SECTION 12D - AUDIO SYSTEMS

CAUTION:

This v ehicle will be equipped with a Supplemental Restraint System (SRS). A SRS

will consist of either seat belt pre-tensioners and a driver’s side air bag, or seat

belt pre-tensioners and a driver’s and front passenger’s side air bags. Refer to

CAUTIONS, Section 12M, before performing any service operation on or around

SRS components, the steering mechanism or wiring. Failure to follow the

CAUTIONS could result in SRS deployment, resulting in possible personal injury

or unnecessary SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests

of safety, the LPG fuel system should be isolated by turning 'OFF' the manual

service valve and then draining the LPG service lines, before any service work is

carried out on the vehicle. Refer to the LPG leaflet included with the Owner's

Handbook for details or LPG Section 2 for more specific servicing information.

1. GENERAL INFORMATION

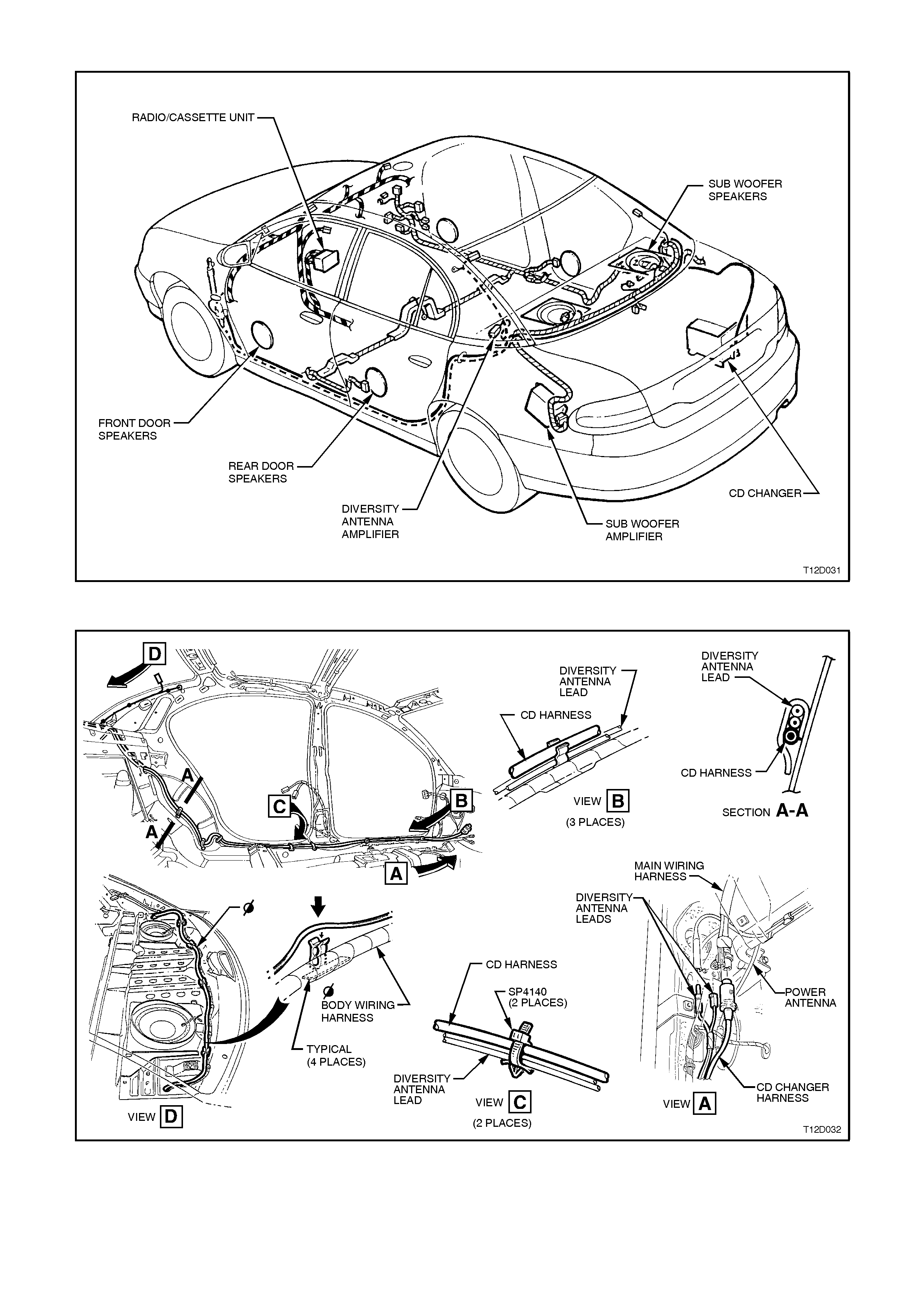

All VT models ar e f itted with a high perf ormanc e ‘double DIN’ size AM/FM ster eo radio/c as s ette player combination.

Berlina models are fitted as standard with radio/cassette/single Compact Disc (CD) player with power antenna

control. T he audio system fitted to Calais com prises a radio/cas sette player with a 10 disc CD player/changer f itted

to the vehicle (refer to

2.11 COMPACT DISC PLAYER/CHANGER INSTALLATION in this Section).

All radio/cassette player assemblies incorporate Personal Identification Number (PIN) security code theft deterrent

and flashing LED features.

All vehicles have speakers mounted in each upper corner of the instrument dash panel.

All VT models except Calais have 150 mm diameter ‘twin cone’ speakers mounted in the front and rear door trim

side pockets.

Calais vehicles are fitted with unique 150 mm diameter ‘twin cone’ speakers mounted in the front door trim side

pockets and 150 mm coaxial speakers mounted in the rear door trim side pockets.

The audio system on the Calais features personal identity memories which individually memorises the following

settings for different ignition keys:

Last used volume level Last used mode

FM1- radio memory presets FM2- radio memory presets

AM- radio memory presets Bass control settings

Treble control settings Speaker balance setting

Speaker fader setting Time/Frequency priority settings

Local On/Off setting

Techline

The audio s ystem fitted to the Calais also f eatures a pair of ‘subwoofer’ speaker and brac ket assem blies, m ounted

on top of the rear parcel shelf. These rear parcel shelf mounted speakers are powered by an additional amplifier

located in the lefthand side of the rear compartment, refer to 2.12 SUBWOOFER AMPLIFIER in this Section.

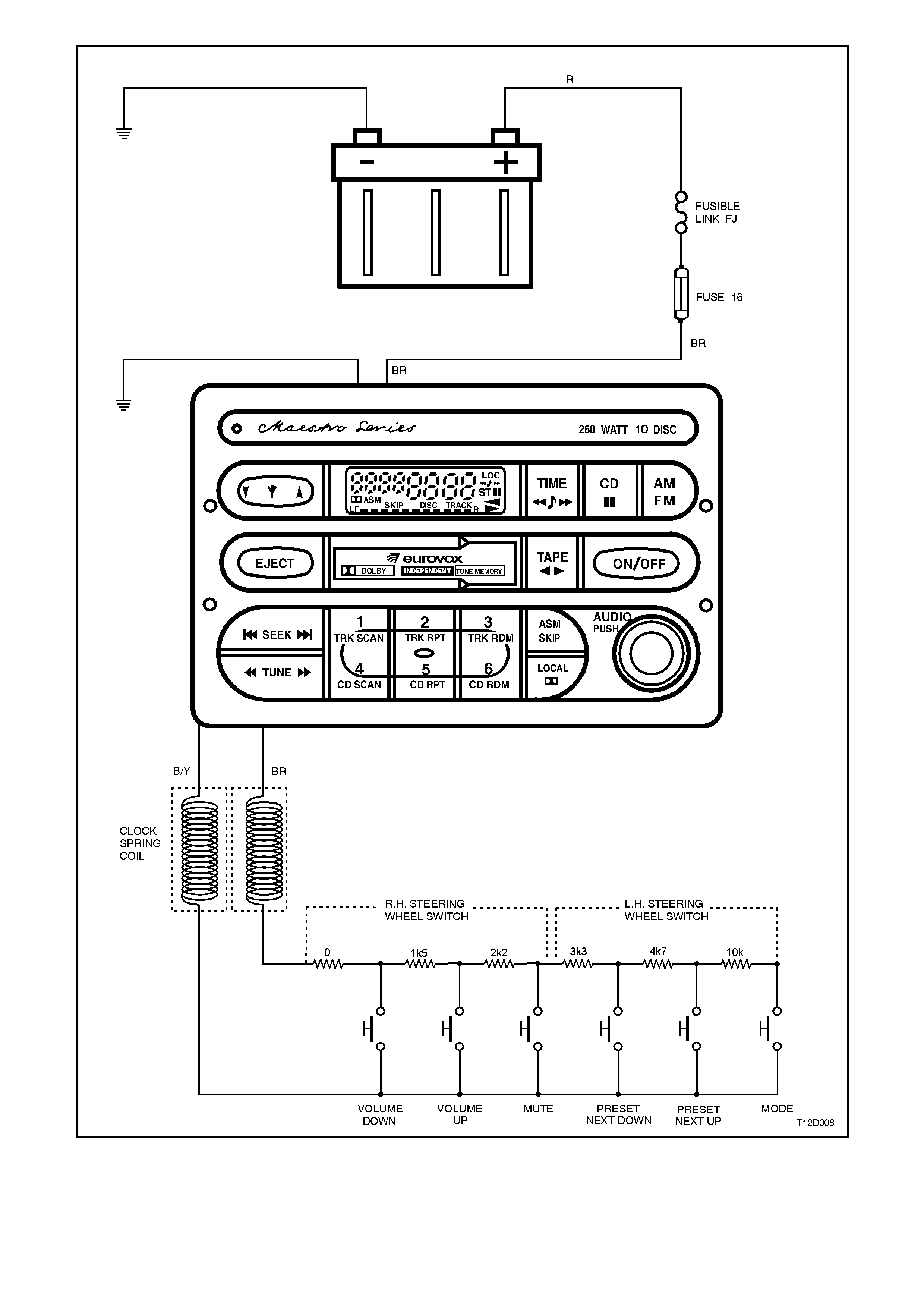

The Calais includes steer ing wheel mounted s tereo contr ols. Control of the radio, tape and CD player func tions c an

be accomplished without the need for the driver’s hands being removed from the steering wheel.

The radio reads the switch resistance from the steering wheel stereo controls via the clock spring coil harness.

A manual pull up, pus h down mast type antenna is fitted as s tandard equipm ent on VT Ex ecutive m odels. A power

antenna, controlled via the radio, is available as an option on base models . Ref er to 2.8 POWER ANTENNA in this

Section.

Berlina and Calais have a height adjustable power antenna fitted as standard equipment. The power antenna

operation on these models is controlled via a switch located on the radio facia and in conjunction with the body

control module (BCM), refer to Section 12J-1 BODY CONTROL MODULE.

To aid in the reception of FM radio signals a diversity antenna system is fitted to Calais.

The diversity antenna system consis ts of a diversity antenna, which is an integral par t of the rear window glass, and

a diversity antenna module. The diversity antenna module is located under the rear parcel shelf trim on the

passenger side and amplifies the signal received by the diversity antenna. The am plified signal is sent to the radio

via a coaxial cable.

The radio receives signals from both the diversity and the fender mounted mast antenna and uses the stronger

signal for radio reception. This use of two antennae located in different positions on the vehicle makes the radio

reception less likely to be affected by signal nulls (multipathing) experienced in moving vehicles.

Operating instructions for the audio system accompany the VT Owner’s Handbook in the vehicle’s glove

compartment.

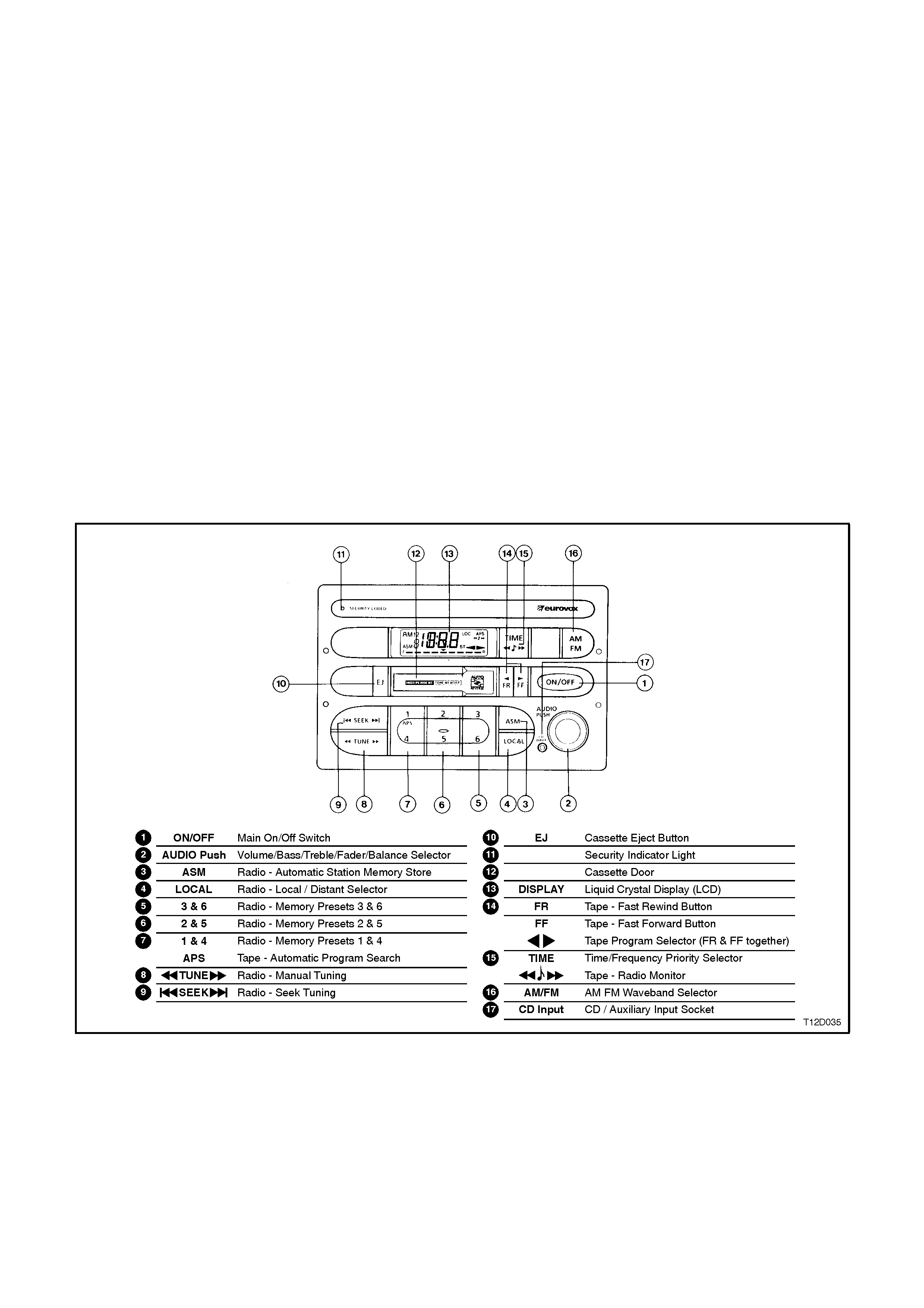

Fig. 12D-1 shows the radio/cassette player fitted to base models.

Figure 12D-1

Fig. 12D-2 shows the radio/cassette/CD player available on base models with automatic power antenna.

Figure 12D-2

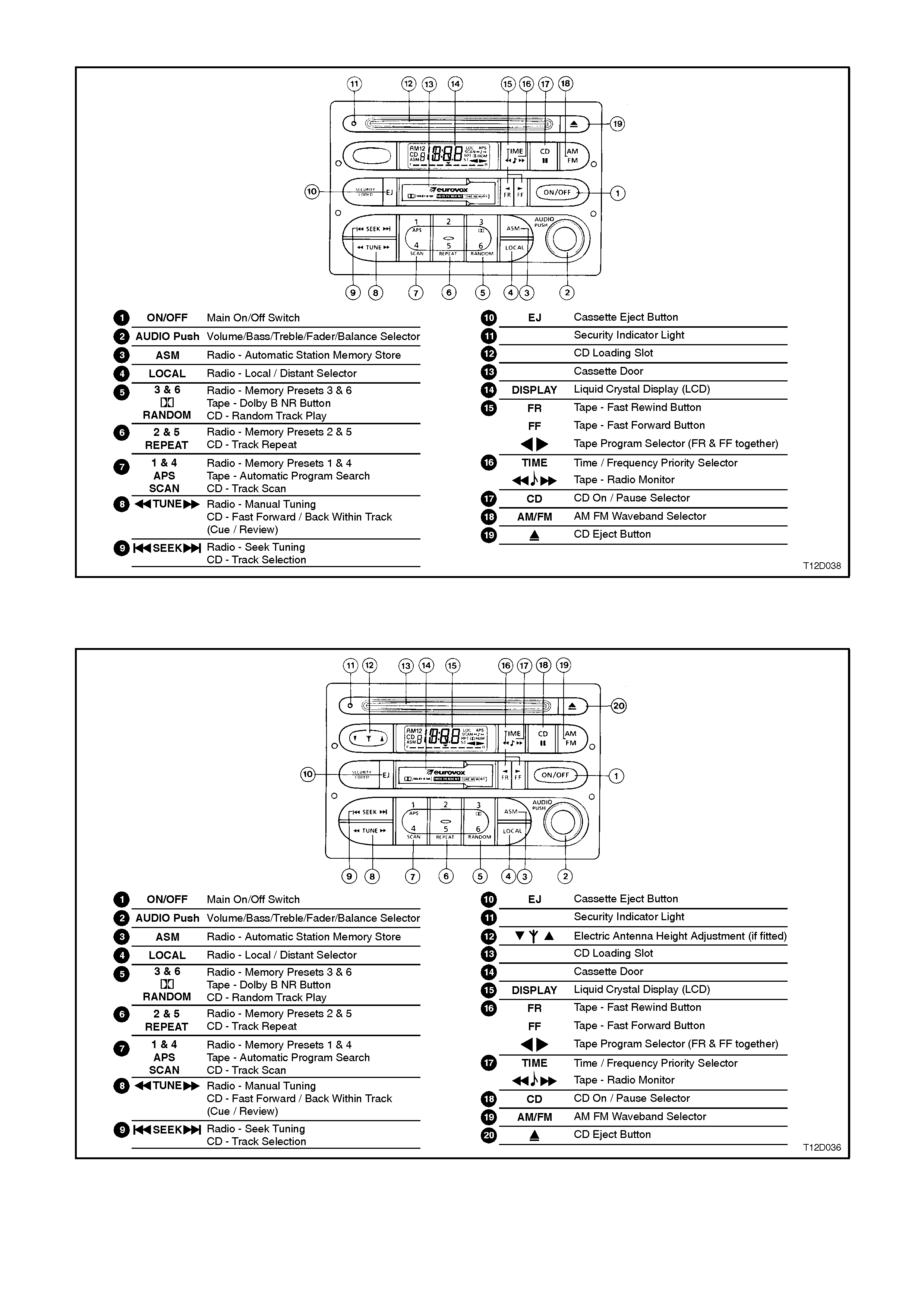

Fig. 12D-3 shows the radio/cassette/CD player fitted to VT Berlina models with power antenna.

Figure 12D-3

Fig. 12D-4 shows the radio/cassette/CD changer fitted to VT Calais models with CD changer and power antenna.

Figure 12D-4

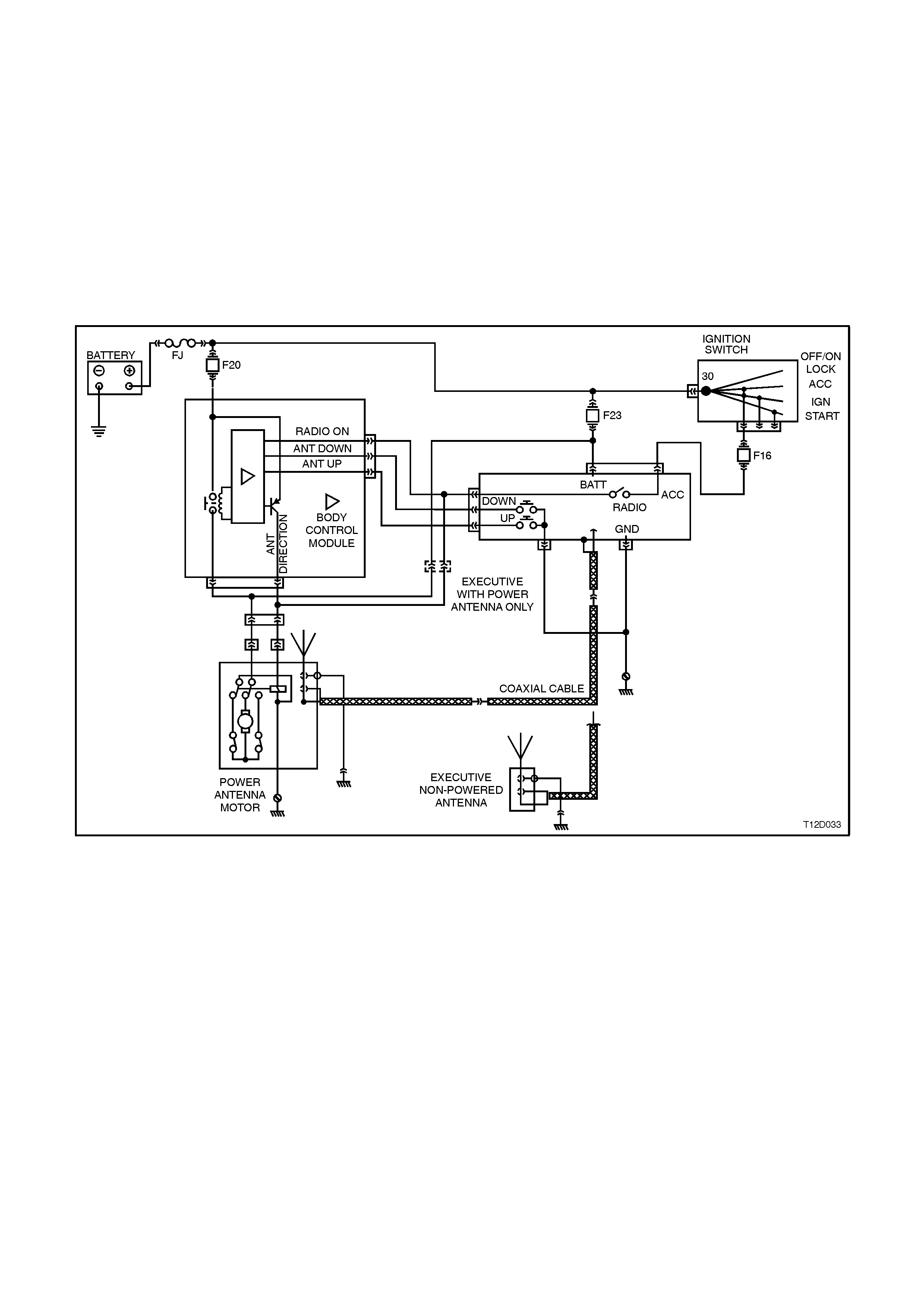

1.1 POW E R ANTENNA OPERATION

For Berlina and Calais, the operation of the power antenna is controlled by the body control m odule and a height

adjustm ent switch located on the radio/cass ette/CD player control panel adjacent to the liquid cr ystal display. For

service information re fer to Sections 12J-1 LOW SERIES BCM and Section 12J-2 HIGH SERIES BCM.

For VT Commodores with the power antenna option, the operation of the antenna is controlled by the

radio/cassette/CD player. When the radio is switched on, the antenna mast is raised to its full height, and

retracts when the radio is switched off, or a tape or CD is played.

For vehicles with a high series BCM, when the radio is turned ON and with the ignition key in the ACC position,

control circuitry within the radio supplies voltage to the antenna assembly lead for 8 seconds after a delay of

approximately 3 seconds after the radio is turned ON. This allows the motor to raise the antenna mast to full

height for optimum radio reception.

Approximately 15 seconds after switching the ignition and/or radio OFF, the module terminal 3 supplies voltage

to the antenna red lead and the mast is retracted fully.

Figure 12D-5

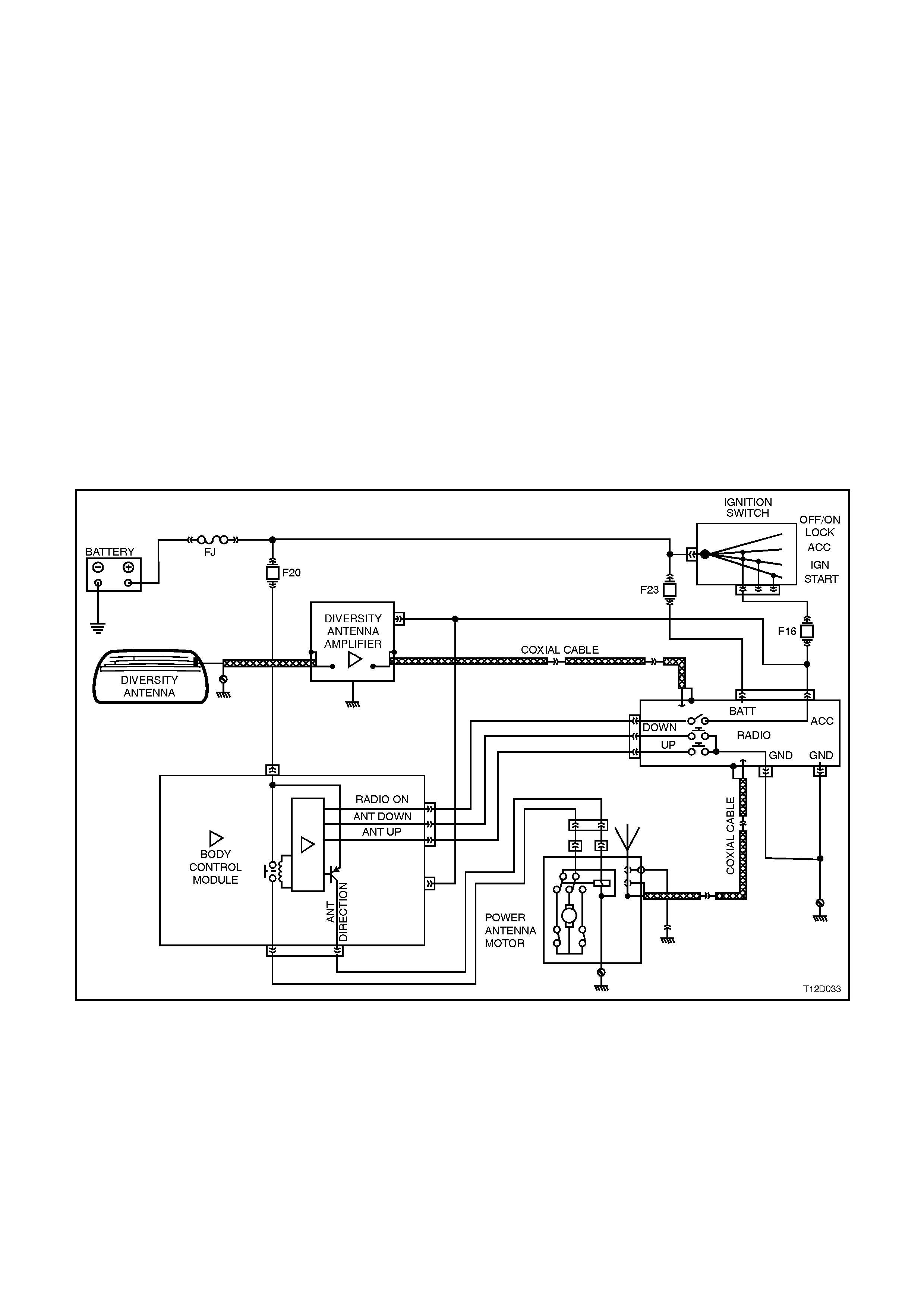

1.2 DIVERSITY ANTENNA OPERATION

To aid in the consistent reception of FM radio signals, the Calais model is equipped with a diversity antenna

system.

