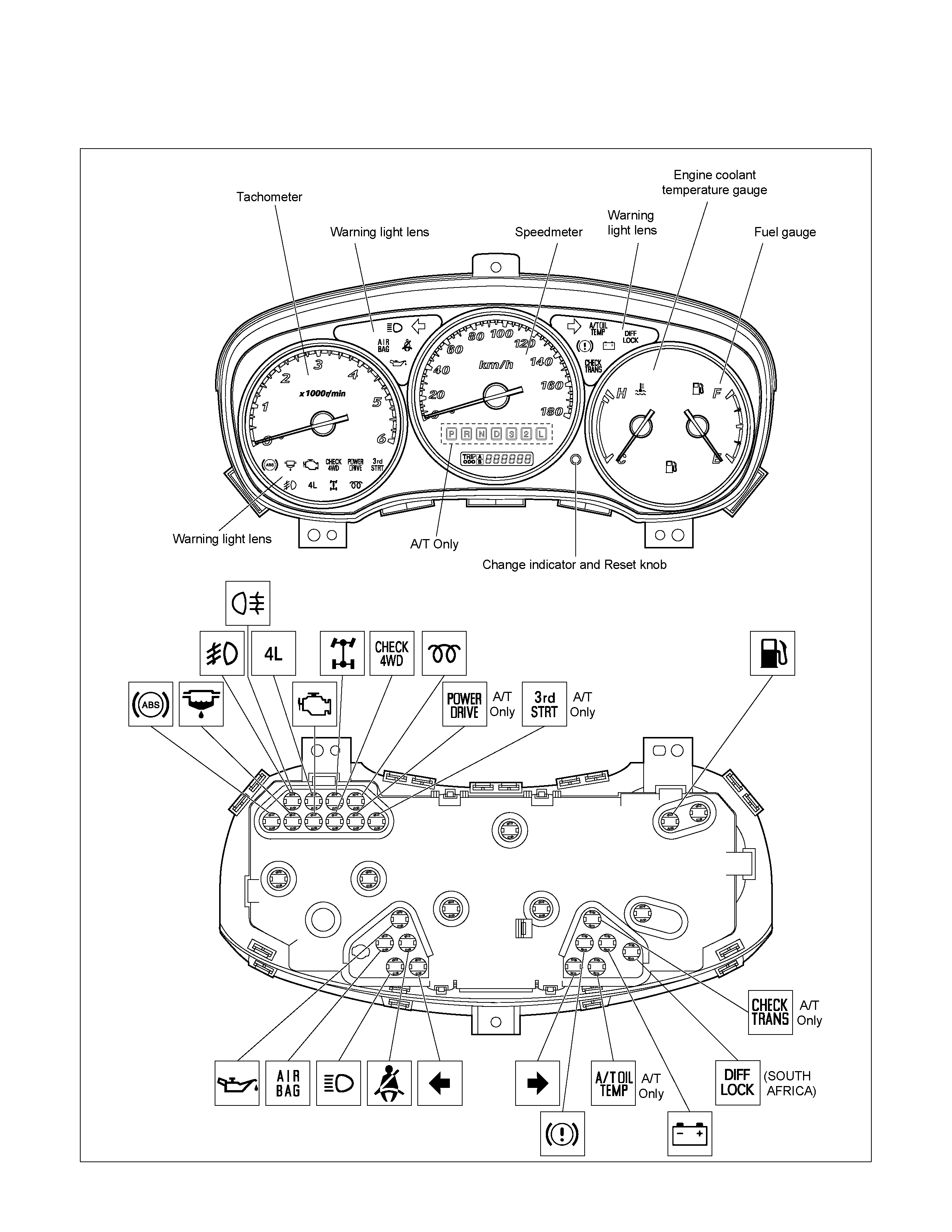

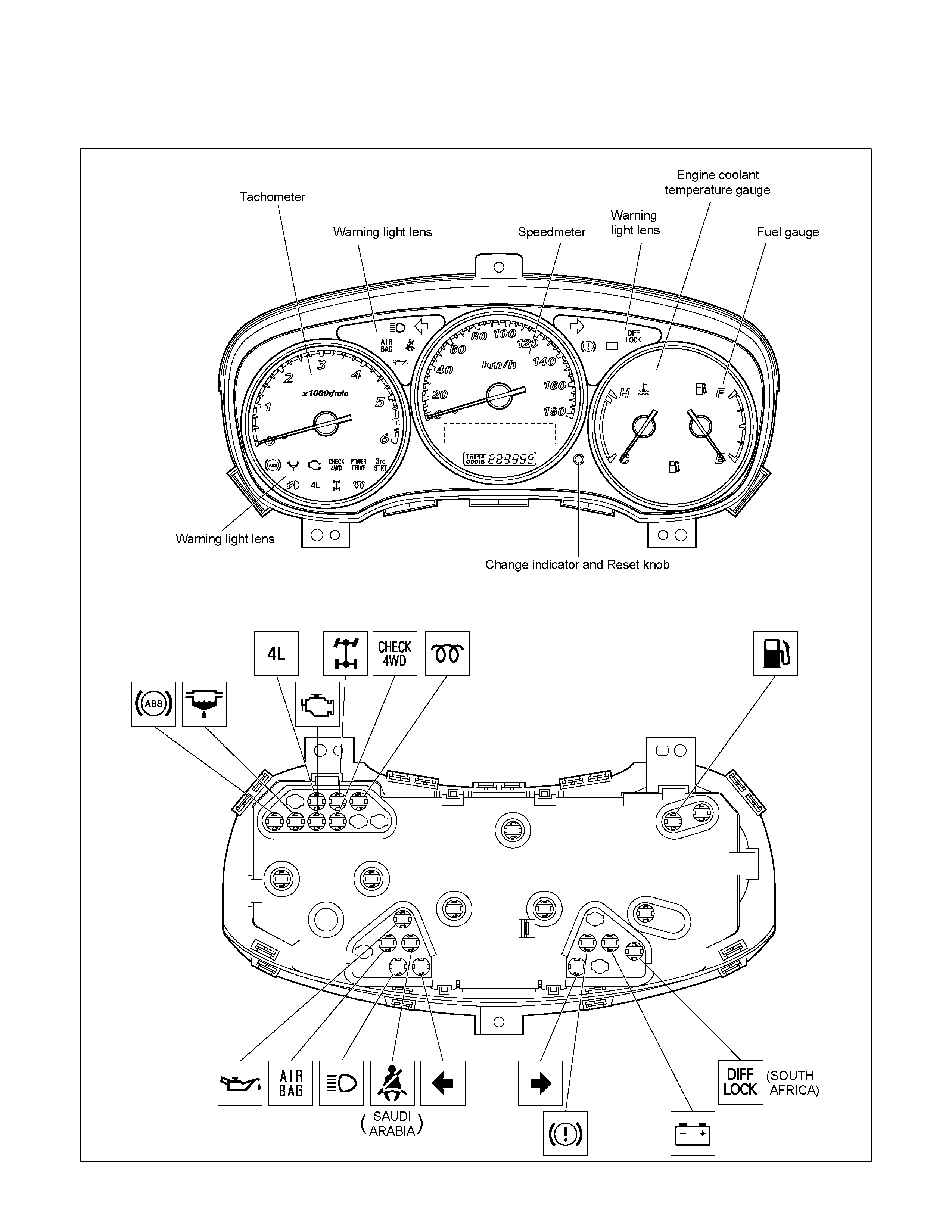

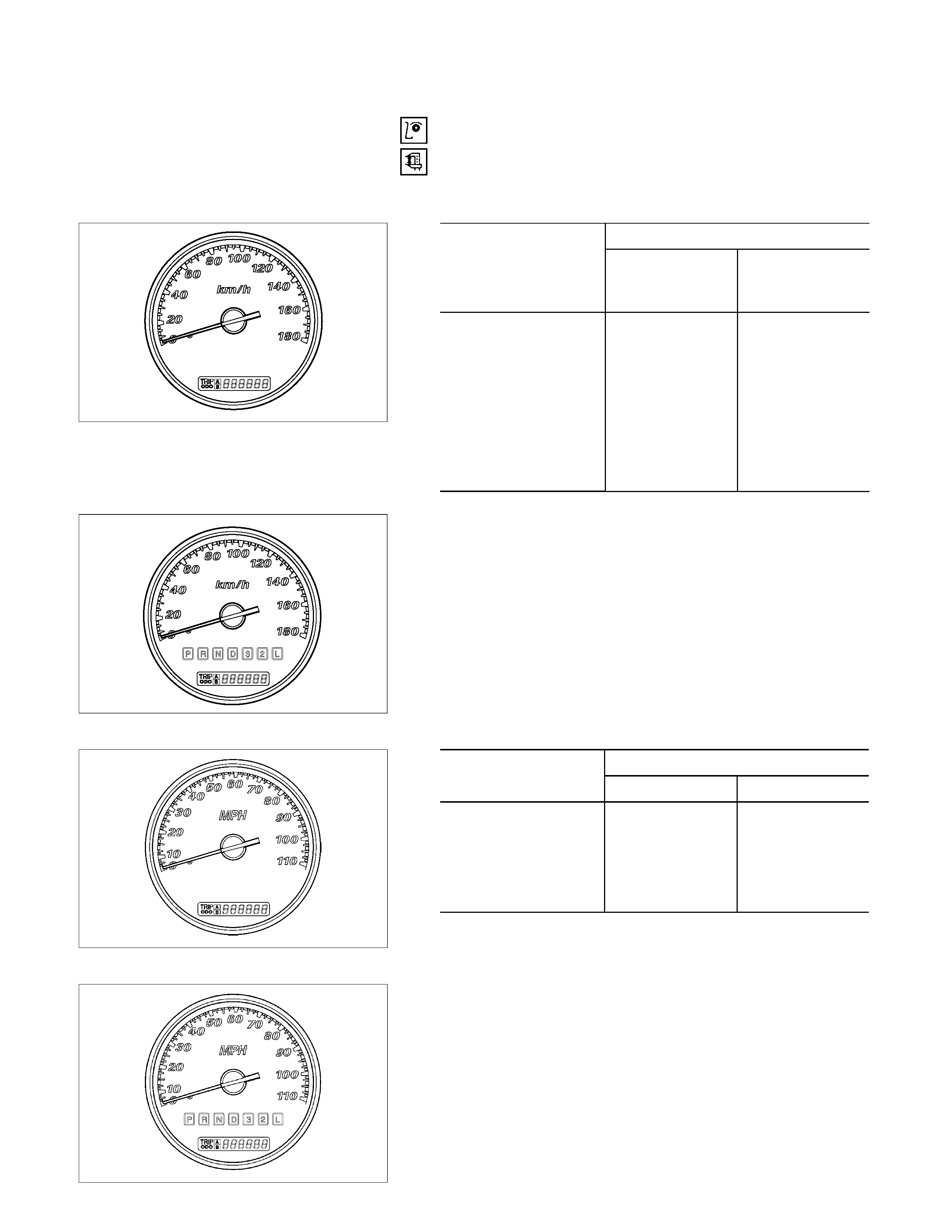

Meter Warning Light and Indicator

Light

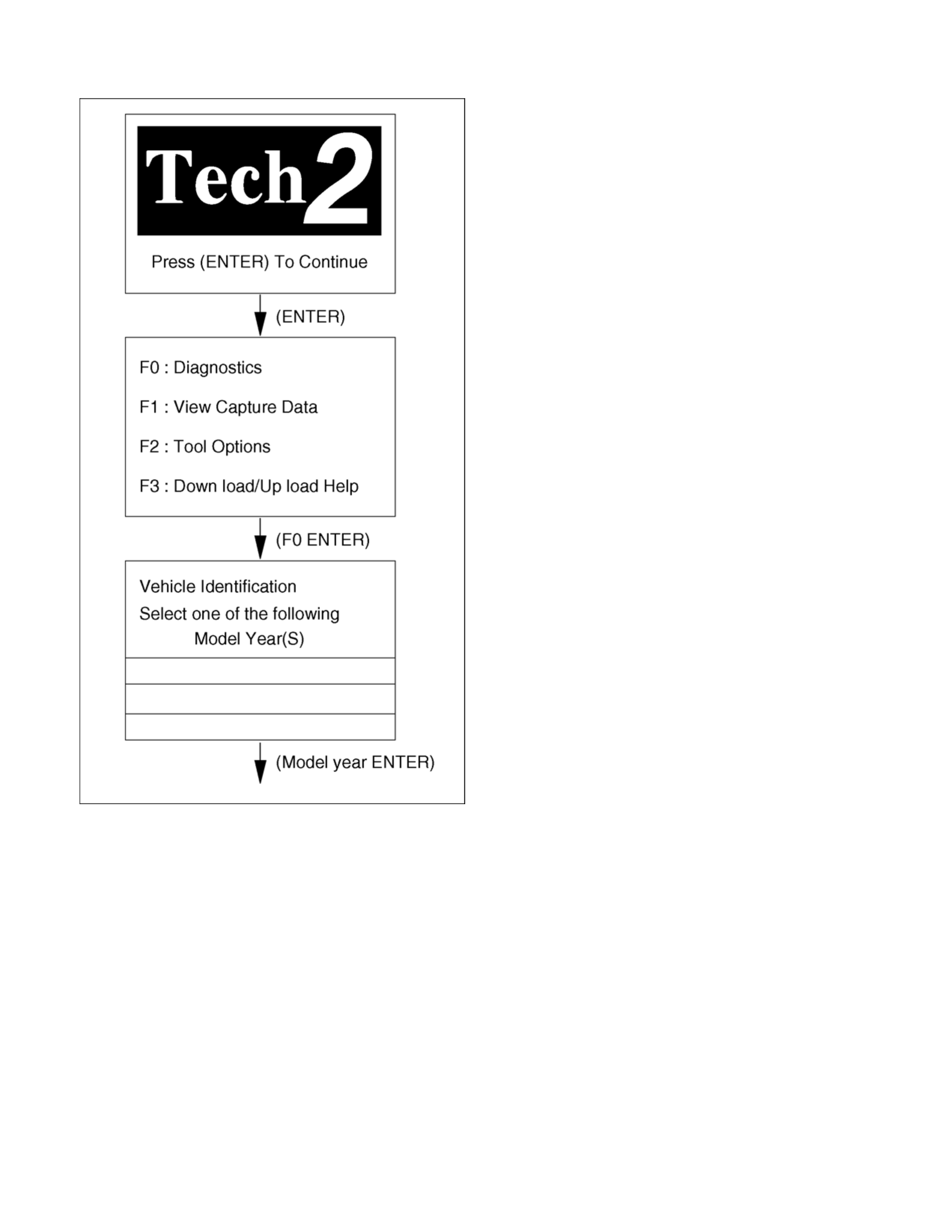

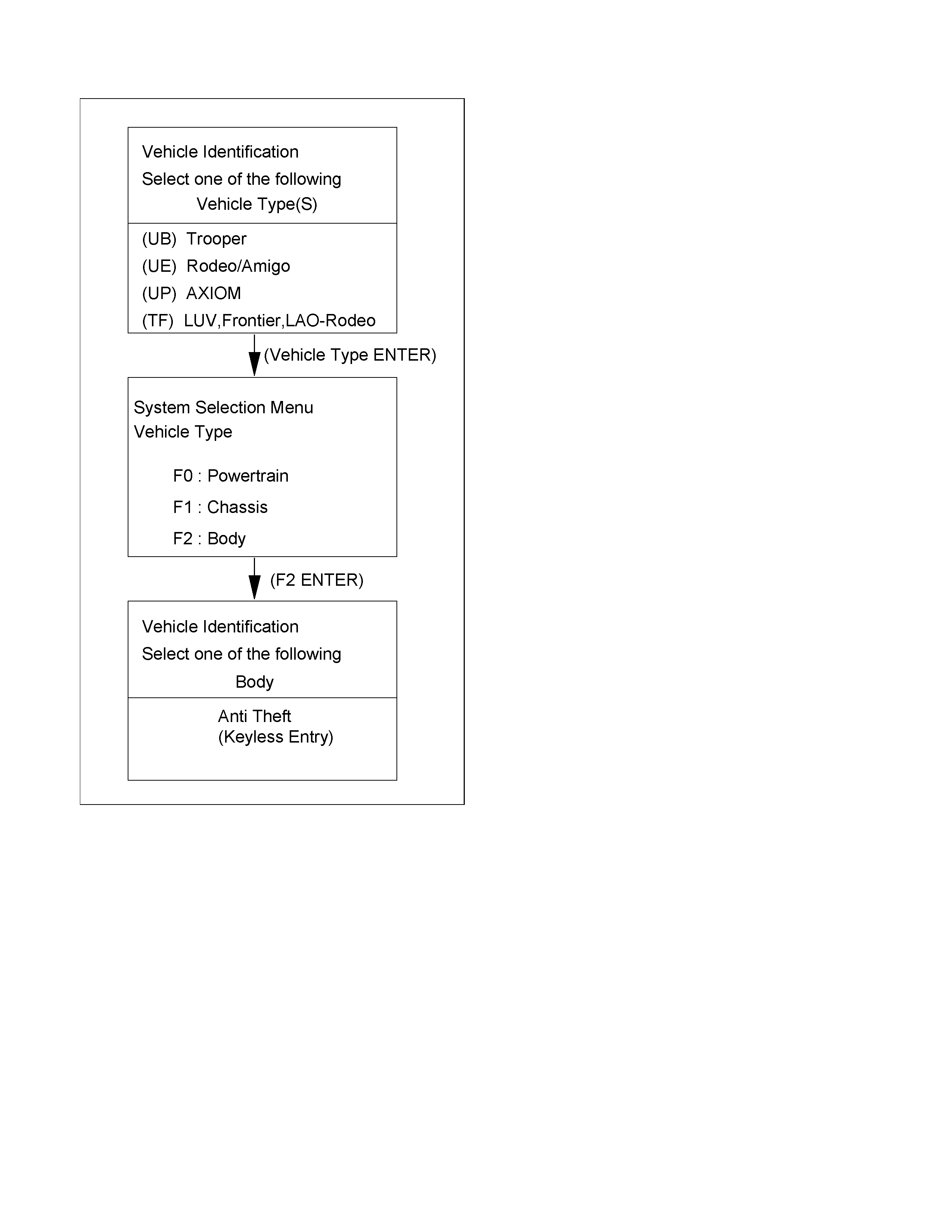

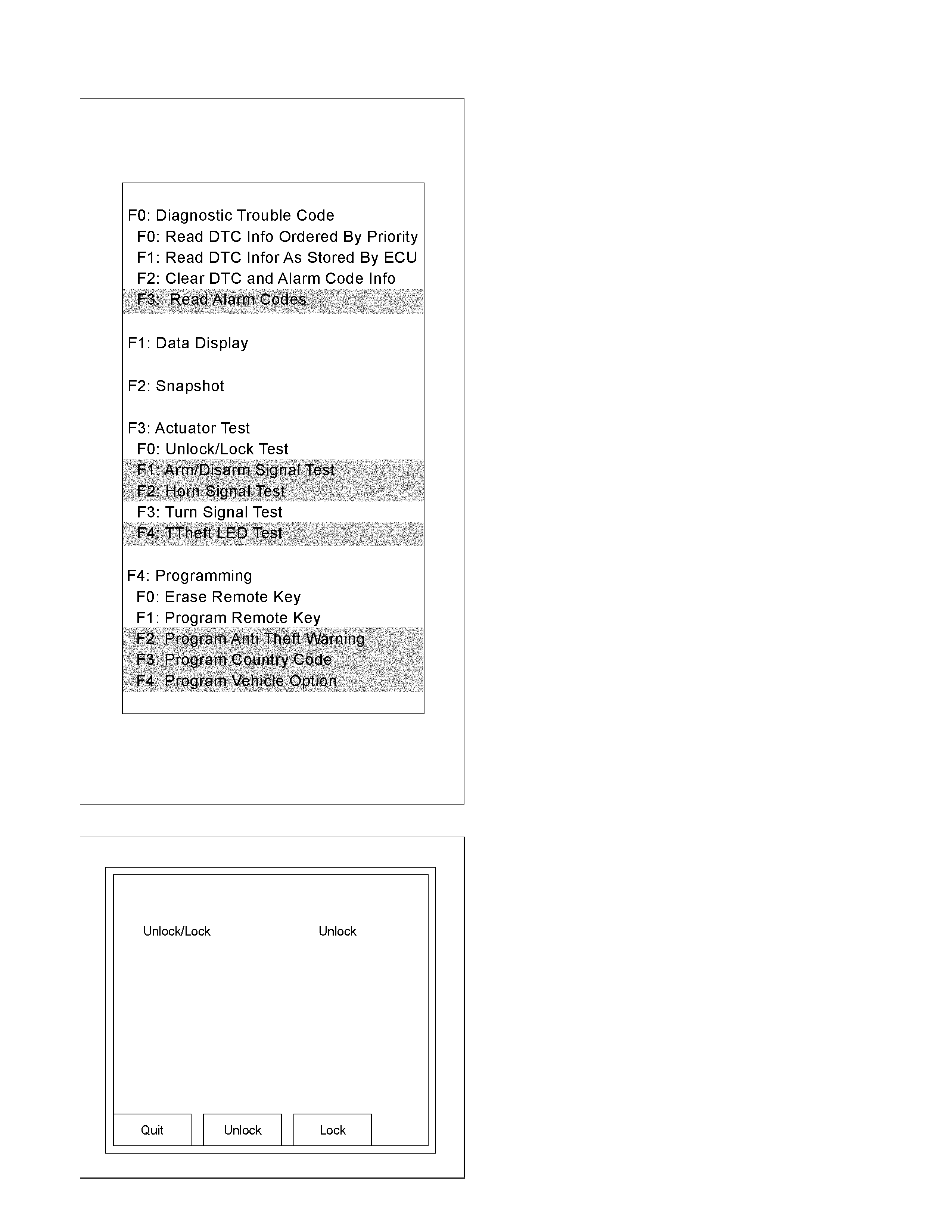

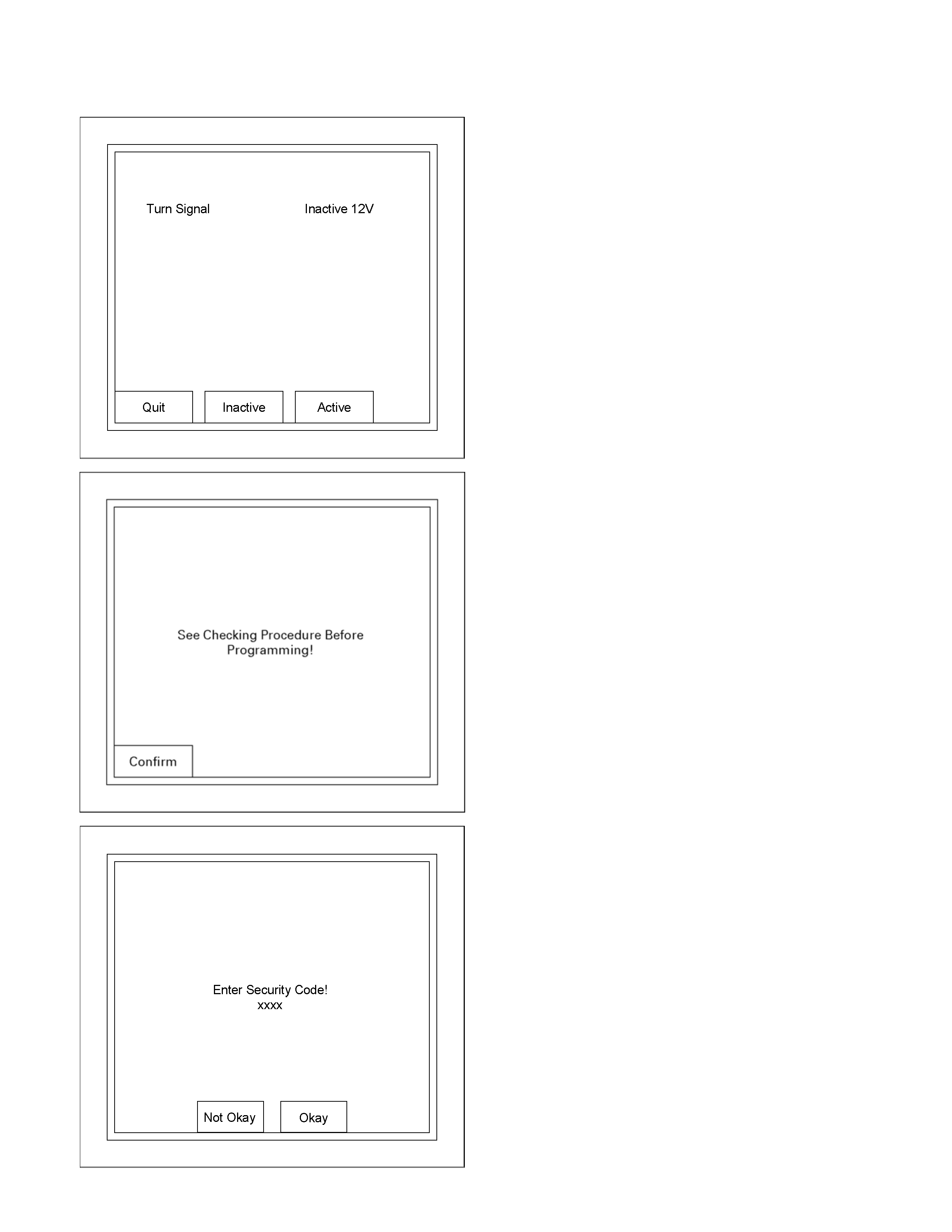

Techline

Techline

GENERAL INFORMATION

The body and chassis electrical system operates on a twelve volt power supply with negative ground polarity.

The main harness consists of the engine harness, the instrument harness, the body harness, and the chassis

harness.

The harnesses use a split corrugated tube to protect the wires from the elements.

Wire size is determined by current flow, circuit length, and voltage drop.

All wires have color-coded insulation.

Wire color-codes are shown in the circuit diagrams.

This makes it easier to trace circuits and to make the proper connections.

Each circuit consists of the following:

1. Power source - The battery and the alternator

2. Wires - To carry electrical current through the circuit

3. Fuses - To protect the circuit against current overload

4. Relays - To protect voltage drop between the battery and the circuit parts and to protect the switch points

against burning

5. Switches - To open and close the circuit

6. Load - Any device, such as a light or motor, which converts the electrical current into useful work

7. Ground - To allow the current to flow back to the power source

NOTES FOR WORKING ON ELECTRICAL ITEMS

Battery

BATTERY CABLE

Disconnecting the Battery Cable

1. All switches should be "OFF" position.

2. Disconnect the battery ground cable.

3. Disconnect the battery positive cable.

CAUTION:

It is important that the battery ground cable be

disconnected first.

Disconnecting the battery positive cable first can result in

a short circuit.

Connecting the Battery Cable

Follow the disconnecting procedure in the reverse order to

connect the battery cables.

CAUTION:

Clean the battery terminal and apply light coat of grease

to prevent terminal corrosion.

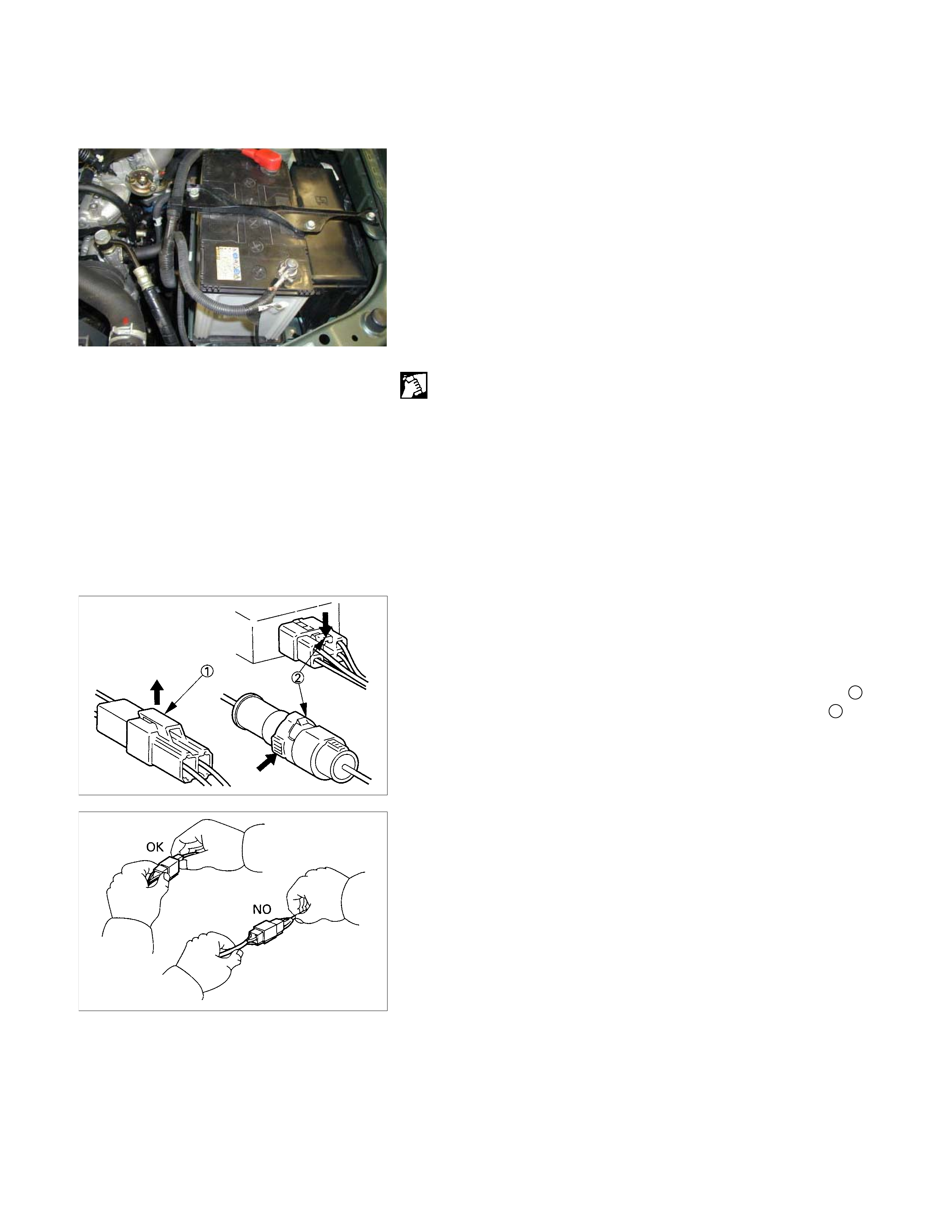

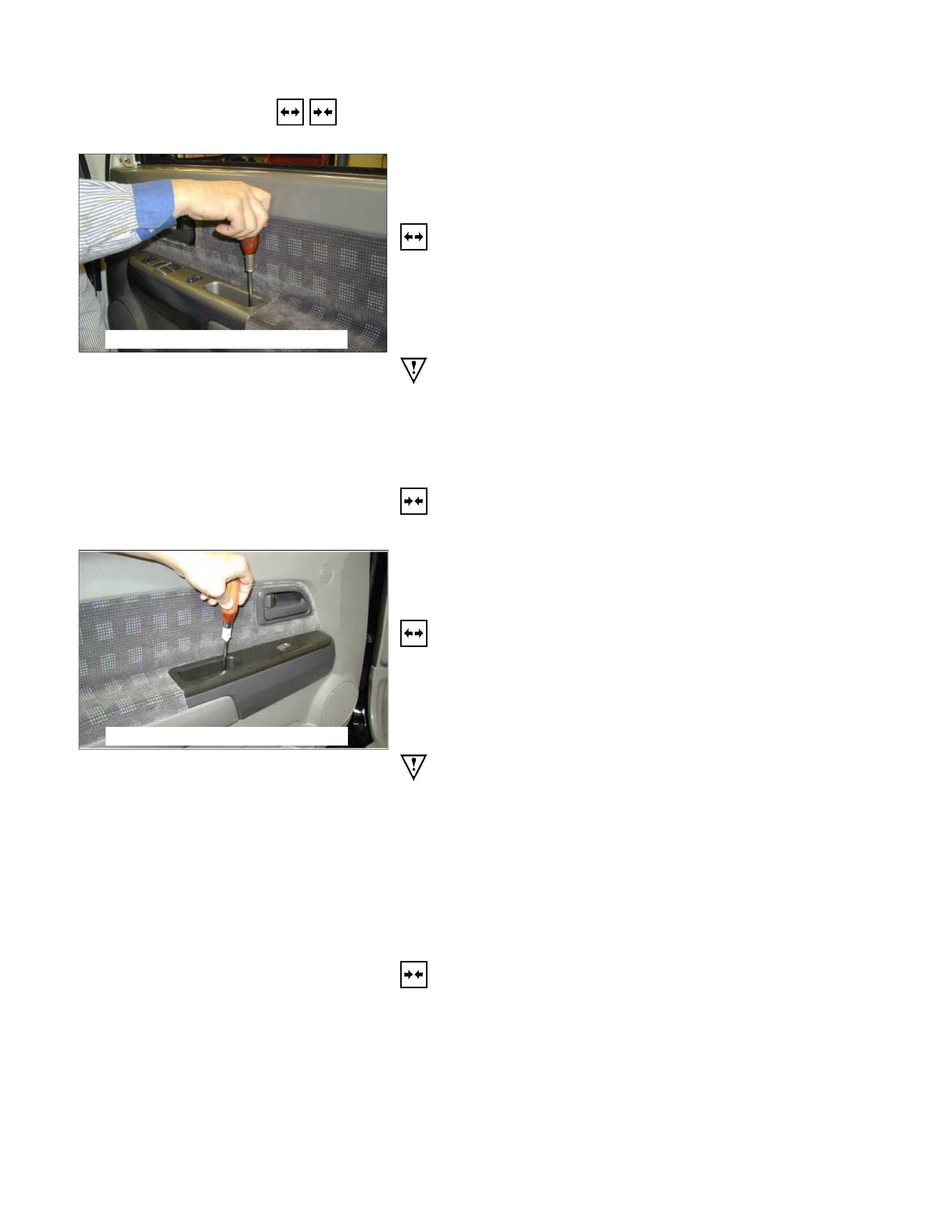

CONNECTOR HANDLING

Disconnecting the Connectors

Some connectors have a tang lock to hold the connectors

together during vehicle operation.

Some tang locks are released by pulling them towards you 1.

Other tang locks are released by pressing them forward 2.

Determine which type of tang lock is on the connector being

handled.

Firmly grasp both sides (male and female) of the connector.

Release the tang lock and carefully pull the two halves of the

connector apart.

Never pull on the wires to separate the connectors.

This will result in wire breakage.

Connecting the Connectors

Firmly grasp both sides (male and female) of the connector.

Be sure that the connector pins and pin holes match.

Be sure that both sides of the connector are aligned with each

other.

Firmly but carefully push the two sides of the connector

together until a distinct click is heard.

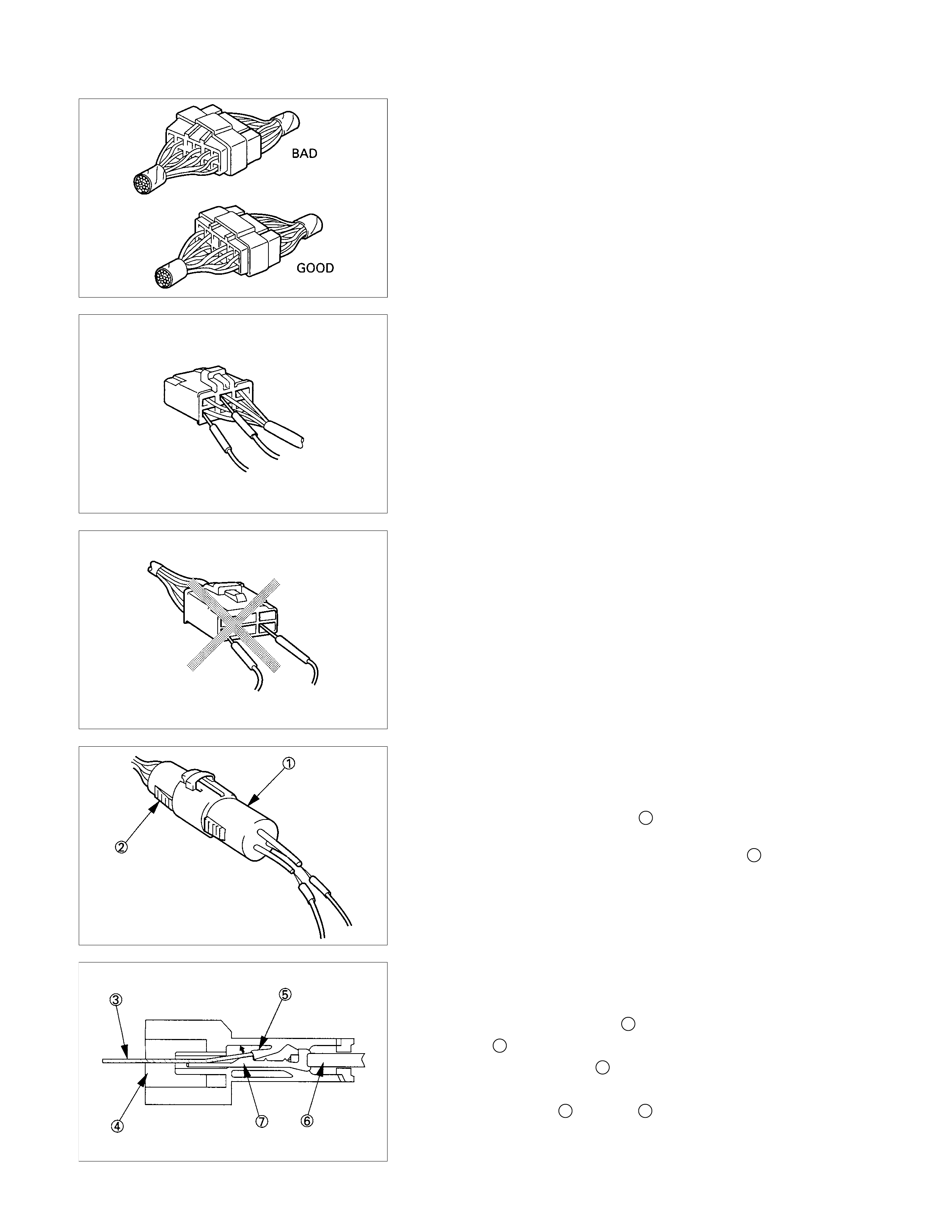

Connector Inspection

Use a circuit tester to check the connector for continuity.

Insert the test probes from the connector wire side.

CAUTION

Never insert the circuit tester test probes into the

connector open side to test the continuity.

Broken or open connector terminals will result.

Waterproof Connector Inspection

It is not possible to insert the test probes into the connector

wire side of a waterproof connector.

Use one side of a connector 1 with its wires cut to make the

test.

Connect the test connector to the connector 2 to be tested.

Connect the test probes to the cut wires to check the

connector continuity.

Connector Pin Removal

Connector Housing Tang Lock Type

1. Insert a slender shaft 3into the connector housing open

end 4.

2. Push the tang lock 5up (in the direction of the arrow in the

illustration).

Pull the wire 6 with pin 7free from the wire side of the

connector.

Pin Tang Lock Type

1. Insert a slender shaft 3into the connector housing open

end 4.

2. Push the tang lock 8flat (toward the wire side of the

connector).

Pull the wire 6 with pin 7free from the wire side of the

connector.

Connector Pin Insertion

1. Check that the tang lock 8 is fully up.

2. Insert the pin 7 from the connector wire side 9.

Push the pin in until the tang lock closes firmly.

3. Gently pull on the wires 6to make sure that connector pin

is firmly set in place.

Fuse Replacement

The replacement fuse must have the same amperage

specification as the original fuse.

Never replace a burn out fuse with a fuse of a different

amperage specification.

Doing so can result in an electrical fire or other serious circuit

damage.

Parts Handling

Be careful for parts handling and any part should not be

dropped or thrown, otherwise short circuit or disorder may

result.

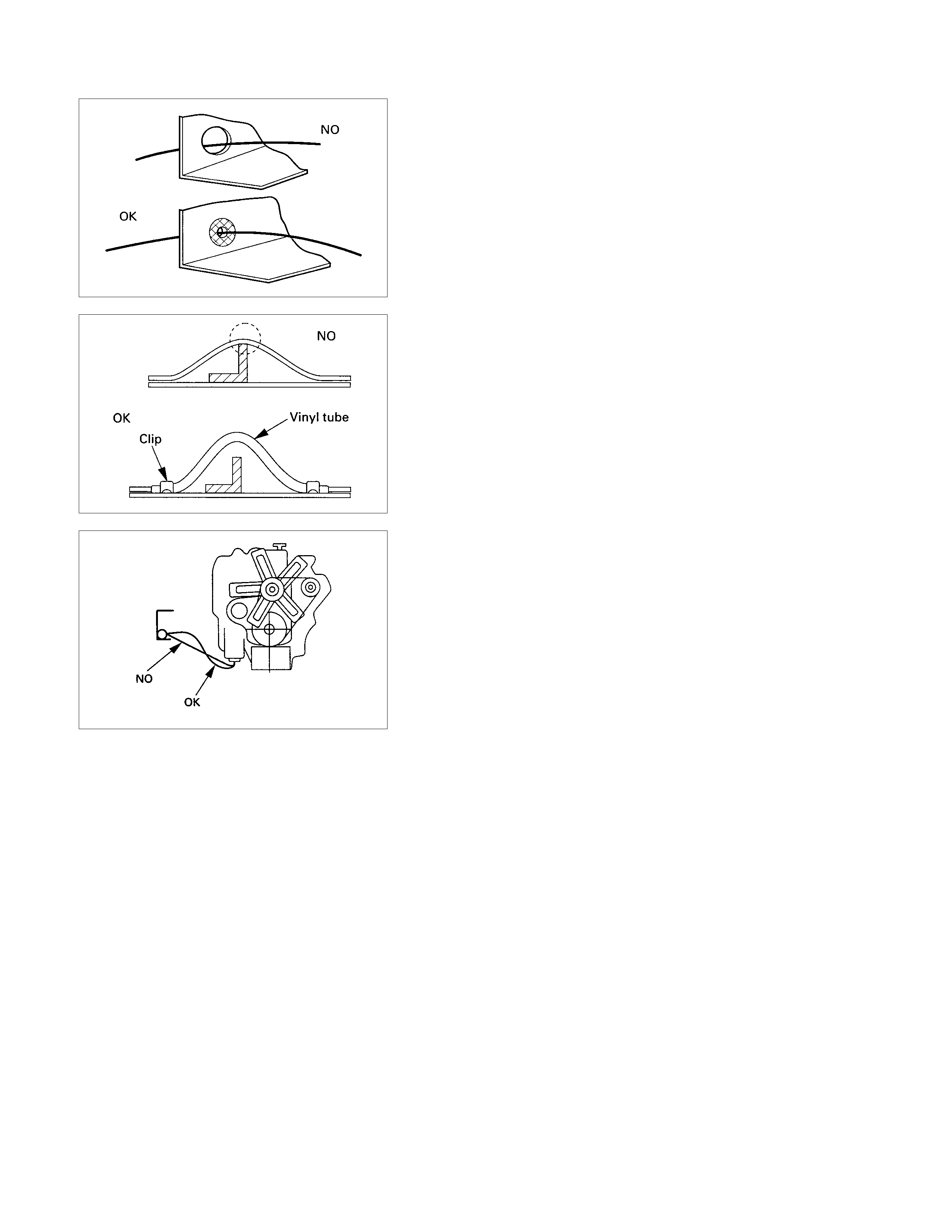

Wiring Harness

1. When assembling the parts, be careful not to bite or wedge

the wiring harness.

2. All electrical connections must be kept clean and tight.

3. Use a grommet or guard tube to protect the wiring harness

from contacting a sharp edge or surface.

4. Position the wiring harness with enough clearance from the

other parts and guard the wiring harness with a vinyl tube

to avoid direct contact.

5. The wiring harness between engine and chassis should be

long enough to prevent chafing or damage due to various

vibrations.

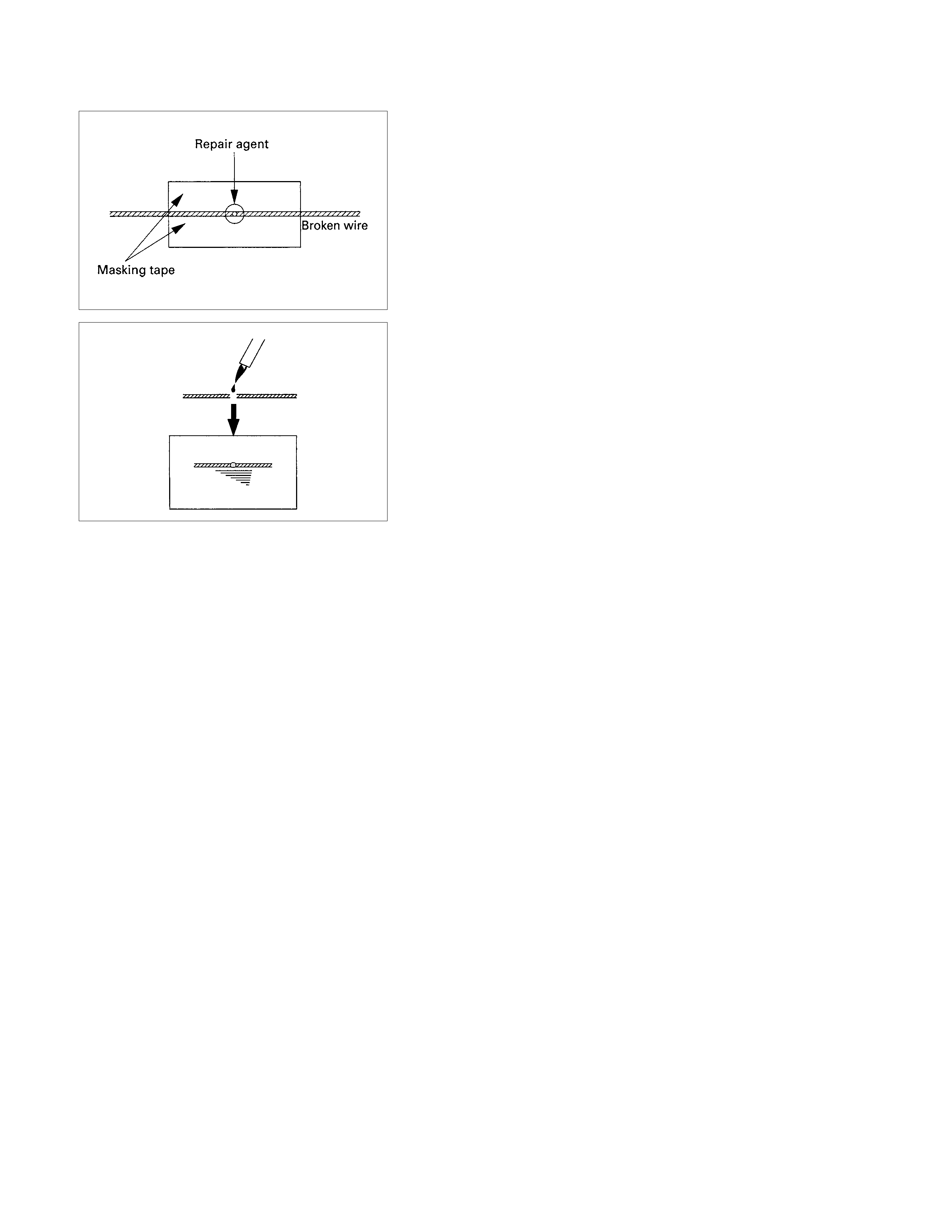

SPLICING WIRE

Open the Harness

If the harness is taped, remove the tape.

To avoid wire insulation damage, use a sewing "seam ripper"

(available from sewing supply stores) to cut open the harness.

If the harness has a black plastic conduit, simply pull out the

desired wire.

Cut the wire

Begin by cutting as little wire off the harness as possible.

You may need the extra length of wire later if you decide to cut

more wire off to change the location of a splice.

You may have to adjust splice locations to make certain that

each splice is at least 1-1/2" (40 mm) away from other splices,

harness branches, or connectors.

Strip the insulation

When replacing a wire, use a wire of the same size as the

original wire.

Check the stripped wire for nicks or cut strands.

If the wire is damaged, repeat the procedure on a new section

of wire.

The two stripped wire ends should be equal in length.

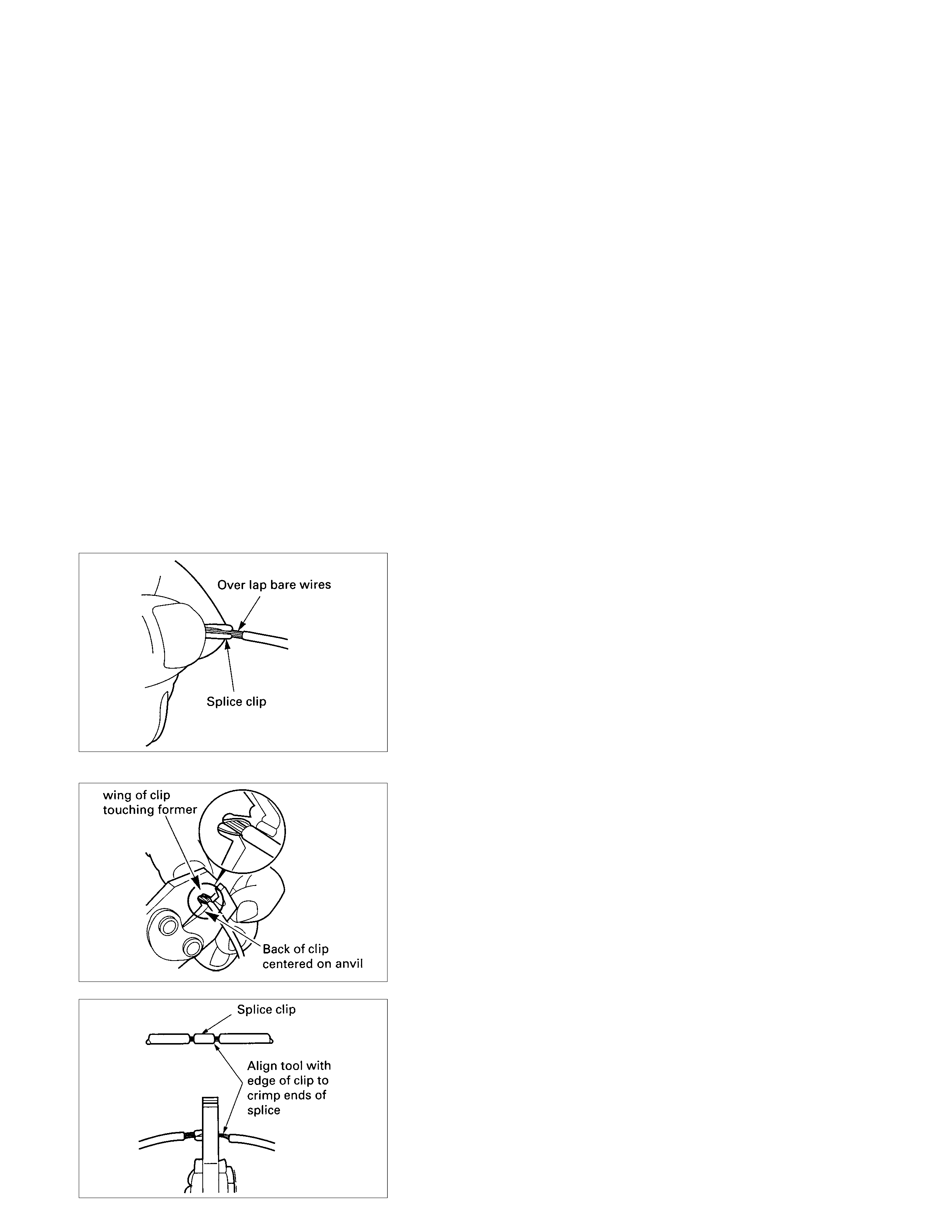

Crimp the Wires

Select the proper clip to secure the splice.

To determine the proper clip size for the wire being spliced,

follow the directions included with your clips.

Select the correct anvil on the crimper.

(On most crimpers your choice is limited to either a small or

large anvil.)

Overlap the two stripped wire ends and hold them between

your thumb and forefinger.

Then, enter the splice clip under the stripped wires and hold it

in place.

• Open the crimping tool to its full width and rest one handle

on a firm flat surface.

• Center the back of the splice clip on the proper anvil and

close the crimping tool to the point where the back of the

splice clip touches the wings of the clip.

• Make sure that the clip and wires are still in the correct

position. Then, apply pressure until the crimping tool

closes.

Before crimping the ends of the clip, be sure that:

• The wires extend beyond the clip in each direction.

• No strands of wire are cut loose.

• No insulation is caught under the clip.

Crimp the splice again, once on each end.

Do not let the crimping tool extend beyond the edge of the clip

or you may damage or nick the wires.

Solder

Apply 60/40 rosin core solder to the opening in the back of the

clip.

Follow the manufacturer's instructions for the solder

equipment you are using.

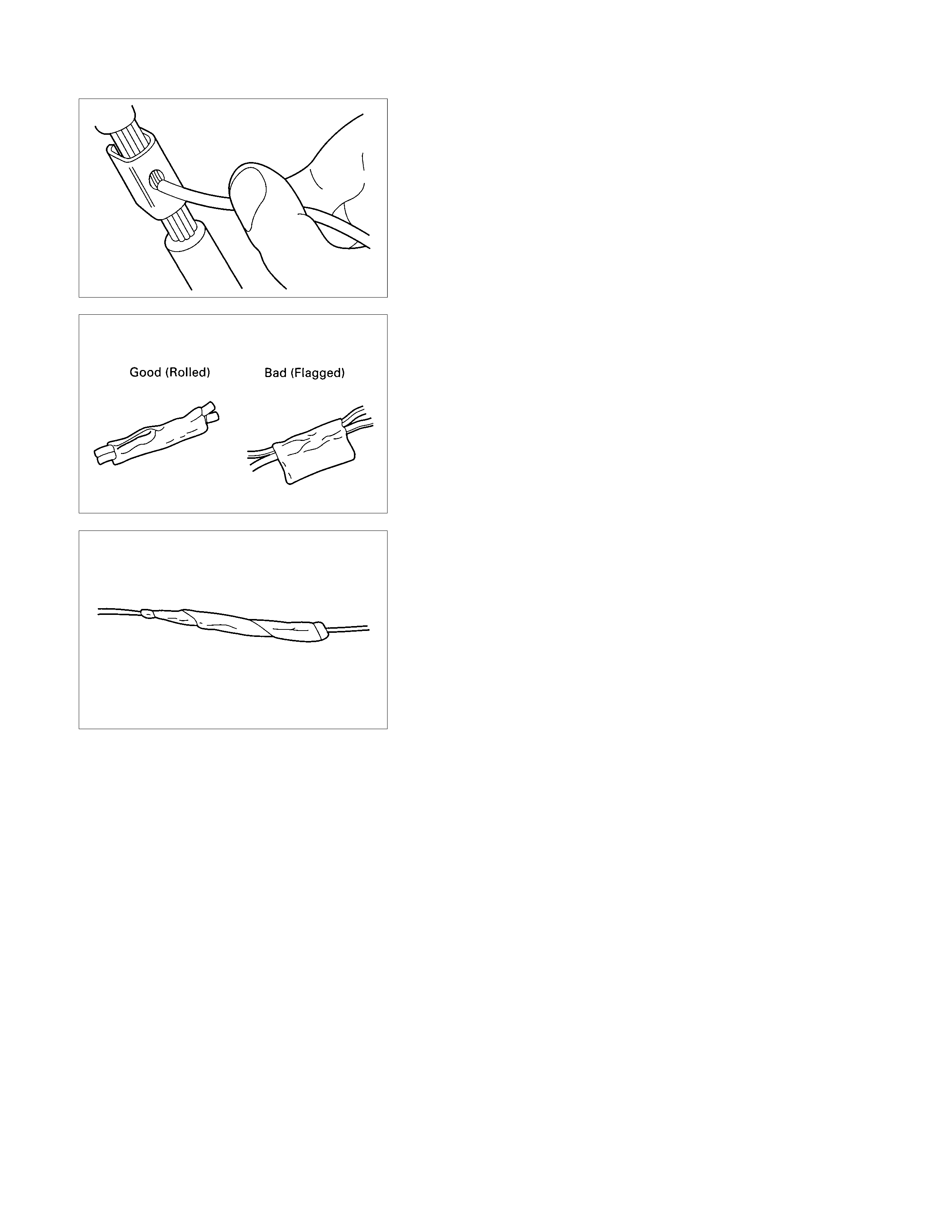

Tape the Splice

Center and roll the splicing tape.

The tape should cover the entire splice.

Roll on enough tape to duplicate the thickness of the insulation

on the existing wires.

Do not flag the tape.

Flagged tape may not provide enough insulation, and the

flagged ends will tangle with the other wires in the harness.

If the wire does not belong in a conduit or other harness

covering, tape the wire again.

Use a winding motion to cover the first piece of tape.

SYMBOLS AND ABBREVIATIONS

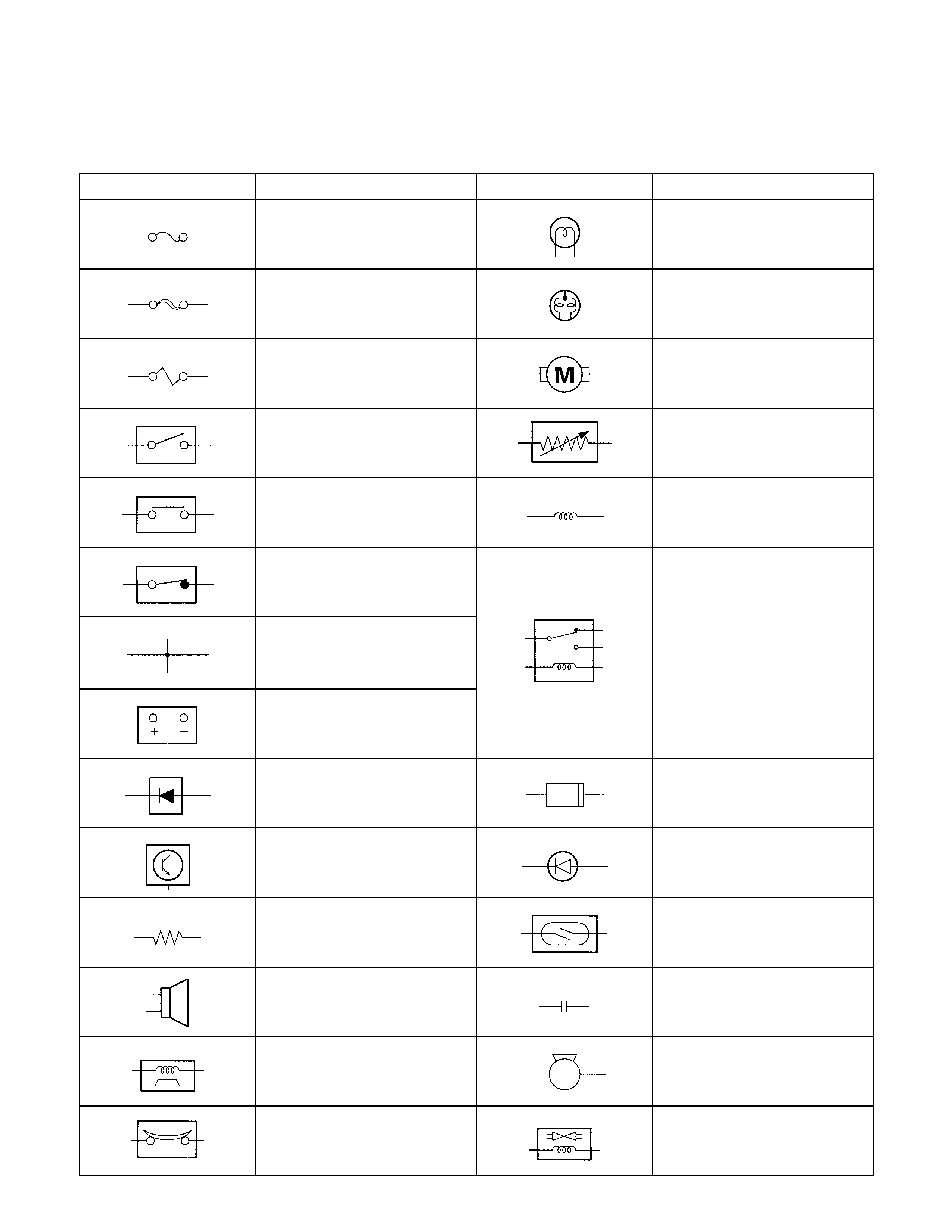

SYMBOLS

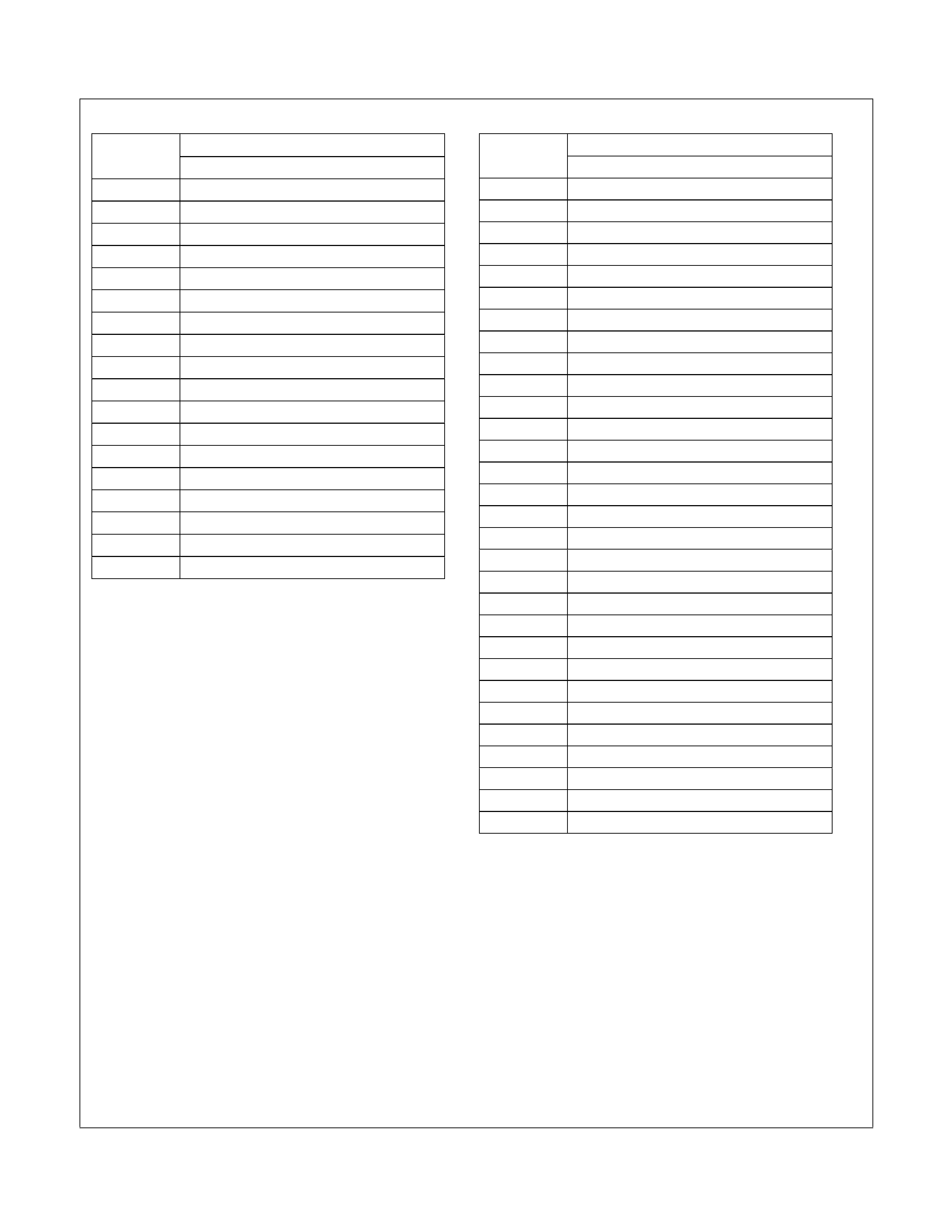

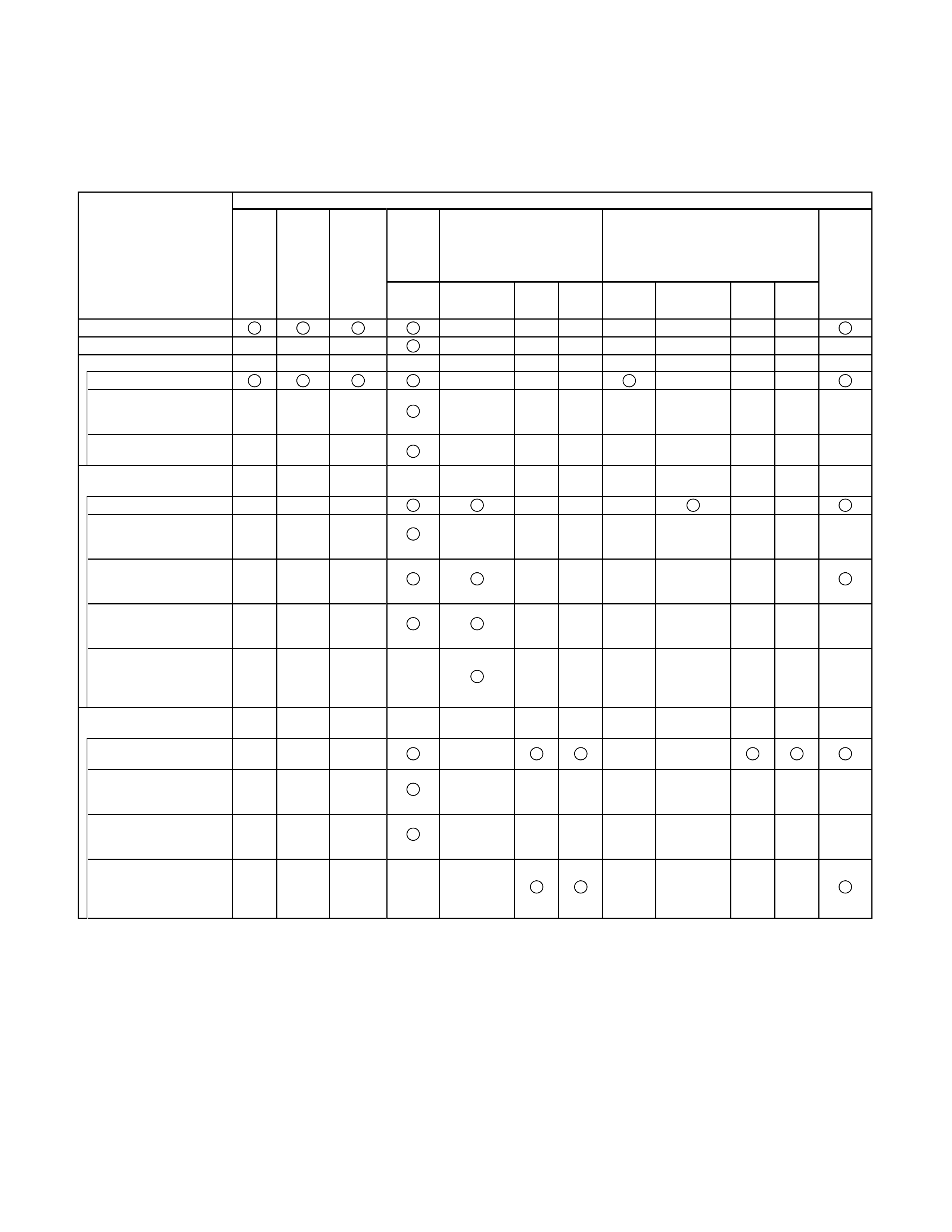

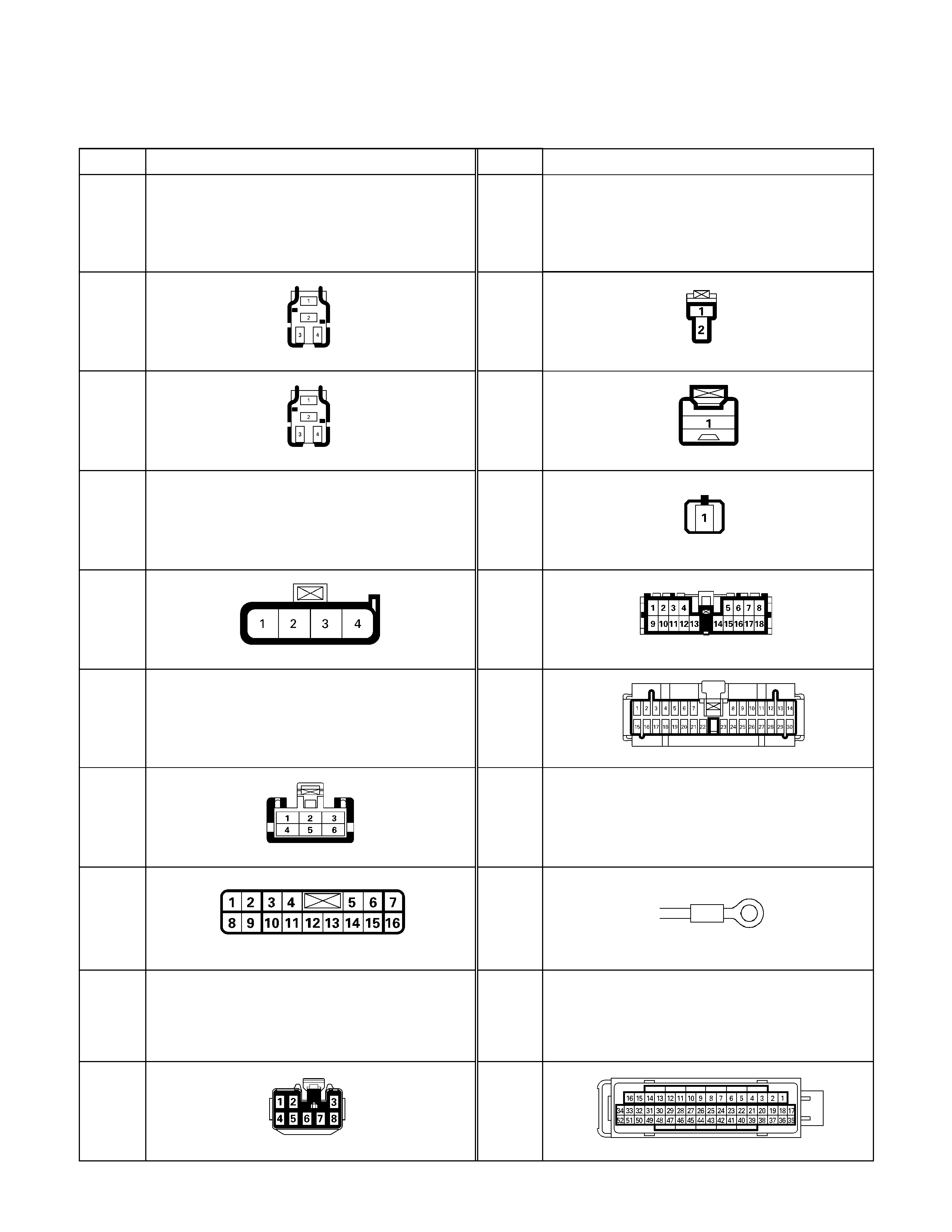

Symbol Meaning of Symbol Symbol Meaning of Symbol

Fuse

Bulb

Fusible link

Double filament bulb

Fusible link wire

Motor

Switch

Variable resistor Rheostat

Switch

Coil (inductor), solenoid,

magnetic valve

Switch (Normal close type)

Contact wiring

Relay

Battery

Diode

Connector

Electronic Parts

Light emitting diode

Resistor

Reed switch

Speaker

Condenser

Buzzer

Horn

Circuit breaker

Vacuum switching valve

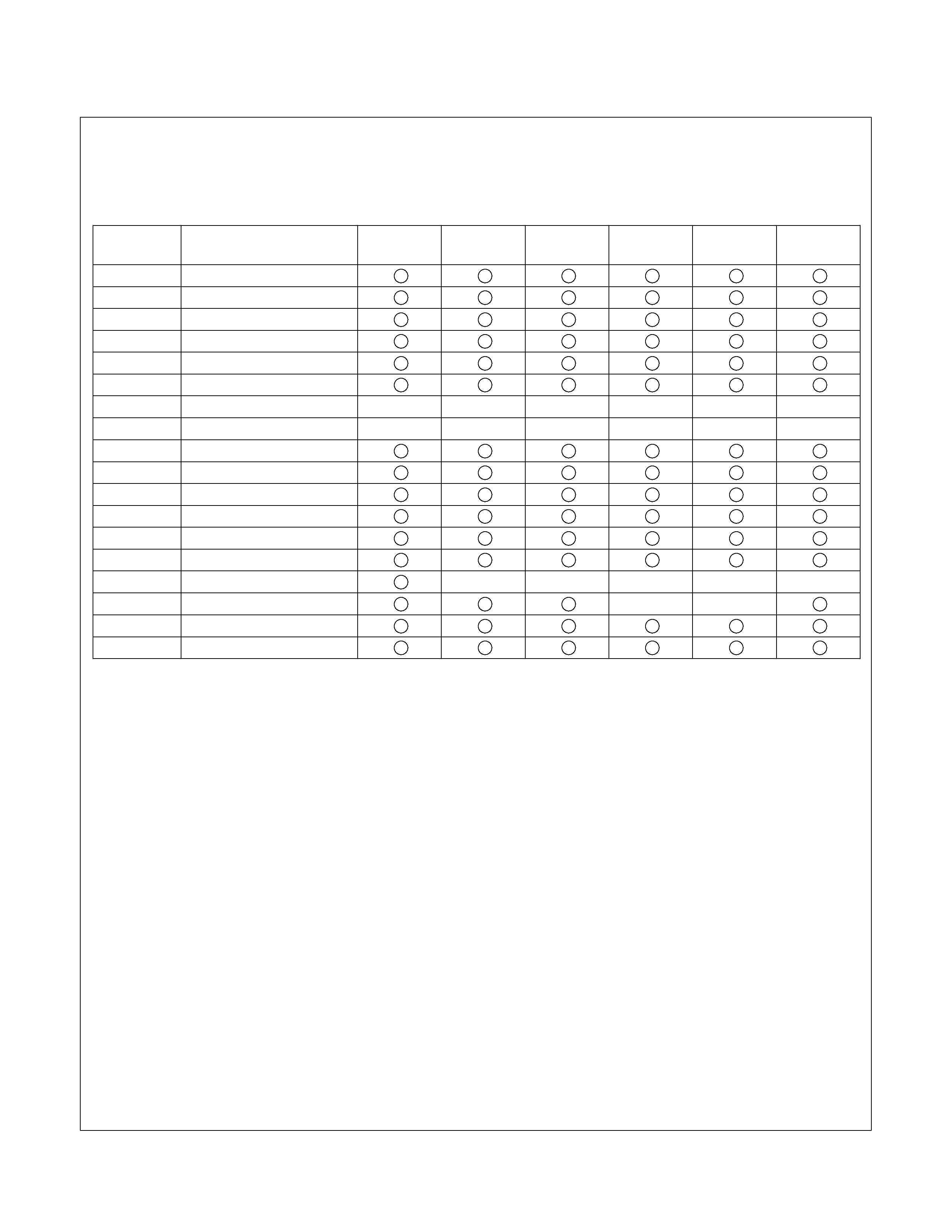

ABBREVIATIONS

Abbreviation Meaning of abbreviation Abbreviation Meaning of abbreviation

4×2 Two-wheel drive HVAC Heater, Ventilation, and Air

Conditioning

4×4 Four-wheel drive IAT Intake Air Temperature

A Ampere (S) IC Integrated circuit

ABS Anti-lock brake system IG Ignition

AC Alternating current KS Knock Sensor

A/C Air conditioner kW Kilowatt

ACC Accessories LH Left hand

APP Accel Pedal Position LWB Long wheel base

ASM Assembly MAF Mass Air Flow

BARO Barometric Pressure MPI Multipart fuel injection

CARB Carburetor M/T Manual transmission

C/B Circuit breaker PIM Powertrain Interface Module

CKP Crankshaft Position QOS Quick On Start system

CMP Camshaft Position RH Right hand

CSD Cold start device RR Rear

DIS Direct ignition system RWAL Rear wheel anti-lock brake system

DLC Data Link Connector SRS Supplemental restraint system

ECGI Electronic control gasoline injection ST Start

ECM Engine control module STD Standard

ECT Engine Coolant Temperature SW Switch

ECU Electronic control unit SWB Short wheel base

EFE Early fuel evaporation TAC Throttle Actuator Control

EHCU Electronic Hydraulic control Unit TCM Transmission control module

EOP Enigne Oil Pressure TP Throttle Position

EVAP Evaporative Emission V Volt

FL Fusible link VSS Vehicle Speed Sensor

FRT Front VSV Vacuum switching valve

H/L Headlight W Watt (S)

HO2S B1S1 Heated Oxygen Sensor Bank 1

Sensor 1 W/ With

HO2S B1S2 Heated Oxygen Sensor Bank 1

Sensor 2 W/O Without

HO2S B2S1 Heated Oxygen Sensor Bank 2

Sensor 1 WOT Wide open throttle

HO2S B2S2 Heated Oxygen Sensor Bank 2

Sensor 2 W/S Weld Splice

PARTS FOR ELECTRICAL CIRCUIT

WIRING

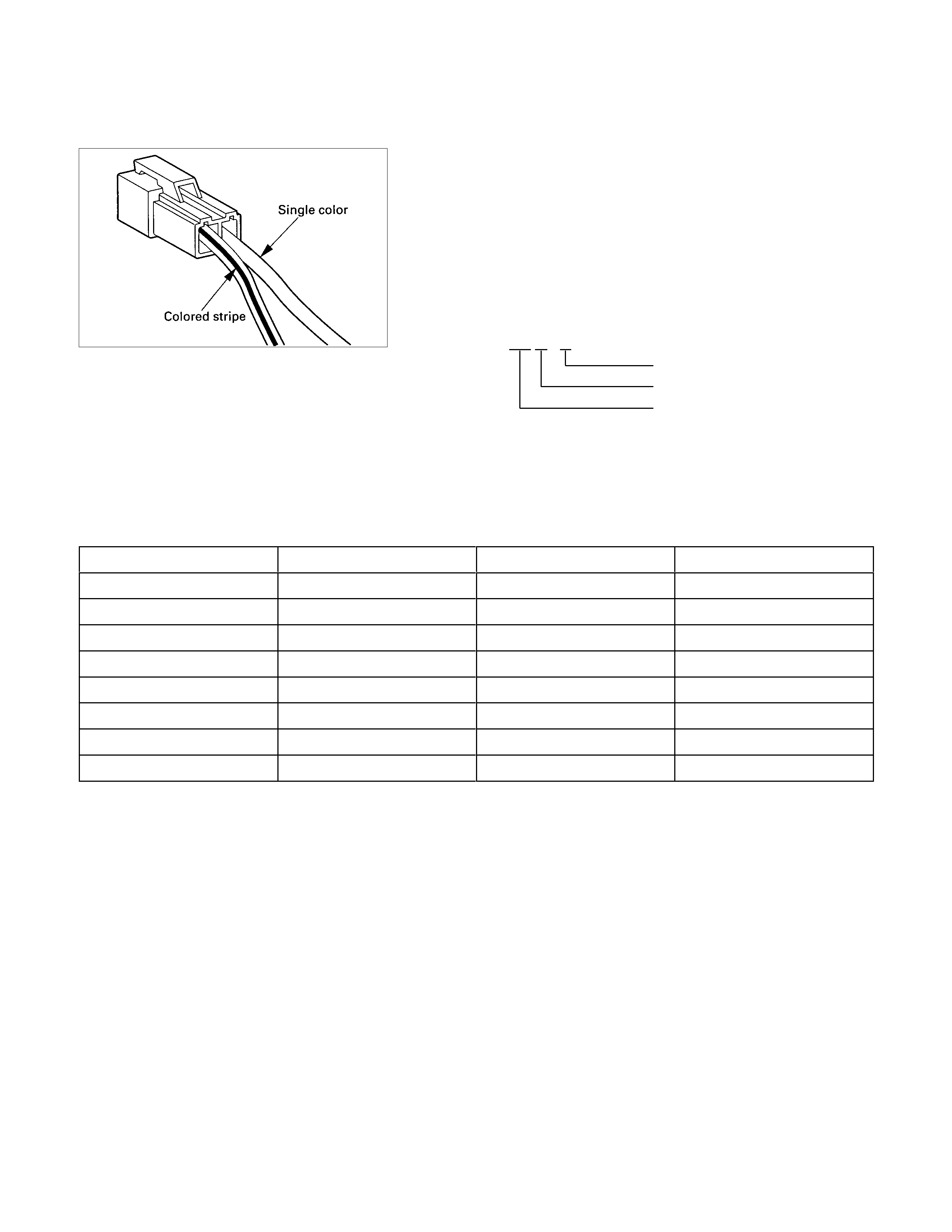

Wire Color

All wires have color-coded insulation.

Wires belonging to system's main harness will have a single

color.

Wires belonging to a system's sub-circuits will have a colored

stripe.

Striped wires use the following code to show wire size and

colors.

Example: 0.5 G / R Red (Stripe color)

Green (Base color)

Wire size (0.5mm2)

Abbreviations are used to indicate wire color within a circuit

diagram.

Refer to the following table.

Wire Color-Coding

Color-Coding Meaning Color-Coding Meaning

B Black BR Brown

W White LG Light green

R Red GR Grey

G Green P Pink

Y Yellow LB Light blue

L Blue V Violet

O Orange T Tan

DB Dark Blue DG Dark Green

Distinction of Circuit by Wire Base Color

Base color Circuits Base color Circuits

B Starter circuit and grounding circuit Y Instrument circuit

W Charging circuit L, O, BR, LG,

R Lighting circuit GR, P, LB, V, Other circuits

G Signal circuit T, DB, DG

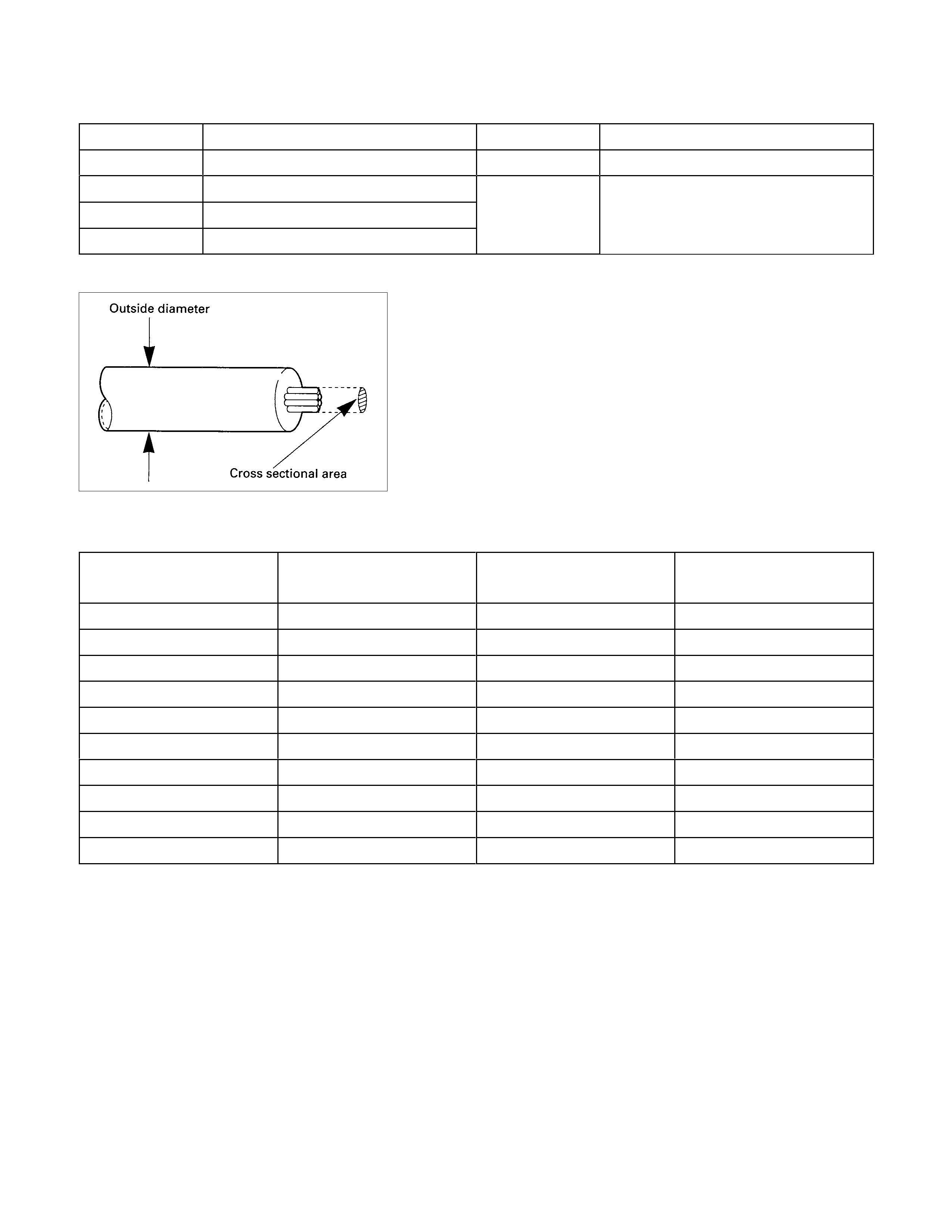

Wire Size

Wire size is specified with the metric gauge system.

The metric gauge system gives the wire size in cross sectional

area measured in square millimeters.

Wire Size Specifications

Normal size Cross sectional area

(mm2) Outside diameter

(mm) Allowable current

(A)

0.3 0.372 1.8 9

0.5 0.563 2.0 12

0.85 0.885 2.2 16

1.25 1.287 2.5 21

2 2.091 2.9 28

3 3.296 3.6 37.5

5 5.227 4.4 53

8 7.952 5.5 67

15 13.36 7.0 75

20 20.61 8.2 97

Normal Blown

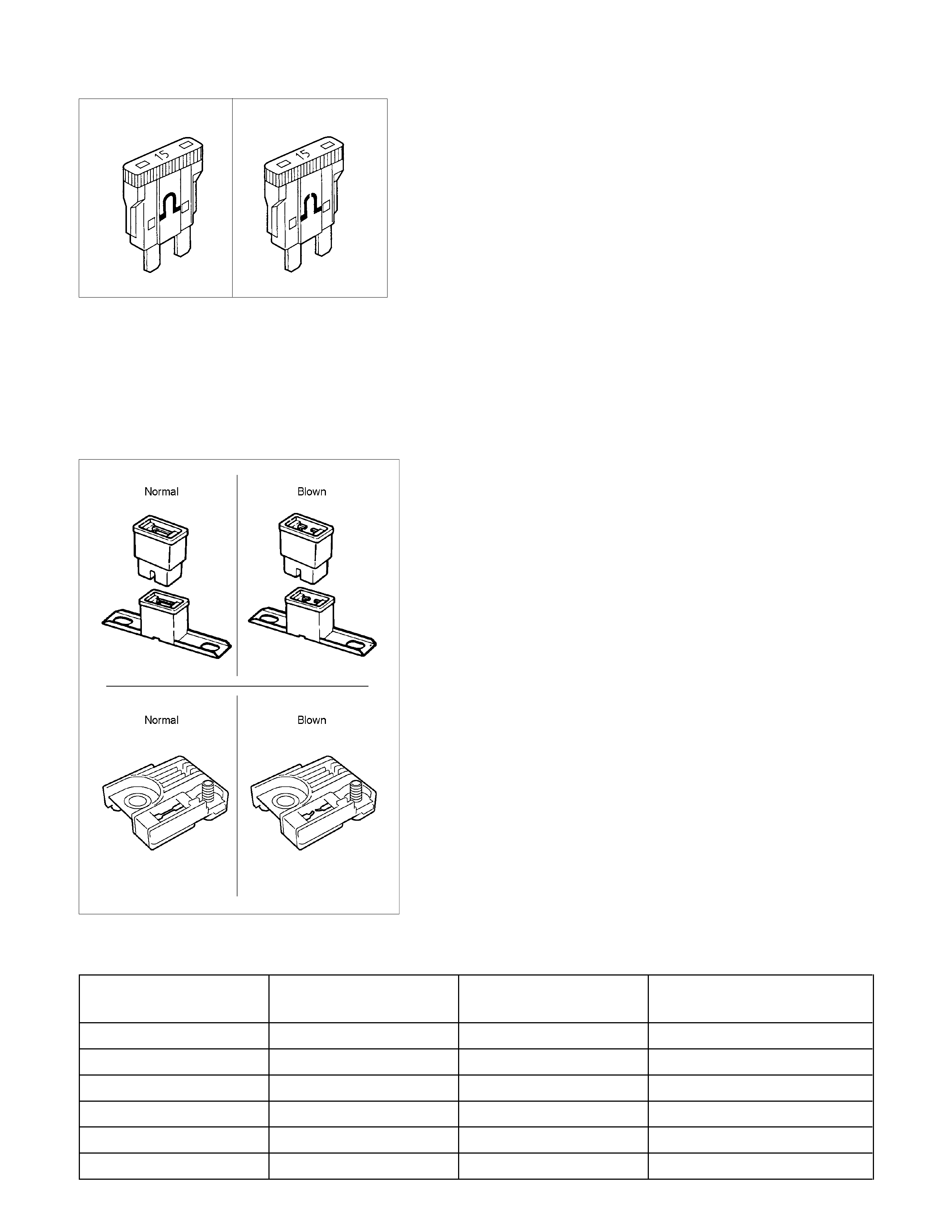

FUSE

Fuses are the most common form of circuit protection used in

vehicle wiring.

A fuse is a thin piece of wire or strip of metal encased in a

glass or plastic housing.

It is wired in series with the circuit it protects.

When there is an overload of current in a circuit, such as a

short of a ground, the wire or metal strip is designed to burn

out and interrupt the flow of current.

This prevents a surge of high current from reaching and

damaging other components in the circuit.

Determine the cause of the overloaded before replacing the

fuse.

Never replace a blown fuse with a fuse of a different amperage

specification.

Doing so can result in an electrical fire or other serious circuit

damage.

A blown fuse is easily identified.

RTW68AMH000101

FUSIBLE LINK

The fusible link is primarily used to protect circuits where high

amounts of current flow and where is would not be practical to

use a fuse.

For example, the starter circuit.

When a current overload occurs, the fusible link melts open

and interrupts the flow of current so as to prevent the rest of

the wiring harness from burning.

Determine the cause of the overload before replacing the

fusible link.

The replacement fusible link must have the same amperage

specification as the original fusible link.

Never replace a blown fusible link with fusible link of a different

amperage specification.

Doing so can result in an electrical fire or other serious circuit

damage.

A blown fusible link is easily identified.

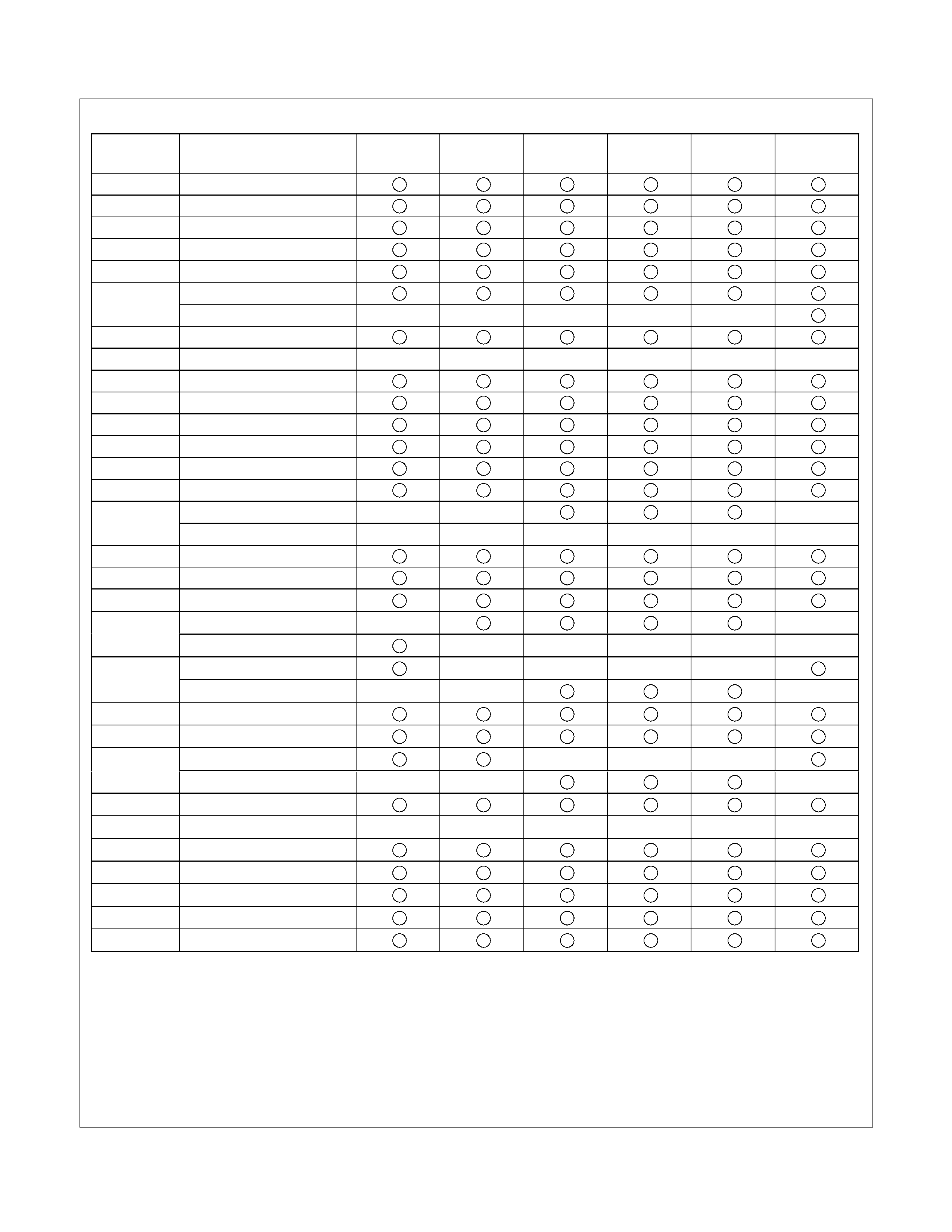

Fusible Link Specifications

Type Rating Case Color Maximum Circuit Current

(A)

Connector 20A 10

Connector 30A Pink 15

Connector 40A Green 20

Bolted 50A Red 25

Bolted 60A Yellow 30

Bolted 80A Black 40

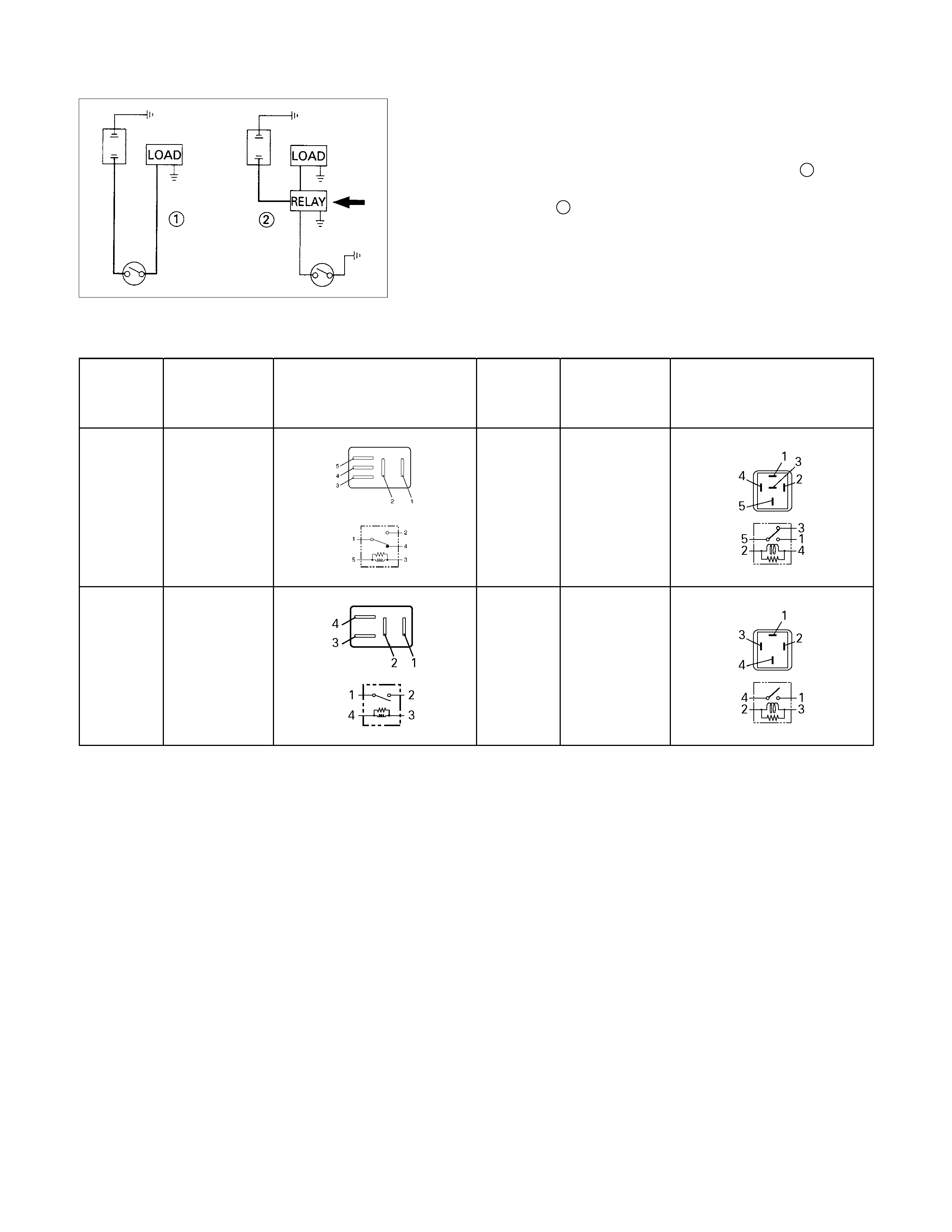

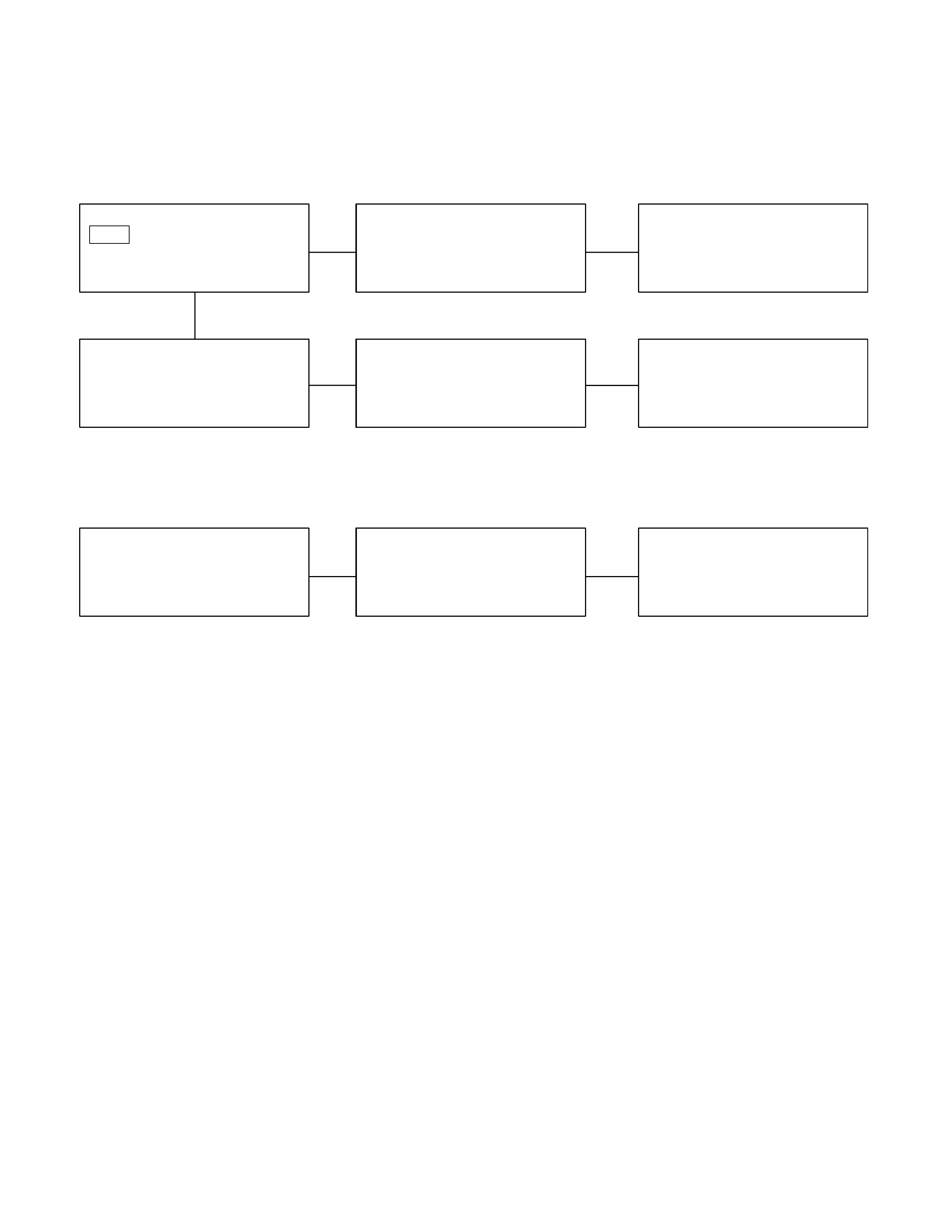

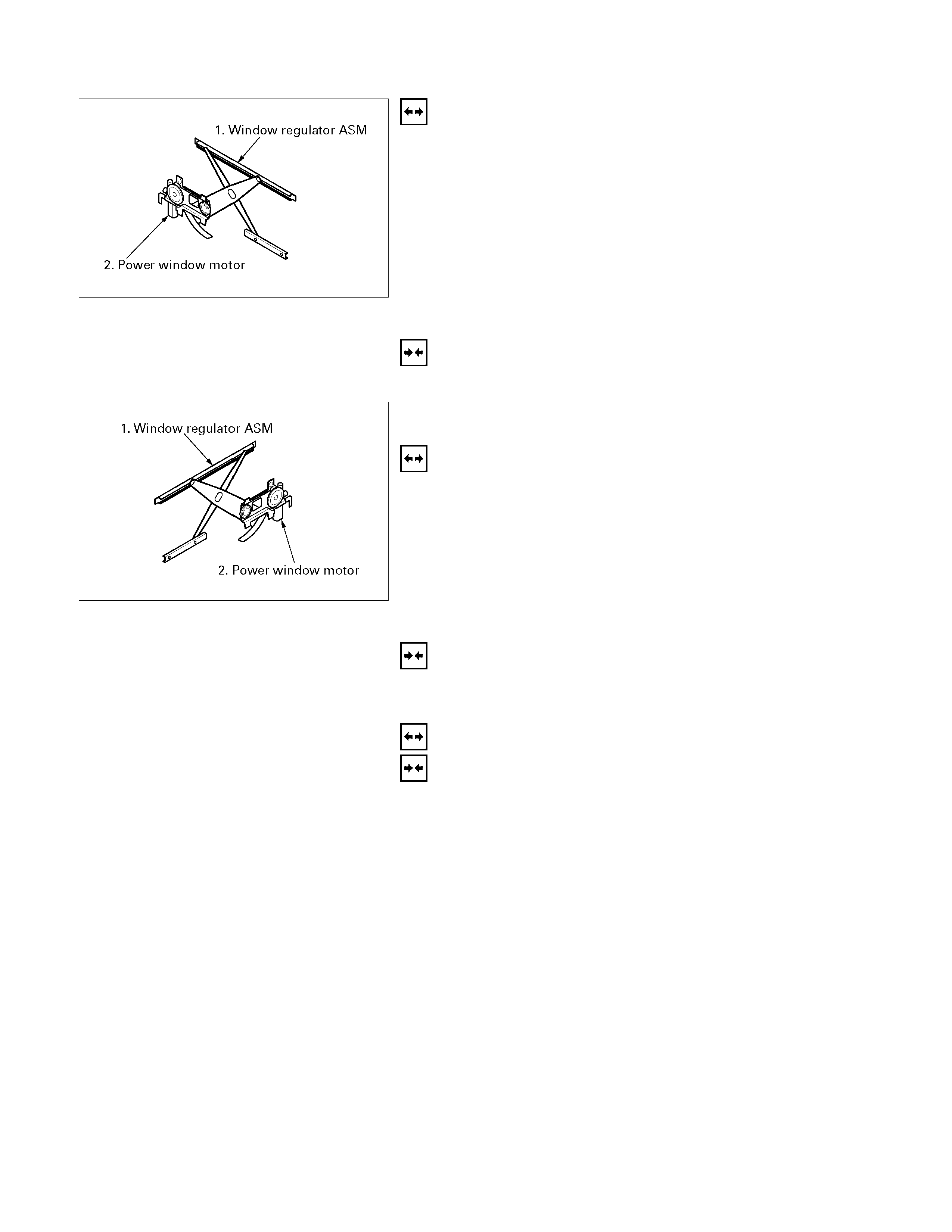

RELAY

Battery and load location may require that a switch be placed

some distance from either component.

This means a longer wire and a higher voltage drop 1. The

installation of a relay between the battery and the load reduces

the voltage drop 2.

Because the switch controls the relay, amperage through the

switch can be reduced.

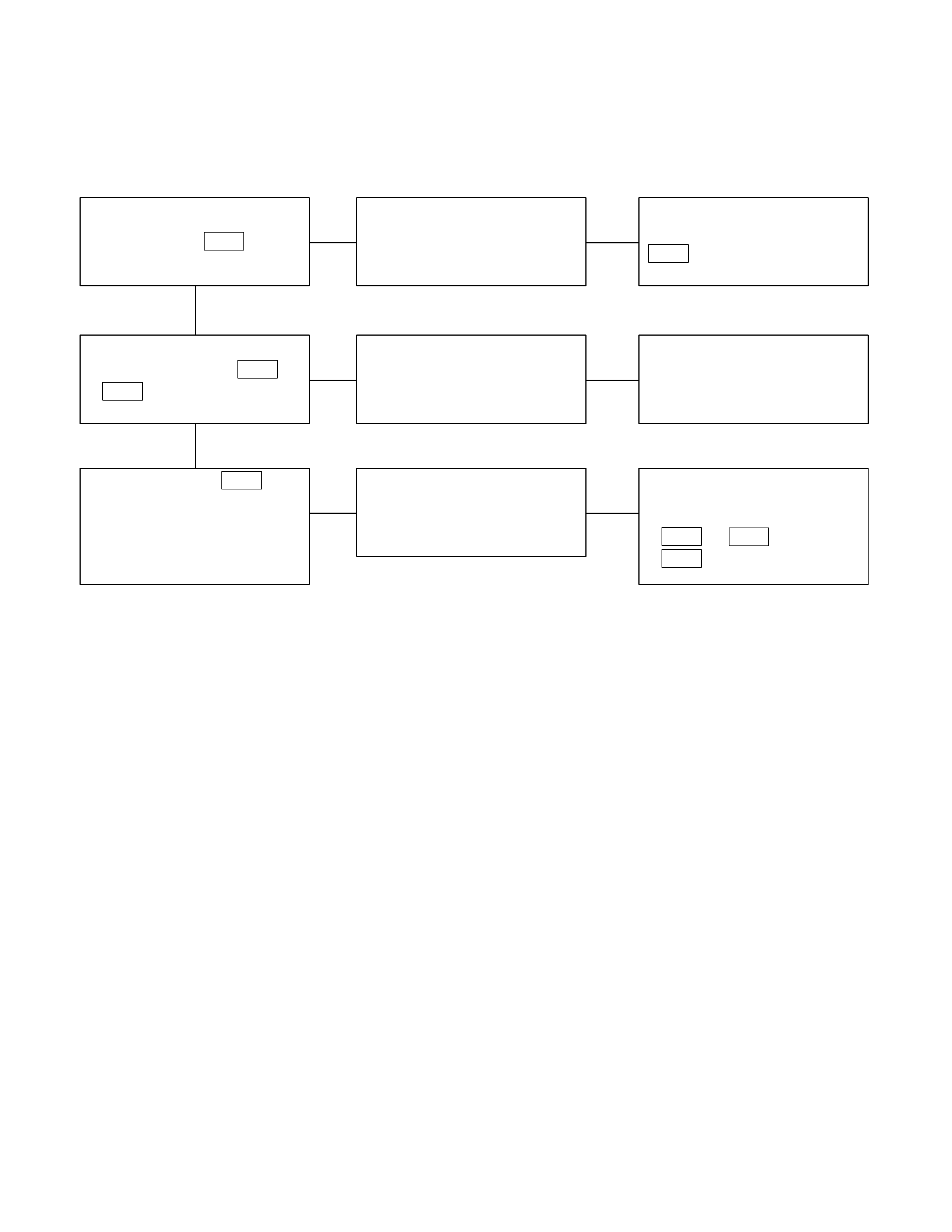

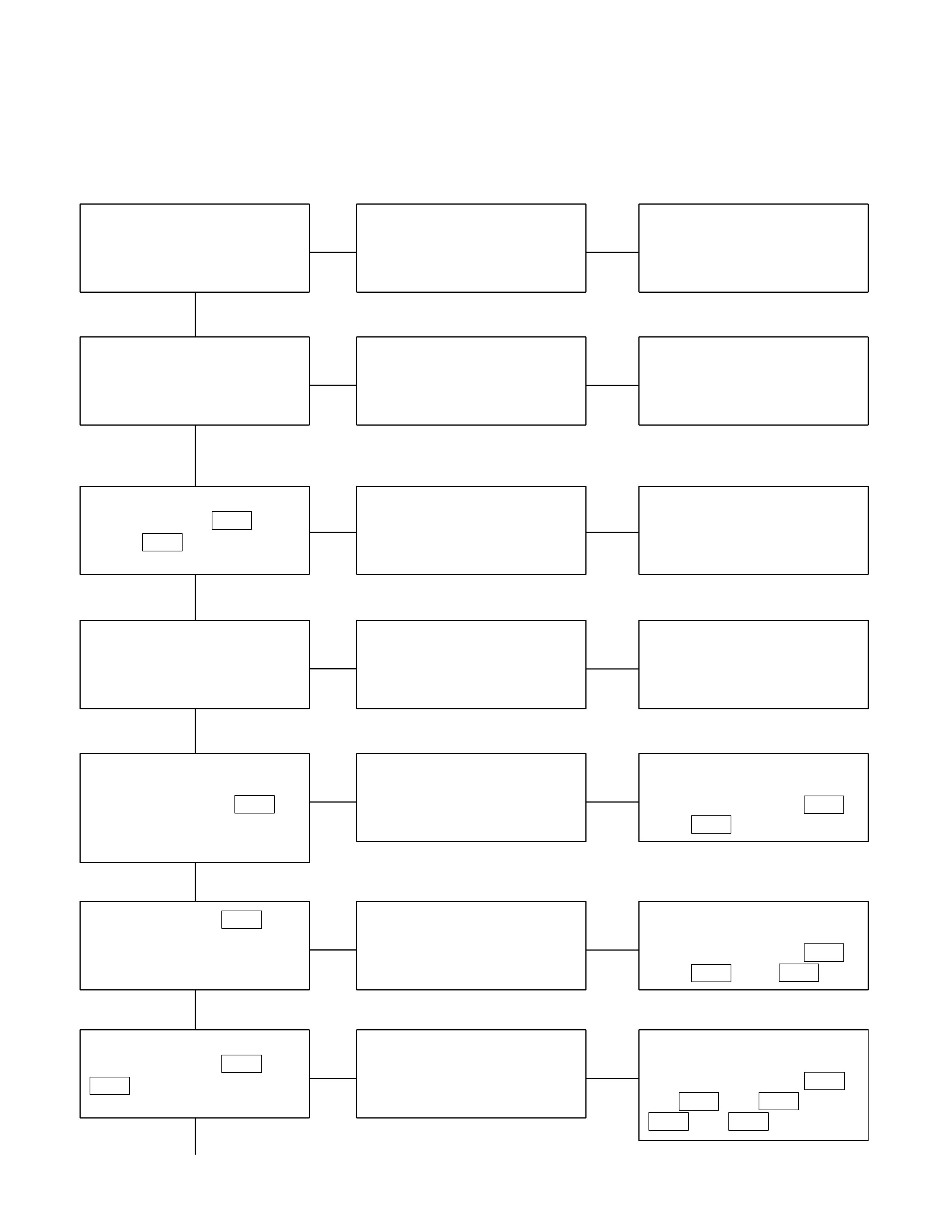

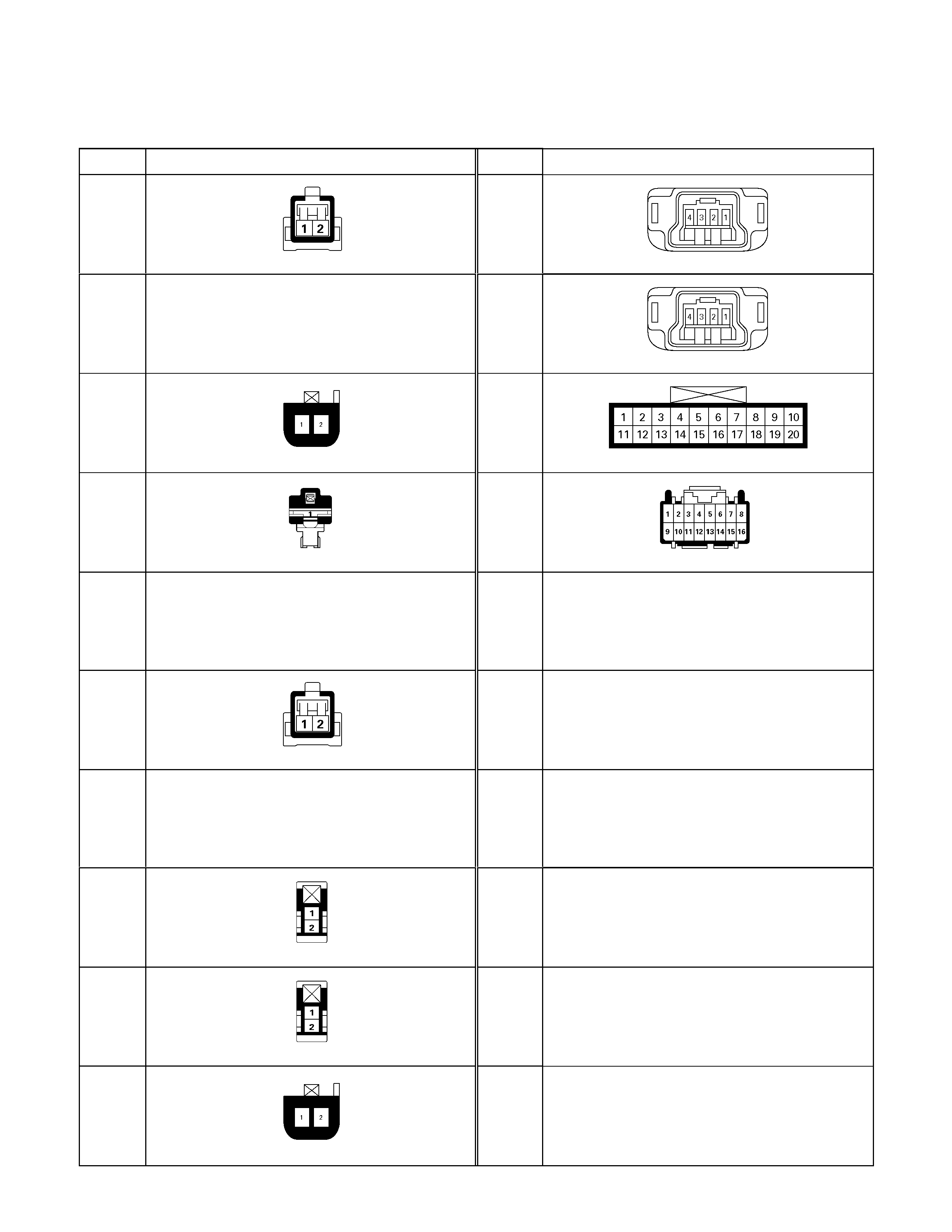

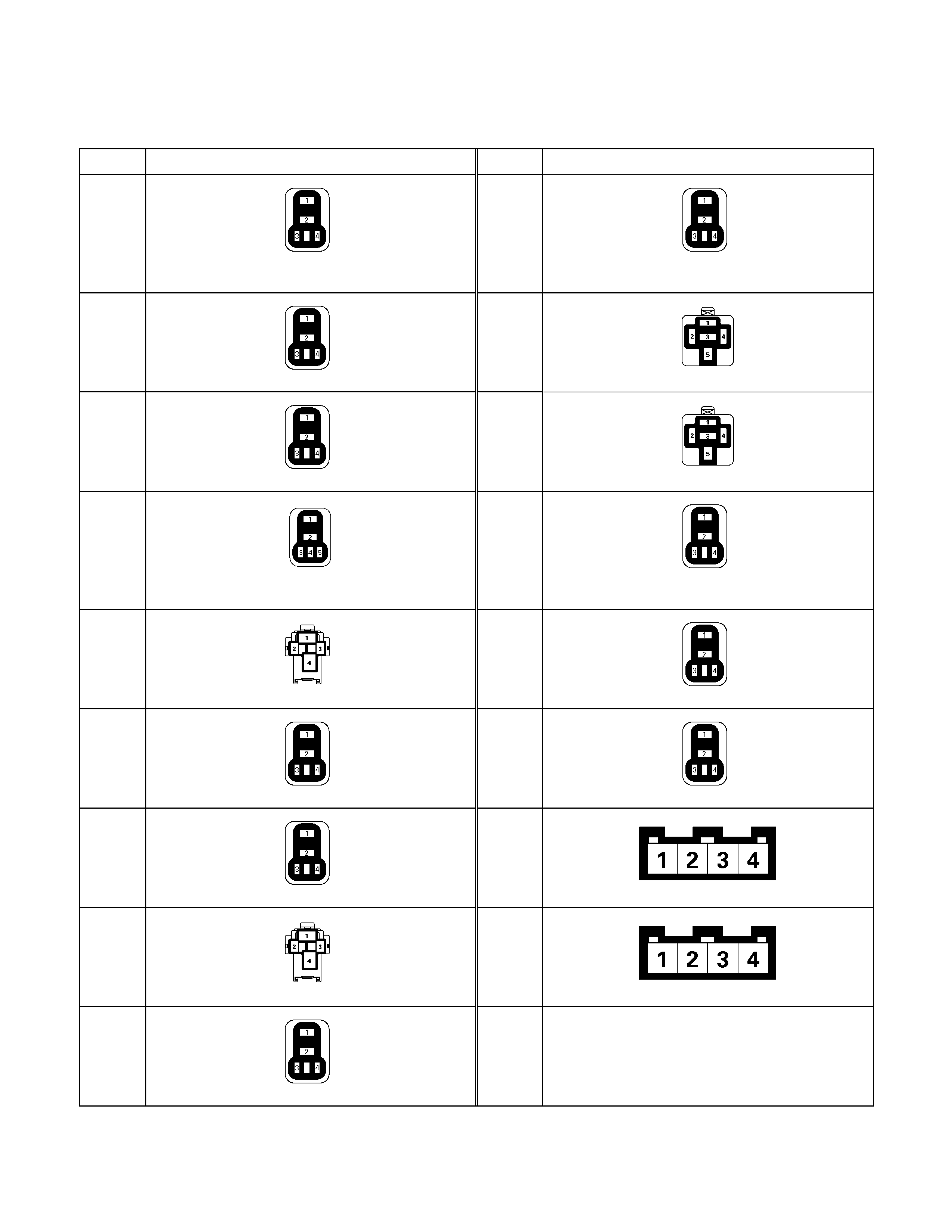

Relay Specifications and Configurations

Name/

Color

Rated

voltage/ Coil

resistance Internal circuit Name/

color

Rated

Voltage/Coil

resistance Internal circuit

1T

(MICRO

ISO)

/Black

12V

Approx. 92Ω

Minimum

operating

voltage: 7V at

20°C (77°F)

1M (MINI

ISO)

/Black

12V Approx.

94Ω Minimum

operating

voltage: 7V at

20°C (77°F)

1M

(MICRO

ISO)

/Black

12V

Approx. 132-3

Ω Minimum

operating

voltage: 7V at

20°C (77°F)

1M

(power)/

Black

12V Approx.

94Ω Minimum

operating

voltage: 7V at

20°C (77°F)

* Relay contact shown in the wiring diagram indicates condition before actuation.

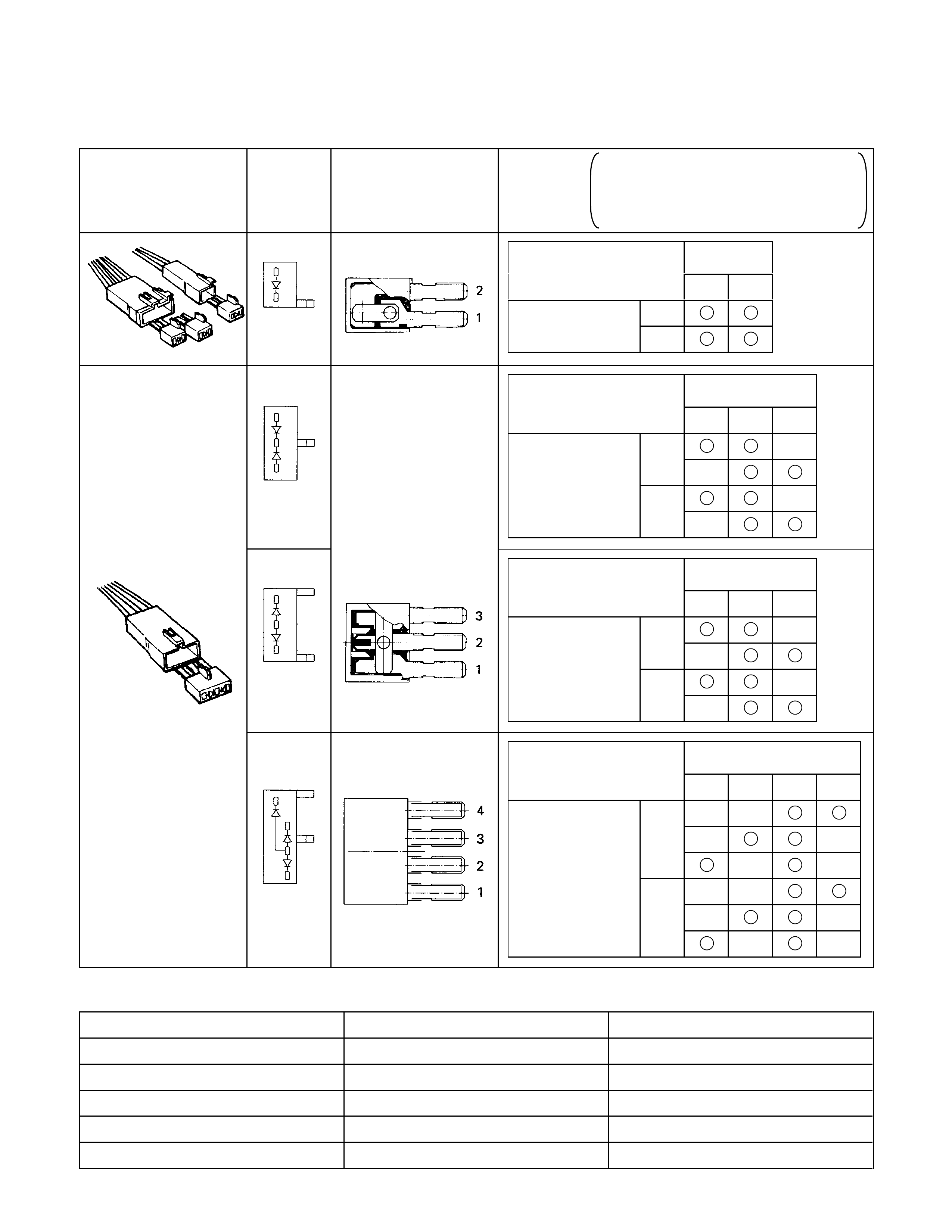

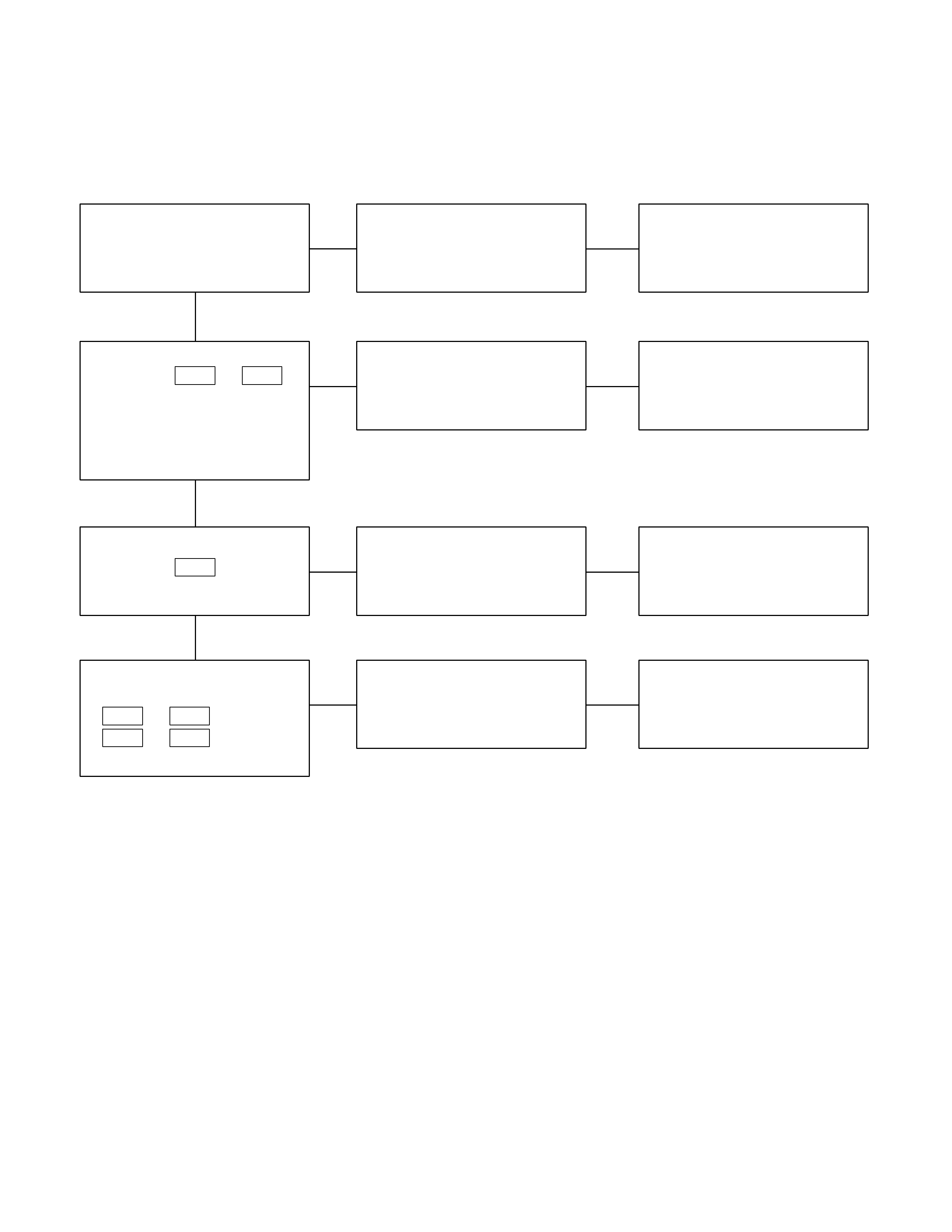

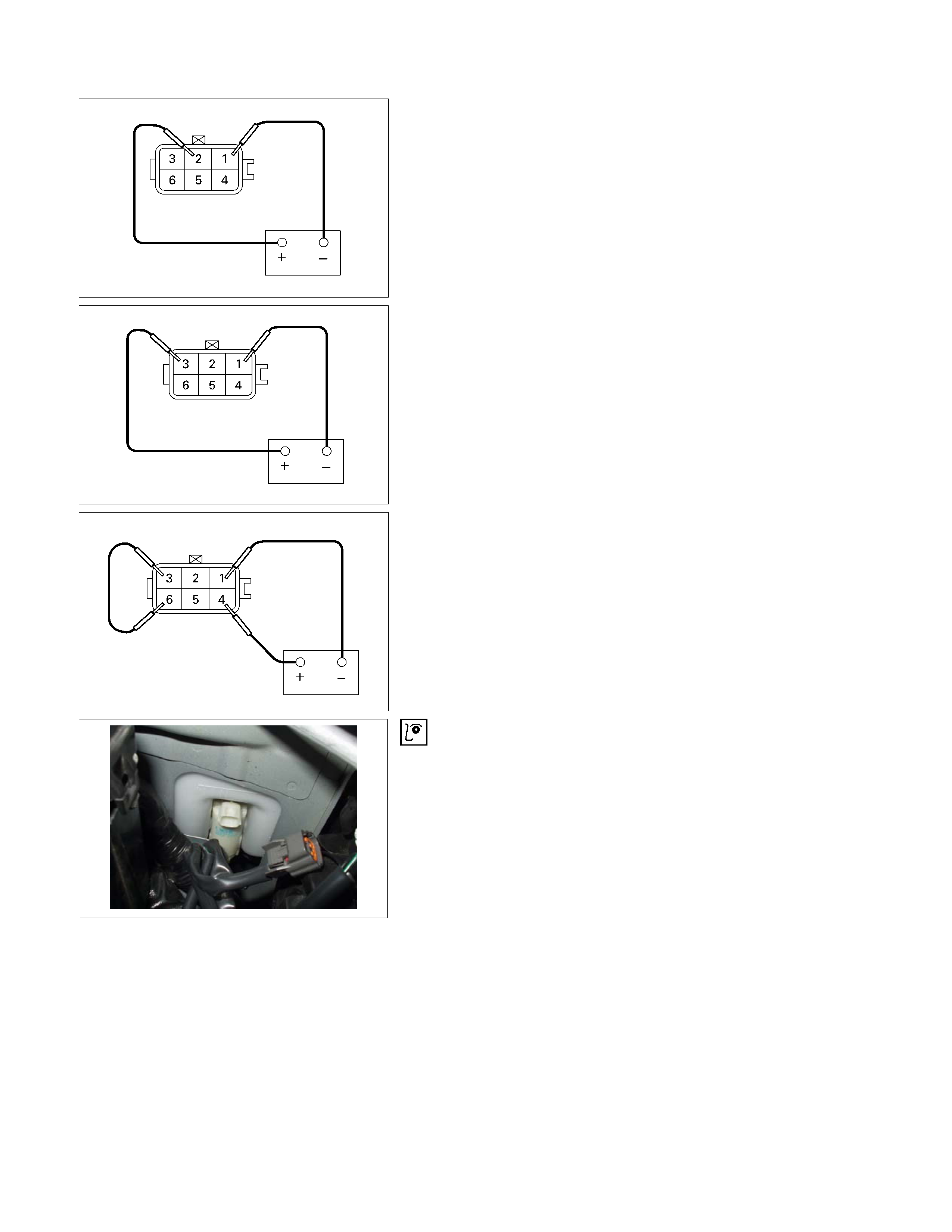

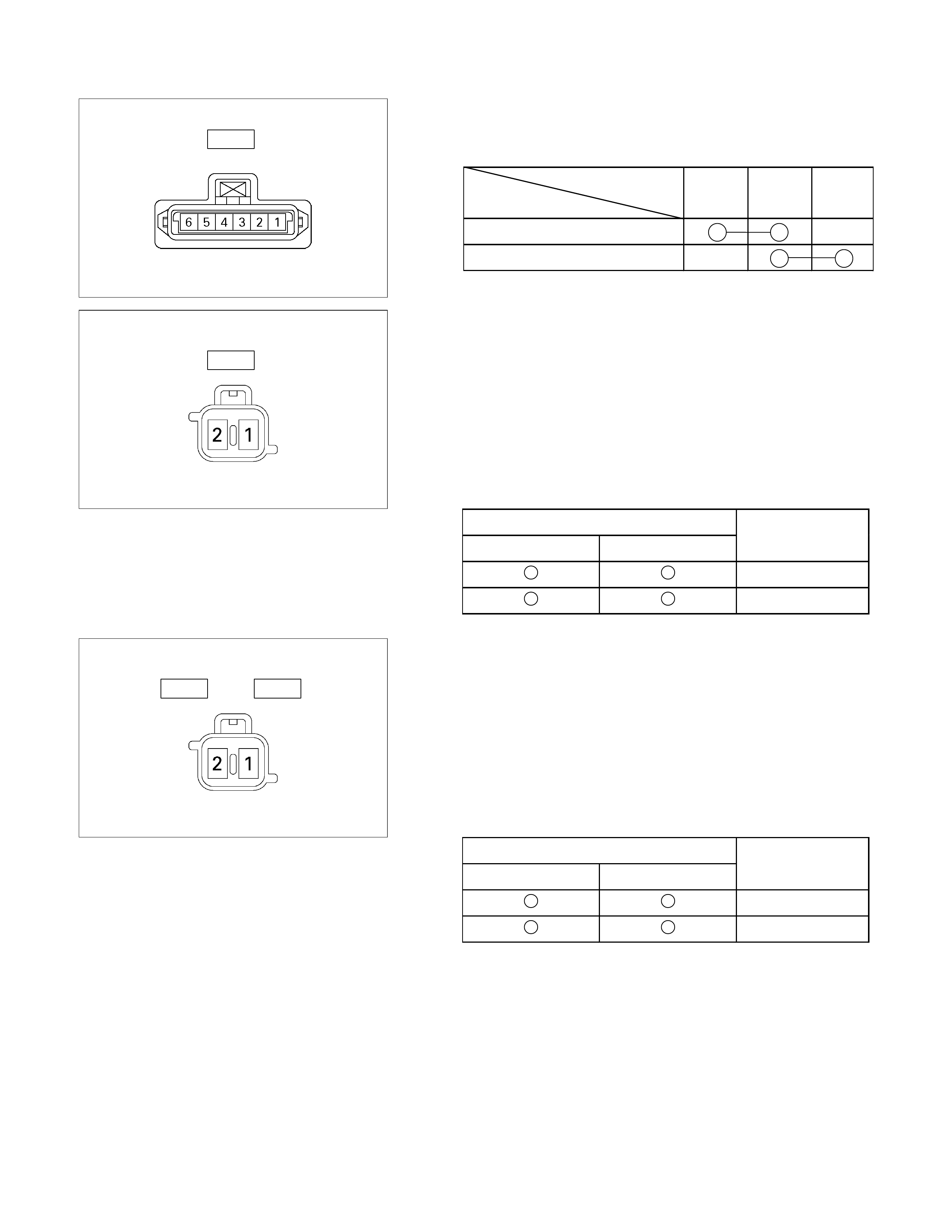

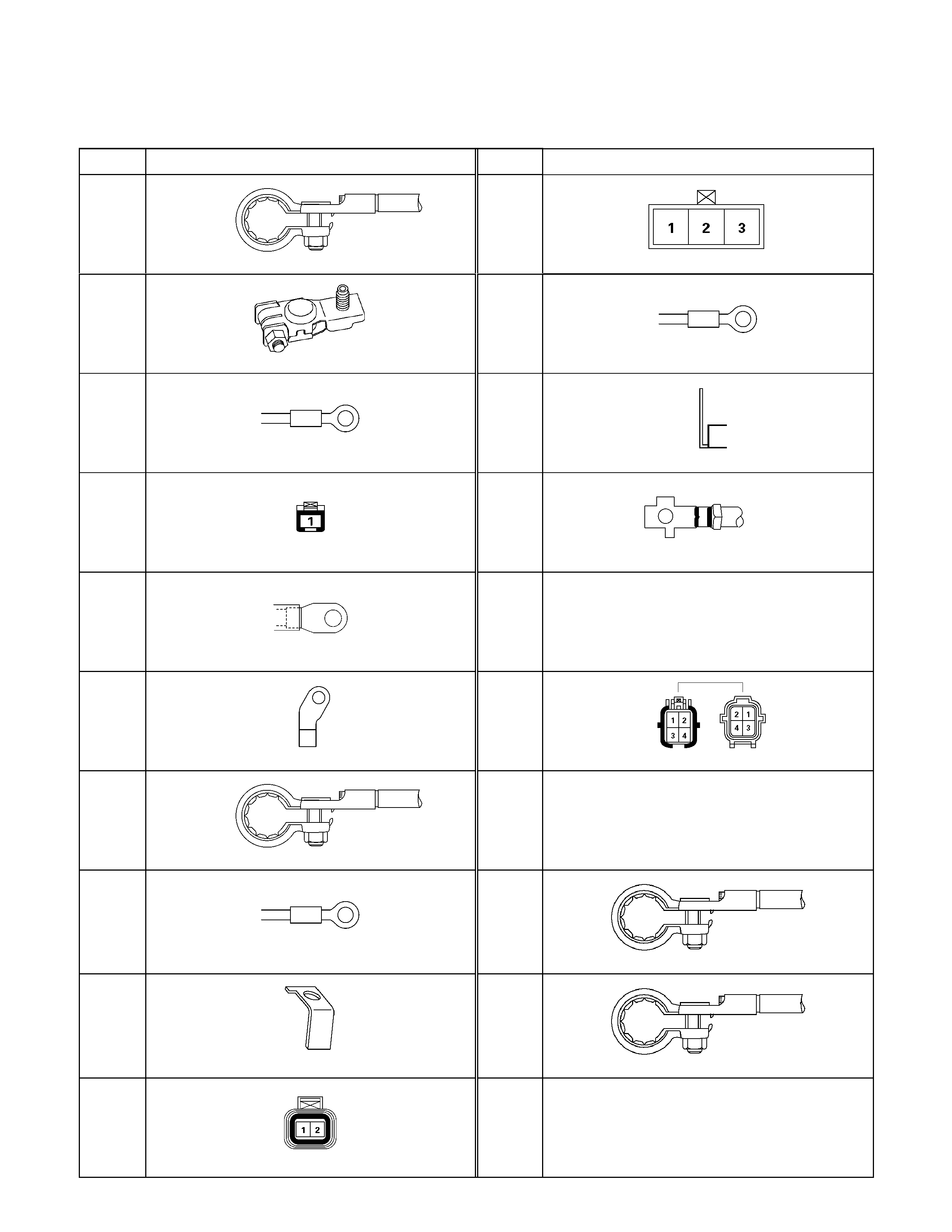

DIODE

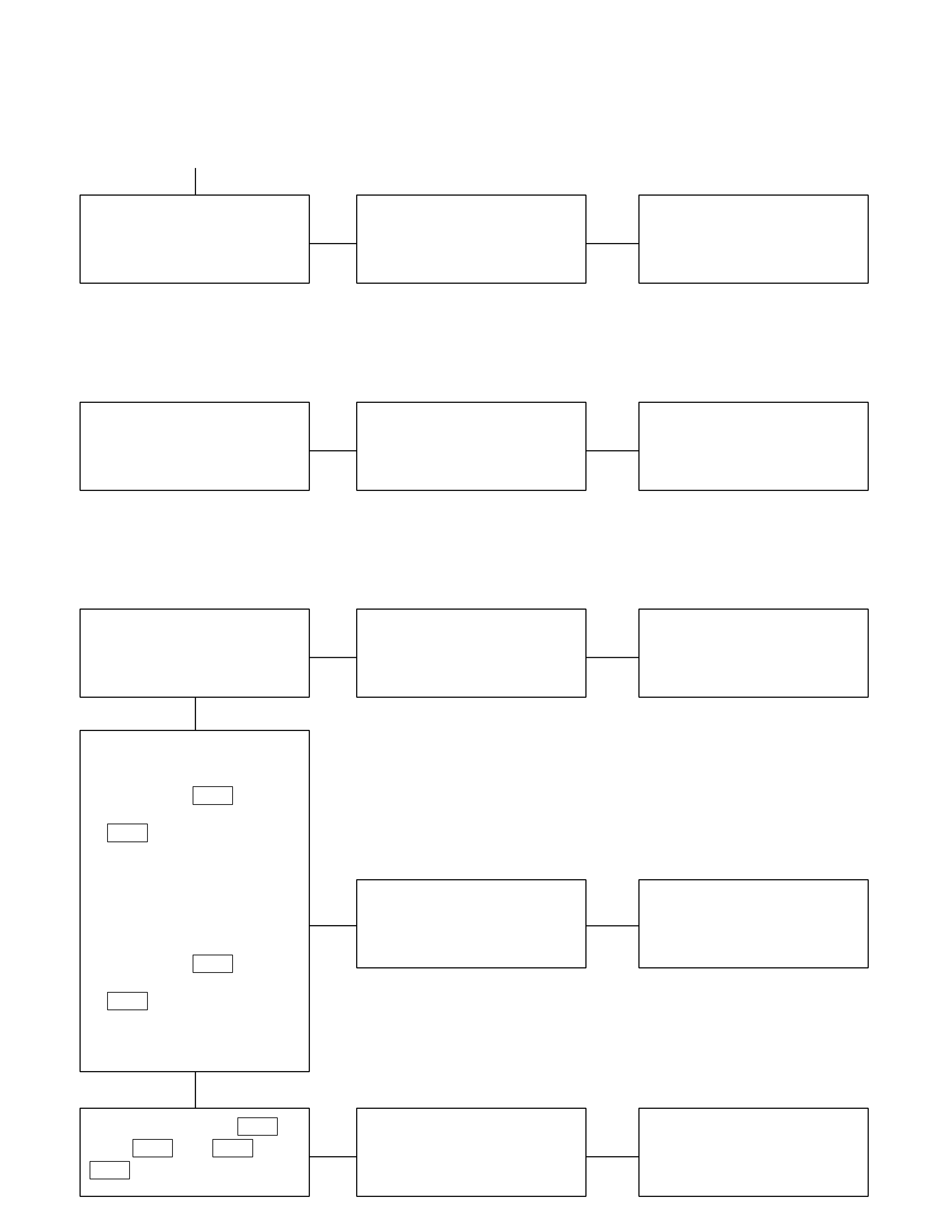

Diode Specifications and Configurations

SHAPE

MARK/

COLOR

CONSTRUCTION CHECKING

THERE SHOULD BE CONTINUITY IN

EITHER A OR B WHEN A CIRCUIT

TESTER IS CONNECTED WITH

DIODE TERMINAL

BLACK

21

CONNECTION A + -

PATTERN B - +

TERMINAL NO.

