SECTION 12B - LIGHTING SYSTEM

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

1. GENERAL I NFORMATI O N

The front lamp assem blies fitted to V2 Series Models are a resytled version of the assembly as fitted to VT Series

Models. The front lamp assembly in V2 Series Models incorporates projector type low beam, a reflector type high

beam, front turn signal lamp and park lamp in one unit.

The pr ojec tor type headlamp fitted to V2 Series Models c ontain long lif e quar tz halogen bulbs and a clear outer lens

with complex reflector optics on high beam. The front turn signal lamp has also been revised to compliment the

headlamp styling.

The side repeater lamps fitted to V2 Series Models carry over from VT Series II Models and include a clear lens

with amber bulb. F or inf or mation relating to the bulb r eplacement, r emoval and reinst allation proc edur es f or the side

repeater lamps, refer to 2.11 SIDE REPEATER LAMPS in Section 12B LIGHTING SYSTEM of the VT Series I

Service Information

The door courtesy, footwell, glovebox, console, instrument panel and load compartment lamps as fitted to V2 Series

Models carr y over from VT Ser ies I Models . For inf or mation relating to the door cour tes y, footwell, glovebox, cons ol,

instrument panel and load compartment lamps, refer to Section 12B LIGHTING SYSTEM in the VT Series I

Service Information.

The lic ence plate lam p fitted to V2 Series Models c arry over from VX Series Executive, Acc laim, S and SS Models.

For information relating to the licence plate lamps, refer to 2.12 LICENCE PLATE LAMP/BULB — EXECUTIVE

AND ACCLAIM SEDAN, S AND SS MODELS in Section 12B LIGHTING SYSTEM of the VX Series Service

Information.

The rear lam p as sem blies f or the V2 Series Models ar e a r evised vers ion of the r ear lam p ass em bly as fitted to VX

Series Executive, Acclaim, S and SS Models. They comprise a turn signal lamp, stop and tail lamp and back-up

lamp in one unit.

The c entre high m ount stop lam p on V2 Ser ies Models is an LED type lamp assem bly and is mounted on top of the

rear parcel shelf panel at the lower edge of the rear windscreen. The centre high mount stop lamp assembly is

unique to V2 Series Models.

Unique style front fog lam ps are fitted as standard equipm ent on V2 Series Models and are mounted into the front

bumper facia assembly.

The steering column mounted headlamp and turn signal switch fitted to V2 Series Models carries over

from VX Series II Models. For information relating to the headlamp and turn signal switch, refer to

Section 12B LIGHTING SYSTEM in the VX Series II Service Information.

All the remaining lamp control switches fitted to V2 Series Models carries over from VT Series I Models. For

information relating to the lamp control switches, refer to Section 12B LIGHTING SYSTEM in the VT Series I

Service Information.

Techline

Techline

Techline

Techline

2. SERVICE OPERATIONS

2.1 AIMING OF HEADLAMPS AND FOG LAMP S

CAUTION: During headlamp aiming procedures, do not use a cloth or similar material to cover the lens of

the headlamp assembly not being adjusted. Damage to the headlamp assembly will result if the headlamp

beam is obstructed in this manner.

The headlamps and fog lamps must be correctly aimed in order to optimise the road illumination and safety features

built into the vehicle lighting system. The headlam ps /f og lamps must be c hec k ed for cor re ct aim whenever a bulb or

headlamp/fog lamp assembly is replaced as well as after any adjustments or repairs to the front end sheet metal.

Headlamp aiming machines are in general use. When using one of these machines, ensure that it is in good

condition and carefully follow the instructions of the manufacturer.

Regardless of the method us ed f or chec king headlam p and f og lamp aim, the vehicle m us t be at kerb weight, i.e full

fuel level, oil, water and spare tyre but no passengers. The tyres must be uniformly inflated to their specified

pressure.

NOTE: If the vehic le will regular ly carr y an unusual load in the rear c ompartment or tow a trailer , these loads s hould

be on the vehicle when the headlamps/fog lamps are checked.

HEADLAMP AIM

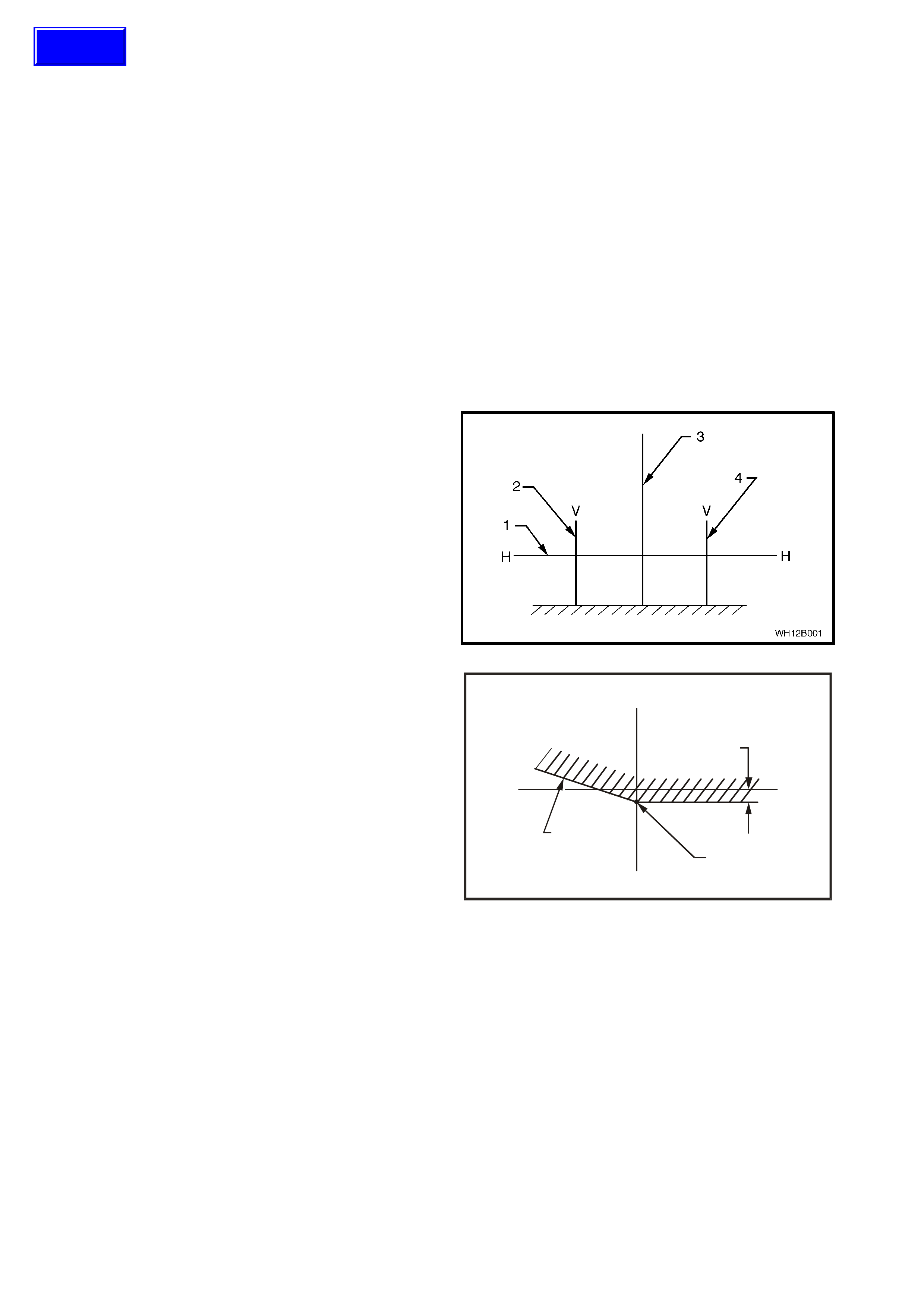

1. If suitable test equipm ent is not available, s et up a

screen or use a vertical wall, in conjunction with a

flat hor izontal f loor. Par k the vehicle imm ediately in

front of the screen and mark horizontal (1) and

vertical centre lines of the left (2) and right (4)

headlamps (corresponding to the c entre of the low

beam bulb) and the vehicle centre line (3) on the

screen or wall.

2. Park the vehicle 10 metres in f r ont of the s cr een or

wall ensuring that the vehicle is aligned with the

vehicle centre line mark on the screen.

Figure 12B-1

3. Individually aim each headlamp to a point ( 1) on its

vertical centre line, 110 mm below the headlamp

horizontal centre line. Item (2) is the cut-off line.

WH12B002

V

HH

V

110 mm

2

1

Figure 12B-2

Techline

a. Adjust the inboard adjuster (1) to achieve the

correct beam height up and down the vertical

centre line.

b. Adjust the outboard adjuster (2) to centralise

the beam along the horizontal centre line.

