SECTION 12C - INSTRUMENTS, WIPERS/WASHERS

& HORN

CAUTION:

This v ehicle will be equipped with a Supplemental Restraint System (SRS). A SRS

will consist of either seat belt pre-tensioners and a driver's side air bag, or seat

belt pre-tensioners and a driver's and front passenger's side air bags. Refer to

CAUTIONS, Section 12M, before performing any service operation on, or around

any SRS components, the steering mechanism or wiring. Failure to follow the

CAUTIONS could result in SRS deployment, resulting in possible personal injury

or unnecessary SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests

of safety, the LPG fuel system should be isolated by turning 'OFF' the manual

service valve and then draining the LPG service lines, before any service work is

carried out on the vehicle. Refer to the LPG leaflet included with the Owner's

Handbook for details or LPG Section 2 for more specific servicing information.

1. GENERAL DESCRIPTI ON

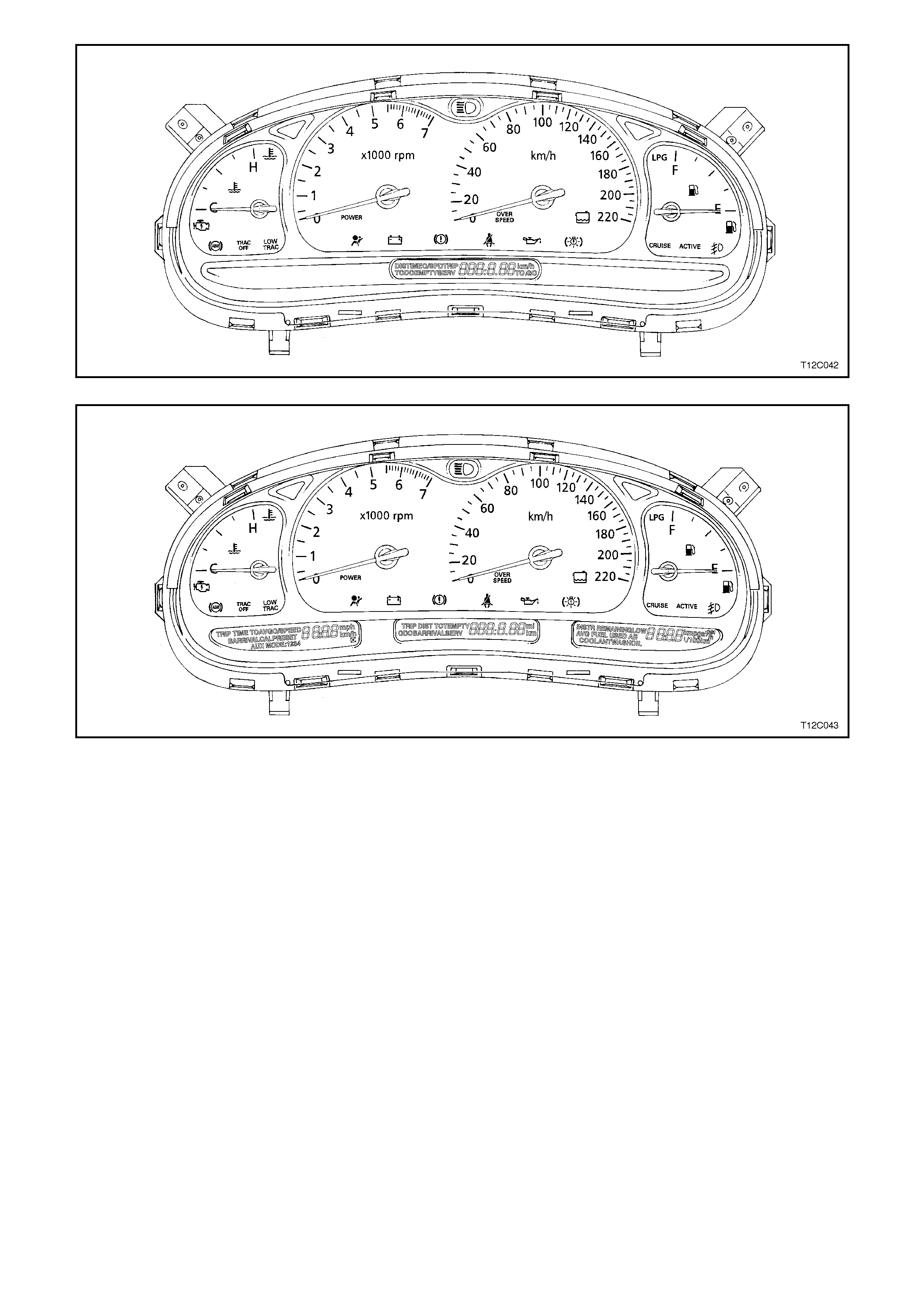

Two versions of instrument cluster assemblies are used on VT Series Models, one with a single window trip

computer display and the other with a triple window display.

A trip computer is standard equipment on all VT Series Models.

The instrum ent cluster assem bly on VT Series Models consists of specific style analogue type instrument gauges.

An electronic s peedometer is s ituated to the right of c entre, with the odom eter and trip - odometer readings stored

on the trip com puter. A tachometer is located to the left of centre, an elec tronic tem perature gauge to the left of the

tachometer and a bi-metal fuel gauge to the right of the speedometer. W arning lights are located at the bottom of

the instruments above the odometer.

Instrument cluster illumination is by bulbs located in sockets, which are a twist fit into the rear of the instrument

case.

Located in the centre lower section of the instrument cluster on Executive, S, SS and Acclaim is a single window

Liquid Crystal Display (LCD) trip computer. A triple window trip computer is standard on VT Series Berlina and

Calais Models. Refer to 1.4 TRIP COMPUTER - SINGLE WINDOW TYPE or 1.5 TRIP COMPUTER - TRIPLE

WINDOW TYPE in this Section for an explanation of trip computer functions.

The trip c omputer on both instrum ent cluster ass emblies is operated by means of a switch ass embly located to the

left of the instrument cluster in the instrument facia.

NOTE:

If installing a new trip computer, the original odometer reading must be transferred into the replacement trip

computer. This can be done by authorised Holden dealers using TECH 2.

Techline

Techline

Techline

Figure 12C-1

Figure 12C-2

Incorporated inside the instrument cluster is an audible warning chime which will sound when one or more of the

following warning lamps illuminate in the warning lamp cluster.

The addition of the audible warning chime f eature is used to em phasise the following conditions, with the tone and

frequency of the chime varied to allow different warnings to be identified by sound.

Over speed - triggered when over speed warning lamp is turned on.

Low fuel level - triggered when low fuel warning lamp is turned on.

High Temp - when high temperature warning lamp is turned on.

Park Brake ON - triggered when park brake warning lamp is turned on and vehicle speed is greater than

approximately 8 km/h.

Low Oil - triggered when low oil lamp is turned on.

SRS Warning - triggered when SRS warning lamp is turned on.

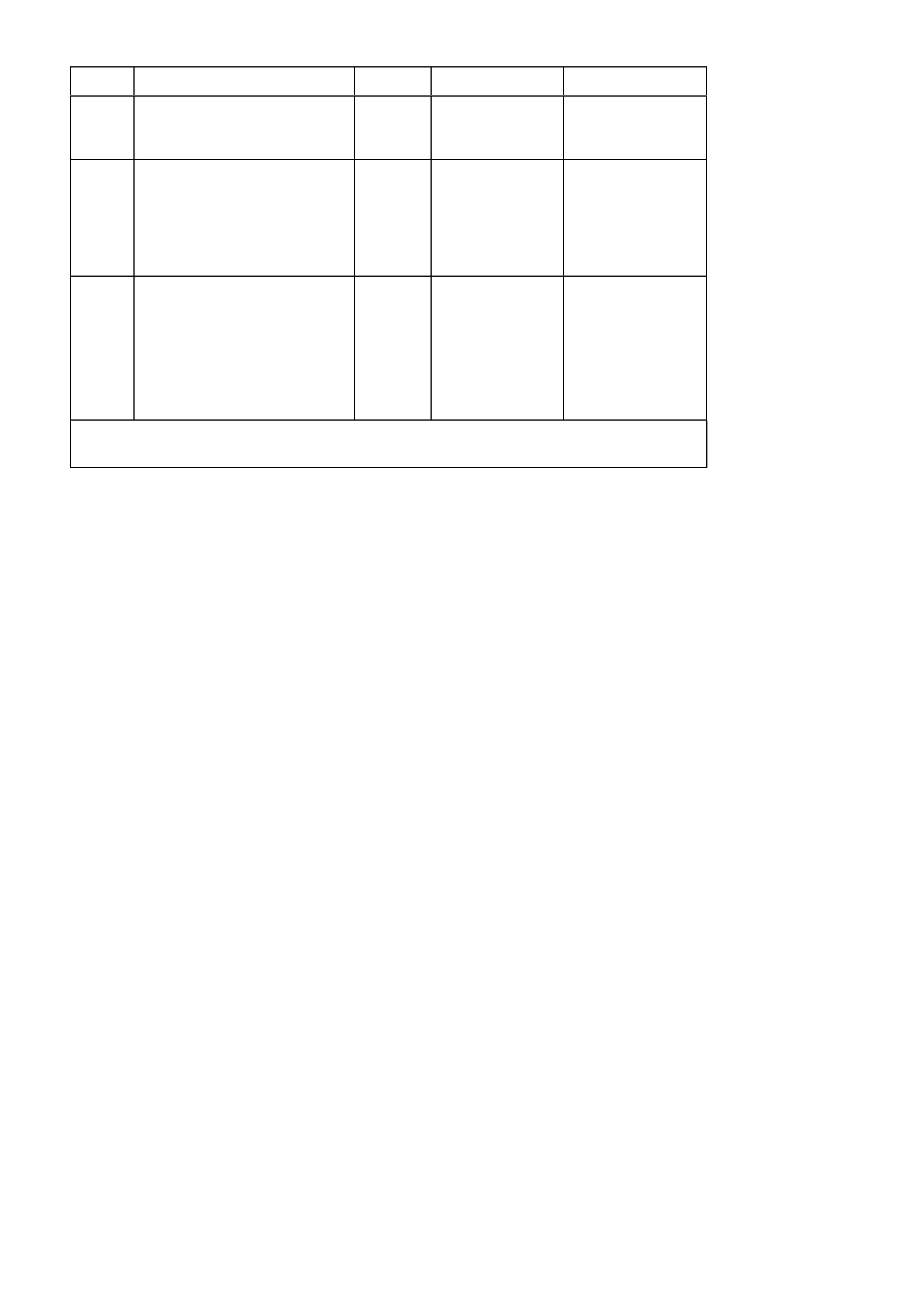

The following chart sets out the chime tones for each warning.

DESCRIPTION TRIGGER FOR AUDIBLE WARNING SEQUENCE OF TONES

OVERSPEED Whenever first time over speed warning light is

turned on except for lamp check. C, F

UNDERSPEED Whenever over speed warning light is turned

off if it is in customise mode. F, C

LOW FUEL Whenever fuel light is turned ‘ON’ or whenever

fuel light starts flashing. G, GO

Repeated four times.

PARK BRAKE Whenever Park Brake warning light is turned

on and vehicle speed is greater than 8 km/h.,

except for lamp check.

C, D, E

Repeated four times.

HIGH TEMP. Whenever High temperature warning light is

first turned on except for lamp check. C, D, E

Repeated four times.

LOW OIL Whenever Low Oil Pressure warning light is

first turned on except for lamp check and

engine is running.

C, D, E

Repeated four times.

SRS WARNING Whenever SRS warning light is first turned on

except for lamp check. D, E, F

Repeated three times.

SET Whenever Set function is used. CI, FI

AUXILIARY Whenever Auxiliary Mode is used. CI, FI

ON/OFF Whenever ON/OFF function is used. CI, FI

MODE CHANGE Whenever displayed mode changes. CI

BUTTON PRESS Whenever button is pressed. FI

The corresponding frequencies of the tones are listed in the following table.

TONE GO C C

SHARP DEFGBICIFI

FREQUENCY

(Hz) 392 523 554 587 659 698 784 988 1046 1397

NOTE:

Should it be necessary to electric weld on any vehicle at any time, removal of the instrument cluster is mandatory.

Failure to do so will result in damage to the instrument gauge circuitry.

On all VT Series Models the clock is incorporated in the radio/cassette player LCD window.

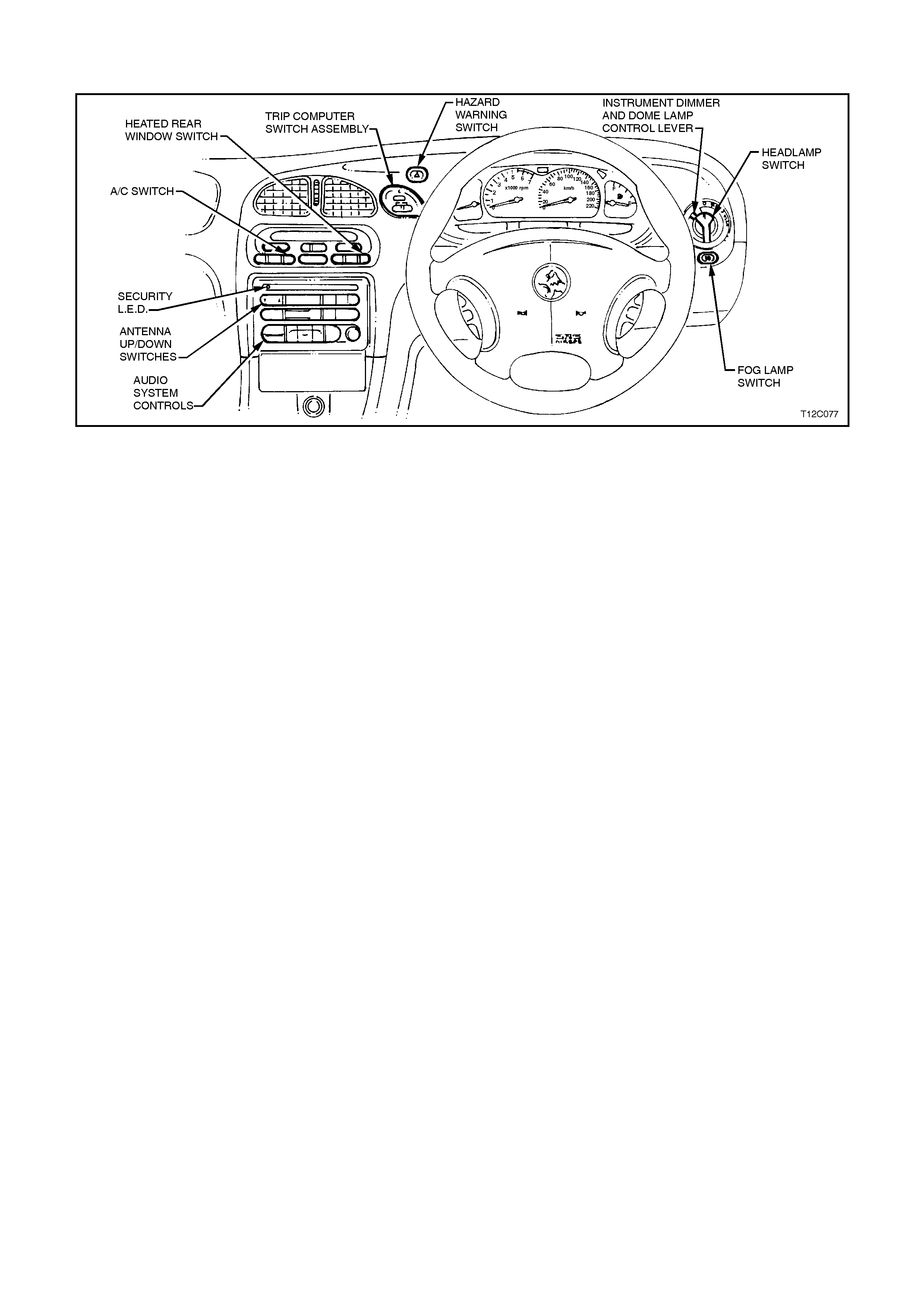

1.1 INSTRUME NT FACIA SWITCHES

Fig. 12C-3 illustrates the various switch locations in the instrument facia for all models.

Figure 12C-3

Two different types of headlamp switches are used, one each for the different type of BCM used in VT Series

Models. Refer to Section 12J-1 BODY CONTROL MODULE for Low Series BCM identification details or

Section 12J-2 BODY CONTROL MODULE for High Series BCM identification details.

The headlamp switch used for the Low Series BCM incorporates a switch for two levels of instrument cluster

illumination (high and low level intensity) and a three-position switch for off, parking and headlamps on.

With High Series BCM, the headlam p s witch incorpor ates a variable intens ity instr um ent cluster illum ination control,

a four-position switch for off, parking and headlamps on and an auto headlamps on switch mode.

For testing of the instrument facia switches, refer to Section 12B, LIGHTING SYSTEM.

Switches for the power antenna up and down control on Calais models are located in the radio control panel.

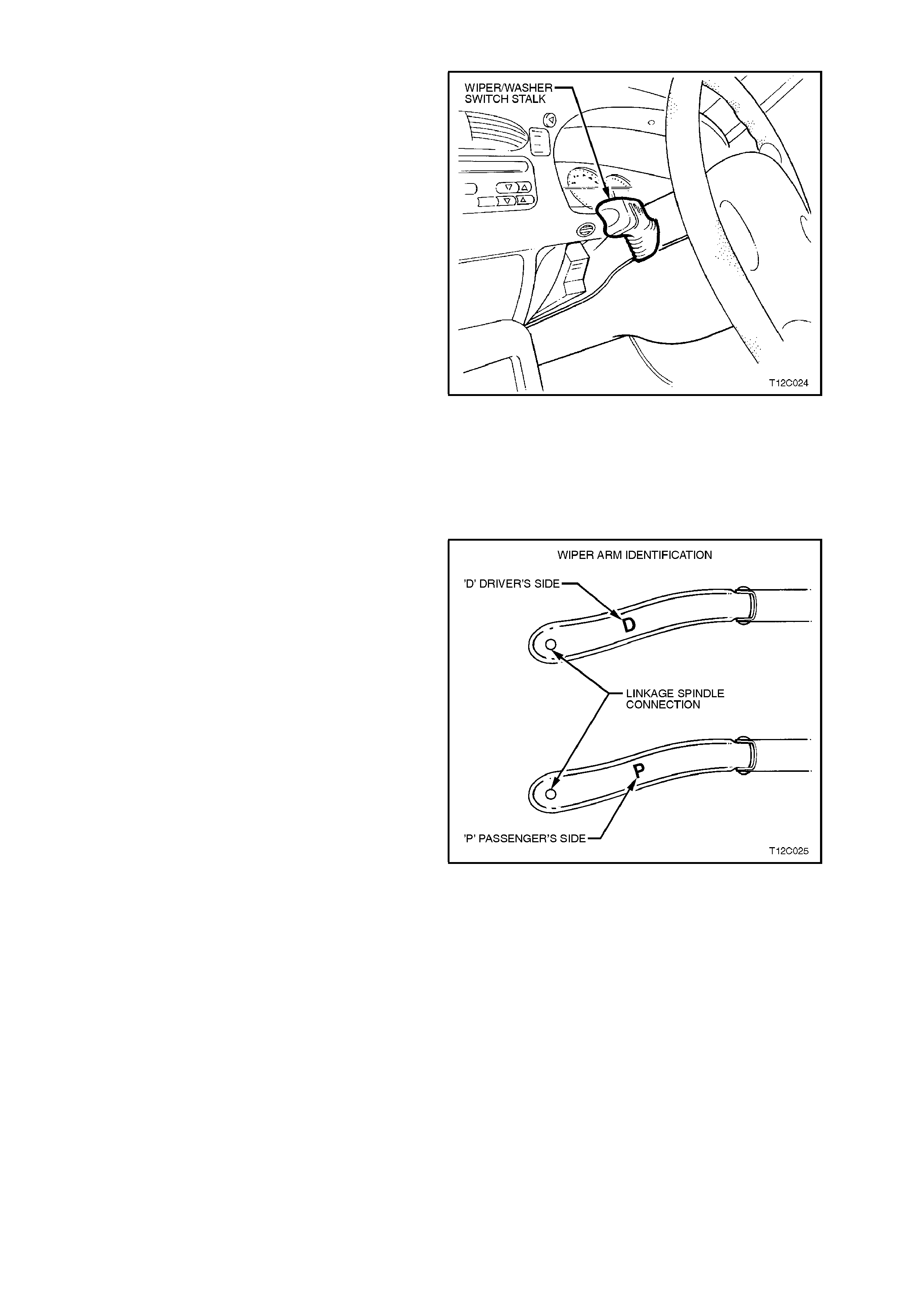

1.2 WIPERS AND WASHERS

All VT Series Models are fitted with windshield

washers and four speed (m ist, interm ittent, low and

high speed) windshield wipers. Wagons are

equipped with a tailgate washer and single speed

wiper. All washers and wipers are controlled from

the left-hand steering column stalk switch. There

are specific switch assemblies for sedan and

wagon model applications and these are also

dependant on which series of BCM is fitted.

The rear wiper on wagons will usually have an

intermittent sweep. However, on wagons built with

an automatic transmission, the rear wiper will

change to a continuous sweep when reverse gear

is selected.

On vehicles with low series BCM, the wiper

intermittent dwell control circuitry is integrated

inside the BCM.

On vehicles fitted with high series BCM, the module

controls the intermittent dwell time based upon the

vehicle road speed and the s etting of an adjustable

control on the left-hand control stalk.

For details on BCM control of the windshield

wipers and washers, depending on model variant,

refer to either Section 12J-1 LOW SERIES BCM

or Section 12J-2 HIGH SERIES BCM.

Figure 12C-4

The windshield wiper blade arms are the fold back

type assemblies, with a specific arm and blade for

each side of the vehicle. T he arm s are identif ied by

a letter ‘D’ for the drivers side and the letter ‘P’ for

the passengers side on the under side of the arm,

refer F ig. 12C-5. The wiper blades can be identified

by their length; the drivers side wiper arm is 550

mm long and the pass engers side wiper arm is 500

mm long.

A windshield reservoir (sedan) or a common

windshield/tailgate reservoir (wagon) is located in

the right-hand front wheel house. A filler cap is

provided in the engine compartment, adjacent to

the battery to allow filling of the reservoir.

Specific washer pumps are used for sedan and

wagon models. The pump used for wagon models

has dual outlets for the windshield and tailgate.

For the identification of the washer pumps and

reservoir location, refer to Fig. 12C-65 and Fig.

12C-75 in this Section. Figure 12C-5

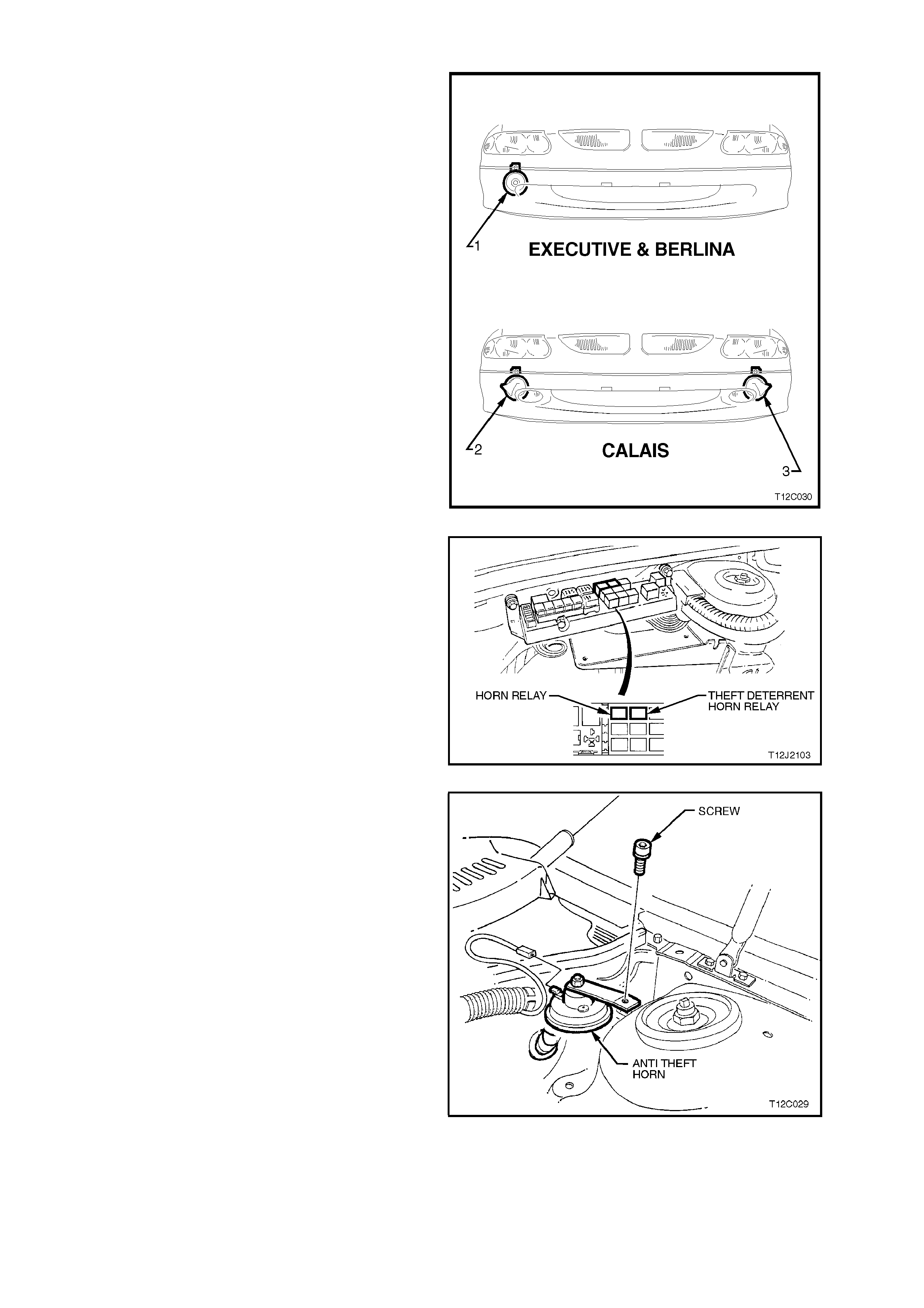

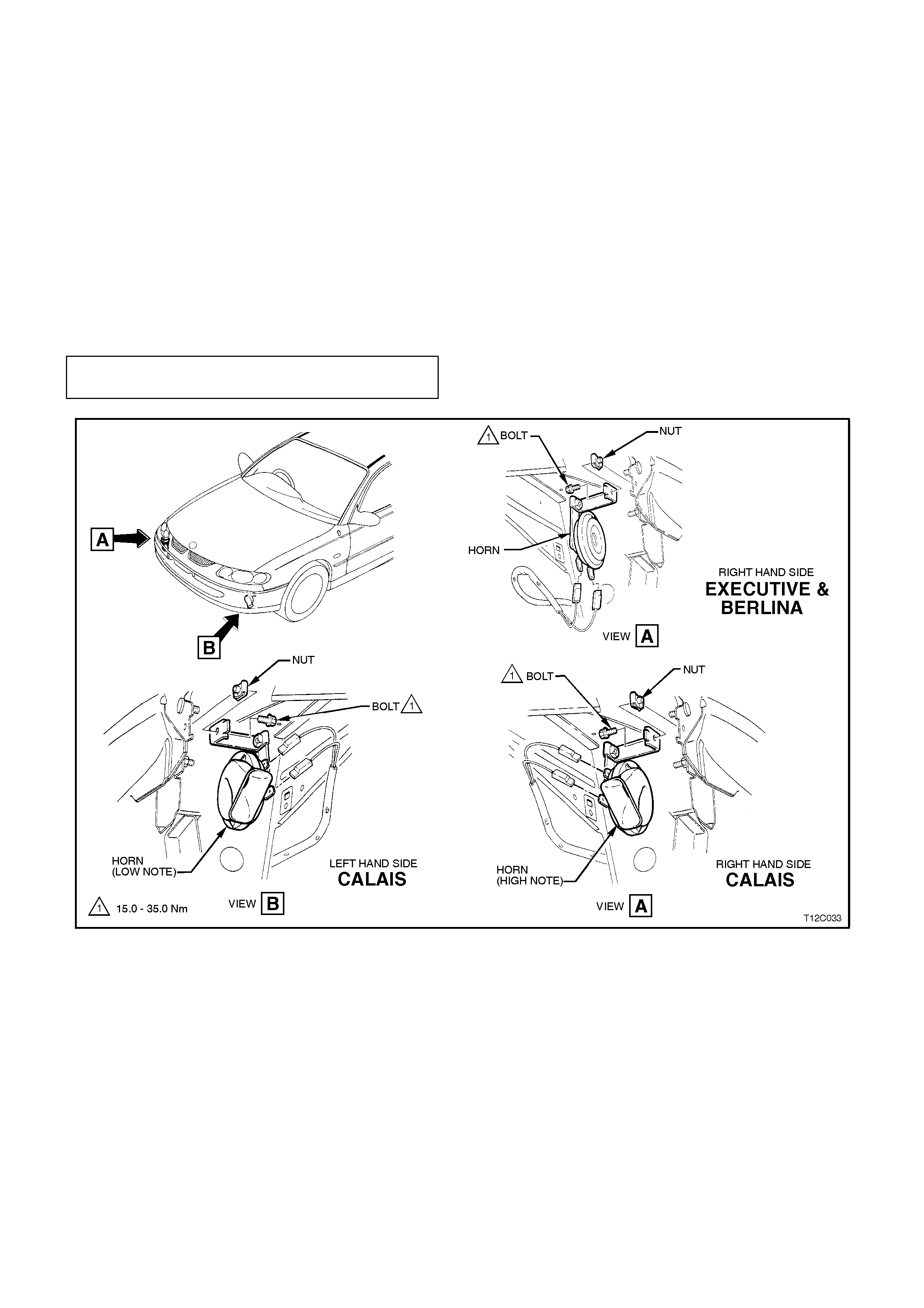

1.3 HORN

VT Series Executive and Berlina Models have a

single, disc type low note (400 Hz) horn (1)

mounted on the right-hand wheel house panel

behind the bumper facia.

VT Series Calais Models are fitted with trumpet

type high (500 Hz) and low note (400 Hz) horns, the

high note horn (2) is mounted on the right-hand

wheel house panel and the low note horn (3) on the

left-hand front wheel house panel behind the

bumper facia.

Figure 12C-6

The horn/s ar e operated by depressing the steering

wheel horn bar which earths a spring loaded

contact in the steering column switch housing

assembly. This energises a horn relay (located in

the engine compartment relay housing) and the

horn/s sound. The horn assem blies use a solenoid

operated diaphragm to generate sound.

Figure 12C-7

On vehicles with High Series BCM, a thef t deter rent

system horn is fitted inside the engine

compartment, behind the left hand strut tower.

Also located in the engine compartment relay

housing is a theft deterrent s ystem horn relay, refer

Fig. 12C-7.

Figure 12C-8

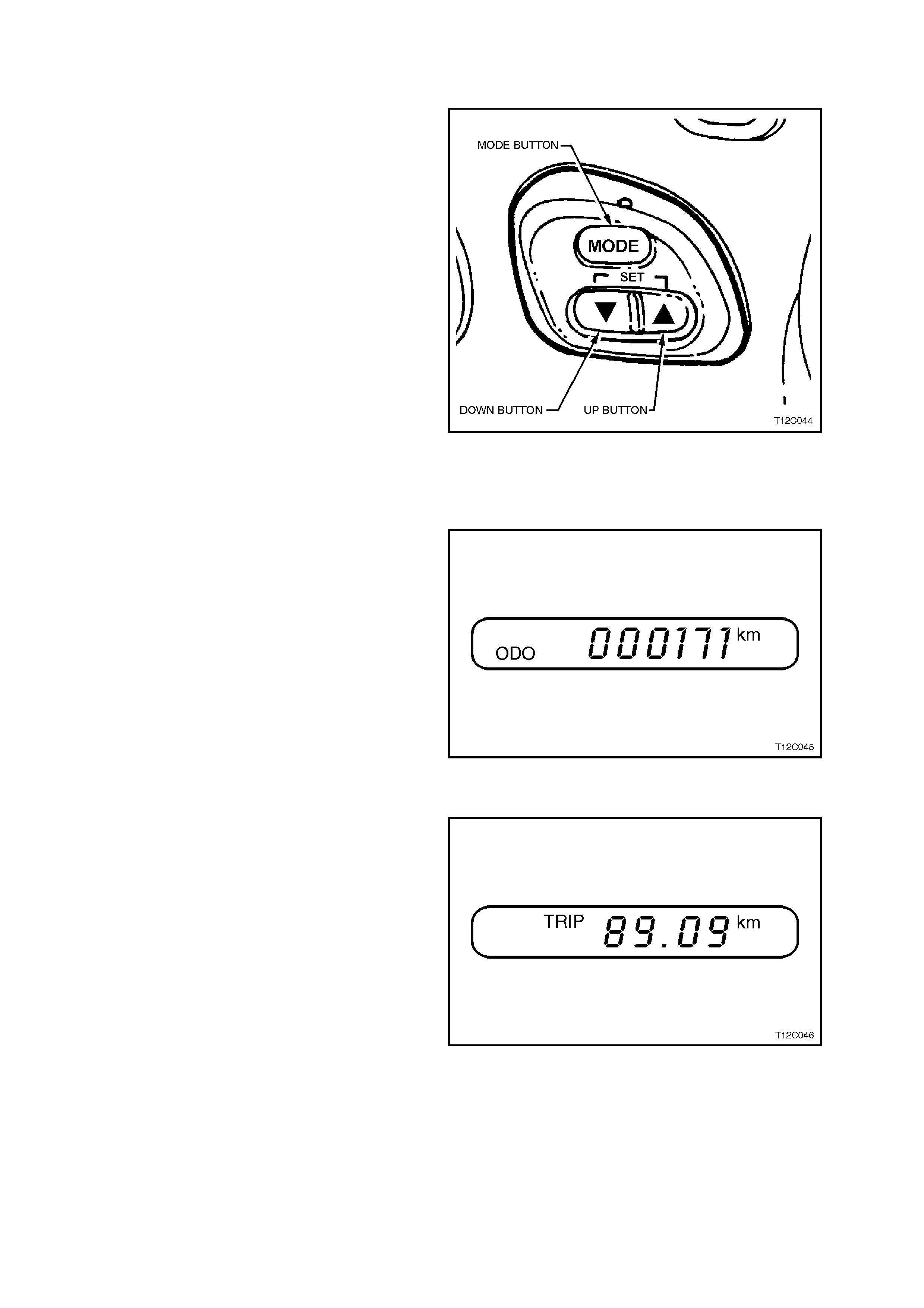

1.4 TRIP COMPUTER - SINGLE WINDOW TYPE

OPERATION

The buttons for the trip com puter are loc ated to the

left of the gauges. The window for the trip computer

is located directly beneath the gauges.

When the ignition is turned on, the trip computer

will display the same group of functions as when

the ignition was last turned ‘OFF’.

To reset the computer, hold down the Up Button (⇑

⇑⇑

⇑)

and the Down Button (⇓

⇓⇓

⇓) simultaneously. This will

reset all f unctions , with the exception of DIST ANCE

TO EMPTY, OVERSPEED WARNING,

ODOMETER, TIME TO ARRIVAL, DISTANCE TO

ARRIVAL and REMAINING FUEL .

To scroll between the four basic, more commonly

used functions press the MODE button.

NOTE:

If the wrong buttons have been accidentally

pressed, c aus ing the display to show other than the

normal readings, turn the ignition off, then on again. Figure 12C-9

BASIC FUNCTIONS

ODOMETER

The odometer records kilometres travelled since

the vehicle was built.

Figure 12C-10

TRIP

Shows the kilometres travelled from the start of a

particular trip. Reset the reading to zero by

pressing the ⇑

⇑⇑

⇑ and ⇓

⇓⇓

⇓ buttons together when this

window is shown.

Figure 12C-11

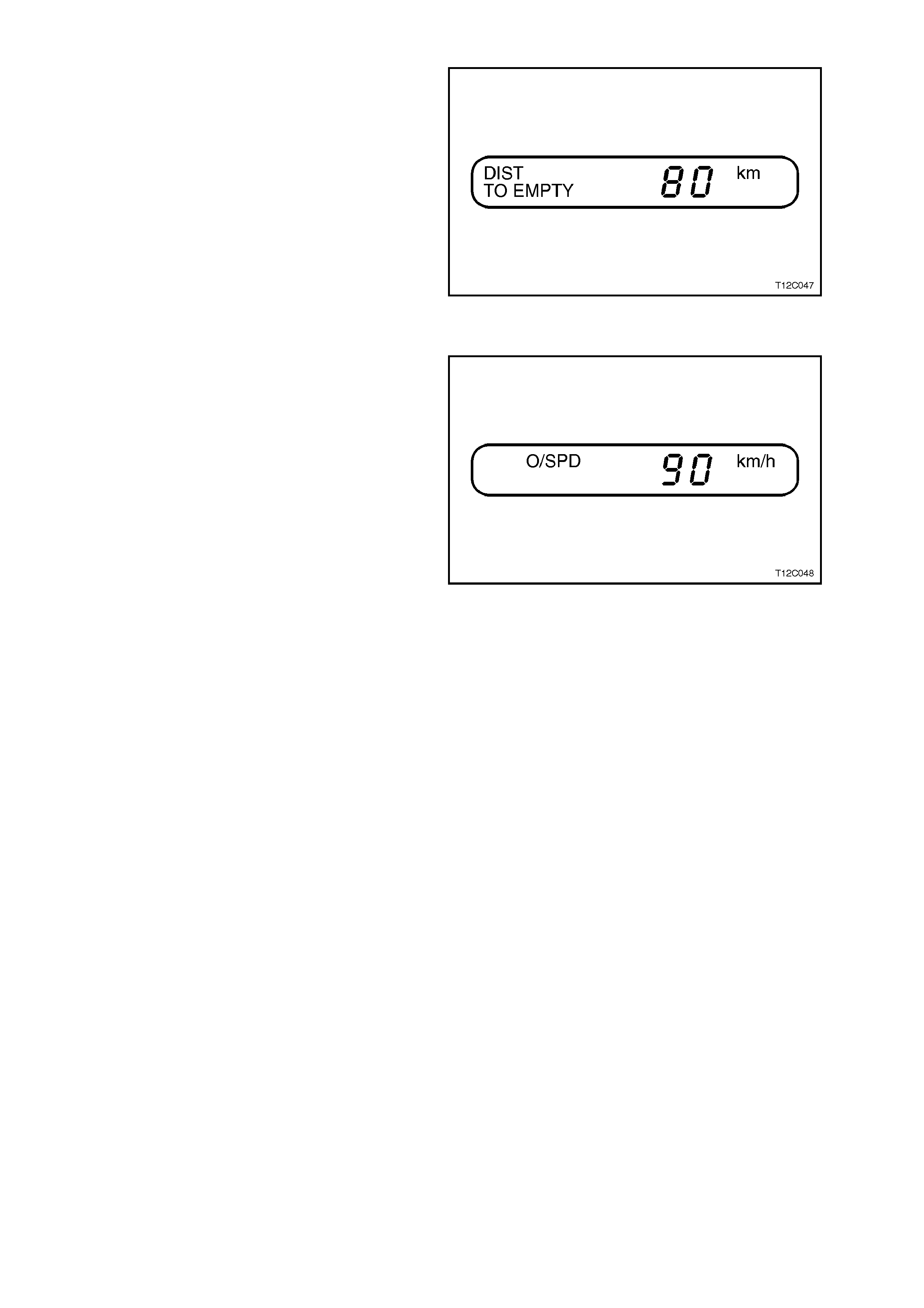

DISTANCE TO EMPTY

DISTANCE TO EMPTY is an estimate of how far

current fuel will last. It is based on previous fuel

usage and is frequently updated. Therefore, as

conditions become suited to more economical

driving the DISTANCE TO EMPTY may actually

increase, for example from city to highway driving.

Figure 12C-12

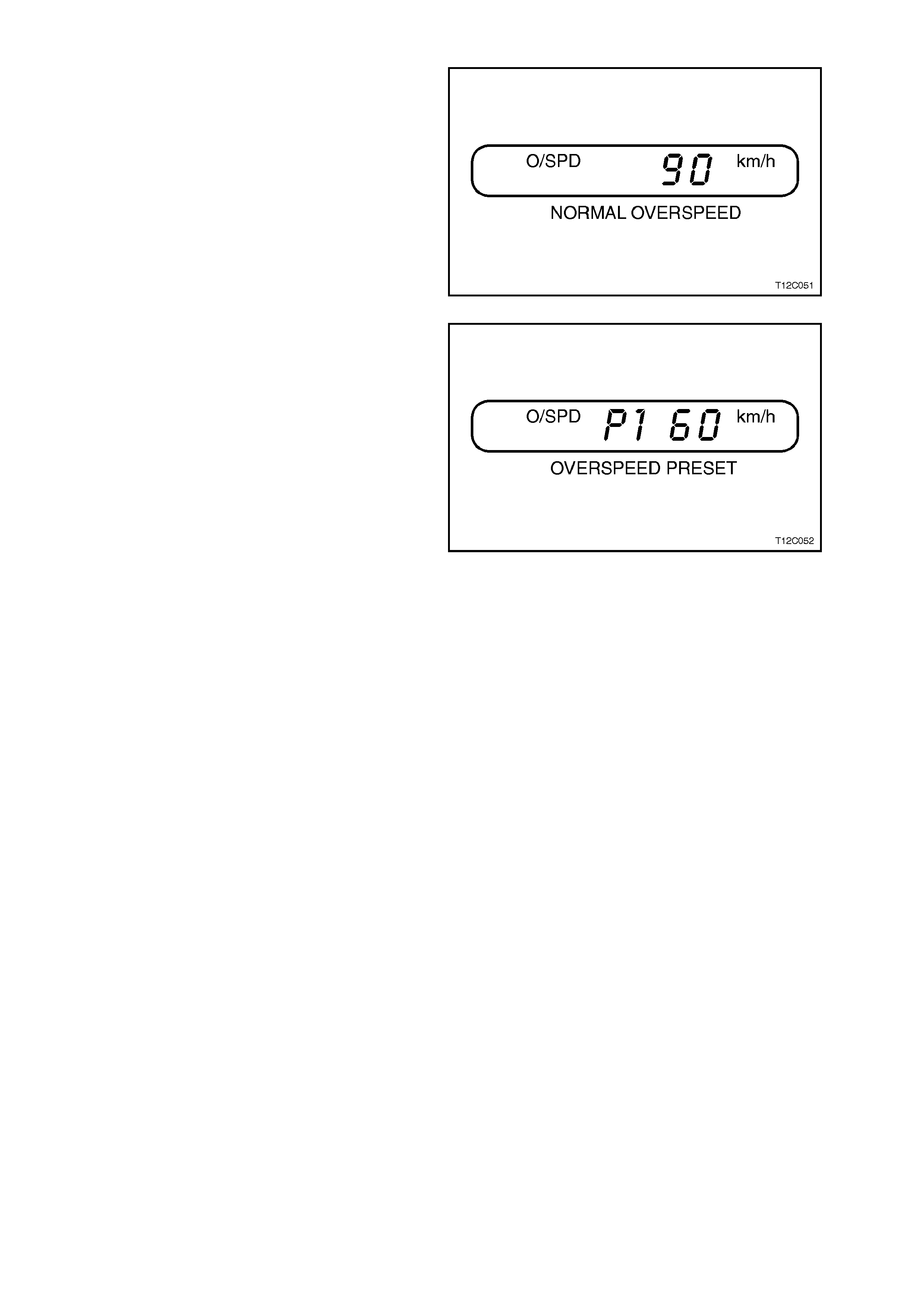

OVERSPEED

Set the speed not to be exceed. For example, if

driving in a 90 km/h zone, set OVERSPEED to 90

by tapping the ⇑

⇑⇑

⇑ or ⇓

⇓⇓

⇓ buttons. W hen vehicle speed

exceeds 90 km /h the O VERSPEED warning light in

the instrument panel and an audible chime will

warn that set speed has been exceeded. At that

time the trip computer will automatically show

overspeed display, allowing adjustments as

required.

