SECTION 3A - DIAGNOSIS - VT WAGON

3. GENERAL INFORM ATION

Excluding the diagnostic procedures published in this Section, LPG system diagnosis procedures for VT Wagon

Models carr y over from those detailed in Section 3 DIAGNOSIS, under VT Sedan With Production LPG, in the VT

Series Service Information CD, noting the following:

1. Connector YR50 is only applicable to VT Sedan Models. O n VT Wagon Models, the LPG tank connec tor YR51

is used in lieu of YR50, refer to wiring diagrams in Section 12P WIRING DIAGRAMS.

2. If a diagnostic procedure requests the smart unit and solenoid valve be removed, refer to

2.8 SMART UNIT AND SOLENOID VALVE in Section 2A.

3. If a diagnostic procedure requests the fuel gauge assembly be removed, refer to 2.12 TANK FUEL GAUGE in

Section 2A.

NOTE:

Due to a change to the PCM PROM sof tware at the start of VT LPG produc tion (but af ter publication of Volume 9)

some diagnostic procedures published in the VT Series Service Information CD may lead to incorrect diagnosis.

The change to the PROM software resulted in the LPG relay being switched OFF after 3 seconds of the ignition

being switched ON (the LPG relay remains switched ON if the engine is running or being cranked).

As a result of this, the following diagnostic procedures have been r epublished to reflec t the corr ect operation of the

LPG system and can be used on VT Wagon and Sedan Models with production fitted LPG systems.