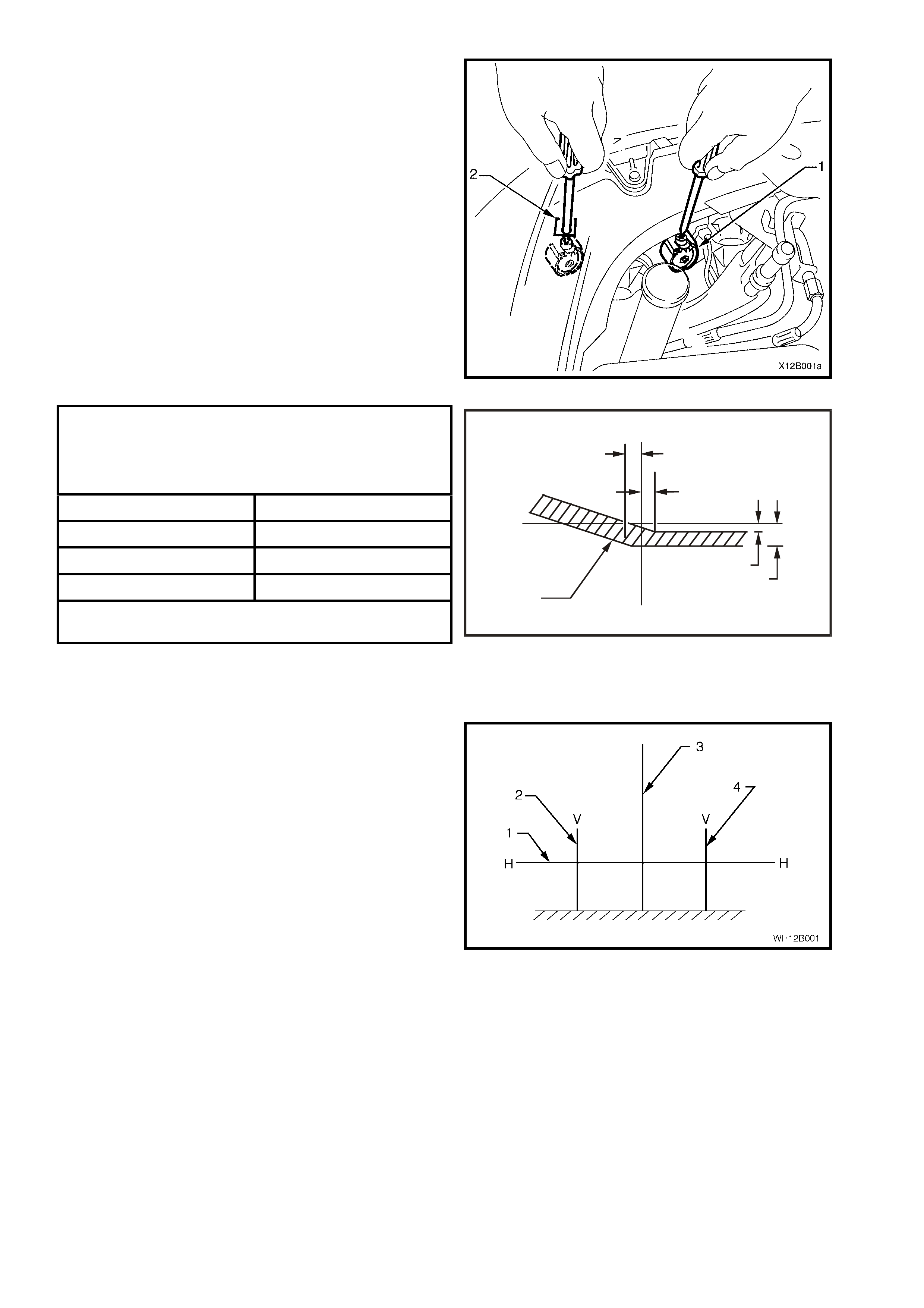

4. T he allowable variations on headlam p aim ing point

settings shown in Fig. 12B-1 are specified in the

chart below:

Figure 12B-3

HEADLAMP AIMING

Acceptable Variations In Headlamp Aiming Points

(Refer to Fig 12B-4)

HL 100 mm

HR 0 mm

V1 100 mm

V2 120 mm

Maximum allowable vertical variation between any pair

of headlamps is not to exceed 20 mm

NOTE: Cut-off line (1) must be within the lower

outboard zone, refer to Fig. 12B-4.

WH12B004

V

H

H

V

1V2

V1

HL

HR

Figure 12B-4

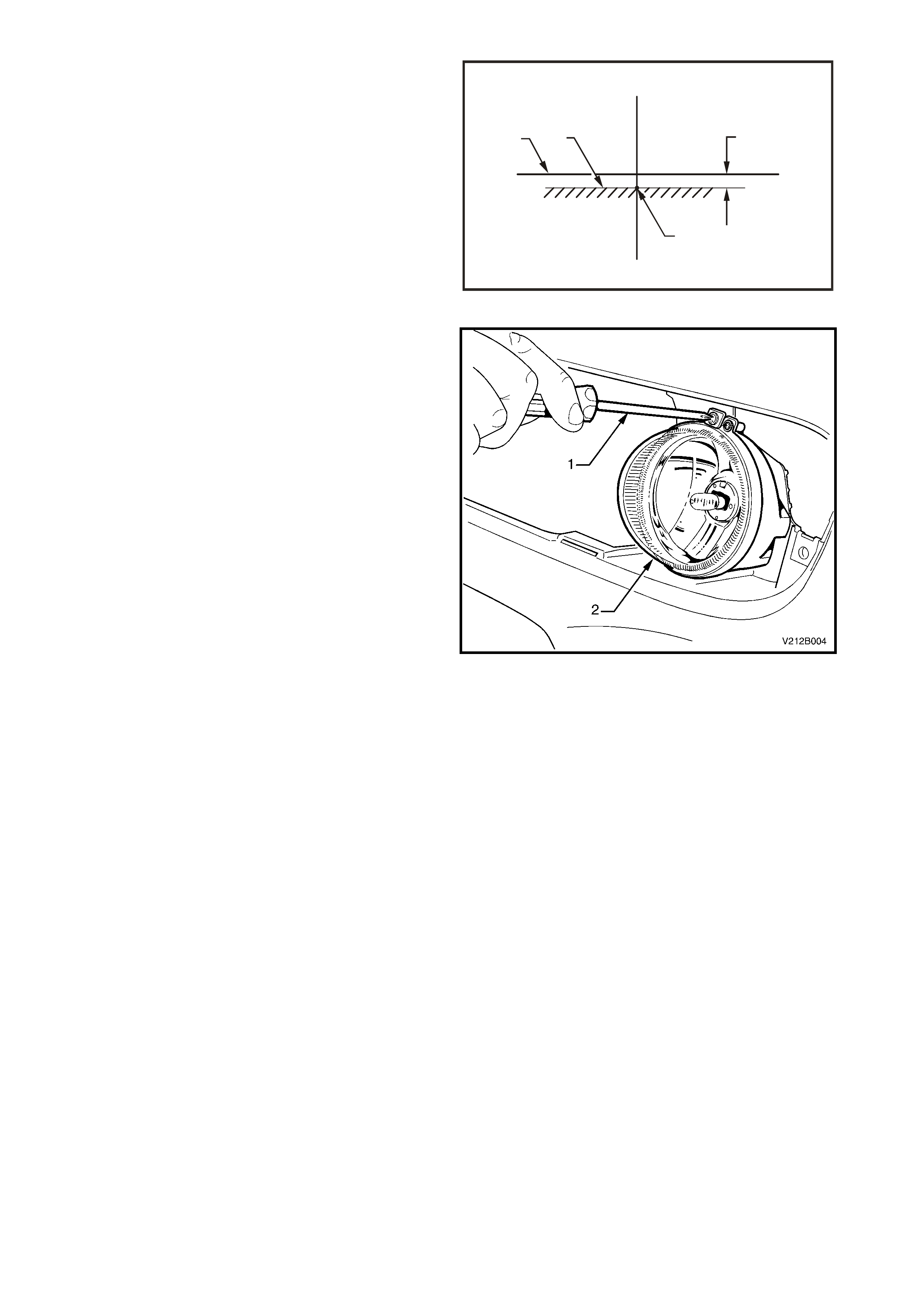

FOG L AMP AIM

1. If suitable test equipm ent is not available, s et up a

screen or use a vertical wall, in conjunction with a

flat hor izontal f loor. Par k the vehicle imm ediately in

front of the screen and mark horizontal (1) and

vertical centre lines of the left (2) and right (4) fog

lamps, and the vehicle centre line (3) on the

screen.

2. Park the vehicle 10 metres in front of the screen,

ensuring that the vehicle is aligned with the centre

line mark on the screen.

Figure 12B-5

3. Remove the lower air intake grille from the front

facia assembly, refer to Section 1D BUMPER

BARS, in this Service Information.

4. Turn the fog lamps on. Individually aim each fog

lamp to a central point on its vertical centre line

(2), with the cut off line (3) 200 mm below the fog

lamp horizontal centre line (1).

WH12B005

20 0 mm

2

3

1

V

HH

V

Figure 12B-6

a. Fog lamp aim adjustment is carried out by

rotating the adjuster screw (1) located above

the lamp housing (2).

b. Turning the adjuster screw counter-clockwise

lowers the beam.

c. Turning the adjuster screw clockwise raises

the beam.

d. The adjustment can be carried out by using a

No. 2 Phillips head screw driver.

NOTE: There is no pr ovis ion f or adjus ting the f og lamp

beam along the horizontal centre line. Fog lamps are

fixed to a vertical centre line.

Figure 12B-7

2.2 HEADLAMP AND TURN SIGNAL/PARK LAMP ASSEMBLY

REMOVE

1. Open the engine compartment.

2. Disconnect the battery earth lead.

3. For RH side headlamp and turn signal/park lamp

assembly only, disconnect the battery positive

lead, remove the battery retaining clamp and

remove the battery from the engine compartment.

