SECTION J - OPTIONS AND ACCESSORIES

CAUTION:

HSV vehicles are equipped with a Supplemental Restraint System (SRS). An SRS

consists of seat belt pre-tensioners (fitted to all front seats), and a driver’s-side air

bag or a driver’s-side air bag AND a passenger’s-side air bag. Refer to CAUTIONS,

Section 12M, before performing any service operation on or around SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in personal injury or unnecessary SRS system repairs.

PURPOSE

The purpose of this supplement is to provide information on the special options and accessories fitted to the HSV

VT and HSV VS models . T his inf or mation is designed to s upplement that c ontained in the Holden VT and VS ser ies

Service Information CD’s and details are given where differences occur between the HSV models and standard

Holden models . A s er ies of ins tr uc tion drawings detail the des ign c hanges and indicate s pec if ic part number s , fitting

instructions and relevant notes for vehicle servicing.

NOTE:

If specific technical data on a HSV model is not contained in this supplement, obtain data for that model from the

relevant Holden VT or VS series Service Manual Supplement. References are made throughout this section to

Holden Series Service Information CD’s, to assist in providing information for specific service operations.

CAUTION:

W hen hois ting (or j acking) HSV models , ensure that the lifting head of the hoist lifts on the chas sis before the arm

of the hoist contacts the side-skirt

SUNROOF

GENERAL

The HSV specific Sunroof is f itted as standard equipm ent on HSV Senator and Grange m odels and is available as

an option on other HSV VT m odels. The Sunroof is a tinted glass, electrically operated, two-way sliding and tilting

type, equipped with an internal sliding blind and fr ont edge wind deflector. T he Sunroof is oper ated by a roc k er type

switch (which is back-lit) centr ally located in the vehicle's headlining in f ront of the Sunroof vent aperture. Sunroof s

are equipped with a Sunroof Control Unit which provides several pre-programmed functions and the facility to

programme an additional option.

The pr e-programmed functions are:

Soft touch

By a single touch of the switch the roof can be fully opened to the max imum tilt position or the m axim um slide

position.

Variable tilt position

The panel c an be closed f rom tilt in f our steps by continuously press ing the switch and r eleasing in the des ired

position

Jamming protection (Safety Feature)

When closing the sunroof by soft touch or by autoclose, the sunroof automatically opens when it encounters an

obstacle. The roof will continue to try to close until the obstacle is removed.

Autoclose function

Three seconds after switching off the ignition the sunroof will close automatically. This can be prevented by

pressing the switch once within 3 seconds after the ignition is switched off.

One - way closing

This feature always closes the panel from above, assuring a flush fit of the panel.

The optional programmable function is:

Comfort position in the sliding range

W ith this f eature you will be able to program a preset stopping position of the panel in the sliding range of the

sunroof. The panel will stop at the preset position when opened via the soft touch operation.

OPERATION

Panel movement into the venting and sliding positions is controlled by:

Continuous control (pressing the switch longer than 0.3 seconds):

Full control over the panel movement in slide position

Releasing the switch will stop the panel movement

A full stop in maximum slide and closed position.

Four steps down tilt adjustment (pressing the switch longer than 0.3 seconds):

When closing the sunroof from minimum tilt position by pressing the switch continuously, the panel will stop

briefly in four intermediate positions.

Releasing the switch will stop the panel movement.

To continue the stepped operation, press the switch again.

One touch contro l (pressing and releasing the switch within 0.3 seconds):

Automatic panel movement towards full open or full closed position (slide and tilt).

Anti-jamming protection while closing.

The panel movement can be interrupted by pressing the switch.

Auto-close:

When the ignition is switched off, the roof will close after a 3-second delay.

Anti-jamming protection while closing.

Pressing the switch within 3 seconds after the ignition switch off will cancel Auto-close.

Closing the roof is still possible after Auto-close has been active.

Auto-close will not be activated if any other function is active.

Programming memory position

Any position in the sliding range of the panel can be programmed as a “comfort position”.

The panel will stop at that position when opened by One touch control.

One way closing

To ensure perfect positioning of the panel after closing, the panel will always close from above (even when

closed from a slide position).

Interior trim -

Sunshade

Sunshade operation depends on panel movement as below:

Moving the glass panel to tilt pos ition, the sunshade automatic ally opens to a vent position and can be m oved

to full open position by hand.

Moving the glass panel into s lide position, the sunshade will m ove together and can also be further opened by

hand.

Closing the sunshade always has to be done manually. The sunshade can only be closed com pletely when the

glass panel is in closed position.

Wind deflector

The wind defector automatically comes up when the panel moves into sliding positions and goes down when

the panel closes again.

SERVICE OPERATIONS

NOTE:

Dealers are to contact Hollandia Sunroofs directly by telephone on (02)9540-4811 before carrying out any service

operation on the Sunroof.

Several Fault Diagnosis Charts are included in this section. These charts list Possible Causes and Solutions and

provide a reference to a particular paragraph to resolve the fault. Some recommended solutions refer to the

Installation Manual and the relevant extr acts f rom that m anual ar e included at the rear of this s ection. Also included

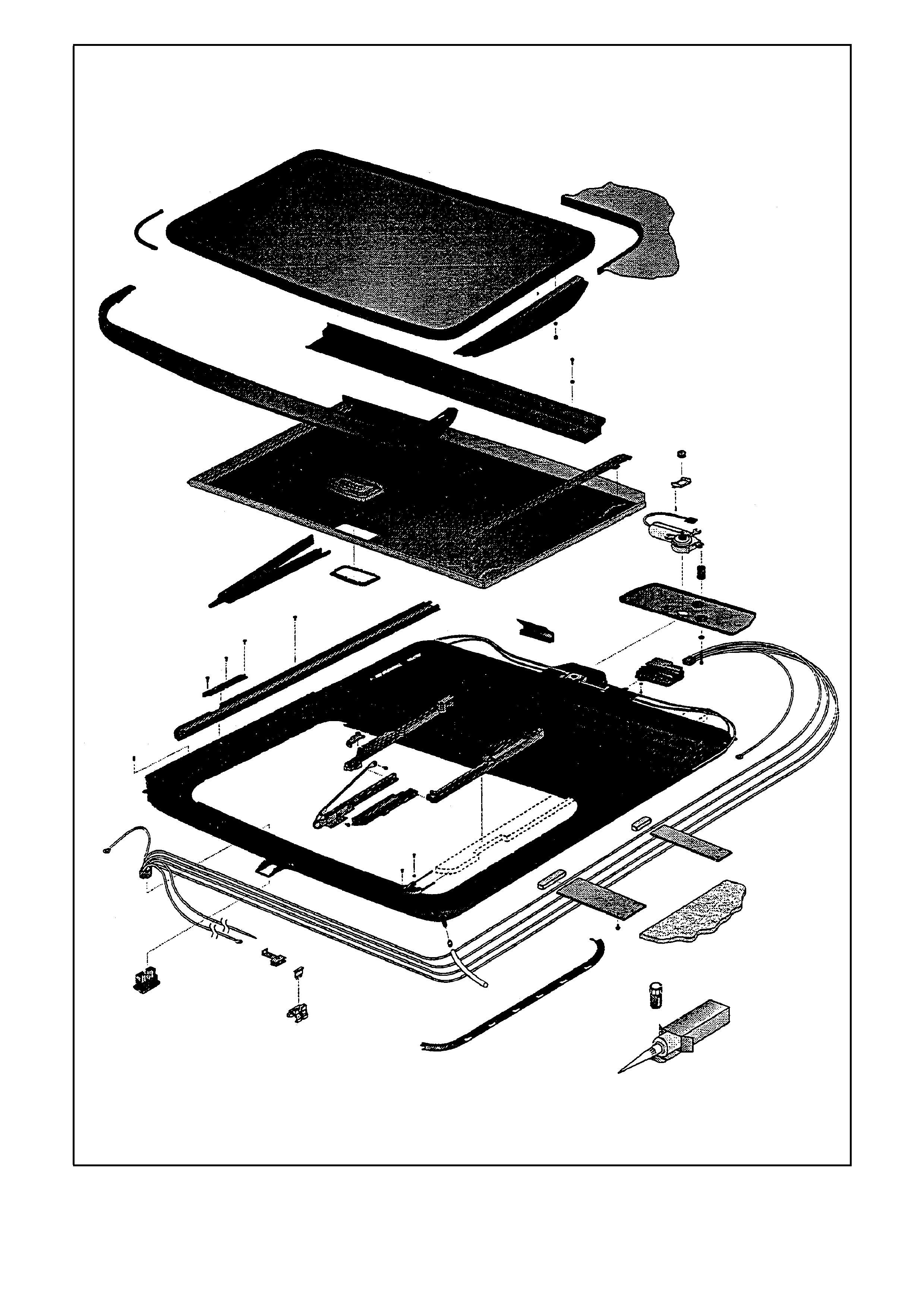

in this section is Figure J- 1 which shows an exploded view of the sunroof construction.

FAILURES

Repair Advice For Mechanical Failures

PROBLEM POSSIBLE CAUSE SOLUTION

While cycling the panel from tilt to

close it begins sliding rearward Blocking catch is broken Replace blocking catch, see 3.10

While cycling fully open panel

forward, it begins tilting under roofskin Blocking catch is broken Replace blocking catch, see 3.10

Panel is misaligned side to side Timing of drive cables

incorrect Retime drive cables, see 3.5

Panel sliding too slowly (with 13.5V

power supply panel should not take

more than 7 sec. to cycle from full

retraction to closure)

Weak battery

Misaligned panel creating drag

or friction

Weak motor. Test as indicated

in 2.2.4

Dirty mechanism

Charge or replace

Retime drive cables, see 3.5

Replace motor, see 3.1

Clean and grease mechanism or

replace if necessary, see 3.9

Glass panel stopping prematurely Sunroof control unit adjusted

improperly

Obstacle in mechanism or

guide track

Synchronise sunroof control unit,

see 3.3

Find object and remove

Sunshade fails to open when glass

panel is opened to tilt position. Retraction mechanism broken Replace retraction mechanism,

see 3.8.

Repair Advice For Rattling Noises

PROBLEM POSSIBLE CAUSE SOLUTION

Drainchannel rattles Inspect for insulator tape

between drainchannel and

mechanism

Add insulator tape

Steel panel ventilation tray rattling Curvature of front ventilation

tray incorrect

Insufficient contact between

rail and ventilation tray

tumbling mechanism

Wires insufficientl y secured

Correct curvature, manual

adjustment

Correct rear side ventilation tray

to improve rail contact

Secure wires

Rattling in motor area Cover plate on motor has

loose screws Tighten coverplate screws

Repair Advice For Wind Noises

PROBLEM POSSIBLE CAUSE SOLUTION

Panel closed, excessive windnoise Glass panel seal not tight to

trimring

Blocking catch broken

Correct glass panel adjustment,

see 3.11 or installation manual

5.3

Replace blocking catch, see 3.10

Panel vented emitting whistling sound Vinyl headliner material

wrapped around sunshade too

thin, creating large wind

channel between rail and side

of sunshade

Place insulating tape along either

outboard edge of sunshade to

close channel.