Techline

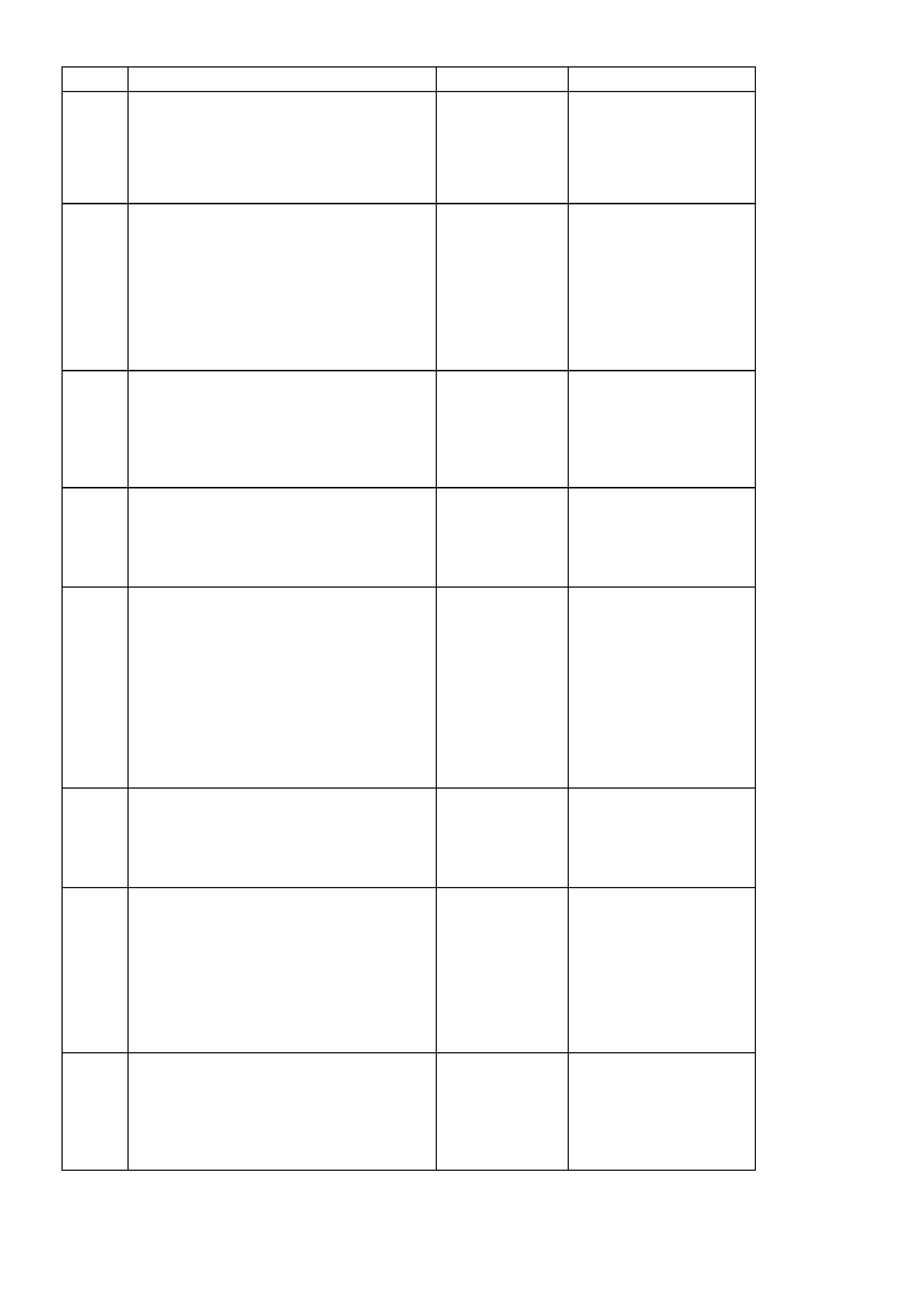

3.1 ENGINE CRANKS BUT WILL NOT START ON LPG

SHEET 1

TEST DESCRIPTION

The numbers below refer to step numbers in the following diagnostic chart.

1. The LPG VEHICLE PRELIMINARY DIAGNOSIS CHECK must be the first step when diagnosing any LPG

system problem.

2. These initial checks are designed to verify that the engine is capable of operating on LPG.

3. Voltage is supplied to the LPG lockoff from the smart unit when the ignition is first turned on and when the

engine is cranking or running. If voltage is not present at these times the lockoff will not be energised and LPG

will not flow to the converter.

4. This test confirms correct converter operation. Incorrect converter pressures can cause the engine not to start.

5. This test determines if the ADP is causing the no start condition.

6. Vacuum leaks or blockages can cause a variety of system operating problems. All hoses and vacuum lines

should be checked.

