SECTION 9A1 – RESTRAINTS - RESTRAINT

CONTROL SYSTEM

Service Precaution

Diagnosis Information

Diagnostic Procedures

Diagnostic Codes

How To Read Trouble Codes

How To Clear Trouble Codes

Scan Tool Diagnostics

Basic Knowledge Required

Basic Electrical Circuits

"Flash Code" Diagnostics

DATA LIST (Tech2)

Diagnostic Trouble Codes

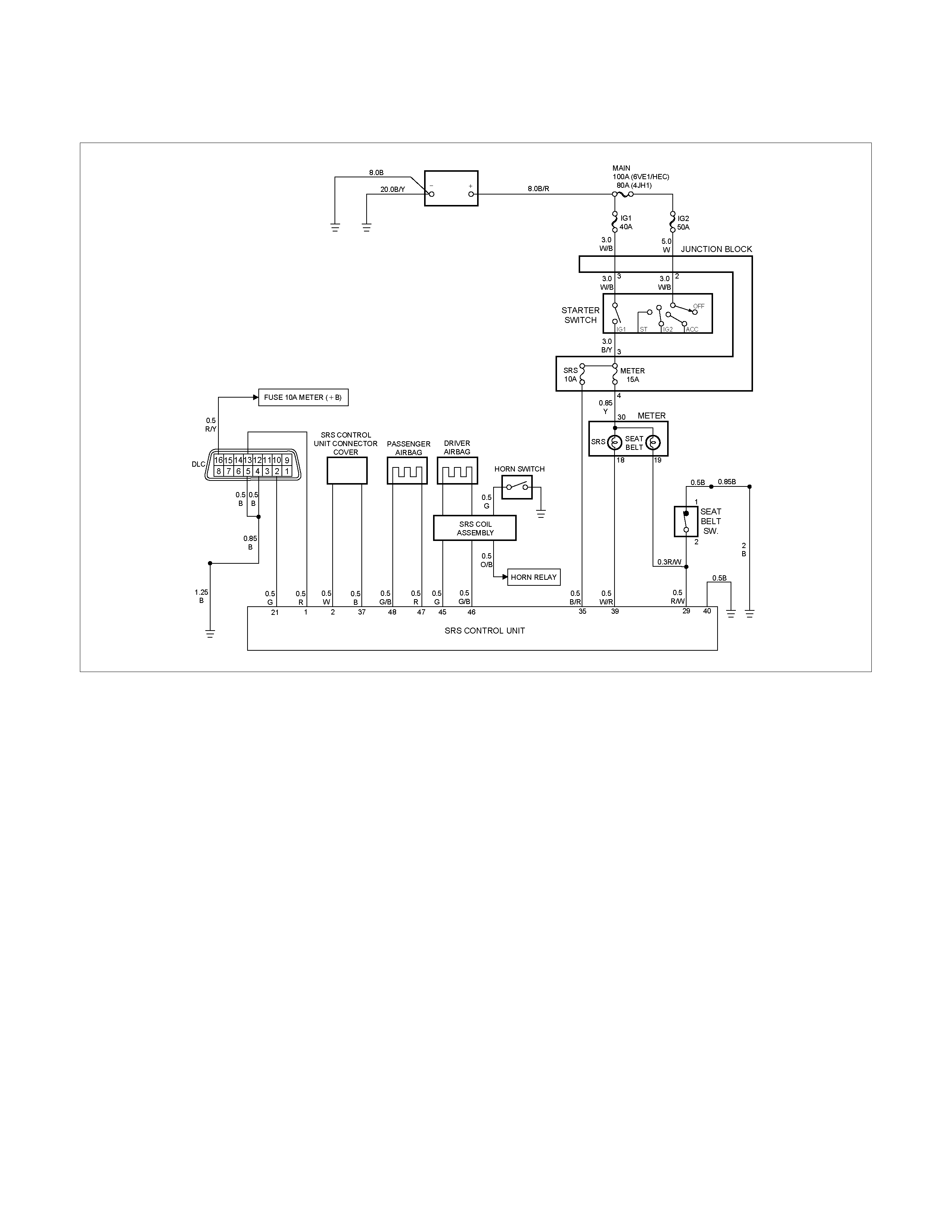

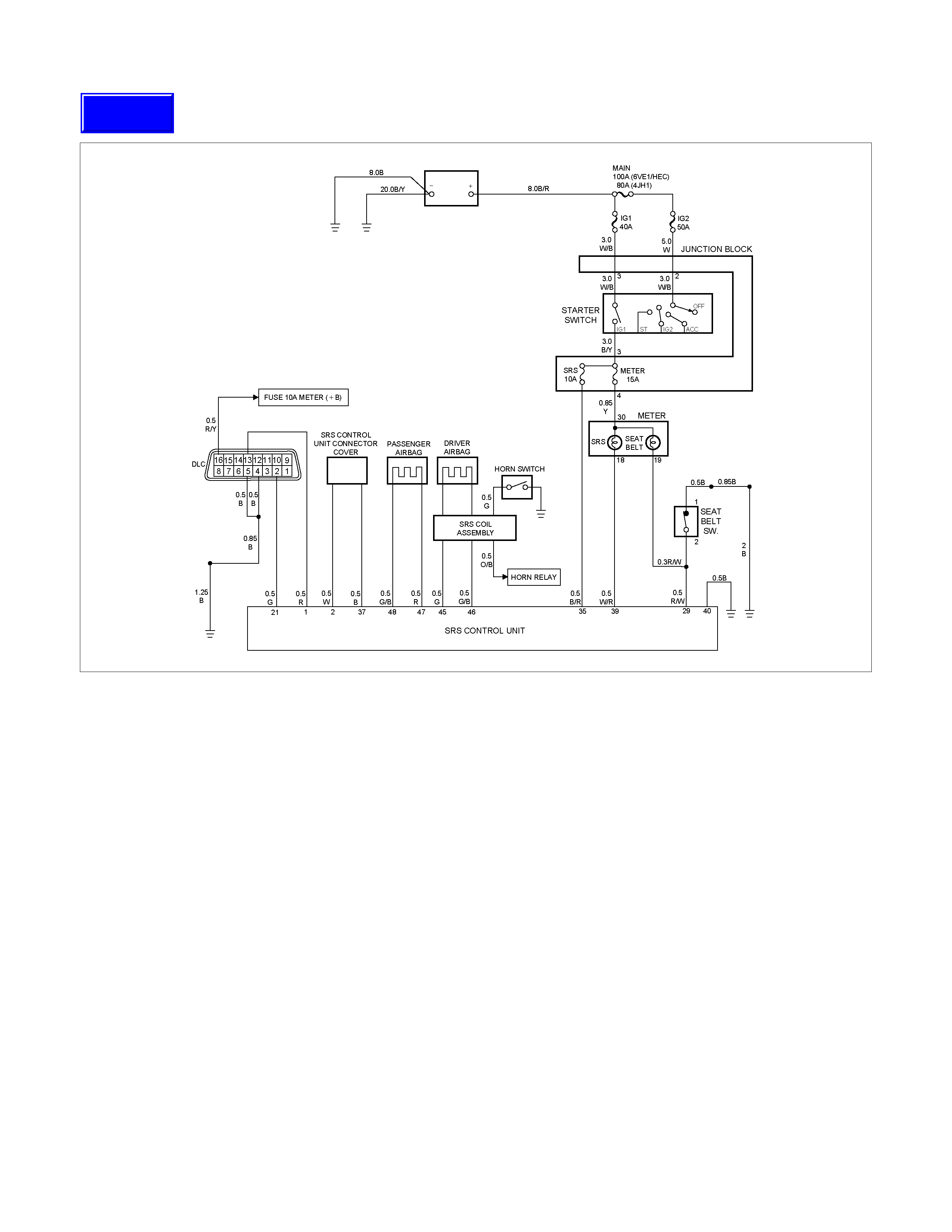

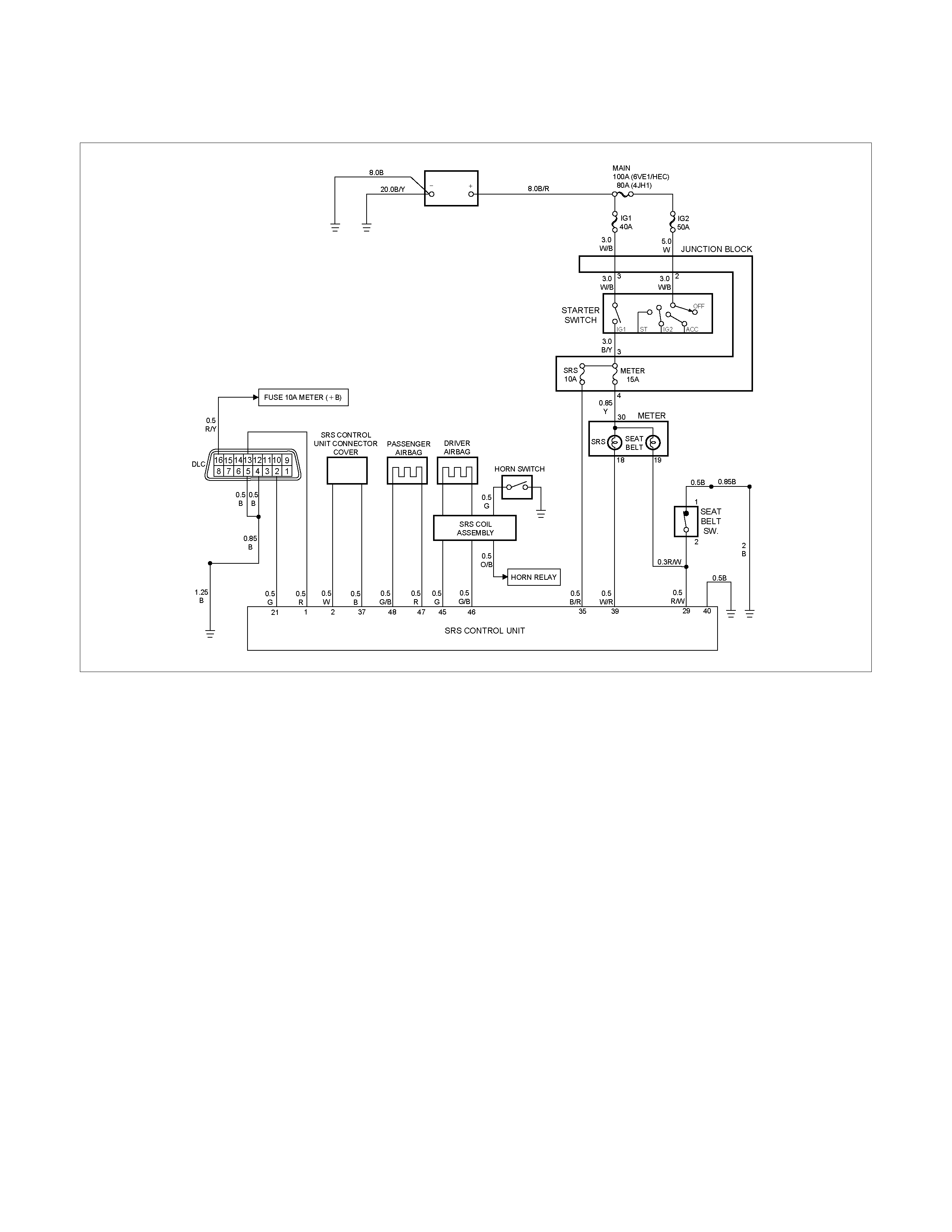

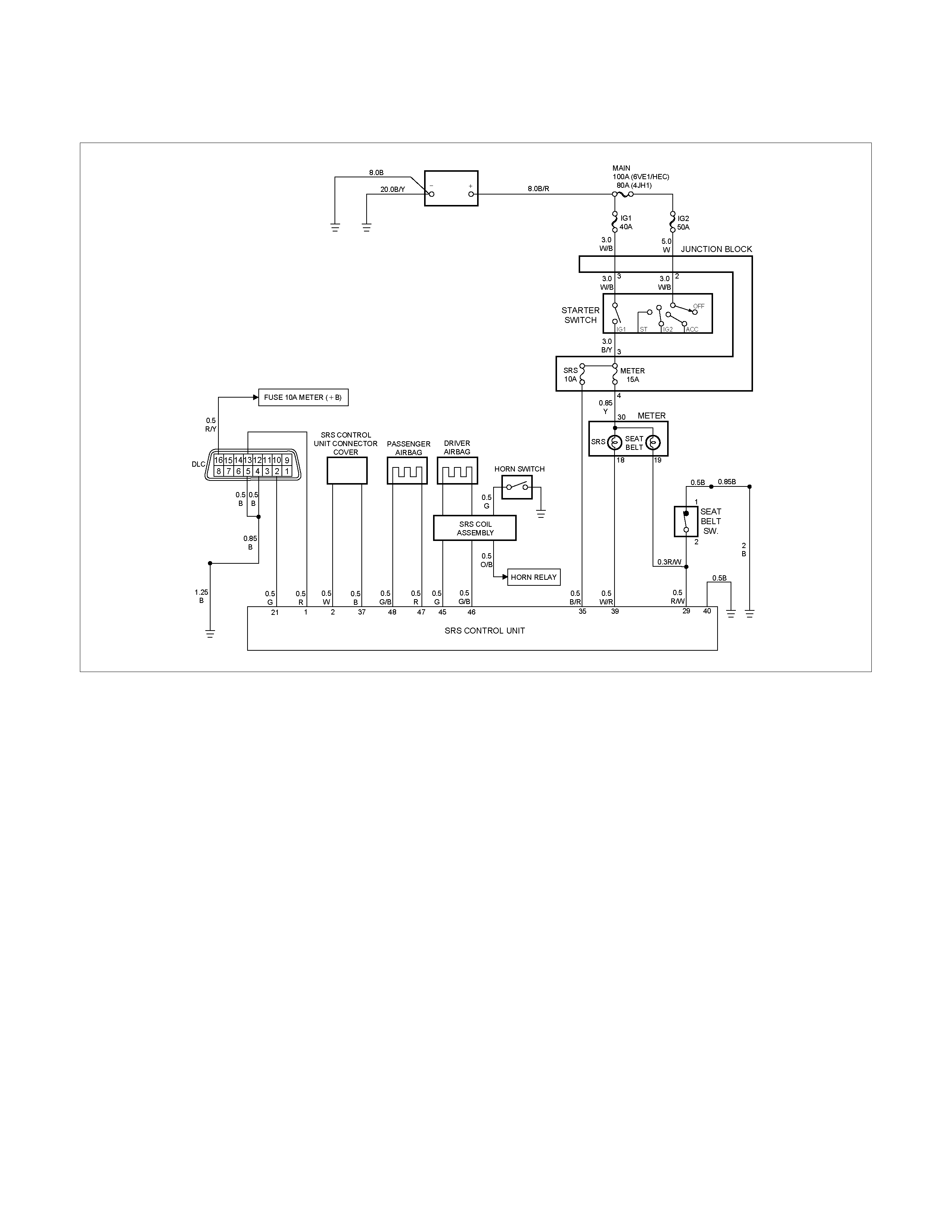

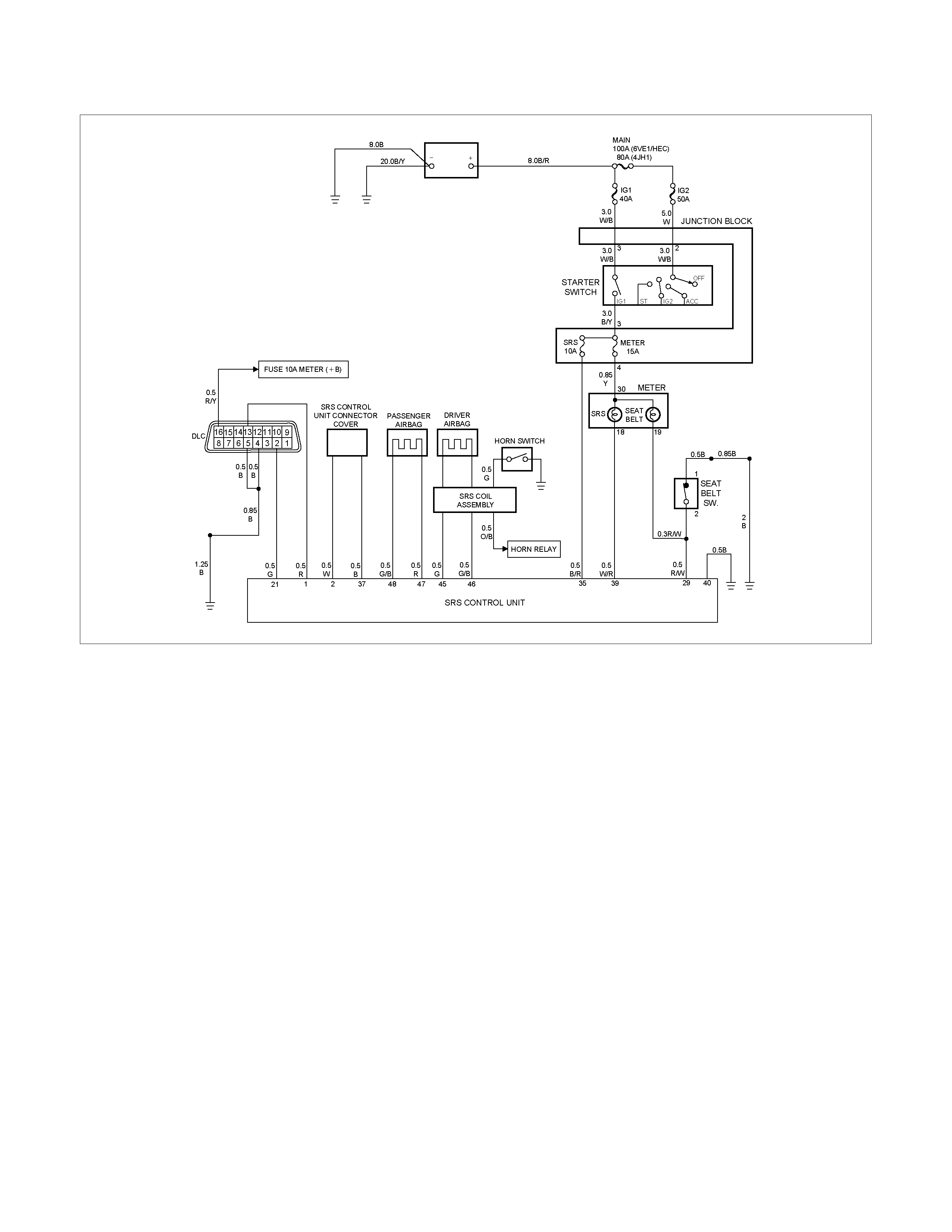

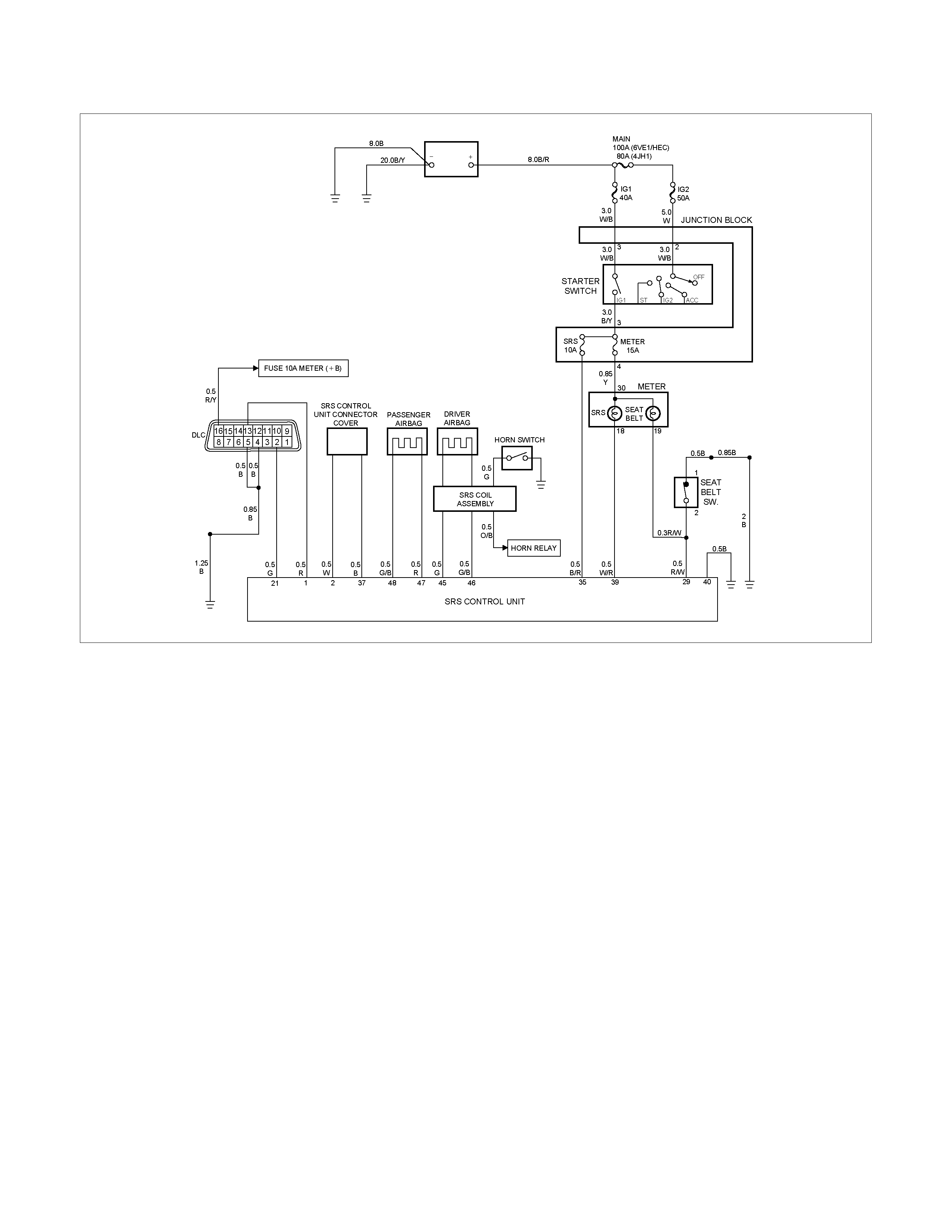

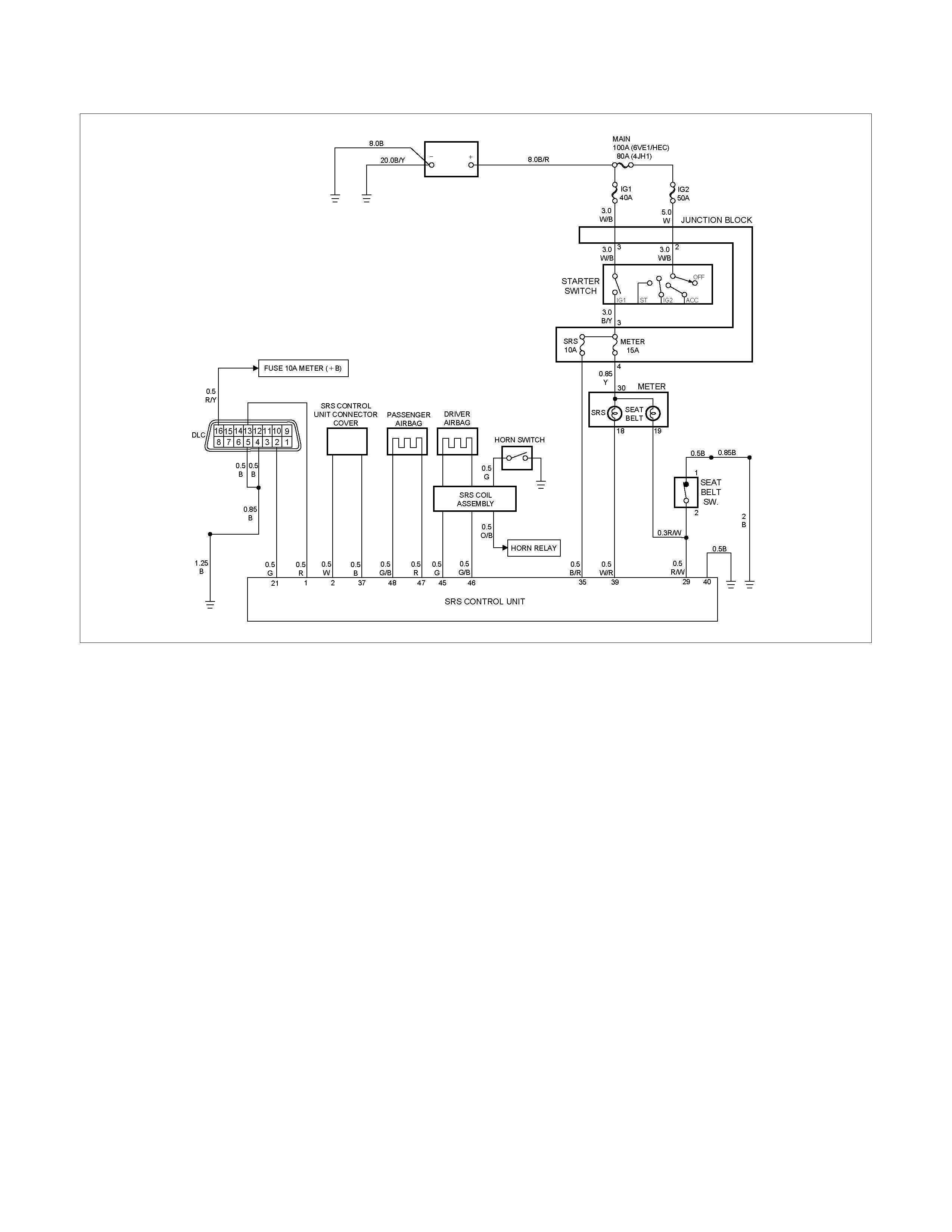

System Schematic

Chart A SRS control unit Inte grity Che ck

Chart B "AIR BAG" Warning Lamp Comes "ON" Steady

Chart C "AIR BAG" Warning Lamp Does Not Come "ON" Steady

DTC B0016 (Flash Code 16) Passenger Airbag Squib Circuit (Stage1) Low Resistance

DTC B0017 (Flash Code 17) Passenger Airbag Squib Circuit (Stage1) High Resistance

DTC B0018 (Flash Code 18) Passenger Airbag Squib Circuit (Stage1) Voltage Range/Performance

DTC B0022 (Flash Code 22) Driver A irbag Squib Circuit (Stage1) Low Resistance

DTC B0024 (Flash Code 24) Driver Airbag Squib Circuit (Stage1) Voltage Range/Performance

DTC B0026 (Flash Code 26) Driver A irbag Squib Circuit (Stage1) High Resistance

DTC B0033 (Flash Code 33) ECU Connector Poor Connection

DTC B0051 (Flash Code 51) Squib Circuit Activated (Clash)

DTC B0053 (Flash Code 53) Deployment Command Despite Present Trouble Code

DTC B0670 (Flash Code 63) Airbag Telltale Circuit Malfunction

DTC B1000 (Flash Code 72) SDM Internal Fault

DTC U1000 (Flash Code 75) Class2 Data Link Malfunction

DTC U1*** (Flash Code 73) Unknown Message

DTC U1300 (Flash Code 76) Class2 Data Link Low

DTC U1301 (Flash Code 76) Class2 Data Link High

Techline

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS SYSTEM

REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specifications.

Following these instructions can help you avoid

damage to parts and systems.

Diagnostic Information

CAUTION: When fasteners are removed, always

reinstall them at the same location from which they

were removed. if a fastener needs to be replaced,

use the correct part number fastener for that

application. if the correct part number fastener is

not available, a fastener of equal size and strength

(or stronger) may be used. fasteners that are not

reused, and those requiring thread locking

compound will be called out. the correct torque

value must be used when installing fasteners that

require it. if the above conditions are not followed,

parts or system damage could result.

Diagnostic Procedures

WARNING: TO AVOID DEPLOYMENT WHEN

TROUBLESHOOTING THE SRS, DO NOT USE

ELECTRICAL TEST EQUIPMENT SUCH AS A

BATTERY-POWERED OR AC-POWERED

VOLTMETER, OHMMETER, ETC., OR ANY TYPE OF

ELECTRICAL EQUIPMENT OTHER THAN THAT

SPECIFIED IN THIS MANUAL. DO NOT USE A NON

POWERED, PROBE-TYPE TESTER.

INSTRUCTIONS IN THIS MANUAL MUST BE

FOLLOWED CAREFULLY, OTHERWISE PERSONAL

INJURY MAY RESULT.

The diagnostic procedures used in this section are

designed to aid in finding and repairing SRS problems.

Outlined below are the steps to find and repair SRS

problems quickly and effectively. Failure to carefully

follow these procedures may result in extended

diagnostic time, incorrect diagnosis and incorrect parts

replacement.

1. Perform The “SRS Diagnostic System Check”.

The “SRS Diagnostic System Check” should always

be the starting point of any SRS diagnostics. The

“SRS Diagnostic System Check” checks for prope

r

