SECTION 2 - SERVICE OPERATIONS

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will

consist of either seat belt pre-tensioners and a driver's side air b ag, or seat belt pre-

tensioners and a driver's and front passenger's side air bags. Refer to CAUTIONS,

Section 12M, before performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS d eployment, result ing in po ssible person al injury or unnecessary

SRS system repairs.

IMPORTANT:

When any LPG system component has been replaced or overhauled, or when the engine assembly has been

replaced or overhauled, the adaptive learn drive cycle procedures must be carried out as described in. This is

because the values st ored in the Adaptive Digital Pr ocess or operational c ells apply only to the previous condition of

the engine or components.

2.1 DRAINING THE SERVICE LINES

WARNING:

The vehicle CANNOT be operated on LPG in the

works hop, unless the works hop is a "Spec ialis t G as

Workshop" (in accordance with the current

Australian Standards AS2746 - 1985) and LPG is

specifically required for testing.

Therefore, at the completion of the following

procedure, with the manual ser vice valve c losed, all

the LPG in the service lines is exhausted and the

vehicle running on petrol, then and only then can

the vehicle be driven into the workshop.

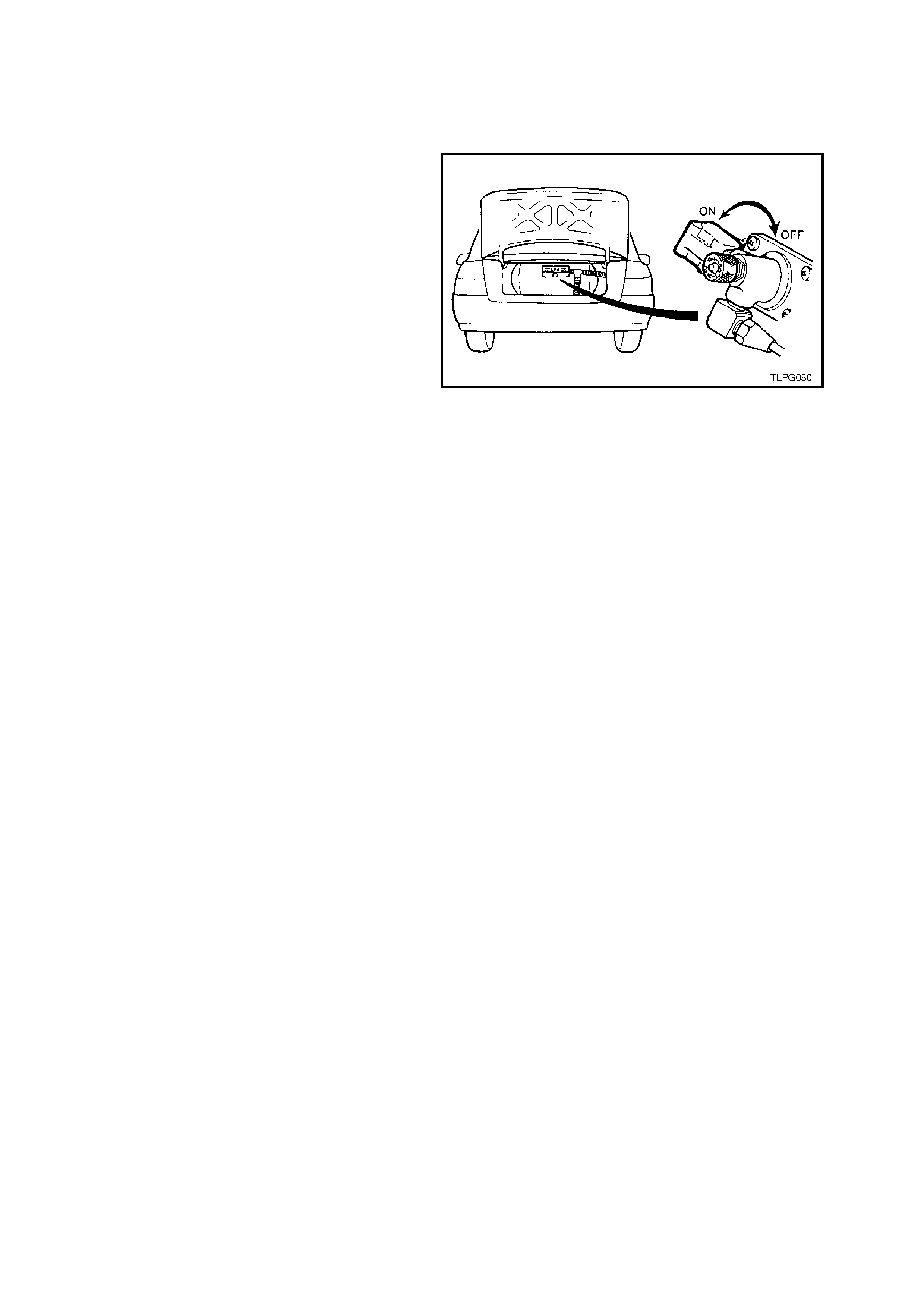

1. Park the vehicle in a well ventilated area, away

from any ignition source.

2. Remove the LPG cylinder valve box cover.

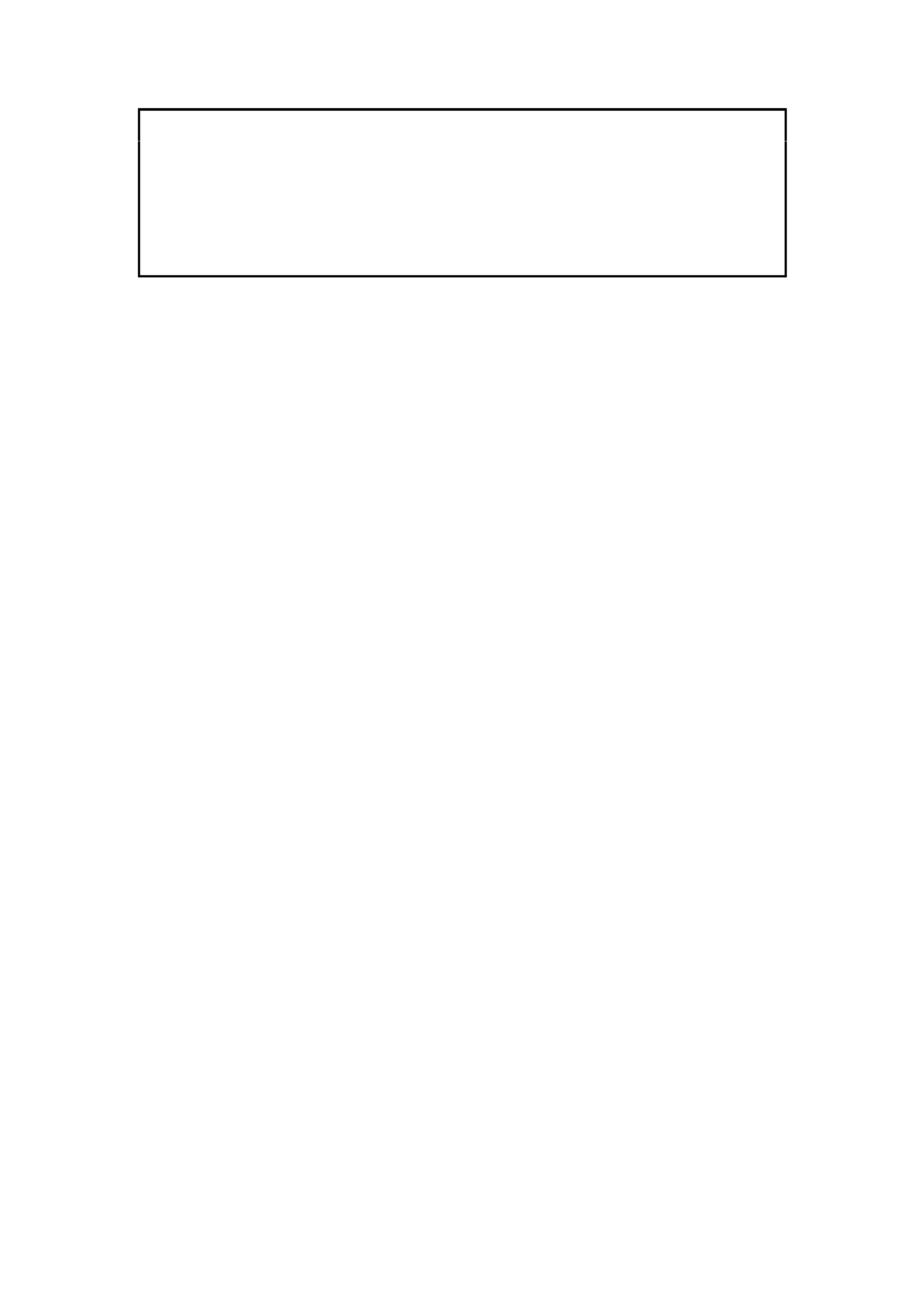

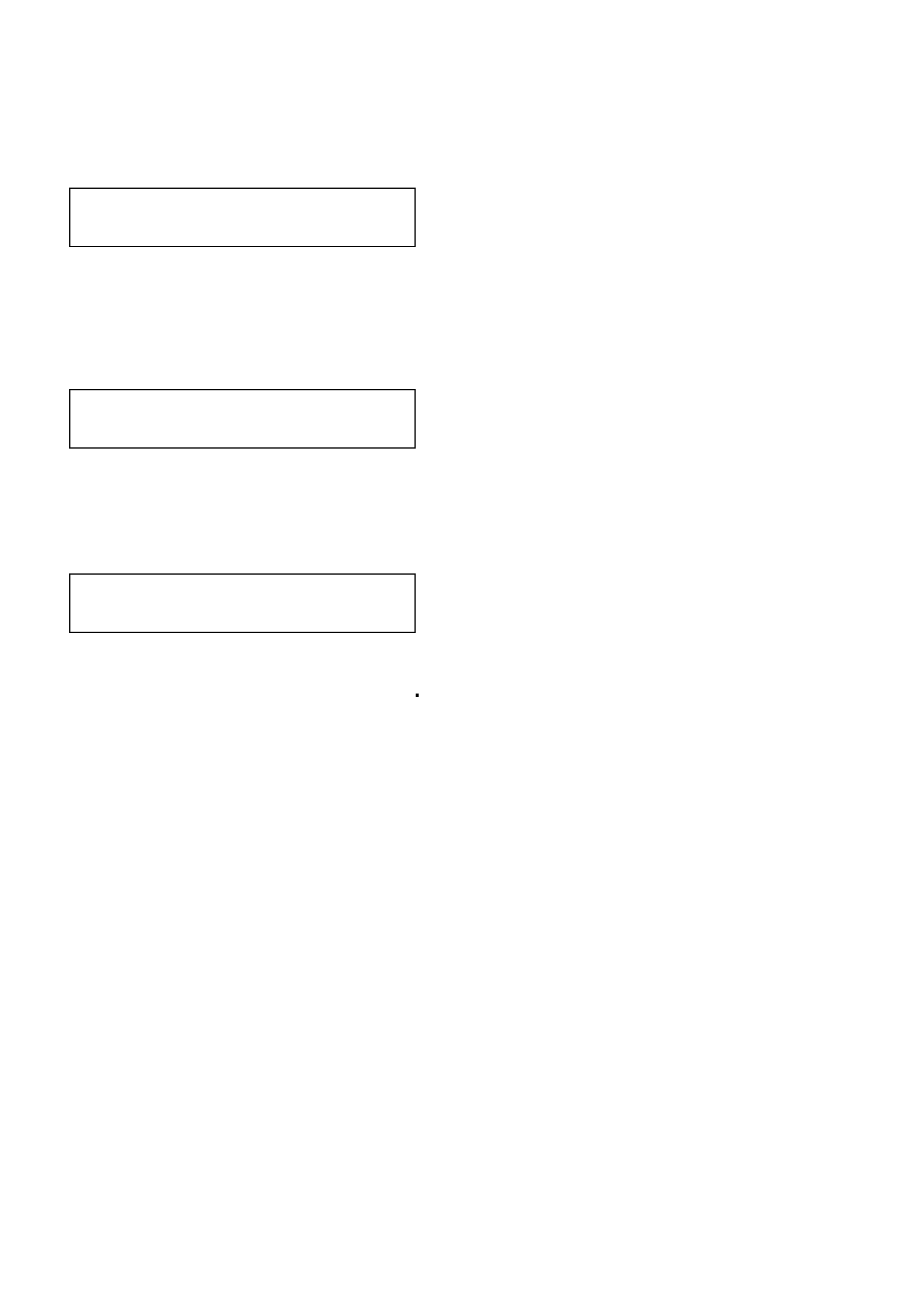

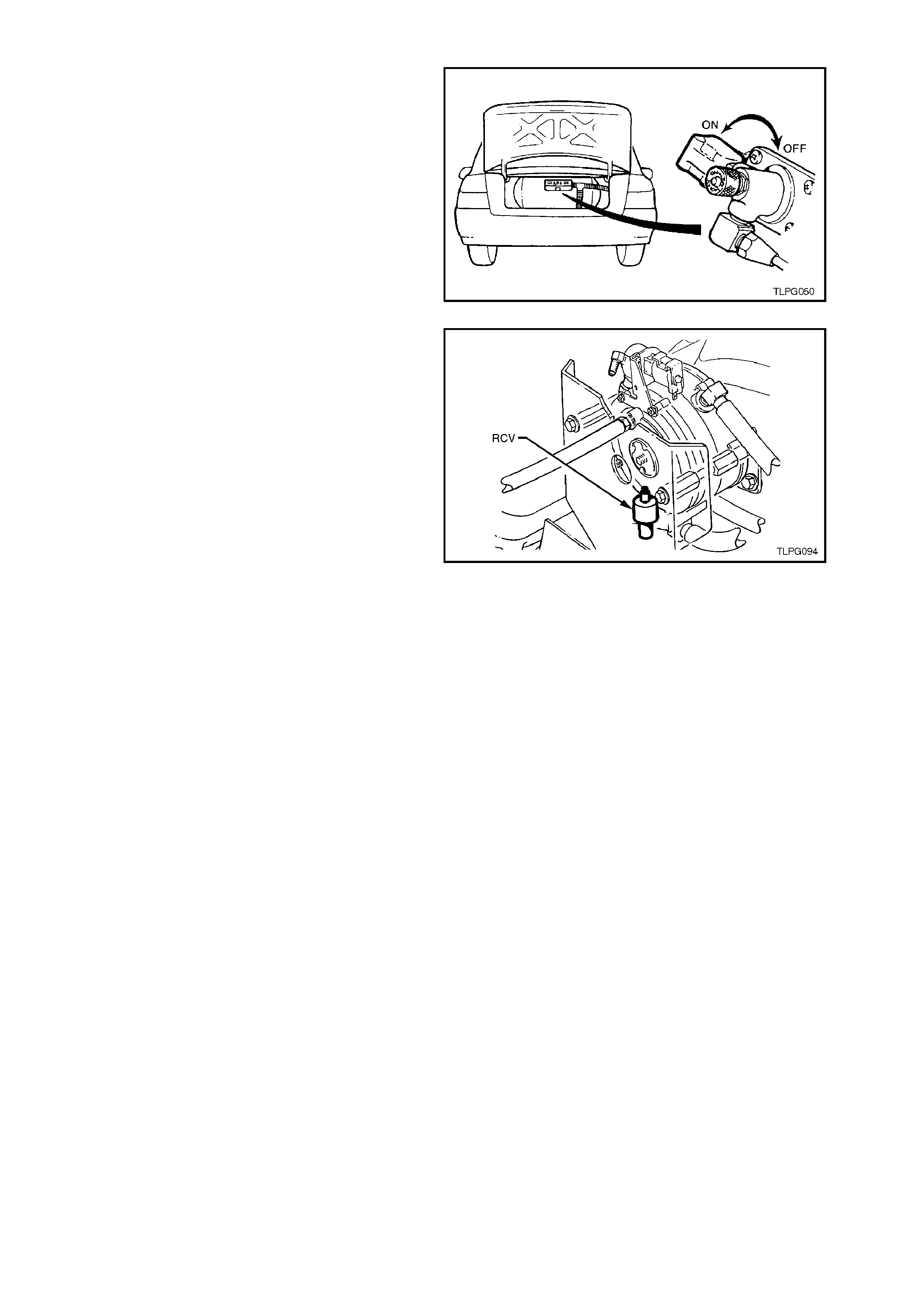

3. Turn 'OFF' the manual service valve.

CAUTION:

If at any time the manual service valve becomes

stuck, no service operations on the system will

be possible. Should for any reason the valve

stick, the cylinder will have to be returned to

the cylinder manufacturer (APA) to arrange a

replacement cylinder.

Contact: APA Industries

190 Colchester Road

Kilsyth

Victoria 3137

Phone - (03) 9720 2855

Fax - (03) 9761 4495

Email - APA @ APAIND.COM.AU

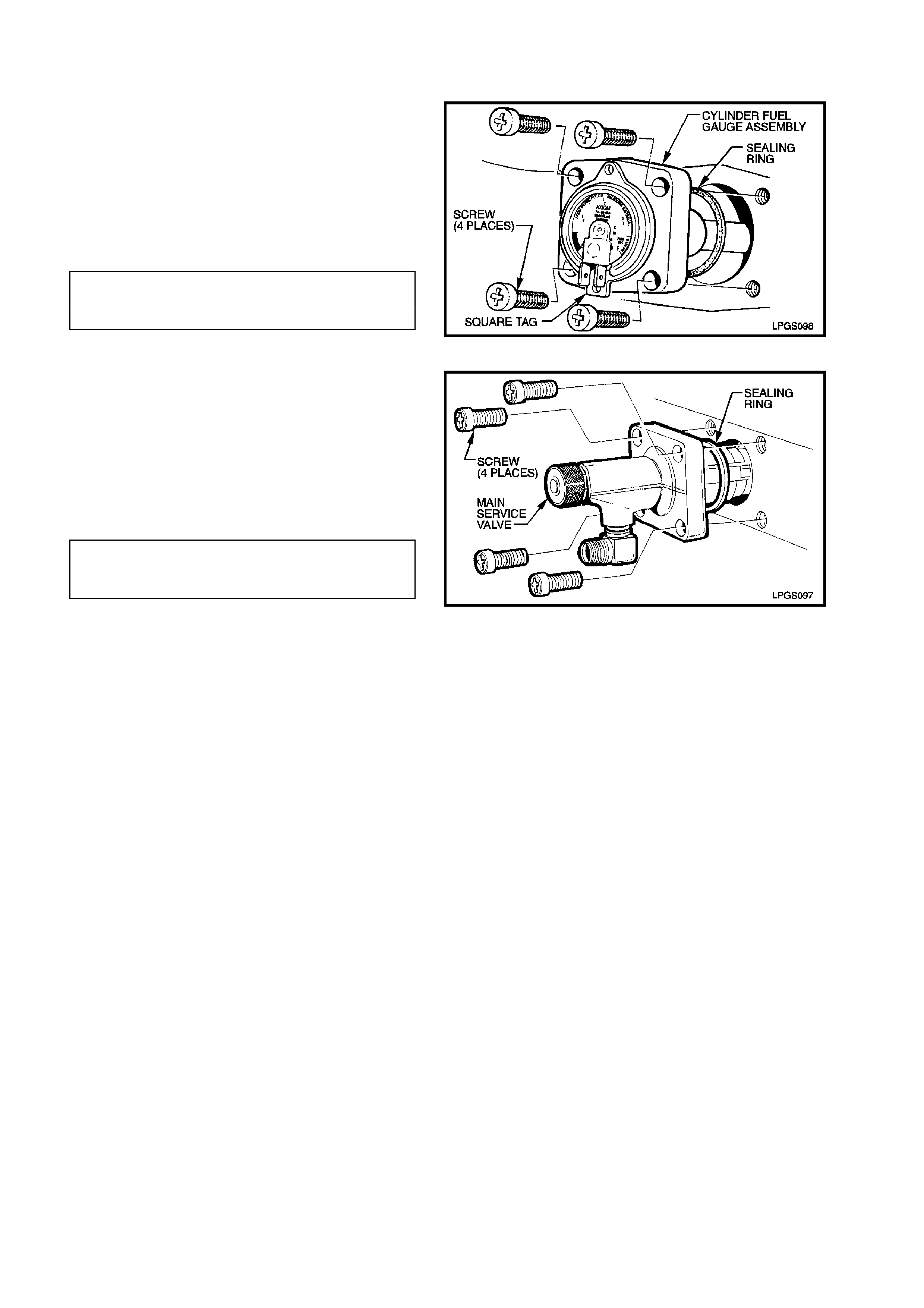

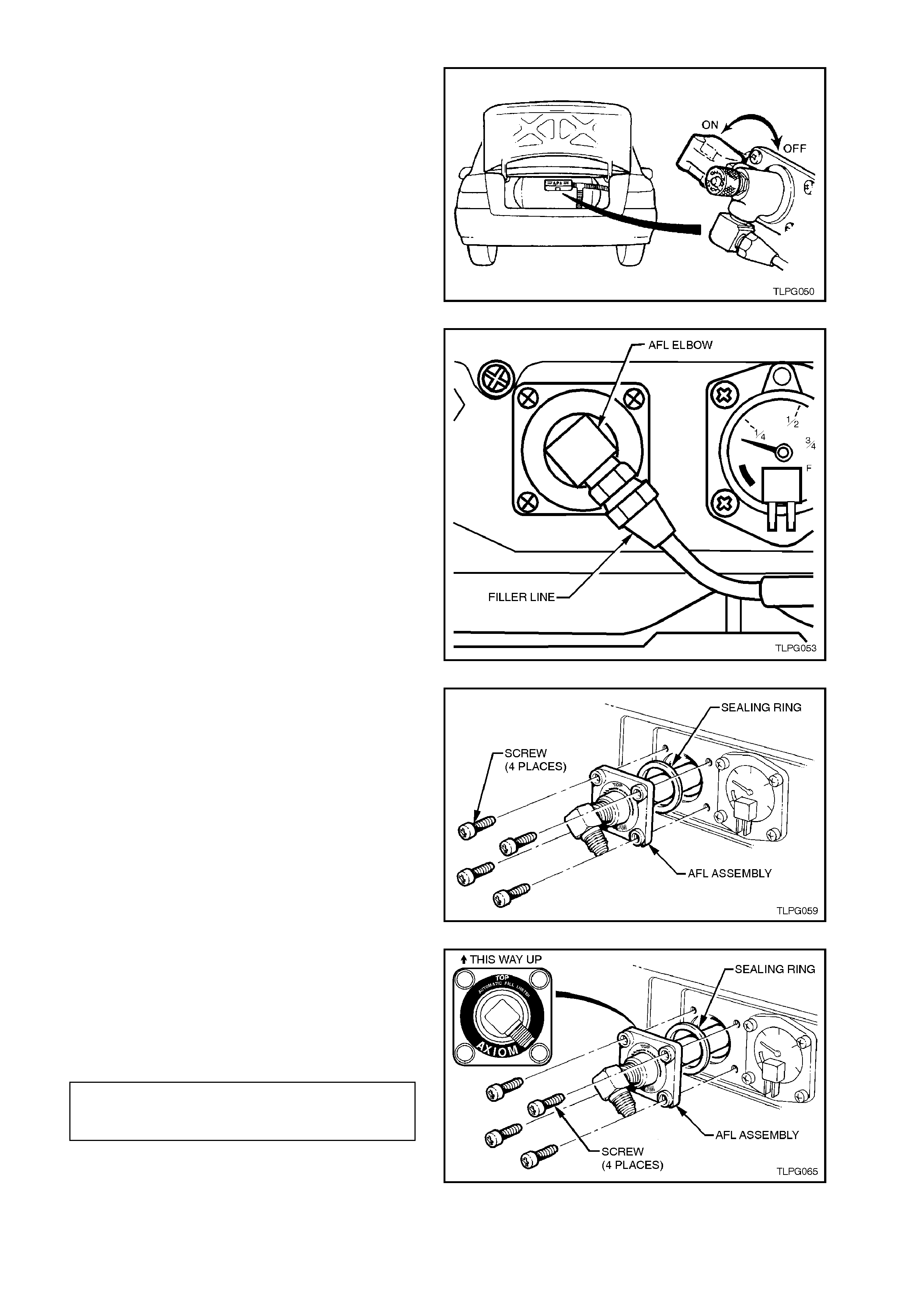

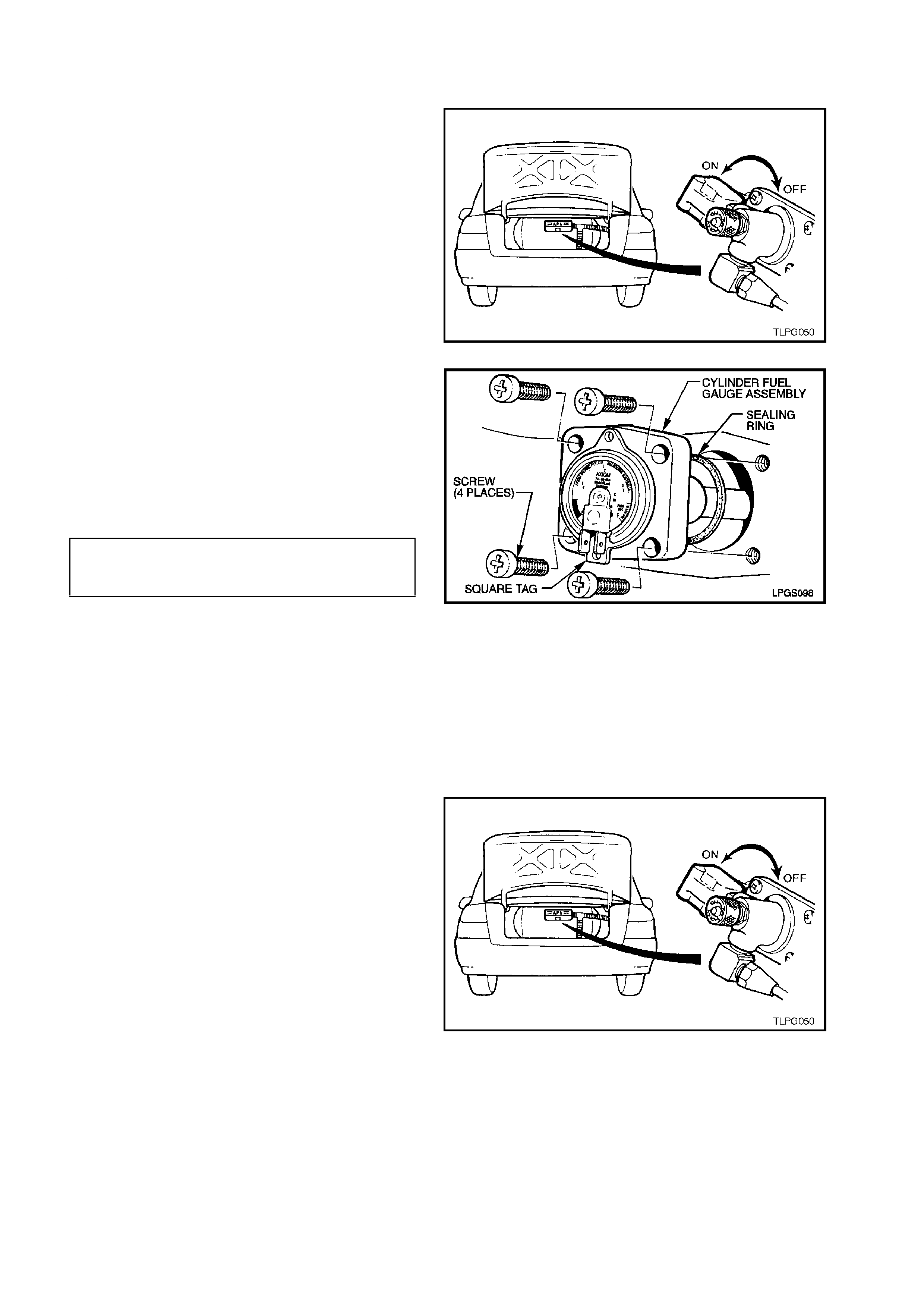

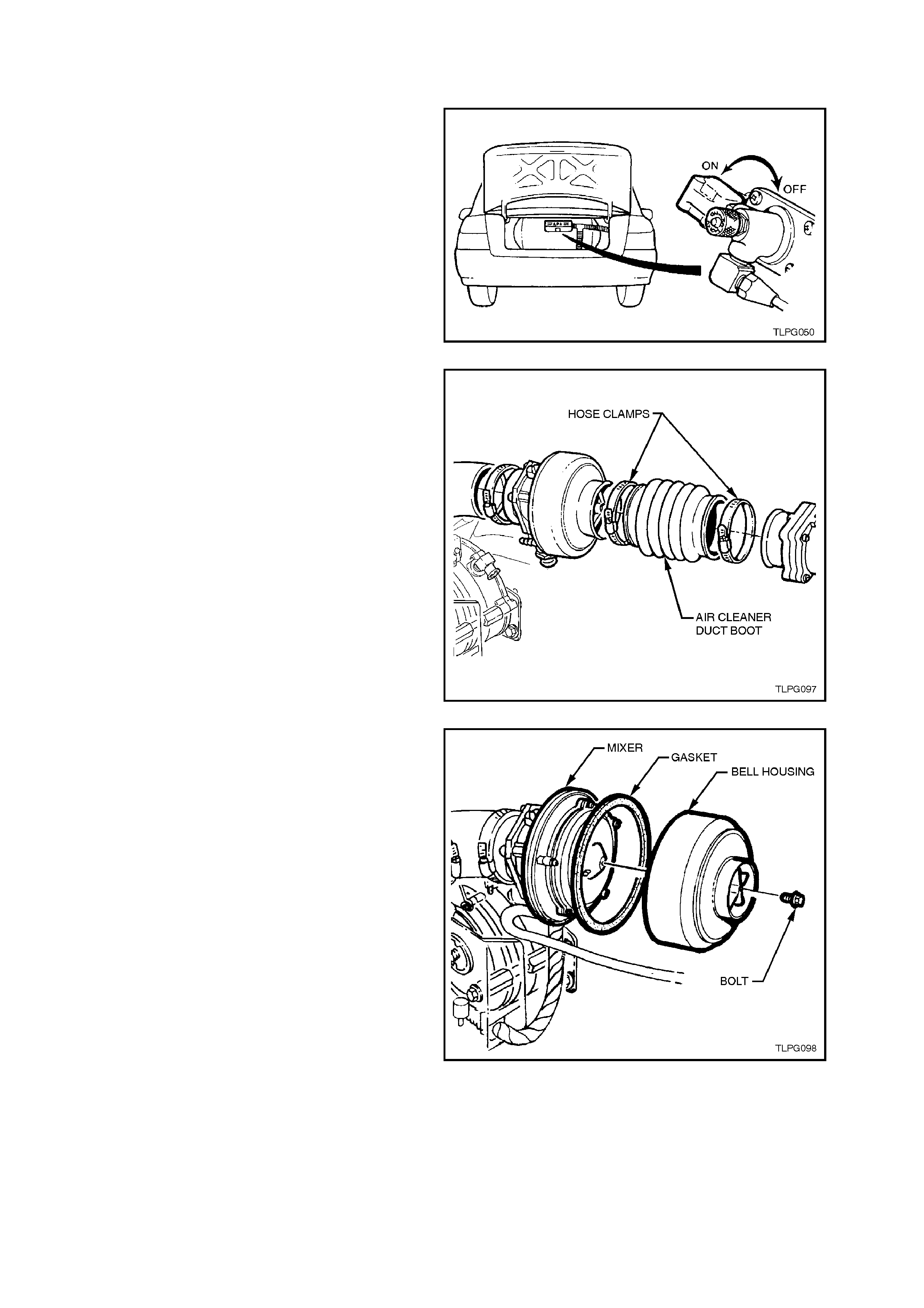

Figure 2-1

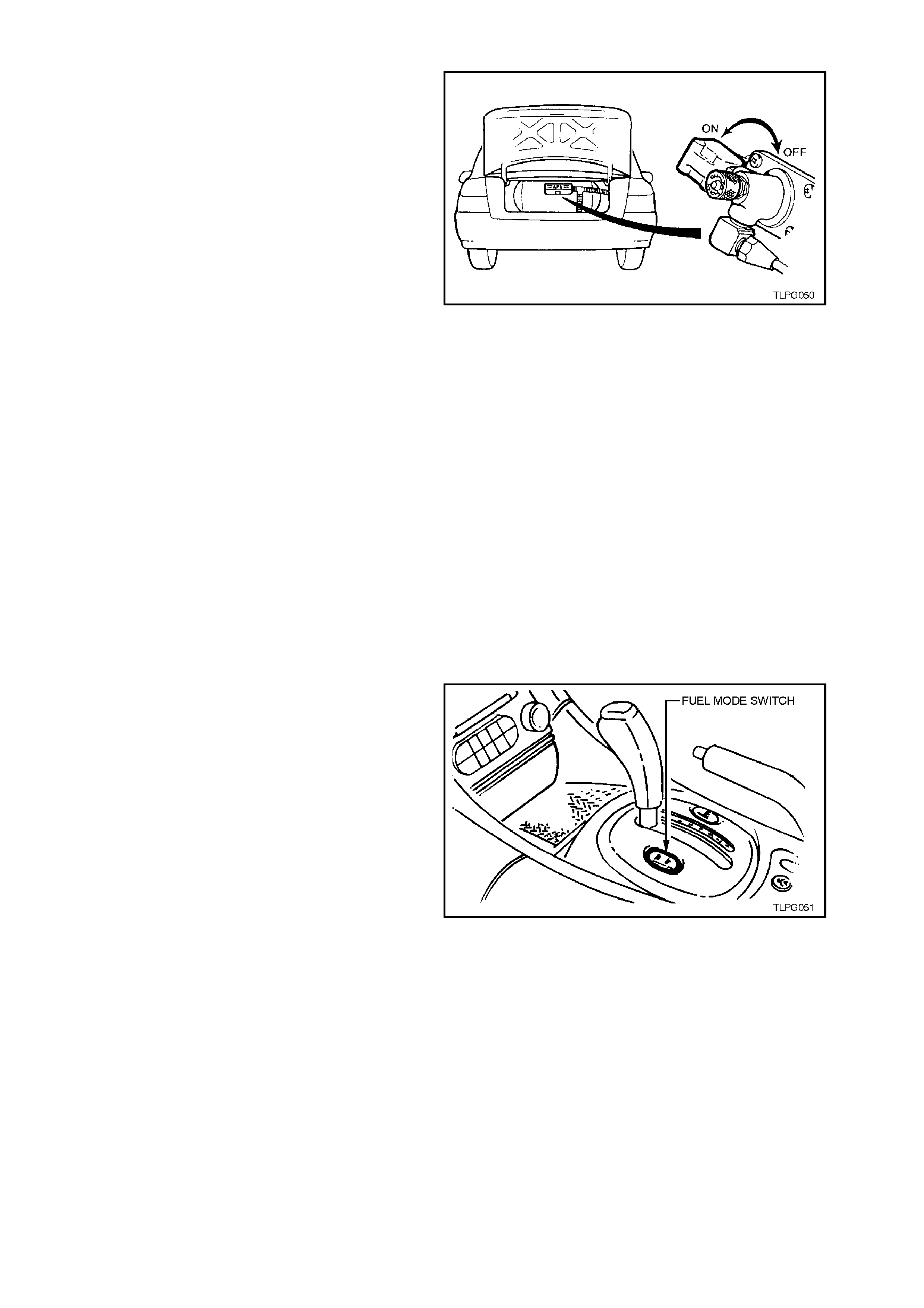

4. Place the fuel mode switch in the 'LPG'

position.

5. Start the engine and allow to run on LPG until

the engine stalls, then crank the engine

several times to ensure the service lines are

empty of LPG.

6. Place the fuel mode switch in the 'PETROL'

position.

NOTE 1:

Disconnect the battery earth lead before performing

any service operations.

NOTE 2:

If it is not pos s ible to star t and run the engine out of

LPG, the service lines should be cracked open to

allow them to be emptied of LPG in accordance

with the current Australian Standards AS 2746 -

1985.