7. This test confirms correct mixer operation.

8. This test confirms correct A DP set up.

Techline

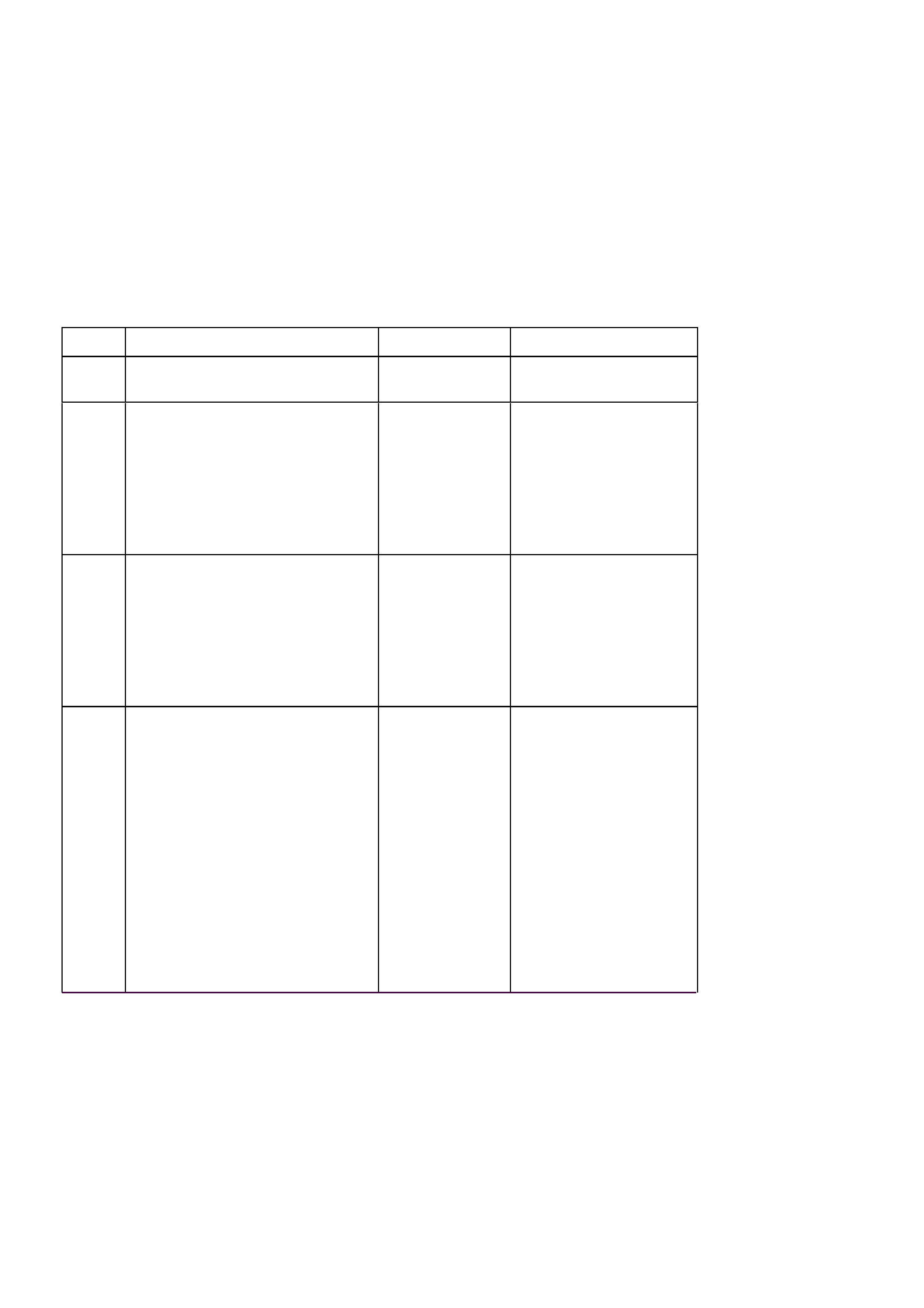

STEP ACTION YES NO

1. 1. Has an LPG VEHICLE PRELIMINARY

DIAGNOSIS CHECK been

performed?

Go to step 2. Perform an LPG

VEHICLE PRELIMINARY

DIAGNOSIS CHECK,

refer Section 3 in

VT Sedan With

Production LPG.

2. INITIAL CHECKS:

1. Has LPG been selected via the fuel

mode switch?

2. Is correct LPG PROM installed in the

PCM?

3. Is the manual service valve open?

4. Is there any LPG present in the LPG

cylinder, check contents gauge?

If yes to all,

go to Step 3. Repair any faults.

Recheck starting on LPG.

3. 1. Check for voltage at LPG lockoff

connector YE2 circuit 965 (Blue/Yellow

wire).

2. Is voltage above 9 volts for 3 seconds

when the ignition is first turned on or

while the engine is cranking?

Go to Step 4. Go to Diagnostic Chart

ENGINE CRANKS BUT

WILL NOT START ON

LPG (2) on the following

chart in this Section.

4. 1. Test for presence of LPG in system by

checking converter pressures. (Refer

2.15 CONVERTER in Section 2, of VT

Sedan With Production LPG.

2. Are converter pressures OK?

Go to Step 5. Go to Diagnostic Chart

ENGINE CRANKS BUT

WILL NOT START ON

LPG (3) in this Section.

5. 1. Ignition ON, select Petrol via the fuel

mode switch.

2. Start engine and bring to 2000 RPM.

3. Select the LPG mode via the fuel

mode switch.

4. Does the engine continue to run?

Set up ADP and

adjust LPG

mixture. Refer

2.23 ADP

SET-UP

PROCEDURE in

Section 2, of

VT Sedan With

Production LPG.

Recheck starting

on LPG.

Go to Step 6.

6. 1. Check for vacuum leaks in vacuum or

vapour feed lines between mixer and

converter, or a blocked balance line,

FCV or Regulator Check Valve.

2. Are there any leaks or blockages?

Repair vacuum

leaks or

blockages.

Recheck starting

on LPG.

Go to Step 7.

7. 1. Test mixer operation (refer 2.18

MIXER in Section 2, of VT Sedan With

Production LPG.

2. Is mixer operating correctly?

Go to Step 8. Check and repair any air

leaks between mixer and

throttle body, if no leaks

overhaul mixer. Refer

2.18 MIXER in Section 2,

of VT Sedan With

Production LPG.

Recheck starting

on LPG.

8. 1. Set up ADP and adjust LPG mixture

(refer 2.23 ADP SET-UP

PROCEDURE in Section 2, of VT

Sedan With Production LPG and

recheck starting on LPG.