BLACK

321

- +

CONNECTION + -

PATTERN + -

- +

B

A

TERMINAL NO.

BLACK

321

- +

CONNECTION + -

PATTERN + -

- +

B

A

TERMINAL NO.

BLACK

4321

+ -

A- +

CONNECTION - +

PATTERN - +

B+ -

+ -

TERMINAL NO.

Maximum Rating (Temp.=25°C)

Items Rating Remarks

Peak reverse voltage 400V

Transient peak reverse voltage 500V

Average output current 1.5A Temp.=40°C

Working ambient temperature -30°C∼80°C

Storage temperature -40°C∼100ßC

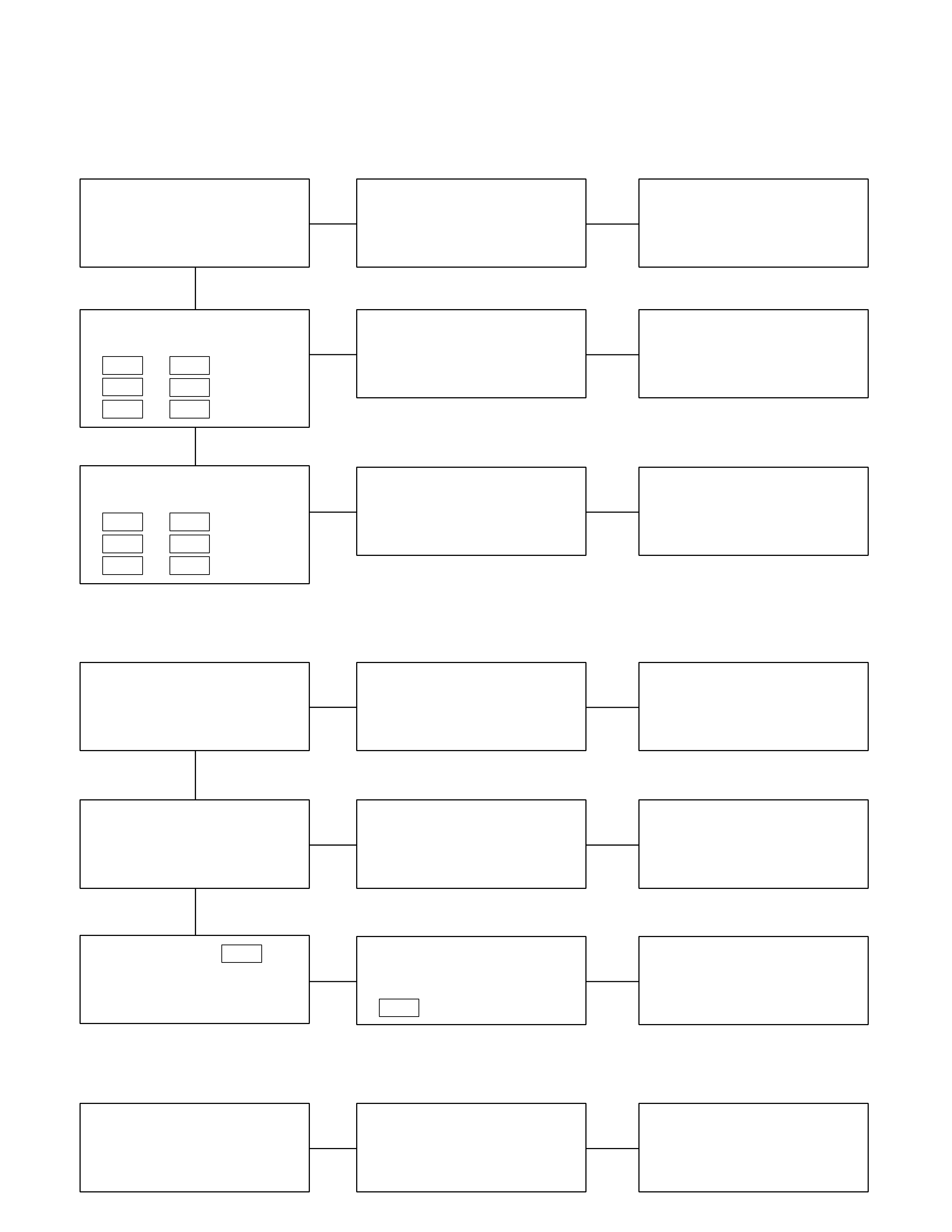

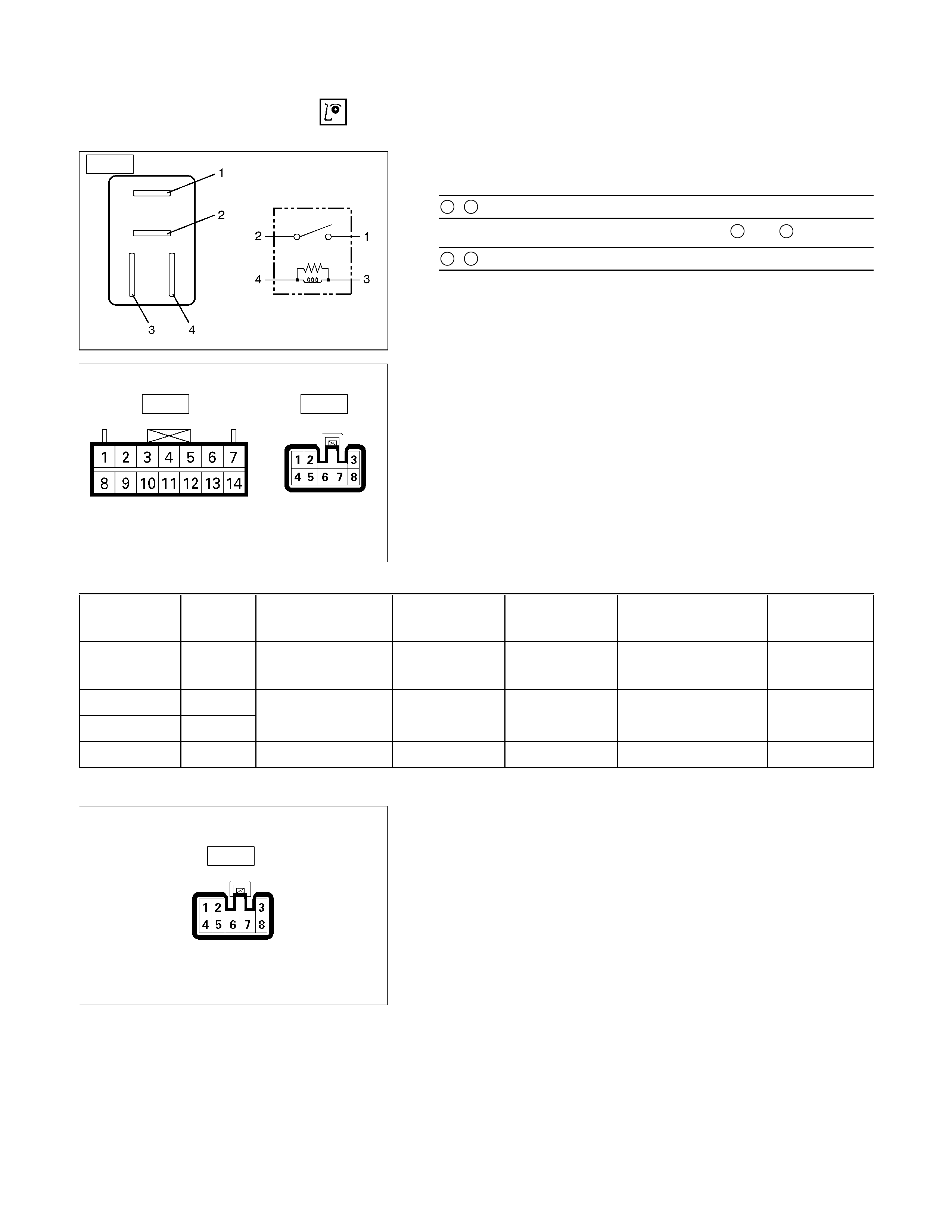

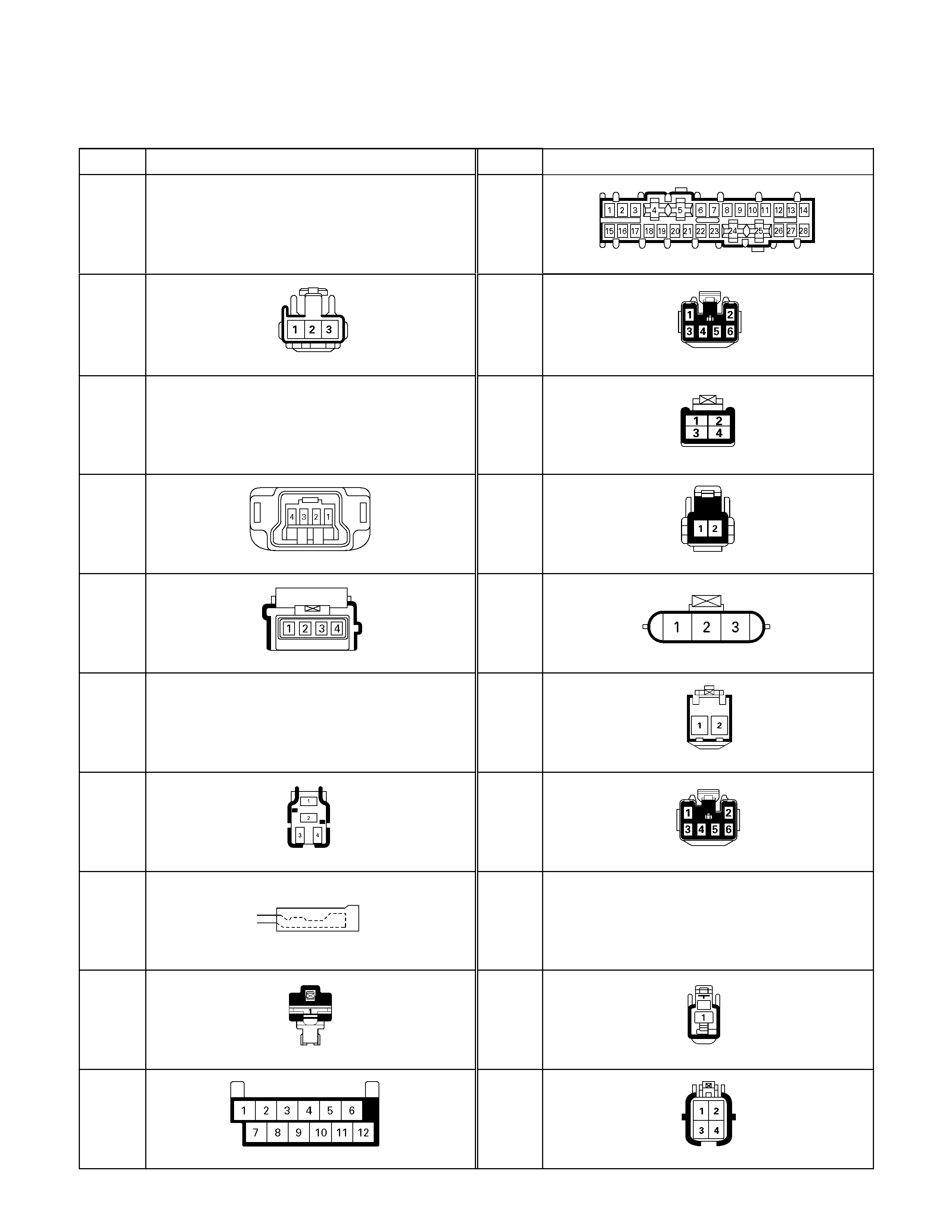

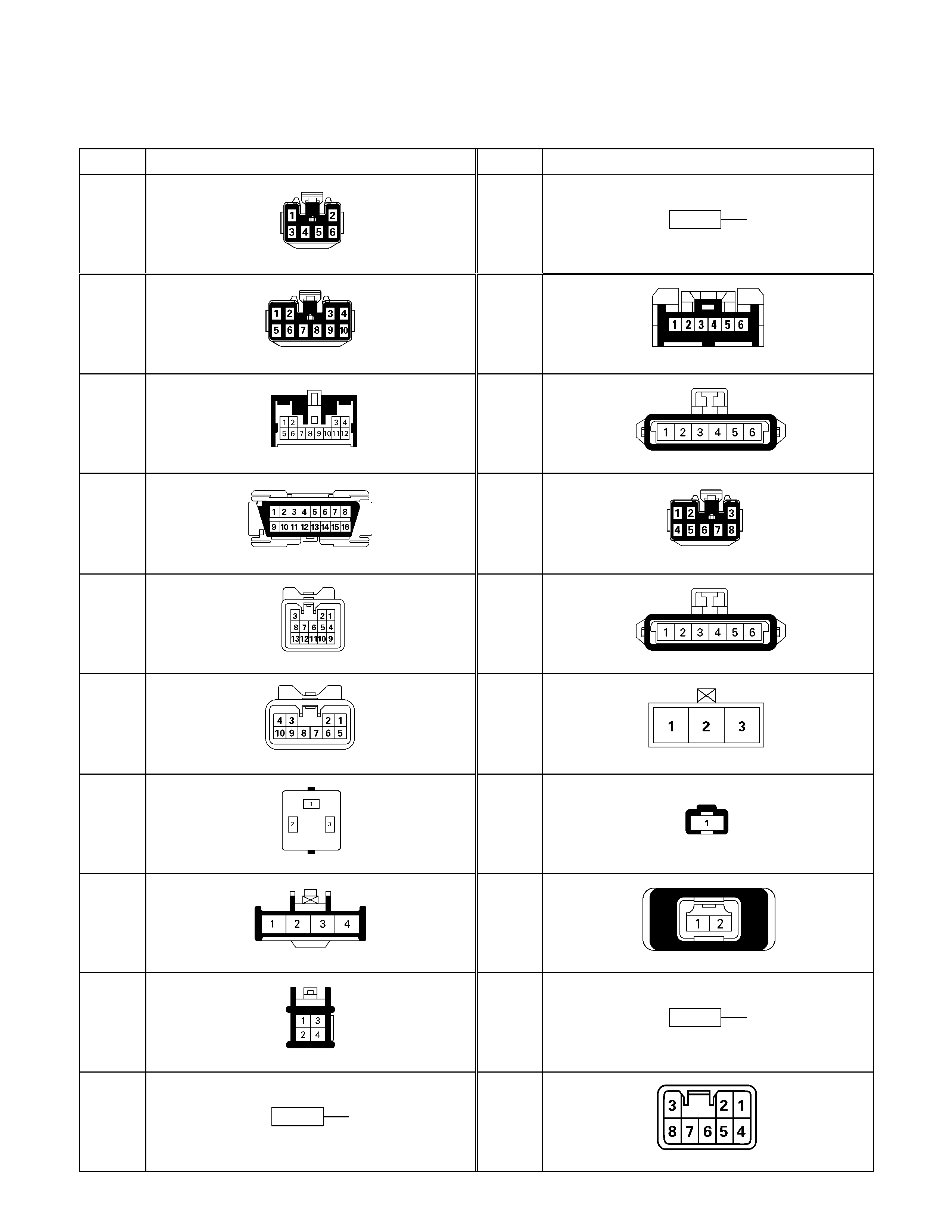

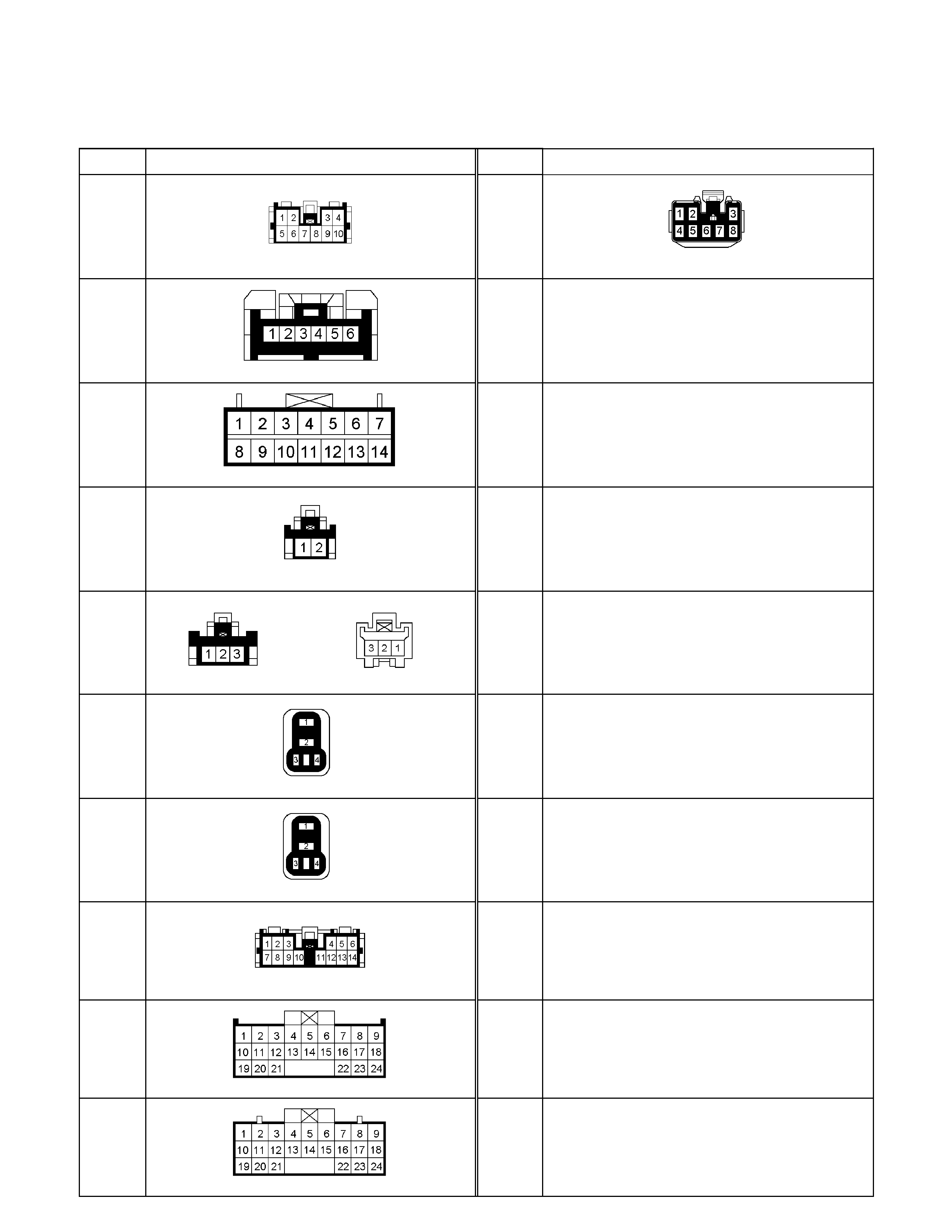

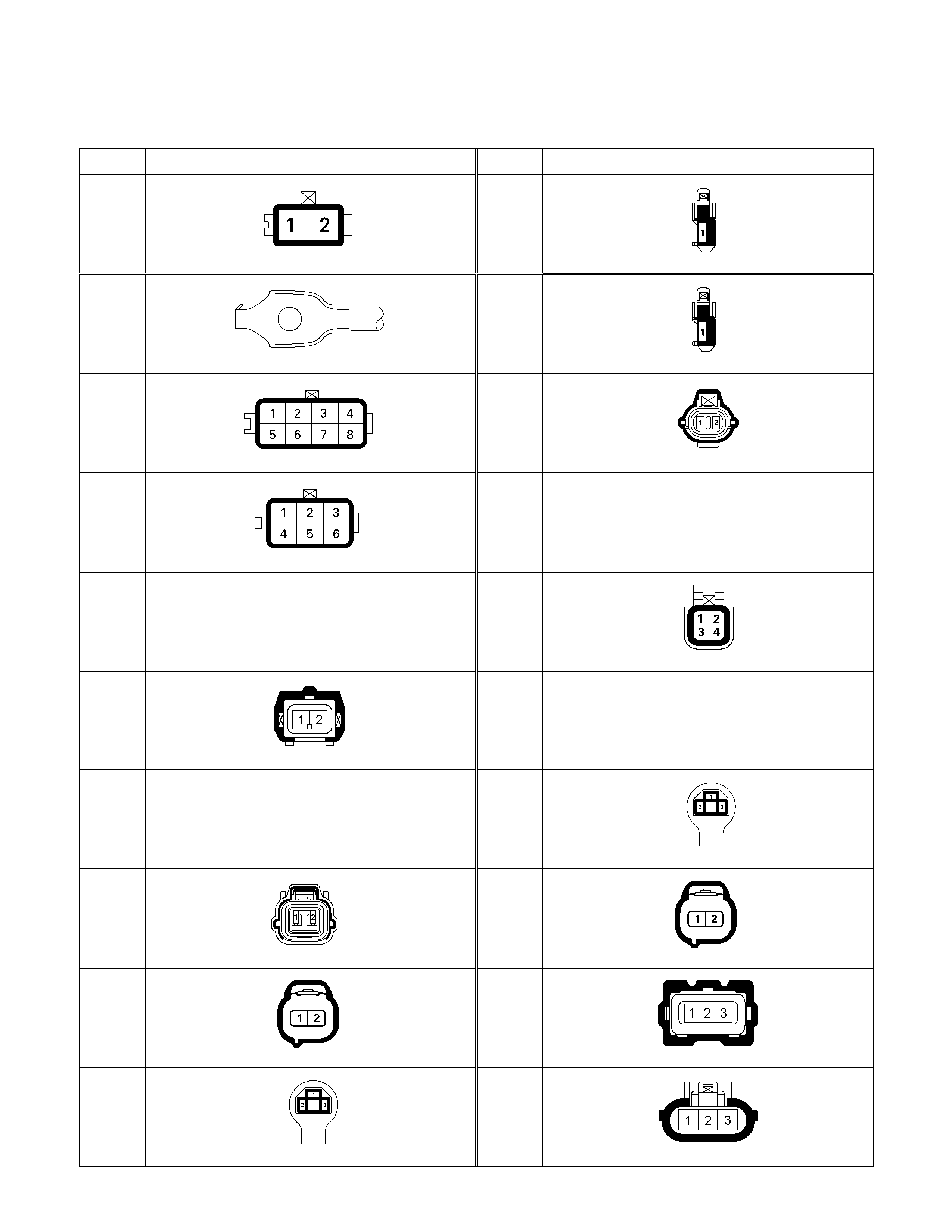

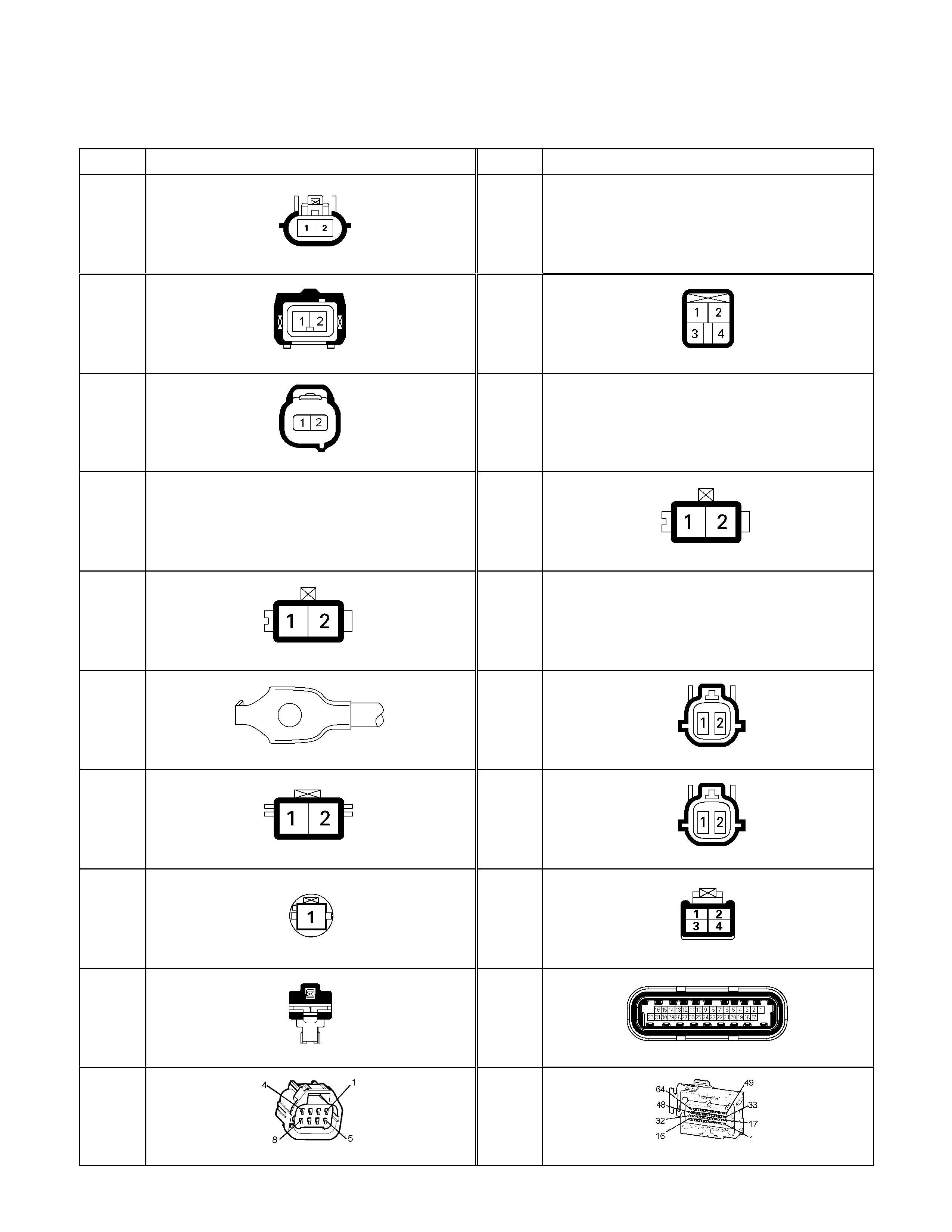

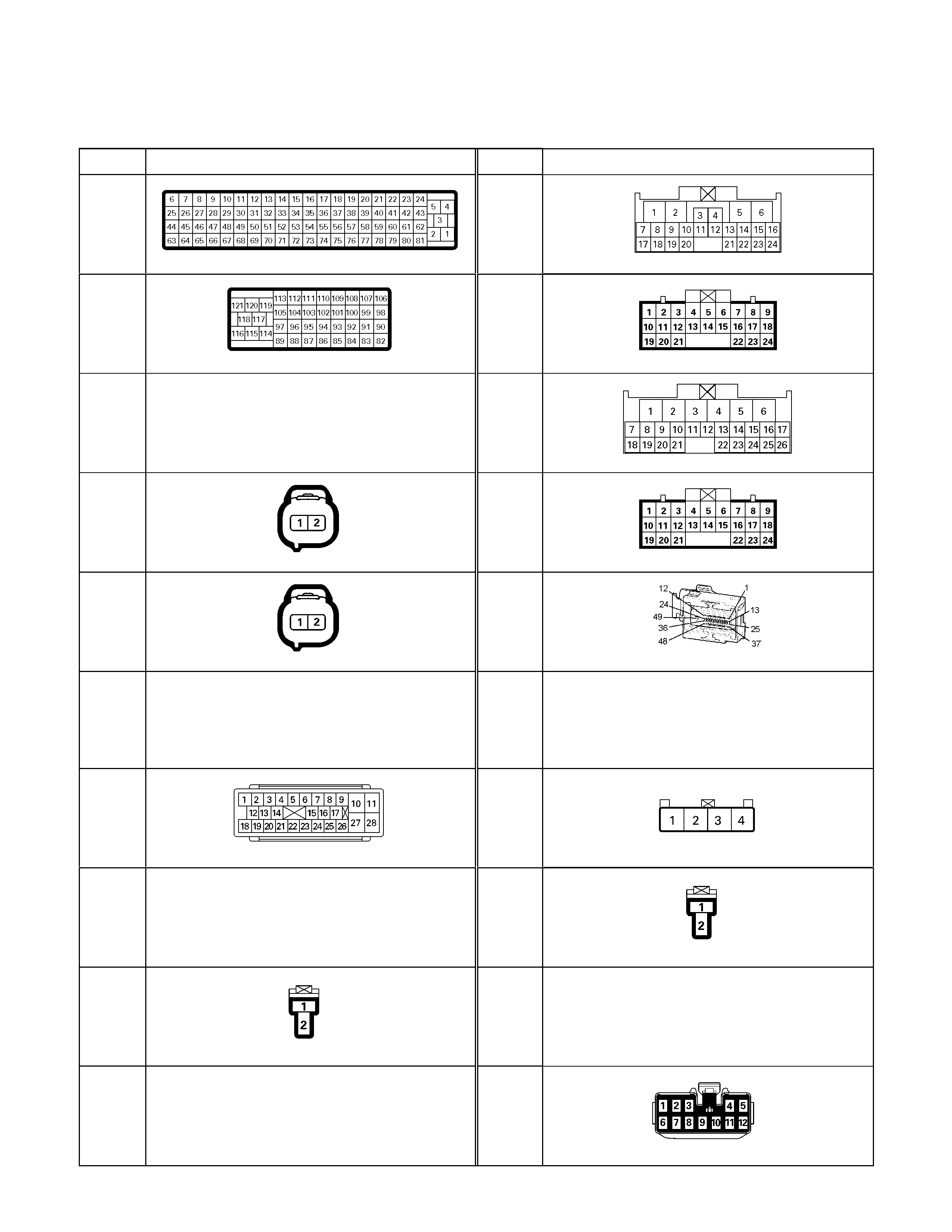

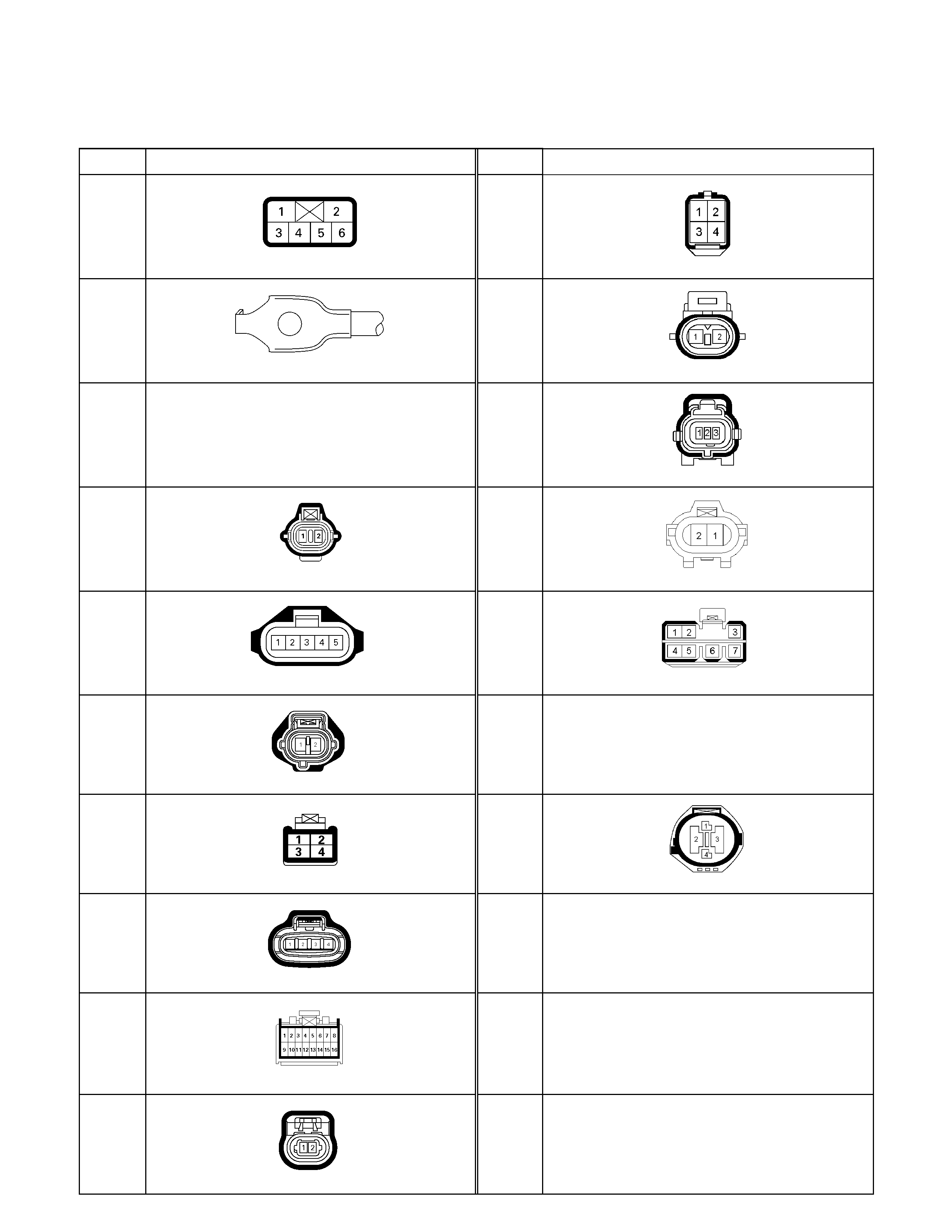

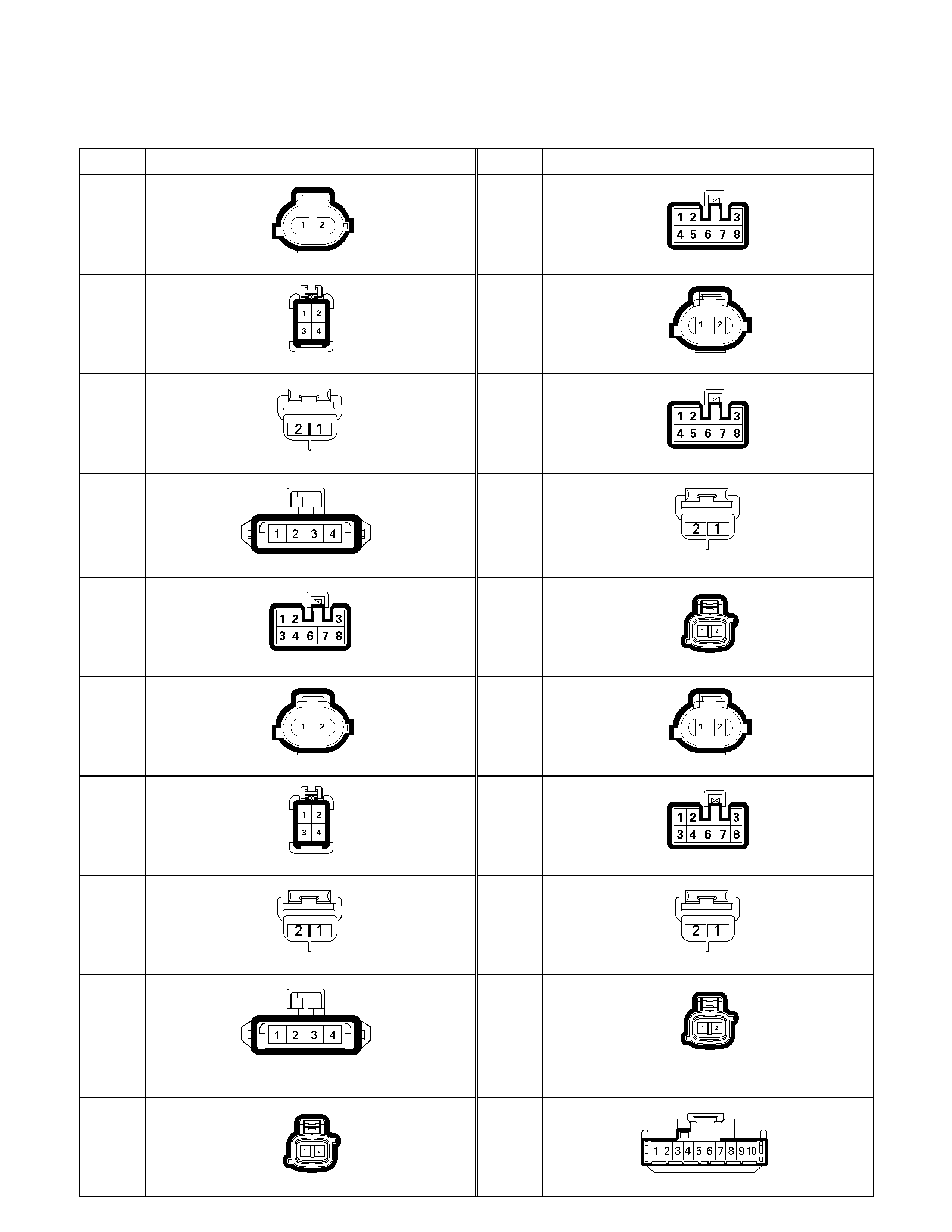

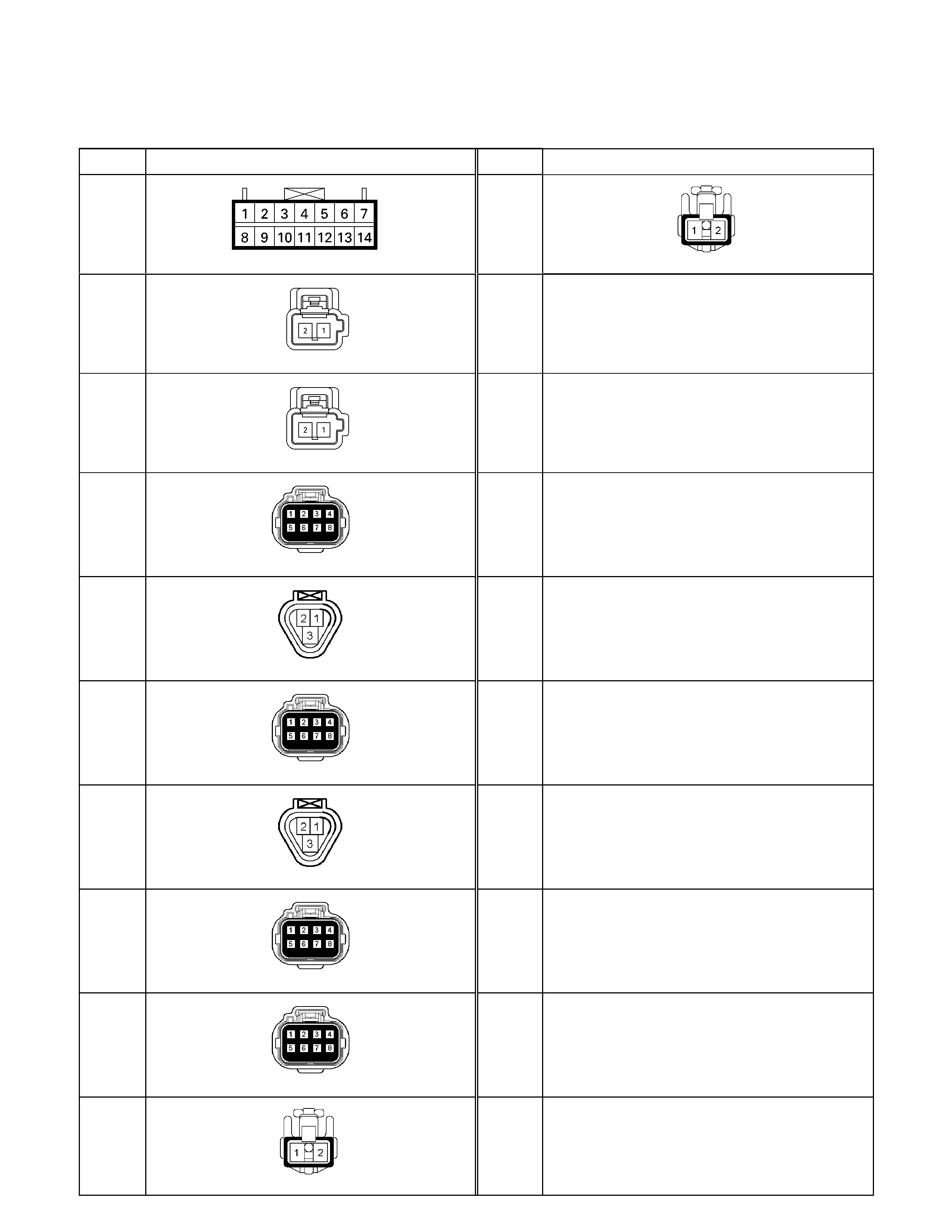

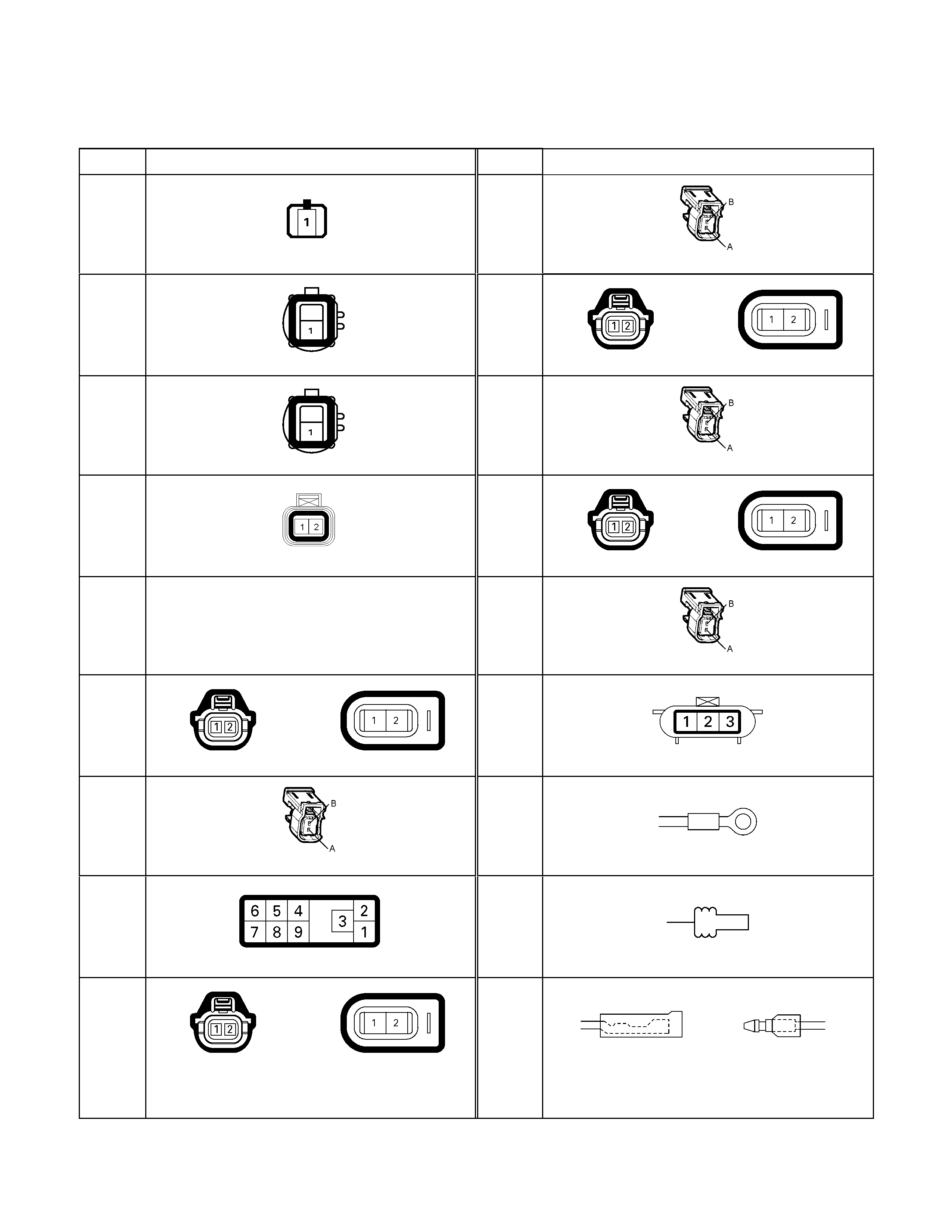

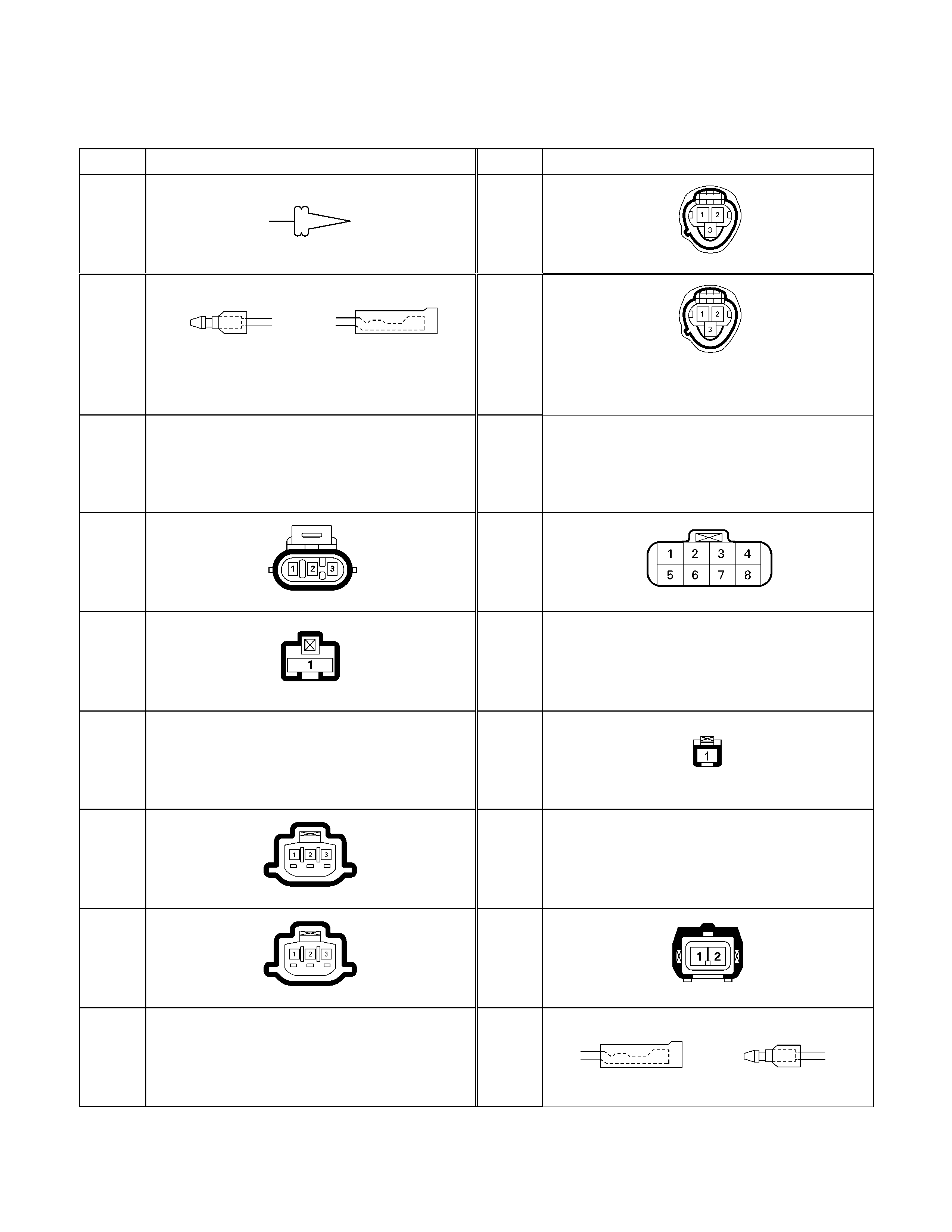

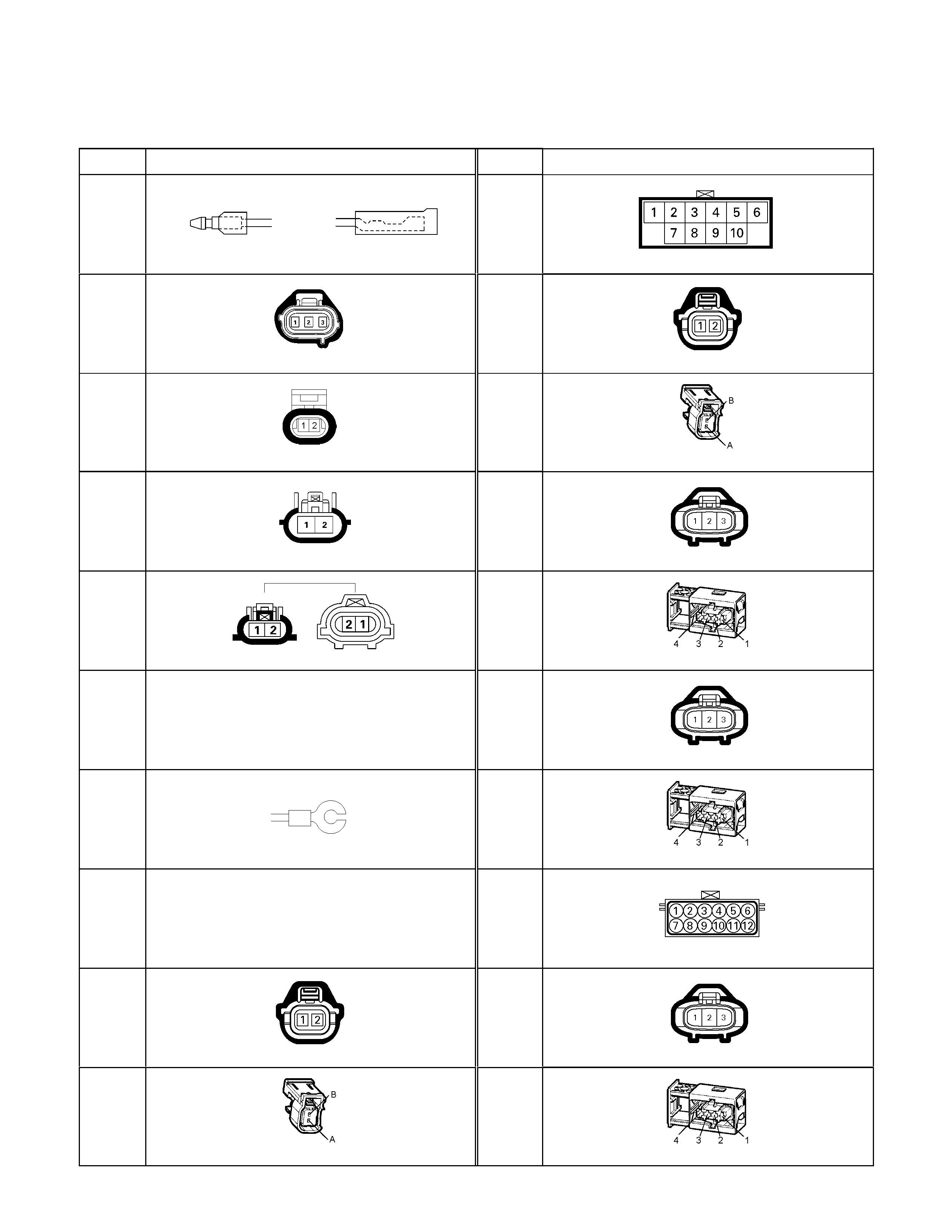

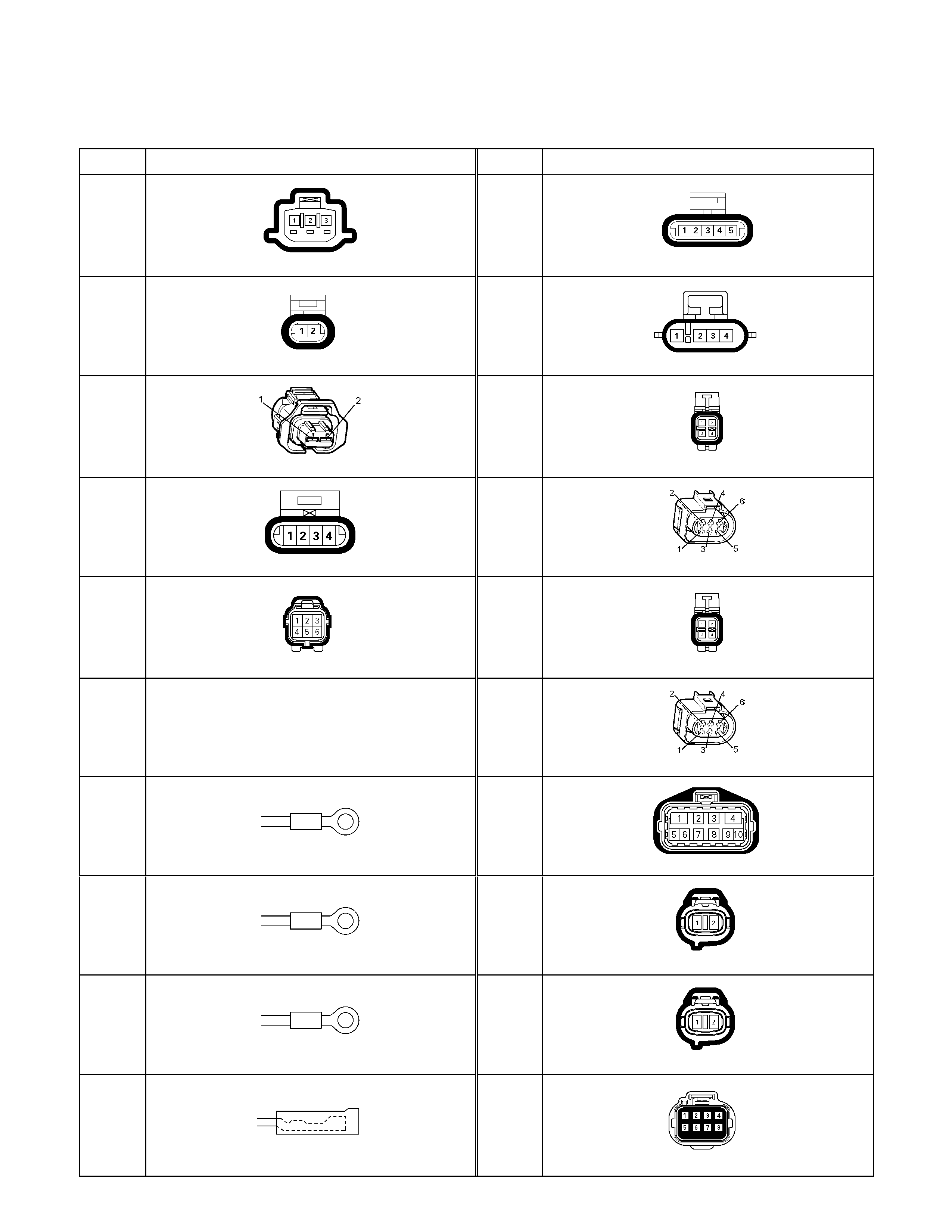

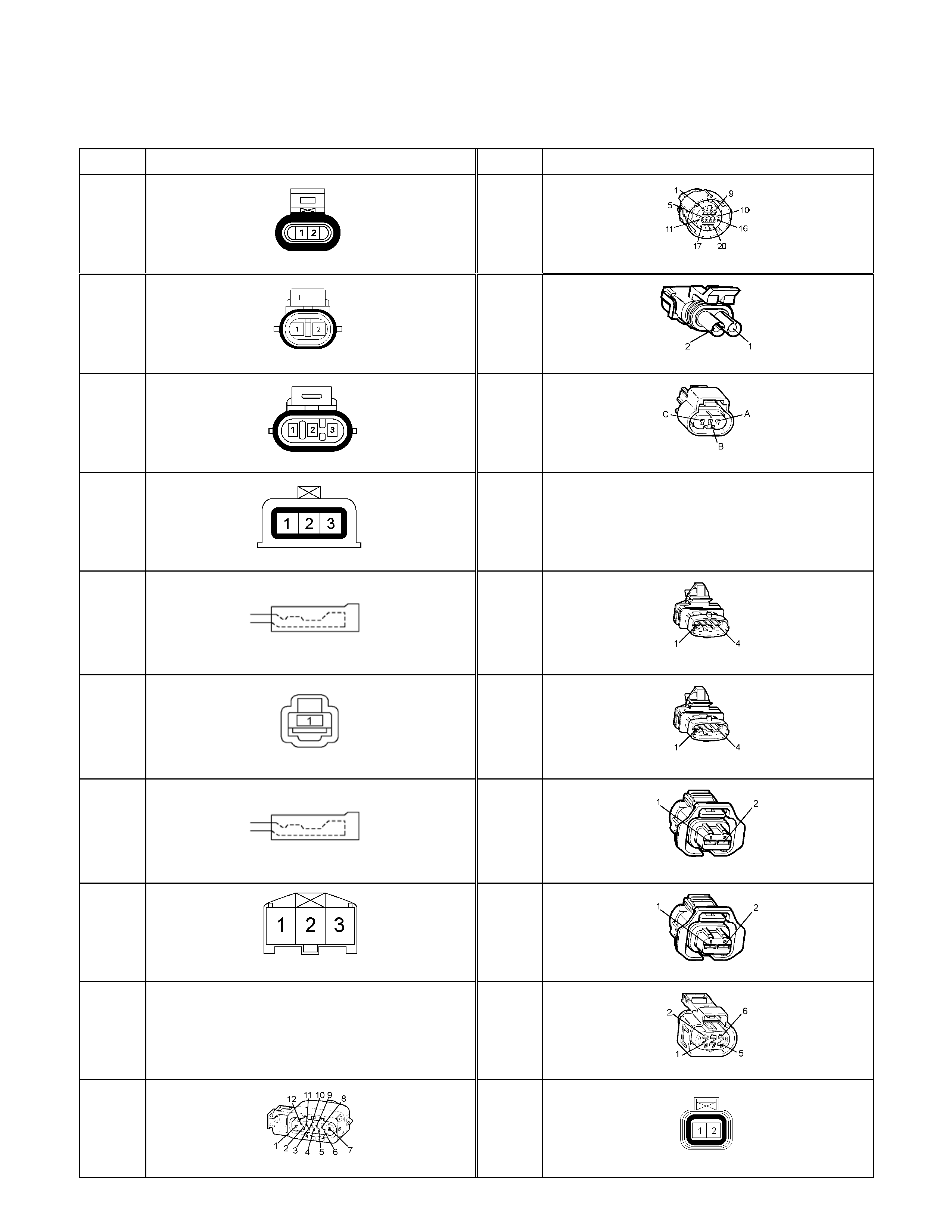

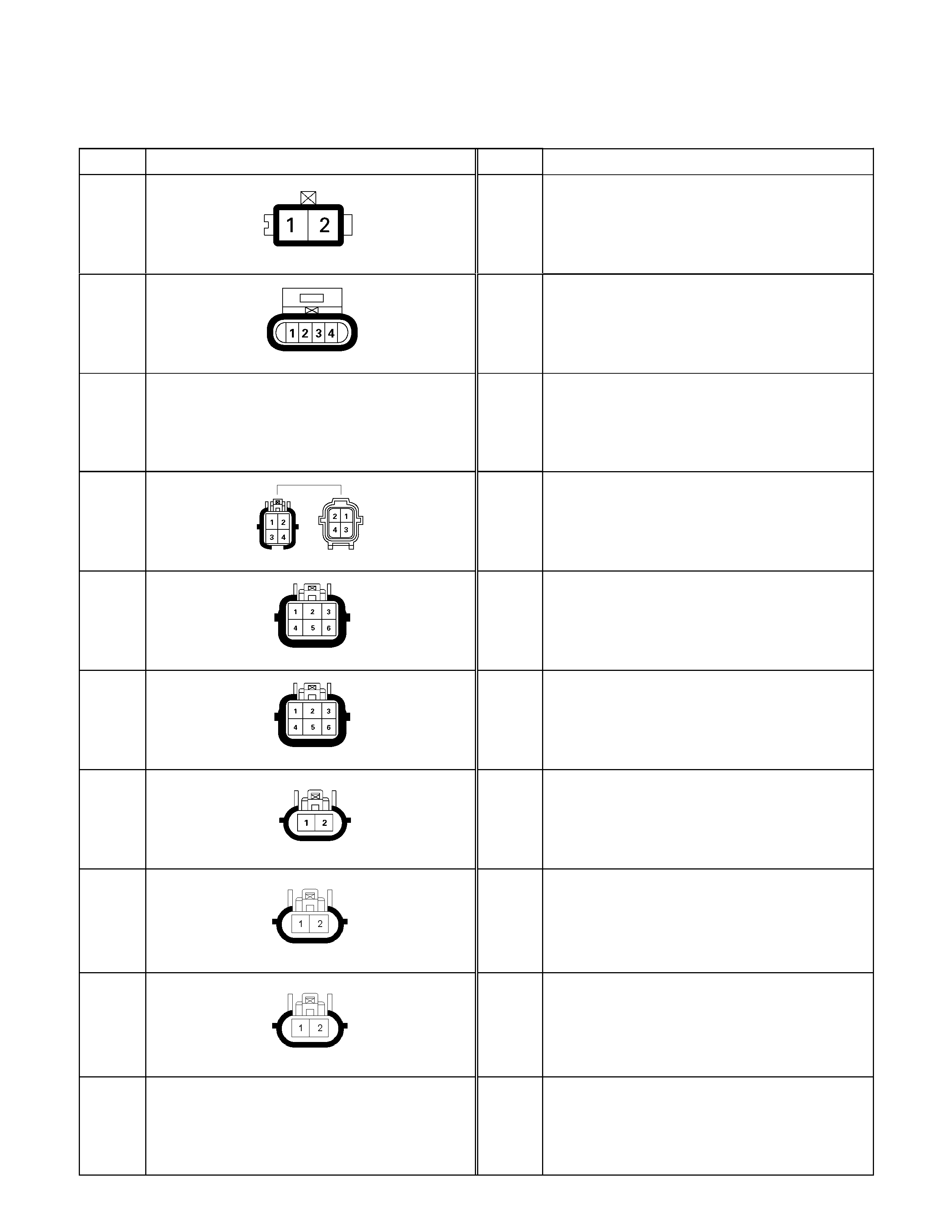

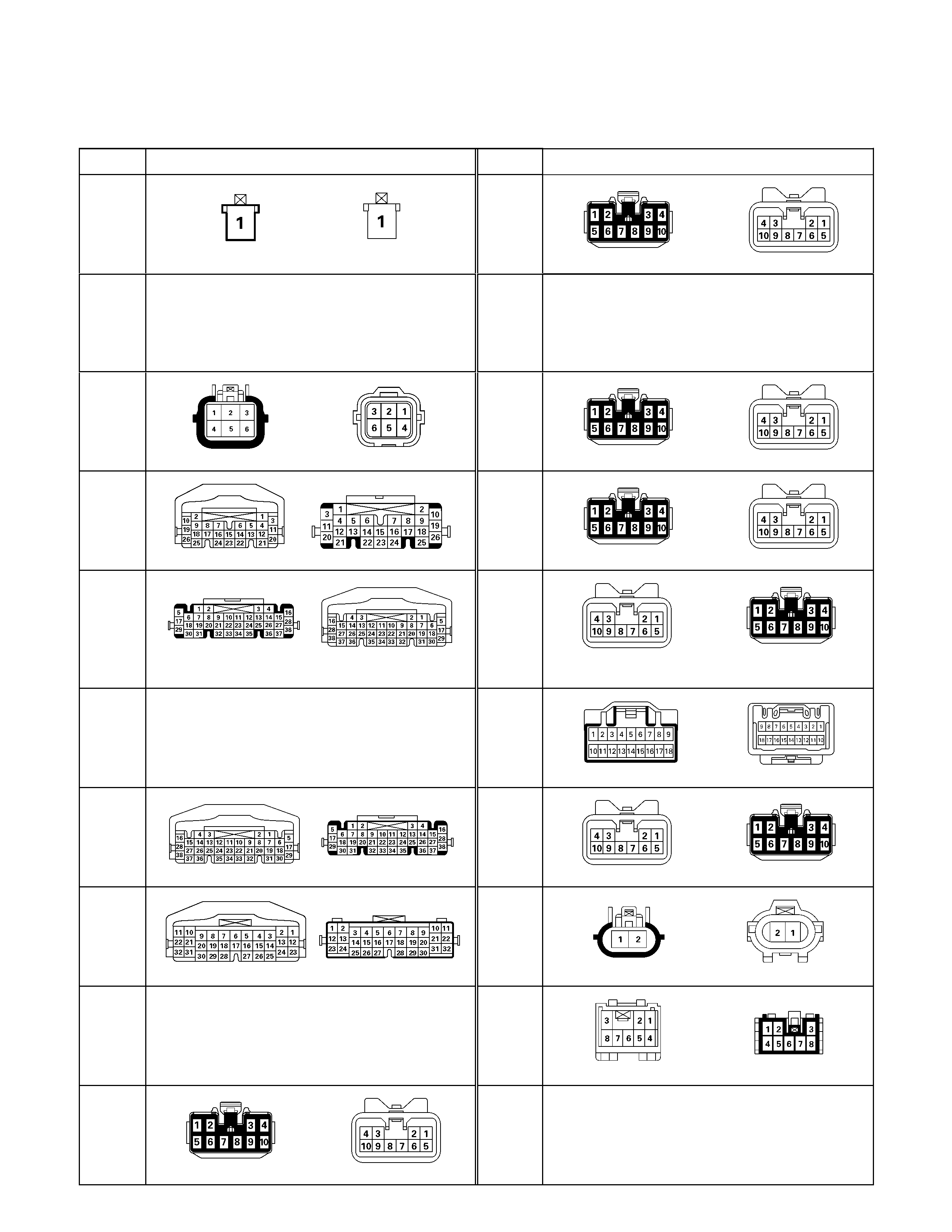

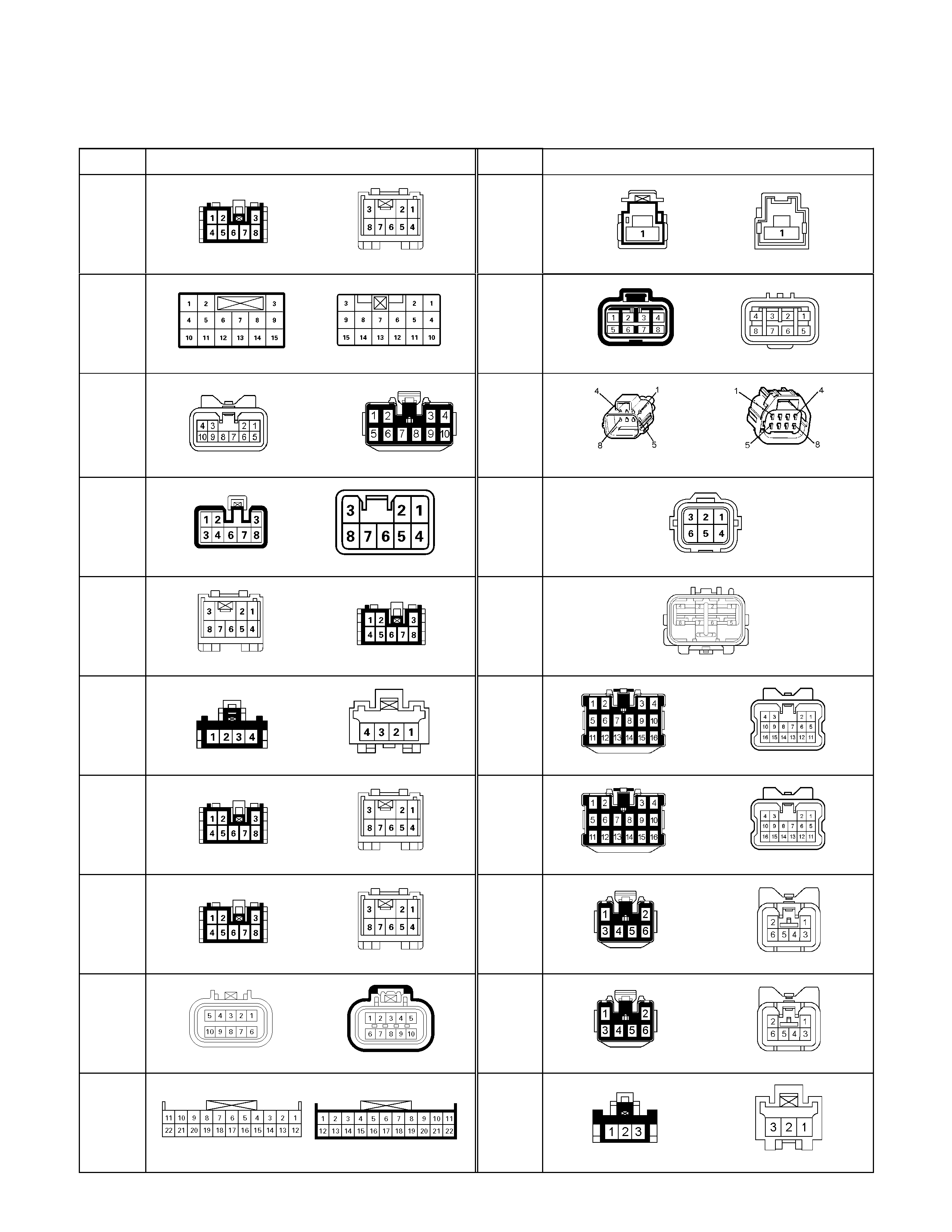

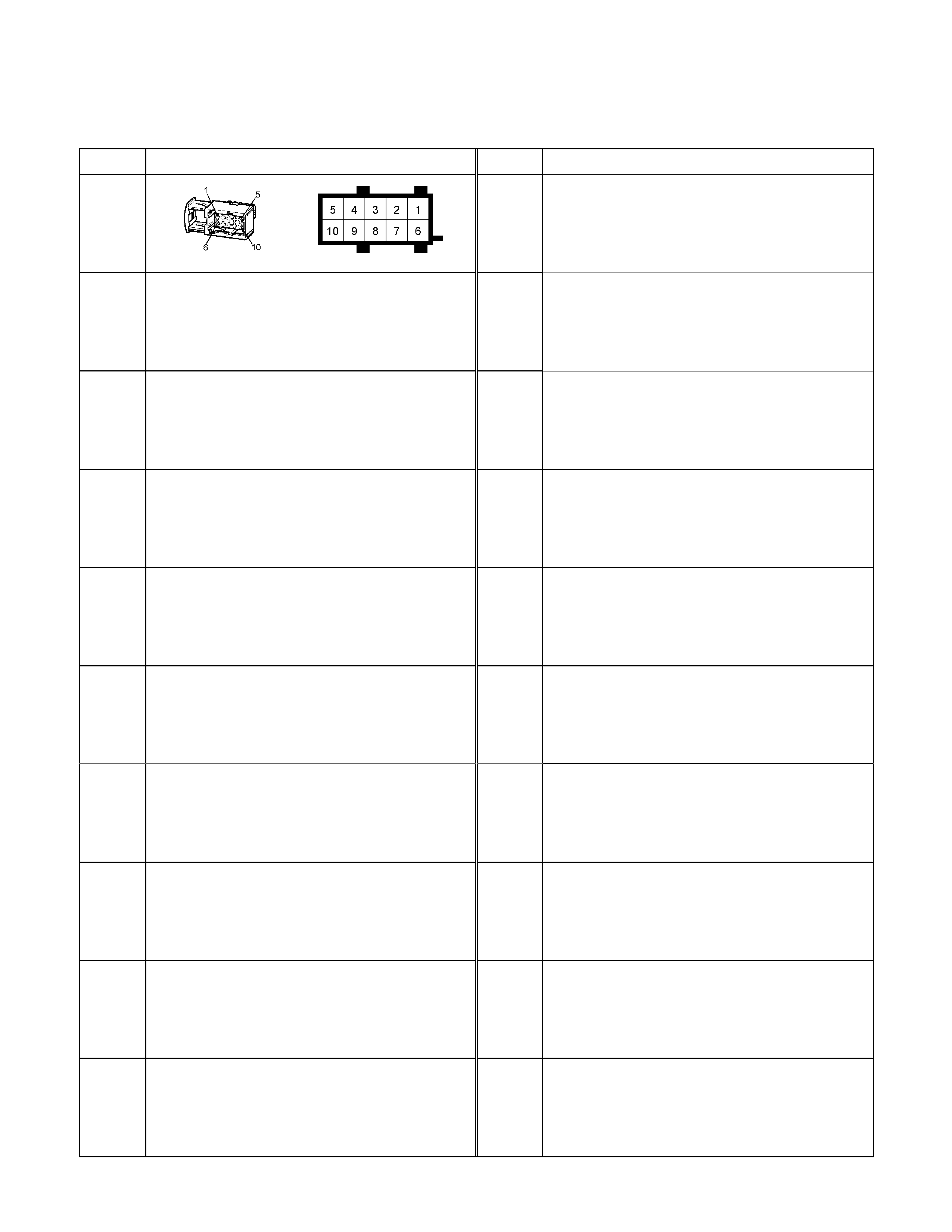

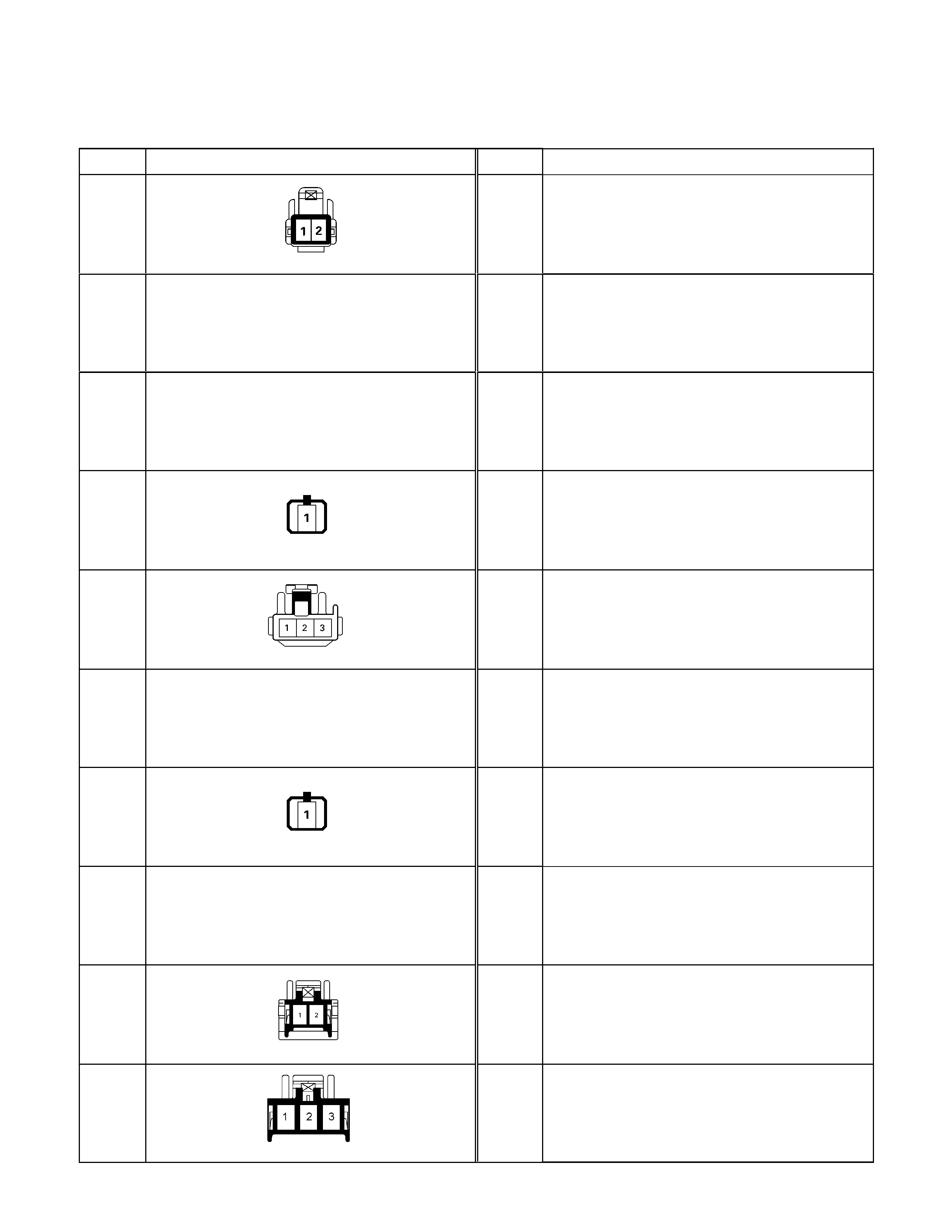

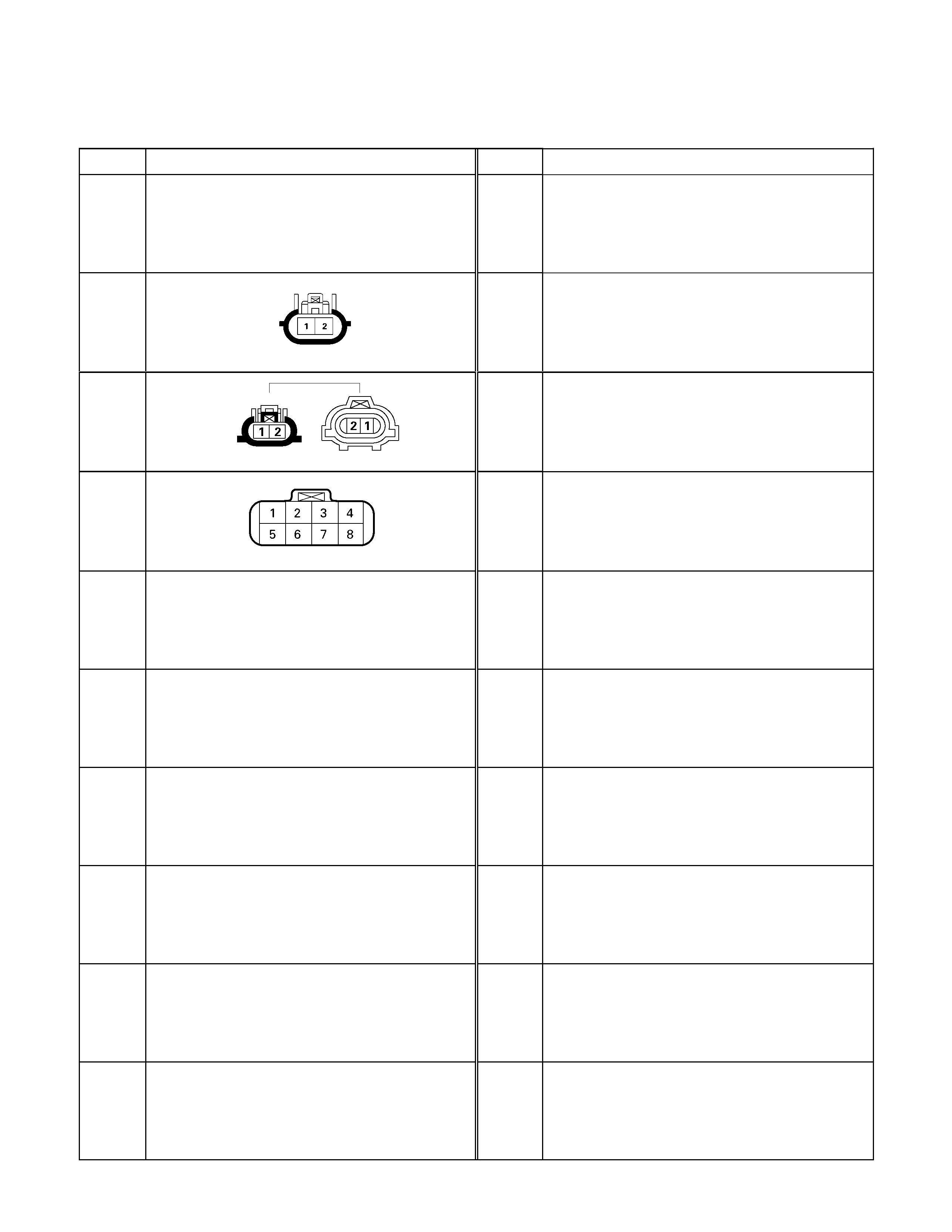

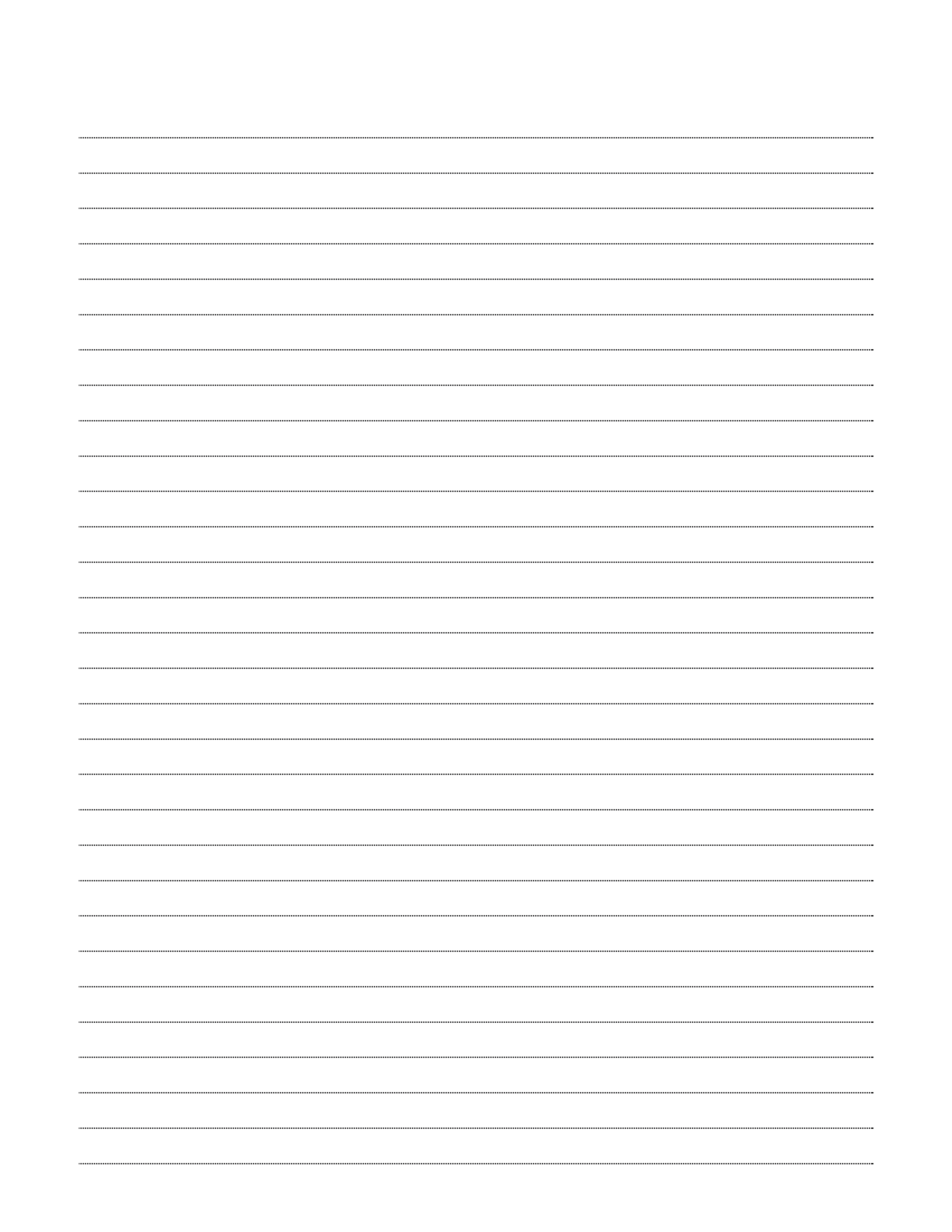

CONNECTOR

The connector pin shape determines whether the connector is

male or female.

The connector housing configuration does not determine

whether a connector is male or female.

The symbol illustrated in the figure is used as connector in the

circuit this section.

Connector is identified with a number.

The applicable terminal number is shown for each connector.

Connector terminal numbers are clearly shown.

Male side connector terminal numbers are in sequence from

upper right to lower left.

Female side connector terminal numbers are in sequence

from upper left to lower right.

NOTE:

For those connectors on which specific terminal numbers

on symbols are shown, the terminal numbers or symbols

are used in the circuit diagram, irrespective of the above

rule.

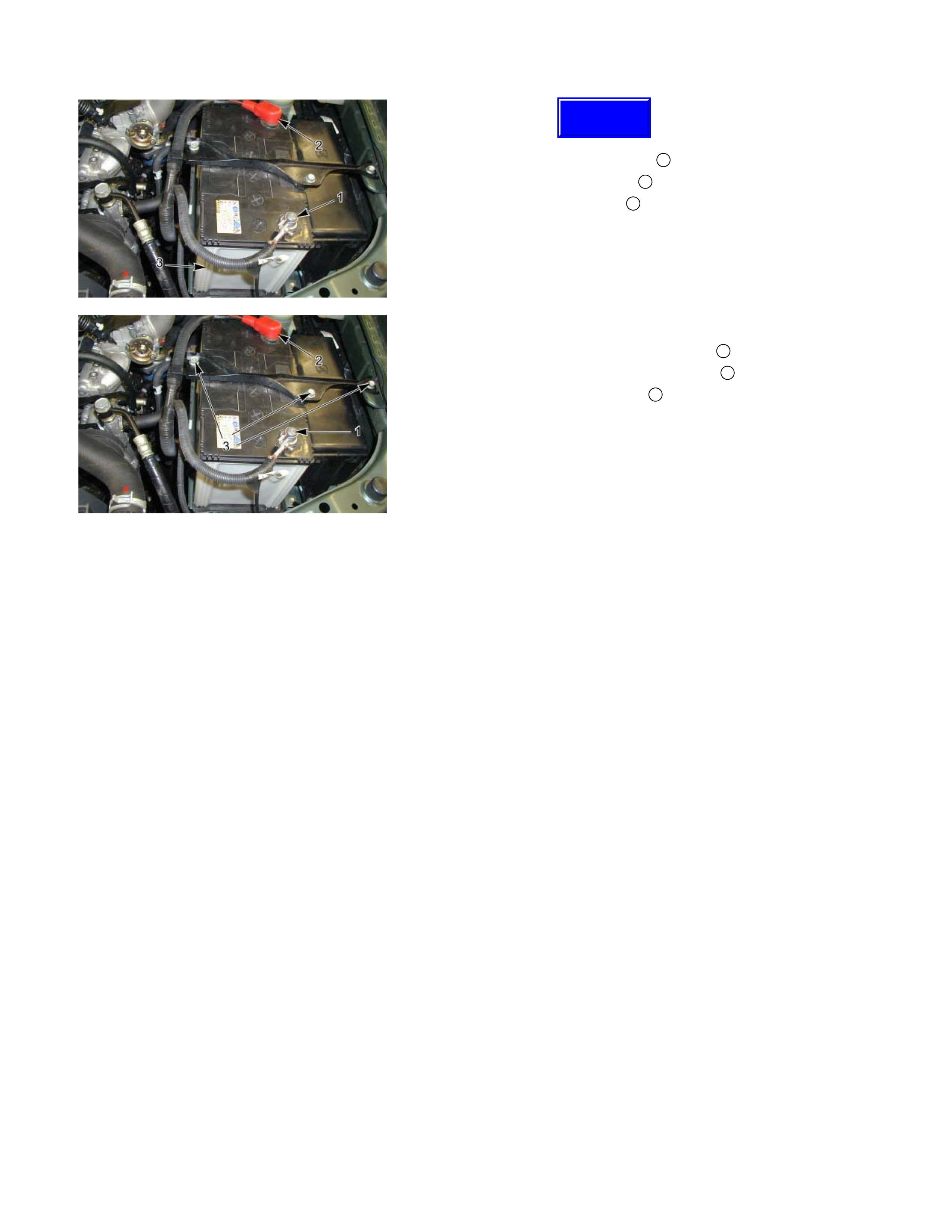

Battery-1

BATTERY

Inspection

1. Check the battery terminals 1 for corrosion.

2. Check the battery cables 2 for looseness.

3. Check the battery case 3 for cracks and other damage.

4. Check the battery electrolyte level.

Battery-2

Battery Replacement

1. Disconnect the battery ground cable 1.

2. Disconnect the battery positive cable 2.

3. Remove the battery clamp 3.

4. Remove the battery

Caution:

It is important that the battery ground cable be removed

first.

Removing the battery positive cable first can result in a

short circuit.

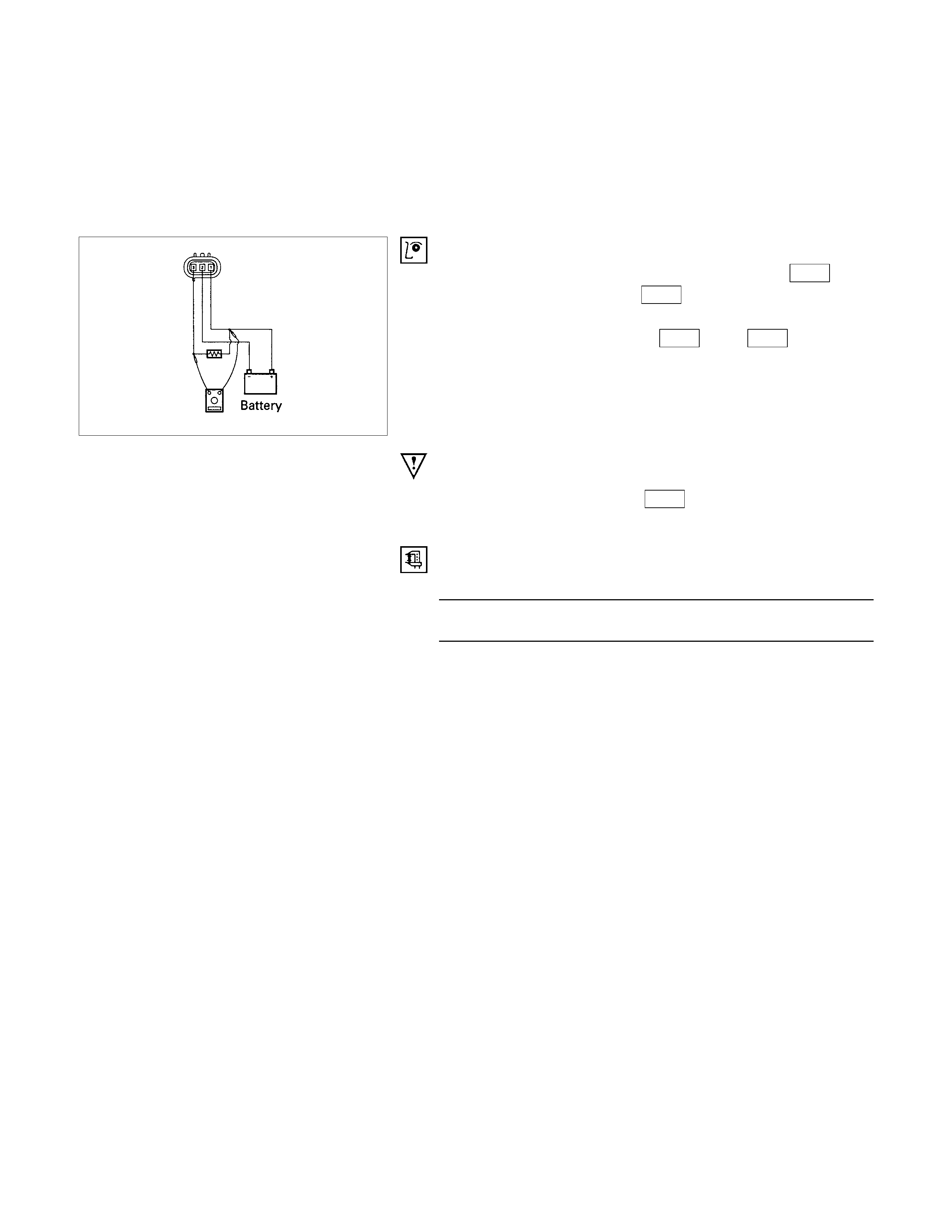

Jump Starting the Engine with a Booster Battery

The following description assumes that you are using a

booster battery mounted on a second vehicle.

The listed steps (with some minor modifications) are also

applicable if you are using a naked booster battery or special

battery charging equipment.

Caution:

Never push or tow the vehicle in an attempt to start it.

Extensive damage to the emission system and other

vehicle parts will result.

(Only catalytic converter vehicle)

Treat both the discharged battery and the booster battery

with great care when using jumper cables.

Carefully follow the procedure outlined below.

Always be aware of the dangers of sparking.

Failure to follow the following procedure can result in:

a. Serious personal injury, specially to your eyes.

b. Extensive property damage from a battery explosion,

battery acid discharge, or electrical file.

c. Extensive damage to the electronic components o

f

both vehicles.

Do not use a 24 volt booster battery.

Serious damage to the vehicle's electrical sy stem and

electronic components will result.

Techline

Jump Starting Procedure

1. Set the parking brake on both vehicles.

2. If one or both vehicles is equipped with a manual

transmission, place the gear shift in the "NEUTRAL"

position.

3. Turn off the ignition on both vehicles.

4. Turn off all vehicle lights and accessories.

5 Be sure that the two vehicles are not touching.

Attach the end of one jumper cable to the booster battery

positive terminal.

6

A

ttach the other end of the same cable to the discharged

battery positive terminal.

7. Once again, check that the booster battery has a 12 volt

rating.

8. Attach one end of the remaining booster cable to the

booster battery negative terminal.

9.

A

ttach the other end of the booster cable to a solid ground

(such as the air conditioner compressor mounting bracket

or the alternator mounting bracket) in the engine room o

f

the vehicle with the discharged battery.

Be sure that the ground connection is at least 500 mm (20

in) from the discharged battery.

Caution:

Do not attach the booster cable to the discharged battery

negative terminal.

11. Start the engine of the vehicle with the booster battery.

Check that all unnecessary electrical accessories are off.

12. Start the engine of the vehicle with the discharged battery.

13. Remove the jumper cables in the reverse order to which

they were attached.

Caution:

Be absolutely sure to remove the negative jumper cable

from the vehicle with the discharged battery first.

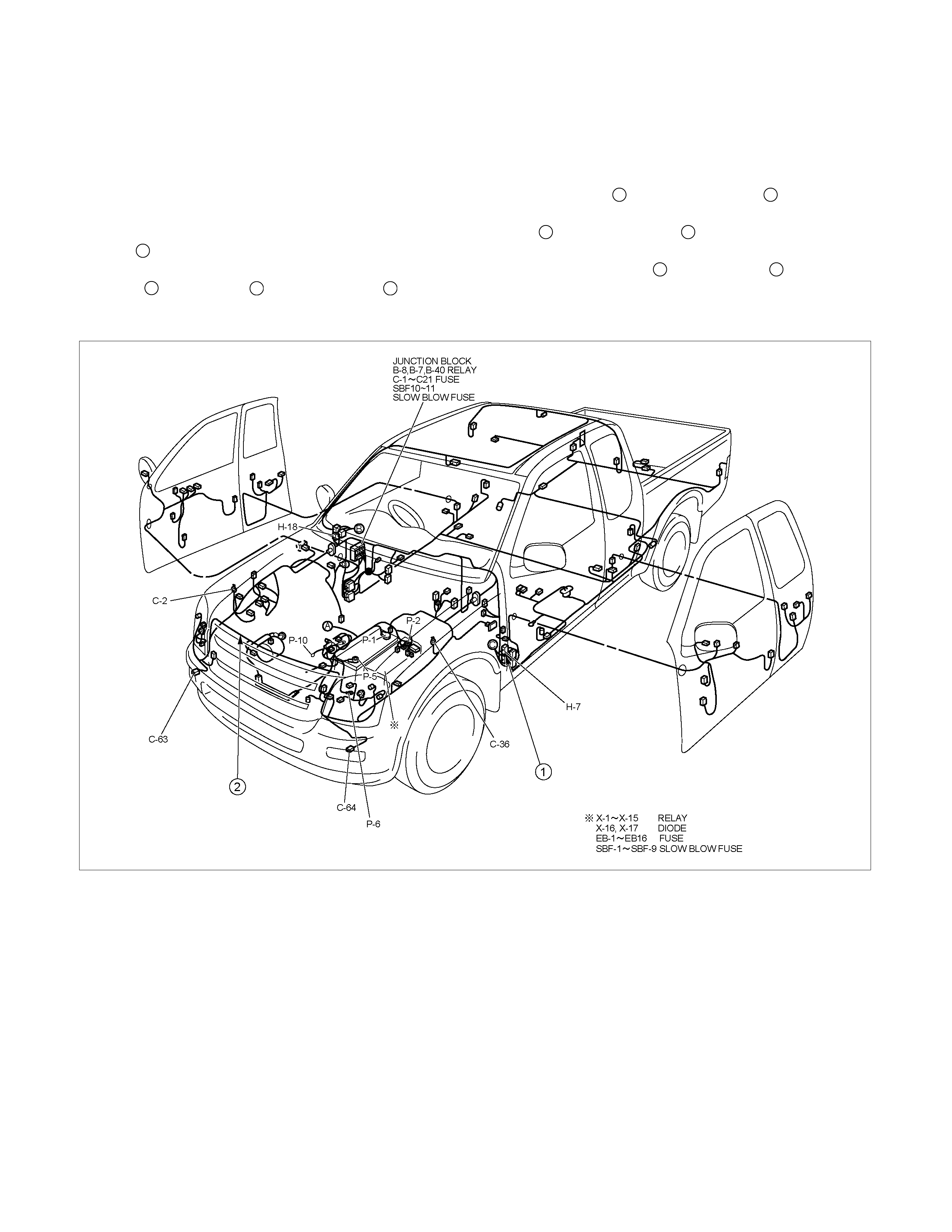

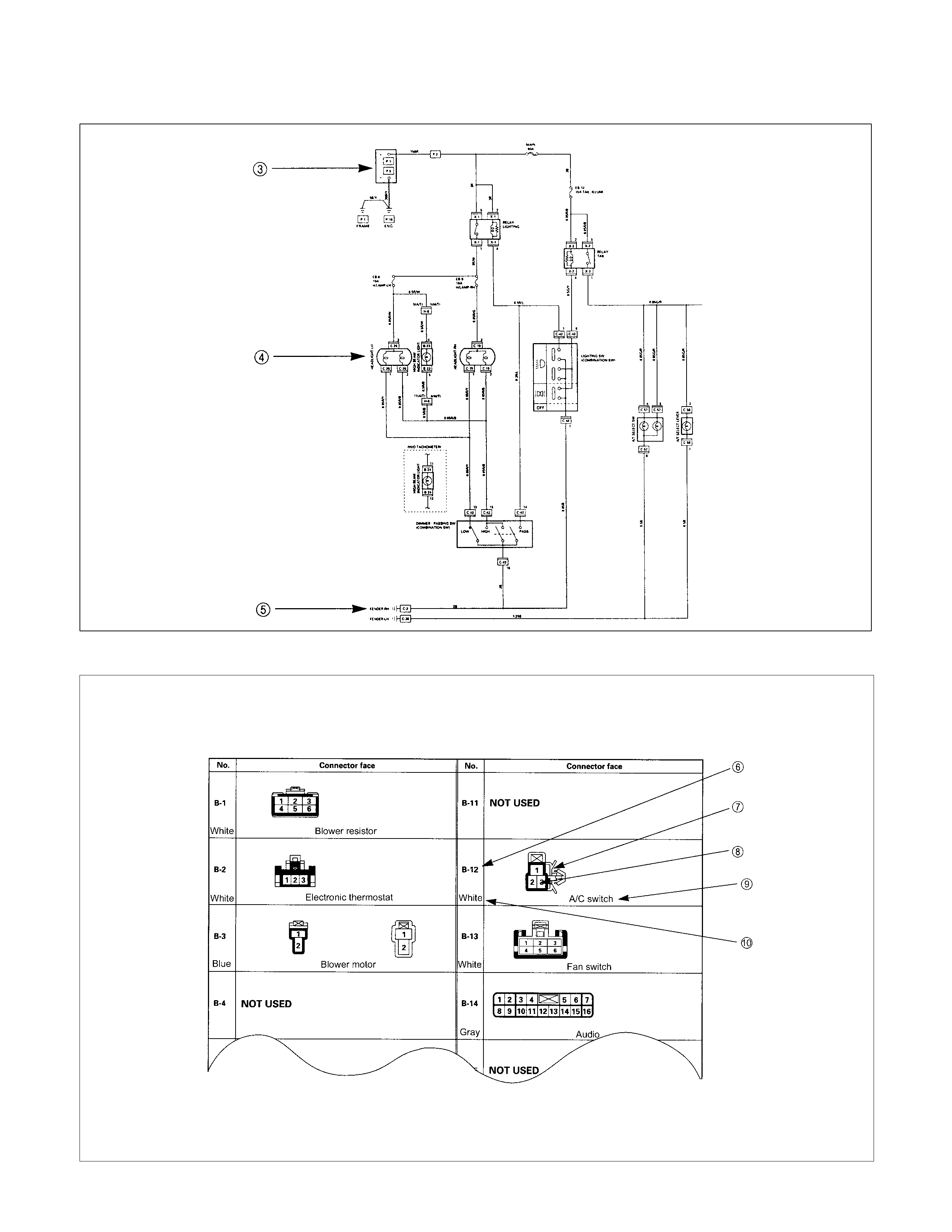

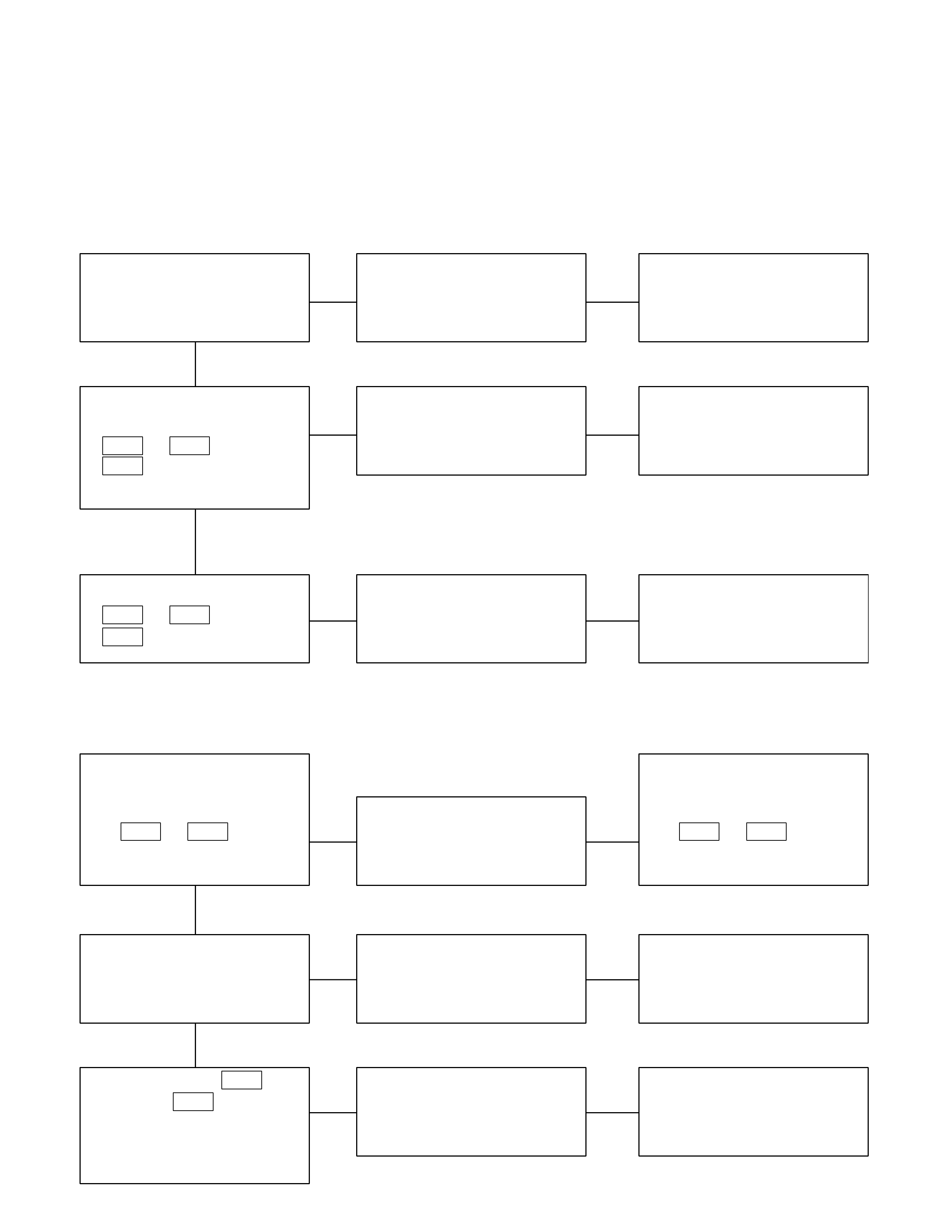

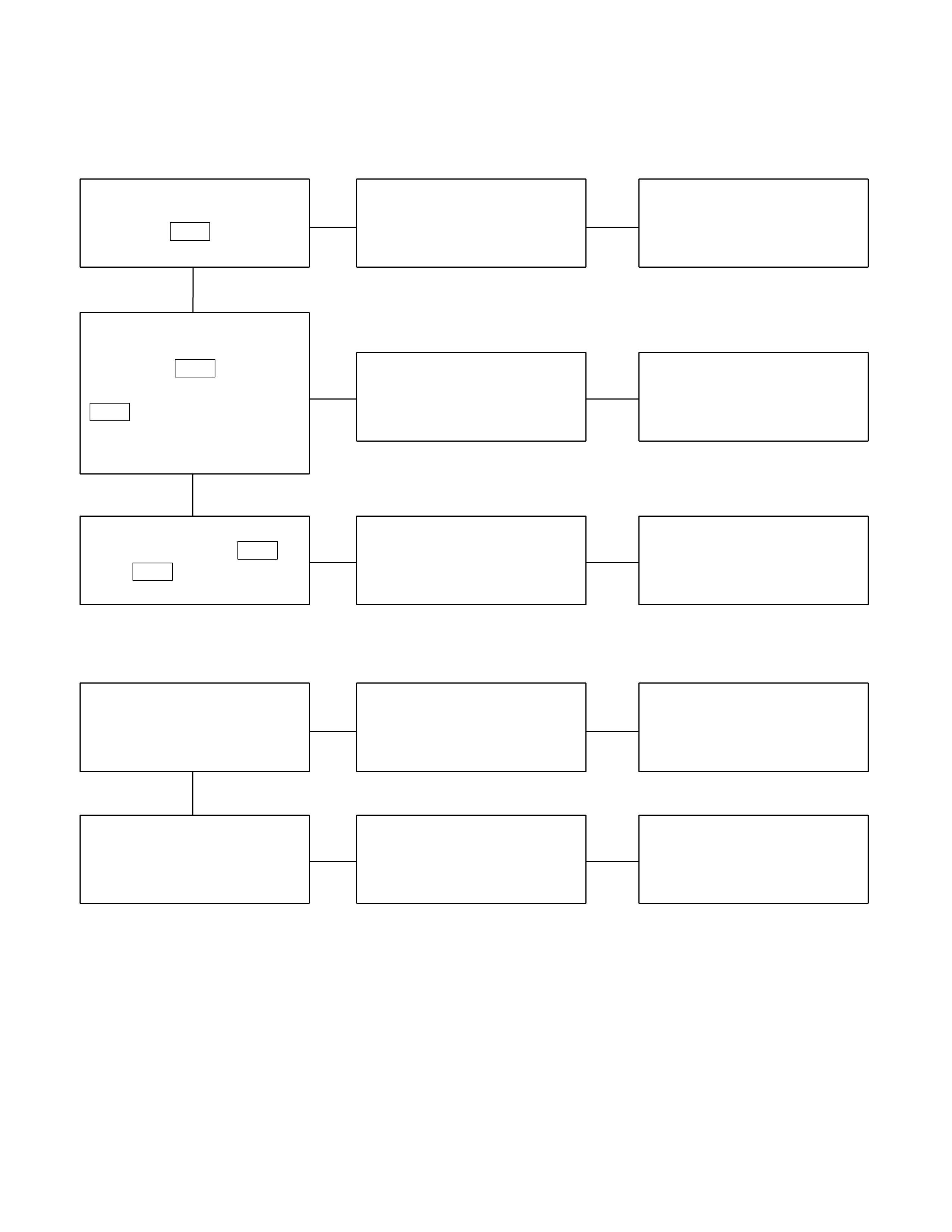

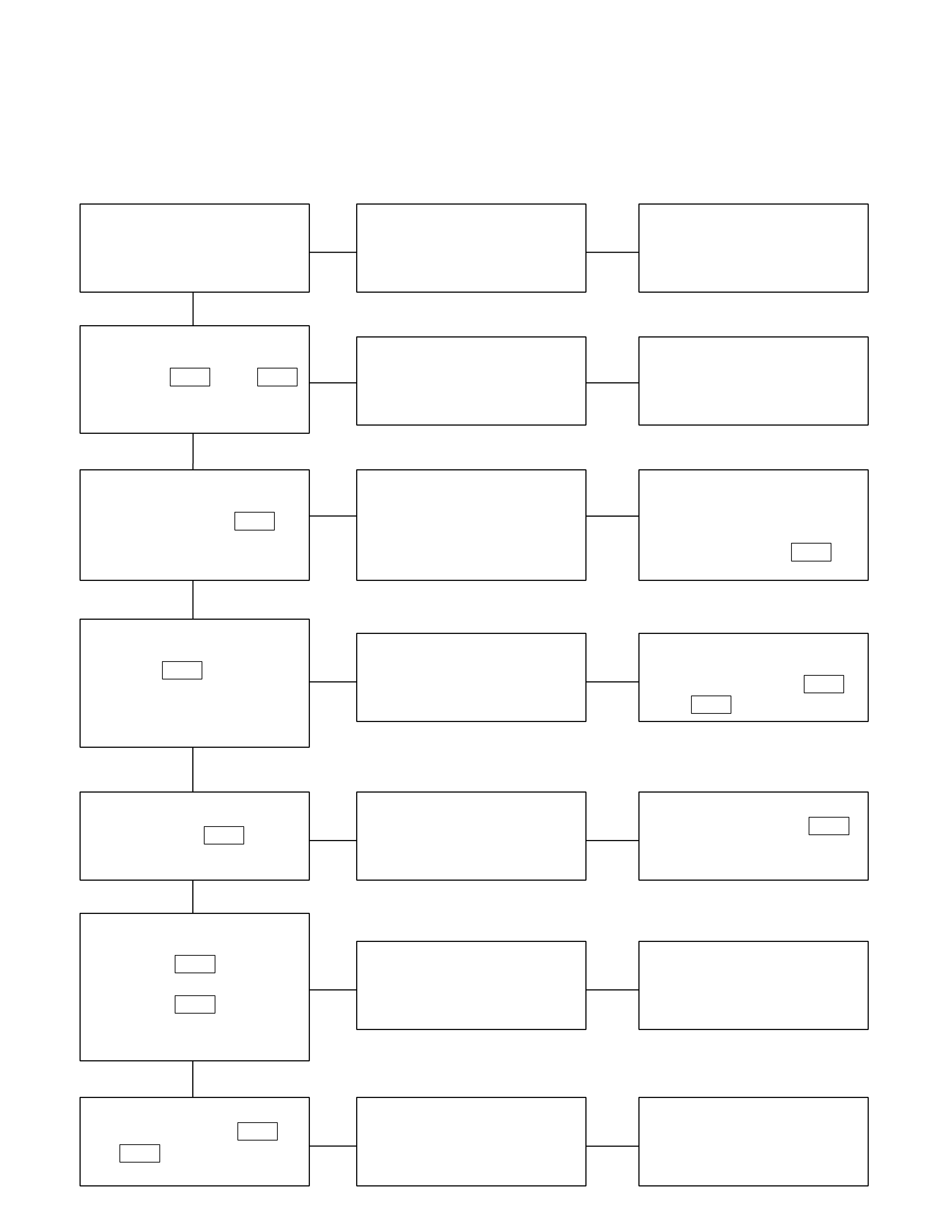

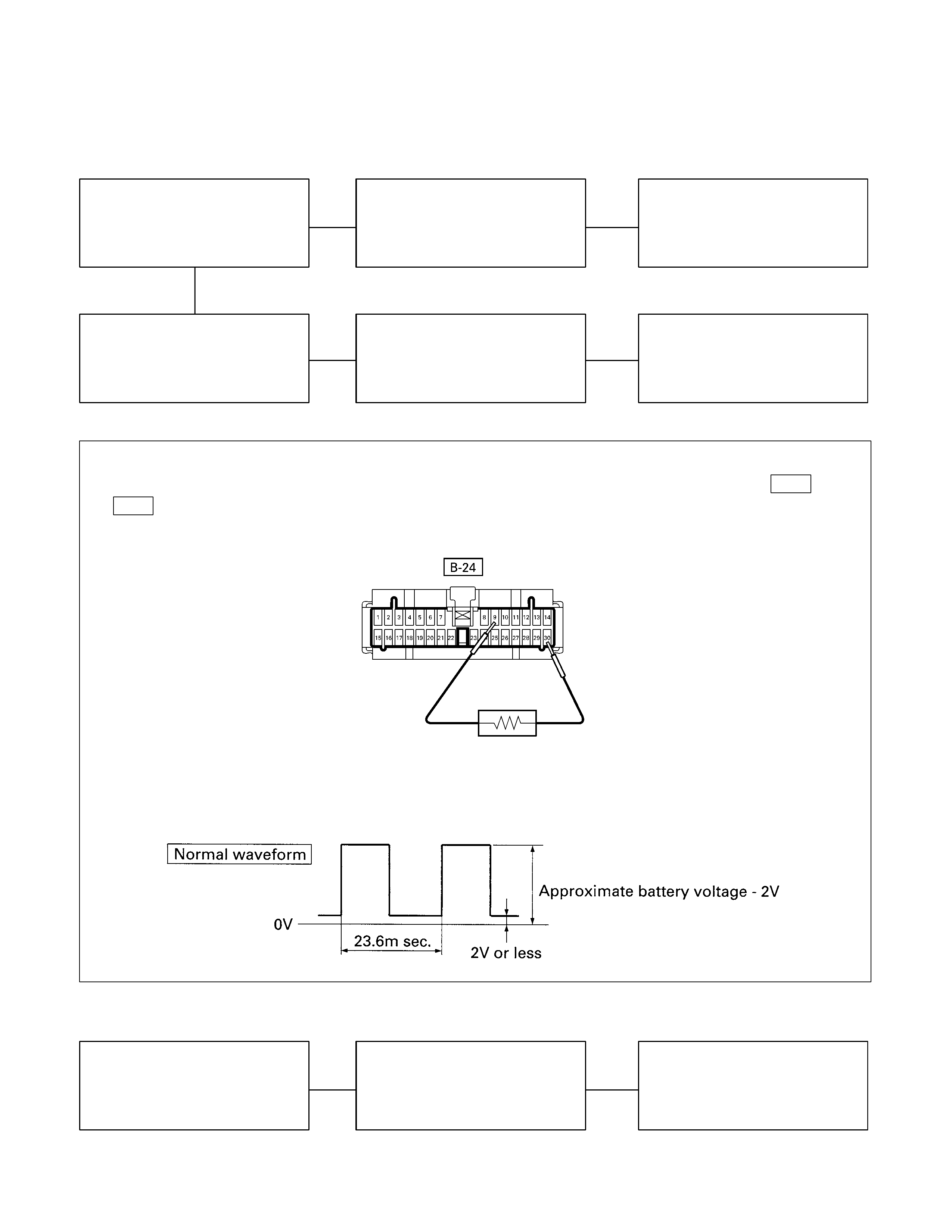

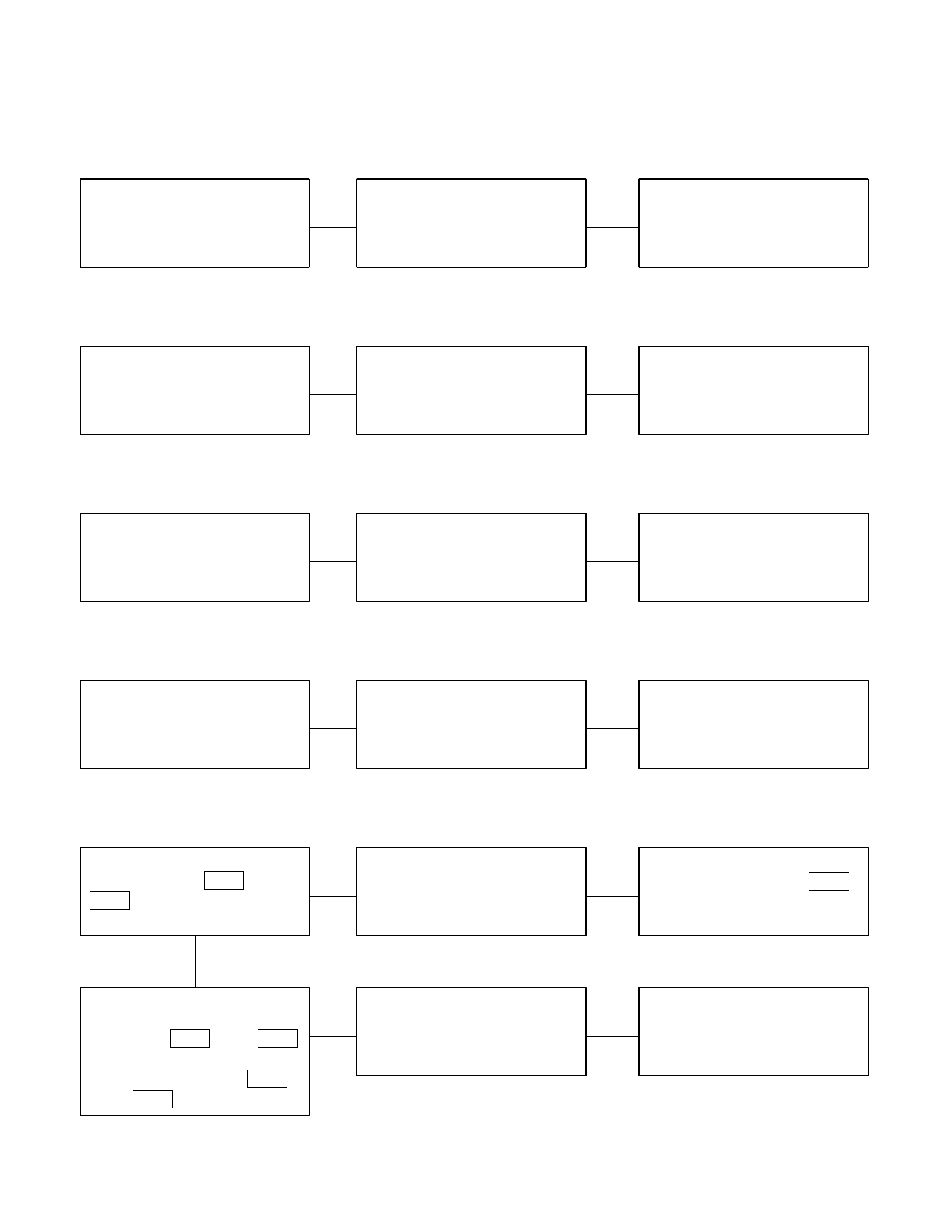

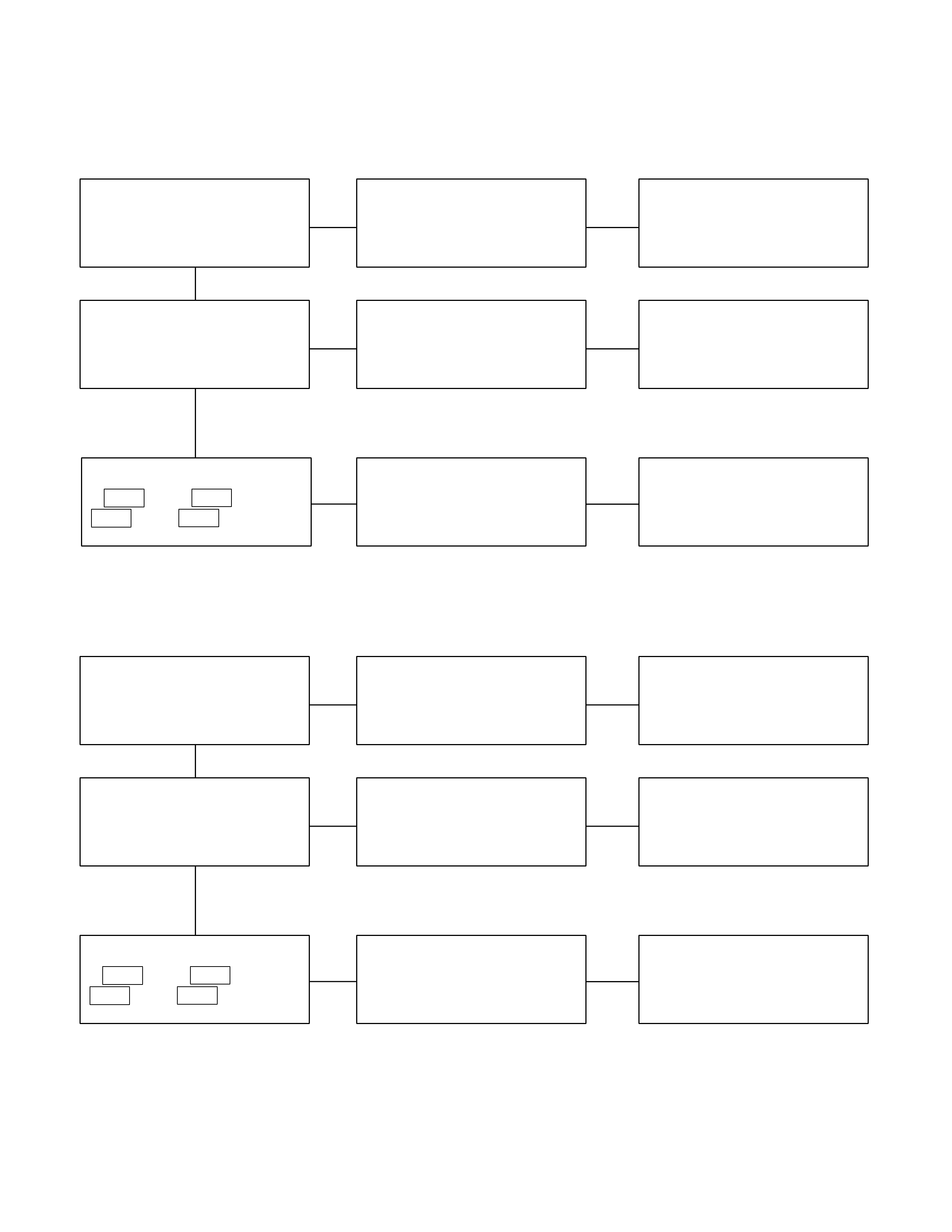

READING THE CIRCUIT DIAGRAM

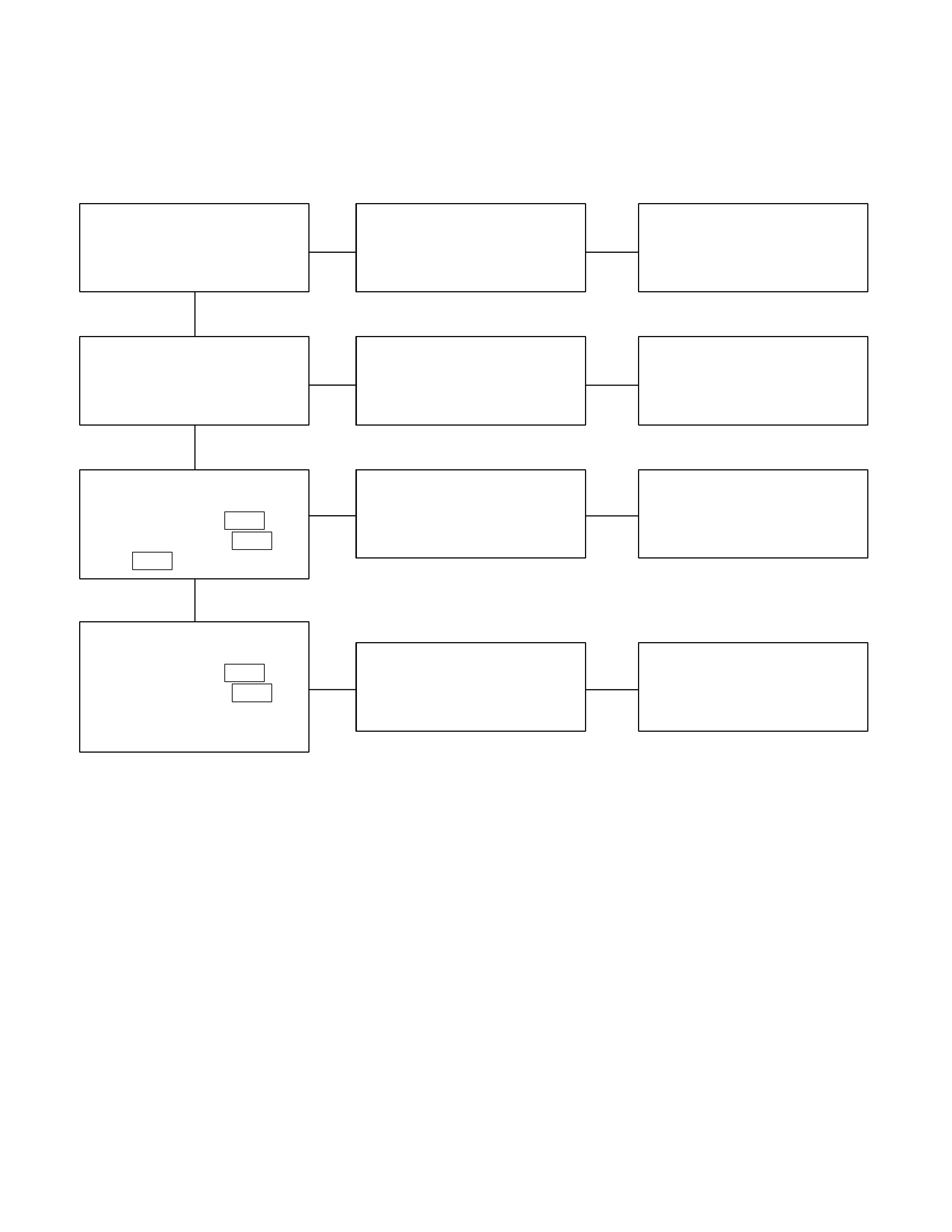

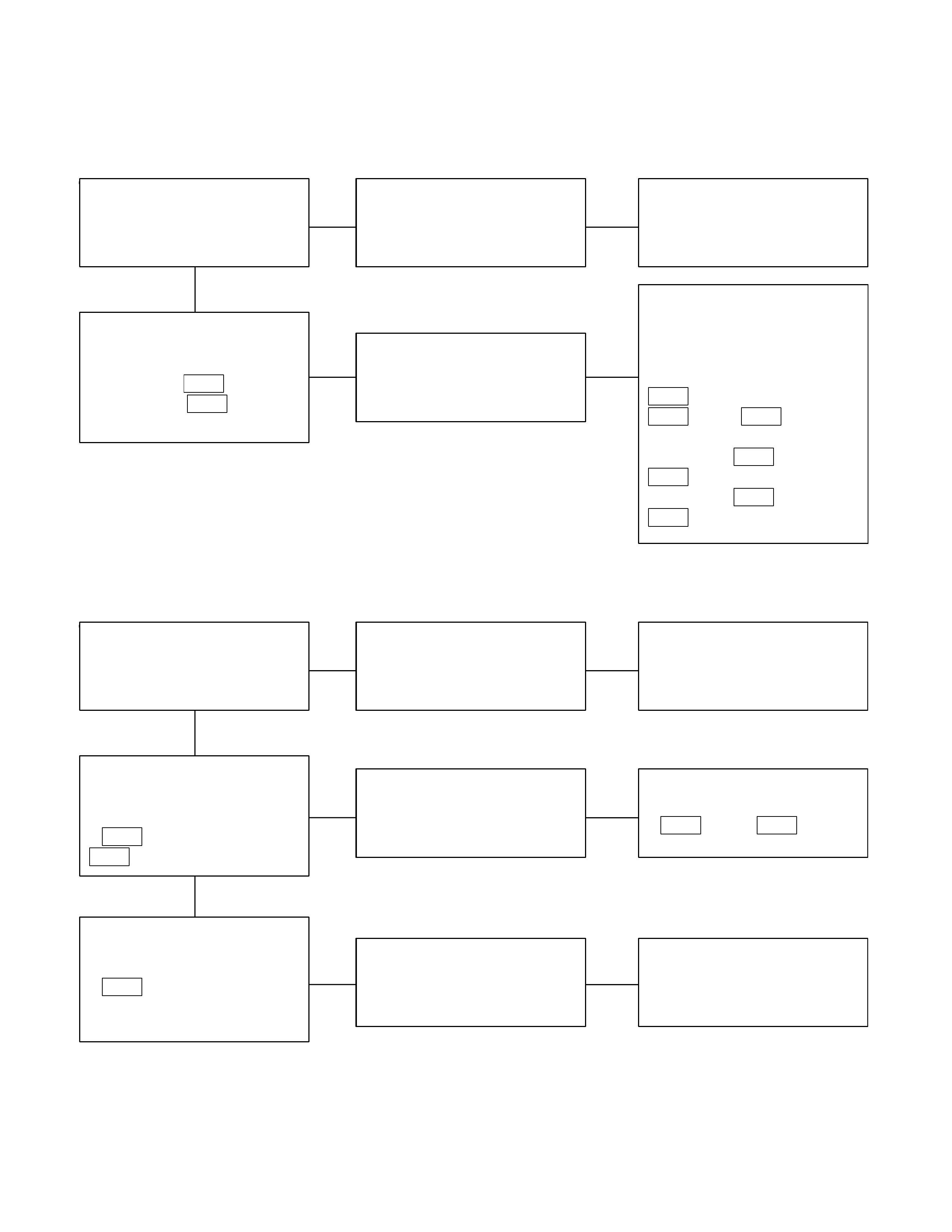

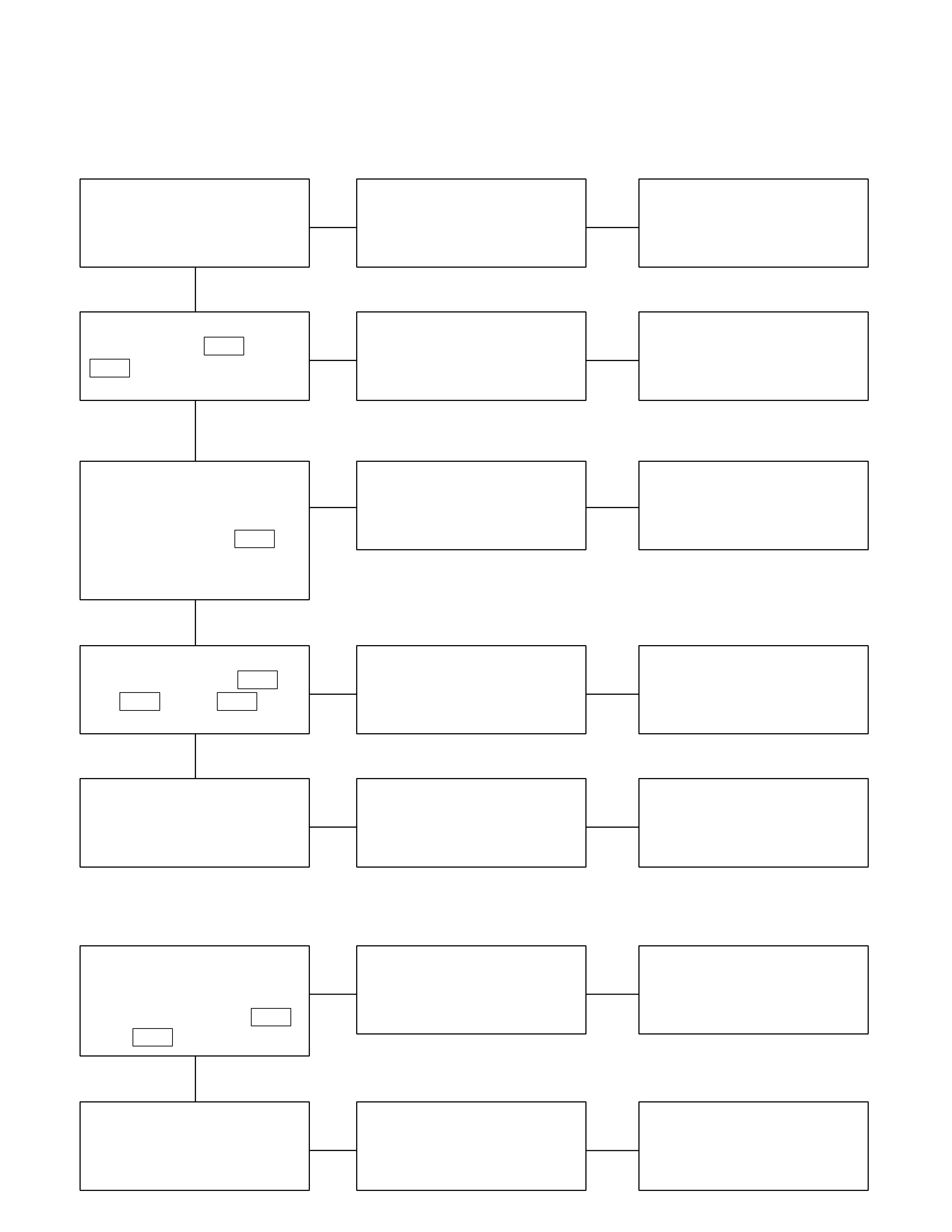

In this manual, each system has its own parts location illustration and circuit diagram.

And connector configurations used in the circuit diagram are shown at the end of this manual.

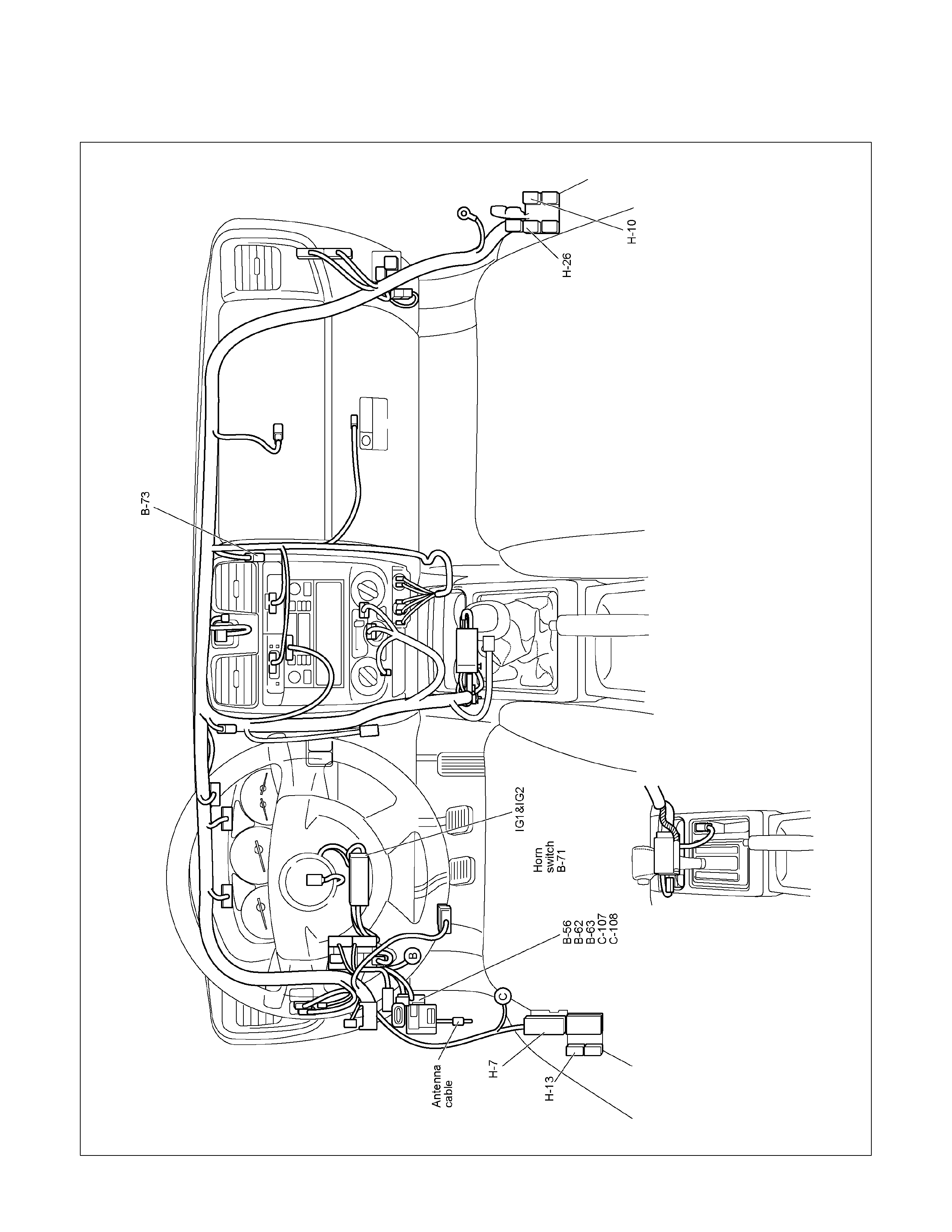

PARTS LOCATION: The parts location shows the location of the connectors 1 and the harnesses 2 used in the

each system.