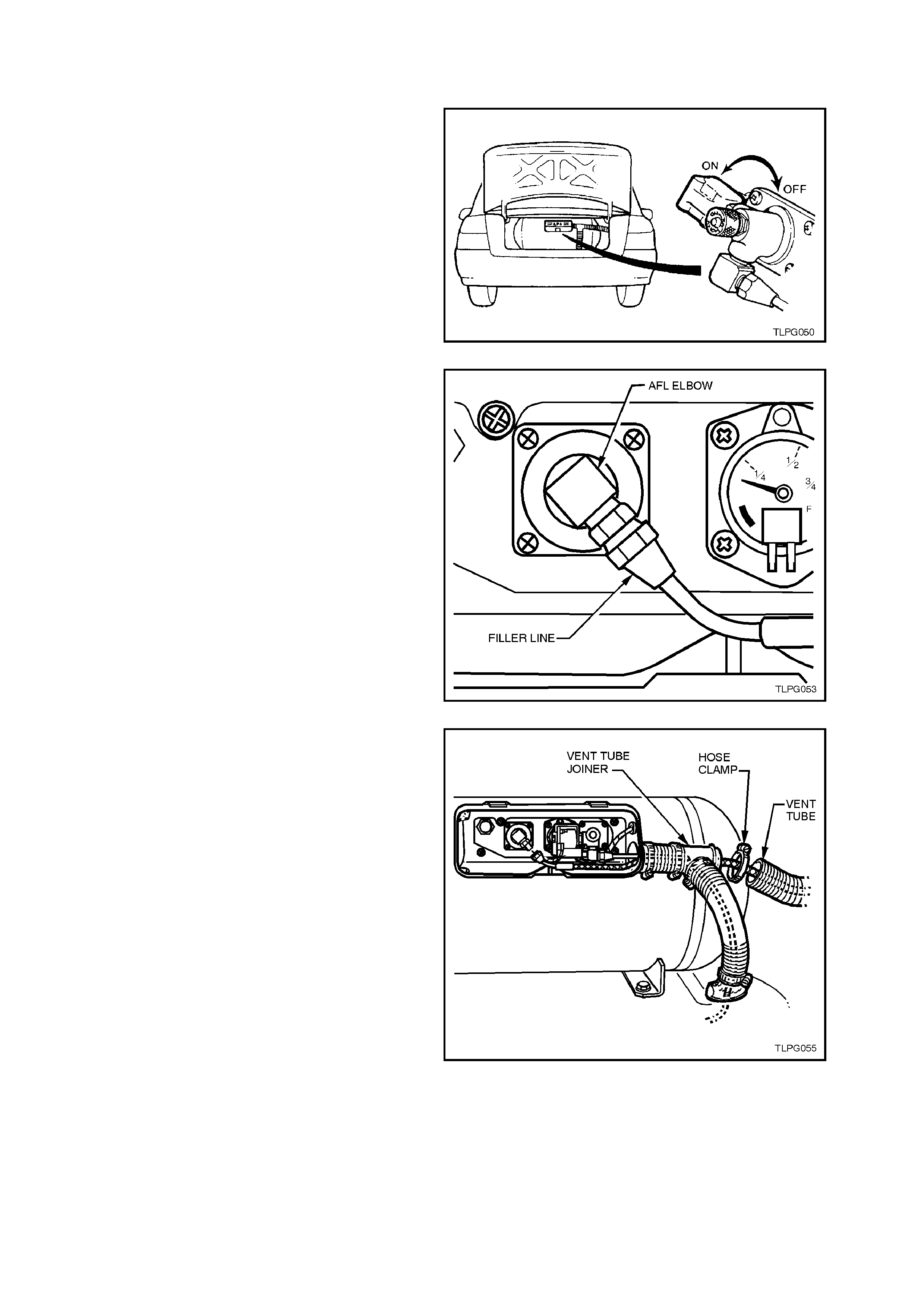

Figure 2-2

2.2 LPG CYLINDE R UNLOADING PROCEDURE

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the LPG service lines, refer to

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

4. Remove rear service line, refer

2.13 SERVICE LINES in this Section.

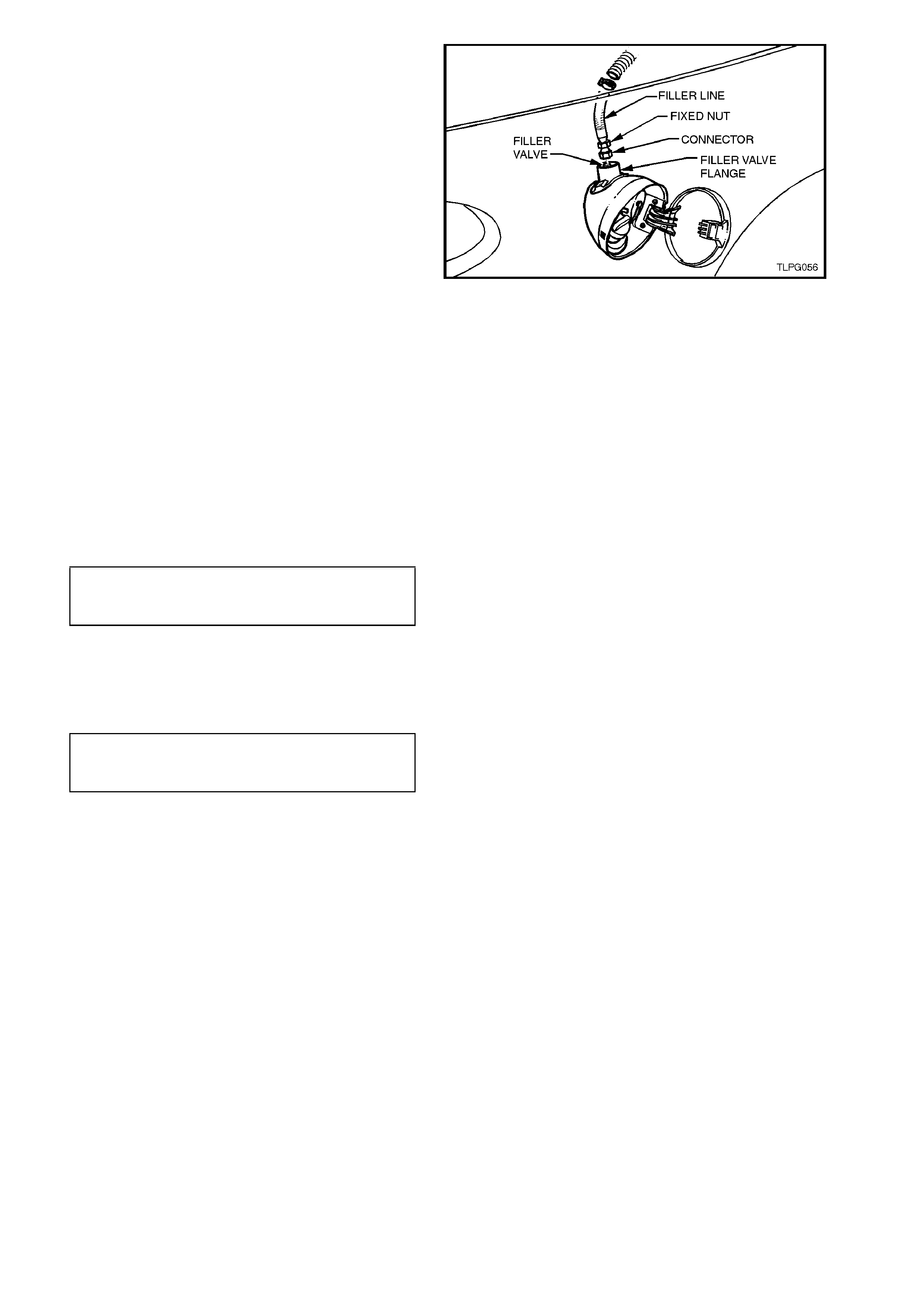

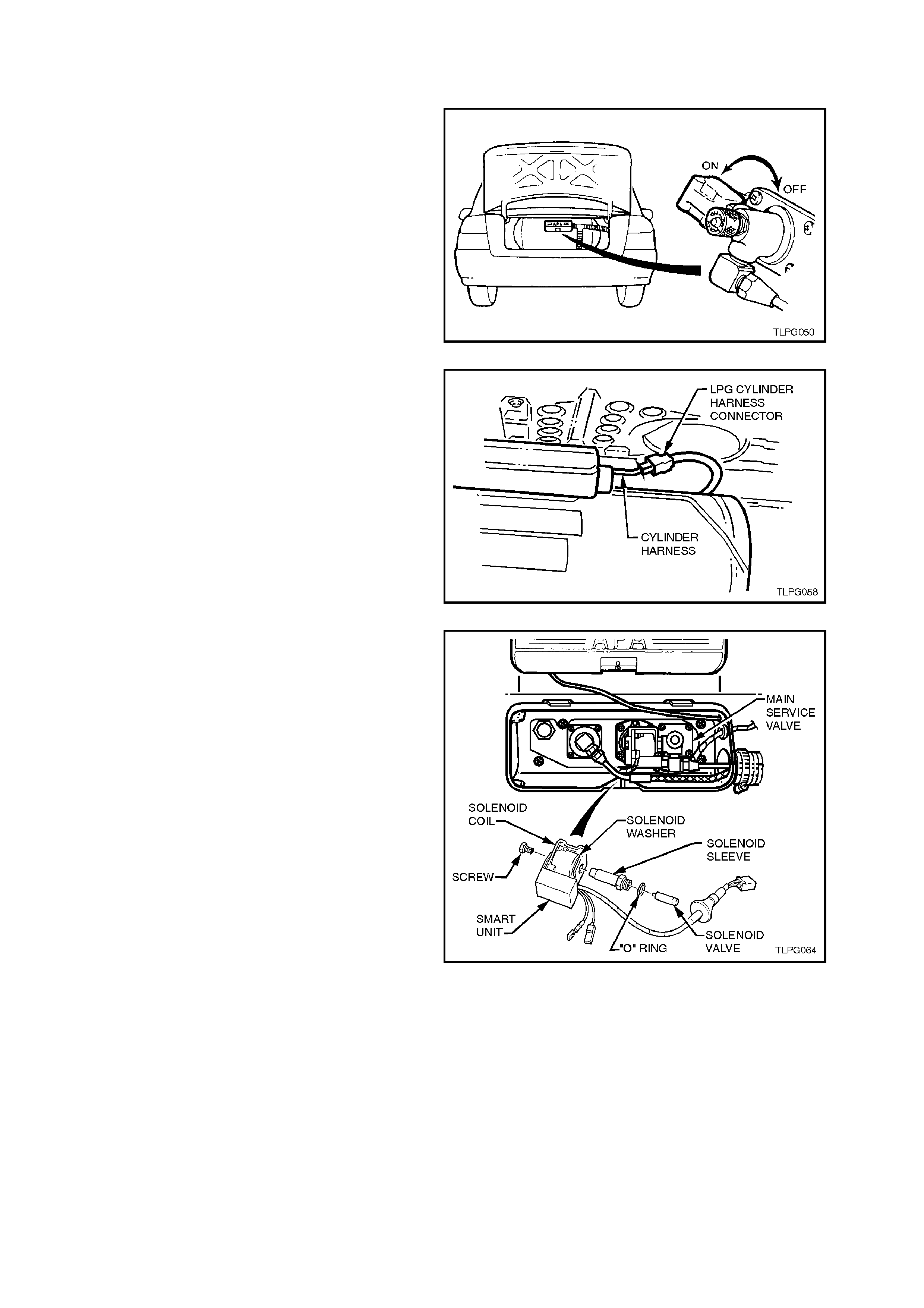

Figure 2-3

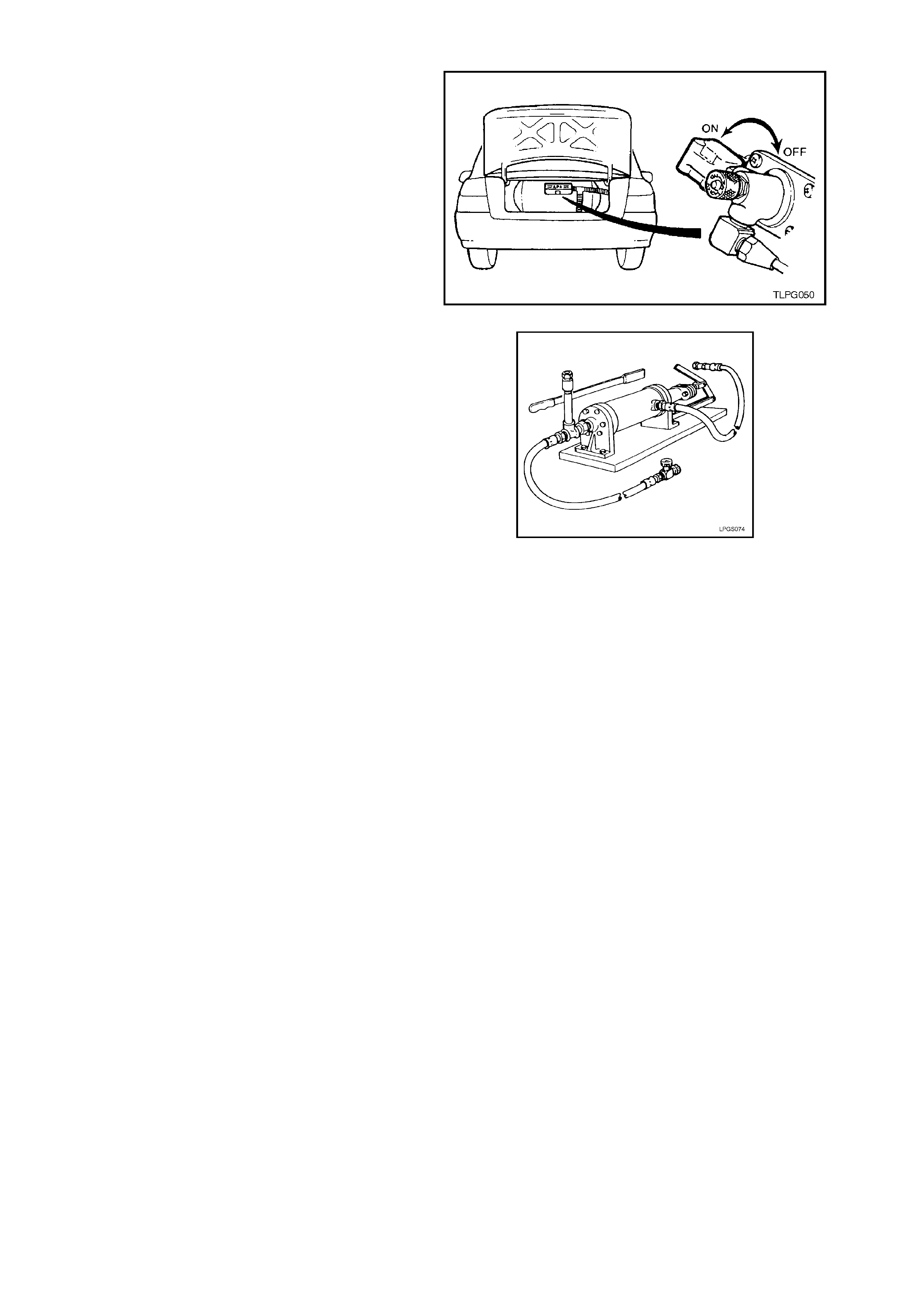

5. Connect an LPG pump (such as an Apollo

LPG pump or equivalent, refer

Section 7. SPECIAL TOOL S) to solenoid and

manual service valve assembly connection.

6. Pump out the LPG cylinder following the

instructions as outlined by the LPG pump

manufacturer for the particular pump you are

using and in accordance with the current

Australian Standards AS2746 - 1985.

CAUTION:

The LPG cylinder MUST be pumped out until

completely empty. Figure 2-4

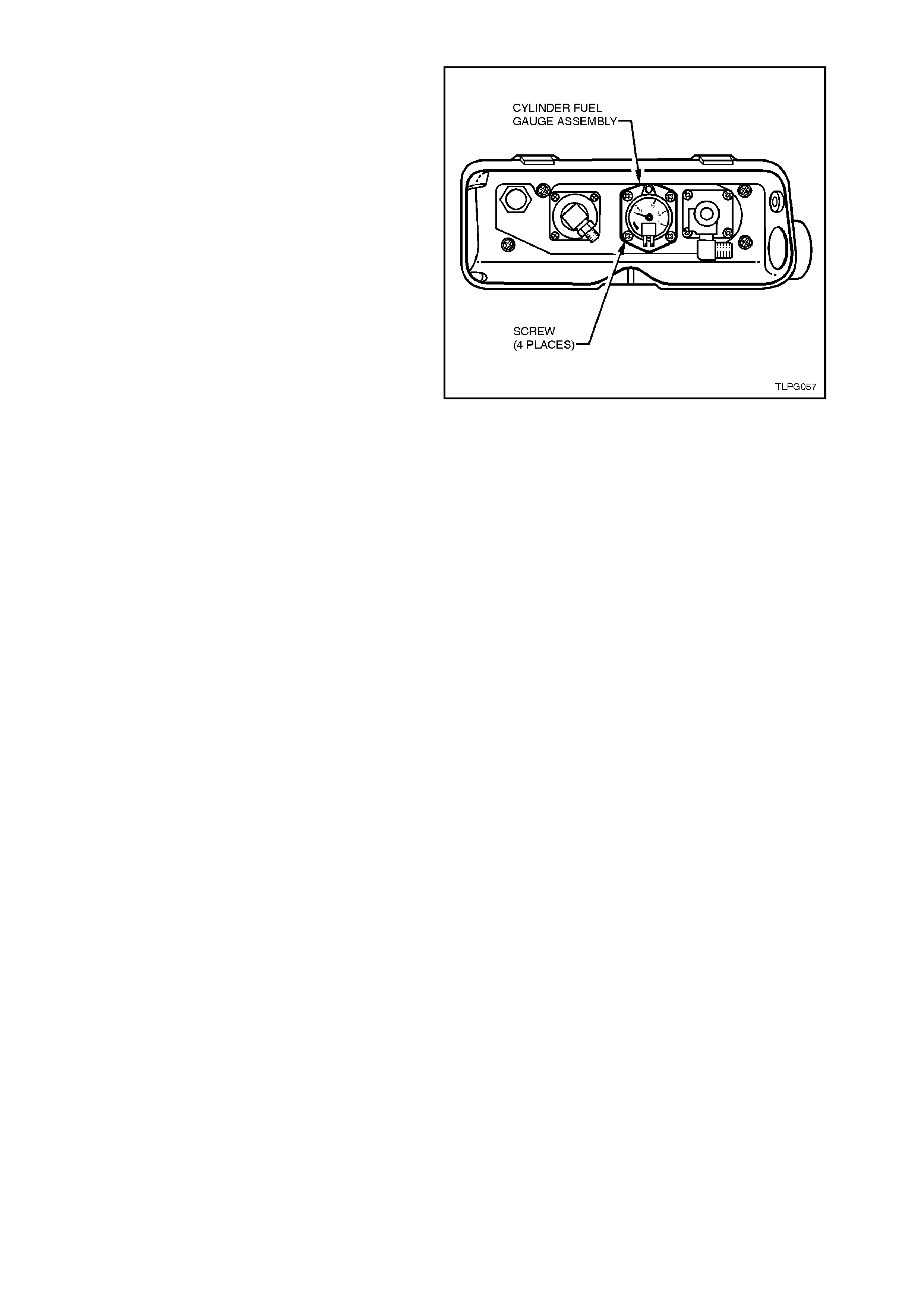

7. When you are sure the LPG cylinder is

completely empty, open the manual service

valve. Remove wiring connections from fuel

gauge and unscrew the cylinder fuel gauge

assembly retaining screws one turn and then

rock the cylinder fuel gauge assembly to

relieve any residual pressure in the LPG

cylinder.

NOTE:

To remove the fuel gauge, it will be necessary to

remove the smart unit and solenoid valve from the

manual service valve and the filler line from the

AFL valve, refer to the relevant service operations

in this Section for additional information on

removing these components.

8. Continue to loosen cylinder fuel gauge

assembly screws one turn at a time. Continue

rocking the cylinder fuel gauge assembly to

ensure the LPG cylinder has no residual

pressure. Remove cylinder fuel gauge

assembly scre ws.

9. Remove cylinder fuel gauge assembly, being

careful not to damage the float.

10. Purge the LPG cylinder with nitrogen to ensure

there is no residue of LPG in the cylinder.

CAUTION:

AFTER ANY VALVE OR COMPONENT HAS

BEEN REMOVED AND REINSTALLED TO THE

LPG CYLINDER, THE LPG CY LINDER MUST BE

PRESSURE AND LEAK TESTED IN

ACCORDANCE WITH THE CURRENT

AUSTRALIAN STANDARD AS2030.1 BEFORE

THE LPG CYLINDER IS PUT BACK INTO

SERVICE IN THE VEHICLE.

Figure 2-5

11. Reinstall cylinder fuel gauge assembly, refer

2.12 CYLINDER FUEL GAUGE ASSEMBLY

in this Section.

2.3 LEAK TESTING

The following leak test procedure is to be carried

out on the LPG system high pressure com ponents

and is to be performed at each normal

maintenance service.

The leak test is to be carried out in the open air in a

well-ventilated area, away from any ignition source

and PRIOR to bringing the vehicle into the

workshop.

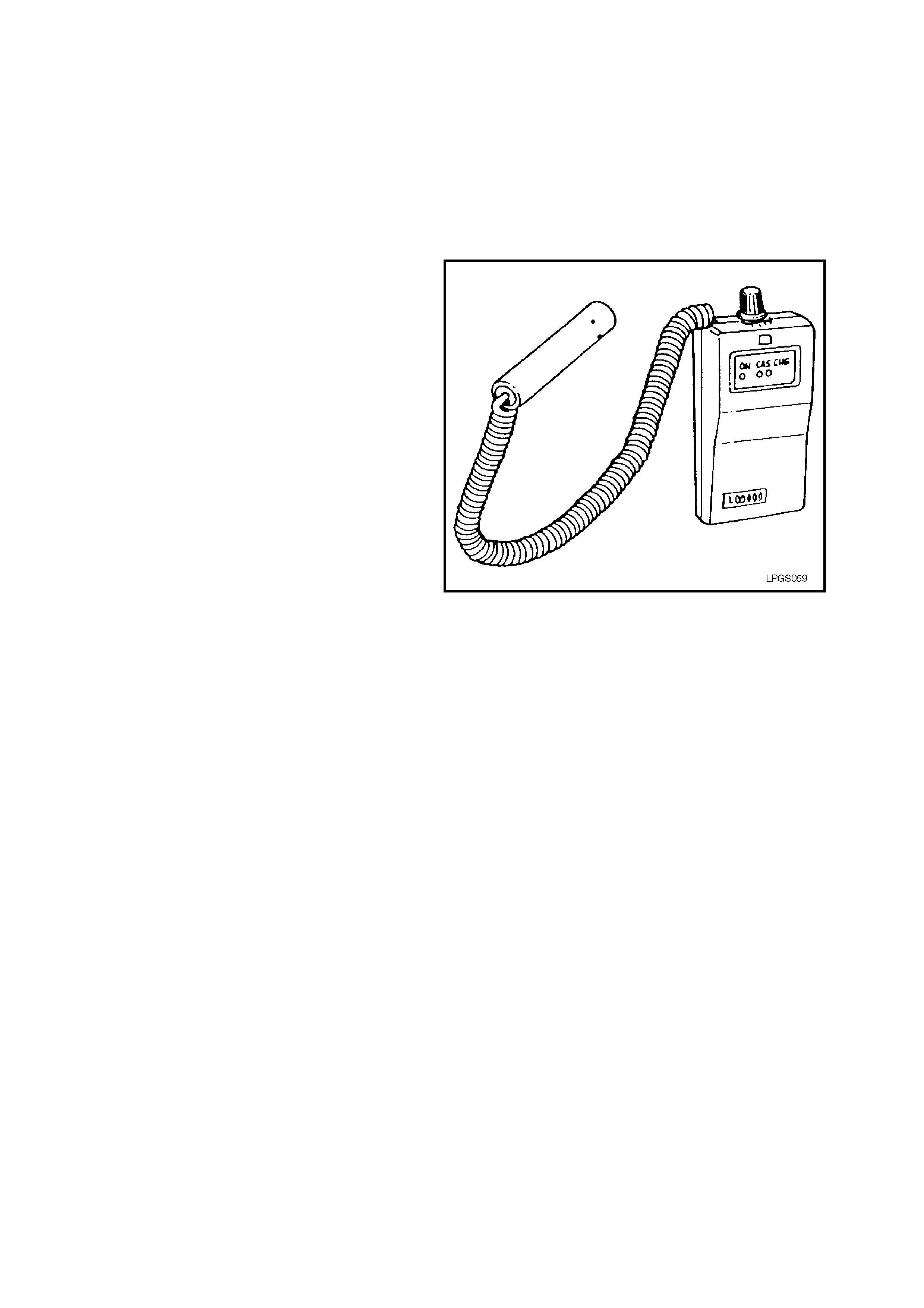

COMBUSTIBLE GAS DETECTORS

If a com bustible gas detector is to be used for leak

testing of the LPG system, the combustible gas

detector should be capable of detecting 25 parts

per million (P.P.M.) of LPG in air. A detector such

as a LD-9001 LP Gas Leak Detector or equivalent

is recommended.

Whichever leak detector is used, it is important to

follow the manufacturer's instructions in regard to

adjustment and setting the instrument prior to

conducting the leak test.

Care in interpretation is necessary, as the detector

can respond to the presence of any of several

vapours that are combustible, some of which may

not be LPG, such as oil smears, joining

compounds, etc. They may also detect residual

LPG vapours that are present for reasons other

than leakage, and which must be cleared before a

valid test for leakage can be made.

If a leak is present, a detector will signal its

existence but not its size, and will indicate its

general location, but may not be able to locate it

exactly. So, a proving or follow up check with foam

is often desirable.

Figure 2-6

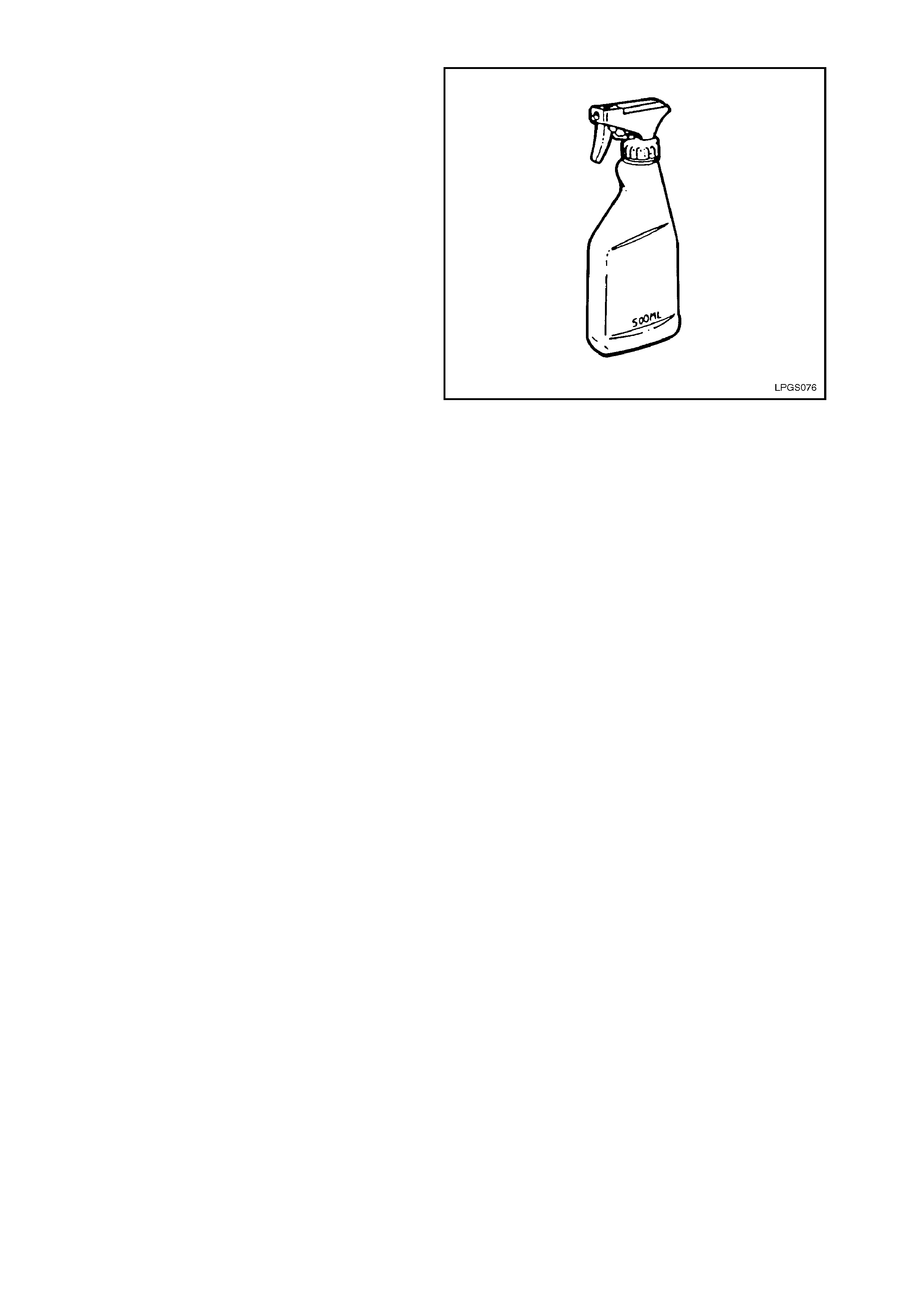

FOAM

If foam is to be used, the foaming agent should be

a propriety leak tes t s olution, f or mulated spec if ic ally

for the purpose, s uch as G am eco Leak Check TM or

a similar solution. T he solution should be fres h and

the whole of the area to be tested should be

coated, and time allowed for bubbles to form. All

areas under test must be able to be observed

during the leak test.

W hichever foaming agent is used, it is impor tant to

follow the manufacturer's instructions.

Foam testing is more effective for small leaks.

Large leak s tend to blow the solution away from the

leak without forming a bubble, so care in

application is necessary.

The leak test is performed by directing a spray of

solution at each of the possible leak points in the

high pressure side of the system.

After applying the solution, look c ar ef ully for no less

than 15 seconds.

A leak is indicated by the presence of gas bubbles

(foaming) in the solution at the leak source.

NOTE:

LPG IS HEAVIER THAN AIR SO TEST

THOROUGHLY BELOW ALL COMPONENTS

AND FITTINGS.

If a leak is detected at a joint, the relevant

component/s must be rem oved as described in the

appropriate component service operation in this

Section, all mating threads thoroughly cleaned,

then resealed using the specified sealant and

tightened to the correct torque specification. Once

installed, thoroughly leak test the component/s

again.

At the completion of each test, dry the leak test

area of the foaming agent with low pressure

compressed air or shop cloths and spray

imm ediate area with a water dispersing agent such

as WD40 or RP7, etc.

Figure 2-7

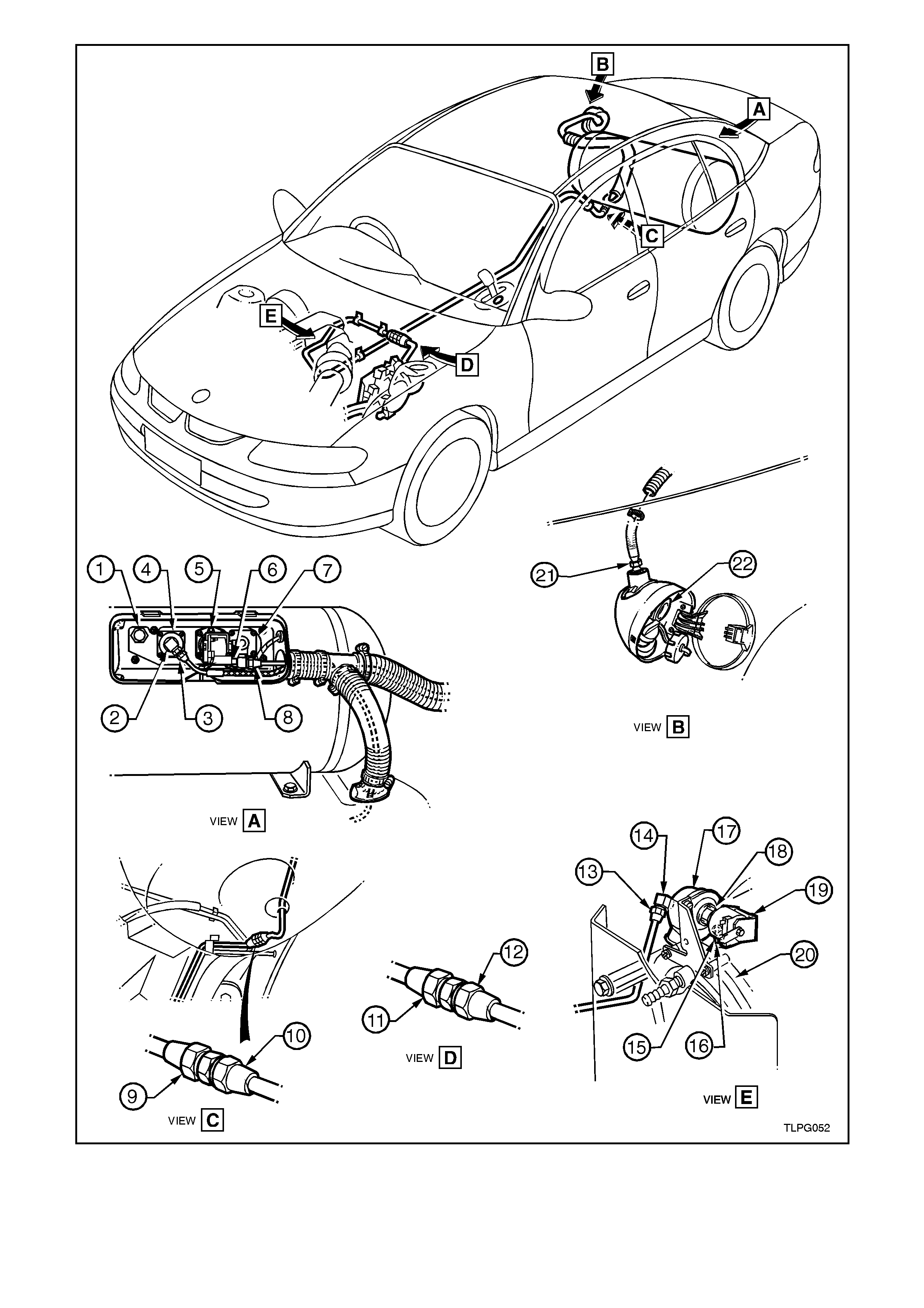

LEAK TEST PROCEDURE

With 3 litres of LPG in the LPG cylinder, leak test

the com plete LPG s ystem f ollowing the instr uctions

below

1. Park the vehicle in a dry, well ventilated area.

DO NOT SMOKE OR ALLOW NAKED FLAMES

OR ANY IGNITION SOURCE NEAR THE

VEHICLE DURING THE TESTING OPERATIONS.

2. Ensure the vehicle is operating on LPG and

run the engine for at least 30 seconds to fully

pressurise the system, then stop the engine.

3. The recommended sequence of testing is as

follows:

A. Referring to Figure 2-8, view A, open rear

compartment lid, remove the valve box

cover and leak test at and around the:

Pressure relief v alve (1).

AFL inlet elbow to AFL (2).

Rear service line to AFL inlet elbow

connection (3).

AFL to LPG cylinder (4).

Cylinder fuel gauge assembly (5).

Solenoid and manual service valve

assembly (6).

Solenoid and manual service valve

assembly to LPG cylinder (7).

Rear service line to solenoid and manual

service valve assembly connection (8).

B. Referring to Figure 2-8, view B:

Open filler box door and leak test at and

around the filler valve check ball (22).

Remove the rear c ompartm ent carpet from

the right side wheelhouse to gain acces s to

the inner side of the filler valve assembly,

refer to Section 1A1 BODY. Leak test at

and around the filler line to filler valve

connection.

C. Referring to Figure 2-8, view C, raise rear

of vehicle and support on safety stands,

refer to Section 0A GENERAL

INFORMATION for the location of jacking

points. Leak test at around the:

Rear service line to intermediate service

line joiner connection (9).

Intermediate service line to rear service

line joiner connector (10).

D. Referring to F igure 2-8, view D, leak test in

the engine compartment at and around the:

Intermediate service line to front service

line joiner connection (11).

Front service line to intermediate service

line joiner connection (12).

E. Referr ing to Figure 2-8, view E, leak test in

the engine compartment at and around the:

Front ser vice line to loc kof f inlet c onnec tion

(13).

Lockoff inlet connection to lockoff (14).

Lockoff to lockoff outlet connection (15).

Lockoff outlet connection to converter (16).

Lockoff (17, 18, 19).

Converter mounting faces (20).

At the com pletion of the leak test, c lose the manual

service valve, start the engine and run the engine

until all the LPG in the service line is exhausted.

With the engine stopped, switch to ‘petrol’ and s tart

the engine. The vehicle can now be driven into the

workshop.

NOTE:

The vehicle cannot be operated on LPG in the

works hop unless the work shop is a “Spec ialist Gas

W ork shop”, ref er to Australian Standard AS 2746 -

1985.

Figure 2-8

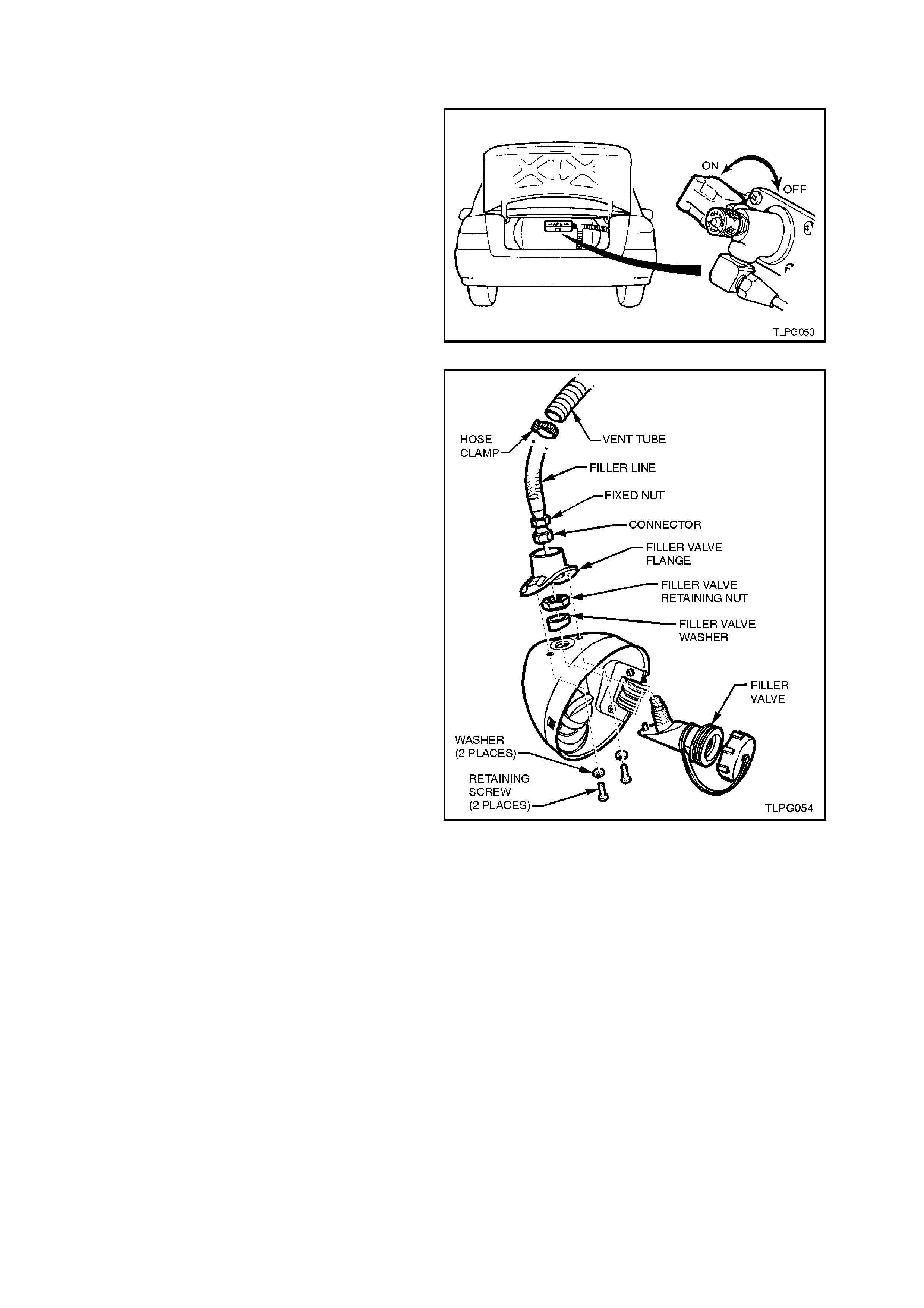

2.4 FILLER VALVE

REMOVE

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the LPG service lines, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

4. Remove the rear c ompartment car pet f r om the

right hand side wheelhouse to gain access to

the inner side of the f iller valve ass embly, ref er

to Section 1A1 BODY.