OVERSPEED is adjustable in 5 km/h units and

works at speeds between 20 km/h and 200 km/h.

Tap the ⇑

⇑⇑

⇑ or ⇓

⇓⇓

⇓ buttons as requir ed or hold a button

to scroll quickly to a speed. Brief ly press the ⇑

⇑⇑

⇑ and

⇓

⇓⇓

⇓ buttons together to set the OVERSPEED to the

speed at which the vehicle is currently travelling.

Press and hold both the ⇑

⇑⇑

⇑ and ⇓

⇓⇓

⇓ buttons for at least

2 seconds (when this display is showing) to turn the

OVERSPEED warning on or off.

OVERSPEED presets can also be chosen, refer

OVERSPEED ADJUSTING in this Section.

Figure 12C-13

ADDITIONAL FUNCTIONS

The following details the additional functions that have been provided in the trip computer.

CUSTOMISE MODE

The trip computer features can by customised. W hen the vehicle is stationary, hold down the MODE button while

turning the ignition from OFF to ON. The trip computer then steps you through a series of choices:

CHOICE 1: ODO (odom eter) window shown or skipped. Use the ⇑

⇑⇑

⇑ or ⇓

⇓⇓

⇓ button to select YES or NO as to whether

the odometer will be displayed when the ignition is ON. Note that the odometer will still count in the background

(and will appear when the ignition is OFF), even if the display is set to NO. When the display is flashing on your

selection, press the MODE button to go the next choice.

CHOICE 2: TRIP distance - feature available or sk ipped. Use the ⇑

⇑⇑

⇑ or ⇓

⇓⇓

⇓ button until your choice is flashing. Press

the MODE button to go to choice 3.

CHOICE 3: DISTANCE T O GO - f eature available or s kipped. T his choice will activate an additional s et of displays:

DISTANCE T O GO and T IME TO GO. Use the ⇑

⇑⇑

⇑ or ⇓

⇓⇓

⇓ button until choice is f lashing. Press the MO DE button to go

to choice 4.

CHOICE 4: Adjust DISTANCE T O G O def ault s etting. T he DISTANCE T O GO c an be re set ( when not in c us tomise

mode) by pressing the ⇑

⇑⇑

⇑ and ⇓

⇓⇓

⇓ buttons together. T he distance res ets to 500 km , which is the def ault setting. W hen

in customise mode, choice 4 enables the default setting to be altered up or down with the ⇑

⇑⇑

⇑ or ⇓

⇓⇓

⇓ buttons. When

correct, press the MODE button to go to choice 5.

CHOICE 5: UNDERSPEED chime. OVERSPEED provides a chime when your travelling speed exceeds

OVERSPEED chosen s peed. An additional chime c an be activated to indicated when travelling speed drops below

OVERSPEED. Choice 5 in cus tom ise m ode is to turn the sec ond chim e, the "unders peed" c him e of f or on. Us e the

⇑

⇑⇑

⇑ or ⇓

⇓⇓

⇓ button until your choice is flashing. Press the MODE button to end customise mode.

To activate customise mode again, turn the ignition OFF, then turn ON while holding down the MODE button.

Customise mode will end automatically if vehicle speed exceeds 10 km/h or if the ignition is turned off and on.

ADDITIONAL DISPLAYS

Two additional displays can be activated using

customise mode. DISTANCE TO GO and TIME TO

GO are turned on and off as a set, they cannot be

individually activated.

When activated, press the MODE button to scroll

through the Tr ip Computer displays. T here will now

be six displays instead of four. The new displays

will be slotted in between the TRIP display and the

DISTANCE TO EMPTY display. Customise mode

can be used to deactivate the displays, if required.

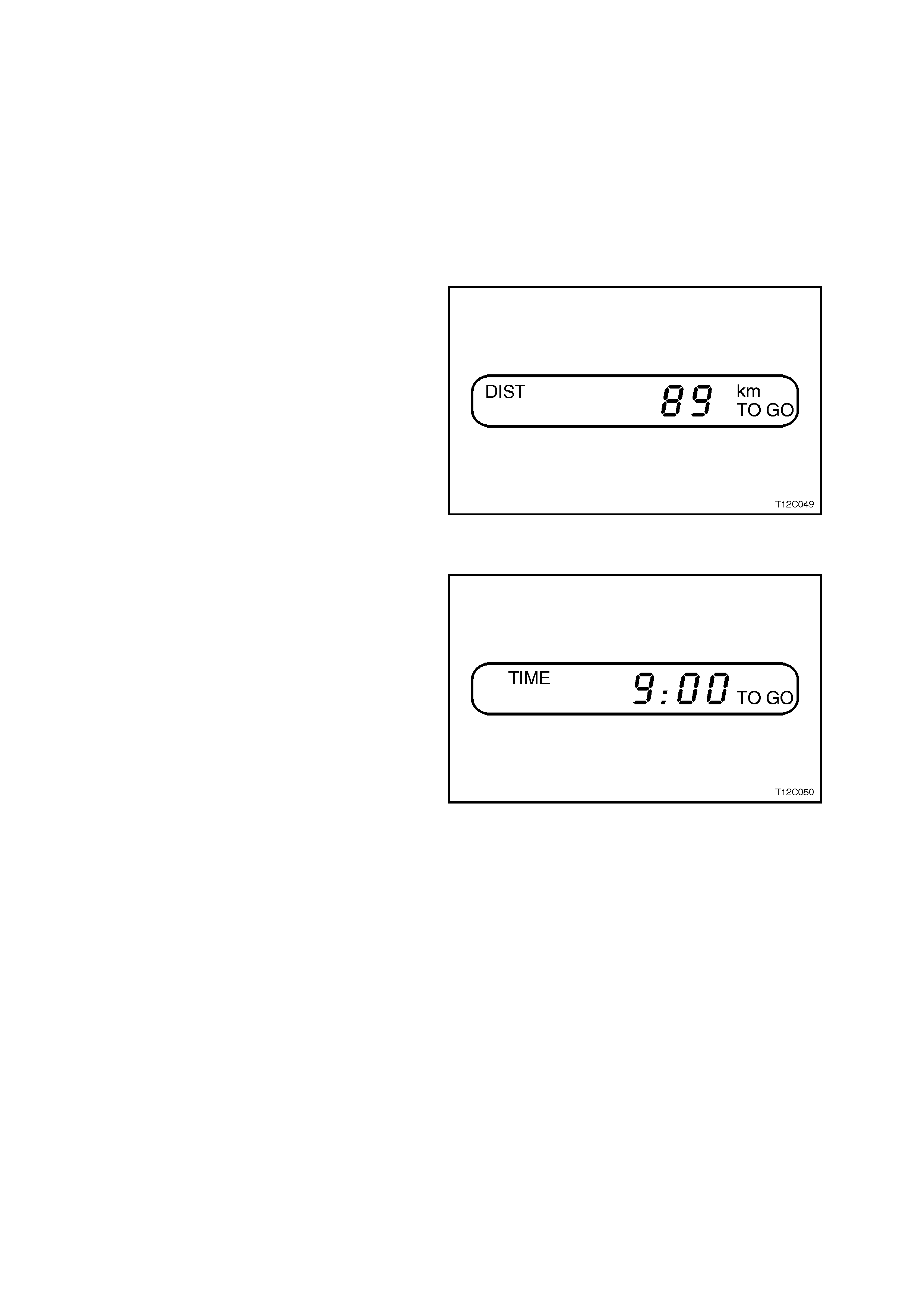

DISTANCE TO GO

At the start of a trip an estimate of distance to

arrival (from maps, road signs etc.) should be

made. Tap the ⇑

⇑⇑

⇑ or ⇓

⇓⇓

⇓ buttons until the display

shows estimated trip distance. W hen the vehicle is

driven the trip com puter will constantly update tim e

to arrival, based on changing driving speeds . The ⇑

⇑⇑

⇑

or ⇓

⇓⇓

⇓ buttons can be used to adjust the kilometres

any time this display is shown.

Figure 12C-14

TIME TO GO

Shows time to arrival in hours and minutes.

TIME TO GO is only shown if the DISTANCE TO

GO is more than zero.

Figure 12C-15

Even if DISTANCE TO GO is turned off using

customise mode, it can still be temporarily turned

on by the following quick method:

Press MODE button until the TRIP display is

shown, press the ⇑

⇑⇑

⇑ and ⇓

⇓⇓

⇓ buttons together to zero

the trip display, then increase the distance up by

pressing the ⇑

⇑⇑

⇑ button.

However, when the trip distance reaches zero the

function will turn off again. Use the customise

mode to permanently turn the above displays on.

OVERSPEED A DJUSTING

Instead of adjusting OVERSPEED up and down in

5 km increments, you can set four commonly used

speeds, e.g. 60, 80, 100 and 110.

Hold down the MODE button for 2 seconds when

the OVERSPEED display is shown. T he dis play will

change from normal OVERSPEED to

OVERSPEED PRESET.

Figure 12C-16

P1 is the first preset number, with a default setting

of 60 km/h.

Tap the ⇑

⇑⇑

⇑ button to see the second preset, P2,

which has a default setting of 80 km/h, P3 has a

default setting of 100 km/h and P4 of 110 km/h.

Tap the ⇑

⇑⇑

⇑ or ⇓

⇓⇓

⇓ buttons to m ove between the preset

numbers.

The OVERSPEED PRESET display has now

replaced the normal OVERSPEED display in the

set of displays. Tap the MODE button to scroll

through the other displays.

To change the display back to normal

OVERSPEED, again hold down the MODE button

for 2 seconds while the OVERSPEED PRESET

display is shown.

Figure 12C-17

ALTERING OVERSPEED PRESETS

The default settings of 60, 80, 100 and 110 km/h can be changed for your individual preference.

The vehicle must be standing still when changing OVERSPEED PRESETS. T o alter, ensure the required preset is

showing, e.g. P2 80 km/h. T hen, br ief ly press the ⇑

⇑⇑

⇑ and ⇓

⇓⇓

⇓ buttons together. T he display starts to flash. Us e the ⇑

⇑⇑

⇑ or

⇓

⇓⇓

⇓ button to adjust the setting. When correct, briefly press the ⇑

⇑⇑

⇑ and ⇓

⇓⇓

⇓ buttons together. Each preset can be changed

in this way.

The presets are automatically arranged in ascending order.

One or more presets can be assigned to OFF, by reducing the pr eset down to 0 (OFF). W hen dr iving three or less

presets will be available to choos e from . To turn back on, select the OFF preset (when the vehicle is standing still)

and use the ⇑

⇑⇑

⇑ button to increase the number.

OVERSPEED PRESETS must be altered when the vehicle is standing still. If the ⇑

⇑⇑

⇑ and ⇓

⇓⇓

⇓ buttons are briefly

pressed while driving, the OVERSPEED setting will be changed to the speed at which you are travelling (in multiples

of 5 km/h).

If the ⇑

⇑⇑

⇑ and ⇓

⇓⇓

⇓ buttons are pressed for 2 seconds, either while driving or standing still, OVERSPEED will be turned

completely OFF or ON.

SERVICE DUE

A service reminder message is built into the trip computer.

The reminder message will first appear 1,000 km before the service is actually due, giving time to arrange for the

service to be c arried out. The m essage will be shown on the T rip com puter fo r 10 sec onds whenever the vehic le's

ignition is switched ON or OFF, until the tr ip com puter is reset. When the s ervice is over due the mess age will f lash

for 10 seconds when the ignition is turned ON or OFF.

•SERV 1500 km will show when the vehicle has travelled 1,000 km since it was built.

•SERV 10000 km will show when the vehicle has travelled 9,000 km since it was built

•SERV 20000 km will show when the vehicle has travelled 19,000 km since it was built.

•SERV 30000 km will show when the vehicle has travelled 29,000 km since is was built etc.

When a service is performed on the vehicle, this

reminder should be reset so that it does not prompt

until the next service is nearly due. Otherwise, it will

keep on reminding of a service that is already

complete:

To reset the service reminder message:

1. Turn the ignition OFF.

2. Hold down the ⇑

⇑⇑

⇑ and ⇓

⇓⇓

⇓ mode buttons on the trip computer together.

3. Turn the ignition ON (mode buttons still depressed).

4. Release mode buttons after approximately 3 seconds.

5. Use the mode button to step through trip computer screens until the service due reminder screen appears on

the LCD (usually only one press).

6. Press and hold both the ⇑

⇑⇑

⇑ and ⇓

⇓⇓

⇓ mode buttons until an audible beep is heard (approximately 3 seconds).

7. Turn the ignition OFF.

NOTE1:

The service due indicator message has now been reset, therefore, the next service due reminder message will not

be displayed until 1000 km before the next service is due.

NOTE2:

The Service Due message is calculated only by distance. Remember that if driving infrequently special servicing

may be required.

ADDITIONAL TRIP COMPUTER NOTES

Two warning lights are linked to the trip computer displays.

1. When the fuel tank level first dr ops below 8 litres ( approx .) , the DIST ANCE TO EMPTY display is autom atic ally

shown for 10 seconds, after which the trip computer returns to its previous display.

2. When the OVERSPEED warning symbol is first shown, the OVERSPEED trip computer display is automatically

shown for 10 s econds. This is to show what the pre-selected speed is and allow adjustm ent if required. After

10 seconds, the trip computer returns to its previous display.

Some of the displays will change the units of measurem ent over tim e. For exam ple, the TIME TO GO will show 10

minute units above 2 hours to arrival, will show 5 m inute units below 2 hours to arr ival and will show 1 minute units

below 10 minutes to arrival.

If the HOT warning is displayed when driving it indicates that the engine water tem perature is dangerously hot. An

audible warning chime is designed to bring this to the attention of the operator. The vehicle should be stopped as

soon as it is safe to do so.

NOTE:

The message will only be displayed for 10 seconds.

If the SERV ERROR warning is displayed on the trip computer a fault in the trip computer system is indicated and

the vehicle should be taken to a Holden Dealer.

1.5 TRIP COMPUTER - TRIPLE WINDOW TYPE

OPERATION

The buttons f or the tr ip com puter are loc ated to the

left of the gauges. As in the s ingle window type, the

triple windows for the trip computer are located

directly beneath the gauges.

The basic, more commonly used functions of the

trip computer f ollow. T ap the MODE button to s c roll

between these three sets of displays.

The speed related displays are in the left window,

distance related displays in the centre and fuel

related displays on the right.

The trip c omputer c an be reset when AVG SPEED

or TRIP TIME are shown on the left window.

Resetting does not affect the ODOMETER,

OVERSPEED, DISTANCE TO EMPTY or INST

FUEL.

For customising details of the trip computer, and

additional operating notes, refer to

CUSTOMISE MODE in this Section.

BASIC FUNCTIONS

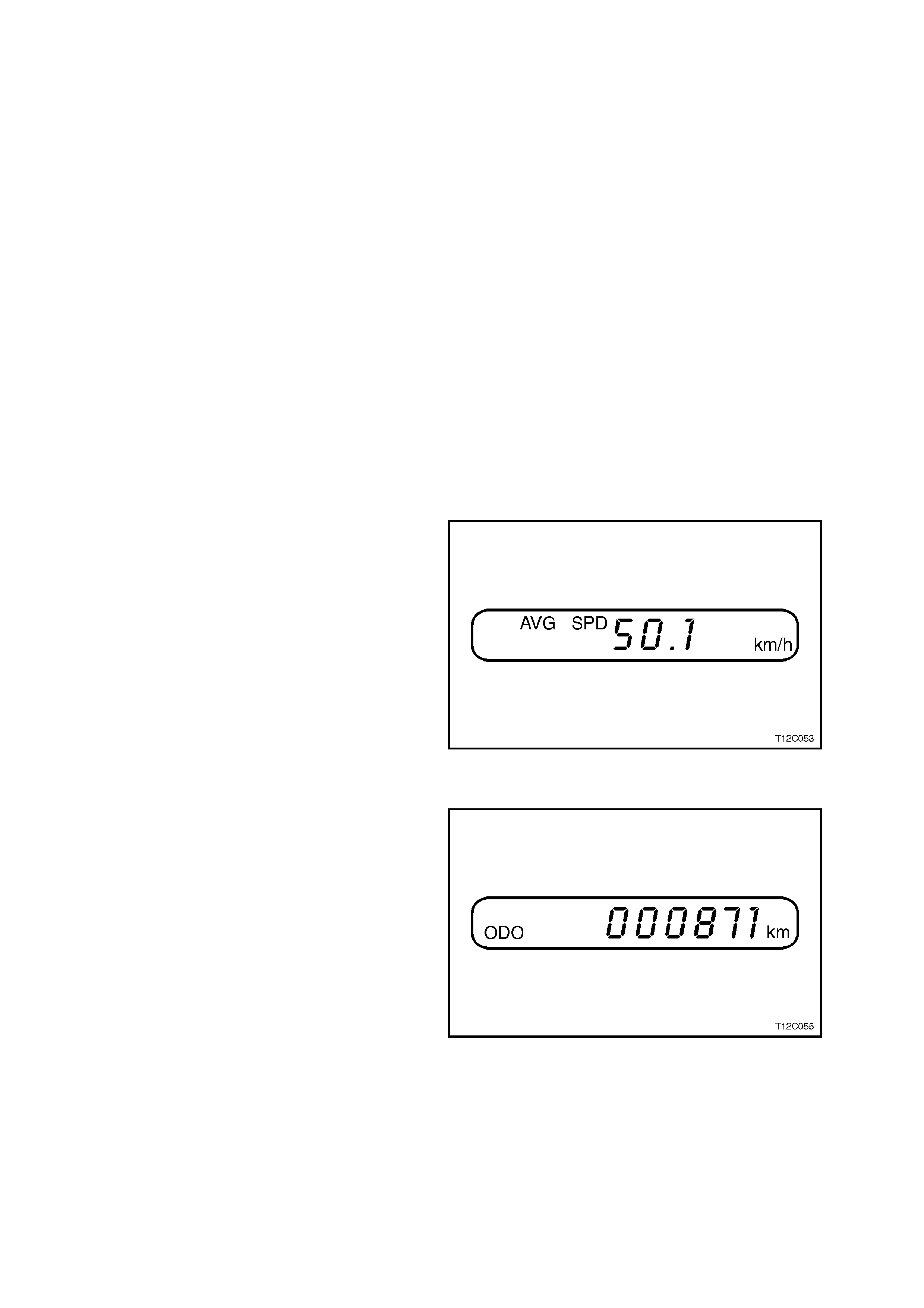

AVERAGE SPEED

Shows the average speed (while the engine is

running) since the trip computer was reset.

Figure 12C-18

ODOMETER

The odometer records kilometres travelled since

the vehicle was built.

Figure 12C-19

AVERAGE FUEL

Shows average fuel used since the trip computer

was reset. After resetting, some large numbers

may initially be shown, due to the short distance

travelled and the high fuel used when accelerating.

Figure 12C-20

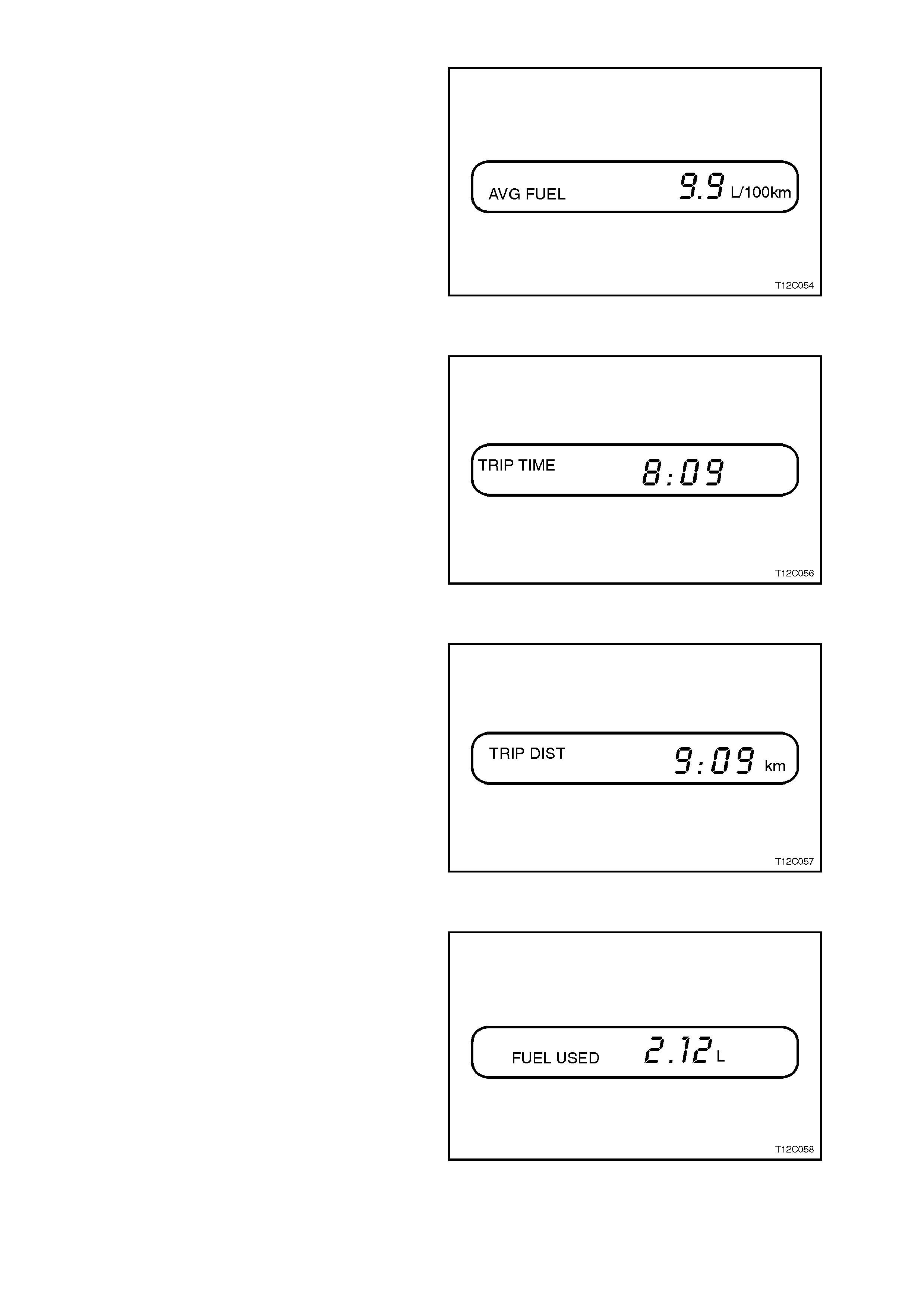

TRIP TIME

Shows the engine running time since the trip

computer was reset.

Figure 12C-21

TRIP DISTANCE

Shows the kilometres travelled from the start of a

particular trip. Reset the reading to zero by

pressing the ⇑

⇑⇑

⇑ and ⇓

⇓⇓

⇓ buttons together when this

window is shown.

Figure 12C-22

FUEL USED

Shows the total litres of fuel used since the trip

computer was reset.

Figure 12C-23

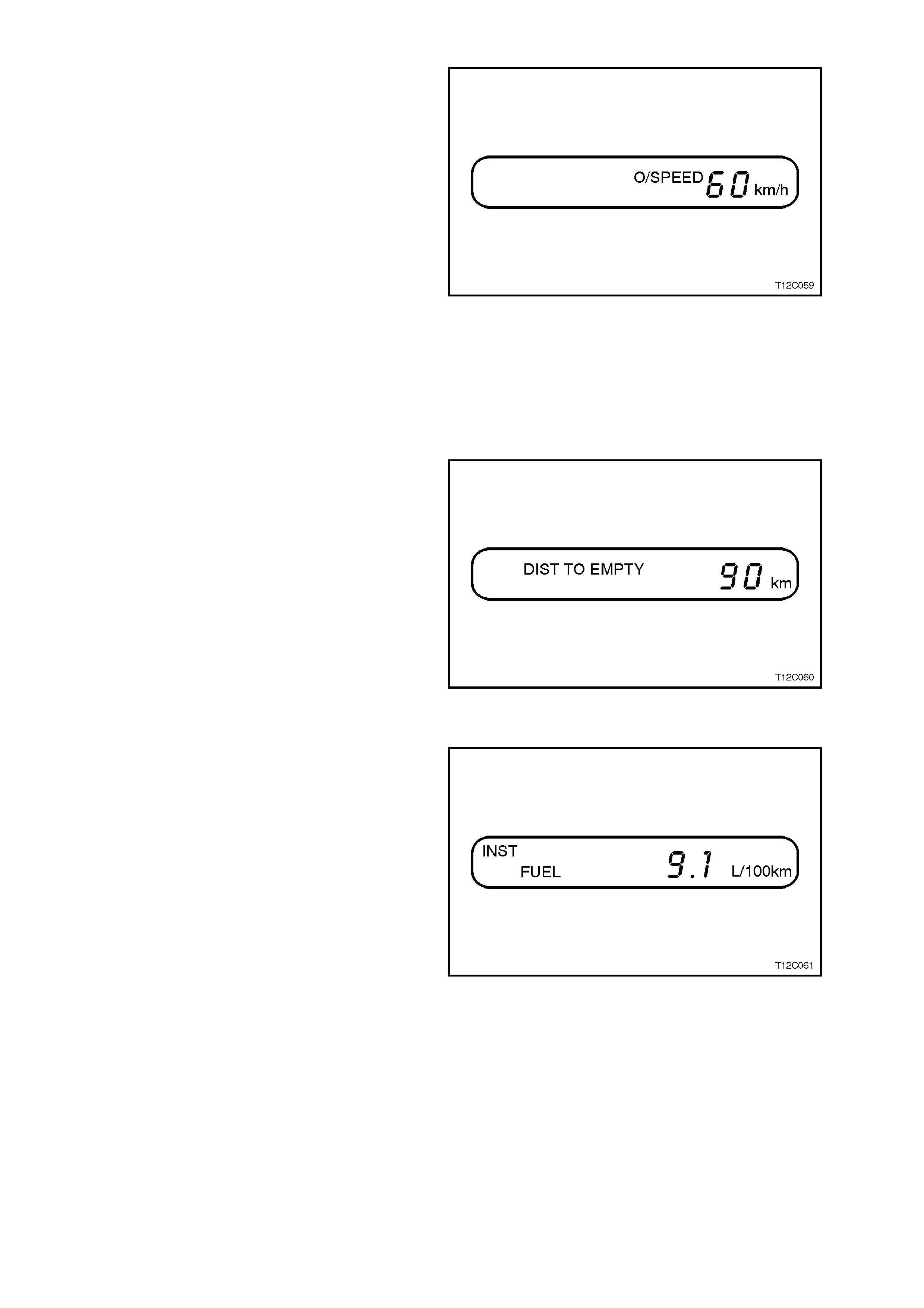

OVERSPEED

Set the speed not to be exceeded. For example if

driving in a 90 km/h zone, set OVERSPEED to 90

by tapping the ⇑

⇑⇑

⇑ or ⇓

⇓⇓

⇓ buttons. W hen vehicle speed

exceeds 90 km /h the O VERSPEED warning light in

the instrument panel and a chime will warn that

speed has been exceeded. At that time the trip

computer will automatically show overspeed

display, allowing adjustments as required.

OVERSPEED is adjustable in 5 km/h units and

works at speeds between 20 km/h and 200 km/h.

Tap the ⇑

⇑⇑

⇑ or ⇓

⇓⇓

⇓ buttons or hold a button to scroll

quickly to a speed. Briefly press the ⇑

⇑⇑

⇑ and ⇓

⇓⇓

⇓

buttons together to set OVERSPEED to the speed

at which the vehicle is currently travelling.

Press and hold both the ⇑

⇑⇑

⇑ and ⇓

⇓⇓

⇓ buttons for at least

2 secs (when this window is shown) to turn

OVERSPEED ON or OFF.

OVERSPEED presets can also be chosen, refer

OVERSPEED ADJUSTING in this Section.

Figure 12C-24

DISTANCE TO EMPTY

DISTANCE TO EMPTY is an estimate of how far

current fuel will last. It is based on previous fuel

usage and is frequently updated. Therefore, as

conditions become suited to more economical

driving the DISTANCE TO EMPTY may actually

increase, for example from city to highway driving.

Figure 12C-25

INSTANTANEOUS FUEL

Shows instantaneous fuel usage in litres per 100

km when driving. When speed drops below 10

km/h the usage is shown in litres per hour.

Figure 12C-26

ADDITIONAL DISPLAYS

Additional displays can be activated using

customise m ode. Ref er CUSTOMISE MO DE in this

Section. DISTANCE TO ARRIVAL, TIME TO

ARRIVAL and REMAINING FUEL are turned on

and off as a set, they cannot be individually

activated.

When the displays are activated, press the MODE

button to scroll through all the Trip Computer

displays. There will now be four sets of displays,

instead of thr ee. The new displays will be slotted in

between the TRIP display and the DISTANCE TO

EMPTY display. Customise mode can be used to

deactivate the following displays, if required.

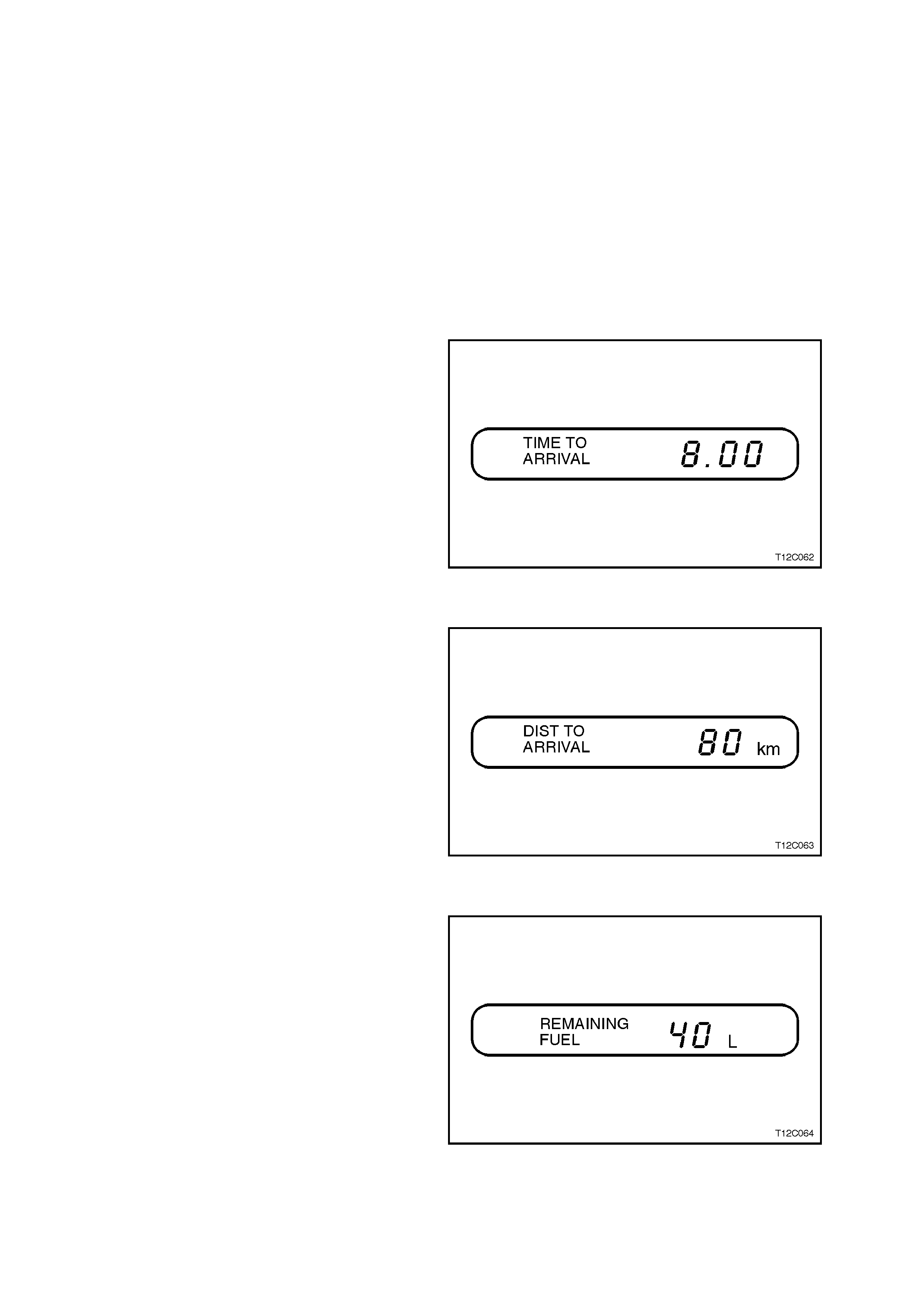

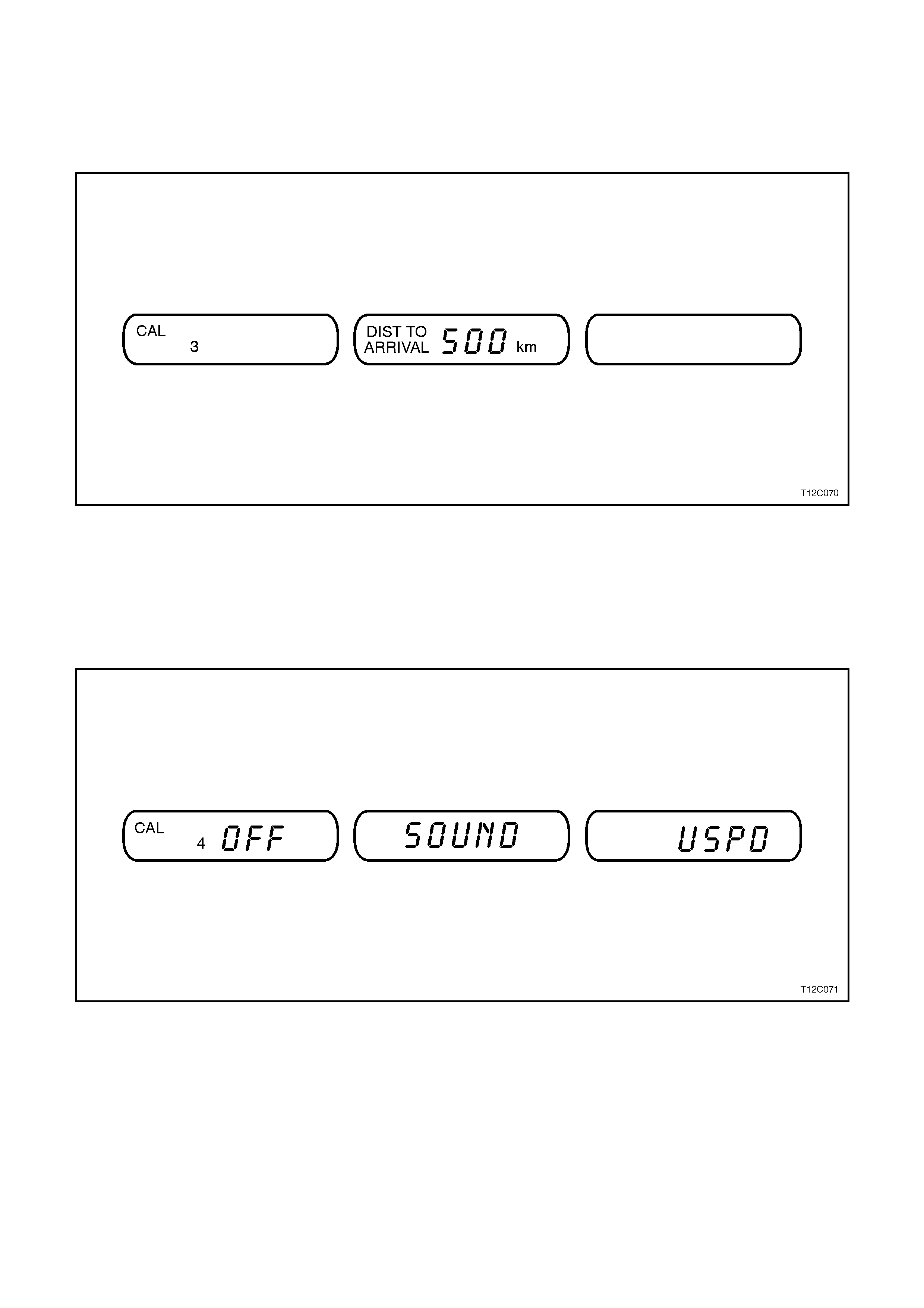

TIME TO ARRIVAL

Shows trip time to arrival in hours and minutes,

based on DISTANCE TO ARRIVAL.

Figure 12C-27

DISTANCE TO ARRIVAL

At the start of a trip estimate distance to arrival

(from maps, road signs etc.). Tap the ⇑

⇑⇑

⇑ or ⇓

⇓⇓

⇓

buttons until the display shows estimated trip

distance. When the vehicle is driven the computer

will constantly update time to arrival, based on

changing driving speeds. The ⇑

⇑⇑

⇑ or ⇓

⇓⇓

⇓ buttons can be

used to adjust the kilometres any time this display

is shown.

Figure 12C-28

REMAINING FUEL

Shows the litres of fuel left in the fuel tank , r ounded

to the nearest 5 litres.

When fuel level is low, LO will be displayed.

Figure 12C-29

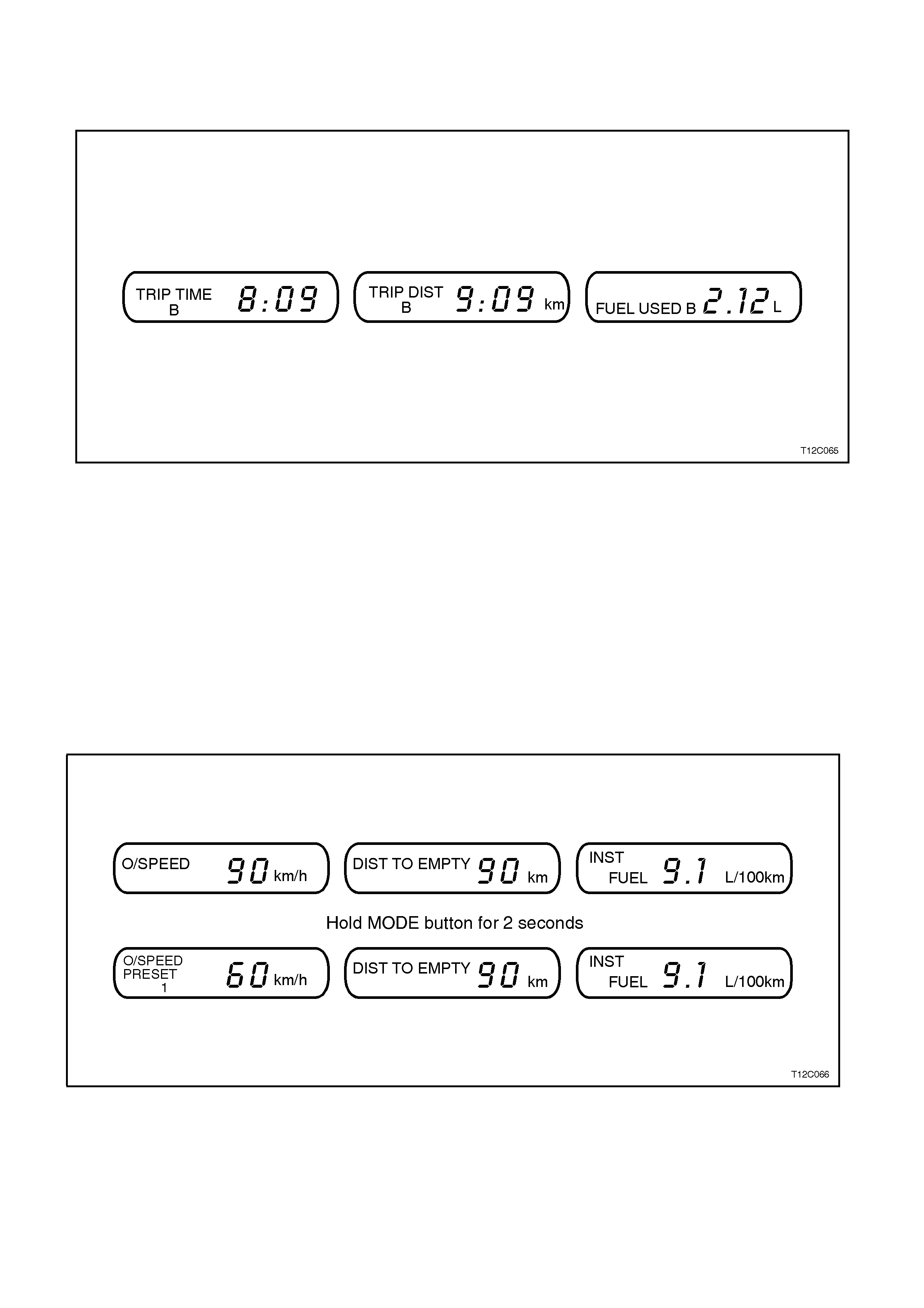

TRIP B

W hen the Trip B set of windows has been turned on (using the custom ise mode) and are showing on the display,

hold the MODE button down for 2 seconds. The trip computer will show Trip B details.

Figure 12C-30

Press the MODE button to view displays. Two diff erent sets of trip displays are now counting, the original set of trip

displays (labelled A while B is turned on) and a new set of tr ip displays, labelled B. T his is useful on a long trip, as

Trip B can be reset at the beginning of the journey and then locked away (by pressing the MODE button for 2

seconds when Trip B is shown). TIME TO ARRIVAL, DISTANCE TO ARRIVAL and REMAINING FUEL will again

be shown on the display, but Trip B will still be c ounting away in the bac kground and the or iginal trip display can be

used for short distances during the journey. Trip B can be viewed at any time by pressing the MODE button for 2

seconds when DISTANCE TO ARRIVAL is shown.

OVERSPEED A DJUSTING

Instead of adjusting O/SPEED up and down in 5 km increments (refer OVERSPEED in this Section), you can

instead set four commonly used speeds, e.g. 60, 80, 100 and 110.

Hold down the MODE button for 2 seconds when the O/SPEED is shown. The display will change from normal

O/SPEED to O/SPEED PRESET.

Figure 12C-31

PRESET 1 is the first preset number, with a default setting of 60 km/h.

Tap the ⇑

⇑⇑

⇑ button to see the second PRESET, which has a default setting of 80 km/h, PRESET 3 has a default

setting of 100 km/h and PRESET 4 of 110 km/h. Tap the ⇑

⇑⇑

⇑ or ⇓

⇓⇓

⇓ buttons to move between the PRESET numbers.

The O/SPEED PRESET display has now replaced the normal O/SPEED display. Tap the MODE button to scroll

through the other displays.

To change the display back to normal O/SPEED, again hold down the MODE button for 2 seconds while the

O/SPEED PRESET display is shown.

ALTERING OVERSPEED PRESETS

The default settings of 60, 80, 100 and 110 km/h can be changed to suit individual preferences.