2. Does engine start on LPG?

System OK. Go to Diagnostic Chart

ENGINE CRANKS BUT

WILL NOT START ON

LPG (2) on the following

chart in this Section.

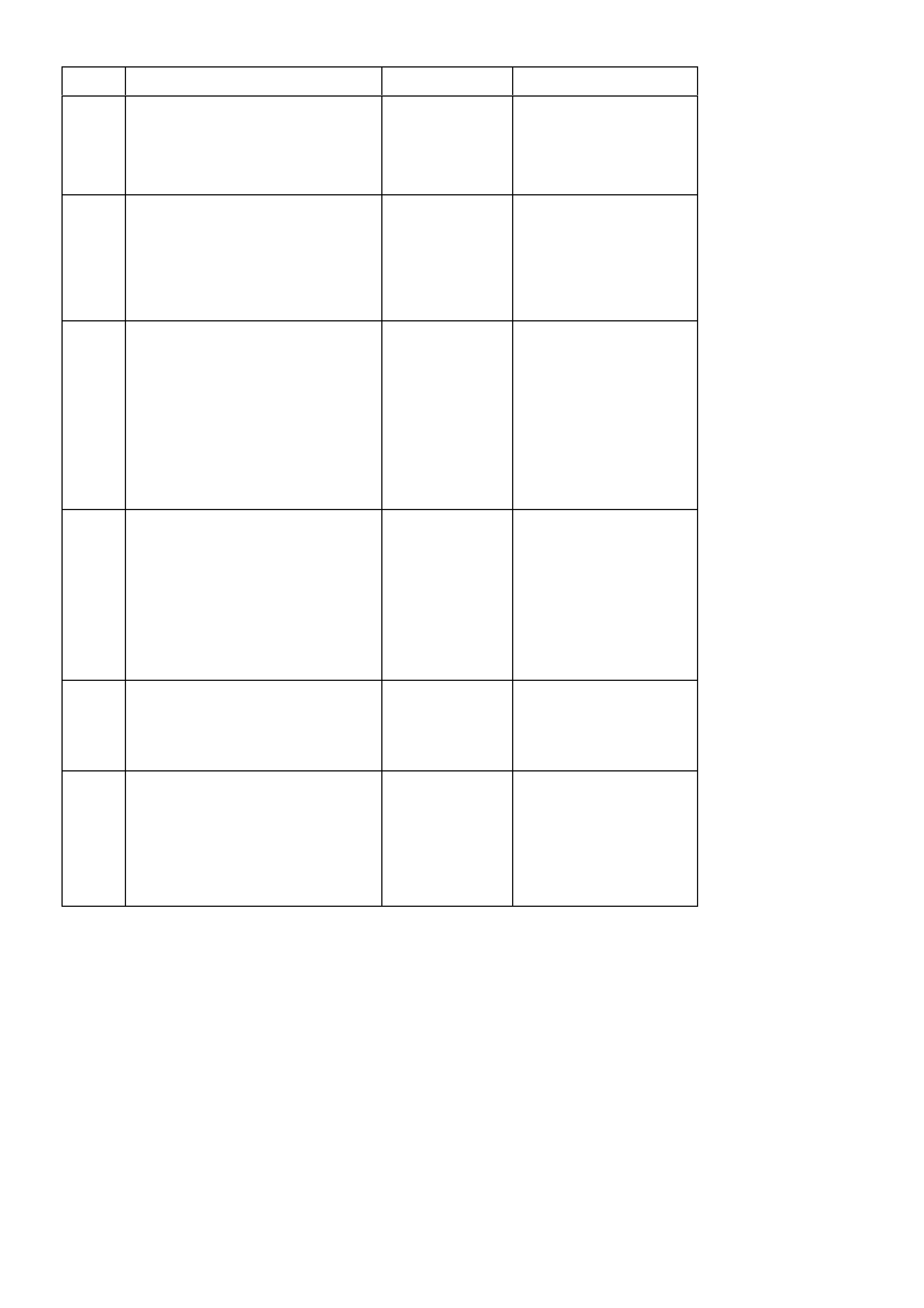

SHEET 2

TEST DESCRIPTION

The numbers below refer to step numbers in the following diagnostic chart.

1. The smart unit and the ADP receive voltage from the LPG relay via fuse F9. If fuse F9 is blown the smart unit

will not operate.