The diversity antenna system consists of a diversity antenna, diversity antenna module and coaxial leads.

The diversity antenna is an integral part of the rear window glass. The thin conductors that form the diversity

antenna are laid on the inside of the glass in the s ame manner as the r ear window demis ter elements . A terminal

is located on the passenger side of the rear window allowing connection of the diversity antenna to the diversity

antenna module lead.

The diversity antenna module amplifies the signal received from the diversity antenna. It then transmits the

amplified signal to the radio’s diversity antenna input.

The diversity antenna module is located beneath the trim on the passenger side of the rear parcel shelf. The

module is connected to the diversity antenna via one of two coaxial leads, the other lead, located under the

passenger side rocker panel cover, connects the module to the radio’s diversity antenna input extension lead.

Another single wire lead is used to supply the diversity antenna module with 12 V for its operation and the

module is earthed through its case to the vehicle body.

To prevent interference, it is very important that the module and coaxial leads are earthed securely.

The radio receives signals from both the diversity antenna system and the conventional fender mounted mast

type antenna. Internal circuitry w ithin the radio decides which antenna is located in the cleaner signal area. It then

uses that antenna for its radio reception.

When the vehicle is in motion the radio constantly monitors both antenna inputs and swaps between them in

order to maintain the best possible radio reception.

Figure 12D-6

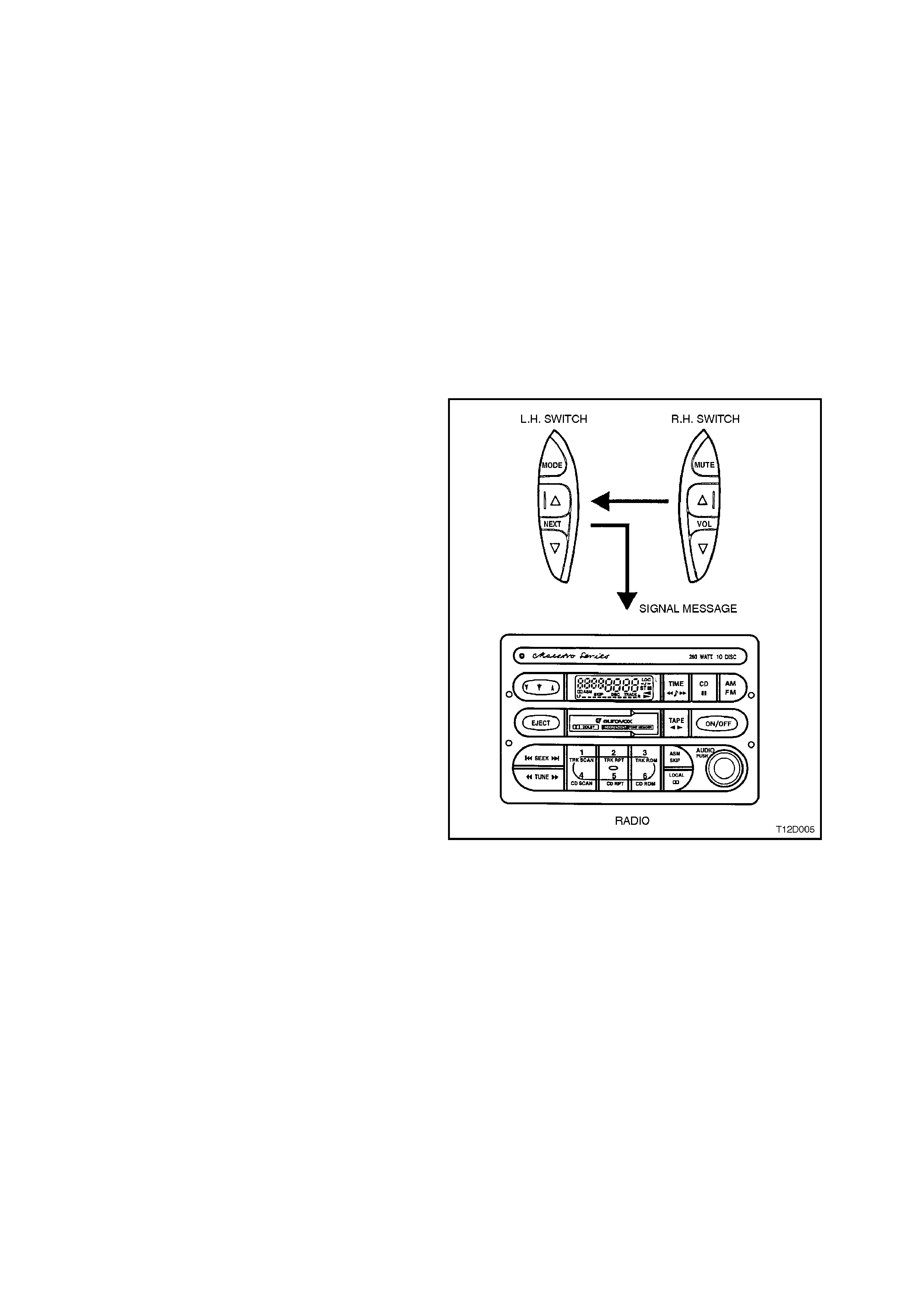

1.3 HORN BAR STEREO CONTROL OPERATION

There are two major components of the horn bar

stereo control system. These components are as

follows:

1. Right hand switch assembly -

Located to the right hand side of the horn bar,

the right hand switch assembly has three

momentary contact switches that are used to

control VOLUME UP, VOLUME DOWN and

MUTE functions of the stereo.

2. Left hand switch assembly -

Located to the left hand side of the horn bar,

the left hand switch assembly has three

momentary contact switches that are used to

control NEXT UP, NEXT DOWN and MODE

SELECTION.

OPERATION

When a button is pressed on the horn bar control,

the radio decides the function required by

measuring the resistance of the contact pressed.

Each contro l switch has a unique resis tance value,

and this is used by the radio to determine which

command has been issued.

Figure 12D-7

Figure 12D-8

2. SERVICE OPERATIONS

2.1 RADIO/CASSETTE PLAYER

REMOVE

1. Disconnect battery earth cable.

2. Lower instrument panel lower cover - left side.

3. Open instrument panel compartment and

remove left hand side lower trim assembly,

refer to Section 1A3 INSTRUMENT PANEL

AND CONSOLE.

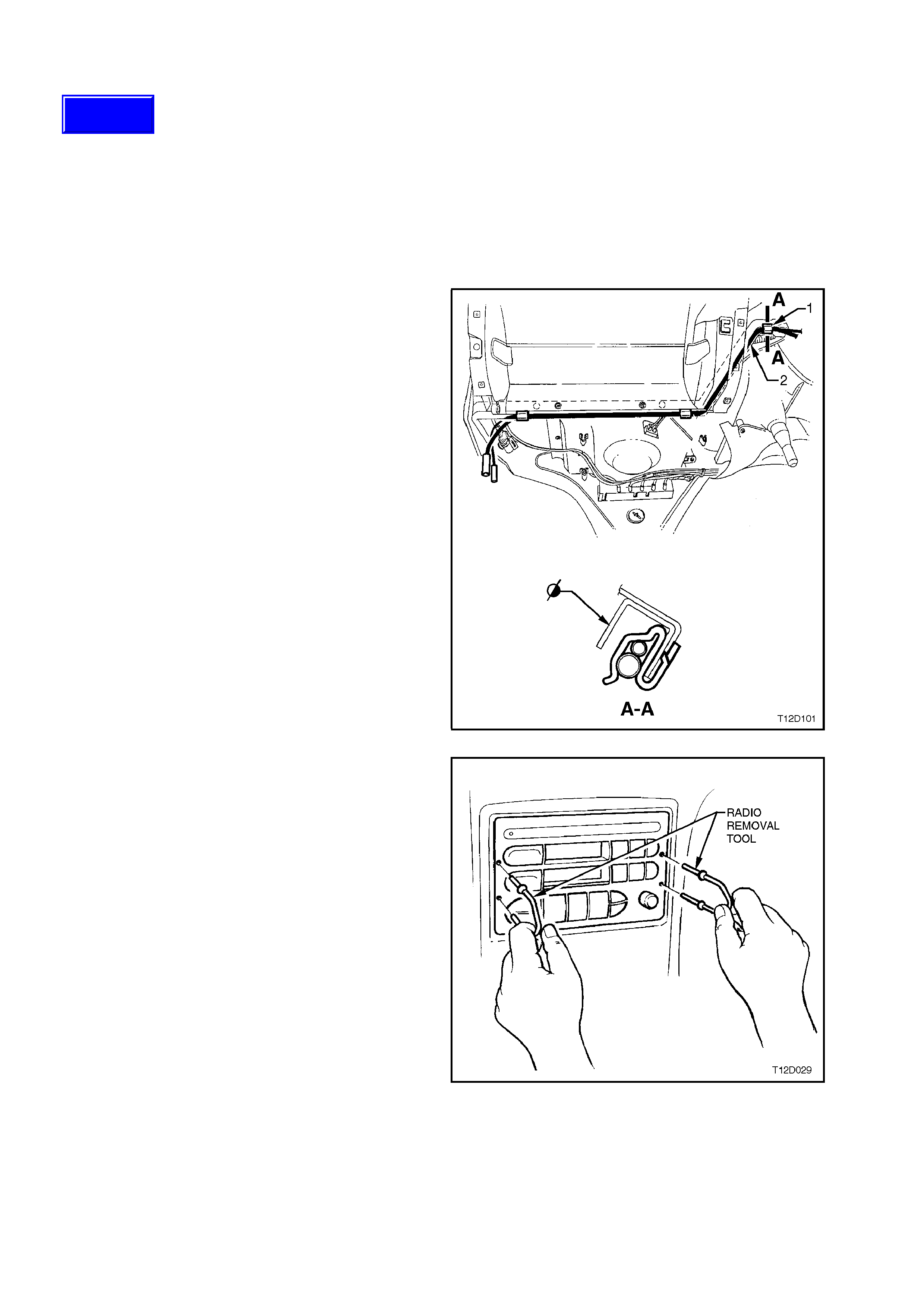

4. Unhook excess antenna lead (2) coiled

through clip (1) on right hand side of

instrument carrier rail.

Figure 12D-9

5. Using special service tool 179 1308 0000,

insert into access holes on either side of

radio/cassette player and push service tool to

release retaining spring clips.

6. Pull radio/cassette player out sufficiently to

access wiring harness and antenna

connectors at rear of unit.

Figure 12D-10

Techline

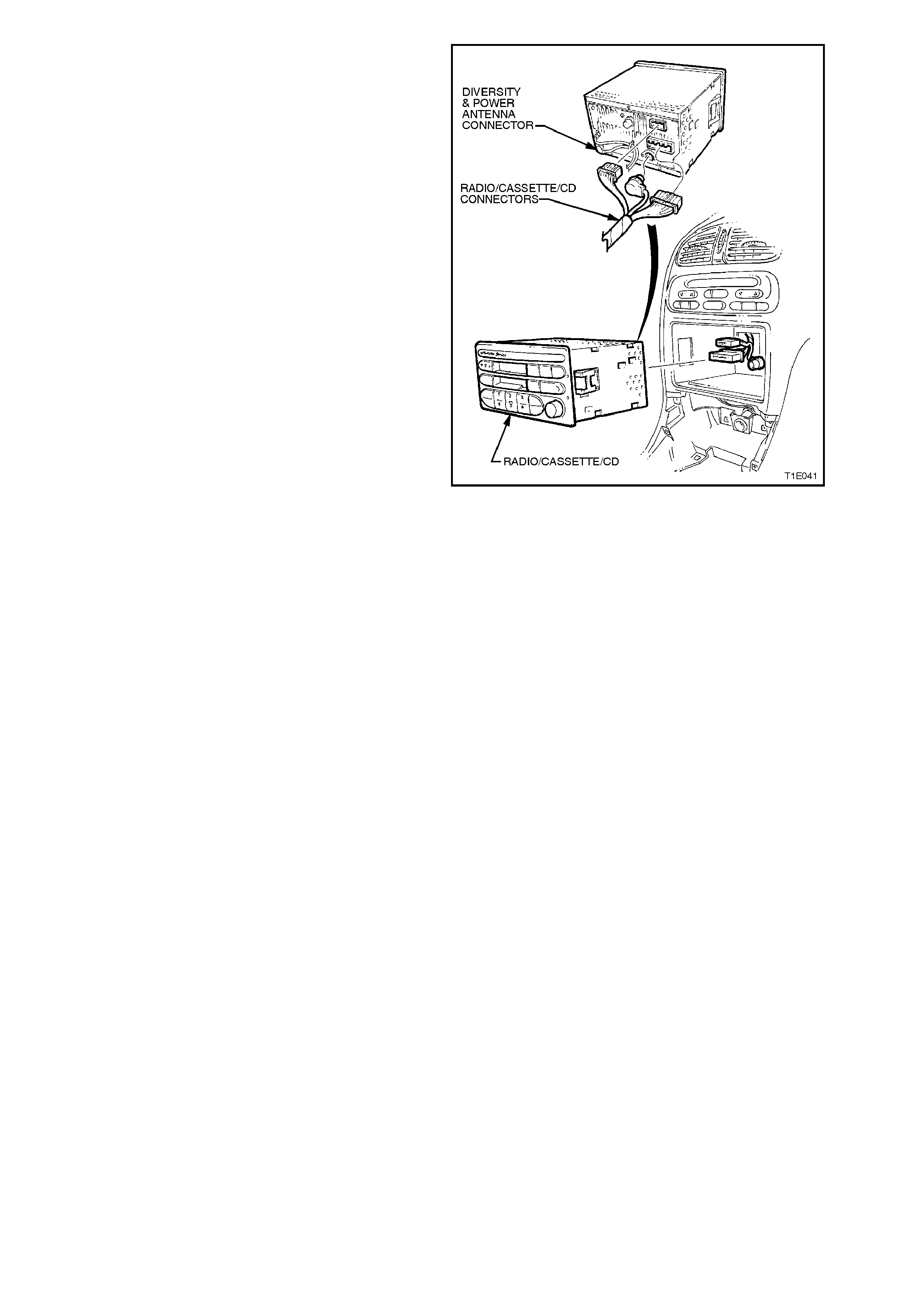

7. Disconnect radio/cassette wiring harness and

if present CD connectors.

8. Release antenna leads from flexible tab on

rear of radio.

9. Disconnect mast antenna and if fitted diversity

antenna connections from rear of

radio/cassette play er.

10. Remove radio/cassette player.

Figure 12D-11

REINSTALL

Installation is the revers e of the rem oval procedure

noting the following points:

1. Ensure antenna leads are secured by flexible

tab on rear of radio.

2. Locate wiring and antenna leads from behind

radio carrier and gently pull all leads from

behind, whilst sliding radio into position.

NOTE:

This is necessary to ensure that none of the leads

are jammed or damaged behind the radio.

If care is not taken antenna lead may be

crushed between radio and radio carrier,

causing intermittent reception problems.

3. Check for correct operation.

2.2 FRONT INSTRUMENT PANEL SPEAKERS - ALL MODELS

REMOVE

1. Disconnect battery earth cable.

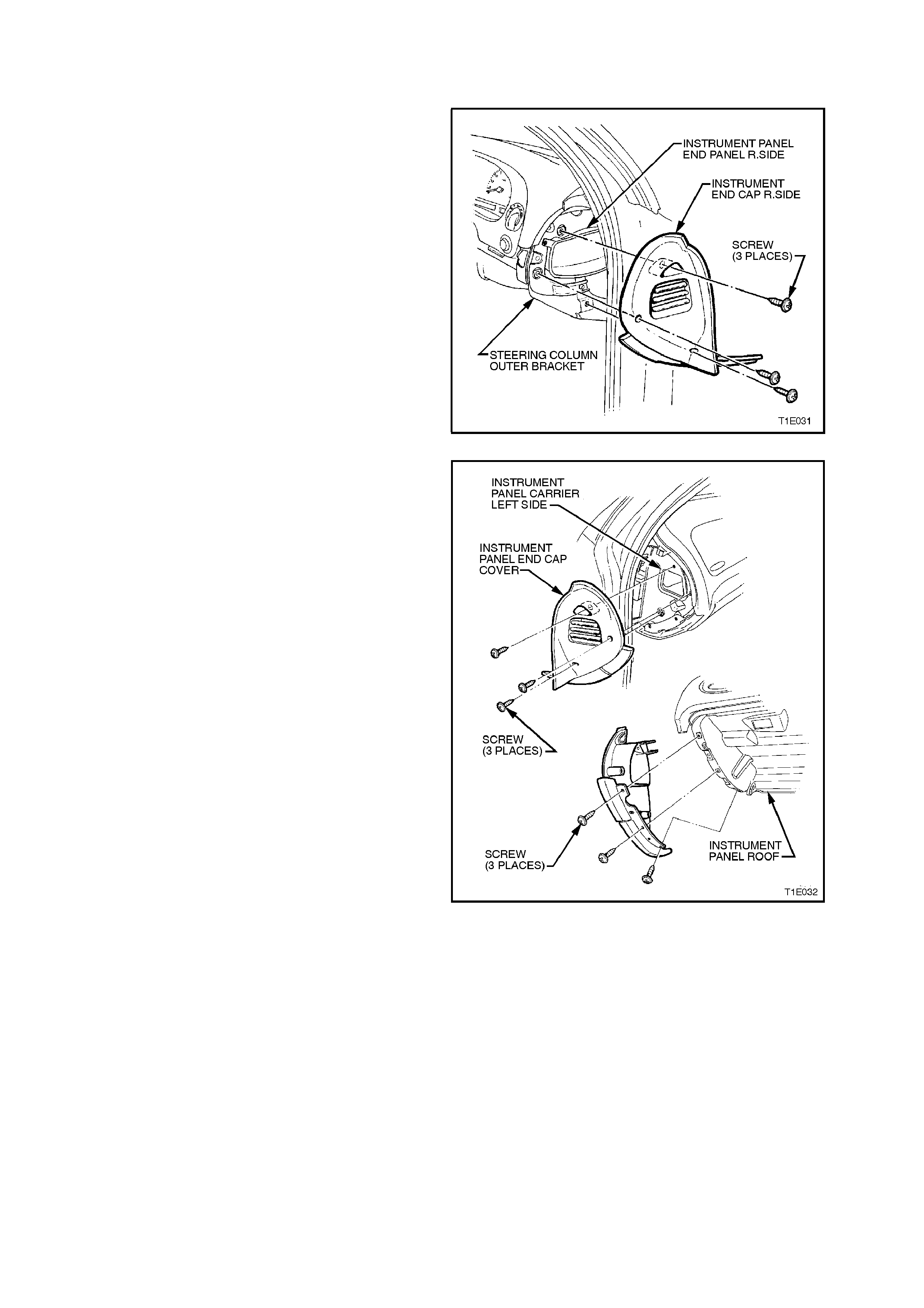

2. Remove the three screws and remove

instrument panel end cap cover right hand

side.

Figure 12D-12

3. Remove the six retaining screws for

instrument panel end cap cover left hand side.

Figure 12D-13

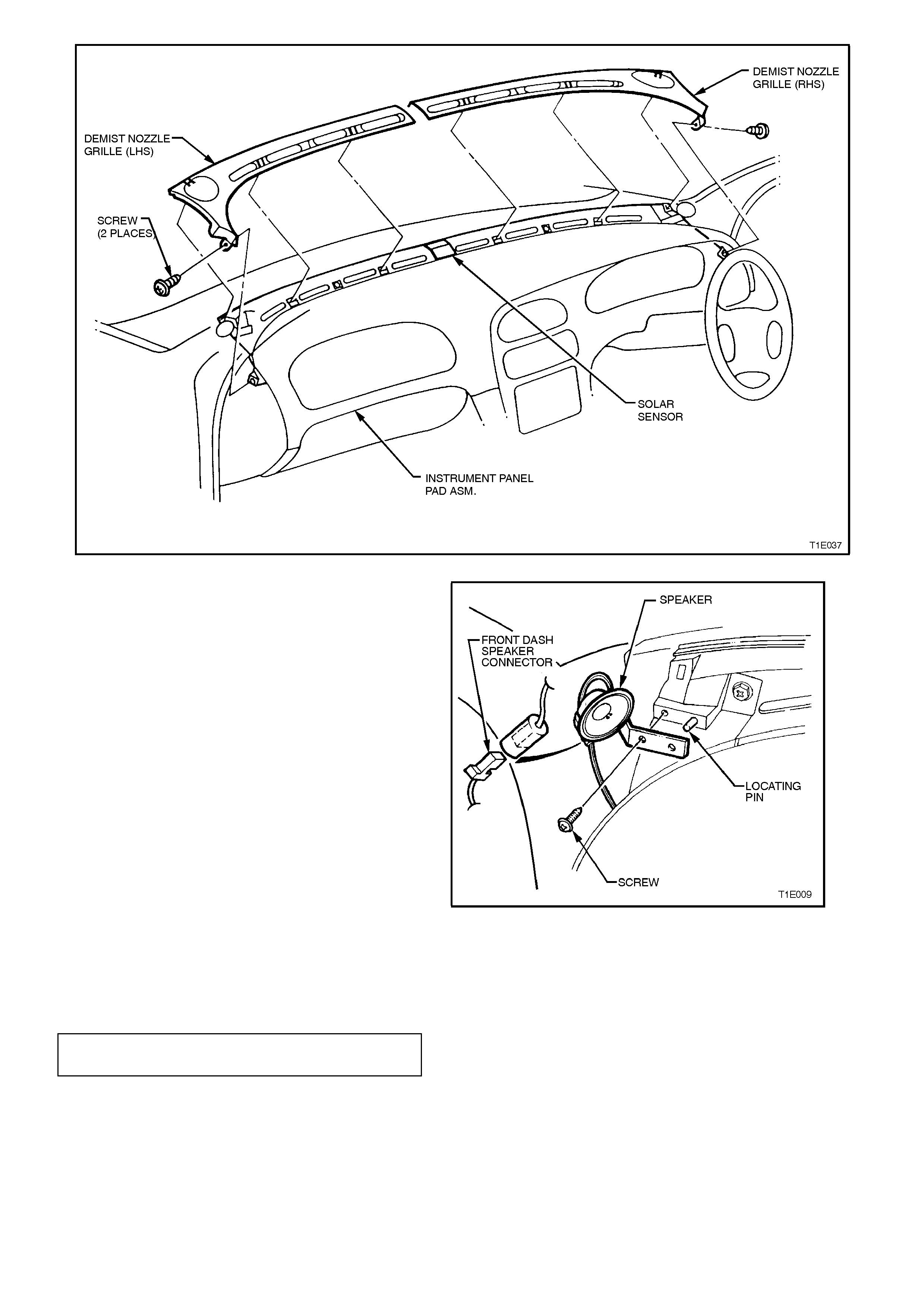

4. Remove retaining screw from the demist

nozzle right hand and remove.

5. Remove retaining screw from the demist

nozzle left hand and remove.

NOTE:

On all vehicles, care must be taken to avoid

damage to the solar sensor (if fitted).

Figure 12D-14

6. Disconnect left and right front dash speaker

harness connectors. Using a Phillips head

screw driver, remove screw attaching front

dash speakers and remove both speakers.

NOTE:

The c onnector loc k ing tab may be hidden under the

anti-rattle foam wrap.

Figure 12D-15

REINSTALL

Installation is the reverse of the r emoval proc edure.

Tighten speaker screws to the specified torque.

