SECTION 12H - ELECTRICALLY ADJUSTABLE

REAR VISION MIRRORS

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will

consist of either seat belt pre-tensioners and a driver's side air bag, or seat belt pre-

tensioners and a driver's and front passenger's side air bags. Refer to CAUTIONS,

Section 12M, before performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deplo yment, resulting in possible p ersonal injury or unnecessary

SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of

safety, the LPG fuel system should be isolated by turning 'OFF' the manual service

valve and then draining the LPG serv ice lines, before any service w ork is carried out

on the vehicle. Refer to the LPG leaflet included with the Owner's Handbook for

details or LPG Section 2 for more specific servicing information.

1. GENERAL INFORMATION

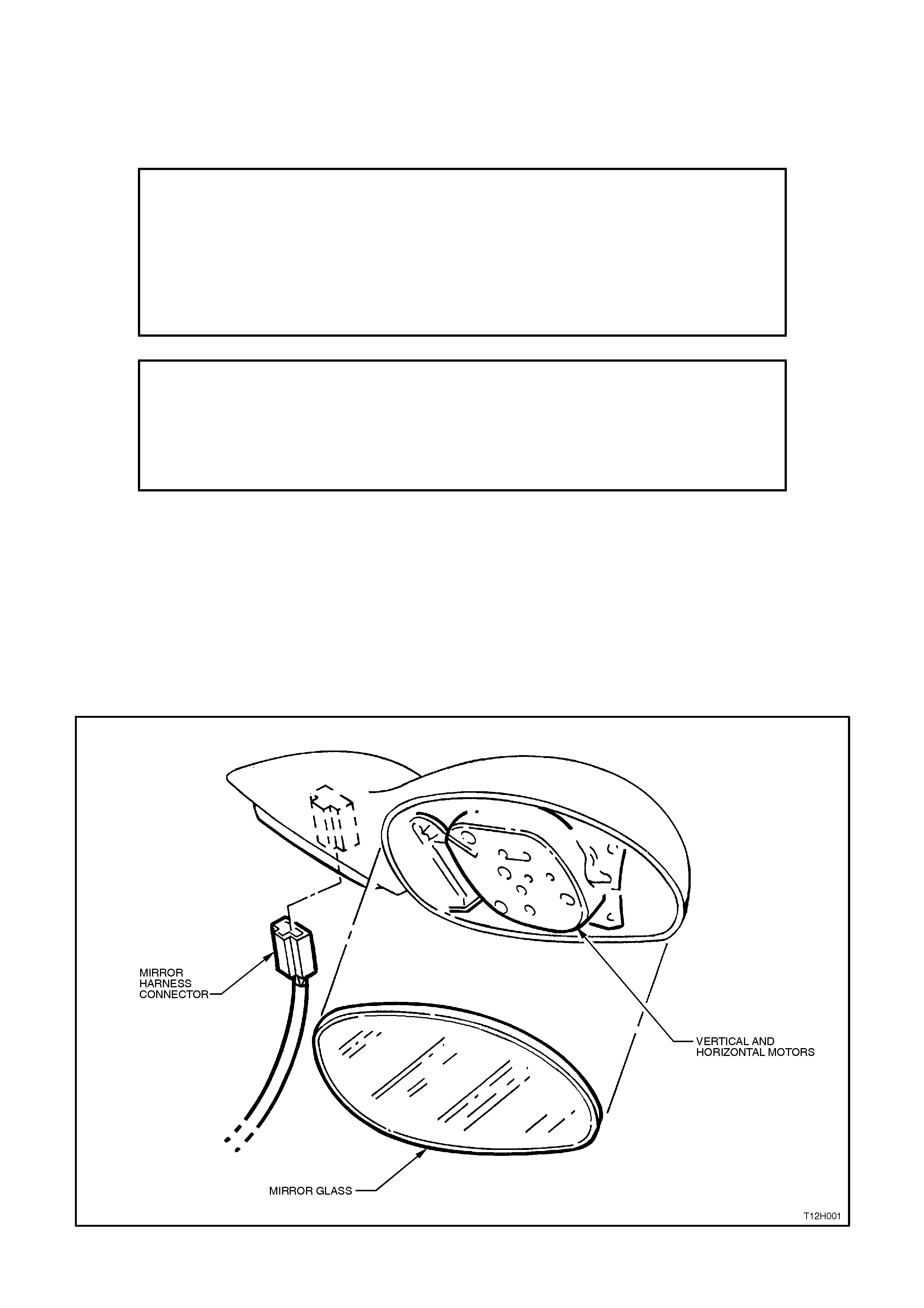

Electrically adjustable rear vision mirrors are fitted as standard equipment on all VT Series Models.

Each exterior mirror assembly has two internal reversible motors: one to adjust the mirror face up and down

(vertical position), the other to adjust the mirror face right and left (horizontal position).

The rear vision mirrors are adjusted from the interior of the vehicle by a mirror control switch mounted in the driver's

side front door pull handle.

The control switch has two controls. A slide select switch that has two positions: Left mirror and Right mirror, and a

toggle type direction switch, which is used to control the direction of movement of the mirror face.

