CONTENTS

Y24SE ENGINE DRIVEABILITY AND EMISSIONS

ABBREVIATIONS CHARTS

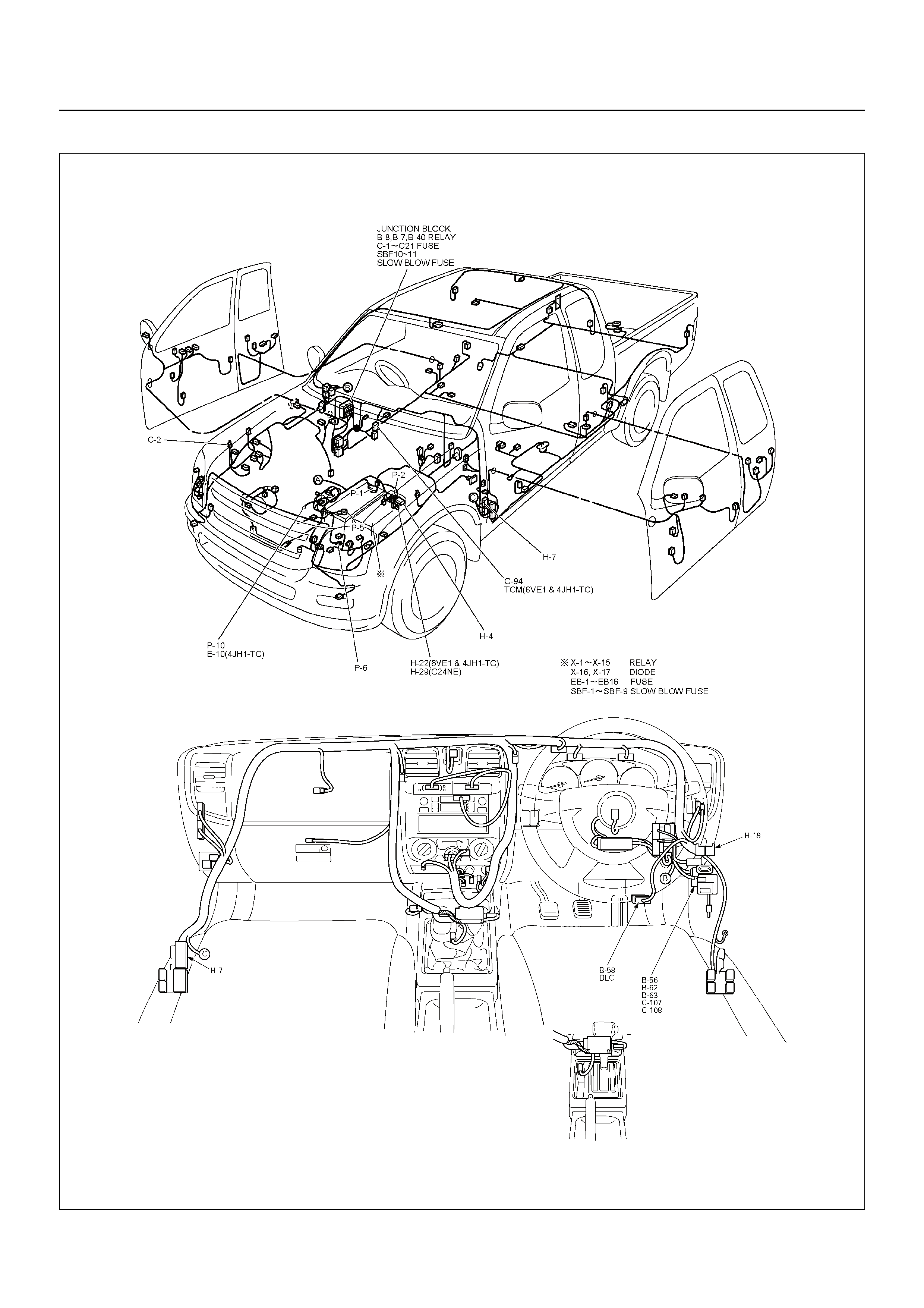

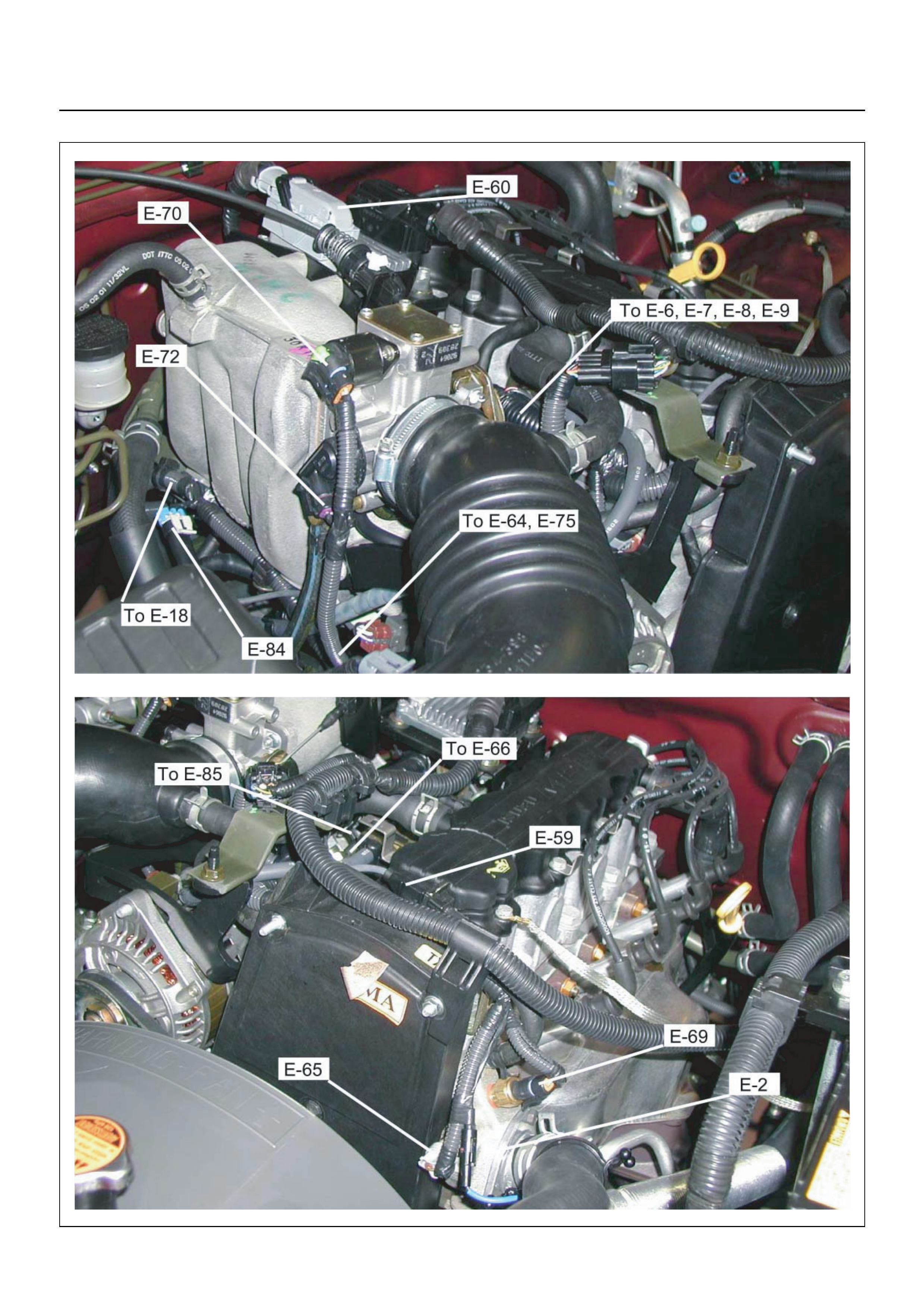

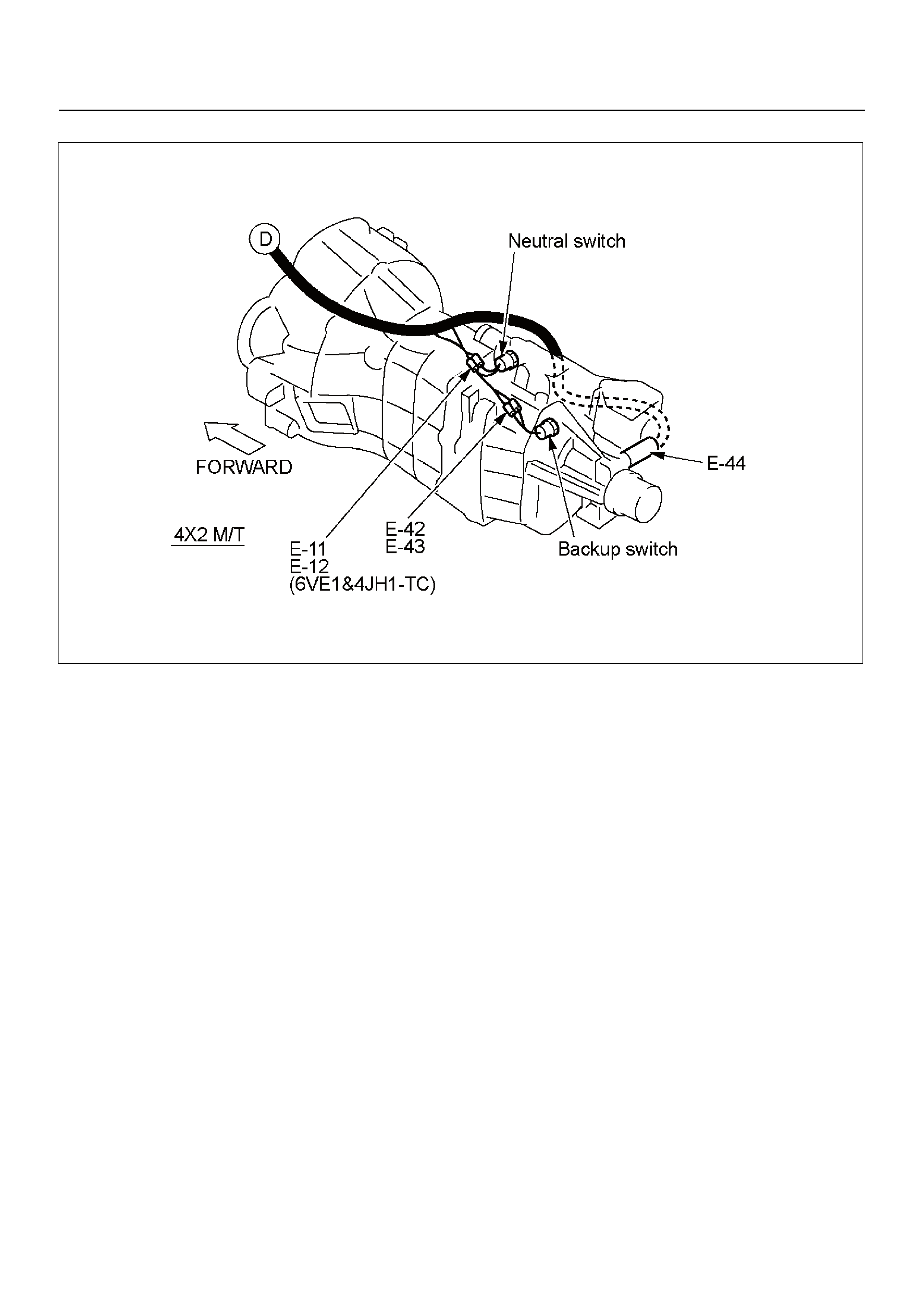

COMPONENT LOCATOR

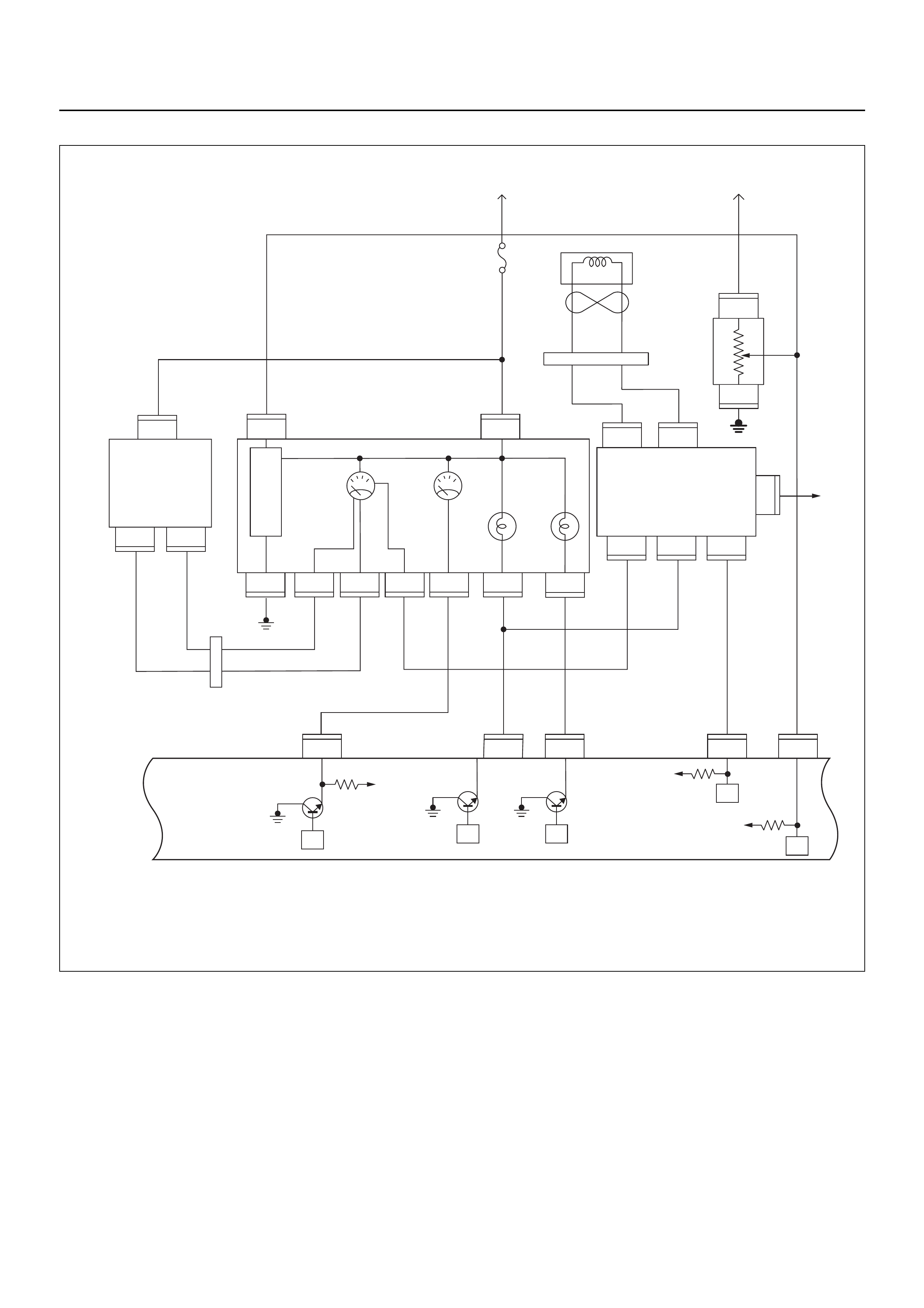

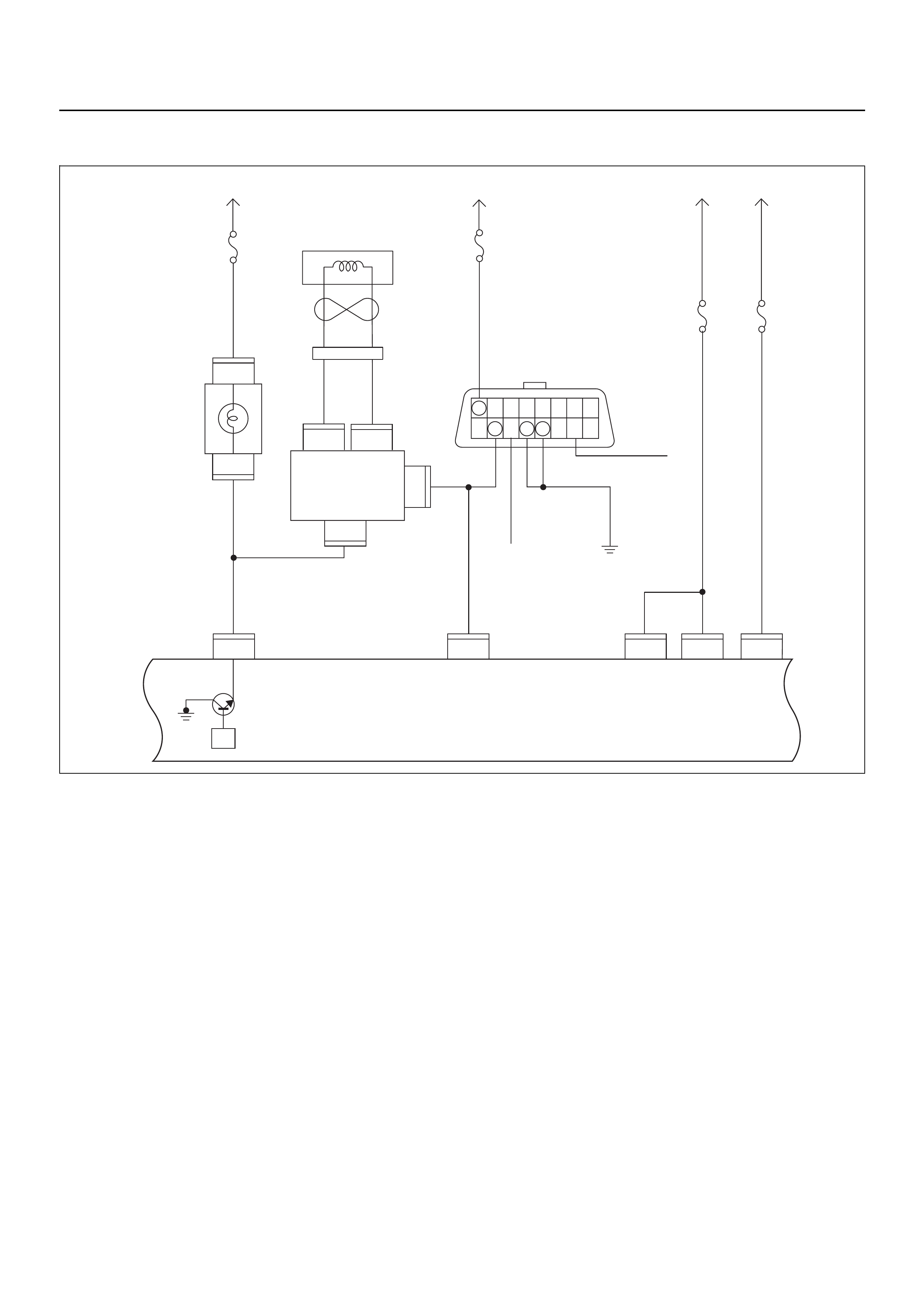

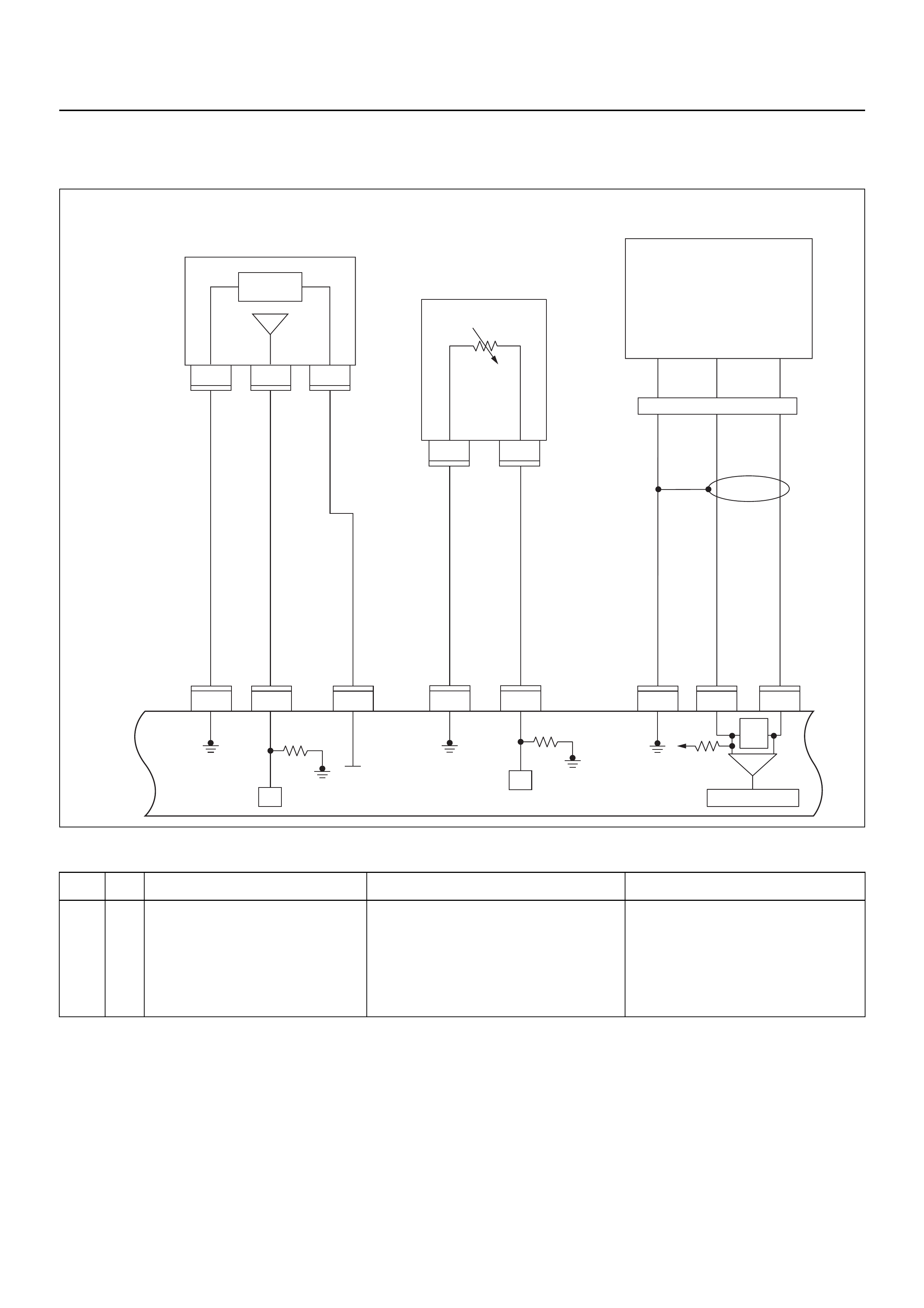

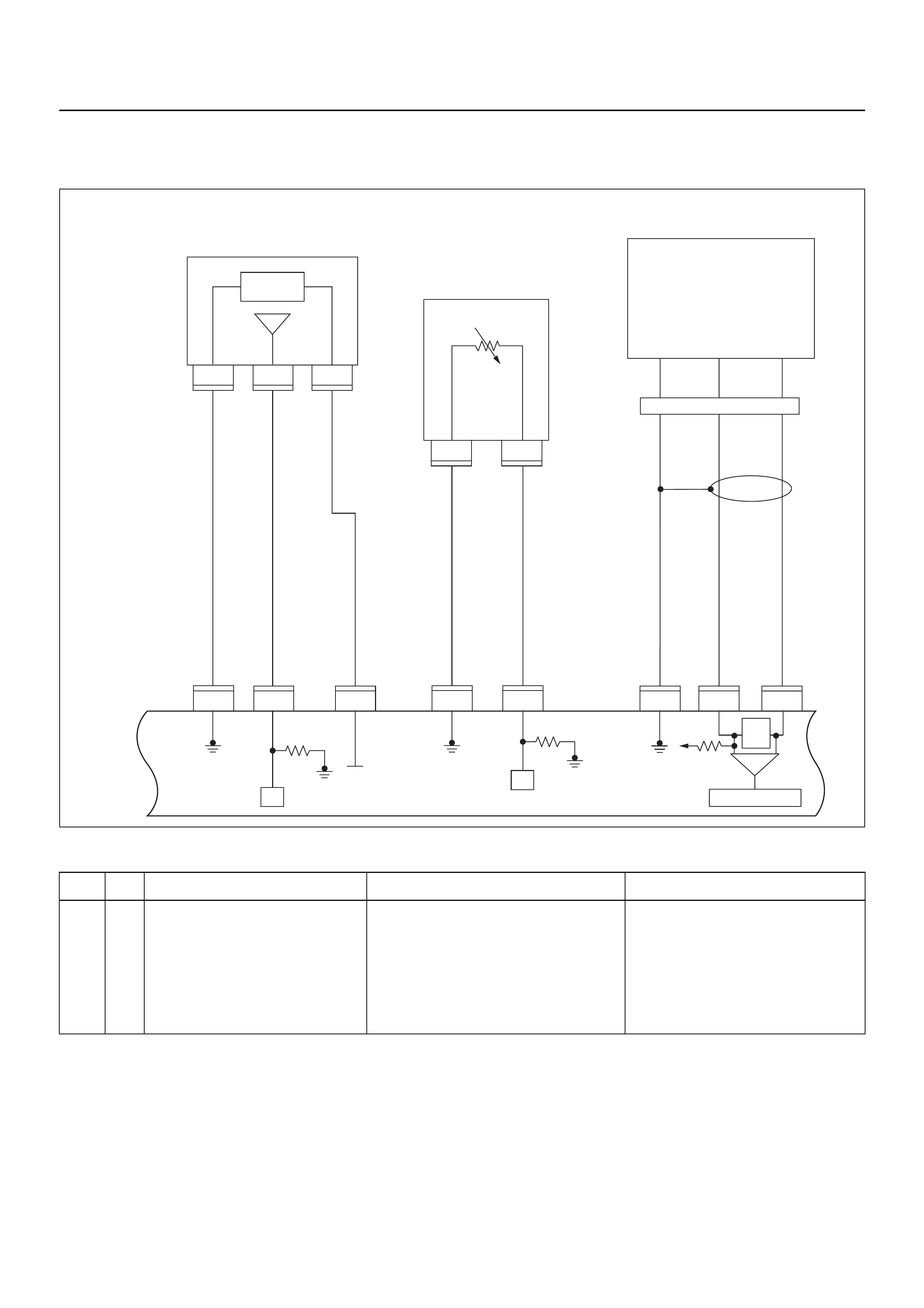

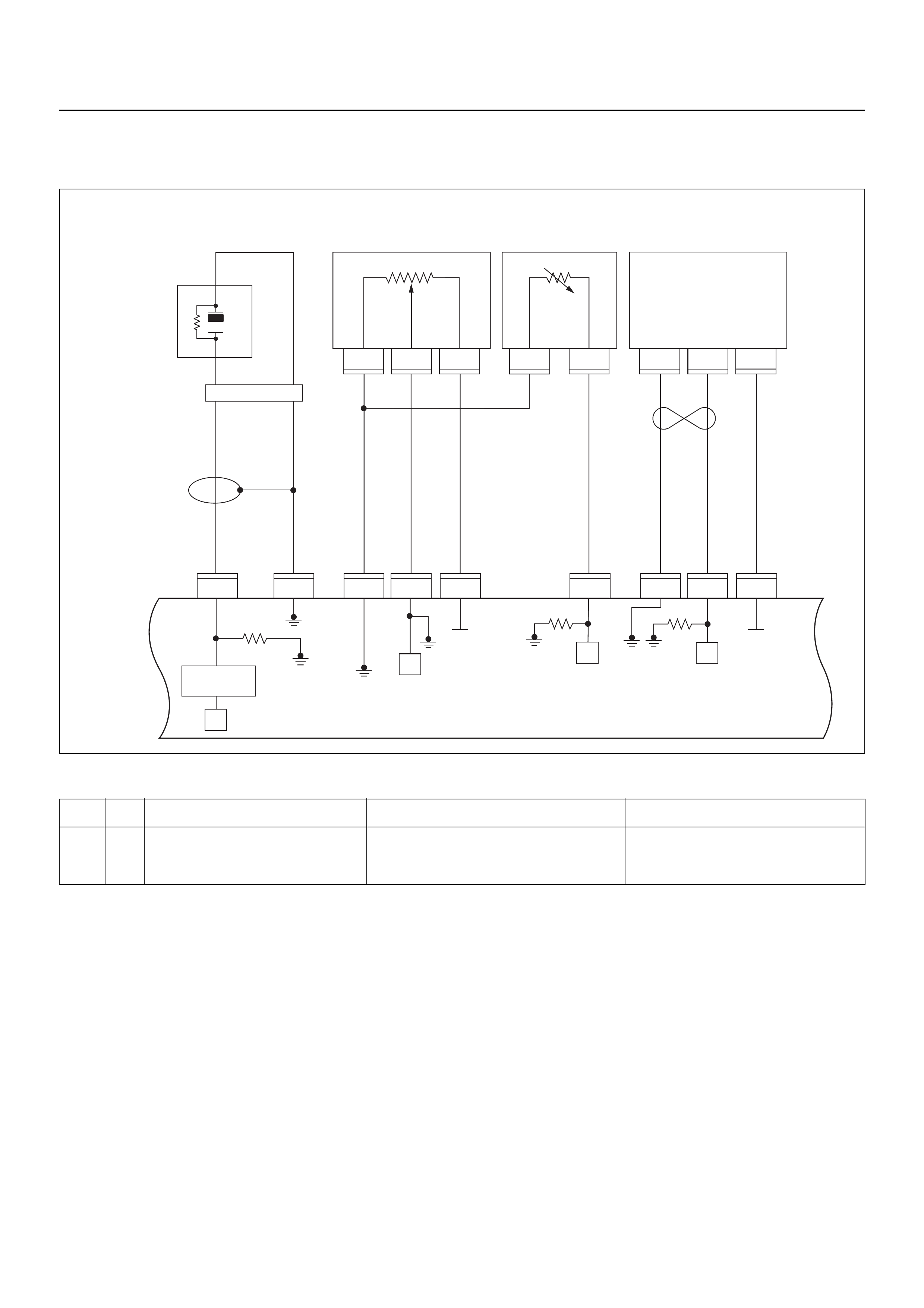

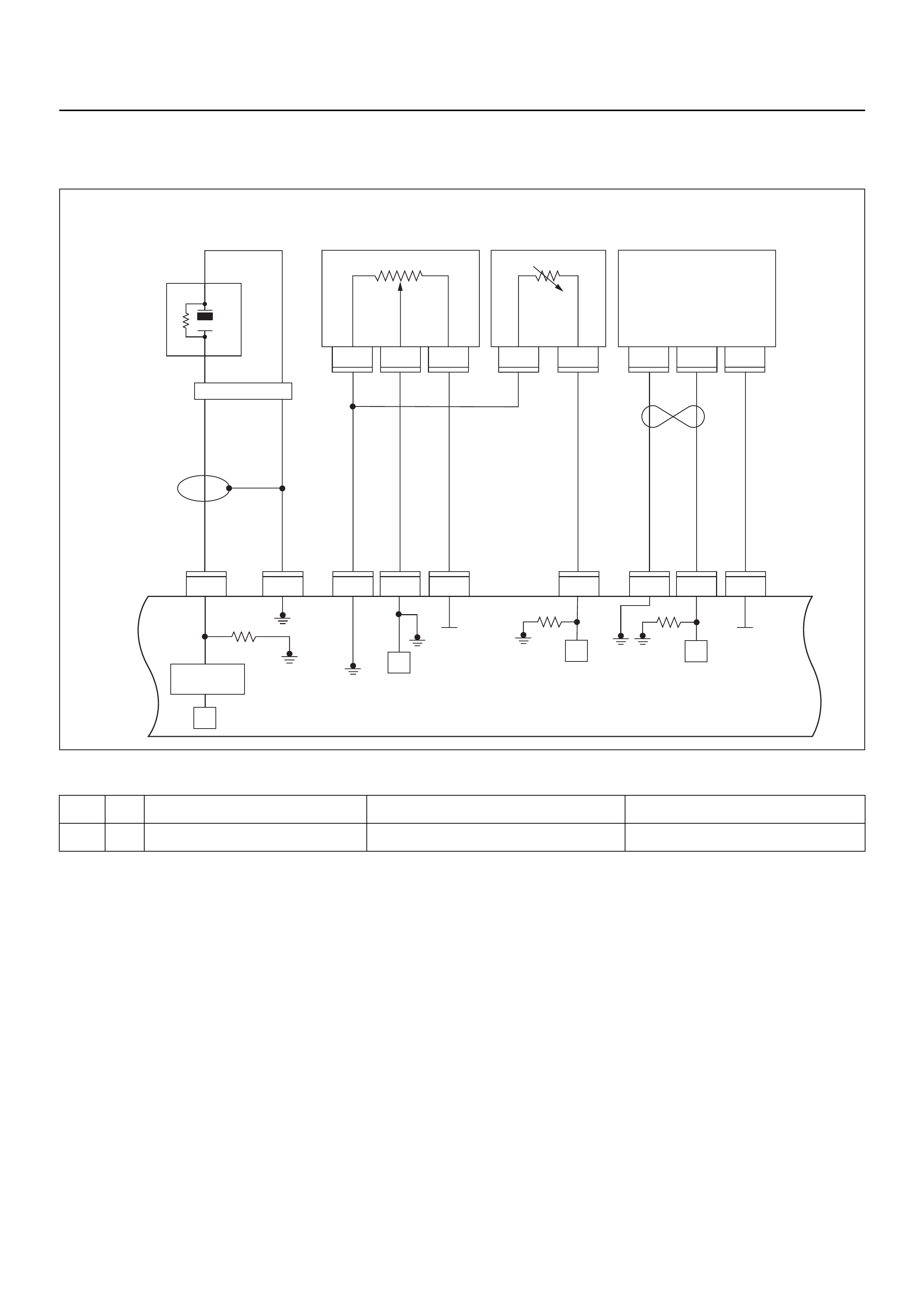

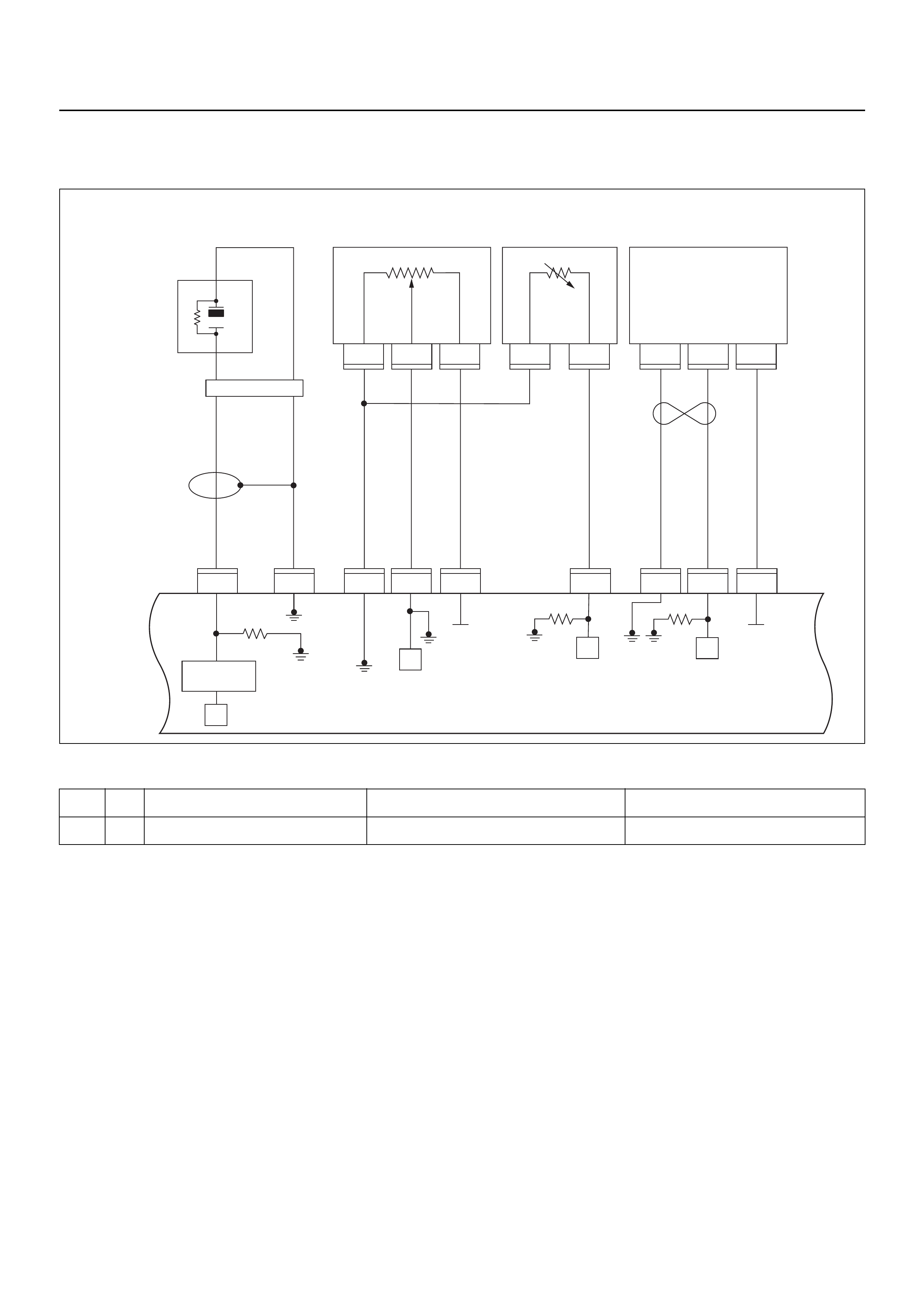

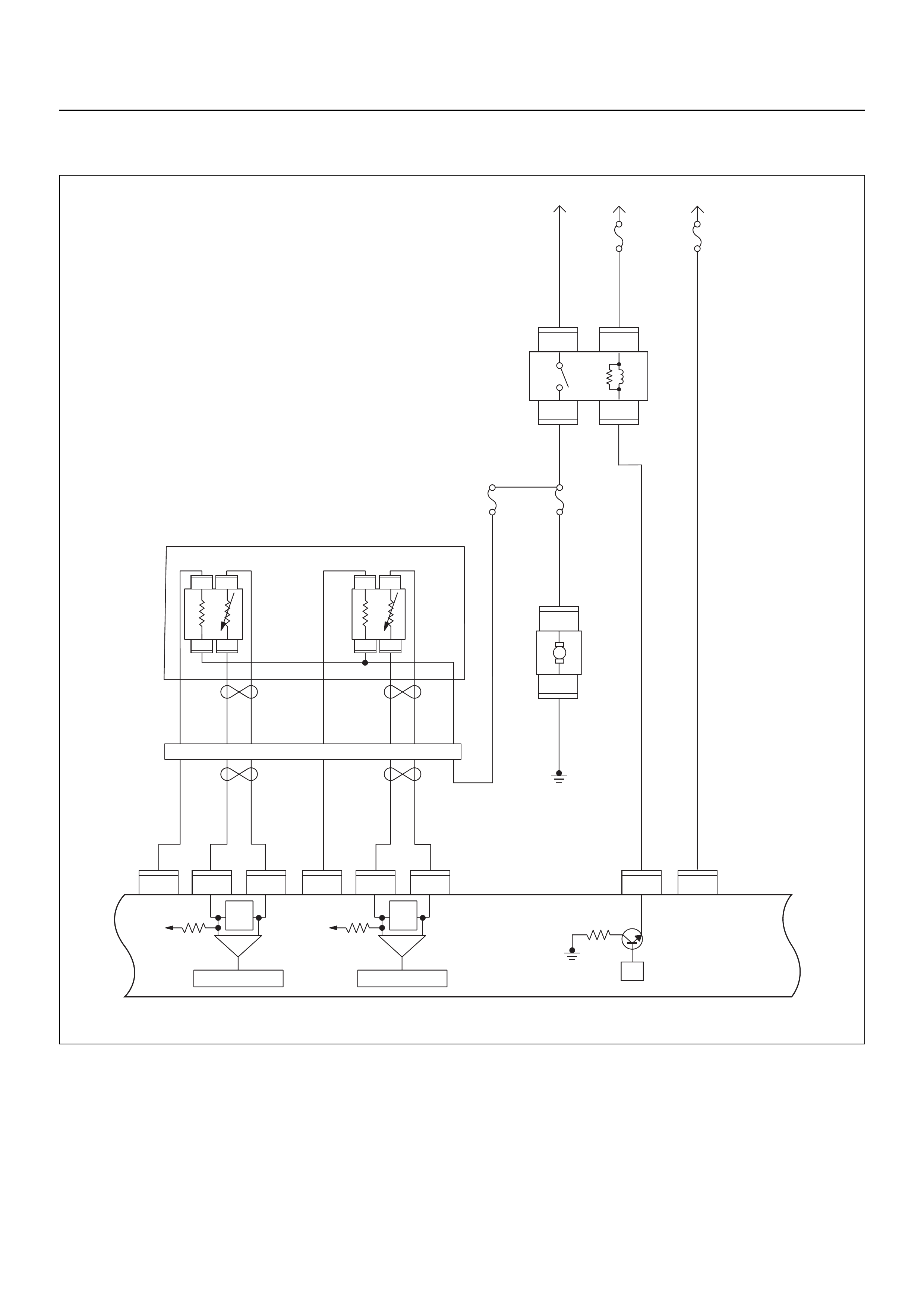

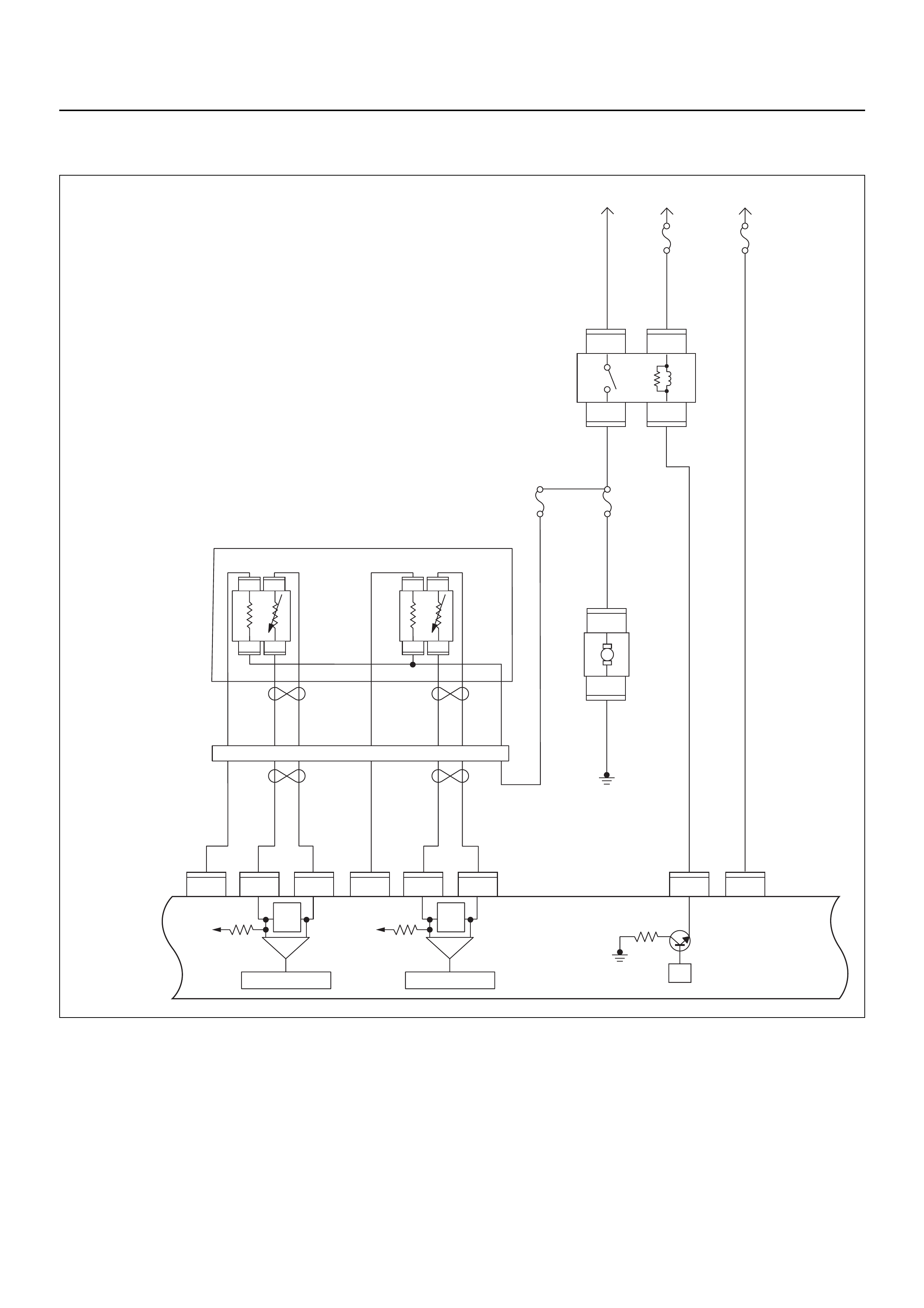

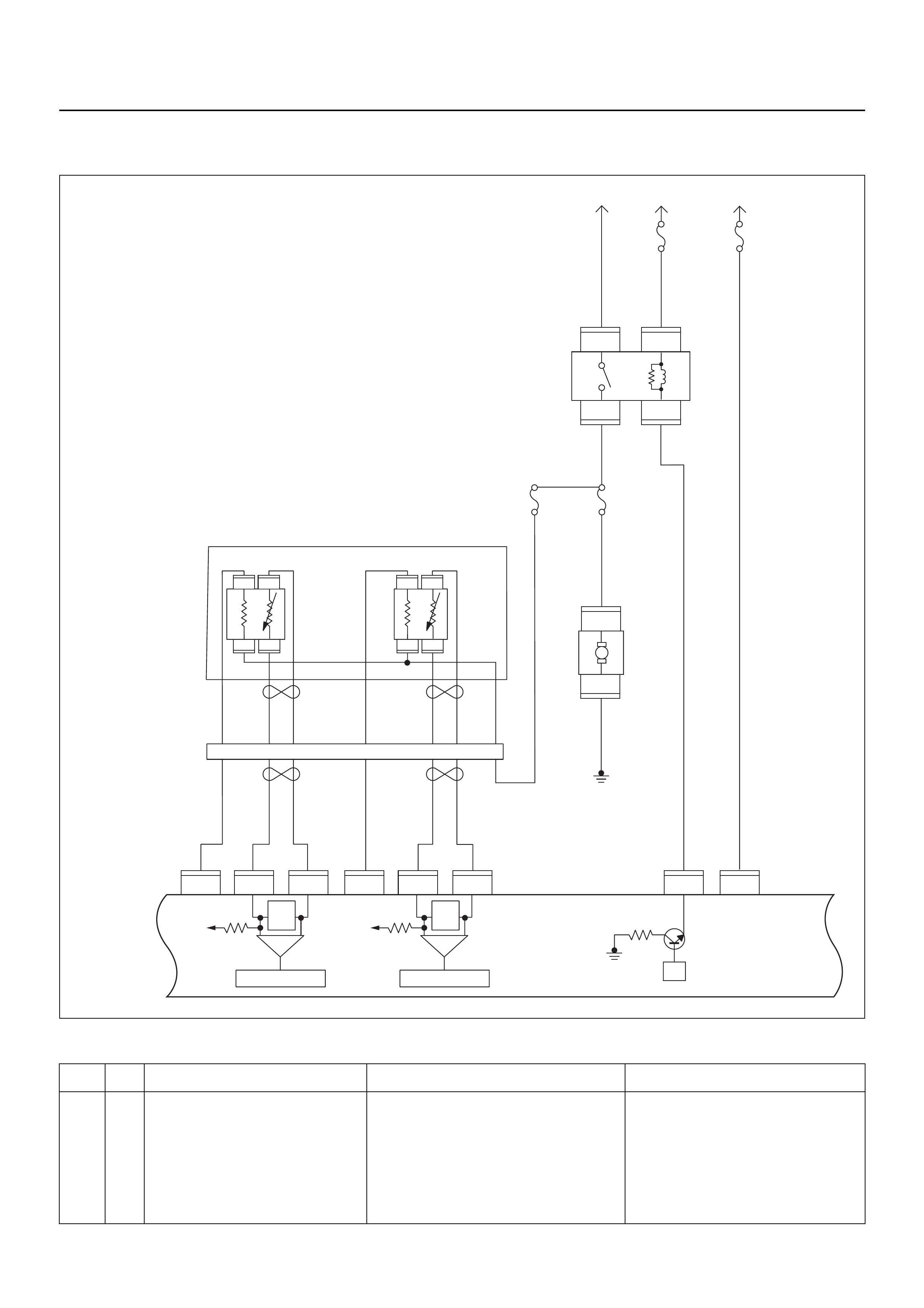

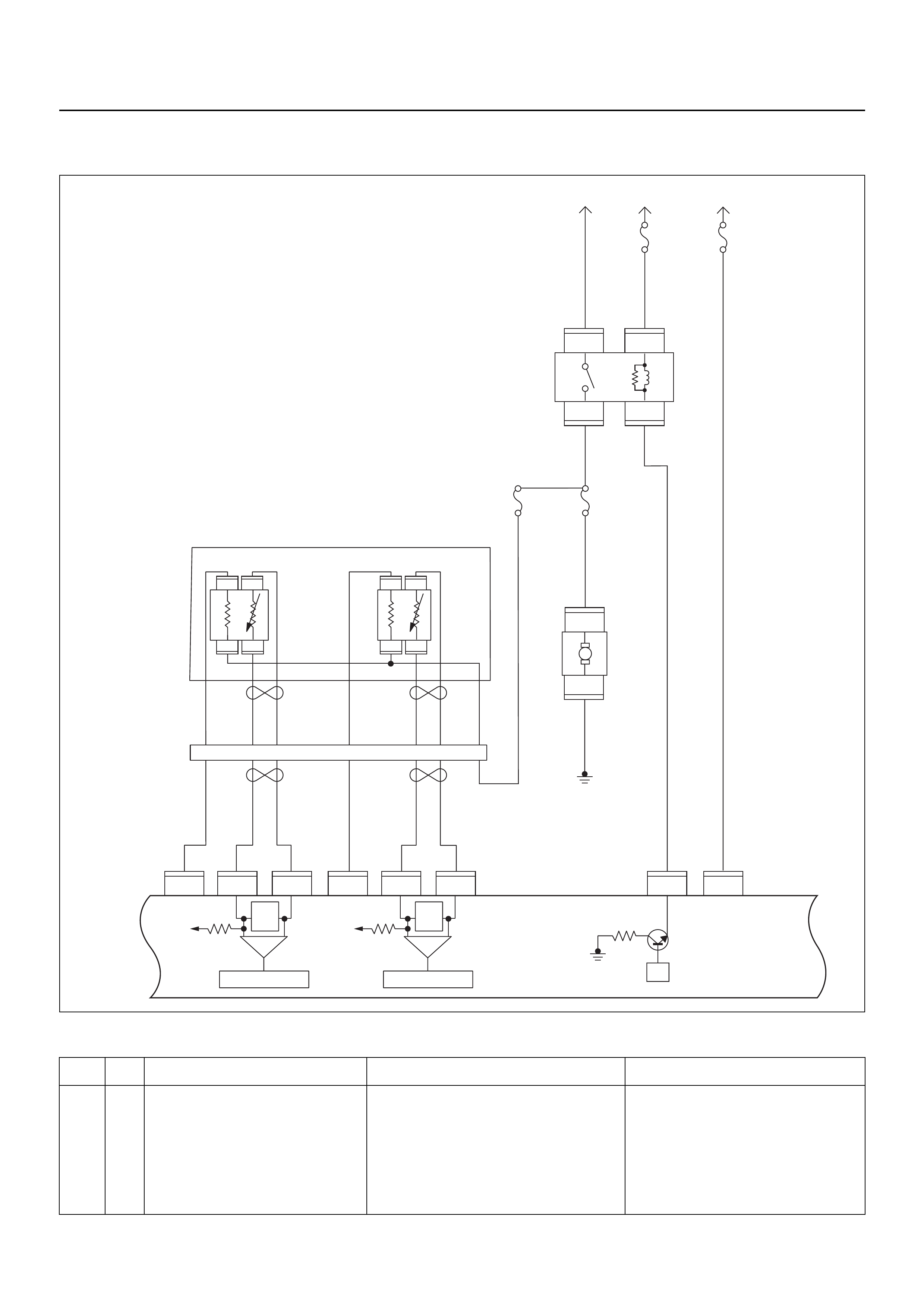

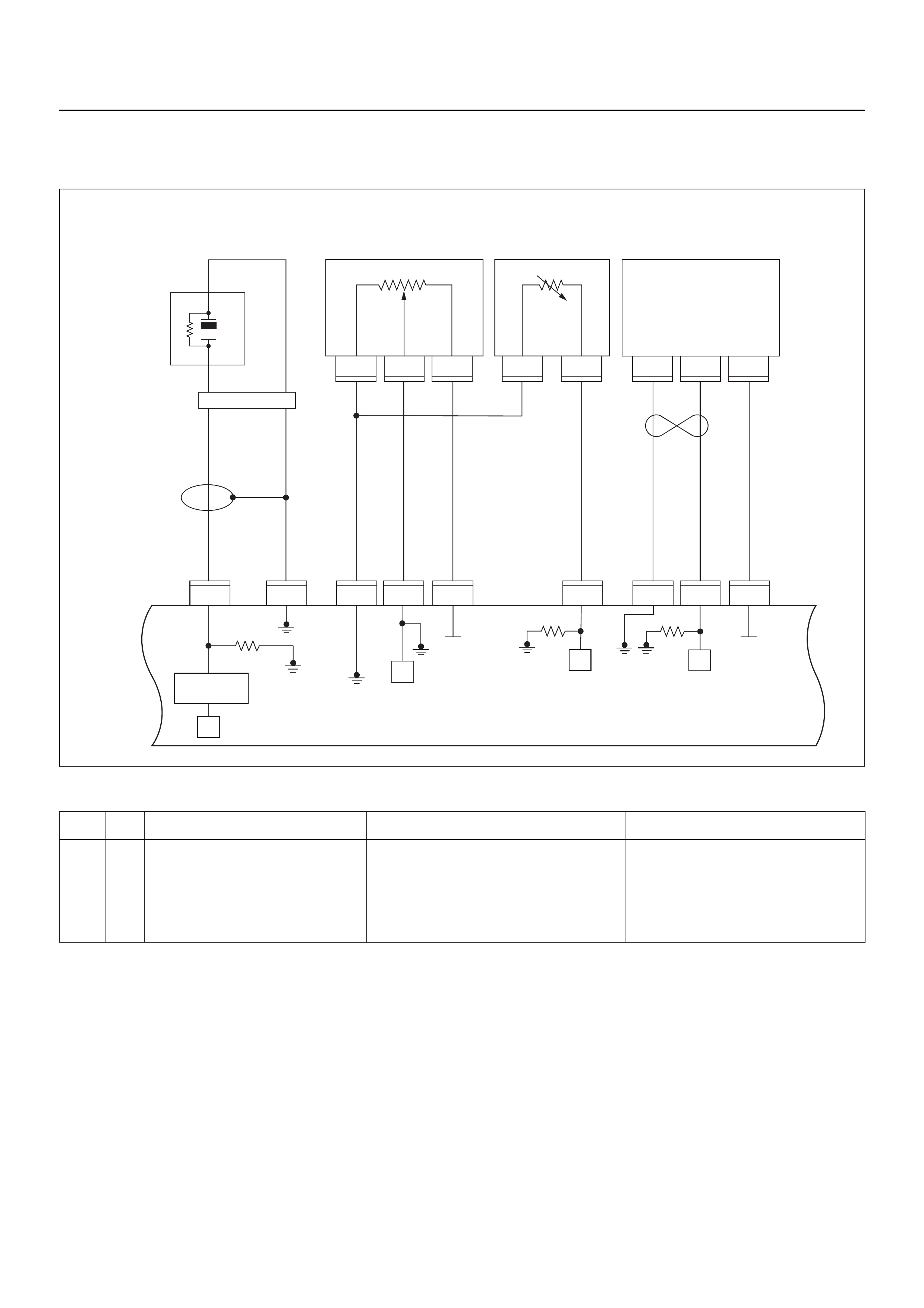

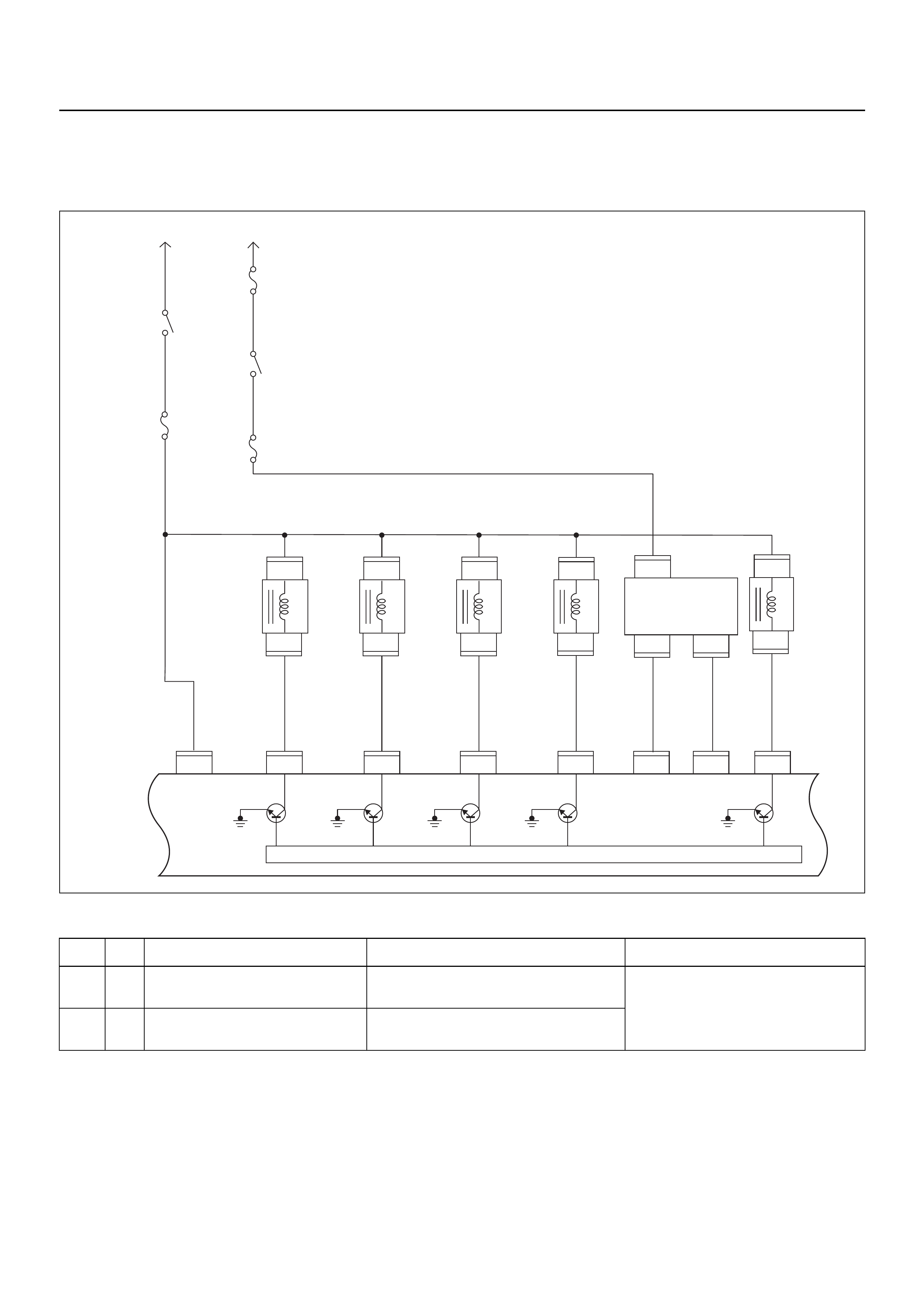

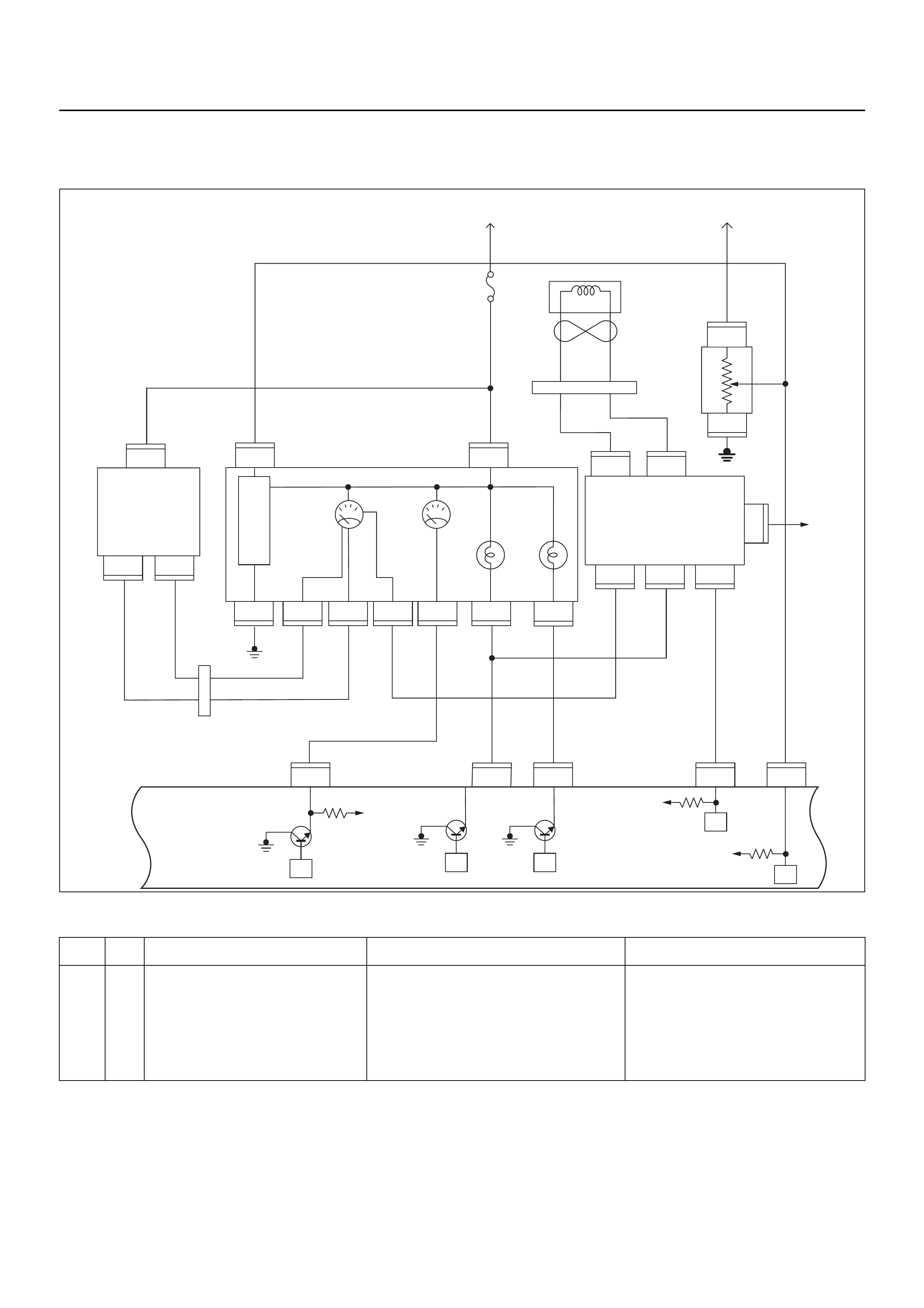

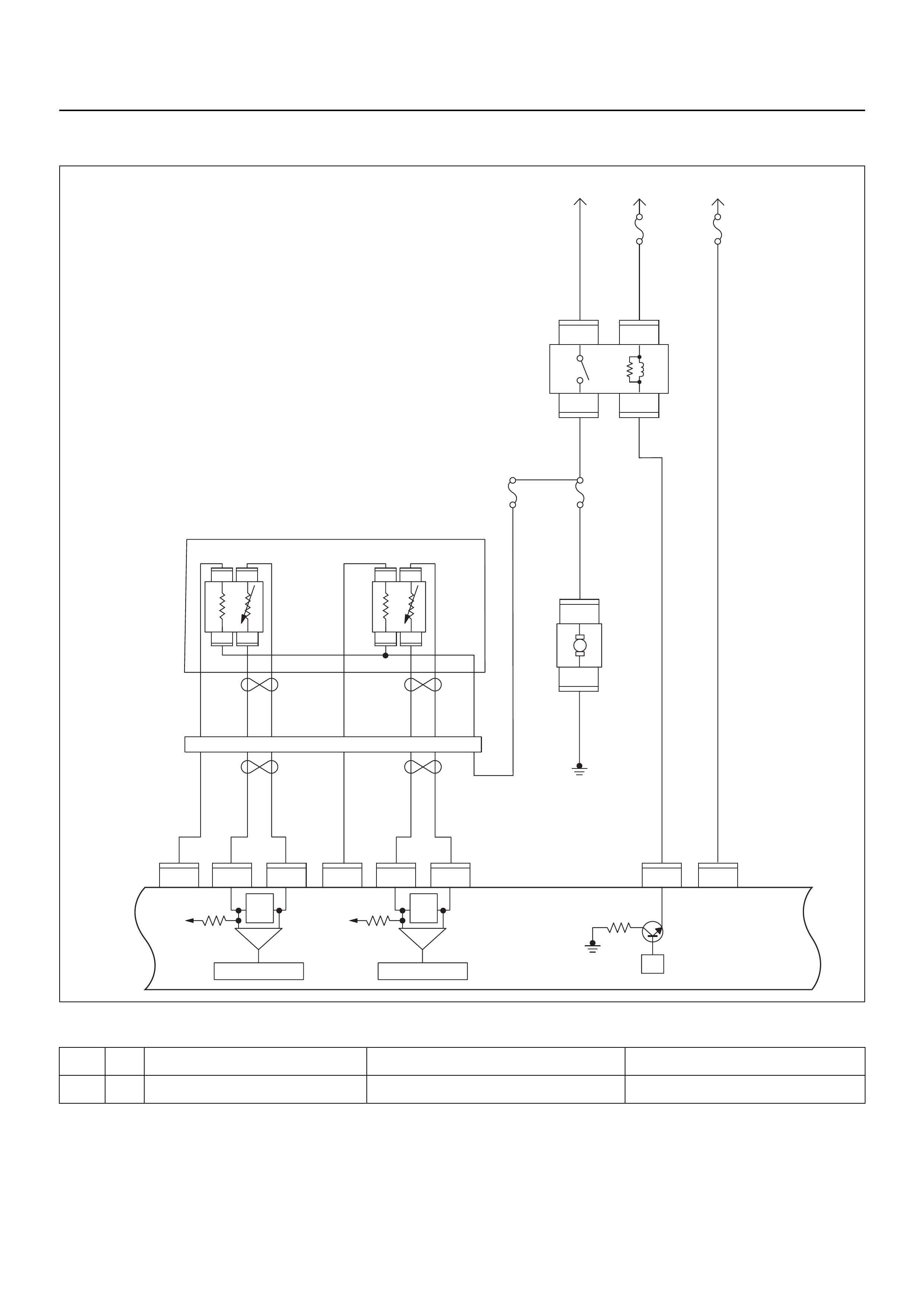

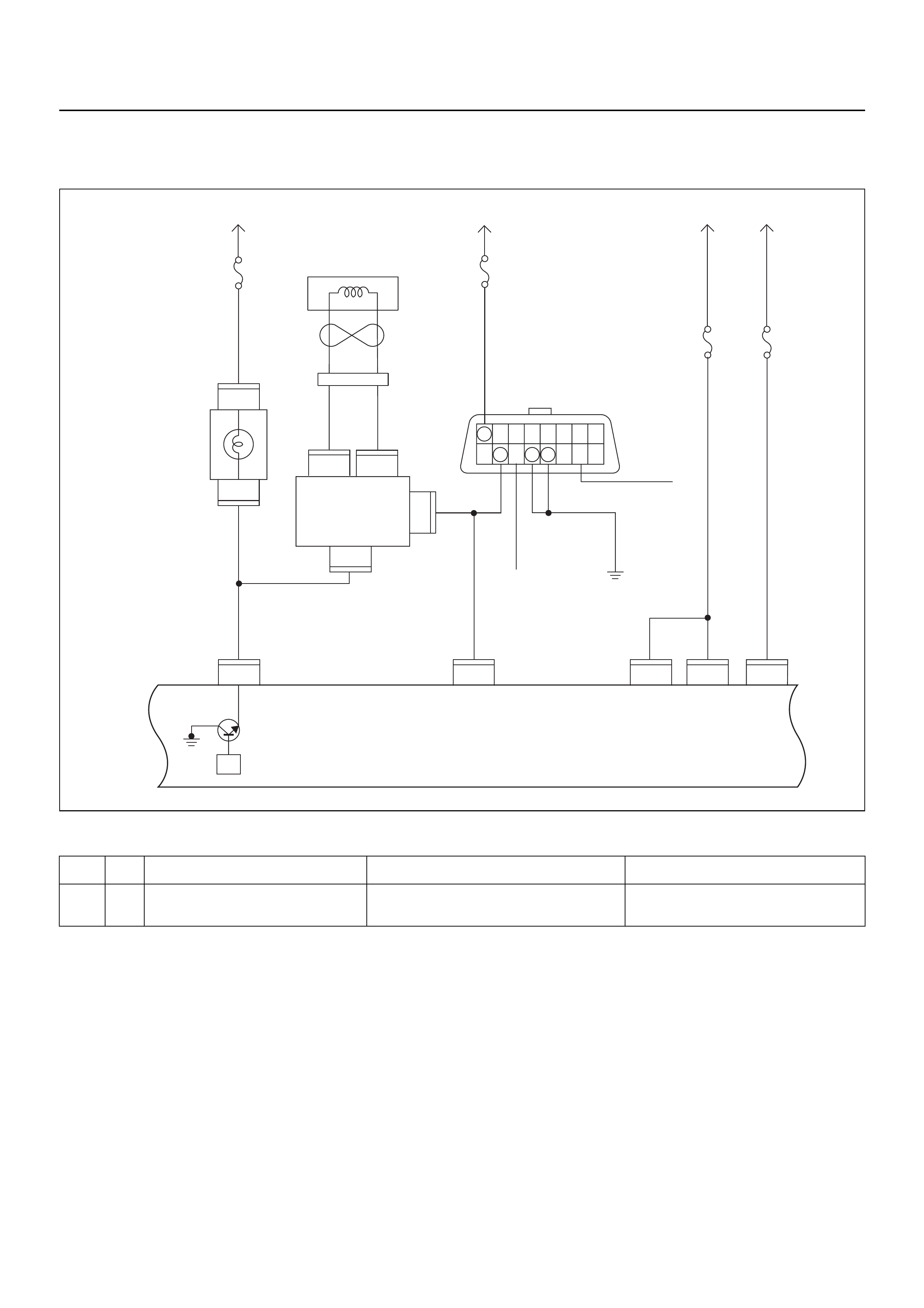

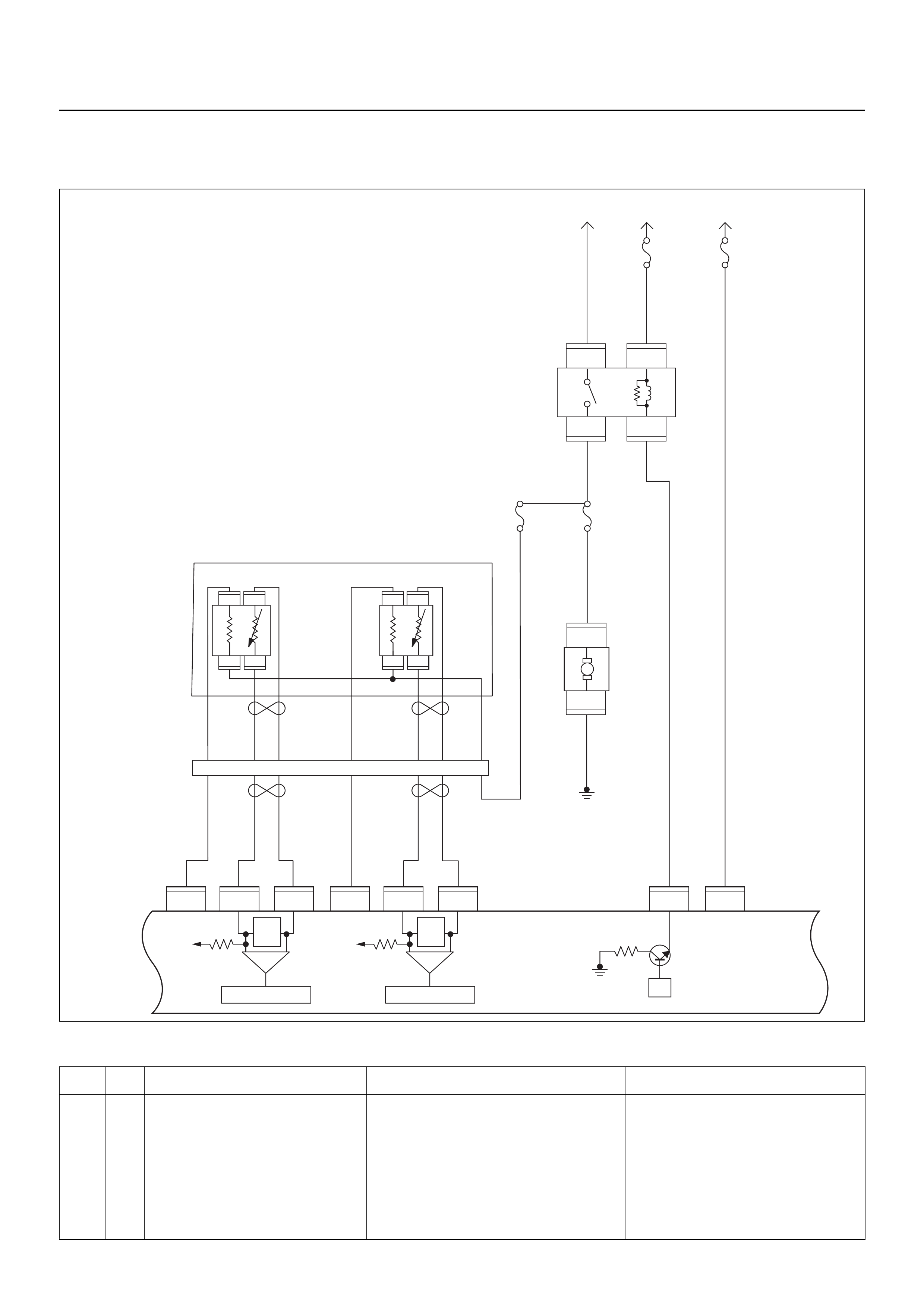

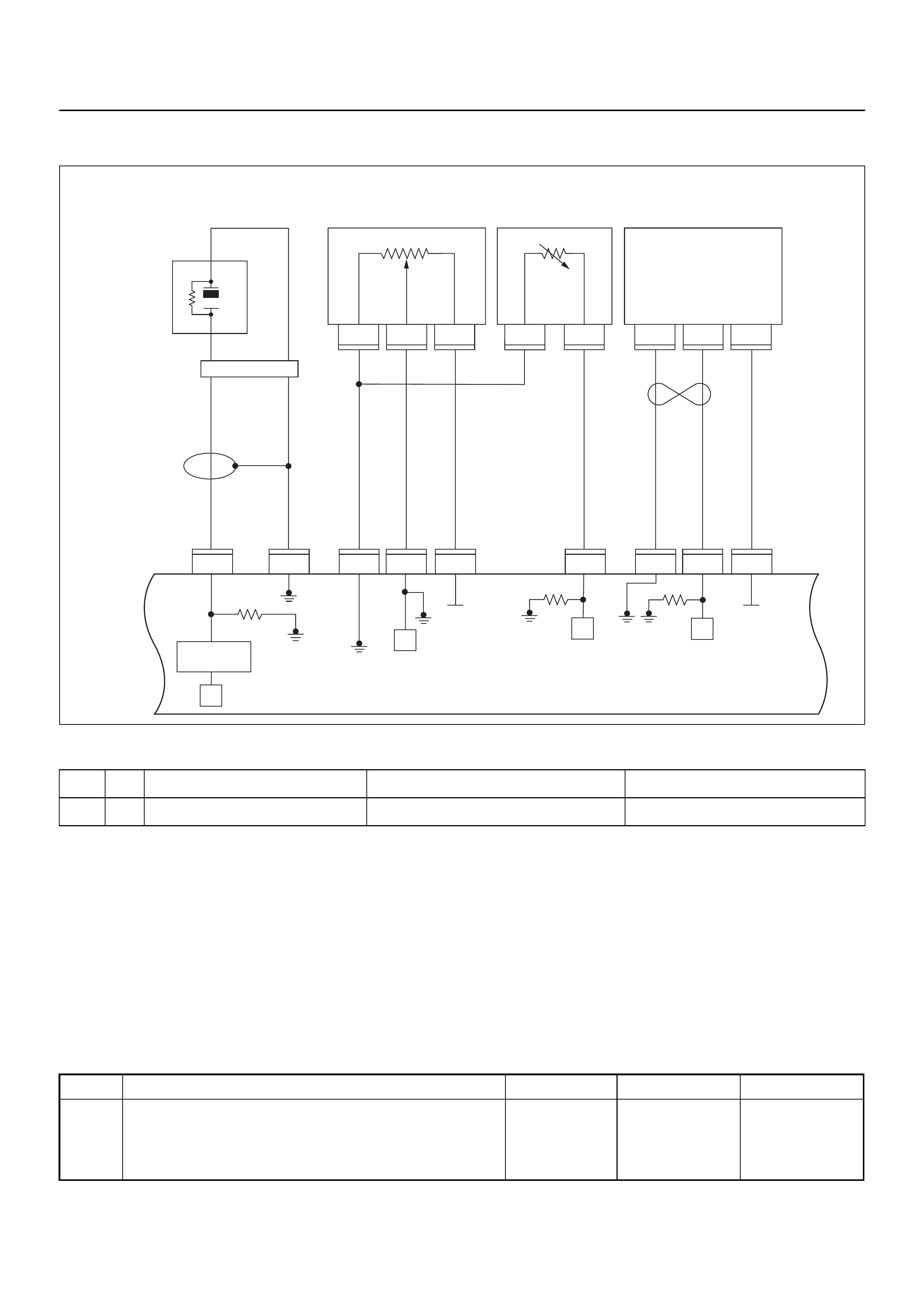

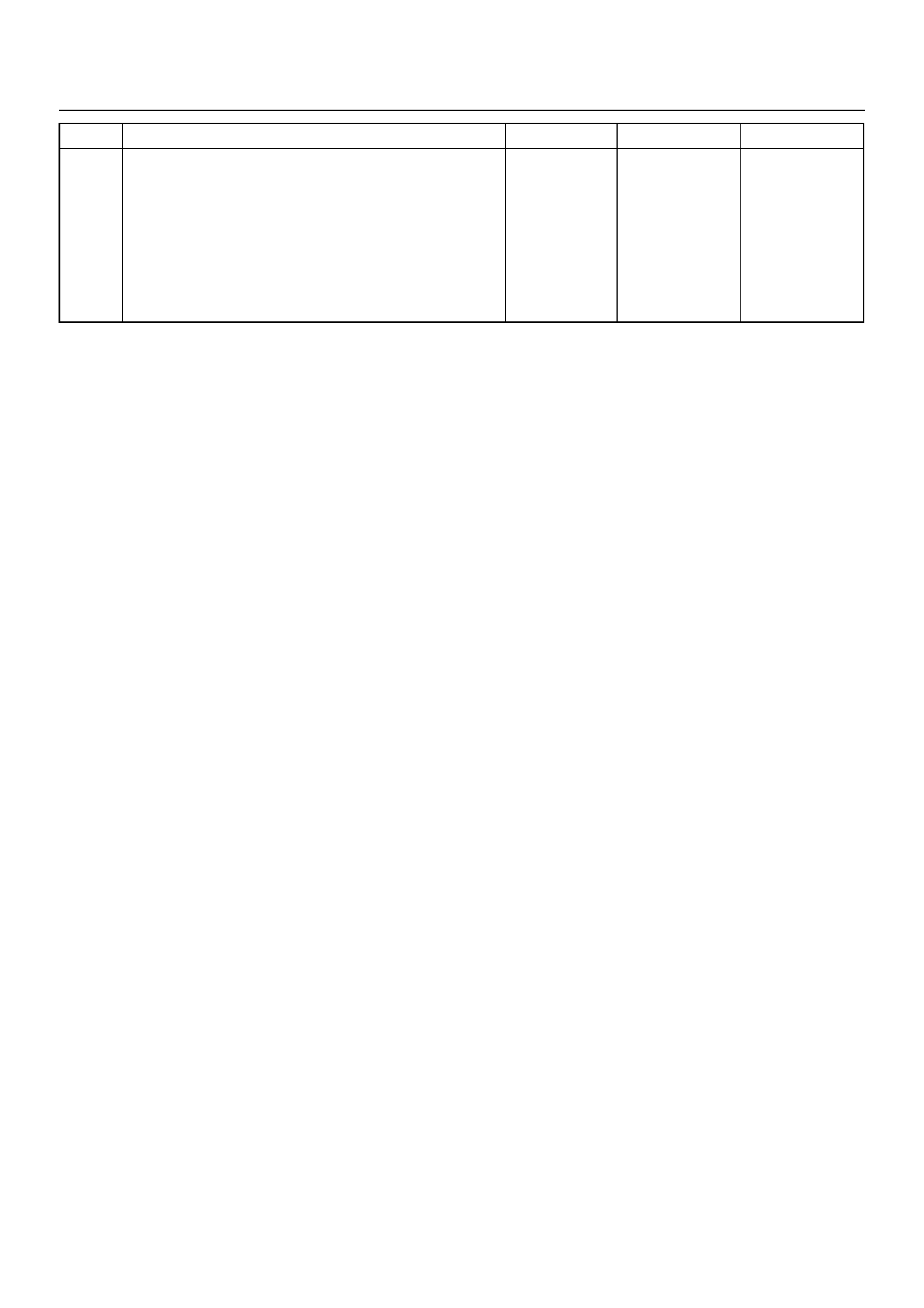

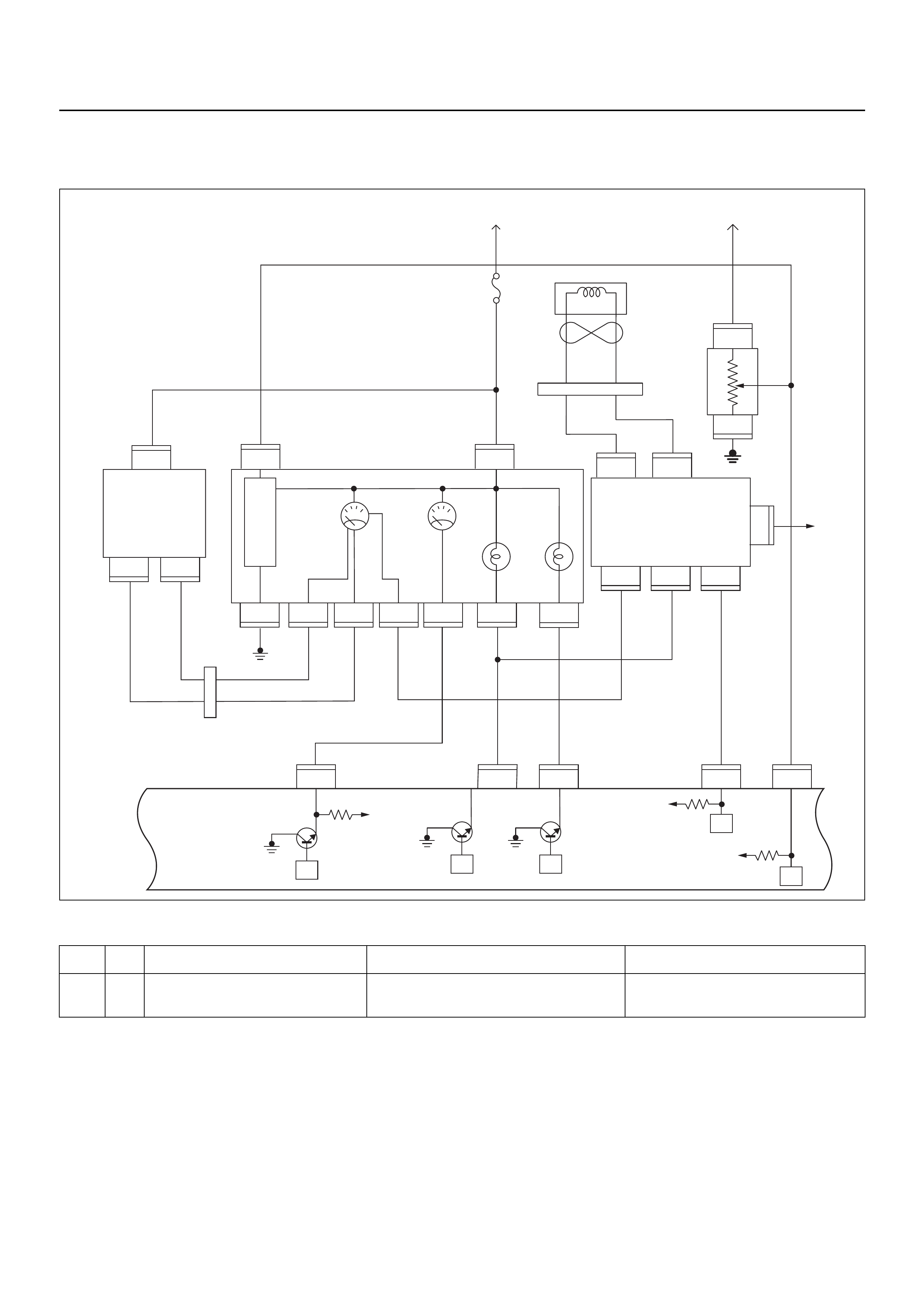

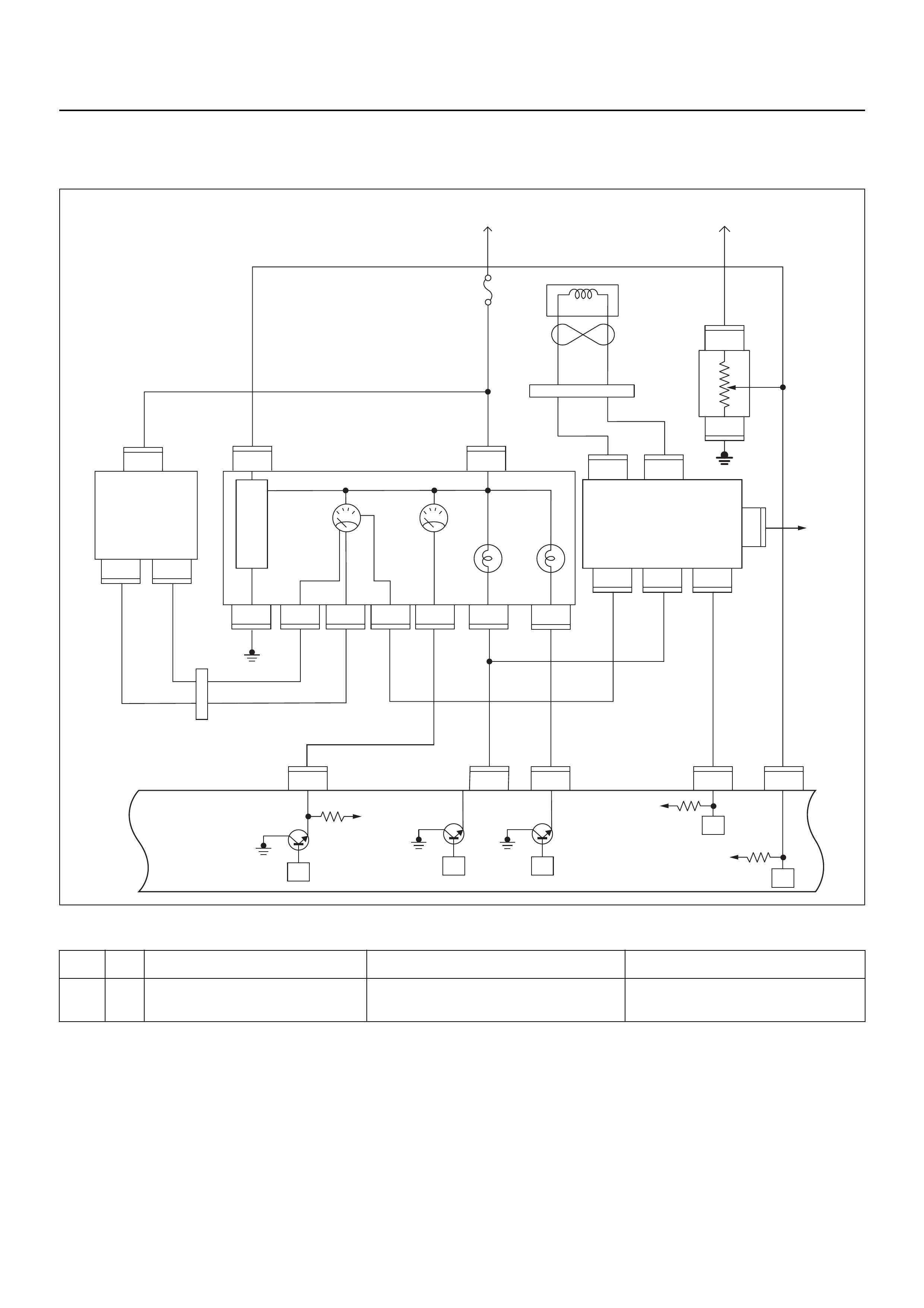

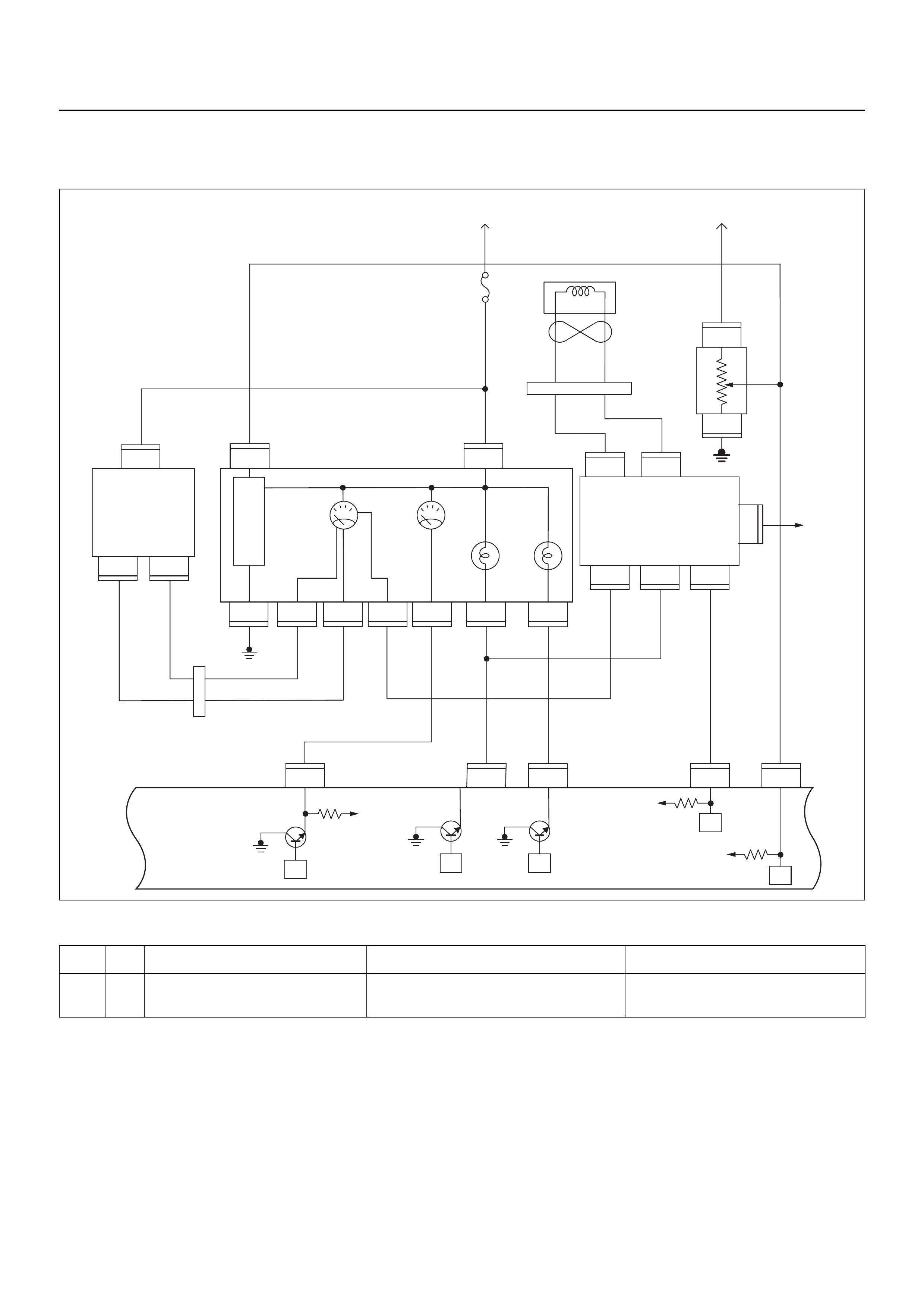

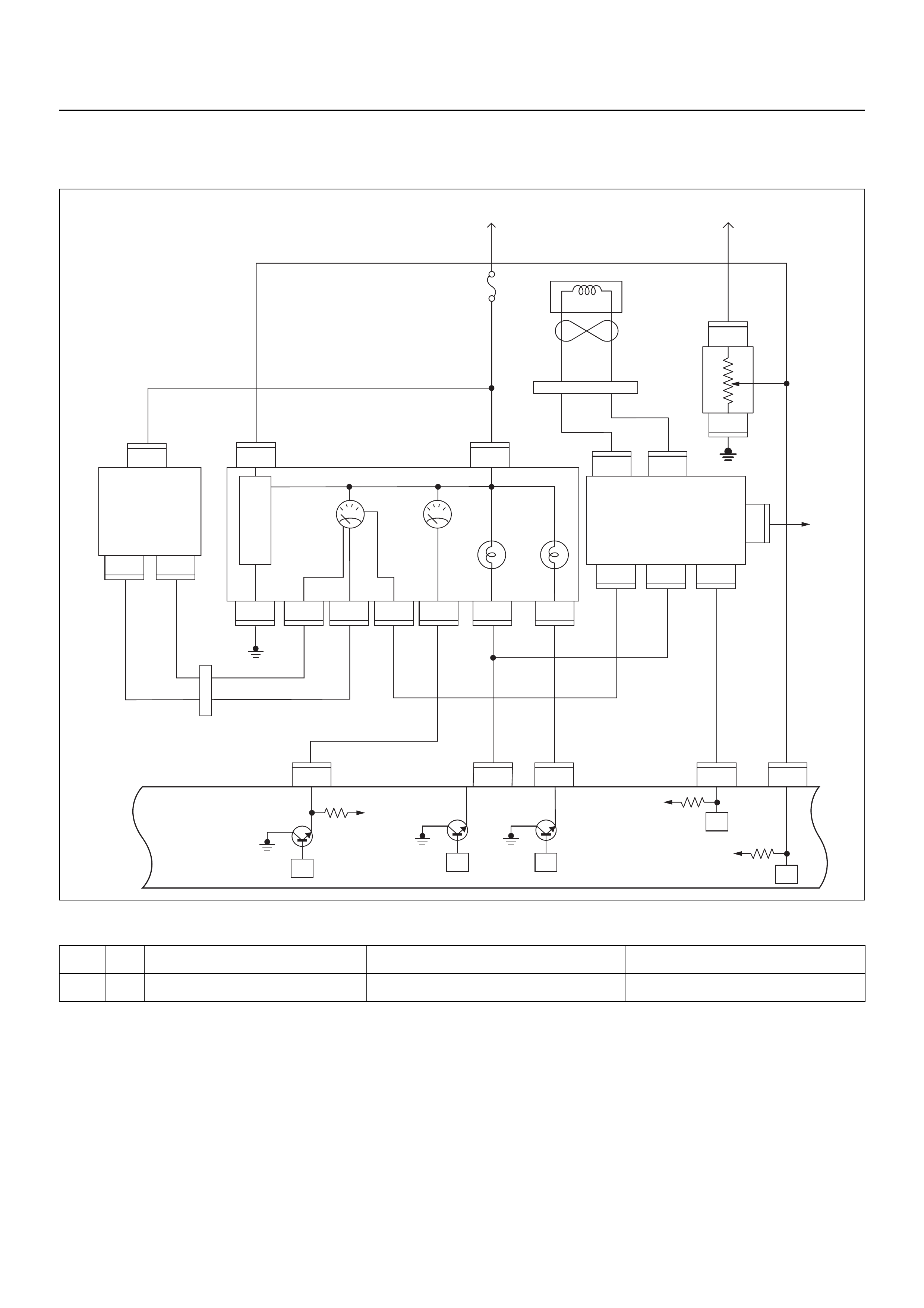

ECM CIRCUIT DIAGRAM

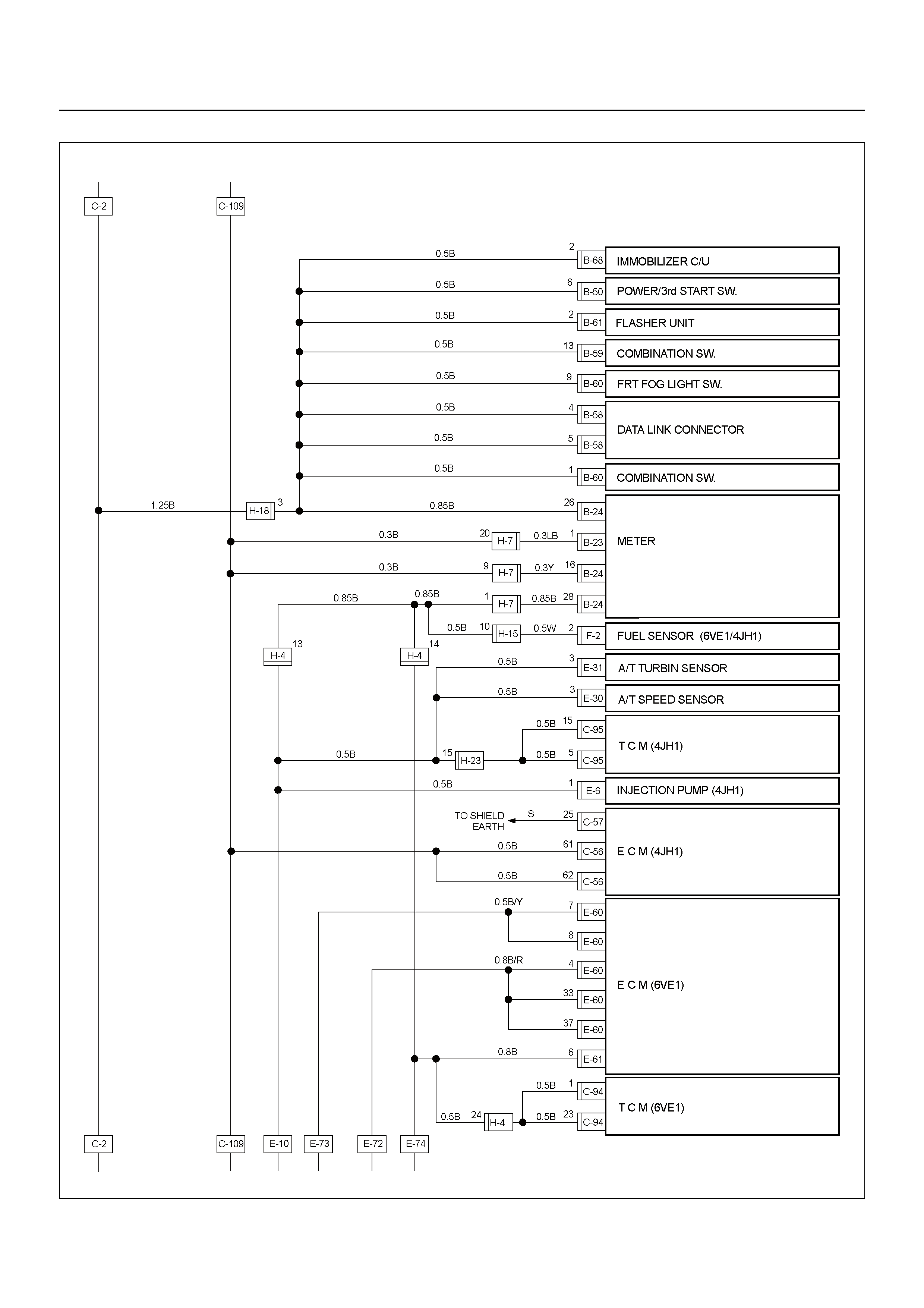

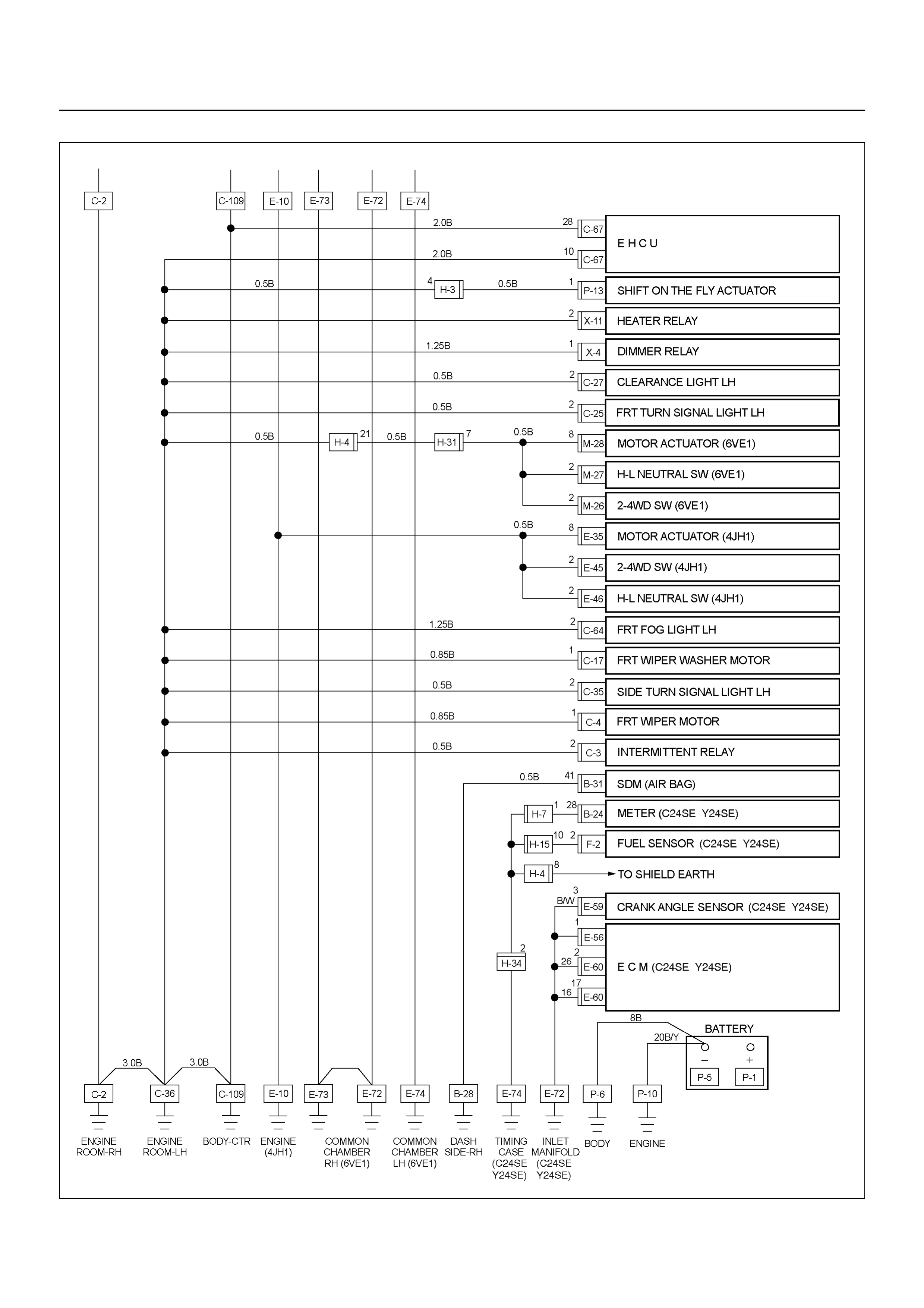

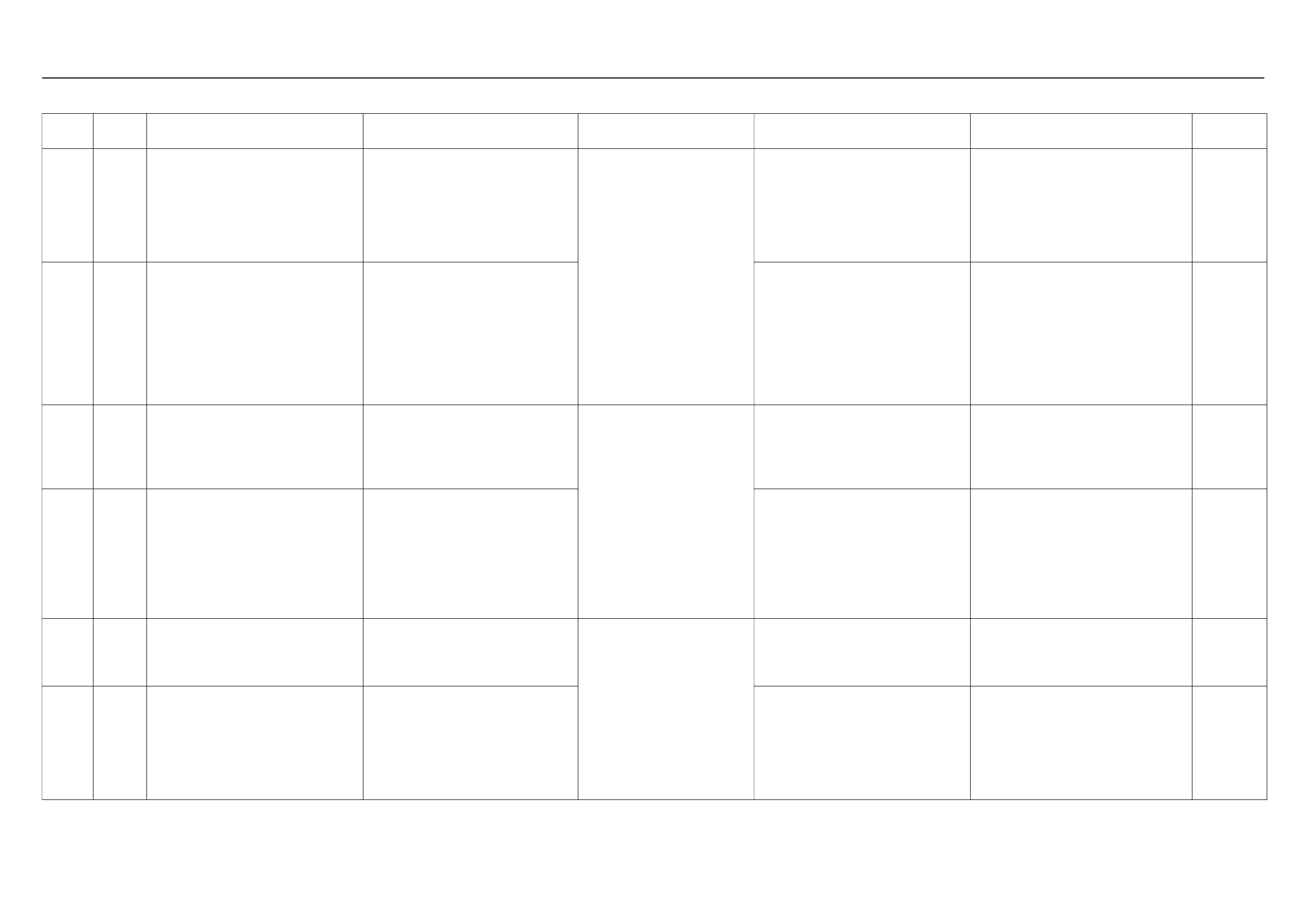

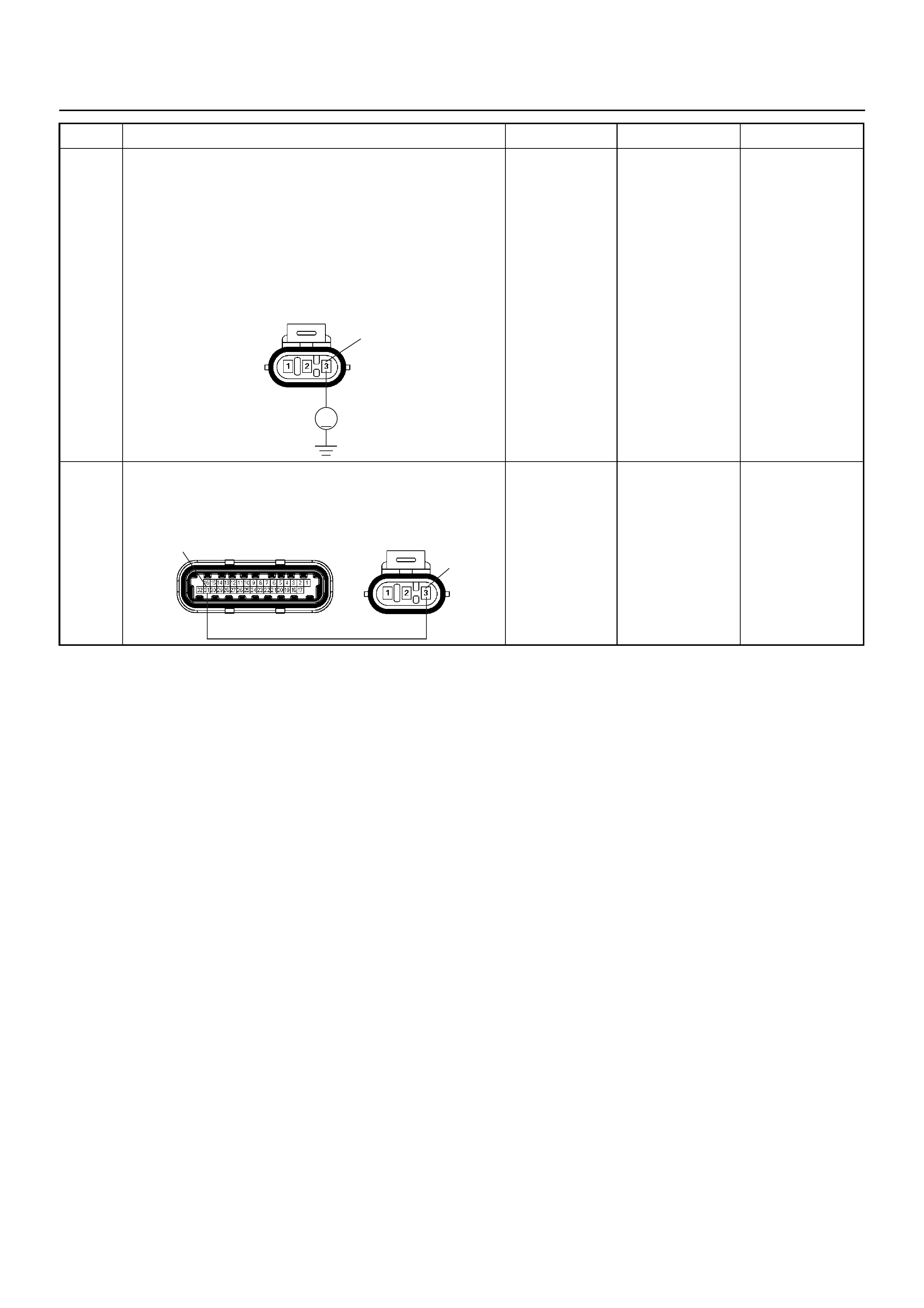

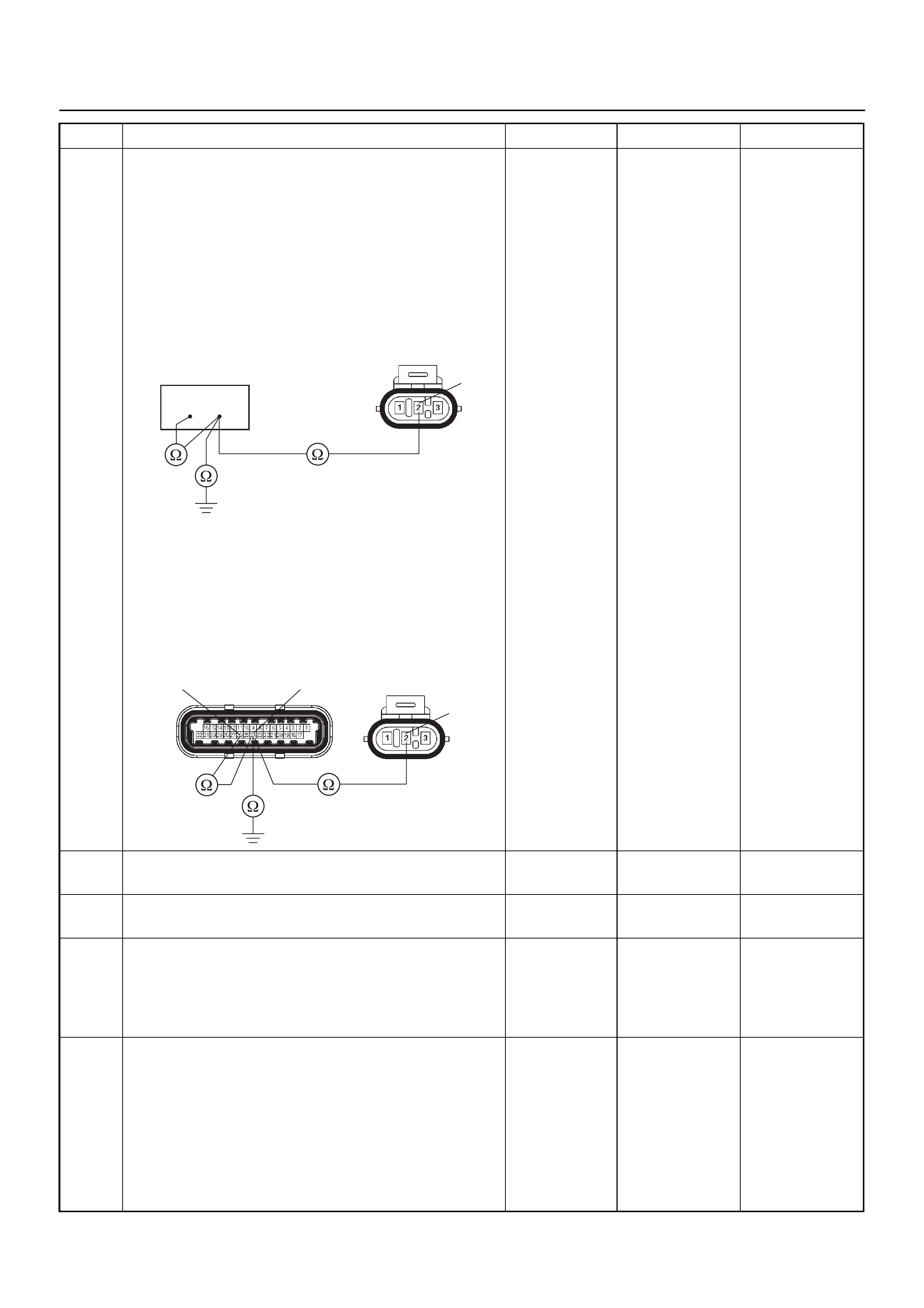

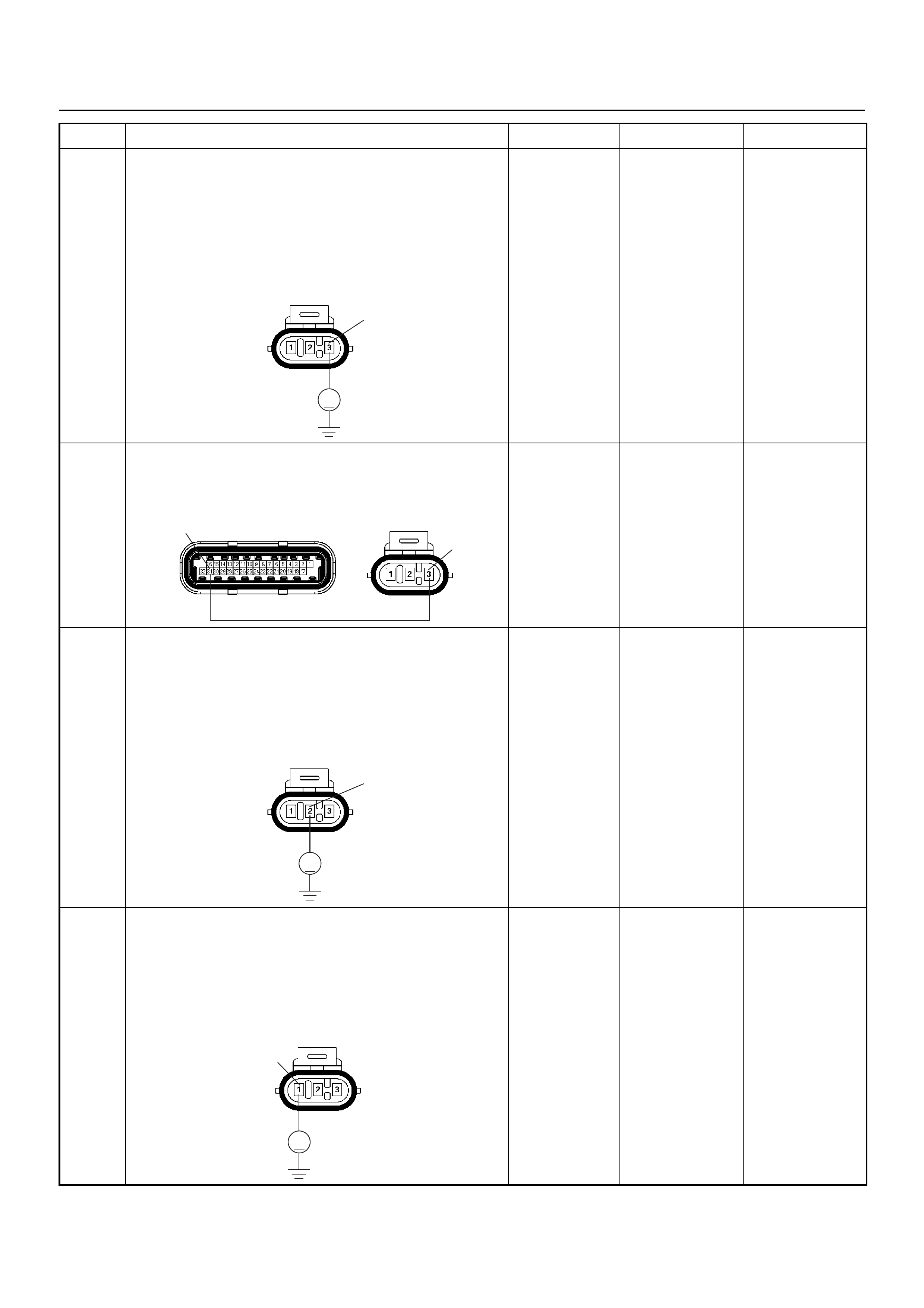

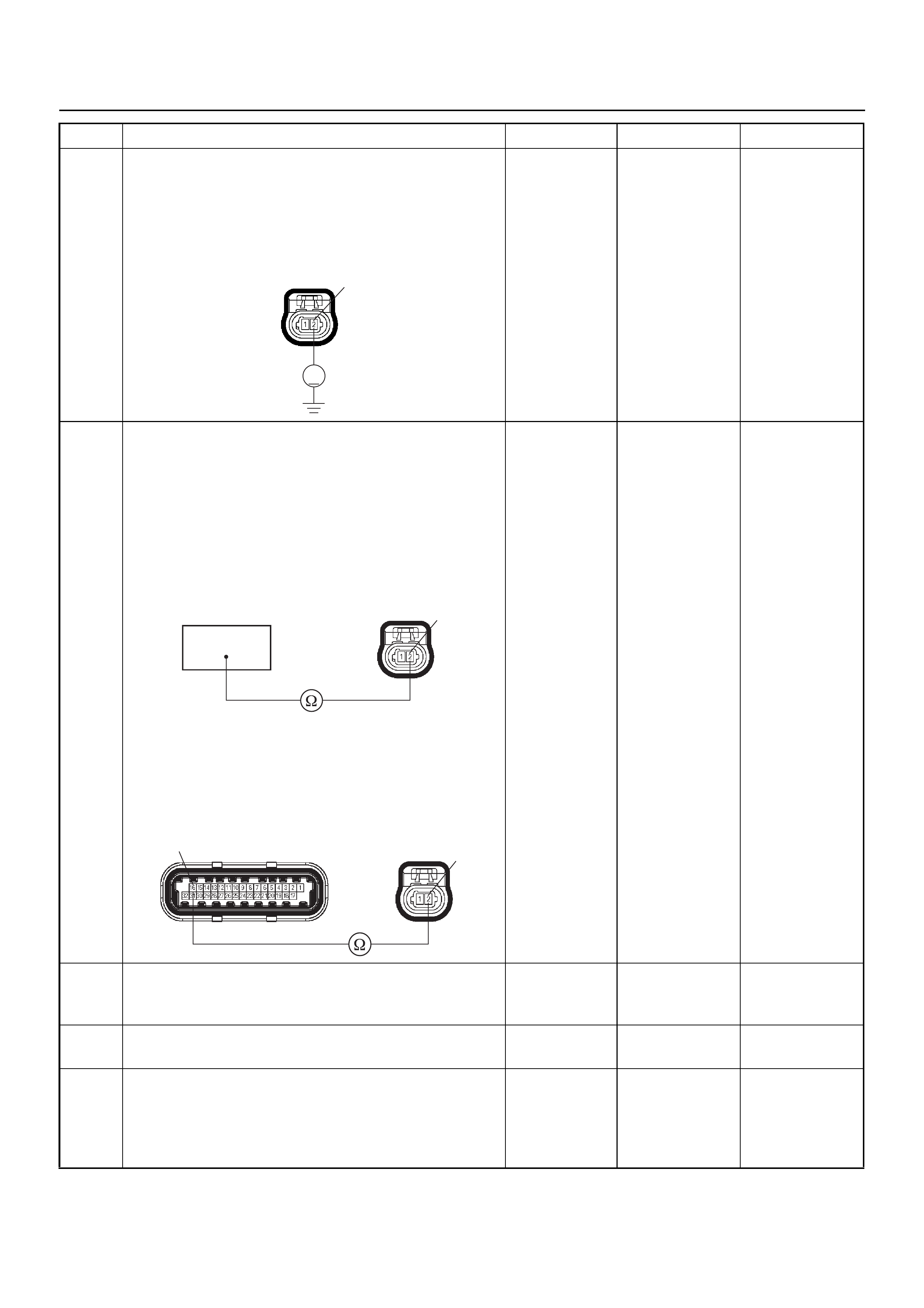

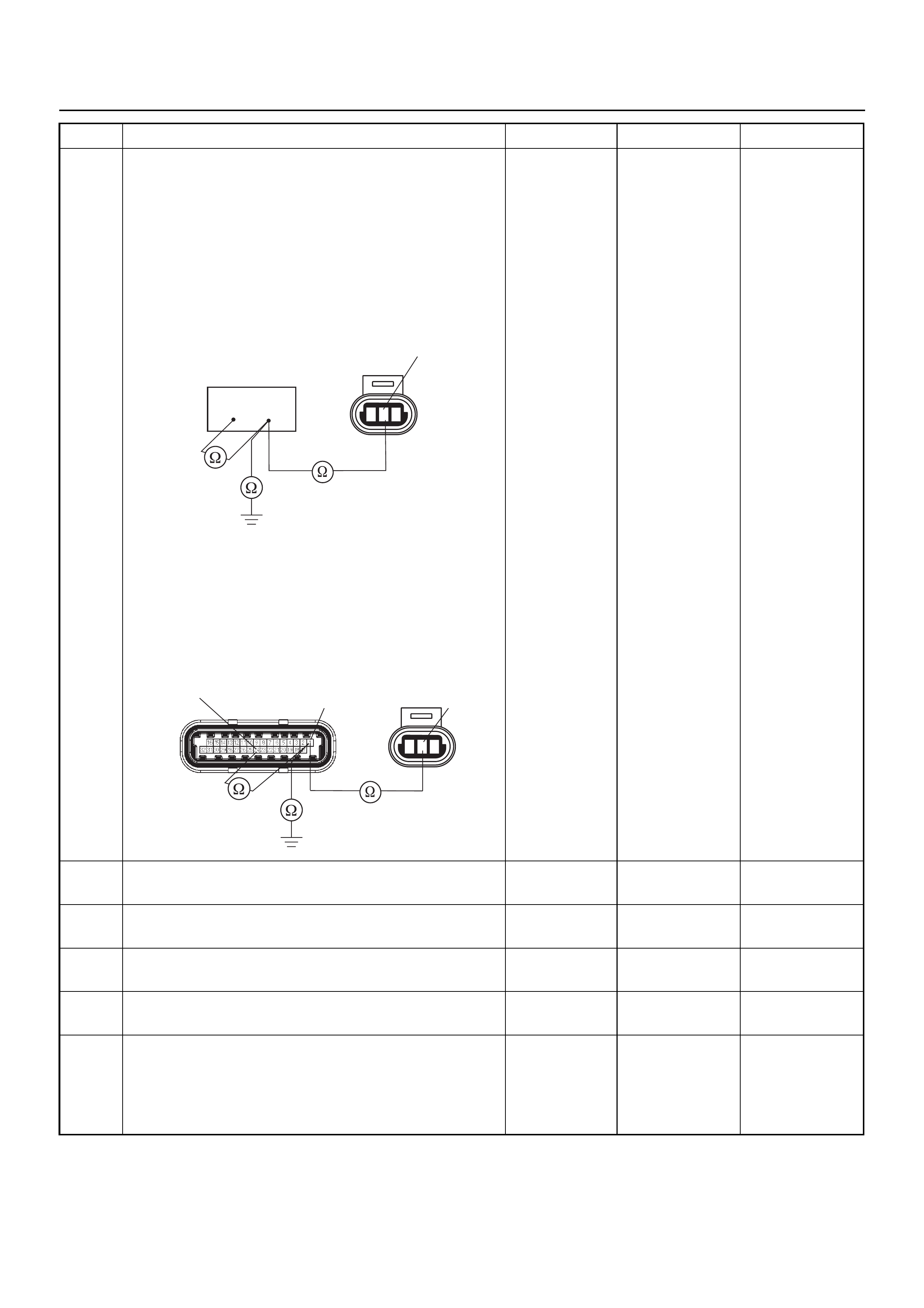

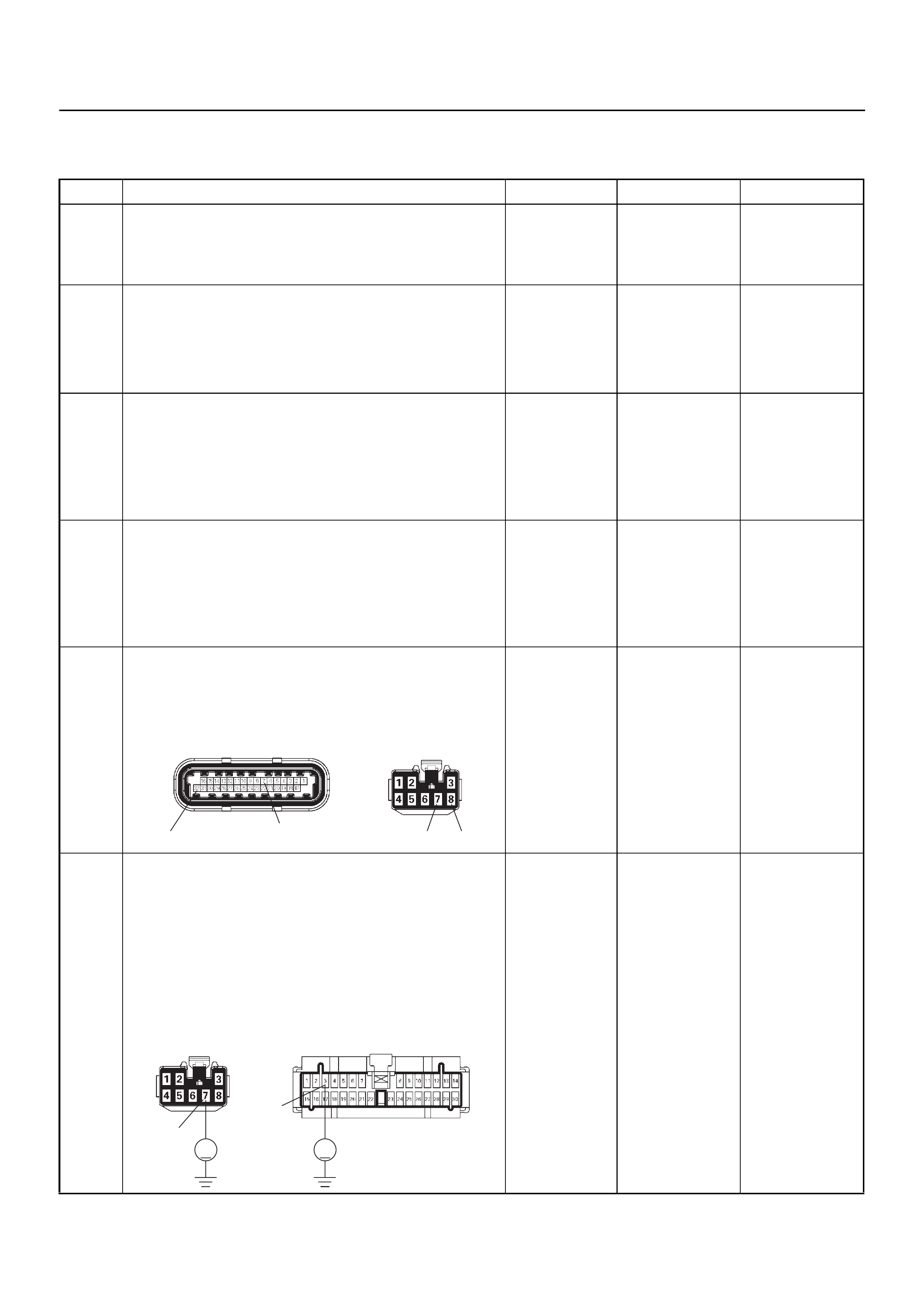

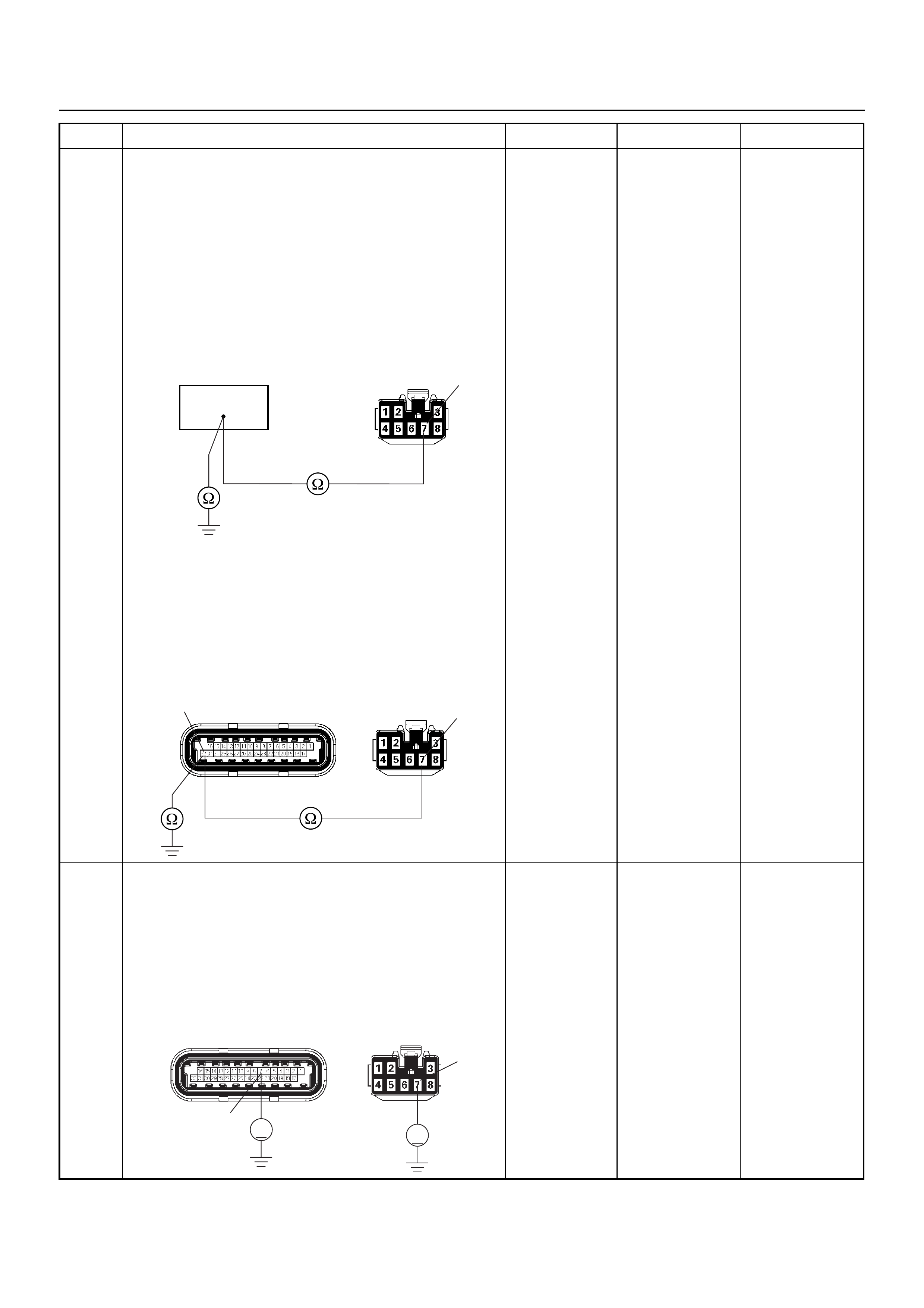

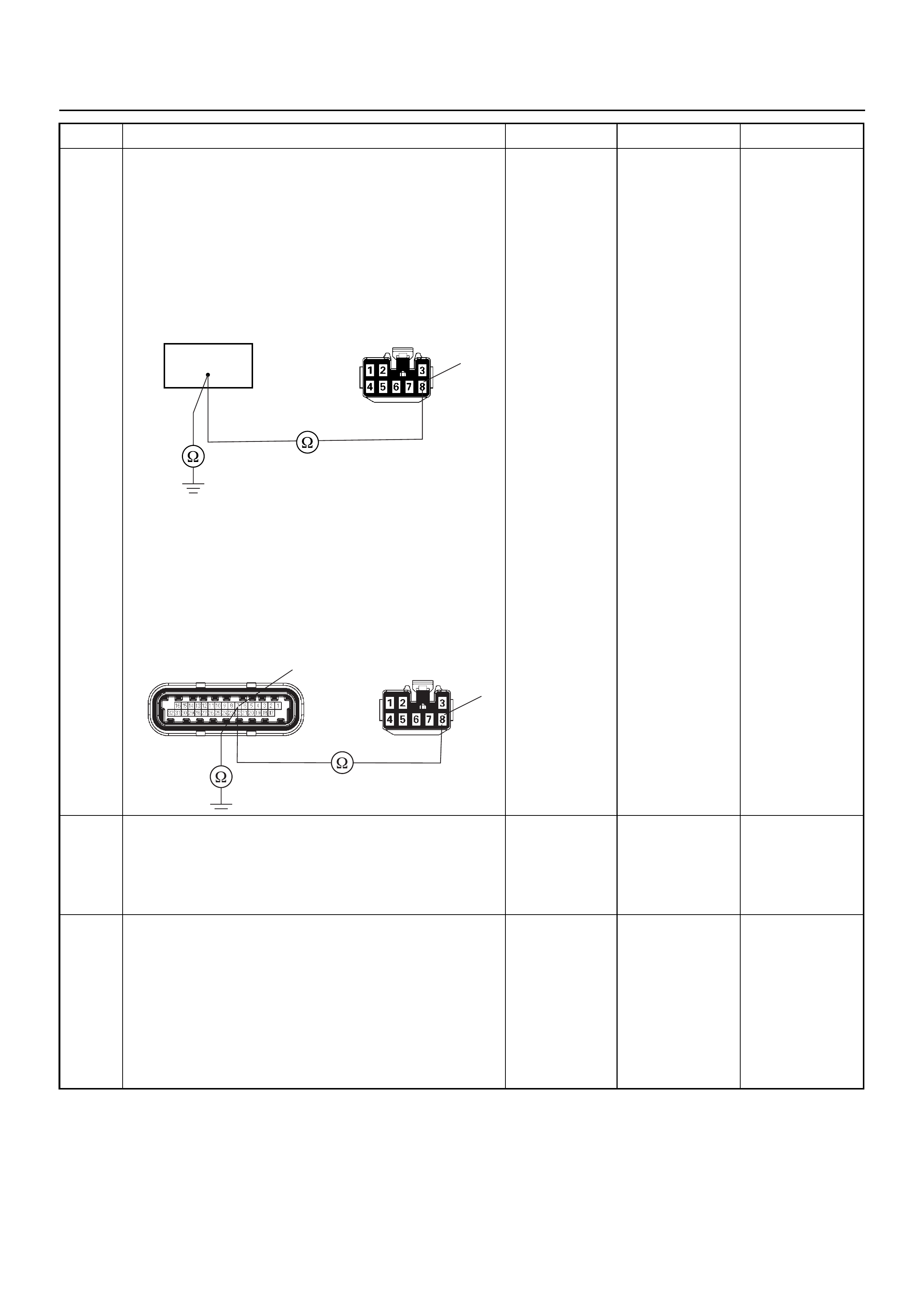

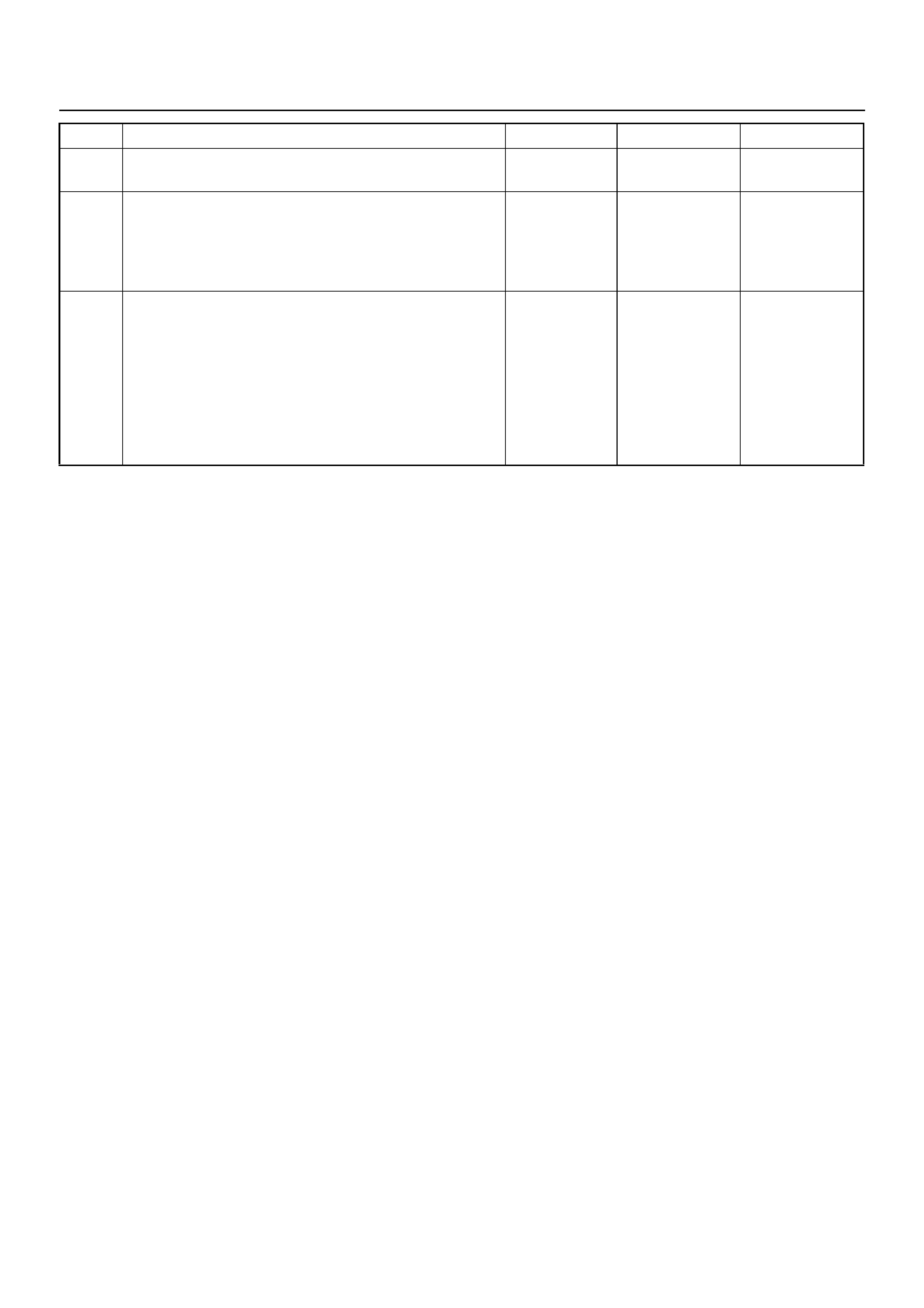

GROUND POINT CHART (1/4)