See installation manual 4.1.5

Steel panel vented emitting whistling

sound Vinyl headliner material

wrapped around trimtray too

thin, creating large wind

channel between rail and side

of trimtray

Place insulating tape along either

outboard edge of trimtray to

close channel. See installation

manual 4.1.5

Repair Advice For Water Leaks

PROBLEM POSSIBLE CAUSE SOLUTION

Water coming through panel opening

area Blocked draintubes

Misaligned or kinked

draintubes

Housing frame distorted,seal

to rail disconnected

Rear rail bracket has broken

seal

Inspect draintubes clean

opening, blow out tubes

Correct routing of draintubes.

See installation manual 3.2

Correct frame curvature if

necessary reseal rail to frame

Reseal at rear rail seal point, see

3.9

Headliner wet in front Either frame seam has

inco rrect seal Reseal at seam

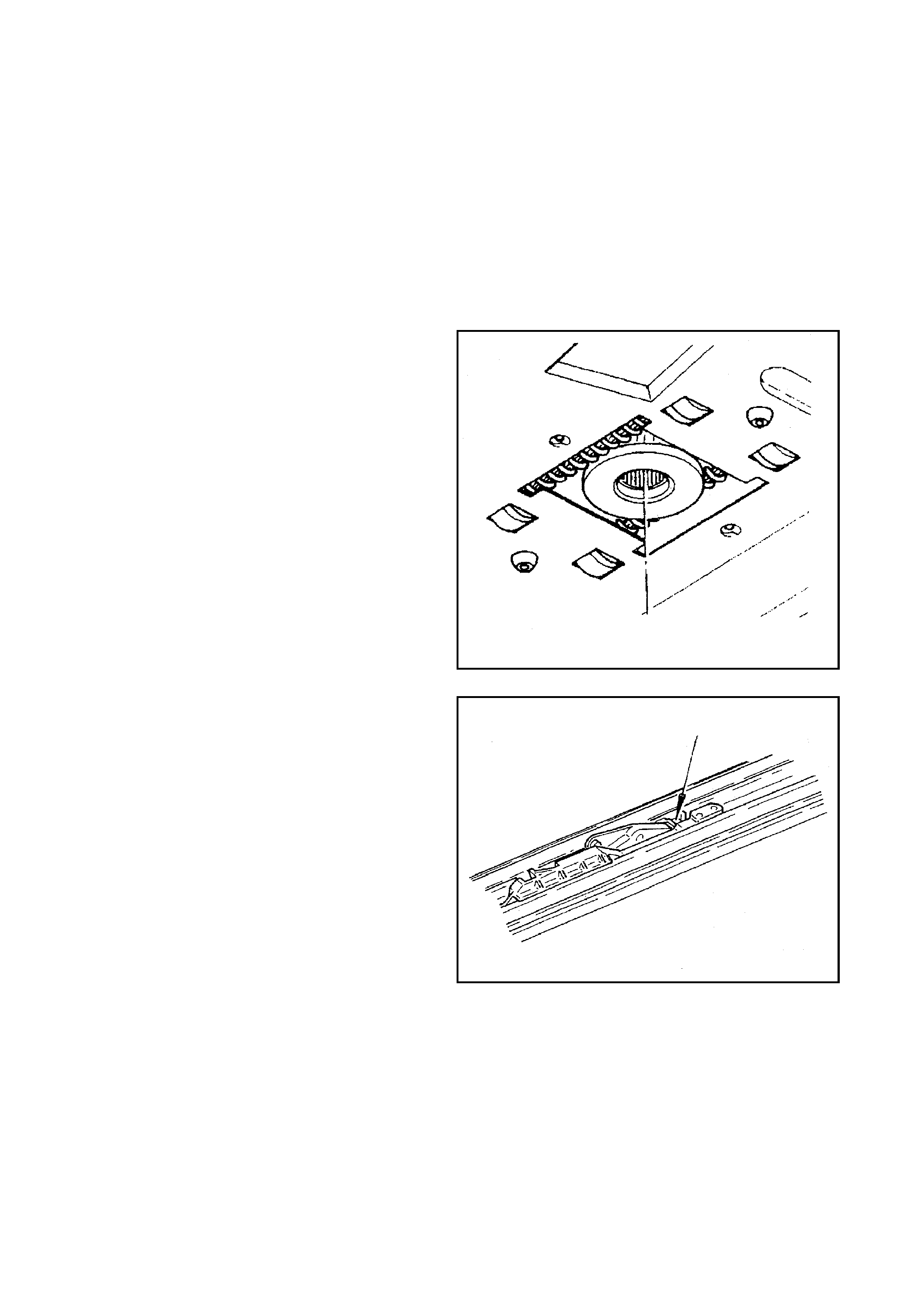

Figure J-1 - HSV Sunroof - Exploded View

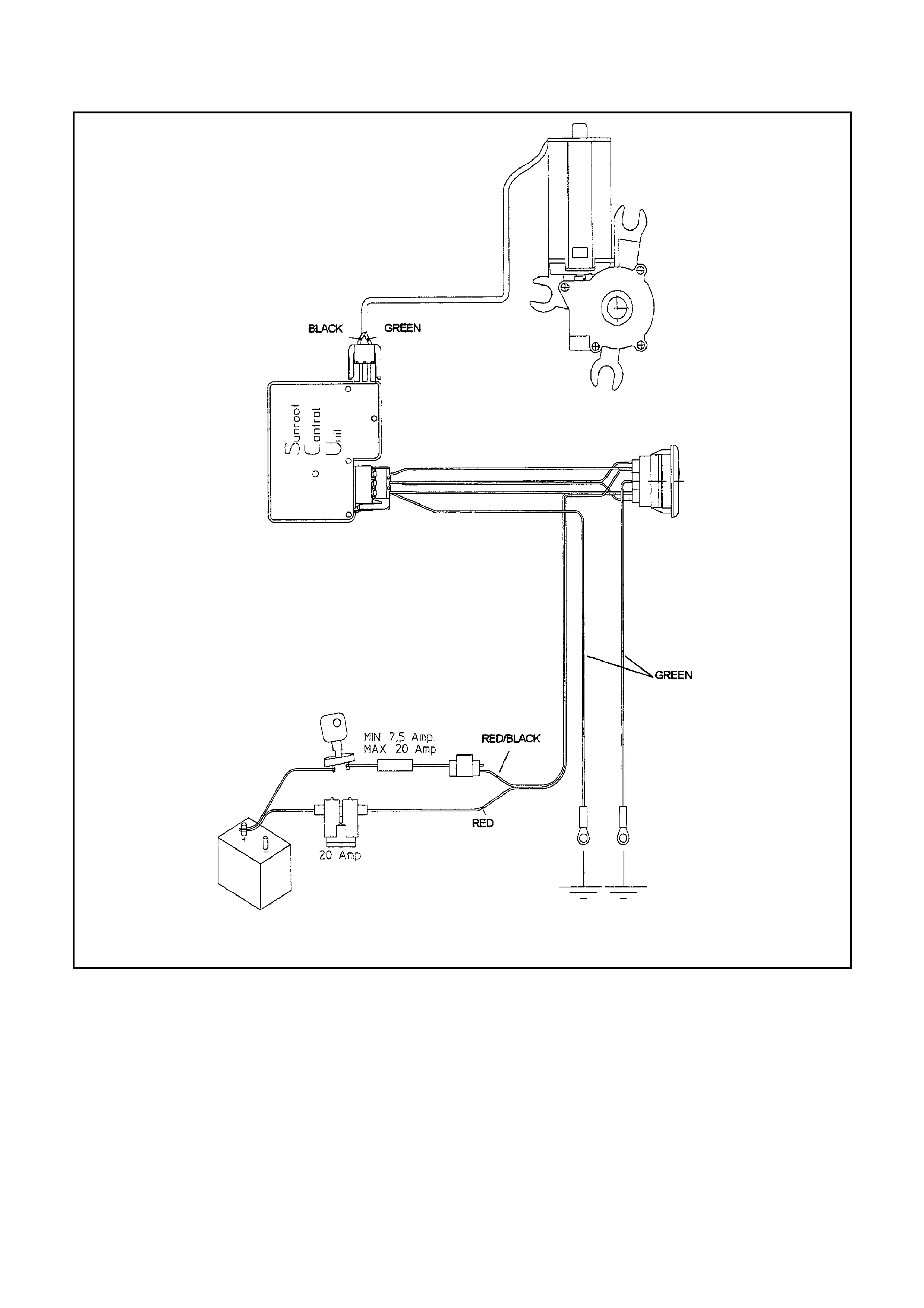

TESTING ELECTRICAL COMPONENTS

Make sure that during the test of electrical components, the TVS unit is connected to a power source containing 12

to 14V. If the Sunroof is installed, the battery needs to be attached and operable. During testing the

ignition/accessory switch should be on. This test can be accomplished with a test light or voltage meter. Cable

harness and motor inspection requires the headliner to be removed.

Fuse

Visually inspect the fuse for damage.

Wire harness

Check if the power supply on the red and red/black wires is OK. Inspect for broken/damaged wires. Inspect for

proper connection to the sunroof control unit. The wire harness connector is numbered to aid in proper installation:

1 = red

2 = brown / red

3 = brown

4 = green

5 = red / black

Switch

Inspect for proper power supply to the TVS operating switch, accomplished by using a test light on the connector at

the switch bracket, operate switch connector to assure movement in front and rear sliding positions.

Motor

Disconnect the motor wire (green/black) from the sunroof control unit. Dismount the motor. Using a double wire of

sufficient length, connect direct to battery, inspect the motor for proper operation in both directions. This is

accomplished by reversing the connection of the double wire. The motor has an inbuilt thermal cut-out device that

automatically switches the motor off during periods of overload. After a cooling down period the motor will function

properly.

Sunroof Control Unit

Testing is covered in the electric trouble-shooting guide. The following failures could be the result of a broken

Sunroof Control Unit

Auto close function defective.