4. Remove the front bumber facia, refer to

Section 1D BUMPER BARS in this Service

Information.

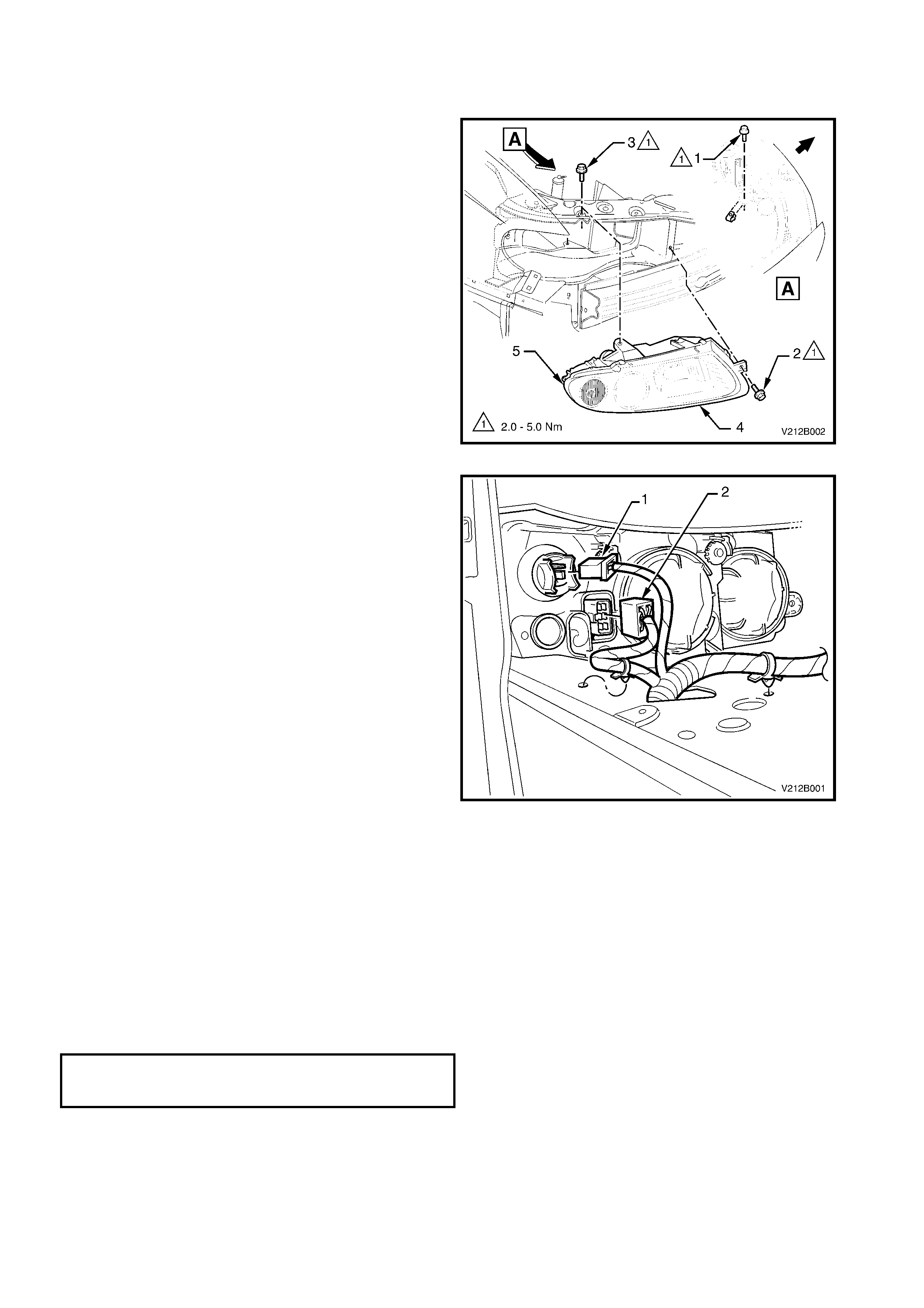

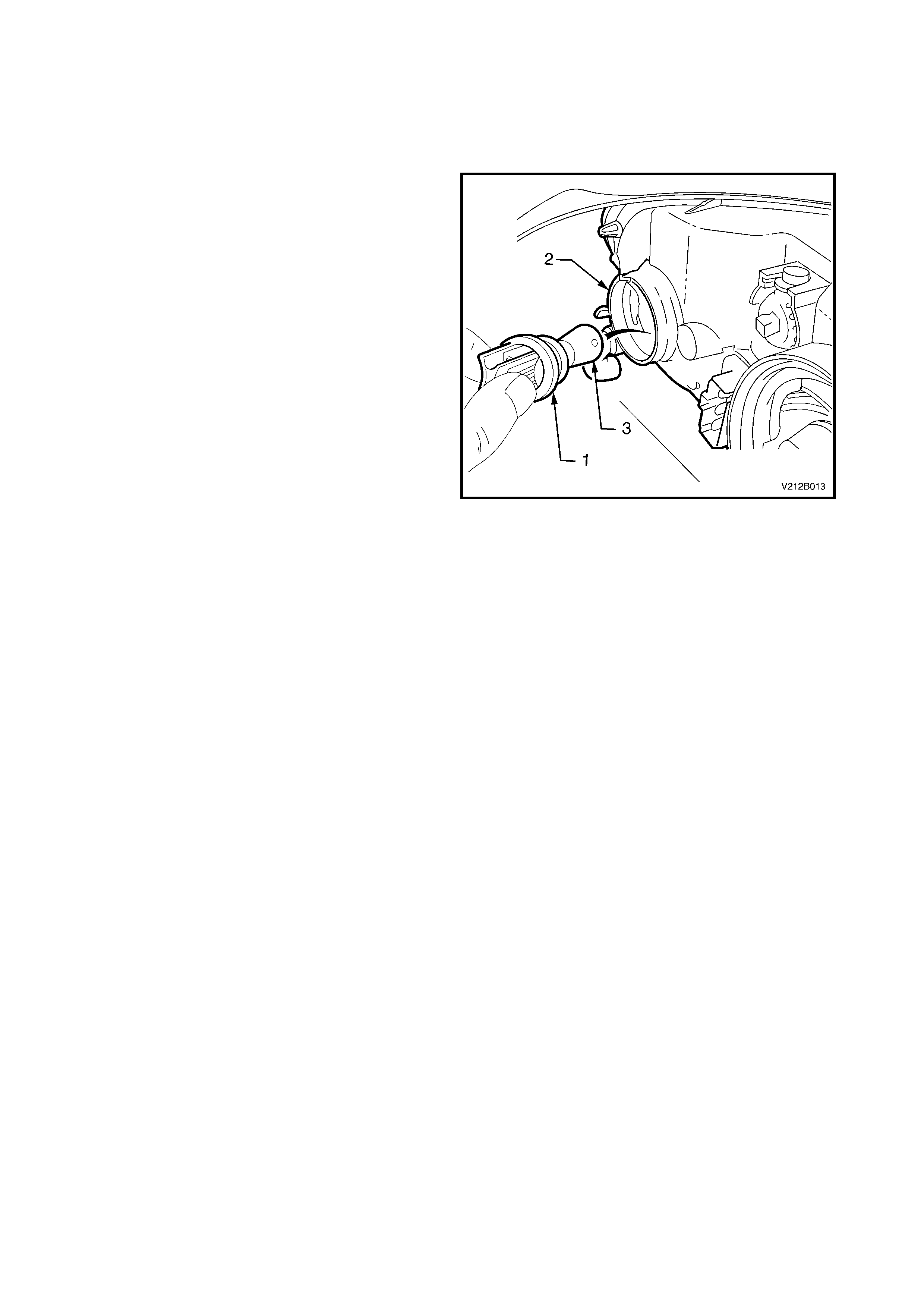

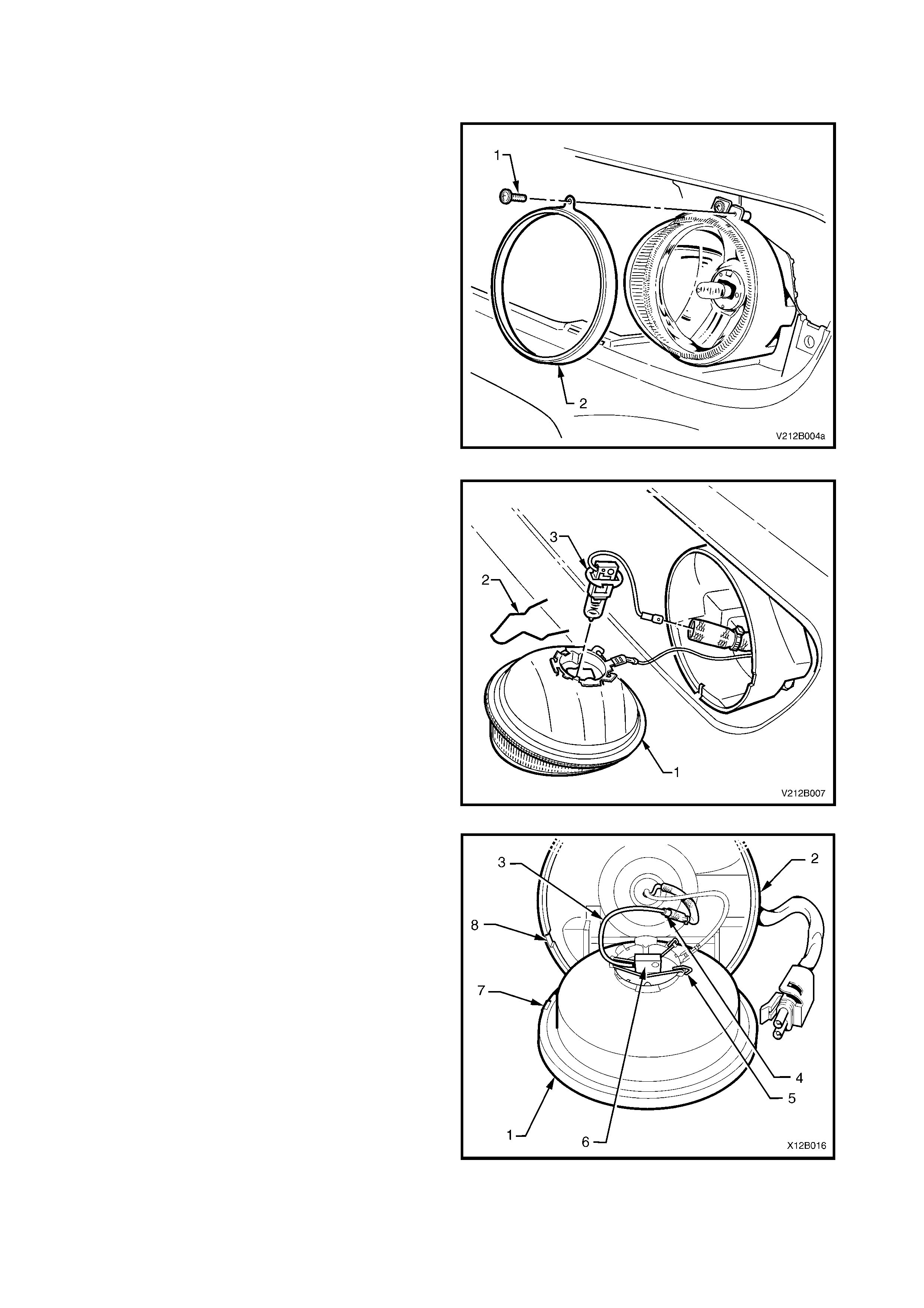

5. Remove the lower retaining screw (1).

6. Remove the centre retaining screw (2).

7. Remove the upper retaining screw (3).

Figure 12B-8

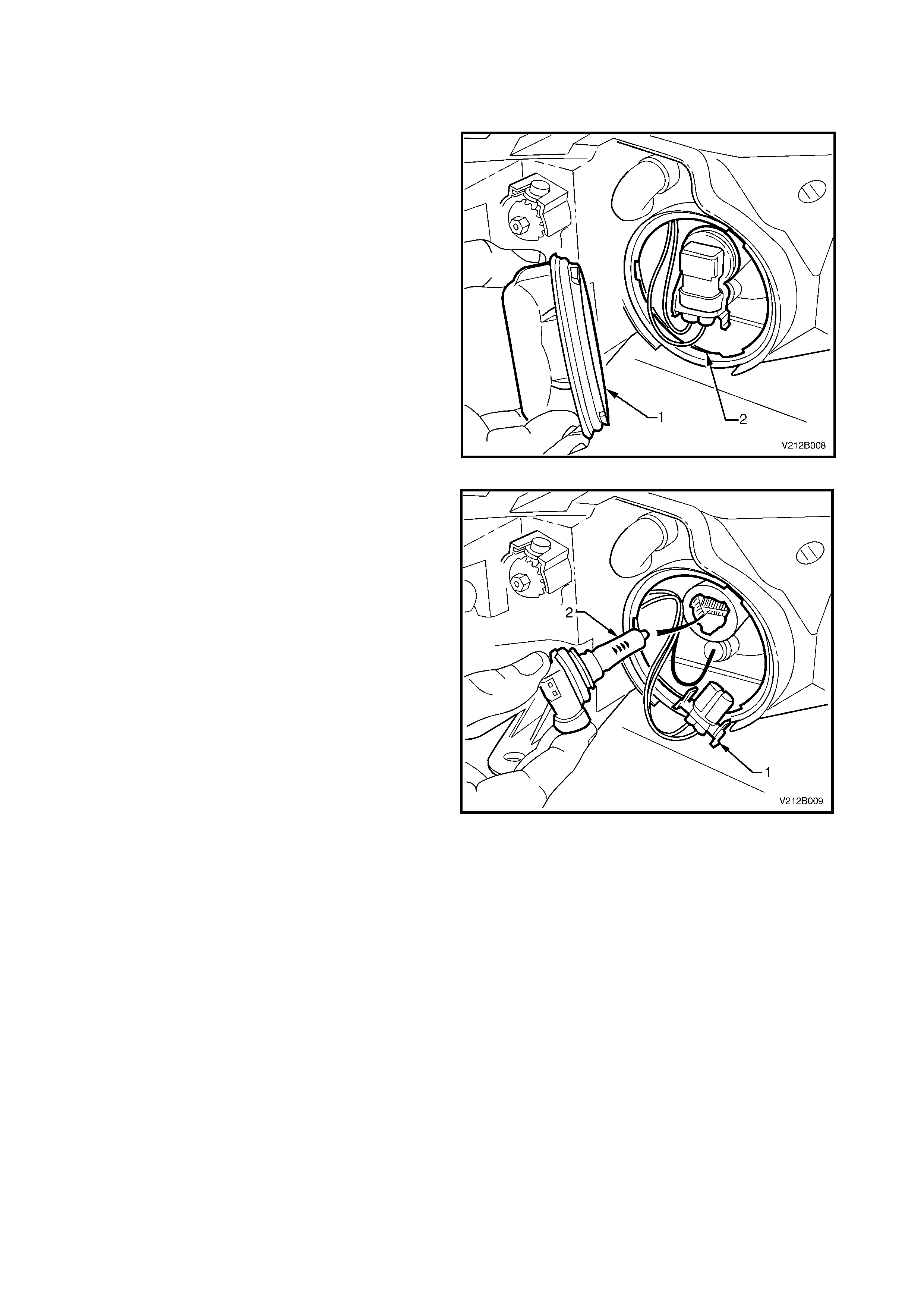

8. Partially remove the headlamp and turn signal/park

lamp assembly until the two harness connectors

are accessible.

9. Disconnect the turn signal wiring harness

connector (1) from the turn lamp.

10. Squeeze the smaller ends of the headlamp wiring

harness connector (2) together and pull rearwards

to disconnect from the headlamp.

11. Remove the headlamp and turn signal/park lamp

assembly (4), taking care not to damage the

rubber seal (5), refer to Fig. 12B-8.

Figure 12B-9

REINSTALL

The installation procedure for the headlamp and turn

signal/park lamp is the reverse of the removal

procedure noting the following:

• The rubber seal around the headlamp and turn

signal/park lamp assembly should be correctly

located.

• The headlamp and turn signal/park lamp retaining

screws should be installed and tightened to the

correct torque setting in the reverse sequence to

the removal procedure.

HEADLAMP AND TURN SIGNAL/PARK

LAMP TO BODY ATTACHING SCREWS

TORQUE SPECIFICATION 2 – 5 Nm

• Check the headlamp and turn signal/park lamp

assembly operation following installation.

• When the headlamp and turn signal/park lamp

assembly has been removed/replaced, the

headlamp aim should be checked and adjusted if

necessary.

2.3 HIGH BEAM BULB

REPLACE

1. Open the engine compartment.

2. Disconnect the battery earth lead.

3. For vehicles with GEN III V8 engine, remove the

four scrivets securing the upper radiator support

cover and remove cover.