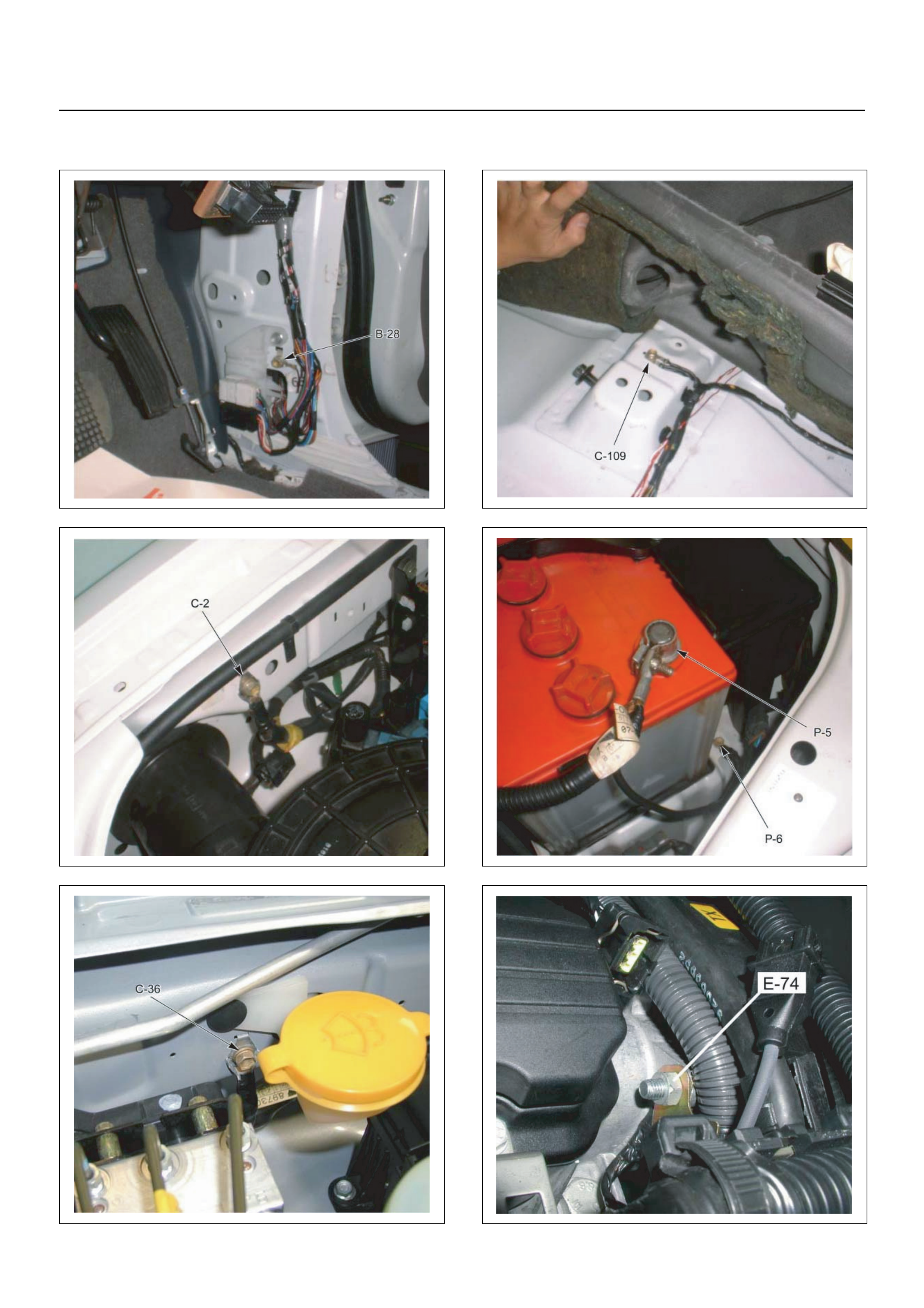

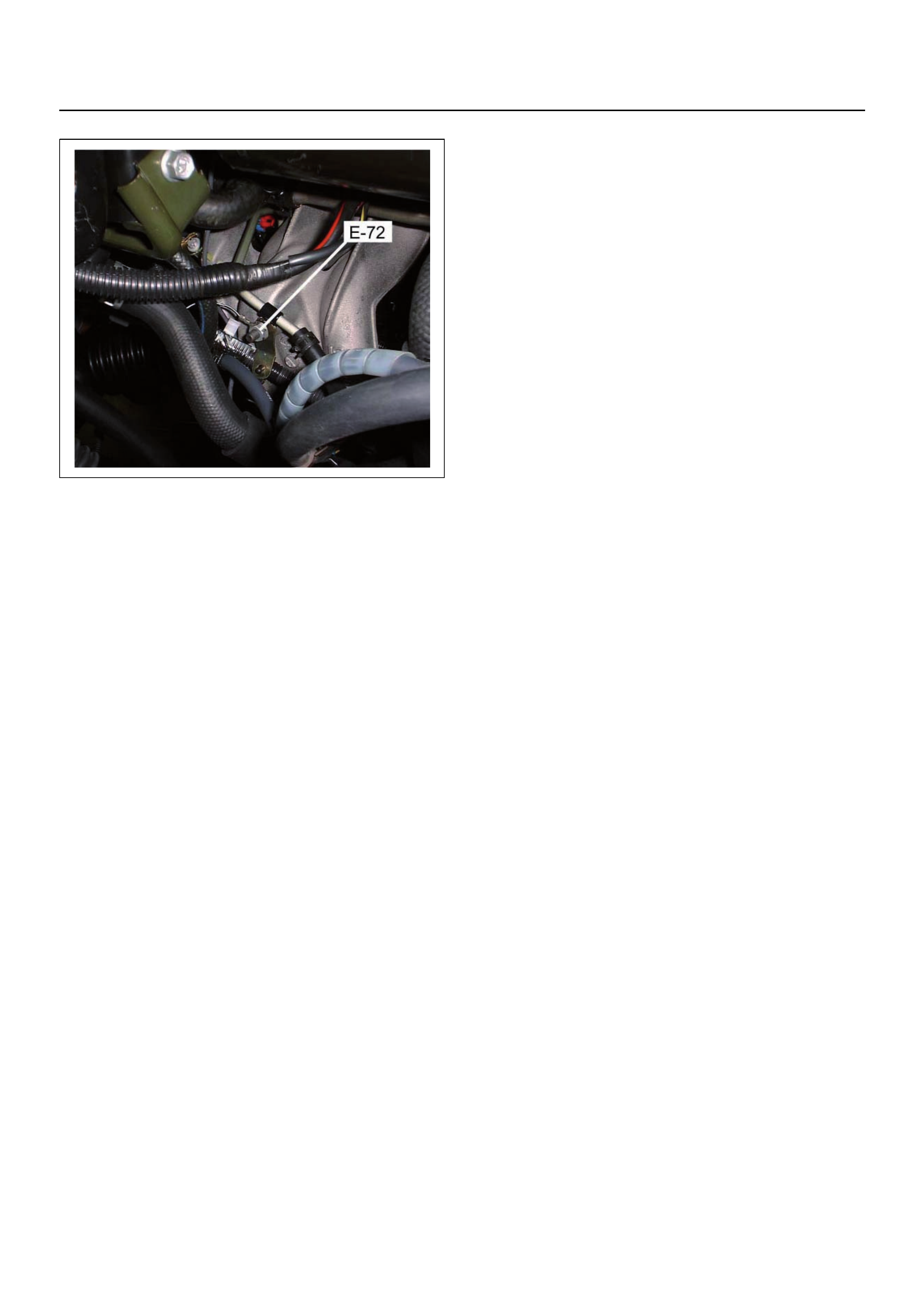

LOCATION

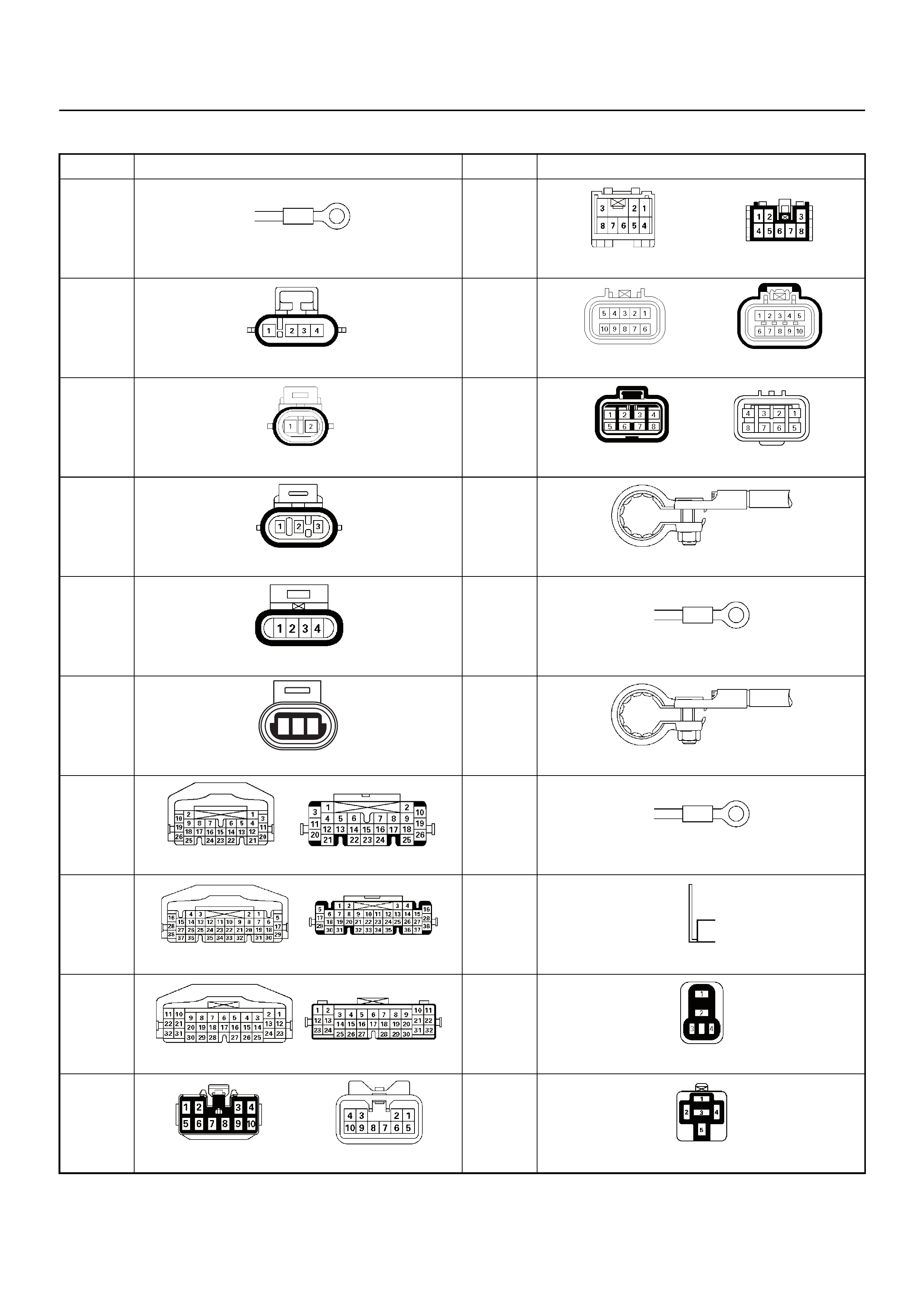

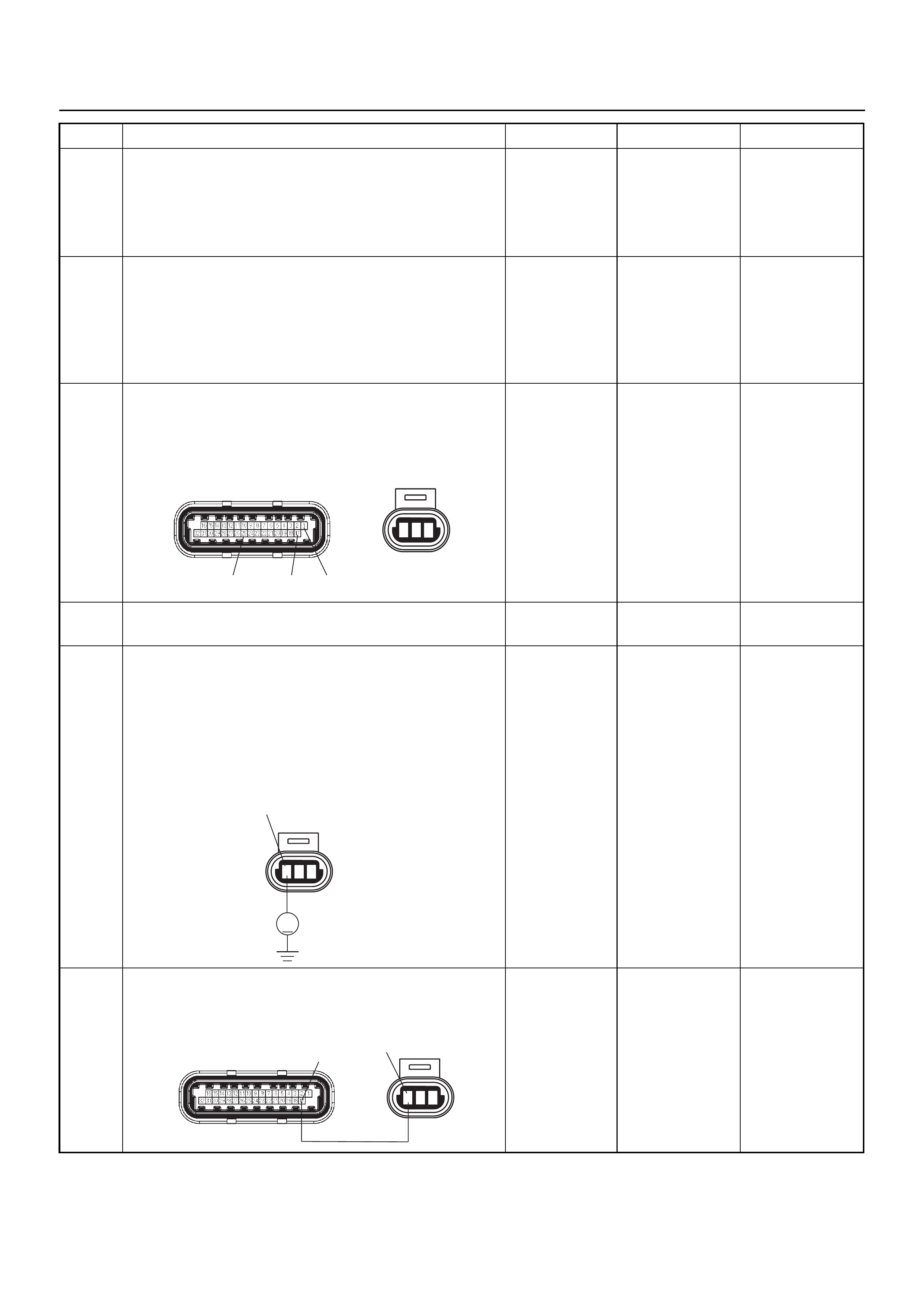

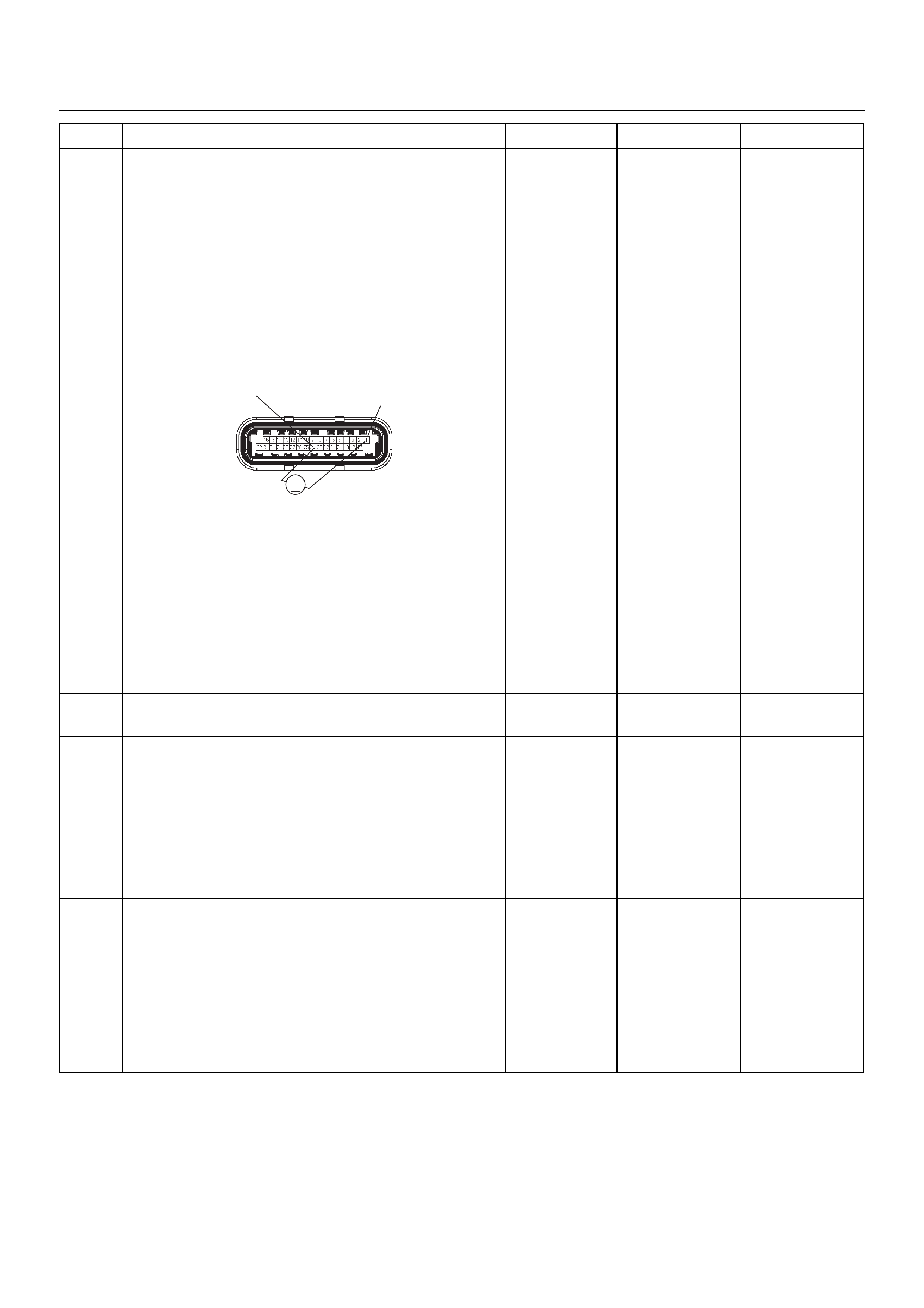

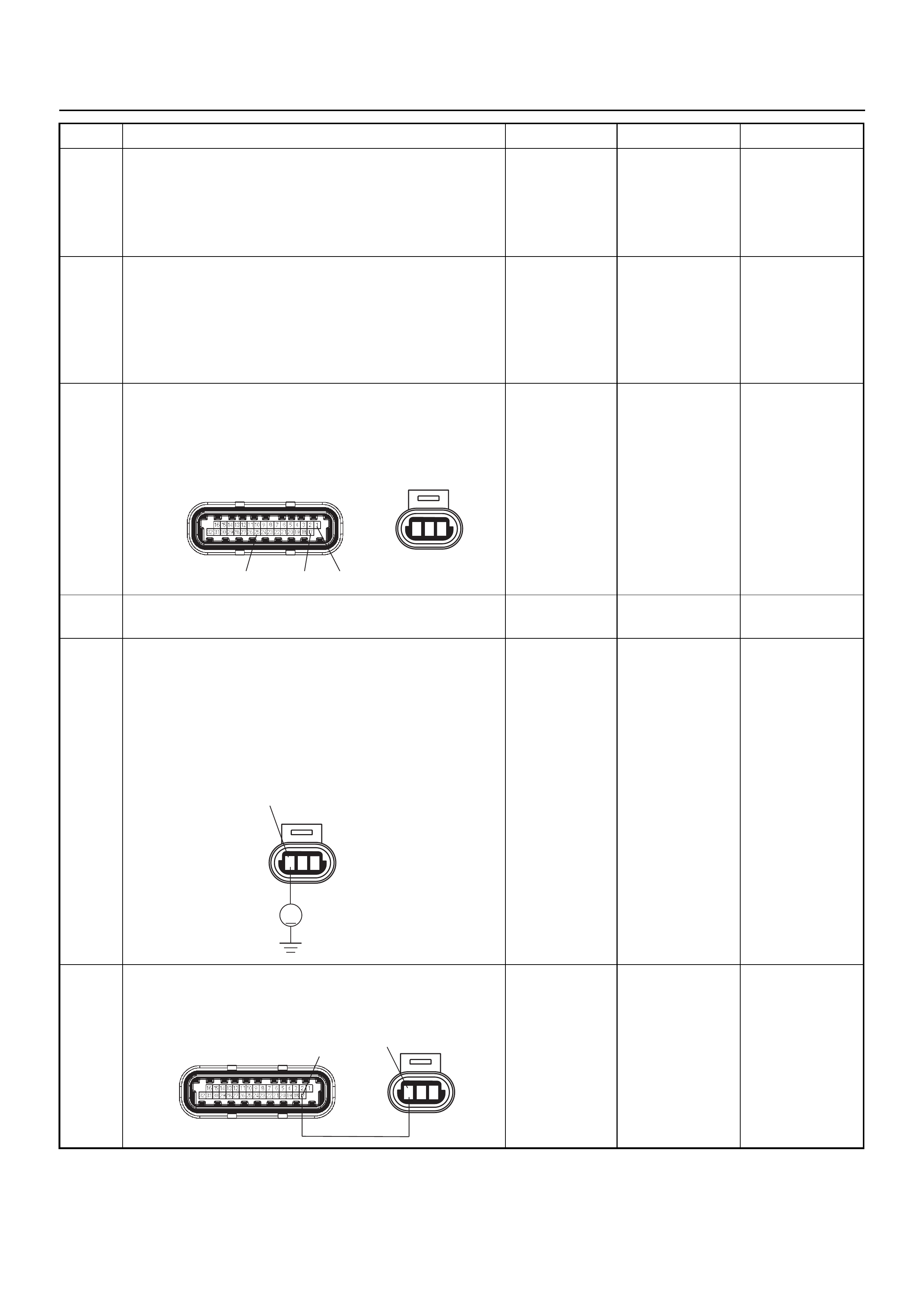

CABLE HARNESS & CONNECTOR

LOCATION

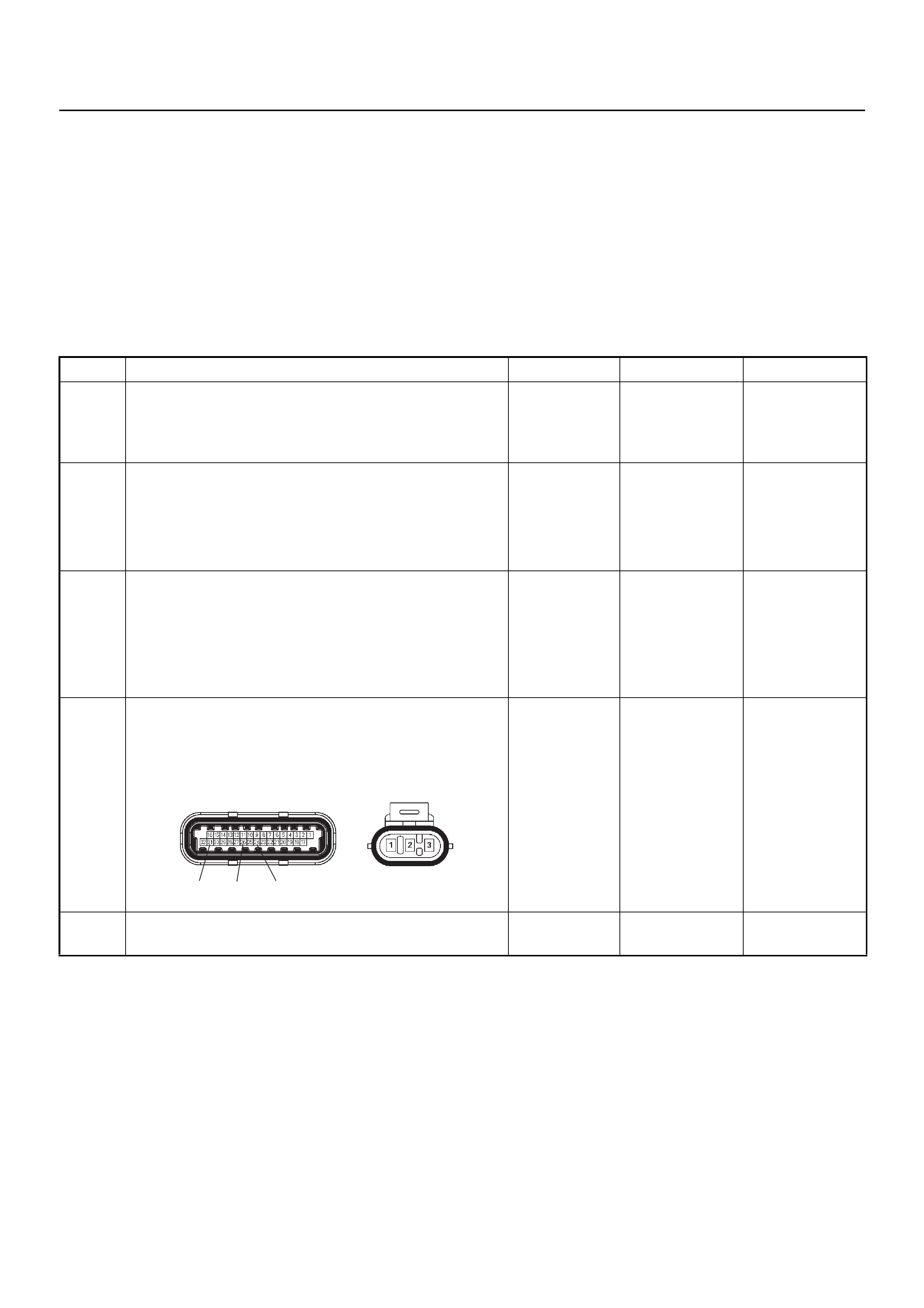

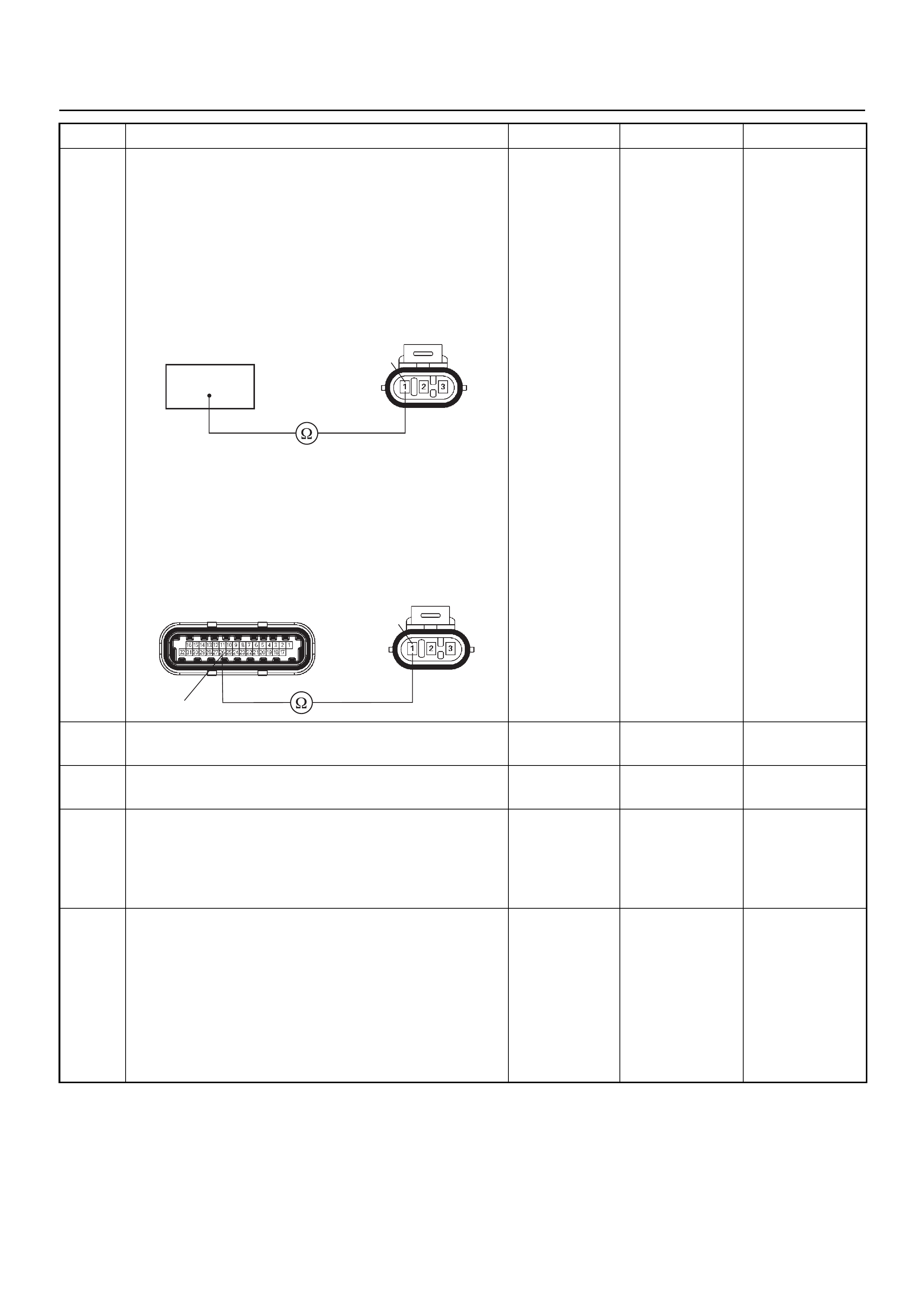

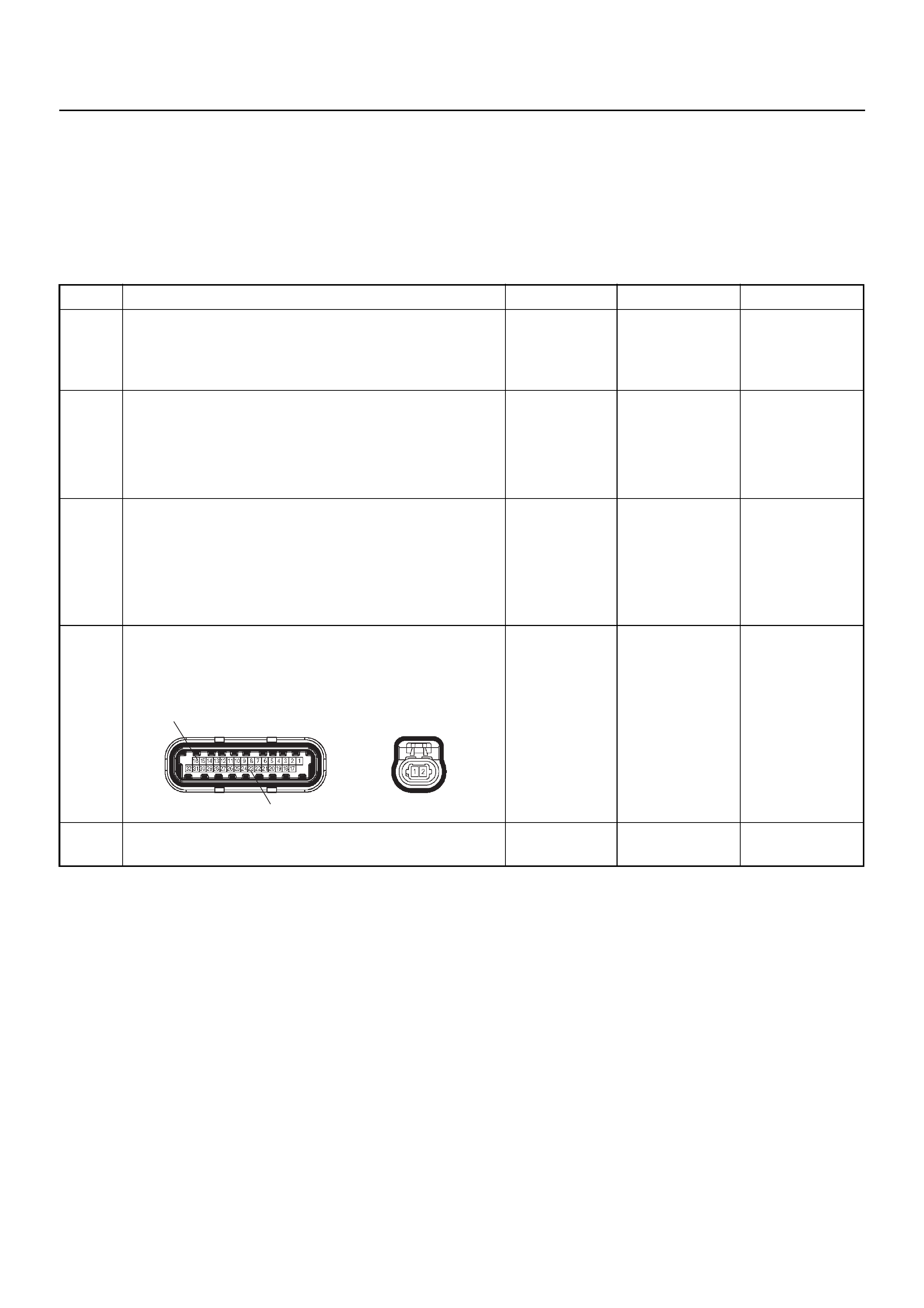

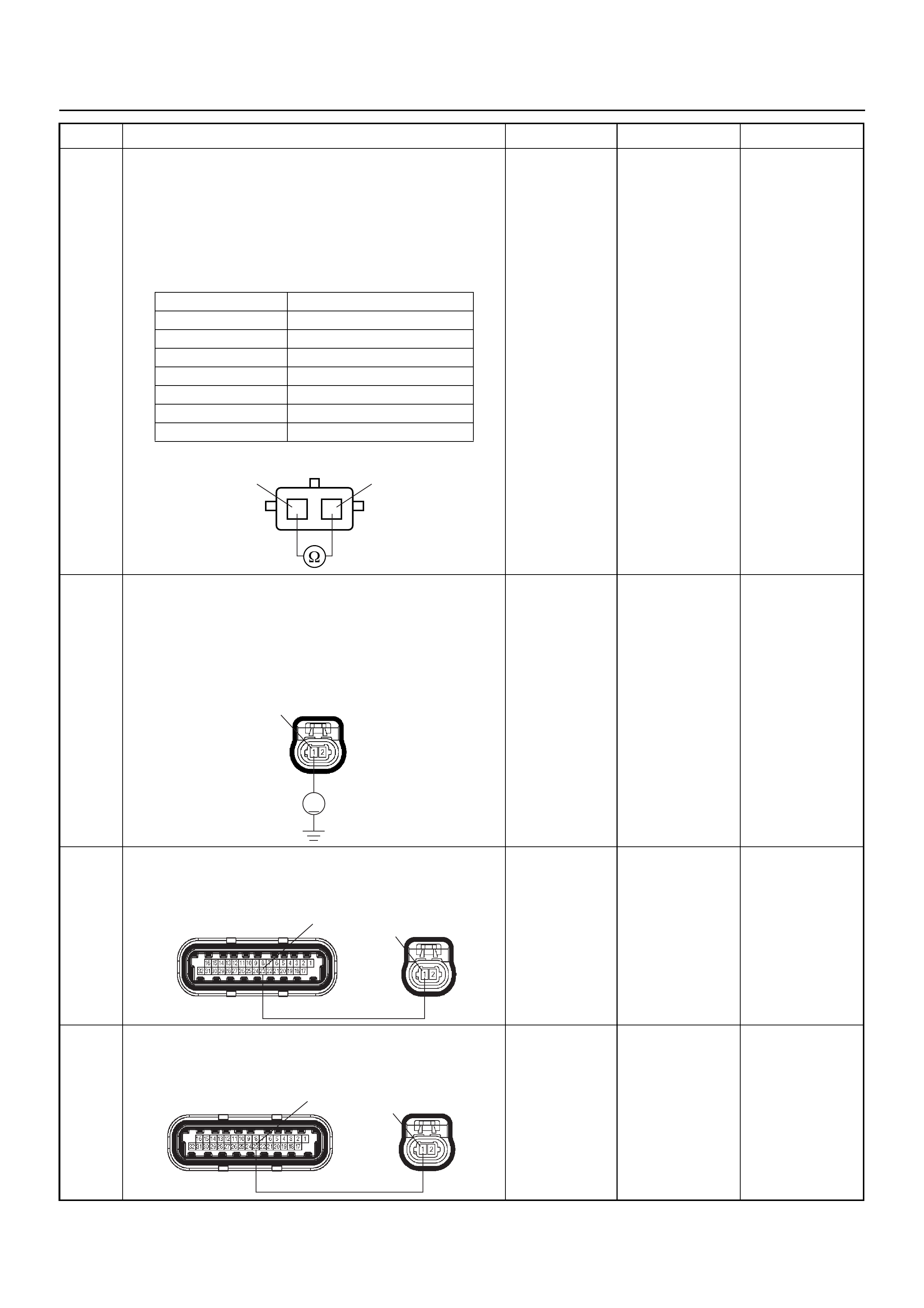

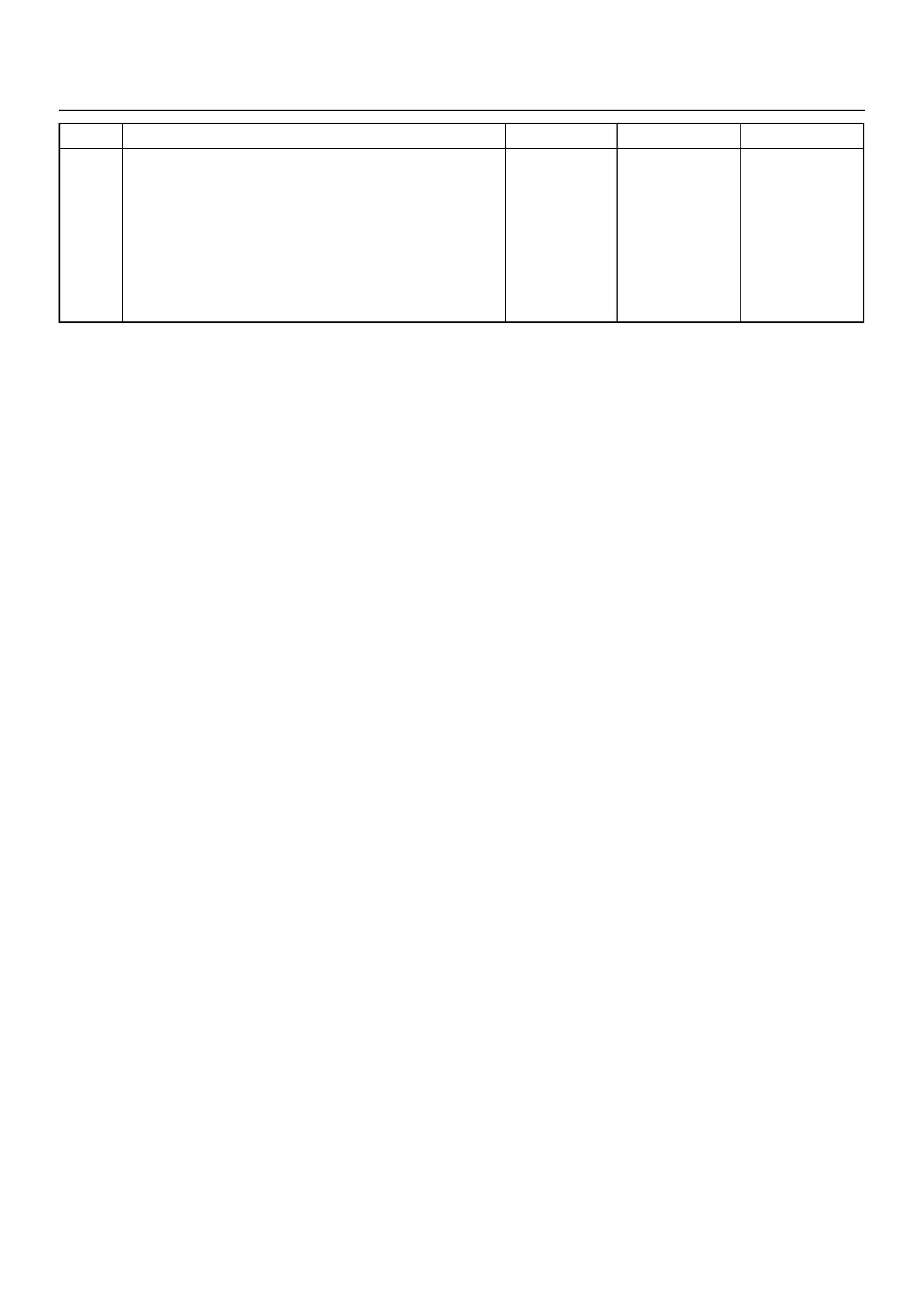

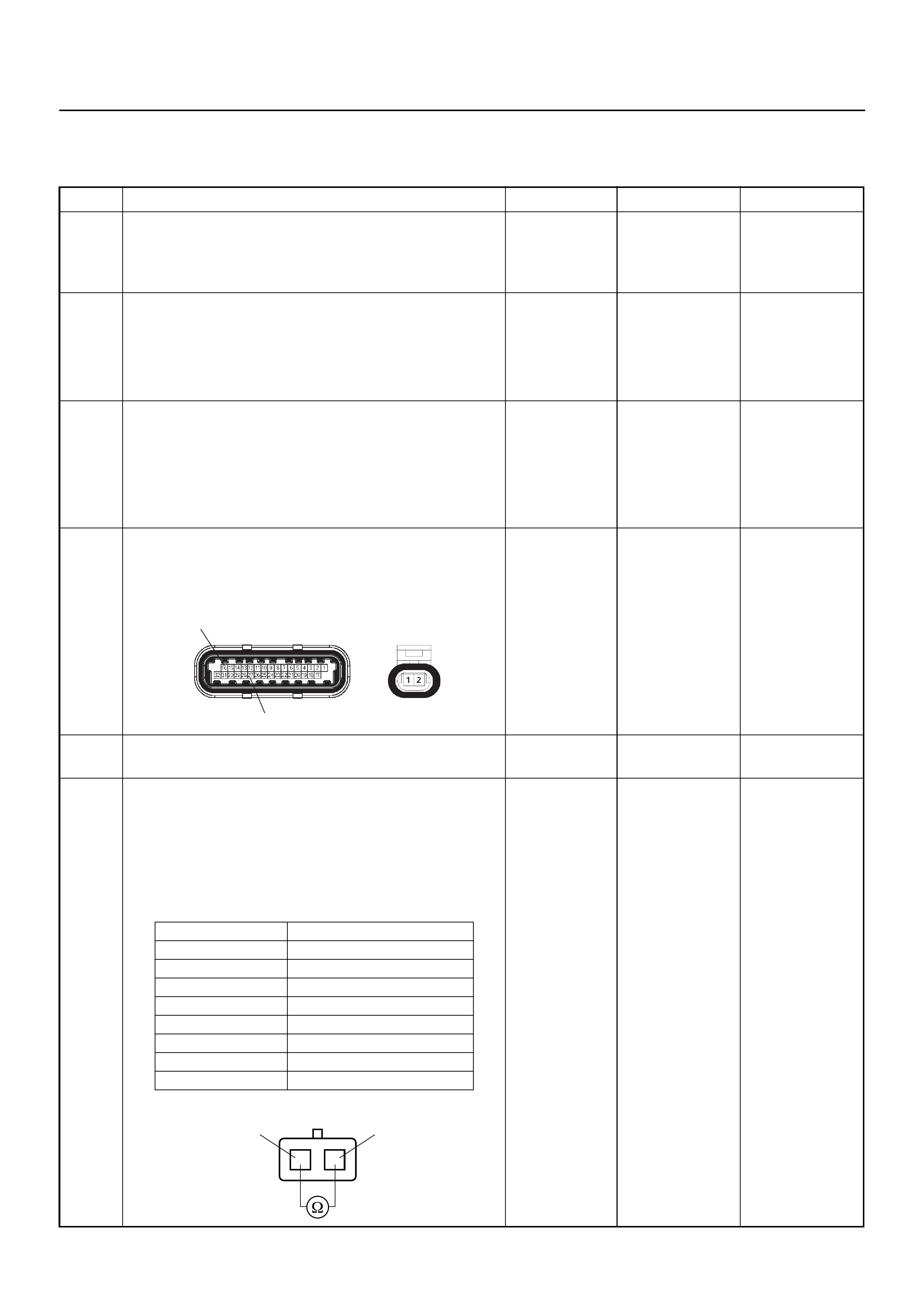

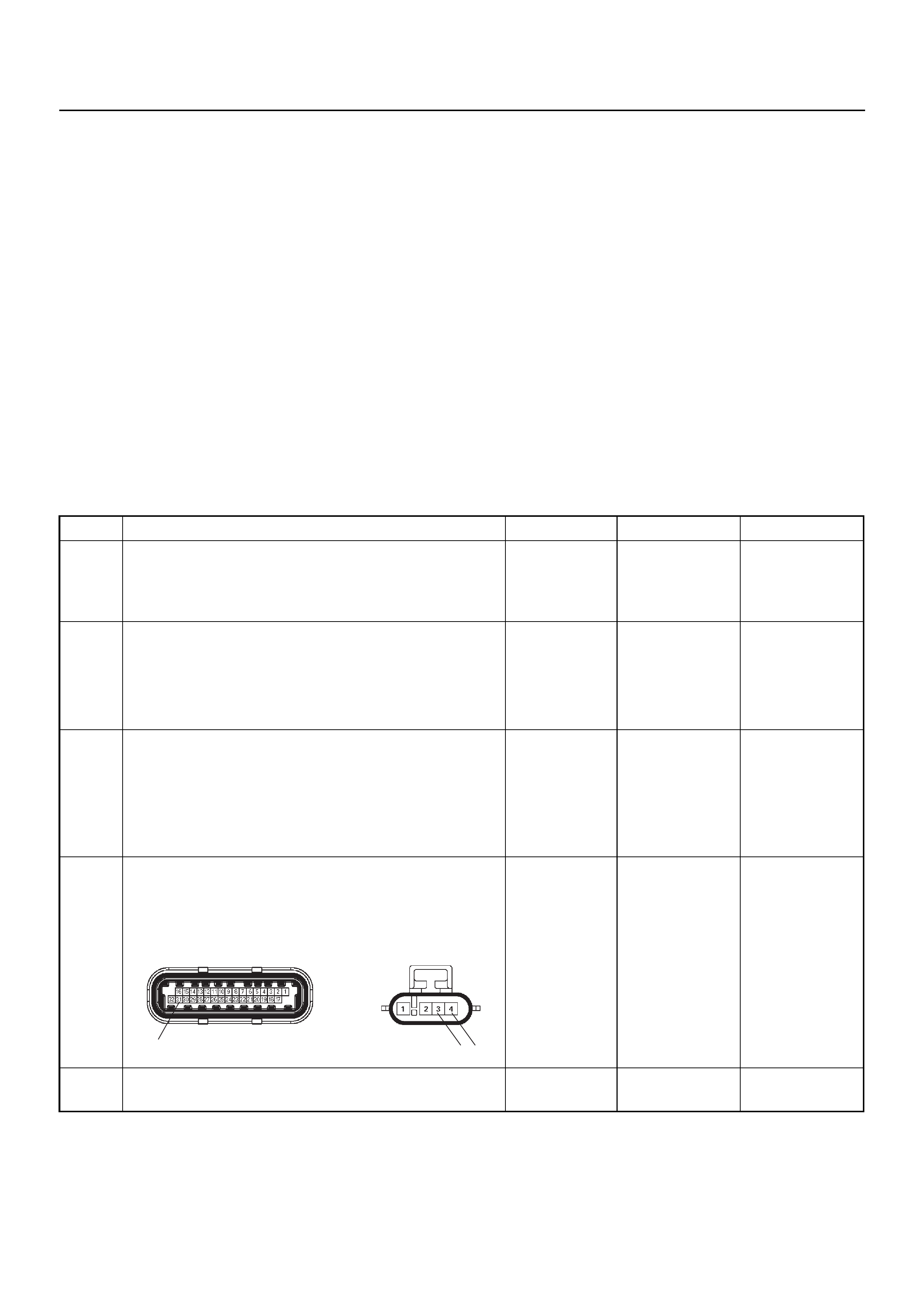

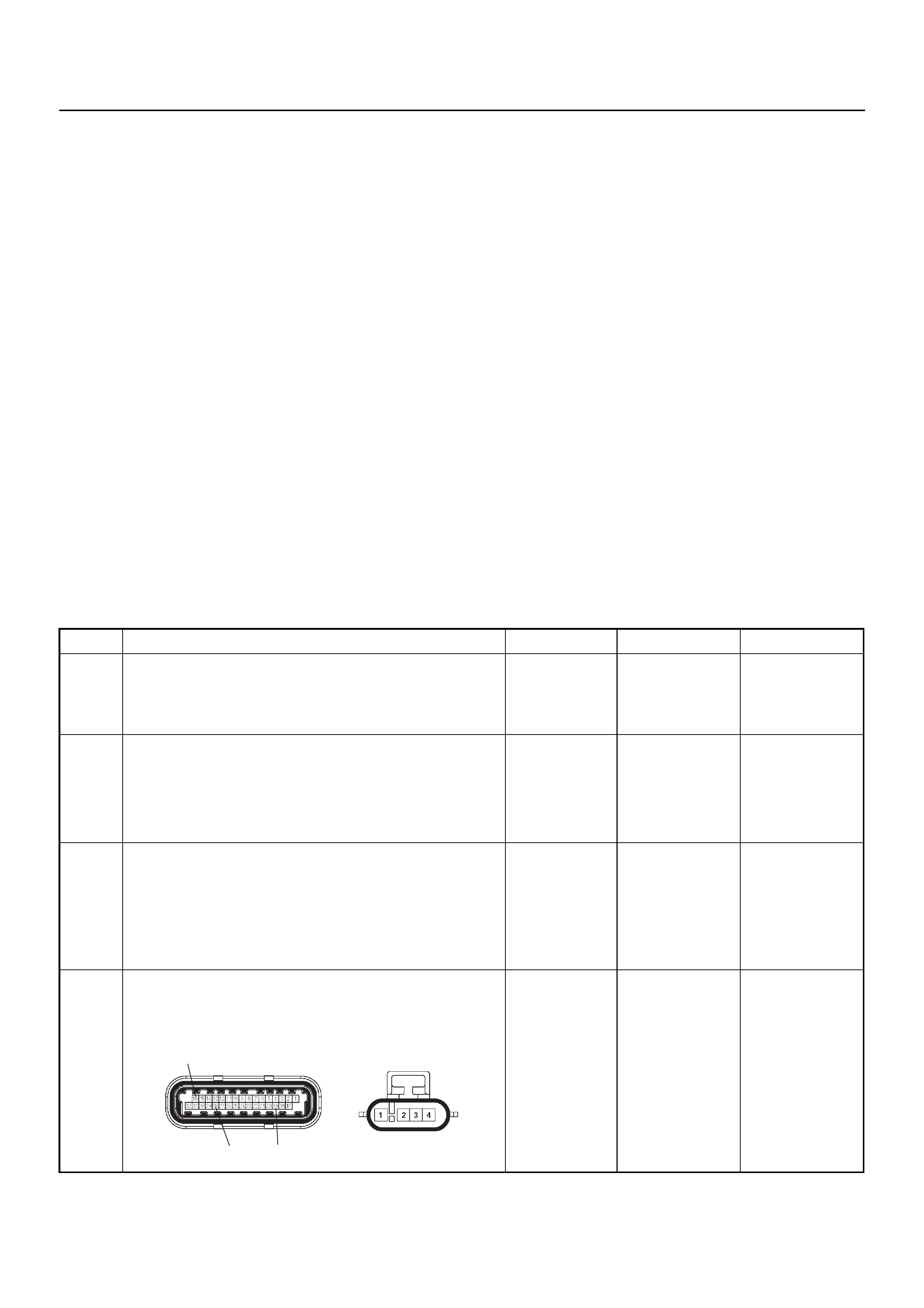

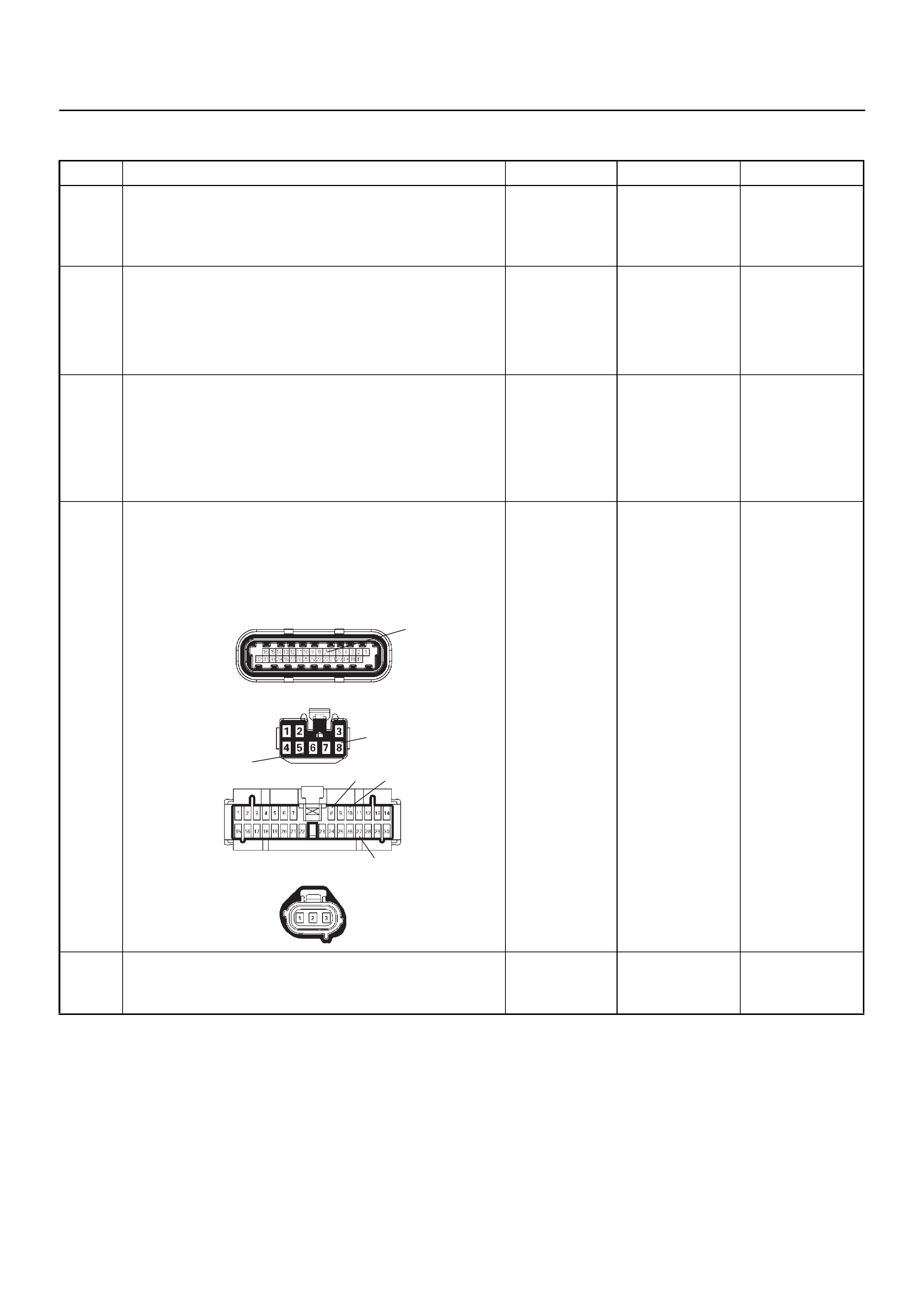

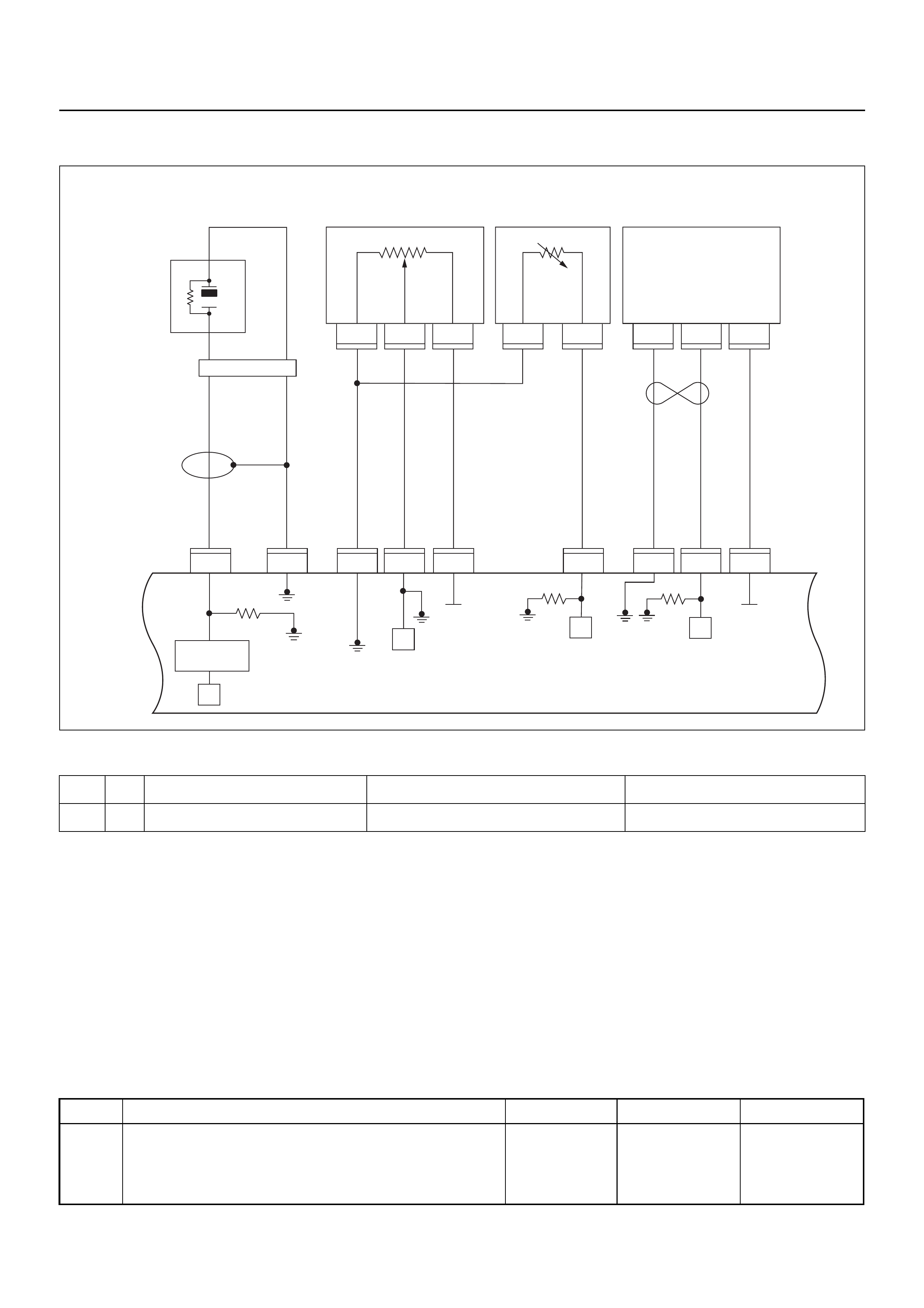

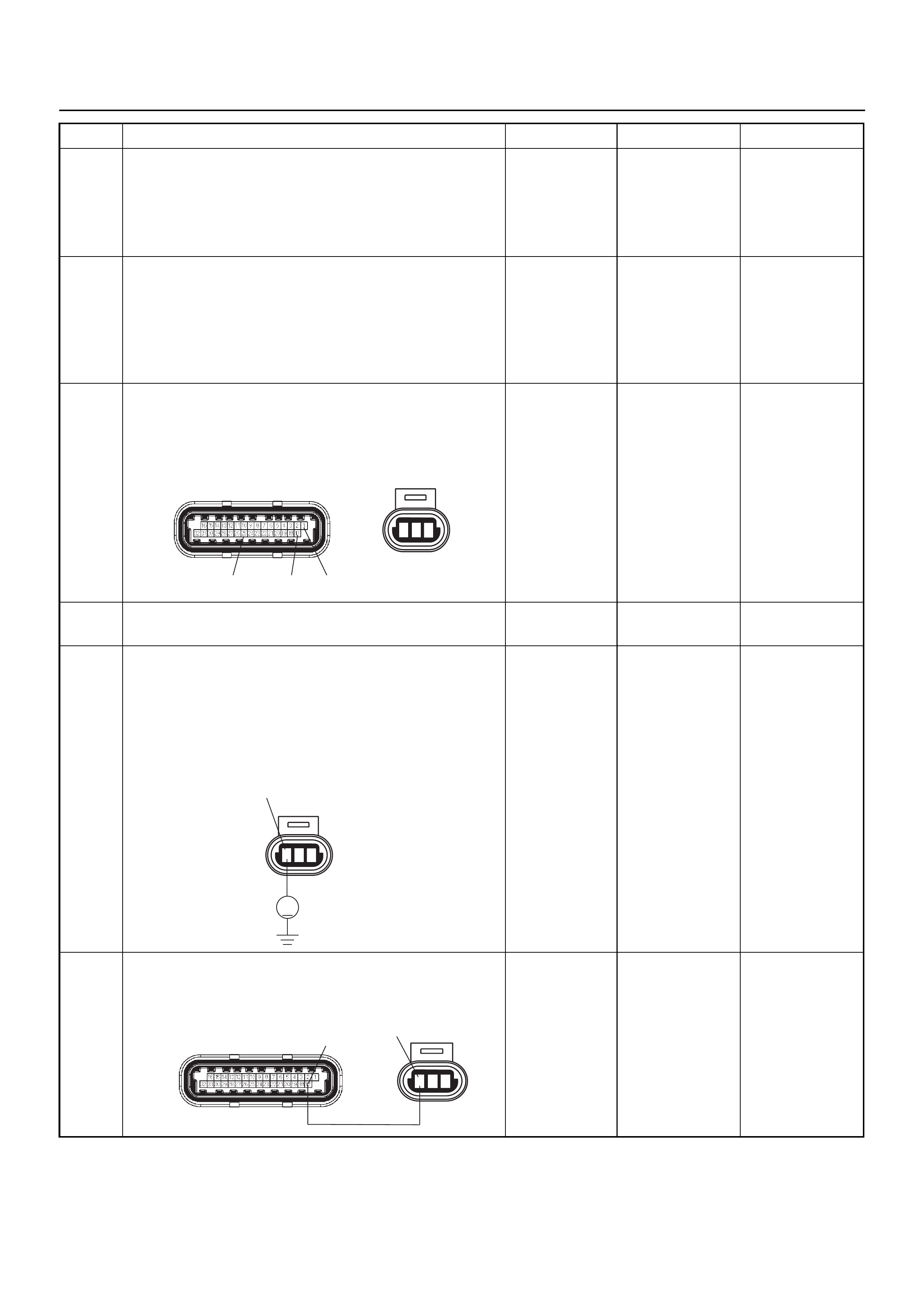

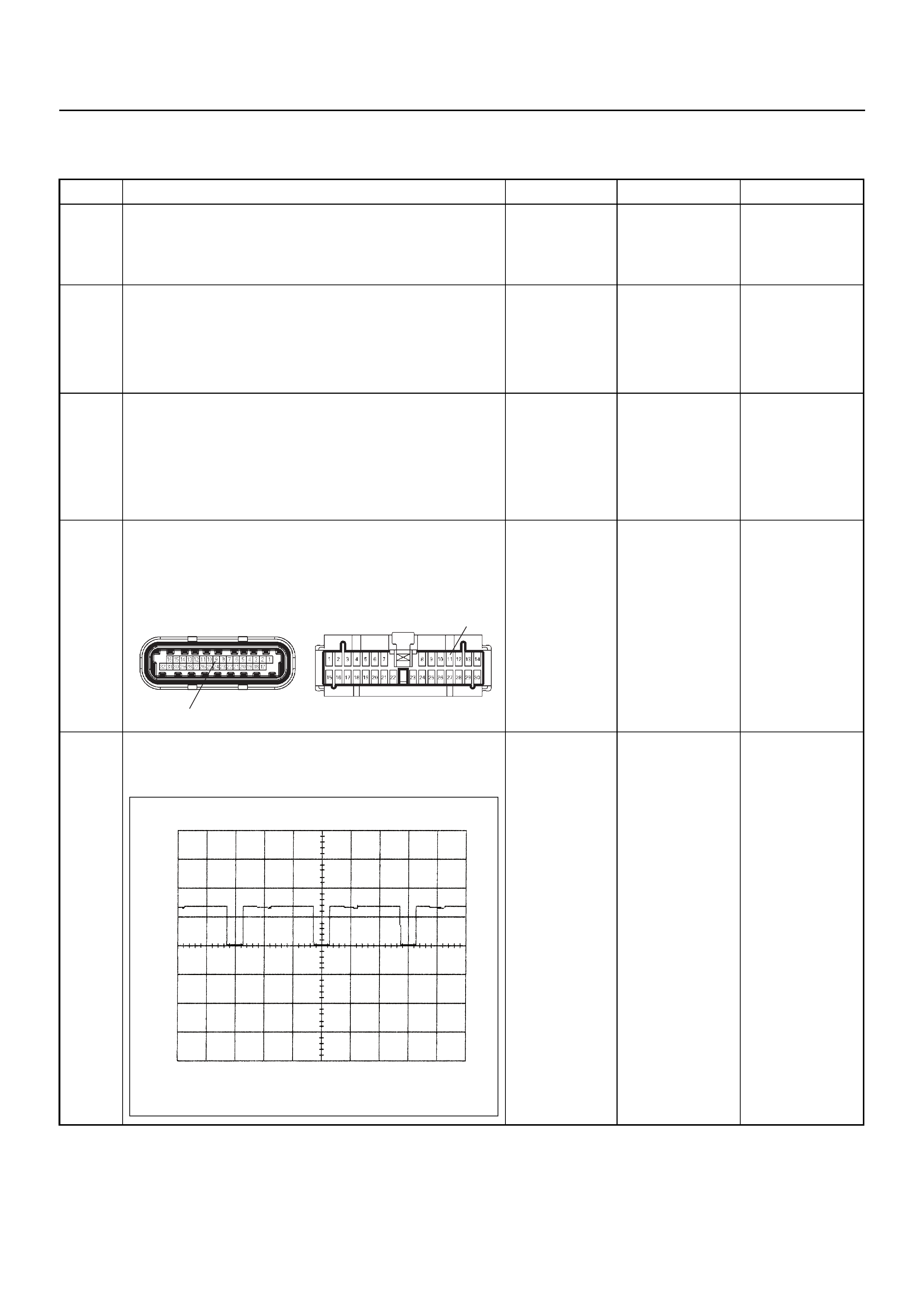

CONNECTOR LIST

RELAY AND FUSE

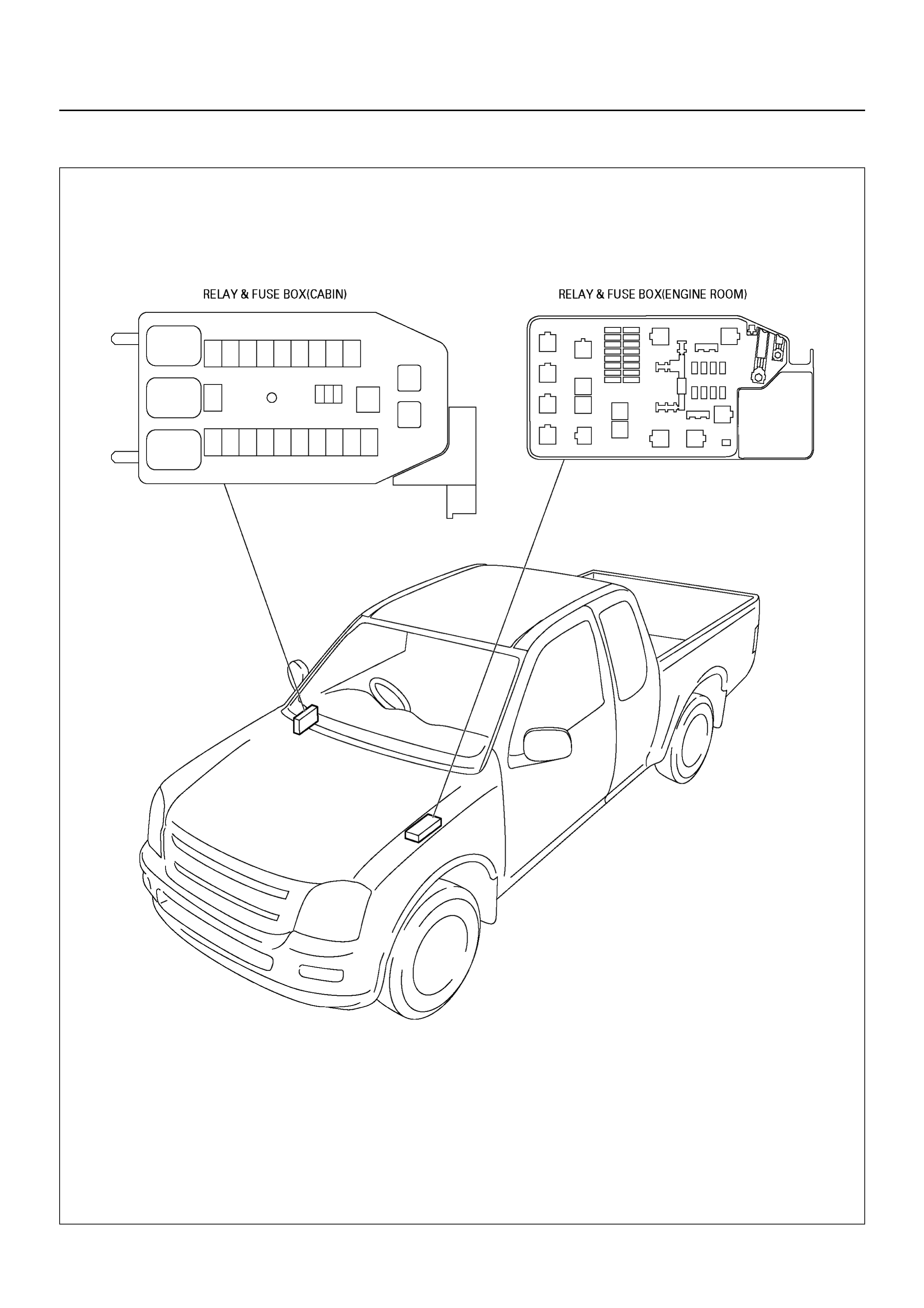

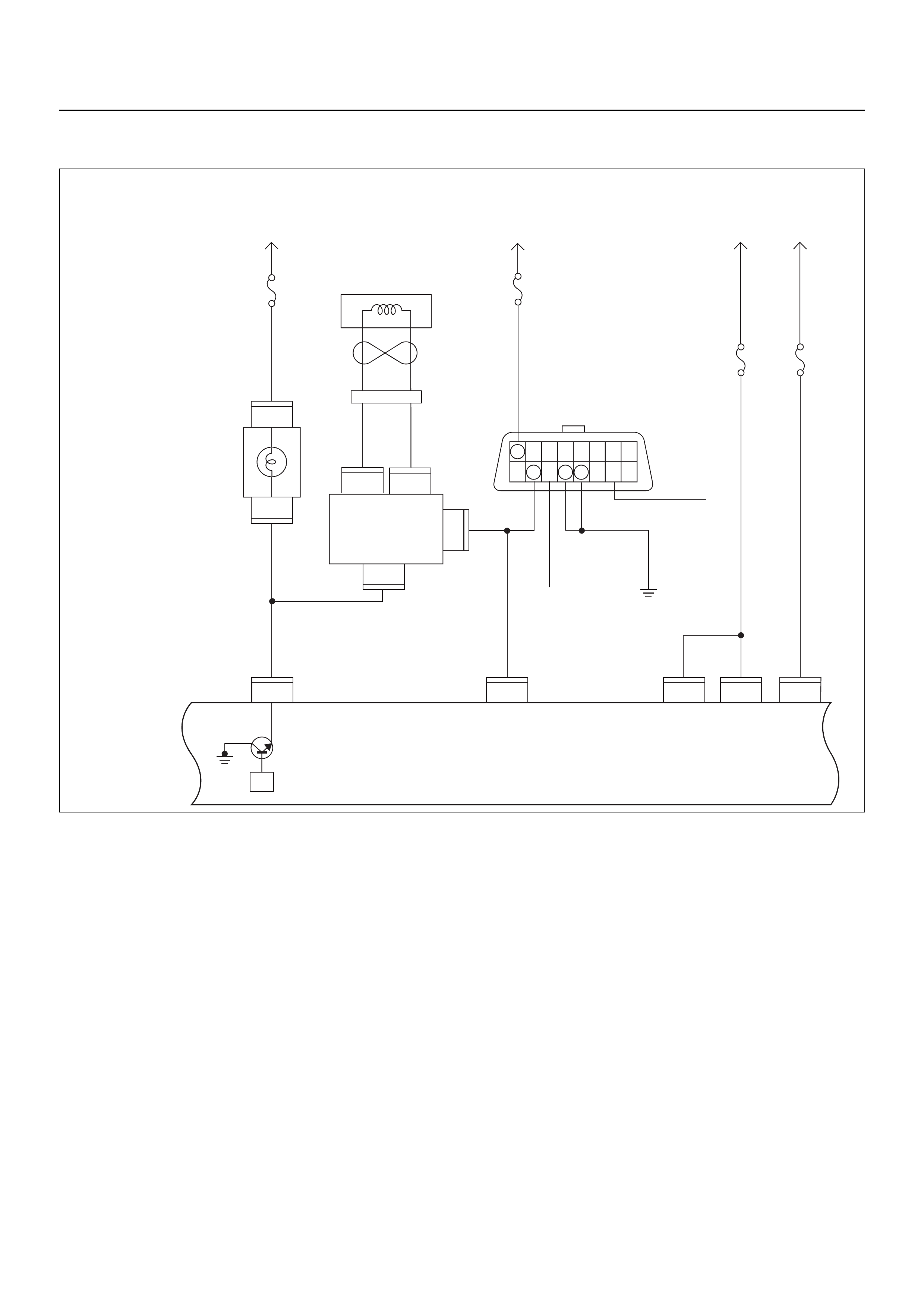

RELAY AND FUSE BOX LOCATION

RELAY AND FUSE BOX LOCATION

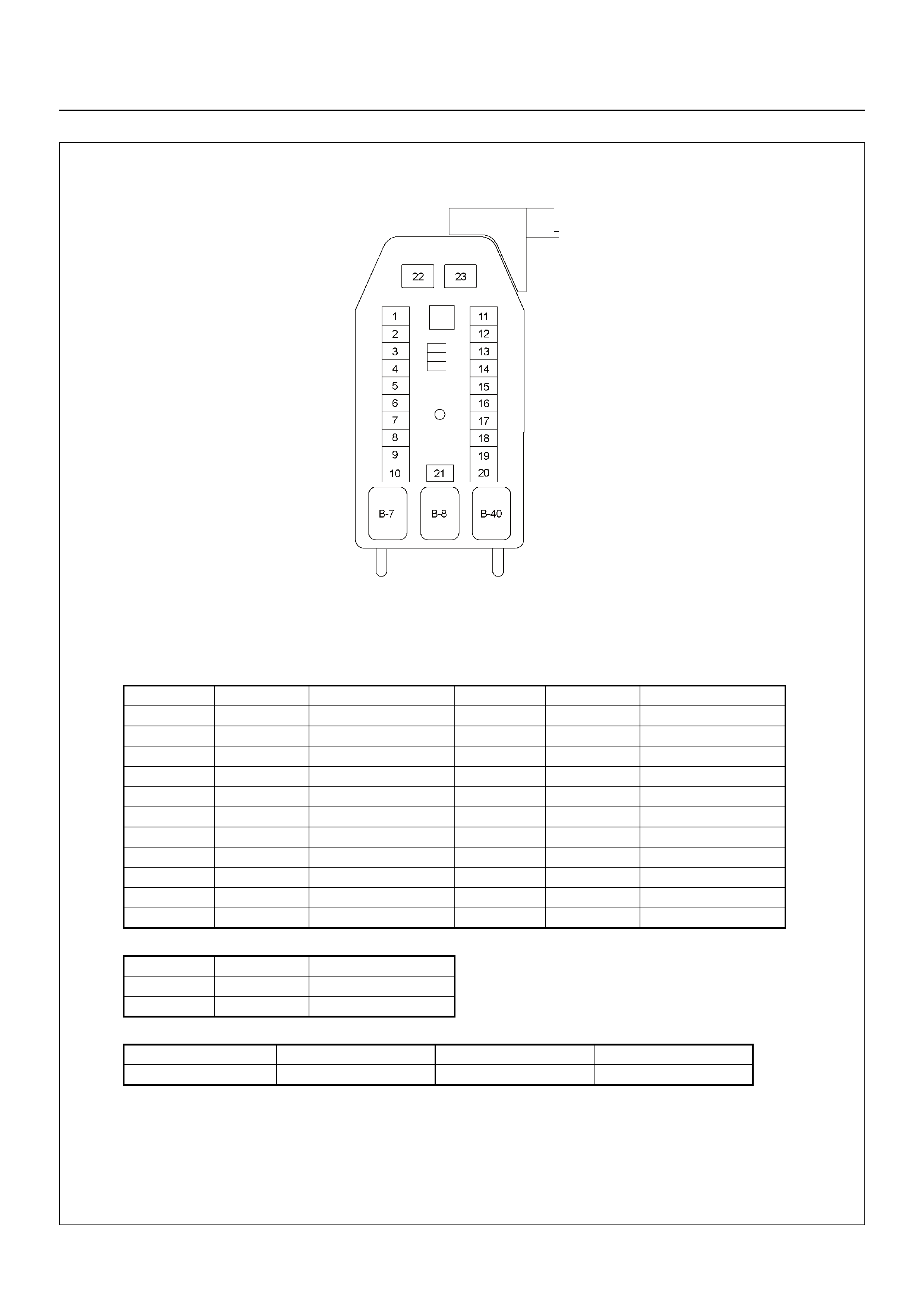

FUSE AND RELAY LOCATION

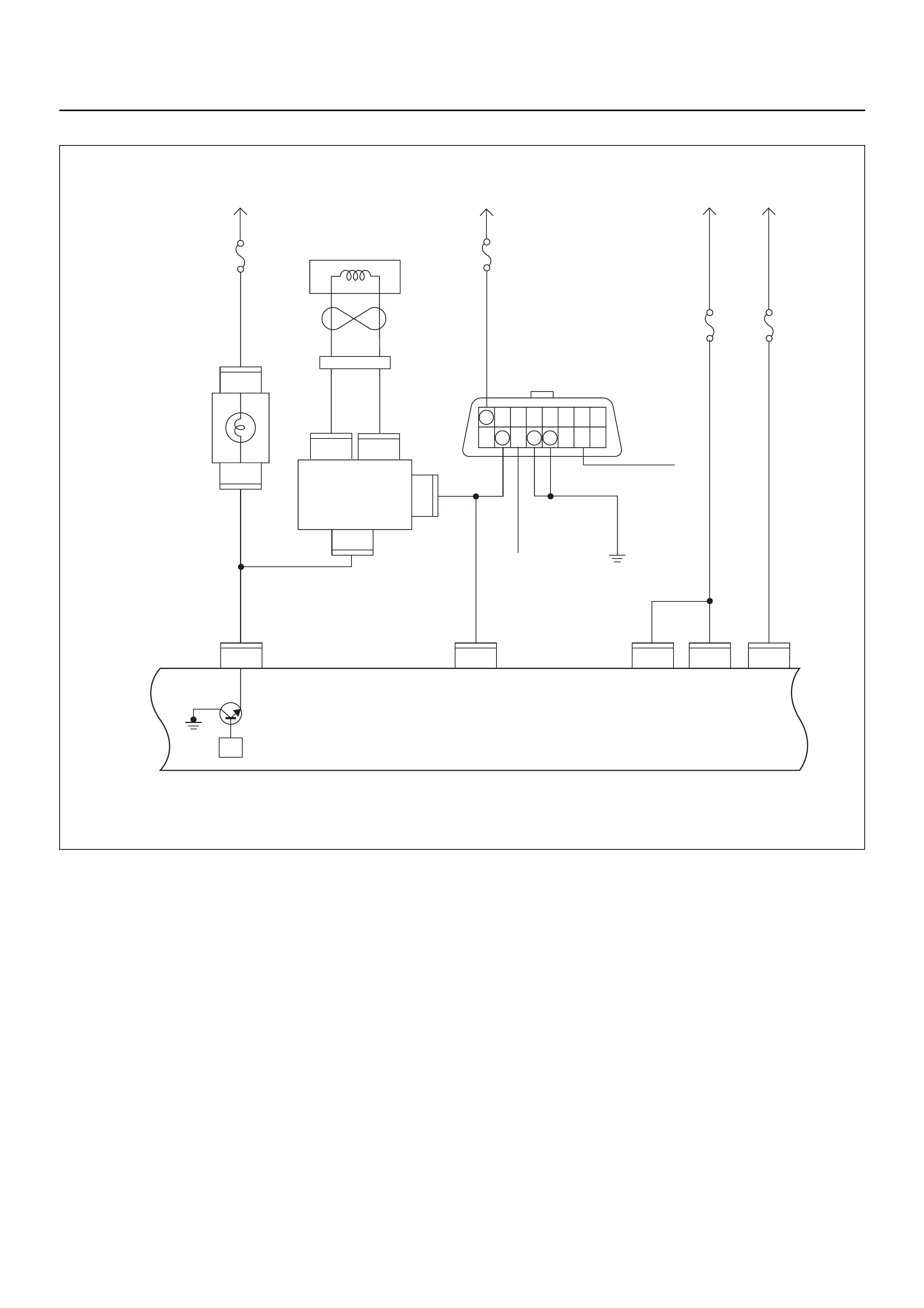

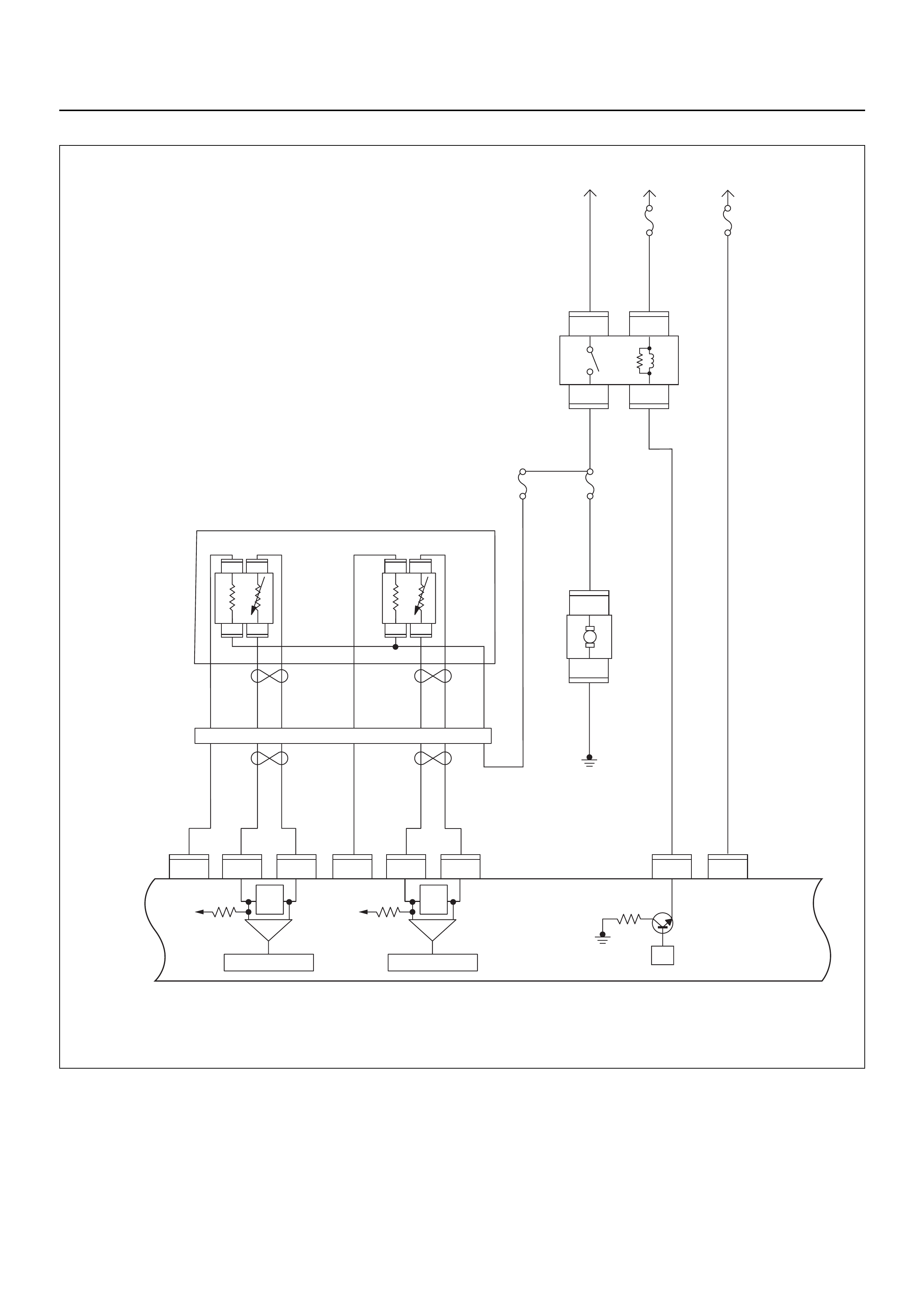

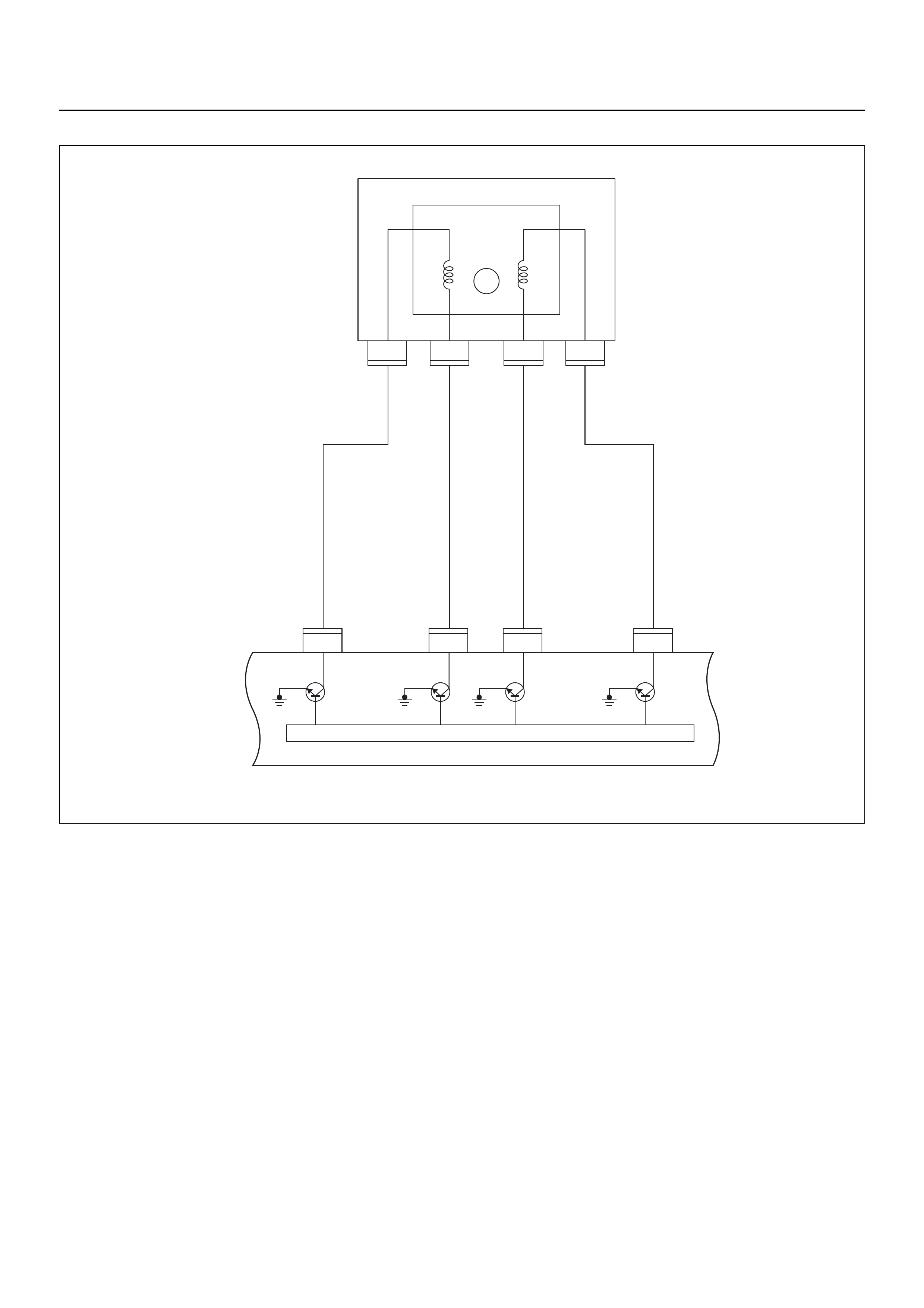

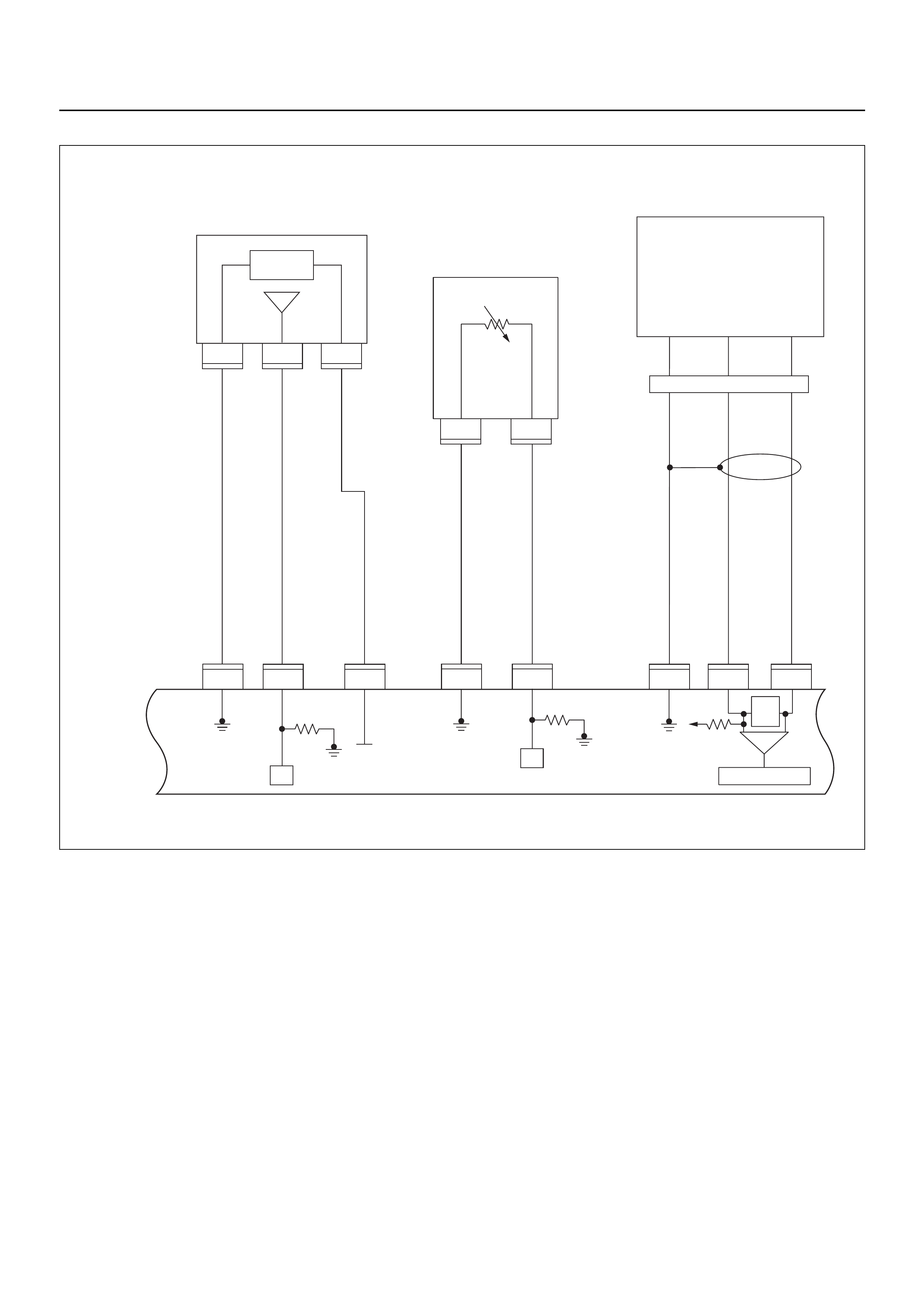

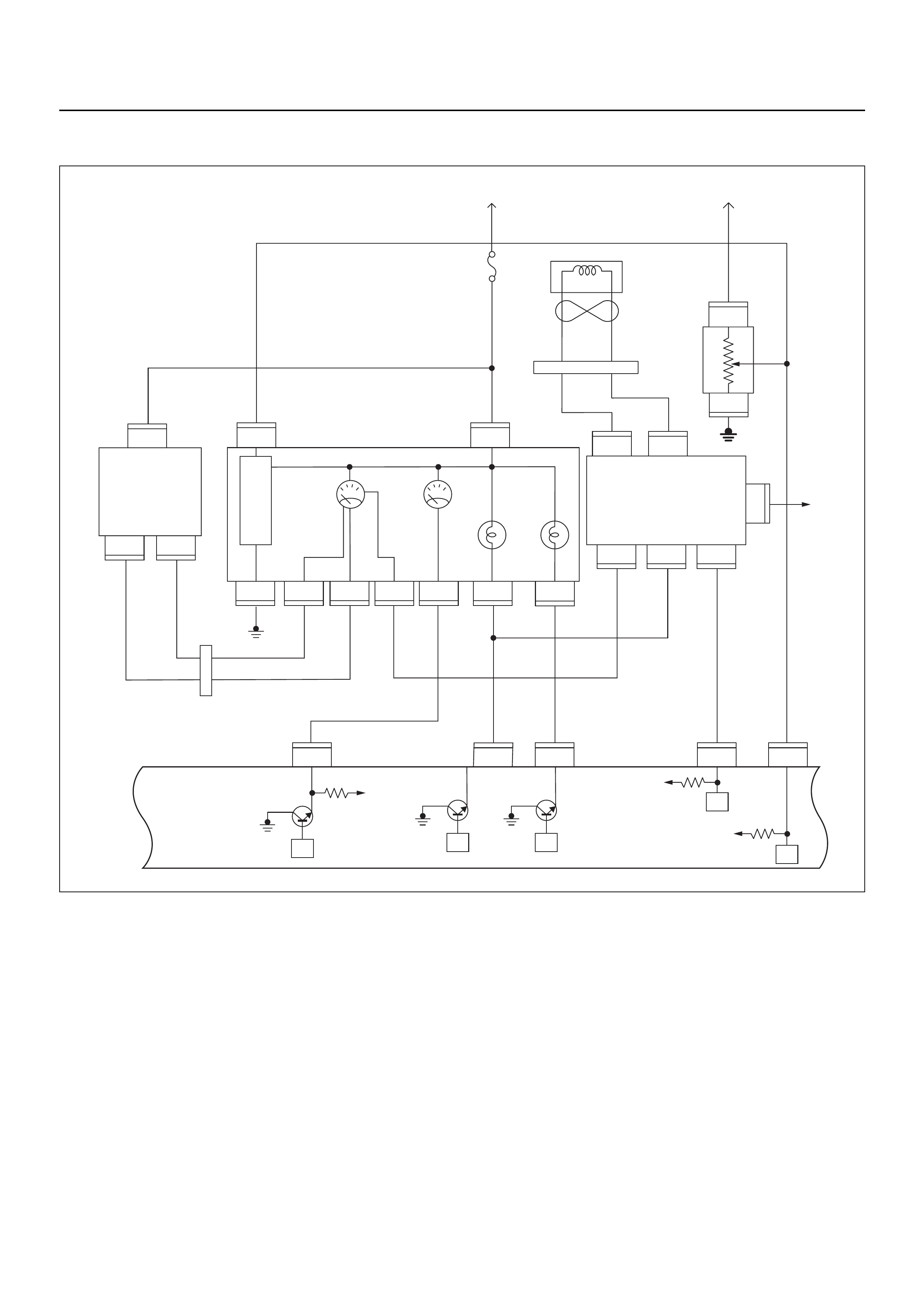

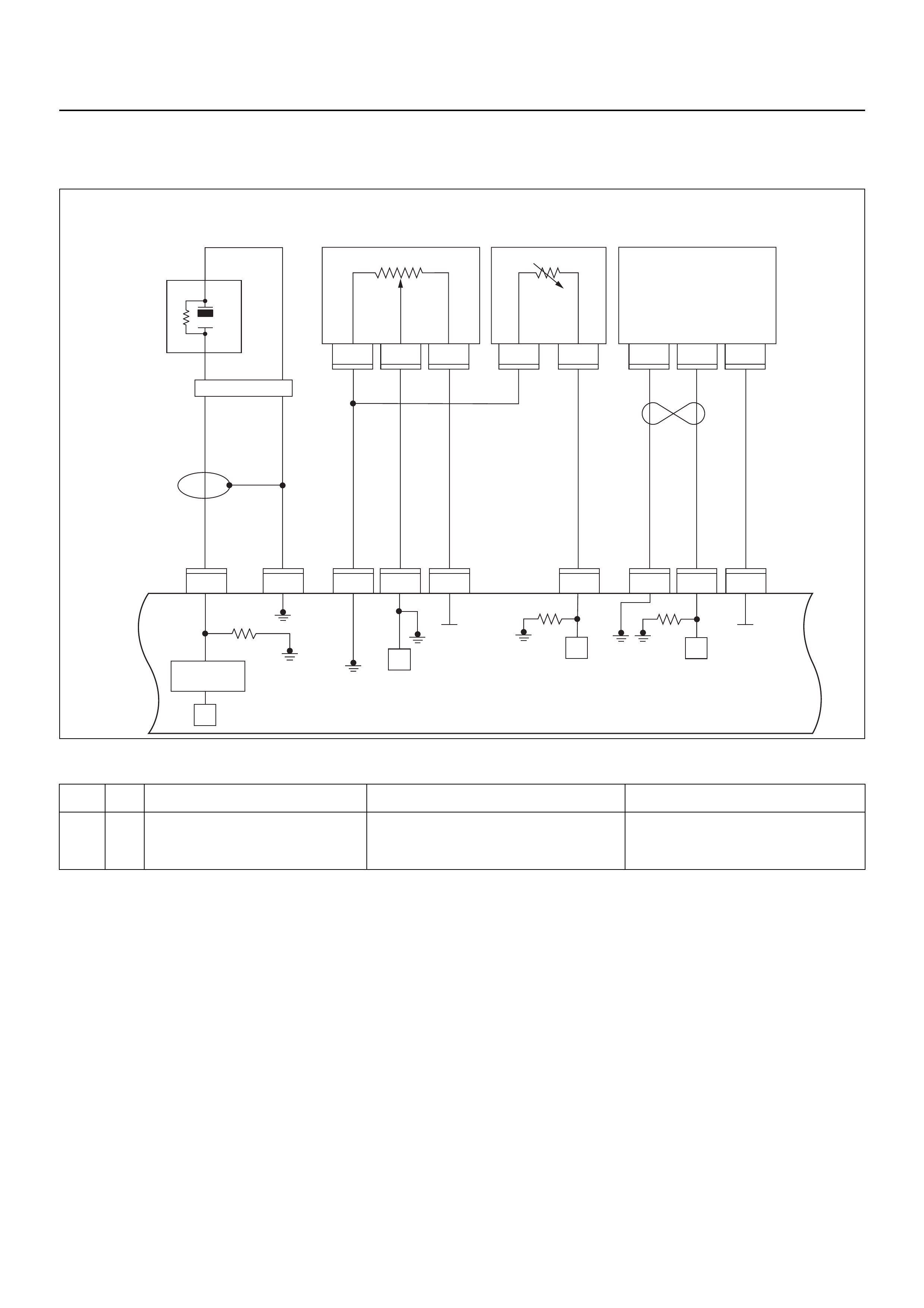

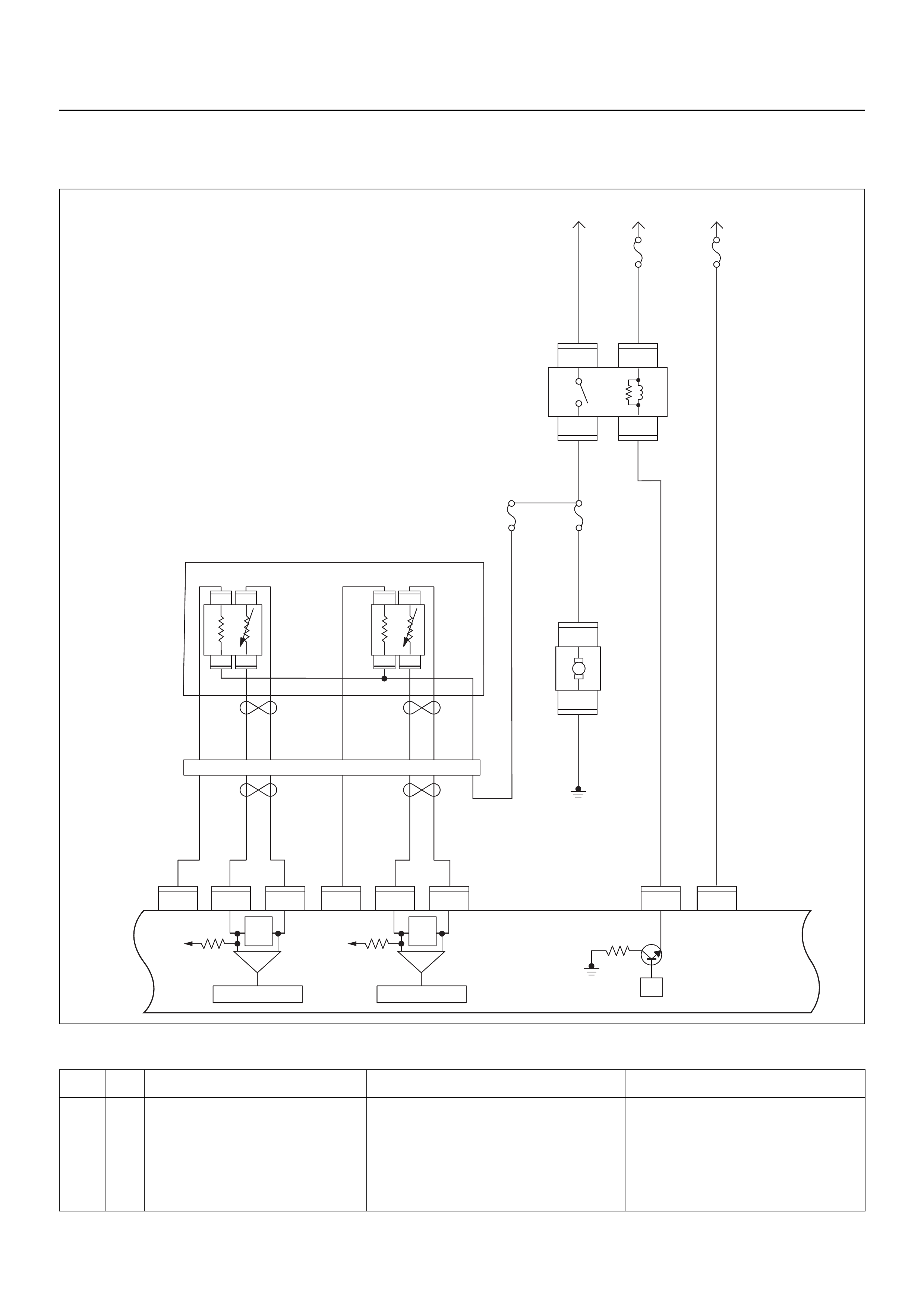

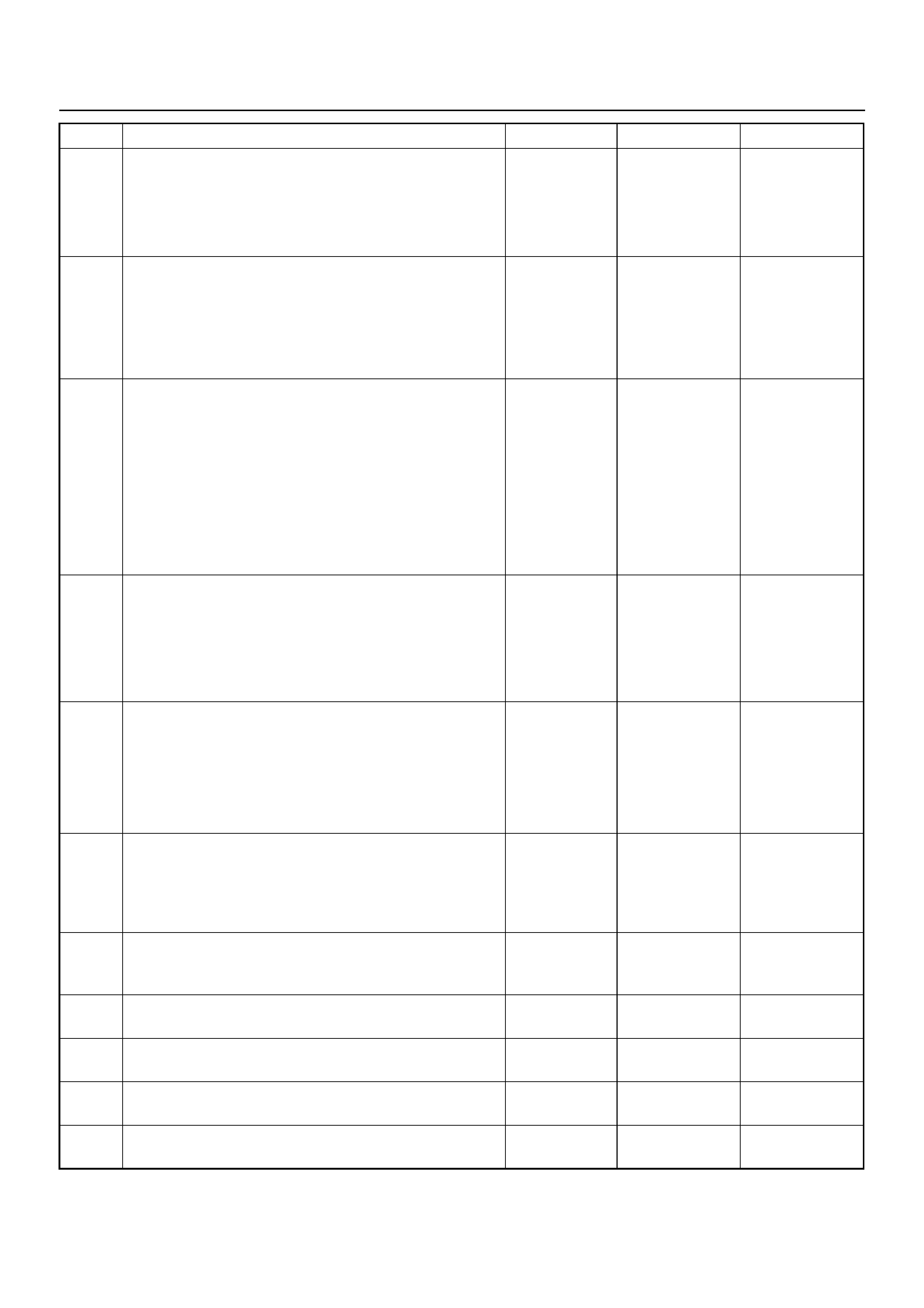

ECM WIRING DIAGRAM (1/8)

ECM WIRING DIAGRAM (2/8)

ECM WIRING DIAGRAM (3/8)

ECM WIRING DIAGRAM (4/8)

ECM WIRING DIAGRAM (5/8)

ECM WIRING DIAGRAM (6/8)

ECM WIRING DIAGRAM (7/8)

ECM WIRING DIAGRAM (8/8)

ECM CONNECTOR PIN ASSIGNMENT &

OUTPUT SIGNAL

GENERAL DESCRIPTION FOR ECM AND

SENSORS

Engine Control Module (ECM)

Manifold Absolute Pressure (MAP) Sensor

Throttle Position Sensor (TPS)

Idle Air Control (IAC) Valve

Crankshaft Position (CKP) Sensor

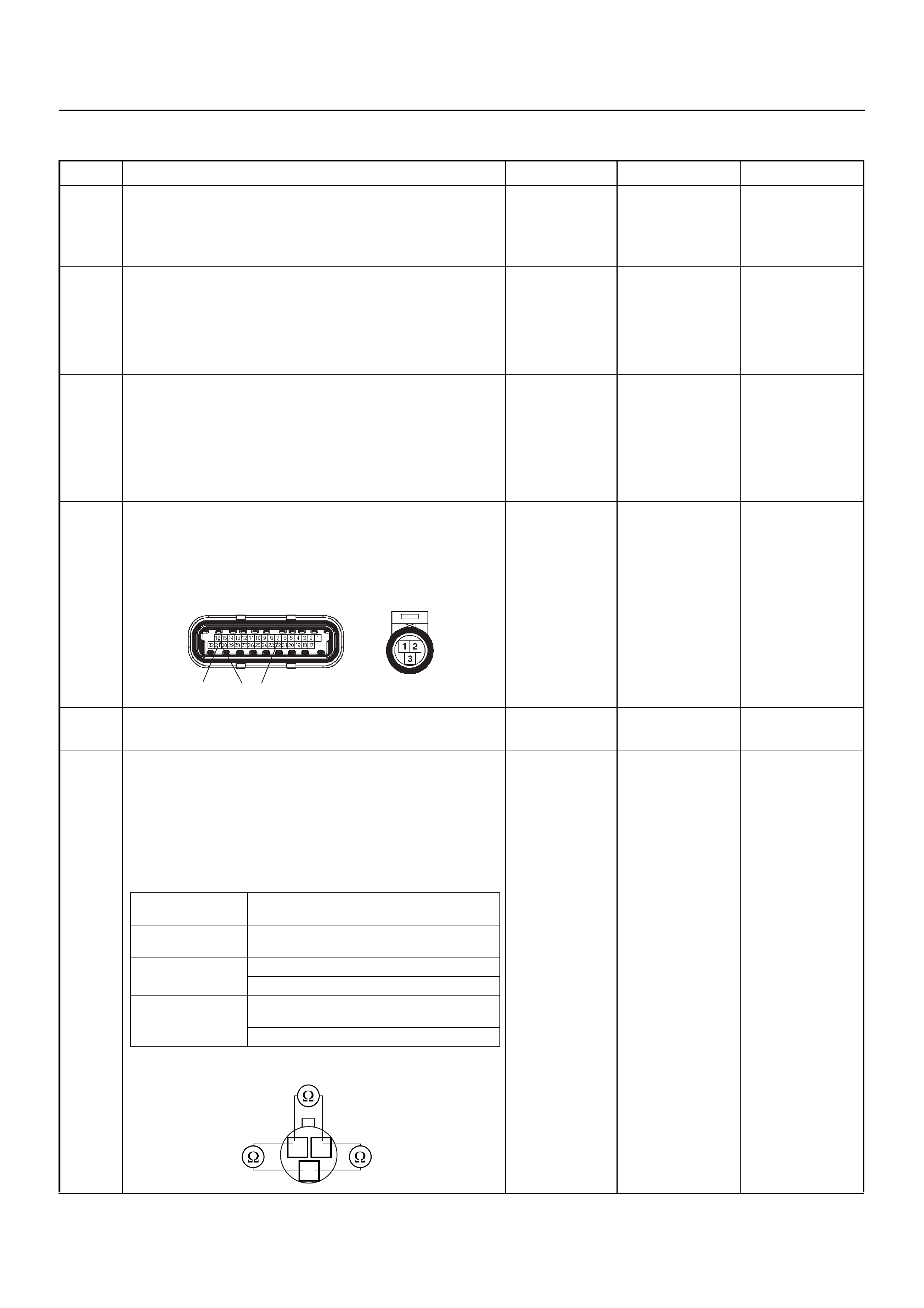

Knock (KS) Sensor

Engine Coolant Temperature (ECT) Sensor

Intake Air Temperature (IAT) Sensor

Vehicle Speed Sensor (VSS)

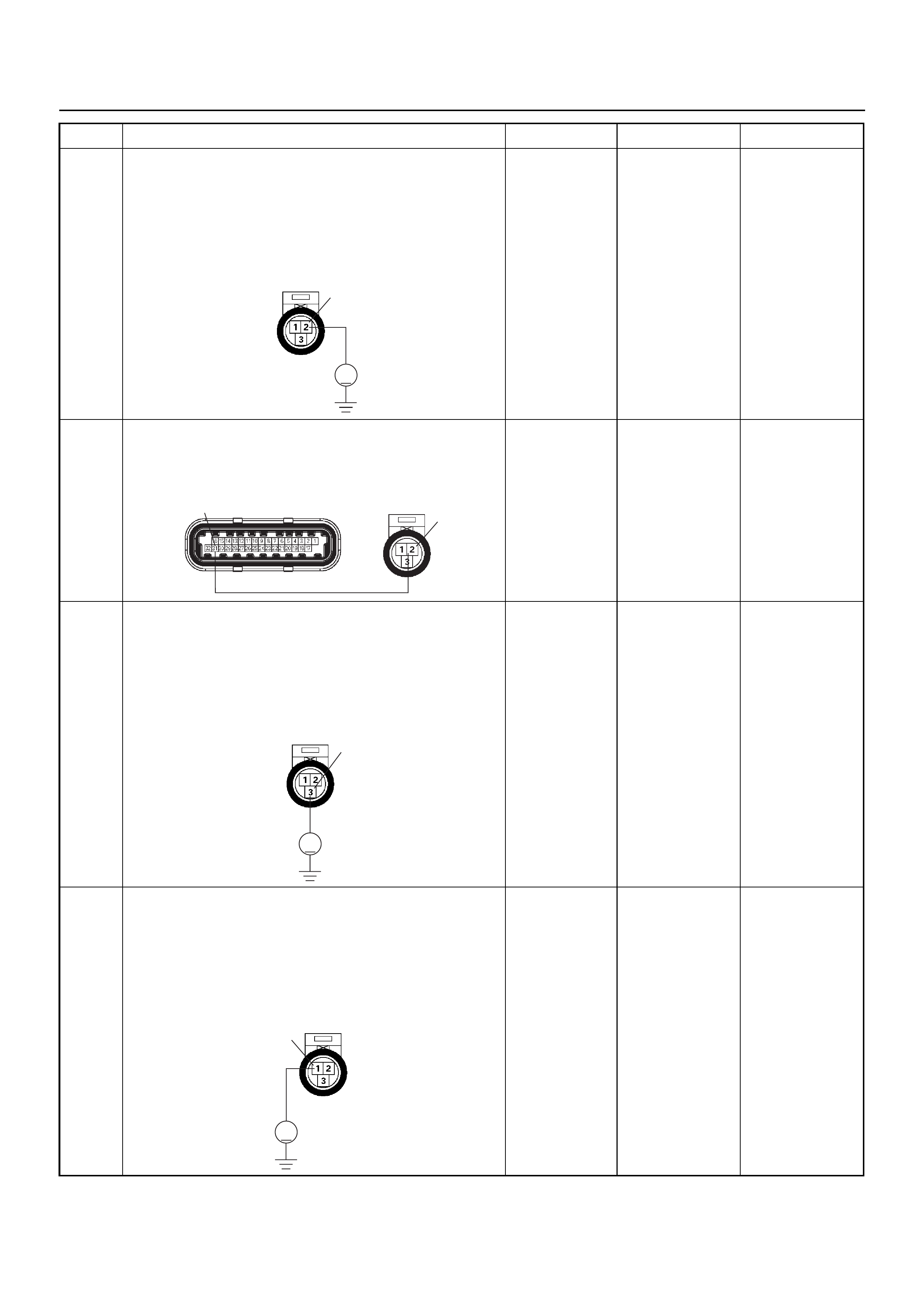

Heated Oxygen (O2) Pre Sensor

Heated Oxygen (O2) Post Sensor

Vertical G (RRID) Sensor

GENERAL DESCRIPTION FOR FUEL

METERING

Battery Voltage Correction Mode

Clear Flood Mode