“AIR BAG” warning lamp operation and checks fo

r

SRS trouble codes using both “Flash Code” and

“Scan Tool” Methods.

2. Refer To The Proper Diagnostic Chart As

Directed By The “SRS Diagnostic System

Check”.

The “SRS Diagnos tic System Chec k ” will lead you to

the correct chart to diagnose any SRS problems.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis and incorrect

parts replacement.

3. Repeat The “SRS Diagnostic System Check”

After Any Repair Or Diagnostic Procedur es Have

Been Performed.

Preforming the “SRS Diagnostic System Check”

after all repair or diagnostic procedures will assure

that the repair has been made correctly and that no

other conditions exist.

Diagnostic Codes

The SRS control unit maintains a history record of all

diagnostic codes that have been detected since the

SRS codes were last cleared during service.

1. Active Codes - Faults that are presently detected this

ignition cycle. Active codes are stored in RAM

(Random Access Memory).

2. History Codes - All f aults detec ted s ince the las t time

the history fault m emory was cleared. History codes

are stored in EEPROM. (Electronically Erasable

Programmable Read only Memory)

How To Read Trouble Codes

All codes (Active and history) can be read (or cleared)

by using a scan tool or equivalent.

If a PDT is not available, have the vehicle serviced by

HOLDEN dealer.

How To Clear Trouble Codes

Trouble codes can only be cleared by using a Scan

Tool. If a “scan tool” is not available then inform the

owner of the stored codes and suggest that the codes

are cleared upon the next visit to an Holden dealership.

Scan Tool Diagnostics

A scan tool can be used to read current and history

codes and to clear all history codes after a repair is

complete. The scan tool must be updated to

communicate with the SRS through a replaceable

cartridge or a manufacturer's update before it can be

used for SRS diagnostics. To use the scan tool,

connect it to the DLC connector and turn the ignition

switch “ON”. Then follow the manufacturer's directions

for communication with the SRS. The scan tool reads

serial data from the SRS control unitSRS control unit

“Serial Data” output (terminal 21) to the DLC connector

(terminal 2).

Basic Know ledge Required

Before using this section of the Service Manual, there is

some basic knowledge which will be required. Without

this knowledge, you will have trouble using the

diagnostic procedures in this section. Use care to

prevent harm or unwanted deployment. Read all

cautions in the service manual and on warning labels

attached to SRS components.

Basic Electrical Circuits

You should understand the basic theory of electricity

including series and parallel circuits, and understand

the voltage drops across series resistors. You should

know the meaning of voltage (volts), current (amps),

and resistance (ohms). You should understand what

happens in a circuit with an open or a shorted wire. You

should be able to read and understand a wiring

diagram.

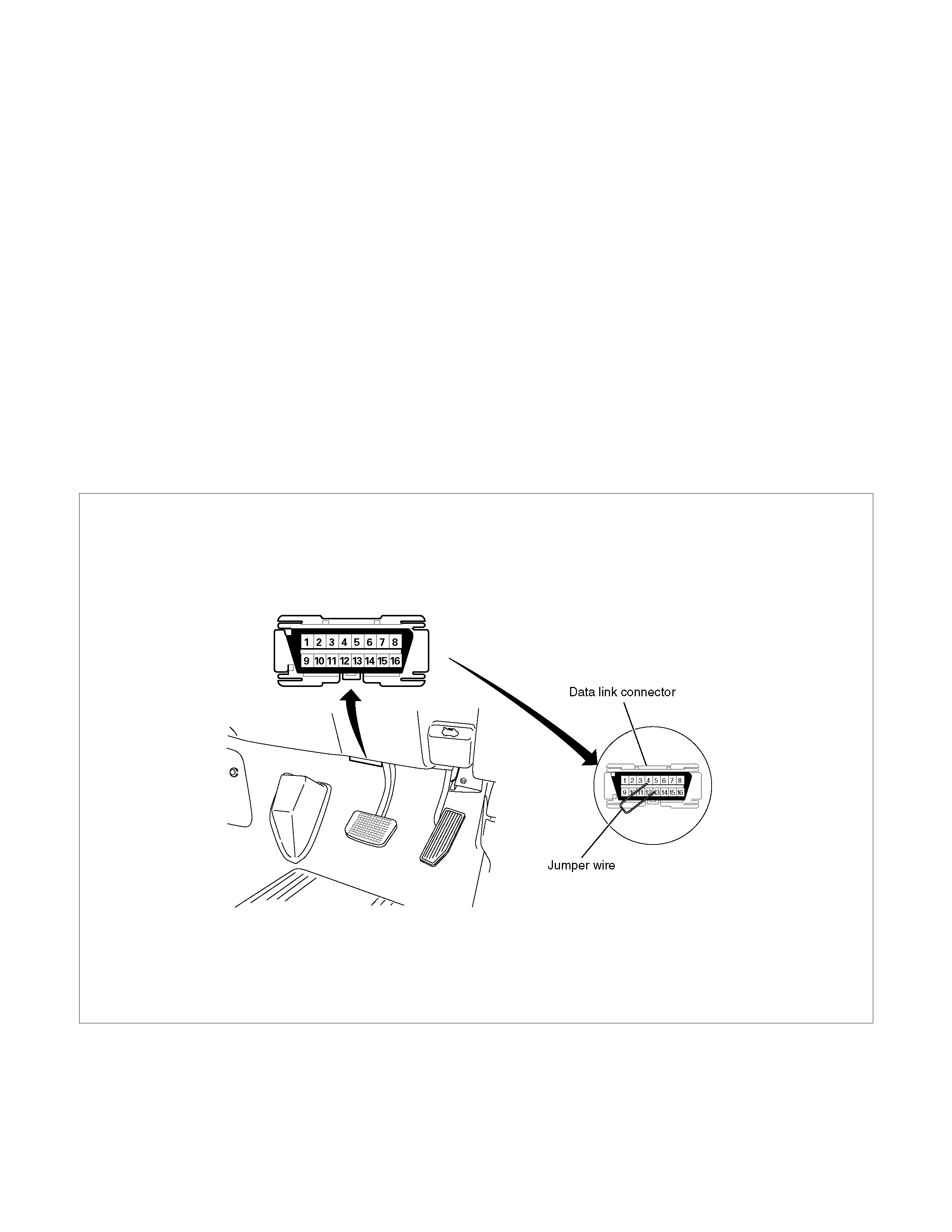

“Flash Code” Diagnostics

Flash code diagnostics can be used to read active

codes and to determine if history codes are present but

cannot be used to clear codes or read history codes.

Flash code diagnostics is enabled by grounding by

terminal 4 shorting to terminal 13 of the DLC connector

with the ignition switch “ON”. Grounding terminal 4 of

the DLC connector pulls the “Diagnostics Request”

input (Terminal 1) of the SRS control unit low and

signals the SRS control unit to enter the flash code

diagnostic display mode.