The vehicle must be stationary when changing an O/SPEED PRESET. To alter, ensure the preset to change is

showing, e.g. PRESET 2 80 k m /h. T hen, brief ly pres s the ⇑

⇑⇑

⇑ and ⇓

⇓⇓

⇓ buttons together. The display starts to flash. Us e

the ⇑

⇑⇑

⇑ or ⇓

⇓⇓

⇓ button to adjust the setting. When c orrec t, briefly press the ⇑

⇑⇑

⇑ and ⇓

⇓⇓

⇓ buttons together. Each PRESET can

be changed in this way.

The PRESETs are automatically arranged in ascending order.

One or more PRESET can be assigned to OF F, by reducing the preset down to 0 (O FF ). When dr iving only three or

less PRESETs will be available to choose from. To turn back on, select the OFF PRESET (when the vehicle is

stationary) and use the ⇑

⇑⇑

⇑ button to increase the number.

An O/SPEED PRESET must be altered when the vehicle is stationary. If the ⇑

⇑⇑

⇑ and ⇓

⇓⇓

⇓ buttons are briefly pressed

while driving, the OVERSPEED setting will be changed to the speed at which you are travelling.

If the ⇑

⇑⇑

⇑ and ⇓

⇓⇓

⇓ buttons are pressed together for more than 2 seconds, either while driving or stationary, O/SPEED will

be turned completely OFF or ON.

ADDITIONAL FUNCTIONS

The following details the additional functions that have been provided in the trip computer.

CUSTOMISE MODE

The trip computer uses in its calculations different calibration num bers. These figures are pre-set for the standard

vehicle and do not have to be adjusted. However, each vehicle does vary due to tyre size, tolerances etc., and

therefore the facility is provided to adjust each figure for greater accuracy. Also provided in customise mode are

different choices about displays.

To enter customise mode, press and hold the MODE button while the ignition is turned from OFF to ON. After

entering customise mode, tap the MODE button to view each calibration/choice or alter the settings as described

below.

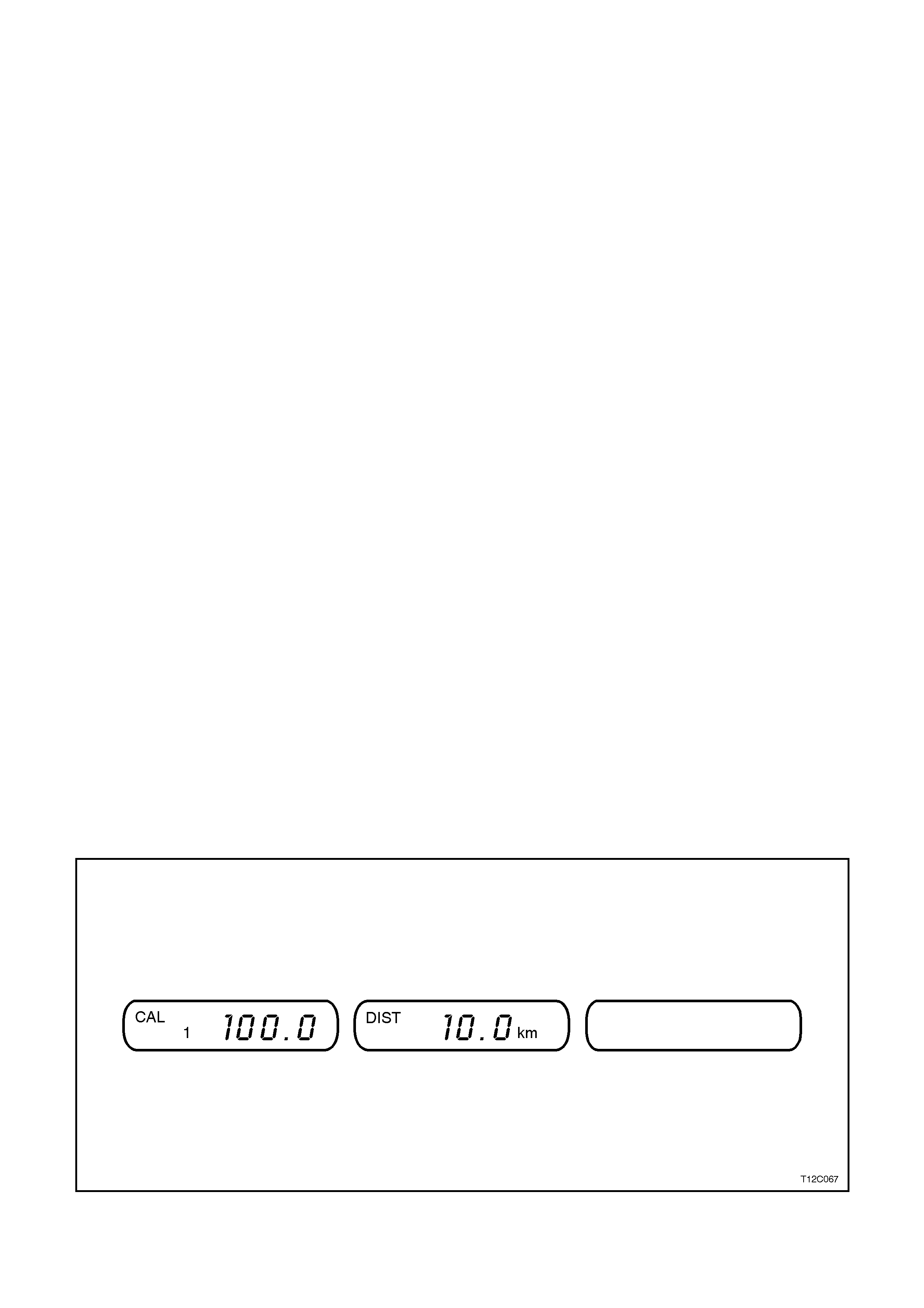

CALIBRATION 1: DISTANCE CALIBRATION

If necessary to check/adjust distance calibration, line the vehicle front wheels against a highway kilometre shield

post before entering customise mode. Press both the ⇑

⇑⇑

⇑ and ⇓

⇓⇓

⇓ buttons together when TRIP DIST is showing in

the centre window (to zero the TRIP DIST ). Dr ive to another s hield pos t (between 10 k m and 500 km) and st op with

the front wheels lined up again. Note the real distance between the shield pos ts and the distanc e on the TR IP DIST

display. If different, enter customise mode. The TRIP DIST will be shown in the centre window. Press the ⇑

⇑⇑

⇑ or ⇓

⇓⇓

⇓

buttons to adjust the centre display to show the real distance indicated by the shield posts.

NOTE:

1 The left display (the distance calibration %) will automatically adjust with the centre display. The default distance

calibration is 100.0%. The maximum it can be adjusted to is 120.0%, the minimum is 80%.

NOTE:

2 Altering the distance calibration does not affect the odometer.

Press the MODE button to go to the next calibration number.

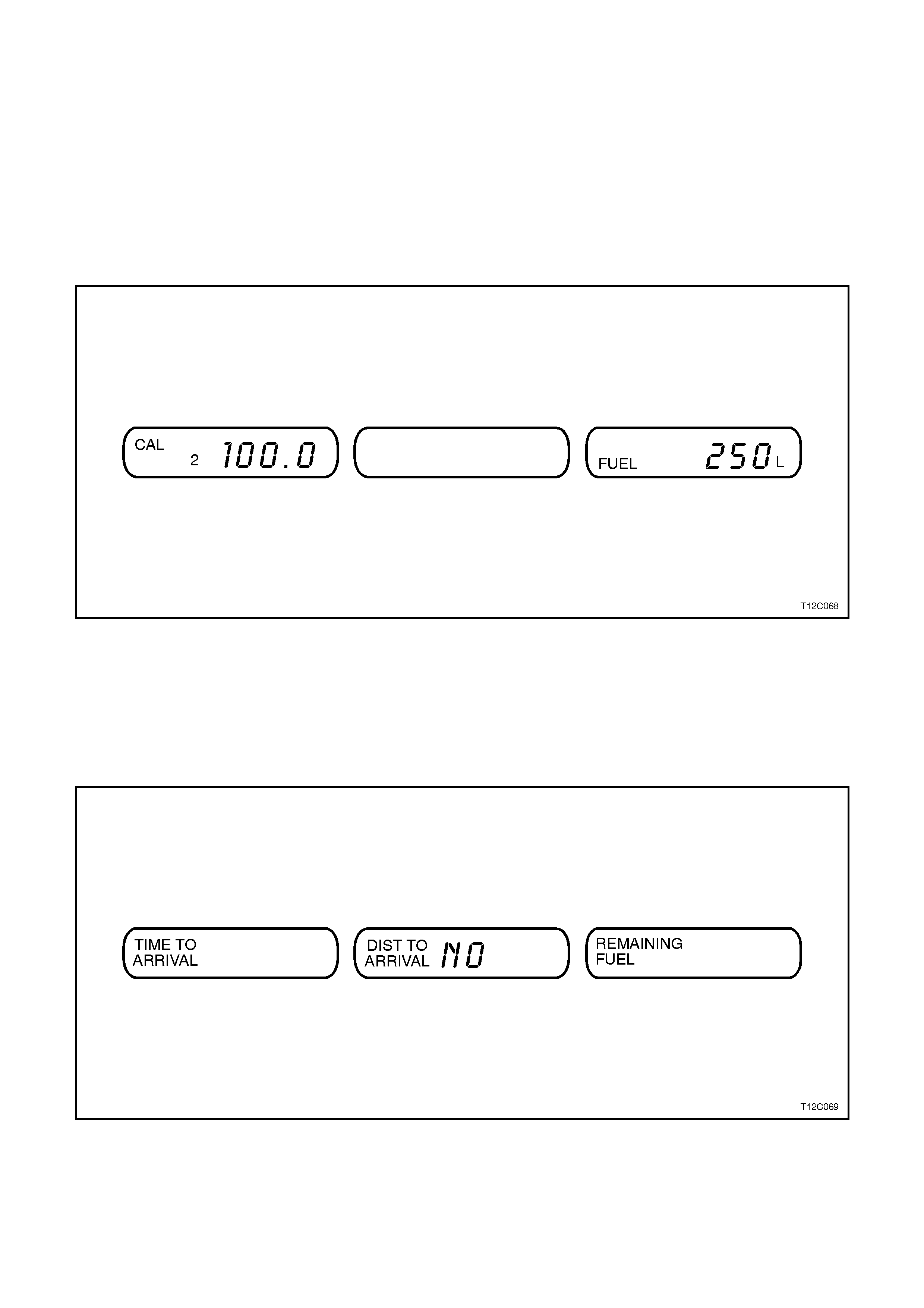

Figure 12C-32

CALIBRATION 2: FUEL FLOW CALIBRATION NUMBER

If necessary to check/adjust fuel flow calibration number, calculate the following before entering customise mode.

Press both the ⇑

⇑⇑

⇑ and ⇓

⇓⇓

⇓ buttons together when FUEL USED is s howing in the r ight - hand window (to zero the FUEL

USED). Then, for at least five consecutive fuel fills, record the total litres added (but no more than 500 litres),

according to the service station fuel bowser. If this is different to the FUEL USED reading, enter customise mode

and tap the MODE button once, to show CAL 2. The FUEL USED will be shown on the right - hand display. Press

the ⇑

⇑⇑

⇑ or ⇓

⇓⇓

⇓ buttons to adjust the right - hand display to show the actual total fuel us ed ac cor ding to the s ervic e s tation

fuel bowser.

NOTE:

The left display (the fuel flow calibration %) will automatically adjust with the right display. The default fuel calibration

is 100.0%. The maximum it can be adjusted to is 120.0%, the minimum is 80%.

Figure 12C-33

Press the MODE button to go to the next choice.

CHOICE: SKIP DISTANCE TO ARRIVAL

To activate an additional set of displays: TIME TO ARRIVAL, DISTANCE TO ARRIVAL and REMAINING FUEL,

press ⇑

⇑⇑

⇑ or ⇓

⇓⇓

⇓ button to select YES or NO.

For an explanation of these displays refer ADDITIONAL DISPLAYS in this Section.

Figure 12C-34

Press the MODE button to go to the next calibration number.

CALIBRATION 3: ADJUST DISTANCE TO ARRIVAL DEFAULT SETTING

DISTANCE TO ARRIVAL can be reset (when not in customise mode) by pressing the ⇑

⇑⇑

⇑ and ⇓

⇓⇓

⇓ buttons together. The

distance resets to 500 k m, which is the def ault setting. When in cus tomis e mode, the def ault setting can be altered

up or down by pressing ⇑

⇑⇑

⇑ or ⇓

⇓⇓

⇓ buttons.

This can be used to quickly recall details of a regularly travelled trip.

Figure 12C-35

Press the MODE button to go to the next choice.

CHOICE: UNDERSPEED CHIME

OVERSPEED provides a chime when travelling speed exceeds OVERSPEED setting, and another chime when

travelling speed drops below UNDERSPEED setting. Customise mode provides a choice for turning the second

chime, the "underspeed" chime OFF or ON. Press ⇑

⇑⇑

⇑ or ⇓

⇓⇓

⇓ button to turn underspeed chime OFF or ON.

Figure 12C-36

Then press MODE button to end Customise mode.

NOTE:

Customise mode will end automatically if vehicle speed exceeds 10 km/h or if the ignition is turned off and on.

SERVICE DUE

A service reminder message is built into the trip computer.

The reminder message will first appear 1,000 km before the service is actually due, giving time to arrange for the

service to be perform ed. The message will be shown on the Trip com puter for 10 seconds whenever the vehicle's

ignition is switched ON or OFF, until the tr ip com puter is reset. When the s ervice is over due the mess age will f lash

for 10 seconds when the ignition is turned ON or OFF.

•SERV 1500 km will show when the vehicle has travelled 1,000 km since it was built.

•SERV 10000 km will show when the vehicle has travelled 9,000 km since it was built.

•SERV 20000 km will show when the vehicle has travelled 19,000 km since it was built.

•SERV 30000 km will show when the vehicle has travelled 29,000 km since is was built etc.

When a service is performed on the v ehicle, this reminder should be reset so that it does not prompt until

the next service is nearly due. Otherwise, it will keep on reminding of a service that is already complete:

W hen a ser vice is perform ed on the vehicle, this rem inder should be reset s o that it does not prom pt until the nex t

service is nearly due. Otherwise, it will keep on reminding of a service that is already complete:

To reset the service reminder message:

1. Turn the ignition OFF.

2. Hold down the ⇑

⇑⇑

⇑ and ⇓

⇓⇓

⇓ mode buttons on the trip computer together.

3. Turn the ignition ON (mode buttons still depressed).

4. Release mode buttons after approximately 3 seconds.

5. Use the mode button to step through trip computer screens until the service due reminder screen appears on

the LCD (usually only one press).

6. Press and hold both the ⇑

⇑⇑

⇑ and ⇓

⇓⇓

⇓ mode buttons until an audible beep is heard (approximately 3 seconds).

7. Turn the ignition OFF.

NOTE1:

The servic e due indicator mes sage has now been res et, therefore, the next ser vice due reminder m essage will not

be displayed until 1000 km before the next service is due.

NOTE2:

The Service Due message is calculated only by distance. Remember that if driving infrequently special servicing

may be required.

ADDITIONAL TRIP COMPUTER NOTES:

If the wrong buttons have been accidentally pressed, causing the window to show other than normal, turn the

ignition OFF then ON again when the vehicle is standing still.

Two warning lights are linked to the trip computer displays:

1. When the fuel tank level first dr ops below 8 litres ( approx .) , the DIST ANCE TO EMPTY display is autom atic ally

shown for 10 seconds, after which the trip computer returns to its previous display.

2. When the OVERSPEED warning symbol is first shown, the OVERSPEED trip computer display is automatically

shown for 10 seconds. This is to show what your pre-selected speed is and allow you to adjust it if required.

After 10 seconds, the trip computer returns to its previous display.

Some displays will change the units of meas urement over tim e. For ex ample, the TIME T O ARRIVAL will s how 10

minute units above 2 hour s to ar r ival, will show 5 m inute units below 2 hours to arr ival and will show 1 m inute units

below 10 minutes to arrival.

Calais Model vehicles have a priority key system which identifies settings used by two individual keys (priority 1 or

priority 2). If the vehicle is fitted with this system the trip computer will remember the last selected settings. W hen

the ignition is turned on with a particular key the last set of displays and overspeed settings for that key owner will

be used.

NOTE:

An X symbol, shown in the left trip computer window, indicates a fault in the trip computer.

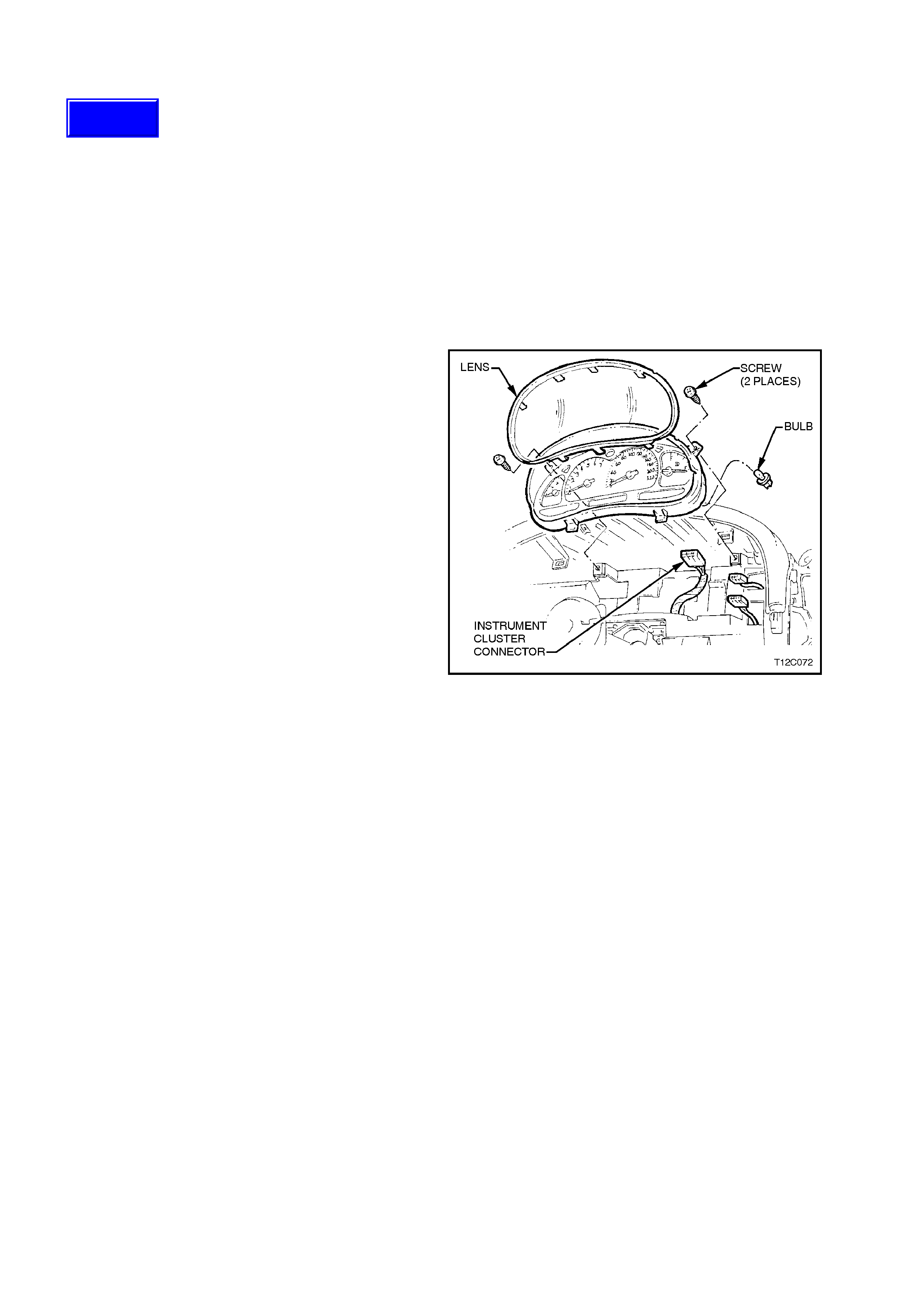

2. INSTRUMENT SERVICE OPERATIONS

2.1 INSTRUME NT CLUSTER

REMOVE

1. Disconnect the battery earth lead.

CAUTION:

If vehicle is equipped with SRS (AIRBAG),

disable the system. Refer to ‘SUPPLEMENTAL

RESTRAINT SYSTEM, Section 12M (Version

6.2) or Section 12M (Versiom 8.0/8.1).

2. Remove the Instrument panel facia, refer

Section 1A3 INSTRUMENT PANEL &

CONSOLE.

3. Remove the two (2) screws securing the

instrument cluster to the instrument panel.

4. Pull instrument cluster out, disconnecting rear

of cluster from instrument connector, feed

cluster out between instrument panel pad and

steering wheel.

Figure 12C-37

REINSTALL

Installation of the instrument cluster is the reverse

of removal procedure.

IMPORTANT:

If vehicle is equipped with SRS AIRBAG),

enable the system. Refer to ‘SUPPLEMENTAL

RESTRAINT SYSTEM, Section 12M - (Version

6.2) or Section 12M - (Version 8.0/8.1).

1. On completion of installation, check that all

instrum ent cluster, instr um ent fac ia switch and

clock functions are operating correctly.

NOTE 1:

If installing a new instrument cluster or trip

computer, the original odometer and trip odometer

readings must be transferred into the replacement

instrum ent cluster. This can be done by authorised

Holden dealers using TECH 2.

NOTE 2:

Before replacing any instrument cluster assembly

that is suspected of being faulty, first carry out

instrument cluster input checks, refer

2.2 INSTRUMENT CLUSTER INPUTS in this

Section.

Techline

If these tests prove that the inputs to the instrument

cluster are OK, carry out checks of the gauge

assembly, refer 5.3 INSTRUMENT CLUSTER

DIAGNOSTICS in this Section.

Following these steps will ensure correct diagnosis

of a system fault and needless replacement of

components which are not faulty.

DISASSEMBLE

Disassembly of the instrument cluster assembly is

limited to lens and bulb replacement, refer to Fig.

12C-37

CAUTION:

During the following service operation, when

removing or reinstalling the instrument gauge lens,

grip around the edges. Finger marks on the lens and

instrument gauge assembly faces are difficult to

remove.

1. Carefully remove the instrument cluster lens by

releasing the tabs securing the lens to the

instrument cluster housing refer Fig.12C-37.

2. Remove all warning lamp and instrument cluster

assembly illumination bulbs and sockets by

twisting sockets to release them from case.

REASSEMBLE

Reassembly is the reverse of disassembly

procedure.

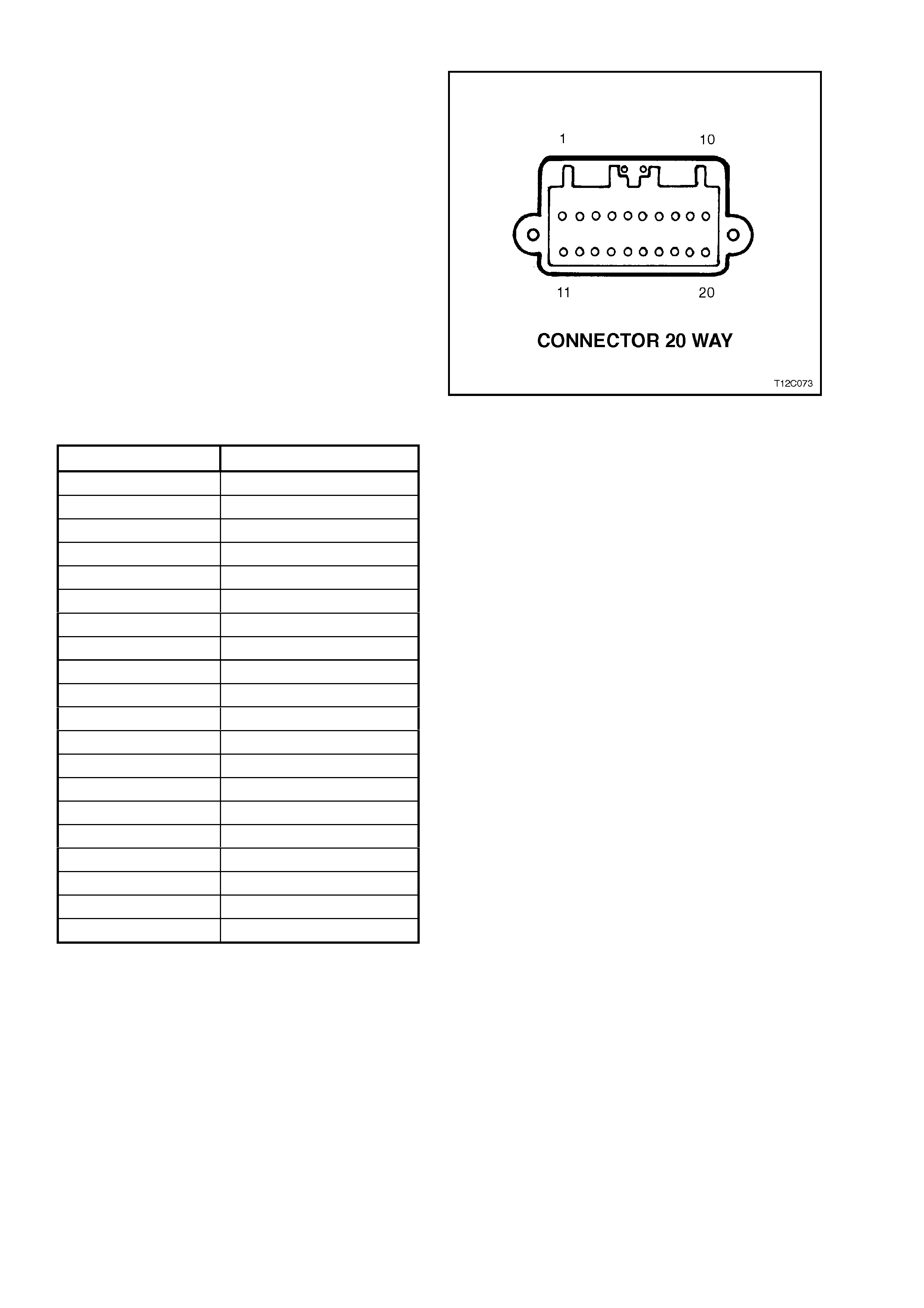

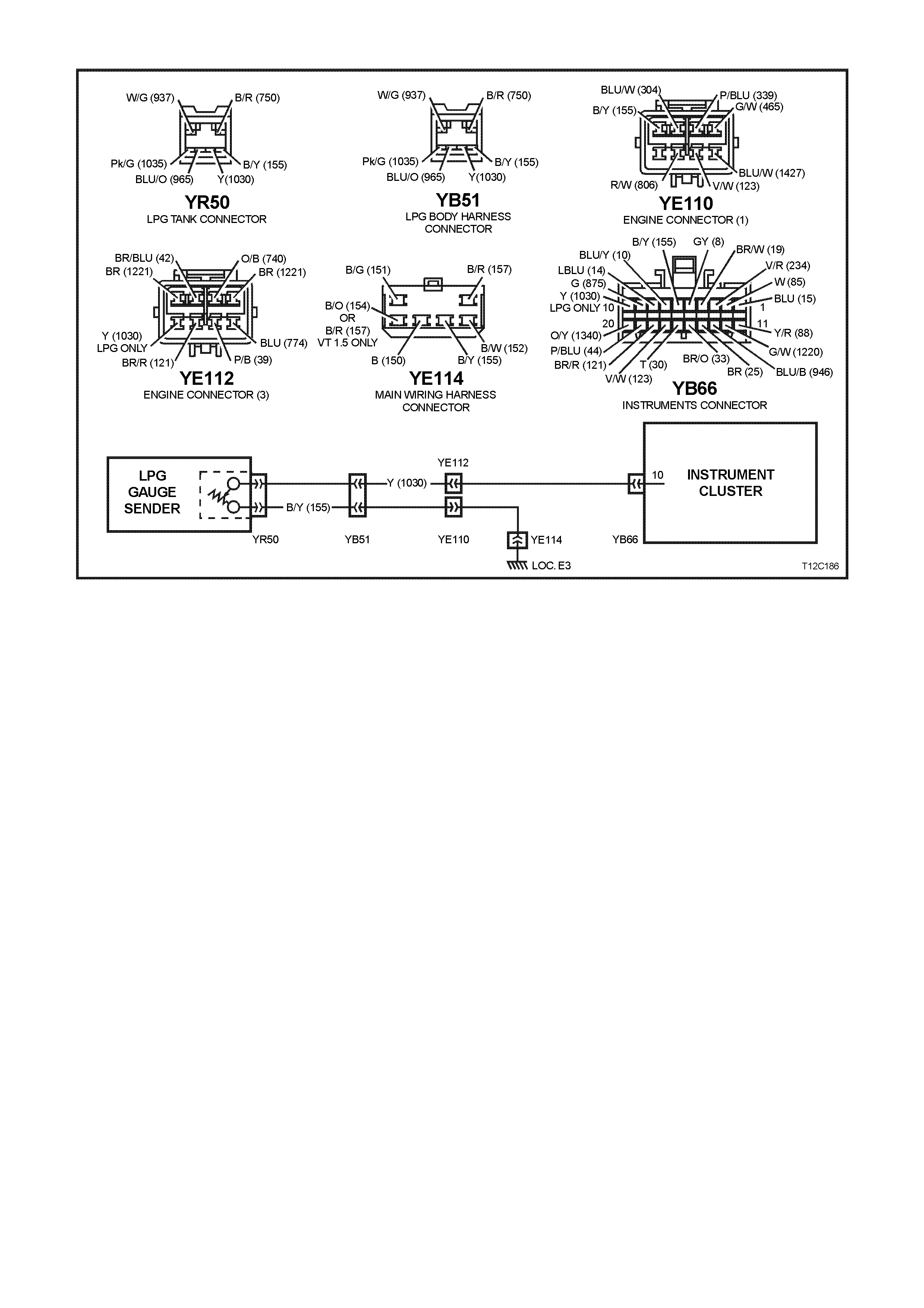

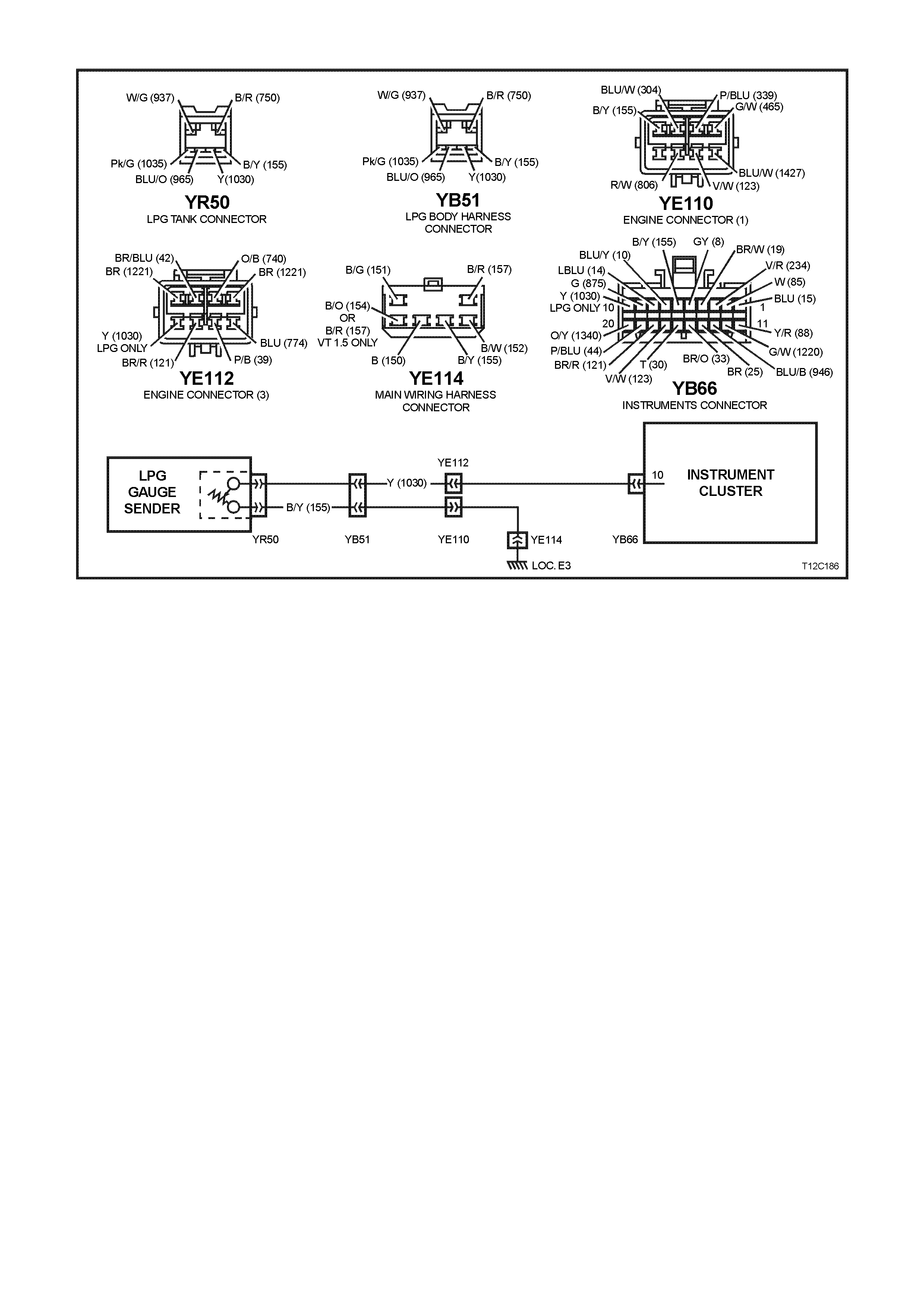

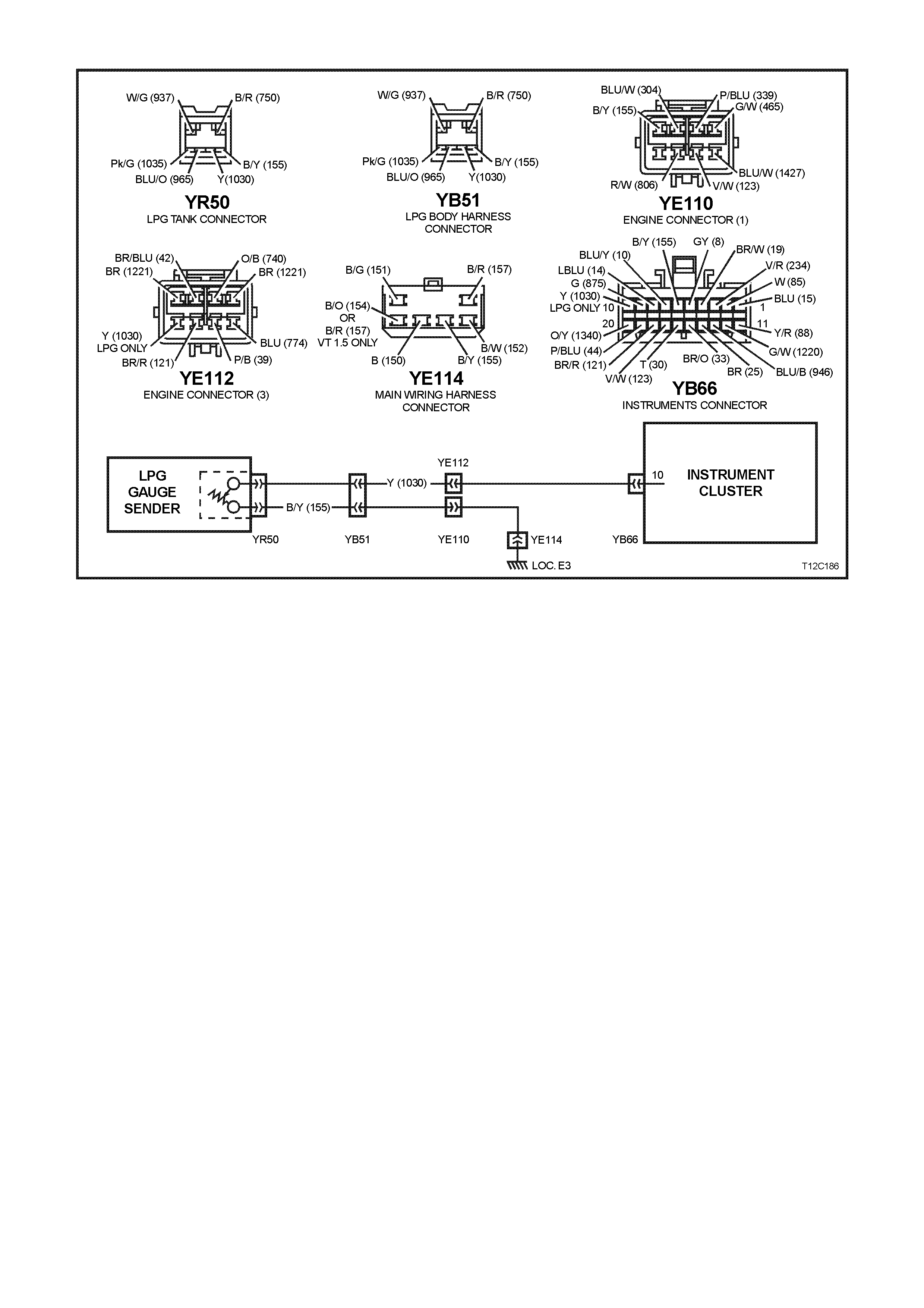

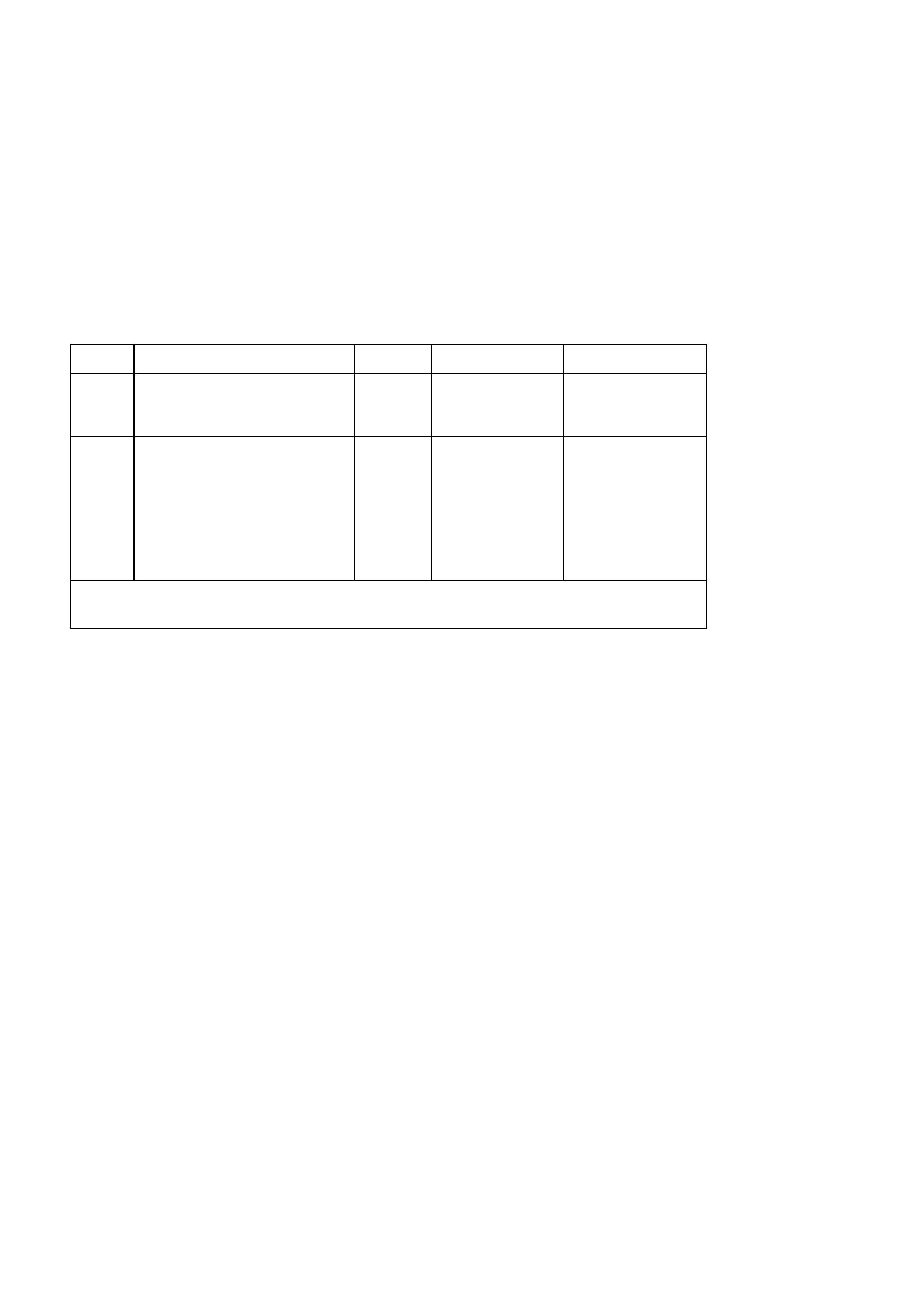

2.2 INSTRUME NT CLUS TER INPUTS

The following chart details the instrument cluster

connector terminal identification.

Figure 12C-38

PIN NUMBER FUNCTION

1 Right Turn

2 Cruise Engaged

3 Fog Lamps ON

4 Park Lights

5 Illum. - Switch Negative

6 Ground

7 High Beam

8 Left Turn

9 ABS Off

10 LPG Fuel Sender

11 Low Traction

12 Serial Data

13 Trip Comp. Switch input

14 Generator

15 Brake (P&F)

16 Fuel Sender

17 Speed In

18 Tacho In

19 Ignition

20 Battery

CHECK

To check the input voltage or wiring continuity

between the various sensors/senders to the

instrument cluster connector refer to

5. DIAGNOSTICS in this Section.

2.3 SE NDER UNITS

VEHICLE SPEED SENDER

MANUAL TRANSMISSION

For all details of the m anual trans m ission vehic le speed sensor rem oval, testing, reinstallation instr uctions, ref er to

Section 6C1 POWERTRAIN MANAGEMENT V6 ENGINE or Section 6C2 POWERTRAIN MANAGEMENT V8

ENGINE.

AUTOMATIC TRANSMISSION

For all details of the automatic transmission vehicle speed sensor removal, testing, reinstallation instructions, refer

to Section 6C1 POWERTRAIN MANAGEM ENT V6 ENGINE or Section 6C2 POWERTRAIN MANAGEM ENT V8

ENGINE.