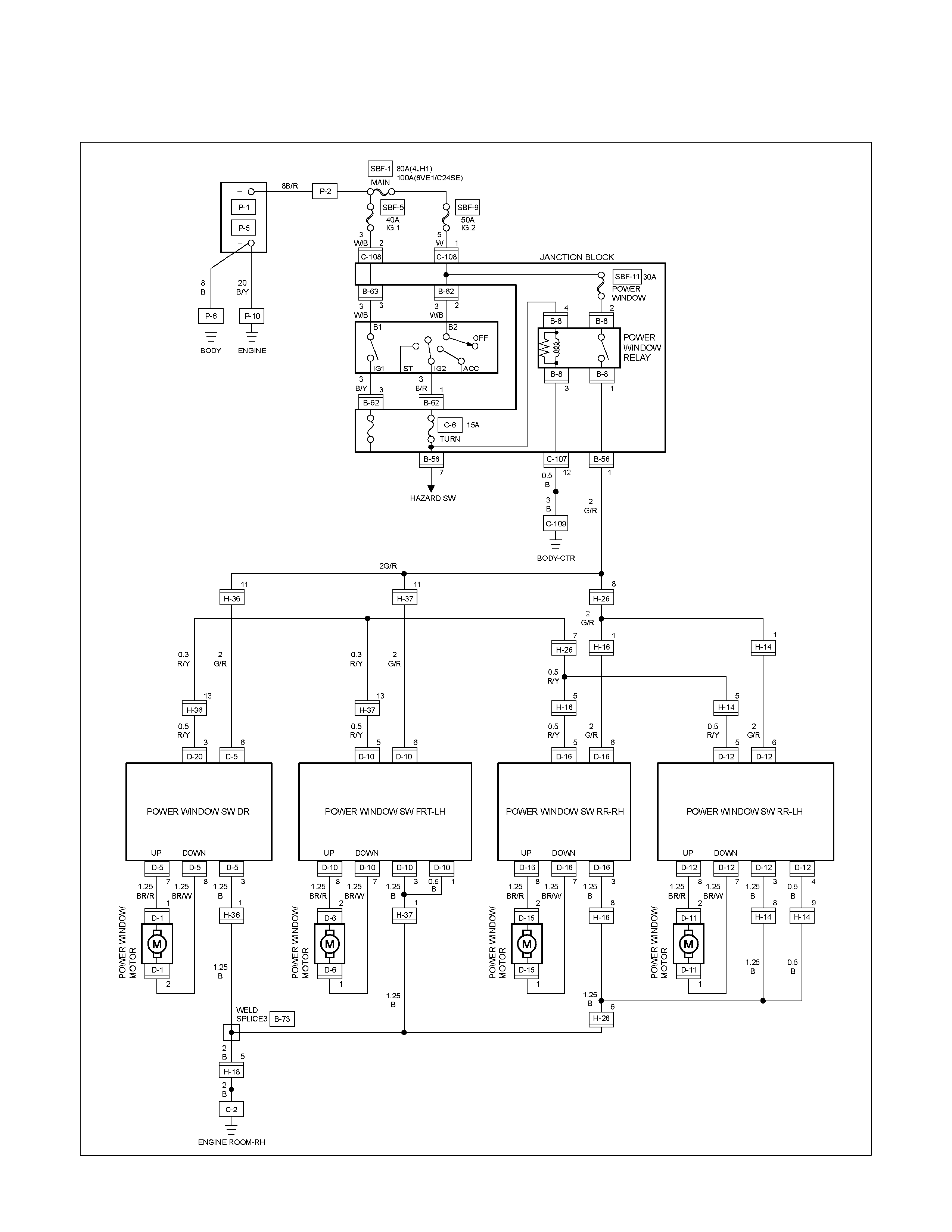

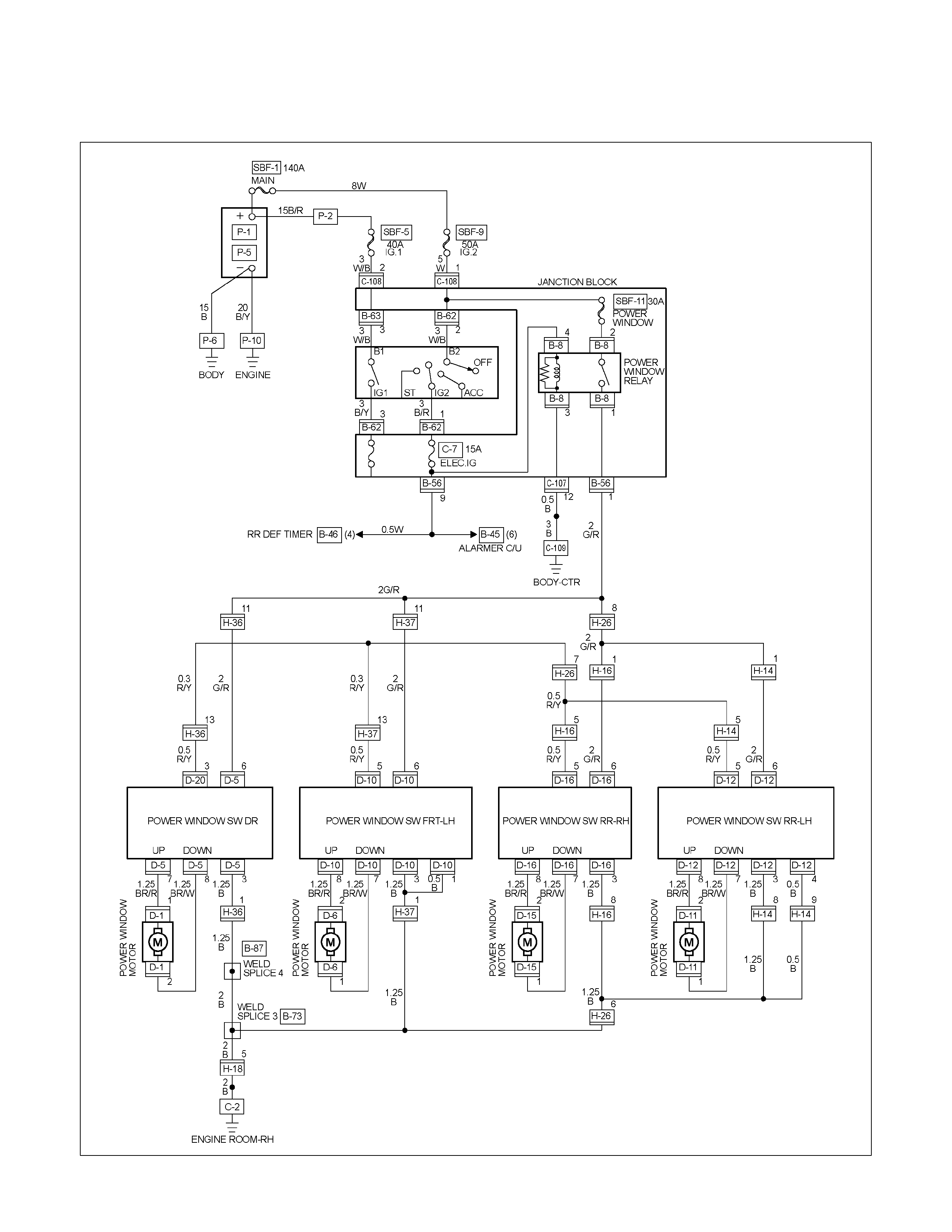

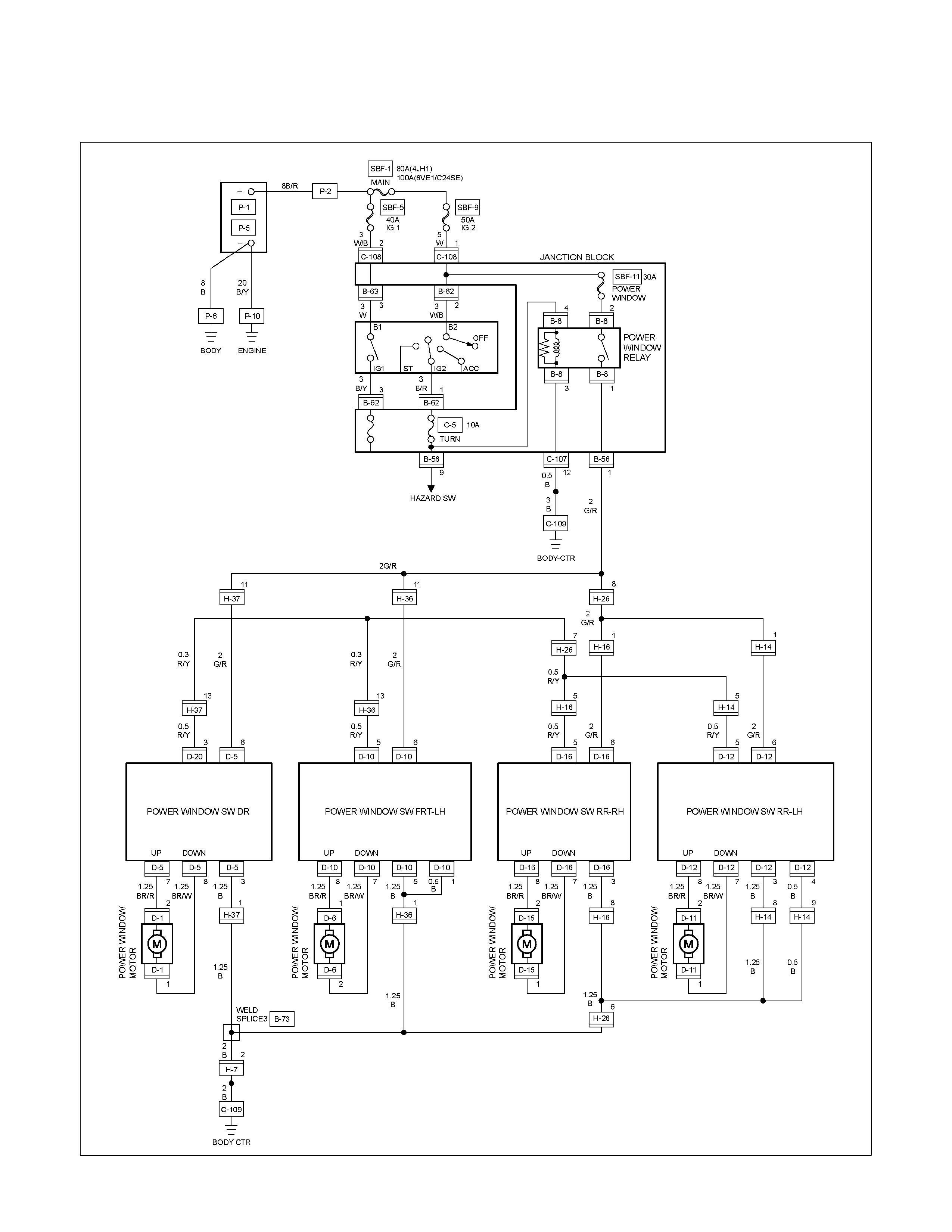

CIRCUIT DIAGRAM: The circuit diagram shows the power supply 3, the load or loads 4 and the grounding

point(s) 5.

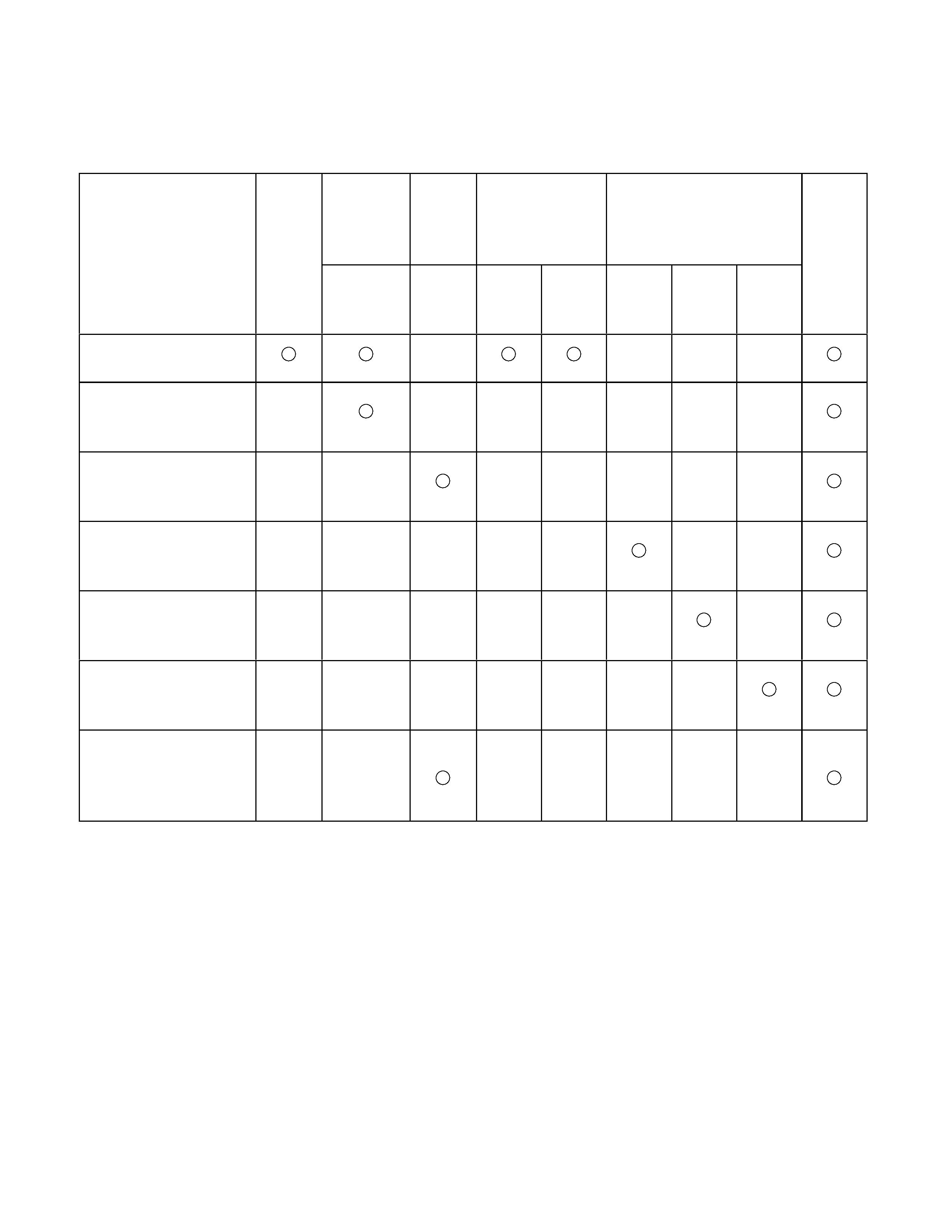

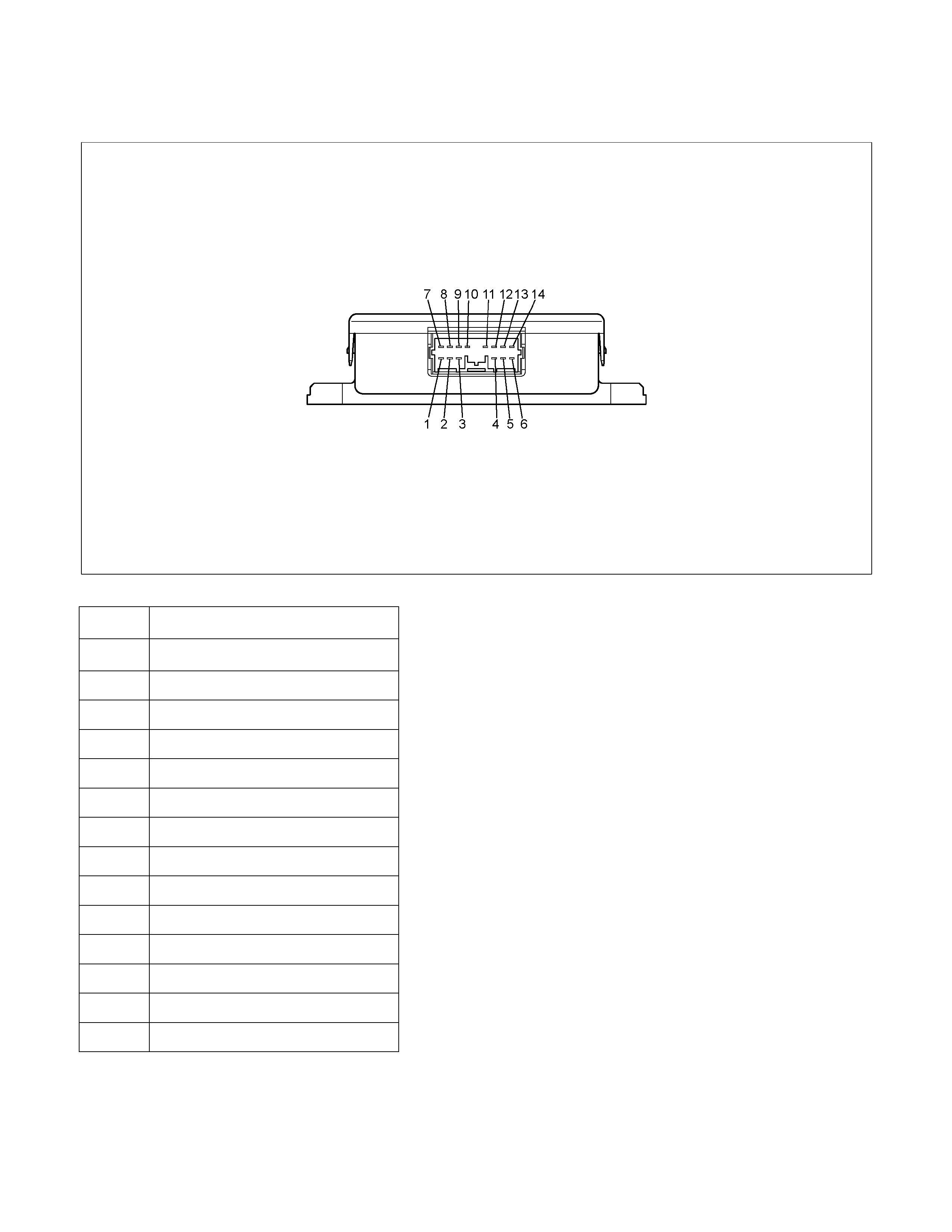

CONNECTOR LIST: The connector configuration shows each connector's number 6, configuration 7 and the pin

numbers 8, parts name 9 , connector color 10 .

PARTS LOCATION

RTW38DMF000201

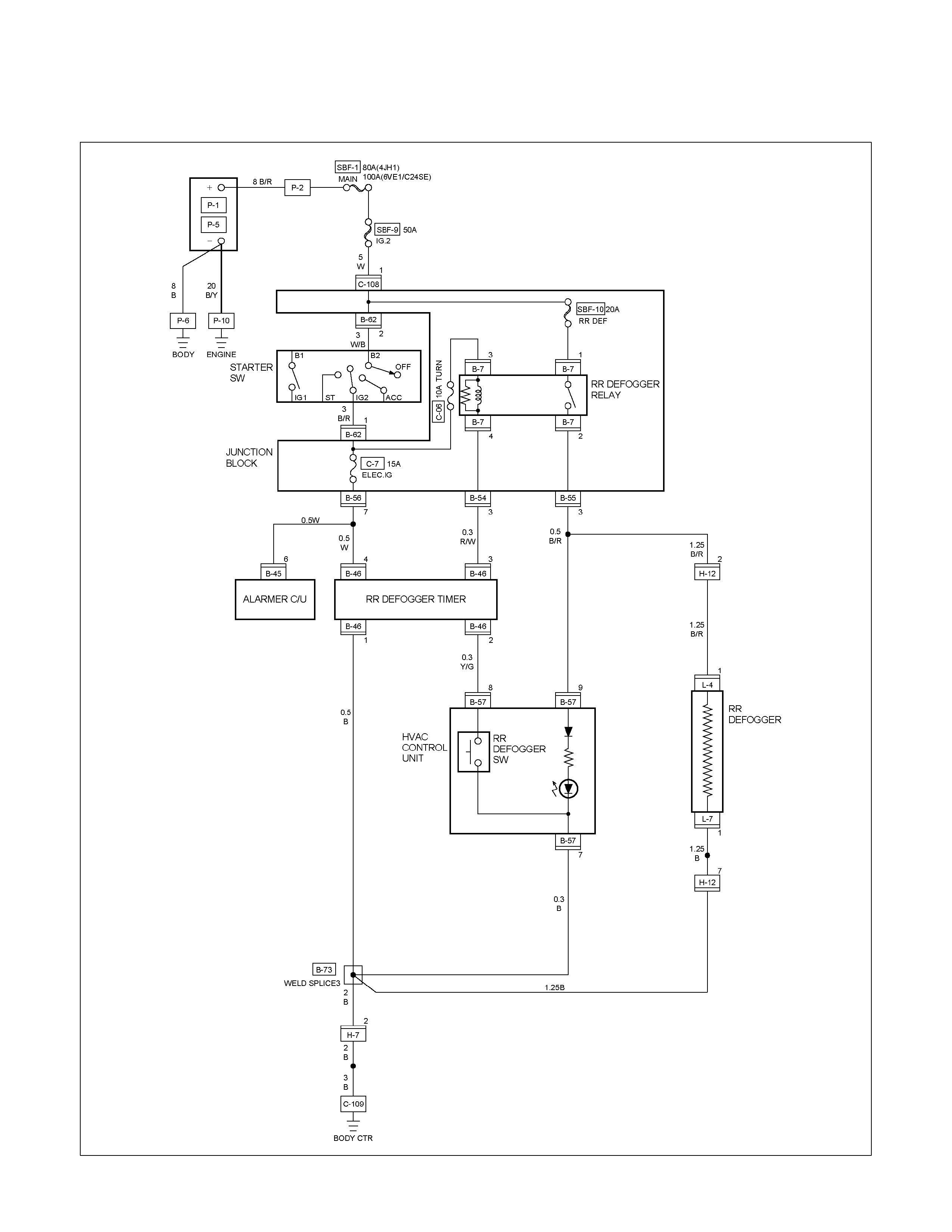

CIRCUIT DIAGRAM

CONNECTOR LIST

MAIN DATA AND SPECIFICATIONS

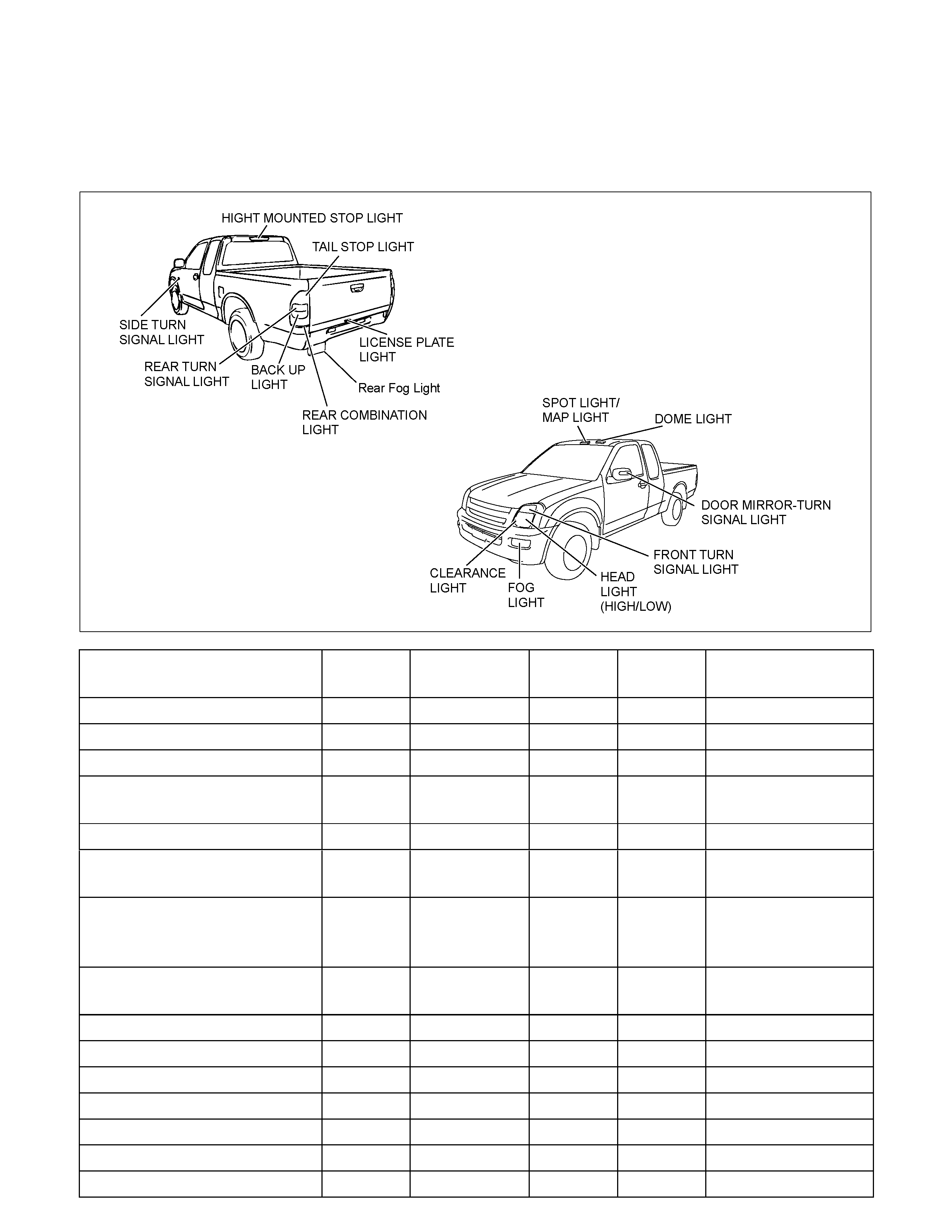

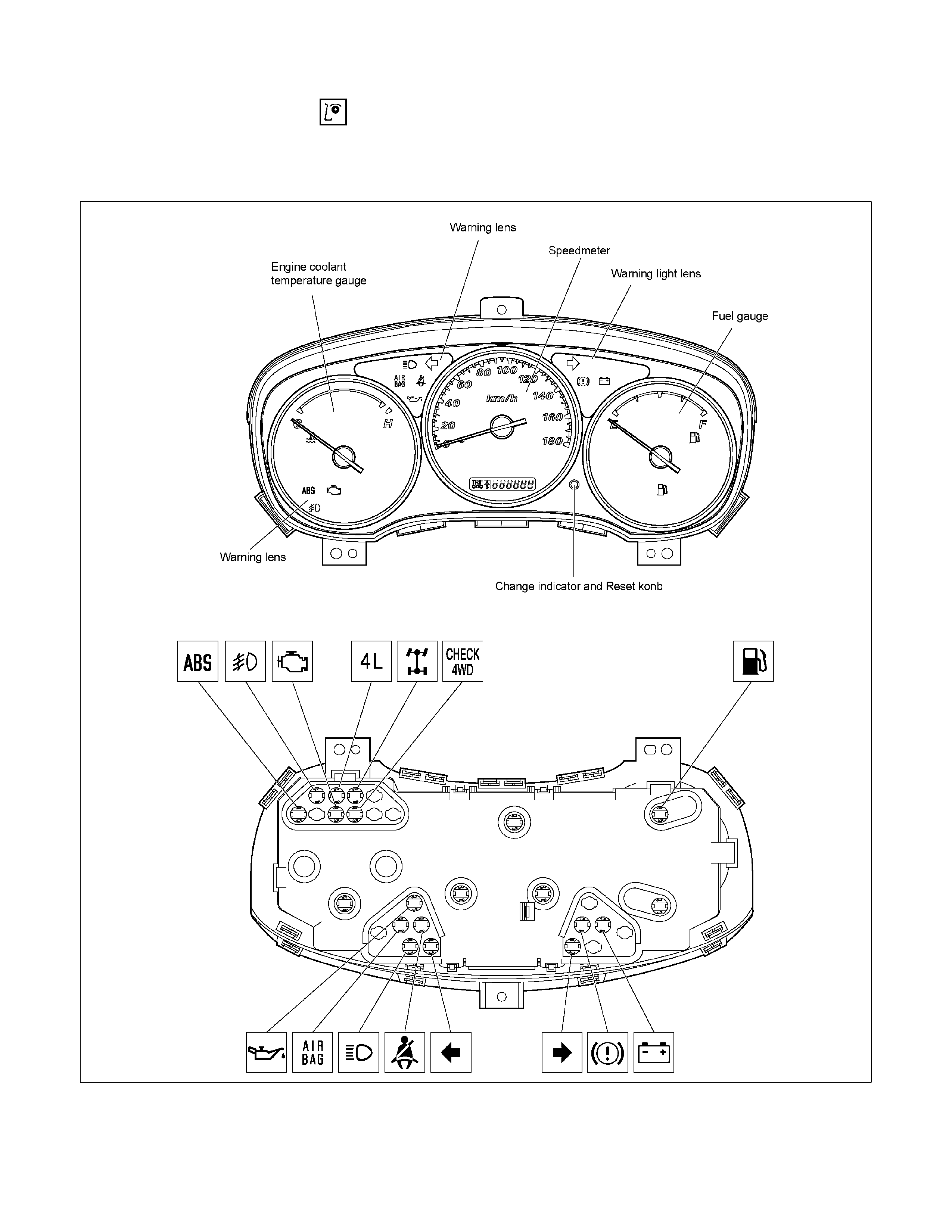

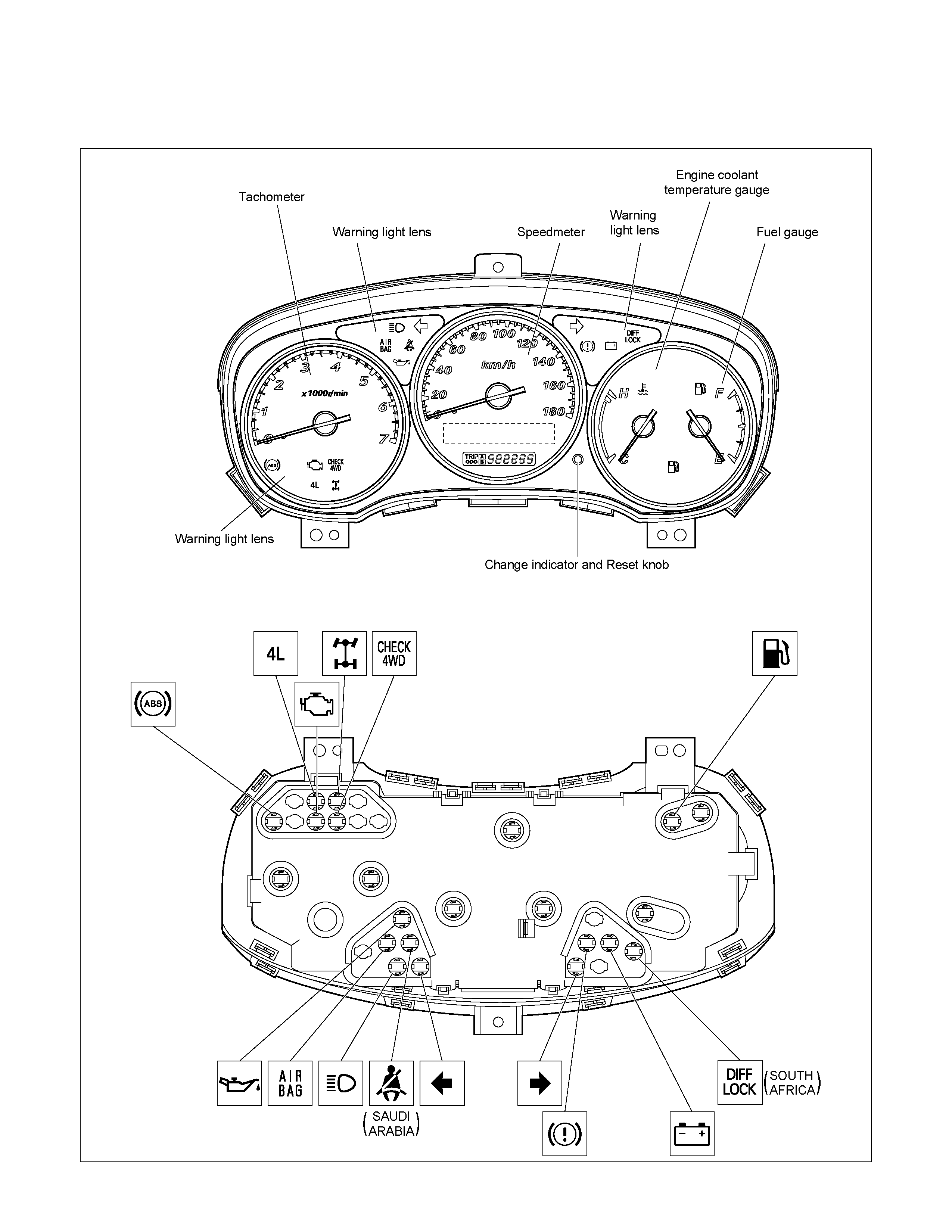

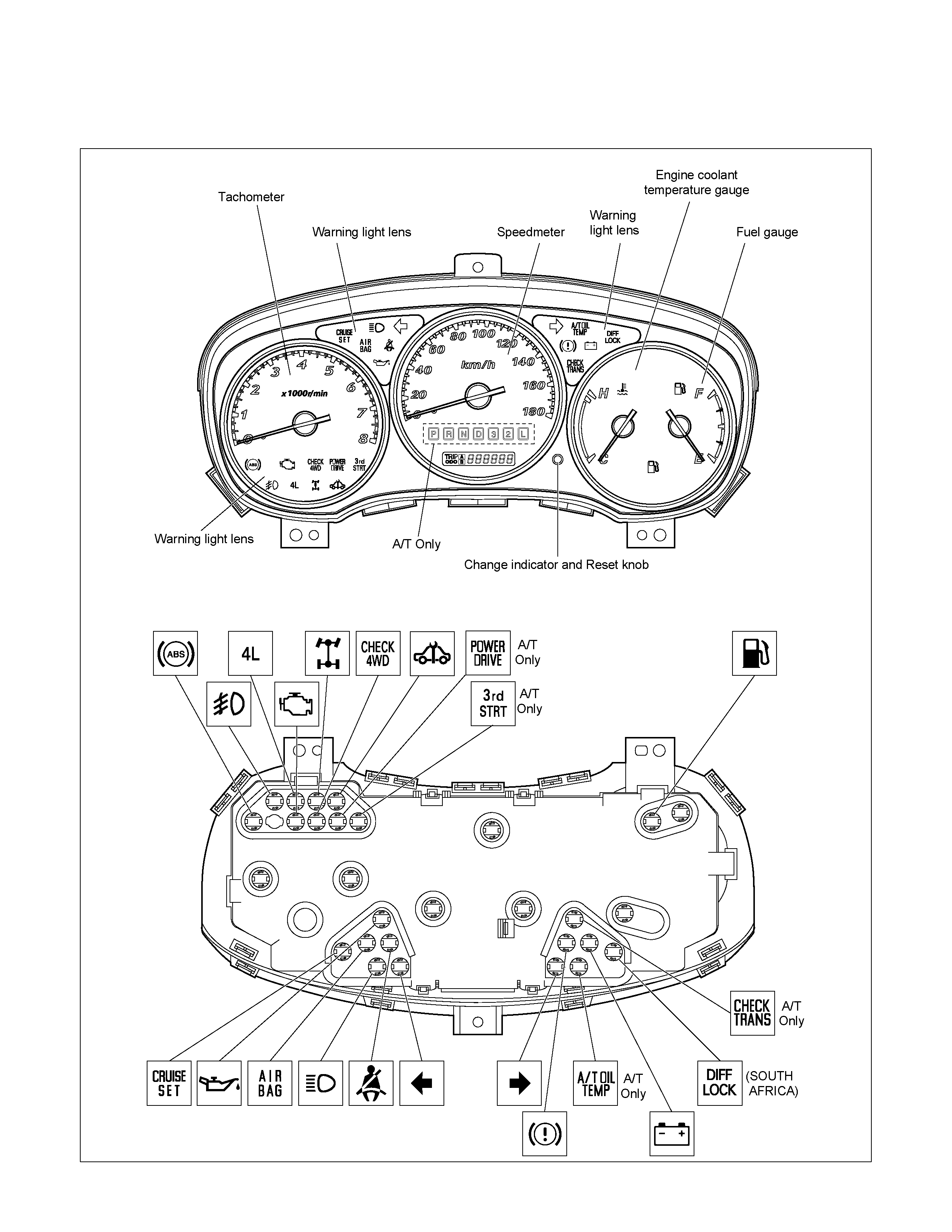

BULB SPECIFICATIONS

This illustration based on LHD

RTW68AMF004901

Light Name Bulb No. Rated Power

V-W Number

of Bulbs Lens

Color Remarks

Headlight H4 12-60/55 2 White Halogen

High mounted stop light W5W 12-5 4 RED

Fog light H3 12-55 2 White

Front turn signal light PY21W 12-21 2 White Bulb Lens color

Amber

Clearance light W5W 12-5 2 White

Door mirror-turn signal light

(out side mirror type) - - 2 White LED (Illuminated

color Amber)

Side turn signal light W5W 12-5 2 White with

amber

inner lens

Rear turn signal light PY21W 12-21 2 White Bulb Lens color

Amber

Rear fog light P21W 12-21 1 Red

Tail and stop light P21/5W 12-21/5 2 Red

Back up light P21W 12-21 2 White

License plate light W5W 12-5 2 White

A/C-Heater control light - 12-0.7 1 -

Dome light - 12-10 1 White

Spot light/ Map light - 12-5 2 White

Light Name Rated Power

V-W Number of

Bulbs Lens

Color Remarks

W/O Tacho 5Illumination light 14-2 W/ Tacho 7 White

Turn Signal 14-1.12 2 Green

High Beam 14-1.12 1 Blue

Low Fuel 14-1.12 1 Amber

A/T Oil Temp 14-1.12 1 Red

Brake system 14-1.12 1 Red

4WD 14-1.12 1 Green

Seat belt 14-1.12 1 Red

Oil pressure 14-1.12 1 Red

ABS 14-1.12 1 Amber

SEDIMENTER 14-1.12 1 Red

AIR BAG 14-1.12 1 Red

Brake 14-1.12 1 Red

Charge 14-1.12 1 Red

Check Trans 14-1.12 1 Red

Check 4WD 14-1.12 1 Red

Power drive 14-1.12 1 Amber

3rd start 14-1.12 1 Green

4L 14-1.12 1 Green

Cruise Set 14-1.12 1 Green

Check Engine 14-1.12 1 Amber

SVS 14-1.12 1 Amber

Front Fog 14-1.12 1 Green

Rear fog light 14-1.12 1 Amber

Glow 14-1.12 1 Amber

P LED 1 Green

R LED 1 Green

N LED 1 Green

D LED 1 Green

3 LED 1 Green

2 LED 1 Green

Indicator/

Warning

light

A/T shift

indicator

L LED 1 Green

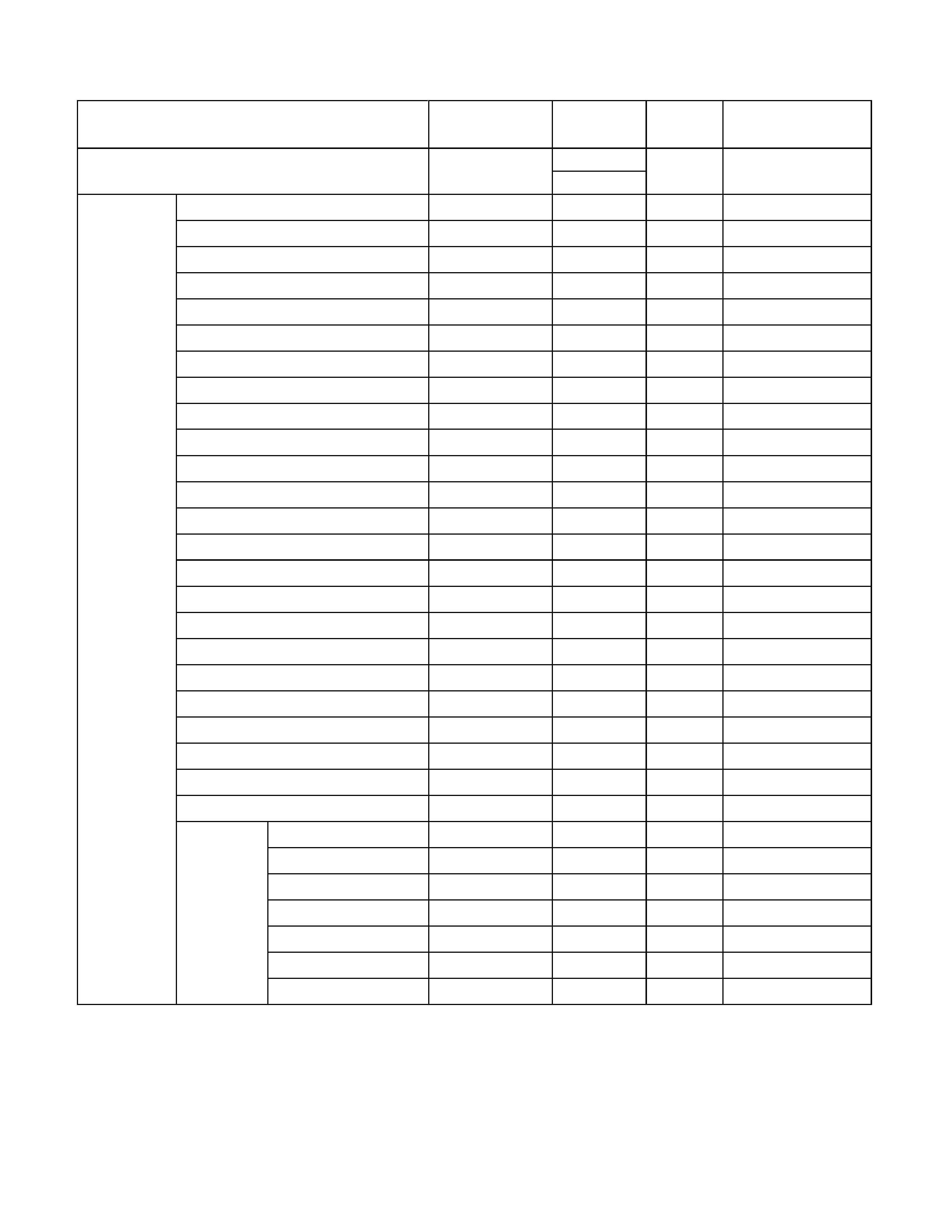

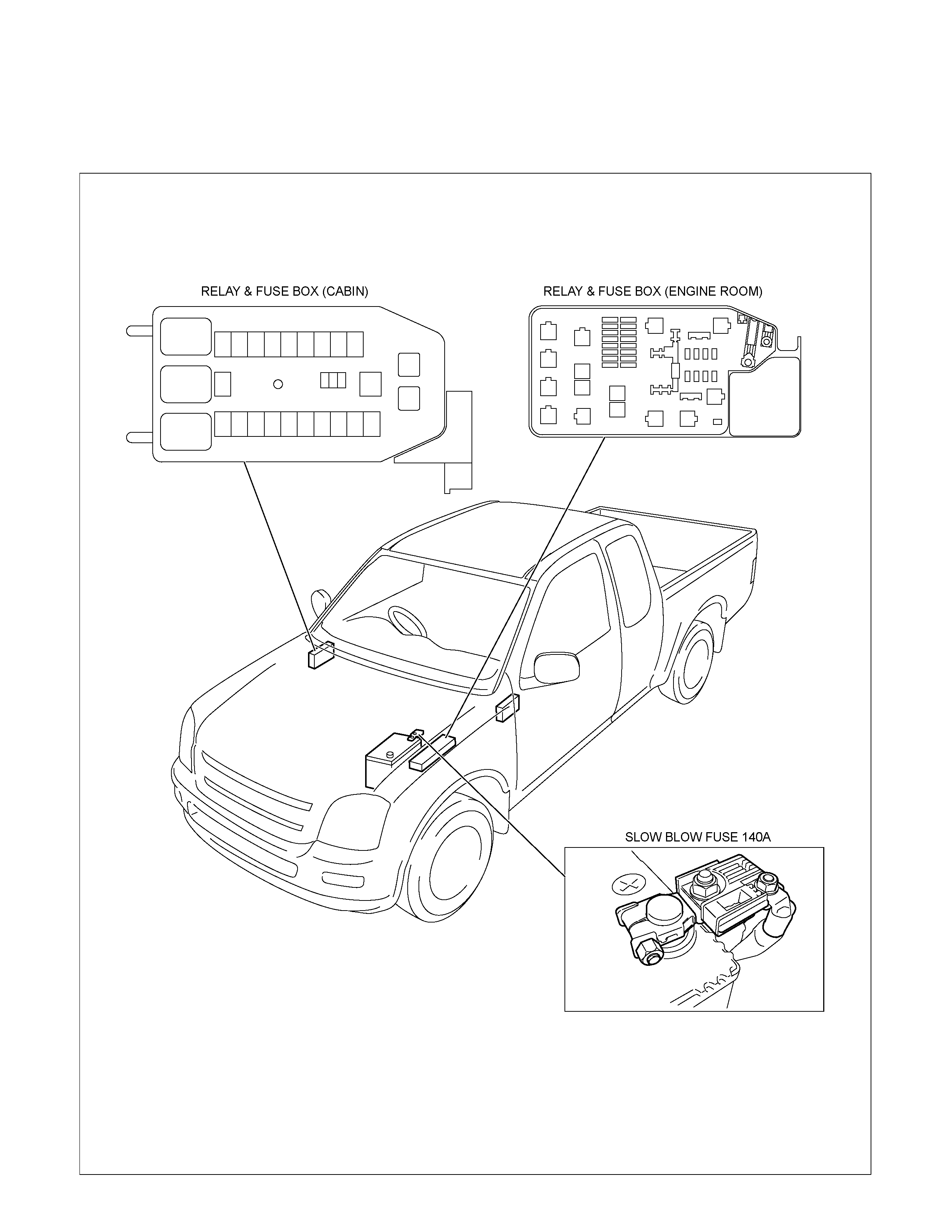

RELAY AND FUSE

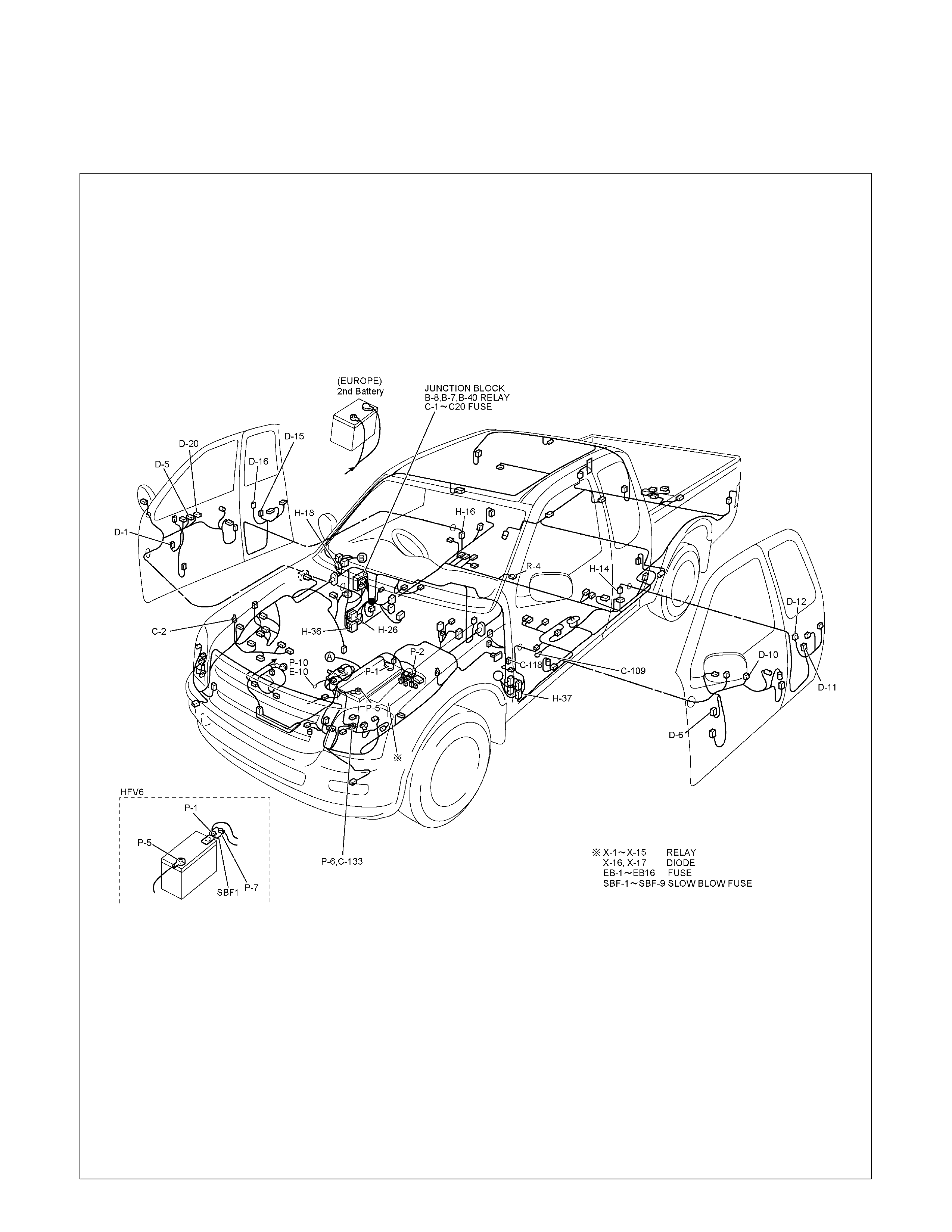

RELAY AND FUSE BOX LOCATION (RHD)

RTW68AXF009901

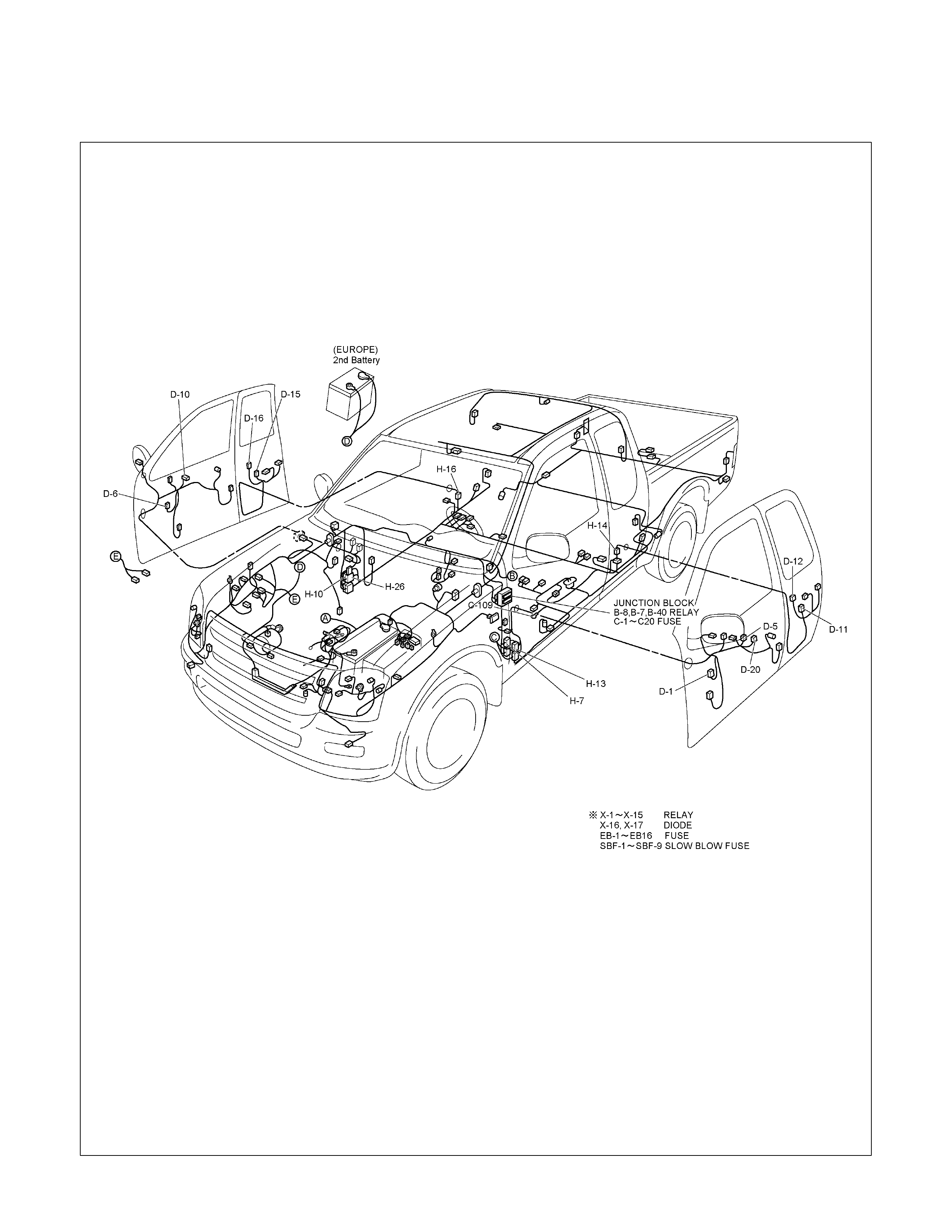

RELAY AND FUSE BOX LOCATION (LHD)

RTW48ALF000201

RELAY LOCATION

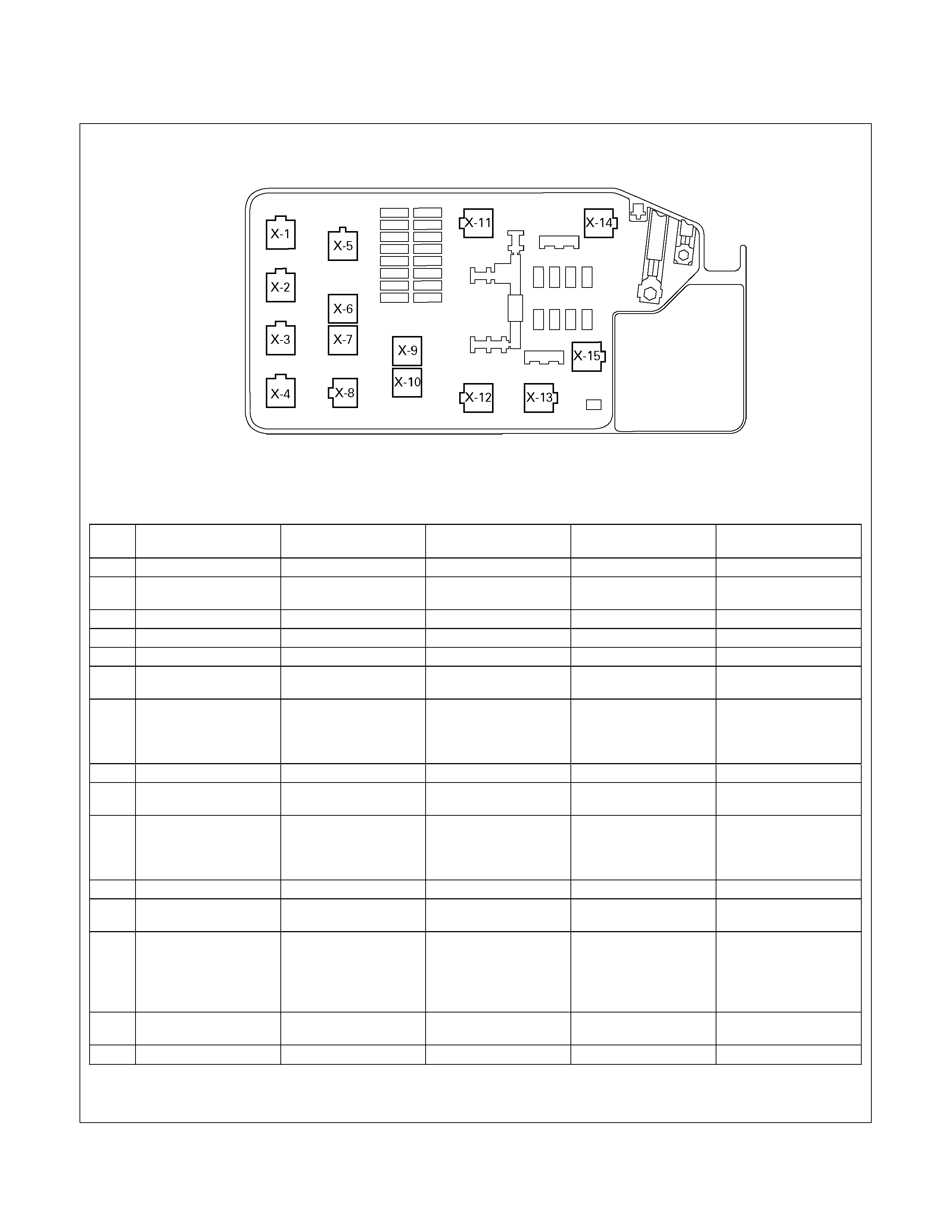

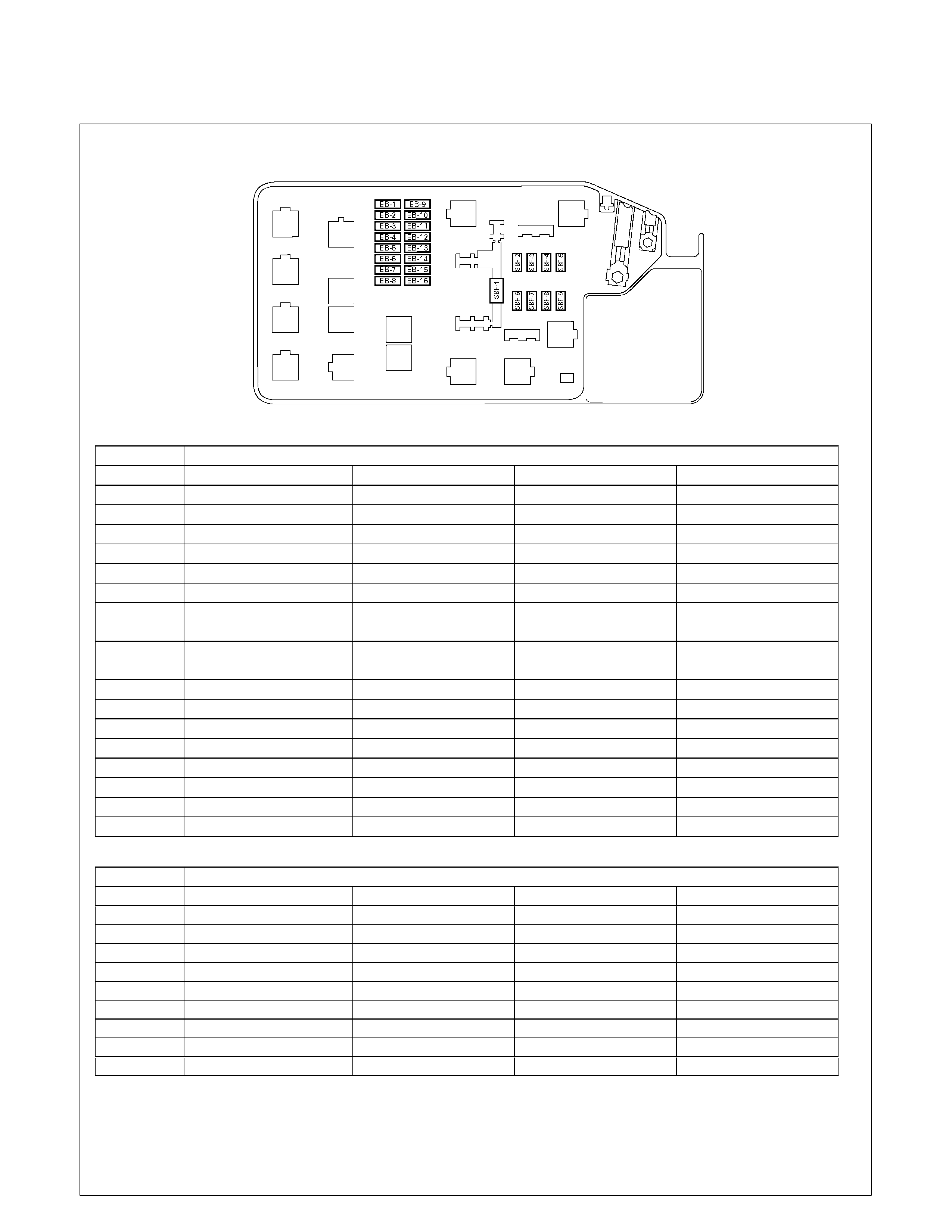

RELAY & FUSE BOX (ENGINE ROOM)

RHD

NO. RELEY (C24SE) RELAY (6VE1) RELAY

(4JA1-TC 4JH1-TC) RELAY (4JA1-L) RELAY (HFV6)

X-1 RELAY; TAIL LIGHT ← ← ← ←

X-2 RELAY; FUEL PUMP ← RELAY; FRT FOG

LIGHT ← RELAY; FUEL PUMP

X-3 RELAY; HORN ← ← ← ←

X-4 RELAY; DIMMER ← ← ← ←

X-5 ⎯ ⎯ RELAY; GLOW ← ⎯

X-6 RELAY; STARTER ← RELAY; STARTER

CUT (EURO 3) RELAY; CSD ⎯

X-7 RELAY; HEAD LIGHT

(Except AUSTRALIA)

RELAY; COND. FAN

(AUSTRALIA)

RELAY; HEAD LIGHT RELAY; HEAD LIGHT

(EURO 3) RELAY; HEAD LIGHT ⎯

X-8 ⎯ ⎯ RELAY; STARTER ← ⎯

X-9 RELAY; FRT FOG

HEAD LIGHT ← RELAY; COND. FAN ⎯ ⎯

X-10 RELAY; COND. FAN RELAY; COND. FAN RELAY; RR FOG

(EURO 3)

RELAY; HEAD LIGHT

(Except EURO 3)

⎯ RELAY; FRT FOG

LIGHT

X-11 RELAY; HEATER RELAY; HEATER RELAY; HEATER RELAY; HEATER ←

X-12 RELAY; STARTER

CUT (AUSTRALIA) RELAY; STARTER

CUT RELAY; STARTER

CUT (Except EURO 3) ⎯ REL AY; ECM MAIN

X-13 RELAY; STARTER

CUT (Except

AUSTRALIA)

RELAY; HEAD LIGHT

(AUSTRALIA)

RELAY; ECM MAIN RELAY; ECM MAIN RELAY; COND. FAN RELAY; STARTER

X-14 RELAY; A/C COMP RELAY; A/C COMP RELAY; A/C COMP RELAY; STARTER

CUT RELAY; A/C COMP

X-15 RELAY; THERMO RELAY; THERMO RELAY; THERMO RELAY; THERMO RELAY; HEAD LIGHT

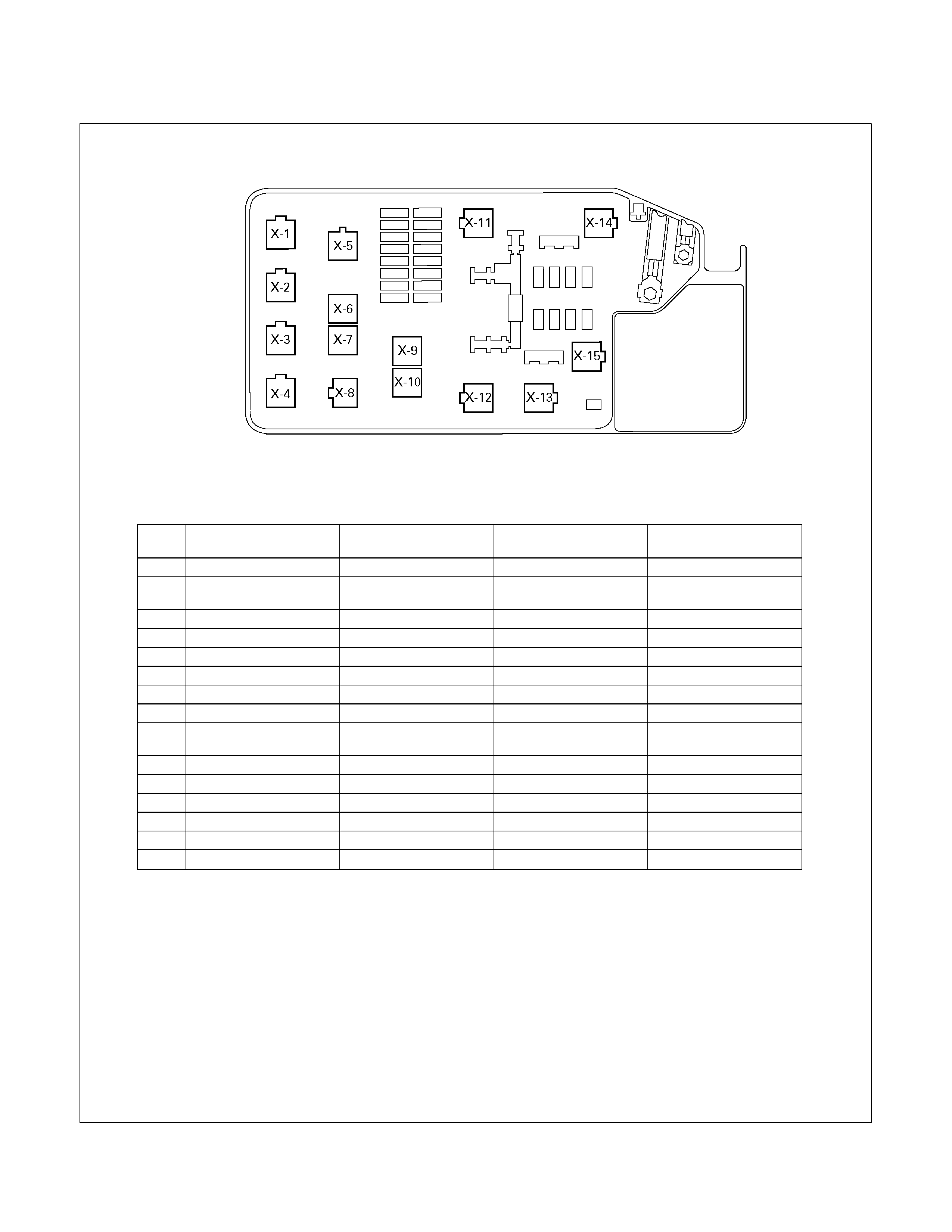

RELAY LOCATION

RELAY & FUSE BOX (ENGINE ROOM)

LHD

NO. RELEY (C24SE) RELAY; (6VE1) RELAY

(4JA1-TC 4JH1-TC) RELAY (4JA1-L)

X-1 RELAY; TAIL LIGHT ← ← ←

X-2 RELAY; FUEL PUMP ← RELAY; FRT FOG

LIGHT ←

X-3 RELAY; HORN ← ← ←

X-4 RELAY; DIMMER ← ← ←

X-5 ⎯ ⎯ RELAY; GLOW ←

X-6 RELAY; STARTER ← RELAY; STARTER CUTRELAY; CSD

X-7 RELAY; HEAD LIGHT ← ← ←

X-8 ⎯ ⎯ RELAY; STARTER ←

X-9 RELAY; FRT FOG

HEAD LIGHT ← RELAY; COND FAN ⎯

X-10 RELAY; COND. FAN RELAY; COND. FAN RELAY; RR FOG ⎯

X-11 RELAY; HEATER ← ← ←

X-12 ⎯ RELAY; STARTER CUTSHORT CONNECTOR ⎯

X-13 RELAY; STARTER CUT RELAY; ECM MAIN ← RELAY; COND. FAN

X-14 RELAY; A/C COMP ← ← REL AY; STARTER CUT

X-15 RELAY; THERMO ← ← ←

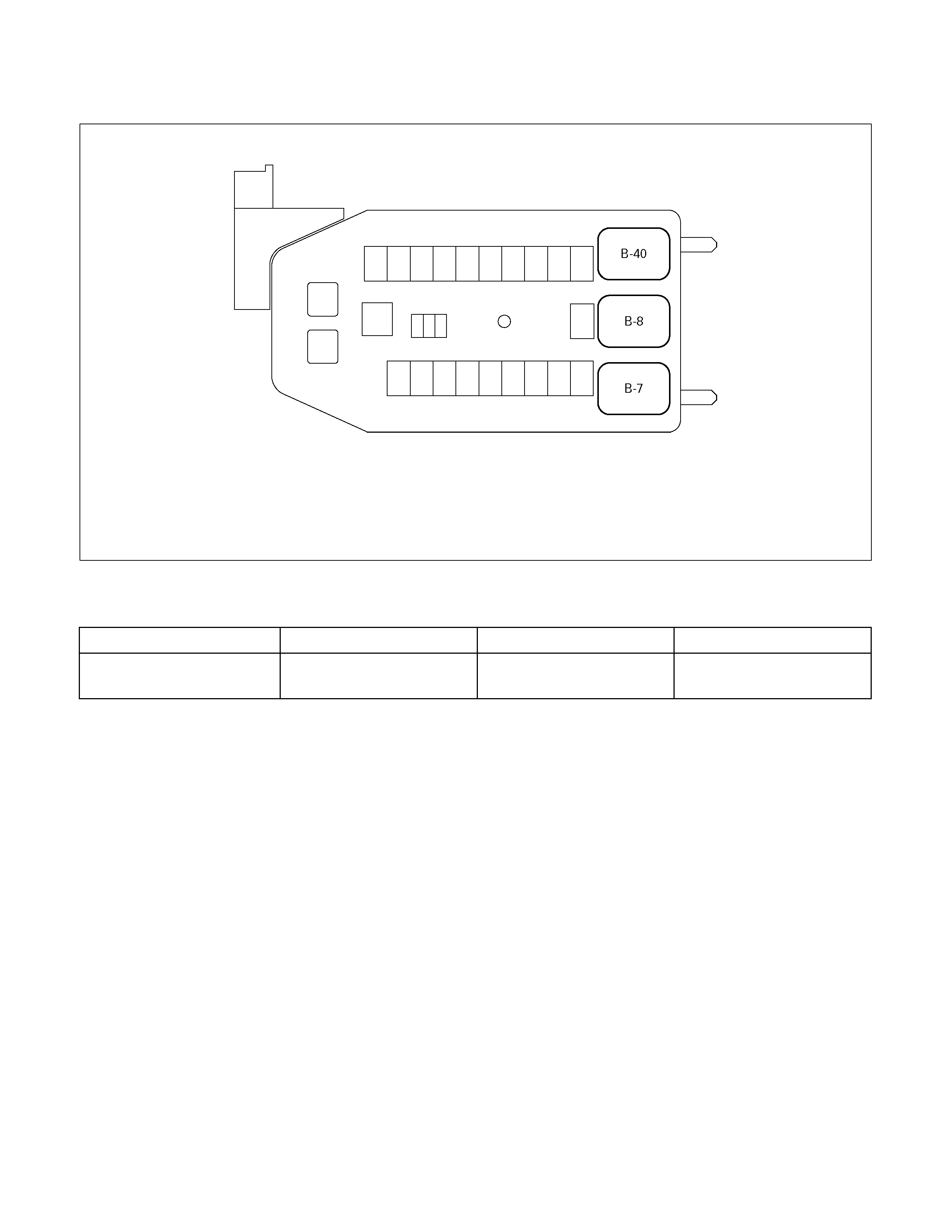

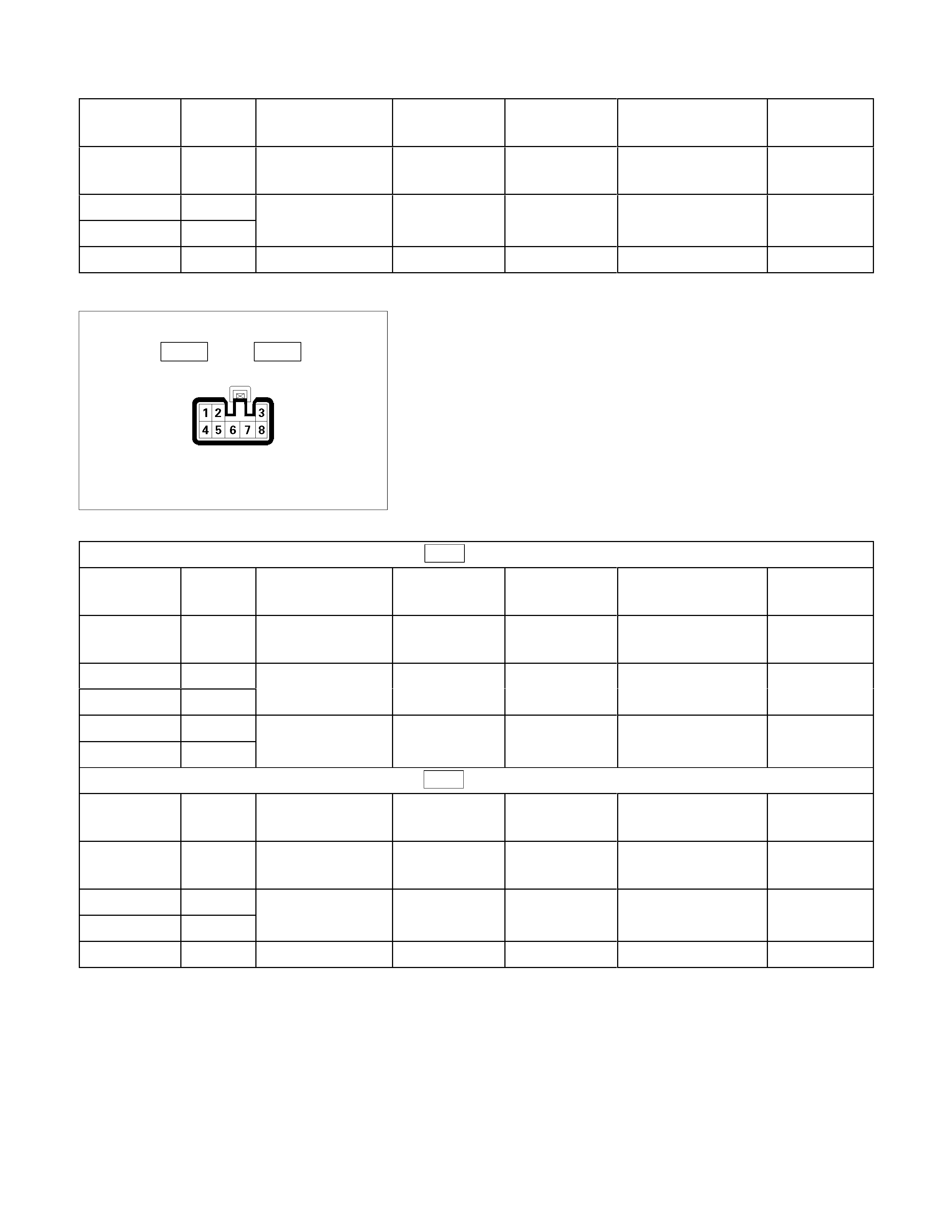

RELAY LOCATION

RELAY & FUSE BOX (CABIN)

RELAY

Connector No. B-7 B-8 B-40

Relay name REAR DEFOGGER POWER WINDOW (NO RELAY)

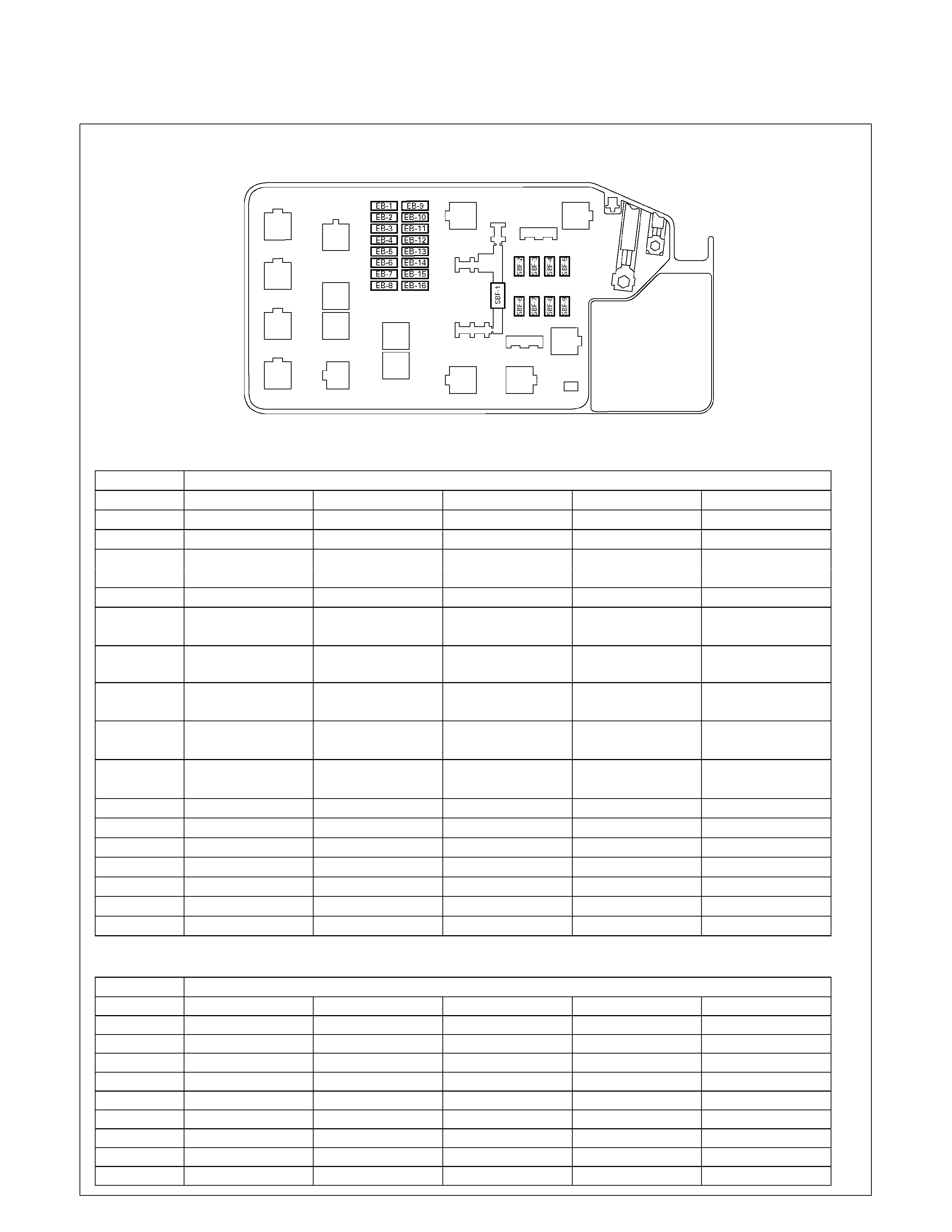

FUSE AND SLOW BLOW FUSE LOCATION

RELAY & FUSE BOX (ENGINE ROOM)

RHD

∗1 AUSTRALIA

FUSE ∗2 EMISSION SYSTEM EURO3

ENGINE MODEL

FUSE NO. C24SE 6VE1 4JH1-TC 4JA1-L HFV6

EB-1 15A ECM 20A ECM 10A ECM ⎯ 15A ECM

EB-2 ⎯ 10A ECM(B) 10A RR FOG ⎯ 15A O2S/PRE

EB-3 15A FRT FOG 10A TCM 15A FRT FOG ← 10A ECM

20A TRAILER ∗1

EB-4 10A ACG(S) 15A FRT FOG ⎯ 10A ACG(S) 10A TCM

EB-5 10A TAIL-RH 10A ILLUMI 10A ILLUMI 10A ILLUMI 10A TAIL-RH

10A TAIL-RH ∗2

EB-6 10A TAIL - LH 10A TAIL 10A TAIL ← 10A TAIL - LH

10A TAIL – LH ∗2

EB-7 10A H/L(RH) ← 10A H/L(RH) 10A H/L(RH) 10A H/L(RH)

10A H/L(RH)LO ∗2

EB-8 10A H/L(LH) ← 10A H/L(LH) 10A H/L(LH) 10A H/L(LH)

10A H/L(LH)LO ∗2

EB-9 20A F/PUMP 20A O2 SENSOR 10A TRAILER ∗2 ⎯ 20A TRAILER

20A TRAILER ∗1

EB-10 10A O2 SENSOR 20A F/PUMP 10A ACG(S) ⎯ 15A O2S POST

EB-11 ⎯ ⎯ 10A H/L(RH)HI ∗2⎯ 15A IG. COIL RH

EB-12 ⎯ ⎯ 10A H/L(LH)HI ∗2 ⎯ 15A IG. COIL LH

EB-13 10A A/C ← ← ← 10A A/C

EB-14 10A 4WD ← ← ← 10A 4WD

EB-15 10A HORN ← ← ← 10A HORN

EB-16 10A HAZARD ← ← ← 10A HAZARD

SLOW BLOW FUSE ∗ BATTERY TERMINAL

ENGINE MODEL

FUSE NO. C24SE 6VE1 4JA1-TC / 4JH1-TC 4JA1-L HFV6

SBF-1 100A MAIN ← 80A MAIN ← 140A MAIN ∗

SBF-2 ⎯ ⎯ 20A COND, FAN ⎯ 20A FRT FOG

SBF-3 ⎯ ⎯ 60A GLOW 20A COND, FAN 60A RAD. FAN

SBF-4 20A COND, FAN ← 30A ECM 50A GLOW 20A F/PUMP

SBF-5 40A IG 1 ← ← ← ←

SBF-6 ⎯ 40A ABS-1 ← ← ←

SBF-7 ⎯ 30A ABS-2 ← ← ←

SBF-8 30A BLOWER ← ← ← ←

SBF-9 50A IG 2 ← ← ← ←

FUSE AND SLOW BLOW FUSE LOCATION

RELAY & FUSE BOX (ENGINE ROOM)

LHD

FUSE ∗3 WITH HEADLIGHTS LEVELING

ENGINE MODEL

FUSE NO. C24SE 6VE1 4JH1-TC 4JA1-L

EB-1 15A ECM 20A ECM 10A ECM ⎯

EB-2 ⎯ 10A ECM(B) 10A RR FOG ⎯

EB-3 15A FRT FOG 10A TCM 15A FRT FOG ←

EB-4 10A ACG(S) 15A FRT FOG ⎯ 10A ACG(S)

EB-5 10A TAIL-RH 10A ILLUMI 10A TAIL-RH ←

EB-6 10A TAIL-LH 10A TAIL 10A TAIL-LH ←

EB-7 10A H/L(RH) 10A H/L(RH) 10A H/L(RH) ←

10A H/L(RH)LO ∗3 10A H/L(RH)LO ∗3

EB-8 10A H/L(LH) 10A H/L(LH) 10A H/L(LH) ←

10A H/L(LH)LO ∗3 10A H/L(LH)LO ∗3

EB-9 20A F/PUMP 20A O2 SENSOR 10A TRAILER ⎯

EB-10 10A O2 SENSOR 20A F/PUMP 10A ACG(S) ⎯

EB-11 10 A H/L(RH)HI ∗3 ⎯ 10A H/L(RH)HI ∗3 ←

EB-12 10A H/L(LH)HI ∗3 ⎯ 10A H/L(LH)HI ∗3 ←

EB-13 10A A/C ← ← ←

EB-14 10A 4WD ← ← ←

EB-15 10A HORN ← ← ←

EB-16 10A HAZARD ← ← ←

SLOW BLOW FUSE

ENGINE MODEL

FUSE NO. C24SE 6VE1 4JA1-TC / 4JH1-TC 4JA1-L

SBF-1 100A MAIN ©

80A MAIN ←

SBF-2 ⎯ ⎯ 20A COND, FAN ⎯

SBF-3 ⎯ ⎯ 60A GL OW 20A COND, FAN

SBF-4 20 A COND, FAN ← 30A ECM 50A GLOW

SBF-5 40A IG 1 ← ← ←

SBF-6 ⎯ 40A ABS-1 ← ←

SBF-7 ⎯ 30A ABS-2 ← ←

SBF-8 30A BLOWER ← ← ←

SBF-9 50A IG 2 ← ← ←

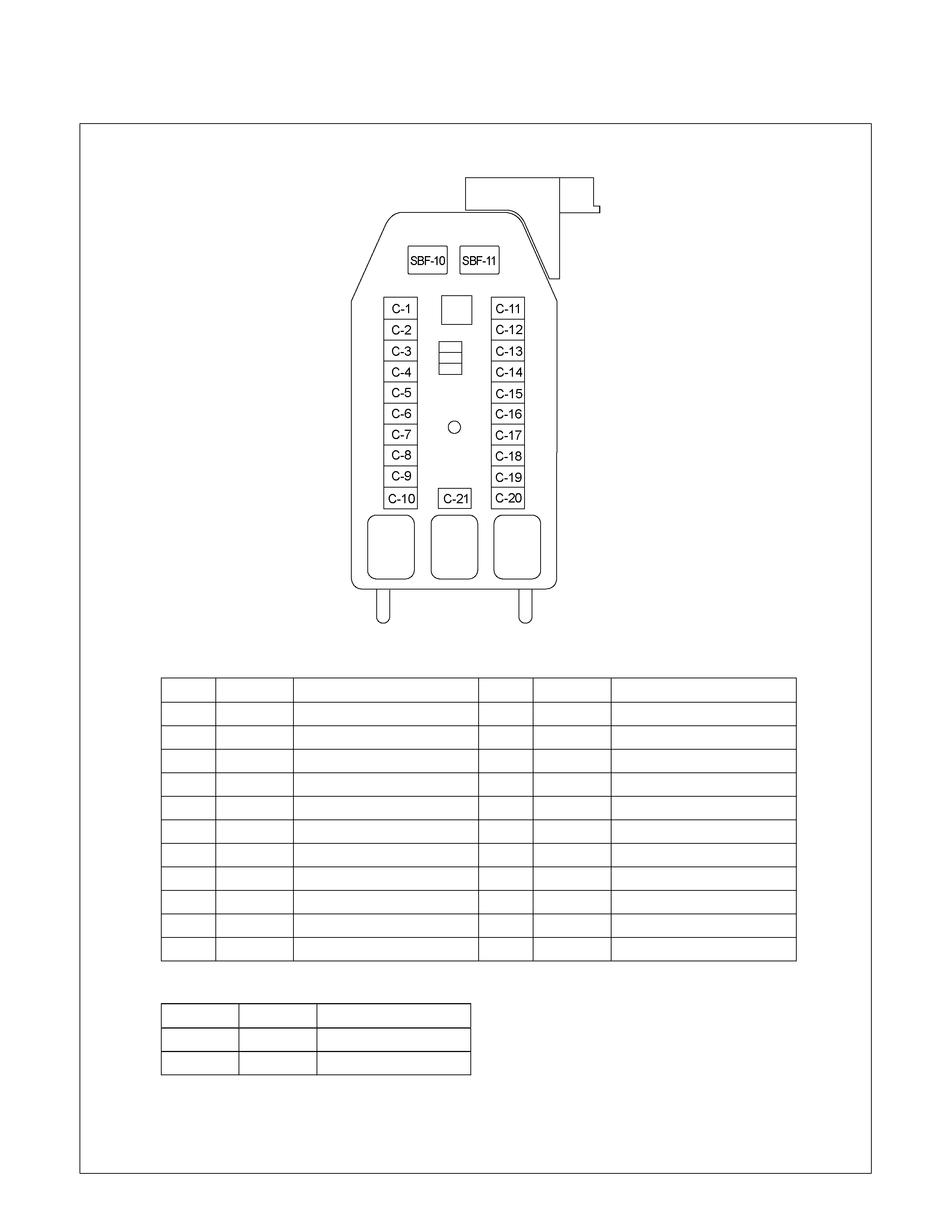

FUSE LOCATION

RHD/LHD

RTW38DMF000101

FUSE

NO. C apacity Indication on label NO. C apacity Indication on label

C -1 ⎯ ⎯ C -12 20A C IGER/ACC SO CKET

C -2 10A A B S/4W D C -13 15A AU D IO (+B )

C -3 10A TR A ILER C -14 20A D O O R LO C K

C -4 15A B A C K LIG H T C -15 10A M ETER (+B )