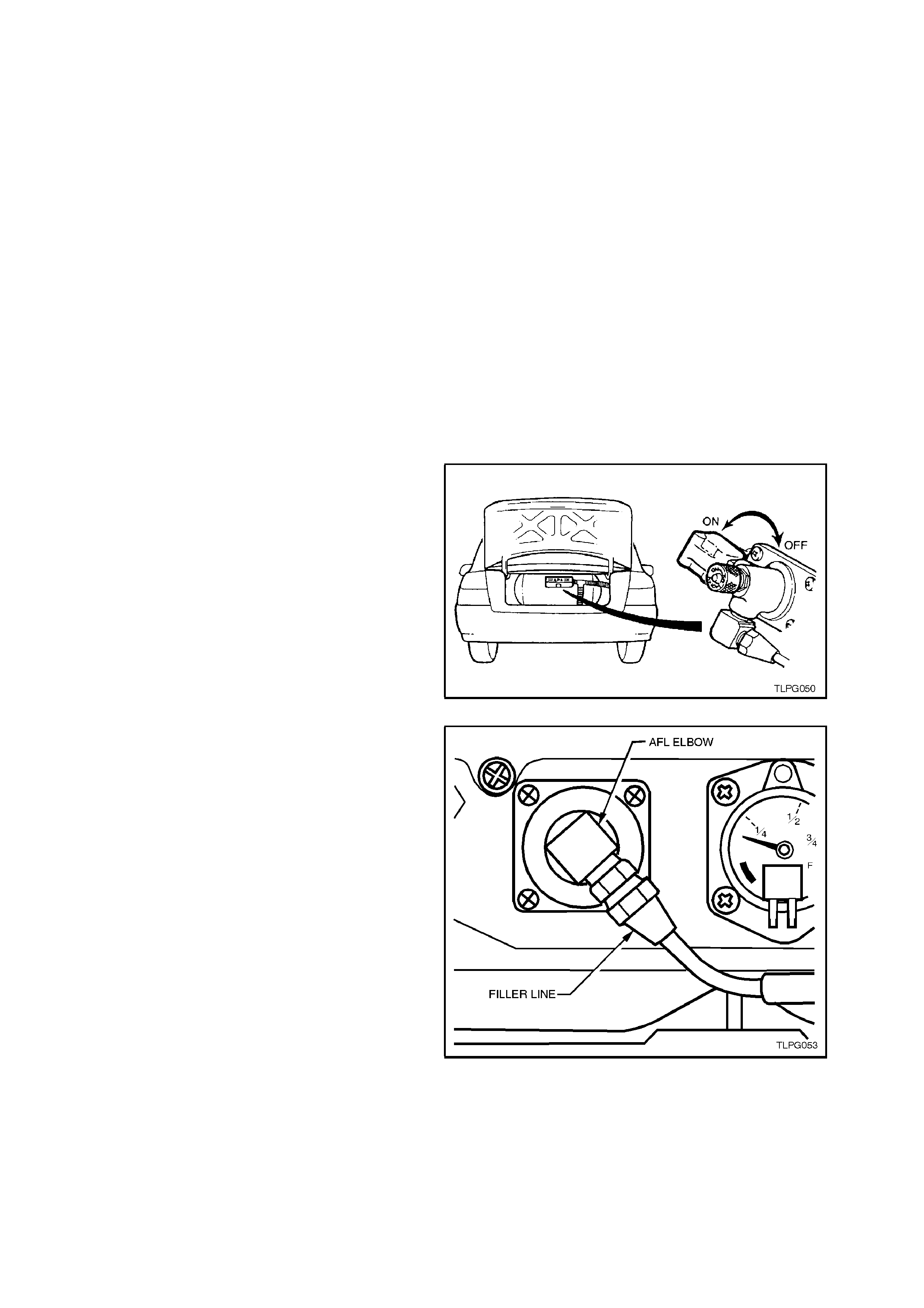

5. Loosen the vent tube hose clamp at the inner

side of the filler valve and pull vent tube away

from the filler valve flange to gain access to

the filler line connector.

6. Crack open the filler line connector from the

filler valve and allow the residual gas to

escape.

7. Unscrew the filler line connector from the filler

valve and move filler line and vent tube away

from the filler valve flange.

CAUTION:

The filler line may contain LPG under pressure.

8. Remove the two screws securing the filler

valve flange to the rear quarter panel and

using a wide bladed screwdriver, carefully

prise the filler valve flange from the rear

quarter panel.

NOTE:

The filler valve flange is adher ed to the rear quar ter

panel with silicon.

9. Loosen and remove filler valve retaining nut

and remove filler valve.

Figure 2-9

Figure 2-10

REINSTALL

1. Clean filler valve and filler line connector

mating threads.

2. Install filler valve and tighten filler valve

retaining nut to the correct torque

specification.

FILLER VALVE RETAINING NUT

TO FILLER VALVE 50.0 - 60.0 Nm

TORQUE SPECIFICATION

3. Apply silicon sealer, to Holden specification

HN 1886, to mating surface and all voids of

filler valve flange. Install filler valve flange and

tighten retaining screws to the correct torque

specification.

FILLER VALVE FLANGE

RETAINING SCREW 7.0 - 9.0 Nm

TORQUE SPECIFICATION

4. Apply Loctite 577 sealant to filler valve

threads, connect filler line connector to filler

valve and tighten to the correct torque

specification.

FILLER LINE CONNECTION TO

FILLER VALVE 12.0 - 18.0 Nm

TORQUE SPECIFICATION

5. Reconnect battery earth lead.

6. Leak test LPG system, refer to

2.3 LEAK TESTING in this Section.

7. Reinstall vent tube to filler valve flange.

8. Reinstall rear compartment carpet, refer to

Section 1A1 BODY.

2.5 FILLER LINE

REMOVE

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the LPG service lines, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

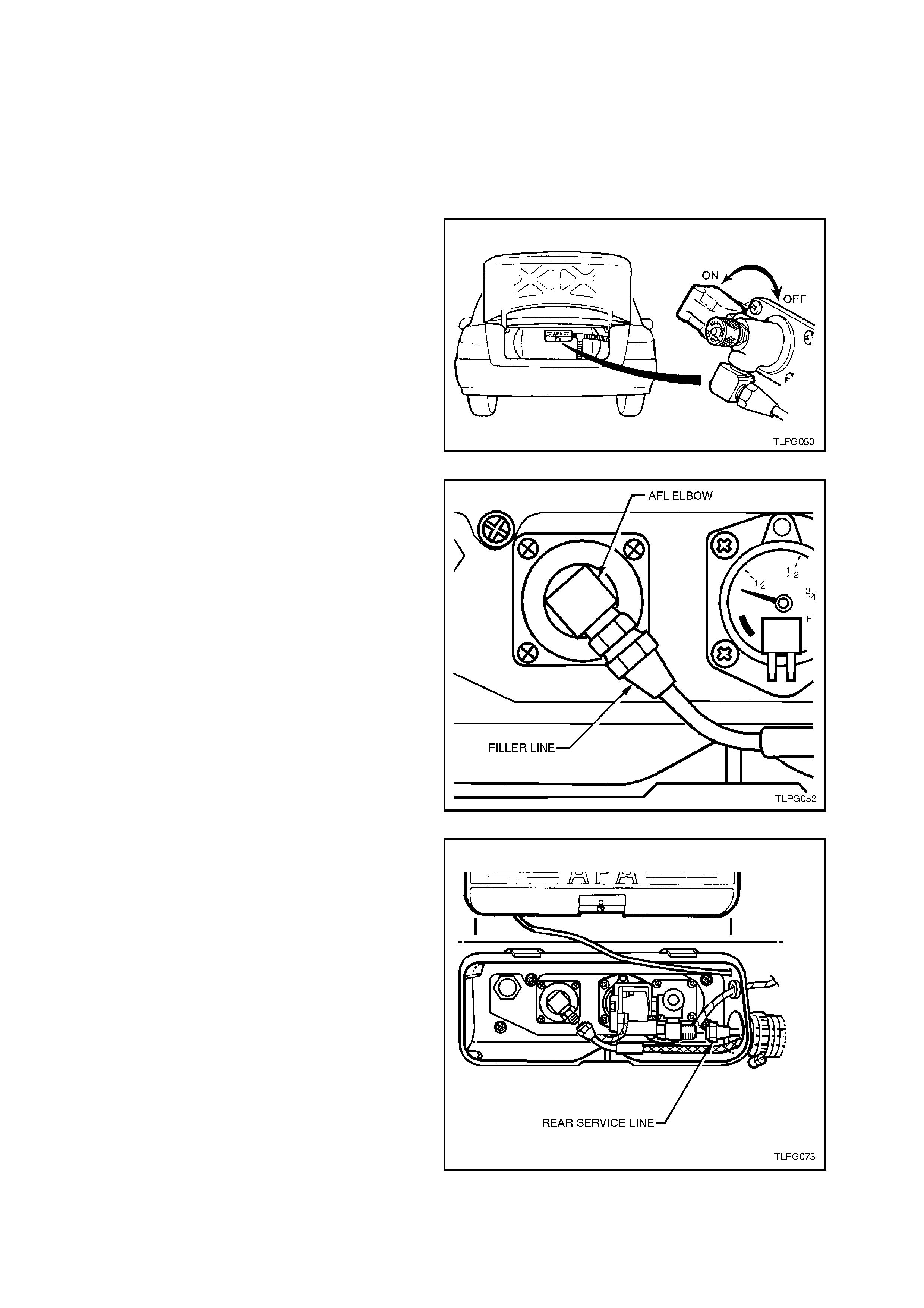

Figure 2-11

4. From inside the LPG cylinder valve box, while

holding AFL elbow, crack open filler line to

AFL elbow connector and allow residual LPG

to escape.

CAUTION:

The filler line will contain LPG under pressure.

Once all the LPG in the line has dispersed,

unscrew filler line connector completely from

AFL elbow.

Figure 2-12

5. Disconnect vent tube from vent tube joiner at

the right side of joiner, refer to Fig 2-13.

Figure 2-13

6. Remove the rear c ompartment car pet f r om the

right hand side wheelhouse to gain access to

the inner side of the f iller valve ass embly, ref er

to Section 1A8 BODY.

7. Loosen vent tube hose clam p at the inner side

of the filler valve and pull vent tube from filler

valve flange to gain access to the filler line

connector.

8. Loosen and unscrew the filler line connector

from the filler valve.

9. Move filler line and vent tube away from filler

valve flange and pull filler line out of vent tube

(at filler valve end) until filler line is clear of the

vent tube connector.

10. W ithdraw filler line from vent tube at vent tube

connector.

Figure 2-14

REINSTALL

Reinstallation of the filler line is the reverse of the

removal procedure, noting the following:

1. Ensure the filler line mating threads, filler valve

threads, and AFL valve threads are free of

sealant or contaminants.

2. Apply Loctite 577 sealant to filler valve threads

and tighten filler line to filler valve to the correct

torque specification

FILLER LINE CONNECTOR TO

FILLER VALVE 12.0 - 18.0 Nm

TORQUE SPECIFICATION

3. Apply Loctite 577 sealant to AFL valve threads

and tighten filler line to AFL valve to the correct

torque specification

FILLER LINE CONNECTOR

TO AFL VALVE 12.0 - 18.0 Nm

TORQUE SPECIFICATION

4. Leak test LPG system, refer to 2.3 LEAK

TESTING in this Section.

2.6 LPG CYLINDE R

CAUTION:

AFTER ANY VALVE OR COMPONENT HAS

BEEN REMOVED AND REINSTALLED TO THE

LPG CYLINDER, THE LPG CYLINDER M UST BE

PRESSURE AND LEAK TESTED IN

ACCORDANCE WITH CURRENT AUSTRALIAN

STANDARD AS2030.1 BEFORE THE LPG

CYLINDER IS REFITTED TO THE VEHICLE.

NOTE:

THE LPG CYLINDER M UST BE PRESSURE AND

LEAK TESTED ACCORDING TO THE LAWS OF

THE STATE IN WHICH THE VEHICLE IS

REGISTERED. THIS TESTING MUST ONLY BE

DONE BY A LICENSED INSTALLER OR

TESTING STATION.

REMOVE

1. Park the vehicle in a well ventilated area, away

from any ignition source.

2. Drain the service lines of LPG, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

4. Unload the LPG cylinder of LPG, refer

2.2 LPG CYLINDER UNLOADING

PROCEDURE in this Section.

Figure 2-15

5. From inside the LPG cylinder valve box, while

holding AFL elbow, crack open filler line to AFL

elbow connector and allow residual LPG to

escape.

CAUTION:

The filler line will contain LPG under pressure.

Once all the LPG in the line has dispersed,

unscrew filler line connector completely from

AFL elbow.

6. Remove the rear service line, refer

2.13 SERVICE LINES in this Section.

Figure 2-16

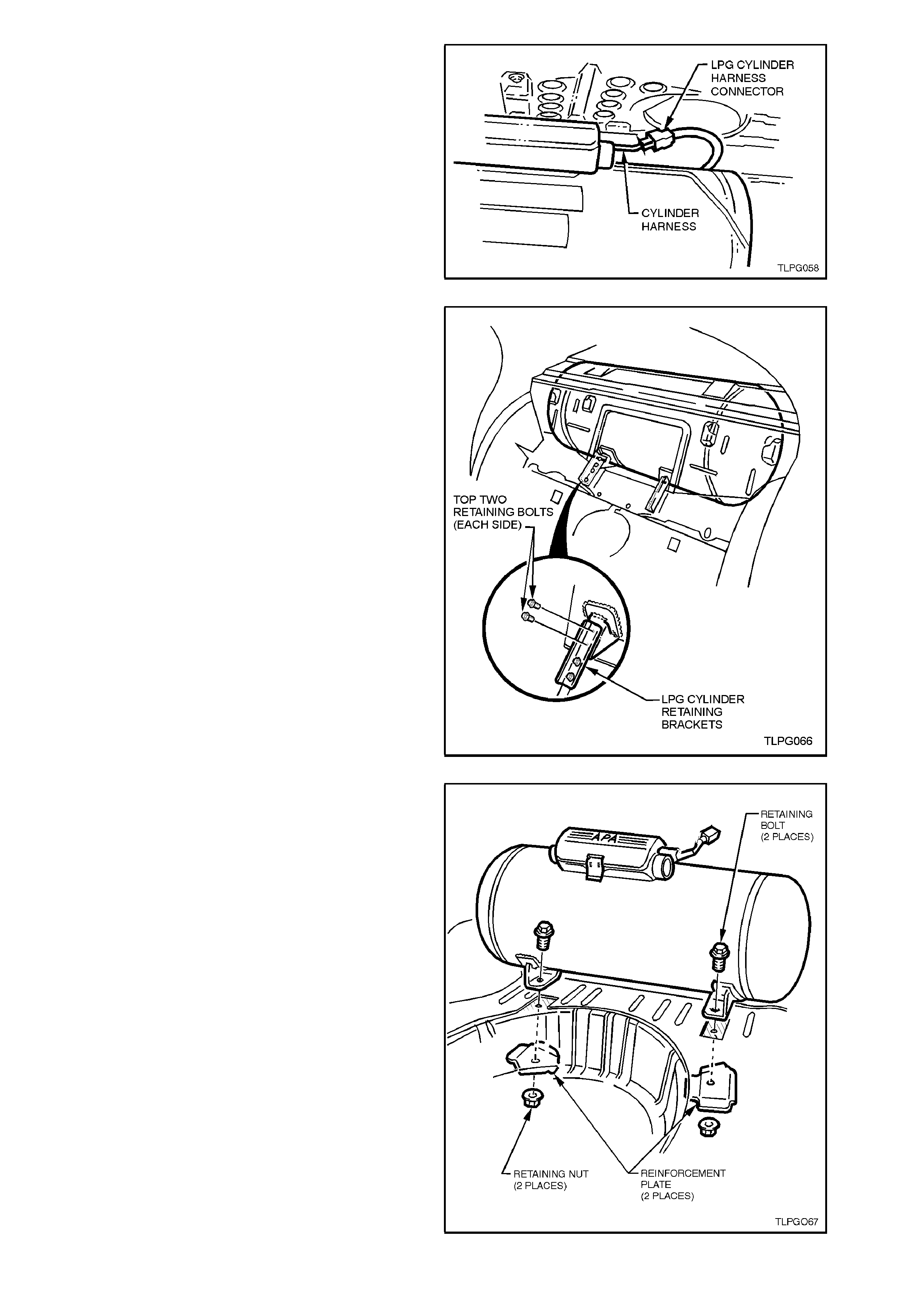

7. Disconnect LPG body harness connector from

LPG cylinder harness connector, refer to Fig 2-

17.

Figure 2-17

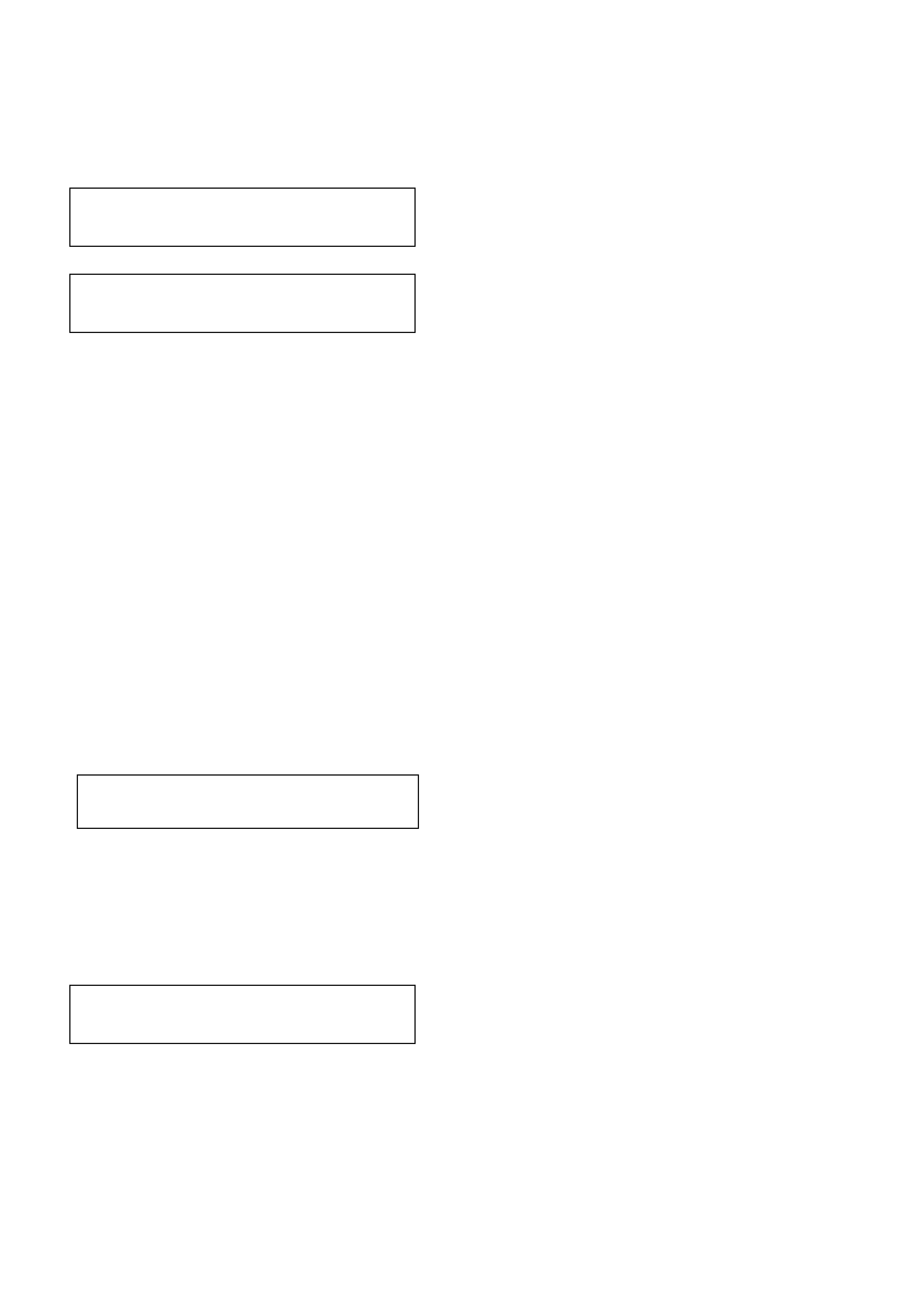

8. Remove rear seat back, refer

Section 1A7 SEATS AND SEA T BELTS.

9. Remove the top two retaining bolts on each

side of the LPG cylinder retaining brackets,

refer Fig 2-18.

Figure 2-18

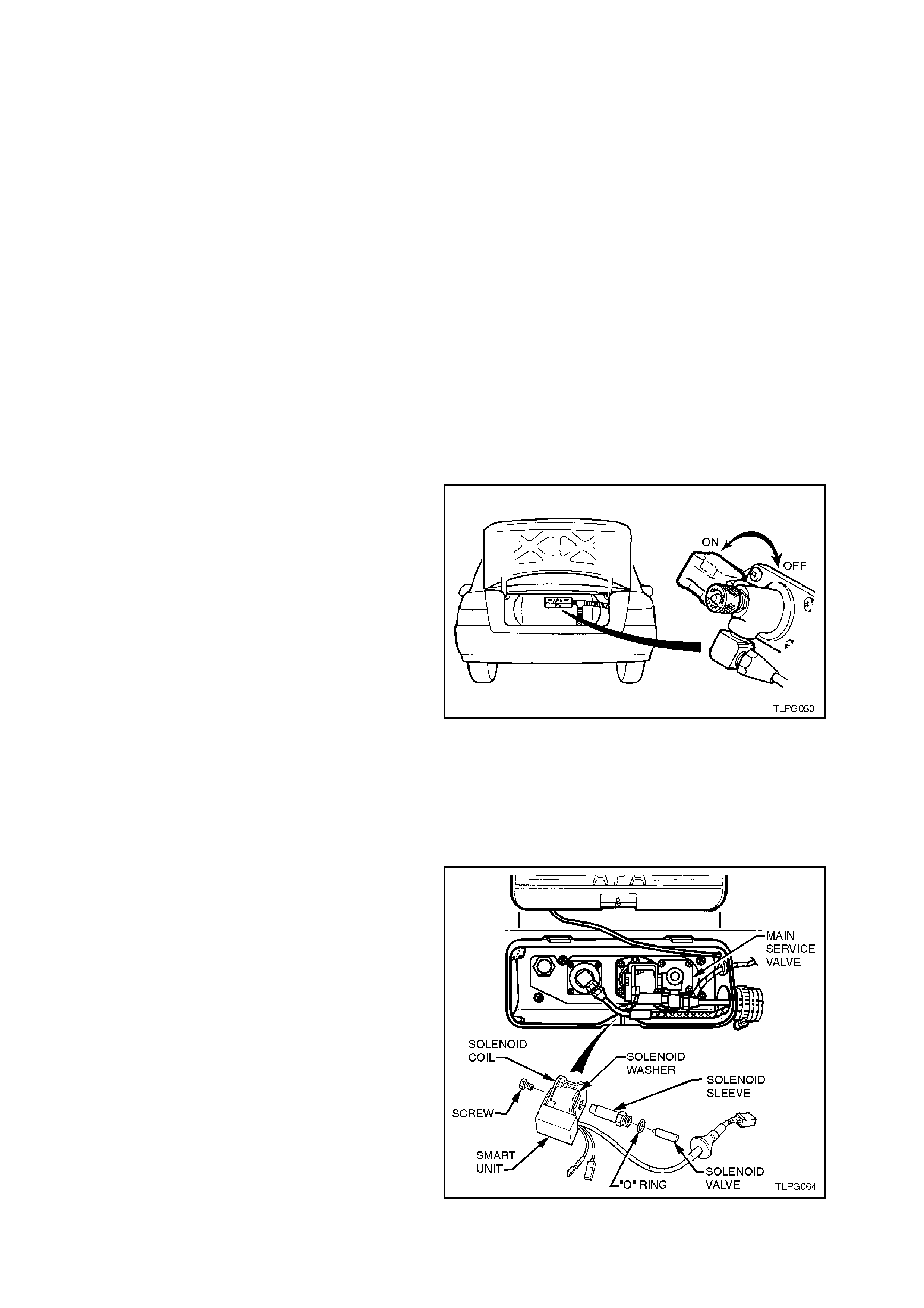

10. Fold back rear com partment car pet away from

LPG cylinder rear mounting points.

11. The following operation requires the aid of an

assistant.

From beneath the vehicle, remove the two

LPG cylinder retaining nuts and reinforcement

plates while the assistant holds the mounting

bolts in the luggage compartment from

rotating.

12. Remove LPG cylinder from rear compartment.

Figure 2-19

REINSTALL

Reinstallation of the LPG cylinder is the reverse of

the removal procedure, noting the following:

1. Ensure the two LPG cylinder reinforcement

plates are installed and all fasteners are

tightened to the correct torque specification.

FRONT LPG CYLINDER

RETAINING BOLTS 10.0 - 12.0 Nm

TORQUE SPECIFICATION

REAR LPG CYLINDER

RETAINING NUT 70.0 - 90.0 Nm

TORQUE SPECIFICATION

2. Clean rear service line mating threads on

solenoid and manual service valve assembly,

intermediate to rear service line joiner, both

rear service line connectors, AFL valve and

filler line connector.

3. Apply Loctite 577 sealant to intermediate to

rear service line joiner threads, ensuring that

flared surfaces are free of sealant and

contaminants. Assemble rear service

connector to intermediate to rear service line

joiner, refer 2.13 SERVICE LINES, in this

Section.

4. Apply Loctite 577 sealant to solenoid and

manual service valve assembly threads,

ensuring that flared surfaces are free of

sealant and contaminants. Install rear service

line connector to solenoid and manual service

valve assembly, refer 2.13 SERVICE LINES,

in this Section.

5. Tighten both rear service line connectors to

the correct torque specification.

REAR SERVICE LINE

CONNECTORS

TORQUE SPECIFICATION 12.0 - 18.0 Nm

6. Apply Loctite 577 sealant to LPG cylinder AF L

elbow threads, ensuring that flared surfaces

are free of sealant and contaminants. Install

filler line c onnector to LPG c ylinder AFL elbow

and tighten filler line connector to the correct

torque specification.

FILLER LINE CONNECTOR

TO AFL ELBOW SCREW 12.0 - 18.0 Nm

TORQUE SPECIFICATION

7. Leak test LPG system, refer

2.3 LEAK TESTING in this Section.

2.7 SOLENOID AND MANUAL SERVICE VALVE ASSEMBLY

CAUTION:

If at any time the manual service valve

becomes stuck, no service operations on the

system will be possible. Should for any reason

the valve stick, the cylinder will have to be

returned to the cylinder manufacturer (APA) to

arrange a replacement cylinder.

Contact: APA Industries

190 Colchester Road

Kilsyth

Victoria 3137

Phone -(03) 9720 2855

Fax - (03) 9761 4495

Email [email protected]M.AU

NOTE:

The m anual service valve is three valves in one. A

manual shut off valve, an electrically operated

solenoid valve and an excess flow valve.

EXCESS-FLOW VALVE TEST

CAUTION:

ENSURE THERE ARE NO NAKED FLAMES OR

OTHER SOURCES OF IGNITION IN THE

VICINITY.

ENSURE ALL SAFETY PRECAUTIONS LISTED

AT THE FRONT OF THIS SECTION ARE

ADHERED TO WHILE PERFORMING THIS

TEST.

DO NOT PERFORM THIS TEST ON A VEHICLE

WITH A HOT ENGINE.

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the service lines of LPG, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

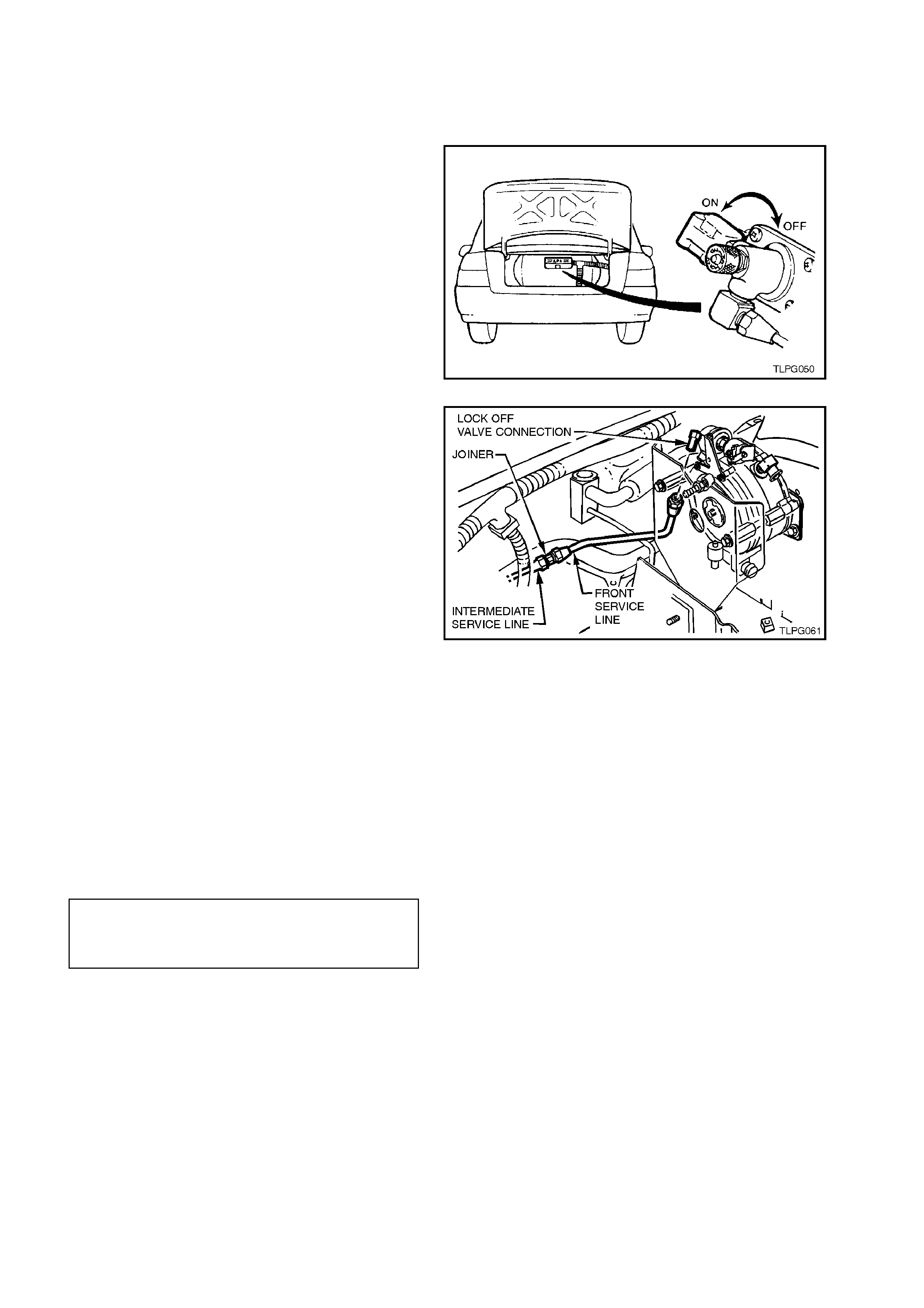

Figure 2-20

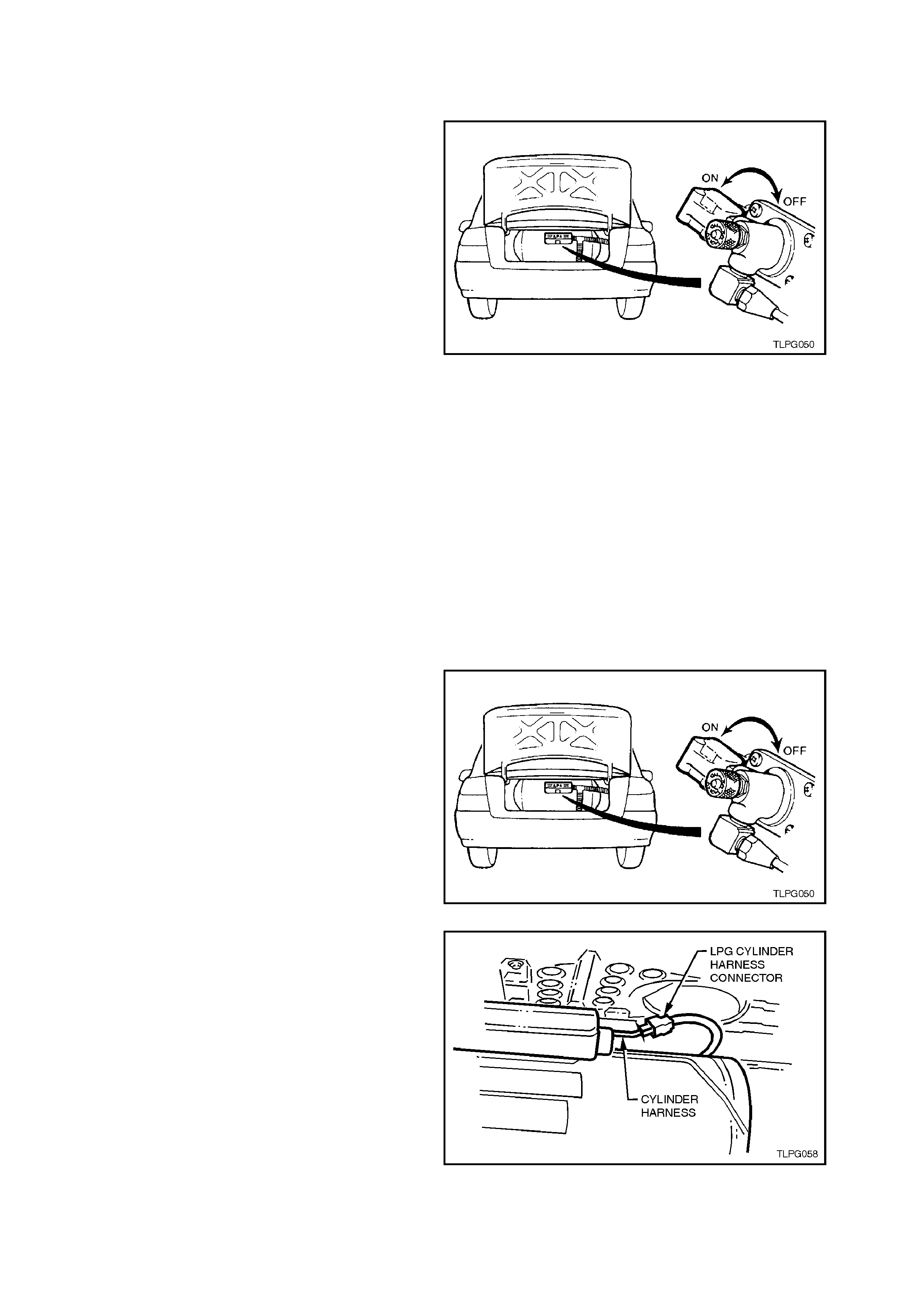

4. Remove the smart unit and solenoid

assembly, including the solenoid valve, refer to

2.8 SMART UNIT AND SOLENOID VALVE, in

the Section.

5. Reinstall the solenoid sleeve (with o-ring)

WITHOUT the solenoid valve.

Figure 2-21

6. Disconnect the front service line at the lockoff

valve to allow LPG to flow from this line when

the manual service valve is opened, refer to

2.13 SERVICE LINES in this Section.

7. Quickly open the manual service valve and

listen for the sound of the excess-flow valve

operating.

8. If the excess flow valve is operating correctly,

it can be heard to click shut when the manual

service valve is opened quickly.

CAUTION:

TO ENSURE THAT THE LEAST AMOUNT OF

LPG ESCAPES INTO TH E ATMO SPHERE, O NLY

OPEN THE M ANUAL SERVICE VALVE FOR T HE

MINIMAL TIME POSSIBLE TO PERFORM THIS

TEST.

Figure 2-22

9. Reinstall the front service line to the lockoff

valve as per the reinstallation procedure in

2.13 SERVICE LINES in this Section.

10. Remove the solenoid sleeve on the manual

service valve. Reinstall the solenoid valve,

solenoid sleeve and smart unit as per the

reinstallation procedure in

2.8 SMART UNIT AND SOLENOID VALVE in

this Section.

11. Leak test LPG system, refer

2.3 LEAK TESTING in this Section.

12. Once installed, check vehicle operation on

LPG and petrol.

REPLACE

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the LPG service lines, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

4. Unload the LPG cylinder of LPG, refer to

2.2 LPG CYLINDER UNLOADING

PROCEDURE, steps 4 to 10, in this Section.

Figure 2-23

5. Disconnect LPG body harness connec tor from

LPG cylinder harness connector, refer to Fig

2-24.

Push LPG cylinder harness back into cylinder

valve box area.

Figure 2-24

6. If not already removed, remove solenoid

assembly from manual valve, refer

2.8 SMART UNIT AND SOLENOID VALVE in

this Section.

7. Unscrew the four manual service valve

attaching screws and remove manual service

valve from LPG cy linder, refer to Fig. 2-26.

8. Install new cylinder fuel gauge assembly to

LPG cylinder sealing ring, install cylinder fuel

gauge assembly taking care to install

assembly with gauge up the right way. Install

and tighten cylinder fuel gauge assembly

attaching screws to the correct torque

specification. Reconnect wiring harness

connectors to gauge terminals.

CYLINDER FUEL GAUGE ASSEMBLY

TO LPG CYLINDER ATTACHING 5.0 - 7.0 Nm

SCREW TORQUE SPECIFICATION

Figure 2-25

9. Install new manual service valve to LPG

cylinder sealing ring and the new manual

service valve assembly. Take care to install

the valve so that the valve elbow for the

service line connection is pointing In the

correct direction. Install and tighten the four

manual service valve attaching screws to the

correct torque specification.

MANUAL SERVICE VALVE TO LPG

CYLINDER ATTACHING SCREW 5.0 - 7.0 Nm

TORQUE SPECIFICATION

10. Reconnect LPG body wiring harness

connector to LPG cylinder harness connector

and reinstall grommet.

11. Reinstall rear service line, refer

2.13 SERVICE LINES in this Section.

12. Pressure and leak test LPG cylinder in

accordance with the current Australian

Standard AS2030.1

13. Carry out system leak testing, refer

2.3 LEAK TESTING in this Section.

Figure 2-26

2.8 SMART UNIT AND SOLENOID VALVE

REMOVE

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the service lines of LPG, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

Figure 2-27

4. Disconnect LPG cylinder harness connector

from LPG cylinder harness connector.

Push LPG cylinder harness back into cylinder

valve box area.

Figure 2-28

5. Remove smart unit retaining screw from end

of the assembly.

6. Slide the smart unit and solenoid coil from the

manual service valve.

7. Loosen and remove solenoid sleeve from

manual service valve, ensuring that solenoid

valve is also removed.

Separate solenoid valve from the sleeve.

Discard the solenoid sleeve to manual service

valve 'O' ring.

8. Disconnect LPG cylinder harness connectors

from cylinder contents gauge terminals.

NOTE:

To aid in disconnection the connectors from the

cylinder contents gauge, remove the contents

gauge (two screws) from the LPG cylinder and then

disconnect the harness connectors, refer

2.12 CYLINDER FUEL GAUGE ASSEMBLY -

CONTENTS GAUGE in this Section for additional

information on removing the contents gauge.

Figure 2-29

REINSTALL

Reinstallation of the smart unit and solenoid coil to

the manual service valve is the reverse of removal

procedures, noting the following points:

1. Ensure new 'O' ring is fitted to solenoid sleeve.

2. Tighten solenoid sleeve to the manual service

valve to the correct torque specification.

SOLENOID SLEEVE TO MANUAL

SERVICE VALVE

TORQUE SPECIFICATION 15 - 18 Nm

3. Once installed, ensure that the smart unit

retaining screw is tightened to the correct

torque specification.

SMART UNIT

RETAINING SCREW

TORQUE SPECIFICATION 1 - 3 Nm

4. Leak test LPG system, refer to

2.3 LEAK TESTING in this Section.

5. Once installed, check vehicle operation on

LPG and petrol.

