SECTION 12B - LIGHTING SYSTEM

CAUTION:

This v ehicle will be equipped with a Supplemental Restraint System (SRS). A SRS

will consist of either seat belt pre-tensioners and a driver’s side air bag, or seat

belt pre-tensioners and a driver’s and front passenger’s side air bags. Refer to

CAUTIONS, Section 12M, before performing any service operation on or around

SRS components, the steering mechanism or wiring. Failure to follow the

CAUTIONS could result in SRS deployment, resulting in possible personal injury

or unnecessary SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests

of safety, the LPG fuel system should be isolated by turning 'OFF' the manual

service valve and then draining the LPG service lines, before any service work is

carried out on the vehicle. Refer to the LPG leaflet included with the Owner's

Handbook for details or LPG Section 2 for more specific servicing information.

1. GENERAL DESCRIPTI ON

The front lamp assemblies on VT Series Models comprise a sem i-sealed headlamp and a turn signal lamp and a

parking lamp.

For all VT models, the parking lamp is in the headlamp assembly with the turn signal next to it.

The headlamp features a dual pocket reflector, quartz halogen bulbs and a parking lamp bulb. The reflector is of

homofocal design, with both inner and outer pockets used for high beam.

The turn signal lamp has a c lear appear anc e lens. The illumination bulb has a orange c olour ed glass and has of f s et

locating pins on its base.

Fitted into each front fender, is a turn signal side repeater lamp assembly.

The rear lamp ass emblies f or the station wagon compr ise a turn signal lamp, s top and tail lam p and back -up lamp

in one unit. All sedan vehicles have a rear quarter lamp housing with stop/tail and turn signal bulbs. For Calais the

turn signal bulb glass is coloured orange and has off set locating pins. T he orange c oloured bulb glas s provides the

amber light behind the clear lamp lens. The bulb used for Commodore Executive, Berlina, S and SS models has

clear glass and standard parallel locating pins, which illuminates an amber lens.

Also, different rear quarter lamp harnesses with specific bulb sockets are used for each type of bulb locating pin

style.

All sedan models have separate decklid lam ps with back-up lam p bulb and an additional tail lamp bulb is provided

for Berlina and Calais. The rear licence plate lamps are specific for sedan and station wagon models.

On sedan models, the licence plate lamps are located in the rear compartment lid decor panel, above the licence

plate. Station Wagon has two lamps attached to the tailgate lock trim assembly.

Specific style fog lamps are fitted to the front bumper bar assembly for Calais and SS Models as standard

equipment.

The fog lamps are controlled by a switch assembly located in the instrument facia, below the headlamp switch.

The fog lamps operate when the headlamps are switched on and the fog lamp switch button depressed. If the

headlamps are operating on high beam, switching on the fog lamps turns the headlamp low beam off. If the

headlamps are on low beam, they remain on when the fog lamps are switched on.

All vehicles are fitted with hazard warning flashers, which are operated by a switch in the instrument facia, located

below the air outlets.

All vehicles are fitted with courtesy lamps in the passenger compartment (dome lamp), ignition lock and glove

compartment. Additional interior lighting, depending on vehicle type, is provided by courtesy lamps in door trims,

front and rear footwells, rear compartment, front reading lamp assemblies, rear reading lamps and console bin

lamp.

Operation of the parking/tail and headlamps is controlled by a headlamp switch located in the instrument facia, to

the right of the steering wheel. Headlamp high beam or headlamp flash control is by the headlamp and turn signal

control switch stalk to the right of the steering column.

In conjunction with the headlamp, fog lam p and headlamp and turn signal control switches, various relays, located

in the engine compartment relay housing and passenger com partment fuse panel, are used for headlamp, hazard

warning, turn signals and fog lamp control.

Techline

Turn signal control is by the headlamp and turn signal control switch stalk to the right of the steering column.

Stop lamps operation is controlled by a stop lamp switch fitted into a tubular clip in the brake pedal support.

Back-up lamp operation is controlled by the switch screwed into left hand the side of the transmission case for

manual transmission, or by the neutral start/back-up lamp switch (vehicles with automatic transmission) which is

attached to the side of the gearshift assembly, beneath the console cap.

There are two series of Body Control Module (BCM) installed in VT Series Com m odor e, and selection is dependent

on model s tyle. Comm odore Exec utive is f itted with the Low Series BCM while Berlina and Calais ar e f itted with the

High Series BCM. The BCM provides additional lighting system enhancements. These features are:

1. Automatic Lights Off.

This system deactivates the head and park/tail lamps when the ignition has been switched from on to off and the

drivers door is opened. The lamps switch back on when the ignition is switched on, if the headlam ps switch is still

turned on. On Berlina, Calais, an adjustable time delay can be applied before the headlamps are automatically

switched off.

2. Dome Lamp Delay.

Additional control of the dom e lam p operation by the BCM allows for 30 second delay period to turn the dom e lam p

off after all doors are closed. On vehicles with High Series BCM, should the dome lamp be left on by the dome lamp

switch, and with ignition off, the BCM will turn off the dome lamp after a maximum period of two hours to prevent

battery drain.

On vehicles with High Series BCM, additional features include:

3. Instrument Dimming Control.

Incorporated in the headlamp switch assembly is a control for variable instrument cluster illumination intensity.

4. Rear Lamp Failure Warning System (High Series BCM only).

This system checks for bulb or fuse failure associated with the stop or tail lamps including the high level stop lamp.

For additional information on these systems, including diagnostics, refer Section 12J-1, LOW SERIES BODY

CONTROL MODULE or Section 12J-2, HIGH SERIES BODY CONTROL MODULE.

2. SERVICE OPERATIONS

2.1 AIMING OF HEADLAMPS AND FOG LAMPS

The headlamps and fog lamps (if fitted) must be

correctly aimed in order to obtain the maximum

road illum ination and safety that has been built into

the vehicle lighting system . The headlam ps and f og

lamp s m us t be chec ked for c orr ec t aim whenever a

bulb or headlamp/fog lamp assembly is replaced,

and after any adjustments or repairs to the front

end sheet metal.

Headlamp aiming machines are in general use.

When using one of these machines, ensure that it

is in good condition and carefully follow the

instructions of the manufacturer.

Regardless of the method used for checking

headlamp and fog lam p aim, the vehic le must be at

kerb weight, that is, with fuel, oil, water and spare

tyre but no passengers. The tyres must be

uniformly inflated to their specified pressure.

NOTE:

If the vehicle will regularly carry an unusual load in

the rear compartment or tow a trailer, these loads

should be on the vehicle when the headlamps/fog

lamps are checked.

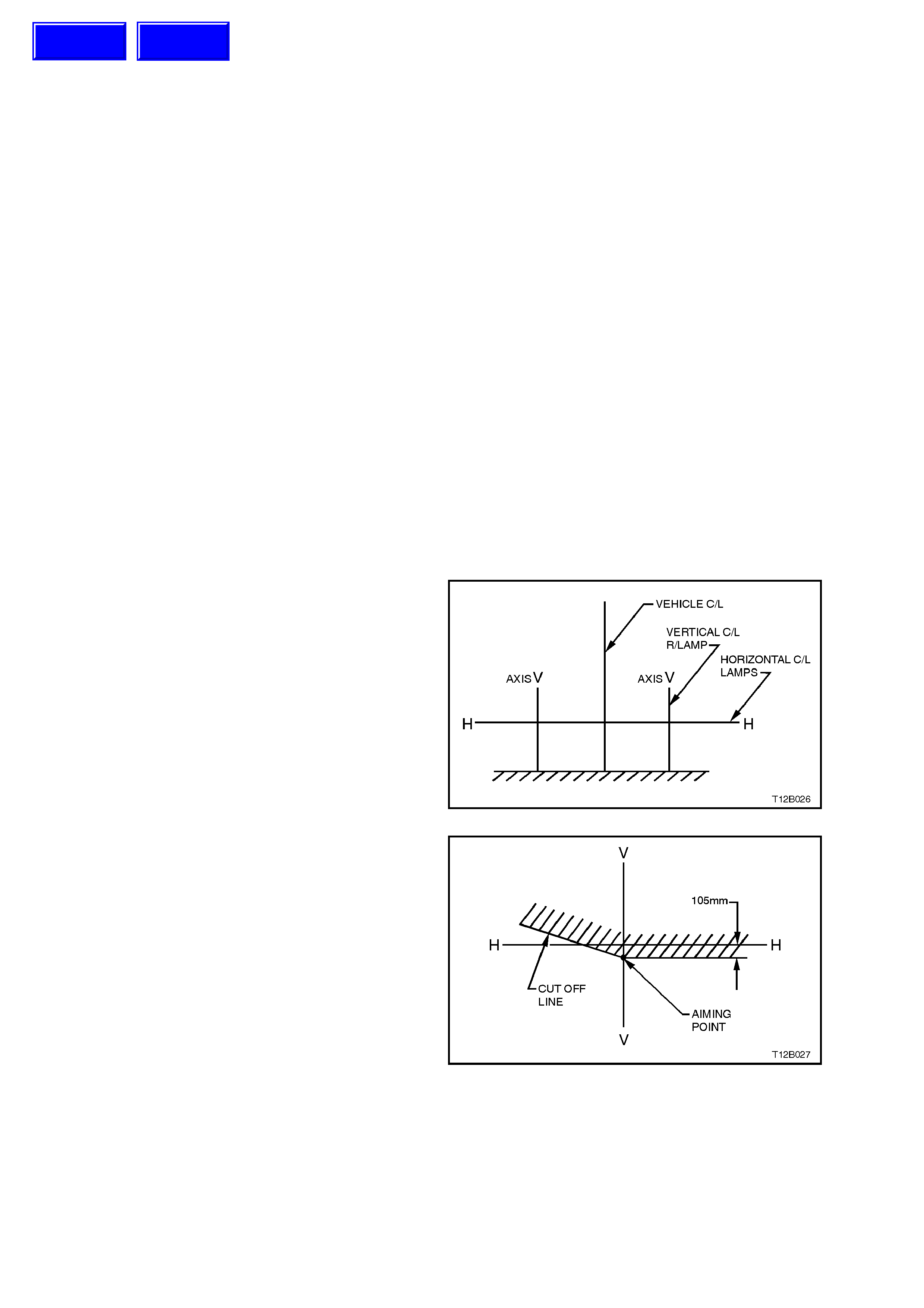

HEADLAMP AIM

1. If suitable test equipment is not available, set

up a screen or use vertic al wall, in conjunction

with a flat horizontal floor. Park vehicle

immediately in front of screen and mark

horizontal and vertical centre lines of left and

right headlam ps, and vehic le c entre line on the

screen or wall.

2. Park vehicle 7.6 metres in front of screen or

wall ensuring the vehicle is aligned with

vehicle centre line mark on screen.

Figure 12B-1

3. Individually aim each headlamp to a point on

its vertical centre line, 105 mm below the

headlamp horizontal centre line.

Figure 12B-2

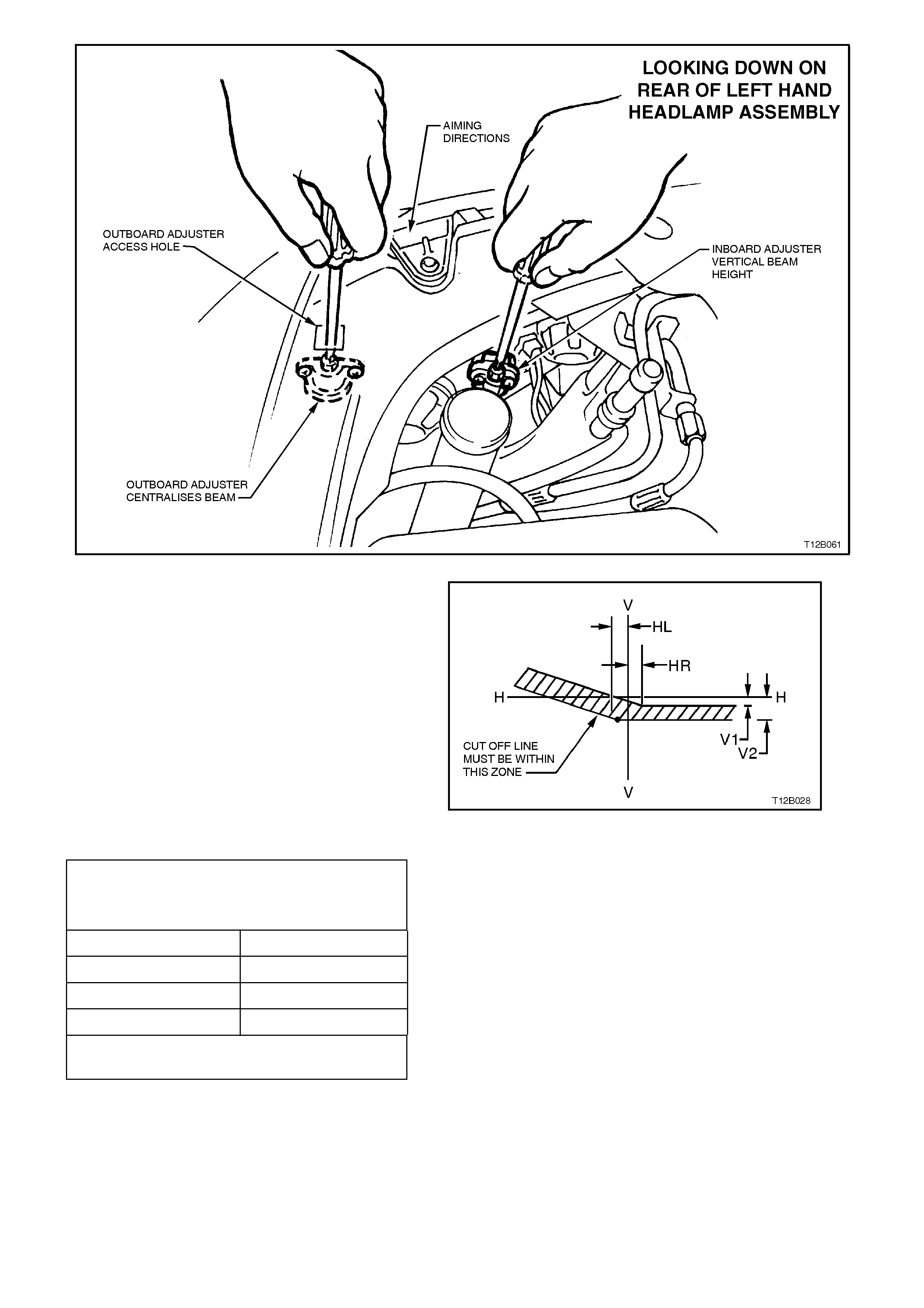

a. Adjust inboard adjuster to achieve correct

vertical beam height.

b. Adjust outboard adjuster to centralise beam.

Aiming directions for each adjuster are visible on

the headlamp assembly.

Techline

Techline

Figure 12B-3

4. The allowable variations on headlamp aiming

point settings shown in Fig. 12B-1 are

specified as follows:

Figure 12B-4

HE ADLAMPS AIMING.

ACCEPTABLE VARIATIONS IN HEADLAMP

AIMING POINTS

HL 100 mm

HR 0 mm

V1 95 mm

V2 115 mm

Maximum Allowable Vertical Variation Between

Any Pair Of Headlamps Is Not To Exceed 20 mm

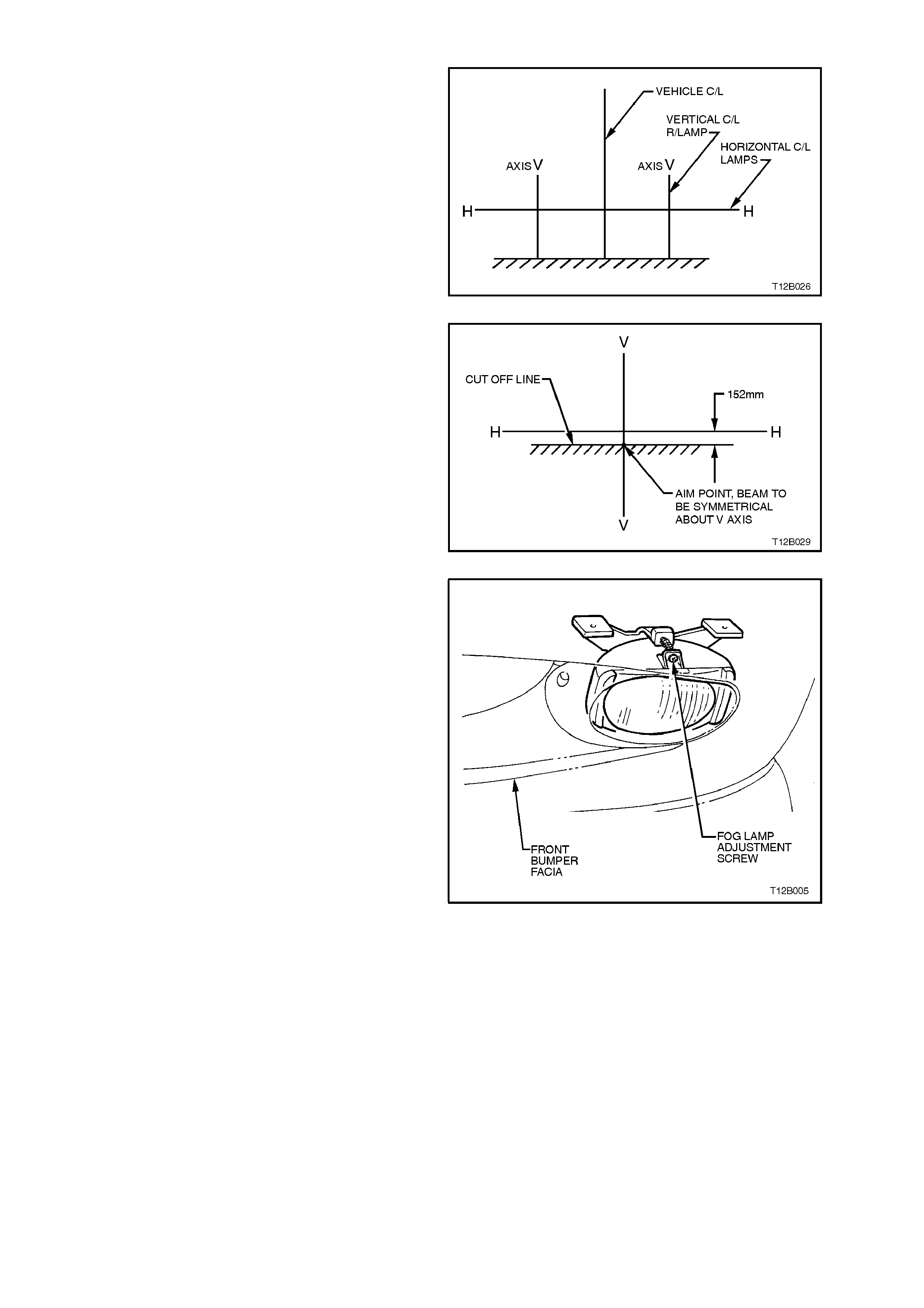

FOG LAMP AIM

1. If suitable headlamp aiming check equipment

is not available, set up a screen or use a

vertical wall, in conjunction with a flat

horizontal floor. Park vehicle immediately in

front of screen and mark horizontal and

vertical centre lines of left and right

headlamps, and vehicle centre line on the

screen.

2. Park vehicle 7.6 metres in front of screen,

ensuring the vehicle is aligned with centre line

mark on screen.

Figure 12B-5

3. Check headlamp aim and adjust as required,

refer previous instructions.

4. W ith headlamps turned on low beam, turn fog

lamps on. Individually aim each fog lamp to a

point symmetrical about ‘V’ axis and 152 mm

below headlamp horizontal centre line.

Figure 12B-6

NOTE:

There is no pr ovis ion f or hor izontal adjustment. Fo g

lamps are fixed to vertical centreline.

Fog lamp aim adjustment is by rotating the

adjuster at the front of the lamp housing.

Turning the adjuster anti-clockwise lowers the

beam, turning clock wise raises the beam . The

adjustment is made using a No. 2 ‘Philips

Head’ screw driver.

Figure 12B-7

2.2 HEADLAMP BULB

REPLACE

1. Open engine compartment.

Driver’s side headlamp only

V6 engine models:

Disconnect battery terminals, remove battery

retaining clam p and m anoeuvre batter y to gain

access to headlamp dust cap.

V8 engine models:

Disconnect battery terminals, remove battery

retaining clamp and remove battery from

engine compartment.

Driver’s and passenger side

2. From inside engine compartment, remove

dust cap from rear of headlamp housing

assembly by turning dust cap anti-clockwise,

and pull away from housing. If dust cap seal

stays on headlamp housing, remove seal and

install onto cap.

3. Carefully pull wiring harness connector from

rear of bulb.

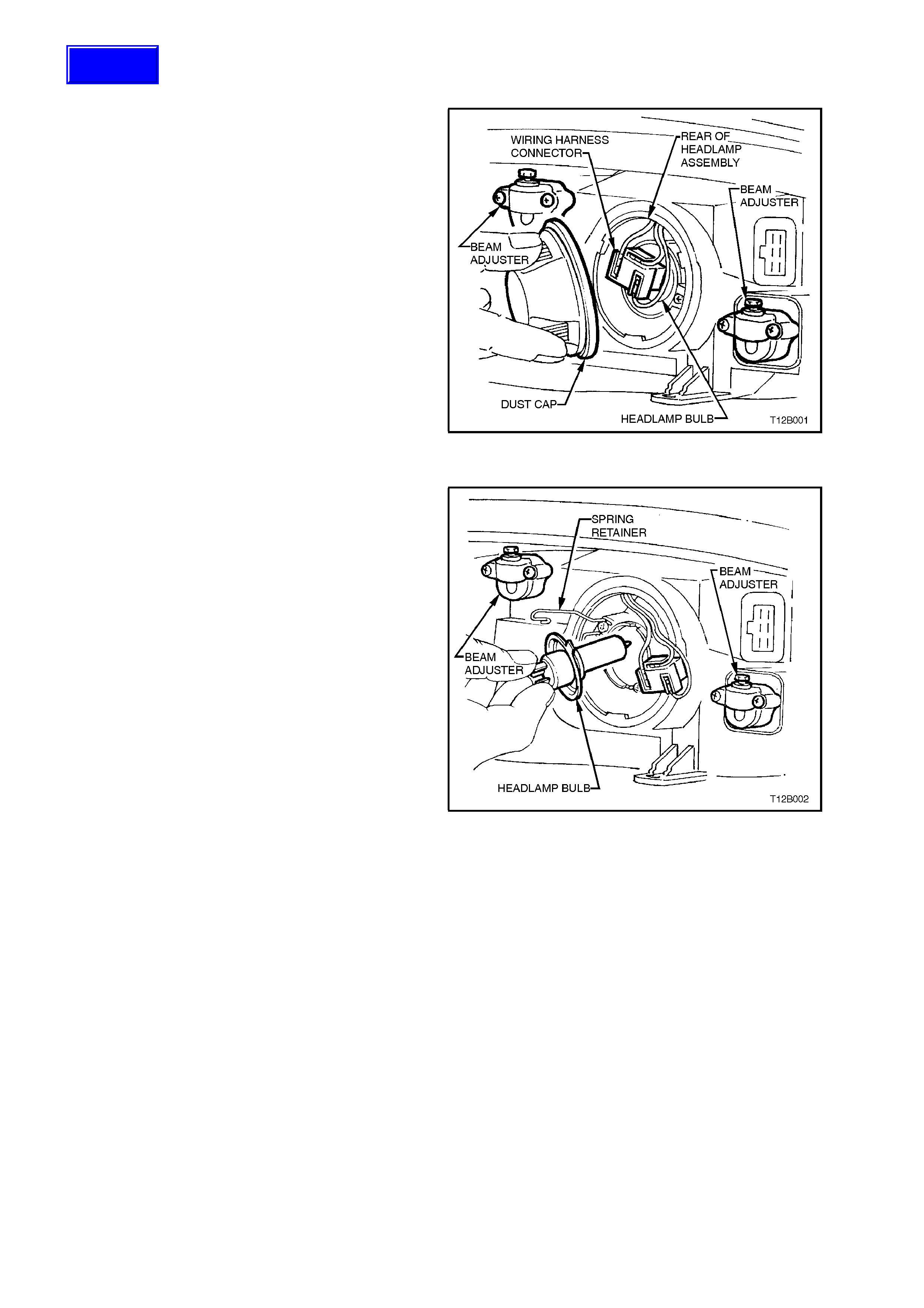

Figure 12B-8

4. Depress and unclip bulb spring retainer and

pivot clear of bulb. Remove bulb from

reflector.

NOTE:

Do not handle quartz envelope of headlam p bulb. If

touched accidentally, wipe immediately with

methylated spirits or bulb performance will

deteriorate.

5. Refit new bulb into reflector, ensuring correct

mating of bulb base locating tangs with

reflector cut-outs. Refit spring retainer and

wiring harness connector.

NOTE:

The different sized locating tangs on the bulb base

and mating cut-outs in the reflector will allow the

bulb to seat correctly into the reflector in one

location only. This ensures correct relationship of

the bulb to the reflector.

6. Inspect rubber seal in dust cap to ensure that

it is not dam aged and that it is s eated c orr ec tly

in cap. Replace seal if damaged.

7. Install cap to rear of headlamp housing with

cap tang located facing down. Lock cap into

place by turning clockwise.

Driver’s side only

Reinstall battery if removed, secure battery

retaining clamp and reconnect battery

terminals.

Driver’s and passenger sides

8. Check headlamp operation and re-aim

headlamps (headlam p aim varies from bulb to

bulb), refer to 2.1 AIMING OF HEADLAMPS

AND FOG LAMPS in this Section.

Figure 12B-9

Techline

2.3 PARKING LAMP BULB

REPLACE

1. Open engine compartment hood.

Driver’s side headlamp only

V6 engine models:

Disconnect battery terminals, remove battery

retaining clam p and m anoeuvre batter y to gain

access to headlamp dust cap.

V8 engine models:

Disconnect battery terminals, remove battery

retaining clamp and remove battery from

engine compartment.

Driver’s and passenger side

2. From inside engine compartment, remove

dust cap from rear of headlamp housing

assembly by turning dust cap anti-clockwise,

and pull away from housing. If dust cap seal

stays on headlamp housing, remove seal and

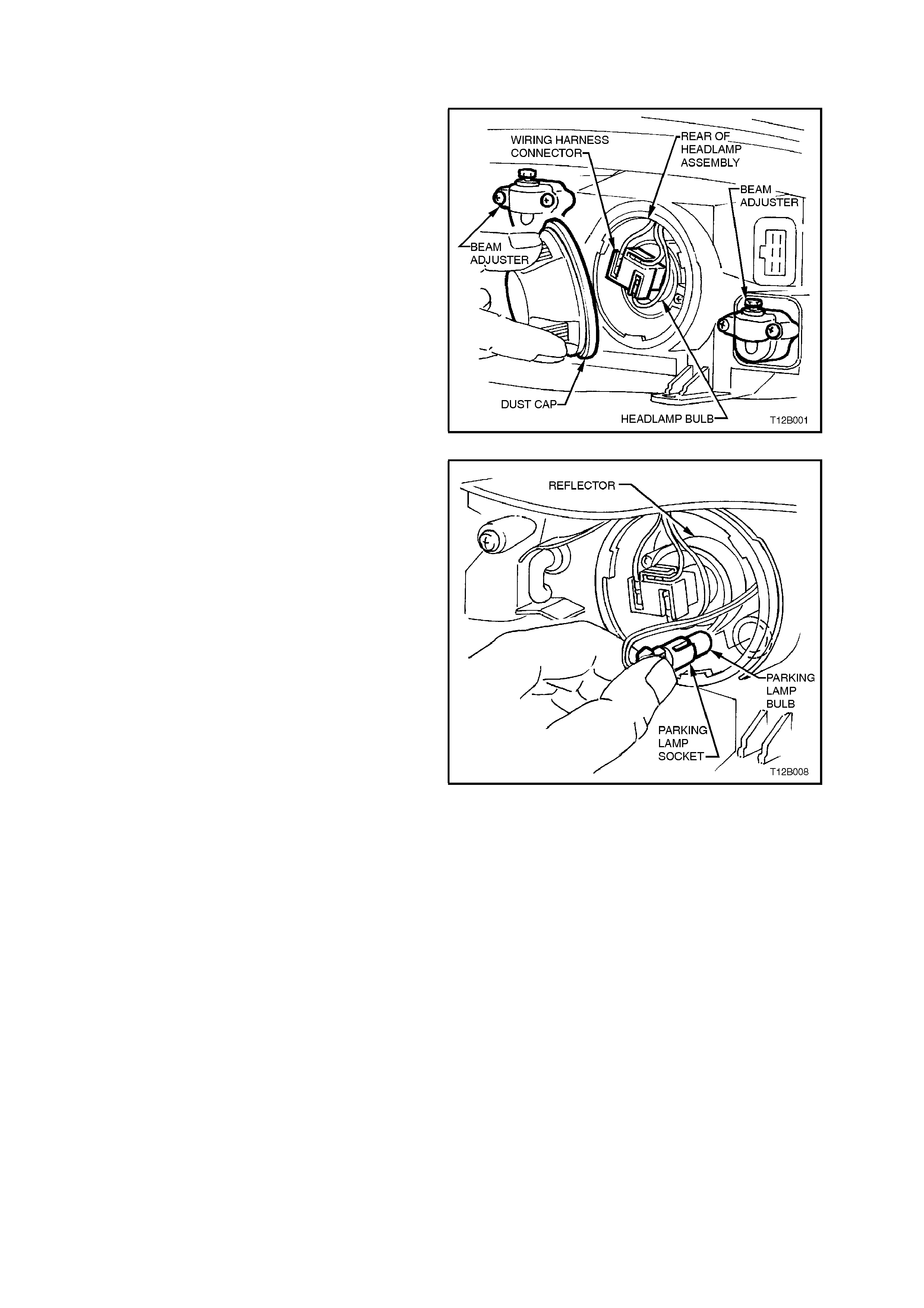

install onto cap. Figure 12B-10

3. Remove parking lamp socket from reflector.

Alternatively, use pointed nose pliers to pull

out parking lamp socket if access is difficult.