C -5 15A M ETER C -16 10A D O M E LIGHT

C -6 10A TU R N LIG H T C -17 10A A N TI THEFT

C -7 15A ELEC .IG C -18 15A STO P LIGHT

C -8 15A EC U C -19 ⎯ ⎯

C -9 20A FR T WIPER & W A SH ER C -20 10A STA R TER

C -10 15A EN G IN E C -21 10A SR S

C -11 10A A U D IO

SLOW BLOW FUSE

NO. C apacity Indication on label

SB F-10 20A R R DEF

SB F-11 30A P O W ER WINDOW

FUSE BOX

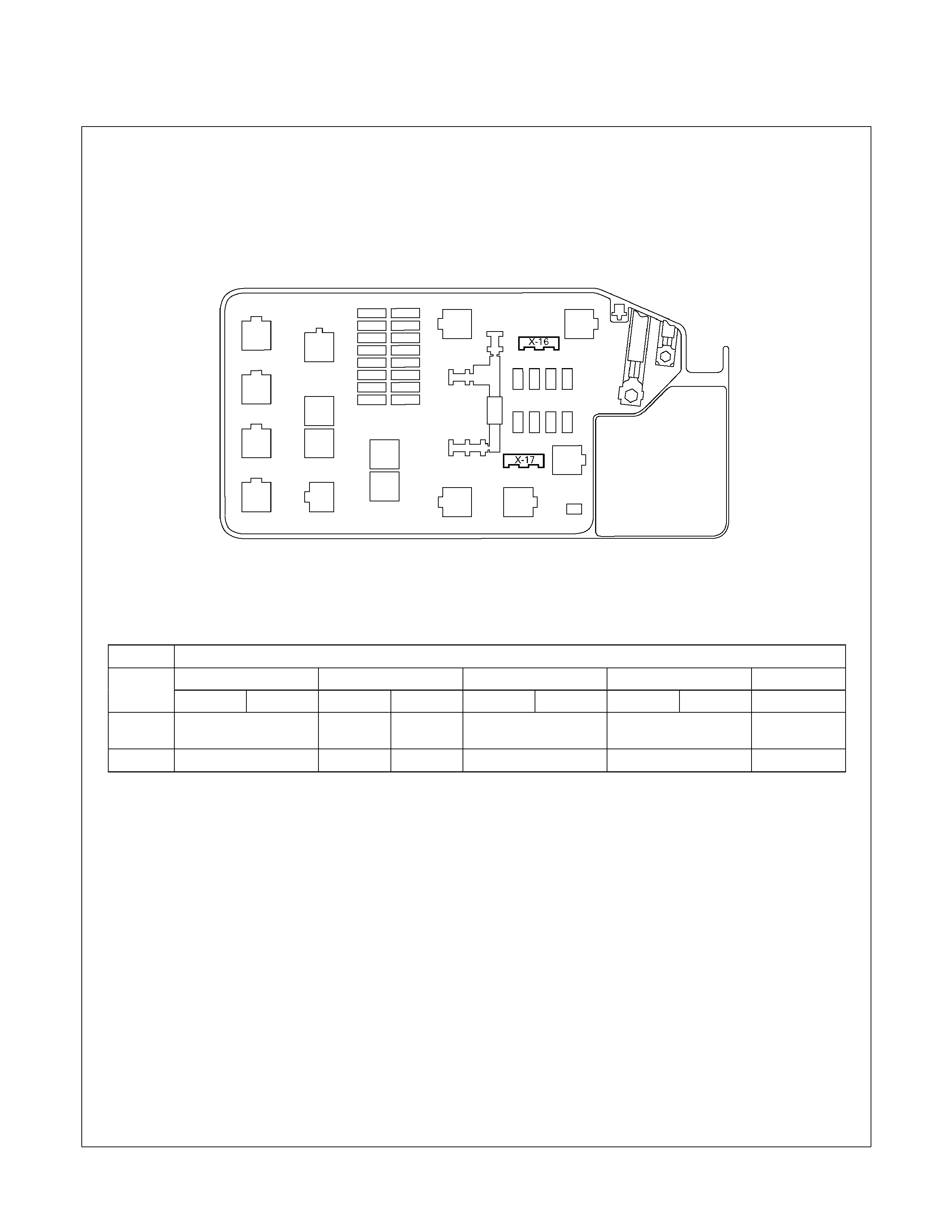

DIODE LOCATION

RELAY & FUSE BOX

DIODE

C24SE 6VE1 4JA1-TC / 4JH1-TC 4JA1-L HFV6

No. RHD LHD RHD LHD RHD LHD RHD LHD RHD

X-16 ⎯ AUTO

CRUISE ⎯ A/T A/C

⎯

X-17 ⎯ A/T A/T ⎯ ⎯ ⎯

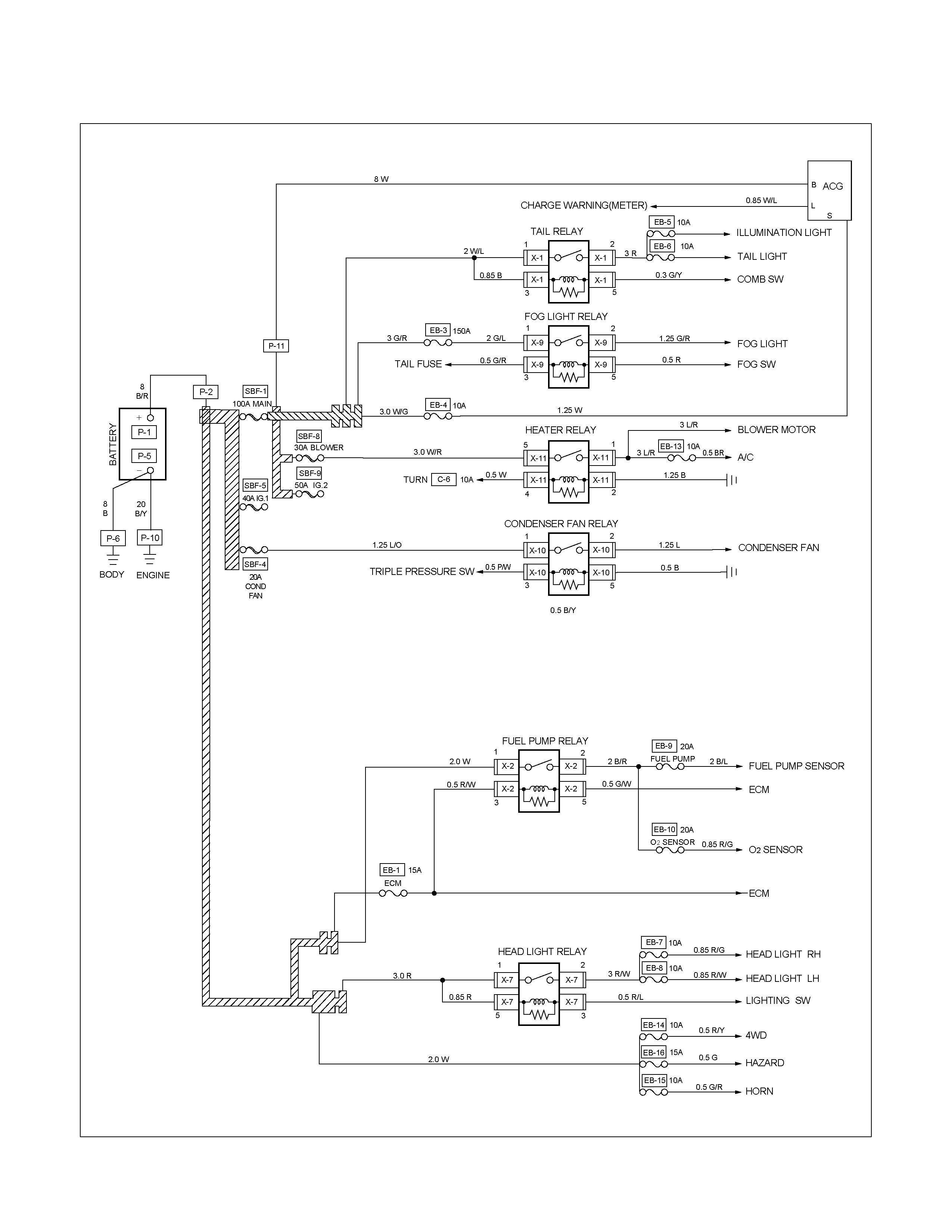

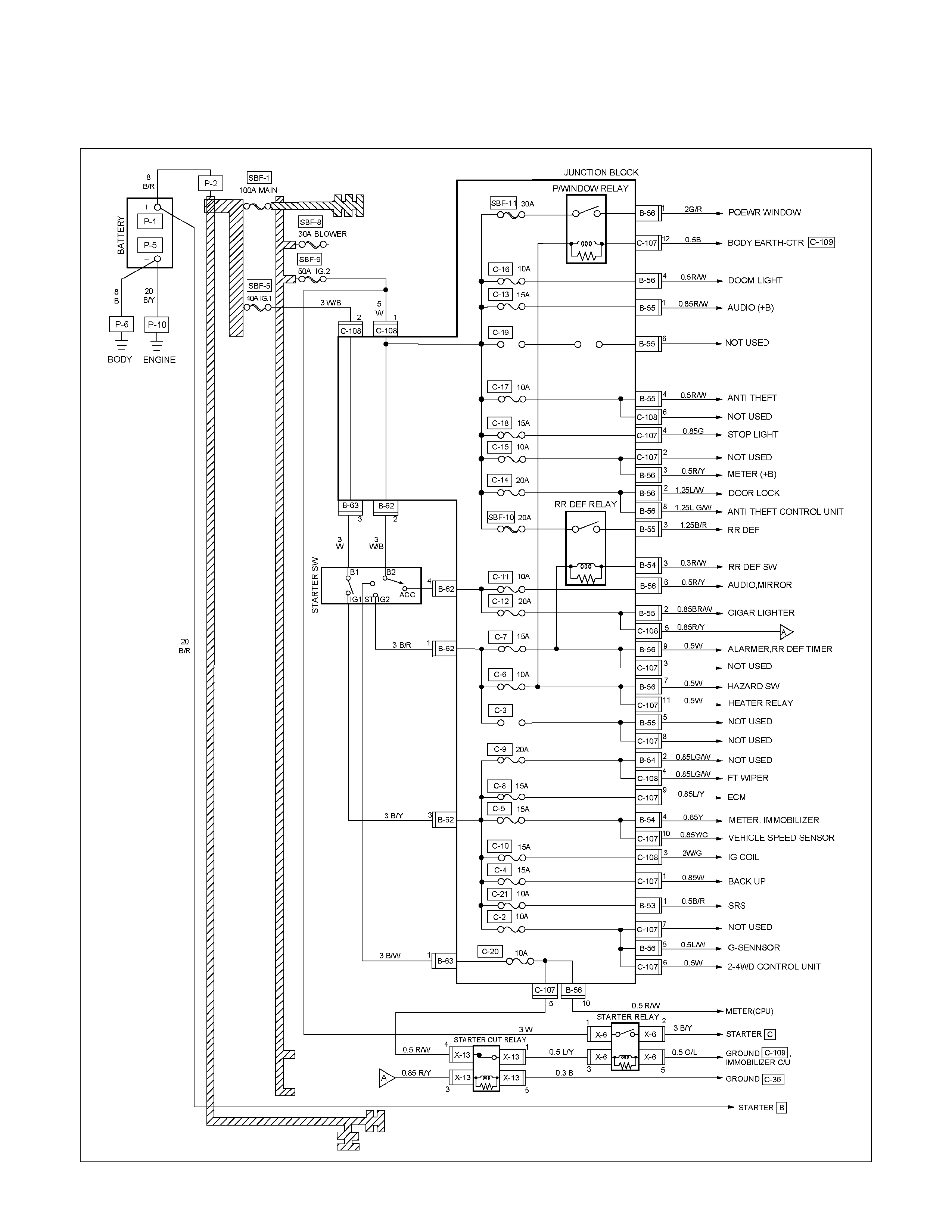

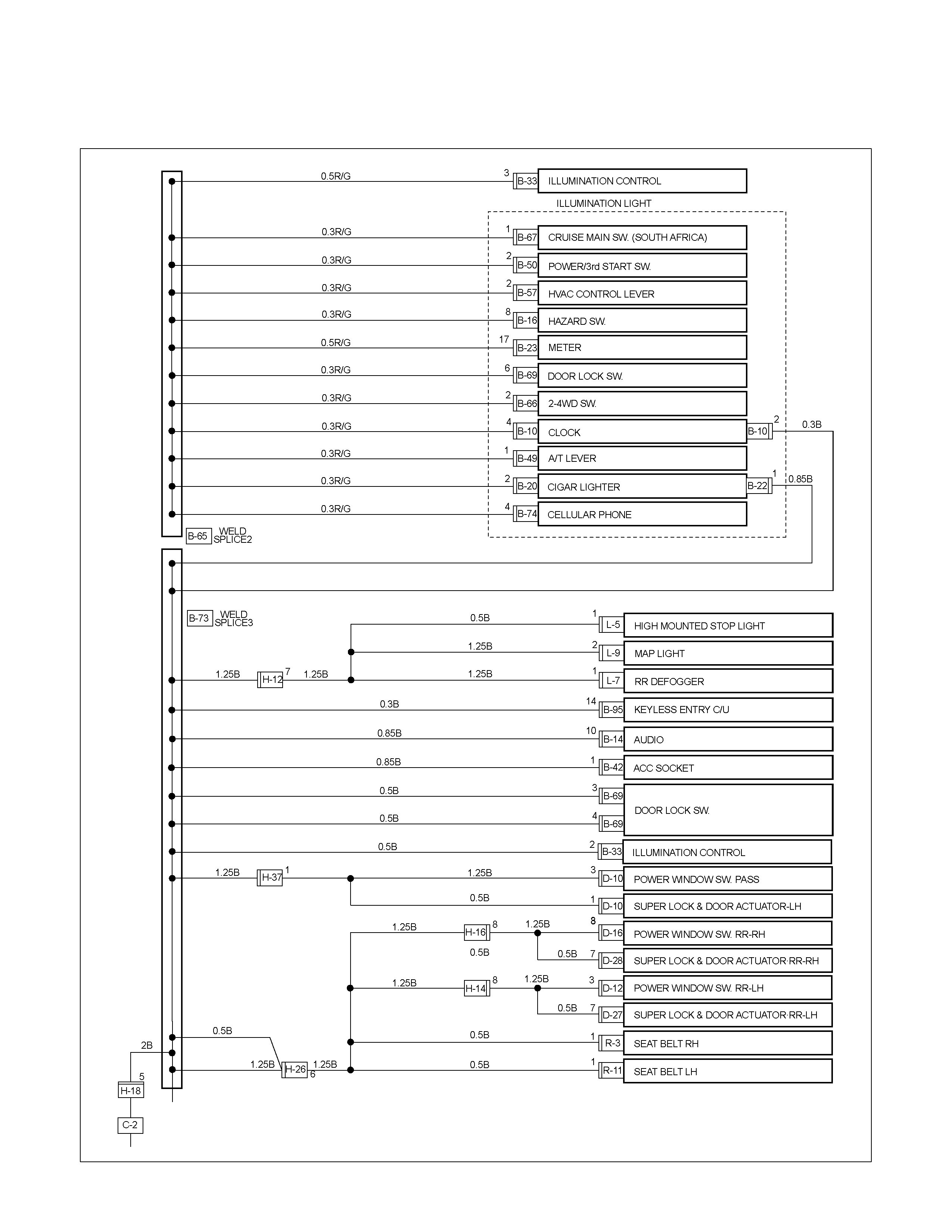

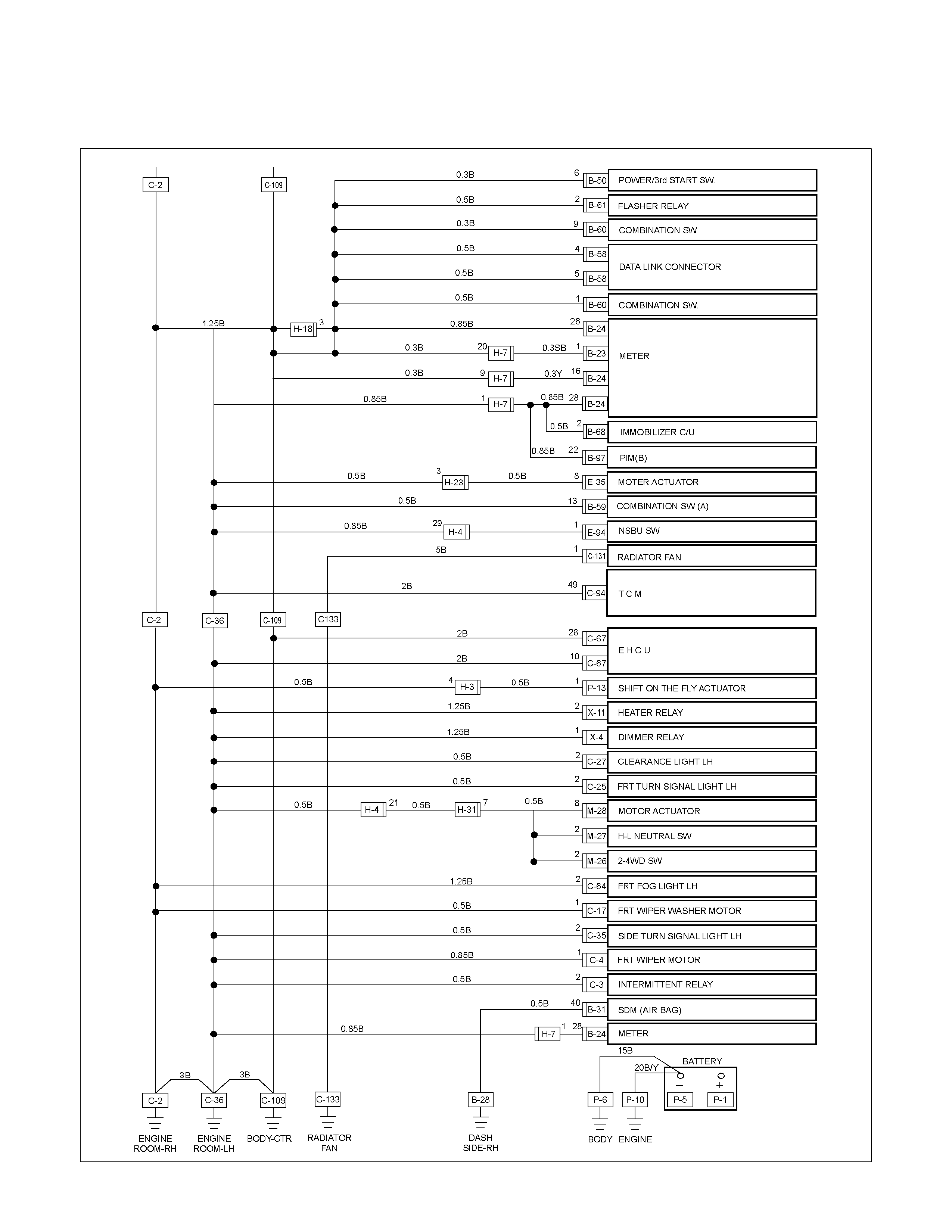

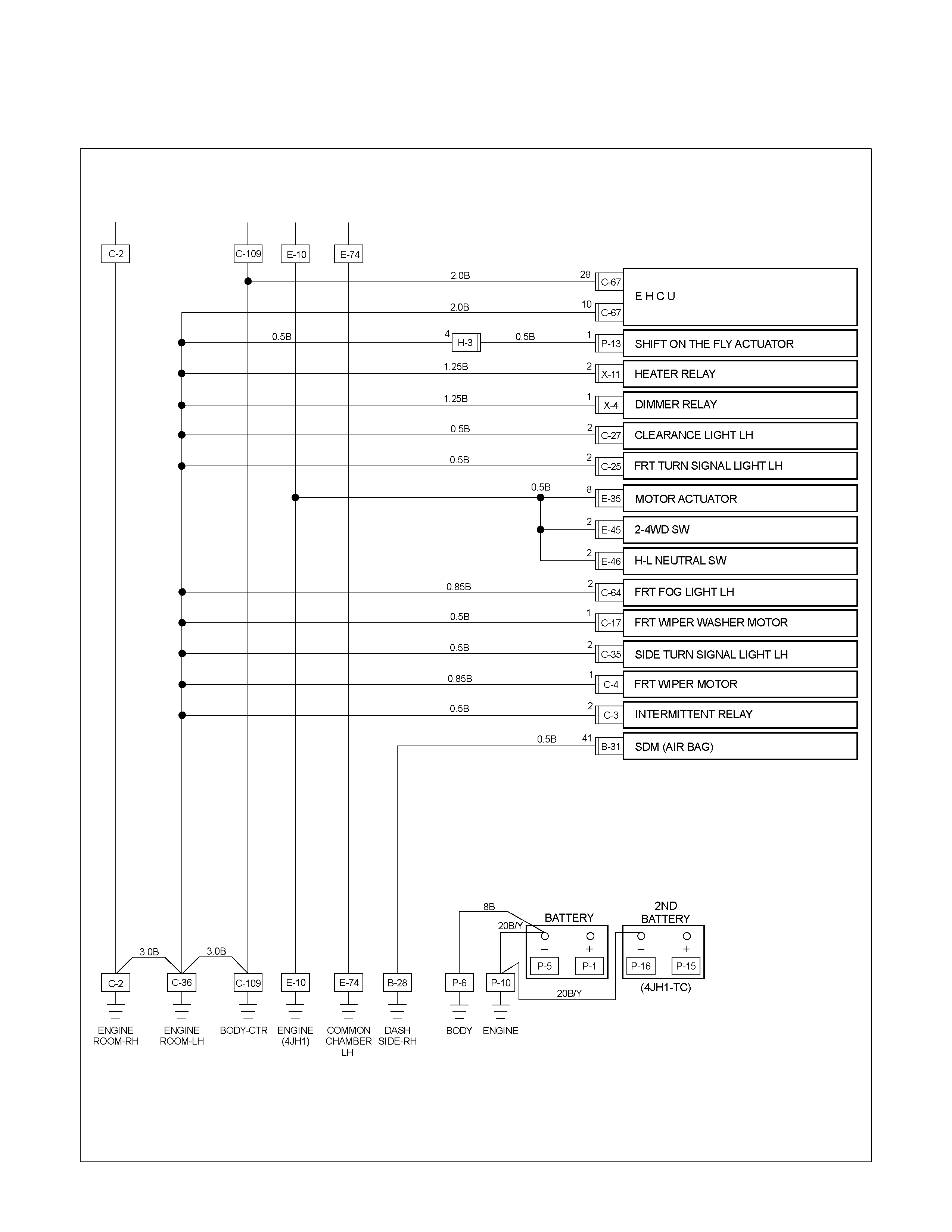

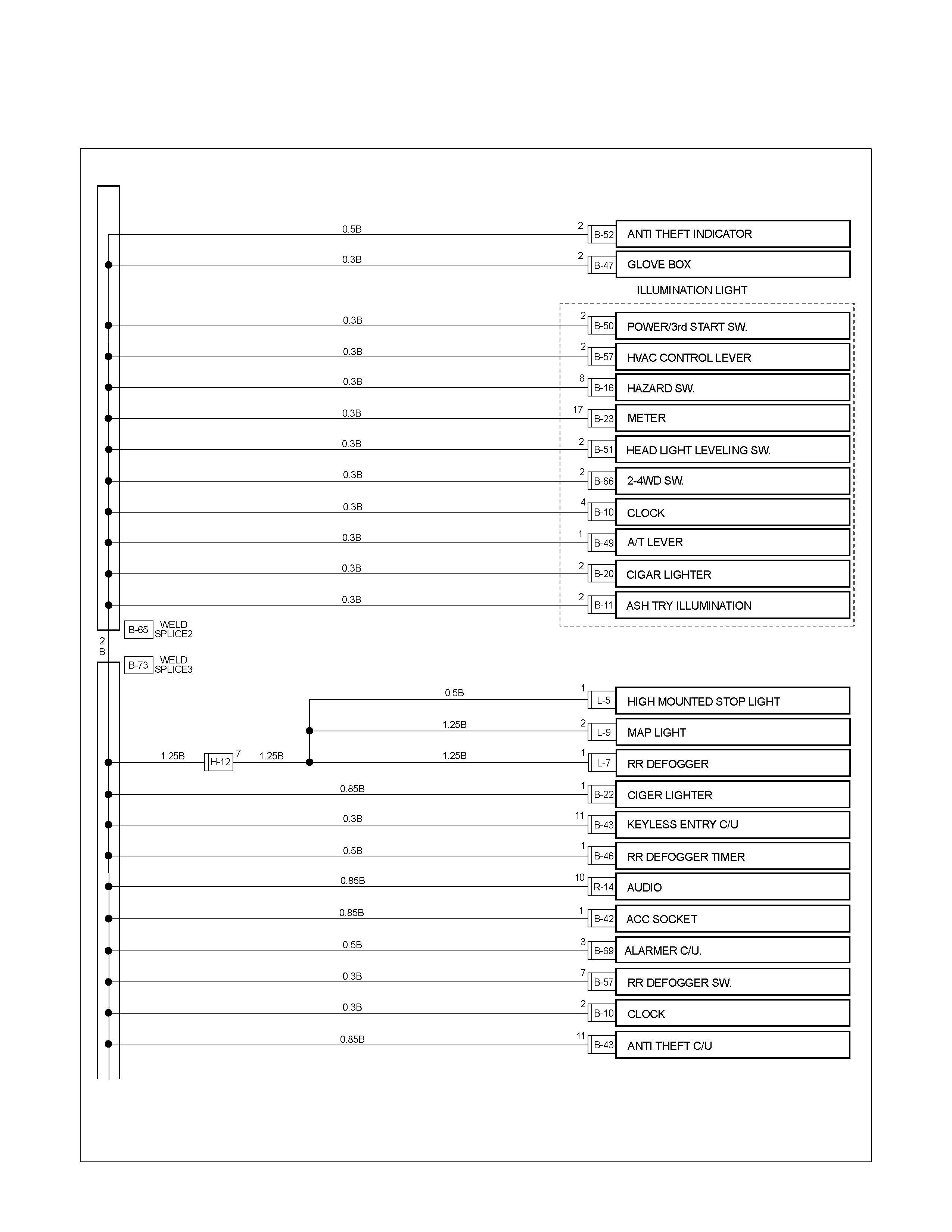

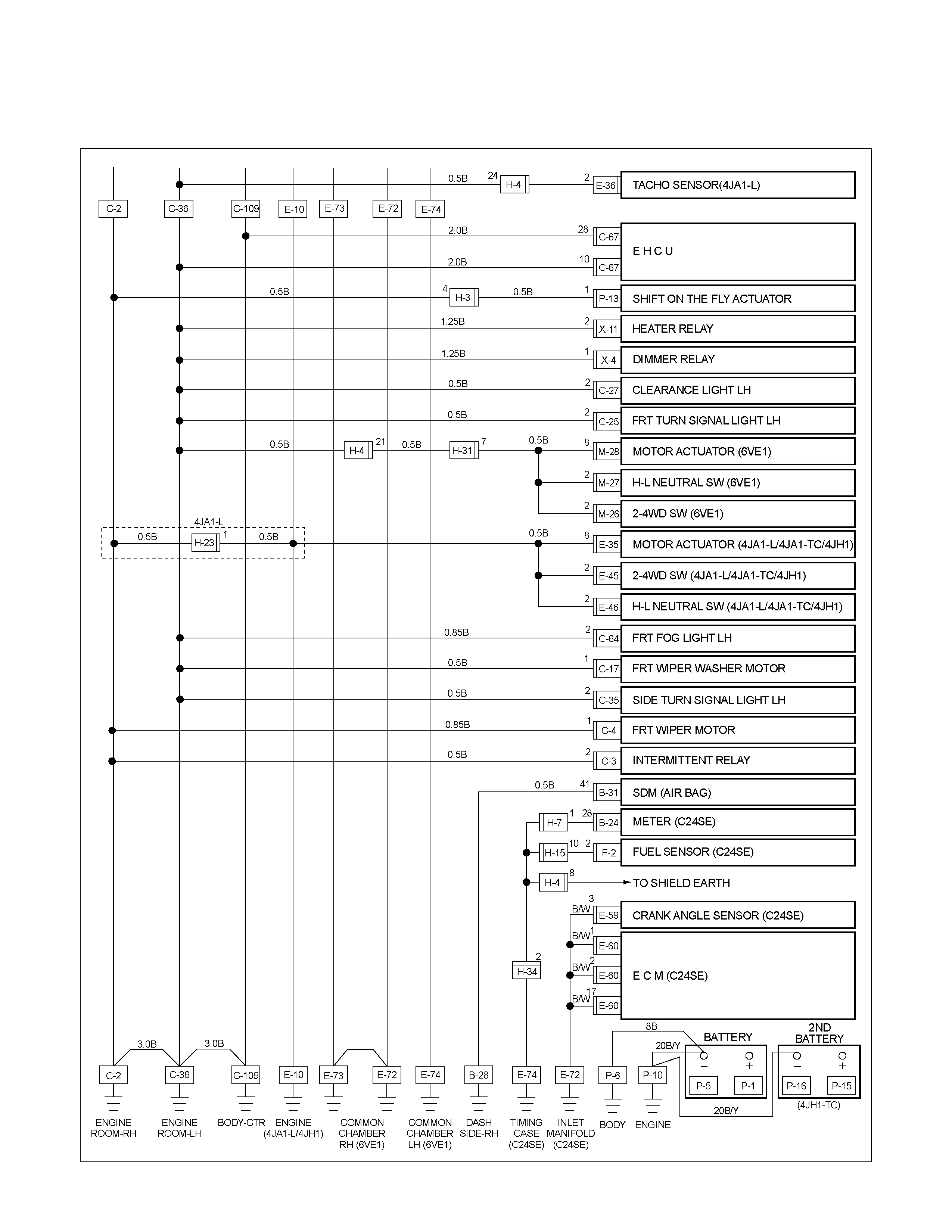

FUSE BLOCK CIRCUIT C24SE Sheet 1/2

RTW68AXF005801

FUSE BLOCK CIRCUIT C24SE Sheet 2/2

RTW68AXF005901

FUSE BLOCK CIRCUIT 6VE1 Sheet 1/2

RTW68AXF006001

FUSE BLOCK CIRCUIT 6VE1 Sheet 2/2

RTW68AXF006101

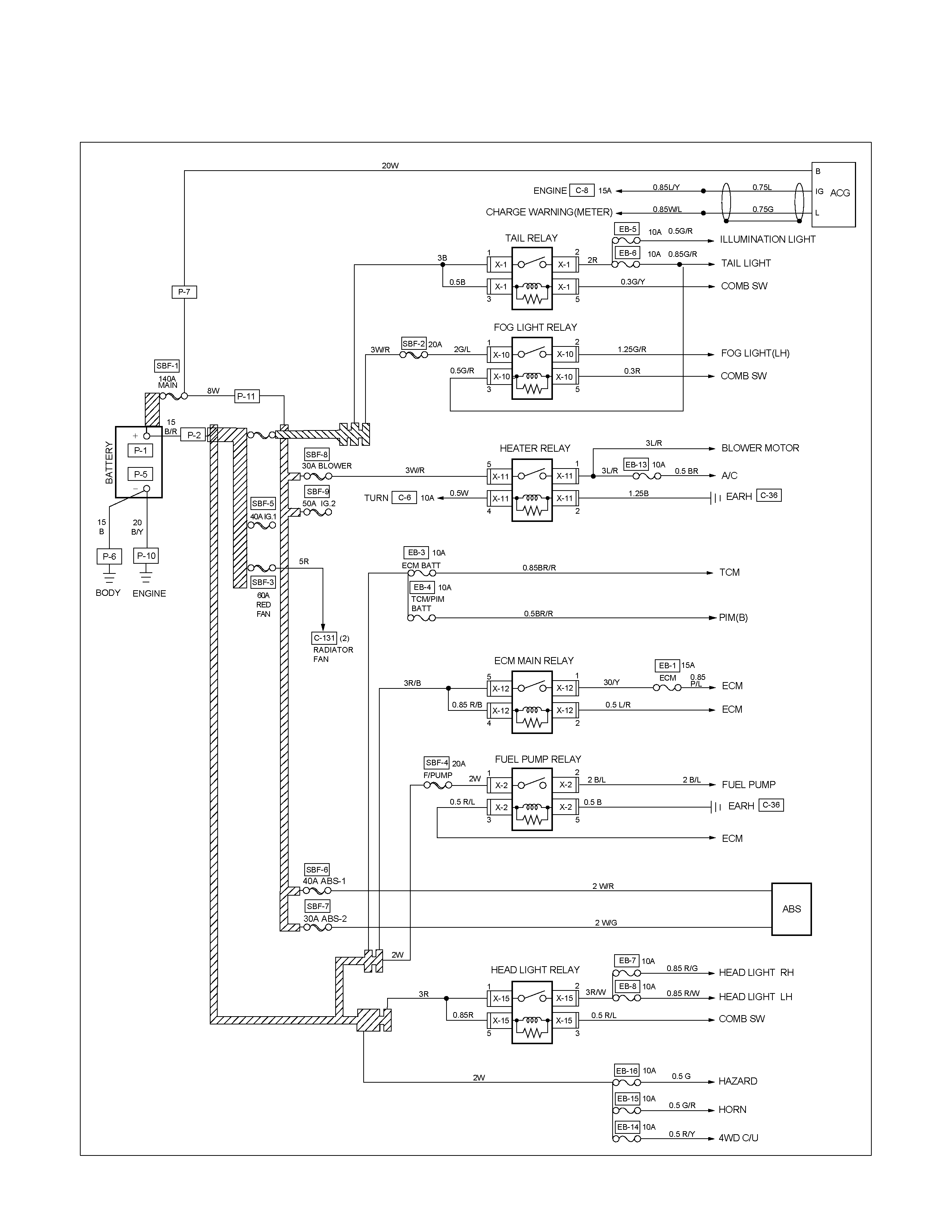

FUSE BLOCK CIRCUIT HFV6 Sheet 1/2

RTW68AXF010001

FUSE BLOCK CIRCUIT HFV6 Sheet 2/2

RTW68AXF010101

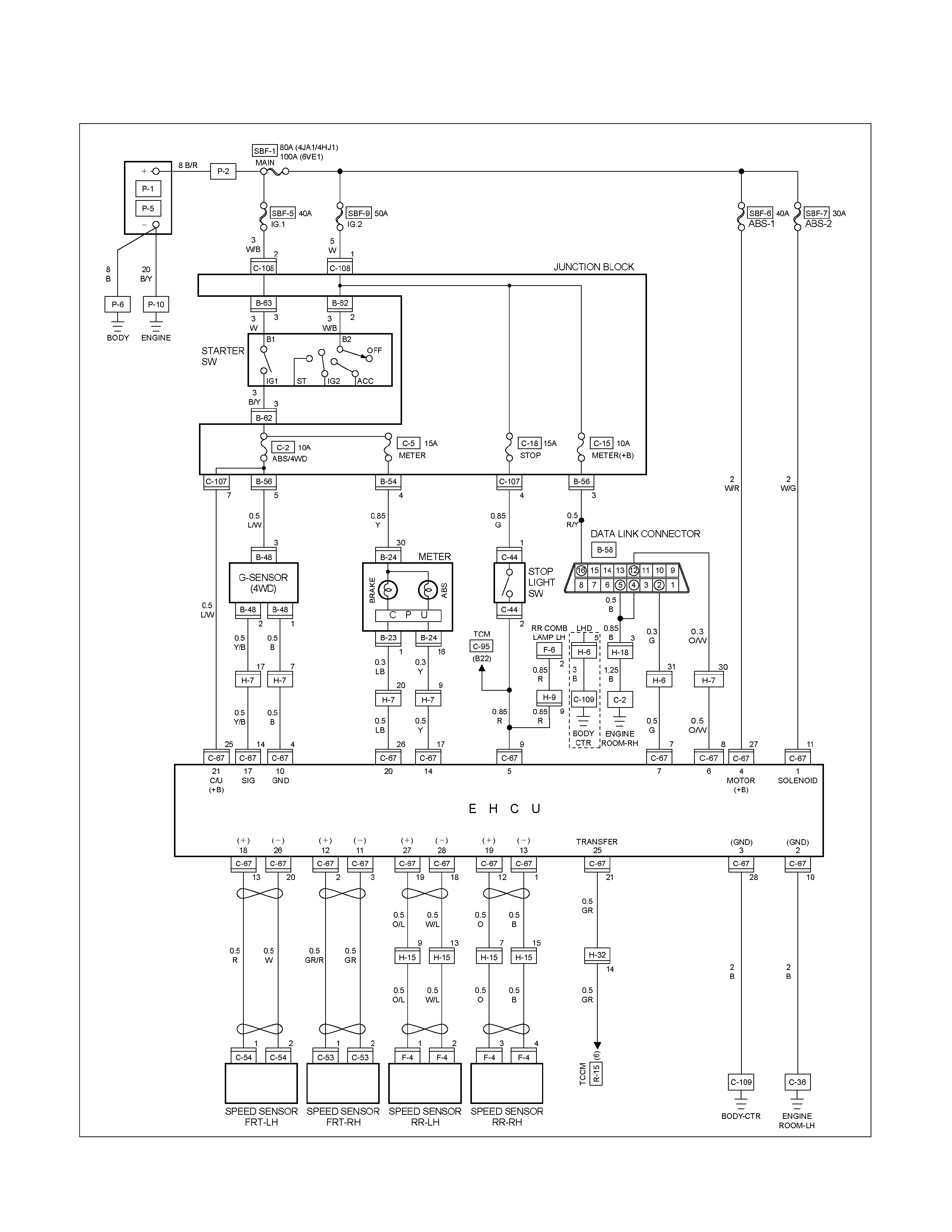

FUSE BLOCK CIRCUIT 4JA1-TC / 4JH1-TC (RHD) Sheet 1/2

RTW68AXF006201

FUSE BLOCK CIRCUIT 4JA1-TC / 4JH1-TC (RHD) Sheet 2/2

RTW68AXF006301

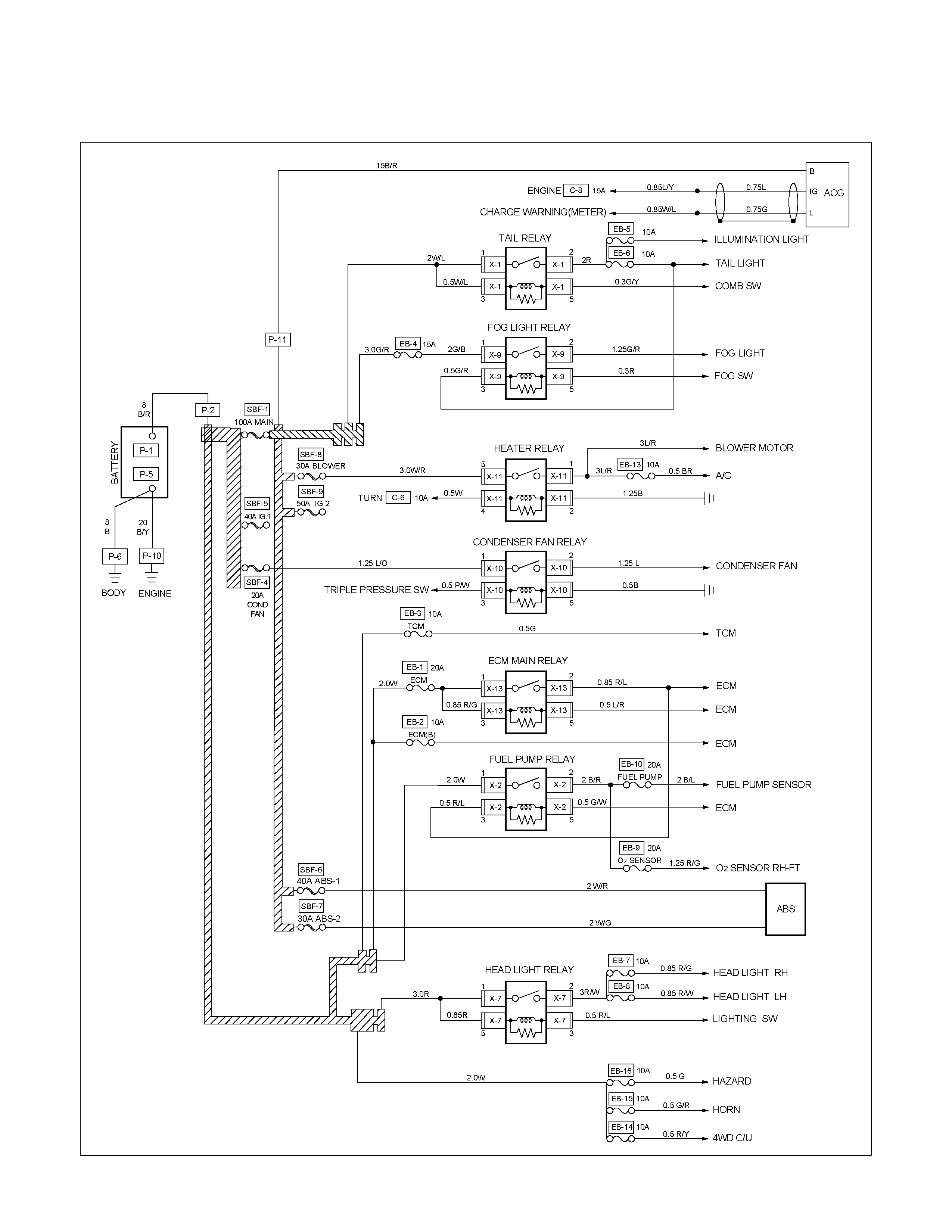

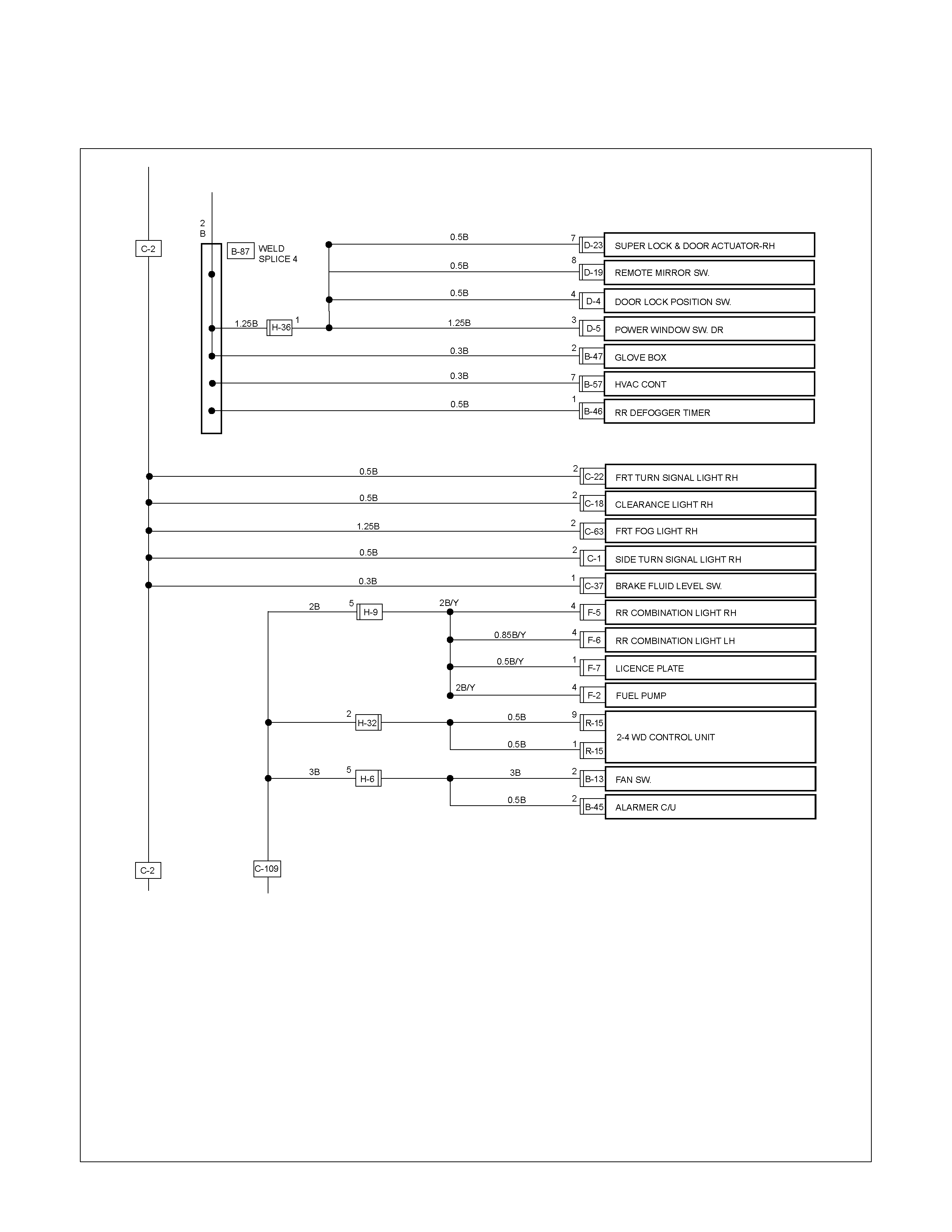

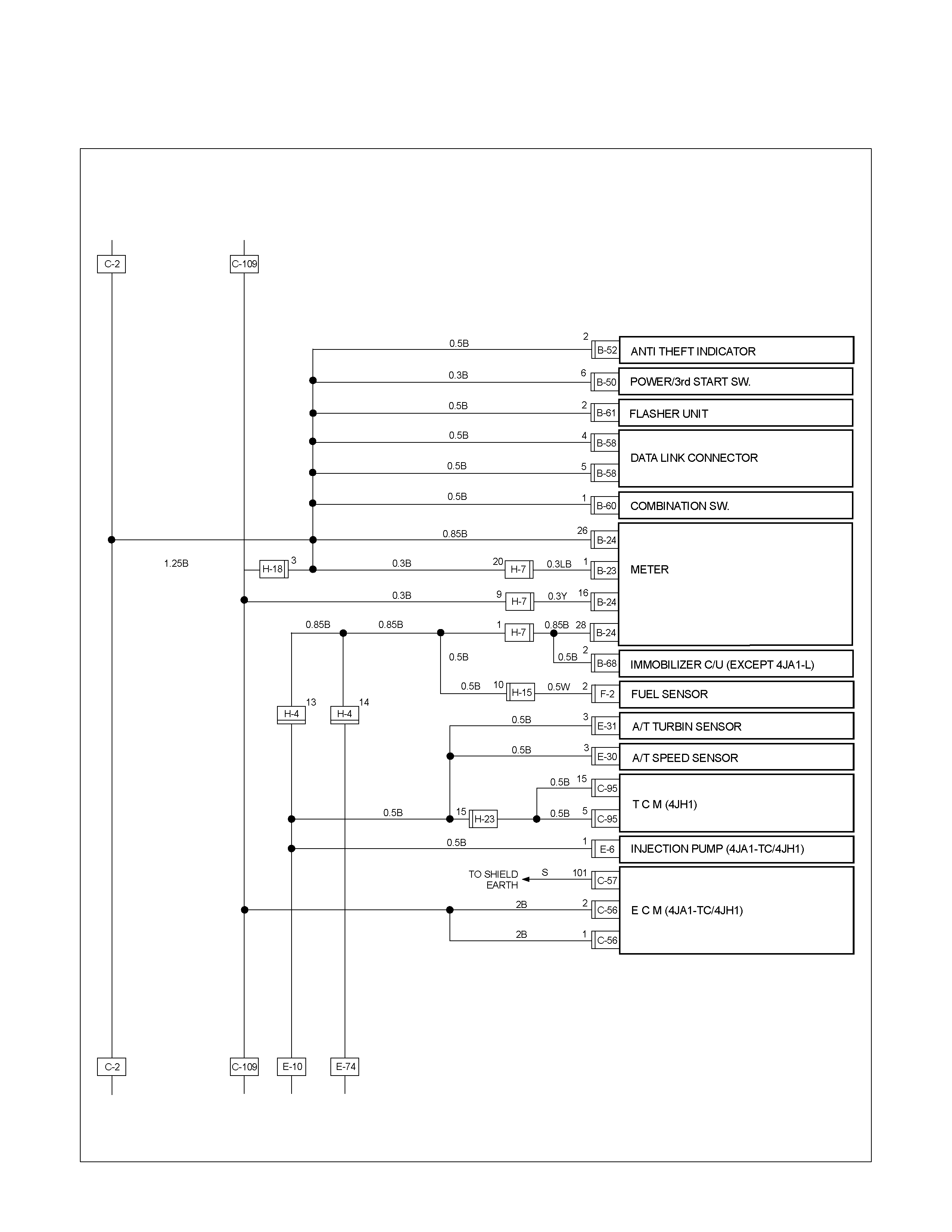

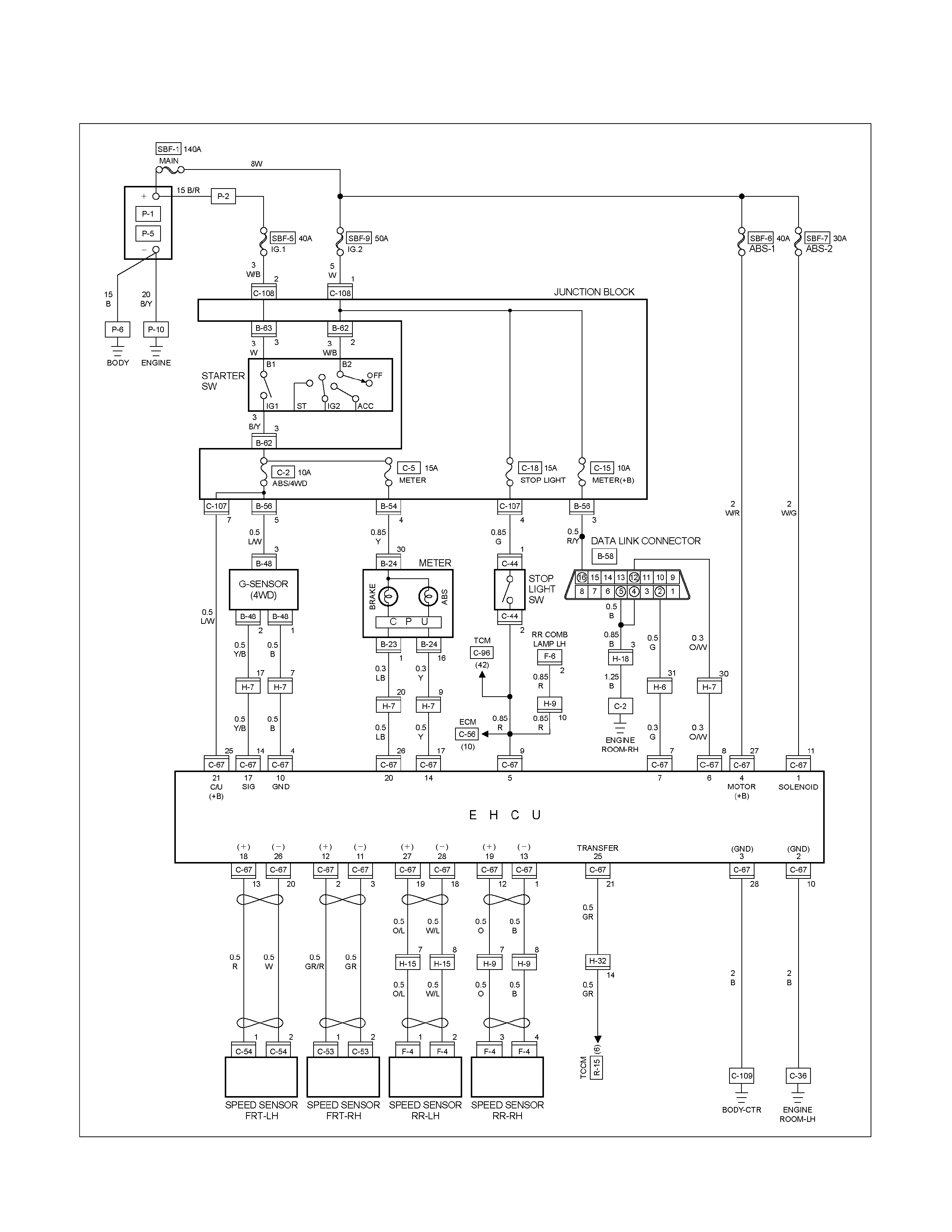

FUSE BLOCK CIRCUIT 4JA1-TC / 4JH1-TC (LHD) Sheet 1/2

RTW68AXF006401

FUSE BLOCK CIRCUIT 4JA1-TC / 4JH1-TC (LHD) Sheet 2/2

RTW68AXF006501

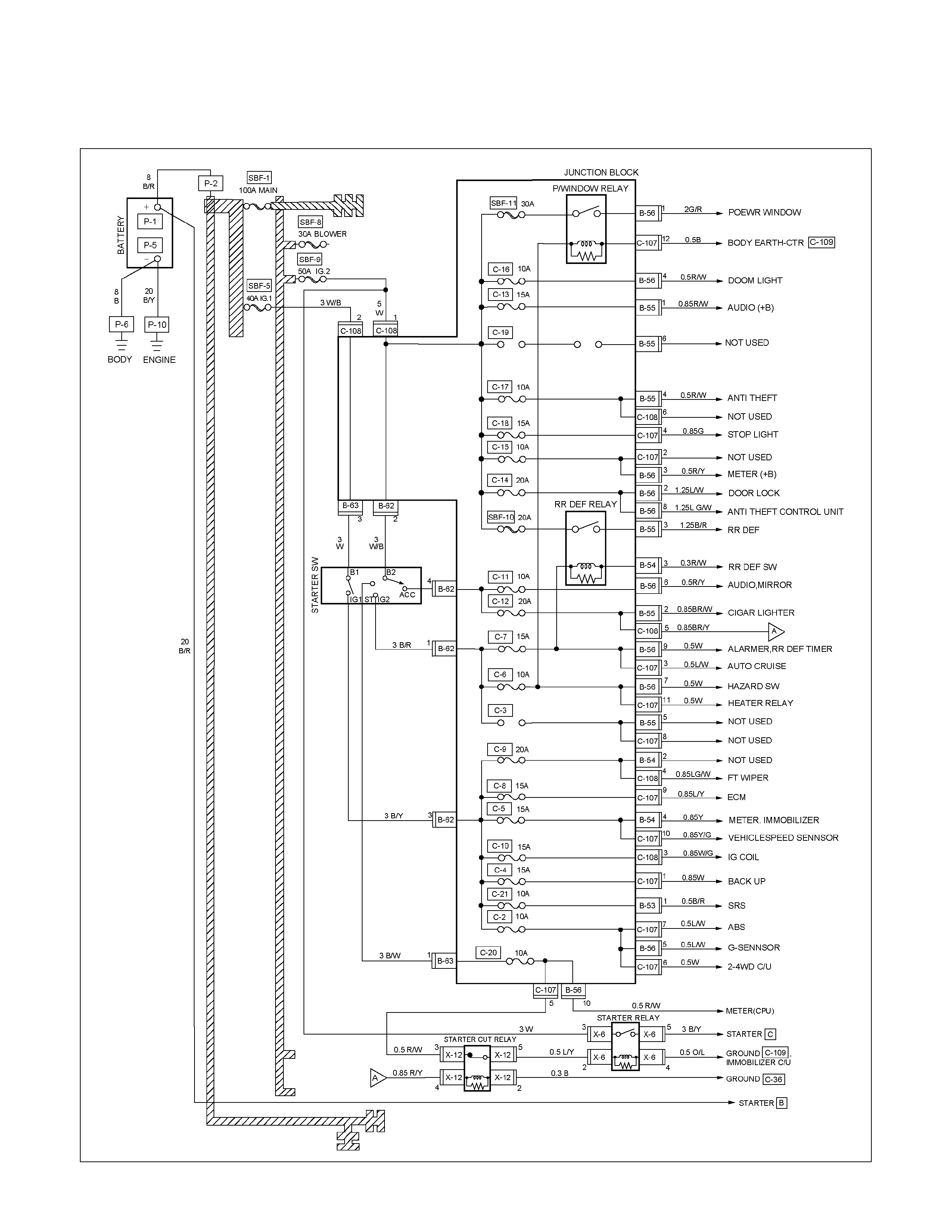

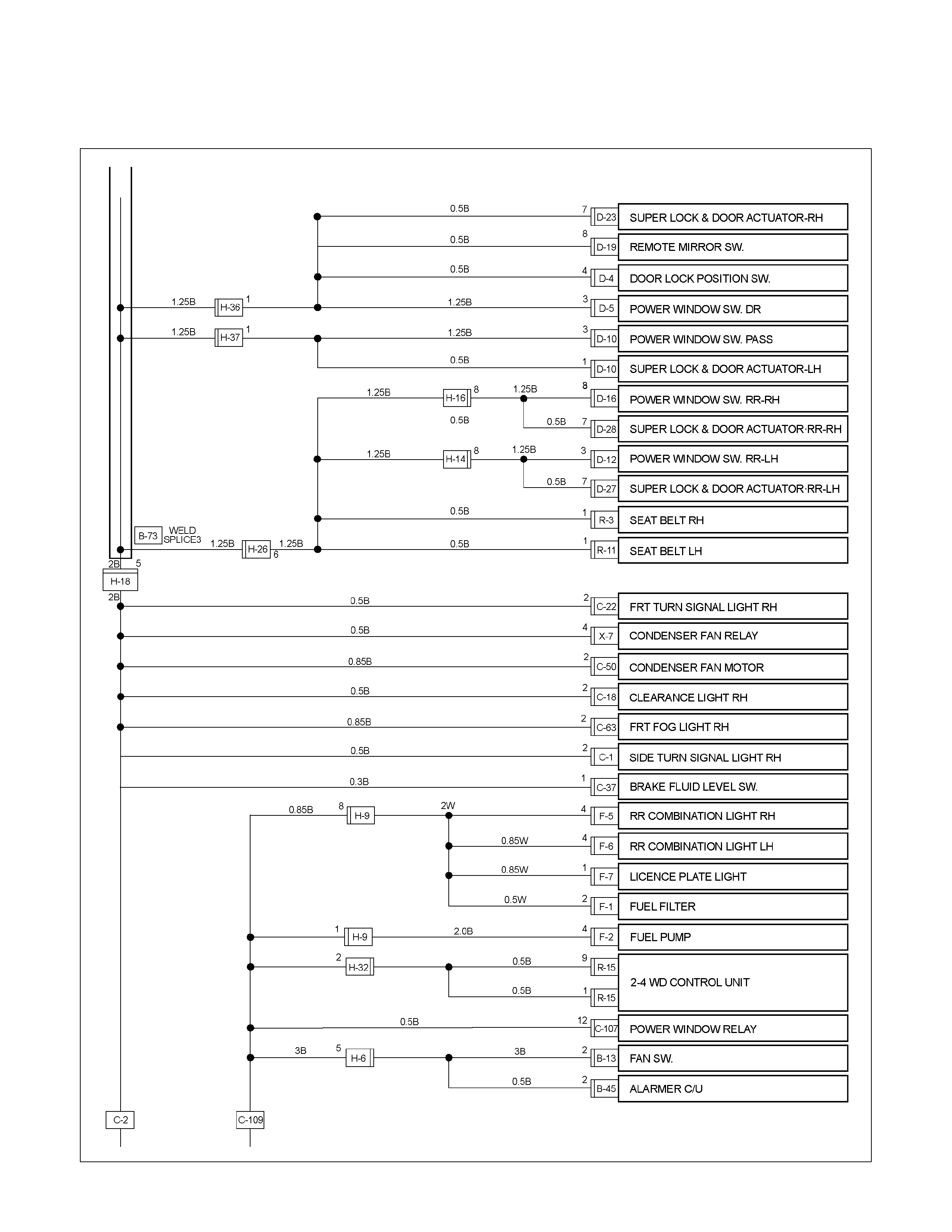

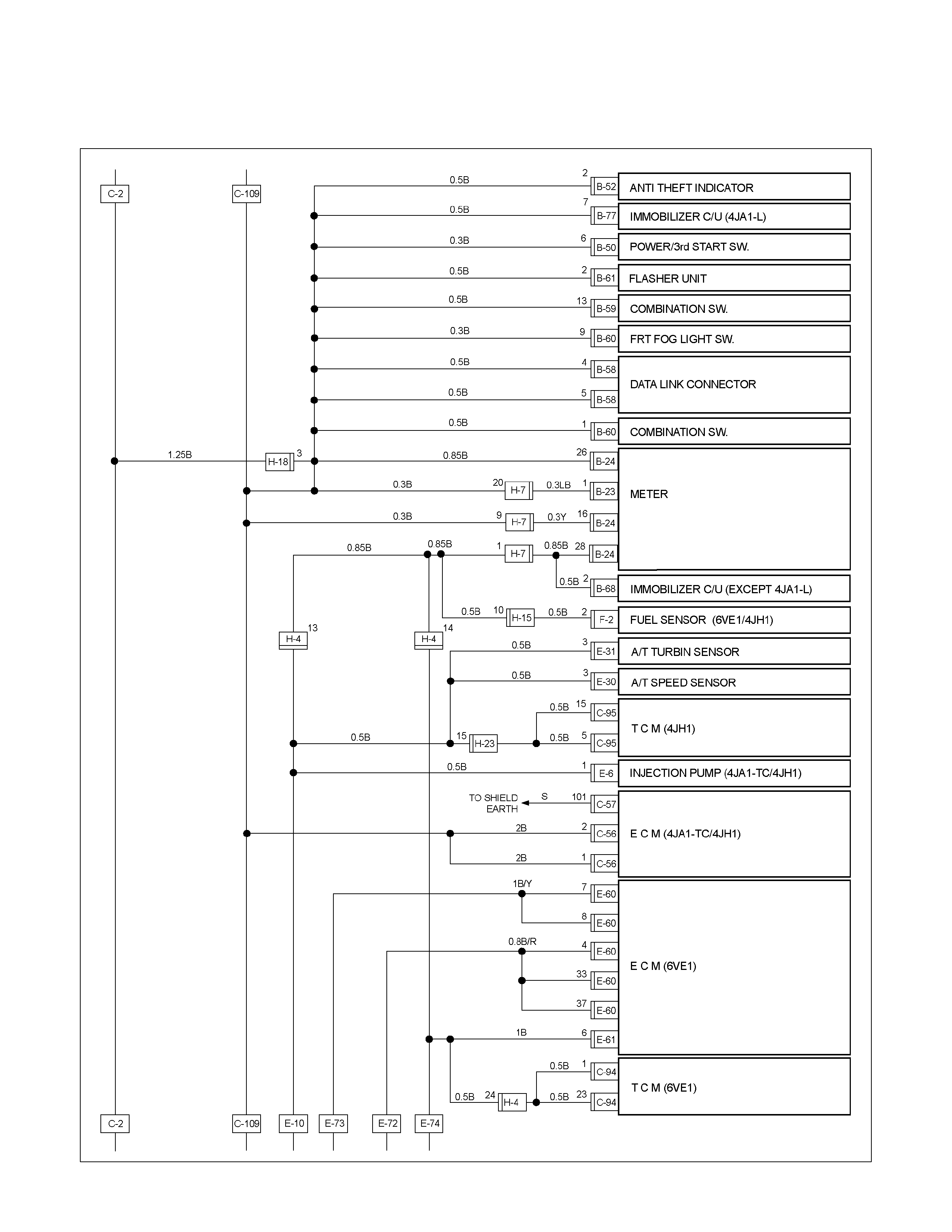

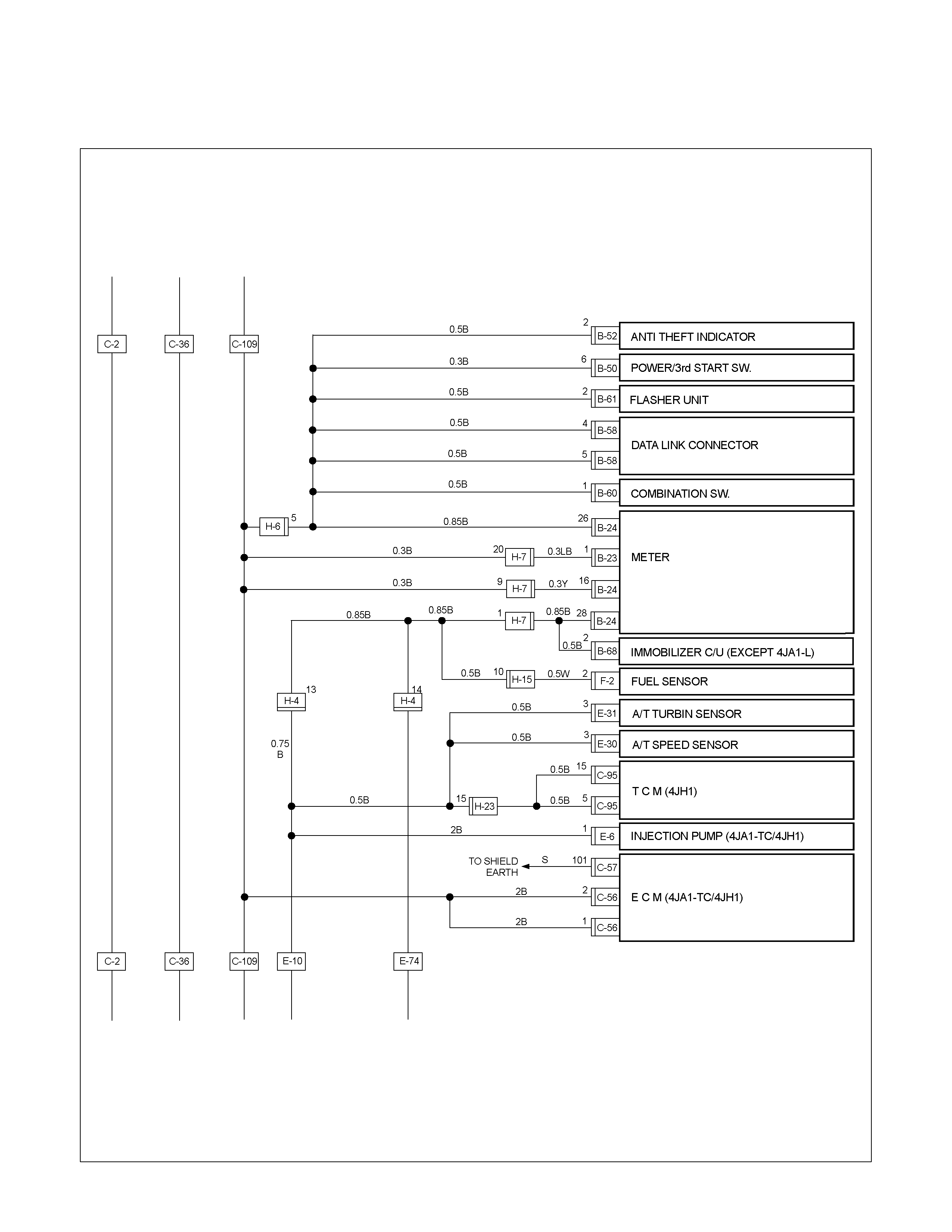

FUSE BLOCK CIRCUIT 4JA1-L Sheet 1/2

RTW68AXF006601

FUSE BLOCK CIRCUIT 4JA1-L Sheet 2/2

RTW68AXF006701

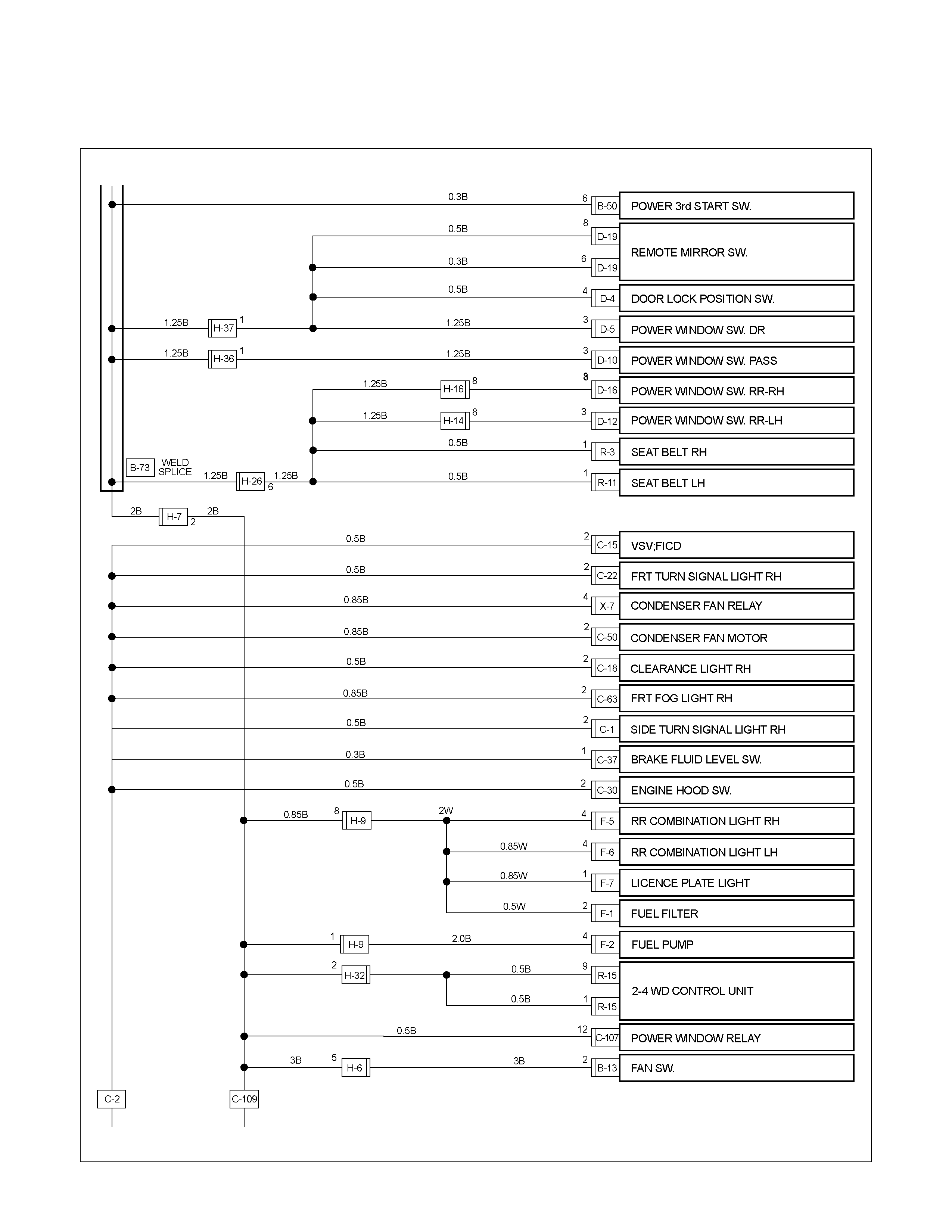

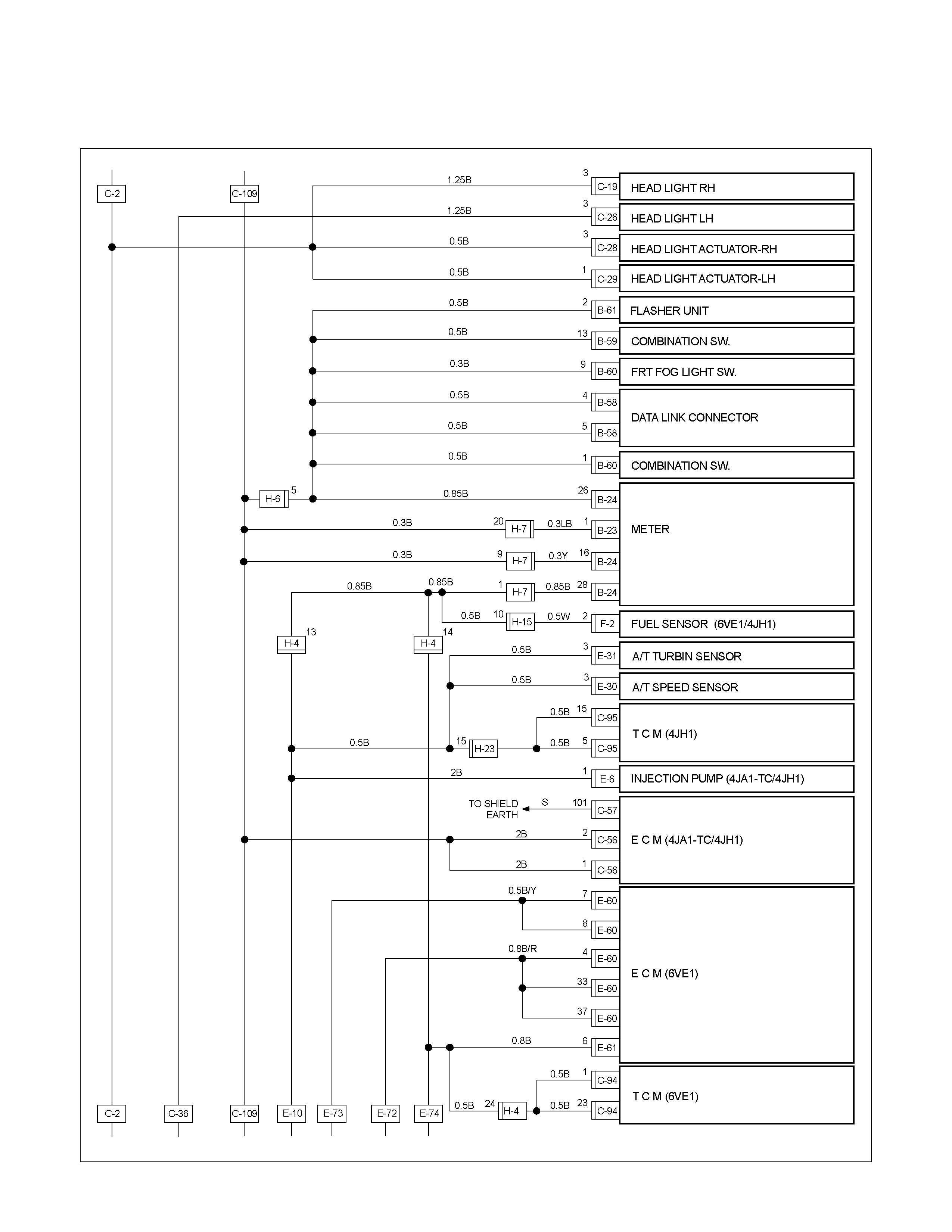

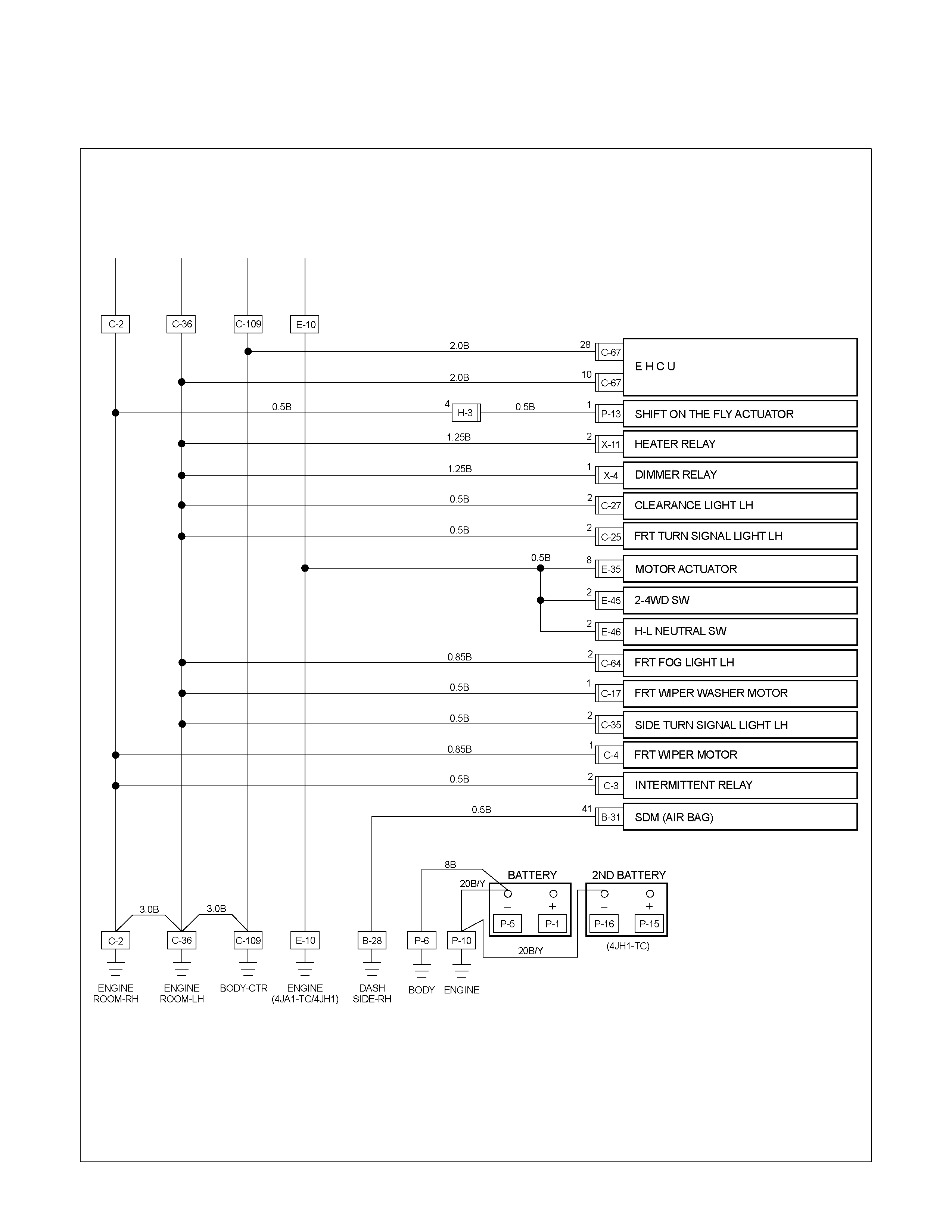

Grounding Point

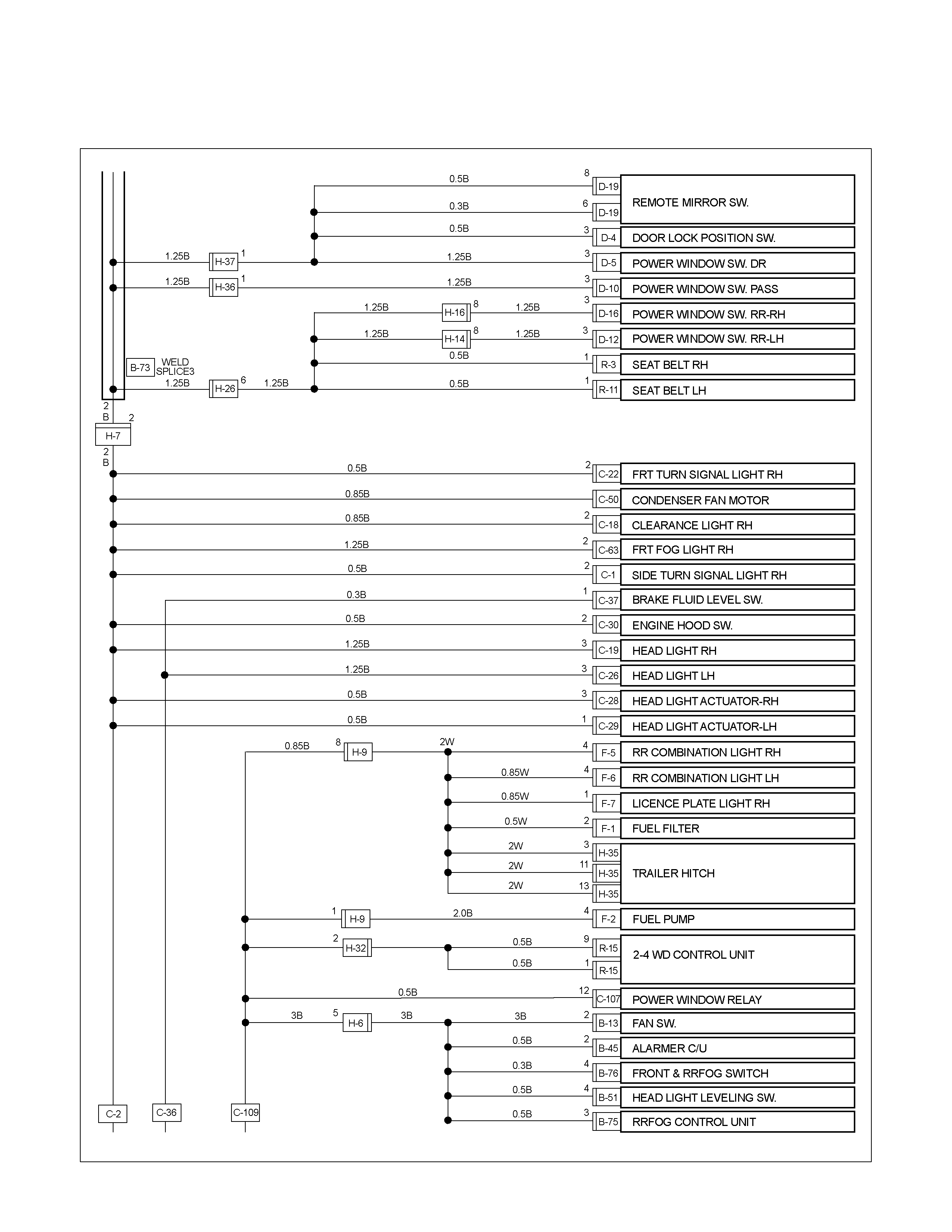

GROUND POINT (RHD) G.EXP Sheet 1/4

RTW68AXF006801

GROUND POINT (RHD) G.EXP Sheet 2/4

RTW68AXF006901

GROUND POINT (RHD) G.EXP Sheet 3/4

RTW68AXF007001

GROUND POINT (RHD) G.EXP Sheet 4/4

RTW68AXF007101

GROUND POINT (RHD) AUSTRALIA HFV6 Sheet 1/3

RTW68AXF010201

GROUND POINT (RHD) AUSTRALIA HFV6 Sheet 2/3

RTW68AXF010301

GROUND POINT (RHD) AUSTRALIA HFV6 Sheet 3/3

RTW68AXF010401

GROUND POINT (RHD) EUROPE Sheet 1/4

RTW68AXF007201

GROUND POINT (RHD) EUROPE Sheet 2/4

RTW68AXF007301

GROUND POINT (RHD) EUROPE Sheet 3/4

RTW68AXF007401

GROUND POINT (RHD) EUROPE Sheet 4/4

RTW68AXF007501

GROUND POINT (LHD) G.EXP Sheet 1/4

RTW68AXF007601

GROUND POINT (LHD) G.EXP Sheet 2/4

RTW68AXF007701

GROUND POINT (LHD) G.EXP Sheet 3/4

RTW68AXF007801

GROUND POINT (LHD) G.EXP Sheet 4/4

RTW68AXF007901

GROUND POINT (LHD) EUROPE Sheet 1/4

RTW68AXF008001

GROUND POINT (LHD) EUROPE Sheet 2/4

RTW68AXF008101

GROUND POINT (LHD) EUROPE Sheet 3/4

RTW68AXF008201

GROUND POINT (LHD) EUROPE Sheet 4/4

RTW68AXF008301

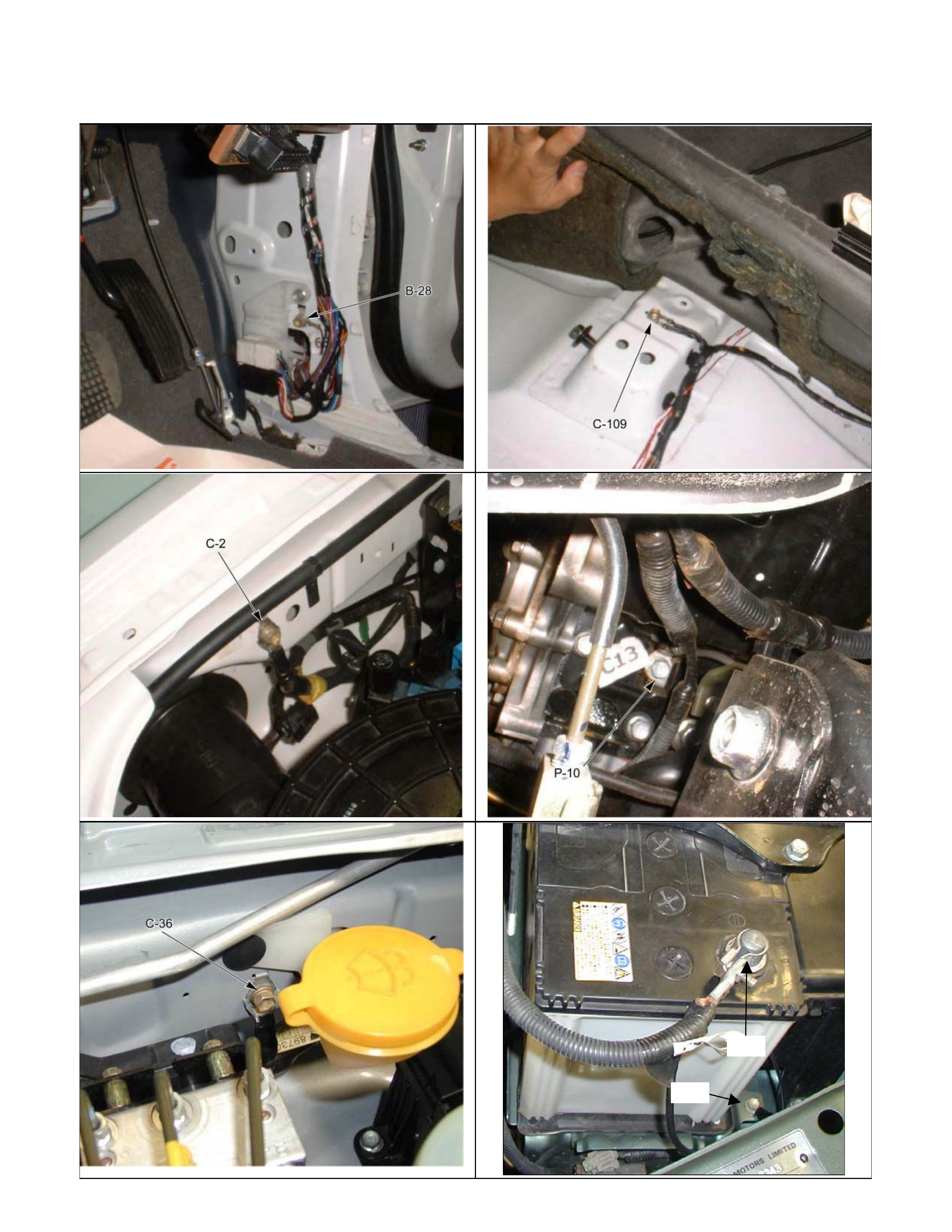

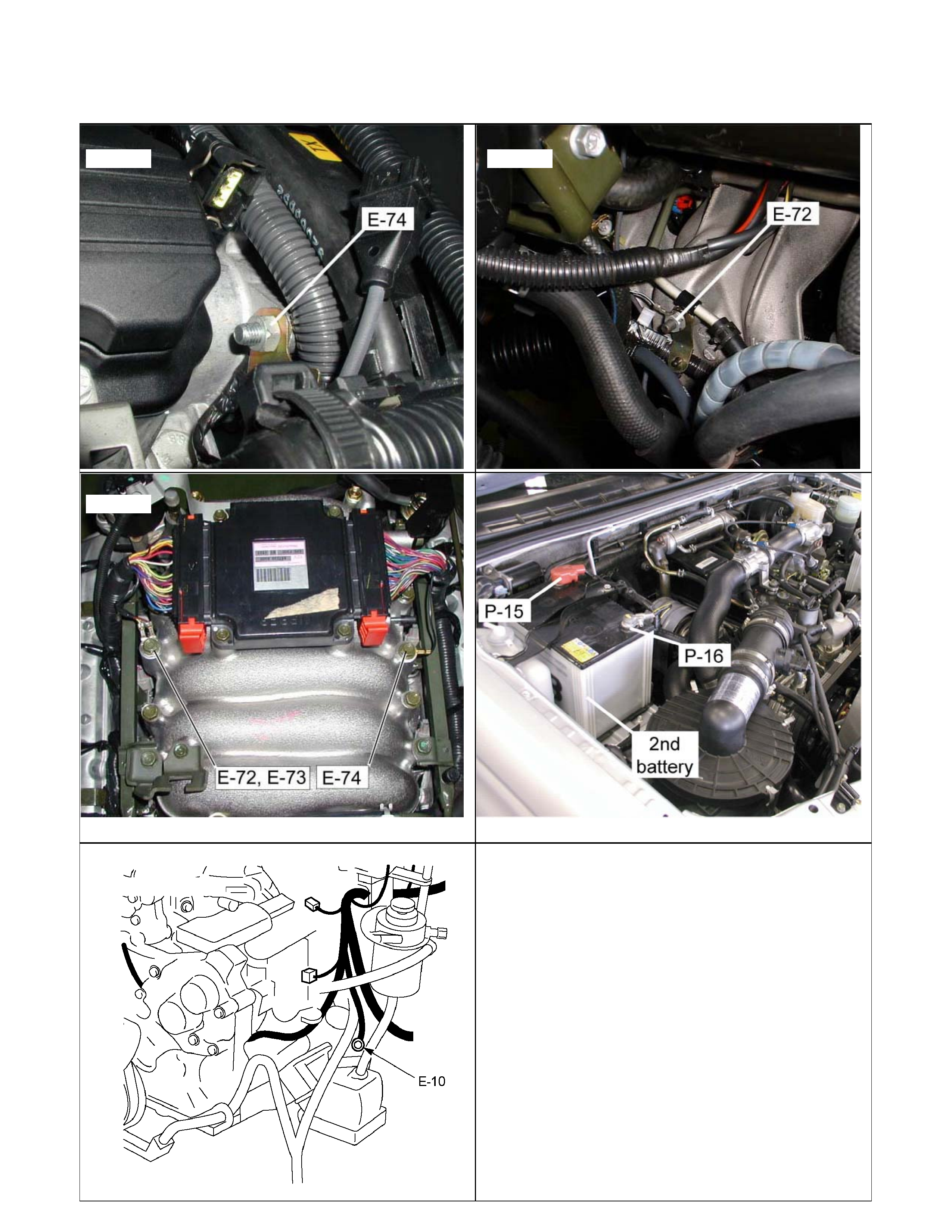

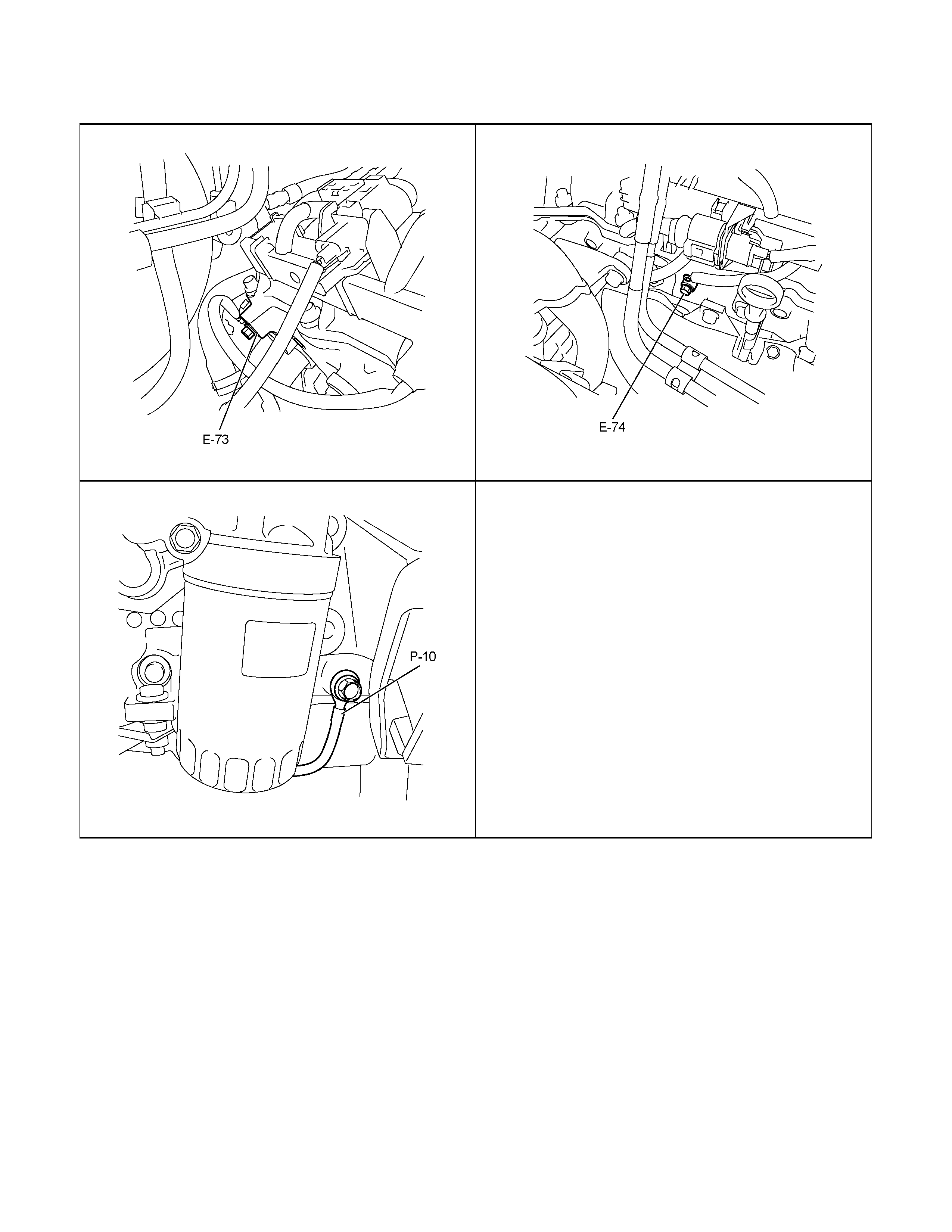

GROUND POINT LOCATION

P−5

P−6

GROUND POINT LOCATION

C24NE C24NE

6VE1

4JA1-TC/4JH1-TC

GROUND POINT LOCATION

HFV6 HFV6

HFV6

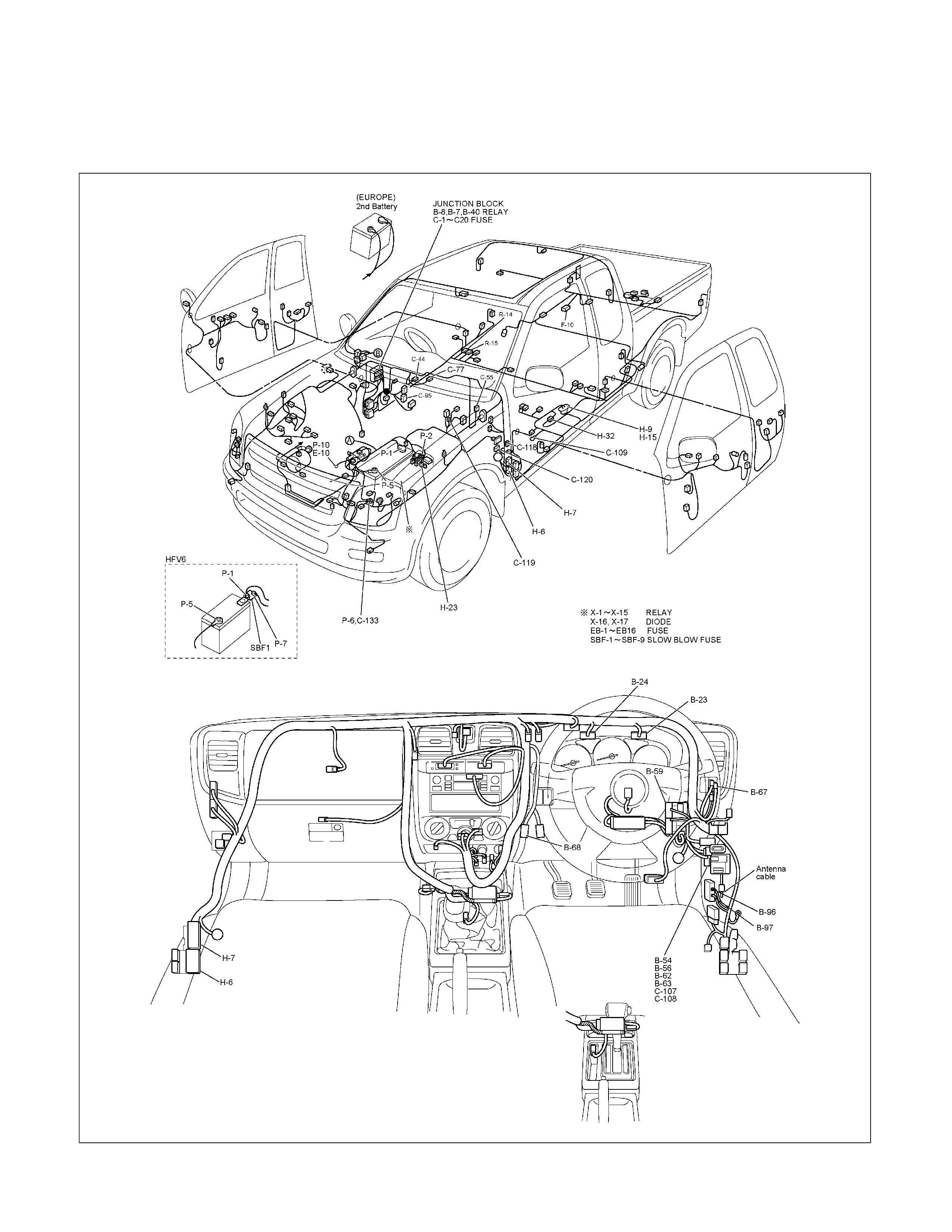

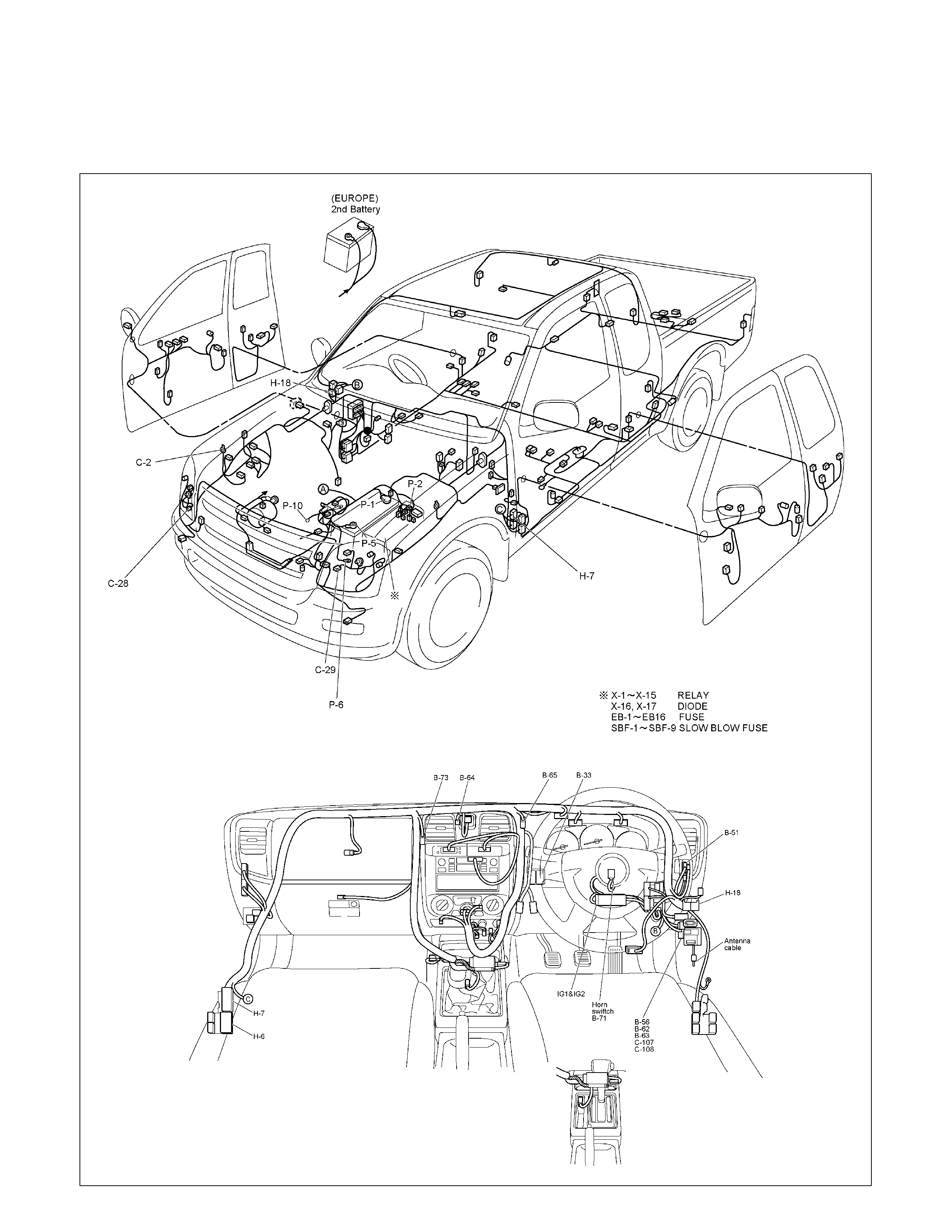

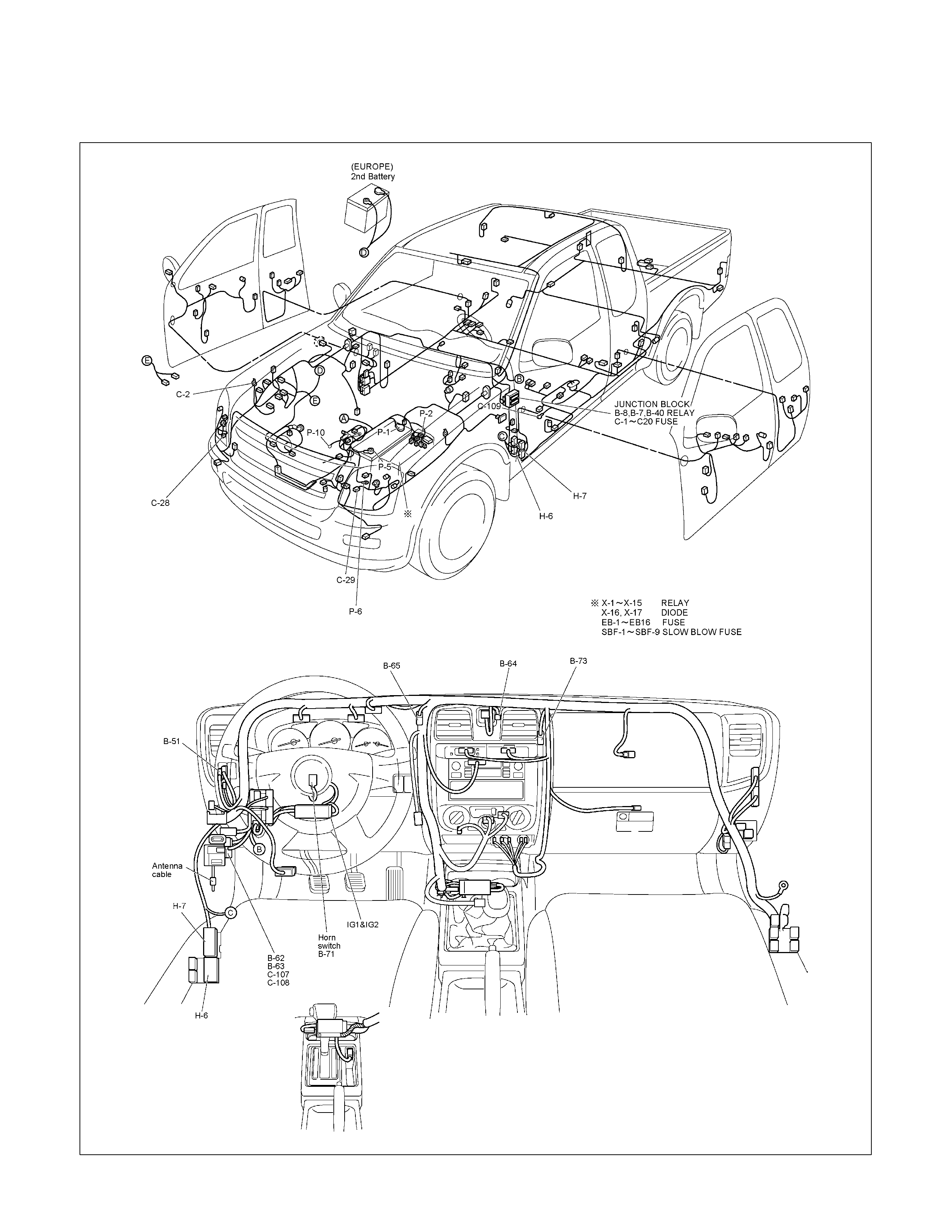

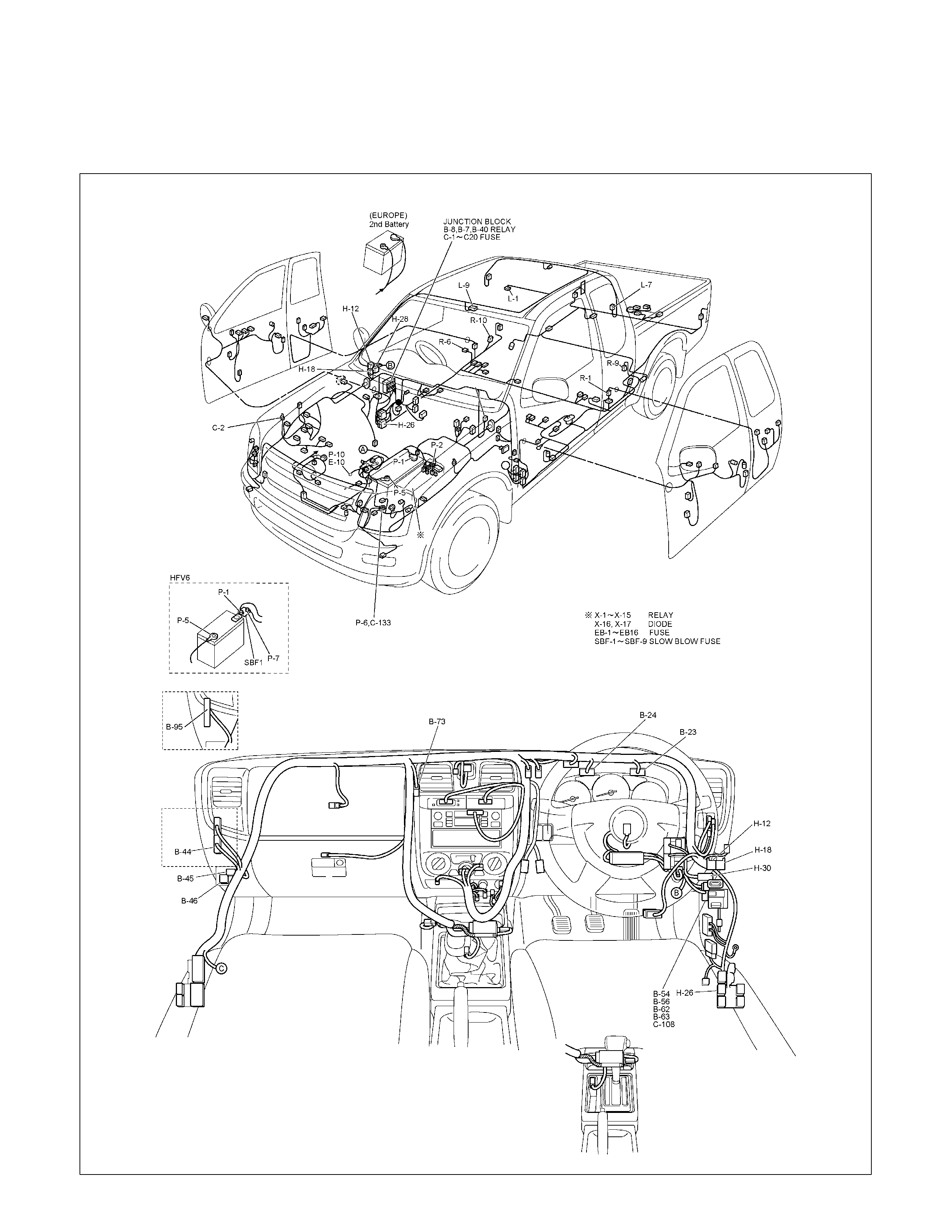

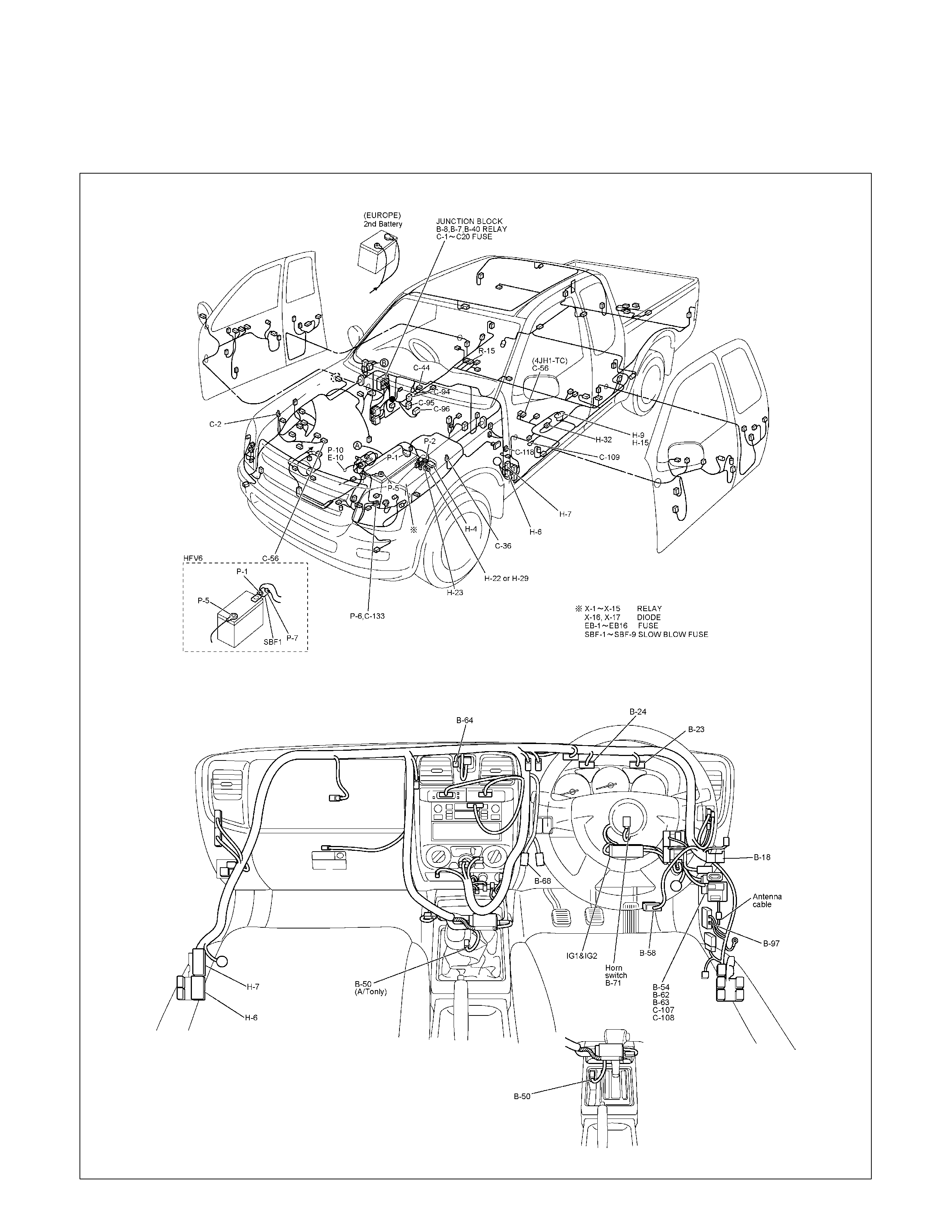

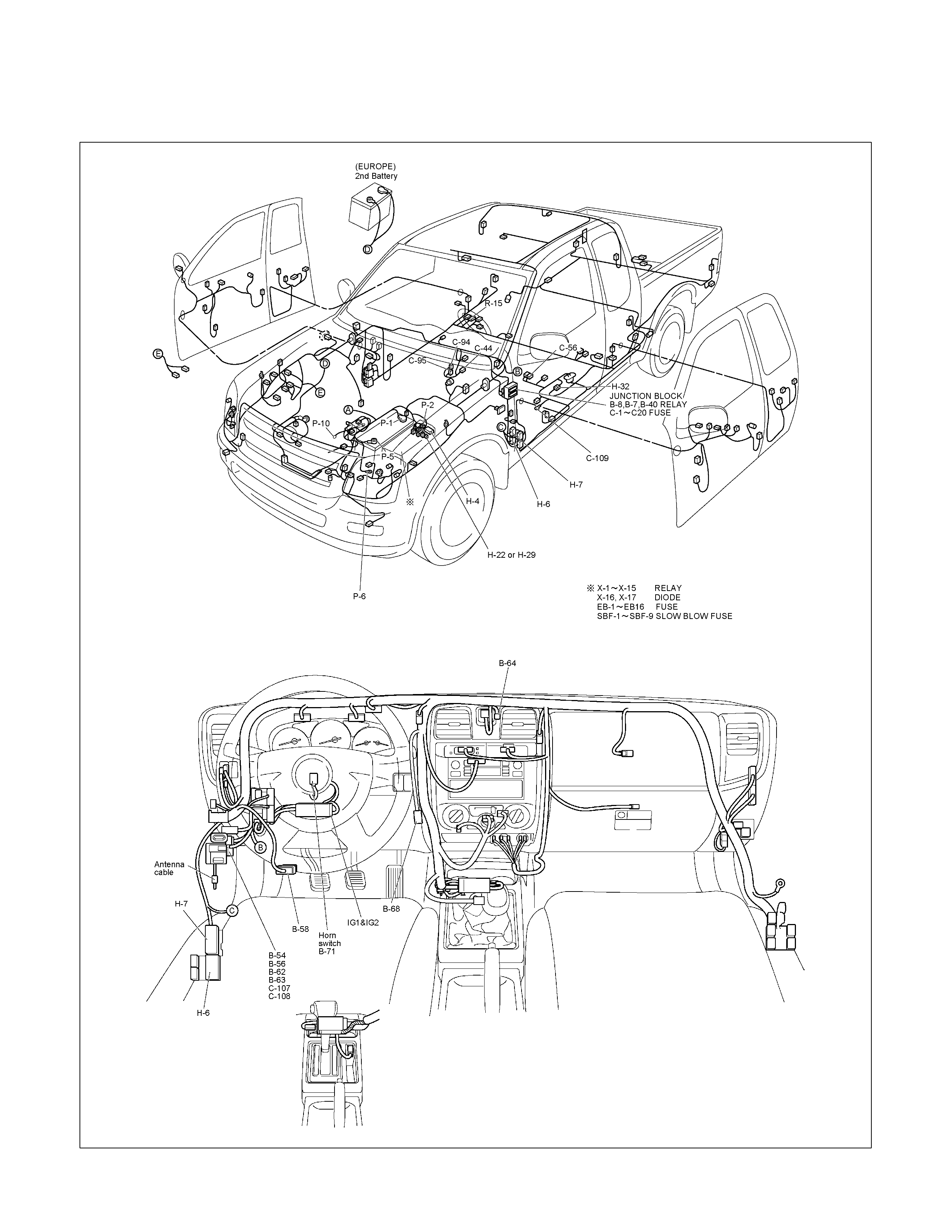

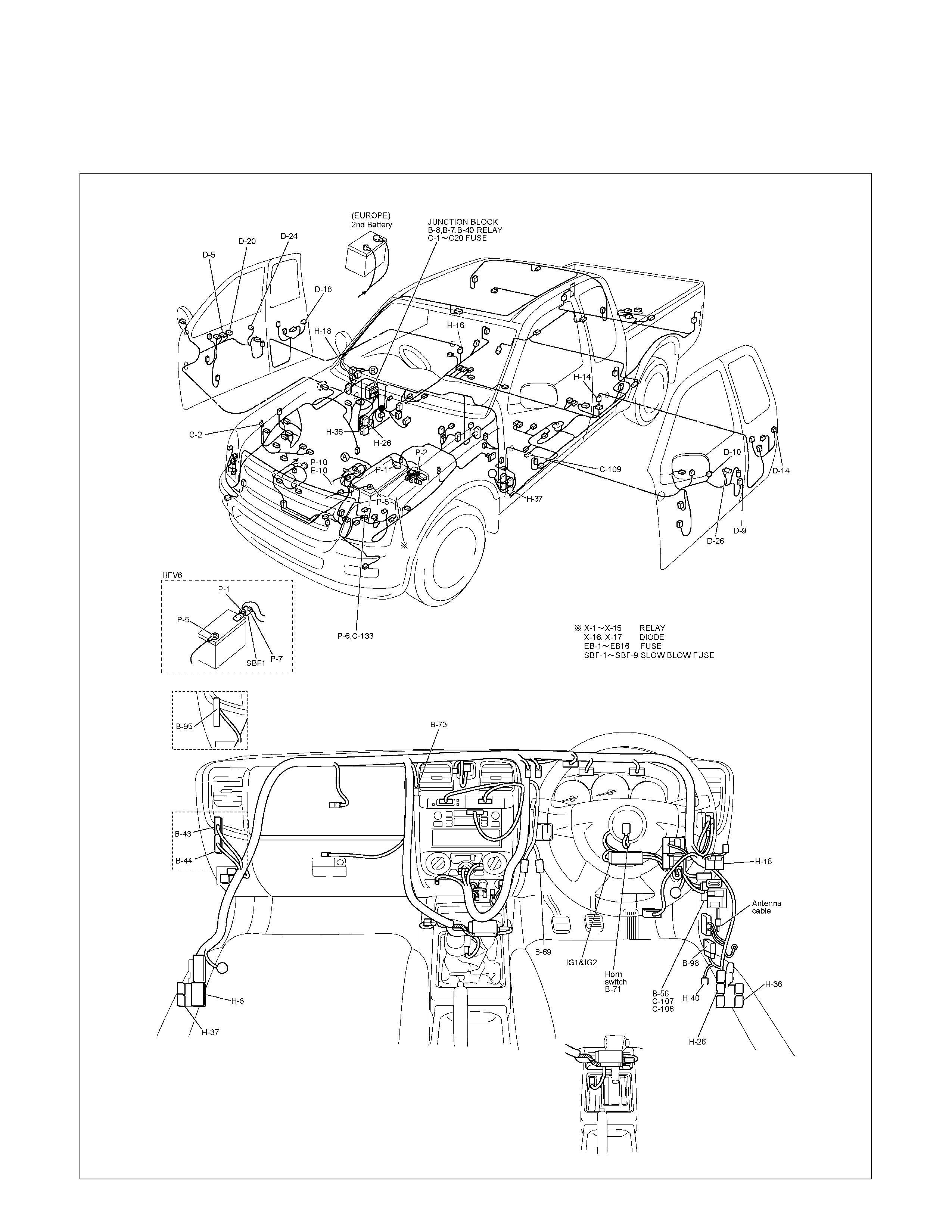

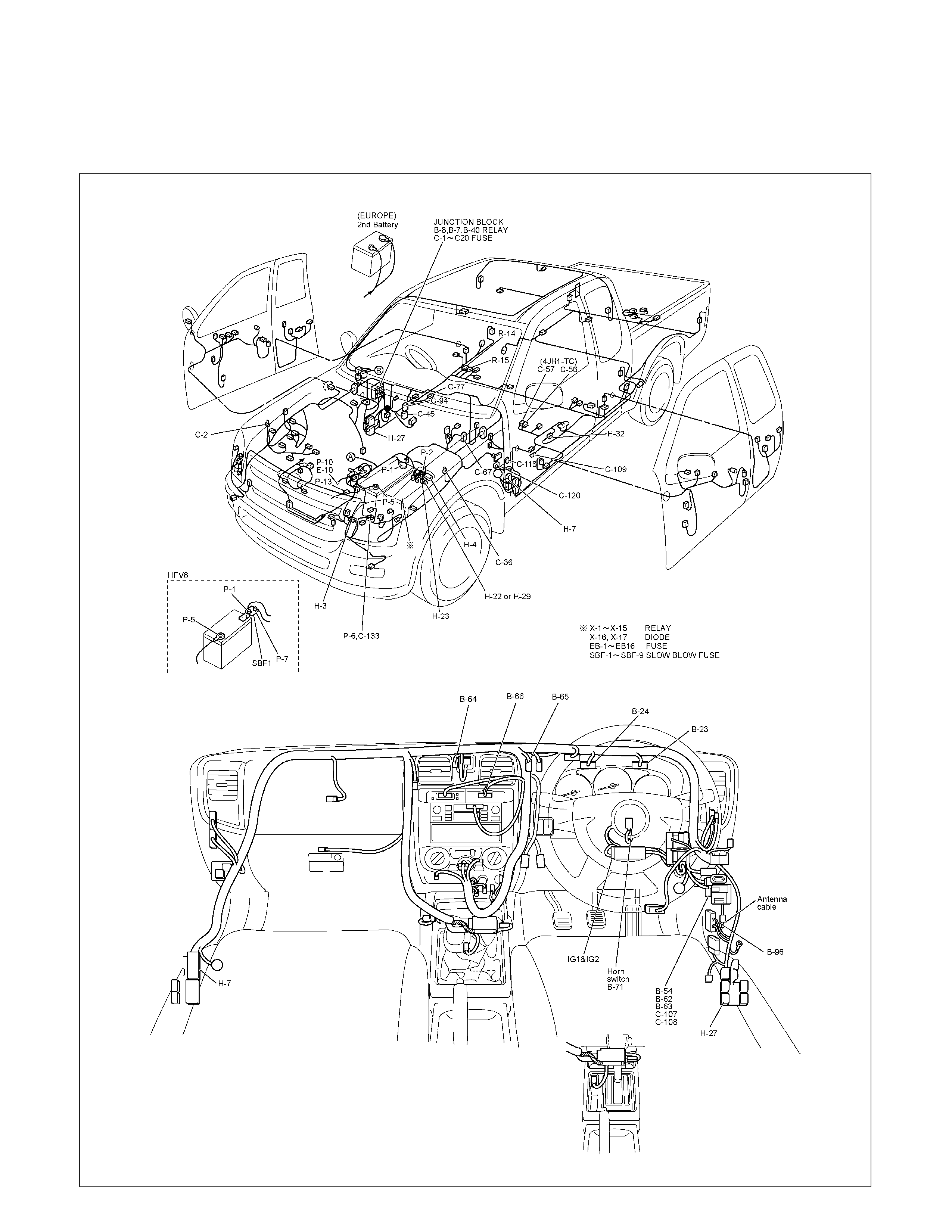

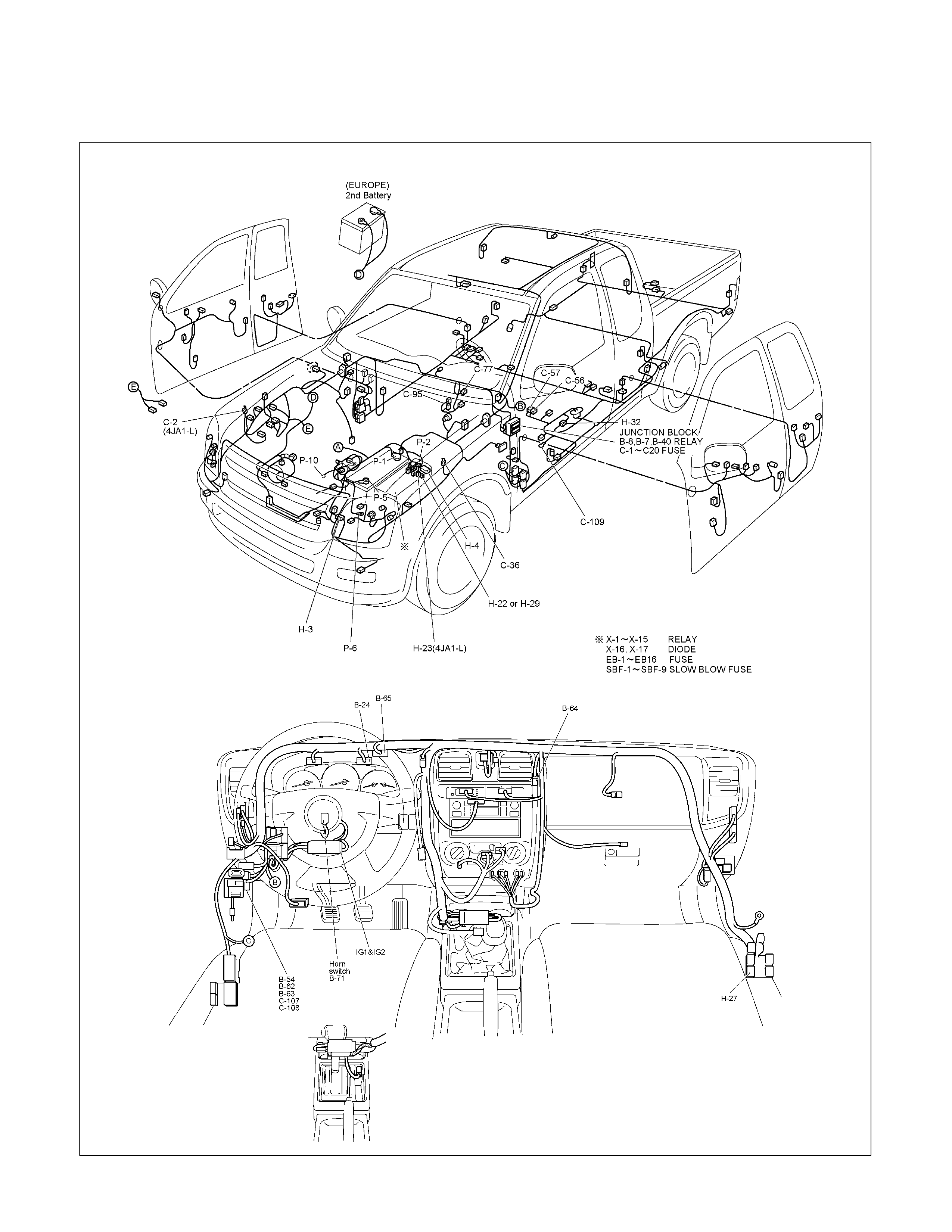

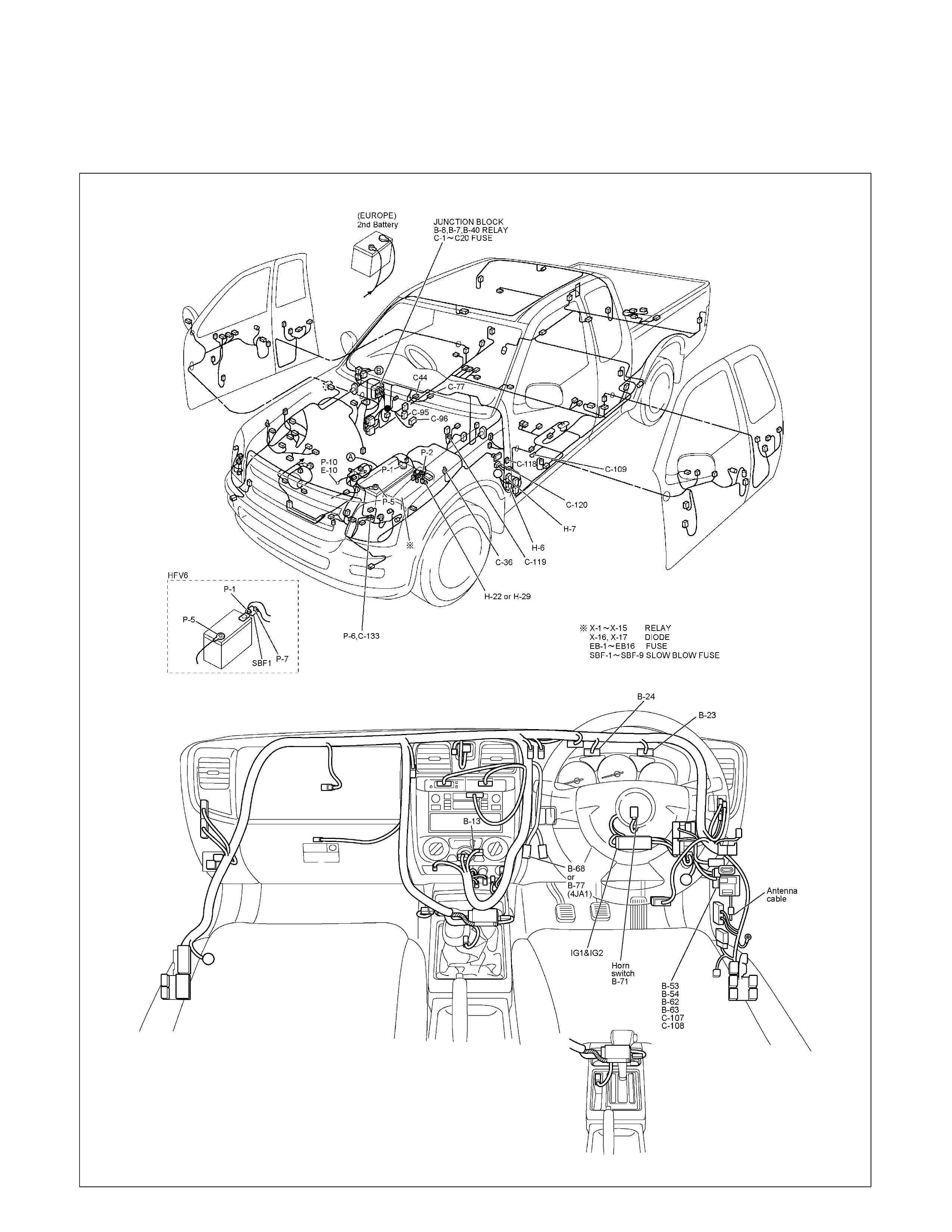

CABLE HARNESS ROUTING

RTW38DXF007401

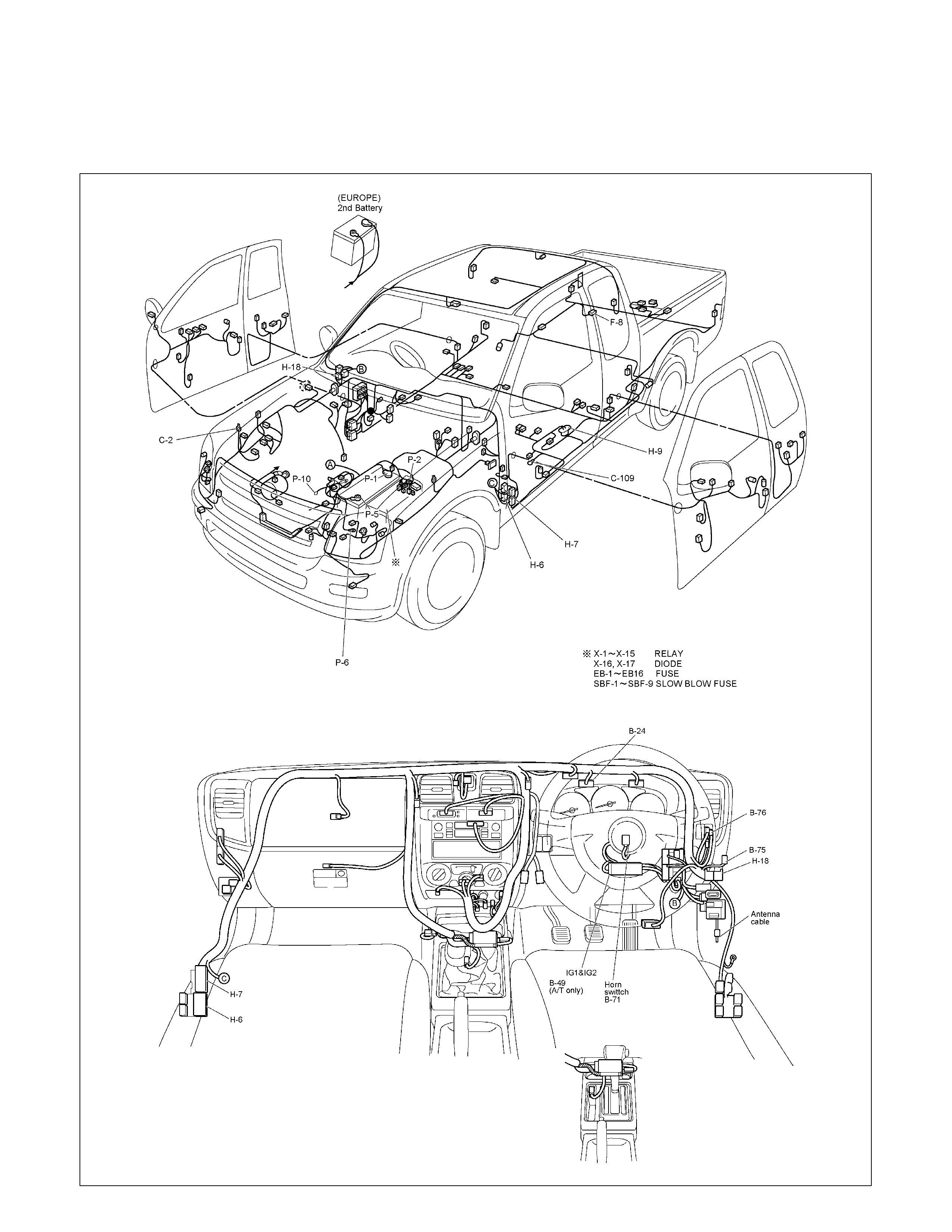

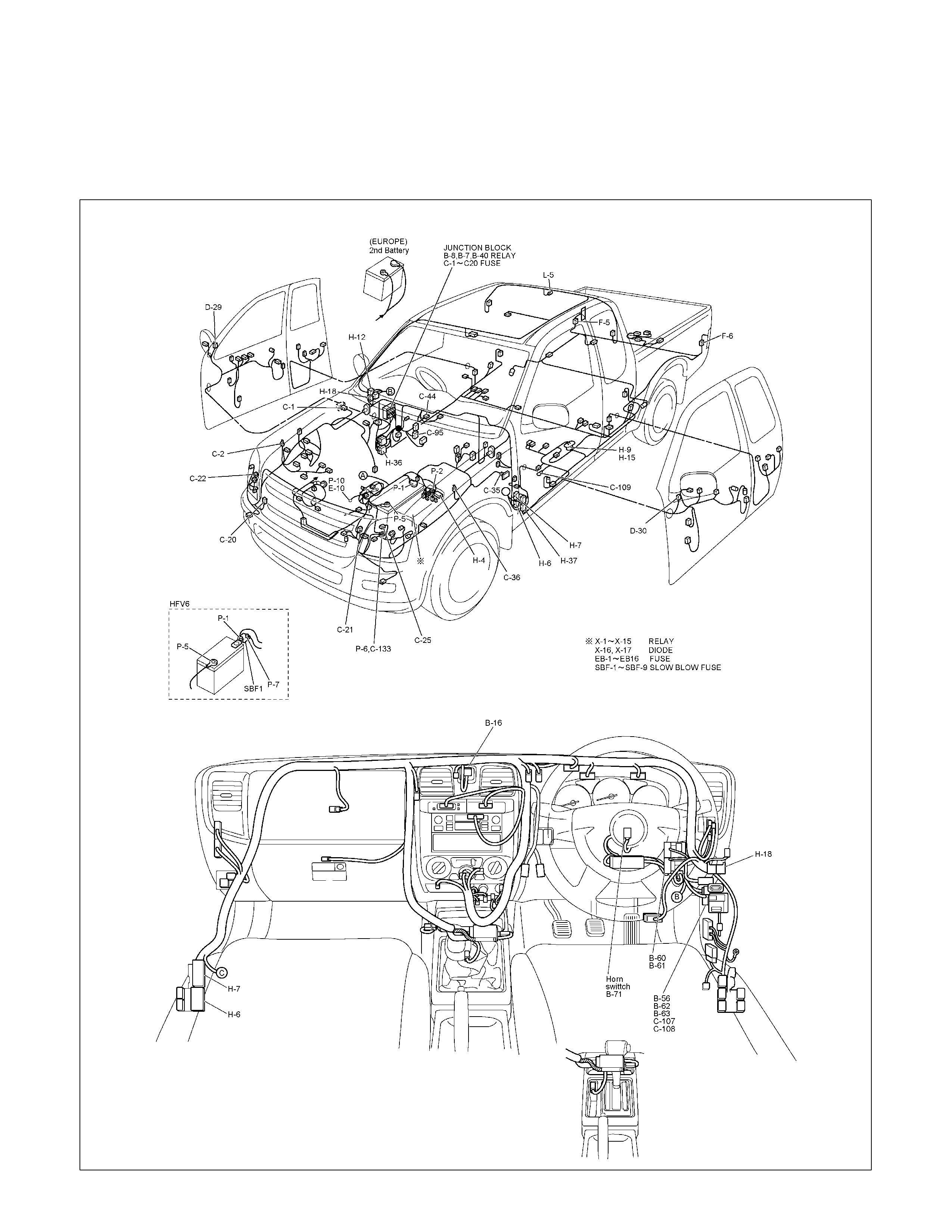

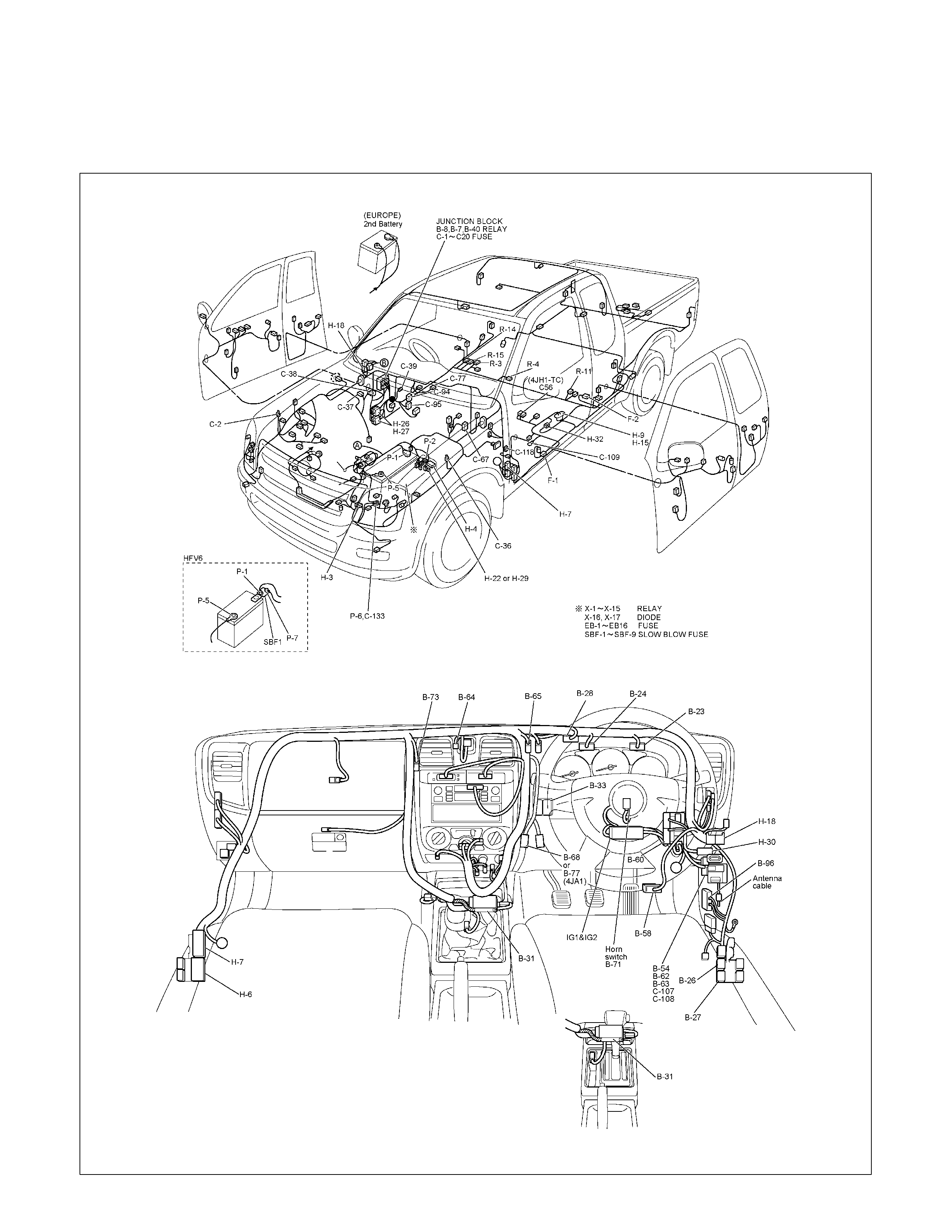

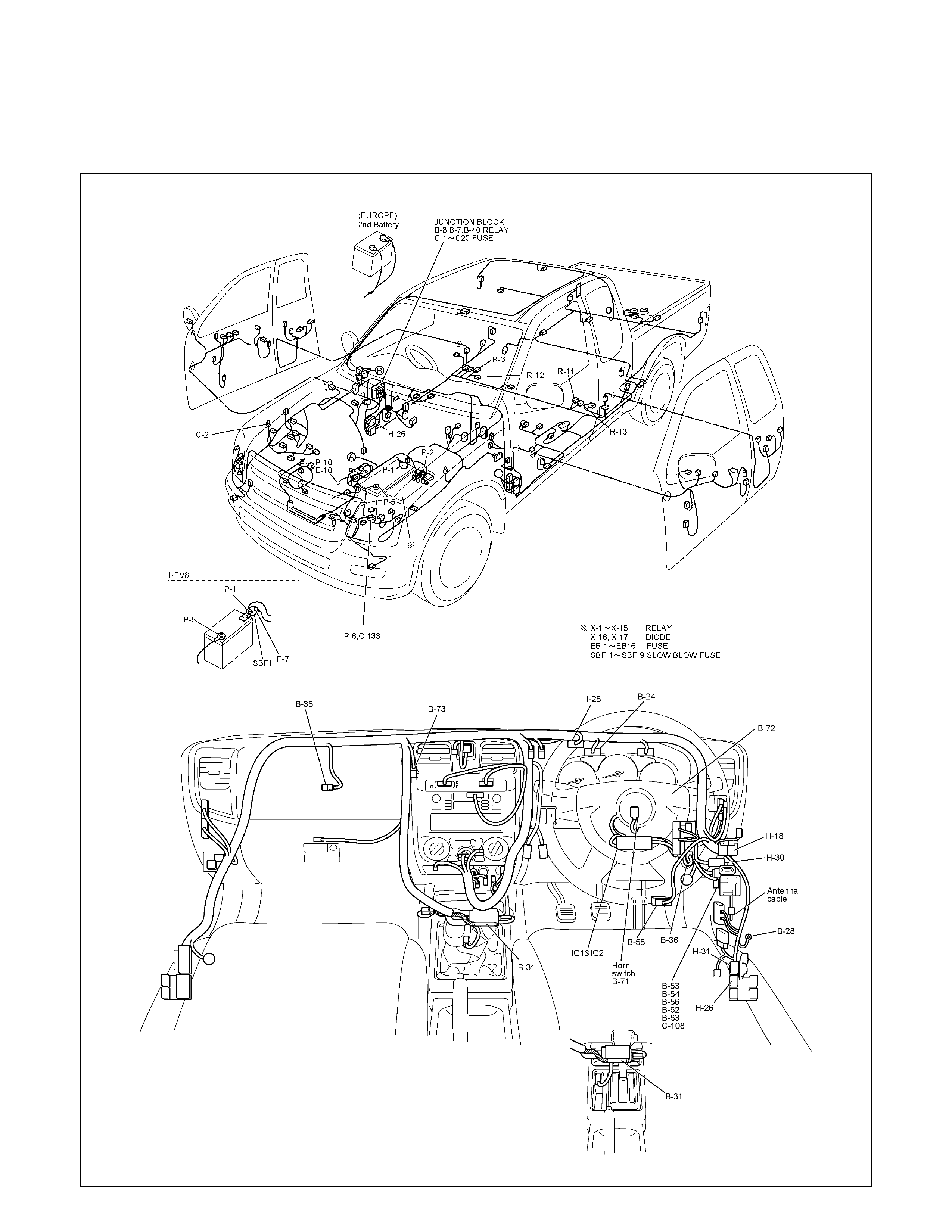

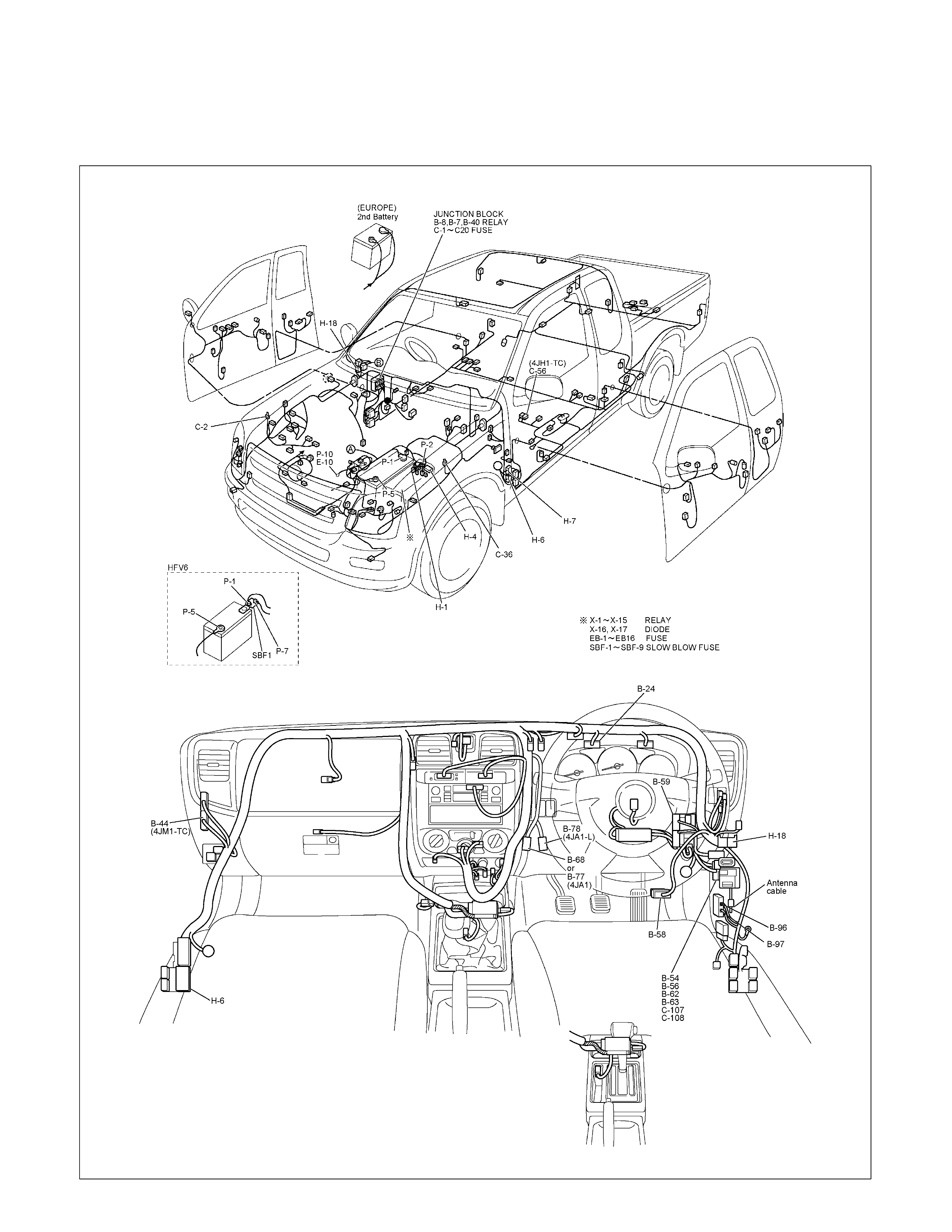

MAIN CABLE HARNESS (RHD)

RTW48AXF004101

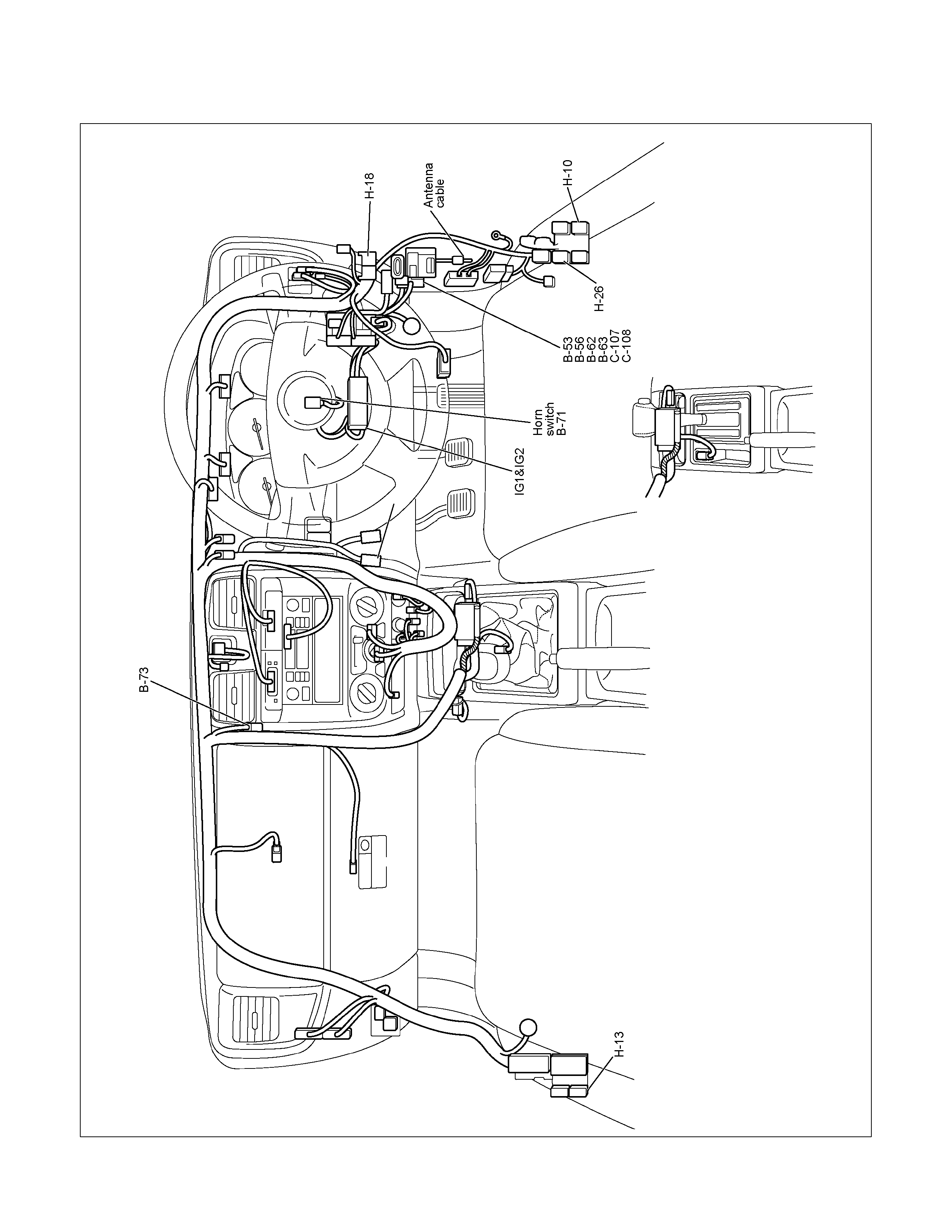

INSTRUMENT HARNESS (RHD)

810R300071

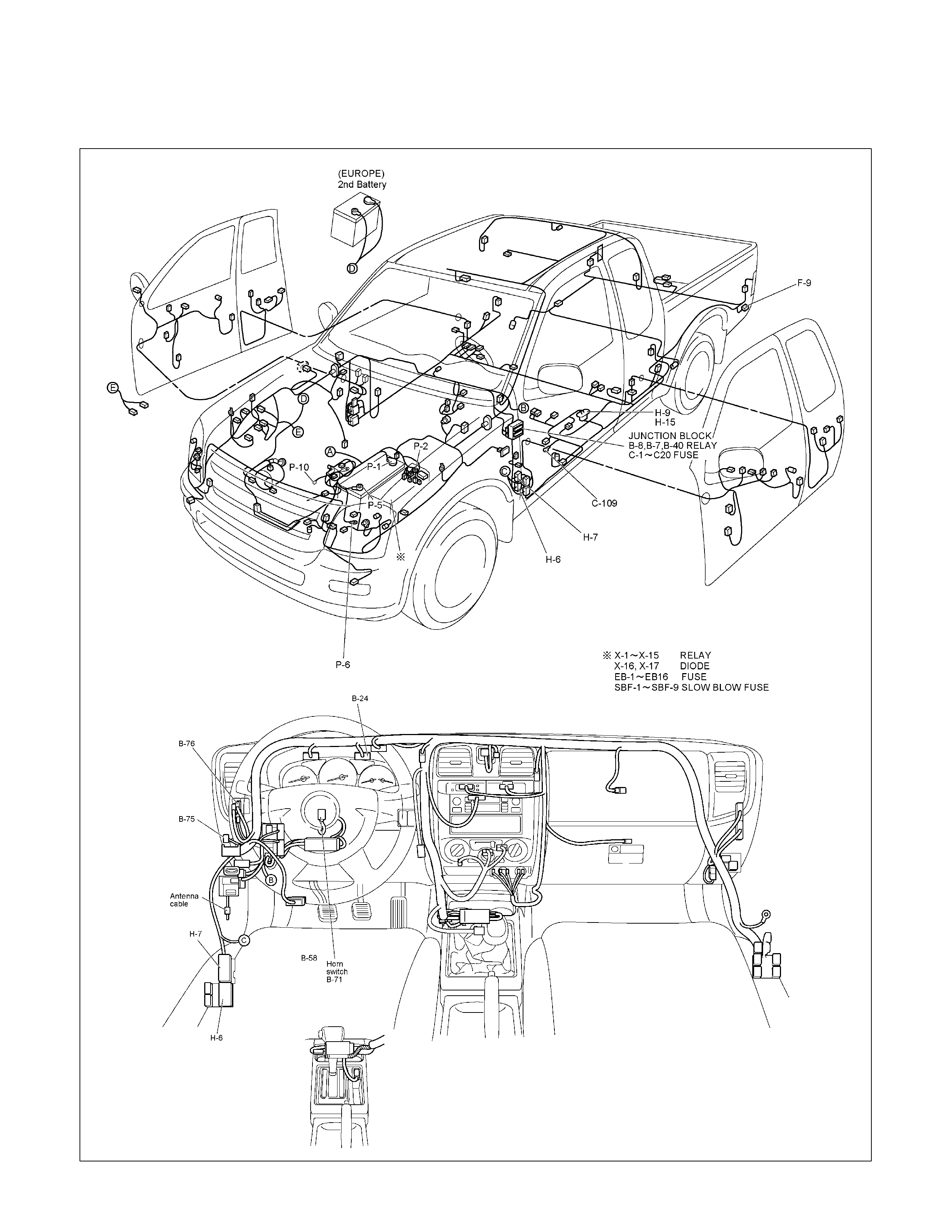

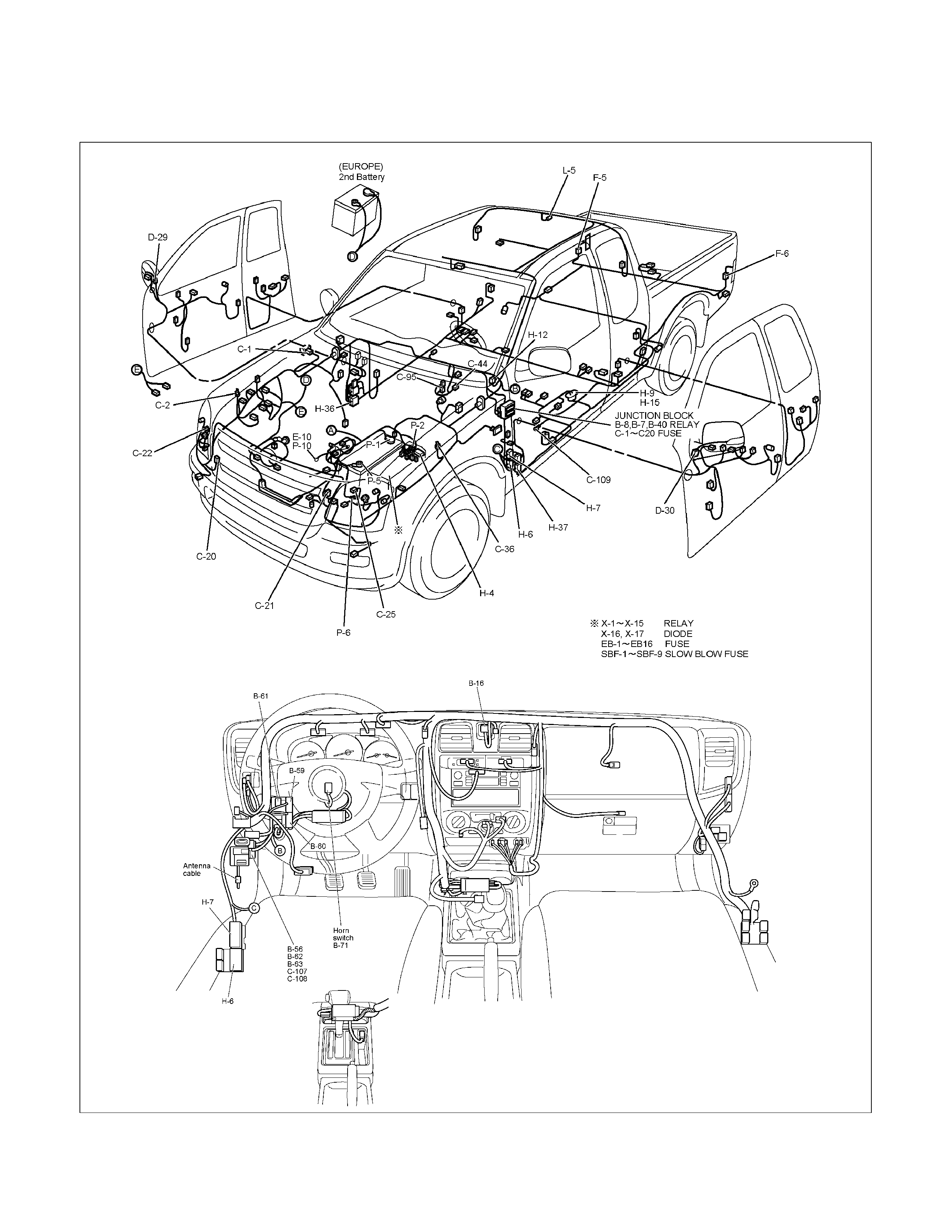

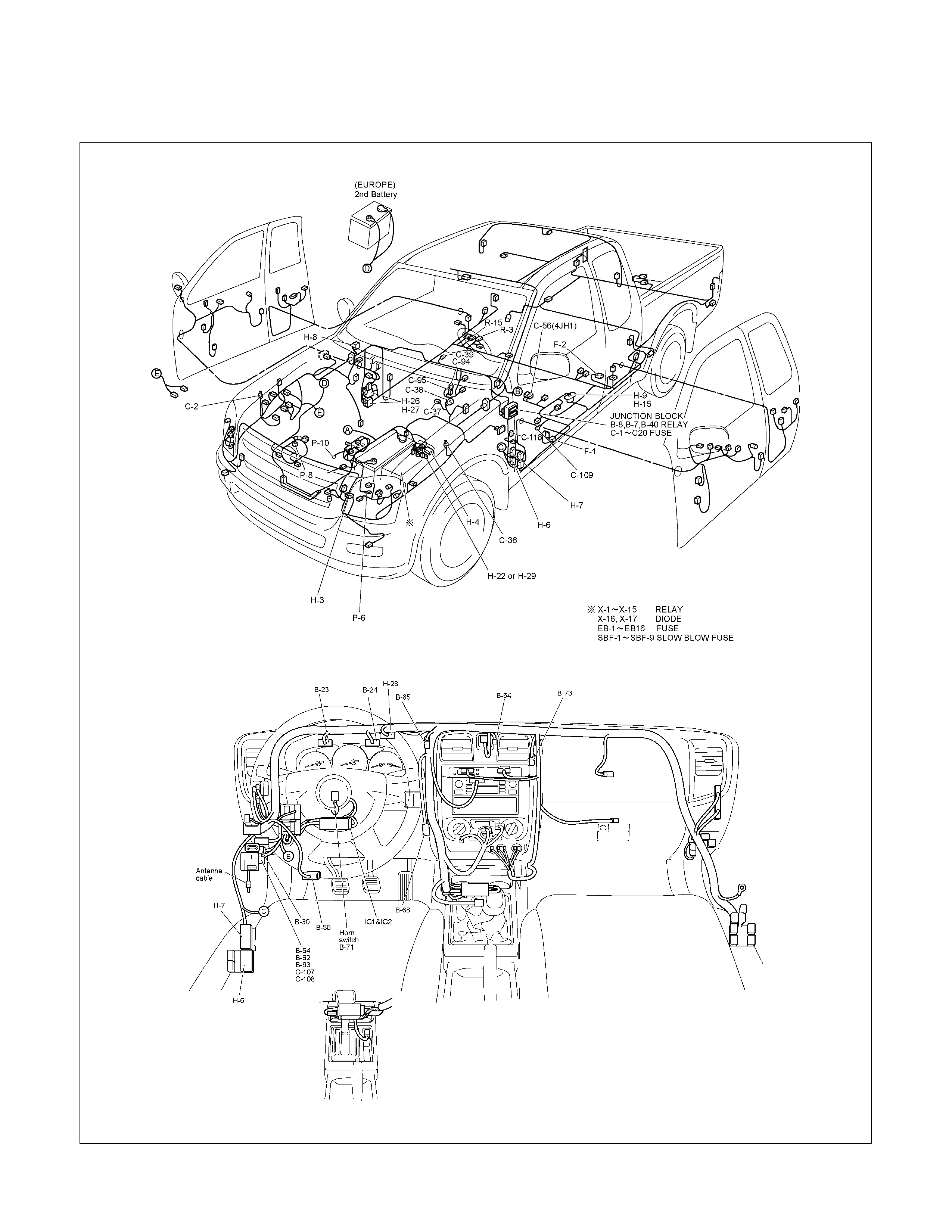

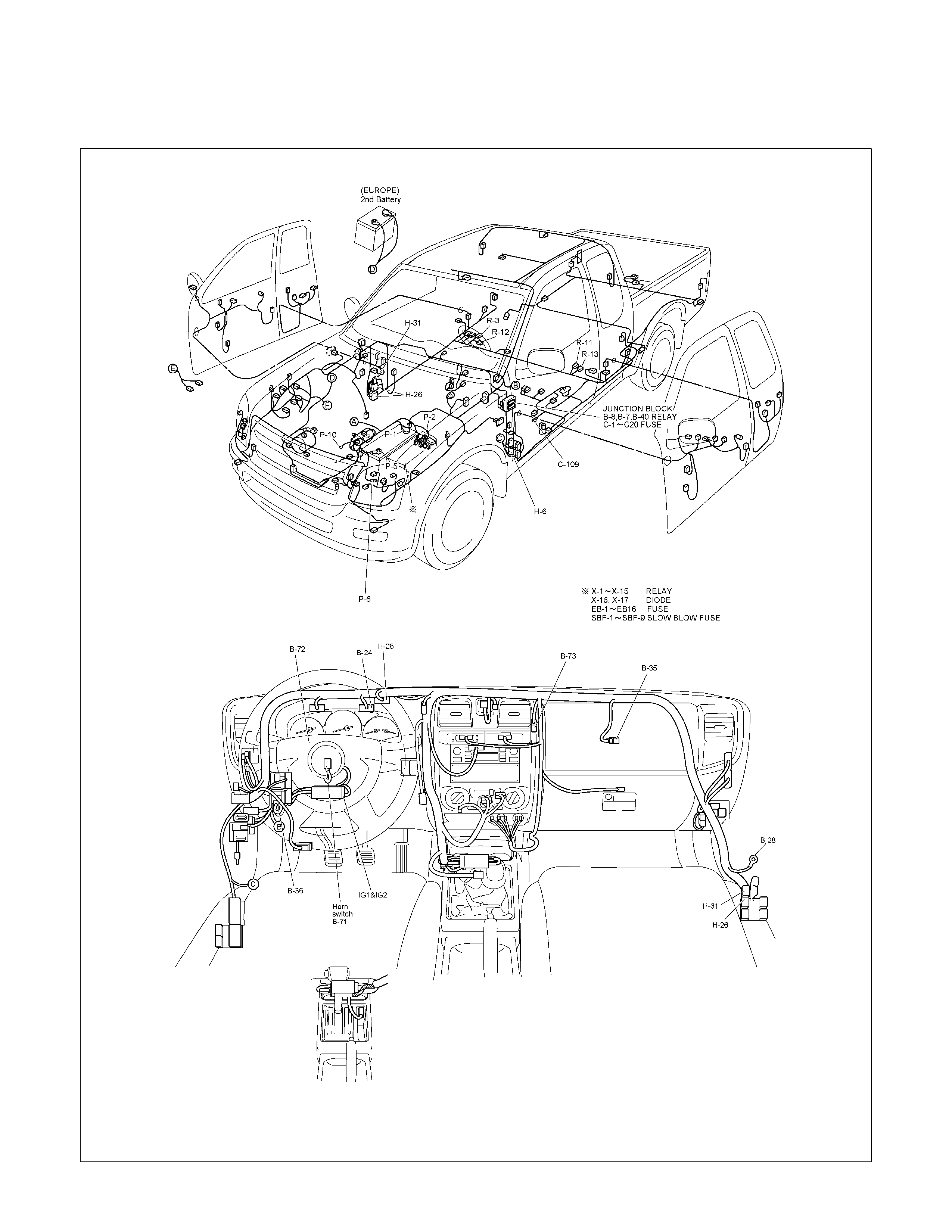

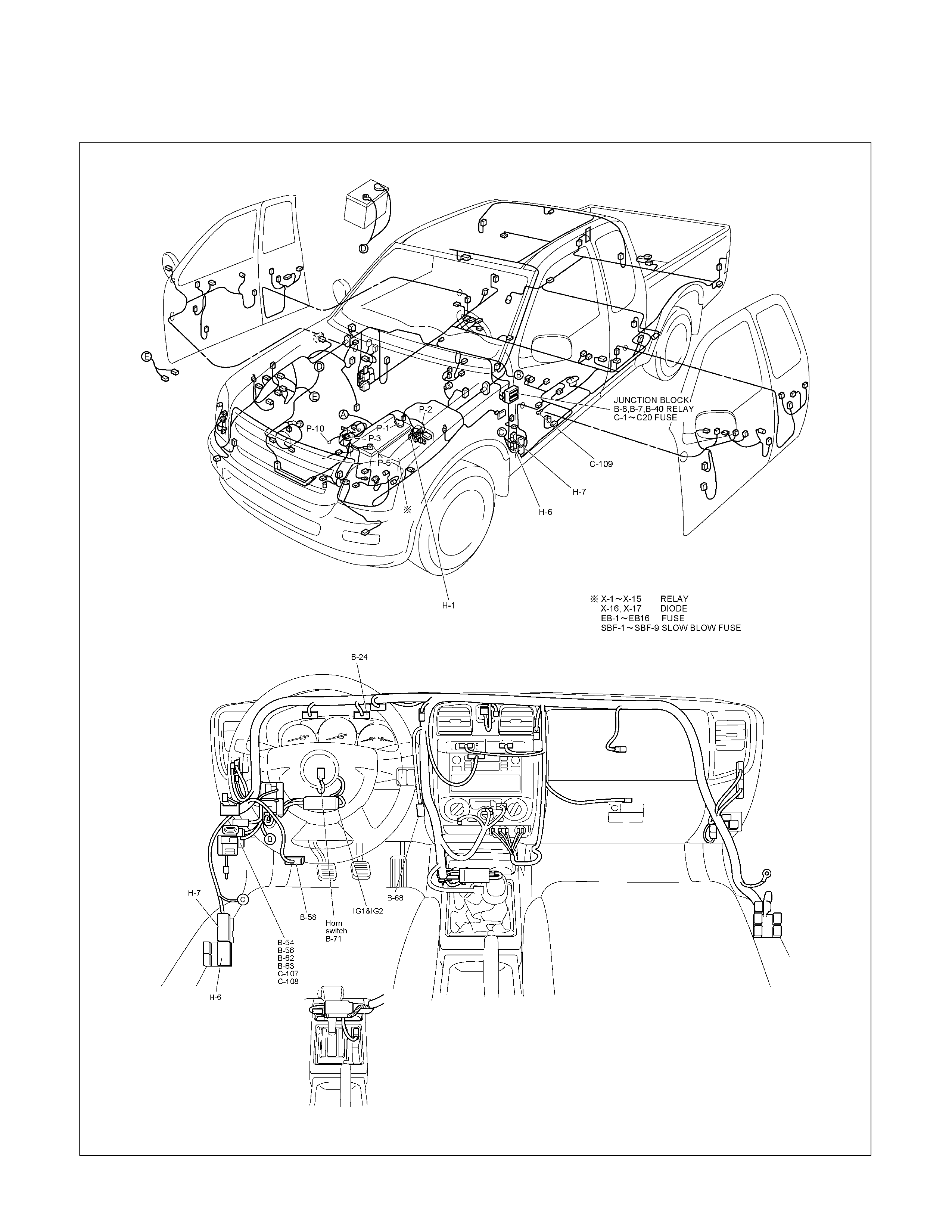

MAIN CABLE HARNESS (LHD)

RTW48AXF004101

INSTRUMENT HARNESS (LHD)