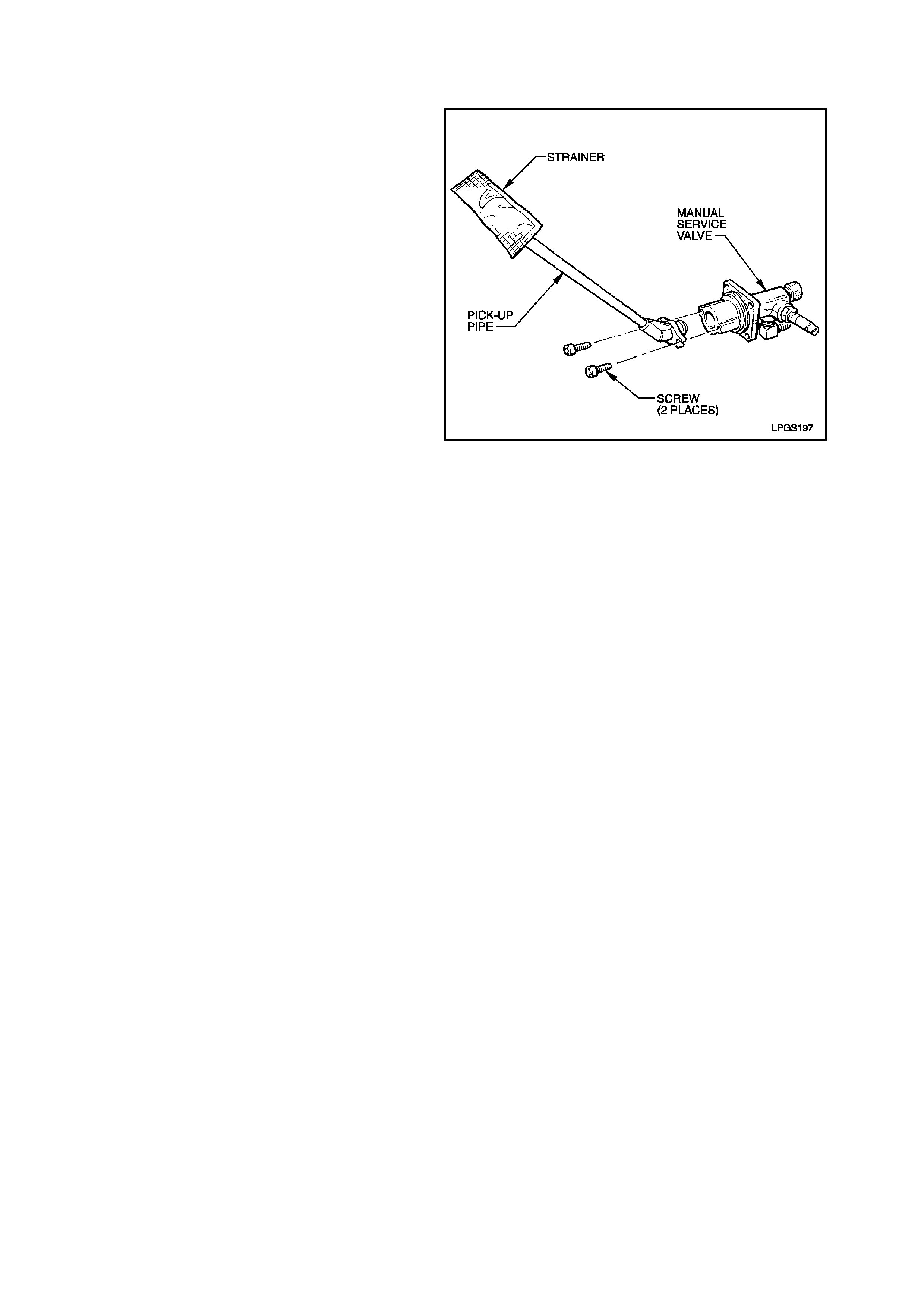

2.9 PICK-UP PIPE AND STRAINER

REMOVE

1. Remove the solenoid and manual service

valve, refer 2.7 SOLENOID AND MANUAL

SERVICE VALVE ASSEMBLY in this Section.

2. Remove the two screws retaining the LPG

pick-up pipe to the manual service valve and

twist the pick-up pipe out of manual service

valve.

REINSTALL

Reinstallation of the LPG pick-up pipe and strainer

is the reverse of the removal procedure, noting the

following point.

Ensure the o-ring on the end of the pick-up pipe is

installed correctl y.

Figure 2-30

2.10 AUTOMATIC FILL LIMITER

TEST

NOTE:

When performing this test, the vehicle must be on

level ground.

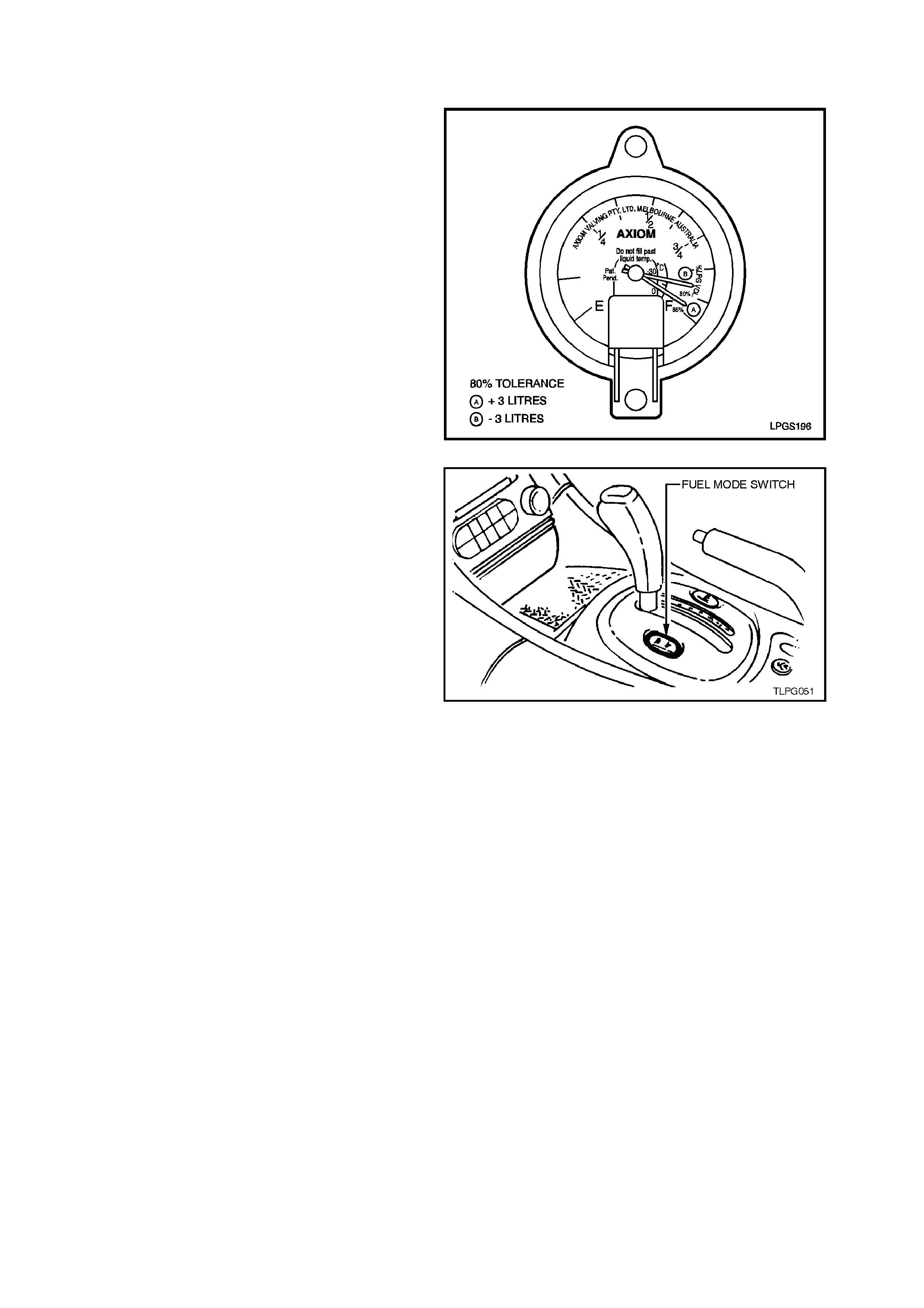

1. Fill the LPG cylinder until the automatic fill

limiter cuts out.

2. Check the LPG c ontents gauge at the cylinder.

If the gauge reads approximately 80% +/- 3%

full, the automatic fill limiter is operating

correctly. If the gauge is reading outside this

specification, the remaining part of this

procedure must be performed:

NOTE:

It is advisable to bounce the vehicle a couple of

times when checking the gauge reading to remove

any hysteresis that may be present in the gauge

which would create an inaccurate reading.

Figure 2-31

3. The vehic le must be operated on LPG until the

LPG cylinder is completely empty of LPG.

NOTE 1:

The vehicle operator should be advised that the

vehicle should be operated on LPG until the LPG

cylinder is completely empty. Once emptied, the

vehicle should then be driven to the dealership on

petrol.

NOTE 2:

It is impossible to switch the f uel mode f rom LPG to

petrol while the vehicle is moving. Therefore, the

vehicle operator must select a location where

running out of LPG will not present a traffic hazard

or danger.

4. Check the fuel contents gauge on the LPG

cylinder is displaying empty and the engine will

not start with the fuel mode switch in the 'LPG '

position.

5. Fill the LPG cylinder and note the number of

litres taken.

The LPG cylinder 'fallible' capacity is 74 litres ± 2

litres.

Figure 2-32

NOTE 3:

If at any time the LPG cylinder is overfilled, the

contents of the cylinder must be reduced to a safe

level by either running the engine NON-STOP on

LPG for suf fic ient tim e to consum e the ex cess fuel,

or rem oving the exces s fuel f rom the LPG cylinder,

refer 2.2 LPG CYLINDER UNLOADING

PROCEDURE in this Section.

NOTE 4:

If the LPG cylinder fallible capacity is within the

specified limits yet the initial test failed (the gauge

was reading outside the specified parameters),

check the calibration of the contents gauge. Refer

to 2.12 CYLINDER FUEL GAUGE ASSEMBLY

(Contents Gauge) in this Section.

REPLACE

The automatic fill limiter should only be replaced if

it proves to be faulty.

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the LPG service lines, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

4. Unload the LPG cylinder of LPG, refer 2.2

LPG CYLINDER UNLOADING PROCEDURE

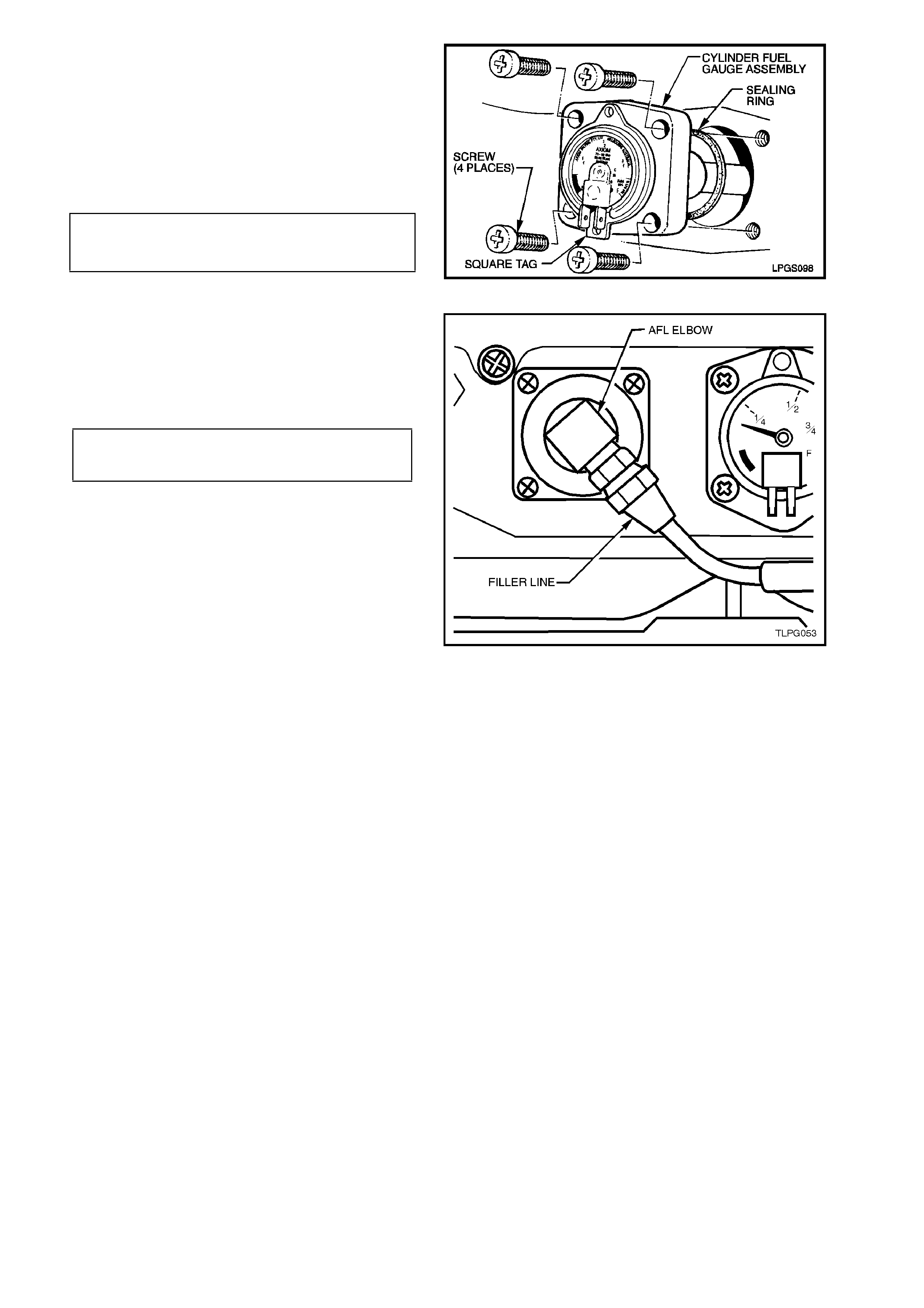

in this Section. Figure 2-33

5. From inside the LPG cylinder valve box, while

holding AFL elbow, crack open filler line to

AFL elbow connector and allow residual LPG

to escape.

CAUTION:

The filler line will contain LPG under pressure.

Once all the LPG in the line has dispersed,

unscrew filler line connector completely from

AFL elbow.

Figure 2-34

6. Unscr ew the four autom atic fill lim iter retaining

screws and remove automatic fill limiter from

the LPG cylinder.

Figure 2-35

7. Install new automatic fill lim iter to LPG cylinder

sealing ring and the autom atic fill limiter. Tak e

care to install the automatic fill lim iter the right

way up. Install and tighten the four automatic

fill limiter attaching screws to the correct

torque specification.

AUTOMATIC F ILL LIMITER TO LPG

CYLINDER ATTACHING SCREW 5.0 - 7.0 Nm

TORQUE SPECIFICATION

Figure 2-36

8. Install new cylinder fuel gauge assembly to

LPG cylinder sealing ring, install cylinder fuel

gauge assembly taking care to install

assembly with gauge up the right way. Install

and tighten cylinder fuel gauge assembly

attaching screws to the correct torque

specification. Reconnect wiring harness

connectors to gauge terminals.

CYLINDER FUEL GAUGE ASSEMBLY

TO LPG CYLINDER ATTACHING 5.0 - 7.0 Nm

SCREW TORQUE SPECIFICATION

Figure 2-37

9. Apply Loctite 577 sealant to filler line

connector threads, ensuring that flared

surf aces ar e f ree of sealant and contaminants .

Connect filler line to AFL elbow and tighten to

the correct torque specification.

FILLER LINE CONNECTOR TO

AFL ELBOW SCREW 12.0 - 18.0 Nm

TORQUE SPECIFICATION

10. Pressure and leak test LPG cylinder in

accordance with the current Australian

Standard AS2030.1.

11. Carry out system leak testing, refer

2.3 LEAK TESTING in this Section.

Figure 2-38

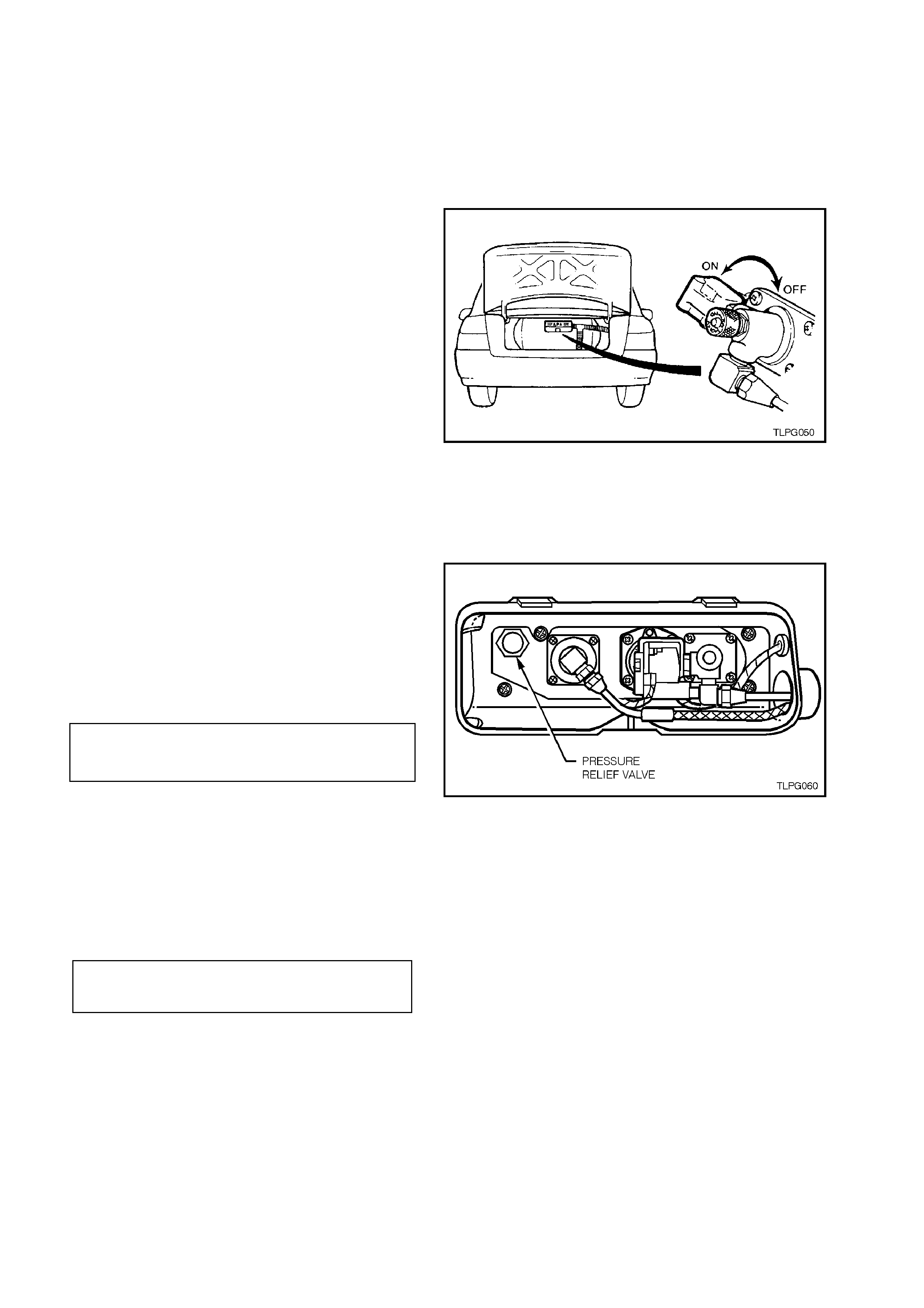

2.11 PRESSURE RELIEF VALVE

NOTE:

The press ure relief valve should only be replaced if

it proves to be leaking.

REPLACE

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the service lines of LPG, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

4. Unload the LPG cylinder of LPG, refer

2.2 LPG CYLINDER UNLOADING

PROCEDURE in this Section.

5. Using a 1 1/16 inch socket and breaker bar,

loosen and remove the pressure relief valve

from the LPG cy linder.

NOTE:

It may be necessary to install a tube over the end of

the breaker bar to enable greater leverage to be

applied for loosening the valve.

Figure 2-39

6. Ensure that new relief valve and LPG cylinder

mating threads are clean.

Apply an anaerobic sealant, such as

Permabond A129 to the valve threads and a

small amount to the cylinder mating threads.

7. Tighten pressure relief valve to the correct

torque specification.

PRESSURE RELIEF VALVE

TO LPG CYLINDER 60 - 65 Nm

TORQUE SPECIFICATION

8. Install new cylinder fuel gauge assembly to

LPG cylinder sealing ring, install cylinder fuel

gauge assembly taking care to install

assembly with gauge up the right way. Install

and tighten cylinder fuel gauge assembly

attaching screws to the correct torque

specification.

CYLINDER FUEL GAUGE ASSEMBLY

TO LPG CYLINDER ATTACHING 5.0 - 7.0 Nm

SCREW TORQUE SPECIFICATION

9. Pressure and leak test LPG cylinder in

accordance with the current Australian

Standard AS2030.1.

10. Carry out system leak testing, refer

2.3 LEAK TESTING in this Section.

Figure 2-40

2.12 CYLINDER FUEL GAUGE ASSEMBLY

REPLACE

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the LPG service lines, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

4. Unload the LPG cylinder of LPG, refer

2.2 LPG CYLINDER UNLOADING

PROCEDURE in this Section.

Figure 2-41

5. Install new cylinder fuel gauge assembly to

LPG cylinder sealing ring, install cylinder fuel

gauge assembly taking care to install

assembly with gauge up the right way. Install

and tighten cylinder fuel gauge assembly

attaching screws to the correct torque

specification. Reconnect wiring harness

connectors to gauge terminals.

CYLINDER FUEL GAUGE ASSEMBLY

TO LPG CYLINDER ATTACHING 5.0 - 7.0 Nm

SCREW TORQUE SPECIFICATION

6. Pressure and leak test LPG cylinder in

accordance with the current Australian

Standard AS2030.1.

7. Carry out system leak testing, refer

2.3 LEAK TESTING in this Section.

Figure 2-42

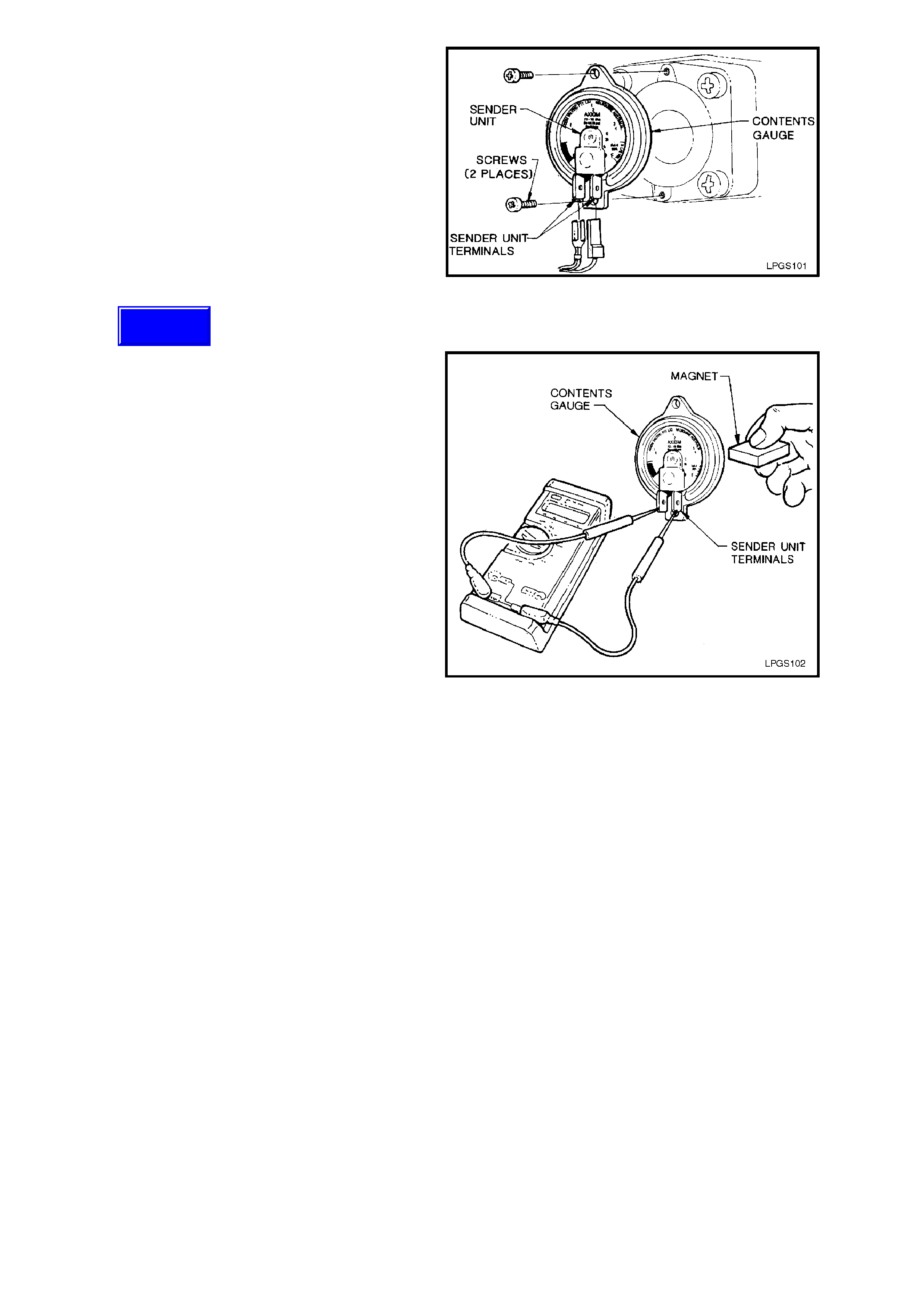

CONTENTS GAUGE

REMOVE

1. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

2. Remove the smart unit and solenoid valve

from the manual service valve, refer to

2.8 SMART UNIT AND SOLENOID VALVE in

this Section.

Figure 2-43

3. Loosen the contents gauge retaining screws (2

places) and remove the contents gauge away

from the LPG cy linder.

4. Disconnect the wiring harness connectors

from the contents gauge terminals and remove

contents gauge.

CAUTION:

DO NOT REMOVE THE FOUR SCREWS

RETAINING THE CYLINDER FUEL GAUGE

ASSEMBLY TO LPG CYLINDER.

Figure 2-44

TEST

1. Connect an ohmmeter to the contents gauge

sender unit terminals.

2. Place a magnet behind the contents gauge,

rotate the magnet to change the position of

gauge needle, resistance should vary from

approximately 40 ohms empty to

approximately 255 ohms full.

If the needle does not move in relation to the

movement of the magnet or the resistance

does not meet specification, the contents

gauge must be replaced.

Figure 2-45

REINSTALL

1. Reconnect wiring harness connectors to

contents gauge terminals.

2. Install contents gauge to cylinder fuel gauge

assembly. Install and tighten contents gauge

attaching screws.

3. Reinstall the smart unit and solenoid valve on

the manual service valve, refer to

2.8 SMART UNIT AND SOLENOID VALVE in

this Section.

4. Reconnect battery earth lead.

Techline

2.13 SERVICE LINES

FRONT SERVICE LINE

REMOVE

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the service lines of LPG, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

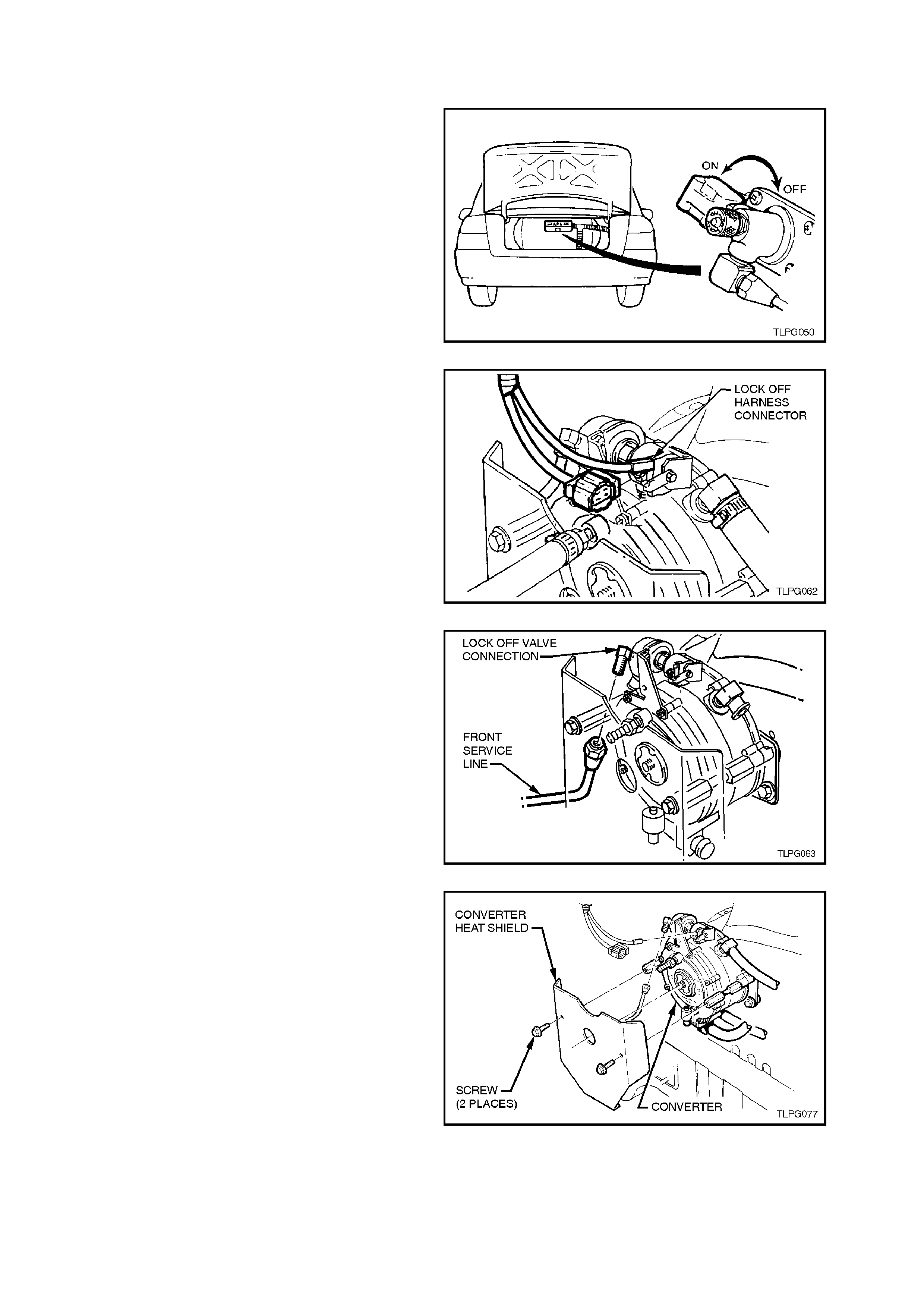

Figure 2-46

4. Loosen and disconnect front service line

connector from LPG lockoff connection, refer

Fig. 2-47.

5. W hile holding f ront to inter mediate service line

joiner from turning, loosen and disconnect

front service line connector from joiner and

remove front service line.

Figure 2-47

REINSTALL

1. Clean mating thr eads of new fr ont s ervic e line,

LPG lockoff connection and front to

intermediate service line joiner connector.

2. Apply Loctite 577 sealant to LPG lockoff

connection and front to intermediate service

line joiner threads, ensuring that flared

surfaces are free of sealant and contaminants.

Assemble f ront s er vic e line connec tor s to LPG

lockoff connection and service line joiner and

tighten to the correct torque specification.

FRONT SERVICE LINE TO

LOCKOFF CONNECTOR

AND JOINER

TORQUE SPECIFICATION

12.0 - 15.0

Nm

NOTE:

Ensure the front service line does not chafe or

come in contact with the body or other

components.

3. Leak test LPG system, refer

2.3 LEAK TESTING in this Section.

INTERMEDIATE SERVICE LINE

The intermediate service line is incorporated into

the fuel and brake pipe harness assembly and,

therefore, not serviced separately. For additional

information, refer to Section 8A FUEL TANK.

REAR SERVICE LINE

REMOVE

1. Park the vehicle in a well ventilated area, away

from any ignition source.

2. Drain the service lines of LPG, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

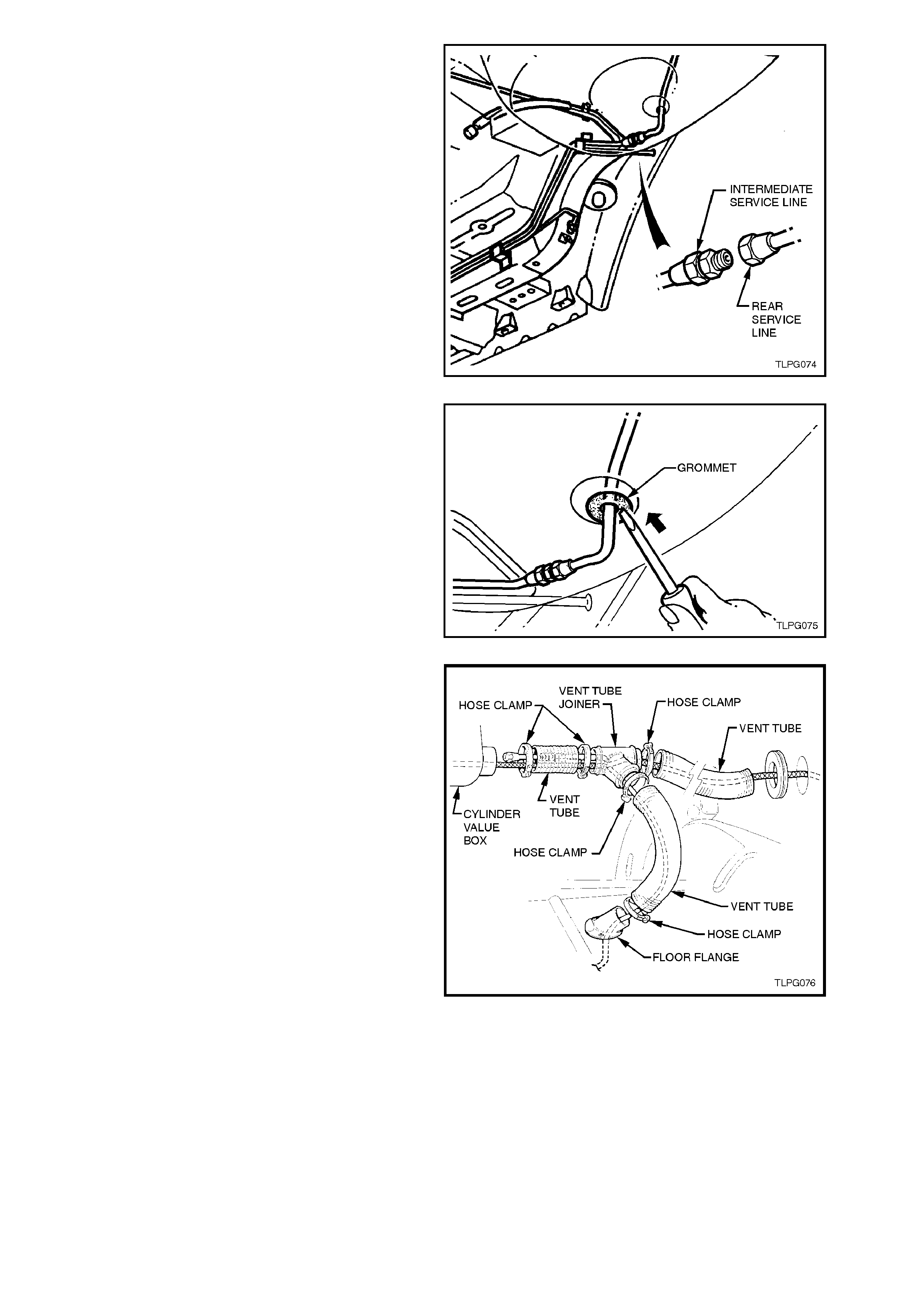

Figure 2-48

4. From inside the LPG cylinder valve box, while

holding AFL elbow, crack open filler line to

AFL elbow connector and allow residual LPG

to escape.

CAUTION:

The filler line will contain LPG under pressure.

Once all the LPG in the line has dispersed,

unscrew filler line connector completely from

AFL elbow.

Figure 2-49

5. From inside the LPG cylinder valve box,

loosen and unscrew the rear service line

connector from solenoid and manual service

valve assembly, refer to Fig. 2-50.

Figure 2-50

6. Jack up rear of vehicle and support on safety

stands, refer to Section 0A GENERAL

INFORMATION for location of jacking points.

7. While holding the intermediate to rear service

line joiner from turning, loosen and unscrew

the rear service connector from the service

line joiner, refer Fig 2-51.

Figure 2-51

8. From under vehicle, push the rear service line

grommet up through body, refer Fig. 2-52.

9. Pull rear service line down until the rear

service line c onnector c lears the cylinder valve

box.

Figure 2-52

10. Disconnect vent tubes at: cylinder valve box,

vent tube joiner (3 clamps), and floor flange,

refer Fig. 2-53.

Remove vent tubes and vent tube joiner from

rear service line (piece by piece).

11. Remove rear service line through luggage

compartment.

Figure 2-53

REINSTALL

Reinstallation of the r ear service line is the reverse

of the removal procedure, noting the following:

1. Clean rear service line mating threads on

solenoid and manual service valve assembly,

intermediate to rear service line joiner, both

rear ser vice line connec tors, AF L valve m ating

threads and filler line connector.

2. Reinstall grommet into body before installing

the vent tubes.

3. Apply Loctite 577 sealant to intermediate to

rear service line joiner threads, solenoid and

manual service valve assembly threads, and

AFL valve threads, ensuring that flared

surfaces are free of sealant and contaminants.

4. Tighten rear service line and filler line

connections to the correct torque

specifications.

REAR SERVICE LINE

CONNECTIONS

TORQUE SPECIFICATION 12.0 - 18.0 Nm

FILLER LINE TO AFL

VALVE CONNECTION

TORQUE SPECIFICATION 12.0 - 18.0 Nm

NOTE:

Ensure the rear service line and filler lines do not

chafe or come in contact with the body or other

components.

5. Tighten vent tube hose clamps to the correct

torque specification.