Deceleration Fuel Cutoff (DFCO) Mode

Engine Speed/ Vehicle Speed/ Fuel Disable

Mode

Acceleration Mode

Fuel Cutoff Mode

Starting Mode

Run Mode

Fuel Metering System Components

Fuel Injector

Fuel Pressure Regulator

Fuel Rail

Fuel Pump Electrical Circuit

Throttle Body Unit

GENERAL DESCRIPTION FOR ELECTRIC

IGNITION SYSTEM

Spark Plug

GENERAL DESCRIPTION FOR EVAPORATIVE

EMISSION SYSTEM

EVAP Emission Control System Purpose

EVAP Emission Control System Operation

System Fault Detection

POSITIVE CRANKCASE VENTILATION (PCV)

SYSTEM

Crankcase Ventilation System Purpose

A/C CLUTCH DIAGNOSIS

A/C Clutch Circuit Operation

A/C Clutch Circuit Purpose

A/C Request Signal

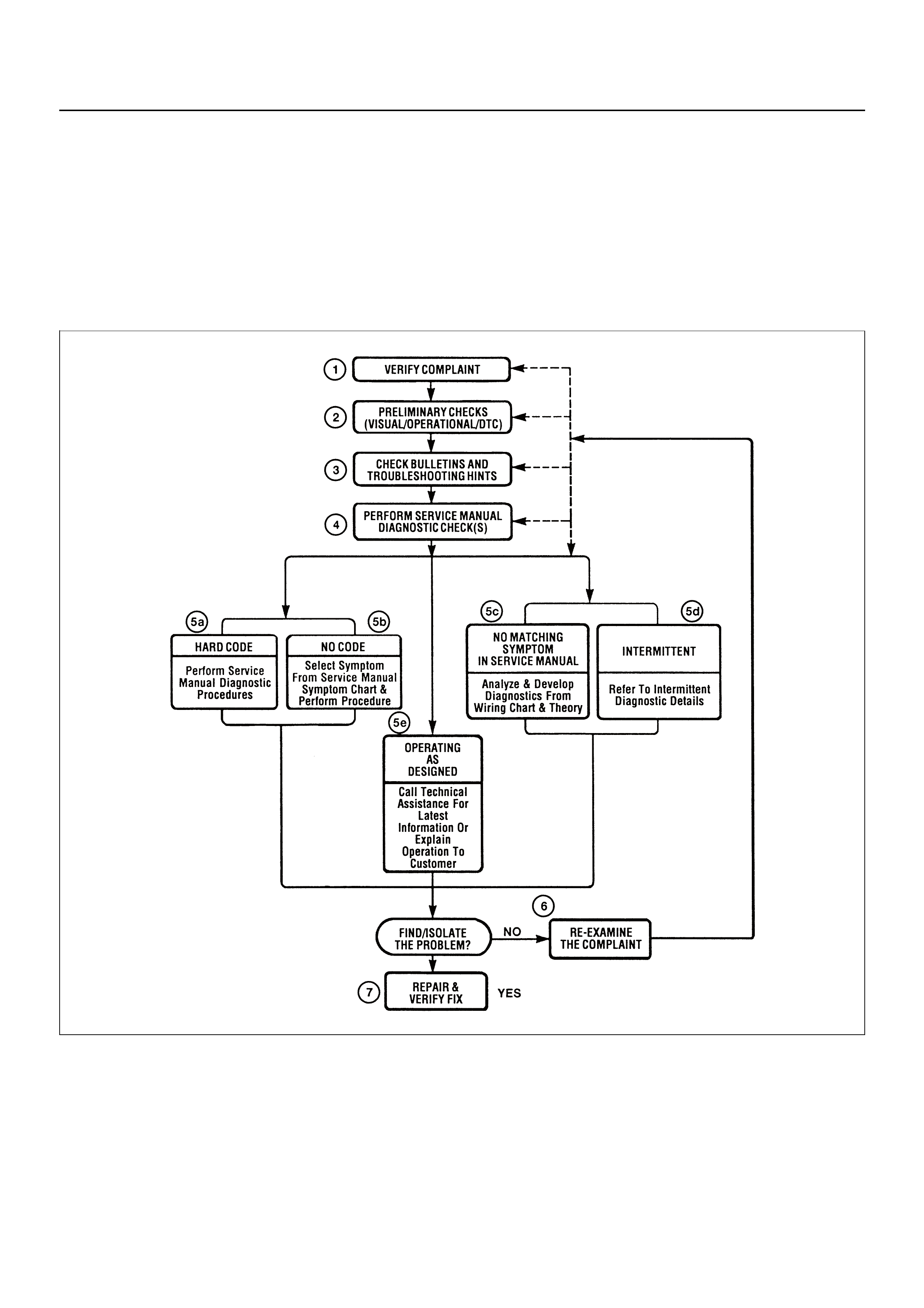

HOLDEN STRATEGY BASED DIAGNOSTICS

Overview

STRATEGY BASED DIAGNOSTICS CHART

Diagnostic Thought Process

1. Verify the Complaint

2. Perform Preliminary Checks

3. Check Bulletins and Troubleshooting

Hints

4. Perform Service Manual Diagnostic

Checks

5a and 5b. Perform Service Manual Diagnostic

Procedures

5c. Technician Self Diagnoses

5d. Intermittent Diagnosis

5e. Vehicle Operates as Designed

6. Re-examine the complaint

7. Repair and Verify Fix

GENERAL SERVICE INFORMATION

On-Board Diagnostic (OBD)

On-Board Diagnostic Tests

The Diagnostic Executive

Diagnostic Information

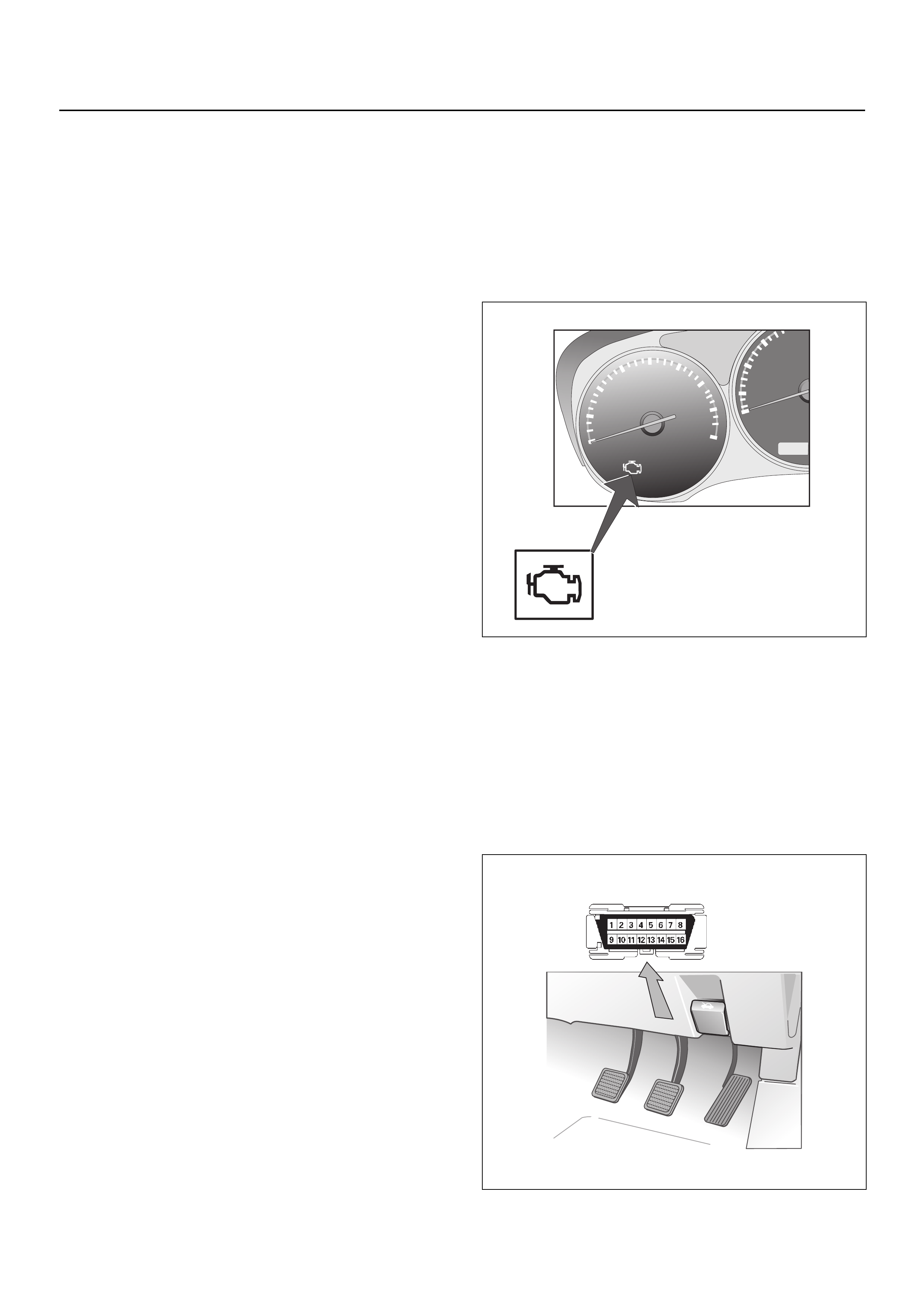

Malfunction Indicator (Check Engine) Lamp

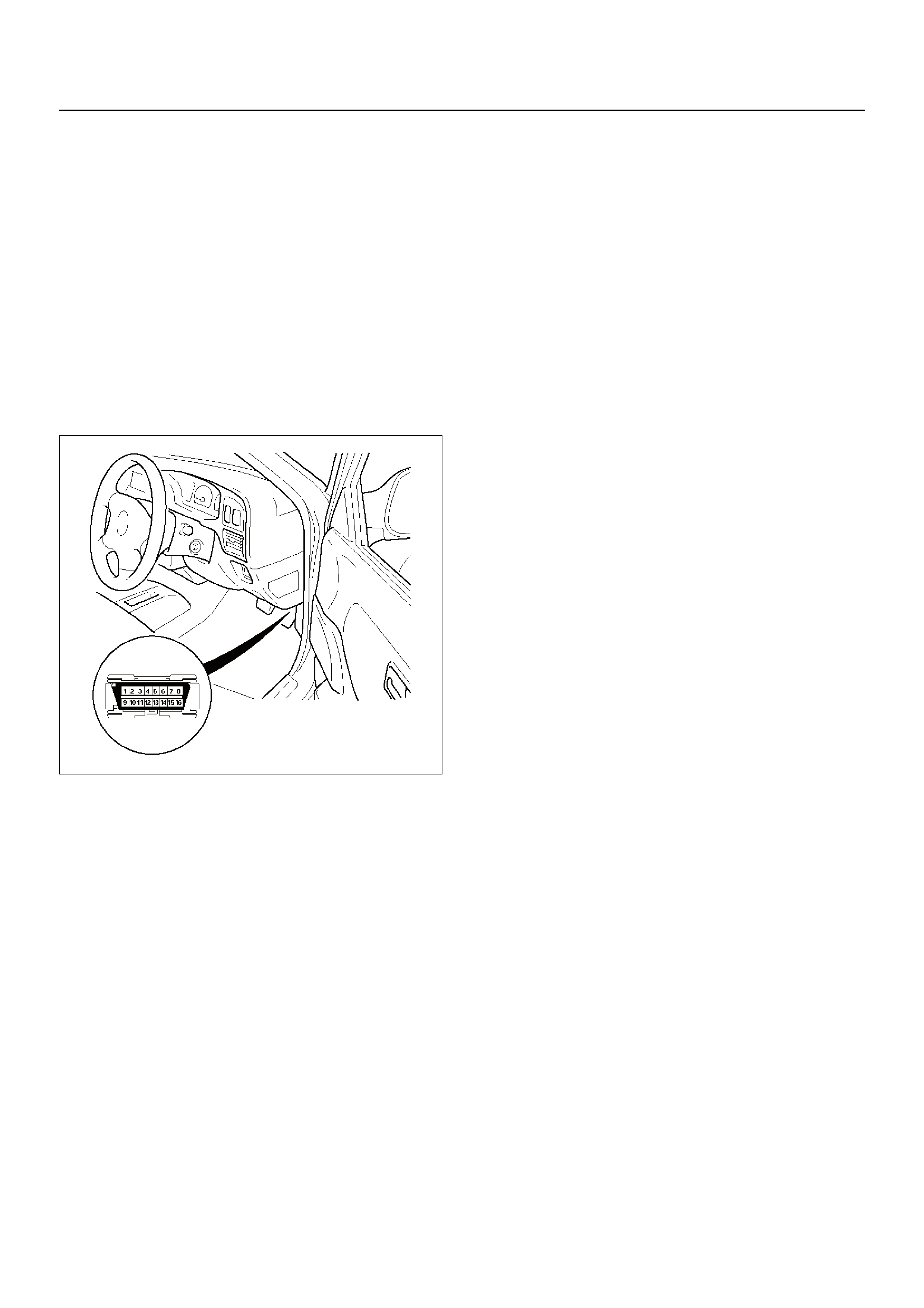

Data Link Connector (DLC)

SECTION 6E

Verifying Vehicle Repair

Reading Diagnostic Trouble Codes Using

Tech 2

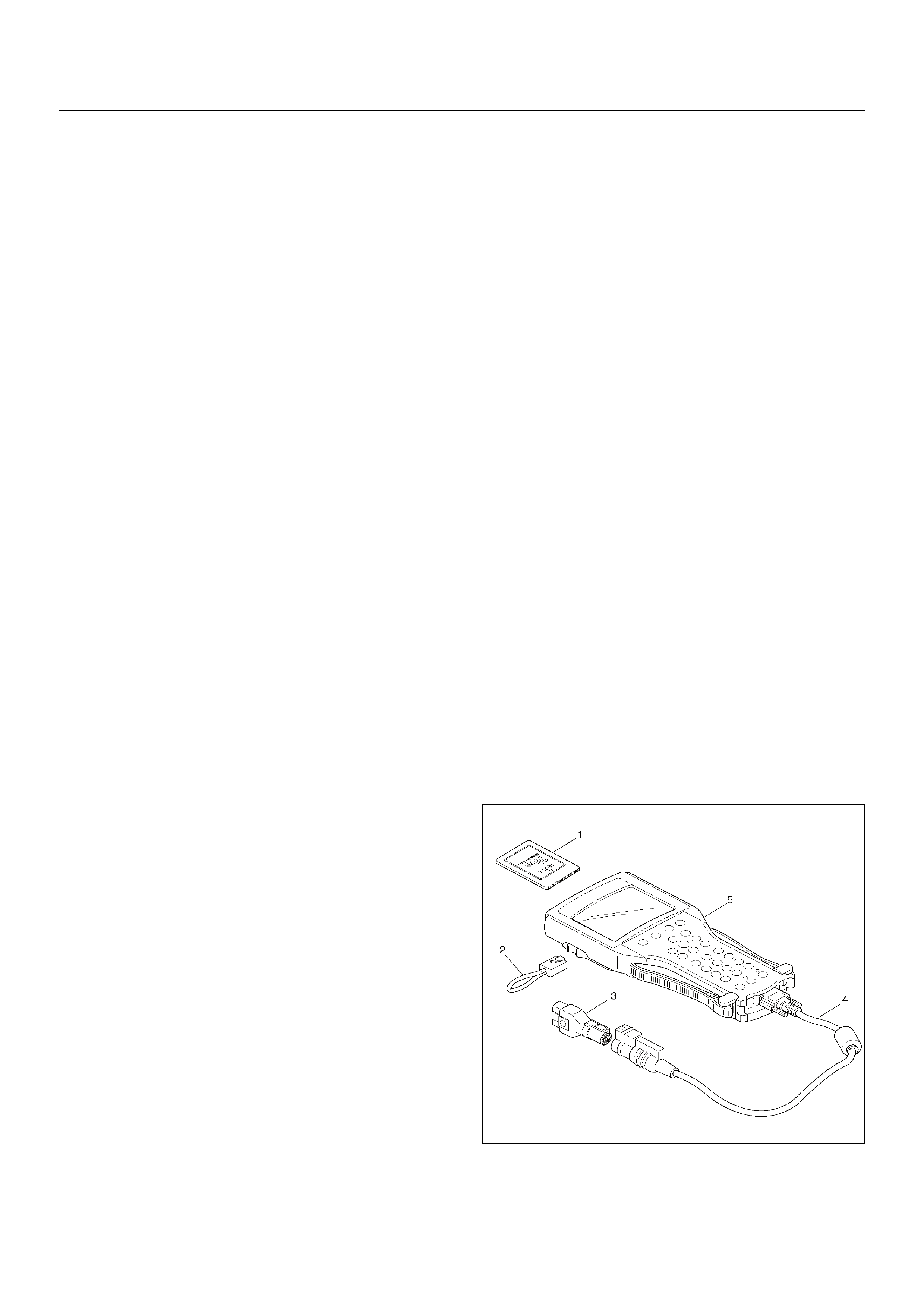

Diagnosis with Tech 2

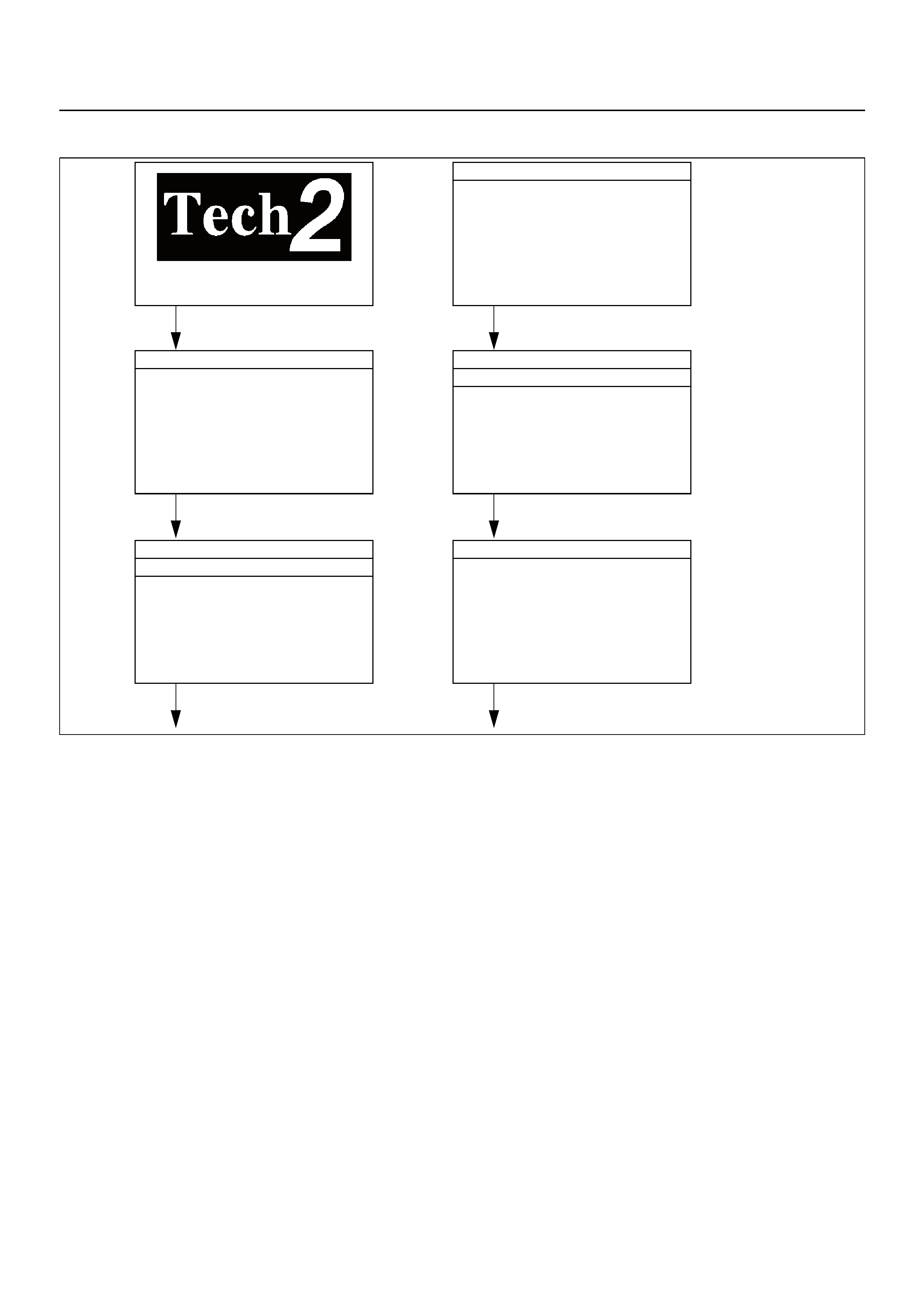

Tech 2 Operating Flow Chart (Start Up)

TYPICAL SCAN DATA & DEFINITIONS

(ENGINE DATA)

ACTUATOR TEST

ECU Control

Injector Cutoff Test

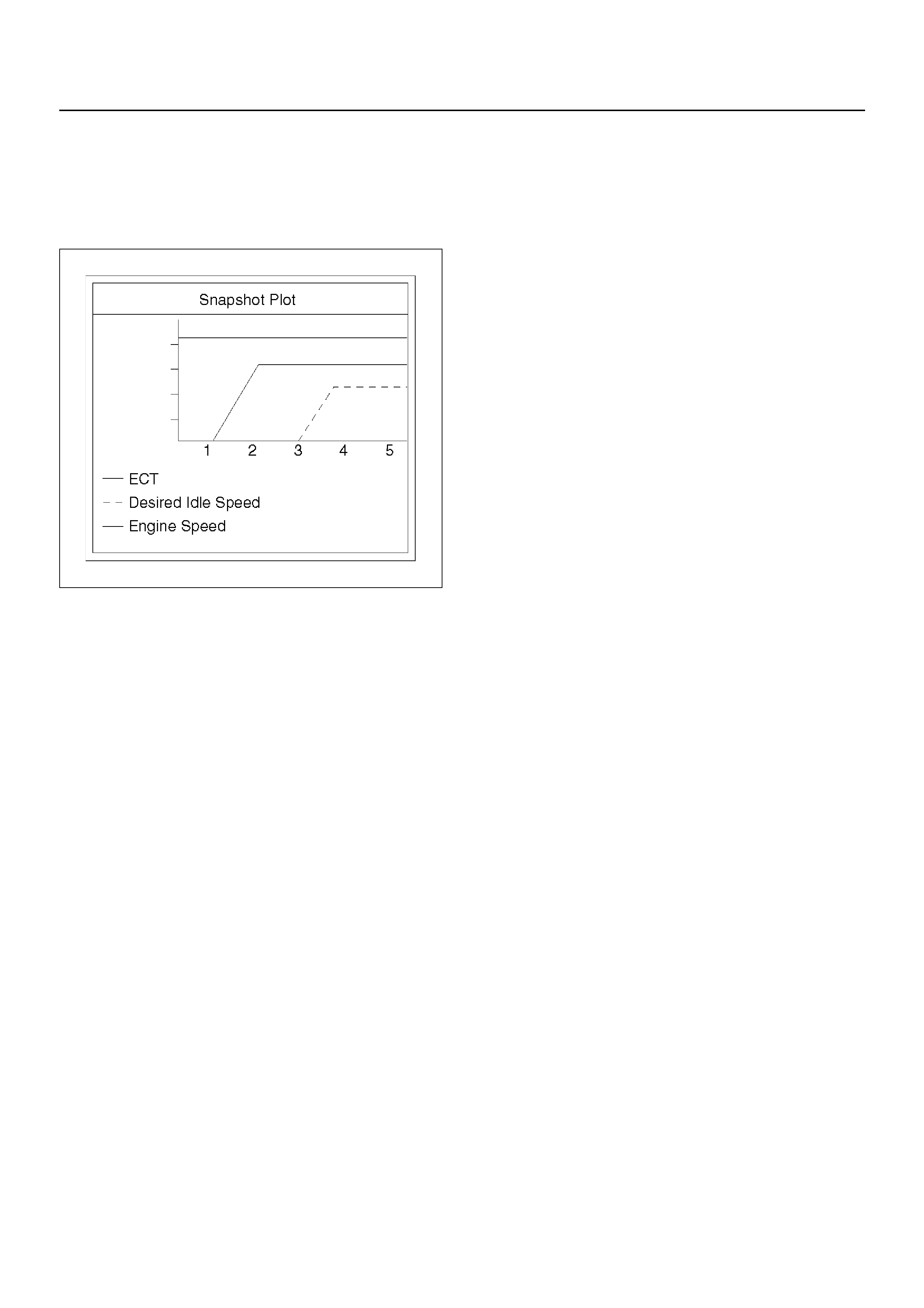

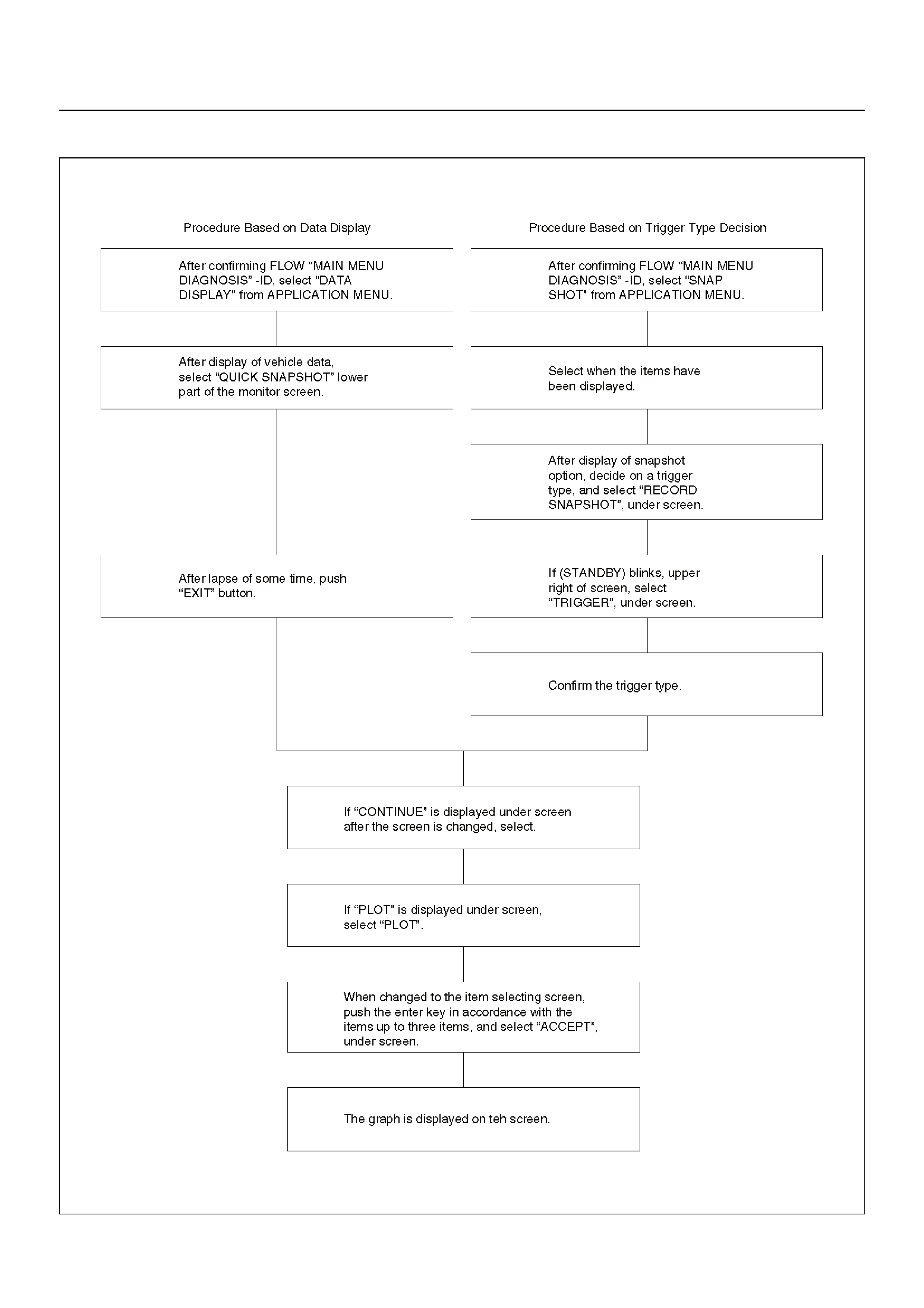

PLOTTING SNAPSHOT GRAPH

Plotting Graph Flow Chart (Plotting graph after

obtaining vehicle information)

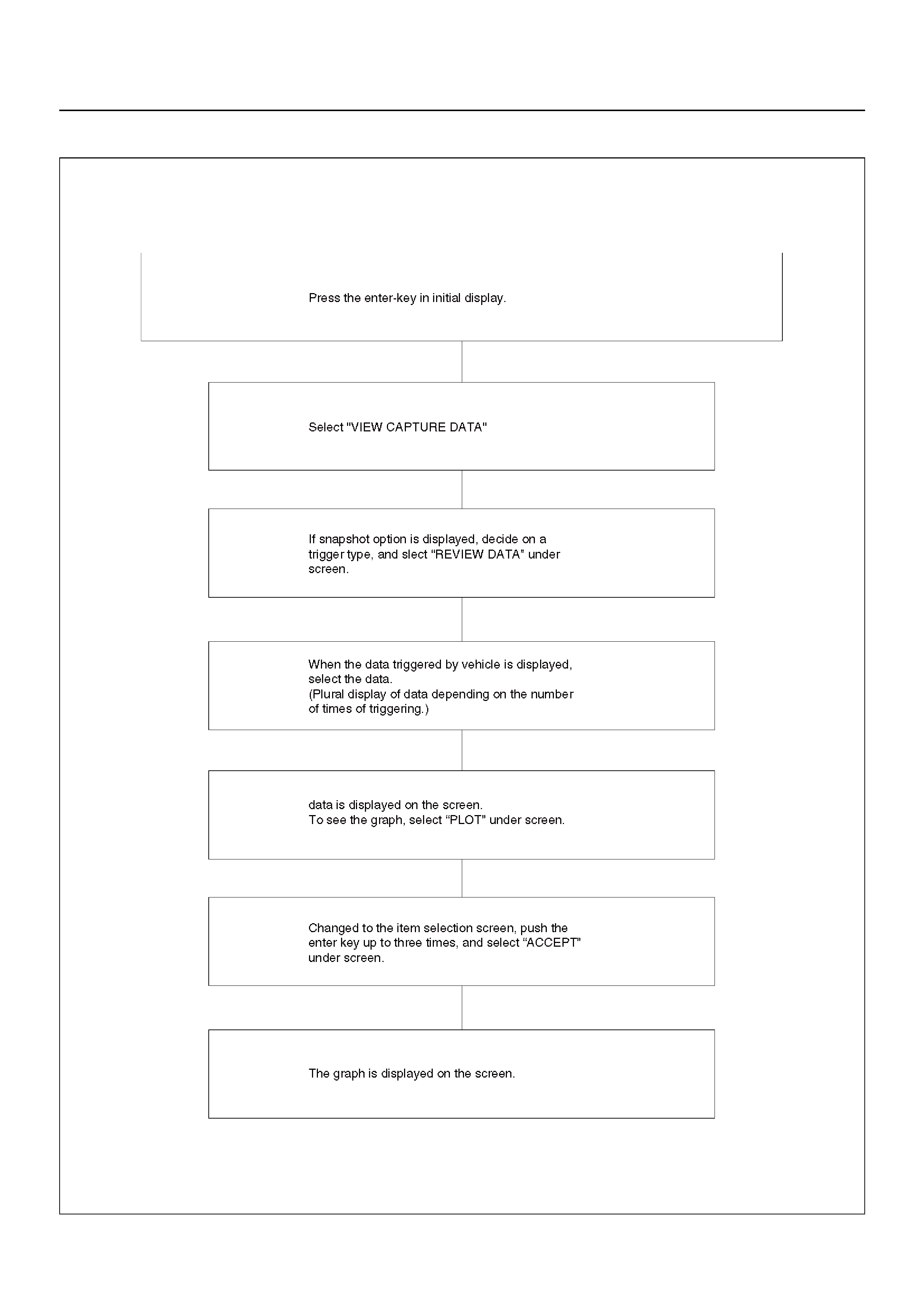

Flow Chart for Snapshot Replay

(Plotting Graph)

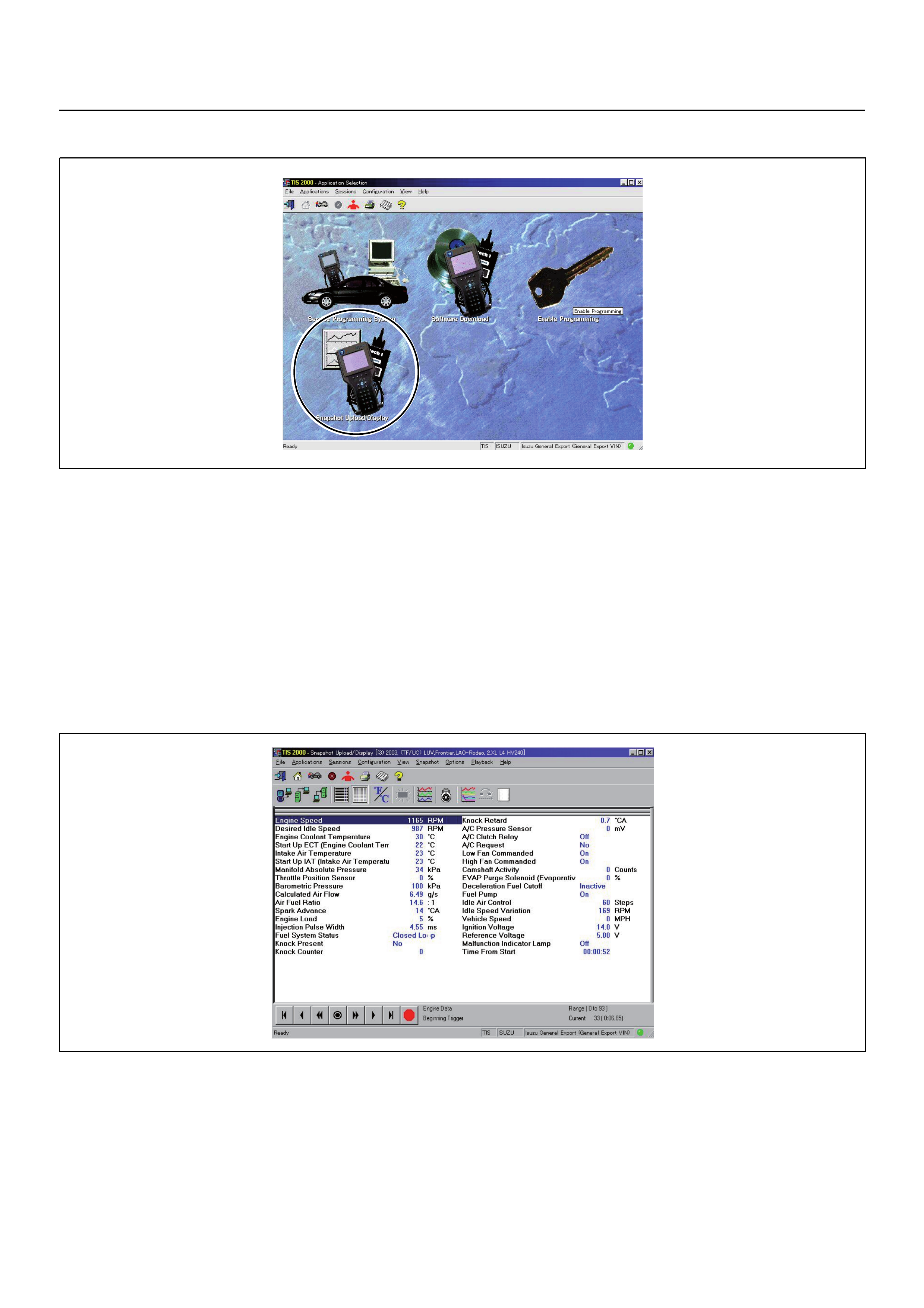

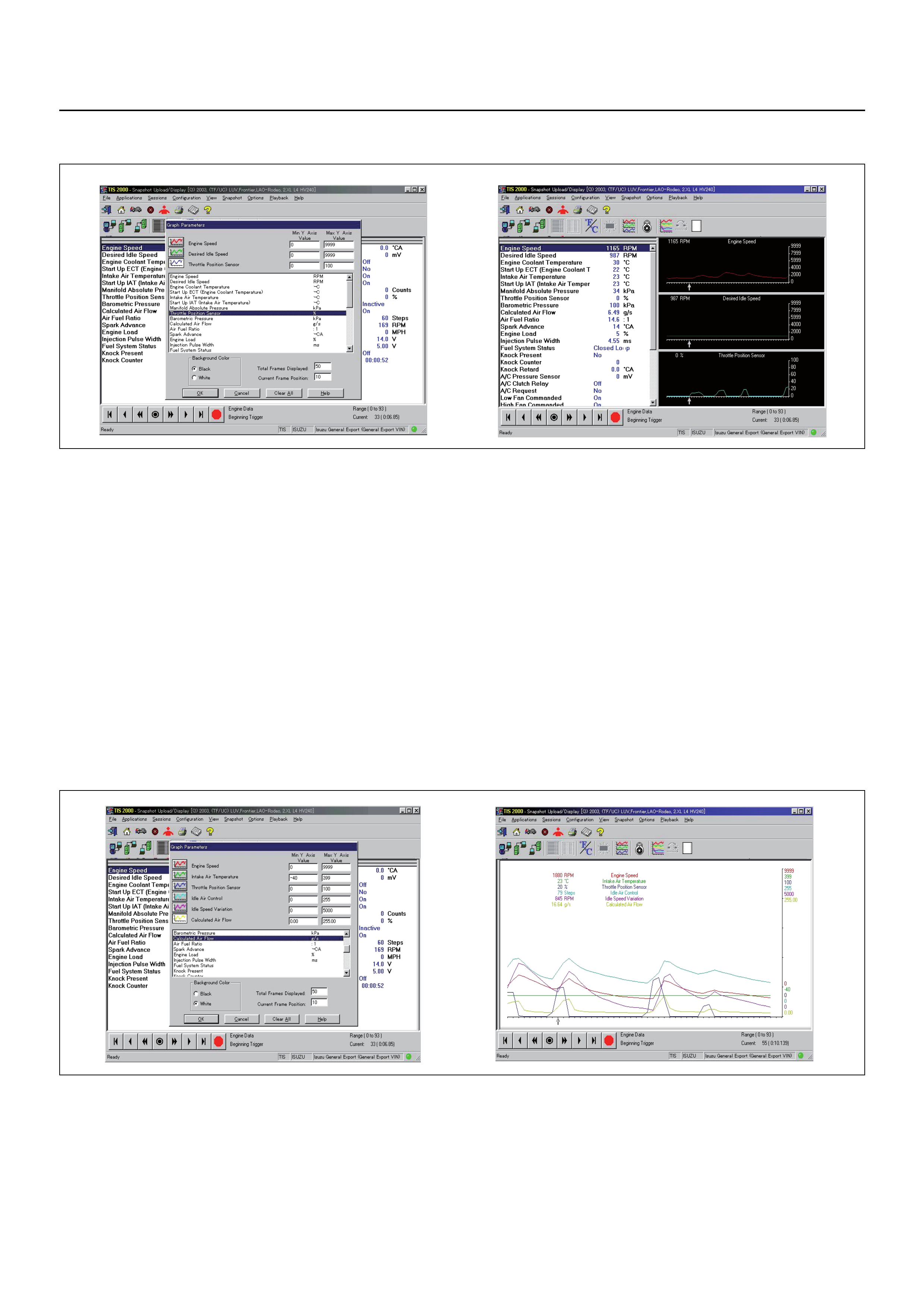

SNAPSHOT DISPLAY WITH TIS2000

SERVICE PROGRAMMING SYSTEM (SPS)