RTW48AXF004001

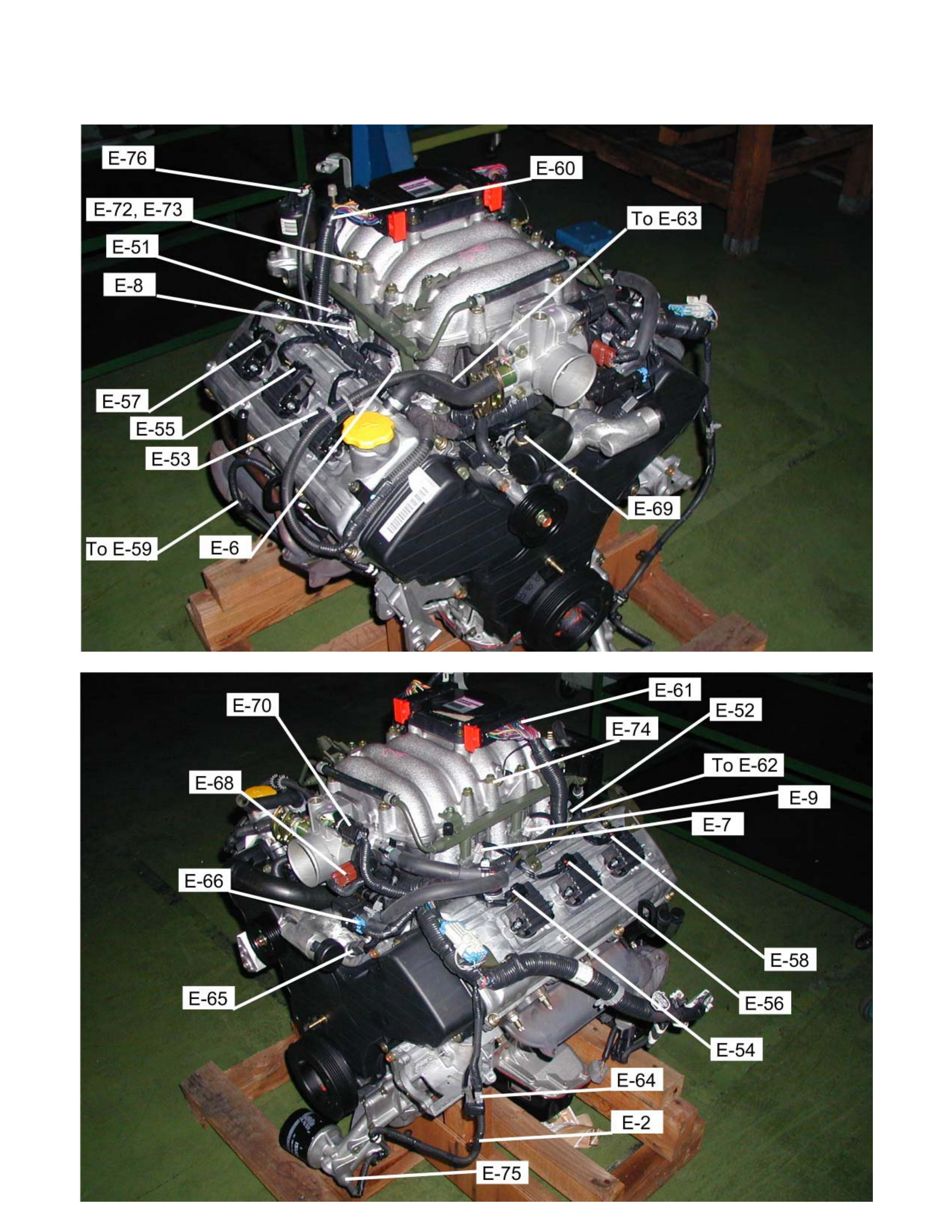

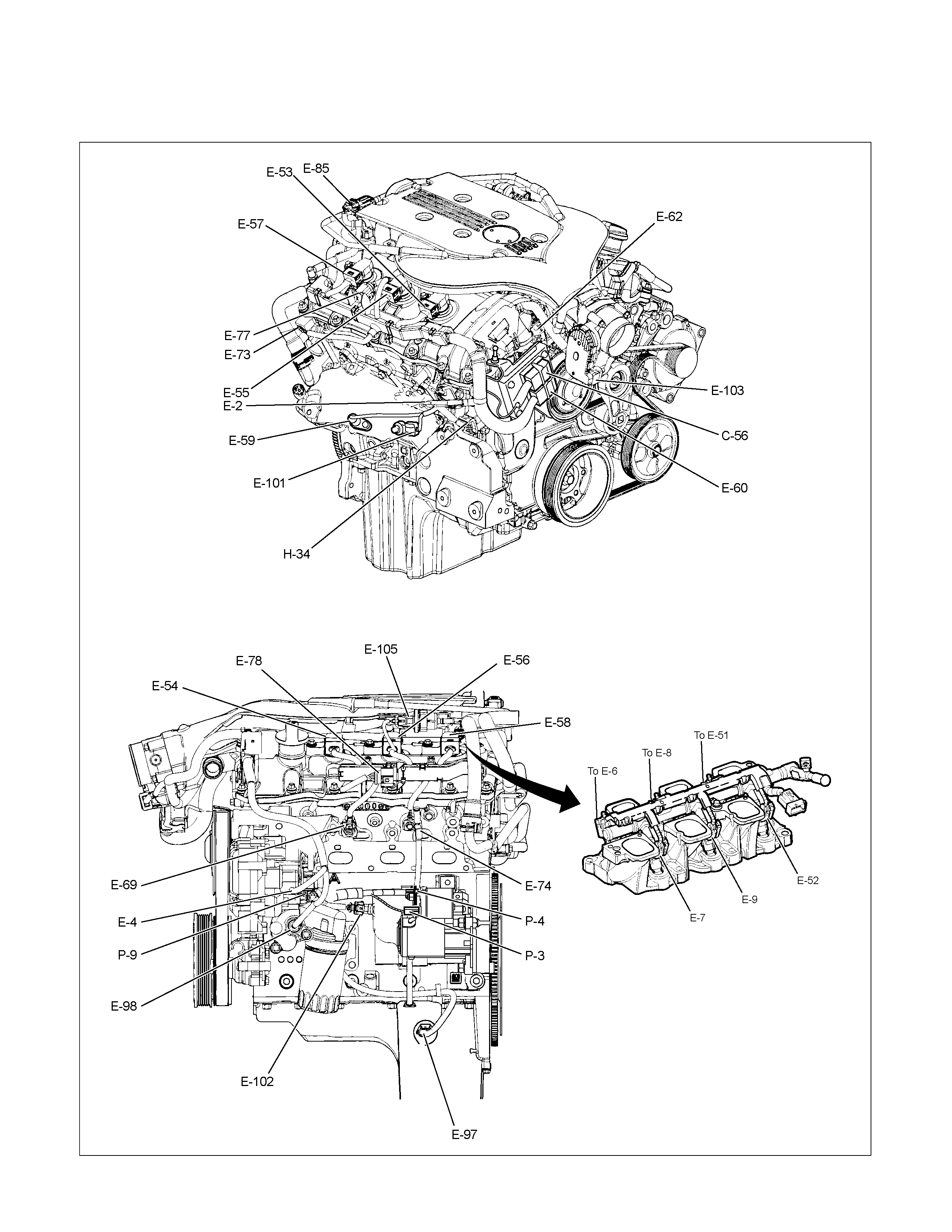

ENGINE HARNESS C24SE

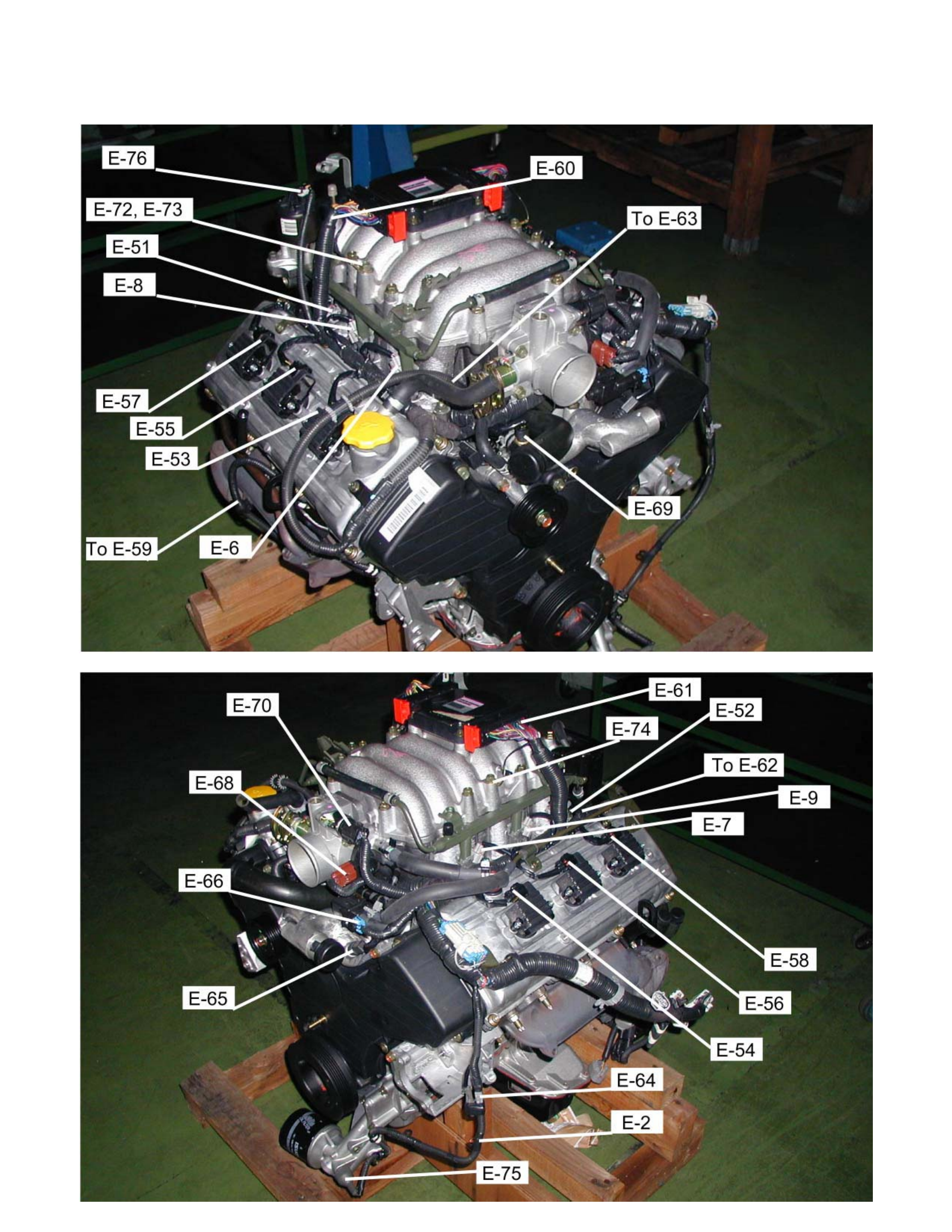

ENGINE HARNESS 6VE1

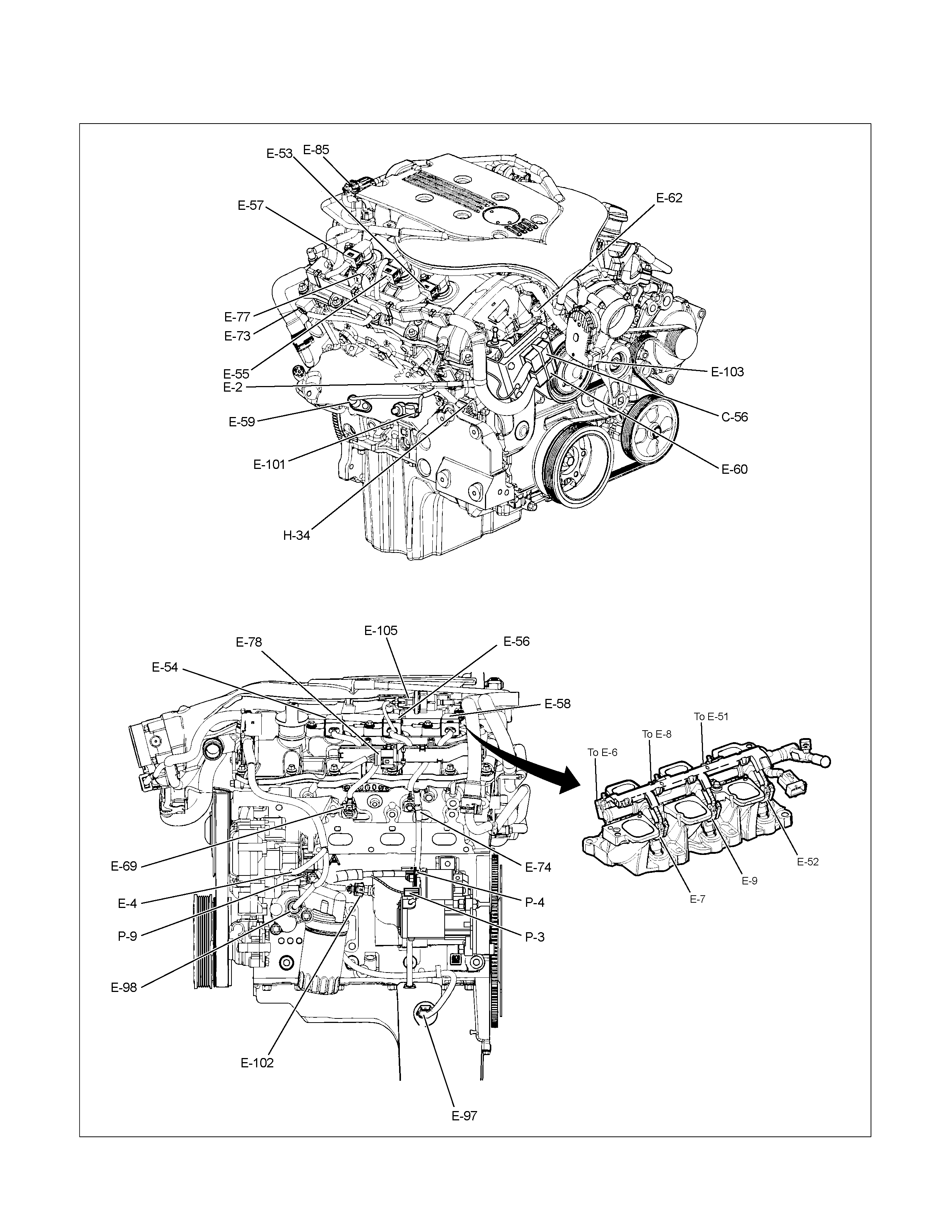

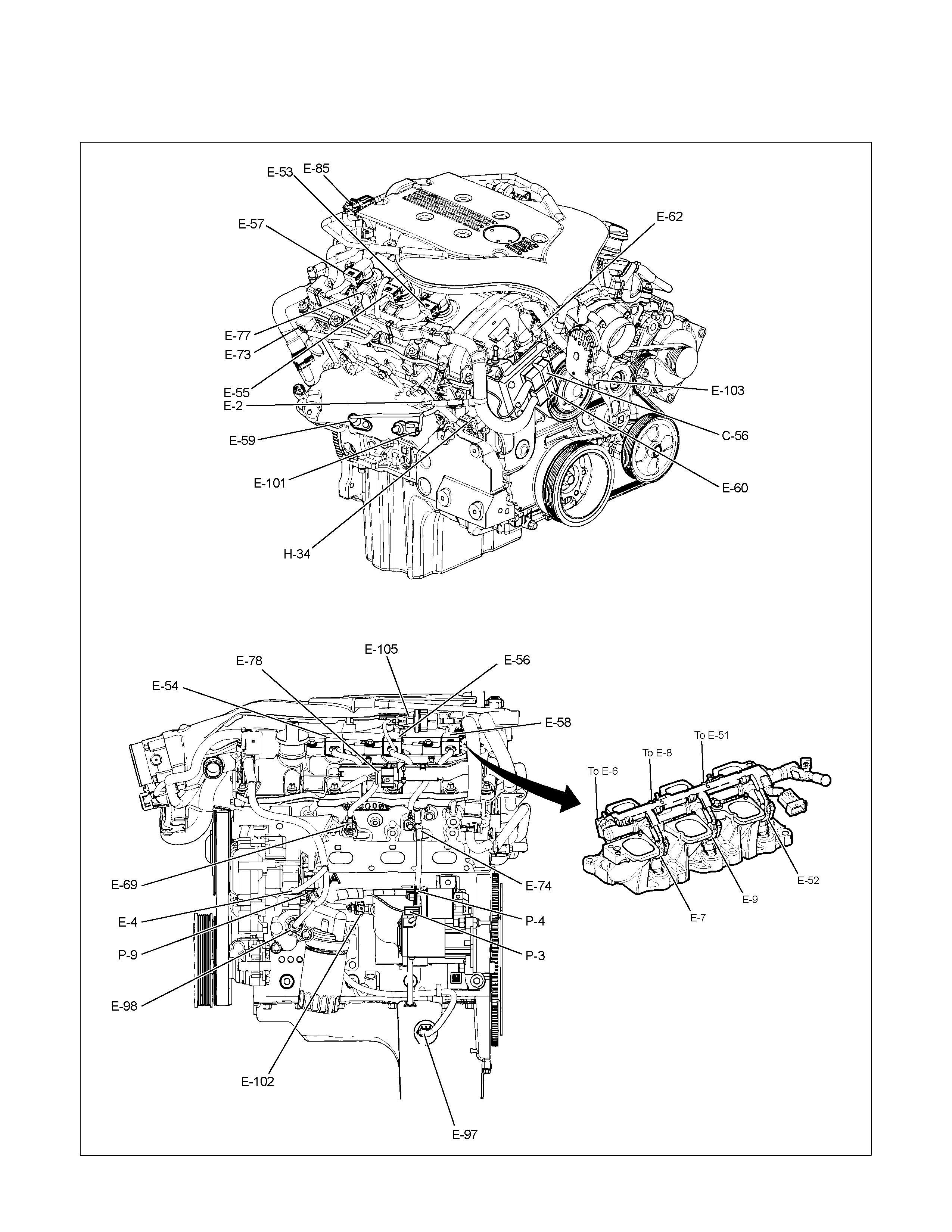

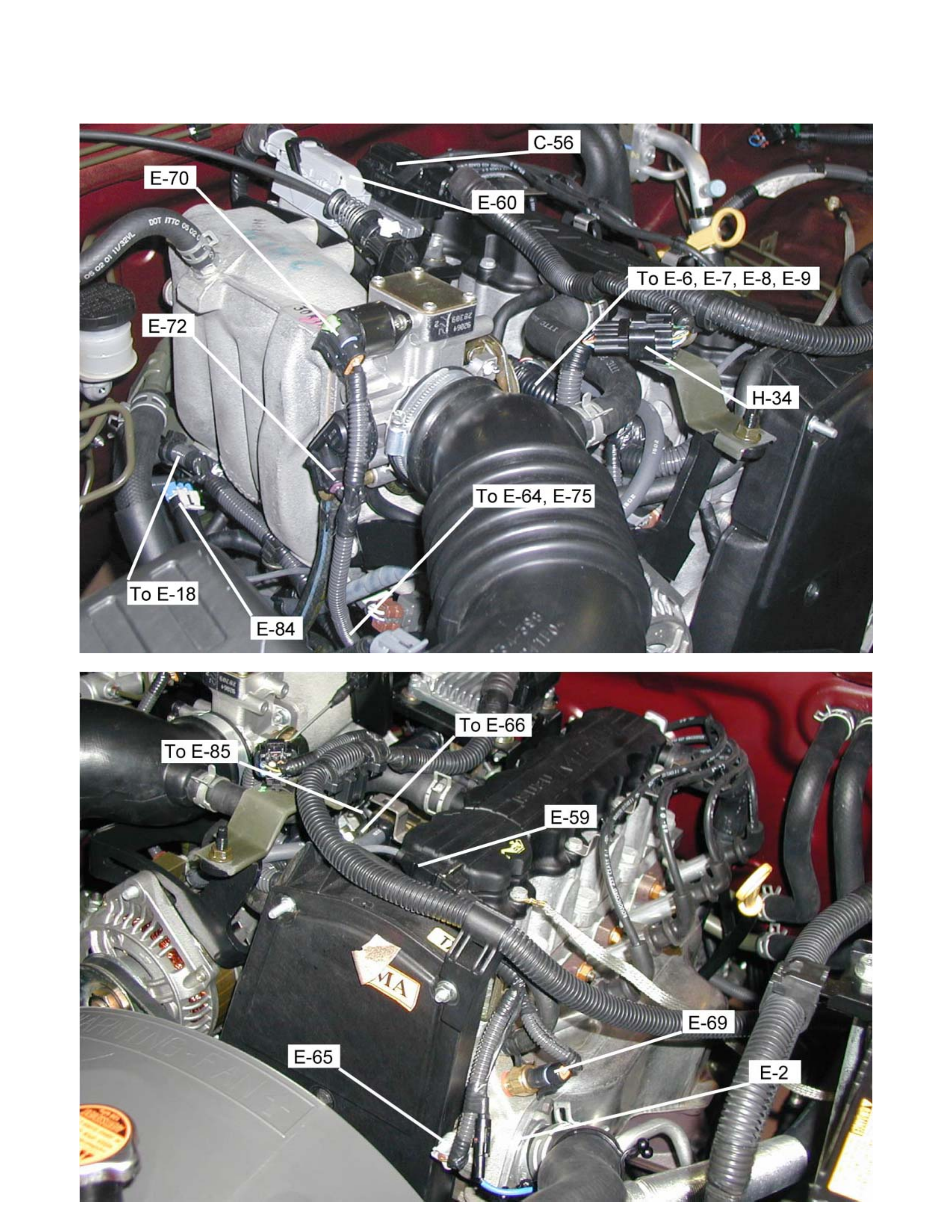

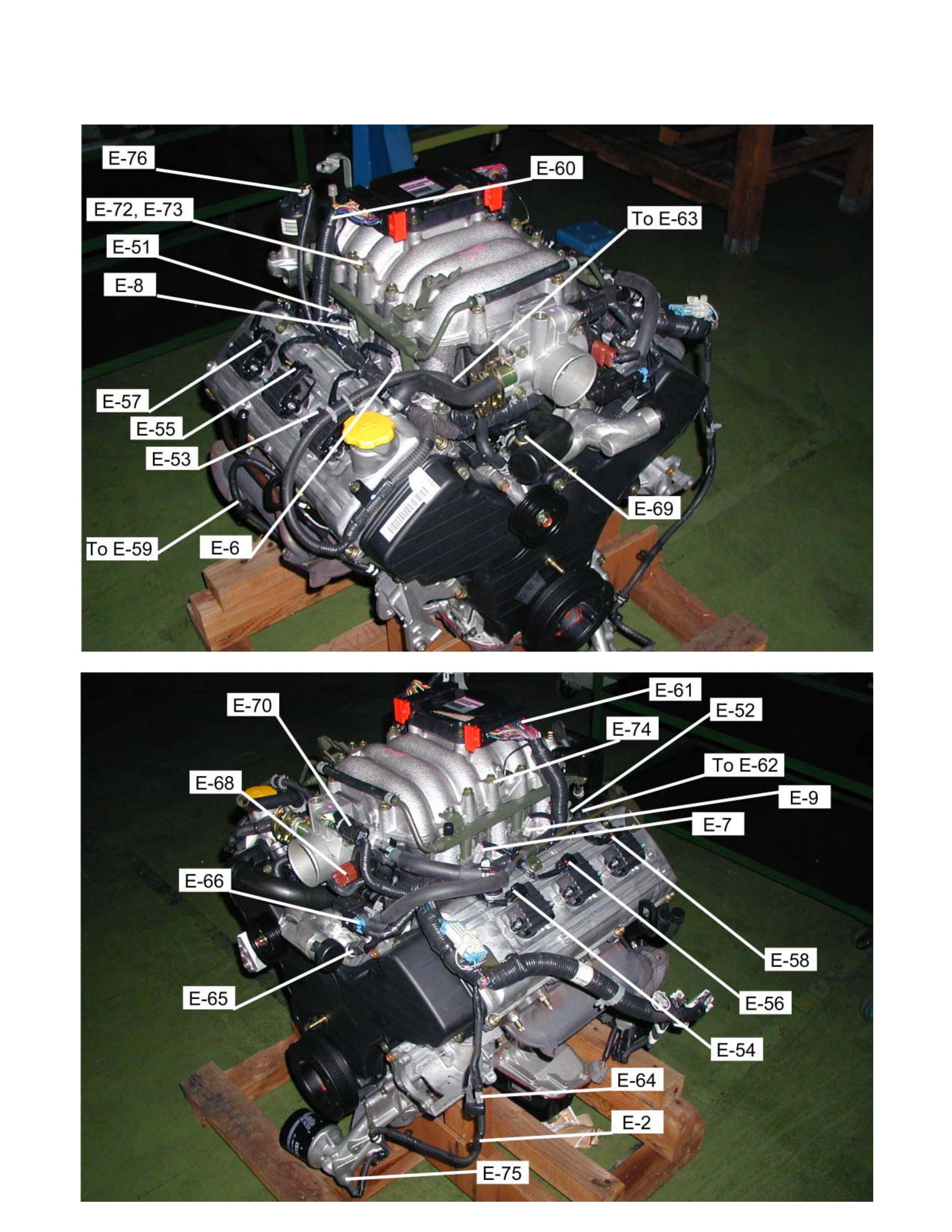

ENGINE HARNESS HFV6

RTW68AXF012201

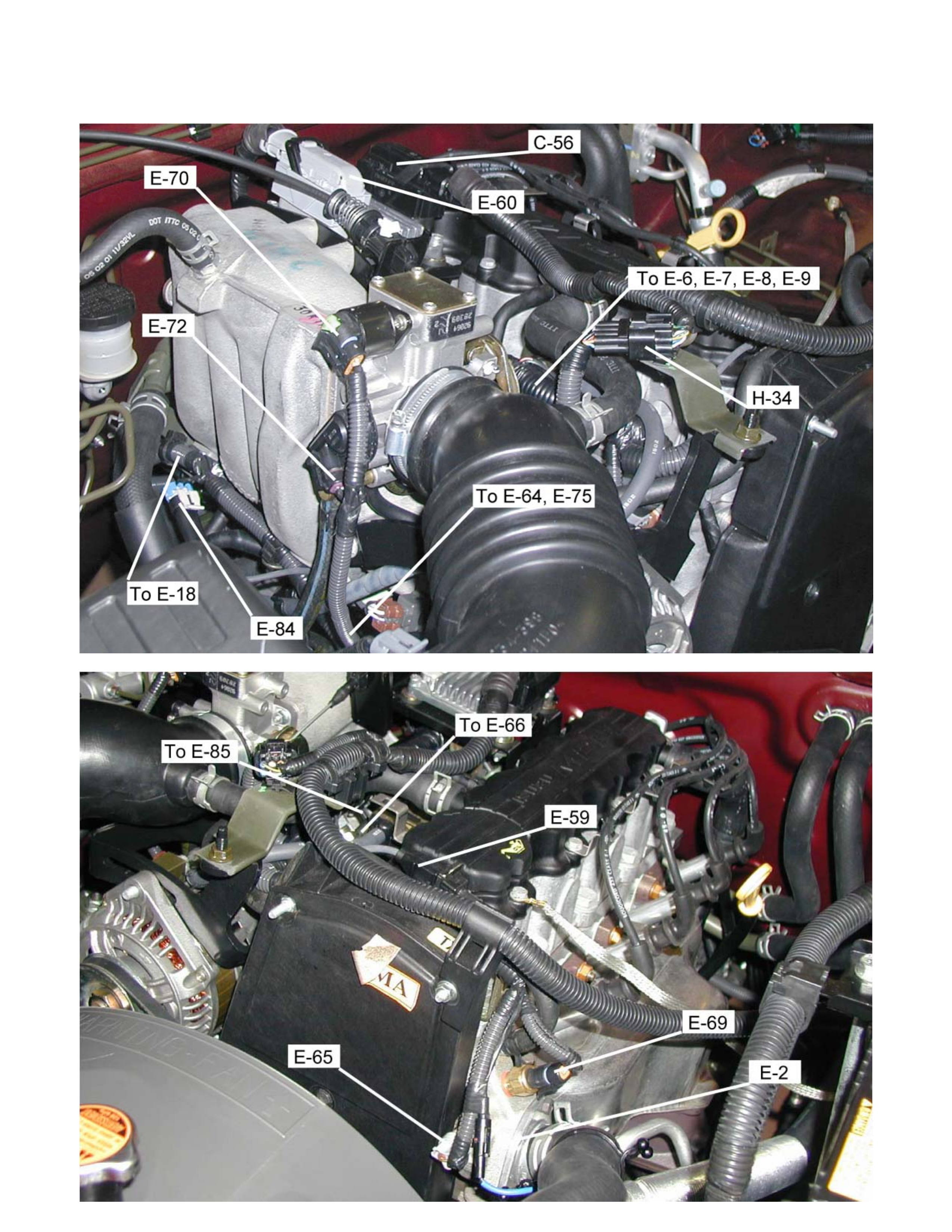

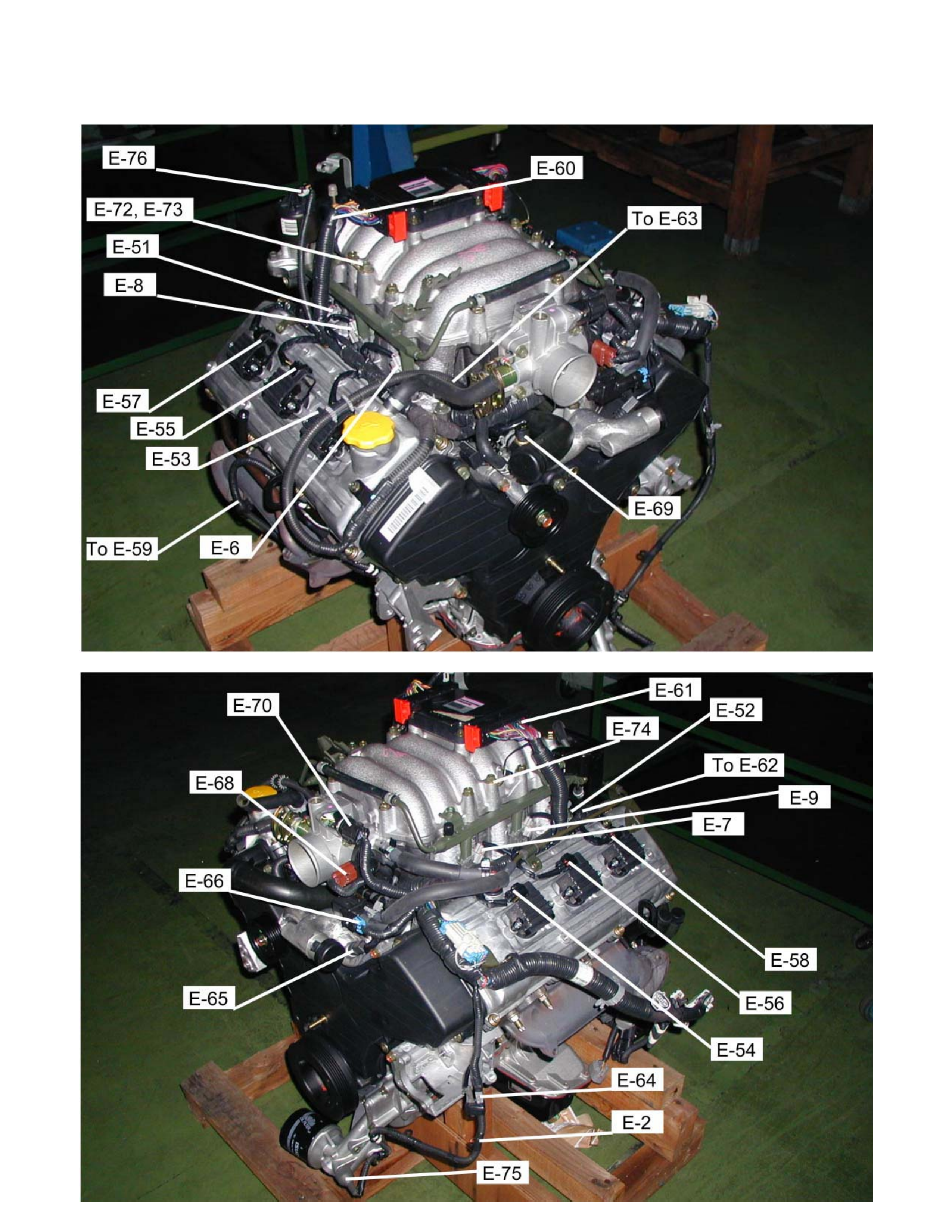

ENGINE HARNESS 4JA1-TC / 4JH1-TC / 4JA1-L

4JA1-TC, 4JH1-TC

4JA1-L

RTW38DX007601 & RTW48AMF001401

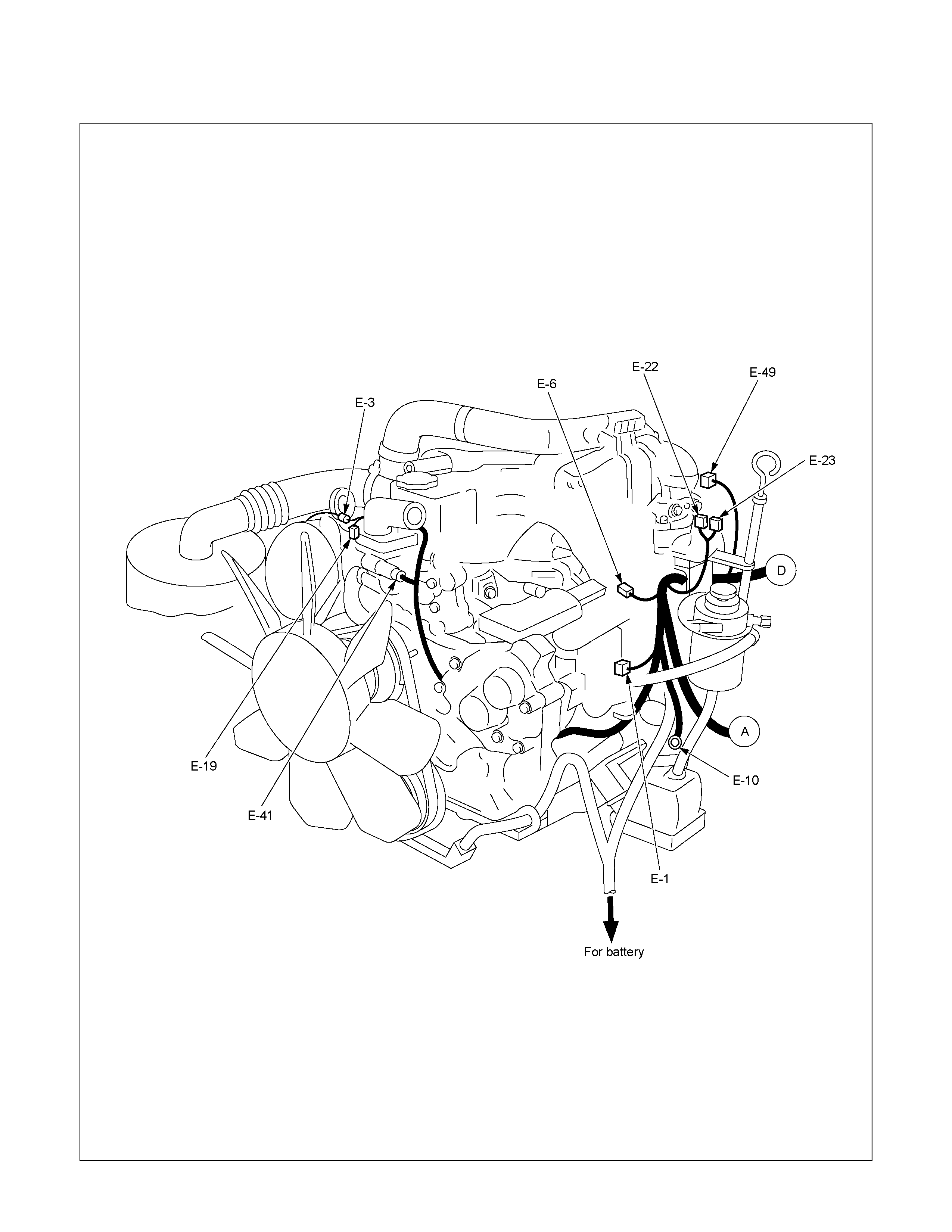

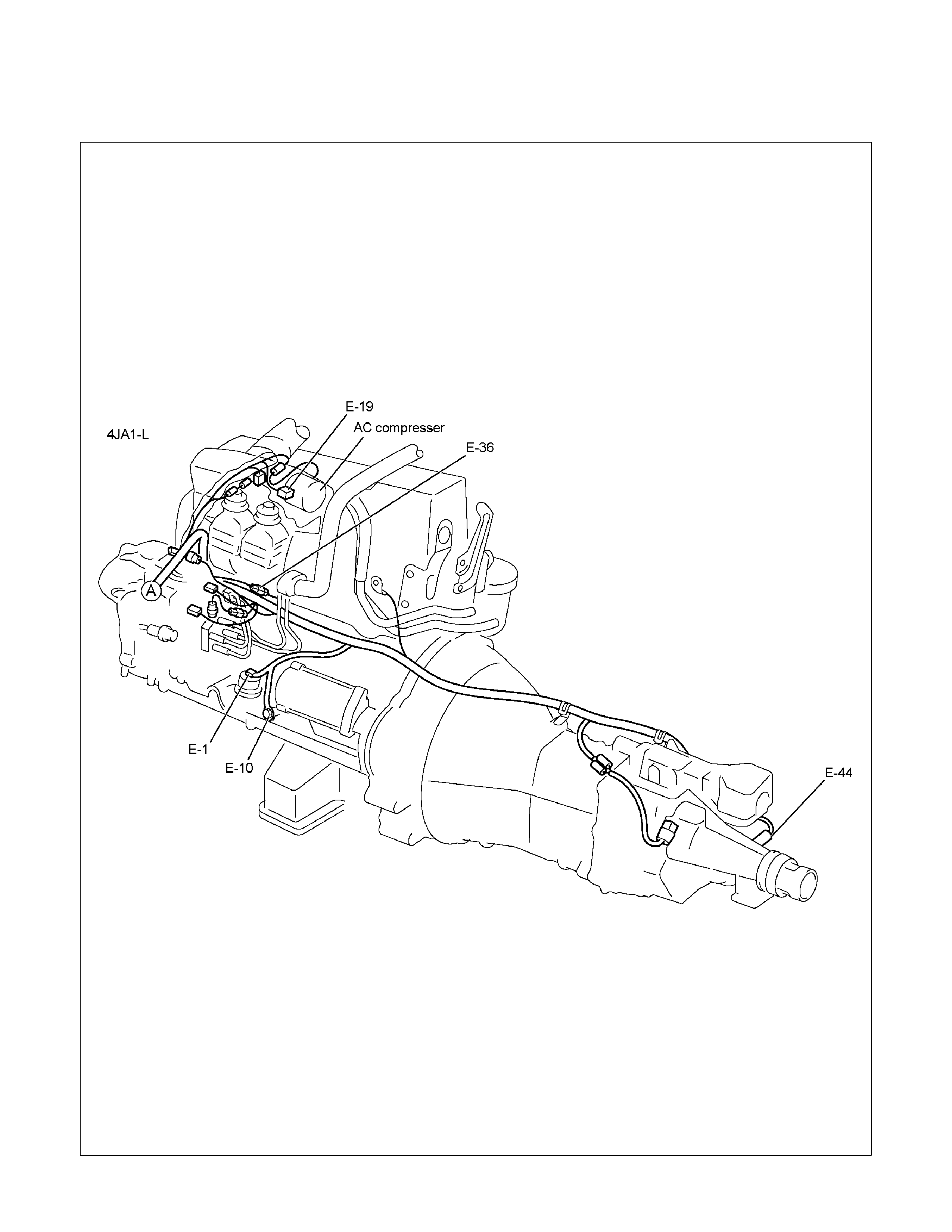

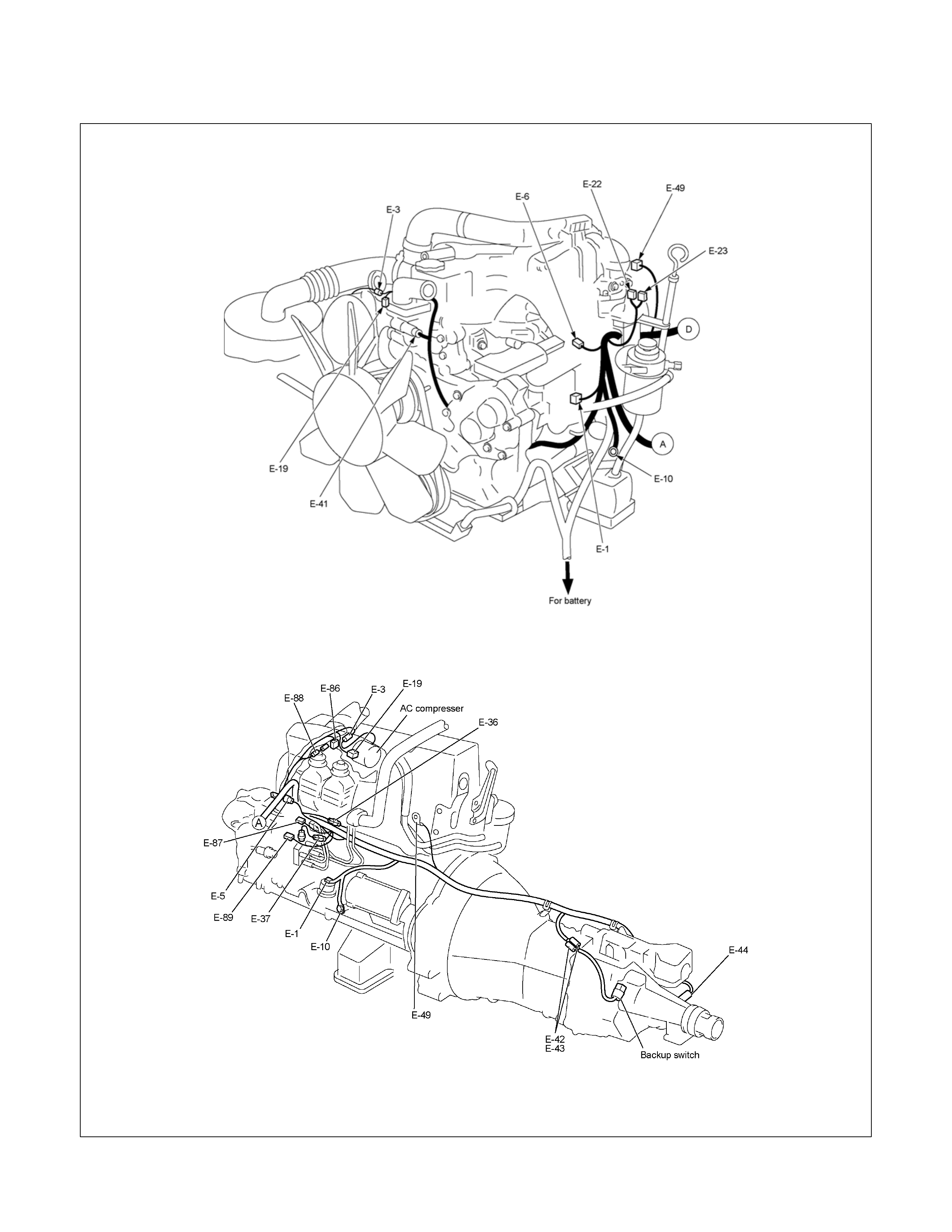

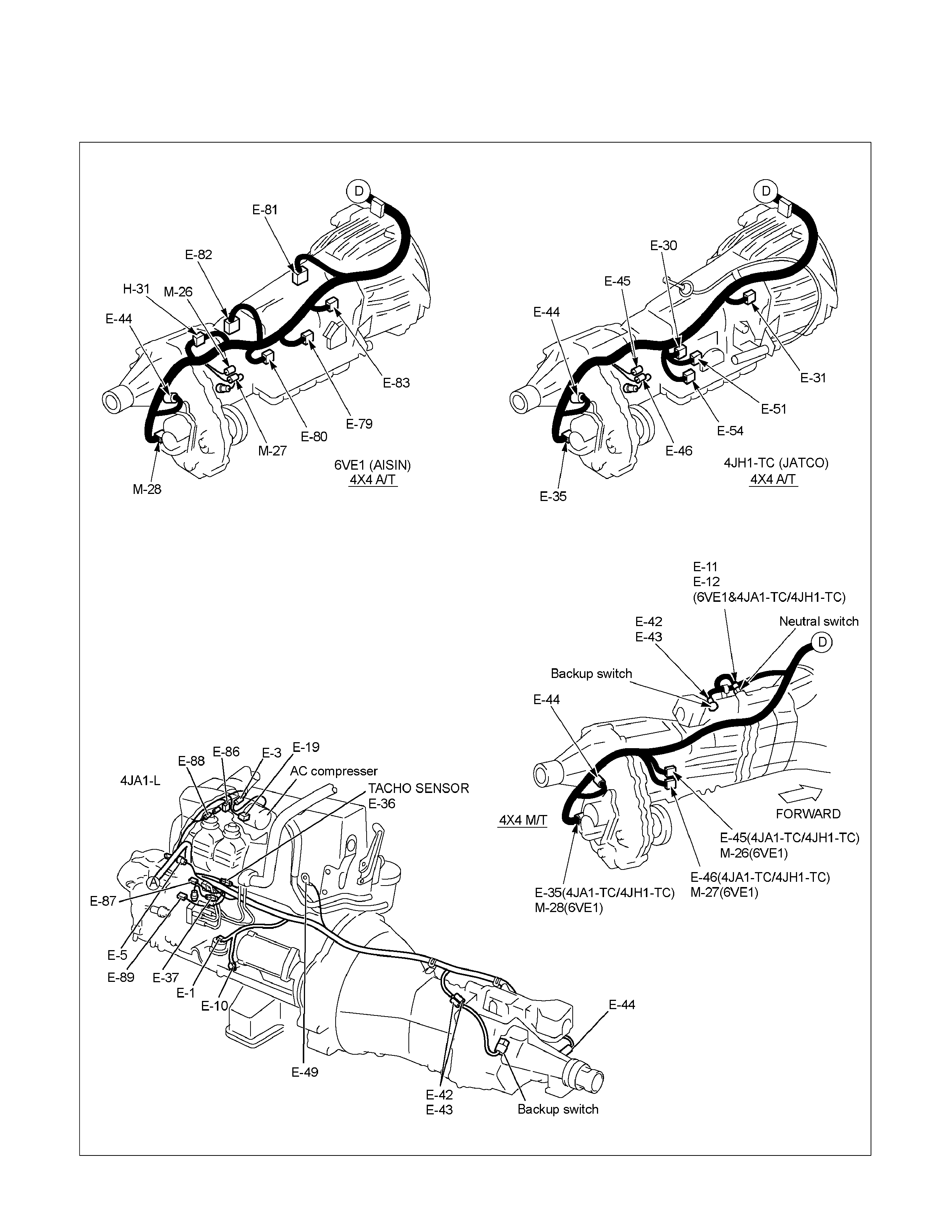

TRANSMISSION HARNESS

RTW68AXF014701

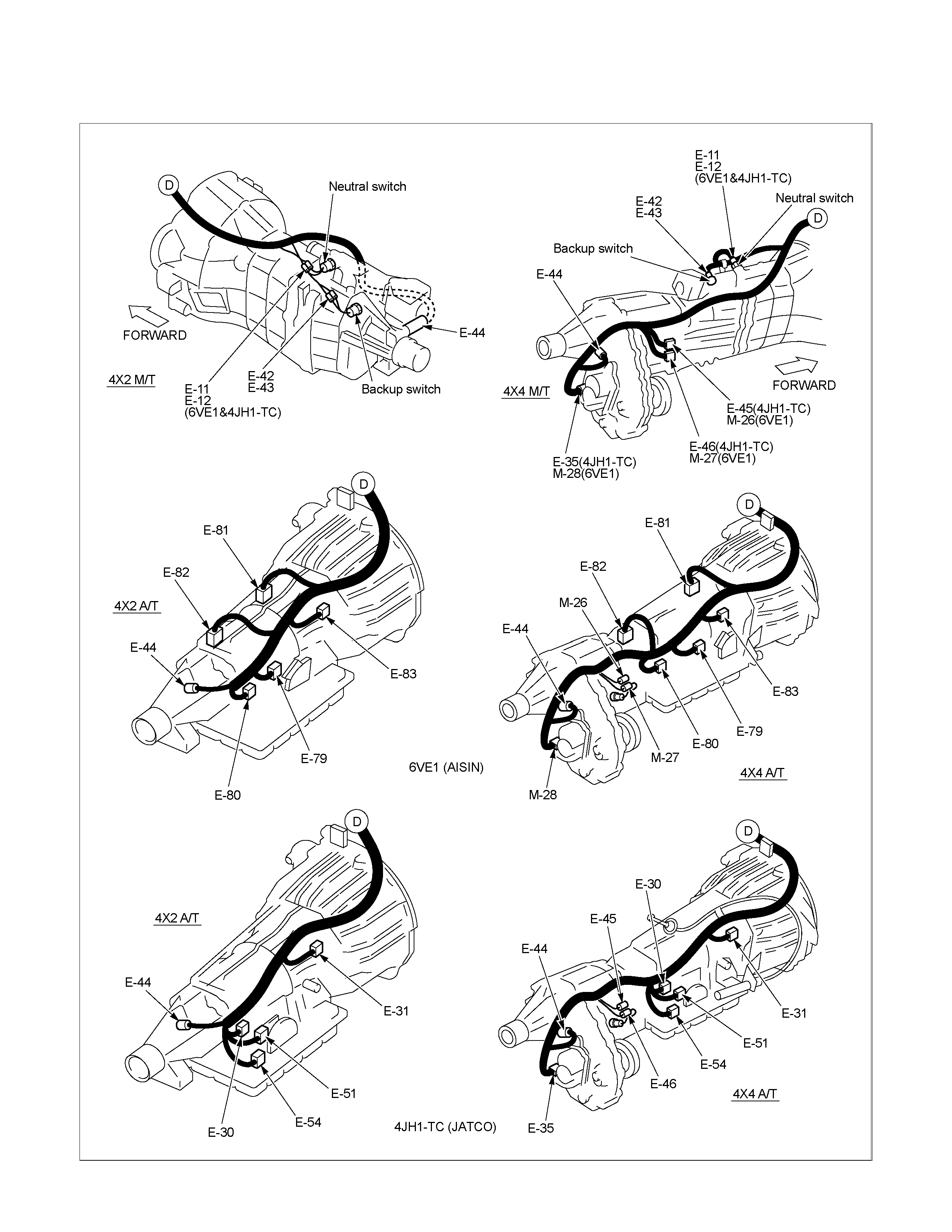

TRANSMISSION HARNESS

RTW68AXF012801

SYSTEM REPAIR

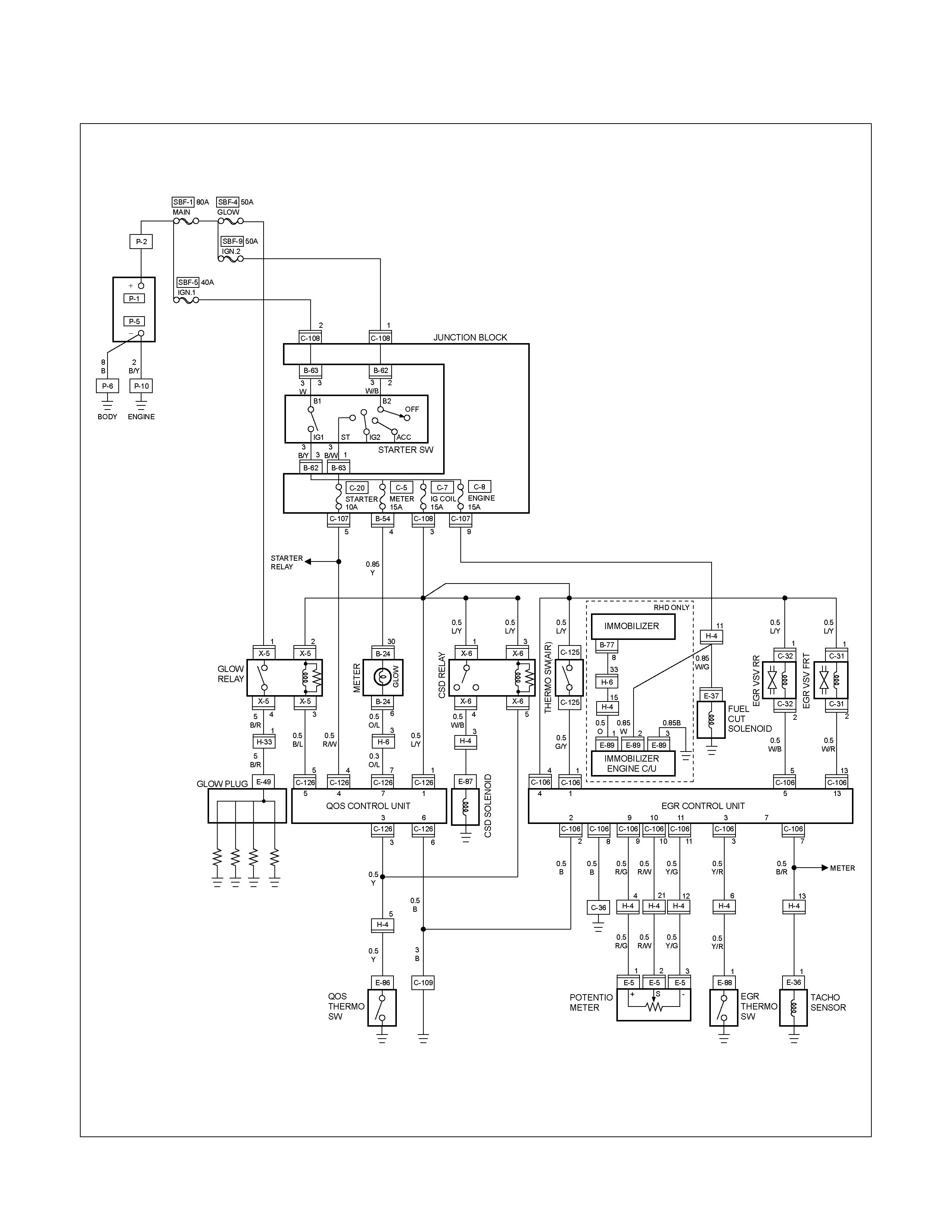

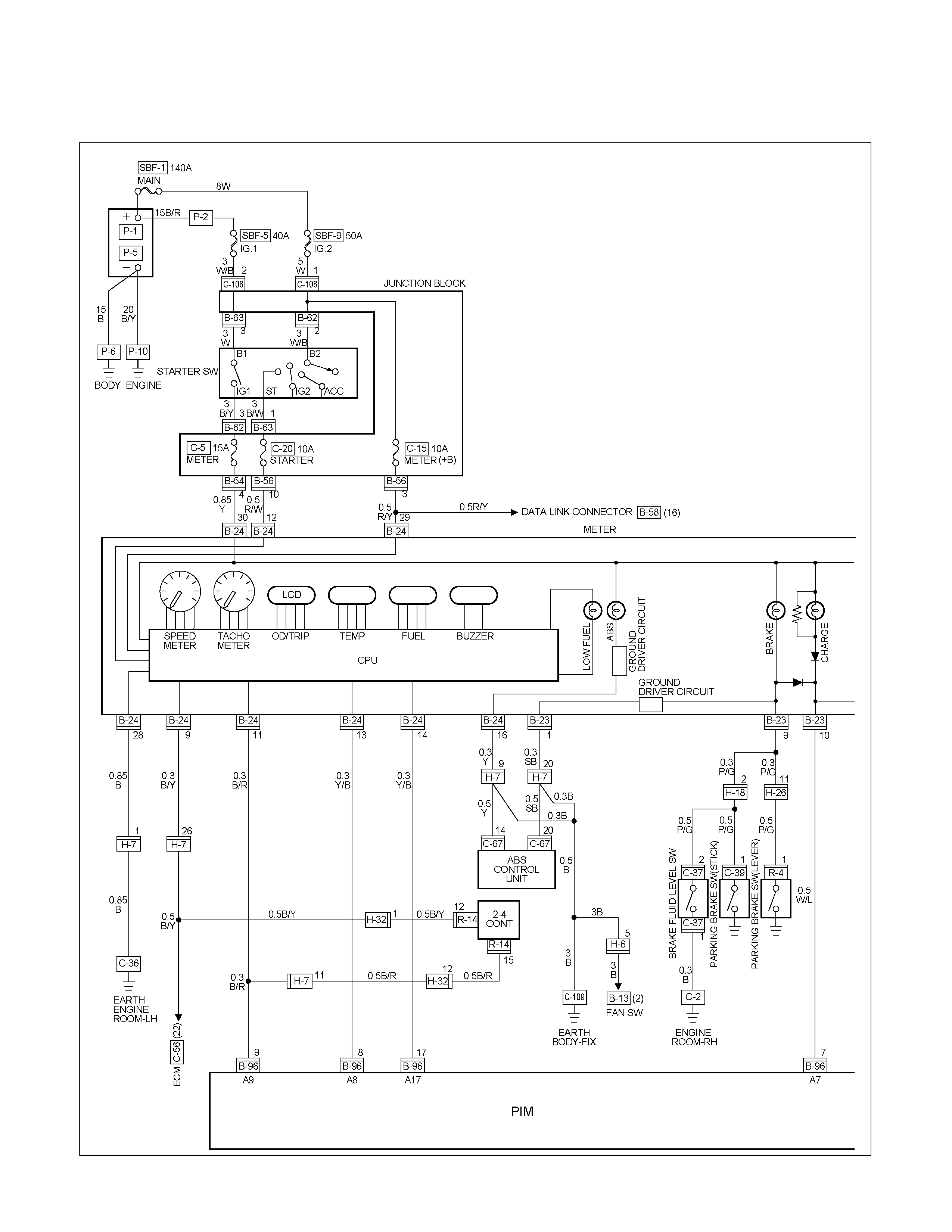

START AND CHARGING

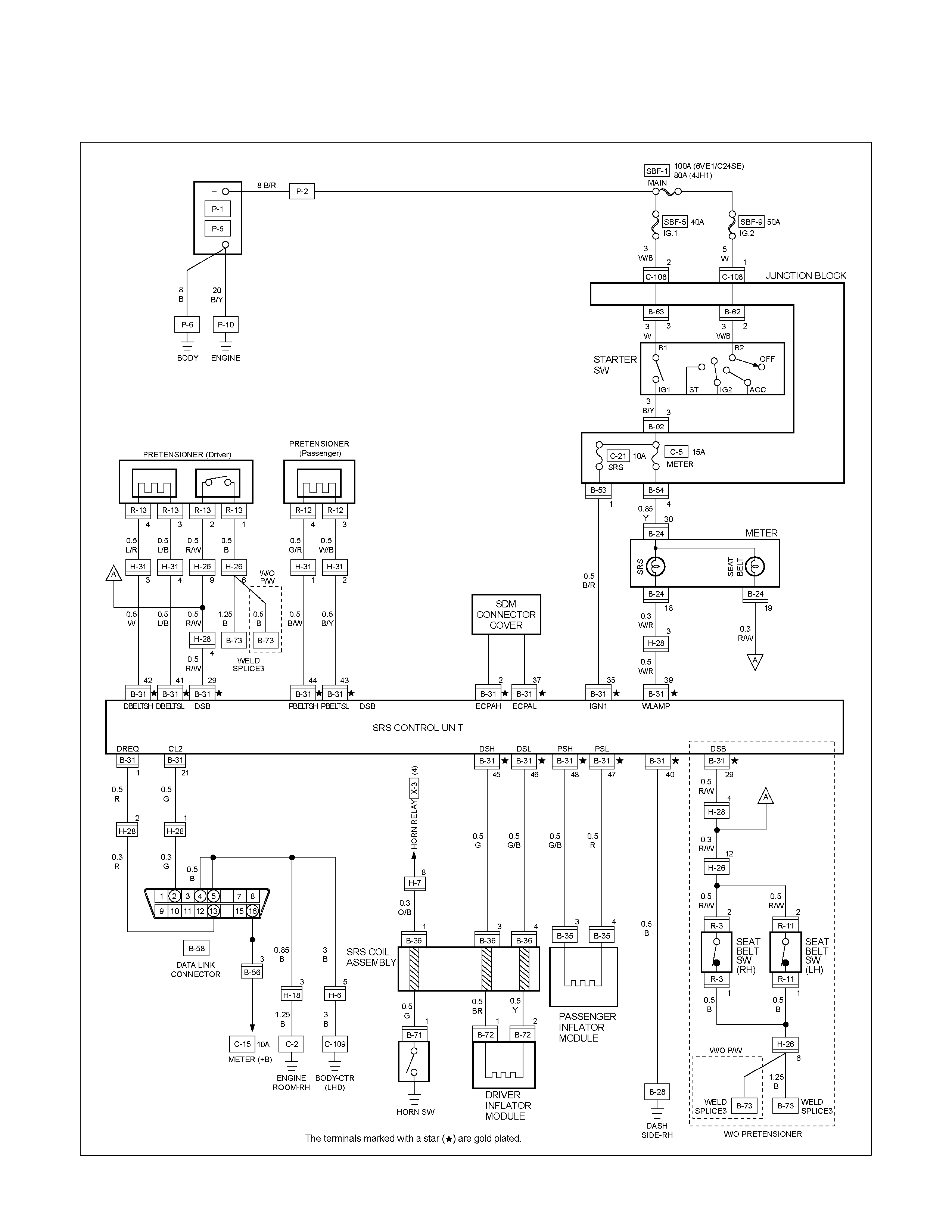

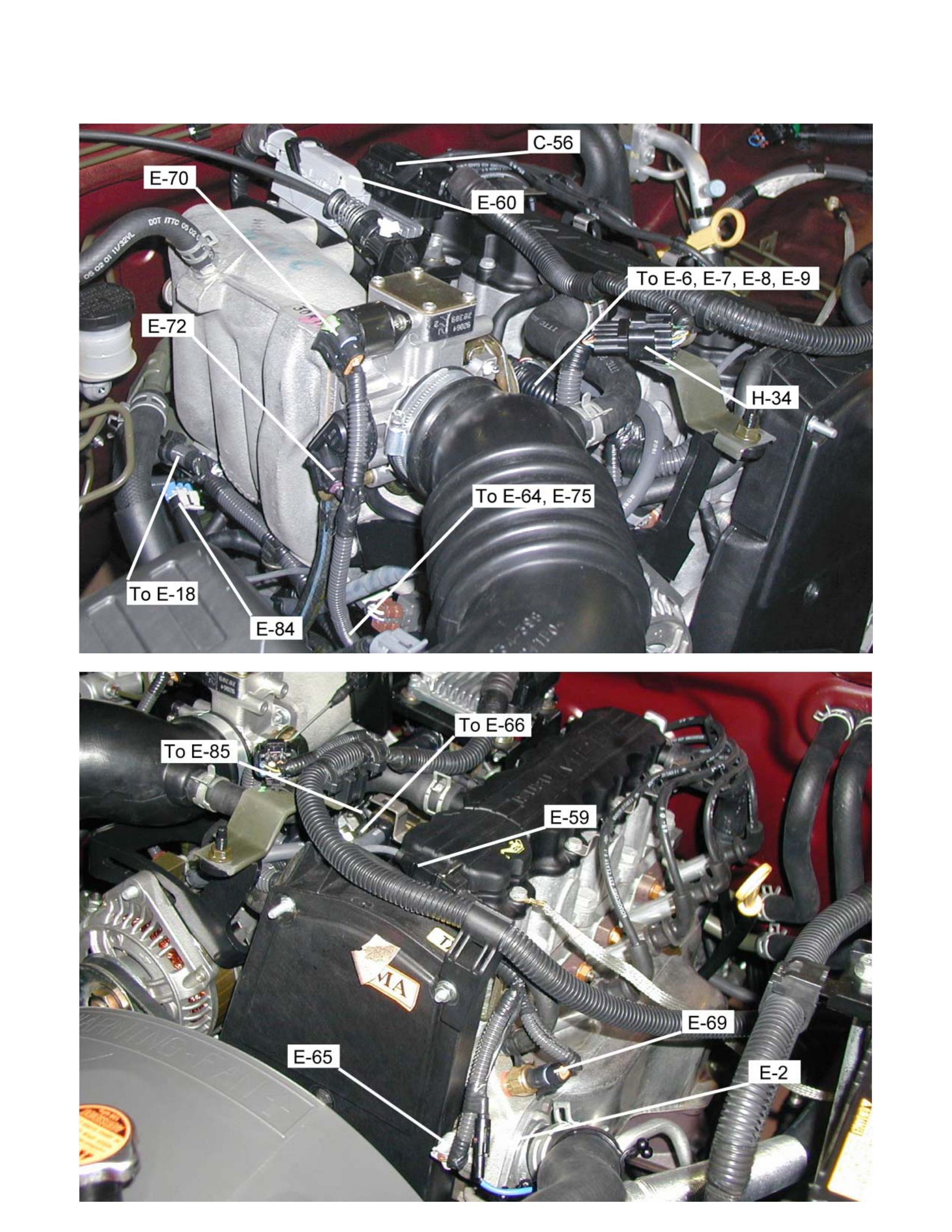

PARTS LOCATION (RHD)

RTW68AXF013801

PARTS LOCATION (RHD)

RTW68AXF013901

PARTS LOCATION (LHD)

RTW48AXF012801

PARTS LOCATION (LHD)

RTW48AXF012901

PARTS LOCATION HFV6

RTW68AXF012201

PARTS LOCATION

RTW68AXF012801

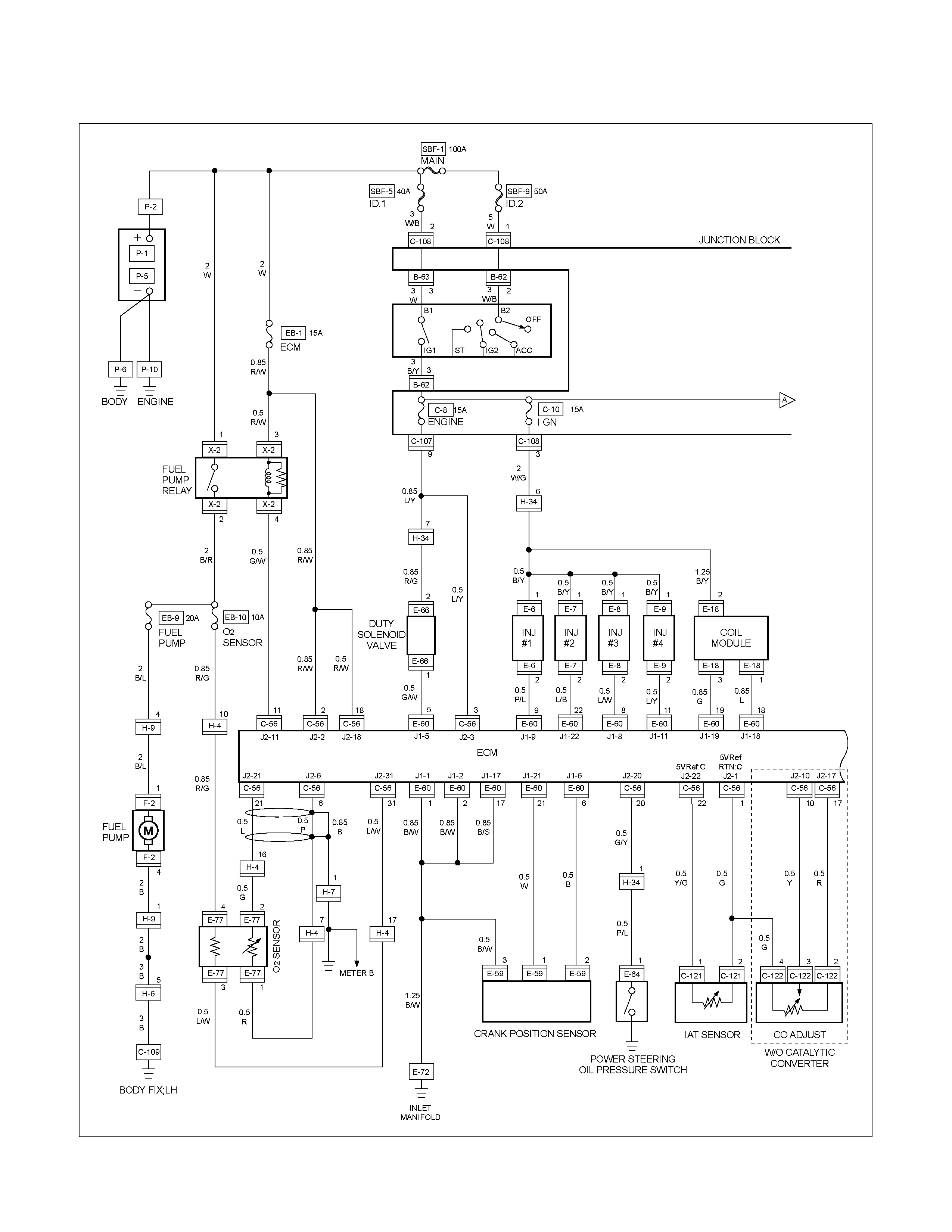

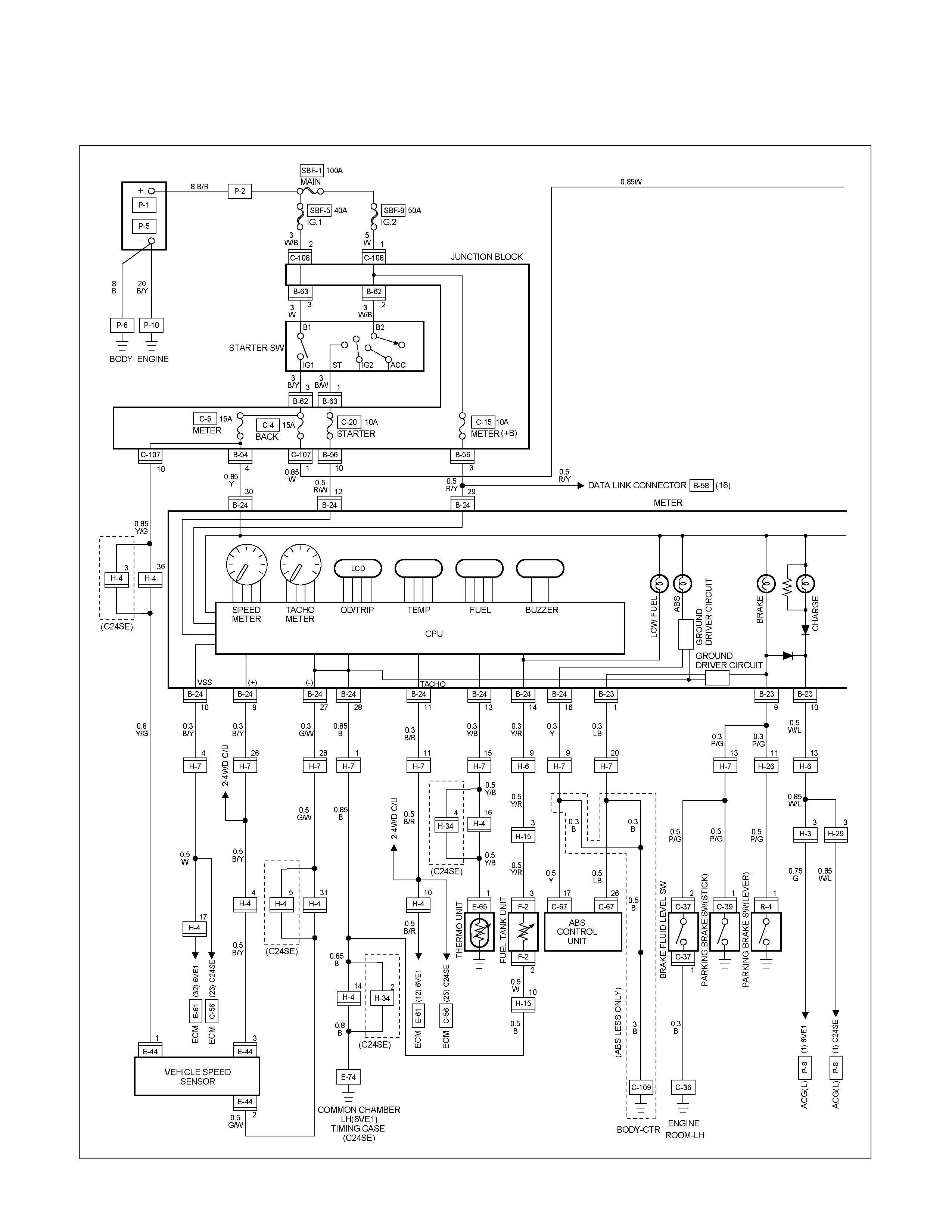

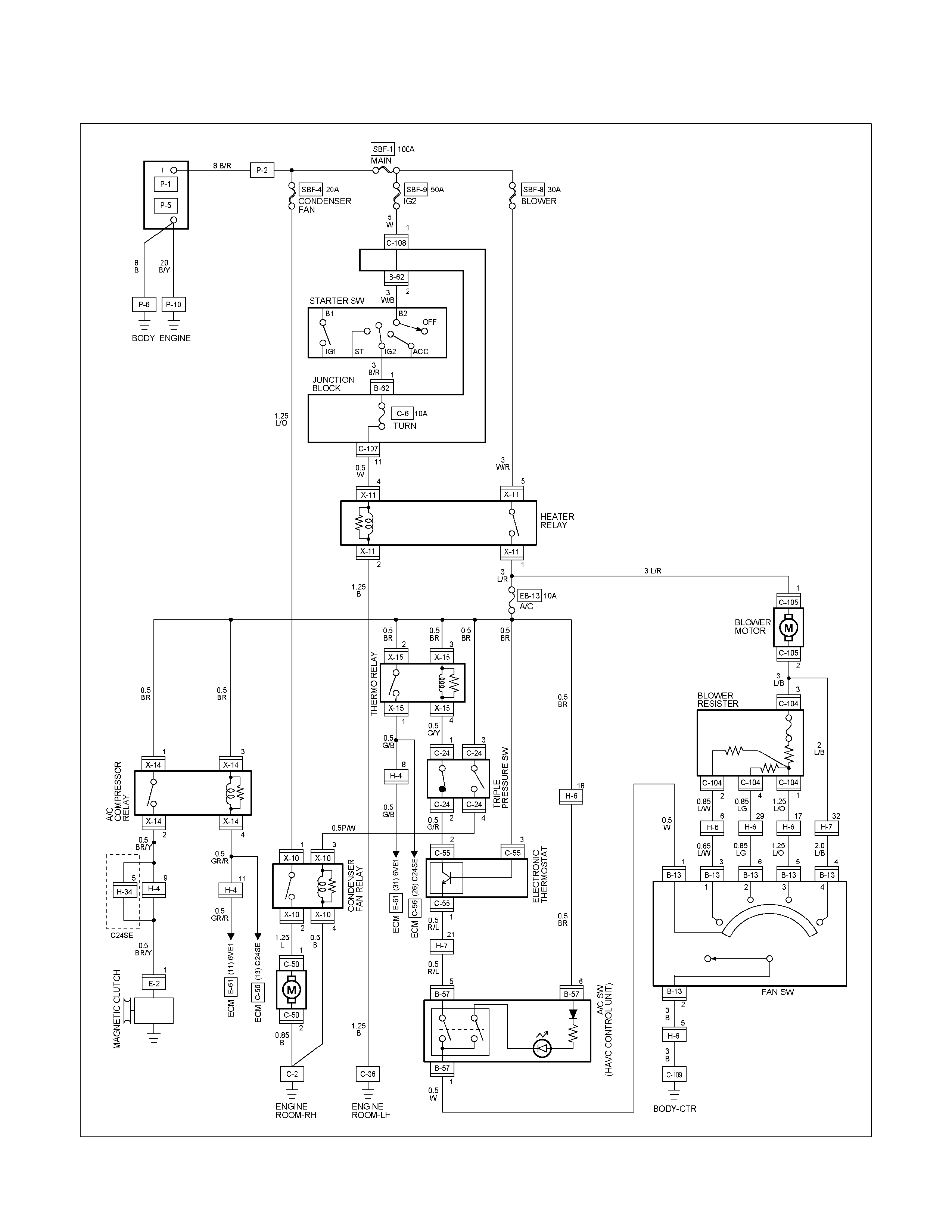

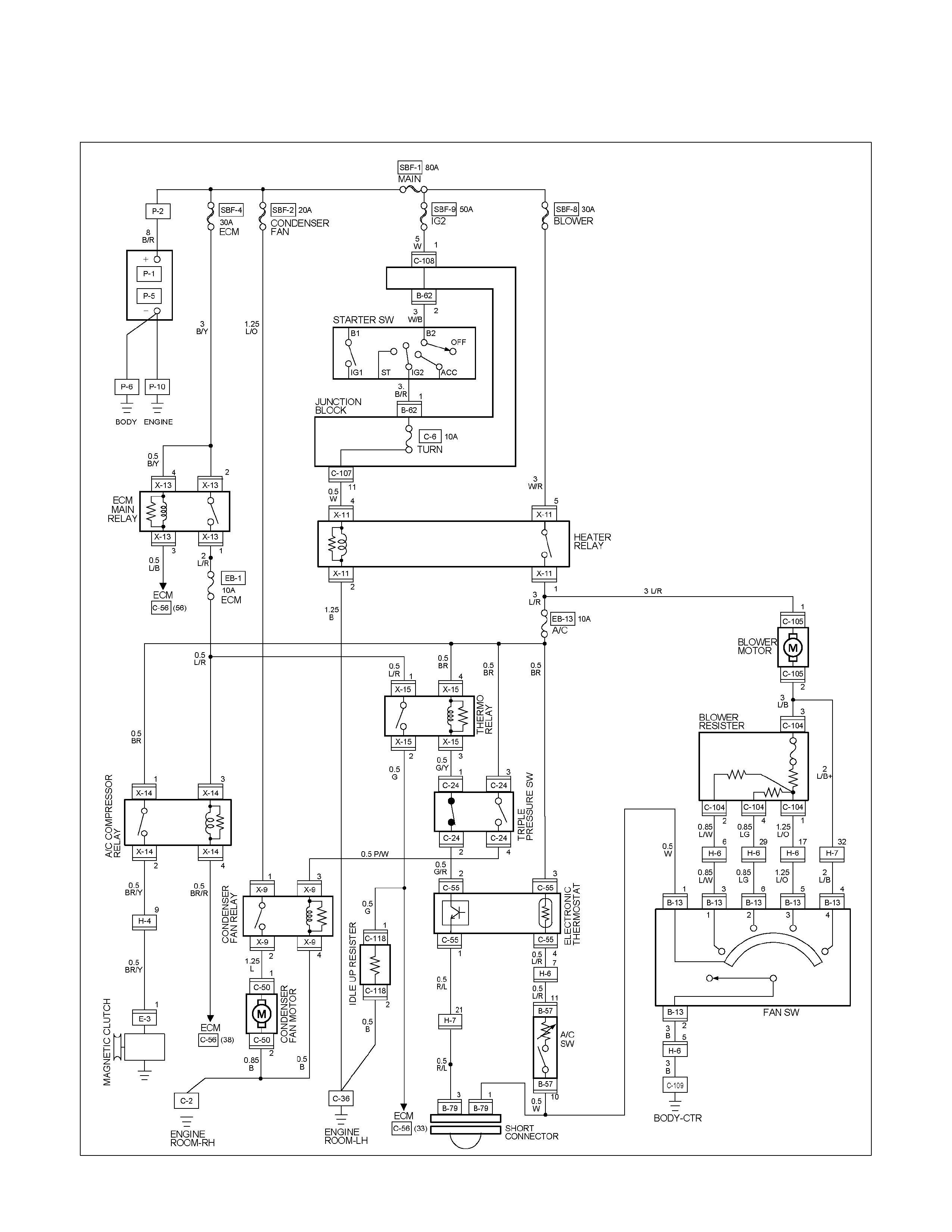

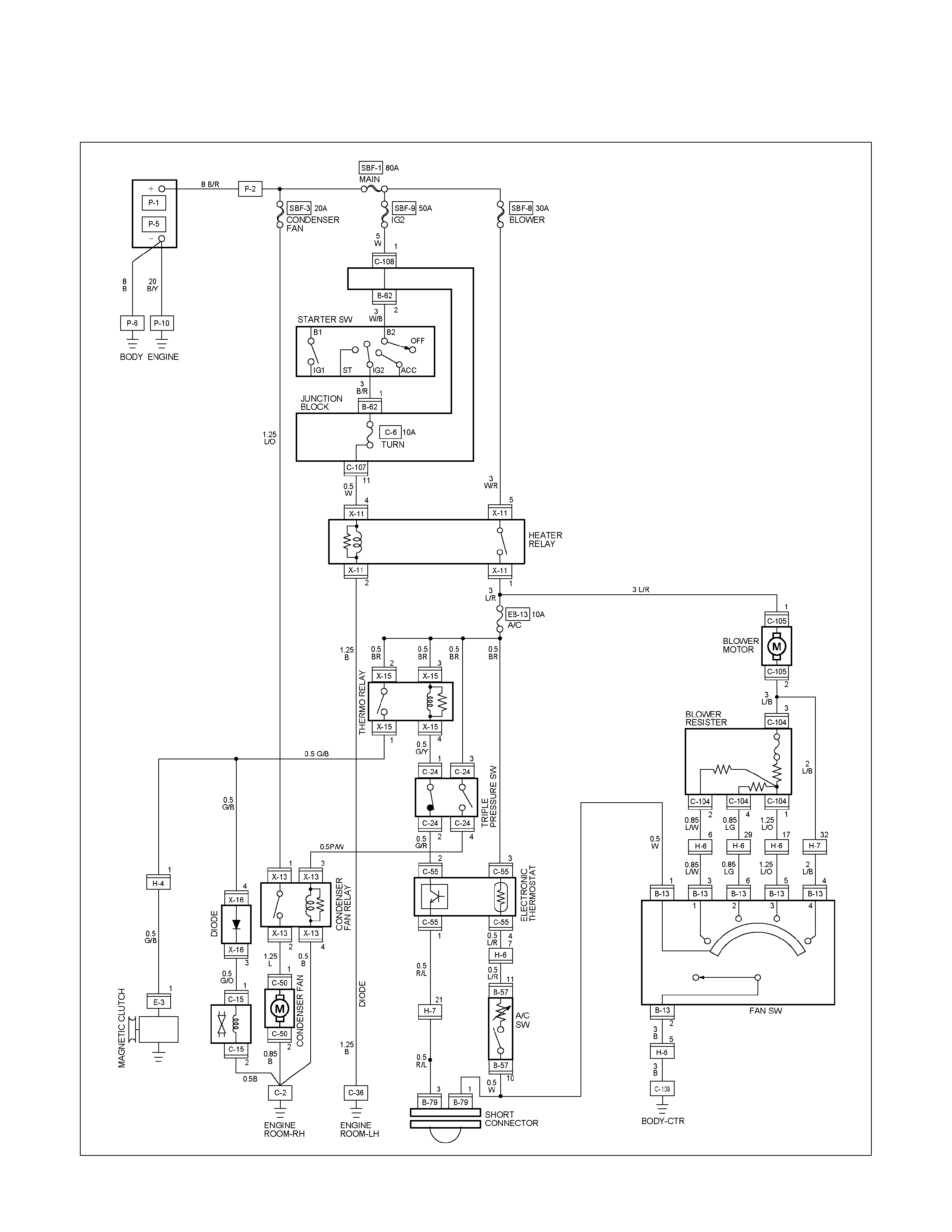

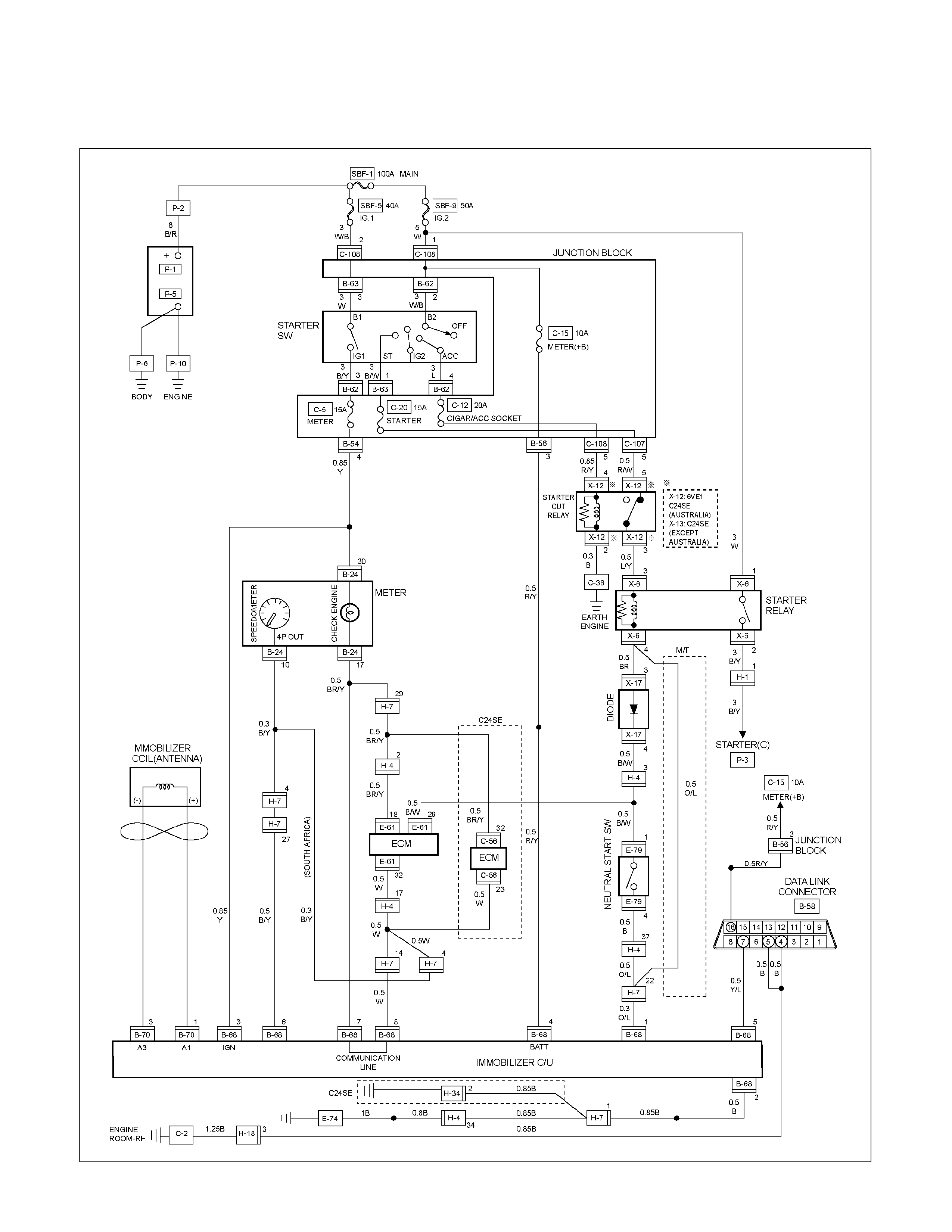

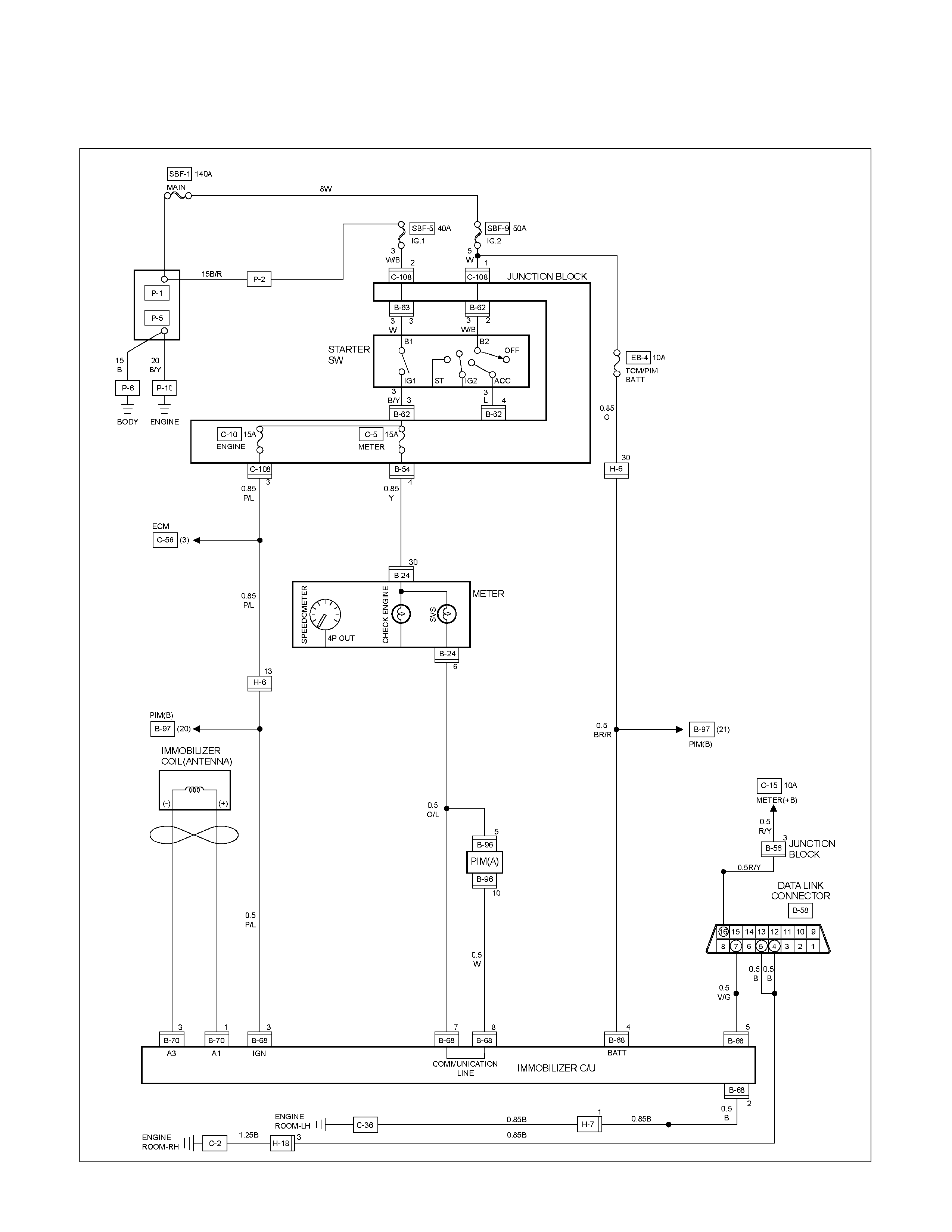

CIRCUIT DIAGRAM C24SE

RTW680XF005001

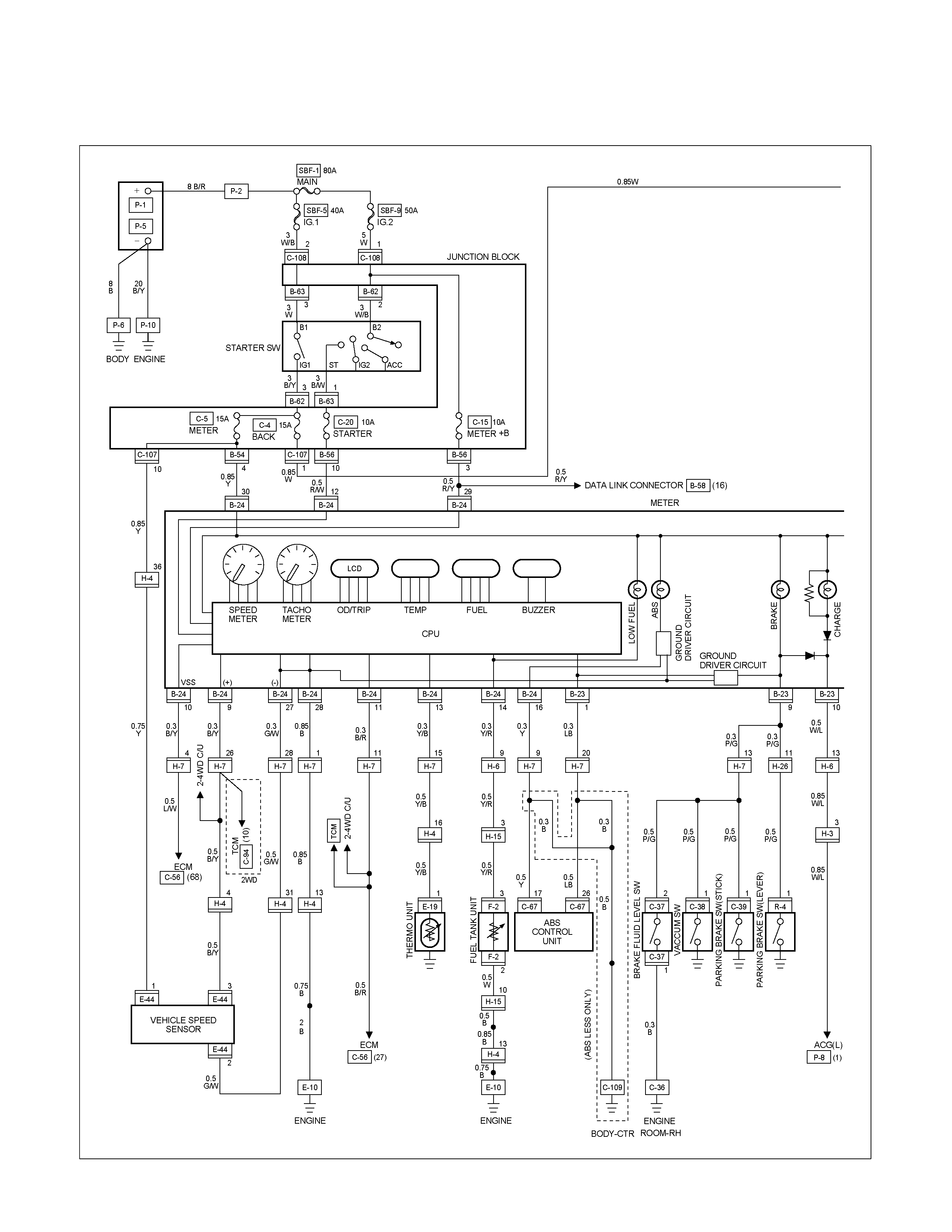

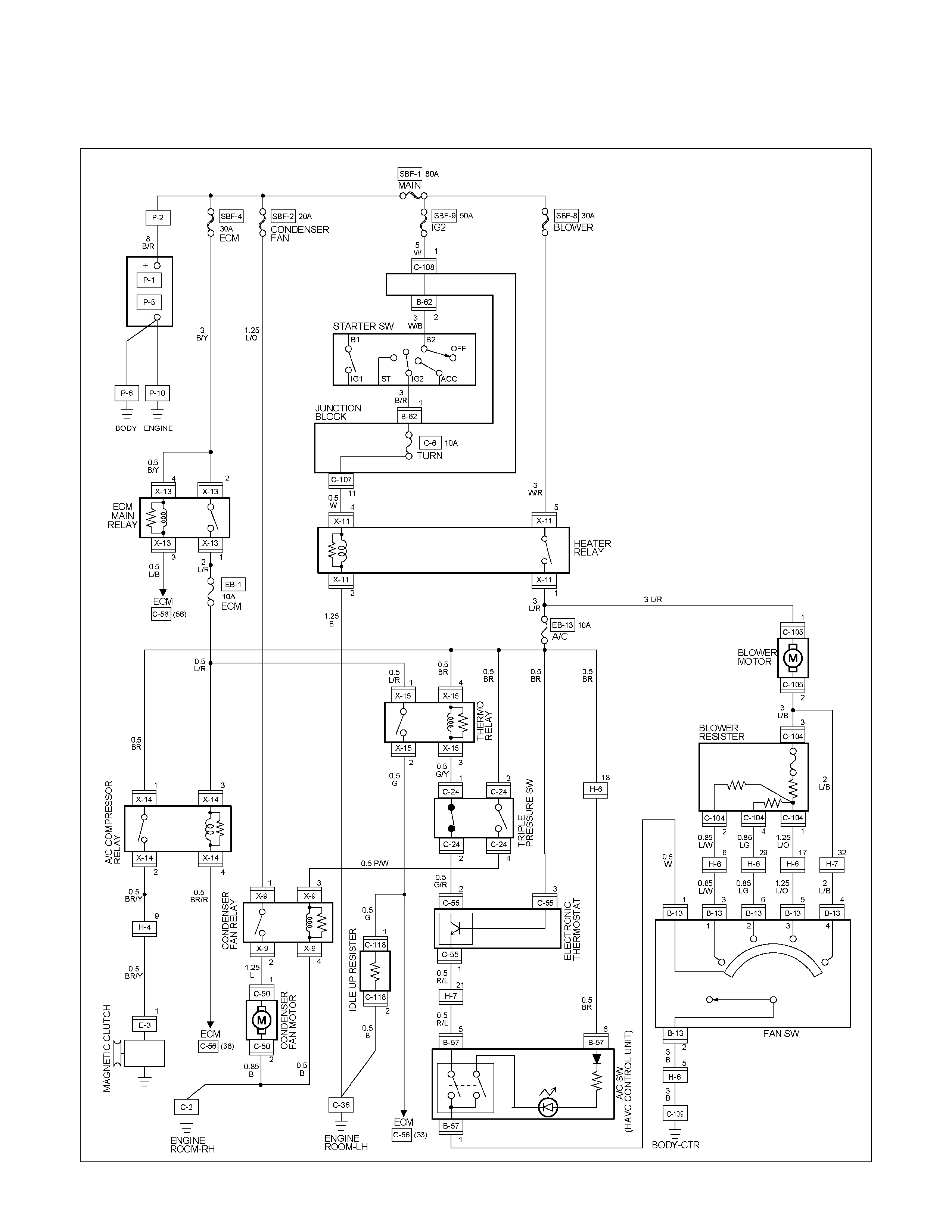

CIRCUIT DIAGRAM 6VE1

RTW680XF005101

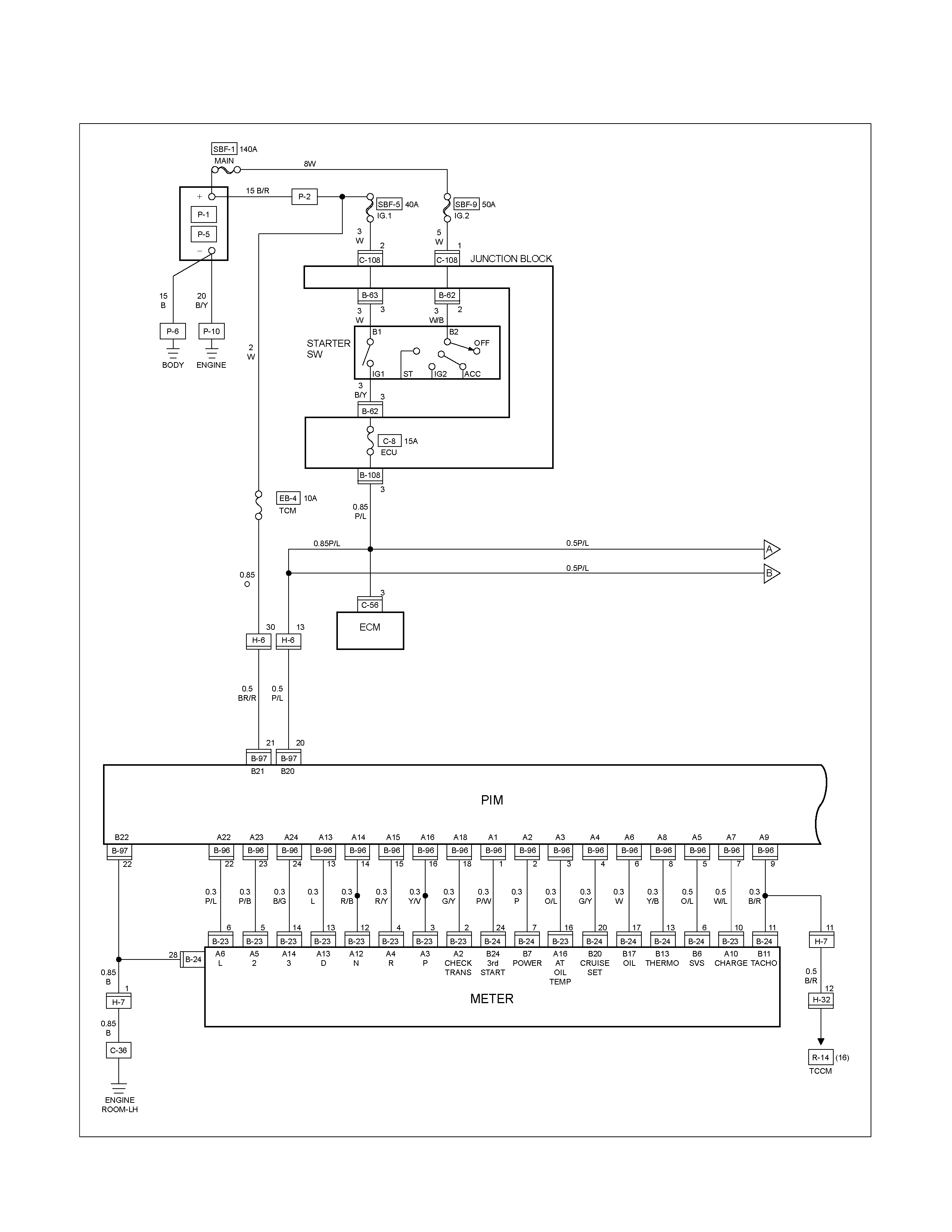

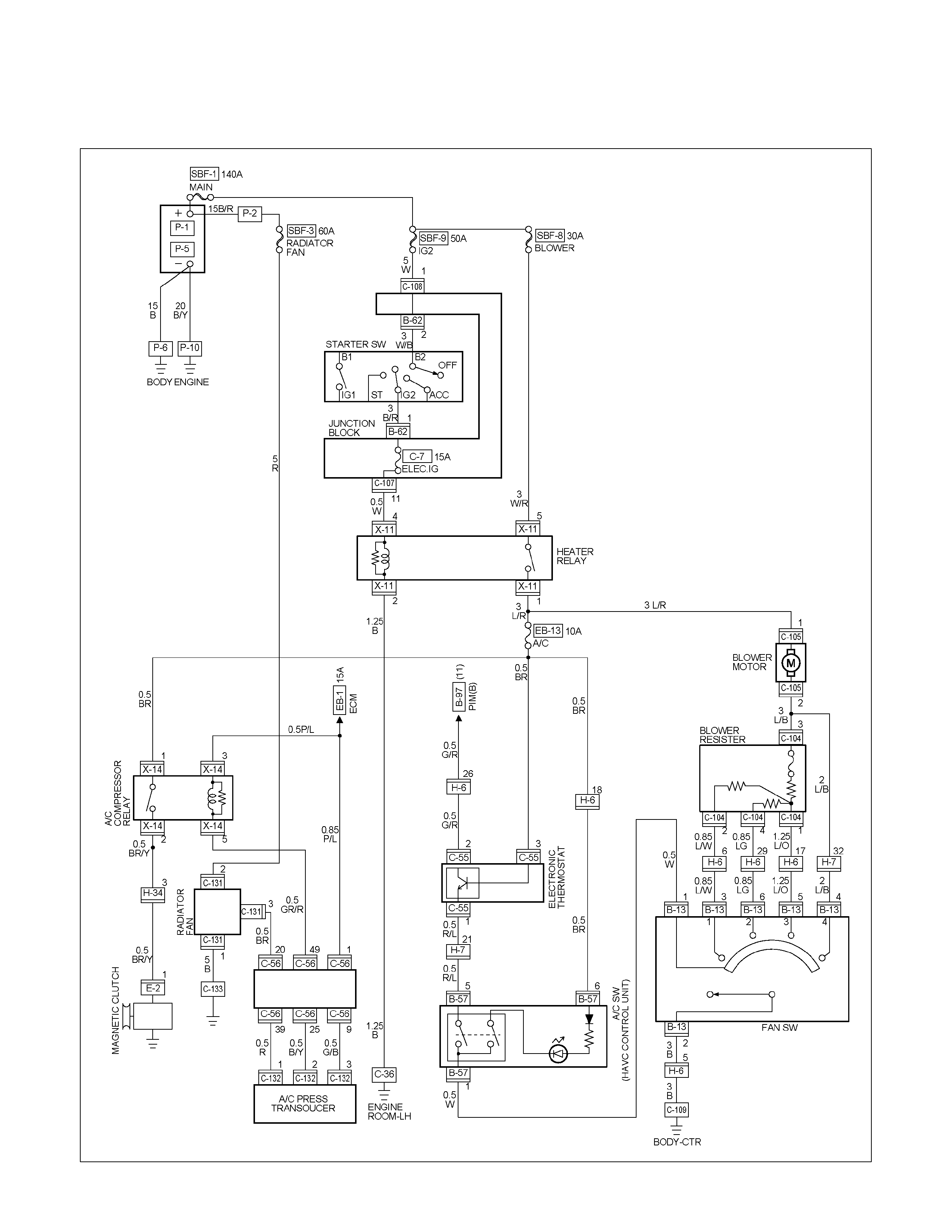

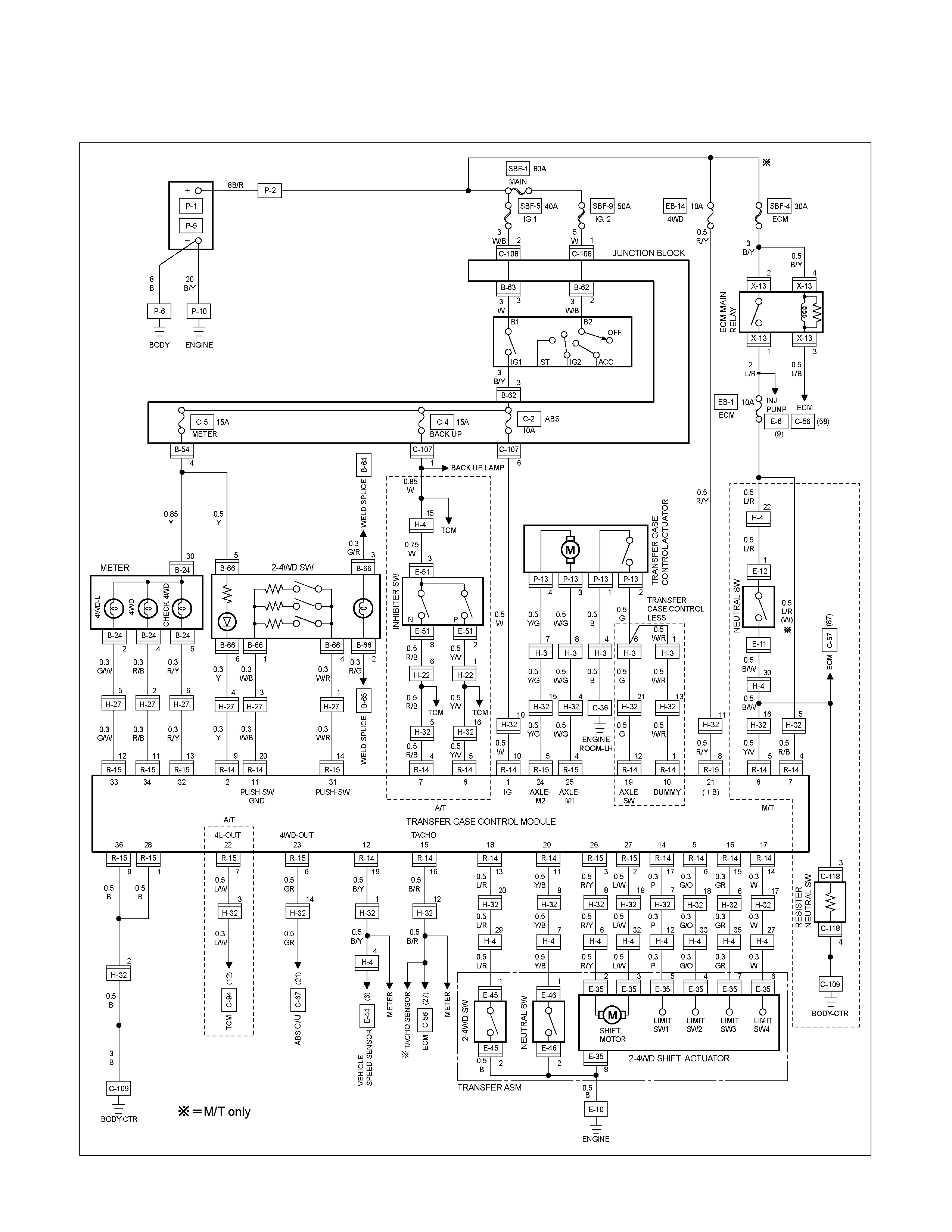

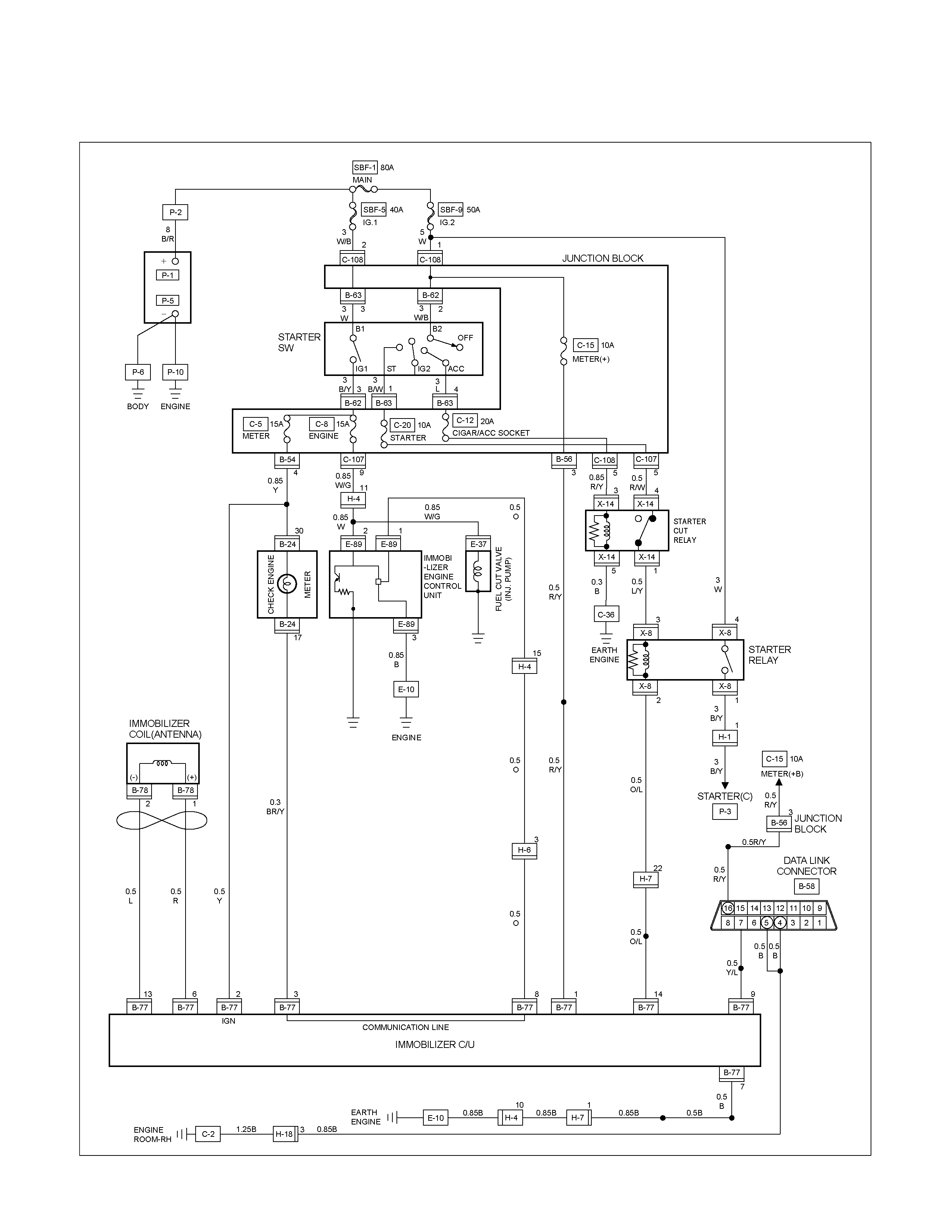

CIRCUIT DIAGRAM HFV6

RTW68AXF010501

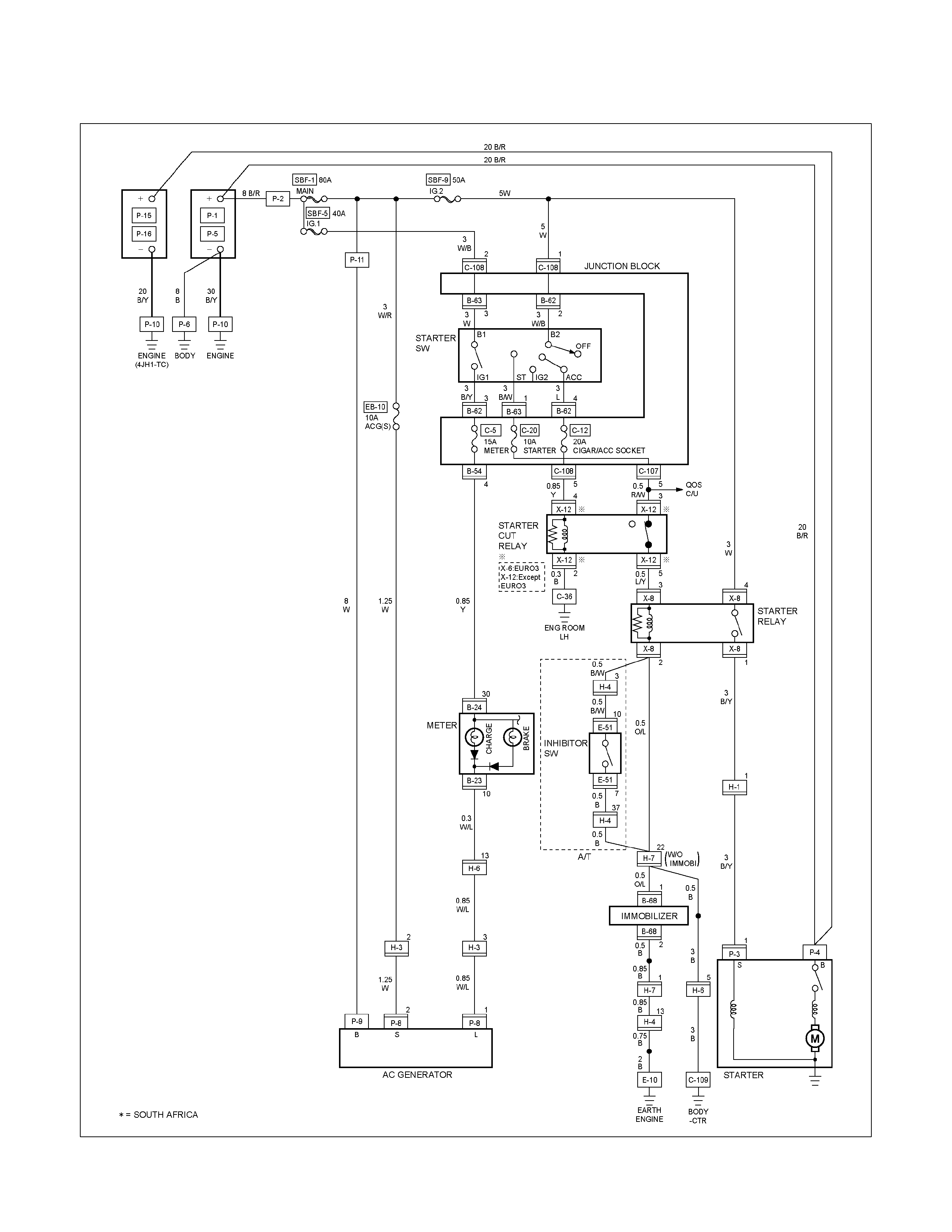

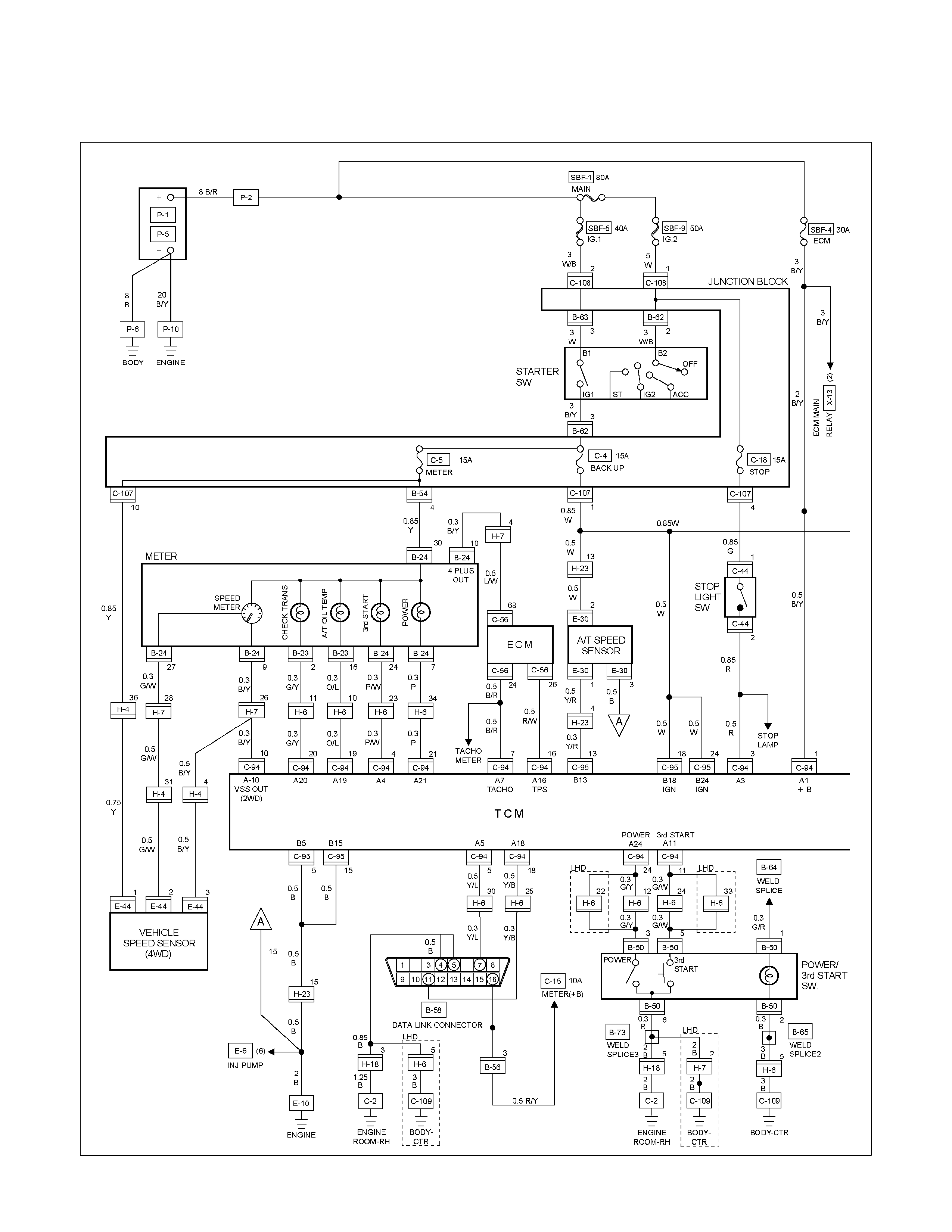

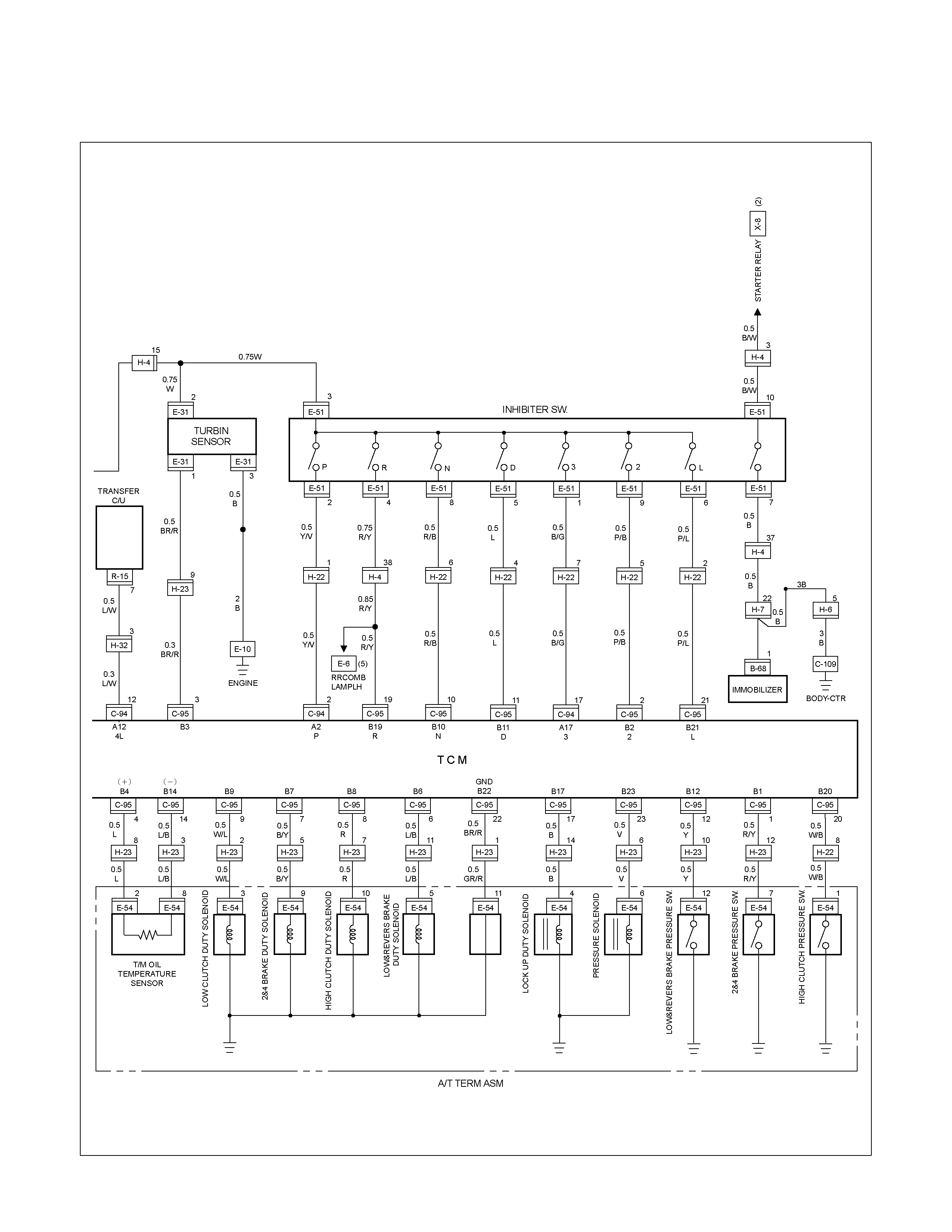

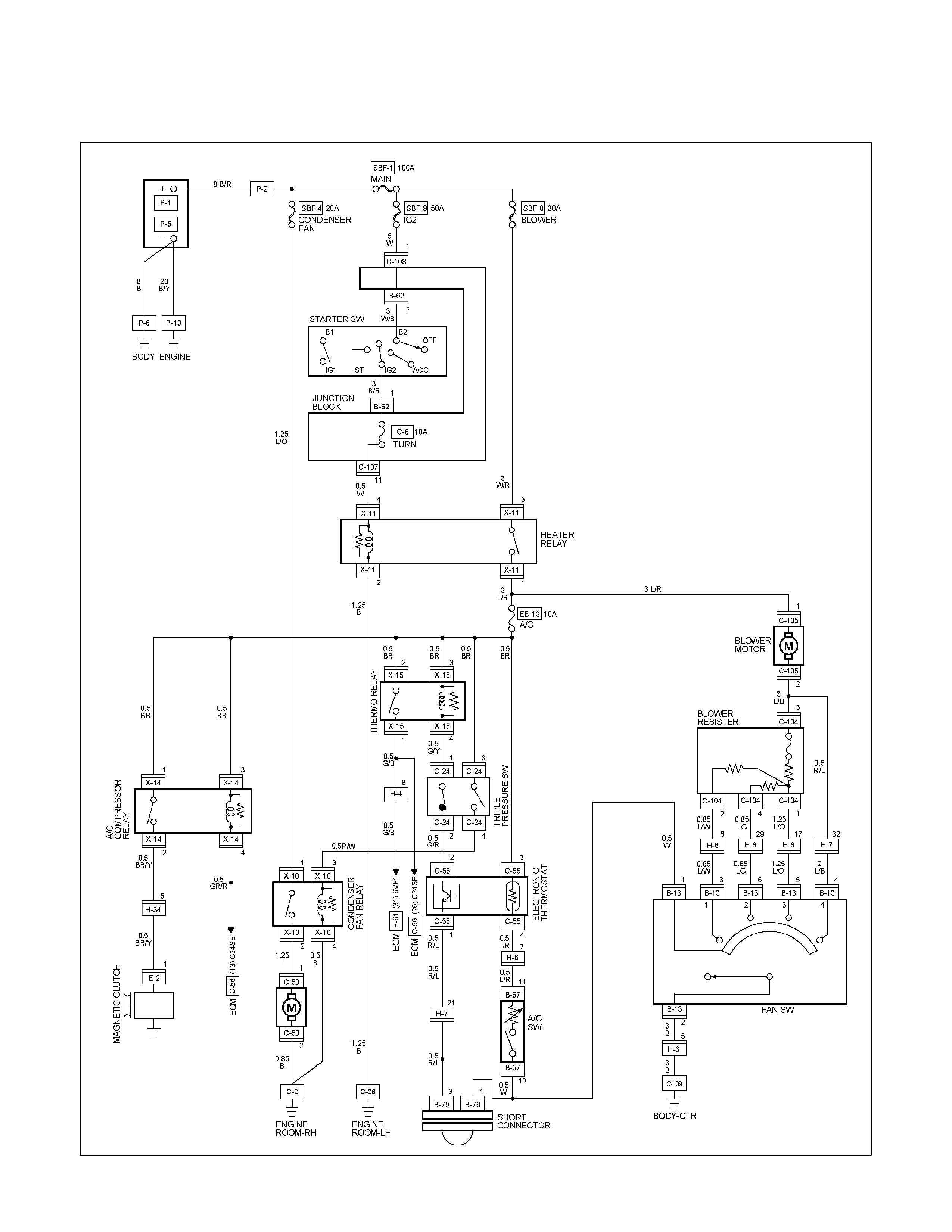

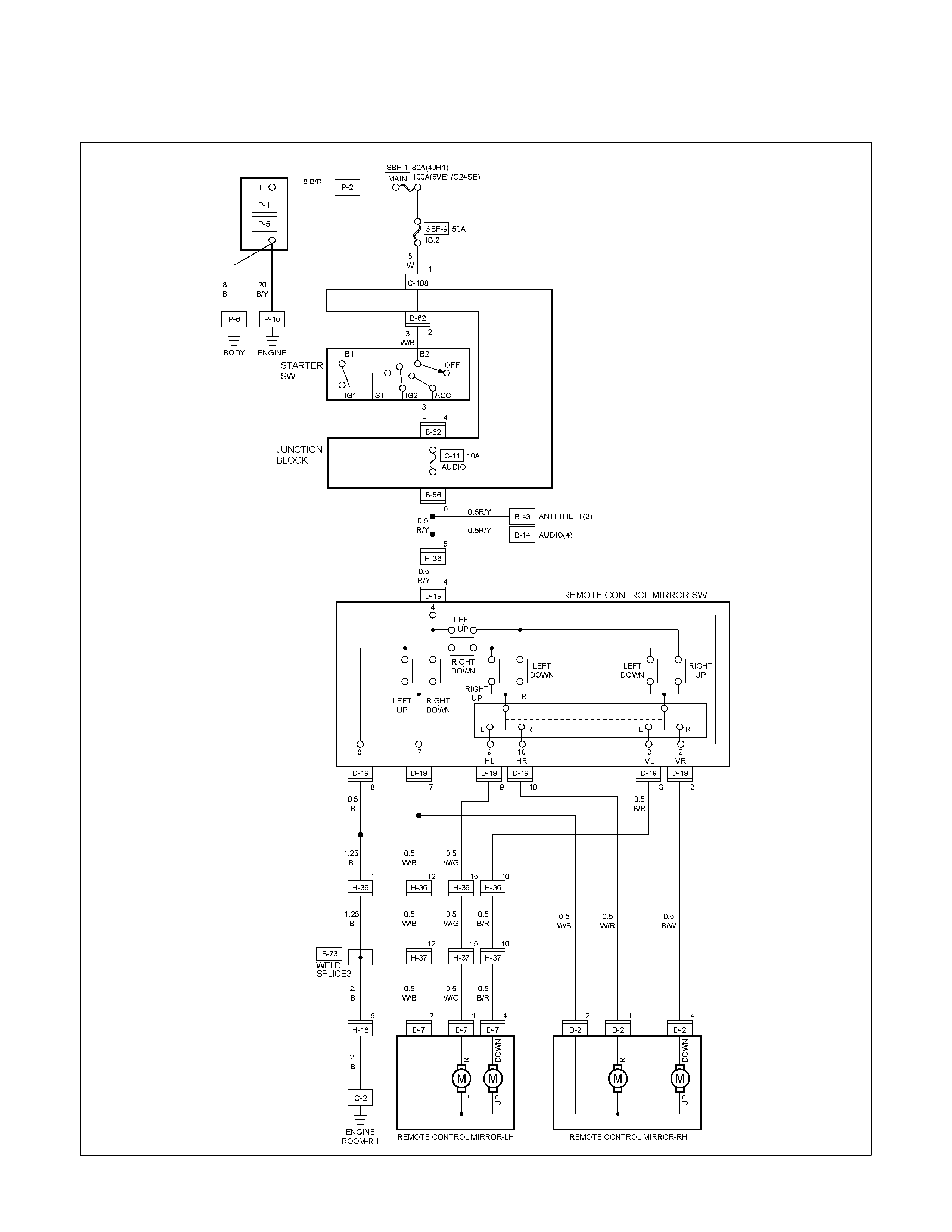

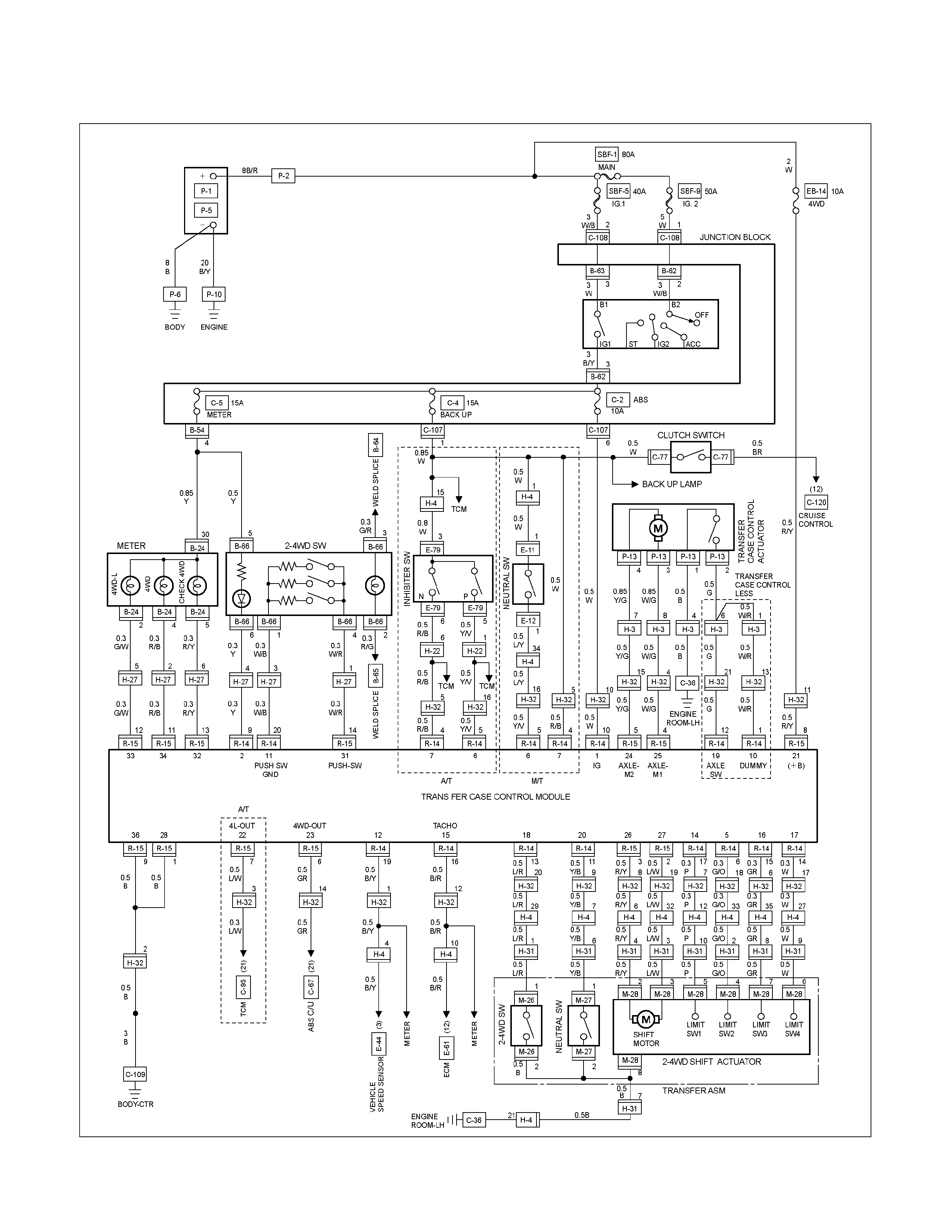

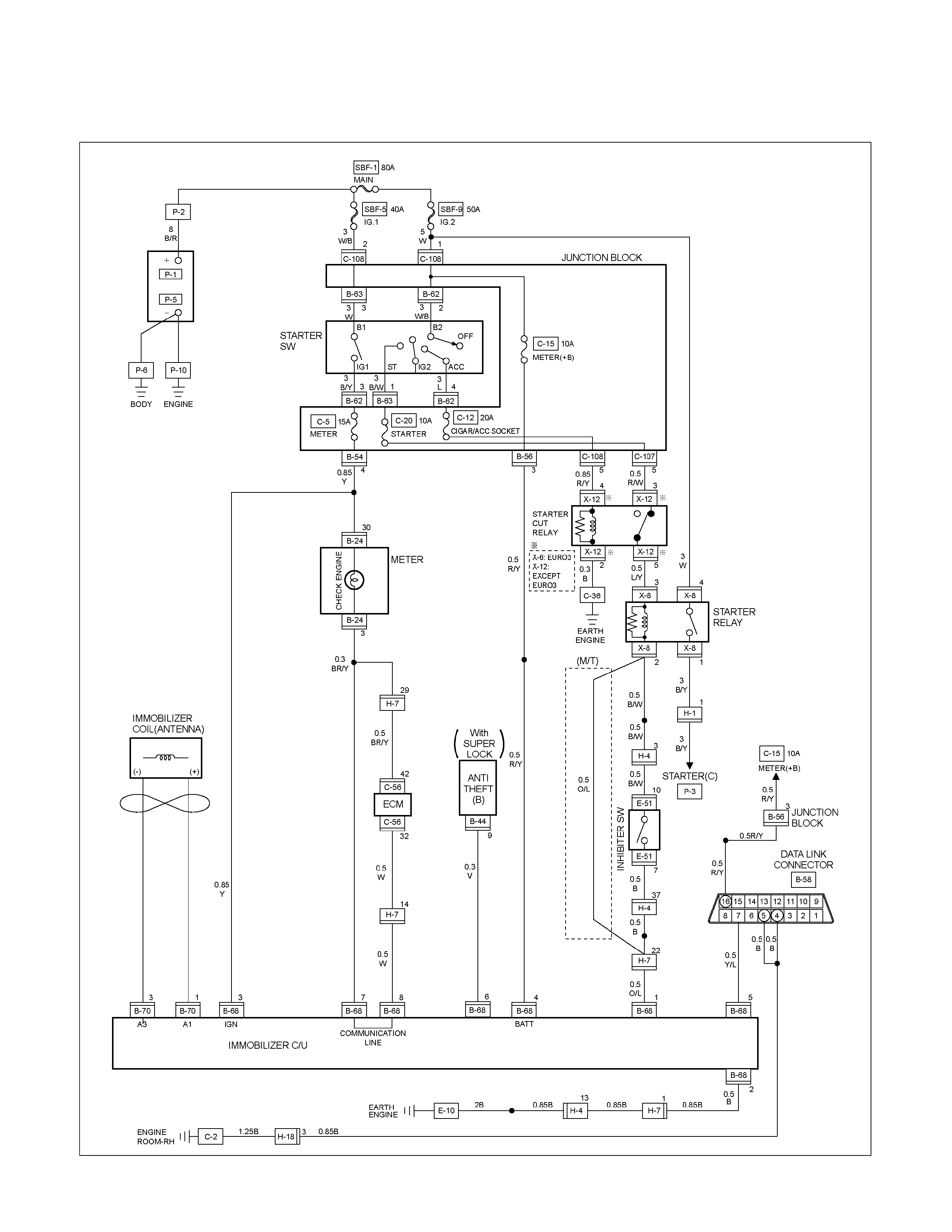

CIRCUIT DIAGRAM 4JA1-TC / 4JH1-TC (RHD)

RTW680XF005201

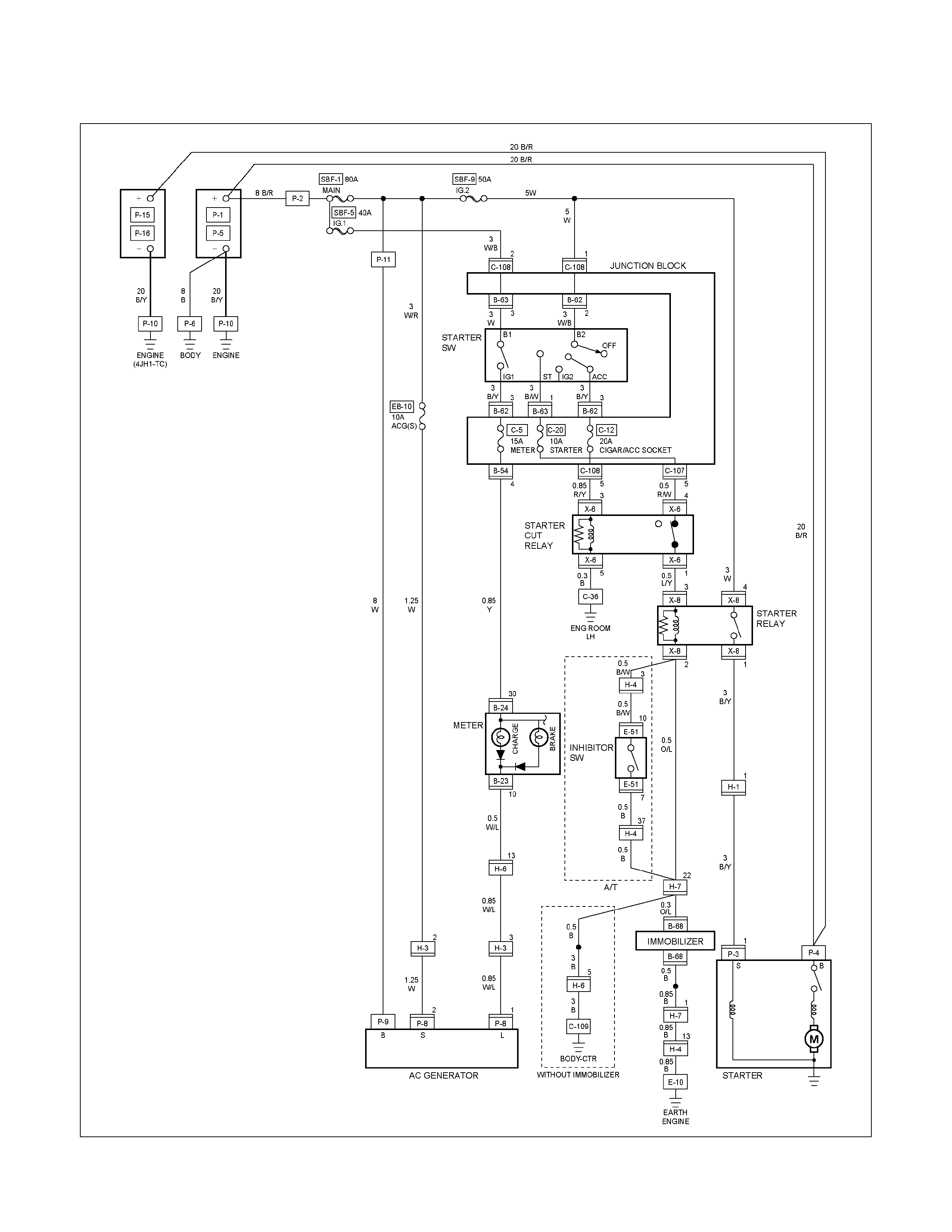

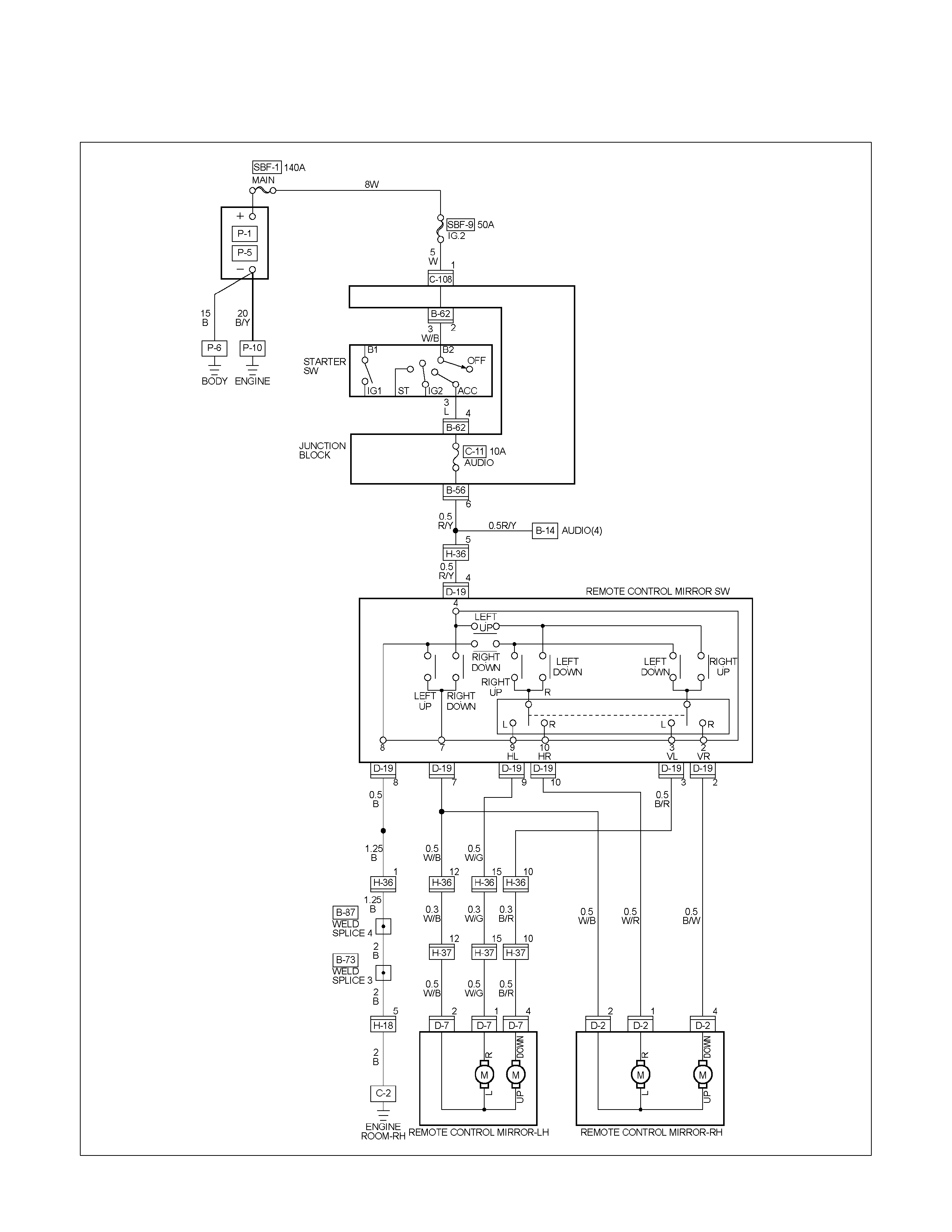

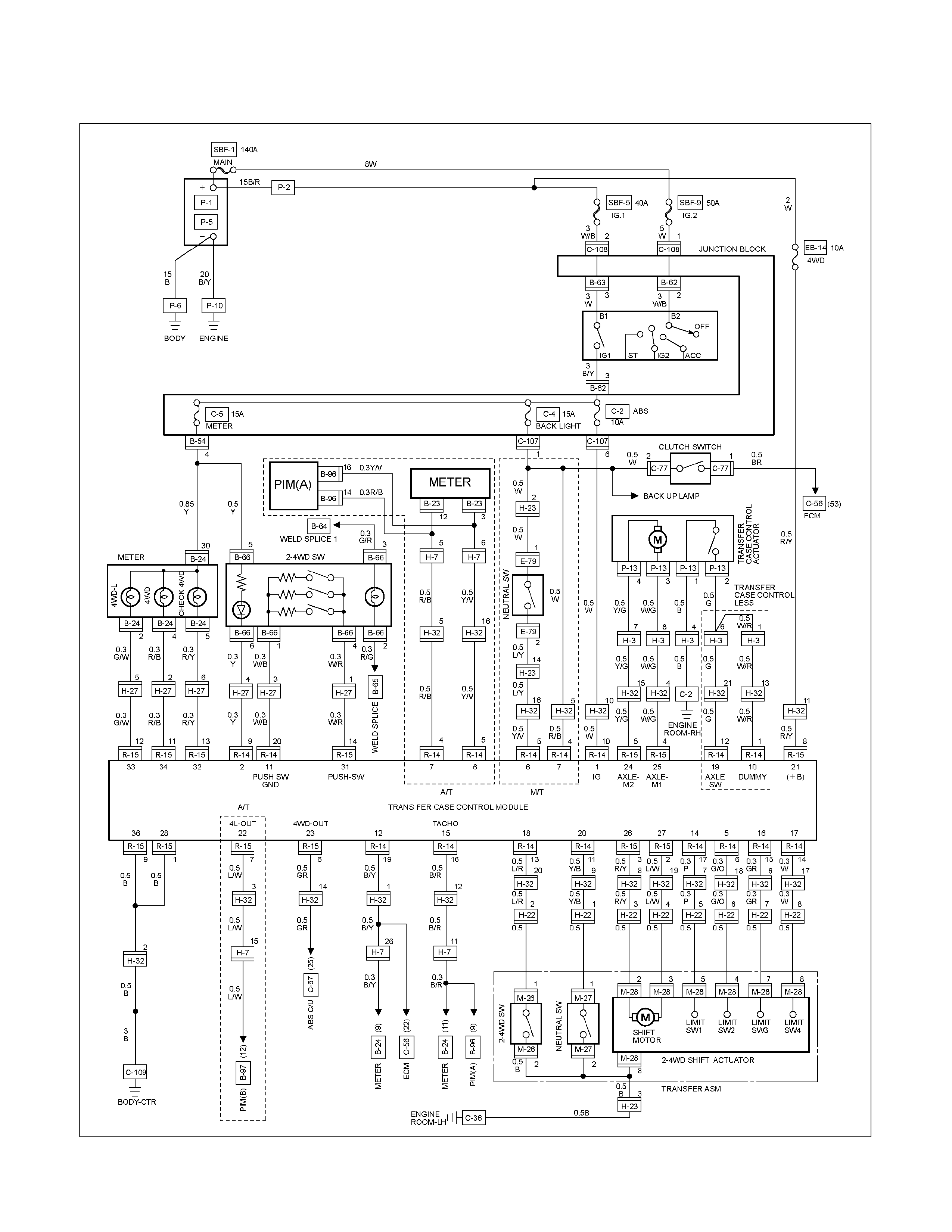

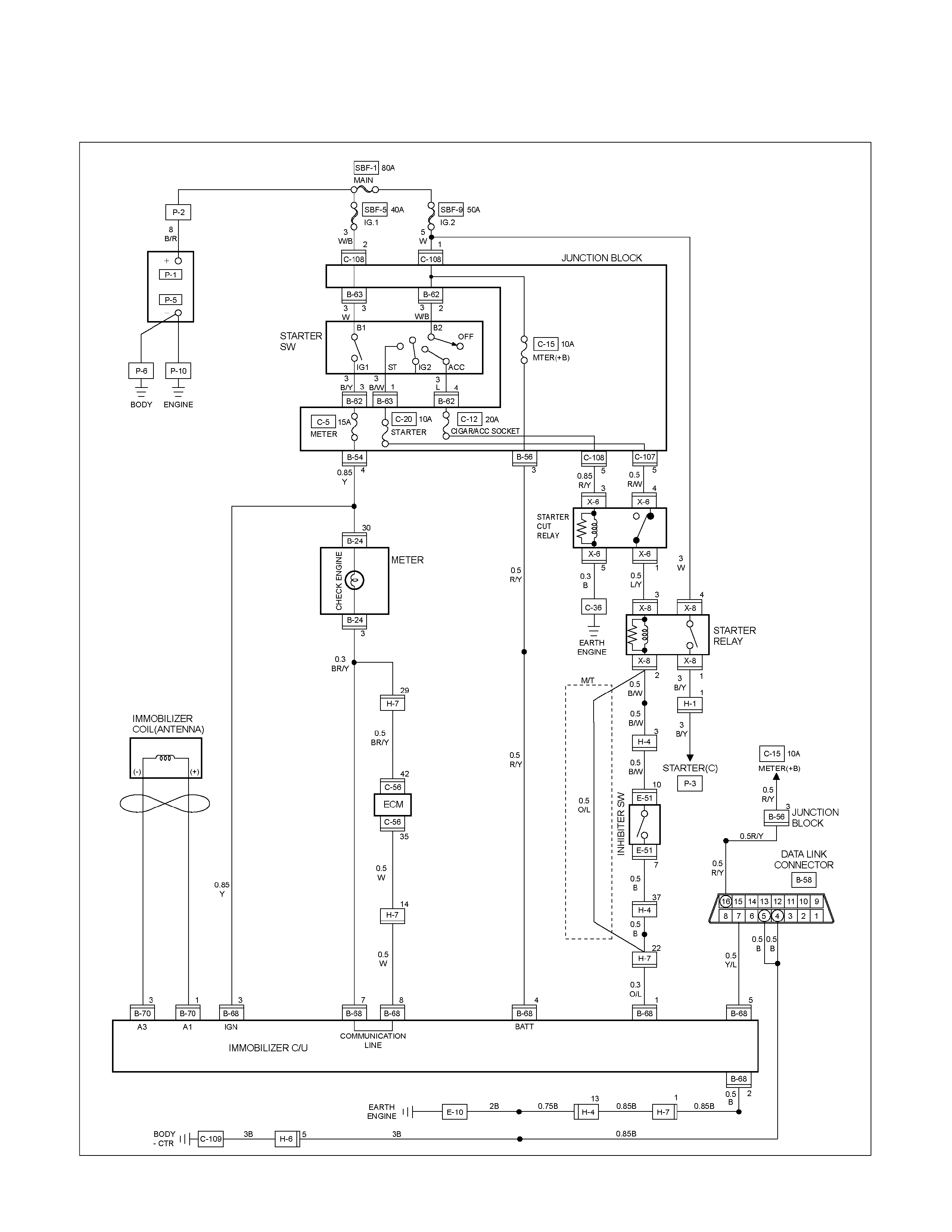

CIRCUIT DIAGRAM 4JA1-TC / 4JH1-TC (LHD)

RTW680XF005301

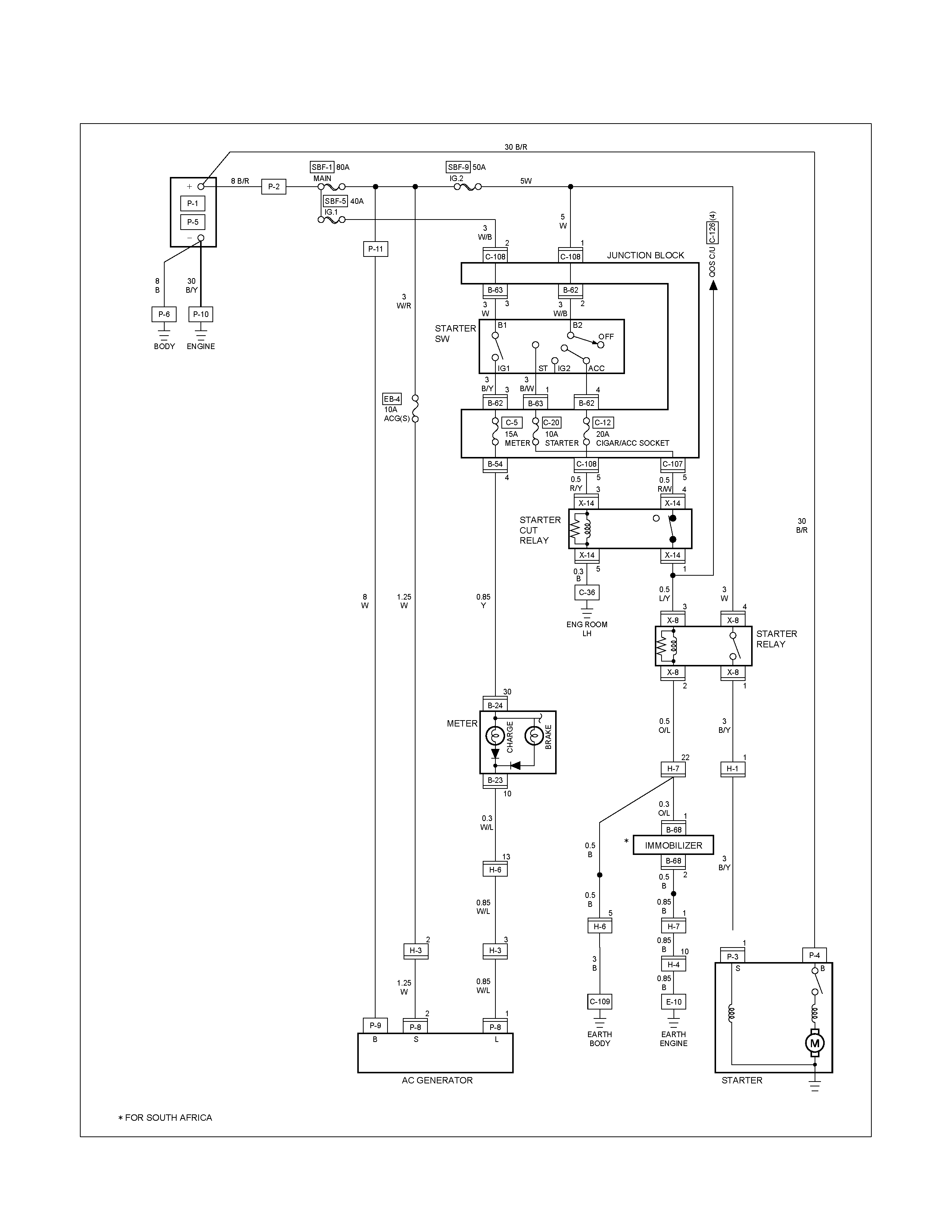

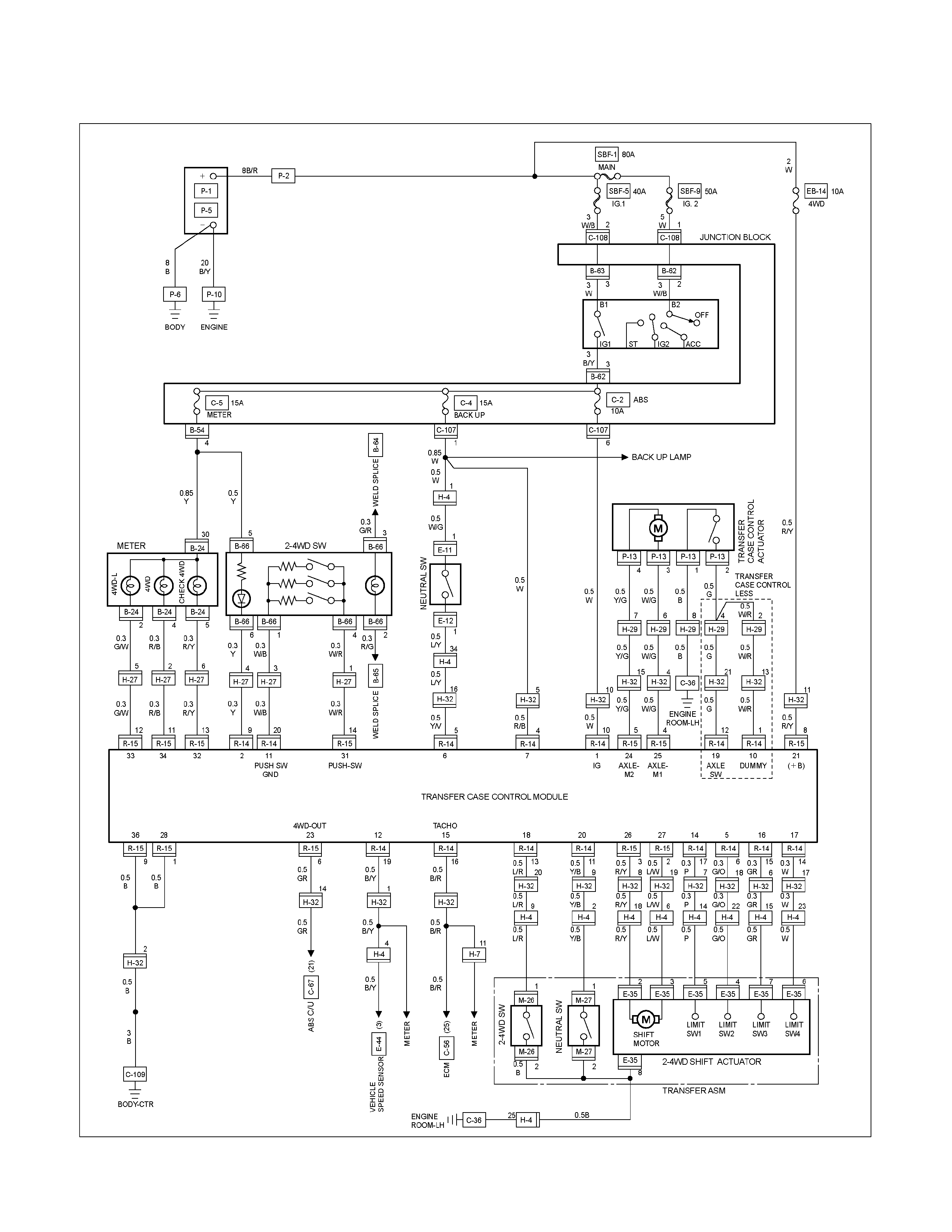

CIRCUIT DIAGRAM 4JA1-L

RTW680XF005401

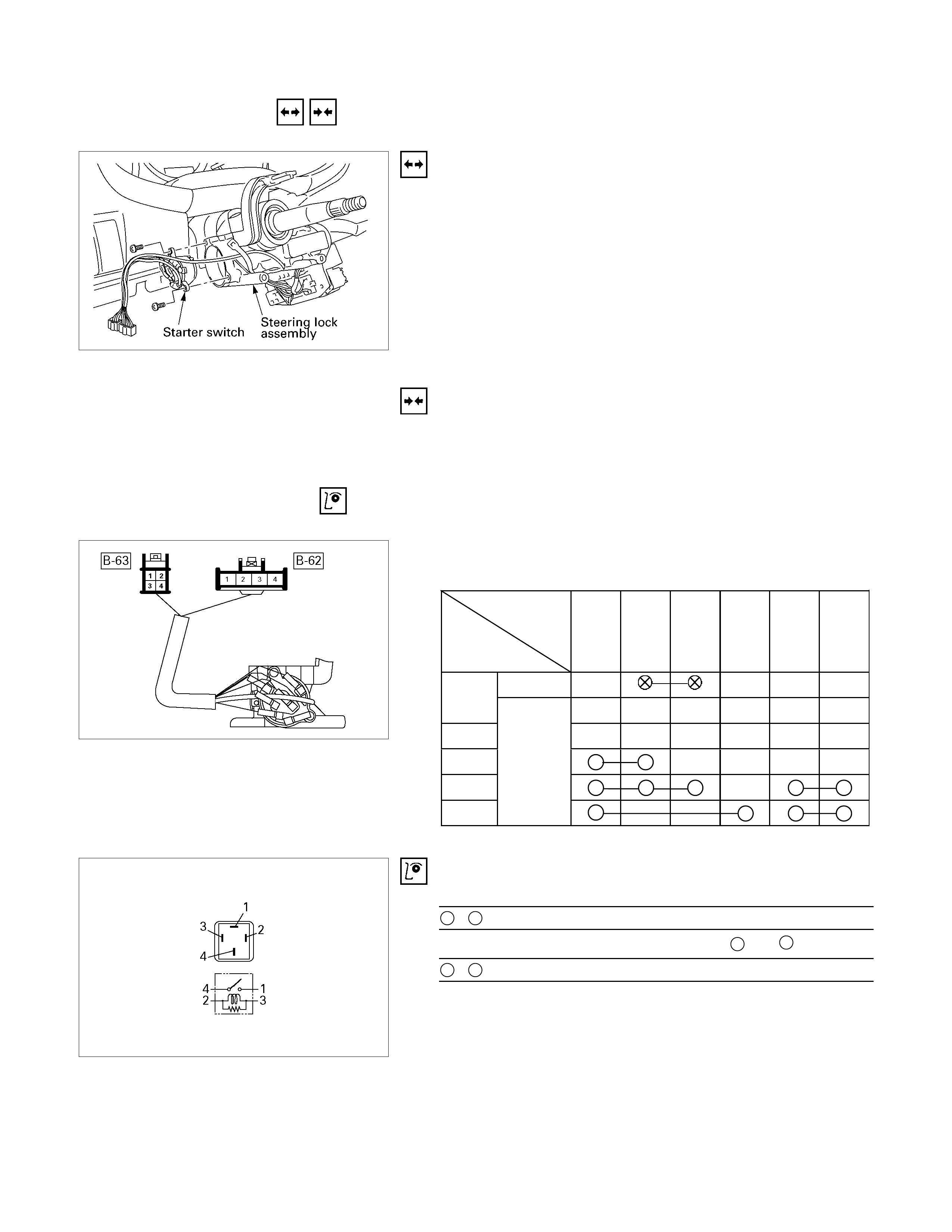

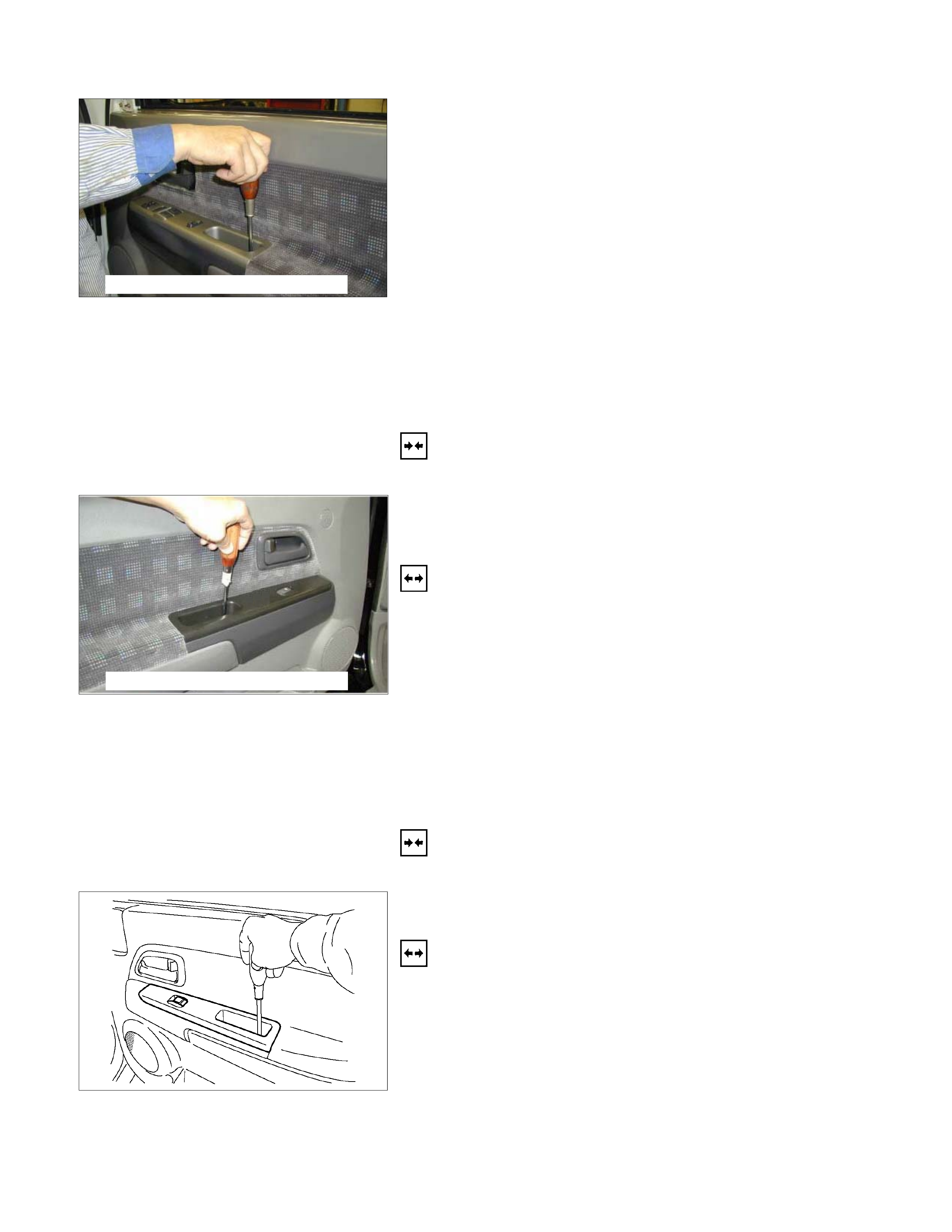

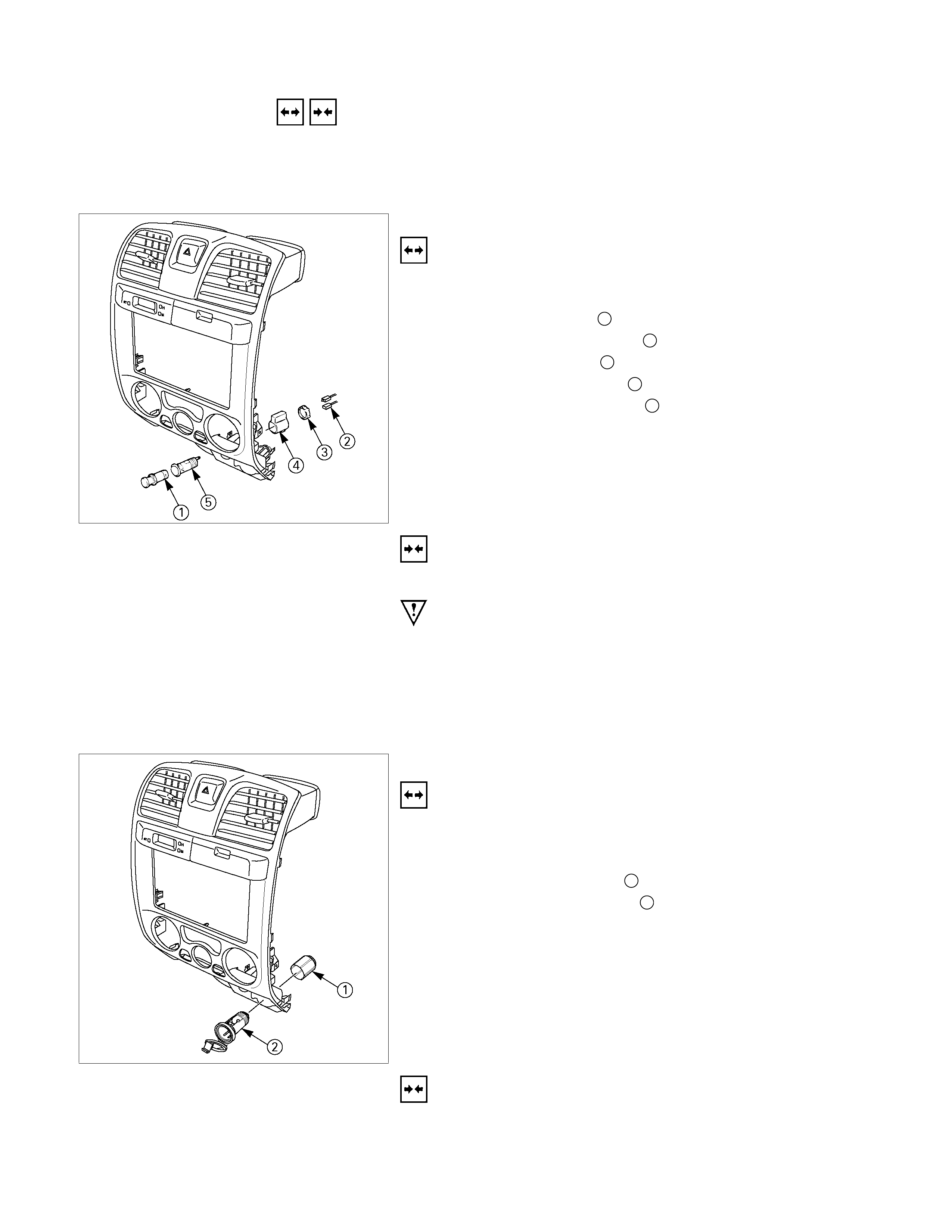

REMOVAL AND INSTALLATION

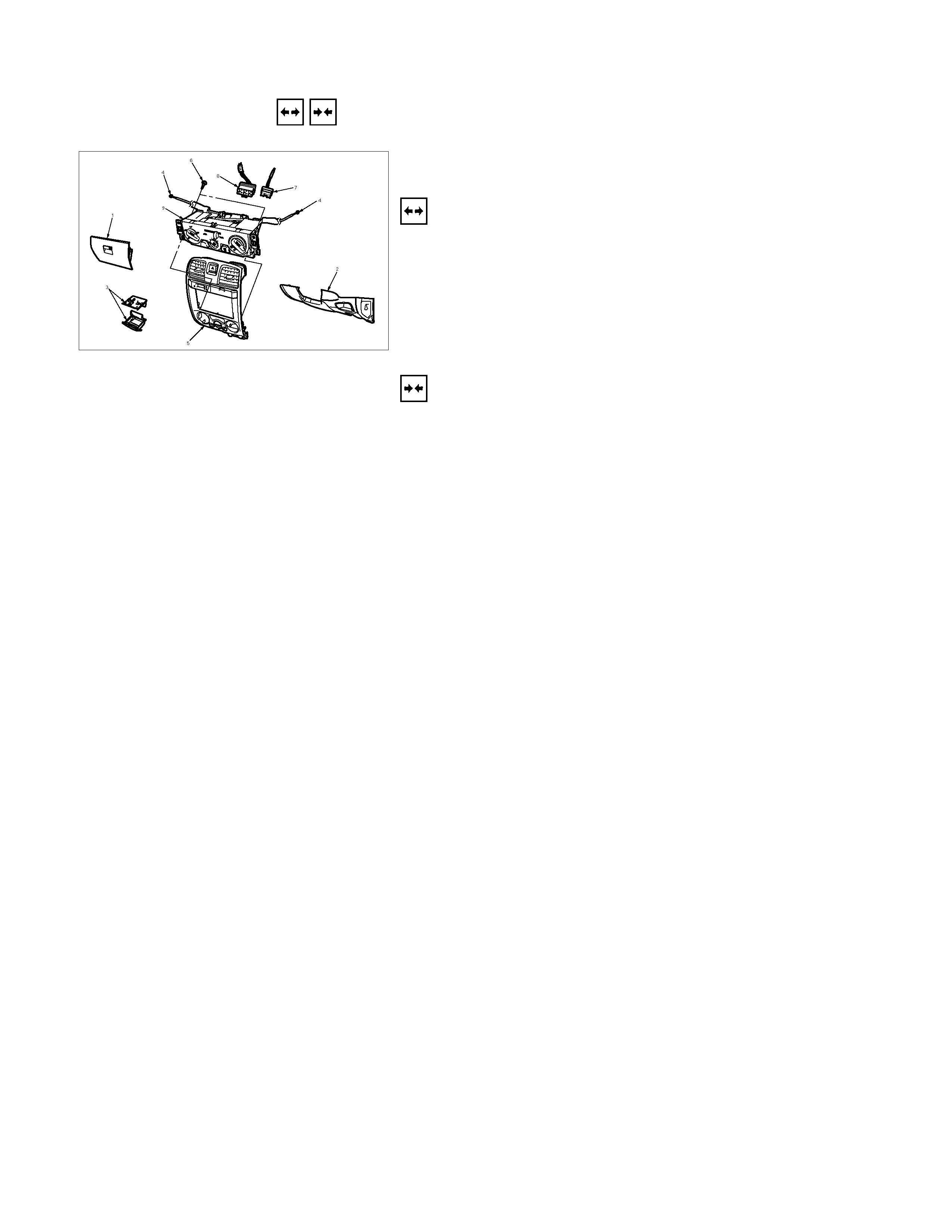

This illustration is based on RHD model

STARTER SWITCH

Removal

1. Steering Lock Assembly

• Refer to Section 3B" STEERING COLUMN" for steering

lock assembly removal steps.