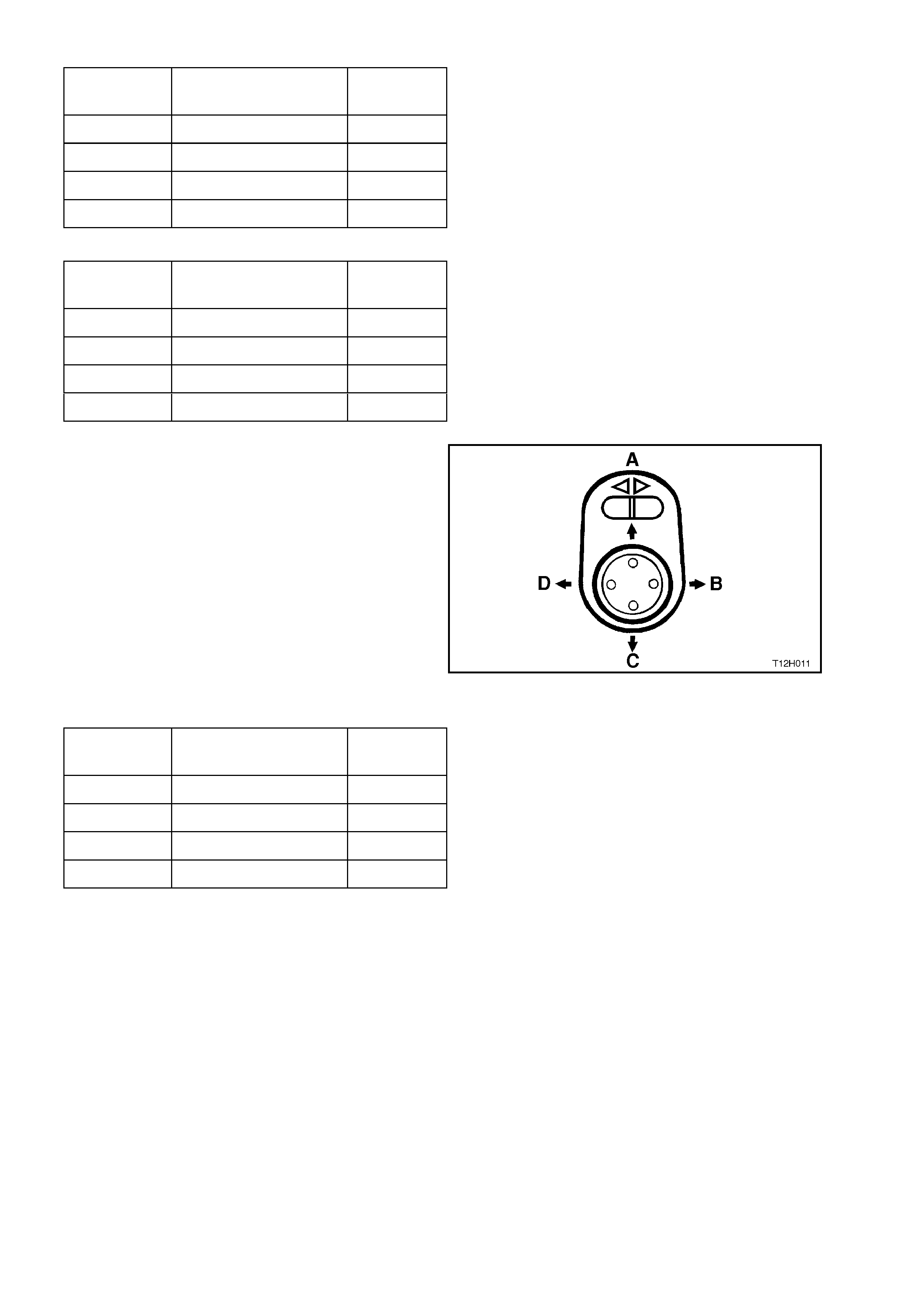

Figure 12H-1

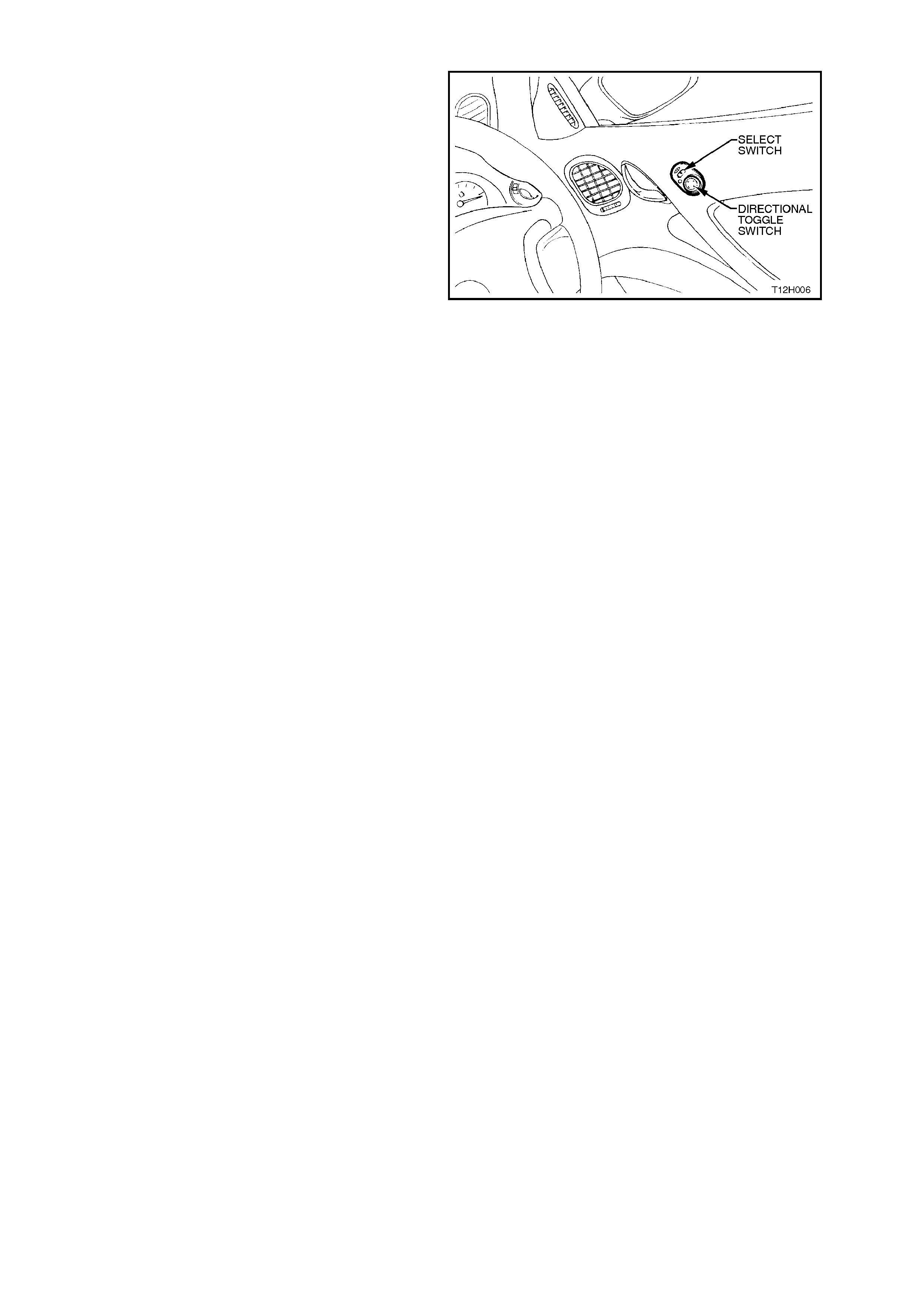

1.1 CONTROL SWITCH OP ERATION

The mirror control switch is two switches in one; a

select switch which is used to select either the left

or right hand m irror, and a directional toggle s witch

which is used to move the mirror face in the

required direction.

The dire ctional toggle switch is designed to operate

in only one direction at a time and is activated by

depressing the edge of the toggle, causing the

toggle to ‘cock’ in the required direction.