VENT TUBE HOSE CLAMP

TORQUE SPECIFICATION 1.0 - 3.0

Nm

6. Leak test LPG system, refer

2.3 LEAK TESTING in this Section.

2.14 LPG LOCKOFF

REMOVE

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the service lines of LPG, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

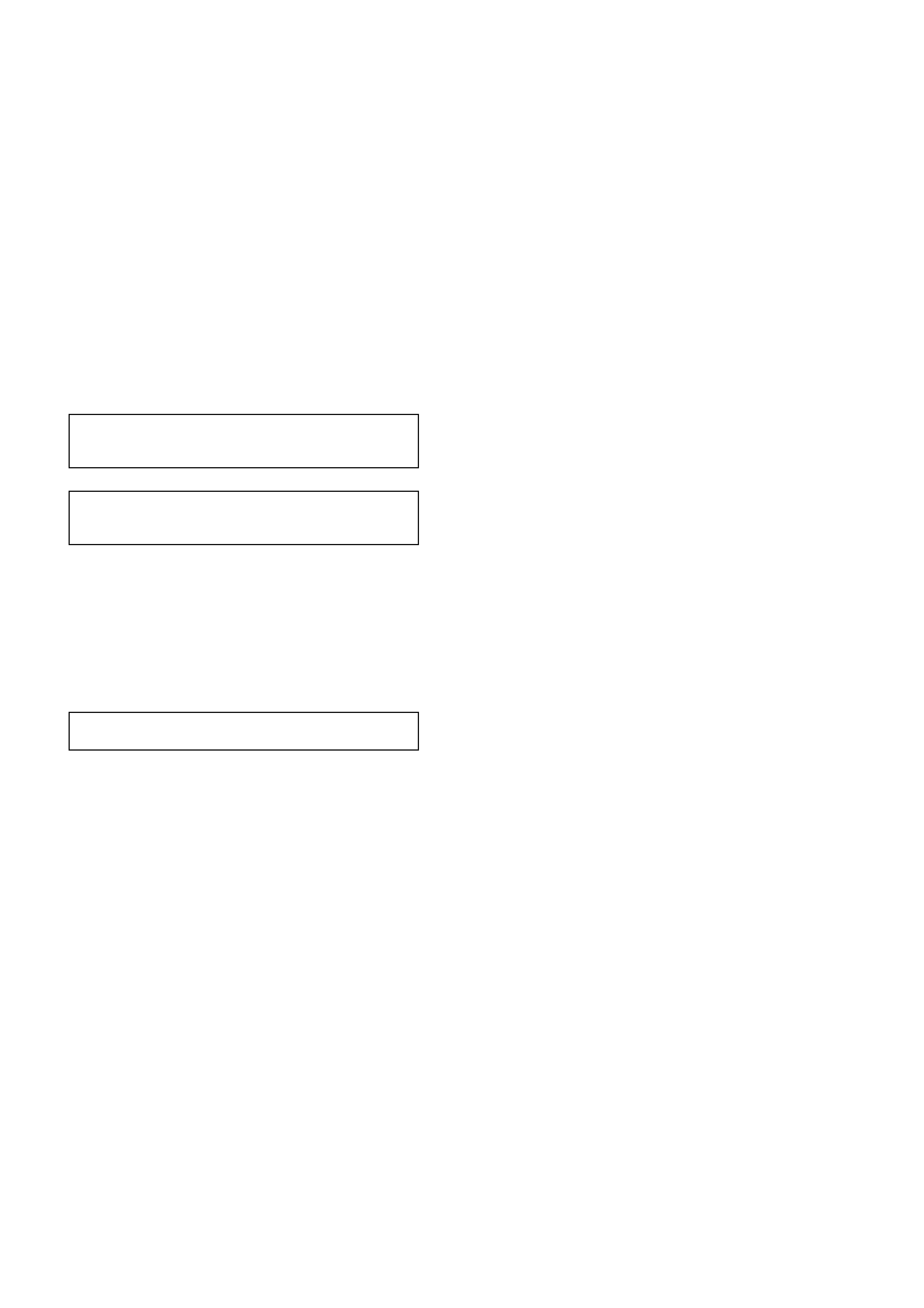

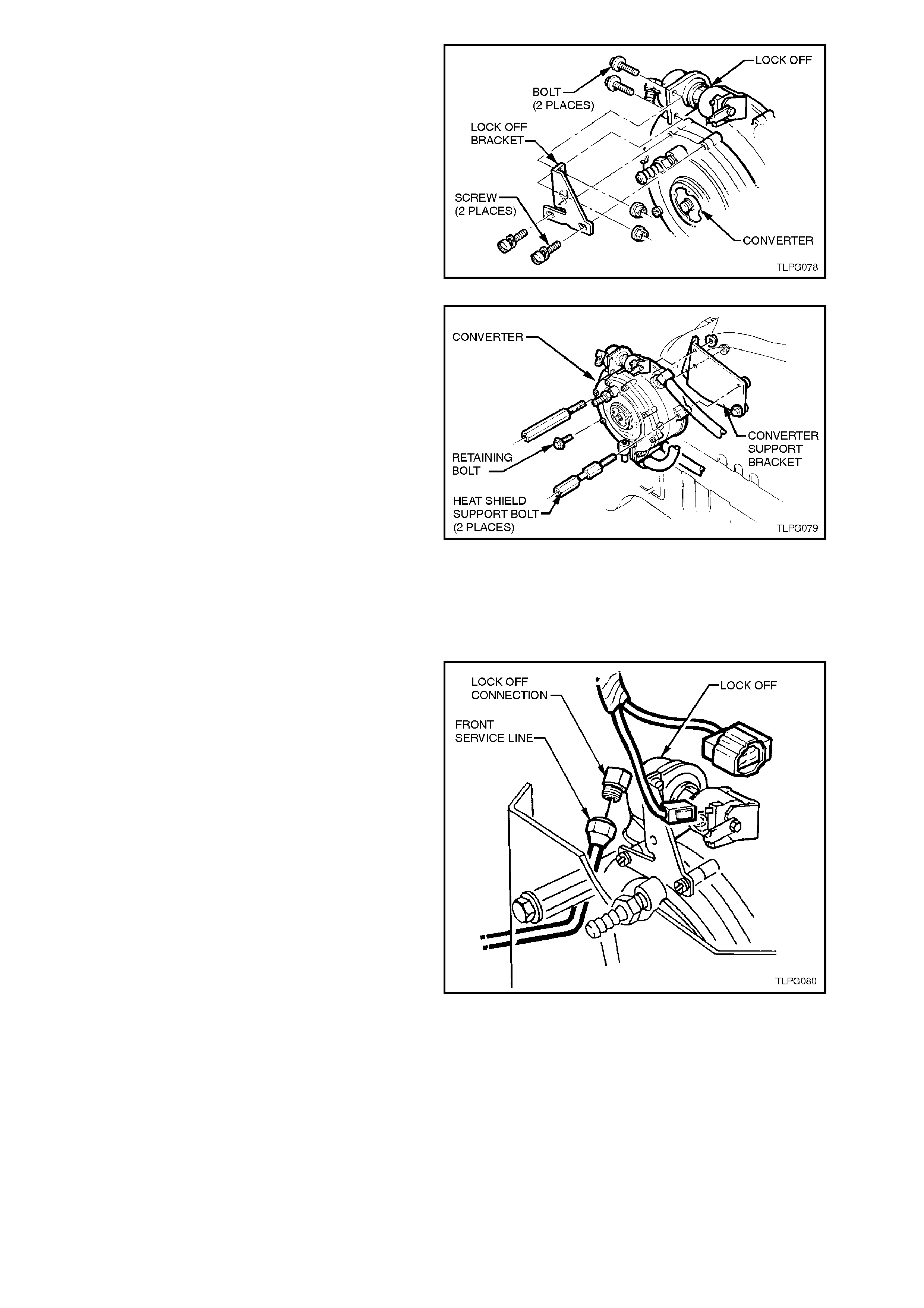

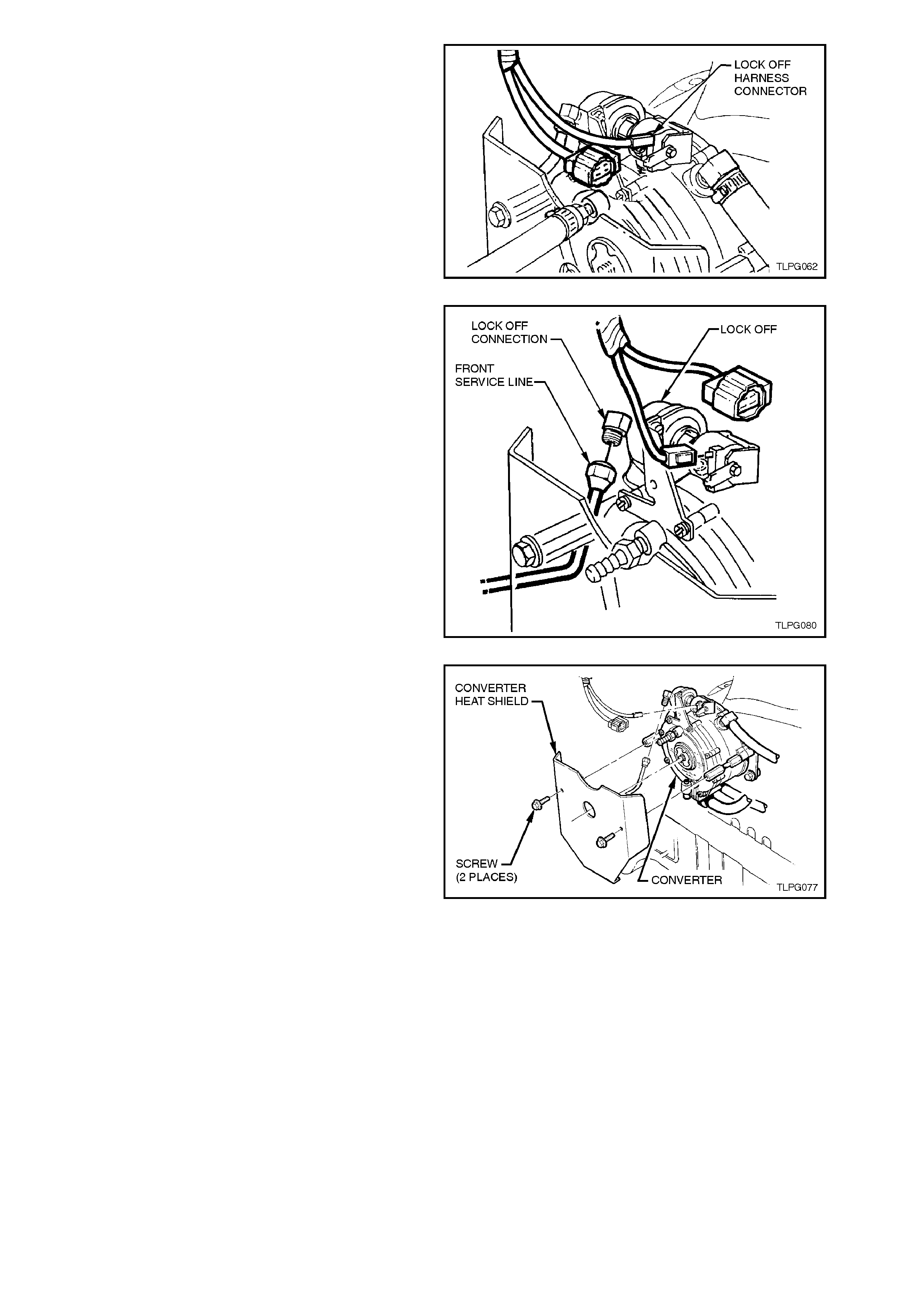

Figure 2-54

4. Disconnect LPG lockoff harness connector

from LPG lockoff.

Figure 2-55

5. Loosen and disconnect front service line to

LPG lockoff connection.

Figure 2-56

6. Remove the two screws securing the

converter heat shield to the converter and

remove heat shield.

Figure 2-57

7. Remove the two screws securing the lockoff

bracket to the converter.

8. Remove the two sc rews and nuts s ecuring the

lockoff bracket to the lockoff and remove

lockoff bracket.

Figure 2-58

9. Loosen LPG lockoff outlet connection at

converter.

10. Loosen and remove the two heat shield

support bolts and the converter retaining bolt.

11. Lift up converter as far as possible and

unscrew LPG lockoff assembly from

converter.

12. Lower converter down into its mounting

position and temporally install converter to

converter support bracket.

Figure 2-59

FILTER ELEMENT REPLACEMENT

The following filter elem ent replacement procedure

can be performed with or without the LPG lockoff

installed to the converter.

CAUTION:

If conducting the following procedure with the

LPG lockoff still installed to the converter, the

service lines must first be d rained of LPG, ref er

2.1 DRAINING THE SERVICE LINES in this

Section.

NOTE:

A filter element replacement kit is available and

contains the following components:

LPG lockof f cup to valve body attaching scr ew

'O' ring.

LPG lockoff to valve body gasket.

Filter element.

Cup lid to valve body 'O' ring.

Bobbin to valve body 'O' ring.

Mobile coil assembly.

Filter Element replacement is as follows:

1. If necessary, loosen and disconnect front

service line connector from LPG lockoff

straight nipple connection.

2. Disconnect LPG engine harness lockoff

terminal LP4G from LPG lockoff spade

terminal.

Figure 2-60

3. Loosen and remove LPG lockoff cup to valve

body attaching screws. Separate cup

assembly from valve body.

Remove cup lid from cup, remove filter

element.

Remove and discard cup lid to valve body 'O'

ring and attaching screw to cup sealing 'O'

ring.

4. Replace filter, 'O' rings and cup gasket with

new parts.

5. Reassem bly is the reverse of the disassem bly

procedure. Ensure that the magnet is cleaned

and located in the cup.

6. Tighten the cup to valve body attaching screw

to the correct torque specification.

LPG LOCKOFF CUP TO VALVE BODY

ATTACHING SCREW 3.0 - 5.0 Nm

TORQUE SPECIFICATION

Figure 2-61

7. Connect inlet of LPG lockoff to pressurised

nitrogen.

Check for any flow of nitrogen from the LPG

lockoff outlet fitting.

The LPG lockoff should completely block off

the flow of nitrogen up to the specified

pressure rating.

If the LPG lockoff allows any amount of the

pressurised nitrogen to flow the LPG lockoff

should be replaced.

LPG LOCKOFF PRESSUERE 1200

RATING SPECIFICATION kPa

Figure 2-62

TEST

1. Check for continuity or short circuit of the

solenoid coil winding by placing the probes of

an ohmm eter on the two terminals of the LPG

lockoff.

If the measured resistance value is not to

specification the LPG lockoff should be

replaced.

LPG LOCKOFF COIL 17 - 27 OHMS

RESISTANCE @ 20°C

Figure 2-63

REINSTALL

Reinstallation of the LPG lockoff is the reverse of

the removal procedure noting the following:

1. Clean mating threads of LPG lockoff inlet,

outlet connection and front service line

connectors.

2. Apply Loctite 577 sealant to LPG lockoff inlet

threads install LPG lockoff to the converter

and tighten securely, if necessary, further

tighten to align lockoff and lockoff bracket.

3. Tighten all fasteners to the correct torque

specification

LOCKOFF BRACKET TO

CONVERTER

ATTACHING SCREW

TORQUE SPECIFICATION

3.0 - 5.0

Nm

CONVERTER RETAINING BOLT TO

SUPPORT BRACKET

TORQUE SPECIFICATION 10.0 - 12.0

Nm

HEAT SHEILD SUPPORT BOLT TO

SUPPORT BRACKET

TORQUE SPECIFICATION 10.0 - 12.0

Nm

HEAT SHEILD RETAINING SCREW

TO HEAT SHEILD SUPPORT BOLT

TORQUE SPECIFICATION 3.0 - 5.0 Nm

4. Apply Loctite 577 to lockoff connector and

tighten front service line to LPG lockoff

connector to the correct torque specification.

FRONT SERVICE LINE

CONNECTOR TO LPG LOCKOFF

TORQUE SPECIFICATION 12.0 - 15.0

Nm

5. Leak test LPG system, refer

2.3 LEAK TESTING in this Section.

2.15 CONVERTER

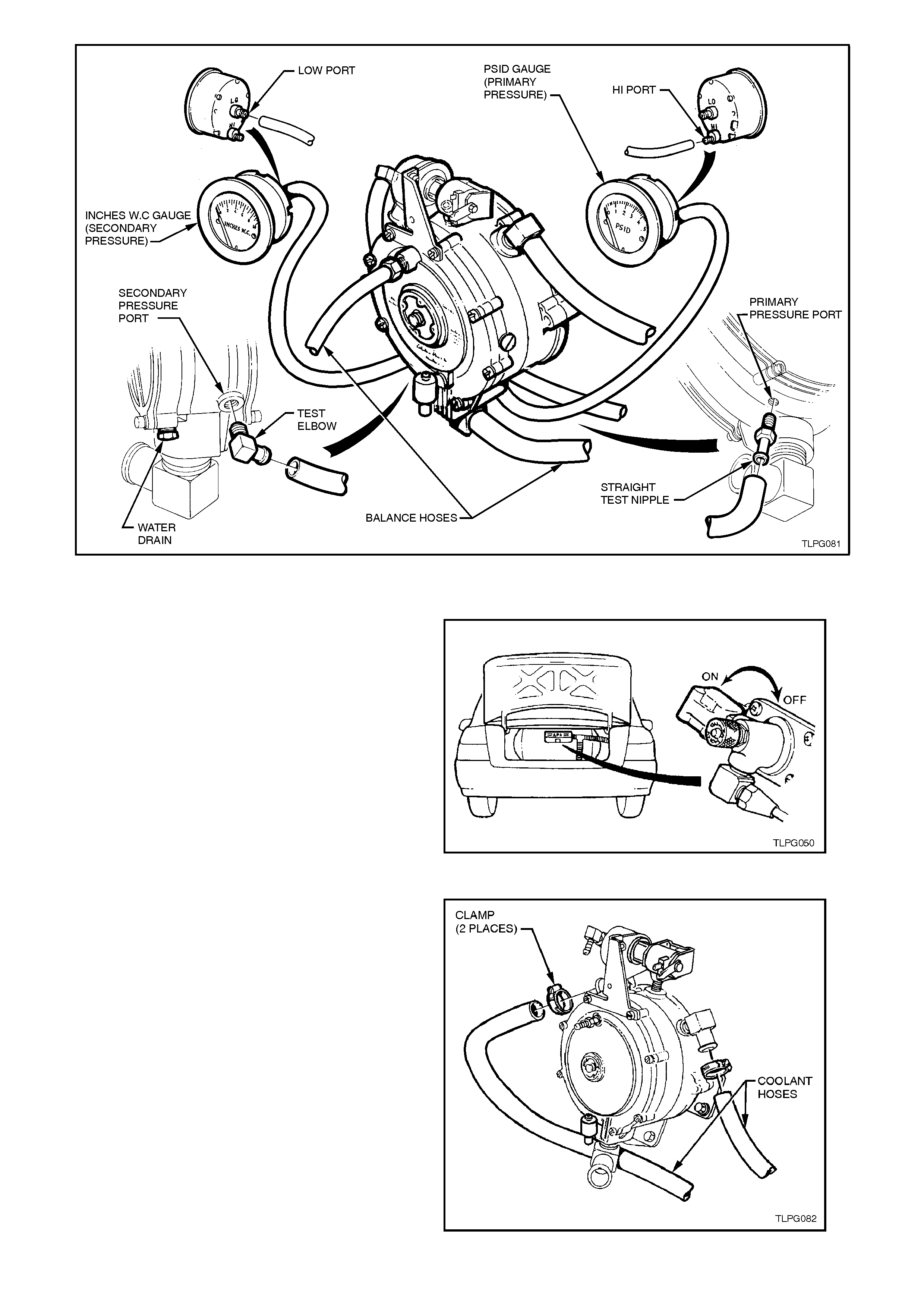

CONVERTER ON VEHICLE TEST PROCEDURE

REMOVE

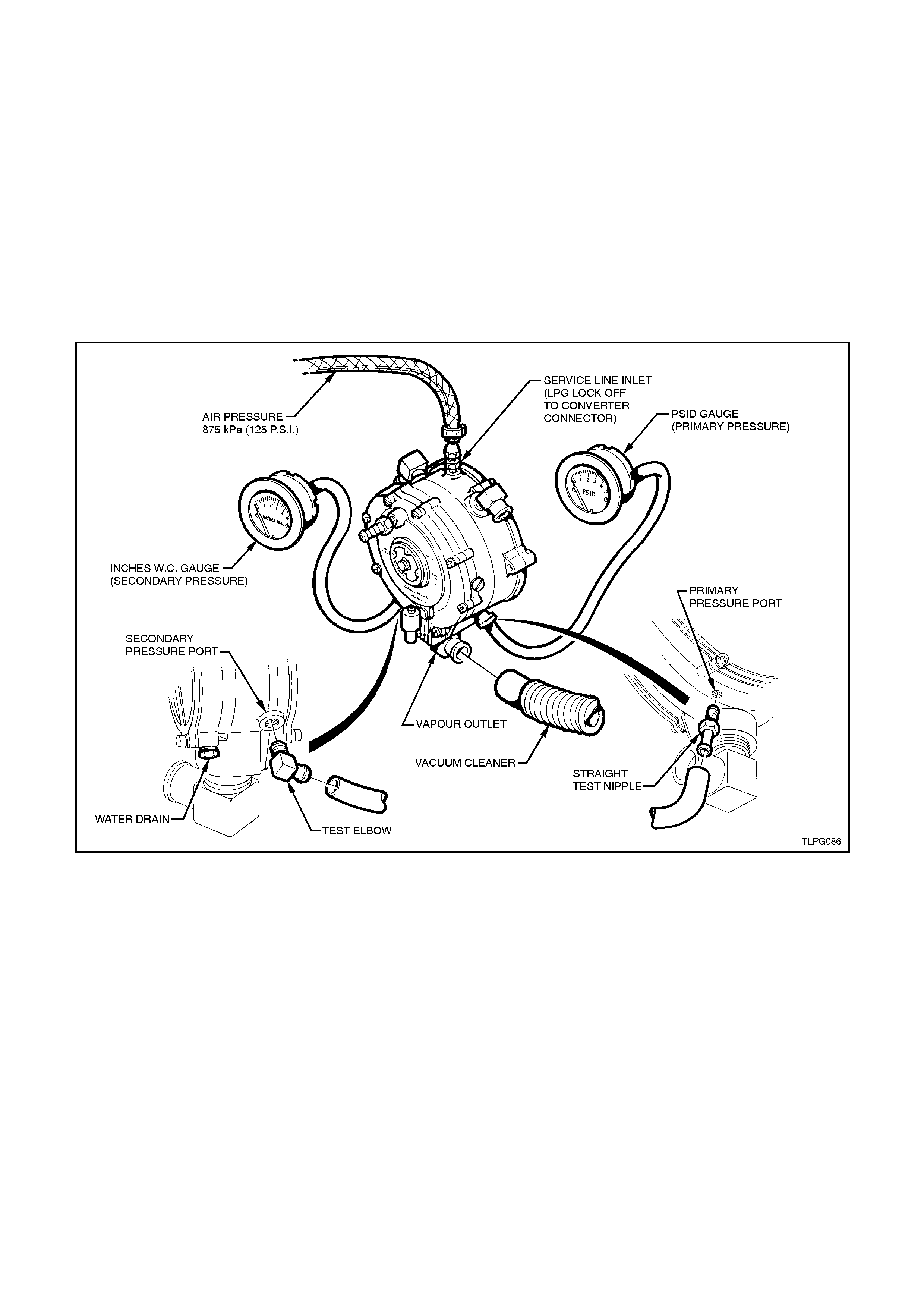

(Refer to Fig. 2-65)

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the service lines of LPG, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

4. Remove plug from the converter primary test

port and install straight test nipple into

converter primary test port.

5. Connect the pressure gauge hose to the

straight nipple and to the HI connection of the

0-5 PSID pressure gauge of LPG tes t kit ( refer

Section 7 SPECIAL TOOL S at the end of this

Section).

6. Remove plug from the converter secondary

test port and install test elbow into secondary

test port.

7. Connect vacuum gauge hose to secondary

test elbow and the LO connection of 0-10

INCHES W.C. vacuum gauge LPG test kit 1.

Figure 2-64

8. Turn 'ON' m anual service valve and check test

connections for leaks.

9. With fuel mode switch in LPG position start

engine and allow to idle.

NOTE:

If engine will not start, crank the engine and record

pressures.

10. Converter primary pressure should be 1.0-1.5

psi (7-10 kPa).

11. Disconnect FCV to converter balance line at

converter.

12. Secondary converter pressure should be

negative 1-1.5 inches W.C. (negative 24-38

mm W.C.).

13. Reconnect balance line and secondary

pressure gauge should fluctuate from 1 - 5

inches W.C. (24-38 mm W.C.)

14. Turn 'OFF' engine, gauges should hold

pressure for at least 5 minutes.

Figure 2-65

REMOVE

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the service lines of LPG, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

4. Depressurise engine cooling system by

removing radiator cap in two stages.

CAUTION:

DO NOT REMOVE RADIATOR CAP WHILE THE

ENGINE COOLANT TEMPERATURE IS ABOVE

50oC AS PERSONAL INJURY MAY RESULT. Figure 2-66

5. Place drain tray beneath vehicle. Loosen

clamps securing engine coolant hoses to

converter coolant inlet and outlet elbows.

Remove c oolant hoses from converter and lay

back away from converter.

Figure 2-67

6. Disconnect LPG lockoff harness connector

from LPG lockoff.

7. Remove diagnostic interconnect connector

assembly from LPG lockoff retaining bracket.

Figure 2-68

8. Loosen and disconnect front service line to

LPG lockoff inlet connection.

Figure 2-69

9. Remove the two screws securing the

converter heat shield to the converter and

remove heat shield.

Figure 2-70

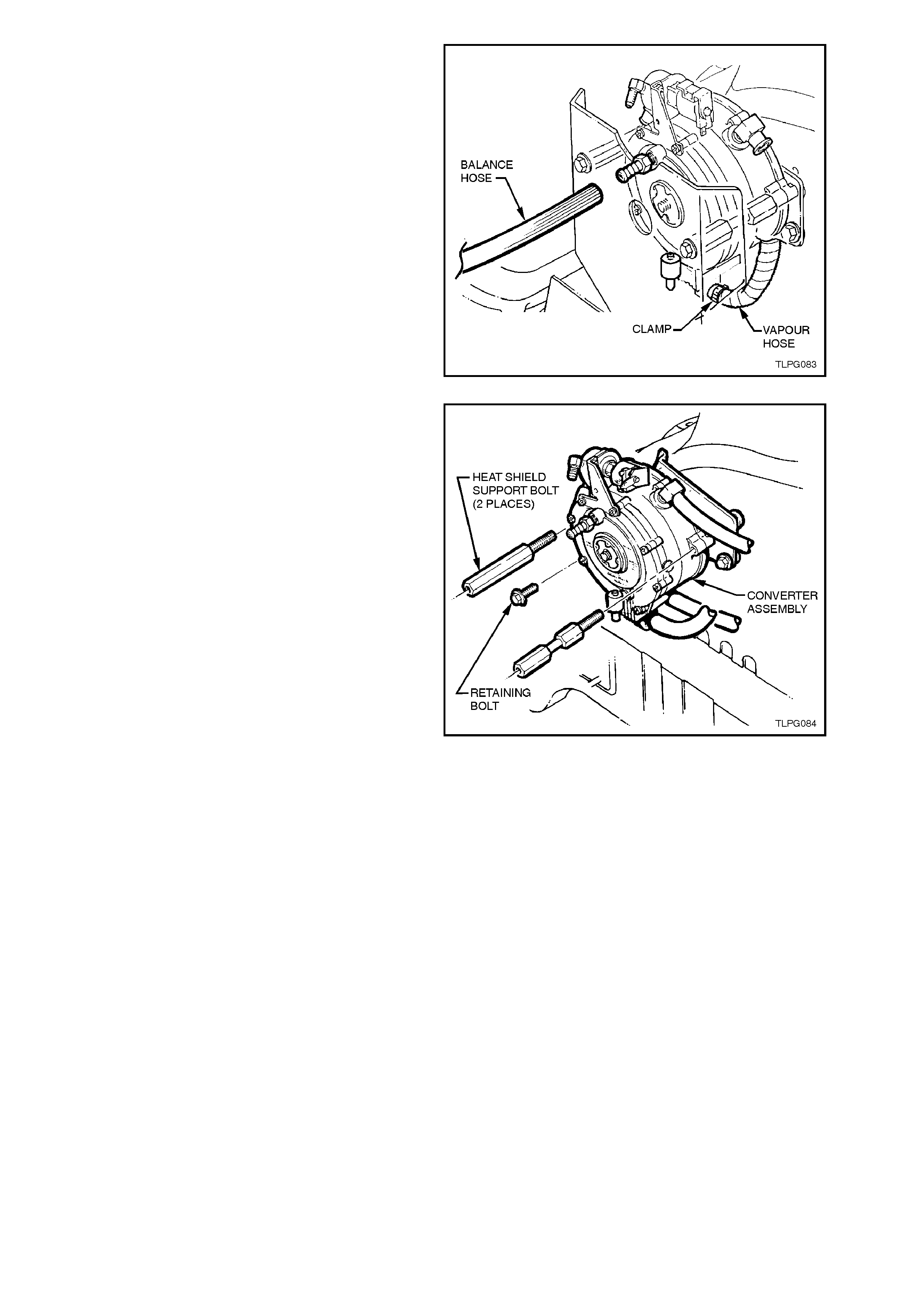

10. Remove FCV balance hose from converter

connections.

11. Loosen mixer to converter vapour hose clamp

at converter vapour outlet and disconnect

vapour hose from converter.

Figure 2-71

12. Loosen and remove the two heat shield

support bolts and the converter retaining bolt.

13. Remove converter assembly .

Figure 2-72

14. Remove engine coolant inlet and outlet

elbows, vapour outlet, FCV balance hose

connection and lockoff assembly if required.

If carrying out the following overhaul

procedure on the converter assembly, loosen

and unscrew the LPG lockoff to converter

connection, remove the connection and LPG

lockoff from the converter.

OVERHAUL

Under normal operating conditions, installation of a complete repair kit in a converter should only be necessary at

the time or distance intervals specified in the VT OWNERS HANDBOOK LPG leaflet, or if the converter has been

out of service for some time causing the gaskets and diaphragms to deteriorate, or after the converter has been

stored after being used.

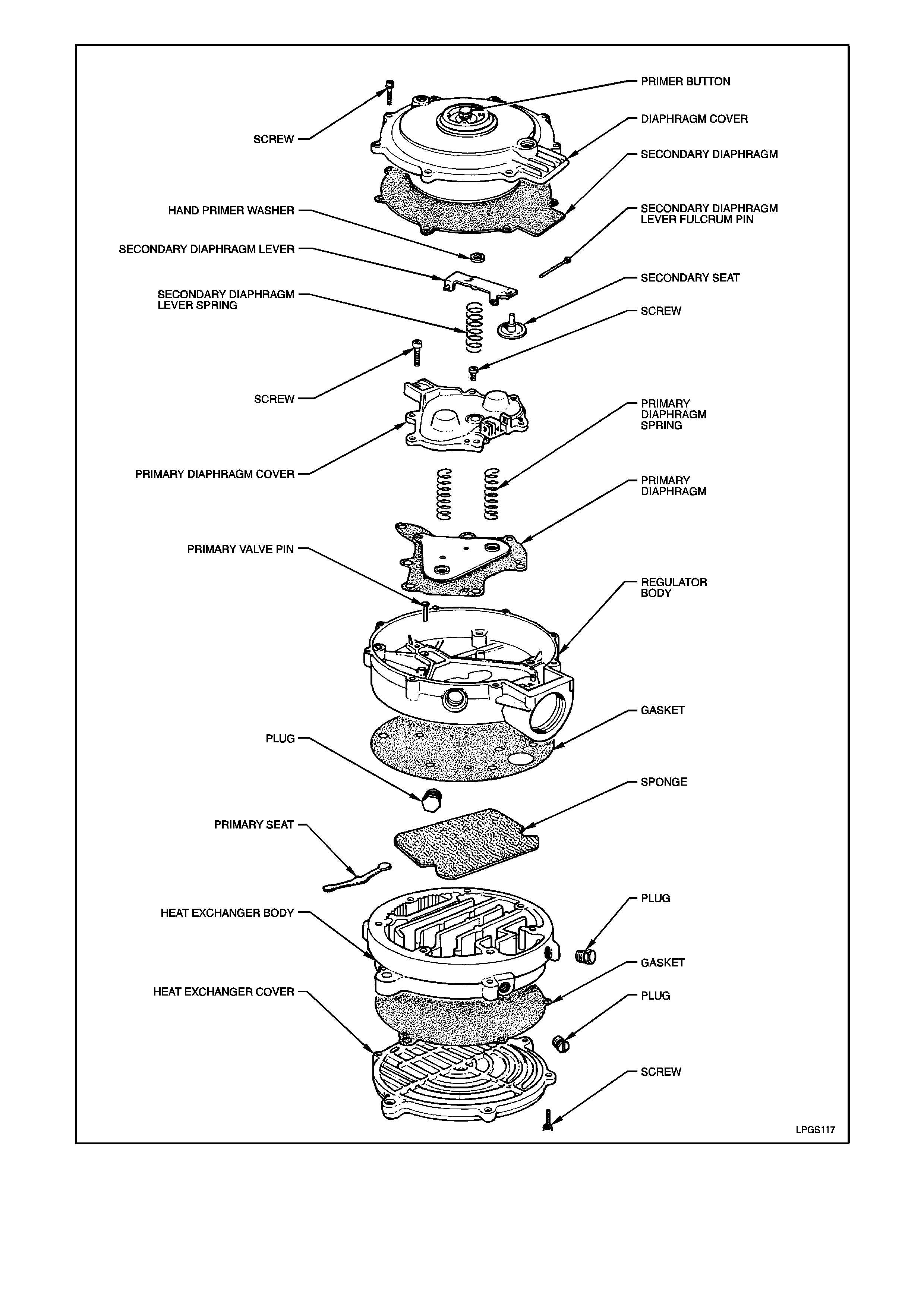

Refer to Figure 2-73 for identification of the converter assembly components.

The converter repair kit contains the following components:

Diaphragm cover to regulator body attaching screws.

Primary diaphragm.

Hand primer washer.

Secondary diaphragm.

Secondary seat.

Primary diaphragm cover to regulator body screws.

Regulator body to heat exchanger body gasket.

Heat exchanger sponge.

Primary valve seat.

Heat exchanger cover to body gasket.

Heat exchanger cover to body attaching screws.

All other converter components are available separately, refer to the VT Parts Information for details.

Figure 2-73

DISASSEMBLE

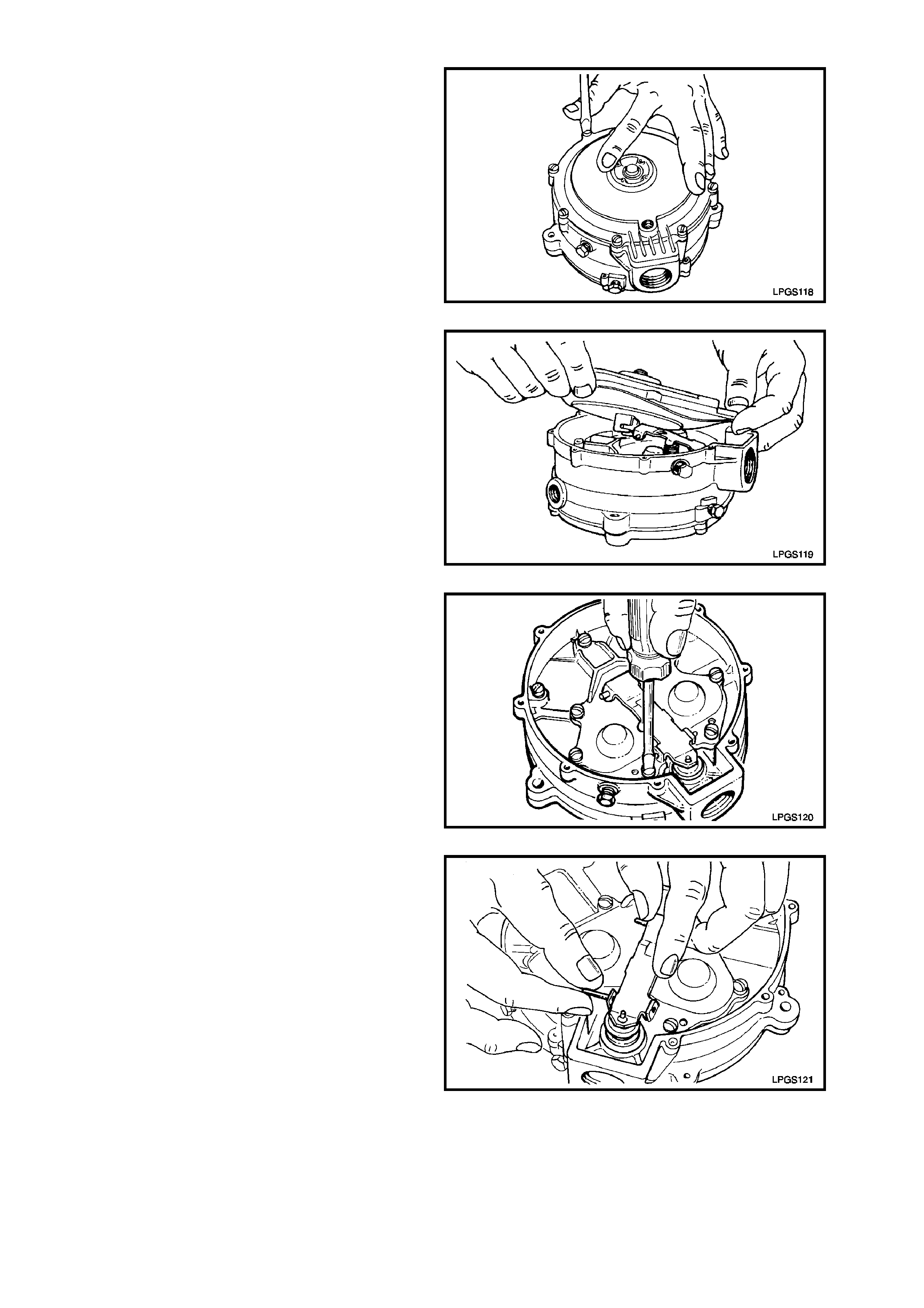

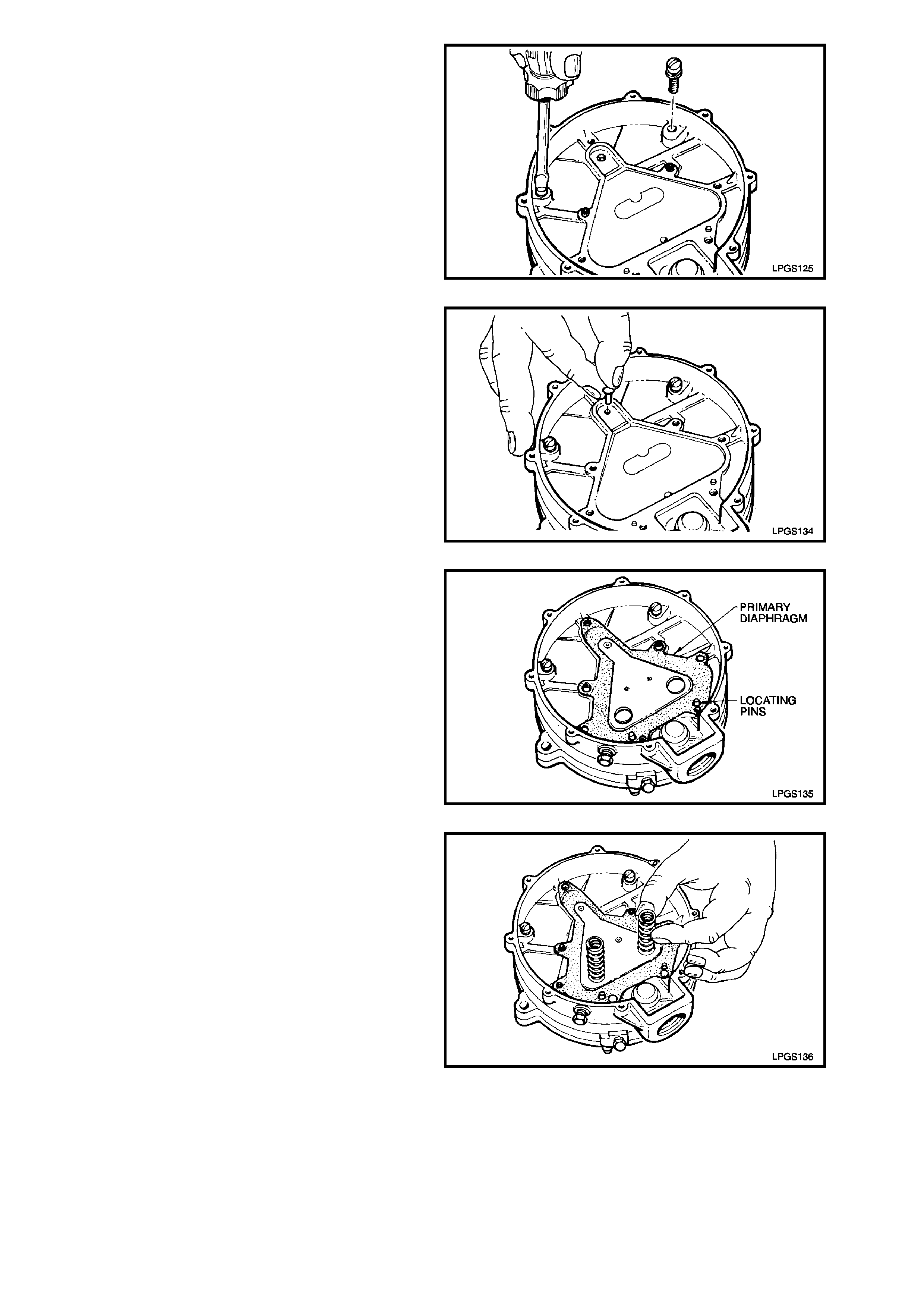

1. Loosen and remove the eight diaphragm c over

to regulator body attaching screws.