Soft touch operation defective

Comfort position can not be programmed

4 step down option defective

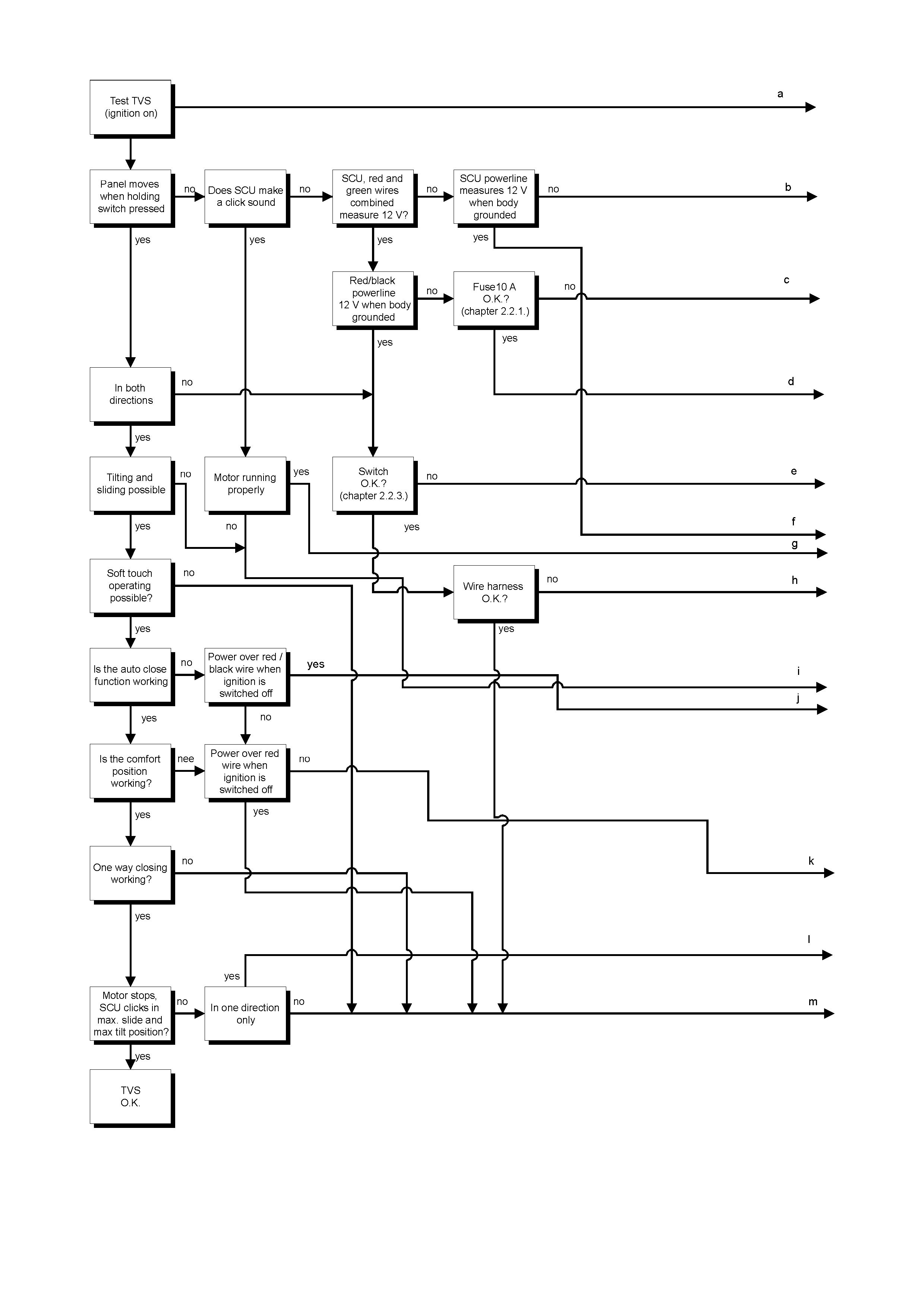

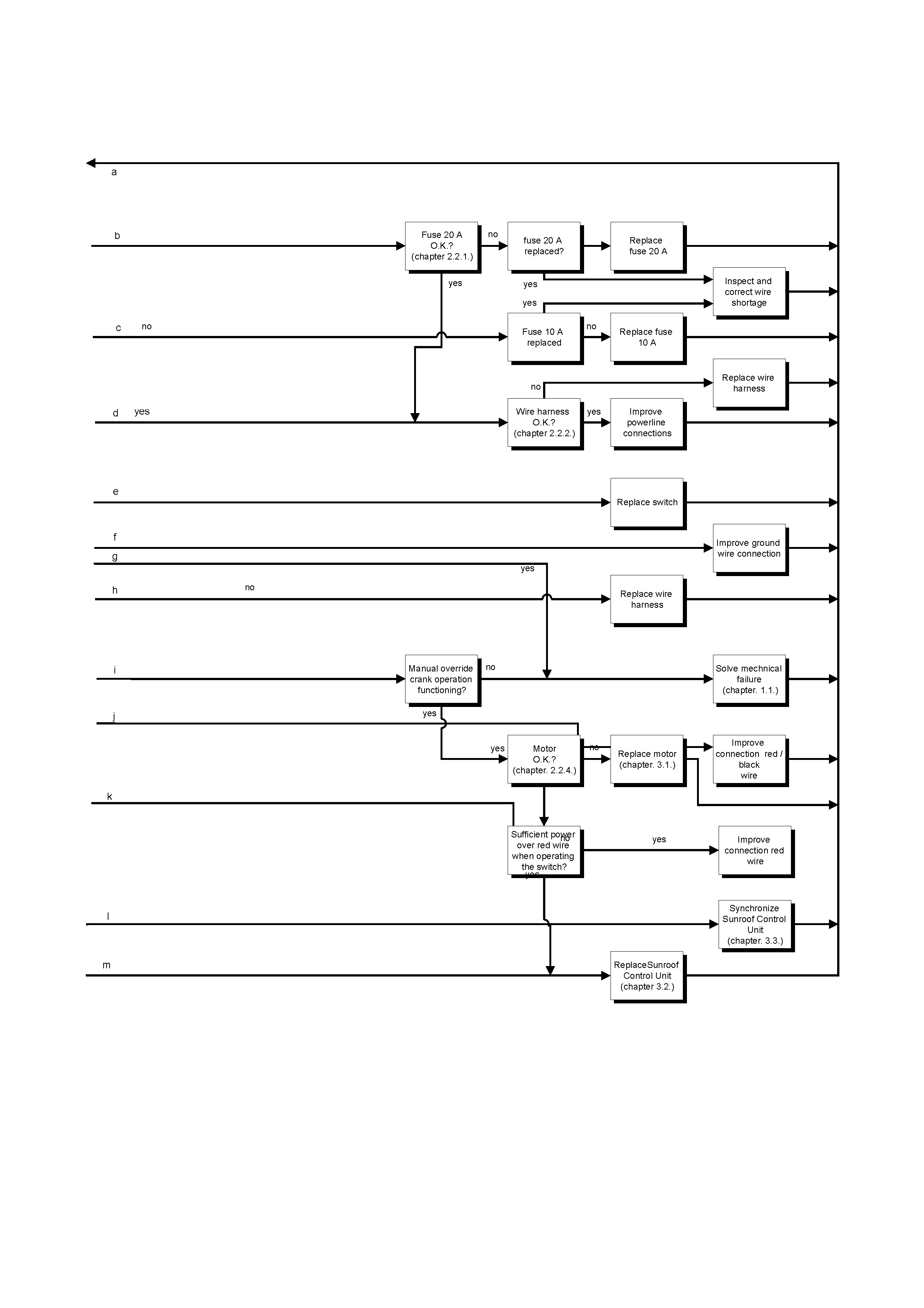

ELECTRICAL TROUBLE SHOOTING TABLE

Table 1 of 2

Table 2 of 2

REPAIRS

This chapter describes all repairs for the TVS 40 series.

3.1 MOTOR REPLACEMENT

1. Remove or drop rear of headliner to access motor cover.

2. Remove cover, motor now drops down.

3. Disconnect the motor wire from the sunroof control unit.

4. Connect new motor to sunroof control unit.

5. Inspect motor for proper operations in both directions.

6. Remount motor and motor cover

7. Inspect the unit for proper electrical and mechanical functioning.

8. Reinstall headliner.

3.2 SUNROOF CONTROL UNIT (S.C.U.) - REPLACEMENT

1. Remove or drop rear of headliner to access

motor cover.

2. Utilising a manual crank, vent the panel

completely.

3. Remove the LH mechanism cover.

4. Utilising the manual crank, close the glass

panel (1.5 revolutions) access the 2.5 mm

brass hole with a pin. Venting the panel, turn

crank 0.25 revolution forward. The pin stops

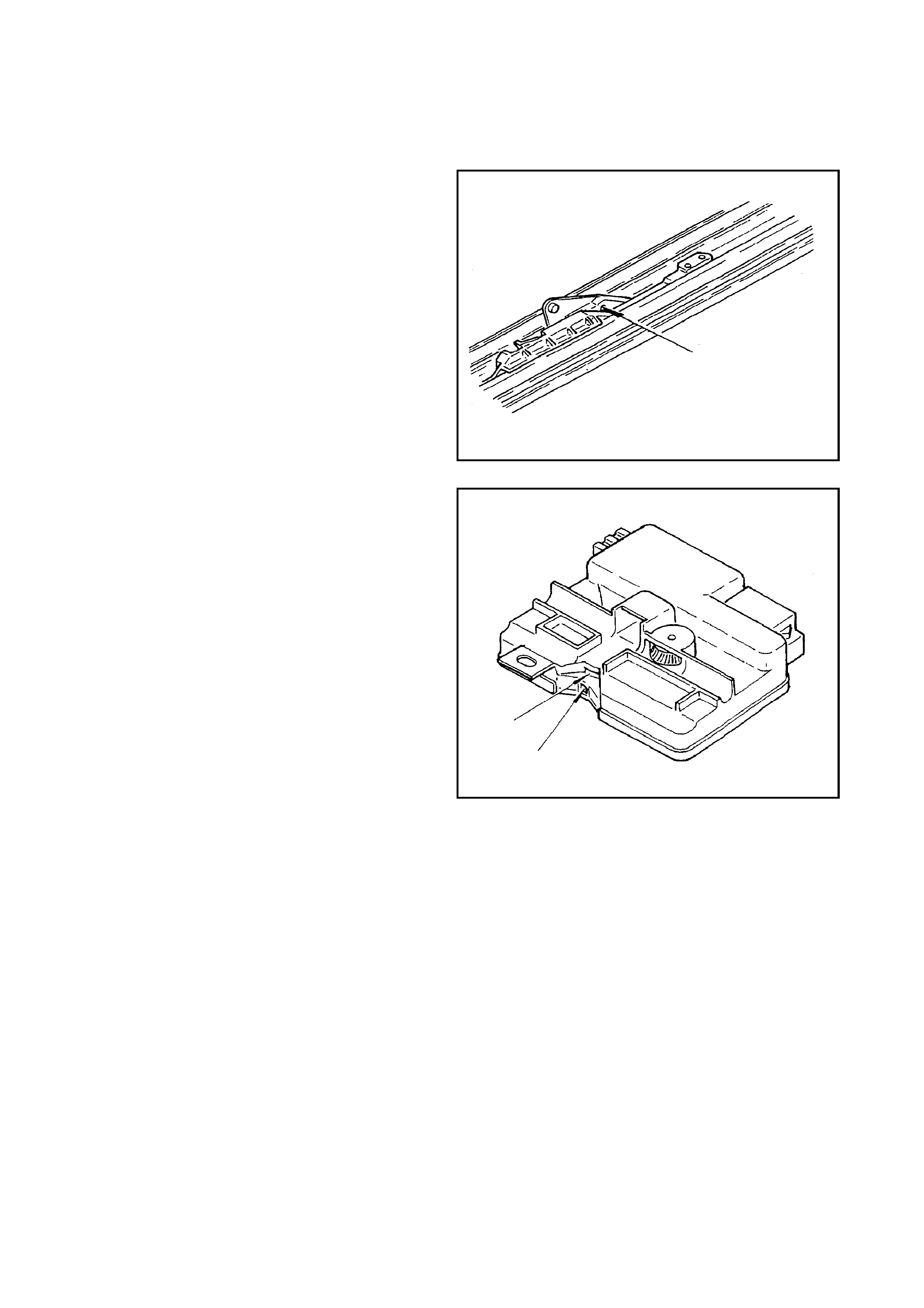

the mechanism at the desired location (see

Figure J-3).