060R300052

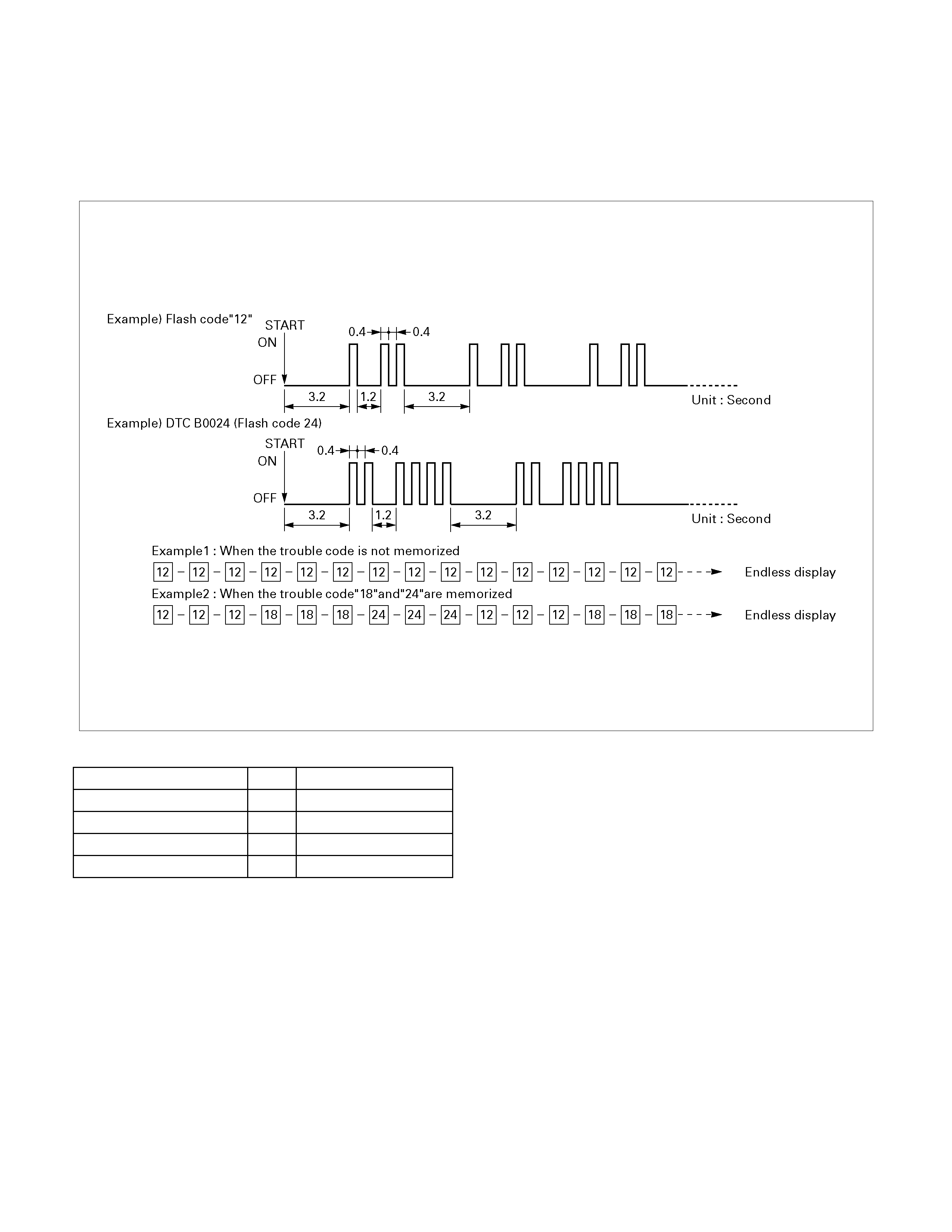

The SRS control unit displays the trouble codes by

flashing the warning lamp. Each code that is displayed

will consist of a number of flashes which represents the

tens digit, a 1.2 second pause, following by a number of

flashes which represents the ones digit of the code.

Each code is displayed one time before moving on to

Two special codes exist when reading in the flash code

mode (Flash Code 12 and Flash Code 13). “Flash

Code 12” will always be the first code displayed when

the flash code mode is enable Code 12 is not an

indication of a SRS problem but an indication that the

flash code mode has been enabled. If there are no

the next code. After all of the codes have been

displayed, the entire code sequence will continually by

repeated until ground is removed from terminal 4 of the

DLC connector.

active or history codes present, the SRS control unit will

display code 12 until ground is removed from the DLC

connector at terminal 4. “flash Code 13” will be

displayed if history codes are present. To read the

history codes a scan tool must be used.

060R300051

DATA LIST (Tech 2)

DISPLAY on Tech 2 UNIT VALUE

Driver Airbag Loop Enabled/Disabled

Passenger Airbag Loop Enabled/Disabled

System Voltage V 12.0

Driver Seat Belt Status Not Backled/Backled

Diagnostic Trouble Codes

Choose and trace an appropriate flowchart by the numbers listed below to find fault and repair.

DTC

(Flash

Code) Description

—

(12) Diagnostic Display Mode (Flash Code only)

—

(13) Diagnostic Display Mode (Flash Code only)

B0016

(16) Passenger Air bag Squib Cir cuit Low Resistance

B0017

(17) Passenger Air bag Squib Cir cuit High Resist ance

B0018

(18) Passenger Air bag Squib Cir cuit Voltag e Range / Perfor m ance

B0022

(22) Driver Airbag Squib Circuit Low Resistance

B0024

(24) Driver Airbag Squib Circuit Voltage Range / Perfor m ance

B0026

(26) Driver Airbag Squib Circuit High Resistance

B0033

(33) ECU Connector Poor Connection

B0051

(51) Squib Circuit Activated (Clash)

B0053

(53) Deploymant Command Despit e Pr esent Tr ouble Code

B0670

(63) Airbag Telltale Cir cuit Malfunction

B1000

(72) SDM Internal Fault (SDM= SRS control unit)

U1000

(75) Class2 Data Link Malf unct ion

U1∗∗∗

(73) Unknown Massage (The ∗∗∗ section change a number accor ding to conditions)