2. Starter Switch

Installation

Follow the removal procedure in the reverse order to install the

starter switch.

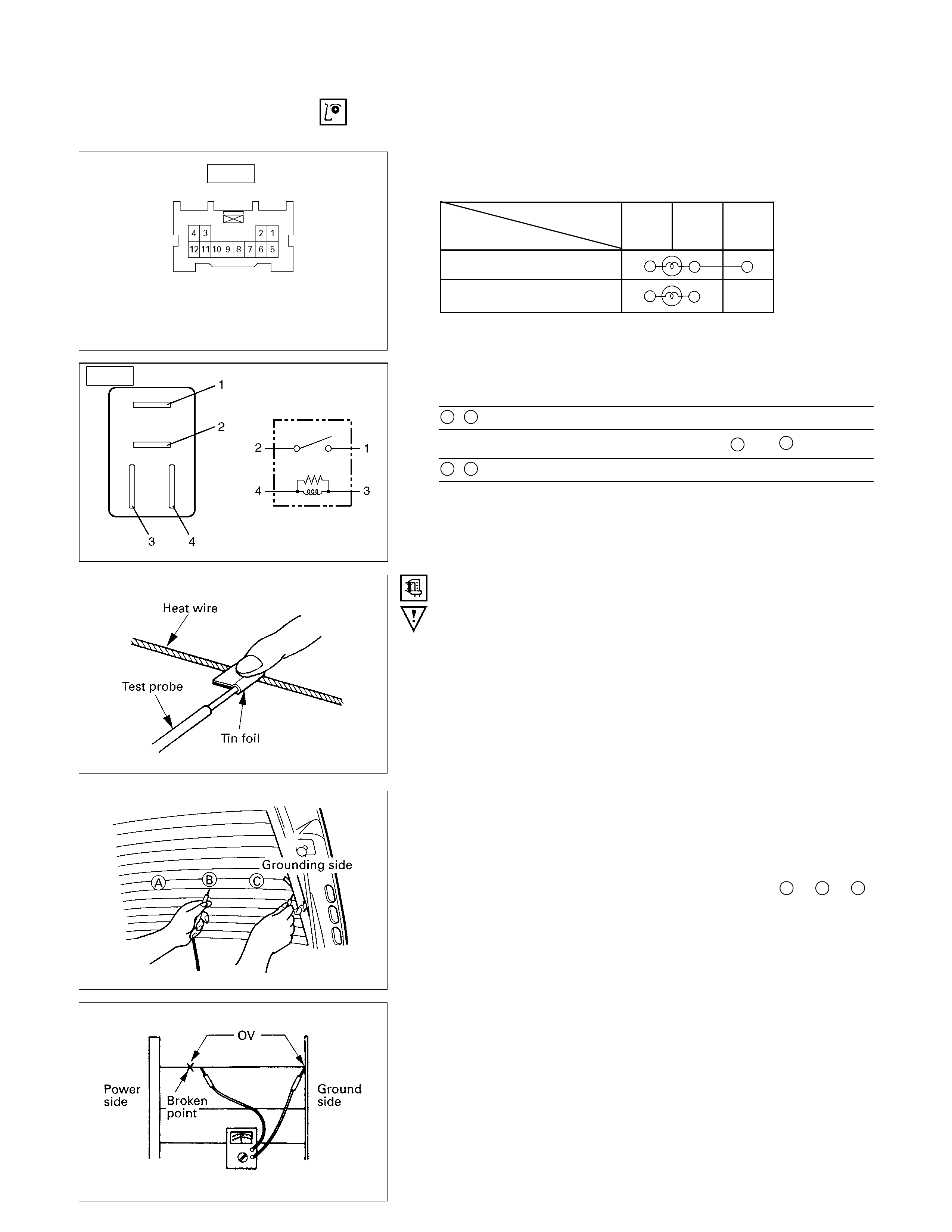

INSPECTION AND REPAIR

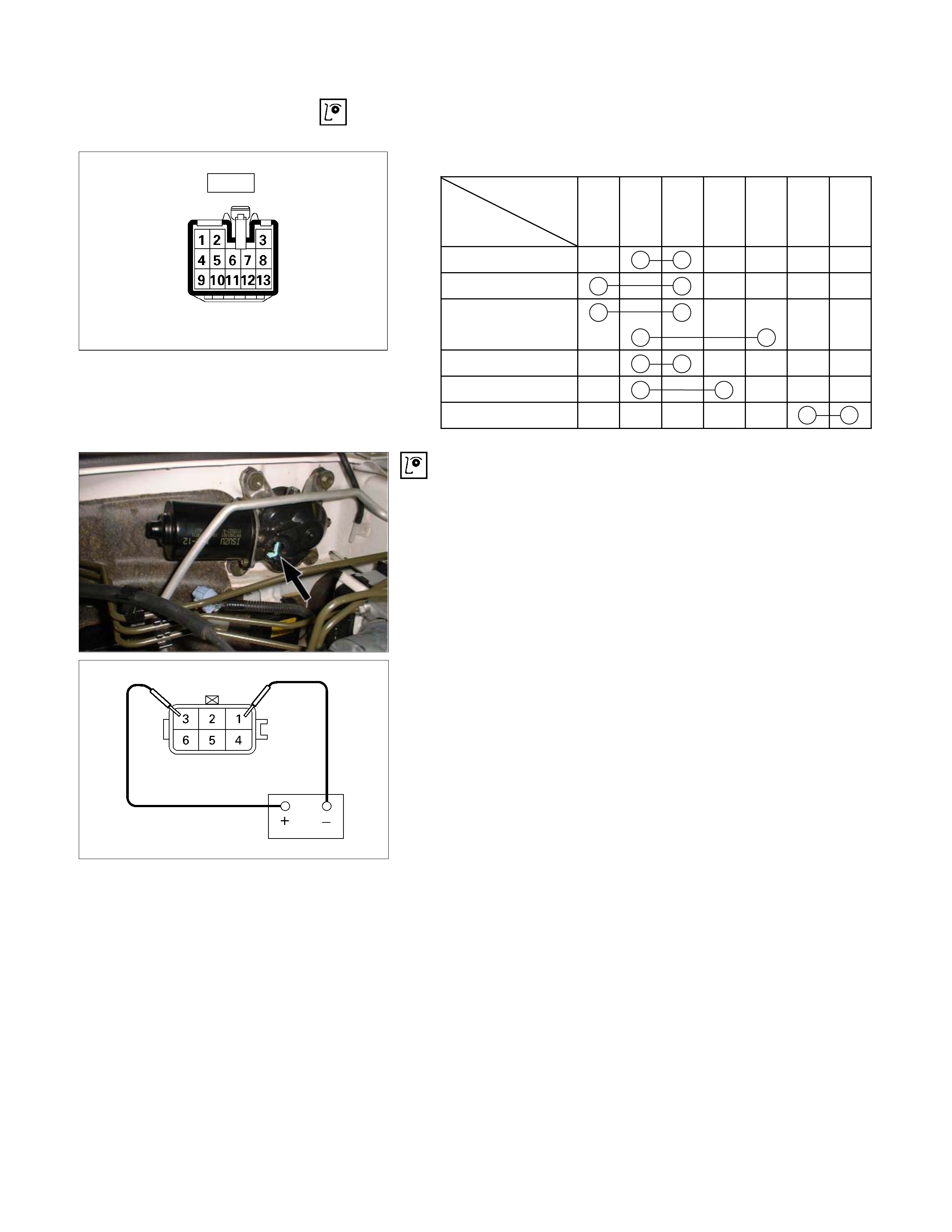

STARTER SWITCH

Switch Connections

Terminal No.

Starter

switch key

position

B-62

2

(B2)

B-62

4

(ACC)

B-62

1

(IG2)

B-63

1

(ST)

B-63

3

(B1)

B-62

3

(IG1)

Removed

OFF

ACC Inserted

ON

START

LOCK

825R300046

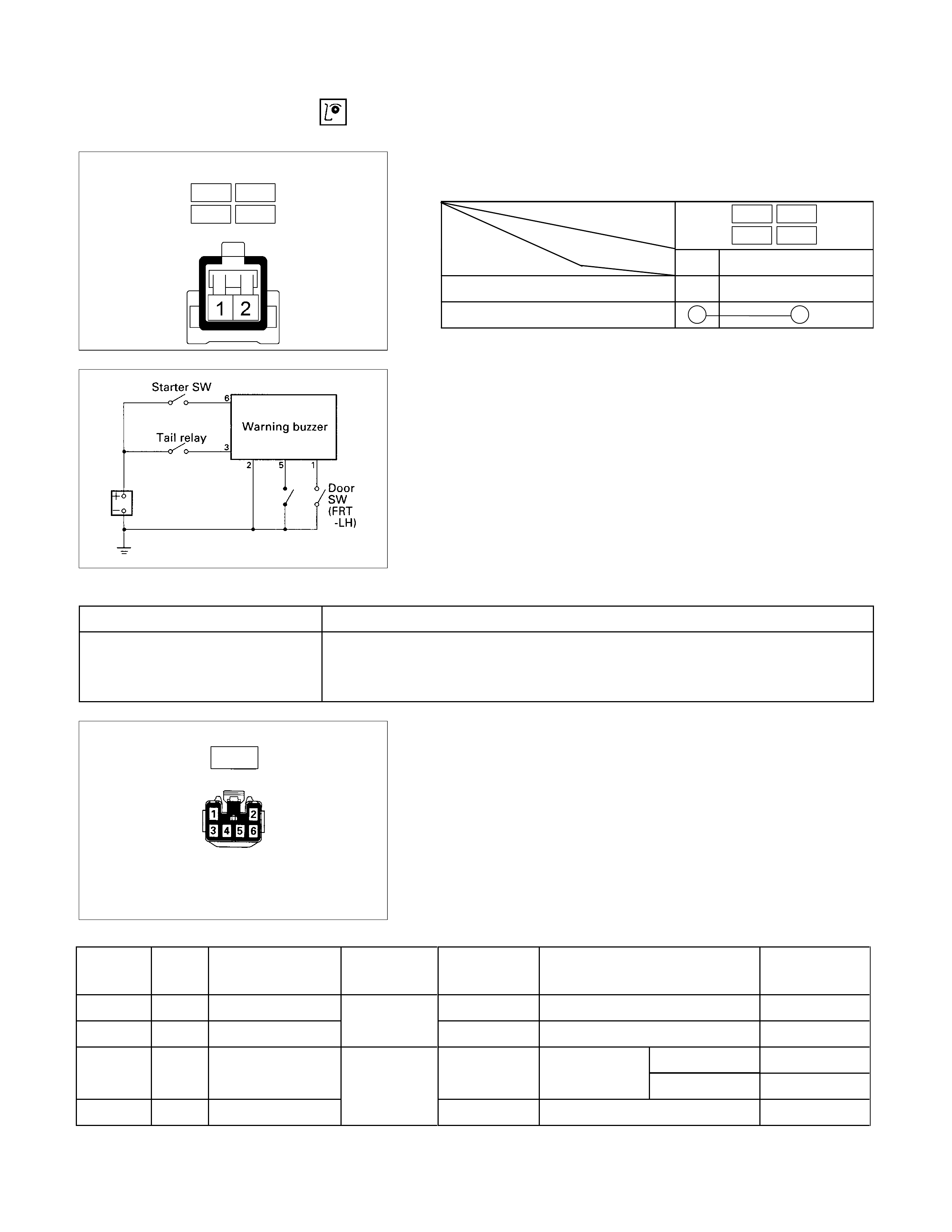

Starter relay

Check continuity between the relay terminals.

1 - 4............................ No continuity

(When battery voltage is applied between 2 and 3)

1 - 4............................ Continuity

ENGINE CONTROL MODULE (ECM)

PARTS LOCATION (RHD)

RTW68AXF013001 & RTW68AXF018601

PARTS LOCATION (LHD)

RTW48AXF013401 & RTW48AXF013501

PARTS LOCATION C24SE

PARTS LOCATION 6VE1

PARTS LOCATION HFV6

RTW68AXF012201

PARTS LOCATION 4JA1-TC / 4JH1-TC

RTW38DXF007601

PARTS LOCATION

RTW68AXF014701

PARTS LOCATION

RTW68AXF012801

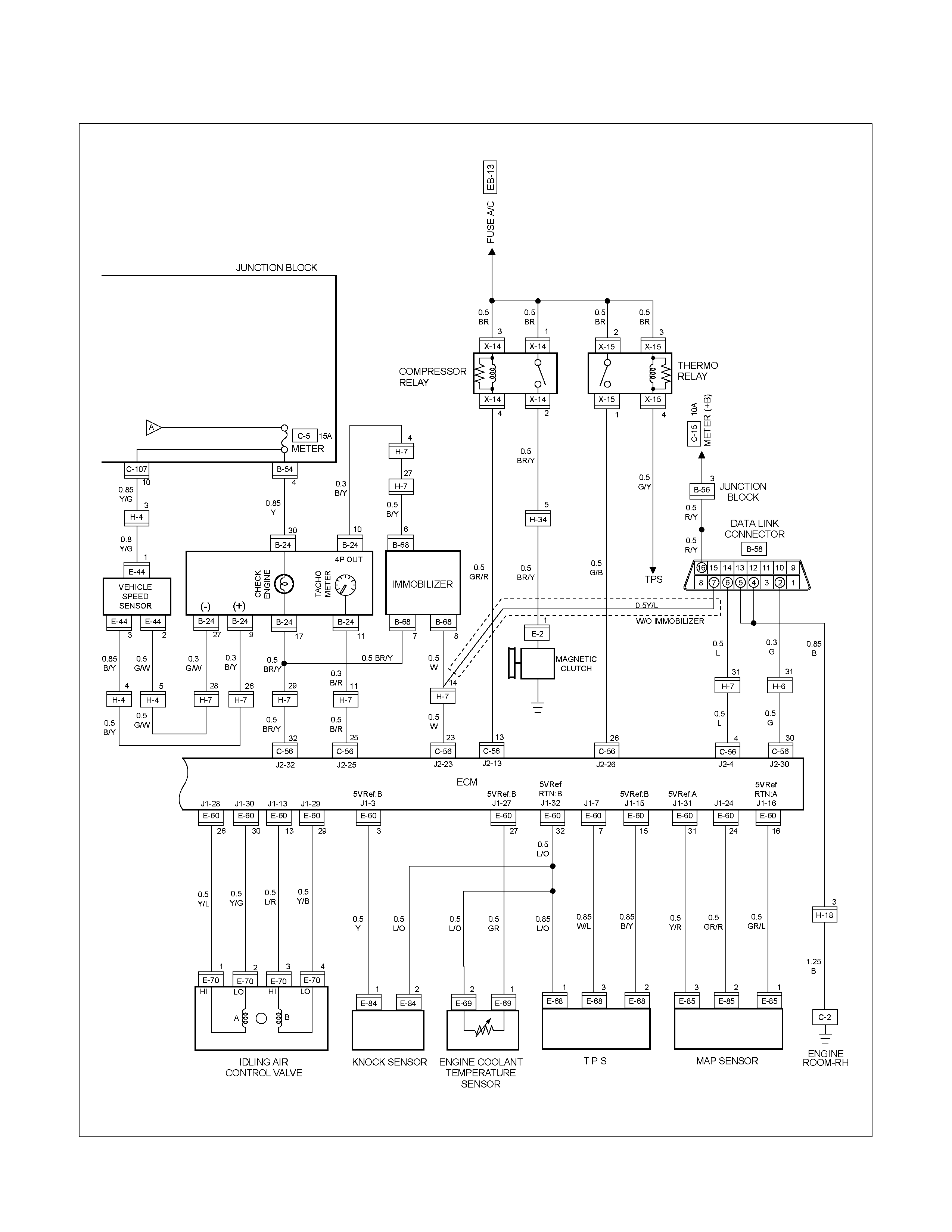

CIRCUIT DIAGRAM C24SE Sheet 1/2

RTW680XF005501

CIRCUIT DIAGRAM C24SE Sheet 2/2

RTW680XF005601

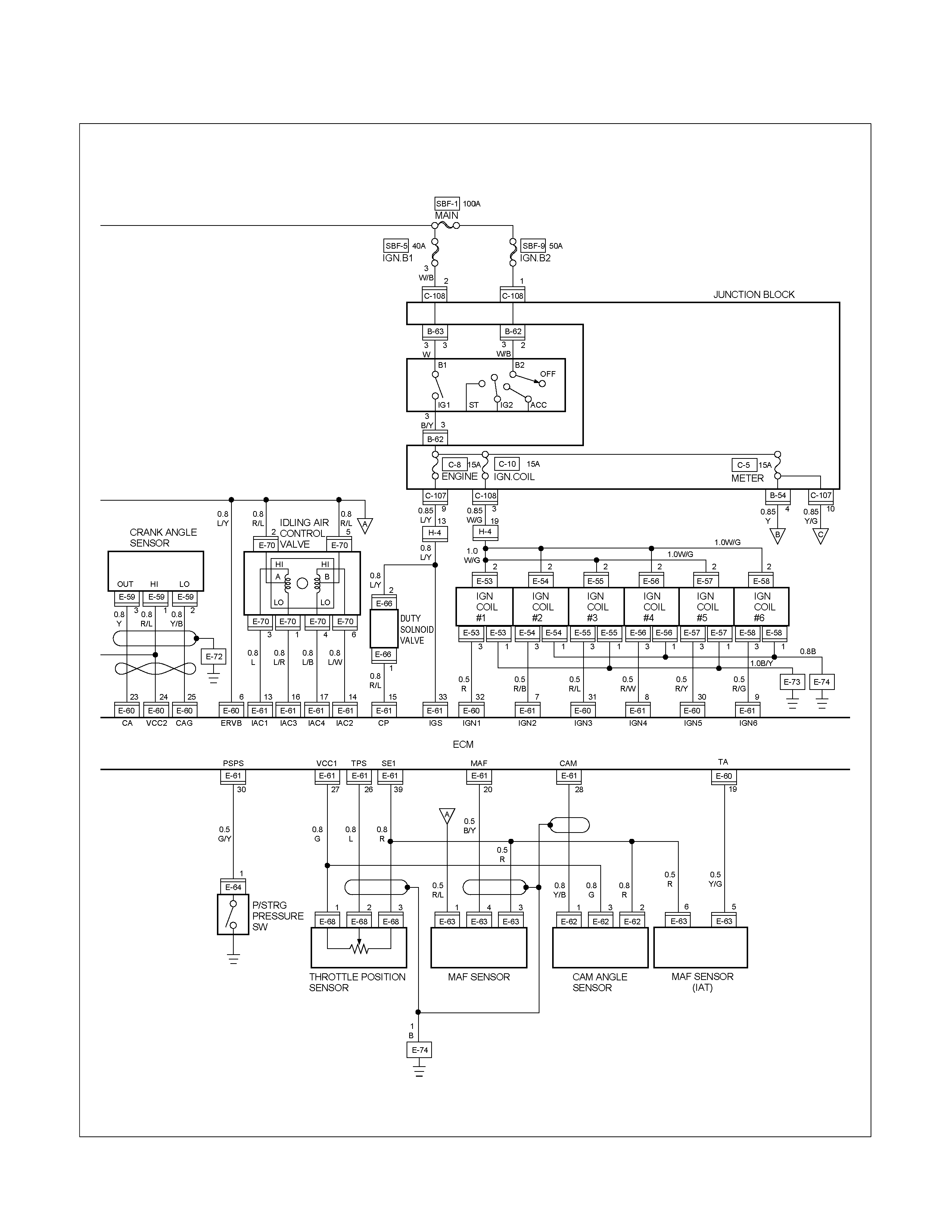

CIRCUIT DIAGRAM 6VE1 Sheet 1/3

RTW680XF005701

CIRCUIT DIAGRAM 6VE1 Sheet 2/3

RTW680XF005801

CIRCUIT DIAGRAM 6VE1 Sheet 3/3

RTW680XF005901

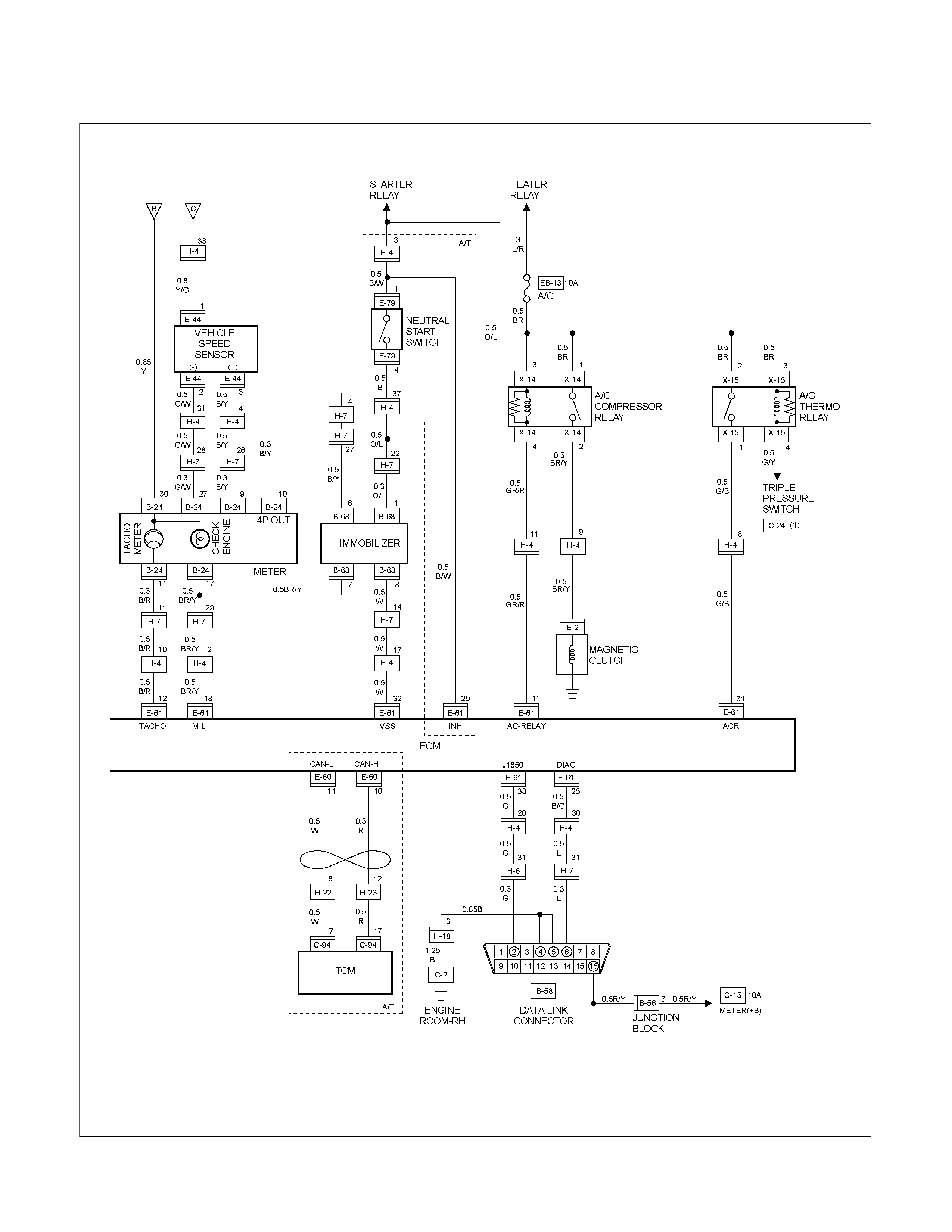

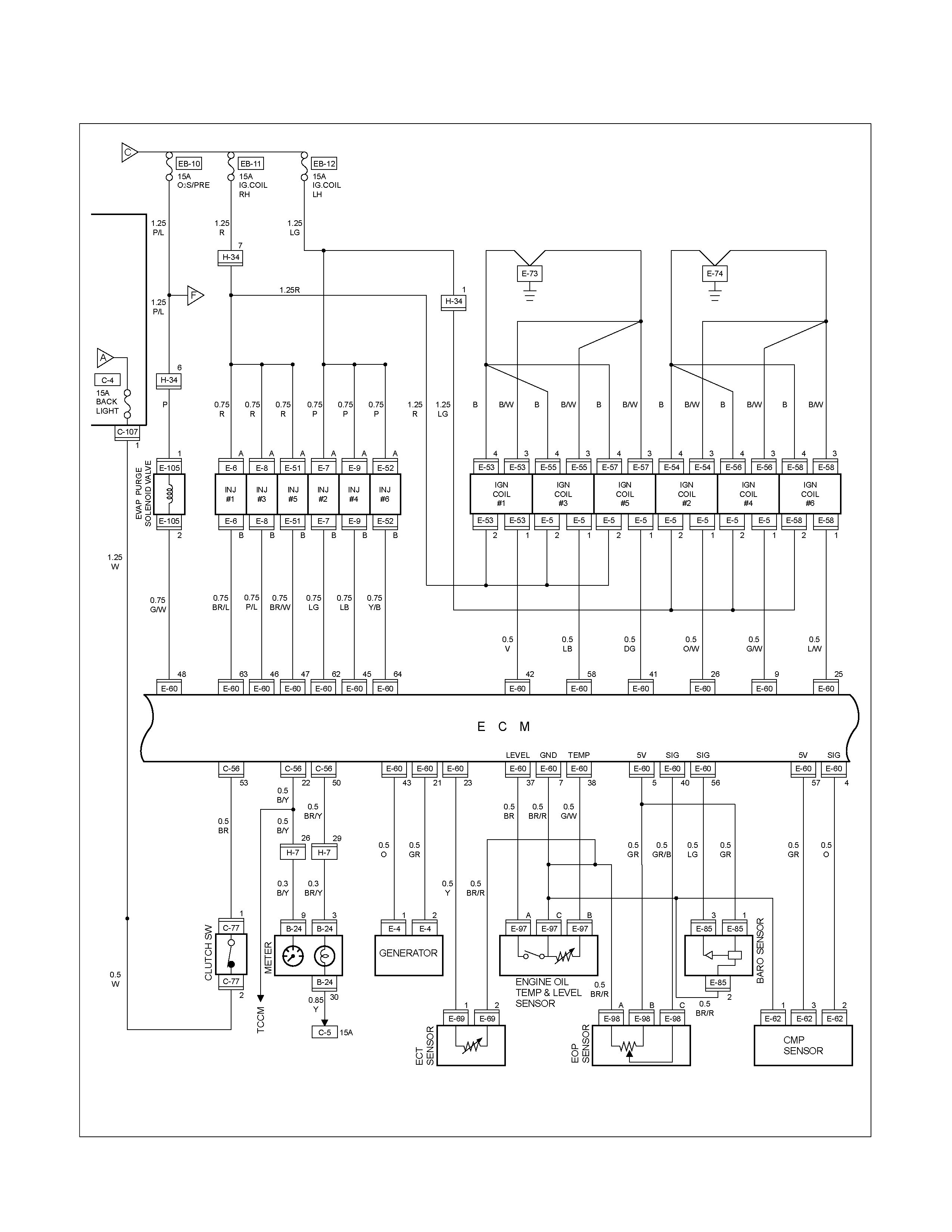

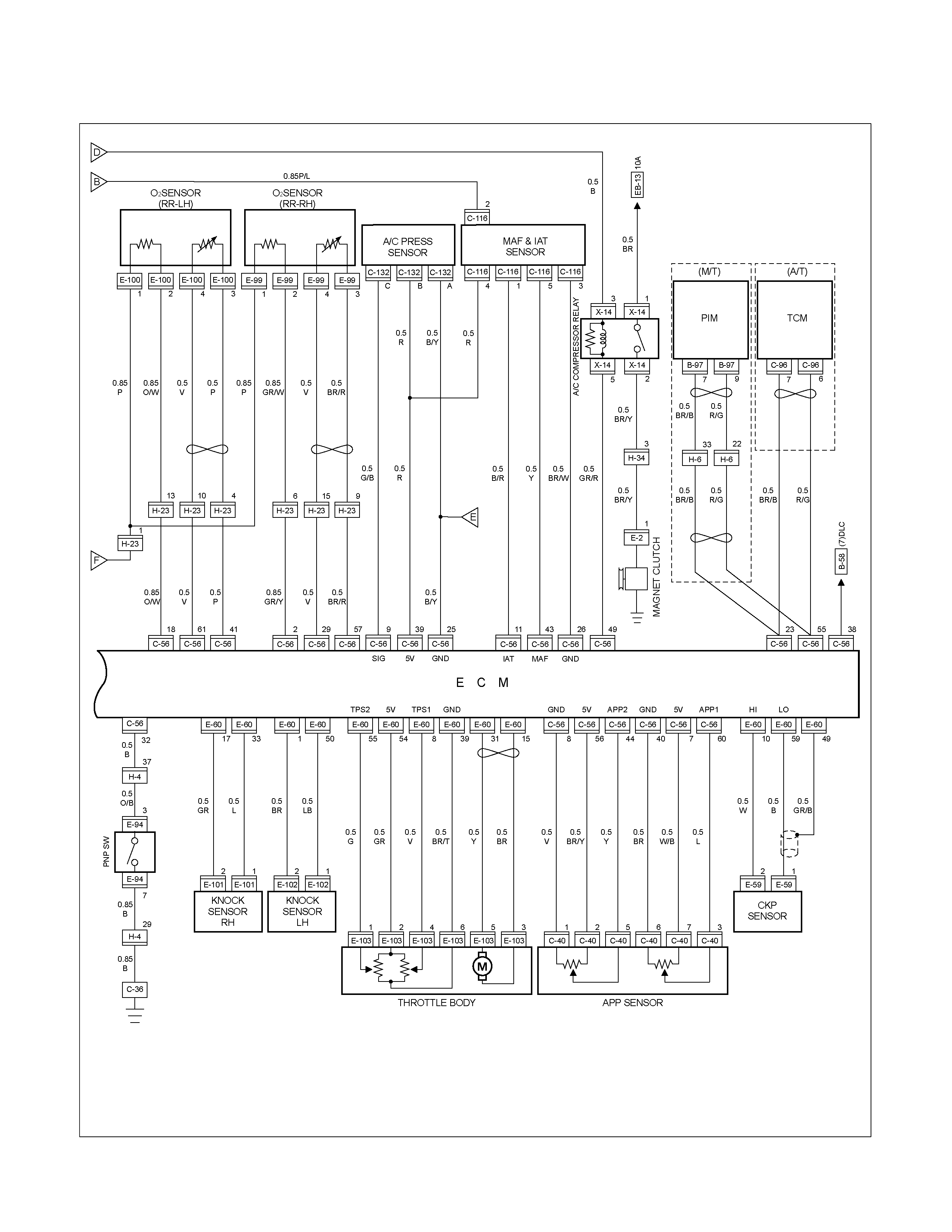

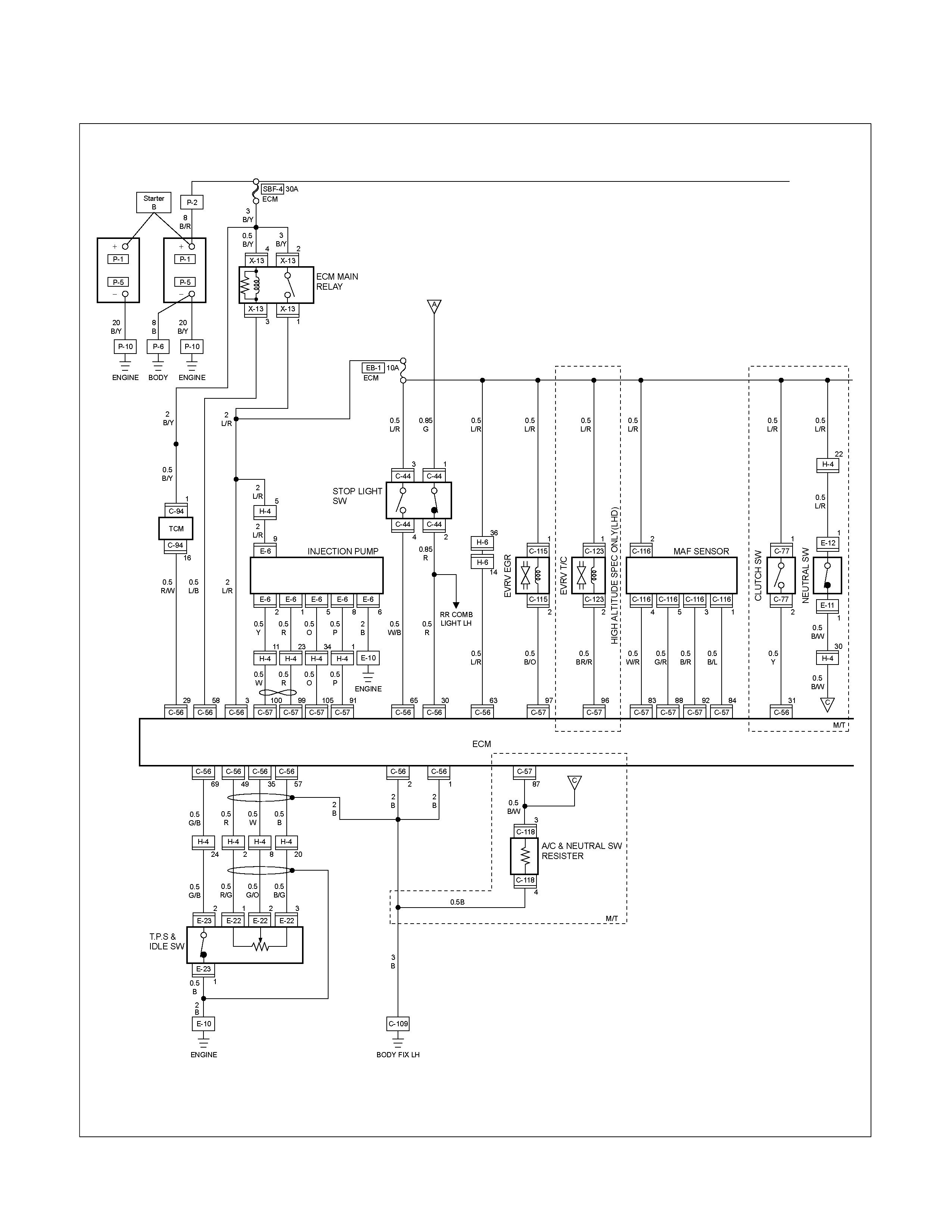

CIRCUIT DIAGRAM HFV6 Sheet 1/3

RTW680XF016201

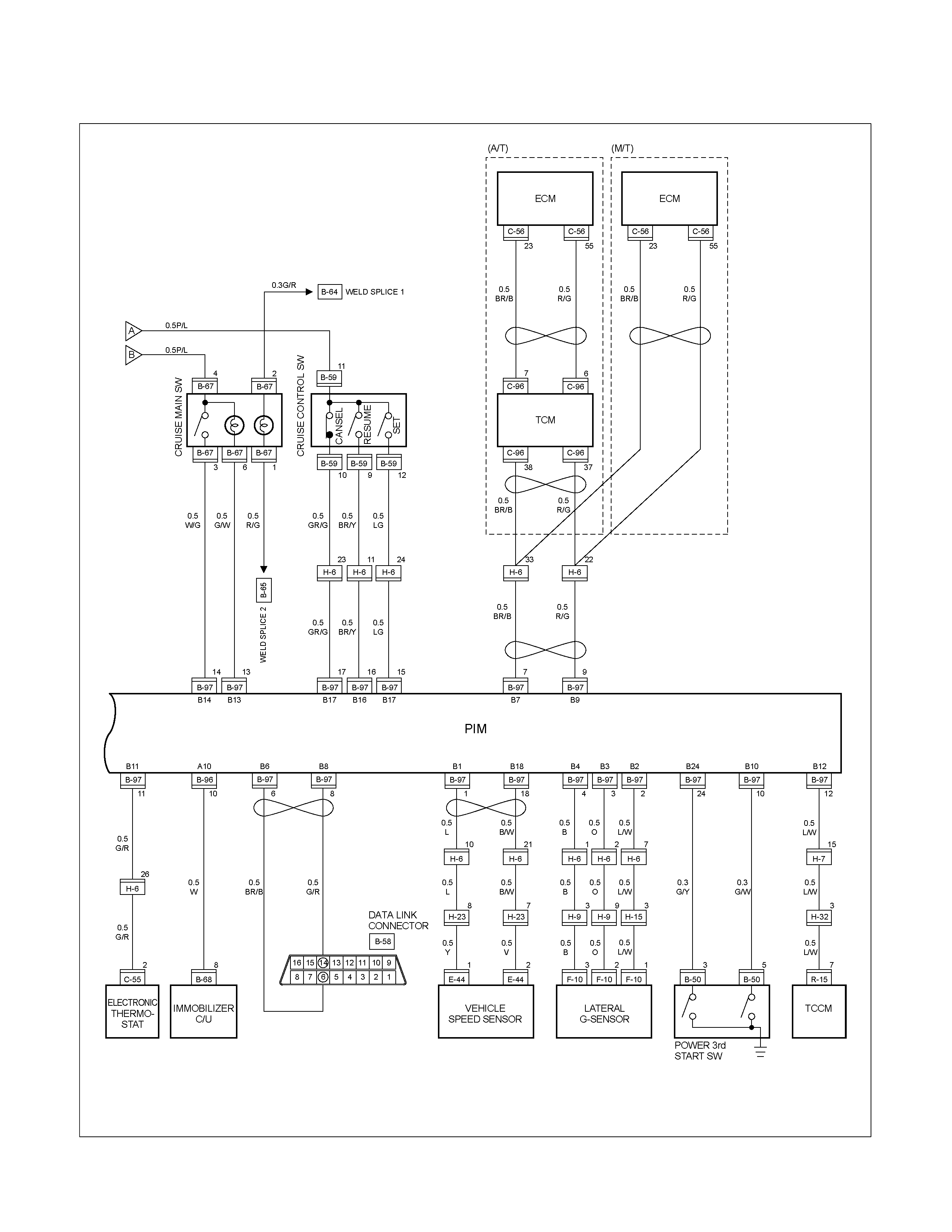

CIRCUIT DIAGRAM HFV6 Sheet 2/3

RTW680XF016301

CIRCUIT DIAGRAM HFV6 Sheet 3/3

RTW680XF016401

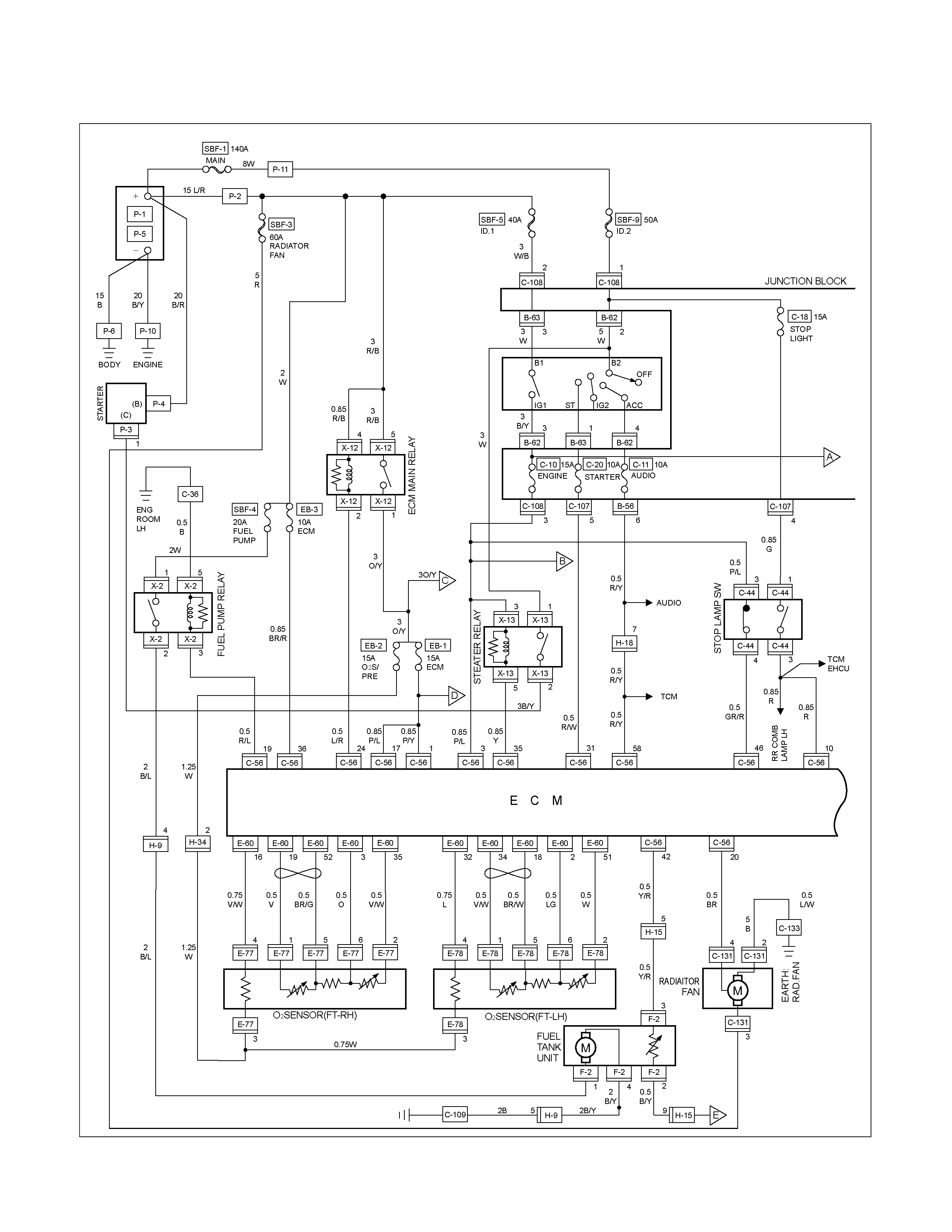

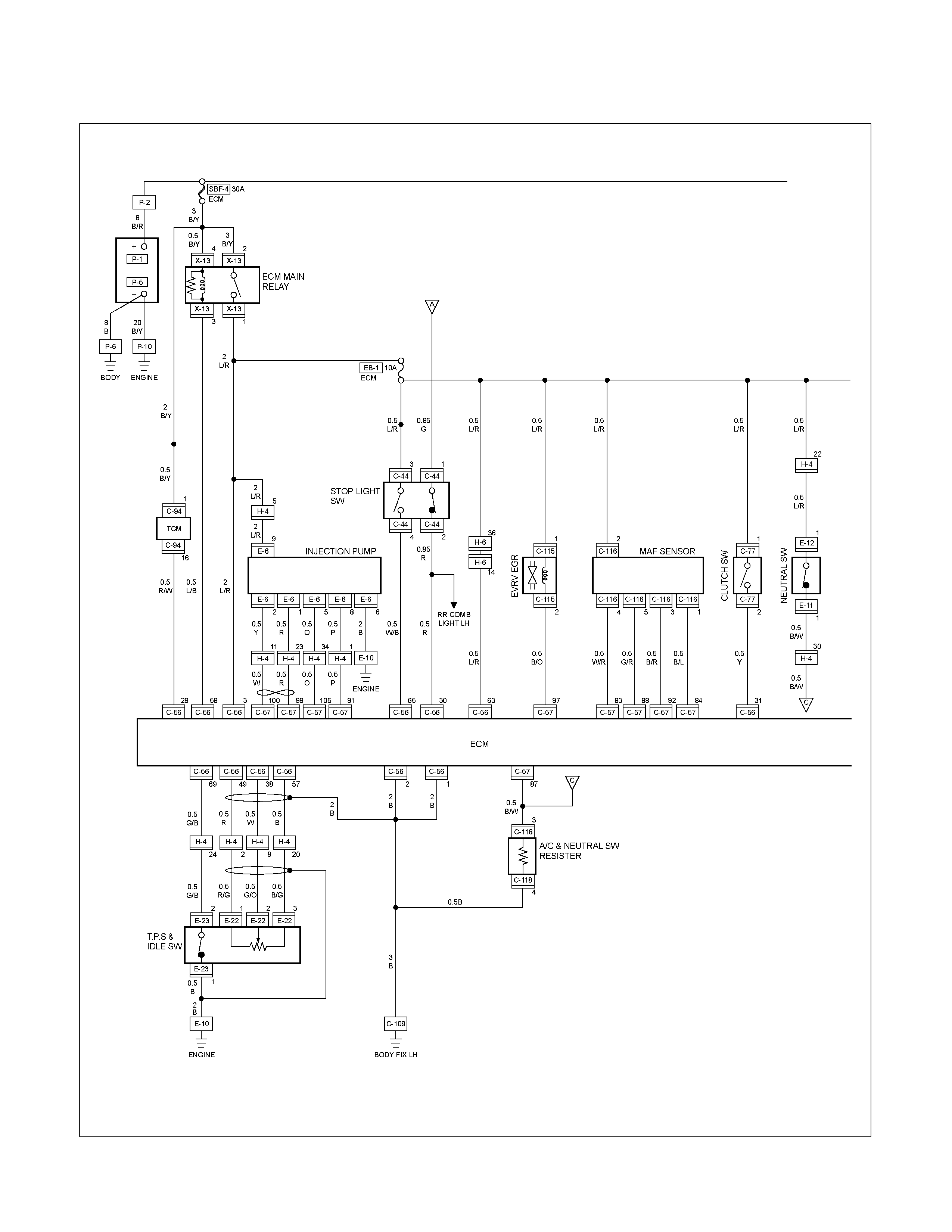

CIRCUIT DIAGRAM 4JH1-TC Sheet 1/2

RTW680XF006001

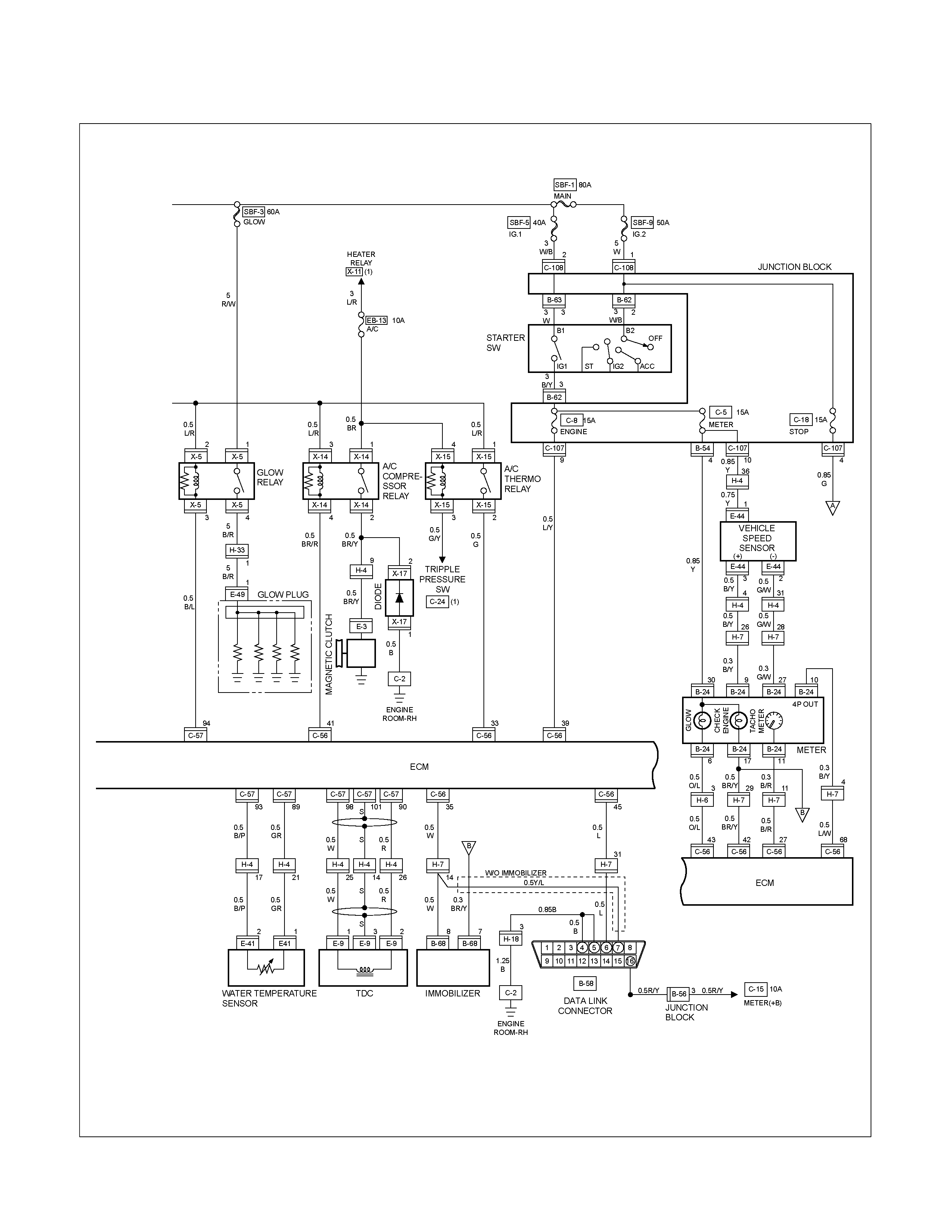

CIRCUIT DIAGRAM 4JH1-TC Sheet 2/2

RTW680XF006101

CIRCUIT DIAGRAM 4JA1-TC Sheet 1/2

RTW680XF006201

CIRCUIT DIAGRAM 4JA1-TC Sheet 2/2

RTW680XF006301

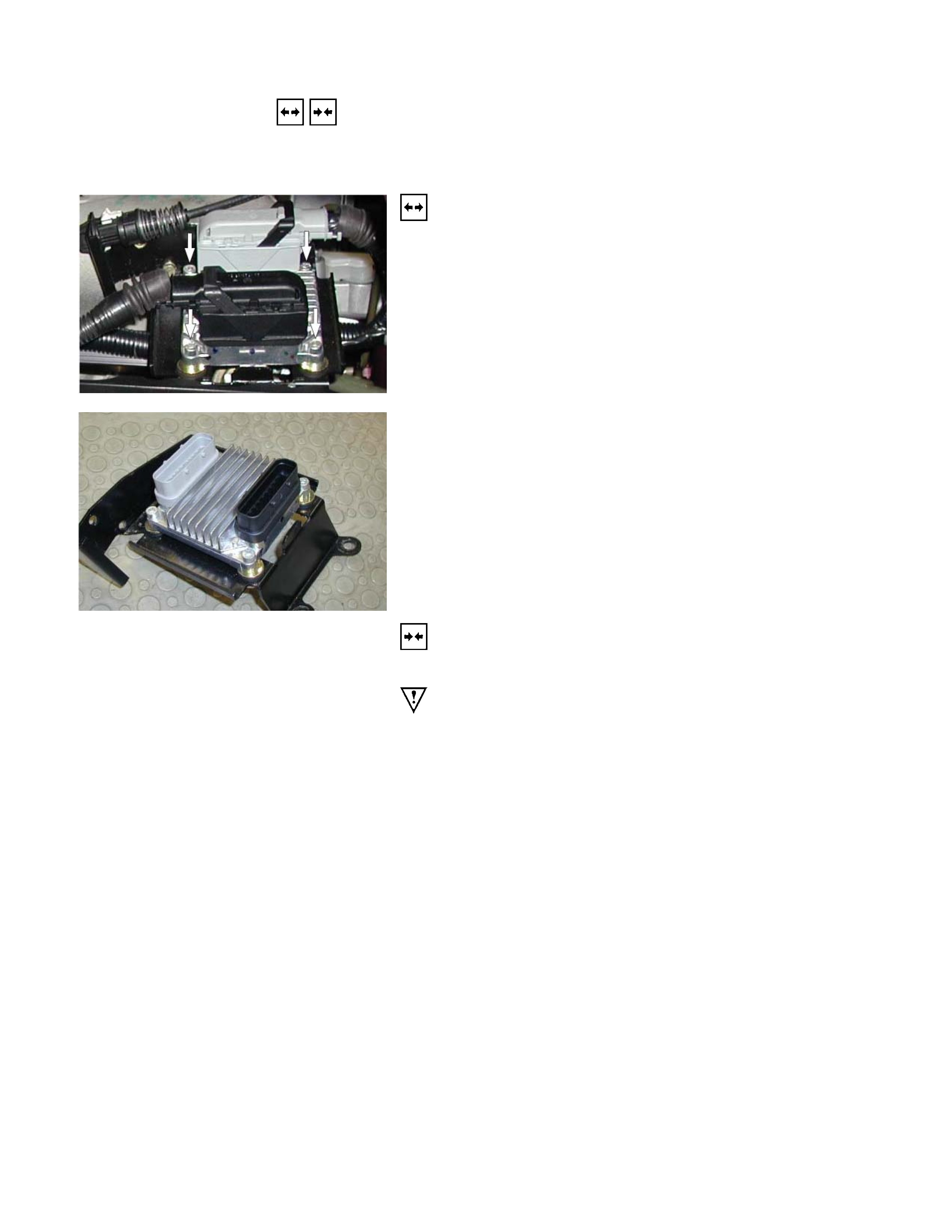

REMOVAL AND INSTALLATION

ECM (ENGINE CONTROL MODULE):

C24SE

Removal

1. Lift both the ECM harness connector locking levers and

remove the two harness connectors form the ECM.

2. Remove the four socket head screws securing the ECM to

the mounting bracket.

3. Remove the ECM from the engine compartment.

4. Pull out the ECM.

5. Disconnect both red and tan connectors.

Refer to the Section 6E-ENGINE of this Manual.

IMPORTANT: The replacement ECM must be programmed.

“SPS (Service Programming System) and immobilizer

programming (if equipped) is/are necessary”

Installation

Follow the removal procedure in the reverse order to install the

ECM.

Pay close attention to the important points mentioned in the

following paragraphs.

Connector

Be absolutely sure that ECM is securely connected.

This will prevent a poor contact and open circuit.

REMOVAL AND INSTALLATION

ECM (ENGINE CONTROL MODULE):

6VE1

Removal

1. Pull both the red ECM harness connector locks toward the

front of the vehicle, and remove the two harness

connectors form the ECM.

2. Remove the four hex-head screws securing the ECM to the

common chamber.

3. Remove the ECM from the engine compartment.

4. Pull out the ECM.

5. Disconnect both red and tan connectors.

Refer to the Section 6E-ENGINE of this Manual.

IMPORTANT: The replacement ECM must be programmed.

“SPS (Service Programming System) and immobilizer

programming (if equipped) is/are necessary”

Installation

Follow the removal procedure in the reverse order to install the

ECM.

Pay close attention to the important points mentioned in the

following paragraphs.

Connector

Be absolutely sure that ECM is securely connected.

This will prevent a poor contact and open circuit.

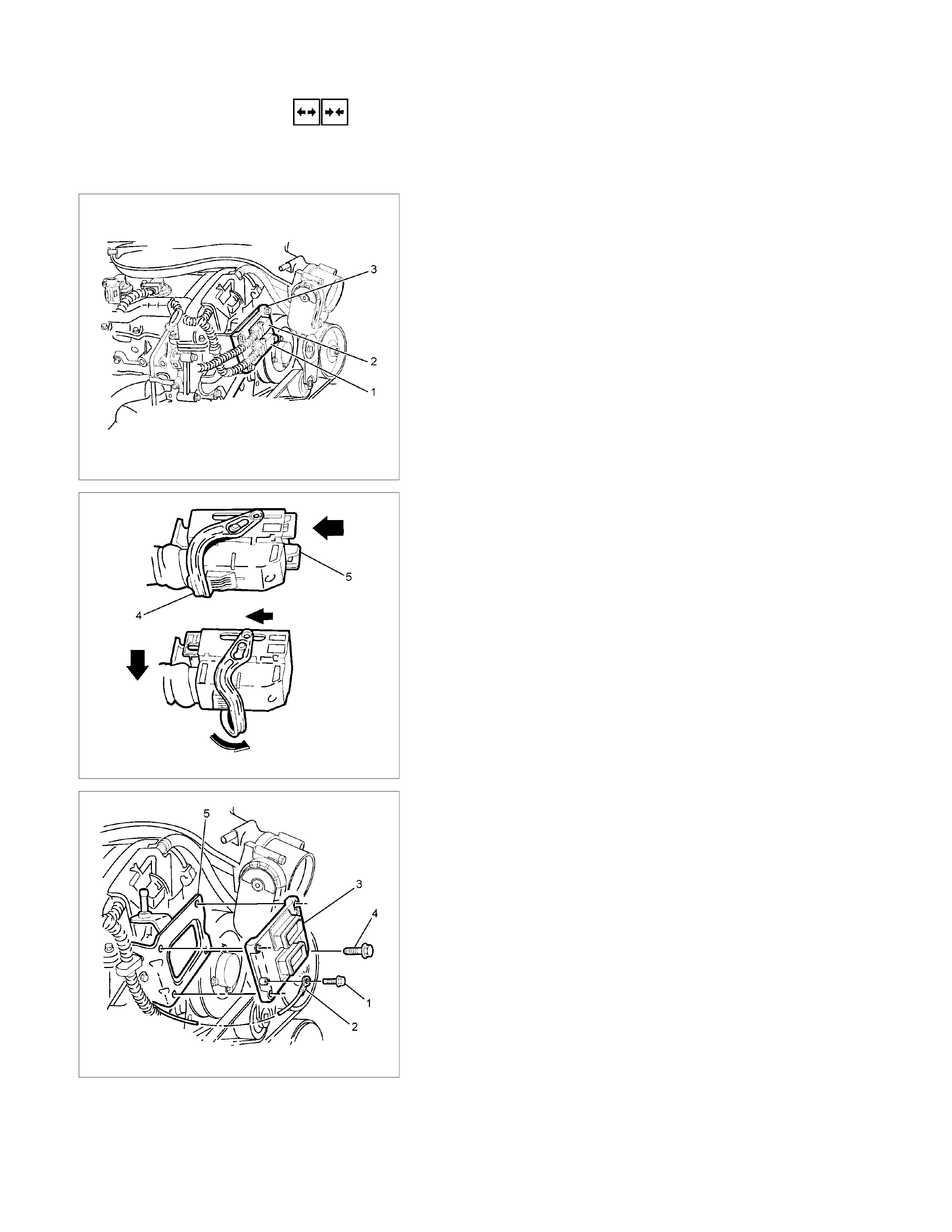

REMOVAL AND INSTALLATION

ECM (ENGINE CONTROL MODULE):

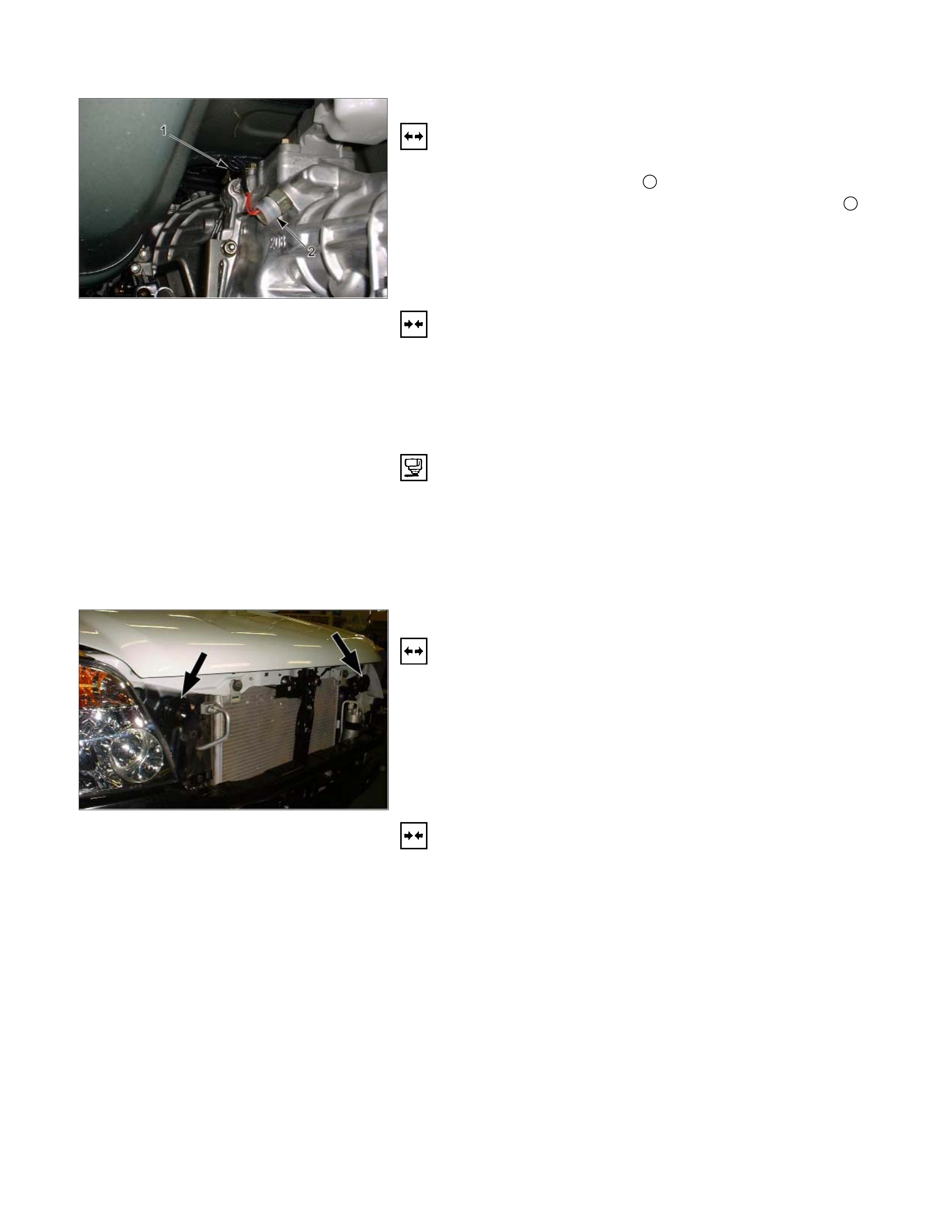

HFV6

RTW68ASH000601

Removal

1. Turn the ignition switch off.

2. Disconnect the battery.

3. Remove the ECM from the engine compartment.

4. Disconnect the engine harness connector (1) and the

engine room harness connector (2) from the ECM (3).

RTW68ASH000701

5. To release each connector, lift the connector locking leve

r

(4) whilst simultaneously pushing the connector locking

slide (5)

RTW68ASH000801

6. Remove the screw (1) attaching the ground

terminal (2) to the ECM (3).

7. Remove the nut (4), four places, attaching the ECM to the

mounting bracket (5) and remove the ECM.

Refer to the Section 6E-ENGINE of this Manual.

IMPORTANT: The replacement ECM must be programmed.

“SPS (Service Programming System) and immobilizer

programming (if equipped) is/are necessary”

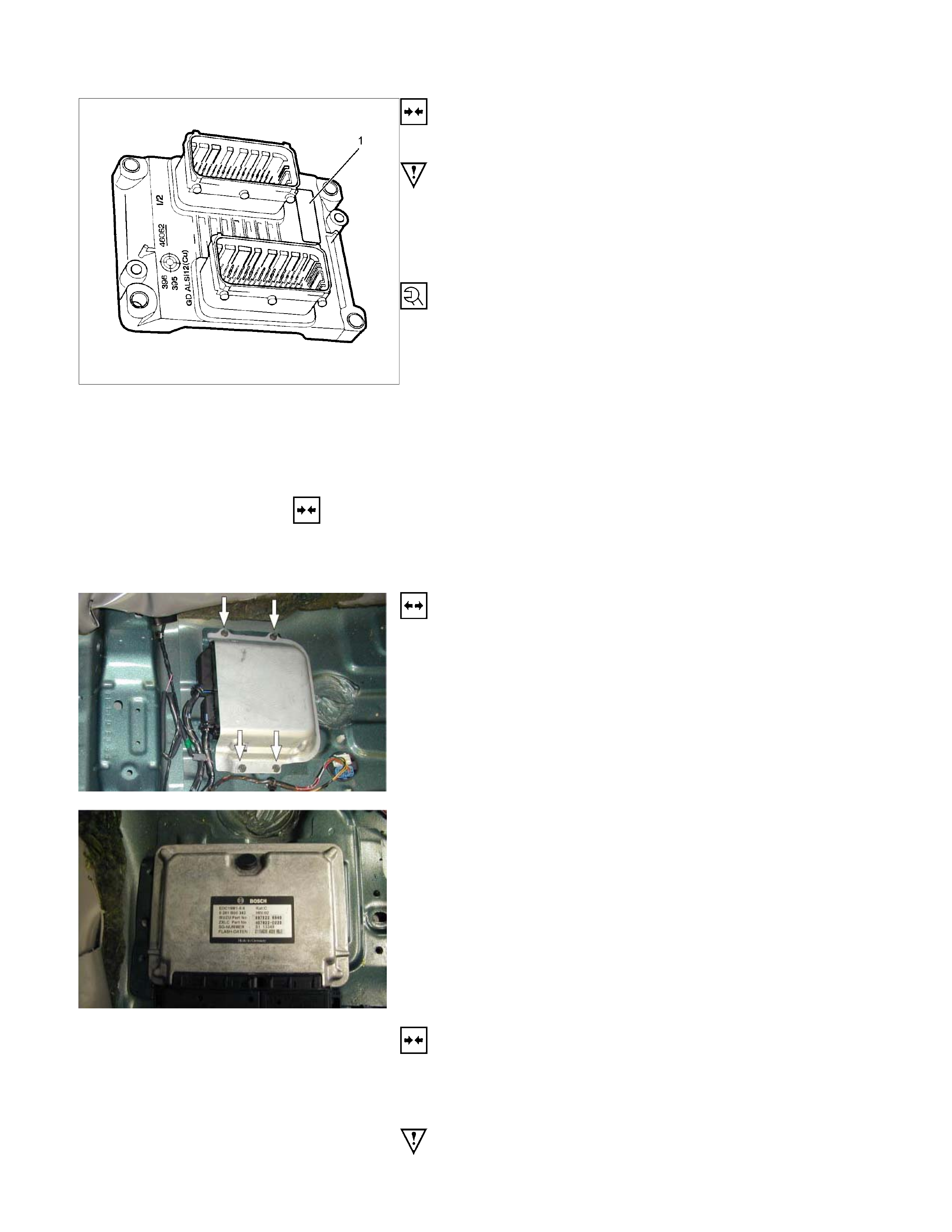

RTW68ASH000901

Installation

Follow the removal procedure in the reverse order to install the

ECM.

Pay close attention to the important points mentioned in the

following paragraphs.

During installation of the ECM, the label (1) is positioned at the

top right-hand corner.

ECM attaching bolt

Torque: 10 N⋅m (1.0 kgf⋅m)

Ground terminal attaching screw

Torque: 4.5 N⋅m (0.4 kgf⋅m)

Connector

Be absolutely sure that ECM is securely connected.

This will prevent a poor contact and open circuit.

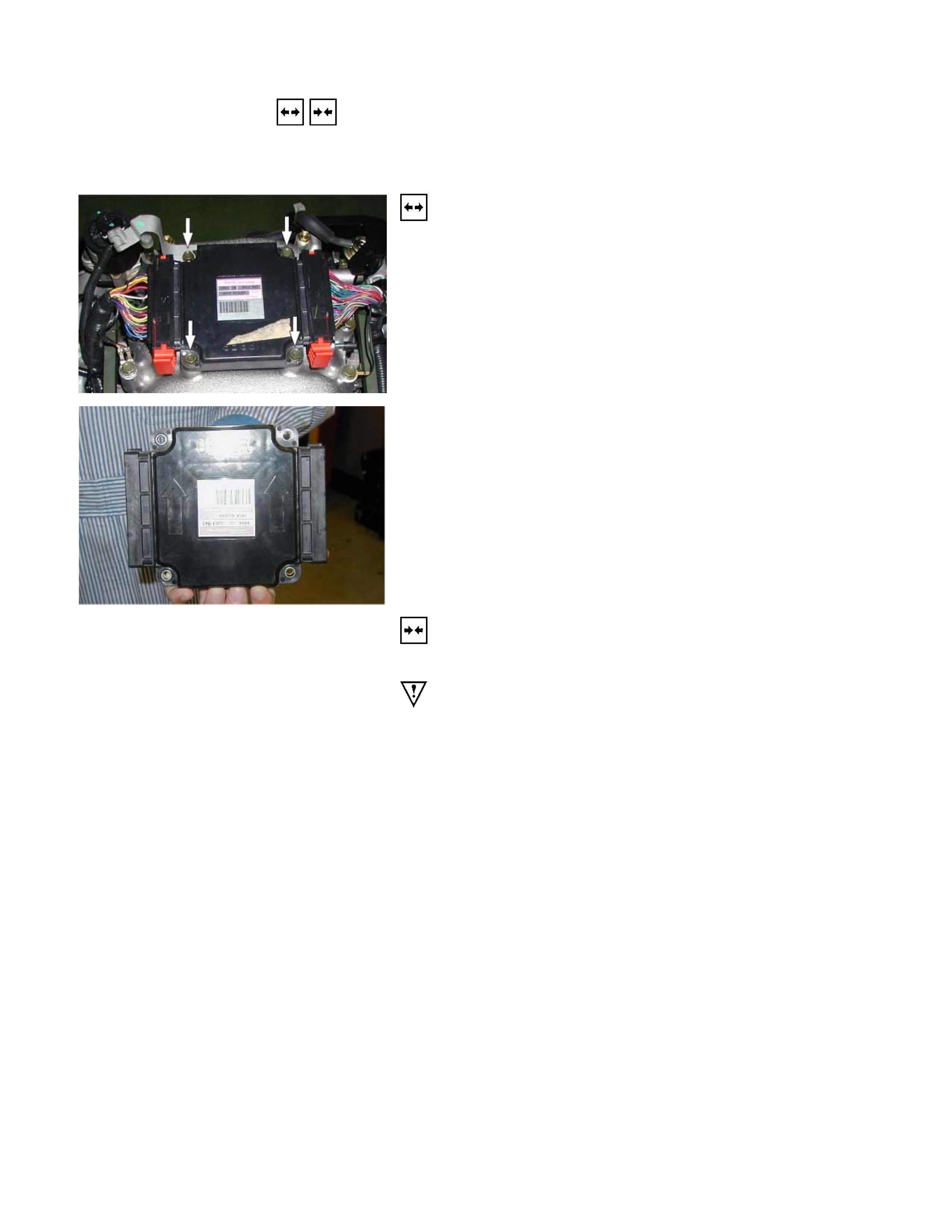

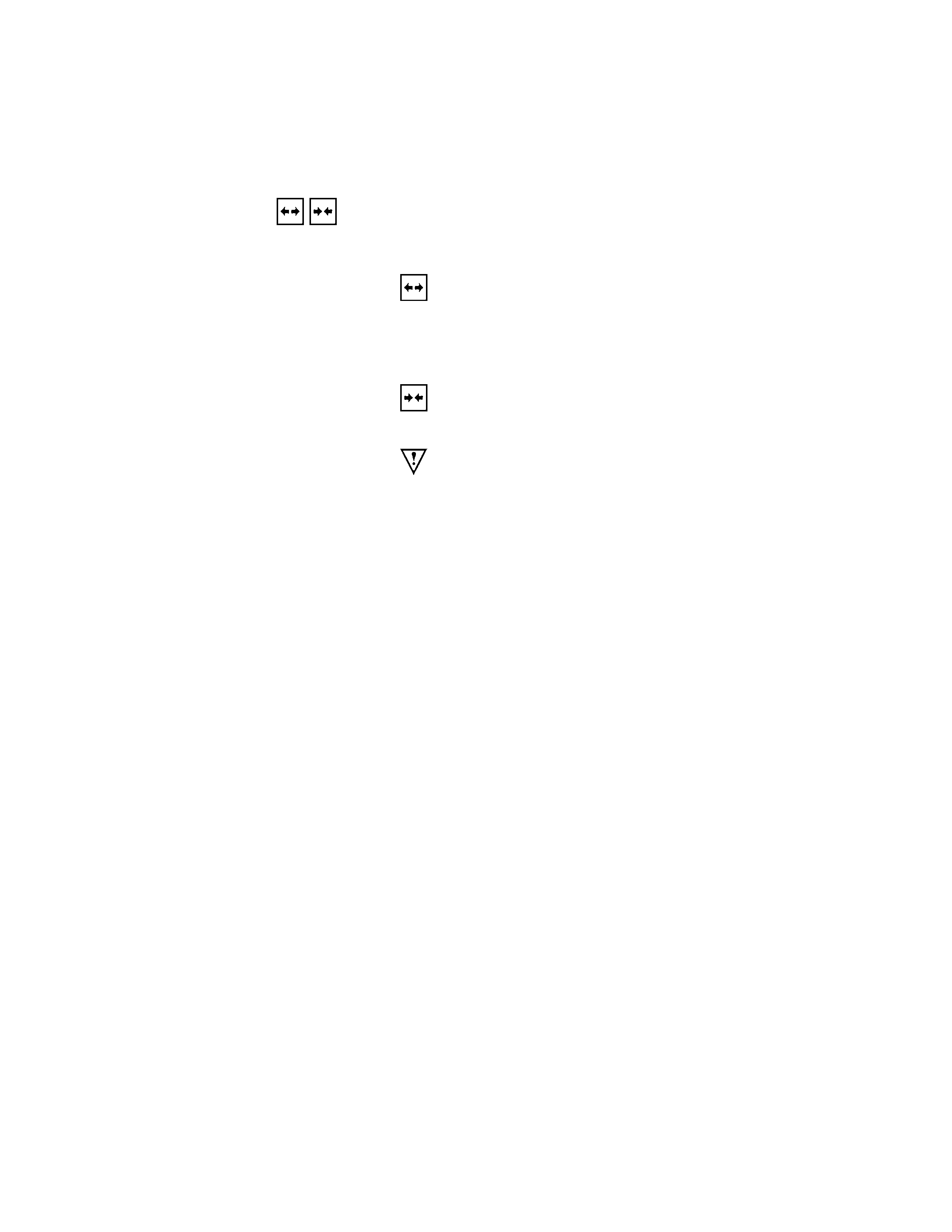

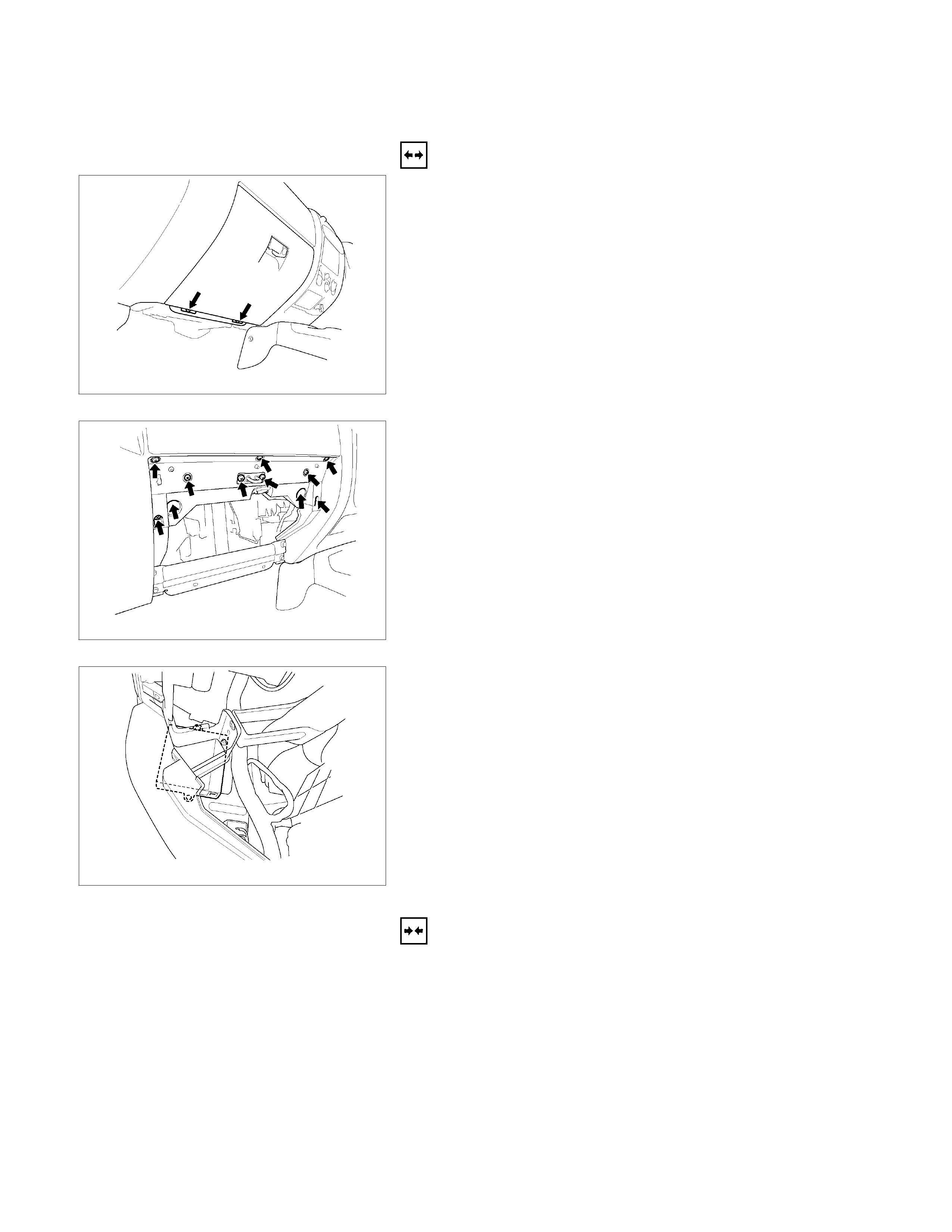

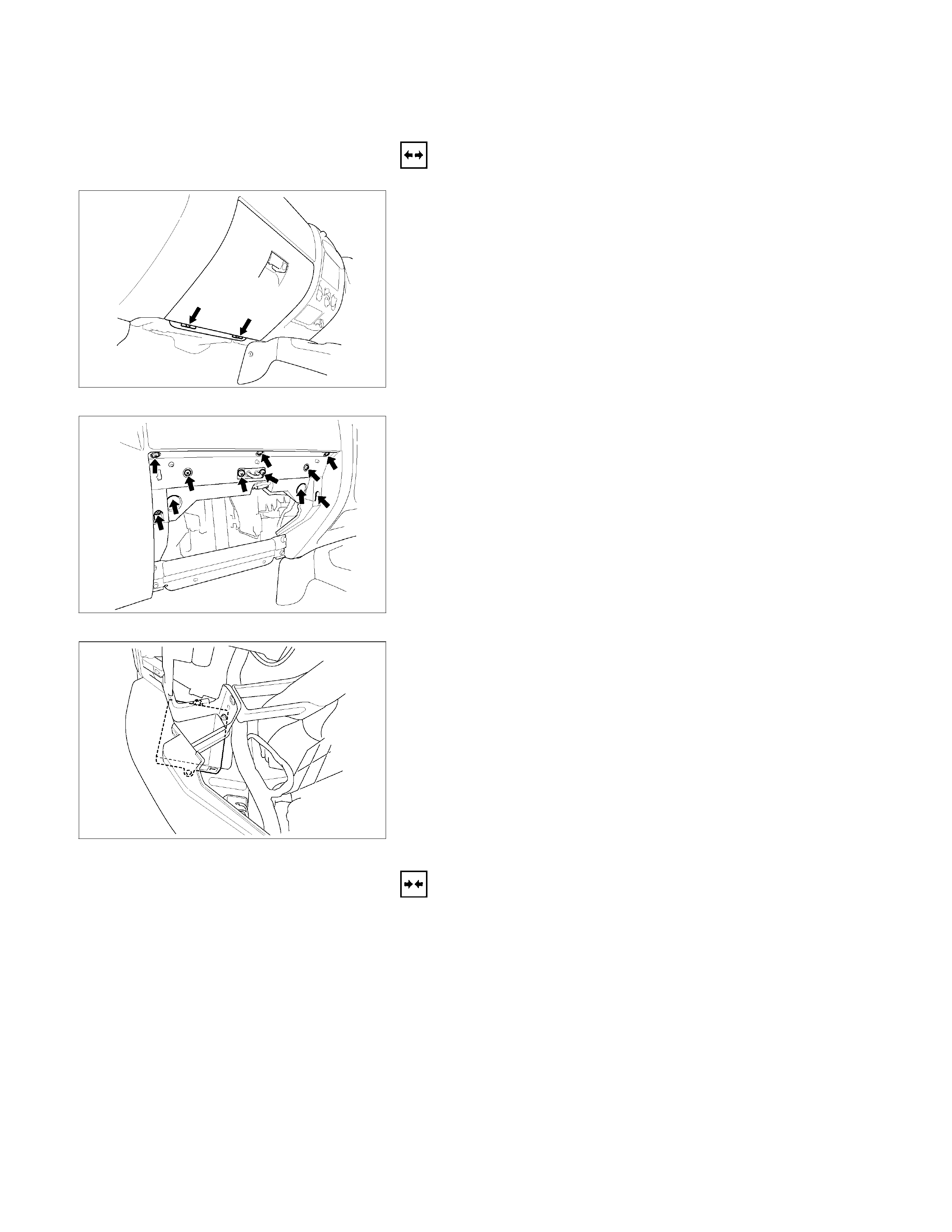

REMOVAL AND INSTALLATION

ECM (ENGINE CONTROL MODULE):

4JA1-TC / 4JH1-TC

Removal

1. Remove the passenger side front seat – refer to Section 10

CAB.

2. Remove the passenger side front door opening scuff plate.

3. Raise the carpet to gain access to the four hex-head bolts

securing the ECM and ECM cover to the floor pan.

4. Remove the four hex-head bolts.

5. Pull the two harness connector locks away from the

harness connectors and then remove the connectors form

the ECM.

6. Remove the ECM from the vehicle.

Refer to the Section 6E-ENGINE of this Manual.

IMPORTANT: The replacement ECM must be programmed.

“SPS (Service Programming System) and immobilizer

programming (if equipped) is/are necessary”

Installation

Follow the removal procedure in the reverse order to install the

ECM.

Torque passenger seat securing bolts to the specified value –

refer to Section 10 CAB

Pay close attention to the important points mentioned in the

following paragraphs.

Connector

Be absolutely sure that ECM is securely connected.

This will prevent a poor contact and open circuit.

REMOVAL AND INSTALLATION

FUEL PUMP

Removal

1. Remove the fuel tank.

Refer to the Section 6C-ENGINE FUEL of this Manual.

• Disconnect the fuel pipe.

Installation

Follow the removal procedure in the reverse order to install the

fuel pump.

Pay close attention to the important points mentioned in the

following paragraphs.

Rubber Seal

Be absolutely sure that the fuel pump rubber seals correctly

seated.

Connector

Be absolutely sure that the fuel pump connector is securely

connected.

This will prevent a poor contact and an open circuit.

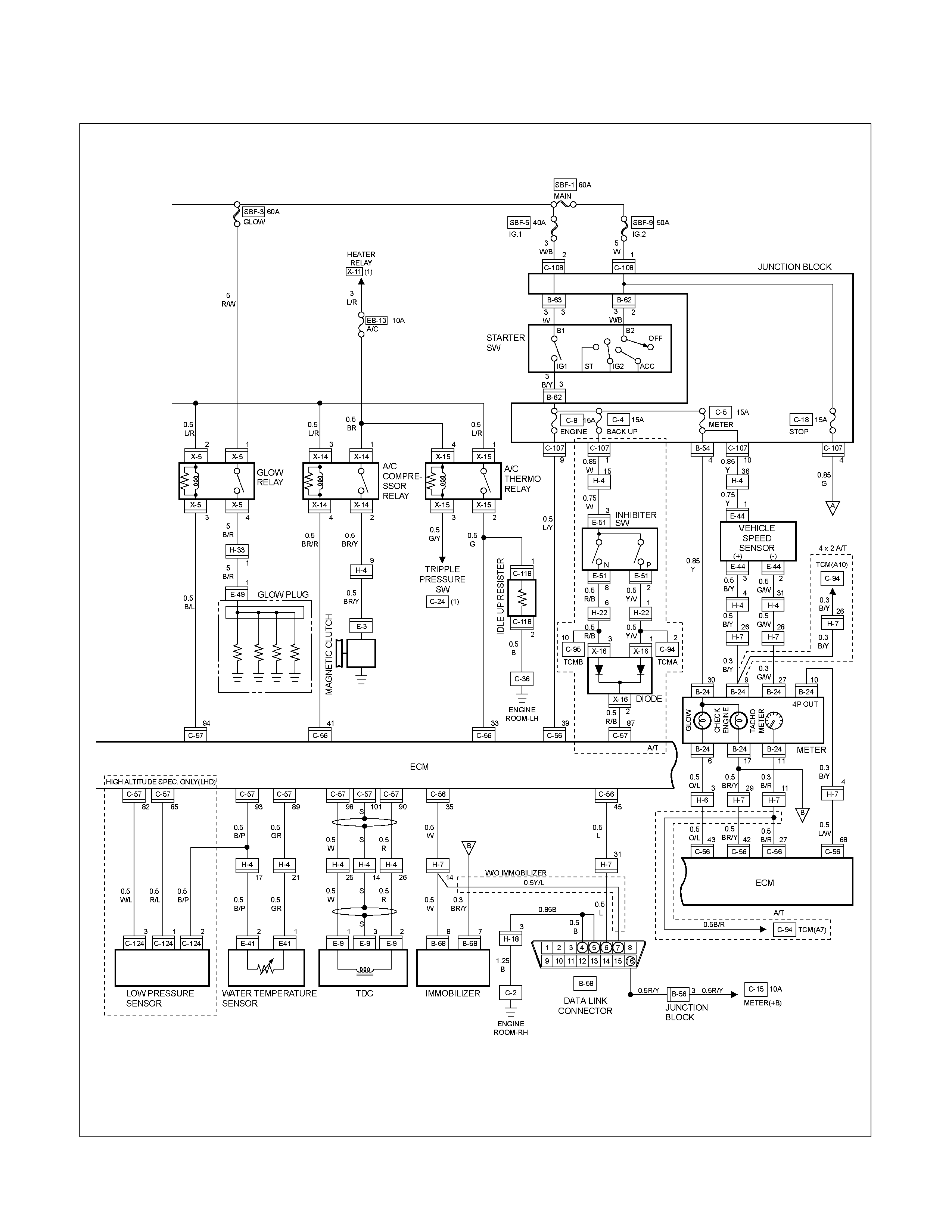

POWERTRAIN INTERFACE MODULE (PIM) : HFV6

PARTS LOCATION HFV6

RTW68AXF018001 & RTW68AXF018101

PARTS LOCATION HFV6

RTW68AXF012201

CIRCUIT DIAGRAM HFV6 Sheet 1/2

RTW68AXF013601

CIRCUIT DIAGRAM HFV6 Sheet 2/2

RTW68AXF013701

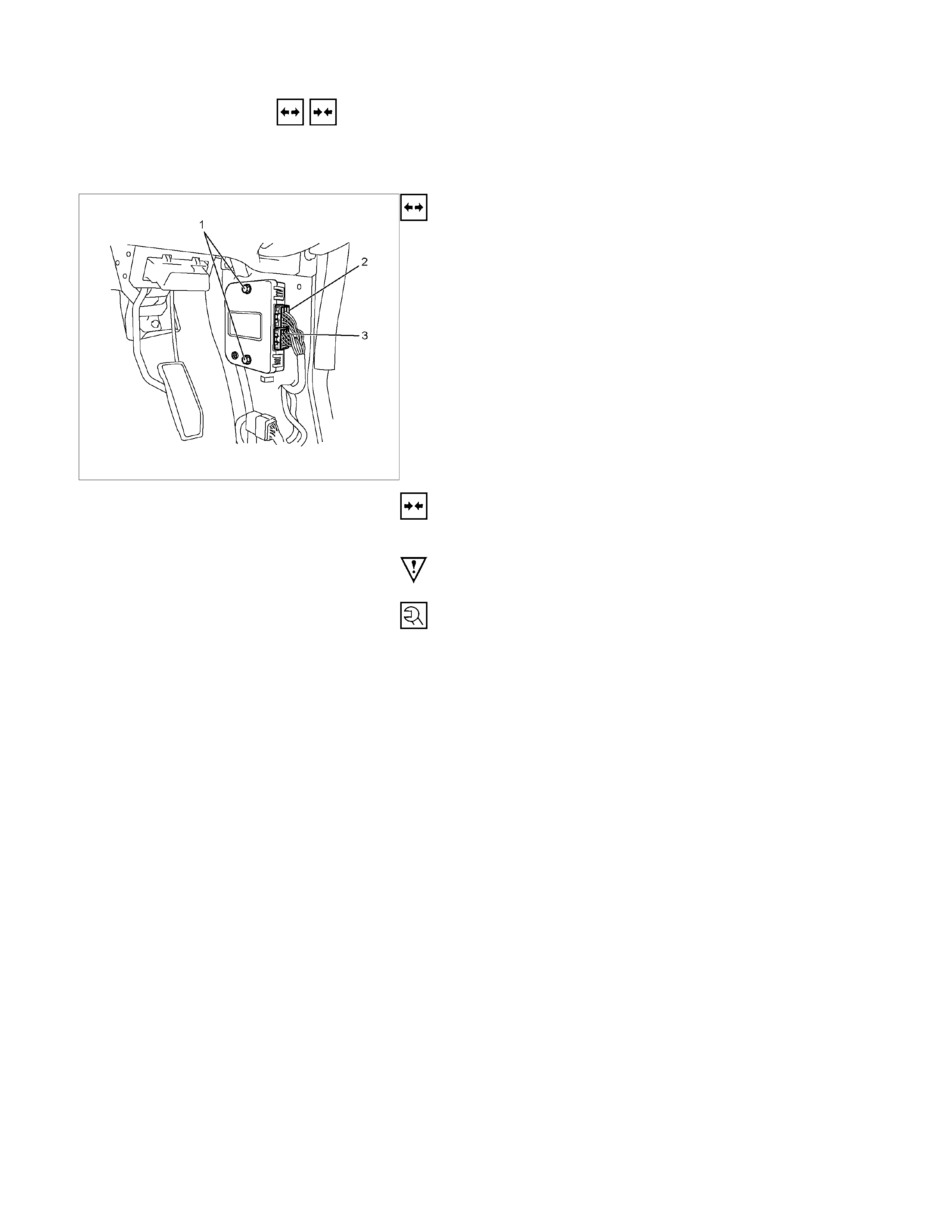

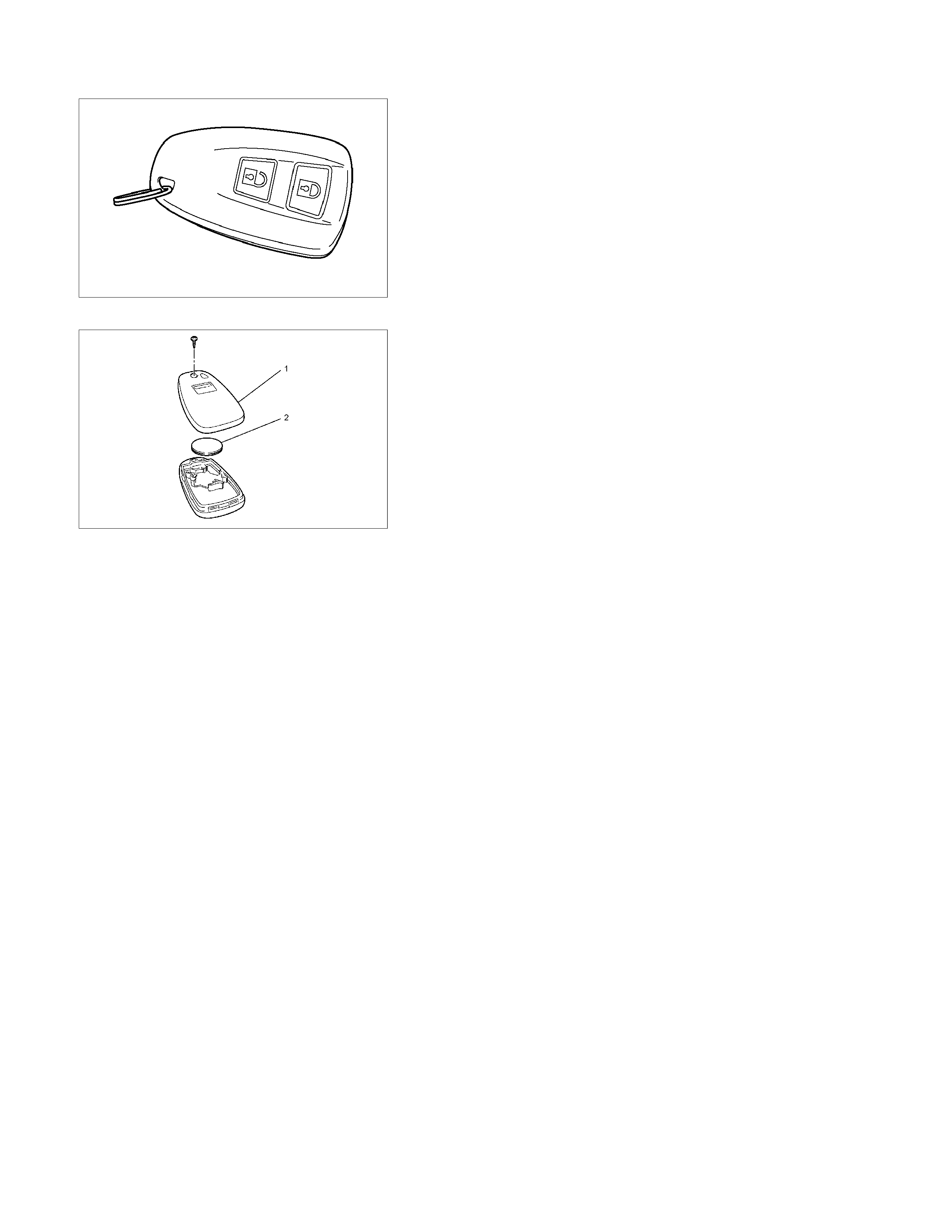

REMOVAL AND INSTALLATION

PIM (POWERTRAIN INTERFACE

MODULE):

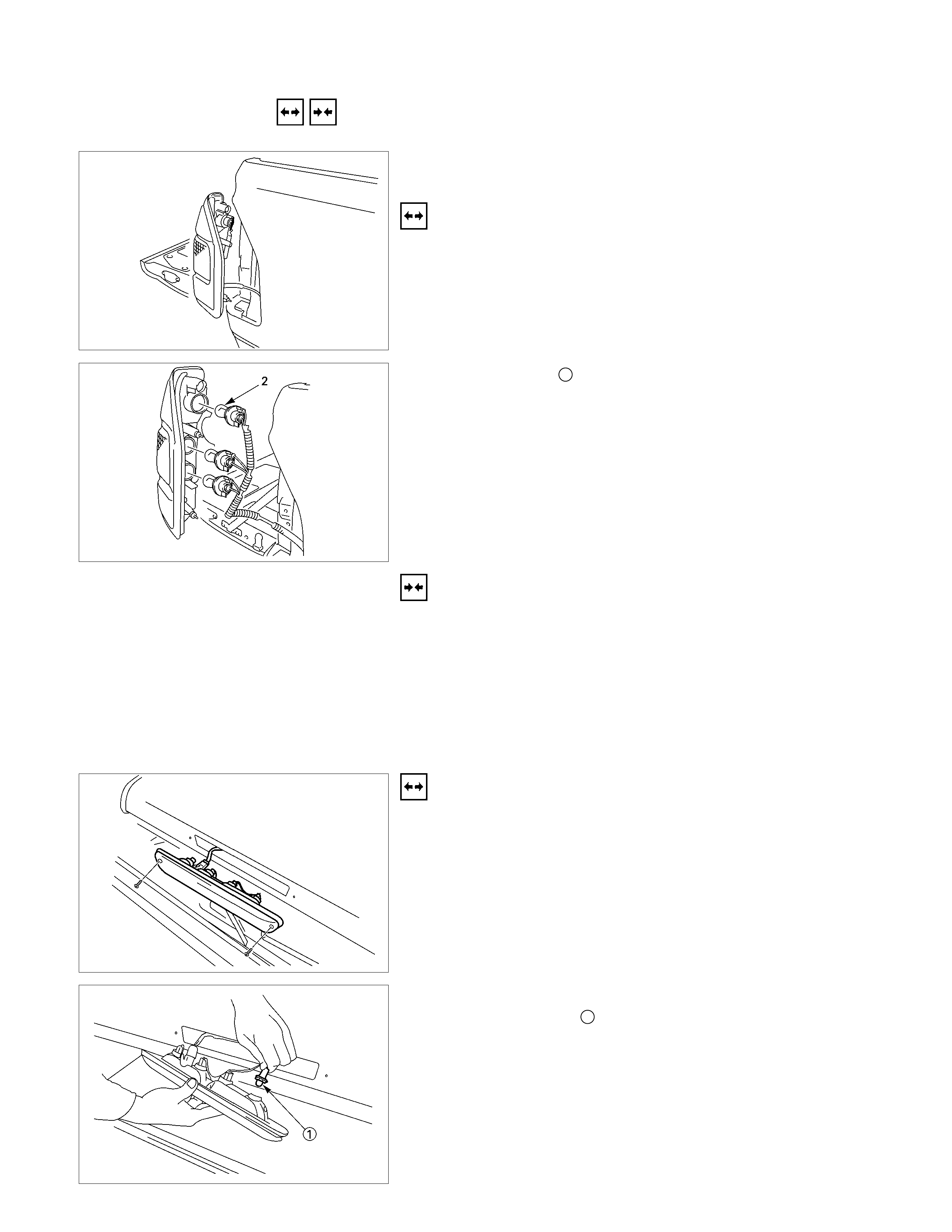

RTW68ASH001201

Removal

1. Turn the ignition switch off.

2. Disconnect the battery.

3. Remove the sill plate and dash side trim cover. Refer to the

Section 10 CAB of this Manual.

4. Remove the bolt (1) and remove the PIM from vehicle

body.

5. Disconnect the PIM harness connector (2), (3).

Installation

Follow the removal procedure in the reverse order to install the

PIM.

Pay close attention to the important points mentioned in the

following paragraphs.

PIM attaching bolt

Torque: 10 N⋅m (1.0 kgf⋅m)

Connector

Be absolutely sure that PIM is securely connected.

This will prevent a poor contact and open circuit.

EXHAUST GAS RECALCULATION (EGR): 4JA1-L ONLY

PARTS LOCATION (RHD)

RTW48AXF0136 & RTW48AMF000101

PARTS LOCATION (RHD)

RTW48AXF013701

PARTS LOCATION (LHD)

RTW48AXF01381 & RTW48AMF000101

PARTS LOCATION (LHD)

RTW48AXF013901

CIRCUIT DIAGRAM

RTW680XF006401

LIGHTING

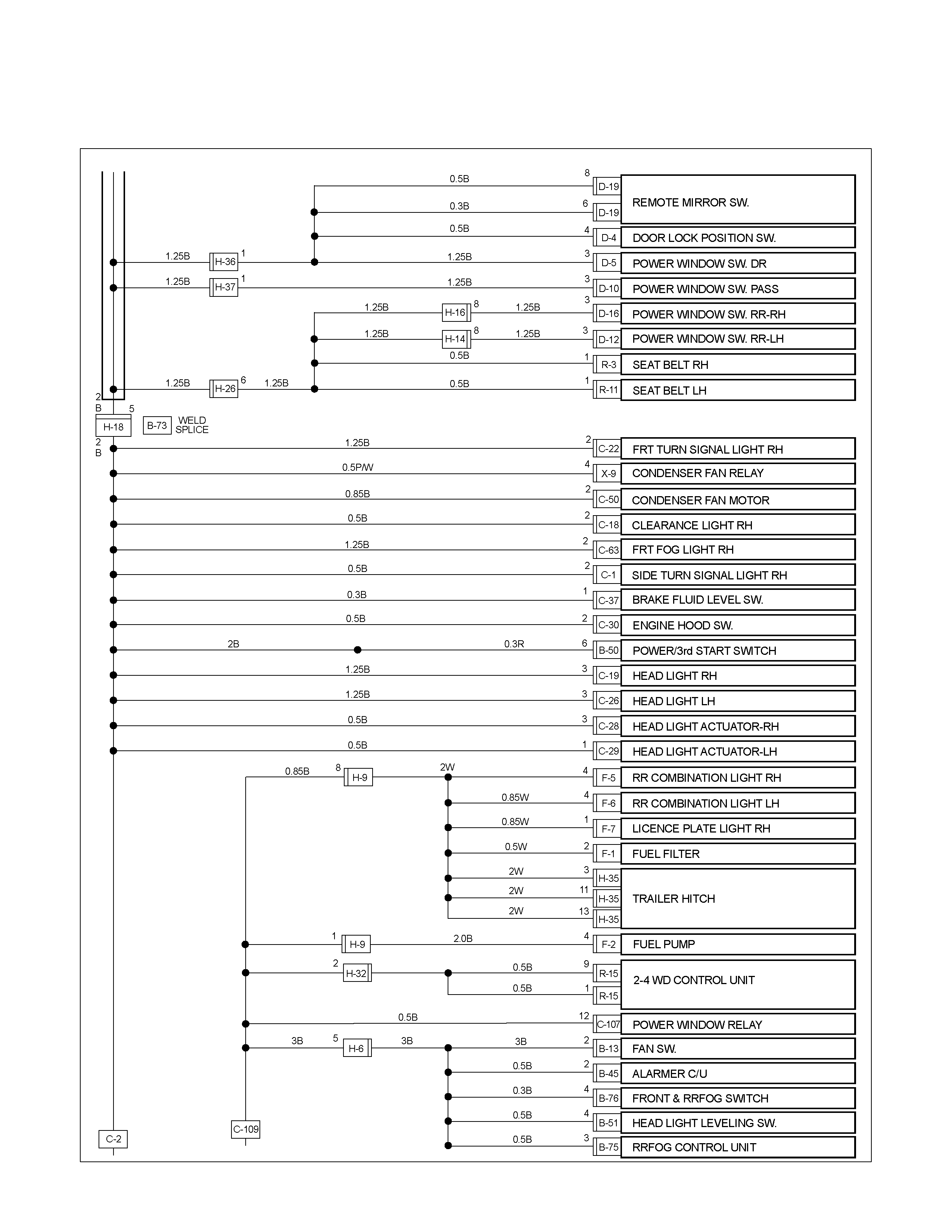

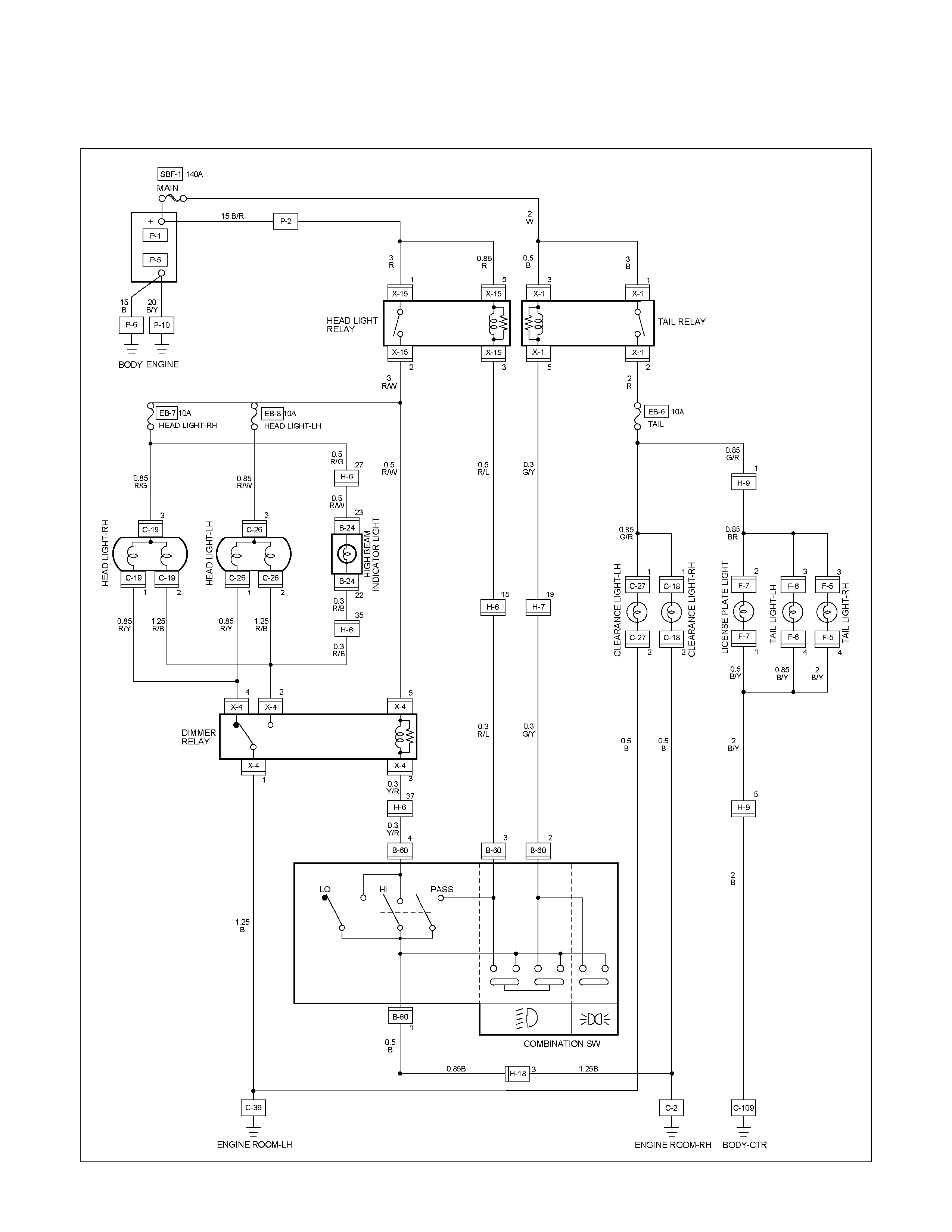

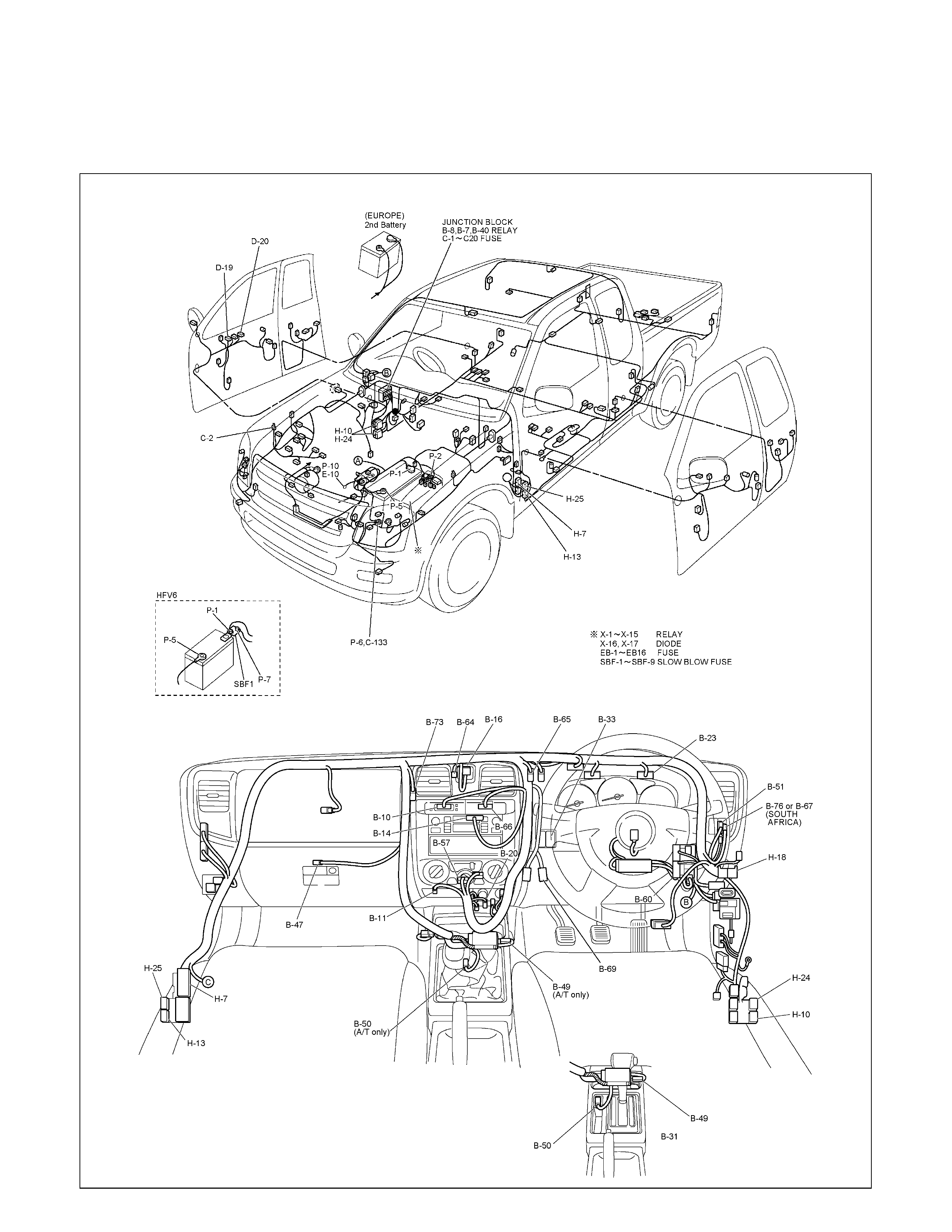

PARTS LOCATION (RHD)

RTW68AXF014001 & RTW48AXF014601

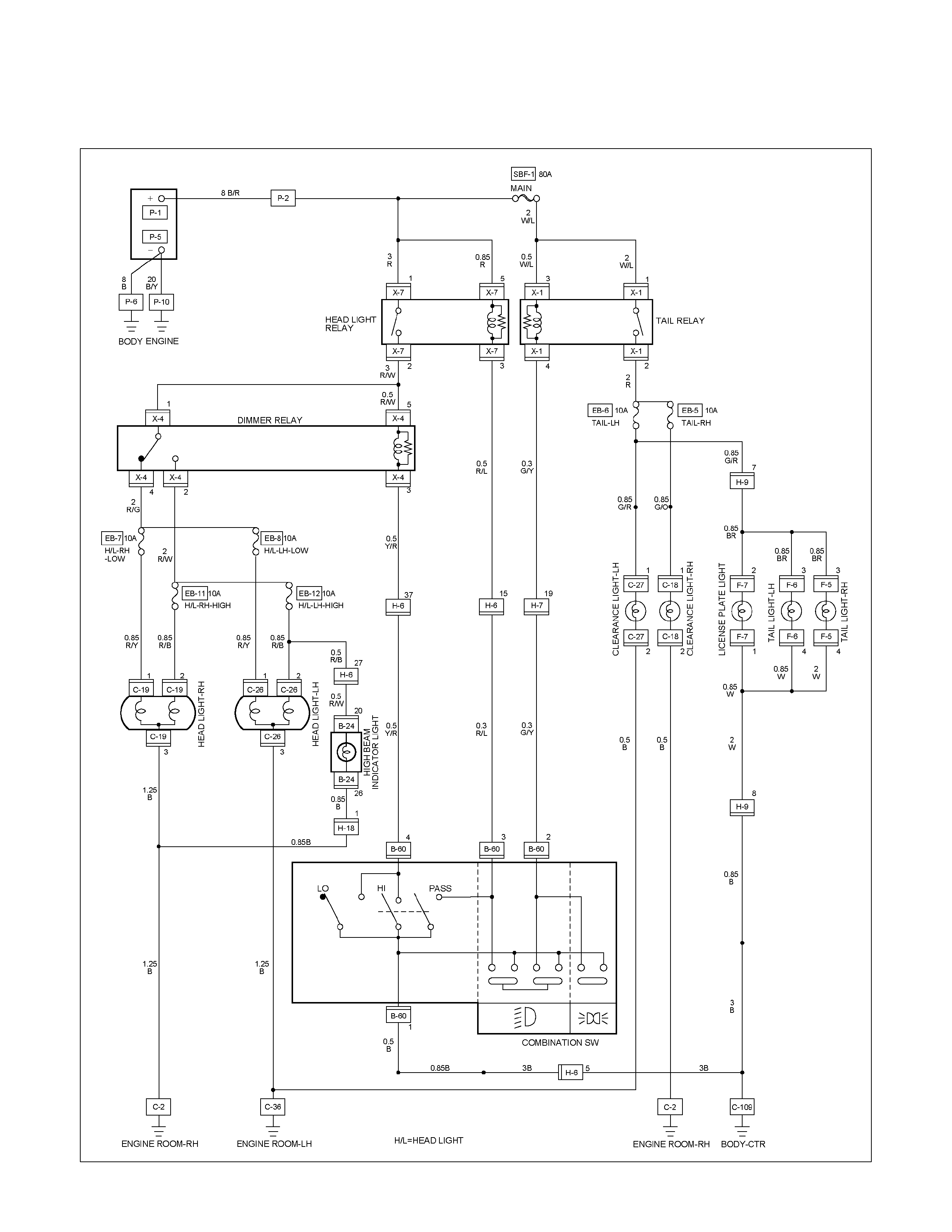

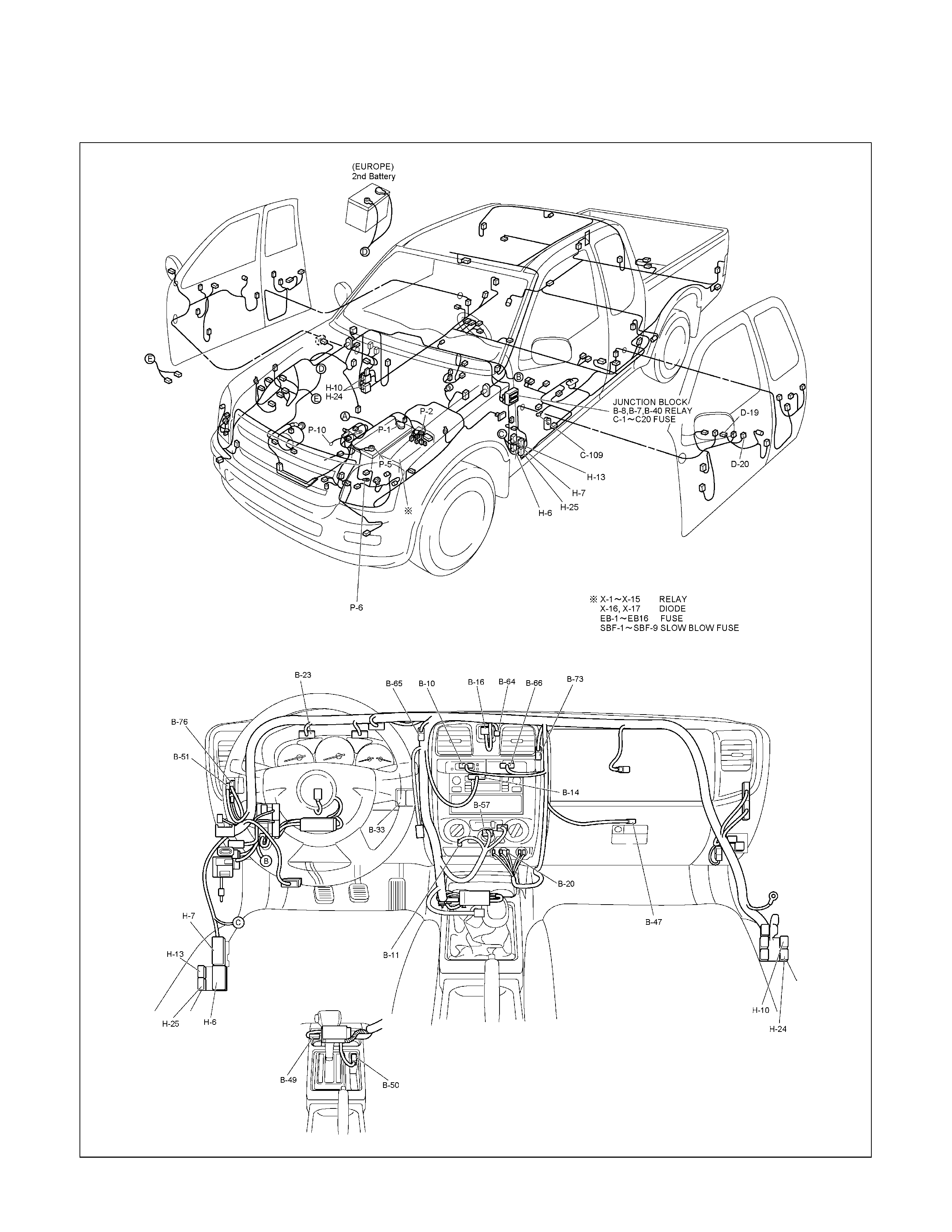

PARTS LOCATION (LHD)

RTW48AXF014701 & RTW48AXF014801

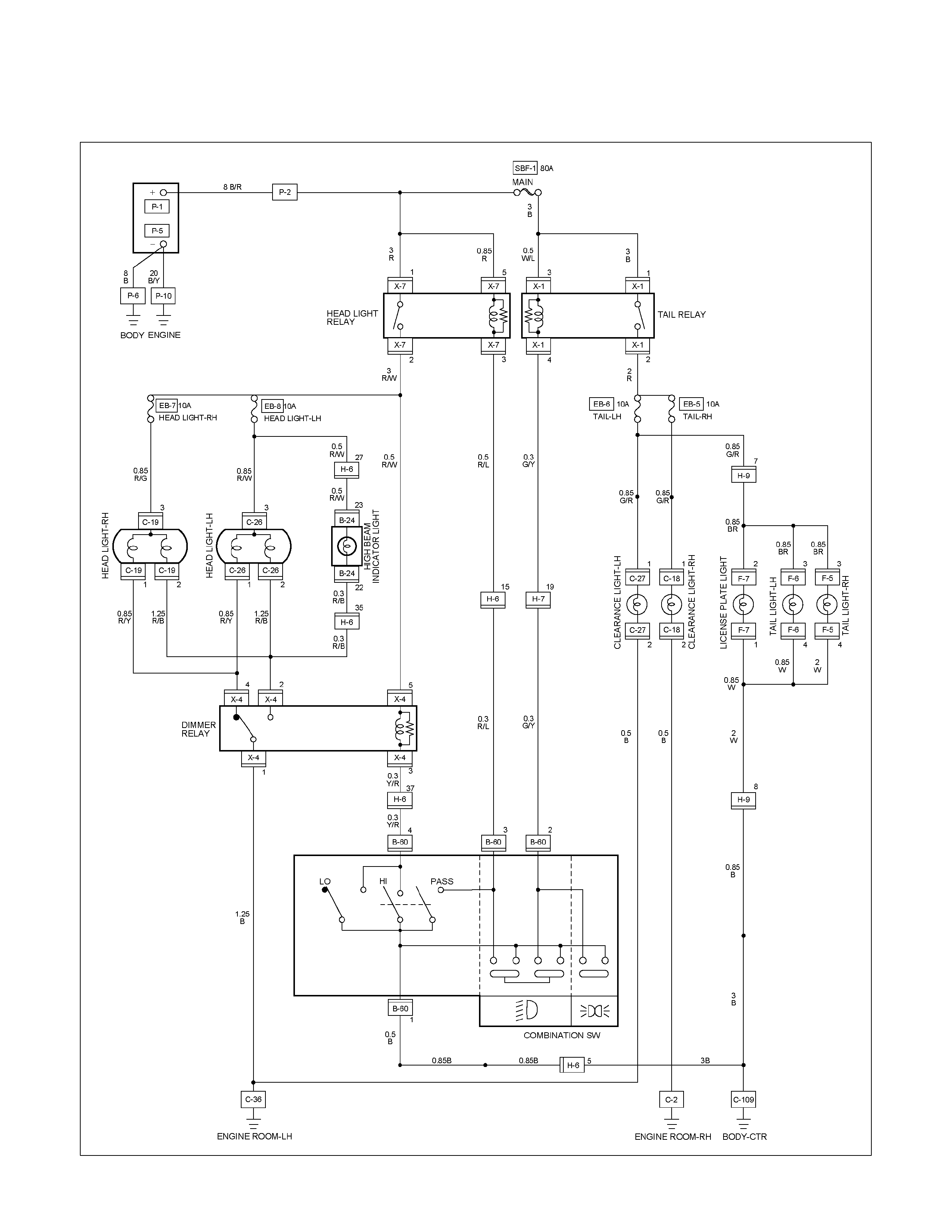

CIRCUIT DIAGRAM (RHD) WITHOUT EMISSION SYSTEM EURO3

RTW680XF006501

CIRCUIT DIAGRAM (RHD) HFV6 WITH EMISSION SYSTEM EURO3

RTW68AXF010601

CIRCUIT DIAGRAM (RHD) EXCEPT HFV6 WITH EMISSION SYSTEM EURO3

RTW680XF006601

CIRCUIT DIAGRAM (LHD) WITHOUT HEADLIGHTS LEVELING

RTW680XF006701

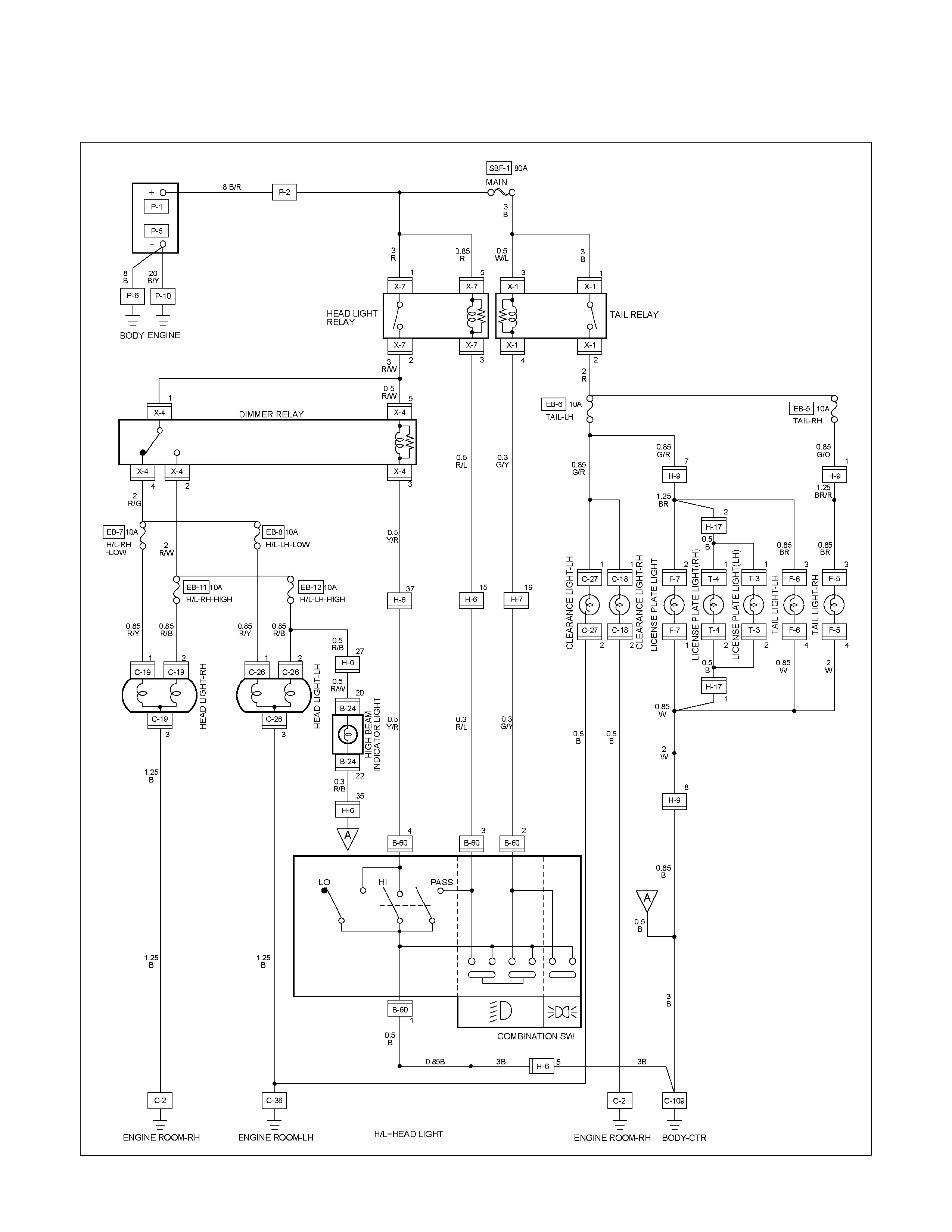

CIRCUIT DIAGRAM (LHD) WITH HEADLIGHTS LEVELING

RTW680XF006801

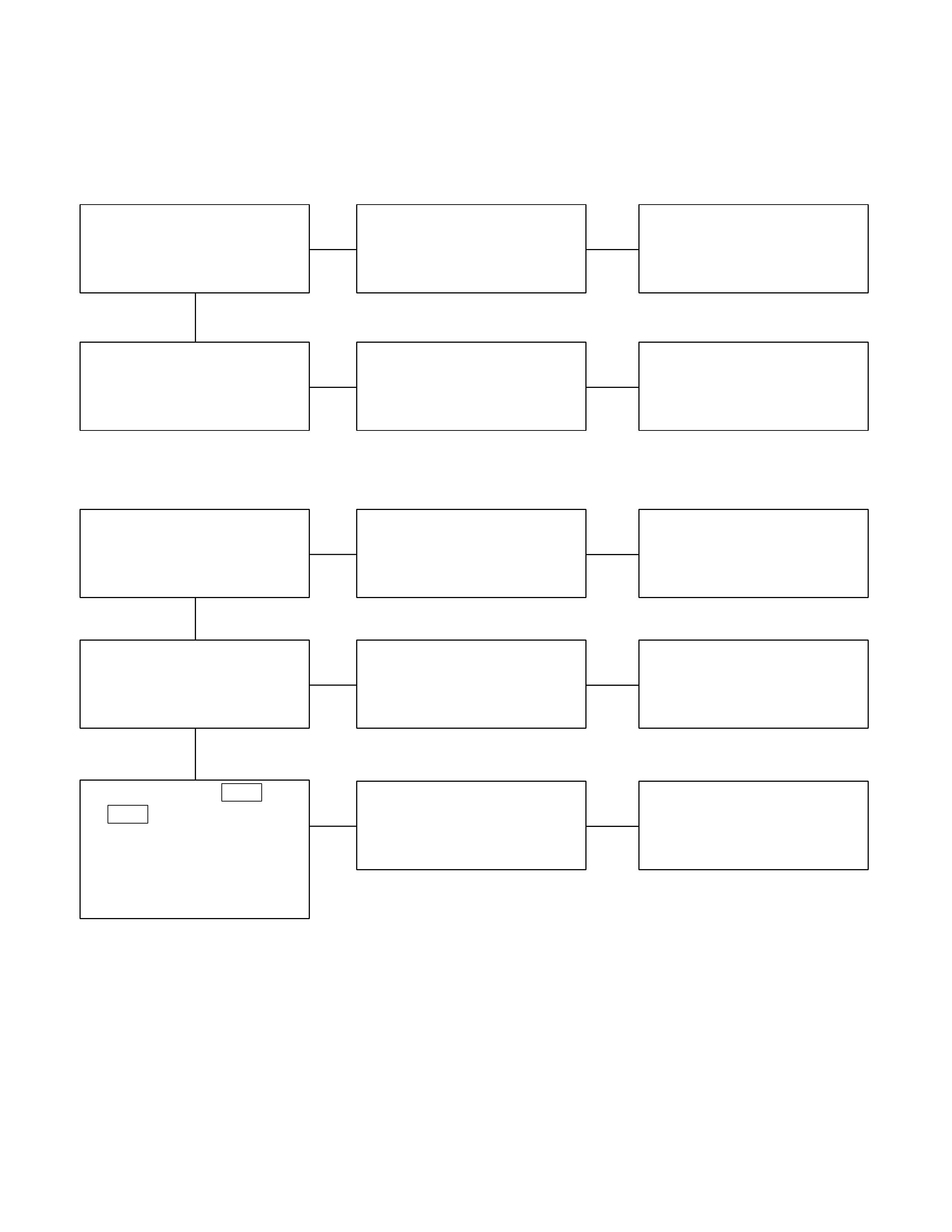

TROUBLE SHOOTING

HEADLIGHT

1. Both the headlights (high and low beam) do not light

Checkpoint Trouble Cause Countermeasure

Repair the wiring

Poor ground point contact

NG

Repair open circuit or

connector contact

Repair open circuit

Repair or replace the

combination switch

Voltage between 1 B-60 -

ground

Open circuit between lighting

relay and lighting switch

Open circuit between battery

positive terminal and lighting

relay

Combination switch continuity

Poor switch contact or sw

faulty

Voltage between

5 X-7 - ground and

1 X-7 - ground

Reinstall or replace the

lighting relay

Lighting relay

Poor relay contact or relay

faulty

NG

NG

NG

NG

OK

OK

OK

OK

Ground point contact (C-36)

Repair open circuit

Wiring continuity betw een

B-60 - C-36

Open circuit

NG

OK

∗

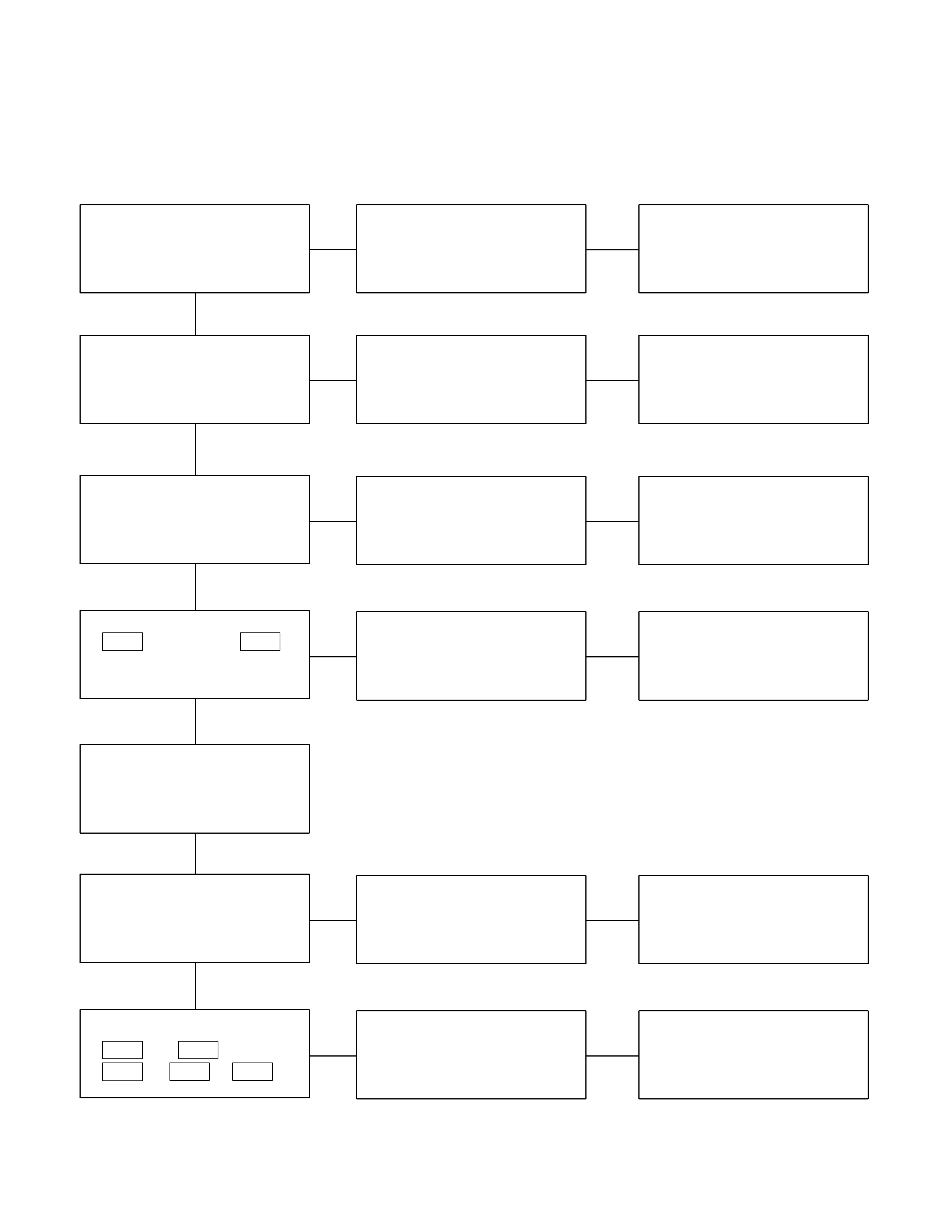

2. High or low beam does not light on both headlights

Checkpoint Trouble Cause Countermeasure

Repair or replace the

combination switch

Dimmer⋅passing switch

continuity

Poor switch contact or switch

faulty

NG

Repair open circuit or

connector contact

Voltage between

4 X-4 - ground and

4 B-60 - ground

Open circuit between

headlight and dimmer⋅passing

switch

NG

OK

3. RH (or LH) high and low beam does not light

Replace the headlight bulb

Headlight connector continuity

Blown filament or air leakage

NG

Repair or replace the wire

and/or connector

Wiring continuity betw een

connector 3 C-19 - fuse No.

EB-7 or 3 C-26 fuse No.

EB-8

Open circuit and/or poor

connector contact

NG

OK

Reinstall or replace fuse No.