Pull bulb from socket.

4. Insert new bulb into soc k et and r eins tall s ocket

into reflector.

5. Inspect rubber seal in dust cap to ensure that

it is not dam aged and that it is s eated c orr ec tly

in cap.

Install cap to rear of headlamp housing and

lock cap into place by turning clockwise.

Driver’s side only

Reinstall battery if removed, secure battery

retaining clamp and reconnect battery

terminals.

Driver’s and passenger sides

6. Check parking lamp operation. Figure 12B-11

2.4 INBOARD HIGH BEAM BULB

REPLACE

1. Open engine compartment.

Driver’s side headlamp only

V6 engine models:

Disconnect battery terminals, remove battery

retaining clam p and m anoeuvre batter y to gain

access to headlamp dust cap.

V8 engine models:

Disconnect battery terminals, remove battery

retaining clamp and remove battery from

engine compartment.

Driver’s and passenger side

2. From inside engine compartment, remove

inboard high beam dust cap from rear of

headlamp housing assembly by turning dust

cap anti-clockwise, and pull away from

housing. If dust cap seal stays on headlamp

housing, remove seal and install onto cap.

3. Disconnect harness connector from bulb.

Depress and unclip bulb retaining clip to

release, and allow to fall c lear of bulb. Pull out

bulb.

Figure 12B-12

4. Install new bulb into reflector, ensuring that

locating lug on bulb housing aligns with squar e

edge on bulb and locating lugs on bulb mate

with holes on bulb housing. Reconnect bulb

retaining clip. Connect bulb harness

connector.

NOTE:

Do not handle quartz envelope of inboard high

beam bulb. If touched accidentally, wipe

immediately with methylated spirits or bulb

performance will deteriorate.

5. Inspect rubber seal in dust cap to ensure that

it is not damaged and that it is seated

correctly. Reinstall dust cap onto rear of

headlamp housing and lock into place by

turning clockwise.

Driver’s side only

Reinstall battery if removed, secure battery

retaining clamp and reconnect battery

terminals.

Driver’s and passenger sides

6. Test operation of inboard high beam lamp

bulb.

Figure 12B-13

2.5 FRONT TURN SIGNAL LAMP BULB

REPLACE

NOTE:

If replacing a front turn signal lamp bulb, ensure

the correct type is fitted. For all models, the bulb

glass is coloured orange and has offset locating

pins.

1. Open engine compartment.

Driver’s side headlamp only

V6 engine models:

Disconnect battery terminals, remove battery

retaining clam p and m anoeuvre batter y to gain

access to headlamp dust cap.

V8 engine models:

Disconnect battery terminals, remove battery

retaining clamp and remove battery from

engine compartment.

Driver’s and passenger side

2. From inside engine compartment, twist to

release bulb socket from behind headlamp

assembly.

3. Depress bulb into socket and rotate to

remove.

4. Inspect O-ring on bulb socket for dam age and

correct seating. Replace O-ring if necessary.

5. Install new bulb into socket, install socket into

housing and twist to lock into position.

Driver’s side only

Reinstall battery if removed, secure battery

retaining clamp and reconnect battery

terminals.

Driver’s and passenger sides

6. Check turn signal lamp operation.

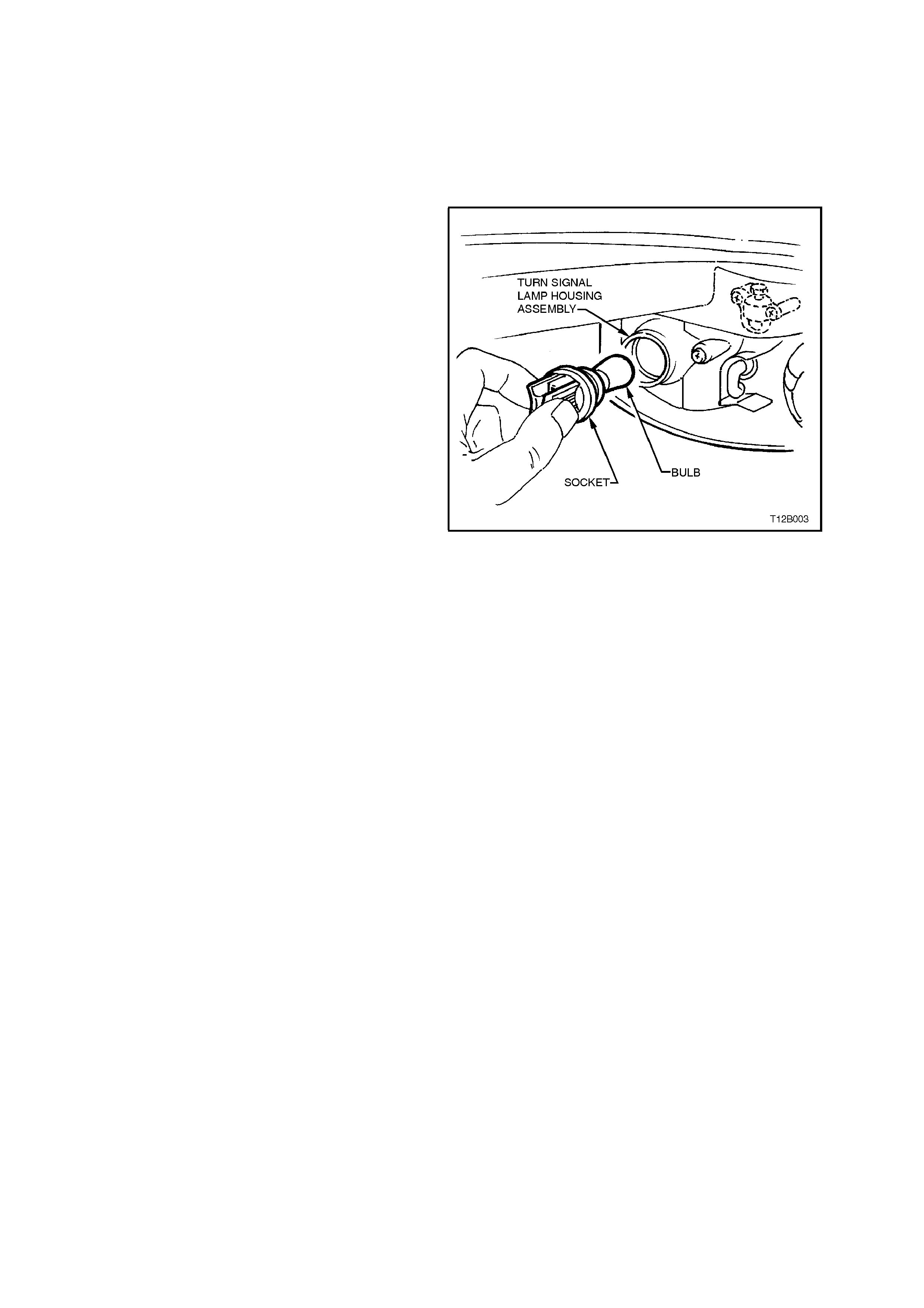

Figure 12B-14

2.6 HEADLAMP AND TURN SIGNAL/PARKING LAMP ASSEMBLY

REMOVE

1. Open engine compartment.

Driver’s side headlamp only

V6 engine models:

Disconnect battery terminals, remove battery retaining clamp and manoeuvre battery.

V8 engine models:

Disconnect battery terminals, remove battery retaining clamp and remove battery from engine compartment.

Driver’s and passenger side

2. From inside engine compartm ent, disconnect wiring harness connector from headlamp assem bly. Remove

turn signal lamp bulb socket from headlamp assembly.

3. Remove bumper facia retaining scrivets (two) from behind number plate.

4 .Rem ove sc r ews sec uring bumper facia sides to f ront fender wheel arch opening and r adiator s uppor t upper

panel.

5. With the facia suppor ted, pull the fac ia side m em bers out, dis connect the f acia side s upports, then s lide the

facia forward removing the facia assembly, refer Fig. 12B-15.

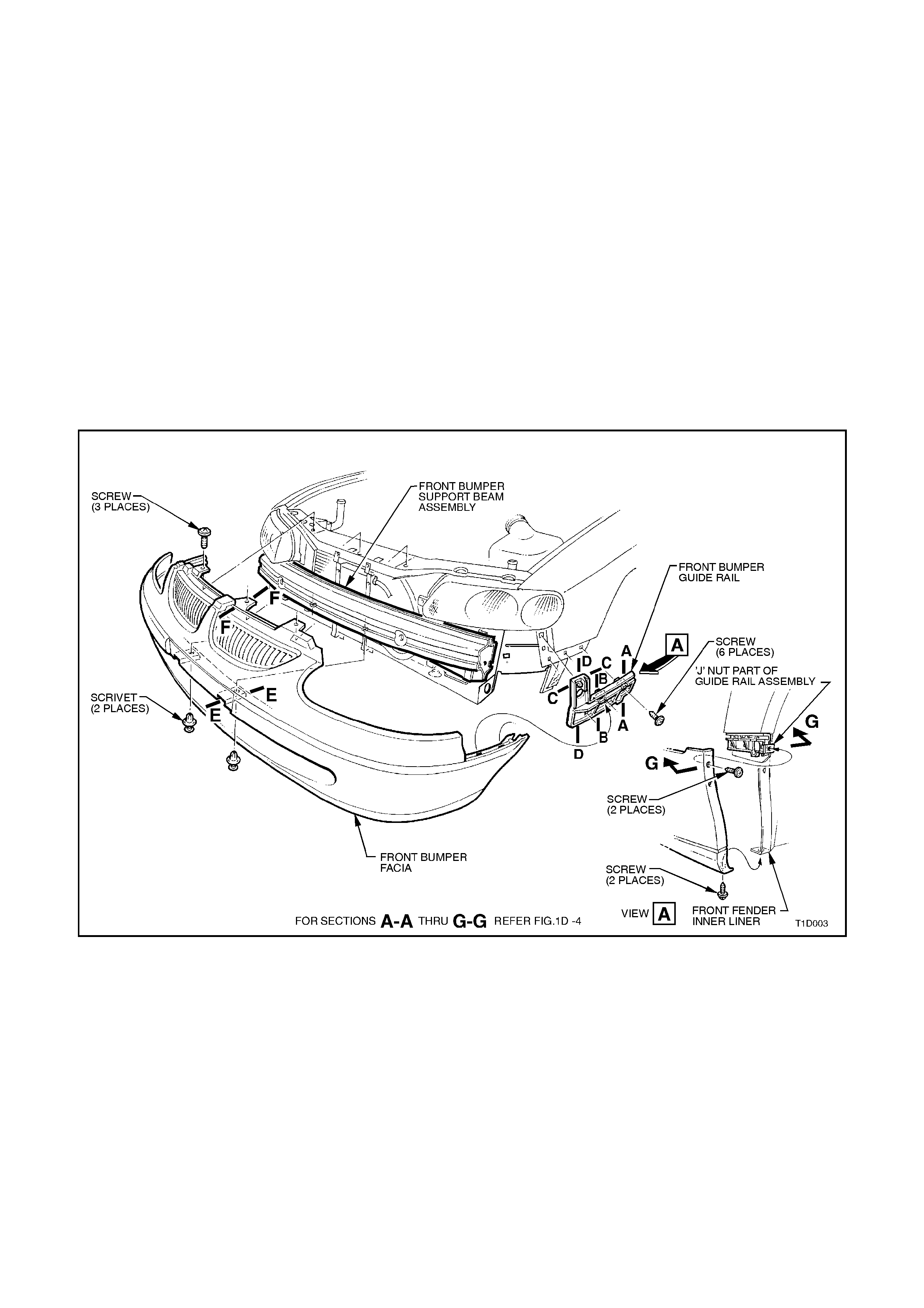

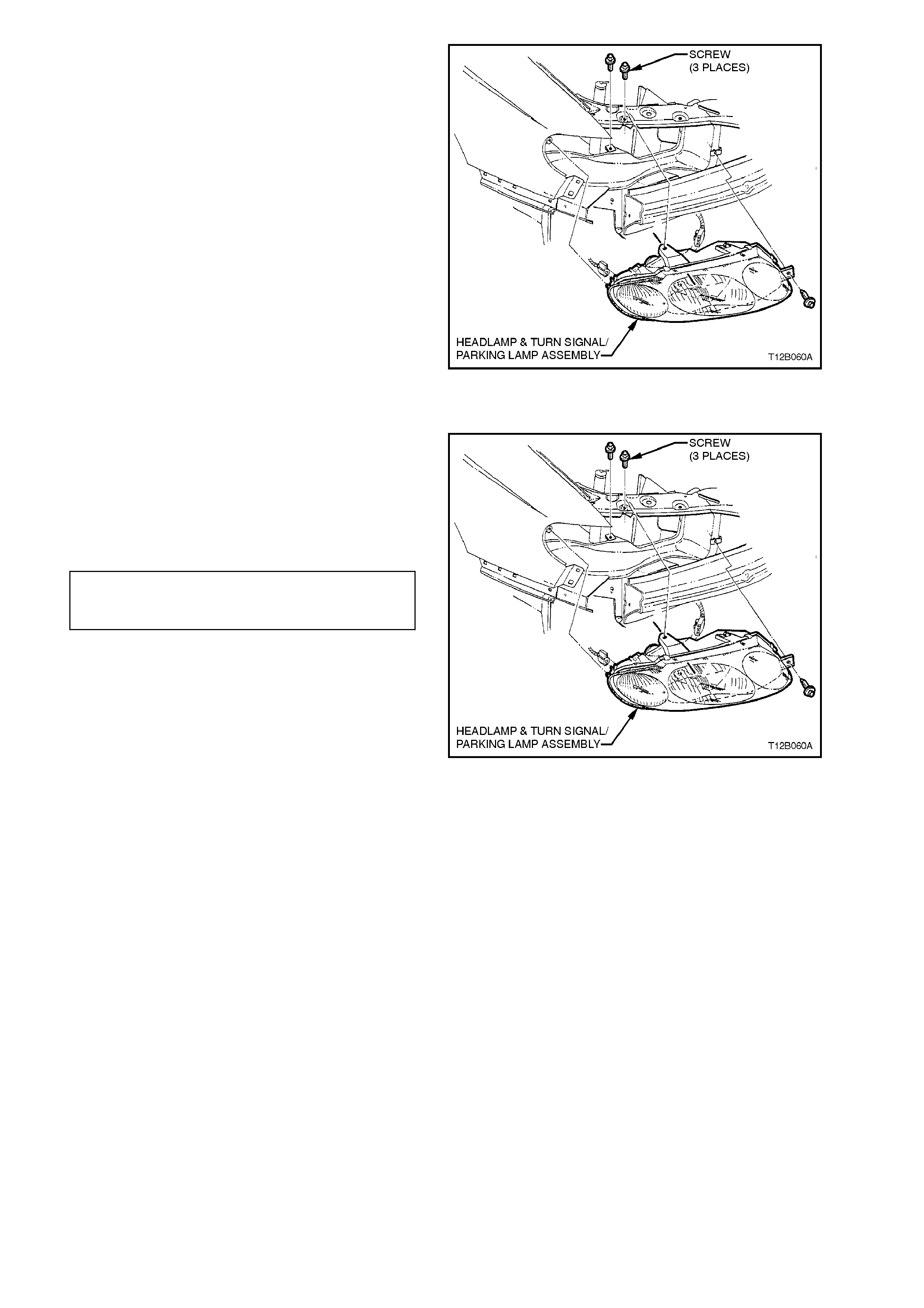

Figure 12B-15

6. Remove headlamp r etaining scr ews (3 places )

and remove headlamp & turn signal/ parking

lamp assembly..

Figure 12B-16

REINSTALL

Reinstallation of the headlamp & turn signal/

parking lamp assembly is the reverse of removal

procedures noting the following points:

1. Install headlamp & turn signal/ parking lamp

assembly and tighten retaining screws to the

correct torque specification.

HEADLAMP & TURN SIGNAL/

PARKING LAMP ASM. RETAINING 2 - 5 Nm

SCREW TORQUE SPECIFICATION

2. Reintall front bumper facia assembly by

snapping the facia onto the retainers at guide

rails, one side at a time.

3. Ensure correct fender, hood and headlamp

clearance, adjust facia if necessary, refer

Section 1D BUMPER BARS.

4. Reconnect all wiring harness connectors and

check operation of headlamp and turn signal/

parking lamps and if fitted, fog lamps.

5. Check headlamp (and fog lamp if fitted) aim,

refer to 2.1 AIMING OF HEADLAMP AND

FOG LAMPS in this section.

Figure 12B-17

6. Install front facia grille.

Driver’s side only

Reinstall battery if removed, secure battery

retaining clamp and reconnect battery

terminals.

NOTE:

When installing headlamp assembly, use care to

ensure that the turn s ignal/parking lam p lens is not

scratched by fender extension peak, and no

damage is made to the front bumper bar facia.

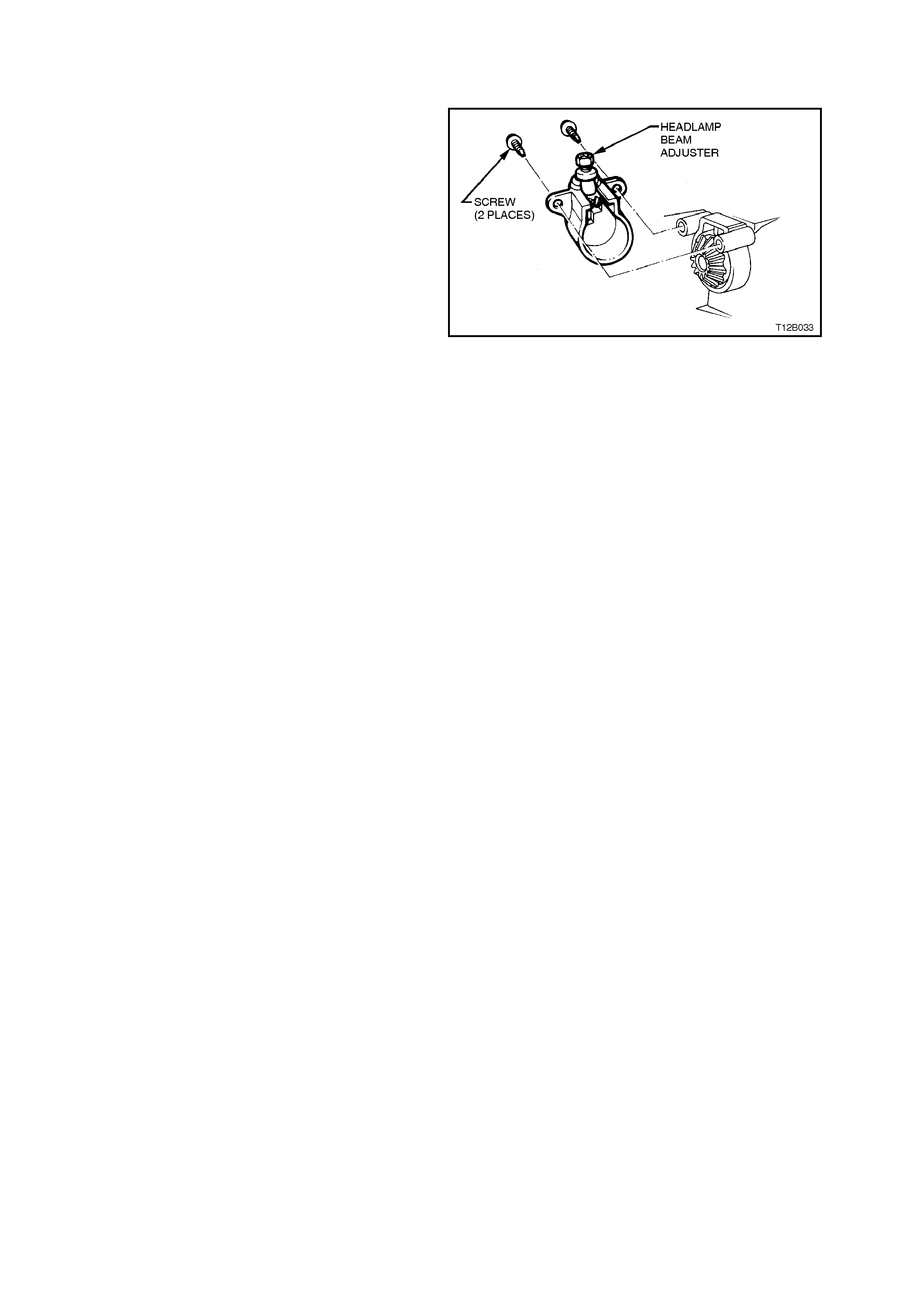

2.7 HEADLAMP ADJUSTER

REMOVE

1. Remove headlamp assembly refer to

2.6 HEADLAMP AND TURN

SIGNAL/PARKING LAMP ASSEMBLY in this

Section.

2. Remove two screws securing headlamp

adjuster to headlamp assembly and remove

adjuster.

3. Inspect adjuster and replace if worn or

damaged.

REINSTALL

Installation of the headlam p adjuster is the reverse

of removal procedures noting the following point:

1. Align bevel gear to avoid tooth abutment with

mating gear prior to tightening securing

screws.

Figure 12B-18

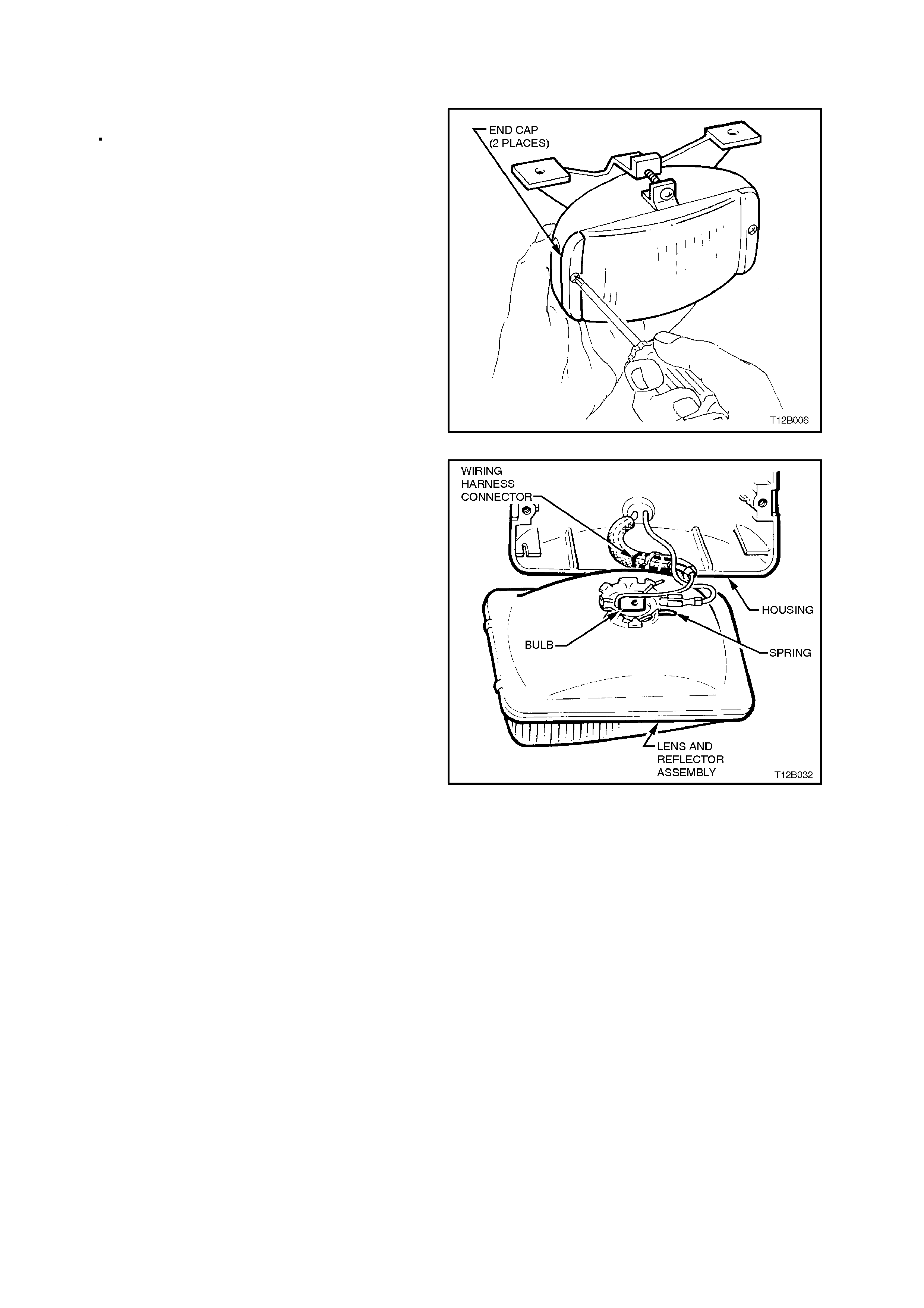

2.8 FOG LAMP BULB CALAIS AND SS MODELS

REPLACE

1. Remove fog lamp assembly, refer to

2.9 FOG LAMP ASSEMBLY - CALAIS AND

SS MODEL in this Section.

2. Remove lens and reflector assembly to

housing end cap retainer screws, remove end

caps.

Figure 12B-19

3. Pull lens and reflector assembly out from

housing.

4. Disconnect bulb lead from wiring harness

connector.

5. Squeeze halves of spring retainer together

and pivot spring backward clear of bulb. Lift

out bulb and remove.

6. Connect new bulb lead to wiring harness

connector, install bulb into correct locating

notches in reflector and reconnect spring

retainer.

NOTE:

Do not handle quartz envelope of bulb. If touched,

wipe immediately with methylated spirits or bulb

performance will deteriorate.

7. Reinstall lens and reflector assembly into

housing. Install end caps and screws, tighten

screws.

8. Reinstall fog lamp assembly, refer to

2.9 FOG LAMP ASSEMBLY - CALAIS AND

SS MODELS in this Section.

9. Check fog lamp operation and aim, refer to

2.1 AIMING OF HEADLAMPS AND FOG

LAMPS in this Section.