U1300

(76) Class2 Data Link Low

U1301

(76) Class2 Data Link High

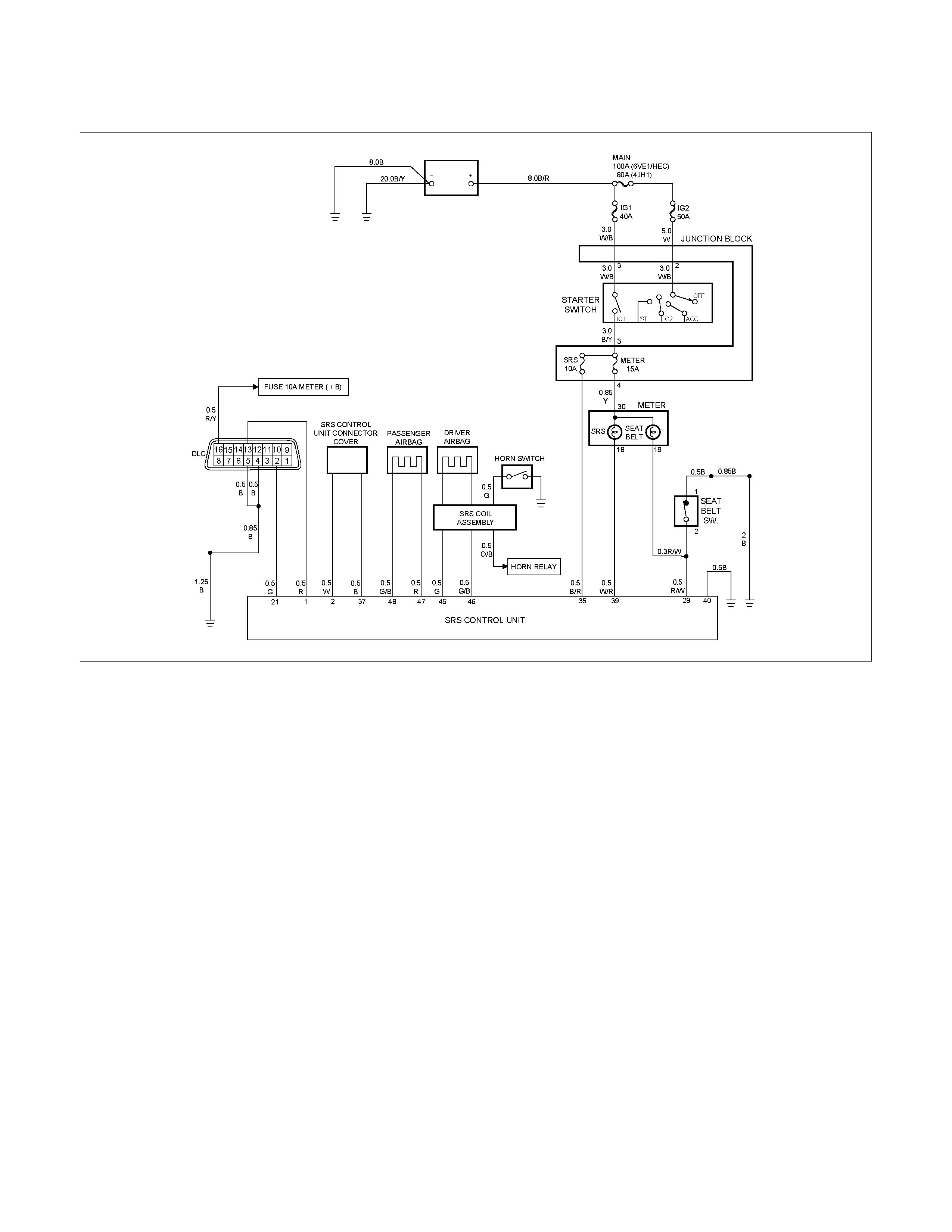

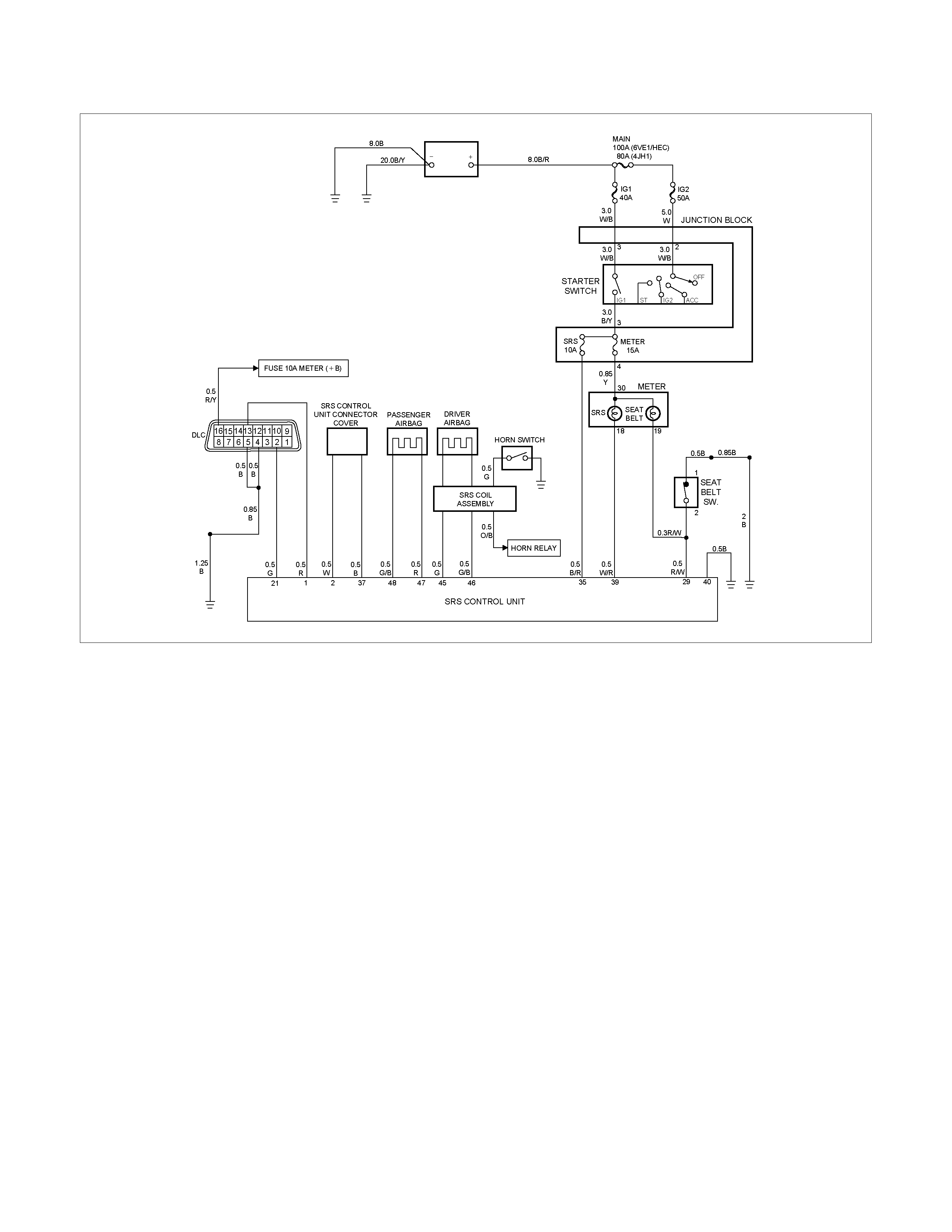

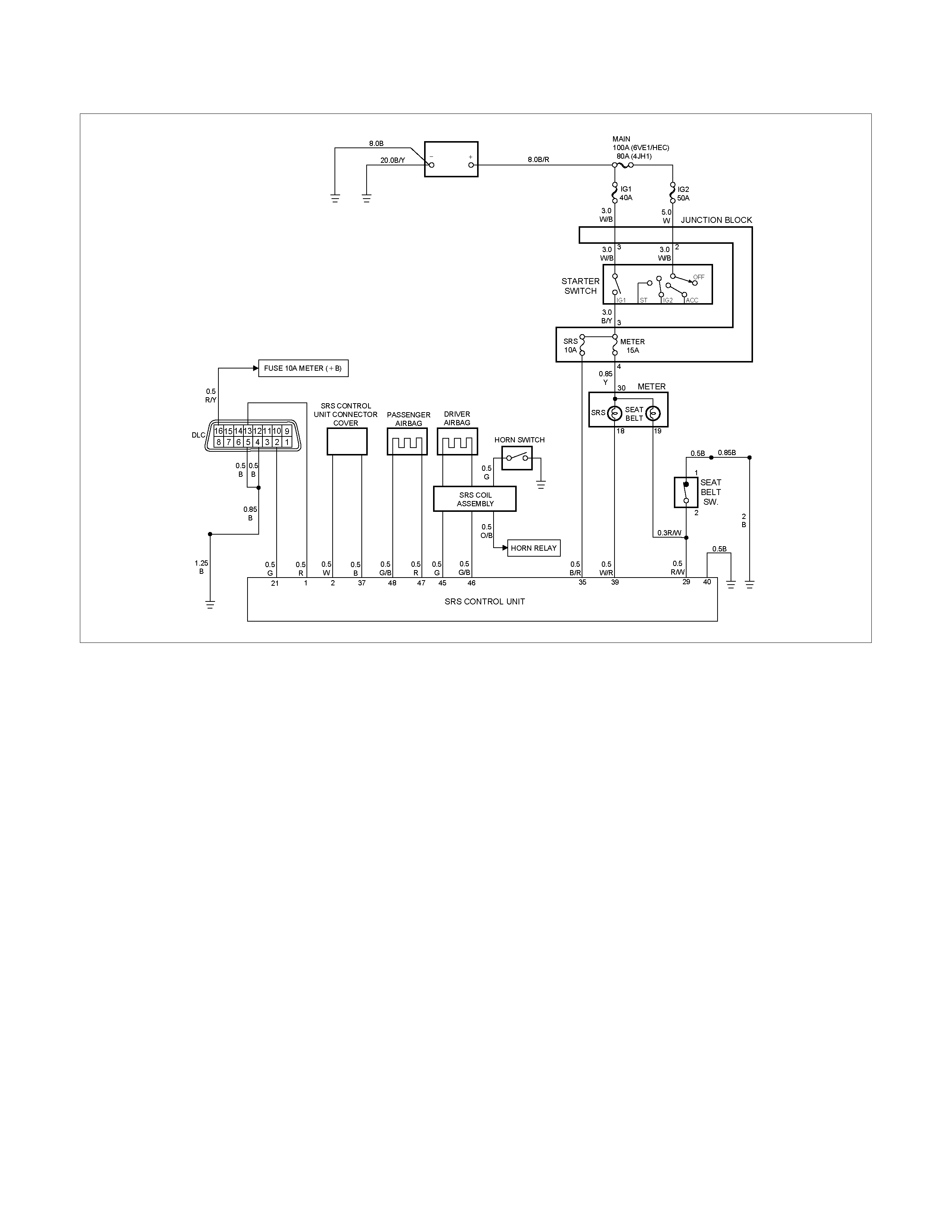

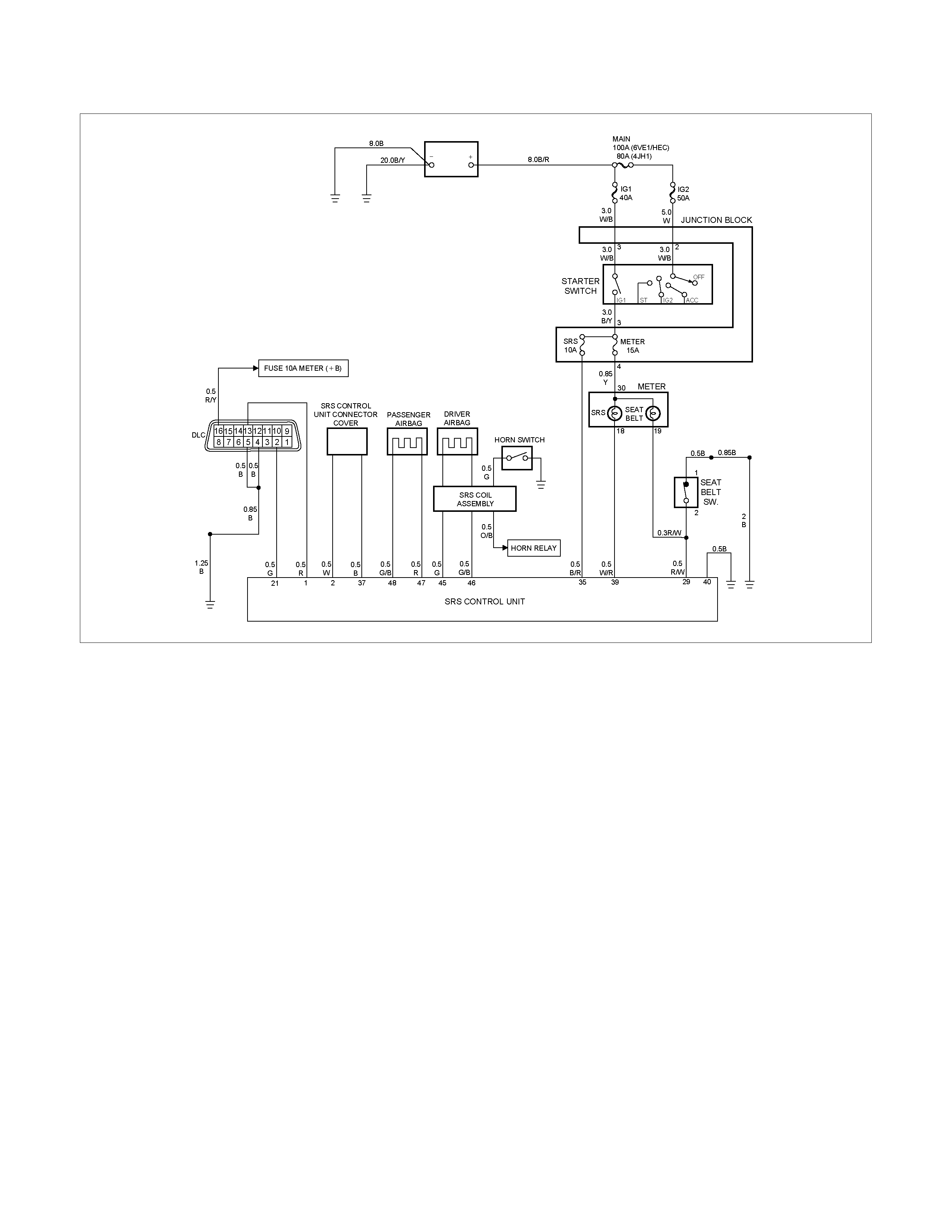

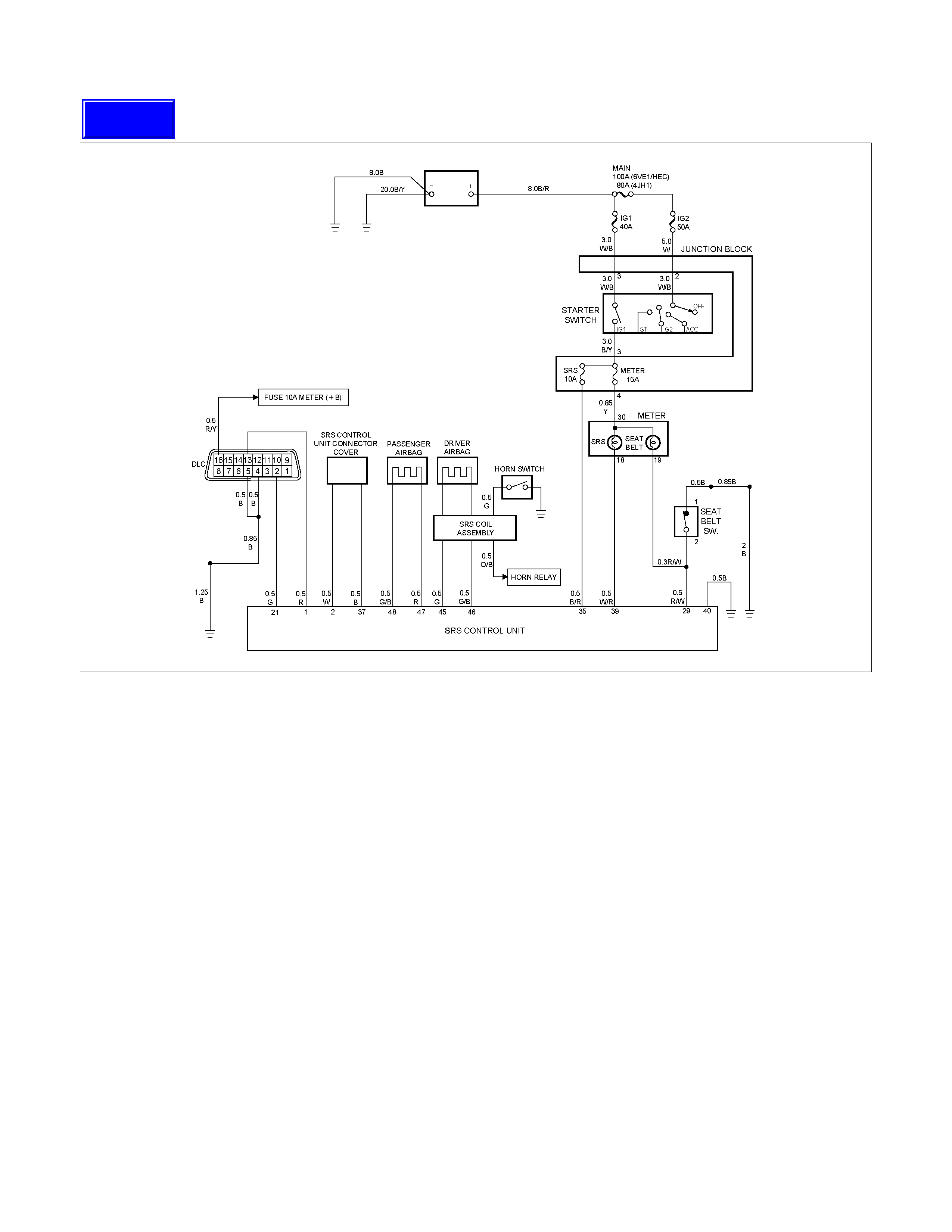

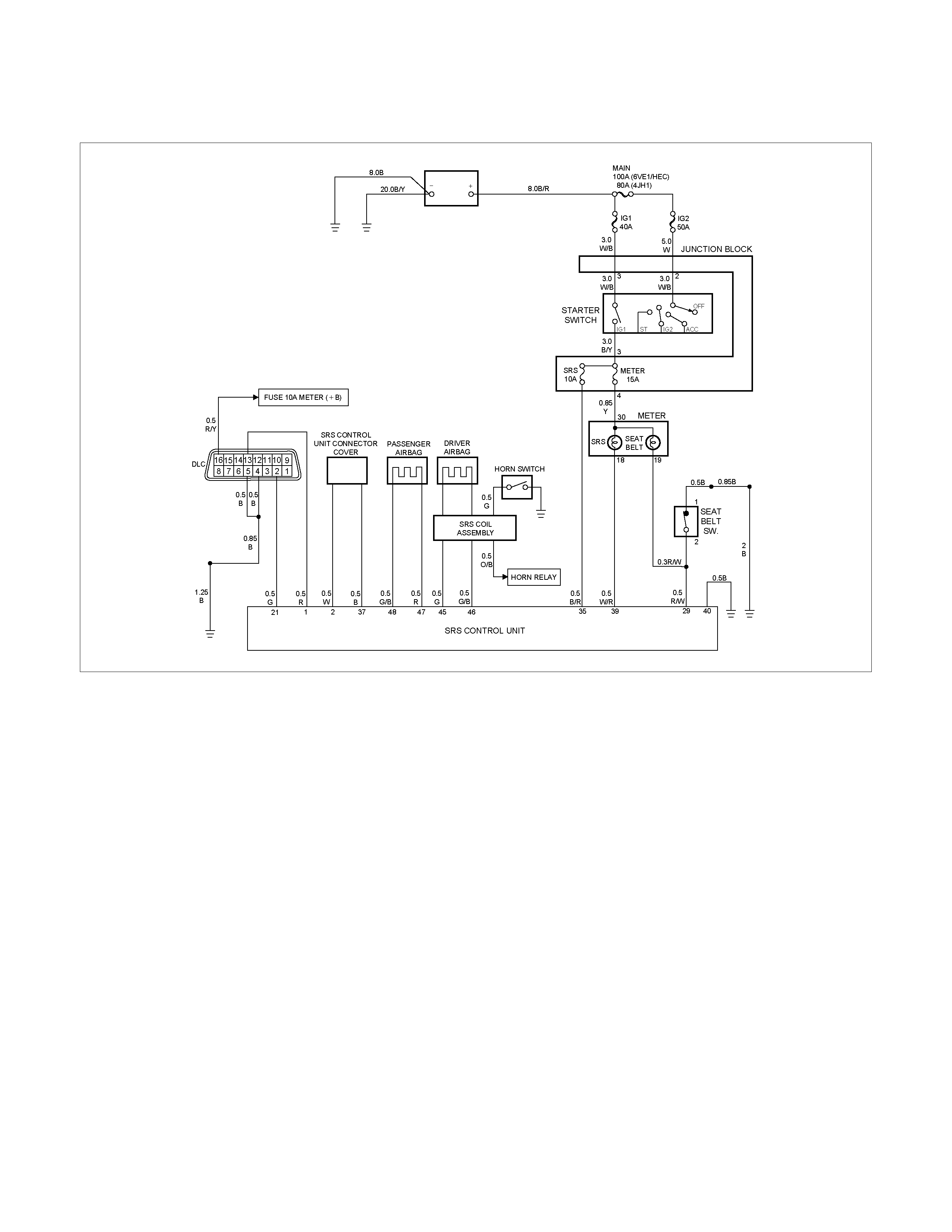

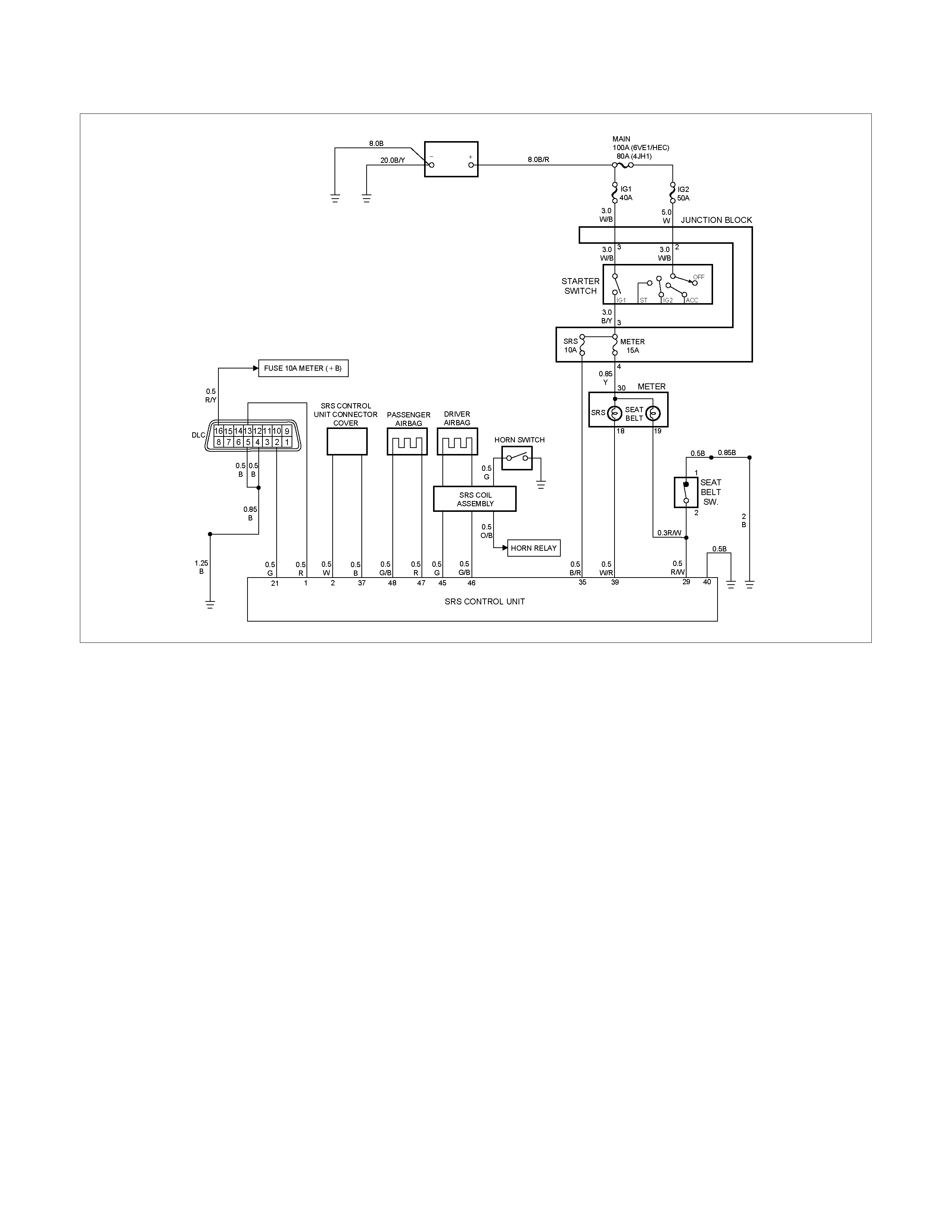

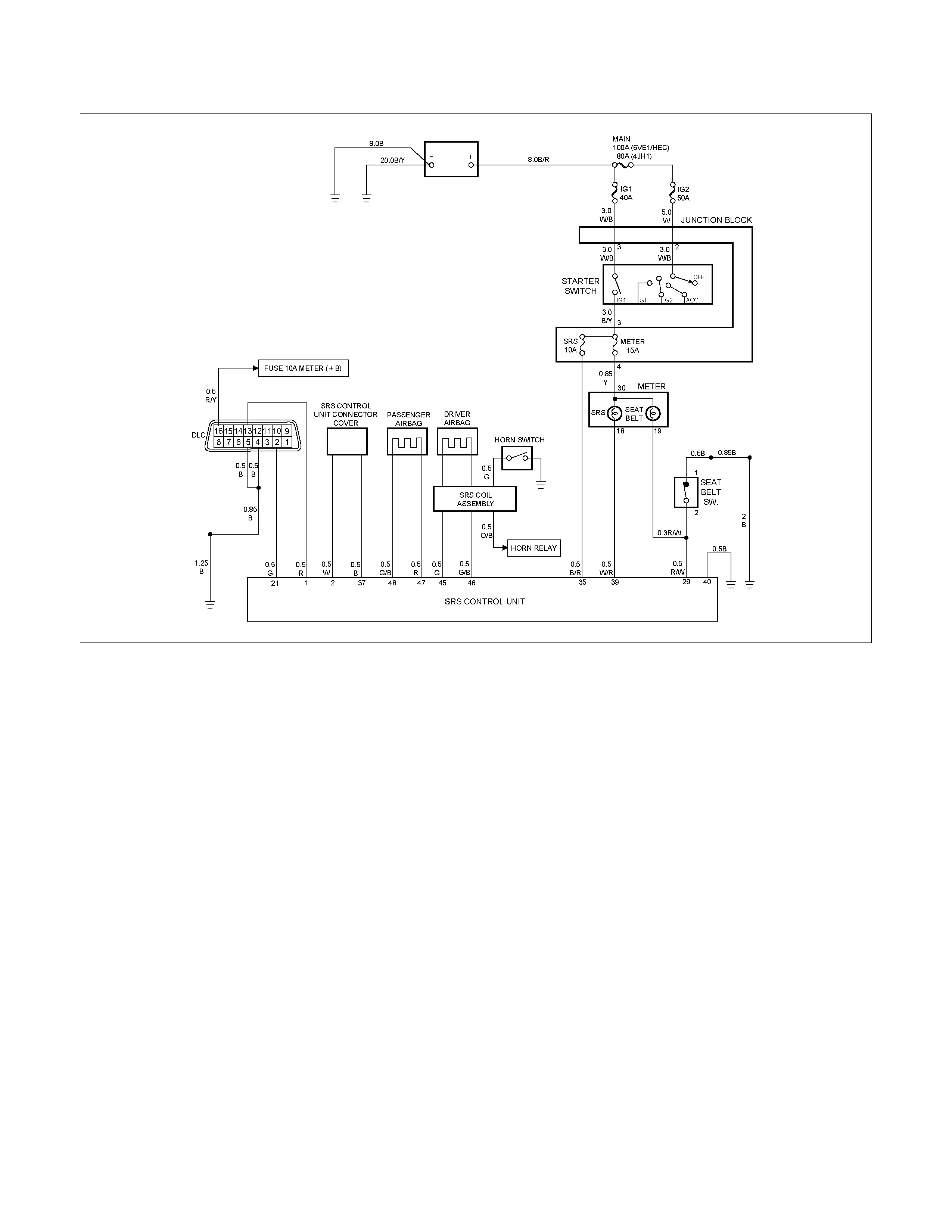

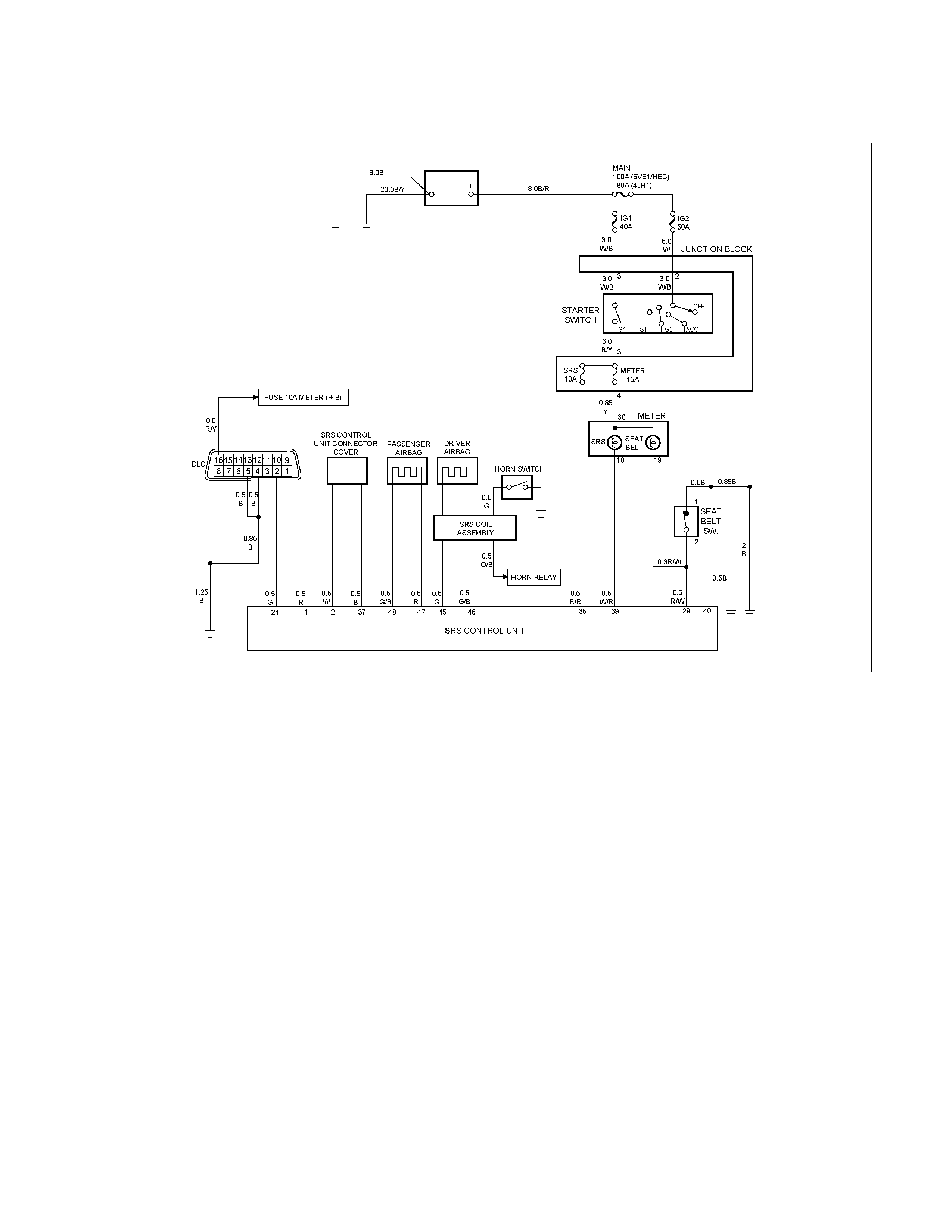

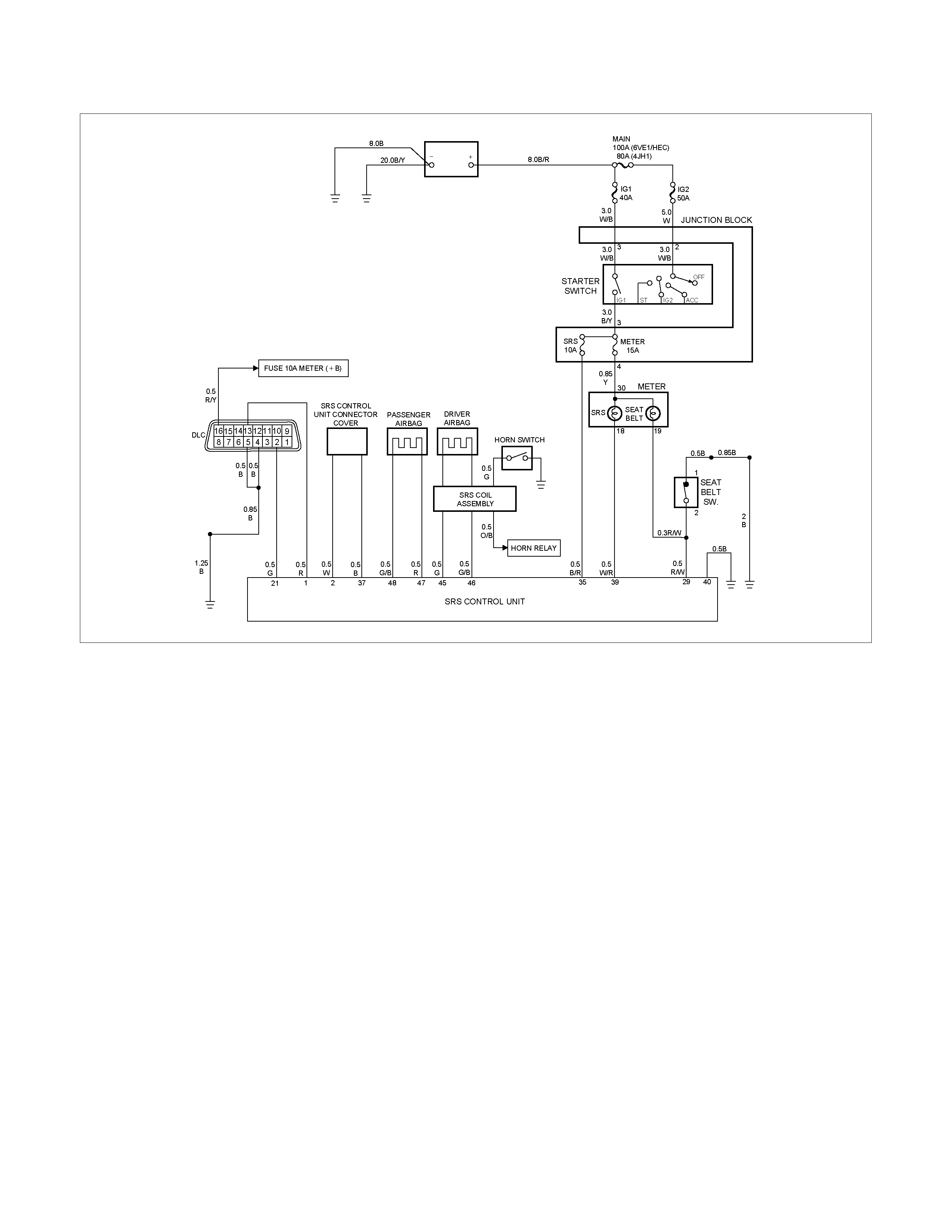

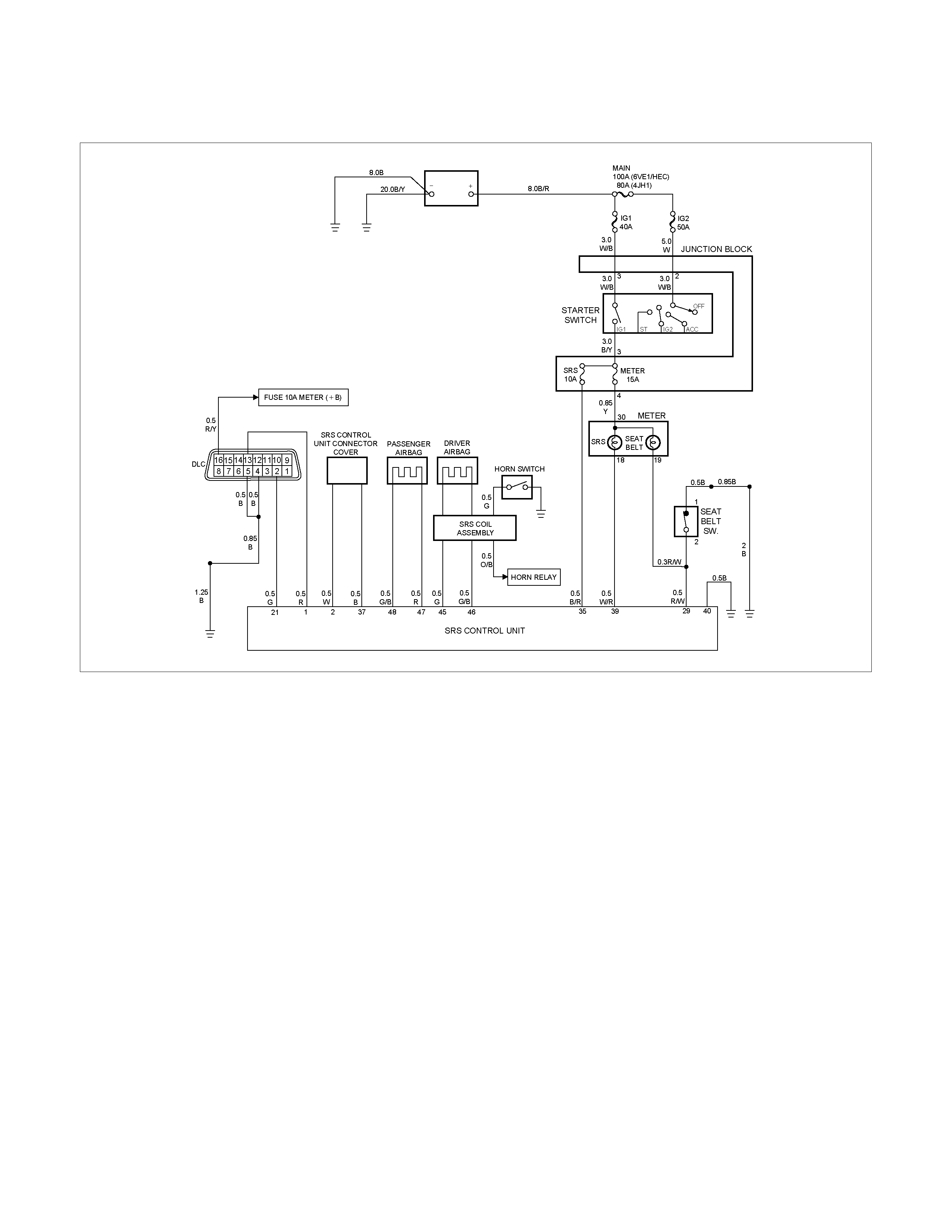

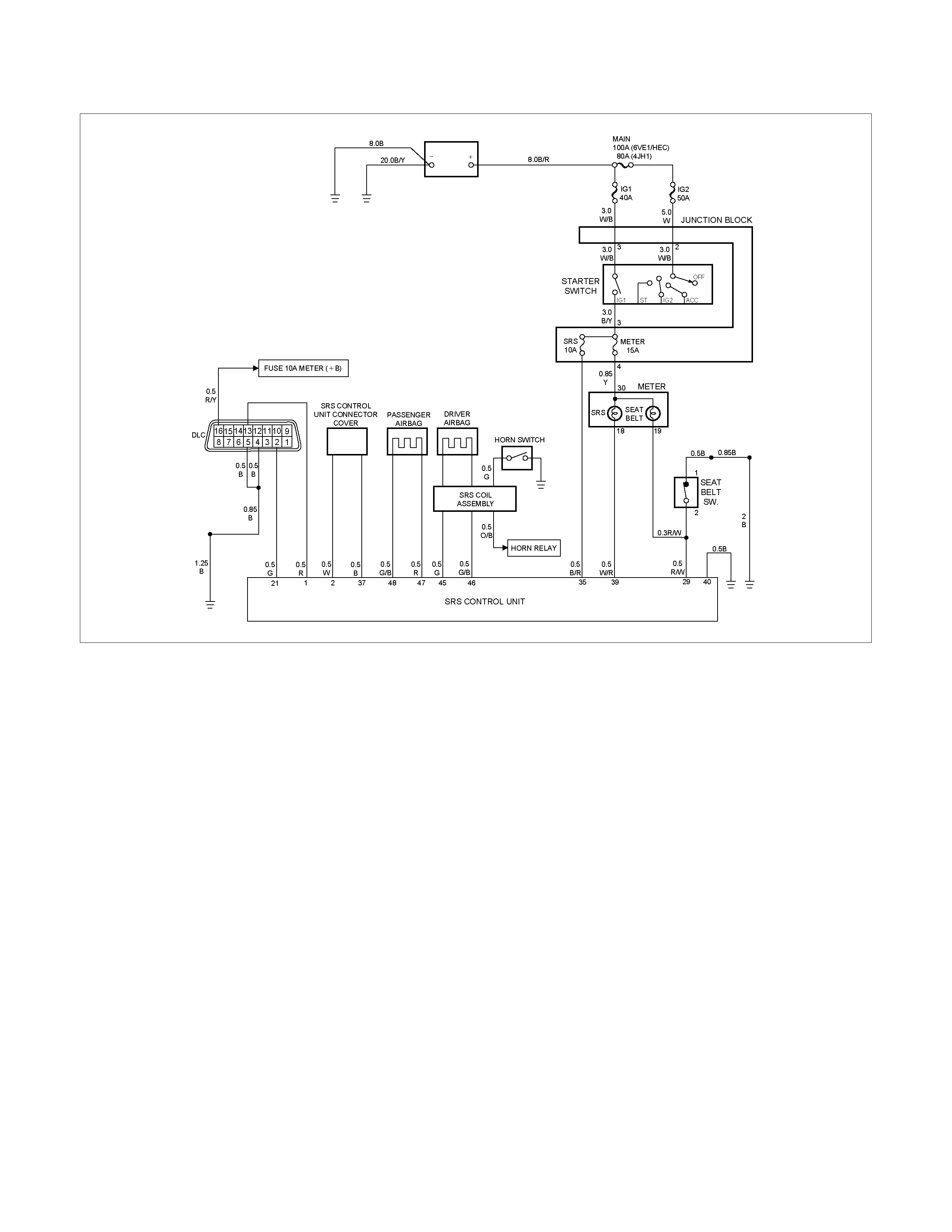

System Schematic

RTW39JMF000101

SRS Diagnostic System Check

The diagnostic procedures used in this section are

designed to find and repair SRS malfunctions. To get

the best results, it is important to use the diagnostic

charts and follow the sequence listed below:

A Perform the “SRS Diagnostic System Check.”

The “SRS Diagnostic System Check” must be the

starting point of any SRS diagnostics. The “SRS

Diagnostic System Check” checks for proper “AIR

BAG” warning lamp operation, the ability of the SRS

control unit to communicate through the “Serial

Data” line and whether SRS diagnostic trouble codes

exist.

B Refer to the proper diagnostic chart as directed by

the “SRS Diagnostic System Check.”

The “SRS Diagnostic System Check” will lead you to

the correct chart to diagnose any SRS malfunctions.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis and incorrect

parts replacement.

C Repeat the “SRS Diagnostic System Check” after

any repair or diagnostic procedures have been

preformed.

Performing the “SRS Diagnostic System Check”

after all repair or diagnostic procedures will ensure

that the repair has been made correctly and that no

other malfunctions exist

Circuit Description

When the ignition switch is first turned “ON”, “Ignition 1”

voltage is applied from the “SRS” fuse to the SRS

control unit at the “Ignition 1” input terminals “35”. The

SRS control unit responds by flashing the “AIR BAG”

warning lamp seven times, while performing tests on

the SRS.

Notes On System Check Chart

1. The “AIR BAG” warning lamp should flash seven

times after ignition is first turned “ON”.

2. After the “AIR BAG” warning lamp flashes seven

times, it should turn “OFF”

3. This test checks for the proper operation of the