EB-7 or No. EB-8

Fuse No. EB-7 (10A) or

No. EB-8 (10A) (Relay and

fuse box)

(No. EB-7 RH, No. EB-8: LH)

Poor installation or blown fuse

NG

OK

4. High or low beam does not light on one headlight (RH or LH)

Replace the headlight

assembly

Headlight connector continuity Blown filament

NG

Repair open circuit or

connector contact

Wiring continuity betw een

headlight and dimmer⋅passing

switch

Open circuit between

headlight and dimmer⋅passing

switch

NG

OK

5. Headlight does not go out

Checkpoint Trouble Cause Countermeasure

Replace the lighting relay

Lighting relay continuity

between connector 5 X-7

- 2 X-7 (Should be no

continuity)

Relay point fused

NG

Replay the combination switch

Lighting switch continuity

between connector 4 B-60

-1 B-60 when switch is

OFF(Should be no continuity)

point fused or faulty

NG

OK

OK

Repair or replace the

combination switch

Dimmer⋅passing switch con-

tinuity between connector

3 B-60 - 1 B-60 when switch

is not operating

(Should be no continuity)

Switch point fused or faulty

NG

Repair short circuit

between 3 X-7 - 3 B-60

and 4 X-1 - 2 B-60

Check if headlight goes out

when connector C-36 is

disconnected

Short circuit

NG

OK

∗

∗

6. Insufficient headlight brightness

Replace the headlight bulb

Headlight bulb

Bulb filament faulty

NG

Repair the wiring

Dimmer⋅passing switch

Wire continuity between con-

nector 1 B-60 - C-36

Poor ground point contact

NG

OK

Clean the light lens

Headlight lens

Lens dirty

NG

OK

7. Passing light does not function when dimmer switch is operated

Checkpoint Trouble Cause Countermeasure

Repair or replace the dimmer

switch

Dimmer switch

Poor switch point contact

NG

Repair open circuit between

3 X-7 - 3 B-60

Voltage between

3 B-60 - ground (Should

be battery voltage present)

Open circuit

NG

OK ∗

8. Headlight beam does not change when dimmer switch is operated

Repair or replace the dimmer

switch

Dimmer switch Loose beam lever or foreign

material in switch

NG

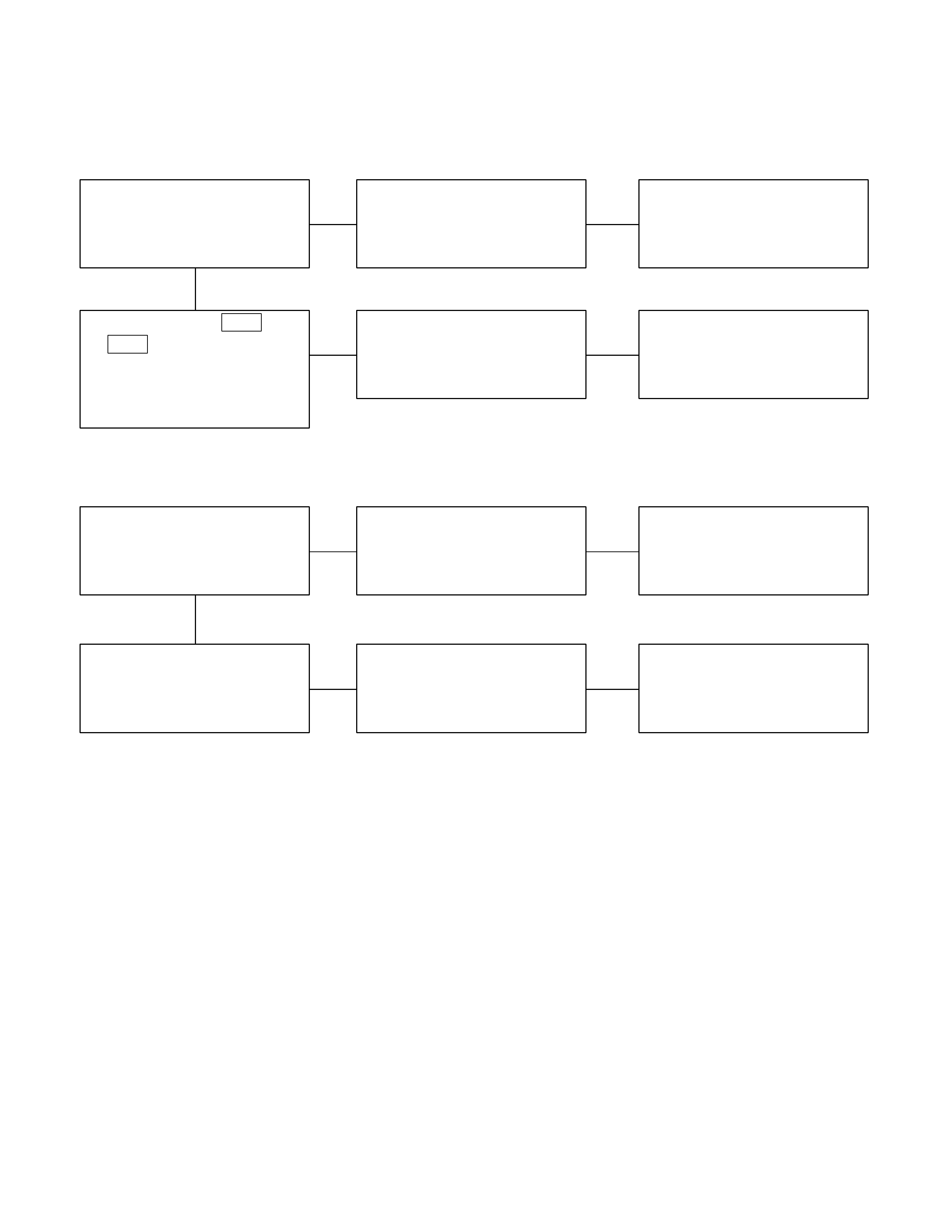

TAIL LIGHT, LICENSE PLATE LIGHT, CLEARANCE LIGHT

1. All lights do not light

Checkpoint Trouble Cause Countermeasure

Repair or replace the

combination switch

Lighting switch continuity

between connector

2 B-60 - 1 B-60

Poor switch point or connector

contact

NG

Reinstall or replace the tail

relay

Tail relay

Poor relay contact or relay

faulty

NG

OK

Reinstall or replace the fuse

No. EB-6 (LH), EB-5 (RH)

Fuse No. EB-6 (LH) or EB-5

(RH) (10A, Relay and fuse

box)

Poor fuse contact or blown

NG

OK

2. Tail light does not light

Replace the bulb or repair

connector contact

Tail light bulb continuity

Bulb burned out or poor

connector contact

NG

Repair open circuit or

connector contact

Continuity between connector

3 F-5 - 4 F-5 (RH)

or 3 F-6 - 4 F-6 (LH)

Open circuit or poor connector

contact

NG

OK

3. License plate light does not light

Checkpoint Trouble Cause Countermeasure

Repair open circuit or

connector contact

Continuity between

connector 1 F-7 - 2 F-7 or 1

T-4 - 2

T-4 / 1

T-3 - 2

T-3

(

LHD HEADLIGHTS LEVELING

)

Open circuit or poor connector

contact

NG

Replace the bulb or repair

connector contact

License plate light bulb

continuity

Bulb burned out or poor

connector contact

NG

OK

4. Clearance light does not light

Replace the bulb or repair

connector contact

Clearance light bulb continuity Bulb burned out or poor

connector contact

NG

LIGHTING SYSTEM

REMOVAL AND INSTALLATION

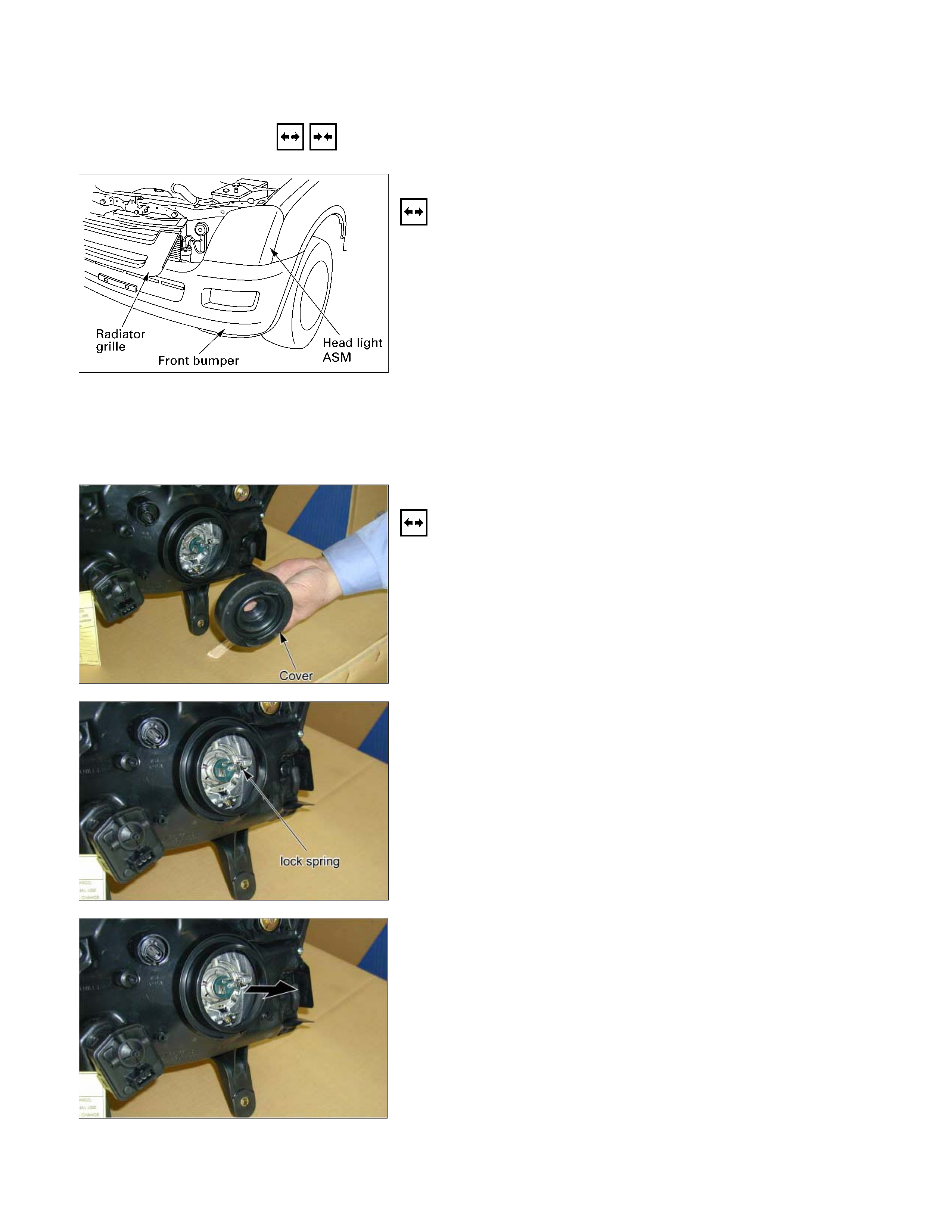

HEADLIGHT

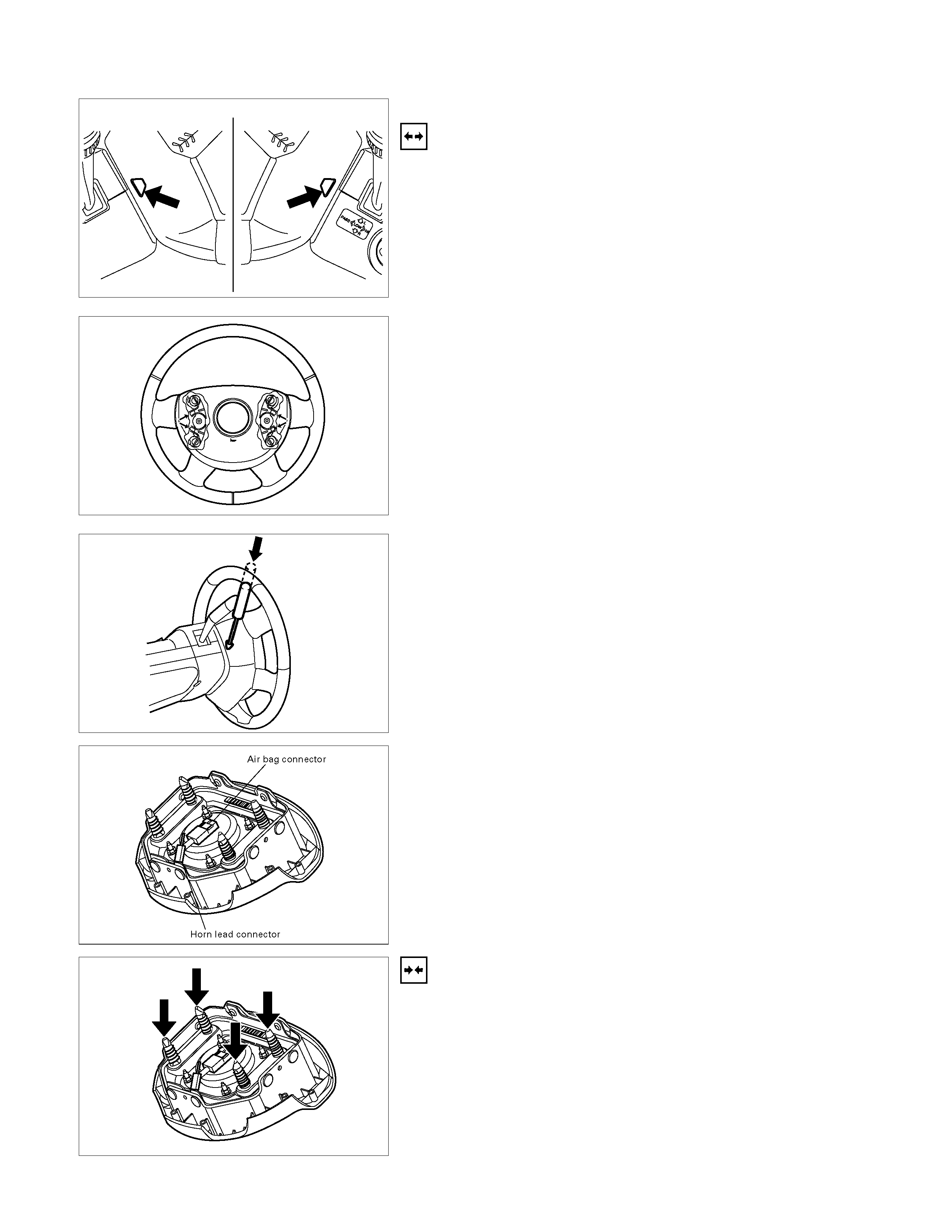

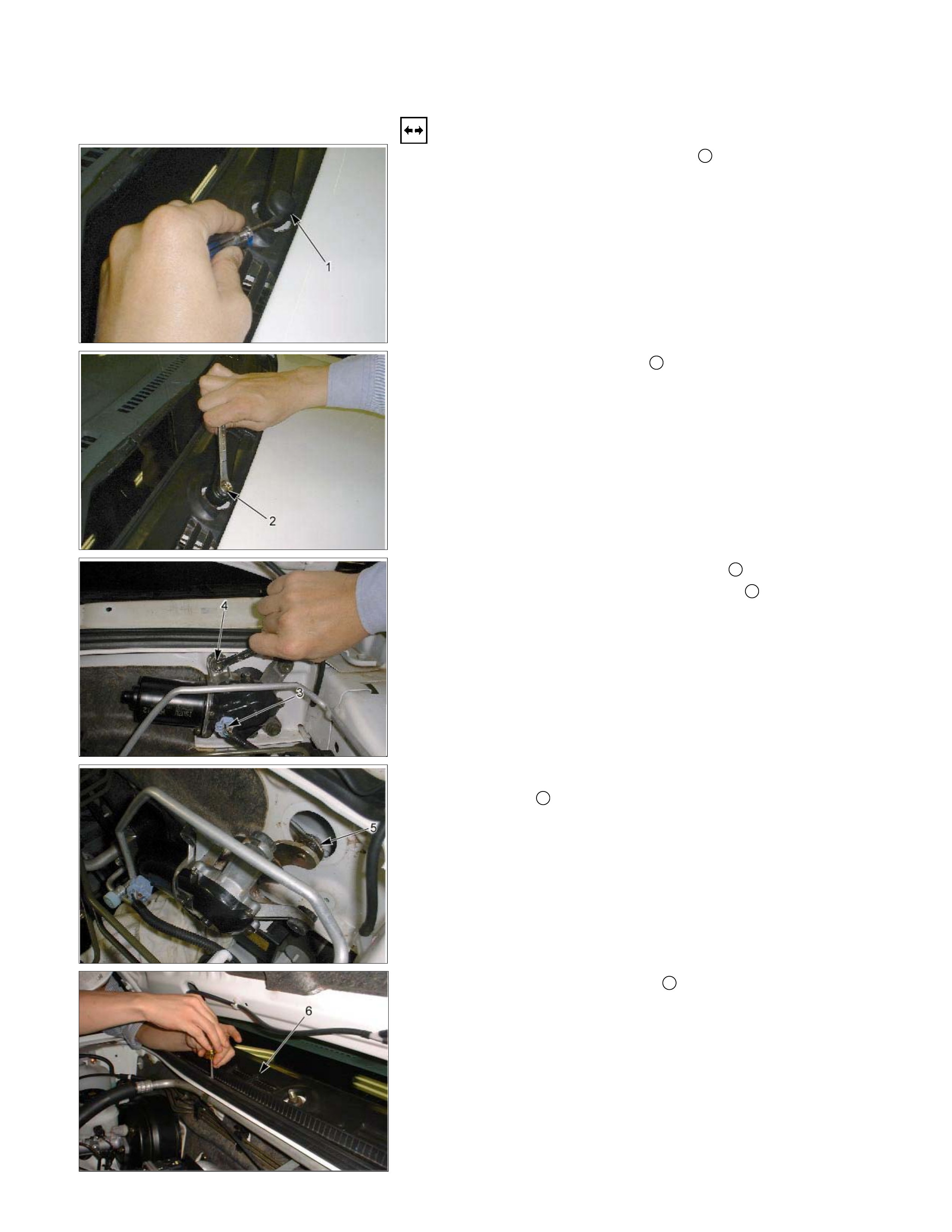

Removal

1. Remove the radiator grille center bolt.

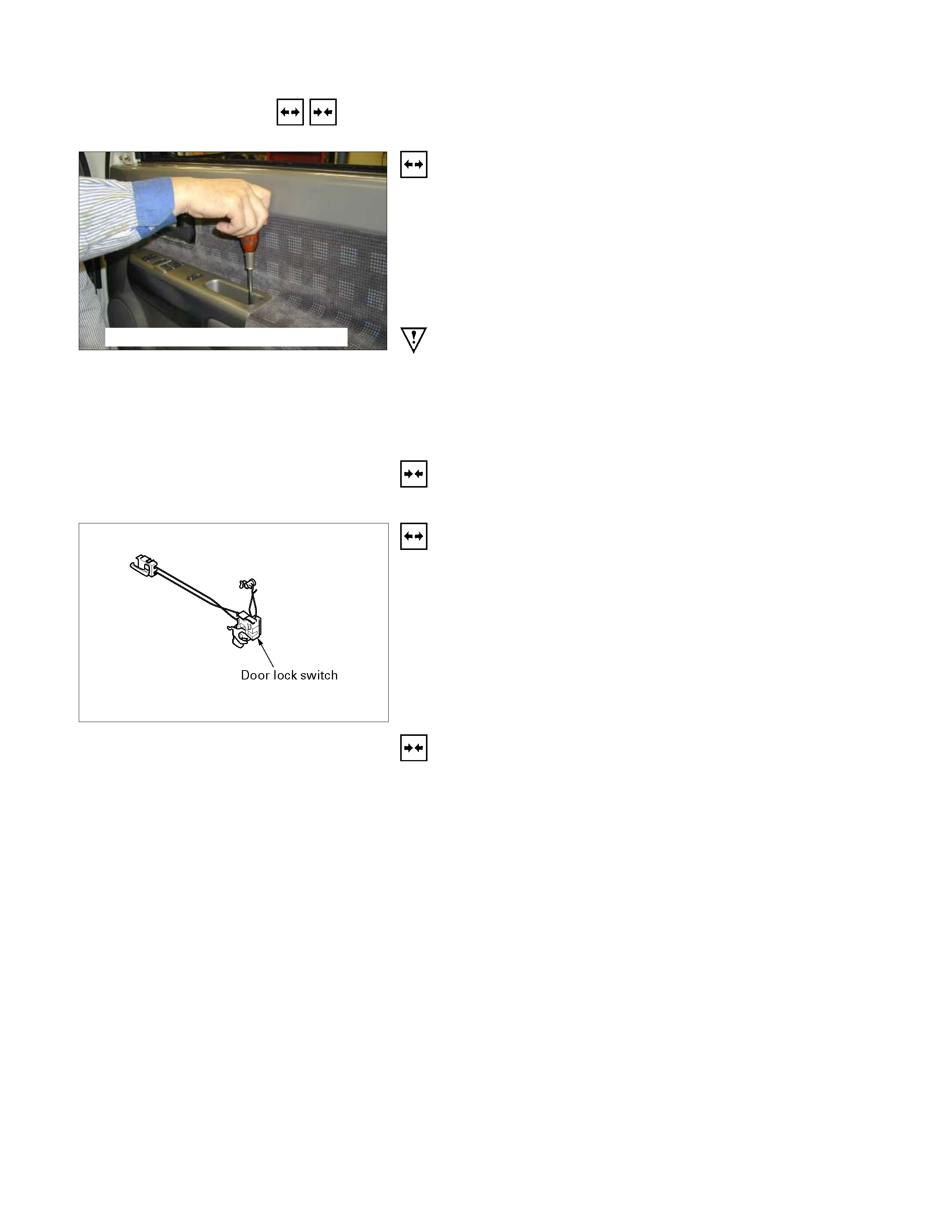

2. Use a screwdriver to raise the clip and release the lock.

Place a clean rag beneath the screwdriver tip to protect the

body painted surfaces.

3. Remove the radiator grille.

4. Remove the front bumper.

5. Disconnect the headlight connector.

6. Remove the headlight assembly.

7. Remove the headlight cover.

• Remove the guide.

8. Remove the headlight.

HALOGEN HEADLIGHT

Removal

1. Remove the head light socket.

2. Remove the headlight cover.

3. Out side the lock spring.

4. Remove the bulb.

Installation

Follow the removal procedure in the reverse order to install the

headlight.

Pay close attention to the important points mentioned in the

following paragraphs.

Connector

Be absolutely sure that the headlight connector is securely

connected.

This will prevent a contact and an open circuit.

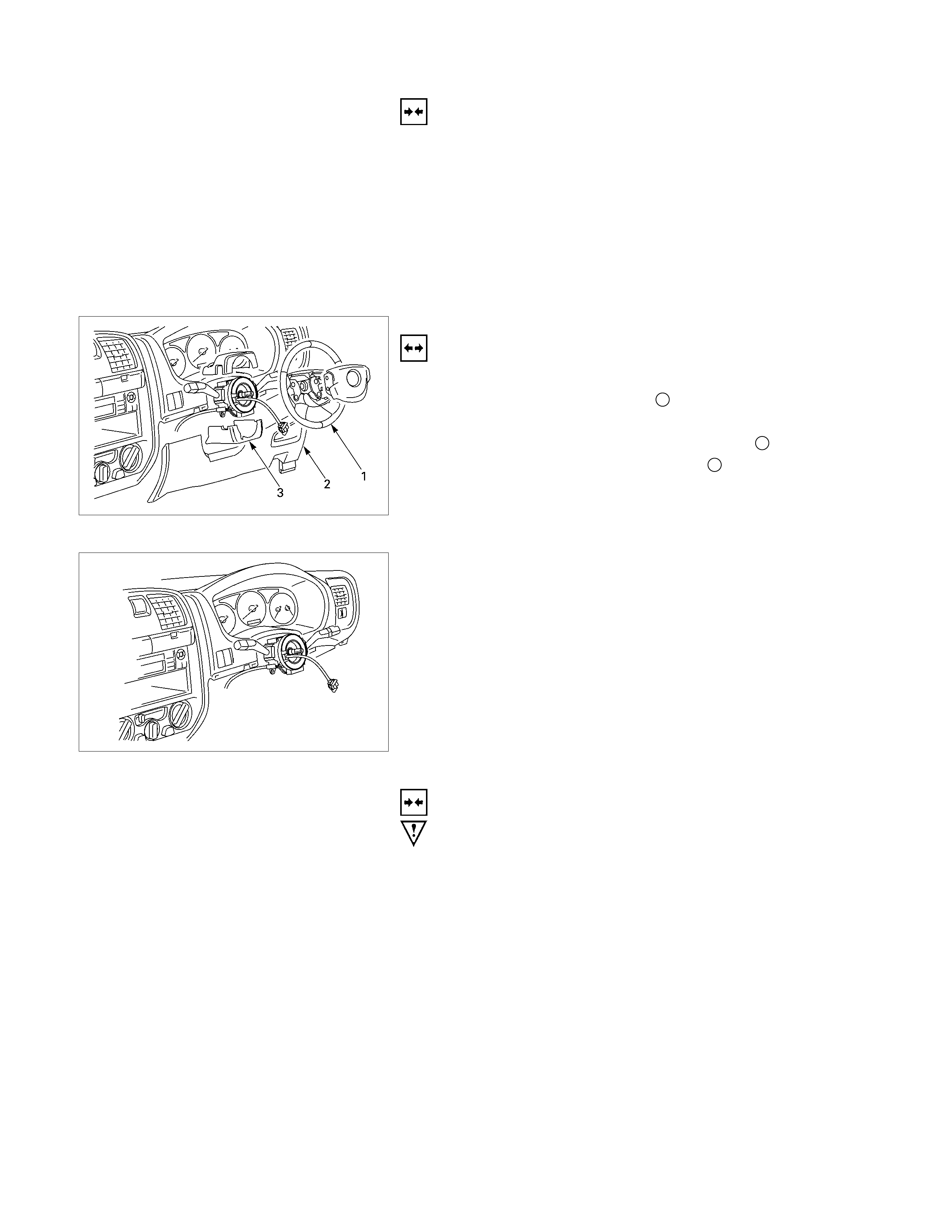

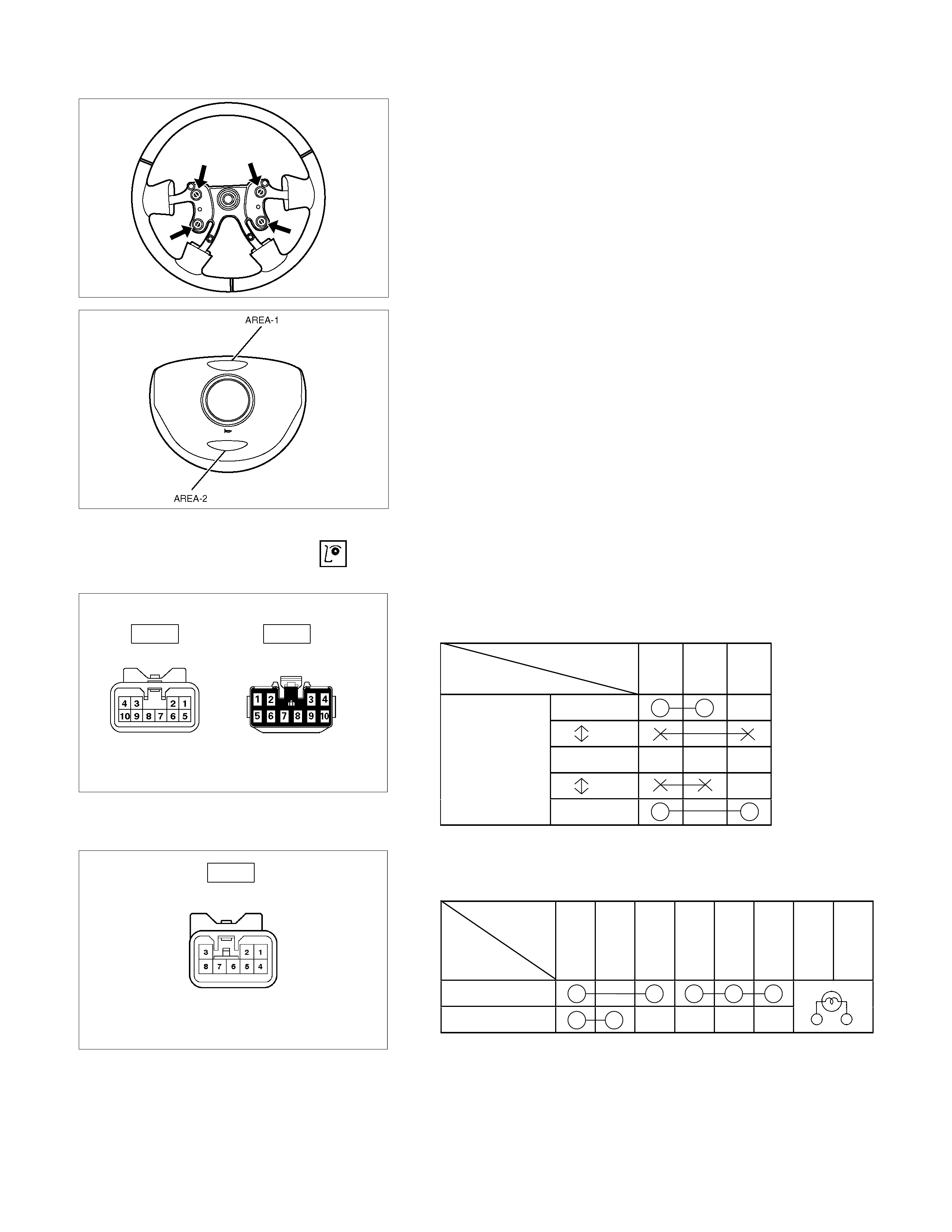

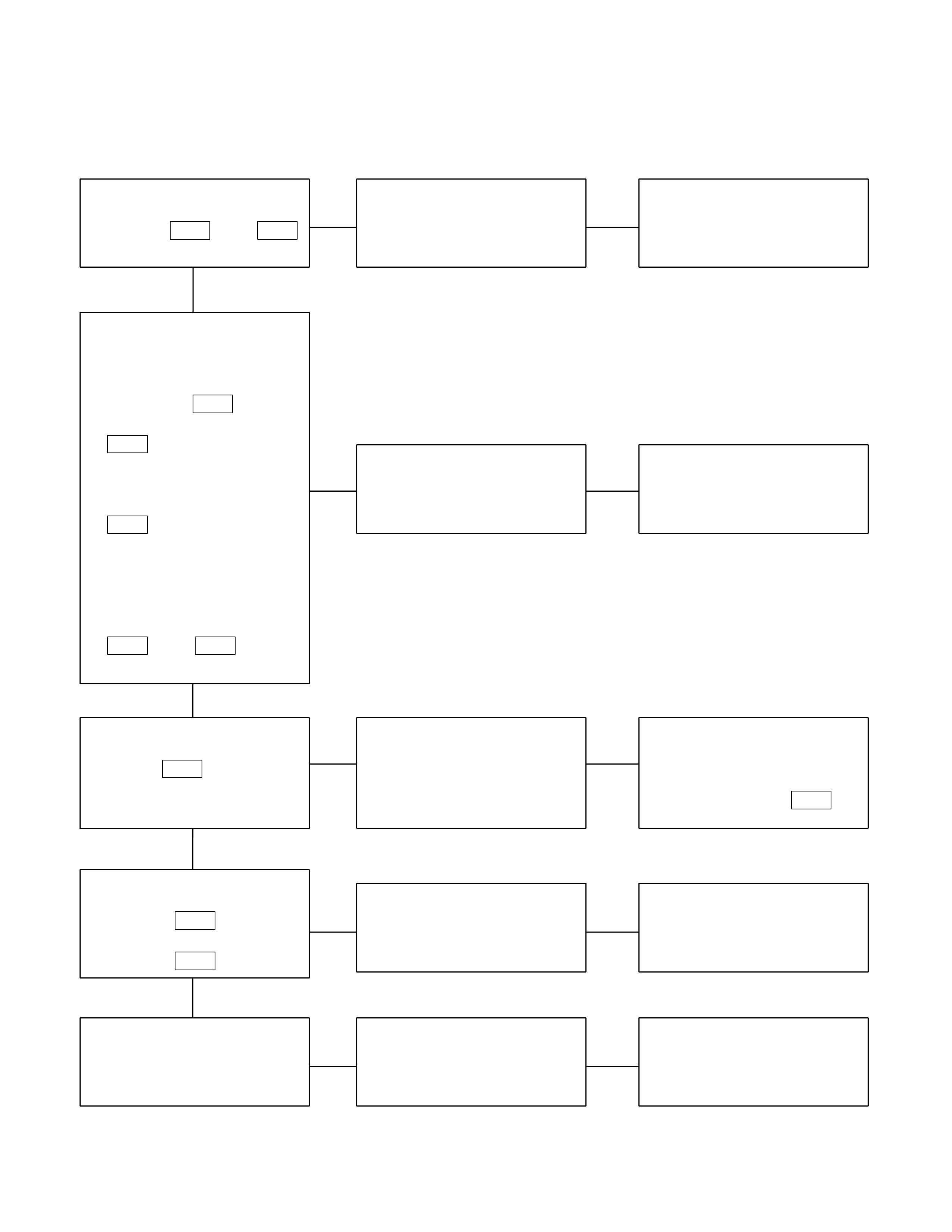

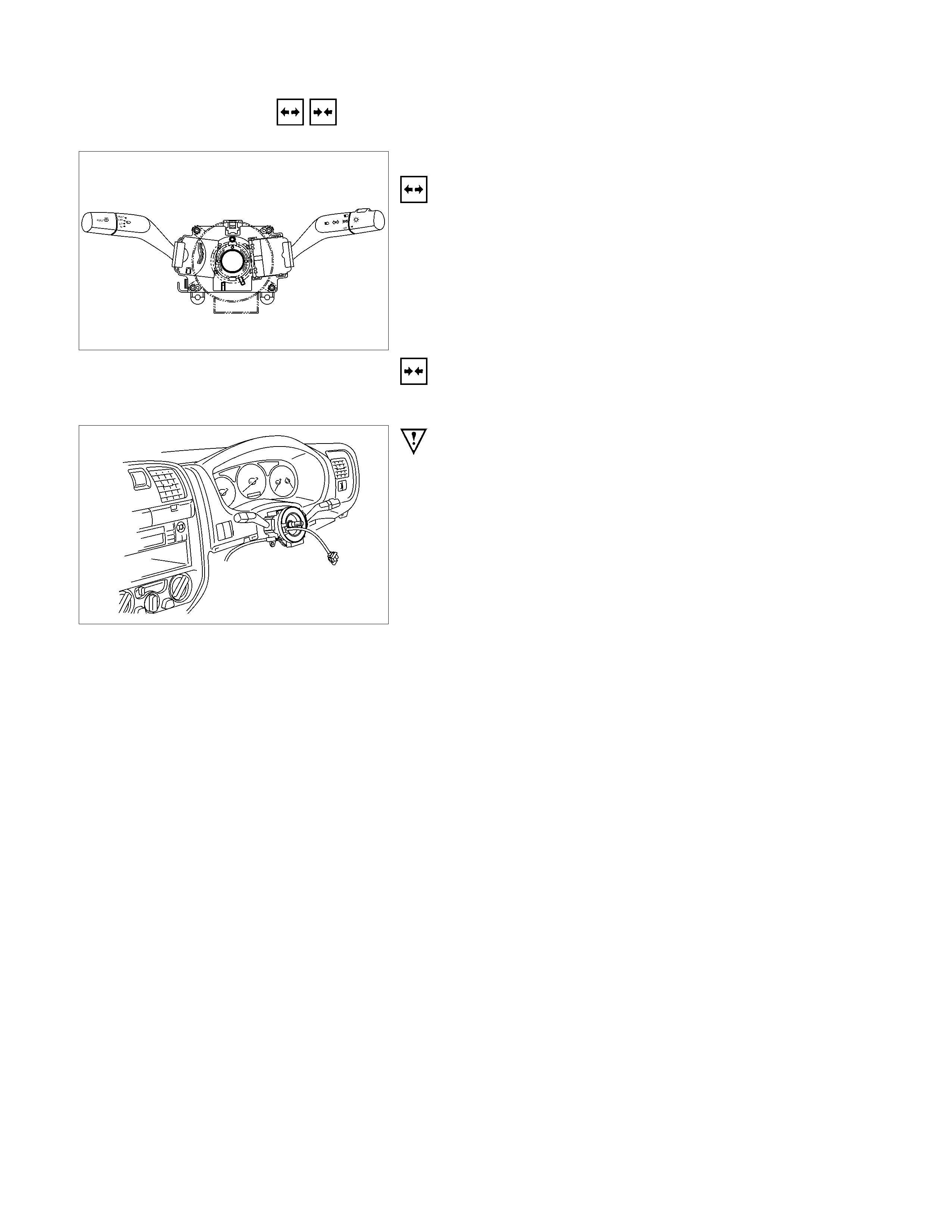

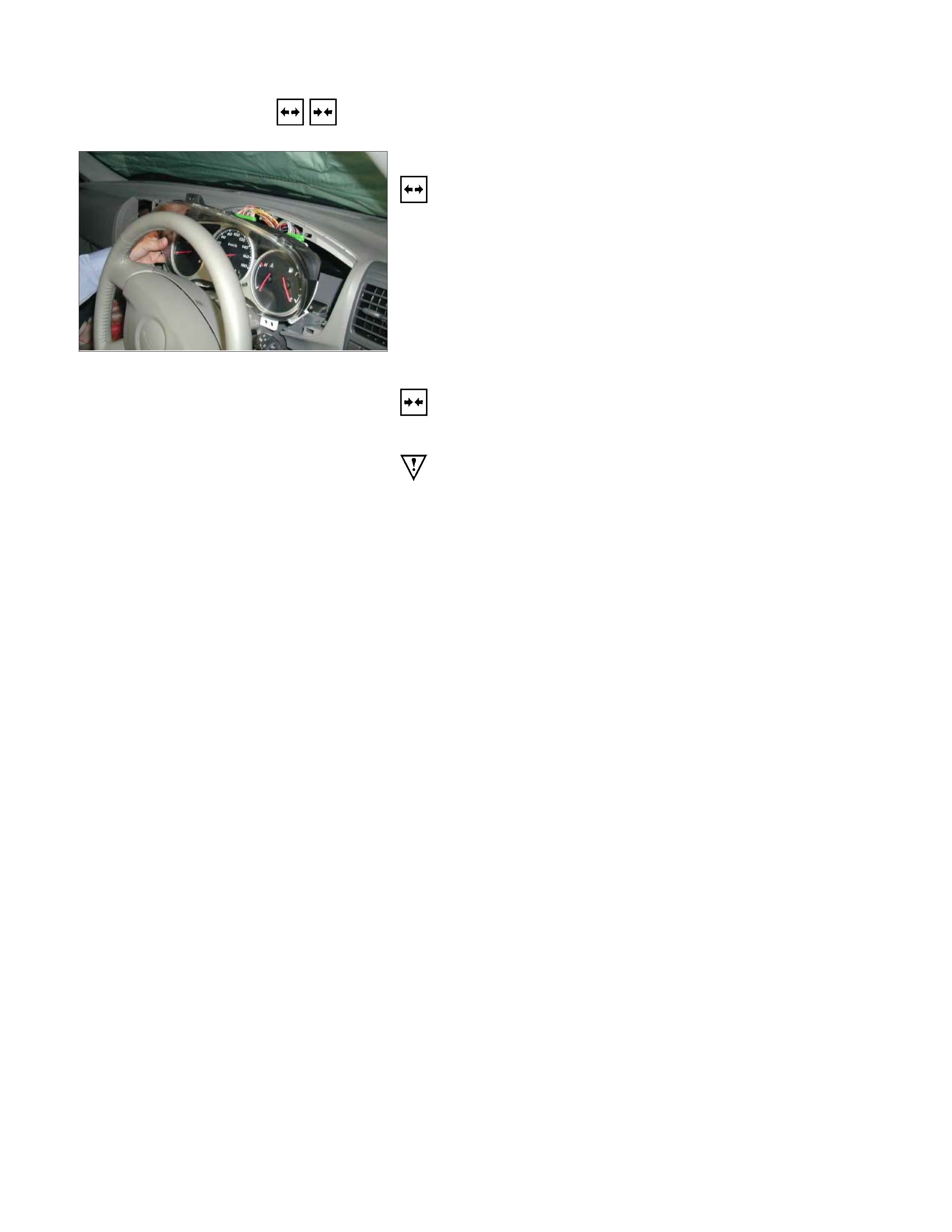

This illustration is based on RHD model

LIGHTING SWITCH

Removal

1. Disconnect the battery ground cable.

2. Remove the steering wheel 1.

Refer to the “STEERING” Section of this manual.

3. Remove the Instrument panel lower cover 2.

4. Remove the steering column cover 3.

This illustration is based on RHD model

5. Disconnect the connector.

6. Remove the lighting switch from the steering shaft.

Installation

Follow the removal procedure in the reverse order to install the

lighting switch.

Pay close attention to the important points mentioned in the

following paragraphs.

Connector

Be absolutely sure that the lighting switch connector is

securely connected.

This will prevent a poor contact and an open circuit.

Wire Harness

Do not pinch the wire harnesses between the cluster and the

meter hood during the cluster installation procedure.

Wire damage will result.

FRONT TURN LIGHT

Removal

RTW38DSH000601

1. Turn the socket counterclockwise to disconnect it from the

front turn light housing.

2. Pull the bulb from the socket.

Installation

Follow the removal procedure in the reverse order to install the

front turn light.

Pay close attention to the important points mentioned in the

following paragraphs.

Connector

Be absolutely sure that the clearance light connector is

securely connected.

This will prevent a poor contact and an open circuit.

CLEARANCE LIGHT

Removal

RTW38DSH000601

1. Turn the socket counterclockwise to disconnect it from the

clearance light housing.

2. Pull the bulb from the socket.

Installation

Follow the removal procedure in the reverse order to install the

clearance light.

Pay close attention to the important points mentioned in the

following paragraphs.

Connector

Be absolutely sure that the clearance light connector is

securely connected.

This will prevent a poor contact and an open circuit.

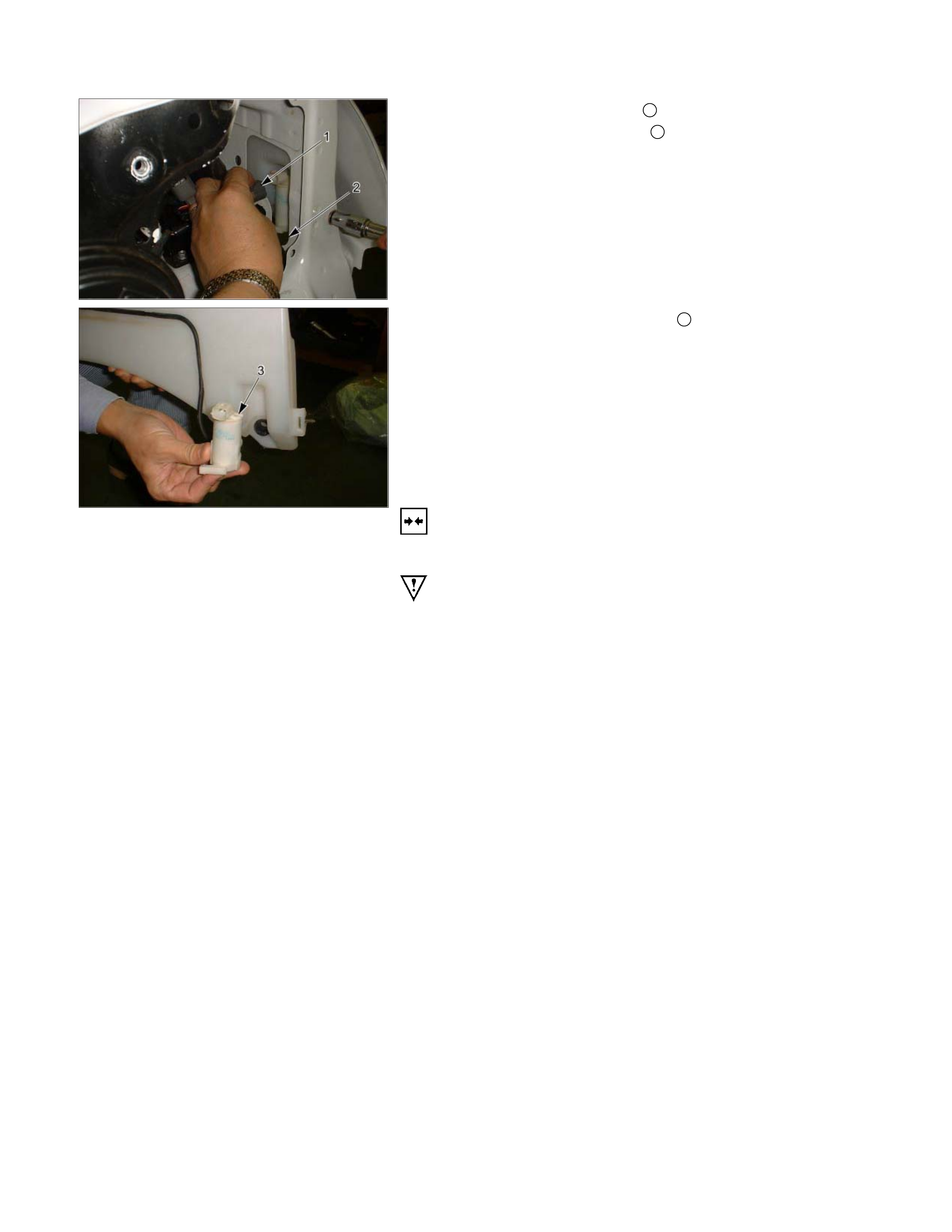

LICENSE PLATE LIGHT

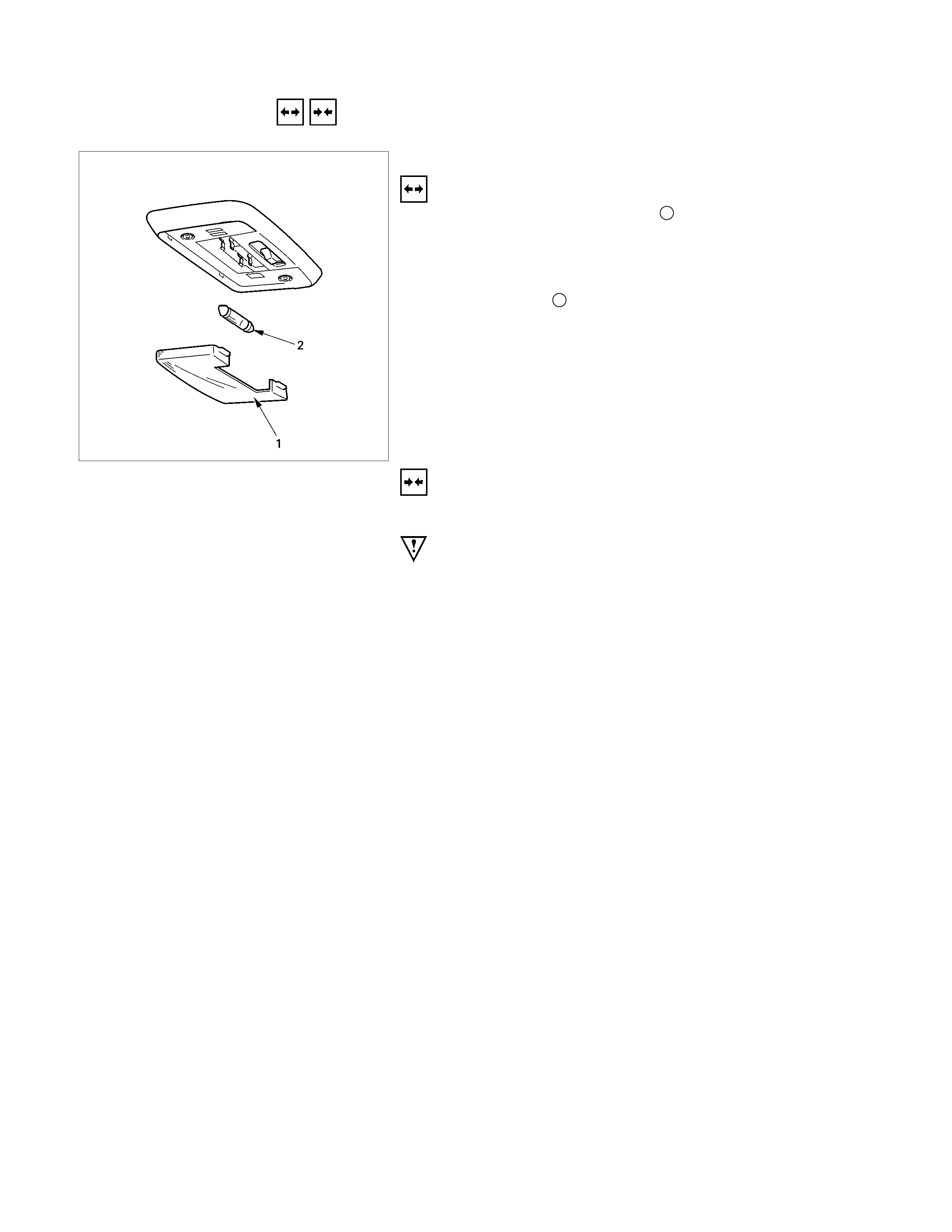

Removal

1. Remove the lens cover 1 and the connector 2.

2. Pull the bulb 3 to remove it.

Installation

Follow the removal procedure in the reverse order to install the

license plate light.

Pay close attention to the important points mentioned in the

following paragraphs.

Bulb

Be absolutely sure that the license plate light bulb is correctly

installed.

This will prevent a poor contact and open circuit.

HEADLIGHT BEAM SWITCH

(COMBINATION SWITCH)

Removal

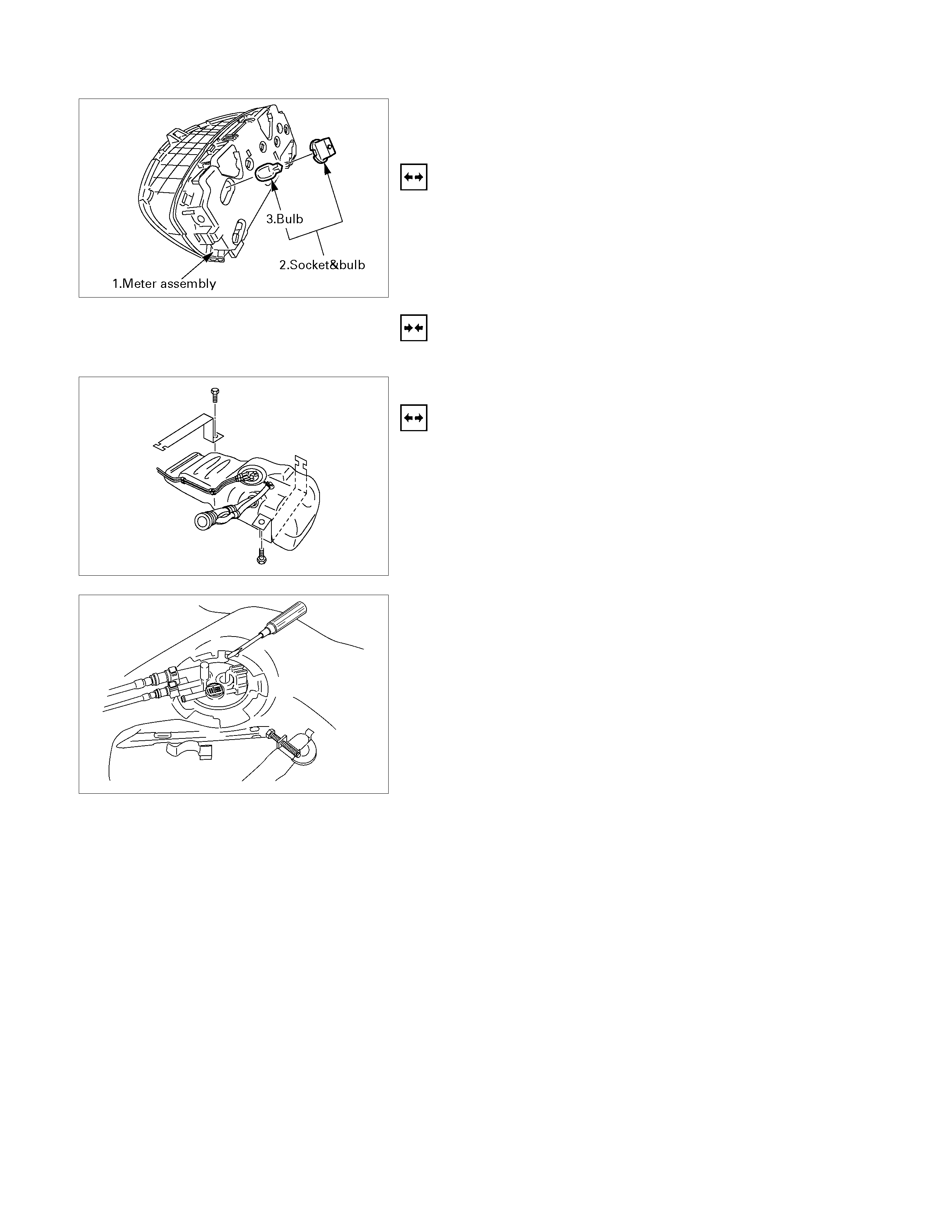

1. Disconnect the battery ground cable.

2. Remove the screws on the lower part of the steering wheel.

3. Remove the horn pad.

4. Remove the wiring connector.

5. Remove the steering wheel fixing nuts.

6. Remove the steering wheel.

Refer to the "STEERING" Section of this manual.

7. Remove the Instrument panel lower cover.

8. Remove the steering column cover.

9. Disconnect the connector.

10. Remove the headlight beam switch (lever) from the

steering shaft (combination switch).

Installation

Follow the removal procedure in the reverse order to install the

headlight beam switch (lever).

Pay close attention to the important points mentioned in the

following paragraphs.

Connector

Be absolutely sure that the headlight beam switch connector is

securely connected.

This will prevent a poor contact and an open circuit.

Wire Harness

Do not pinch the wire harnesses between the cluster and the

meter hood during the cluster installation procedure.

Wire damage will result.

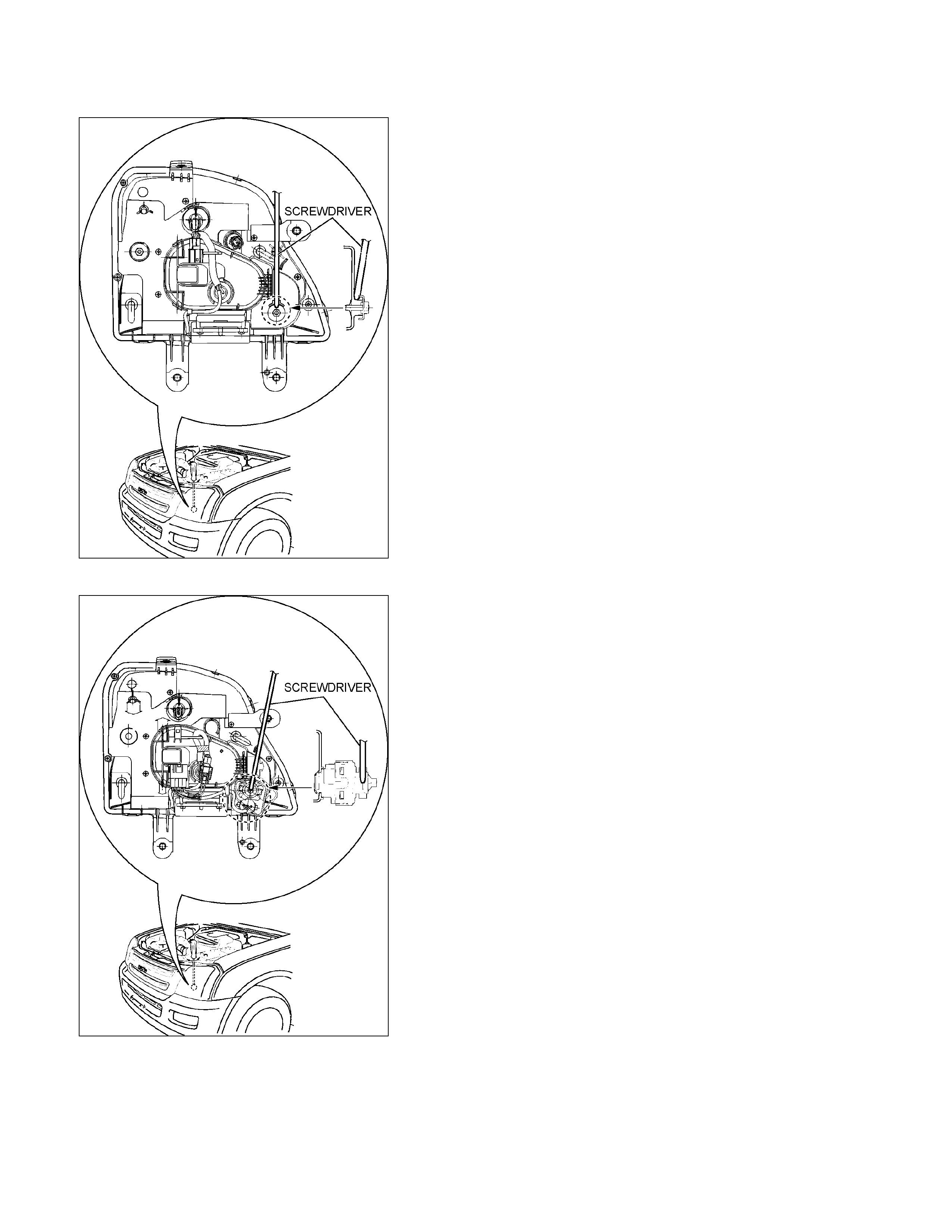

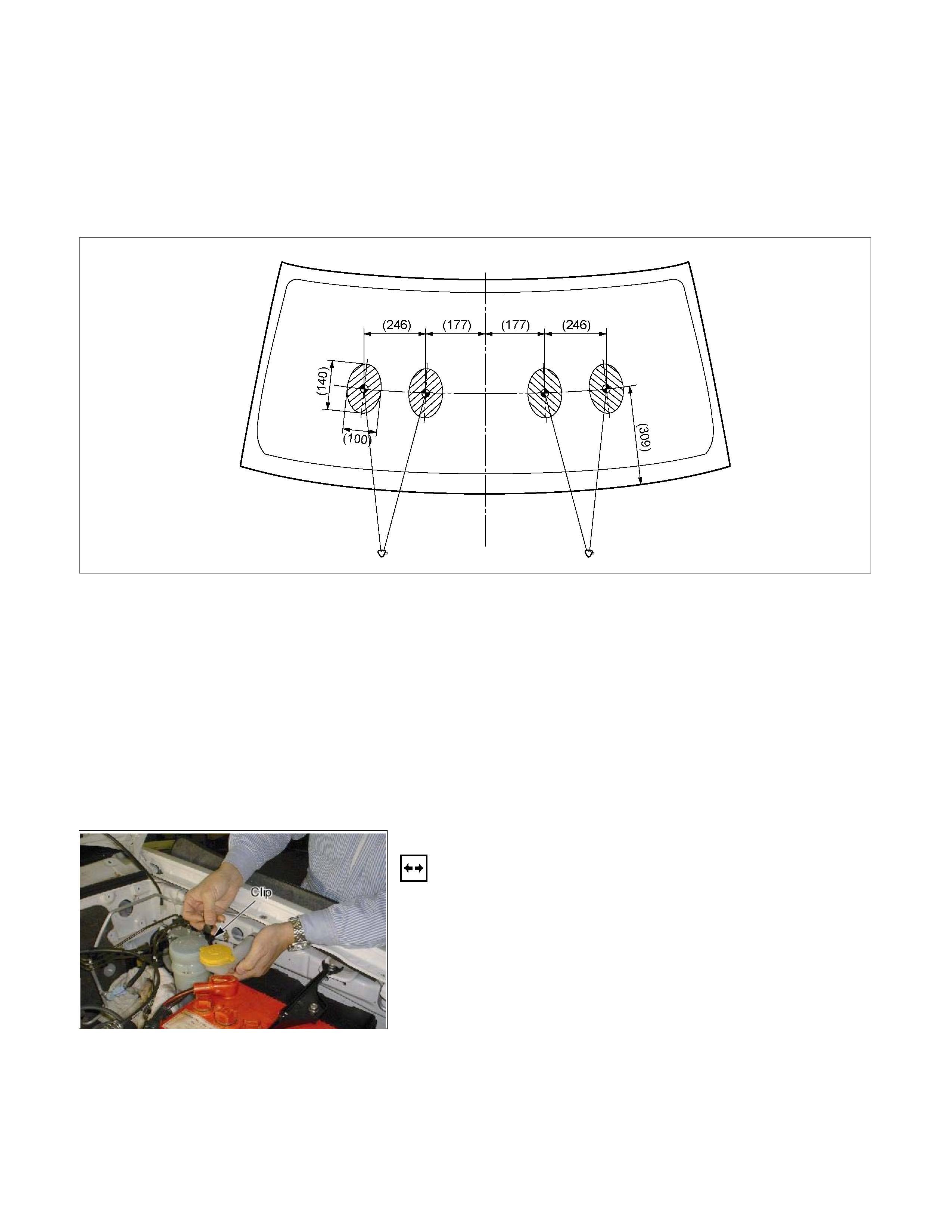

AIMING OF HEADLIGHT

Before adjusting the headlights, park the vehicle on a level

surface. Remove any cargo from the vehicle to bring it to curb

weight. Check the tire inflation pressures and correct as

required. Clean the headlight lenses.

Without Head light Leveling

RTW48DMH000101

With Head light Leveling

RTW48DMH000301

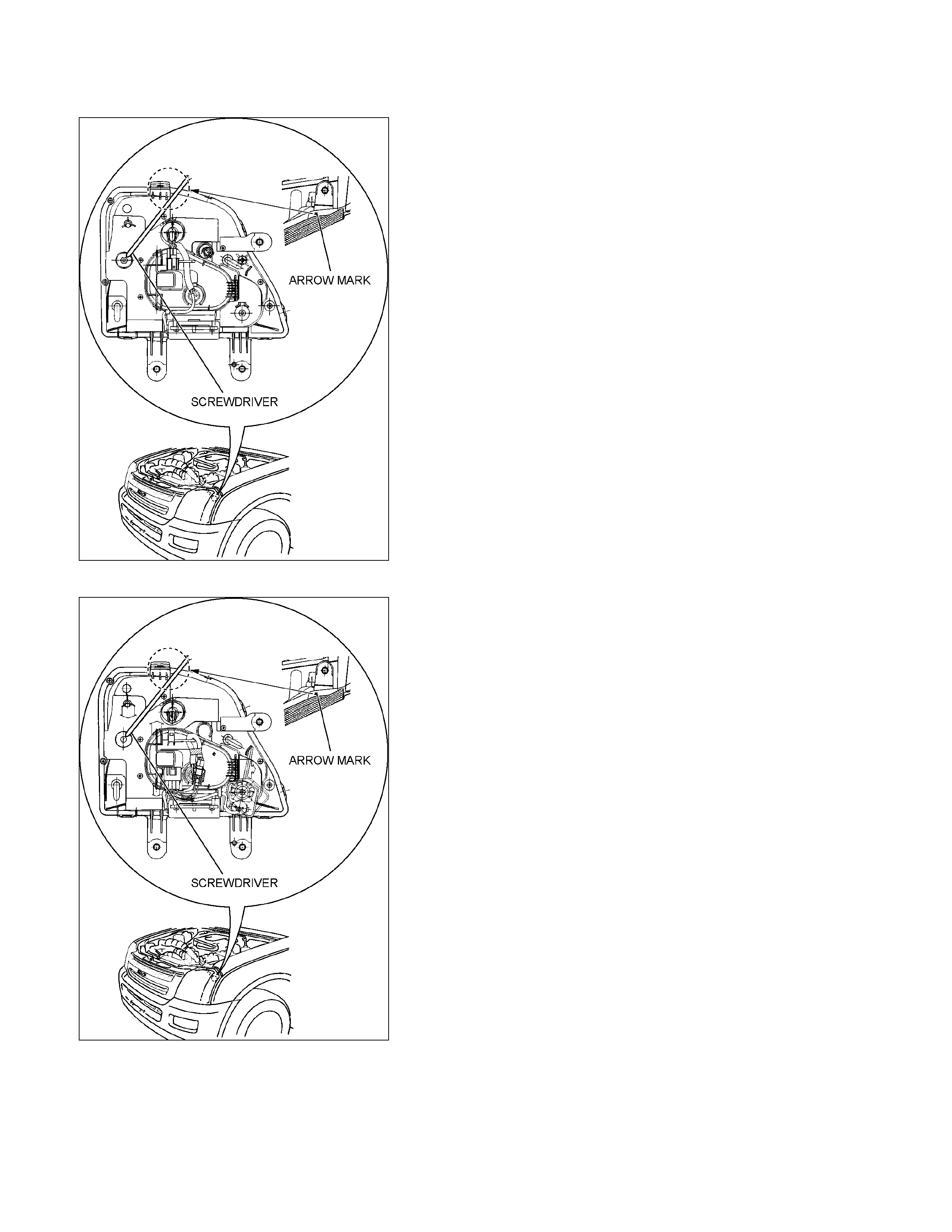

VERTICAL ADJUSTMENT

Use a Phillips-head screwdriver with a long shaft. Hold the

screwdriver straight up-and-down as shown in the illustration.

Without Head light Leveling

RTW48DMH000201

With Head light Leveling

RTW48DMH000401

HORIZONTAL ADJUSTMENT

Use a Phillips-head screwdriver with a long shaft. Hold the

screwdriver at an angle as shown by the arrow in the

illustration.

Installation

To install, follow the removal steps in the reverse order.

Noting the following point:

1. After installing the headlight, be sure to adjust the headlight

aim.

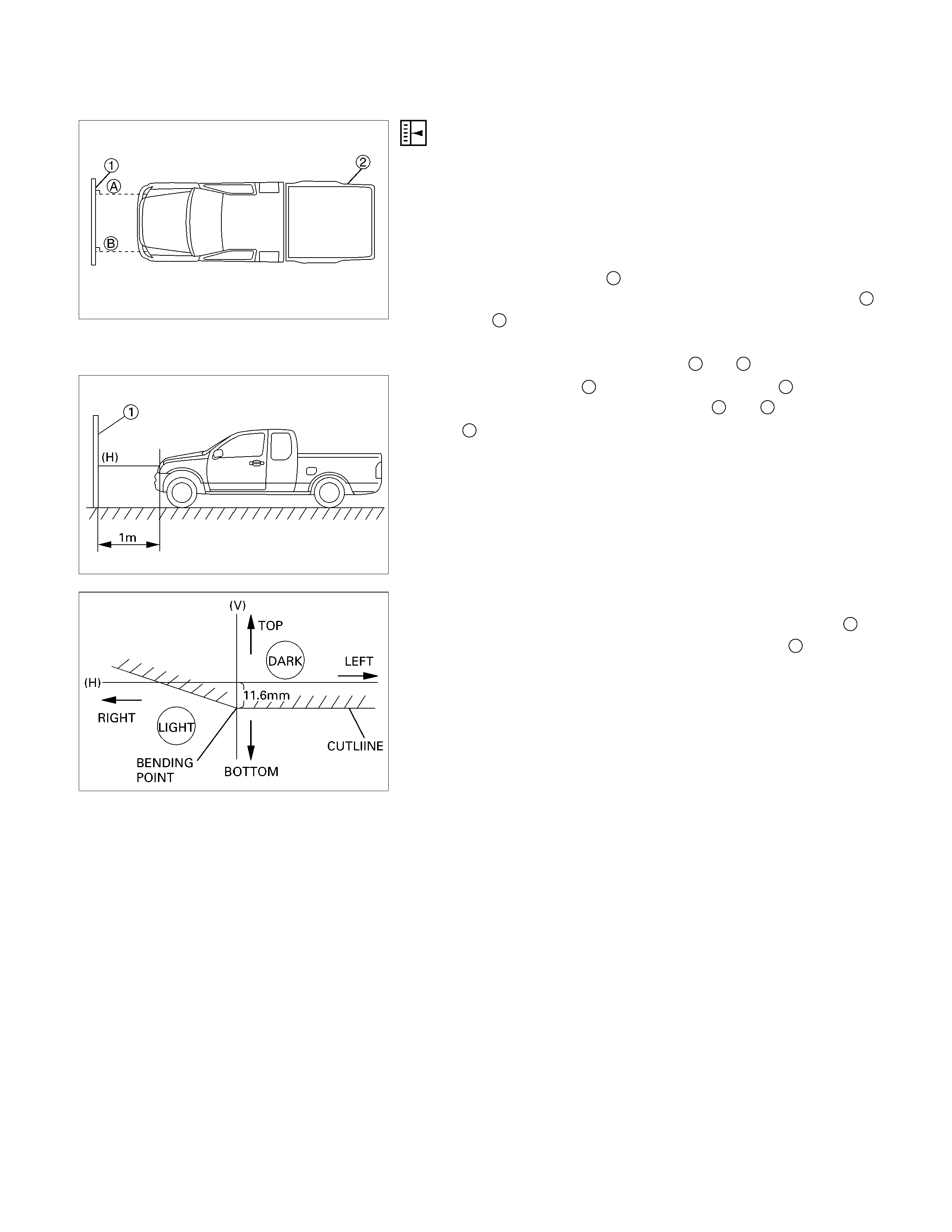

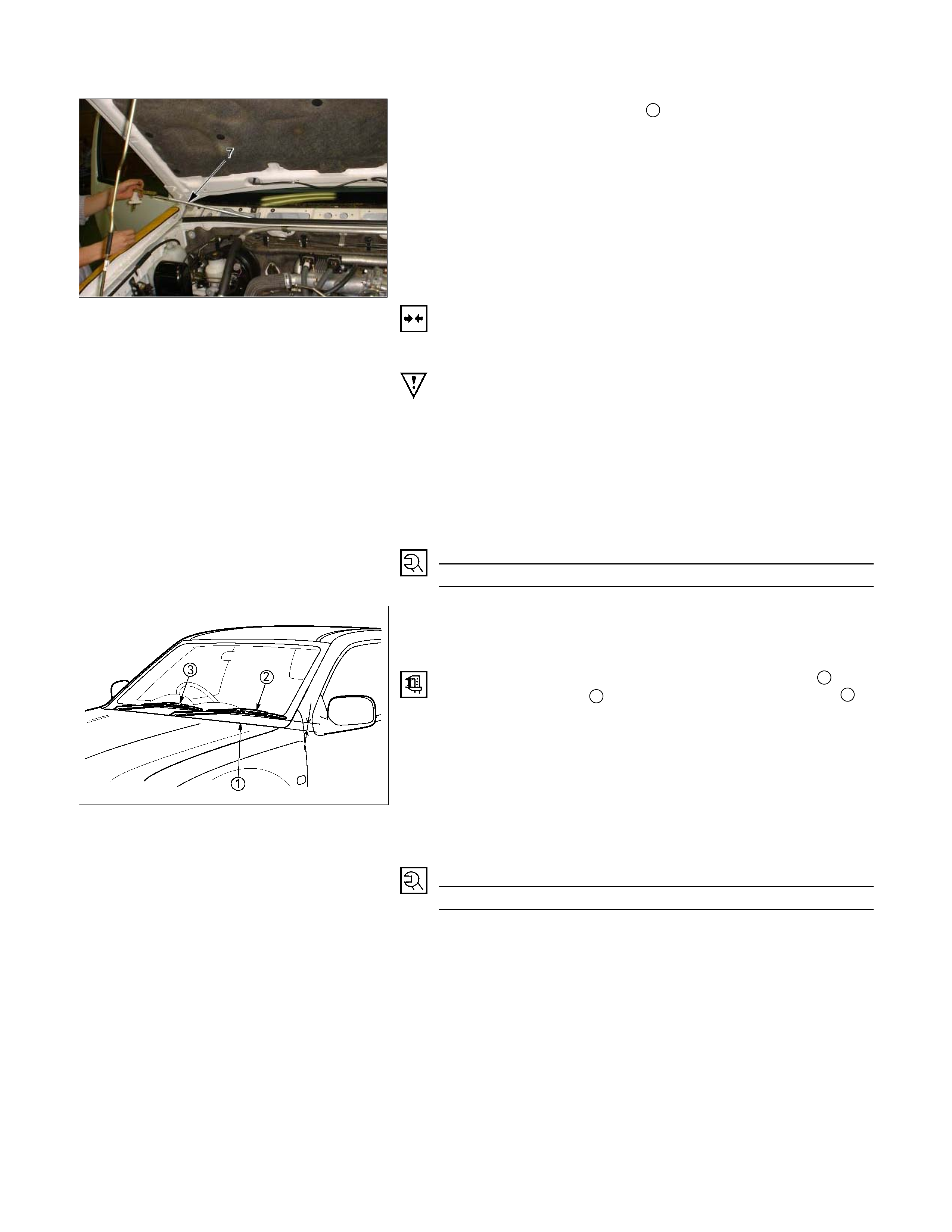

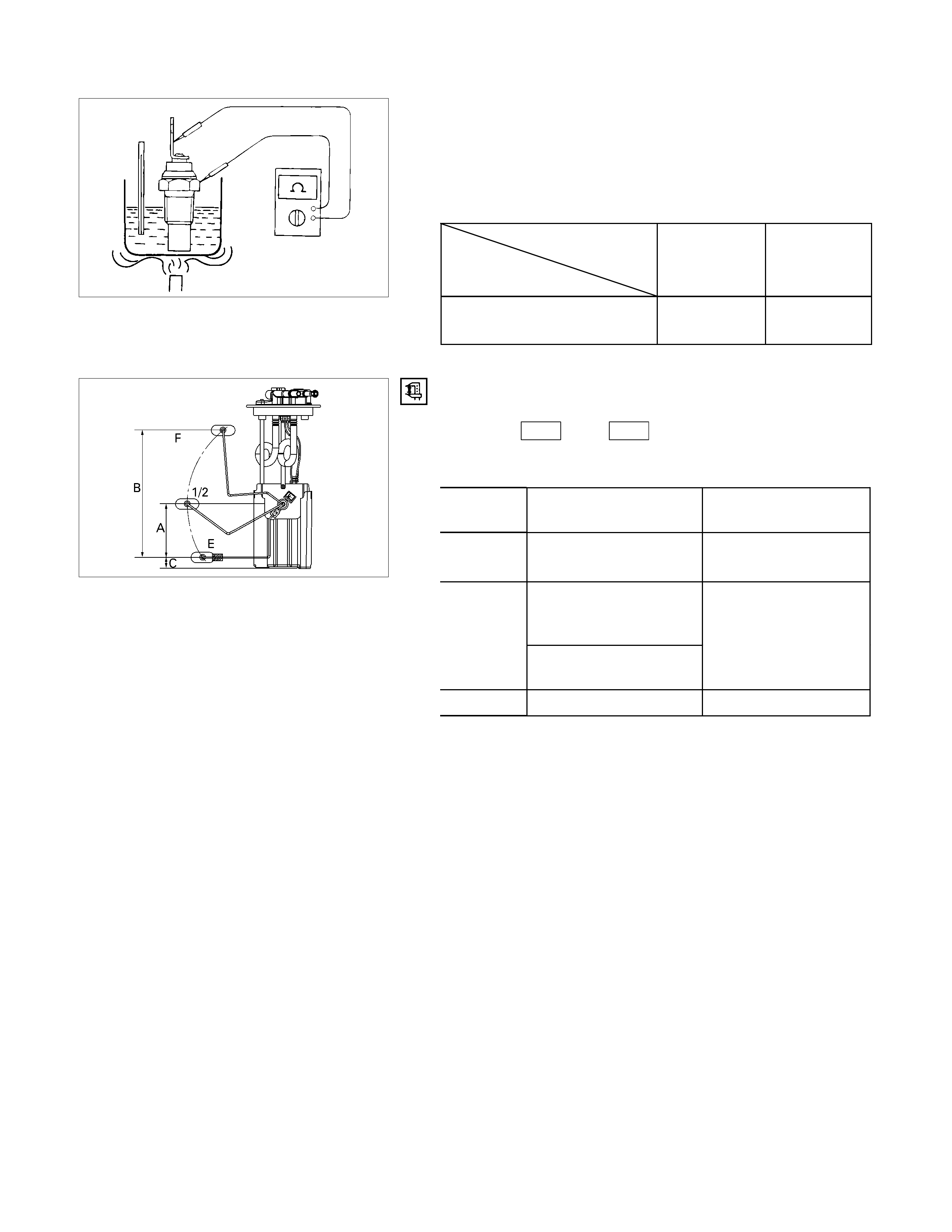

HEADLIGHT ADJUSTMENT

Preparation

Place the vehicle with 1 person in driver seat on a level

surface and check to see if the inflation pressure of the tires is

correct, the lenses are clean, the battery is sufficiently

charged, and adjust to place vehicle by using the screen.

1. Set a vertical screen on a level surface.

2. Toward the screen 1from the bulb center mark of the

headlight, extend parallel lines to the floor. Mark point A

and B on the screen at the intersection of parallel line and

the screen.

3. Draw vertical lines through point A and B on the screen.

4. Keep the vehicle 2 1m apart from the screen 1.

5. Draw a horizontal line through point A and Bon the screen

1.

6. Turn the headlight low beam on.

7. Adjust the CUTLINE 11.6 mm below the horizontal line H.

8. Adjust the BENDING POINT to the vertical line V.

NOTE:

Always adjust vertical adjustment first.

INSPECTION AND REPAIR

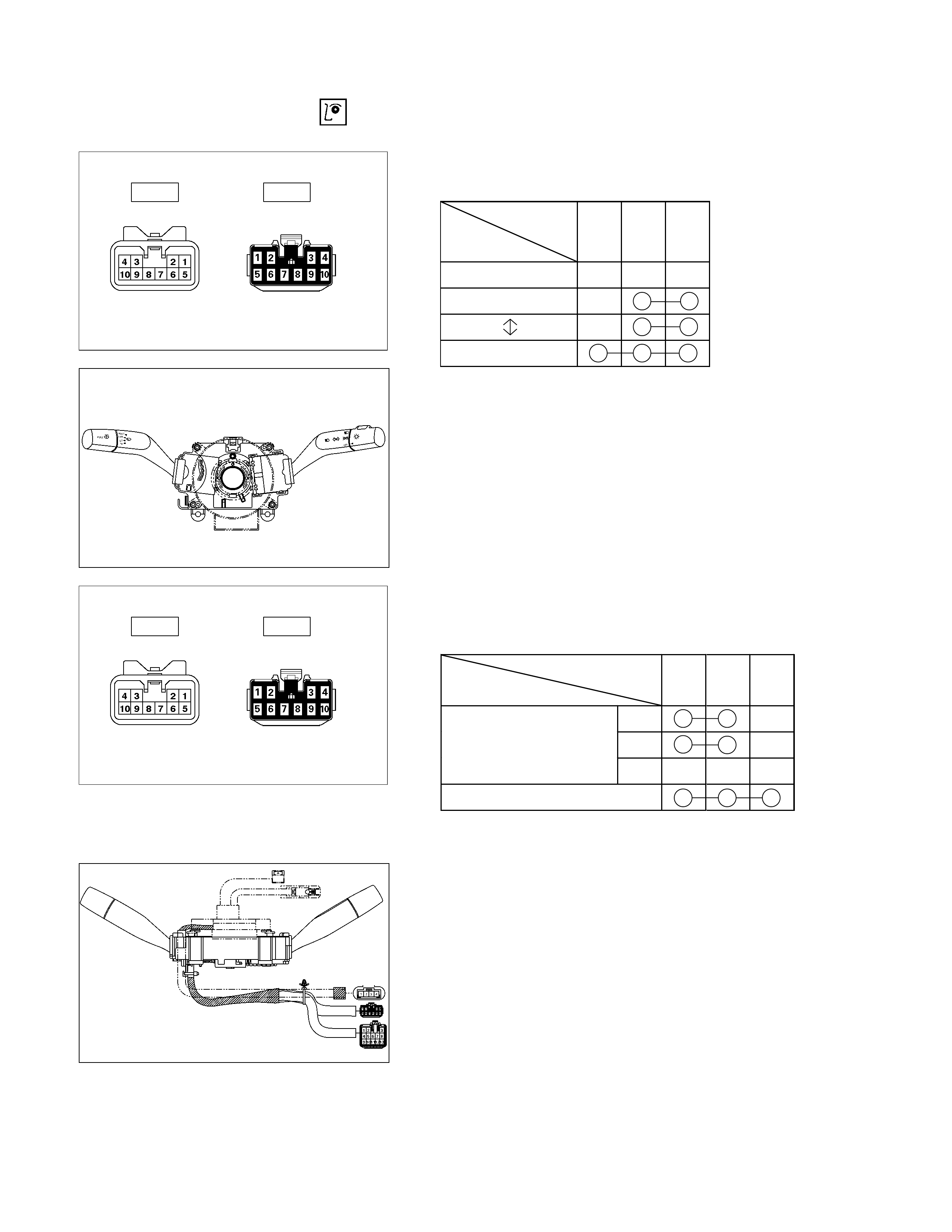

Switch side Harness side

B-60 B-60

LIGHTING SWITCH

Lighting Switch Connections

Terminal

SW No.

position 3 2 1

OFF

Tail

Headlight

Switch side Harness side

B-60 B-60

HEADLIGHT BEAM SWITCH

Headlight Beam and Passing Switch

Connections

Terminal NO.

SW position 1 4

HI

At “Dimmer” position

LO

At “Passing” Position

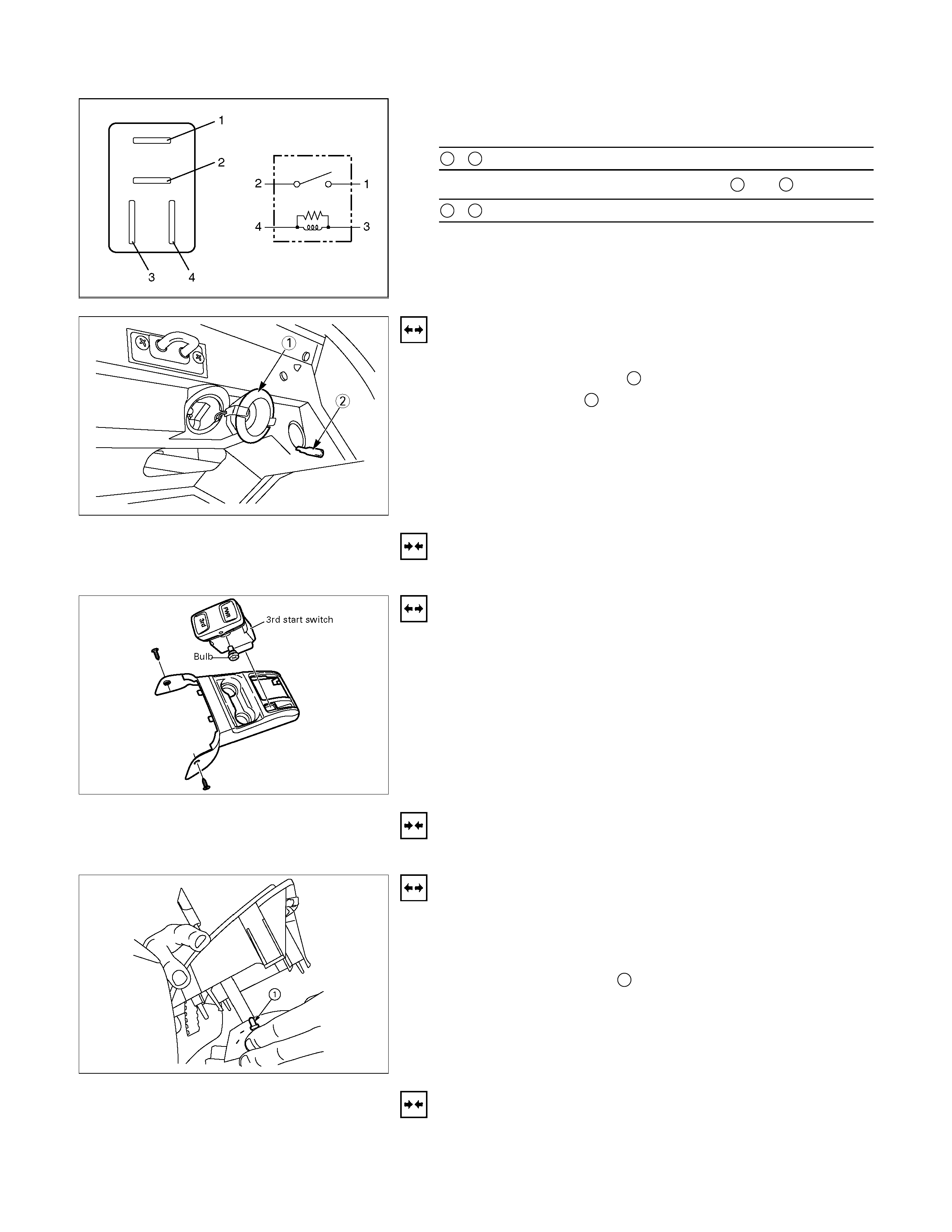

LIGHTING RELAY, TAIL RELAY

Check continuity between the relay terminals.

2 - 1............................ No continuity

(When battery voltage is applied between 3 and 4)

2 - 1............................ Continuity

GLOVE BOX ILLUMINATION

Removal

1. Remove the bulb cover 1.

2. Remove the bulb 2.

Installation

To install, follow the removal steps in the reverse order.

POWER/3rd START SW

Removal

• Refer to the “Front consol” Section 10 of this manual.

1. Disconnect the battery ground cable.

2. Remove the power/3rd start switch.

3. Remove the bulb.

Installation

To install, follow the removal steps in the reverse order.

A/T LEVER LIGHT BULB

Removal

• Refer to the “Front consol” Section 10 of this manual.

1. Remove the A/T lever cover.

2. Remove the light bulb 1.

Installation

To install, follow the removal steps in the reverse order.

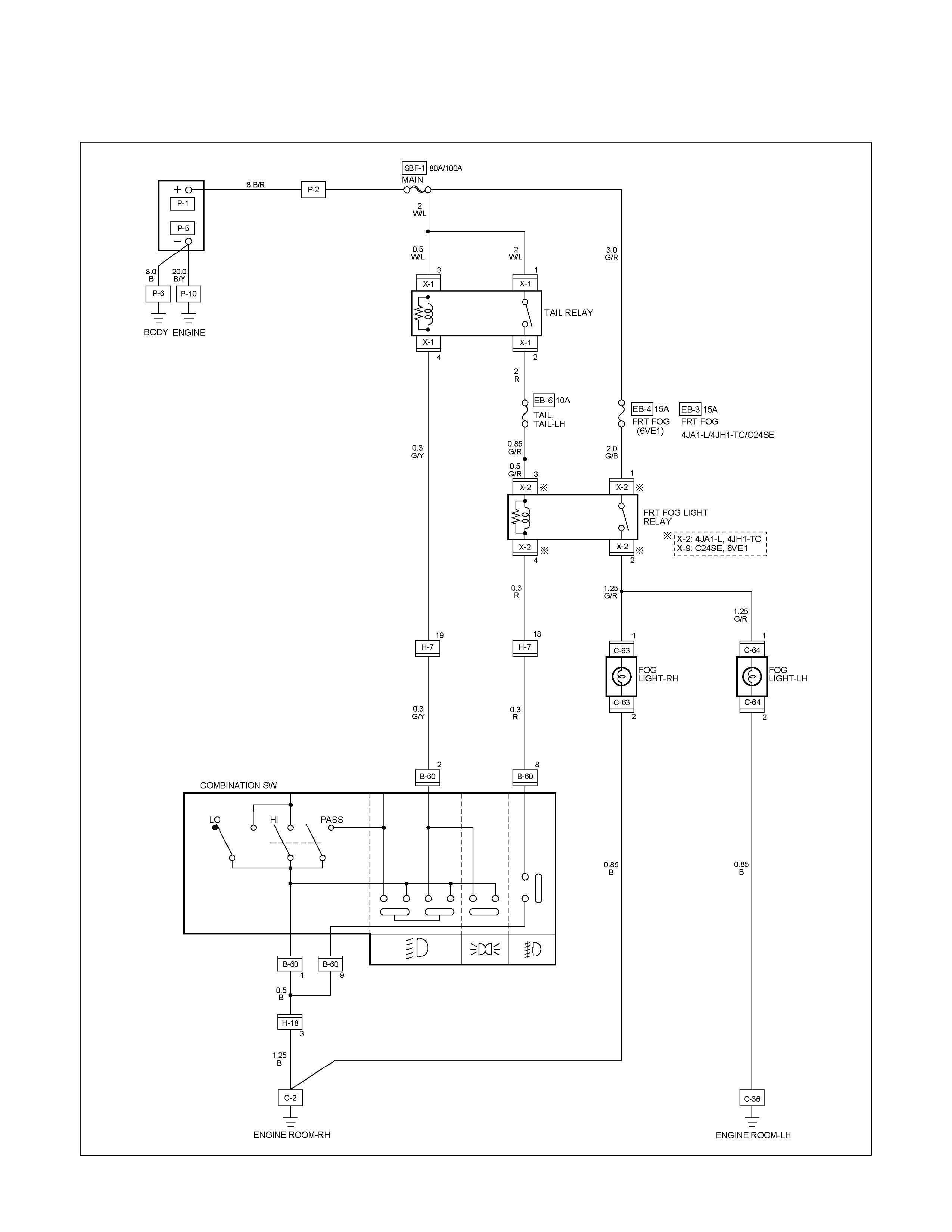

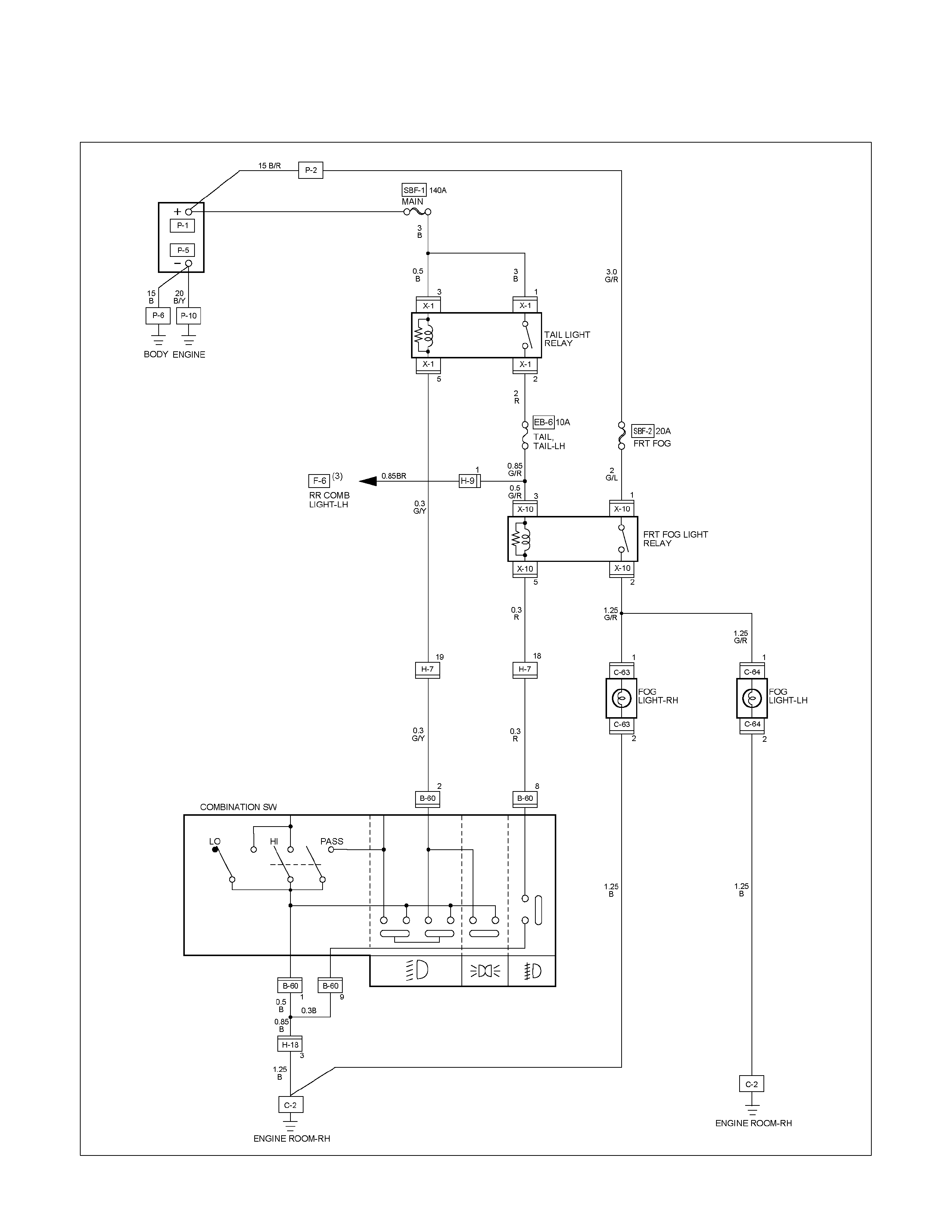

FRONT FOG LIGHT

PARTS LOCATION (RHD)

RTW68AXF014101 & RTW68AXF014201

PARTS LOCATION (LHD)

RTW48AXF015201 & RTW48AXF015301

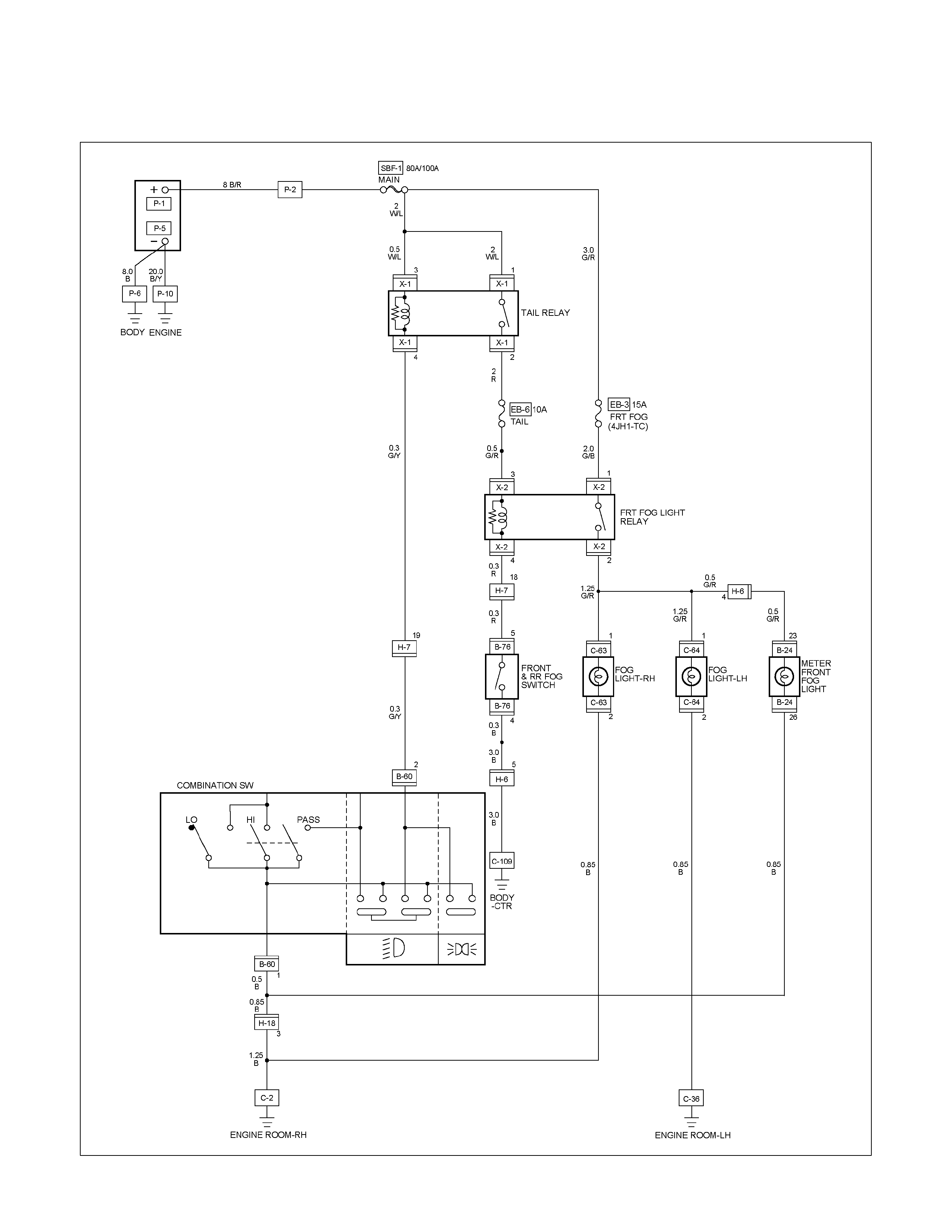

CIRCUIT DIAGRAM (RHD) EXCEPT HFV6 WITHOUT REAR FOG LIGHT

RTW680XF006901

CIRCUIT DIAGRAM (RHD) HFV6 WITHOUT REAR FOG LIGHT

RTW68AXF010701

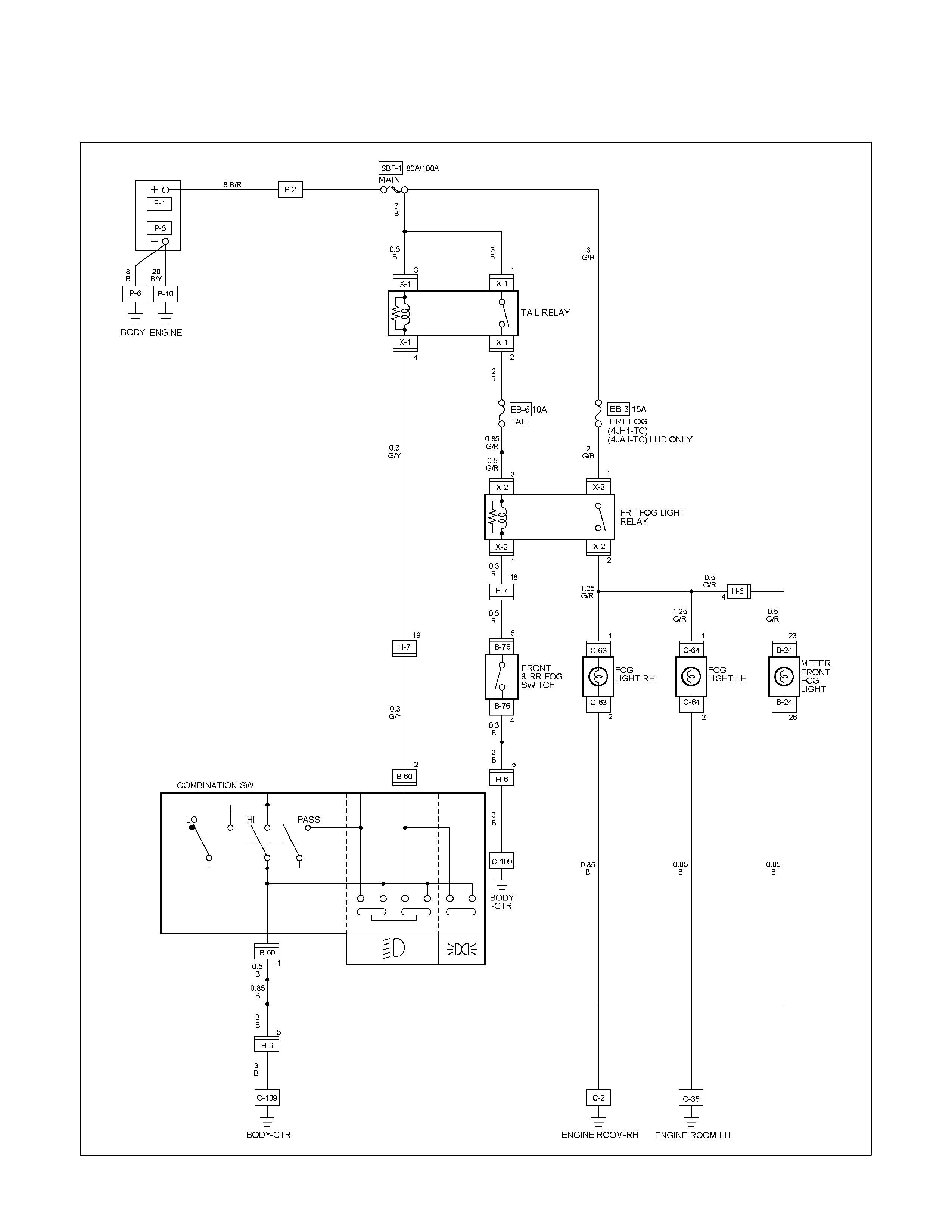

CIRCUIT DIAGRAM (RHD) WITH REAR FOG LIGHT

RTW680XF007001

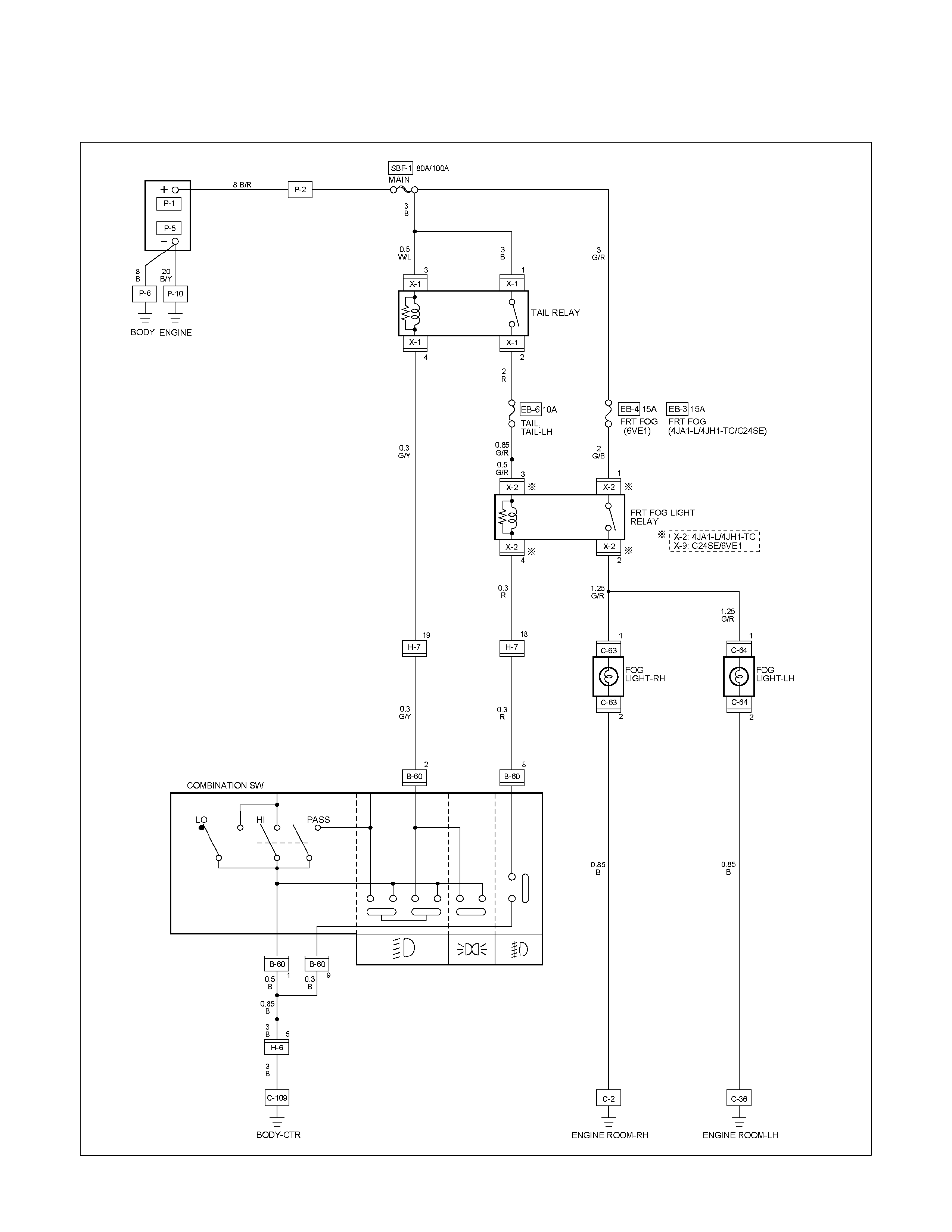

CIRCUIT DIAGRAM (LHD) WITHOUT REAR FOG LIGHT

RTW680XF007101

CIRCUIT DIAGRAM (LHD) WITH REAR FOG LIGHT

RTW680XF007201

FRONT FOG LIGHT

Removal

1. Remove the radiator grille.

2. Remove the front bumper

3. Disconnect the fog light connector.

4. Remove the fog light.

5. Remove the bulb from the socket.

• Remove the socket by turning it counterclockwise.

Installation

Follow the removal procedure in the reverse order to install the

fog light.

Pay close attention to the important points mentioned in the

following paragraphs.

Bulb

Be absolutely sure that the fog light bulb is correctly installed.

This will prevent a poor contact and open circuit.

FRONT FOG LIGHT ADJUSTMENT

Vertical Adjustment

Turn the adjusting screw (1) with a screwdriver to adjust the

aim of the fog light vertically.

RTU4Z0SH000601

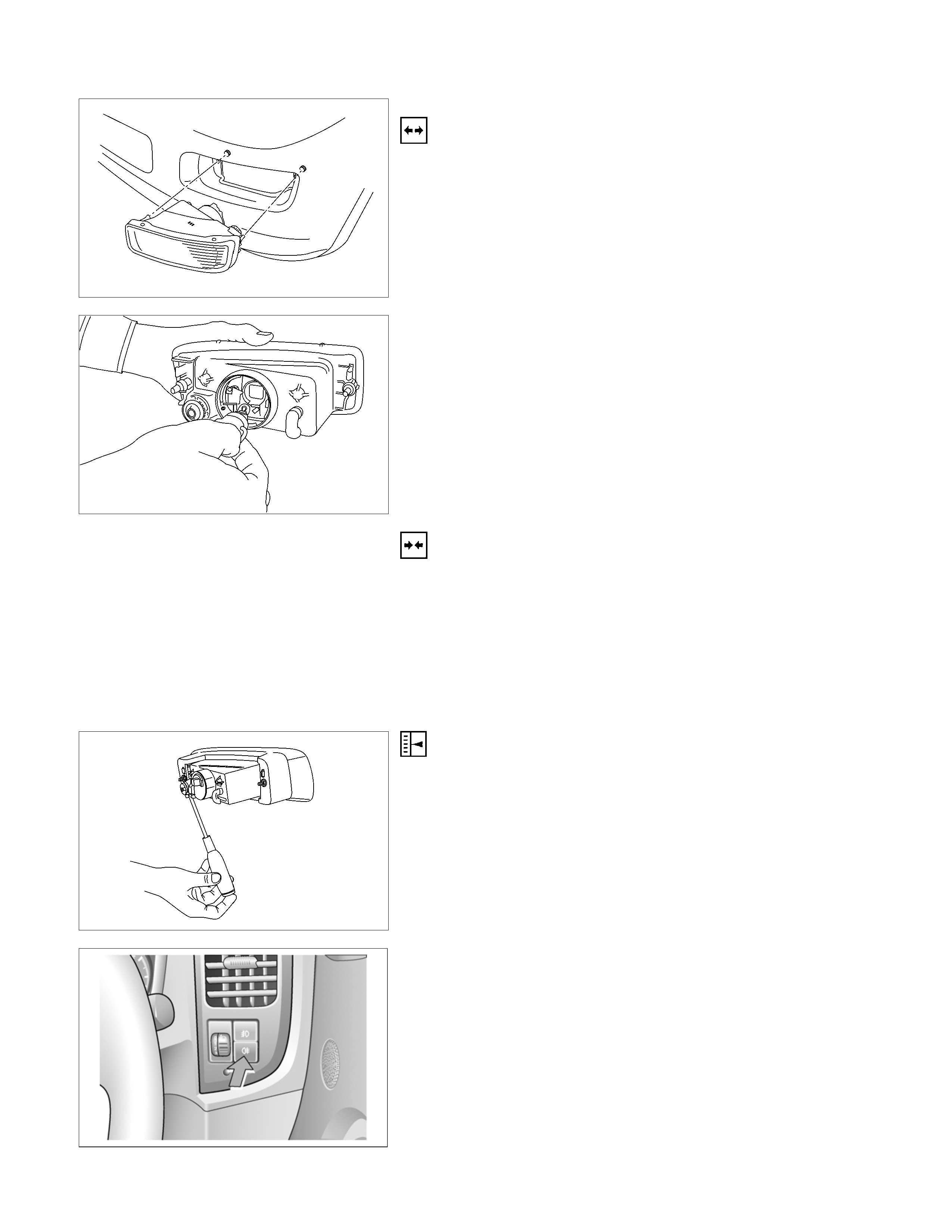

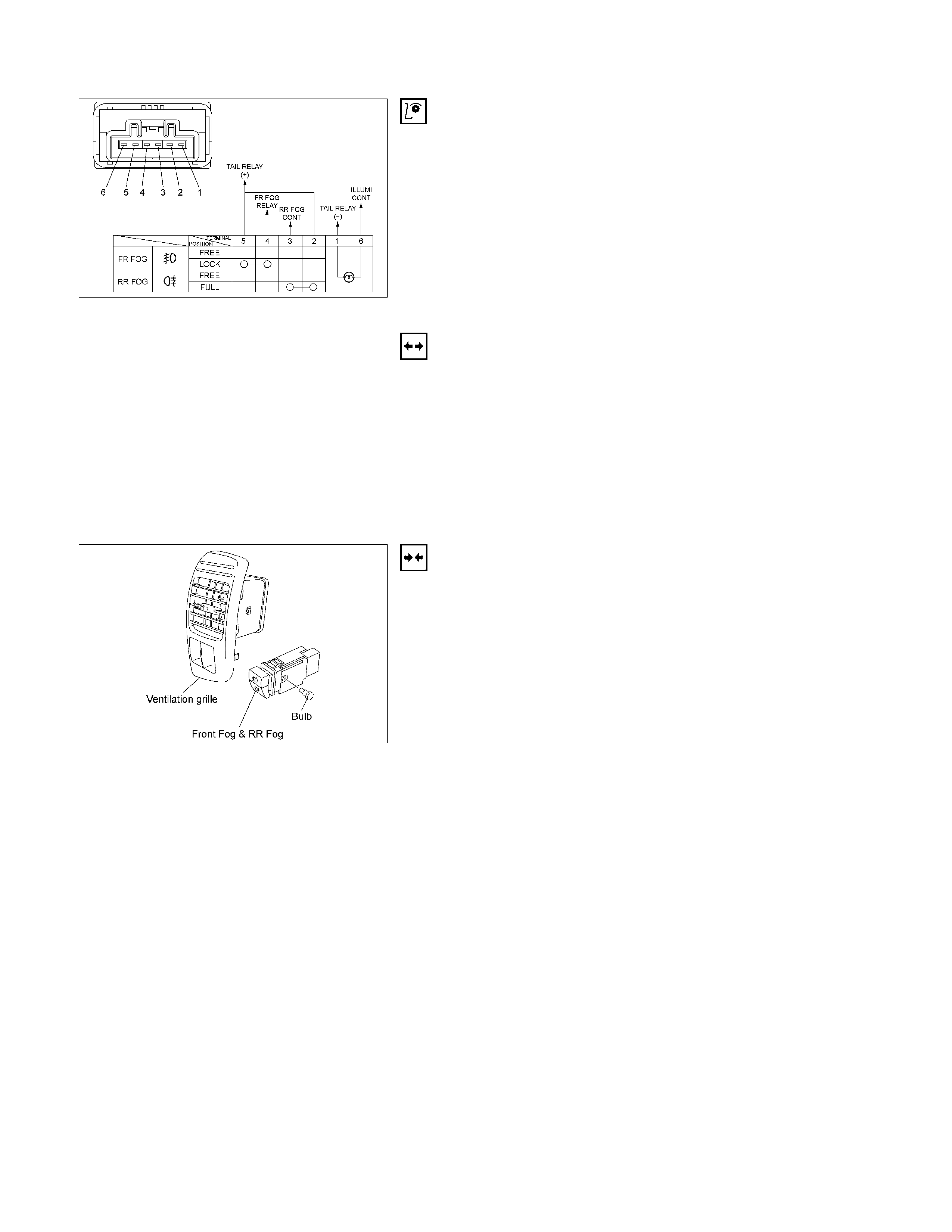

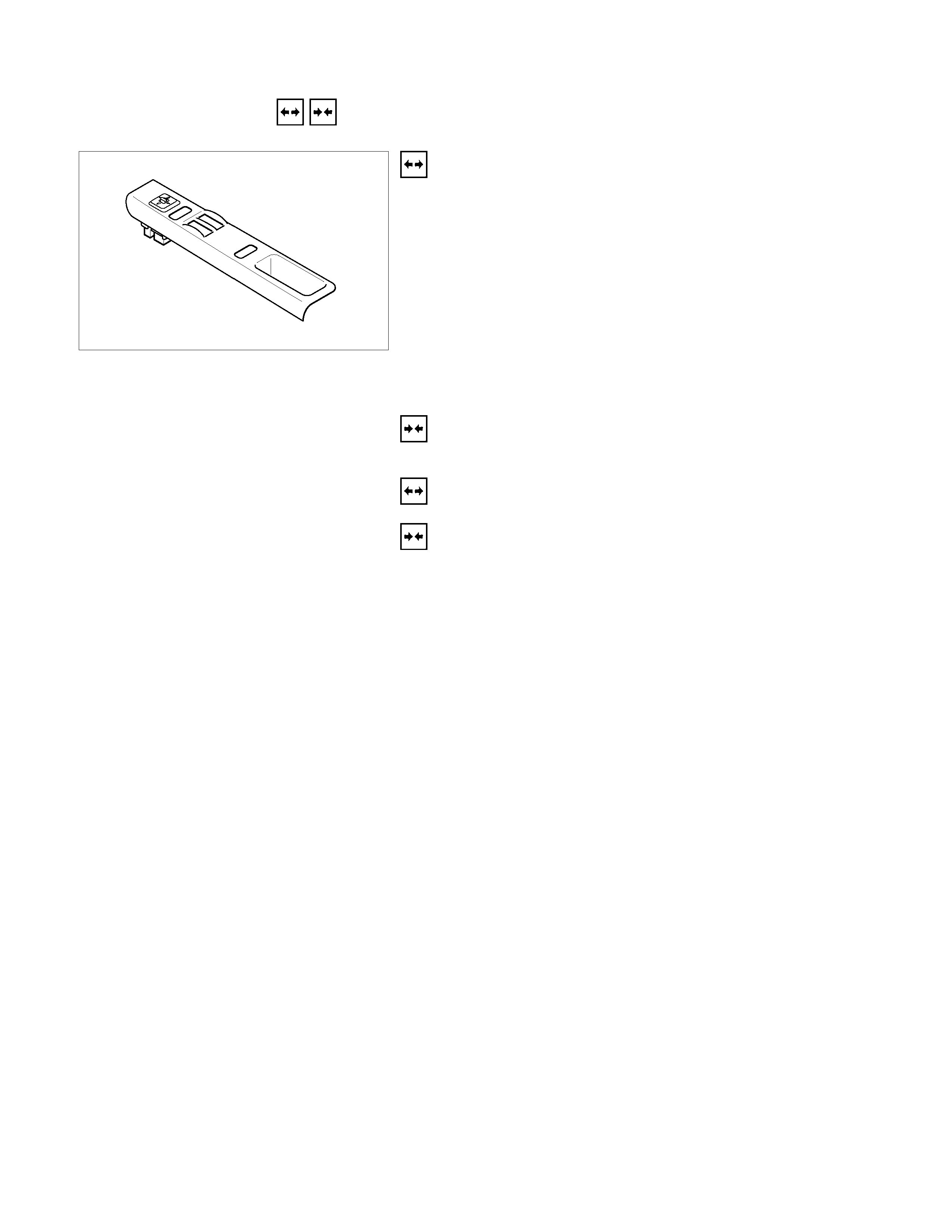

FRONT FOG & REAR FOG SWITCH

RTW48ASH000401

Inspection

Check to see if there is any continuity between the terminals of

the front fog light switch.

Replace the switch when the result of inspection is found

abnormal.

Removal

Preparation:

Disconnect the battery ground cable.

1. Ventilation grille

2. Harness connector

3. Front fog light & Rear fog light switch

To remove the switch, push the lock from the back side of

the cluster assembly.

4. Remove the bulb.

RTW48ASH000301

Installation

To install, follow the removal steps in the reverse noting the

following point.

1. Push in the switch with your fingers until it locks securely.

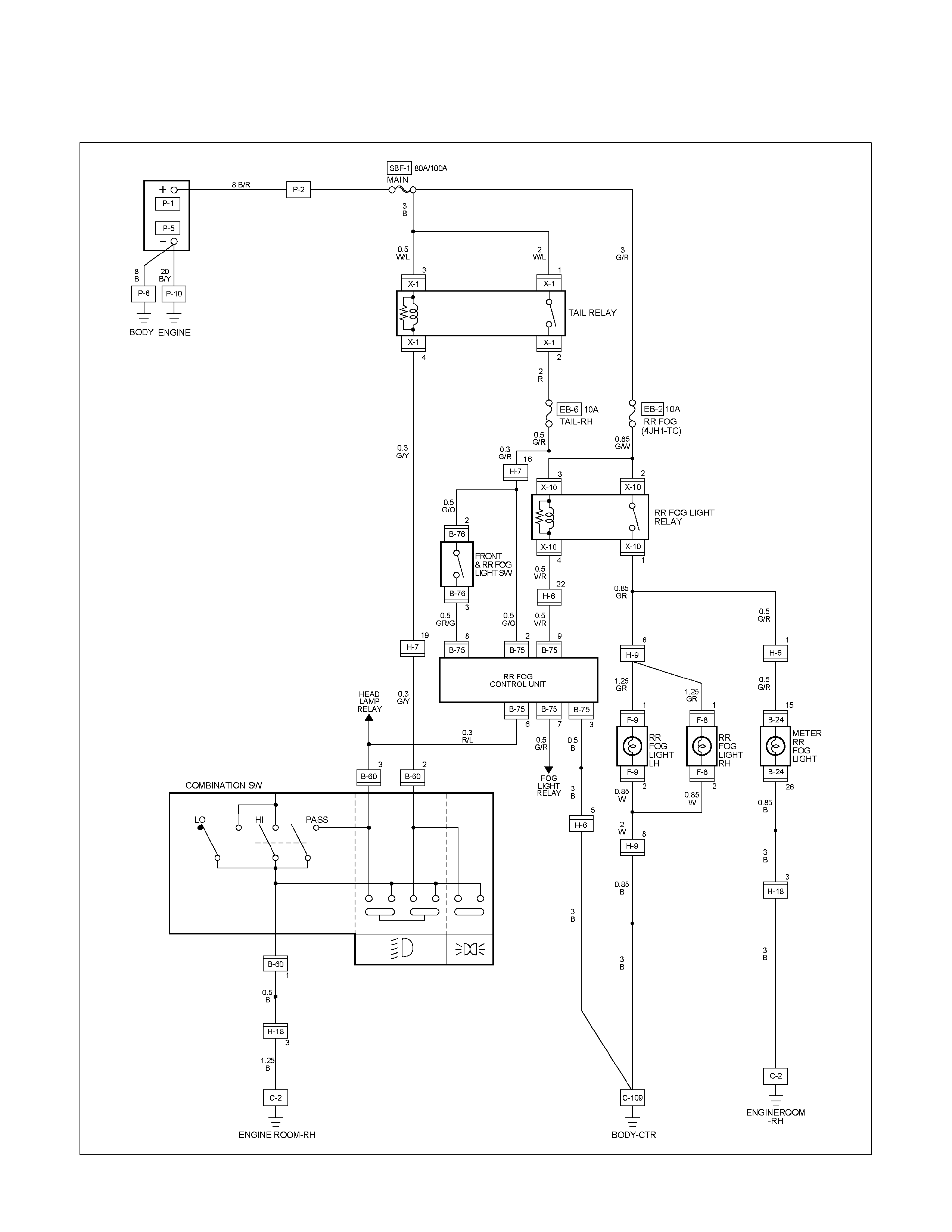

REAR FOG LIGHT

PARTS LOCATION (RHD)

RTW48AXF015401 & RTW48AXF015501

PARTS LOCATION (LHD)

RTW48AXF015601 & RTW48AXF015701

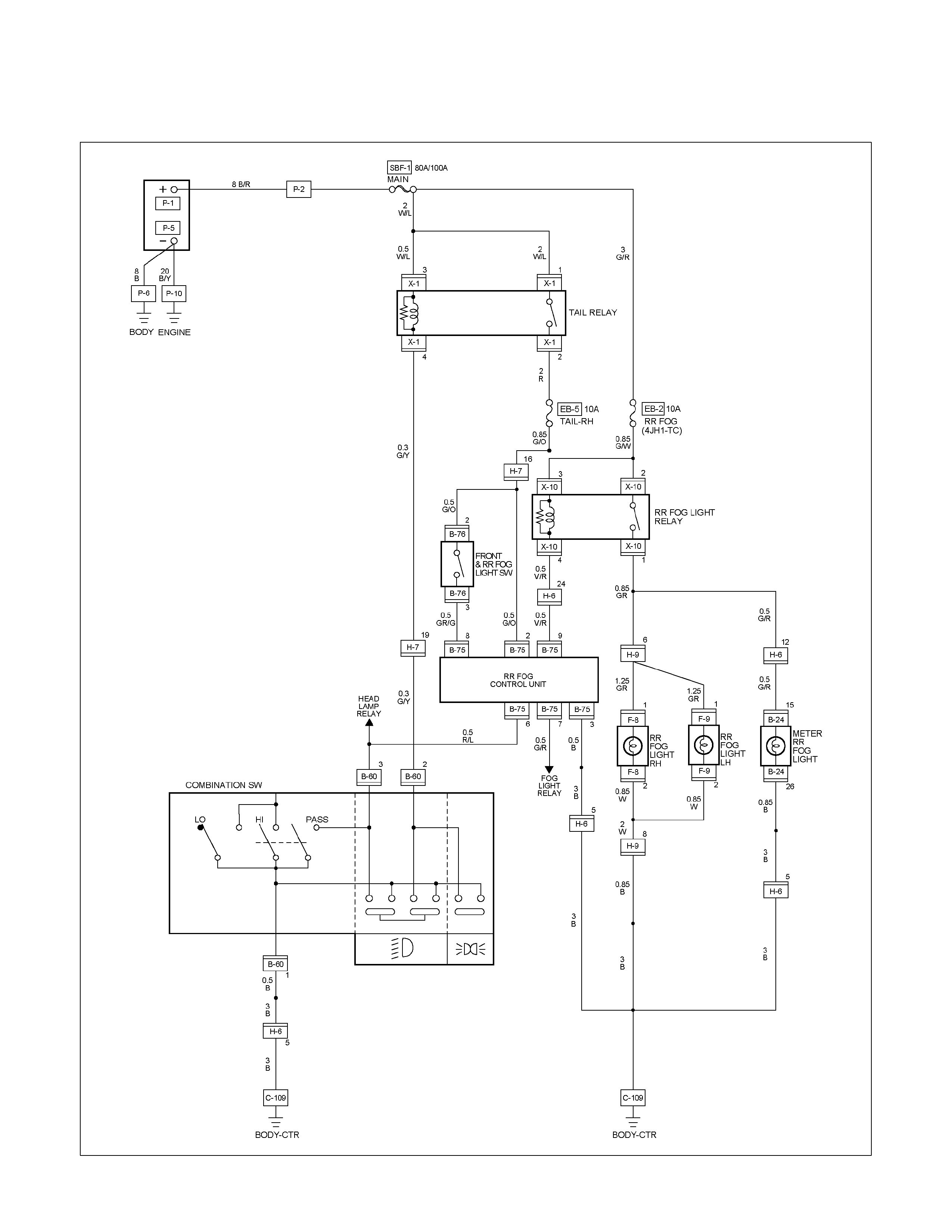

CIRCUIT DIAGRAM (RHD)

RTW680XF007401

CIRCUIT DIAGRAM (LHD)

RTW680XF007301

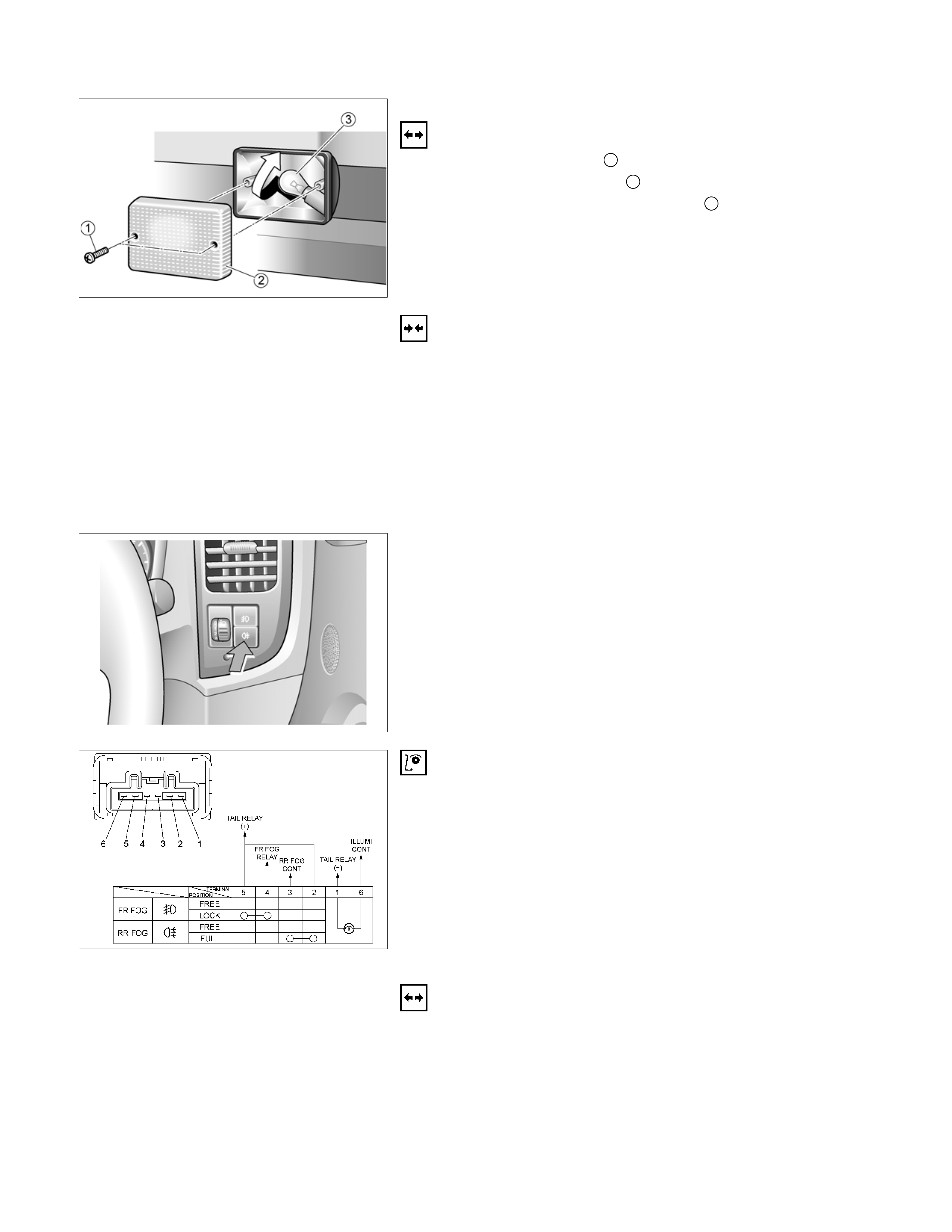

RTW48ASH000701

REAR FOG LIGHT

Removal

1. Remove the screws 1.

2. Remove the lens cover 2.

3. Rear fog push turn the bulb 3 counterclockwise to

disconnect it from the light housing.

Installation

Follow the removal procedure in the reverse order to install the

rear fog light.

Pay close attention to the important points mentioned in the

following paragraphs.

Bulb

Be absolutely sure that the license plate light bulb is correctly

installed.

This will prevent a poor contact and open circuit.

RTU4Z0SH000601

FRONT FOG & RR FOG SWITCH

RTW48ASH000401

Inspection

Check to see if there is any continuity between the terminals of

the leveling switch.

Replace the switch when the result of inspection is found

abnormal.

Removal

Preparation:

Disconnect the battery ground cable.

1. Ventilation grille

2. Harness connector

3. Front fog light & Rear fog light switch

To remove the switch, push the lock from the back side of

the cluster assembly.

4. Remove the bulb.

HEADLIGHT LEVELING

PARTS LOCATION (RHD)

RTW48AXF015801 & RTW48AXF015901

PARTS LOCATION (LHD)

RTW48AXF016001 & RTW48AXF016101

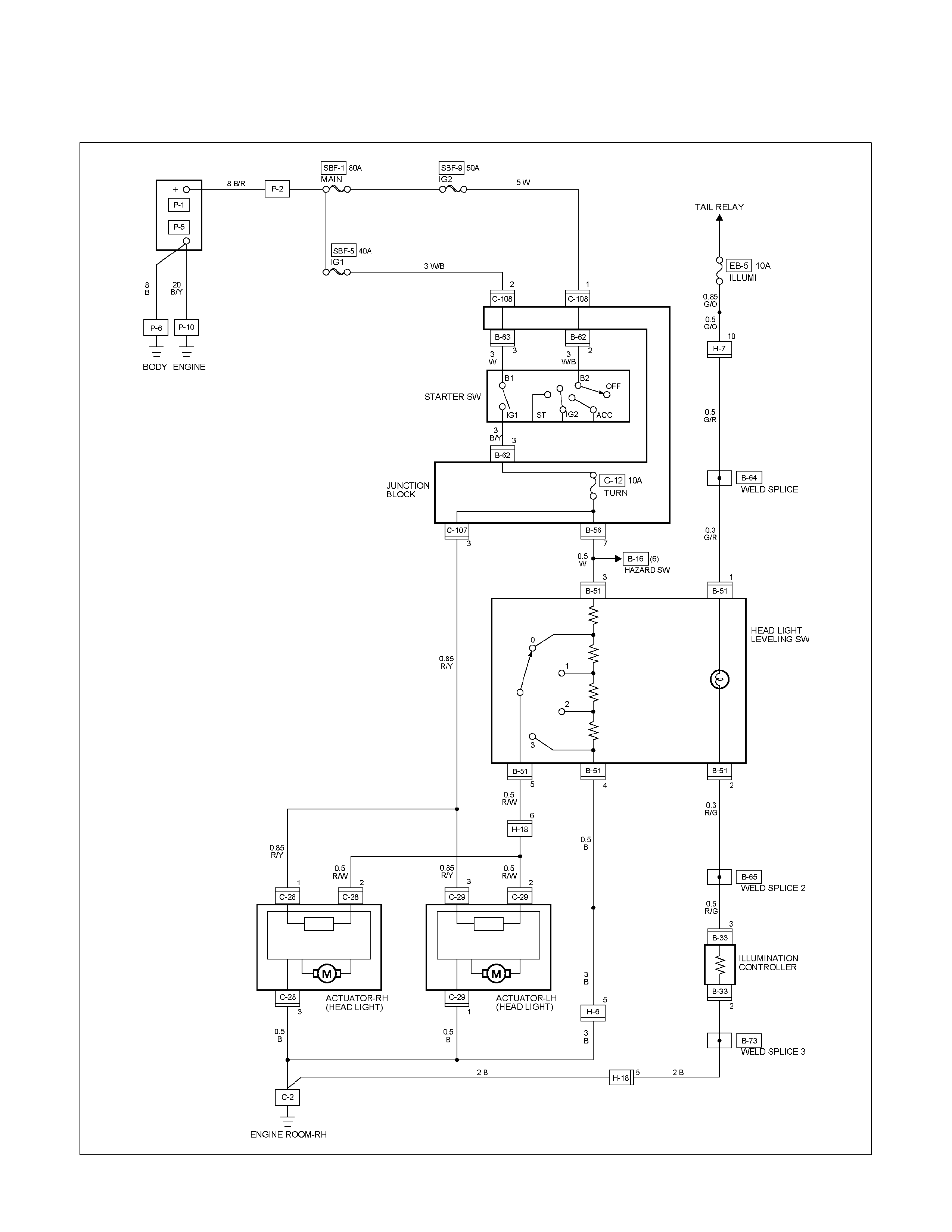

CIRCUIT DIAGRAM (RHD)

RTW680XF007601

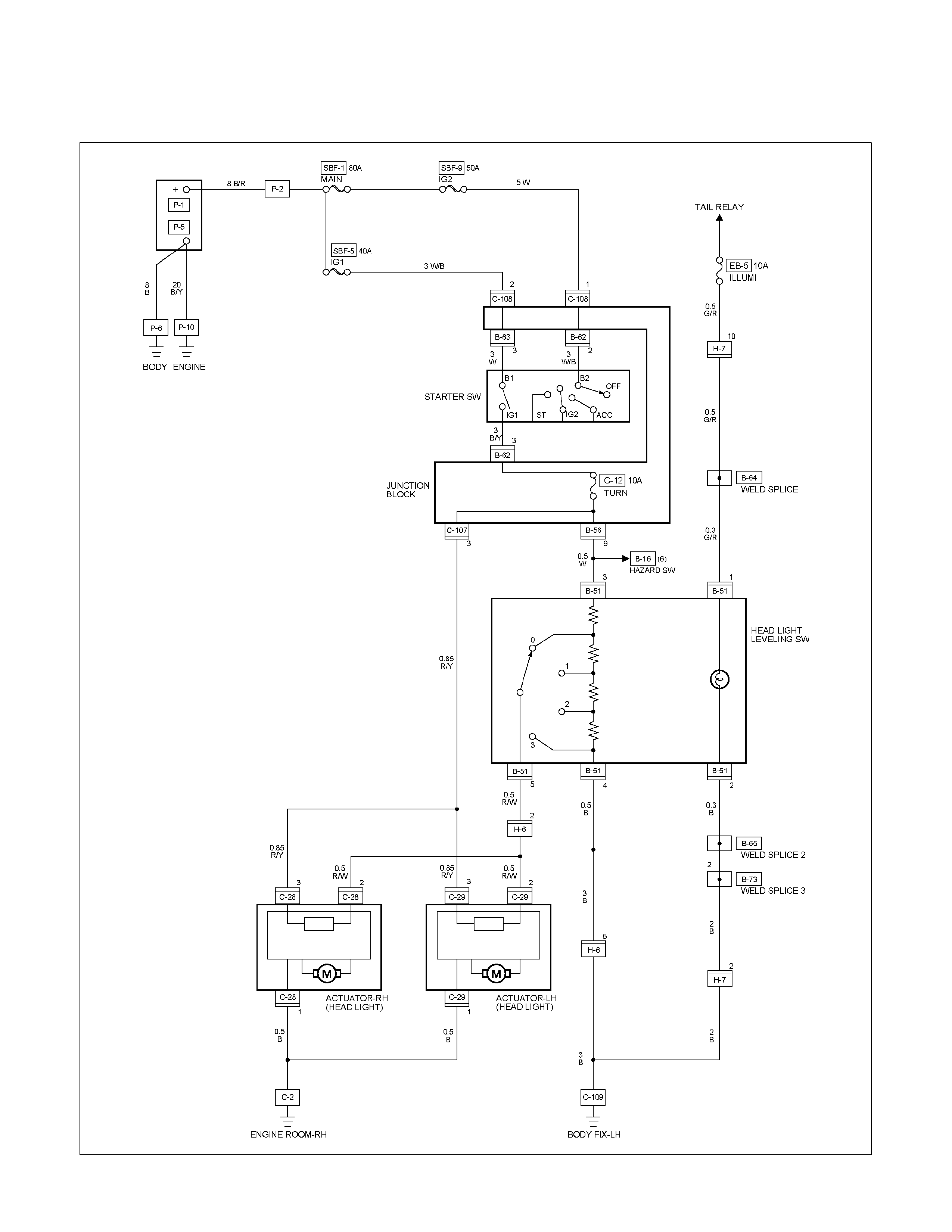

CIRCUIT DIAGRAM (LHD)

RTW680XF007501

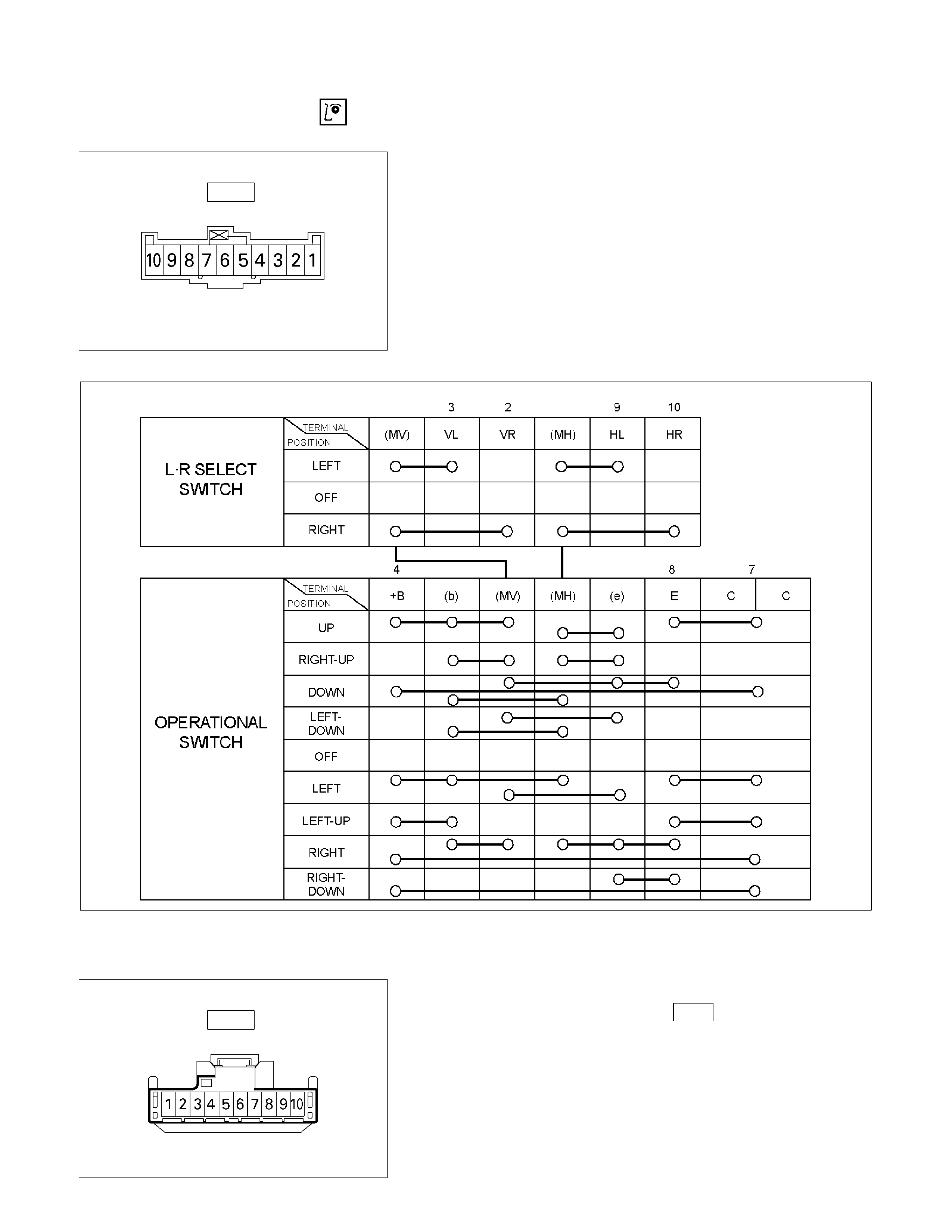

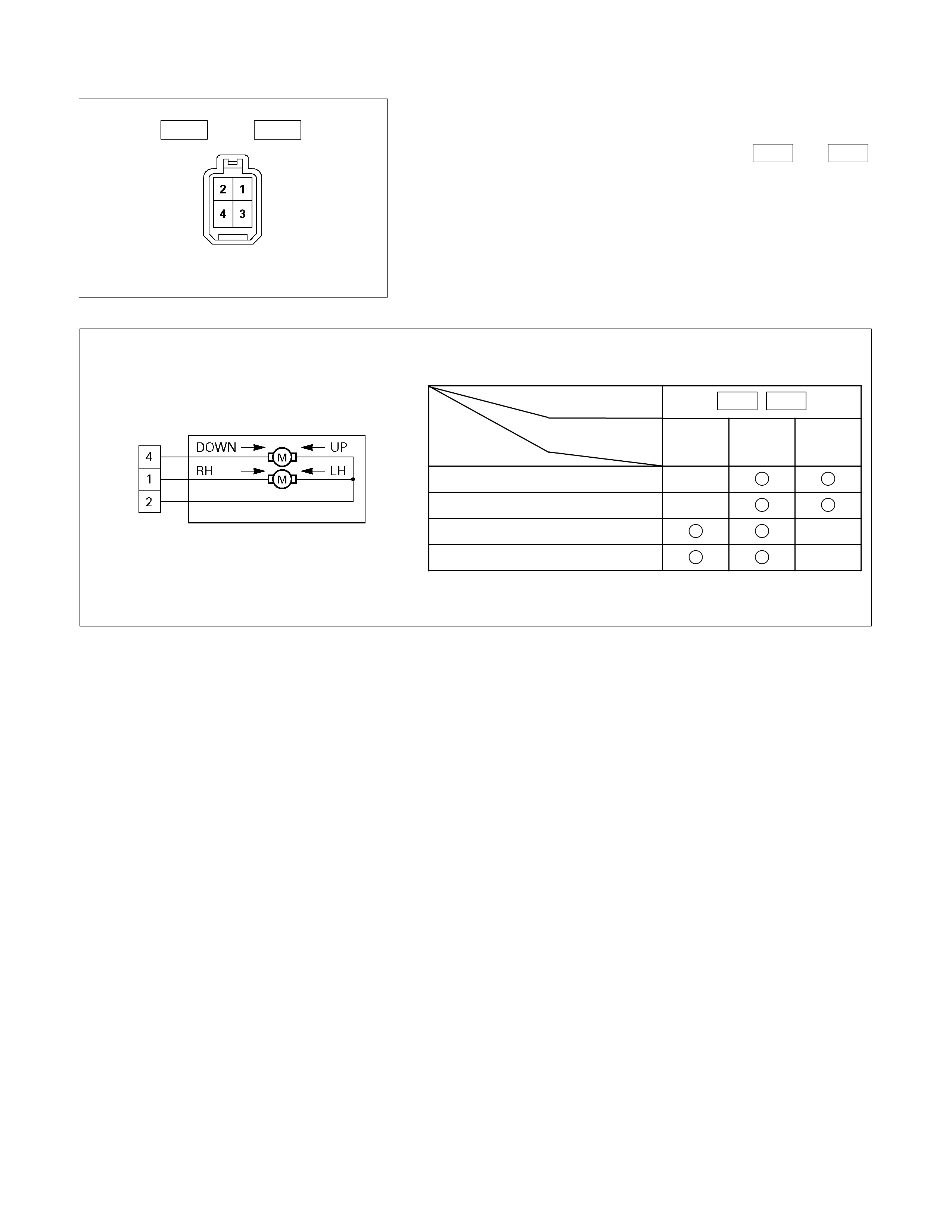

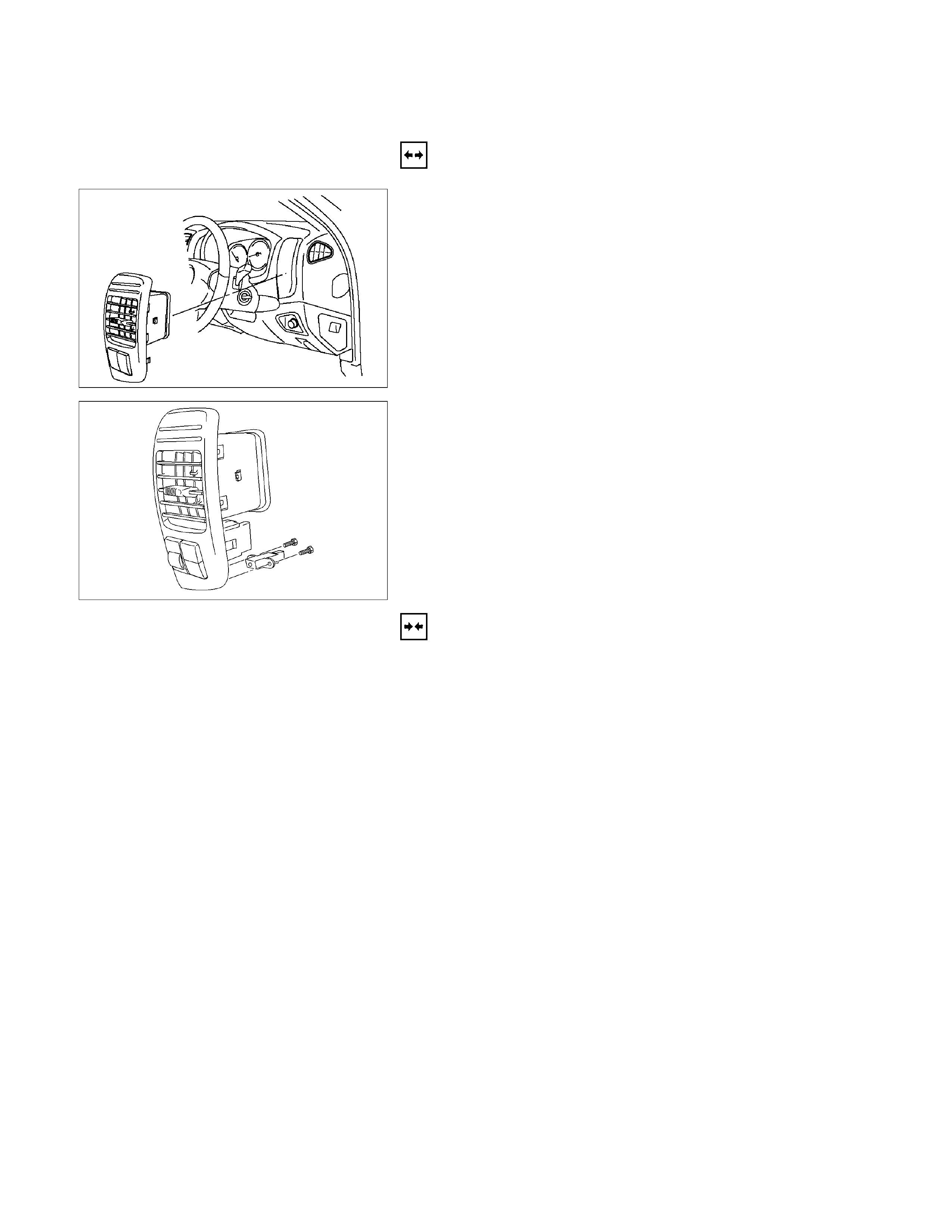

HEADLIGHT LEVELING SWITCH

Incorrect beam angle due to load change can be corrected.