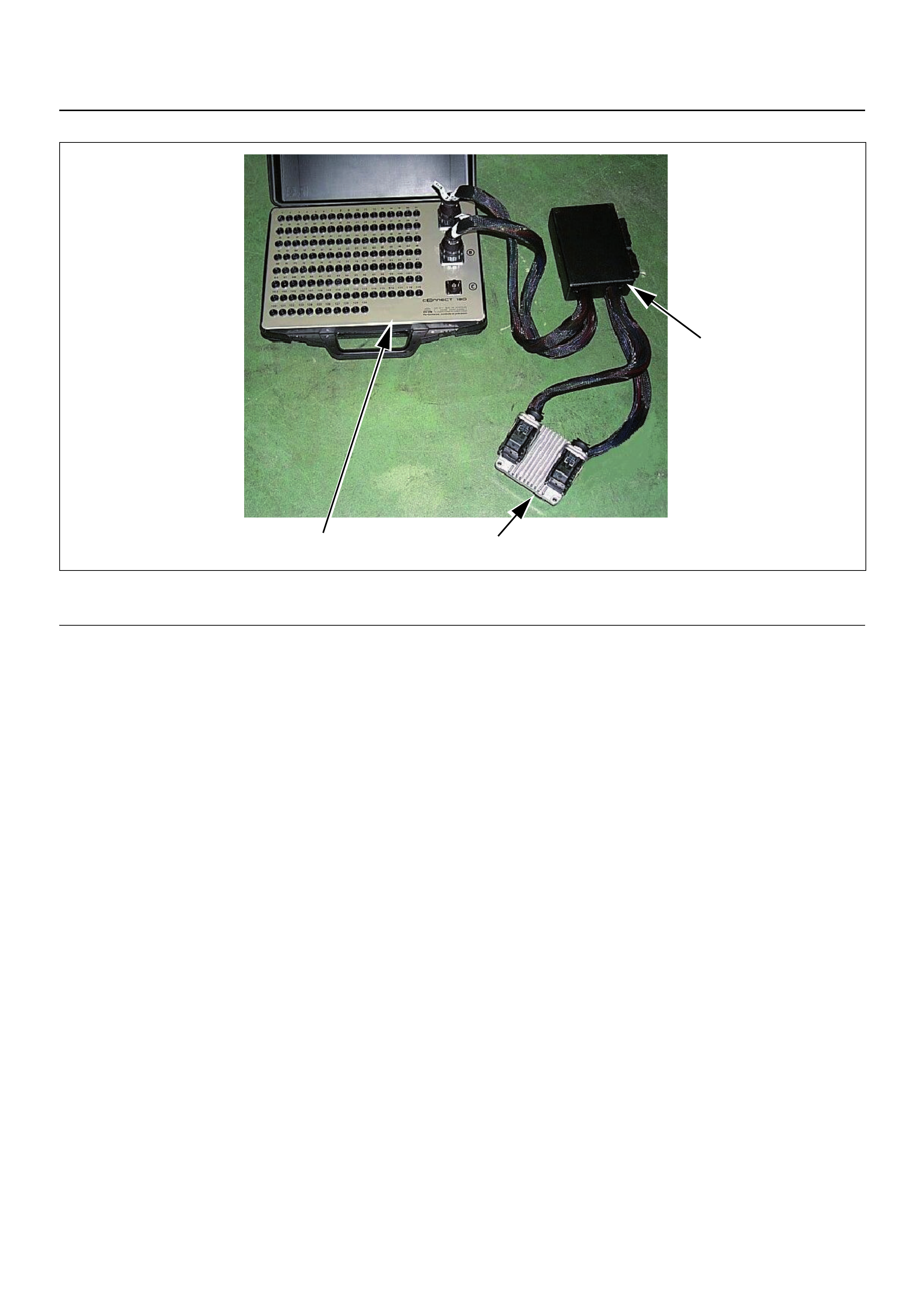

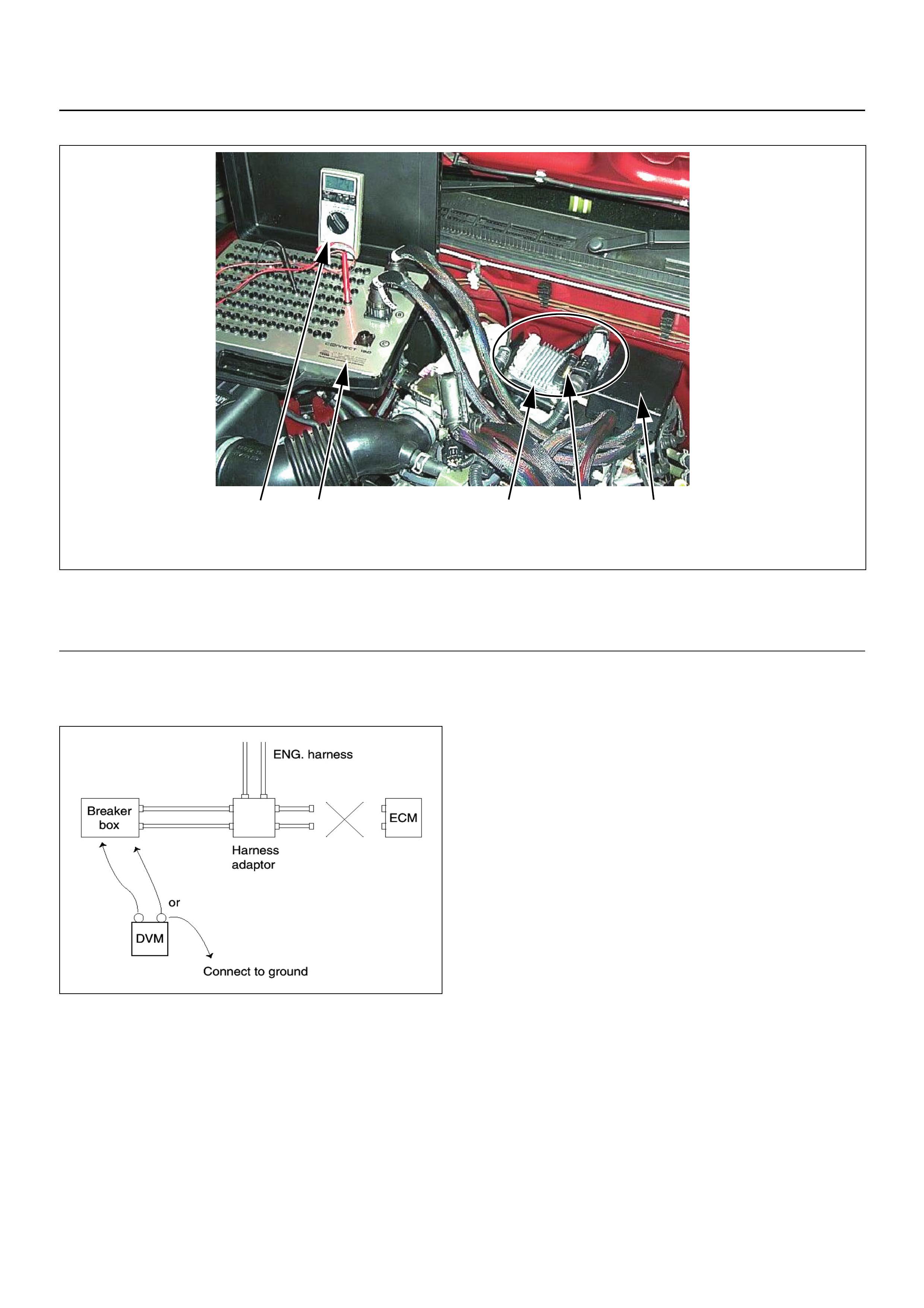

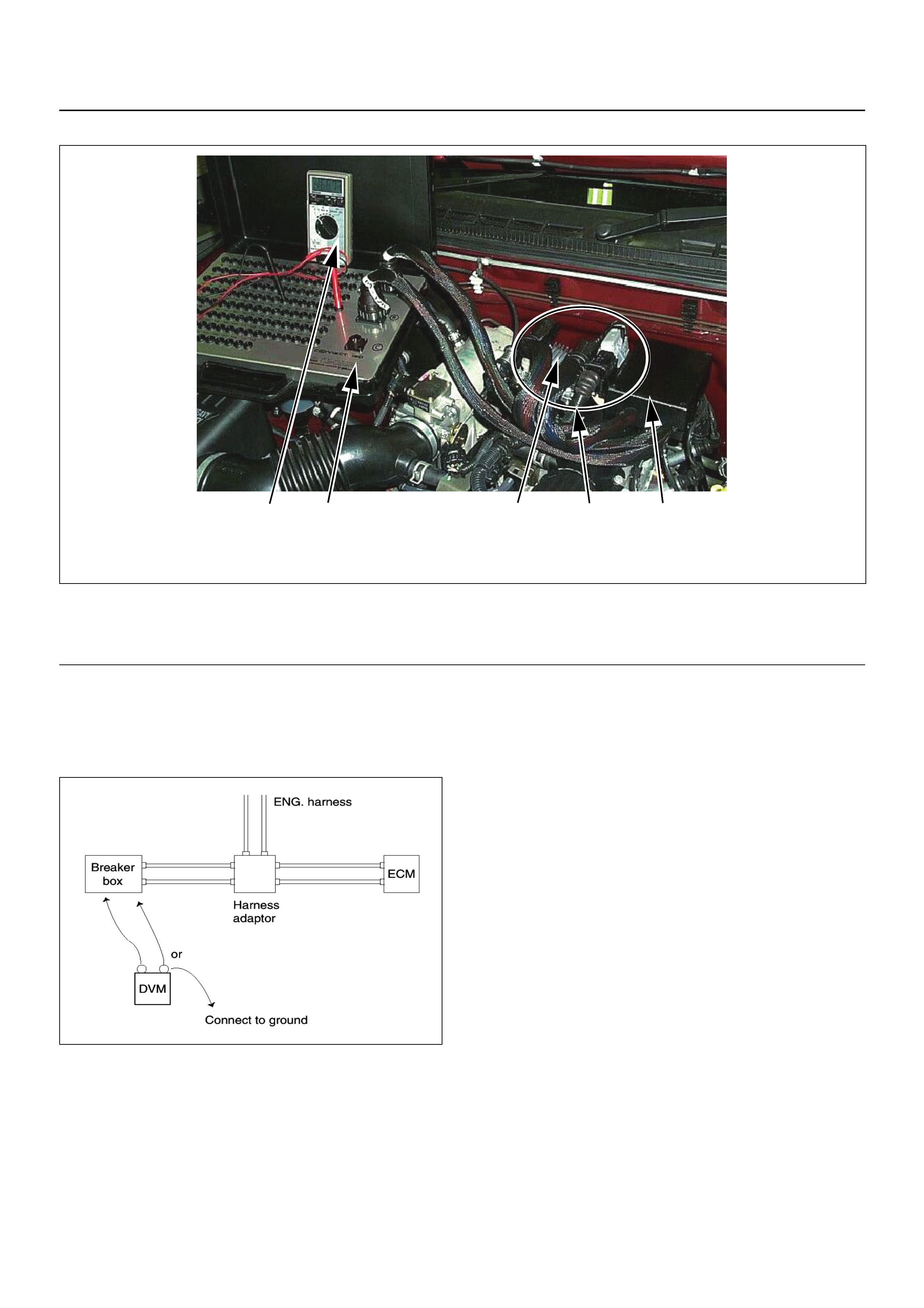

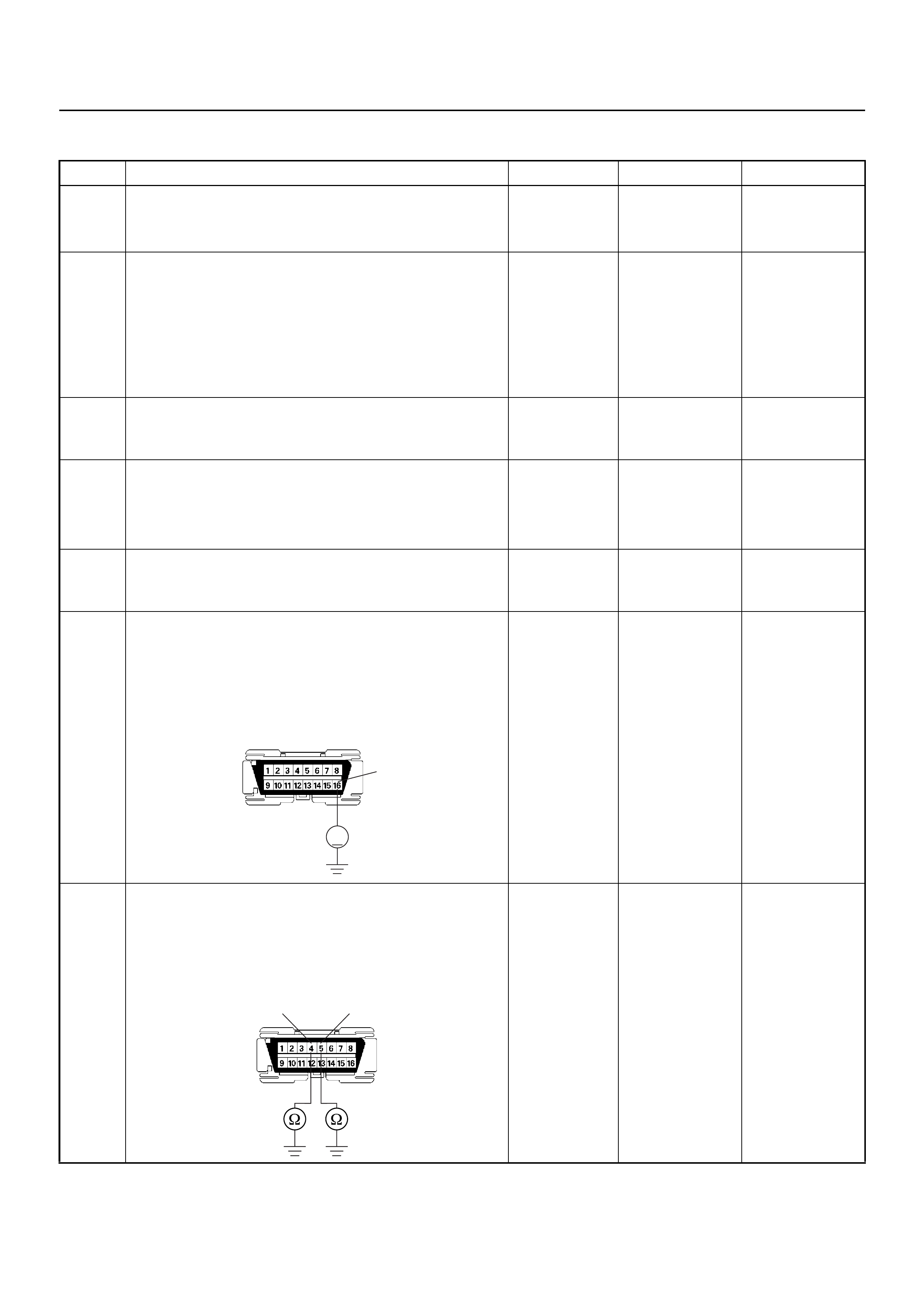

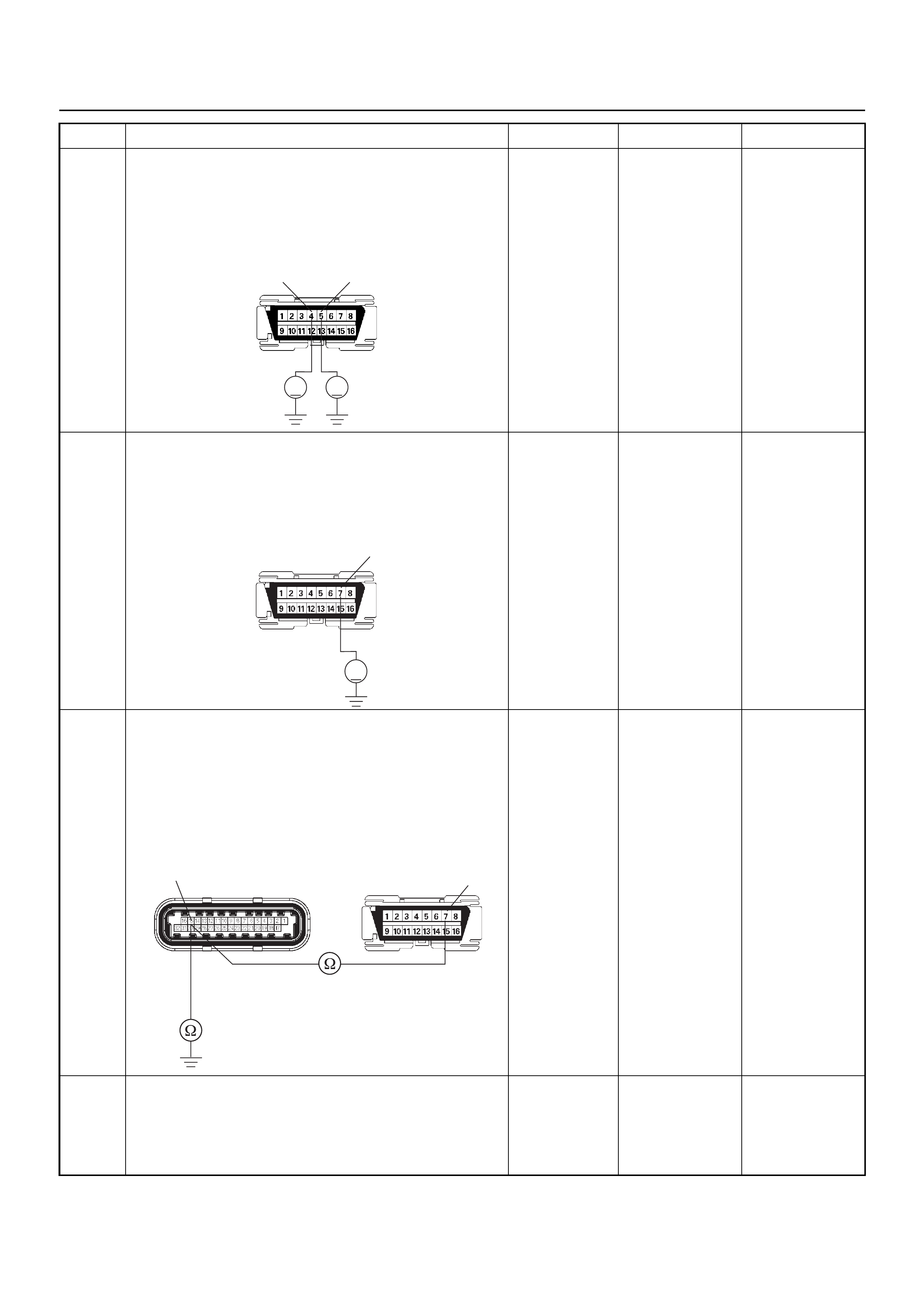

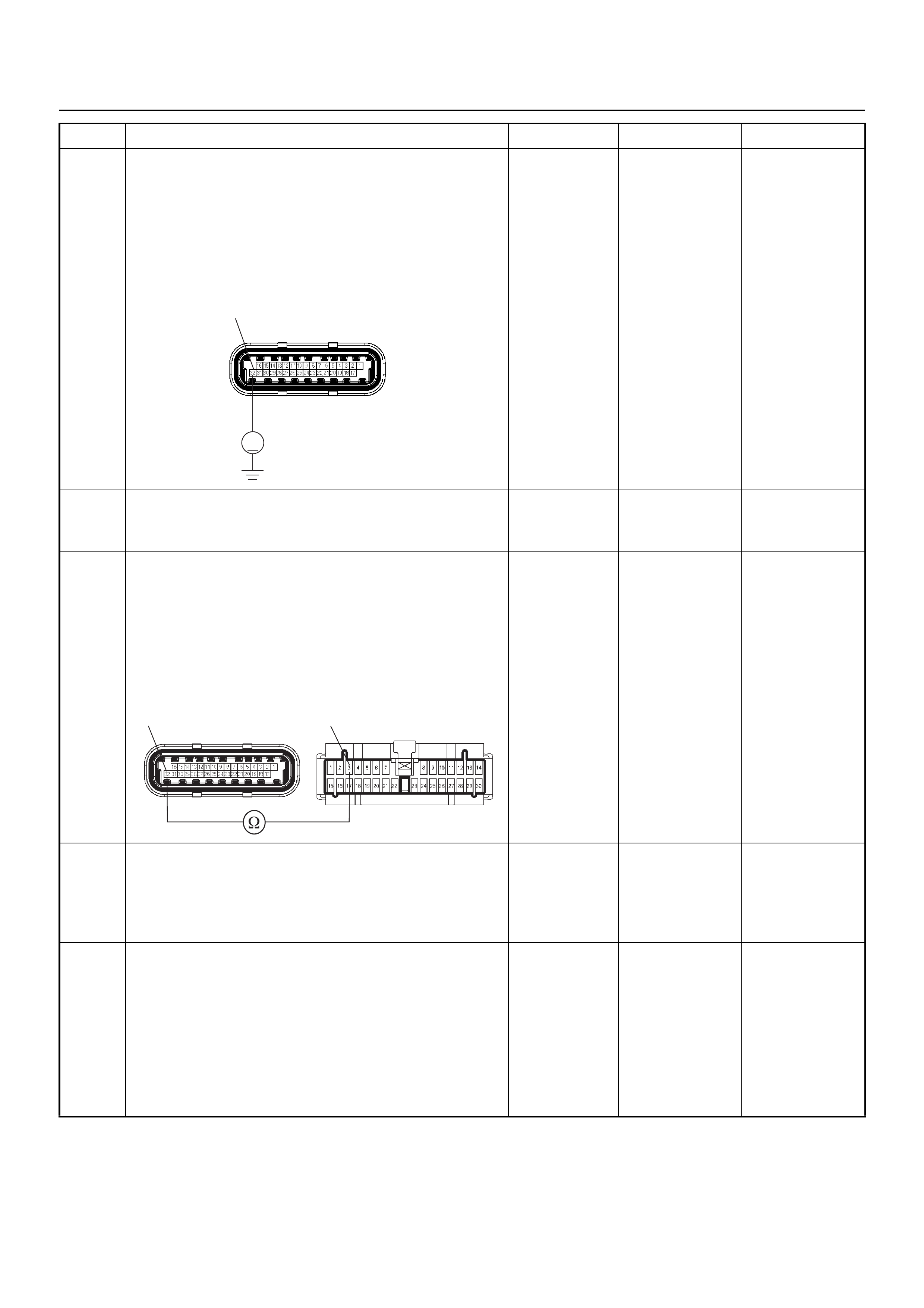

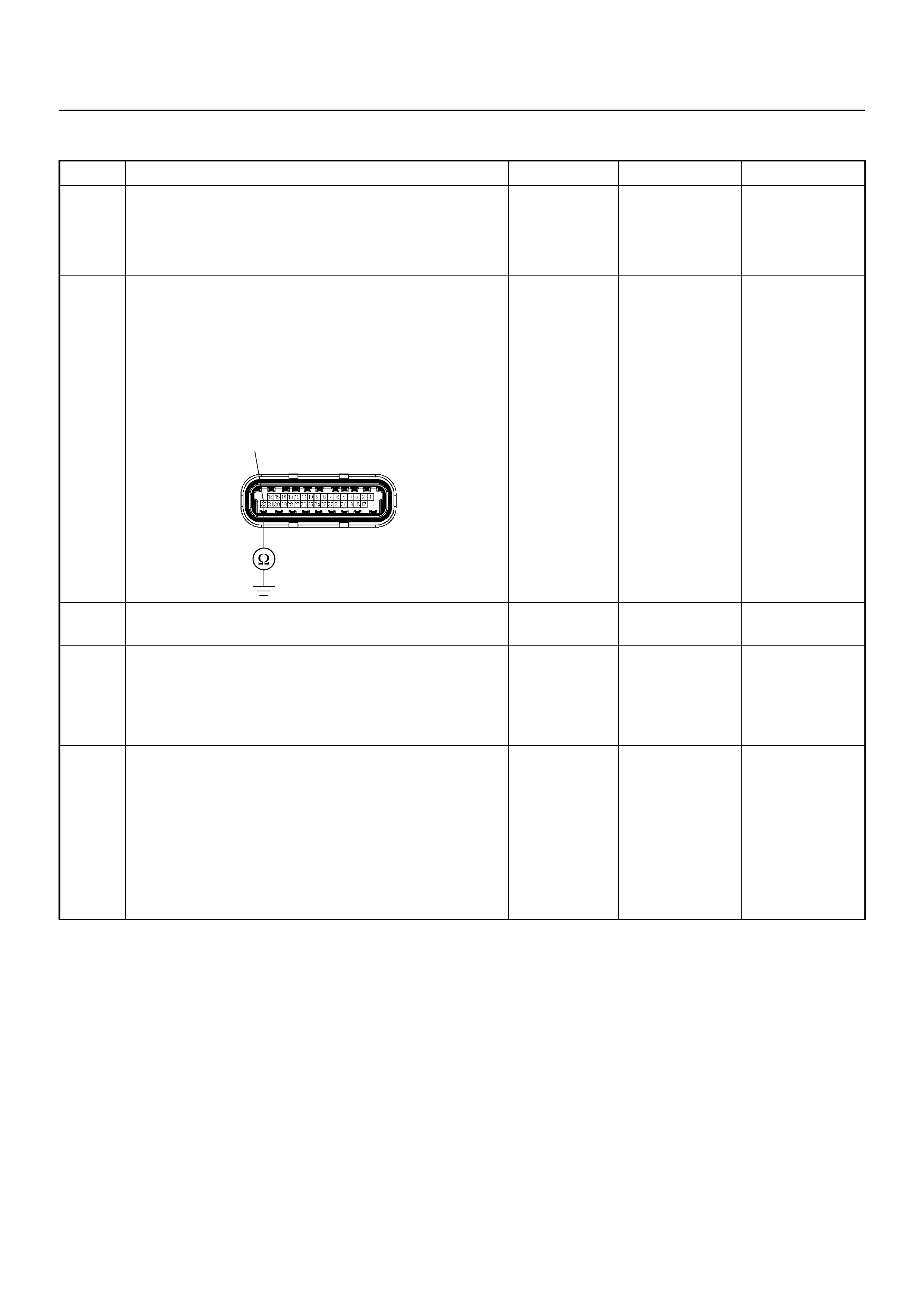

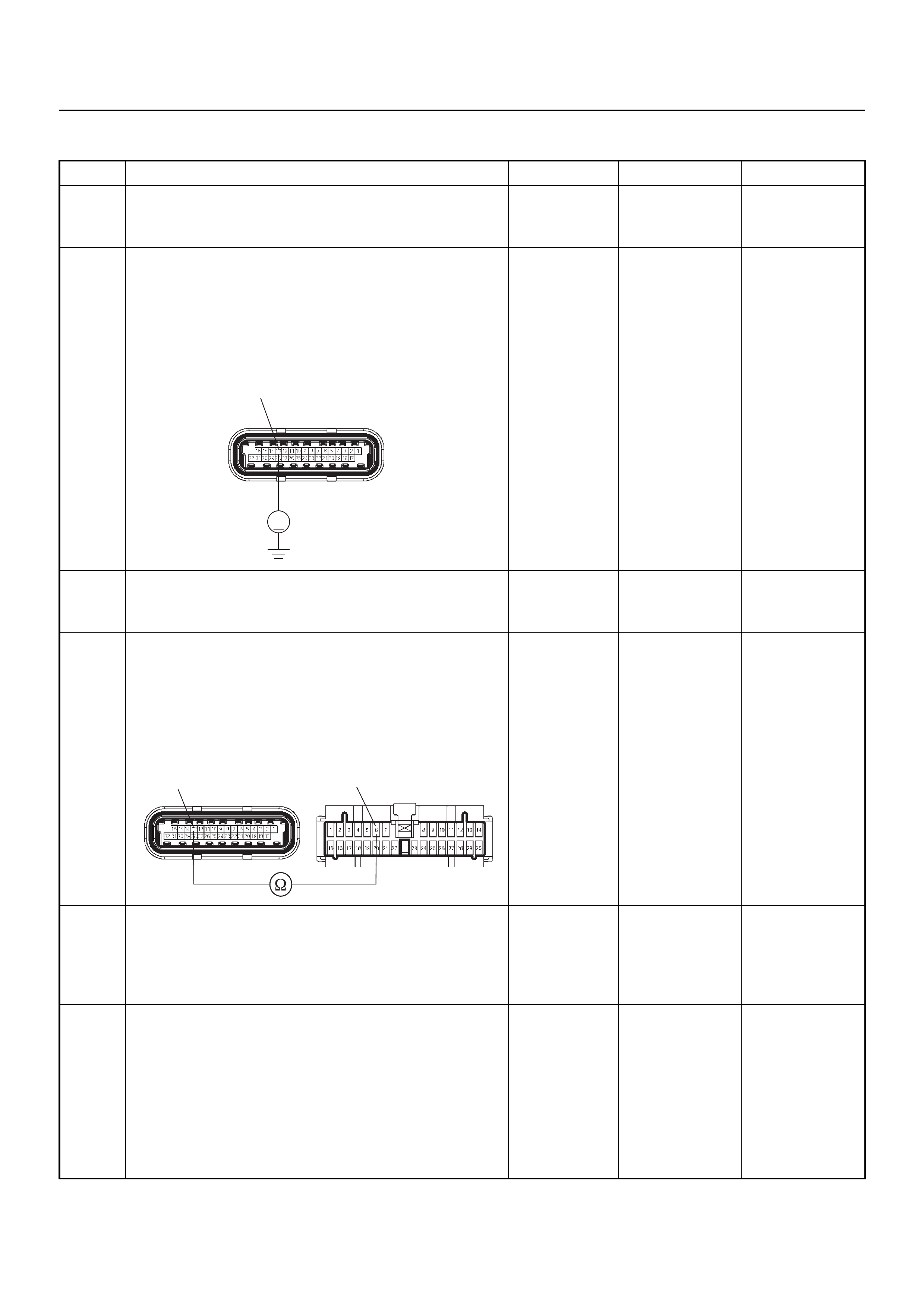

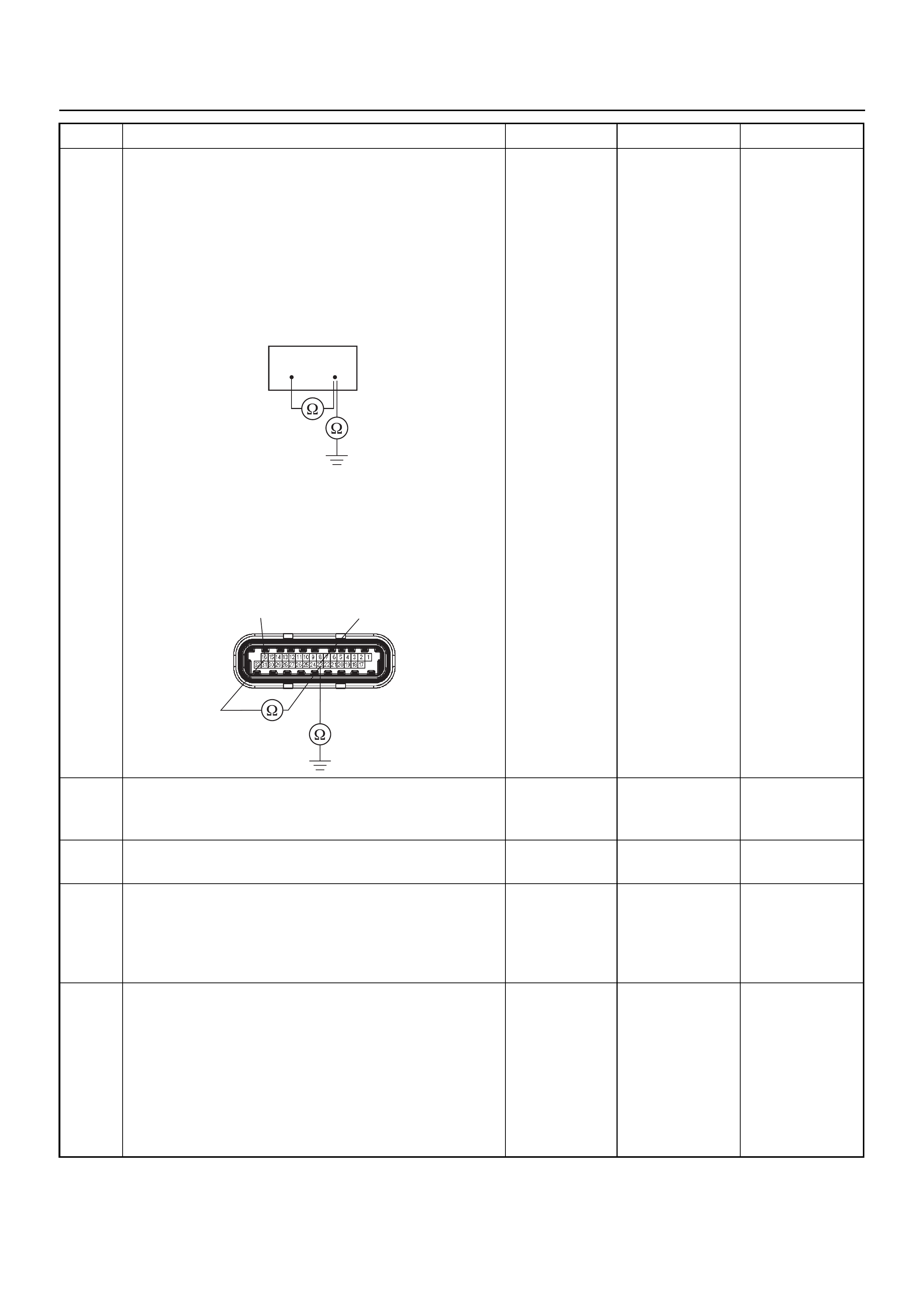

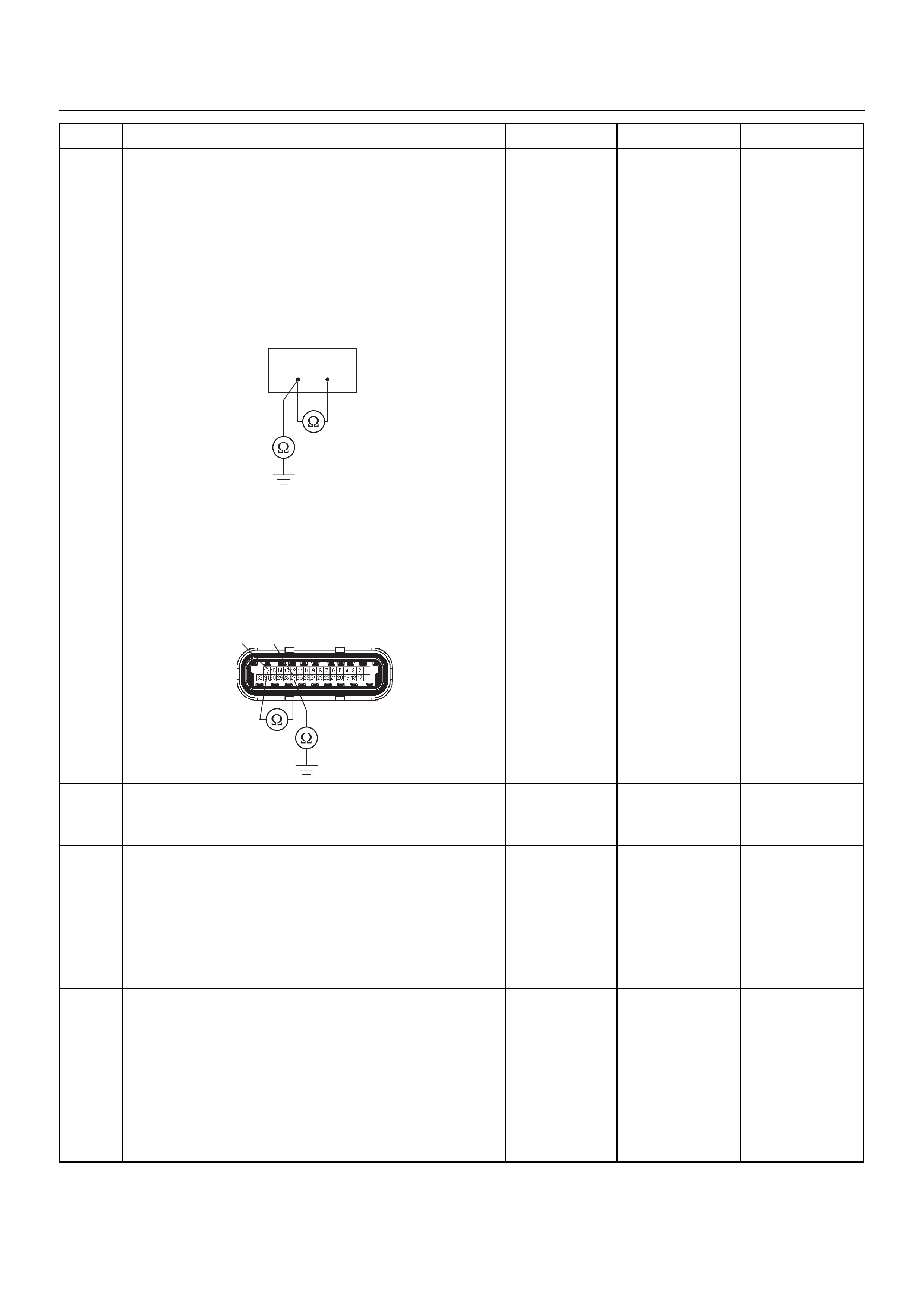

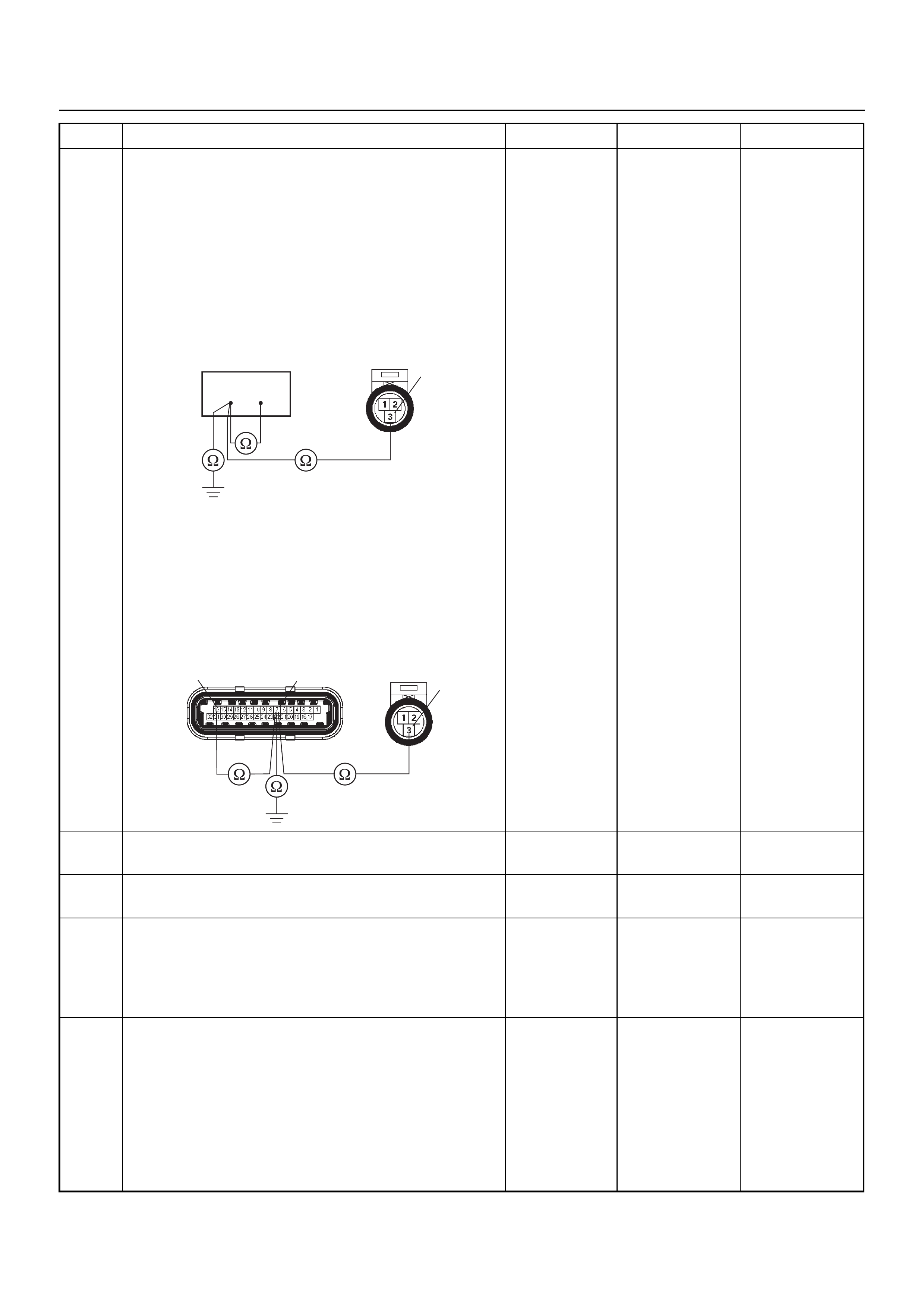

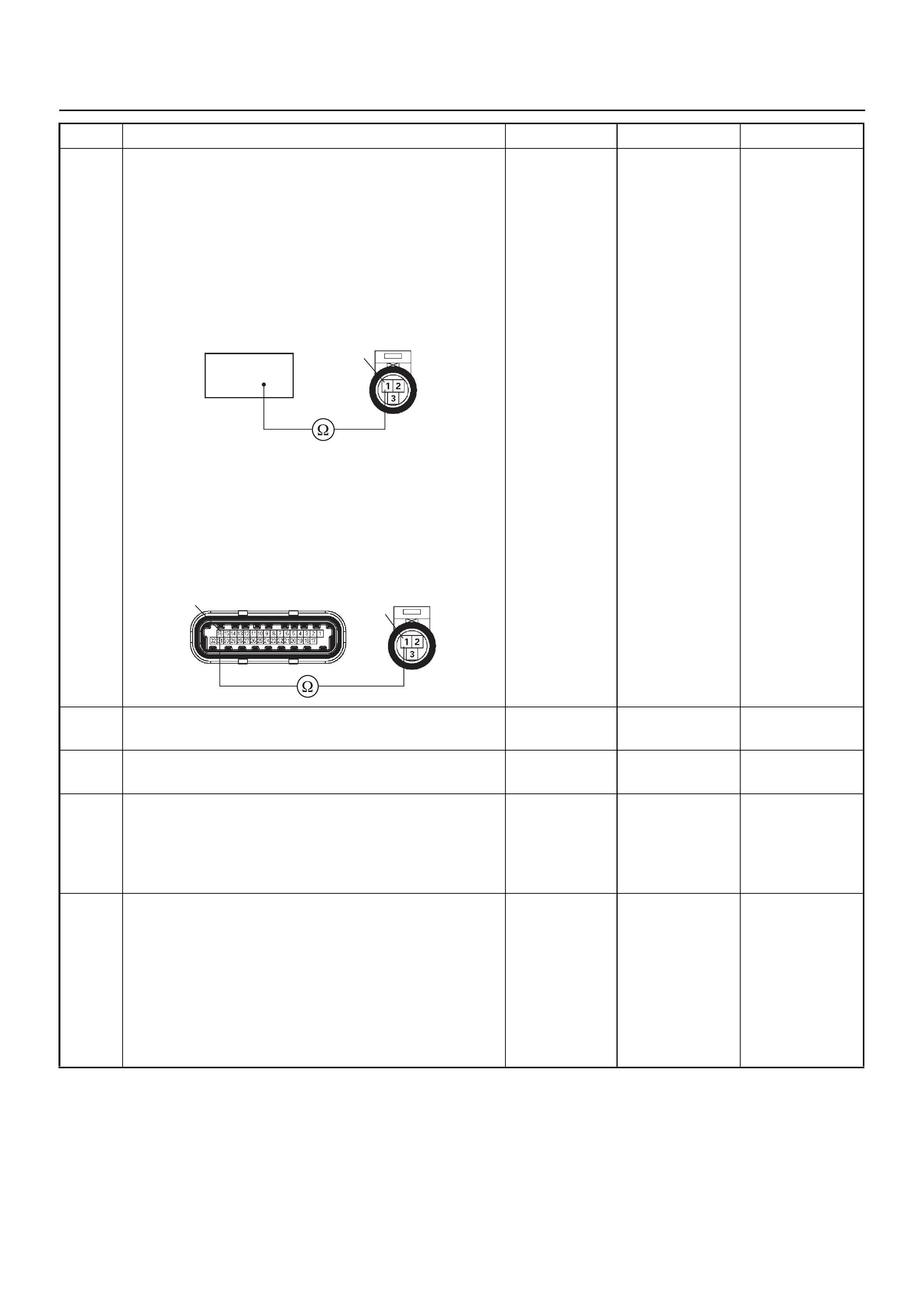

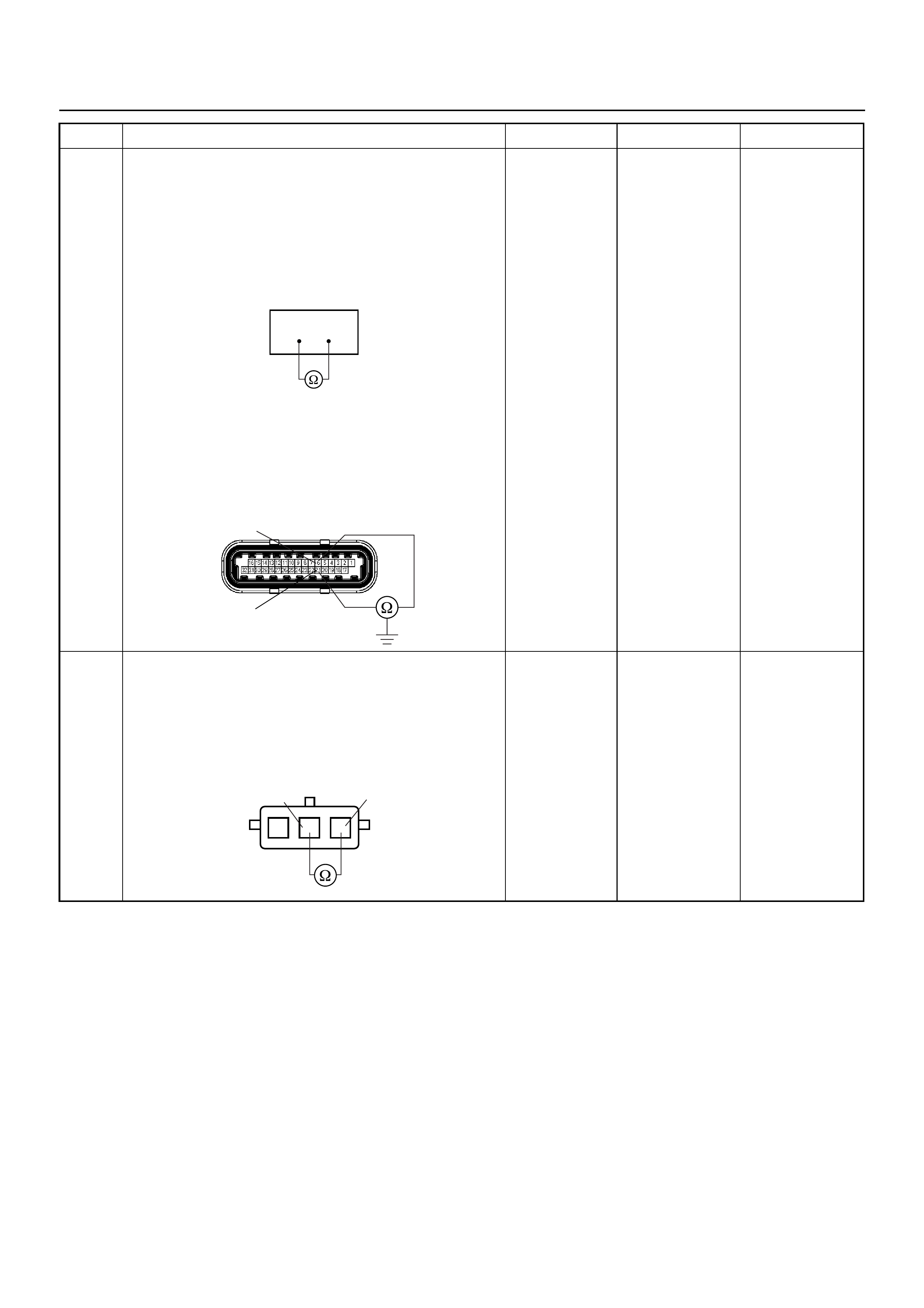

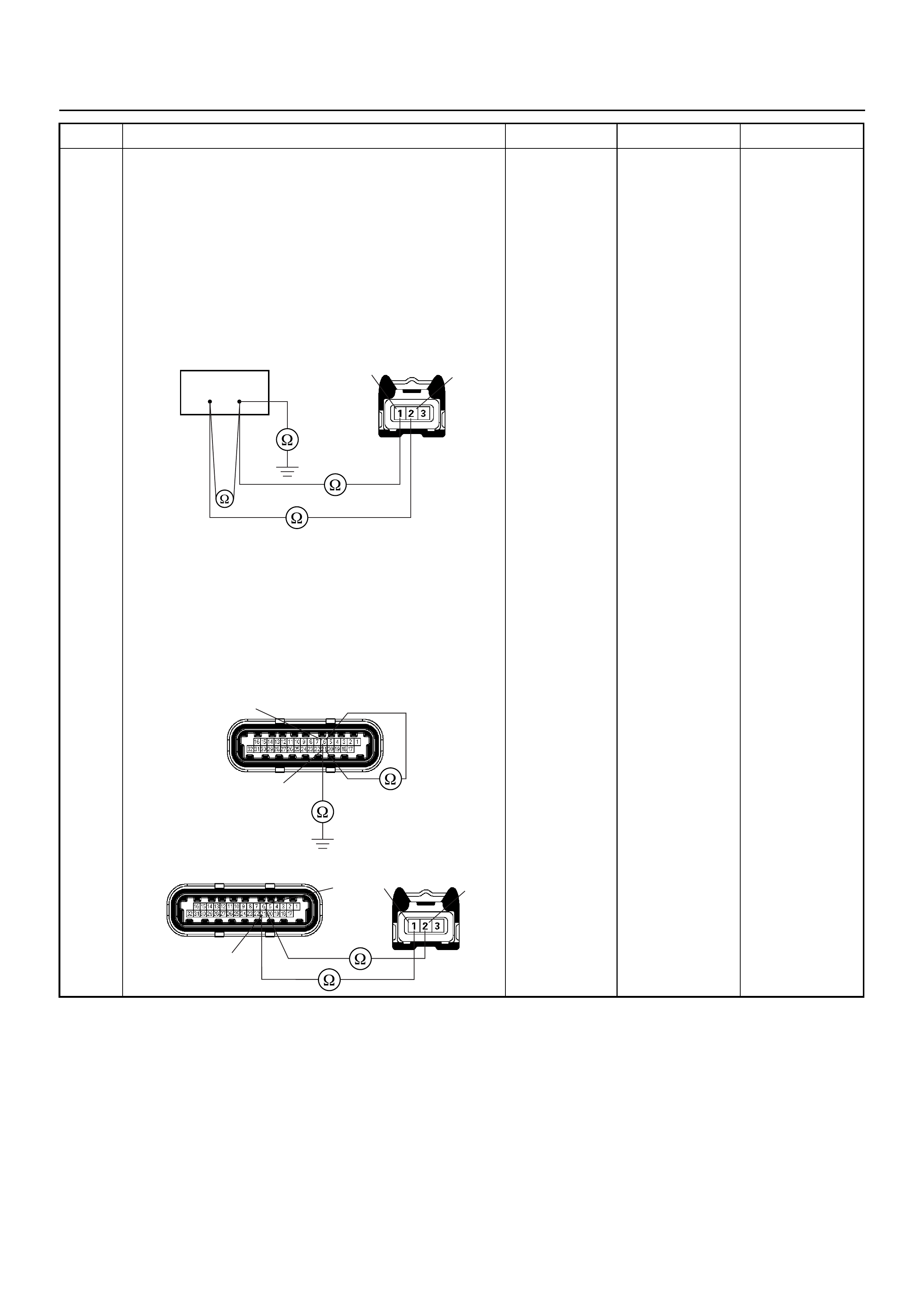

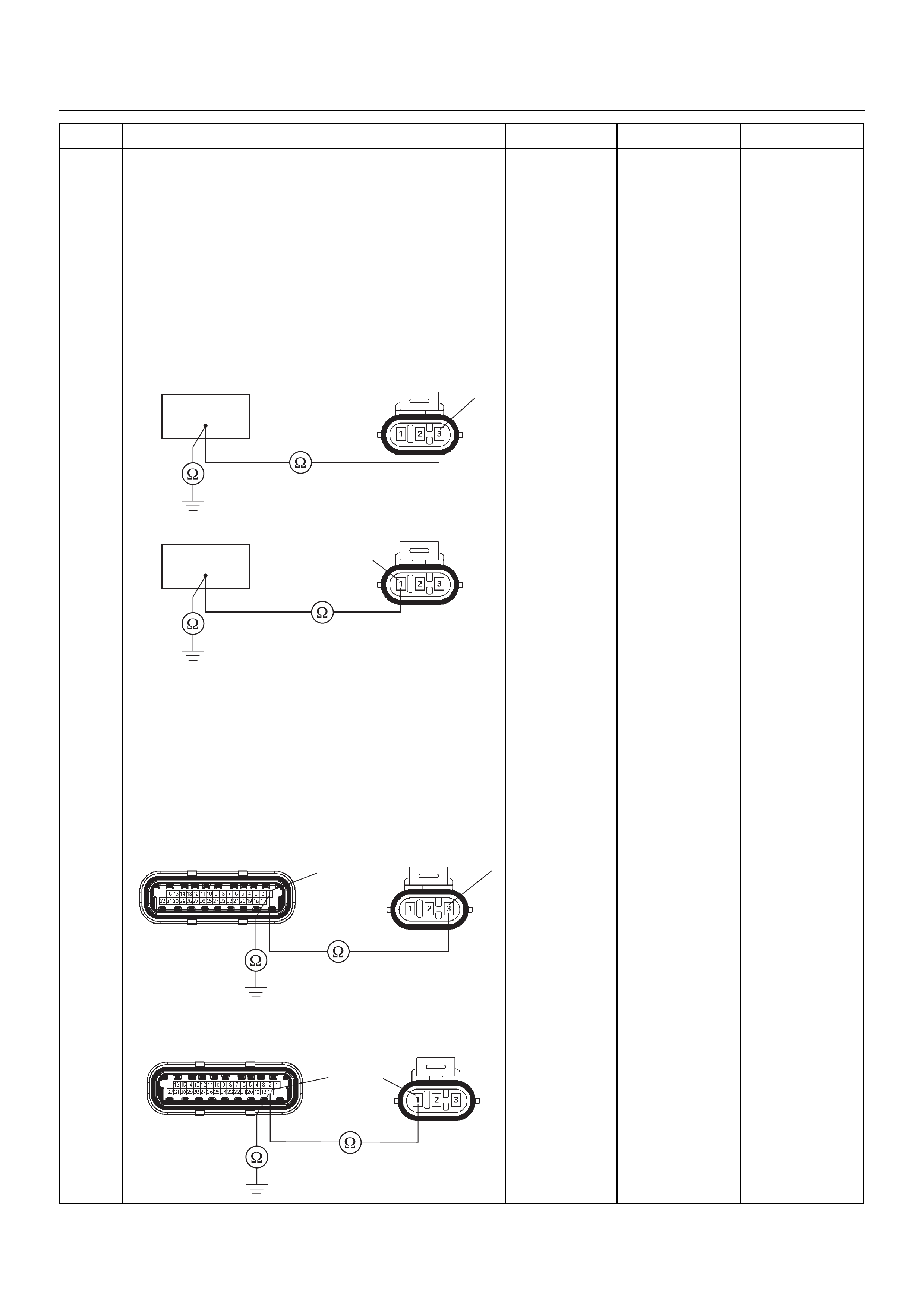

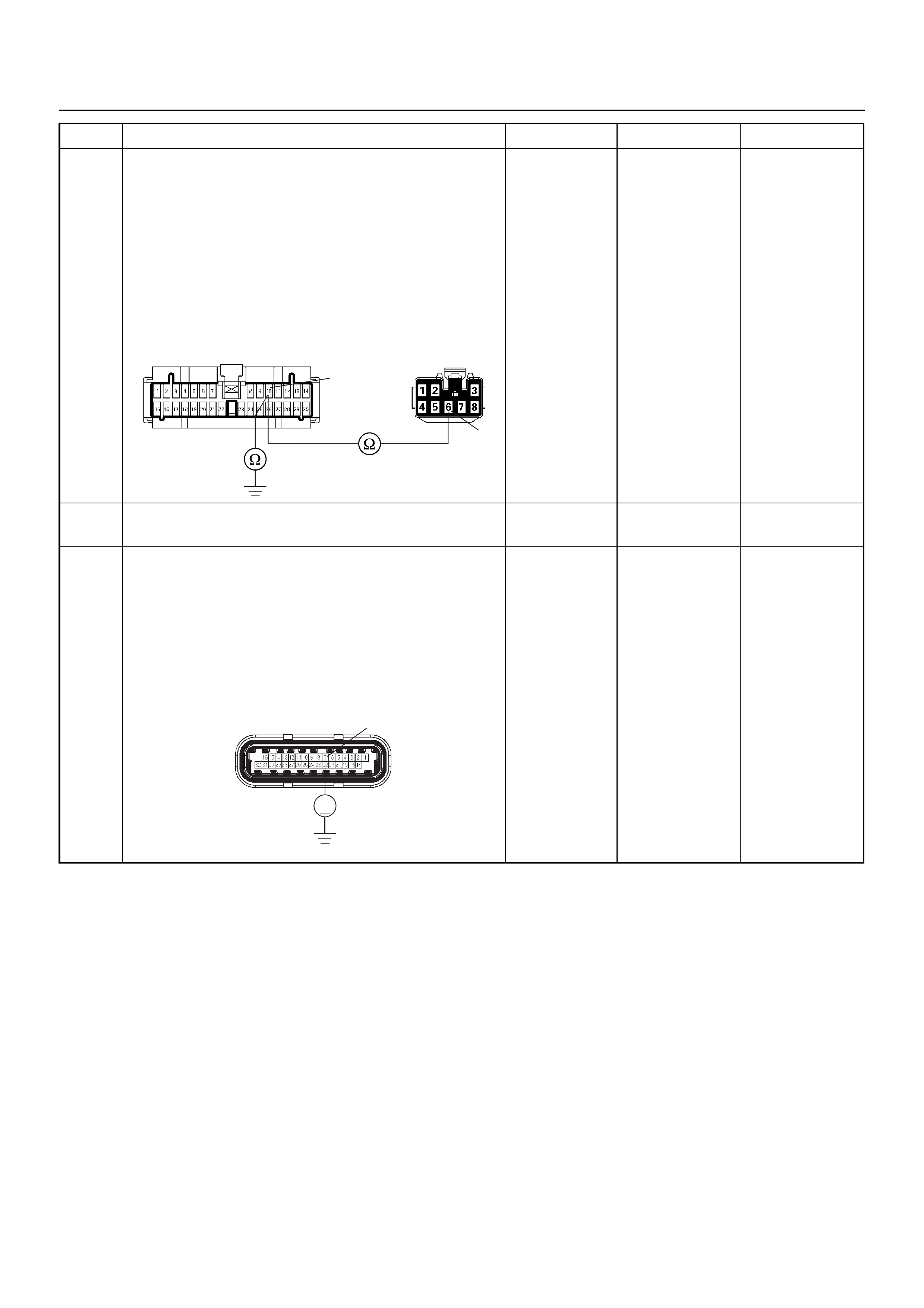

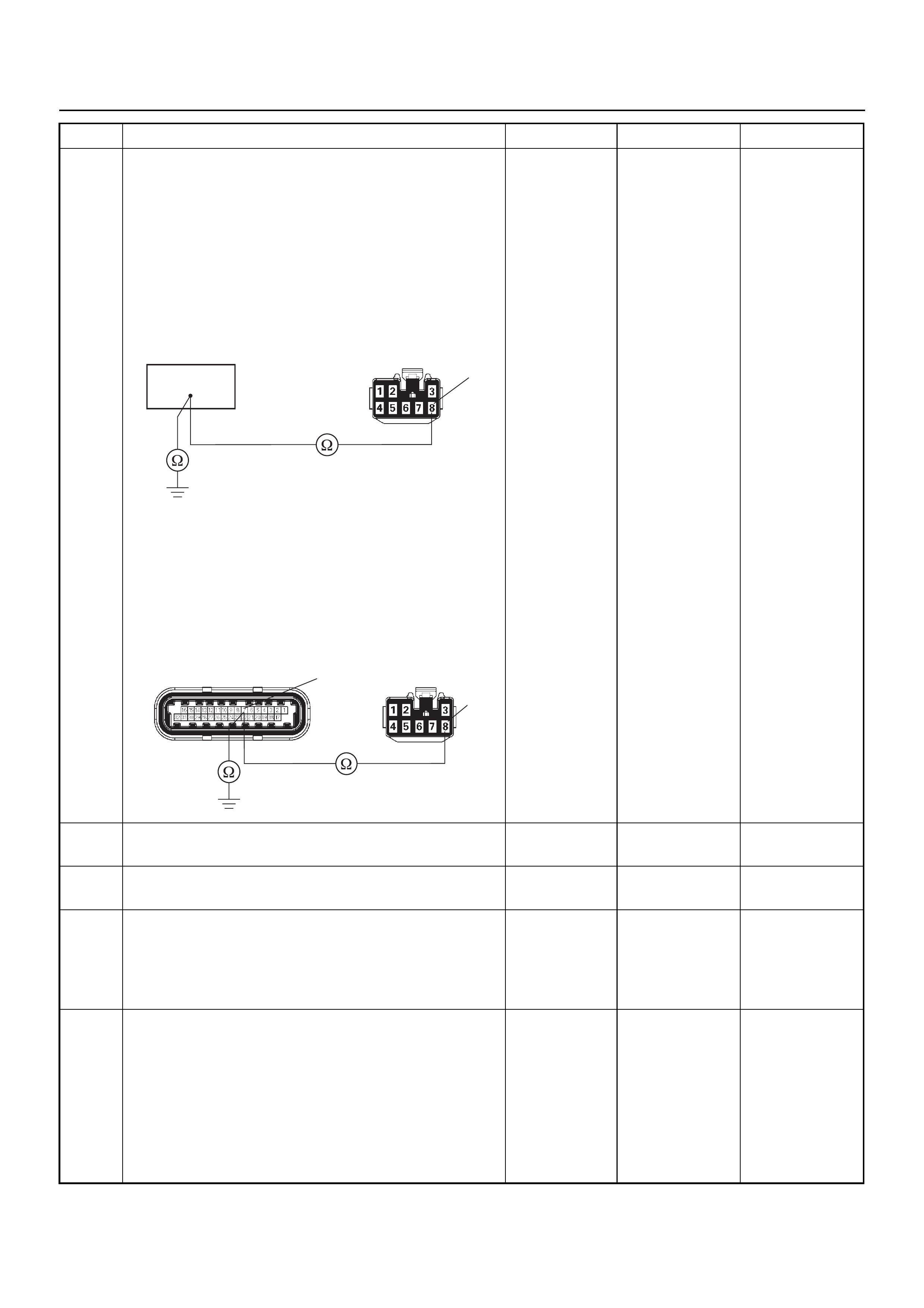

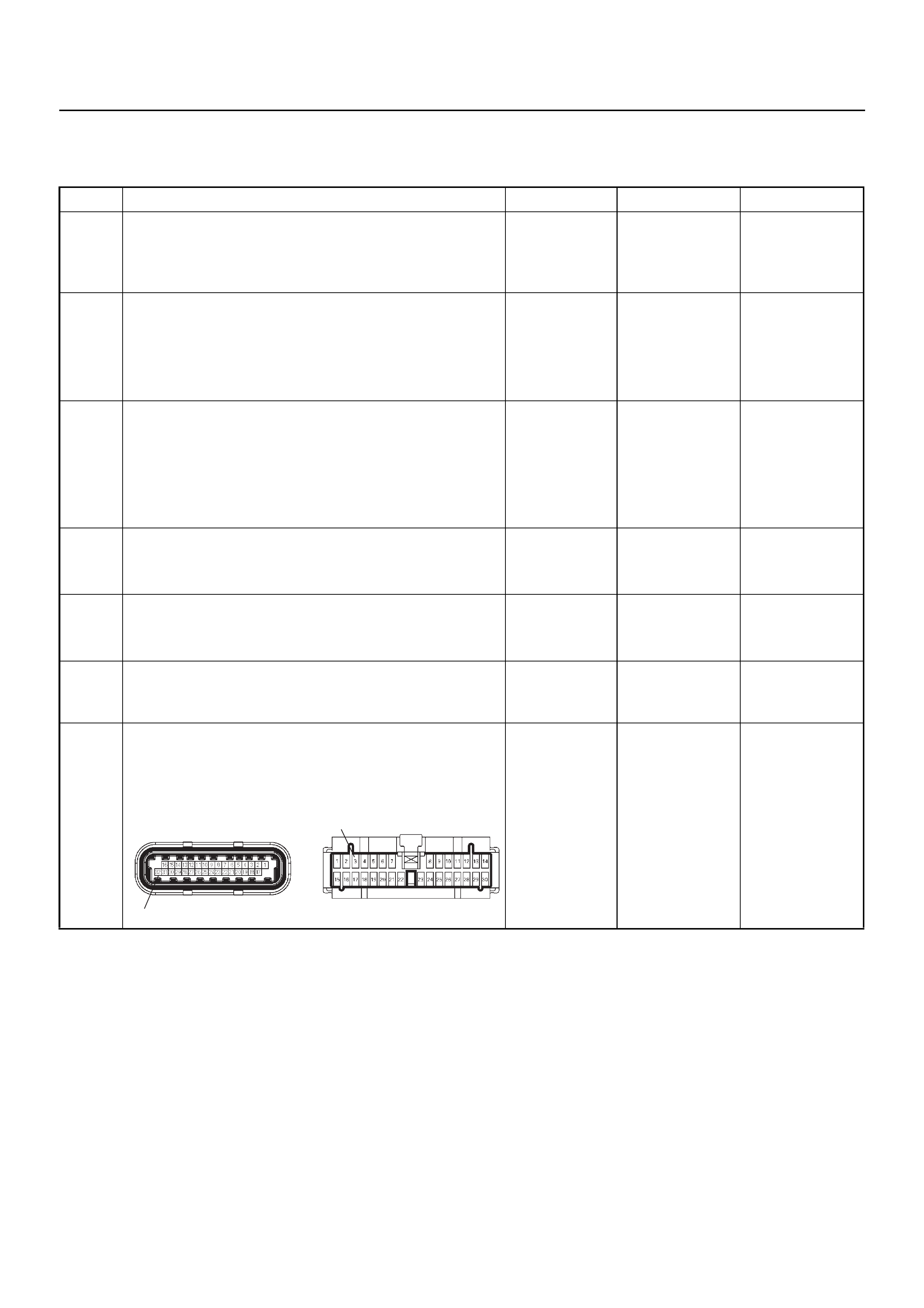

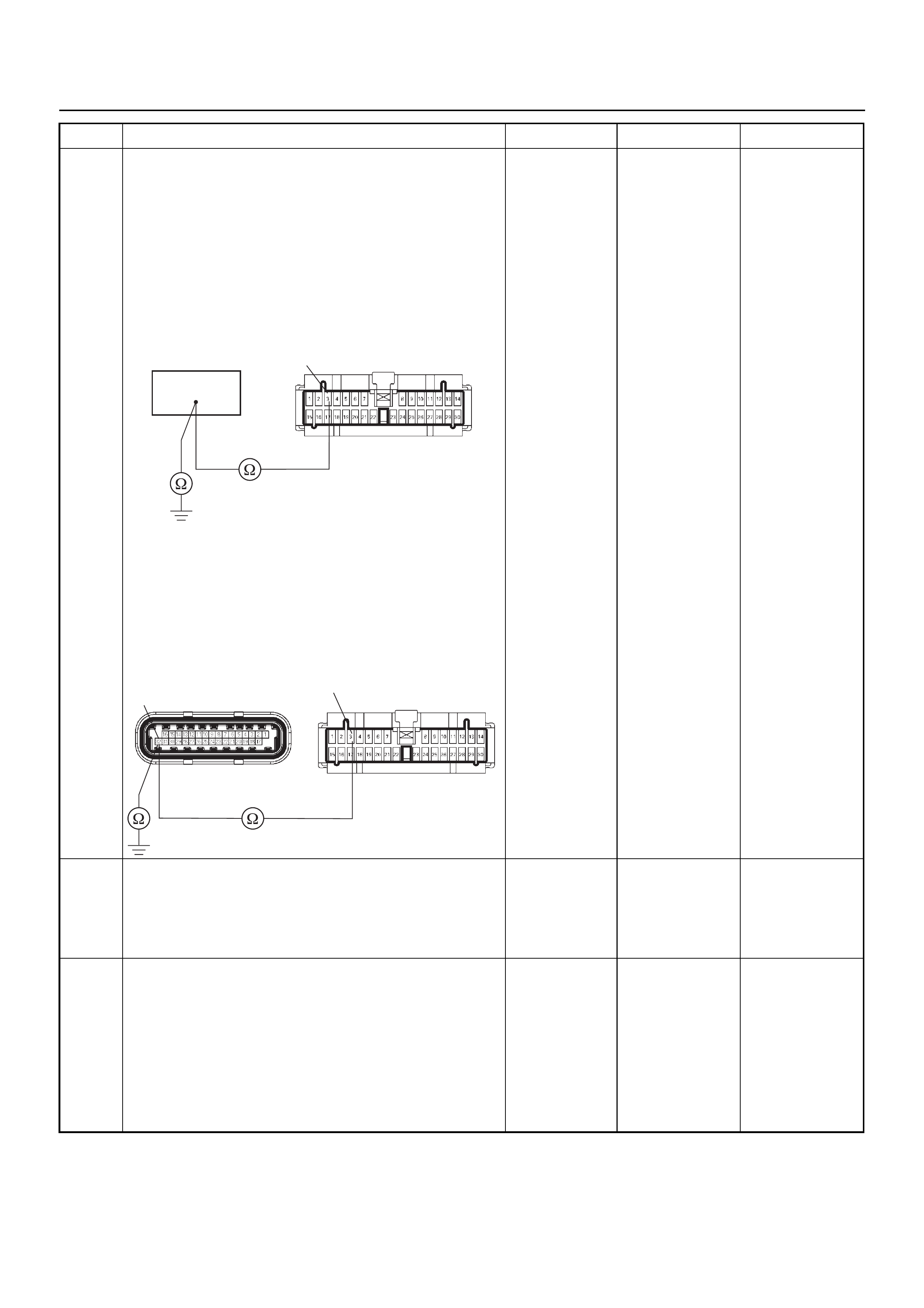

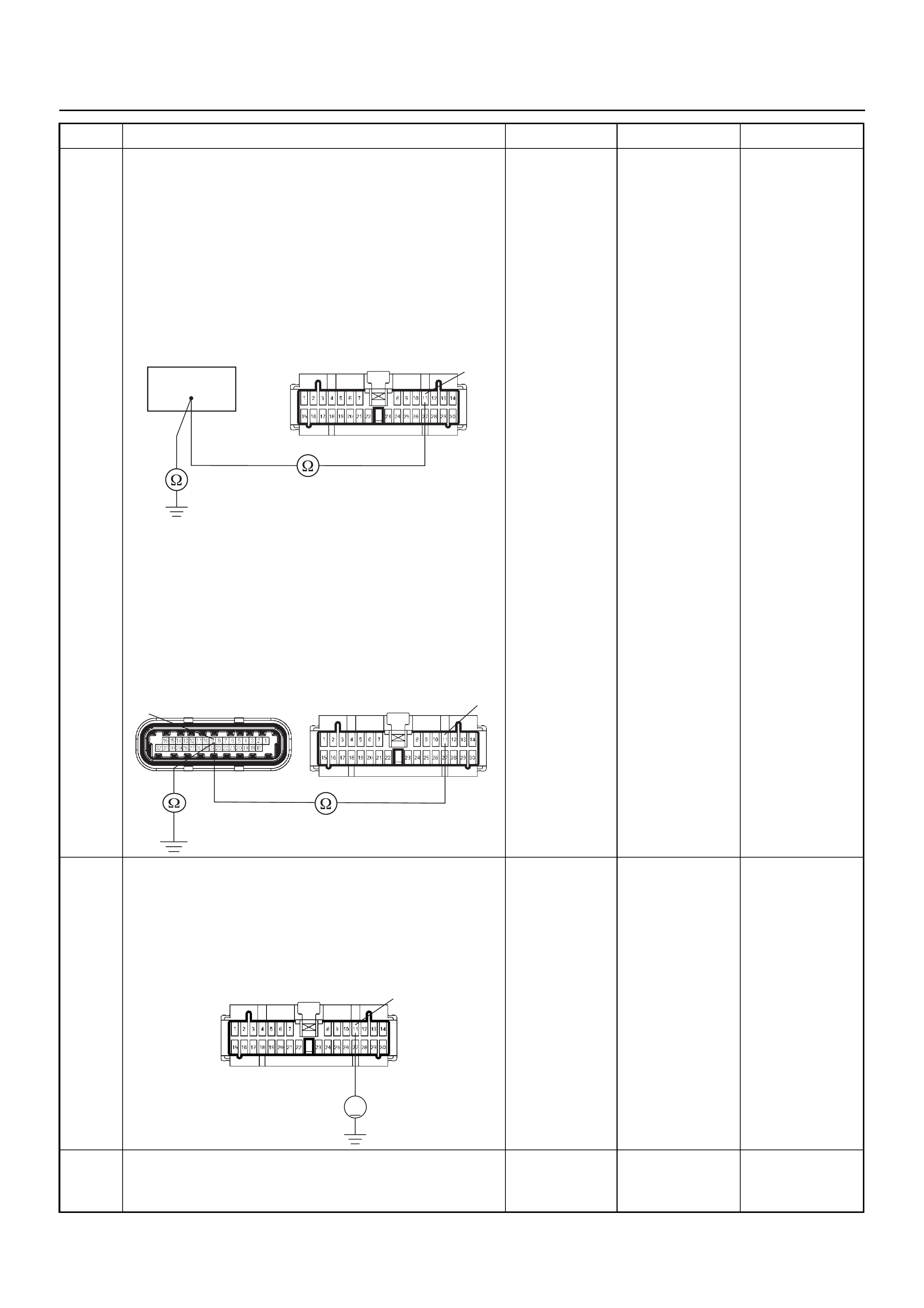

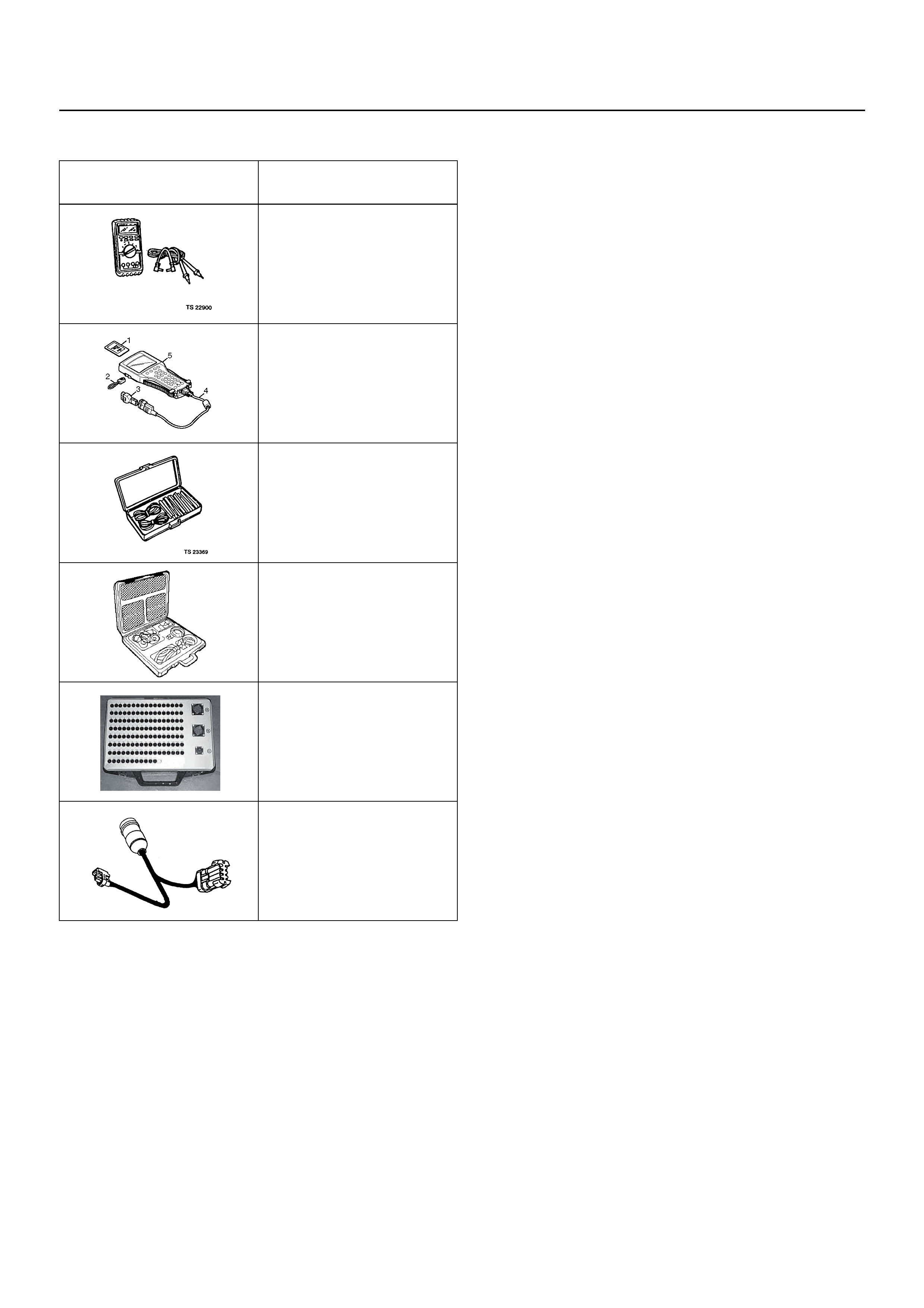

HOW TO USE BREAKER BOX

Breaker Box Connection Type A

Breaker Box Connection Type B

ON-BOARD DIAGNOSTIC (OBD) SYSTEM

CHECK

Circuit Description

Diagnostic Aids

Test Description

ON-BOARD DIAGNOSTIC (OBD) SYSTEM

CHECK

NO CHECK ENGINE LAMP (MIL)

Circuit Description

Diagnostic Aids

No Check Engine Lamp (MIL)

CHECK ENGINE LAMP (MIL) “ON”

STEADY

Circuit description

Diagnostic Aids

Check Engine Lamp (MIL) “ON” Steady

NO SERVICE VEHICLE SOON LAMP (SVS)

Circuit description

Diagnostic Aids

NO SERVICE VEHICLE SOON LAMP (SVS)

SERVICE VEHICLE SOON (SVS) “ON”

STEADY

Circuit description

Diagnostic Aids

Service Vehicle Soon (SVS) “ON”

Steady

FUEL METERING SYSTEM CHECK

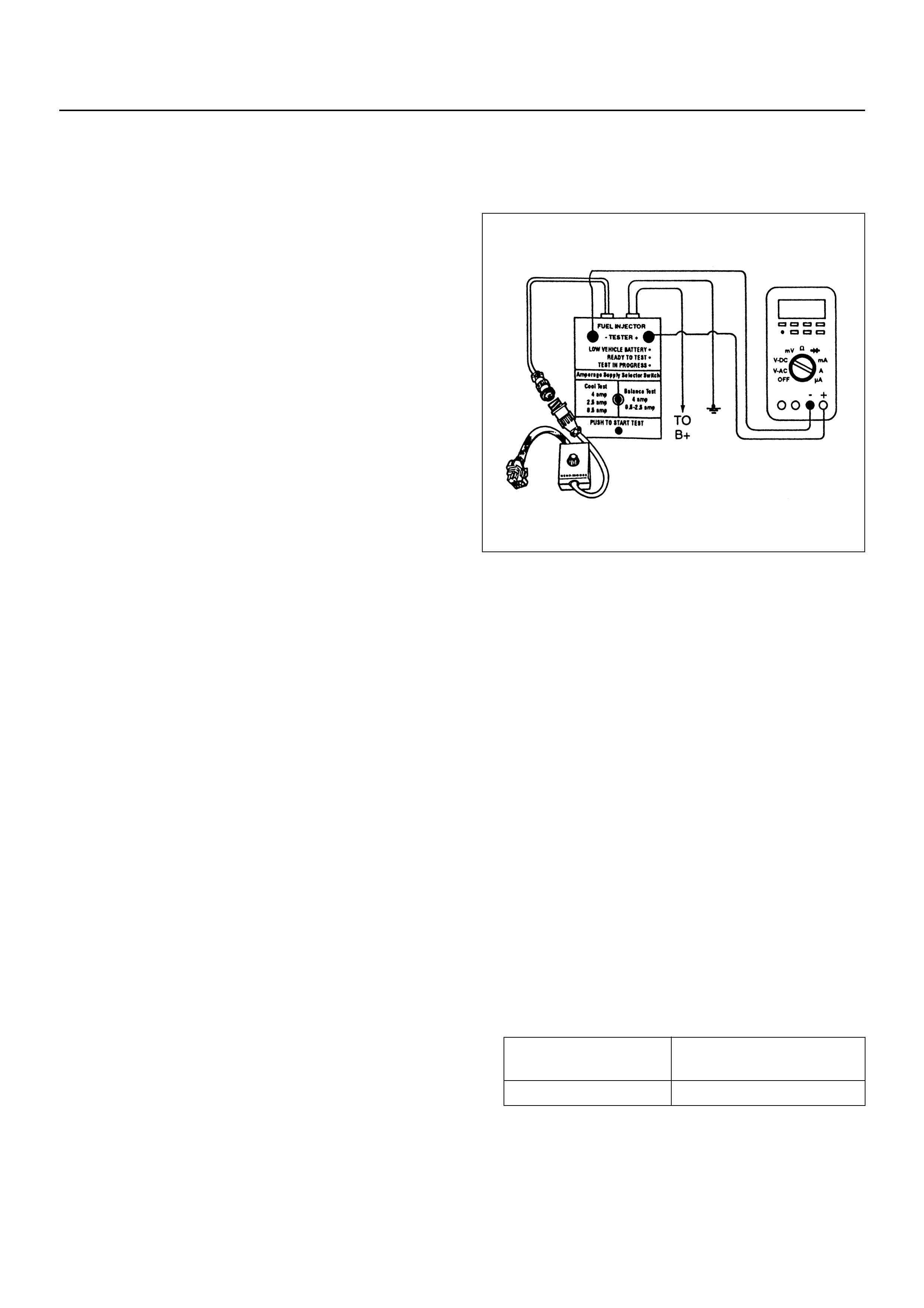

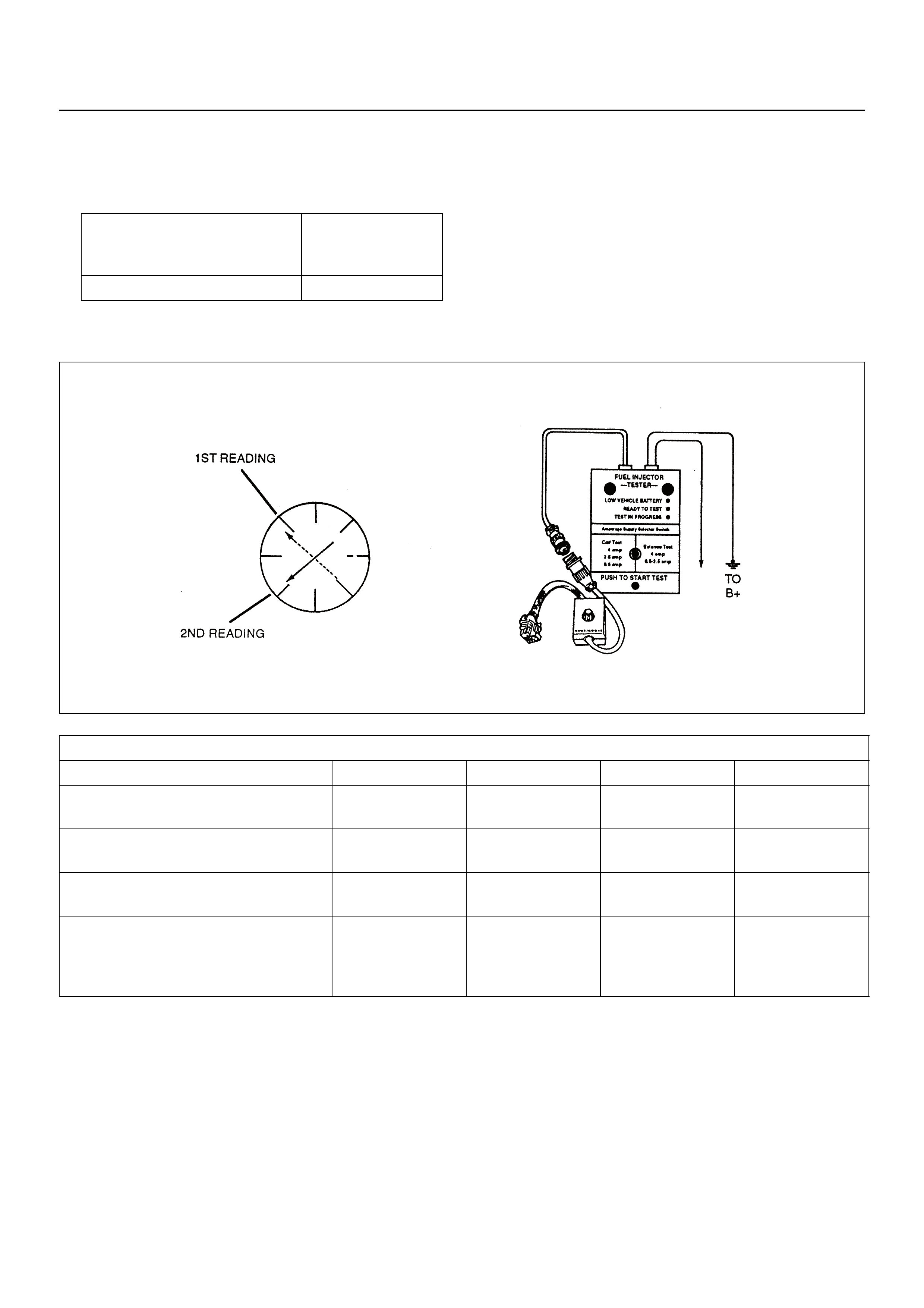

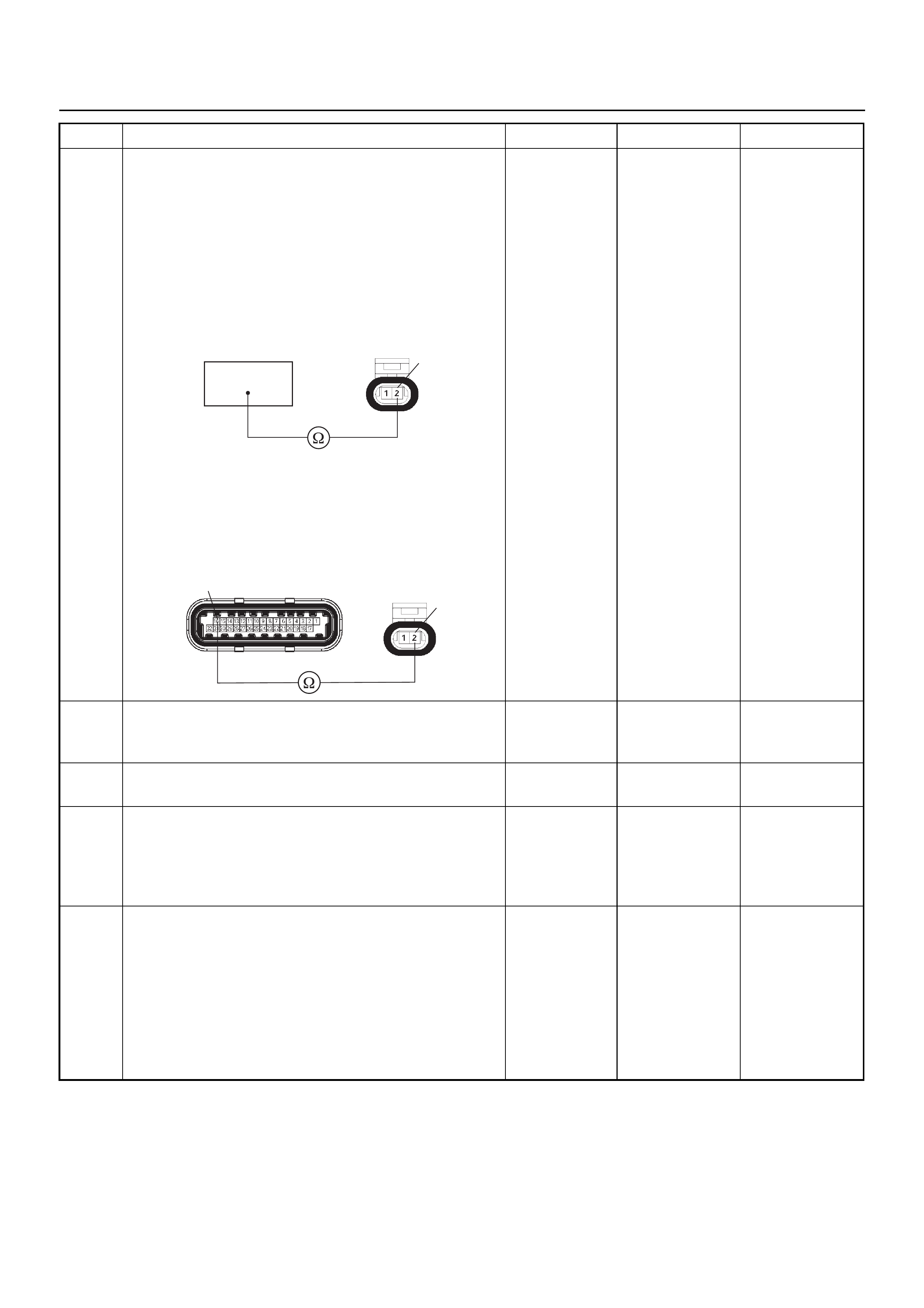

FUEL INJECTOR COIL TEST PROCEDURE

AND FUEL INJECTOR BALANCE TEST

PROCEDURE

Test Description

Injector Coil Test Procedure (Steps 1-6)

and Injector Balance Test Procedure

(Steps 7-11)

Injector Coil Test Procedure (Steps 1-6)

and Injector Balance Test Procedure

(Steps 7-11)

FUEL SYSTEM ELECTRICAL TEST

Circuit Description

Diagnostic Aids

Fuel Pressure Relief Procedure

Fuel Pressure Gauge Installation

Fuel System Electrical Test 8

FUEL SYSTEM DIAGNOSIS

Circuit Description

Test Description

Fuel Pressure Relief Procedure

Fuel Pressure Gauge Installation

Fuel System Diagnosis

ECM DIAGNOSTIC TROUBLE CODES

(DTC)

DTC DIAGNOSTIC TABLE

DIAGNOSTIC TROUBLE CODE (DTC) P0107

MANIFOLD ABSOLUTE PRESSURE

CIRCUIT LOW INPUT

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0107

Manifold Absolute Pressure Circuit Low

Input

DIAGNOSTIC TROUBLE CODE (DTC) P0108

MANIFOLD ABSOLUTE PRESSURE CIRCUIT

HIGH INPUT

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0108

Manifold Absolute Pressure Circuit High

Input

DIAGNOSTIC TROUBLE CODE (DTC) P0112

INTAKE AIR TEMPERATURE SENSOR LOW

INPUT

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0112

Intake Air Temperature Sensor Low

Input

DIAGNOSTIC TROUBLE CODE (DTC) P0113

INTAKE AIR TEMPERATURE SENSOR

HIGH INPUT

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0113

Intake Air Temperature Sensor High Input

DIAGNOSTIC TROUBLE CODE (DTC) P0117

ENGINE COOLANT TEMPERATURE

SENSOR LOW INPUT

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0117

Engine Coolant Temperature Sensor Low

Input

DIAGNOSTIC TROUBLE CODE (DTC) P0118

ENGINE COOLANT TEMPERATURE

SENSOR HIGH INPUT

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0118

Engine Coolant Temperature Sensor High

Input

DIAGNOSTIC TROUBLE CODE (DTC) P0122

THROTTLE POSITION SENSOR LOW

INPUT

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0122

Throttle Position Sensor Low Input

DIAGNOSTIC TROUBLE CODE (DTC) P0123

THROTTLE POSITION SENSOR HIGH

INPUT

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0123

Throttle Position Sensor High Input

DIAGNOSTIC TROUBLE CODE (DTC) P0131

O2 SENSOR CIRCUIT LOW VOLTAGE

(BANK 1 SENSOR 1 PRE)

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0131

O2 Sensor Circuit Low Voltage

(Bank 1 Sensor 1 PRE)

DIAGNOSTIC TROUBLE CODE (DTC) P0132

O2 SENSOR CIRCUIT HIGH VOLTAGE

(BANK 1 SENSOR 1 PRE)

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0132

O2 Sensor Circuit High Voltage

(Bank 1 Sensor 1 PRE)

DIAGNOSTIC TROUBLE CODE (DTC) P0134

O2 SENSOR NO ACTIVITY DEFECTED

CIRCUIT (BANK 1 SENSOR 1 PRE)

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0134

O2 Sensor Circuit No Activity Detected

(Bank 1 Sensor 1 PRE)

DIAGNOSTIC TROUBLE CODE (DTC) P0135

O2 SENSOR HEATER CIRCUIT

(BANK 1 SENSOR 1 PRE)

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0135

O2 Sensor Heater Circuit

(Bank 1 Sensor 1 PRE)

DIAGNOSTIC TROUBLE CODE (DTC) P0137

O2 SENSOR CIRCUIT LOW VOLTAGE

(BANK 1 SENSOR 2 POST)

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0137

O2 Sensor Circuit Low Voltage

(Bank 1 Sensor 2 POST)

DIAGNOSTIC TROUBLE CODE (DTC) P0138

O2 SENSOR CIRCUIT HIGH VOLTAGE

(BANK 1 SENSOR 2 POST)

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0138

O2 Sensor Circuit High Voltage

(Bank 1 Sensor 2 POST)

DIAGNOSTIC TROUBLE CODE (DTC) P0140

O2 SENSOR NO ACTIVITY DEFECTED

CIRCUIT (BANK 1 SENSOR 2 POST)

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0140

O2 Sensor Circuit No Activity Detected

(Bank 1 Sensor 2 POST)

DIAGNOSTIC TROUBLE CODE (DTC) P0141

O2 SENSOR HEATER CIRCUIT

(BANK 1 SENSOR 2 POST)

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0141

O2 Sensor Heater Circuit

(Bank 1 Sensor 2 POST)

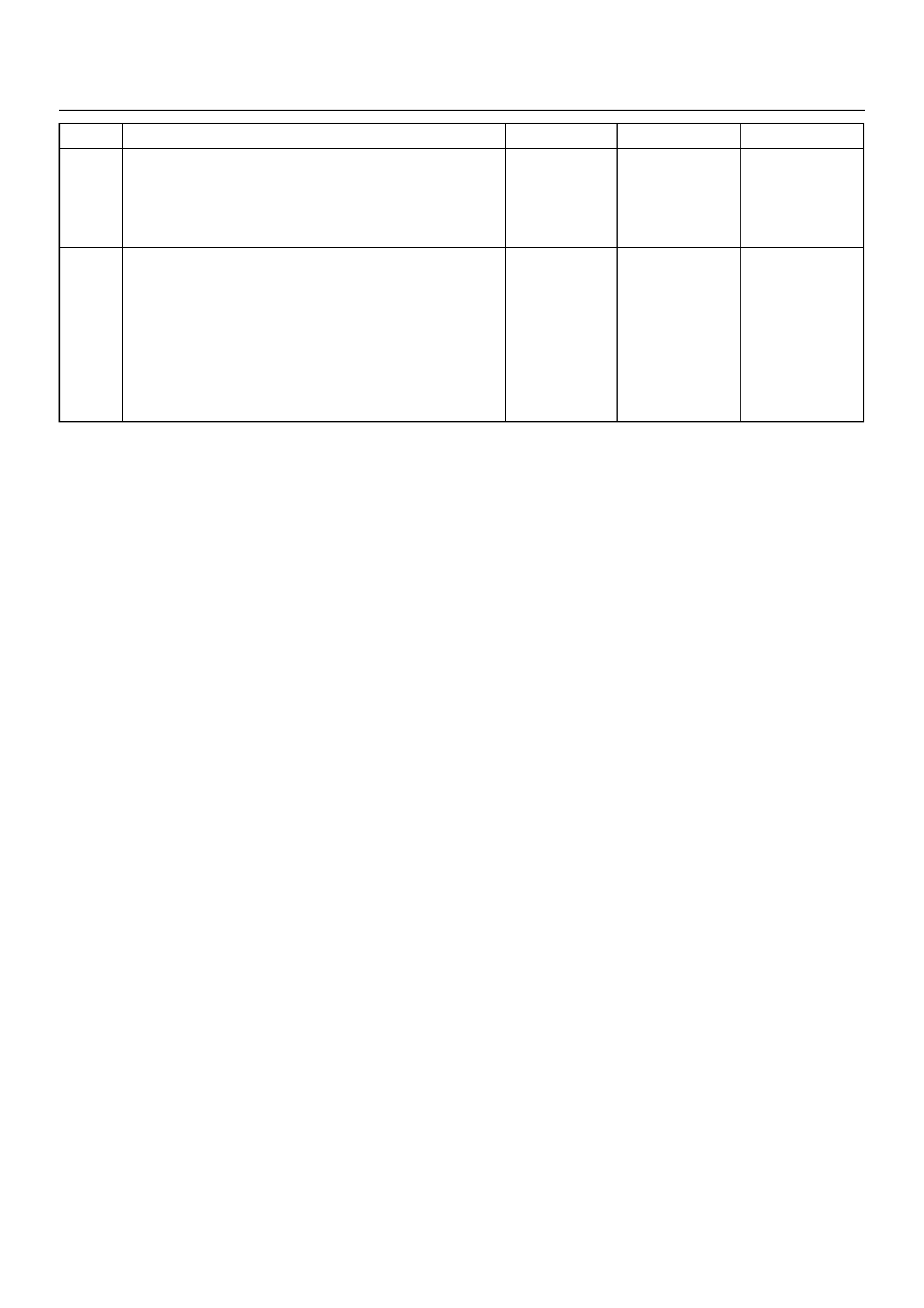

DIAGNOSTIC TROUBLE CODE (DTC) P0201

INJECTOR 1 CONTROL CIRCU IT

DIAGNOSTIC TROUBLE CODE (DTC) P0202

INJECTOR 2 CONTROL CIRCU IT

DIAGNOSTIC TROUBLE CODE (DTC) P0203

INJECTOR 3 CONTROL CIRCU IT

DIAGNOSTIC TROUBLE CODE (DTC) P0204

INJECTOR 4 CONTROL CIRCU IT

Circuit Description

Diagnostic Aids

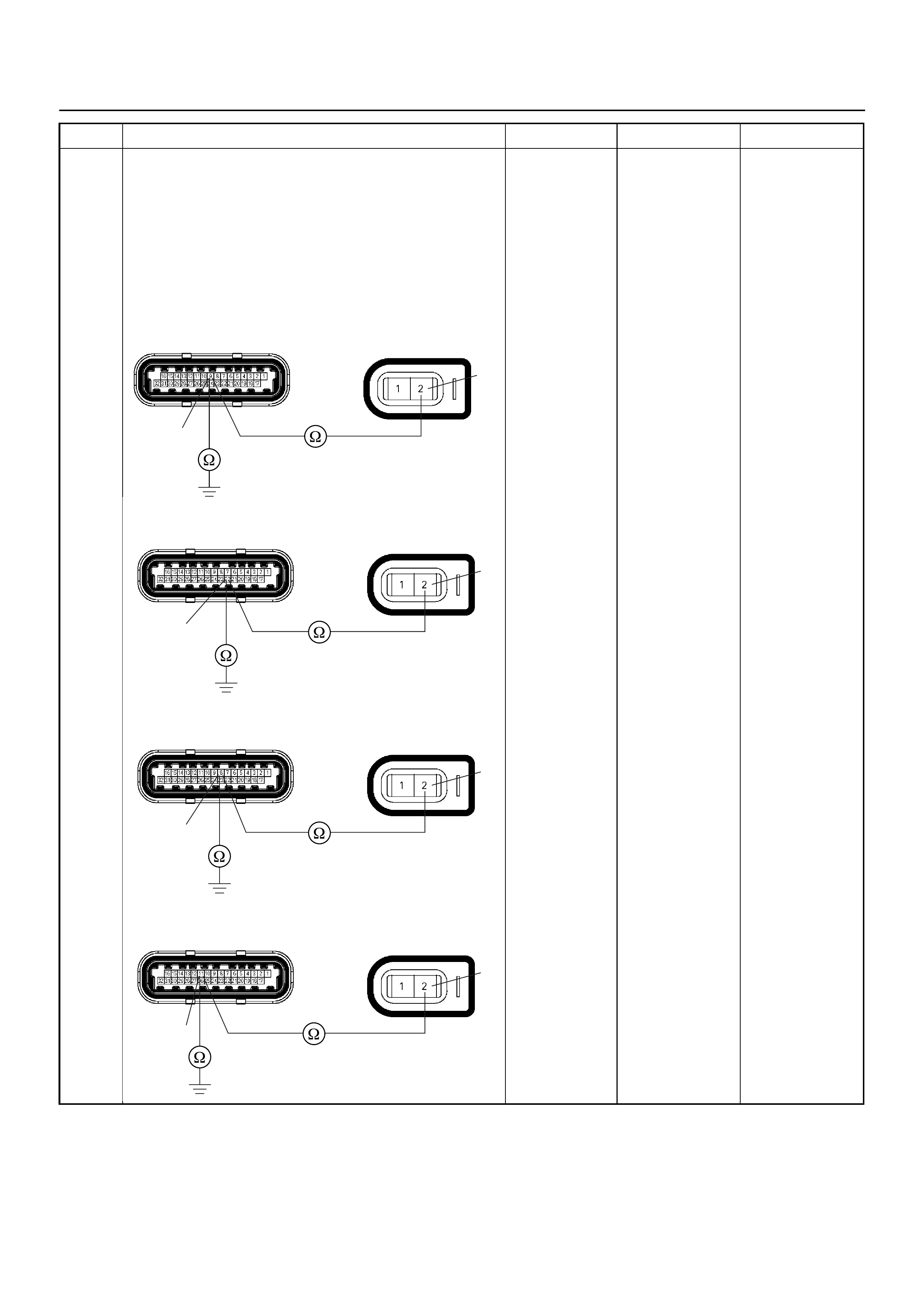

Diagnostic Trouble Code (DTC) P0201

Injector 1 Control Circuit

Diagnostic Trouble Code (DTC) P0202

Injector 2 Control Circuit

Diagnostic Trouble Code (DTC) P0203

Injector 3 Control Circuit

Diagnostic Trouble Code (DTC) P0204

Injector 4 Control Circuit

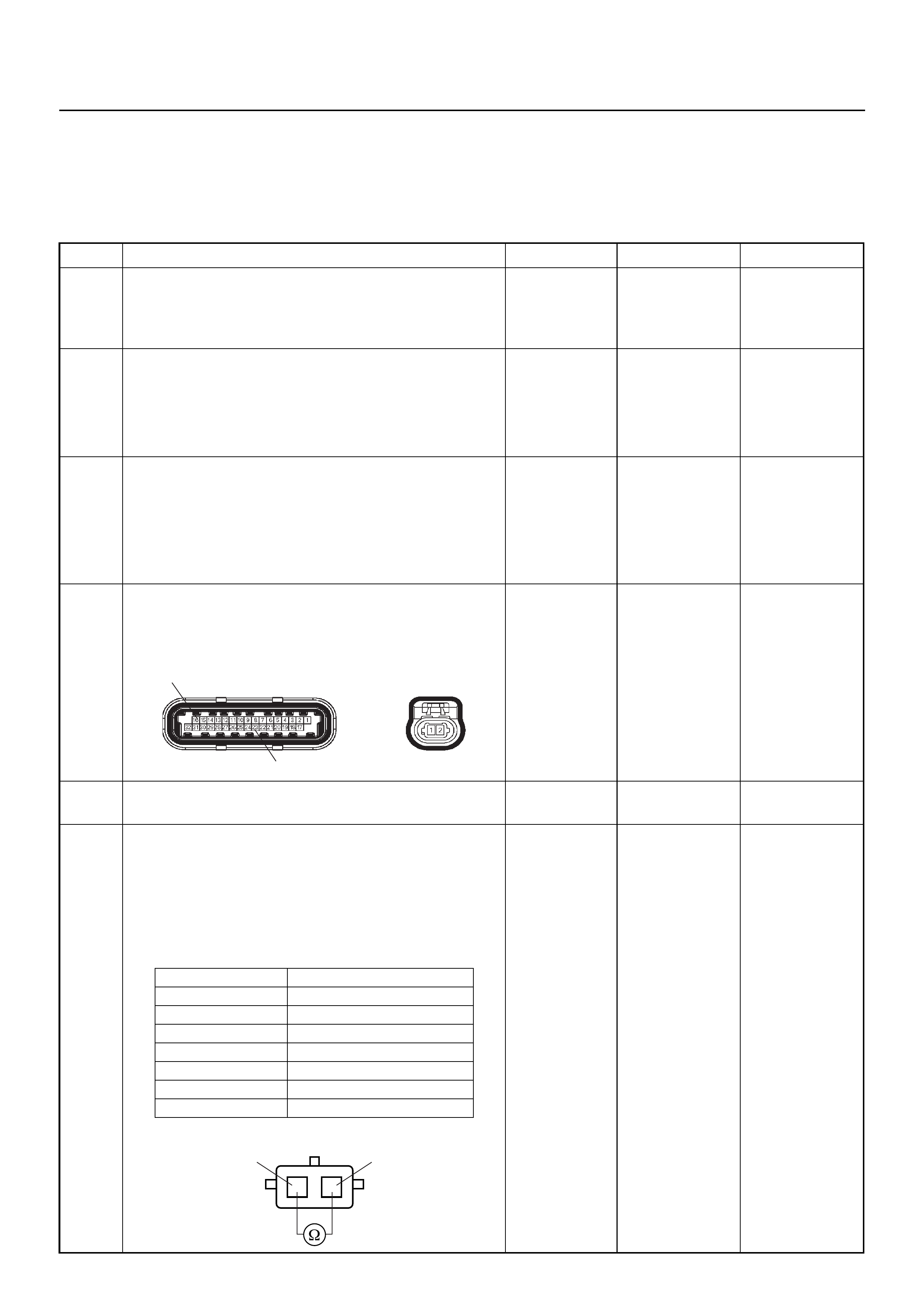

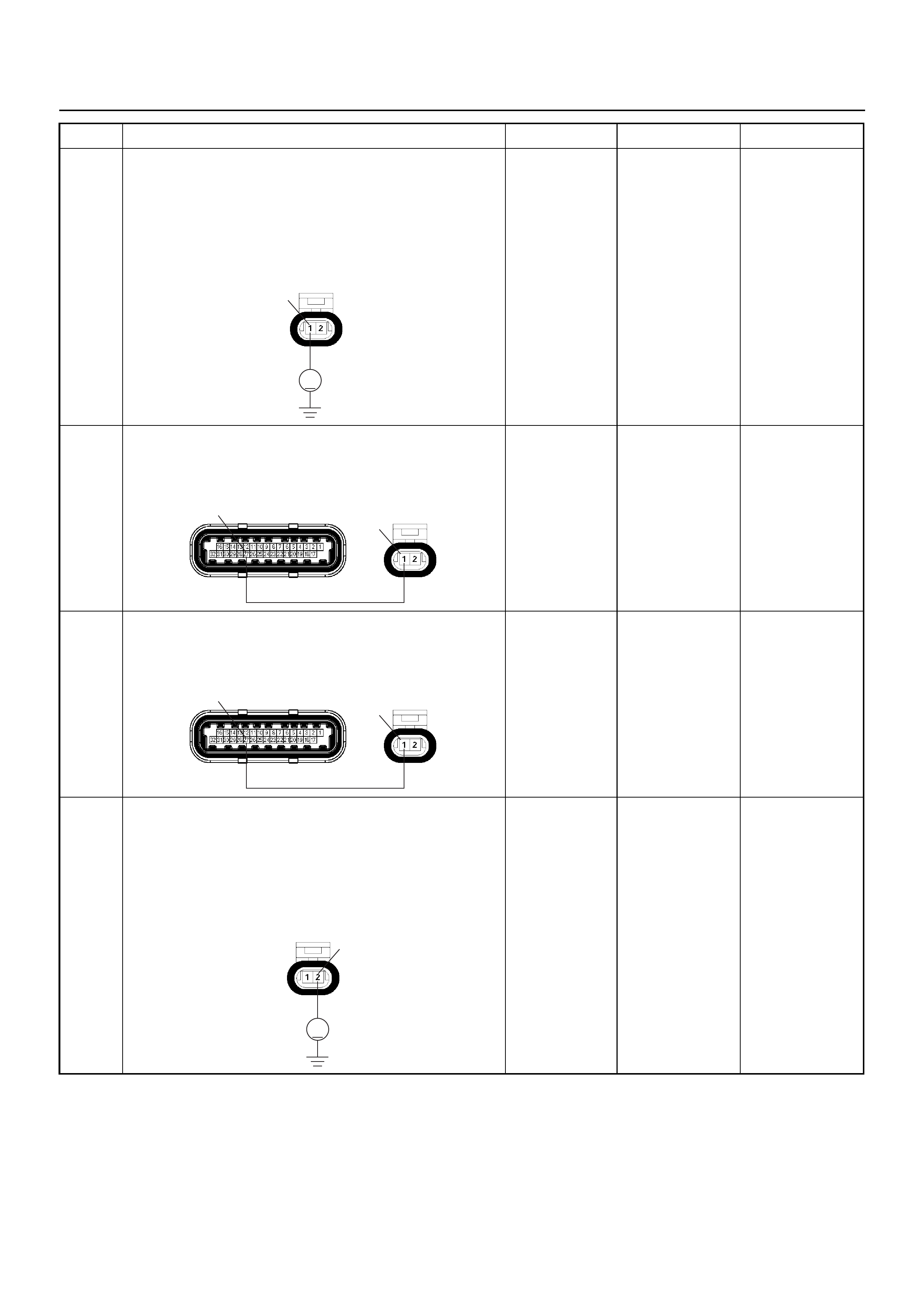

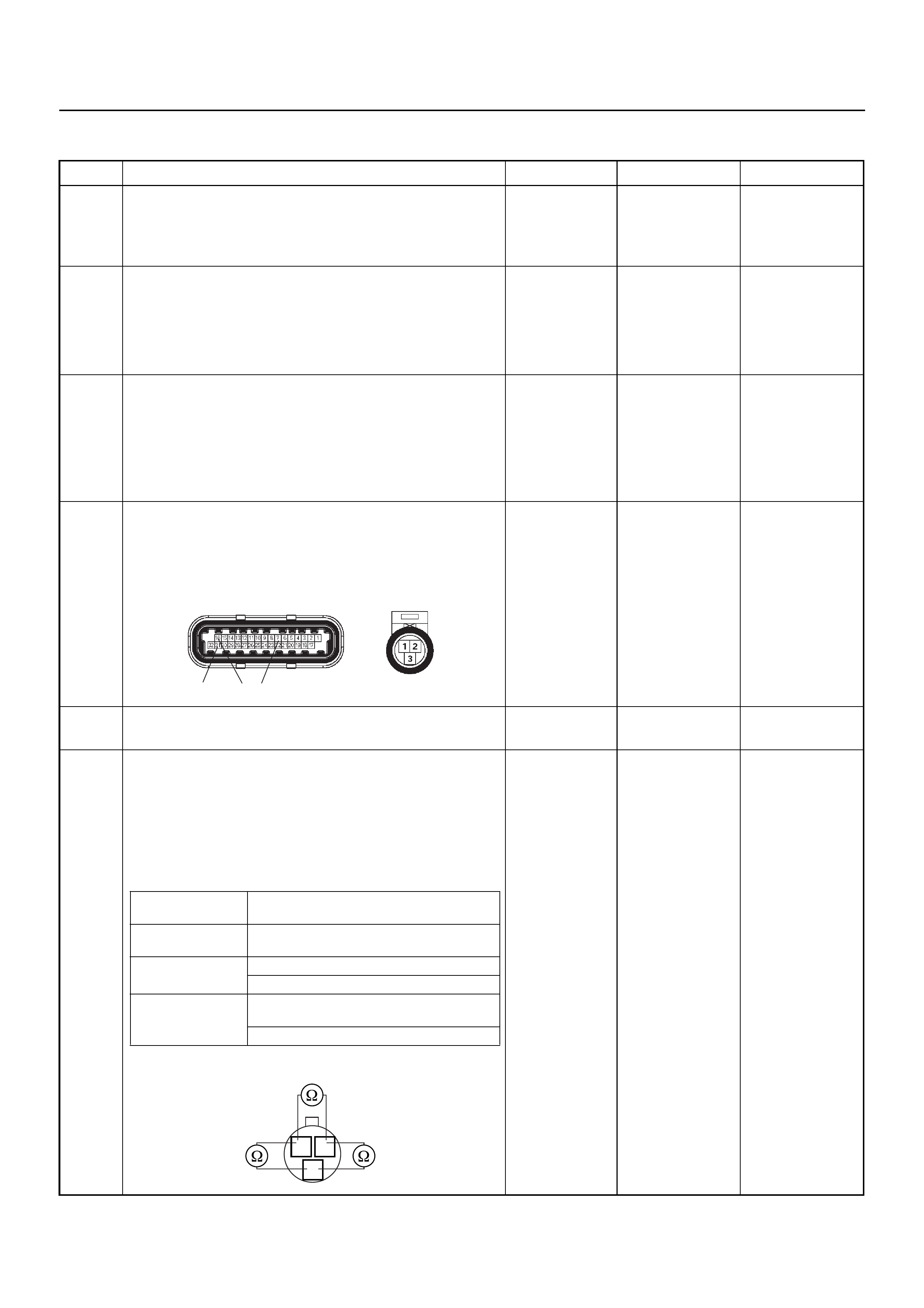

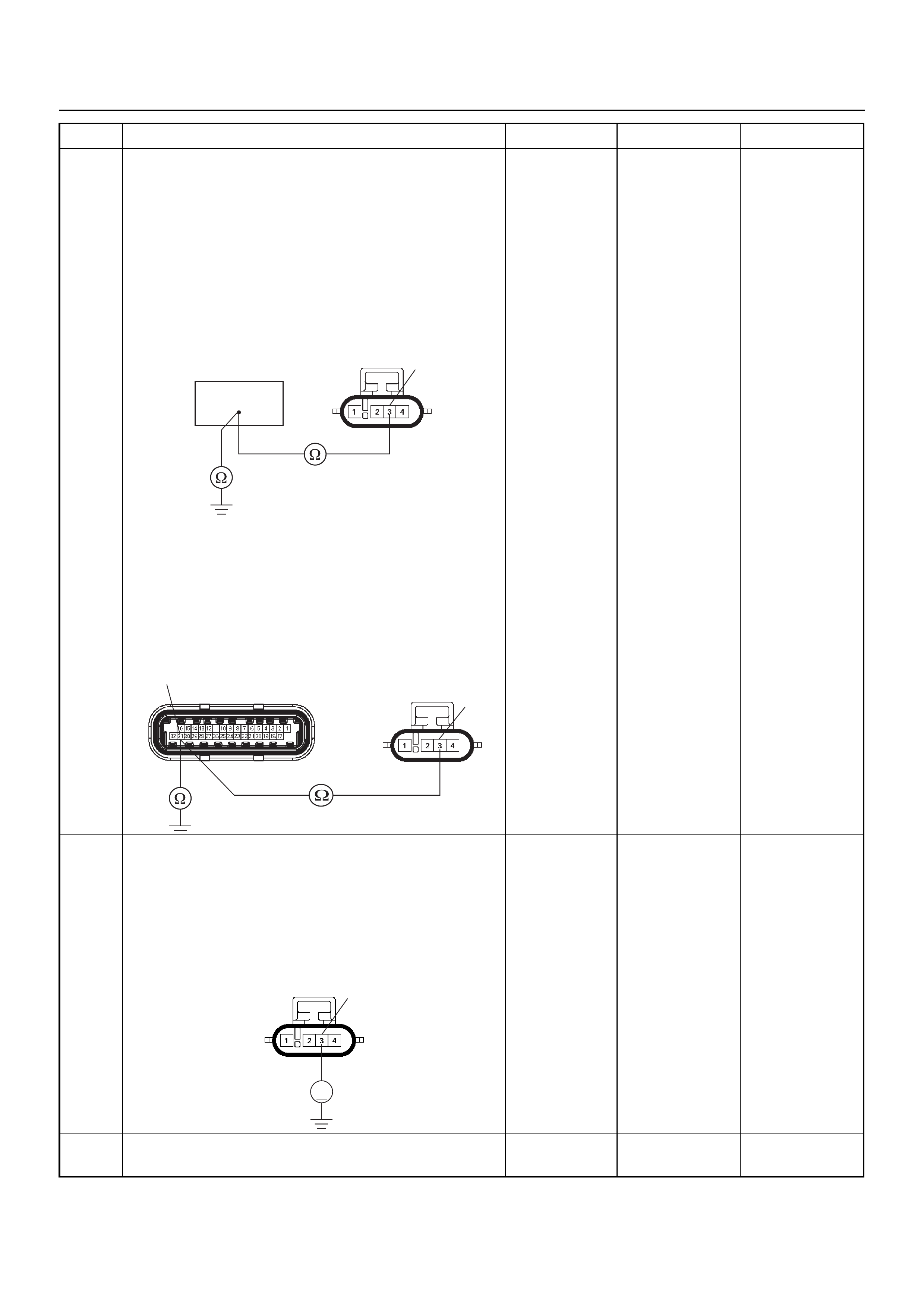

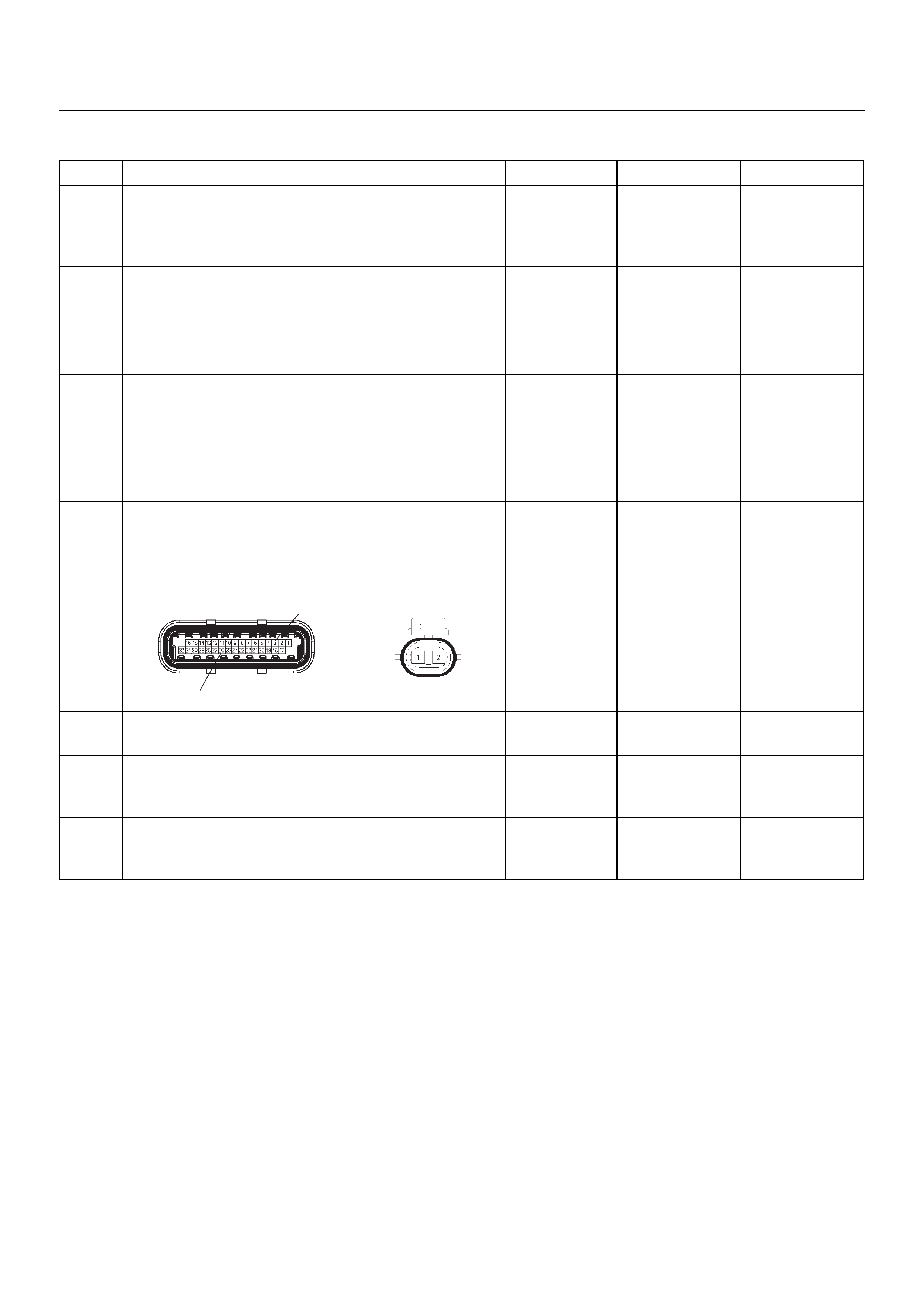

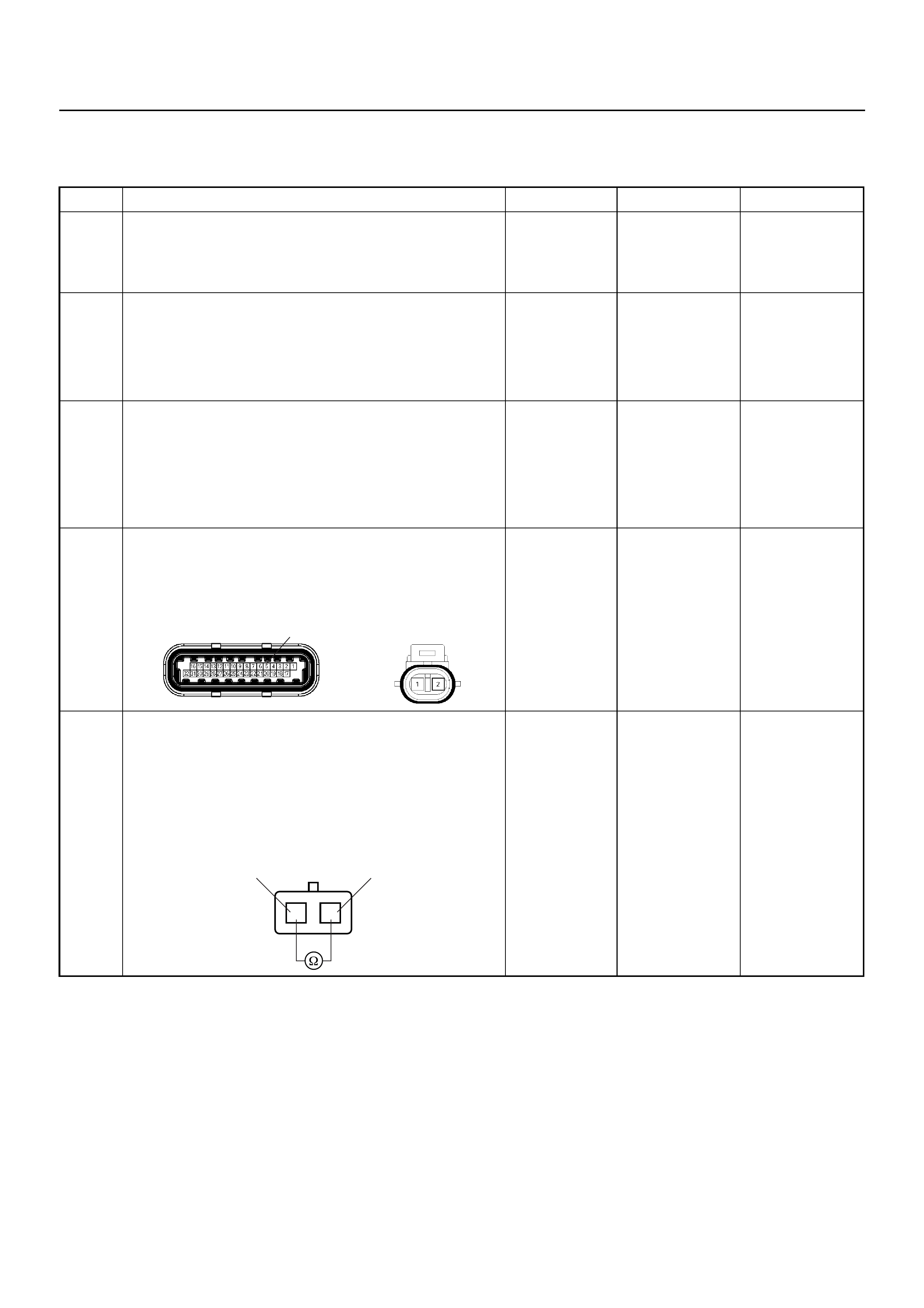

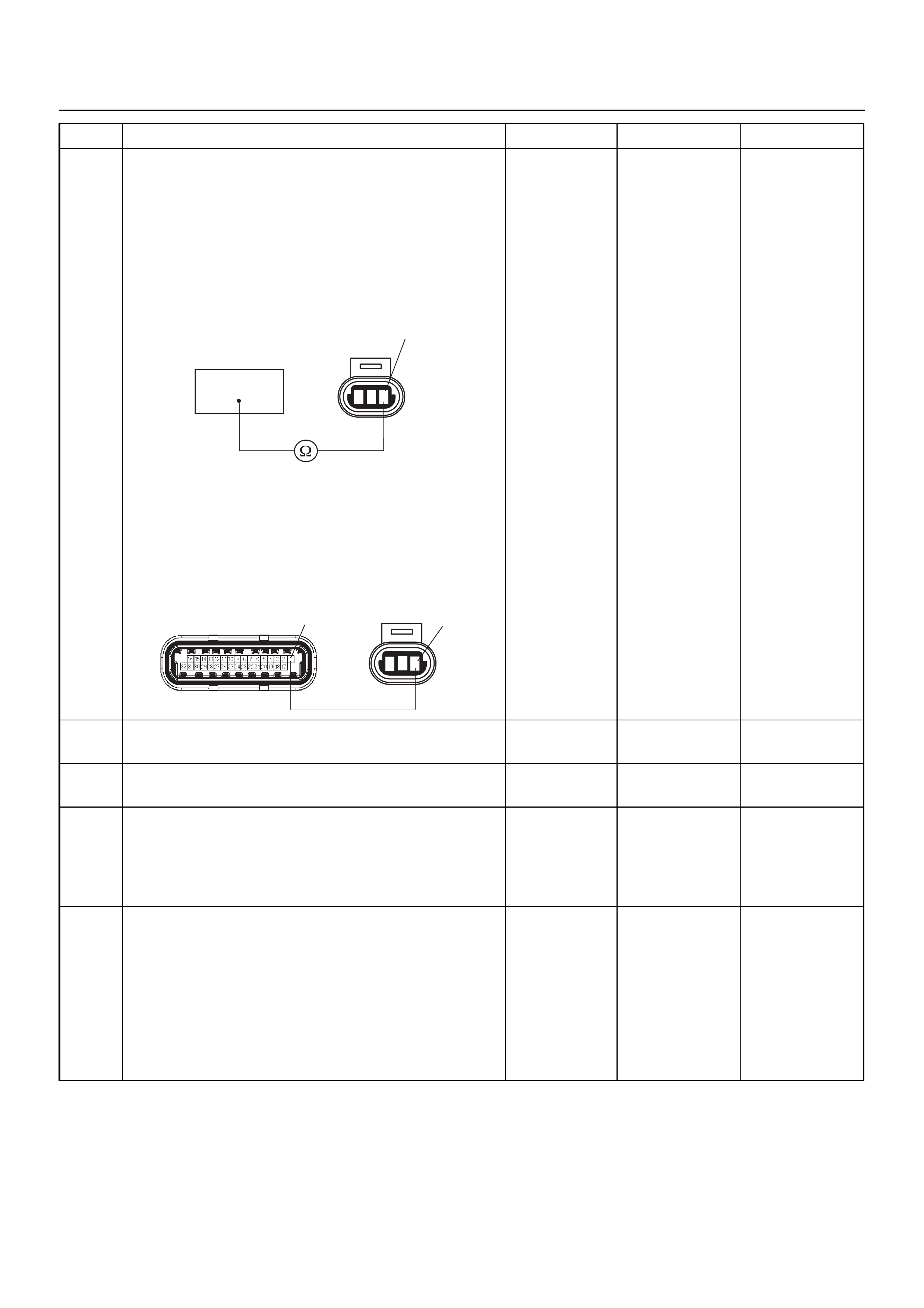

DIAGNOSTIC TROUBLE CODE (DTC) P0325

KNOCK SENSOR (KS) CIRCUIT

MALFUNCTION

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0325

Knock Sensor Module Circuit

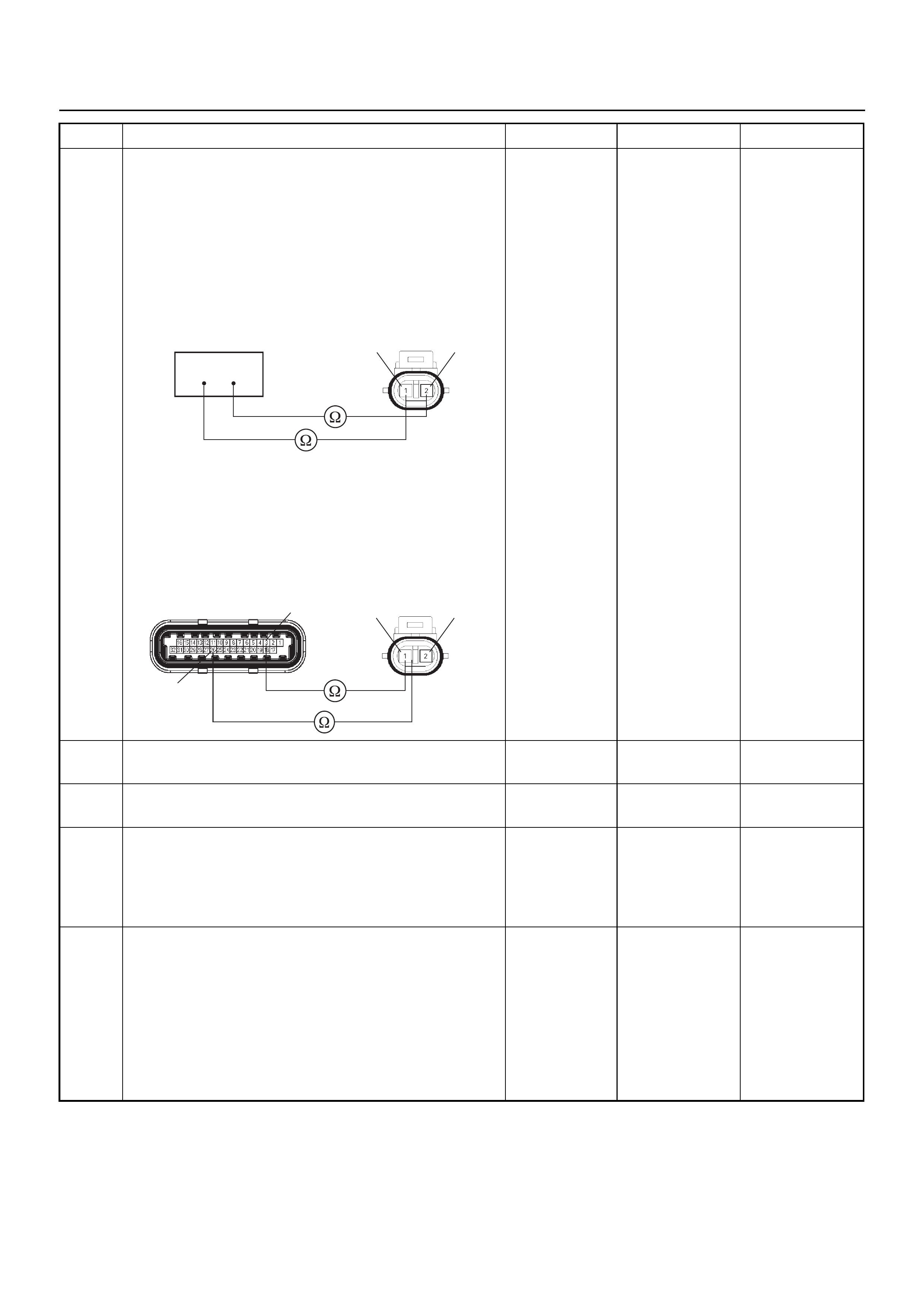

DIAGNOSTIC TROUBLE CODE (DTC) P0327

KNOCK SENSOR (KS) CIRCUIT LOW

INPUT

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0327

Knock Sensor Circuit

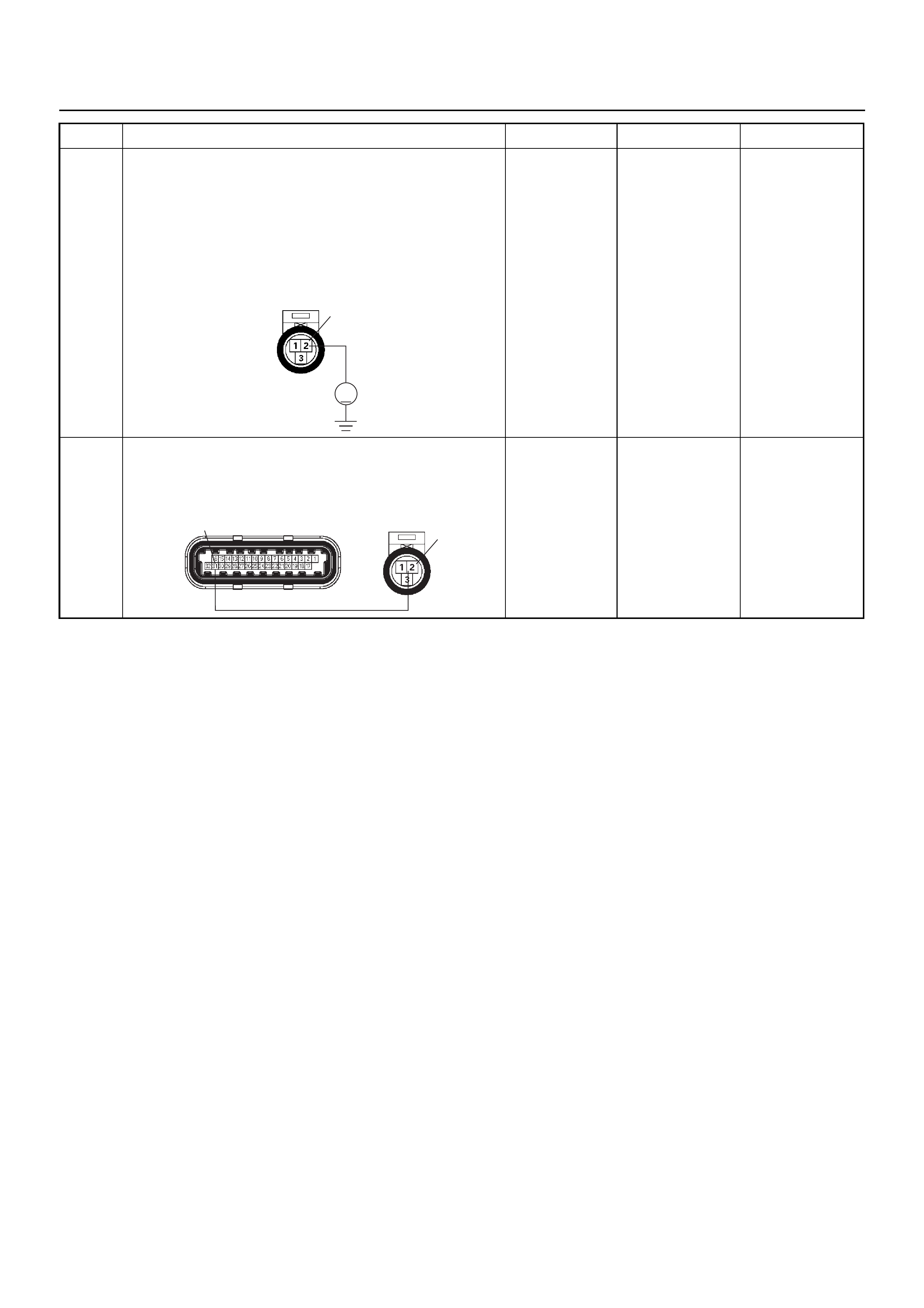

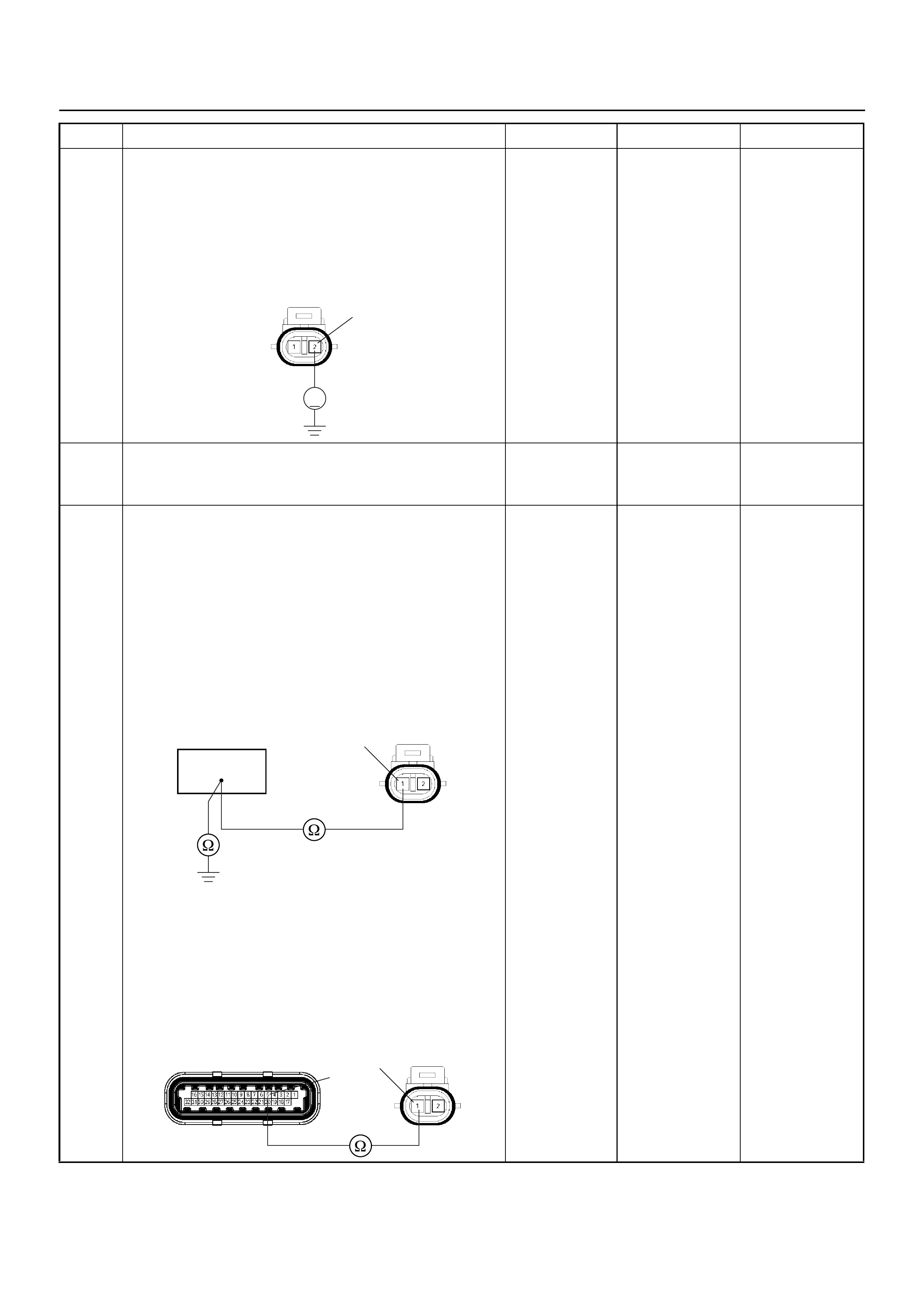

DIAGNOSTIC TROUBLE CODE (DTC) P0336

CRANKSHAFT POSITION (CKP) SENSOR

CIRCUIT RANGE/PERFORMANCE (58X)

