SECTION 0A - GENERAL INFORMATION

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

1. GENERAL INFORMATION

1.1 V2 SERIES INTRODUCTION

1.2 MY2003 UPDATE

1.3 UNDERBODY HOIST PAD LOCATIONS

2. MODEL AVAILABILITY AND BASE EQUIPMENT

3. POWERTRAIN COMBINATIONS

4. TRANSMISSION RATIOS

5. ENGINE DATA

6. EXTERIOR DIMENSIONS

7. VEHICLE WEIGHTS

8. SERIAL NUMBERS

8.1 LOCATION OF IDENTIFICATION PLATES

8.2 SAFETY COMPLIANCE PLATE

8.3 BODY AND OPTION IDENTIFICATION PLATE

8.4 FUEL CONSUMPTION LABEL

8.5 VEHICLE IDENTIFICATION NUMBER PLATE

(BODY LOCATION)

8.6 VEHICLE IDENTIFICATION NUMBERING SYSTEM

MY2002 MODELS

MY2003 UPDATE MODELS

8.7 ENGINE SERIAL NUMBER

8.8 MANUAL TRANSMISSION SERIAL NUMBER

8.9 AUTOMATIC TRANSMISSION SERIAL

NUMBER

MY2002 MODELS

MY2003 UPDATE MODELS

8.10 FINAL DRIVE IDENTIFICATION

9. ADDITIONAL GENERAL INFORMATION

9.1 ELECTRICAL TRANSIENTS AND RADIO

FREQUENCY INTERFERENCE

ELECTRICAL TRANSIENTS

RADIO FREQUENCY INTERFERENCE

9.2 STATIC ELECTRICITY

9.3 PUSH OR TOW STARTING

10. CONSOLIDATED TOOL LI ST

MY2002 MODELS

MY2003 UPDATE MODELS

Techline

Techline

Techline

Techline

Techline

Techline

1. GENERAL I NFORMATI O N

1.1 V2 SERIES INTRODUCTION

The V2 Series Monaro is a new coupe (2-door) body design based on the VX Series Commodore. Sheetmetal

changes for V2 Series Monaro include new front doors, rear quarter panels, rear compartment lid (reduced rear

overhang), roof panel and a revised A-pillar rake (increased 2 degrees).

Other changes for V2 Series Models include:

• Modified side skirts.

• New front and rear bumper facias.

• Encapsulated glass in place of rear door window.

• New two passenger rear seat.

• New eight-way EZ Entry front seats.

• New EZ Entry memory type driver’s seat (CV8 only).

• New floor mats.

• New headlining.

• New door sill applique.

• New puddle lamp.

• Retuned sports suspension.

• Multi-link rear suspension.

• A revised Vehicle Identification Numbering (VIN) System.

• The 2003 Model Year update was introduced during October 2002.

The powertrain combinations available for V2 Series Models carry over from VX Series II Models.

1.2 MY2003 UPDATE

The MY2003 V2 Series update is a minor mechanical upgrade of the MY2002 V2 Series Models. The major

changes to the MY2003 V2 Series Models are:

• New condenser, radiator and cooling fans fitted to all Models.

• New engine cooling vent hose and radiator outlet hose fitted to CV8 Models.

• New radiator inlet hose fitted to CV6 Models.

• New air conditioning discharge hose fitted to all Models.

• New air conditioning liquid line fitted to all Models.

• New power steering fluid cooler with extra fins fitted to CV8 Models.

• Revised automatic transmission with new force motor and quick connect fittings for CV6 Models.

• Revised m anual tr ans mission s hif t lever (10 mm longer with a 30-degree twist in the s tub lever) f or CV8 Models

fitted with the six-speed manual transmission.

• New heavy-duty automatic transmission with new force motor and quick connect fittings for CV8 Models.

• Revised side and floor panels for improved occupant protection.

• Modified floor carpet and deadener to accommodate the revisions to the side and floor panels.

• New load limiting seat belts for improved occupant safety.

• A revised Vehicle Identification Numbering (VIN) System.

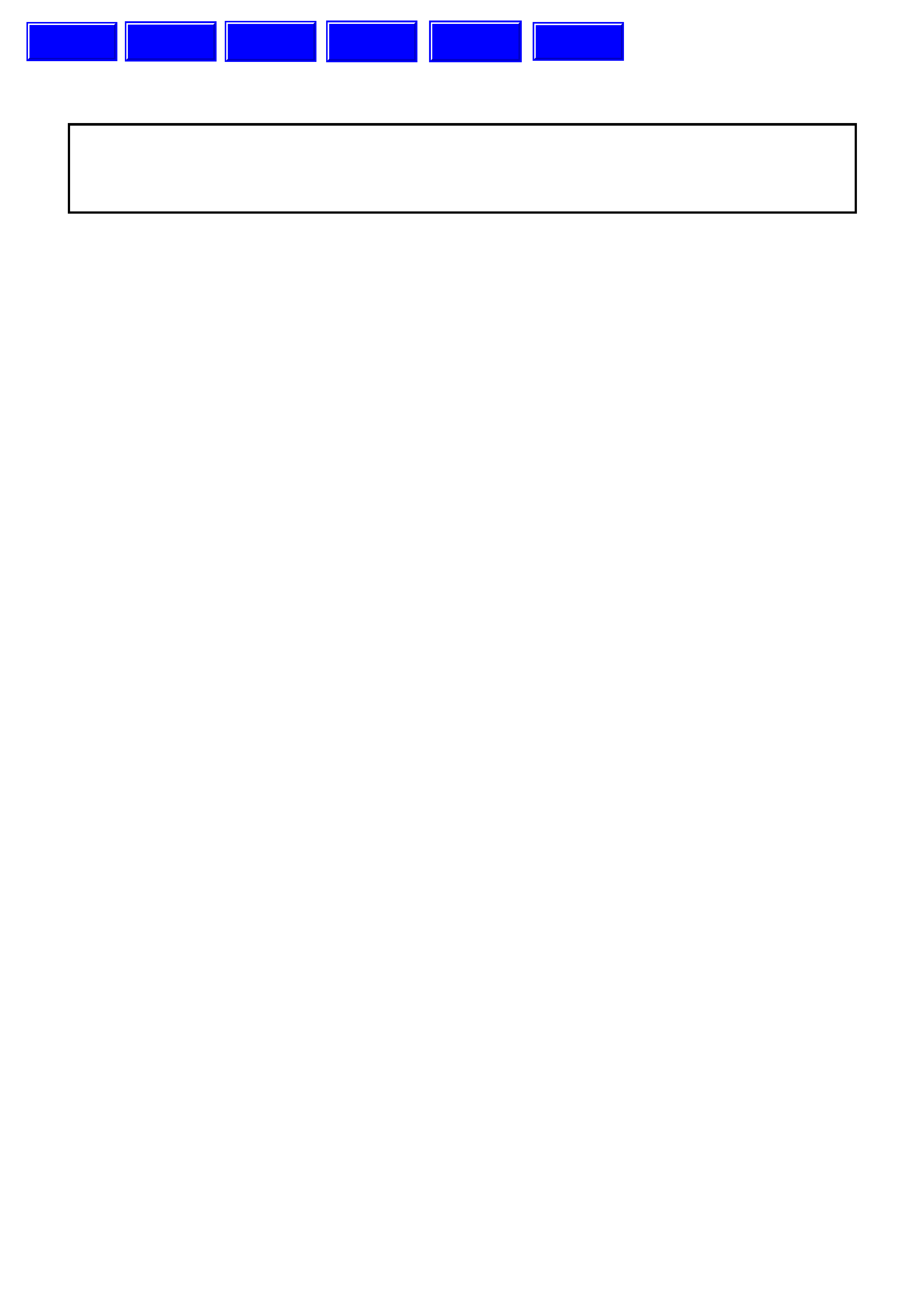

1.3 UNDERBODY HOIST PAD LOCATIONS

NOTE: When using a trolley jack to rais e the vehic le it is important that the jack be positioned under the suspension

cross -m ember or hois t pad loc ations (1). Do not jack under the sus pension control arm . T he vehicle should always

be supported by jack stands at the hoist pad locations when raised.

Figure 0A-1

2. MODEL AVAILABILITY AND BASE EQUIPMENT

MODEL NAME MODEL NO. ENGINE TRANSMISSION FINAL

DRIVE

RATIO TYRES WHEELS

CV6 8VK37 3.8 SEFI

SUPERCHARGED

V6 4-SPEED AUTO 3.07:1 235/45 R17 93V 8.00J X 17

CV8 8VX37 5.7 SEFI GEN III V8 4-SPEED AUTO 3.07:1 235/40 R18 91W 8.00J X 18

3. POWERTRAIN COMBINATIONS

ENGINE TRANSMISSION TYPE

MODEL

AVAILABILITY FIRST GEA R

RATIO FINAL DRIVE

RATIO

3.8 SEFI

SUPERCHARGED V6 4-Speed Automatic CV6 3.06:1 3.07:1

6-Speed Manual CV8 2.66:1 3.46:1

5.7 SEFI GEN III V8 4-Speed Automatic CV8 3.06:1 3.07:1

4. TRANSMISSION RATIOS

GEAR 6-SPEED MANUAL 4-SPEED AUTOMATIC.