2. This test checks the continuity of the smart unit earth circuit. If the smart unit does not have a good earth then

it will not operate.

3. This test checks to see if the smart unit is supplying voltage to the LPG lockoff. If voltage is present at the

smart unit then the circuit between the smart unit and the LPG lockoff is open or shorted to earth.

NOTE:

The smart unit has a current protection device on this circuit. If circuit 965 is shorted to earth the smart unit will

shutdown. The ignition must be cycled from on to off to reset the smart unit.

4. With the ignition on and LPG selected, battery voltage should be supplied to circuit 1035 (Pink/Green wire)

when the LPG relay is energised by the PCM.

5. This test checks if the LPG relay is operating correctly.

6. With Petrol selected via the fuel mode switch, battery voltage should be present at PCM terminal E1 circuit 935

(Red/Yellow wire).

7. When LPG is selected via the fuel mode switch the PCM earths terminal E1 causing circuit E1 circuit 935

(Red/Yellow wire) to be pulled low (less than 0.2 volts).

8. When operating in the LPG mode, the PCM pulses the 5 volt pull up in the smart unit to earth via circuit 937 at

a 50% duty cycle. Therefore the voltage at PCM terminal E5 should be 2 to 3 volts when the ignition is first

turned on or when the engine is cranking.

9. This test check the continuity of circuit 937(White/Green wire).

10. This test checks if circuit 937(White/Green wire) is shorted to earth.

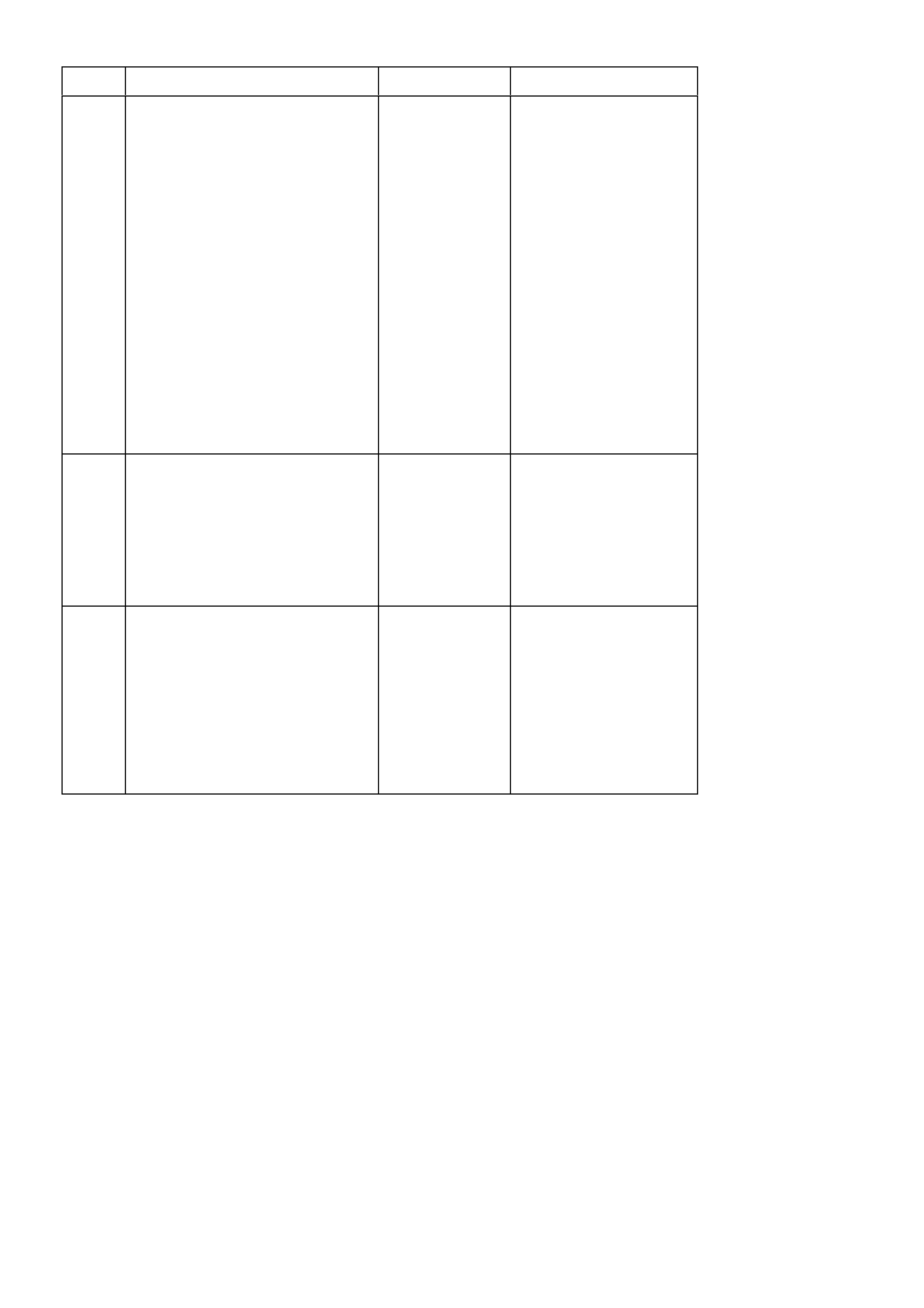

STEP ACTION YES NO

1. 1. Is fuse F9 OK? Go to Step 2. Replace fuse.

Check for short in LPG

lockoff circuit 965.

Recheck starting

on LPG

2. 1. Check continuity of smart unit

earth circuit 750 (Black/Red

wire) between smart unit

connector YR51 and a known

good earth.

2. Is there continuity?

Go to step 3. Repair open in circuit 750

(Black/Red wire).

Recheck starting

on LPG.

3. 1. Ignition ON, LPG selected.

2. Check voltage at smart unit

connector YR51 circuit 965

(Blue/Red wire).

3. Is voltage above 9 volts for

three seconds when the

ignition is first turned on or

while the engine is being

cranked?

Repair open or

short to earth in