Figure 2-74

2. Lift up diaphragm cover and diaphragm from

regulator body.

Move diaphragm cover and diaphragm away

from low pressure outlet by approximately 25

mm to disengage the two prongs of the

diaphragm link from the secondary diaphragm

lever.

3. Remove diaphragm cover and diaphragm

from regulator body

Figure 2-75

4. Loosen and remove primary diaphragm cover

to regulator body screw that retains sec ondary

diaphragm lever fulcrum pin.

Figure 2-76

5. Slide secondary diaphragm lever fulcrum pin

from primary diaphragm cover and remove.

Figure 2-77

6. Remove secondary diaphragm lever and

spring from primary diaphragm cover.

Figure 2-78

7. Remove the remaining six primary diaphragm

cover to regulator body retaining screws.

NOTE:

Removal of these screws releases the primary

diaphragm cover from the regulator body thereby,

allowing the primary diaphragm springs to be

released.

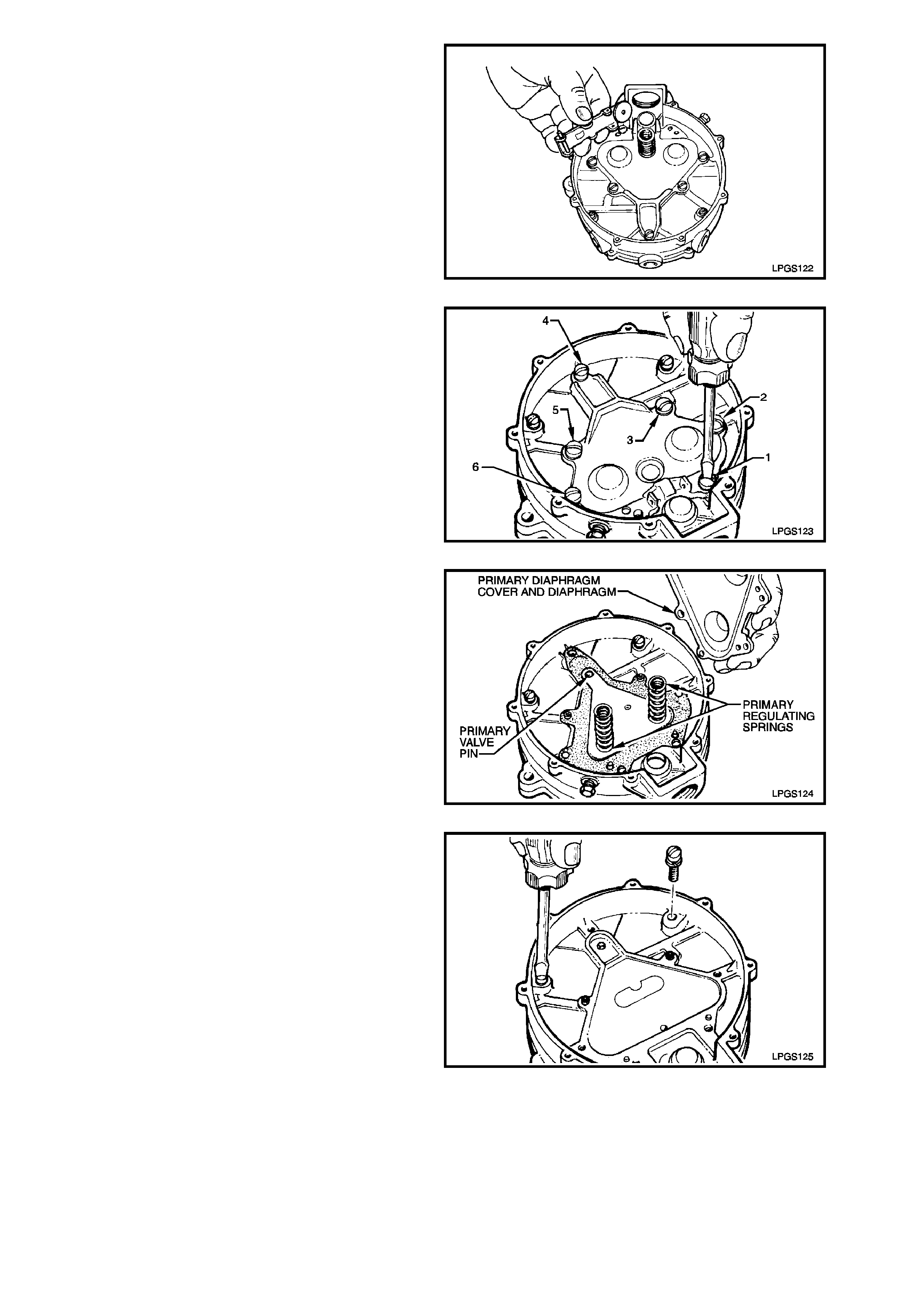

Figure 2-79

8. Remo ve primar y diaphragm cover and prim ary

diaphragm springs from regulator body.

Rem ove primary diaphragm and pr imary valve

pin from regulator body.

Figure 2-80

9. Loosen and remove the two remaining

regulator body to heat exchanger body

attaching screws.

Figure 2-81

10. Loosen and separate r egulator body fr om heat

exchanger body. Discard gasket.

Figure 2-82

11. Remo ve and discar d primary seat and sponge

from hear exchanger body.

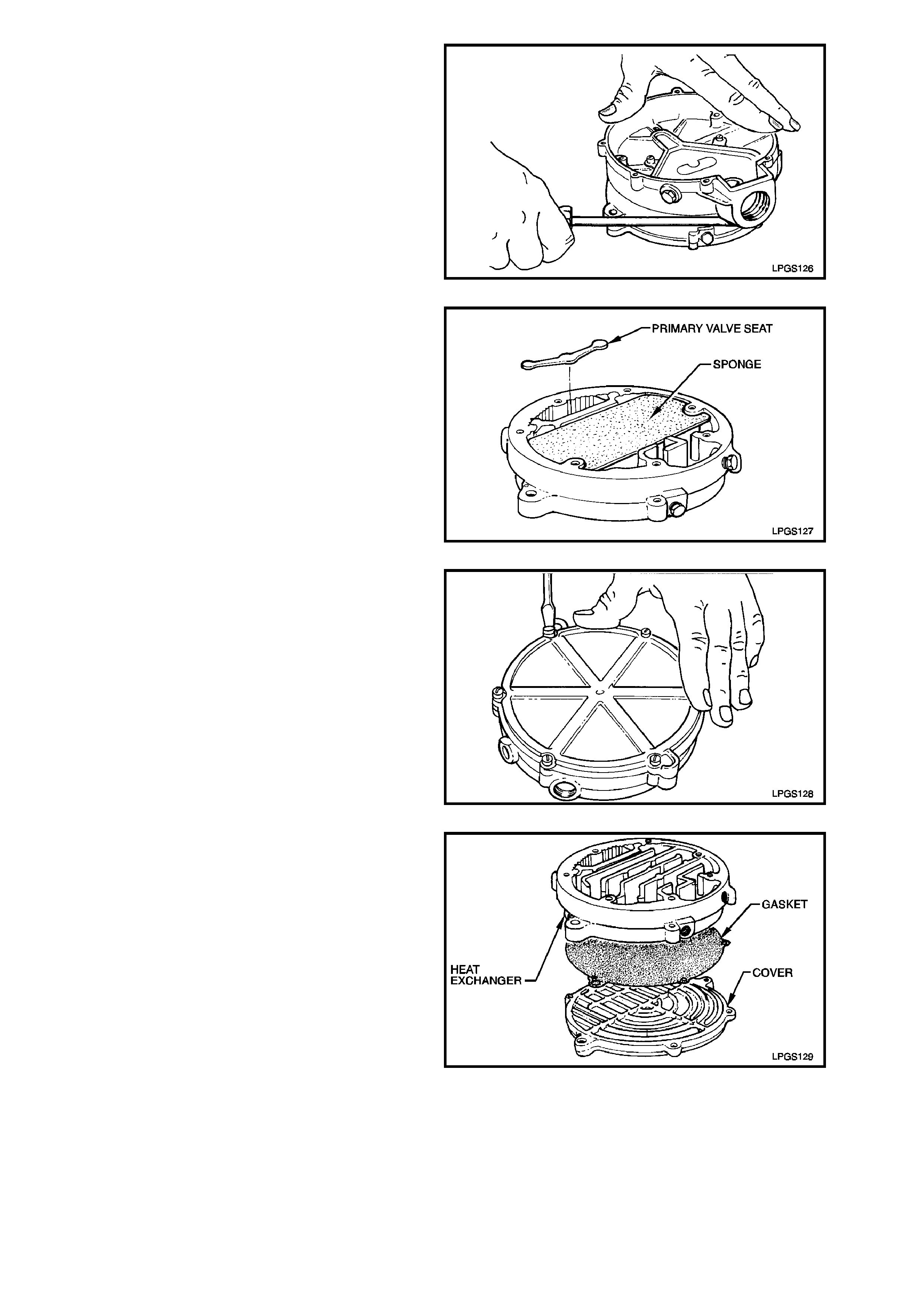

Figure 2-83

12. Loosen and remove heat exchanger cover to

heat exchanger body attaching screws.

Figure 2-84

13. Separate heat exchanger cover from heat

exchanger body and discard gasket.

Figure 2-85

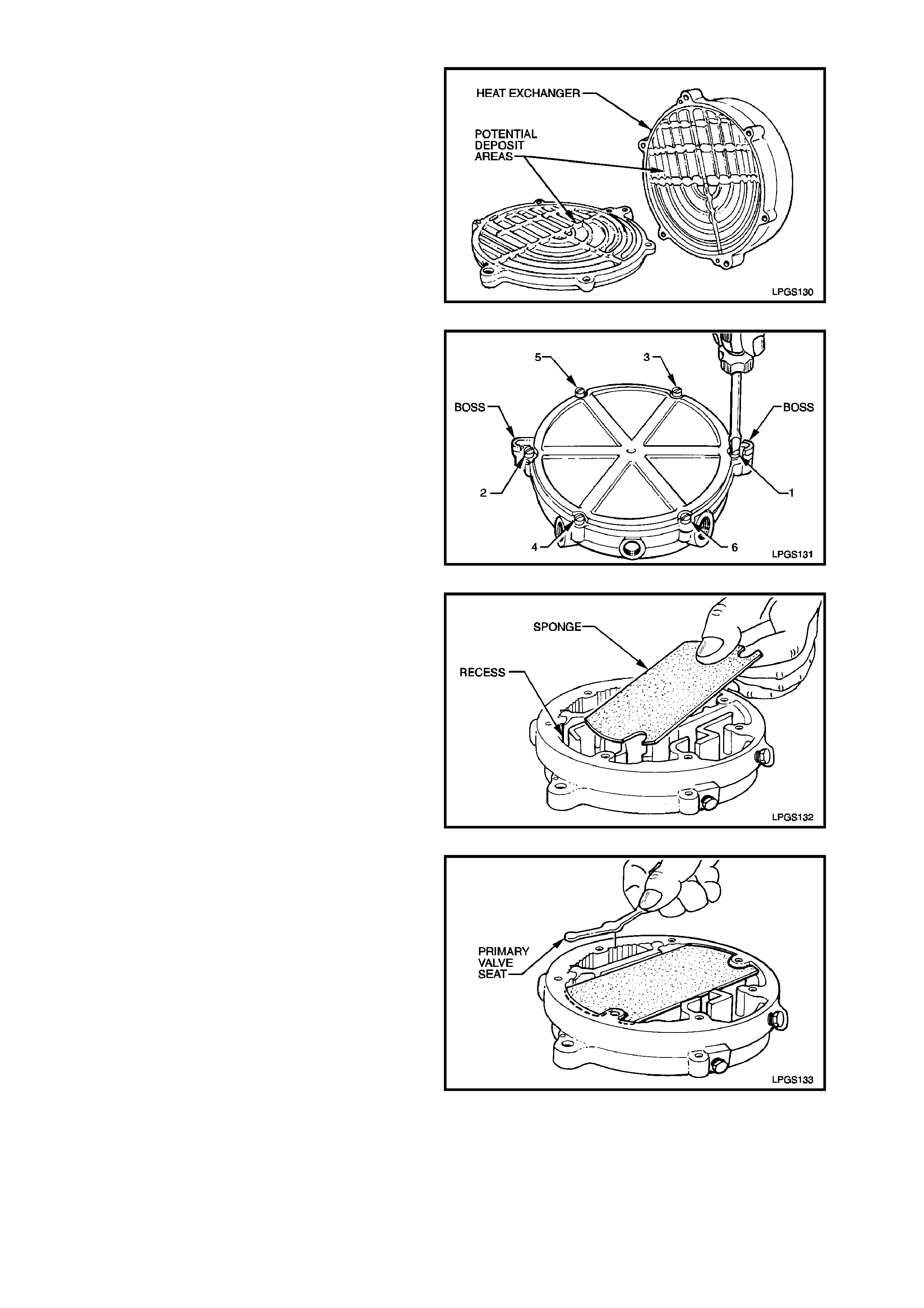

REASSEMBLE

1. Clean all parts in a suitable cleaning solution

and thoroughly dry and inspect all

components.

Care should be taken to clean all deposits

from heat exchanger body.

Figure 2-86

2. Using a new gasket, reassemble heat

exchanger cover to heat exchanger body,

matching mounting bosses in cover with those

on exchanger body. Install and tighten

attaching screws securely and in the sequence

shown.

Figure 2-87

3. Place sponge in cast recess on heat

exchanger body.

NOTE:

Sponge must be accurately located in recess.

Figure 2-88

4. Install new primary seat into heat exchanger

body.

Figure 2-89

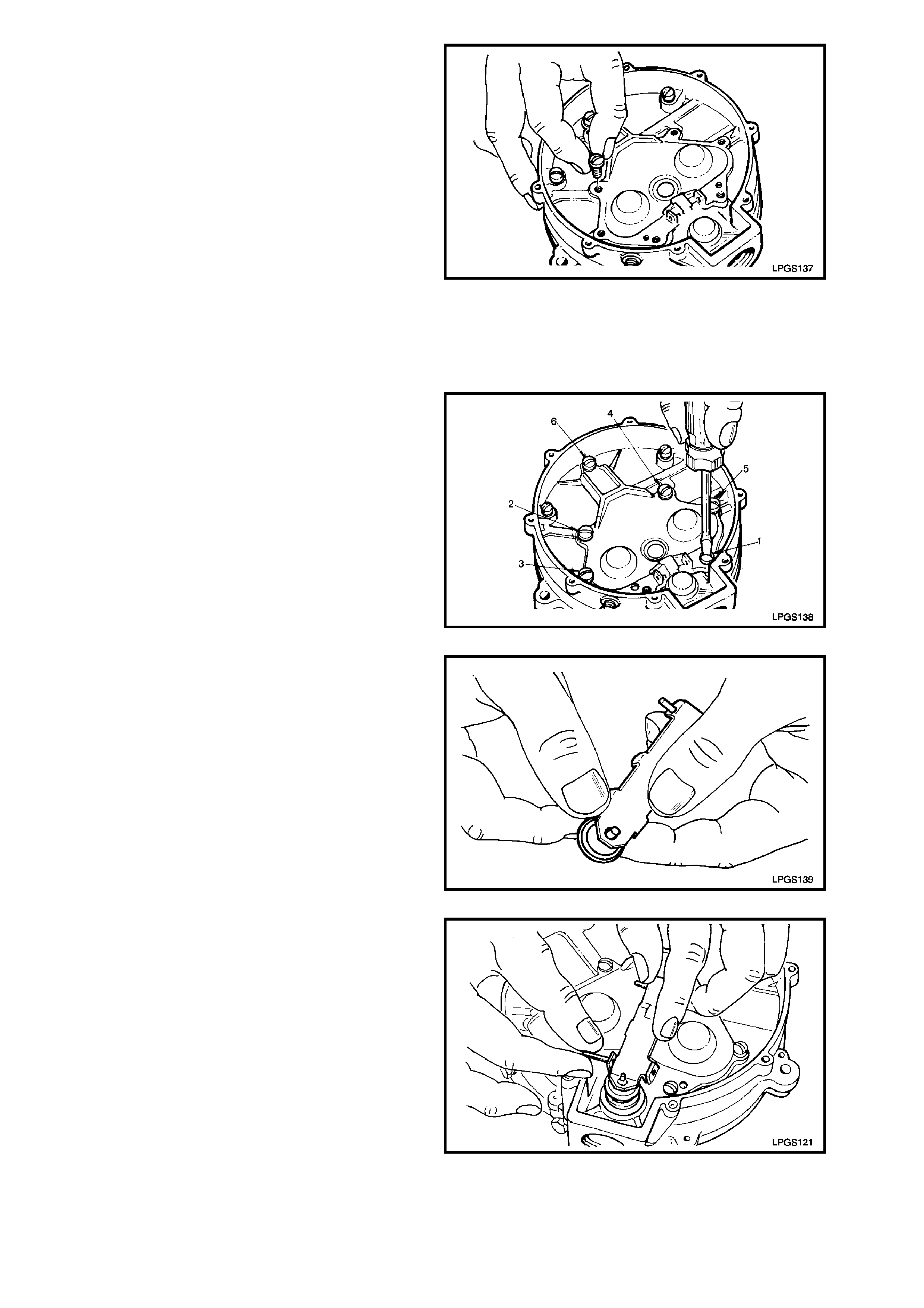

5. Place regulator body to heat exchanger gasket

on primary pin boss and two locating pins on

underside of regulator body.

Use two screws to locate regulator body and

gasket on heat exchanger as shown.

Tighten screws just until head engages

regulator body.

Figure 2-90

6. Place primary valve pin into regulator body

hole.

Figure 2-91

7. Install primary diaphragm over locating pins

and screw bosses in regulator body. This is

essential so as to ensure proper alignment

and assembly of primary diaphragm springs

and primary diaphragm cover.

Figure 2-92

8. Place the two primary diaphragm springs upon

locating perches on the back plate of the

primary diaphragm assembly.

Figure 2-93

9. Place the primary diaphragm cover over

primary diaphragm springs and push cover

down on the springs until it contacts the

regulator body.

NOTE:

Cups in the primary diaphragm cover are used to

locate the primary diaphragm springs. The springs

must locate in these cups.

10. While holding down the primary diaphragm

cover, insert the six cover to regulator body

attaching screws ensuring that the two shallow

headed screws are installed in the correct

locations (screws shown as 2 and 4 in Fig. 2-

95).

NOTE:

Do not install the attaching screw used to retain the

secondary diaphragm lever fulcrum pin at this

stage.

Figure 2-94

11. Tighten primary diaphragm cover screws until

they contact the cover.

Then tighten screws securely and in the order

shown.

Figure 2-95

12. Remove old secondary seat from secondary

diaphragm lever and replace with a new seat.

Figure 2-96

13. Reinstall secondary diaphragm lever to

primary diaphragm cover.

Insert fulcrum pin whilst holding the lever in

place.

Figure 2-97

14. Reinstall remaining primary diaphragm cover

to regulator body attaching screw used to

retain fulcrum pin. Tighten screw securely.

Figure 2-98

15. Reinstall secondary diaphragm lever spring by

slipping it under the secondary diaphragm

lever.

Ensure that the spring is correctly located

between the retaining tangs on the lever and

also the retaining area in the primary

diaphragm cover.

Figure 2-99

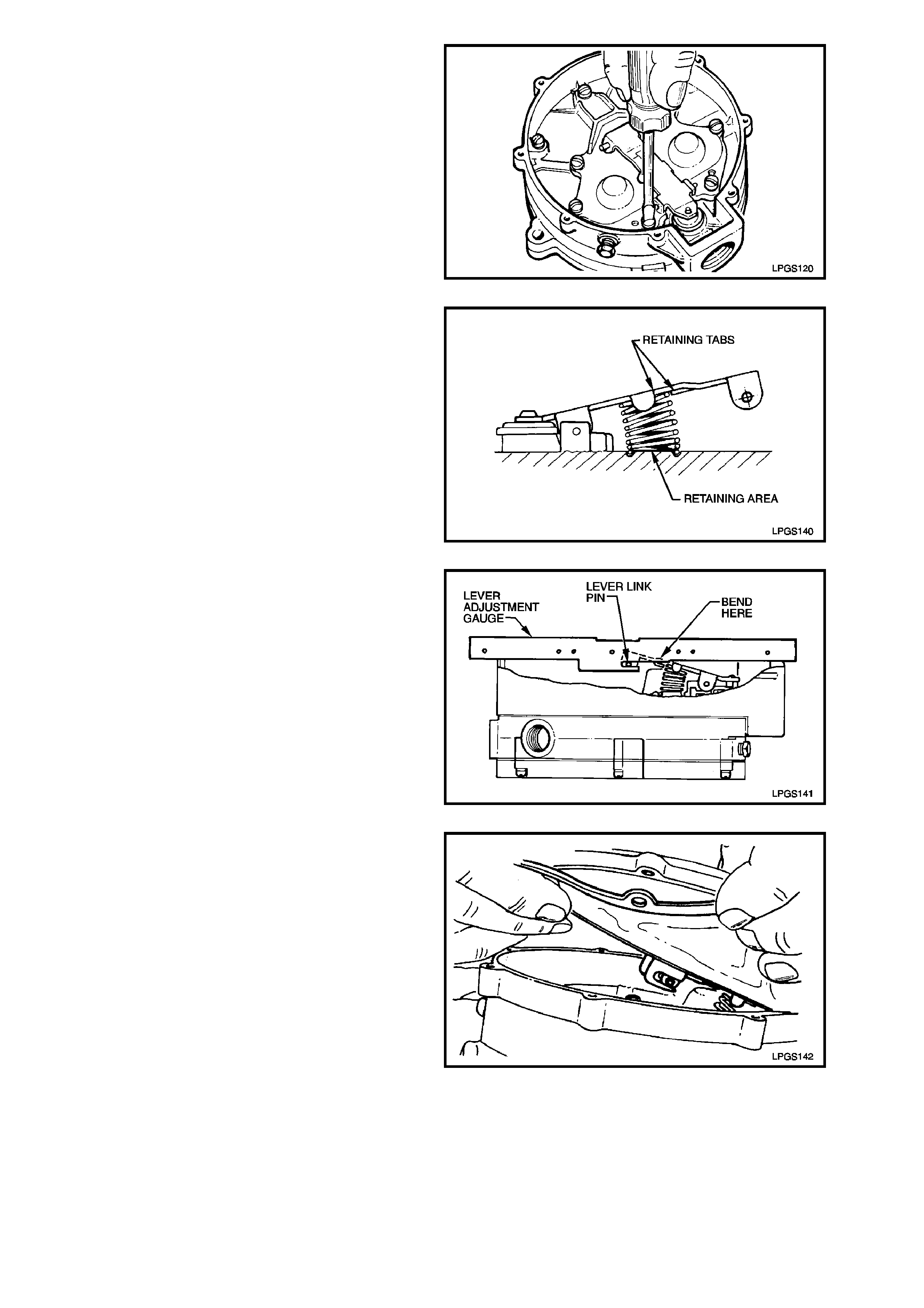

16. Using the secondary diaphragm lever

adjustment gauge, (part of LPG TEST KIT

ITK-1, refer Section 7 SPECIAL TOOLS at

the end of this Section), ensure that the resting

position of the secondary diaphragm lever is

within specification as shown in Fig. 2-100.

Height of secondary lever link pin should

correspond to the slot in the measuring gauge.

If the height of the secondary diaphragm lever

link pin is not to specification then gently bend

the secondary diaphragm lever until the

specified height is achieved.

Figure 2-100

17. Assemble the new secondary diaphragm by

attaching the secondary diaphragm slots to the

secondary diaphragm lever link pin.

Figure 2-101

Refer to Fig. 2-102 for the correct relationship

of the diaphragm on the lever link pin.

Figure 2-102

18. Install diaphragm cover onto regulator body,

ensuring that secondary diaphragm is correctly

located between cover and regulator body.

Install attaching screws and tighten until all

screws contact the cover.

Continue to tighten the attaching screws in the

sequence shown until all are seated, then

torque screws to the correct torque

specification.

DIAPHRAGM COVER TO REGULATOR

BODY ATTACHING SCREW 3.0 - 5.0 Nm

TORQUE SPECIFICATION Figure 2-103

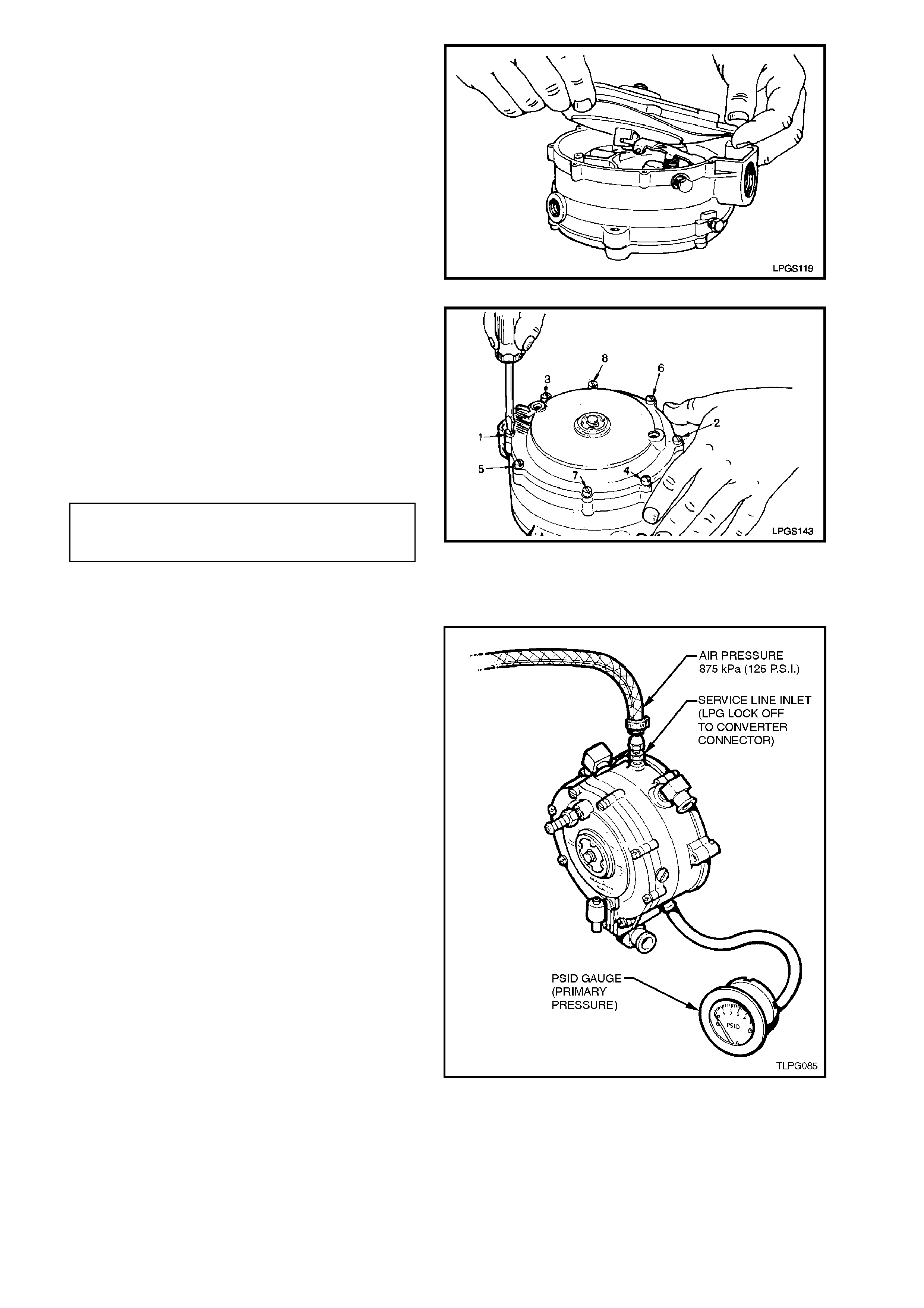

CONVERTER OFF VEHICLE TEST

With the converter removed from the vehicle, refer

2.15 CONVERTER - REMOVE procedure in this

Section, proceed as follows:

1. Remove plug from the converter primary test

point and install straight test nipple into

converter primary test point.

2. Connect the pressure gauge hose to the

straight test nipple and to the 'HI' connection of

the of the 0 - 5 PSID pressure gauge of LPG

test kit 1.

3. Remove plug from the converter secondary

test point and install test elbow into secondary

test point.

4. Connect vacuum gauge hose to test elbow

and the 'LOW' connection of 0 - 10 INCHES

W.C. vacuum gauge of LPG test kit 1.

5. Remove converter to LPG lockoff connector

from LPG lockoff and reinstall into converter.

Tighten connector securely.

6. Connect an air supply into the converter to

LPG lockoff connector and adjust air supply

pressure to 875 kPa (125 psi).

7. Note the pressure reading on the primary

pressure gauge. Primary converter pressure

should be 7 - 10 kPa (1.0 - 1.5 psi).

8. Disconnect air supply, The converter should

hold primary pressure for at least five minutes.

NOTE:

The following step involves the use of a domestic

vacuum cleaner as a vacuum source.

Figure 2-104

9. Reconnect regulated air supply to the

converter to LPG lockoff connector. While

watching the primary pressure gauge, bring

the vacuum nozzle of the vacuum cleaner to

the converter vapour outlet. W hen the primar y

pressur e gauge needle m oves (indic ating s tart

point of vapour supply out of secondary), note

and record the secondary vacuum gauge

reading.

Secondary converter pressure should be

negative 1 - 1.5 inches W.C. (negative 24 - 38

mm W.C.).

If during this test the specified primary and/or

secondary pressures cannot be achieved, the

converter must be overhauled as per previous

instructions in this Section.

Figure 2-105

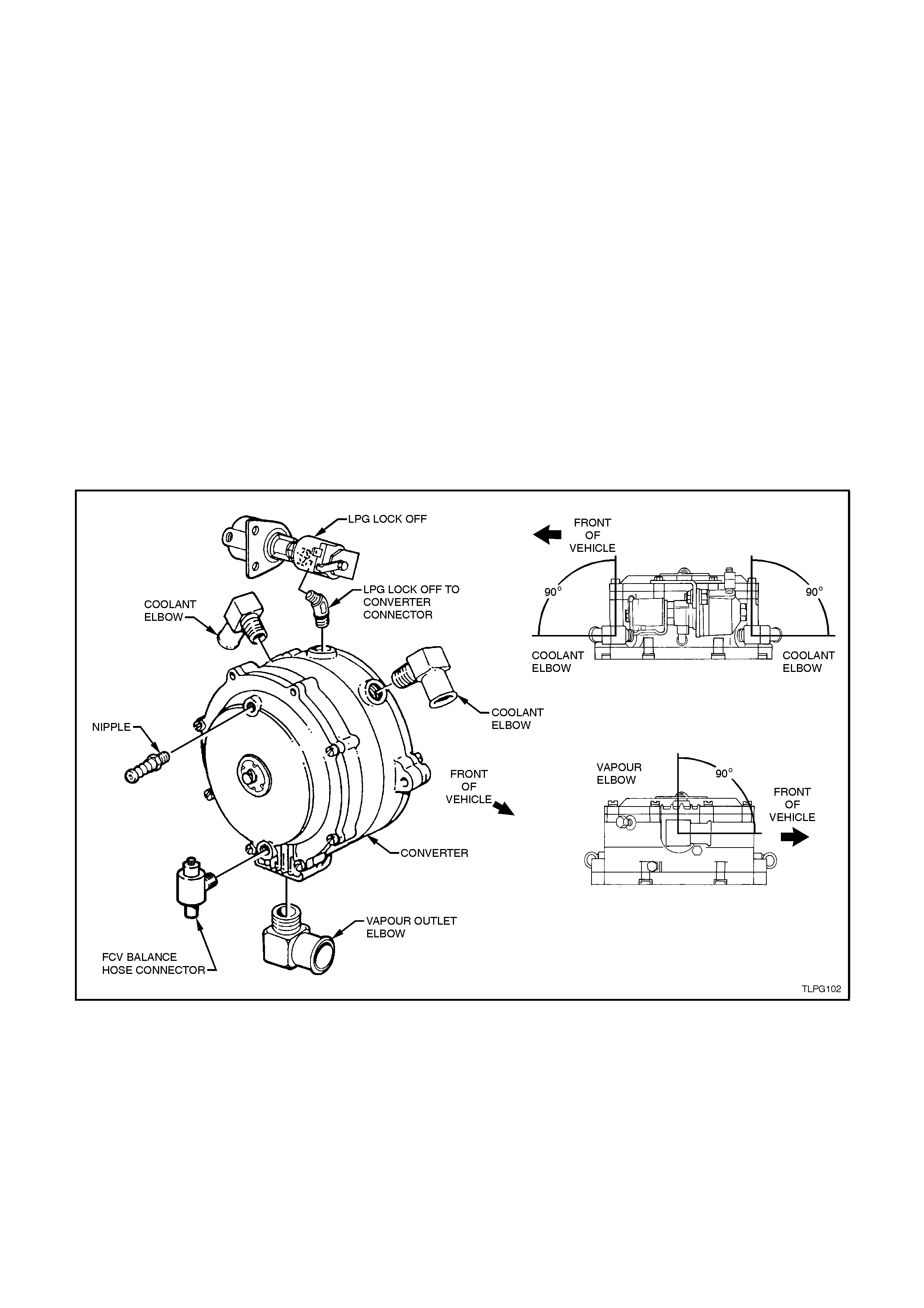

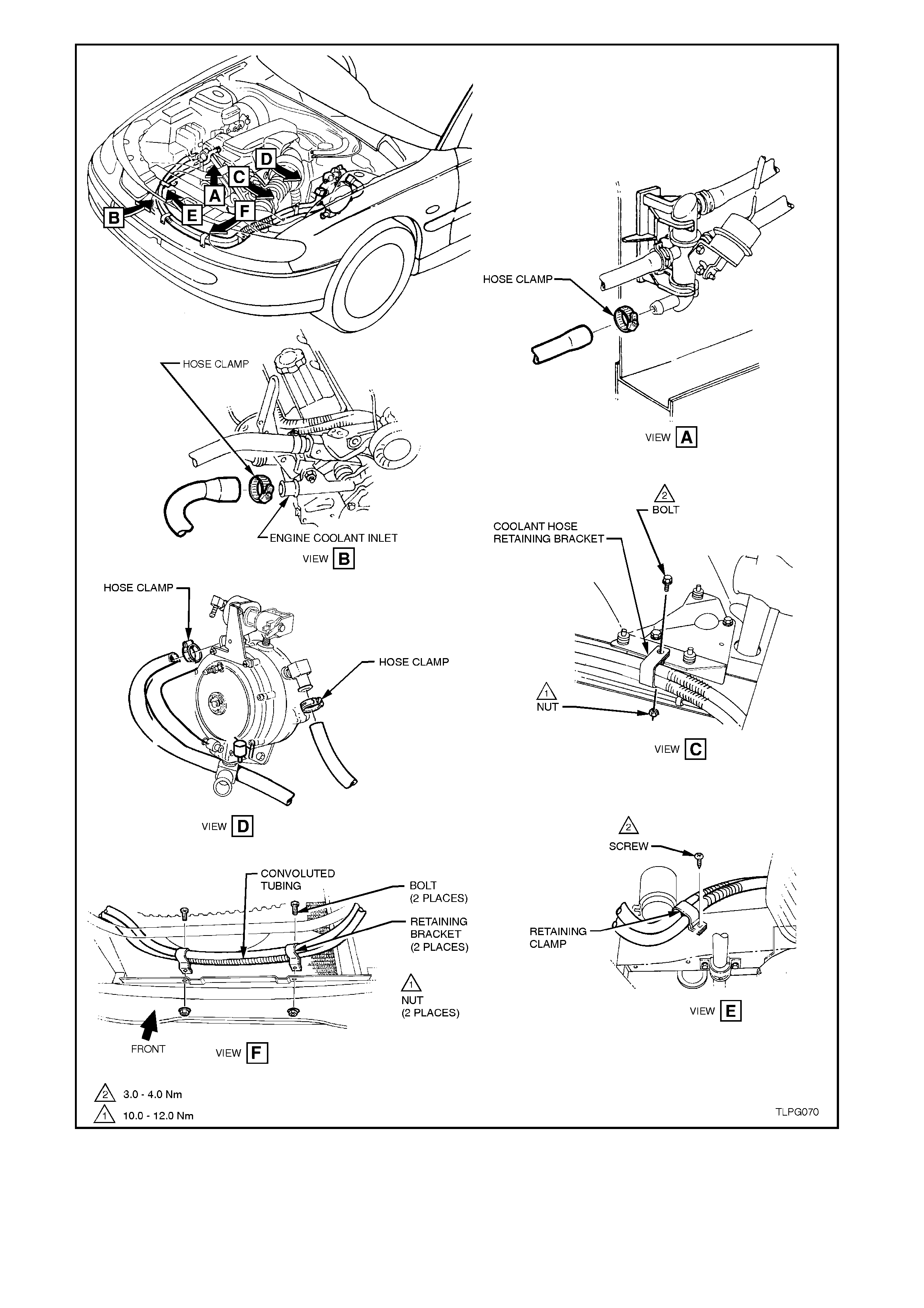

REINSTALL

Reinstallation of the converter is the reverse of the

removal procedure, noting the following points:

1. If removed, ensure that the engine coolant

inlet and outlet elbows, vapour outlet, FCV

balance hose connection threads and

converter mating threads are clean.

Apply Loctite 567 sealant to coolant and

vapour elbow threads and tighten these

elbows to positions shown in Fig. 2-106.

2. Ensure that the LPG lockoff to converter

connector and front service line to lockoff

connector mating threads are clean.

If removed, also clean LPG lockoff connector

and LPG lockoff mating threads.

Apply Loctite 577 sealant to LPG lockoff

connector ensuring that flared surfaces are

free of sealant and contaminants. Install LPG

lockoff connector to LPG lockoff and tighten

securely.

Install LPG lockof f to the converter and tighten

securely and if necessary, further tighten it so

as to align it with the retaining bracket.

Figure 2-106

3. Tighten all fasteners to the correct torque

specification

LOCKOFF BRACKET

TO CONVERTER

ATTACHING SCREW

TORQUE SPECIFICATION

3.0 - 5.0

Nm

CONVERTER RETAINING BOLT

TO SUPPORT BRACKET

TORQUE SPECIFICATION 10.0 - 12.0 Nm

HEAT SHEILD SUPPORT BOLT

TO SUPPORT BRACKET

TORQUE SPECIFICATION 10.0 - 12.0 Nm

HEAT SHEILD RETAINING

SCREW TO HEAT

SHEILD SUPPORT BOLT

TORQUE SPECIFICATION

3.0 - 5.0

Nm

4. Apply Loctite 577 to lockoff connector and

tighten front service line to LPG lockoff

connector to the correct torque specification.