1ST 2.66:1 3.06:1

2ND 1.78:1 1.63:1

3RD 1.30:1 1.00:1

4TH 1.00:1 0.70:1

5TH 0.74:1 N/A

6TH 0.50:1 N/A

REV 2.90:1 2.29:1

5. ENGINE DATA

ENGINE

DESIGNA TION 3.8 LITRE

SUPERCHARGED 5.7 LITRE SEFI

(GEN III)

Piston

Displacement

Nom. - cm3 3791 5667

Compression

Ratio 8.5:1 10.1:1

Number of

Cylinders 6 8

Bore x Stroke -

mm 96.5 X

86.3 99 X 92

Taxable H.P.

RAC OR SAE 34 48.6

Power kW

DIN @ RPM 171 kW @ 5200

PULP* 225 kW @ 5200

Torque Nm

DIN @ RPM 375 Nm @ 3000

PULP* 460 Nm @ 4400

*PULP – Premium Unleaded Petrol

6. EXTERIOR DIME NSI O NS

BODY DIMENSIONS

VEHICLE LENGTH 4802 mm

VEHICLE WIDTH 1824 mm

VEHICLE HEIGHT 1400 mm

WHEELBASE 2788 mm

OVERHANG - FRONT 943 mm

OVERHANG - REAR 1071 mm

TREAD - FRONT 1569 mm

TREAD - REAR 1587 mm

7. VEHICLE WEIGHTS

VEHICLE WEIGHTS CV6

AUTOMATIC CV8

AUTOMATIC CV8

MANUAL

KERB MASS 1603 kg 1645 kg 1640 kg

REAR AXLE LOAD 1140 kg 1140 kg 1140 kg

PAYLOAD 340 kg 340 kg 340 kg

NOTE: All figures are estimates only.

Payload figures must include luggage, goods, passengers and a full

tank of fuel. If you are towing, then the weight on the tow bar ball

must also be included.

Rear Axle Load is the maximum for all conditions.

8. SERIAL NUMBERS

The complete vehicle and various com ponents of the vehicle are identified by number plates or numbers stam ped

into the part. It is essential that when compiling warranty claims or product and field reports, the vehicle

identification number (VIN) is quoted in conjunction with the identification number of the component affected.

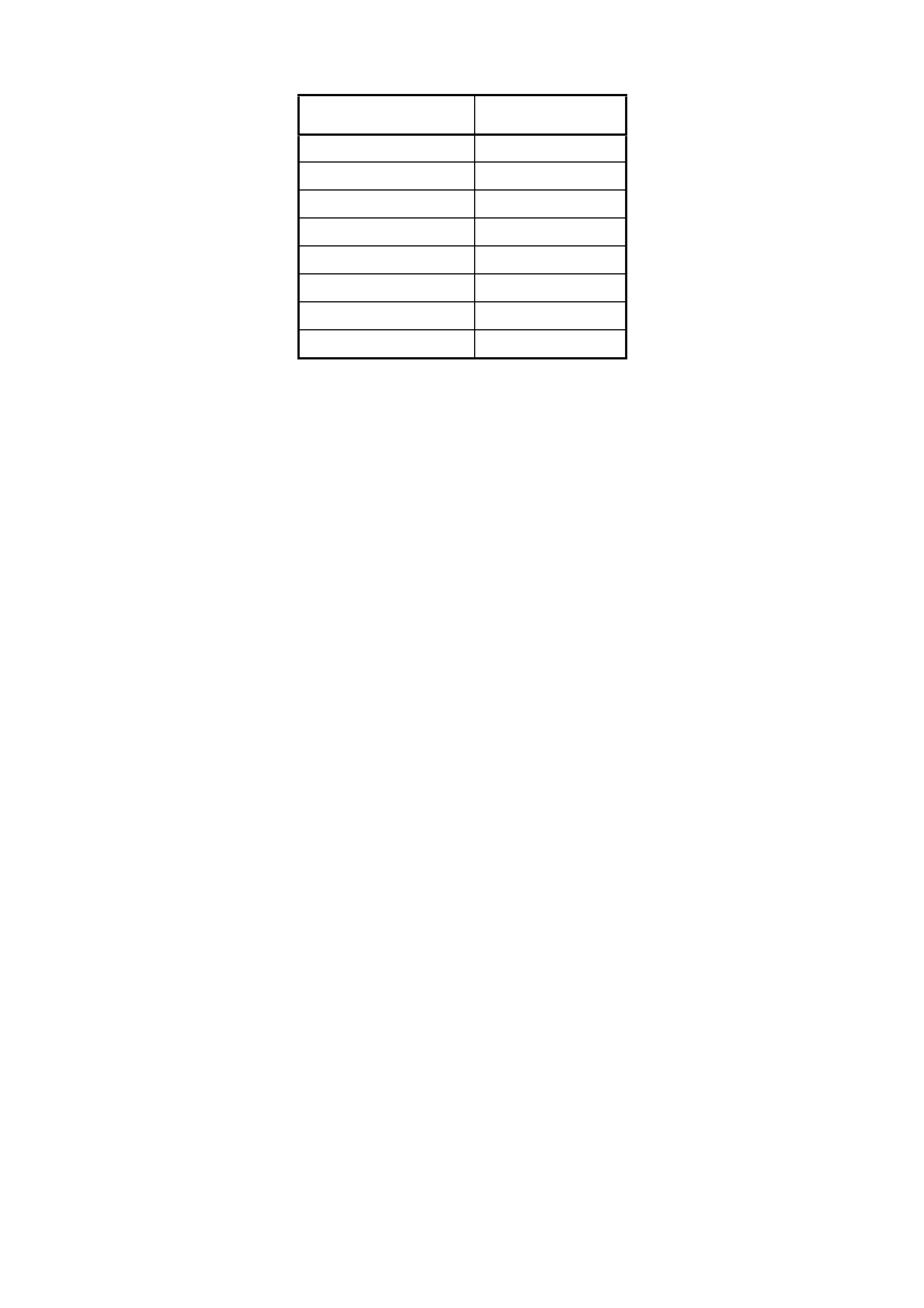

8.1 LOCATION OF IDENTIFICATION PLATES

Identification plates are attached to the upper left side of the dash panel (4), front radiator support panel (3), and

under the windshield lower lef t c orner ( 5). The Vehicle Identif ic ation Number is also s tamped into the f loor ( 2) below

the front right-hand seat, refer to Figure 0A-2.

Figure 0A-2

Legend

1. Carpet flap (under right-hand seat)

2. Vehicle Identification Number

(stamped under right-hand seat)

3. Body and Option Identification Plate

(front upper panel)

4. Safety Compliance Plate

(engine side of dash panel)

5. Vehicle Identification Number Plate

(under windscreen)