5. Remove cover, motor now drops down.

6. Disconnect the motor wire from the S.C.U and

remove the motor.

7. Disconnect the wire harness from the S.C.U.

8. Remove the S.C.U. with screw, drop the front,

slide back.

Figure J-3

9. Inspect the new S.C.U. for proper alignment of

spots on gearwheel (see Figure J -4). Dropping

the front of the S.C.U. low enough for cable

clearance slide forward, engage lip of cable

plate in S.C.U. slot. Straighten S.C.U.

horizontally and tighten screw.

Figure J-4

NOTE:

If the spots are not aligned, turn the top mount

cable gear until each spot appears aligned over

one another in the view finders.

10. Reconnect both wire connectors to the S.C.U.

and remount motor and cover.

11. Check proper functioning of sunroof

12. Mount headliner.

13. Remount the LH mechanism cover.

3.3 SYNCHRONIZATION OF THE SUNROOF CONTROL UNIT (S.C.U.)

1. Remove or drop rear of headliner to access

motor cover.

2. Utilising the manual crank, vent the panel

completely.

3. Remove the LH mechanism cover.

4. Utilising the manual crank, close the glass

panel (1.5 revolutions) access the 2.5 mm

brass hole with a pin. Venting the panel, turn

crank 0.25 revolution forward. The pin stops

the mechanism at the desired location (see

Figure J-3).

5. Remove cover, motor now drops down.

6. Disconnect the motor wire from the S.C.U.

7. Disconnect the wire harness from the S.C.U.

8. Remove the S.C.U. with screw, drop the front,

slide back.

9. To align the two spots in the view f inders, turn

the exposed black cable gear mounted in top

center of the S.C.U. W hen each spot appears

directly in line with the other, top to bottom,

stop

NOTE:

If the spots are not aligned turn the top mount

cable gear until each appears aligned over one

another in the view finders.

10. Remount S.C.U. dropping the front of the

S.C.U. low enough for cable clearance, slide

forward, engage lip of cable plate in S.C.U.

slot. Straighten S.C.U. horizontally and tighten

screw.

11. Reconnect both wire connectors to the S.C.U.

12. Check proper functioning of sunroof

13. Mount headliner.

14. Remount the LH mechanism cover.

3.4 DRIVE CABLES REPLACEMENT

1. Remove covers, panel, drain channel, wind

deflector and sunshade or trim tray and

ventilation tray and adjustment bracket.

2. Place mechanism in closed position.

3. Remove rear of headliner to access motor

cover.

4. Remove motor cover, motor now drops down.

5. Disconnect the motor wire from the sunroof

control unit.

6. Remove the S.C.U. with screw, drop the front,

slide back.

7. Remove the gearwheel housing by removing

the two screws.

8. Remove gearwheel by inserting screwdriver,

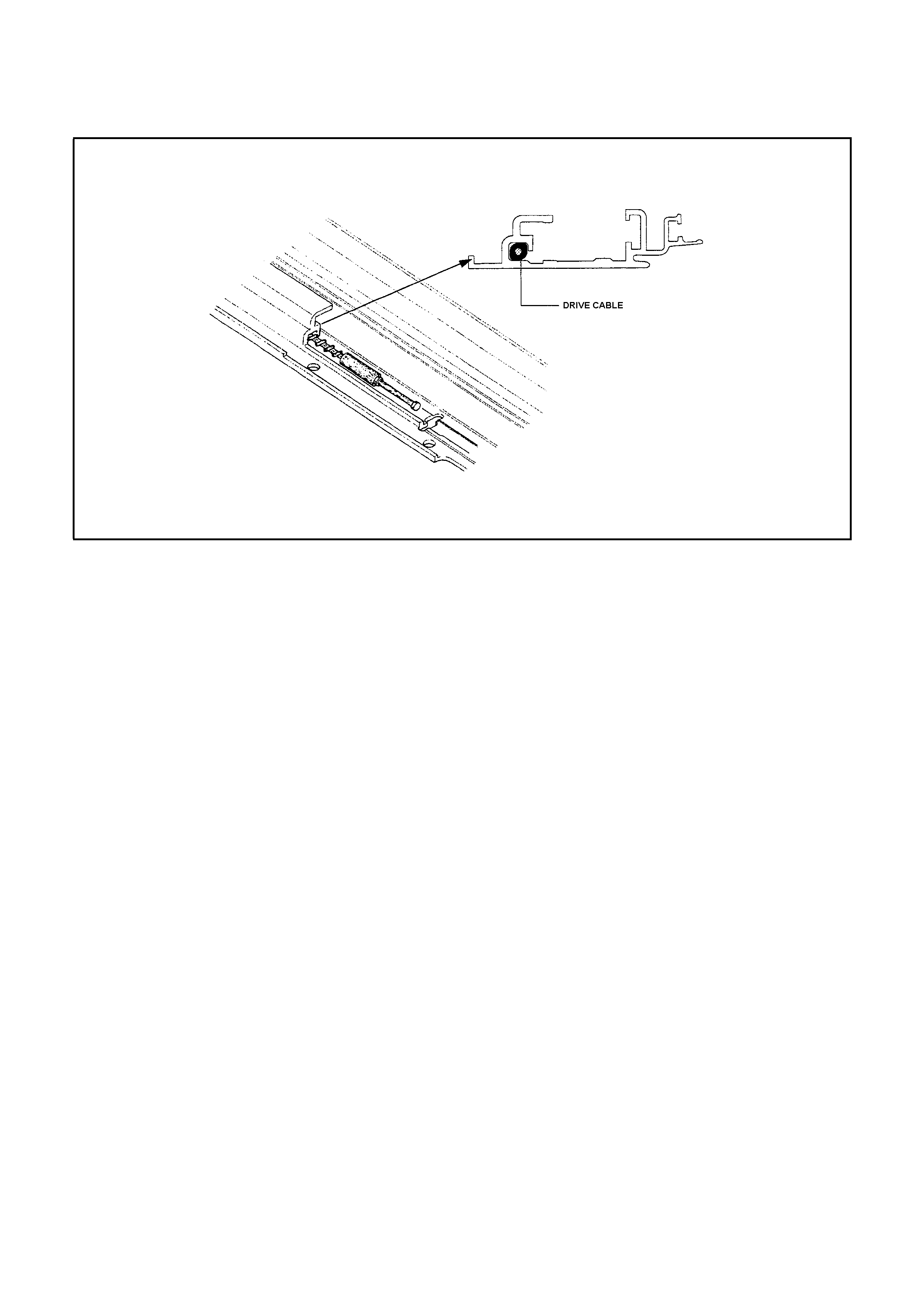

push forward, it drops down (see Figure J-5).

Figure J-5

9. Place a screwdriver in the mechanism as

indicated in Figure J-6. Push this mechanism

rearward into the slide position. Continue

pushing backwards by placing hand on fr ont of

mechanism, 3 locator screws become

accessible.

10. Rem ove the locator being c areful to r em em ber

the positioning of screws and the blocking

catch.

11. Pull mechanism all the way forward.

12. Push the mechanism into tilt position as in step

9. Be sure you do not inadvertently dislodge

the mechanism. Keep the front of the

mechanism down.

13. Remove the front screw and slide the

retraction mechanism forward. Do not take

out.

14. Slide mechanism in tilt position further forward.

15. Remove the torx screw which connects the

curve on panel to the adjustment bracket.

Remove the aluminium curve on panel from

the long lever. Pivot the adjustment bracket

forward.

Figure J-6.

16. You can now see the cable. Lift out cable and

pull forward out of the guide rail track.

17. Inspec t for proper length of new cable, grease

and slide into rail. Make sure the oval shaped

copper head of the cable seats firmly and

diagonally across the guide channel (see

Figure J-7).

Figure J-7

18. To check that cable is positioned properly

grasp long lever in tilt position with one hand,

the pivoting adjustment bracket in the other

hand and slide backwards, it should slide into

place (if blocked turn cable slightly to reseat

copper oval head properly).

19. Pivot arm of adjustment bracket back down

into place. Slide the curve on panel back into

place over cap on long lever and rem ount the

torx screw.

20. Push m echanism into slide position as in step

9 (hold adjustment bracket stable while doing

so). If mechanism stops after approximately

100 mm (4 in.) preventing a full rearward

positioning, you failed to hold the adjustment

bracket stable, repeat step 20.

21. Slide whole mechanism rearwards to allow

remounting of locator.

22. Slide the retraction rearwards, remount screw

and locator.

23. Repeat steps 10 through 22 to replace other

cable.

24. Slide both LH/RH mechanisms to the front

position.

25. Push LH/RH mechanisms to closed position.

Insert a pin in each 2.5 mm brass hole.

(pointed object). Slide mechanism forward

until pin stops the mechanisms movement at

the desired location (see Figure J-3).

26. Mount the new gearwheel. Being sure to

center it evenly between the walls of the hole

in the motor bracket. Note that the core or

center of the gear has splines (teeth). The

splines do not extend completely to one side

of the gears inner core. This is the down

(bottom) side for mounting (see Figure J-5).

27. Mount the new gearwheel housing.

28. Mount the sunroof control unit. Inspect to be

sure the two timing spots are aligned in the

view finders (top to bottom ) (s ee Figure J-4).

Dropping the front of the S.C.U. low enough

for cable clearance slide forward, engage lip

of cable plate in S.C.U. slot. Straighten S.C.U.

horizontally and tighten screw.

NOTE:

If the timing spots are not aligned, turn the top

mount cable gear until each appears aligned over

one another in the view finders (see Figure J-4).