FRONT SERVICE LINE

CONNECTOR TO LPG LOCKOFF

TORQUE SPECIFICATION 12.0 - 15.0 Nm

5. Leak test LPG system, refer

2.3 LEAK TESTING in this Section.

6. Refill cooling system with coolant to the

correct concentration level, refer

2.3 CHECKING AND FILLING COOLING

SYSTEM, and pressure test the system, refer

2.7 PRESSURE TESTING.

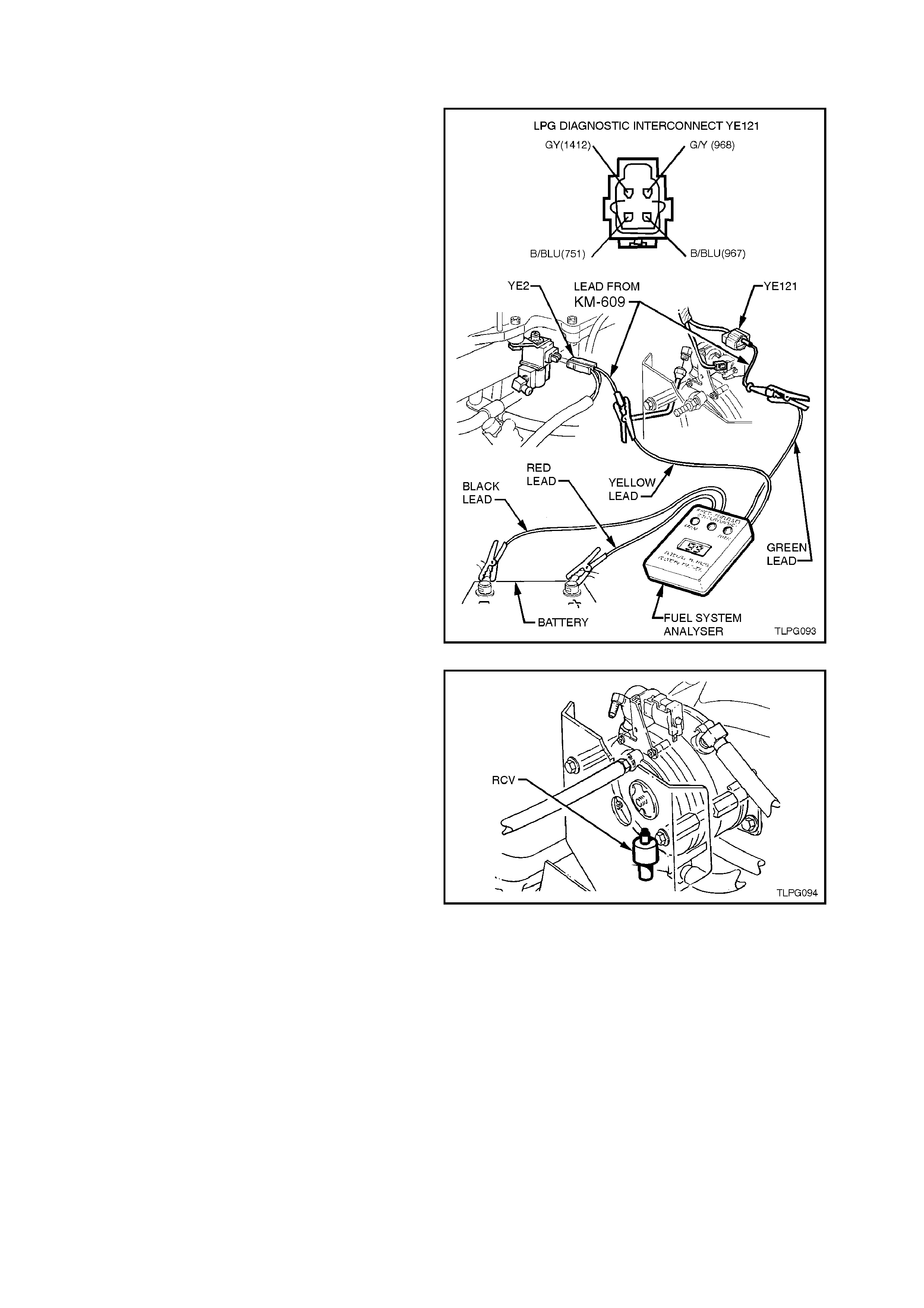

2.16 REGULATOR CHECK VALVE (RCV )

TEST

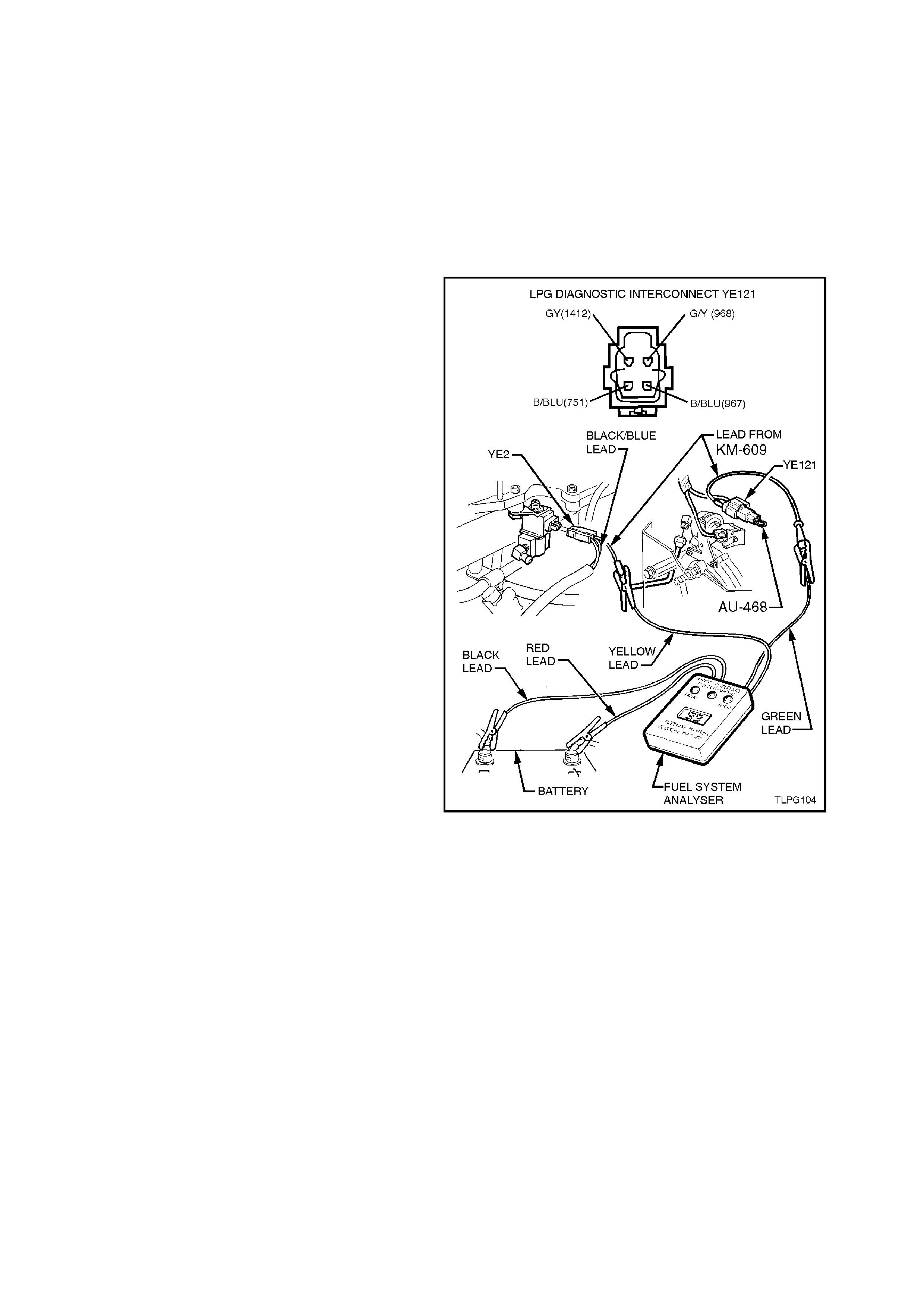

1. Connect the black lead of the Fuel System

Analyser (FSA) to the negative battery

terminal.

NOTE:

The black lead of the FSA should be the first lead

connected and the last lead disconnect.

2. Connect the red lead of the FSA to the batter y

positive terminal.

3. Using an appropriate connecter lead from KM-

609, connect the green lead from the FSA to

the LPG diagnostic interconnect, YE121, grey

wire (circuit 1412), refer to Fig. 2-107.

4. Using an appropriate connecter lead from KM-

609, back probe FCV wiring harness

connector YE2, black/blue wire (circuit 1062)

and connect it to the yellow lead from the F SA,

refer to Fig. 2-107.

NOTE:

The FSA should display 99. If the FSA does not

display 99, check FSA connections to the battery,

FCV and diagnostic interconnect connector. If

these connections are okay and the FSA has no

display, the FSA is faulty.

Figure 2-107

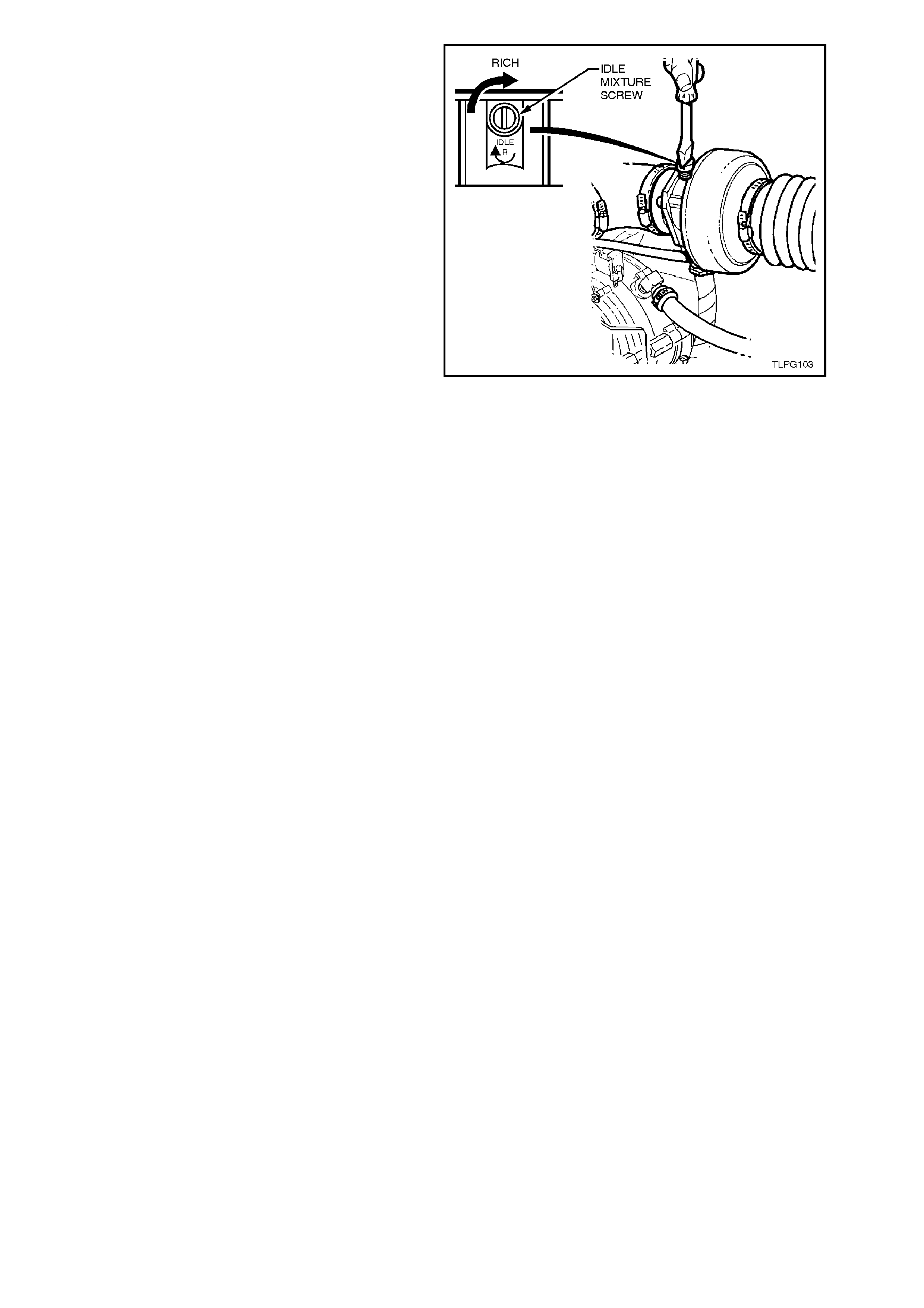

5. Start the engine and take note of the duty

cycles displayed on the FSA.

6. Place a finger over the RCV atmospheric port

(large opening) and take note of the duty

cycles displayed on the FSA, refer to Fig. 2-

108.

There should be little or no change in the duty

cycle.

7. Place a 3/8” inside diameter hose over the

RCV atmospheric port (large opening). Apply a

small amount of air pressure to the open end

of the hose ( physically blow through hose) and

take note of the duty cycles displayed on the

FSA.

If duty cycles do not change, it indicates the

RCV is not opening as requir ed and should be

replaced.

Figure 2-108

REMOVE

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the service lines of LPG, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

Figure 2-109

4. If necessary, remove the two screws securing

the heat shield to the converter heat shield

support bolts and remove heat shield.

5. Unscrew the RCV from the converter.

REINSTALL

Reinstallation of the RCV is the reverse of the

removal procedure.

Figure 2-110

2.17 FUEL CONTROL VALVES

REMOVE

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the service lines of LPG, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

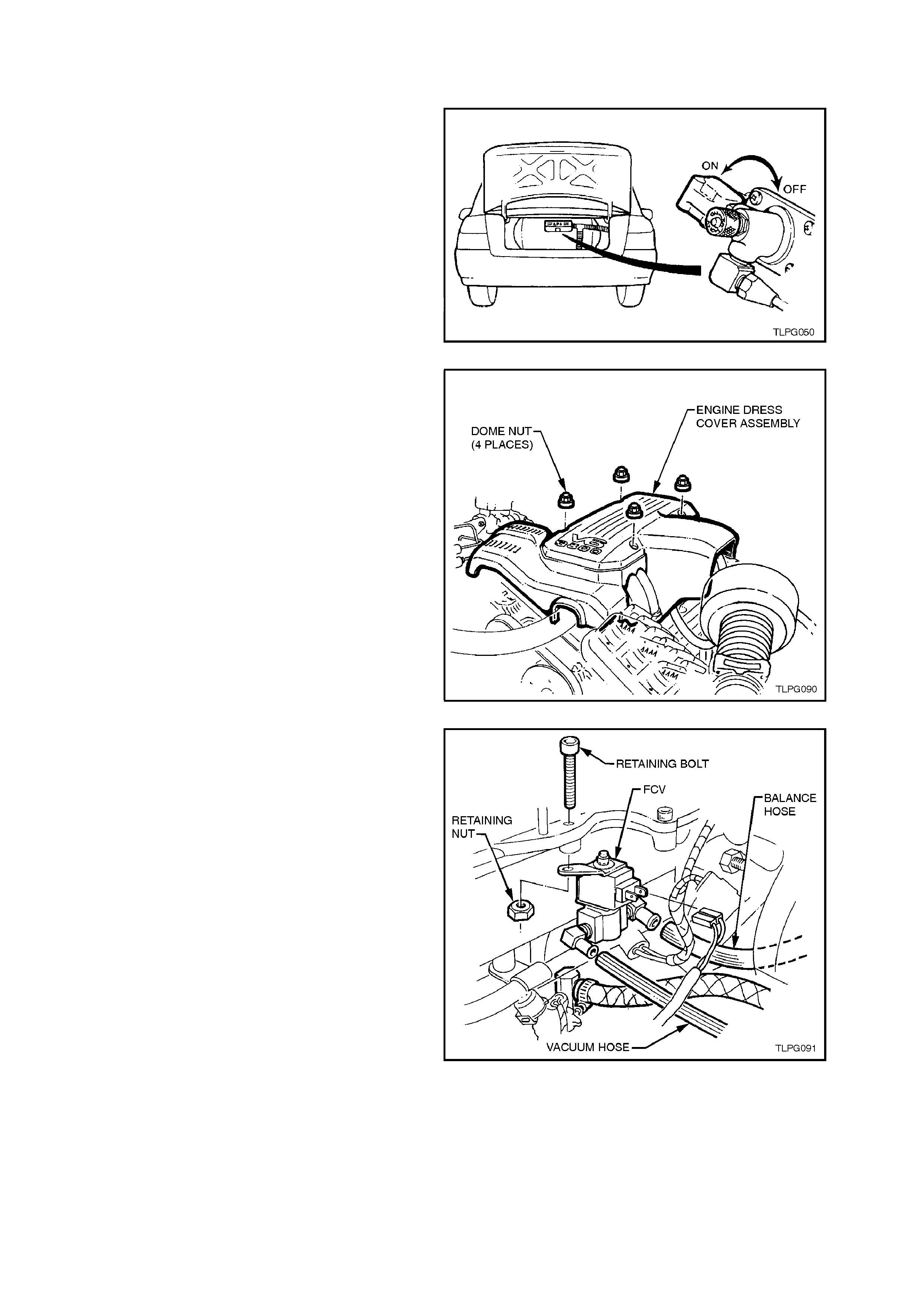

Figure 2-111

4. Remove the four nuts securing the engine

dress cover and remove cover.

Figure 2-112

5. Disconnect LPG wiring harness connector

from FCV, refer to Fig. 2-113 in this Section.

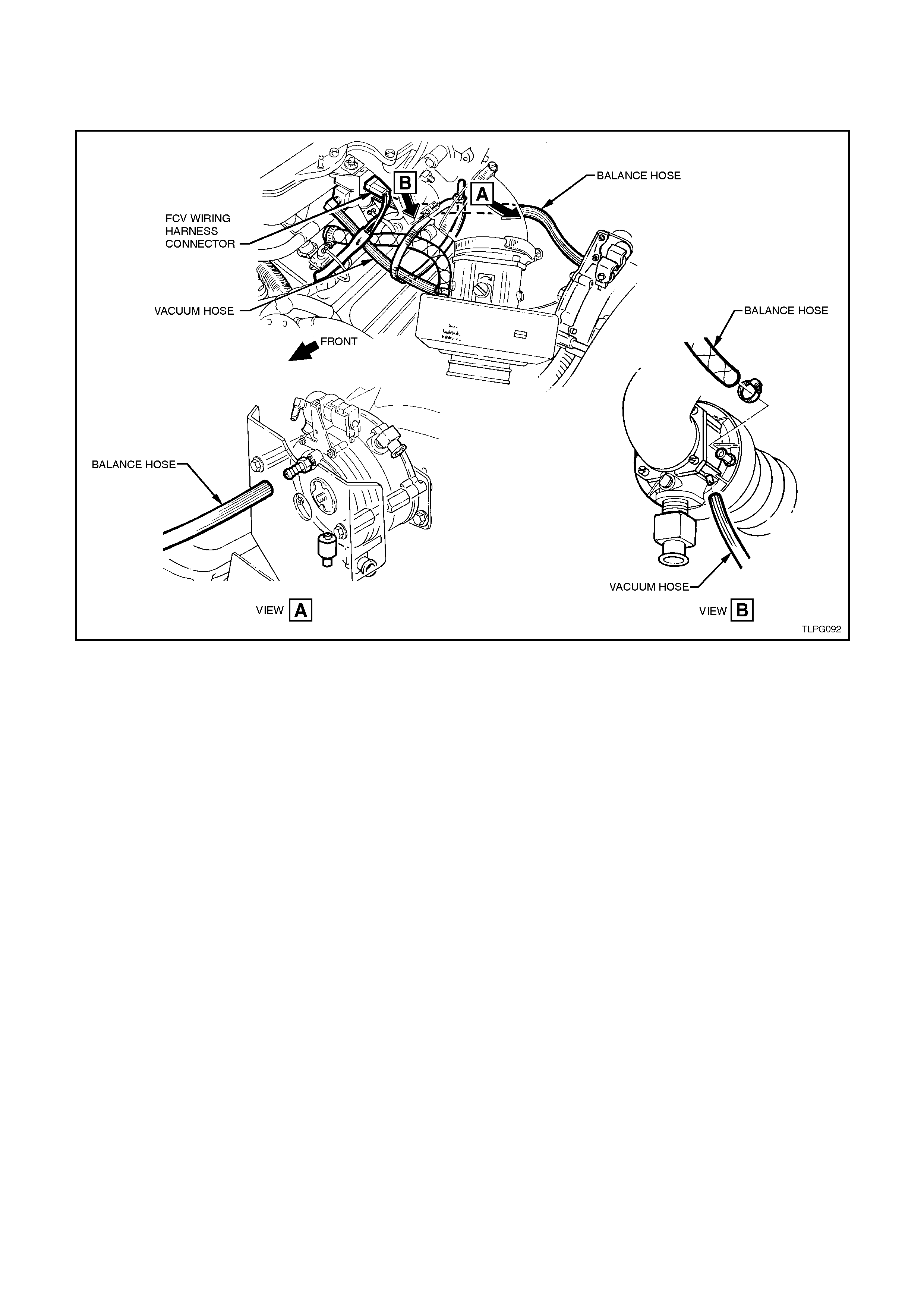

6. Remove balance hos e and vacuum hose f rom

FCV.

7. Loosen and remove FCV retaining bolt and nut

and remove FCV.

Figure 2-113

TEST

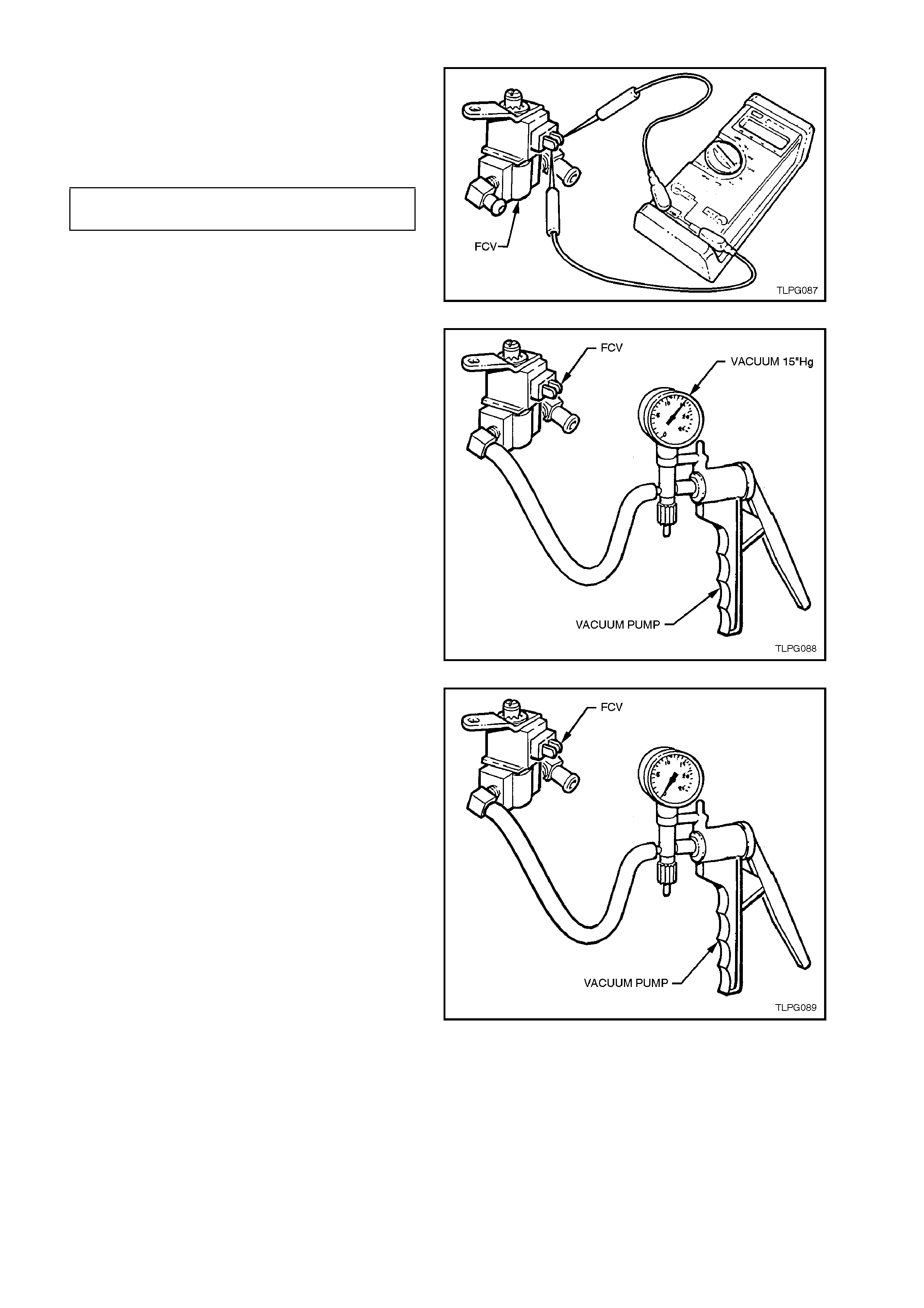

1. Connect an Ohmmeter to coil terminals of

FCV, refer to Fig. 2-114.

If the coil resistance of the FCV is not as

specified, the fuel control valve should be

replaced.

FUEL CONTROL VALVE 20 - 28 OHMS

COIL RESISTANCE @ 20°C

Figure 2-114

2. Connect a vacuum pump such as Tool No.

J23738-A, to the vacuum connector of the fuel

control valve assembly, refer Fig. 2-115.

3. Operate the vacuum pump until 15 inches Hg.

of vacuum is applied to the FCV.

Figure 2-115

4. Note the time taken for the vacuum to bleed

off through the FCV.

If 15 inches Hg. Of vac uum cannot be c r eated,

or the bleed off time is less than three to five

seconds, then the FCV should be replaced.

Figure 2-116

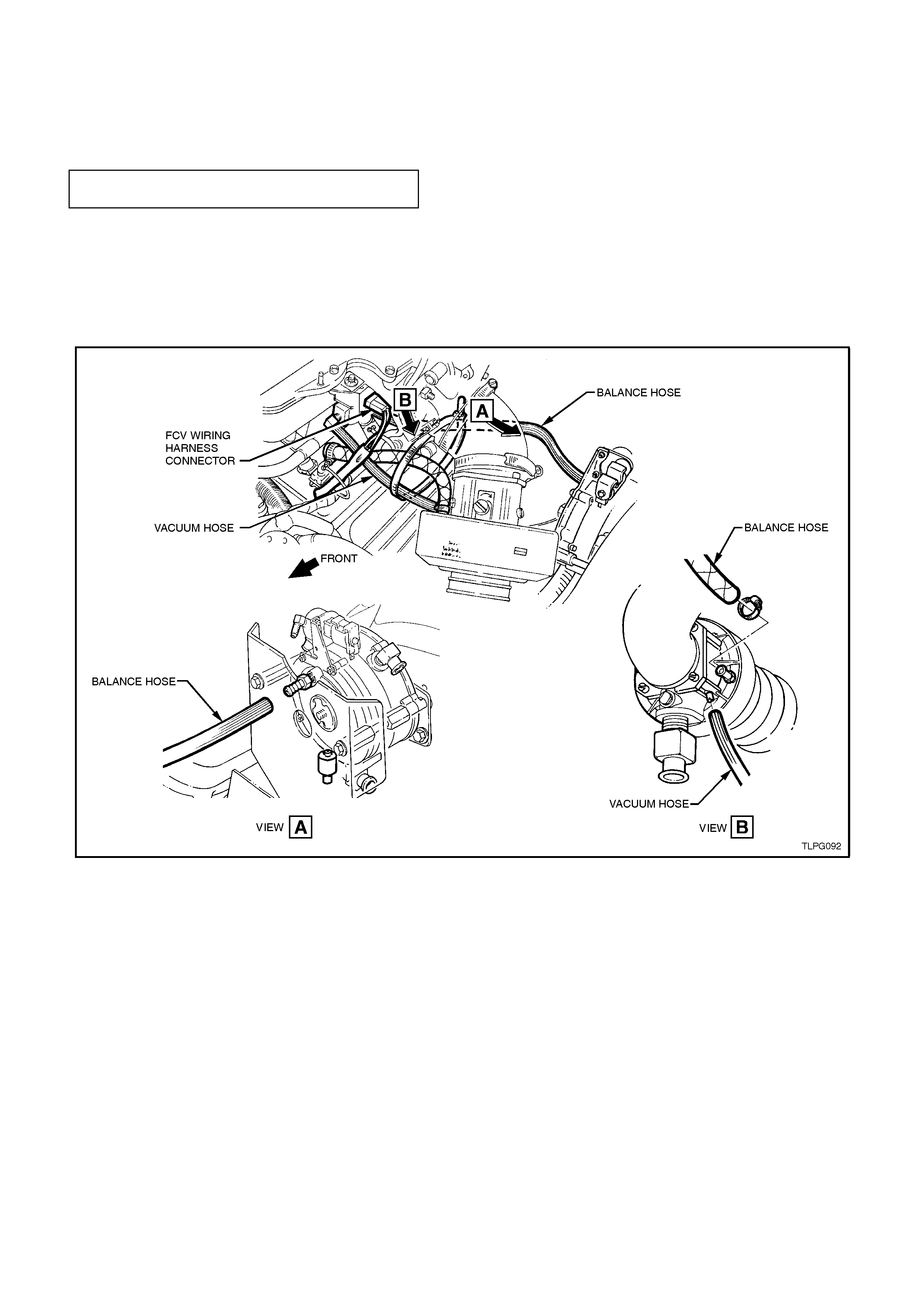

REINSTALL

Reinstallation of the FCV is the reverse of the

removal procedure noting the following:

1. Ensure FCV retaining nut is tightened the to

the correct torque specification.

FCV RETAINING NUT

TORQUE SPECIFICATION 3.0 - 5.0

Nm

2. Ensure hoses are routed correctly, refer to

Fig.

2-117 .

3. Connect LPG wiring harness connector to

FCV, ensuring that it is routed correctly, refer

Fig. 2-117 in this Section.

Figure 2-117

2.18 MIXER

TEST

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the service lines of LPG, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

Figure 2-118

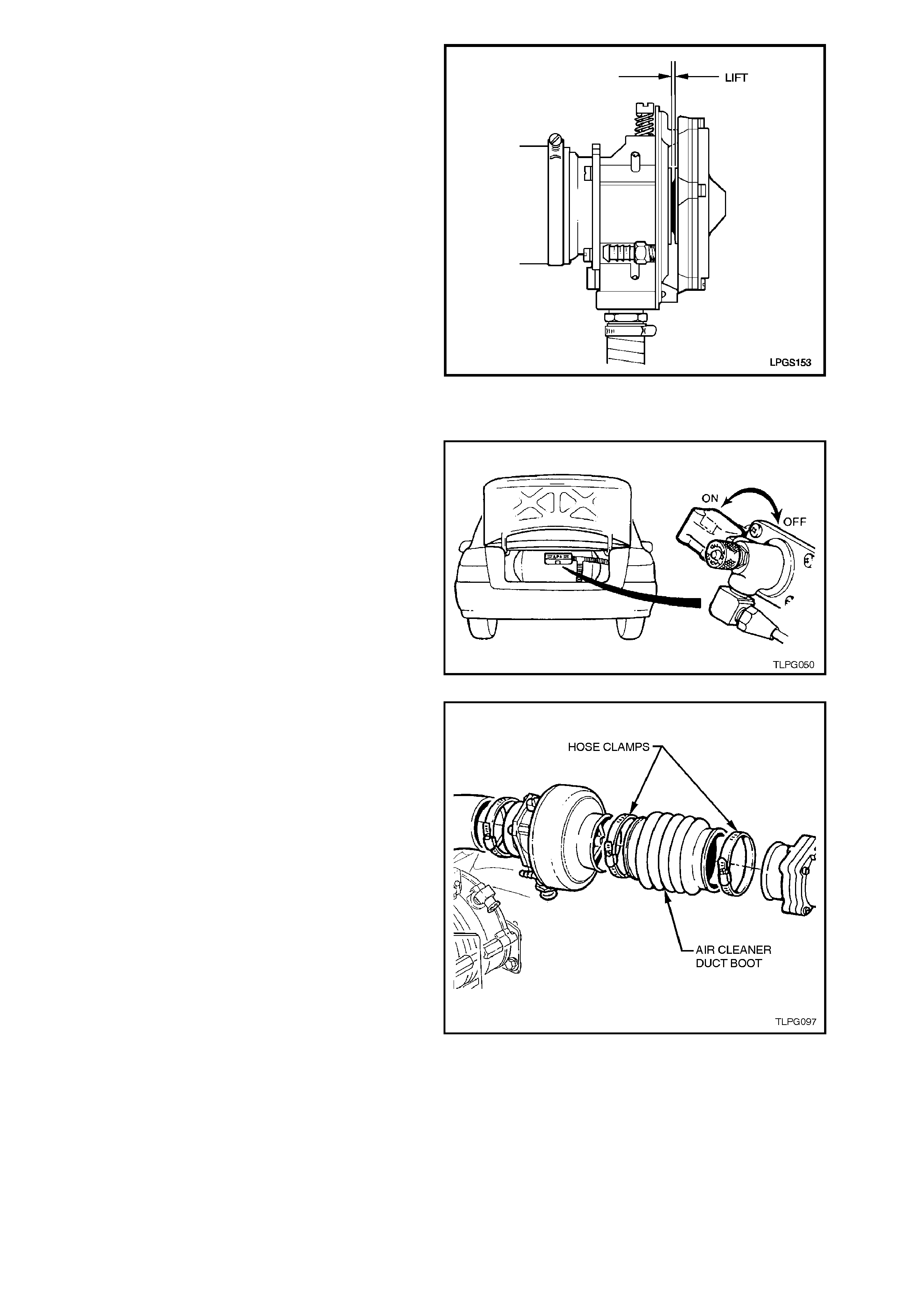

4. Loosen clamps on either end of air duct boot,

between mixer and MAF sensor, remove air

duct boot.

Figure 2-119

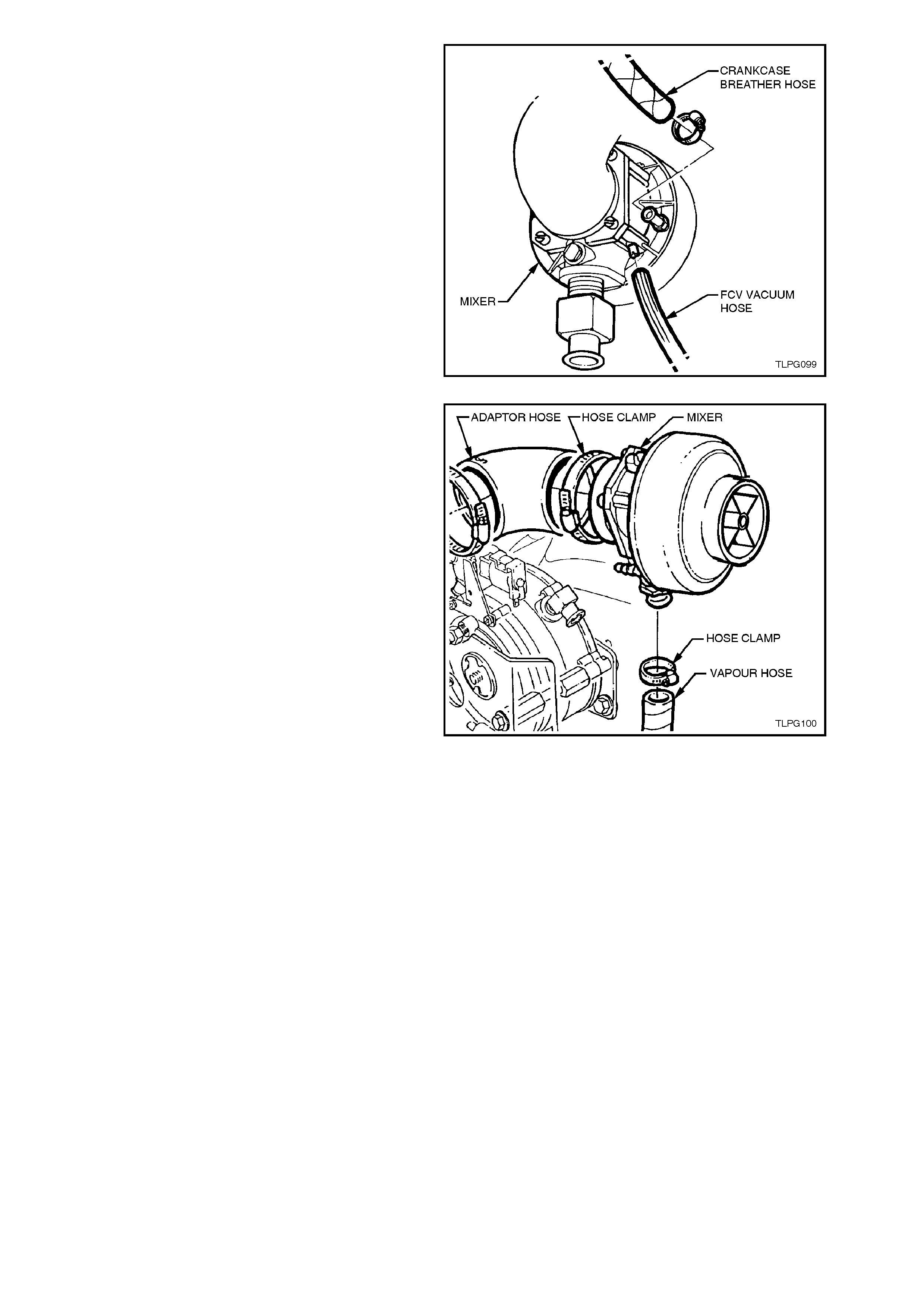

5. Loosen and remove bell housing to air valve

cover attaching bolt and separate bell housing

and gasket from mixer body.

Figure 2-120

6. With fuel mode switch in 'PETROL' position

start engine and allow to idle.

7. Observe mixer diaphragm position. Diaphragm

should lift slightly as engine is cranked. Also,

diaphragm lift should increase as engine RPM

is increased.

8. If diaphragm does not lift as RPM increases,

check for vacuum leaks between mixer and

throttle body. If no vacuum leaks, overhaul

mixer, refer 2.18 MIXER - OVERHAUL this

Section.