FRONT INSTRUMENT PANEL

SPEAKERS 1 - 3 Nm

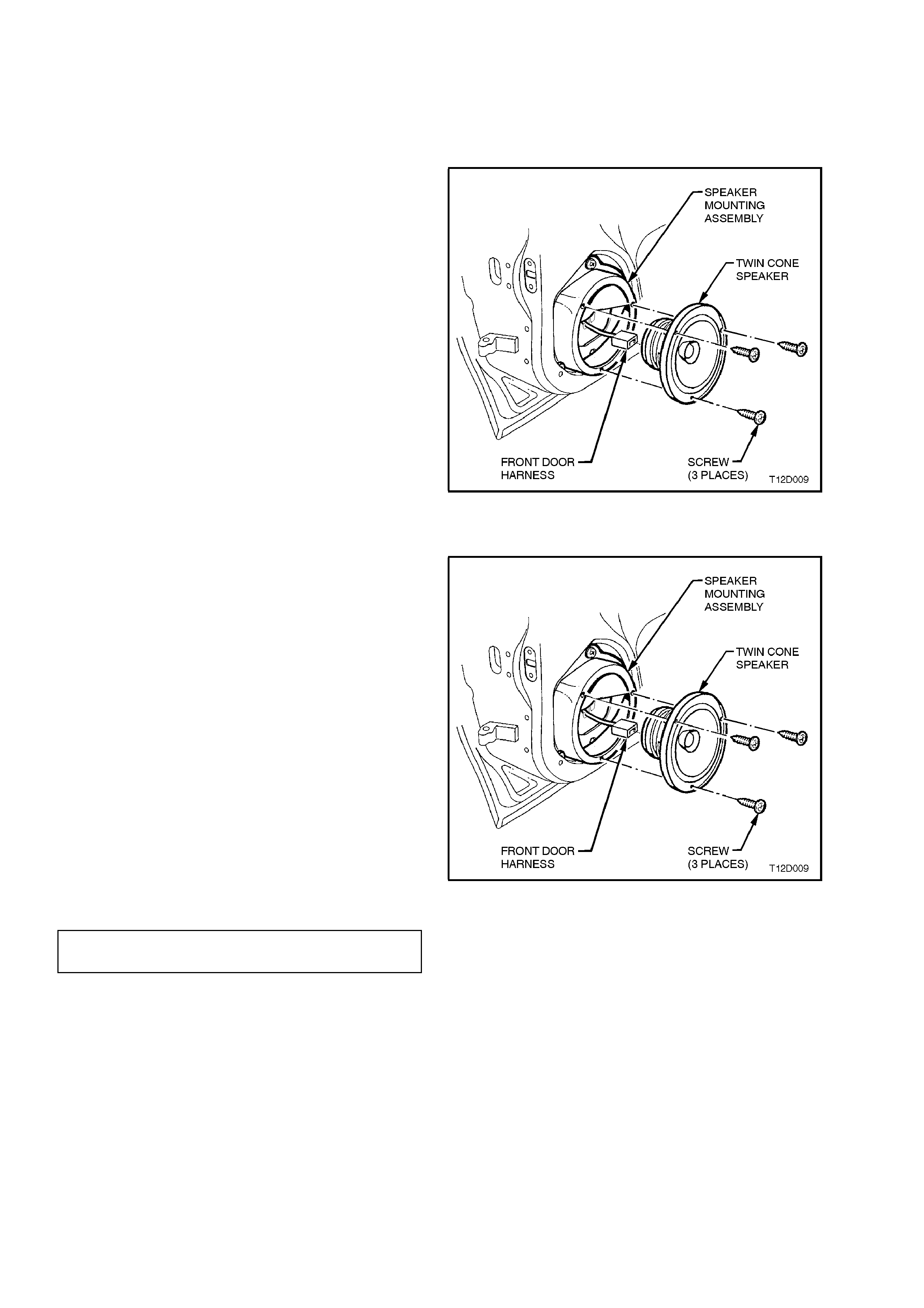

2.3 FRONT DOOR SPEAKERS - ALL MODELS

REMOVE

1. Remove door trim from front door. Refer to

Section 1A5 FRONT AND REAR DOOR

ASSEMBLIES.

2. Remove speaker assembly to speaker box

attaching screws.

3. Remove speaker from speaker box.

Release wiring harness from tab on rear of

speaker box.

Disconnect wiring harness from speaker

connector and remove speaker.

Figure 12D-16

REINSTALL

Installation is the reverse of the rem oval procedure

noting the following:

1. Ensure electrical connector is properly

attached to speaker.

2. Before installing speaker, visually inspect

speaker mounting box cavity for protrusions

that will touch the underside of the speaker

cone on installation, i.e. cable ties etc.

Resecure wiring harness to tab on rear of

speaker box.

3. Carefully reinstall speaker attaching screws

ensuring that speaker frame is not distorted

when screws are tightened.

NOTE:

Angled insertion of speaker attaching screws can

lead to speaker distortion. Make sure screws are

installed square to speaker frame. Figure 12D-17

FRONT DOOR SPEAKER

ATTACHING SCREWS 1 - 3 Nm

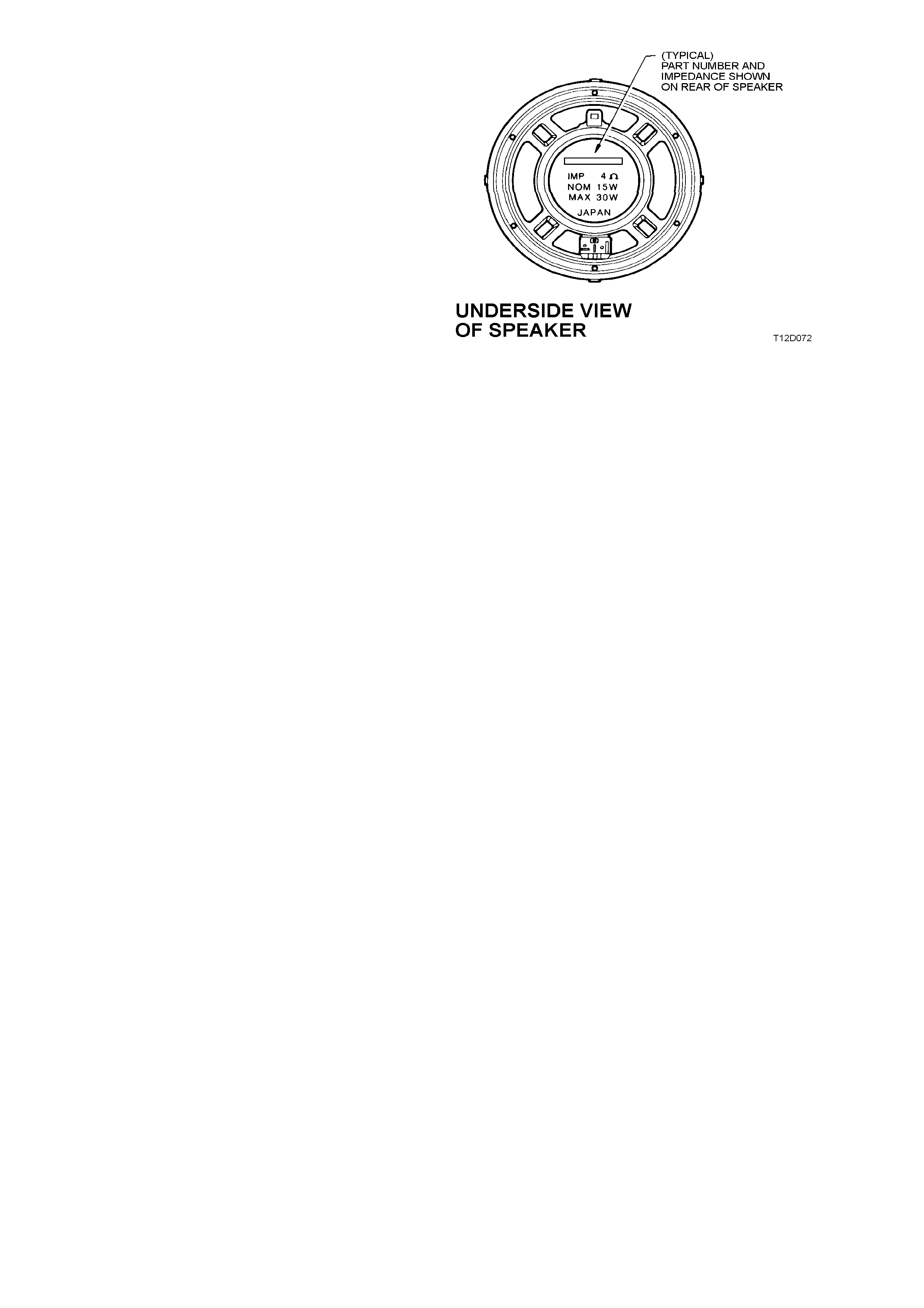

NOTE:

There are specific front speaker assemblies for

base model and Calais application. Refer to Fig.

12D-18 for identification details . Check that the part

numbers and resistance values are correct, as

incorrect speaker fitment can affect system

operation, resulting in unnecessary complaints.

Check speaker operation once installation has

been completed.

Figure 12D-18

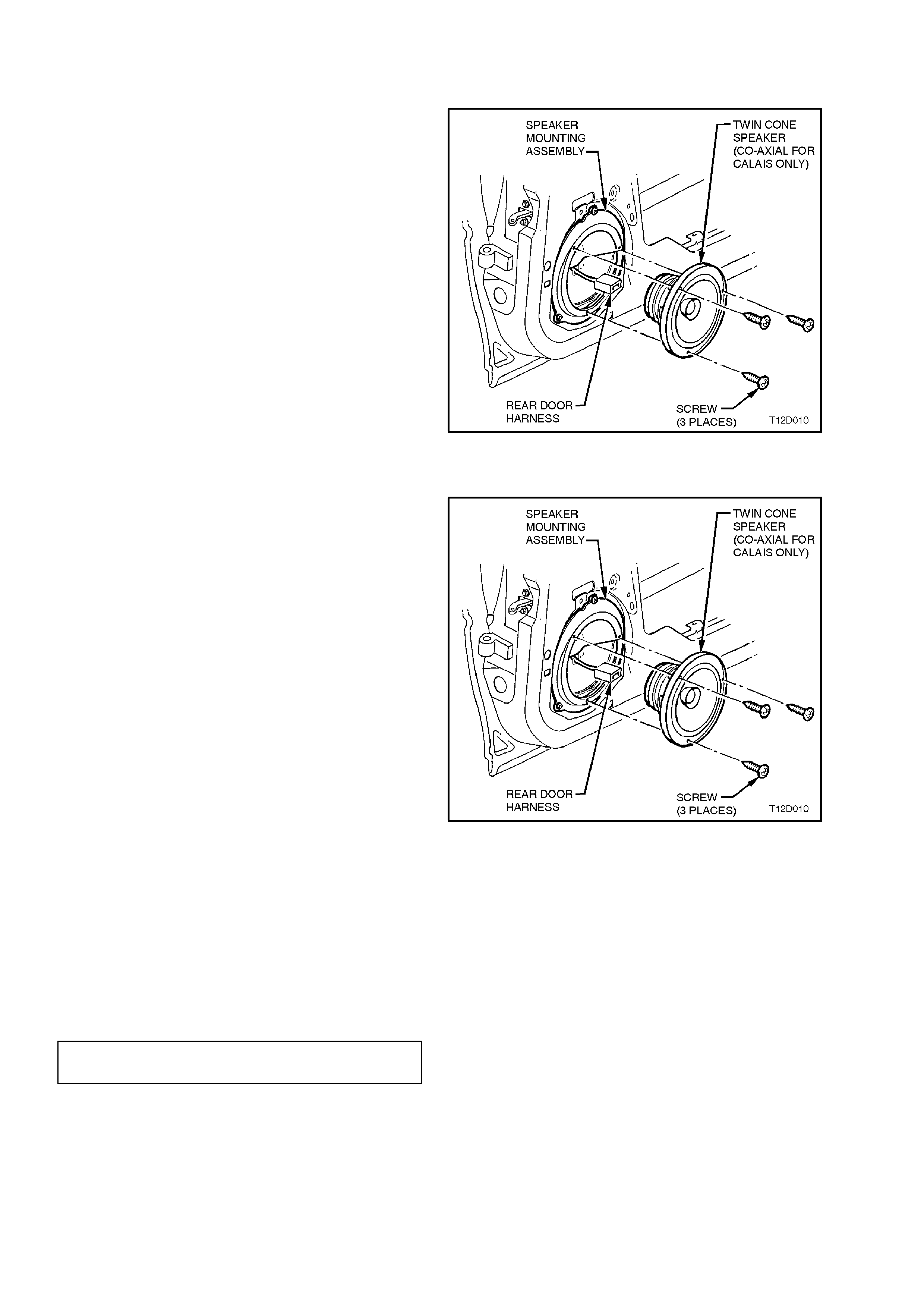

2.4 REAR DOOR SPEAKERS

REMOVE

1. Remove door trim from rear door. Refer to

Section 1A6 FRONT AND REAR DOOR

ASSEMBLIES.

2. Remove speaker assembly to speaker box

attaching screws.

3. Remove speaker from speaker box.

Release wiring harness from tab on rear of

speaker box.

Disconnect wiring harness from speaker

connector and remove speaker.

Figure 12D-19

REINSTALL

Installation is the reverse of the rem oval procedure

noting the following points:

NOTE:

There are specific rear speaker assemblies for

base model and Calais application. Refer to Fig.

12D-18 for identific ation details. Check that the part

numbers and resistance values are correct, as

incorrect speaker fitment can affect system

operation, resulting in unnecessary complaints.

1. Ensure electrical connector is properly

attached to speaker.

2. Before installing speaker, visually inspect

speaker mounting box cavity for protrusions

that will touch the underside of the speaker

cone on installation, ie. cable ties etc.

Resecure wiring harness to tab on rear of

speaker box.

3. Carefully reinstall speaker attaching screws

ensuring that speaker frame is not distorted

when screws are tightened.

NOTE:

Angled insertion of speaker attaching screws can

lead to speaker distortion. Make sure screws are

installed square to speaker frame and are tightened

to the correct torque specification.

Figure 12D-20

Check speaker operation once installation has been

completed.

REAR DOOR SPEAKER

ATTACHING SCREWS 1 - 3 Nm

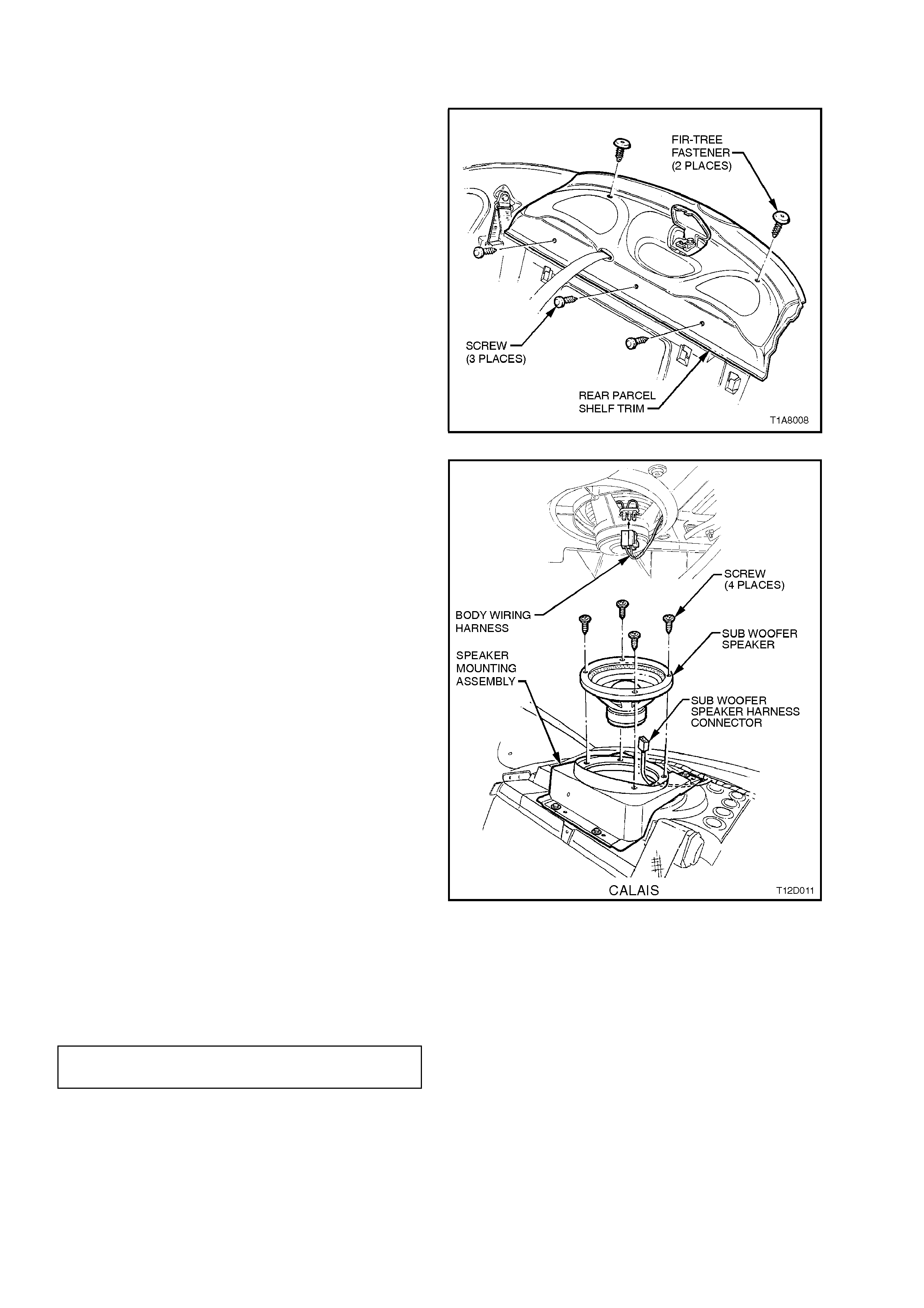

2.5 SUBWOOFER SPEAKERS - CALAIS

REMOVE

1. Disconnect battery earth cable.

2. Remove rear seat cushion and back

assemblies (refer to Section 1A7 SEATS

AND SEAT BELT ASSEMBLIES).

3. Remove the centre seat belt lower attachment

(refer to Section 1A7 SEATS AND SEAT

BELT ASSEMBLIES).

4. Open flap to child restraint fitting and unbolt

child restraint fitting.

5. From the rear compartment, carefully tap out

the fasteners securing the trim to the rear

parcel shelf.

6. Disassemble webbing guide (unclip from

parcel shelf).

7. Pull flap in parcel shelf forward, feed seatbelt

tongue and anchor through hole and remove

parcel shelf trim. Figure 12D-21

8. From the rear compartment, carefully remove

wiring harness connections to lefthand side

and righthand side sub-woofers.

9. From within passenger compartment, remove

four screws securing each sub-woofer and

carefully lift from mounting bracket.

REINSTALL

Installation is the reverse of the rem oval procedure

noting the following:

1. Ensure electrical connector is properly

attached to speaker.

2. Before installing speaker, visually inspect

speaker mounting box cavity for protrusions

that will touch the underside of the speaker

cone on installation i.e. cable ties etc.

3. Carefully reinstall speaker attaching screws

ensuring that speaker frame is not distorted

when screws are tightened.

When refitting parcel shelf trim, check to ensure

that foam sealing ring has not f olded back on itself .

Take care when refitting to ensure foam sealing

ring is not dislodged or folded back during this

process.

NOTE:

Angled insertion of speaker attaching screws can

lead to speaker distortion. Make sure screws are

installed square to speaker frame.

Figure 12D-22

SUBWOOFER SPEAKER

ATTACHING SCREWS 1 - 3 Nm

2.6 CALAIS AUDIO SYSTEM

Figure 12D-23

Figure 12D-24

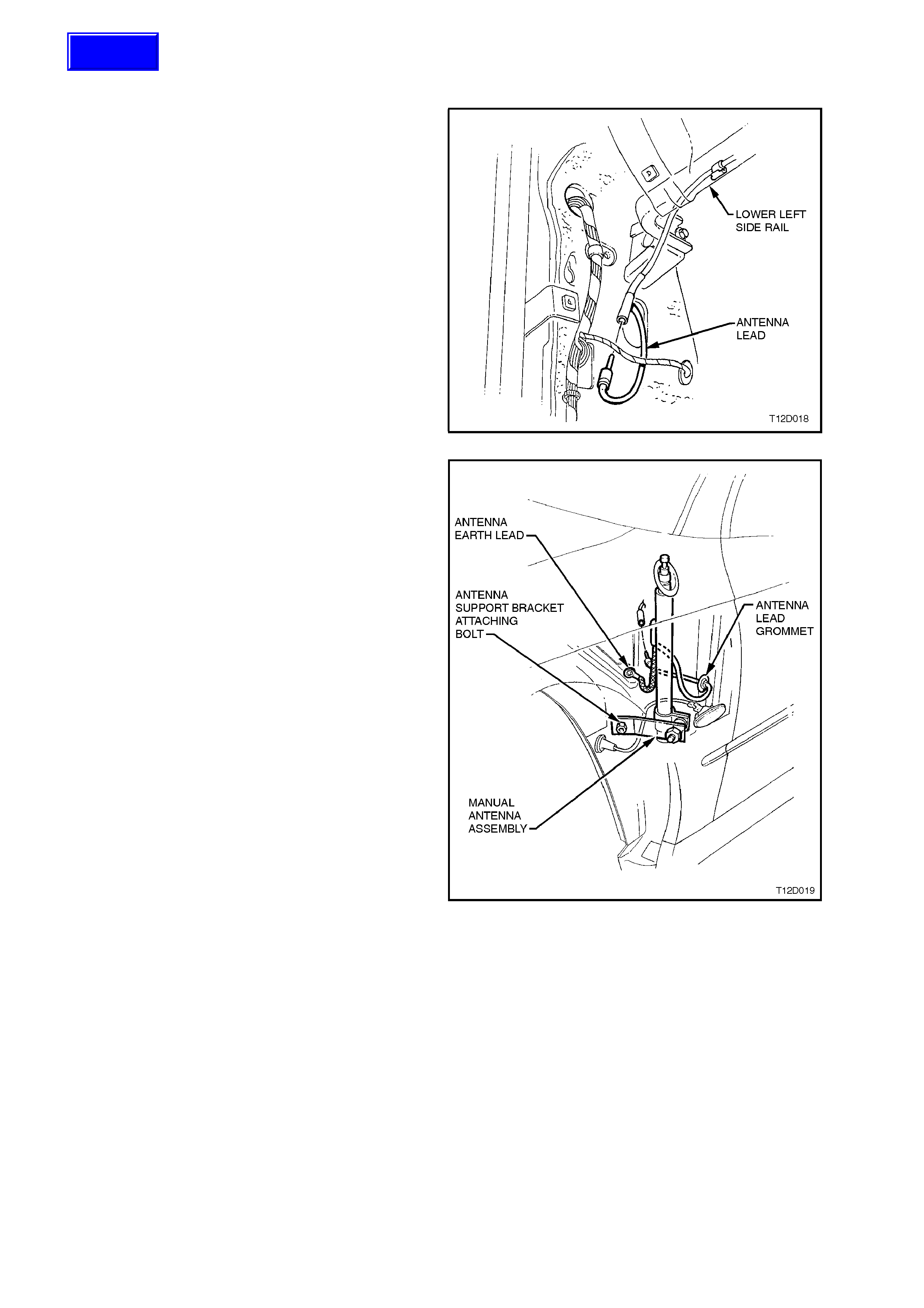

2.7 MANUAL ANTENNA

REMOVE

1. From inside vehicle, remove glove

compartment and instrument panel lower trim,

refer to Section 1A3 INSTRUMENT PANEL &

CONSOLE.

2. Release the forward section of rocker panel

cover.

3. Remove the upper retainer screw and the

screw beneath the rocker panel cover securing

the shroud lower trim assembly to the rocker

panel.

4. Pull the shroud lower trim assembly rearward

from the retainer removing the assembly.

5. Disconnect antenna lead from main wiring

harness connecting socket near powertrain

control module at left hand cowl panel.

6. Remove nut, retainers and screws securing

left hand fender inner liner and remove inner

liner. Figure 12D-25

7. Push antenna mast down to fully retracted

position.

8. Remove screw connecting earth braid to inner

fender earth terminal.

9. While supporting antenna, remove M8 bolt

attaching antenna bracket to inner fender

panel.

10. Remove antenna lead grommet from inner

fender panel and pull lead out f rom pas senger

compartment.

11. Withdraw antenna down from bezel and

remove, complete with lead and grommet.

12. If necessary, loosen antenna bracket screw

and remove bracket from antenna.

Figure 12D-26

Techline

REINSTALL

Manual antenna installation is the reverse of

removal procedures, noting the following points:

1. If removed, leave antenna bracket screw

loose.

2. Ensure that antenna and earth leads are

routed correctly and securely connected.

3. With antenna pushed up agains t stop in bezel,

tighten antenna bracket to inner fender panel

attaching bolt to the correct torque

specification.

ANTENNA BRACKET TO INNER

FENDER PANEL ATTACHING

BOLT TORQUE SPECIFICATION 3.0 - 6.0 Nm

Tighten bracket screw to the correct torque

specification.

ANTENNA BRACKET SCREW

TORQUE SPECIFICATION 2.0 - 5.0 Nm

Check radio operation and reception.

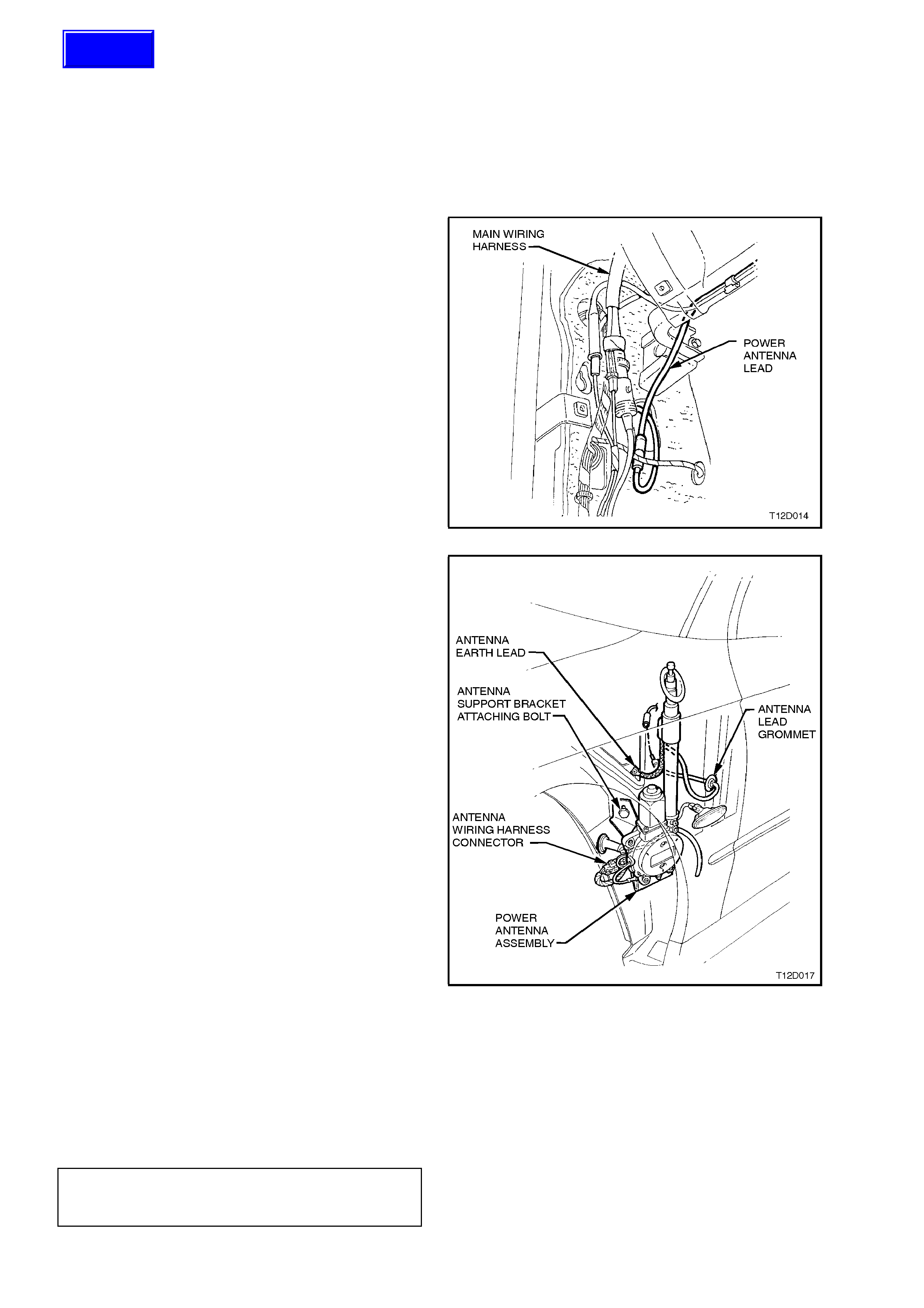

2.8 P O WER ANTENNA

POWER ANTENNA SWITCHES

The power antenna direc tional control s witches are

integrated with the radio and as such cannot be

serviced separately.