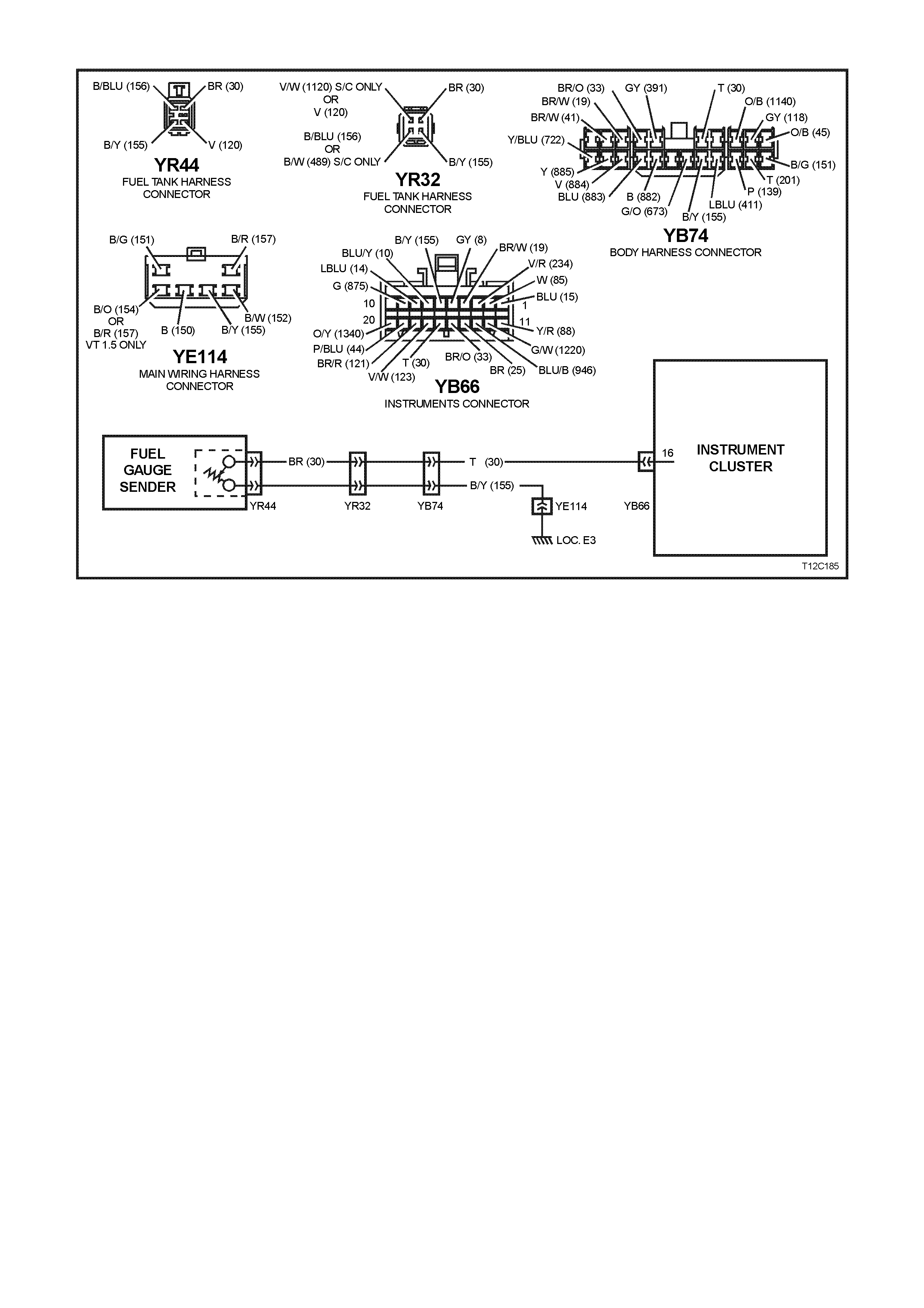

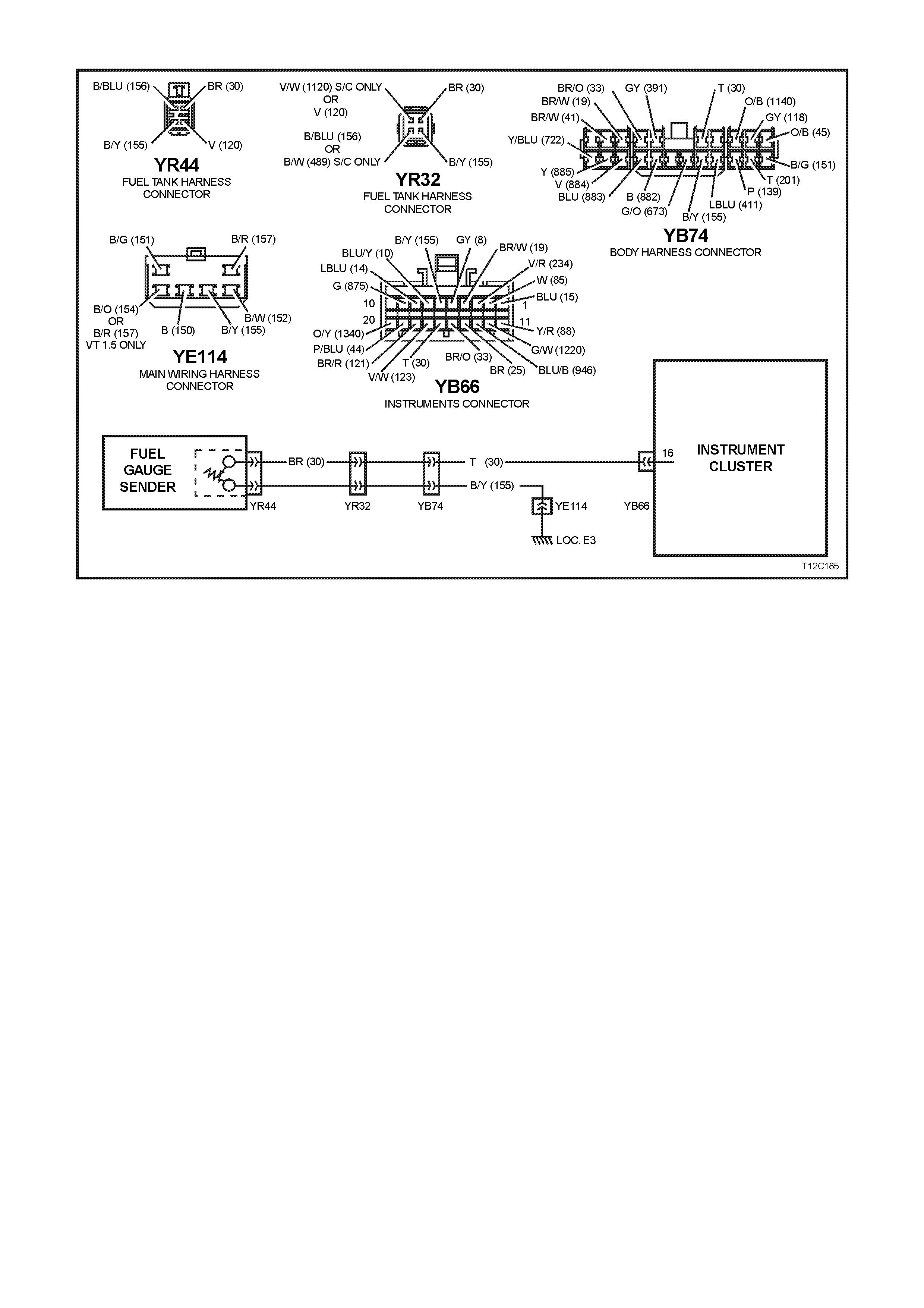

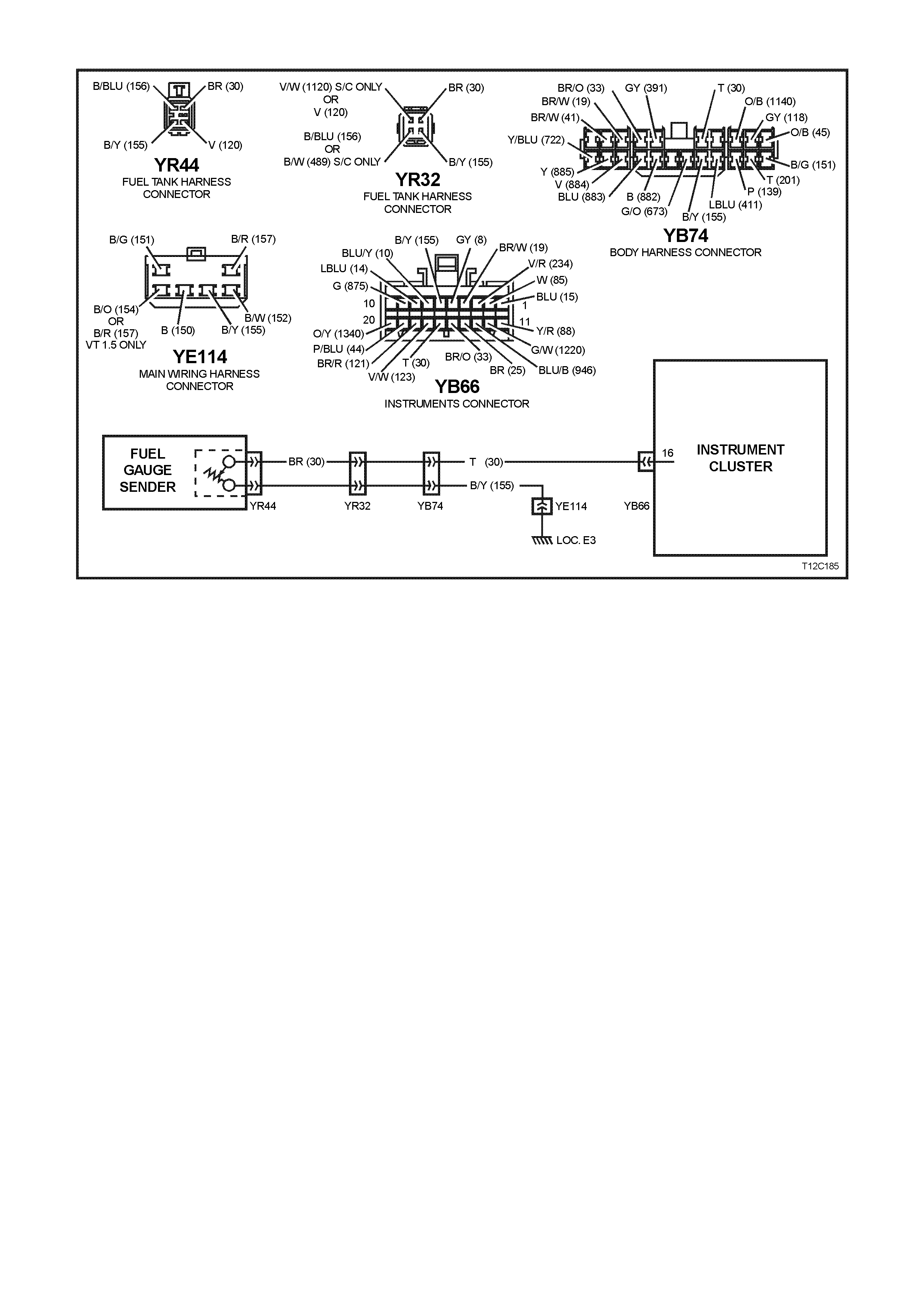

FUEL GAUGE SENDER UNIT

TEST - SENDER UNIT OPERATION

With sender unit removed from fuel tank, use an ohmmeter to measure resistance between sender unit terminals,

at the specified float positions.

FLOAT LEVEL DECK

HIGHT RESISTANCE

SETTING OHMS FLOAT POSITION

3 - 10 mm 37.5 - 42.5

246.7 - 253.3

Empty

Full

NOTE:

When the float is positioned half way, a resistance of 110 Ohms - 115 Ohms can be expected.

If resistance is not as specified at a particular float position, replace sender unit.

Techline

Techline

Techline

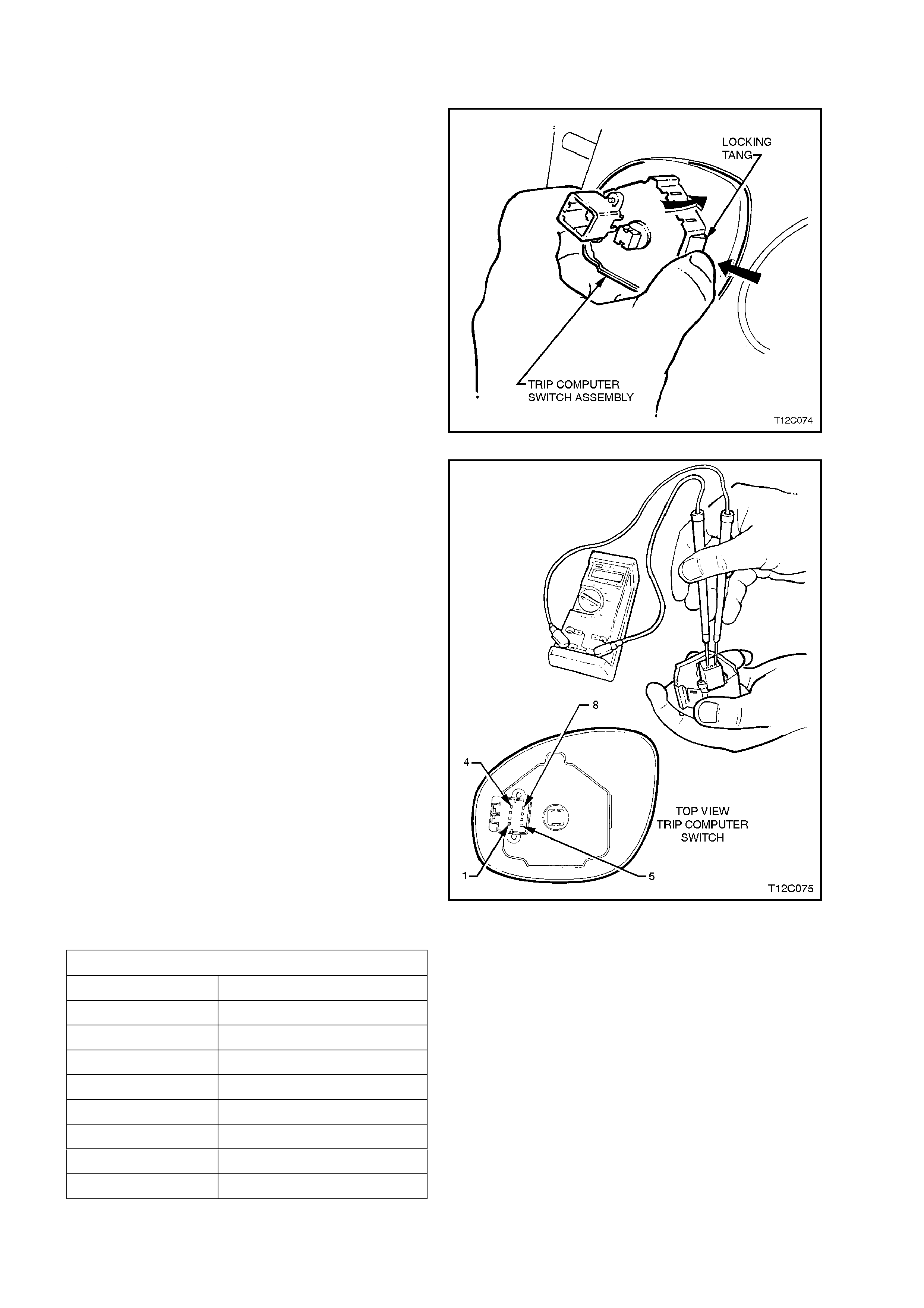

2.4 TRIP COMPUTER SWITCH ASSEMBLY

REMOVE

1. Disconnect the battery earth lead.

CAUTION:

If vehicle is equipped with SRS (AIRBAG),

disable the system. Refer to ‘SUPPLEMENTAL

RESTRAINT SYSTEM, Section 12M - (Version

6.2) or Section 12M - (Version 8.0/8.1).

2. Remove the Instr um ent panel fac ia far enough

to gain access to trip computer switch

connector, refer Section 1A3 INSTRUMENT

PANEL & CONSOLE

3. Depress locking tang on trip computer switch

instrument harness connector and pull

connector from switch.

4. From behind instrument facia, squeeze

together switch to instrument facia retainers

and push switch out from facia.

Figure 12C-39

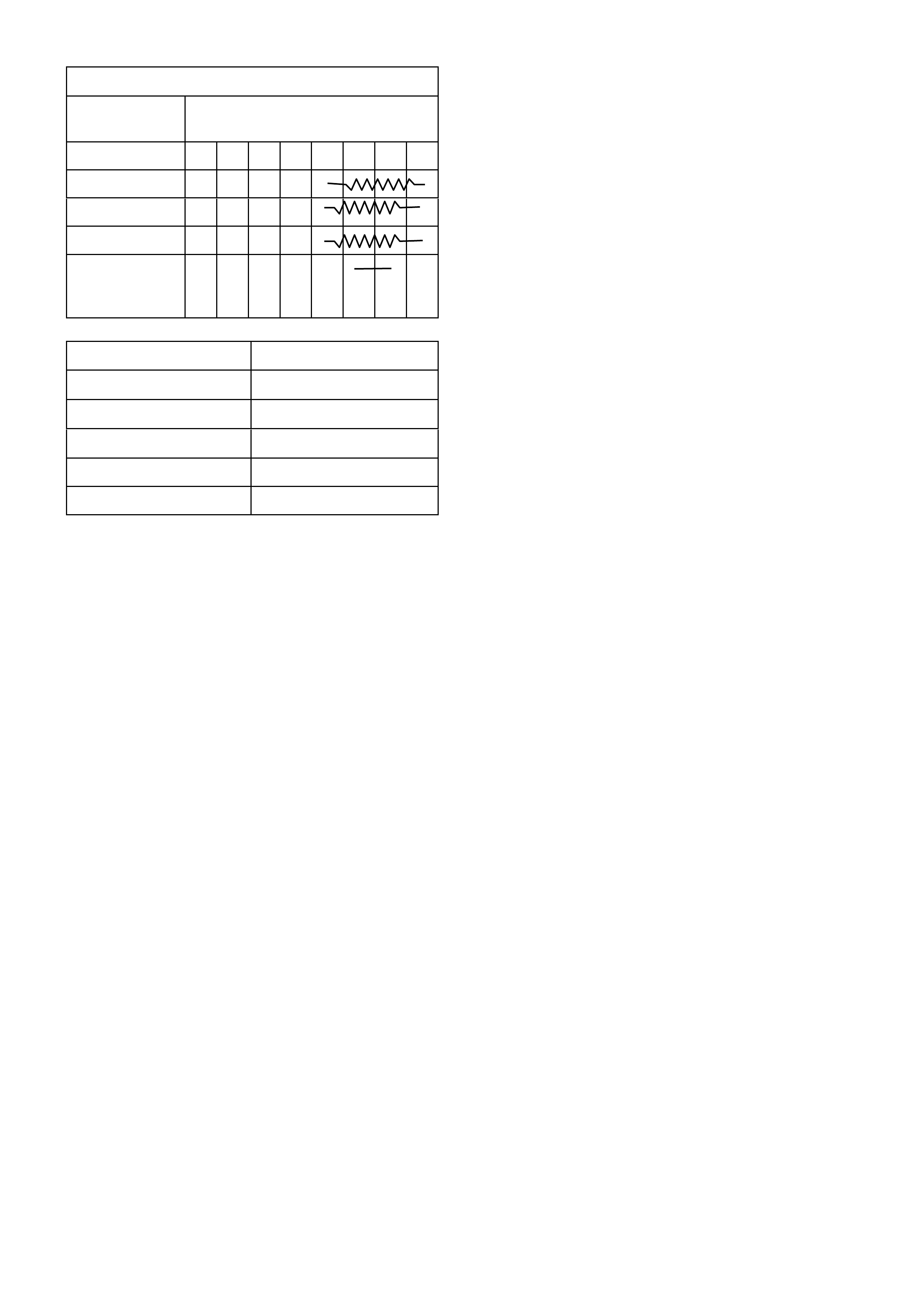

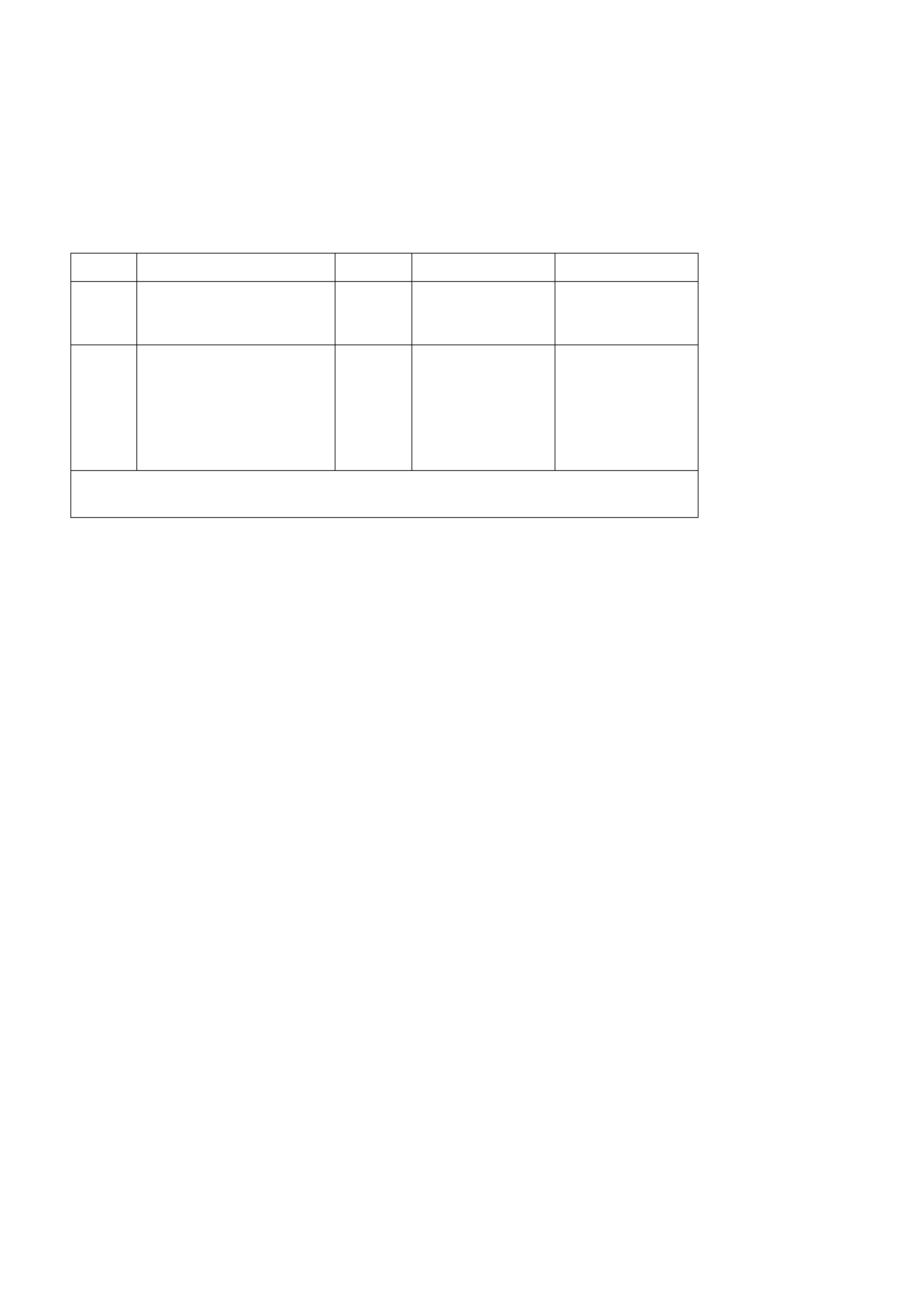

TESTING SWITCH

With the aid of an ohmmeter, check resistance of

trip computer switch contacts using the following

chart.

If resistance is not as specified at switch position,

replace the switch assembly.

Figure 12C-40

CONNECTOR DETAILS

PIN FUNCTION

1 NOT CONNECTED

2 NOT CONNECTED

3 SECURITY LED

4 NOT CONNECTED

5 ENCODED SWITCH

6 ILLUMINATION GROUND

7 ILLUMINATION POSITIVE

8 GROUND

TRIP COMPUTER SWITCH CONTACTS

BUTTON

DEPRESSED Terminal No.

12345678

MODE X X

UP X X

DOWN X X

Illumination

Bulb and

Circuit

XX

FUNCTION RESISTANCE

MODE 20 KΩ

UP 10 KΩ

DOWN 4.99 KΩ

SECURITY LED --

ILLUMINATION --

REINSTALL

Reinstallation is the reverse of removal

procedures.

IMPORTANT:

If vehicle is equipped with SRS AIRBAG),

enable the system. Refer to ‘SUPPLEMENTAL

RESTRAINT SYSTEM, Section 12M - (Version

6.2) or Section 12M - (Version 8.0/8.1).

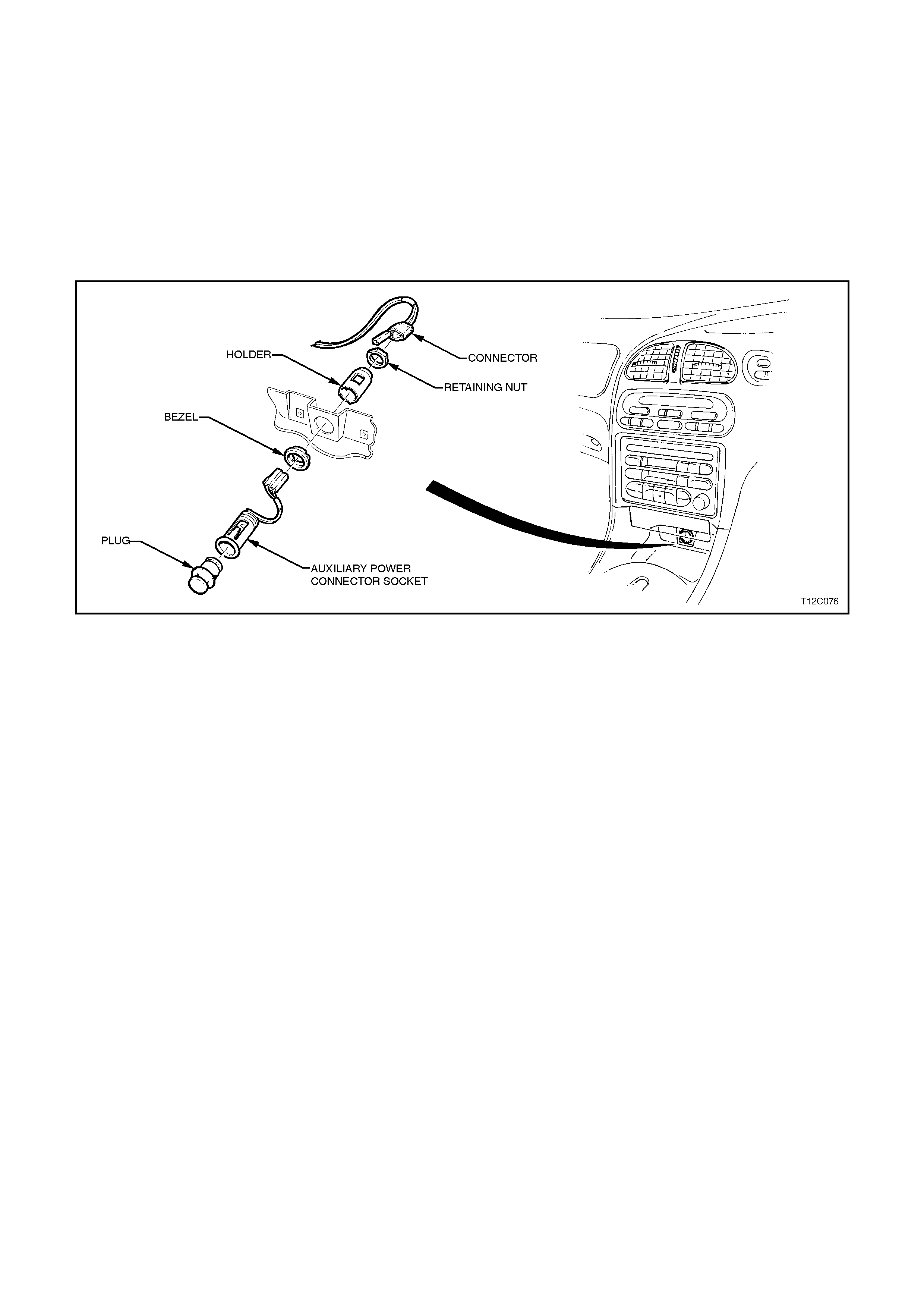

2.5 INSTRUME NT PANEL AUXILIARY POWER CONNECTOR

REMOVE

1. Disconnect the battery earth lead.

CAUTION:

If vehicle is equipped with SRS (AIRBAG), disable the system. Refer to ‘SUPPLEMENTAL RESTRAINT

SYSTEM, Section 12M (Version 6.2) or Section 12M - (Version 8.0/8.1).

2. Remove the instrument panel centre facia assembly refer Section 1A3 INSTRUMENT PANEL & CONSOLE.

3. Rem ove the auxiliary power connec tor retainer nut f rom the rear of the ins trum ent panel centr e facia as sem bly

removing the connector assembly.

Figure 12C-41

REINSTALL

Installation is the reverse of removal procedure.

IMPORTANT:

If vehicle is equipped with SRS AIRBAG), enable the system. Refer to ‘SUPPLEMENTAL RESTRAINT

SYSTEM, Section 12M (Version 6.2) or Section 12M - (Version 8.0/8.1).

3. WIPERS AND WASHERS SERVICE OPERATIONS

3.1 FRONT WIPER ARM

REMOVE

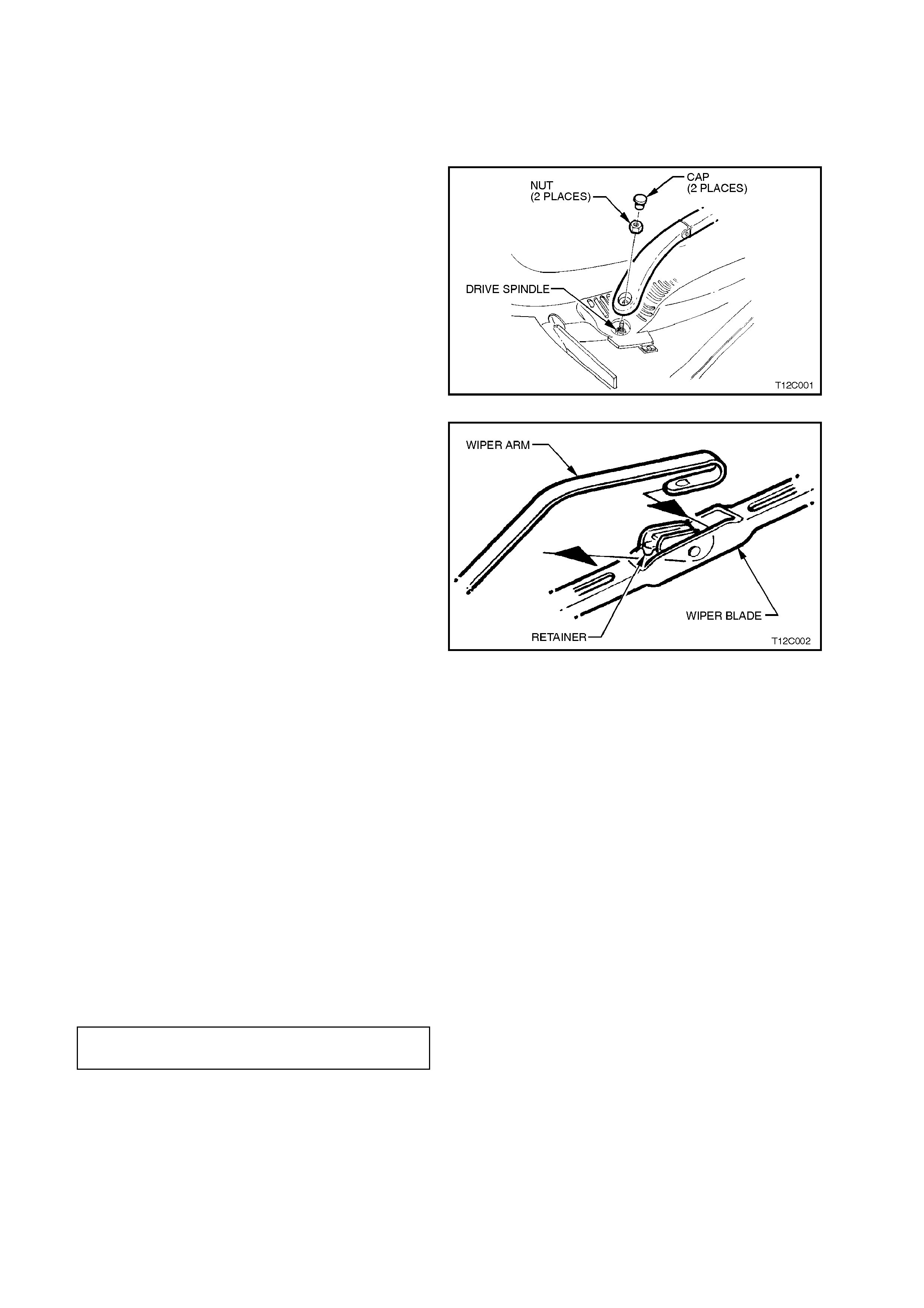

1. Open engine hood.

2. Using a small sc r ew driver or s cr ibe, gently pry

the cap from the front wiper arm.

3. Remove the nut securing the front wiper arm

to the drive spindle.

4. Remove wiper arm from drive spindle, taking

care not to allow wiper arm to contact rear

edge of engine hood.

Figure 12C-42

5. If required, remove wiper blade from arm by

lifting up the retainer on the wiper blade and

pulling blade from arm.

Figure 12C-43

REINSTALL

1. If removed, slide wiper blade into wiper arm

until the wiper blade retainer locks into

position.

2. Ensure that the wiper motor linkages are in

the PARKED position.

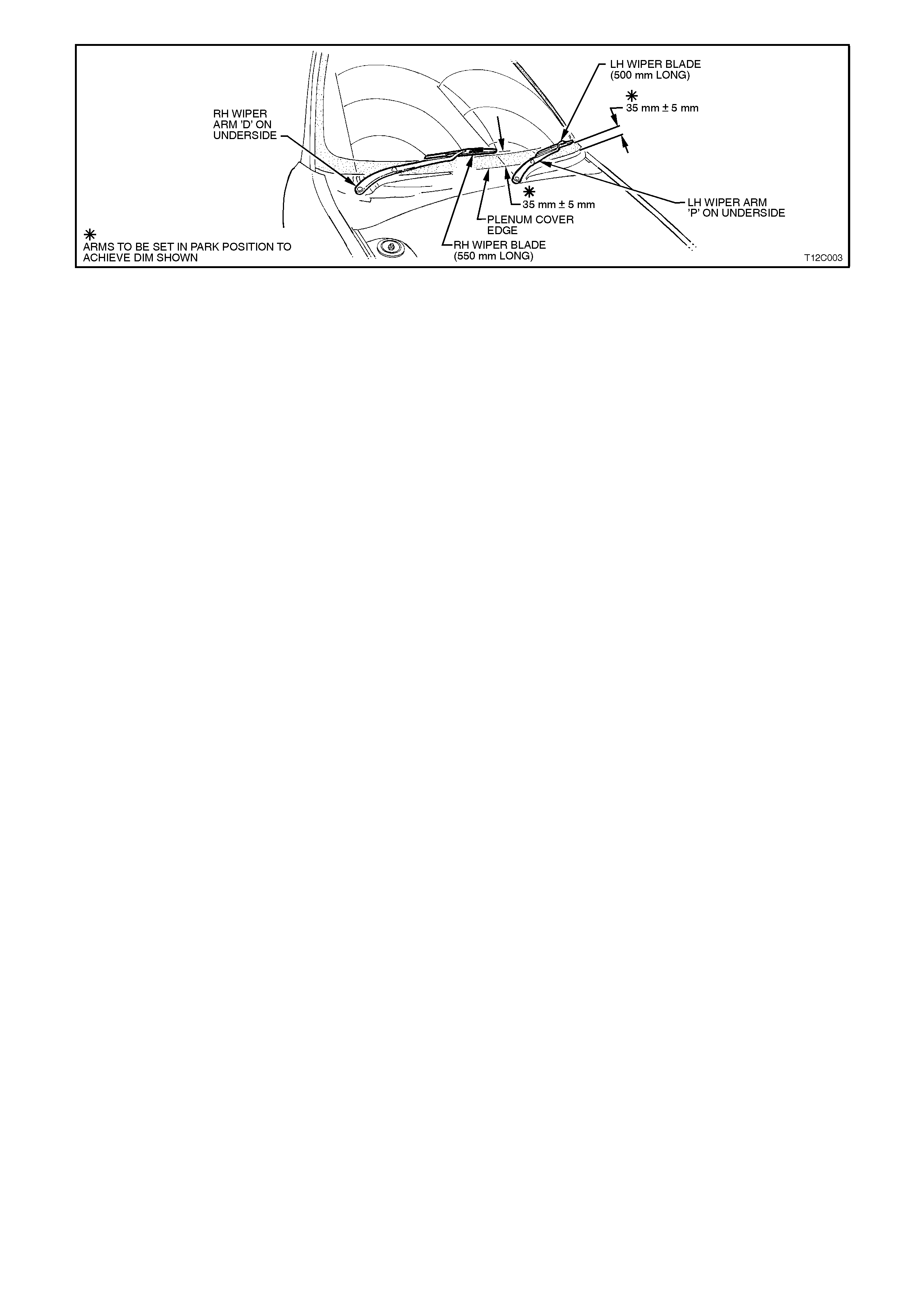

3. Reinstall wiper arm assembly onto drive

spindle so that the blade is positioned with the

tip 35 mm ± 5 mm above the edge of the

plenum cover, refer Fig. 12C-44.

NOTE: Ensure the correct wiper arm and blades

are fitted to each side of the vehicle, ref er Fig 12C-

44.

4. Reinstall the nut securing the front wiper arm

to the drive spindle and tighten to the correct

torque specification.

WI PER ARM NUT

TORQUE SPECIFICATION 20 - 25 Nm

5. Reinstall wiper arm cap.

Figure 12C-44

3.2 REAR WIPER ARM

REMOVE

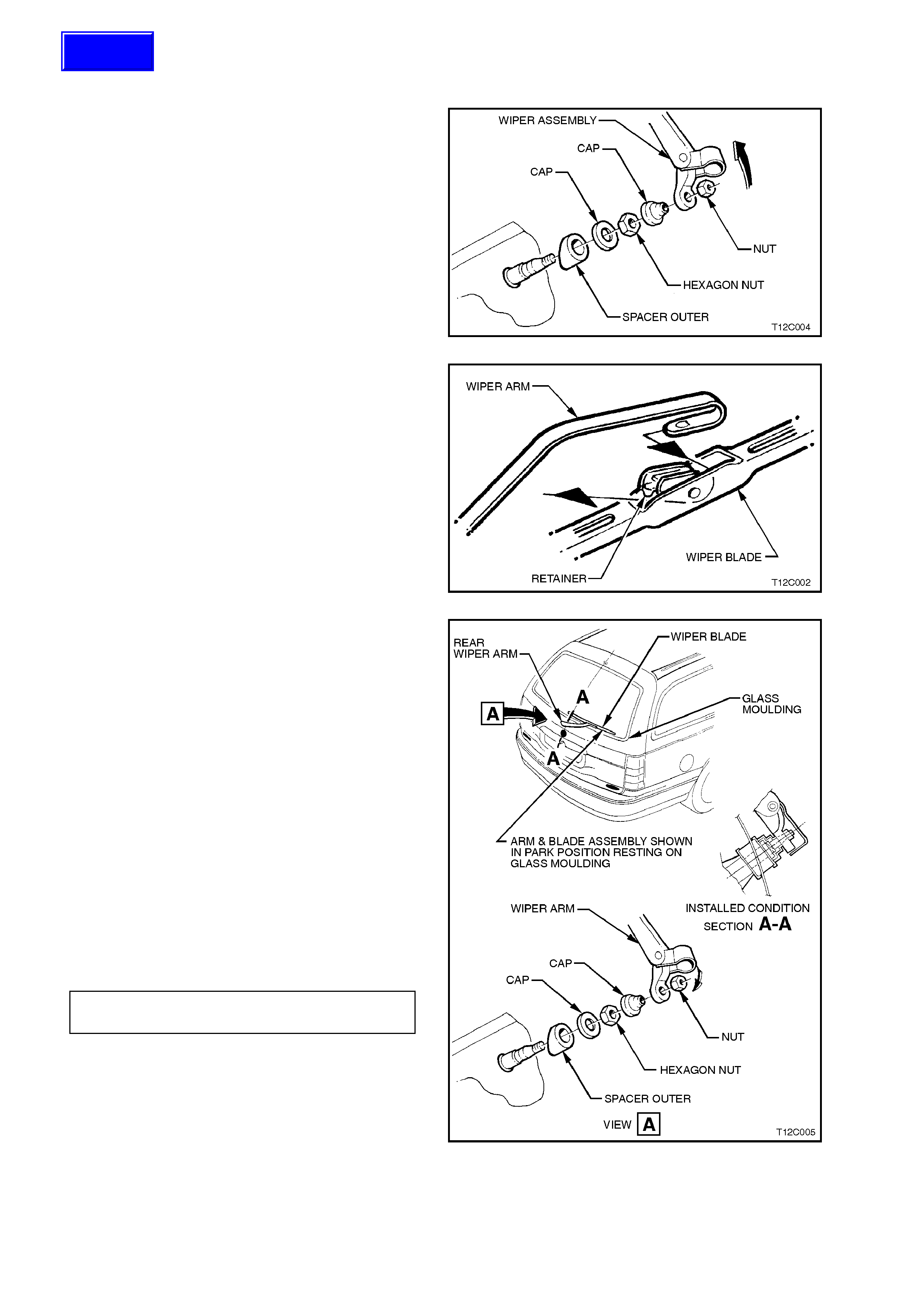

1. Lift up trim cap from wiper m otor drive spindle

end of wiper arm.

2. Remove wiper arm to drive spindle securing

nut and remove wiper arm.

Figure 12C-45

3. If required, remove wiper blade from arm by

lifting up the retainer on the wiper blade and

pulling blade from arm.

Figure 12C-46

REINSTALL

1. If removed, slide wiper blade into wiper arm

until the wiper blade retainer locks into

position.

2. Ensure the wiper motor is in the PARKED

position.

3. Reinstall wiper arm assembly onto drive

spindle so that the wiper blade rests on the

glass moulding, refer Fig. 12C-47.

NOTE:

To ensure arm will not wipe over moulding in the

park position, push arm onto wiper spindle with the

arm in the vertical position and then rotate wiper

arm clockwise until blade rests on glass moulding.

4. Reinstall the nut sec uring the wiper arm to the

drive spindle and tighten to the correct torque

specification.