DIAGNOSTIC TROUBLE CODE (DTC) P0337

CRANKSHAFT POSITION (CKP) SENSOR

CIRCUIT LOW INPUT (58X)

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0336

Crankshaft Position Sensor Circuit Range/

performance (58x)

Diagnostic Trouble Code (DTC) P0337

Crankshaft Position Sensor Circuit Low

Input (58x)

DIAGNOSTIC TROUBLE CODE (DTC) P0351

IGNITION 1 CONTROL CIRCUIT

DIAGNOSTIC TROUBLE CODE (DTC) P0352

IGNITION 2 CONTROL CIRCUIT

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0351

Ignition 1 Control Circuit

Diagnostic Trouble Code (DTC) P0352

Ignition 2 Control Circuit

DIAGNOSTIC TROUBLE CODE (DTC) P0443

EVAPORATIVE EMISSION (EVAP) CONTROL

SYSTEM PURGE CONTROL VALVE CIRCUIT

MALFUNCTION

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0443

Evap. Emission Control System Purge Control

Circuit

DIAGNOSTIC TROUBLE CODE (DTC) P0502

VEHICLE SPEED SENSOR (VSS) CIRCUIT

LOW INPUT

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0502 Vehicle

Speed Sensor Circuit Low Input

DIAGNOSTIC TROUBLE CODE (DTC) P0562

SYSTEM VOLTAGE LOW

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0562

System Voltage Low

DIAGNOSTIC TROUBLE CODE (DTC) P0563

SYSTEM VOLTAGE HIGH

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0563

System Voltage High

DIAGNOSTIC TROUBLE CODE (DTC) P0601

ECM MEMORY CHECKSUM

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0601

ECM Memory Checksum

DIAGNOSTIC TROUBLE CODE (DTC) P0602

PROGRAMMING ERROR

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0602

Programming Error

DTC P0650 MALFUNCTION INDICATOR

LAMP (MIL) CONTOROL CIRCUIT

MALFUNCTION

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P0650

Malfunctio n Indi ca tor La m p (M IL ) Con tr ol

Circuit Malfunction

DIAGNOSTIC TROUBLE CODE (DTC) P1167

FUEL SUPPLY SYSTEM RICH DURING

DECELERATION FUEL CUT OFF

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P1167

Fuel Supply System Rich During Deceleration

Fuel Cutoff

DIAGNOSTIC TROUBLE CODE (DTC) P1171

FUEL SUPPLY SYSTEM LEAN DURING

POWER ENRICHMENT

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P1171

Fuel Supply System Lean During Power

Enrichment

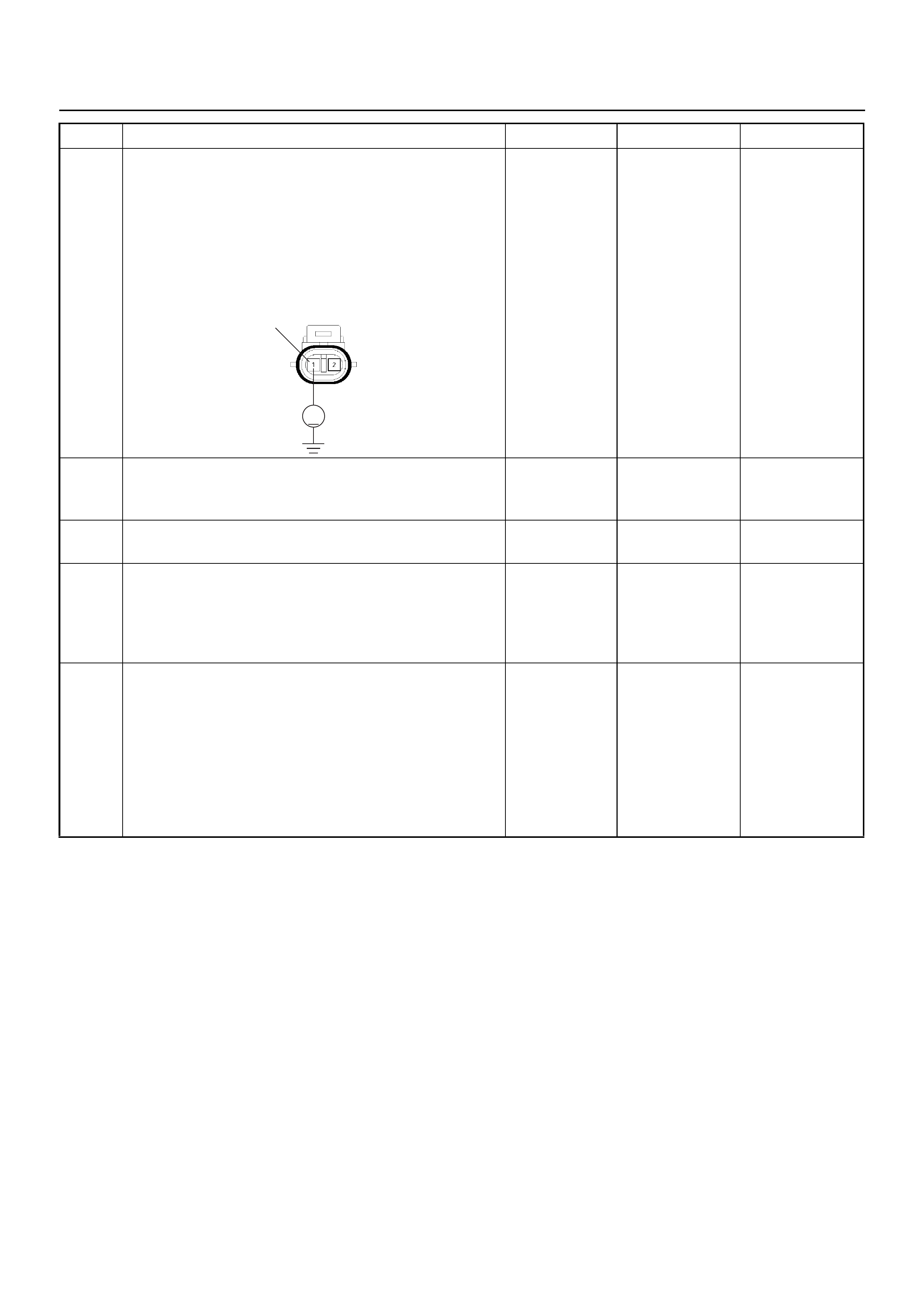

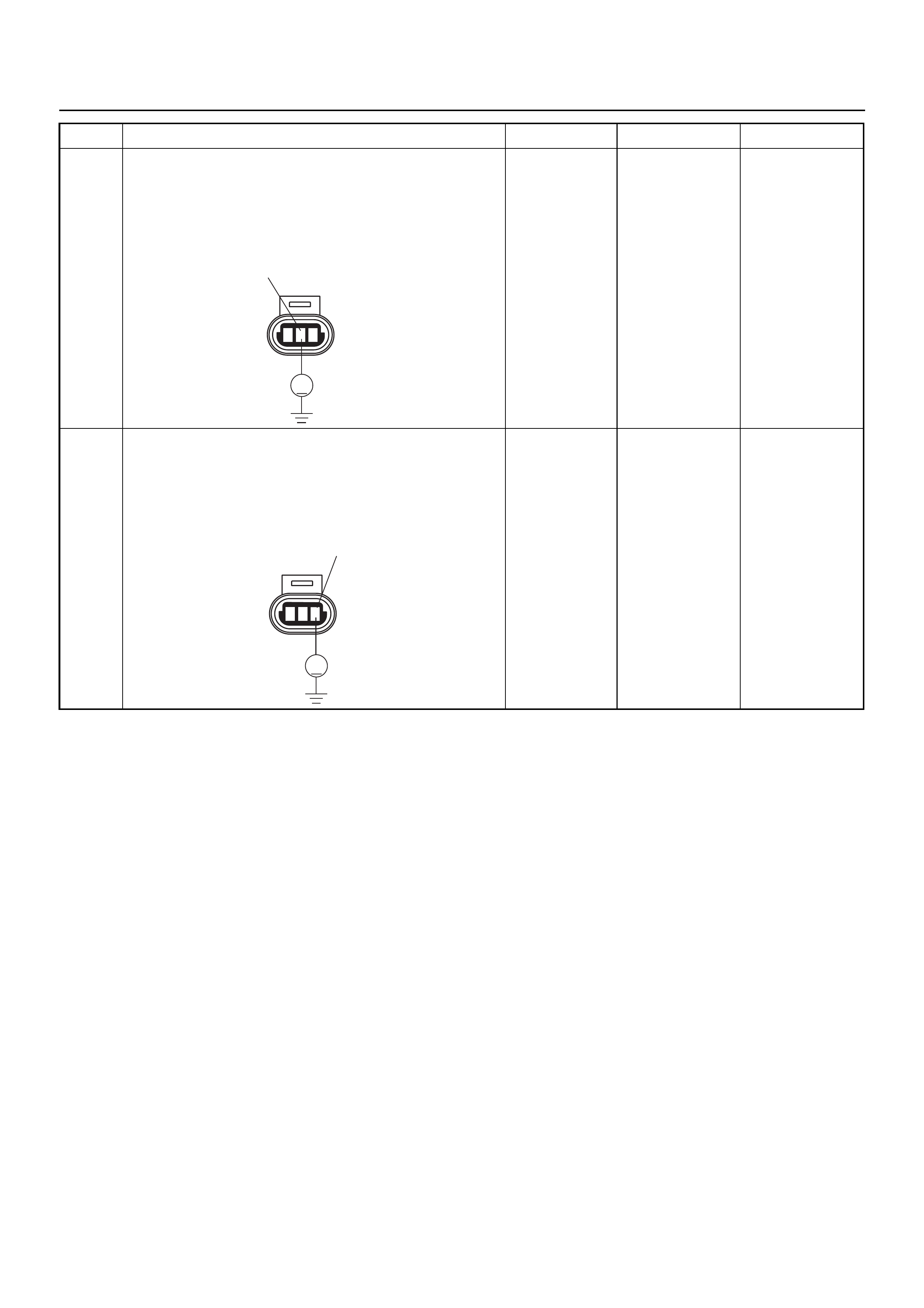

DIAGNOSTIC TROUBLE CODE (DTC) P1391

RRID G Sen. Rationality

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P1391

RRID G Sen. Rationality

DIAGNOSTIC TROUBLE CODE (DTC) P1392

RRID G Sen. Short Low

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P1392

RRID G Sen. Short Low

DIAGNOSTIC TROUBLE CODE (DTC) P11393

RRID G Sen. Short High

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P11393

RRID G Sen. Short High

DIAGNOSTIC TROUBLE CODE (DTC) P1625

ECM SYSTEM RESET

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P1625

ECM System Reset

DIAGNOSTIC TROUBLE CODE (DTC) P1626

IMMOBILISER NO SIGNAL

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P1626

Immobiliser No Signal

DIAGNOSTIC TROUBLE CODE (DTC) P1631

IMMOBILISER WRONG SIGNAL

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P1631

Immobiliser Wrong Signal

DIAGNOSTIC TROUBLE CODE (DTC) P1648

WRONG SECURITY CODE ENTERED

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P1648

Wrong Security Code Entered

DIAGNOSTIC TROUBLE CODE (DTC) P1649

IMMOBILISER FUNCTION NOT

PROGRAMMED

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P1649

Immobiliser Function Not Programmed

DIAGNOSTIC TROUBLE CODE (DTC) P1693

TACHOMETER OUTPUT LOW VOLTAGE

Circuit Description

Diagnostic Aids

Diagnostic Trouble Code (DTC) P1693

Tachometer Output Low Voltage

SYMPTOM DIAGNOSIS

PRELIMINARY CHECKS

VISUAL/PHYSICAL CHECKS

INTERMITTEN T PRO B LE MS

ENGINE CRANKS BUT WILL NOT RUN

HARD START SYMPTOM

ROUGH, UNSTABLE, OR INCORRECT IDLE,

STALLING SYMPTOM

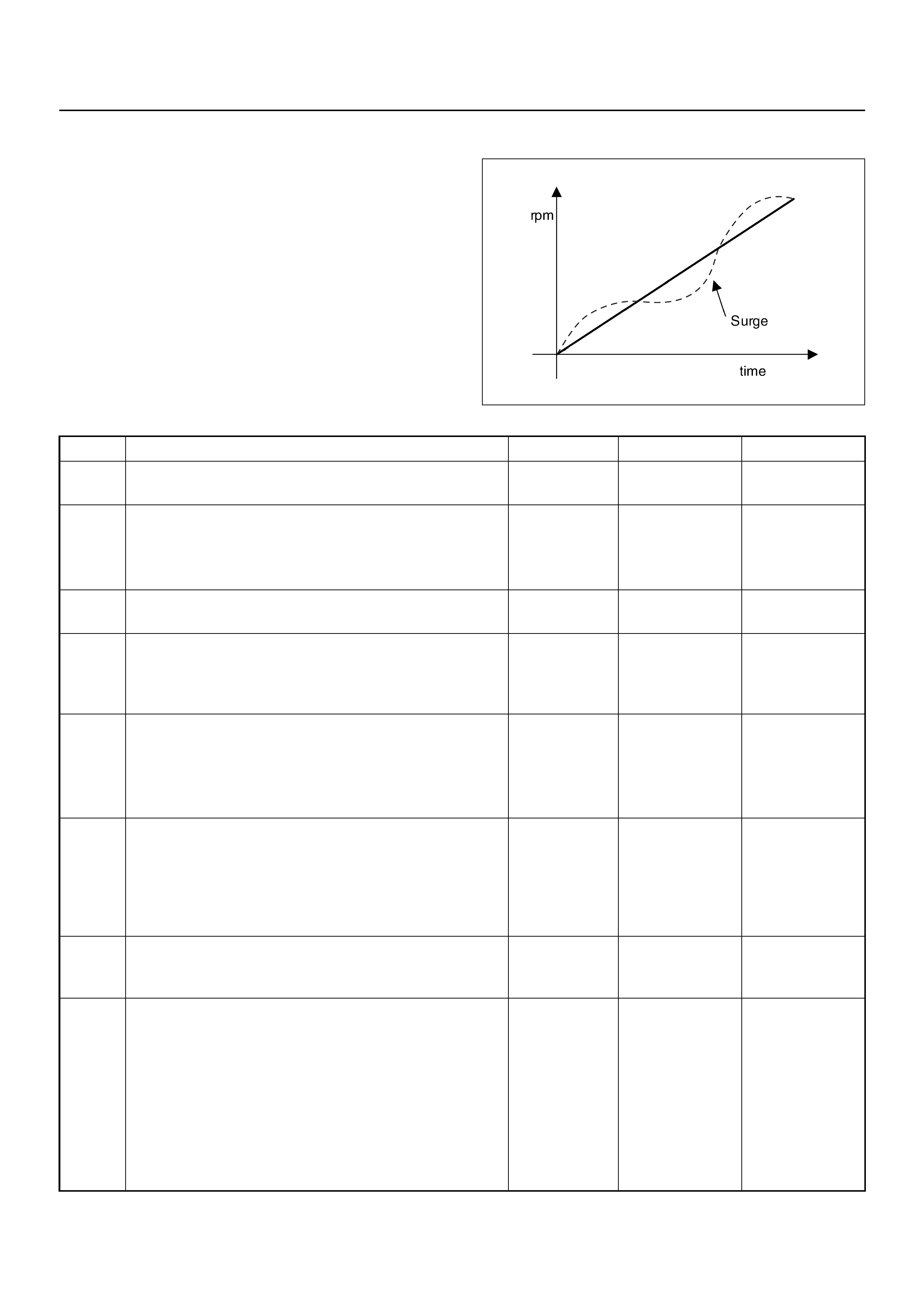

SURGES AND/OR CHUGS SYMPTOM

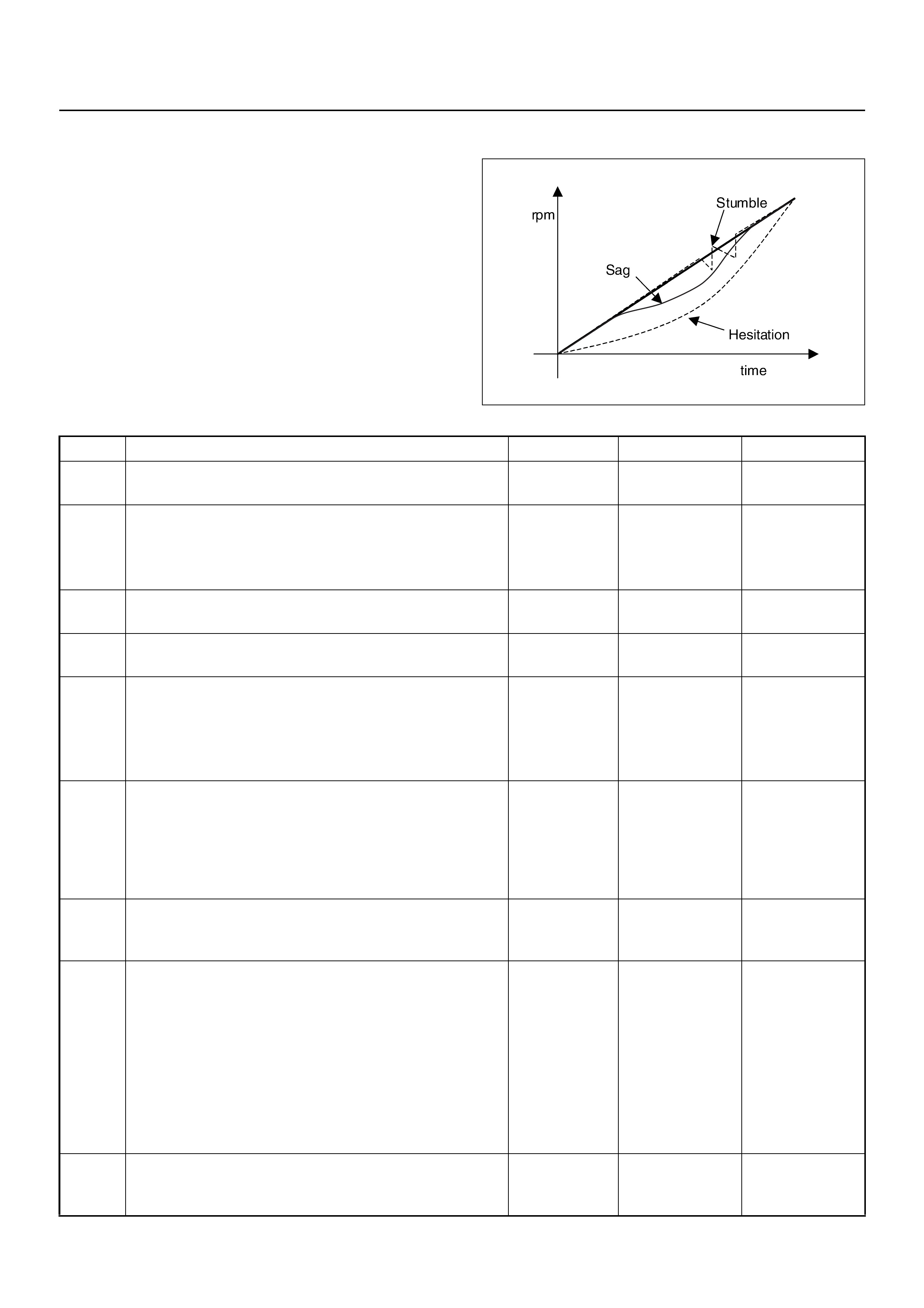

HESITATION, SAG, STUMBLE SYMPTOM

CUTS OUT, MISSES SYMPTOM

LACK OF POWER, SLUGGISH OR

SPONGY SYMPTOM

DETONATION/SPARK KNOCK SYMPTOM

POOR FUEL ECONOMY SYMPTOM

EXCESSIVE EXHAUST EMISSIONS OR

ODORS SYMPTOM

DIESELING, RUN-ON SYMPTOM

BACKFIRE SYMPTOM

ON-VEHICLE SERVICE PROCEDURE

ENGINE CONTROL MODULE (ECM)

CRANKSHAFT POSITION (CKP)

SENSOR

ENGINE COOLANT TEMPERATURE (ECT)

SENSOR

INTAKE AIR TEMPERATURE (IAT)

SENSOR

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR

THROTTLE POSITION SENSOR (TPS)

IDLE AIR CONTROL (IAC) VALVE

KNOCK SENSOR (KS)

VERTICAL-G (RRID) SENSOR

HEATED OXYGEN SENSOR (HO2S)

EVAP CANISTER PURGE VALVE

SOLENOID

FUEL PRESSURE RELIEF

FUEL RAIL ASSEMBLY

FUEL INJECTOR

ABBREVIATIONS CHARTS

Abbreviations Appellation

A/C Air Conditioner

A/T Automatic Transmission

ACC Accessory

BLK Black

BLU Blue

BRN Brown

CEL Check Engine Lamp

CKP Crankshaft Position

DLC Data Link Connector

DTC Diagnostic Trouble Code

DVM Digital Volt Meter

ECM Engine Control Module

ECT Engine Coolant Temperature

EEPROM Electrically Erasable & Programmable Read Only Memory

EVAP Evaporative Emission

EVRV Electric Vacuum Regulating Valve

EXH Exhaust

FT Fuel Temperature

GND Ground

GRY Grey

HO2S Heated Oxyge n Sens or

IAC Idle Air Control

IAT Intake Air Temperature

IG Ignition

ITP Intake Throttle Position

KS Knock Sensor

M/T Manual Transmission

MAP Manifold Absolute Pressure

MIL Malfunction Indicator Lamp

OBD On-Bo ar d Dia gn os tic

ORN Orange

OT Oil Temperature

PNK Pink

RED Red

SW Switch

TB Throttle Body

TEMP Temperature

TP Throttle Position

VSS Vehicle Speed Sensor

WHT White

YEL Yellow

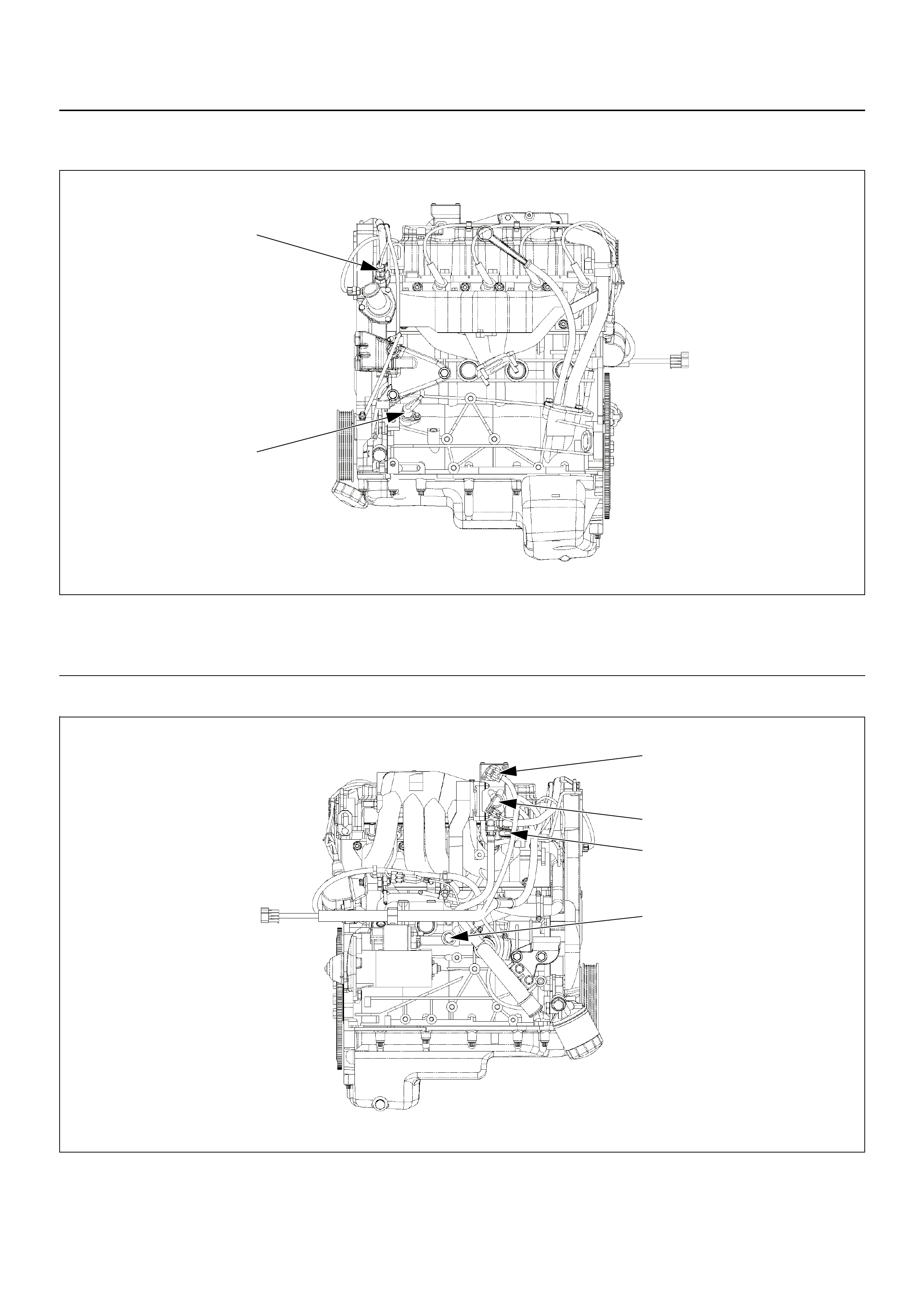

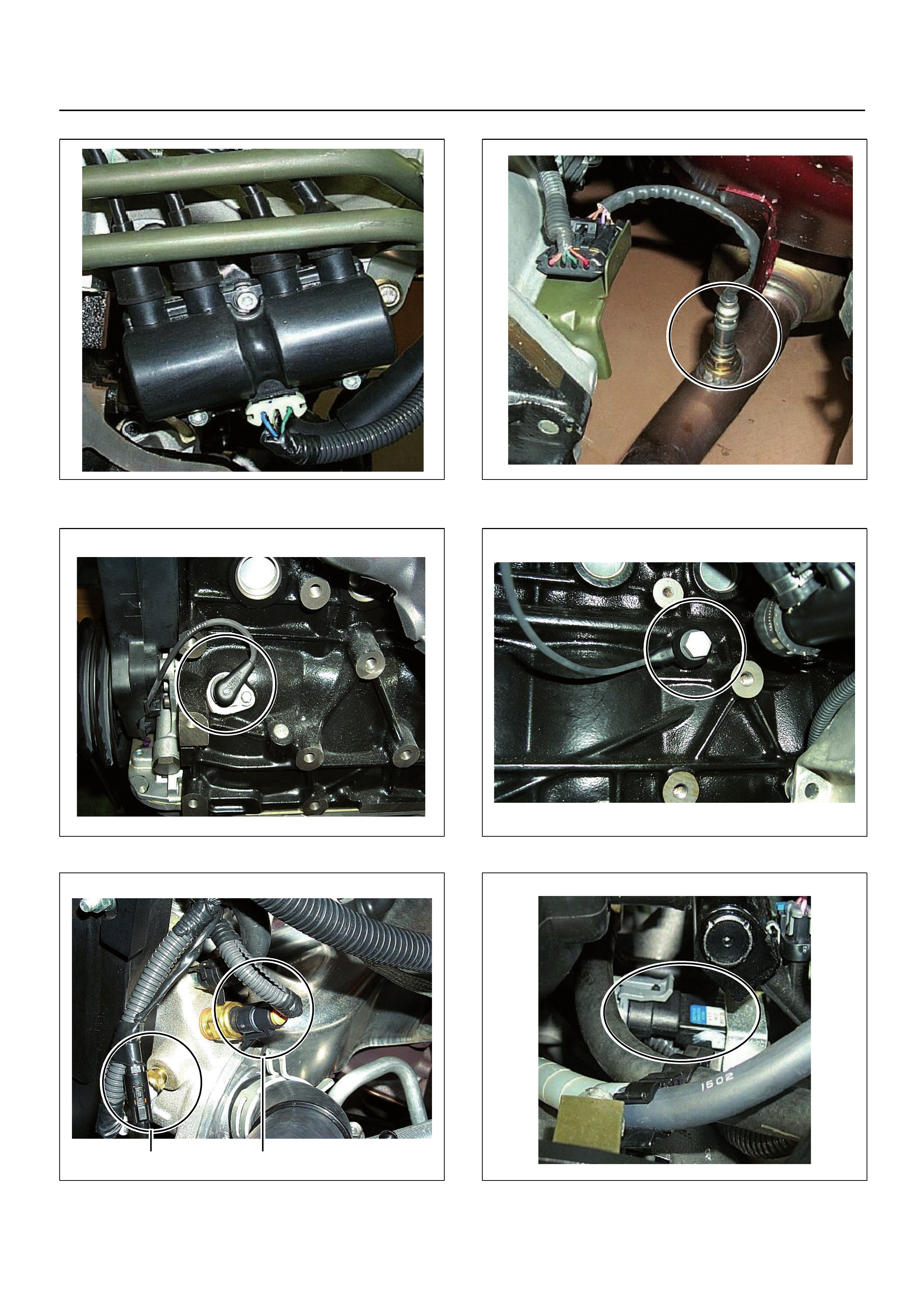

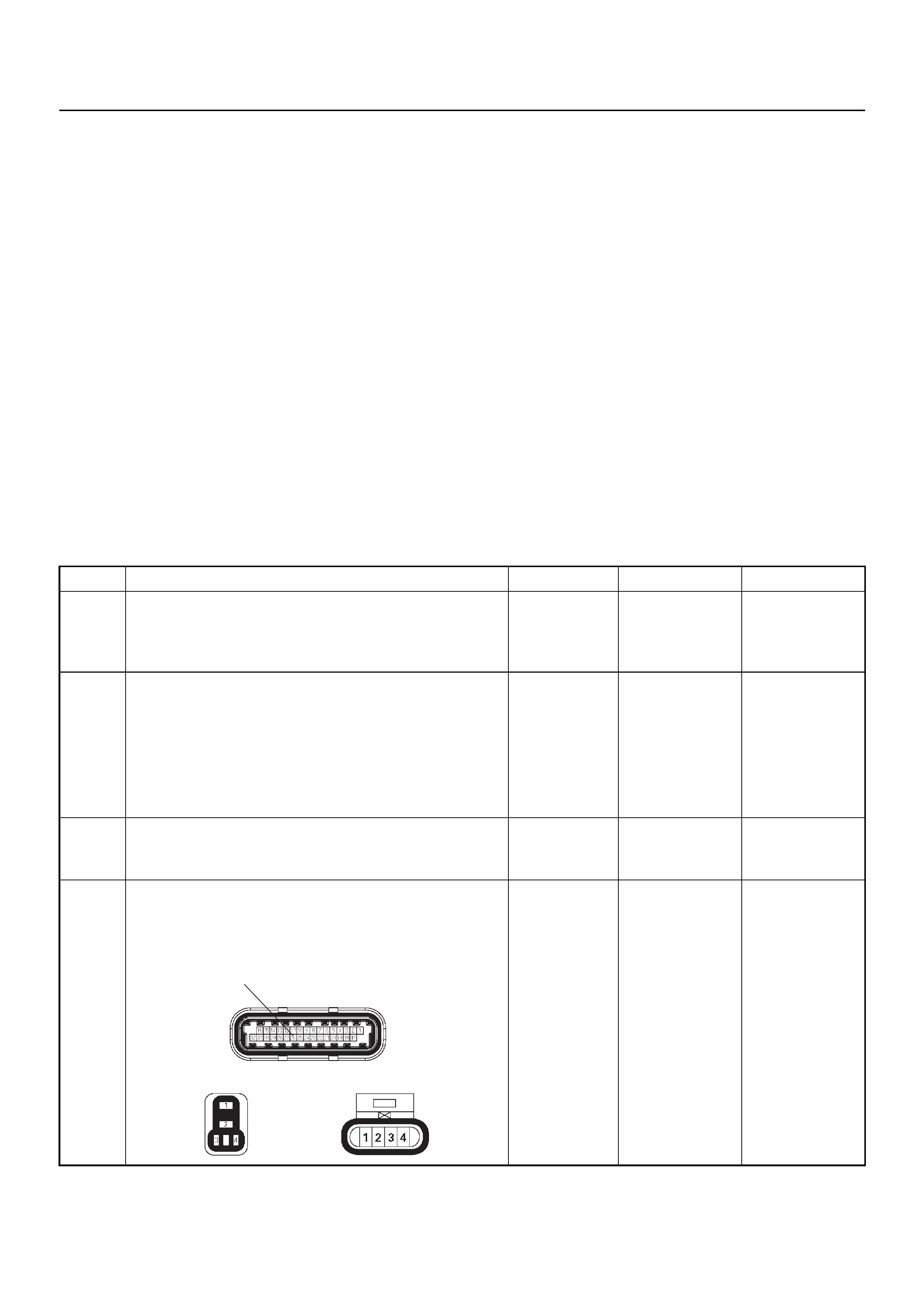

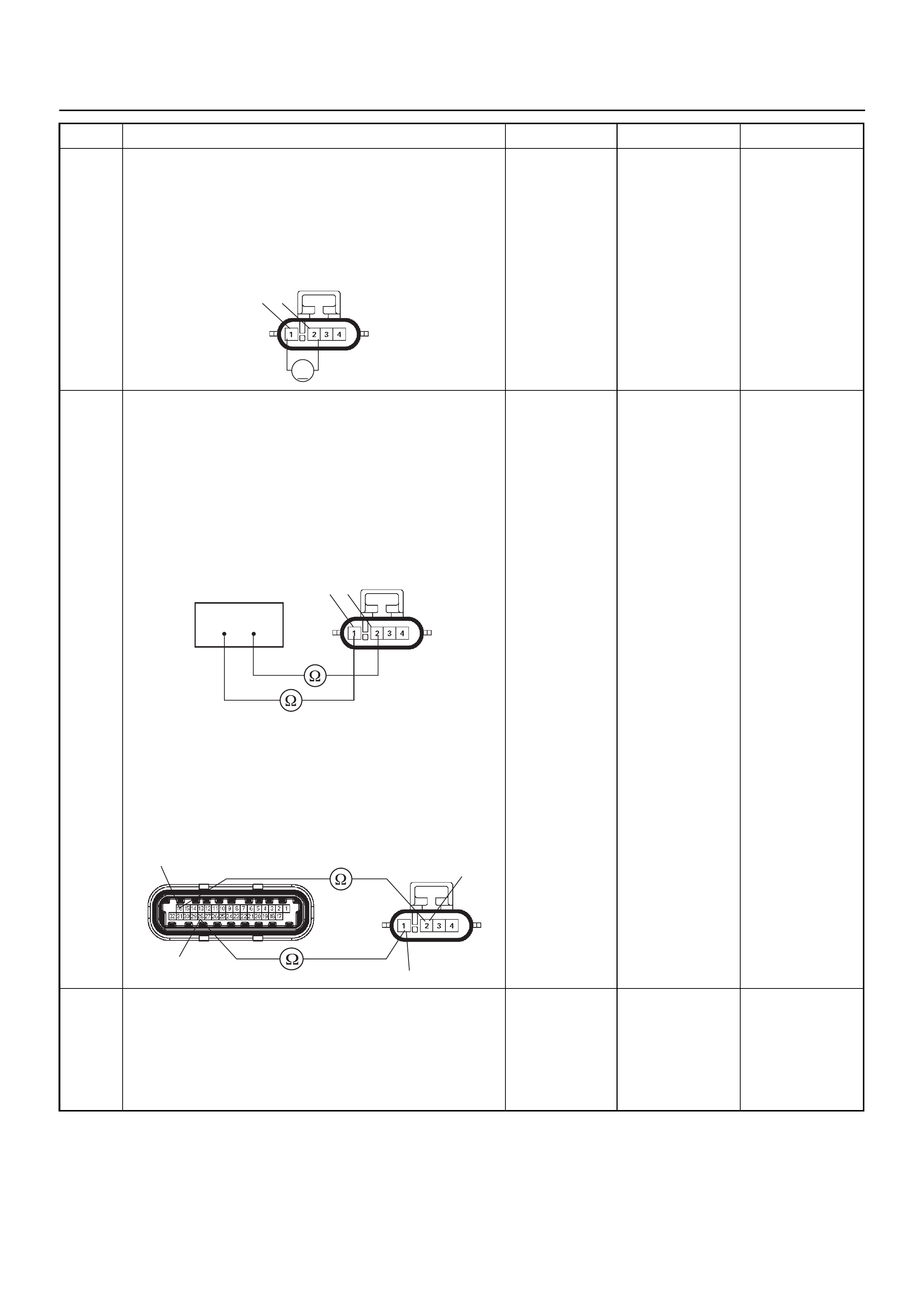

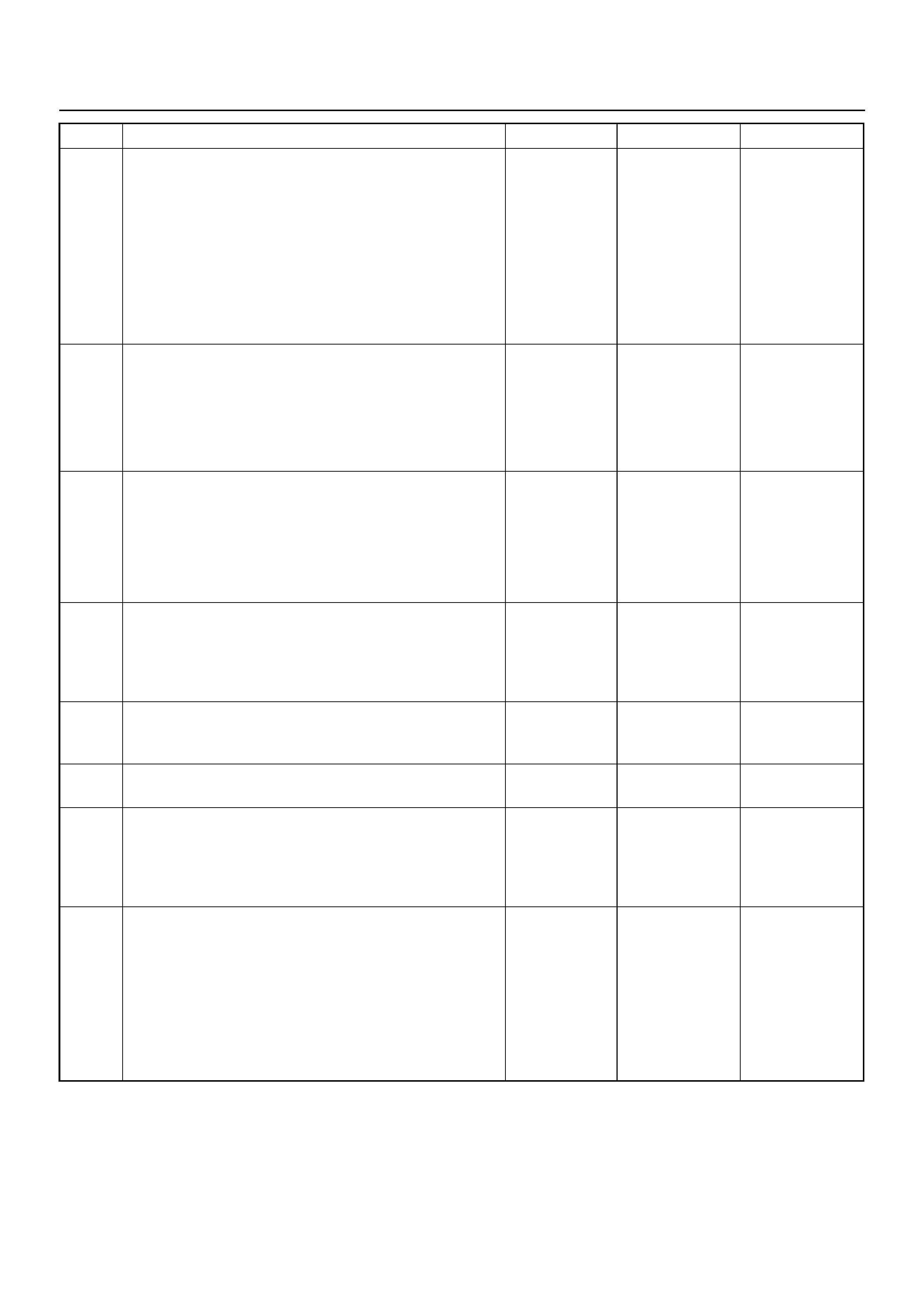

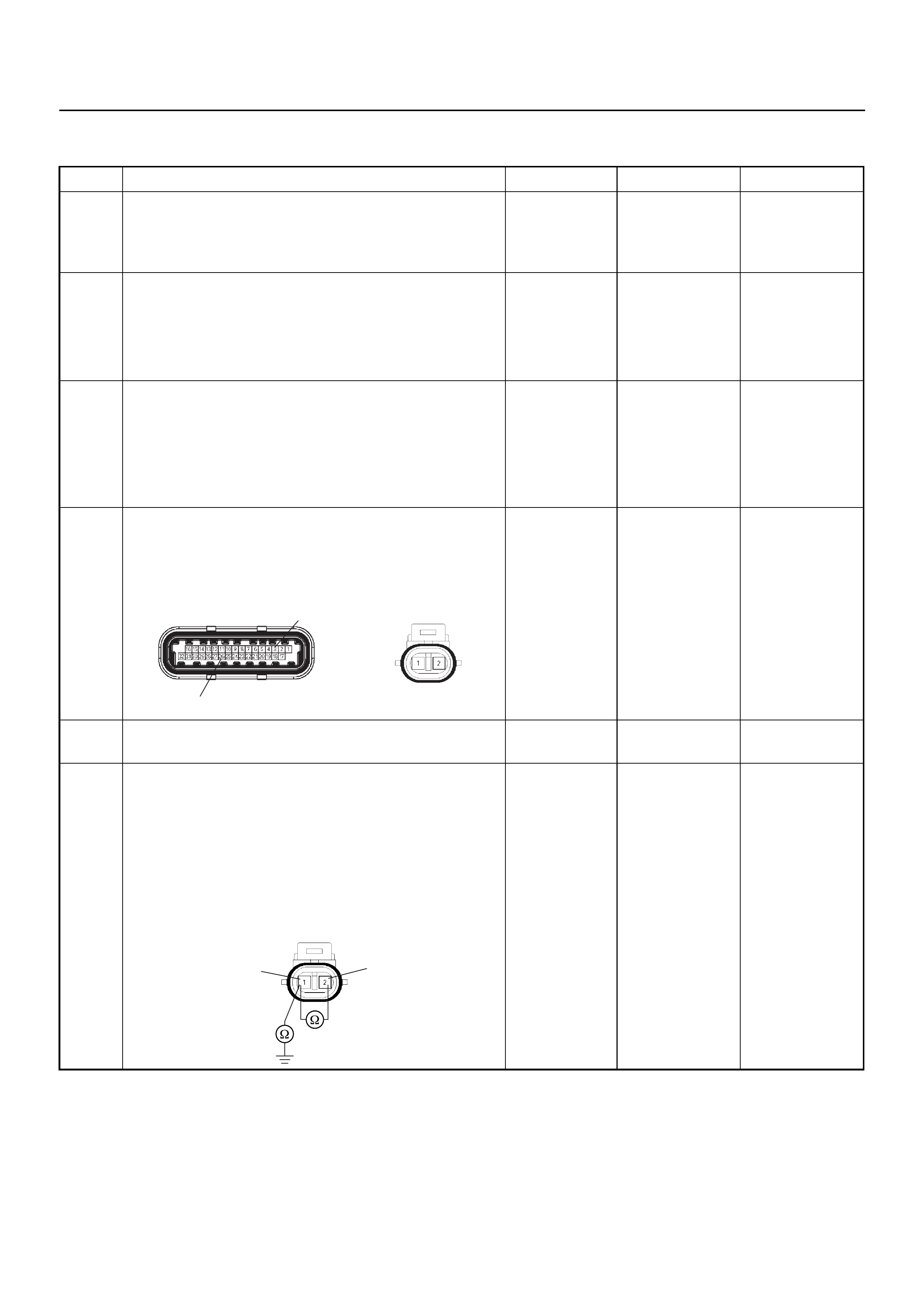

COMPONENT LOCATOR

EndOFCallout

21

1

Legend

(1) Engine Coolant Tem p er at ur e (EC T) Sen sor

(2) Crankshaft Position (CKP) Sensor

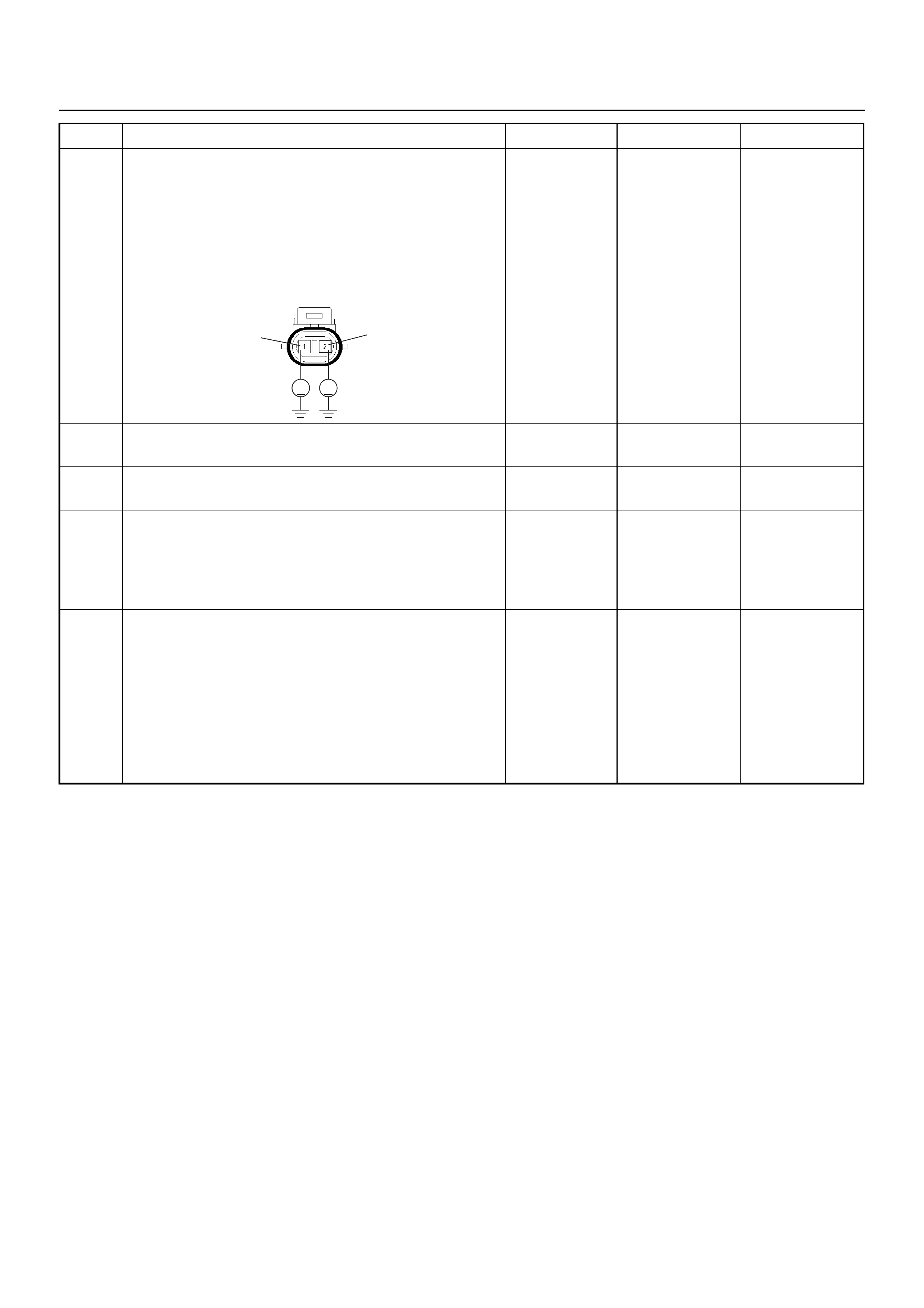

1

1

2

3

4

Legend

(1) Idle Air Control (IAC) Valv e

(2) Throttle Position Sensor (TPS)

(3) Knock Sensor (KS)

(4) Manifold Absolute Pressure (MAP) Sensor

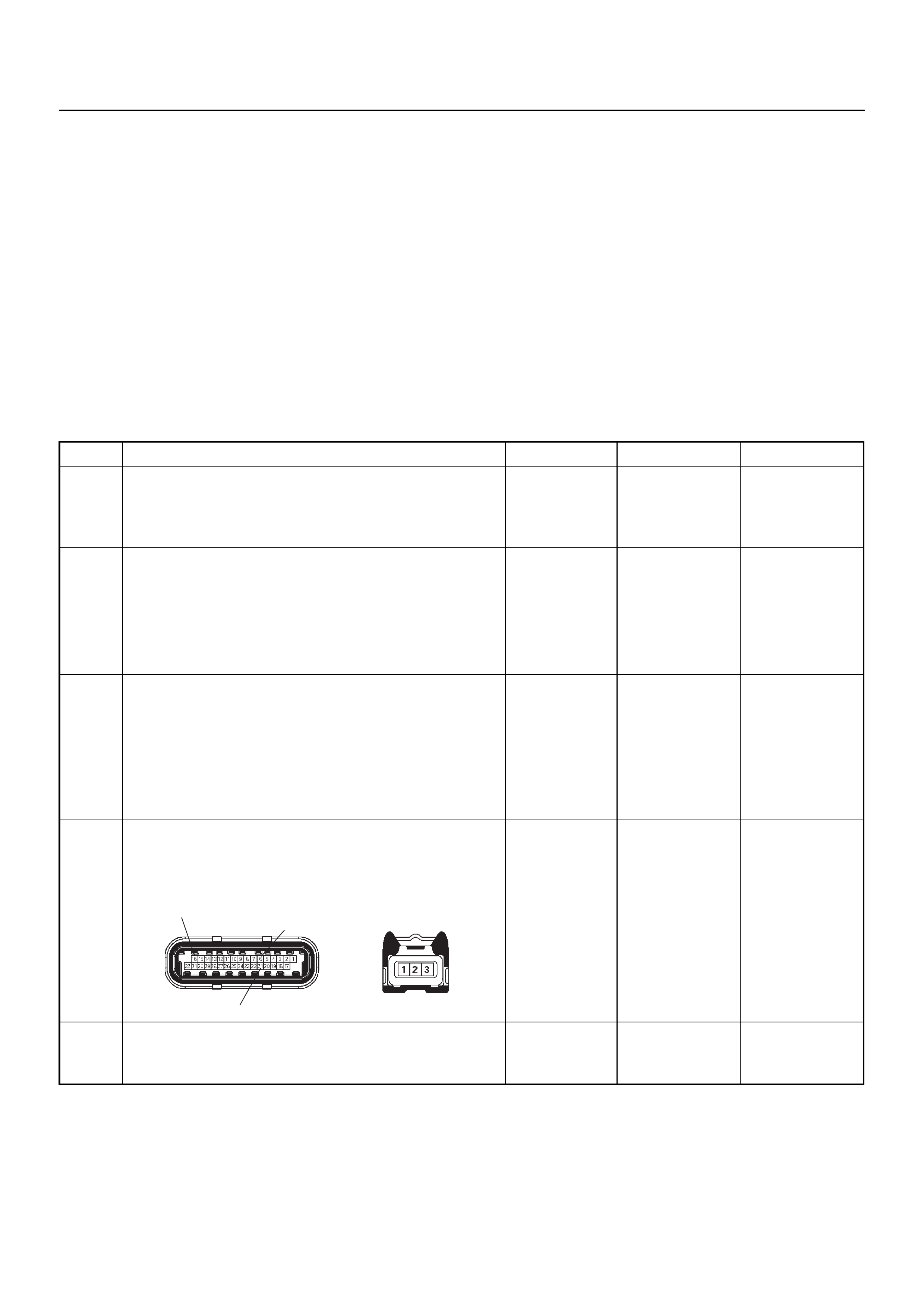

EndOFCallout

1

2

3

4

5

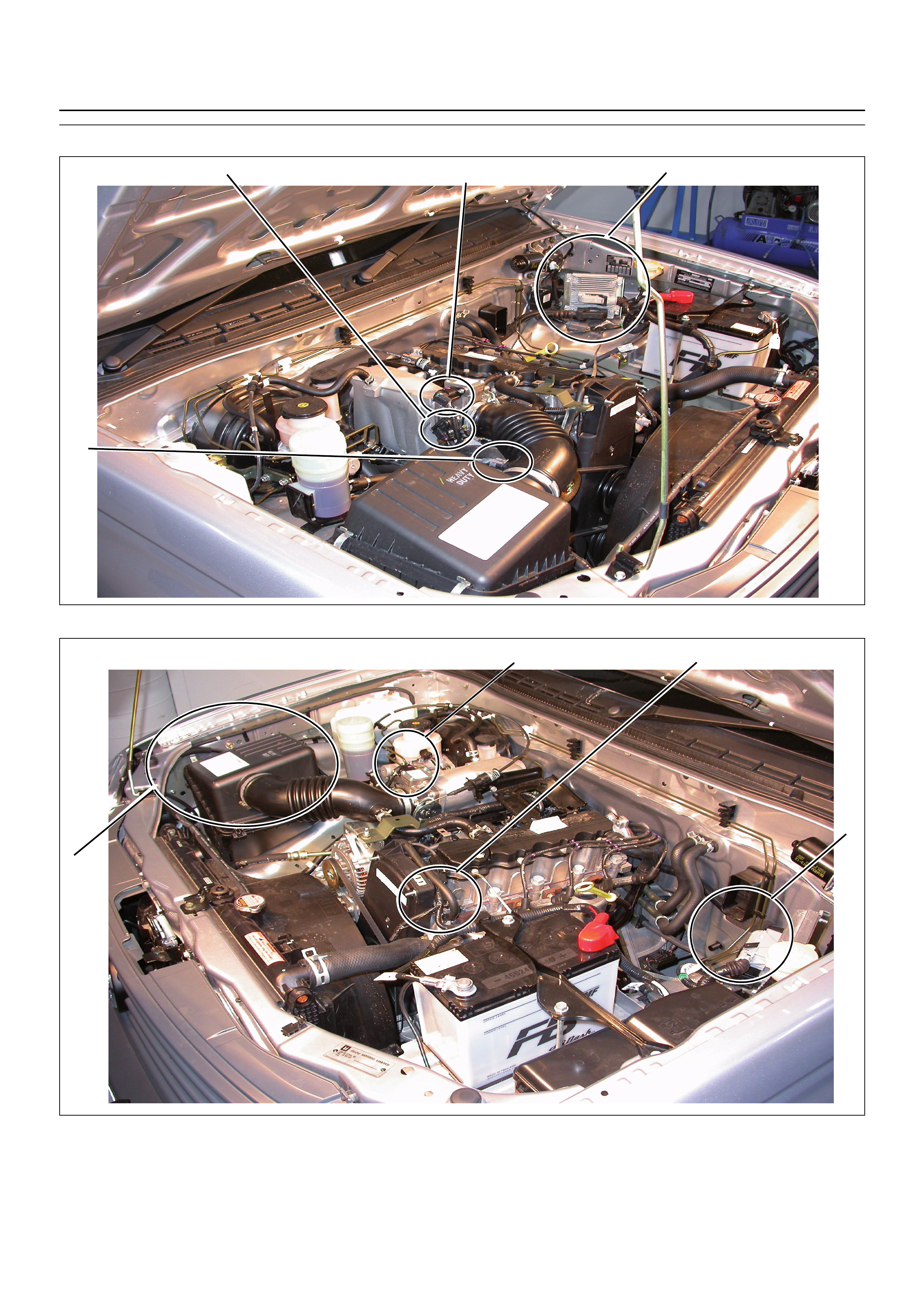

26

1

(1)

(2) Engine Control Module (ECM)

Idle Air Control (IAC) Valve

(3) Throttle Position Sensor (TPS)

(4)

(5) Intake Air Temperature (IAT) Sensor

Air Cleaner

(6) Engine Coolant Temperature (ECT) Sensor

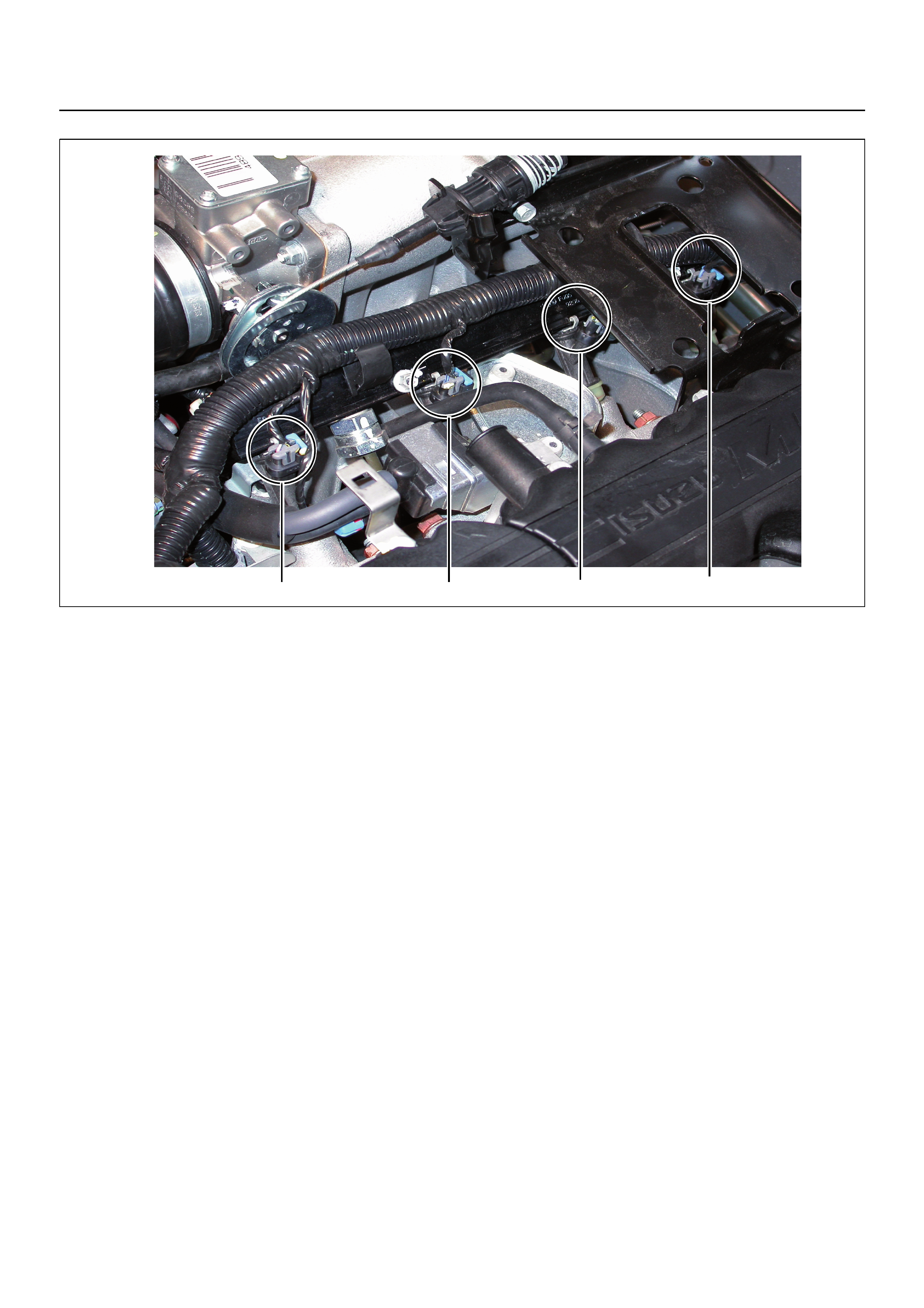

1234

(1)

(2) Injector #1 Cylinder

Injector #2 Cylinder (3)

(4) Injector #3 Cylinder (Under bracket)

Injector #4 Cylinder (Under bracket)

(1) Ignition Coil Module Assembly (1) Heated Oxygen Sensor Pre O2

(1) Crankshaft Position (CKP) Sensor (1) Knock Sensor (KS)

(1)

(2) Engine Coolant Temperature (ECT) Sensor

Thermo Meter Sensor

2 1

(1) Manifold Absolute Pressure (MAP) Sensor

(1)

(2) Throttle Position Sensor

Idle Air Control (IAC) Valve

2

1

(1) EVAP Purge Solenoid

(1) Canister

1

(1)

(2) Fuel Tank

Fuel Pump

21

1 2

(1)

(2) Vehicle Speed Sensor (VSS)

Transmission Assembly

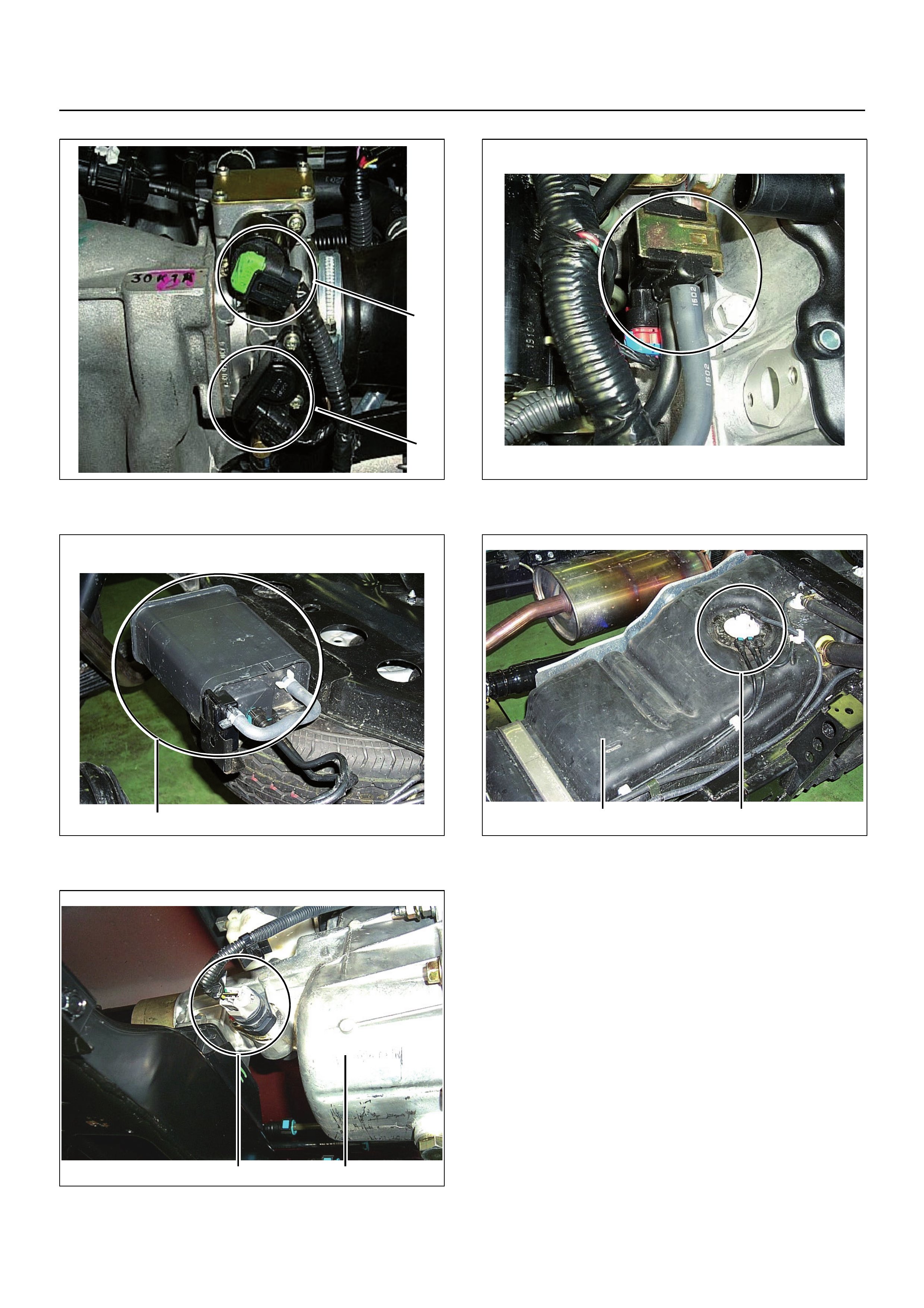

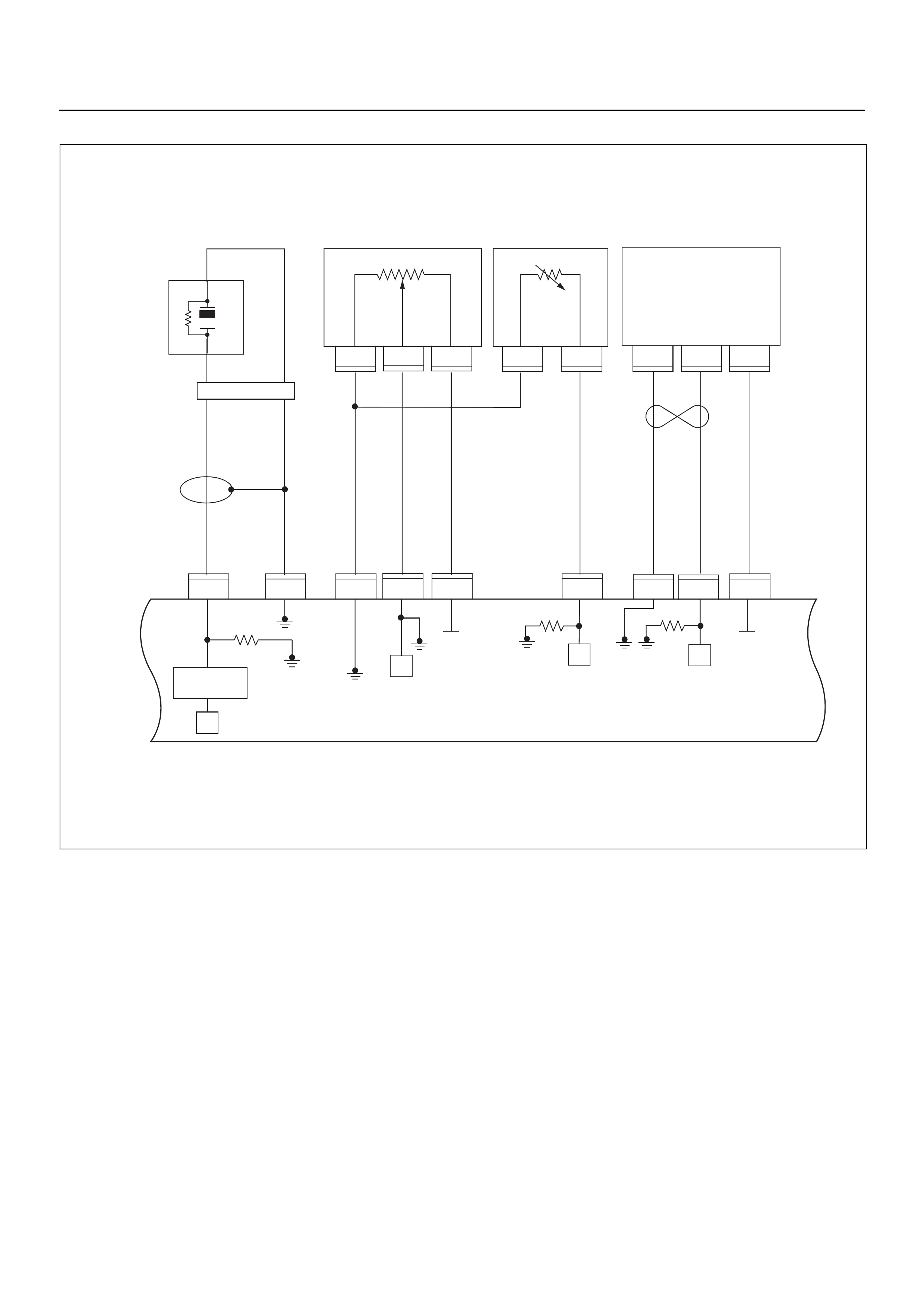

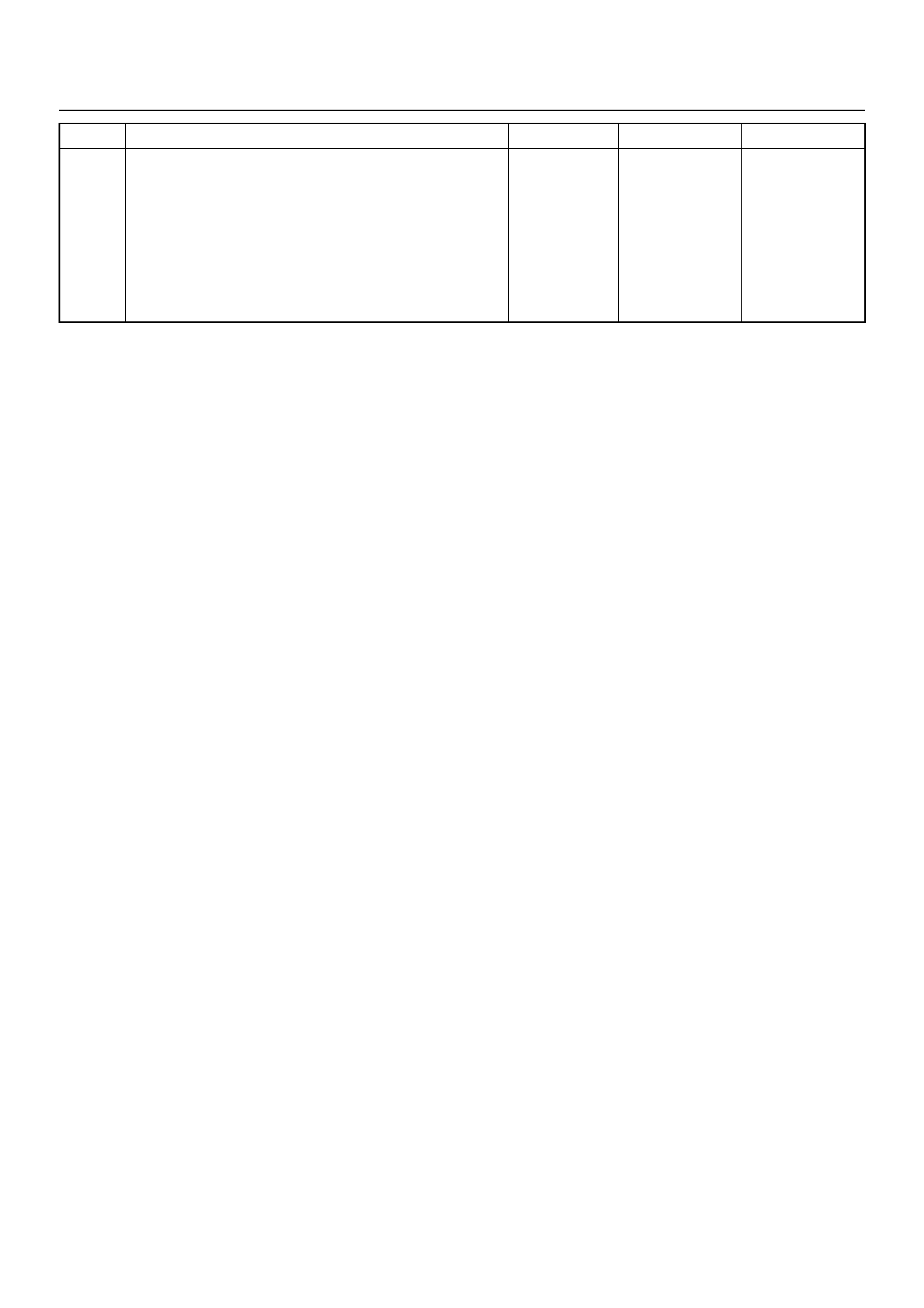

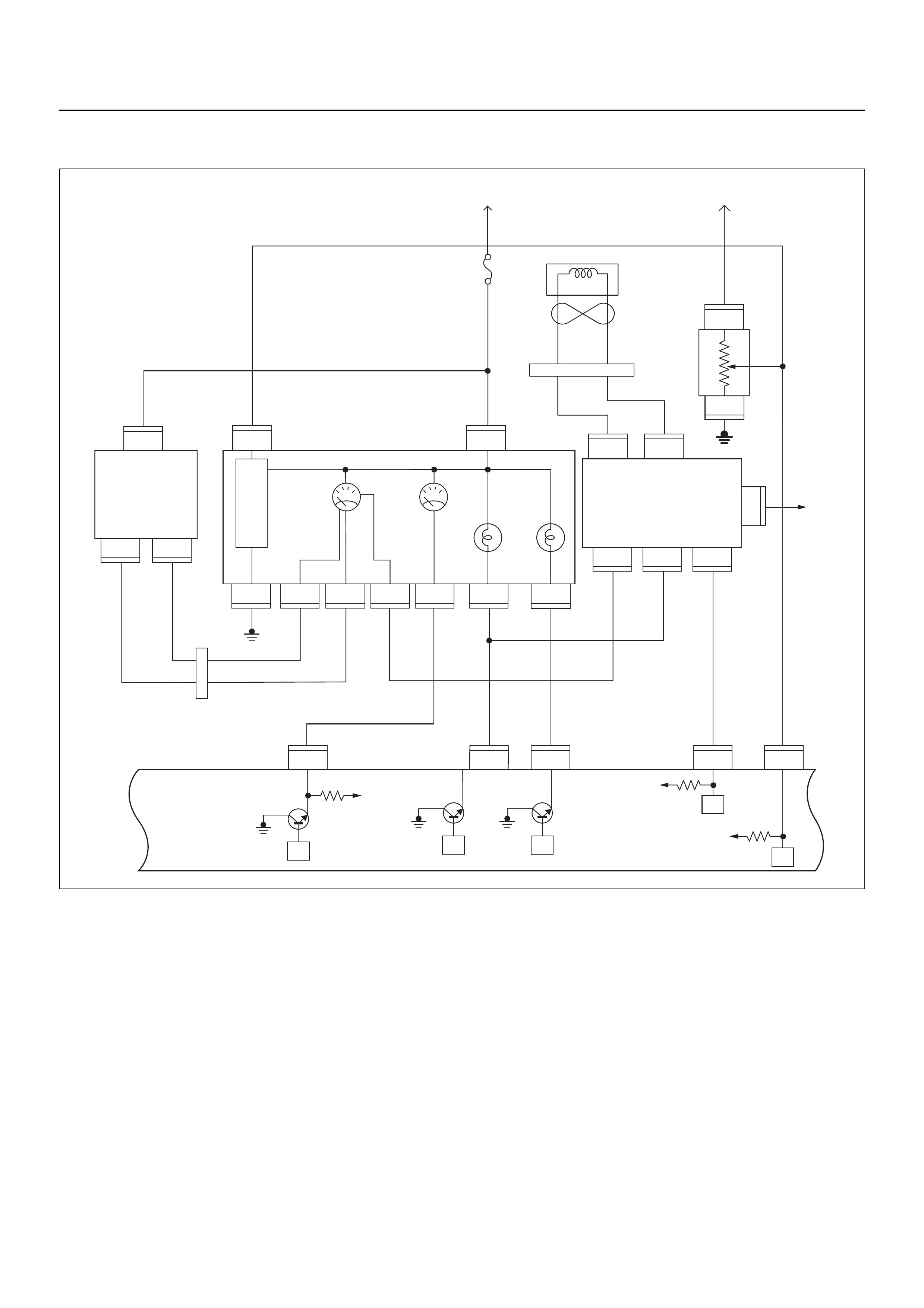

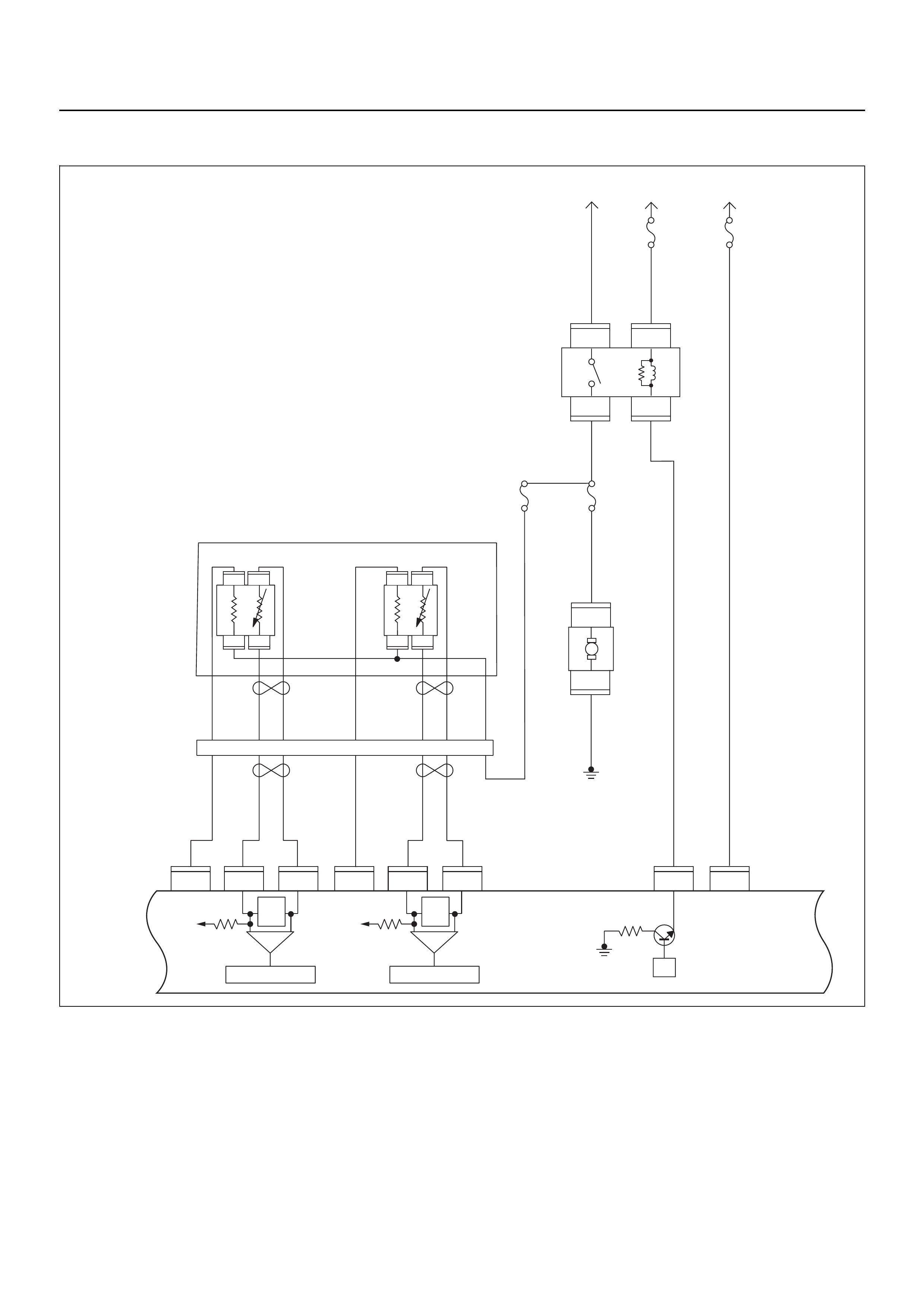

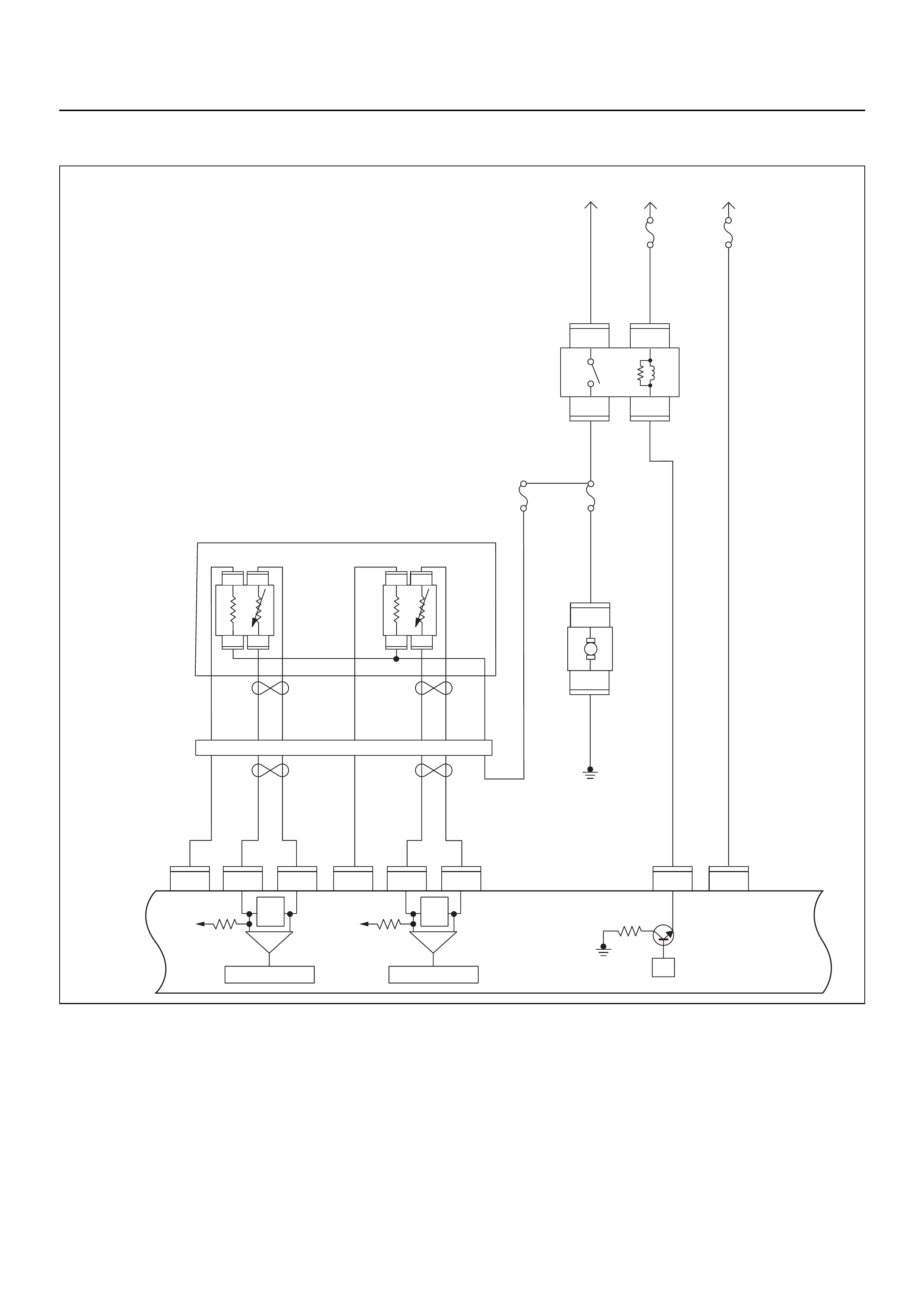

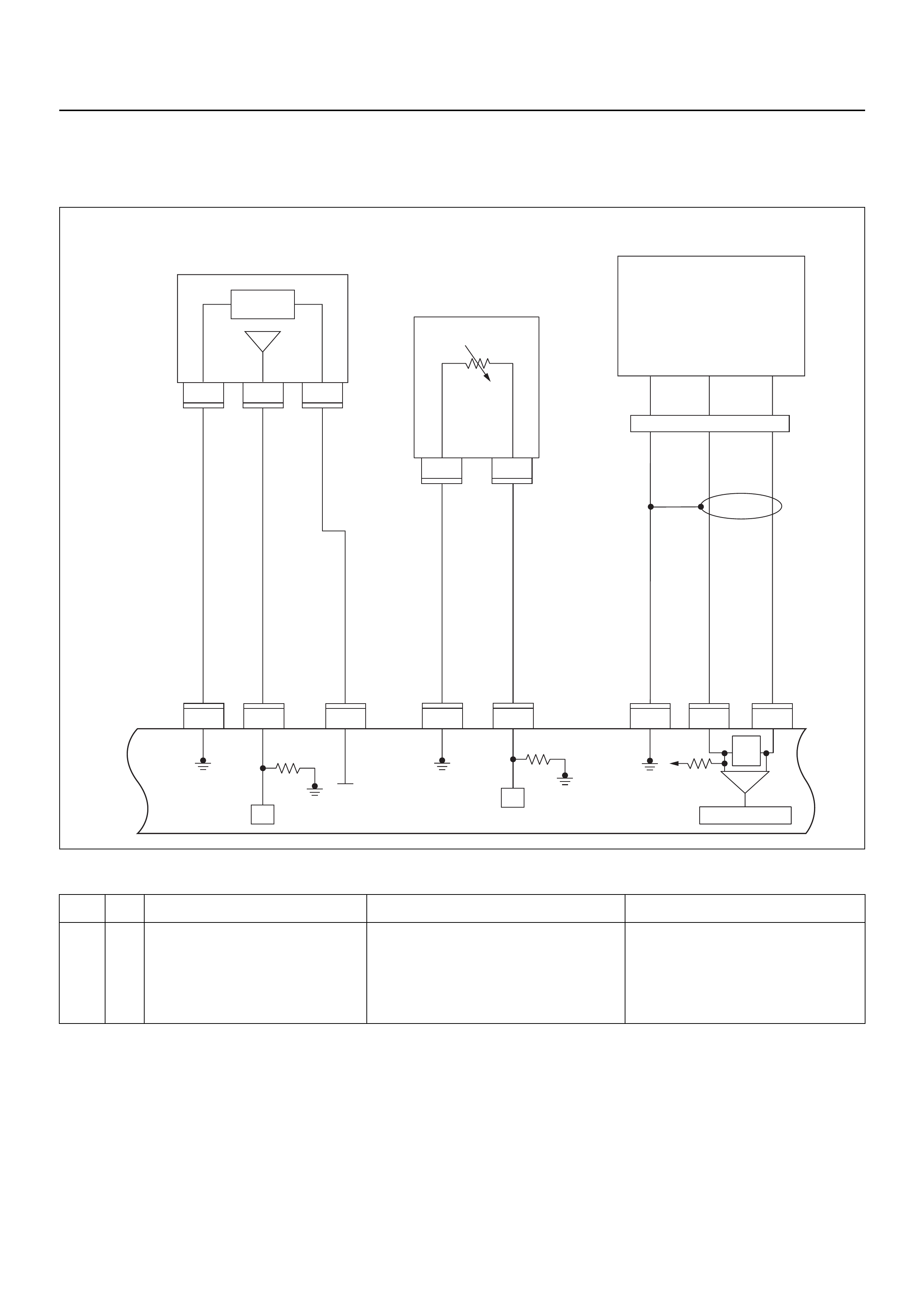

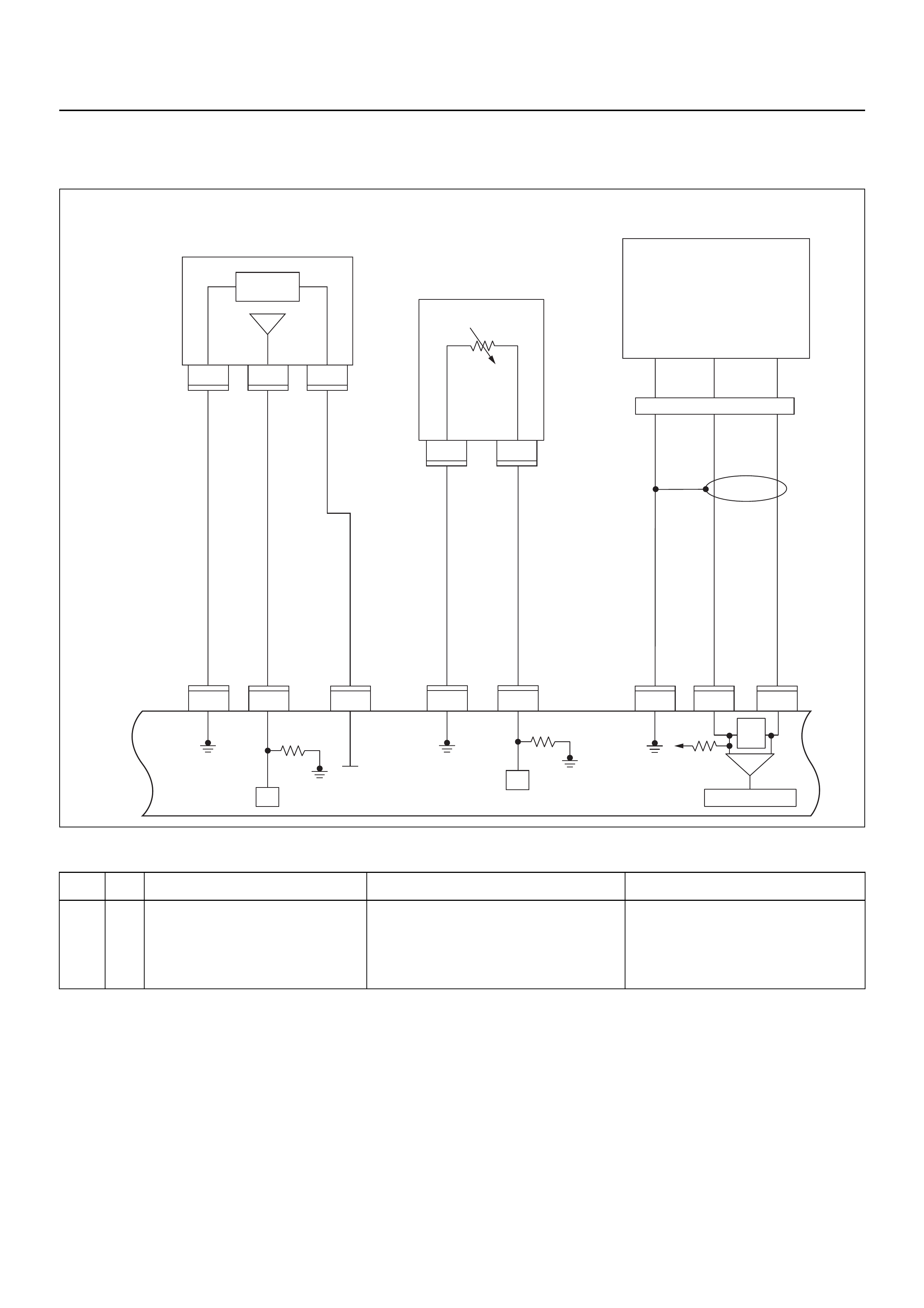

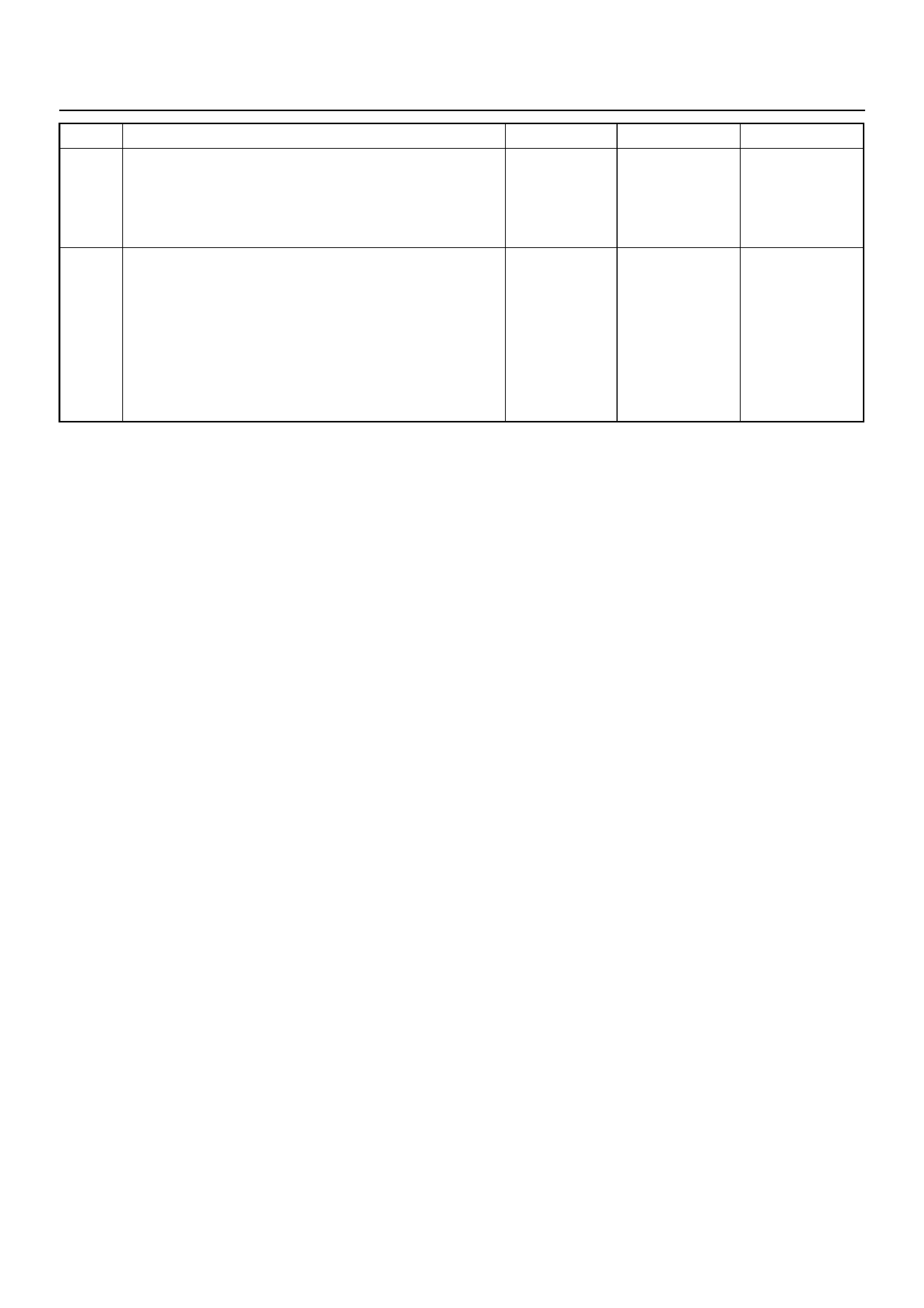

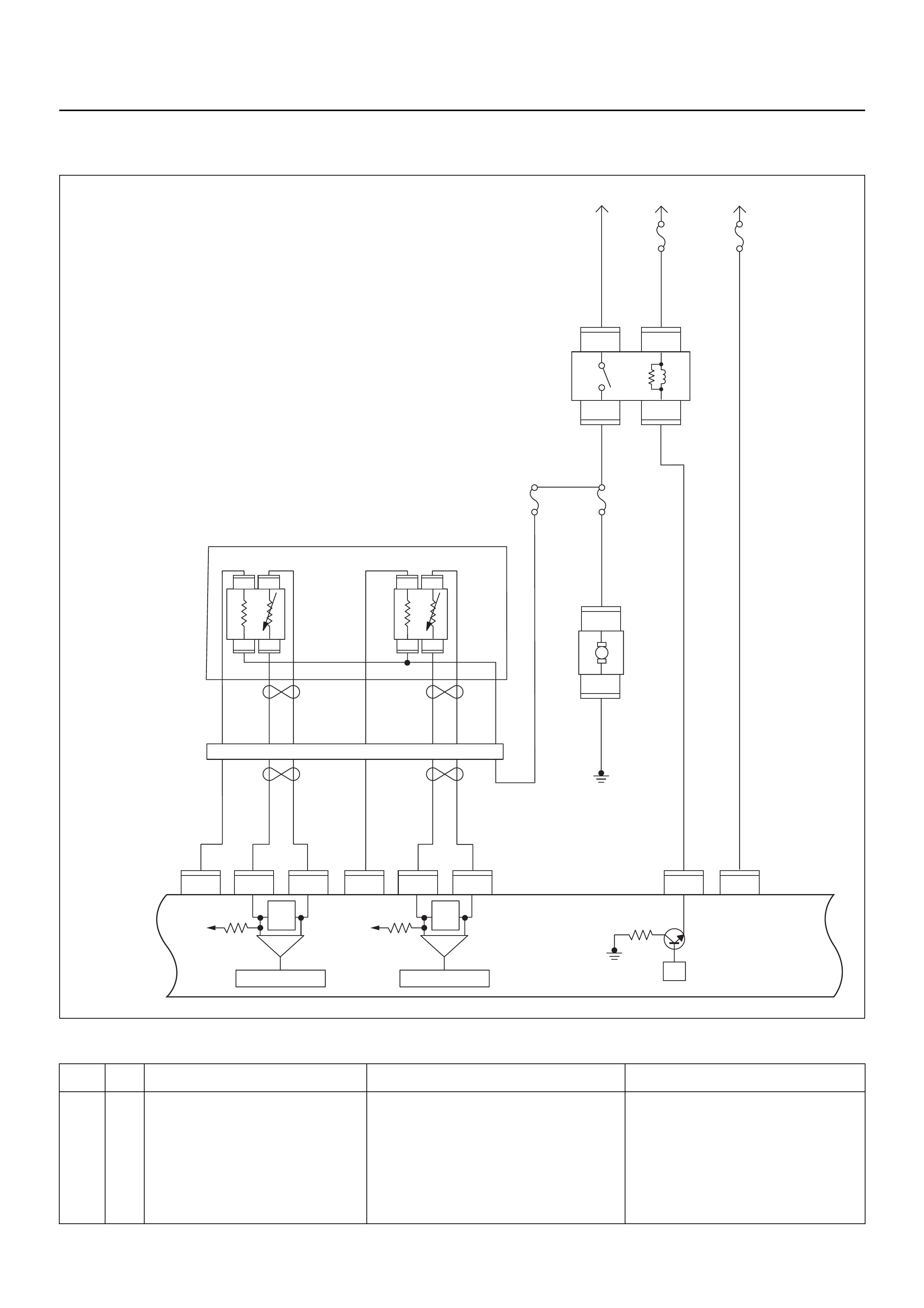

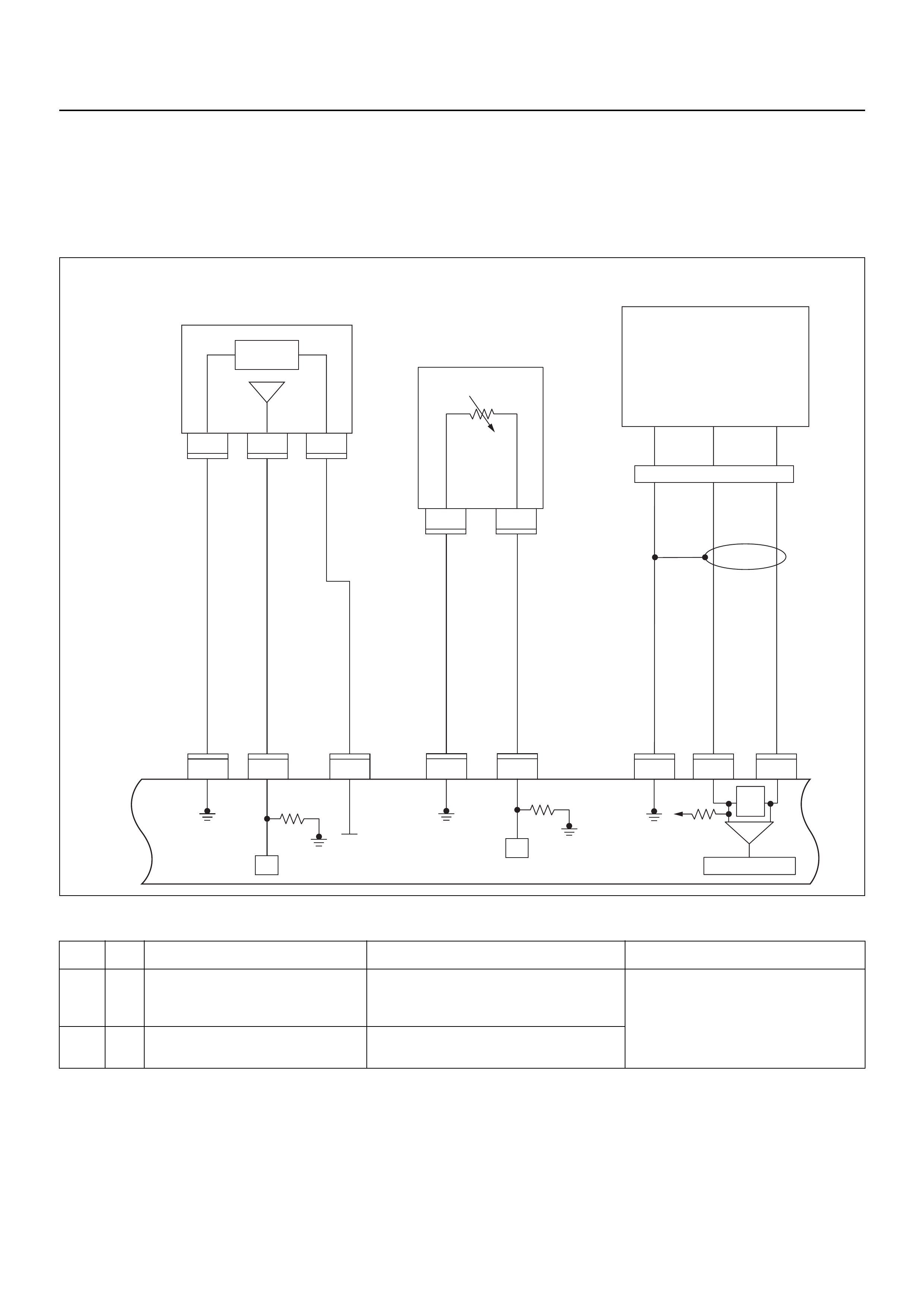

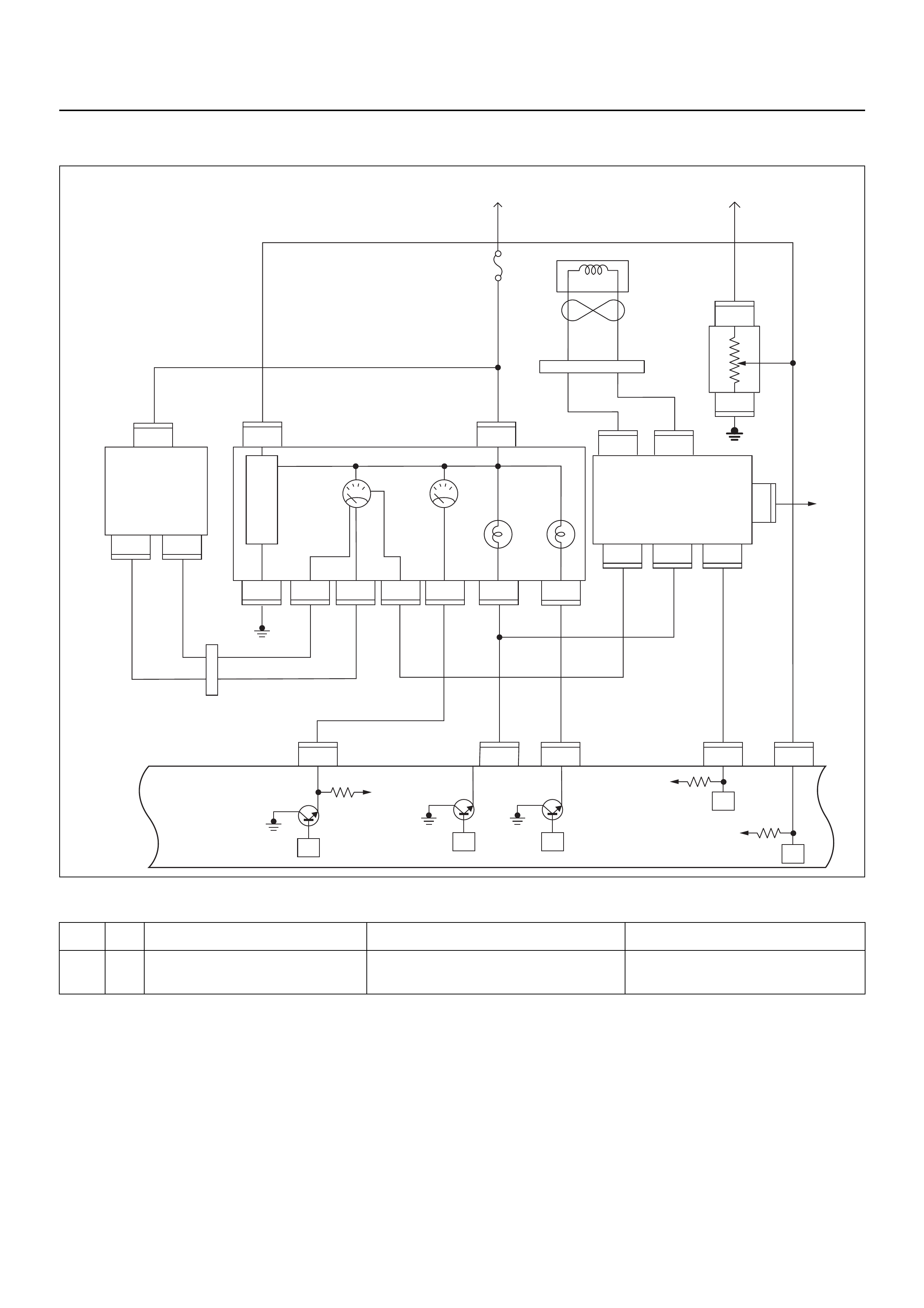

ECM CIRCUIT DIAGRAM

Immobiliser

Coil

(Antenna)