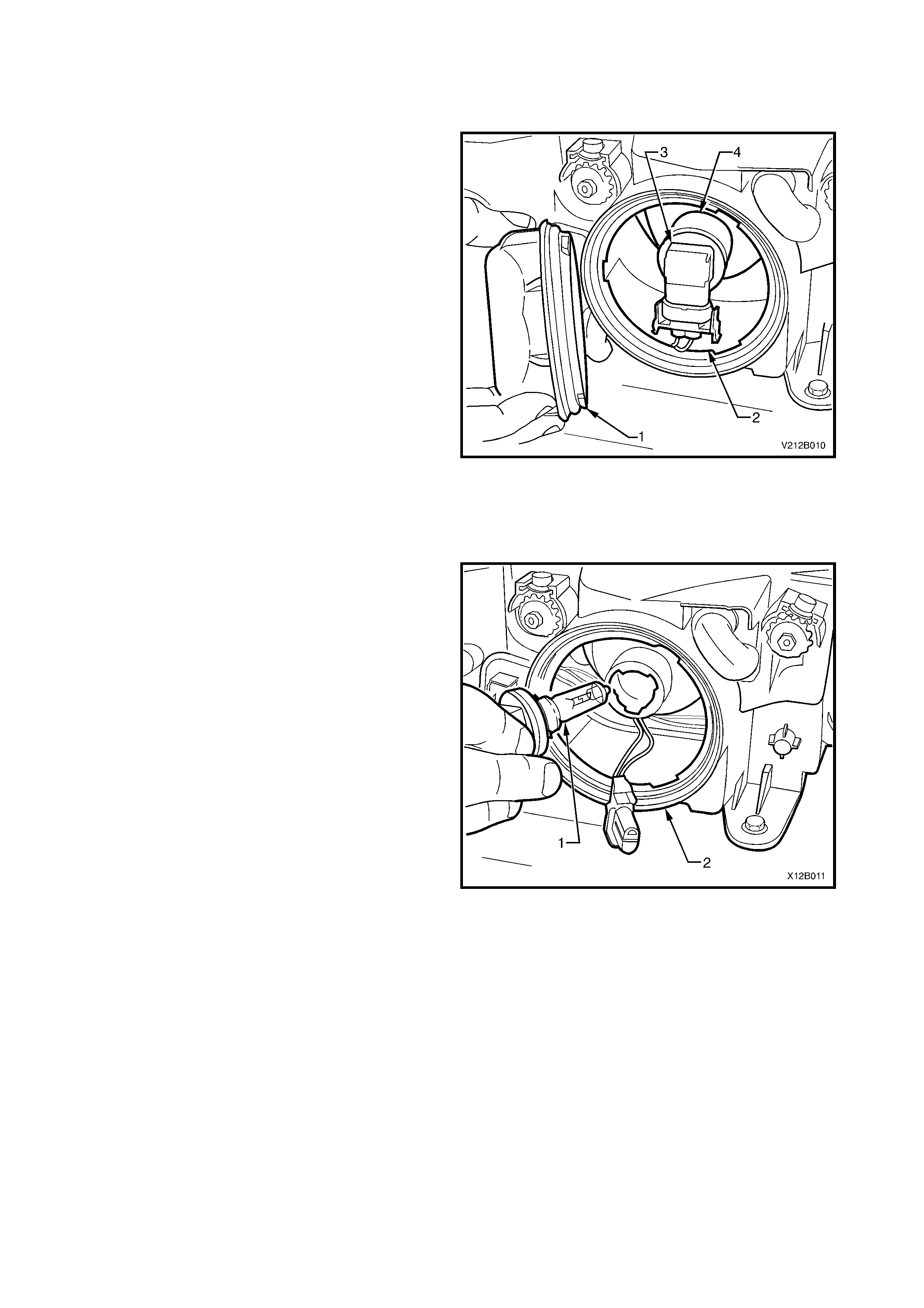

4. From inside the engine compartment, remove the

inboard high beam dust cap (1) from the rear of

the headlam p housing assembly (2) by turning the

dust cap counter-clockwise and pulling away from

housing. If the dust cap seal stays on the

headlamp housing, remove the seal and install

onto the cap.

Figure 12B-10

5. Disconnect the harness connector (1) from the

bulb and holder assembly (2).

NOTE: Do not handle the quartz envelope of the high

beam bulb. If touched accidentally, wipe immediately

with methylated spirits or bulb performance will

deteriorate.

6. Turn the bulb and holder assembly counter-

clock wise an eighth of a turn and rem ove from the

headlamp housing.

7. Install the new bulb into housing, ensuring that the

locating lugs on the bulb and holder assembly

mate with the slots on the headlam p housing, and

lock into place by turning clockwise an eighth of a

turn.

NOTE: The different sized locating tangs on the bulb

base and m ating cut-outs in the reflector allow the bulb

to seat correctly into the reflector in one location only.

This ensures correct relationship of the bulb to the

reflector.

8. Connect the bulb harness connector.

9. Inspect the rubber seal in the dust cap to ensure

that it is not damaged and that it is seated

correctly.

10. Install the dust cap onto the rear of headlamp

housing and lock into place by turning clockwise.

11. Reconnect the battery earth terminal.

12. Check the high beam lamp operation.

13. For vehicles with GEN III V8 engine, reinstall the

upper radiator s upport cover and the four retaining

scrivets.

Figure 12B-11

2.4 HEADLAMP BULB

REPLACE

1. Open the engine compartment.

2. Disconnect the battery earth lead.

3. For RH headlamp only, disconnect the battery

positive lead, remove the battery retaining clamp

and remove the battery from the engine

compartment to gain access to the headlamp dust

cap.

4. For vehicles with GEN III V8 engine, remove the

four scrivets securing the upper radiator support

cover and remove the cover.

5. For the LH headlamp in vehicles fitted with V6

Supercharged engine, remove the filler neck and

cap from the radiator overflow reservoir by

withdrawing the radiator overflow hose and pulling

the filler neck upwards.

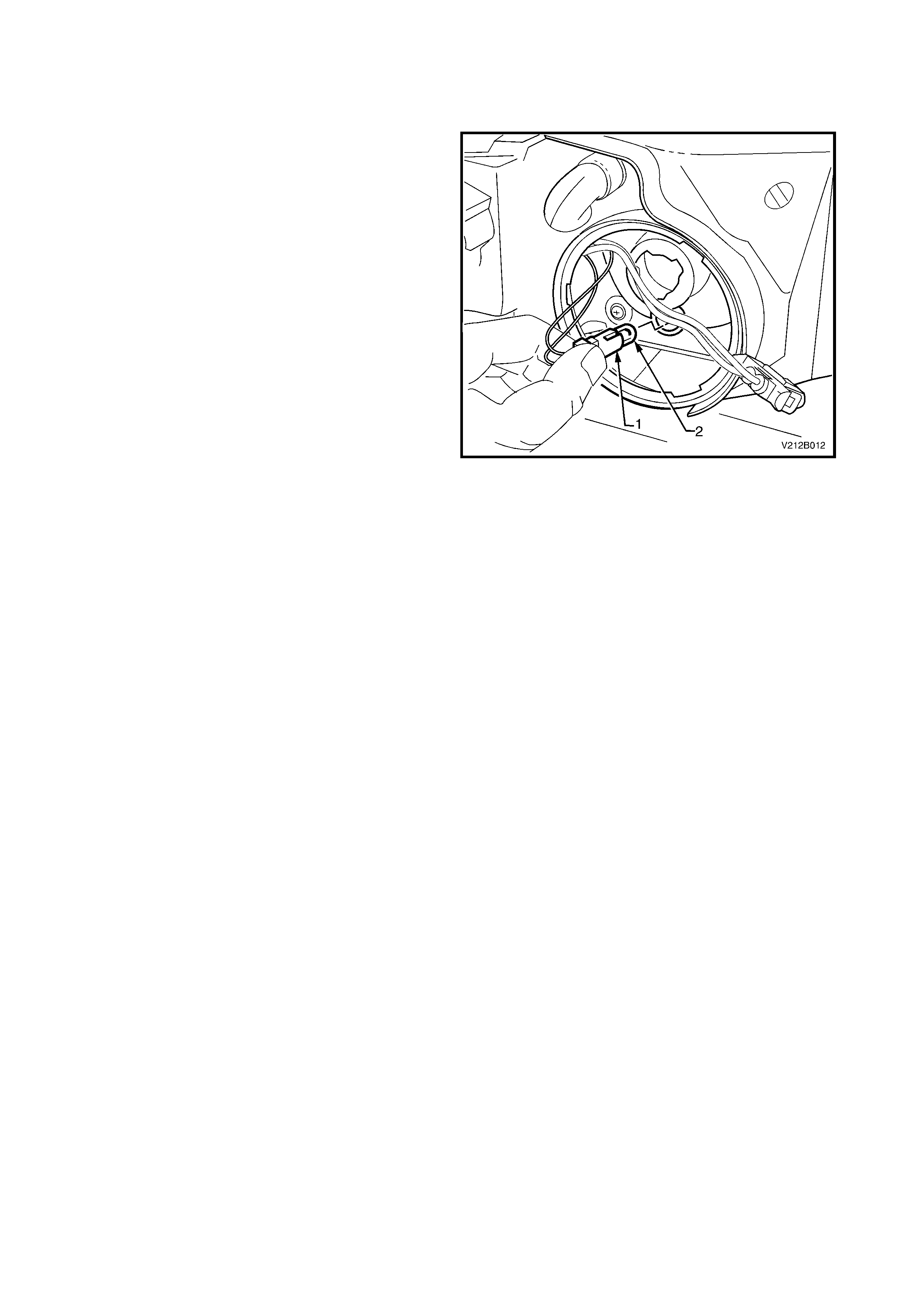

6. From inside the engine compartment, remove the

dust cap (1) from the rear of the headlamp housing

assembly (2) by turning the dust cap counter-

clockwise, and pulling away from housing. If the

dust cap seal stays on the headlamp housing,

remove the seal and install onto the cap.

7. Carefully pull the wiring harness connector (3)

from the rear of the bulb and holder assembly (4).

Figure 12B-12

8. Turn the bulb and holder assembly counter-

clockwise an eighth of a turn and remove from

headlamp housing.

NOTE: Do not handle the quartz envelope of the

headlamp bulb. If touched accidentally, wipe

immediately with methylated spirits or bulb

performance will deteriorate.

9. Install the new bulb (1) into the headlamp housing

(2), ensuring that the locating lugs on the bulb and

holder assembly mate with slots on the headlamp

housing, and lock into place by turning clockwise

an eighth of a turn.

NOTE: The different sized locating tangs on the bulb

base and mating cut- outs in the reflector allow the bulb

to seat correctly into the reflector in one location only.

This ensures correct relationship of the bulb to the

reflector.

10. Connect the bulb harness connector (3).

Figure 12B-13

11. For LH headlamp for vehicles fitted with V6 Supercharged engine, install the filler neck and cap onto the

radiator overflow reservoir and feed the radiator overflow hose back into the filler neck.