WI PER ARM NUT 6 - 14

TORQUE SPECIFICATION Nm

5. Push trim cap onto wiper arm.

Figure 12C-47

Techline

3.3 FRONT AND REAR WIPE R BLADES

REMOVE

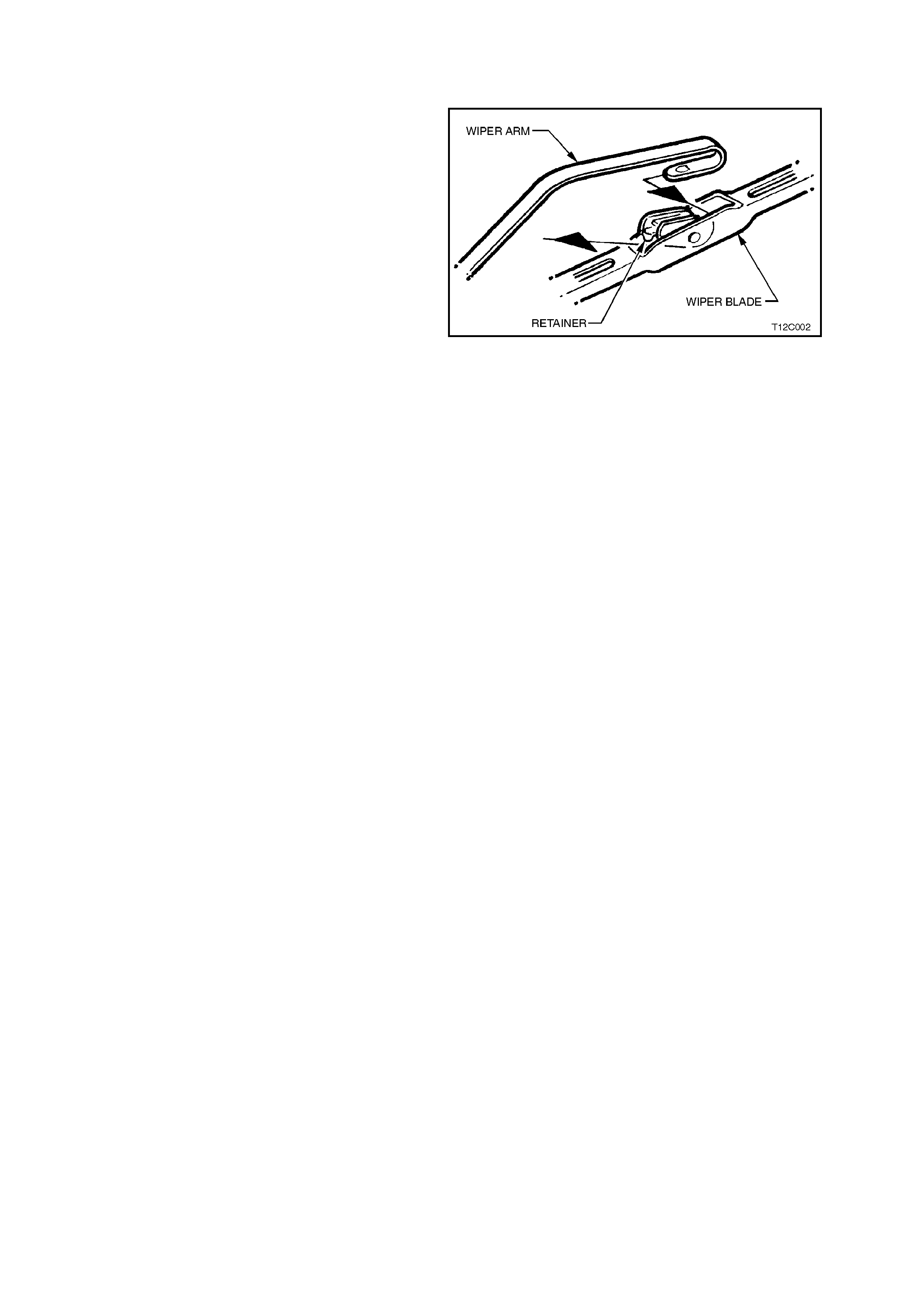

1. W ith engine hood lowered, lift wiper arm from

glass.

2. Remo ve wiper blade from arm by lifting up the

retainer on the wiper blade and pulling blade

from arm.

Figure 12C-48

REINSTALL

1. Slide wiper blade into wiper arm until the wiper

blade retainer locks into position.

2. Lower wiper arm onto glass.

3.4 FRONT AND REAR WIPER BLADE INSERT

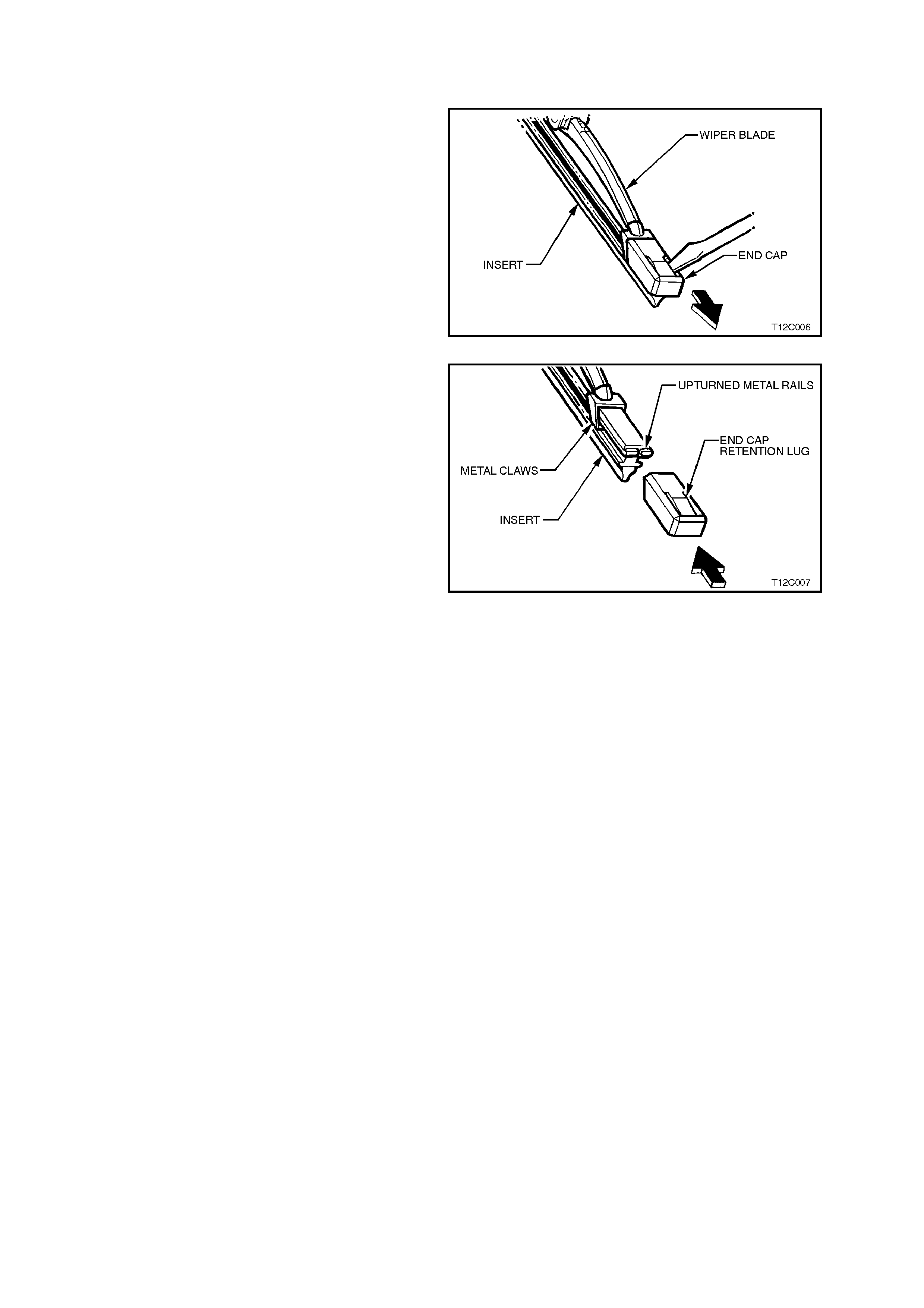

REPLACE

1. Remove wiper blade from arm, refer

3.3 FRONT AND REAR WIPER BLADES in

this Section.

2. Using a sm all screwdriver, lif t the retention lug

and slide the end cap off the wiper insert.

NOTE:

Do not re-use end cap.

3. Slide insert out of wiper blade and discard.

Figure 12C-49

NOTE:

The replacement insert will be supplied with one

end cap and a small retaining clip fitted.

4. Rem ove the small retaining clip f rom the ins ert

and slide the end without the end cap into the

wiper blade ensuring that the insert passes

through each metal claw.

5. Assemble the new end cap onto the end of the

insert, ensuring the retention lug on the end

cap is located securely behind the two

upturned ends of the metal rails, refer Fig

12C-50.

6. Reinstall wiper blade onto arm, refer

3.3 FRONT AND REAR WIPER BLADE in

this Section.

Figure 12C-50

3.5 FRONT WIPER MOTOR AND LINKAGE

CHECKING WIPER MOTOR WIRING

The following operation checks the wiper motor

wiring at the wiper motor connector (YE93) as an

aid to diagnosing a fault in the wiper motor system.

NOTE:

On vehicles with high series BCM, operation of

the interm ediate dwell control can be c heck ed with

TECH 2, refer Section 12J-2 HIGH SERIES BCM.

1. Remove wiper arms, plenum covers, water

deflector and disconnect wiring harness

connector YE93, refer to Steps 1 - 6 in the

following wiper motor removal procedure.

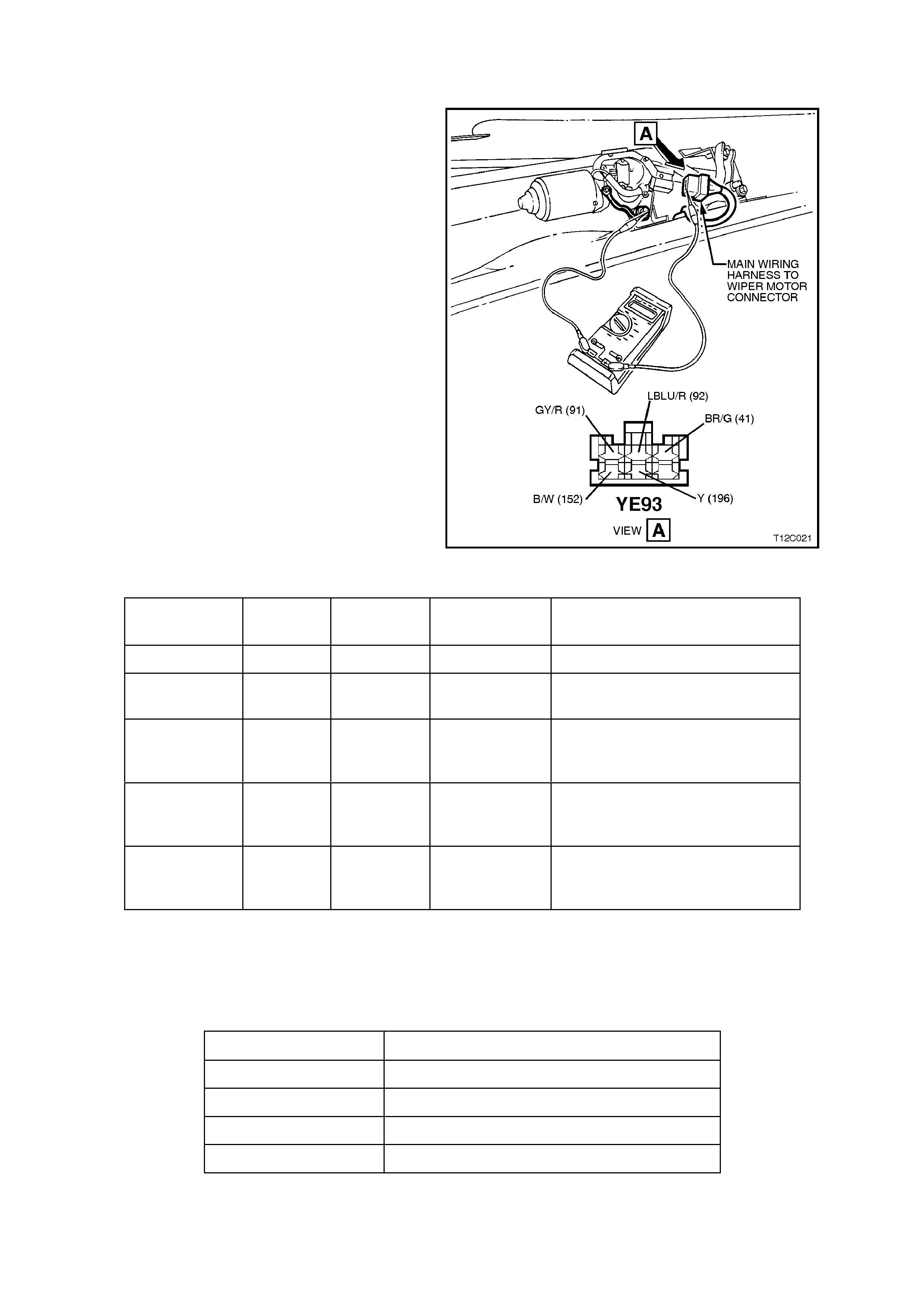

2. Using a multimeter connected with the

negative lead to the black wire term inal of the

wiring harness connector and the positive

lead to the main wiring harness connector

wire terminal nom inated in the f ollowing chart,

check wiper motor wiring as follows:

Figure 12C-51

WIRE

COLOUR CIRCUIT

NO. CIRCUIT MULTIMETER

SETTING RESULT IF WIPER MOTOR

WIRING IS OK

Black/White 152 Earth Resistance 0 ohms (approximately).

Brown/Green 41 Power

source Voltage B+ with ignition in ACC or ON

position.

Grey/Red 91 Low speed Voltage B+ with ignition in ACC or ON

position and wiper switch in low

speed position.

LBlue/Red 92 High speed Voltage B+ with ignition in ACC or ON

position and wiper switch in high

speed position.

Grey/Red 91 INT

Position Voltage B+ cycling with ignition in ACC or

ON position and wiper switch in

INT position.

3. With wiring harness connector YE93

disconnected, check for continuity between

the Yellow wire, circuit 196 and the Grey/Red

wire, circuit 91, as per the following table:

SWITCH POSITION RESULT IF WIPER MOTOR WIRING IS OK

OFF Continuity

INTERMITTENT Continuity

LOW Continuity (low resistance)

HIGH Open circuit

NOTE:

If any of the readings are not as specified, check

and repair faulty circuit as necessary.

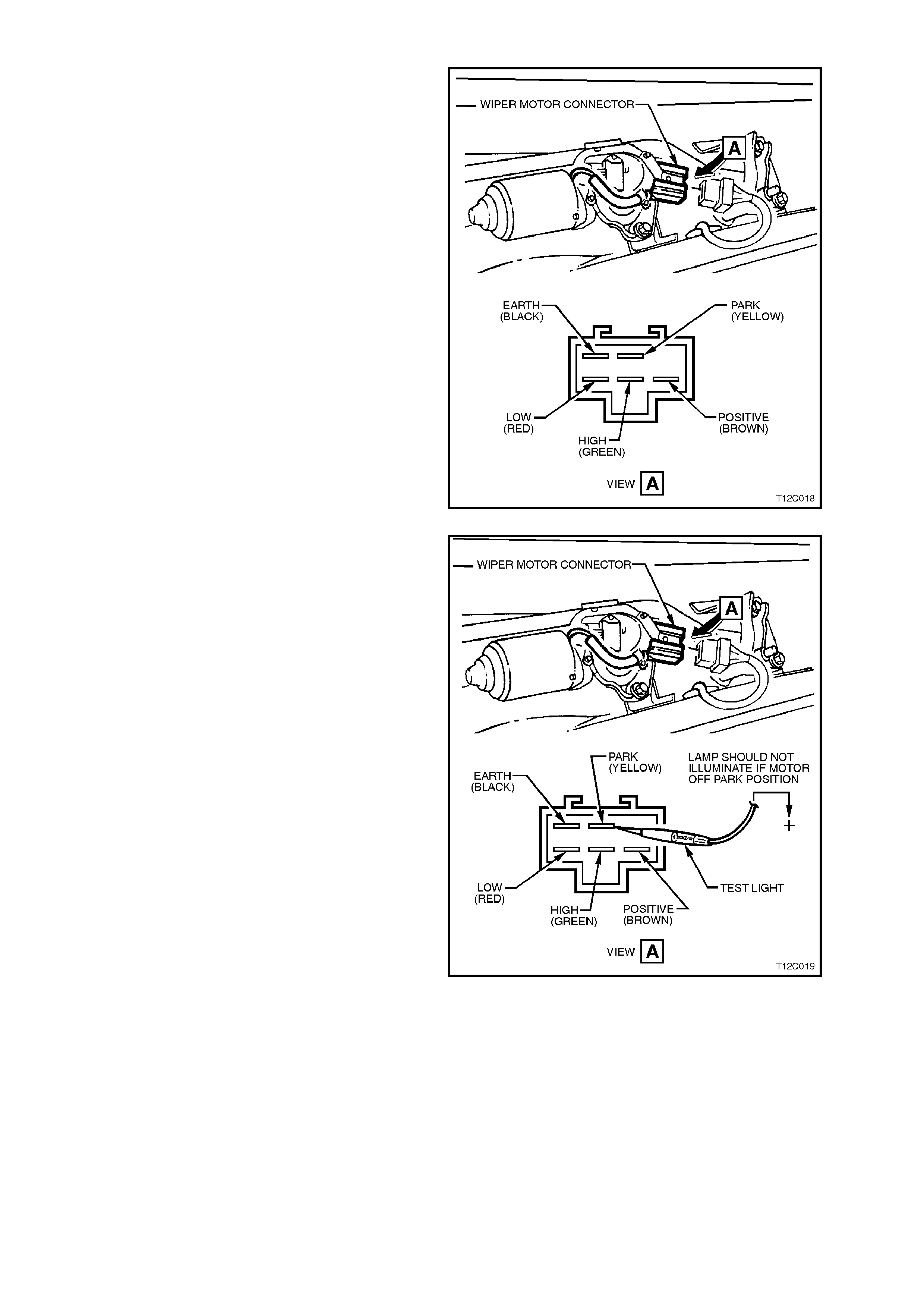

CHECKING WIPER MOTOR OPERATION

The following operation checks the various

functions of the wiper motor. If there is a f ault in the

wiper system, and the following operation proves

that the wiper motor is OK, check the wiper/washer

switch or wiring as described in this Section, or

check the BCM control, depending on model

variant, refer to either Sect ion 12J-1 L O W SERIES

BCM or Section 12J-2 HIGH SERIES BCM.

If the following operation proves that the wiper

motor is faulty, replace the wiper motor assembly.

1. Remove wiper arms, plenum covers, water

deflector and disconnect wiring harness

connector, refer to Steps 1 - 6 in the following

wiper motor removal procedure.

2. Connect a lead from vehicle battery positive

terminal to the Red wire of the wiper motor

connector. T he wiper motor should operate on

low speed.

3. Connect a lead from vehicle battery positive

terminal to the Green wire of the wiper motor

connector. T he wiper motor should operate on

high speed.

Figure 12C-52

4. To check wiper motor PARK operation,

connect a jum per lead from vehicle positive to

Red wire of motor connector and allow motor

to turn linkages approximately 1/4 of a turn

past the PARK position.

To check if the wiper motor is off the parked

position, connect a test lamp between battery

positive and the Yellow wire of the wiper m otor

connector. The lamp should NOT illum inate. If

the lamp does illuminate, contacts within the

wiper motor ar e faulty or check f or Yellow wire

shorted to earth.

Figure 12C-53

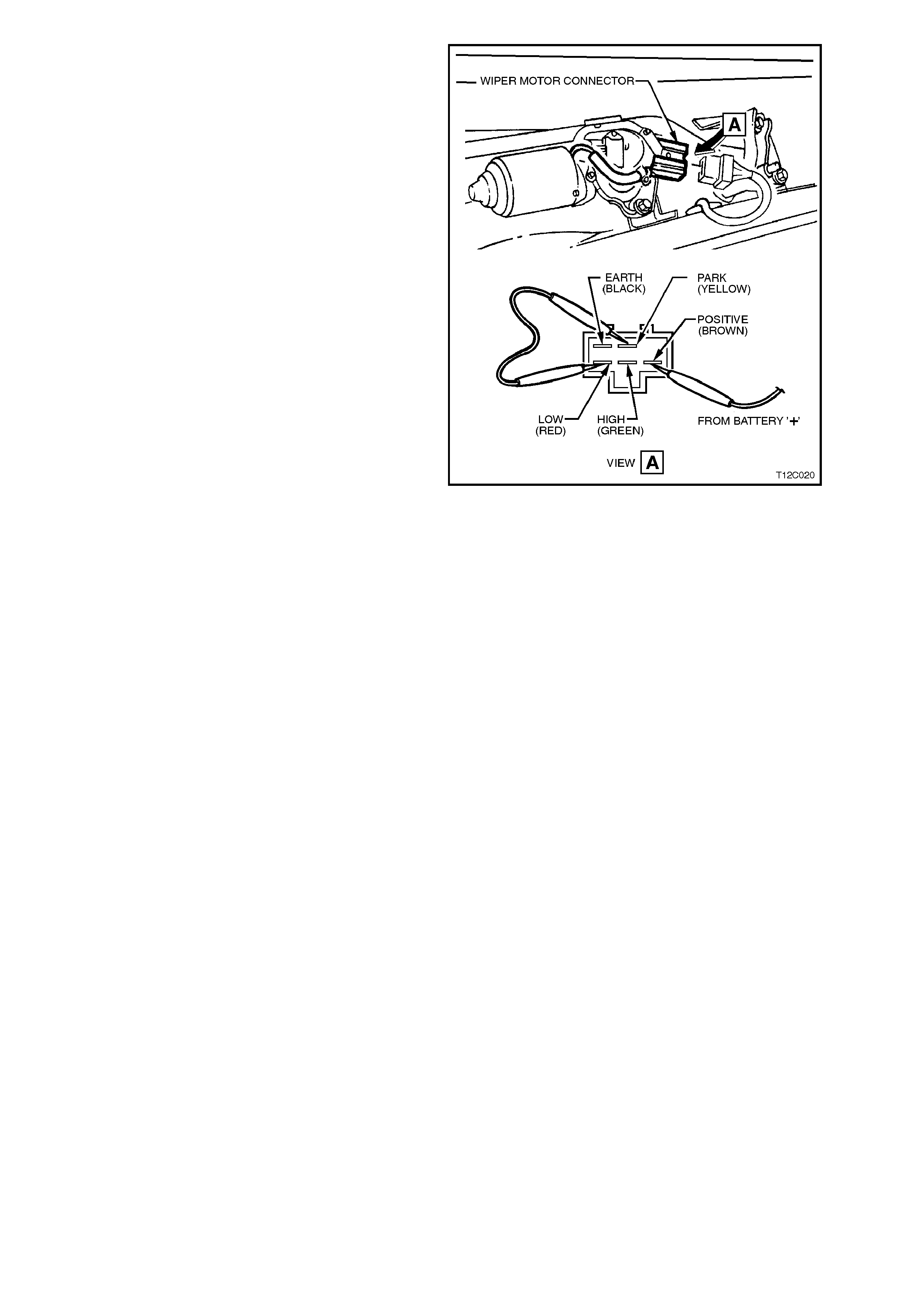

Using a second jumper wire, connect the Red

and Yellow wires of the wiper motor connector

together.

Using jumper leads from battery positive,

connect to Brown wire of wiper motor

connector and the wiper m otor should turn the

wiper linkages to the PARK position and stop.

If the wiper motor does not tur n the link ages or

the linkages do not stop at the PARK position,

the contacts within the wiper motor are faulty

and therefore, the wiper motor must be

replaced.

5. Reconnect wiring harness connector to wiper

motor.

6. Reinstall water deflector, plenum chamber

covers and wiper arm assemblies, refer to the

following removal and reinstallation procedure

of the wiper motor in this Section.

Figure 12C-54

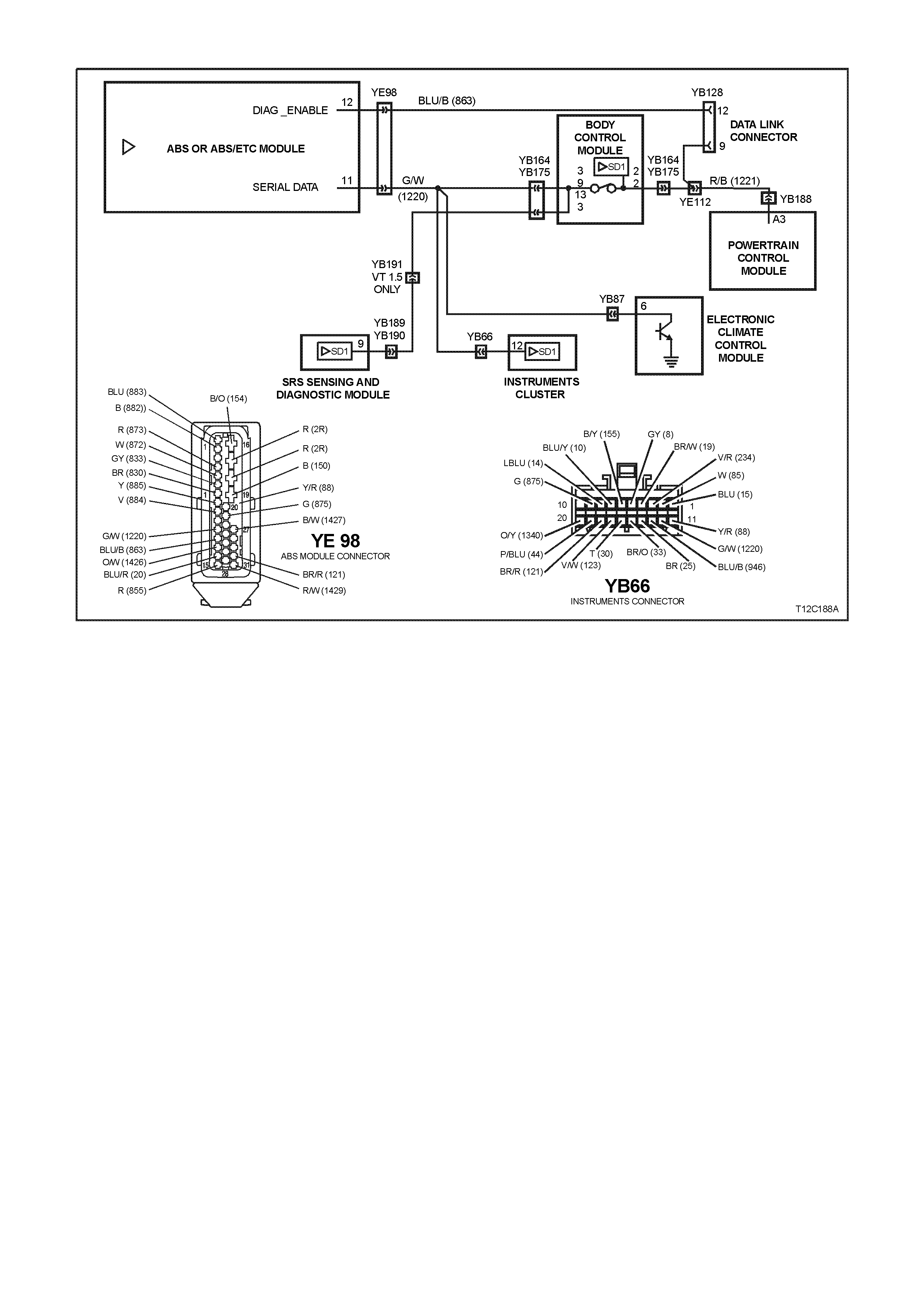

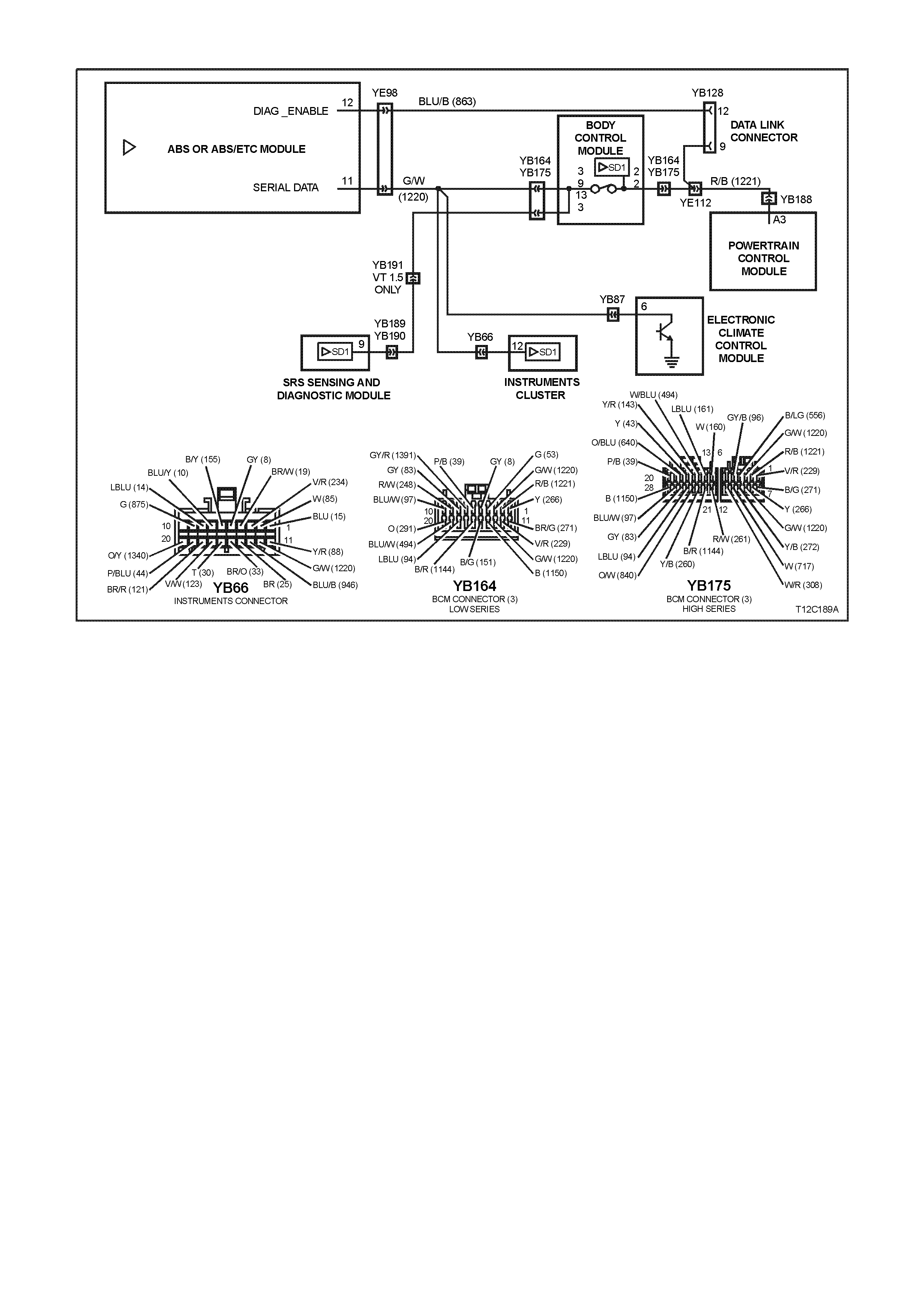

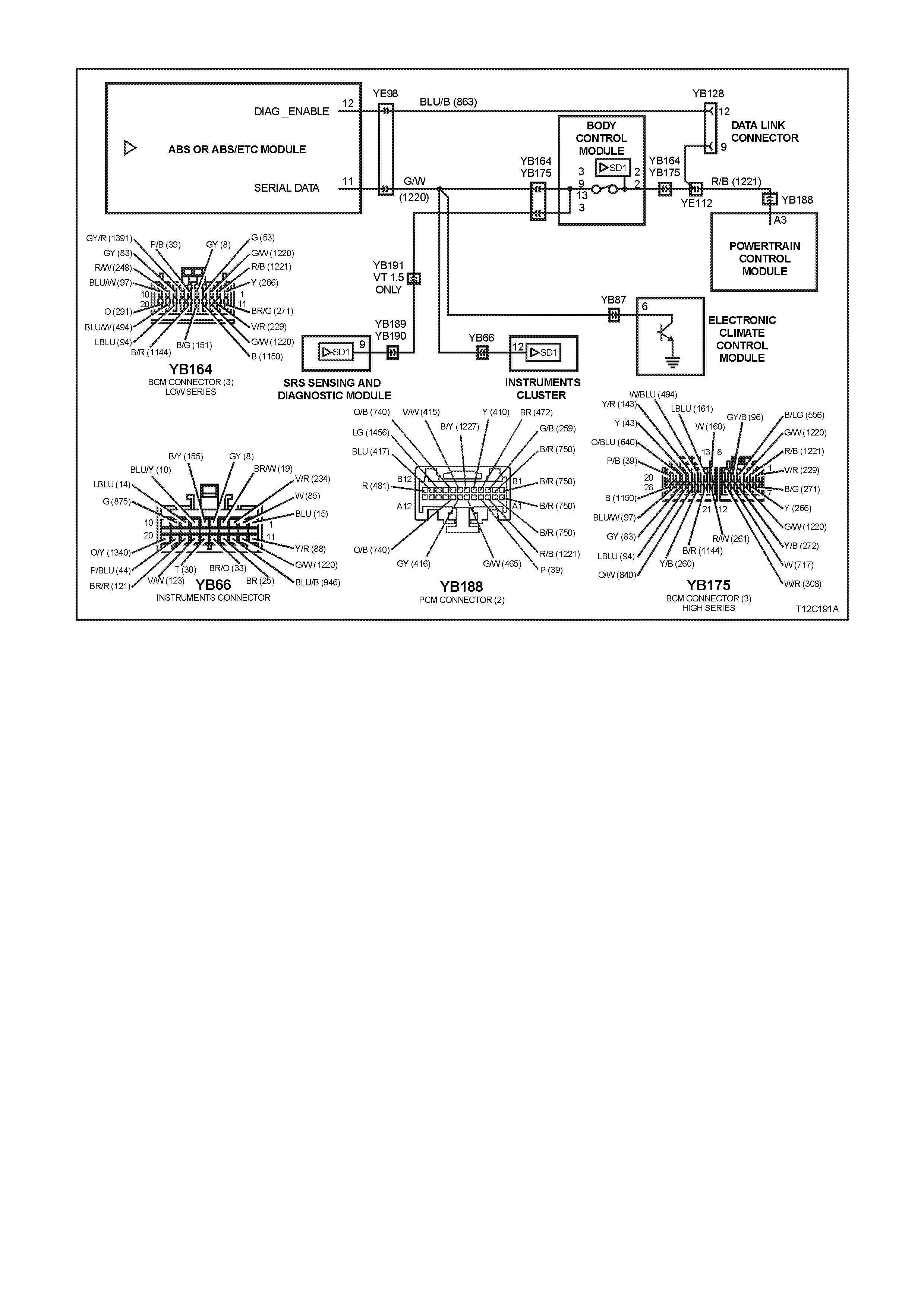

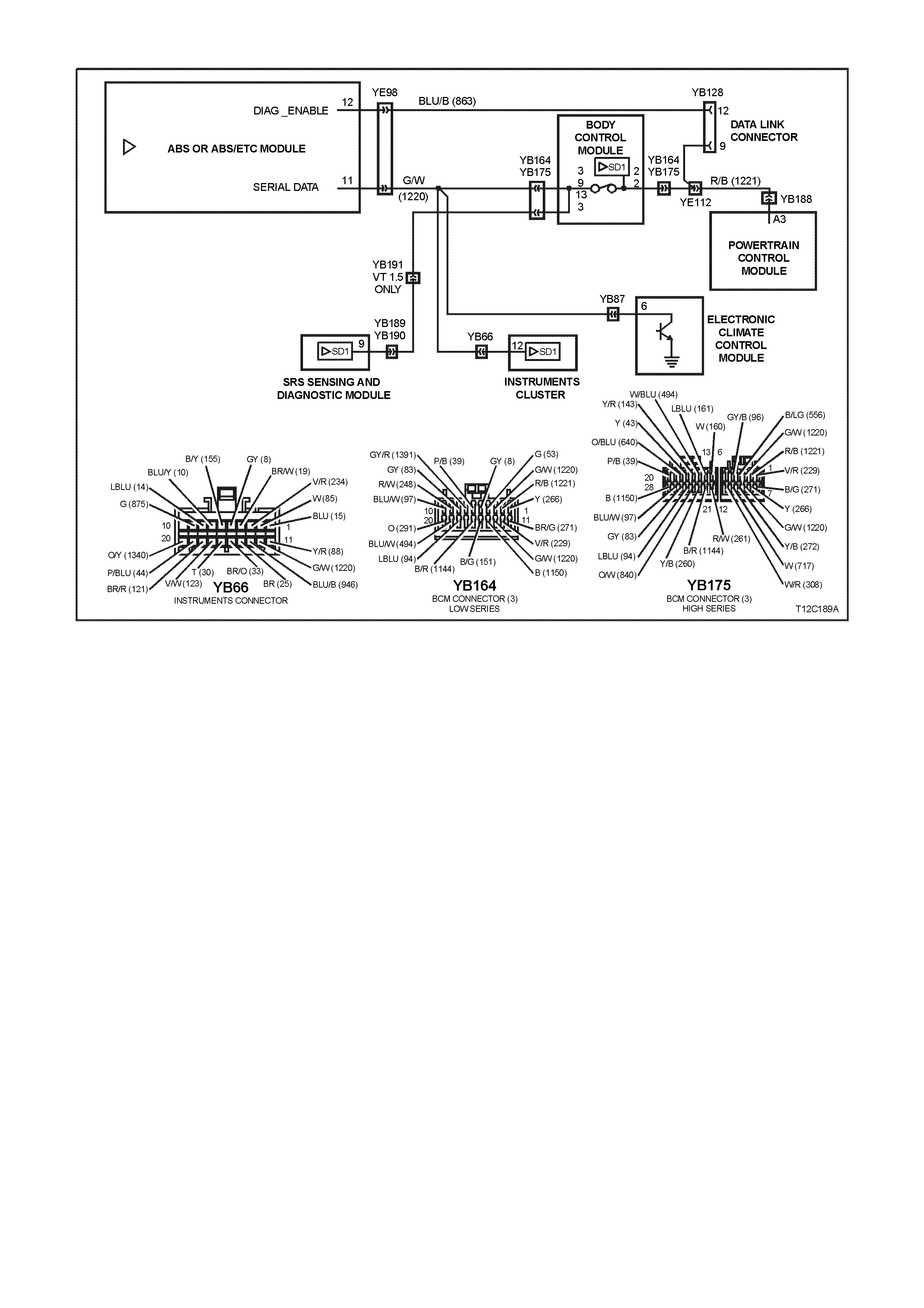

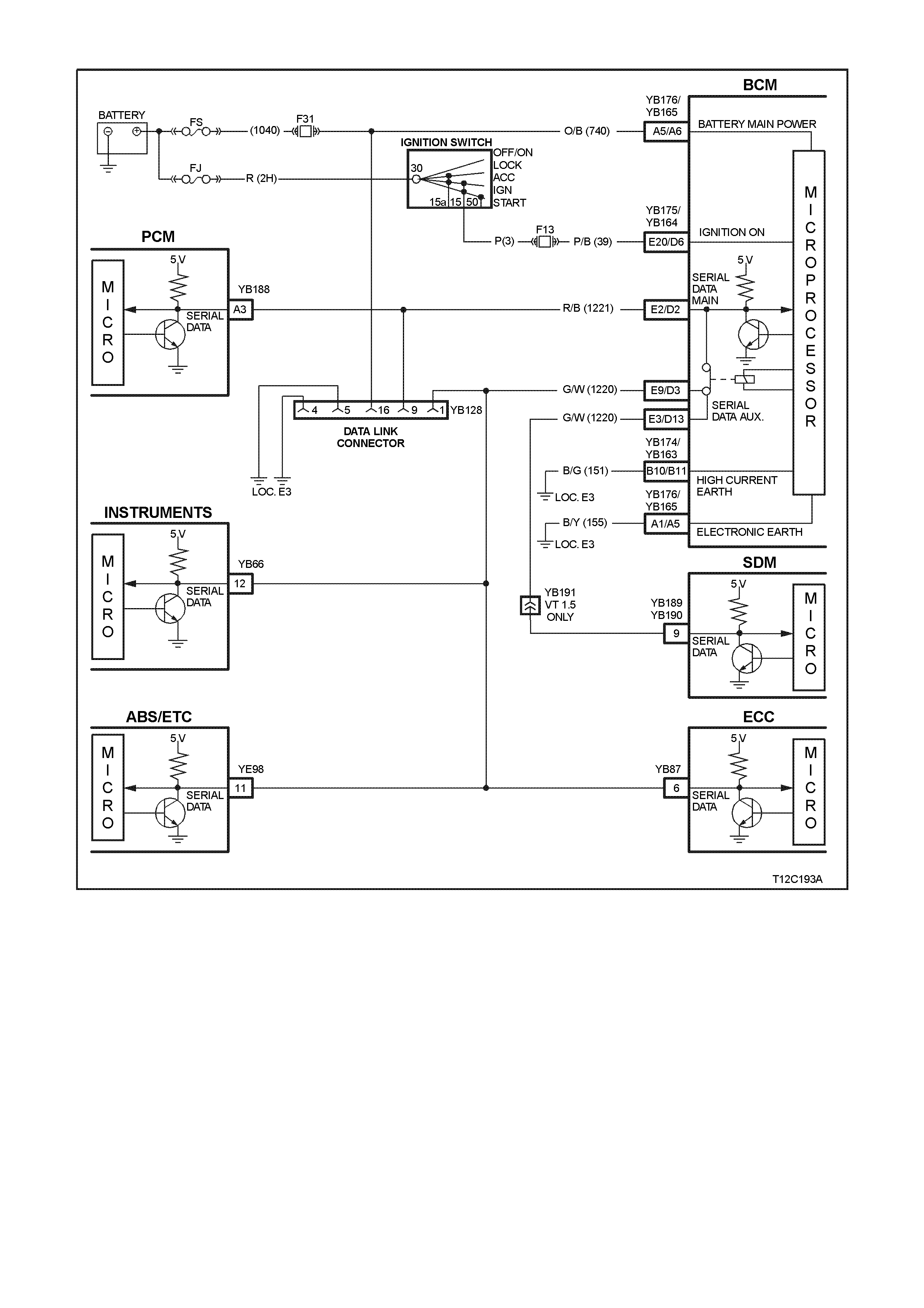

CIRCUIT DIAGRAMS

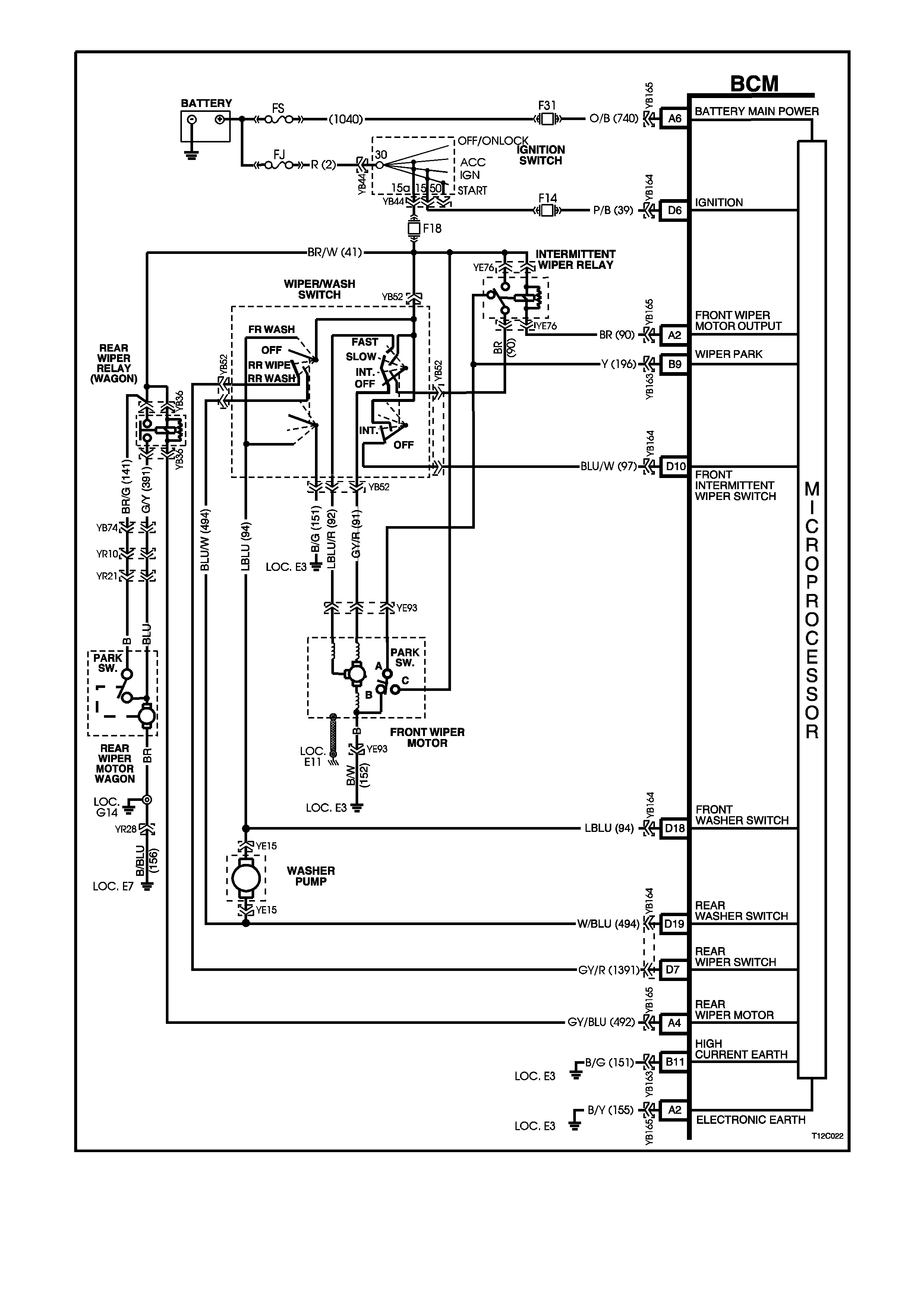

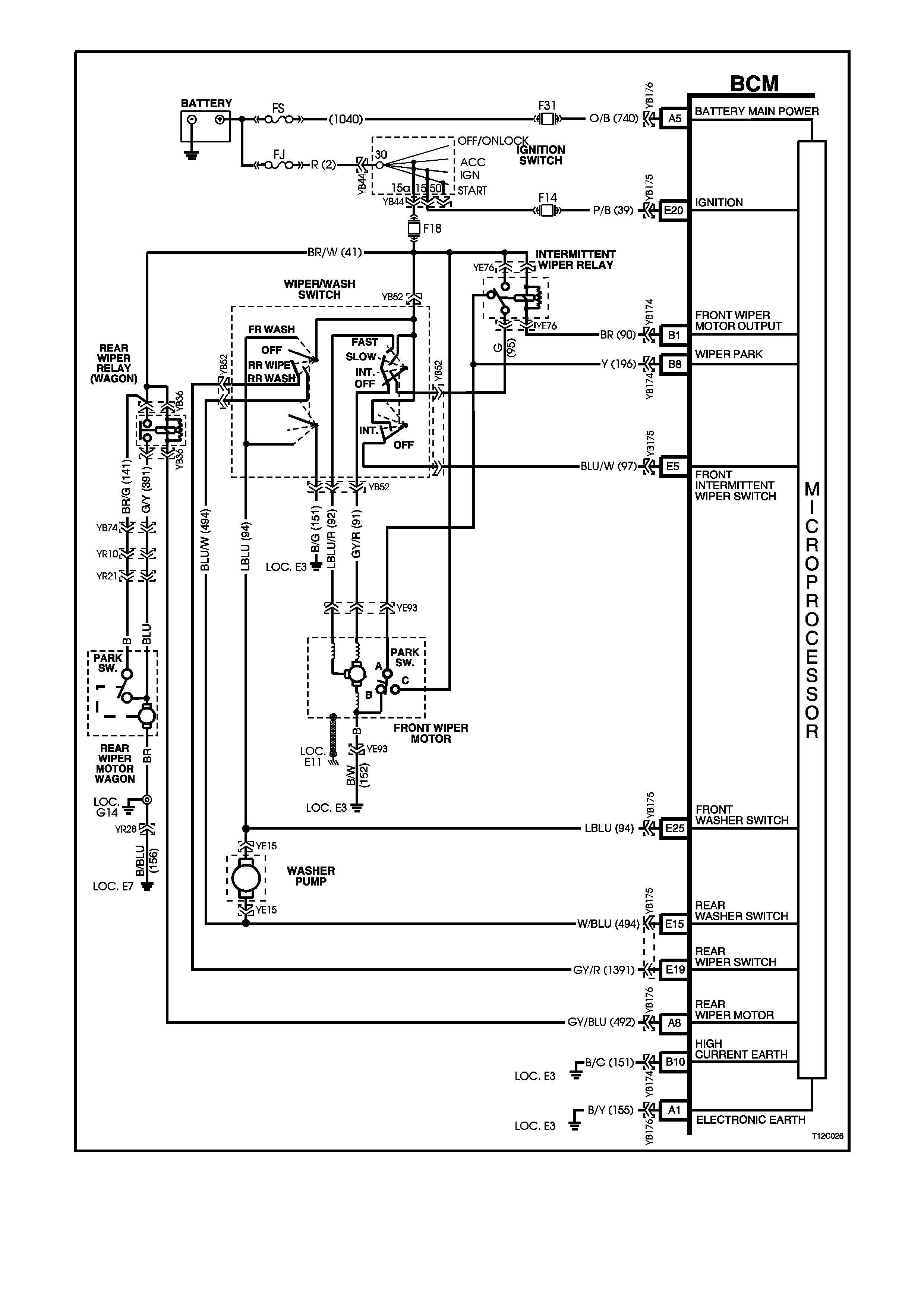

Fig. 12C-55 shows the circuit for the front

wiper/washer system for vehicles with Low Series

BCM and Fig. 12C-56 the circuit for the front

wiper/washer system for vehicles with High Series

BCM.