POWER ANTENNA ASSEMBLY

REMOVE

1. From inside vehicle, remove footwell upper

closing panel left side, instrument panel

compartment and instrument panel

compartment roof, refer to Section 1A3

INSTRUMENT PANEL AND CONSOLE.

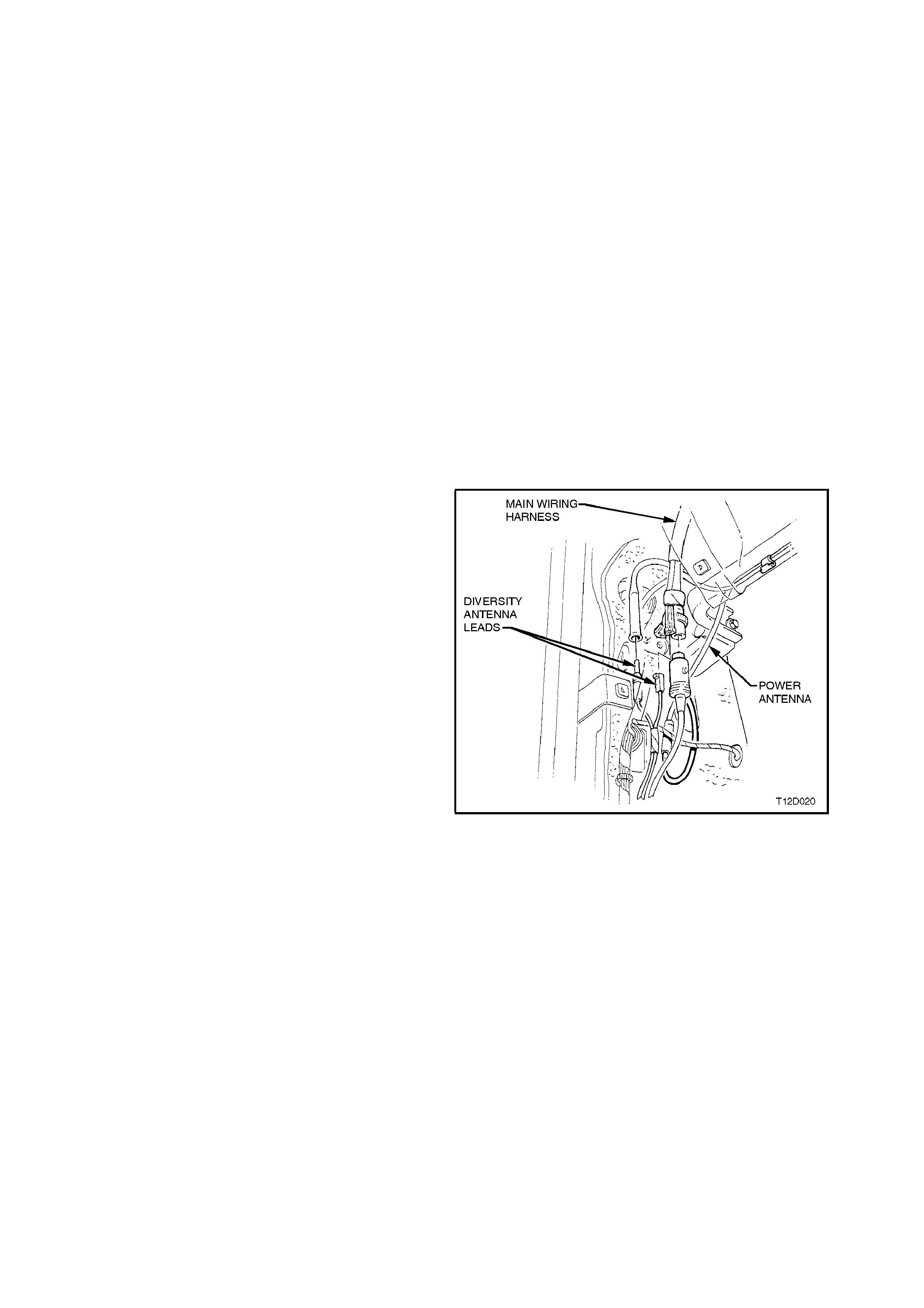

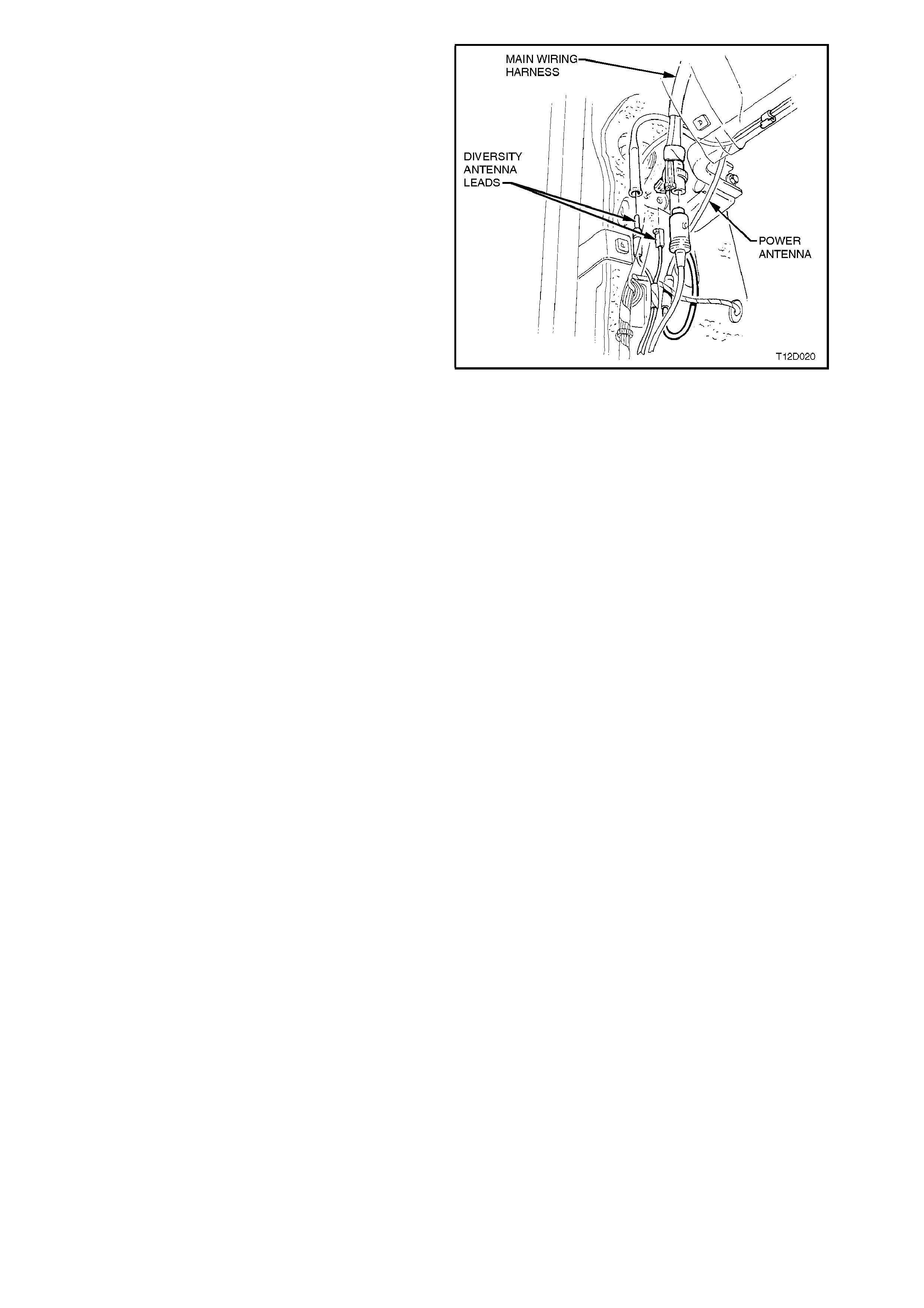

2. Disconnect antenna lead from main wiring

harness connecting socket above powertrain

control module at left hand cowl panel.

Figure 12D-27

3. Set antenna mast to fully retracted position.

4. Remove nut, retainers and screws securing

right hand fender inner liner and remove inner

liner.

5. Remove screw connecting earth braid to inner

fender earth terminal.

6. Disconnect antenna wiring harness connector

from main wiring harness connector in wheel

well.

7. While supporting antenna assembly, remove

antenna support bracket attaching bolt.

8. Remove antenna lead grommet from inner

fender panel and pull lead out f rom pas senger

compartment.

9. Withdraw antenna down through bezel and

remove, complete with leads, grommet and

bracket.

Figure 12D-28

REINSTALL

Reinstallation is the reverse of the removal procedure taking note of the following:

1. Ensure cable and harness are routed correctly .

2. Ensure that antenna and earth leads are routed correctly and securely connected.

3. W ith antenna pushed up against stop in bezel, tighten antenna bracket to inner fender panel attaching bolt to

the correct torque specification.

ANTENNA BRACKET TO INNER

FENDER BOLT

TORQUE SPECIFICATION 5.0 - 12.0 Nm

4. Check antenna operation and radio reception.

Techline

MAST REPLACEMENT

The following procedure is for replacing a damaged or faulty antenna mast and drive cable assembly.

1. Remove power antenna assembly as previously described in this Section.

2. Remove chrome plated nut from top end of mast tube.

3. Extend damaged antenna mast as far as possible by attaching battery negative via a jumper lead to antenna

mounting bracket and battery positive to both the antenna red and white wire terminals.

At end of mast travel, pull out mast and drive cable from antenna housing.

NOTE:

If m ast is too badly damaged to extend, grip tip of m ast with a pair of pliers and pull m ast and drive c able as sem bly

up and out from antenna housing.

4. If necess ary, rem ove contact spring ( metal s leeve) from old m ast and drive cable and ins tall onto replacem ent

mast and drive cable.

5. Feed end of drive cable down mast tube of antenna hous ing with serrated s ide of drive c able fac ing toward the

centre of the housing. Continue to feed drive cable down until it engages with the drive mechanism.

NOTE:

It may be necessary to twist the drive cable clockwise and anti-clockwise slightly to enable end of cable to feed

through opening at base of mast tube before it engages the drive mechanism.

6. W ith the aid of an assistant to hold the antenna and m ast assembly, connect antenna mounting bracket via a

jumper lead to battery negative.

7. Mom entarily connect battery positive to the antenna red wire and drive m echanism should start to r etract drive

cable into antenna housing.

8. With the drive cable engaged to drive mechanism, reconnect battery positive to antenna red wire and allow

drive mechanism to wind in drive cable and mast into mast tube and housing.

9. At this stage the mast might be fully retracted into the mast tube and housing. Reconnect both the red and

white wires to battery positive and allow the mast to extend fully until the motor stops.

Disconnect white wire from battery positive and allow mast to fully retract.

10. Reinstall chrome plated nut to top end of mast tube and tighten securely.

11. Reinstall power antenna assembly as previously described in this Section. Check antenna mast operation.

CHECKING ANTENNA MOTOR OPERATION

NOTE:

The following ‘Checking Antenna Motor Operation’ tests are made at the main wiring harness to antenna motor

connector located at the right hand cowl panel, above the engine management powertrain control module.

The voltages shown are measured to a good earth point on the vehicle body.

VOLTAGE ON ANTENNA HA RNESS WIRES

Red White Action

12V 12V Antenna extends

12V 0V Antenna retracts

0V 12V Antenna does not move

0V 0V Antenna does not move

If the antenna motor does not correctly respond to the inputs as specified, ensure that a good earth connection is

being made through the mounting bracket by measuring the resistance from the bracket to a good earth point. If

more than 1W replace power antenna assembly. Check that the forked earth connector is securely attached to the

antenna mounting.

NOTE:

If there is significant noise on the AM band (with radio tuned to weak station outdoors), then check antenna earth

quality. The antenna earth terminal has a large effect on the screen.

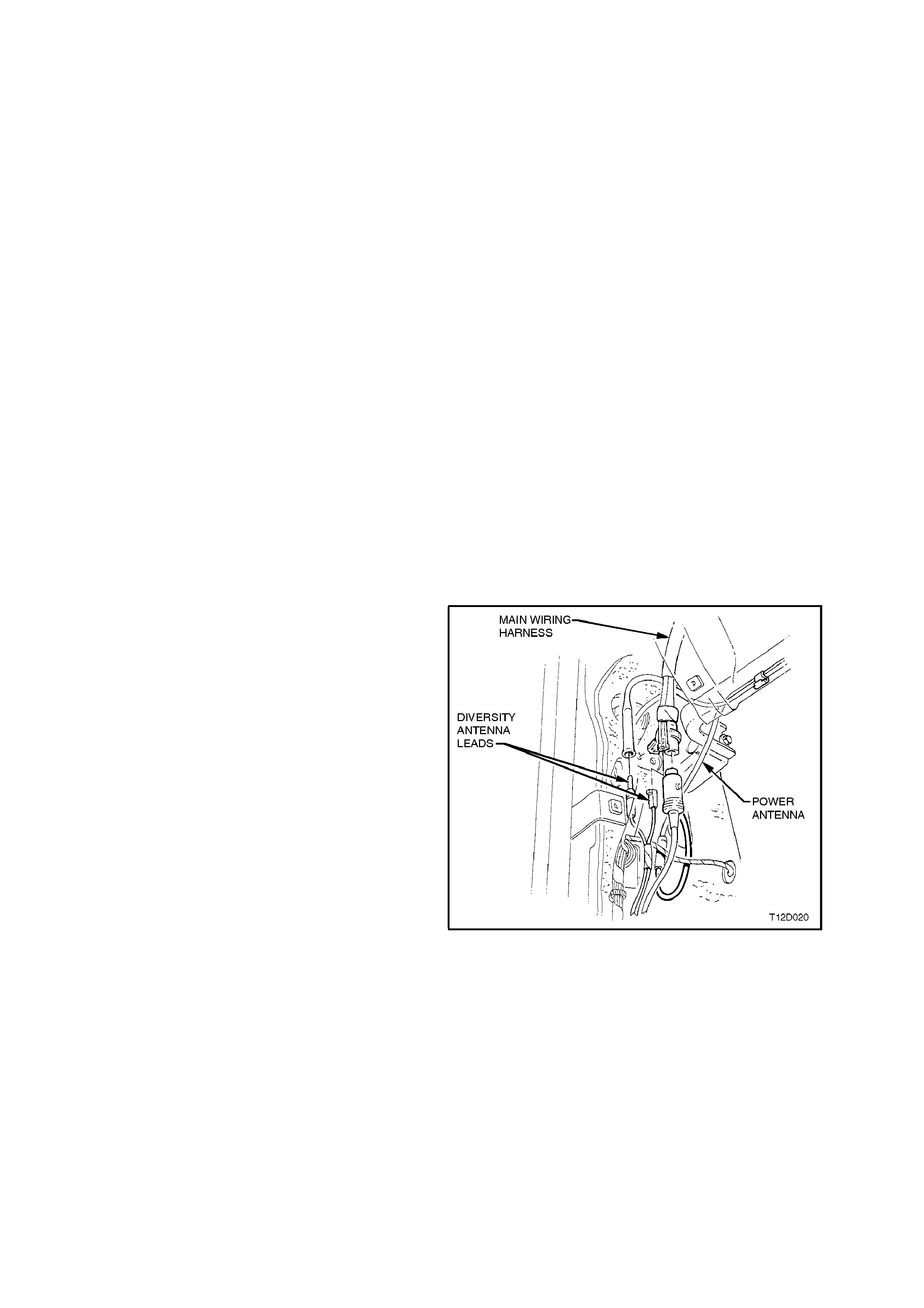

2.9 DIVERSITY ANTENNA

The diversity antenna is an integral part of the rear window assembly. The thin conductors that form the diversity

antenna are laid on the inside of the rear window glass in the same manner as the heated rear window elements.

A single terminal is located on the inside of the r ear window glass, on the pas senger s ide, to allow connection of the

diversity antenna to the diversity antenna module, located under the rear parcel shelf trim.

The diversity antenna module amplifies the radio signal received by the diversity antenna and transmits it to the

radio/cassette player via coaxial cable.

NOTE:

Due to the internal circuitry of the radio receiver, if the fender mounted mast antenna is retracted, faulty or

disconnected, the radio may not use the diversity antenna system for radio reception if the FM signal is weak.

DIVERSITY ANTENNA - TEST

1. Disconnect diversity antenna module connector from diversity antenna terminal.

2. Using an ohmmeter measure the resistance from the diversity antenna terminal to the diversity antenna

conductors on the inside of the rear window glass.

Resistance should be less than 20 W from diversity antenna connector to any point on the diversity antenna

conductors.

NOTE:

Care should be taken when measuring resistance that the diversity antenna conductors are not damaged by the use

of excessive force on the ohmmeter probe.

DIVERSITY ANTENNA MODULE

REMOVE

1. Remove rear seat cushion and back assemblies, refer to Section 1A7 SEATS AND SEAT BELTS.

2. Remove rear parcel shelf trim and side quarter window trim, refer to Section 1A8 HEADLINING & REAR

END TRIM.

3. Remove passenger side lower shroud trim and rocker panel cover, refer to Section 1A1 BODY.

4. Disconnect diversity antenna module harness

to main wiring harnes s connector located near

the PCM.

5. Disconnect diversity antenna module coaxial

cable from radio diversity antenna extension

cable connector located near PCM.

Figure 12D-29

6. Remove diversity antenna module leads from

retaining clips and remove leads from rocker

panel.

7. Remove diversity antenna module connector

from diversity antenna term inal located on rear

window.

8. Remove screw securing diversity antenna

earth terminal to vehicle body.

9. Remove screw securing diversity antenna

am plifier to r ear parc el s helf. Rem ove diversity

antenna module and leads.

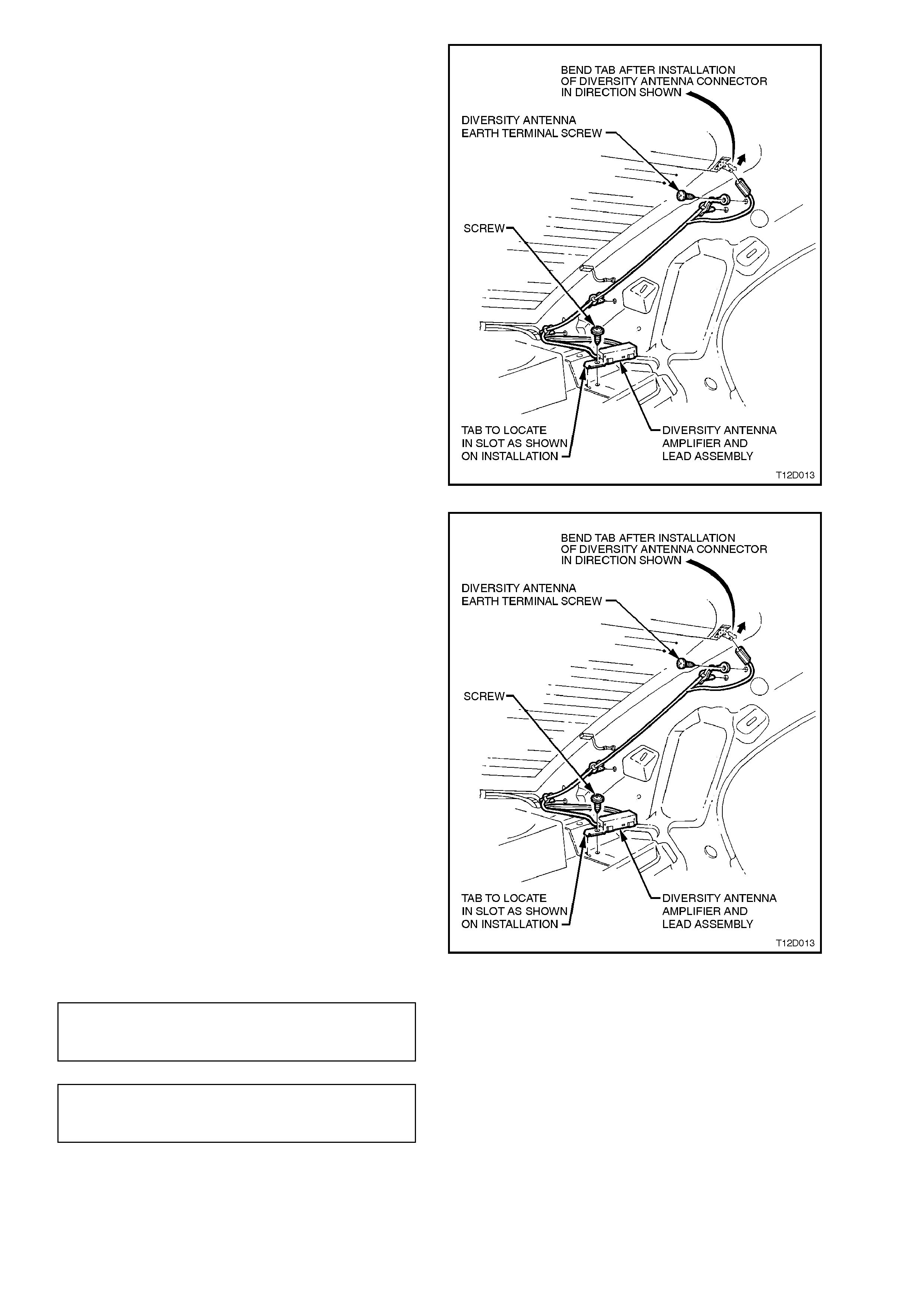

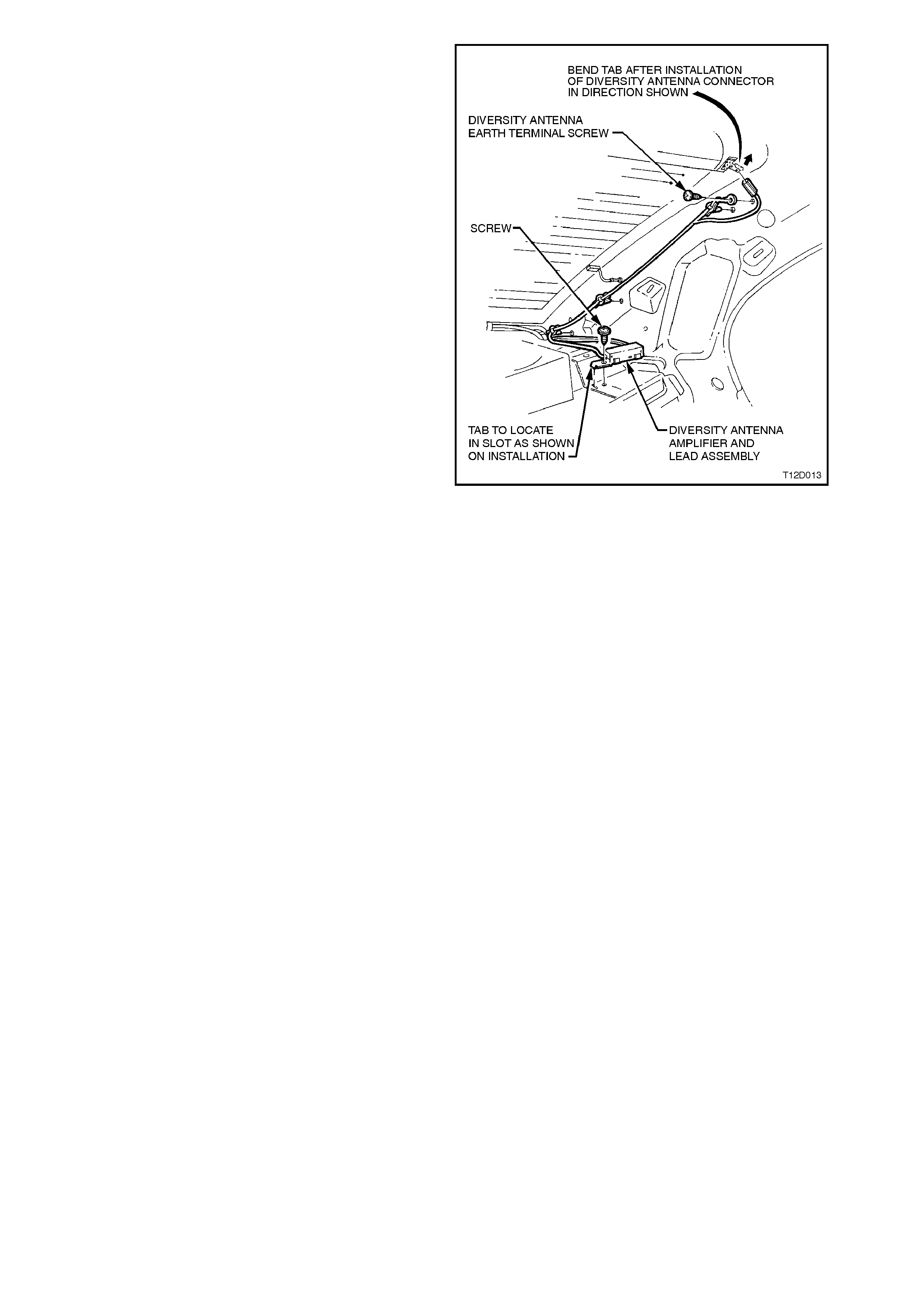

Figure 12D-30

REINSTALL

Reinstallation is the reverse of the removal

procedure noting the following:

1. Ensure that locating tag on diversity antenna

module is correctly engaged into the m ounting

slot on the rear parcel shelf.

Tighten diversity antenna module mounting

screw to the correct torque specification.