F2

F2

4

E69

2

E69

1

E68

1

E68

3

E68

2

E85

2

E85

3

E85

1

2

1

2

3

F2

F2

2

1111

E66

2

24

13

(+)

(–)

X2 X2

X2 X2

C56

321

17

C56

E78 E78E77 E77

25

1

E70

1

E70

2

E70

3

E70

4

1

2

C121

C121

C56

26

C56

3

C56

2

C56

18

E60

5

E60

21

E60

9

E60

22

E60

8

E60

11

E60

1

E60

17

E60

6

M

H31

HI

LO

HI

LO

AB

16151413121110987654321

E78 E78

C56

J2-1

J2-25 J2-17 J2-26 J2-2 J2-18 J2-3 J1-5 J1-6 J1-21 J1-9 J1-22 J1-8 J1-11 J1-1 J1-17 J2-9 J2-32 J2-13 J2-15 J2-7 J2-4 J2-28 J2-20

J2-21 J2-31 J1-28 J1-19 J1-23 J1-20 J1-13 J1-30 J1-29 J1-14 J1-27 J1-16 J1-7 J1-31 J1-24 J1-26

C56

121

C56 E60 E60

31 28 19

E60

23

E60

20

E60

13

E60

30

E60

29

E60

14

E60

27

E60

16

E60

7

E60

31

E60

24

E60

26

1

3

2

HI

Low Low

23

14

23

HI

GND LO

2

231

22231

5

7

8

27

(–)(+)

10

28 3 6

8

X15 X15

E66

1

C56

28

C56

B58

4

C56

7

C56

15

C56

32

C56

13

C56

9

1,4 2,3

3

3014

2

1

C56

20

6

2

X15X15

1

E2

1

X14

2

X14

1

X14

4

X14

3

43

B24B24

B24 B24 B24

11

B24B24 B24 B24

1

J1-3

3

E60

3

RO7_6E1010

B68B70B70

13

B68B68

1

B68

B68

E44

E18

E9E8E7E6

E9E8E7E6 E18 E18

E44

E44

HI 14

ABC

20A

IGN1

40A

ECM

15A

IGN2

50A

Main

100A

Meter

15A

Ign Coil

20A

Engine

15A

10A

E77 E77

F10 F10 F10

2

2.0

BLK

0.5

YEL/

RED

0.8

YEL/

GRN

0.85

YEL

2.0

BLK/

YEL

0.85

BLK/

YEL

3.0

WHT

2.0

WHT

3.0

BLK/

RED

3.0

WHT/

BLK

2.0

WHT

0.5

RED/

WHT

0.5

GRN/

WHT

0.5

BLU/

YEL

0.5

BLU/

YEL

0.85

RED/

WHT

0.5

BLK

2.0

BLU/

BLK

2.0

BLK

2.0

BLU/

BLK

0.5

BLU

WHT

2.0

RED/

GRN

0.5

ORG

0.5

PU

0.5

BRN

0.5

BLK

0.5

BLU/

ORG 0.5

YEL 0.5

ORG 0.5

BLK

0.5

BLU/

YEL

2.0

BLK/

RED

0.5

GRN

0.5

BRN

0.5

YEL

0.5

YEL

0.5

PU

0.5

BRN

0.5

BLK 0.5

BLK/

WHT

0.5

PINK 0.5

BLU/

BLK

0.5

BLU/

WHT

0.5

BLU/

YEL

0.85

GRN 0.85

BLU

0.5

GRN/

WHT

0.5

BLK/

RED

0.5

WHT

0.85

RED/

GRN

0.5

BRN/

RED

0.5

WHT 0.5

YEL/

RED

0.3

BRN/

YEL

0.5

BRN/

YEL

0.5

GRN/

WHT

0.5

BLK/

YEL

0.5

ORG/

BLU

0.5

YEL/

BLU

0.5

BRN/

YEL

0.5

GRN/

BLK

0.3

BLK/

YEL

0.5

YEL

0.5

BLU/

PUR

0.5

GRY/

BLU

0.5

GRY/

RED

0.5

YEL/

RED

0.5

YEL/

RED

0.5

WHT/

BLU

0.5

BLU/

ORG

0.5

YEL/

BLK

0.5

BLU/

RED

0.5

YEL/

GRN

0.5

YEL/

BLU

0.85

BLK/

BLU

0.5

YEL/

GRN 0.5

GRY

0.5

BLU/

ORG

E59

Meter

A/C

Pressure

Switch

A/C

Compressor

Relay

Thermo

Relay

IGN

SW

IGN

SW

IGN

SW

Coil Module

Vehicle Speed

Sensor (VSS)

Crankshaft

Position (CKP)

Sensor Injector

Fuel Rail

Battery

Fuel

Pump

Relay

SW Ignition

Vertical G-Sensor

Fuel

Pump

Idle Air

Control (IAC)

Valve

Knock

Sensor

Intake Air

Temperature

(IAT) Sensor

Fuel

Pump

O2

Sensor

Manifold

Absolute

Pressure (MAP)

Sensor

O2 Sensor

Pre

O2 Sensor

Post

Coolant

Temperature

(ECT)

Sensor

Throttle

Position (TPS)

Sensor

Magnetic

Clutch

Sensor

Immobiliser

Control Unit

(ICU)

Diagnostic

Connector

Starter

Relay

Engine Control Module (ECM)

EVAP

Purge

Solenoid

Valve

Fuel

Sender

Unit

MIL

Lamp

SVS

Lamp

Speedo

Meter

Tacho

Meter

CPU

OFF

ACC

IGN2

ST

IGN1

E84

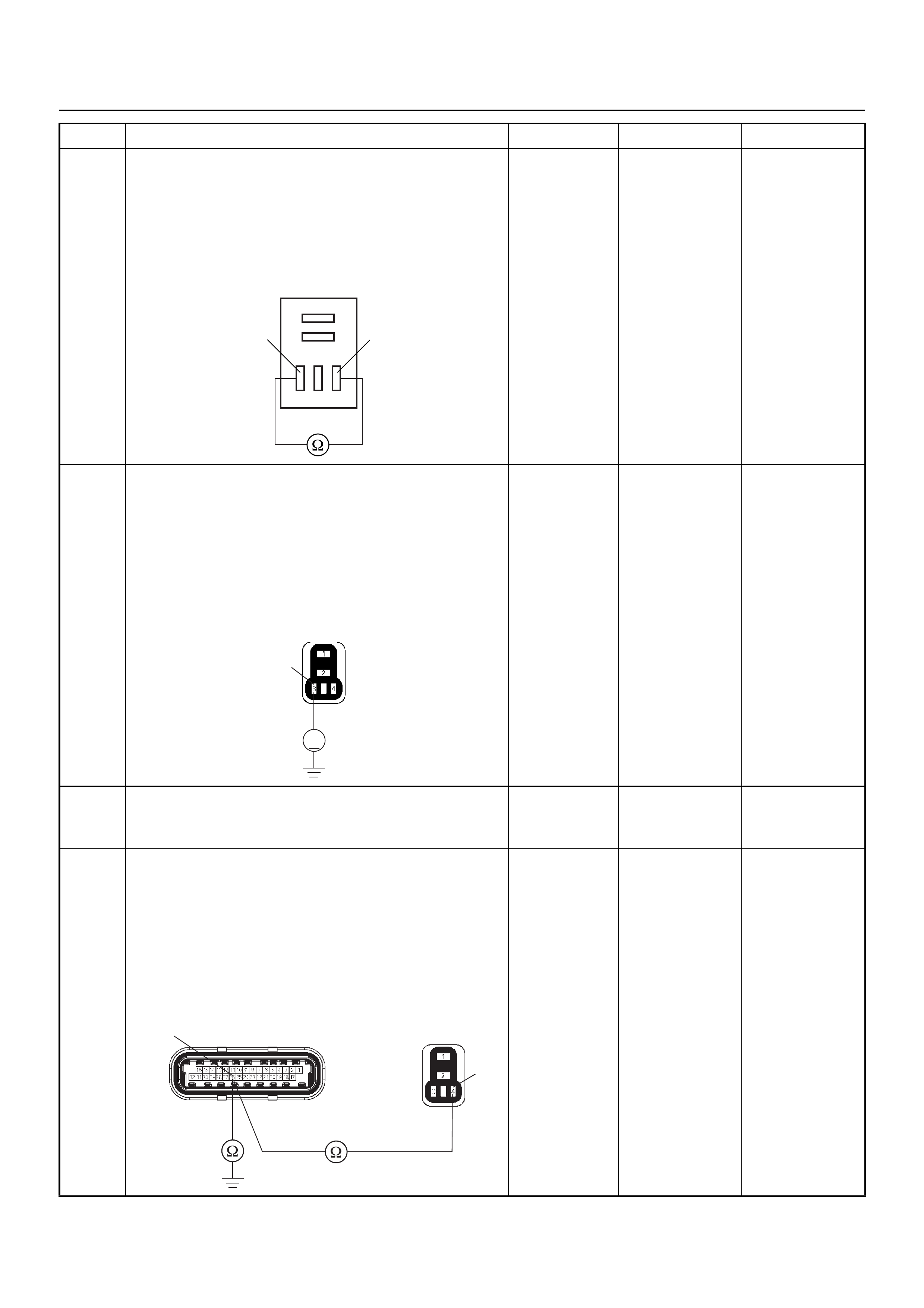

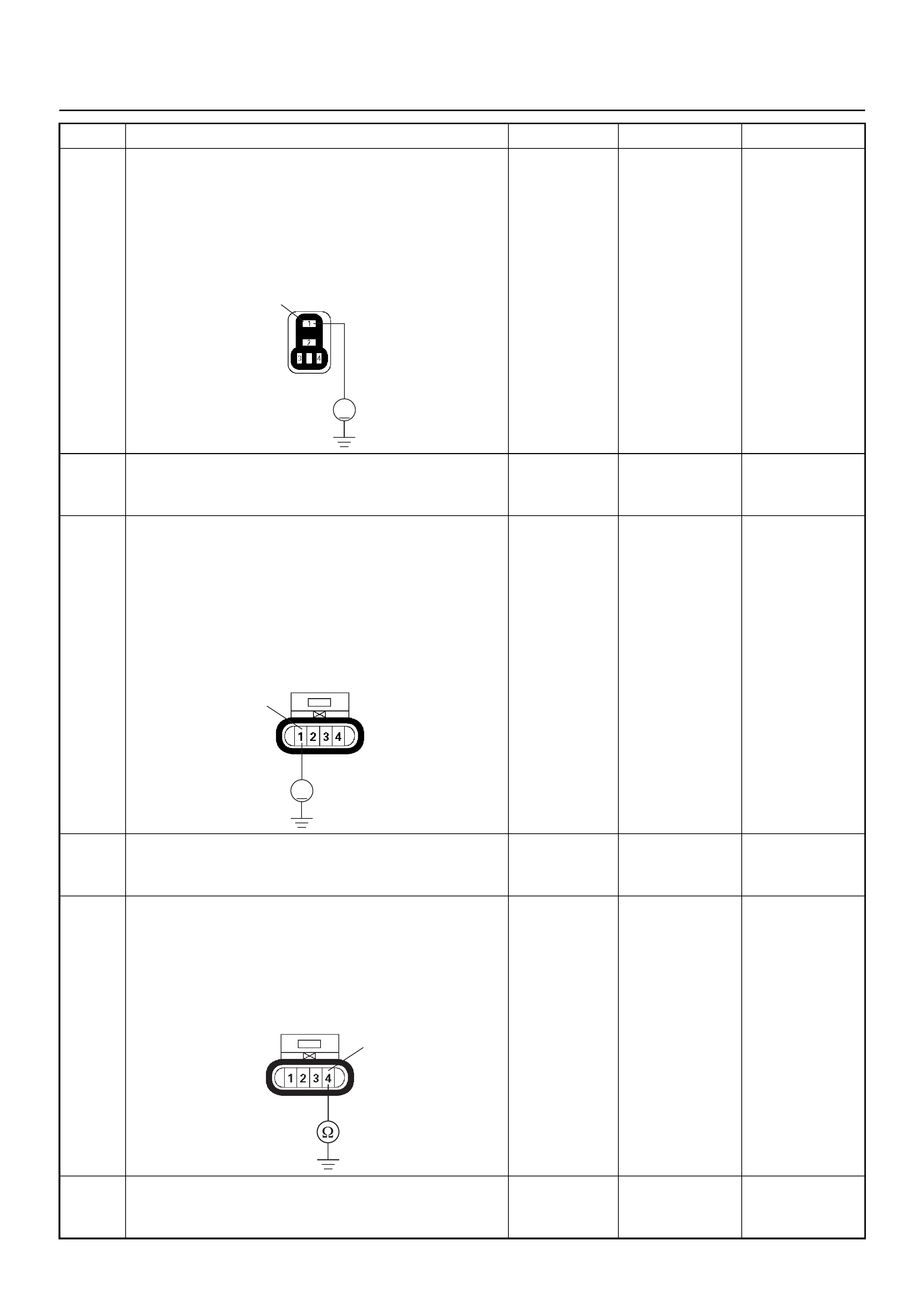

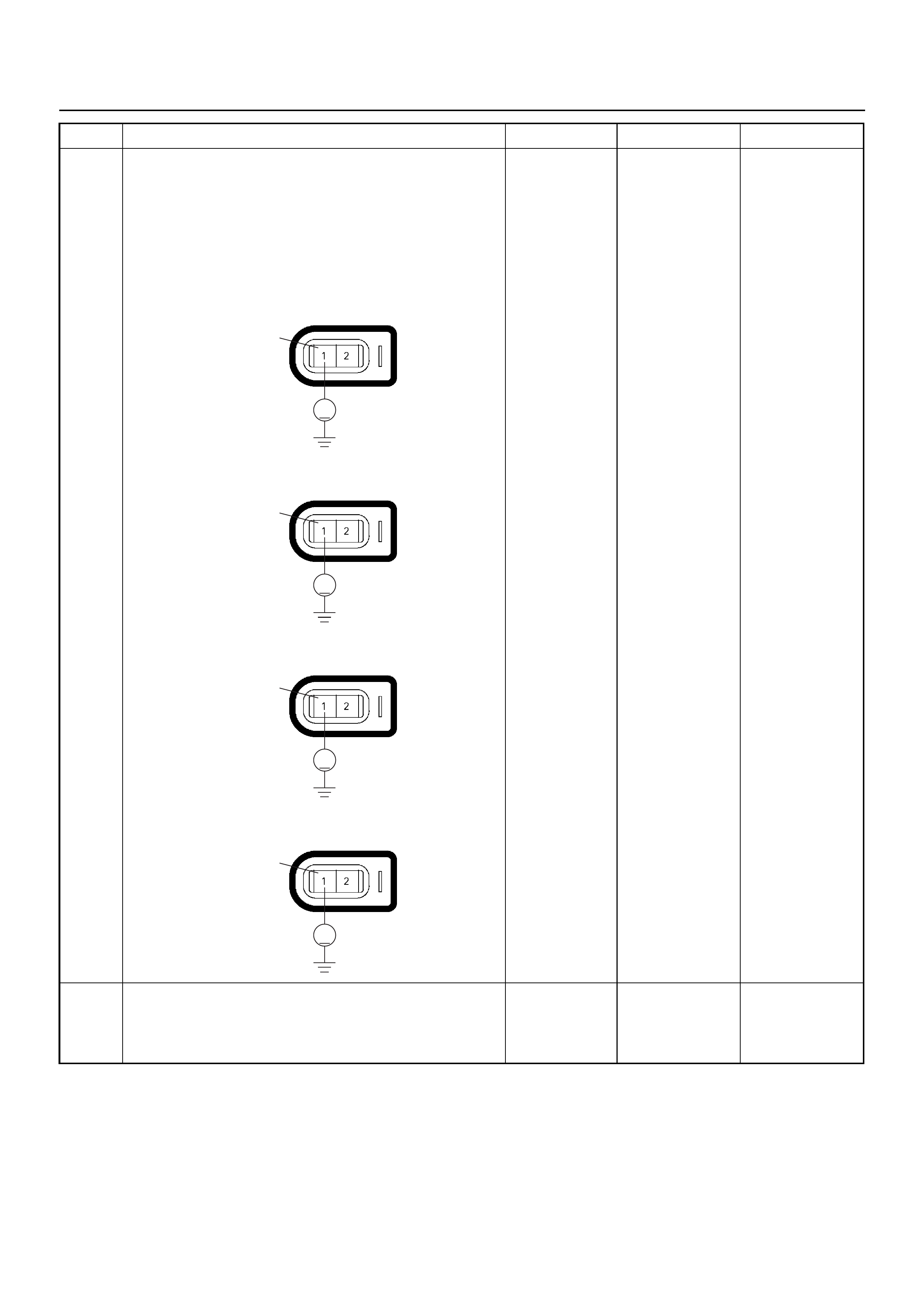

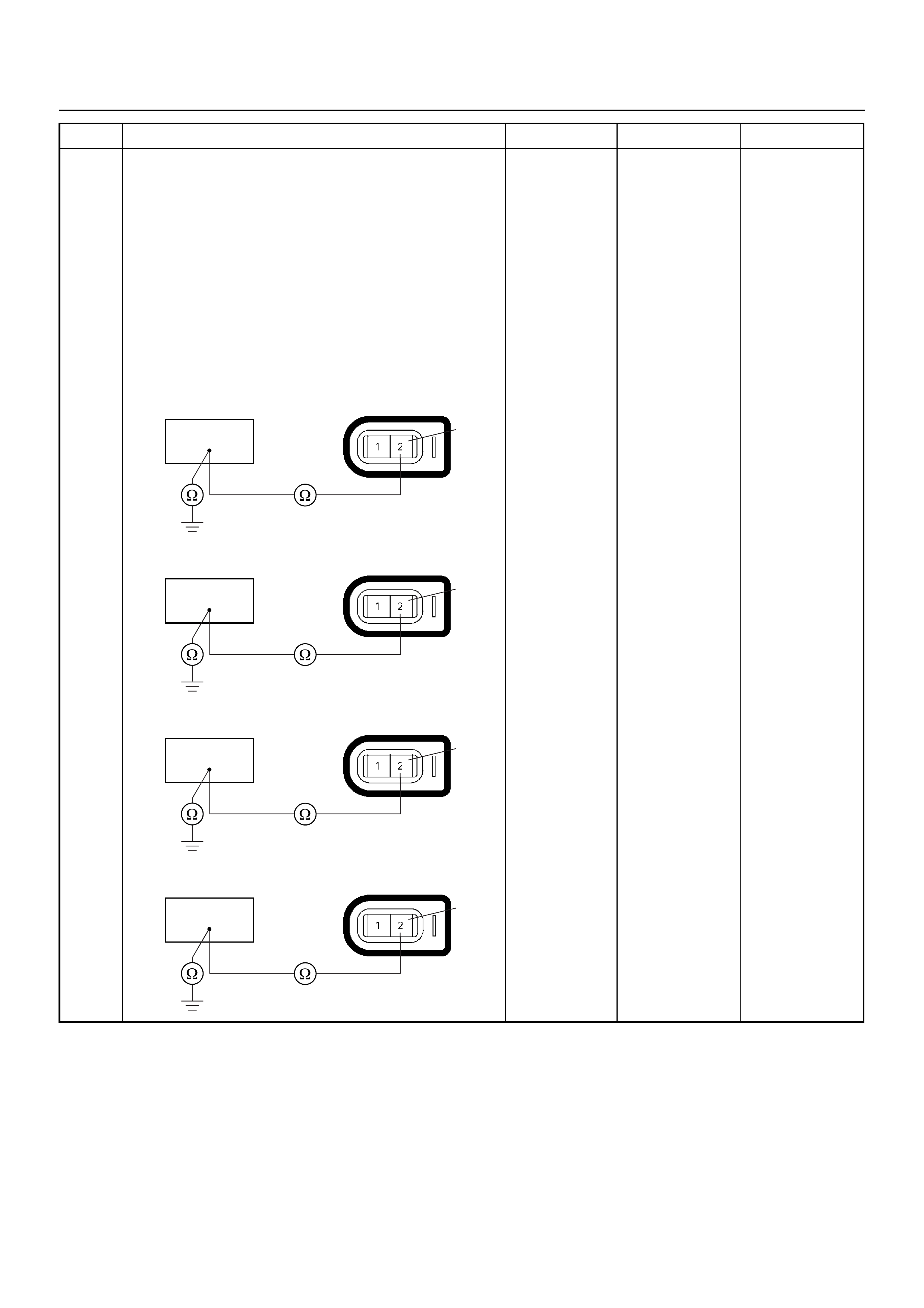

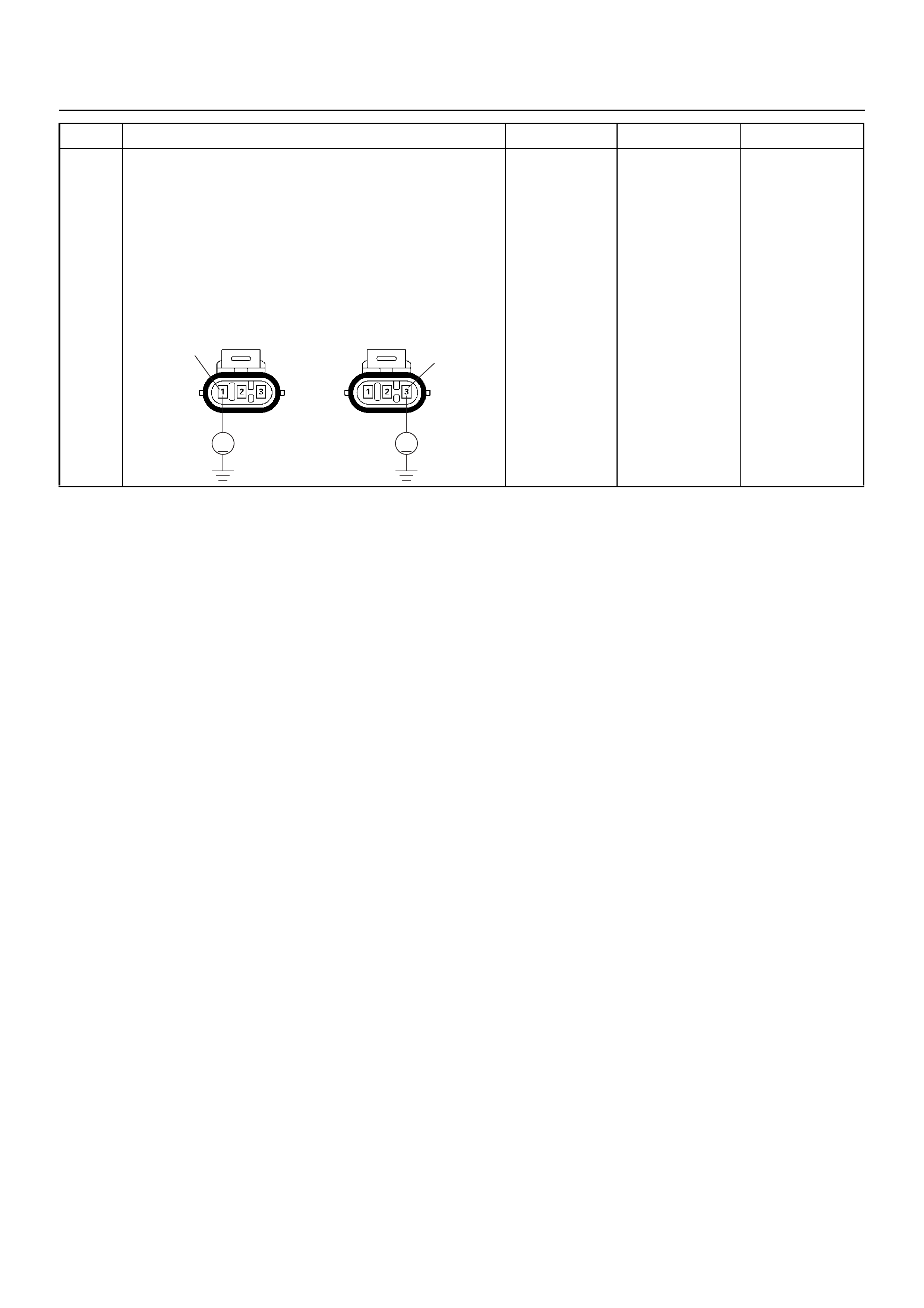

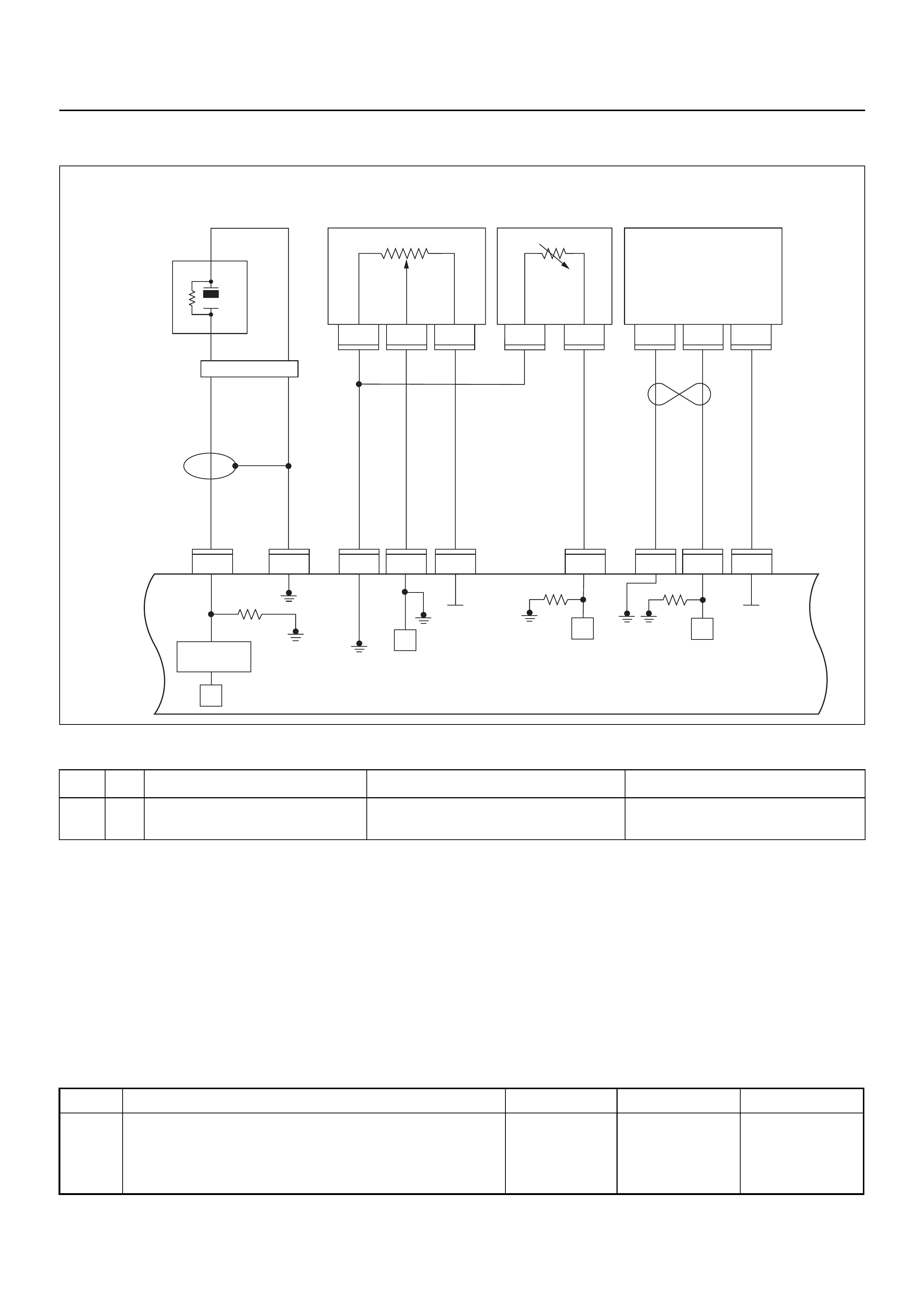

GROUND POINT CHART (1/4)

GROUND POINT CHART (2/4)

GROUND POINT CHART (3/4)

GROUND POINT CHART (4/4)

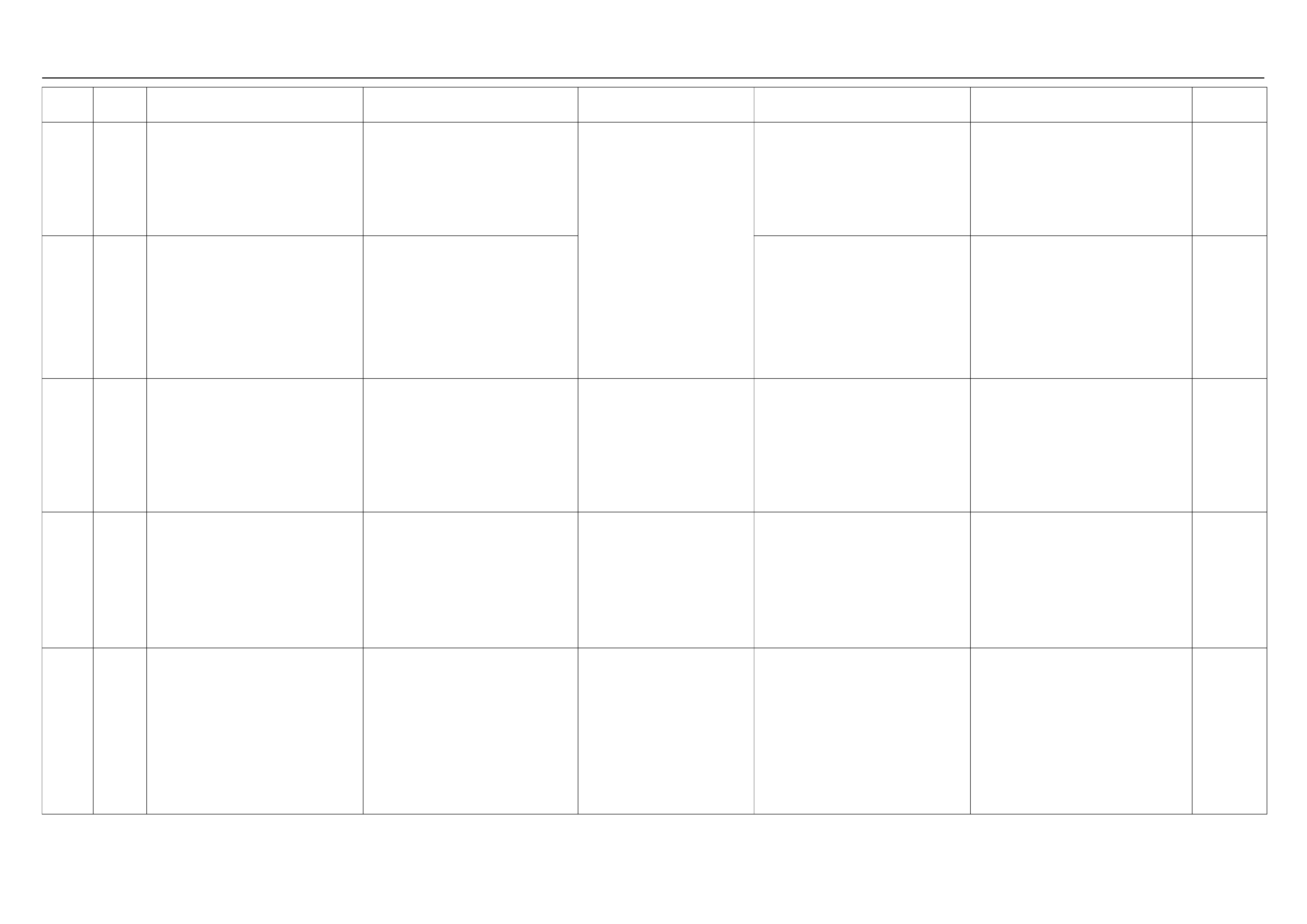

LOCATION

CABLE HARNESS & CONNECTOR LOCATION

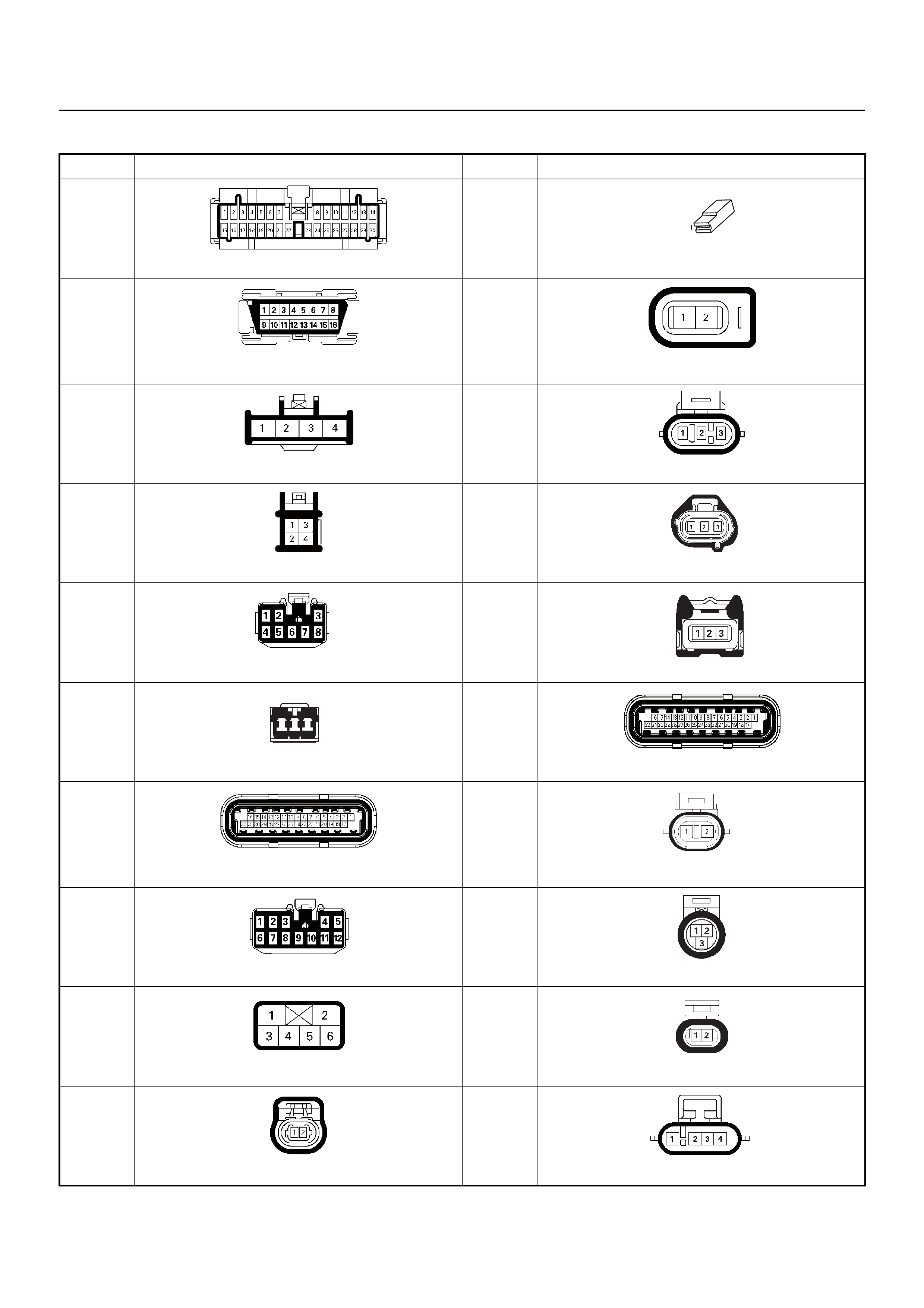

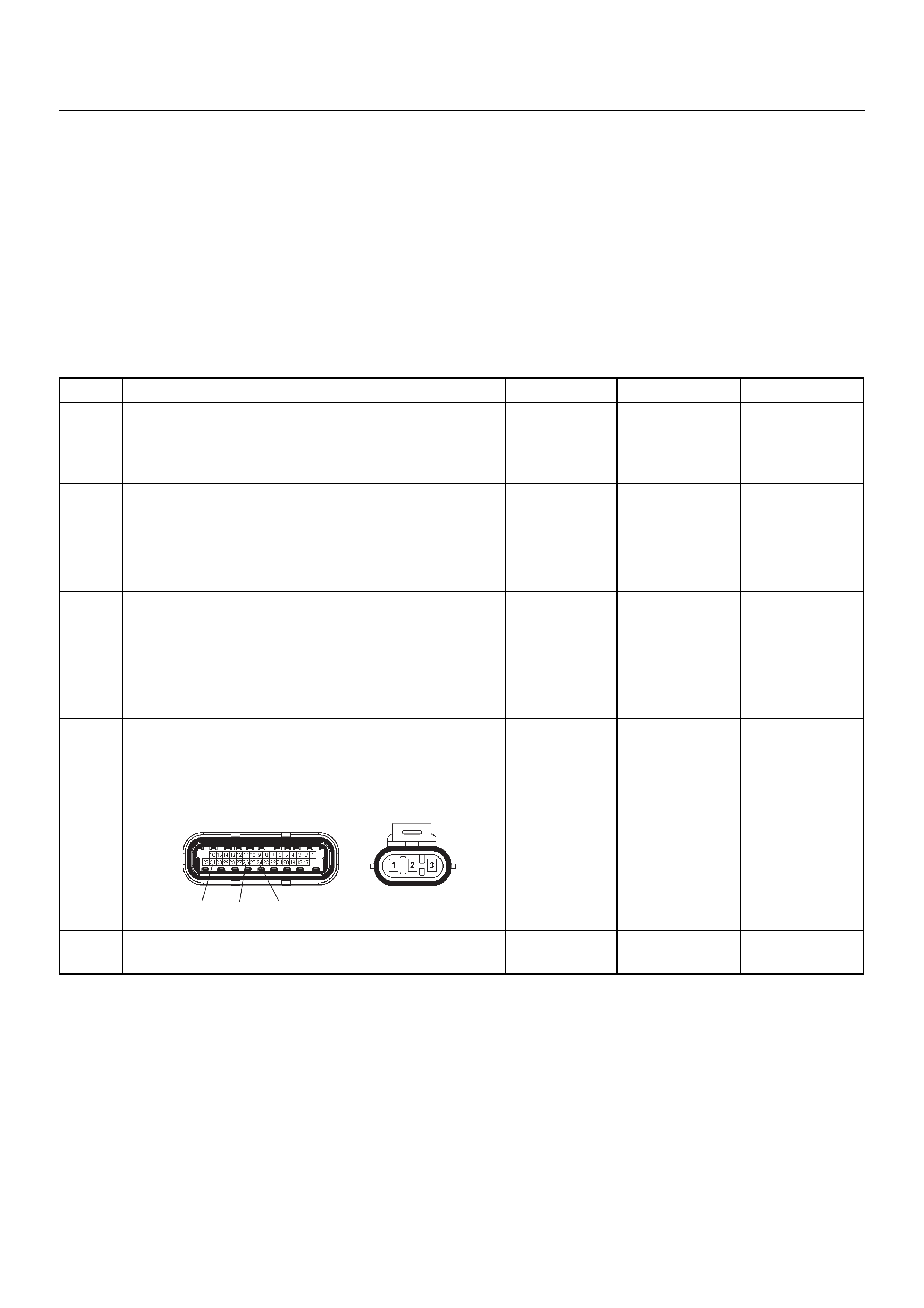

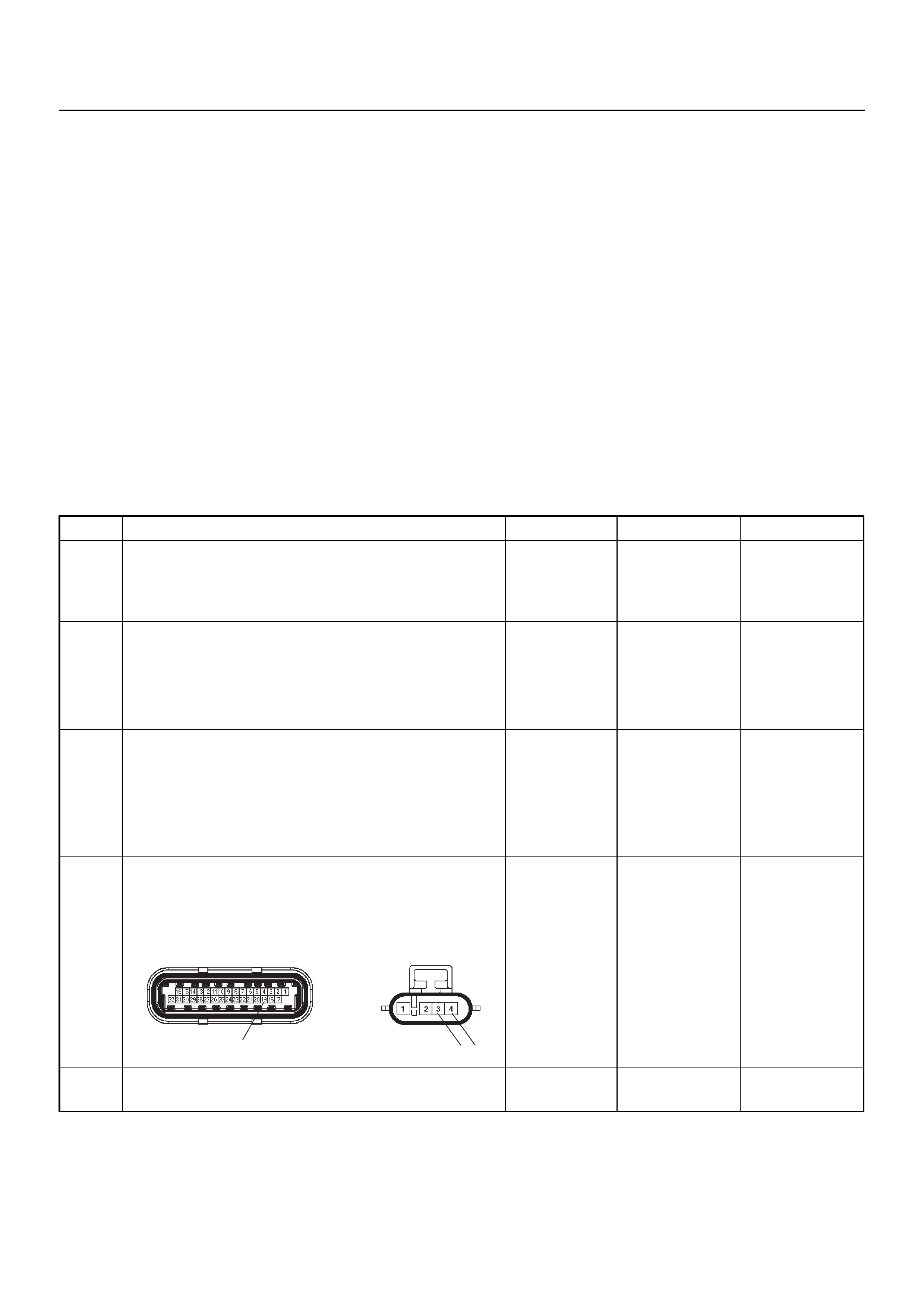

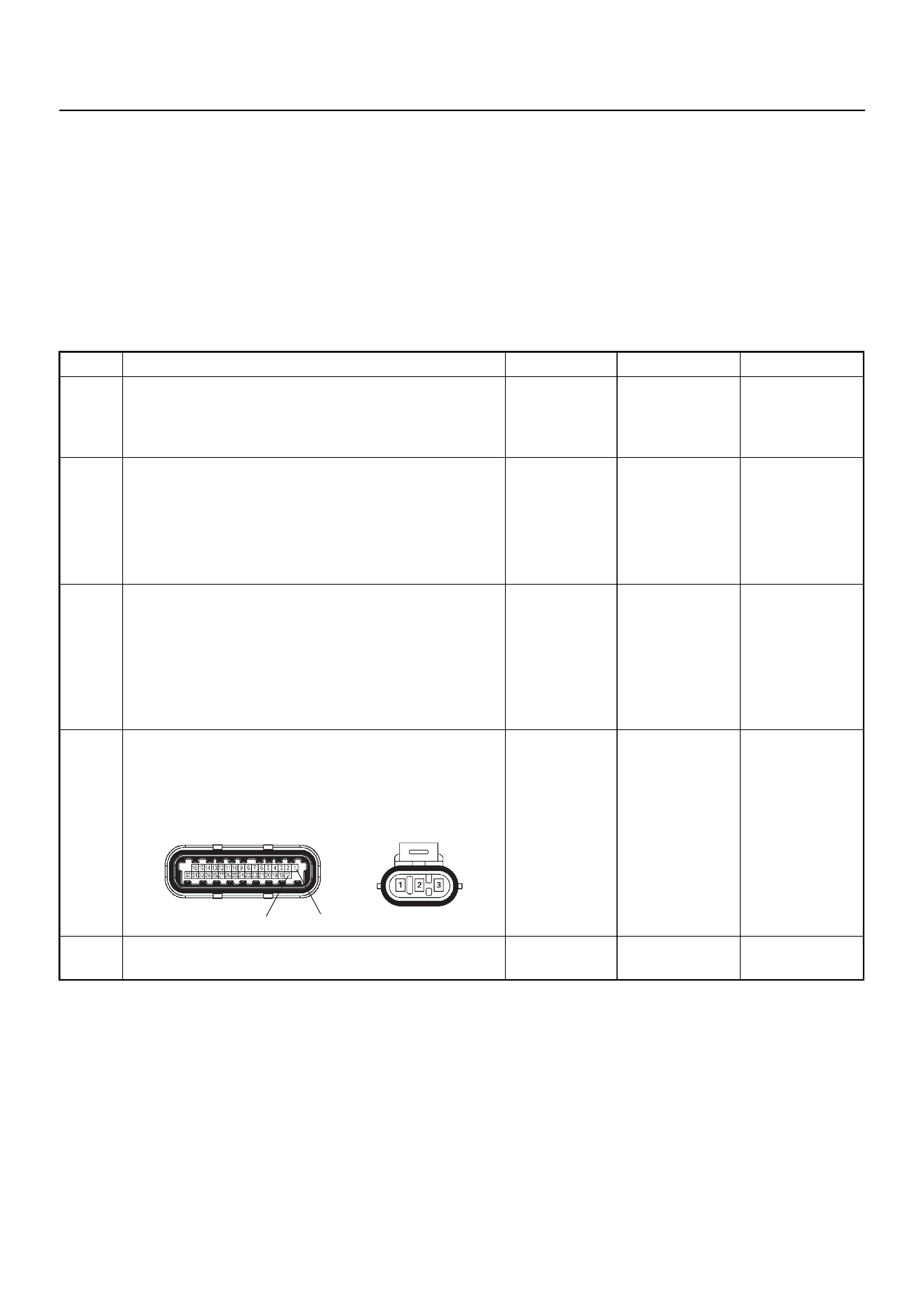

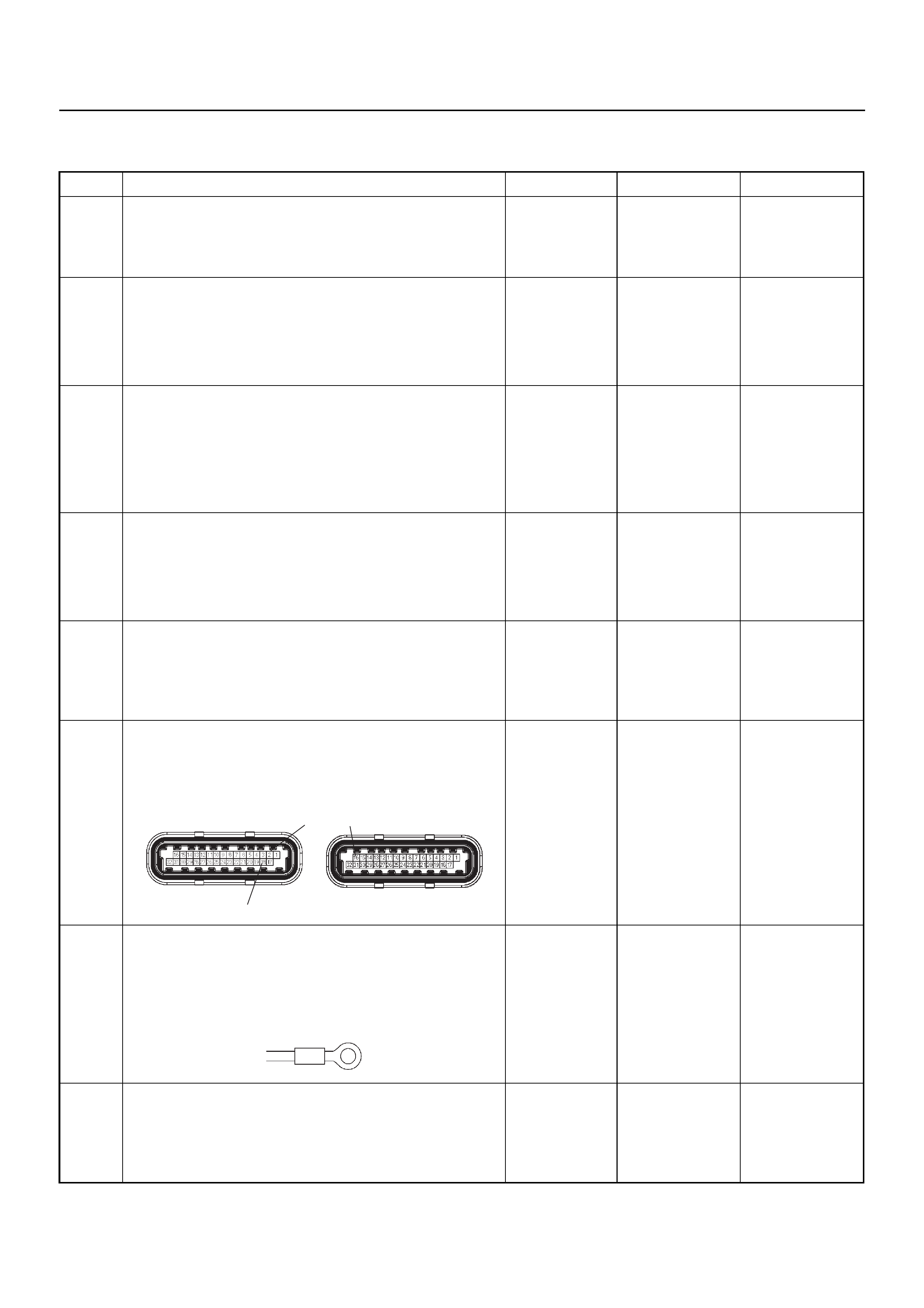

CONNECTOR LIST

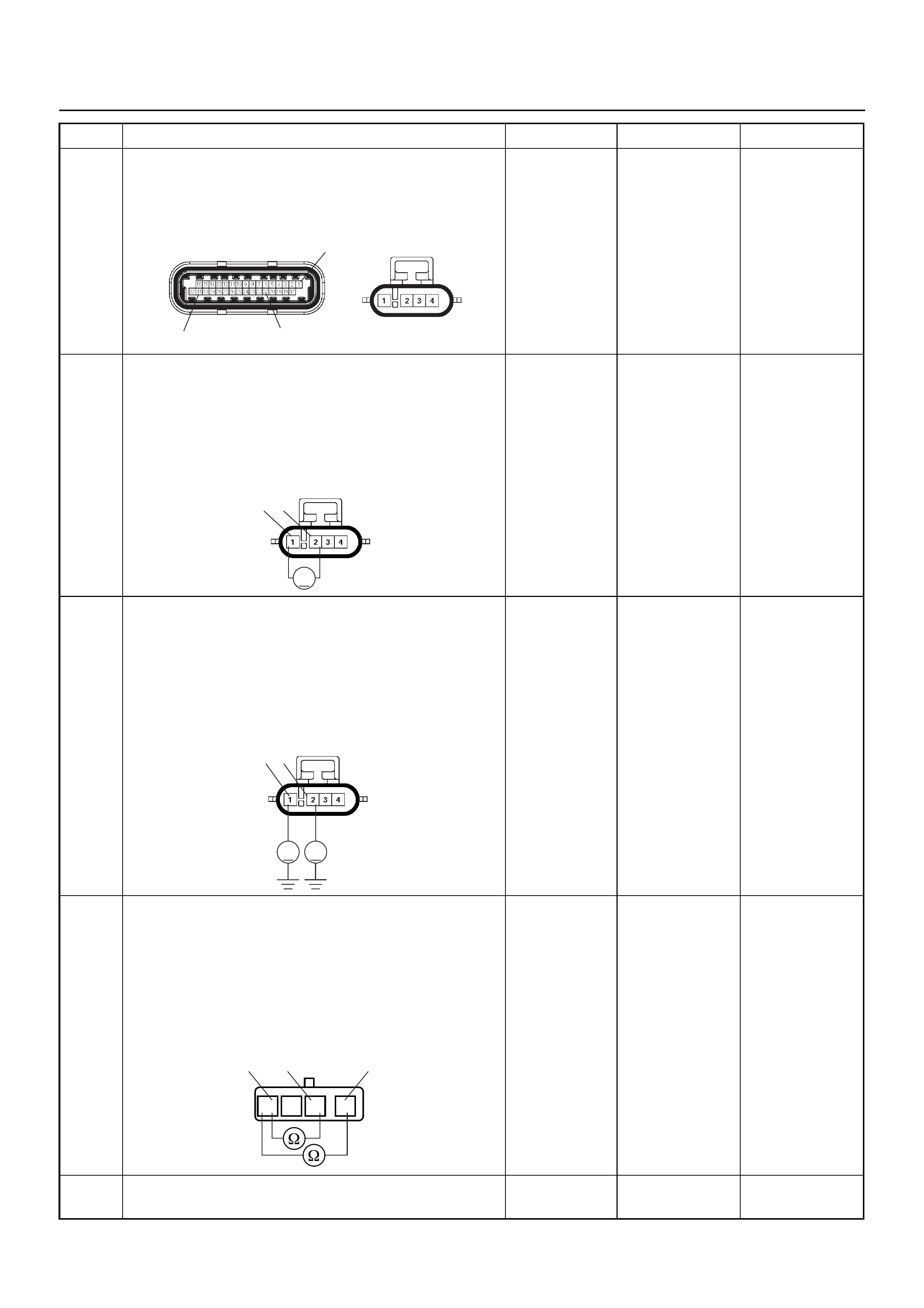

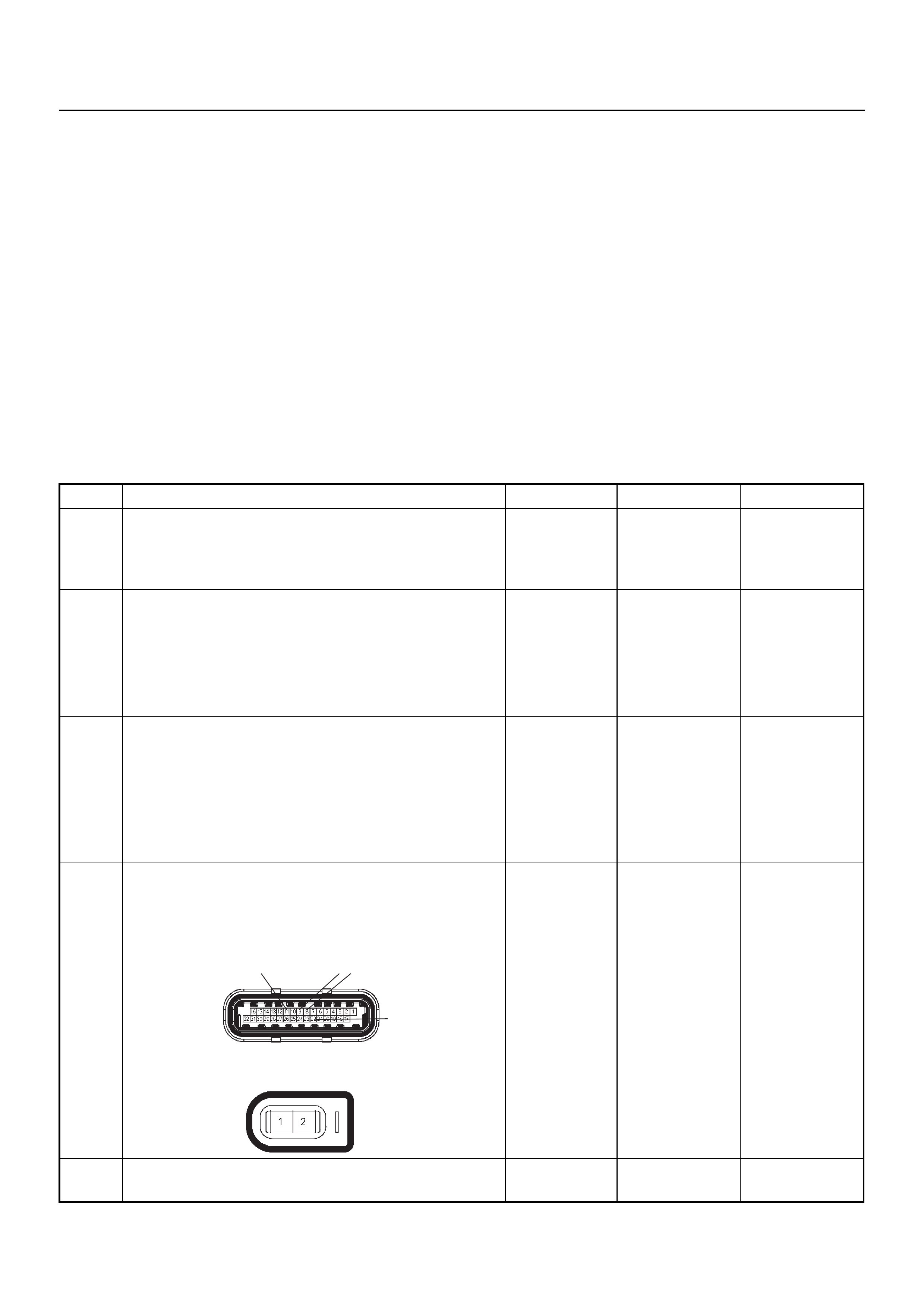

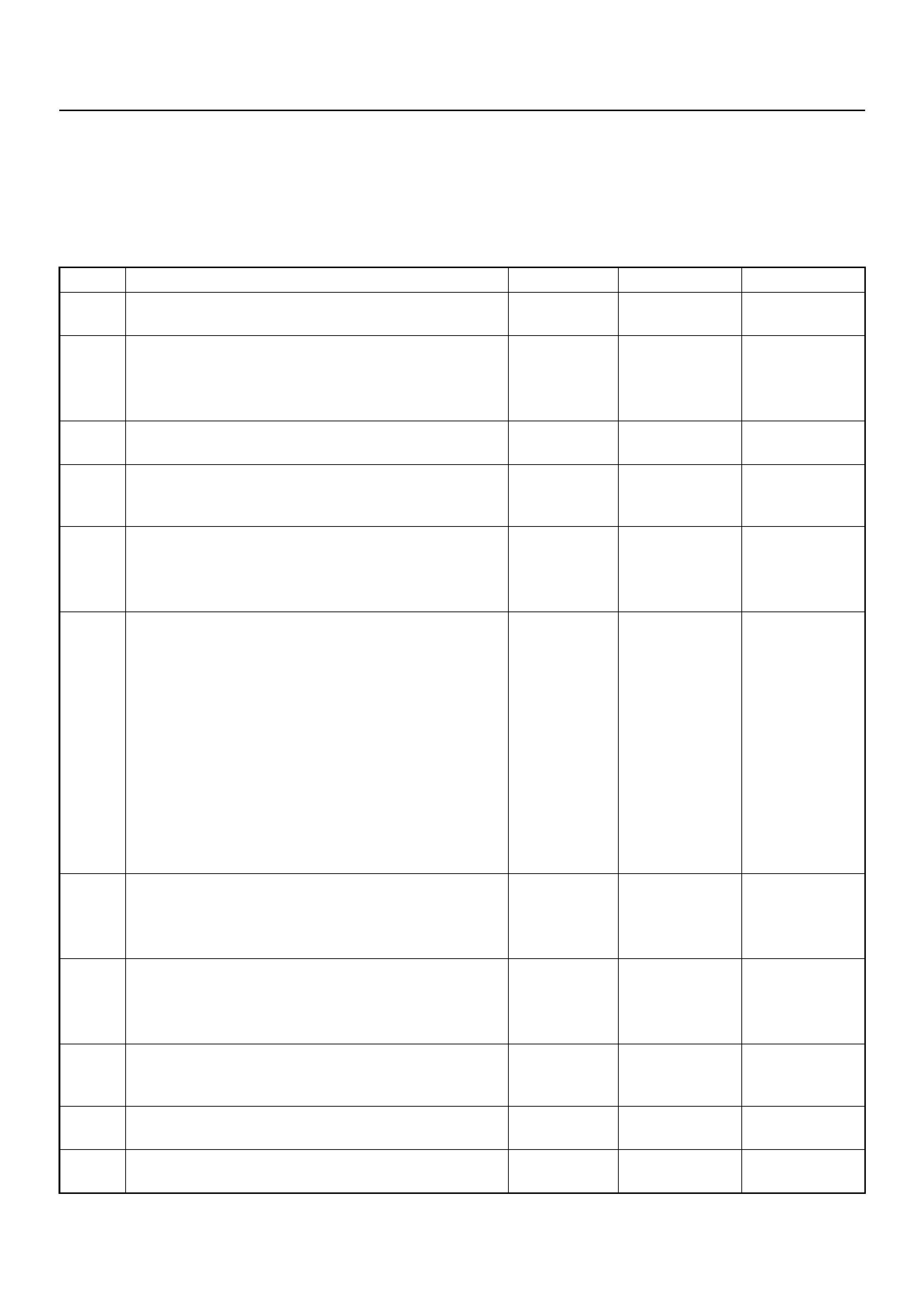

No. Connector face No. Connector face

B-24

Green Meter

E-2

Magnetic Clutch Sensor

B-58

Black Diagnostic Connector

E-6

E-7

E-8

E-9

Grey Fuel Injector

B-62

White Ignition Switch (IGSUB : G1)

E-18

Ignition Coil Module

B-63

White Ignition Switch (IGSUB : G2)

E-44

Vehicle Speed Sensor

B-68

White Immobiliser

E-59

Crankshaft Position Sensor

B-70

White Immobiliser Coil Antenna

E-60

ECM

C-56

ECM

E-66

EVAP Canister Purge Valve

C-107

White J/B E2

E68

Throttle Position Sensor (TPS)

C-108

White J/B E1

E-69

Coolant Temper ature Sensor (EC T)

C-121

IAT Sensor

E-70

Idle Air Control Valve (IAC)

123

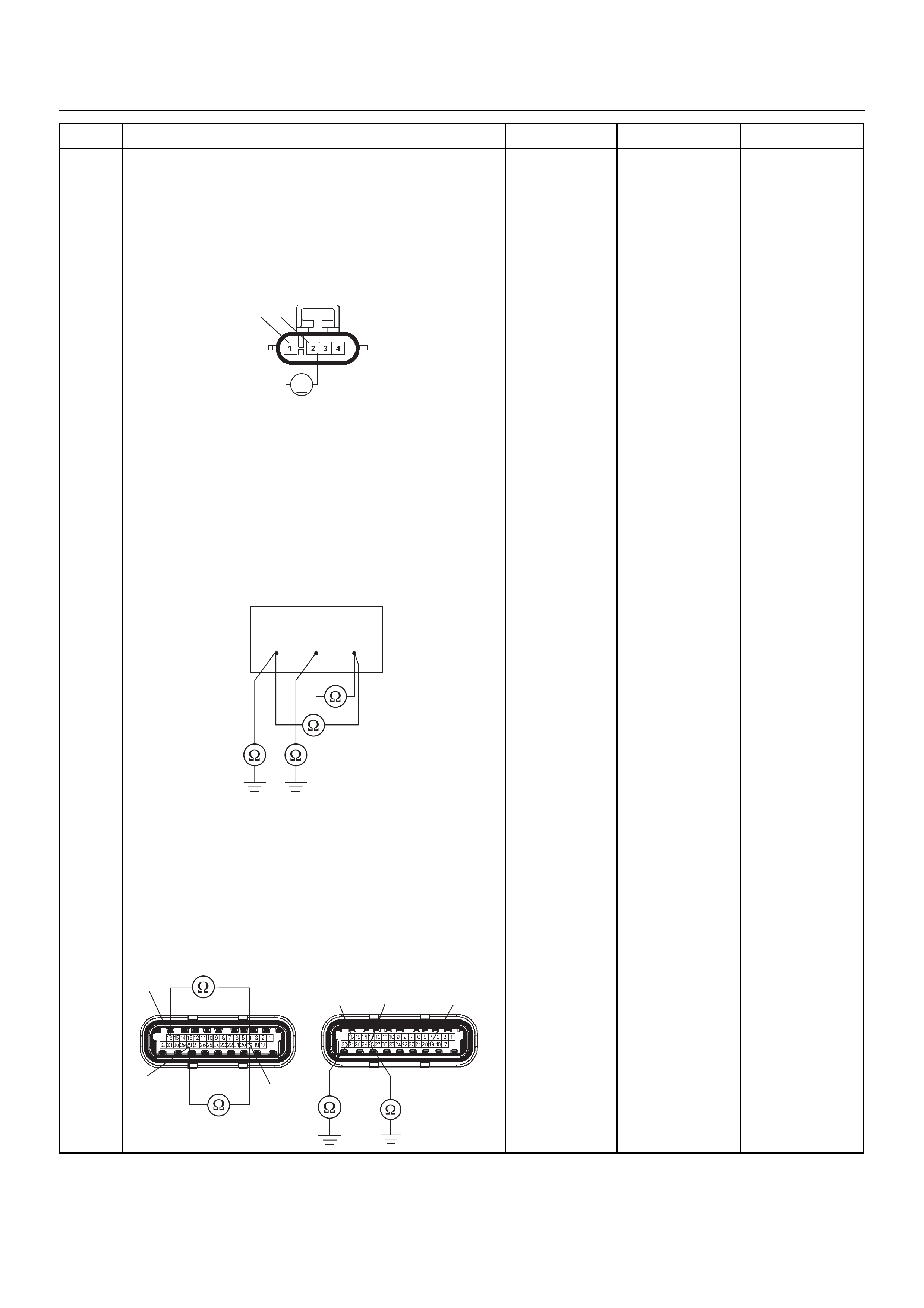

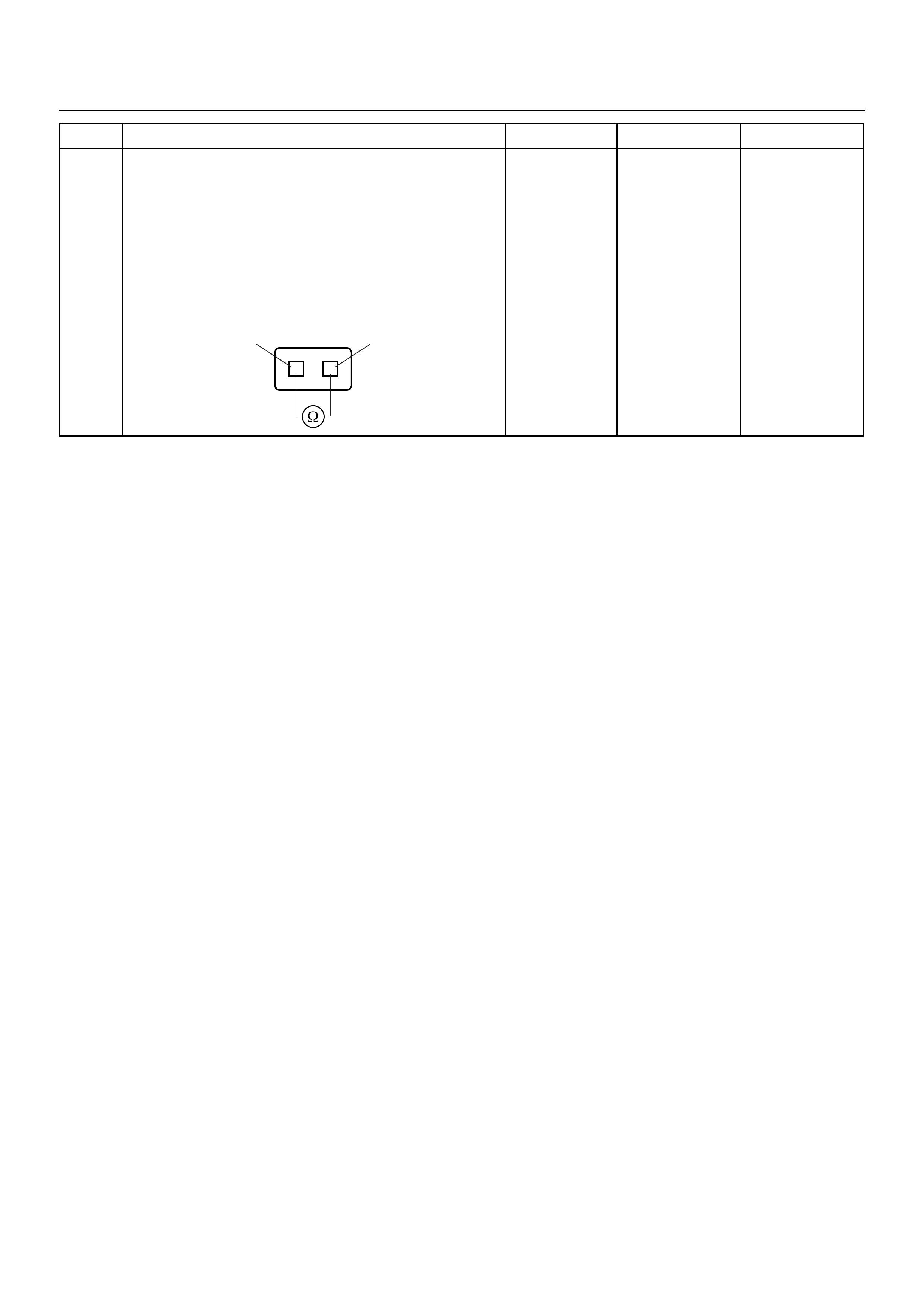

No. Connector face No. Connector face

E-72

E-74

Engine Earth-A & B

H-18

White Engine Room ~ INST

E-77

&

E-78

O2 Sensor (Pre & Post)

H-31

Engine Room ~ Mission

E-84

Knock Sensor (KS)

H-34

Engine ~ Engine Room

E-85

MAP Sensor

P-1

Silver Battery (+)

F-2

White Fuel Pump & Sender Unit

P-2

Silver Relay & Fuse Box

F-10

Vertical G-Sensor

P-5

Silver Battery (-)

H-4

White Engine Room ~ Mission

P-6

Silver Body Earth (Ground)

H-6

White Engine Room ~ INST

P-10

Silver Engine Ground

H-7

White Engine Room ~ INST

X-2

X-14

X-15

Black Relay; Fuel Pump, A/C Comp, Thermo Fan

H-9

Blue Engine Room ~ Chassis

X-11

Black Relay; Heater

123

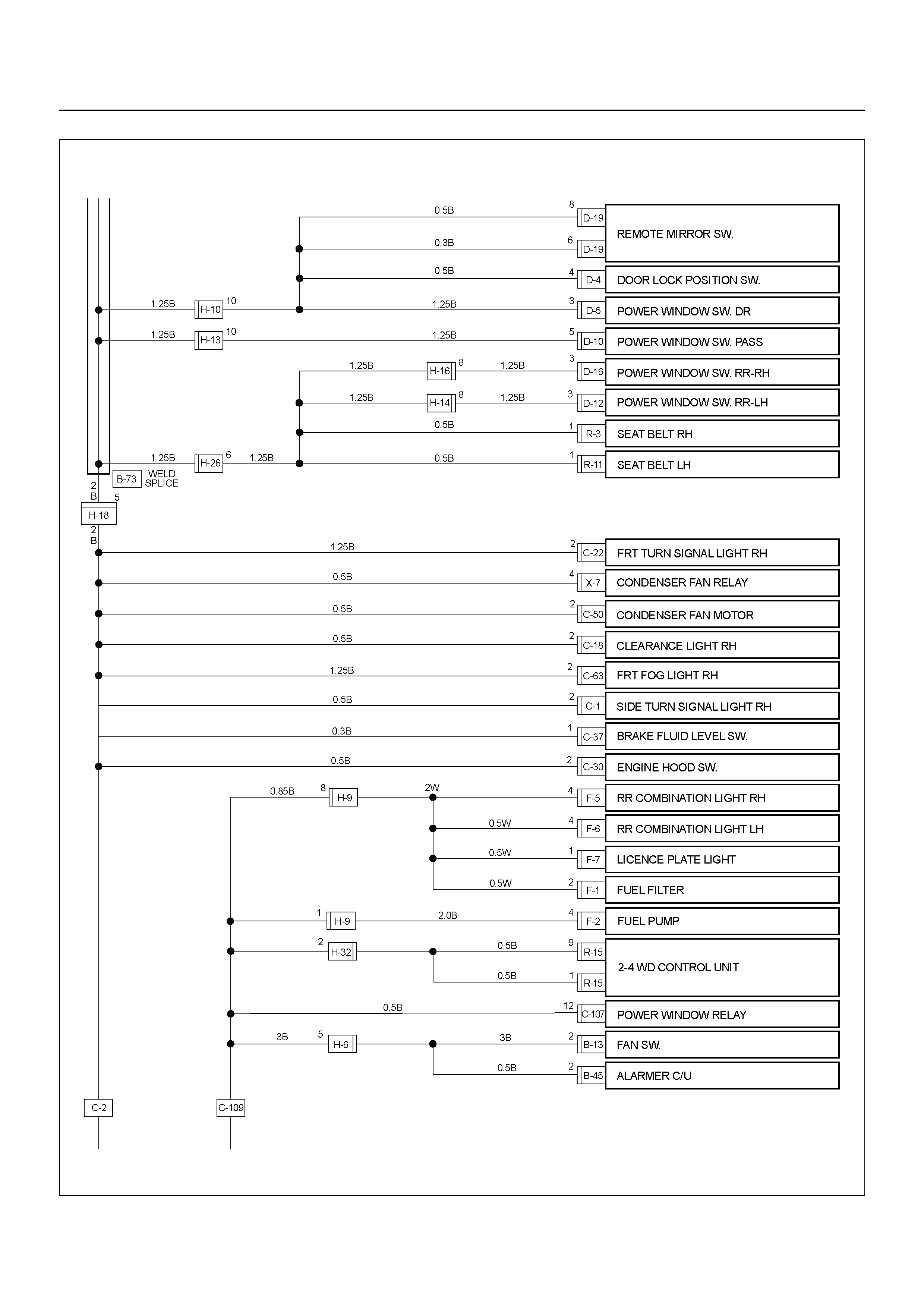

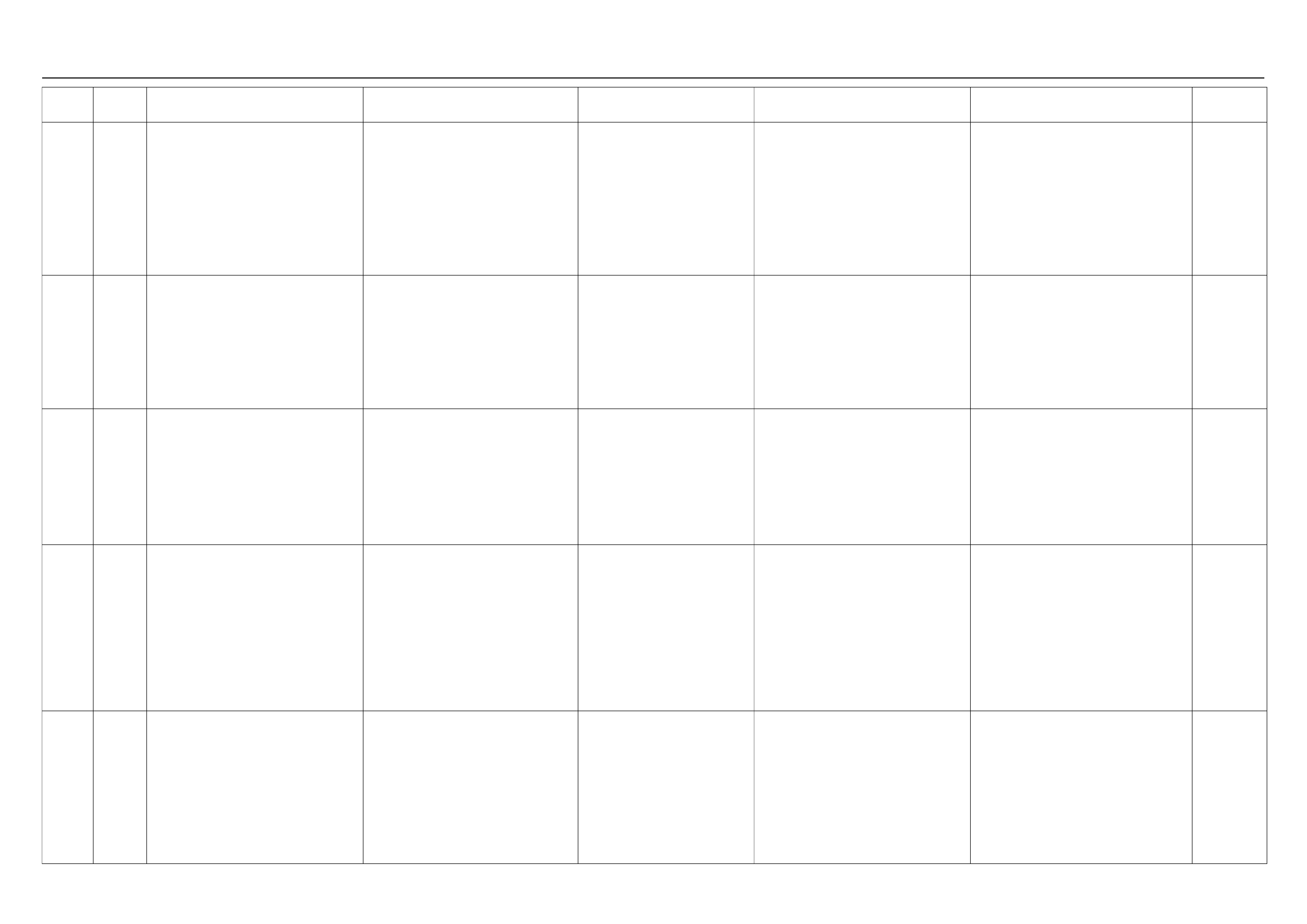

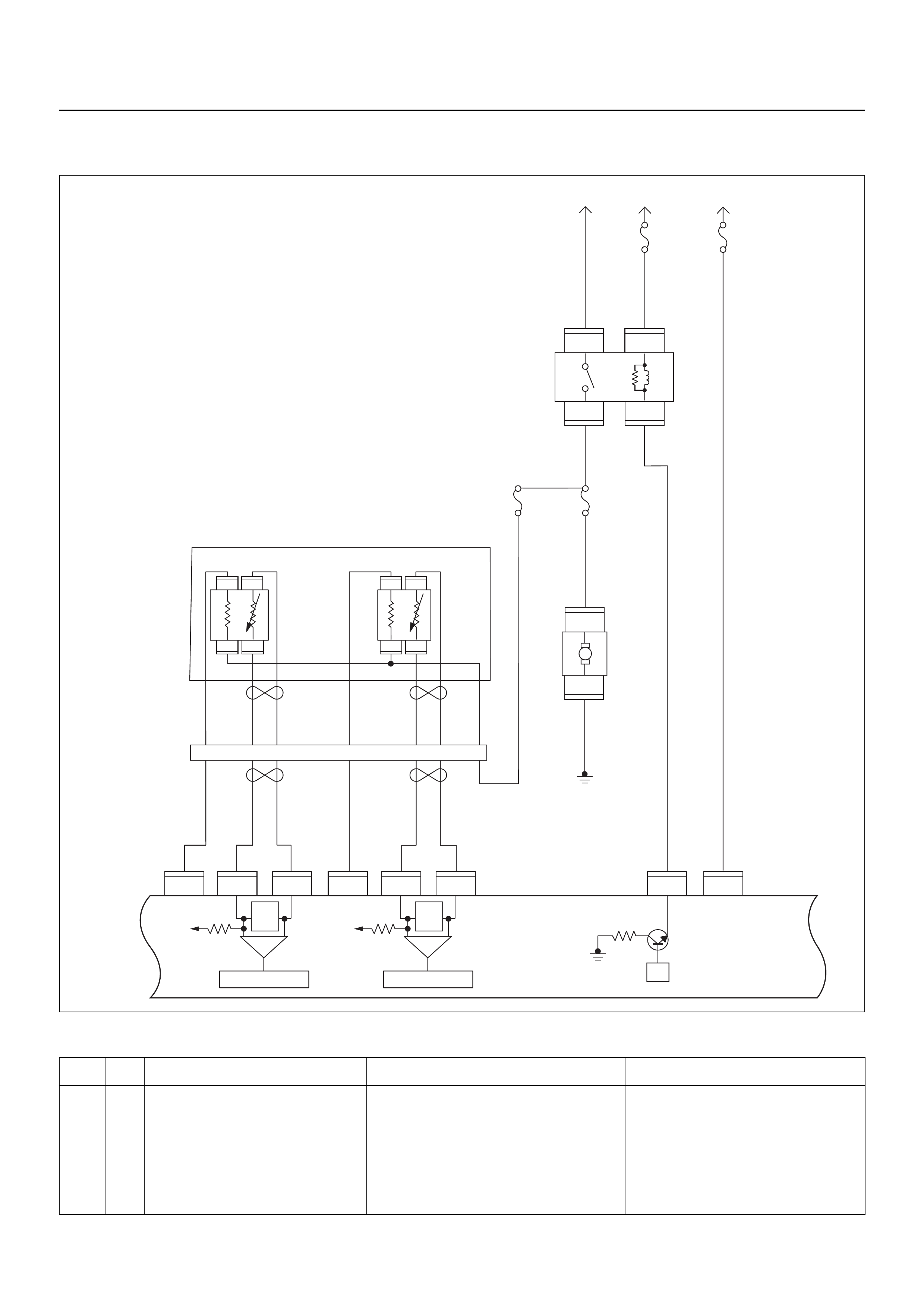

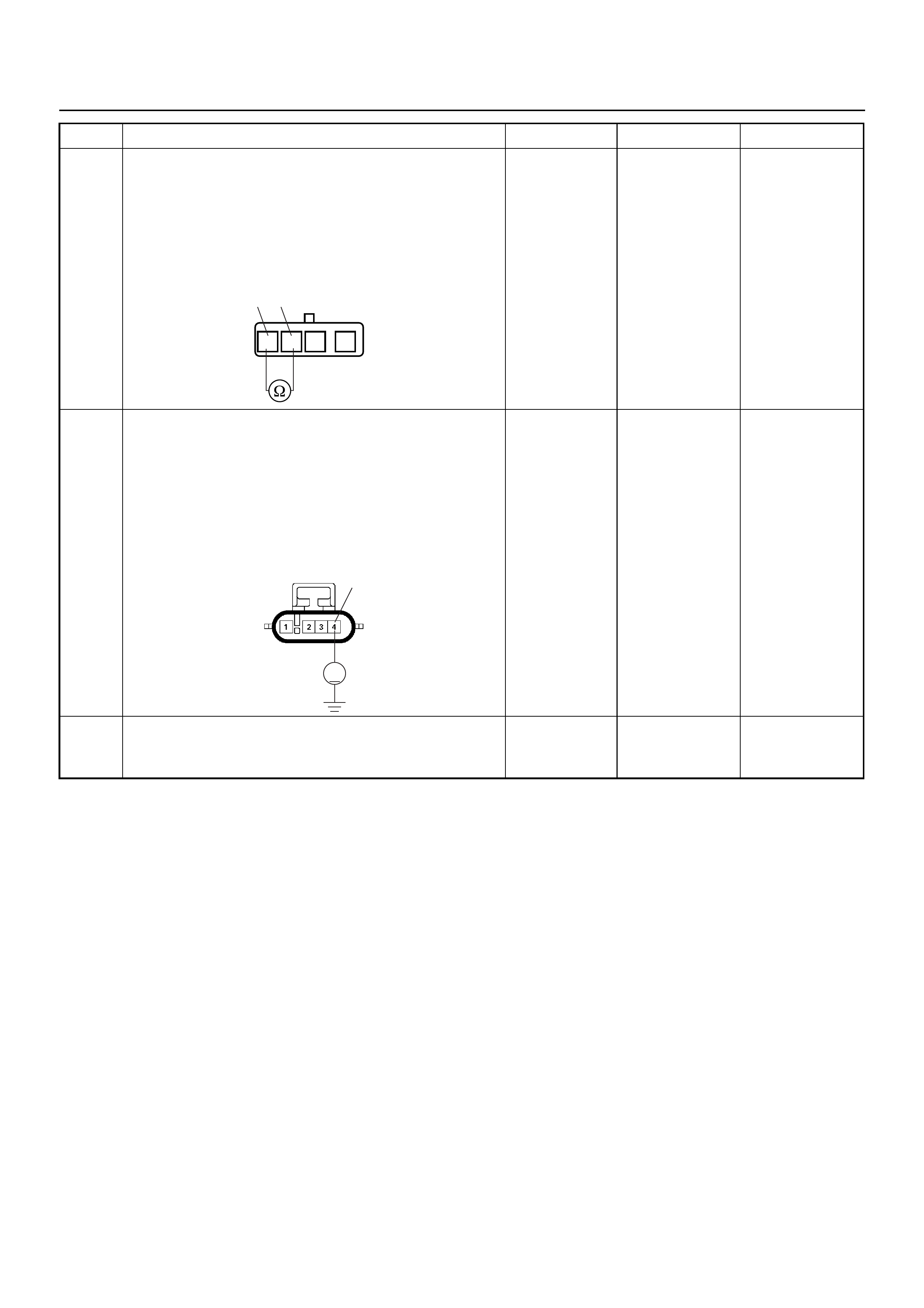

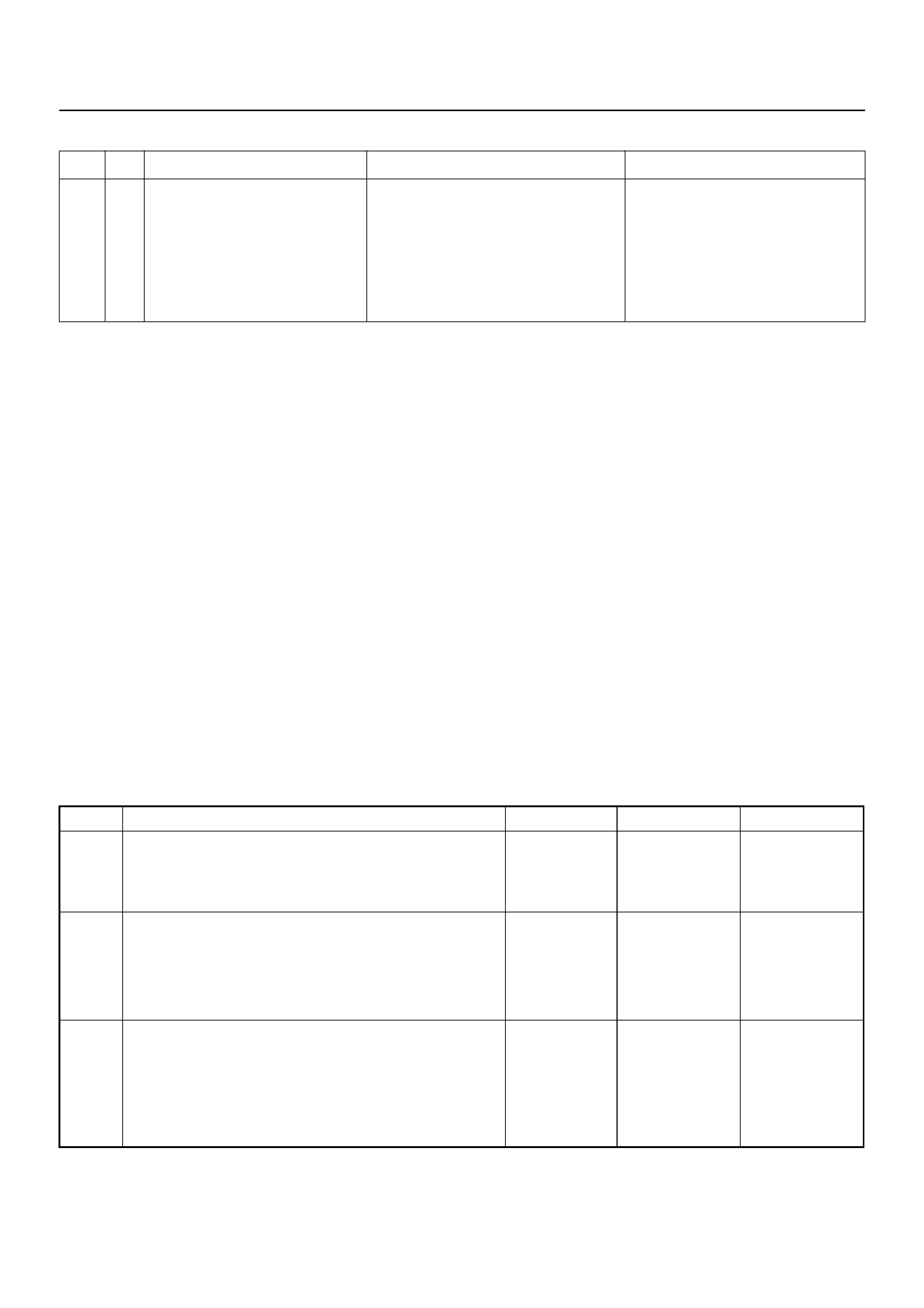

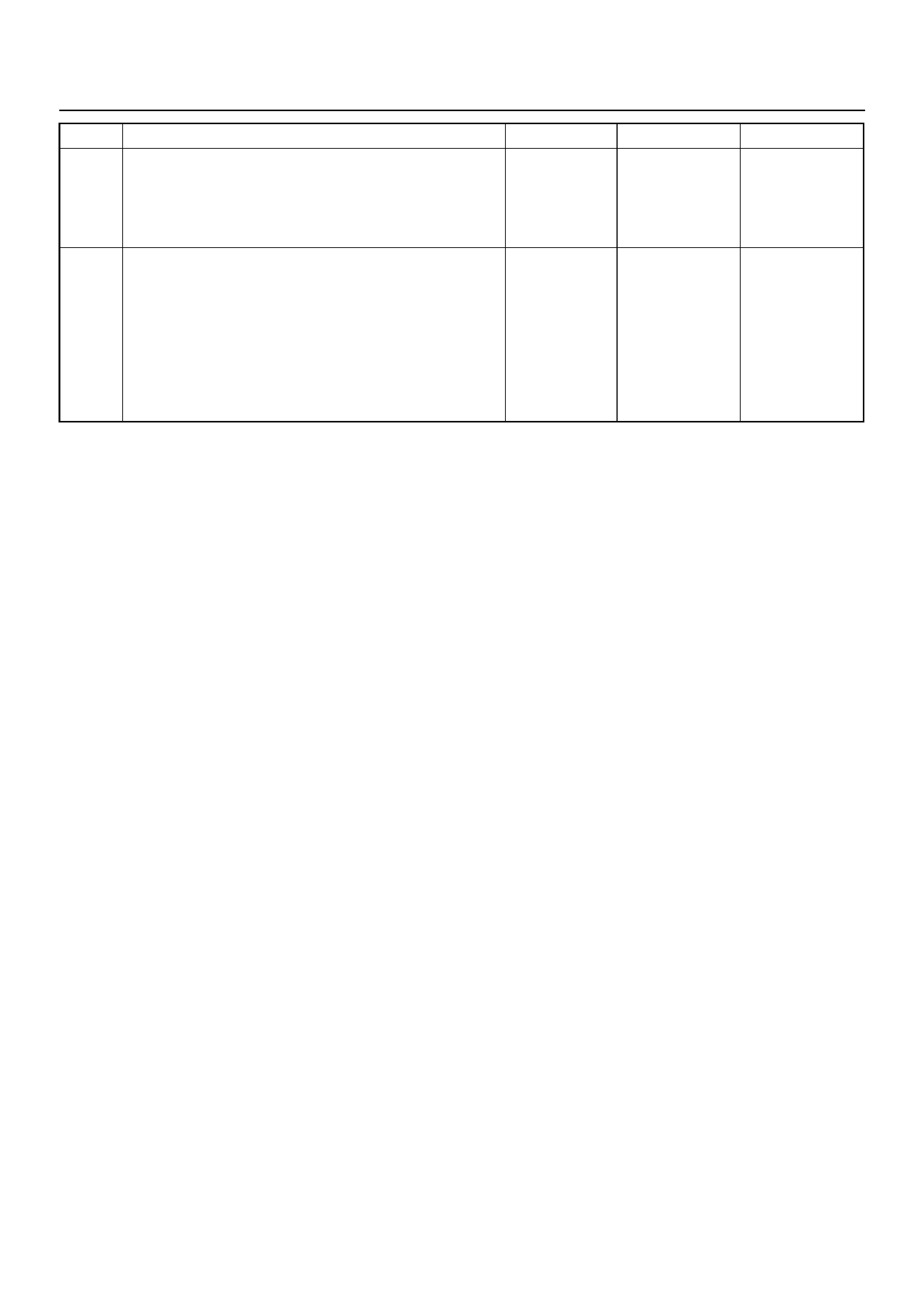

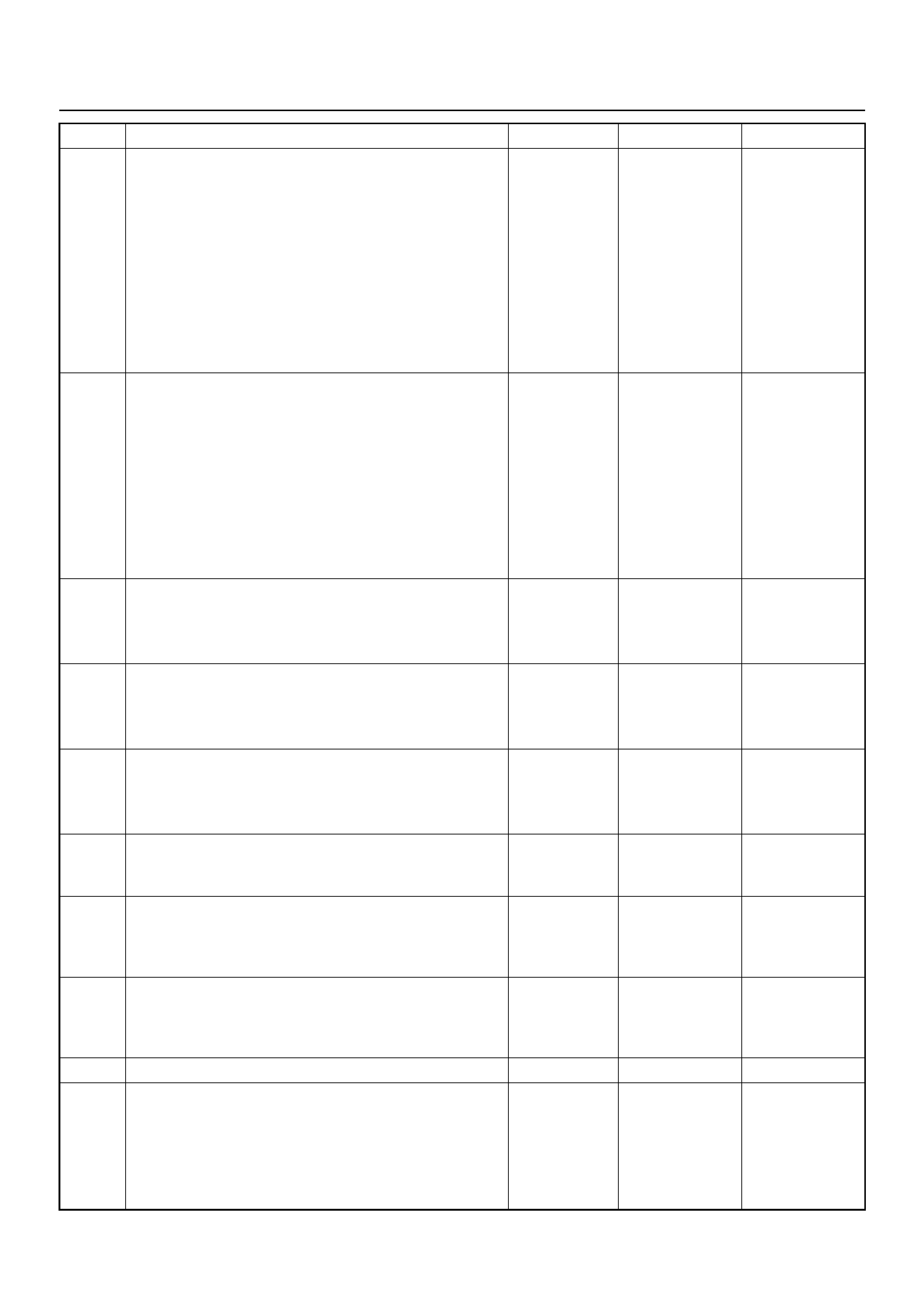

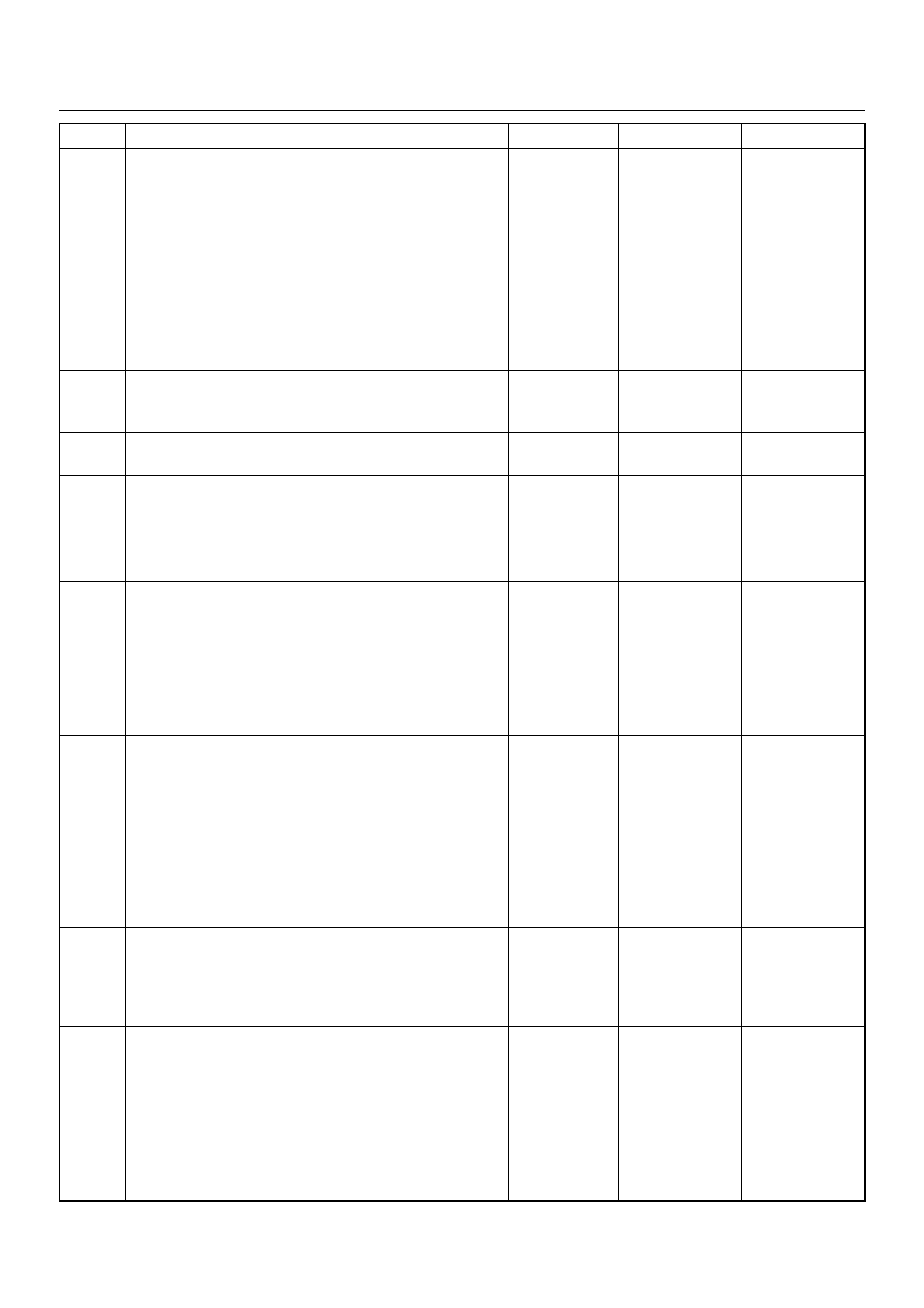

RELAY AND FUSE

RELAY AND FUSE BOX LOCATION

RELAY AND FUSE BOX LOCATION

RELAY & FUSE BOX

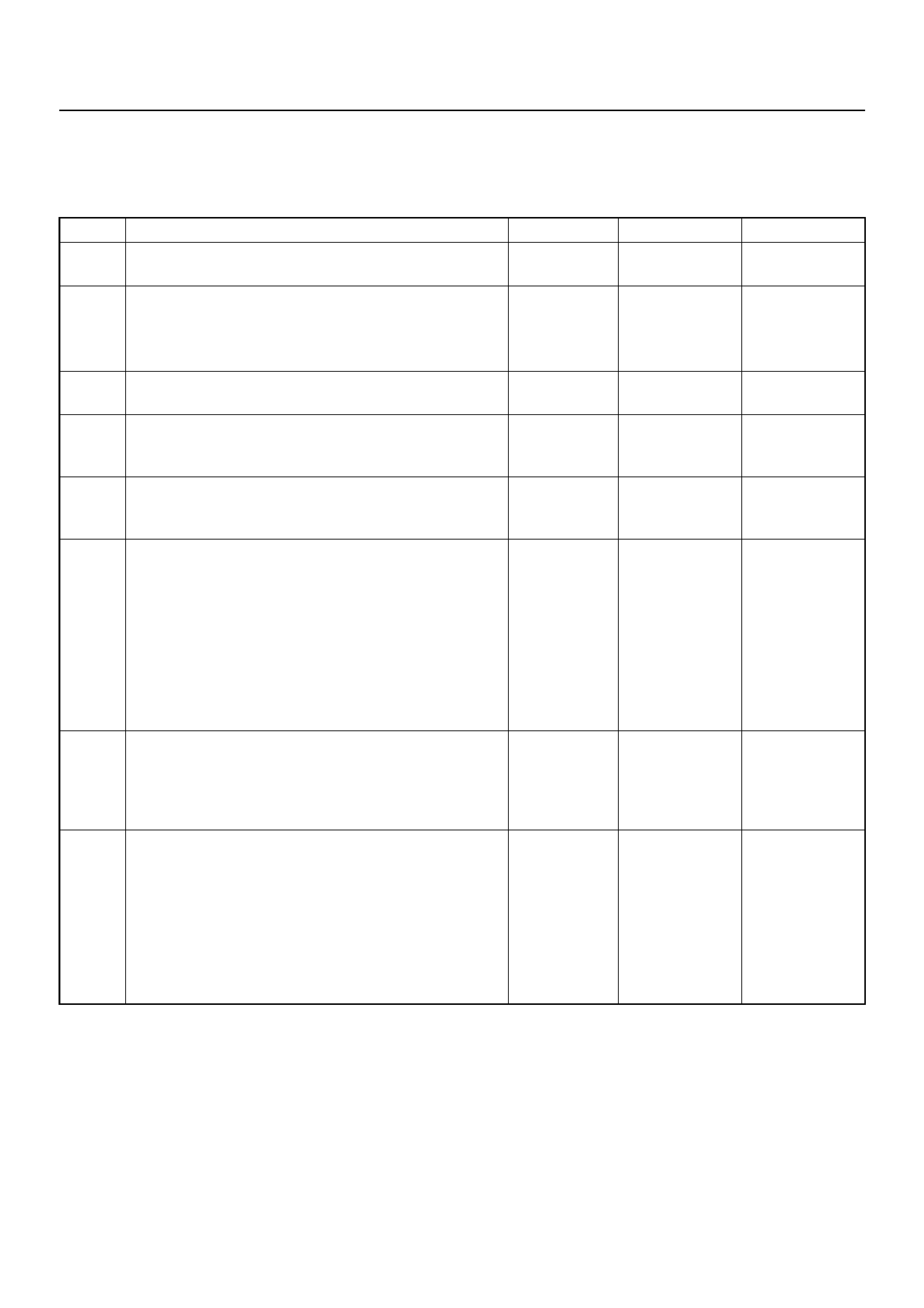

RELAY

No. RELAY (Y24SE)

X-1 RELAY; TAIL LIGHT

X-2 RELAY; FUEL PUMP

X-3 RELAY; HORN

X-4 RELAY; DIMMER

X-5 —

X-6 RELAY; STARTER

X-7 RELAY; COND, FAN

X-8 RELAY; —

X-9 —

X-10 —

X-11 RELAY; HEATER

X-12 STARTER CUT

X-13 RELAY; HEAD LIGHT

X-14 RELAY; A/C COMP

X-15 RELAY; A/C THERMO

FUSE

SLOW BLOW FUSE

ENGINE MODEL

FUSE NO. Y24SE

EB-1 15A ECM

EB-2 —

EB-3 20A TRAILER

EB-4 10A ACG (S)