Figure 12B-20

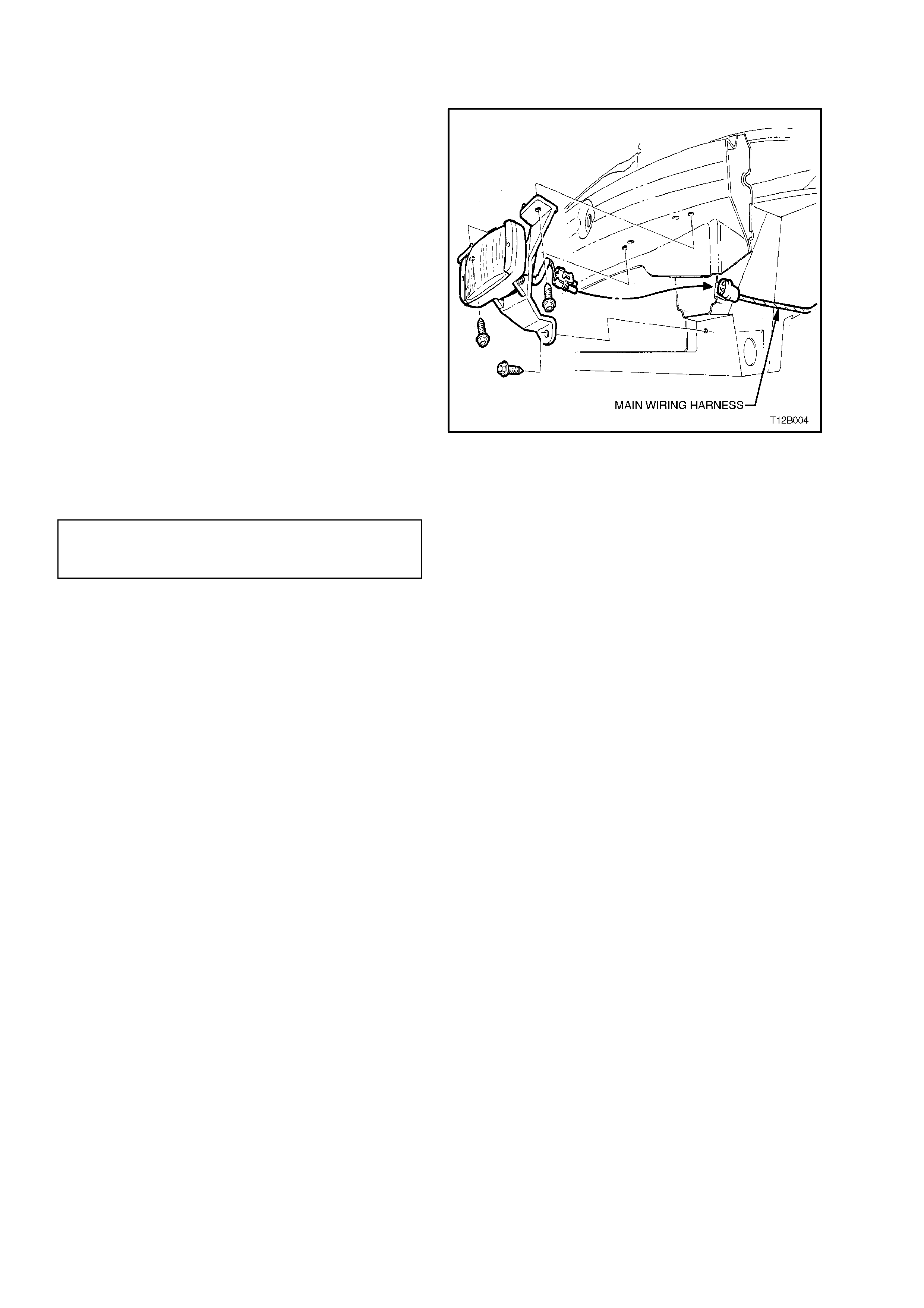

2.9 FOG LAMP ASSEMBLY - CALAIS AND SS MODELS

REMOVE

1. From inside wheelhouse, disconnect main

wiring harness from fog lamp harness

connector.

2. From behind bumper bar, remove three

mounting frame to bumper bar beam screws,

remove fog lamp assembly.

REINSTALL

Reinstallation of the fog lamp assembly is the

reverse of rem oval procedur es, noting the following

points:

1. Install fog lamp assembly to bumper bar

beam, ensuring that locating screw in lamp

mounting frame is located in the mating hole in

the bumper bar beam.

2. Tighten lamp mounting frame to bumper bar

beam and facia screws to the correct torque

specification. Figure 12B-21

FOG LAMP MOUNTING FRAME TO

BUMPER BAR BEAM AND FACIA

SCREW TORQUE SPECIFICATION 2 - 5 Nm

3. Check fog lamp operation. Recheck fog lamp

aim, refer to 2.1 AIMING OF HEADLAMPS

AND FOG LAMPS in this Section.

2.10 FOG LAMP SWITCH

REMOVE

1. Disconnect battery earth lead.

CAUTION:

Disable the SRS (Air Bag). Refer to DISABLING

THE SRS, Section 12M SUPPLEMENTAL

RESTRAINT SYSTEM.

2. Release steering column height adjusting

lever and completely lower steering column,

lock lever in this position.

Place a clean shop rag over and around

steering column upper cover. This step is

important so as to prevent any possibility of

damage to cover when removing the

instrument facia.

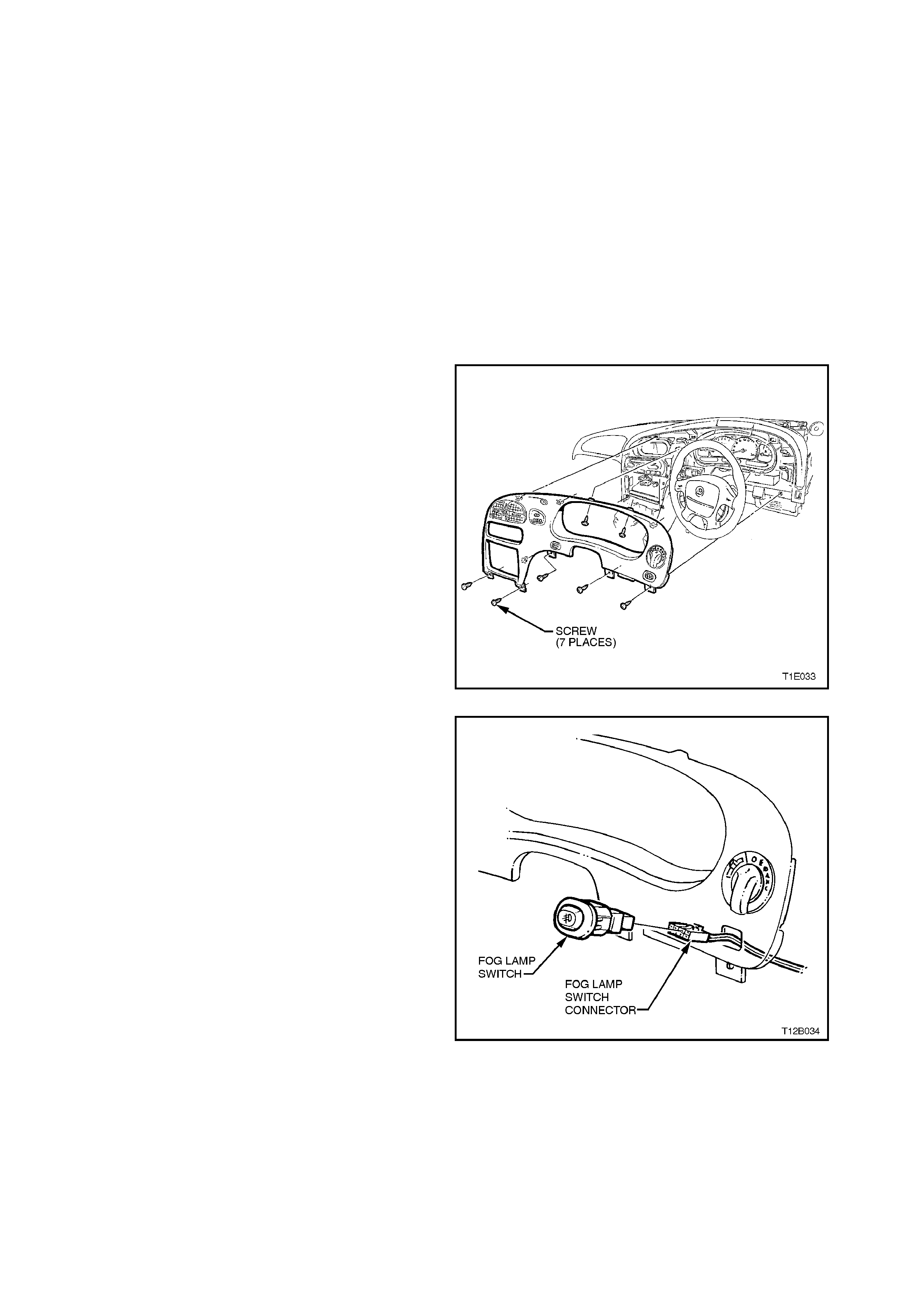

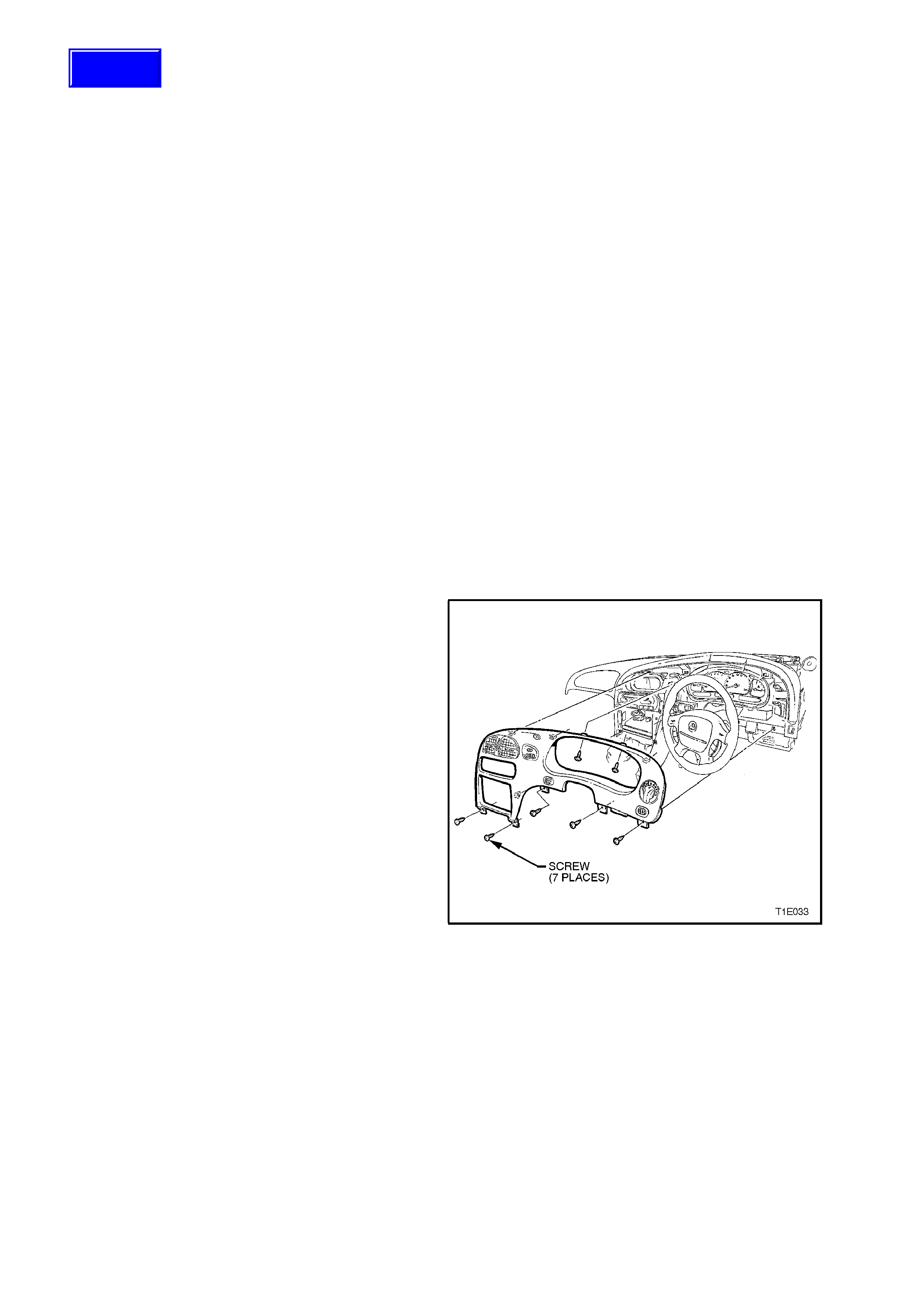

3. Remove instrument facia panel in order to gain

access to rear of fog lamp switch. For further

information refer to Section 1A3 INSTRUMENT

PANEL AND CONSOLE.

Figure 12B-22

4. Depress retaining tang on instr ument harness to

fog lamp switch connector, pull connector from

switch.

5. Squeeze together retaining tangs at side of

switch and push switch out from facia.

Figure 12B-23

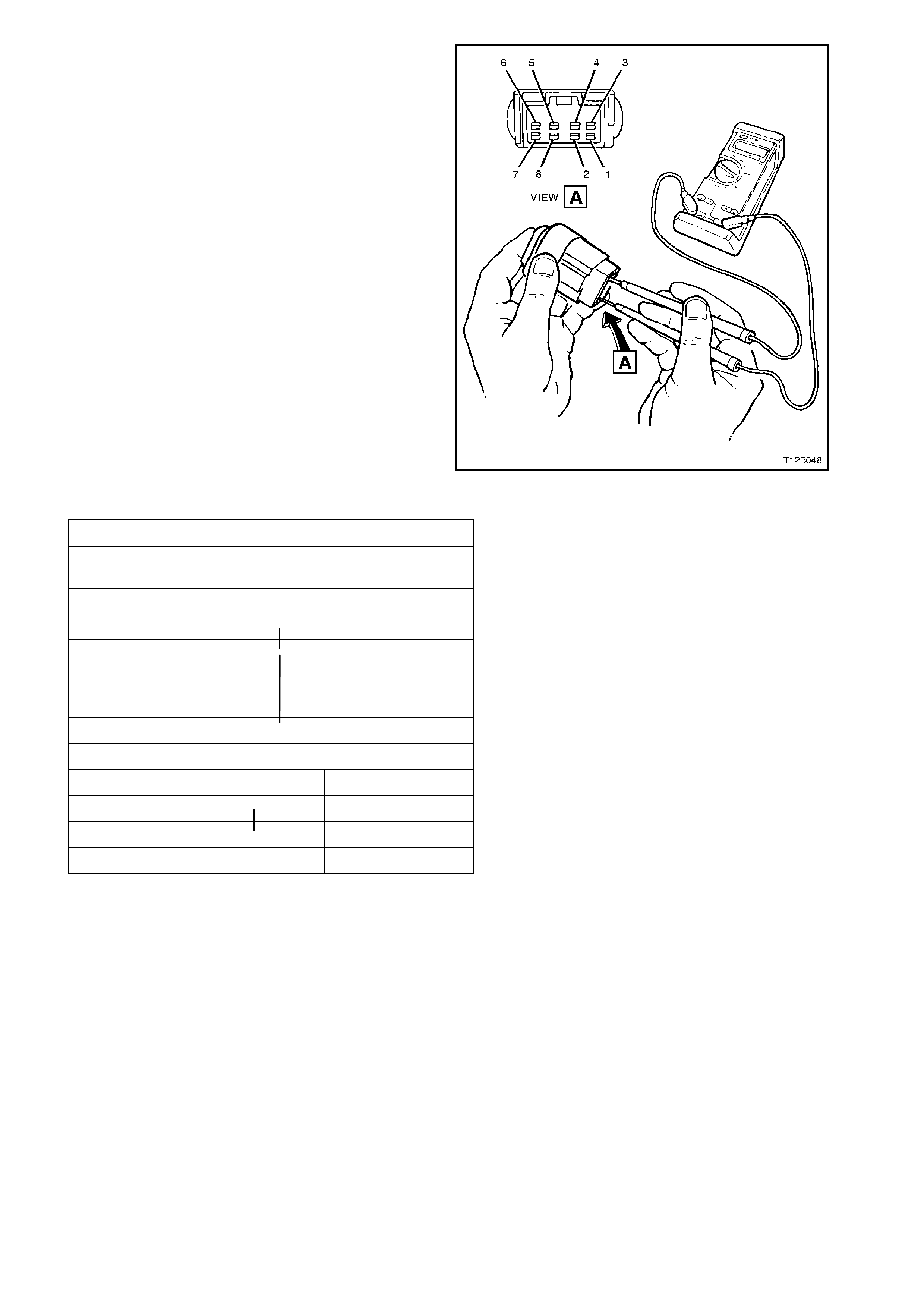

TEST

W ith the aid of an ohmmeter, check continuity of fog

lamp switch contacts using the following chart.

If continuity is not as specified at any switch position,

replace switch assembly.

Figure 12B-24

FOG LAMP SWITCH CONTACTS

TERMINAL

NO. SWITCH

STATUS

OFF ON

1 O PARK LAMPS

2 O FOG LAMPS

3

4

5O

6

7 O Illumination +

●

8 O Illumination –

REINSTALL

Installation of the fog lamp switch is the reverse of

removal procedures, noting the following points:

1. If, when instrument facia was pulled away

from instrument panel pad, the pad retaining

clips came away with the facia lugs, pull clips

from lugs and reinstall into pad holes.

If fitted, ensure that steering column to

instrument facia screen lip is fitted correctly to

edge on instrument panel pad. Refit

instrument facia and ensure that it is held to

the instrument panel pad securely.

2. Check fog lamp operation and ensure that

switch illumination bulb illuminates when the

headlamps are turned on.

IMPORTANT:

Enable the SRS (Air Bag). Refer to ENABLING

THE SRS, Section 12M SUPPLEMENTAL

RESTRAINT SYSTEM.

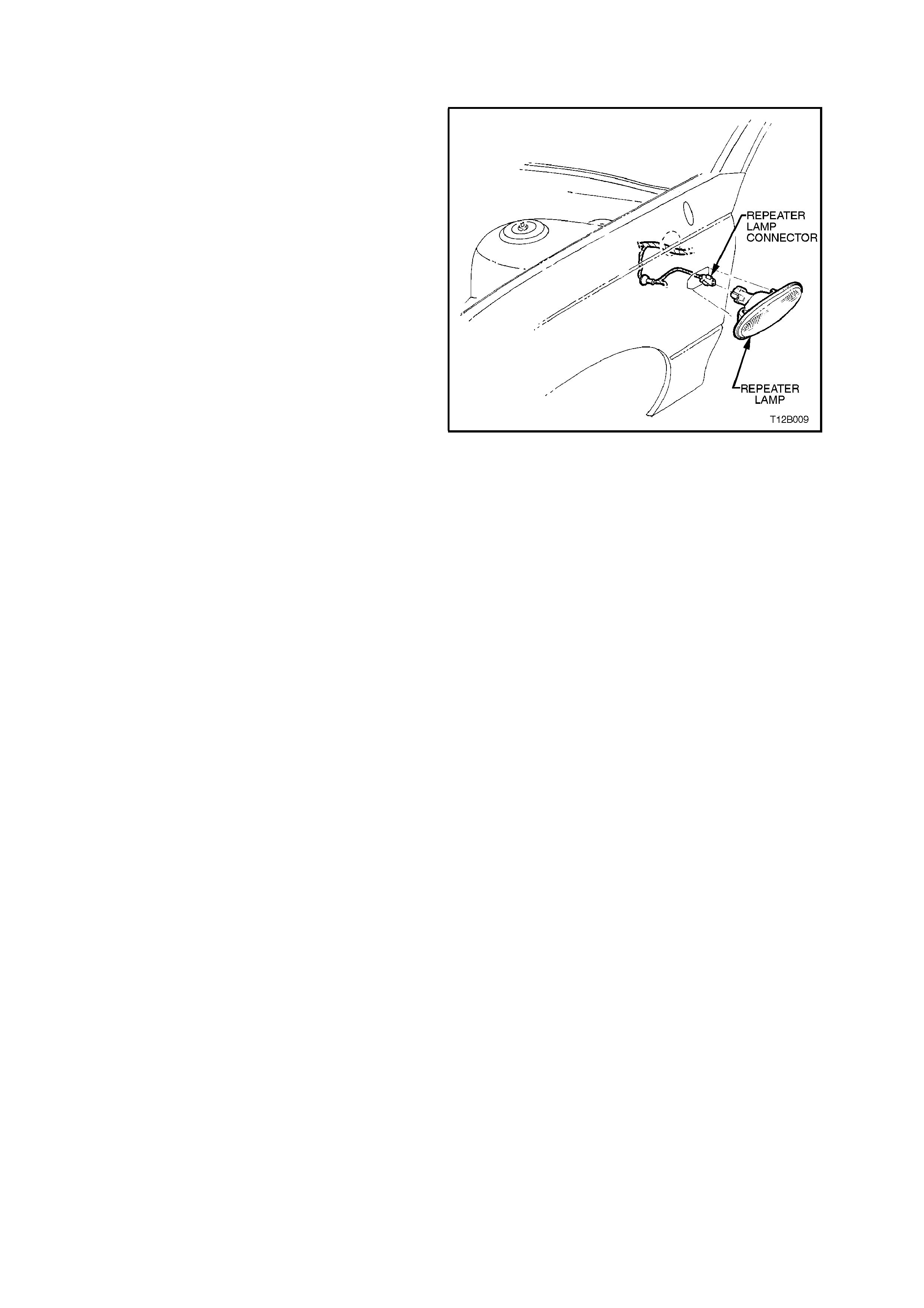

2.11 SIDE REPEATER LAMP

REMOVE

1. Grip rear edge of lamp hous ing with finger tips

and pull housing forward and outwards from

fender panel. Once hous ing has releas ed fr om

fender panel, remove housing and twist bulb

socket to release from housing.

2. If required, pull bulb from socket to replace.

3. Inspect lamp housing and bulb socket seals

for damage, replace if necessary.

REINSTALL

1. If necessary, install new bulb to socket.

2. Assemble repeater lamp housing to socket

and twist socket to lock into housing.

3. Install lamp housing into fender opening with

housing locking nib facing forward and

engaging into opening.

4. Push rear of lamp housing into fender

opening, ensuring lamp housing is securely

locked to fender.

5. Check repeater lamp operation.

Figure 12B-25

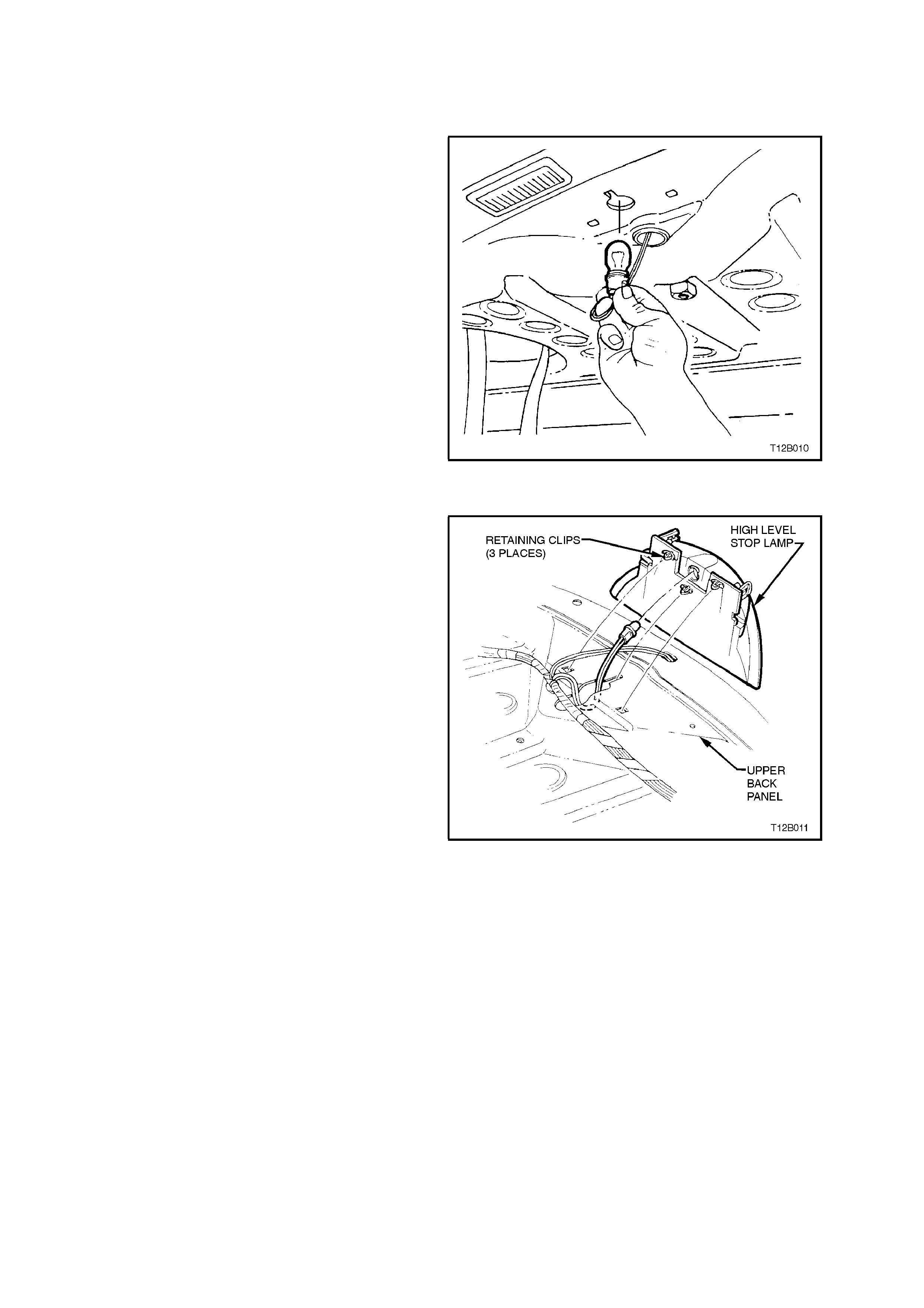

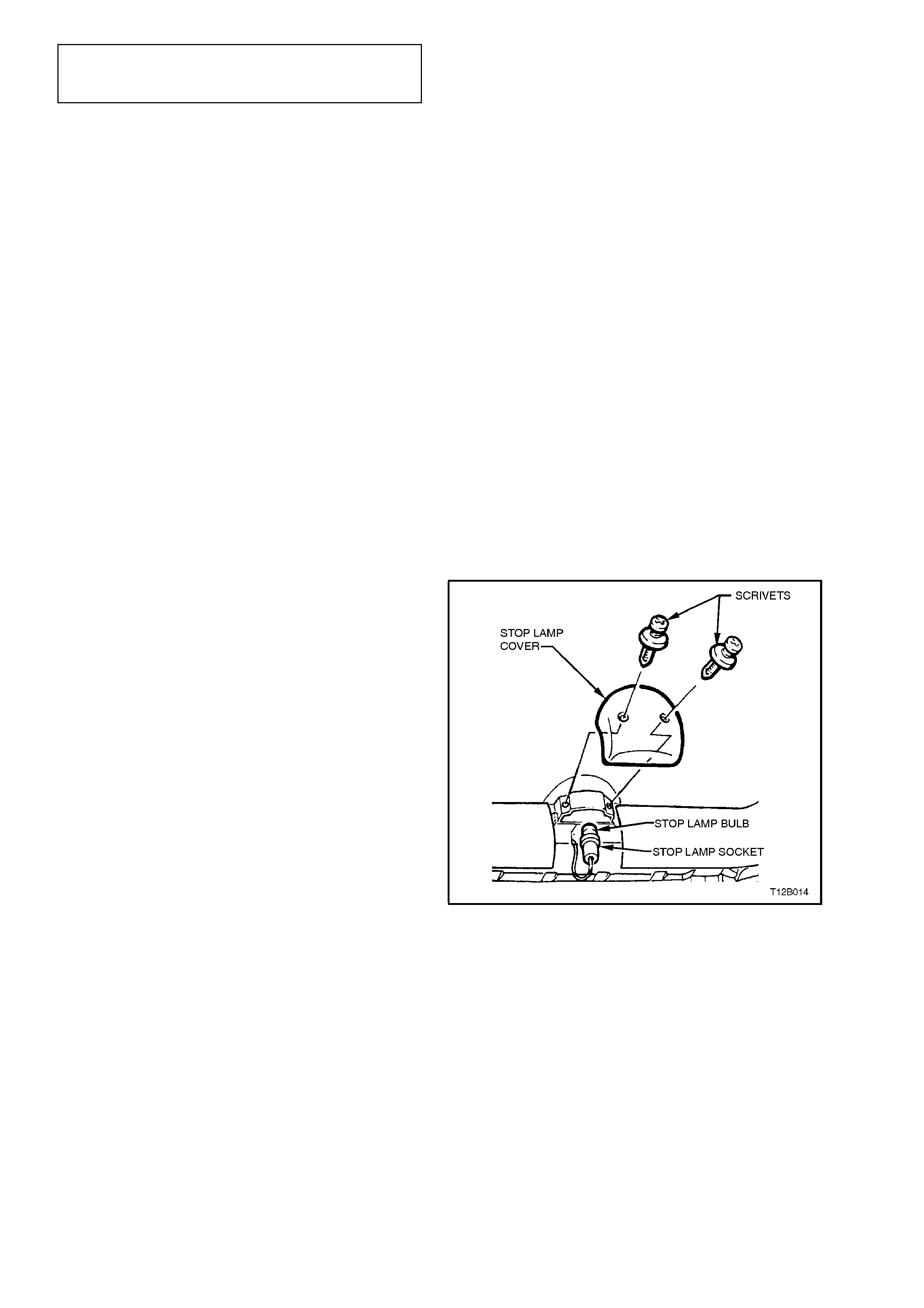

2.12 HIGH LEVEL STOP LAMP

SEDAN MODELS WITHOUT REAR COMPARTMENT LID SPOILER

BULB REPLACEMENT

Access to the bulb is through the rear c ompartment

and up through the upper rear panel opening

beneath the stop lamp mounting.