Figure 12D-31

DIVERSITY ANTENNA MODULE

EARTHING SCREW TORQUE

SPECIFICATION 1 - 3 Nm

DIVERSITY ANTENNA MODULE

MOUNTING SCREW TORQUE

SPECIFICATION 1 - 3 Nm

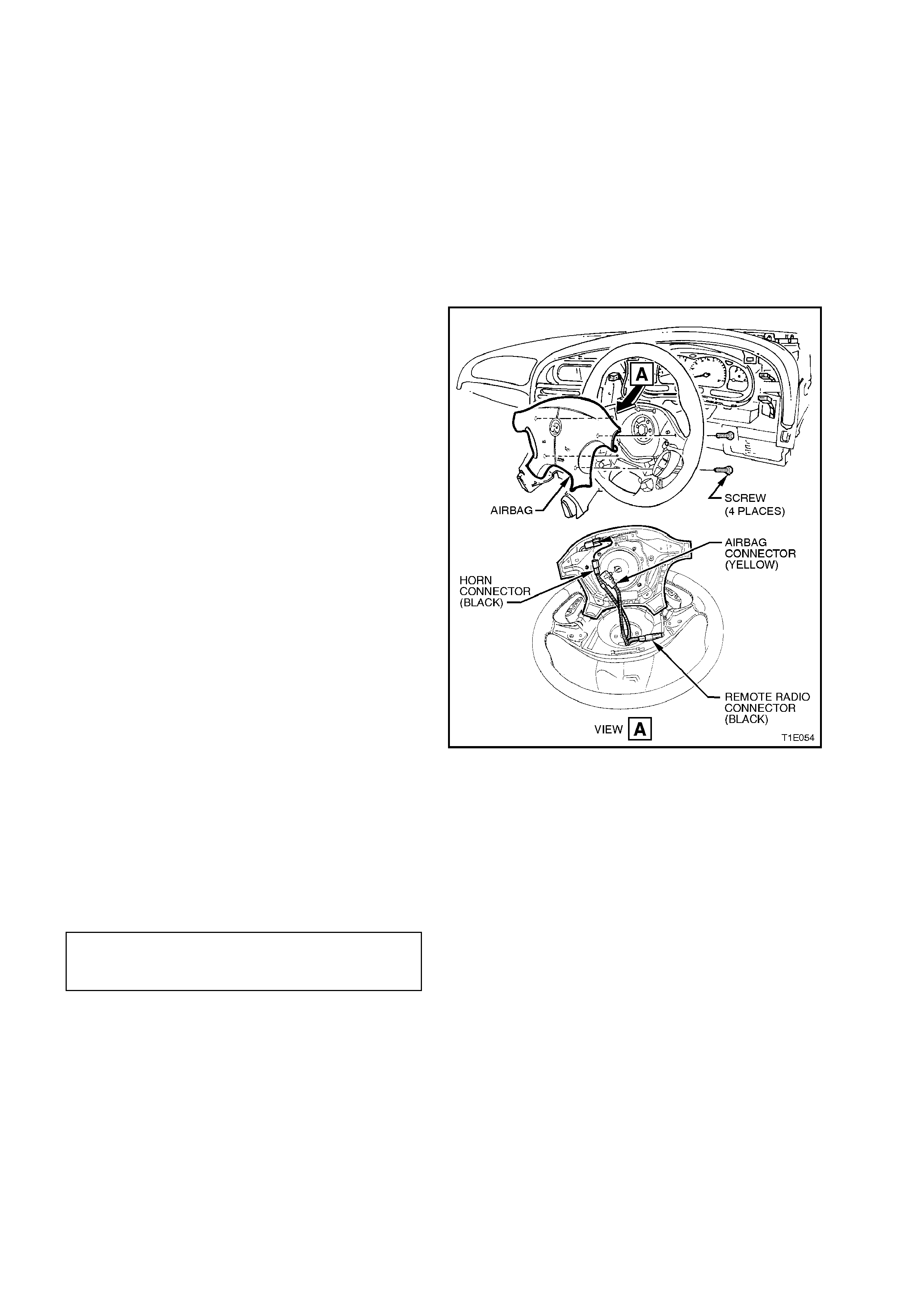

2.10 HORN BAR STEREO CONTROLS

The horn bar stereo control system c onsists of two

control switch assemblies which are located on

each side of the driver’s side air bag and a radio

connection.

The horn bar s ter eo contr ols utilise the c loc k s pr ing

coil harness as a data link to the radio.

REMOVE

CAUTION:

Disable the SRS (Air Bag). Refer to DISABLING

THE SRS, Section 12M SUPPLEMENTAL

RESTRAINT SYSTEM.

1. Remove air bag assembly from steering

wheel, refer to Section 9A STEERING.

2. Disconnect horn bar stereo control harness

from steering column harness connector.

3. Remove horn bar stereo switch assembly to

steering wheel attaching screws and remove

horn bar stereo switch assembly.

NOTE:

The horn bar stereo switch assembly consists of

two switch blocks connected together by a wiring

harness.

Figure 12D-32

REINSTALL

Installation is the revers e of the rem oval procedure

noting the following.

1. Tighten horn bar stereo switch assembly to

steering wheel attaching screws to the correct

torque specification.

STEREO SWITCH TO STEERING

WHEEL ATTACHING SCREW

TORQUE SPECIFICATION 1 - 3 Nm

IMPORTANT:

Enable the SRS (Air Bag). Refer to ENABLING

THE SRS, Section 12M SUPPLEMENTAL

RESTRAINT SYSTEM.

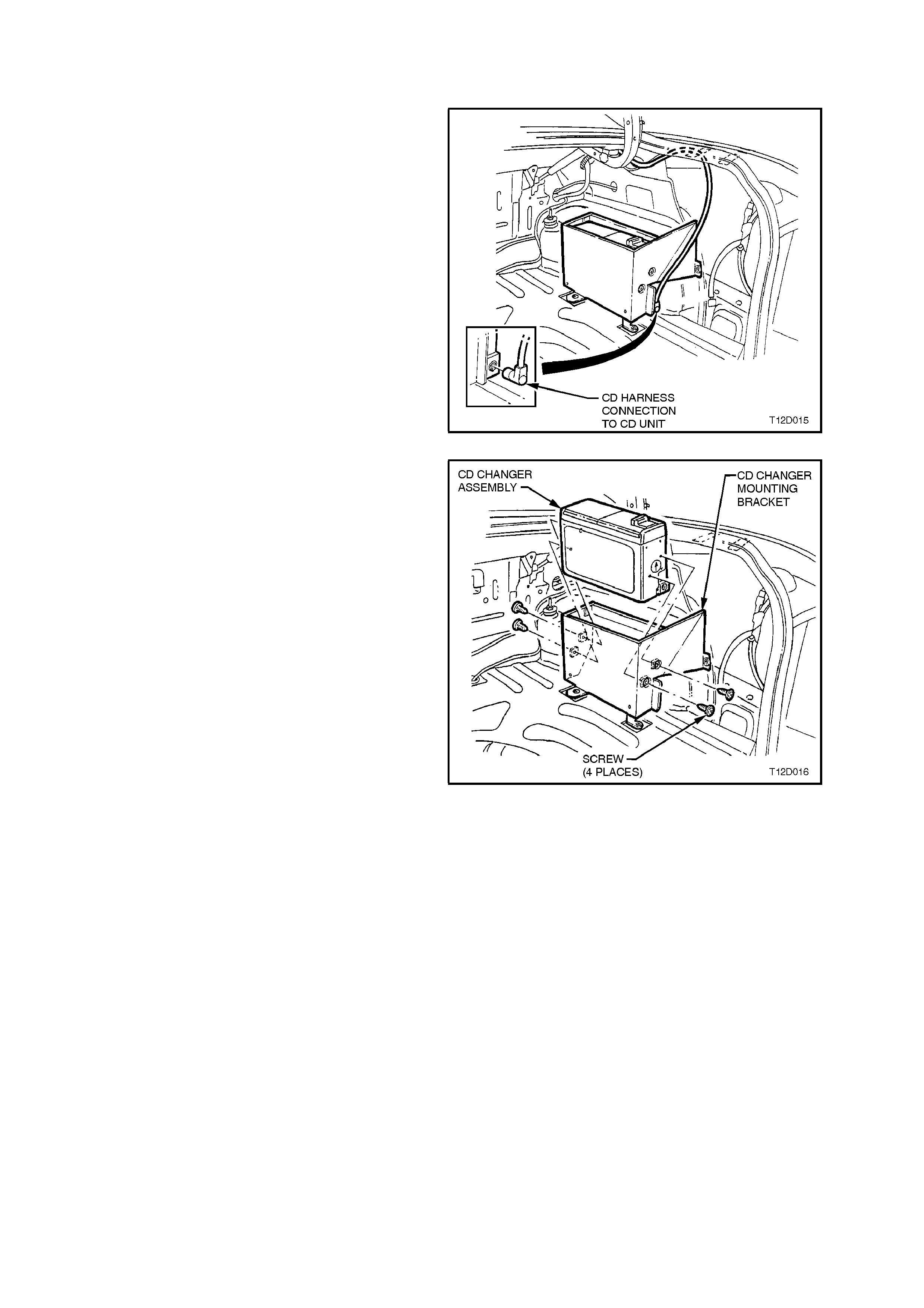

2.11 COMPACT DISC PLAYER/ CHANGER INSTALLATION - CALAIS

REMOVE

1. Open decklid and remove carpet, refer to

Section 1A1 BODY.

2. Rem ove two trim retainer s from right side rear

compartment wheelhouse carpet trim (on CD

changer assem bly) and remove right side rear

compartment wheelhouse trim. Refer to

Section 1A1 BODY.

3. Disconnect CD changer harness connector.

Figure 12D-33

4. Remove CD changer to mounting bracket

retaining screws (four screws) and withdraw

CD changer from mounting bracket.

Figure 12D-34

REINSTALL

1. Reinstallation is the reverse of the removal

operations.

2. Check CD changer operation.

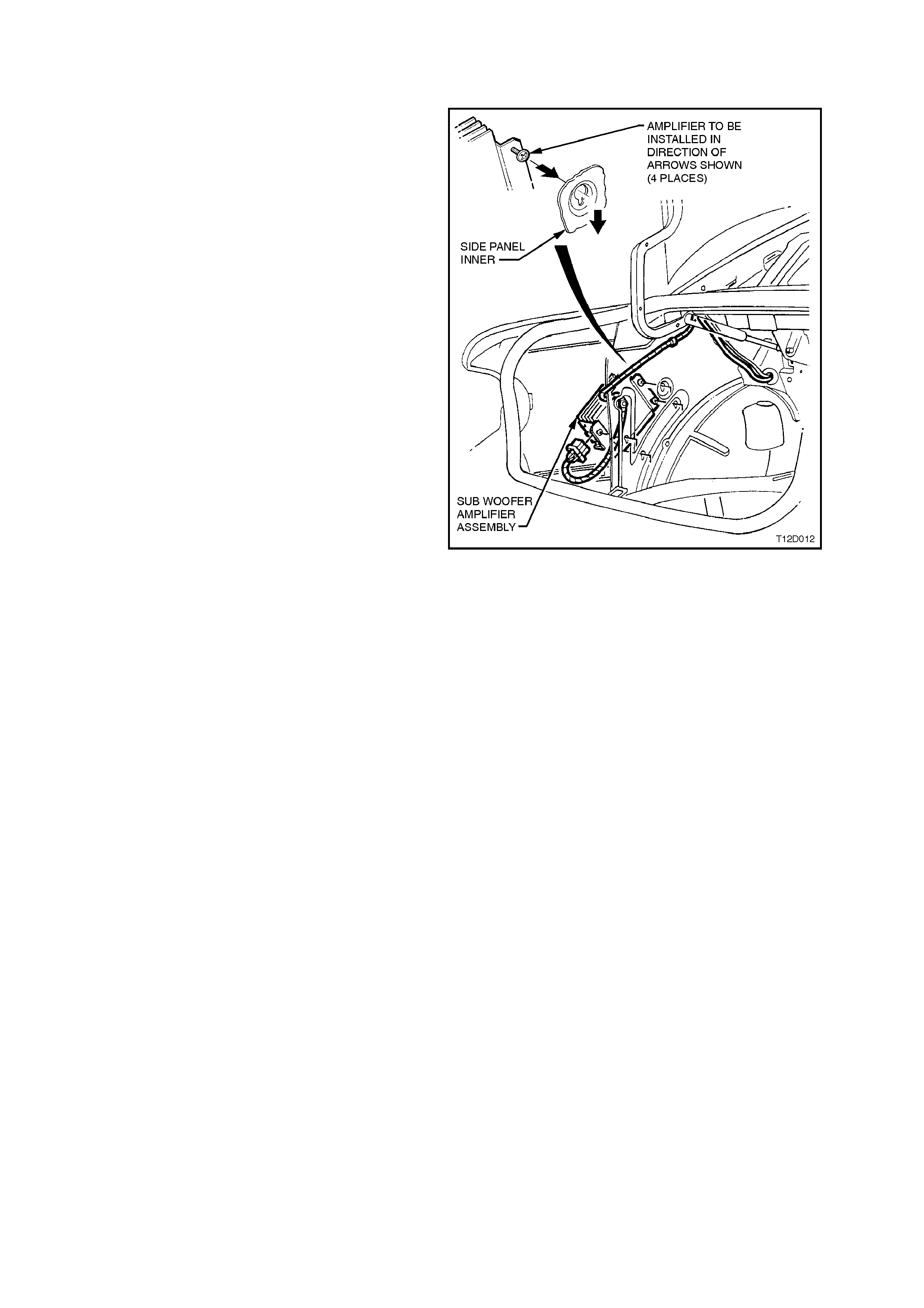

2.12 SUBWOOFER AMPLIFIER

REMOVE

1. Open decklid and remove carpet, refer to

Section 1A1 BODY.

2. Remove trim retainer from left side rear

compartment wheelhouse carpet trim and

remove left side rear compartment

wheelhouse trim, refer to Section 1A1 BODY.

3. Loosen subwoofer amplifier retaining screws

(four screws) and slide amplifier upwards to

release screw heads from slots in side inner

panel.

4. Withdraw subwoofer amplifier assembly from

rear compartment.

5. Disconnect subwoofer amplifier assembly

harness connector.

Figure 12D-35

REINSTALL

1. Reverse removal operations.

2. Check subwoofer amplifier operation.

3. DIAGNOSIS

This radio problem diagnosis is split into several parts.

1. The first part is a short description of the principles of radio operation. It is by no means exhaustive, and is to

serve only to give an understanding of how radios work in order to better understand how to solve problems

when they occur.

2. Many radio problem s are caused by basic earthing and short-circuiting problems, which can be quickly found

using the checks included in the ‘Basic Checks’ in this Diagnosis Section.

3. The m ost com mon fault is that of ‘s tatic’ and so an explanation of what it is, what causes it, and how to fix it is

also included.

4. Diagnostic flow charts are included to help diagnose common complaints.

PRINCIPLES OF OPERATION

RADIO RECEPTION

High quality radio rec eption is obvious ly more dif ficult to ac hieve in a moving vehicle than from a st ationary location.

Radio systems fitted to vehicles incorporate sophisticated electronics to enhance radio reception by extending the

useable listening range whilst eliminating extraneous noises, such as static.

Many owners complain of ‘reception problems’ which are normal radio operating characteristics, particularly with

FM. Such complaints arise as a result of owner misconception as to what constitutes normal radio reception.

Naturally, radio replacement under these circumstances will not affect the radio operating characteristics and has

the potential to create additional owner dissatisfaction. T hus a careful, well informed explanation of radio reception

expectations is more lik ely to enhance the owner’s understanding and satis faction, as well as avoiding unneces sary

repair costs and inconvenience to the owner of the vehicle.

FM RECEPTION IN VEHICLES

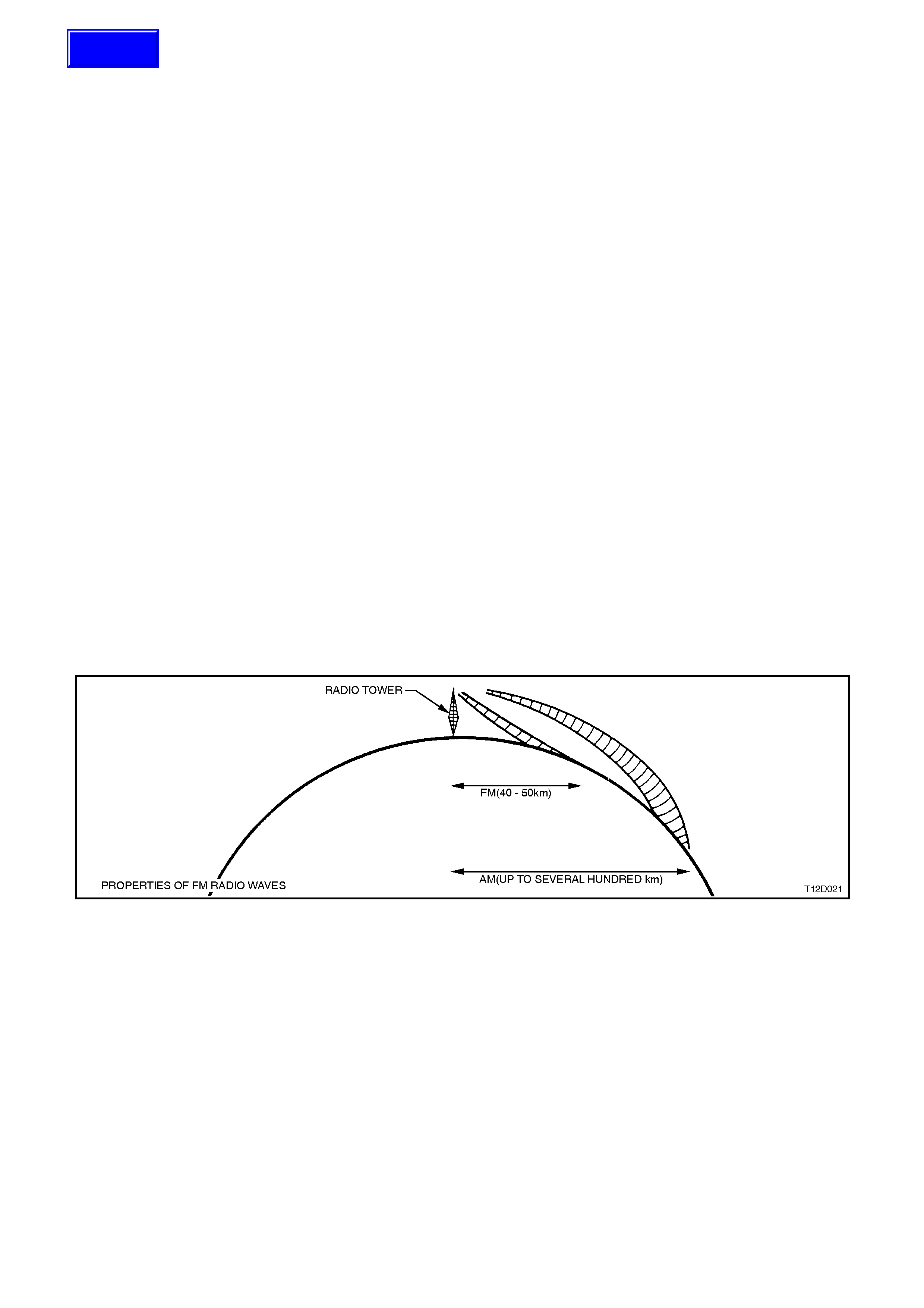

FM stereo’s maximum range is normally limited to 40 to 50 km. The strength of the FM signal is related to the

distance between the receiver and the transmitter. FM signals follow the line of sight, exhibiting many similar

character istics to those of light. That is , similarly to sunlight, FM radio waves are cut of f by the horizon. Since m ost

FM transmitter towers are nominally 100 metres from the ground, useable reception cannot extend much beyond

the horizon. FM signals will not bend around corners, but as with light, may be reflected (or blocked) by large

objects such as hills and buildings.

Figure 12D-36

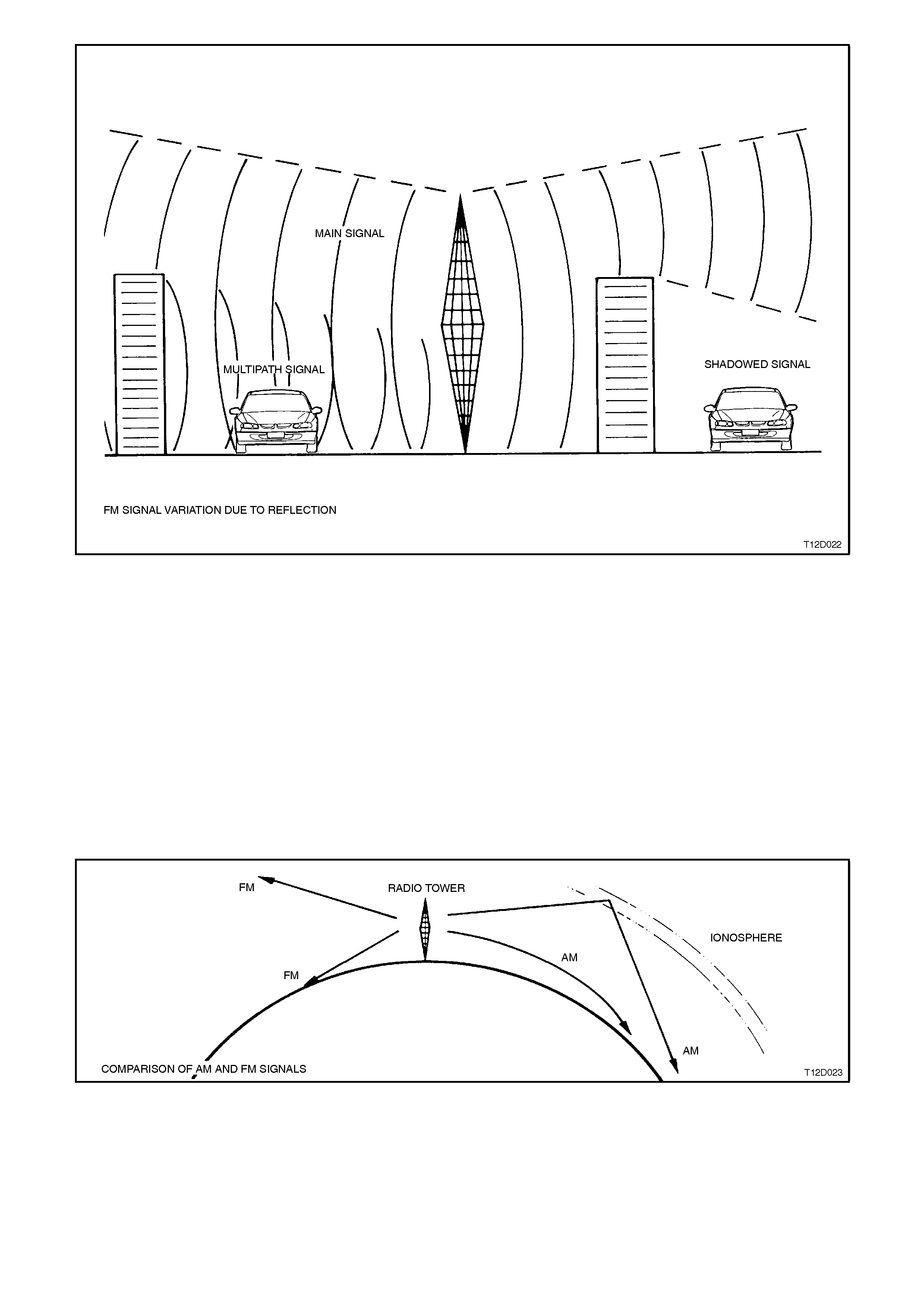

Although FM signals will not bend around corners, they can be reflected by large structures, hills, or buildings, for

example. Because of these characteristics, a reflected signal and a direct signal can reach the radio’s antenna at

the sam e time, r esulting in the signals inter fering with each other or c ancelling each other out. This obviously leads

to a distortion of the received signal or a loss of sound, and is known as multi-path interference.

Multi-path interference occurs only with FM reception and can be characterised by changes in distortion (static)

levels occurring as the vehicle is moving. This is due to the vehicles antenna entering and leaving FM signal

interference areas.

FM signal waves have short wavelength, which also means that the interference area is small - in the region of

several centim etres across . Because of the s mall s ize of interferenc e areas, a vehicle m ay pass through many in a

short tim e. When the vehicle is s tationary in an interf erence area, m oving it half a m etre will place the antenna in a

region of clear signal.

A vehicle fitted with a two antenna FM divers ity sys tem helps reduc e m ultipath interf erence by ensuring that at least

one antenna is outside the cancelled signal region.

Flutter or fading is caused when a vehicle passes into an area where the direct signal can be overshadowed by a

building, large structure or hill.

Techline

Figure 12D-37

Atmospheric conditions can also affect FM reception. Unexplained loss of sensitivity can be caused by high

humidity. Cloudy days are also better for reception than clear days. With electronic tuning radios, users can

sometimes be confused by abbreviated radio station call signs. People who tune their radio to these abbreviated

call signal frequencies may be slightly off the correct frequency.

NOTE:

FM station call signs are spaced 100 kHz apart in Australia, ie. 93.9, 94.0, 94.1, etc.

AM station call signs are spaced 9 kHz apart, i.e. 999, 1008, 1017, etc.

AM RECEPTION IN VEHICLES

In contrast to FM s ignals, AM signals will bend around co rner s and s kip along the ground. This is due to AM s ignals

having longer wavelength and lower frequency. The signal can be reflected by the layer of atmosphere known as

the ionosphere. This phenomenon gives AM a longer reception range than FM.

Figure 12D-38

AM reception is affected by static induced by electrical power lines, traffic lights, electronic signs and thunderstorms.

Fade of AM signals can also be expected when driving through tunnels, underpasses, and in city centres.