Figure 12H-2

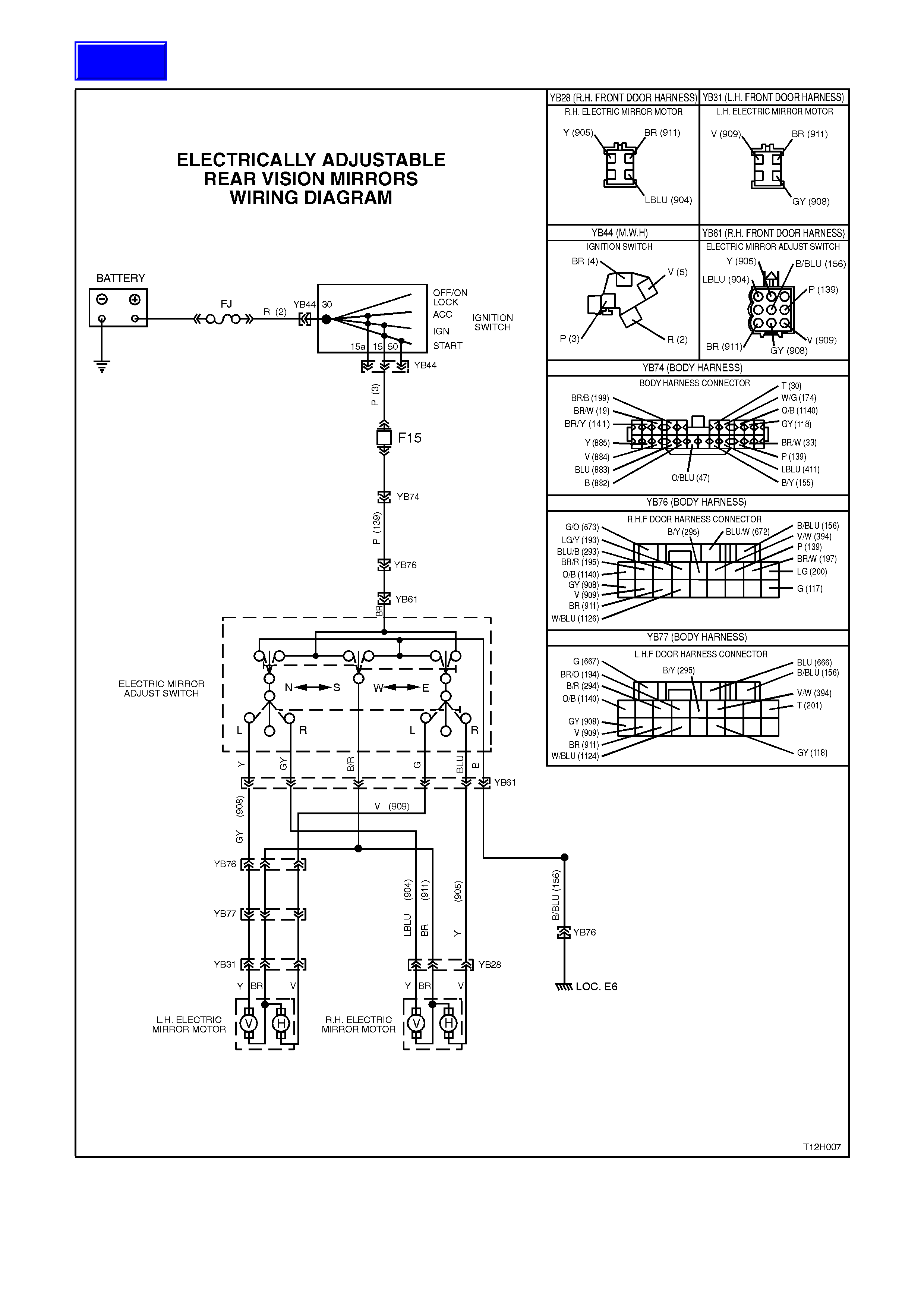

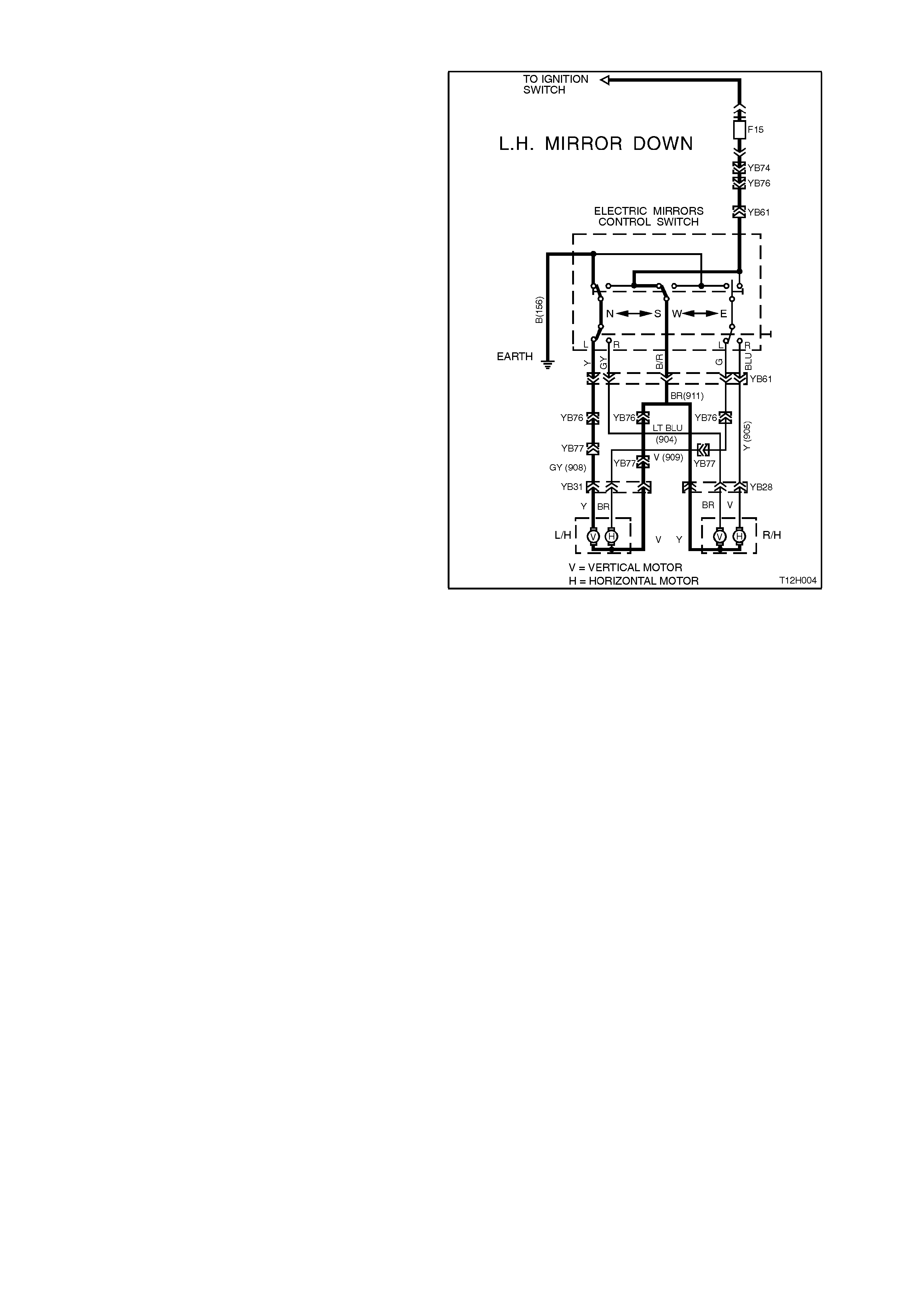

1.2 CIRCUIT OPERATION

With the switches in the positions shown in Fig.

12H-3, the LH exterior rear view mirror is moved

DOWNWARDS. Battery voltage from fuse F15 is

applied through the directional contacts of the

mir ror switch to circ uit 911 (Brown wire) to one side

of all mirror asse mbly motors.

The LH mirror vertical motor has a path to earth

through circuit 908 (Gr ey wire), through the LH s ide

select switch contacts, through the directional

contacts and circuit 156 (Black wire).

This allows the LH side vertical motor to operate

and turns the mirror DOWNWARDS until the

directional toggle switch is released.

W hen the directional toggle switch is depressed to

move the mirror UPW ARDS, the LH mirror vertical

motor receives voltage, however, the voltage is

reversed. Power is supplied through fuse F15,

through the directional toggle and LH side select

switch contacts , through circ uit 908 (Gr ey wire) and

through the motor. The motor is earthed through

circuit 911 (Brown wire), through the directional

switch contacts and circuit 156 (Black wire).

Figure 12H-3

The LH mirror INWARD and DOWNARD operation,

operates similarly. When the directional switch is

moved to the OUTWARD position, battery voltage

from fuse F15 is applied through the directional

centre contacts of the mirror control switch to circuit

911 (Brown wire) to one side of all mirr or ass embly

motors.