EB-5 10A TAIL-RH

EB-6 10A TAIL-LH

EB-7 10A H/LIGHT-RH

EB-8 10A H/LIGHT-LH/ILLUMI

EB-9 20A FUEL PUMP

EB-10 10A O2 SENSOR

EB-11 —

EB-12 —

EB-13 10A AIR CON

EB-14 —

EB-15 10A HORN

EB-16 10A HAZARD

ENGINE MODEL

FUSE NO. Y24SE

SBF-1 100A MAIN

SBF-2 —

SBF-3 —

SBF-4 20A COND, FAN

SBF-5 40A IG 1

SBF-6 —

SBF-7 —

SBF-8 30A BLOWER

SBF-9 50A IG 2

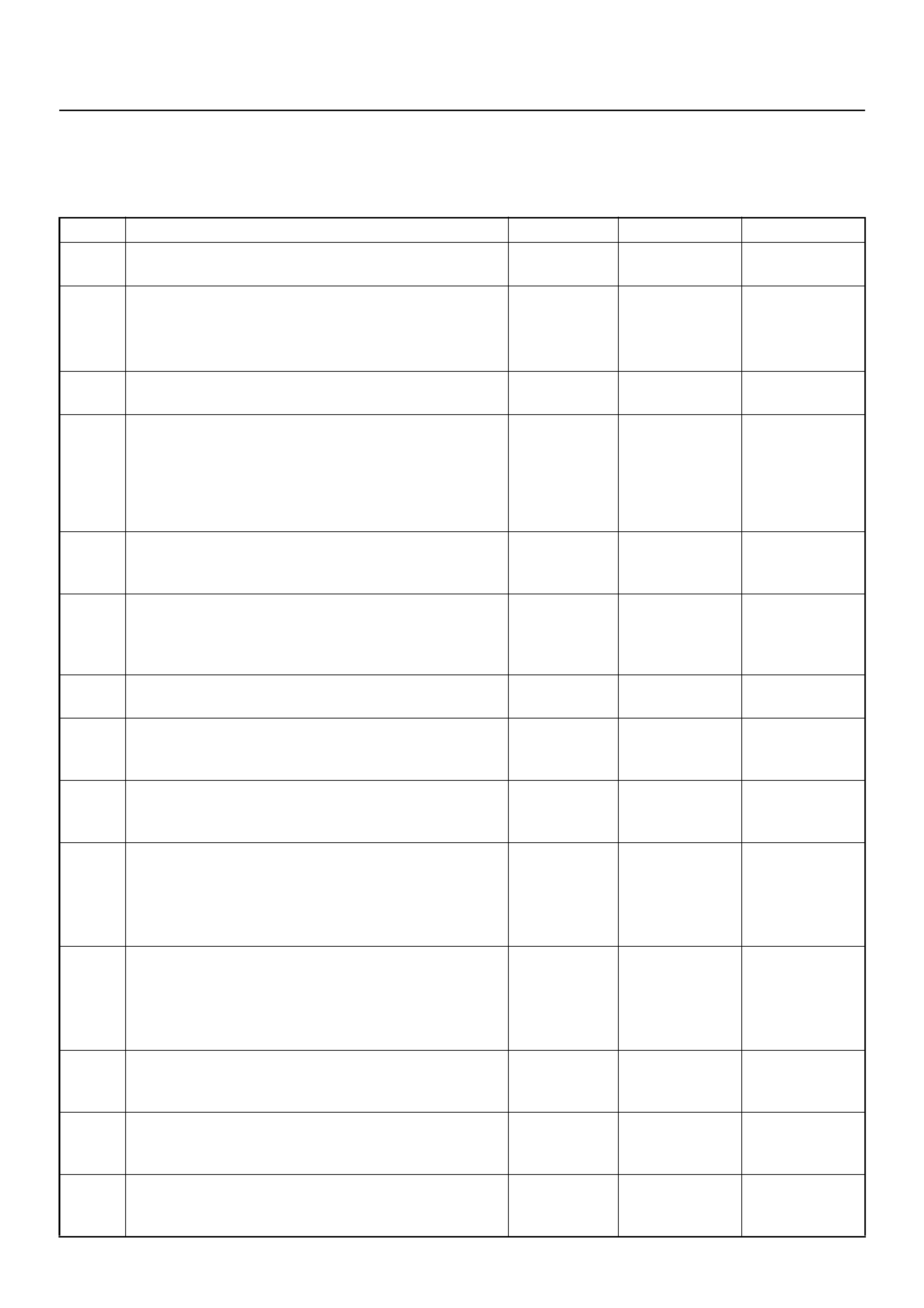

FUSE AND RELAY LOCATION

FUSE

SLOW BLOW FUSE

RELAY

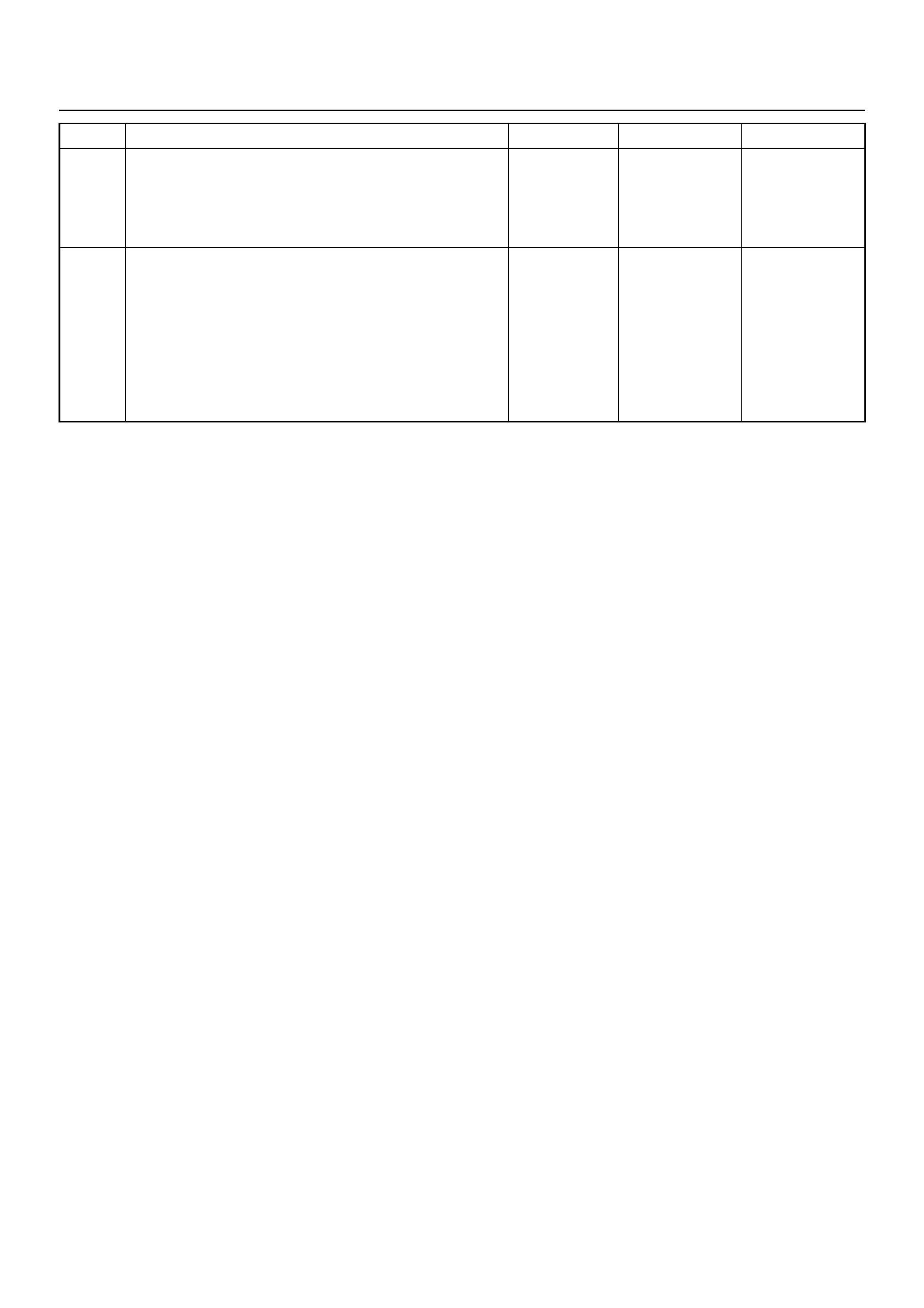

No. Capacity Indication on label No. Capacity Indication on label

1 — — 12 20A CIGER & ACC

2 10A ABS/4WD 13 15A AUDIO (+B)

3 10A TRAILER 14 20A DOOR LOCK

4 15A BACK UP 15 10A METER (+B)

5 15A METER 16 10A DOME LIGHT

6 10A TURN LIGHT 17 10A ANTI THEFT

7 15A ELEC.IG 18 15A STOP LIGHT

8 15A ENGINE / ECU 19 15A —

9 20A FRT WIPER/WASER 20 10A STARTER

10 15A IG. COIL 21 10A SRS

11 10A AUDIO

No. Capacity Indication on label

22 20A RR DEF

23 30A POWER WINDOW

Connector No. B-7 B-8 B-40

Y24SE REAR DEF POWER WINDOW No Relay

FUSE BOX

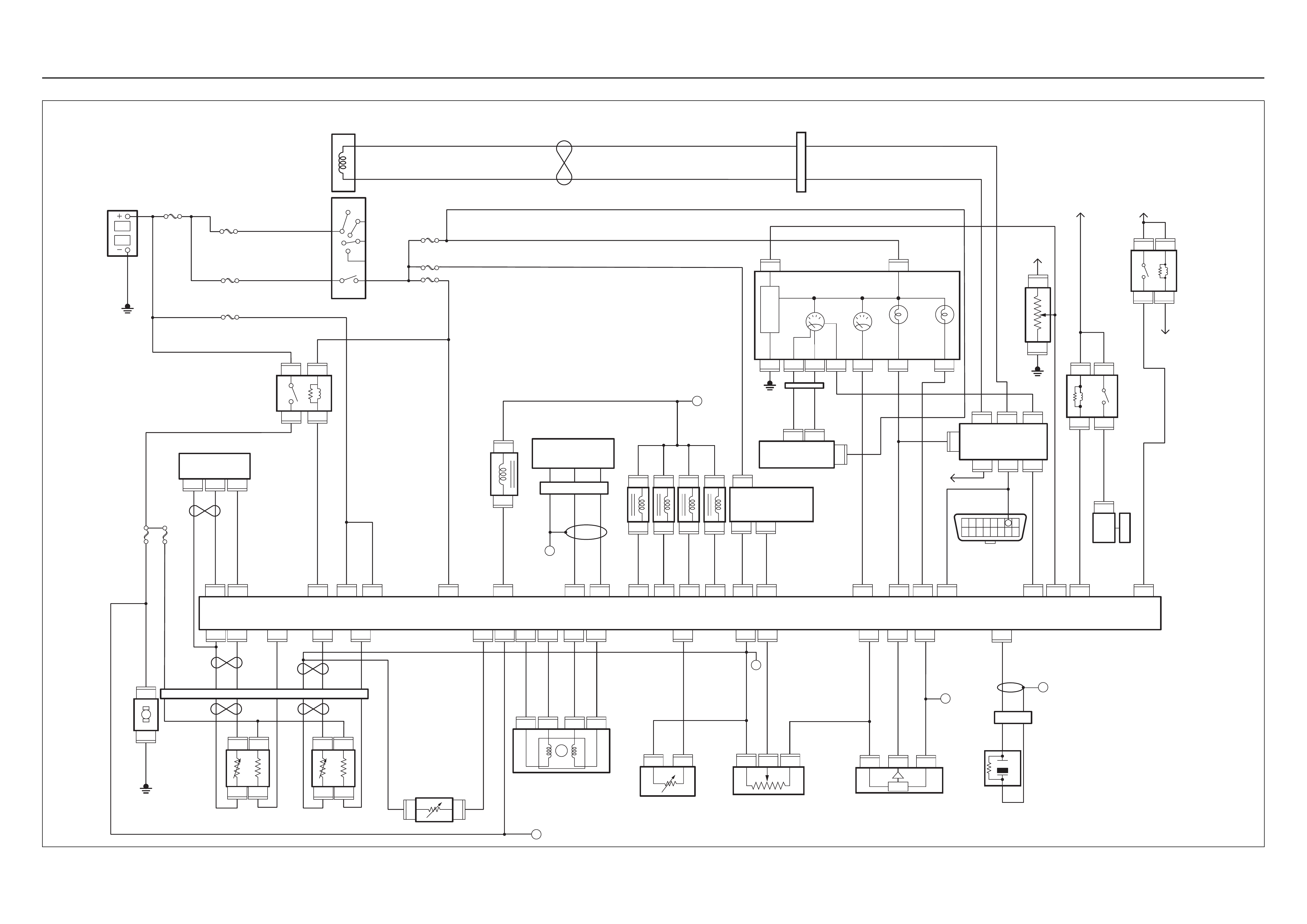

ECM WIRING DIAGRAM (1/8)

C56

7

5

C56

B58

B68

B68

3

B24

32 15

C56

218J2J2J2 J2 J2

C56

3

C56

B24

30

31

(+)(–)

B70 B70

Battery

Voltage

0.85

RED/

YEL

0.85

YEL

Engine

Room-RH

μP

0.5

BRN/

YEL

0.3

BRN/

YEL

Engine

Control

Module

(ECM)

MIL

Lamp

Immobiliser

Coil

(Antenna)

Immobiliser

Control

Unit (ICU)

Meter

15A

Ignition

SW

0.85

RED/

WHT

0.5

RED/

WHT

0.5

BLU/

YEL

2.0

WHT 3.0

BLK/

RED

0.5

YEL/

BLU

Batt

Pwr

MIL

Lamp Batt

Pwr Ign

Pwr

KWP2000

Serial Data

0.85

BLK

Class 2

Class 2

Diagnostic

Connector

16151413121110 9

87654321

Meter

15A

Ignition

SW

Engine

I5A

Battery

Voltage

ECM

I5A

RO7_6E1001

ECM WIRING DIAGRAM (2/8)

VIgn

VIgn

Engine

Control

Module

(ECM)

Fuel

Level

VSSSVS LampMIL Lamp

Tacho Sig

32

14 30

2

C56

13

C56

7J2 J2J2J2

C56

9J2

C56

4

IGN

SW

F2

F2

B68

B24

B24E44

E44E44

B24 B24 B24 B24 B24 B24

B68 B68

B68

IGN

SW

RO7_6E1002

μPμP

μP

μP

μP

Meter

15A

VIgn

MIL

Lamp SVS

Lamp

Speedo

Meter Tacho

Meter

0.85

YEL

0.5

YEL/

RED

0.8

YEL/

GRN

0.3

BRN/

YEL

0.5

GRN/

WHT

0.5

BLK/

RED

0.3

BRN/

YEL

0.5

BLK/

YEL

0.5

WHT

C56

0.5

BRN/

YEL

0.5

ORG/

BLU

2(–)

3

1

(+)

Vehicle

Speed

Sensor

(VSS) Starter

Relay

Fuel

Sender

Unit

METER

6

6

11 310278

B24

28

78

1

3

3

(–) (+)

1

Immobiliser

Coil

(Antenna)

B70 B70

CPU Immobiliser

Control

Unit (ICU)

ECM WIRING DIAGRAM (3/8)

μP

IGN

SW Battery

Voltage

Batt PwrFuel Pump

Pwr

O2 Heater

(Pre)

O2 Heater

(Post)

Battery

Voltage

2.0

WHT

0.5

BLU/

YEL

Engine

15A

450

mV

A/D Converter

Vcc

+5V -+

450

mV

A/D Converter

Vcc

+5V -+

2.0

RED/

BLK

Fuel

Pump

Relay

0.85

RED/

WHT

0.5

GRN/

WHT

RO7_6E1003

Engine

Control

Module

(ECM)

C56

1

C56

F2

F2

21

C56

31J2J1J1J1 J2 J2 J2 J2

E60

16

E60

28

E60

19

32

41

32

41

C56

26

C56

2

2.0

RED/

GRN

O2

Sensor

10A

Fuel

Pump

Heated 02 Sensors

Fuel

Pump

20A

2.0

BLK

0.5

BLU/

ORG

0.5

YEL

0.5

BLU/

YEL

0.5

BLK

0.5

BLK

0.5

BRN 0.5

YEL 0.5

PU 0.5

YEL

0.5

BRN 0.5

PU 0.5

BRN

0.5

ORG

2.0

BLK/

BLU

M

O2 Sensor

POST

O2 Sensor

PRE

LOWLOW

HI

HI

ECM

15A

X2

1

X2

X2 X2

3

1

4

42

E77 E77

E77

E78E78

E78E78

E77

H31

ECM WIRING DIAGRAM (4/8)

Fuel

Pump

20A

Fuel

Pump

Relay

2.0

BLK/

BLU 0.85

BLK/

YEL

0.85

RED/

GRN

2.0

BLK/

YEL

3.0

BLK/

RED

2.0

BLK/

RED

3.0

WHT/

BLK

2.0

WHT

Battery

Voltage Battery

Voltage

0.5

PINK

0.85

BLK/

BLU

Injector

#1

Cylinder

Injector

#2

Cylinder

Injector

#3

Cylinder

Injector

#4

Cylinder

0.5

BLU/

BLK

0.5

BLU/

WHT

Coil Module

0.5

BLU/

YEL

EVAP

Purge

Solenoid

Valve

0.5

GRN/

WHT

0.85

GRN 0.85

BLU

μP

IGN

Switch

IGN

Coil

20A

Main

100A

Engine

Control

Module

(ECM)

E60

8

E60

22

E60

9

E60

20J1 J1 J1 J1 J1 J1 J1 J1

E60

E18

E18 E18

11

E60

1

1,4 2,3

3

22

1

E66

1

E9

2

E60

17

E60

5

RO7_6E1004

E66

1

1

E9

E8

2

E8

1

E7

2

E7

1

E6

2

E6

Fuel Pump

on INJ 1 INJ 2 INJ 3 INJ 4 1,4 IGN

Coil 2,3 IGN

Coil EVAP

ECM WIRING DIAGRAM (5/8)

Idle Air

Control (IAC)

Valve

HI

LO

HI

LO

AB

0.5

YEL/

BLU

0.5

YEL/

GRN

0.5

BLU/

RED

0.5

YEL/

BLK

Engine

Control

Module

(ECM)

E60

29

E60

14

E60

E70 E70 E70E70

12 34

30

E60

13J1 J1 J1 J1

RO7_6E1005

μP

IAC D IAC C IAC B IAC A

ECM WIRING DIAGRAM (6/8)

E60

16

E60

31

321

E60

24

E60

E85

2

C121

1

C121

32 1

E85

E85

26J1 J1 J1 J1 J1 J1 J1 J1

E60

6

E60

21

Manifold

Absolute

Pressure (MAP)

Sensor

Crankshaft

Position(CKP)

Sensor

μP

0.5

GRY/

BLU

AB

AB

CHIGH LOW

E59

GND

0.5

GRY/

RED

0.5

YEL/

RED

0.5

BLU/

ORG

0.5

WHT

0.5

BLK 0.5

BLK/

WHT

5 Volts

Ref

MAP

Sensor

5V Ref

Signal

GND Signal

GND Signal

GND

MAP

Signal IAT Signal

RO7_6E1007

Engine

Control

Module

(ECM)

Intake

Air

Temperature (IAT)

Sensor

0.5

GRN 0.5

YEL/

GRN

μP

E60

23

E60

16

450

mV

A/D Converter

Vcc

+5V -+

ECM WIRING DIAGRAM (7/8)

1

C56

μP

E60

27

12231

12

E60

31

E60

7

E60

26

E60

3J1 J1 J1 J1 J1J1 J2 J2 J2

E60

E68 E68 E68 E69 E69 F10 F10 F10

16

C56

17 25

C56

1

A

23

CB

B

A

E84

0.5

GRY

μP

μP

5Volts

Ref 5Volts

Ref

RO7_6E1008

Knock

Sensor

0.5

YEL

0.5

WHT/

BLU

0.5

BLU/

ORG

0.5

BLU/

ORG

0.5

YEL/

RED

0.5

PUR/

BLU

0.5

GRY/

BLU

0.5

BLK 0.5

ORG 0.5

BLU/

WHT

Engine

Coolant

Temperature (ECT)

Sensor Vertical

G-Sensor

Throttle

Position Sensor

(TPS)

Knock Filter

Module

Engine

Control

Module

(ECM)

μP

ECM WIRING DIAGRAM (8/8)

X15

1

X15

X15X15

2

34

C56

20

43

21

C56

X14 X14

X14X14

28J2 J2

E2

AC Relay AC Req

RO7_6E1009

IGN

SW

A/C

10A

A/C

Compressor

Relay

0.5

BRN/

YEL

0.5

BRN/

RED

0.5

GRN/

BLK

Magnetic

Clutch

Sensor

μP

A/C Pressure S/W

Thermo

Relay

μP

Engine

Control

Module

(ECM)

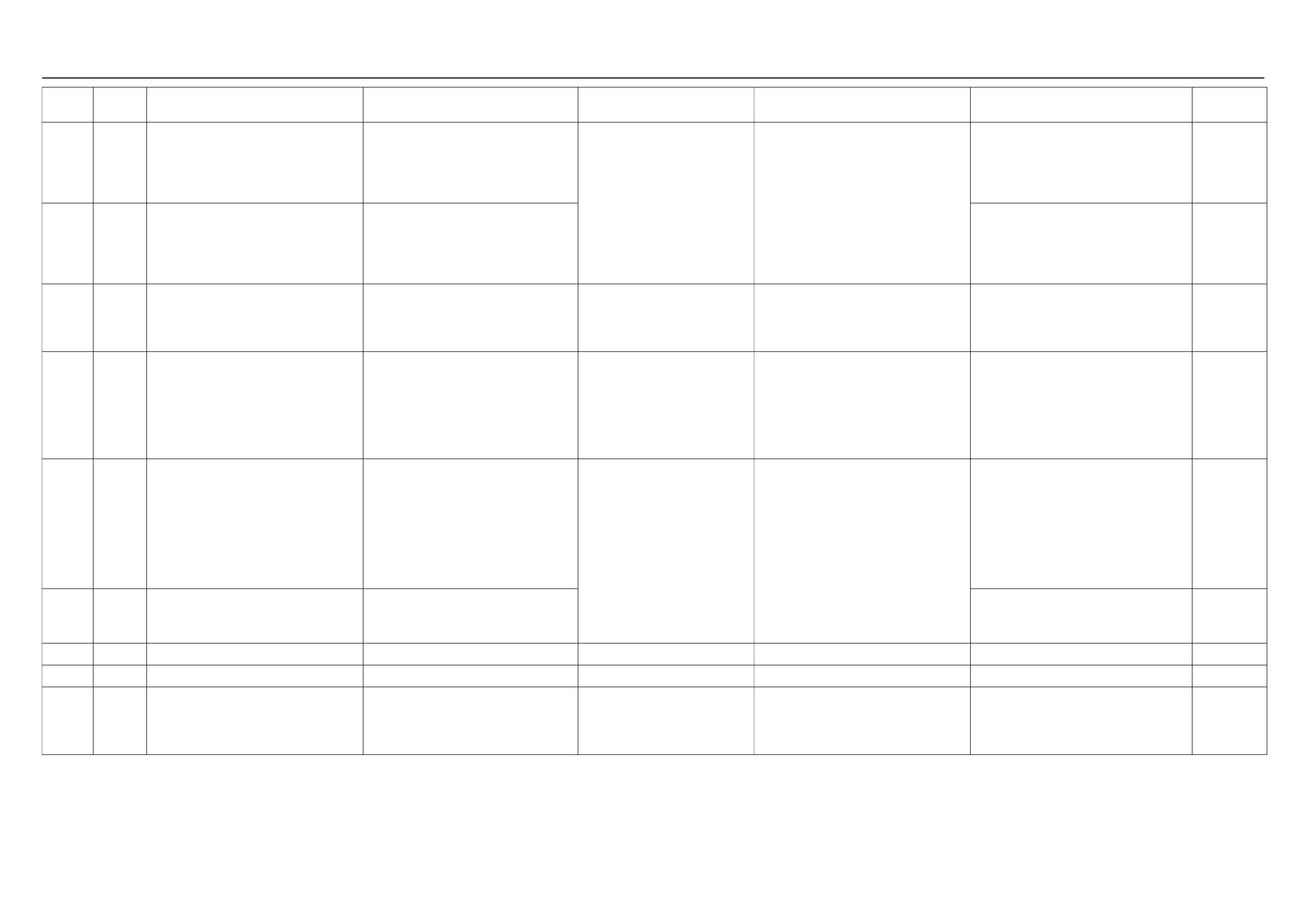

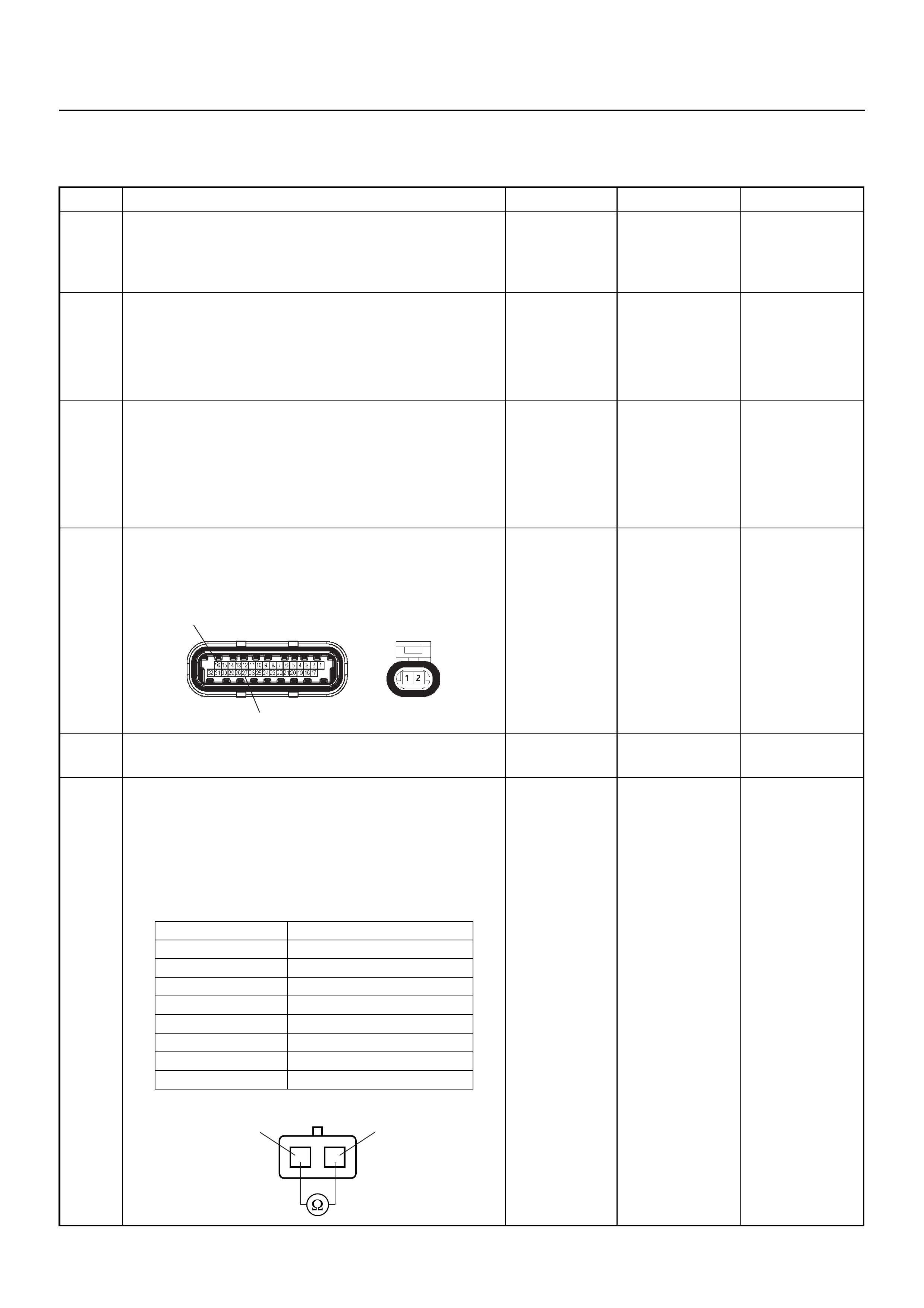

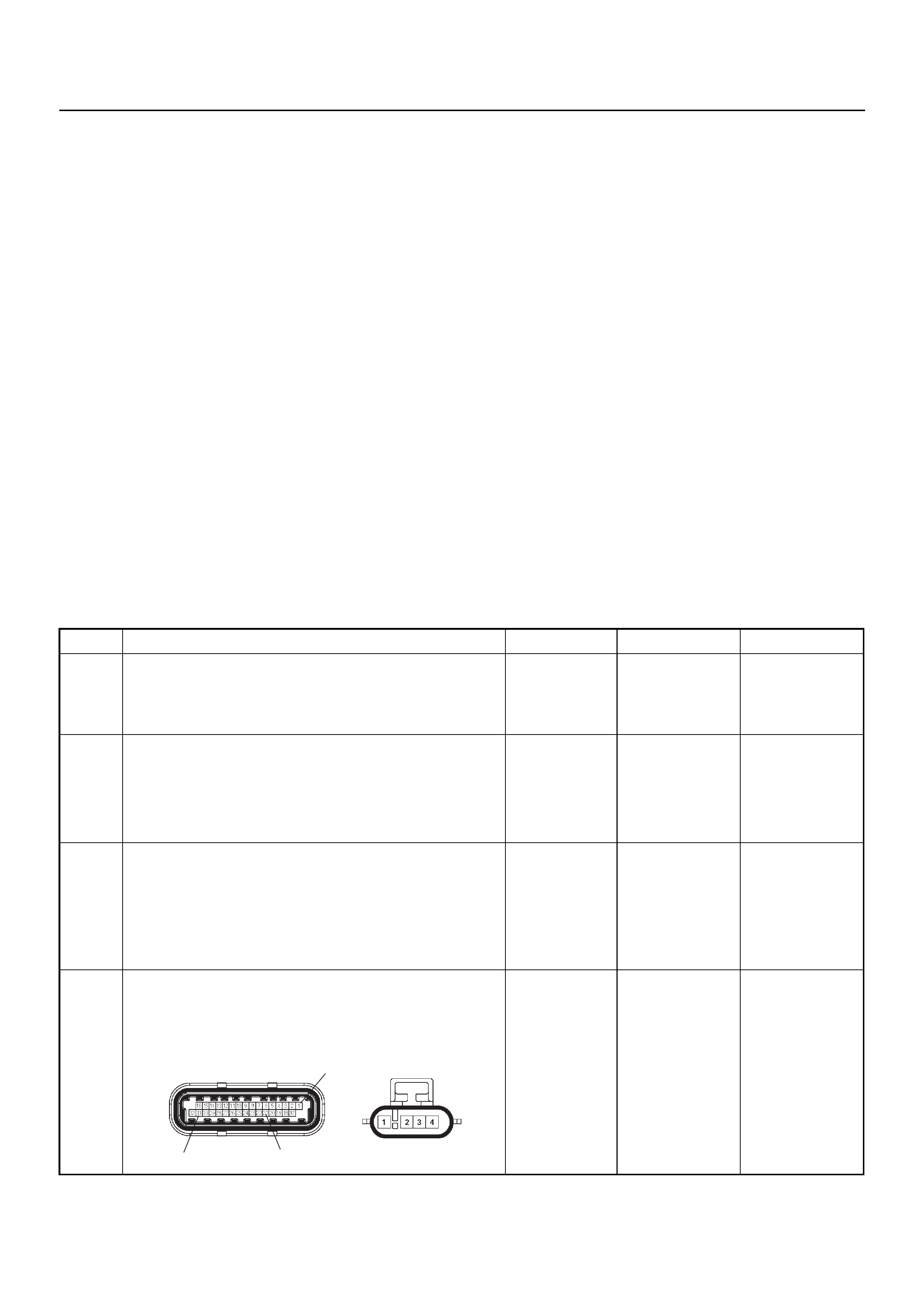

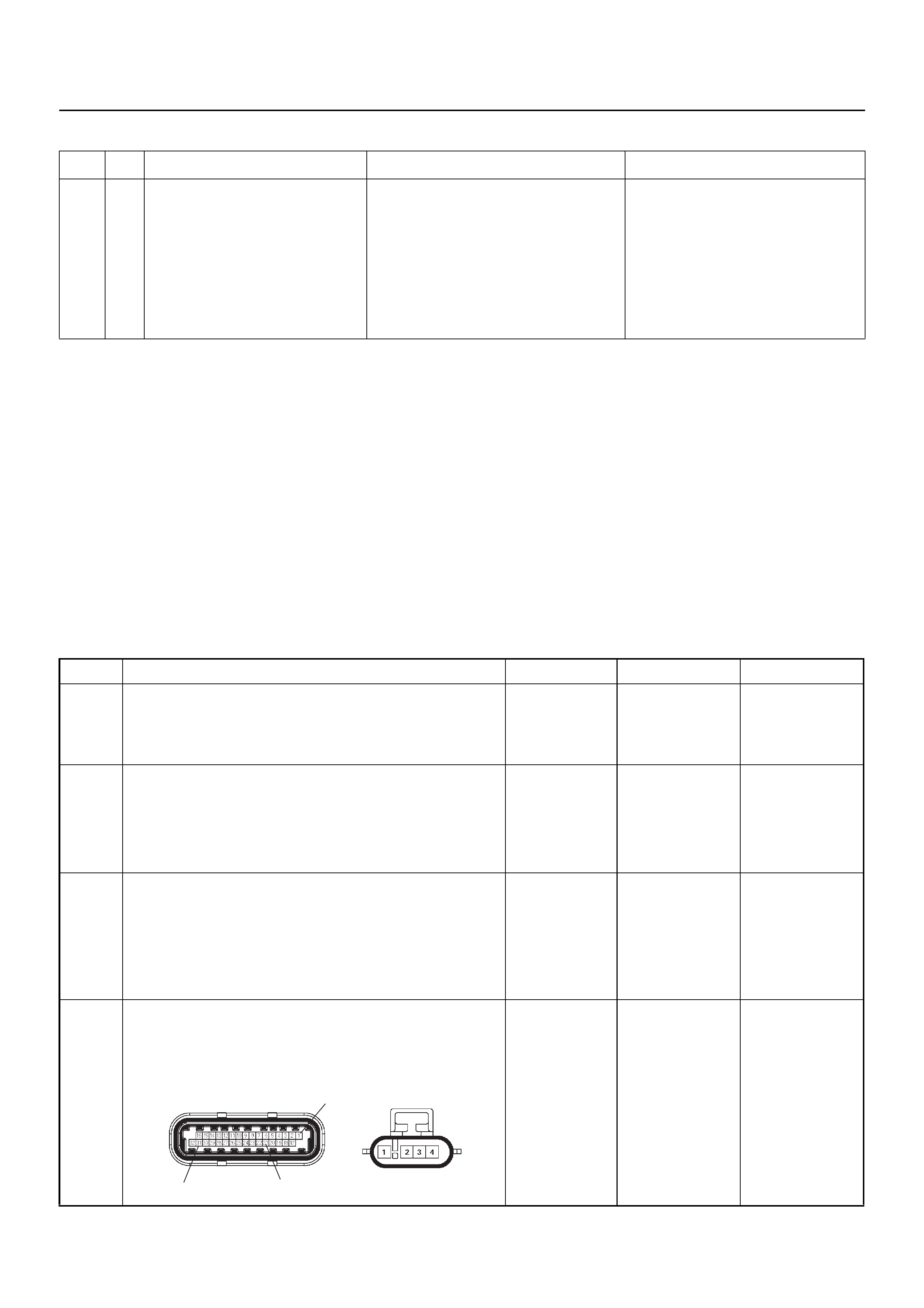

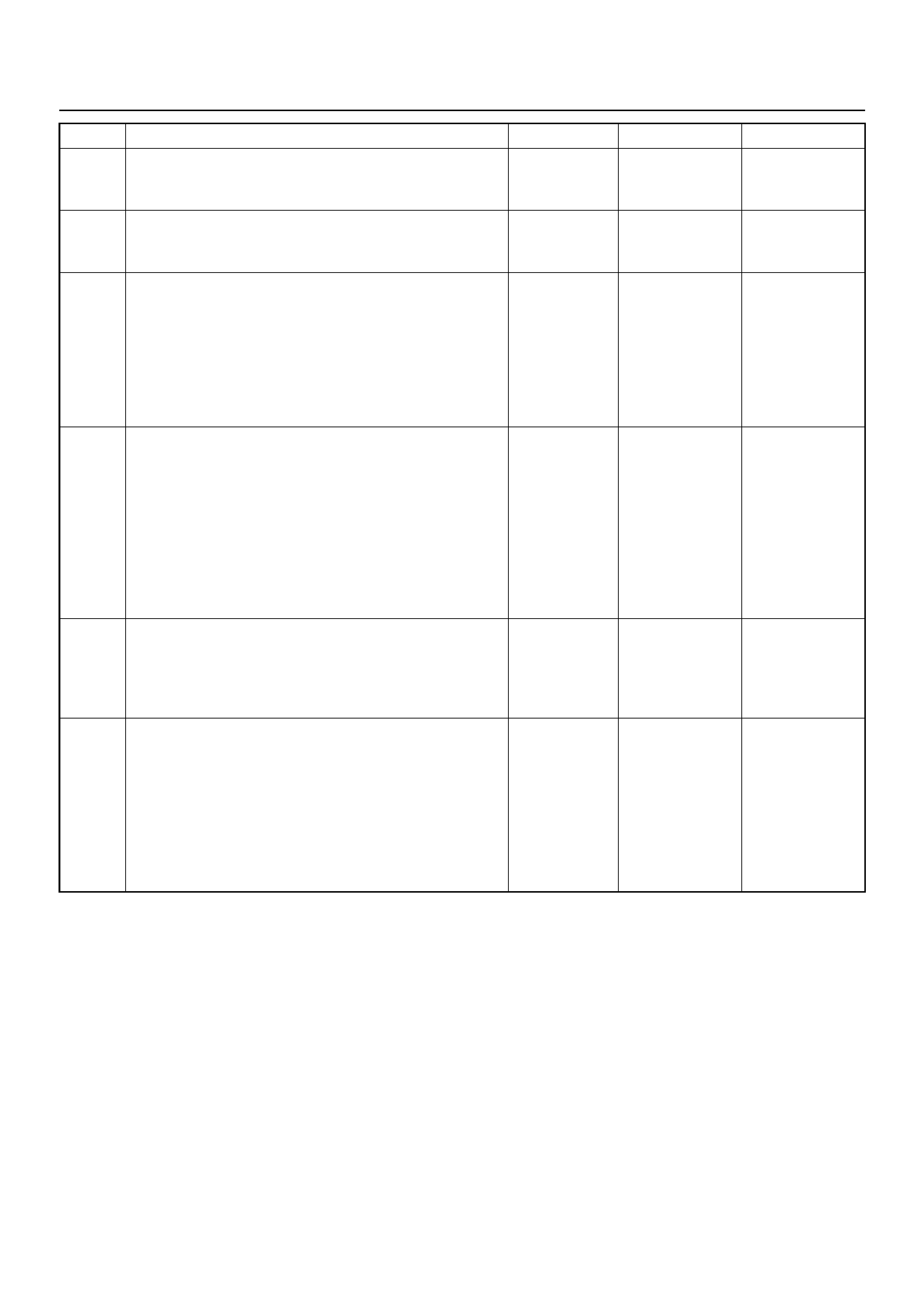

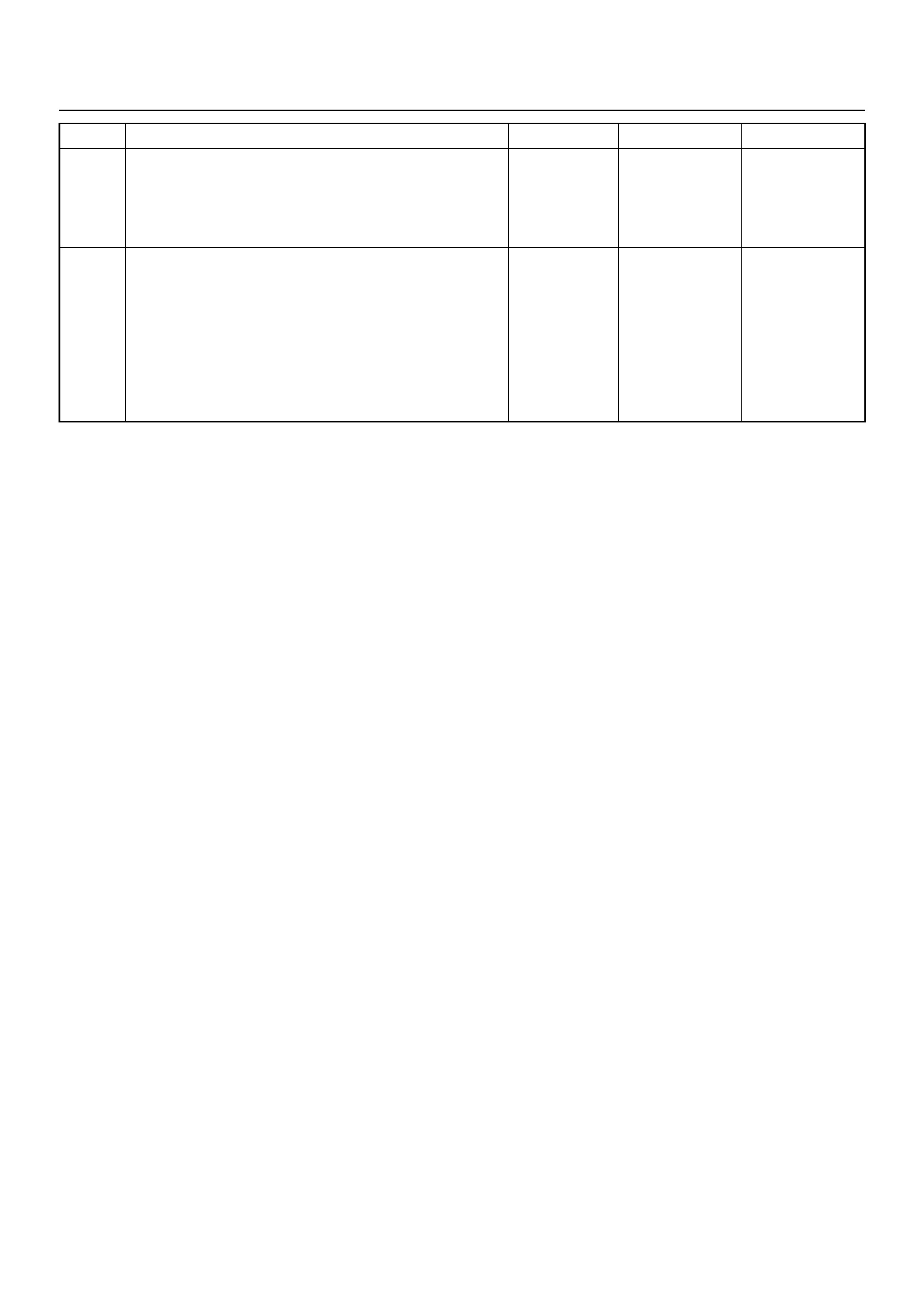

ECM CONNECTOR PIN ASSIGNMENT & OUTPUT SIGNAL

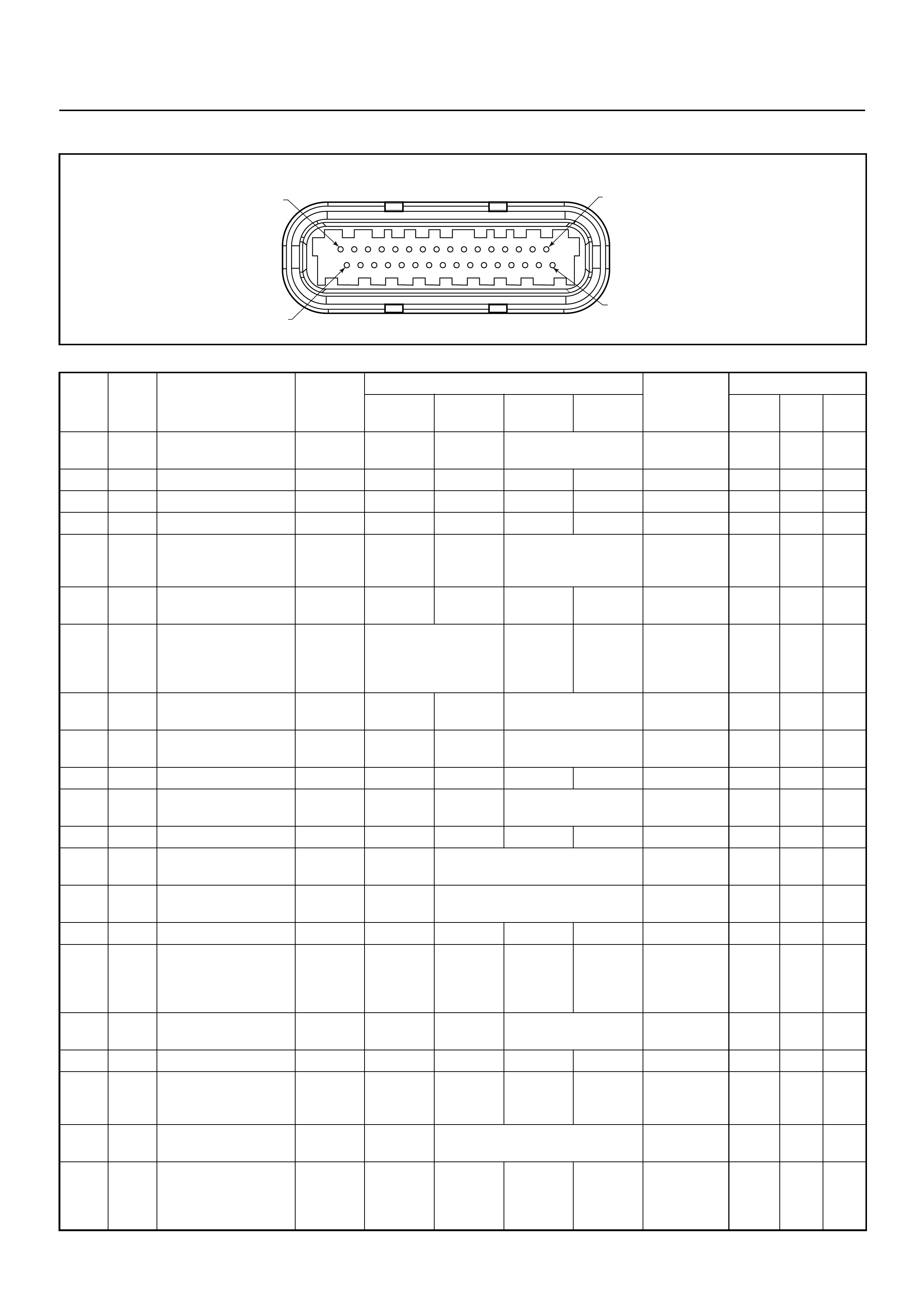

Connector (GREY) J1 Port: View Looking Into ECM Case

1

17 16

32

PIN16PIN1

PIN17 PIN32

Pin

No.

B/Box

No. Pin Function Wire

Color

Signal or Continuity ECM

Connection

Tester Position

Key SW

Off

Key SW

On

Engine

Idle

Engine

2000rpm Range (+) (-)

J1-1 1 Coil Module No. 1 &

No. 4 GRN Less than

1V Battery

voltage Pulse waveform Connect DC V 1 GND

J1-2 2 No Connection - - - - - - - - -

J1-3 3 Knock Sensor Signal YEL - - - - - - - -

J1-4 4 No Connection - - - - - - - - -

J1-5 5 EVAP Purge Solenoid

Valve GRN/

WHT Less than

1V Battery

voltage Wave form/ battery

voltage while solenoid

is not activated

Connect DC V 5 GND

J1-6 6 Crankshaft Position

(CKP) Sensor (High) BLK - - - - - - - -

J1-7 7 Throttle Position

Sensor (TPS) Output

Signal

WHT/BLU Approx. 6.0kΩ at idle /

Approx. 1.7kΩ at WOT

Approx. 2.3kΩ at idle /

Approx. 6.6kΩ at WOT

- - Disconnect Ω7 1 6 /

31

J1-8 8 No. 3 Injector BLU/WHT Less than

1V Battery

voltage Pulse waveform Connect DC V 8 GND

J1-9 9 No. 1 Injector PINK Less than

1V Battery

voltage Pulse waveform Connect DC V 9 GND

J1-10 10 No Connection - - - - - - - - -

J1-11 11 No. 4 Injector YEL Less than

1V Battery

voltage Pulse waveform Connect DC V 11 GND

J1-12 12 No Connection - - - - - - - - -

J1-13 13 Idle Air Control Valve

(IACV) Coil A High YEL/BLU Less than

1V Less than 1V / Battery voltage

Square waveform Connect DC V 13 GND

J1-14 14 Idle Air Control Valve

(IACV) Coil B Low YEL/BLK Less than

1V Less than 1V / Battery voltage

Square waveform Connect DC V 30 GND

J1-15 15 No Connection - - - - - - - - -

J1-16 16 TPS, IAT, ECT &

Crankshaft Position

Sensor Signal Ground

5VRTN A

BLU/ORG Continuity

with

ground

- - - Connect Ω16 GND

J1-17 17 Coil Module No 2 & No

3BLU GRN Battery

voltage Pulse waveform Connect DC V 17 GRD

J1-18 18 No Connection - - - - - - - - -

J1-19 19 Oxygen Sensor Heater

(Post) BLU/YEL Continuity

with

ground

- - - Connect Ω19 GND

J1-20 20 Fuel Pump On Signal BLK/BLU Less than

1V Battery Voltage Connect DC V 20 GRD

J1-21 21 Crankshaft Position

(CKP) Sensor Signal

(LOW)

BLK/WHT - - Wave

form or

approx.

3.7V

Wave

form or

approx.

7.7V

Connect AC V 21 6

J1-22 22 No.2 Injector BLU/BLK Less than

1V Battery

voltage Wave form Connect DC V 22 GND

J1-23 23 Inlet Air Temp. (IAT)

Sensor Signal YEL/GRN Less than

1V Approx. 1.8V at IAT 30°C Connect DC V 23 16

J1-24 24 MAP Sensor Signal GRY/RED Less than

1V Approx.

4.8V Approx.

1.3V Approx.

0.9V Connect DC V 24 16

J1-25 25 No Connection - - - - - - - - -

J1-26 26 Knock Sensor & MAP

Sensor Signal Ground

5VRTN A

GRY/BLU Continuity

with

ground

- - - Connect Ω26 GND

J1-27 27 Engine Coolant Temp.

(ECT) Sensor Signal GRY Less than

1V Approx. 2.5V at ECT 80°C Connect DC V 27 16

J1-28 28 Oxygen Sensor Signal

(Post) BLK Less than

1V Approx.

0.4V 0.1 - 0.9V Connect DC V 28 16

J1-29 29 Idle Air Control Valve

(IACV) Coil B High BLU/RED Less than

1V Less than 1V / Battery voltage

Square waveform Connect DC V 29 GND

J1-30 30 Idle Air Control Valve

(IACV) Coil A Low YEL/GRN Less than

1V Less than 1V / Battery voltage

Square waveform Connect DC V 30 GND

J1-31 31 Manifold Absolute

Pressure (MAP) &

Throttle Position (TPS)

Sensor 5 Volt Ref

YEL/RED Less than

1 V Approx.. 5V Connect DC V 31 16

J1-32 32 No Connection - - - - - - - - -

Pin

No.

B/Box

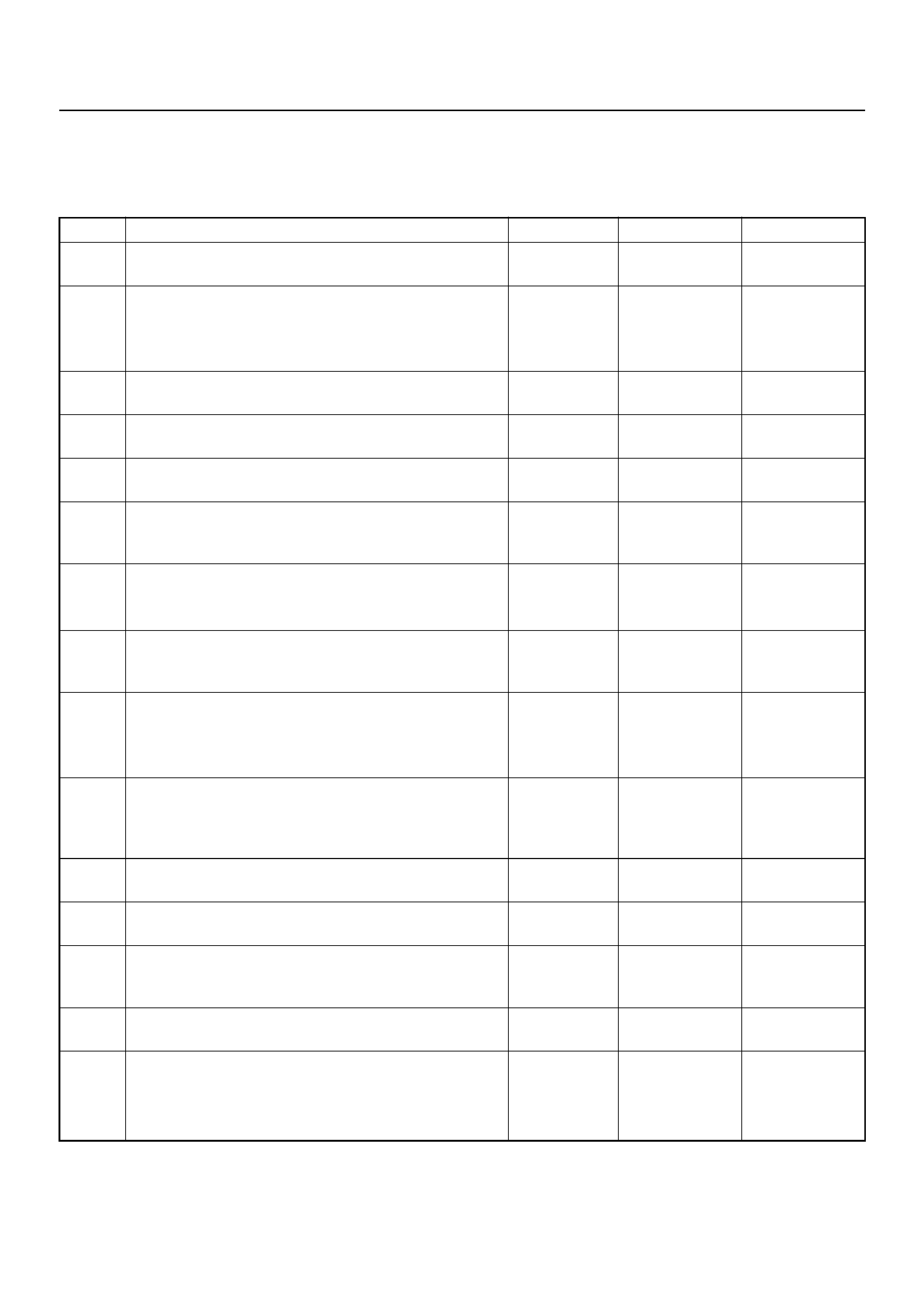

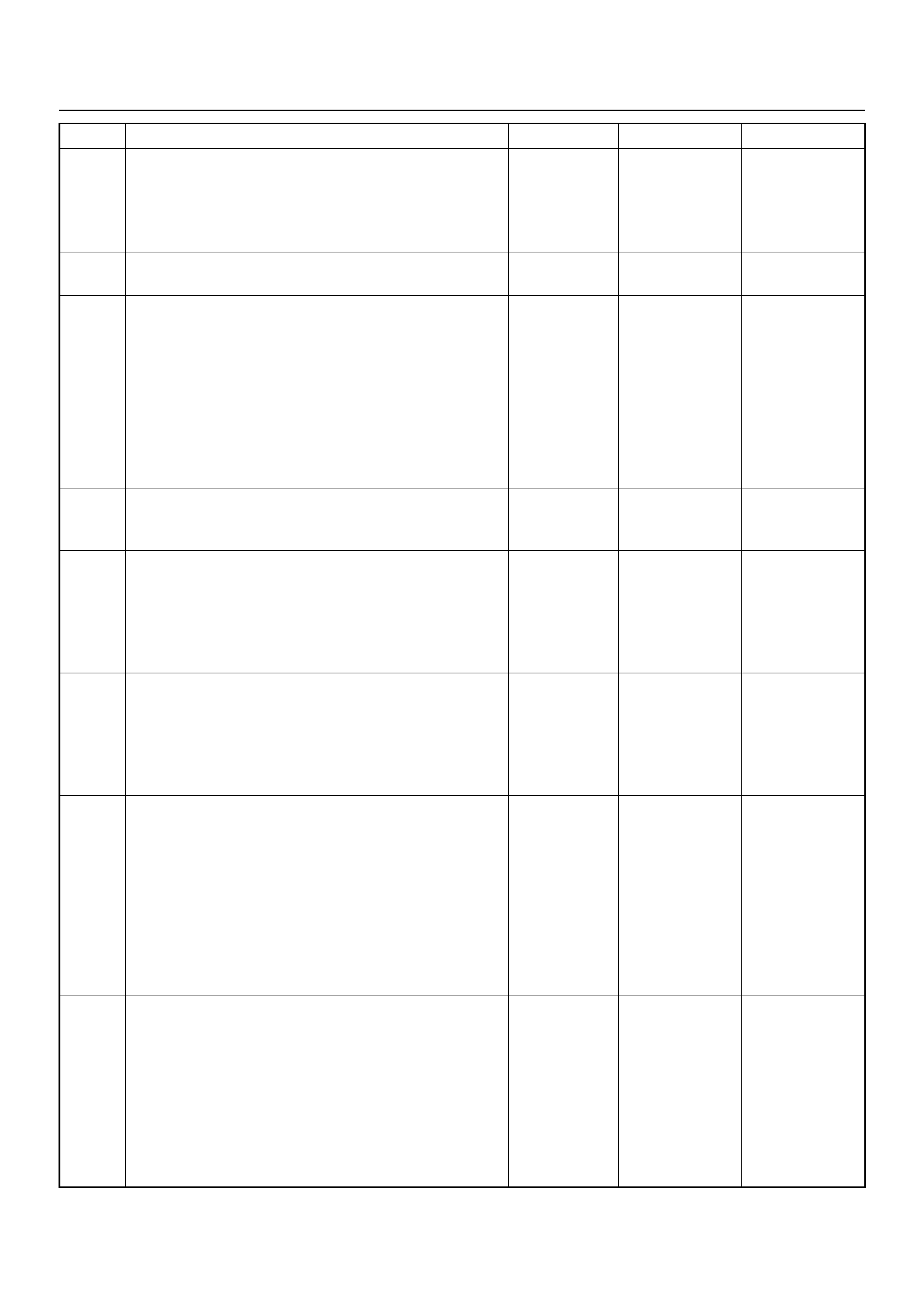

No. Pin Function Wire

Color

Signal or Continuity ECM

Connection

Tester Position

Key SW

Off

Key SW

On

Engine

Idle

Engine

2000rpm Range (+) (-)

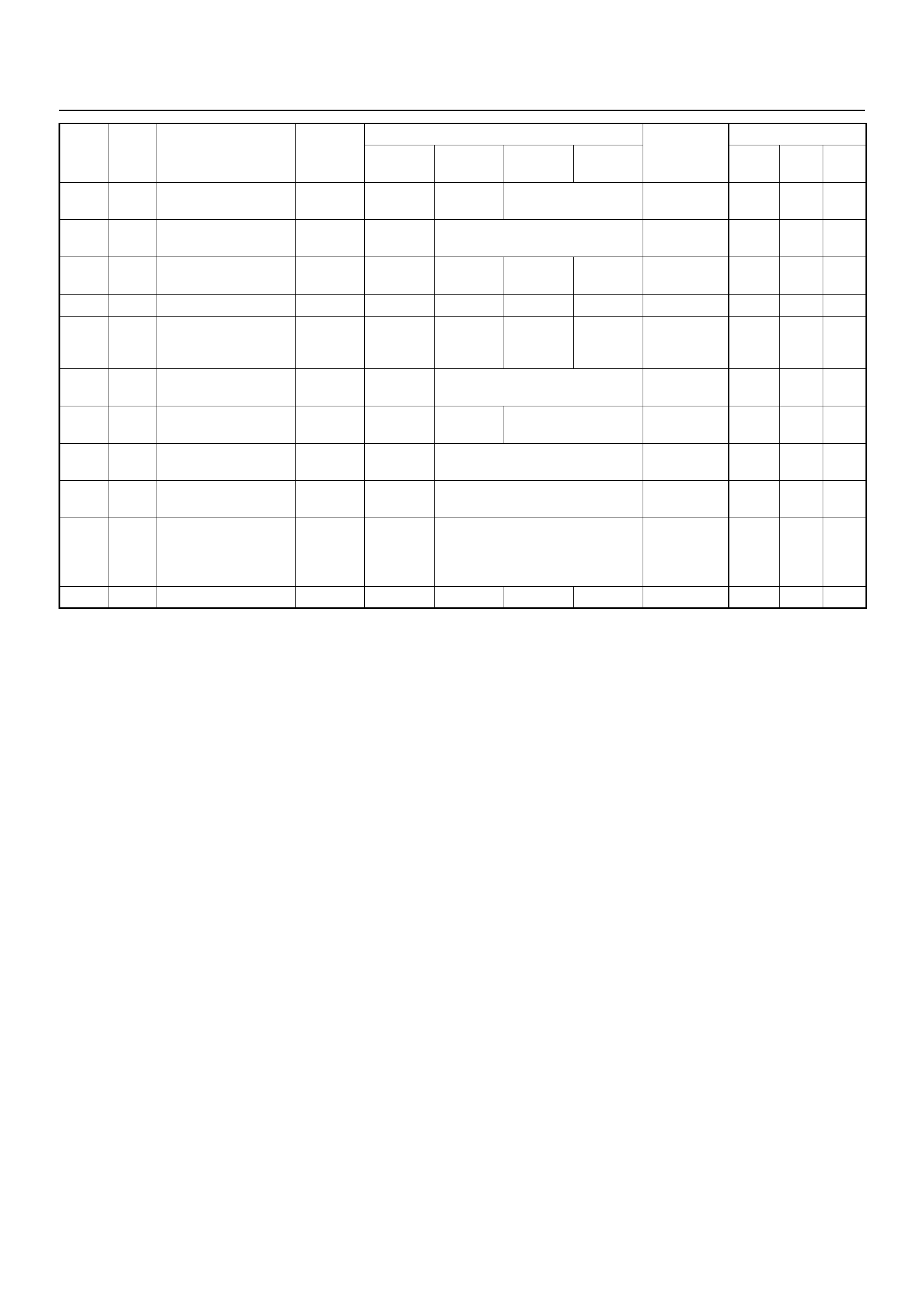

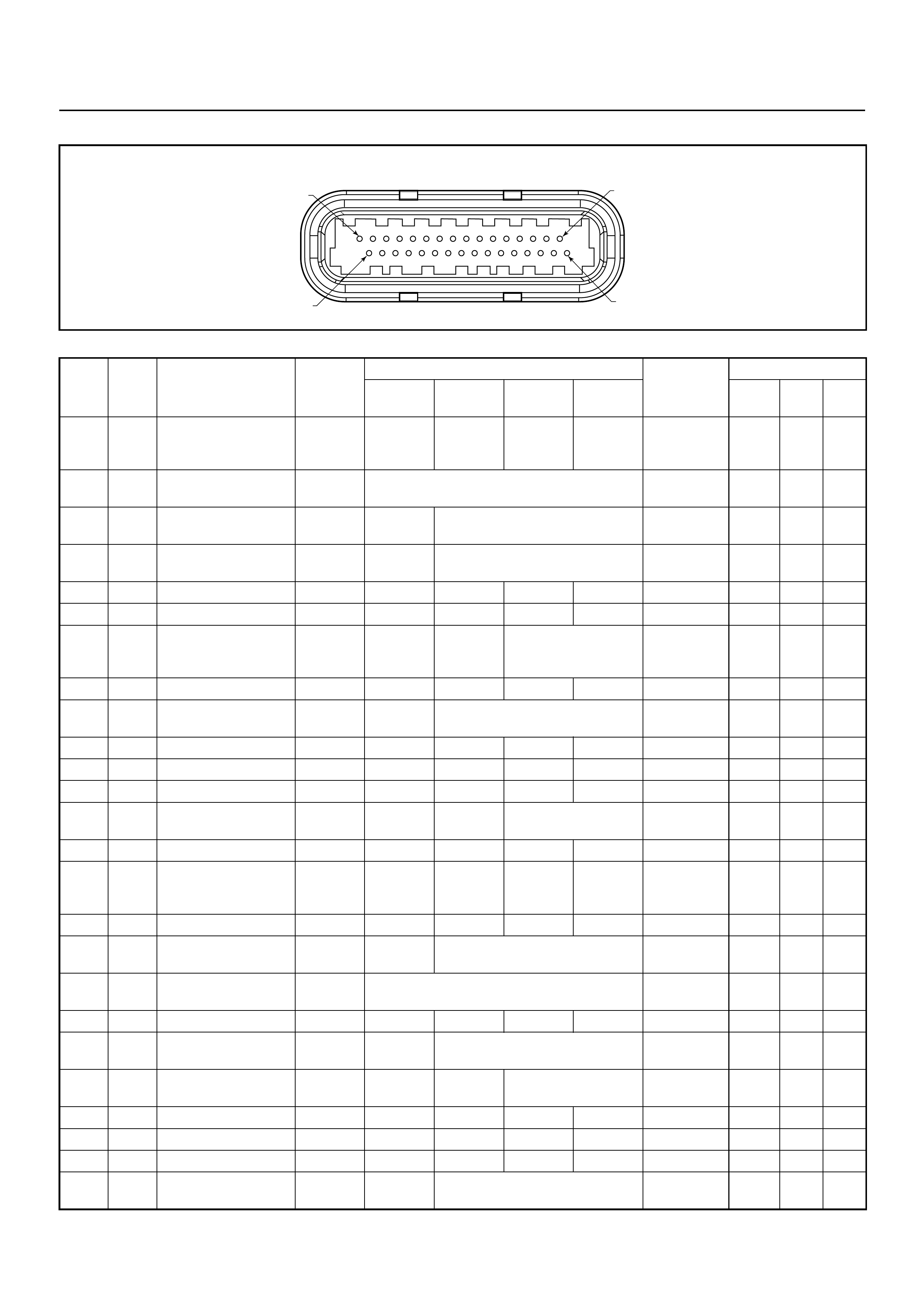

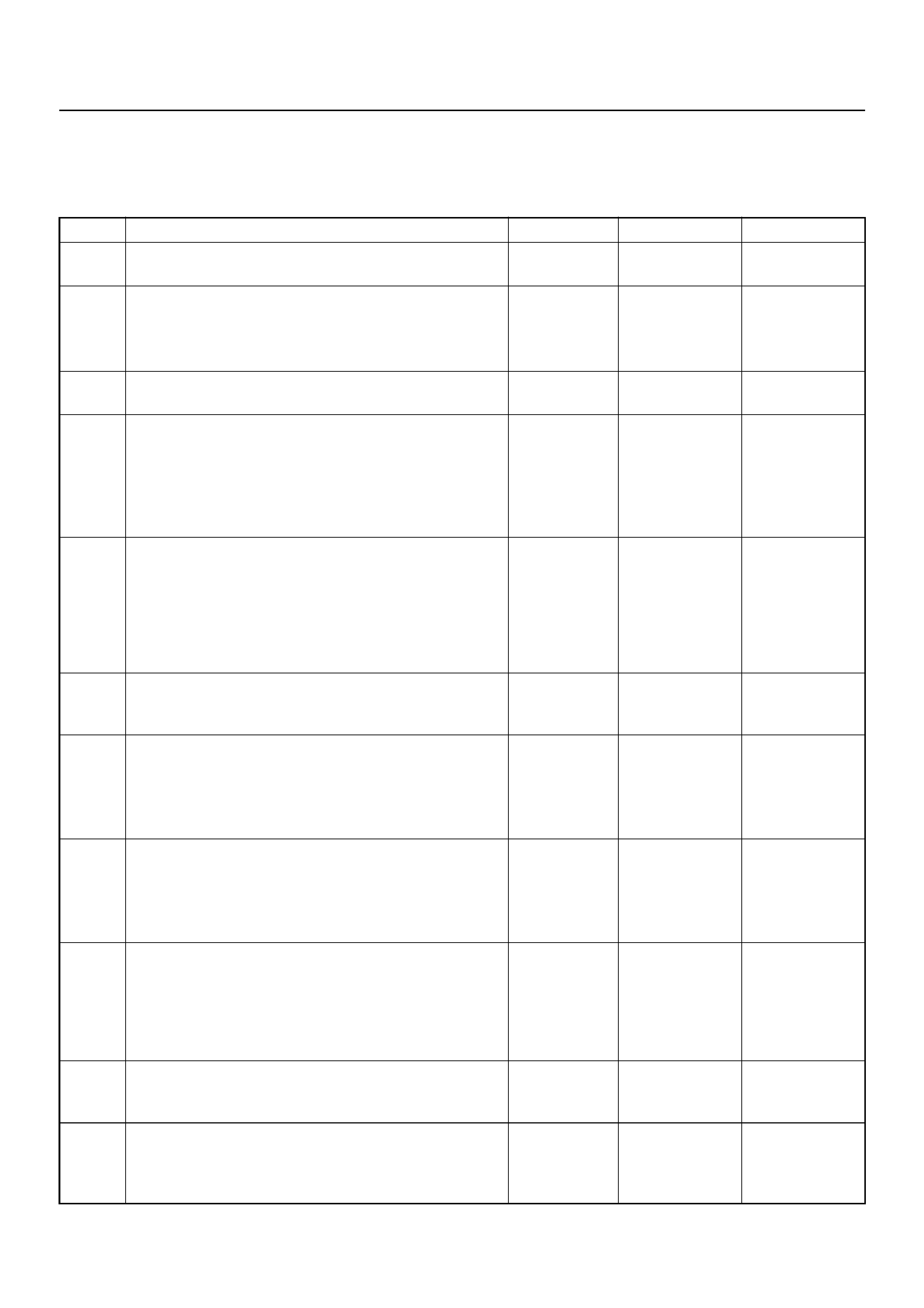

Connector (BLACK) J2 Port: View Looking Into ECM Case

1

17 16

32

PIN32

PIN1

PIN17

PIN16

Pin

No.

B/Box

No. Pin Function Wire

Color

Signal or Continuity ECM

Connection

Tester Position

Key SW

Off

Key SW

On

Engine

Idle

Engine

2000rpm Range (+) (-)

J2-1 33 Oxygen Sensor (Pre)

& Lateral G-Sensor

(Ground)

BLK Continuity

with

ground

- - - Connect Ω33 GND

J2-2 34 Battery Power Supply RED/

WHT Battery voltage Connect DC V 34 GND

J2-3 35 Ignition Power Supply BLU/YEL Less than

1V Battery voltage Connect DC V 35 GND

J2-4 36 Fuel Level Signal YEL/RED Less than

1V Varying voltage with fuel contents Connect DC V 36 GND

J2-5 37 No Connection - - - - - - - - -

J2-6 38 No Connection - - - - - - - - -

J2-7 39 Vehicle Speed Signal

VSS (Immobiliser

Control Unit B8)

WHT - - Approx. 16Hz by wave

form or approx. 4.8V at

20km/h

Connect AC V 39 GND

J2-8 40 No Connection - - - - - - - - -

J2-9 41 Tachometer Signal

from ECM BLK/RED Less than

1 V Wave form Connect AC V 41 GRD

J2-10 42 No Connection - - - - - - - - -

J2-11 43 No Connection - - - - - - - - -

J2-12 44 No Connection - - - - - - - - -

J2-13 45 SVS Lamp ORG/BLU Less than

1V Less than

1V Battery voltage while

lamp is turned off Connect DC V 45 GND

J2-14 46 No Connection - - - - - - - - -

J2-15 47 Diagnostic Connector

KWP 2000 Serial Data

& ICU

YEL/BLU---- ----

J2-16 48 No Connection - - - - - - - - -

J2-17 49 Vertical G-Sensor BLU/WHT Less than

1 V Approx.. 5V Connect DC V 49 GRD

J2-18 50 Battery Power Supply RED/

WHT Battery voltage Connect DC V 50 GND

J2-19 51 No Connection - - - - - - - - -

J2-20 52 Thermo Relay GRN/BLK Less than

1V Battery voltage when A/C request is

activated Connect DC V 52 GND

J2-21 53 Oxygen Sensor signal

(Pre) BLU/ORG Less than

1V Approx.

0.4V 0.1 - 0.9V Connect DC V 53 33

J2-22 54 No Connection - - - - - - - - -

J2-23 55 No Connection - - - - - - - - -

J2-24 56 No Connection - - - - - - - - -

J2-25 57 Vertical G-Sensor ORG Less than

1V 1.8 to 3.3 Volts

During movement Connect AC V 57 33

J2-26 58 Fuel Pump Relay GRN/

WHT Less than

1V Less than

1V /

Battery

voltage

while fuel

pump is

activated

Battery voltage Connect DC V 58 GND

J2-27 59 No Connection - - - - - - - - -

J2-28 60 A/C Compressor

Relay BRN/RED Less than

1V Battery

voltage Less than 1V Connect DC V 60 GND

J2-29 61 No Connection - - - - - - - - -

J2-30 62 No Connection - - - - - - - - -

J2-31 63 Oxygen Sensor Heater

(Pre) YEL Continuity

with

ground

- - - Connect Ω63 GND

J2-32 64 Malfunction Indicator

Lamp (MIL)

(Immobiliser Control

Unit Terminal B7)

BRN/YEL Less than

1V Less than

1V Battery voltage while

lamp is turned off Connect DC V 64 GND

Pin

No.

B/Box

No. Pin Function Wire

Color

Signal or Continuity ECM

Connection

Tester Position

Key SW

Off

Key SW

On

Engine

Idle

Engine

2000rpm Range (+) (-)

GENERAL DESCRIPTION FOR ECM AND

SENSORS

Engine Control Module (ECM)

The Engine Control Module (ECM) is located on the left-

hand side of the engine bay behind the battery and fuse

panel. The ECM controls the following:

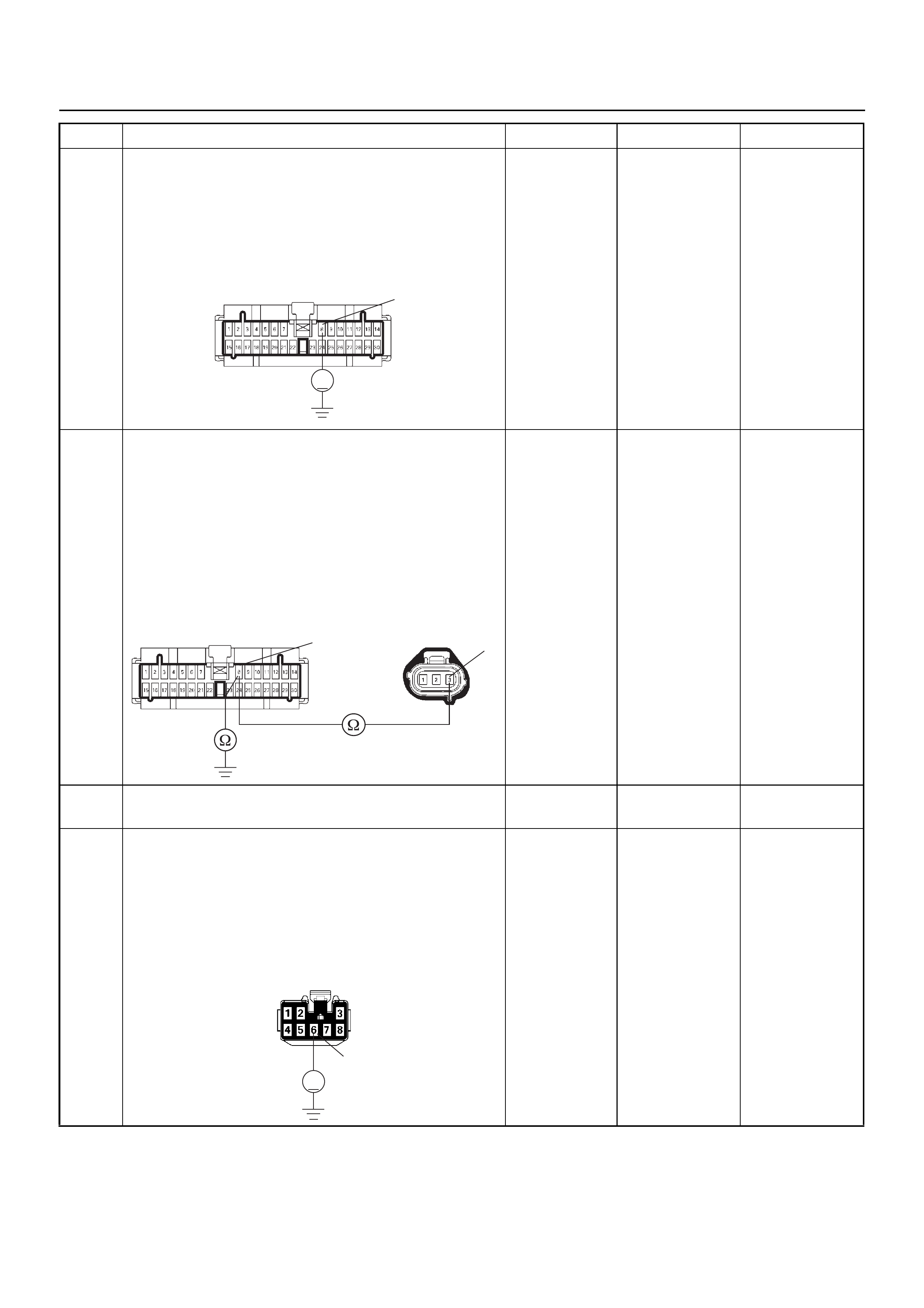

• Fuel metering system

• Ignition timing

• On-board diagnostics for electrical functions.

The ECM constantly observes the information from

various sensors. The ECM controls the systems that

affect vehicle performance and it also performs the

diagnostic function checks of the system.

The function can recognize operational problems, and

warn the driver through the check engine lamp

(MIL lamp), and store diagnostic trouble code (DTC).

DTCs identify the problem areas to aid the technician in

making repairs.

The input / output devices in the ECM include analog to

digital converts, signal buffers, counters and drivers.

The ECM controls most components with electronic

switches which complete a ground circuit when

switched on.

Inputs (operating condition read):

• battery voltage

• electrical ignition

• exhaust oxygen content

• inlet manifold pressure

• inlet air temperature

• engine coolant tempera ture

• crankshaft position

• knock signal

• throt tle po sit ion

• vehicle speed

• rough ride signal

• power steering pressure

• air conditioning request on or off.

Outputs (systems controlled):

• ignition control

• fuel control

• idle air control

• fuel pump

• EVAP canister purge valve

• air conditioning

• diagnostics functions.

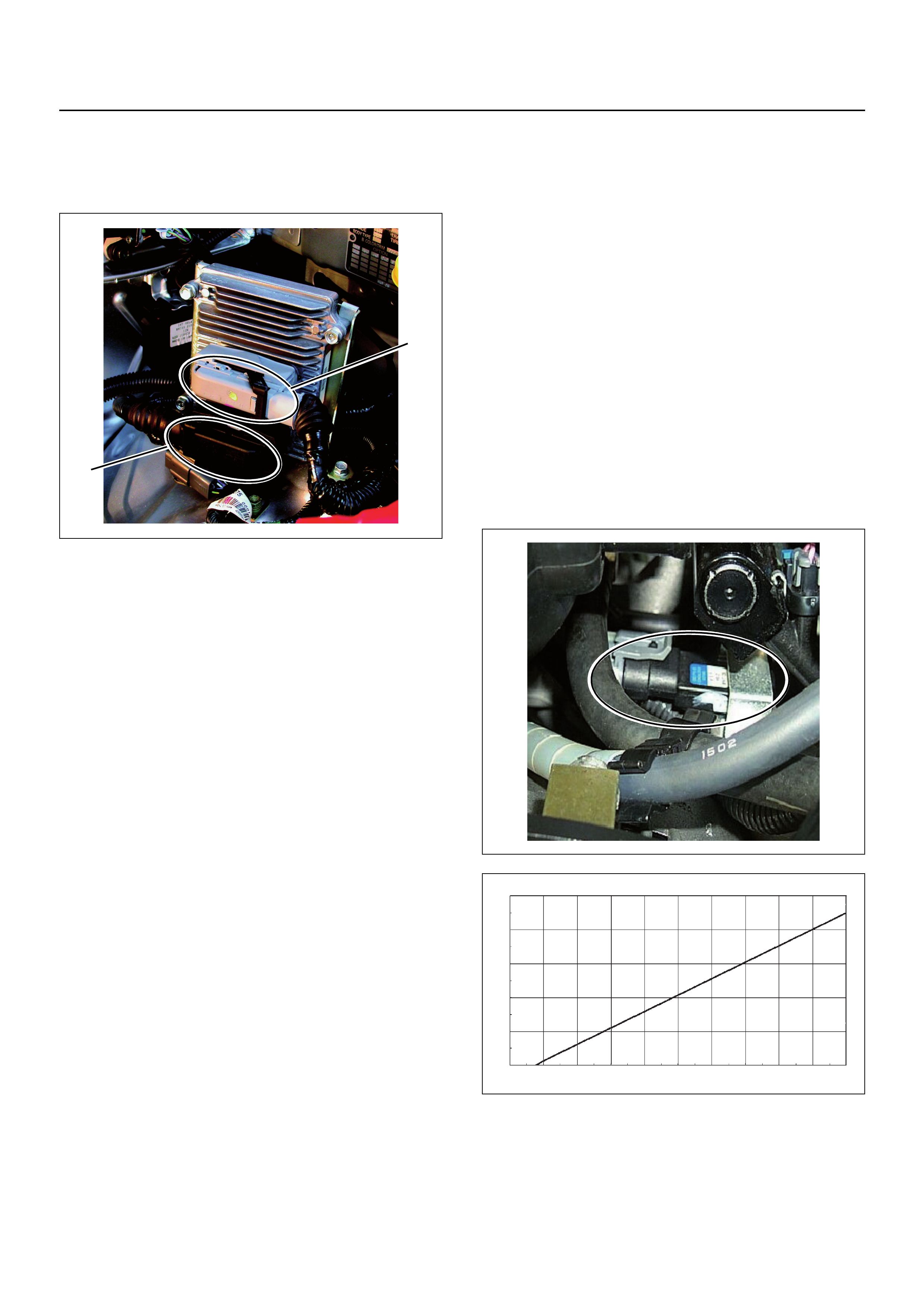

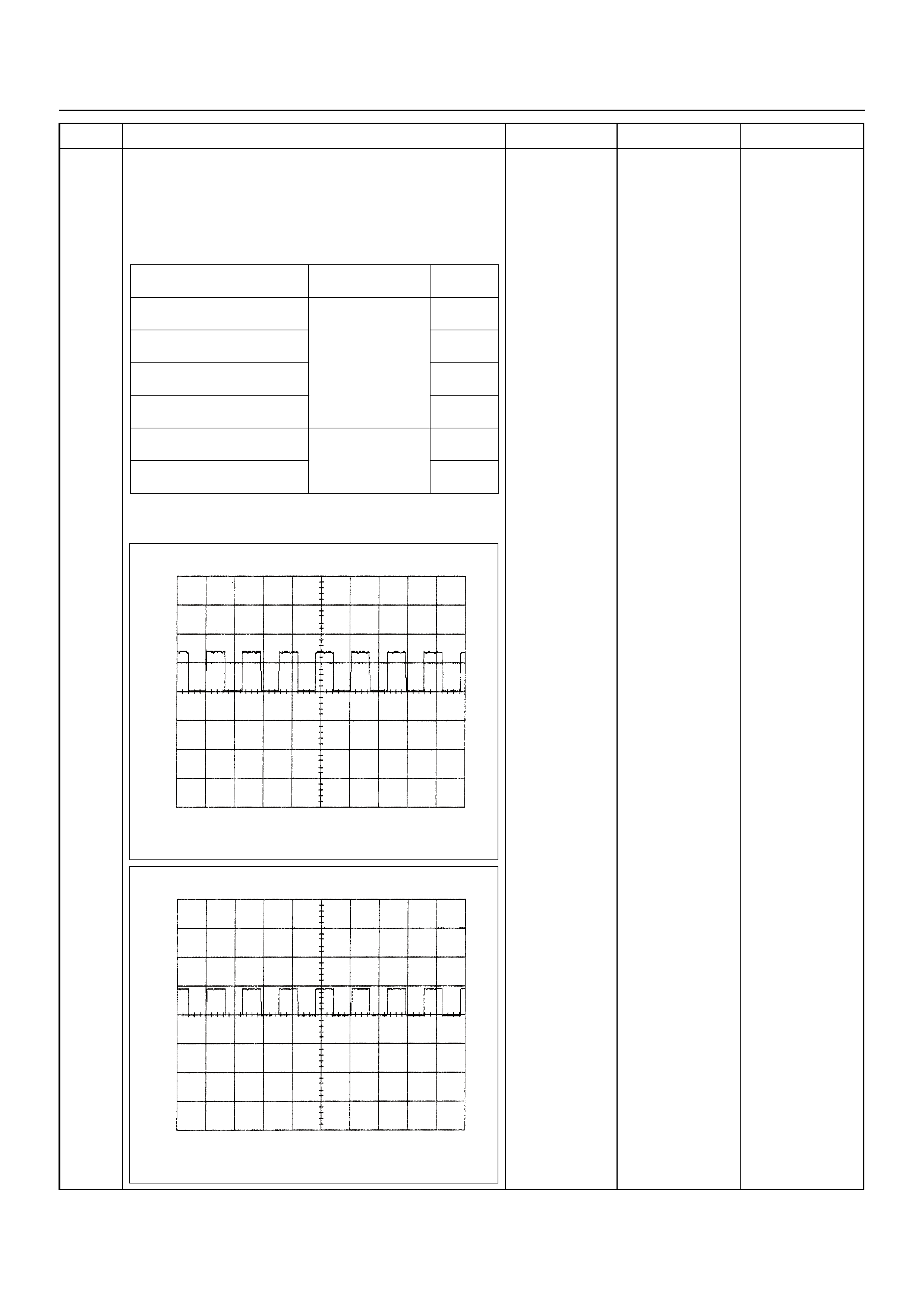

Manifold Absolute Pressure (MAP) Sensor

The MAP sensor is a strain gauge. The airflow pressure

places strain on the transducer, altering its resistance

which changes the voltage output. In other words it

measures a pressure value. It is installed to the inlet

manifold. Output voltage of the MAP sensor is as low as

the pressure is low.

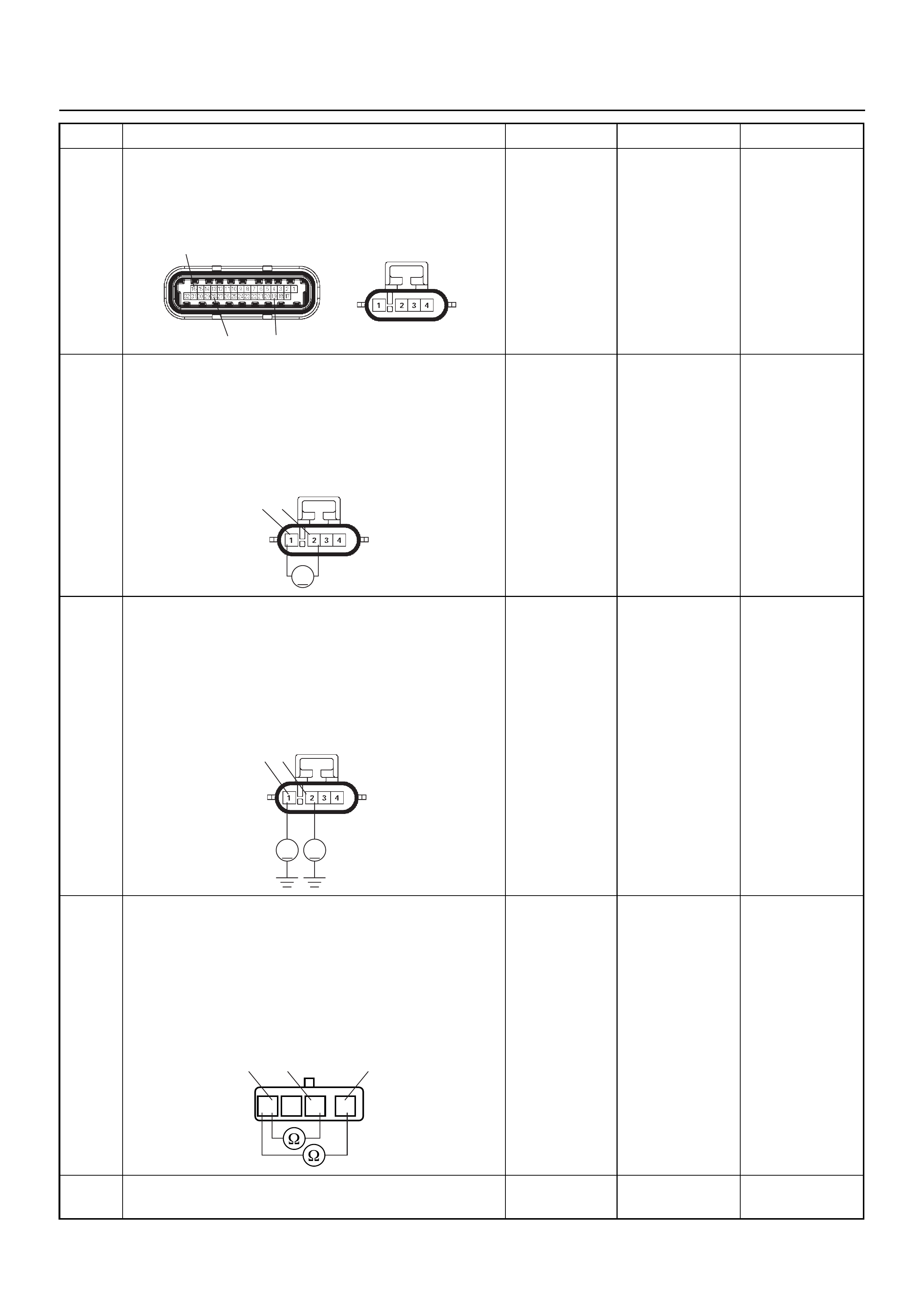

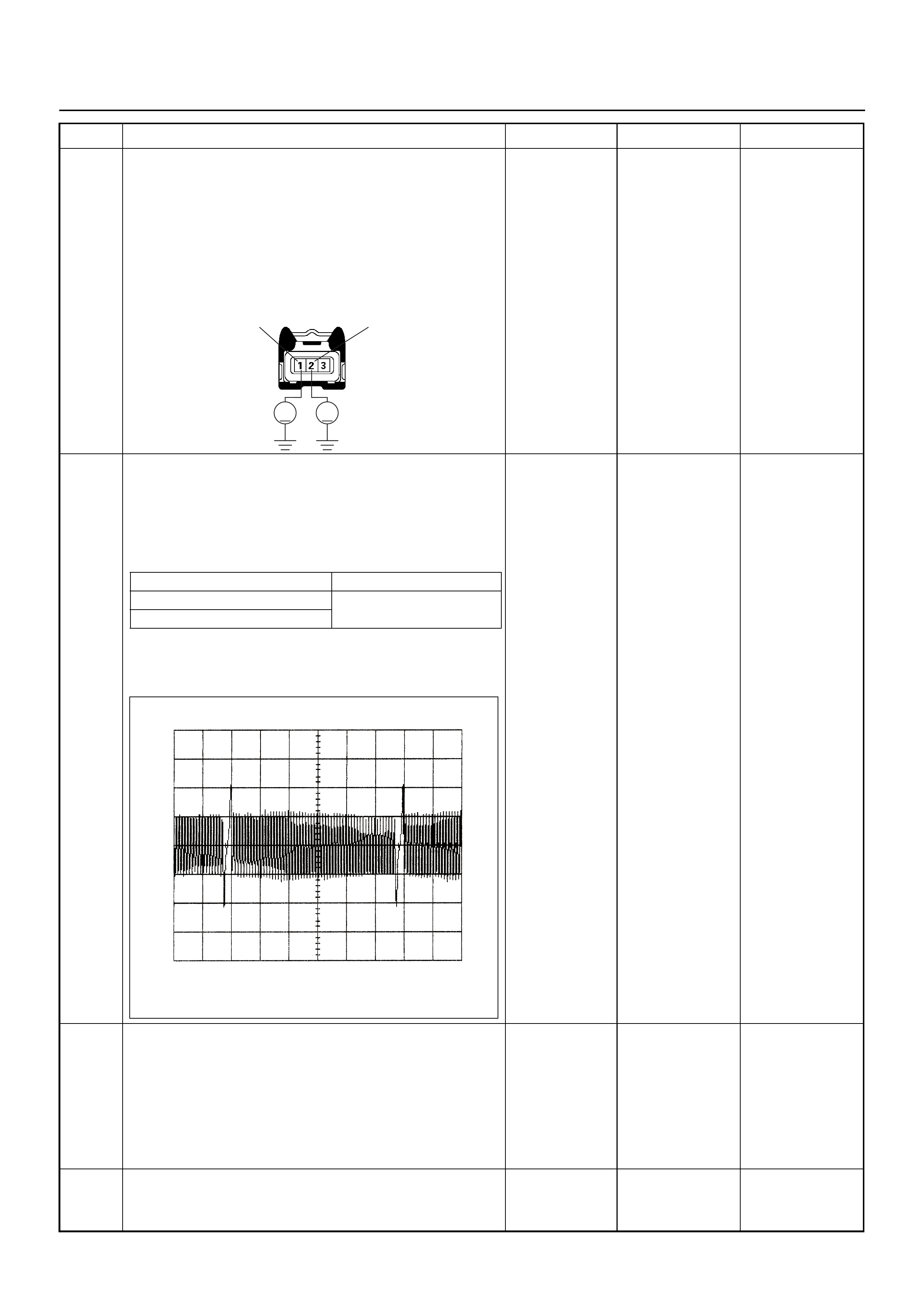

(1) J1 Port

(2) J2 Port

2

1

O

utput

V

o

l

tage

(V)

0

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

10 20 305 1525354540 50 55

Pressure (KPa)

Characteristic of MAP Sensor (Reference)

60 65 7570 8580 90 95 100

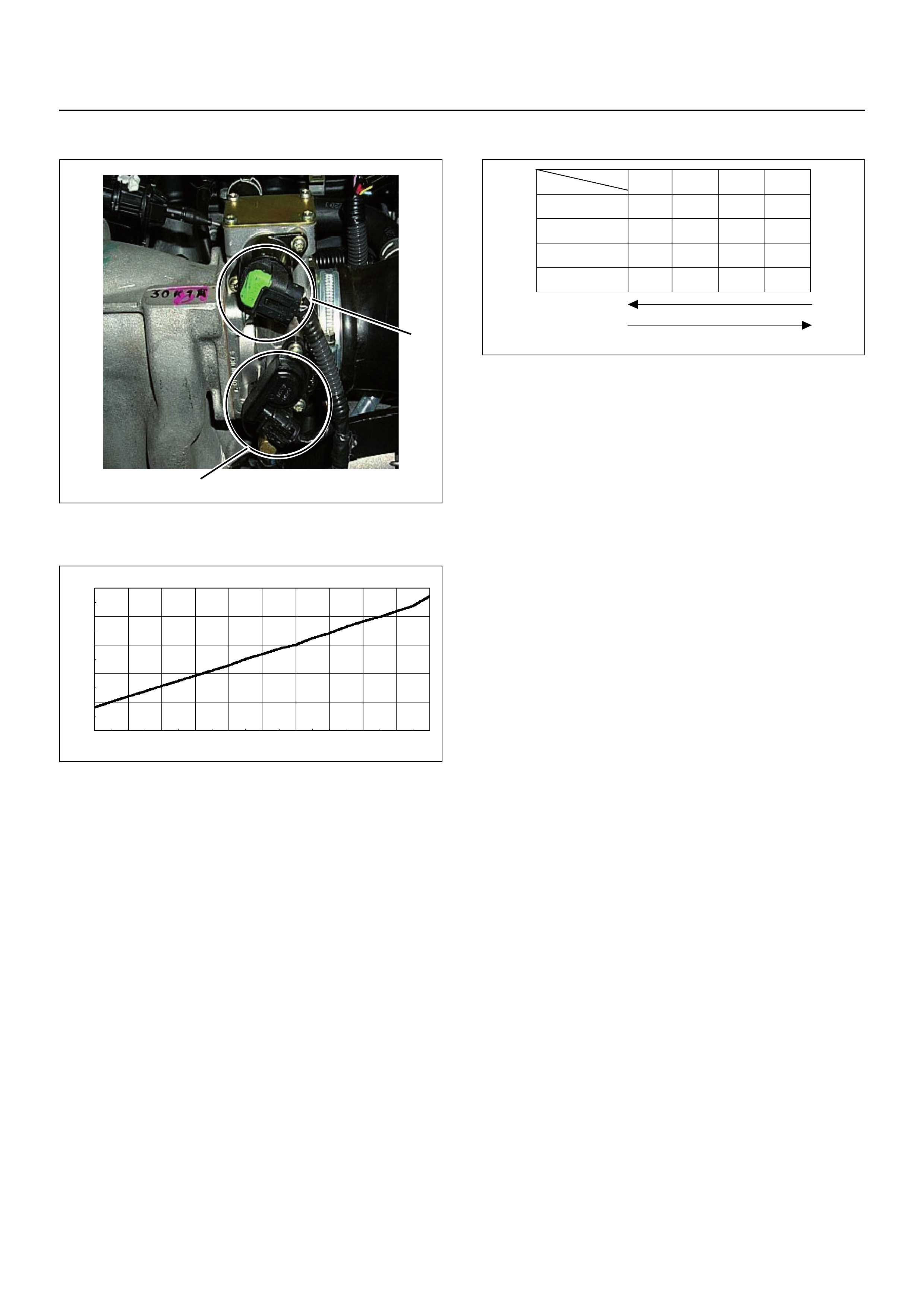

Throttle Position Sensor (TPS)

The TPS is a potentiometer connected to the throttle

shaft on the throttle body.

The engine control module (ECM) monitors the voltage

on the signal line and calculates throttle position, as the

throttle valve angle is changed when the accelerator

pedal is moved. The TPS signal also changes as the

throttle valve moves. As the throttle valve opens, the

output voltage proportionally increases as shown in the

above grap h .

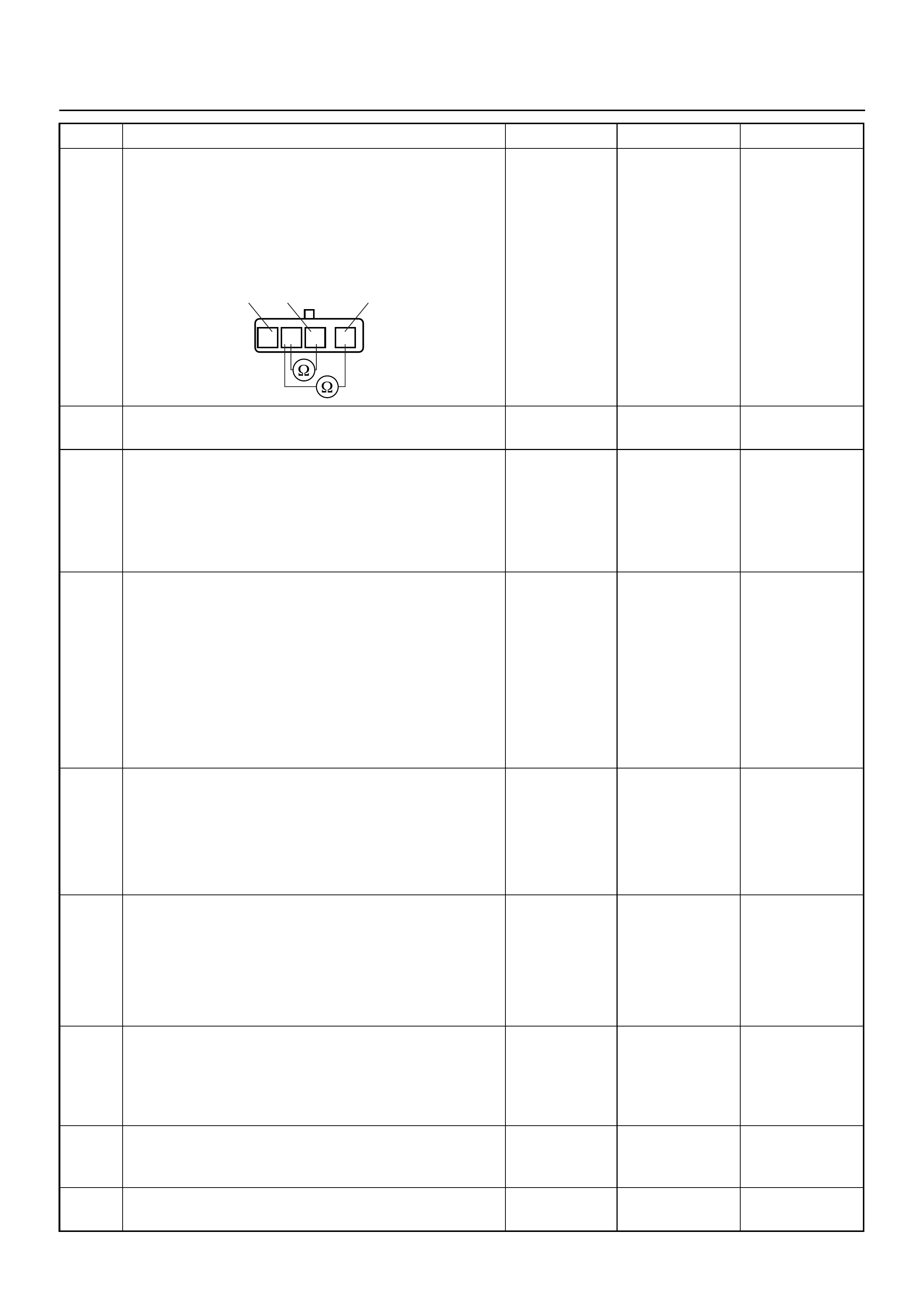

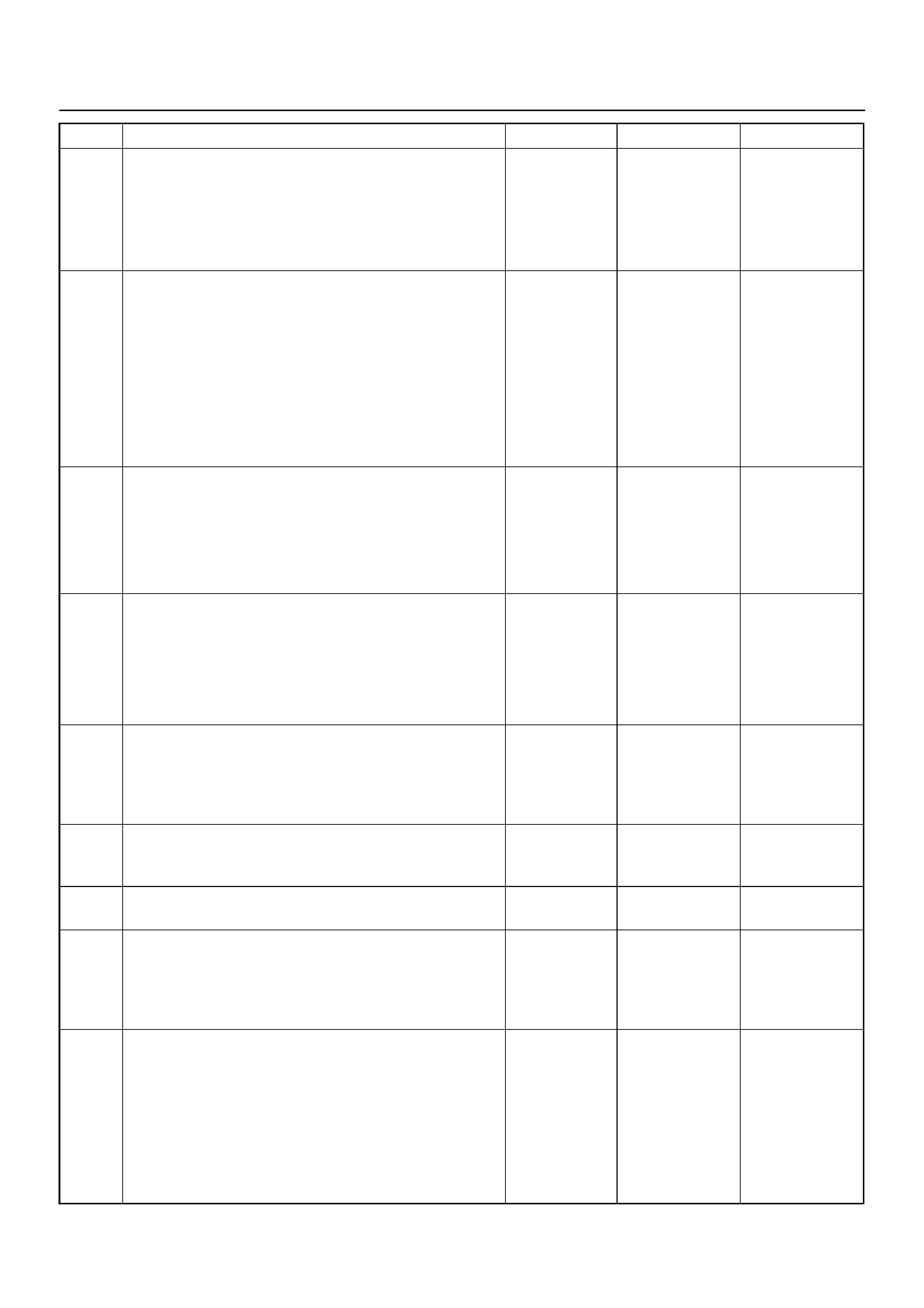

Idle Air Control (IAC) Valve

The idle air control valve (IAC) valve is two directional

and gives 2-way control. With power supply to the coils

controlled steps by the engine control module (ECM),

the IAC valve's pintle is moved to adjust idle speed,

raising it for fast idle when cold or there is extra load

from the air conditioning or power steering.

By moving the pintle in (to decrease air flow) or out (to

increase air flow), a controlled amount of the air can

move around the throttle plate. If the engine speed is

too low, the engine control module (ECM) will retract the

IAC pintle, resulting in more air moving past the throttle

plate to increas e th e en gin e spee d .

If the engine speed is too high, the engine control

module (ECM) will extend the IAC pintle, allowing less

air to move past the throttle plate, decreasing the

engine speed.

The IAC pintle valve moves in small step called counts.

During idle, the proper position of the IAC pintle is

calculated by the engine control module (ECM) based

on battery voltage, coolant temperature, engine load,

and engine speed.

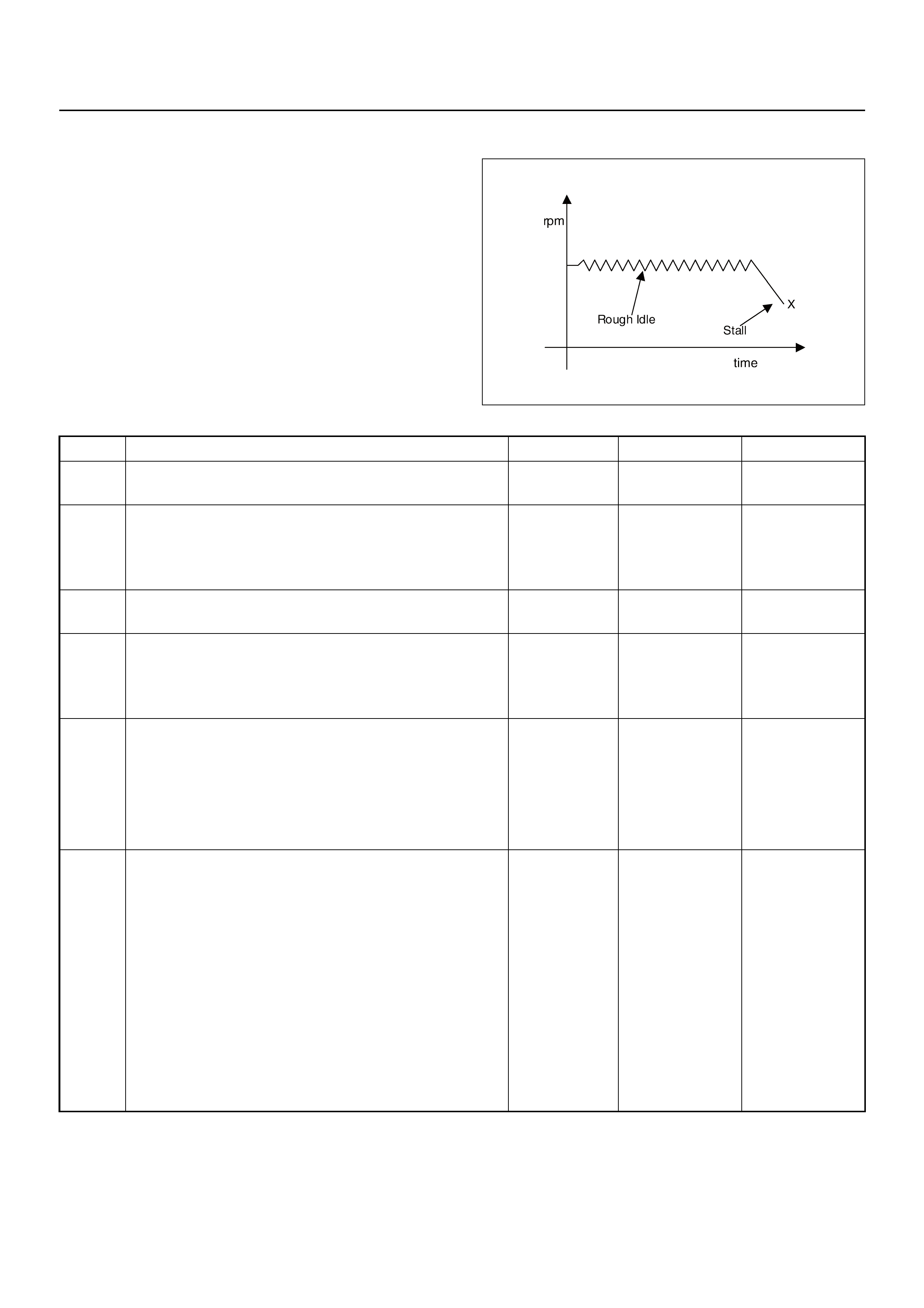

If the engine speed drops below a specified value, and

the throttle plate is closed, the engine control module

(ECM) senses a near-stall condition. The engine control

module (ECM) will then calculate a new IAC pintle valve

position to prev en t sta lls.