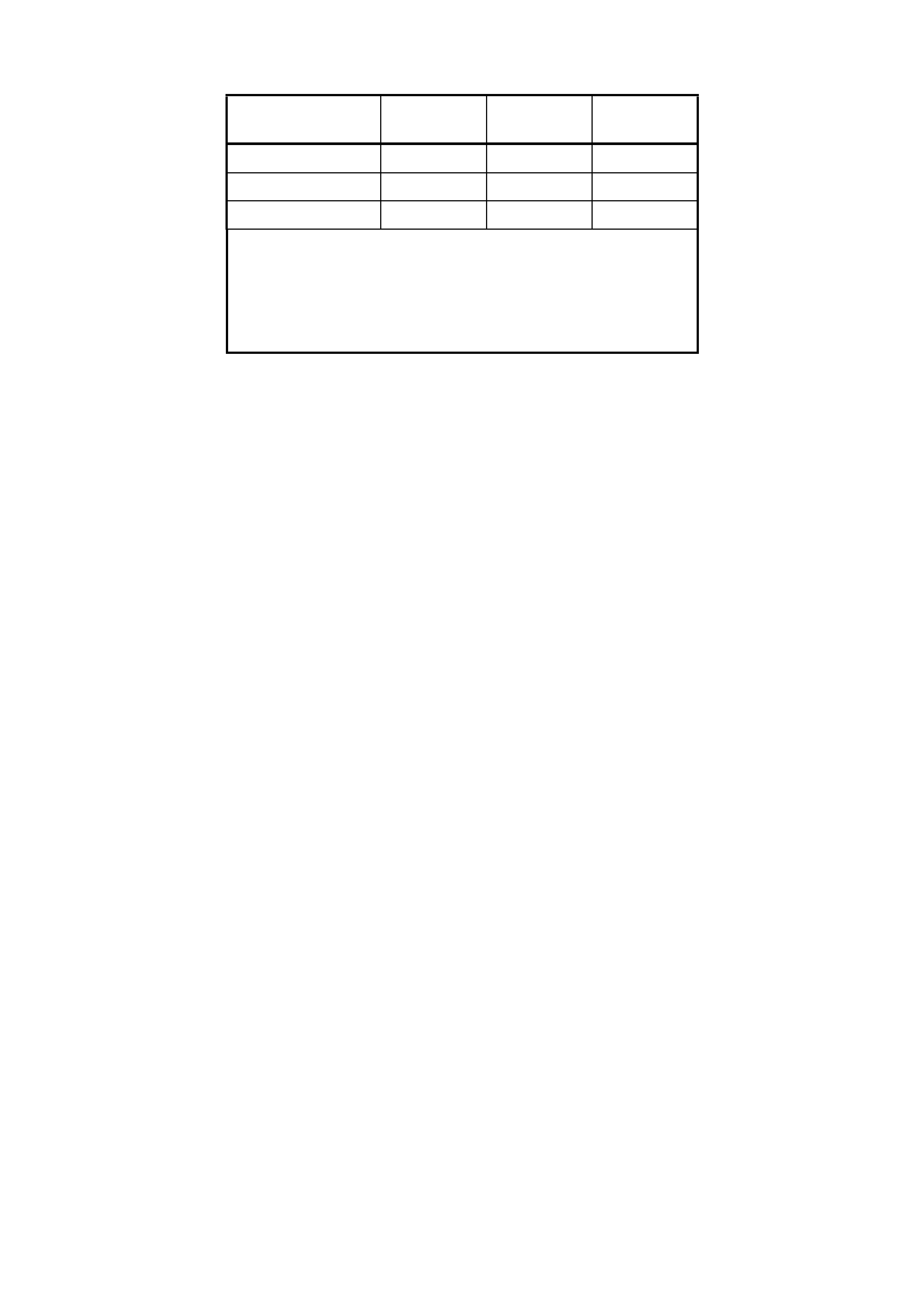

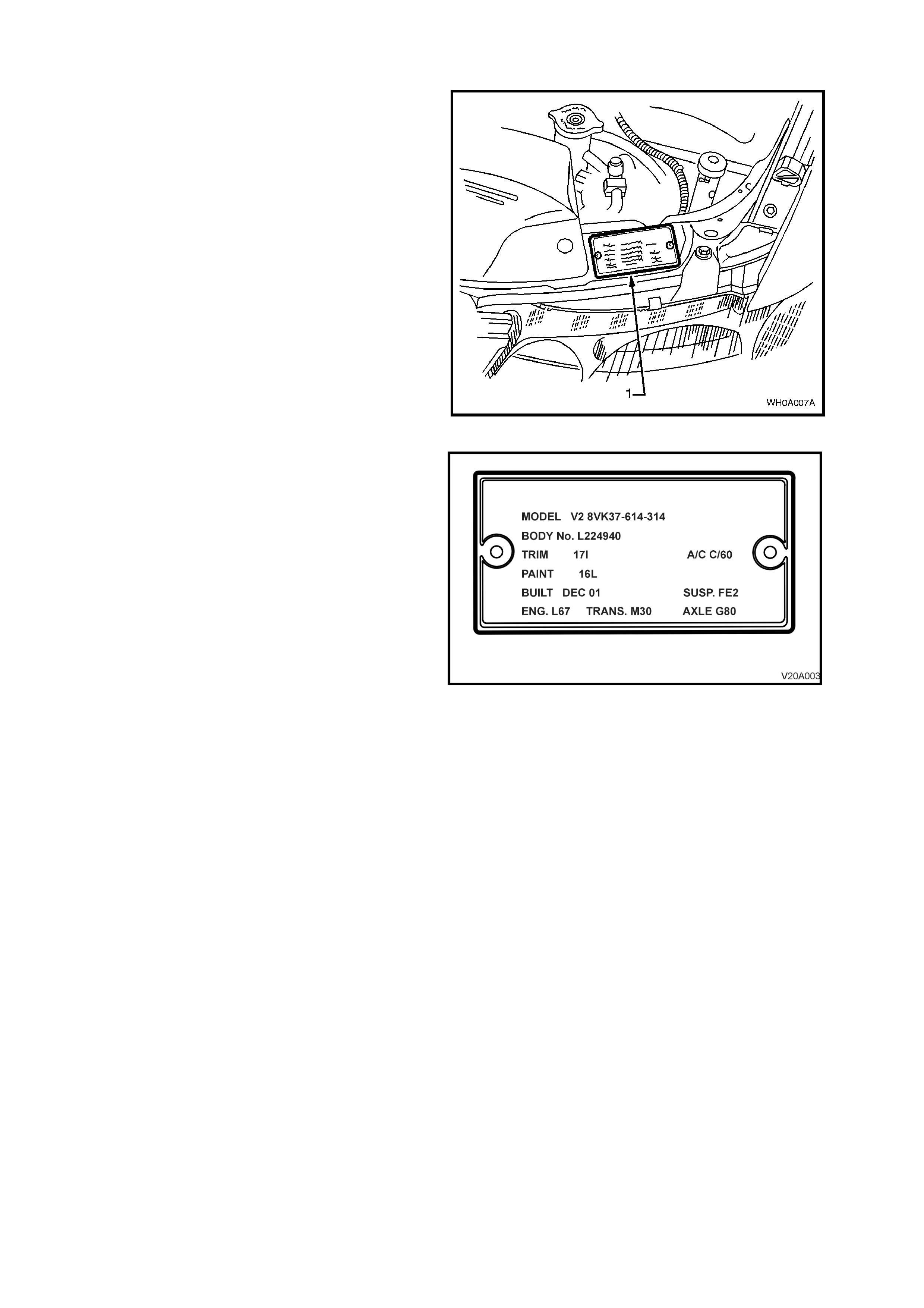

8.2 SAFETY COMPLIANCE PLATE

Plate stamped with the following inform ation, Refer

to Figure 0A-3:

COMPLIANCE PLATE APPROVAL NUMBER.

VEHICLE CATEGORY CODE.

NAME APPEARING ON COMPLIANCE PLATE

APPROVAL.

MAKE/MODEL.

GROSS VEHICLE MASS (KG)

SEATING CAPACITY.

DATE OF MANUFACTURE (* Variable

information).

VEHICLE IDENTIFICATION NUMBER (* Variable

information).

Figure 0A-3

Legend

1. Safety Compliance Plate.

Figure 0A-4

8.3 BODY AND OPTION IDENTIFICATION PLATE

The body and option identification plate (1) is

stamped with the following information, refer to

Figure 0A-6.

Figure 0A-5

MODEL

Combination of letters and numbers identifying the

body style, the mechanical pack and smart pack

options.

NOTE: A listing of Production Option numbers and

Smart Pack Option numbers can be found by

referring to the latest spare parts information

(Partfinder) for the applicable model.

BODY

Production build number, in continuous sequence

regardless of model, body type and series.

TRIM

Trim combination.

PAINT

Exterior paint material and colour identification.

BUILT

The date of manufacture by calendar month and

year in which the body shell and power train are

conjoined and the vehicle is driven or moved from

the production line.

SUSP

Suspension option code identification number, i.e.

FE2.

ENGINE, TRANSMISSION AND AXLE

Identification option codes for specific engine,

transmission and final drive.

A/C

Identification option code C60 identifies vehicles

fitted with air conditioning.

Figure 0A-6

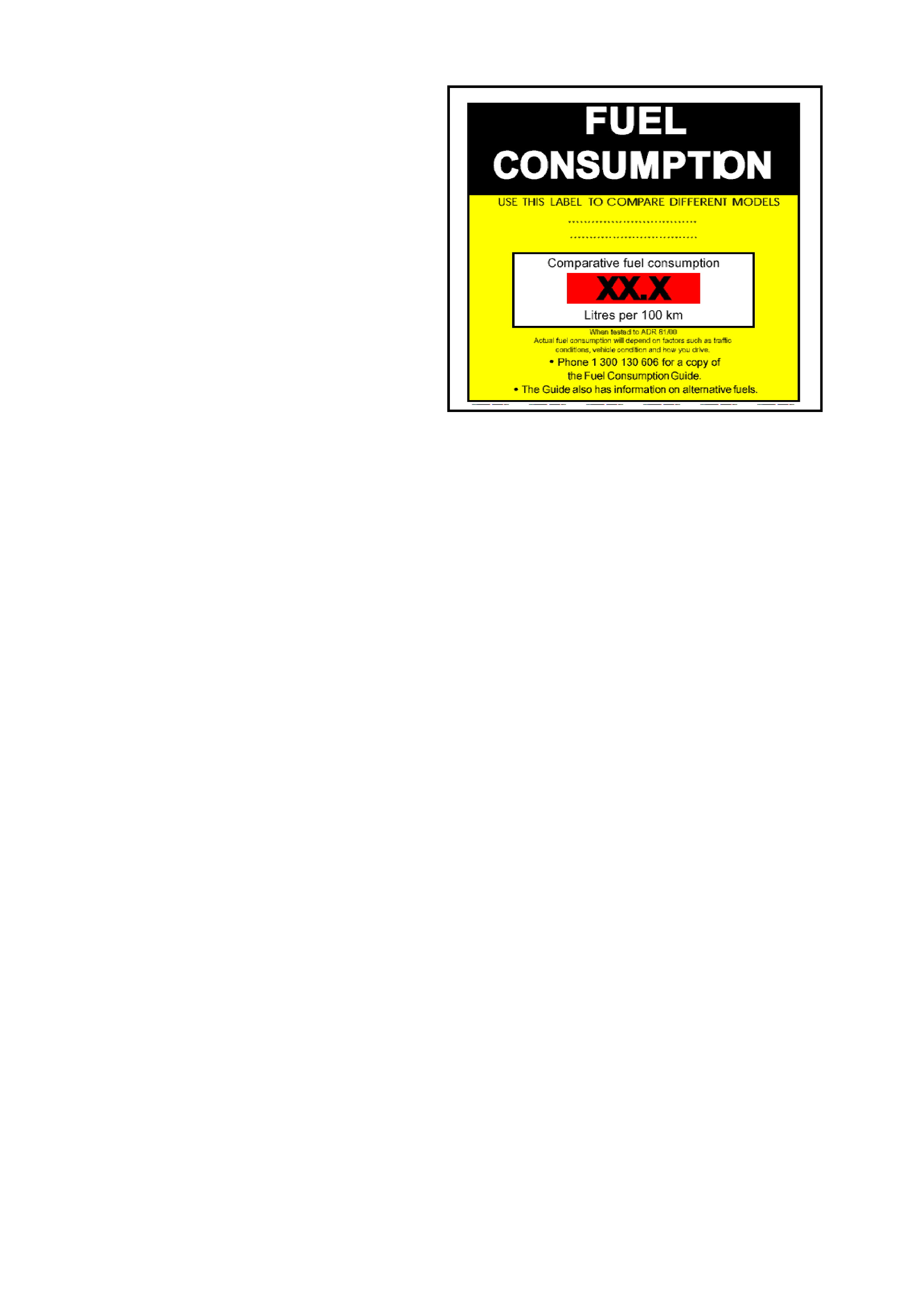

8.4 FUEL CONSUMP TION LABEL

ADR 81/00 requires that from 1st January 2001, a

label similar to that shown in Figure 0A–7 is

attached to the windscreen of any new vehicle

which is displayed for sale.