The LH mirror horizontal motor has a path to earth

through circuit 909 (Violet wire), through the LH

side select switch contacts, through the directional

contacts and through circuit 156 (Black wire).

This allows the LH side hor izontal motor to operate

and turns the mirror OUTWARDS until the

directional toggle switch is released.

W hen the directional toggle switch is depressed to

move the mirror INWARDS, the LH mirror

horizontal motor receives voltage, however the

voltage is reversed. Power to the motor is supplied

through fuse F15, through the directional and LH

side select switch contacts, through circuit 909

(Violet wire) and through the motor. The motor is

earthed through circuit 911 (Brown wire), through

the directional switch contacts and circuit 156

(Black w ire).

The RH mirror assembly operates in a similar

manner as the LH mirr or assem bly when the select

and directional switches contacts are selected,

except:

To m ove the RH mirr or down, power is supplied via

circuit 911 (Brown wire) and earthed through

circuits 904 (Light Blue wire) and 156 (Black wire).

To move the RH mirror up, power is supplied

through circuit 904 and earthed through circuits 911

and 156. To move the RH mirror out, power is

supplied via circ uit 911 and earthed thr ough c irc uits

905 and 156. To move the RH mirror in, power is

supplied through circuit 905 and earthed through

circuits 911 and 156.

Figure 12H-4

2. SERVICE OPERATIONS

2.1 MIRROR ASSEMBLY

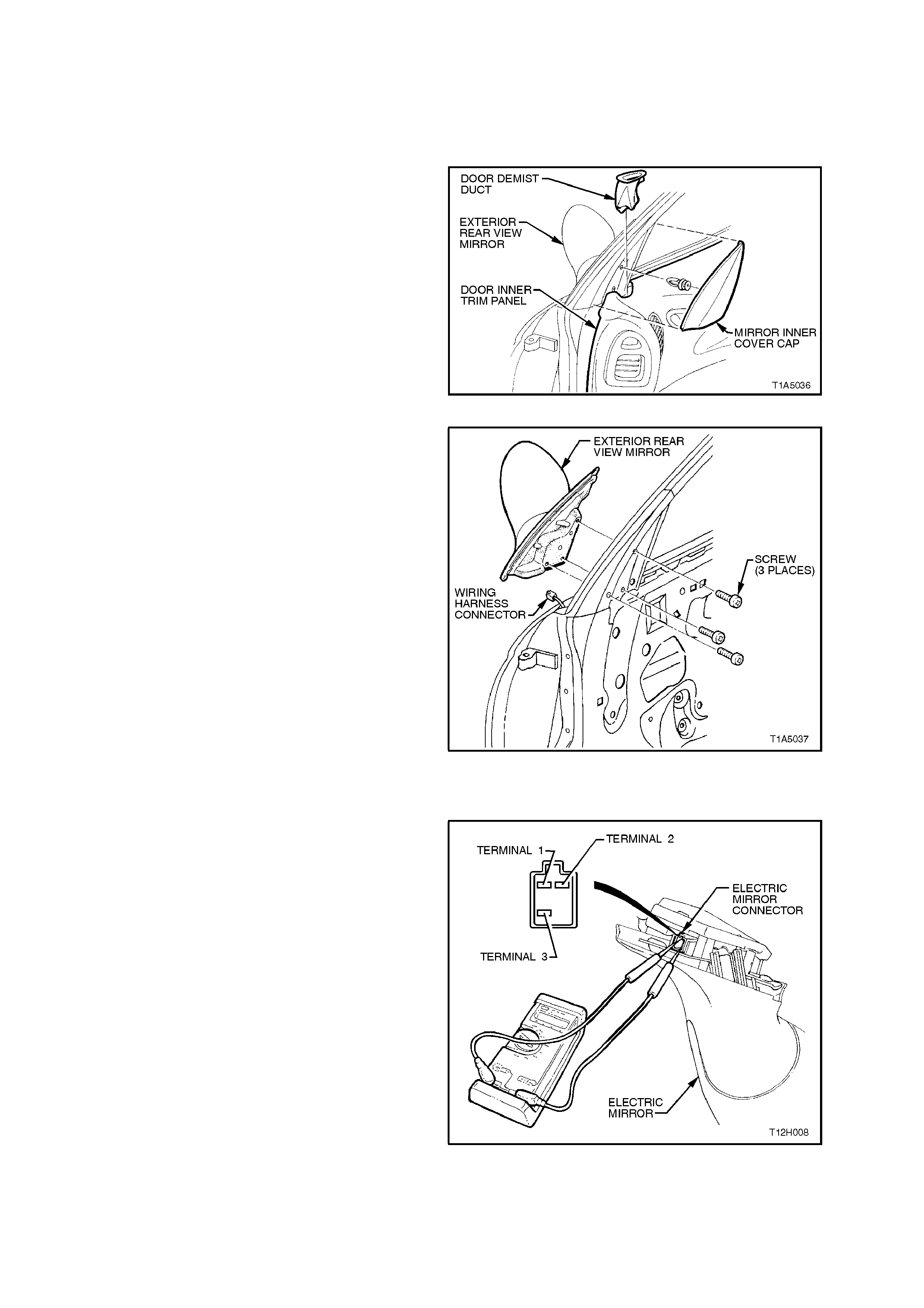

REMOVE

1. Disconnect battery earth lead.

2. Remove the mirror inner cover cap by gently

pryi ng cap away from door.

3. Remove door demist duct to allow access to

the exterior rear view mirror retaining screws

by pulling duct up and out of door trim.