If the IAC valve is disconnected and reconnected with

the engine running, the idle speed will be wrong. In this

case, the IAC must be reset. The IAC resets when the

key is cycled “On” then “Off”. When servicing the IAC, it

should only be disconnected or connected with the

ignition “Off”.

The position of the IAC pi ntle valv e affec ts eng ine star t-

up and the idle characteristic of the vehicle.

If the IAC pintle is fully open, too much air will be

allowed into the manifold. This results in high idle

speed, along with possible hard starting and lean air/

fuel ratio.

(1) Throttle Position Sensor (TPS)

(2) Idle Air Control (IAC) Valv e

1

2

Output V oltage (V)

0

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

10 20 305 1525354540 50 55

Throttle Angle (%)

Characteristic of TPS (Reference)

60 65 7570 8580 90 95 100

Step

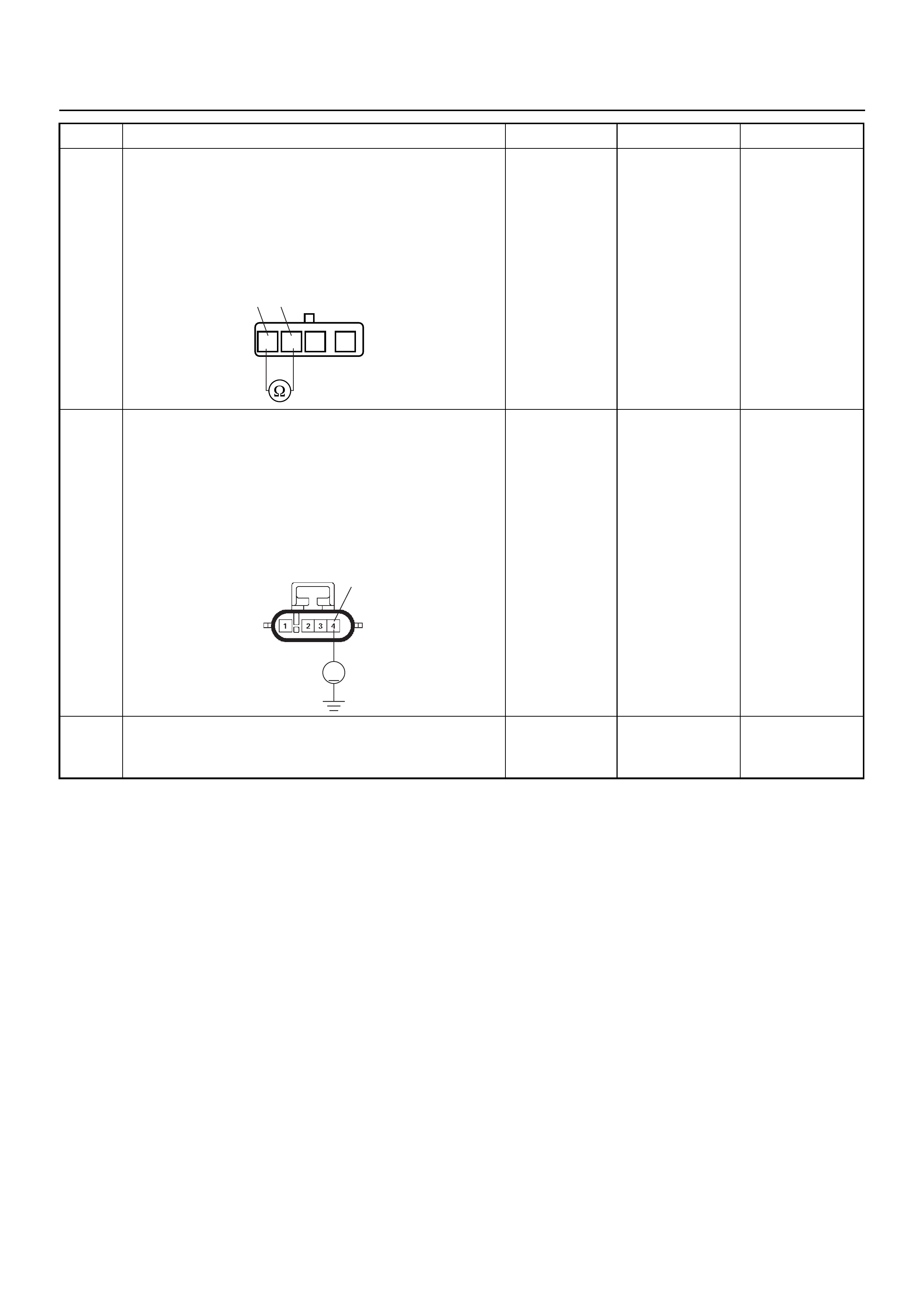

Coil

ABCD

Coil A High

(ECM J1-28)

On On

Coil A Low

(ECM J1-30)

On On

Coil B High

(ECM J1-13)

On On

Coil B Low

(ECM J1-29)

On On

(IAC Valve Close Direction)

(IAC Valve Open Direction)

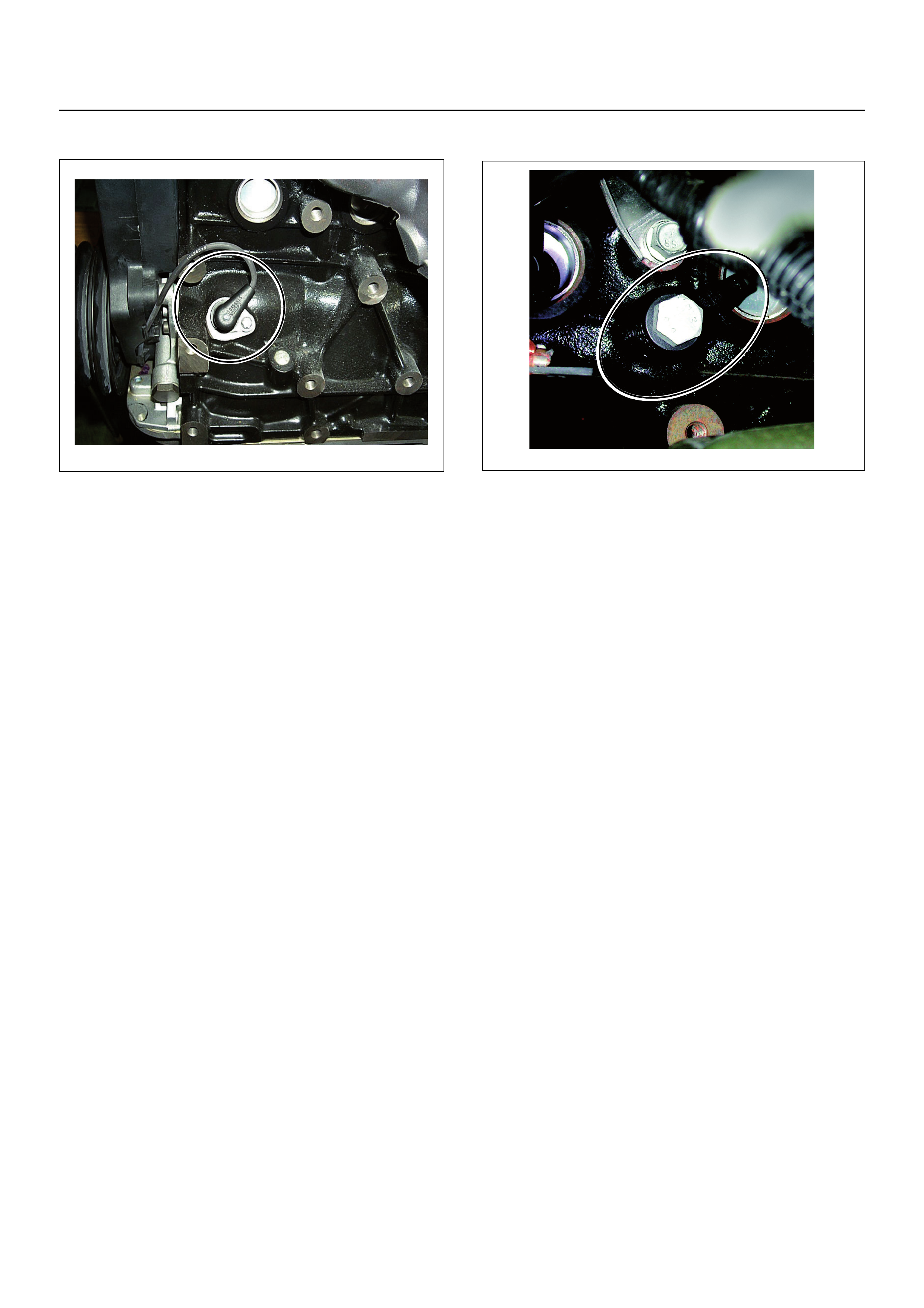

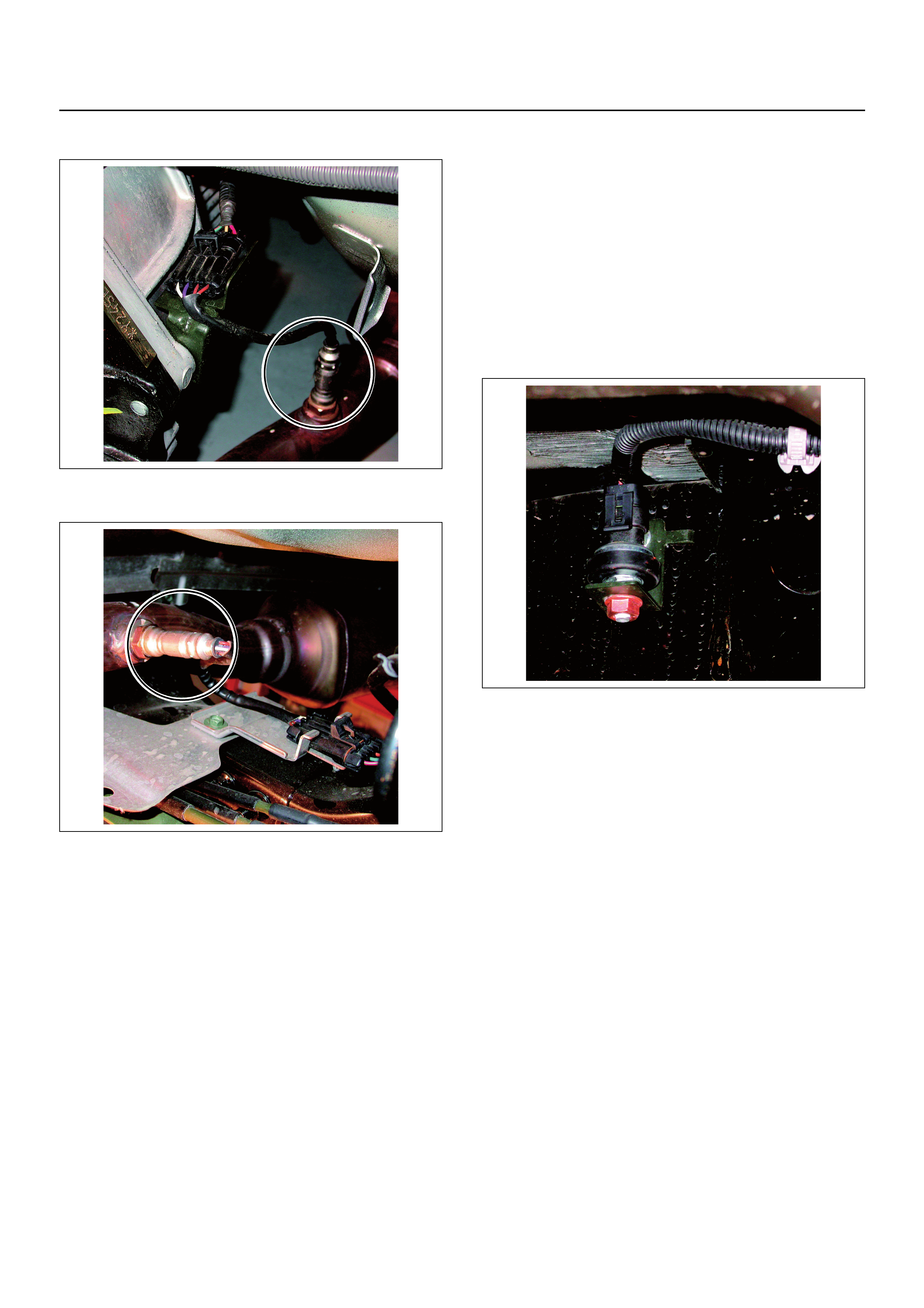

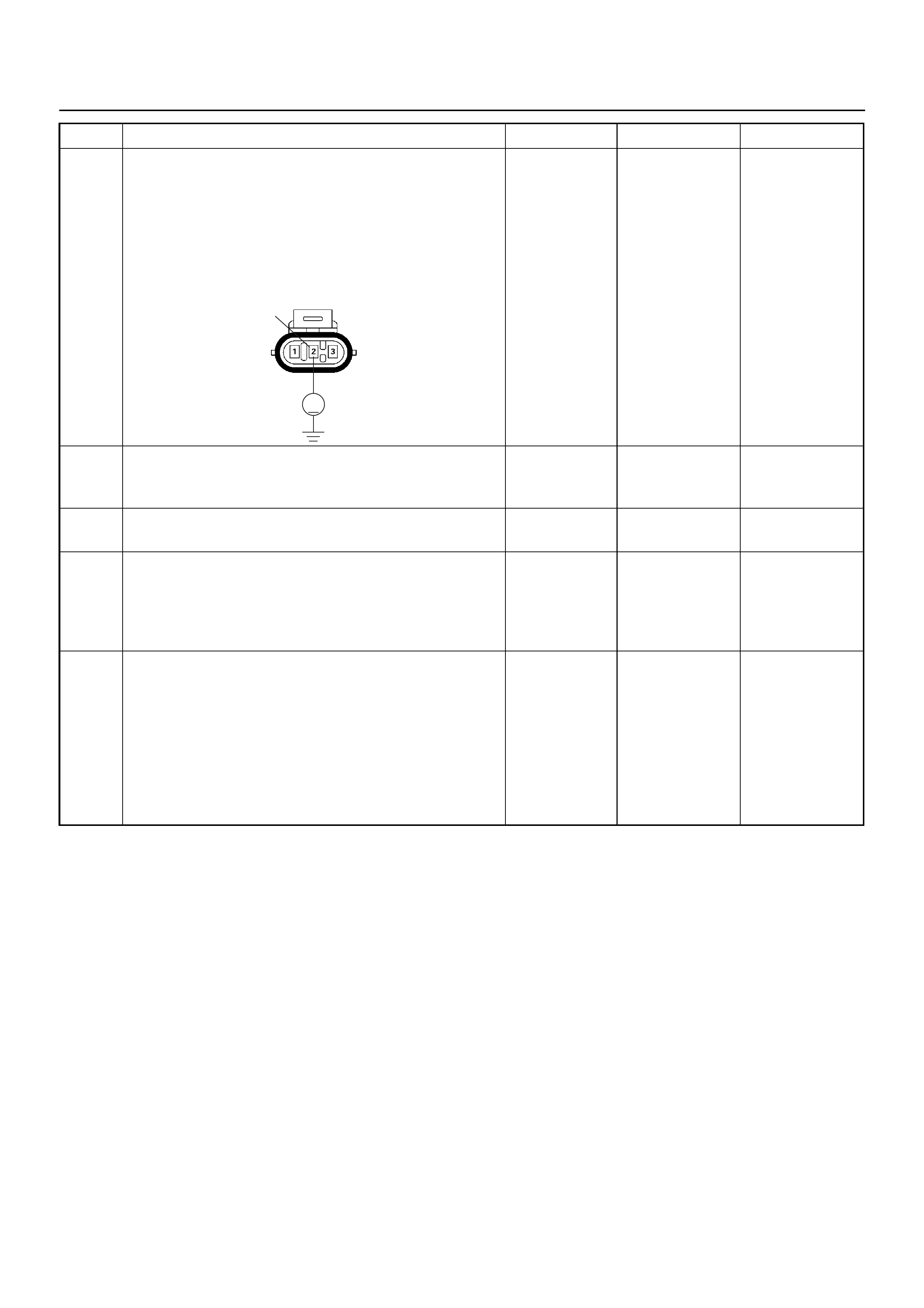

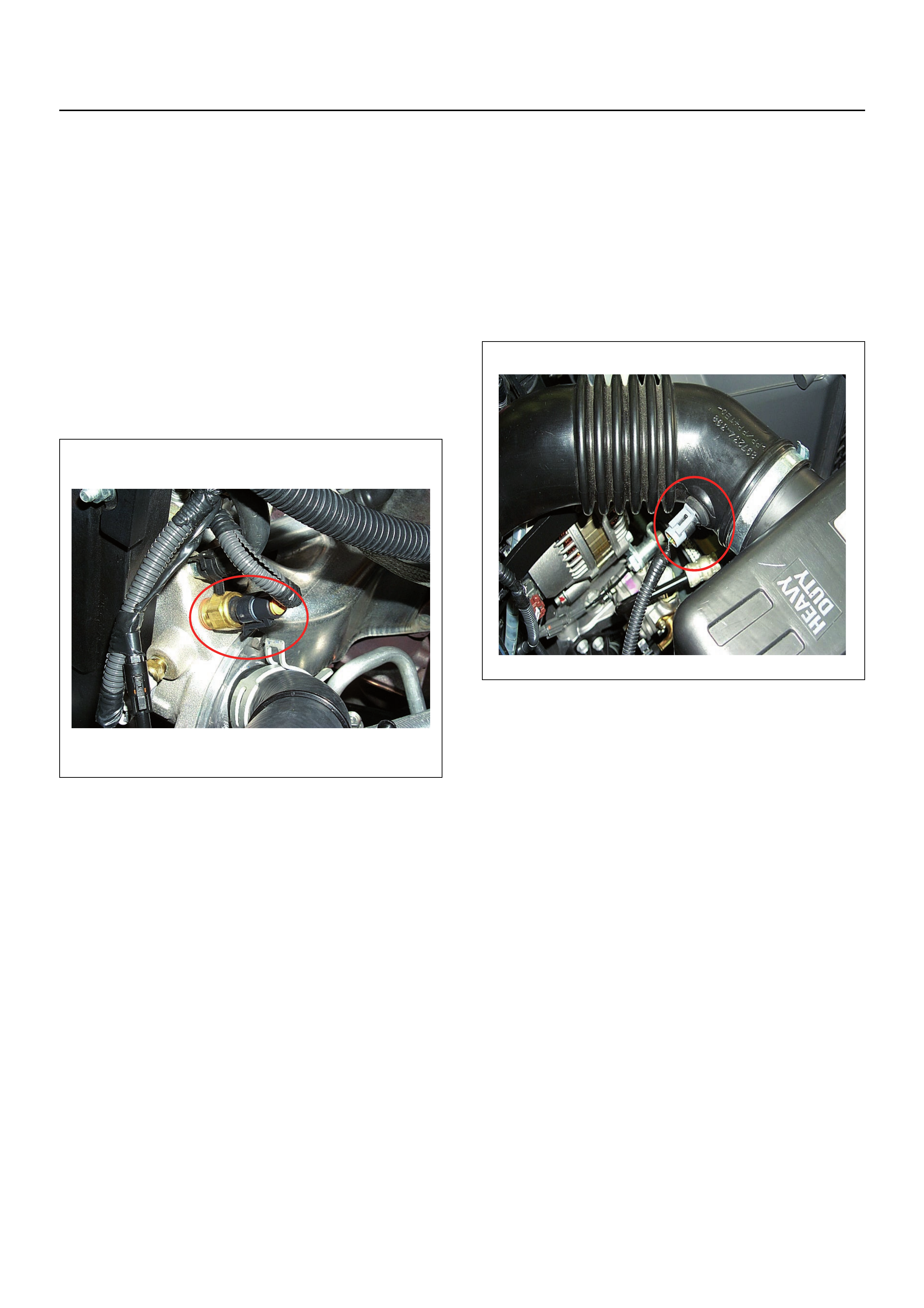

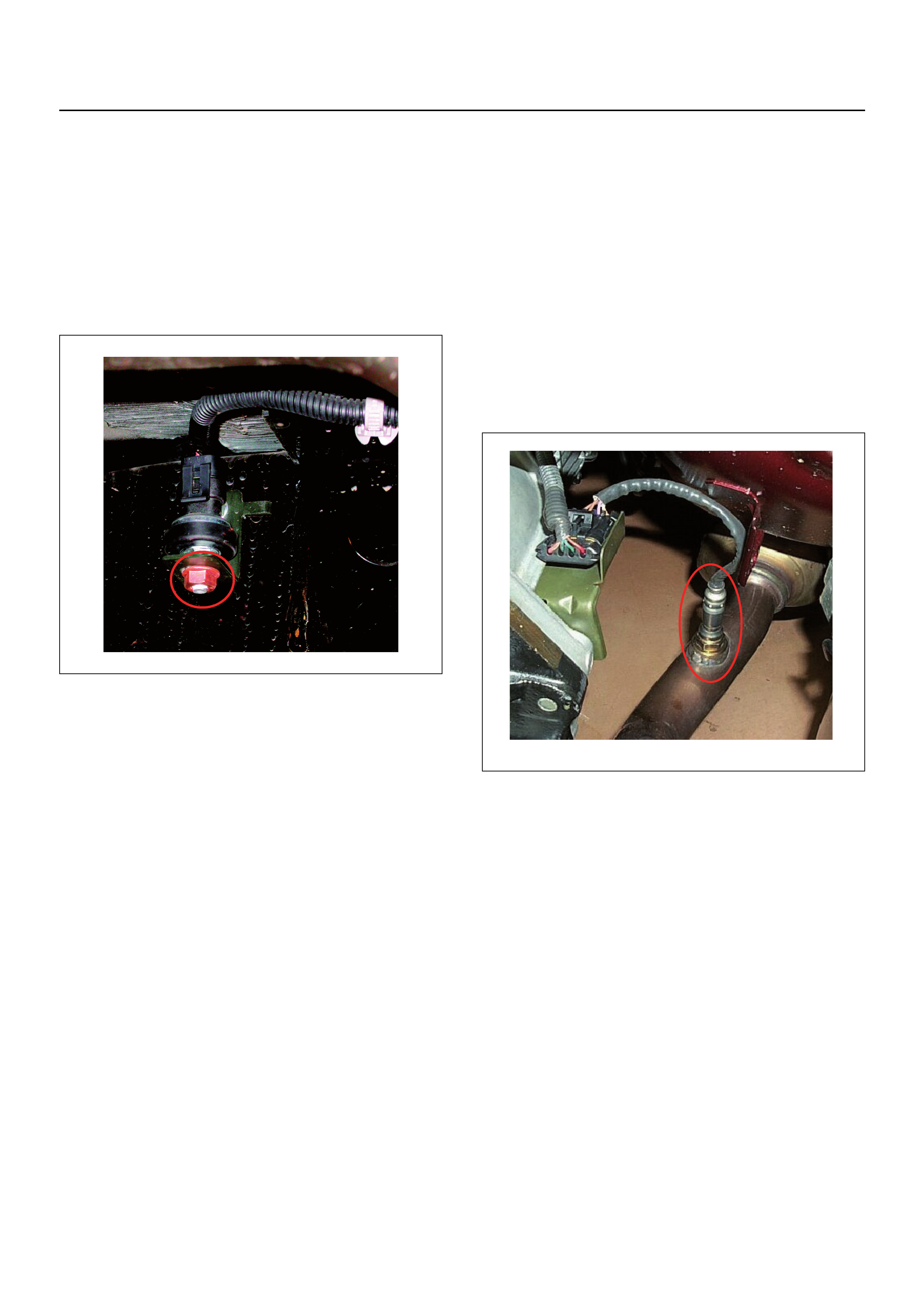

Crankshaft Position (CKP) Sensor

The crankshaft position (CKP) sensor, which sends a

signal necessary for deciding on injection timing to the

ECM, is mounted on the left-hand side of the cylinder

block behind the A/C compressor.

The crankshaft has a 58 teeth press-fit timing disc, from

which the CKP sensor reads the position of the

crankshaft at all times. It converts this to an electrical

signal, which it sends to the ECM.

Using the 58 X signals per rotation and the timing-mark

signal sent by the CKP sensor, the ECM is able to

accurately calculate engine speed and crank position.

The ECM converts the 58 X signals into a square

waveform. This converted signal is sent from the ECM

terminal J2 Pin 9 to the tachometer.

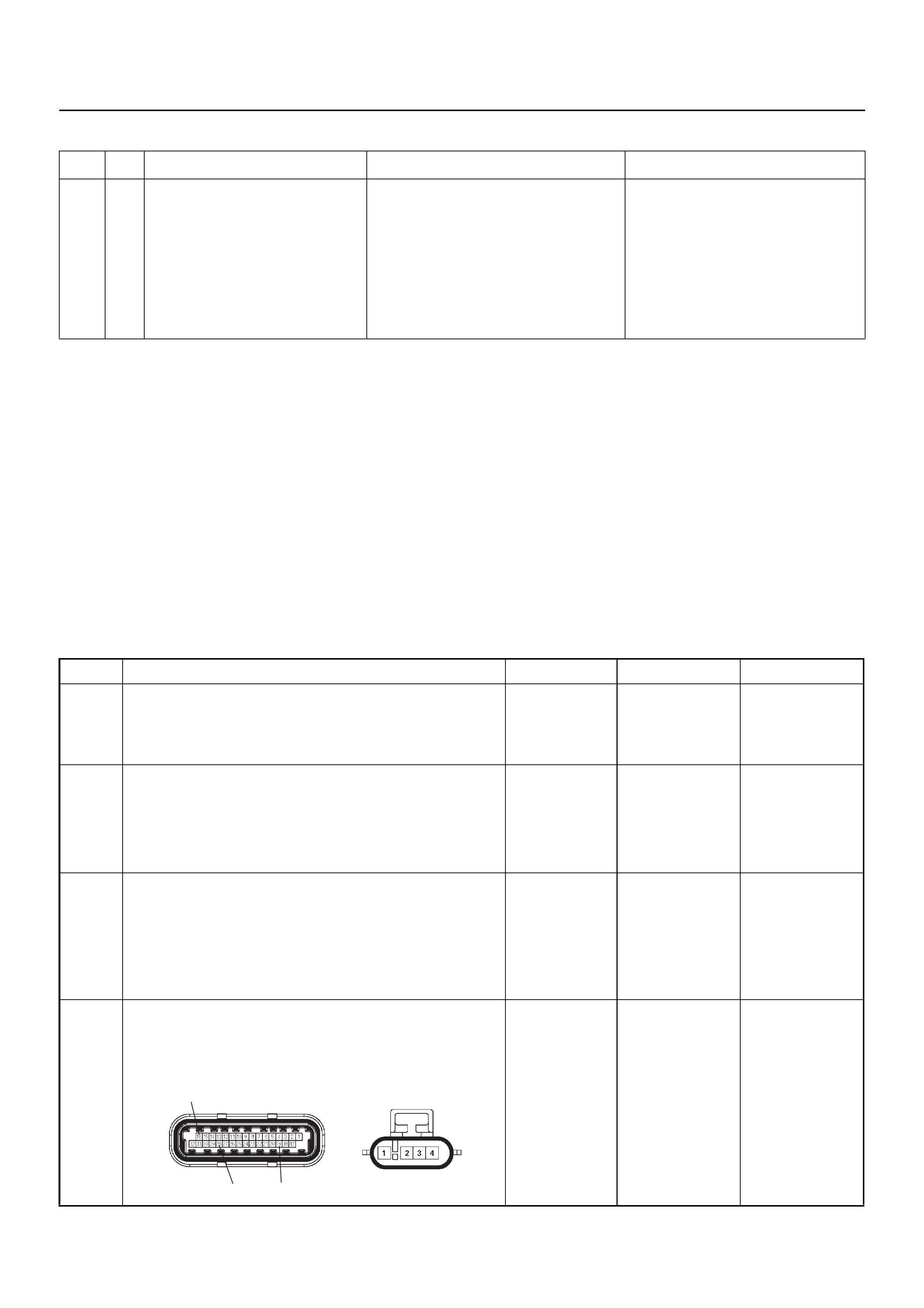

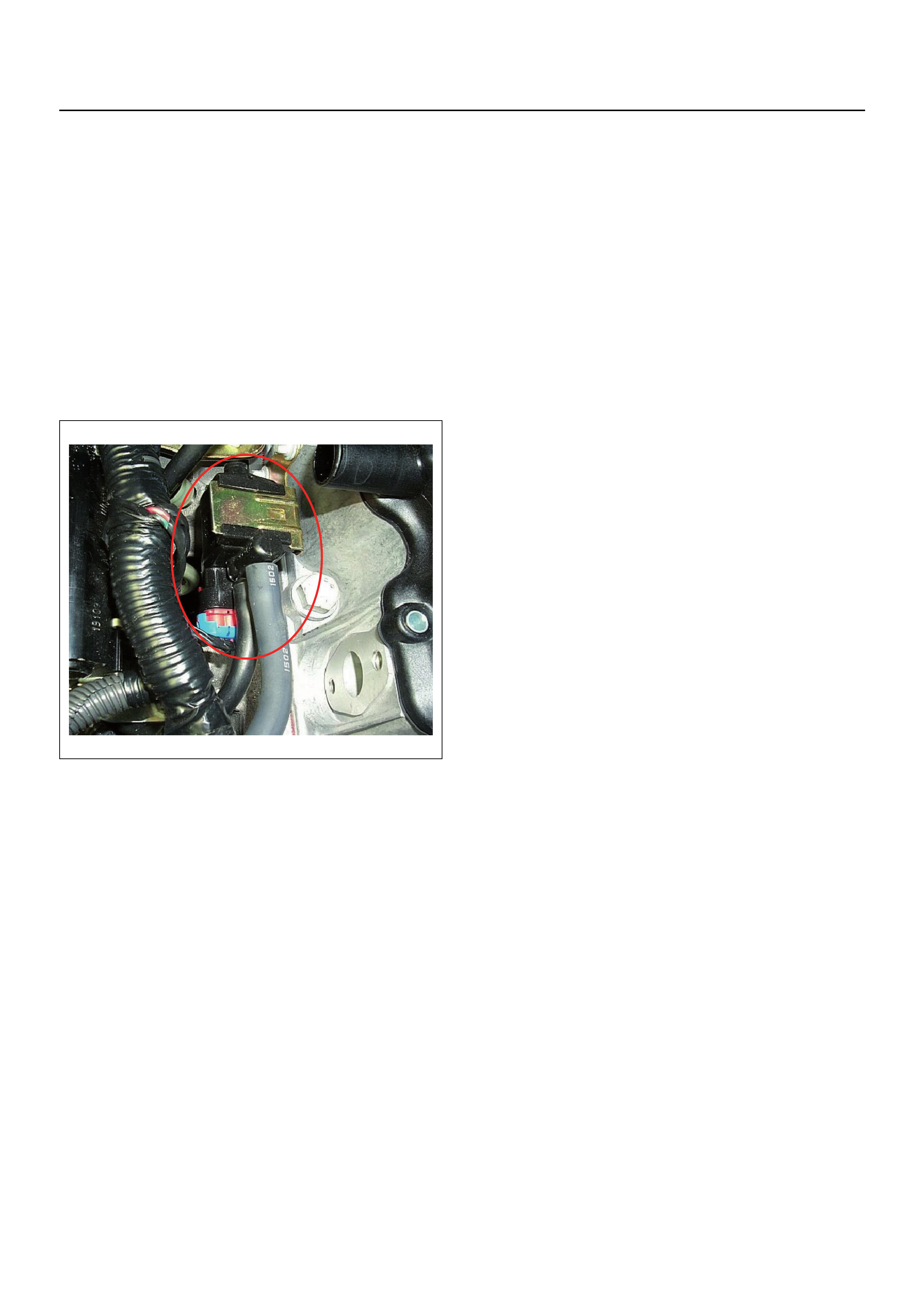

Knock Sensor (KS)

The engine Knock Sensor (KS) is mounted on the

driver’s side of the engine block, slightly forward of the

starter motor. It has a short wiring harness attached to

the sensor body and has a two pin connector that

connects to the main engine wiring harness.

The Knock Sensor signal is used by the ECM to provide

optimum ignition timing while minimising engine knock

or detonation.

If knock occurs in any of the cylinders, the ignition will

be retarded by three degrees. If the knocking then

stops, the ignition will be restored to what it was before

in steps of 0.75 degrees. Should knocking continue

despite of the ignition timing being retarded, the ECM

will retard the ignition an additional step of three

degrees, and so on, up to a maximum of 12.75 degre es.

The knock sensor is tuned to detect the frequ ency of the

vibration created by combustion knock. The vibration is

transfered to the knock sensor through the cylinder

block.

Inside the sensor is an element that is excited by this

vibration, and this element exerts a compressive force

onto a piezo-electric sensor. The compressive force

causes a charge transfer inside the sensor which

produces an AC voltage. The amount of AC voltage

produced is proportional to the amount of knock.

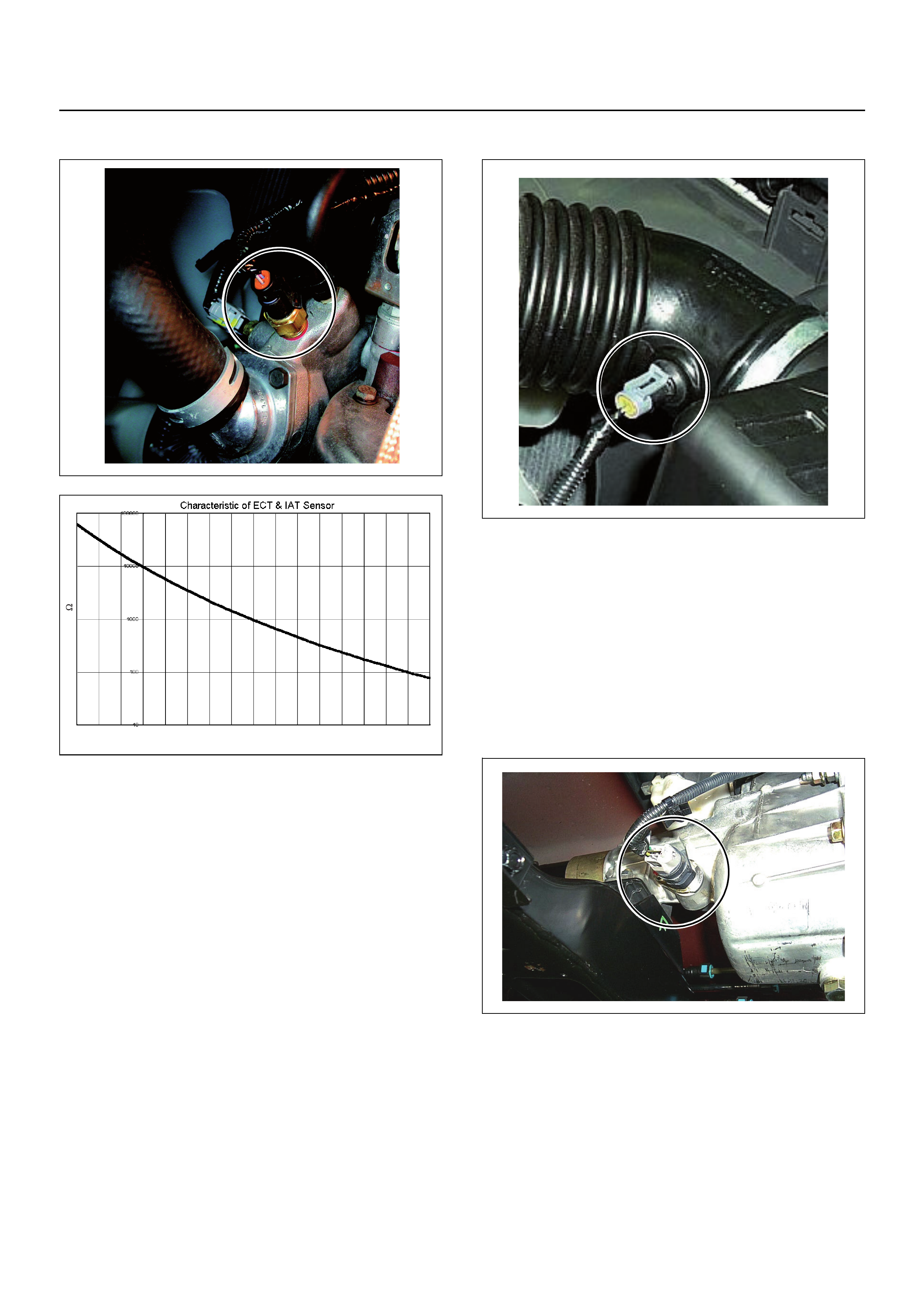

Engine Coolant Temperature (ECT) Sensor

The ECT sensor is a thermistor. As the temperature

changes so does the resistance value, and it changes

output voltage. In other words it measures a

temperature value. It is installed on the coolant stream

at the outlet of the engine block. Low coolant

temperature produces a high resistance.

The ECM supplies 5 volts signal to the ECT sensor

through resisters in the ECM and measures the voltage.

The signal voltage will be high when the engine

temperature is cold, and it will be low when the engine

temperature is hot.

Intake Air Temperature (IAT) Sensor

The IAT sensor is a thermistor. A temperature changes

the resistance value. And it changes voltage. In other

words it measures a temperature value. Low air

temperature produces a high resistance.

The ECM supplies 5 volts signal to the IAT sensor

through resistors in th e ECM an d mea sure s the vo ltage .

The signal voltage will be high when the air temperature

is cold, and it will be low when the air temperature is

hot.

Vehicle Speed Sensor (VSS)

The VSS is a magnet rotated by the transmission output

shaft. The VSS uses a Hall effect element. It interacts

with the magnetic field created by the rotating magnet. It

outputs a pulse signal. It’s operating 12 volts supply

comes from the meter fuse and its ouput signal is is

supplied direct to the instrument cluster connector B24

pins 8 and 27.

-30

Resistance ( )

-20 -10 0 10 20 30 40 50

Temperature (ºC)

60 70 80 90 100 110 120 130

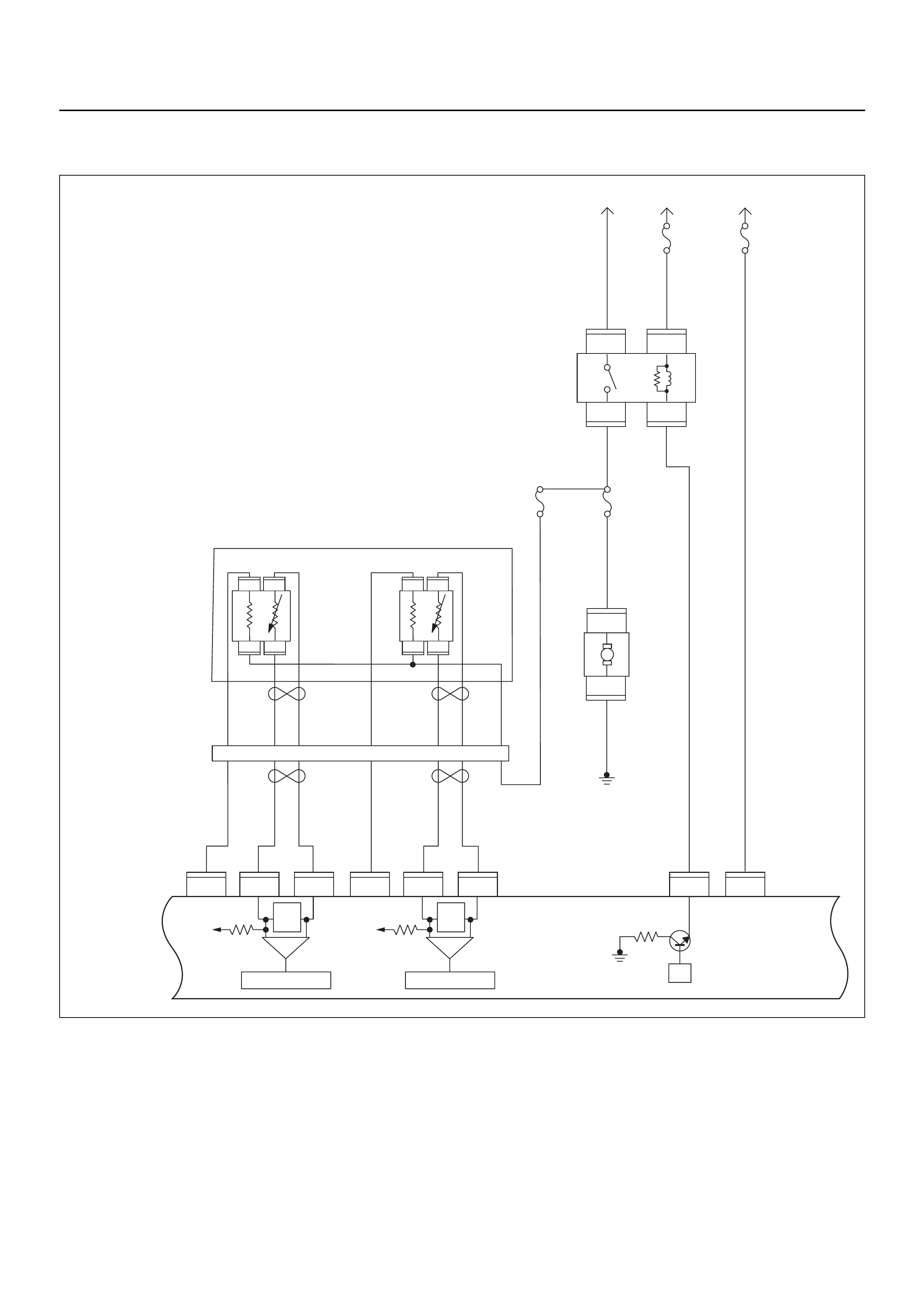

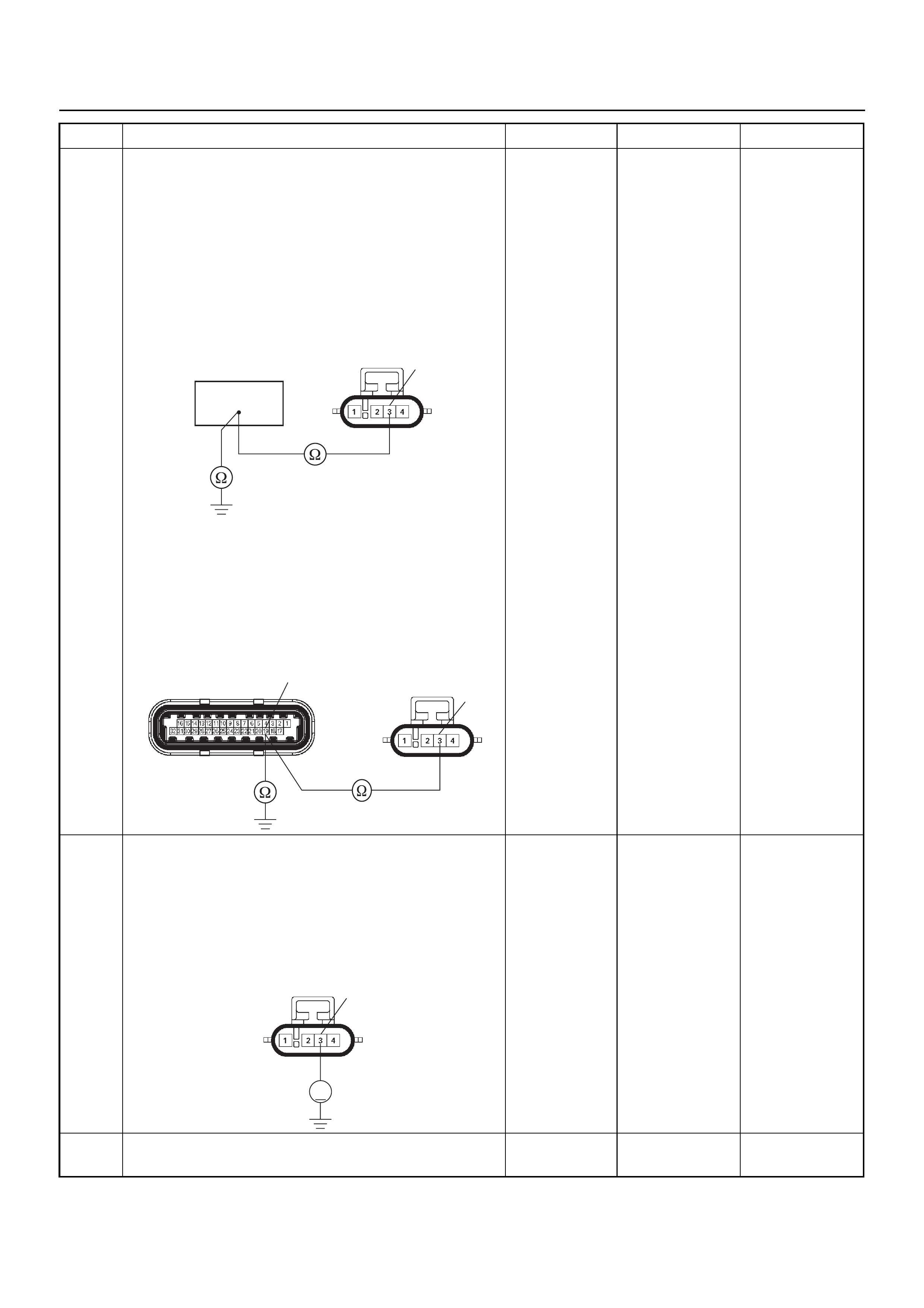

Heated Oxygen (O2 Pre) Sensor

Heated Oxygen (O2 Post) Sensor

The heated oxygen sensors consist of a 4-wire low

temperature activated zir conia oxygen analyzer elem ent

with heater for operating temperature of 315°C. There

are two oxygen sensors, one fitted before the catalatic

converter (Pre 02 sensor) and one fitted after the

catalatic converter (Post 02 sensor). A short wiring

harness is attached to the top of the sensor which

connects to a 4 pin male and female vehicle wiring

harness.

A constant 450 millivolt is supplied by the ECM to the,

02 sensors. The oxygen level presen t in the exhaust gas

reacts with the 02 sensor producing a change to the

ECM output voltage.

The oxygen level present in the exhaust gas is reported

to the ECM by this output voltage which should

constantly fluctuate from approximately 100 to 1000mV.

The ECM calculates the pulse width command for the

injectors to produce the proper combustion chamber

mixture.

Low oxygen sensor output voltage is a lean mixture

which will result in a rich command to compensate.

High oxygen sensor output voltage is a rich mixture

which result in a lean command to compensate.

When the engine is first started the system is in “Open

Loop” operation. In “Open Loop”, the ECM ignores the

signal from the oxygen sensors. When various

conditions (ECT, time from start, engine speed &

oxygen sensor output) are met, the system enters

“Closed Loop” operation. In “Closed Loop”, the ECM

calculates the air fuel ratio based on the signals from

the two oxygen sensors.

Vertical G (RRID) Sensor

The Vertical G (RRID) Sensor is bolted above the rear

axle on the driver’s side inside the chassis rail.

The RRID sensor monitors vertical movements from the

rear of the vehicle. If the vehicle is travelling over rough

terrain a voltage between 1.8 volt to 3.3 volt is

transmitted from the sensor to the ECM which controls

the fuel air mix to optimum vehicle driveability and

exhaust emissions. If the vehicle is stationary the

voltage from this sensor is approximately 1.8 volt.

GENERAL DESCRIPTION FOR FUEL

METERING

The fuel metering system starts with the fuel in the fuel

tank. An electric pump, located in the fuel tank, pumps

fuel to the fuel rail through an in-line filter.

The pump is designed to provide fuel at a pressure

above the pressure needed by the injectors.

A pressure regu lator in the fuel r ail keeps fuel av ailable

to the injectors at a constant pressure.

A return line delivers unused fuel back to the fuel tank.

The basic function of the air/fuel metering system is to

control the air/fuel delivery to the engine. Fuel is

delivered to the engine by individual injectors mounted

in the inlet manifold.

The main control sensors are the heated oxygen

sensors located in the exhaust system. The heated

oxygen sensors report to the ECM how much oxygen is

in the exhaust gas. The ECM changes the air/fuel ratio

to the engine by controlling the amount of time that each

fuel injector is “On”.

The best mixture to minimize exhaust emissions is 14.7

parts of air to 1 pa rt of gasoline by weight, which allows

the catalytic converter to operate most efficiently.

Because of the constant measuring and adjusting of the

air/fuel ratio, the fuel injection system is called a “closed

loop” system.

The ECM monitors signals from several sensors in

order to determ ine the fuel needs of th e engine. Fuel is

delivered under one of se veral conditions called “mode ”.

All modes are controlled by the ECM.

Battery Voltage Correction Mode

When battery voltage is low, the ECM will compensate

for the weak spark by increasing the following:

•The amount of fuel delivered.

•The idle rpm.

Clear Flood Mode

Clear a flooded en gine by push ing th e accelerato r ped al

down all the way. The ECM then de-energises the fuel

injectors. The ECM holds the fuel injectors de-energized

as long as the throttle remains above 75% and the

engine speed is below 800 rpm. If the throttle position

becomes less than 75%, the ECM again begins to pulse

the injectors ON and OFF, allowing fuel into the

cylinders.

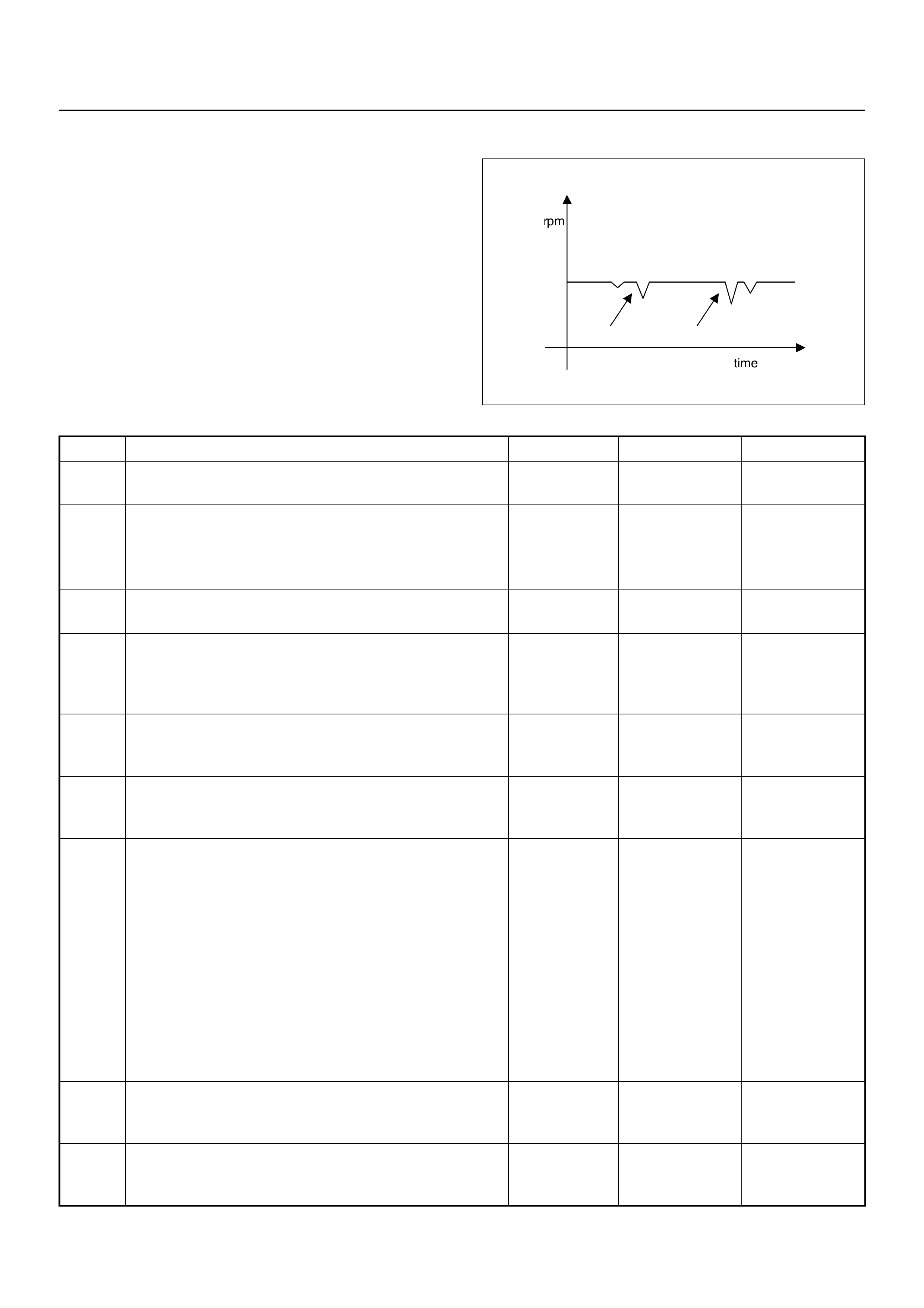

Deceleration Fuel Cut Off (DFCO) Mode

The ECM reduces the amount of fuel injected when it

detects a decrease in the throttle position and the air

flow. When deceleration is very fast, the ECM may cut

off fuel completely, until enable conditions meet the

engine revolution less 1000 rpm or manifold absolute

pressure less than 10 kpa.

Engine Speed/ Vehicle Speed/ Fuel Disable

Mode

The ECM monitors engine spe ed. It switches off th e fuel

injectors when the engine speed increases above 6000

rpm. The fuel injectors are turned back on when engine

speed decreases below 3500 rpm.

Acceleration Mode

The ECM provides extra fuel when it detects a rapid

increase in the throttle position and the air flow.

Fuel Cut Off Mode

No fuel is delivered by the fuel injectors when the

ignition is OFF. This prevents engine run-on. In

addition, the ECM suspen ds fu el delivery if n o reference

pulses are detected (engine not running) to prevent

engine flooding.

Starting Mode

When the ignition is first switched ON, the ECM

energises the fuel pump relay for two seconds to allow

the fuel pump to build up pressure. The ECM then

checks the engine coolant temperature (ECT) sensor

and the throttle position sensor to determine the proper

air/fuel ratio for starting.

The ECM controls the amount of fuel delivered in the

starting mode by adjusting how long the fuel injectors

are energized by pulsing the injectors for very short

times.

Run Mode

The run mode has the following two conditions:

•Open loop

•Closed loop.

When the engine is first started, the system is in “Open

Loop” operation. In “Open Loop,” the ECM ignores the

signal from the heated oxygen sensors (HO2S). It

calculates the air/fuel ratio based on inpu ts fr om the TP,

ECT, and MAP sensors.

The system remains in “Open Loop” until the following

conditions are met:

•The HO

2S have a varying voltage output showing

that it is hot enough to operate properly (this depends

on temperature).

•The ECT has reached a specified temperature.

•A specific amount of time has elapsed since starting

the engine.

•Engine speed has been greater than a specified rpm

since start-up.

The specific values for the above conditions vary with

different engines and are stored in the programmable

read only memory (PROM). When these conditions are

met, the system enters “Closed Loop” operation. In

“Closed Loop,” the ECM calculates the air/fuel ratio

(injector on-time) based on the signal from the two

HO2S. This allows the air/fuel ratio to stay very close to

14.7:1.

Fuel Metering System Components

The fuel metering system is made up of the following

parts:

• fuel injector

• throttle body

• fuel rail

• fuel pressure regulator

•ECM

• crankshaft position (CKP) sensor

• idle air control (IAC) valve

• fuel pump.

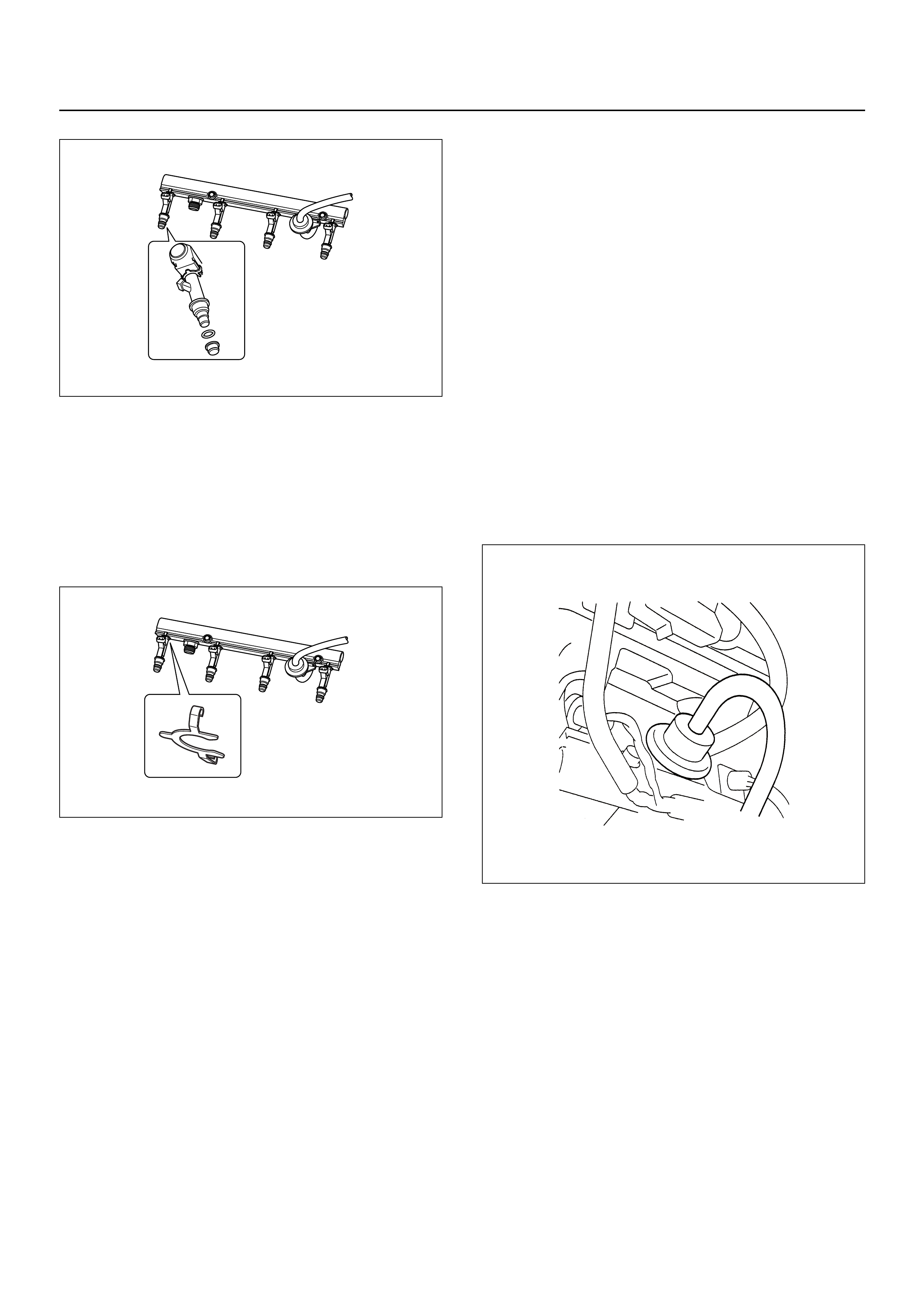

Fuel Injector

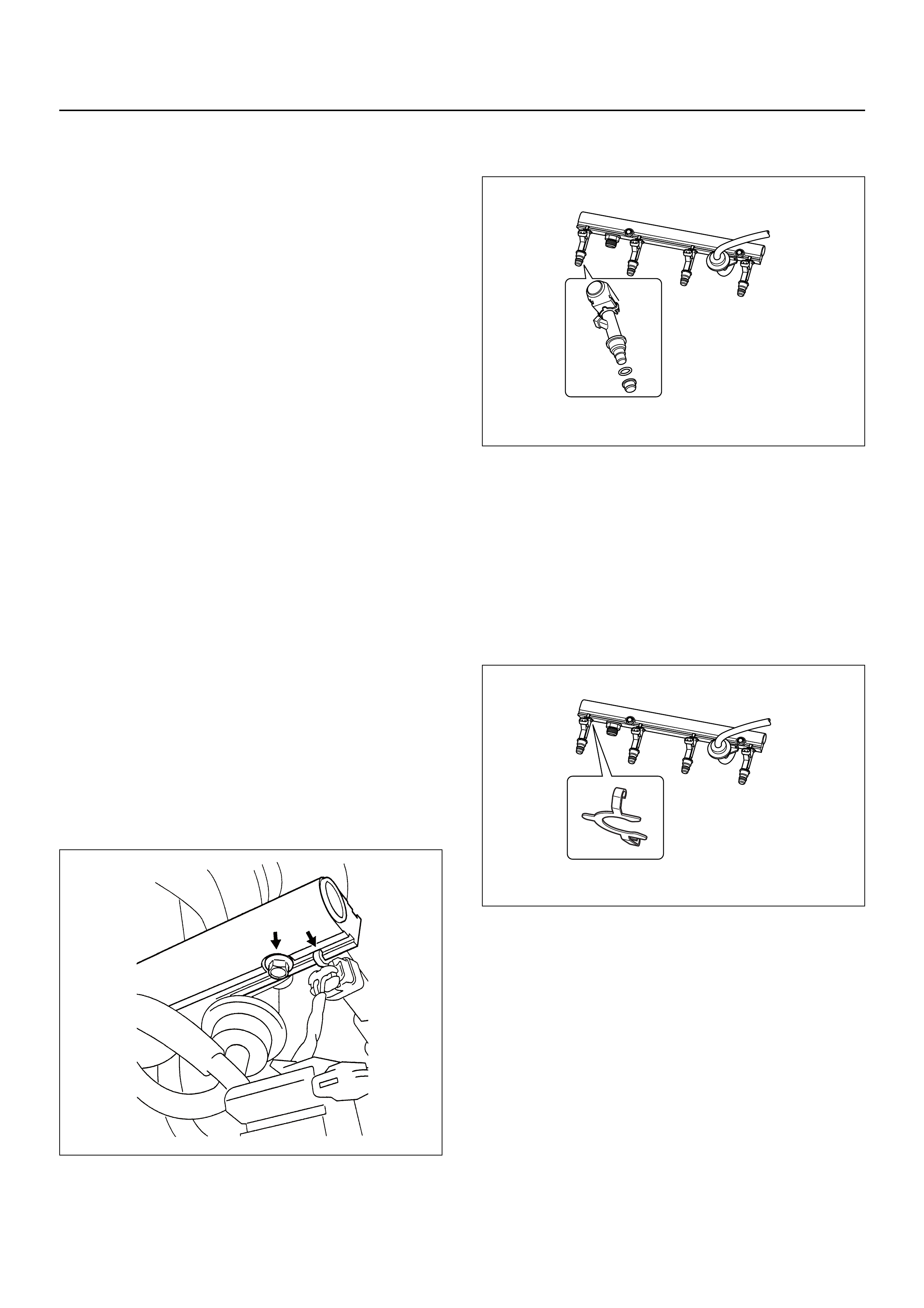

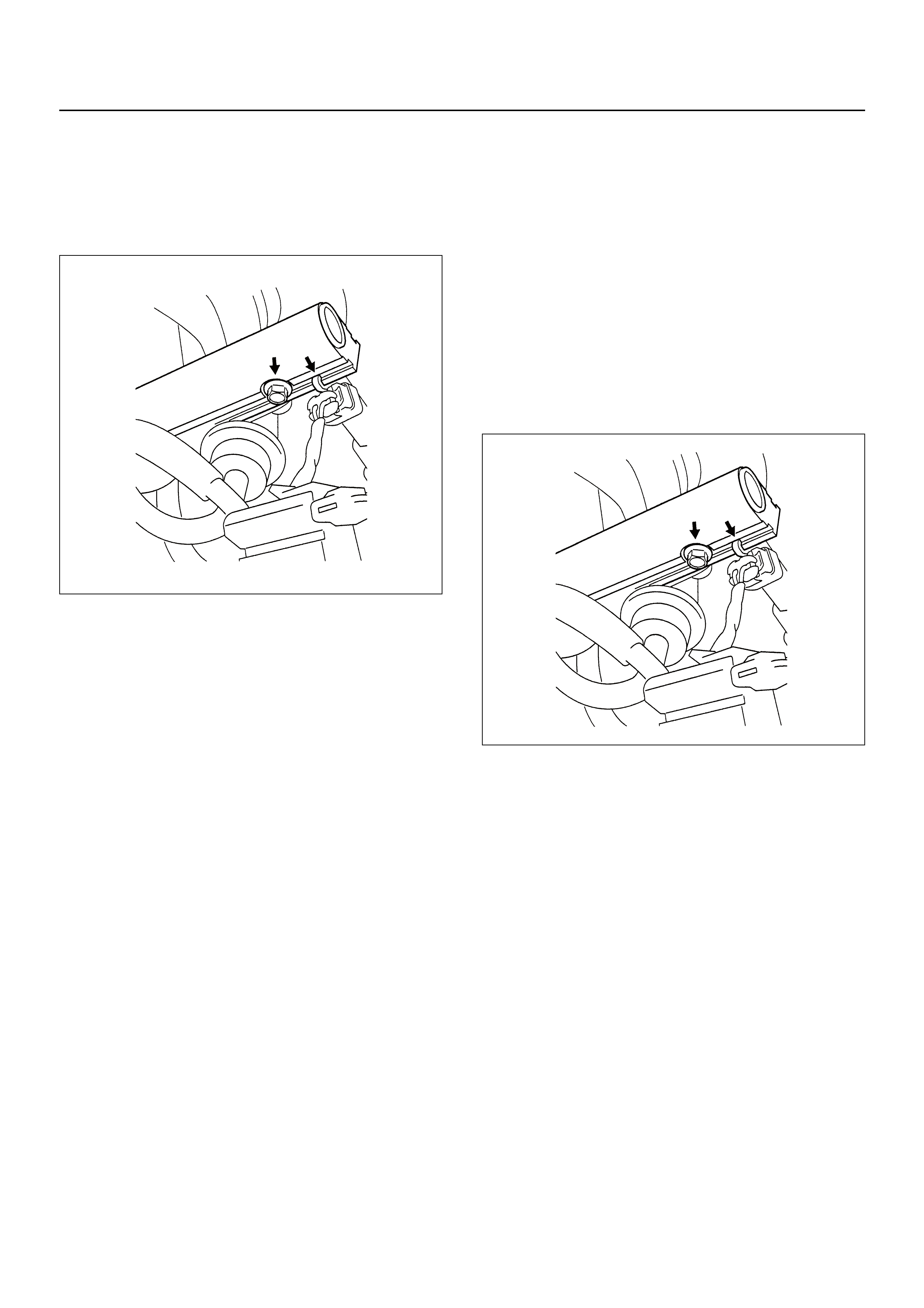

The group fuel injection fuel injector is a solenoid

operated device controlled by the ECM. The ECM

energises the solenoid, which opens a valve to allow

fuel delivery.

The fuel is injected under pressure in a conical spray

pattern at the opening of the inlet valve. Excess fuel not

used by the injectors passes through the fuel pressure

regulator before being returned to the fuel tank.

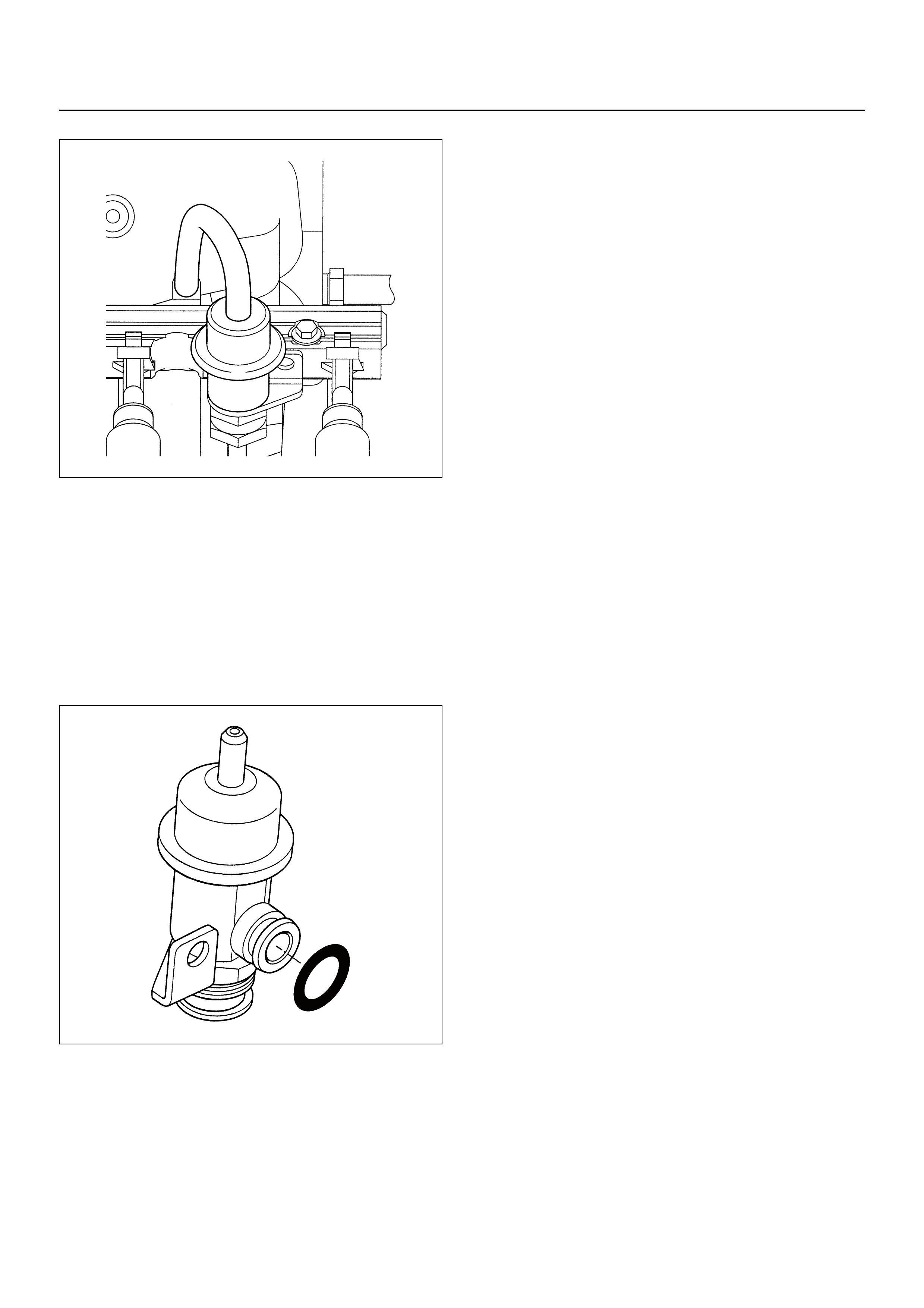

Fuel Pressure Regulator

The fuel pressure regulator is a diaphragm operated

relief valve. Its mounted on the fuel rail with fuel pump

pressure on one side and manifold pressure on the

other. The fuel pressure regulator maintains the fuel

pressure available to the injector at three times

barometric pre ssure adjuste d for engine lo ad. It may be

serviced separately.

If the pressure is too low or performance is poor , DTC

P0131 or P1171 will be the result. If the pressure is too

high, DTC P0132 or P1167 will be the result. Refer to

Fuel System Diagnosis for information on diagnosing

fuel pressure conditions.

Fuel Rail

The fuel rail is mounted to the top of the engine and

distributes fuel to the individual injectors. Fuel is

delivered to the inlet tube of the fuel rail by the fuel lines.

The fuel goes through the fuel rail to the pressure

regulator. The pressure regulator maintains a constant

fuel pressure at the injectors. Excessive fuel is returned

to the fuel tank.

Fuel Pump Electrical Circuit

When the ignition key is first turned to the ON position,

the ECM energises the fuel pump relay for two seconds

to build up the fuel pressure quickly. If the engine is not

started within two seconds, the ECM shuts the fuel

pump off and waits until the engine is cranked. When

the engine is cranked and the 58X crankshaft position

signal has been detected by the ECM, the ECM

supplies 12 volt to the fuel pump relay to energize the

electric in-tank fuel pu m p.

An inoperative fuel pump will cause a “no-start”

condition. A fuel pump which does not provide enough

pressure will result in poor performance.

Thottle Body Unit

The throttle body has a throttle plate to control the

amount of air delivered to the engine. The Thottle

position sensor and IAC valve are also mounted on the

throttle body.

Vacuum ports located behind the throttle plate provide

the vacuum signals needed by various components.

Engine coolant is directed th rough a cavity in the th rottle

body to warm up the throttle valve and to prevent icing.

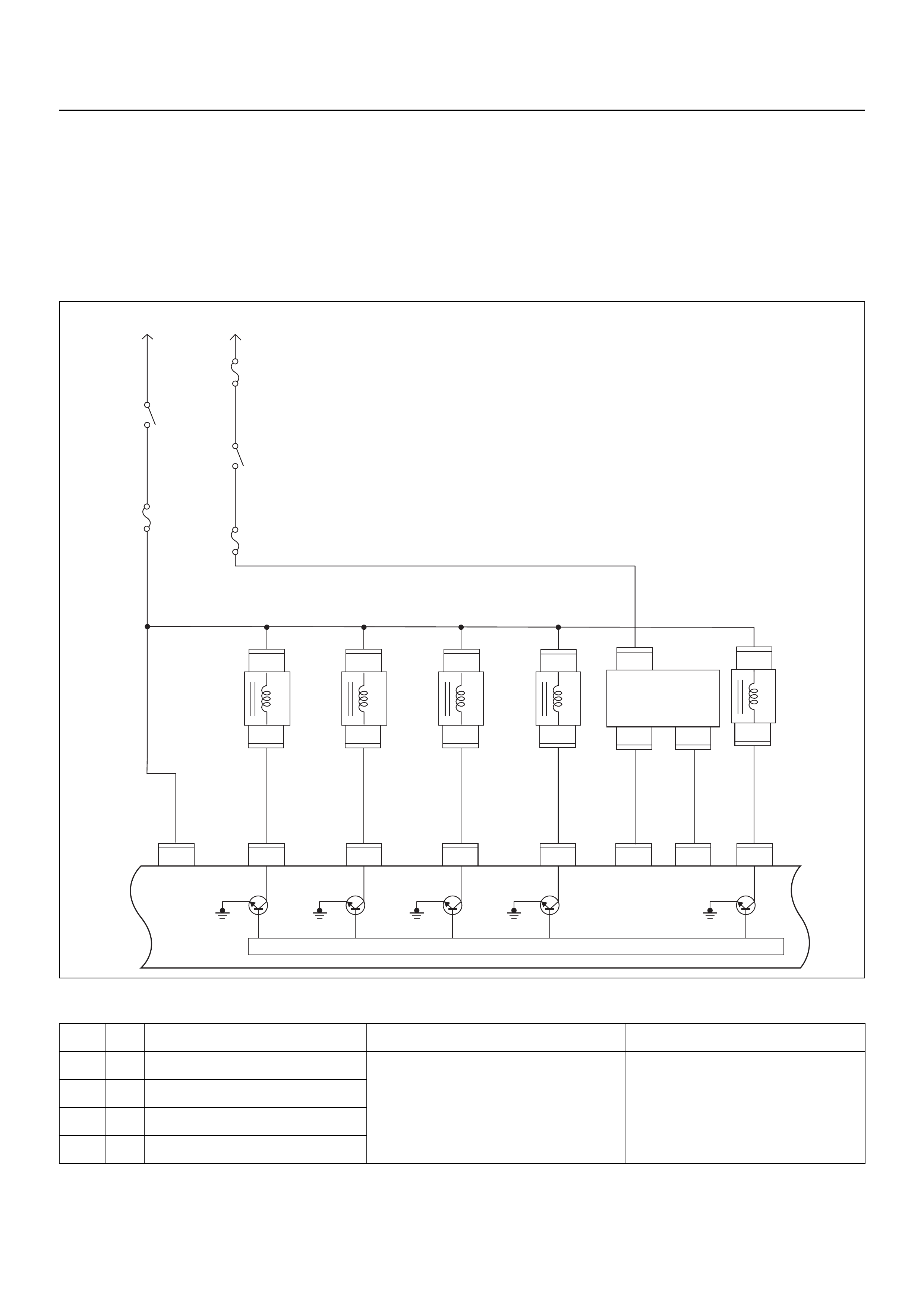

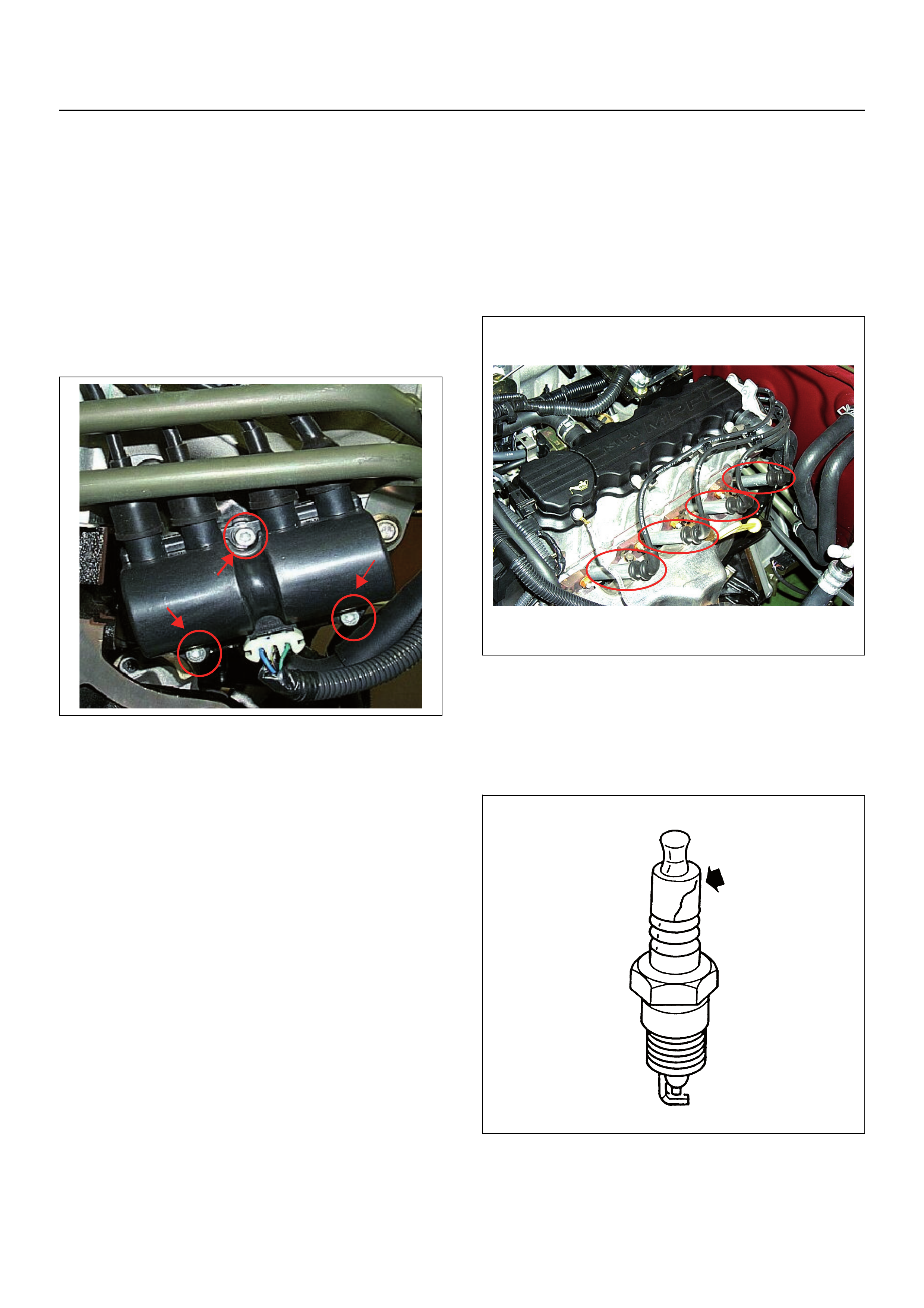

GENERAL DESCRIPTION FOR

ELECTRIC IGNITION SYSTEM

The engine use two ignition coils, on e pe r two cylinder s.

A two wire connecto r prov ide s a batte ry volta ge prim ary

supply through the ignition fuse.

The ignition control spark timing is the ECM’s method of

controlling the spark advance and the ignition dwell.

The ignition control spark a dvance and the ignition dwell

are calculated by the ECM using the following inputs.

• engine speed

• crankshaft position (CKP) sensor

• engine coolant tempera ture (ECT) sensor

• throttle position sensor

• vehicle speed sensor

• ECM and ignition system supply voltage.

Ignition coil works to generate only the secondary

voltage be receiving the primary voltage from ECM.

The primary voltage is generated at the coil driver

located in the ECM. The coil driver gener ate the primary

voltage based on the crankshaft position signal. In

accordance with the crankshaft position signal, the

ignition coil driver determines the adequate ignition

timing and also the cylinder number to ignite.

Ignition timing is determined by the coolant

temperature, inlet air temperature, engine speed,

engine load, knock sensor signal, etc.

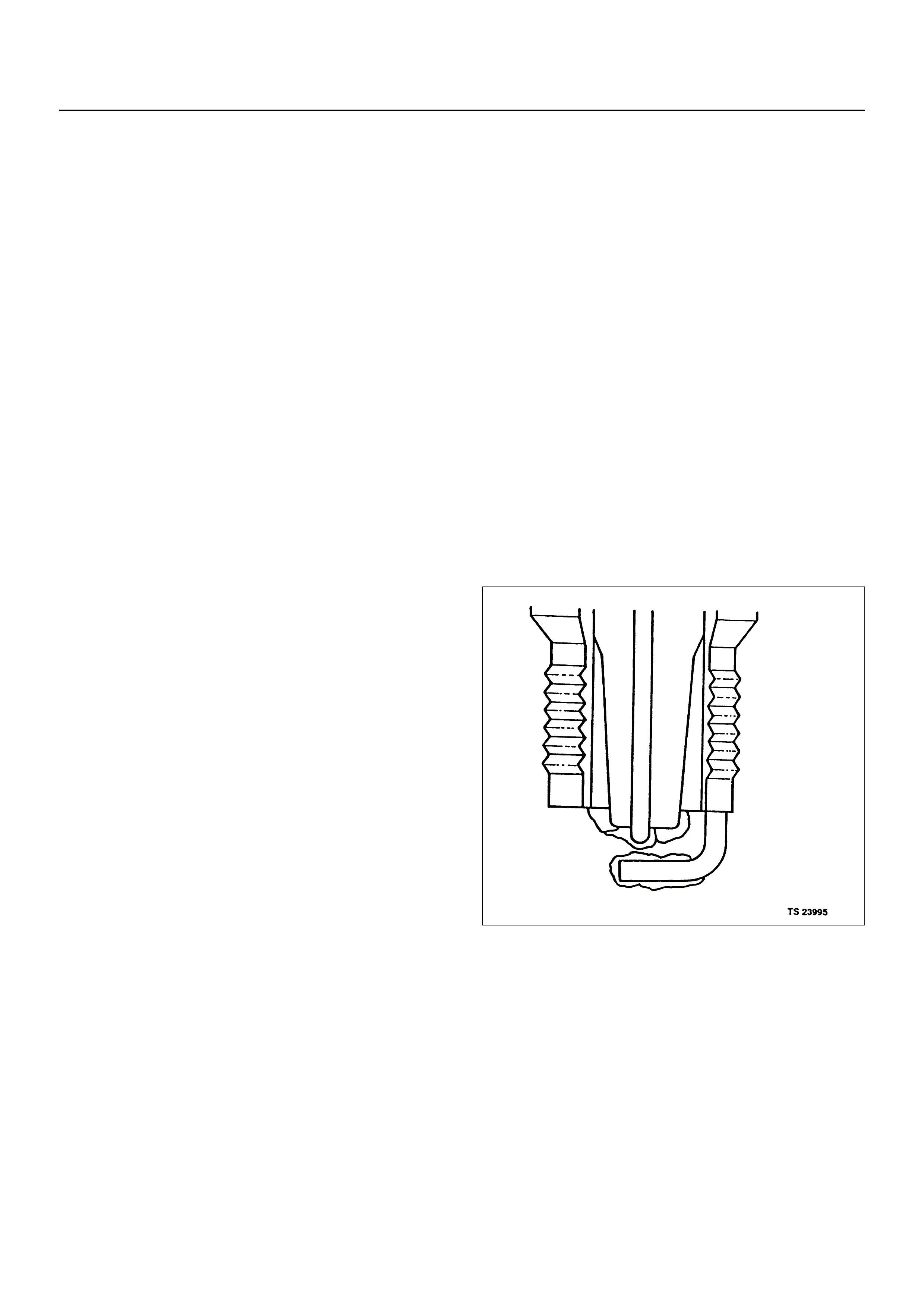

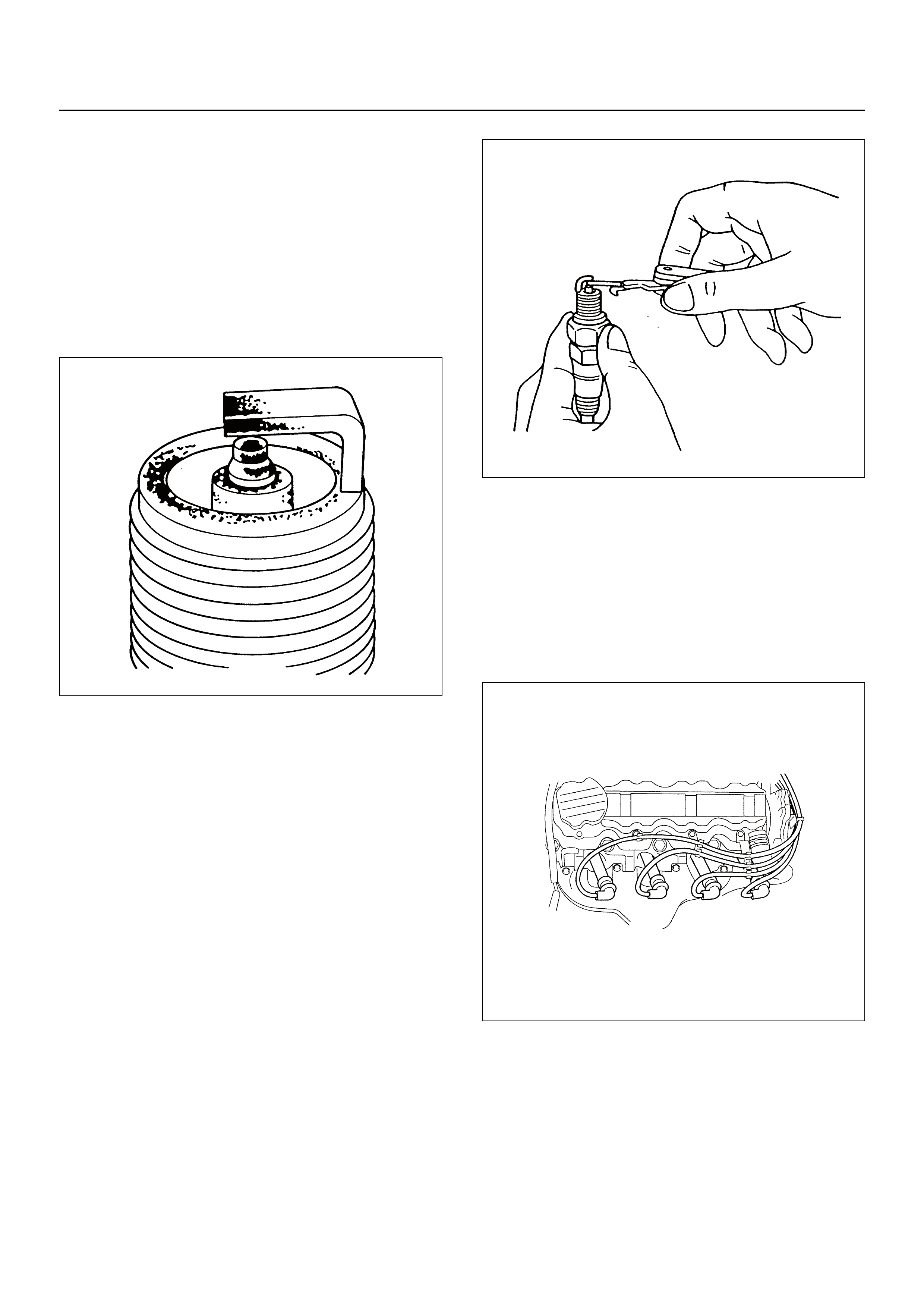

Spark Plug

Although worn or dirty spar k p lugs ma y give satisfactory

operation at idling speed, they frequently fail at higher

engine speeds. Faulty spark plugs may cause poor fuel

economy, power loss, loss of speed, hard starting and

generally poor engine performance. Follow the

scheduled maintenance service recommendations to

ensure satisfactory spark plug performance. Refer to

Section 6G - Engine Lubrication.

Normal spark plug operation will result in brown to

greyish-tan deposits appearing on the insulator portion

of the spark plug. A small amount of red-brown, yellow,

and white powdery material may also be present on the

insulator tip around the centre electrode. These

deposits are normal combustion by-products of fuels

and lubricating oils with additives. Some electrode wear

will also occur. Engines which are not running properly

are often referred to as “misfiring.” This means the

ignition spark is not igniting the air/fuel mixture at the

proper time. While o ther ignition and fu el system causes

must also be considered, possible causes include

ignition system conditions which allow the spark voltage

to reach ground in some other manner than by jumping

across the air gap at the tip of the spark plug, leaving

the air/fuel mixture unburned. Misfiring may also occur

when the tip of the spark plug becomes overheated and

ignites the mixture before the spark jumps. This is

referred to as “pre-ignition.”

Spark plugs may also misfire due to fouling, excessive

gap, or a cracked / broken insulator. If misfiring occurs

before the recommended replacement interval, locate

and correct the cause.

Carbon fouling of the spark plug is indicated by dry,

black carbon (soot) deposits on the portion of the spark

plug in the cylinder. Excessive idling and slow speeds

under light engine loads can keep the spark plug

temperatures so low that these deposits are not burned

off. Very rich fuel mixtures or poor ignition system

output may also be the cause. Refer to DTC P1167.

Oil fouling of the spark plug is indicated by wet oily

deposits on the portion of the spark plug in the cylinder,

usually with little electrode wear. This may be caused by

oil during break-in of new or newly overhauled engines.

Deposit fouling of the spark plug occurs when the

normal red-brown, yellow or white deposits of

combustion by-products become sufficient to cause

misfiring. In some cases, these deposits may melt and

form a shiny glaze on the insulator around the centre

electrode. If the fouling is found in only one or two

cylinders, valve stem clearances or inlet valve seals

may be allowing excess lubricating oil to enter the

cylinder, particularly if the deposits are heavier on the

side of the spark plug facing the inlet valve.

Excessive gap means that the air space between the

centre and the side electrodes at the bottom of the

spark plug is too wide for consistent firing. This may be

due to improper gap adjustment or to excessive wear of

the electrode during use. A check of the gap size and

comparison to the gap specified for the vehicle in

Engine Ignition will tell if the gap is too wide. A spark

plug gap that is too small may cause an unstable idle

condition. Excessive gap wear can be an indication of

continuous operation at high speeds or with engine

loads, causing the spark to run too hot. Another

possible cause is an excessively lean fuel mixture.

Low or high spark plug installation torque or improper

seating can result in the spark plug running too hot and

can cause excessive centre electrode wear. The plug

and the cylinder head seats must be in good contact for

proper heat transfer and spark plug cooling. Dirty or

damaged threads in the head or on the spark plug can

keep it from seating even though the proper torque is

applied. Once spark plugs are properly seated, tighten

them to the correct torque specification. Refer to

Section 6A - Engine Mechanical. Low torque may result

in poor contact of the seats due to a loose spark plug.

Over tightening may cause the spark plug shell to be

stretched and will result in poor contact between the

seats. In extreme cases, exhaust blow-by and damage

beyond simple gap wear may occur.

Cracked or broken insulators may be the result of

improper installation, damage during spark plug re-

gapping, or heat shock to the insulator material. Upper

insulators can be broken when a poorly fitting tool is

used during installation or removal, when the spark plug

is hit from the outside, or is dropped on a hard surface.

Cracks in the upper insulator may be inside the shell

and not visible. Also, the breakage may not cause

problems until oil or moisture penetrates the crack later.

A broken or cracked lower insulator tip (around the

centre electrode) may result from damage during re-

gapping or from “heat shock” (spark plug suddenly

operating too hot).

• Damage during re-gapping can happen if the gapping

tool is pushed against the centre electrode or the

insulator around it, causing the insulator to crack.

When re-gapping a spark plug, make the adjustment

by bending only the ground side terminal, keeping the

tool clear of other parts.

• “Heat shock” breakage in the lower insulator tip

generally occurs during several engine operating

conditions (high speeds or heavy loading) and may

be caused by over-advanced timing or low grade

fuels. Heat shock refers to a rapid increase in the tip

temperature that causes the insulator material to

crack.

Spark plugs with less than the recommended amount of

service can sometimes be cleaned and re-gapped, then

returned to service . However, if there is an y doubt abou t

the serviceability of a spark plug, replace it. Spark plugs

with cracked or broken insulators should always be

replaced.

GENERAL DESCRIPTION FOR

EVAPORATIVE EMISSION SYSTEM

EVAP Emission Control System Purpose

The evaporative emission control system is based on

the charcoal canister storage method. Fuel vapours are

transfered from the fuel tank to an activated carbon

(charcoal) storage devise to hold the vapours when the

vehicle is not operating.

The canister is located on the rear axle housing by the

frame cross-member.

When the engine is running, the fuel vapour is purged

from the carbon element by inlet air flow and consumed

in the normal combustion process.

EVAP Emission Control System Operation

The EVAP canister purge is controlled by a solenoid

valve that allows the manifold vacuum to purge the

canister. The engine control module (ECM) supplies a

ground to energise the solenoid valve (purge on). The

EVAP purge solenoid control is pulse-width modulated

(PWM) (switched on and off several times a second).

The duty cycle is determined by engine operating

conditions including load, throttle position, coolant

temperature and ambient temperature. The duty cycle is

calculated by the ECM. The output is command ed wh en

the appropriate conditions have been met. These

conditions are:

•the engine is fully warmed up,

•the engine has been running for a specified time,

•the IAT reading is above 10°C (50°F),

•purge/Vacuum Hoses. Made of rubber compounds,

these hoses route the gasoline fumes from their

sources to the canister and from the canister to the

intlet air flow, and

•EVAP Canister. Mounted on a bracket ahead of the

fuel tank, the canister stores fuel vapours until the

ECM determines that engine conditions are right for

them to be removed and burned.

Poor idle, stalling or poor driveability can be caused by:

•a malfunctioning purge solenoid,

•a damaged canister, and

•hoses that are split, cracked, or not connected

properly.

System Fault Detection

The EVAP leak detection strategy is based on applying

vacuum to the EVAP system and monitoring vacuum

decay. At an appropriate time, the EVAP purge solenoid

is switched “ON,” allowing the engin e va cu um t o dr aw a

small vacuum on the entire evaporative emission

system.

After the desired vacuum level has been achieved, the

EVAP purge solenoid is switched “Off,” sealing the

system. A leak is detected by monitoring for a decrease

in vacuum level over a given time period, all other

variables remaining constant.

If the desired vacuum level can not be achieved in the

test described above, a large leak or a faulty EVAP

purge control solenoid valve is indicated.

Leaks can be caused by the following conditions:

•missing or faulty fuel cap,

•disconnected, damaged, pinched, or blocked EVAP

purge line,

•disconnected, damaged, pinched, or blocked fuel

tank vapour line,

• disconnected or faulty EVAP purge control solenoid

valve,

•open ignition feed circuit to the purge solenoid,

•damaged EVAP canister,

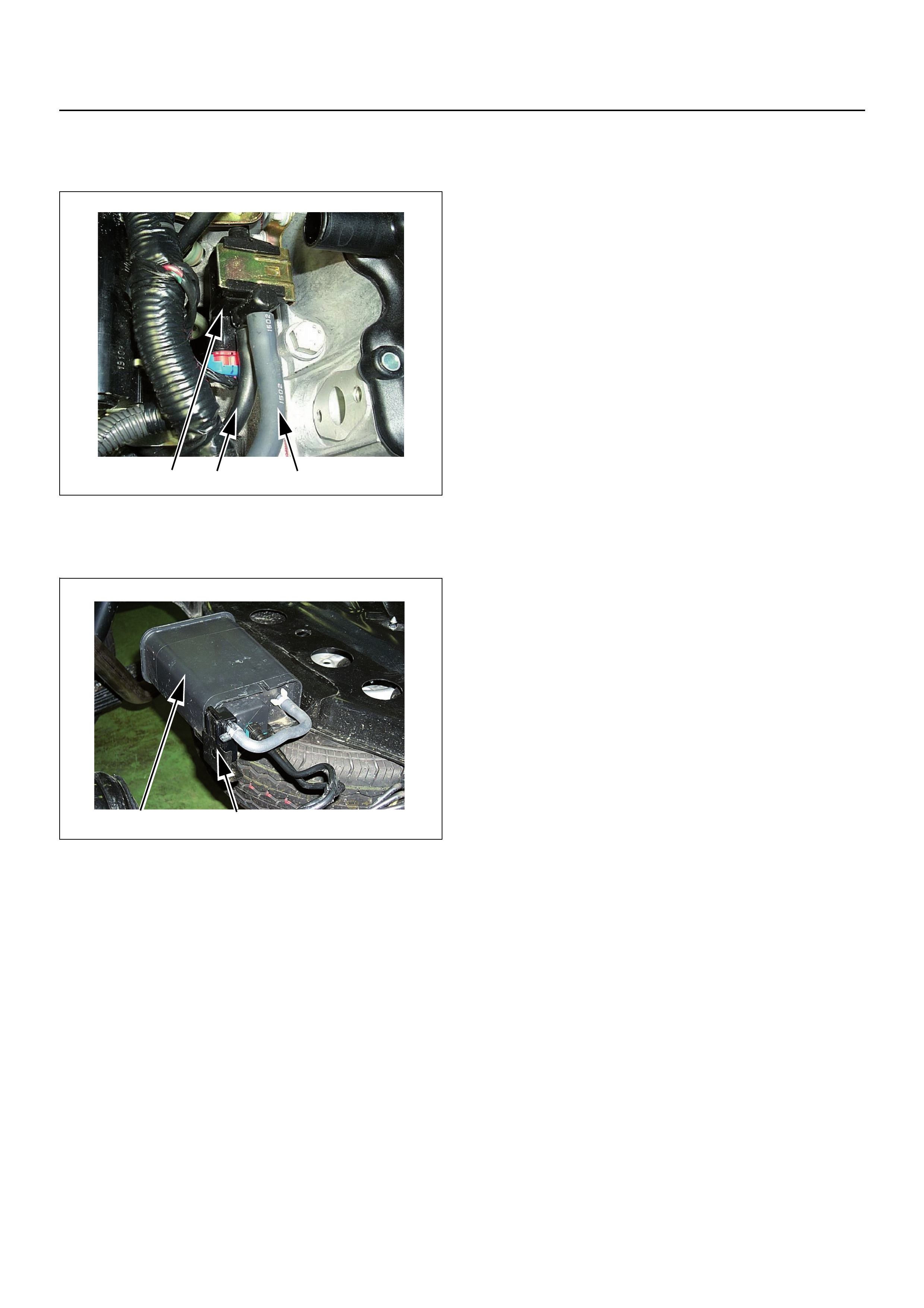

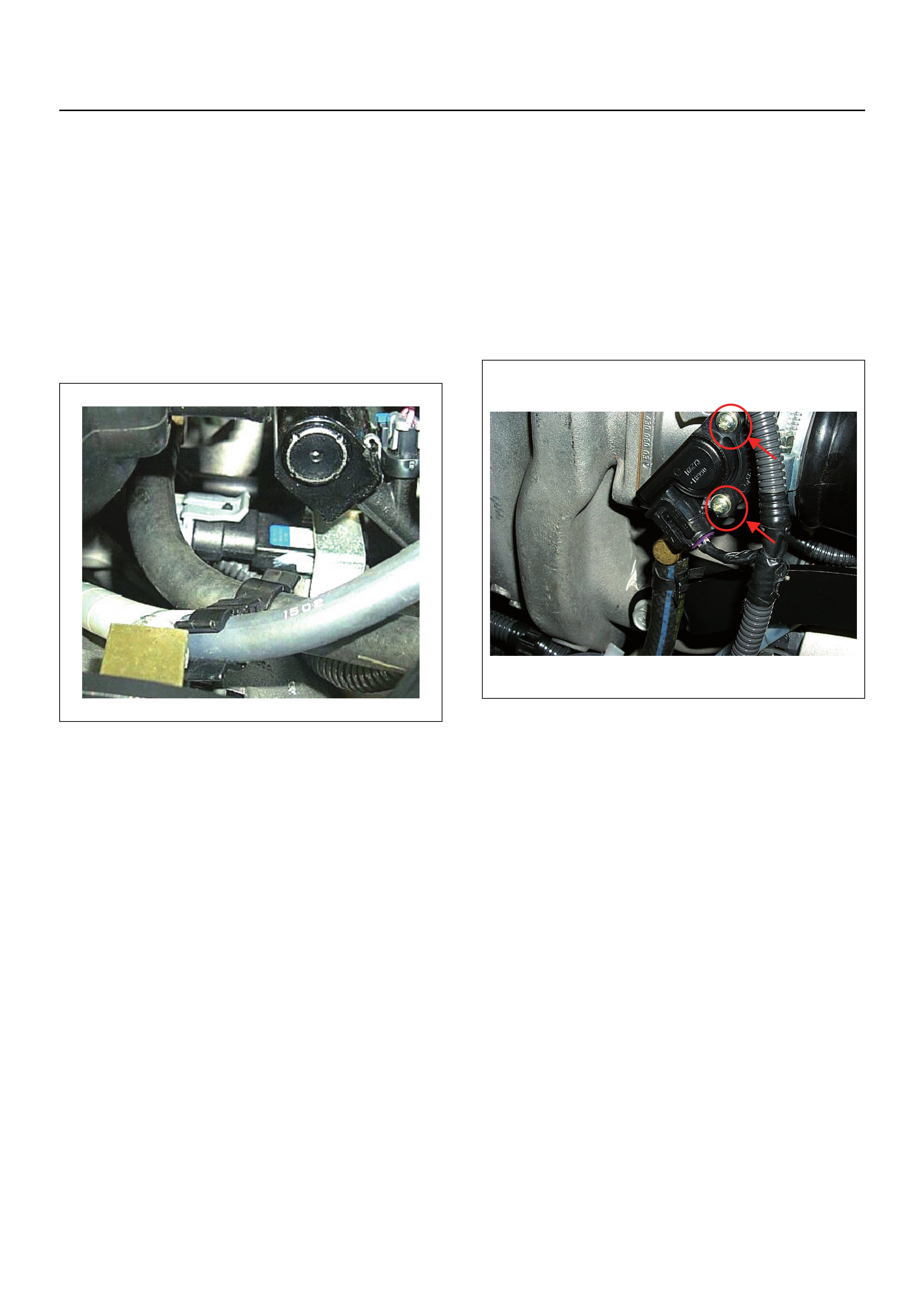

(1) Purge Solenoid Valve

(2) From Canister to Purge Solenoid Valve

(3) From Purge Soleno id Valve to Inlet manifold

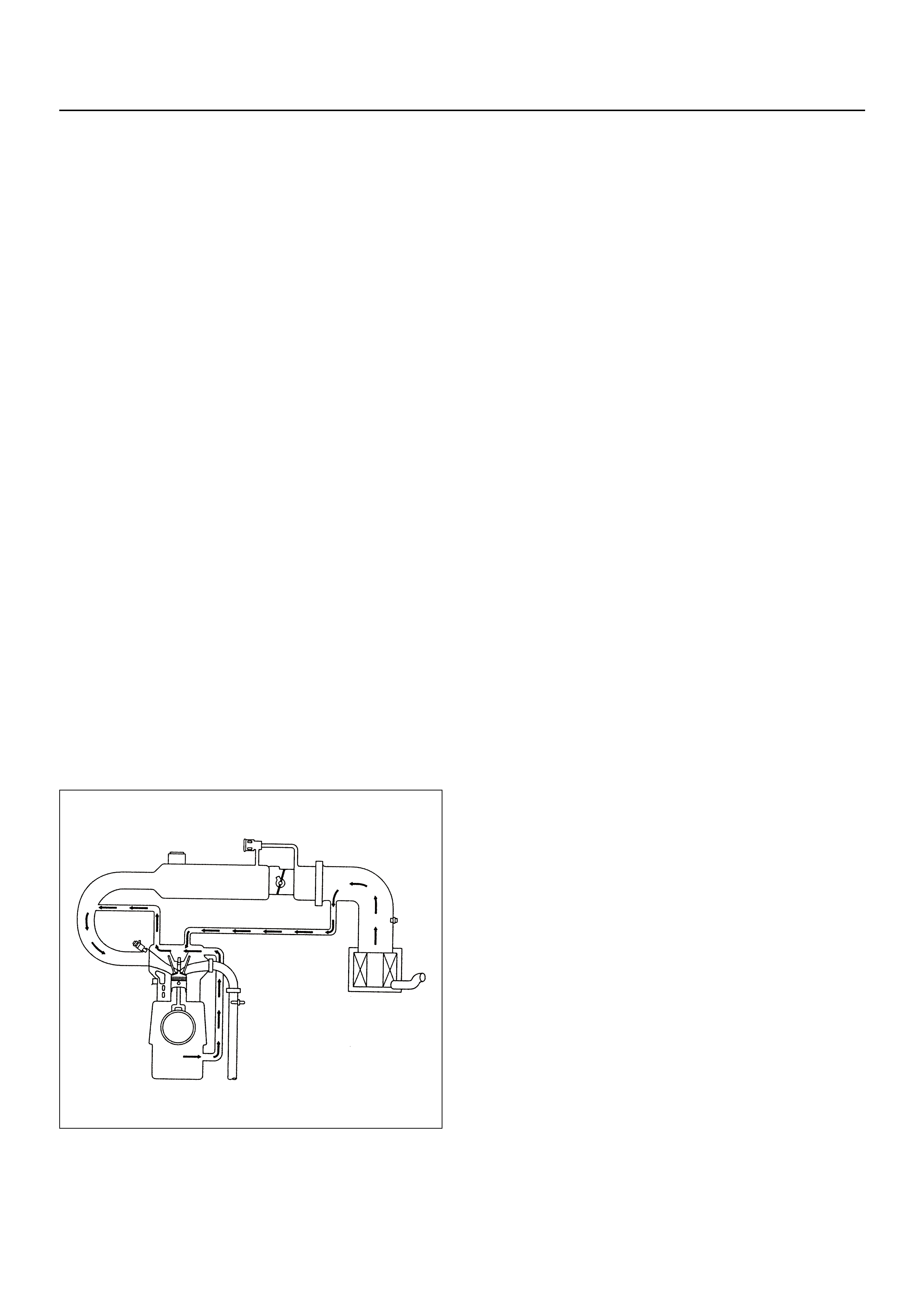

(1) Canister

(2) Air Separator

1 3 2

1 2

•leaking fuel sender assembly O-ring, and

• leaking fuel tank or fuel filler neck.

The ECM supplies a ground to energise the purge

control solenoid valve (purge “On” ). The EVAP purge

control is switched “On” and “Off,” several times a

second. The duty cycle is determined by engine

operating conditions including load, throttle position,

coolant temperature an d ambient temperatu re. The duty

cycle is calculated by the ECM and the output is

commanded when the appropriate conditions have

been met.

The system checks for conditions that cause the EVAP

system to purge continuously and commands the EVAP

purge solenoid “Off” with EVAP purge solenoid duty

ratio being “0%”. If fuel tank vacuum level increases

during the test, a continuous purge flow condition is

indicated. This can be caused by the following

conditions:

•EVAP purge solenoid leaking,

•EVAP purge and engine vacuum lines switched at the

EVAP purge control solenoid valve, and

• EVAP purge control solenoid valve driver circuit

grounded.

POSITIVE CRANKCASE

VENTILATION (PCV) SYSTEM

Crankcase Ventilation System Purpose

The crankcase ventilation system is used to control

crankcase vapours in the combustion process instead

of venting them to the atmosphere. Fresh air from the

throttle body is supplied to the crankcase and mixed

with blow-by gases. This mixtu re is then pa ssed throug h

the positive crankcase ventilation (PCV) port into the

inlet manifold.

While the engine is running, exhaust gases and small

amounts of the fuel/air mixture escape past the piston

rings and enter the crankcase. These gases are mixed

with clean air entering through a tube from the air inlet

duct.

During normal, part-throttle operation, the system is

designed to allow crankcase gases to flow through the

PCV hose into the inlet manifold to be burnt by normal

combustion.

A plugged positive crankcase ventilation port or PCV