1. Twist bulb socket to release from lamp. Pull

socket down into rear compartment and pull

bulb from socket.

NOTE:

It may be necessary to use a pair of pointed nose

pliers to hold and release bulb socket.

2. Install new bulb into socket and install bulb

socket into housing.

Figure 12B-26

LAMP REPLACEMENT

Fig. 12B-27 illustrates the installation of the high

level stop lamp for sedan models without rear

compartment lid air spoiler.

To remove lamp assembly, remove rear parcel

shelf, refer to Section 1A8 HEADLINING AND

REAR END TRIM. Remove bulb and socket as

described previously. Disengage retaining clips

securing high level stop lamp to upper back panel

and remove lamp assembly.

On reinstallation of high mount stop lamp, ensure

that stop lamp housing is pushed fully rearward

before engaging retaining clips.

Figure 12B-27

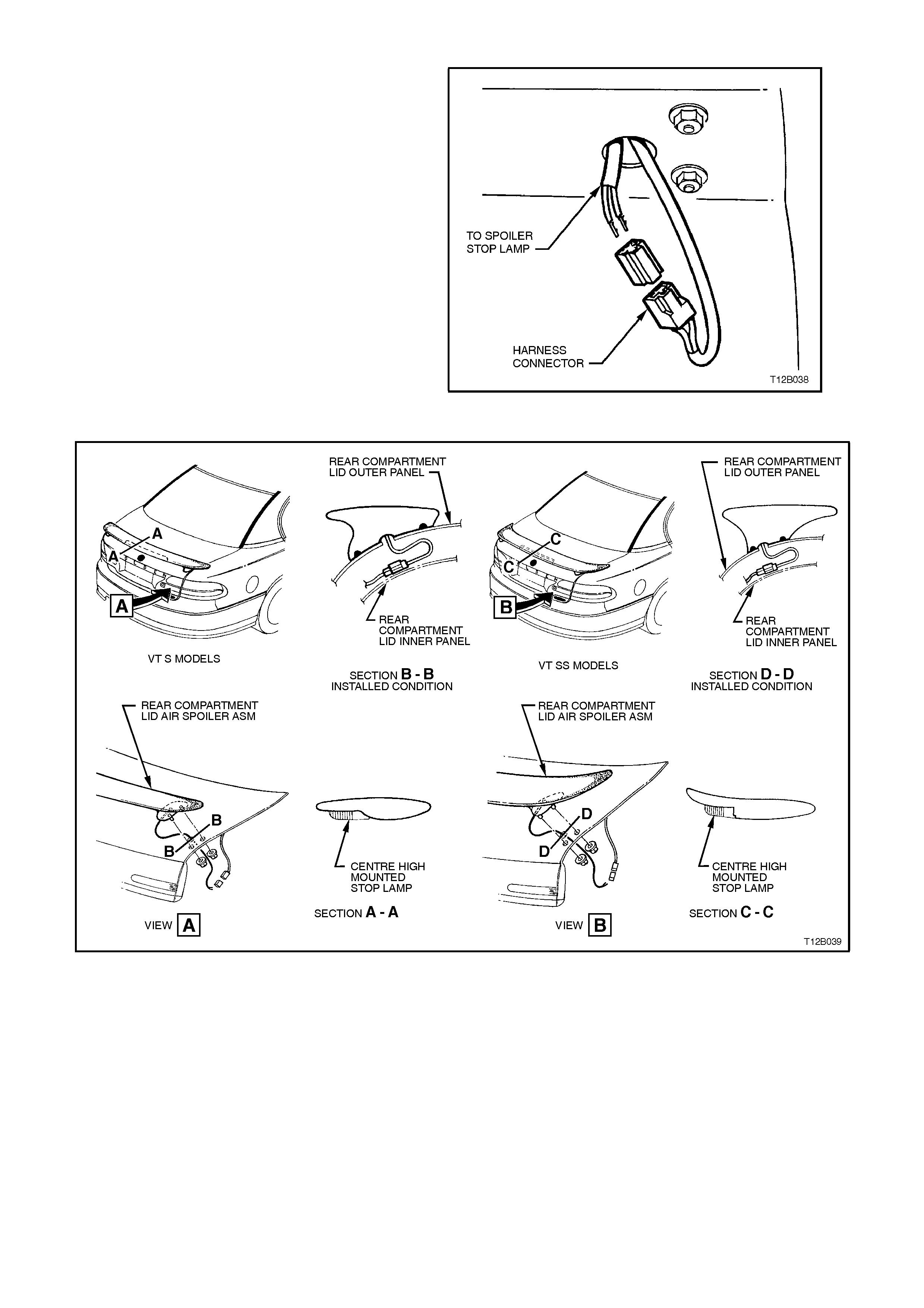

S AND SS MODELS

Fig. 12B-28 illustrates the installation of the high

level stop lamp for S and SS sedan models with

rear compartment lid air spoiler.

REMOVE

To remo ve lamp assembly:

1. Open rear compartment lid and locate high

mounted stop lamp to wiring harness

connectors.

2. Disconnect high mounted stop lamp to wiring

harness connectors and remove connector

from stop lam p harness. T his will allow s poiler

to be removed.

3. Remove rear compartment lid air spoiler (4

bolts), ensuring no damage is made to rear

compartment lid paintwork, and remove

spoiler. Note that sealant may be present.

Figure 12B-28

Figure 12B-29

4. Using fine bladed screwdriver, gently prise

high level stop lamp assembly screw cover

plate from spoiler. Cover plate is attached with

3 pieces of double sided tape.

5. Remove high level stop lamp assembly to

spoiler attaching screws.

6. Remove high level stop lamp from spoiler,

disengaging harness rubber grommet from

hole in spoiler and feed out harness through

spoiler, remove lamp assembly.

HIGH MOUNT STOP LAMP TO

SPOILER ATTACHING SCREW

TORQUE SPECIFICATION

1 - 3 Nm

REINSTALL

To reinstall lamp assembly:

1. Feed harness through hole in spoiler and into

rear compartment.

2. Assem ble lamp ass embly to spoiler and install

high mount stop lamp assembly to spoiler

attaching screws. Tighten screws to the

correct torque specification. Replace screw

cover plate using 3 pieces of double sided

tape.

3. If installing new lam p assem bly, push harness

sleeve toward lamp assembly and secure

sleeve position with some electrical tape.

4. Attach lamp wiring connector to lamp

assembly. Reconnect lamp assembly wiring

harness connectors and check lamp

operation.

5. To install rear compartment lid air spoiler, refer

to Section 1A9 EXTERIOR

ORNAMENTATION.

STATION WAGON

BULB REPLACEMENT

1. Open tailgate and remove tailgate trim cover

at rear of high level stop lamp (2 scrivets).

2. From inside cavity of tailgate trim, twist and

unlock bulb socket from lamp assembly and

pull socket out from cavity.

3. Twist and remove bulb from socket.

4. Install new bulb to socket, refit holder to lamp

assembly. Reinstall tailgate trim cover and

check stop lamp operation.

Figure 12B-30

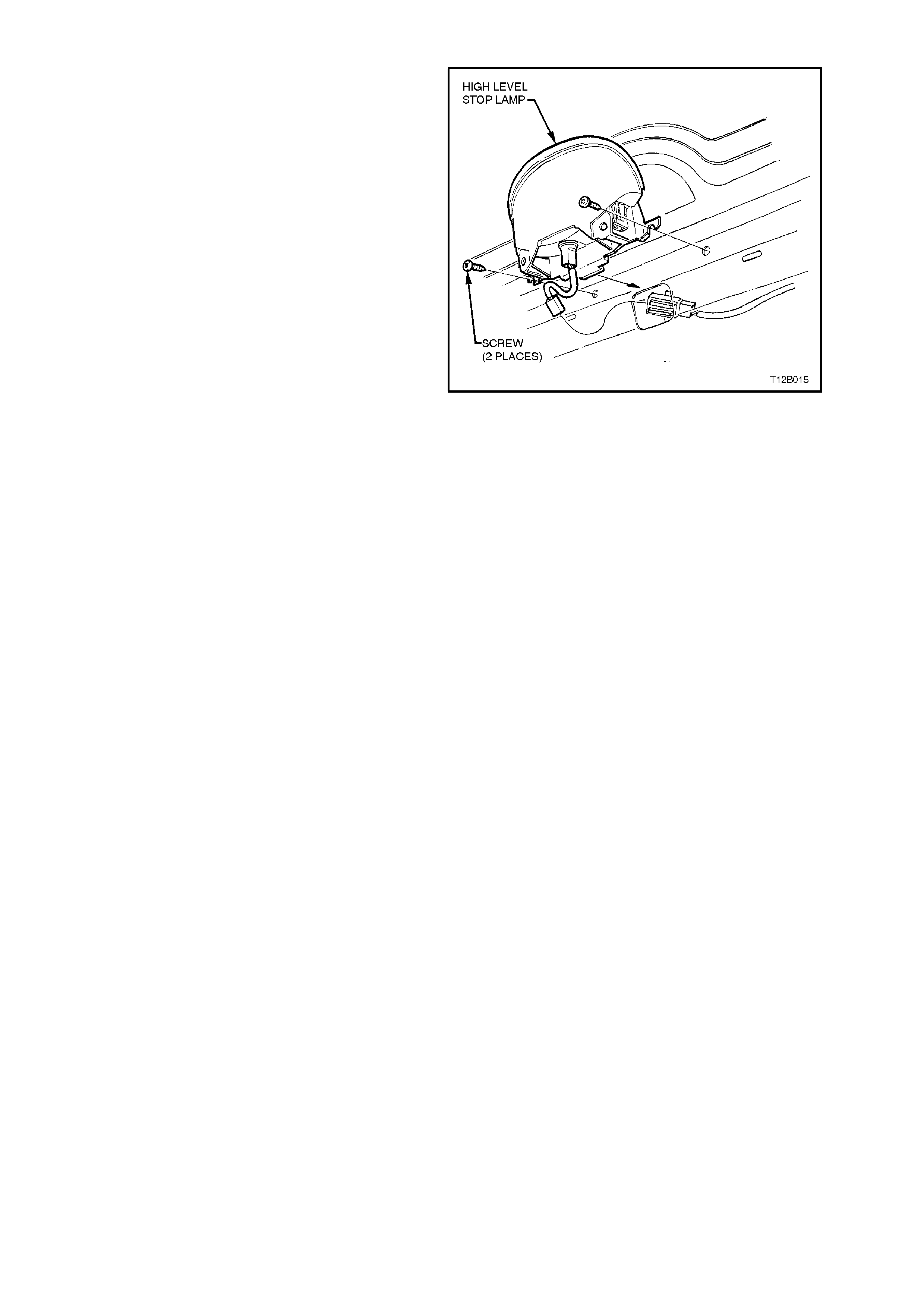

HIGH LEVEL STOP LAMP REPLACEMENT

1. Remove tailgate trim, refer to

Section 1A4 REAR COMPARTMENT LID

AND TAILGATE.

2. Remove high level stop lamp cover at rear of

high level stop lamp (2 scrivets).

3. Twist and unlock bulb socket from lamp

assembly.

4. Remove lamp assembly to tailgate attaching

screws (2) and remove lamp assembly.

5. Reinstall lamp assembly in reverse order of

removal.

6. Check stop lamp operation.

Figure 12B-31

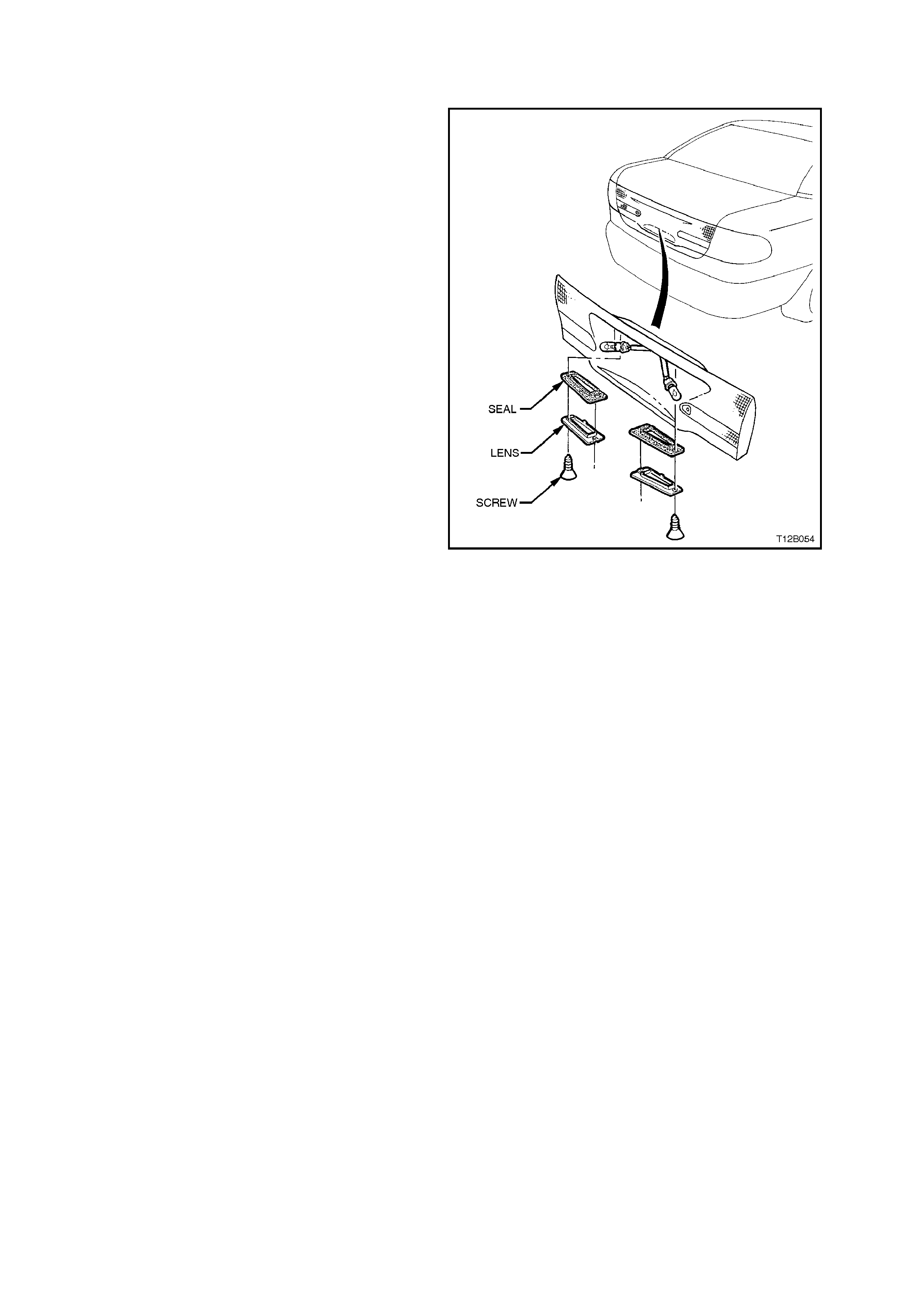

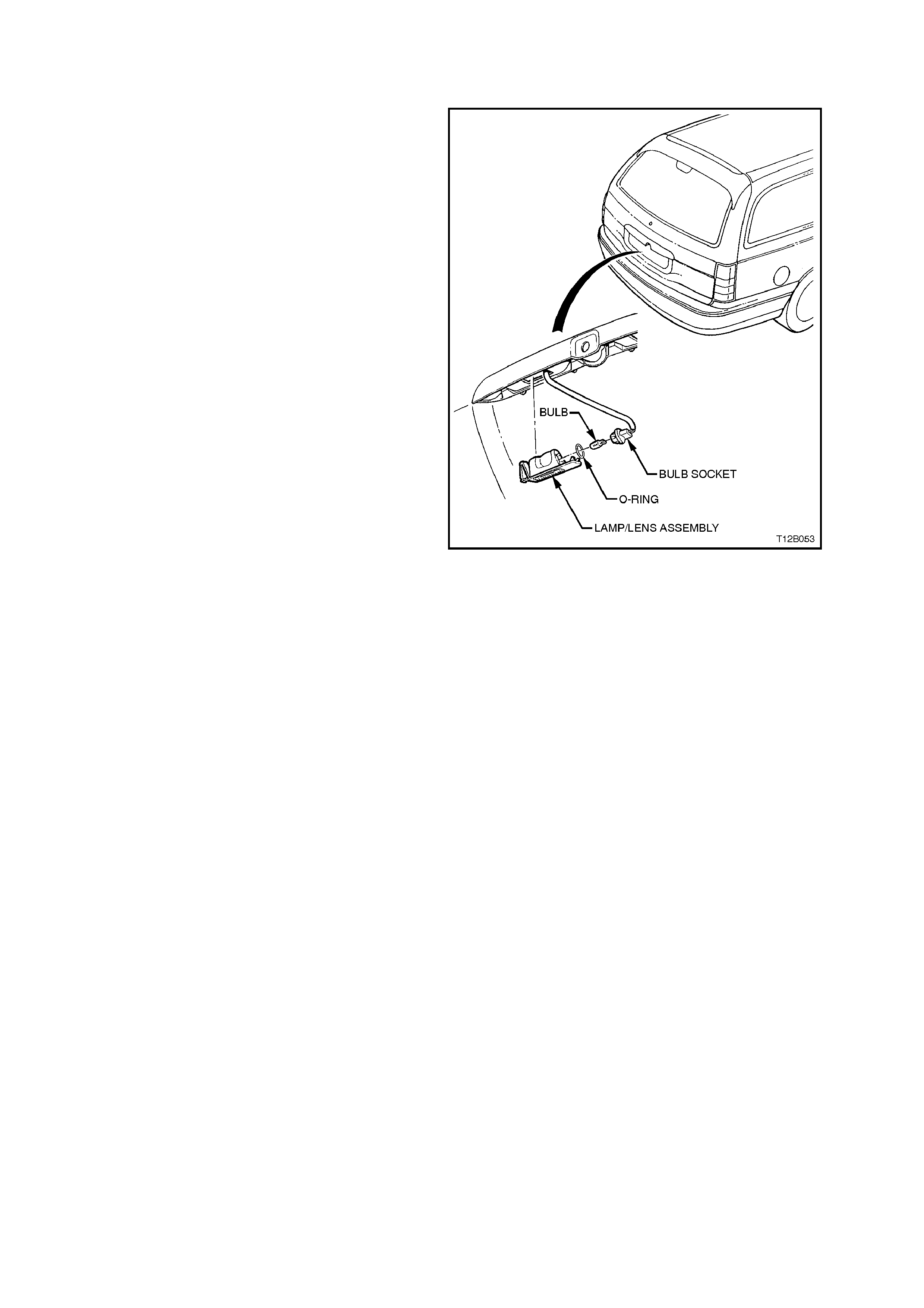

2.13 LICENCE PLATE LAMP/BULB - SEDAN

REMOVE

1. Remove screws securing lamp lens to decklid

lamp assembly and remove lamp lens.

2. Pull bulb from socket.

3. Inspect bulb socket sealing ring for damage,

replace if required.

REINSTALL

1. Push new bulb into bulb socket.

2. Check lamp operation.

Figure 12B-32

2.14 LICENCE PLATE LAMP - STATION WAGON

BULB REPLACEMENT

1. Slide tab on licence plate lamp lens to

disengage lamp assembly from tailgate lock

trim and remove lens complete with bulb.

2. Replace bulb and install lens.

NOTE:

There is a locating tag on one end of lens at the

bulb contact. This is to ensure that lens will only

assemble to tailgate lock trim in one direction only.

Figure 12B-33

REMOVE

1. Remove tailgate trim, refer to Section 1A4

REAR COMPARTMENT LID AND

TAILGATE.

2. From inside tailgate, disconnect wiring

connectors from licence plate lamp assembly.

3. Slide tab on licence plate lamp lens to

disengage lamp assembly from tailgate lock

trim and remove lens complete with bulb.

REINSTALL

1. Installation is the reverse of removal

procedures.

2. Check lamp operation.

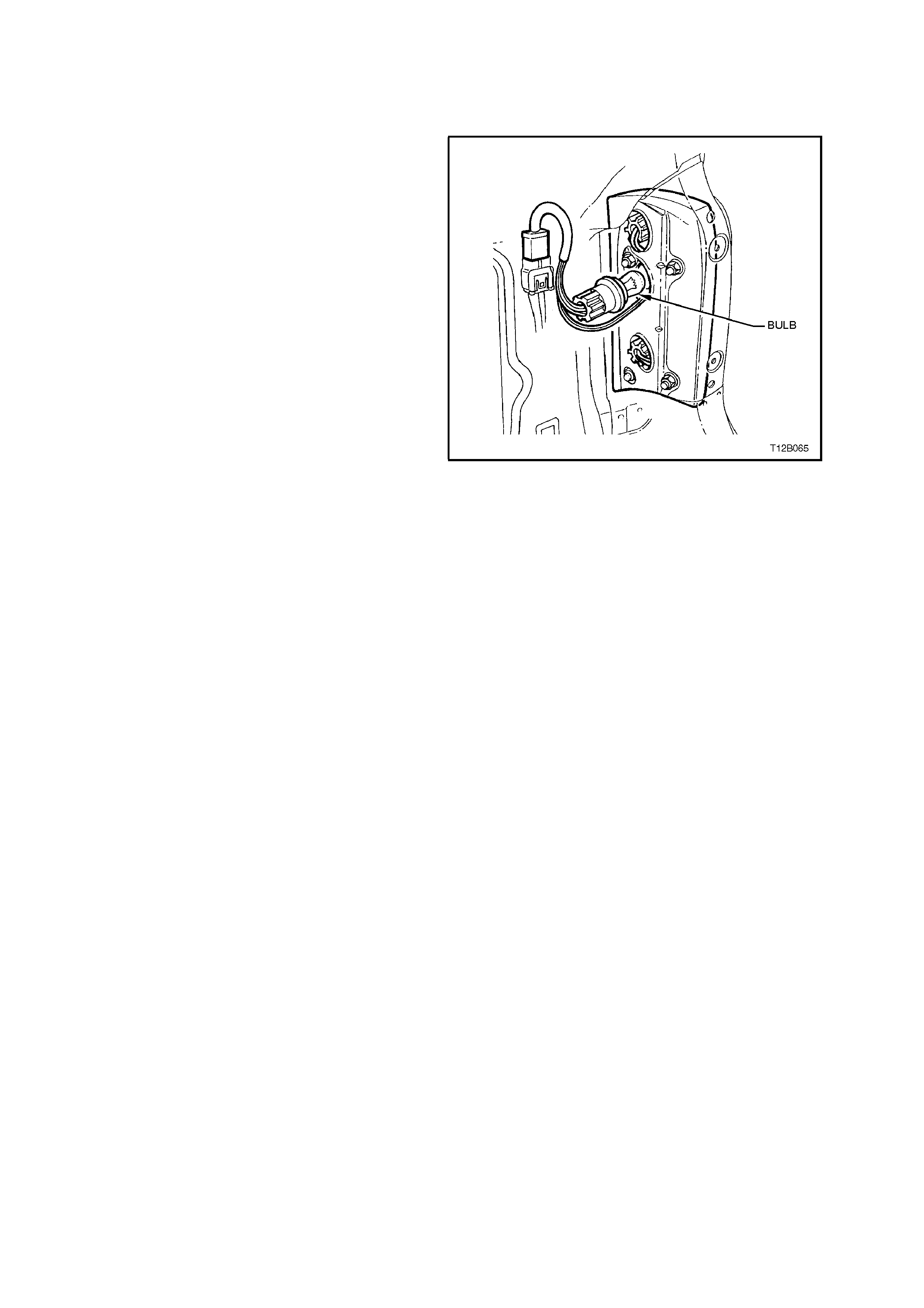

2.15 S EDAN REAR LAMP BULBS

STOP/TAIL AND TURN SIGNAL LAMP BULBS

REPLACE

1. Open rear compartment.

2. Remove rear lamp assembly refer to

2.17 REAR LAMP ASSEM BLY- SEDAN in this

Section.

3. Remove appropriate bulb socket by turning

and removing socket.

4. Remove bulb from socket by depressing bulb

into its socket and then rotate to remove.

Inspect bulb socket to lamp housing seals for

damage, replace if necessary.

5. Insert new bulb into socket and refit socket

into lamp housing, ensuring socket locks

securely into place. Note that there are

different socket types for stop/tail lamps and

turn signal lamps. These are colour coded.

NOTE:

If replacing a rear quarter turn signal lamp bulb,

ensure the cor rect type is fitted. For Calais models ,

the turn signal bulb glass is coloured orange and

has offset locating pins, whereas the bulb used for

Executive, SS, and Berlina has clear glass and

standard parallel locating pins.

Also, different rear quarter lamp harnesses with

specif ic bulb sock ets are used for eac h type of bulb

locating pin style.

6. Check rear lamp operation.

Figure 12B-34

2.16 STATION WAGON REAR LAMP BULBS

STOP/TAIL AND TURN SIGNAL LAMP BULBS

REPLACE

1. Open rear tailgate.

2. Remove rear lamp cover trim, taking care not

to damage cover trim surround.

3. Remove appropriate bulb socket by turning

and removing socket.

4. Remove bulb from socket by depressing bulb

into its socket and then rotate to remove.

Inspect bulb socket to lamp housing seals for

damage, replace if necessary.

5. Insert new bulb into socket and refit socket

into lamp housing, ensuring socket locks

securely into place. Note that there are

different socket types for stop/tail lamps and

turn signal lamps. These are colour coded

and will only install to cor rect m ating apertures

in housing.

6. Check rear lamp operation. Figure 12B-35

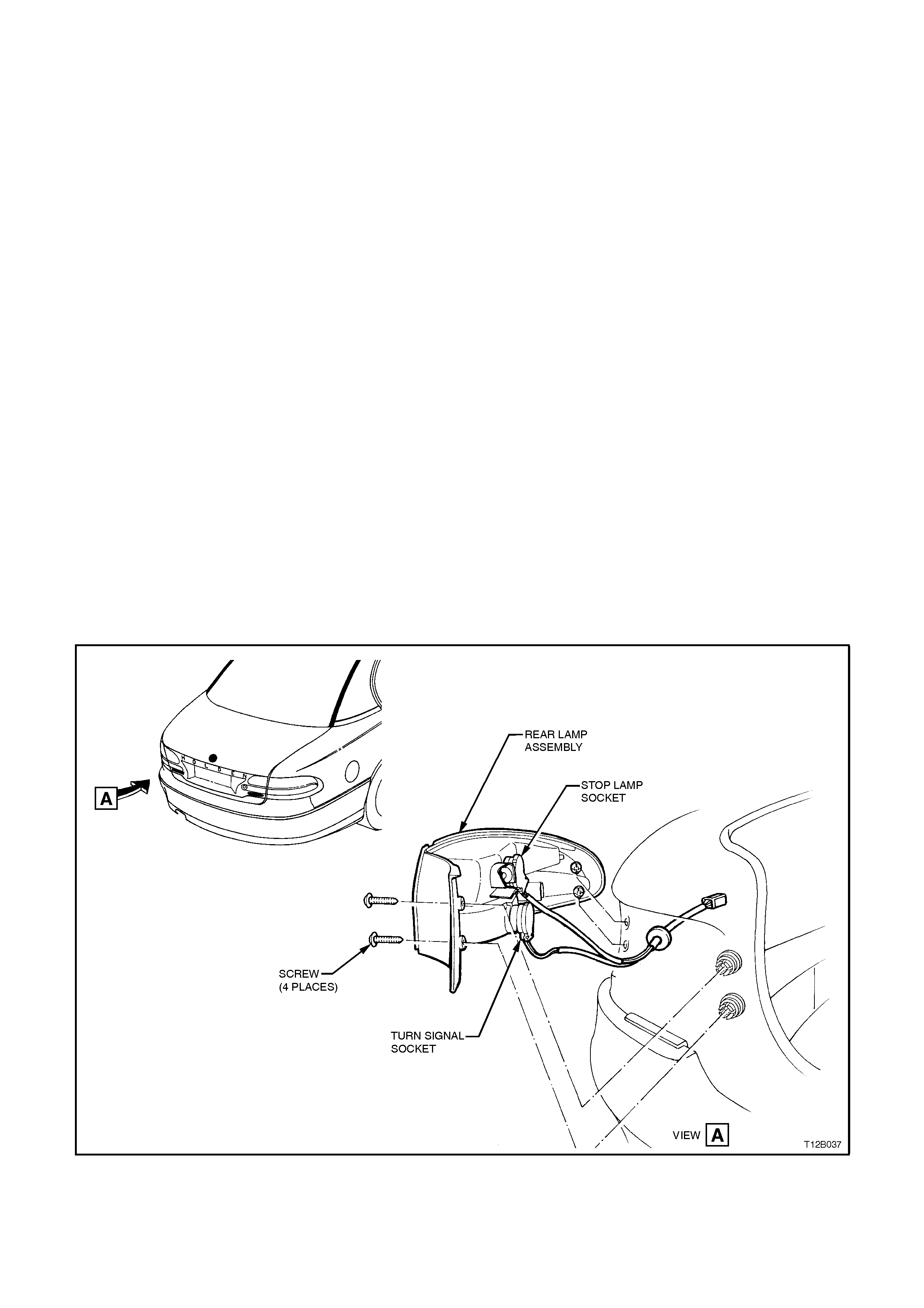

2.17 REAR LAMP ASSEMBLY - SEDAN

REAR QUARTER LAMP ASSEMBLY

REMOVE

1. Open rear compartment.

Remove rear quarter lamp assembly to body

attaching screws (two screws).