A four position switch, 0-3, can alter the beam angle through

1.7 degrees on the long wheel base model and 2.17 degrees

on the short wheel base model.

RTW68ASH000501

Inspection

Check to see if there is any continuity between the terminals of

the leveling switch.

Replace the switch when the result of inspection is found

abnormal.

Removal

Preparation:

Disconnect the battery ground cable.

1. Ventilation grille

2. Harness connector

3. Headlight leveling switch

To remove the switch, push the lock from the back side of

the cluster assembly.

Installation

To install, follow the removal steps in the reverse noting the

following point.

1. Push in the switch with your fingers until it locks securely.

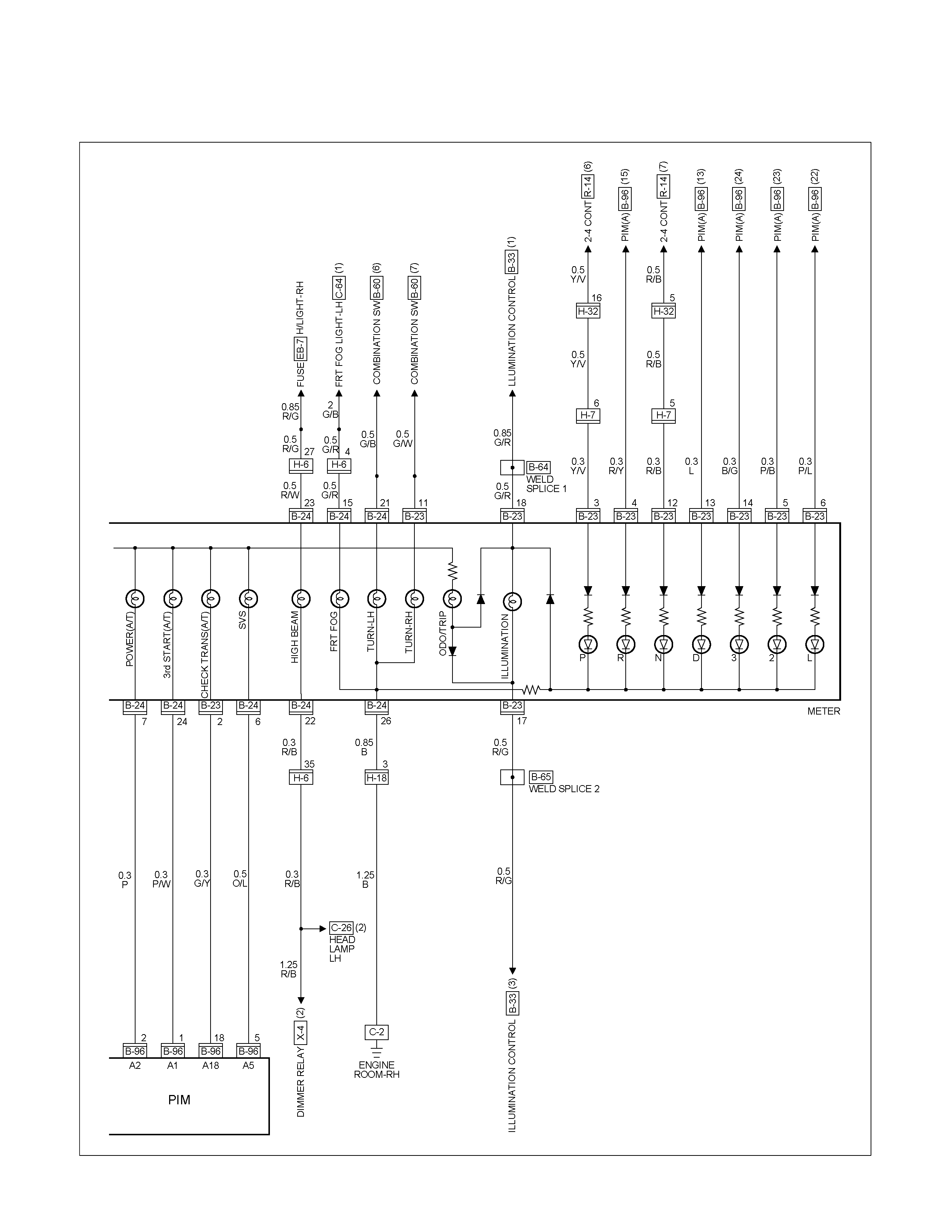

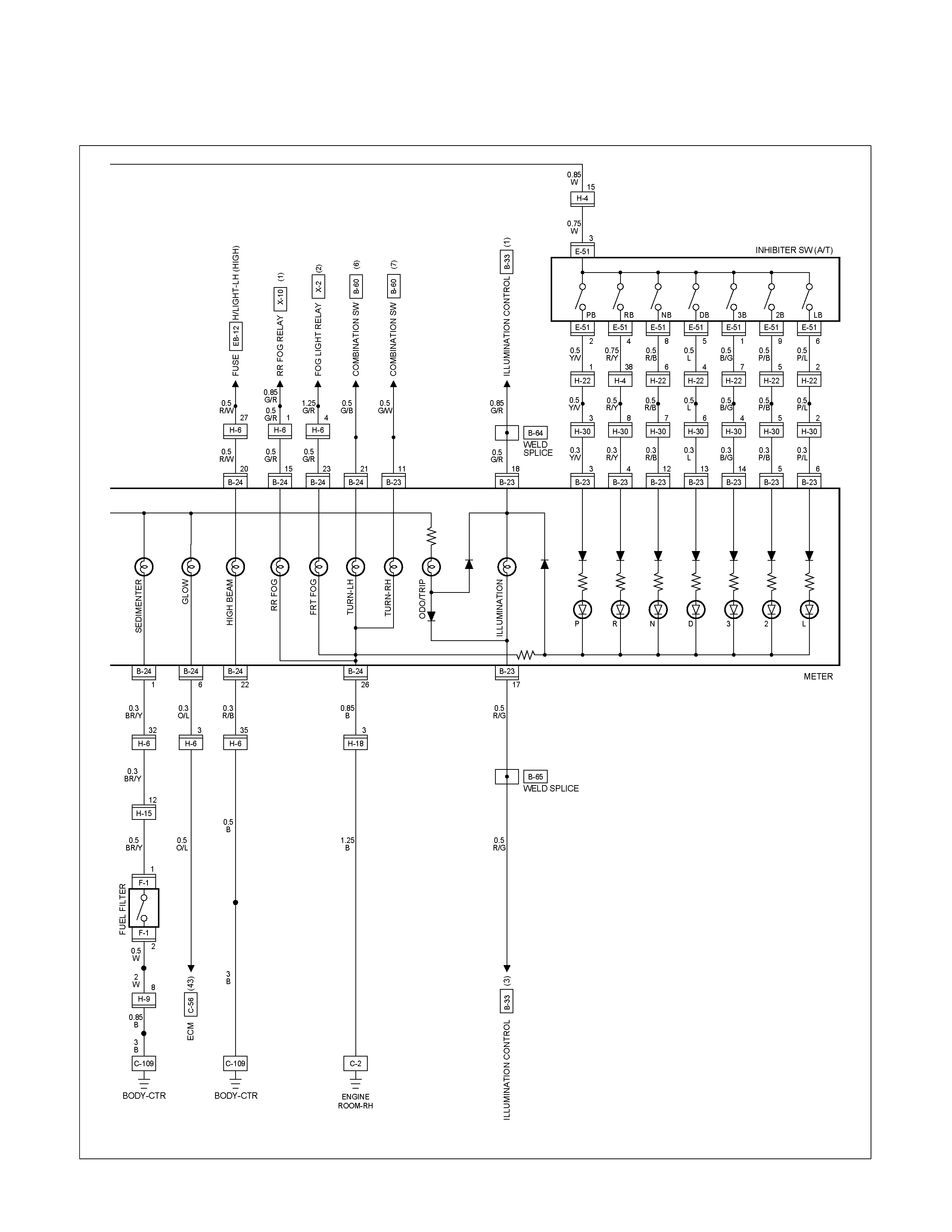

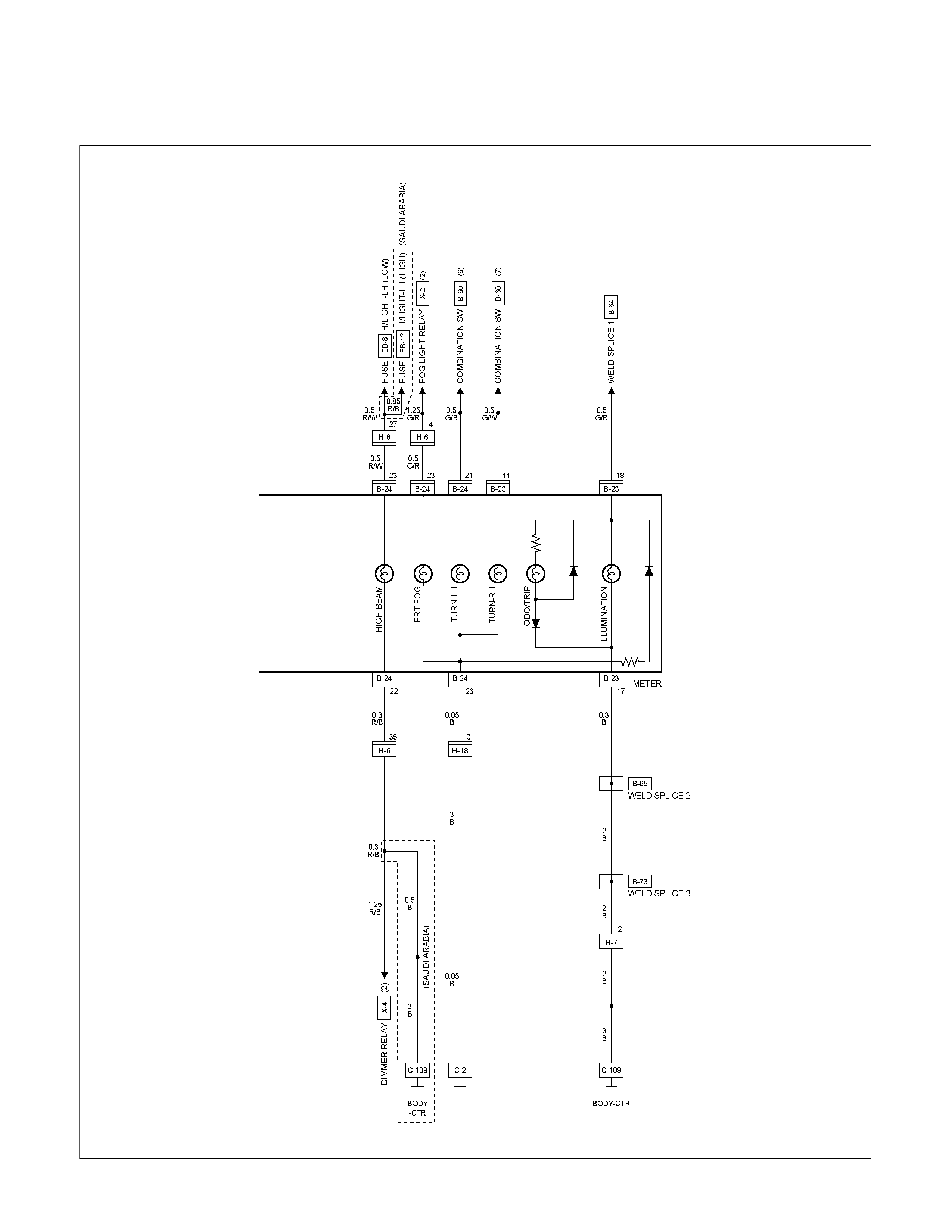

ILLUMINATION

PARTS LOCATION (RHD)

RTW68AXF014301 & RTW68AXF014401

PARTS LOCATION (LHD)

RTW48AXF016401 & RTW48AXF016501

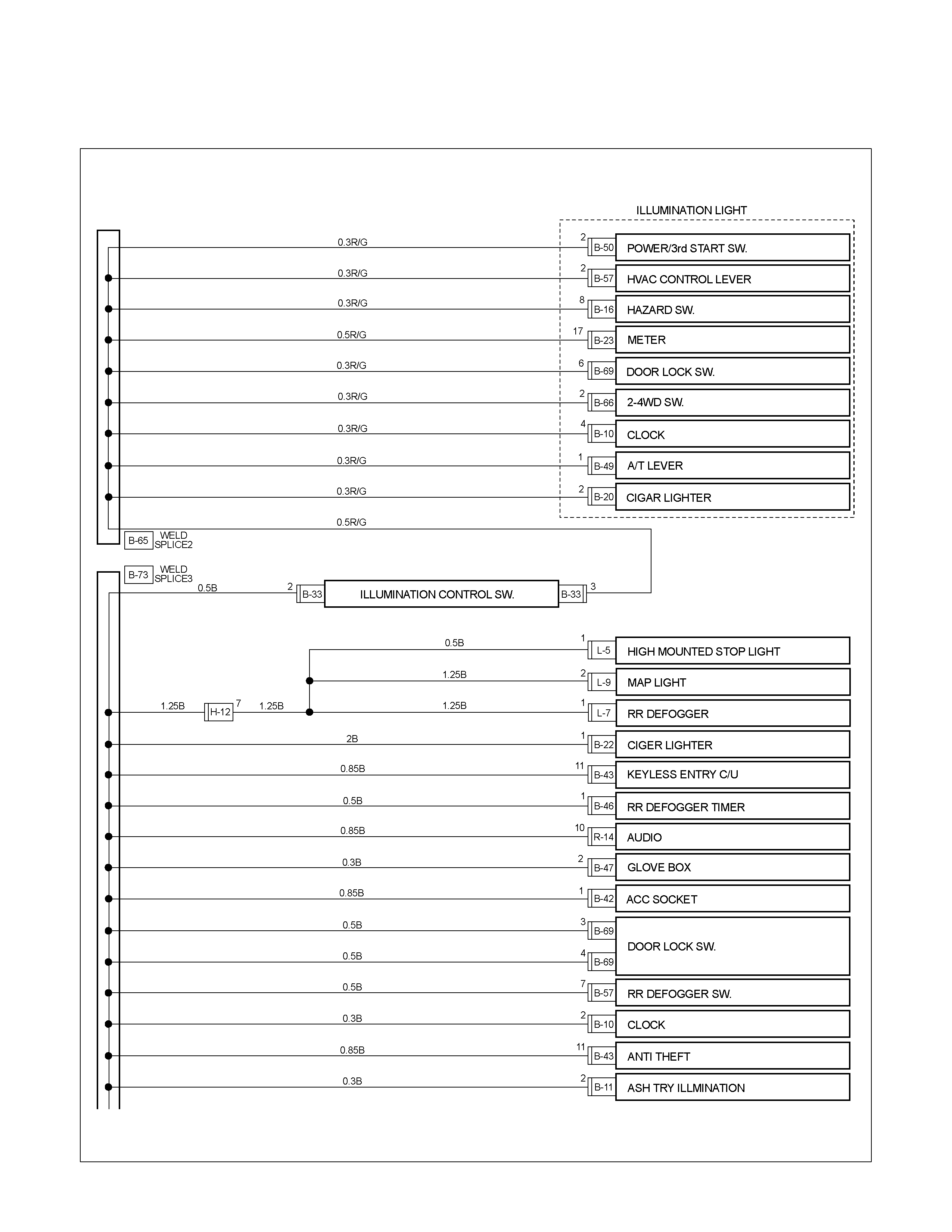

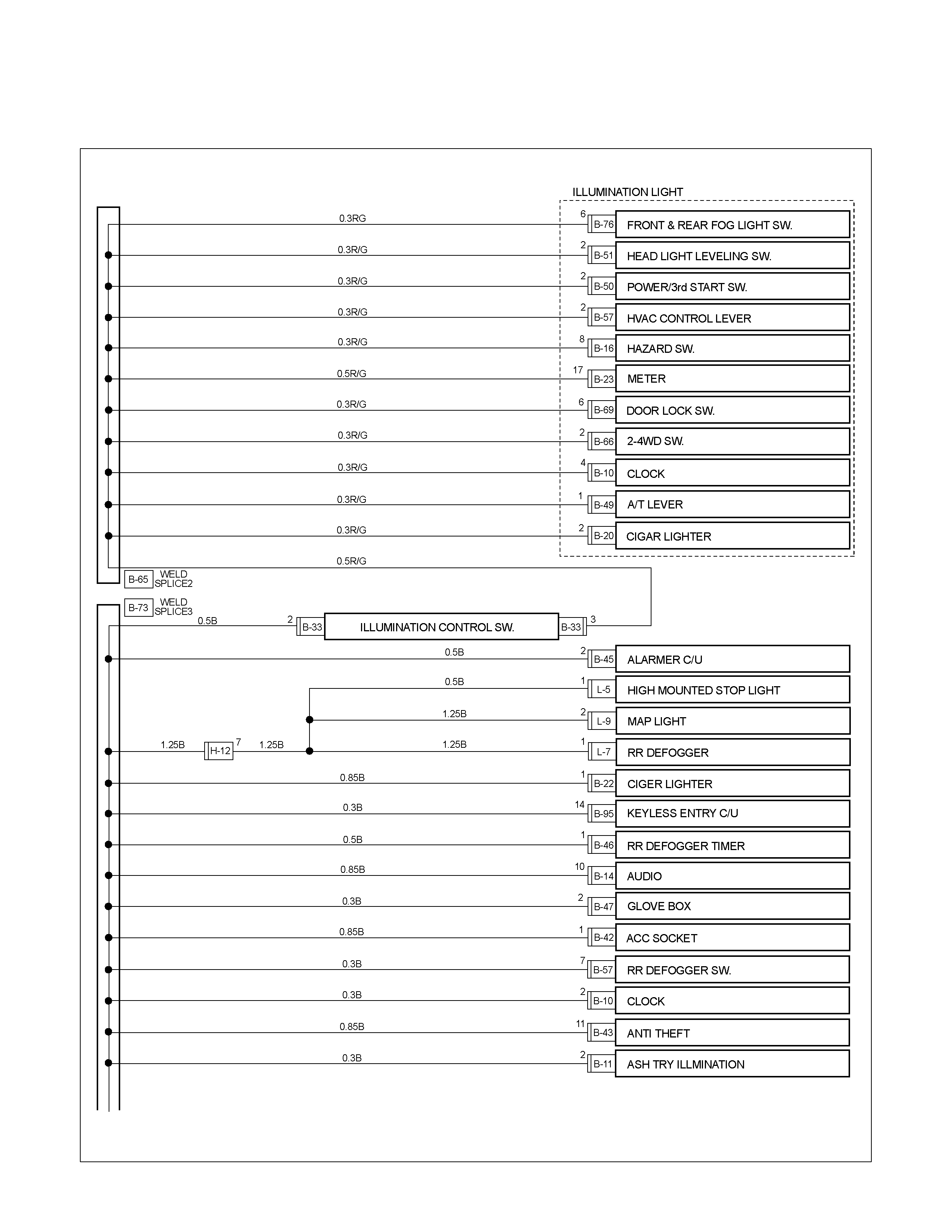

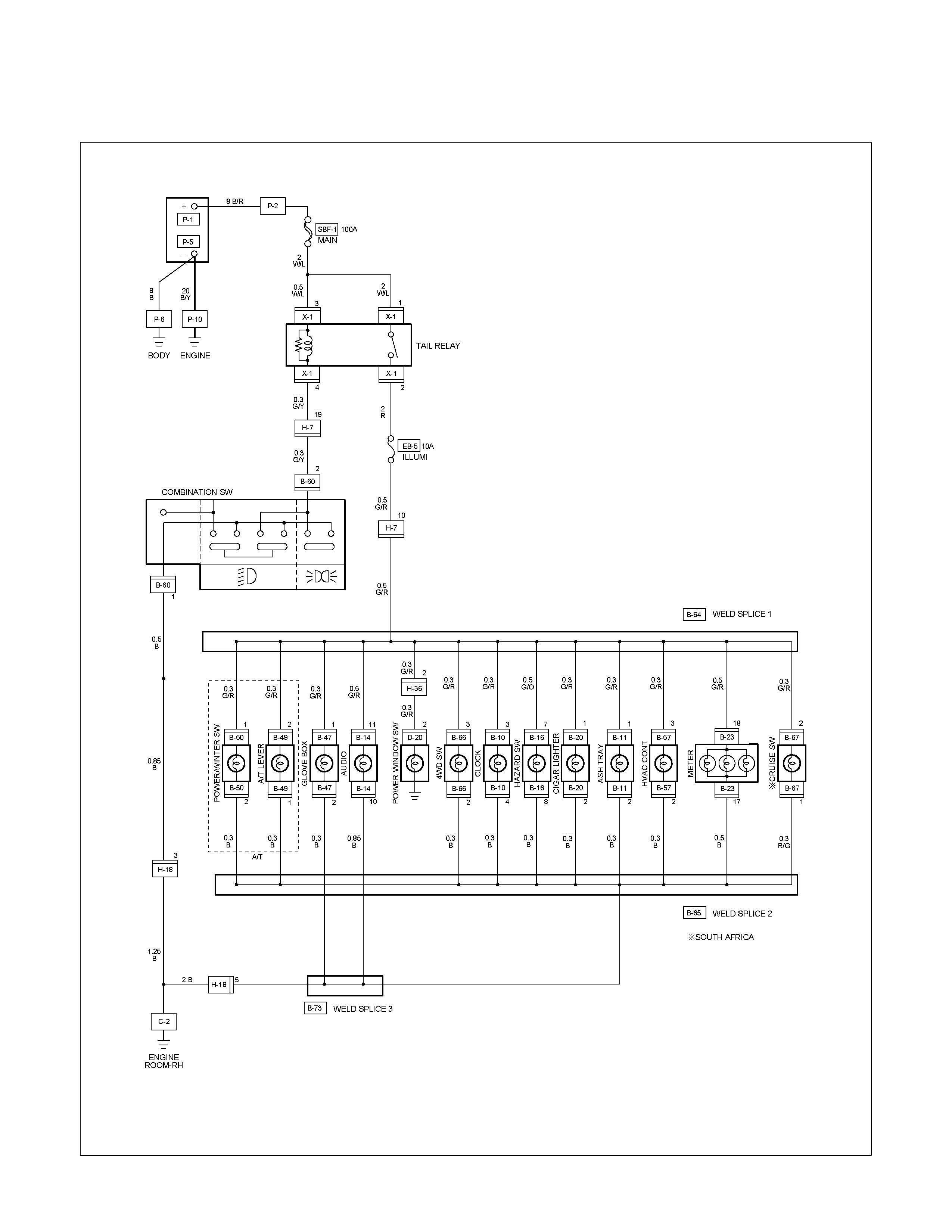

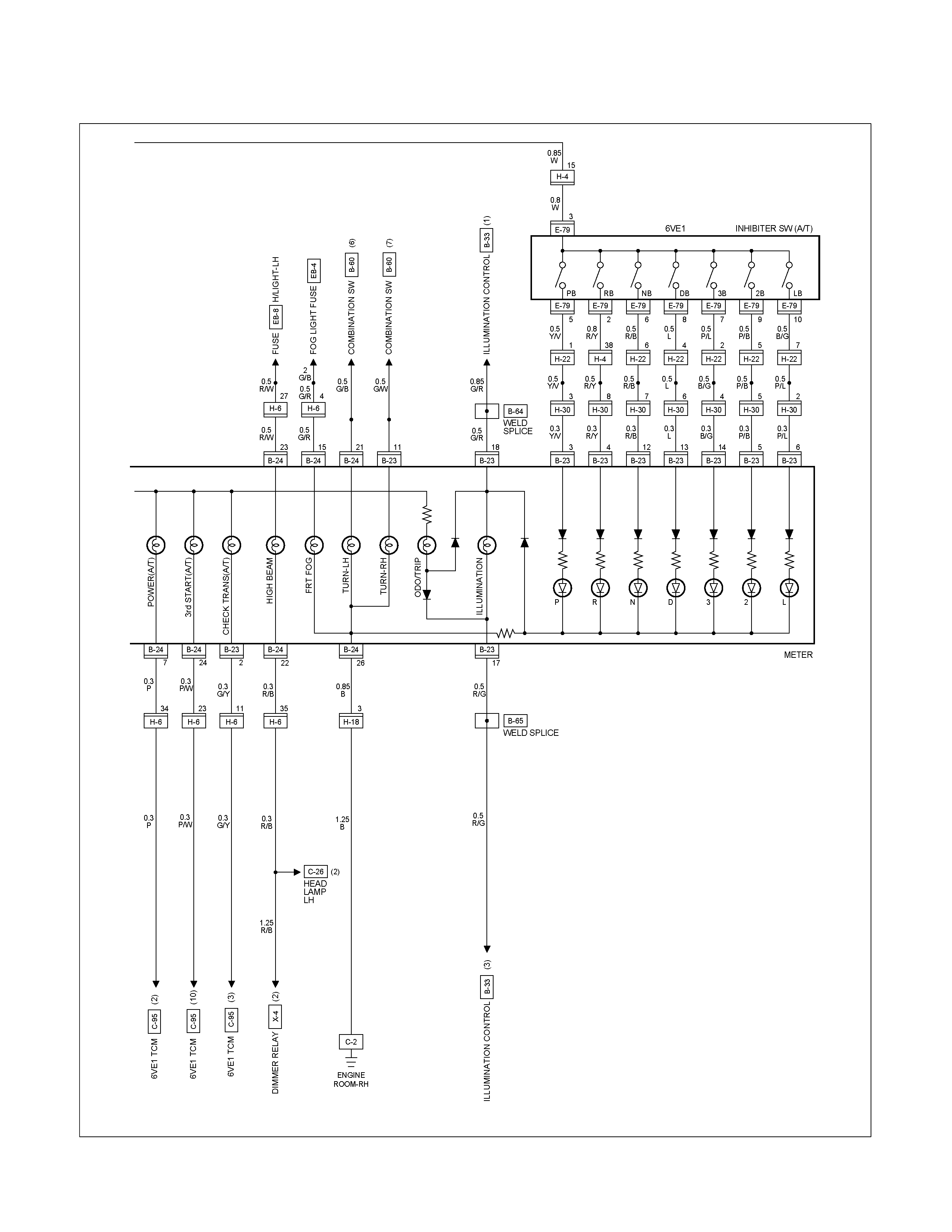

CIRCUIT DIAGRAM (RHD) WITHOUT ILLUMINATION CONTROL

RTW680XF007701

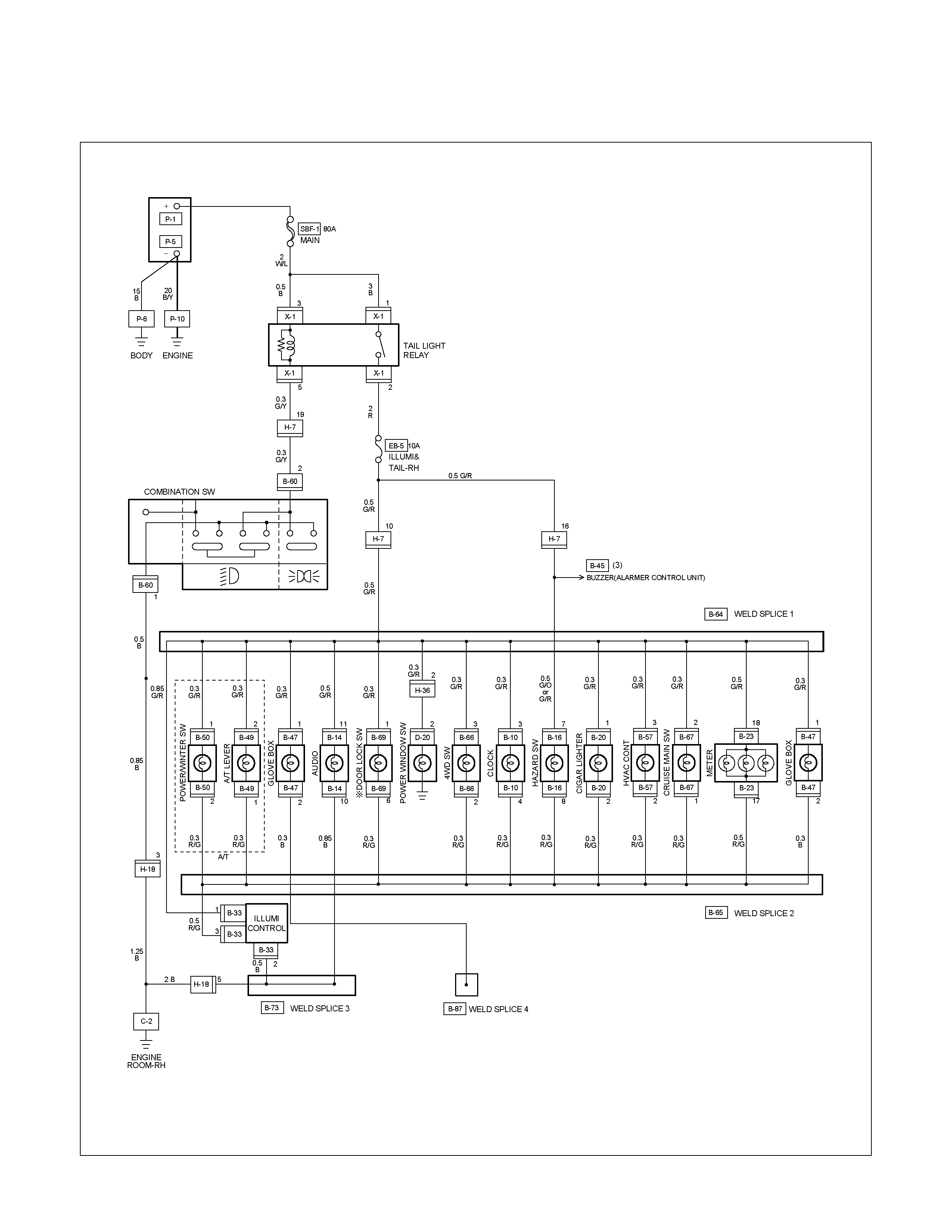

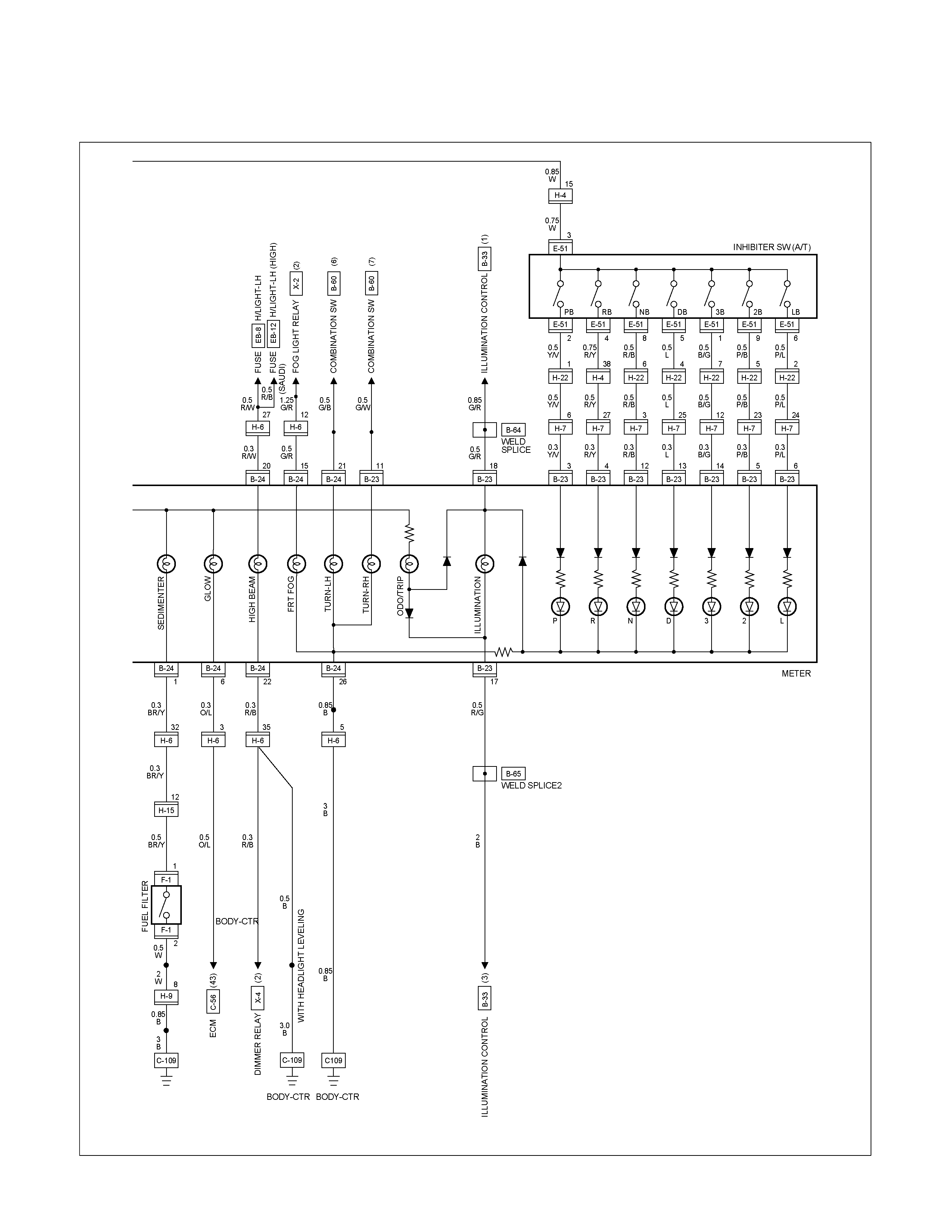

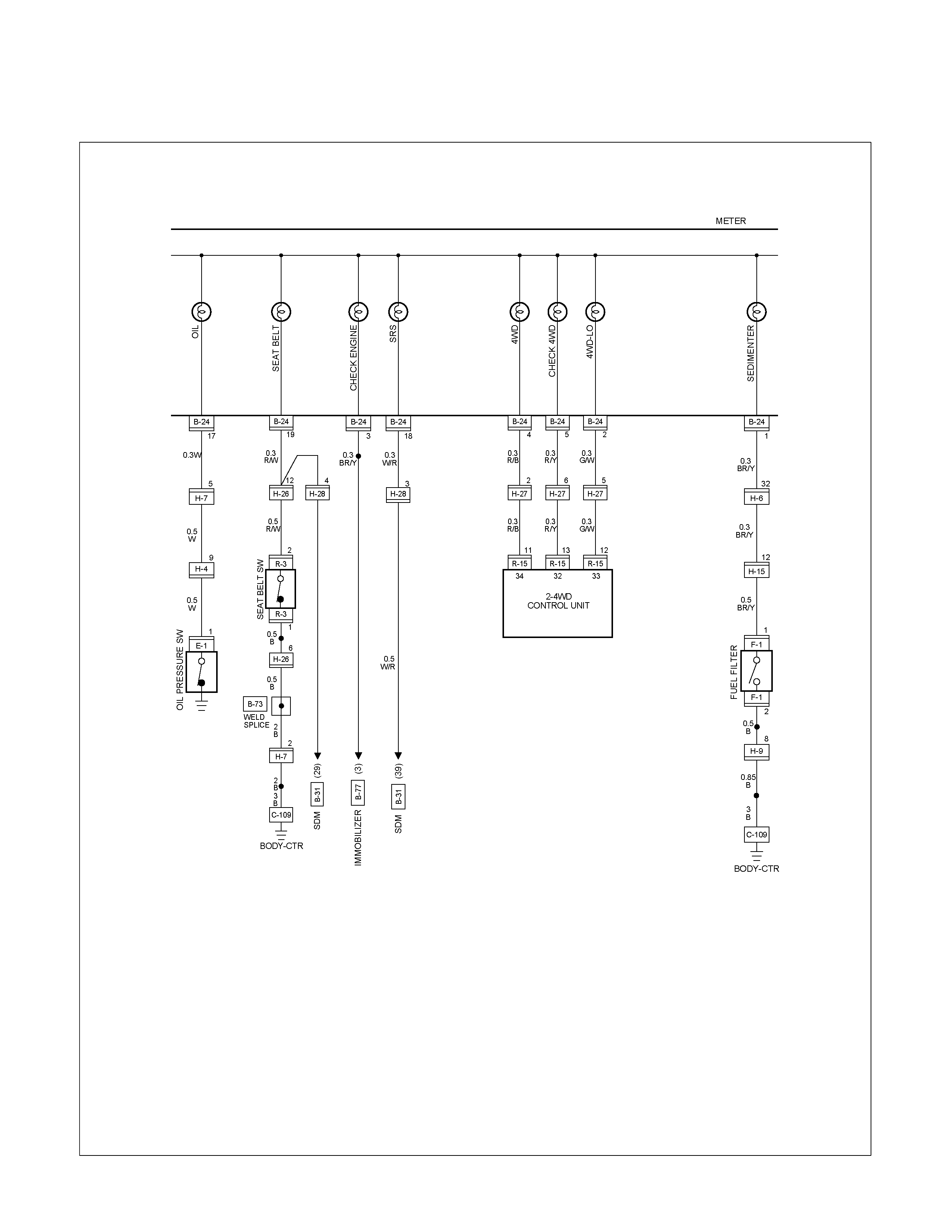

CIRCUIT DIAGRAM (RHD) EXCEPT HFV6 WITH ILLUMINATION CONTROL

RTW680XF007801

CIRCUIT DIAGRAM HFV6 WITH ILLUMINATION CONTROL

RTW68AXF010801

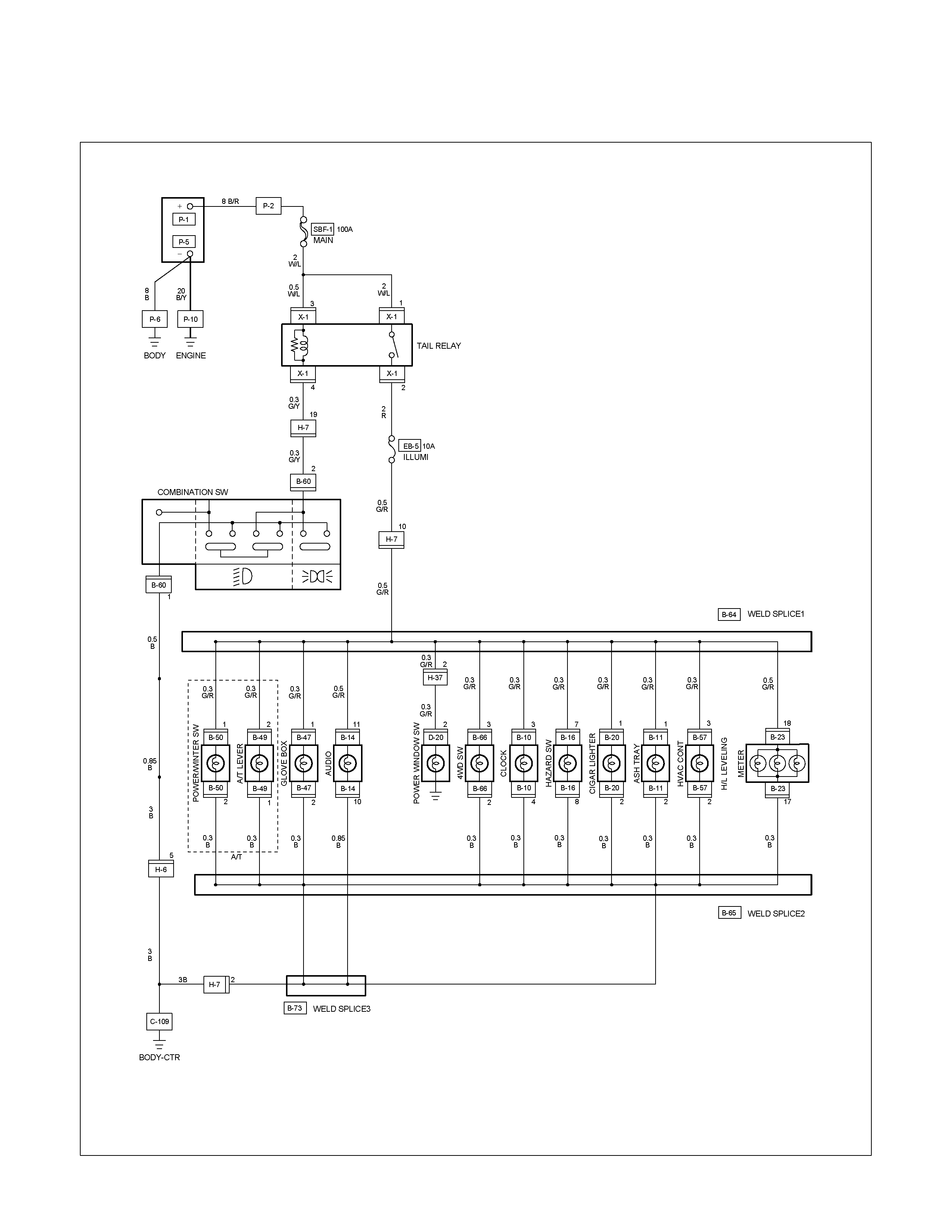

CIRCUIT DIAGRAM (LHD) WITHOUT ILLUMINATION CONTROL

RTW680XF007901

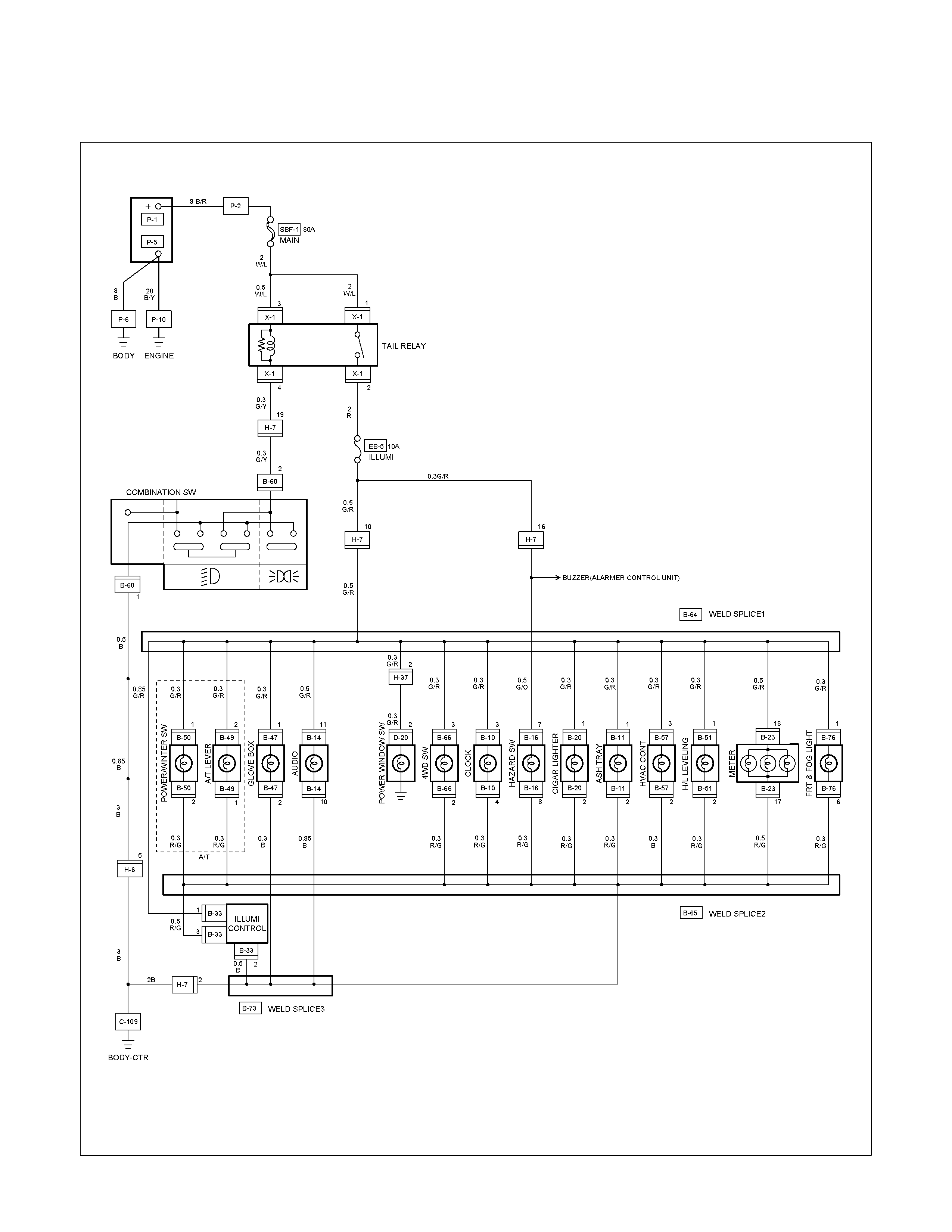

CIRCUIT DIAGRAM (LHD) WITH ILLUMINATION CONTROL

RTW680XF008001

RTU4Z0SH000901

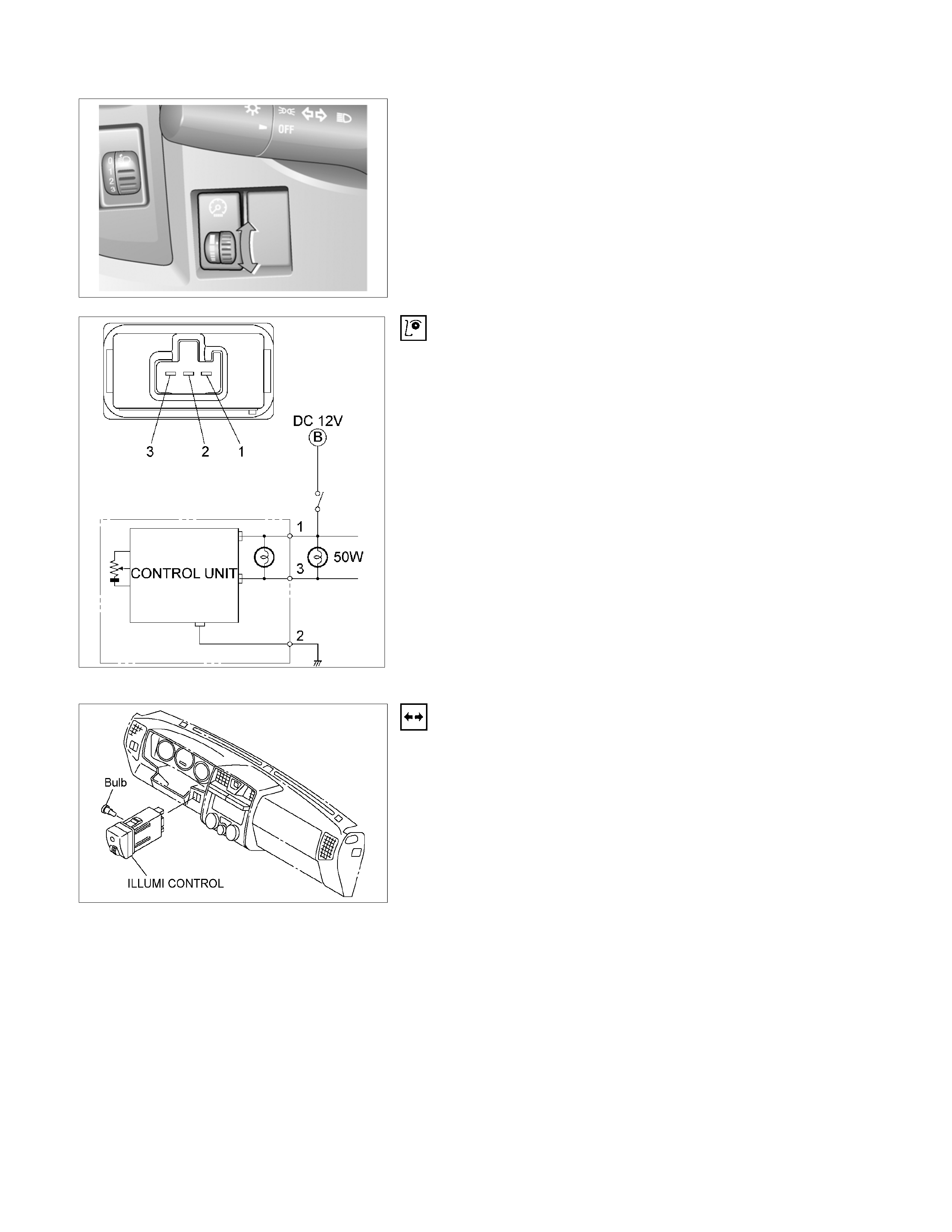

ILLUMINATION SWITCH

RTW48ASH000601

Inspection

Check to see if there is any continuity between the terminals of

the switch.

Replace the switch when the result of inspection is found

abnormal.

RTW48ASH000501

Removal

Preparation:

Disconnect the battery ground cable.

1. Instrument panel driver lower cover assembly

Refer to the removal steps Sec.10

2. Harness switch

3. Illumination control

To remove the switch, push the lock from the back side of

the cluster assembly.

4. Remove the bulb.

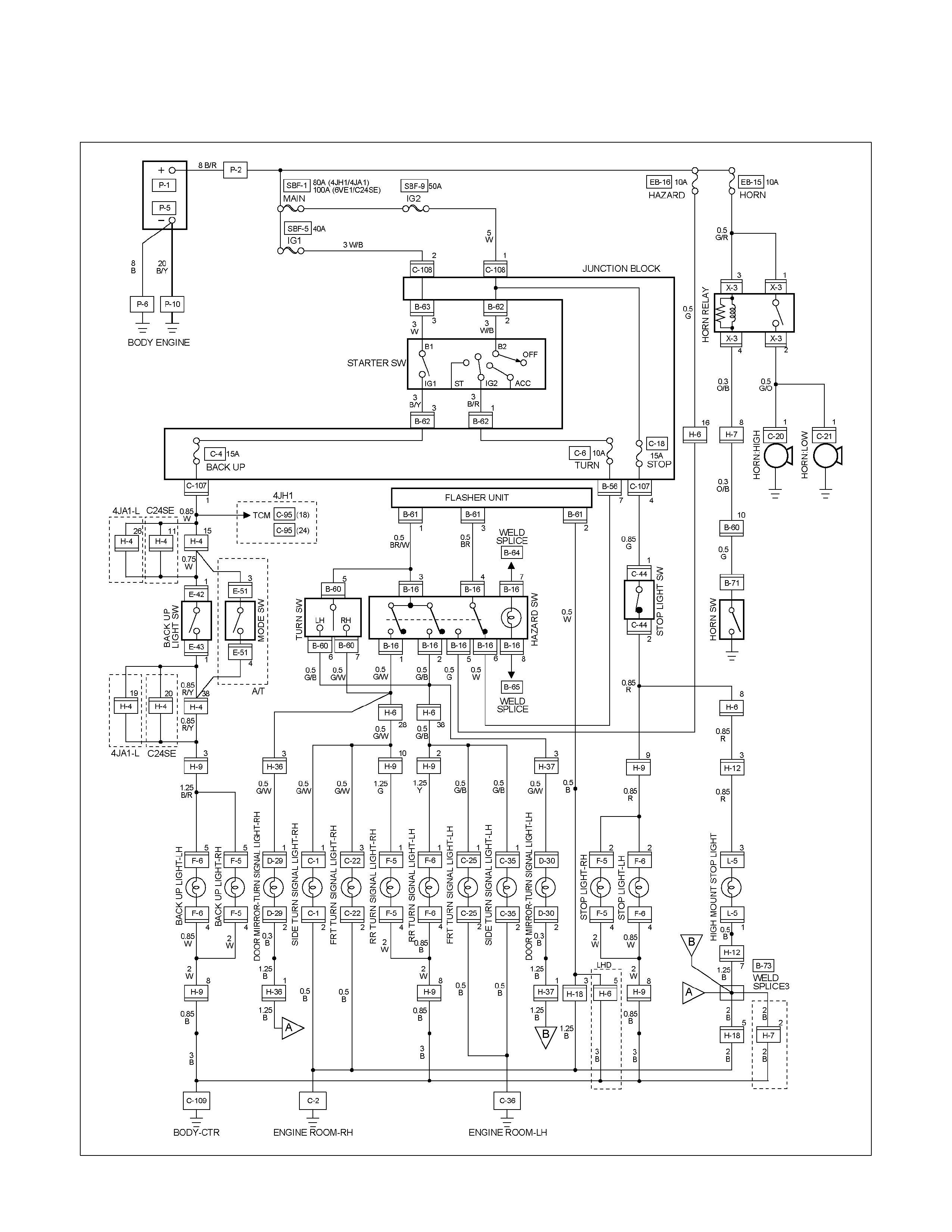

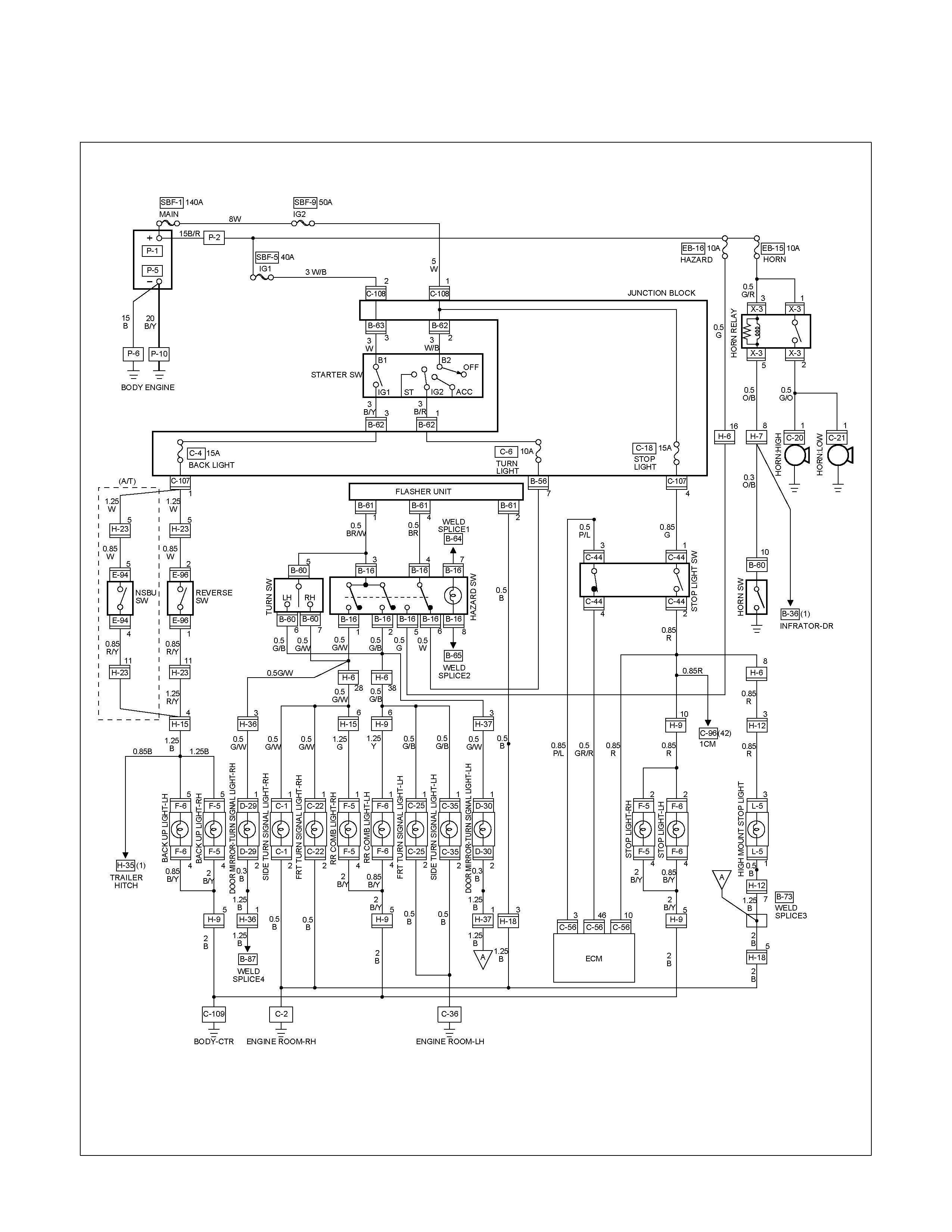

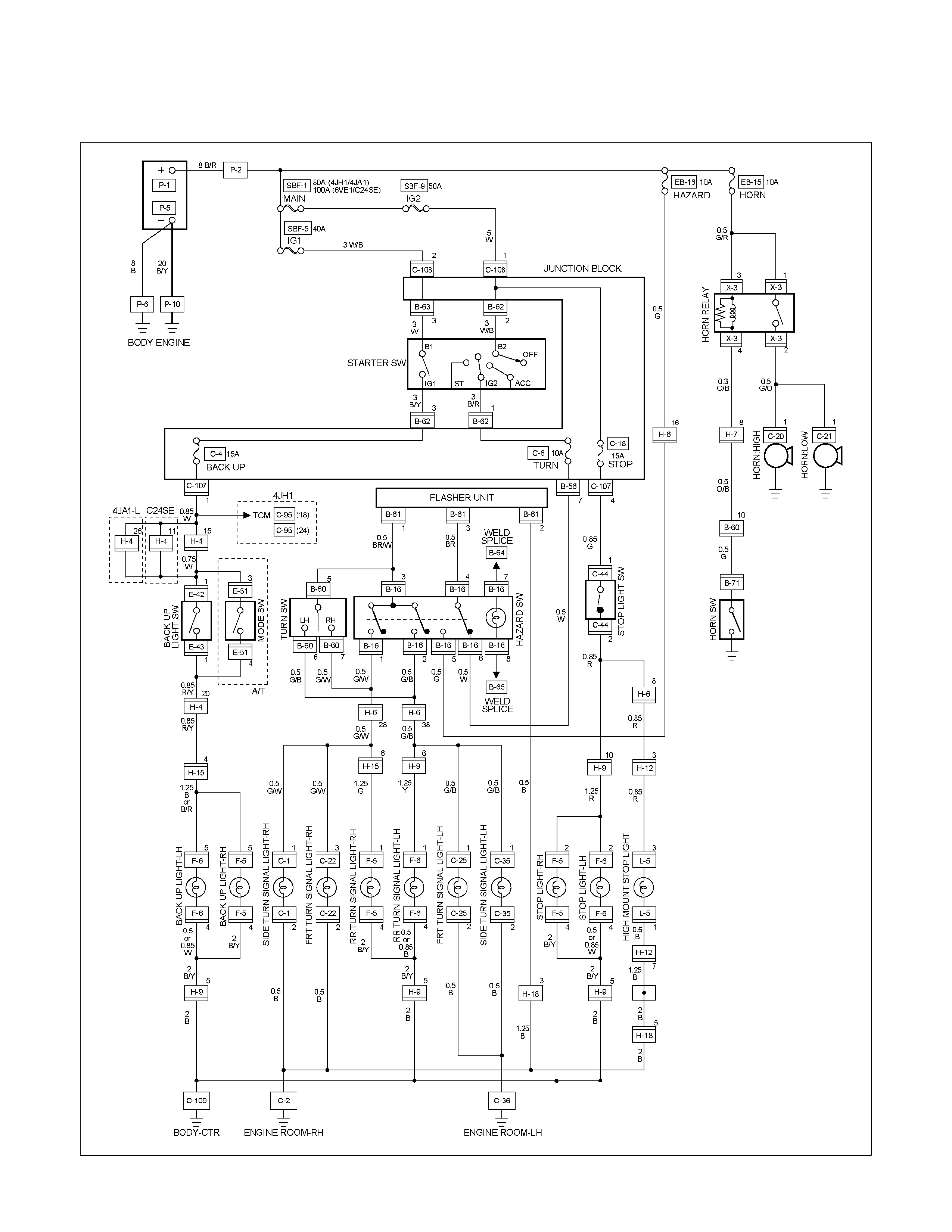

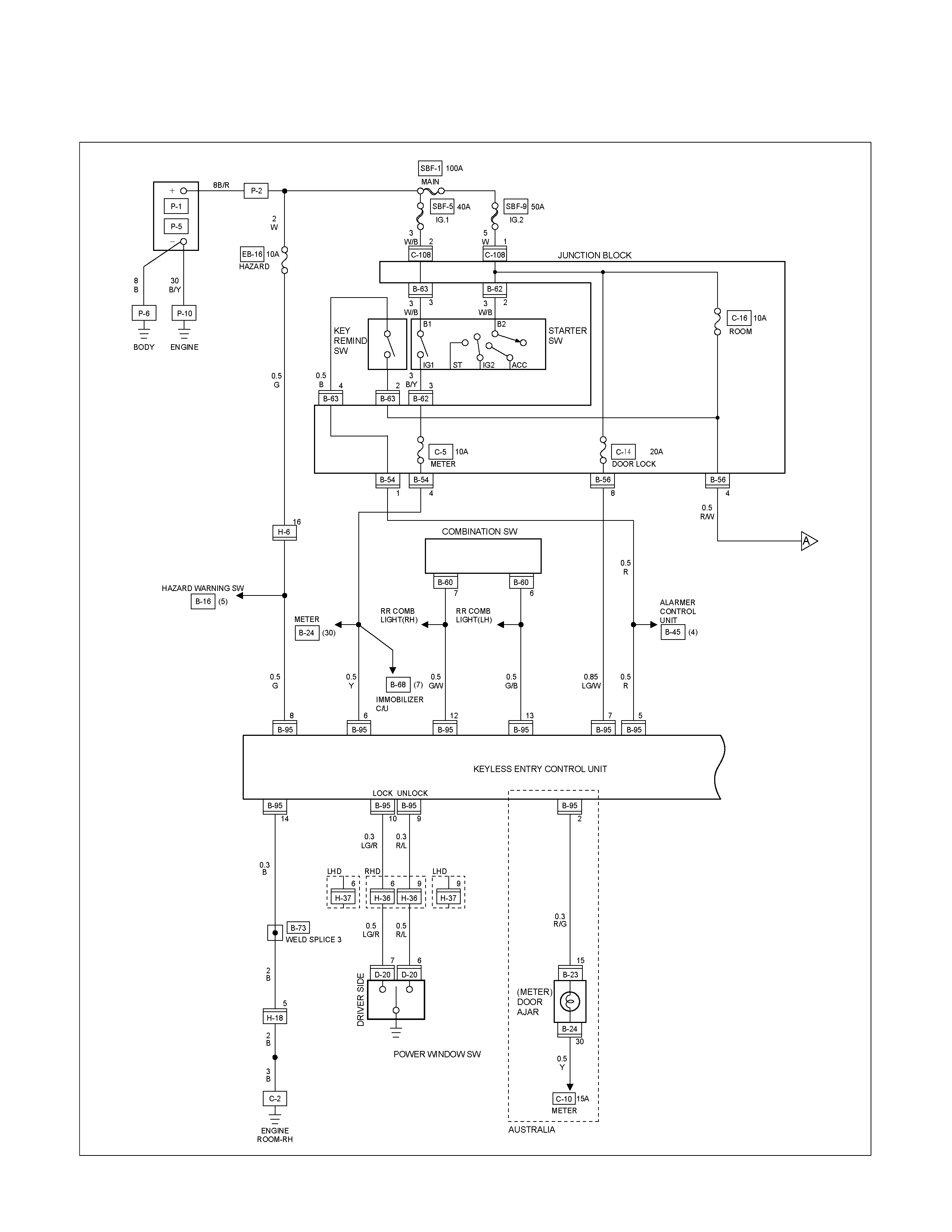

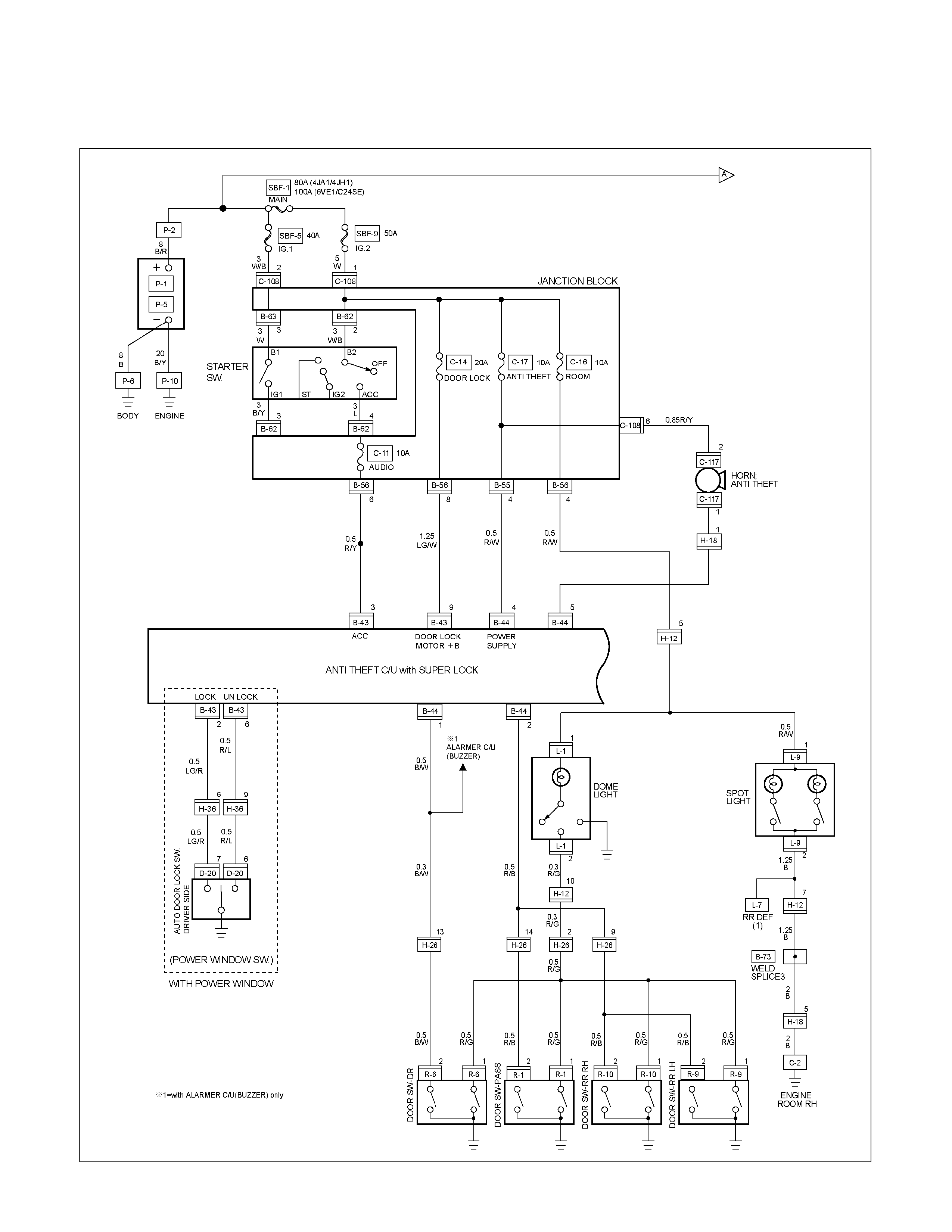

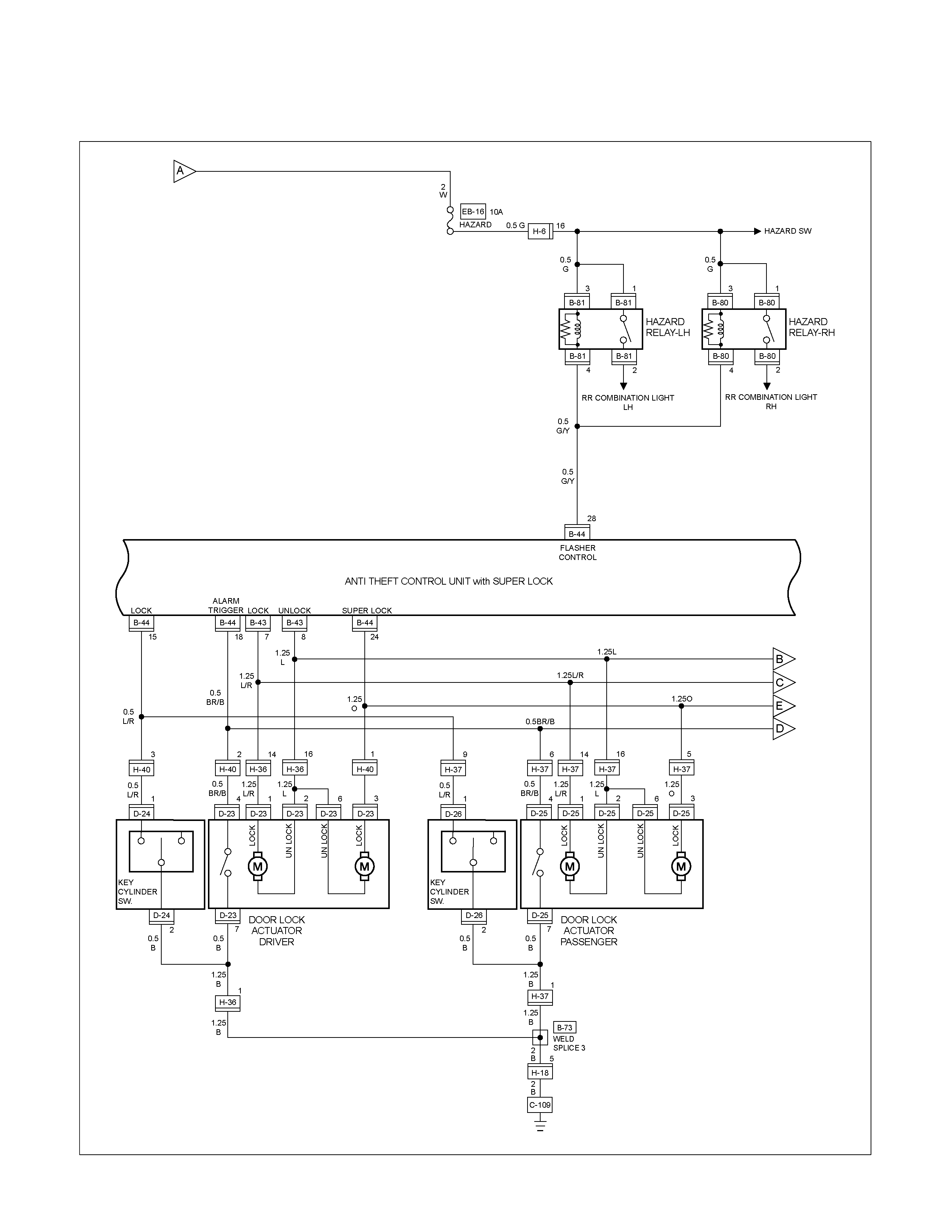

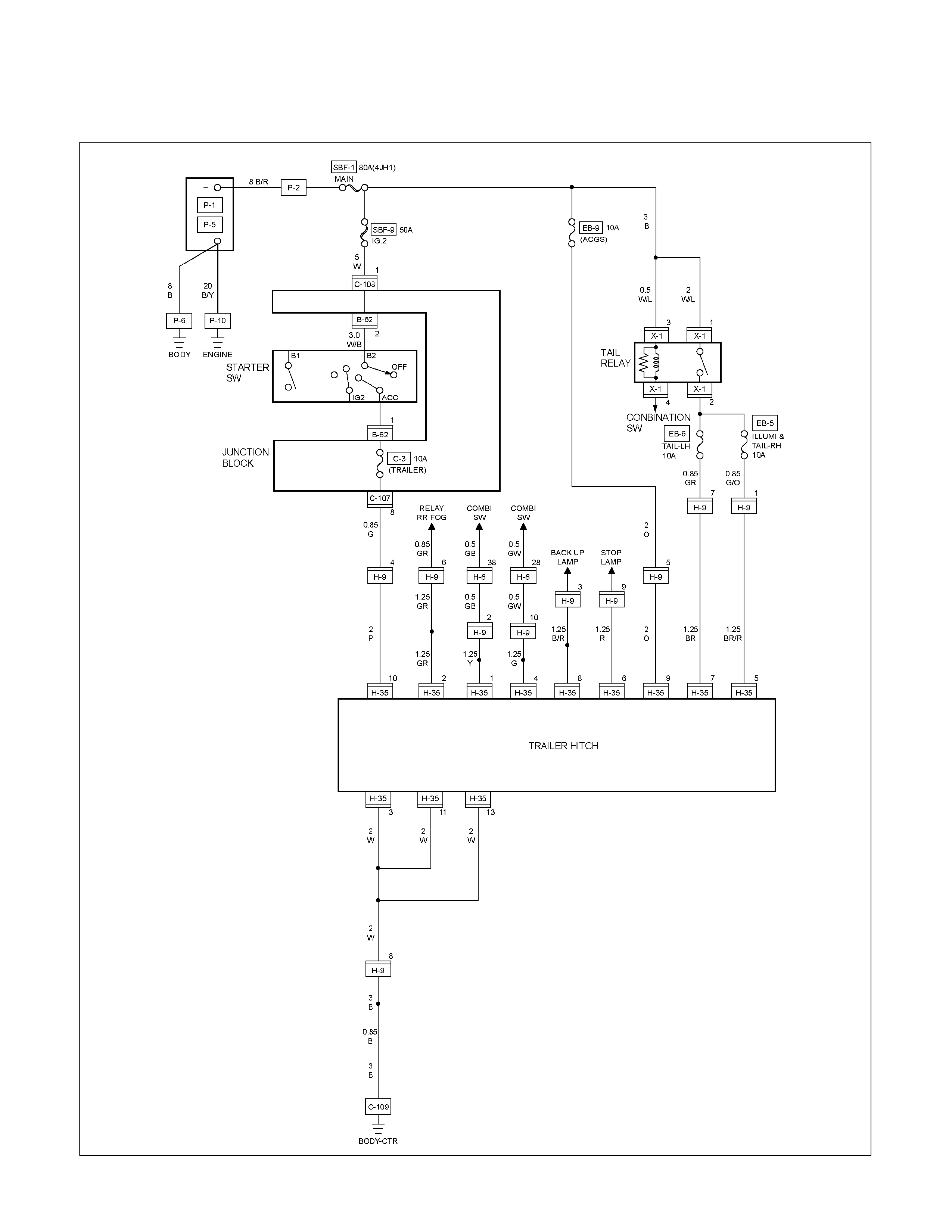

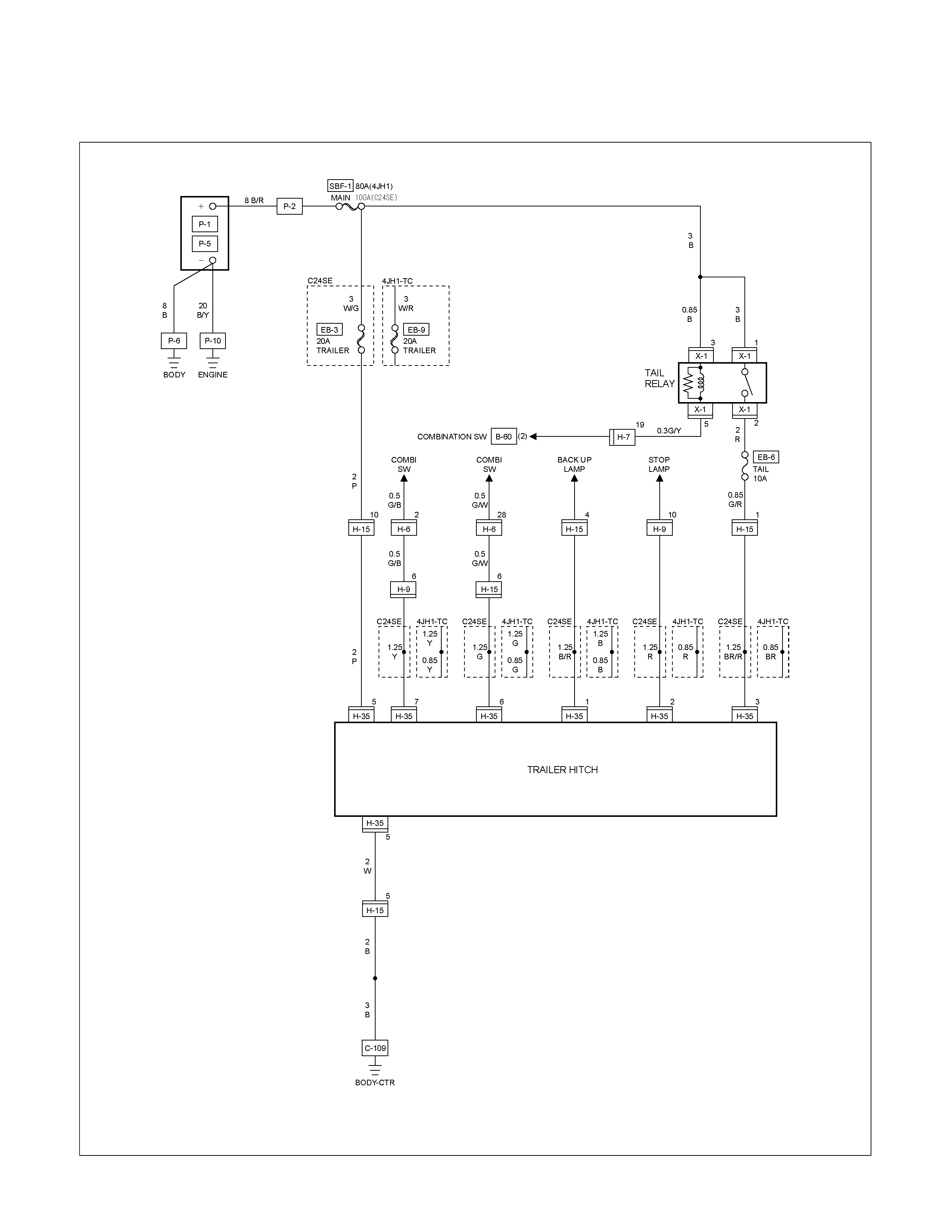

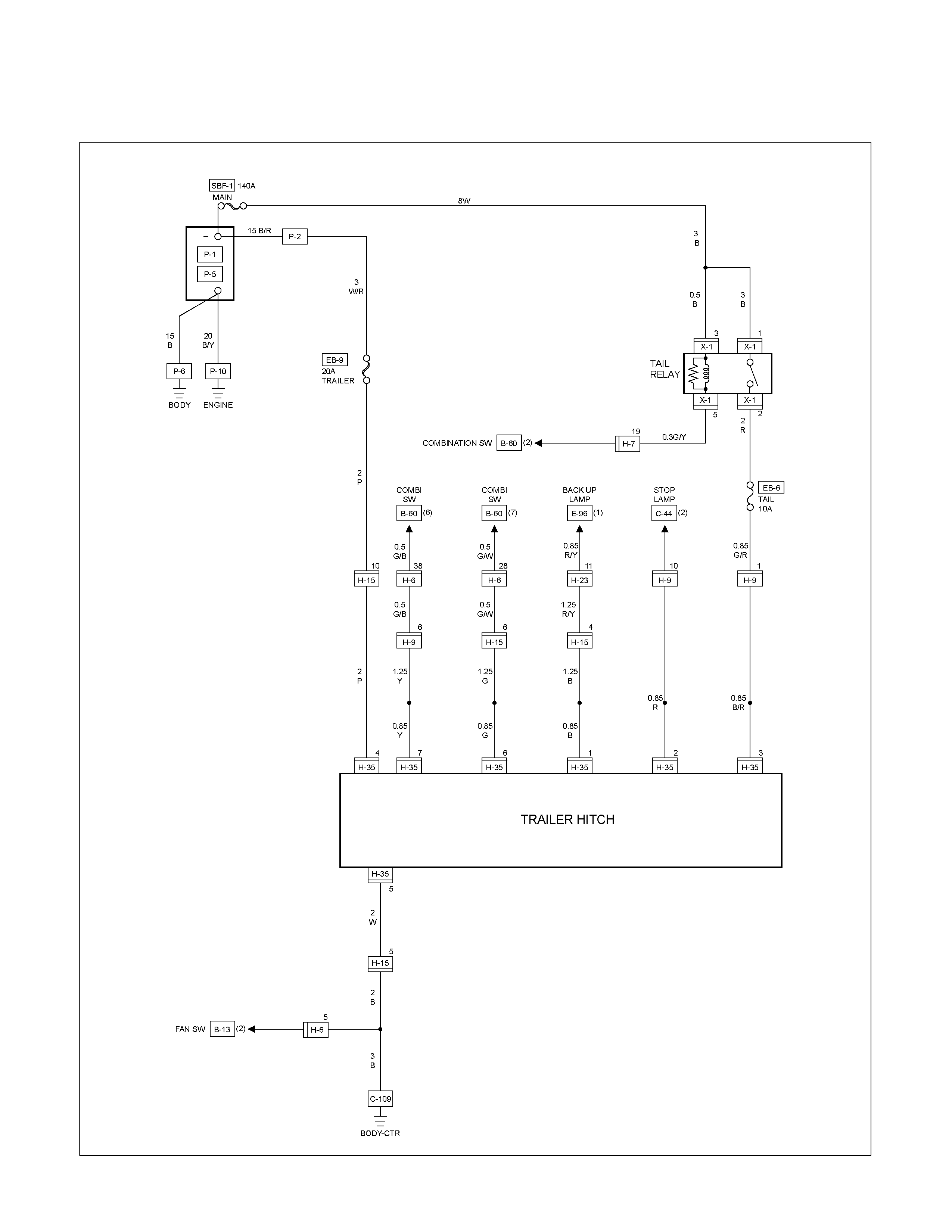

HAZARD WARNING FLASHER, TURN SIGNAL LIGHT, BACK UP

LIGHT, HORN AND STOP LIGHT

PARTS LOCATION (RHD)

RTW68AXF014501 & RTW68AXF014601

PARTS LOCATION (LHD)

RTW68AXF009301 & RTW48AXF16901

PARTS LOCATION (LHD)

RTW68AXF012201

PARTS LOCATION

RTW38DXF007501

PARTS LOCATION

RTW48AXF013001

CIRCUIT DIAGRAM EXCEPT AUSTRALIA

RTW680XF008101

CIRCUIT DIAGRAM HFV6 AUSTRALIA

RTW68AXF010901

CIRCUIT DIAGRAM EXCEPT HFV6 AUSTRALIA

RTW680XF008201

TROUBLESHOOTING

STOPLIGHT AND HIGH MOUNTED STOPLIGHT

1. One side of stoplight does not light

Checkpoint Trouble Cause Countermeasure

Replace the bulb or repair

connector contact

Burned out bulb or poor

connector contact

NG

Repair open circuit or

connector contact

Repair open circuit or

connector contact

Open circuit or poor connector

contact

Continuity between

9 H-9 - 2 F-6 (LH) (or

2 F-5 (RH))

Open circuit or poor connector

contact

Continuity between

8 H-9 - 4 F-6 (LH) (or

4 F-5 (RH))

NG

NG

OK

OK

Stoplight bulb continuity

2. Both sides of stoplight do not light

Adjust the switch insta llation

position

Stop light switch (or brake

switch) function

Incorrect the switch installation

or adjustment

NG

Repair open circuit or

connector contact

Voltage between 2 F-6

ground or 2 F-5 - ground

with brake pedal depressed

(Should be battery voltage

present)

Open circuit or poor connector

contact between stoplight

switch (or brake switch) and

stoplight

NG

OK

Reinstall or replace fuse No.

SBF-9 (50A)

or 1

C-108 - 4

C-107

Fuse No. C-18 (15A)

Fuse No. SBF-9 (50A, Fuse

and Relay box)

or 1

C-108 - 4

C-107

Fuse No. C-18 (15A)

Poor fuse contact or blown

NG

OK

3. High mounted stoplight does not light

Checkpoint Trouble Cause Countermeasure

Repair or replace the high

mounted stoplight

Continuity between 3 L-5 -

1 L-5

High mounted stoplight

malfunction

NG

Repair an open circuit or

connector contact between

3 L-5 - 5 H-18 (RHD) or

2 H-7 (LHD)

Voltage between 1 L-5 -

ground with brake pedal

depressed

(Should be battery voltage

present)

Open circuit or poor connector

contact

NG

OK

Repair grounding point contact

C-2

Grounding point C-2

Poor grounding point contact

NG

OK

TURN SIGNAL LIGHT AND HAZARD WARNING LIGHT

1. Turn signal light does not light on both sides (RH and LH)

Checkpoint Trouble Cause Countermeasure

Replace the flasher unit

Flasher unit malfunction

NG

Repair or replace the

combination switch

Turn signal switch continuity

between connector

5 B-60 - 6 B-60 and

5 B-60 - 7 B-60 when

turn signal switch operates

Short circuit between

connector 3 B-61 - 1 B-61

when turn signal switch

operates with starter switch

in “ON” position (Turn

signal light should be ON)

Poor switch point contact or

faulty switch

NG

OK

Reinstall or replace fuse No.

EB-16 (10A)

Fuse No. EB-16 (10A, Fuse

box)

Poor fuse contact or blown

fuse

NG

OK

OK

Repair open circuit or

connector contact

Continuity between

connector 2 B-61 -ground

(Should be continuity)

Open circuit or poor connector

contact

NG

2. Turn signal light does not light on one side (RH or LH)

Checkpoint Trouble Cause Countermeasure

Repair open circuit or

connector contact

Open circuit or poor connector

contact

NG

(LH)

Continuity between

1 C-25 - 6 B-60 (FRT),

1 C-35 - 6 B-60 (SIDE)

1 F-6 - 6 B-60 (RR)

(RH)

Continuity between

3 C-22 - 7 B-60 (FRT),

1 C-1 - 7 B-60 (SIDE)

1 F-5 - 7 B-60 (RR)

Repair or replace the

combination switch

Turn signal switch continuity

Poor switch point contact or

faulty switch

NG

OK

OK

Repair open circuit or

connector contact

Open circuit or poor connector

contact

NG

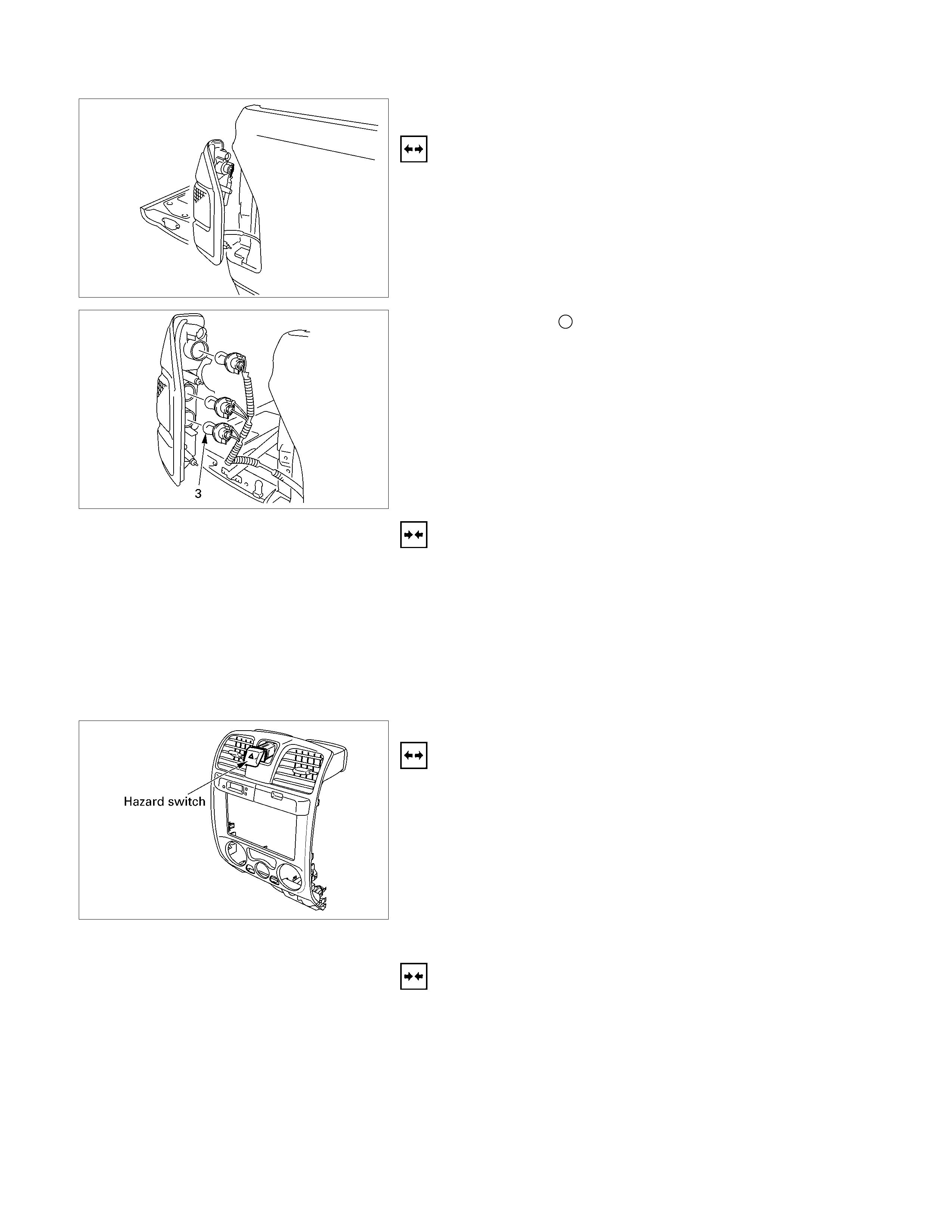

3. Hazard warning light does not light

Repair or replace the hazard

SW.

Hazard SW. malfunction

NG

Voltage between 5 B-16 -

ground (Should be battery

voltage present)

Hazard SW. continuity

Reinstall or replace the fuse

No. EB-16 (10A)

Fuse No. EB-16 (10A, Relay

and fuse box)

Poor fuse contact or blown

fuse

NG

OK

OK

Repair open circuit or

connector contact

Open circuit or poor

connector contact between

fuse No. EB-16 (10A) -

5 B-16

NG

4. Flashing rate too fast (One side)

Replace the bulb or repair

open circuit

Inspect bulb Burned out bulb

NG

BACKUP LIGHT

1. Backup light does not light on one side (RH or LH)

Checkpoint Trouble Cause Countermeasure

Repair grounding point contactPoor ground contact

NG

Grounding point

Replace the bulb or repair

connector contact

Backup light bulb continuity Burned out bulb or poor

connector contact

NG

OK

2. Backup light does not light on both sides

Repair or replace the switch

Poor switch point contact of

faulty switch

NG

Voltage between 5 F-6

(5 F-5 ) - ground with

starter switch ON and shift

lever into reverse position

(Should be battery voltage

present)

Back up light switch (mode

switch) continuity

Reinstall or replace fuse No.

C-4 (15A)

Fuse No. C-4 (15A, Fuse box)

Poor fuse contact or blown

fuse

NG

OK

OK

Repair open circuit or

connector contact

Open circuit or poor connector

contact

NG

HORN

1. Both sides of horn do not sound

Checkpoint Trouble Cause Countermeasure

Repair the grounding point

Poor ground contact

NG

Horn relay

Grounding point

Reinstall or replace fuse No.

EB-15 (10A)

Fuse No EB-15 (10A, Relay

and fuse box)

Poor fuse contact or blown

fuse

NG

OK

OK

Reinstall or replace the horn

relay

Poor relay contact or faulty

horn relay

NG

Voltage between connector

3 X-3 - ground or 1 X-3

- ground (Should be battery

voltage present)

OK

Repair open circuit or

reconnect the connector

Open circuit or poor connector

contact between fuse No. EB-

15 (10A) and horn relay

NG

Remove steering pad and

steering wheel

OK

Horn switch continuity

OK

Repair or replace the horn

switch

Poor switch point contact or

faulty switch

NG

Continuity between

4 X-3 - 10 B-60

2 X-3 - 1 C-20 (1 C-21 )

OK

Repair open circuit or

connector contact

Open circuit or poor connector

contact

NG

2. One side of horn does not blow

Checkpoint Trouble Cause Countermeasure

Repair open circuit or

reconnect the connector

Open circuit or poor connector

contact

NG

Voltage between 1 C-20

(1 C-21 ) - ground with

horn switch depressed

(Should be battery voltage

present)

Replace the horn assembly

Horn continuity between

connectors Faulty horn assembly

NG

OK

3. Insufficient horn volume

Clfean and/or remove the

foreign material

Stain foreign material in the

horn

NG

Horn

Recharge or replace the

battery

Battery condition Discharged battery

NG

OK

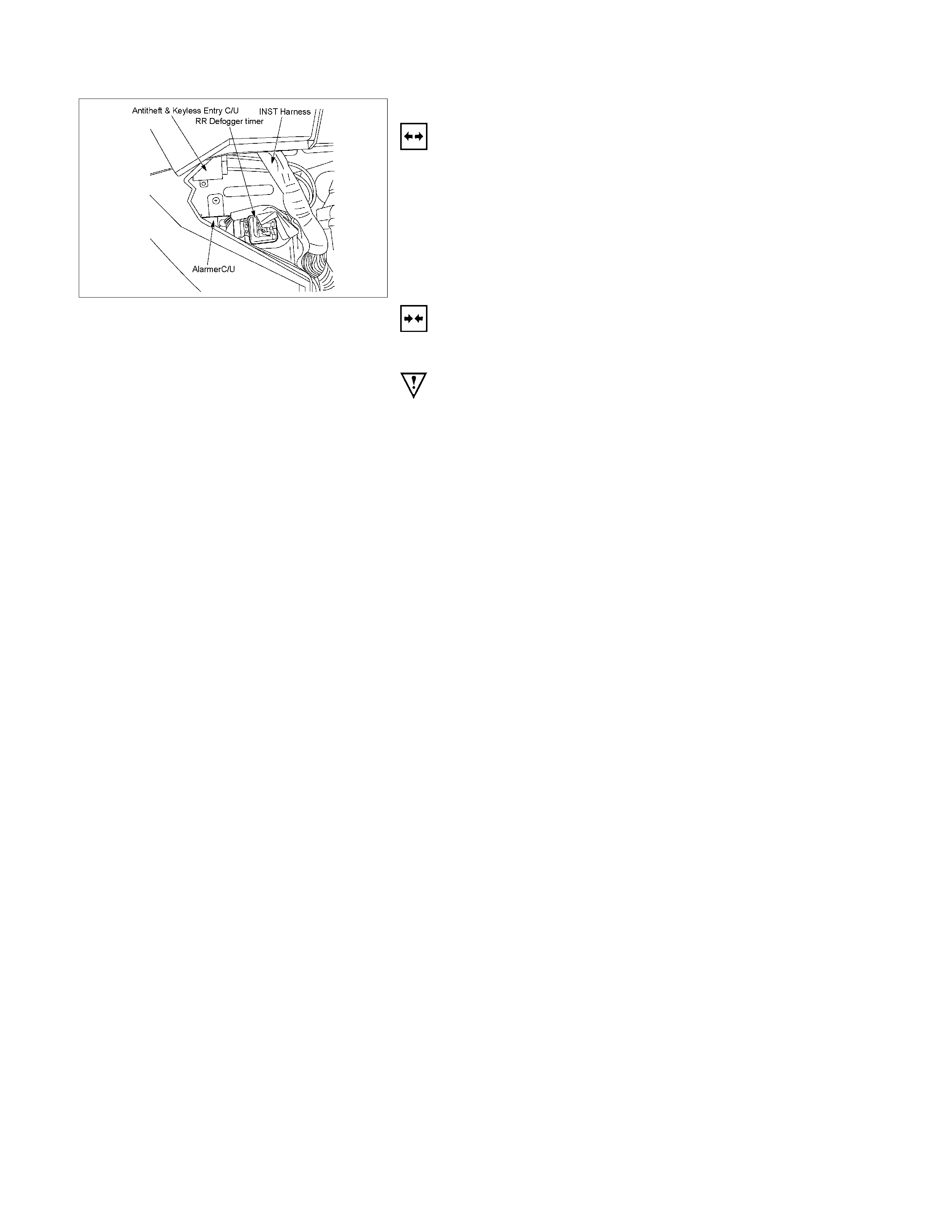

REMOVAL AND INSTALLATION

REAR COMBINATION LIGHT

Stoplight

Removal

1. Open the rear gate.

2. Remove the screws of rear combination light.

3. Remove the rear combination light assembly.

4. Turn the bulb 2 counterclockwise to remove it.

Installation

Follow the removal procedure in the reverse order to install the

rear combination light.

Pay close attention to the important points mentioned in the

following paragraphs.

Bulb

Be absolutely sure that each bulb is correctly installed.

This will prevent a poor contact and an open circuit.

HIGH MOUNTED STOPLIGHT

Remove the bulb socket

1. Remove the high mounted stoplight ASM.

• Remove the screws.

• Disconnect the connector.

2. Remove the bulb socket.

• Turn the bulb 1 counterclockwise to remove it.

Installation

Follow the removal procedure in the reverse order to install the

rear combination light.

Pay close attention to the important points mentioned in the

following paragraphs.

Bulb

Be absolutely sure that each bulb is correctly installed.

This will prevent a poor contact and an open circuit.

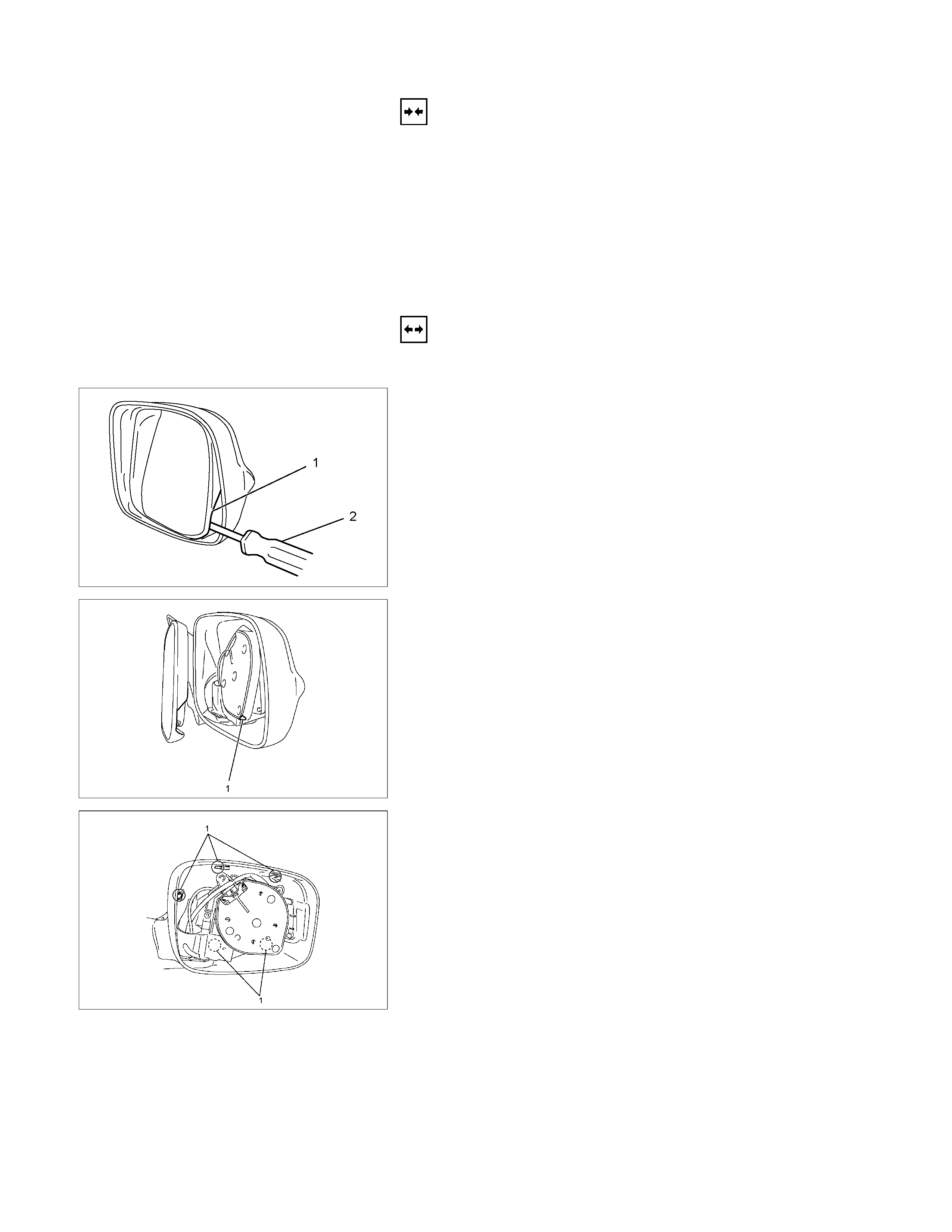

DOOR MIRROR - TURN SIGNAL LIGHT

Removal

1. Pull the lower outside corner of the mirror toward you.

RUW580SH000701

2. Press the blade of an ordinary screwdriver (2) into the

mirror outside groove near the mirror base hole (1).

RUW580SH000801

3. Turn the blade of the screwdriver 90 degrees to separate

the parts (1).

RUW580SH000901

4. Use an ordinary screwdriver inserted into the inner groove

(1) of the outside mirror case to pry off the outside panel (it

pasts up on butyl tape). Do this at 5 points around the

groove.

RUW580SH001001

5. Insert an ordinary screwdriver into the inner groove (1) o

f

the door mirror - turn signal light. Pry the light free.

6. Disconnect the connector (2).

Installation

Follow the removal procedure in the reverse order to install the

door mirror - turn signal light.

Pay close attention to the important points mentioned in the

following paragraphs.

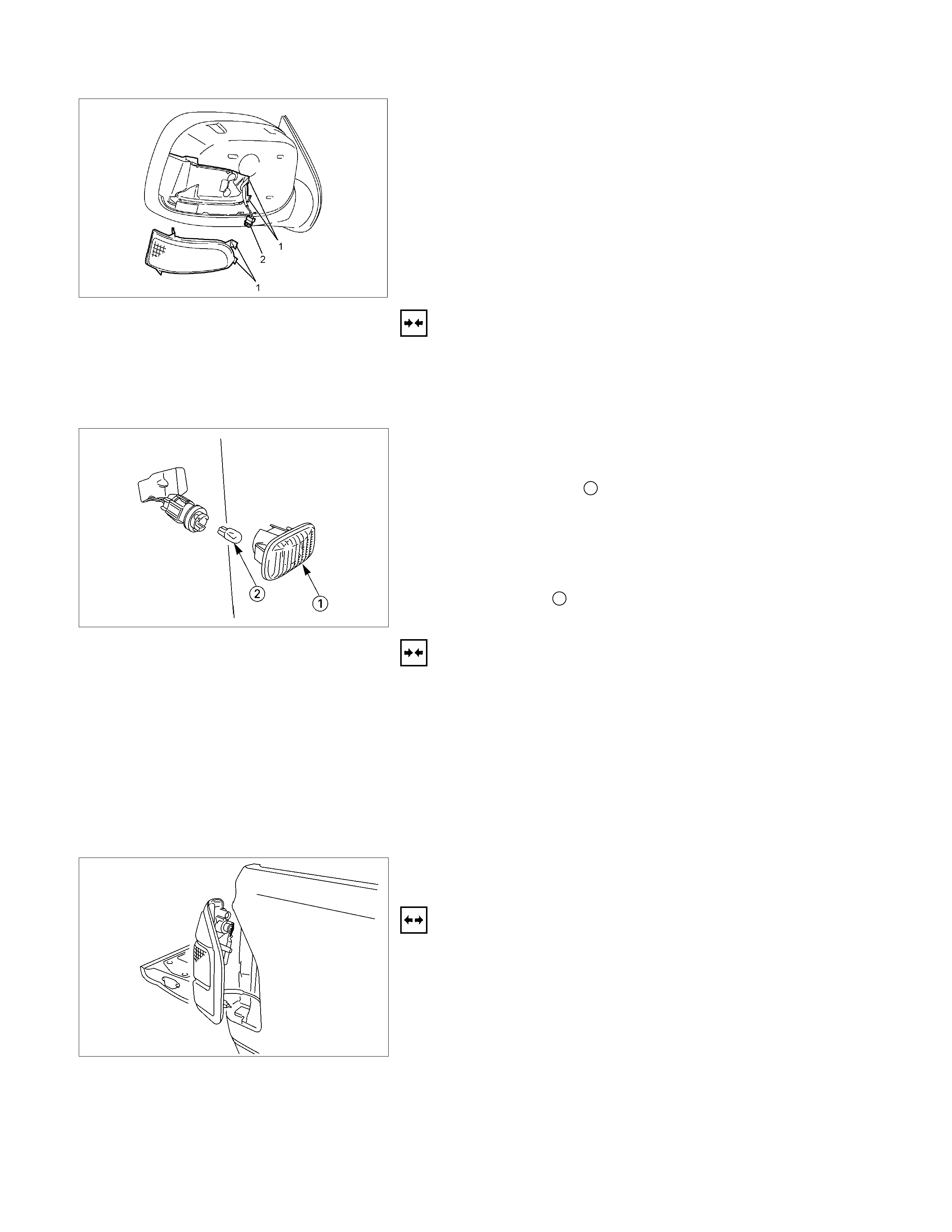

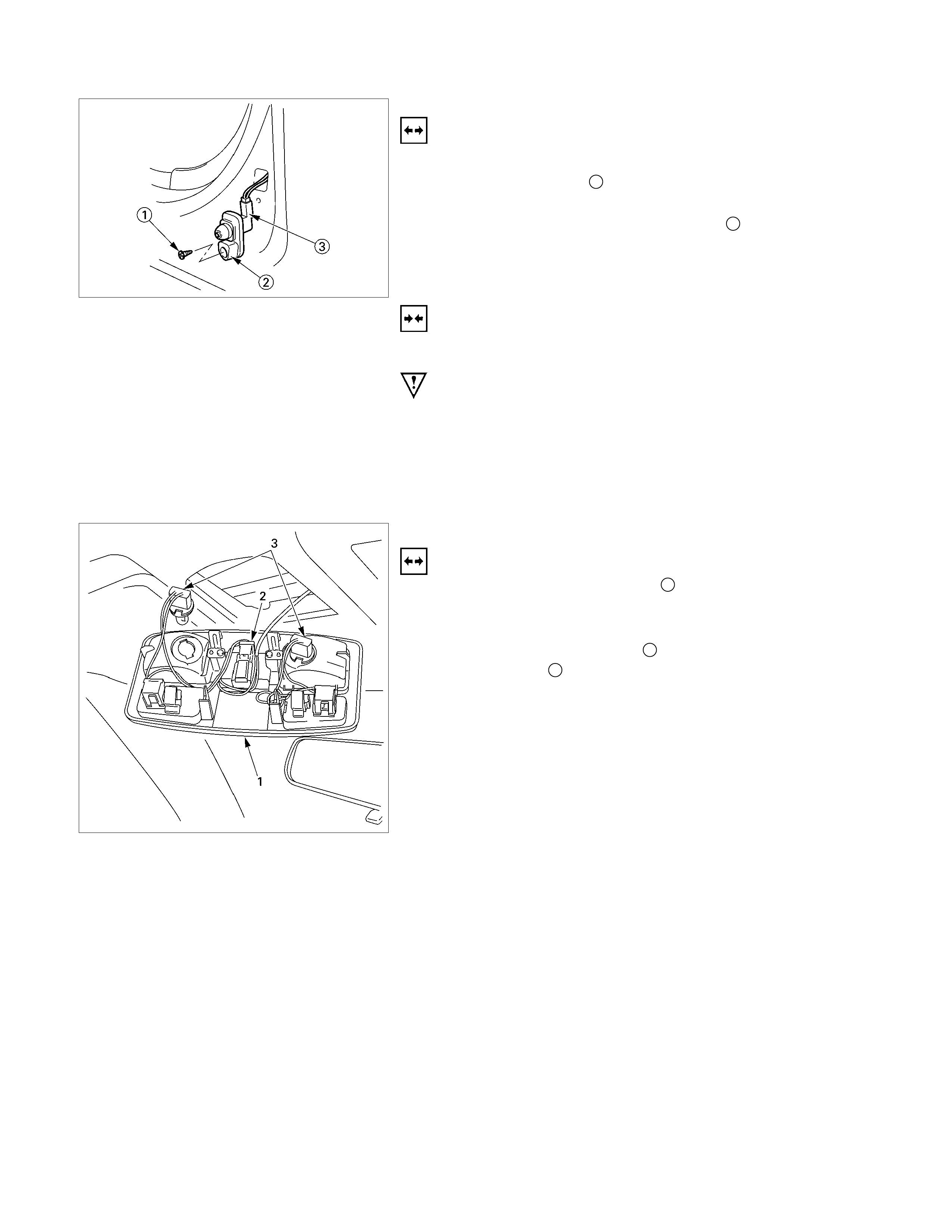

SIDE TURN LIGHT

Removal

1. Remove the lens 1.

• Pull the light/bulb toward you while pushing the light

housing in the rear direction of the vehicle to release its

lock.

• Remove the socket by turning it counterclockwise.

2. Pull the bulb 2 to remove it.

Installation

Follow the removal procedure in the reverse order to install the

side turn light.

Pay close attention to the important points mentioned in the

following paragraphs.

Bulb

Be absolutely sure that the side turn light bulb is correctly

installed.

This will prevent a poor contact and an open circuit.

REAR COMBINATION LIGHT

Turn Signal Light

Removal

1. Open the rear gate.

2. Remove the screws.

3. Remove the rear combination light assembly.

4. Turn the bulb 1 counterclockwise to remove it.

Installation

Follow the removal procedure in the reverse order to install the

rear combination light.

Pay close attention to the important points mentioned in the

following paragraphs.

Bulb

Be absolutely sure that the rear combination light bulb is

correctly installed.

This will prevent a poor contact and an open circuit.

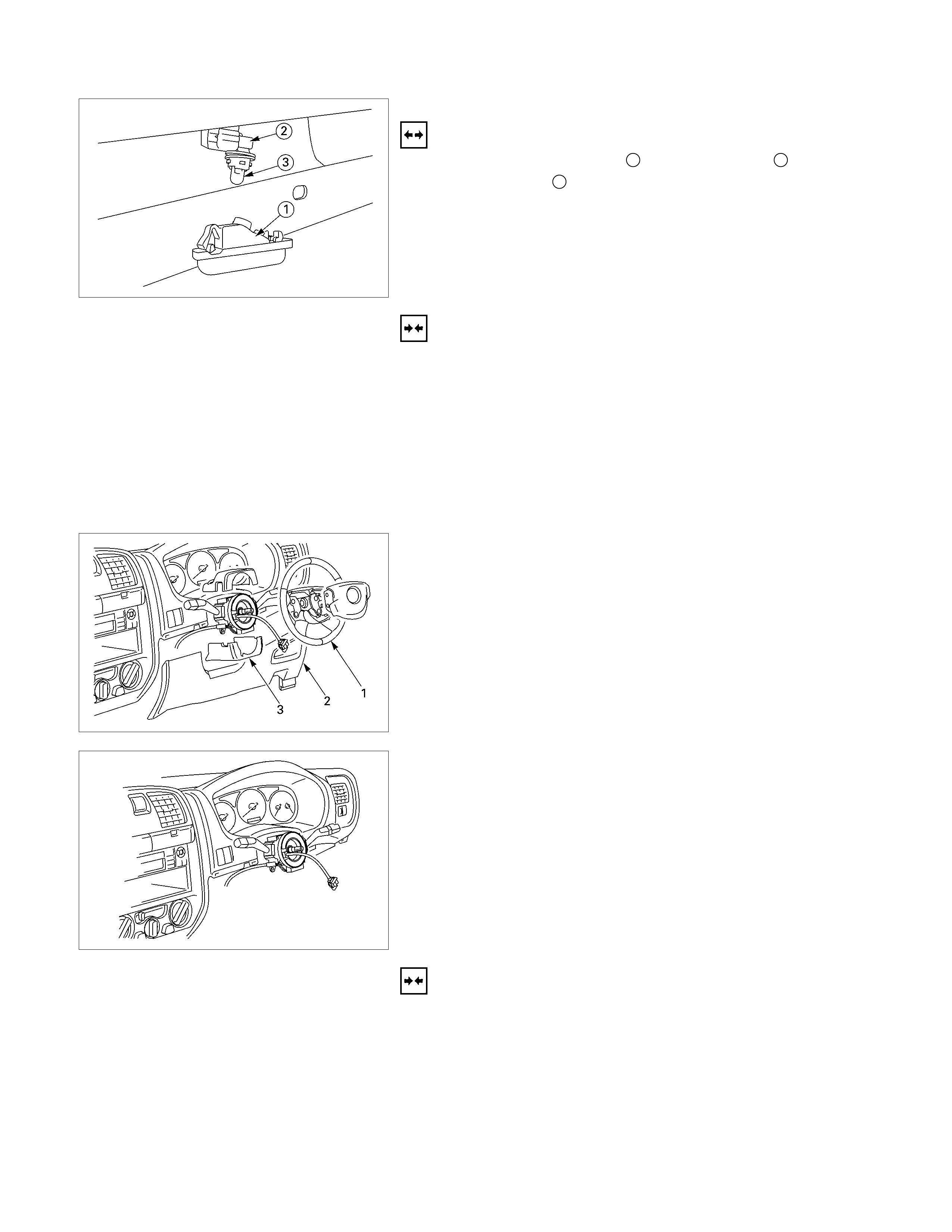

This illustration is based on RHD model

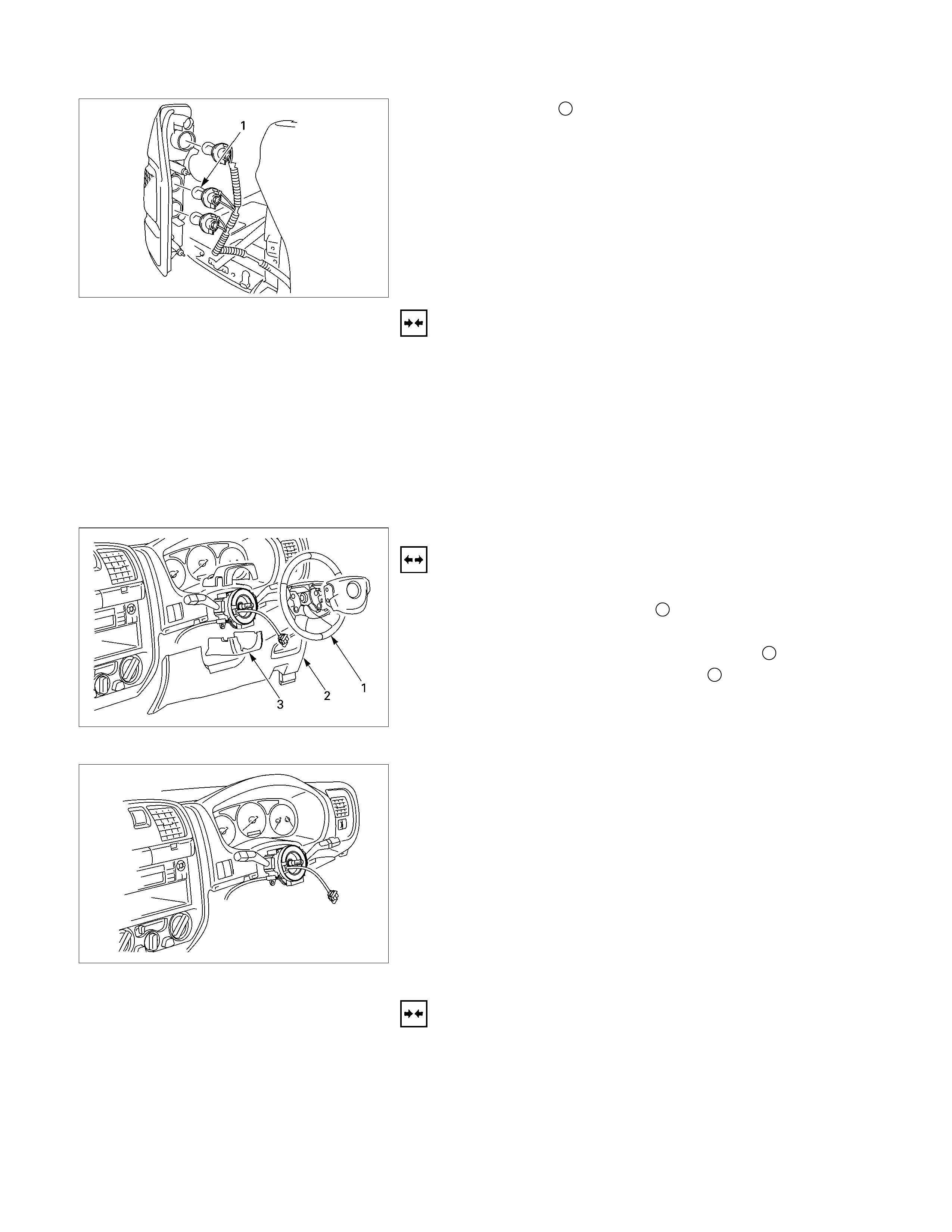

TURN SIGNAL SWITCH

Removal

1. Disconnect the battery ground cable.

2. Remove the steering wheel 1.

Refer to the “STEERING” Section of this Manual.

3. Remove the instruments panel lower cover 2.

4. Remove the steering column cover 3.

This illustration is based on RHD model

5. Disconnect the connector.

6. Remove the turn signal switch from the steering shaft.

Installation

Follow the removal procedure in the reverse order to install the

turn signal switch (lever).

Pay close attention to the important points mentioned in the

following paragraphs.

Connector

Be absolutely sure that the turn signal switch connector is

securely connected.

This will prevent a poor contact and at an open circuit.

REAR COMBINATION LIGHT

Back Up Light

Removal

1. Open the rear gate.

2. Remove the screws.

3. Remove the rear combination light assembly.

4. Turn the bulb 3 counterclockwise to remove it.

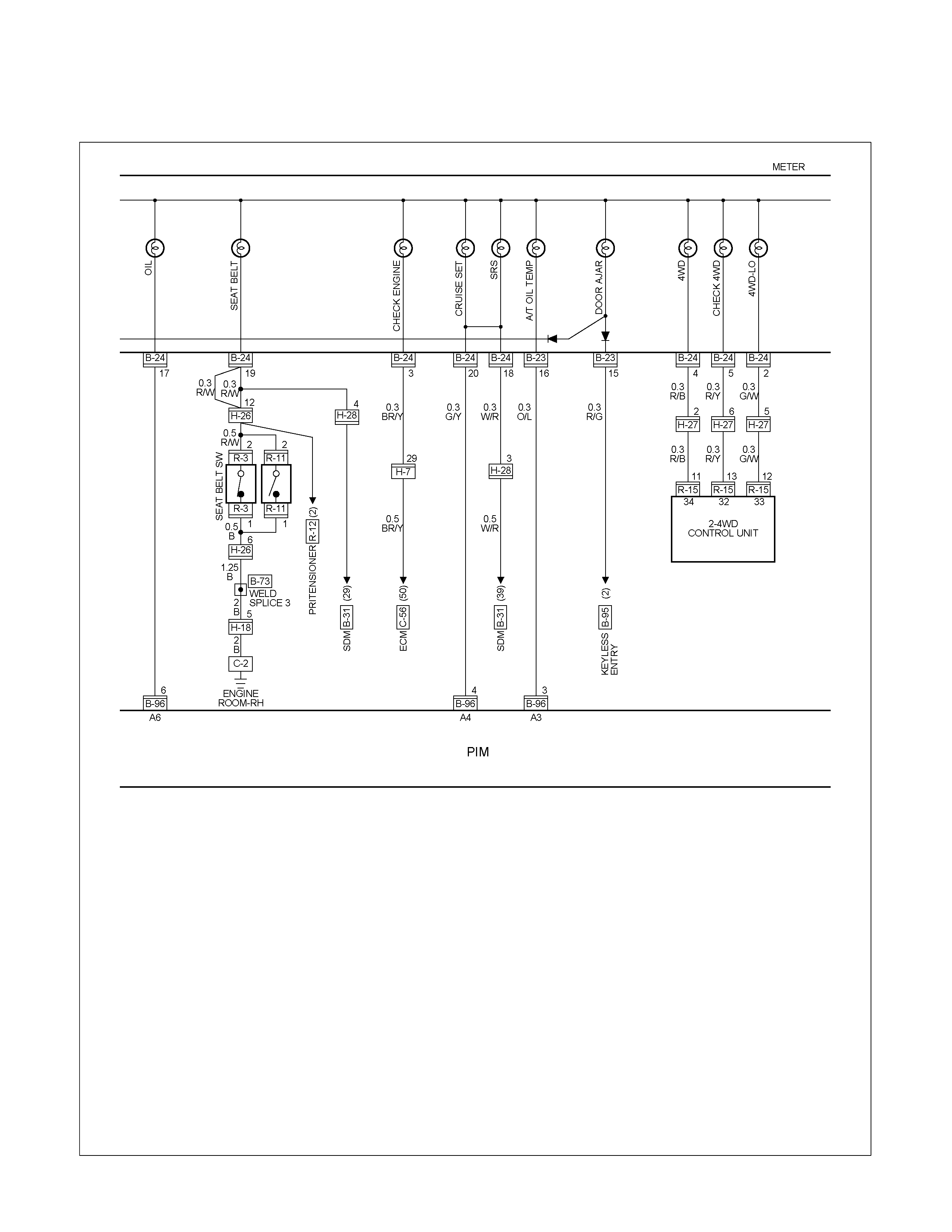

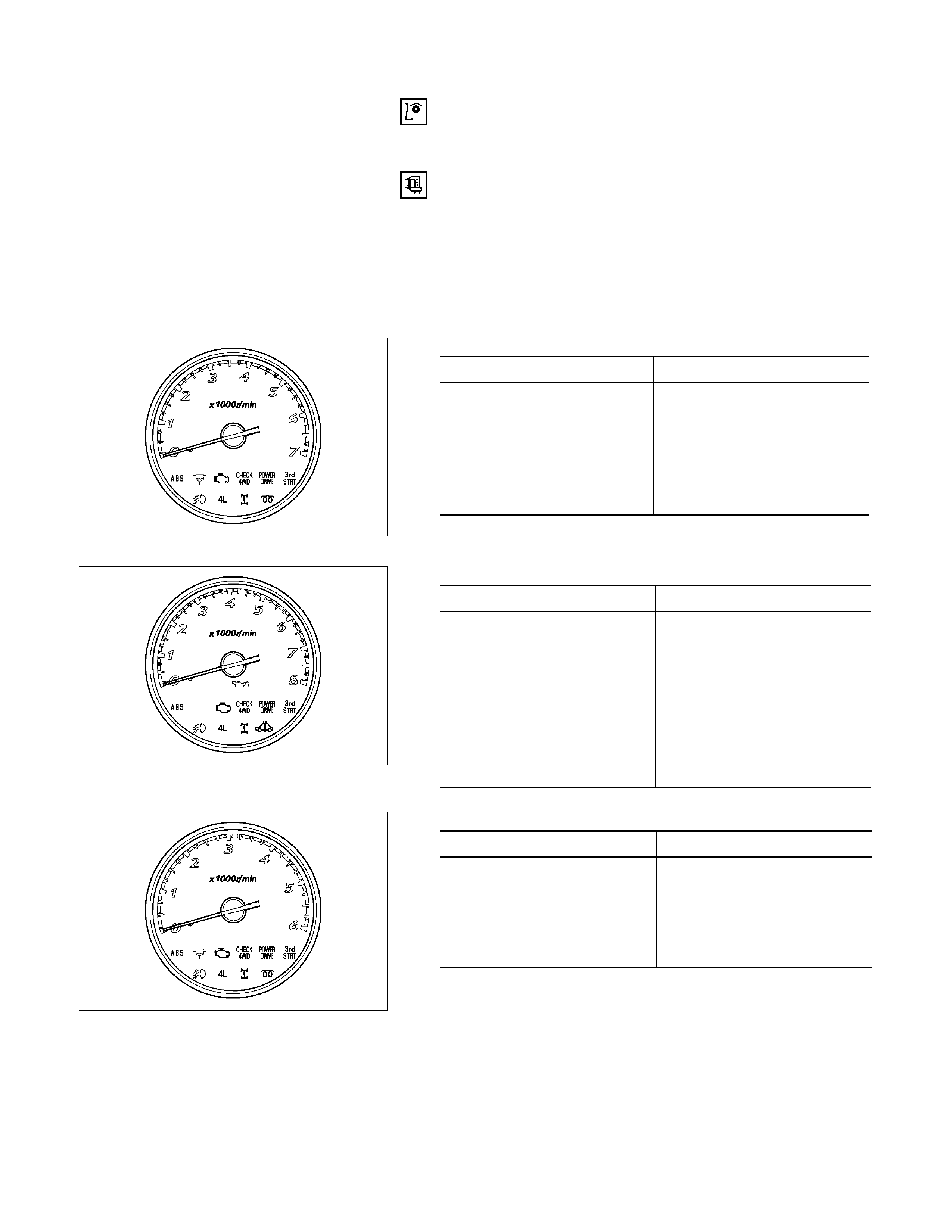

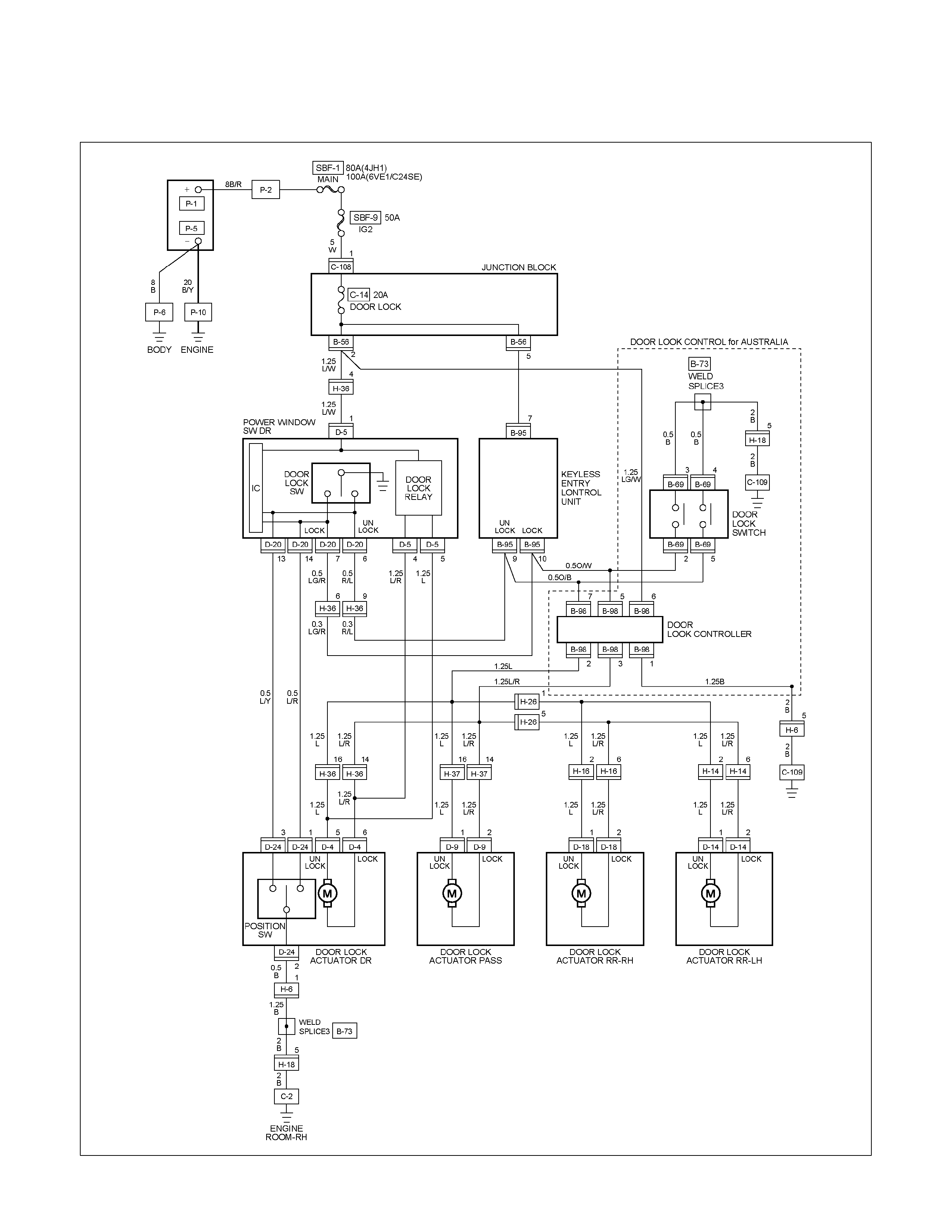

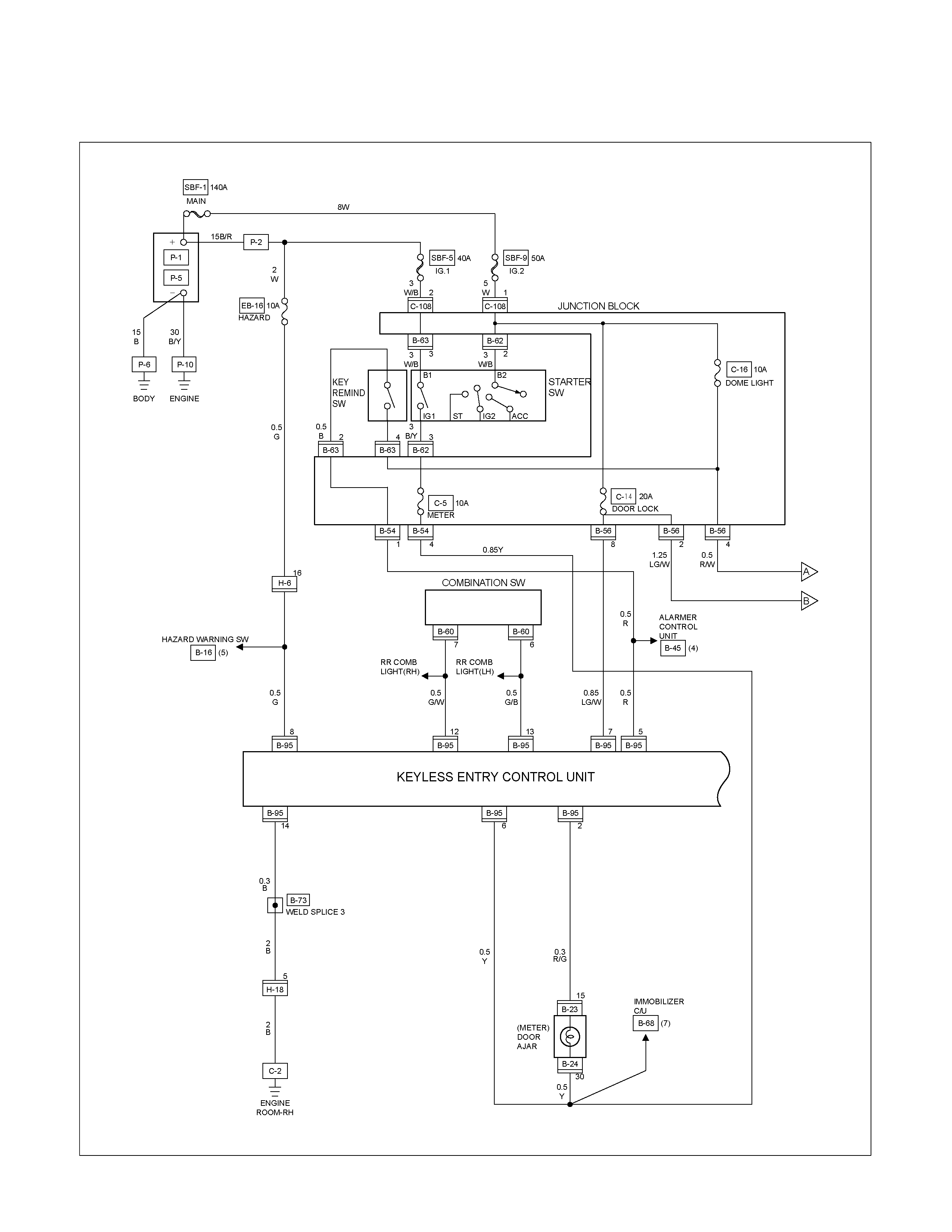

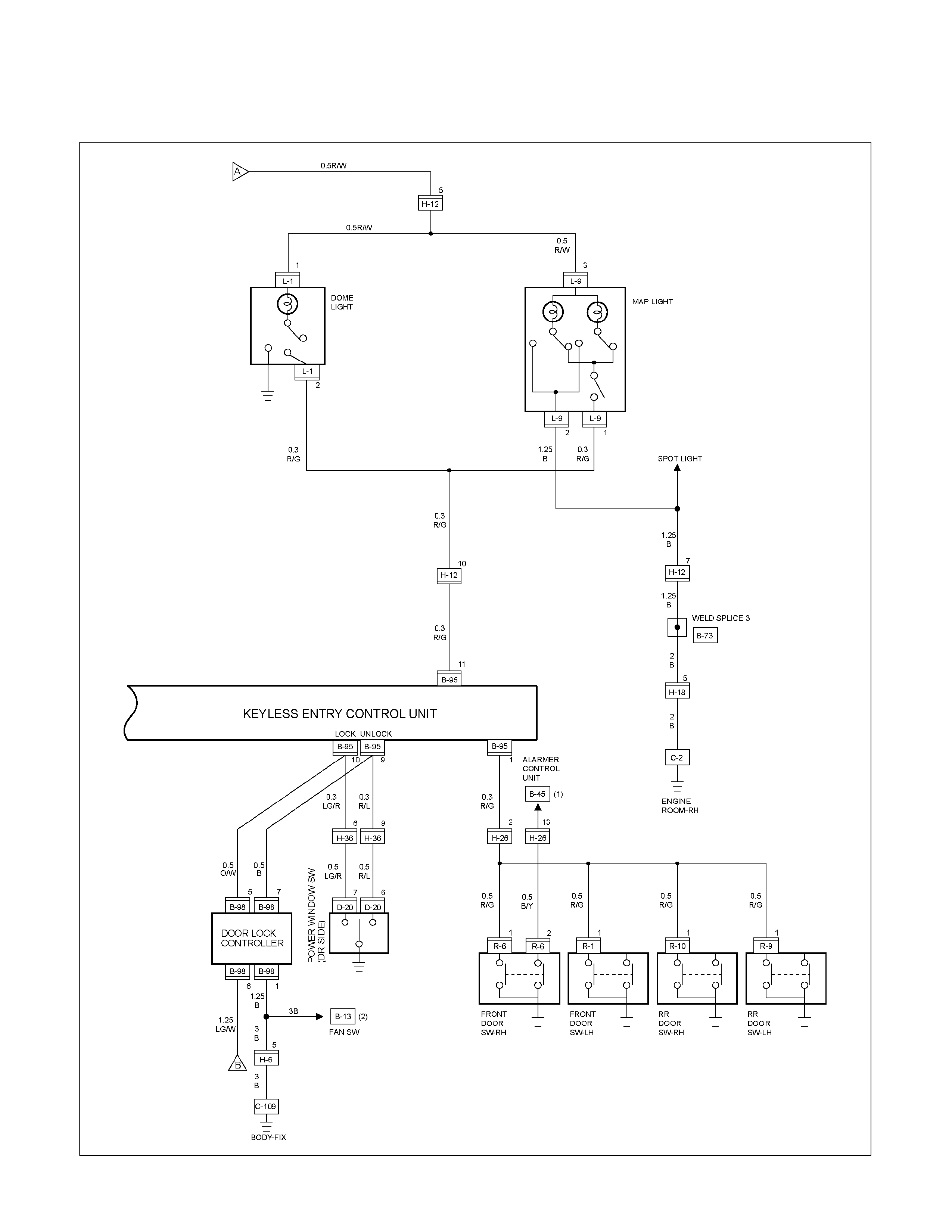

Installation