The f uel c onsumption f igures quoted are the results

of tests carried out in accordance with an

Australian standard for fuel consumption testing.

Each vehicle is tested under identical conditions.

The results therefore enable a comparison to be

made between vehicles.

This label should be removed from the windscreen

immediately prior to the vehicle being delivered to

the owner.

Figure 0A-7

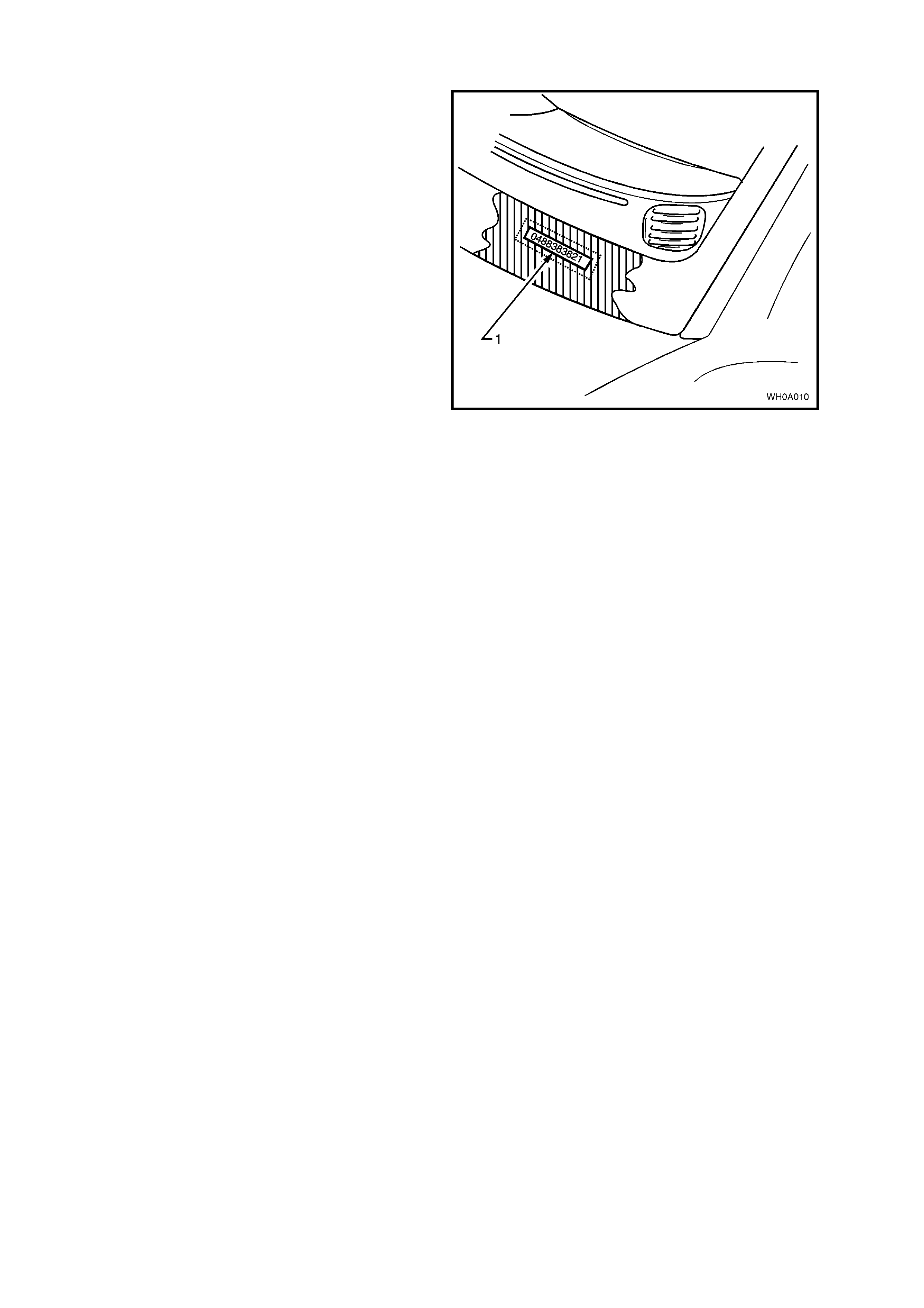

8.5 VEHICLE IDENTIFICATION NUMBER PLATE LOCATION (BODY LOCATION)

The body mounted Vehicle Identification Number

(VIN) plate (1) is located under the windscreen and

is viewed through the windscreen aperture.

The VIN plate is secured to the body by unique

rosette headed rivets.

NOTE: The VIN is also stamped into the floor

sheetmetal under the front right-hand seat, refer to

8.1 LOCATION OF IDENTIFICATION PLATES in

this Section.

Figure 0A-8

8.6 VEHICLE IDE NTIFICATION NUMBERING SYSTEM

A new Vehicle Identification Numbering (VIN) system was introduced with the introduction of the MY2002

V2 Series Models during October 2002. However, all MY2002 V2 Series Models used the VIN system as

previously used in VX Series I. Figure 0A-9 provides the details of the MY2002 type VIN system, while

Figure 0A-10 provides details of the new VIN system used on all MY2003 V2 Series Models.

MY2002 MODELS

The Vehicle Identification Numbering System (VIN) is based on the uniform Car Model Designation

System. The reason for this is to identify the vehicle in one coded series of Characters.

The significance of these characters or blocks of characters are explained below, using an example

identification number 6H8 V2 X 37 F 2 L 123456.

MODEL DESIGNATION

WMI Code

Model Series Code

Degree of Luxury

BODY STYLE CODE

ENGINE CODE

MODEL YEAR CODE

ASSEMBLY PLANT CODE

SERIAL SEQUENCE NUMBER

6H8 V2 X 37 F 2 L 123456

MODEL DESIGNATION

WMI Code – 6H8 – World manufacturer’s identifier allocated to Holden

Model Series Code - V2 = V2 Series

Degree of Luxury - K – CV6

- X – CV8

Body Style Code - 37 – Coupe

ENGINE CODE

Engine Identification Code (R – signifies Supercharged 3.8 engine, F – signifies 5.7 engine)

MODEL YEAR CODE

2 – Identifies Model Year 2 = 2002

This number relates to GM Internal Operation Only.

ASSEMBLY PLANT CODE

Australian Assembly Plant Identification Code:-

L – Adelaide (Elizabeth)