LPG lockoff

circuit 965

between smart

unit and lockoff.

Recheck starting

on LPG.

Go to Step 4.

4. 1. Ignition ON, LPG selected.

2. Check for voltage at smart unit

connector YR51 circuit 1035

(Pink/Green wire).

3. Is battery voltage present for

three seconds when the

ignition is first turned on or

while engine is being cranked?

Go to Step 8. Got to Step 5.

5. 1. Is LPG relay OK.

Refer 2.21 in Section 2, of

VT Sedan With Production

LPG, for LPG relay location.

Go to step 6. Replace LPG Relay.

Recheck starting

on LPG.

6. 1. Ignition ON, select Petrol Mode

via the fuel mode switch.

2. Check voltage at PCM terminal

E1 circuit 935 (Red/Yellow

wire).

3. Is battery voltage present?

Go to step 7. Repair open in circuit 935

(Red/Yellow wire)

between the LPG

relay and PCM.

Recheck starting

on LPG.

STEP ACTION YES NO

7. 1. Ignition ON, Petrol Mode

selected via the fuel mode

switch.

2. Check voltage at PCM terminal

E1 circuit 935 (Red/Yellow

wire).

3. Does voltage drop from battery

voltage to less than 0.2 volts

for three seconds when LPG is

selected via the fuel mode

switch?

Go to step 8. Check PCM connector

terminal retention, if OK,

Replace PCM.

Recheck starting

on LPG.

8. 1. Select LPG via the fuel mode

switch.

2. Check voltage at PCM terminal

E5 circuit 937 (White/Green

wire).

3. Turn the ignition on, is voltage

approximately 5 volts for three

seconds when the ignition is

first turned on or when the

engine is cranking?

Check smart unit

connector

terminal retention

if OK, replace

Smart Unit.

Verify repair.

Go to step 9.

9. 1. Check continuity of circuit 937

(White/Green wire) between

smart unit connector YR51 and

PCM connector YB194

terminal E5.

2. Is there continuity?

Go to step 10. Repair open in circuit 937

(White/Green wire).

Verify repair.

10. 1. Check for a short to earth in

circuit 937 (White/Green wire)

between smart unit connector

YR51 and PCM connector

YB194 terminal E5.

2. Is there a short to earth?

Repair short to

earth in circuit

937 (White/

Green wire).

Verify repair.

Check PCM connector

terminal retention, if OK,

Replace PCM.

Recheck starting

on LPG.