2. Pull rear quarter lamp housing sideways out

from panel so locating pegs on side of lamp

assembly snap free from retainers. While

supporting lamp housing, r emove bulb soc kets

by turning and removing socket.

Figure 12B-36

REINSTALL

1. Insert bulb sockets into rear quarter lamp

housing, ensuring sockets lock securely into

place.

2. Ensure that rear quarter lamp harness

grommet is seated correctly. Assemble lamp

housing to body, ensuring locating pegs snap

into retainers and install and tighten attaching

nuts to the correct torque specification.

REAR QUARTER LAMP HOUSING

TO BODY ATTACHING NUT

TORQUE SPECIFICATION 3 - 4 Nm

3. Check rear lamp operation.

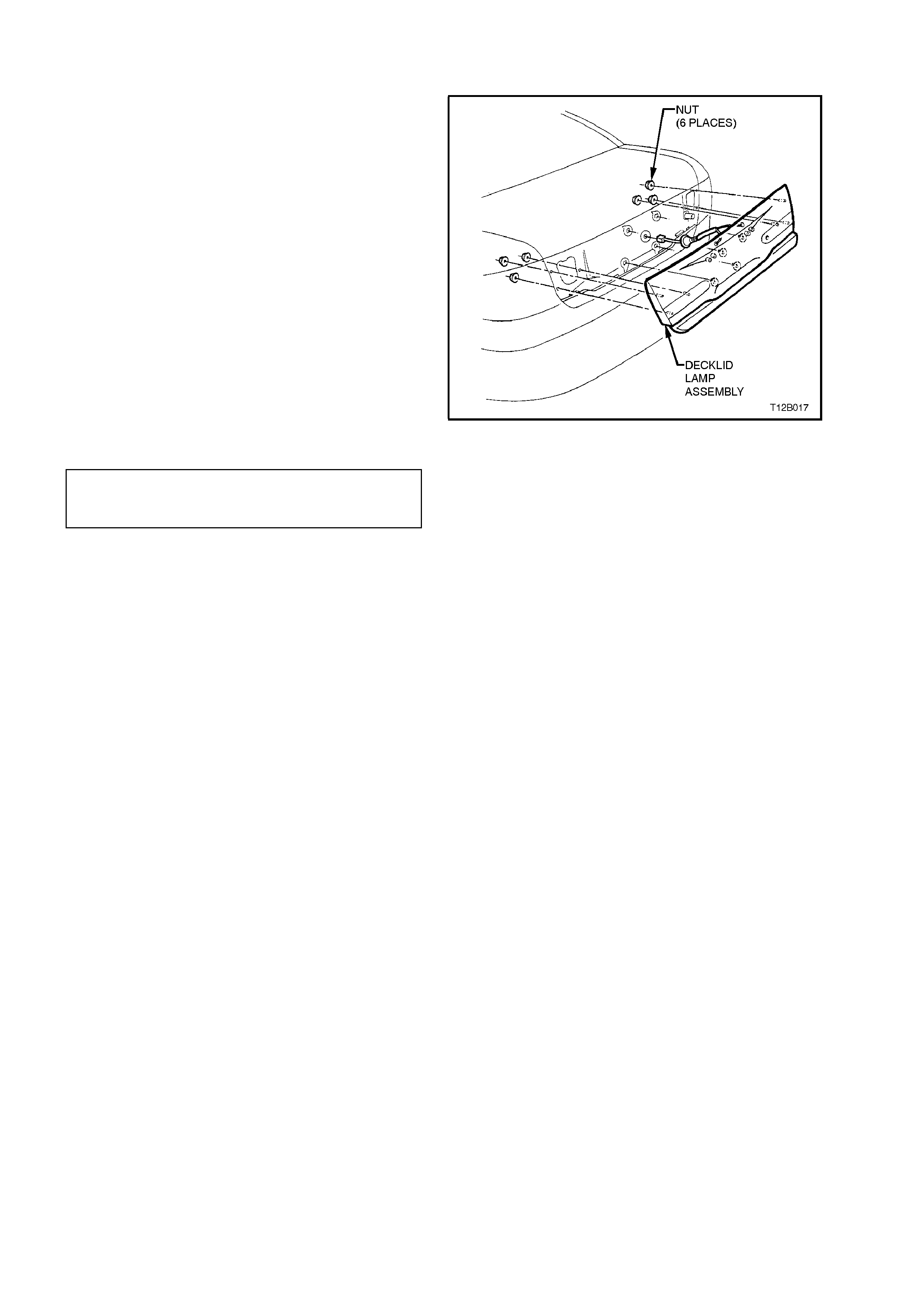

DECKLID LAMP ASSEMBLY

REMOVE

1. Open decklid.

2. From inside deck lid, dis c onnect wiring harnes s

from decklid lamp assembly.

3. Remove lamp assembly to decklid attaching

nuts. Pull lamp assembly outer edge from

decklid and slide outward, disengaging lamp

housing tongue from decklid extension

moulding.

REINSTALL

1. Check condition of lamp housing to decklid

rubber sealing gasket and replace if damaged.

2. Assemble lamp housing to decklid, engaging

lamp assembly tongue in and around moulding

mounting boss grommet. Install and tighten

attaching nuts to the correct torque

specification. Figure 12B-37

DECKLID LAMP HOUSING TO

DECKLID ATTACHING NUT

TORQUE SPECIFICATION 3 - 4 Nm

3. Reconnect wiring harness connector.

4. Check rear lamp operation.

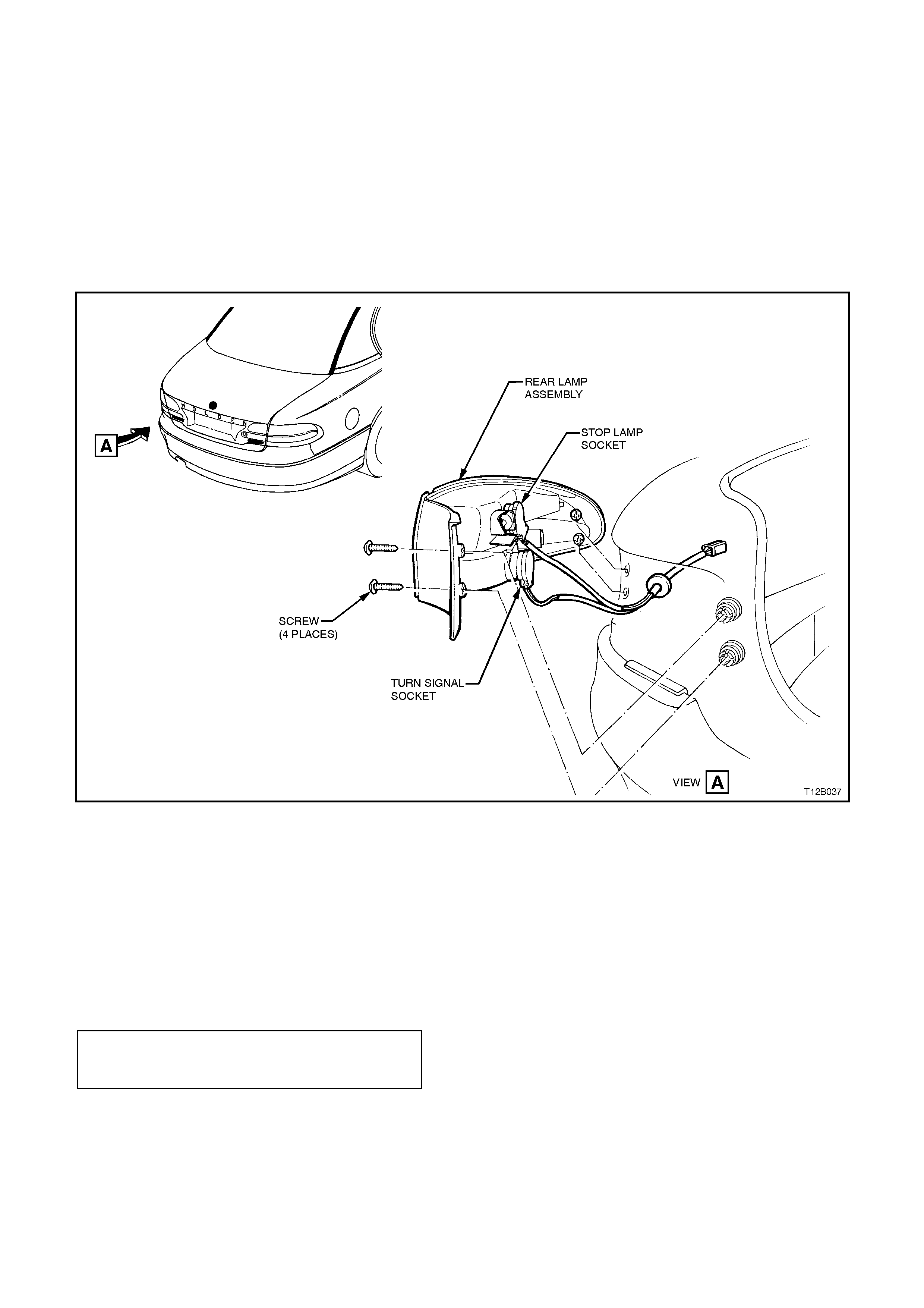

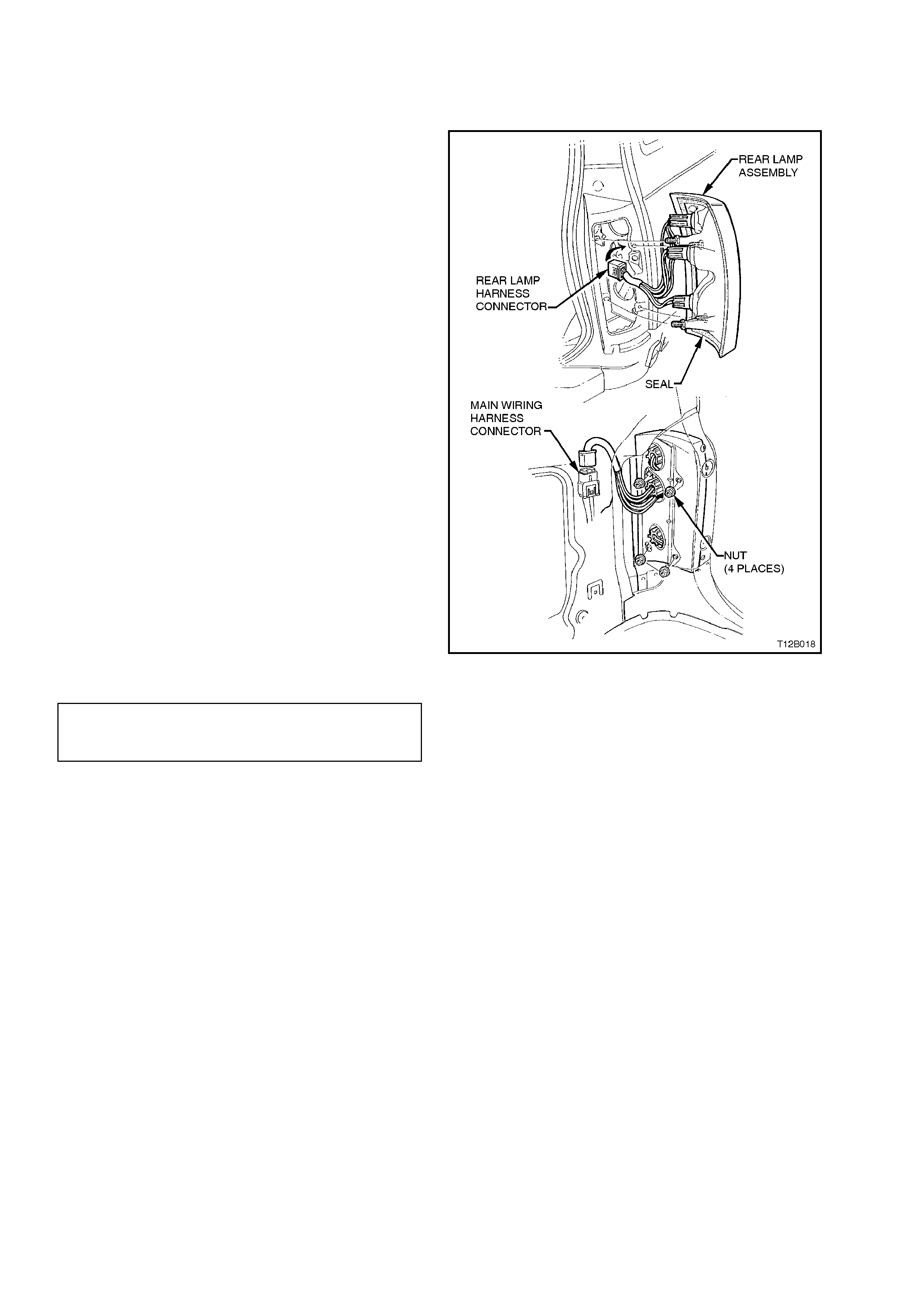

2.18 REAR LAMP ASSEMBLY - STATION WAGON

REMOVE

1. Open vehicle tailgate.

2. Remove rear lamp cover trim, taking care not

to damage cover trim surround.

Remove four nuts retaining lamp housing to

rear end panel.

3. Remove wiring harness connector, remove

housing.

REINSTALL

Installation is the reverse of removal procedures,

noting the following points:

1. If necessary, install bulbs to sockets and refit

sockets to lamp assembly.

2. Tighten lamp retaining screws to the correct

torque specification.

3. Check rear lamp operation.

Figure 12B-39

REAR LAMP HOUSING

RETAINING SCREW

TORQUE SPECIFICATION 1 - 3 Nm

2.19 INTERIOR LAMPS

NOTE:

The interior lighting configuration is dependant on

the vehicle model and trim level.

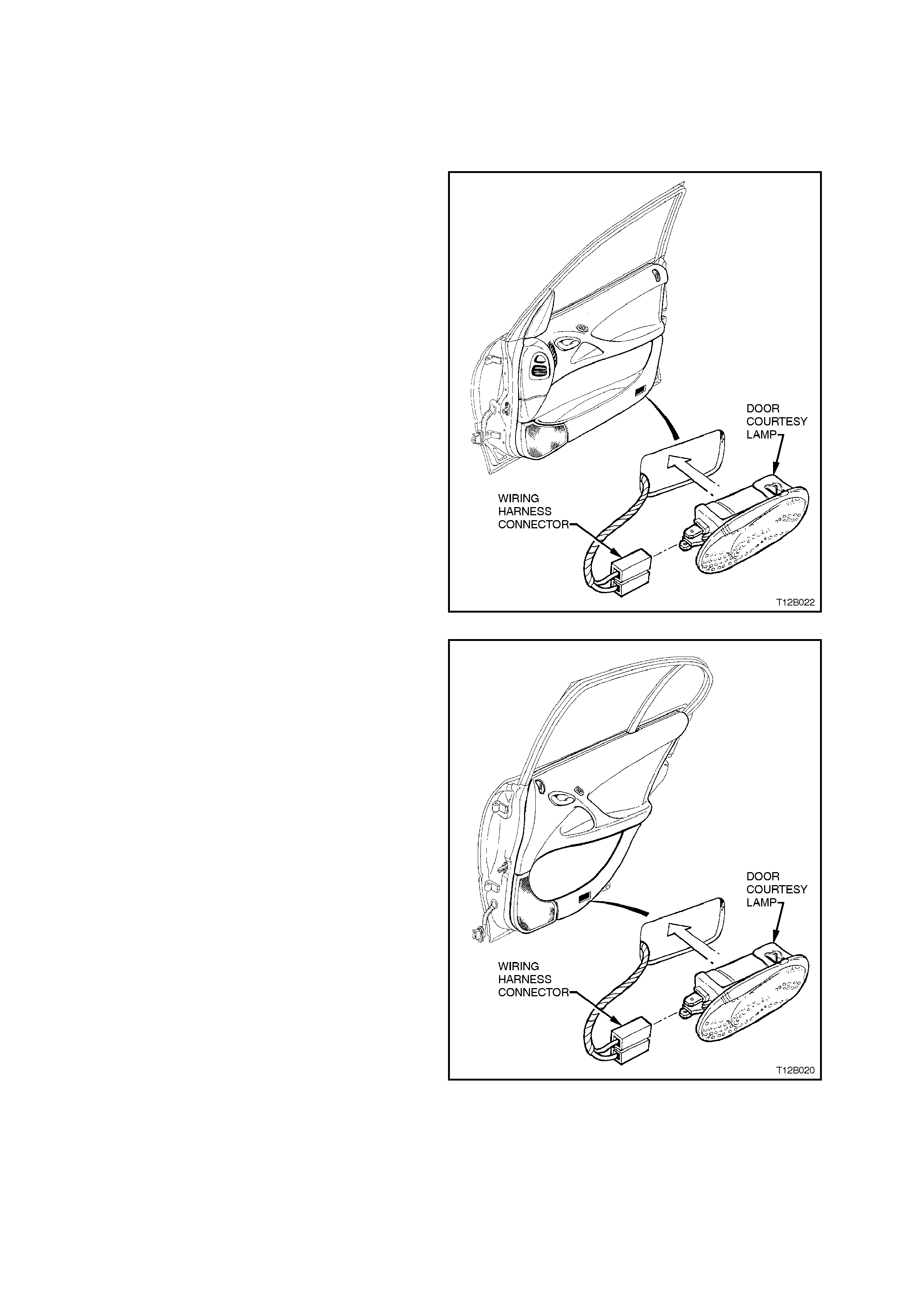

DOOR COURTESY LAMPS

Figs. 12B-40 and 12B-41 illustrate the installation of

the front and rear door courtesy lamps. To gain

access to bulb, use a fine bladed screwdriver

inserted between notch in lens surround and edge

of lens, lever lens from surround.

To rem ove bulb from lens, bend back lever contact

retaining the bulb and remove bulb.

Figure 12B-40

Figure 12B-41

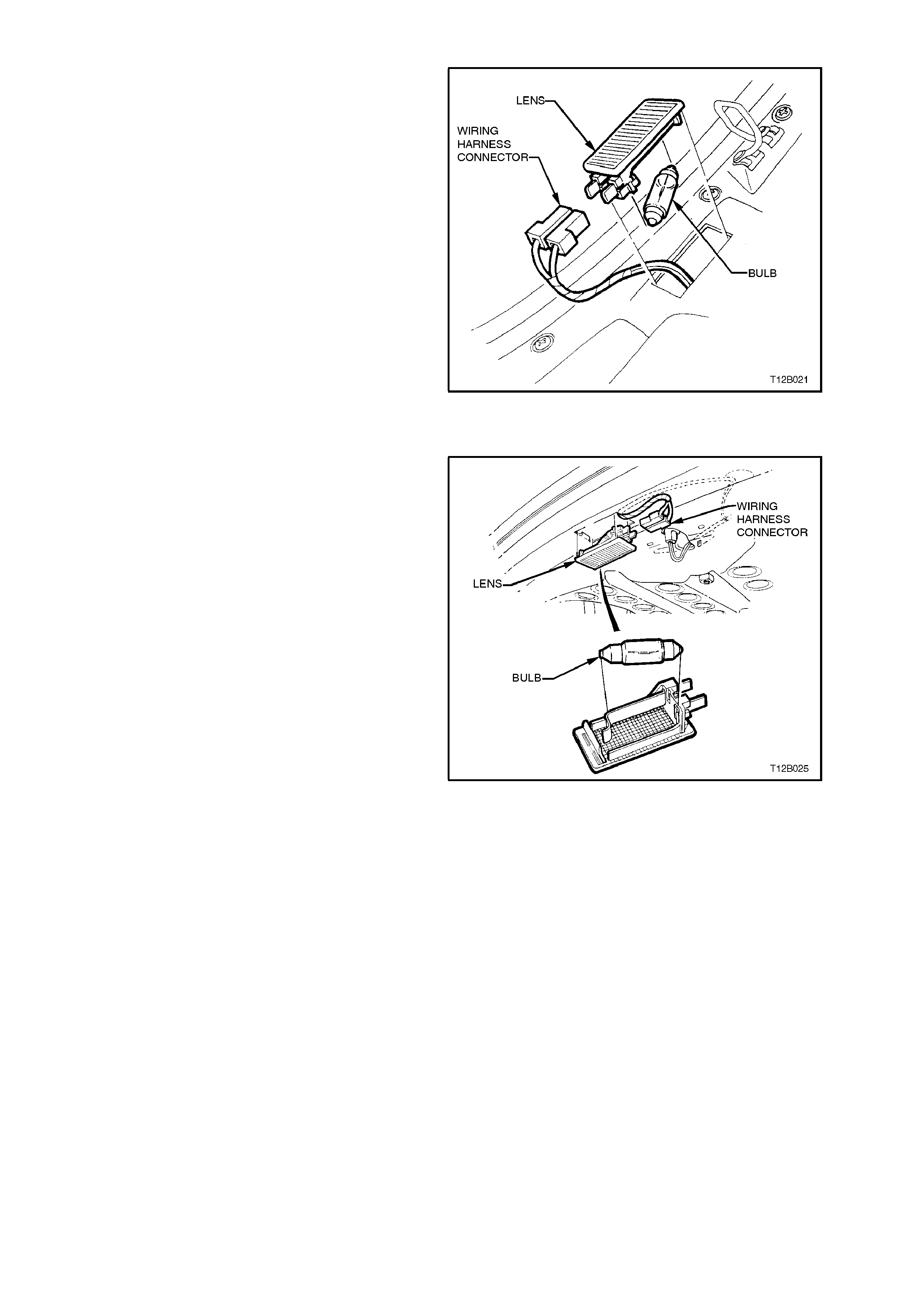

GLOVE COMPARTMENT LAMP

Fig. 12B-42 illustrates the installation of the glove

compartment lamp. To gain access to bulb, use a

fine bladed screwdriver to carefully lever out lens

from instrument panel.

To rem ove bulb from lens, bend back lever contact

retaining the bulb and remove bulb.

Figure 12B-42

REAR COMPARTMENT LAMP - SEDAN

Fig. 12B-43 illustrates the installation of the rear

compartment lamp and switch. To gain access to

bulb, use a fine bladed screwdriver to carefully

lever out lens.

To rem ove bulb from lens, bend back lever contact

retaining the bulb and remove bulb.

Figure 12B-43

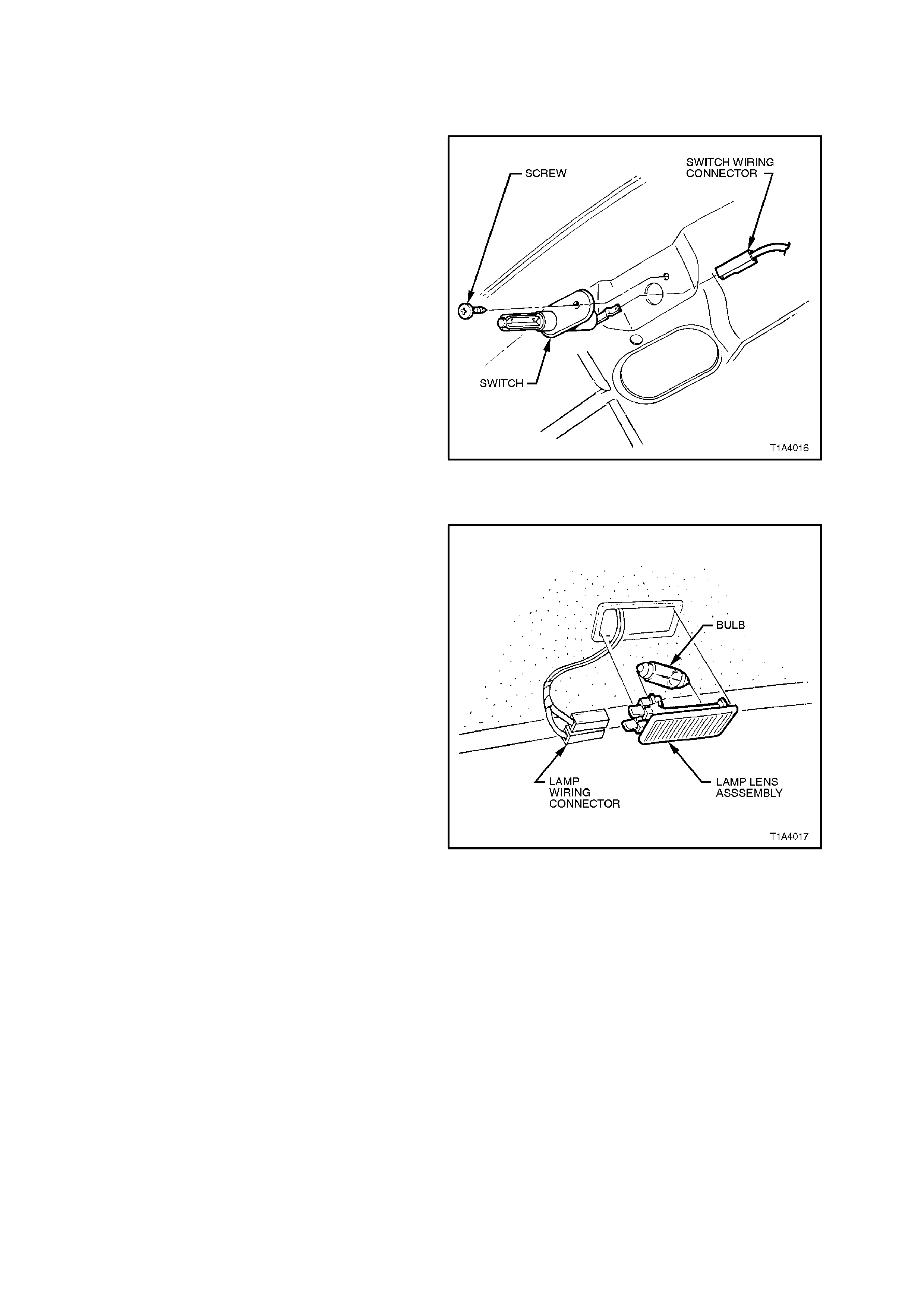

REAR COMPARTMENT LAMP SWITCH

The rear compartment lamp is operated by a

switch attached to the decklid.

REMOVE

1. Remove attaching screw and pull switch out

far enough to gain access to wiring harness

connectors.

2. Disconnect wiring harness connectors and

remove switch.

REINSTALL

Reverse removal operations.