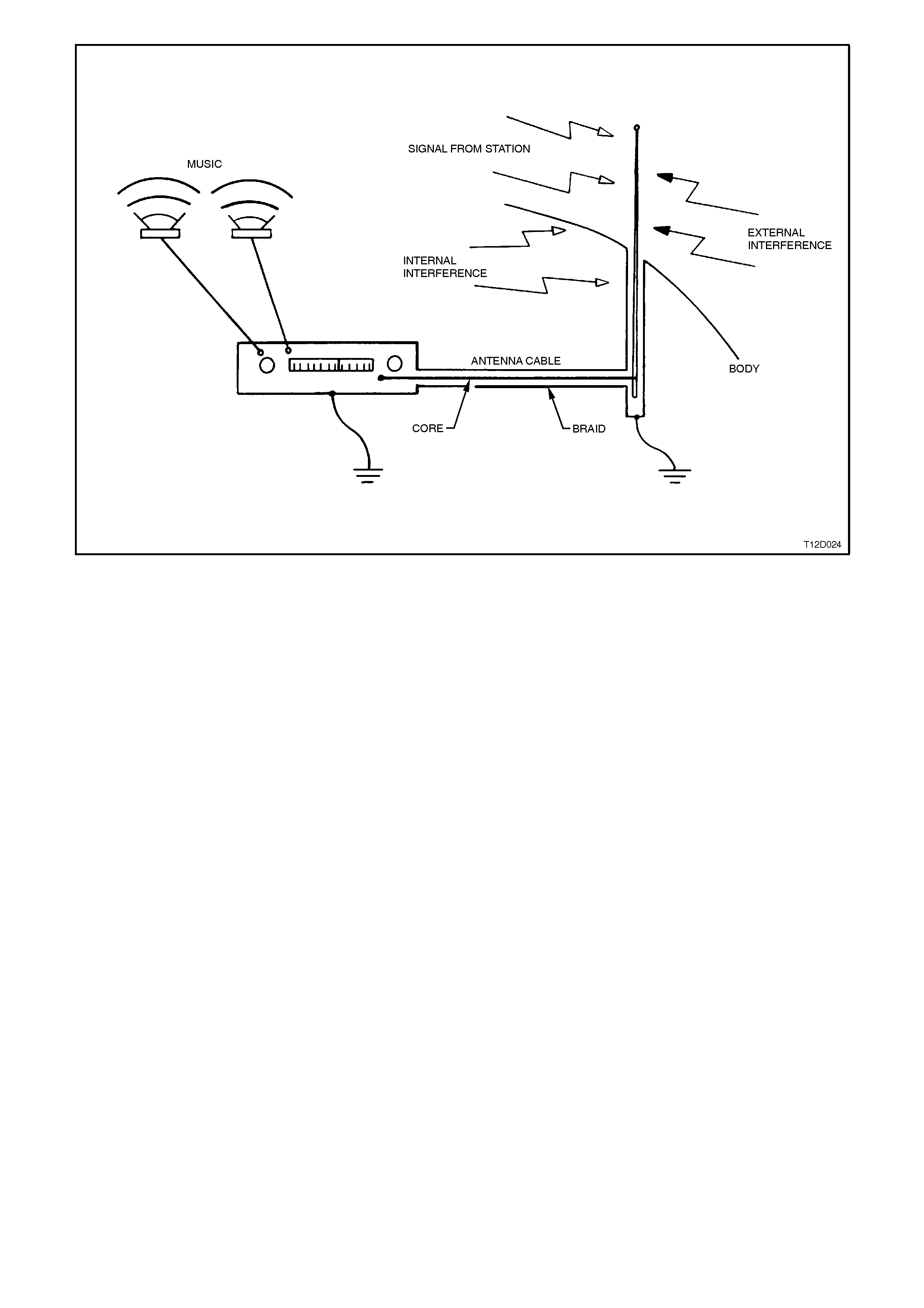

Figure 12D-39

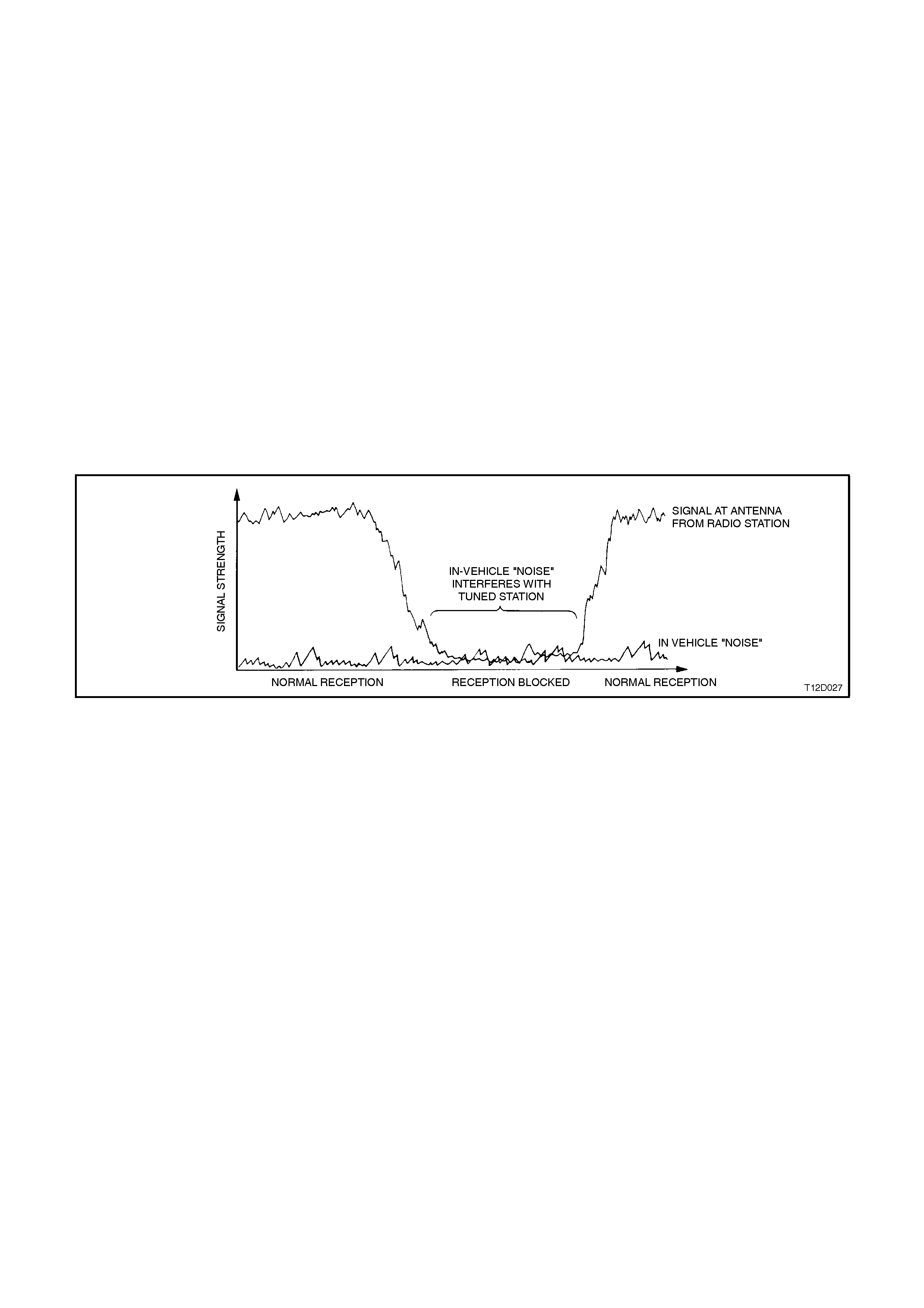

As shown, signals from radio stations are picked up by the antenna and fed to the radio while being shielded from

interference sources by the braid. This is a complete electrical circuit, any breaks in the circuit, such as poor

connections, will result in poor reception.

Interference is due to the antenna system picking up signals other than those from the desired station. These

undesirable signals may be produced by electric al equipment in the vehicle itself , such as ignition, which is termed

‘internal interference’. Conversely, interference from sources outside the vehicle, such as from power lines, is

known as ‘external interference’.

Internal interference is minimised by the shielding around the antenna wire, which prevents internal noise being

picked up and fed to the radio. The shielding around the core takes the form of a ‘braid’, which completes the

electrical circuit along which signals travel to the radio. Faults in this shielding system allow interference to reach the

radio and hence be reproduced at the speakers as noise.

It is therefore important that the shield of the antenna cable is effectively earthed at both the radio (to the radio

case) and at the antenna end (to the vehicle body), to ensure that:

1. Minimal interference is received by the radio.

2. The optimum radio sensitivity is achieved.

BASIC CHECKS

Proper performance of the radio system depends greatly on earthing of the antenna and radio case to the vehicle

body, as it eliminates stray currents in the antenna circuit. Stray currents may be induced by wires running parallel

to the path of the radio or antenna wiring, or may be due to ‘noisy’ in-vehicle electrical items.

With an ohmmeter, the resistances or connection quality can be checked for the major parts of the radio.

When using an ohmmeter to measure very low resistances, the lead resistance becomes considerable, and must

be subtracted from all subsequent readings. That is, touch the leads together, note the reading, and subtract this

from all subsequent readings.

NOTE:

A very good contact point is required to m eas ure earth res istance. T his point mus t not have curr ent f lowing through

it during m easurement, ther efore ensuring that the ignition is tur ned OFF. Avoid measuring using the sc rew on the

door jam b switch. The best place to meas ure earth resis tance is to use one of the self tapping s crews retaining the

A-pillar drip rail. Since these screws are sometimes not properly earthed, one of the screws may be removed to

take measurements directly to the body sheet metal.

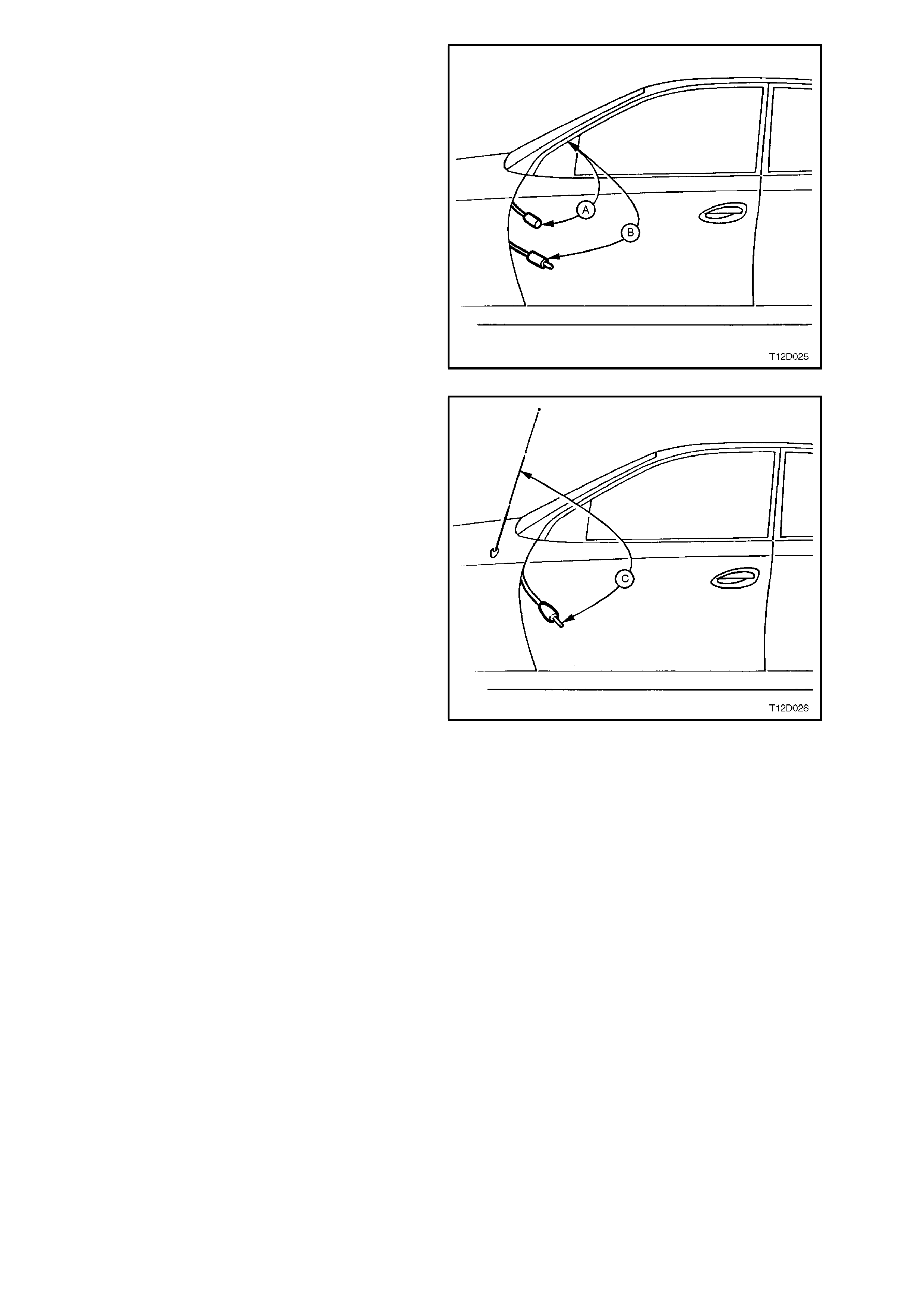

1. Remove battery earth lead.

NOTE:

Failure to disc onnect battery earth lead may lead to

incorrect resistance measurements due to stray

currents.

2. Disconnect antenna extension lead from

behind passenger side kick trim.

3. Measure resistance from the outer of the

antenna lead to vehicle body (A).

Resistance reading 0.3 ohm max.

4. Measure resistance from outer of the antenna

extension lead to vehicle body (B).

Resistance reading 0.6 ohm max.

Figure 12D-40

5. Check continuity of path from antenna cable

core to antenna m ast by measuring r esistance

(C).

Resistance reading 0.4 ohm max.

NOTE:

This test can in fact only be performed on power

antennas, since manually operated antennas are

fitted with in-line capacitors with the antenna body,

which misleadingly indicates an open circuit when

resistance is measured.

On vehicles with manually operated antennas,

disconnect antenna lead from antenna lead

extension and measure resistance of extension

lead cable core from radio to antenna lead

connection ends.

Resistance values significantly higher than those

specif ied indicates poor c onnections which m u st be

rectified before proper radio performance will be

obtained.

6. Check for shorts between antenna core and

braid by disconnecting from radio and

measuring the resistance between the two.

The measured value should indicate an open

circuit (very high or infinite resistance).

7. Disconnect antenna extension lead at both

ends and test core for continuity.

Figure 12D-41

COMMON RADIO PROBLEMS

STATIC

Static is a buzzing or crack ling noise caused by the radio pick ing up unwanted radio waves and converting them to

noise output by the speakers.

The unwanted radio waves (interference) come from several sources, which can be put into two groups; internal

and external. As the names sugges t, ex ternal inter f er enc e comes f r om outside the vehicle, and is dif f ic ult to c ontrol,

while internal interference is generated by the vehicle.

It must be emphasised that a radio system in good condition will protect itself from much static. Before trying to

locate and rem ove a sour ce of interf erence it m us t firs t be determ ined that the shielding and ear thing of the radio is

in good working order. This can easily be done by performing the tests detailed in the ‘Basic Checks’.

It should be noted that static may occur on weak stations, or when driving under bridges because signals from

ignition and the like become relatively stronger than the radio station signal, causing the ignition interference to

become quite strong. This could be due to stronger than normal ignition interference or a poorly-functioning

antenna.

If the cause cannot be isolated after performing the tests and trying to isolate a source of interference, using the

following procedures, it may be that the radio has an internal fault and requires repair.

EXTERNAL INTERFERENCE

Static which occurs only while travelling in certain localities, such as near electrical transformers, is undoubtedly

external interference.

If there is any doubt whether the suspected source is caus ing inter f er ence, a s imple chec k is to s top the vehicle and

turn off everything but the radio. If the source is external, the interference will continue and little can be done to

eliminate it.

NOTE:

The perceived interference level can be significantly reduced, in noisy environments, by slightly reducing the treble

on the radio tone controls.

INTERNA L INTERFERENCE

Internal interference is that caused by some component of the vehicle’s electrical system, and may take many

forms.

Many of the electrical item s fitted to motor vehicles produce som e sort of radio waves, but these radio waves only

become a problem if they are in the range of frequencies at which the radio receiver picks up and reproduces

signals as sound. For the radio, the vehicle’s electrical system must be designed not to emit radio signals at the

frequencies of the AM and FM bands.

Components are sometim es fitted with suppres sing devic es as par t of their design, and failure of thes e suppr es sor s

may allow the item to start interfering with radio operation.

Interference will be worse on weak stations, since a strong signal normally overpowers the interfering signal.

Interference can occur when the signal strength drops below a certain threshold, such as driving under a bridge,

inside a workshop, or in the shadow of a building. This situation is shown in the following figure.

Figure 12D-42

Static may be caused by many internal sources. If static is at ignition frequency, varying with engine speed, the

ignition is the culprit. However, many electrical faults will cause static which otherwise would not be heard.

Examples of ignition interference sources are:

1. Plug leads breaking down.

2. Carbon tracking (arcing) to earth.

3. Faulty spark plugs.

4. Inoperative interference shields.

The actual cause of the interference can be isolated through carefully noting the circumstances under which the

problem occur s . For example, if it oc c ur s only at speeds above approx imately 80 km /h in an automatic tr ans miss ion

equipped vehicle, quite possibly it is the electrical signal being sent to the torque converter clutch.

Other sources of static can be:

1. Electric cooling fan.

2. Electric fuel pump.

3. Normal computer ‘noise’ at certain frequencies.

4. Windshield wipers or washers.

DIAGNOSING INTERNAL INTERFERENCE

If a vehicle has an interference problem that only occurs when the engine is turned ON, or some other repeatable

circumstance, carry out the following procedure:

1. Park vehicle in an open area, as far away from buildings as possible. Turn the radio onto the band (AM\FM)

and frequency where the complaint occurs, with the ignition on ACC.

2. Reproduce the interference, eg. turn ignition ON.

3. If interference is due to a fan blower motor, etc. and is judged to be objectionable, the component should be

substituted to determine whether it is faulty.

NOTE:

Internal interference is often a symptom of a defective radio system, such as poor antenna earthing, etc. If

substituting a new component does not f ix the c ondition, the pr oblem is ver y likely to be in the radio system, and the

resistance checks in this Section should be performed.

4. Whistles/s queals that occ ur only when the ignition is ON, are probably due to electronic m odules in the vehicle

creating interference when active (power applied). These m odules may be isolated as a cause of interference

by removing power to them and rechecking. This is best done by turning the ignition OFF, rem oving the fuse

that supplies that particular item with power, turning the ignition back on and rechecking. By process of

elimination, the ‘noisy’ module should be able to be found. Once found, substitute the module to find out

whether the interference is normal.

SPEAKERS

Before removing speakers suspected of being noisy or faulty, ensure that any distortion which may be present is not

due to any of the following:

1. Foreign matter such as sand lying on the speaker cone.

2. Cable ties or other such material resting on the back of the speaker cone.

3. Incorrectly fitted speaker mesh or loose trim around speaker assembly.

4. Distortion of speaker assembly caused by the angled insertion of the speaker retaining screws. Speaker

problem s due to this m ay be rec tified by loosening the screws and r etightening, being ca reful not to distor t the

speaker cone again.

CASSETTE PLAYER CARE

To ens ure proper and r eliable operation, the oxides used in tape m anuf acture m us t be cleaned fr om the heads and

capstan drive of the unit, at intervals of no more than 100 hours of operation. Sticky oxide build up on the capstan

can result in tape speed variation, and ultimately in tape damage. Hence it is impor tant that user s are advis ed of the

importance of keeping cassette units clean.

Cassette players may be cleaned using a wet head cleaning tape.

3.1 DIAGNOSTIC PROCEDURES

When using the following diagnostic charts, continually refer to the following circuit diagrams.

RADIO/CASSETTE PLAYER FAULT DIAGNOSIS

The f ollowing chart sets out com m on user com plaints and s ymptom s with refer ence given to which diagnostic c hart

to follow for problem rectification.

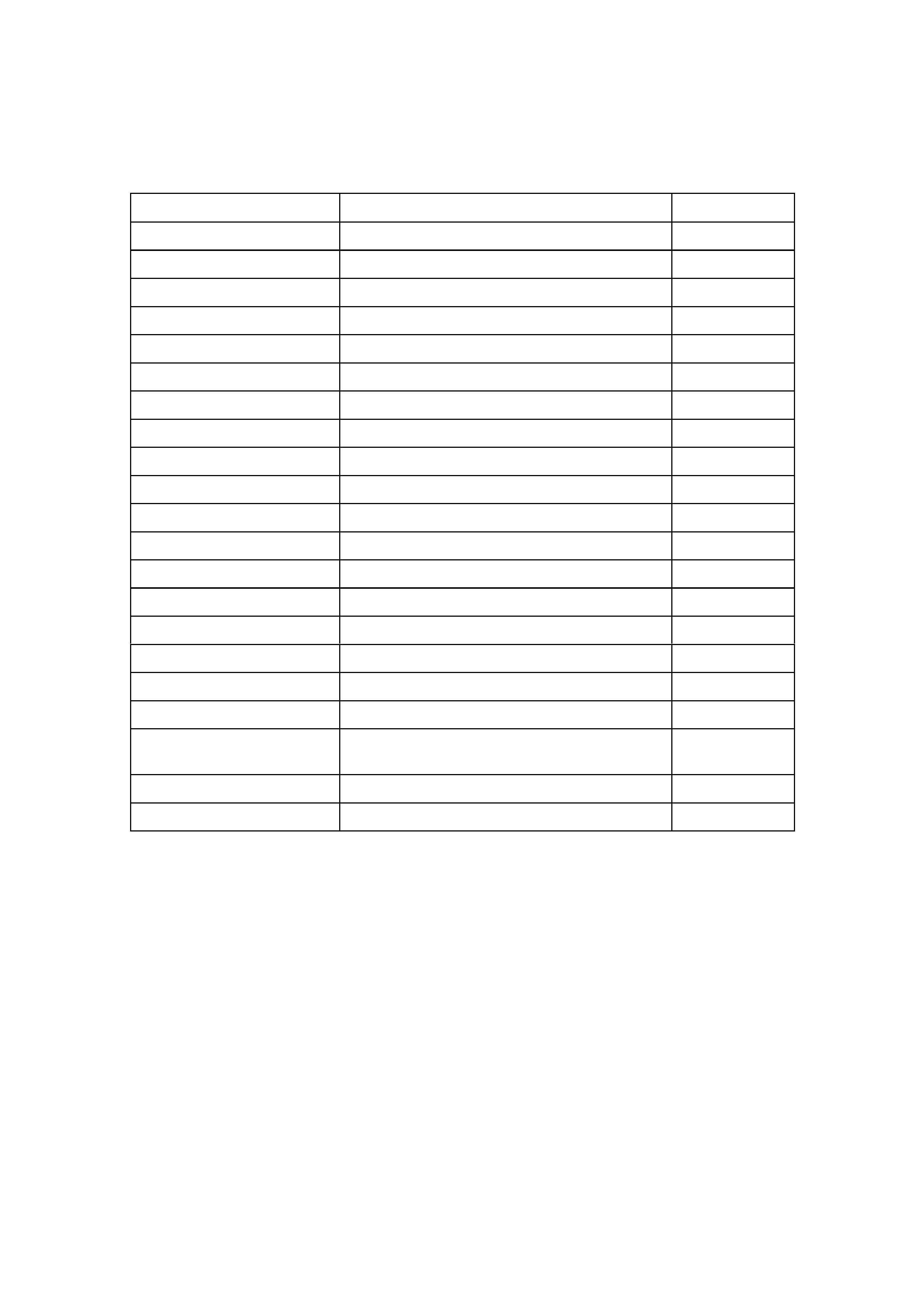

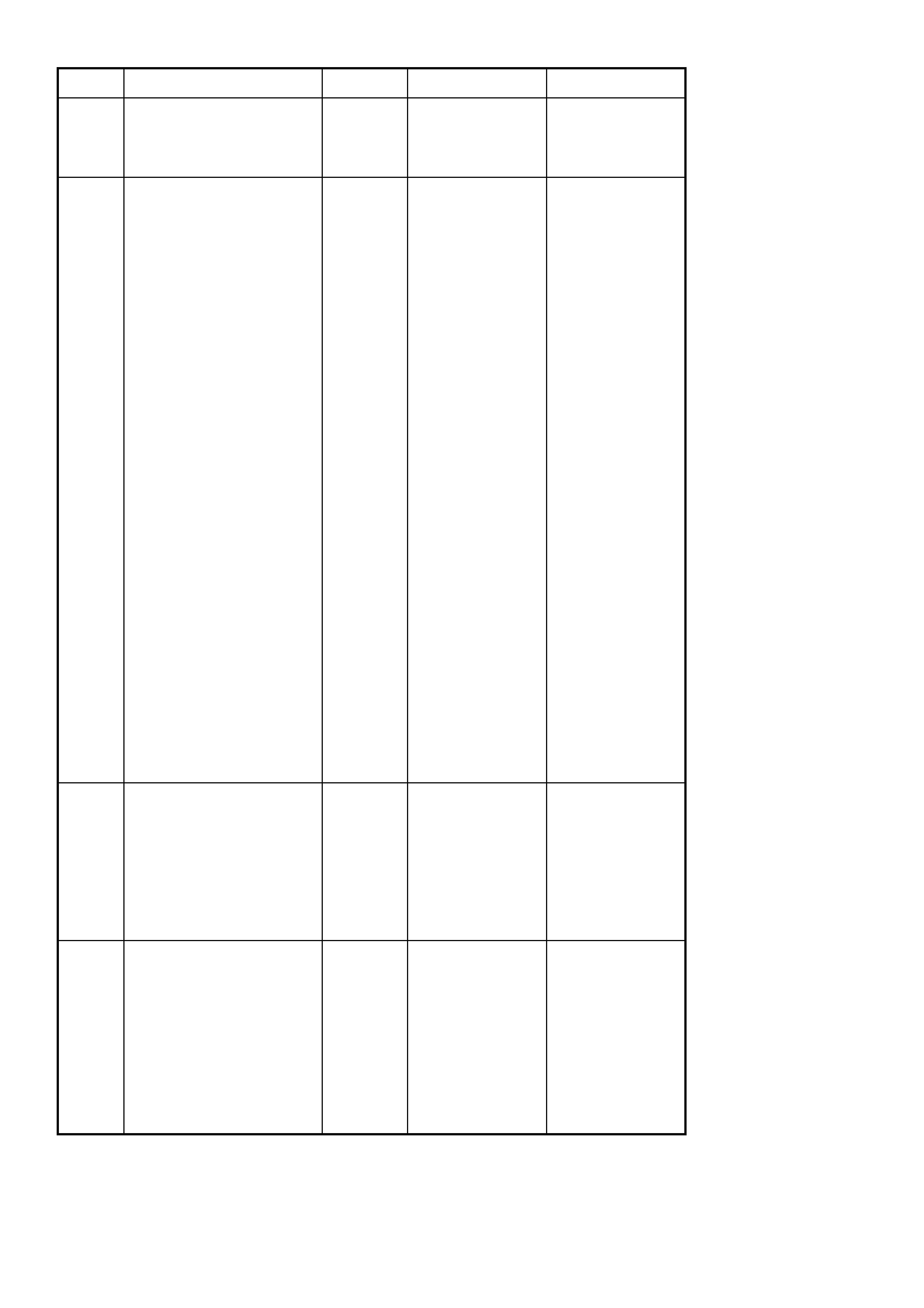

COMPLAINT SYMPTOM TABLE NO.