Figure 12C-55

Figure 12C-56

REMOVE

1. Rem ove wiper arm s, ref er 3.1 FRONT WIPER

ARM in this Section.

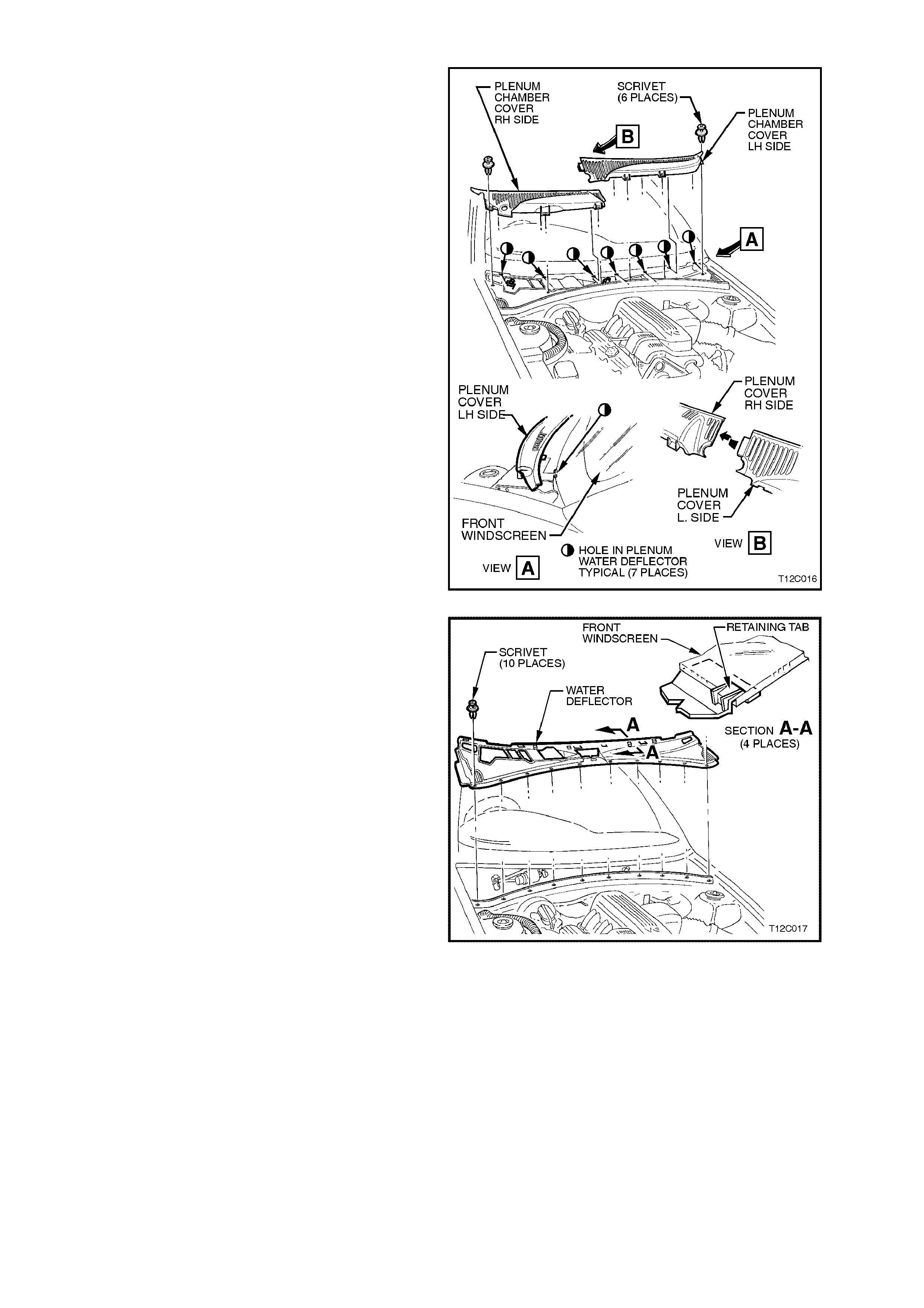

2. Remove the six f asteners s ecuring the plenum

chamber covers to the plenum chamber.

3. Pull the plenum chamber covers forward to

release them from the retainer securing them

to the windscreen, lift covers upwards while

manoeuvring the cover away from the engine

hood hinge and remove covers.

NOTE:

Remove the right - hand plenum cover first.

Figure 12C-57

4. Remove the 10 fasteners securing the water

deflector to the plenum chamber.

5. Pull the water deflector forward to release it

from the retainers securing it to the

windscreen, remove water deflector.

Figure 12C-58

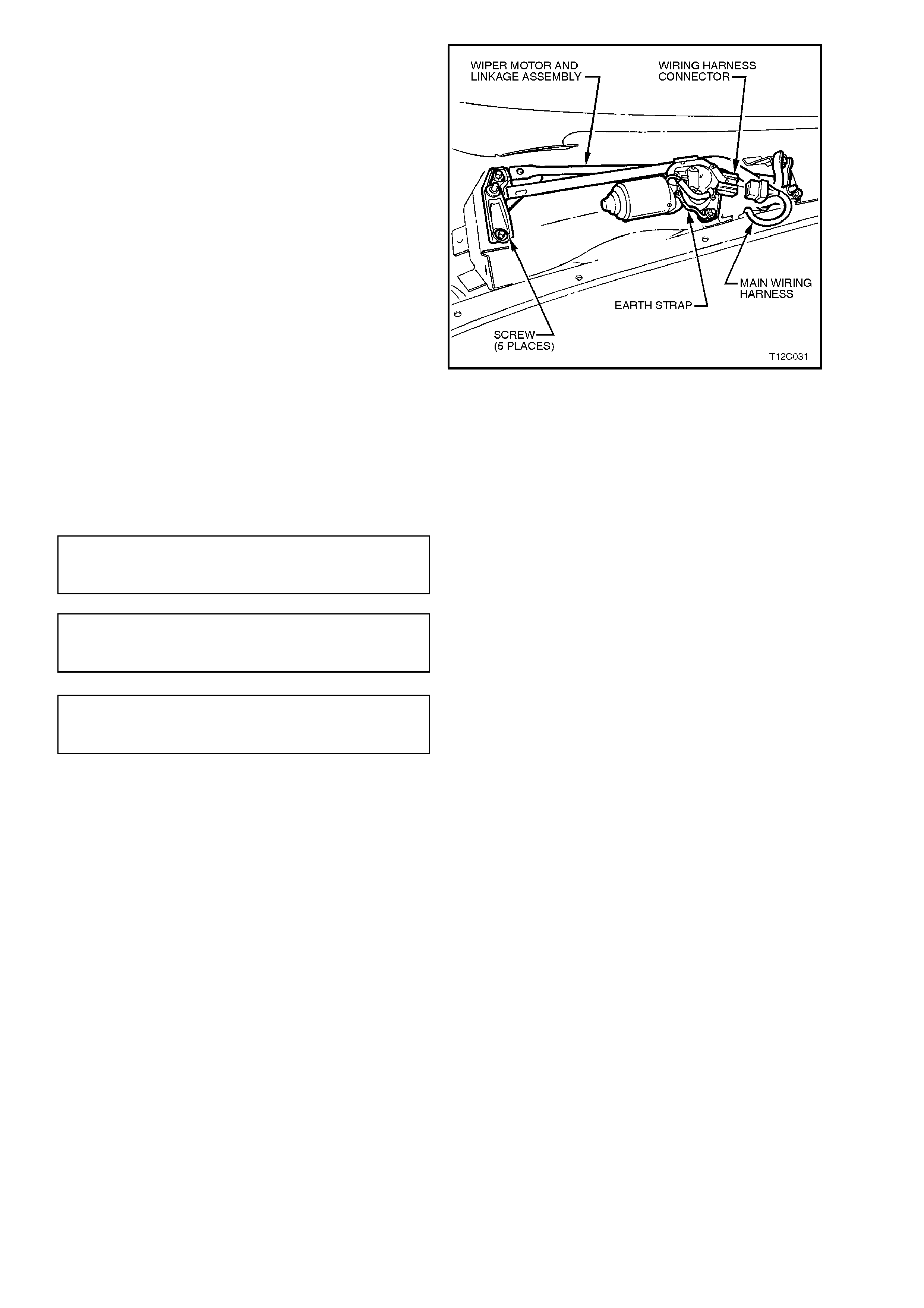

6. Squeeze the tang at the main wiring harness

to wiper motor harness connector and

disconnect wiring harness.

7. Remove the five screws securing the wiper

motor and linkage assembly to the plenum

chamber and remove wiper motor and linkage

assembly.

8. If necessary, remove the nut securing the

wiper linkages to the wiper arm pivot and the

two screws securing the wiper motor to the

wiper linkages and separate the wiper motor

from the wiper linkages.

Figure 12C-59

REINSTALL

Installation of the wiper motor is the reverse of the

removal procedure, noting the following:

1. Ensure all fasteners are tightened to the

correct torque specification.

WI PER MOTOR TO LINKAGE

SECURING SCREWS TORQUE

SPECIFICATION 7 - 9 Nm

WI PER MOTOR CRANK ARM PIVOT

TO WIPER LINKAGE SECURING NUT

TORQUE SPECIFICATION 16 - 20 Nm

WI PER MOTOR AND LINKAGE

ASSEMBLY SECURING SCREW S

TORQUE SPECIFICATION 4 - 6 Nm

NOTE:

Ensure that the wires from the connector do not get

caught or foul the wiper motor linkages.

2. Operate wiper motor before installing the

wiper arm s to ensure it is in the correct PARK

position.

3. When installing the water deflector and

plenum covers, ensure that the retaining tabs

engage under the windscreen.

3.6 WI P ER/WASHER SWITCH

REMOVE

1. Disconnect battery earth lead.

2. Remove ignition keys from ignition switch.

CAUTION:

If vehicle is equipped with SRS (AIRBAG),

disable the system. Refer to ‘SUPPLEMENTAL

RESTRAINT SYSTEM, Section 12M (Version 6.2)

or Section 12M - (Version 8.0/8.1).

3. Lower fuse panel cover.

4. Release steering column height adjuster,

completely lower steering column and leave

lever in the release position.

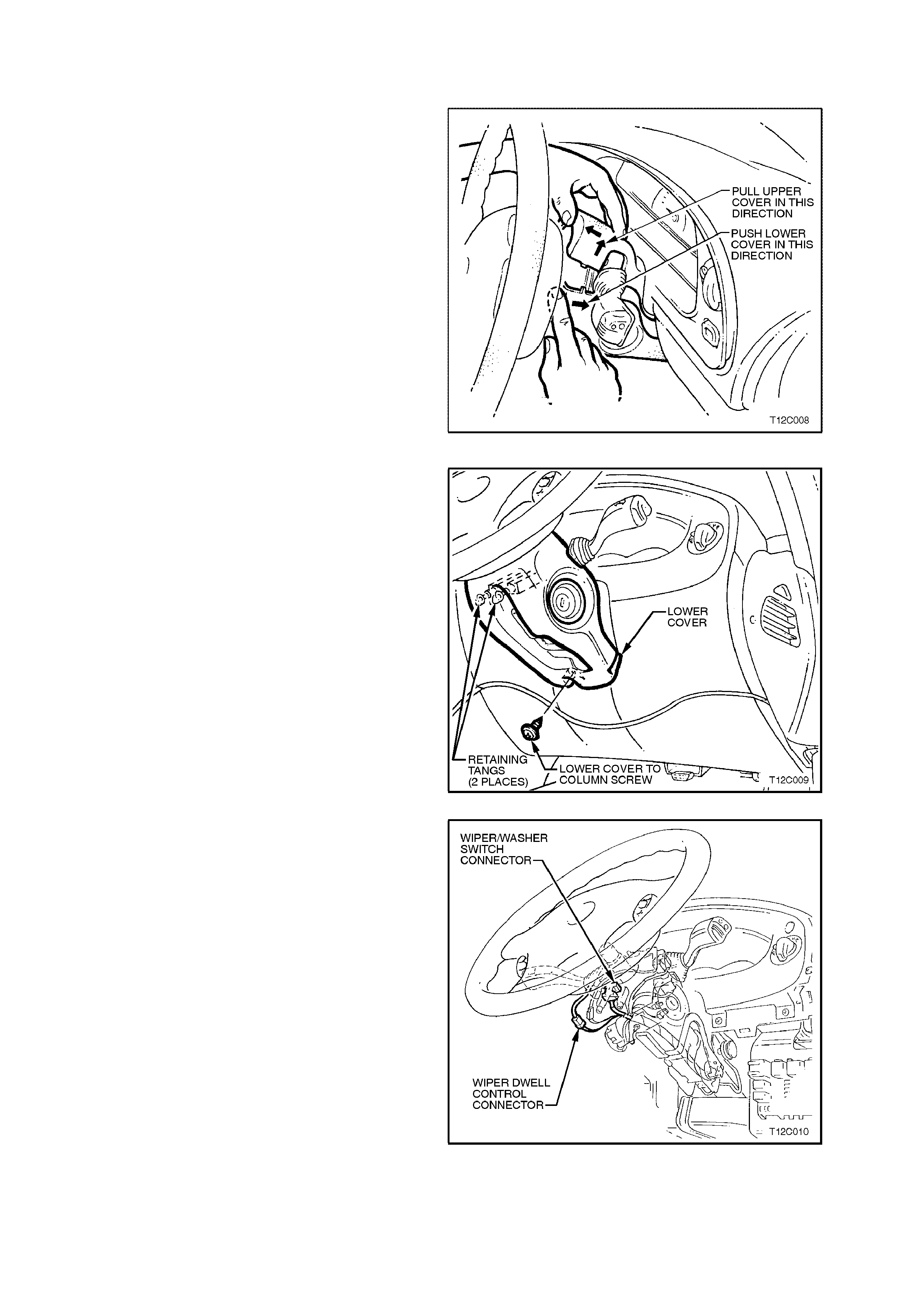

5. Insert finger between the steering wheel and

the lower cover as shown in Fig. 12C-60 and

apply a small amount of pressure (pushing

towards instrument cluster) while lifting the

upper cover up.

6. Remove upper cover by lifting upwards and

rearwards. Figure 12C-60

7. Remove sc rew securing the lower cover to the

steering column.

8. Slide lower cover toward the steering wheel to

release cover from the retaining tangs on the

steering column.

9. While feeding the key reader outer surround

from lower cover, remove cover.

Figure 12C-61

10. On vehicles with high series BCM, disconnect

the wiring harness connector to the wiper dwell

control switch harness connector by

depressing harness retaining tang and pulling

connectors apart.

Figure 12C-62

11. Depress retaining tangs on switch assembly

and withdraw switch from switch housing on

steering column.

12. Lift up wiring harness connector retaining

tangs on either side of switch body and pull

connector from switch and remove switch.

Figure 12C-63

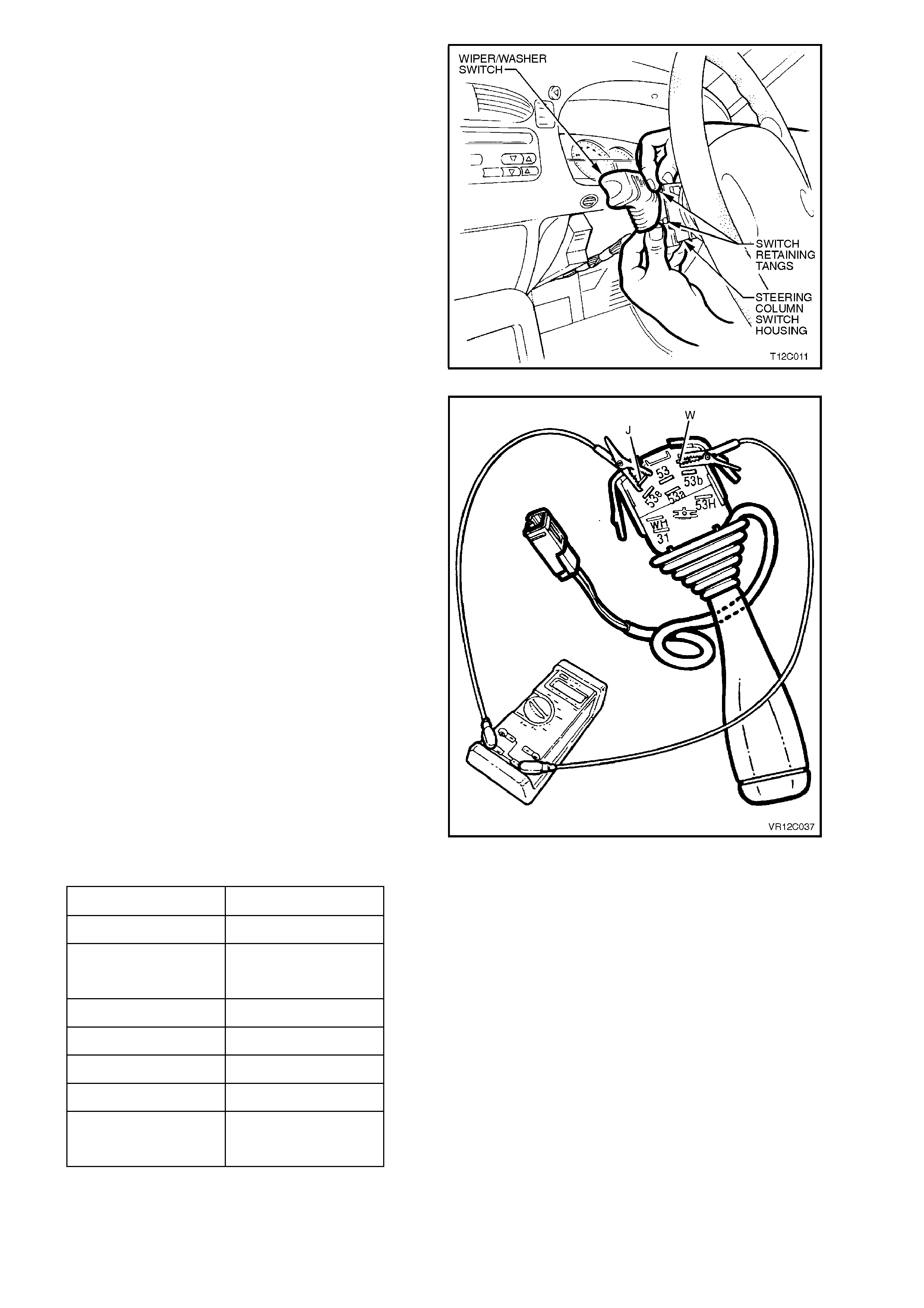

TESTING SWITCH

Using an ohmmeter connected to the various

switch terminals (refer Fig. 12C-64), check the

operation of the wiper/washer switch as per the

following chart.

If continuity is not as specified at any switch

position, replace switch assembly.

NOTE:

With dwell control adjusted fully up, multimeter

should register approximately 5.3 kohms, and with

control adjusted fully down, approximately 680

ohms.

Figure 12C-64

SWITCH POSITION TERMINALS

OFF 53 to 53e

INT 53 to 53e

J to 53a

1 53 to 53a

2 53a to 53b

FRONT. WASH W to 53a

REAR WIPE 53a to 53H

REAR WASH 53a to WH

53a to 53H

REINSTALL

Installation of the wiper/washer switch is the

reverse of the removal procedure, noting the

following:

Check operation of all wiper/washer switch

functions.

IMPORTANT:

If vehicle is equipped with SRS AIRBAG), enable

the system. Refer to ‘SUPPLEMENTAL

RESTRAINT SYSTEM, Section 12M (Version 6.2)

or Section 12M - (Version 8.0/8.1).

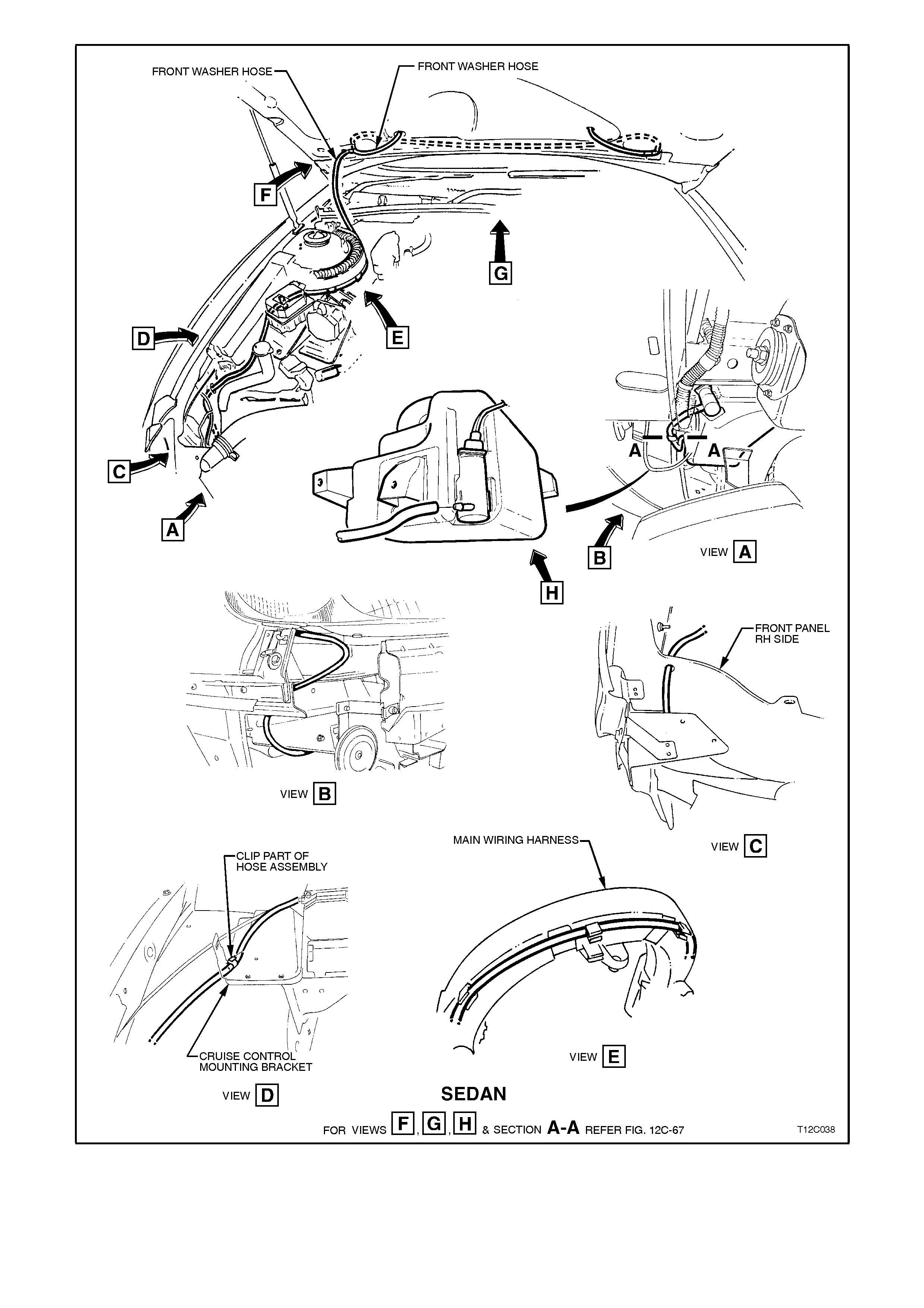

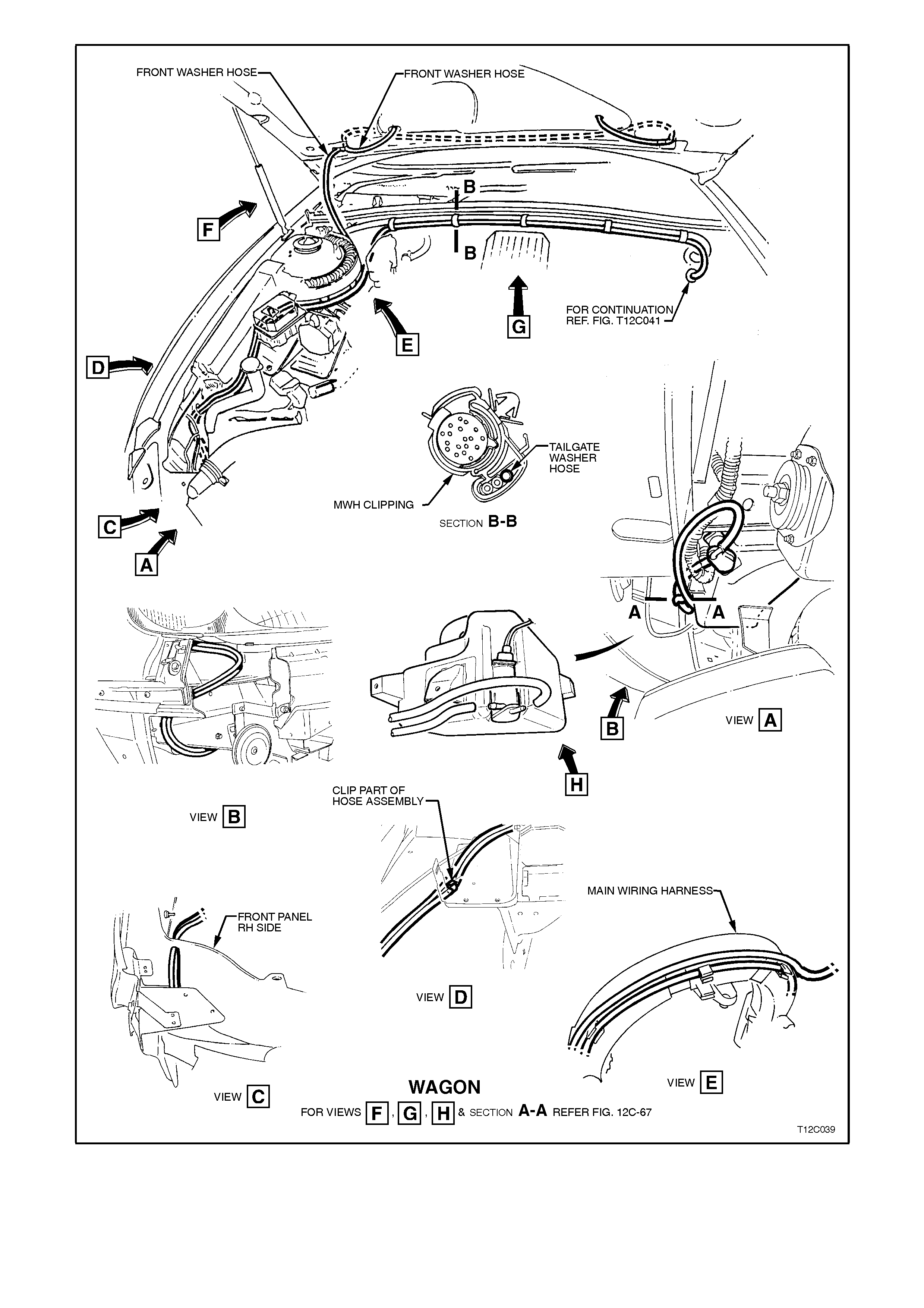

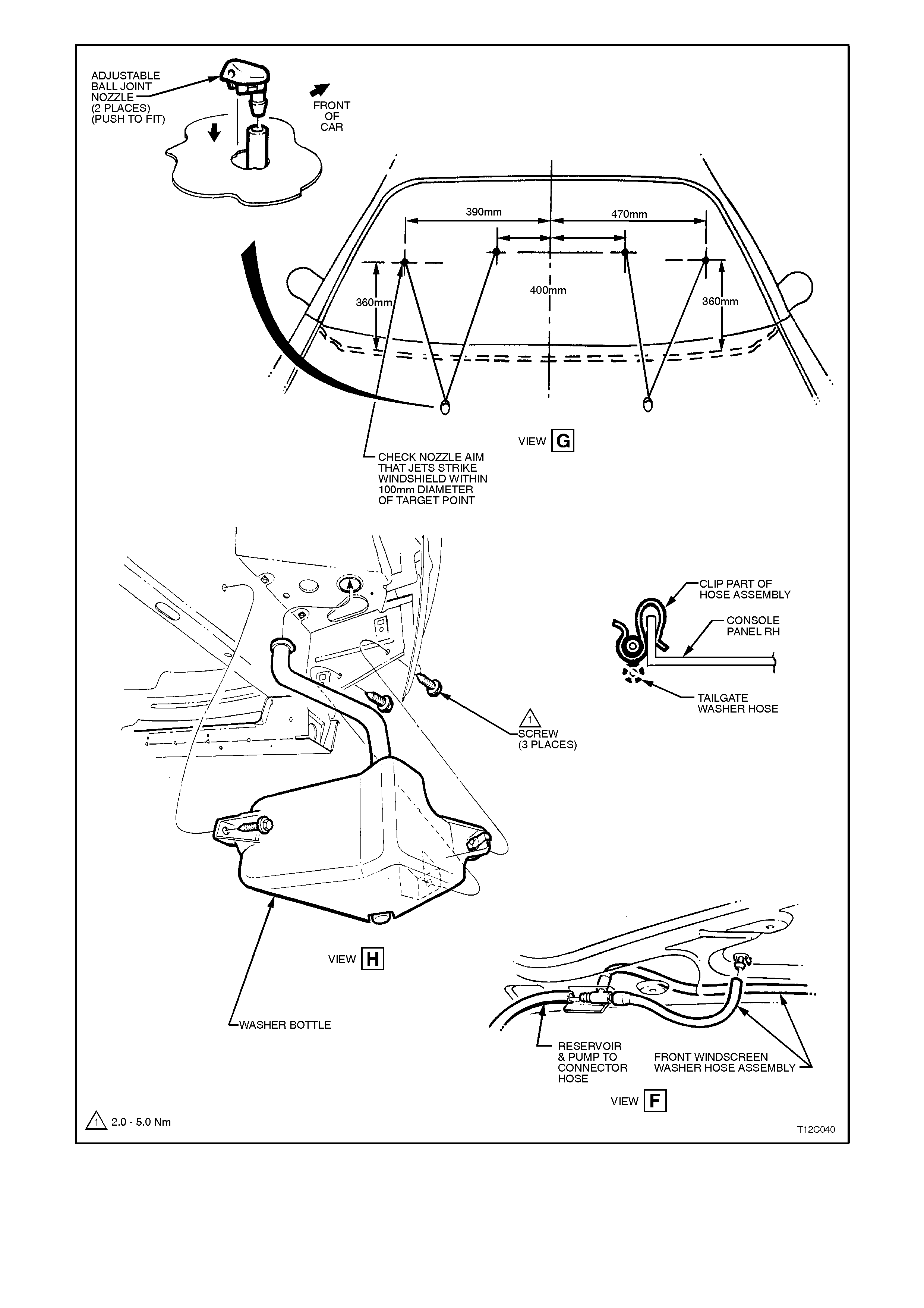

3.7 W INDSHIELD WASHERS

REMOVE AND REINSTALL

Fig. 12C-65, 12C-66 and 12C-67 illustrate the installation of the windshield washer system components.

The spray direction of the washer nozzle can be adjusted by inserting the point of a pin into the ball of the nozzle

and swivelling it to the position nominated in Fig. Fig.12C-67.

Figure 12C-65

Figure 12C-66

Figure 12C-67

CHECKING WASHER PUMP AND WIRING

The f ollowing operation chec ks the power sourc e and earth circuits f or the washer pump. If the following operation

proves that the washer pum p wiring is OK, and the washers are not work ing, there is a f ault in the pump or ther e is

a blockage in either the washer hoses or nozzles. If the wiring check indicates a fault, c heck wiring continuity. Also,

if necessary, check wiper/washer switch, refer 3.6 WIPER/WASHER SWITCH, in this Section.

1. Remove wiring harness connector from washer pump.

2. Connect a multimeter across washer pump wiring harness connector and check pump wiring as follows:

FRONT WASHERS

WIRE

COLOUR CIRCUIT

No. CIRCUIT MULTIMETER

SETTING RESULT IF WIPER

MOTOR IS OK

LBlue 94 Power

source Voltage Multimeter + lead

connected to LBlue wire

and - lead connected to

White/Blue wire

connector.

B+ with ignition in ACC or

ON position and

wiper/washer lever pulled

back.

White/Blue 494 Earth Resistance Multimeter leads

connected to White/Blue

wire and earth.

Approximately 0 ohms

with wiper/washer lever

pulled back.

REAR WASHERS

LBlue 94 Earth Resistance Multimeter leads

connected to White/Blue

wire and earth.

Approximately 0 ohms

with wiper/washer lever

pushed forward.

White/Blue 494 Power

source Voltage Multimeter + lead

connected to White/Blue

wire and - lead connected

to LBlue wire of

connector.

B+ with ignition in ACC or

ON position and

wiper/washer lever

pushed forward.

If wiring check s OK, apply 12 volts across the pump term inals and the pum p should operate. If pump oper ates, but

water does not spray from nozzles, revers e connections and check to see if water now sprays from nozzles. If water

still does not spray from nozzles, check for a blockage in the washer hoses, nozzles or pump.

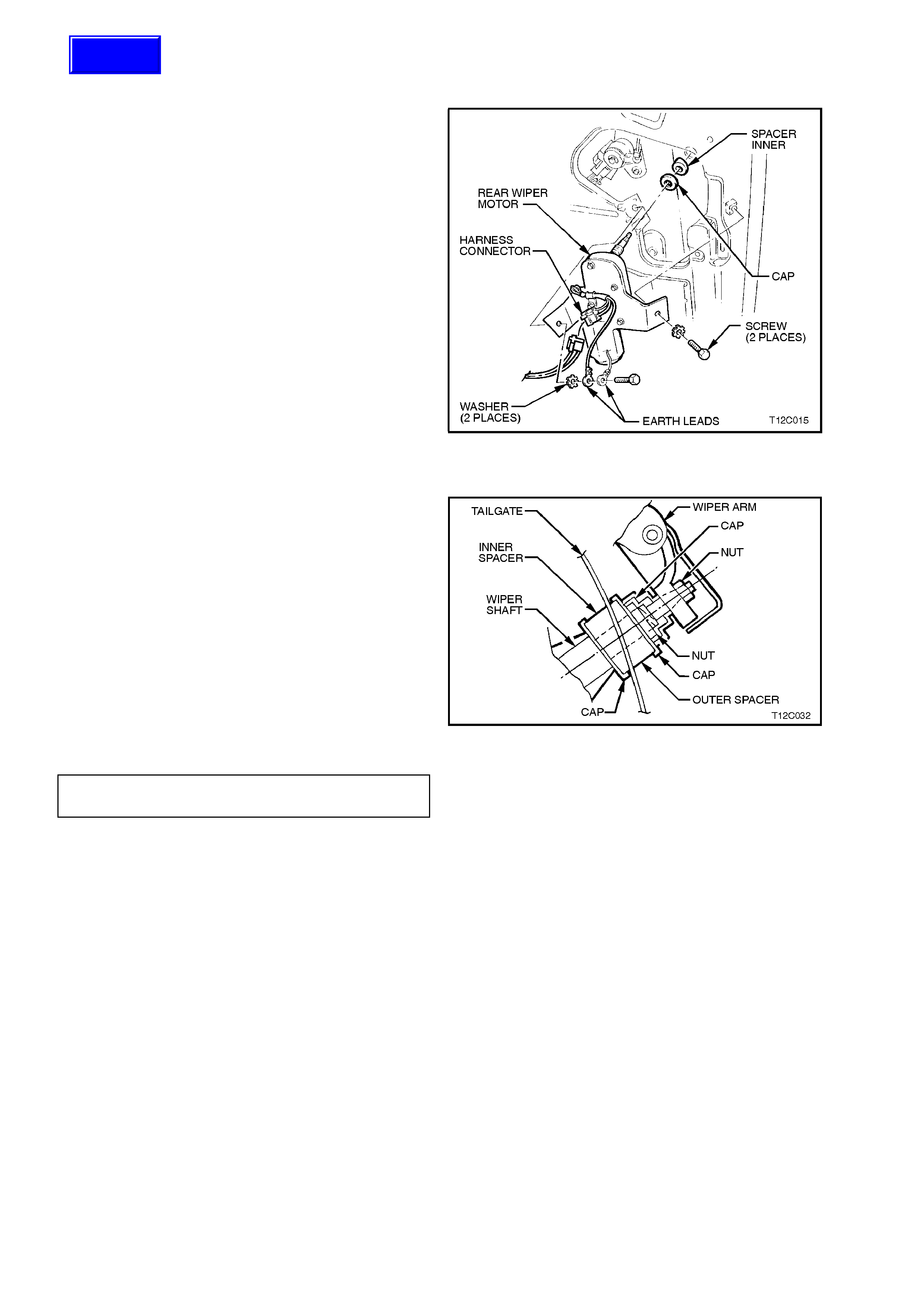

3.8 REAR WIPER MOTOR

REMOVE

1. Remove rear wiper arm, refer

3.2 REAR WIPER ARM, in this Section.

2. Remove tailgate interior trim panel, refer

Section 1A4 REAR COMPARTMENT LID &

TAILGATE.

3. Depress retaining tang on rear compartment

harness connector and disconnect from rear

wiper motor connector.

4. Remove the two screws securing the rear

wiper motor to the tailgate, remove wiper

motor and bracket assembly.

5. Remove inner spacer and cap from wiper

motor shaft.

Figure 12C-68

REINSTALL

Installation of the r ear wiper motor is the rever se of

the removal procedure, noting the following points

1. Ensure the inner and outer spacers are fitted

onto the wiper shaft correctly, refer Fig. 12C-

69.