Figure 12H-5

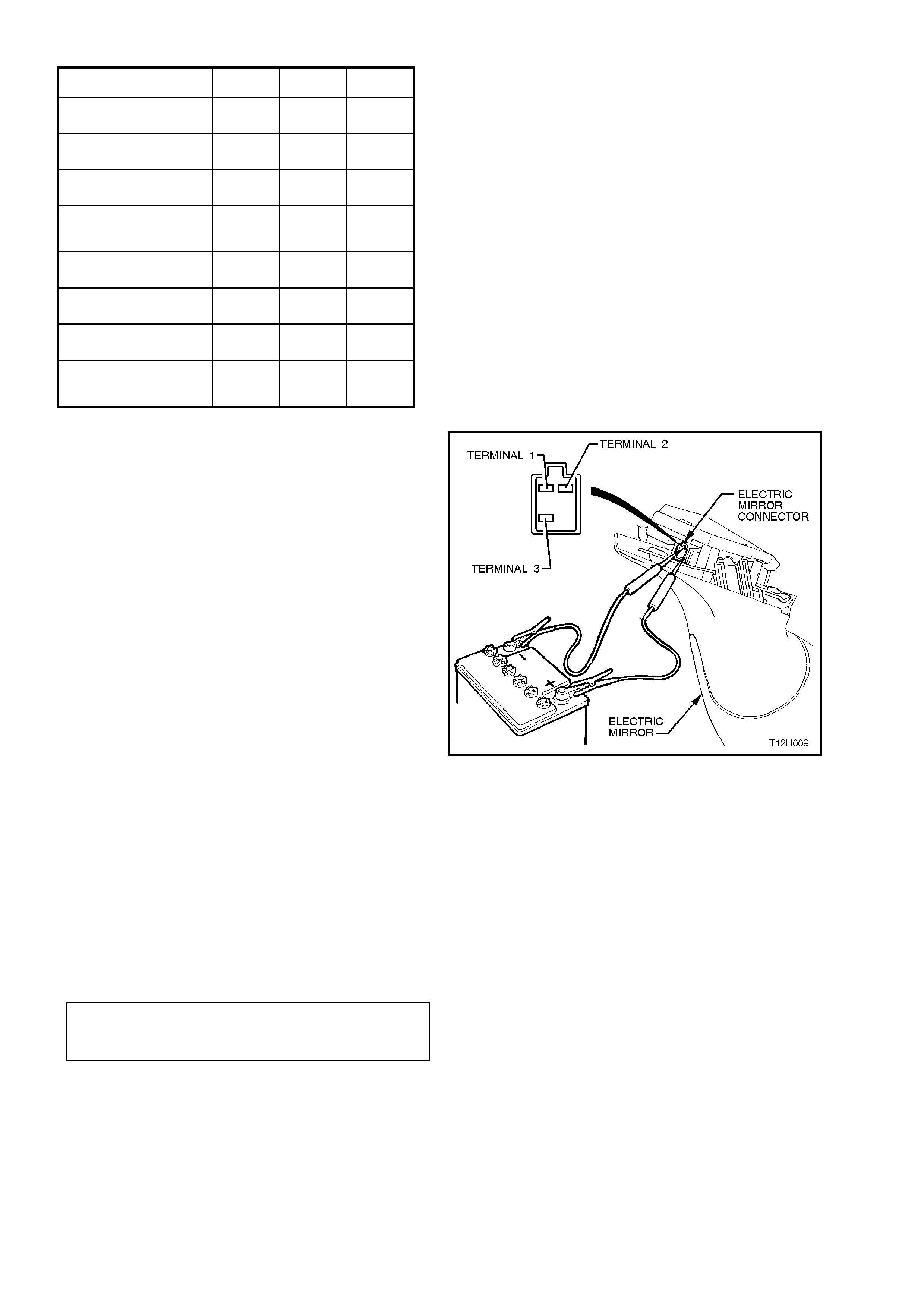

4. Using a right angled screwdriver, remove the

three screws securing the mirror to the door

and while supporting the mirror, disconnect the

mirror wiring harness connector.

5. Remove mirror assembly.

NOTE:

Fig. 12H-6 shows the door with the inner trim panel

removed. To remove the three exterior rear vision

mirror retaining screws, the inner door trim does

not have to be removed.

Figure 12H-6

TEST

The following operations, per formed with the m irror

assembly removed from the vehicle, check the

mirror assembly horizontal and vertical motors. If

the following operations prove that a mirror

assembly is faulty, replace the mirror assembly.

Using an ohmmeter c onnec ted to the electr ic mirror

connector, refer Fig. 12H-7, check continuity of

mirror wiring between the following terminals:

• Ter. 1 and Ter. 2

• Ter. 1 and Ter. 3

• Ter. 2 and Ter. 3

If the ohmmeter indicates an open circuit or a very

high resistance (more than 200 ohms) replace the

mirror assembly. If the mirror motor resistance is

acceptable, proceed to Step 2.

Figure 12H-7

2. Referring to Fig. 12H-8, connect leads from a

12 volt battery to the mirror harnes s connector

term inals nominated in the f ollowing c hart and

observe mirror movement.

FUNCTION TER. 1 TER. 2 TER. 3

LH MIRROR -IN -+

LH MIRROR - OUT +-

LH MIRROR - UP +-

LH MIRROR -

DOWN -+

RH MIRROR - IN +-

RH MIRROR - OUT -+

RH MIRROR - UP +-

RH MIRROR -

DOWN -+

+ = battery positive (12 volts)

- = battery negative

If the movement of the mirror is not as per the

above chart, replace mirror assembly.

Figure 12H-8

REINSTALL

Installation of the exterior rear vision mirror is the

reverse of the removal procedure, noting the

following:

1. Ensure wiring harness and connector for the

mirror are correctly routed.

2. Ensure the three mirror to door securing

screws are tightened to the correct torque

specification.

MIRROR TO DOOR

SECURING SCREW

TORQUE SPECIFICATION 2.5 - 3.0 Nm

3. Ensure that when installing the door demist

duct, that it clips into position.

4. Check mirror operation.

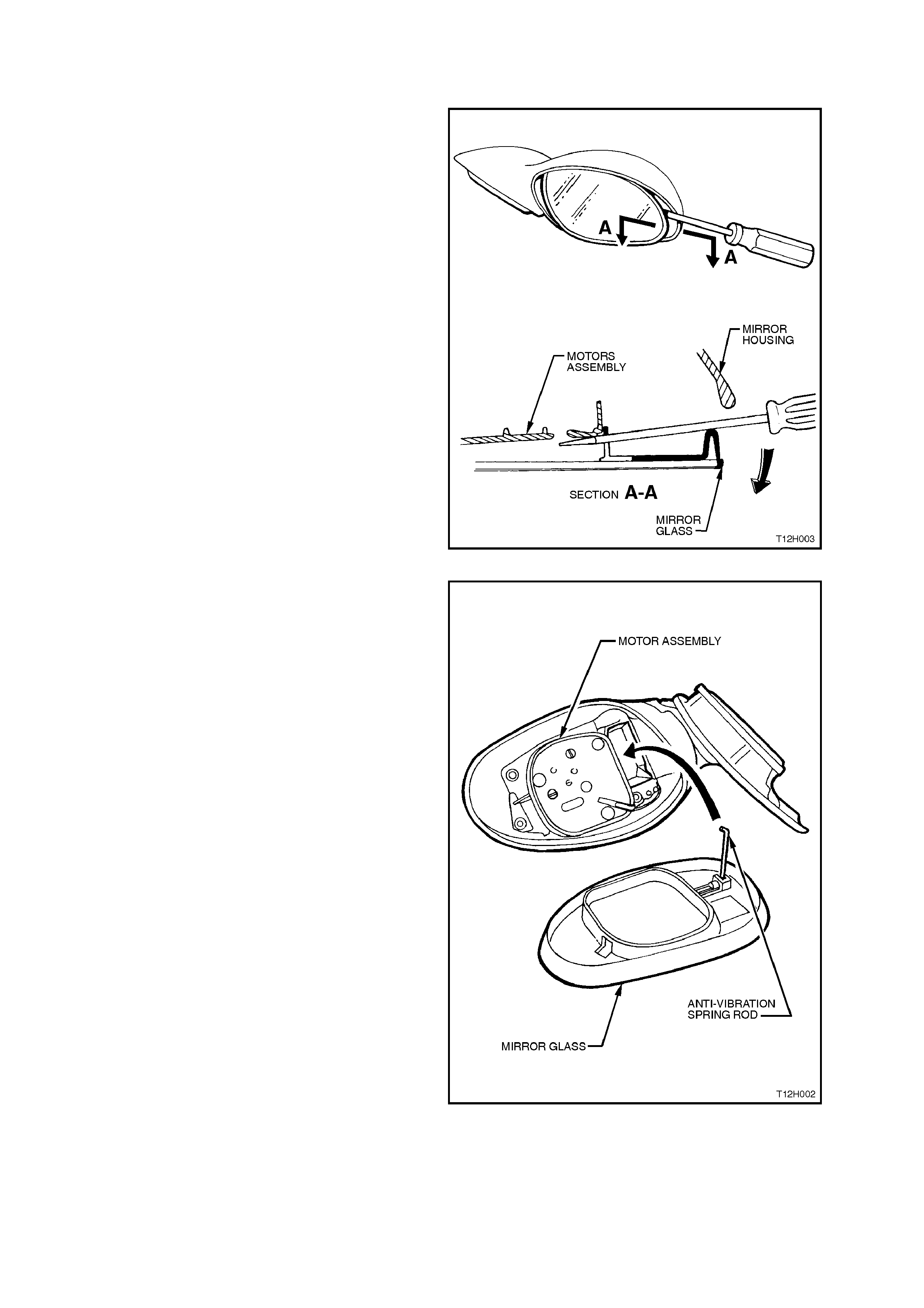

2.2 MIRROR GLASS

REPLACE

Adjust m irror glass so that it is in the fully “UP” and

fully “IN” position.