Power No power/illumination 1

Sound No sound/Low sound 1,2

One speaker low/not working 1,2

Distortion/Poor sound 1,2,3

Noise 1,2,3

Radio No or weak reception 3

Vehicle Interference 3

External Interference 3

Search tune skipping stations 3

Tape Tape speed too fast/slow 4

Noise 1,2,4

Jammed cassette mechanism 4

Will not eject tape 4

Can’t insert tapes 4

CD Player CD Changer error messages 5

Cannot select CD mode 5

CD player skips 5

CD player repeats same passage of sound 5

Horn Bar Stereo Controls

(Calais) No/unexpected operation 6

Power Antenna Fails to extend 7

Fails to retract 7

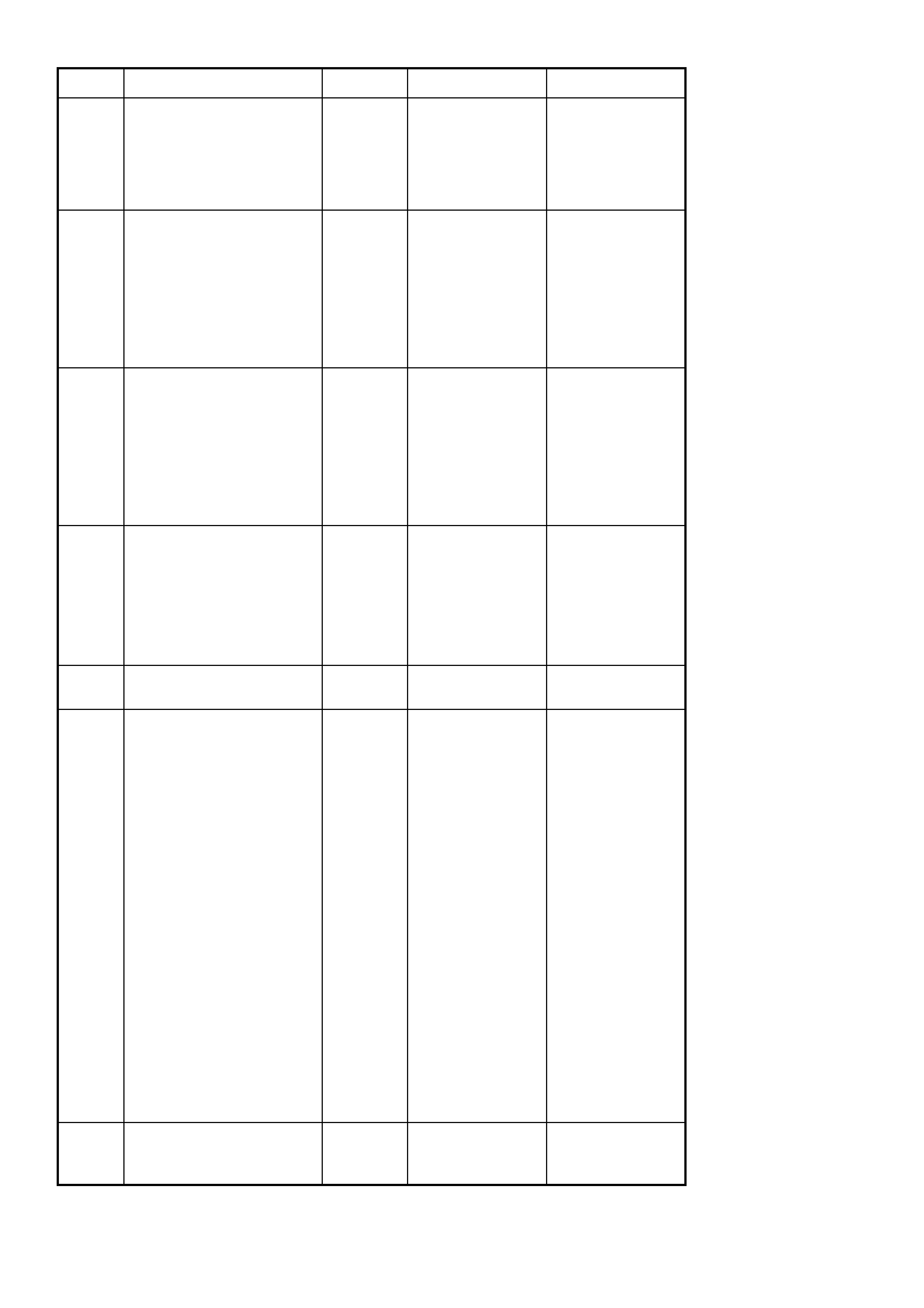

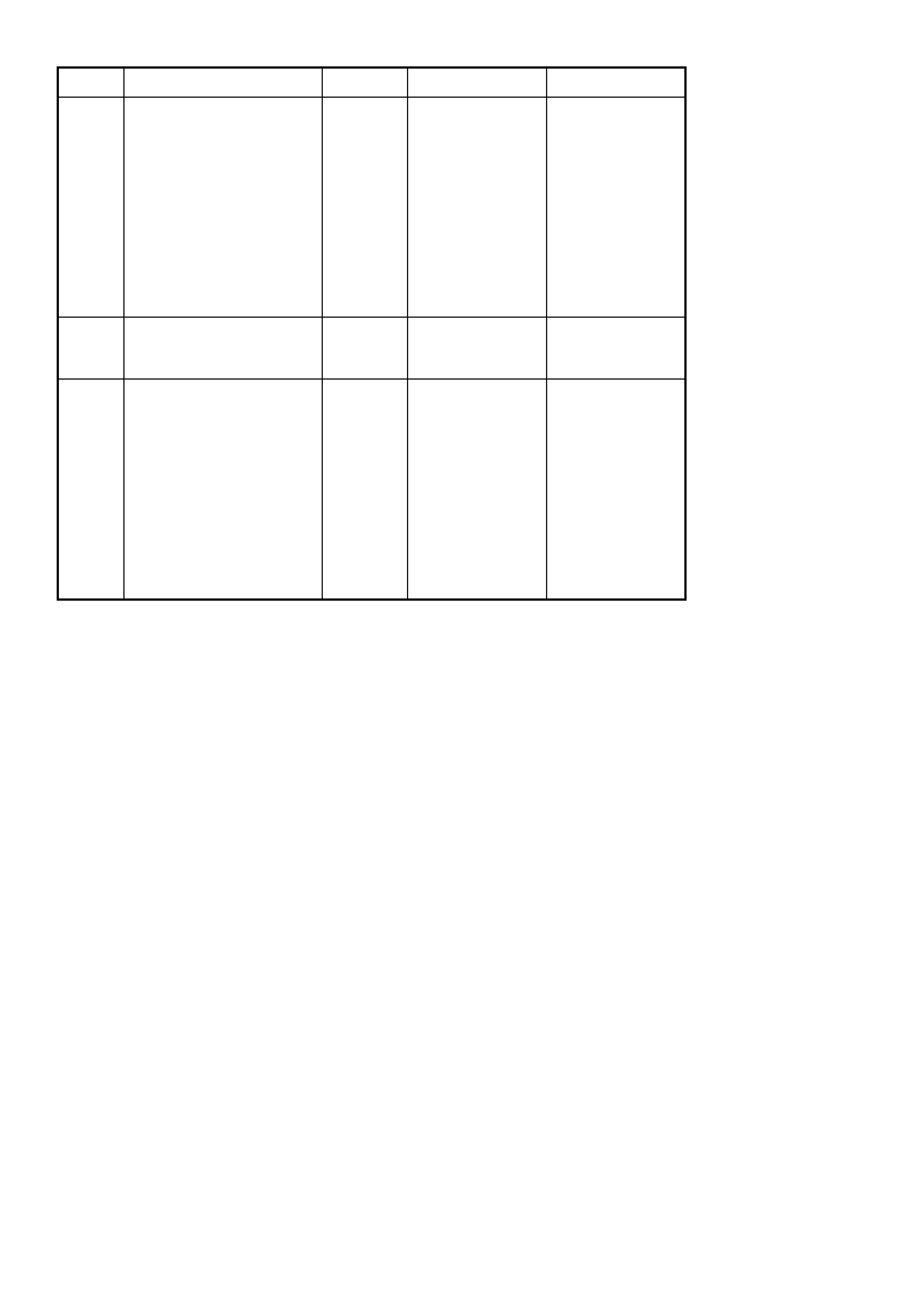

TABLE NO. 1 POWER AND SOUND DIAGNOSIS

STEP ACTION RESULT YES NO

1• Turn ignition switch to

ACC position

• Turn radio on

• Does the display

illuminate correctly?

Go to Step 5 Go to Step 2

2• Partially remove radio,

refer to 2.1

RADIO/CASSETTE

PLAYER in this

Section

• Is connector firmly

pushed into rear of

radio?

Go to Step 3 Push connector

firmly into back of

radio and verify

correct operation.

3• Using multimeter,

check voltage of circuit

4 on radio connector

YB72 (BR).

• Is there at least 11

volts on the

ignition/accessory

main radio connector?

Go to Step 4 Go to Step 16

4• Using multimeter,

check continuity of

earth circuit 1151 at

connector YB72 (B/W)

using suitable body

earth location.

• Is there continuity?

Remove and

return for repair. Rectify the earth

connection

problem and

verify repair.

5• Is there sound from all

speakers? Go to Step 6 Go to Step 2 of

Table 2

6• Check the terminals at

the rear of the affected

speakers. For door

speakers, check that

they are in good

condition and do not

contact the body work.

Look for signs that

contact with the body

work may have

occurred previously.

• Tap door panels to

verify that terminals will

not make contact with

body work, and

insulate terminals if

necessary.

• Are there indications

that the speaker

terminals have made

contact with the body

work?

Insulate terminals

and recheck

speaker

operation.

Go to Step 14

Go to Step 7

7• Is the sound distorted

in all modes (radio,

cassette, CD)?

Go to Step 8 See relevant

diagnostic chart

in this section.

STEP ACTION RESULT YES NO

8• Using multimeter,

check voltage of circuit

4 on radio connector

YB72 (BR).

• Is there at least 11

volts on the

ignition/accessory

main radio connector?

Go to Step 9 Rectify the

voltage

connections and

verify repair.

9• Is connector firmly

pushed into rear of

radio?

Go to Step 10 Push connector

firmly into back of

radio and verify

correct operation.

10 • Use fader and balance

controls to decide

whether distortion is

from one or more

speakers.

• Is distortion from one

speaker only?

Go to Step 11 Return radio for

repair.

11 • Is there foreign matter

such as dirt in the

speaker cone?

Clear the speaker

of foreign matter

and verify repair.

Go to Step 12

12 • Ensure speaker

terminals do not touch

body work.

• Is the connector firmly

on the speaker?

Go to Step 13 Push connector

firmly onto

speaker and

verify repair.

13 • Check that the correct

speaker has been

fitted to the vehicle.

Note that low series

models and Calais

have different speaker

designations with

different impedance

values. The

appropriate type must

be fitted for correct

operation, refer to 2.3

FRONT DOOR

SPEAKERS - ALL

MODELS and

2.4 REAR DOOR

SPEAKERS in this

Section.

• Is the correct speaker

installed?

Go to Step 14 Fit correct

speaker and

verify repair.

14 • Connect a working

substitute speaker.

• Does the speaker work

clearly?

Install new

speaker,

ensuring correct

impedance and

verify repair.

Go to Step 15

15 • Is the wiring to the

speaker damaged? Repair fault in

harness Remove and

return for repair.

STEP ACTION RESULT YES NO

16 • Check fuse F16.

• Is fuse OK?

Go to Step 17 Replace fuse and

investigate cause

of blown fuse.

17 • Check continuity of

wiring harness from

ignition switch

connector YB44 (BR)

to radio harness YB72

(BR).

• Is there continuity?

Investigate

source of voltage

interruption from

ignition switch

and battery.

Repair wiring

harness and

verify repair.

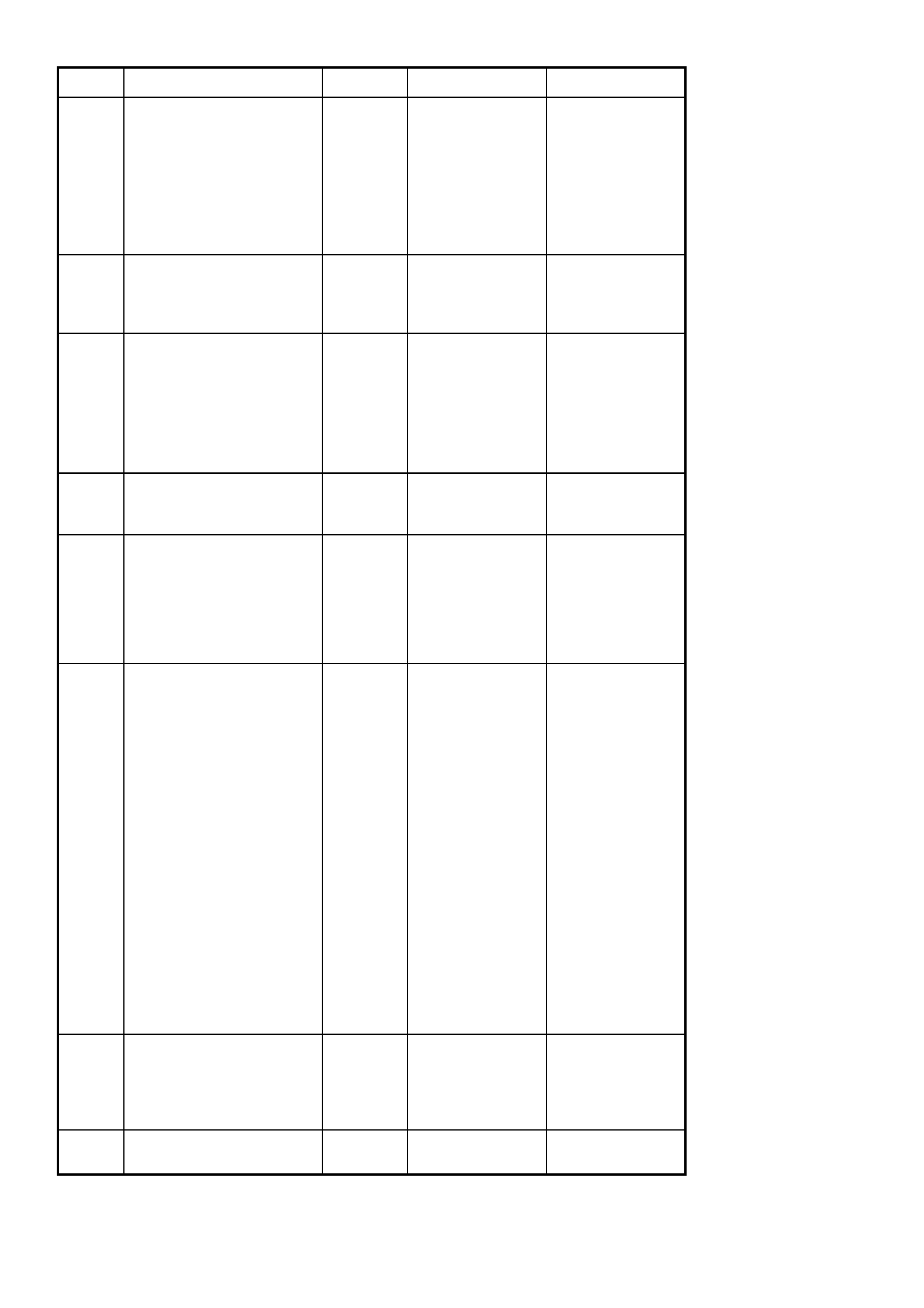

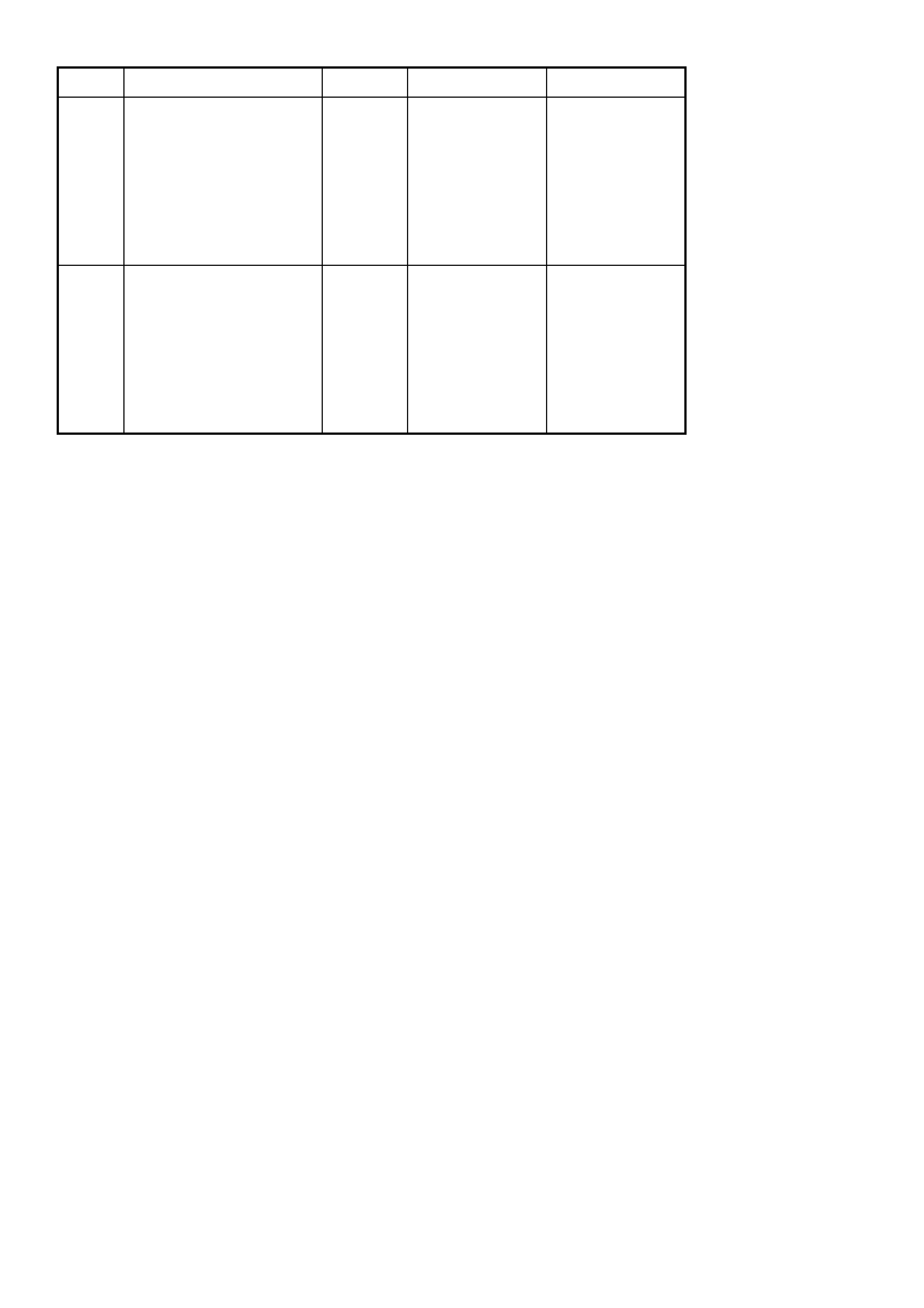

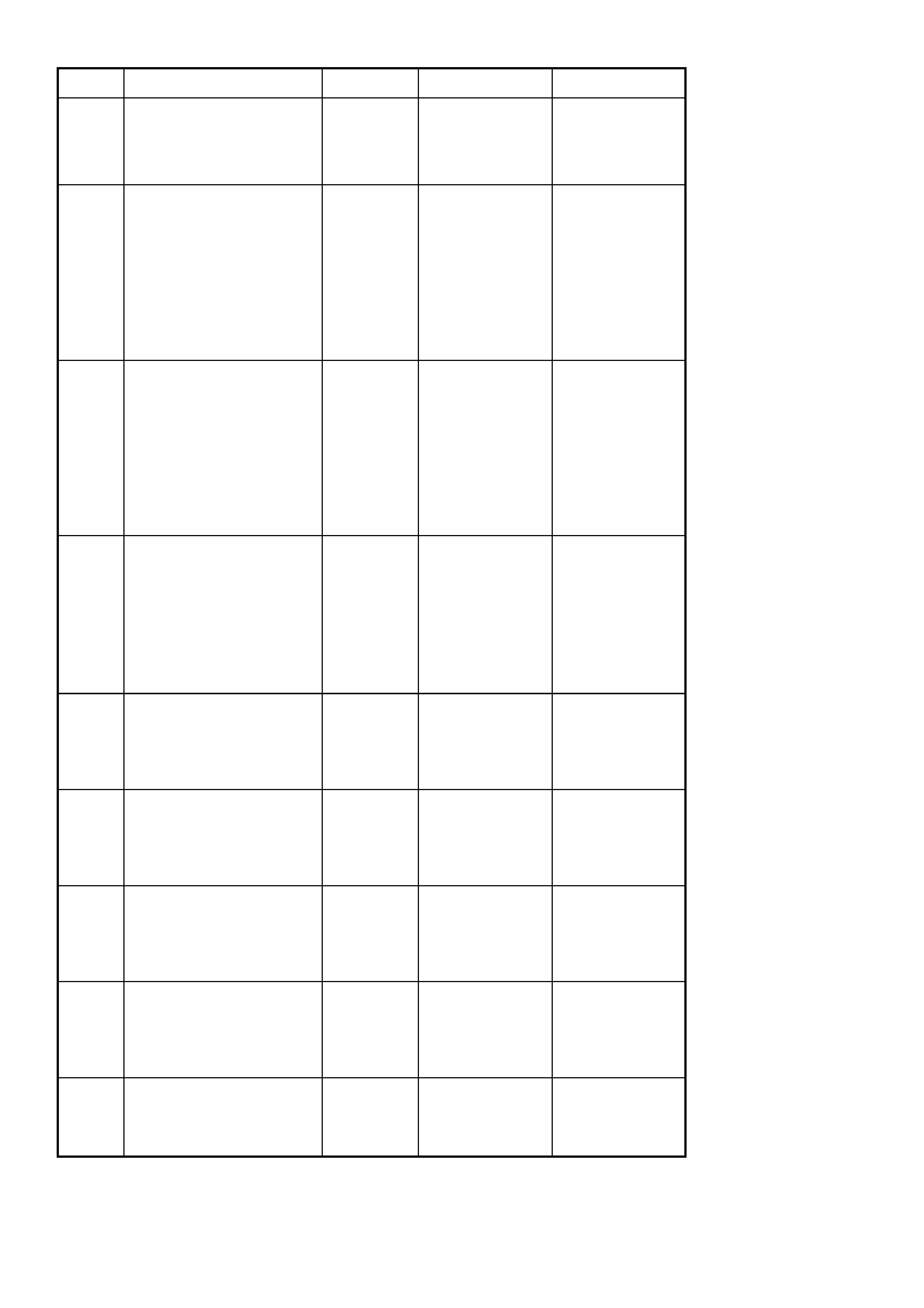

TABLE NO. 2 INTERMITTENT FAULT DIAGNOSIS

STEP ACTION RESULT YES NO

1• Does customer

complain of sound

dropping out during all

modes intermittently?

Go to Step 2 See relevant

diagnostic table

in this Section.

2• Does the drop-out

occur only in one or

two speakers?

Go to Step 3 Go to Step 4

3• Check connections at

the relevant speaker

and harness

connectors between

speaker assembly and

radio. Inspect

terminals for damage

or poor fit.

• Check the terminals at

the rear of the affected

speakers. For door

speakers, check that

they are in good

condition and do not

contact the body work.

Look for signs that

contact with the body

work may have

occurred previously.

• Tap door panels to

verify that terminals will

not make contact with

body work, and

insulate terminals if

necessary.

• Do the connections

appear OK, even when

pulled and

manipulated?

Go to Step 10 in

TABLE 1

POWER AND

SOUND

RELATED

PROBLEMS in

this Section

Repair harness

or replace

speaker if

terminals are

damaged, and

verify correct

operation.

4• Check connections at

rear of radio, inspect

terminals for damage

or poor fit.

• Do the connections

appear OK, even when

pulled and

manipulated?

Go to Step 5 Repair harness

and verify correct

operation.

5• Using multimeter,

check for continuity of

cellular telephone

mute circuit 656

(Yellow/Black) on radio

connector YB72 to

body earth.

• Does this circuit

indicate continuity to

earth?

Cellular

telephone mute

line has shorted

to earth, locate

short circuit

and/or damage to

harness and

verify repair.

Remove radio

and return for

repair

OR

Calais only -

Go to Step 6

STEP ACTION RESULT YES NO

6• Does customer

complain of settings

(ie, volume, mode,

radio station,

bass/treble etc)

changing when ignition

is turned from ACC to

ON when starting the

car?

Refer to Note 1 at

the end of this

Table.

Go to Step 7

7• Does customer

complain of settings

(ie, volume, mode,

radio station,

bass/treble, antenna

height etc) changing,

or intermittent erratic

audio system operation

when driving the car.

Refer to Note 2 at

the end of this

Table.

Remove radio

and return for

repair.

NOTE 1

Inform customer that the priority key settings are restored from the BCM when the vehicle is unlocked with the

rem ote using its priority k ey signal. These s ettings will be restored when the ignition is turned to ACC position. T he

BCM will request the priority key settings of the key in the ignition when the ignition is cycled. If a different key is

then used to start the car, or the car was not locked and a different key used to start the car the BCM will use the

priority key settings for the current key. This may result in the settings changing when the ignition is cycled, and is

part of normal operation.

Suggest to customer that the key used to start the car should be the same key used to unlock the car.

NOTE 2

If there is an intermittent open circ uit or short circuit to body earth in the priority key circuit (Grey) f rom the BCM to

the radio then the priority key settings may alternate. As the priority key changes, the radio settings will change to

reflect the values stored in each key. This will result in volume, mode, radio station, bass/treble settings to change

for apparently no reason.

This can additionally cause the radio to switch on and off erratically if one priority key sets the radio on and the other

turns it off.

The priority line circuit will need to be investigated for a short- or open circuit, refer to

Section 12P WIRING DIAGRAMS.