Figure 12B-44

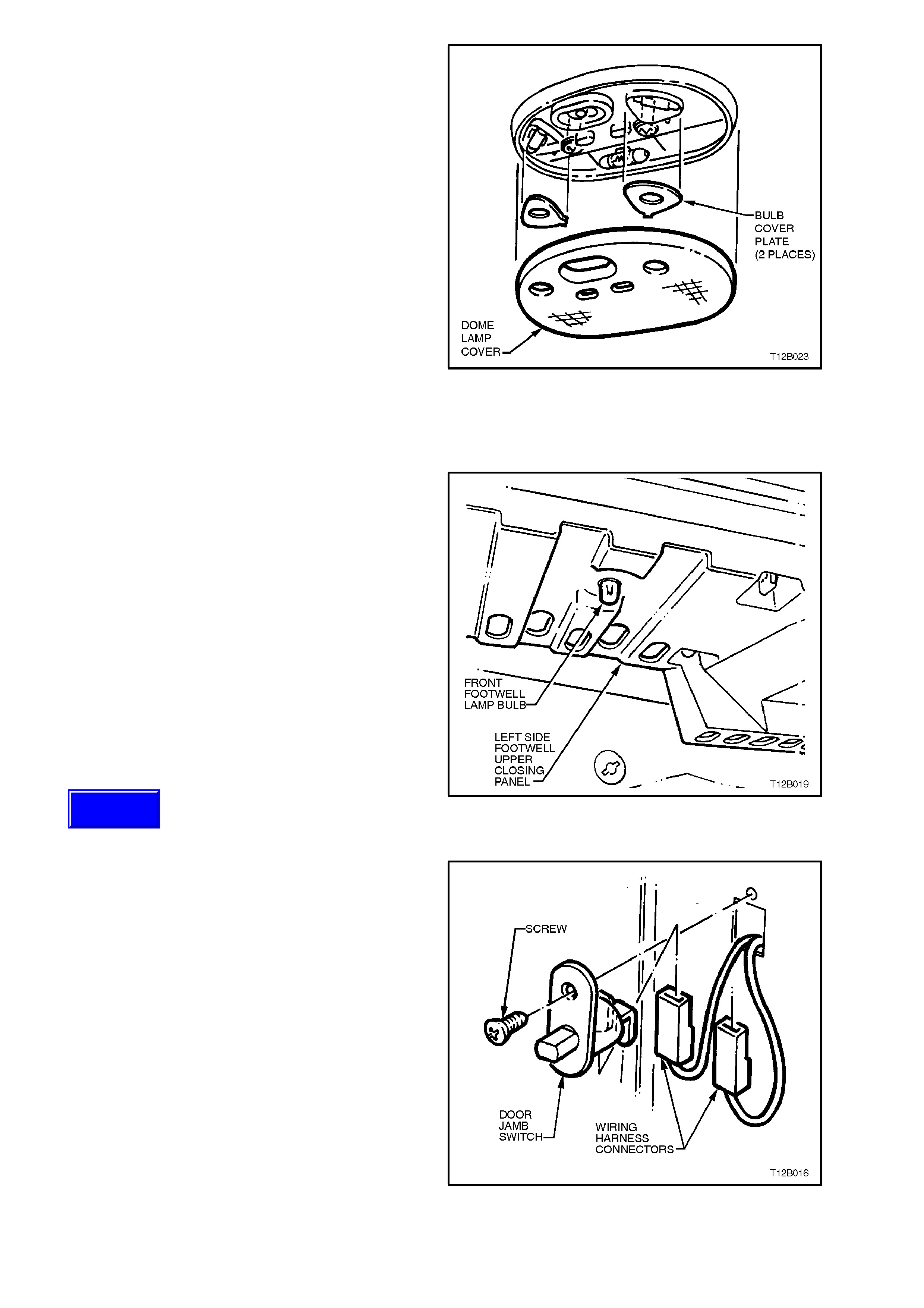

REAR COMPARTMENT LAMP - STATION WAGON

Fig. 12B-45 illustrates the installation of the rear

compartment lamp for station wagon. To gain

access to bulb, use a fine bladed screwdriver to

carefully lever out lens from surround.

To rem ove bulb from lens, bend back lever contact

retaining the bulb and remove bulb.

Figure 12B-45

REAR COMPARTMENT LAMP SWITCH

The rear compartment lamp is operated by a

switch attached to the tailgate.

REMOVE

1. Remove attaching screw and pull switch out

far enough to gain access to wiring harness

connectors.

2. Disconnect wiring harness connectors and

remove switch.

REINSTALL

Reverse removal operations.

Figure 12B-46

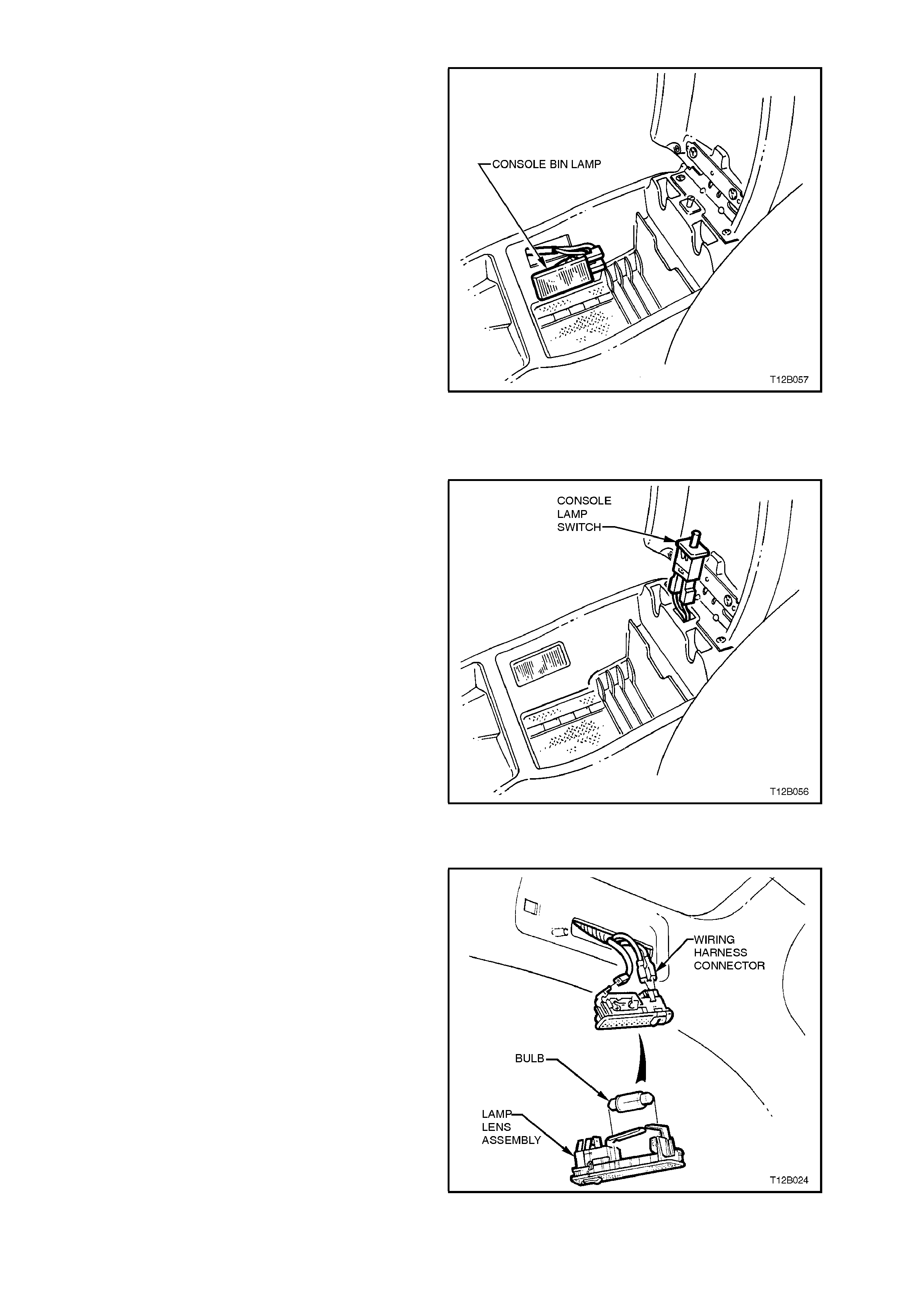

DOME AND FRONT READING LAMPS

Fig. 12B-47 illustrates the installation of the dome

lamp assembly for models without reading lamps.

To gain access to bulb, use a fine bladed

screwdriver inserted between notch in lens

surround and edge of lens. Carefully lever out lens

from housing, gently prising from all four notches,

ensuring no damage is made to housing surround

or headlining.

Figure 12B-47

Fig. 12B-48 illustrates the installation of the dome

and front reading lamp ass embly for Calais Models .

To gain access to bulb, use a fine bladed

screwdriver inserted between notch in lens

surround and edge of lens. Carefully lever out lens

from housing, gently prising from all four notches,

ensuring no damage is made to housing surround

or headlining.

The dome lamp bulb is a festoon bulb and can be

removed by bending contacts out from bulb. Once

installed, ensure that they are lock ed fir m ly in place

in their socket s.

To gain access to the reading lamp bulbs, remove

bulb cover plates by gently levering thin tab away

from housing using a fine bladed screwdriver.

Reading lamp bulbs are festoon bulbs and can be

removed by bending contacts out from bulb. Once

installed, ensure that they are lock ed fir m ly in place

in their sockets. Reinstall bulb cover plates and

click firmly into place.

Reinstall lens.

Figure 12B-48

FOOTWELL LAMPS

Front footwell lamp bulbs are located in sockets

which are a twist fit into right and left hand

instrument panel side trims.

Bulbs are a push fit into socket. Bulbs are fitted

with a green cover. When installing new bulb,

ensure that new cover is installed onto bulb.

The sockets are part of the main wiring harness.

Figure 12B-49

DOOR JAMB SWITCHES

The door j amb s witches are installed in eac h of the

door hinge pillars. When the door of the vehicle is

closed, a plunger in the switch is depressed,

creating an open circuit in the earth circuit. When

the door is opened, the plunger is released and

completes the circuit to earth.

On vehicles with High Series BCM (refer to

Section 12J-2 HIGH SERIES BODY CONTROL

MODULE), the door jamb switches have dual

contacts. On vehicles with Low Series BCM, the

door jamb switches are a single contact type.

Figure 12B-50

Techline

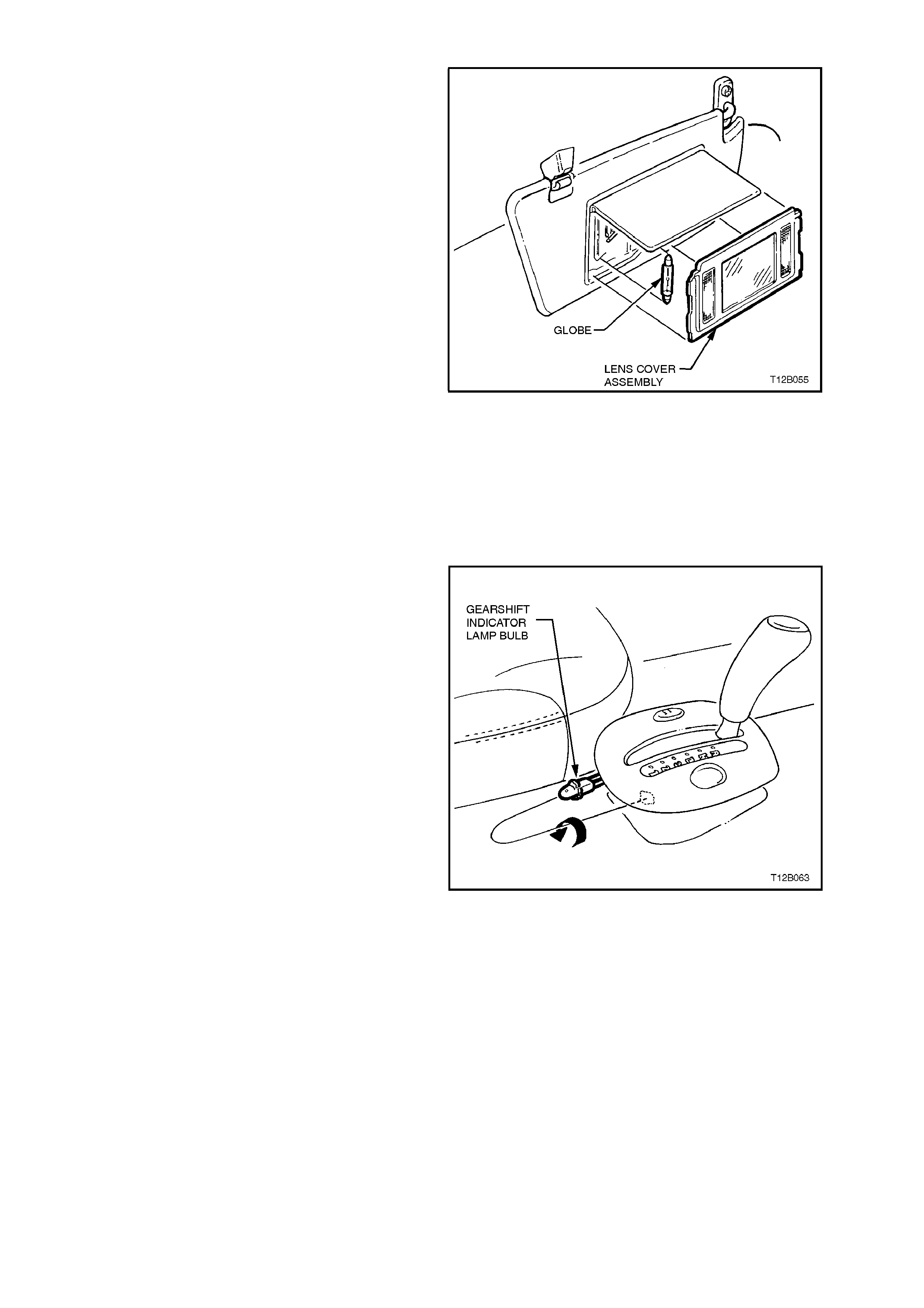

CONSOLE BIN LAMP

From inside of console, use a fine bladed

screwdriver to carefully lever lens fr om console. To

remove lens, pull wiring harness connectors from

lens and remove lens.

Bulb can be replaced by bending back the contact

retaining the bulb and removing the bulb.

Figure 12B-51

CONSOLE BIN LAMP SWITCH

REMOVE

1. Open console bin and pull s witch from c ons ole

bin assembly.

2. Disconnect wiring connector from switch and

remove switch from console bin.

Figure 12B-52

REAR READING LAMP

Fig. 12B-53 illustrates the installation of the rear

reading lamp assembly for Calais sedan models.

To gain ac ces s to bulb, us e f ine bladed sc r ewdriver

and gently lever lens from lens surround, ensuring

no damage is made to lens surround or headlining.

Pull bulb from contacts to remove.

Figure 12B-53

FRONT VANITY MIRROR LAMP - CALAIS ONLY

Fig. 12B-54 illustrates the installation of the front

vanity mirror lamp. Lower visor and lift flap to

expose vanity mirror and lamp assembly. To gain

access to bulb, use fine bladed screwdriver and

gently lever fr ont vanity mirror lamp c over as s embly

from visor and pivot assembly.

NOTE:

Damage to vanity mir ror lamp s urround will occur if

care is not taken when levering lens cover

assembly.

Bulbs (2) are festoon bulbs and can be replac ed by

pulling from contacts.

If replacing lamp housing, pull wiring harness

connectors from lamp housing terminals.

Figure 12B-54

GEARSHIFT INDICATOR LAMP BULB

REPLACE

1. Disconnect battery earth lead.

2. Remove transmission console as described in

Section 1A3 INSTRUMENT PANEL &

CONSOLE.

3. From beneath console cap, disconnect

console wiring harness to illumination

connectors.

4. Disconnect illumination bulb socket and pull

bulb from socket.

5. Install new bulb into socket. Install socket into

holder and twist clockwise to retain.

6. Reinstall transmission console cap assembly,

reverse to removal procedures, ensuring all

connectors are reconnected.

7. Turn headlamps on and ensure bulb

illuminates.

Figure 12B-55

IGNITION LOCK LAMP

CAUTION:

Disable the SRS (Air Bag). Refer to DISABLING

THE SRS Section 12M SUPPLEMENTAL

RESTRAINT SYSTEM.

1. Release steering column height adjusting lever

and allow steering column to move upward.

Leave lever in the released position.

Remove ignition keys from ignition switch.

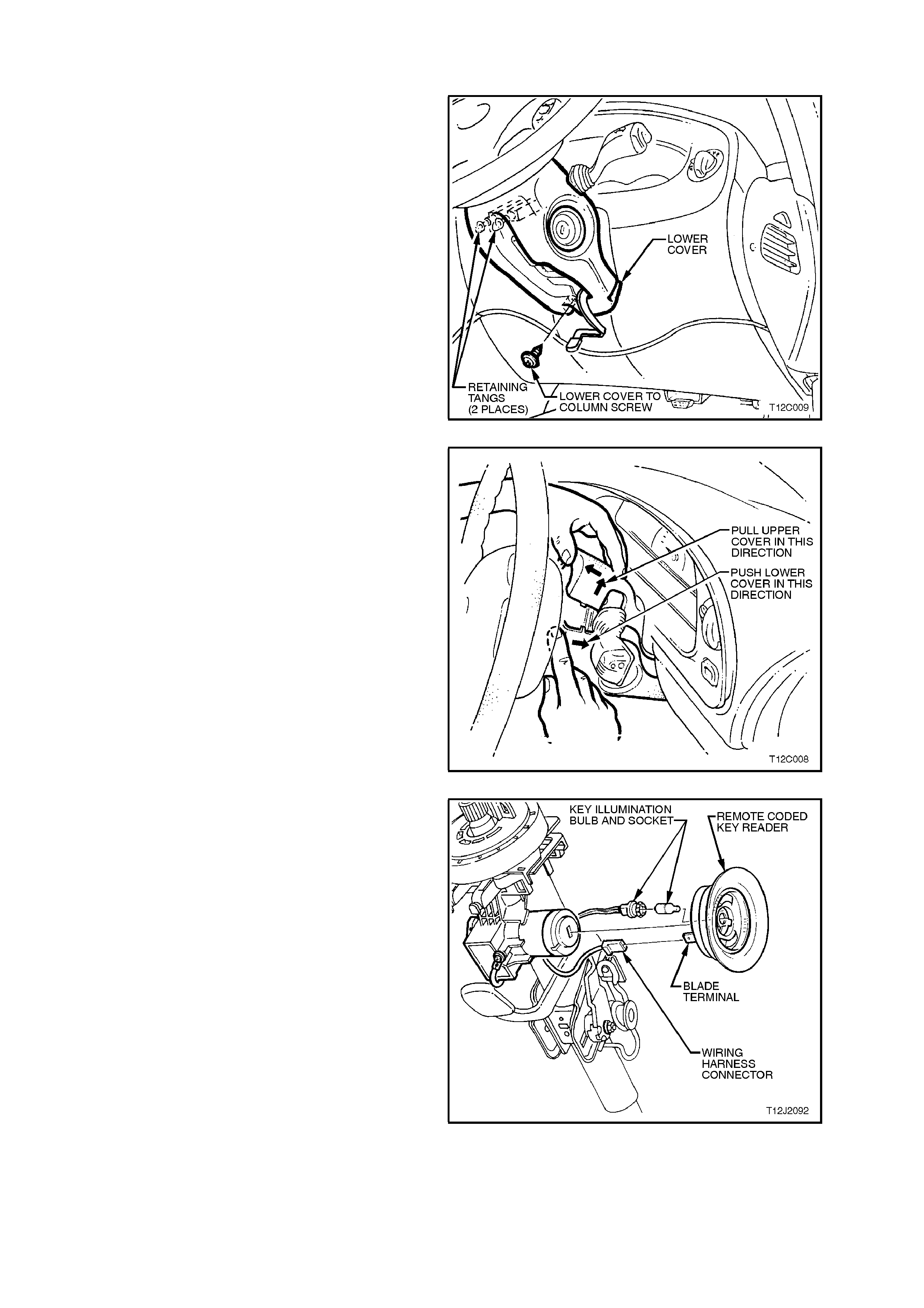

2. Remove steering column lower cover to

column and upper cover attaching screws.

Figure 12B-56

3. Pull steering column upper cover up and

toward steering wheel at the sam e tim e pulling

lower cover down and away from steering

wheel. This will release the steering column

lower cover end retainers from mating slots in

upper cover.

4. Remove steering column covers.

Figure 12B-57

5. Pull ignition lock lamp socket from lamp

housing on key reader assembly.

6. Pull bulb from socket.

7. Replace bulb and reinst all lamp housing to key

reader assembly.

8. Reinstall steering column covers and screw.

IMPORTANT:

Enable the SRS (Air Bag). Refer to ENABLING

THE SRS, Section 12M SUPPLEMENTAL

RESTRAINT SYSTEM.

Figure 12B-58

INSTRUMENT CLUSTER ASSEMBLY LAMP BULBS

The instrument assembly and warning lamp

illumination bulbs ar e a push f it into a s oc ket, which

in turn are a twist fit into the rear of the instrument

case and flexible printed circuit board.

To remove the lamp socket, remove the

instrument cluster, refer to Section 12C

INSTRUMENTS, WIPERS/ WASHERS AND

HORN. Remove the lamp socket from the printed

circuit board and pull bulb from its socket.

Installation is the reverse of removal procedure.

Figure 12B-59

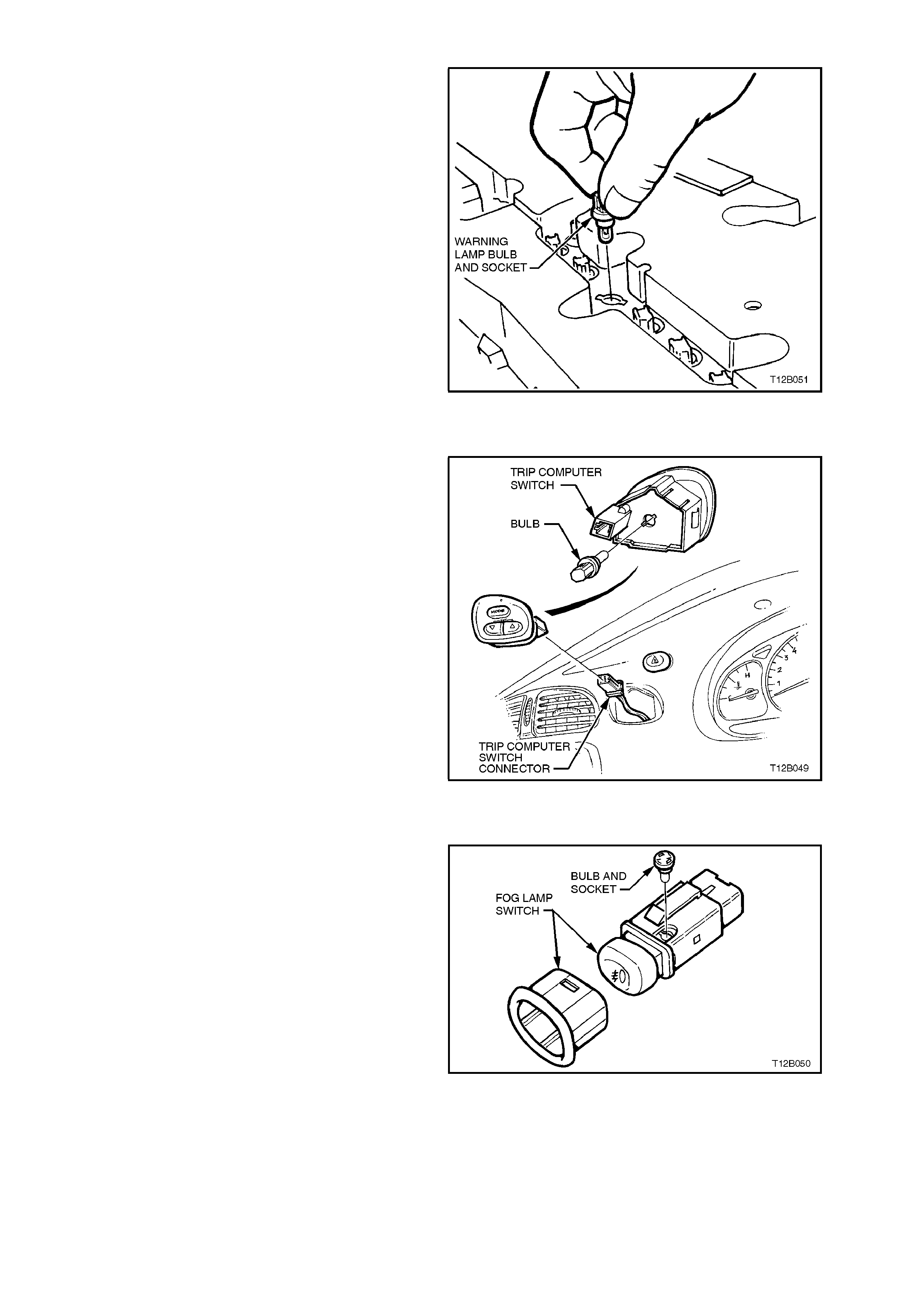

TRIP COMPUTER SWITCH ASSEMBLY ILLUMINATION BULB

The trip computer assembly illumination bulb is a

push fit into a socket, which in turn is a twist f it into

the rear of the trip computer flexible printed circuit

board.

To remove the lamp socket, remove the trip

computer switch assembly, refer to Section 12C

INSTRUMENTS, WIPERS/WASHERS AND

HORN. Remove the lamp socket from the printed

circuit board and pull bulb from its socket.

NOTE:

Procedures for replacing the trip computer

assembly illumination lamps are covered in

Section 12C INSTRUMENTS,

WIPERS/WASHERS AND HORN .

Figure 12B-60

INSTRUMENT FACIA AND CENTRE FACIA ESCUTCHEON SWITCH ILLUMINATION BULBS

The instrument facia and centre facia escutcheon

switch assemblies are illuminated by a bulb and

socket assembly which is a twist fit into the

underside of the switch assembly.

To remove switch assemblies, refer to Section

12C INSTRUMENTS, WIPERS/WASHERS AND

HORN. Then, using a fine bladed screwdriver,

inserted into cross on bulb socket, twist socket anti-

clockwise, remove bulb and socket assembly.

Installation of the bulb and socket assembly is the

reverse of removal procedure.

Figure 12B-61

2.20 STOP LAMP SWITCH

REPLACE

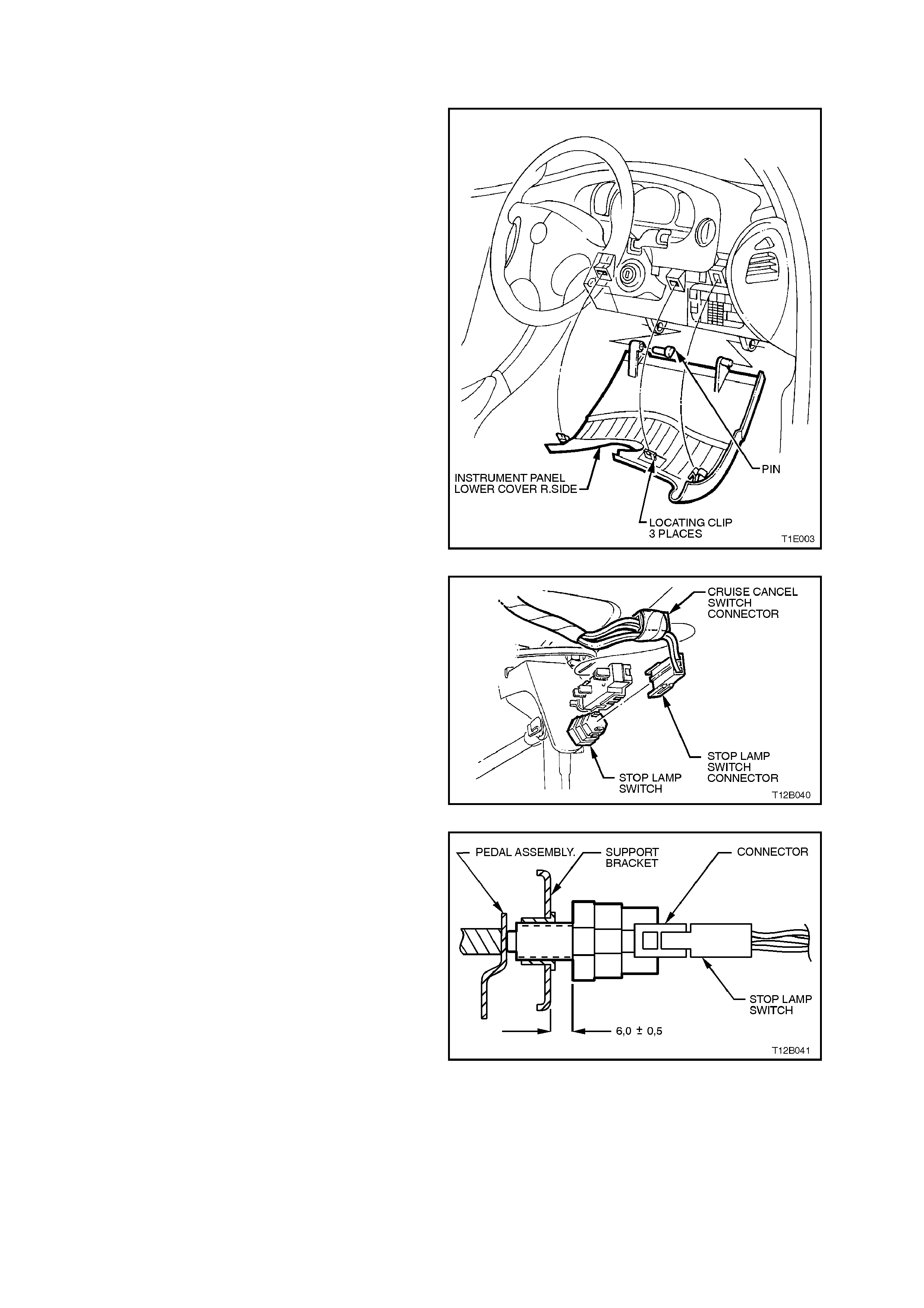

1. Lower instrument panel right hand cover

assembly by pulling firmly to release retaining

clips and allowing cover to swing down.