Insert a screwdriver into the slot on the inside of the

mirror glass and lever mirror glass away from the

motor assembly, refer to Fig. 12H-9.

Remove mirror glass from motor assembly.

Figure 12H-9

Install new mirror glass onto motor assembly,

ensuring that the anti-vibration spring rod is at a

right angle to the mirror glas s and that it aligns with

the corresponding aperture in the mirror housing,

refer to Fig. 12H-10

While supporting the mirror housing, push mirror

glass s quarely onto the m irror m otor ass embly until

it is firmly seated.

Figure 12H-10

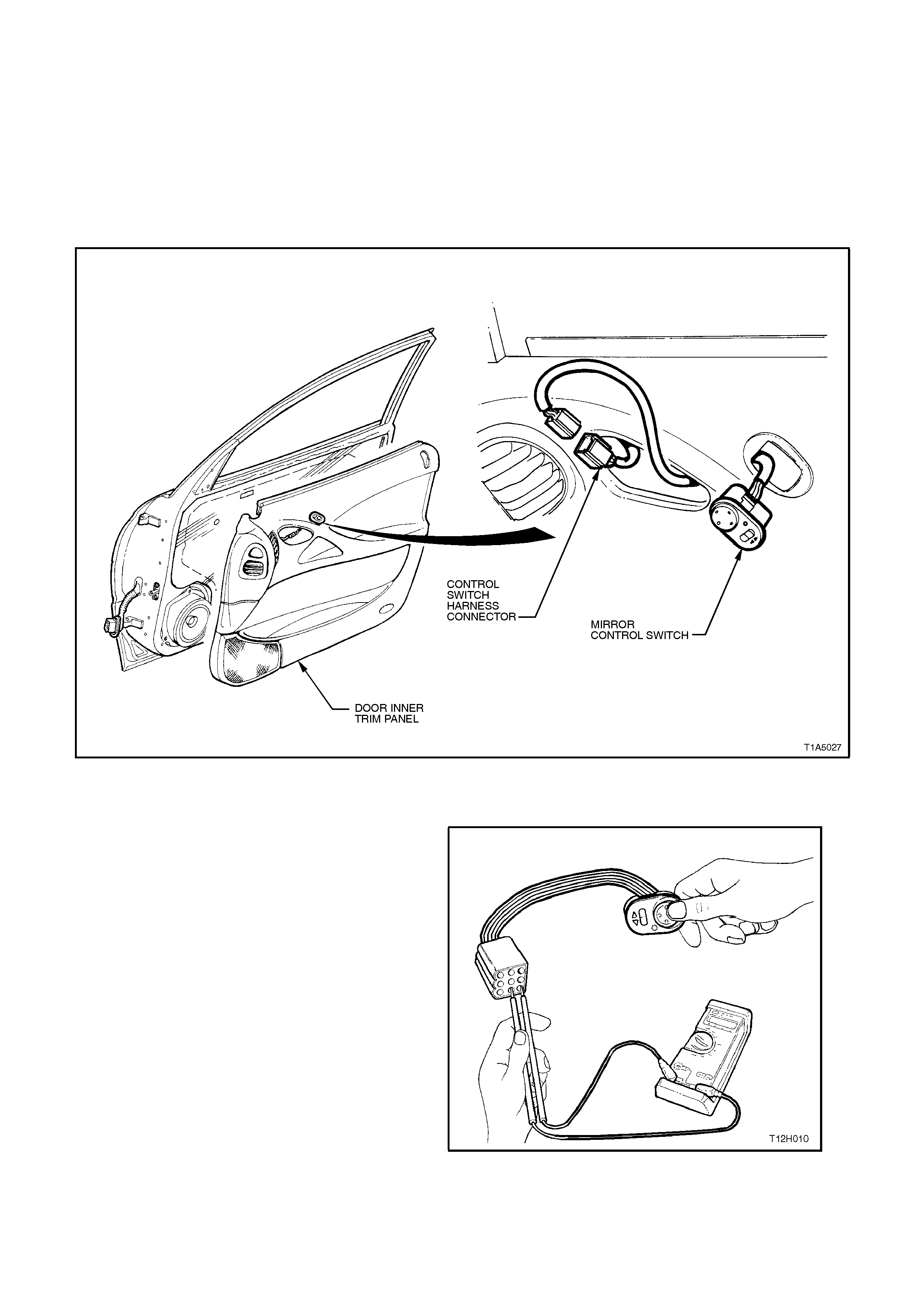

2.3 MIRROR CONTROL SWITCH

REMOVE

1. Remove door inner trim panel, refer to

Section 1A5 FRONT & REAR DOOR

ASSEMBLIES.

2. Disconnect the door electrical harness from

the control switch harness assembly.

3. From inside of door trim assembly, push the

control switch free and remove the switch.

Figure 12H-11

TESTING SWITCH CONTACTS

With reference to the Figs . 12H-12 and 12H- 13 and

the following three charts, the mirror control switch

contacts c an be check ed f or continuity between the

various terminals with the aid of an ohmmeter.

Attach an ohmmeter to the appropriate terminals

nominated in the following two charts.

Select the appropriate mirror on the select switch,

i.e. LH or RH and depress the directional toggle

switch in the direction indicated in the chart. The

ohmm eter should indicate continuity if the switch is

OK.

Figure 12H-12

LEFT HAND MIRROR

FUNCTION SWITCH WIRE

COLOURS VALUE

Out Light Green and Black Continuity

In Light Green and Brown Continuity

Up Yellow and Black Continuity

Down Yellow and Brown Continuity

RIGHT HAND MIRROR

FUNCTION SWITCH WIRE

COLOURS VALUE

Out Blue and Brown Continuity

In Blue and Black Continuity

Up Grey and Black Continuity

Down Grey and Brown Continuity

For the following test of switch contacts, attach an

ohmmeter to the appropriate terminals nominated

in the following chart and then depress and hold the

directional toggle s witch in the dire ction indic ated in

the chart and Fig. 12H-13. The ohmmeter should

indicate continuity if the switch is OK.