29. Connect the motor to the sunroof control unit

(wire one way connector).

30. Remount motor and cover, replace screws.

31. Inspect the sunroof for proper electrical and

mechanical functioning.

32. Remount headliner.

33. Remount adjustment bracket, sunshade or

ventilation tray and trim tray, drain channel,

panel, winddeflector and mechanism covers.

34. Final inspection of unit.

3.5 TIMING OF THE DRIVE CABLES

1. Fully tilt panel

2. Remove LH/RH mechanism covers.

3. Fully close panel.

4. Drop rear of headliner to access motor cover plate.

5. Remove motor cover, motor now drops down.

6. Disconnect sunroof control unit wires and remove the motor.

7. Dismount sunroof control unit with screw, drop the front and slide back.

8. Remove the gearwheel housing by removing the two screws.

9. Remove gearwheel by inserting screwdriver, push forward, it drops down (see Figure J-5).

10. Push m echanisms LH/RH to closed pos ition. Acces s each 2.5 m m br ass hole with a pin ( pointed objec t). Slide

mechanism forward until pin stops the mechanisms movement at the desired location (see Figure J-3).

11. Mount the new gearwheel. Being sure to center it evenly between the walls of the hole in the motor bracket.

Note that the core or center of the gear has splines (teeth). The splines do not extend completely to one side of

the gears inner core. This is the down (bottom) side for mounting (see Figure J-5).

12. Mount the new gearwheel housing.

13. Mount the sunroof control unit. Inspect to be s ure the two white timing spots ar e aligned in the view finder (top

to bottom) (see Figure J-4). Dropping the front of the S.C.U. low enough for cable clearance slide forward,

engage lip of cable plate in S.C.U. slot. Straighten S.C.U. horizontally and tighten screw.

NOTE:

If the white tim ing spots are not aligned, tur n the top m ount cable gear until each appears aligned over one another

in the view finders (see Figure J-4).

14. Connect the motor to the sunroof control unit. (wire one way connector).

15. Remount motor and cover, replace screws.

16. Inspect the sunroof for proper electrical and mechanical functioning.

17. Remount headliner.

18 Remount the LH mechanism cover.

19. Final inspection of unit.

3.6 ADJUSTMENT BRACKET REPLACEMENT

1. Fully tilt panel.

2. Remove the panel.

3. Remove adj ustm ent brack et by rem oving front retaining c lip and torx s crew. T he adjus tment brack et is m oved

sideways from the long lever in rear and mechanism in front.

4. Remove the curve on panel by taking off retaining clip. Mount curve on panel to new adjustment bracket.

5. Reverse above sequences to reinstall the adjustment bracket.

6. Remount panel.

7. Inspect sunroofs electrical and mechanical functioning.

3.7 SEAL REPLACEMENT TVS 40 SERIES

1. Dismount LH / RH mechanism covers, glass panel and exterior covers.

2. Remove seal from panel.

3. Remove all foreign debris from around glass frame.

4. Install new seal, beginning at center front of glass frame retaining channel.

5. Utilising your thumbs, insert seal with enough pressure to be sure of flushness (tight to frame).

6. Trim the glass seal length. when cutting excess leave approximately 6 mm extra then work it into retaining

channel.

7. Remount the panel.

8. Mount the LH / RH mechanism cover.

3.8 RETRACTION MECHANISM REPLACEMENT

1. Retract panel completely.

2. Remove the wind deflector.

3. Remove the two screws and take the retraction mechanism forwards out of rail.

4. Install new retraction mechanism in rail.

5. Remount the wind deflector.

6. Inspect for proper functioning.

3.9 GUIDE RAIL MECHANISM REPLACEMENT

1. Remove LH/RH mechanism covers, panel,

drain channel, wind deflector and sunshade.

2. Tilt mechanism completely.

3. Fully retract mechanism.

4. Remove the locator, retraction mechanism

and rail screw.

5. Remove wind deflector mounting nuts.

6. Slide rail sideways to unlock, then lift front up.

7. With rail front up, grasp retractor mechanism

and remove.

8. Fully close mechanism.

9. Lift and pull rail slowly forward over

mechanism, as soon as the front of drive

cable appears at end of guide, lift out cable,

now pull mechanism carefully forward and lift

out. Inspect the new replacement mechanism

for cleanliness and completeness.

10. Slide the mechanism rearward out of rail for

cable installation access.

11. Install cable, then push mechanism forward on

rail (maintain access to rear rail area).

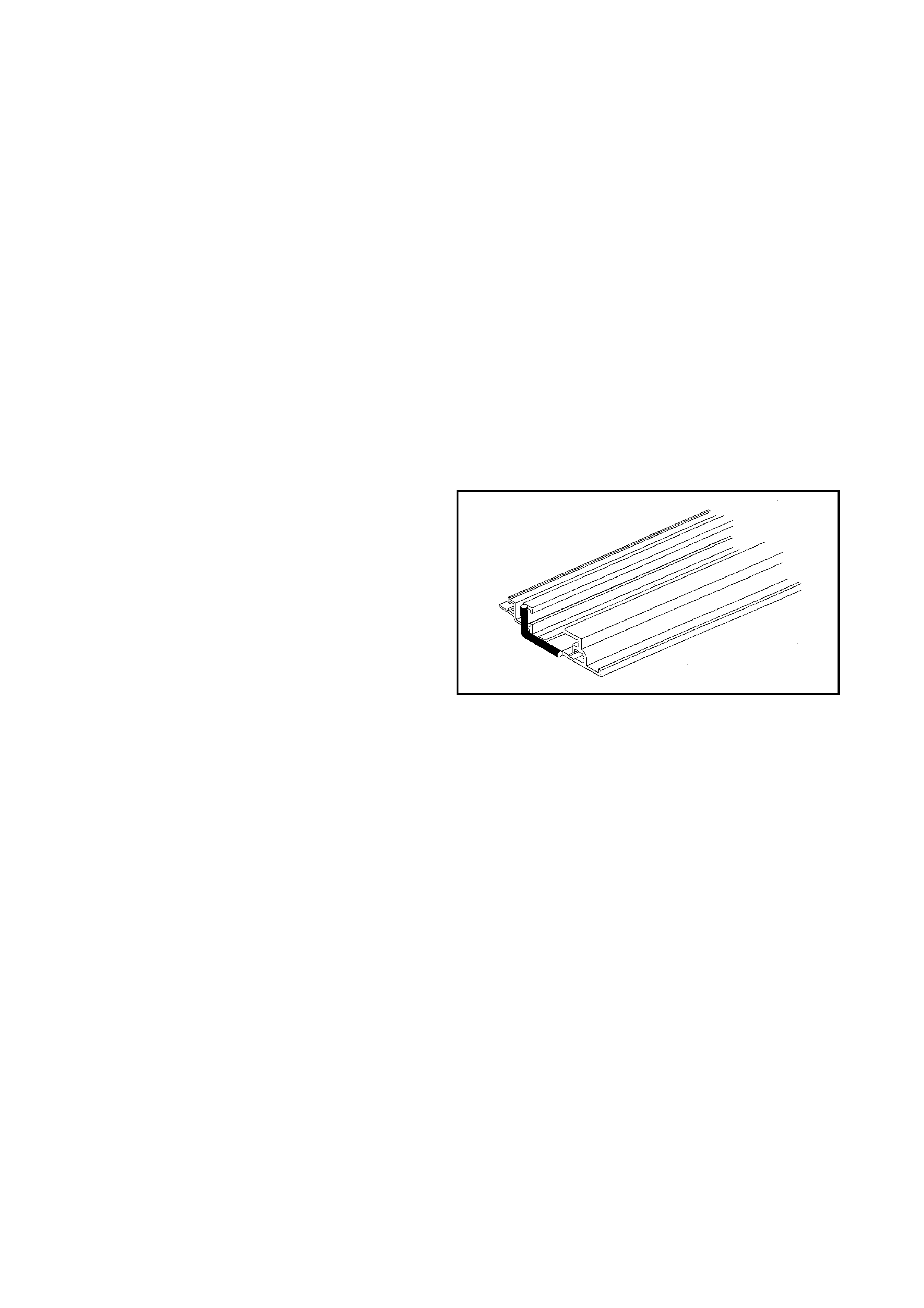

12. Apply a bend of liquid butyl as indicated on

Figure J-8.

13. Slide rail rearward over mechanism and drive

cable while holding the front of the m echanis m

in place. As soon as the rail is fully extended

rearward, drop the f ront to fram e and push rail

rearward into rail stop. Line up the s crew holes

for proper positioning.

14. Retract mechanism totally.

15. Lift front of rail to reinstall retractor

mechanism.

16. Drop rail down, push inboard until it “locks” in

place.

17. Remount all new rail screws starting at front

for proper positioning. Use original positioning

of screws by size.

Figure J-8

18. Replace wind deflector mounting nuts loosely.

19. Tilt mechanism completely.

20. Inspect for proper mechanical functioning of

mechanism.

21. Remount sunshade, drain channel, panel and

wind deflector.

22. Inspect functioning of sunroof, reinstall LH/RH

mechanism covers.

3.10 BLOCKING CATCH REPLACEMENT

1. Remove the LH/RH mechanism covers and panel.

2. Fully retract mechanism.

3. Remove locator.

4. Fully tilt mechanism.

5. Remove blocking catch by lifting out.

6. Clean out broken blocking catch debris.

7. Install new blocking catch in mec hanism, inser t circular eye stud into mec hanism m aking sur e second sm aller

stud falls cleanly into mechanism slot.

8. Fully retract mechanism.

9. Remount locator.

10. Inspect for proper mechanical functioning.

11. Remount the panel and LH/RH mechanism covers.

3.11 SEAL ADJUSTMENT

The proper positioning of the panel should result in the seal firmly contacting either the EPDM trim ring or flanged

metal circ umfer ence of the sunroof opening. If the panel fits properly but gaps remain between seal and tr im ring it

can be corrected as follows:

1. Adjust panel properly against the rear of the trim profile (according to instructions in the installation manual

Chapter 5.3).