Figure 12B-62

2. Remove wiring harness connectors from

switch.

3. Pull switch assembly out from pedal support

tubular clip to remove.

4. Push new switch assembly through pedal

support tubular clip.

Figure 12B-63

5. Hold brake pedal at its ‘REST’ position.

6. Adjust switch position to achieve gap of 5.5 -

6.5 mm.

7. Refit wiring harness connectors to switch and

check stop lamp operation.

8. Reinstall instrument panel lower trim and

cover assemblie s.

Figure 12B-64

TEST

1. Lower instrument panel right hand cover

assembly by pulling firmly to release retaining

clips and allowing cover to swing down.

Figure 12B-65

2. Remove wiring harness connectors from

switch terminals.

3. Connect an ohmm eter across switch term inals

and ohmmeter should indicate open circuit

with brake pedal at rest.

Depress brake pedal and ohmmeter should

indicate continuity.

4. If ohmmeter does not indicate readings as

above, check switch adjustment as described

in 2.20 STOP LAMP SWITCH in this Section.

Retest switch after adjustment.

If switch adjustment is OK, replace switch as

previously described. Figure 12B-66

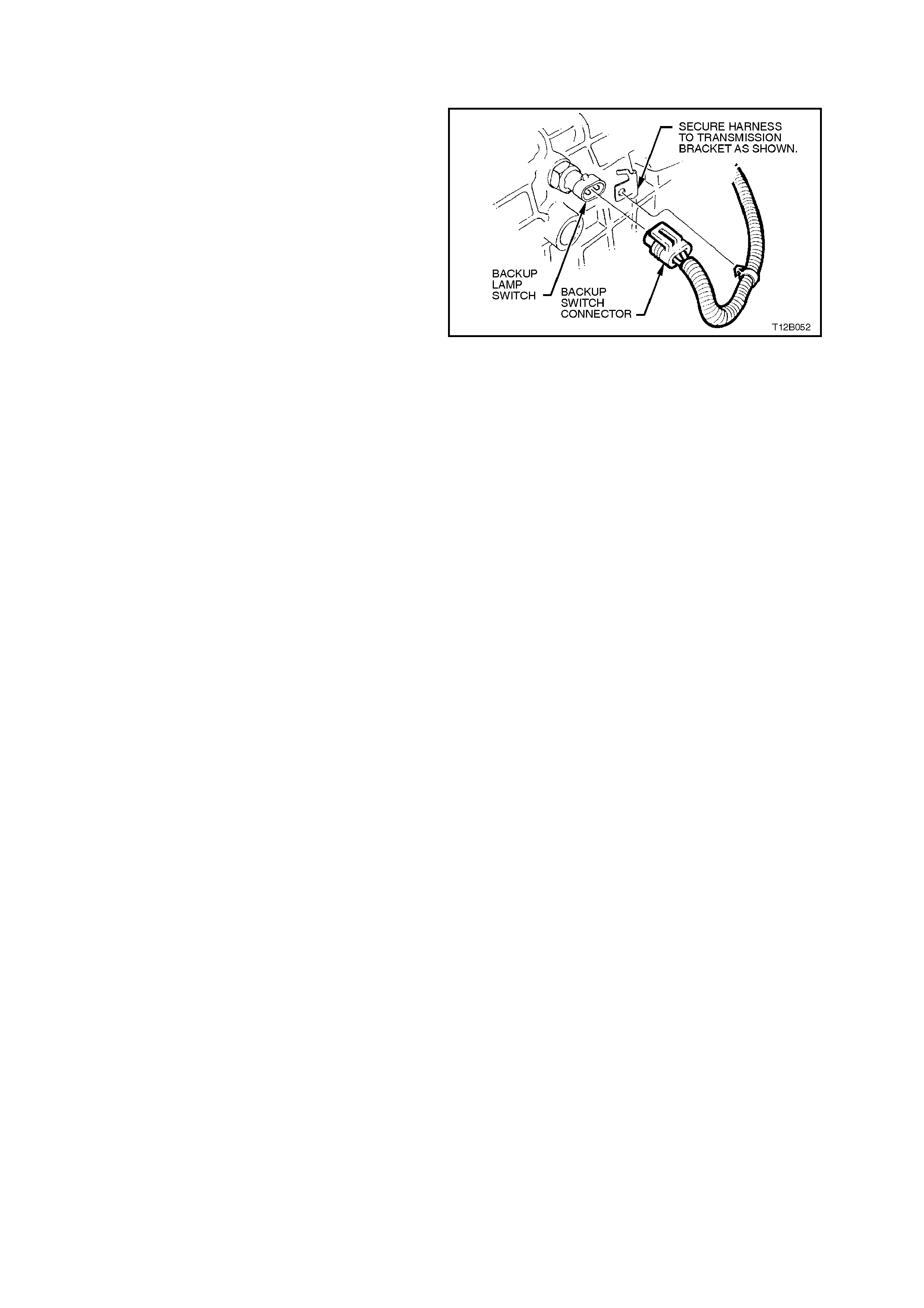

2.21 BACK-UP LAMP S WITCH

MANUAL TRANSMISSION

The back-up lamp switch for vehicles equipped with

manual transmission is non-adjustable. The switch

is screwed into the left hand side of the

transmission case.

For switch testing, removal and installation

procedures refer to Section 7B1 MANUAL

TRANSMISSION V6 ENGINE or Section 7B2

MANUAL TRANSMISSION - V8 ENGINE.

Figure 12B-67

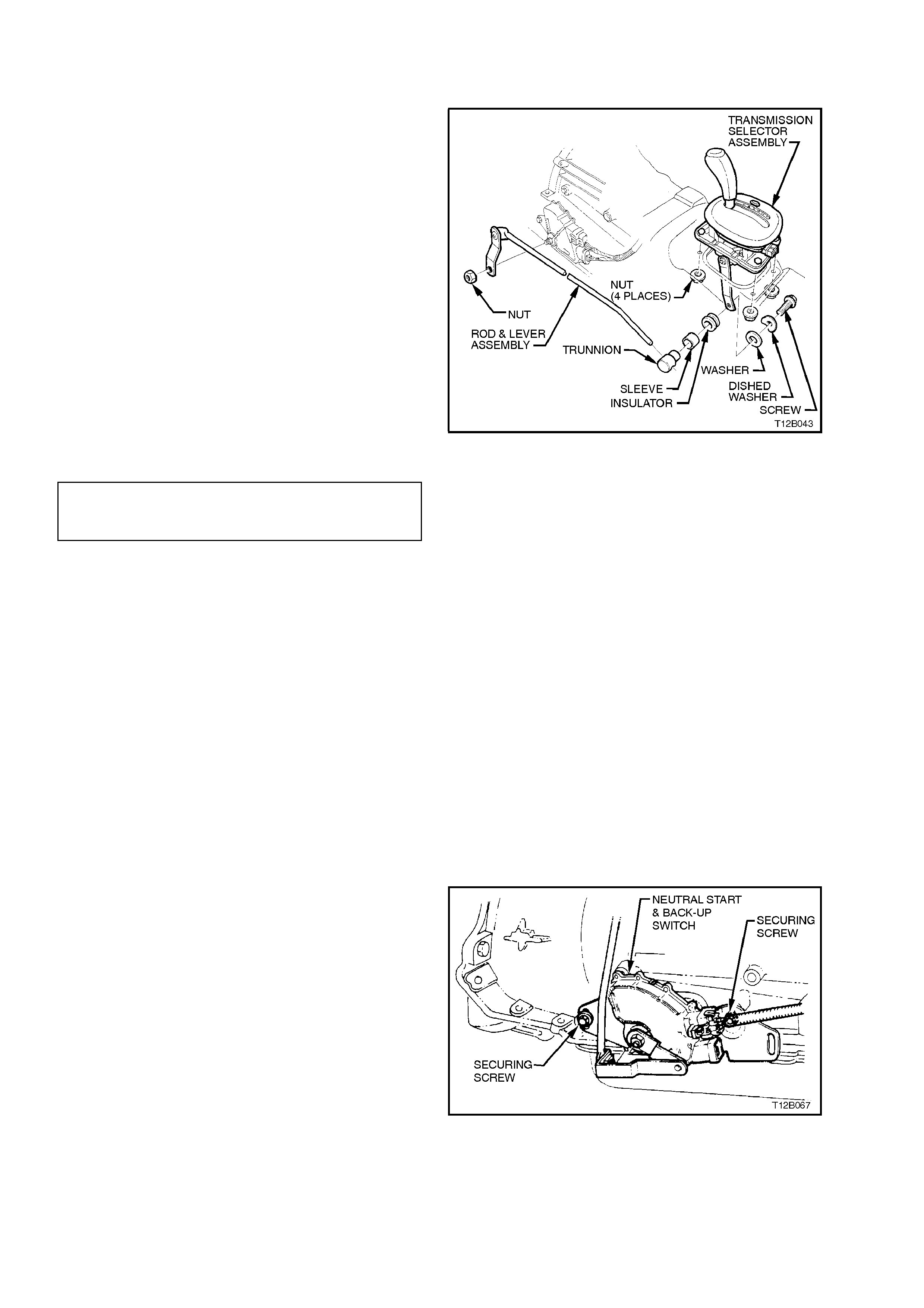

2.22 NE UTRAL START/BACK-UP LAMP SWITCH

ADJUST

Switch operation is controlled by the gearshift

linkage and has no separate adjustment. The

adjustment of the gearshif t linkage theref ore affec ts

the operation of the switch.

Adjustment of the gearshift linkage is as follows:

1. Raise front of vehicle and support on safety

stands. Refer to Section 0A GENERAL

INFORMATION for location of jacking points.

2. Loosen locking bolt at transmission selector

lever.

3. Position transmission selector lever in ‘PARK’.

4. Tighten locking bolt at transmission selector

lever to the correct torque specification.

Figure 12B-68

TRANSMISSION SELECTOR

LEVER LOCKING BOLT

TORQUE SPECIFICATION 20 - 30 Nm

5. Lower vehicle, check linkage and neutral

start/back-up switch operation by turning

ignition switch to the start position. T he starter

motor should operate in Park and Neutral

positions only.

Also check that the position indicator aligns

with the correct range indicator on the

transmission indicator support assembly.

If the indicator requires adjustment, remove

transmission console, refer to Section 1A3

INSTRUMENT PANEL & CONSOLE.

Place transmission selector lever in neutral

position. Lift up and reposition transmission

indicator support scale so that indicator is

positioned centrally with letter ‘N’ on scale.

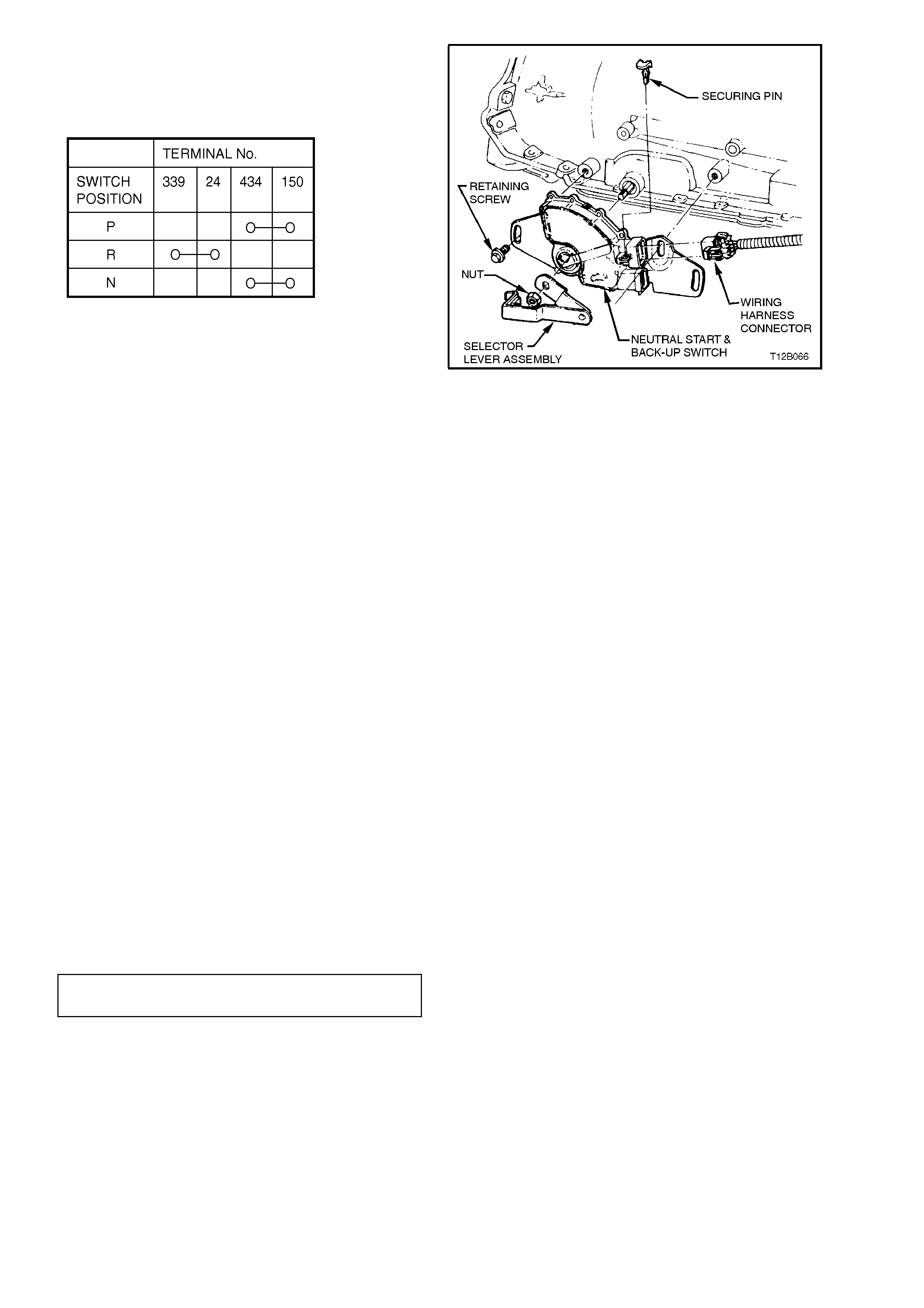

TEST

Before conducting the following test, ensure that

the gearshift linkage is correctly adjusted, refer to

previous instructions on gearshift adjustment.

1. Disconnect battery earth lead.

2. Remove console cap and transmission

indicator support assembly, refer to Section

1A3 INSTRUMENT PANEL AND CONSOLE.

3. Pull back harness connector retainer and

disconnect main wiring harness connector

from neutral start/back-up switch wiring

harness connector.

Figure 12B-69

4. Using an ohmm eter connec ted to s witch wiring

harness c onnector term inals, select each gear

and check for continuity between switch

terminals as per the following chart and Fig.

12B-70.

If continuity between terminals is not as

specified, replace switch as per following

removal and installation instructions.

Figure 12B-70

REMOVE

1. Raise front of vehicle and place on safety

stands, refer to Section 0A GENERAL

INFORMATION for location of jacking points.

2. While holding the lower selector lever

assembly remove the retaining nut, then

carefully remove the lever assembly from the

transmission selector shaft.

3. Prise the wiring harness connector securing

pin from the neutral start and backup lamp

switch assembly, taking care not to break the

pin. Disconnect the wiring harness connector

from the switch assembly.

4. Remove the two retaining s c rews and s lide the

switch assembly over the transmission

selector shaft and remove from the vehicle.

REINSTALL

Installation is the reverse of removal procedures,

noting the following points:

1. When installing the two switch retaining

screws, have them finger-tight until the

adjustment process is completed.

2. When installing the wiring harness connector

securing pin, tak e care not to break the lug on

the switch body during the process.

3. After installing the selector lever retaining nut,

tighten to the specified torque.

SELECTOR LEVER RETAINING

NUT TORQUE SPECIFICATION 15 - 35 Nm

4. After adjusting the neutral start and back-up

lamp switch, check that the engine can only be

started when the transm iss ion selector lever is

in either the ‘P’ (Park) or ‘N’ (Neutral) position.

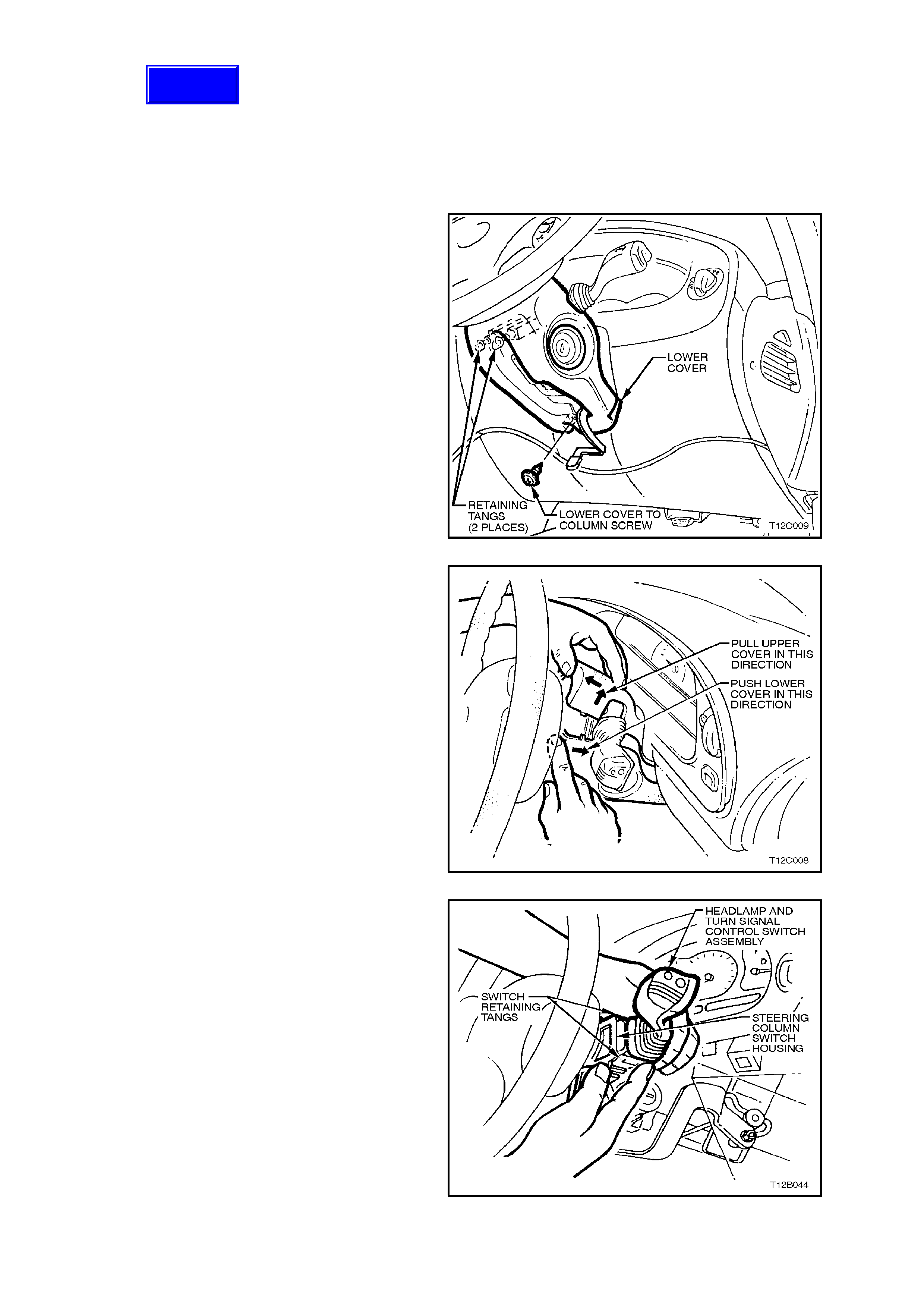

2.23 HEADLAMP AND TURN SIGNAL CONTROL SWITCH ASSEMBLY

REMOVE

1. Disconnect battery earth lead.

CAUTION:

Disable the SRS (Air Bag). Refer to DISABLING

THE SRS, Section 12M SUPPLEMENTAL

RESTRAINT SYSTEM.

2. Release steering column height adjusting lever

and completely lower steering column.

Remove ignition keys from ignition switch.

3. Place a clean shop rag over and around

steering column upper cover. This step is

important so as to prevent any possibility of

damage to cover should there be any contact

with lower edge of instrument facia while

removing the cover.

4. Remove steering column lower cover to

column and upper cover attaching screw.

Figure 12B-71

5. Pull steering column upper cover up and

toward steering wheel at the sam e tim e pulling

lower cover down and away from steering

wheel. This will release the steering column

lower cover end retainers from mating slots in

upper cover

Remove steering column covers.

Figure 12B-72

6. On headlamp and turn signal control switch

with integrated cruise control switch contacts,

disconnect wiring harness connector to switch

cruise control switch harness connector.

7. Depress retaining tangs on switch assembly

and withdraw switch from switch housing on

steering column.

8. Depress wiring harness connector retaining

tangs and pull connectors from rear of switch.

Figure 12B-73

Techline

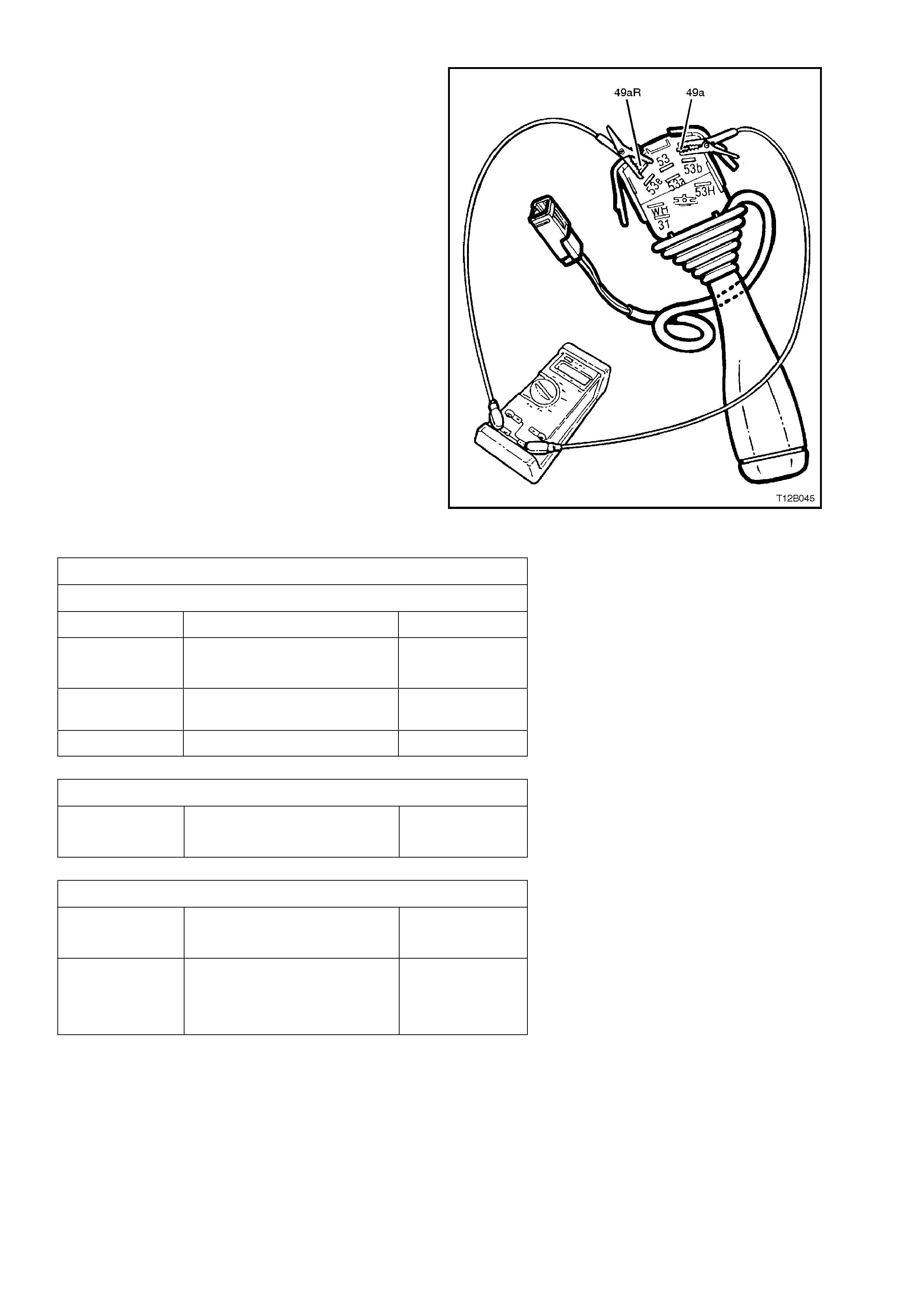

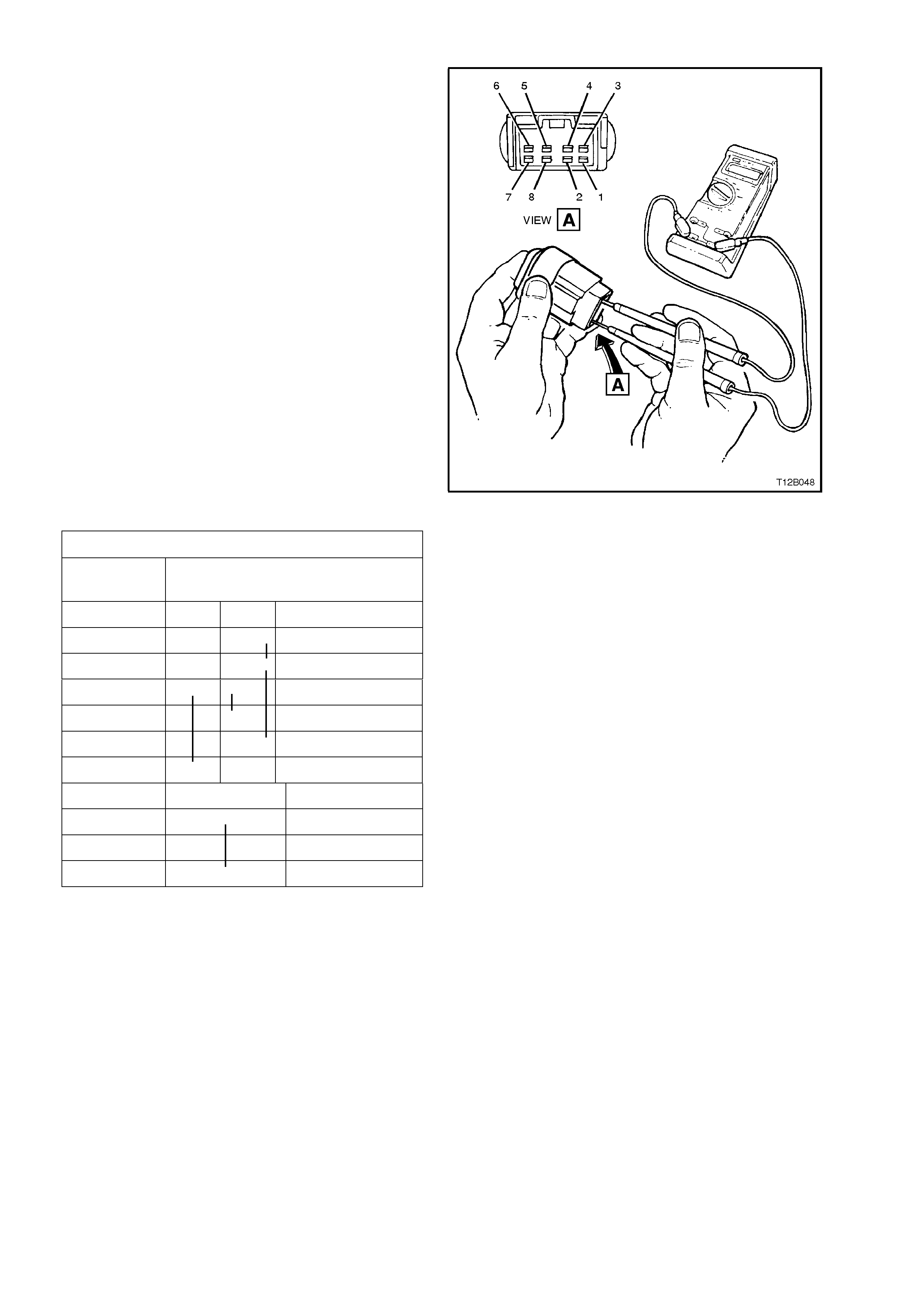

TESTING SWITCH

Using an ohmmeter, check switch contacts for

continuity at each switch position as indicated in the

following chart.