“Serial Data” line. This test will also determine

whether history diagnostic trouble codes are stored

and, if so, identify them.

4. Improper operation of the “AIR BAG” warning lamp

is indicated. This test differentiates a warning lamp

stays “ON” condition from a warning lamp does not

come “ON” condition.

5. This test checks for proper operation of the “Serial

Data” line. This test will also identify the stored

diagnostic trouble codes and whether they are

current or history.

Diagnostic Aids

The order in which diagnostic trouble codes are

diagnosed is very important. Failure to diagnose the

diagnostic trouble codes in the order specified may

result in extended diagnostic time, incorrect diagnosis

and incorrect parts replacement.

SRS Diagnostic System Check

Step Action Yes No

1 Note the “Air Bag” warning lamp as ignition switch is turned “ON.”

Does the “AIR BAG” warning lamp flash seven 7 times? Go to Step 2 Go to Step 3

2 Note the “AIR BAG” warning lamp after it flashed 7 times.

Does the “AIR BAG” warning lamp go “OFF”? Go to Step 4 Go to Step 5

3 Note the “AIR BAG” warning lamp as ignition switch is turned

“ON”.

Does the “AIR BAG” warning lamp come “ON” steady ?

Go to Chart B. Go to Chart C.

4 1. Note the “AIR BAG” warning lamp as that ignition switch is

turned “ON.”

Ignition switch “OFF.”

2. Connect a scan tool to data link connector.

3. Follow direction given in the scan tool instruction manual.

Ignition switch “ON.”

4. Request the SRS diagnostic trouble code display, recode all

history diagnostic trouble code(s). specify as such, on repair

order

Is (are) diagnostic trouble code(s) displayed?

Ignition switch

“OFF.”

When DTC B1000 is

set, go to DTC

B1000 Chart.

For all other history

codes refer to

“Diagnostic Aids”

For that specific

DTC.

A history DTC

indicates the

malfunction has

been repaired or is

intermittent.

SRS is functional

and free of

malfuncitons, no

further diagnosis is

required.

If scan tool indicated

“NO DATA

RECEIVED,” refer to

chassis electrical

section 8.

5 1. Ignition switch “OFF.”

2. Connect a scan tool to data link connector.

3. Follow directions as given in the scan tool instruction

manual.

4. Ignition switch “ON.”

5. Request the SRS diagnostic trouble code display, Recode

all diagnostic trouble code(s), specifying as current or history

on repair order.