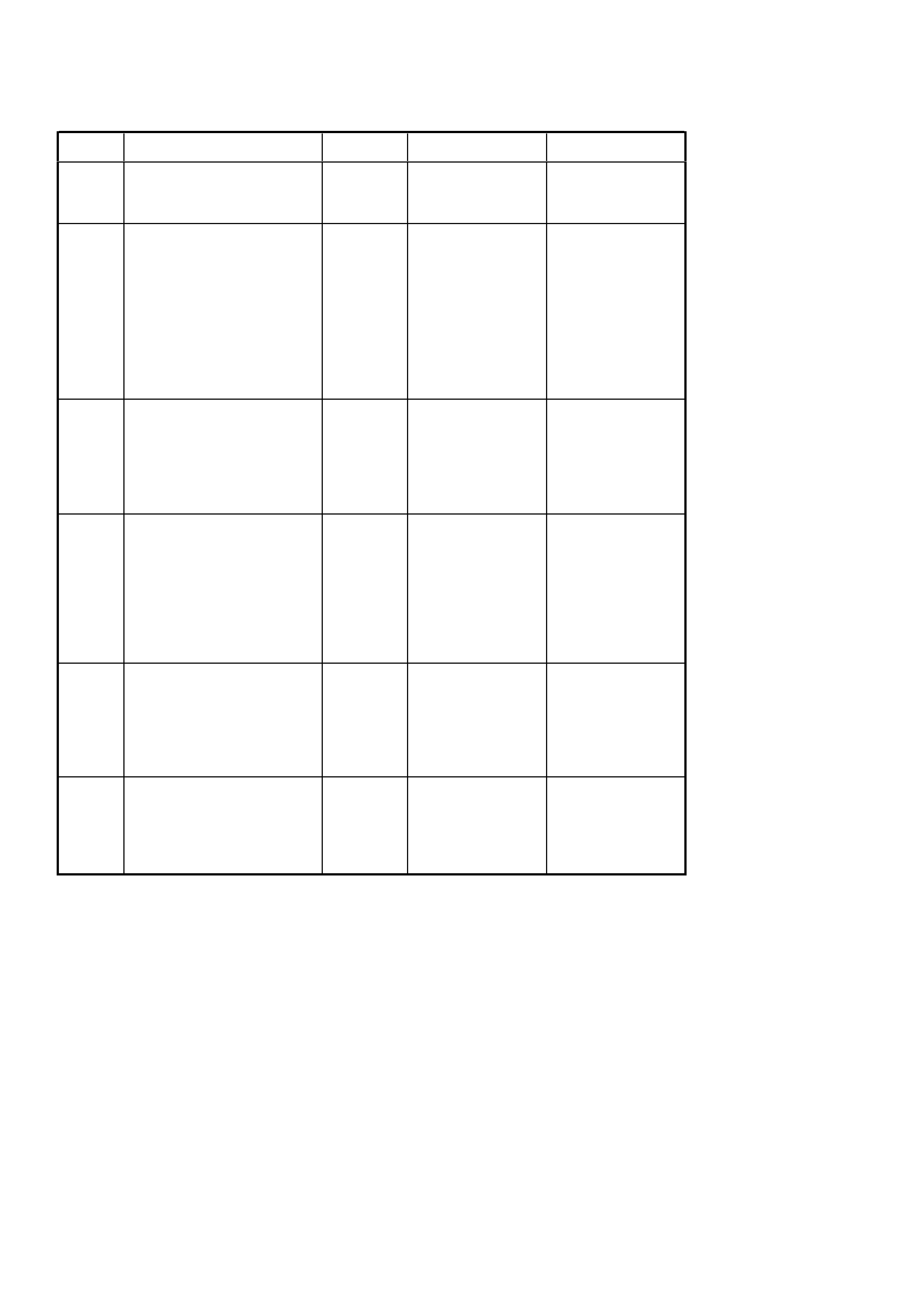

TABLE NO. 3 RADIO/RECEPTION DIAGNOSIS

STEP ACTION RESULT YES NO

1• When radio mode is

selected, is there no

reception or weak

reception?

Go to Step 2 Go to Step 9

2• Fully extend antenna

and move vehicle to

known high quality

reception area.

• Is reception still weak?

Go to Step 3 Reconfirm

problem with

customer.

3• Is the antenna plugged

into the rear of the

unit and behind the

passenger’s side kick

trim?

Go to Step 4 Plug the antenna

into the unit and

behind

passenger’s side

kick trim.

Go to Step 1

4• Is the reported

problem on a Calais

and only with FM

reception?

Go to Step 5 Go to Step 7

5• Drive vehicle to known

good reception area.

• Extend antenna fully

• With the radio turned

on, press and hold the

LOC button and press

the TIME button.

Release both buttons

and watch the radio

display. This performs

an antenna check

diagnostic.

• If diversity antenna and

main antenna are OK

the radio will display

GOOD. Go to Step 6.

• If there is a fault with

the diversity antenna

system, B-S (bad sub-

antenna) will be

displayed. Go to Step

6.

• If there is a fault with

the main antenna, B-M

will be displayed.

• Was GOOD displa yed

during the diagnostics?

Go to Step 7 Go to Step 6

STEP ACTION RESULT YES NO

6• If fitted, check

connections diversity

antenna connections:

• Check diversity

antenna

connections near

rear parcel shelf

and behind

passenger’s side

kick trim.

• Check diversity

antenna connection

on rear window,

• Diversity antenna

earth screw in ‘C’

pillar,

• Diversity antenna

amplifier power

circuit at connector

YB144 (BR).

• Diversity antenna

amplifier earth

circuit

• See also notes

regarding diversity

antenna fault diagnosis

after Table 8 in this

Section

• Are all these

connections OK?

Go to Step 7 Repair necessary

connections and

verify repair.

Go to Step 1

7• Compare the weak

signal in this vehicle

with that coming from

a vehicle which does

not experience this

problem.

• Does the weak signal

sound more evident in

this vehicle than the

comparison car?

Go to Step 8 Explain to the

customer that the

weak signal or

distortion

appears to be

one affected by

the location of the

car. Refer to

Principles of

Operation in 3

DIAGNOSIS in

this Section.

8• Has a new antenna

been attached to the

back of the radio?

Remove and

return unit for

repair.

Go to Step 9

9• Attach a new lead and

retest.

• Is reception still weak?

Remove and

return unit for

repair.

Fit new antenna

and verify repair.

10 • Is there vehicle related

interference, that is, it

disappears when

vehicle’s electrics and

engine are off?

Go to Step 11 Go to Step 13

11 • Can the cause be

located by turning off

various vehicle

components?

Go to Step 12 Remove and

return for repair.

STEP ACTION RESULT YES NO

12 • Is the noise a whine,

such as from the

vehicle’s alternator or

with increase in engine

speed ?

Undertake the

necessary steps

to ensure that the

generator/coil

suppressor and

earth to radio

function are all

fully operational.

Go to Step 10

Go to Step 13

13 • Has a new antenna

extension lead been

installed?

Go to Step 14 Attach a new

antenna

extension lead,

routed away from

the other wiring.

Go to Step 10

14 • Using a multimeter,

check the resistance

from the radio case to

the body earth at

instrument carrier

(refer to Section 12P

WIRING DIAGRAMS.

• Is the resistance

greater than 0.5 ohms

Remove and

return for repair. Remove and

return for repair.

15 • Is there external

interference, that

appears only in certain

locations?

Advise the

customer that

external

interference

cannot be

eliminated unless

the source is

eliminated. To

reduce this

interference,

extend antenna

fully and if the

interference is a

high frequency

noise, use the

treble control to

reduce treble

response.

Go to Step 16

16 • Does the search tune

skip stations? Go to Step 17 Reconfirm

problem with

customer.

17 • Fully extend the

antenna

• Switch off ‘LOC’

feature

• Does the search tune

still skip stations?

Go to Step 18 Reconfirm

problem with

customer.

18 • Test the antenna or

extension lead for fault

• Is antenna or lead

faulty?

•Repair or replace

the faulty

component.

Go to Step 16.

Remove and

return for repair.

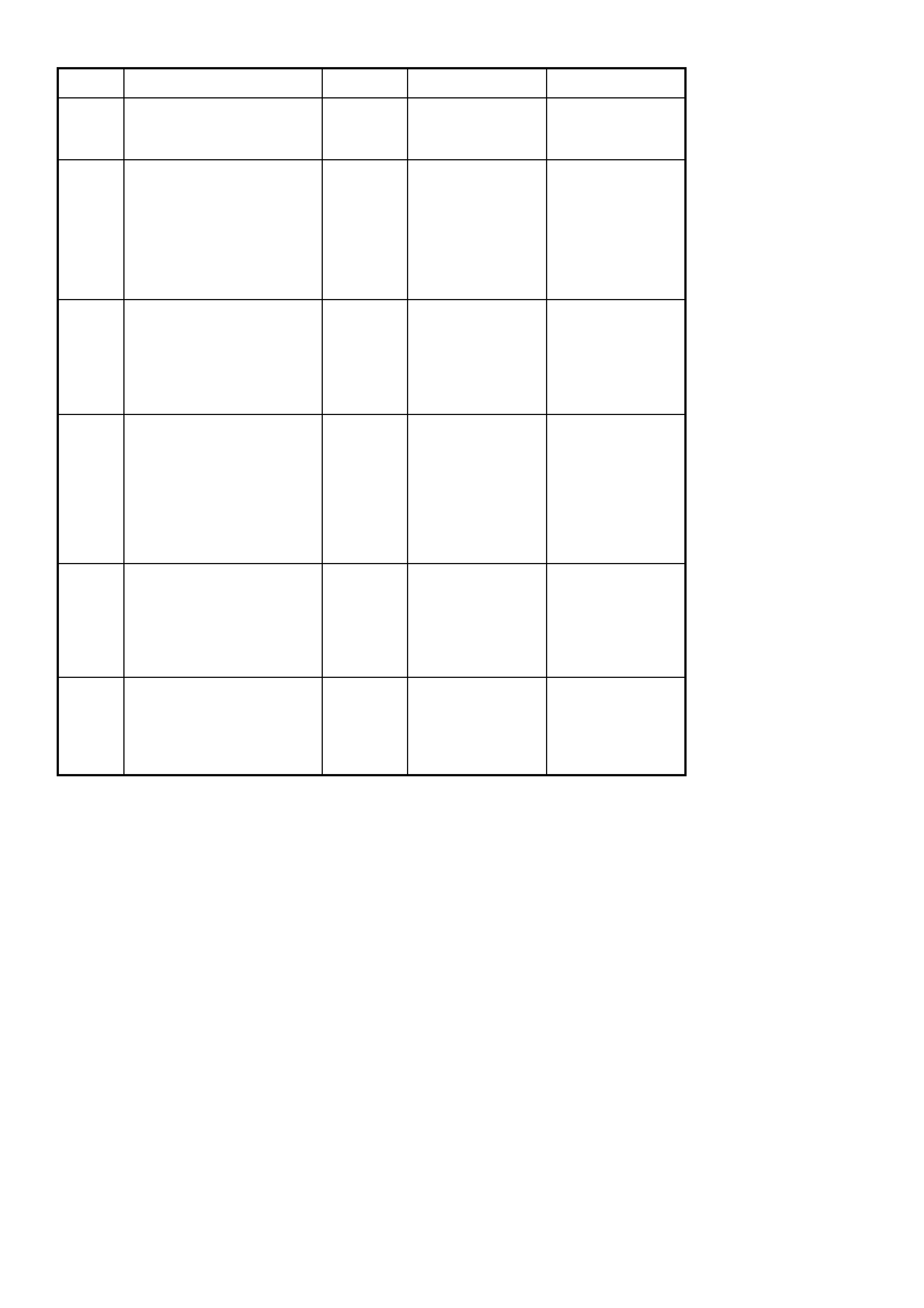

TABLE NO. 4 CASSETTE PLAYER DIAGNOSIS

STEP ACTION RESULT YES NO

1• Can cassettes be

inserted? Go to Step 8 Go to Step 2

2• Is the cassette

mechanism empty? Go to Step 6 Go to Step 3

3• Attempt to eject the

cassette by pressing

the eject button.

• Did the cassette eject

easily?

Go to Step 1 Go to Step 4

4• If the cassette ejected

slightly, push it back

into the unit, then exert

normal pressure (not

force) on eject button

whilst guiding the

cassette upwards.

• Did the cassette eject?

Go to Step 5 Remove and

return radio for

repair.

5• Is the cassette door

bent or damaged so

that door is blocking

cassette entrance?

Remove and

return radio for

repair.

Go to Step 1

6• Does there appear to

be a foreign object

within the mechanism?

Go to Step 7 Remove and

return radio for

repair.

7• Is it possible to remove

the foreign object

without damaging the

unit?

Remove foreign

object and

go to Step 1

Remove and

return radio for

repair.

8• Does the tape play as

though it is in fast-

forward mode?

Remove and

return radio for

repair.

Go to Step 9

9• Does the unit operate

properly in all functions

other than cassette

mode?

Go to Step 12 Go to Step 10

10 • Is the tonal quality poor

which makes the

output sound muffled?

Clean the tape

path using only a

wet cleaning

system,

go to Step 12

Go to Step 11

11 • Does the cassette run

slowly or switch to

auto-reverse before

the end of the tape has

been reached?

Run the offending

cassette on fast-

forward and fast-

rewind for full

length and re-

check tape

function.

Go to Step 12

Reconfirm

problem with

customer.

12 • Insert a tape which you

know works without a

problem.

• Does the unit work

without a problem?

End of diagnostic

procedure. Remove and

return radio for

repair.

TABLE NO. 5 CD PLAYER DIAGNOSIS

STEP ACTION RESULT YES NO

1• When attempting to

use CD changer, does

an error message

appear?

Go to Step 2 Go to Step 8

2• Is it the error “E01” (No

magazine is disc

changer)?

Insert a loaded

disc magazine

into the changer.

Go to Step 3

3• Is it the error “E02” (No

disc in the magazine)? Insert a disc into

the magazine. Go to Step 4

4• Is it the e rror “E04”

(Disc is dirty or upside

down)?

Go to Step 5 Go to Step 6

5• Check that the disc is

clean and free from

scratches and inserted

the correct way up.

• Is CD clean and

inserted properly?

Remove and

return for repair. Rectify problem

and verify repair.

6• Is the error “E 08” (CD

changer is too hot)?

• As with all compact

disc players, the unit

will not operate if the

ambient temperature is

above 55°C, otherwise

permanent laser

damage can occur.

Remove and

return for repair. Go to Step 7

7• Is the error “E99”

(Micro computer is

locked)?

Hold On/Off

button on radio

for more than

6 seconds, then

reload discs.

Remove and

return for repair.

8• Can the CD mode be

selected and activated

on the head unit?

Go to Step 10 Go to Step 9

9• Check the CD

connector on the CD

changer and in the

passenger

compartment.

• Is the CD connector

secure and the

harness undamaged?

Remove and

return for repair. Reconnect or

repair harness

and verify correct

operation.

Go to Step 8

10 • Does the CD changer

skip on rough roads? Go to Step 11 Go to Step 13

11 • Are the spring adjuster

caps on each end of

the CD changer

adjusted with the slot

facing up-down?

Go to Step 12 Adjust the spring

adjuster

appropriately and

verify repair.

STEP ACTION RESULT YES NO

12 • Road test the vehicle.

• Does skipping only

occur under severe

conditions?

Explain to the

customer that CD

skipping is

usually due to

dirty or scratched

CDs. The CD

player does at

times skip on

very rough roads

or if a large

pothole is

encountered.

Go to Step 14

13 • Does the CD skip or

repeat the same

passage of output?

Go to Step 14 Reconfirm

problem with

customer.

14 • Insert and attempt to

play a known clean

and properly playing

CD.

• Does the CD player

continue to skip under

normal driving

conditions?

Remove and

return for repair. Explain to the

customer that CD

skipping is

usually due to

dirty or scratched

CDs. The CD

player does at

times skip on

very rough roads

or if a large

pothole is

encountered.

TABLE NO. 6 HORN BAR STEREO CONTROL FAULT DIAGNOSIS - CALAIS

STEP ACTION RESULT YES NO

1• Switch radio ON with

key in ACC position.

• Do all switches operate

correctly?

Reconfirm

problem with

customer.

Go to Step 2.

2• Using multimeter,

check resistance

across radio connector

YB73 terminals BR

and B/Y.

• Does resistance

indicate open circuit

with no horn bar

buttons pressed?

Go to Step 3. Replace switch

assemblies and

verify repair.

3• Using multimeter,

check continuity of

harness between horn

bar radio controls and

radio YB148 and YB73

(BR to BR and B/Y to

B/Y).

• Is there continuity of

each of the circuits?

Go to Step 4. Repair harness

and verify repair.

4• Using multimeter,

check the resistance of

the circuit when each

of the buttons are

pressed.

• Press MODE switch on

left hand-side of

steering wheel.

Is

resistance

between

20k6 and

22k8?

Go to Step 5. Replace switch

assemblies and

verify repair.

5• Press NEXT ↑ switch

on the left-hand side of

steering wheel.

Is

resistance

between

11k1 and

12k3?

Go to Step 6. Replace switch

assemblies and

verify repair.

6• Press NEXT ↓ switch

on the left-hand side of

steering wheel.

Is

resistance

between

6k7 and

7k4.

Go to Step 7. Replace switch

assemblies and

verify repair.

7• Press MUTE switch on

the right-hand side of

steering wheel.

Is

resistance

between

3k5 and

3k9?

Go to Step 8. Replace switch

assemblies and

verify repair.

8• Press VOL ↑ switch on

the right-hand side of

steering wheel.

Is

resistance

between

1k4 and

1k6?

Go to Step 9. Replace switch

assemblies and

verify repair.

9• Press VOL ↓ switch on

the right-hand side of

steering wheel.

Does

multimeter

indicate

continuity?

Remove and

return for repair. Replace switch

assemblies and

verify repair.

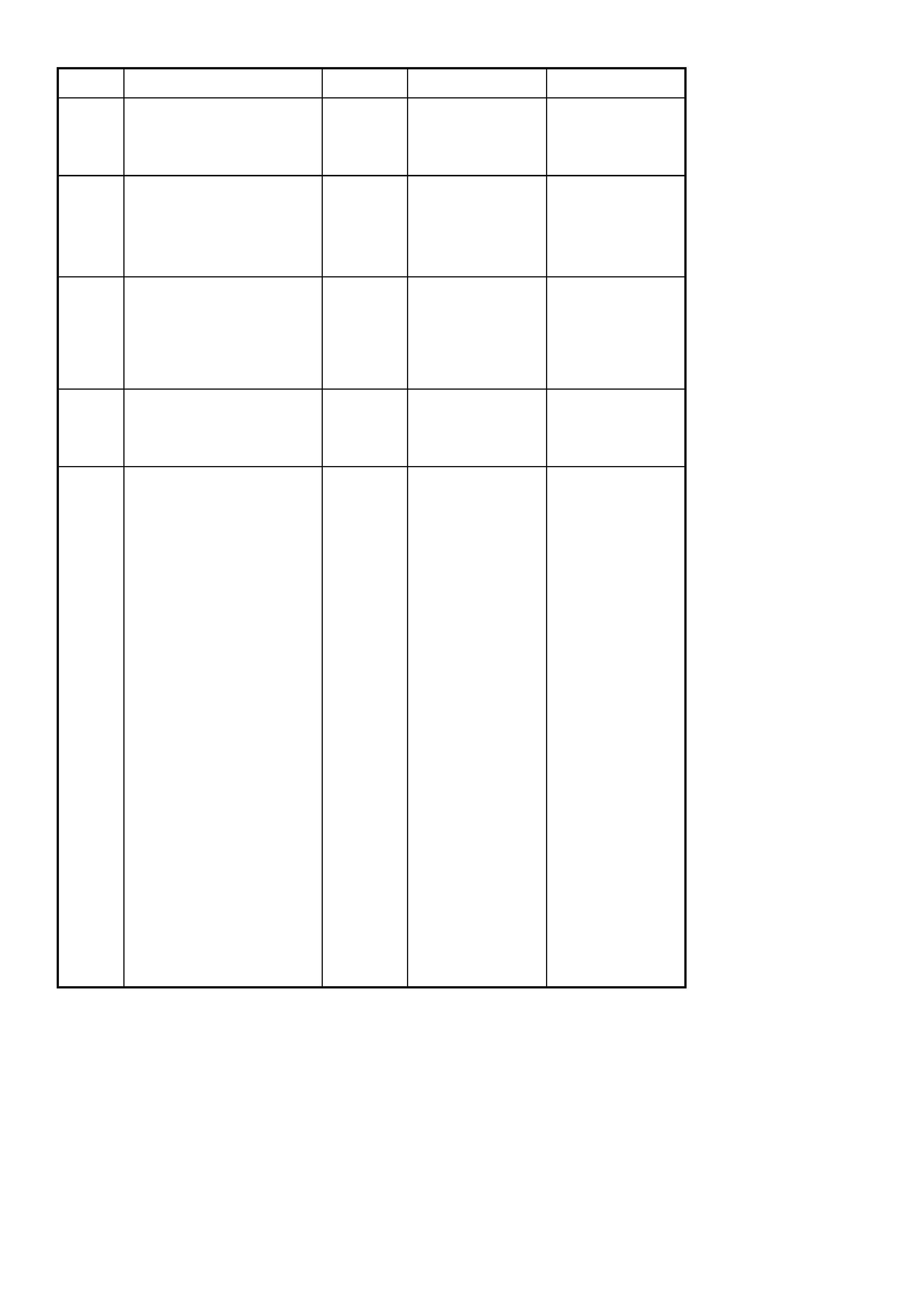

TABLE NO. 7 POWER ANTENNA FAULT DIAGNOSIS - HIGH SERIES BCM

This diagnostic chart is only applicable to vehicles fitted with a power antenna.

For vehicles fitted with a high series BCM, f or diagnosis refer to Section 12J-2 HIGH SERIES BODY CONT ROL

MODULE.

STEP ACTION RESULT YES NO

1• Does power antenna

fail to operate

correctly?

Go to Step 2 Reconfirm

problem with

customer.

2• Using multimeter

check continuity of

circuits 143

(Yellow/Red), 160

(White) and 161 (Light

Blue) between

connectors YB72 and

YB175.

• Is there continuity?

Go to Step 3 Faulty connection

from

radio/cassette to

body control

module. Repair

harness and

verify repair.

3• Using multimeter

check continuity of

circuits 145 (Green),

954 (Grey) between

connectors YB175 and

YB15.

Go to Step 4 Faulty connection

from body control

module to

antenna module.

Repair harness

and verify repair.

4• Using multimeter

check continuity of

circuits 145 (Red), 954

(White) between

connectors YB15 and

power antenna

module.

Go to Step 5 Faulty connection

from power

antenna harness

connector to

power antenna

module. Repair

harness and

verify repair.

5• Is forked earth lead

connector is securely

attached to power

antenna module.

Go to Step 6 Attach forked

earth lead

connector to

power antenna

module and verify

repair.

6• Replace power

antenna module with a

known working one.

Does antenna work

correctly?

End of diagnostic

procedure. Remove and

return for repair.

TABLE NO. 8 POWER ANTENNA FAULT DIAGNOSIS - LOW SERIES BCM

STEP ACTION RESULT YES NO

1• Does power antenna

fail to operate

correctly?

Go to Step 2 Reconfirm

problem with

customer.

2• Using multimeter

check voltage of circuit

45 (Orange/Blue) at

connector YB72 and

YB175.

• Is voltage approx 12

volts?

Go to Step 3 Faulty connection

from voltage to

YB74. Repair

harness and

verify repair.

3• Using multimeter

check continuity of

circuits 145 (Green),

954 (Grey) between

connectors YB74 and

YB15.

Go to Step 4 Faulty connection

from YB74 to

YB15. Repair

harness and

verify repair.

4• Using multimeter

check continuity of

circuits 145 (Red), 954

(White) between

connectors YB15 and

power antenna

module.

Go to Step 5 Faulty connection

from power

antenna harness

connector to

power antenna

module. Repair

harness and

verify repair.

5• Is forked earth lead

connector is securely

attached to power

antenna module.

Go to Step 6 Attach forked

earth lead

connector to

power antenna

module and verify

repair.

6• Replace power

antenna module with a

known working one.

Does antenna work

correctly?

End of diagnostic

procedure. Remove and

return for repair.

DIVERSITY ANTENNA FAULT DIAGNOSIS

Before commencing the diagnostic procedure for the diversity antenna system the following should be checked:

1. Determine whether the reception problem is apparent with FM, AM or both.

Faults aff ecting both FM and AM reception ar e not caused by the diversity antenna system due to the f act that

the diversity antenna system only affects FM reception.

Such faults are more likely to be caused by the conventional fender mounted mast type antenna system.

2. Ensure that the customer complaint is not due to normal operation or the limitations of FM transmissions.

The diversity antenna system is designed to m inimis e distortion in the s ound quality of FM reception and not to

give large increases in FM reception range.

Compare reception quality with that of another vehicle equipped with a diversity antenna system in the same

location and under the same conditions.

DIVERSITY ANTENNA SYSTEM TEST PROCEDURE

NOTE:

When the vehicles conventional antenna is

lowered, disconnected or faulty, the radio will not

use the diversity antenna system to receive FM

radio signals. If no FM stations can be received

then the fault is not due to the diversity antenna

system.

1. Remove passenger side cowl panel cover.

Refer to Section 1A2 BODY DIMENTIONS.

Locate the two antenna connectors near the

PCM. The thinner of the two connectors is the

diversity antenna system connector. The one

larger in diam eter is f or the conventional fender

mounted mast type antenna.

Figure 12D-43

2. Raise mast antenna to full height.

3. Switch the ignition key to the ACC position.

Switch the radio to the FM band and tune to a

‘weak’ station.

NOTE:

A ‘weak’ station can be selected by tuning to

different stations and picking one that is of a lower

intensity or contains more ‘noise’ than the others.

4. Lower mast type antenna. Radio reception of

the ‘weak’ station should now be sm all enough

so that music can no longer be heard or is

extremely faint.

5. If m usic can still be heard s trongly then repeat

steps 3 and 4 with ‘weaker’ stations until

music is virtually non-existent with the mast

antenna lowered.

6. Unplug diversity antenna system connector

(thinner connector) from extension to radio.

Unplug mast type antenna (thicker connector)

from extension to radio.

Figure 12D-44

7. Plug male diversity antenna lead into female

front antenna extension to radio, making sure

that the pin of the male connector is inserted

fully into the cavity in the fem ale connector and

that the outer conductor of the diversity lead

connector is in contact with shielding of the

radio extension connector.

The diversity antenna system is now connec ted

to the radio’s conventional antenna input.

8. The radio should now receive the station with

only a little less s trength than the m ast antenna

did originally.

If the station cannot be heard, the diversity

antenna may be located in a FM signal

interference area.

To determine if this is the case move the

vehicle a few m e ters to s ee if s tations rec eption

improves.

9. If station can be heard clearly then diversity

antenna system is operating correctly.

If the station s till c an not be hear d then the f ault

may be in diversity antenna system. Continue

with next step.

10. Test voltage at diversity antenna module to

main wiring harness connector with k ey in ACC

position. If 12V then continue with next step.

If 0V then trace wire back to fault and repair.

11. Remove passenger side quarter window trim

and parcel shelf. Refer to Section 1A9

HEADLINING AND REAR TRIM.

12. Check connection from diversity antenna

module to rear window connector. Check earth

terminal for a good electrical earth.

Figure 12D-45

13. Disconnect battery earth terminal. Measure the

resistance from the case of the diversity