2. With a grease pencil mark the boundaries of insufficient contact on the panel (at the front).

3. Remove panel.

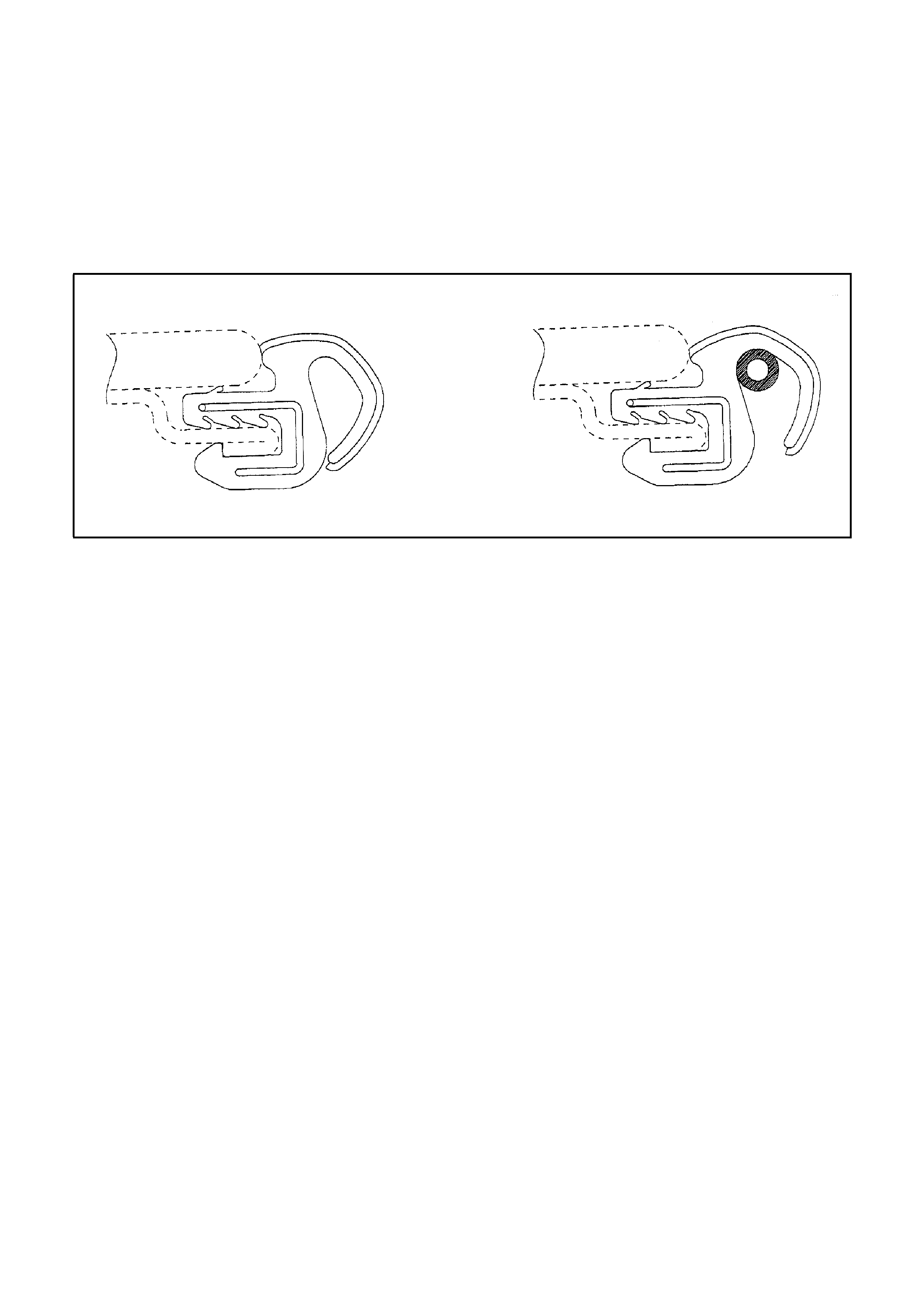

4. In the areas marked, a spacer will be inserted inside the rubber seal. (see Figure J-9). Use a vinyl tube with

outer diameter of 3 mm (.12 in) for spacer material.

5. Glue the spacer material to the seal with super glue.

Figure J-9

6. Remount panel and adjust according to the installation manual Chapter 5.3.

EXTRACTS FROM THE HOLLANDIA INSTALLATION MANUAL

SIDE SUPPORT BRACKETS CENTRE AND REAR

1. Remove clamps and gluetemplate after 30

seconds, Leave the jacks in place! Check

the curvature of the car roof near the

centrebrace with curvature gauge. If the car

roof is more curved than the curvature gauge

then a correction can be made by slightly

raising the jacks until the curvature of the

roofskin is equal to the curvature gauge.

If the curvature of the roofskin less curved

than the curvature gauge then a correction

can be made by lowering the jacks a little bit

until the curvature of the roofskin is equal to

the curvature of the curvature gauge.

NOTE:

Excessive correction can cause distortion in the

roofskin.

2. For each car model the side support brackets

have to be cut and bent to fit. Bending, cutting

and punching equipment can facilitate this

work. Place the wide brackets on each side

close to the centrebrace. The small brackets

are mounted as far to the rear as possible,

between the side rail and the frame.

3. The plastic cover m ust be on the bracket side

supporting the TVS frame.

4. Wrap paper masking tape around the part of

the bracket that will be attached to the side

rails. This avoids possible creaking.

5. Mount the support brackets to the side rails

with the supplied self tapping screws.

6. Remove the jacks.

7. Check the curvature of the car after installing

the support brackets.

INTERIOR TRIMMING

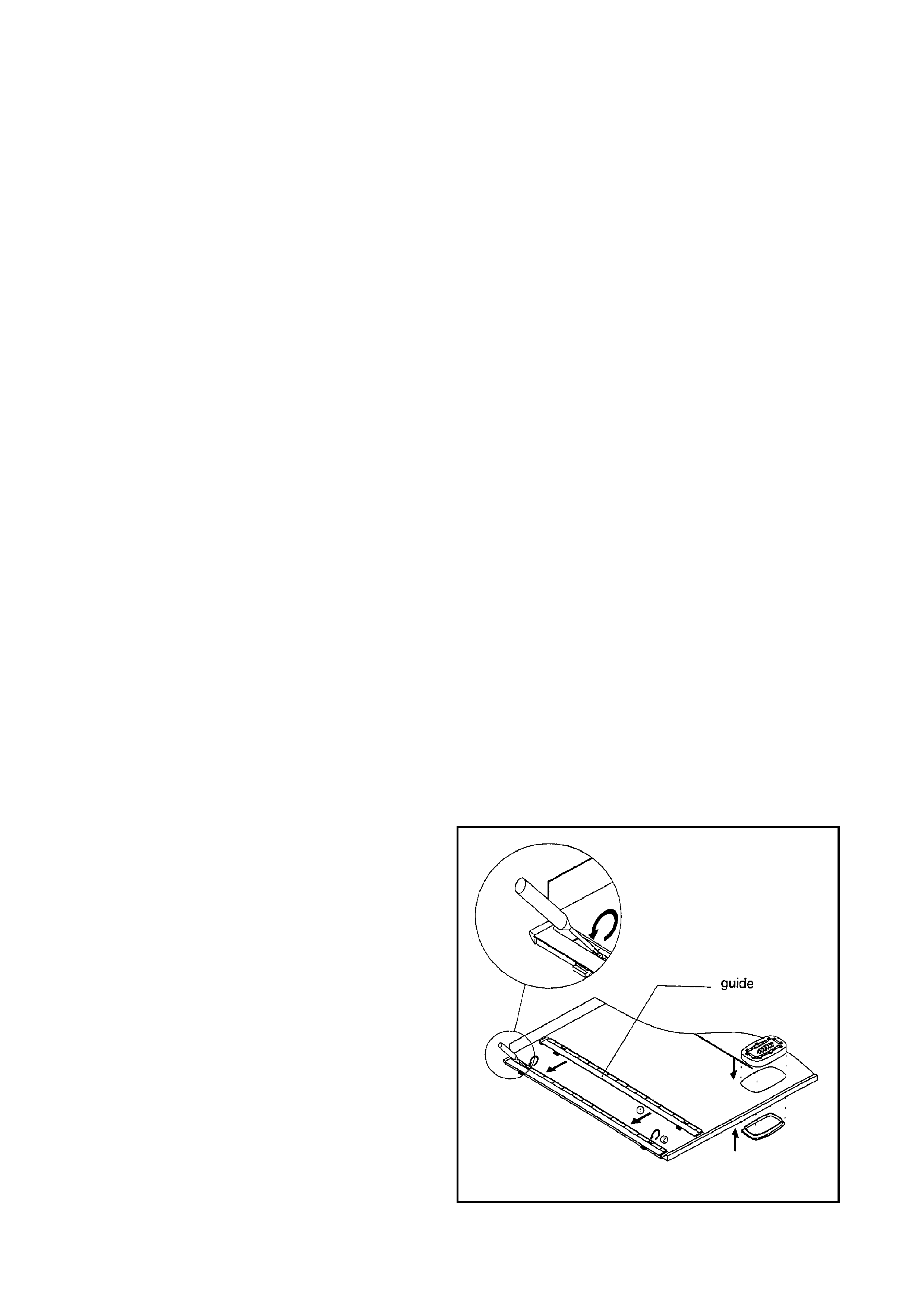

5. Mount the left and a right guide by placing the

integrated slide through the opening in the

side of the sunshade.

Lift the springs up with a screwdriver to apply

tension on the springs (see Figure 10).