12. Inspec t the rubber seal in the dust c ap to ensure that it is not dam aged and that it is seated correc tly in the

cap. Replace the seal if damaged.

13. Install the cap onto the rear of the headlamp housing and lock the cap into place by turning clockwise.

14. For RH headlamp only, position the battery in the correct location, install the battery retaining clamp and

reconnect the battery positive terminal.

15. Reconnect the battery earth terminal.

16. Check the headlamp low beam lamp operation.

17. For vehicles with GEN III V8 engine, install the upper radiator support cover and the four retaining scrivets.

2.5 PARK LAMP BULB

REPLACE

1. Open the engine compartment.

2. Rem ove the high beam bulb and holder ass embly,

refer to 2.3 HIGH BEAM BULB in this Section.

3. Remove the park lamp socket (1) from the

headlamp high beam housing by pulling it firmly

rearwards.

CAUTION: Do not place fingers through the high

beam bulb opening to assist the park lamp socket

from housing.

4. Pull the bulb (2) from the socket.

5. Insert the new bulb into the socket and install the

socket into the reflector.

6. Inspect the rubber seal in the dust cap to ensure

that it is not damaged and that it is seated correctly

in the cap.

7. Install cap onto the rear of headlamp housing and

lock the cap into place by turning clockwise.

8. For the RH headlamp only, position the battery in

the correct location, install the battery retaining

clamp and reconnect the battery terminals.

9. Check the park lamp operation.

10. For vehicles with GEN III V8 engine, install the

upper radiator s upport cover and the four retaining

scrivets.

Figure 12B-14

2.6 FRONT TURN SIGNAL LAMP BULB

REPLACE

NOTE: If replacing a front turn signal lamp bulb,

ensure that the correct type is fitted.

1. Open the engine compartment.

2. Disconnect the battery earth lead.

3. For the RH front turn signal lamp only, disconnect

the battery positive lead, remove the battery

retaining clamp and remove the battery from the

engine compartment.

4. For vehicles with GEN III V8 engine only, remove

the four scrivets securing the upper radiator

support cover and remove the cover.

5. For the LH turn signal lamp in vehicles fitted with

V6 Supercharged engine, remove the filler neck

and cap from the radiator overflow reservoir by

withdrawing the radiator overflow hose and pulling

the filler neck upwards.

6. From inside the engine compartment, twist to

release the bulb socket (1) from behind headlamp

assembly (2).

7. Depress the bulb into the socket and rotate to

remove.

8. Inspect the O-ring on the bulb socket for damage

and correct seating. Replace the O-ring if

necessary.

9. Install the new bulb (3) into the socket.

10. Install the s ocket into the housing and twist to lock

into position.

11. For the LH turn signal lamp in vehicles fitted with

V6 Supercharged engine, ins tall the filler neck and

cap onto the radiator overflow reservoir and feed

the radiator overflow hose back into the filler neck.

12. For the RH f ront turn signal lam p only, position the

battery in the correct location, install the battery

retaining clamp and reconnect the battery

terminals.

13. Check turn signal lamp operation.

14. For RH headlamp in vehicles with GEN III V8

engine, install the upper radiator support cover and

the four retaining scrivets.