SERIAL (Sequence ) NUMBER

Figure 0A-9

Techline

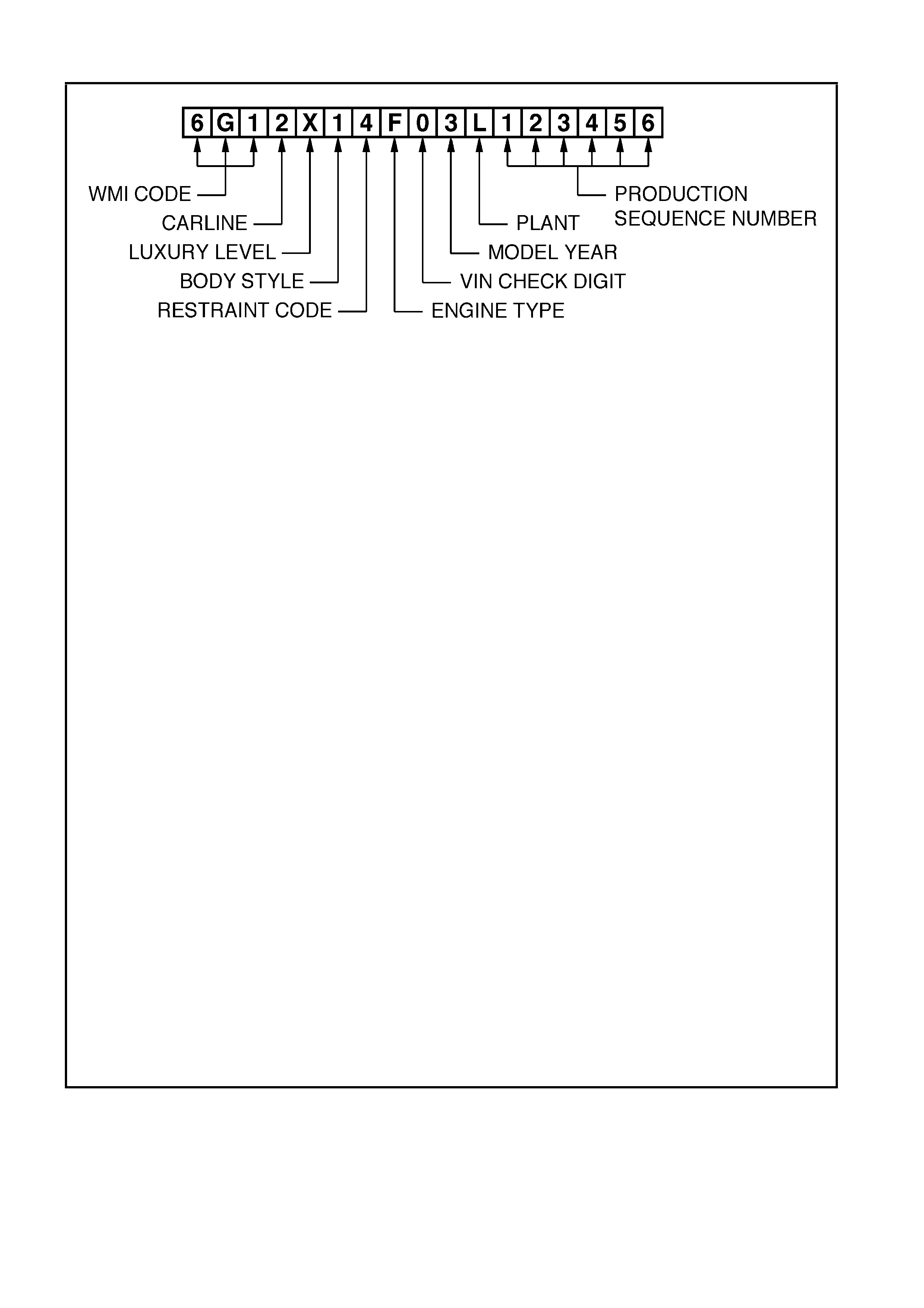

MY2003 UPDATE MODELS

WMI CODE: 6 – Oceania

G – Australia

1 – Holden

CARLINE: 2 – V2 Series

LUXURY LEVEL: K – CV6

X – CV8

BODY STYLE: 1 – 2 door coupe (37)

RESTRAINT CODE: 1 – Active (manual) seat belts

2 – Active (manual) seat belts with driver & passenger inflatable restraint

system – frontal

3 – Active (manual) seat belts with driver inflatable restraint system – frontal

4 – Active (manual) seat belts with driver & passenger inflatable restraint

system – frontal and side

ENGINE TYPE: R – 3.8 litre V6 Supercharged engine

F – 5.7 litre GEN III V8 engine

VIN CHECK DIGIT: Calculated check digit

MODEL YEAR: 3 – 2003

PLANT: L – Adelaide (Elizabeth) South Australia

PRODUCTION SEQUENCE NUMBER:

123456 – Sequential Production Serial Number

NOTE: The pr oduc tion s equence number is s equentially allocated to each vehicle,

regardless of vehicle type.

Figure 0A-10

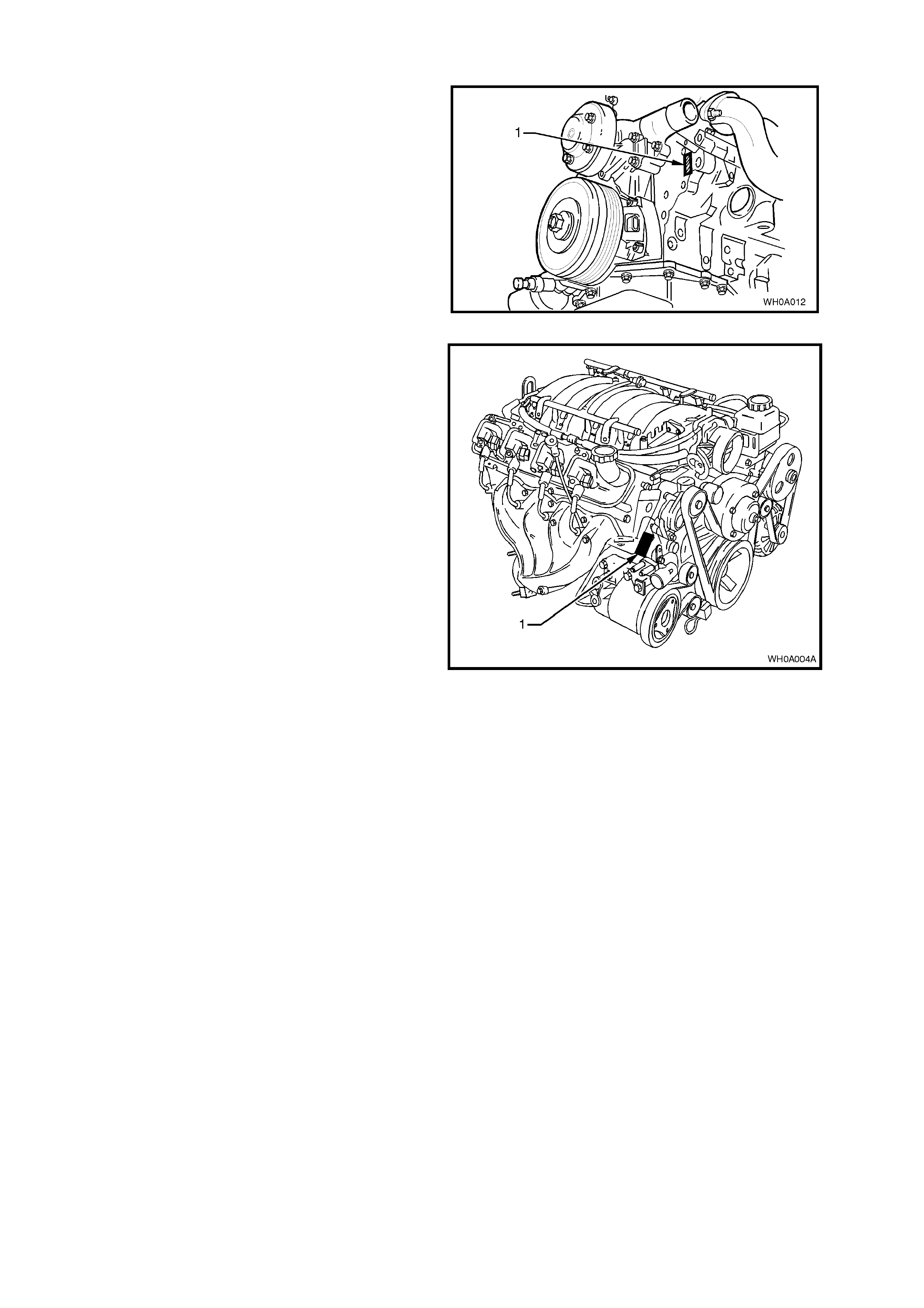

8.7 ENGINE SERIAL NUMBER

The engine num ber (1) f or the 3.8 V6 Superchaged

engine is stamped on the front face of the engine,

below the ignition coil as illustrated in Figure 0A-11.

Figure 0A-11

The 5.7 litre GEN III V8 engine number (1) is

stamped on a pad located adjacent to the engine

coolant outlet pipe, refer to Figure 0A-12.

Figure 0A-12

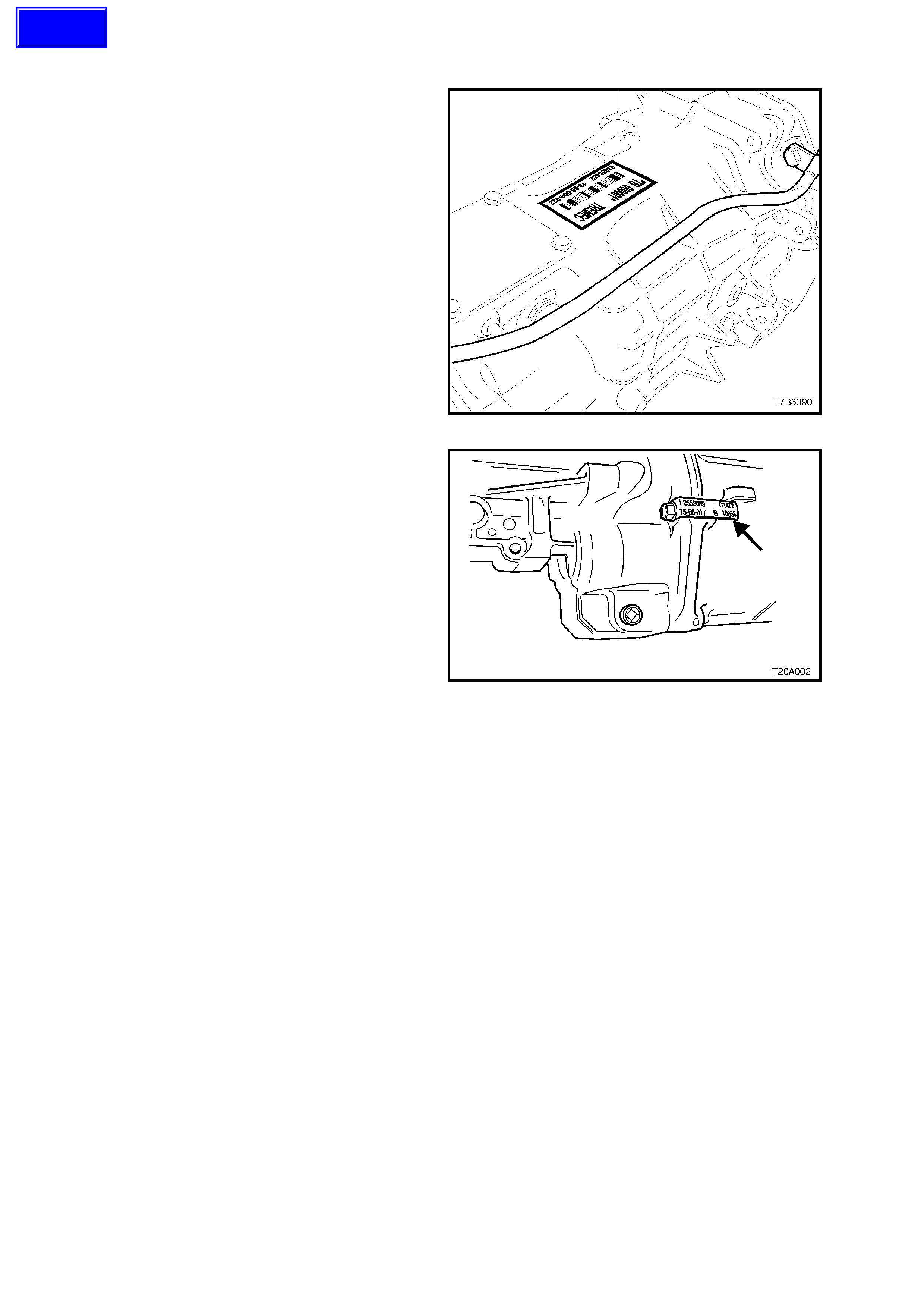

8.8 MANUAL TRANSMISSION SERIAL NUMBER

The Borg-Warner (Tremec) T56 6-speed manual

transmission serial number is located on a self-

adhesive decal attached to the top of the

transmission case refer to Figure 0A-13.