2. To ensure the earth connection, the wiper

motor earth lead must be installed before the

tailgate harness earth lead.

3. Tighten wiper motor securing screws to the

correct torque specification.

Figure 12C-69

WI PER MOTOR SECURING SCREW

TORQUE SPECIFICATION 6 - 14 Nm

Techline

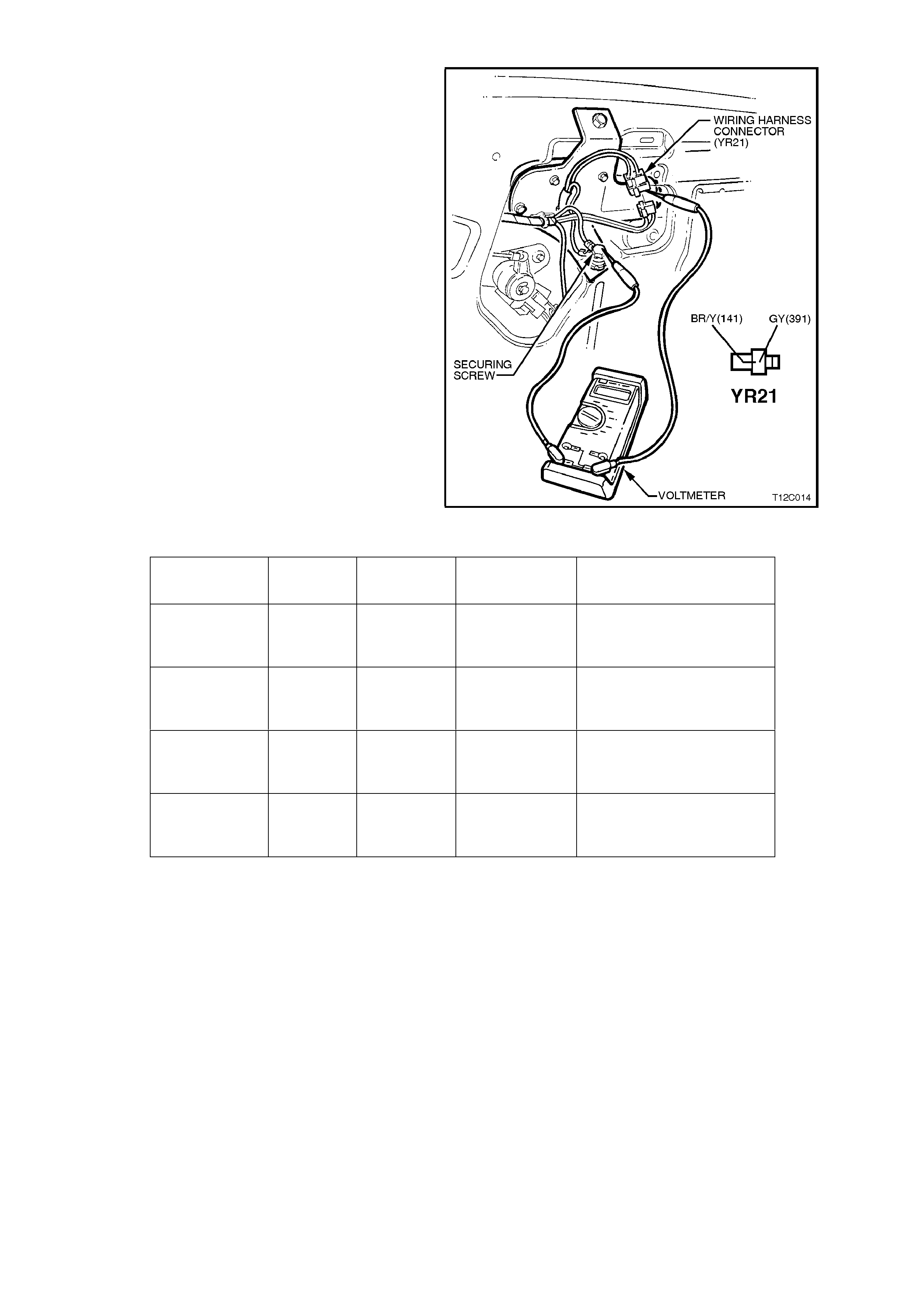

CHECKING WIPER MOTOR WIRING

1. Remove tailgate interior trim panel, refer

Section 1A4 REAR COMPARTMENT LID &

TAILGATE.

2. Depress retaining tang on rear compartment

harness connector and disconnect from rear

wiper motor connector.

3. Using a multimeter connected between one

of the wiper motor securing screws and the

rear compartment harness connector, check

wiper motor wiring as per the following chart.

Figure 12C-70

WIRE

COLOUR CIRCUIT

No. CIRCUIT MULTIMETER

SETTING RESULT IF WIPER

MOTOR IS OK

Brown/White 41 Power

source Voltage B+ with ignition in ACC or

ON position and

wiper/washer switch OFF

Grey 391 Motor drive Voltage 0 volt with ignition in ACC

or ON position and

wiper/washer switch OFF

Brown/White 41 Power

source Voltage B+ with ignition in ACC or

ON position and

wiper/washer switch ON

Grey 391 Motor drive Voltage 0 volt with ignition in ACC

or ON position and

wiper/washer switch ON

CHECKING WIPER MOTOR OPERATION

1. Remove rear wiper arm, refer

3.2 REAR WIPER ARM in this Section.

2. Remove tailgate interior trim panel, refer

Section 1A4 REAR COMPARTMENT LID &

TAILGATE.

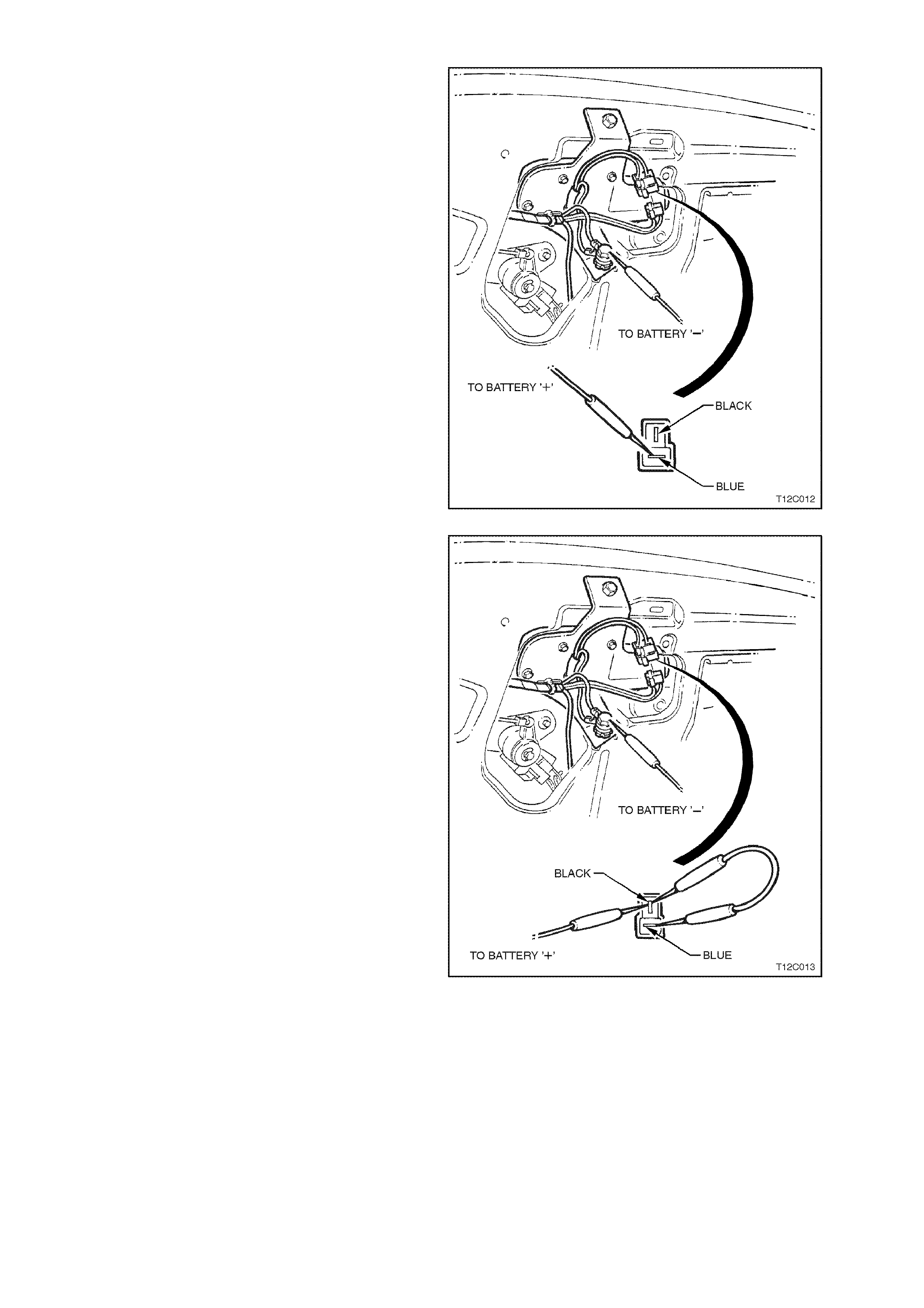

3. Use a jum per lead connected between battery

earth and the wiper mounting bracket and

earth lead (Brown wire).

4. Using a second jumper lead connected to

battery positive, touch jumper lead terminal to

Blue wire terminal of wiper motor connector.

Drive spindle of motor should rotate. If drive

spindle does not rotate, motor is faulty and

must be replaced.

Figure 12C-71

5. To check wiper motor PARKED operation,

connect a bridging wire between the Black and

Blue wires of the wiper motor connector.

Connect a jum per wire from battery positive to

Black wire to wiper motor connector, and wiper

motor spindle should rotate.

Disconnect bridging wire from Blue wire and

wiper motor should continue to rotate until it

reaches the PARK position.

If m otor does not park, the contacts within the

motor are faulty and therefore, the motor m ust

be replaced.

Figure 12C-72

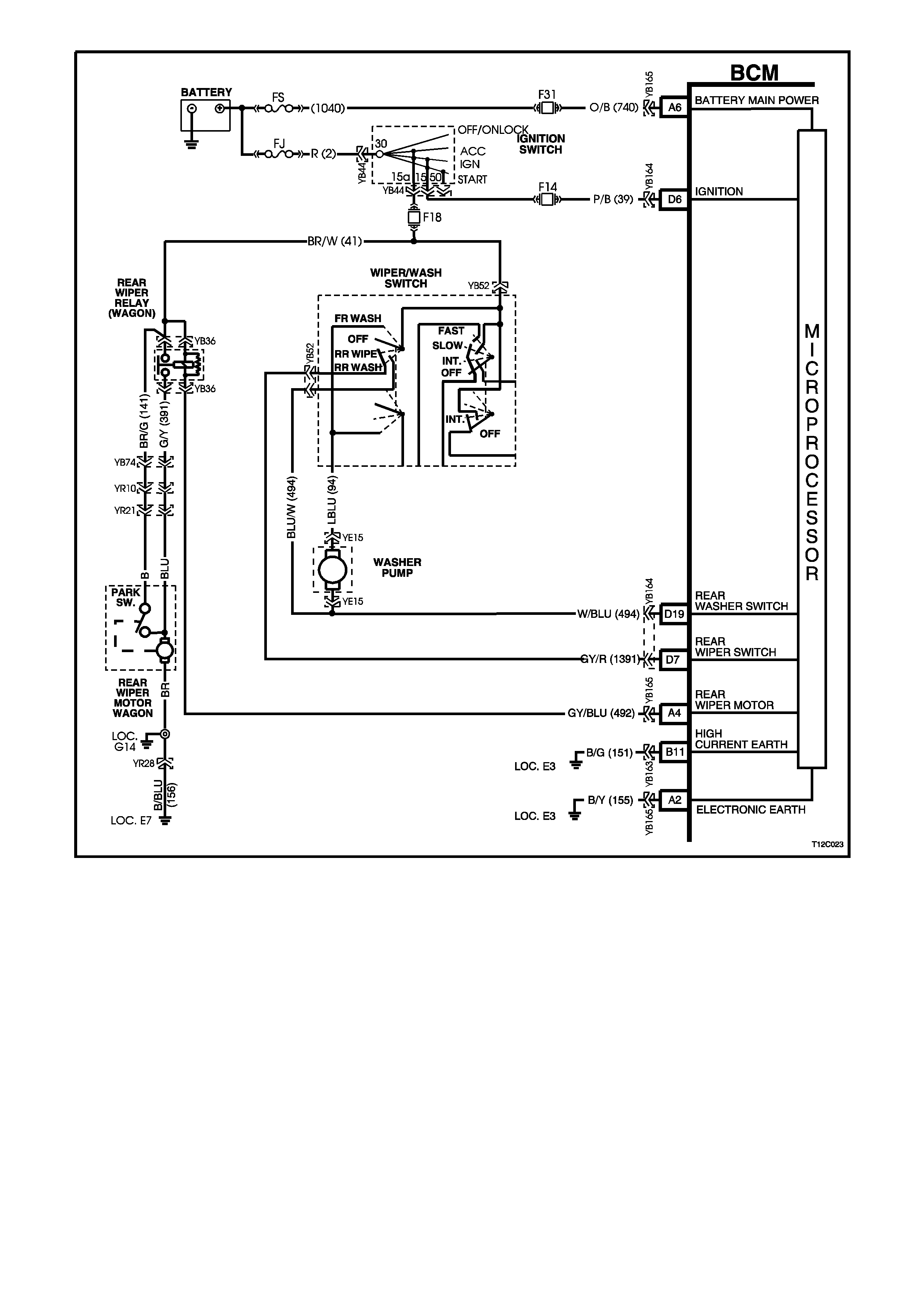

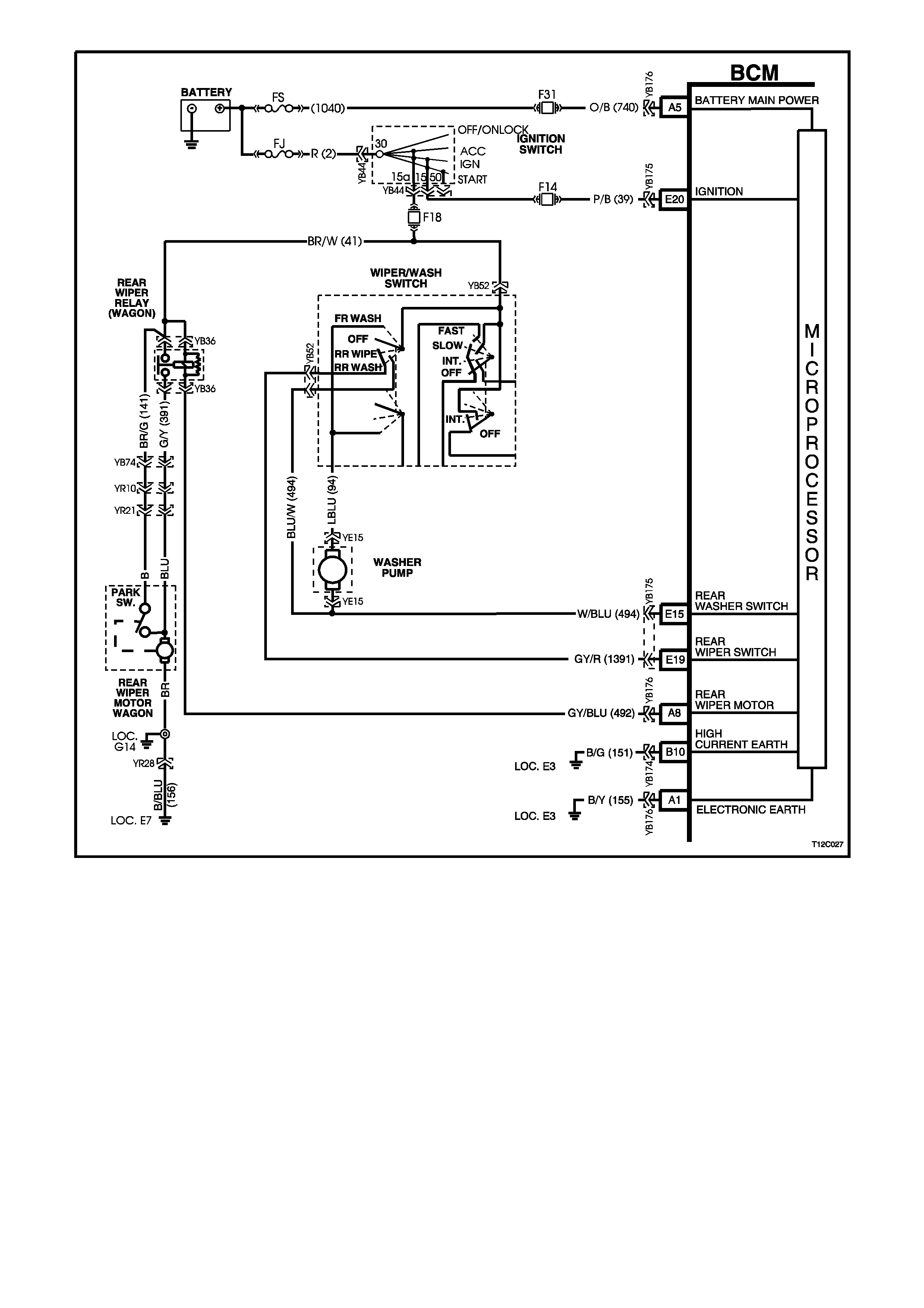

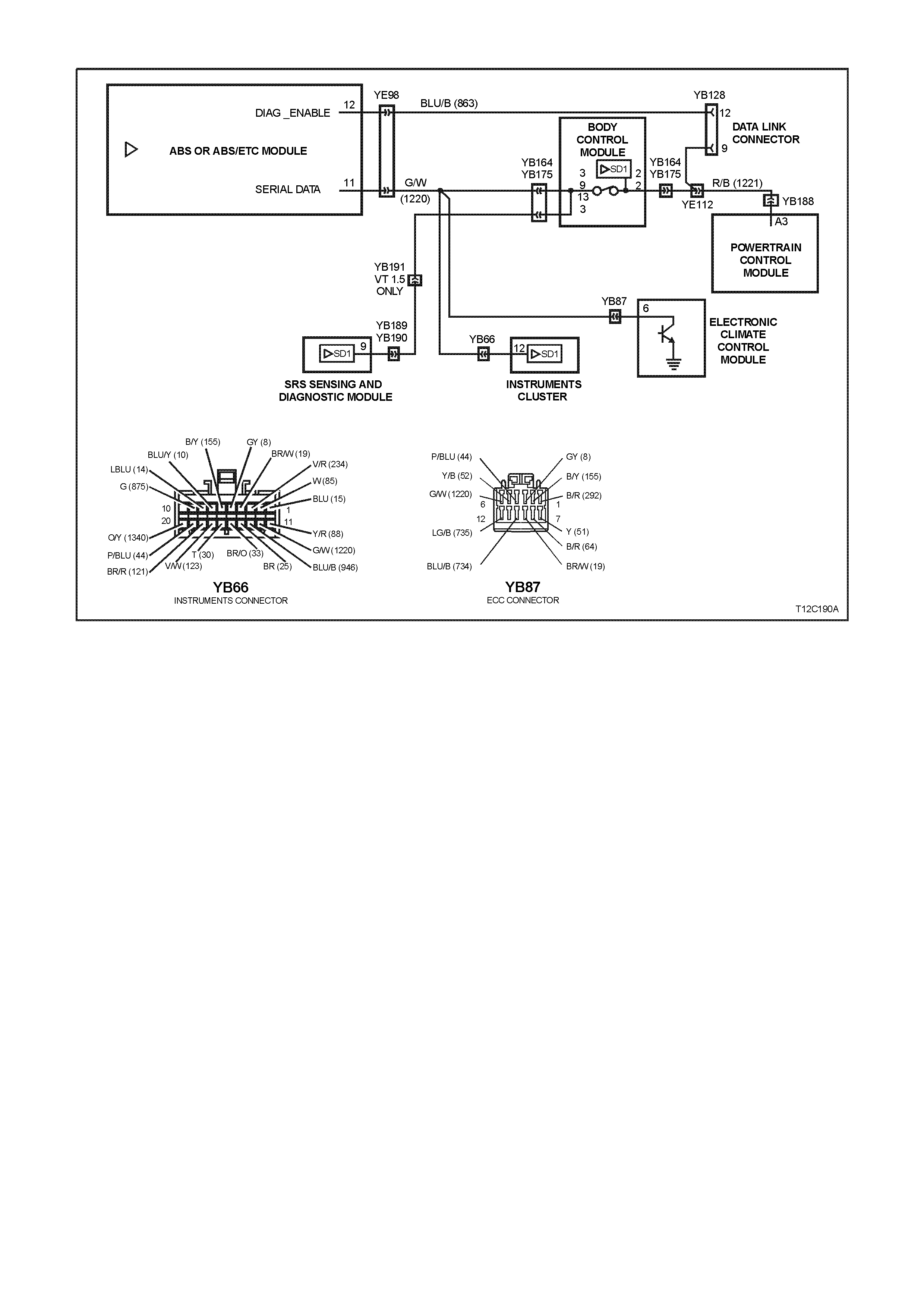

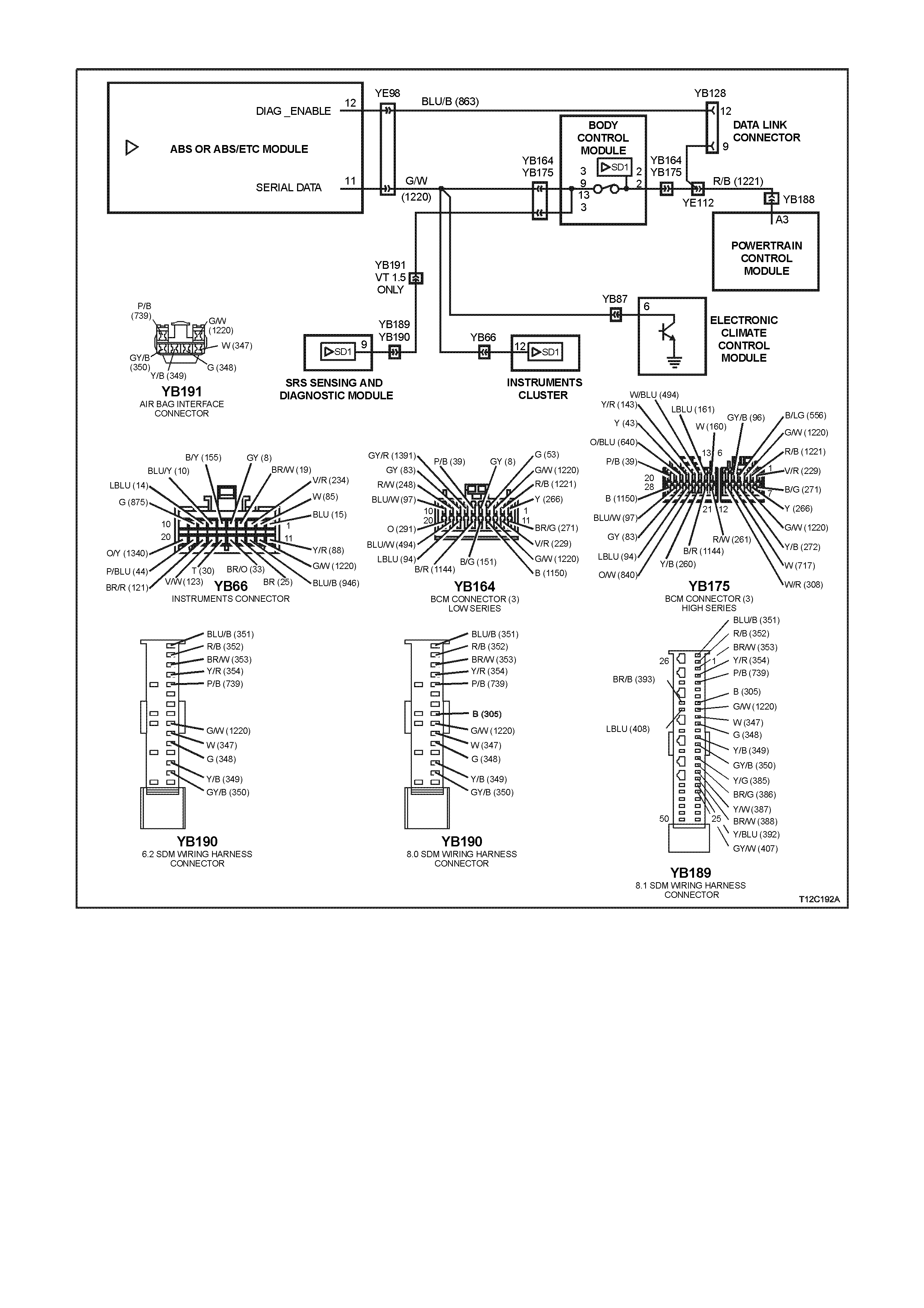

CIRCUIT DIAGRAMS

Fig. 12C-73 shows the circuit for the rear

wiper/washer system for vehicles with Low Series

BCM and Fig. 12C-74 the circuit for the rear

wiper/washer system for vehicles with High Series

BCM.

Figure 12C-73

Figure 12C-74

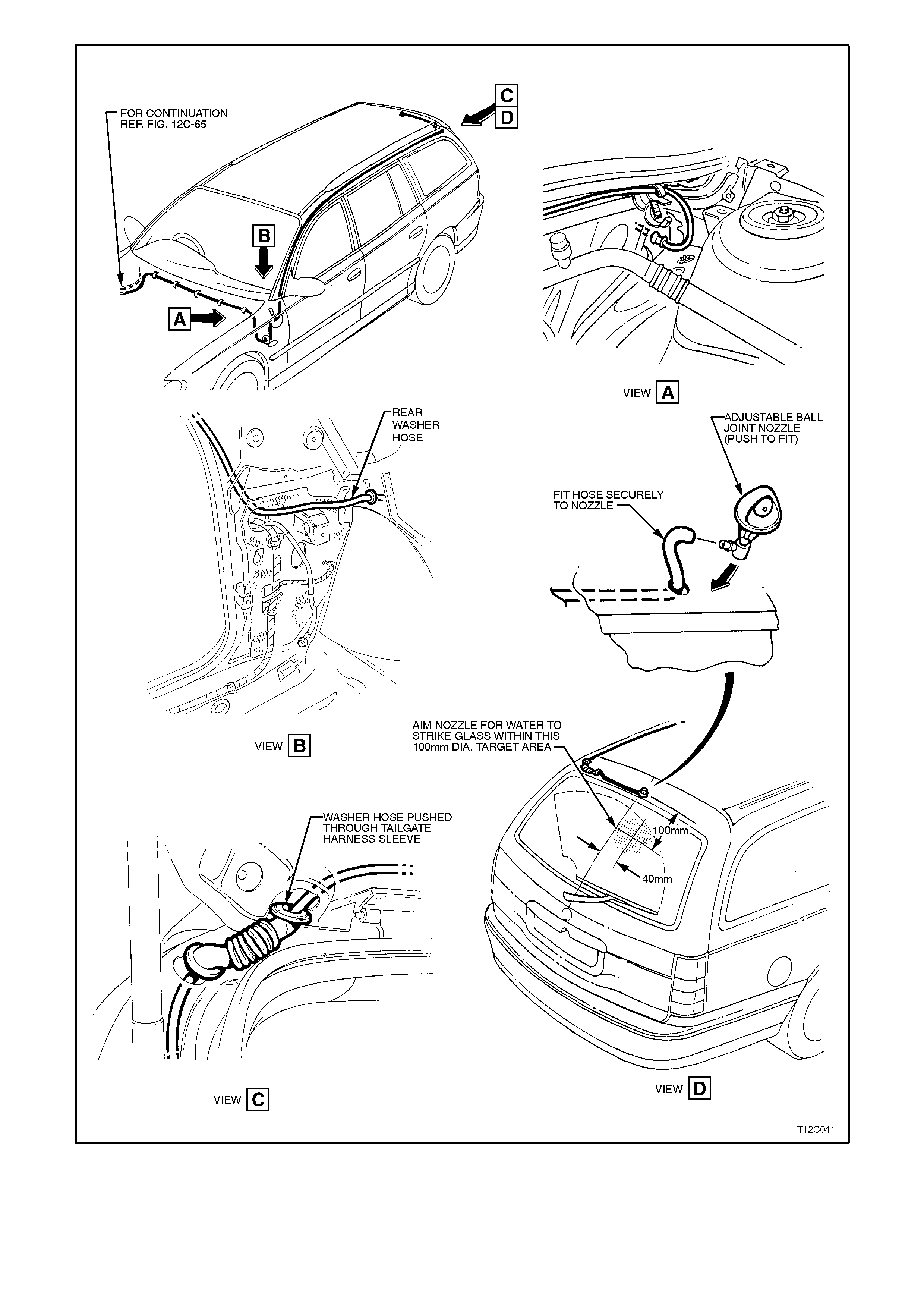

3.9 TAILGATE WASHERS

REMOVE AND REINSTALL

Fig. 12C-75 illustrates the installation of the tailgate washer system.

The spray direction of the washer nozzle can be adjusted by inserting the point of a pin into the ball of the nozzle

and swivelling it to the position nominated in Fig. 12C-75.

CHECKING WASHER PUMP AND WIRING

As a common washer pump with dual outlets is used for the tailgate and windscreen washers, refer

3.7 WINDSHIELD WASHERS - CHECKING WASHER PUMP AND WIRING in this Section, for the procedure on

how to check the operation of the washer pump.

Figure 12C-75

4. HORN SERVICE OPERATIONS

4.1 HORN ASSEMBLY

REMOVE

1. From beneath vehicle, depending on which horn is to be removed, reach up between either the left - hand or

right - hand front wheelhouse panel and disconnect wiring harness connector/s from horn/s.

2. Unscrew horn/s attaching bolt and remove horn/s.

REINSTALL

Installation of the horn is the reverse of the removal procedure, noting the following:

1. Ensure connectors are installed correctly.

2. Ensure horn/s securing bolt/s are tightened to the correct torque specification.

HORN SECURING BOLT

TORQUE SPECIFICATION 15 - 35 Nm

Figure 12C-76

TEST

1. From beneath vehicle, reach up between bumper bar and front panel side support. Connect a voltmeter

between horn positive lead (Green wire) and vehicle body earth.

2. Activate horn and note reading:

No voltage indicates a fault in the horn actuator, wiring harness, relay or connections.

Less than 9 volts indicates resistance in circuit wiring or a short circuit in horn.

9 - 11 volts is normal.

Above 11 volts indicates an open circuit in horn.

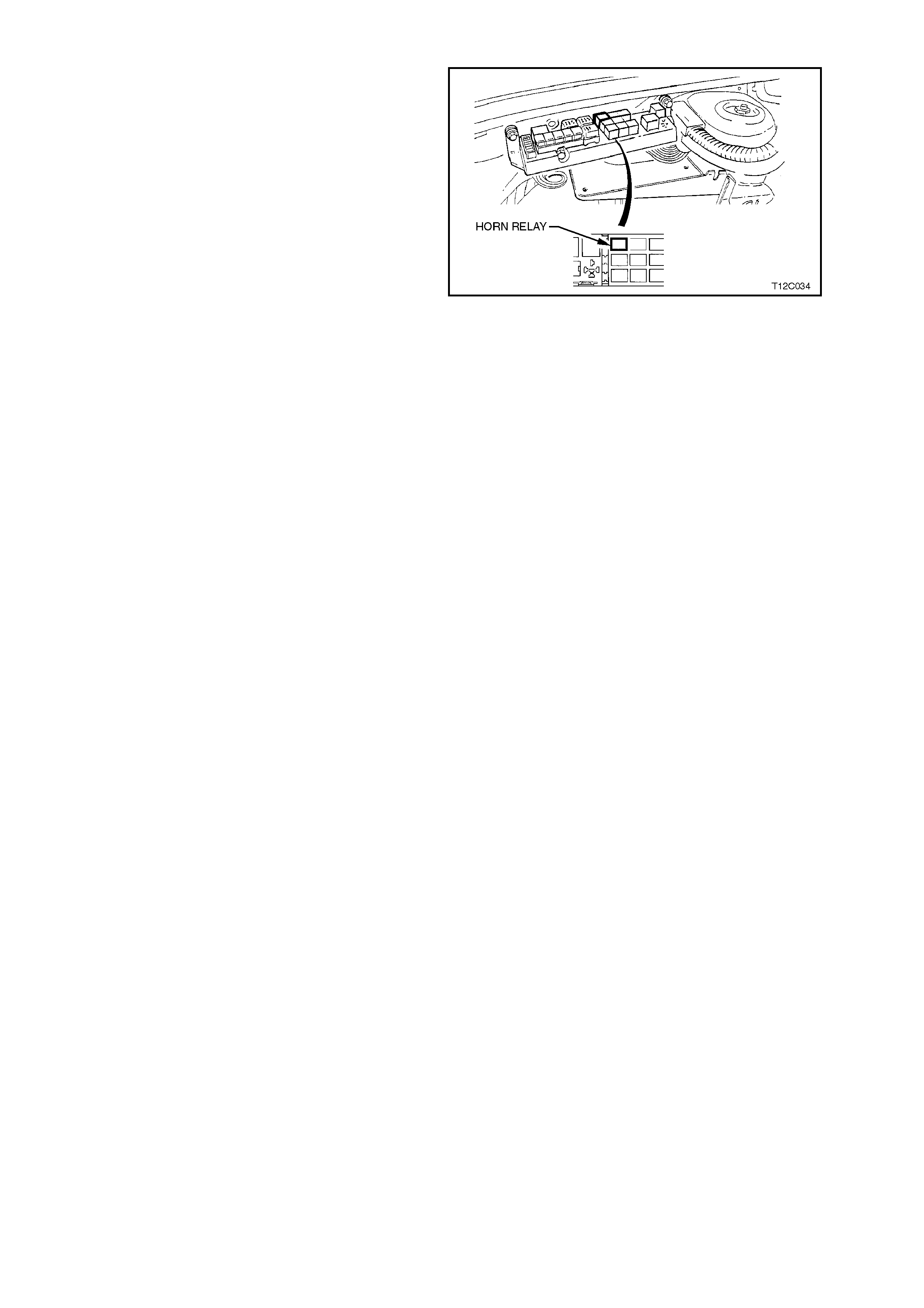

HORN RELAY

The horn relay is located in the engine

compartment relay housing, refer Fig. 12C-77.

Figure 12C-77

HORN ACTUATOR

The horn pad is incorporated into the Supplem ental Restraint System (SRS) airbag inf lator module in the centre of

the steering wheel and therefore, is not serviced separately. For all SRS service operations, refer to

Section 12M (Version 6.2), SUPPLEMENTAL RESTRAINT SYSTEM or Section 12M (Version 8.0/8.1),

SUPPLEMENTAL RESTRAINT SYSTEM.

CAUTION:

If vehicle is equipped with SRS (AIRBAG), disable the system. Refer to ‘SUPPLEMENTAL RESTRAINT

SYSTEM, Section 12M - (Version 6.2) or Section 12M - (Version 8.0/8.1).

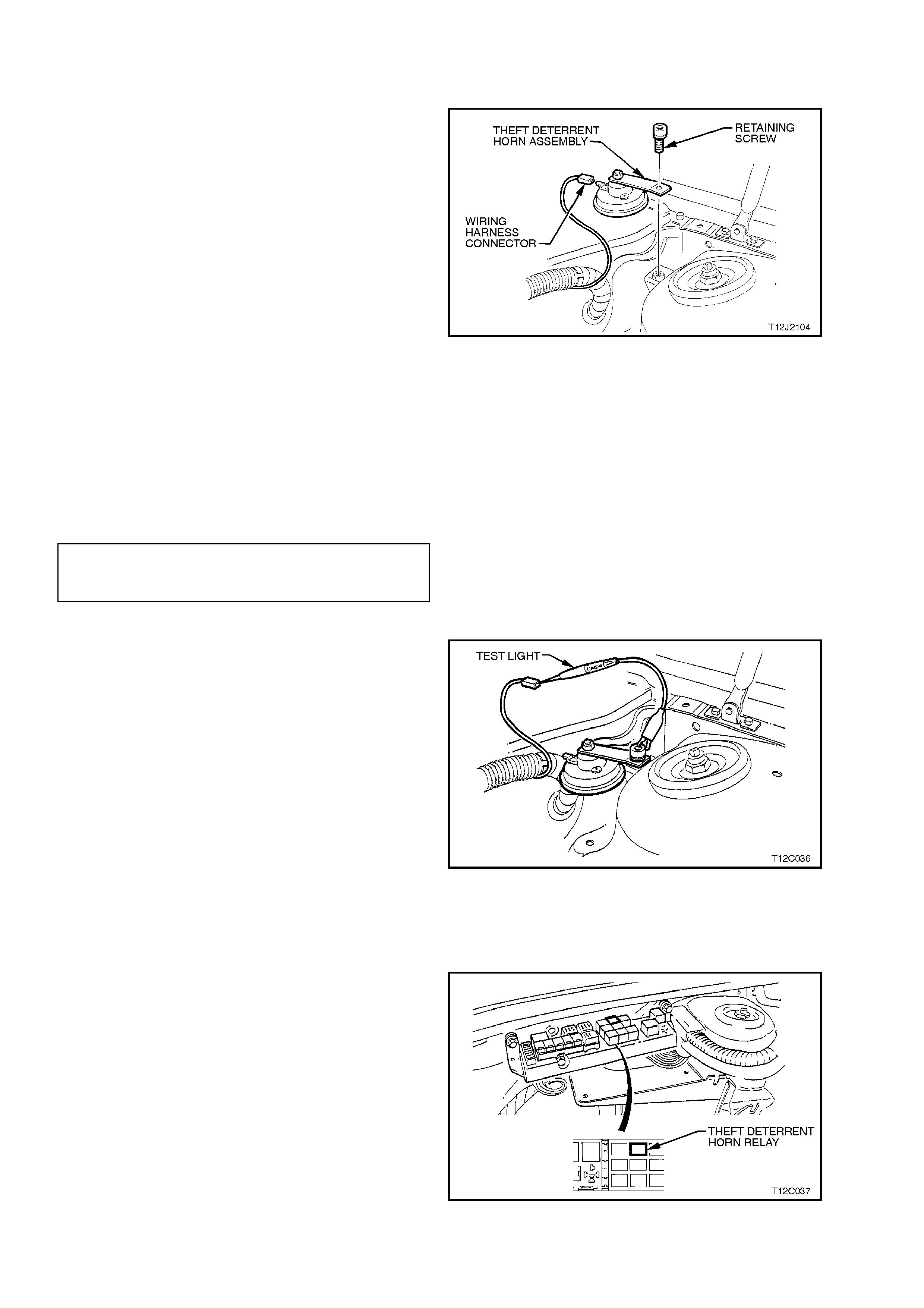

4.2 THEFT DE TE RRENT HORN

REMOVE

1. Disconnect wiring harness connector from

theft deterrent horn.

2. Unscrew horn attaching bolt and remove horn.

Figure 12C-78

REINSTALL

Reinstallation of the theft deterrent horn is the

reverse of the removal procedure, noting the

following:

1. Ensure connector is installed correctly.

2. Ensure theft deterrent horn securing bolt is

tightened to the correct torque specification.

THEFT DETERRENT HORN

SECURRING BOLT TORQUE

SPECIFICATION 20 - 27 Nm

TEST

1. Disconnect wiring harness connector from

theft deterrent horn. Connect a test light

between theft deterrent horn wiring harness

connector and vehicle body earth.

2. Remove theft deterrent horn relay and bridge

terminals 3, circuit 1340 to terminal 5, circuit

129. Test light should illuminate.

- OR -

Activate alarm system. Test light should flash.

If test light illuminates or flashes, it indicates a

faulty theft deterrent horn.

If test light does not illuminate or f lash, it indicates

a fault in BCM, wiring harness, relay or

connections, r efer to Section 12J-2 HIGH SERIES

BCM.

Figure 12C-79

THEFT DETERRENT HORN RELAY

The theft deterrent horn relay is located in the

engine compartment relay housing, refer Fig. 12C-

80.