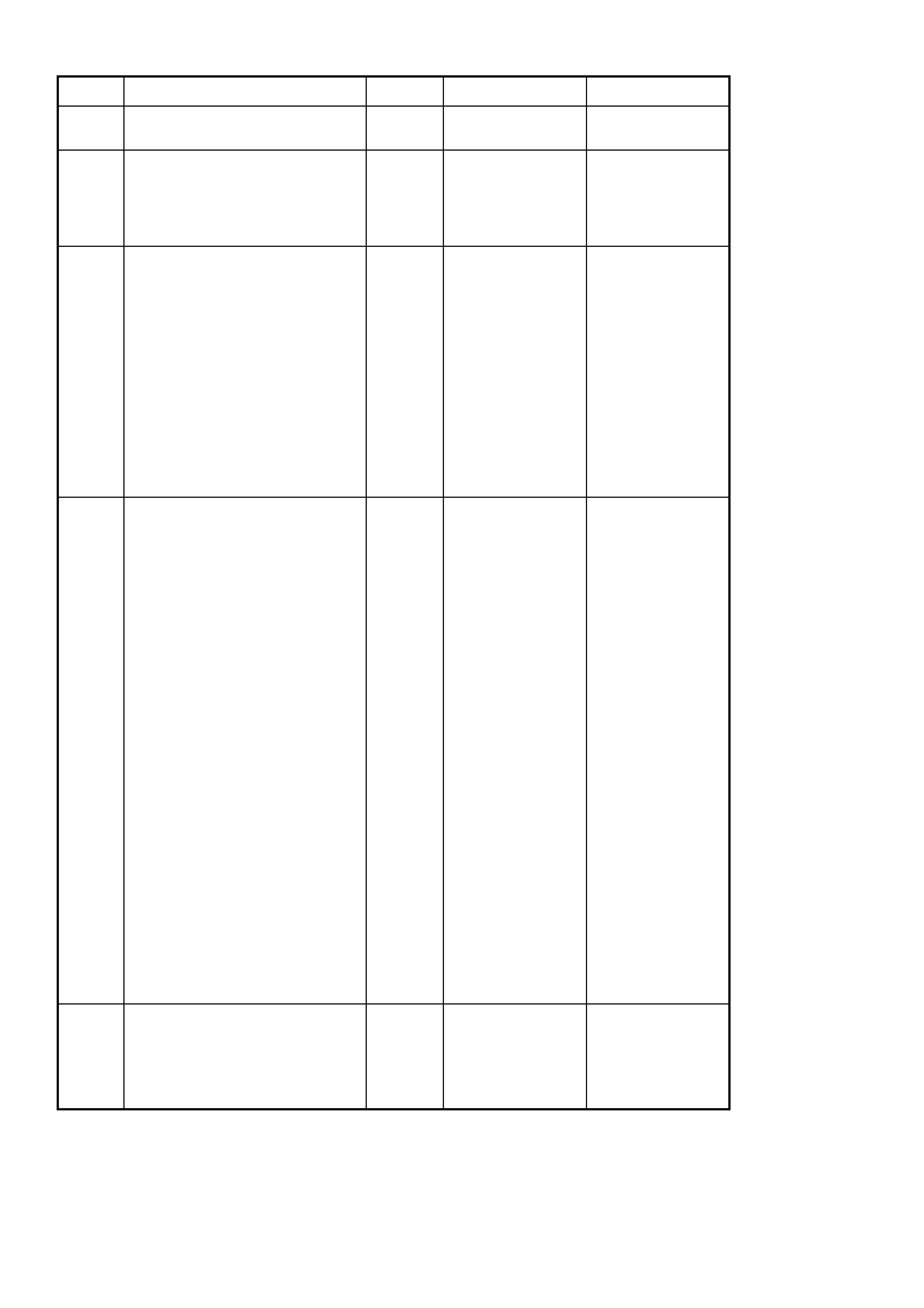

Figure 12H-13

TOGGLE

DIRECTION SWITCH WIRE

COLOURS VALUE

A Black/Red and Brown Continuity

B Black/Red and Black Continuity

C Black/Red and Black Continuity

D Black/Red and Brown Continuity

REINSTALL

Reinstallation of the exterior rear vision mirror control

switch is the reverse of the removal procedure.

3.1 ELECTRIC MIRROR/S INOPERATIVE

STEP ACTION VALUE YES NO

1. • Are both electric rear view

mirrors inoperative? Go to Step 2. Go to Step 3.

2. • Is fuse F15 OK (located in

fuse panel)? Go to step 3. Replace blown

fuse, check wiring

for cause of fuse

blowing.

Re-check system.

3. • Remove RH front door inner

trim panel, refer to Section

1A5 FRONT AND REAR

DOOR.ASSEMBLIES.

• Reconnect mirror control

switch.

• Turn ignition ON.

• Using a test light at the

switch side of connector

YB61, check for power at

brown.

• Does test light illuminate ?

Go to Step 4. Check and repair

open circuit in

circuit 139 (Pink

wire) from fuse

F15 to control

switch.

Re-check system.

4. • Using an ohmmeter, check

circuit 156 for continuity

between connector YB61

(Black wire) and earth

connection (location E6).

• Is wiring OK ?

Go to Step 5. Check and repair

open circuit in

earth circuit 156

(Black w ire).

Re-check system

5. • At connector YB61, check for

continuity in the following

circuits:

Circuit 911 (Brown wire) to

circuit 909 (Violet wire)

(LH mirror horizontal

motor).

Circuit 911 (Brown wire) to

circuit 908 (Grey w ire).

(LH mirror vertical motor).

Circuit 911 (Brown wire) to

circuit 905 (Yellow wire)

(RH mirror horizontal

motor).

Circuit 911 (Brown wire) to

circuit 904 (L/Blue wire)

(RH mirror vertical motor).

• Is wiring OK ?

Go to Step 6. Check and repair

open circuit.

Re-check system.

6. • Check mirror control switch,

refer to 2.3 MIRROR

CONTROL SWITCH, in this

Section.

• Is mirror control switch OK ?

System OK. Replace mirror

control switch.

Re-check system.

3.2 EITHER MIRROR NOT WORKING IN ONE OR MORE DIRECTIONS

STEP ACTION VALUE YES NO

1. • Remove mirror control switch

and test switch contacts,

refer to 2.3 MIRROR

CONTROL SWITCH in this

Section.

• Are mirror switch contacts

OK ?

Go to Step 2. Replace mirror

control switch.

Re-check system.

2. • With connector YB61, check

for continuity in the following

the particular circuit that the

mirror is operating:

LH mirror horizontal: circuit

911 (Brown wire) to circuit

909 (Violet wire).

LH mirror vertical: circuit

911 (Brown wire) to circuit

908 (Grey wire).

RH mirror horizontal: circuit

911 (Brown wire) to circuit

905 (Yellow wire).

RH mirror vertical: circuit

911 (Brown wire) to circuit

904 (L/Blue wire).

• Is wiring OK ?

Go to Step 3. Check and repair

open circuit.

Re-check system.

3. • Check faulty mirror

assembly, refer to 2.1

MIRROR ASSEMBLY, in this

Section.

• Is mirror OK ?

System OK. Replace mirror

assembly.

Re-check system.