This number provides coded information which

could be significant to parts interpretation and

should be referred to when ordering replacement

parts.

Figure 0A-13

In addition, an identification tag is attached to the

transmission under an extension housing bolt, on

the right-hand side, refer to Figure 0A-14.

Figure 0A-14

Techline

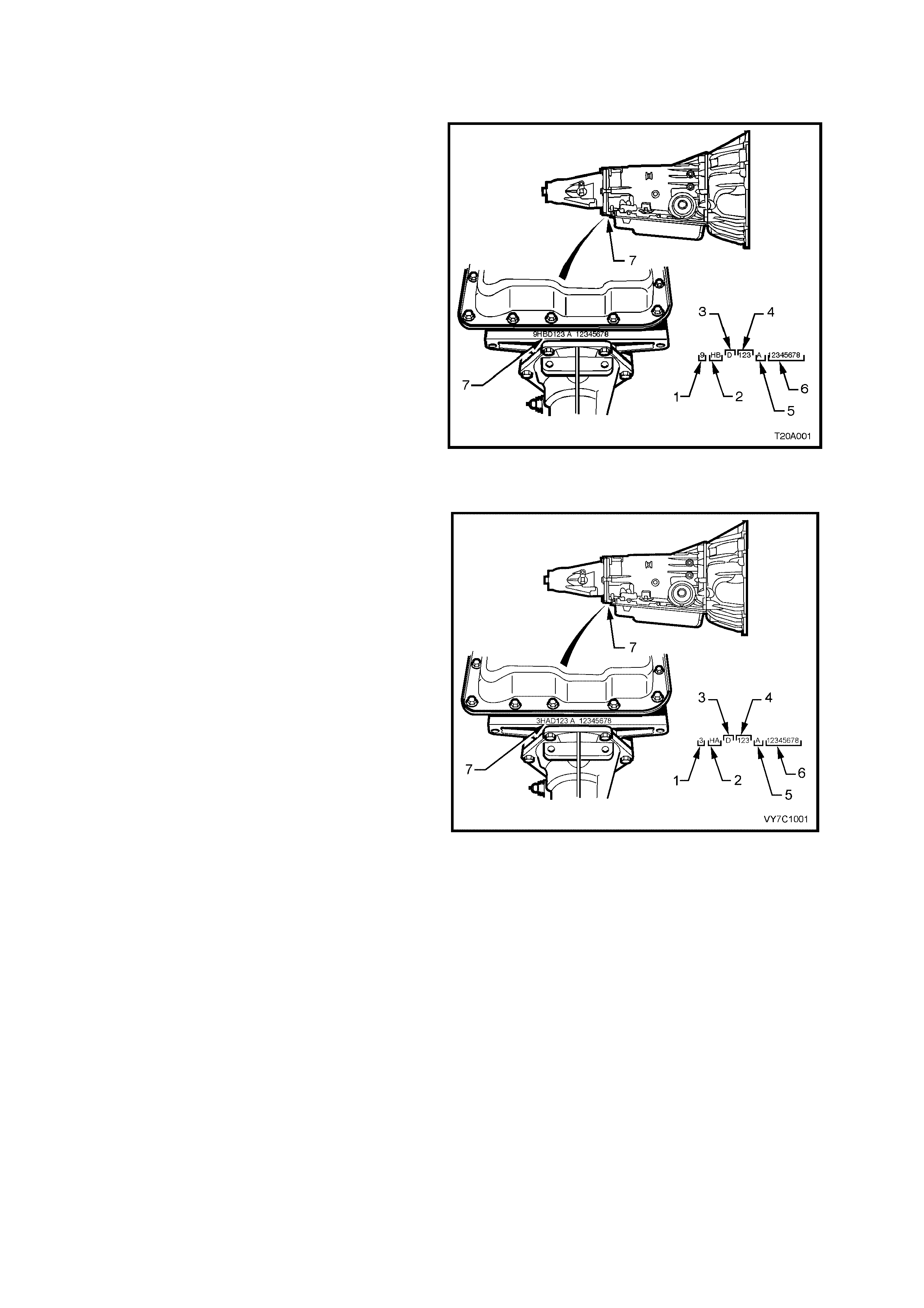

8.9 AUTOMATIC TRANSMIS S ION SERIAL NUMBER

MY2002 MODELS

The MY2002 4L60-E automatic transmission

application and identification can be determined

from the stamping in the rear of the transmission

case at the rear, in the location shown (7), refer to

Figure 0A-15.

Legend

1. Model Year (2 = 2002)

2. Model: V8 – 5.7 GEN III V8 HP

V6 – Supercharged 3.8 HN

3. Transmission Model Identifier (D = 4L60-E)

4. Julian Date (Day of the year)

5. Shift Built (A, B, J = First Shift;

C, H, W = Second Shift)

6. Individual Transmission Serial Number

7. Transmission Identification Number Location

Figure 0A-15

MY2003 UPDATE MODELS

The MY2003 4L60-E automatic transmission

application and identification can be determined

from the stamping in the rear of the transmission

case at the rear, in the location shown (7), refer to

Figure 0A-16.