Is (are) diagnostic trouble code (s) displayed?

Ignition switch

“OFF”.

When DTC B0053 is

set, go to DTC

B0053 chart.

When DTC B0051 is

set, go to DTC

B0051 chart.

When DTC B0018

is set, go to DTC

B0018 chart.

When DTC B0024

is set, go to DTC

B0024 chart.

Diagnose remaining

current DTCs from

lowest to highest.

When only history

DTCs exist, refer to

“Diagnostics Aids”

for that specific

DTC.

A history DTC

indicates the

malfunction has

been repaired or is

intermittent.

If scan tool indicates

“No Data Received,”

refer to chassis

electrical section 8.

Chart A SRS control unit Integrity Check

RTW39JMF000101

Circuit Description

When the SRS control unit recognizes “Ignition 1”

voltage, applied to terminals “35”, is greater than 9

volts, the “AIR BAG” warning lamp is flashed 7 times to

verify operation. At this time the SRS control unit

performs “Turn–ON” tests followed by “Continuous

Monitoring” tests. When a malfunction is detected, the

SRS control unit sets a current diagnostic trouble code

and illuminates the “AIR BAG” warning lamp. The SRS

control unit will clear current diagnostic trouble codes

and move them to a history file when the malfunction is

no longer detected and/or the ignition switch is cycled,

except for DTCs B0051 and B0053.

Chart Test Description

Number(s) below refer to step number(s) on the

diagnostic chart:

1. This test confirms a current malfunction. If no

current malfunction is occurring (history DTC set)

the “Diagnostic Aids” for the appropriate diagnostic

trouble code should be referenced. The SRS control

unit should not be replaced for a history diagnostic

trouble code.

2. This test checks for a malfunction introduced into the

SRS during the diagnostic process. It is extremely

unlikely that a malfunctioning SRS control unit would

cause a new malfunction to occur during the

diagnostic process.

3. When all circuitry outside the SRS control unit has

been found to operate properly, as indicated by the

appropriate diagnostic chart, then and only then

should the SRS control unit be replaced.

Chart A SRS control unit Integrity Check

WARNING: DURING SERVICE PROCEDURES. BE VERY CAREFUL WHEN HA NDLING A SRS CONTROL UNIT.

NEVER STRIKE OR JAR THE SRS CONTROL UNIT. NEVER POWER UP THE SRS WHEN THE SRS CONTROL

UNIT IS NOT RIGIDLY ATTACHED TO THE VEHICLE. A LL SRS CONTROL UNIT AND MOUNTING BRACKET

FASTENERS MUST BE CAREFULLY TORQUED AND THE ARROW MUST BE POINTING TOWA RD THE FRONT

OF THE VEHICLE TO ENSURE PROPER OPERATION OF THE SRS. THE SRS CONTROL UNIT COULD BE

ACTIVATED WHEN POWERED WHILE NOT RIGIDLY A TTACHED TO THE VEHICLE WHICH COULD CAUSE

DEPLOYMENT AND RESULT IN PERSONAL INJURY

Step Action Yes No

1 1. This chart assumes that the “SRS Diagnostic System

Check” and either a symptom chart or a diagnostic trouble

code chart diagnosis have been performed. When all

circuitry outside the SRS control unit has been found to

operate properly, as indicated by the appropriate diagnostic

chart, and the symptom or DTC remains current, the

following

2. Diagnostic procedures m us t be perf orm ed to ver ify the need

for SRS control unit replacement.

3. Ignition switch “OFF”.

4. Reconnect all SRS components , ensur e all c omponents are

properly mounted.

5. Ensure the ignition switch has been “OFF” for at least 15

seconds.

6. Note “AIR BAG” warning lamp as ignition switch is turned

“ON.”

Does warning lamp flash 7 times then go “OFF”?

The symptom or

DTC is no longer

occurring.

Clear SRS

diagnostic trouble

codes.

Repeat “SRS

Diagnostic System

Check”

Go to Step 2

2 Using a scan tool request diagnostic trouble code display.

Is the same symptom or DTC occurring as was when the “SRS

Diagnostic System Check” was first performed?

Go to Step 3 Ignition switch

“OFF”.

Go to the

appropriate chart for

the indicated

malfunction.

3 1. Clear “SRS Diagnostic Trouble Codes”.

2. Ignition switch “OFF” for at least two minutes.

3. Note “AIR BAG” warning lamp as ignition switch is turned

“ON.”

Does warning lamp flash 7 times then go “OFF”?

SRS is functional

and free of

malfunctions.

No further diagnosis

is required.

Go to Step 4

Ignition switch

“OFF”.

Replace SRS control

unit.

Go to Step 4

4 Reconnect all SRS components, ensure all components are

properly mounted.

Was this step finished?

Repeat the “SRS

Diagnostic System

Check”

Go to Step 4

Chart B “AIR BAG” Warning Lamp Comes “ON” Steady

RTW39JMF000101

Circuit Description

W hen the ignition switch is f irst turned “ON” , “Ignition 1”

voltage is applied from the “METER” fuse to “AIR

BAG”, warning lamp which is connected to “SRS

W ar ning Lam p”, term inal “39”. The “ SRS” fuses appl

y

system voltage to the “Ignition 1” inputs, term inals “35”.

The SRS control unit responds by flashing the “AIR

BAG” warning lamp 7 times. If “Ignition 1” is less than

9 volts, the “AIR BAG” warning lamp will come “ON”

solid with no DTCs set.

Chart Test Description

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test checks for an open in the “Ignition 1” circuit

to the SRS control unit.

3. This test checks for the voltage of “Ignition 1”.

4. This test determines whether the malfunction is a

short to ground in SRS waring lamp circuit.

Chart B “AIR BAG” warning lamp comes “ON” Steady

Step Action Yes No

1 1. When meas urements are reques ted in this c har t use 5- 8840-

0285-0 DVM with correct terminal adapter from 5-8840-

0385-0.

2. Ignition switch “OFF.”

3. Connect scan tool to data link connec tor, follow directions as

given in the scan tool instruction MANUAL.

4. Ignition switch “ON.”

5. Request SRS diagnostic trouble code display.

Dose scan tool indicate “No Data Received”?

Go to Step 2 Go to Step 3

2 1. Ignition switch “OFF”.

2. Inspect SRS control unit harness connector connection to

SRS control unit.

Is it securely connected to the SRS control unit?

Ignition switch

“OFF.”

Replace SRS

control unit.

Go to Step 5

Connect SRS

control unit

securely to de–

activate shorting

clip in SRS control

unit harness

connector.

Go to Step 5

3 Using scan tool, request SRS data list.

Is “ignition” more than 9 volts? Go to Step 4 Ignition switch

“OFF.”

Replace SRS

control unit.

Go to Step 5

4 1. Ignition switch “OFF.”

2. Disconnect SRS coil and passenger air bag assemblies.

yellow connector located at base of steering column and

behind the glove box assembly.

Disconnect SRS control unit.

3. Disconnect the connector of “SRS Warning Lamp” of

instrument cluster.

4. Measur e resistance fr om SRS control unit harness c onnector

terminal “40” to ground.

Does 5-8840-0285-0 DVM display “OL” (Infinite)?

Go to Chart A Replace SRS

harness.

Go to Step 5

5 Reconnect all SRS components, ensure all components are

properly mounted.

Was this step finished?

Repeat the “SRS

Diagnostic System

Check”

Go to Step 5

Chart C “AIR BAG” Warning Lamp Does Not Come “ON” Steady

RTW39JMF000101

Circuit Description

W hen the ignition switch is f irst turned “ON” , “Ignition 1”

voltage is applied from the “METER” fuse to the “AIR

BAG” warning lamp which is connected to “SRS

Warning Lamp”, terminal “39”. The “SRS” fuse appl

y

system voltage to the “Ignition 1” inputs, term inals “35”.

The SRS control unit responds by flashing the “AIR

BAG” warning lam p s even tim es. If “Ignition 1” is mo re

than 16 volts, the “AIR BAG” warning lamp will be still

“OFF” solid with no DTCs set.

Chart Test Description

Number(s) below refer to step number(s) on the

diagnostic chart:

1. This test decides whether power is available to SRS

control unit warning lamp power feed circuit.

2. This test determines whether the voltage is present

in the warning lamp circuit.

3. This test determines if the malfunction is in the

instrument cluster.

4. This test checks for open in the warning lamp

circuitry.

5. This test isolates the SRS warning lamp circuit and

check s f or a s hort in the SRS warning lam p c ircuit to

B+.

8. This test checks for a short from the SRS control

unit warning lamp power feed circuit to ground.

9. This test determines whether the short to ground is

due to a short in the wiring.

Chart C “AIR BAG” Warning Lamp Does Not Come “ON” Steady

Step Action Yes No

1 1. When meas urements are r eques ted in this c har t, use 5- 8840-

0285-0 DVM with correct terminal adapter from 5-8840-

0385-0.

2. Ignition switch “OFF.”

3. Remove and inspect “METER” fuse to the “AIR BAG”

warning lamp.

Is fuse good?

Go to Step 2 Go to Step 7

2 1. Ignition switch “OFF.”

2. Disconnect SRS coil and passenger air bag assemblies.

Yellow connector located at base of steering column and

behind the glove box assembly.

3. Disconnect SRS control unit.

4. Ignition switch “ON.”

5. Measure voltage on SRS control unit harness connector from

terminal “39” to terminal “40” (ground).

Is system voltage present on terminal “39”?

Go to Step 4 Go to Step 3

3 1. Ignition switch “OFF.”

2. Remove instrument meter cluster.

3. Check for proper connection to instrument cluster at SRS

warning lamp circuit terminal.

4. If ok, then remove and inspect “AIR BAG” bulb.

Is bulb good?

Go to Step 5 Replace bulb.

Go to Step 6

4 1. Ignition switch “OFF.”

2. Disconnect instrument meter cluster harness connector.

3. Ignition switch “ON.”

4. Measure voltage on SRS contr ol unit harnes s c onnector f rom

terminal “39” to terminal “40” (ground).

Is voltage 1 volt or less?

Go to Chart A Replace SRS

harness.

Go to Step 6

5 1. Install bulb.

2. Measure resistance from instrument meter cluster harness

connector SRS warning lam p circuit terminal to SRS control

unit harness connector terminal “7”.

Is resistance 5.0 ohms or less?

Service instrument

meter cluster.

Install instrument

meter cluster.

Go to Step 6

Replace SRS

harness.

Go to Step 6

6 Reconnect all SRS components, ensure all components are

properly mounted.

Was this step finished?

Repeat the “SRS

Diagnostic System

Check”

Go to Step 6

Step Action Yes No

7 Perform chart C.

Was this step finished? Go to Step 8 Go to Step 1

8 1. Replace “METER” fuse.

2. Ignition switch “ON” wait 10 Sec onds then ignition s witch “ O f f .

“

3. Remove and inspect “METER” fuse.

Is fuse good?

Install “METER”

fuse.

Go to Step 10

Go to Step 9

9 1. Disconnect SRS coil and passenger air bag assemblies.

Yellow connectors located at base of steering column and

behind the glove box assembly.

2. Disconnect SRS control unit.

3. Replace “METER” fuse.

4. Ignition switch “ON” wait 10 seconds.

5. Ignition switch “OFF”.

6. Remove and inspection “METER” fuse.

Is fuse good?

Install “METER”

fuse.

Go to Chart A

Replace SRS

harness.

Replace “METER”

fuse.

Go to Step 10

10 Reconnect all SRS components, ensure all components are

properly mounted.

Was this step finished?

Repeat the “SRS

Diagnostic System

Check”

Go to Step 10

DTC B0016 (Flash Code 16) Passenger Airbag Squib

Circuit Low Resistance

RTW39JMF000101

Circuit Description

When the ignition switch is turned “ON”, the SRS

control unit will perform tests to diagnose critical

malfunctions within itself. Upon passing these tests

“Ignition 1”, and deployment loop voltages are

measured to ensure they are within their respective

normal voltage ranges. The SRS control unit then

proceeds with the “Resistance Measurement Test”.

“Passenger Bag Low” term inal “47” is grounded through

a resistor and the passenger current source connected

to “Passenger Bag High” terminal “48” allows a known

amount of current to flow. By monitoring the voltage

difference between “Passenger Bag High” and

“Passenger Bag Low”, the SRS control unit calculates

the combined resistance of the passenger air bag

assem bly, harness wiring circuits “Pass enger Bag High”

and “Passenger Bag Low” connector terminal contact.

DTC Will Set When

The combined resistance of the passenger air bag

assembly, harness wiring circuits “Passsenger Bag

High” and “Passenger Bag Low”, and connector

terminal contact is above a specified value. This test

is run once each ignition cycle during the “Resistance

Measurement Test” when:

1. No “higher priority f aults” are detected during “T urn–

ON”,

2. “Ignition 1” voltage is in the specified value.

Action Taken

SRS control unit turns “ON” the “AIR BAG” warning

lamp and sets a diagnostic trouble code.

DTC Will Clear When

The ignition switch is turned “OFF.”

Techline

DTC Chart Test Description

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SRS control unit.

3. This test verifies connection of the yellow connector.

4. This test cheek s for proper operation of the shorting

clip in the yellow connector.

5. The tes t checks for a m alfunction pas senger air bag

assembly.

6. This test determines whether the malfunctioning is

due to shortening in the wiring.

Diagnostic Aids

A

n intermittent condition is likely to be caused by a short

between circuits “Passenger Bag High” and “Passenger

Bag Low” or a malfunctioning shorting clip on the

passenger air bag assembly which would require

replacement of the air bag assembly. The test for this

diagnostic trouble code is only run while “AIR BAG”

warning lamp is performing the bulb check. When a

scan tool “Clear Codes” command is issued and the

malfunction is still present, the DTC will not reappear

until the next ignition cycle.

DTC B0016 (Flash Code 16) Passeng er Airbag Squib Circuit Low Resistance

Step Action Yes No

1 Was the “SRS Diagnostic System Check performed?

Go to Step 2

Repeat the

“SRS Diagnostic

System Check”

2 1. Ignition switch in the ‘LOCK’ position.

2. Check that the passenger air bag assembly yellow connect or,

located behind the glove box assembly is correctly installed.

Is the yellow connector correctly installed? Go to Step 3

Install the

passenger air bag

assembly yellow

connector correctly.

Go to Step 6

3

1. Disconnect the passenger air bag assembly, yellow wiring

connector, located behind the glov e box assembly.

2. If OK, reinstall the passenger air bag assem bly connector.

3. Turn the ignition switch to the ‘ON’ position.

Is DTC B0016 current? Go to Step 4 Go to Step 6

4

1. Ignition switch in the ‘LOCK’ position.

2. Disconnect SRS coil and passeng er air bag assembly yellow

wiring connector, located at the base of the steering column

and behind the glove bo x ass embly.

3. Connect 5-8840-2421-0 SRS driver/p assenger load tool and

appropriate adaptors to the SRS coil and passenger air bag

harness connectors.

4. Turn the ignition switch to the ‘ON’ position.

T

C B0016 current? Go to Step 5

Ignition switch in the

‘LOCK’ position.

Replace the

passenger air bag

assembly.

Go to Step 6

5

1. Ignition switch in the ‘LOCK’ position.

2. There has been a decrease in the total circu it resistance of the

passenger inflator deployment loop.

3. Use the high resolution ohmmeter mode of the DMM while

checking circuits “Passenger Bag High” and “Passenger Bag

Low”, and SRS control unit connector terminal “48” and “47” to

locate the root cause.

Was a fault found?

Replace the SRS

harness.

Go to Step 6 Go to Chart A

6

1. Reconnect all removed components, ensuri ng that all are

correctly mounted.

2. Check that all electrical connections are correctly installed.

3. Clear all diagnostic trouble codes.

4. Check that the DTC does not reset.

Does the DTC reset? Go to Step 1 System OK

DTC B0017 (Flash Code 17) Passenger Airbag

Squib Circuit High Resistance

RTW39JMF000101

Circuit Description

When the ignition switch is turned “ON”, the SRS

control unit will perform tests to diagnose critical

malfunctions within itself. Upon passing these tests

“Ignition 1”, and deployment loop voltages are

measured to ensure they are within their respective

normal voltage ranges. The SRS control unit then

proceeds with the “Resistance Measurement Test”.

“Passenger Bag Low” term inal “47” is grounded through

a resister and the passenger current source connected

to “Passenger Bag High” terminal “48” allows a known

amount of current to flow. By monitoring the voltage

difference between “Passenger Bag High” and

“Passenger Bag Low” the SRS control unit calculates

the combined resistance of the passenger air bag

assem bly, harness wiring circuits “Pass enger Bag High”

and “Passenger Bag Low” connector terminal contact.

DTC Will Set When

The combined resistance of the passenger air bag

assembly, harness wiring circuits “Passenger Bag High”

and “Passenger Bag Low”, and connector terminal

contact is above a specified value. This test is run

once each ignition cycle during the “Resistance

Measurement Test” when:

1. No “higher priority f aults” are detected during “T urn–

ON”,

2. “Ignition 1” voltage is in the specified value.

Action Taken

SRS control unit turns “ON” the “AIR BAG” warning

lamp and sets a diagnostic trouble code.

DTC Will Clear When

The ignition switch is turned “OFF.”

DTC Chart Test Description

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SRS control unit.

3. This test verifies proper connection of the yello

w

connector.

4. This test checks for proper contact and/or corrosion

of the yellow connector terminals.

5. The test checks for a malfunctioning passenger ai

r

bag assembly.

6. This test determines whether the malfunction is due

to high resistance in the wiring.

Diagnostic Aids

A

n intermittent condition is likely to be caused by a poor

connection at the passenger air bag assembly harness

connector terminals “1” and “2”, SRS control unit

terminal “48” and “47”, or a poor wire to terminal

connection in circuits “Passenger Bag High” and

“Passenger Bag Low”. This test for this diagnostic

trouble code is only run while the “AIR BAG” warning

lamp is performing the bulb check. When a scan tool

“Clear Codes” command is issued and the malfunction

is still present, the DTC will not reappear until the next

ignition cycle.