Figure 2-121

REMOVE

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the service lines of LPG, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

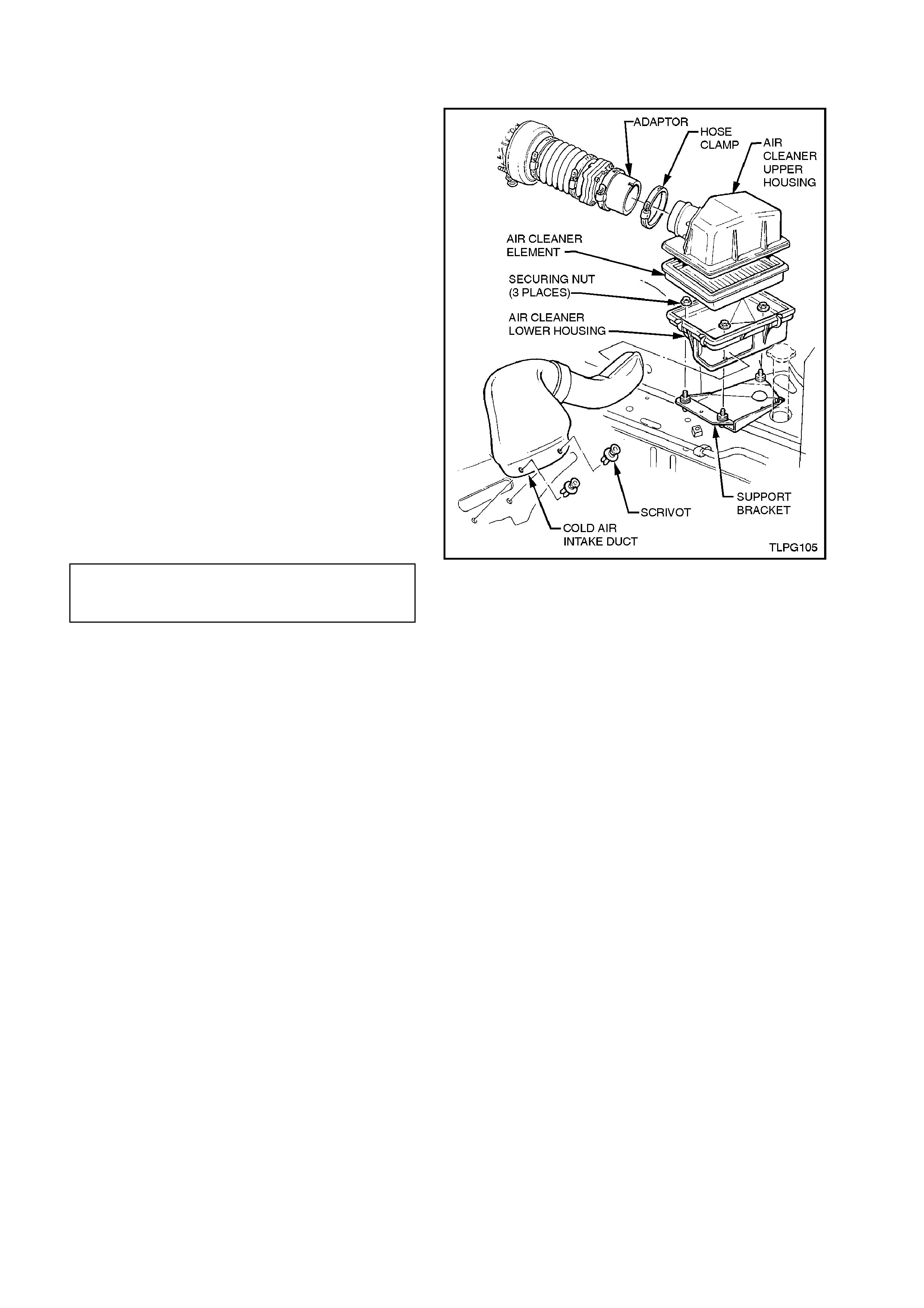

Figure 2-122

4. Loosen clamps on either end of air duct boot,

between mixer and MAF sensor, remove air

duct boot.

Figure 2-123

5. Disconnect the FCV vacuum supply hose and

crankcase breather hose from the mixer

assembly connector.

Figure 2-124

6. Loosen the air cleaner duct boot and adaptor

hose clamps at the mixer ends.

Pull the air cleaner duct boot from the mixer

and then pull the mixer from the adaptor hose.

7. Loosen vapour hose to mixer inlet clamp and

disconnect vapour hose.

Figure 2-125

OVERHAUL

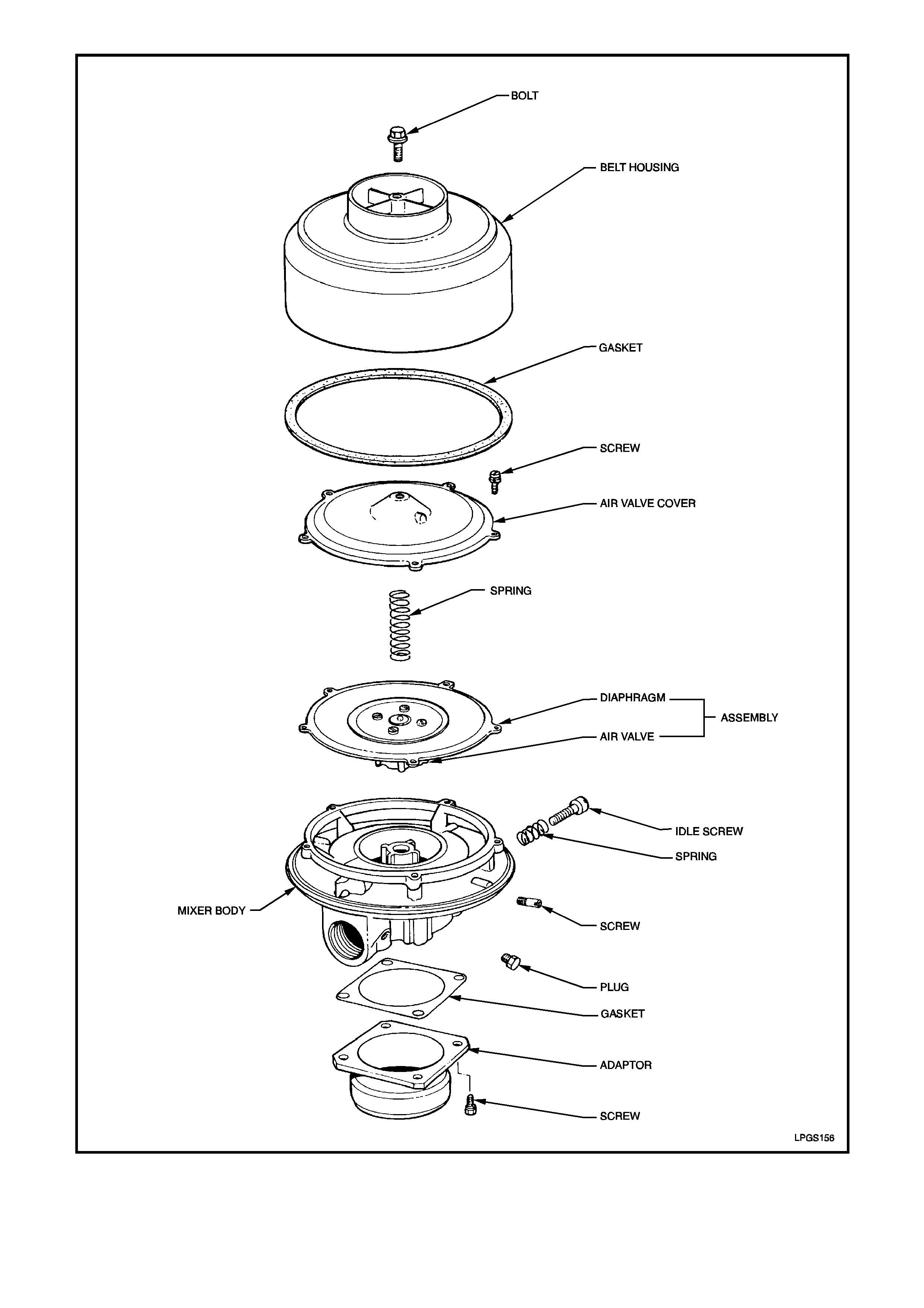

For identification of the various parts within the

mixer assembly refer to Figure 2-126.

NOTE 1:

There is no repair kit available for the mixer

overhaul procedure. All mixer components are

available separately, refer to the latest VT Parts

Information for details.

NOTE 2:

The mixer and components for the mixer on VT

Series Models are not interchangeable with

components from previous models.

Figure 2-126

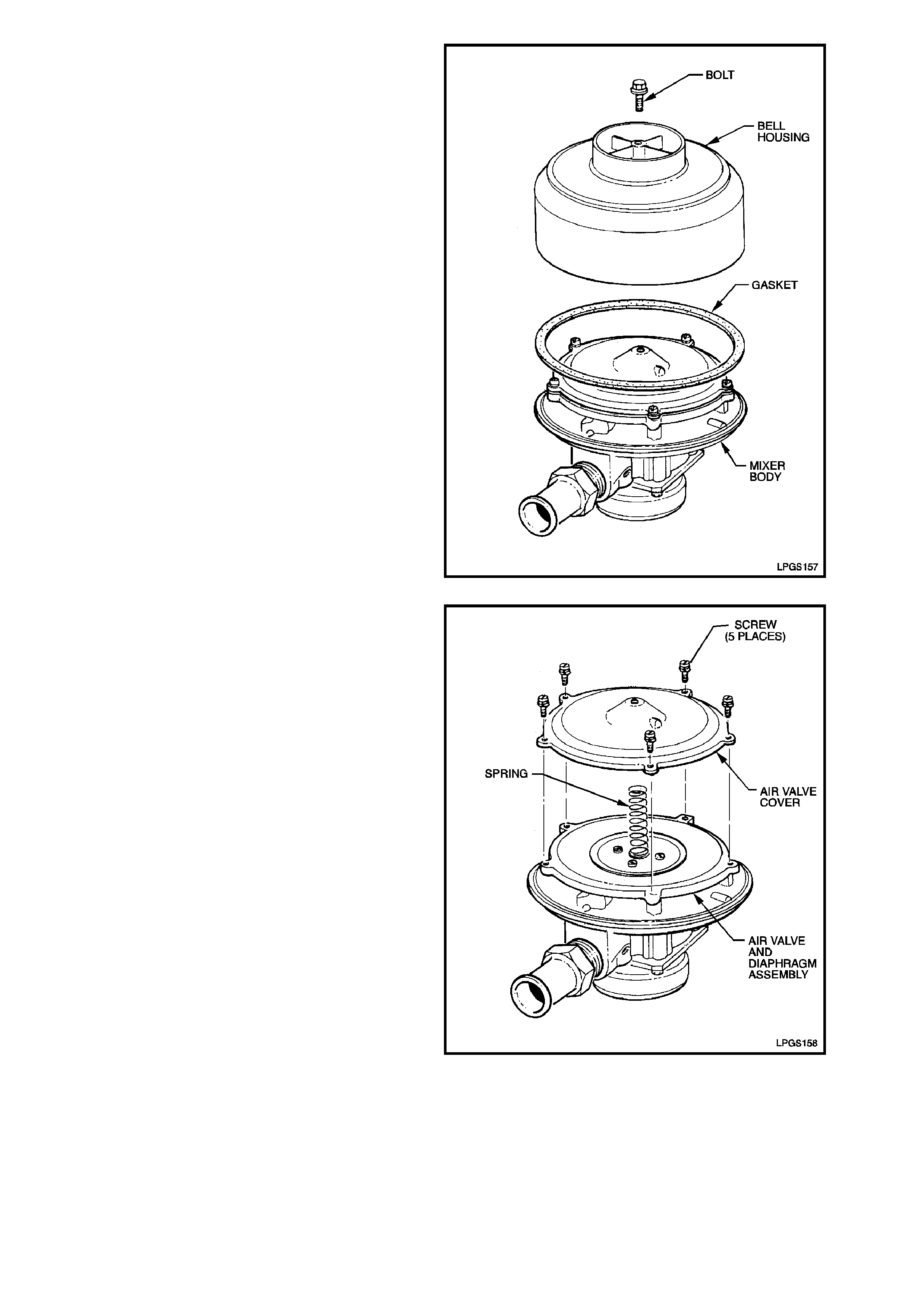

1. Loosen and remove bell housing to air valve

cover attaching bolt and separate bell housing

and gasket from mixer body.

Figure 2-127

2. Remove the five air valve cover to mixer body

attaching screws and remove air valve cover

from mixer body.

Remove spring, diaphragm and air valve

assembly from mixer body.

Check condition of diaphragm and spring for

wear or damage and replace if necessary.

Figure 2-128

3. Clean all parts in a suitable cleaning solution

and inspect condition.

4. If the air valve was removed from the

diaphragm, reassemble the air valve to the

diaphragm ensuring that the air valve r ing is in

position between the air valve and the

diaphragm.

AIR VALVE TO DIAPHRAGM

ATTACHING SCREW 2.0 - 2.5 Nm

TORQUE SPECIFICATION

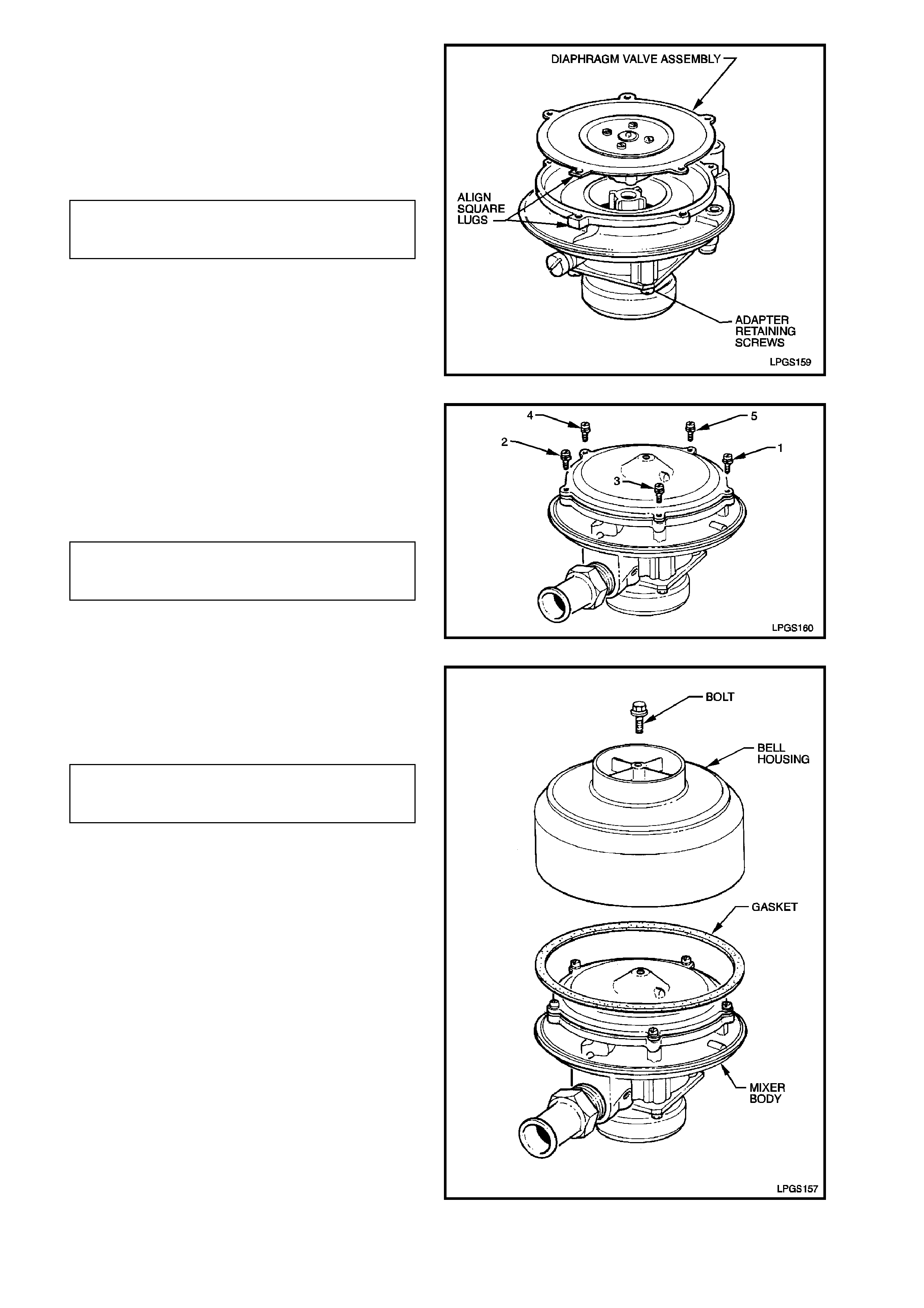

5. Place the diaphragm and air valve assembly

into the mixer body ensuring that the

diaphragm locating square lug is aligned with

the square locating lug on the mixer body.

Figure 2-129

6. Locate the spring onto the diaphragm and

install the air valve cover assembly to the

mixer body.

7. Install the five air valve cover to mixer body

attaching screws and tighten in the sequence

shown to the correct torque specification.

AIR VALVE COVER TO MIXER

BODY ATTACHING SCREW 7.5 - 9.0 Nm

TORQUE SPECIFICATION

Figure 2-130

8. Install new bell housing to mixer body gasket

onto mixer body. Locate bell housing onto

mixer body and install attaching bolt and

tighten to the correct torque specification.

BELL HOUSING TO AIR VALVE

COVER ATTACHING BOLT 1.0 - 3.0 Nm

TORQUE SPECIFICATION

Figure 2-131

REINSTALL

Reinstallation of the mixer is the reverse of the removal procedure noting the following point:

1. Ensure that FCV vacuum hose is routed correctly and connected to the mixer connections, refer Fig. 2-132 in

this Section.

Figure 2-132

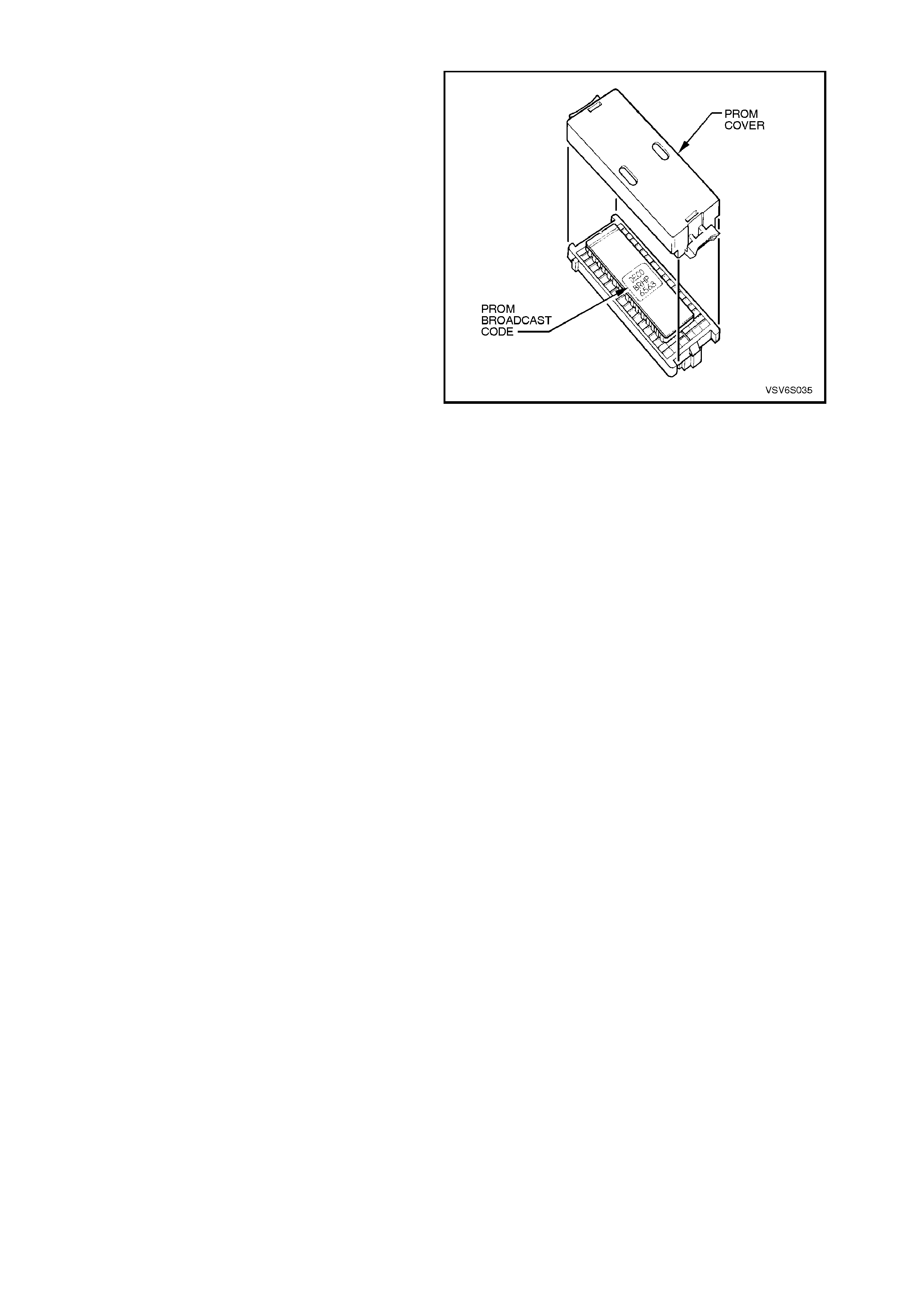

2.19 PROM

A specific PROM is used in the PCM for vehicles

fitted with option KL7, LPG system. For

identification, refer Fig. 2-133.

NOTE :

At time of publication, the PROM broadcast code

for vehicles with LPG was BWLR (TECH 2

identification 1278), however, when PROM

identification is necessar y, ref erence should always

be made to the latest service literature.

REPLACE

For details of PROM replacement refer to

Section 6C1-3 SERVICE OPERATIONS - V6

ENGINE.

Figure 2-133

2.20 ADAPTIVE DIGITAL PROCESSOR

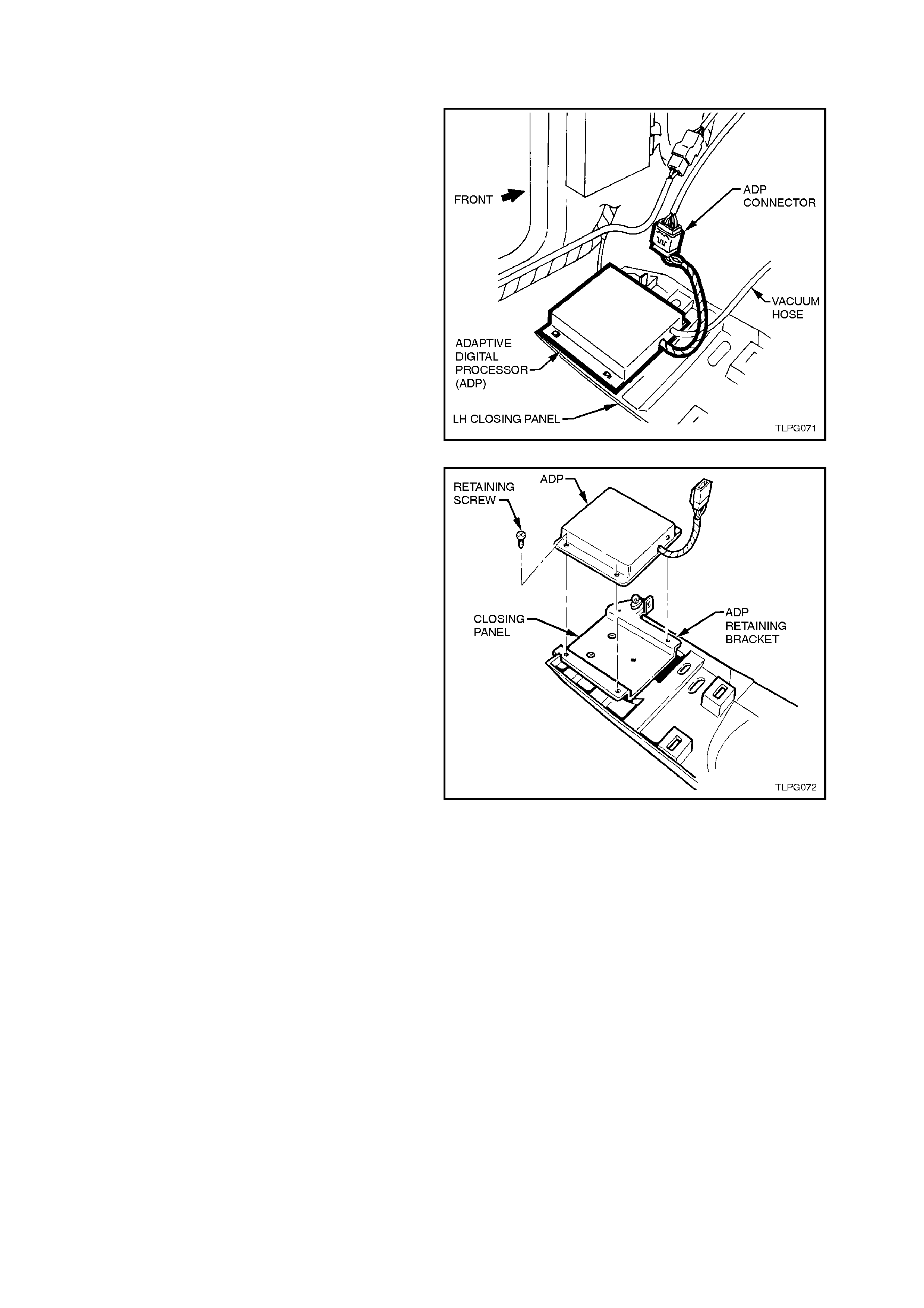

REMOVE

1. Disconnect battery earth lead.

2. Lower LHF instrument panel lower closing

panel, refer to Section 1A3 INSTRUMENT

PANEL AND CONSOLE.

3. Disconnect LPG body harness ADP connec tor

from ADP.

4. Disconnect vacuum line from ADP connection.

Figure 2-134

5. Remove the four ADP to ADP retaining

bracket attaching screws and remove ADP.

REINSTALL

Reinstallation of the ADP is the reverse of the

removal procedure.

Figure 2-135

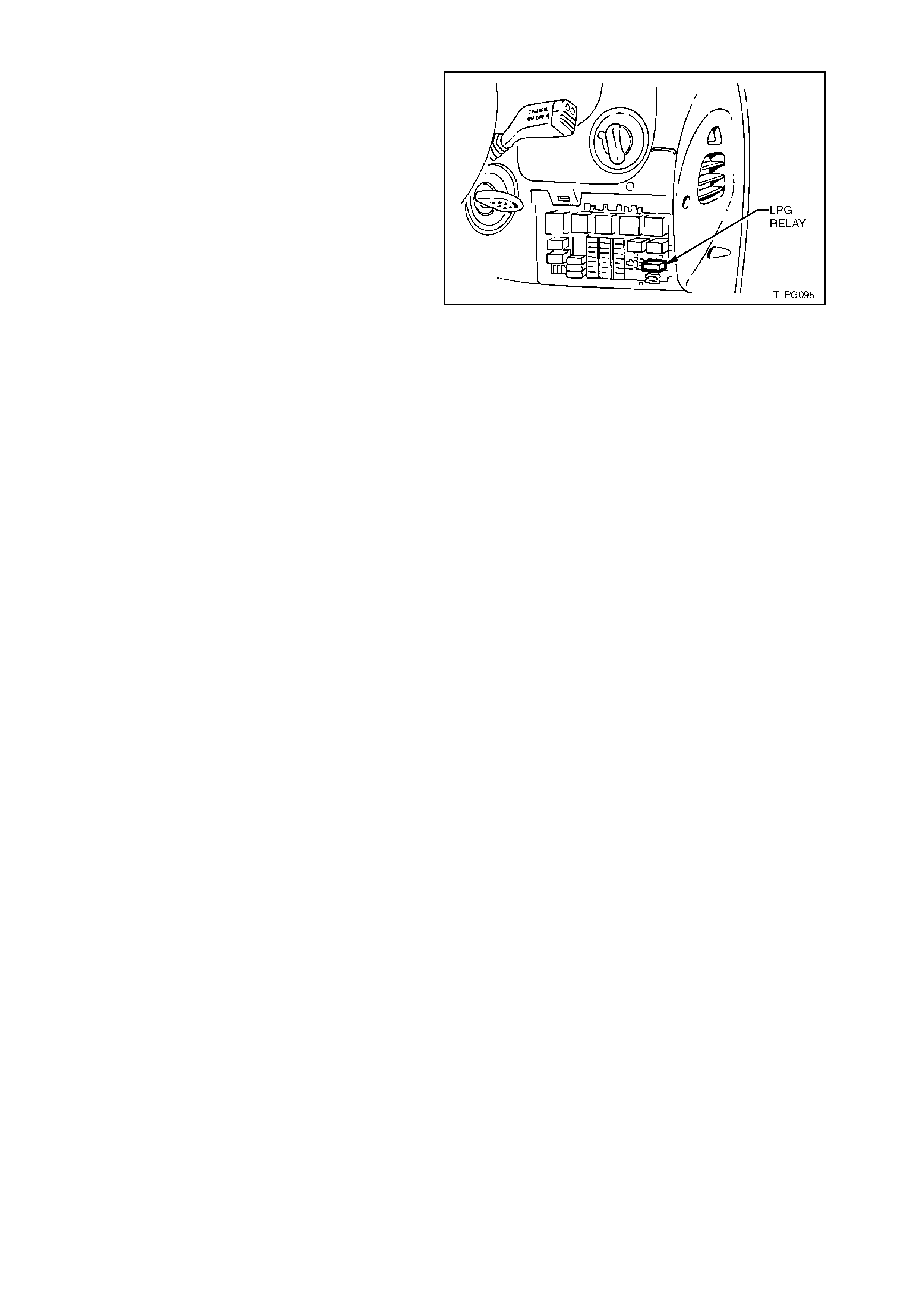

2.21 LPG RELAY

Figure 2-136 shows the location of the LPG relay

(located inside the vehicle, attached to the fuse

panel).

Access to the relay / fuse panel is by lowering the

instrument panel right hand cover assembly. Refer

to Section 1A3 INSTRUMENT PANEL for the

procedure on how to remove this cover.

Figure 2-136

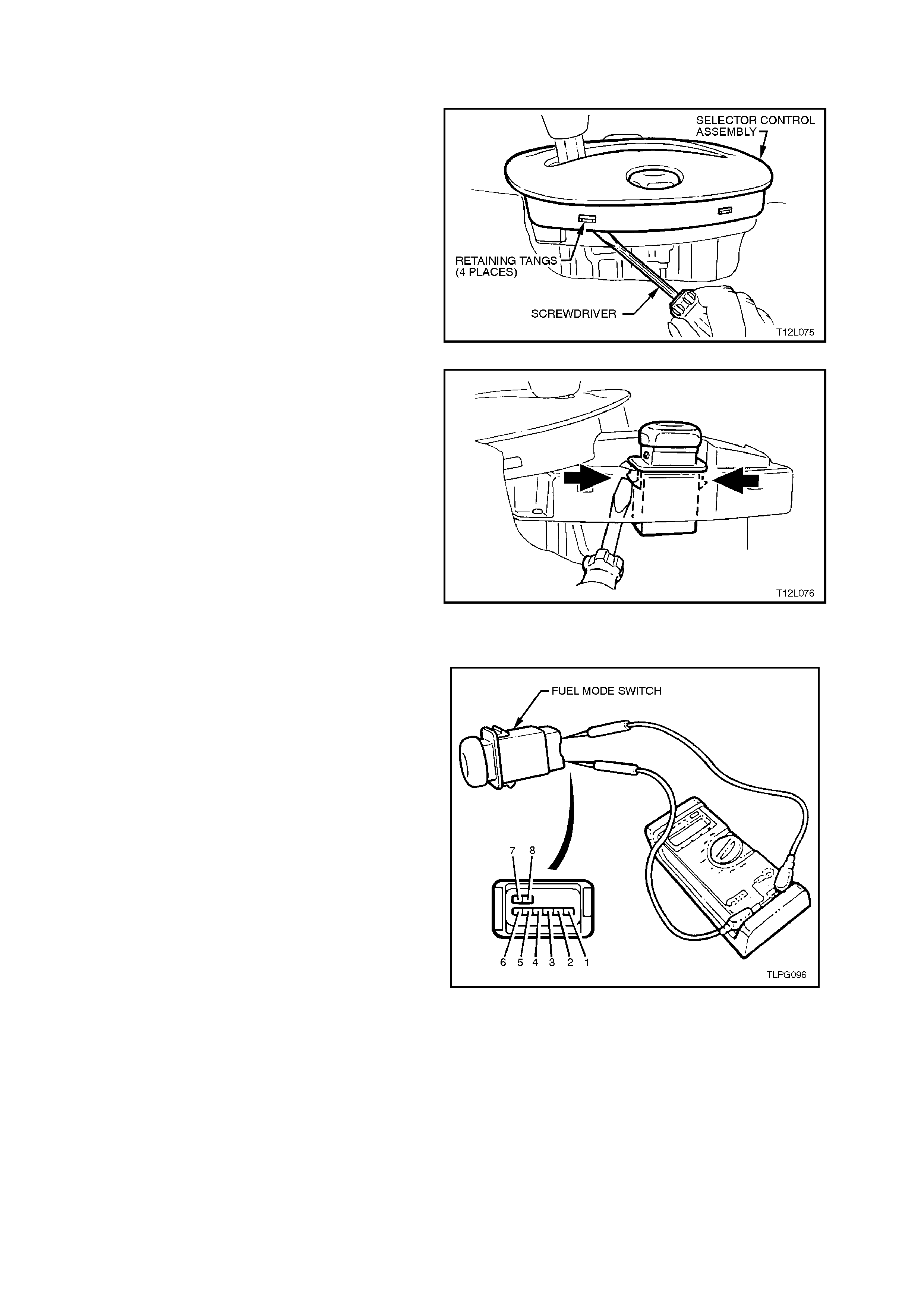

2.22 FUEL MODE SWITCH

REMOVE

1. Remove centre console assembly, refer to

Section 1A3 INSTRUMENT PANEL AND

CONSOLE.

2. Pry shift indicator away from retaining tangs on

selector control assembly and move shift

indicator forward (move shift indicator as far

forward as possible with shift selector lever still

installed) to allow switch to be removed

upwards from selector control assembly.

Figure 2-137

3. From under top of selector control assembly,

using a screw driver, push retaining tangs on

the fuel control switch inward while pushing

switch up and remove.

4. Disconnect wiring harness connector and

remove switch.

Figure 2-138

TEST

Using an ohmmeter connected to the fuel mode

switch, check for continuity between the following

terminals with the switch held IN:

Ter. 1 and Ter. 2

Ter. 1 and Ter. 5

Ter. 2 and Ter. 5

If the ohmmeter indicates an open circuit, replace

the switch assembly.

REINSTALL

Installation of the fuel m ode switch is the r everse of

the removal operation.

Figure 2-139

2.23 ADAP TIVE DIGITAL PROCESSOR SET-UP PROCEDURE

GENERAL INFORMATION

The Adaptive Digital Processor (ADP) controls the

air fuel ratio while the engine is operating on LPG.

The ADP must go through a learning process to

update the operational cells within its m emor y. The

ADP memory clearing, ADP initialisation, idle

mixture adjustment and adaptive learn drive cycle

must be carried out as outlined as follows, to

ensure correct operation of the LPG system.

NOTE:

The following procedures must be carried out

when any LPG system component (mixer,

converter, FCV and ADP) has been replaced or

overhauled, or when the engine assembly has

been replaced or overhauled. This is because

the values stored in the ADP operational cells

apply only to the previous condition of the

engine or components.

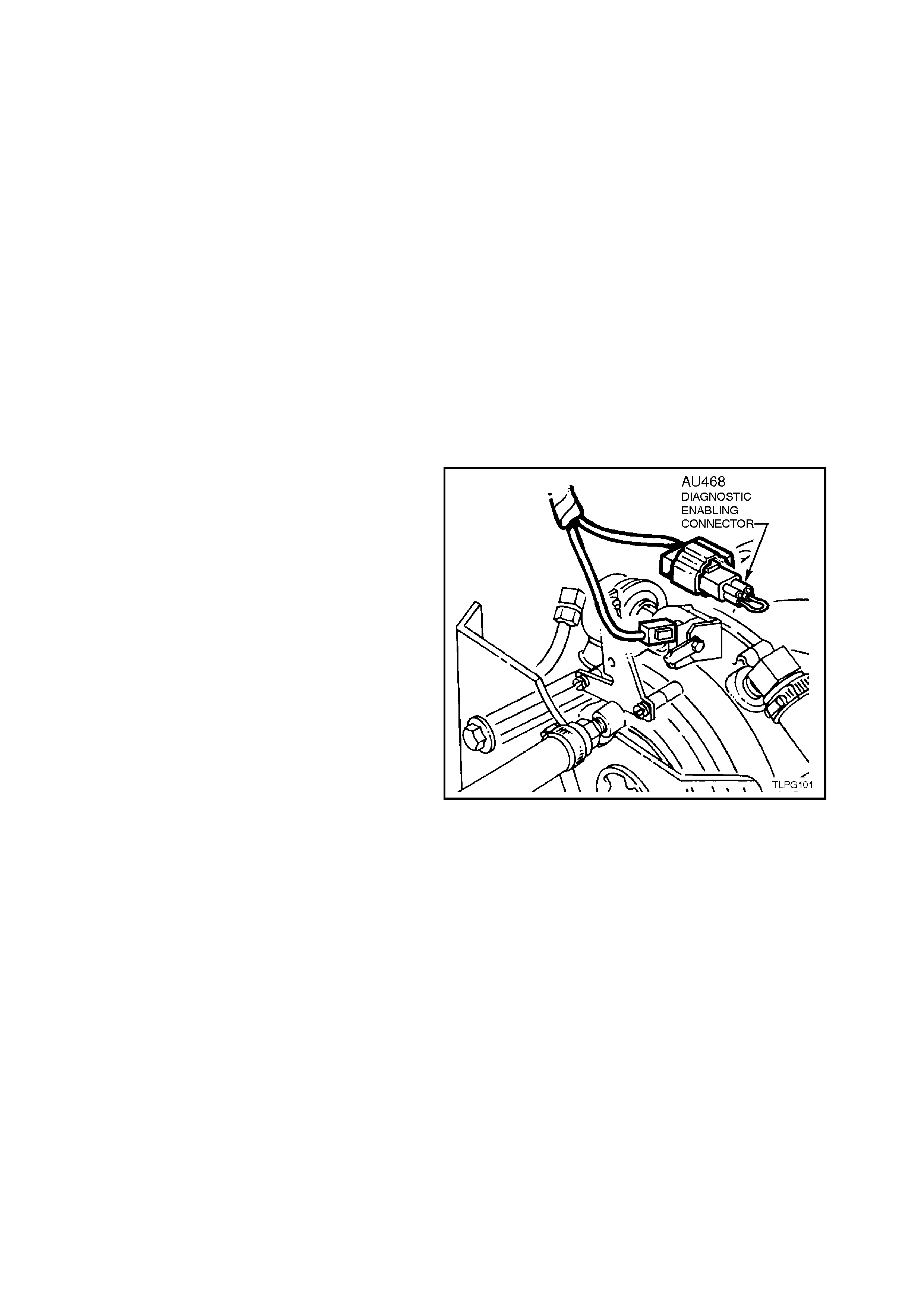

CLEARING ADP MEMORY

The ADP memory can be cleared by installing the

diagnostic enabling connector (AU 468) into the

LPG diagnostic interconnect connector, YE121

(connector located next to the LPG lockoff) while

the engine is at idle and under no load condition f or

approximately 60 seconds.

The system can then be reset by removing the

diagnostic enabling connector (AU 468) from the

LPG diagnostic interconnect, YE121 and following

the following instructions on ADAPTIVE LEARN

DRIVE CYCLE PROCEDURE.

Figure 2-140

ADAPTIVE LEARN DRIVE CYCLE PROCEDURE

Once the diagnostic enabling connector (AU 468)

is removed from the LPG diagnostic interconnect

connector, YE121 the ADP enters its fast learn

mode. The mixture control will alter as the ADP