Figure 10 - Finishing The Sunshade

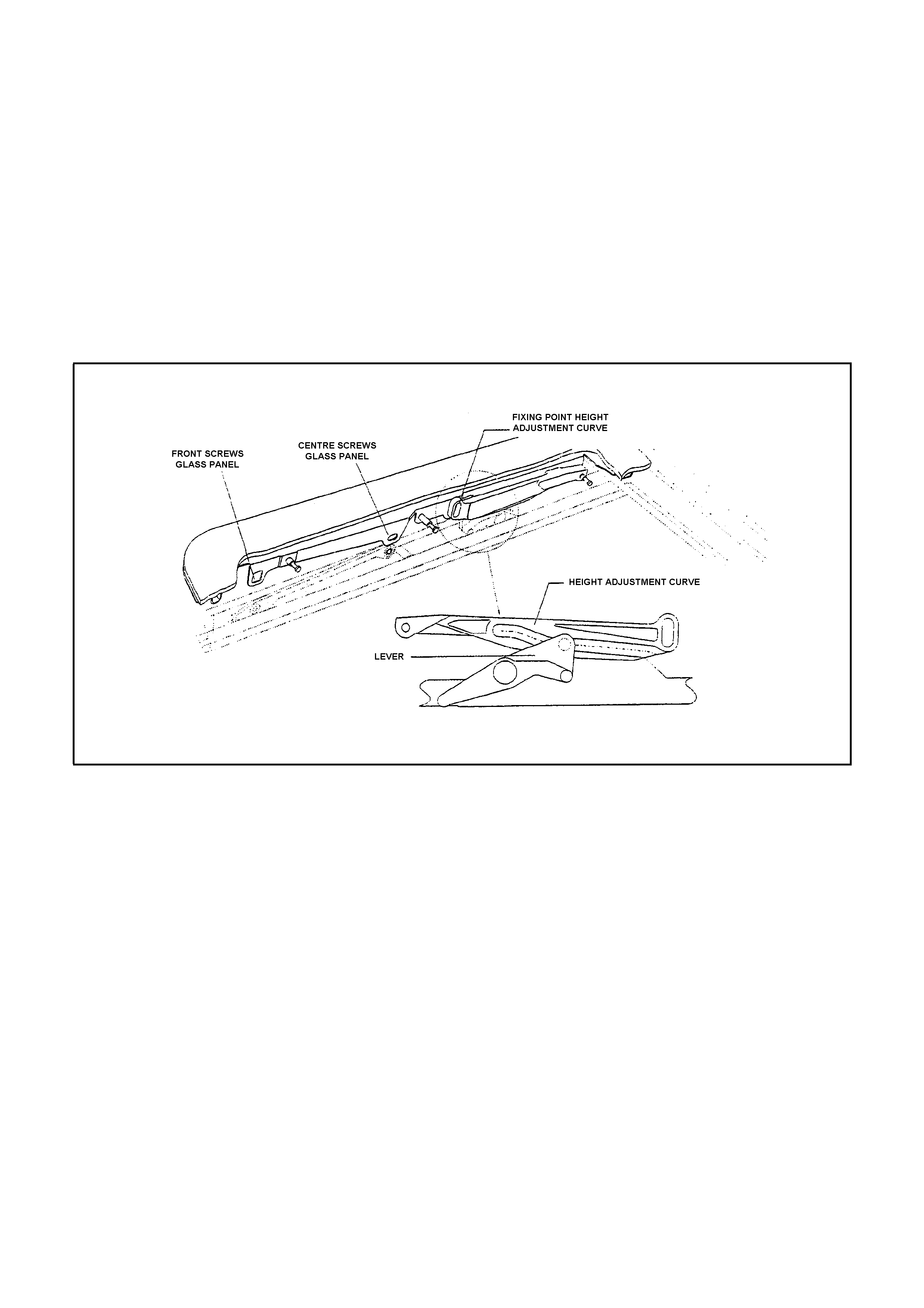

GLASS PANEL (TVS 40)

1. Slide mechanism to tilt position.

2. Inspect rubber seal and glass panel for damage.

3. Place the height adjustable curve, (which is at the rear of the glass panel), over the mechanism. Place vertical

front lip on panel between RH and LH mechanisms.

4. Lift the mechanism mounting bracket from the inside and install 2 front and centre screws, leaving the 4

screws loose.

5. Put glass panel in closed position.

6. Adjust the glass panel to the front. Check with for example a business card the tension of the seal against the

trim ring at the rear.

7. Tighten both centre screws.

8. Adjust height at the front and tighten front screws.

9. Adjust height at the rear by loosening Torx screws of the adjustment curve, adjust the glass level with roof skin

and tighten screws (see Figure 14).

Torque for all M5 screws is 3.5 Nm.

Figure 14 - Adjust The Glass Panel

10. Check functioning of mechanism and adjustments. Repeat operation 6 till 9 to readjust the glass panel if

necessary.

FIRE EXTINGUISHER

GENERAL

HSV VT models are fitted with a HSV design fire extinguisher. The extinguisher is located in the rear luggage

compartment.

SERVICE OPERATIONS

The fire extinguisher should be subjected to a regular visual inspection in accordance with the instructions on the

extinguisher. Par ticularly, the extinguisher should be inspec ted for dam age and to ensure that the integral pres sure

gauge registers the appropriate internal pressure. When discharged or when the internal pressure is outside the

prescribed limits, the extinguishers should be serviced and re-charged by an appropriate supplier. New

extinguishers are available through the HSV spare parts systems.

HSV INTEGRATED SECURITY SYSTEM

GENERAL

The new HSV Integrated Secu rity System (ISS) is fitted as s tandard equipment to all HSV VT and VS m odels. T he

ISS is a micro-processor controlled immobiliser which automatically isolates essential electrical circuits when the

ISS is armed and acc es s or y or ignition ‘ON’ is detected. The immobiliser is disar med us ing a valid ignition key code

and uniquely coded black tags which contain a small chip incorporating specific codes. The HSV ISS has been

improved for the VT range of vehicles. The vehicle no longer requires use of the black ISS tag each time the vehicle

is star ted. The ISS rec ords the ignition k ey code and will disarm when a valid vehic le ignition k ey is detected at the

key slip ring. Up to seven vehicle ignition keys and seven ISS black tags can be assigned to the vehicle if required.

NOTE:

IF THE KEY-HEAD BECOMES UNSERVICEABLE AND FAILS TO DISARM THE ISS, THE ISS MAY BE

DISARMED USING THE BLACK TAG UNTIL A REPLACEMENT KEY IS INTRODUCED.

INTRODUCING NEW KEYS

A red MASTER TAG is also supplied with each ISS. T his tag is used to place the ISS into `Learn’ m ode: touching

the red tag to the status monitor (located in the glove box ) will caus e the LED f lash rate to incr ease which indicates

that learn mode is operative. In this mode, codes for lost tags/keys may be overwritten and new keys/tags m ay be

introduced as follows:

With the ISS in learn m ode, insert ignition k ey and turn ignition switch to ‘IGN ON’ position. T he status m onitor

will change to indicate ignition k ey code has been s uccess fully stored (LED goes of f). ISS will retur n to nor mal

mode. Retouch red tag if more ignition keys are to be introduced.

With ISS in learn mode, touch new black tag to receptacle for approximately 2 secs. Status monitor LED will

change to indicate key code has been successfully stored (LED on). ISS will return to normal mode. Retouch

red tag if more black tags are to be introduced.

NOTE:

THE ISS WILL RECOGNISE SEVEN KEY AND TAG CODES. IF A TAG OR KEY IS LOST, THE

REMAINING/NEW CODES MUST BE ENTERED SEVEN T IMES TO ENSURE THAT THE CO DE FO R T H E LOST

KEY OR TAG HAS BEEN OVERWRITTEN AND CANNOT DISARM THE ISS.

NOTE:

RED TAGS MUST BE STORED IN A SECURE LOCATION REMOTE FROM THE VEHICLE. DO NOT STORE

RED TAG IN VEHICLE. LO SS OF A RED TAG WILL REQ UIRE REPLACEMENT OF T HE ISS SYSTEM IF KEYS

ARE LOST OR DAMAGED

VICE OPERATIONS

If an ignition key has been damaged and does not transfer a valid code, the ISS may be disarmed by touching a

valid black tag to the status monitor: this will transmit code to the BCM and enable vehicle start No periodic

servicing of the ISS is required and no additional information is provided or available on the system. HSV dealers

are not authorised to carry out any servicing operations on the ISS system. All requests for information and/or

assistanc e are to be f orwarded directly to the Service Manager at HSV. Bef ore mak ing this request and at any time

that correct operation of the ISS is suspected, the following functional check should be performed:

Check ISS status monitor (located in glovebox) to ensure ISS is in armed mode—i.e. slow flash

Place a piece of tape over the ignition key slip ring contact to break the electrical circuit between ignition key

and ignition barrel slip ring,

Turn key to start position—vehicle should not start.

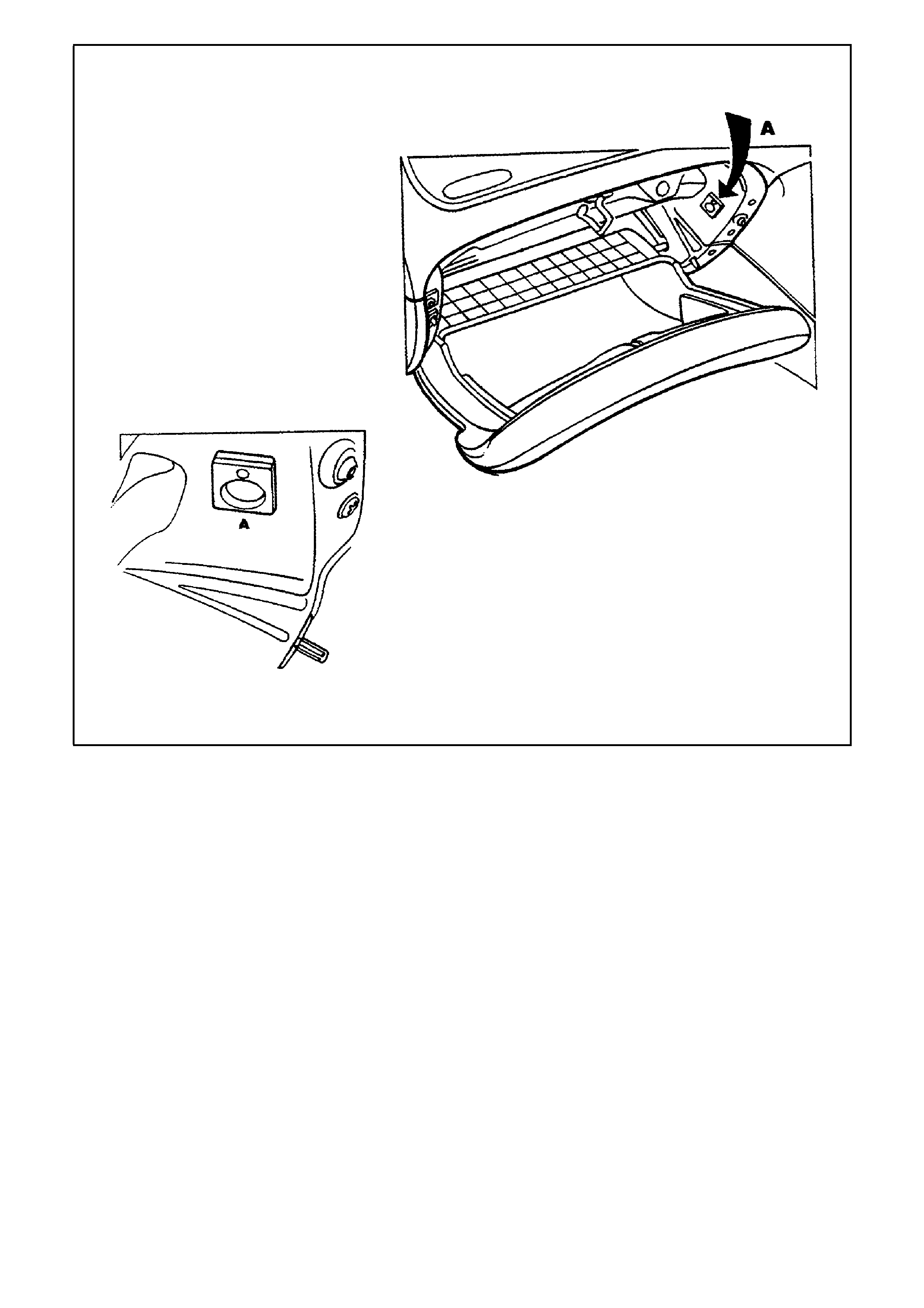

Figure J-10 - HSV VT ISS System

ELECTROCHROMIC M IRRORS

GENERAL

Electrochromic mirrors are a standard fitment to all VT Senator Signature Estate vehicles and to all vehicles fitted

with a Sunroof. The mirror features an electronically controlled mirror cell which changes colour in response to an

applied electrical voltage. This allows autom atic dark ening of the m irror during night dr iving when the headlamps of

a following vehicle shine on an integrated light s ensor. T his function only operates when the integral sens or detec ts

low ambient (i.e. at night time). The mirror also incorporates two manually operated map lights - separately switched

for passenger and driver. (Lights also illuminate in conjunction with interior lamp when activated by door switches.