Figure 12B-15

2.7 REAR QUARTER LAMP ASSEMBLY

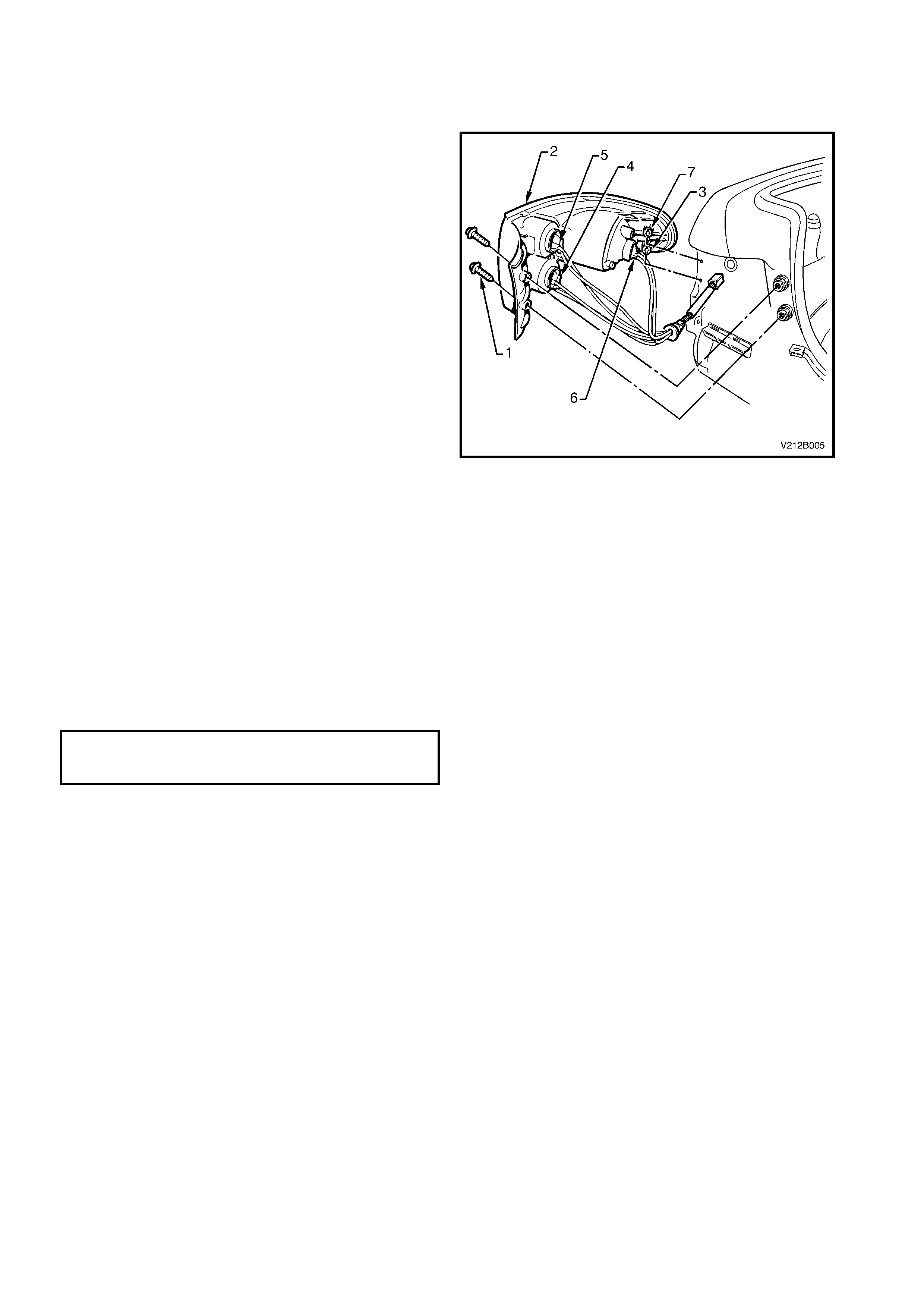

REMOVE

1. Disconnect the battery earth lead.

2. Open the rear compartment lid.

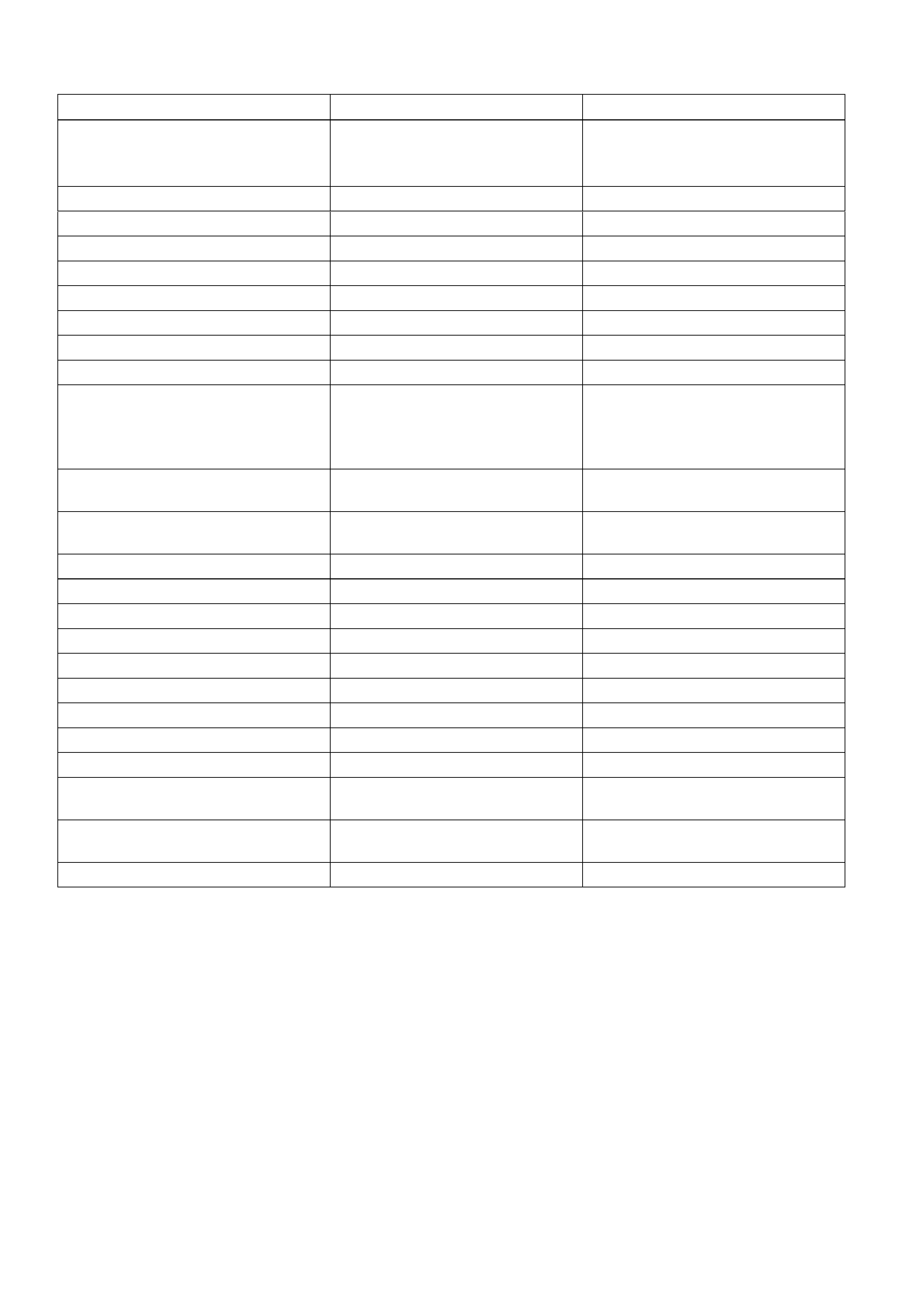

3. Remove the two rear quarter lamp assembly to

body attaching screws (1).

4. Pull the rear quarter lamp housing (2) sideways out

from panel so that the locating peg (3) on the side

of the the lamp assembly snaps free from the

retainer.

5. While supporting the lamp housing:

a. Remove the back-up light bulb (4) by turning

the socket counter-clockwise and removing.

b. Remove the turn signal bulb socket (5) by

turning socket counter-clockwise and

removing.

c. Remove the stop/tail light bulb socket (6) by

turning socket counter-clockwise and

removing.

NOTE: When removing the rear quarter lamp

assem bly fr om the panel, tak e care not to damage the

integral plastic guide peg (7).

Figure 12B-16

REINSTALL

1. Ins ert the bulb soc k ets into the rear quarter lam p

housing, ensuring that the sockets are correctly

located and lock securely into place.

2. Ensuring that the rear quarter lamp harness

grommet is seated correctly, install the lamp

housing, ensuring that the locating peg snaps

into the retainer.

3. Install and tighten the attaching screws to the

correct torque specification.

REAR QUARTER LAMP HOUSING TO

BODY ATTACHING SCREW

TORQUE SPECIFICATION 1 – 3 Nm

NOTE: Harness length will allow back-up light socket

and turn signal bulb soc ket to be fitted to the corr ect

locations only.

4. Check rear quarter lamp operation.

2.8 REAR TURN SIGNAL LAMP BULB

REPLACE

1. Remove the rear quarter lamp assembly, refer to 2.7 REAR QUARTER LAMP ASSEMBLY in this Section.

2. Remove the r ear turn s ignal lamp bulb fr om the soc ket (ref er to item 5 in Figure 12B-16) by depressing the bulb

into the socket and rotating counter-clockwise.

3. Inspect the bulb socket to lamp housing seals for damage and replace if necessary.

4. Insert the new bulb into the sock et and install the socket into the lam p housing, ensuring that the socket locks

securely into place.

5. Reinstall the rear quarter lamp assembly, refer to 2.7 REAR QUARTER LAMP ASSEMBLY in this Section.

6. Check the rear quarter lamp operation.

2.9 STOP/TAIL LAMP BULB

REPLACE

1. Remove the rear quarter lamp assembly, refer to 2.7 REAR QUARTER LAMP ASSEMBLY in this Section.

2. Remove the stop/tail lam p bulb f rom the s ocket (r efer item 6 in F igure 12B-16) by depres sing the bulb into the

socket and rotating counter-clockwise.

3. Inspect the bulb socket to lamp housing seals for damage and replace if necessary.

4. Insert the new bulb into the sock et and install the socket into the lam p housing, ensuring that the socket locks

securely into place.

5. Reinstall the rear quarter lamp assembly, refer to 2.7 REAR QUARTER LAMP ASSEMBLY in this Section.

6. Check the rear quarter lamp operation.

Techline

2.10 BACK-UP LAMP BULB

REPLACE

1. Remove the rear quarter lamp assembly, refer to 2.7 REAR QUARTER LAMP ASSEMBLY in this Section.

2. Remove the back-up lamp bulb from the socket (refer item 4 in Figure 12B-16) by depressing the bulb into its

socket and rotating counter-clockwise.

3. Inspect the bulb socket to lamp housing seals for damage and replace if necessary.

4. Insert the new bulb into the sock et and install the socket into the lam p housing, ensuring that the socket locks

securely into place.

5. Reinstall the rear quarter lamp assembly, refer to 2.7 REAR QUARTER LAMP ASSEMBLY in this Section.

6. Check the back-up lamp operation.

2.11 CENTRE HIGH MOUNT STOP LAMP ASSEMBLY

REMOVE

1. Disconnect the battery earth lead.

2. Open the rear compartment lid.

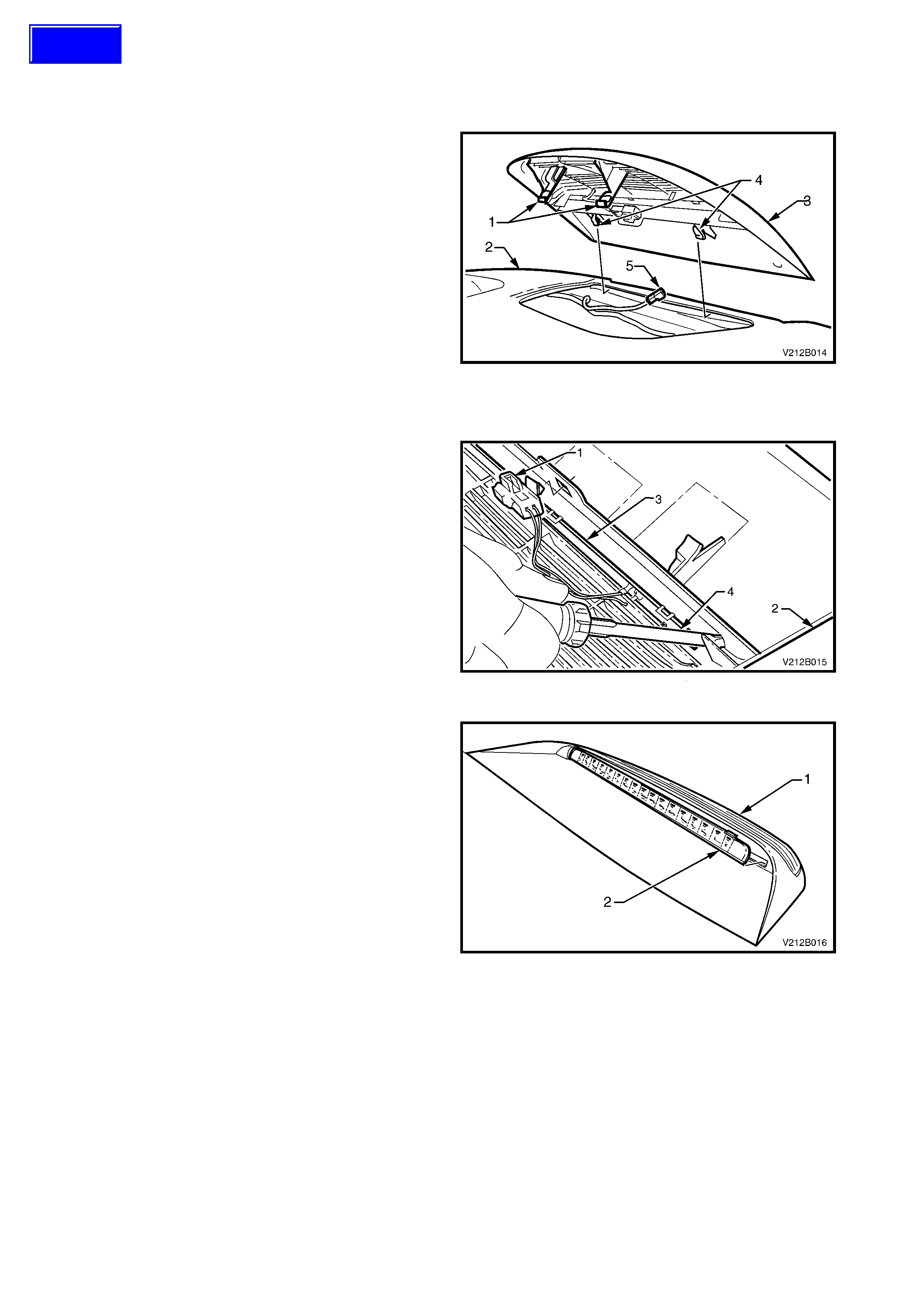

3. F rom inside the rear load com partm ent, disengage

the two retaining tangs (1) from the rear parcel

shelf sheetmetal (2).

4. From inside the vehicle cabin, grasp the edge of

the centre high mount stop lamp (3) and pull the

assembly up and away from the rear windscreen

until the locating tabs (4) are free of the locating

slot.