If continuity between switch terminals is not as

specified, replace switch assembly.

NOTE:

Switch terminal numbering is indicated on the

switch body, adjacent to each terminal.

Figure 12B-74

HEADLAMP AND TURN SIGNAL CONTROL SWITCH ASSEMBLY

TURN SIGNAL SWITCH CONTACTS

Switch Terminals Switch Position Indication If OK

49a and 49aR

49a and 49aL

Switch in central position Open circuit

49a and 49aR Switch in right hand turn

position Continuity

49a and 49aL Switch in left hand turn position Continuity

HEADLAMP FLASH CONTACTS

30 and 56a Flash position

High beam or central position

Continuity

Open circuit

HEADLAMP HIGH BEAM CONTACTS

56 and 56a Flash or central position

High beam position

Open circuit

Continuity

56 and 56b Central position

High beam position

Flash position

Continuity

Open circuit

Continuity

REINSTALL

Reinstallation of the s witch ass em bly is the rever se

of the removal procedure, noting the following

points:

1. Check switch operation once it is installed.

IMPORTANT:

Enable the SRS (Air Bag). Refer to ENABLING

THE SRS, Section 12M SUPPLEMENTAL

RESTRAINT SYSTEM.

2.24 HEADLAMP SWITCH

There are two specific headlamp switch

assem blies used on VT Series Models, with usage

dependant on what category of BCM is installed in

the vehicle.

Switch identification is by the colour of the switch

body. Switch bodies coloured black (two step

dimmer) are used on vehicles with Low Series

BCM. Switches with grey coloured bodies ar e used

for vehicles with High Series BCM. This switch has

spring loaded variable dimmer control knob.

If replacing a headlamp switch, ensure the correct

type is fitted.

REMOVE

1. Disconnect battery earth lead.

CAUTION:

Disable the SRS (Air Bag). Refer to DISABLING

THE SRS, Section 12M SUPPLEMENTAL

RESTRAINT SYSTEM.

2. Release steering column height adjusting lever

and completely lower steering column. Lock

lever in this position.

3. Place a clean shop rag over and around

steering column upper cover. This step is

important so as to prevent any possibility of

damage to cover when removing the

instrument facia.

4. Remove instrument facia, refer to

Section 1A3 INSTRUMENT PANEL &

CONSOLE

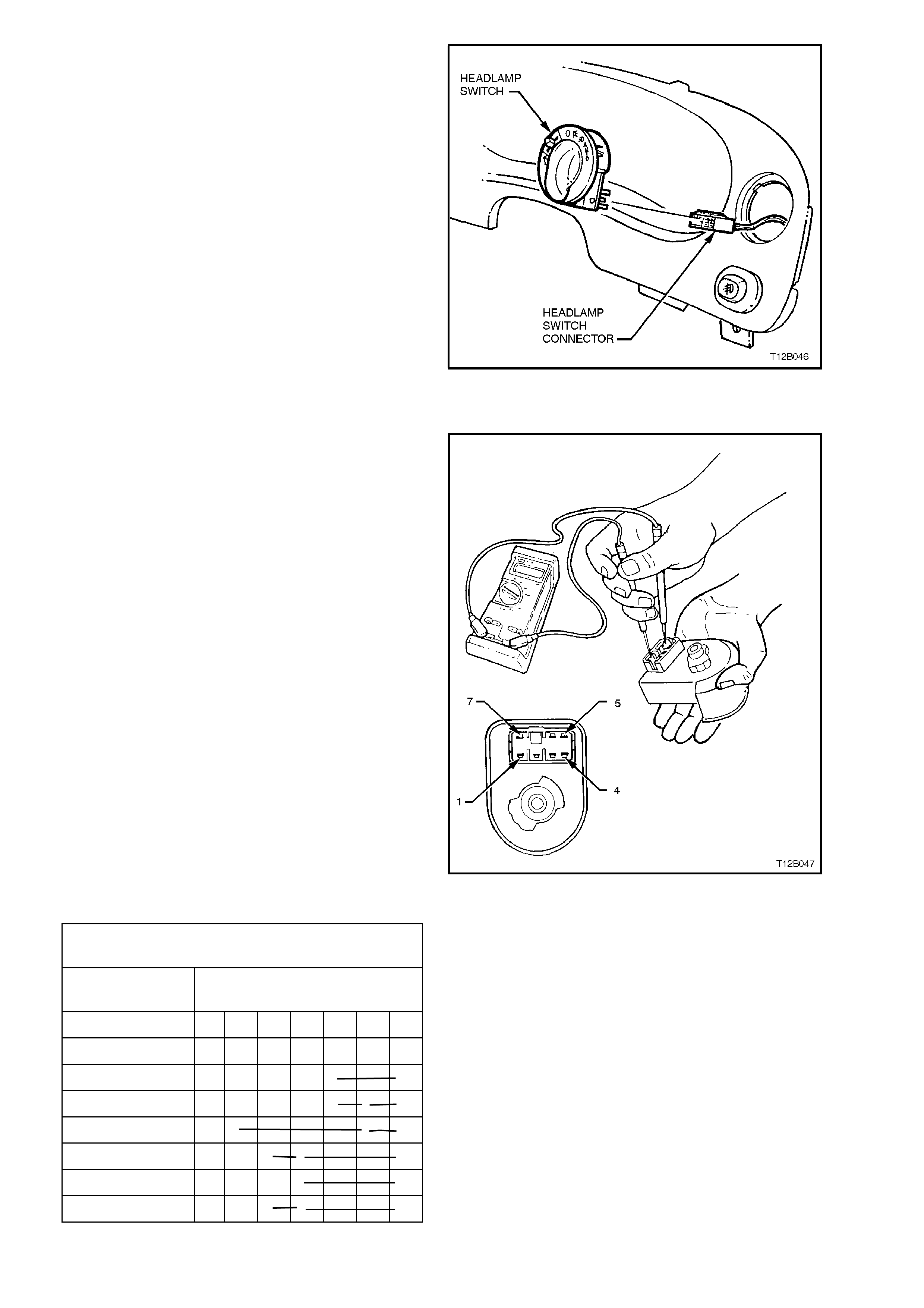

Figure 12B-75

Techline

5. Pull instrument facia out only far enough to

gain access to rear of headlamp switch.

6. Pull connector from headlamp switch

7. Depress retaining tang on instrument harness

headlamp switch connector and remove

switch from facia.

Figure 12B-76

TESTING SWITCH

With the aid of an ohmmeter, check continuity of

headlamp switch contacts, using the following

chart.

If continuity is not as specified at any switch

position, replace switch cluster assembly.

Figure 12B-77

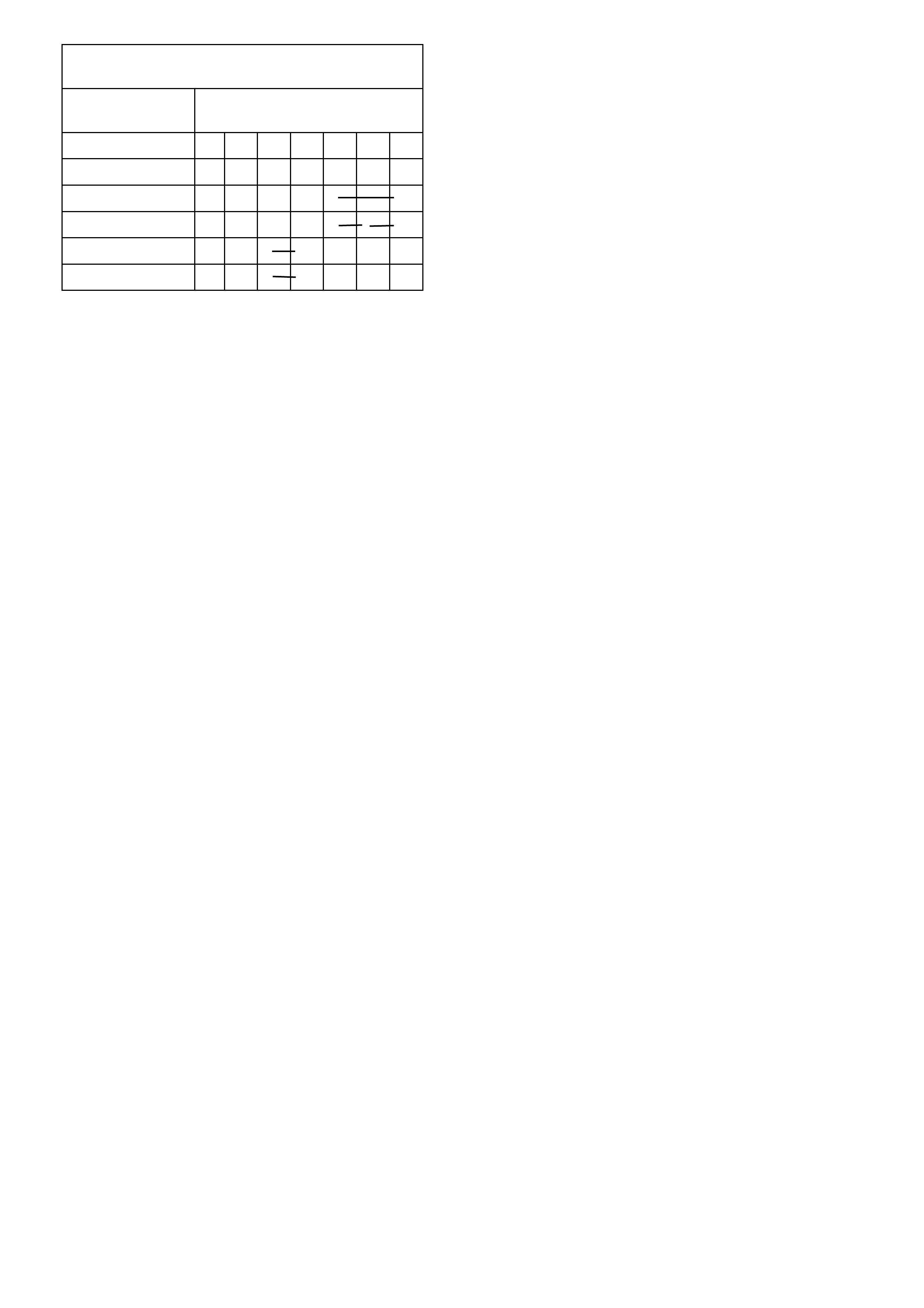

HEADLAMP SWITCH FOR VEHICLES WITH HIGH

SERIES BCM

SWITCH

POSITION TERMINAL NO.

1234567

OFF

PARKLAMPS O O

HEADLAMPS O O O

AUTO (CALAIS) O O O

DIM O O O

NEUTRAL O O

BRIGHT O O O

HEADLAMP SWITCH FOR VEHICLES WITH LOW

SERIES BCM

SWITCH

POSITION TERMINAL NO.

1234567

OFF

PARKLAMPS O O

HEADLAMPS O O O

DIM O O

BRIGHT O O

At low intensity setting, reading should be approx.

2.65 kW and at high intensity setting, approx. 5.3

kW.

REINSTALL

Installation of the headlamp s witch is the r ever se of

the removal procedure, noting the following points:

1. If, when instrument facia was pulled away

from instrument panel pad, the pad retaining

clips came away with the facia lugs, pull clips

from lugs and reinstall into pad holes. Fit

instrument facia and ensure that it is held to

the instrument panel pad securely.

2. Check for correc t operation of headlamps and

switch.

IMPORTANT:

Enable the SRS (Air Bag). Refer to ENABLING

THE SRS Section 12M SUPPLEMENTAL

RESTRAINT SYSTEM.

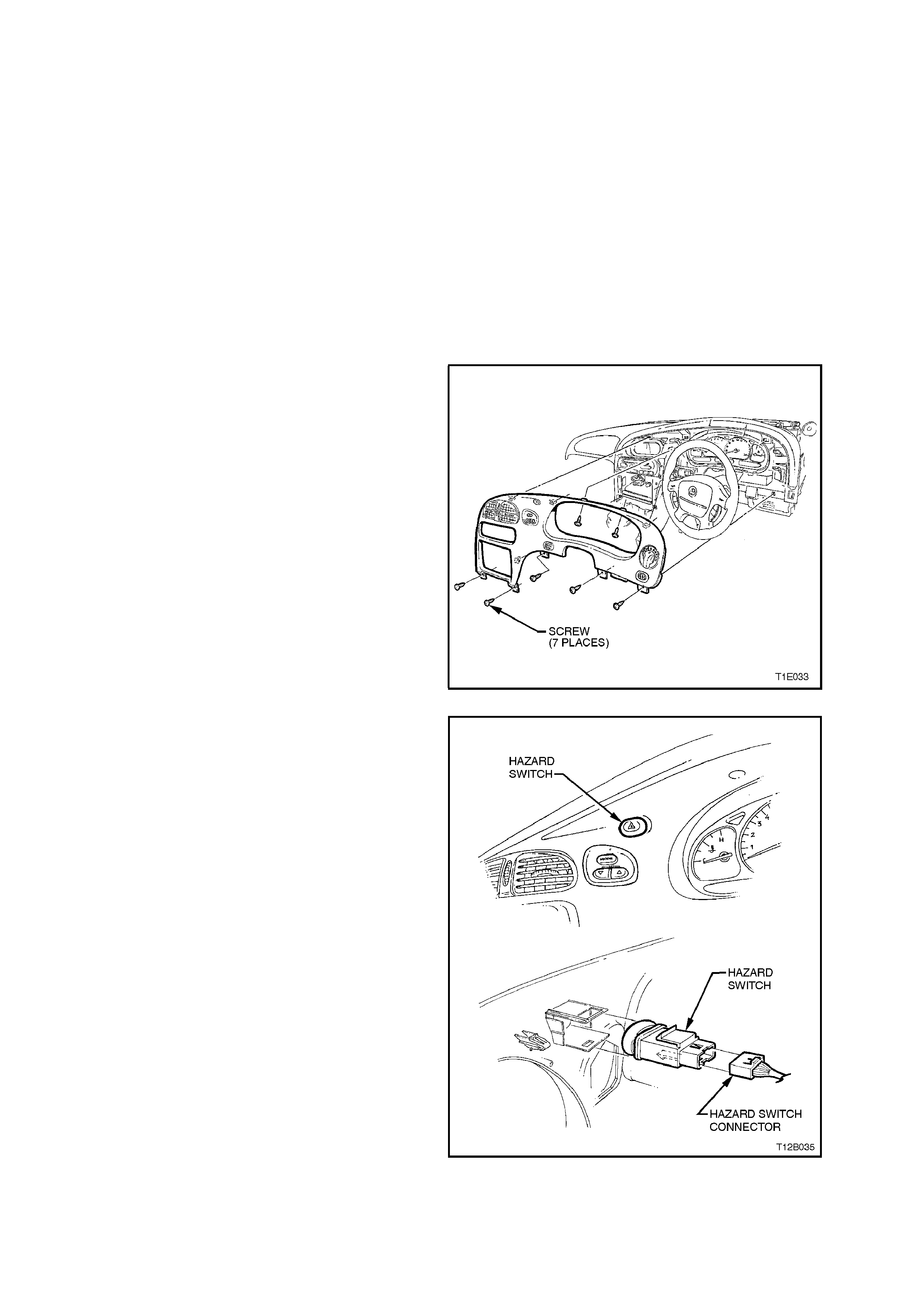

2.25 HAZARD WARNING FLASHER SWITCH

REMOVE

1. Disconnect battery earth lead.

CAUTION:

Disable the SRS (Air Bag). Refer to DISABLING

THE SRS, Section 12M SUPPLEMENTAL

RESTRAINT SYSTEM.

2. Release steering column height adjusting lever

and completely lower steering column, lock

lever in this position.

3. Place a clean shop rag over and around

steering column upper cover. This step is

important so as to prevent any possibility of

damage to cover when removing the

instrument facia.

4. Remove instrument facia, refer to

Section 1A3 INSTRUMENT PANEL &

CONSOLE.

Pull instrument facia out only far enough to

gain access to rear of all instrument facia

switches.

Figure 12B-78

5. Depress retaining tangs on instrument

harness to facia switch connectors and pull

connectors from switches.

6. Remove instrument facia.

7. Squeeze together retaining tangs at side of

switch and push switch out from facia.

Figure 12B-79

TEST

With the aid of an ohmmeter, check continuity of

hazard warning flasher switch contacts, using the

following chart.

If continuity is not as specified at any switch

position, replace switch assembly.

Figure 12B-80

HAZARD WARNING FLASHER SWITCH CONTACTS

TERMINAL

NO. SWITCH

STATUS

OFF ON

1 O TURN SIGNAL

2 O SIDE TURN

3 O O FLASHER RELAY

4 O BATTERY +

5 O SIDE TURN

6 O IGN. SWITCH

7 O ILLUMINATION +

●

8 O ILLUMINATION –

REINSTALL

Installation of the hazard warning flasher switch is

the reverse of removal procedures, noting the

following points:

1. If, when instrument facia was pulled away

from instrument panel pad, the pad retaining

clips came away with the facia lugs, pull clips

from lugs and reinstall into pad holes. Refit

instrument facia and ensure that it is held to

the instrument panel pad securely.

2. Check hazard warning flasher operation and

ensure that switch illum ination bulb illuminates

when the headlamps are turned on.

IMPORTANT:

Enable the SRS (Air Bag). Refer to ENABLING

THE SRS, Section 12M SUPPLEMENTAL

RESTRAINT SYSTEM.

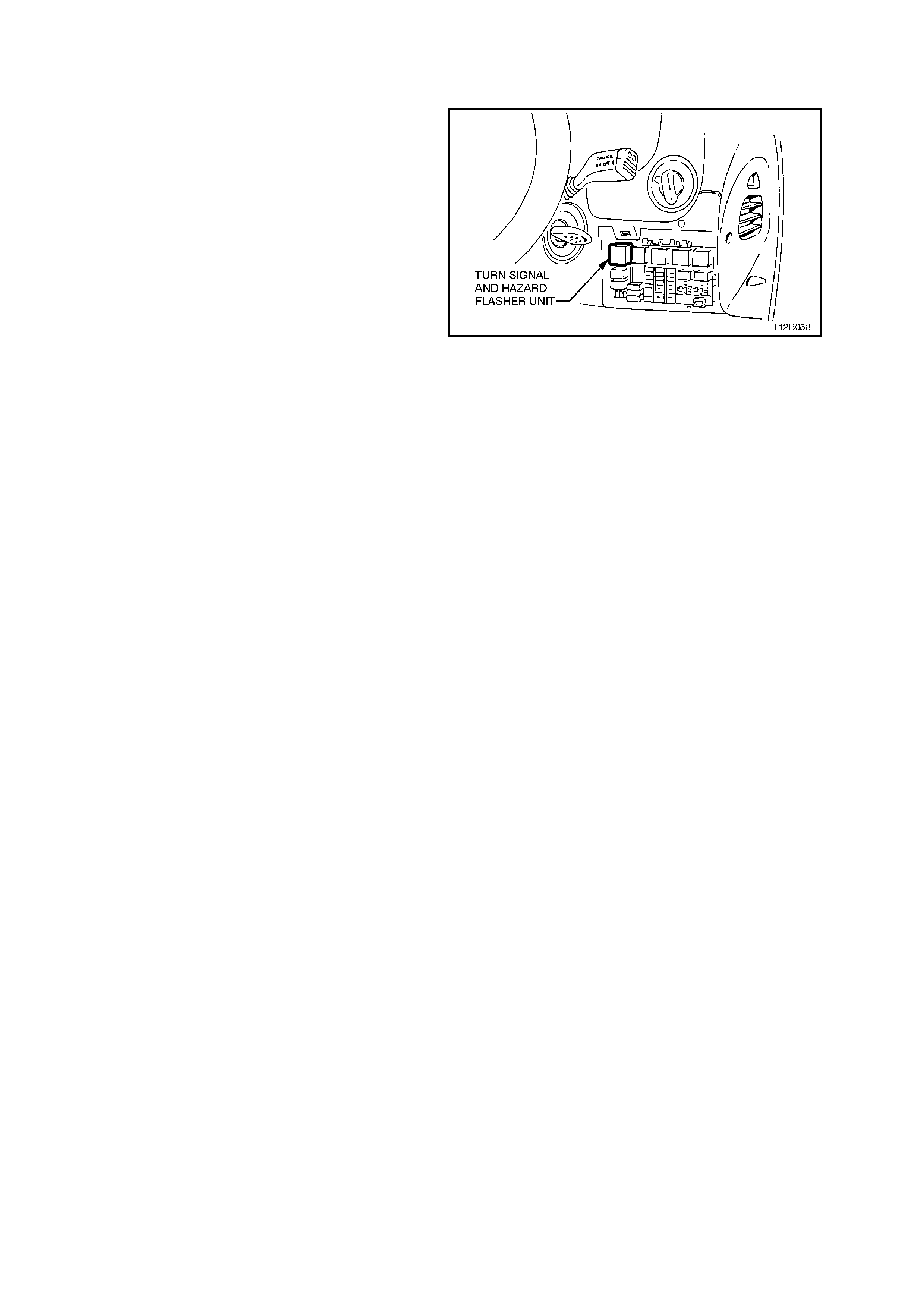

2.26 TURN S IGNAL AND HAZARD FLASHER UNIT

REPLACE

Fig. 12B-81 illustrates the location on the interior

fuse panel and installation of the turn signal and

hazard flasher unit (located inside the vehicle,

attached to the fuse panel).

Access to the turn signal and hazard flasher unit is

by gripping the upper portion of the instrument

panel right hand cover assembly and pulling down,

disengaging the retaining clips.

Figure 12B-81

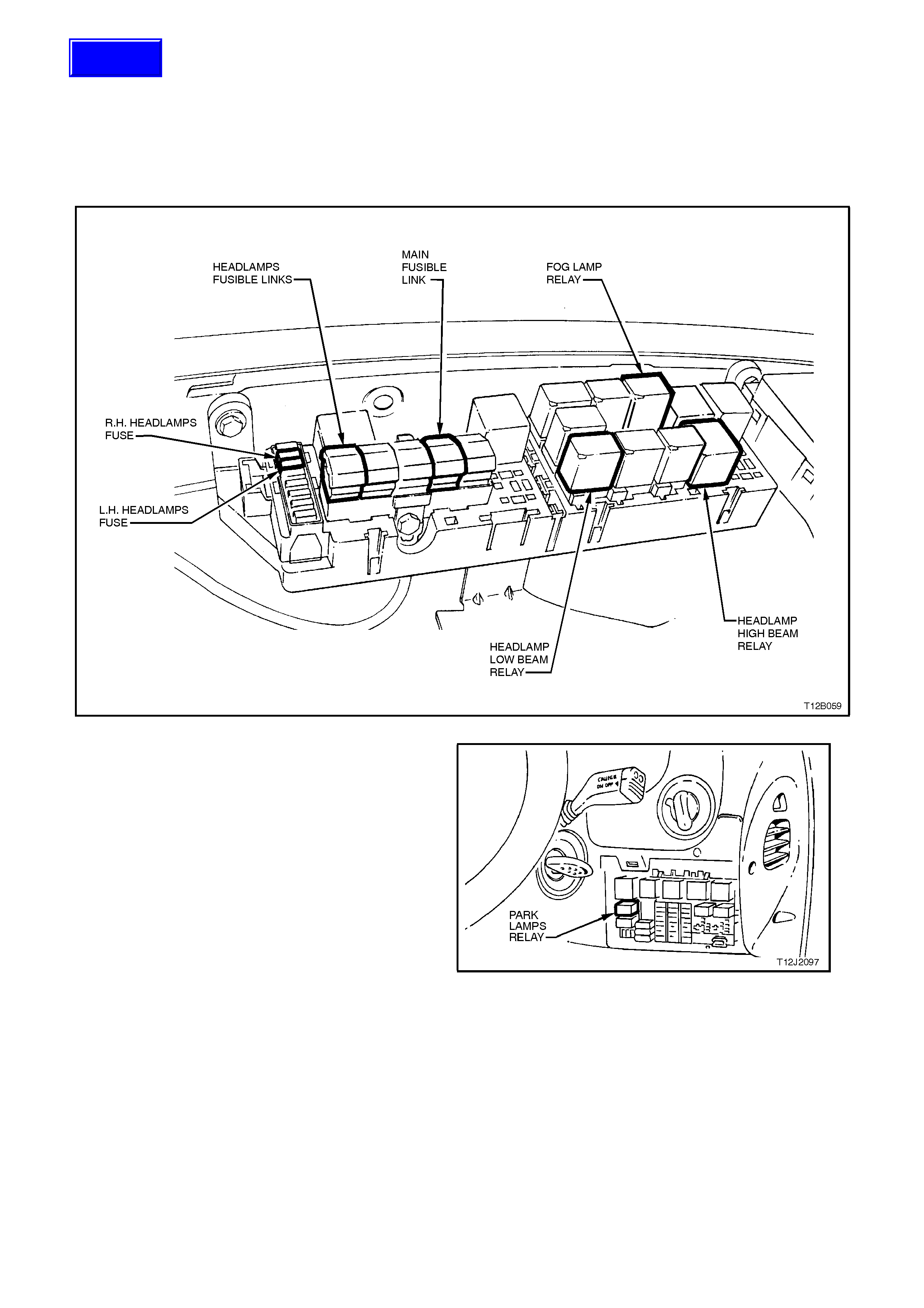

2.27 HEADLAMPS AND PARKING LAMPS RELAYS

REPLACE

Fig. 12B-83 illustrates the location in the engine

compartment relay housing of the relays used for

the headlamp oper ation ( all models) , f og lamp relay

(vehicles with fog lamps) and the fusible link FJ.

Figure 12B-82

The parking lamps relay is located inside the

vehicle, attached to the fuse panel. Access to the

parking lamps relay is by opening the instrument

panel right hand cover.

Figure 12B-83

Techline

3. SPECIFICATIONS

BULB POWER RA TING -

WATTS BASE TYPE

HEADLAMPS

Hi/Lo Beam (Outboard)

Inboard High Beam

60/55

55

H4

H3

FOG LAMPS 55 H3

PARKING LAMPS (Front) 5 Wedge

TURN SIGNAL LAMPS (Front) 21 Offset Pin (Orange glass)

SIDE REPEATER LAMP 5 Wedge

TURN SIGNAL (Sedan - Rear)

Executive, Berlina, S and SS

Calais

21

21

Std. Parallel Pin

Offset Pin (Orange glass)

TURN SIGNAL (Wagon - Rear)

All models 21 Offset Pin (Orange glass)

BACK-UP LAMP 21 Std. Parallel Pin

STOP AND TAIL LAMP 21/5 Std. Parallel Pin

LICENCE PLATE LAMP 5 Wedge

INSTRUMENT CLUSTER

ILLUMINATION LAMP

Executive

Berlina, Calais

3.6

5

Wedge

Wedge

INSTRUMENT CLUSTER

WARNING CLUSTER LAMP 1.2 Wedge

TRIP COMPUTER ILLUMINATION

LAMP 1.2 Wedge

REAR COMPARTMENT 10 Festoon

DOME (Courtesy) LAMP 10 Festoon

FRONT SEAT READING LAMP 5 Std. Parallel Pin

REAR SEAT READING LAMP 5 Wedge

GLOVE COMPARTMENT LAMP

Executive, Berlina, S and SS

Calais

5

10

Festoon

Festoon

FRONT FOOTWELL LAMPS 2.7 Wedge

FRONT VANITY MIRROR LAMP 1.4 Wedge

DOOR COURTESY LAMP 5 Festoon

CONSOLE BIN LAMP 5 Festoon

HIGH MOUNTED STOP LAMP 18 Wedge

HIGH MOUNTED STOP LAMP - S,

SS MODEL 5 LED assembly

FRONT AND REAR CIGAR

LIGHTER LAMP 1.2 Wedge

IGNITION LOCK LAMP 1.2 Wedge

4. TORQUE WRENCH SPECIFI CATIONS

Nm

Headlamp and turn signal/parking lamp assembly

securi ng screws 2 - 5

Calais and SS Fog lamp mounting frame to bumper

bar beam screws 2 - 5

S and SS high level stop lamp to rear spoiler

attaching screws 1 - 3

Station wagon high mounted stop lamp attaching

screws 1 - 3

Dome lamp attaching screws 3 - 5

Door jamb switch attaching screws 3 - 5

Headlamp adjuster attaching screws 3 - 5

Decklid lamp assembly attaching nuts 2 - 5

Decklid lamp housing attaching nuts 3 - 4

Rear compartment lamp switch attaching screw 1 - 3

Rear lamp housing retaining screw 1 - 3

Tailgate lamp switch attaching screw 1 - 3

Transmission selector lever locking bolt 20 - 30

Rear quarter lamp housing attaching nuts 3 - 4

Station wagon rear lamp housing retaining nuts 1 - 3

Selector lever retaining nut 15 - 35