Figure 12C-80

5. INSTRUMENT ASSEMBLY DIAGNOSTICS

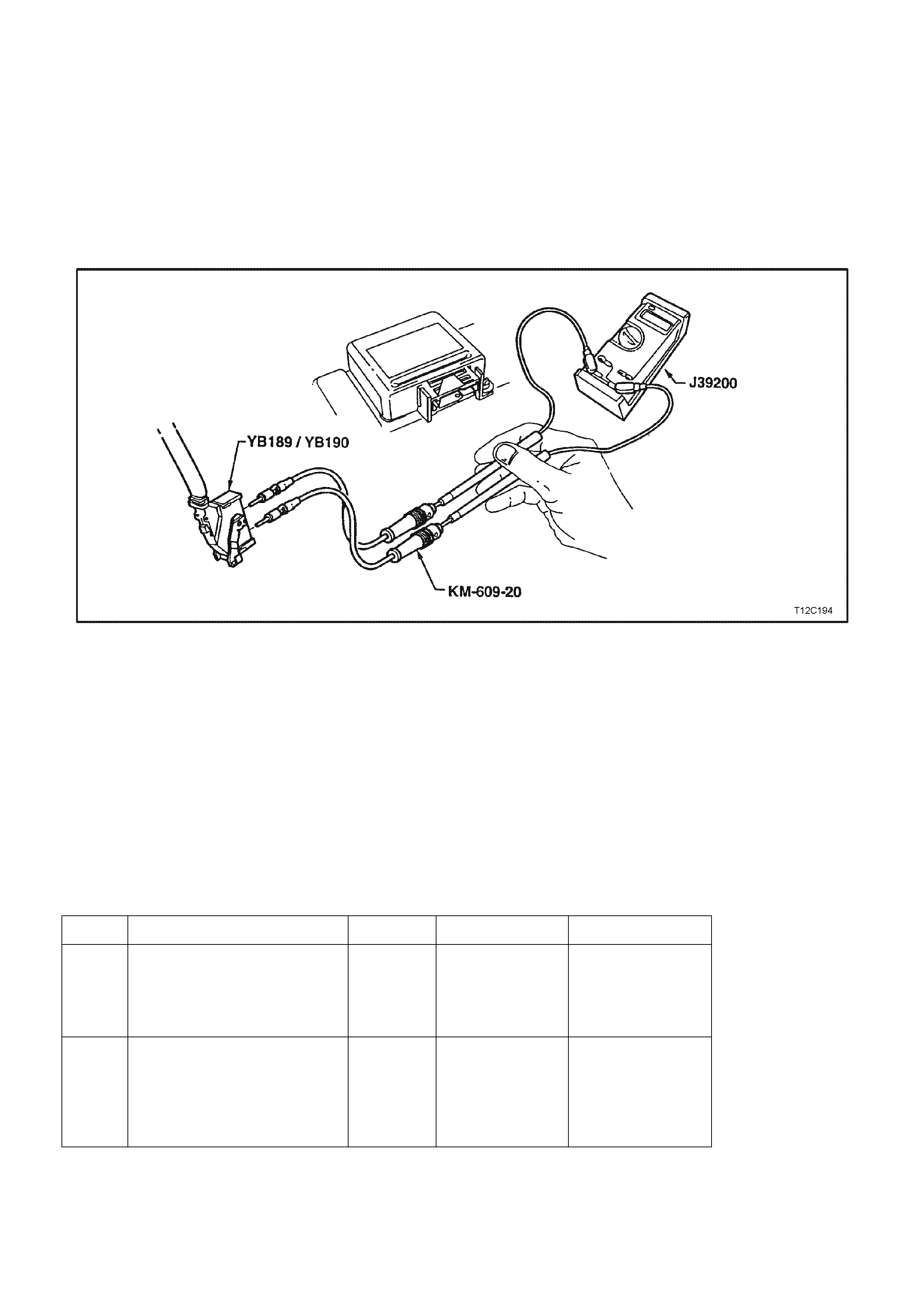

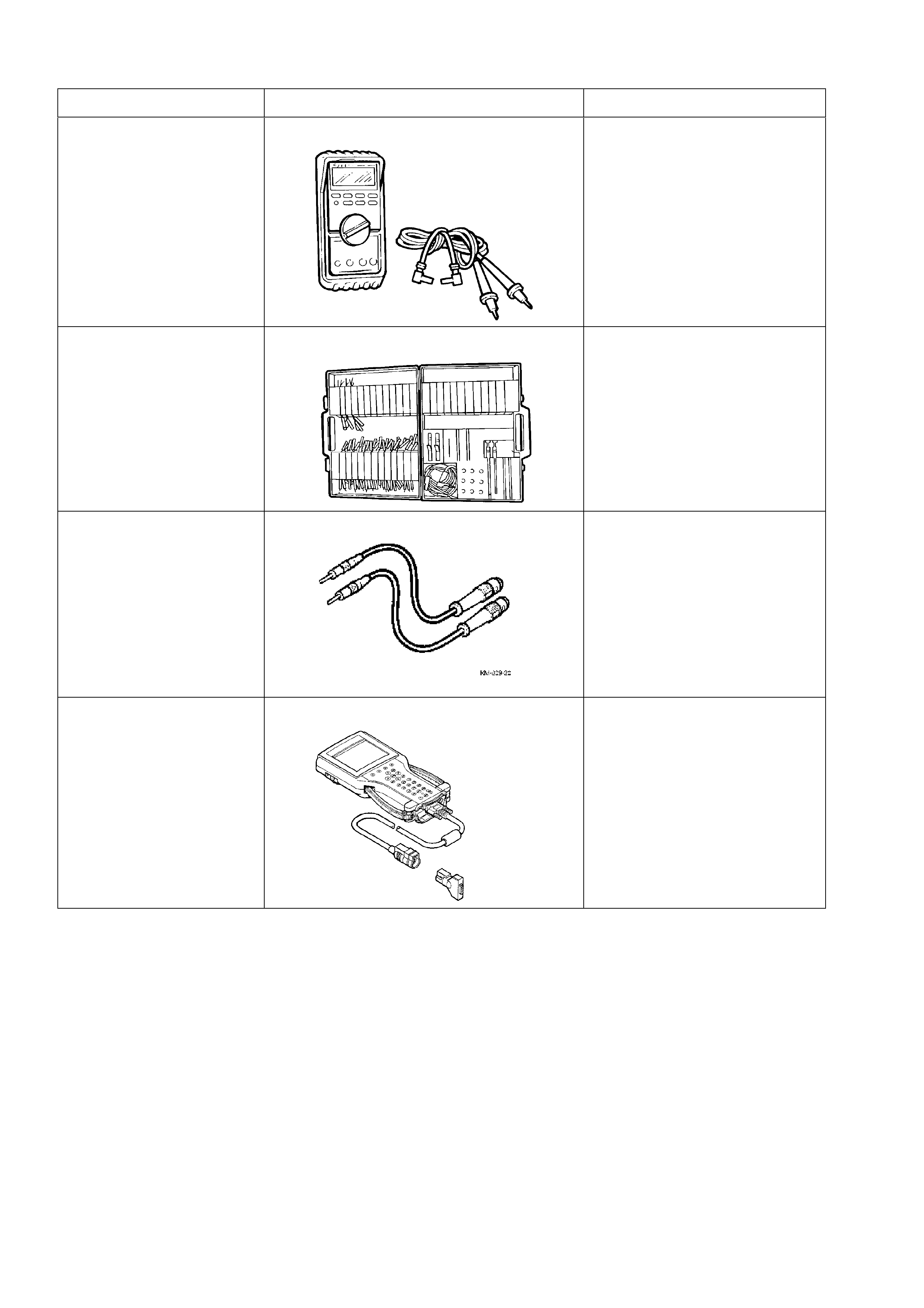

5.1 BASIC KNOWLEDGE REQUIRED

Before attem pting to diagnose the com bined inst rument as sembly you m ust have a good unders tanding of elec tr ical

system basics and the use of circuit testing tools. Without this basic knowledge it will be difficult to use the

diagnostic procedures detailed in this Section.

Some electr ical basics, as well as basic troubles hooting procedures and hints as the use of circuit tes ting tools are

covered in Section 12P WIRING DIAGRAMS.

Basic Electrical Circuits - You should understand the basic theory of electricity, series and parallel circuits, and

voltage drops across series resistors. You should know the meaning of voltage (volts), current (amps), and

resistanc e (ohms). You should understand what happens in a circuit with an open or shorted wire (s horted either to

voltage or earth). You should also be able to read and understand a wiring diagram.

Additionally, a knowledge of AC theory including; inductance, capacitance and impedance would be useful.

Use of Circuit Testing Tools - You should know how to use a jumper lead to test c irc uits . You should be familiar with

the use of a high input im pedanc e (10 Mohm ) digital type multim eter such as Tool No. J 39200 or equivalent and be

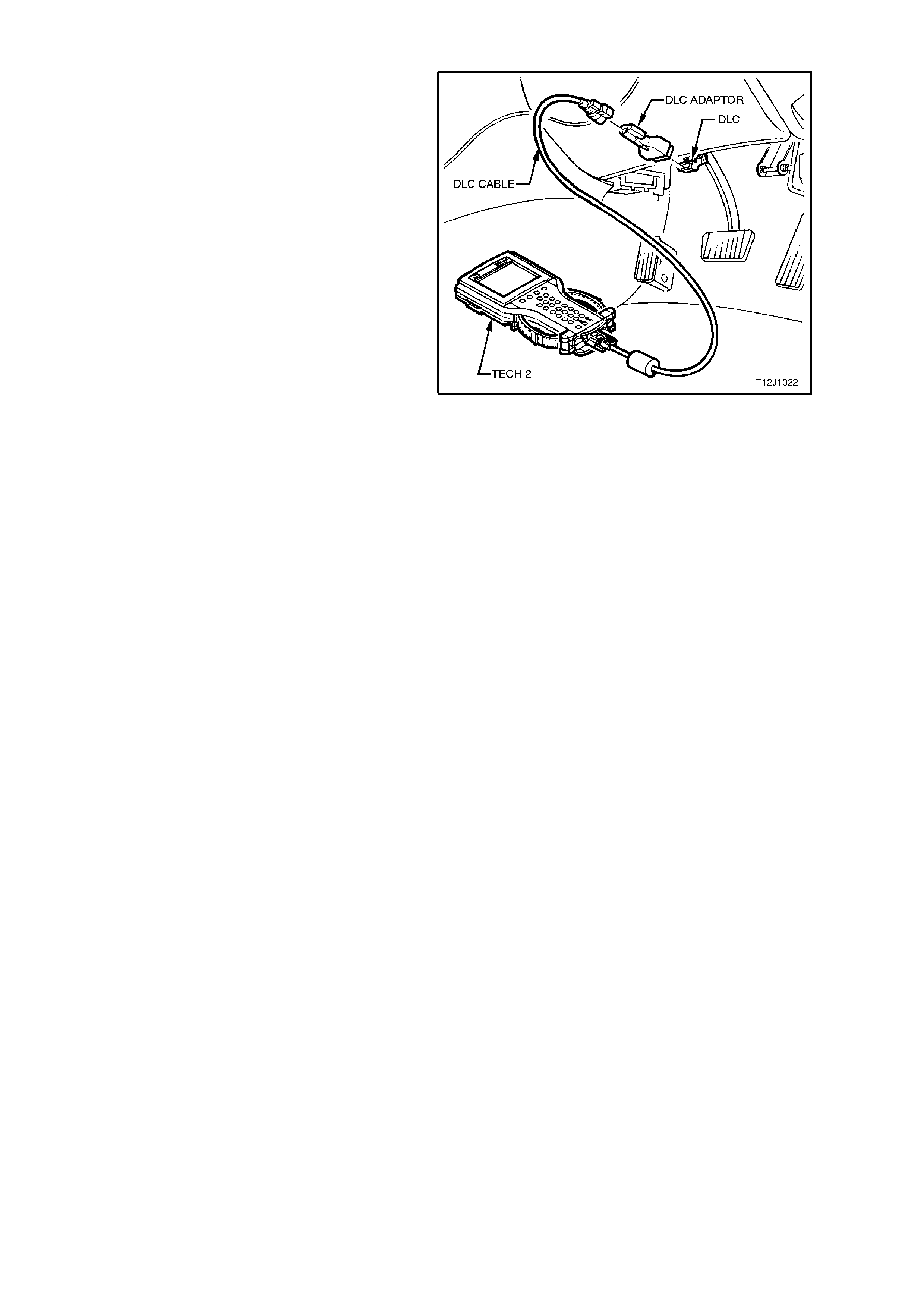

able to measure voltage, current, and resistance. You should be familiar with the proper use of the TECH 2

Diagnostic Scan Tool.

NOTE:

All earth resistance checks done with a high impedance multimeter must be done with the vehicle’s battery

removed.

Techline

Techline

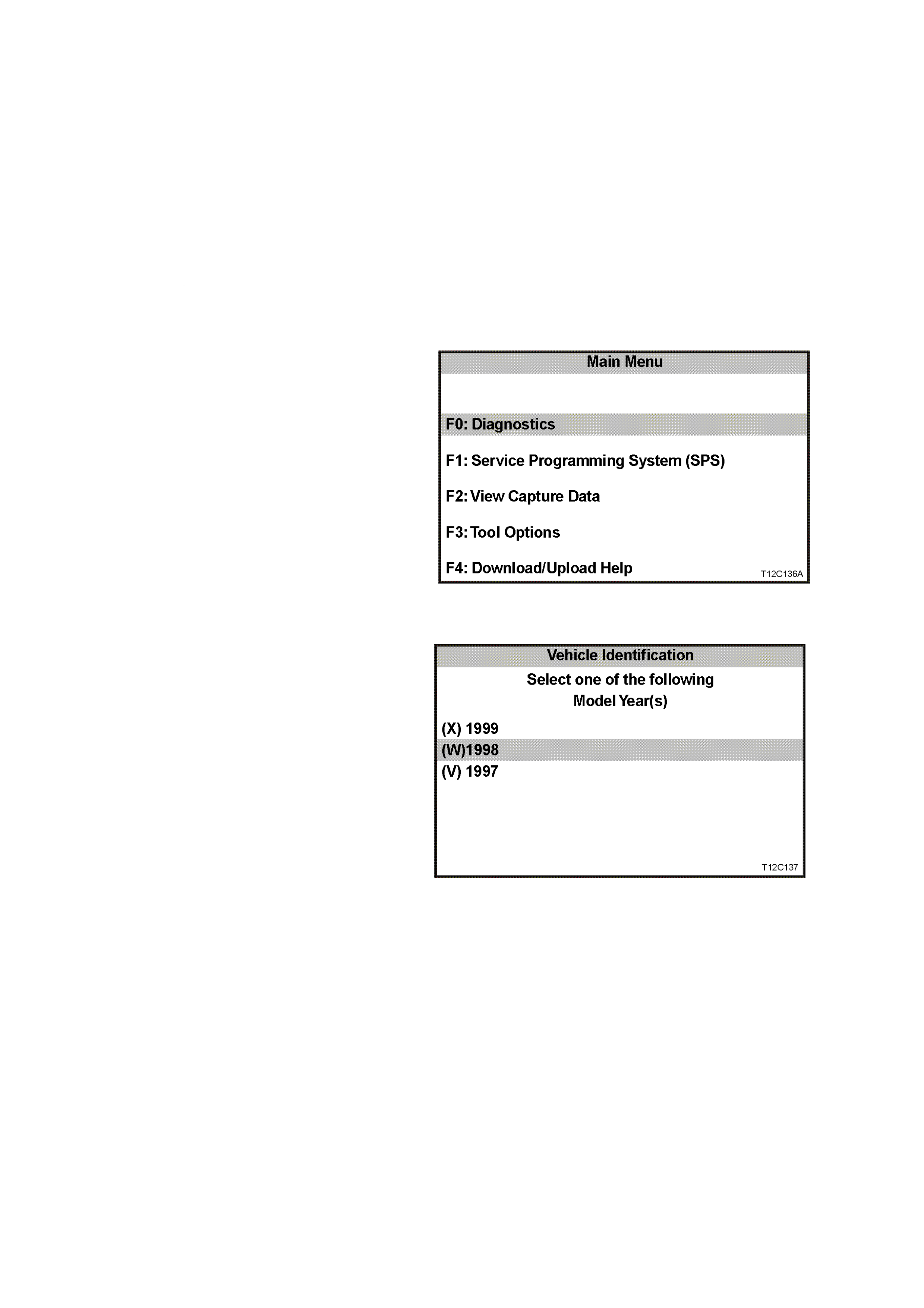

5.2 PRELIMINARY SYSTEM DIAGNOSIS

When investigating any complaint of a combined instrument assembly problem or malfunction, always begin

diagnosis with a circuit check, refer to 5.8 INSTRUMENT DIAGNOSTICS PROCEDURES, DIAGNOSTIC CIRCUIT

CHECK in this Section.

The diagnos tic circuit c heck is a preliminar y procedur e that check s to ensure the com bined ins trum ent assem bly is

communicating on the serial data line as well as helping to identify the problem.

5.3 INSTRUME NT CLUS TER DIAGNOSTICS

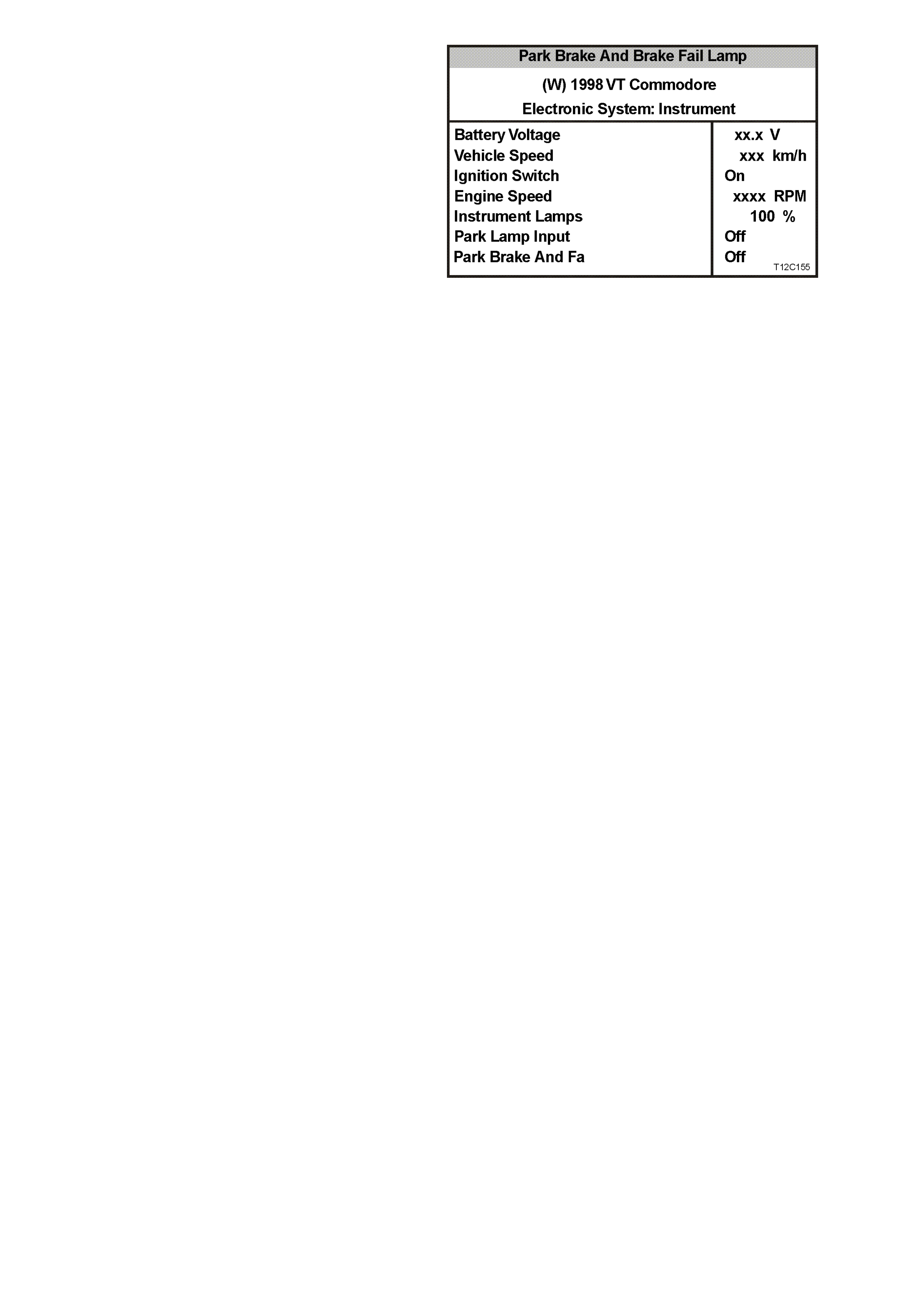

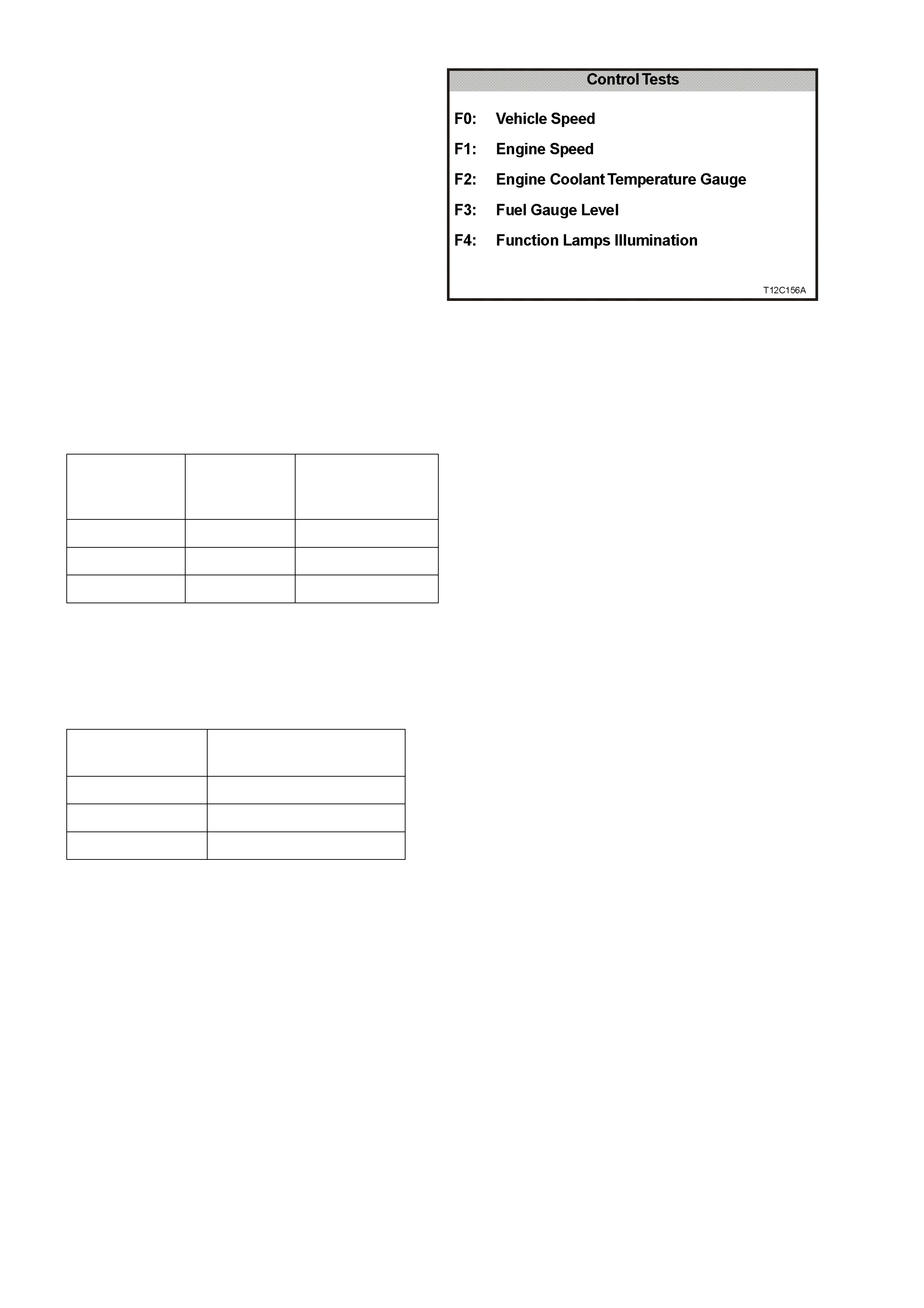

The instrument is equipped with a self-diagnostic capability that can detect and isolate instrument problems or

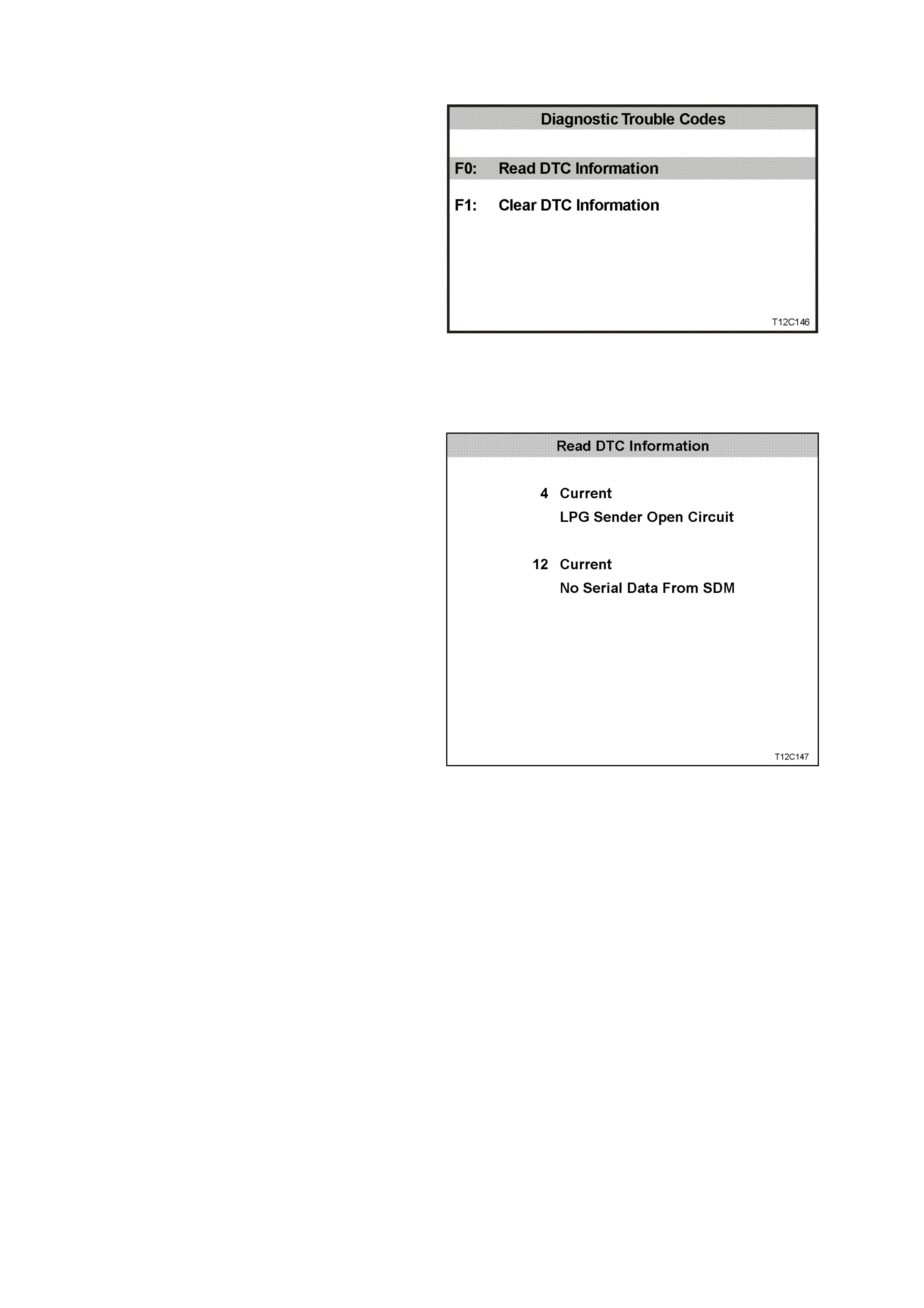

failures. W hen a fault is detected, the instrum ent cluster sets a diagnsotic trouble code (DTC) that represents that

particular problem or failur e. W hen DTC 24, 25 or 26 is set, an icon X is shown in the left-hand ins trument window

on high series vehicles, or SERV ERROR on low series..

Errors can be identified by using TECH 2 to test instruments and force values and conditions into the instrument

cluster. The results of these tests can be used to diagnose problems in the instrument assembly such as

inoperative bulbs and faulty gauges and switches.

Faults within other components can be identified after using TECH 2 to confirm correct operation of the

instruments. For example, if there was a reported fault with the speedometer gauge and TECH 2 diagnosed the

gauge as working correctly, then the fault would lie in the Powertrain Control Module or in the harness from the

speed sensor to the PCM, both of which would then require further testing.

It is important to note that an open circuit fuel (petrol) gauge sender unit is recognised by the instrument cluster self-

diagnosis as ‘t 00 – C’, whereas the TECH 2 Diagnosis Tool will recognise the same fault as DTC 3.

In some instanc es, a DTC may be permanently set. For example, a vehicle which is not f itted with ABS or ABS/ET C

will have DTC 8 permanently set. Similarly, a vehicle which is not fitted with LPG will have DTC 4 permanently set.

Some wiring changes have been made during production of the VT Series. Where these changes apply to the

instrument cluster diagnostics, they are shown as VT 1.5 Only on the diagrams included with the diagnostic charts.

TECH 2 DIAGNOSTIC TOOL USE WITH INTERMITTENCE

The TECH 2 Diagnostic T ool allows manipulation of wiring harnesses, while obser ving the TECH 2 Diagnostic Tool

readout. If the pr oblem seem s to be related to certain param eters that can be c hecked on the T ECH 2 Diagnostic

Tool, they should be checked while driving the vehicle. If there does not seem to be any connection between the

problem and any specif ic circuit, the T ECH 2 Diagnostic T ool can be used to m onitor each par ameter, watching f or

a period of time to see if there is any change in the readings that indicates intermittent operation.

The T ECH 2 Diagnostic Tool s aves tim e in diagnosis and helps to prevent the r eplacem ent of good parts . T he k ey

to using the TECH 2 Diagnostic Tool successfully is the technicians ability to understand the system being

diagnosed, as well as unders tanding the TECH 2 Diagnostic T ool operation and limitations . The technician s hould

read the TECH 2 operators manual to become familiar with the TECH 2 Diagnostic Tool operation.

With an understanding of the data which the tool displays, and knowledge of the circuits involved, the tool can be

very useful in obtaining information which would be more difficult or impossible to obtain with other equipment.

The TECH 2 Diagnostic Tool does not make the use of diagnostic charts unnecessary, nor can it indicate exactly

where a problem is in a particular circuit. Diagnostic Charts incorporate diagnosis procedures that require the use

of a TECH 2 Diagnostic Tool.

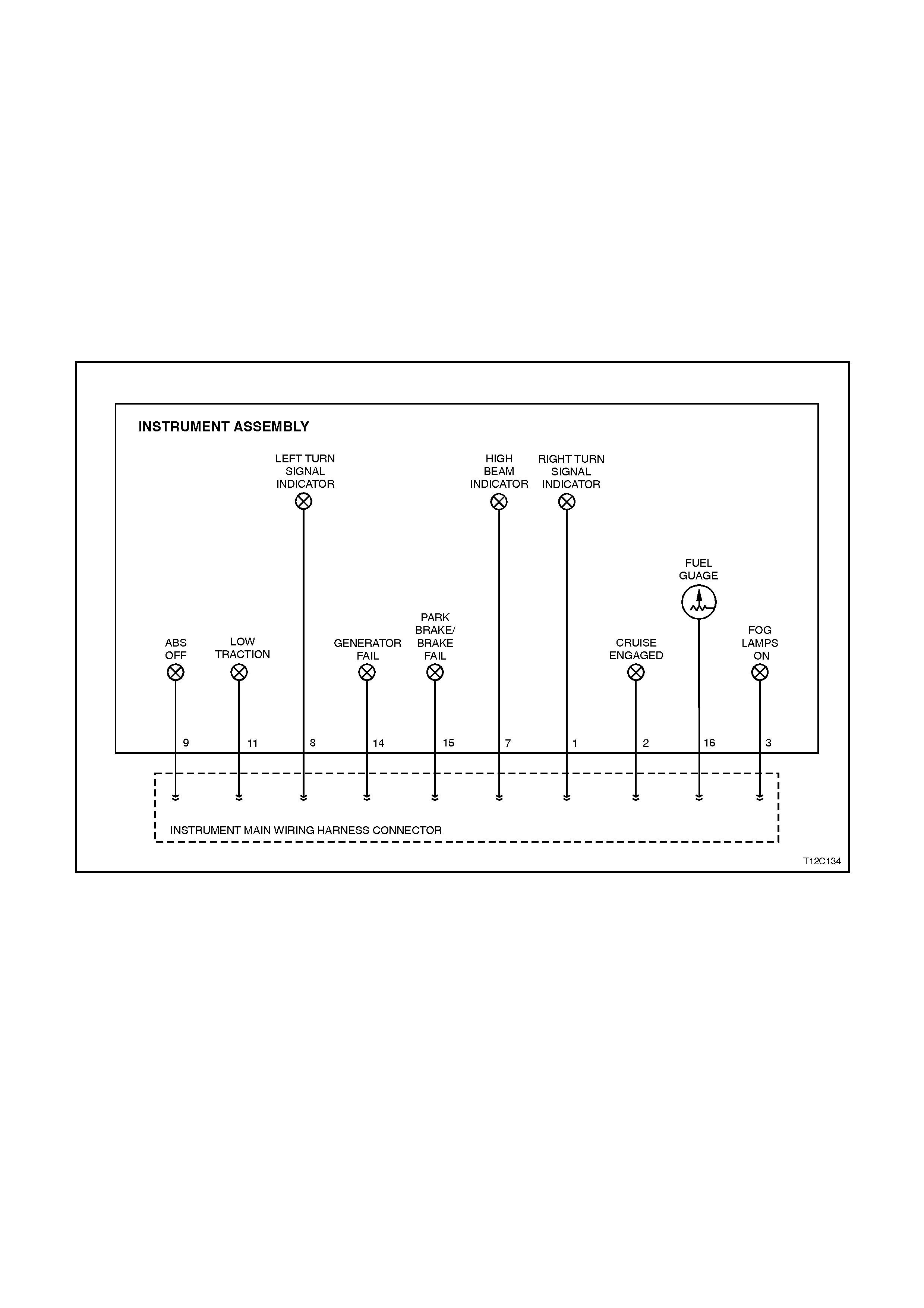

5.4 DIAGNOSING FAULTS NOT COVERED BY TECH 2 DIAG NOSTIC TOOL

Some components of the instrument assembly cannot be diagnosed by the TECH 2, although their operation can

be tested using the F4; Miscellanious Tests function of the TECH 2. These components must be dealt with

separately and include the following instrument tell-tale lamps:

•Fog lamps on lamp

•Cruise engaged lamp

•Low traction lamp

•ABS off lamp

•Park brake/brake fail warning lamp

•Generator lamp

•Turn signal indicator lamps

•High beam lamp

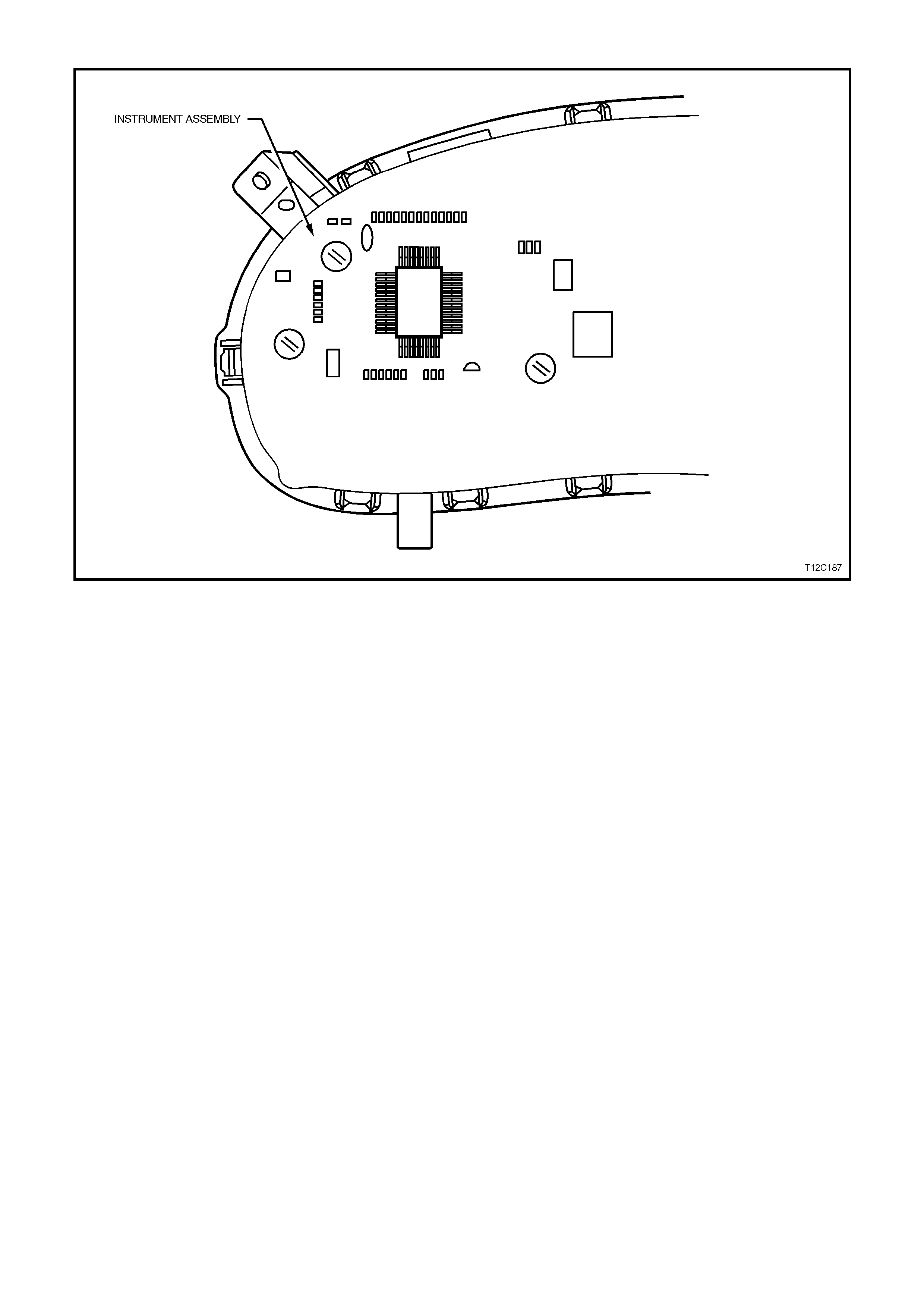

Fig 12C-81 illustrates the components of the instrument assembly which are exclusively not on the serial data line.

Figure 12C-81

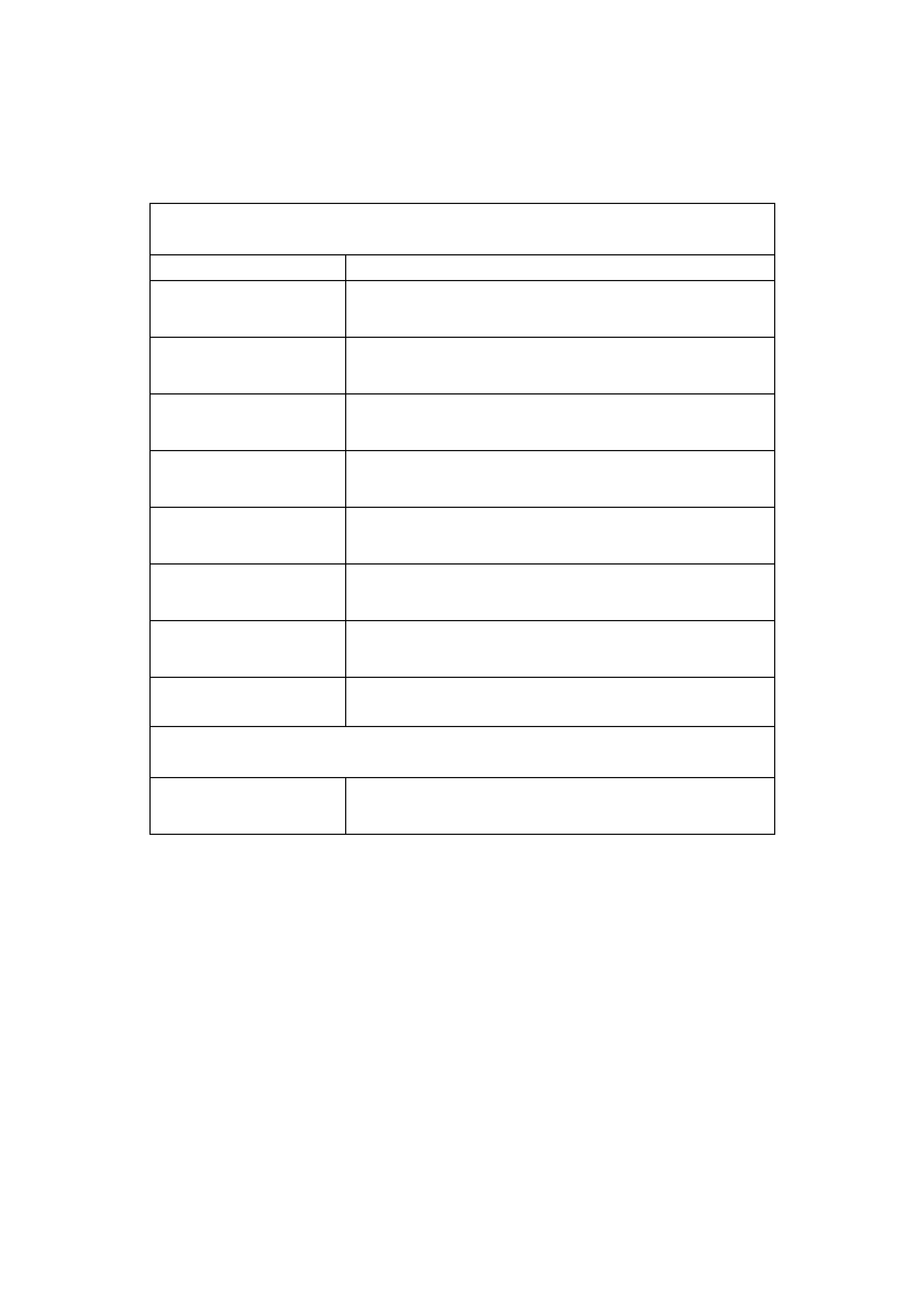

WARNING LAMP APPLICATION CHART

The following table indicates the wiring configuration for the instrument cluster warning lamps.

NOTE:

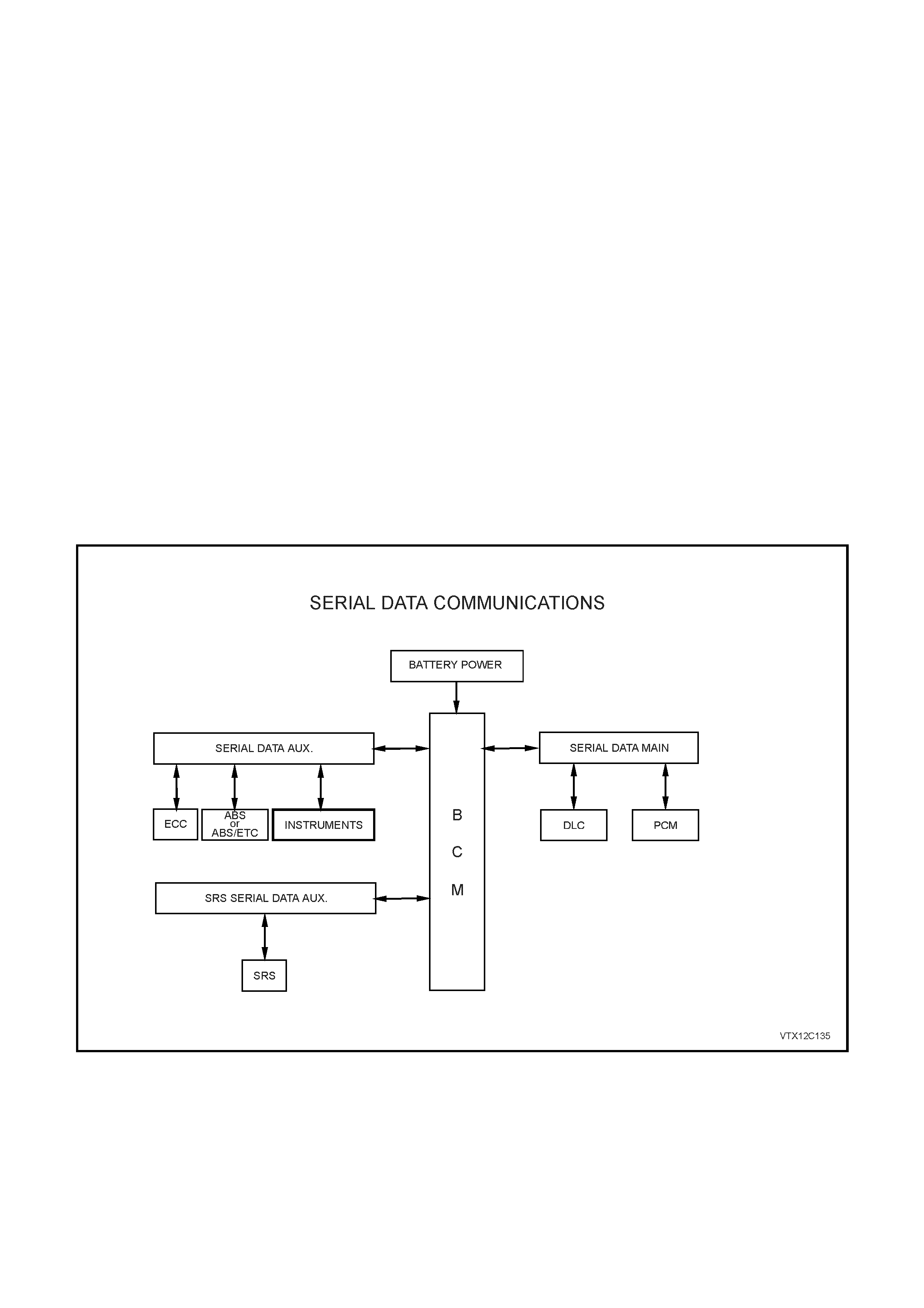

Some lamps may not be installed in all models