5. Disconnect the harness connector (5) from the

centre high m ount stop lam p and remove the lamp

from the vehicle.

Figure 12B-17

DISASSEMBLE

1. Unclip the harness connector (1) from the lamp

housing (2).

2. Starting at one end of the LED assembly (3),

carefully disengage the retaining tab with a small

screwdriver (4).

Figure 12B-18

3. Car efully spread the lam p housing (1) by hand and

work the LED assembly (2) sideways and

rearwards until free of the housing.

Figure 12B-19

REASSEMBLE

The reassembly procedure for the centre high mount stop lamp is the reverse of the disassemble procedure

REINSTALL

The installation procedure for the centre high mount stop lam p is the reverse of the removal procedure, noting the

following:

• Ensure that the locating tabs ar e corr ectly engaged into the s lot in the rear of the parc el shelf prior to engaging

the retaining tabs.

• Check centre high mount stop lamp operation once installed.

Techline

2.12 FOG LAMP ASSEMBLY

REMOVE

1. Disconnect the battery earth lead.

2. Remove the lower air intake grille from the front

facia assembly, refer to Section 1D BUMPER

BARS.

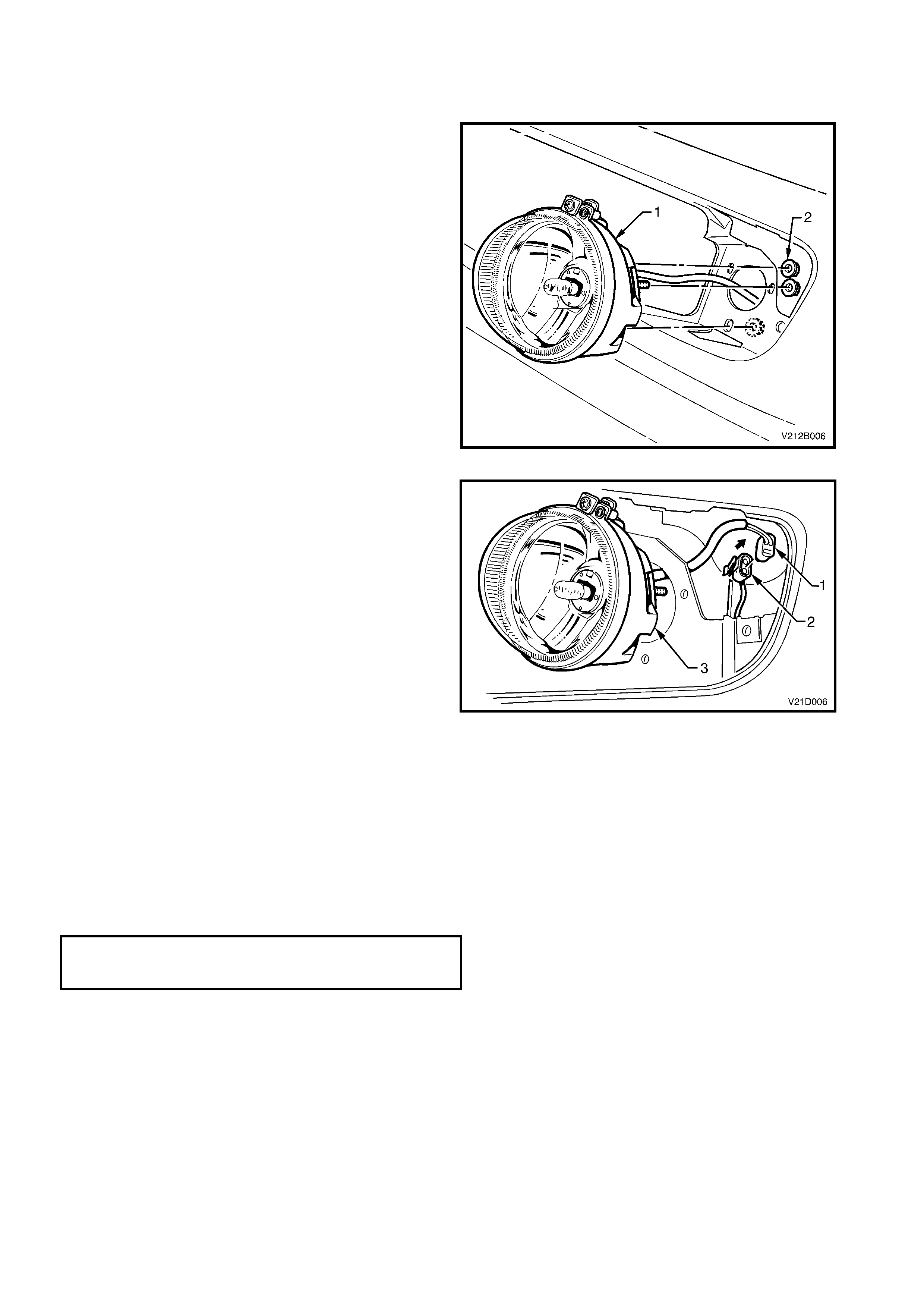

3. From behind the bumper bar facia, remove the

three nuts (2) securing the fog lamp assembly (1)

to bumper bar facia, and parcially remove the fog

lamp assembly.

Figure 12B-20

4. Unclip the fog lamp harness (1) from the front

longitudinal by sliding the connector forward.

5. Dis connect the f oglam p harnes s connec tor (2) and

remove the fog lamp assembly (3).

Figure 12B-21

REINSTALL

The installation procedure for the fog lamp assembly is

the reverse of the removal procedure, noting the

following:

• Ensure that the fog lamp assembly is correctly

orientated with the beam adjustment screw located

to the top.

• Tighten the fog lamp housing to bumper bar facia

nuts to the correct torque specification.

FOG LAMP BRACKET TO FRONT

FACIA RETAINING NUTS

TORQUE SPECIFICATION 2.0 – 2.5 Nm

• Check fog lamp operation and aiming, refer to

2.1 AIMING OF HEADLAMPS AND FOG LAMPS

in this Section.

2.13 FOG LAMP BULB

REPLACE

1. Disconnect the battery earth lead.

2. Remove the lower air intake grille from the front

facia assembly, refer to Section 1D BUMPER

BARS.

3. Remove the screw (1) securing the lens, reflector

and clamp ring assembly to the fog lamp housing

and remove the clamp ring (2).

Figure 12B-22

4. Pull the lens and reflector assembly (1) out from

the housing.

5. Disconnect the bulb and lead assembly (3) from

the wiring harness connector located inside the

insulating sheath.

6. Squeeze the halves of the spring retainer (2)

together and pivot spring backward clear of bulb.

Lift out bulb and remove.

NOTE: Do not handle quartz envelope of bulb. If

touched, wipe immediately with methylated spirits or

bulb performance will deteriorate.

Figure 12B-23

7. Connect the new bulb lead (4) to the wiring

harness connector, install the bulb (4) into the

correct locating notches in the lens and reflector

assembly (1) and reconnect the spring retainer (5).

8. Install the lens and reflector assembly into the

housing (2) ensuring that the protrusion (7) on the

rim of the lens and reflector assembly aligns

correc tly with the c ut-out on the rim of the housing

(8).

9. Install the clamp ring and screw and tighten the

screw.

11. Check fog lamp operation and aim, refer to

2.1 AIMING OF HEADLAMPS AND FOG LAMPS

in this Section.

Figure 12B-24

3. SPECIFICATIONS

BULB POWER RATING - WATTS BASE TYPE

HEADLAMPS

Low Beam Outboard

Inboard High Beam

55

65

H11

H9

FOG LAMPS 55 H3

PARK LAMPS (Front) 5 Wedge

TURN SIGNAL LAMPS (Front) 21 Offset Pin (Orange Glass)

SIDE REPEATER LAMPS 5 Wedge

TURN SIGNAL LAMPS (Rear) 21 Offset Pin (Silver Gl ass)

BACK-UP LAMPS 21 Standard Parallel Pin

STOP/TAIL LAMPS 21/5 Standard Parallel Pin

LICENCE PLATE LAMPS 5 Wedge

INSTRUMENT CLUSTER

ILLUMINATION LAMPS

CV6

CV8

3.6

5

Wedge

Wedge

INSTRUMENT CLUSTER

WARNING LAMPS

1.2

Wedge

TRIP COMPUTER ILLUMINATION

LAMPS

1.2

Wedge

REAR COMPARTMENT LAMPS 10 Festoon

DOME LAMP 10 Festoon

FRONT SEAT READING LAMP (SS) 5 Standard Parallel Pin

REAR SEAT READING LAMP 5 Festoon

GLOVE COMPARTMENT LAMP 5 Festoon

FRONT FOOTWELL LAMPS 2.7 Wedge

FRONT VANITY MIRROR LAMP 1.2 Wedge

DOOR COURTESY LAMPS 5 Festoon

CONSOLE BIN LAMPS 5 Festoon

CENTRE HIGH MOUNT STOP

LAMP N/A LED Assembly

FRONT AND REAR CIGAR

LIGHTER LAMPS

1.2

Wedge

IGNITION LOCK LAMP 1.4 Wedge

4. TORQUE WRENCH SPECIFICATIONS

Nm

Headlamp and Turn Signal/Park Lamp Attaching Screws.... 2 - 5

Rear Quarter Lamp to Body Attaching Screws..................... 1 - 3

Fog Lamp Bracket to Front Facia Attaching Nuts................. 2.0 – 2.5