The mirror operates automatically however, an AUTO/MANUAL switch provides the driver with the option for the

mirror to be darkened during low ambient light conditions regardless of presence or absence of following

headlamps. When reverse gear is selected, the mirror automatically lightens.

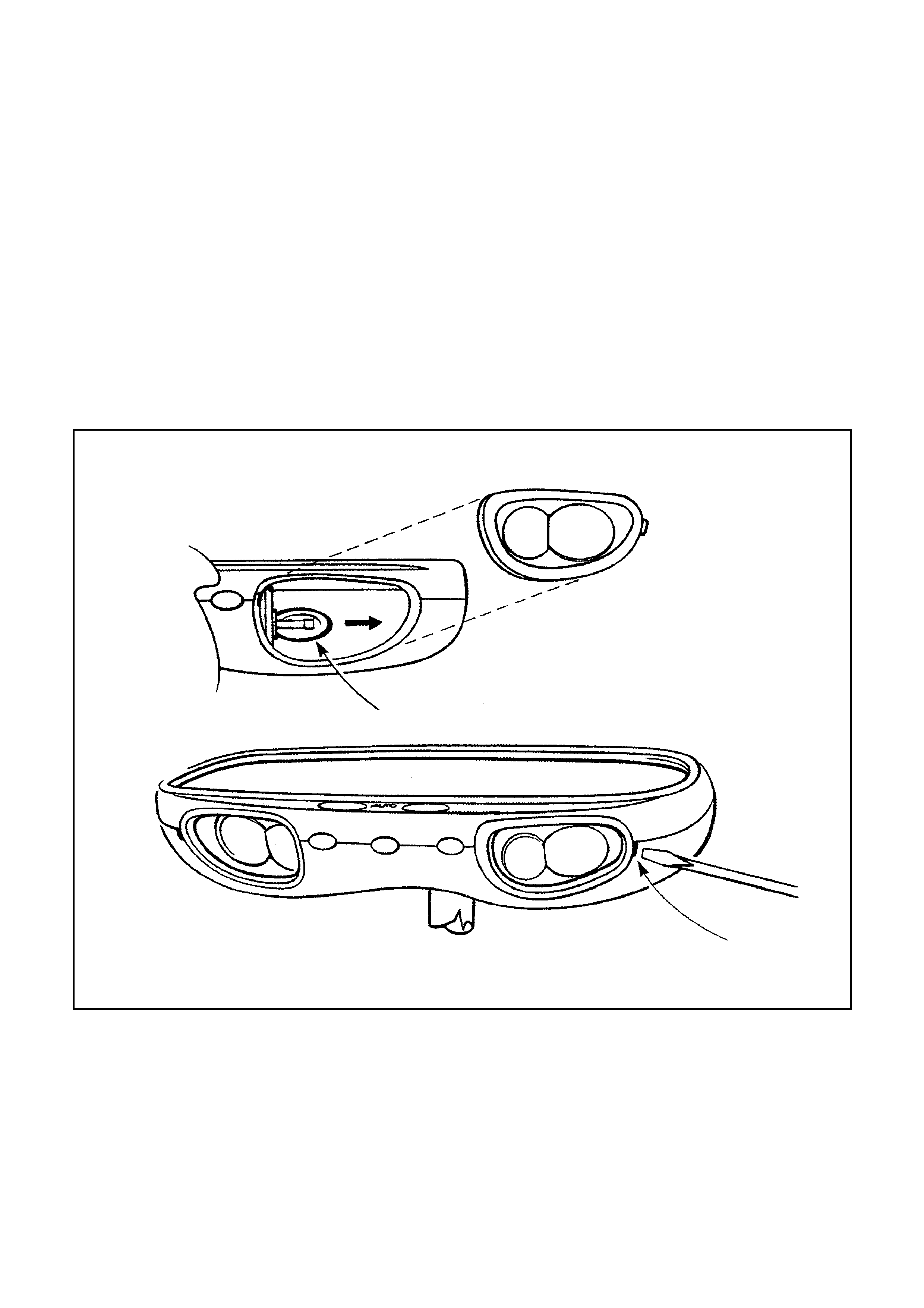

SERVICE OPERATIONS

No specific servicing of the m irror is required. T o replace m ap light globes use a s mall s crew driver to pris e out the

lens assembly to reveal a wedge-base five watt (5.0 W) globe (see Figure J-11). Refit lens assembly by inserting

the end closest to centre of m irror f irst - ens ure lam p bulb pass es through hole in s ide of lens assem bly. The m irror

is fitted with a short harness which connects to the HSV electrochromic mirror harness above the headlining near

the mirror: this harness runs across the headlining and down the `A’ Pillar to the main wiring harness which provides

connections to the battery, door switch, ignition, reverse lamps and ground.

Figure J-11 - HSV Electrochromic Mirror

HSV FOG LAMPS

GENERAL

HSV Fog lamps are fitted directly to the front fas cia of all HSV VT models except Manta (which is fitted with GMHA

lamp s) . The HSV lamp s us e a glas s c onvex r ef lector to provide a wide-angle beam c onc entrated in a r ange of 30 to

40 metres in front of the lamp. The external lens incorporates a clear horizontal section .

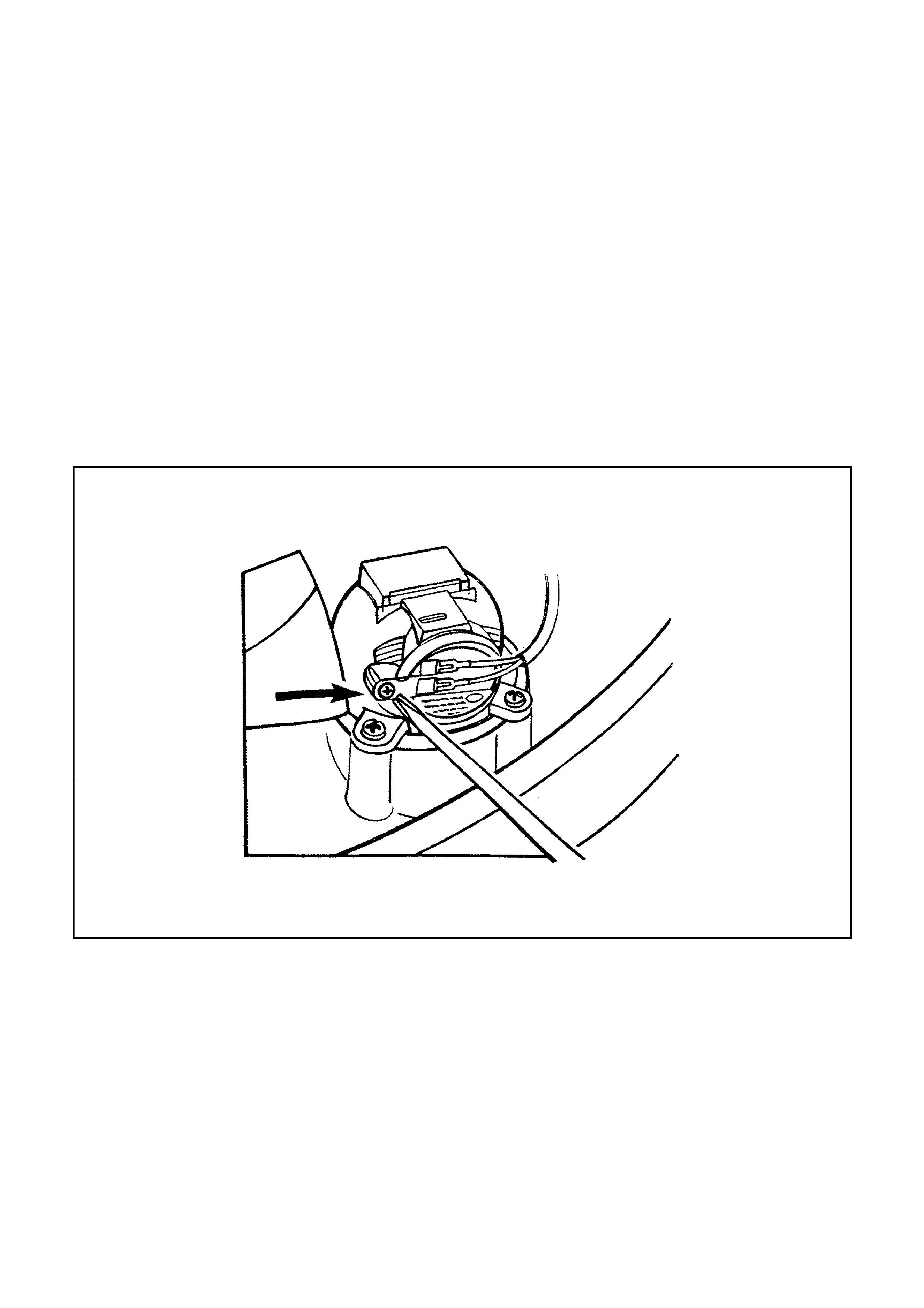

SERVICE OPERATION

No periodic ser vicing of the HSV lam ps is r equired however, occ asional r e-alignm ent may be necessar y. Alignm ent

is altered by m inute adjustm ents of the three mounting sc rews. Fog lamps are adjusted to foc us on a central ‘HOT

SPOT ’ 5.0 centim etres below the above ground height of the lam p (with the car levelled to norm al operating height)

at a distance of 25 metres from the bumper bar of the vehicle. Globes may be replaced without altering the

alignment by removing a water-tight access cover on the underside of the lamp (see Figure J-12): unclip the two

spring clips which retain the globe carrier at the focal point of the reflector. Replacement fog lamps available

through HSV are identified as follows

12C-970601 LAMP FOG LEFT HAND

12C-970602 LAMP FOG RIGHT HAND

NOTE:

CONDENSATION MAY APPEAR ON THE LENS OF THE FOG LAMP WHEN APPROPRIATE AMBIENT

CONDITIONS EXIST. THIS CONDENSATION WILL CLEAR AS THE AMBIENT CONDITIONS CHANGE OR

AFTER FOUR OR FIVE MINUTES OPERATION OF THE FOG LAMPS

Figure J-12 - HSV Fog Lamps