Legend

1. Model Year (3 = 2003)

2. Model: V8 – 5.7 GEN III V8 HA

V6 – Supercharged 3.8 HN

3. Transmission Model Identifier (D = 4L60-E)

4. Julian Date (Day of the Year)

5. Shift Build (A, B, J = First Shift;

C, H, W = Second Shift

6. Individual Transmission Serial Number

7. Transmission Identification Number Location

Figure 0A-16

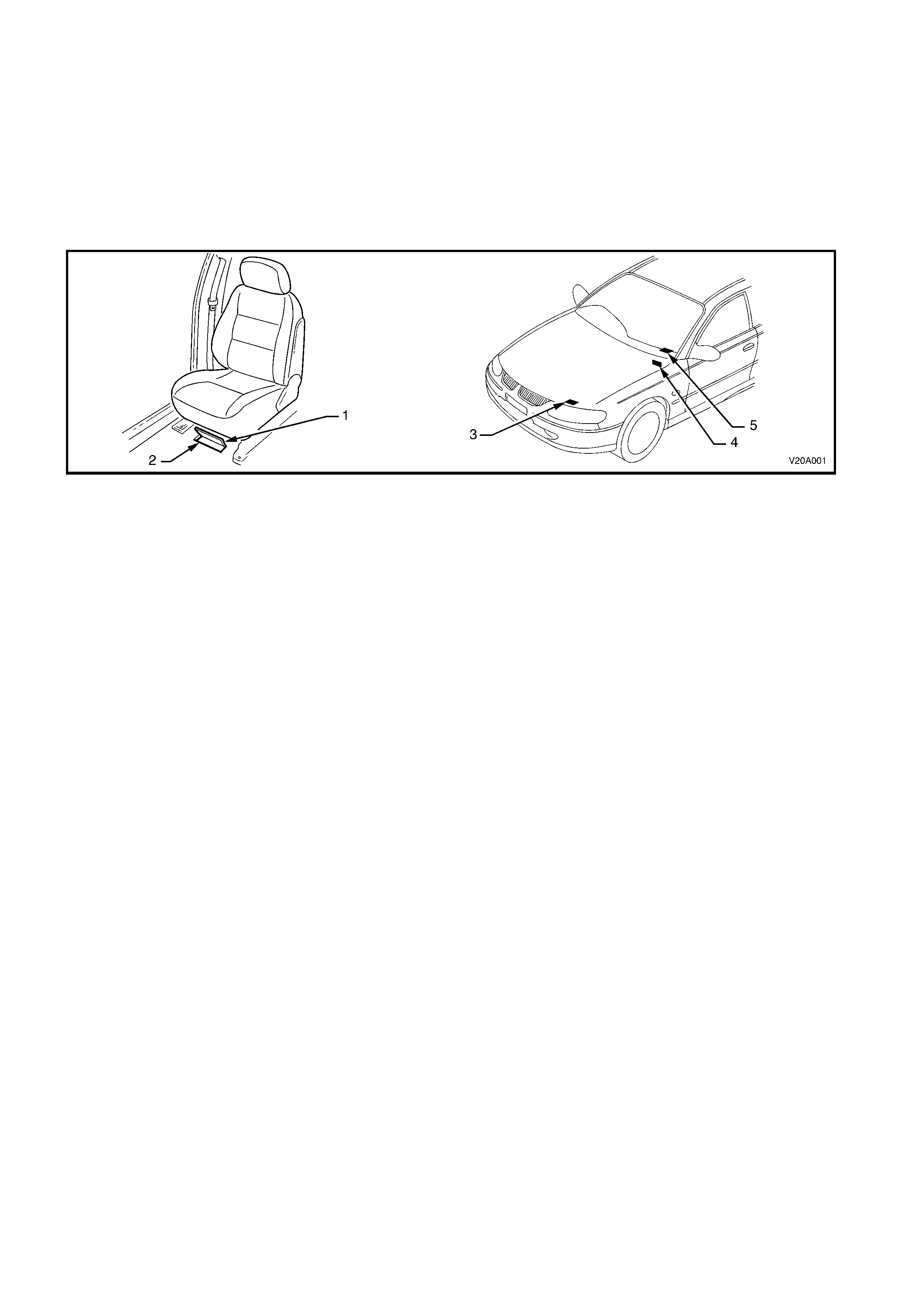

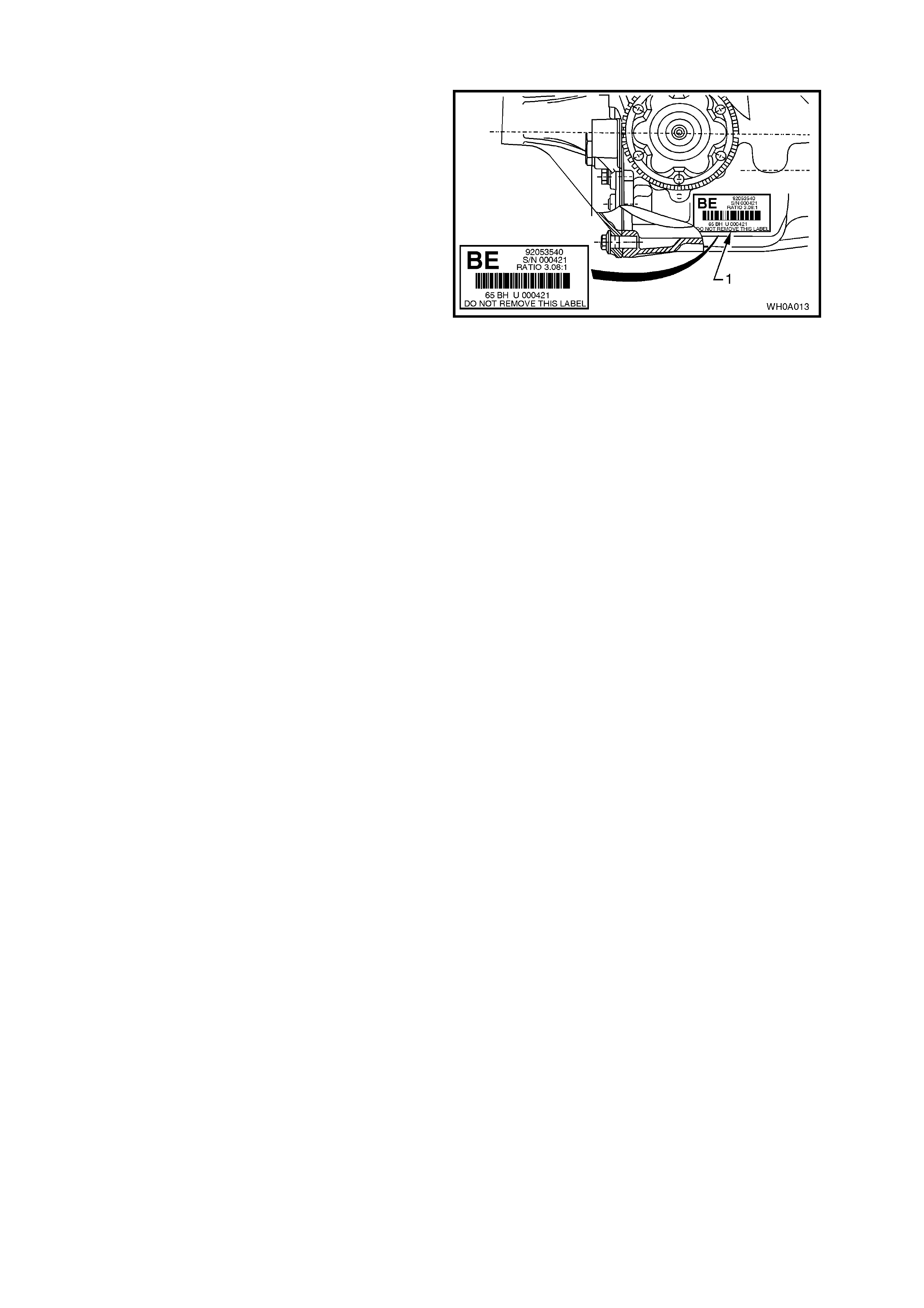

8.10 FINAL DRIVE IDENTIFICATION

An identif ication tag (1) is adhered to the final drive

assembly to the right-hand side of the carrier

housing, refer to Figure 0A-17.

The tag c arries the Holden par t num ber for the final

drive assembly, the final drive ratio and the serial

number of the assembly.

Figure 0A-17

9. ADDI TIONAL GENERAL I NFORMATION

9.1 ELE CTRICAL TRANS I ENTS AND RADIO FREQUENCY INTERFERENCE

Electronic circuits are used in V2 Series Models to perform a number of functions associated with electronic

cruise control, electronic engine and transmission control systems etc. These circuits can be damaged or

malfunction as a result of electrical transients or excessive radio frequency (RF) radiation.

ELECTRICAL TRANSIENTS

Electrical transients are high voltage spikes, produced by the sudden switching or interruption of electric

currents. Older style timing lights and battery chargers can produce serious transients, hence, it is

important to use only good quality equipment suitable for use with electronic systems.

It is also good practice to ensure that the battery is disconnected before using a battery charger.

Indiscriminate fitting of solenoids, indicators or relays can also cause transients.

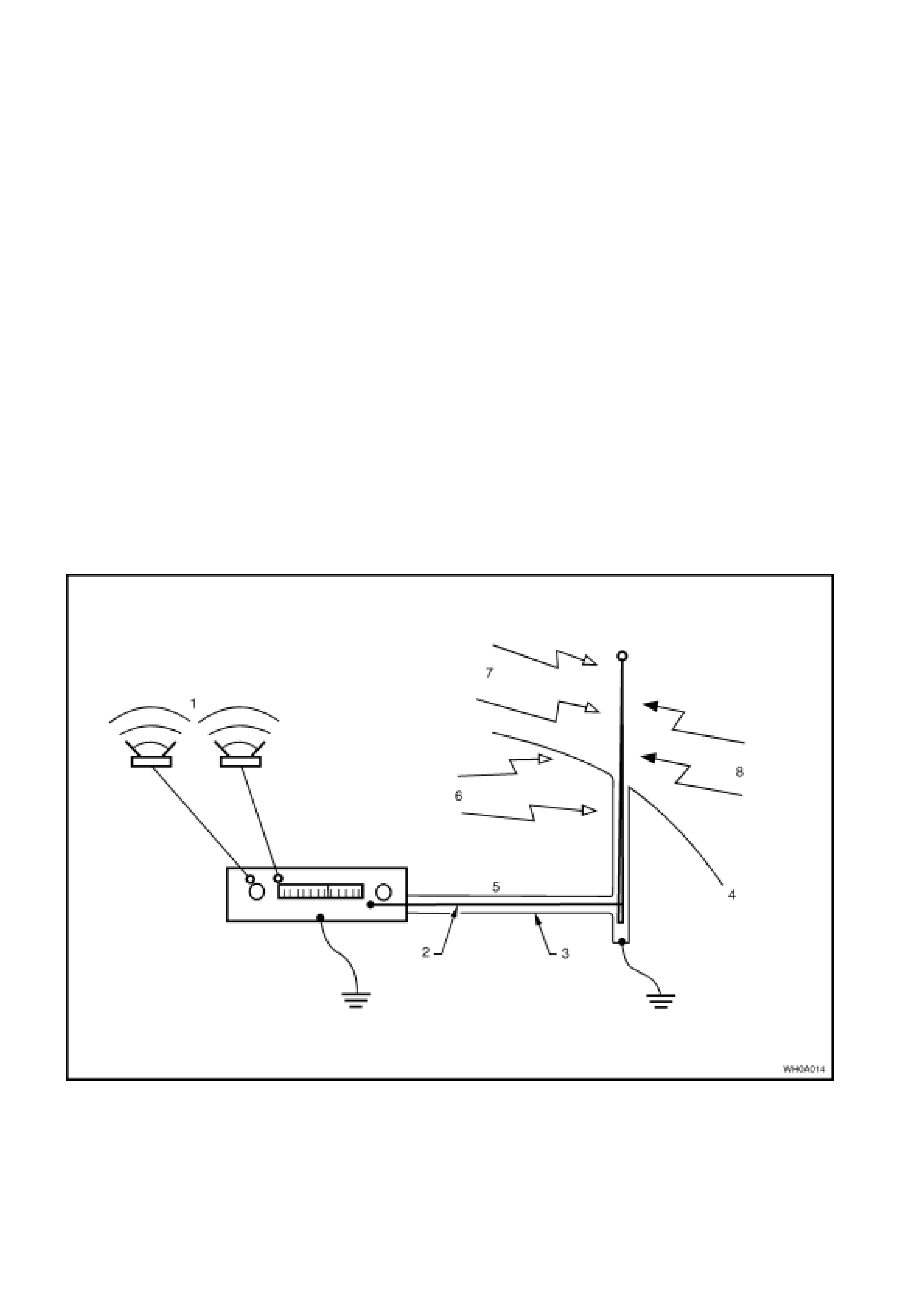

RADIO FREQUENCY INTERFERENCE

One of the chief sources of RF interference is the ignition system. Other sources include CB radio and

radio telephones. The following are normally used to suppress RF interference.