DTC B0017 (Flash Code 17) Passenger Airbag Squib Circuit High Resistance

Step Action Yes No

1 Was the “SRS Diagnostic System Check” Performed? Go to Step 2 Go to The “SRS

Diagnostic System

Check”

2 1. When meas urements are reques ted in this c har t use 5- 8840-

0285-0 DVM with correct terminal adapter from 5-8840-

0385-0.

2. Use scan tool data list function, read and record the

passenger deployment loop resistance.

Is passenger resist. more than 6.5 ohms?

Go to Step 3 Go to Chart A

3 1. Ignition switch “Off.”

2. Make sure the passenger air bag assembly yellow connector

located behind the glove box assembly is seated properly.

Is the yellow connector connected properly?

Go to Step 4 Seat passenger Air

Bag assembly

yellow connector

properly.

Go to Step 7

4 1. Disconnect and inspect the passenger air bag assembly

yellow connector located behind the glove box assembly.

2. If ok, reconnect the passenger air bag assembly connector.

3. Ignition switch “ON.”

Is DTC B0017 current?

Go to Step 5 Go to Step 7

5 1. Ignition switch “Off.”

2. Disc onnect SRS coil and passenger air bag as sembly, yellow

connector located at the base of the steering column and

behind the glove box assembly.

3. Connect 5-8840-2421-0 SRS driver / passenger load tool and

appropriate adapters to SRS coil and passenger air bag

assembly harness connectors.

4. Ignition switch “ON.”

Is DTC B0017 Current?

Go to Step 6 Ignition switch

“Off.”

Replace the

passenger air bag

assembly.

Go to Step 7

6 1. Ignition switch “Off.”

2. There has been an increase in the total circuit resistance of

the passenger inflator deployment loop.

3. Use the high resolution ohmmeter mode of the DVM while

checking circuits “Pasenger Bag High” and “Passenger Bag

Low”, and SRS control unit connector term inal “48” and “47”

to locate the root cause.

Was a fault found?

Replace SRS

harness.

Go to Step 7

Go to Chart A

7 1. Reconnect all com ponents ens ure all com ponent are properly

mounted.

2. Clear diagnostic trouble codes.

Was This step finished?

Repeat the “SRS

Diagnostic System

Check”

Go to Step 7

DTC B0018 (Flash Code 18) Passenger Airbag Squib

Circuit Voltage Range/Performance

RTW39JMF000101

Circuit Description

When the ignition switch is turned “ON”, the SRS

control unit will perform tests to diagnose critical

malfunctions within itself. Upon passing these tests,

“Ignition 1”, and deployment loop voltages are

measured to ensure they are within their respective

normal voltage ranges.

The SRS control unit monitors the voltages at “Drive

r

Bag Low” terminal “46” and “Passenger Bag Low”

term inal “47” to detect short to ground/+B in the air bag

assembly circuits.

DTC Will Set When

Neither of the two air bag assemblies is open.

“Ignition 1” is within the normal operating voltage range.

Once these conditions are me and the voltage at

“Passenger Bag Low” is out of a specified value, DTC

B0018 will set. This test is run once each ignition cycle

and “Continuous Monitoring”.

Action Taken

SRS control unit turns “ON” the “AIR BAG” warning

lamp and sets a diagnostic trouble code.

DTC Will Clear When

This malfunction is no longer occurring and the ignition

switch is turned “OFF”.

DTC Chart Test Description

Number(s) below refer to circled number(s) on the

diagnostic chart.

2. This test determines whether the SRS control unit is

malfunctioning.

3. This test isolates the malfunction to one side of the

passenger air bag assembly yellow connector behind

glove box compartment.

4. This test determines whether the malfunction is in

“Passenger Bag High” circuit.

5. This test determines whether the malfunction is in

“Passenger Bag Low” circuit.

6. This test determines whether the malfunction is in

“Driver Bag High” circuit.

7. This test determines whether the malfunction is in

“Driver Bag Low” circuit.

Diagnostic Aids

A

n intermittent condition is likely to be caused by a short

to ground/+B in the passenger air bag assembly circuit.

Inspect circuits “Passenger Bag High” and “Passenger

Bag Low” carefully for cutting or chafing. If the wiring

pigtail of the passenger air bag assembly is damaged,

the component must be replaced.

DTC B0018 (Flash Code 18) Passenger Airbag Squib Circuit Voltage Range/Performance

Step Action Yes No

1 Was the “SRS Diagnostic System Check” performed? Go to Step 2 Go to the “SRS

Diagnostic System

Check”

2 1. When meas urements are reques ted in this c har t use 5- 8840-

0285-0 DVM with correct terminal adapter from 5-8840-

0385-0.

2. Ignition switch “OFF.”

3. Connect scan tool data link connector. follow directions as

given in the scan tool operator's MANUAL.

4. Ignition switch “ON.”

5. Read passenger sense LO.

Is passenger sense LO less than 2.0 volts or more than 6.0

volts?

Go to Step 3 Go to Chart A

3 1. Ignition switch “OFF.”

2. Disconnect passenger air bag assembly yellow connector

behind the glove box assembly.

3. Leave driver air bag assembly connected.

4. Connect SRS driver / passenger load tool 5-8840-2421-0 and

appropriate adapter to pas senger air bag ass embly harness

connector.

5. Ignition switch “ON.”

Is DTC B0018 current?

Go to Step 4 Ignition switch

“OFF.”

Replace

passenger air bag

assembly .

Go to Step 8

4 1. Ignition switch “OFF”.

2. Disconnect SRS driver / passenger load tool

3. Measure resistance on SRS control unit harness connector

from terminal “48” to terminal “40” (ground).

Does 5-8840-0285-0 display “OL” (Infinite)?

Go to Step 5 Replace SRS

Harness.

Go to Step 8

5 Measure resistance on SRS control unit harness connector from

terminal “47” to terminal “40” (ground).

Does 5-8840-0285-0 display “OL” (Infinite)?

Go to Step 6 Replace SRS

Harness.

Go to Step 8

6 Measure resistance on SRS control unit harness connector from

terminal “48” to terminal “35” (ignition).

Does 5-8840-0285-0 display “OL” (Infinite)?

Go to Step 7 Replace SRS

Harness.

Go to Step 8

7 Measure resistance on SRS control unit harness connector from

terminal “47” to terminal “35” (ignition).

Does 5-8840-0285-0 display “OL” (Infinite)?

Go to Chart A Replace SRS

Harness.

Go to Step 8

8 1. Reconnect all components and ensure all component are

properly mounted.

2. Clear diagnostic trouble codes.

Was this step finished?

Go to the “SRS

Diagnostic system

Check”

Go to Step 8

DTC B0022 (Flash Code 22) Driver Airbag

Squib Circuit Low Resistance

RTW39JMF000101

Circuit Description

When the ignition switch is turned “ON”, the SRS

control unit will perform tests to diagnose critical

malfunctions within itself. Upon passing these tests

“Ignition 1”, and deployment loop voltages are

measured to ensure they are within their respective

normal voltage ranges.

The SRS control unit then proceeds with the

“Resistance Measurement Test” “Driver Bag Low”

terminal “46” is grounded through a current sink and

the driver current source connected to “Driver Bag

High” term inal “45” allows a known am ount of curr ent to

flow. By monitoring the voltage difference between

“Driver Bag High” and “D river Bag Low” the SRS contr ol

unit calculates the combined res istance of the driver air

bag assembly, SRS coil assembly, harness wiring

circuits “Driver Bag High” and “Driver Bag Low” and

connector terminal contact.

Techline

DTC Will Set When

The combined resistance of the driver air bag

assembly, SRS Coil assembly, harness wiring circuits

“Driver Bag High” and “Driver Bag Low”, and connector

terminal contact is above a specified value. This test is

run once each ignition cycle during the “Resistance

Measurement Test” when:

1. No “higher priority f aults” are detected during “T urn–

ON”

2. “Ignition 1” voltage is in the specified value.

Action Taken

SRS control unit turns “ON” the “AIR BAG” warning

lamp and sets DTC B0022.

DTC Will Clear When

The ignition switch is turned “OFF.”

DTC Chart Test Description

Number(s) below refer to circled number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SRS control unit.

3. This test verifies proper connection of the yellow

connector at the base of the steering column.

4. This test checks for proper operation of the shorting

clip in the yellow connector.

5. This test isolate the malfunction to one side of the

SRS coil assembly yellow connector located at the

base of steering column.

6. This test determines whether the malfunction is due

to shortening in the wiring.

7. This test determines whether the malfunction is in

the SRS coil assembly or the driver air bag

assembly.

Diagnostic Aids

An intermittent condition is likely to be caused by a short

between circuit “Driver Bag High” or “Driver Bag Low”

or a malfunctioning shorting clip on the driver air bag

assembly or SRS coil assembly which would require

replacement of the component. The test for this

diagnostic trouble code is only run while the “AIR BAG”

warning lamp is performing the bulb check. When a

scan tool “Clear Codes” command is issued and the

malfunction is still present, the DTC will not reappear

until the next ignition cycle.

DTC B0022 (Flash Code 22) Driv er Airbag Squib Circuit Low Resistance

Step Action Yes No

1 Was the “SRS Diagnostic System Check performed?

Go to Step 2

Repeat the

“SRS Diagnostic

System Check”

2 1. Ignition switch in the ‘LOCK’ position.

2. Check that the SRS coil assembly yellow connector, located at

the base of the steering column is correctly installed.

Is the yellow connector correctly installed? Go to Step 3

Install the driver air

bag assembly

yellow connector

correctly.

Go to Step 7

3

1. Disconnect and inspect the SRS coil assem bly, yellow wiring

connector, located at t he base of the steering colum n

assembly.

2. If OK, reinstall the SRS coil assembly, yellow connector.

3. Turn the ignition switch to the ‘ON’ position.

Is DTC B0022 current? Go to Step 4 Go to Step 7

4

1. Ignition switch in the ‘LOCK’ position.

2. Disconnect SRS coil and passeng er air bag assembly yellow

wiring connector, located at the base of the steering column

and behind the glove bo x ass embly.

3. Connect 5-8840-2421-0 SRS driver/p assenger load tool and

appropriate adaptors to the SRS coil and passenger air bag

harness connectors.

4. Turn the ignition switch to the ‘ON’ position.

Is DTC B0022 current? Go to Step 5 Go to Step 6

5

1. Ignition switch in the ‘LOCK’ position.

2. There has been a decrease in the total circuit resistance of the

driver inflator deployment loop.

3. Use the high resolution ohmmeter mode of the DMM while

checking circuits “Driver Bag High” and “Driver Bag Low”, and

SRS control unit connector terminal “45” an d “46” to locate the

root cause.

Was a fault found?

Replace the SRS

harness.

Go to Step 6 Go to Chart A

6

1. Ignition switch in the ‘LOCK’ position.

2. Disconnect SRS driver/passenger load tool from the driver bag

assembly harness connector.

3. Connect the SRS driver/passenger load tool 5-8840-2421-0 to

the top of the steering column connector.

4. Reconnect the SRS coil assembly harness connector st the

base of the steering column.

5. Turn the ignition switch to the ‘ON’ position.

Is DTC B0022 current?

Ignition switch in the

‘LOCK’ position.

Replace SRS coil

assembly.

Go to Step 7

Ignition switch in the

‘LOCK’ position.

Replace driver air

bag assembly.

Go to Step 7

7

1. Reconnect all removed components, ensuri ng that all are

correctly mounted.

2. Check that all electrical connections are correctly installed.

3. Clear all diagnostic trouble codes.

4. Check that the DTC does not reset.

Does the DTC reset? Go to Step 1 System OK

DTC B0024 (Flash Code 24) Driver Airbag Squib

Circuit Voltage Range/Performance

RTW39JMF000101

Circuit Description

When the ignition switch is turned “ON”, the SRS

control unit will perform tests to diagnose critical

malfunctions within itself. Upon passing these tests,

“Ignition 1”, and deployment loop voltages are

measured to ensure they are within their respective

normal voltage ranges.

The SRS control unit monitors the voltage at “Drive

r

Bag Low” terminal “46” and “Passenger Bag Low”

terminal “47” to detect shorts to ground/+B in the air bag

assembly circuits.

DTC Will Set When

Neither of the two air bag assemblies is open.

“Ignition 1” is within the normal operating voltage range.

This test is run once each ignition cycle and

“Continuous Monitoring”. Once these conditions are

met and the voltage at “Driver Bag Low” is out of a

specified value, DTC B0024 will set.

Action Taken

SRS control unit turns “ON” the “AIR BAG” warning

lamp and sets a diagnostic trouble code.

DTC Will Clear When

The malfunction is no longer occurring and the ignition

is turned “OFF”.

DTC Chart Test Description

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the SRS control unit is

malfunctioning

3. This test isolates the malfunction to one side of the

SRS coil assembly yellow 2–pin connector at the

base of the steering column.

4. This test determines whether the malfunction is in

“Driver Bag High” circuit.

5. This test determines whether the malfunction is in

“Driver Bag Low” circuit.

6. This test determines whether the malfunction is in

“Driver Bag High” circuit.

7. This test determines whether the malfunction is in

“Driver Bag Low” circuit.

8. This test determines whether the malfunction is in

the SRS coil assembly or the driver air bag

assembly.

Diagnostic Aids

An intermittent condition is likely to be caused by a short

to ground/+B in the driver air bag assembly circuit.

Inspect circuits “Driver Bag High” and “Driver Bag Low”

carefully for cutting or chafing.

DTC B0024 (Flash Code 24) Driver Airbag Squib Circuit Voltage Range/Performance

Step Action Yes No

1 Was the “SRS Diagnostic System Check” performed? Go to Step 2 Go to the “SRS

Diagnostic System

Check”

2 1. When meas urements are reques ted in this c har t use 5- 8840-

0285-0 DVM with correct terminal adapter from 5-8840-

0385-0.

2. Ignition switch “OFF.”

3. Connect scan tool data link connector. follow directions as

given in the scan tool operator's manual.

4. Ignition switch “ON.”

5. Read driver sense LO.

Is driver sense LO less than 2.0 volts or more than 6.0 volts?

Go to Step 3 Go to Chart A

3 1. Ignition switch “OFF.”

2. Disconnect SRS coil assembly yellow connector located at

base of the steering column. leave passenger air bag

assembly connected.

3. Connect SRS driver / passenger load tool 5-8840-2421-0 and

appropriate adapter to SRS coil assembly harness

connector.

4. ignition switch “ON.”

Is DTC B0024 current?

Go to Step 4 Go to Step 8

Step Action Yes No

4 1. Ignition switch “OFF.”

2. Disconnect SRS control unit.

3. Disconnect SRS driver / passenger load tool.

4. Measure resistance on SRS control unit harness connector

“45” to terminal “40” (ground).

Does 5-8840-0285-0 display “OL” (infinite)?

Go to Step 5 Replace SRS

harness.

Go to Step 9

5 Measure resistance on SRS control unit harness connector from

terminal “46” to terminal “40” (ground).

Does 5-8840-0285-0 display “OL” (infinite)?

Go to Step 6 Replace SRS

harness.

Go to Step 9

6 Measure resistance on SRS control unit harness connector from

terminal “45” to terminal “35” (ignition).

Does 5-8840-0285-0 display “OL” (infinite)?

Go to Step 7 Replace SRS

harness.

Go to Step 9

7 Measure resistance on SRS control unit harness connector from

terminal “46” to terminal “35” (ignition).

Does 5-8840-0285-0 display “OL” (infinite)?

Go to Chart A Replace SRS

harness.

Go to Step 9

8 1. Ignition switch “OFF.”

2. Disconnect SRS driver / passenger load tool 5-8840-2421-0

from SRS coil assembly harness connector.

3. Connect SRS driver / passenger load tool 5-8840-2421-0 and

appropriate adapter to driver air bag assembly harness

connector. located top of the steering column connector.

4. Reconnect SRS coil assembly harness connector as the base

of steering column.

5. Ignition switch “ON.”

Is DTC B0024 current?

Ignition switch

“OFF.”

Replace SRS coil

assembly.

Go to Step 9

Ignition switch

“OFF.”

Replace driver air

bag assembly.

Go to Step 9

9 1. Reconnect all com ponents ens ure all com ponent are properly

mounted.

2. Clear diagnostic trouble codes.

Was this step finished?

Go to the “SRS

Diagnostic System

Check”

Go to Step 9

DTC B0026 (Flash Code 26) Driver Airbag

Squib Circuit High Resistance

RTW39JMF000101

Circuit Description

When the ignition switch is turned “ON”, the SRS

control unit will perform tests to diagnose critical

malfunctions within itself. Upon passing these tests,

“Ignition 1”, and deployment loop voltages are

measured to ensure they are within their respective

normal voltage ranges.

The SRS control unit then proceeds with the

“Resistance Measurement Test” “Driver Bag Low”

term inal “ 46” is grounded thr ough a c urr ent s ink and the

driver current source connected to “Driver Bag High”

terminal “45” allows a k nown am ount of current to flow.

By monitoring the voltage difference between “Driver

Bag High” and “Driver Bag Low”, the SRS control unit

calculates the c ombined resis tance of the driver air bag

assembly, SRS coil assembly, harness wiring circuits

“Driver Bag High” and “Driver Bag Low” and connector

terminal contact.

DTC Will Set When

The combined resistance of the driver air bag

assembly, SRS Coil assembly, harness wiring circuits

“Driver Bag High” and “Driver Bag Low”, and connector

terminal contact is above a specified value. This test

run once each ignition cycle during the “Resistance

Measurement Test” when:

1. No “higher priority f aults” are detected during “T urn–

ON”

2. “Ignition 1” voltage is in the specified value.

Action Taken

SRS control unit turns “ON” the “AIR BAG” warning

lamp and sets DTC B0026.

DTC Will Clear When

The ignition switch is turned “OFF”.

DTC Chart Test Description

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SRS control unit.

3. This test verifies proper connection of the yellow

connector at the base of the steering column.

4. This test checks for proper contact and/or corrosion

of the connector terminals at the base of steering

column.