4. TORQUE WRENCH SPECIFI CATIONS

Nm

Mirror to Door Securing Screws 2.5 - 3.0

5. SPECIAL TOOLS

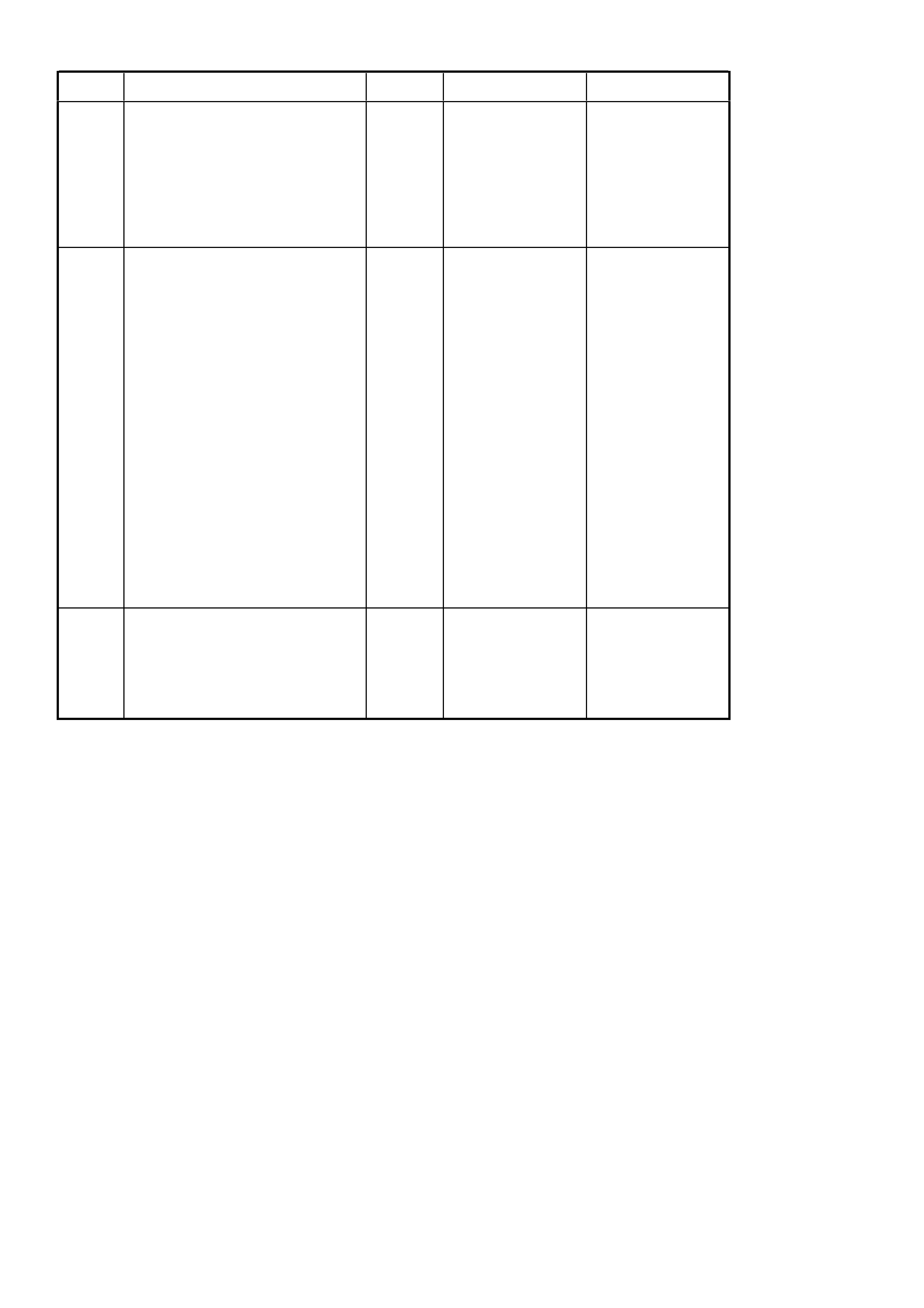

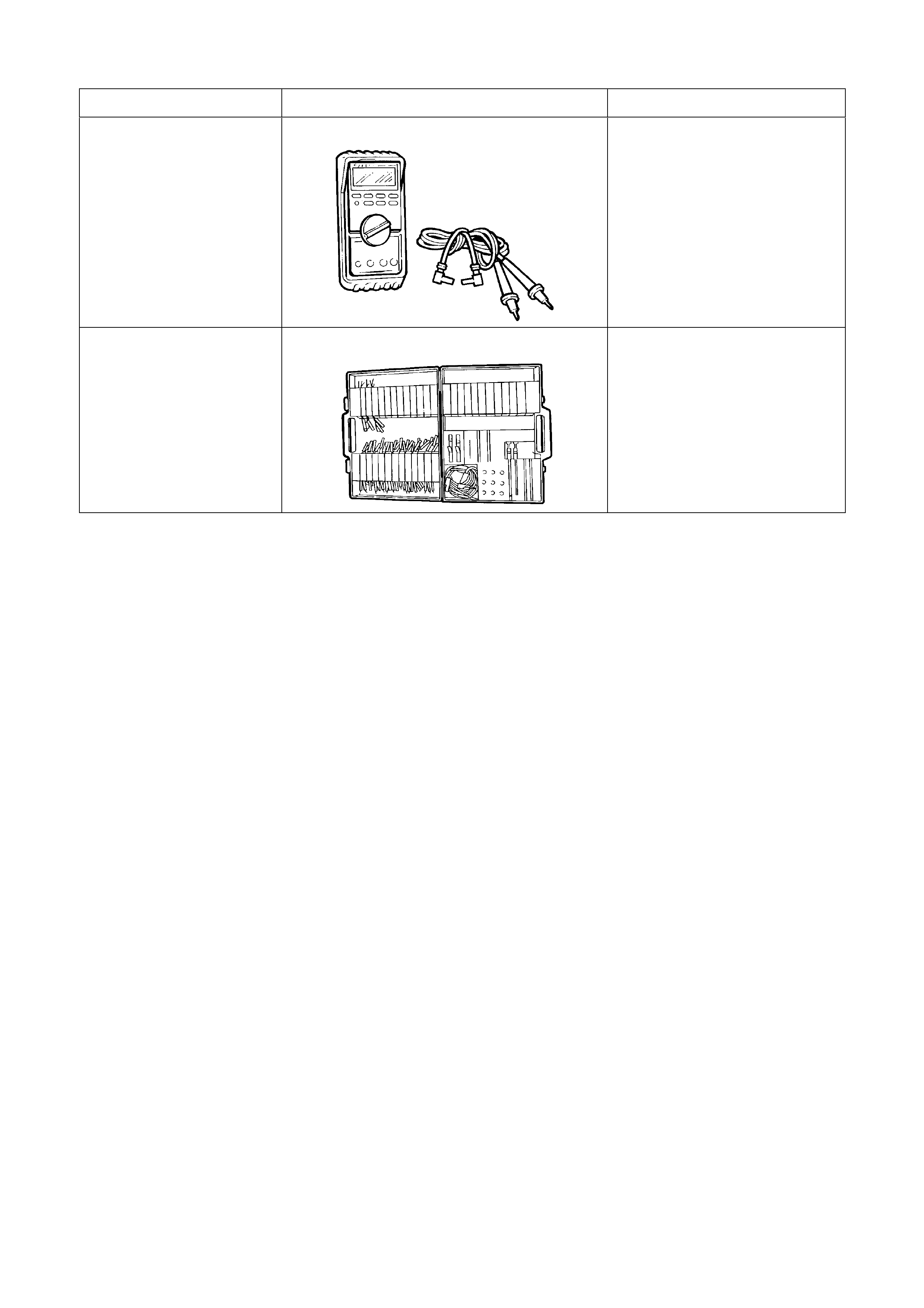

TOOL NO. REF IN TEXT TOOL DESCRIPTION COMMENTS

J39200 DIGITAL MULTIMETER TOOL NO. J39200

PREVIOUSLY RELEASED, OR

USE COMMERCIALLY

AVAILABLE EQUIVALENT.

MUST HAVE 10 MEG OHM

INPUT IMPEDANCE

KM-609 ELECTRONIC KIT USED IN CONJUNCTION

WITH A MULTIMETER FOR

MEASURING VOLTAGES AND

RESISTANCE’S WITHOUT

DAMAGING WIRING

HARNESS CONNECTORS