Resistors eg. High Tension Cables and Connectors.

Capacitors and Choke Coils.

Metal Braid for screening leads or suppression covers made from conductive material for screening

equipment.

To prevent damage to equipment:

Do not replace interference suppressed high tension ignition cables or connectors with unsuppressed

types.

Do not remove or reposition interference suppression filters or capacitors.

Figure 0A-18

Legend

1. Music

2. Core

3. Braid

4. Body

5. Antenna cable

6. Internal Interference

7. Signal from station

8. External interference

9.2 STATIC ELECTRICITY

Care should be exer c ised when handling electronic equipment e.g. the powertrain control module (PCM), to

avoid touching the terminals unnecessarily. Static electricity, which is present on every person, can cause

damage to some electronic components.

9.3 PUSH OR TOW STARTING

Do not push or tow start V2 Series vehicles. Push or tow starting can result in unburned fuel passing

through the exhaust to the catalytic converter, causing damage to the converter.

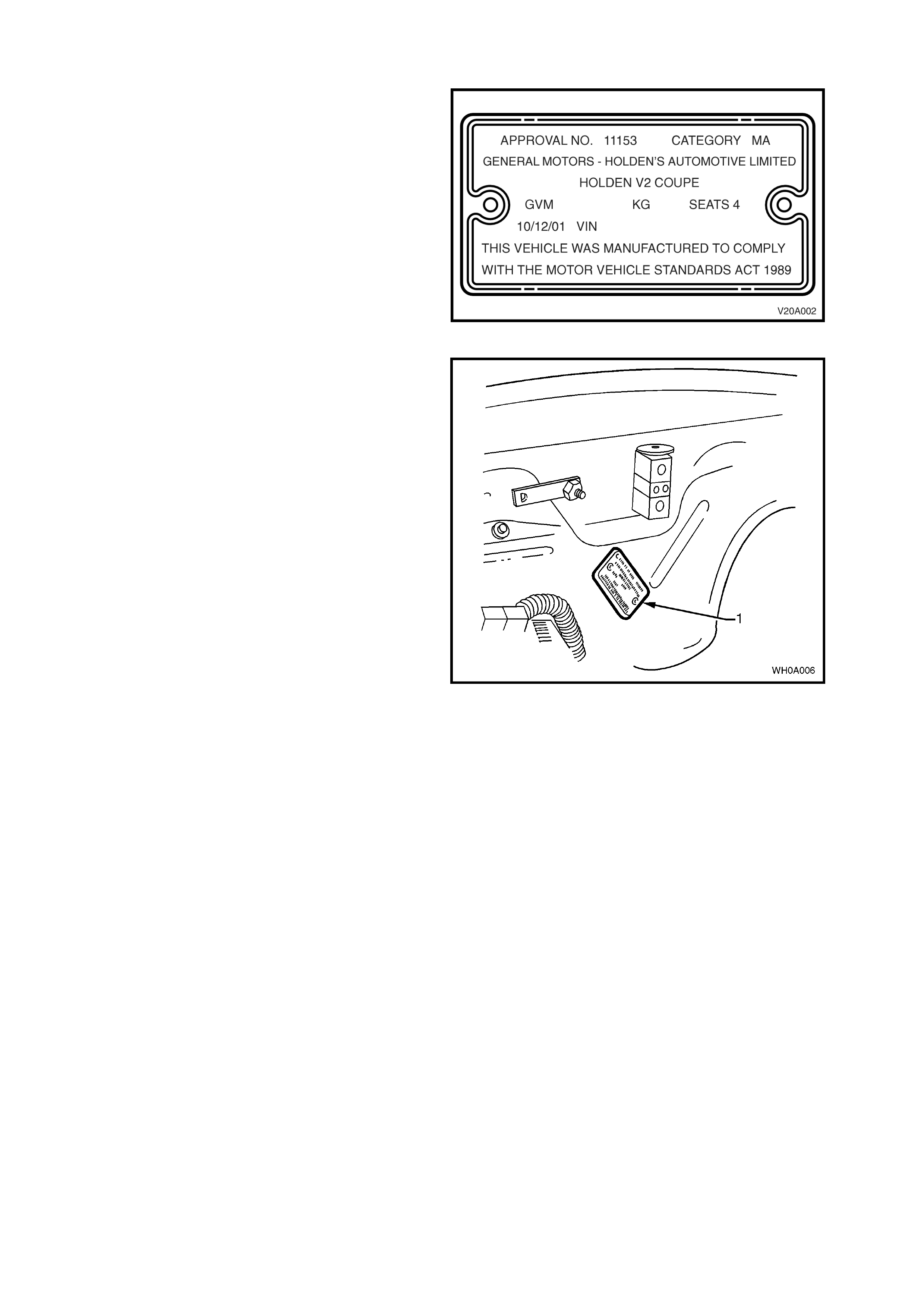

10. CONSOLIDATED TOOL LIST

MY2002 MODELS

Special tools f or V2 Series Models car ry over from VT Series II Models . For information concer ning Special

Tools refer to Section 0A in the VT Series II Service Information.

MY2003 UPDATE MODELS

Apart from the tools listed below, the special tools for MY2003 V2 Series Update Models carry over from VT

Series II Models. For information concerning Special T ools refer to Section 0A in the VT Series II Service

Information.

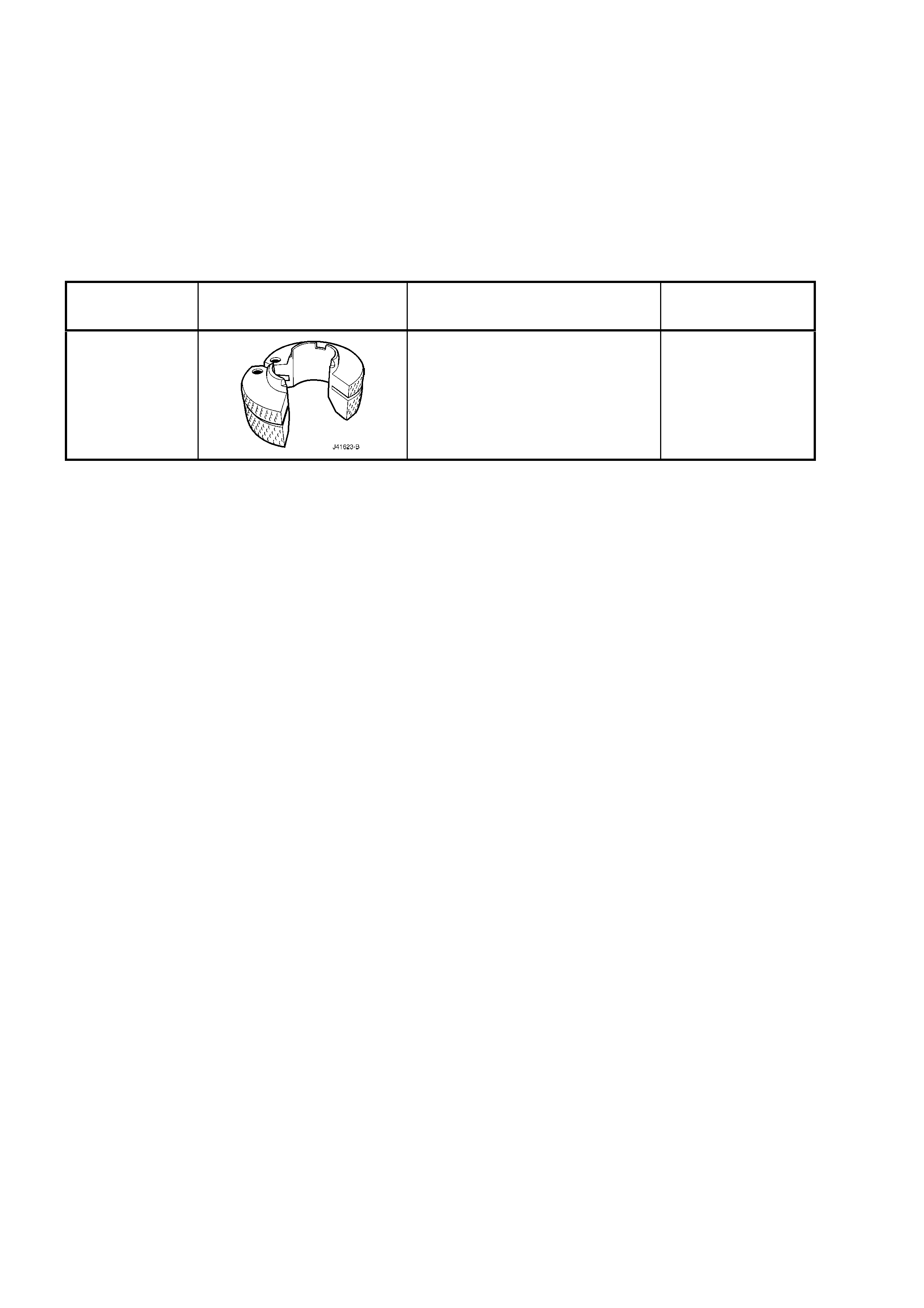

TOOL

NUMBER ILLUSTRATION DESCRIPTION CLASSIFICATION

J41623-B

COOLER PIPE QUICK-

CONNECT

RELEASE TOOL

New release.

Mandatory