5. This test isolate the malfunction to one side of the

SRS coil assembly yellow connector located at the

base of the steering column.

6. This test determines whether the malfunction is due

to high resistance in the wiring.

7. This test determines whether the malfunction is in

the SRS coil assembly or the driver air bag

assembly.

Diagnostic Aids

An interm ittent condition is likely to be caused by a poor

connection at terminals “1” and “2” of the SRS coil

connector at the base of the steering column, terminal

“1” and “2” of the driver air bag assem bly connector at

the top of the steering column, SRS control unit

terminals “45” and “46” or a poor wire to terminal

connection in circuit “Driver Bag High” or “Driver Bag

Low” The test for this diagnostic trouble code is onl

y

run while the “AIR BAG” warning lamp is performing

the bulb check. When a scan tool “Clear Codes”

com mand is issued and the m alfunc tion is still pr esent,

the DTC will not reappear until the next ignition cycle.

DTC B0026 (Flash Code 26) Driver Airbag Squib Circuit High Resistance

Step Action Yes No

1 Perform the “SRS Diagnostic System Check”.

Was the “SRS Diagnostic System Check” performed? Go to Step 2 Repeat the “SRS

Diagnostic System

Check”

2 1. When meas urements are reques ted in this c har t use 5- 8840-

0285-0 DVM with correct terminal adapter from 5-8840-

0385-0.

2. Use scan tool data list function, read and record the driver

deployment loop resistance.

Is driver resistance more than 6.5 ohms?

Go to Step 3 Go to Chart A

3 1. Ignition switch “OFF.”

2. Disconnect SRS coil assembly yellow connector located at

base of steering column is seated properly.

Is the connector connected properly?

Go to Step 4 Seat SRS coil

assembly

connector

properly.

Go to Step 8

4 1. Disconnect and inspect the SRS coil assembly yellow

connector located base of steering column.

2. If ok, reconnect the SRS coil assembly yellow connector.

3. Ignition switch “ON.”

Is DTC B0026 current?

Go to Step 5 Go to Step 8

5 1. Ignition switch “OFF.”

2. Disc onnect SRS coil and passenger air bag as sembly, yellow

2–pin connector loc ated at the base of steering c olumn and

behind the glove box assembly.

3. Connect SRS driver / passenger load tool 5-8840-2421-0 and

appropriate adapter to SRS coil and passenger air bag

assembly harness connectors.

4. Ignition switch “ON.”

Is DTC B0026 current?

Go to Step 6 Go to Step 7

6 1. Ignition switch “Off. “

2. There has been a increase in the total circuit resistance of

the driver deployment loop.

3. Use the high resolution ohmmeter mode of the DVM while

checking circuits “Driver Bag High” and “Driver Bag Low”,

and SRS control unit connector terminal “45” and “46” to

locate the root cause.

Was a fault found?

Replace SRS

harness.

Go to Step 8

Go to Chart A

7 1. Ignition switch “OFF.”

2. Disconnect SRS driver / passenger load tool from SRS coil

assembly harness connector.

3. Connect SRS driver / passenger load tool 5-8840-2421-0 on

the top of steering column.

4. Reconnect SRS coil assembly harness connector as the base

of steering column.

5. Ignition switch “ON.”

Is DTC B0026 current?

Ignition switch

“OFF.”

Replace SRS coil

assembly.

Go to Step 8

Ignition switch

“OFF.”

Replace driver air

bag assembly.

Go to Step 8

8 1. Reconnect all components ensure all component are

properly mounted.

2. Clear diagnostic trouble codes.

Was this step finished?

Repeat the “SRS

Diagnostic System

Check”

Go to Step 8

DTC B0033 (Flash Code33) ECU Connector Poor Connection

RTW39JMF000101

Circuit Description

The connector of SRS control unit is connected

completely. ECPA(Electrical Connector Position

Assurance) circuit is closed after that.

SRS control unit supervises it by self-diagnosis.

DTC Will Set When

ECPA circuit is open.

Action Taken

Connect completely the SRS control unit.

DTC Will Clear When

The ignition switch is turned “OFF”.

DTC (Flash Code33) B0033 ECU Connector Poor Connection

Step Action Yes No

1 Was the “SRS Diagnostic System Check” performed? Go to Step 2 Go to the “SRS

Diagnostic System

Check”

2 Ignition switch “OFF”

Reconnect the ECPA on SRS control unit connector yellow 52-

pin connector located at the base of instrument panel center.

Ignition switch “ON”

Is DTC B0033 current?

Go to Step 3 Reconnect the

ECPA properly.

Go to Step2

3 Clear Diagnostic trouble codes.

Is the action complete? Go to “SRS

Diagnostic System

Check”

Go to Step 3

DTC B0051 (Flash Code 51) Squib Circuit Activated (Crash)

RTW39JMF000101

Circuit Description

The SRS control unit contains a sensing device which

converts vehicle velocity changes to an electrical

signal. The electrical signal generated is processed b

y

the SRS control unit and then compared to a value

stored in m emory. W hen the generated s ignal exceeds

the stored value, the SRS control unit will cause current

to flow through the air bag assembly deploying the ai

r

bags and causing DTC B0051 to set.

DTC Will Set When

The SRS control unit detects a frontal crash, up to 30

degrees off the centerline of the vehicle, of sufficient

force to warrant deployment of the air bags.

Action Taken

SRS control unit turns “ON” the “AIR BAG” warning

lamp records “Crash Data”, and sets a diagnostic

trouble code.

DTC Will Clear When

The SRS control unit is replaced.

DTC Chart Test Description

Number(s) below refer to step number(s) on the

diagnostic chart:

2. If air bag assem bly(s) has not deployed, DT C B0051

may have falsely set.

3. If DT C B0051 has set with no signs of fr ontal impac t,

the diagnostic trouble code has falsely set.

DTC B0051 (Flash Code 51) Squib Circuit Activated (Crash)

WARNING: DURING SERVICE PROCEDURES. BE VERY CAREFUL WHEN HA NDLING A SRS CONROL UNIT.

NEVER STRIKE OR JAR THE SRS CONTROL UNIT. NEVER POWER UP THE SRS WHEN THE SRS CONTROL

UNIT IS NOT RIGIDLY ATTACHED TO THE VEHICLE. A LL SRS CONTROL UNIT AND MOUNTING BRACKET

FASTENERS MUST BE CAREFULLY TORQUED AND THE ARROW MUST BE POINTING TOWARD THE FRONT

OF THE VEHICLE TO ENSURE PROPER OPERATION OF THE SRS. THE SRS CONTROL UNIT CAUSE

DEPLOYMENT AND RESULT IN PERSONAL INJURY.

Step Action Yes No

1 Was the “SRS Diagnostic System Check” performed? Go to Step 2. Go to the “SRS

Diagnostic System

Check”

2 Ignition switch “OFF.”

Have air bag assemblies deployed? Replace

components and

perform

inspections as

directed in

“repairs and

inspections

required after an

accident” in this

section.

clear diagnostic

trouble codes.

Repeat “SRS

Diagnostic System

Check”

Go to Step 3

3 Inspect front of vehicle and undercarriage for sings of impact.

Were signs of impact found? Replace

components and

perform

inspections as

directed in

“Repairs and

Inspections

Required After An

Accident” in this

section.

Clear diagnostic

trouble codes.

Repeat “SRS

Diagnostic System

Check”

Ignition switch

“OFF”.

Replace SRS

control unit.

Reconnect all SRS

system

components,

ensure all

components are

properly mounted.

Repeat “SRS

Diagnostic System

Check”

DTC B0053 (Flash Code 53) Deployment Command

Despite Present Trouble Code

RTW39JMF000101

Circuit Description

The SRS control unit contains a sensing circuit, which

converts vehic le velocity changes to an electrical signal.

The electrical signal generated is processed by the SRS

control unit and then compared to a value stored in

memory. When the generated signal exceeds the

stored value, the SRS control unit will cause current to

flow through the air bag assembly deploying the ai

r

bags. DTC B0053 is set accompanying with DTC

B0051 when a deployment occurs while an air bag

assembly circuit fault is present that could possible

result in a no deployment situation in one or both air bag

assemblies.

DTC Will Set When

The SRS control unit detects a frontal crash, up to 30

degrees off the centerline of the vehicle, of sufficient

force to warrant deployment of the air bags and an

inflator circuit fault is present.

Action Taken

SRS control unit turns “ON” the “AIR BAG” warning

lamp records “Crash Data”, and sets a diagnostic

trouble code.

DTC Will Clear When

The SRS control unit is replaced.

DTC Chart Test Description

Number(s) below refer to step number(s) on the

diagnostic chart:

2. If air bag assembly have not deployed, DTC B0053

may have falsely set.

3. If DTC B0053 has set with no signs of frontal

impact, the diagnostic trouble code has falsely set.

DTC B0053 (Flash Code 53) Deployment Command Despite Present Trouble Code

WARNING: DURING SERVICE PROCEDURES. BE VERY CAREFUL WHEN HA NDLING A SRS CONTROL UNIT.

NEVER STRIKE OR JAR THE SRS CONTROL UNIT. NEVER POWER UP THE SRS WHEN THE SRS CONTROL

UNIT IS NOT RIGIDLY ATTACHED TO THE VEHICLE. A LL SRS CONTROL UNIT AND MOUNTING BRACKET

FASTENERS MUST BE CAREFULLY TORQUED AND THE ARROW MUST BE POINTING TOWA RD THE FRONT

OF THE VEHICLE TO ENSURE PROPER OPERATION OF THE SRS. THE SRS CONTROL UNIT COULD BE

ACTIVATED WHEN POWERED WHILE NOT RIGIDLY A TTACHED TO THE VEHICLE WHICH COULD CAUSE

DEPLOYMENT AND RESULT IN PERSONAL INJURY.

Step Action Yes No

1 Was the “SRS Diagnostic System Check” performed? Go to Step 2 Go to the “SRS

Diagnostic System

Check”

2 Ignition switch “OFF.”

Have air bag assembles deployed? Replace

components and

perform

inspections as

directed in

“Repairs And

Inspections

Required After An

Accident” in this

section.

Clear diagnostic

trouble codes.

Repeat the “SRS

Diagnostic System

Check”

Go to Step 3

3 Inspect front of vehicle and undercarriage for signs of impact.

Were signs of impact found? Replace

components and

perform

inspections as

directed in

“Repairs And

Inspections

Required After An

Accident” in this

section.

Clear diagnostic

trouble codes.

Repeat “SRS

Diagnostic System

Check”

Ignition switch

“OFF.”

Replace SRS

control unit.

Reconnect all SRS

system

components,

ensure all

components are

properly mounted.

Repeat the “SRS

Diagnostic System

Check”

DTC B0670 (Flash Code 63) Airbag Telltale Circuit Malfunction

RTW39JMF000101

Circuit Description

W hen the ignition switch is turned “ON”, battery voltage

is applied to the “AIR BAG” warning lamp and to the

“Ignition 1” input terminal “35”. The SRS control unit

responds by flashing the “AIR BAG” warning lamp

seven times. The SRS control unit monitors the lamp

driver output by comparing the output state at “SRS

Warning Lamp” terminal “39” to the microprocesso

r

com manded s tate. When “Ignition 1” is in the s pecified

value, and the output state does not match the

commanded state of the lamp driver for 500

milliseconds, DTC B0670 is set.

DTC Will Set When

“Ignition 1” voltage is in the specified value and the

output state at the “SRS Warning Lamp” terminal does

not match the commanded state of the lamp driver for

500 milliseconds. This test is run every 100

milliseconds during “Continuous Monitoring” tests and

once per each ignition cycle at the beginning.

Action Taken

SRS control unit attempts to turn “ON” the “AIR BAG”

warning lamp and sets a diagnostic trouble code.

DTC Will Clear When

The ignition switch is turned “OFF.”

DTC Chart Test Description

Refer to Charts B and C to diagnose warning lamp

circuit malfunctions.

DTC B0670 (Flash Code 63) Airbag Telltale Circuit Malfunction

Step Action Yes No

1 Was the “SRS Diagnostic System Check” performed? Go to Step 2 Go to the “SRS

Diagnostic System

Check”

2 1. Malfunctions within the “AIR BAG” warning lamp circuitry will

set this diagnostic trouble code.

2. These malfunctions are addressed in the “SRS Diagnostic

System Check” via Chart B and Chart C.

3. Failure to properly perform the “SRS Diagnostic System

Check” may result in misdiagnosis.

4. Ignition switch “ON.”

5. Clear SRS diagnostic trouble codes.

Is DTC B0670 set?

Ignition switch

“OFF.”

Go to Chart A

Repeat the “SRS

Diagnostic System

Check”

DTC B1000 (Flash Code 72) SDM Internal Fault

(SDM=SRS control unit)

RTW39JMF000101

Circuit Description

DTC B1000 is an indication of a potential internal SRS

control unit malfunction and will set if any of the

following conditions are detected:

1) Microprocessor energy reverse time failure.

2) EEPROM read / write failure.

3) ROM check sum.

4) Calibration check sum fault.

5) Inflators reserve voltage low.

6) Inflators electronic sensor active signal not detected

during commanded deployment.

7) QSDD (High-side/Low-side) FET failure.

8) Frontal accelerometer failure.

9) Phase lock loop lost lock.

10) QSDD communication fault.

DTC Will Set When

A

ny of the above indicated malfunctions are detected by

the SRS control unit. The malfunctions described

above are tested mainly during “Continuous Monitoring”

and some ones run each ignition cycle.

Action Taken

SRS control unit turns “ON” the “AIR BAG” warning

lamp and sets a diagnostic trouble code.

DTC Will Clear When

SRS control unit is replaced.

DTC B1000 (Flash Code 72) SDM Internal Fault (SDM=SRS control unit)

WARNING: DURING SERVICE PROCEDURES. BE VERY CAREFUL WHEN HA NDLING A SRS CONTROL UNIT.

NEVER STRIKE OR JAR THE SRS CONTROL UNIT. NEVER POWER UP THE SRS WHEN THE SRS CONTROL

UNIT IS NOT RIGIDLY ATTACHED TO THE VEHICLE. A LL SRS CONTROL UNIT AND MOUNTING BRACKET

FASTENERS MUST BE CAREFULLY TORQUED AND THE ARROW MUST BE POINTING TOWA RD THE FRONT

OF THE VEHICLE TO ENSURE PROPER OPERATION OF THE SRS. THE SRS CONTROL UNIT COULD BE

ACTIVATED WHEN POWERED WHILE NOT RIGIDLY A TTACHED TO THE VEHICLE WHICH COULD CAUSE

DEPLOYMENT AND RESULT IN PERSONAL INJURY.

CAUTION: If DTC B1000 can not clear by Tech2, it is necessary to replace the SRS control unit.

Step Action Yes No

1 Was the “SRS Diagnostic System Check” performed? Ignition switch

“OFF.”

Replace SRS

control unit.

Repeat the “SRS

Diagnostic System

Check”

Go to the “SRS

Diagnostic System

Check”

DTC U1000 (Flash Code 75) Class2 Data Link Malfunction

RTW39JMF000101

Circuit Description

The communication system of self-diagnosis of SRS

control unit is Class2. The circuit is formed by terminal 2

of a DLC connector, and terminal 21 of SRS control

unit.

DTC Will Set When

Requested data not provided.

Action Taken

The abnorm alities about data link circuit. It is not f ailure

of SRS control unit and SRS airbag.

DTC Will Clear When

Requested data not provided.

Diagnostic Aids

Check the data link circuit between the terminal 2 of a

DTC connector and terminal 21 of SRS control unit for

following conditionl:

• An open circuit

• A short to ground

• A short to battery voltage

DTC U1 ∗

∗∗

∗∗

∗∗

∗∗

∗∗

∗ (Flash Code 73) Unknown Message

RTW39JMF000101

Circuit Description

The communication system of self-diagnosis of SRS

control unit is Class2. The circuit is formed by terminal 2

of a DLC connector, and terminal 21 of SRS control

unit.

DTC Will Set When

Learned source node state of health missing for 5

seconds or no response to reset message.

Action Taken

The abnorm alities about data link circuit. It is not f ailure

of SRS control unit and SRS airbag.

DTC Will Clear When

Learned source node state of health message received

or clear codes command.

Diagnostic Aids

Check the data link circuit between the terminal 2 of a

DTC connector and terminal 21 of SRS control unit for

following conditionl:

• An open circuit

• A short to ground

• A short to battery voltage

About the DTC U1∗

∗∗

∗∗

∗∗

∗∗

∗∗

∗

The ∗∗∗ section changes a number according to

conditions.

DTC U1300 (Flash Code 76) Class2 Data Link Low

RTW39JMF000101

Circuit Description

The communication system of self-diagnosis of SRS

control unit is Class2. The circuit is formed by terminal 2

of a DLC connector, and terminal 21 of SRS control

unit.

DTC Will Set When

When Class2 data signal voltage is low continues for

2.5 seconds.

Action Taken

The abnorm alities about data link circuit. It is not f ailure

of SRS control unit and SRS airbag.

DTC Will Clear When

When set to Class2 data signal voltage is high.

Diagnostic Aids

Check the data link circuit between the terminal 2 of a

DTC connector and terminal 21 of SRS control unit for

following conditionl:

• An open circuit

• A short to ground

• A short to battery voltage

DTC U1301 (Flash Code 76) Class2 Data Link High

RTW39JMF000101

Circuit Description

The communication system of self-diagnosis of SRS

control unit is Class2. The circuit is formed by terminal 2

of a DLC connector, and terminal 21 of SRS control

unit.

DTC Will Set When

When Class2 data signal voltage is high continues for

2.5 seconds.

Action Taken

The abnorm alities about data link circuit. It is not f ailure

of SRS control unit and SRS airbag.

DTC Will Clear When

When set to Class2 data signal voltage is low.

Diagnostic Aids

Check the data link circuit between the terminal 2 of a

DTC connector and terminal 21 of SRS control unit for

following conditionl:

• An open circuit

• A short to ground

• A short to battery voltage