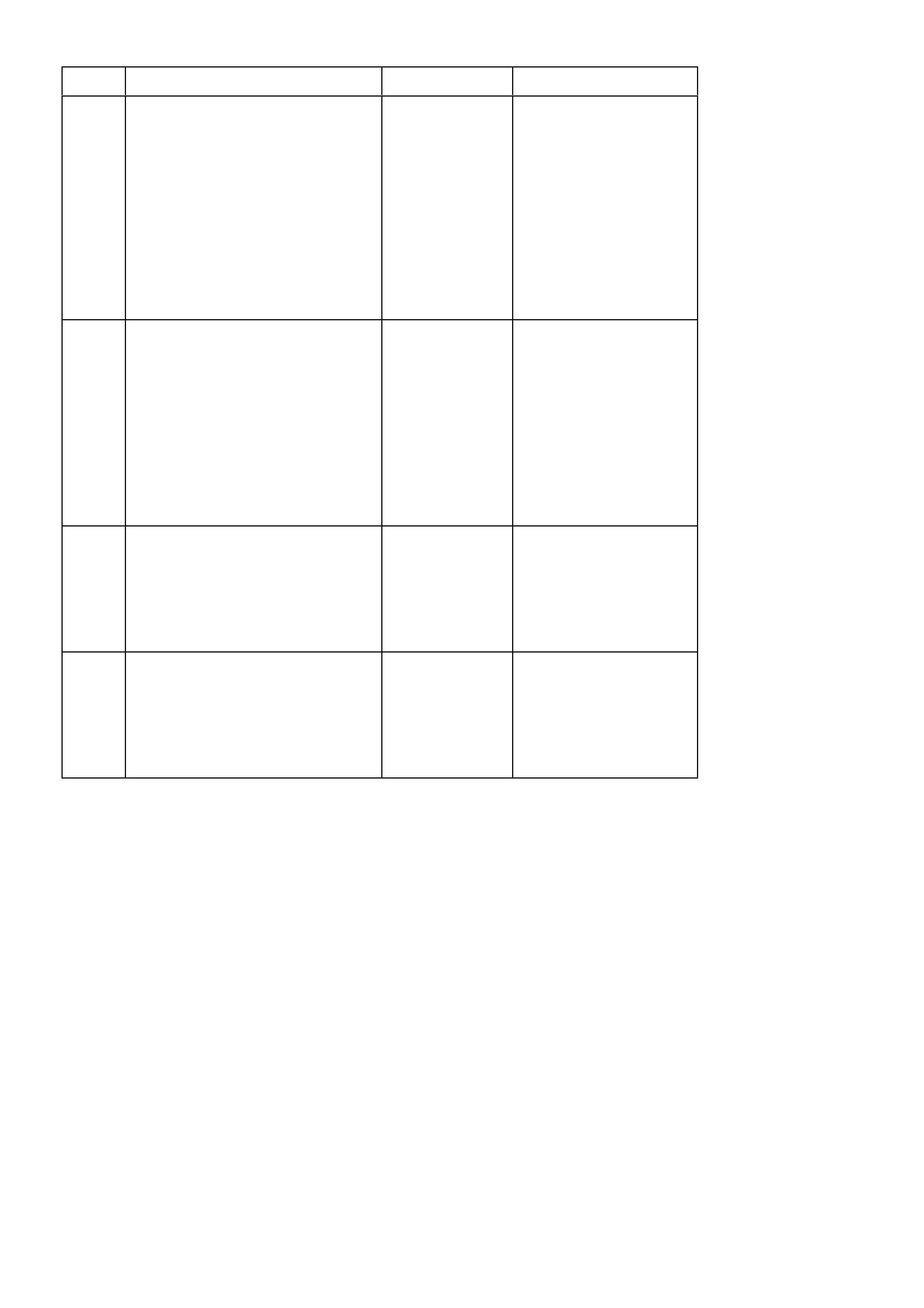

SHEET 3

TEST DESCRIPTION

The numbers below refer to step numbers in the following diagnostic chart.

1. Low primary converter pressure can be cause by low supply pressure or a faulty converter.

2. If the primary converter pressure is too high the converter will have to be overhauled.

3. If the primary converter pressure is within specification but the secondary converter is out of specification the

converter will have to be overhauled.

4. This test checks if the solenoid valve is restricting the flow of LPG.

5. This test checks the flow of LPG from the LPG cylinder to the LPG lockoff.

6. This test determines if the LPG lockoff or the converter is causing the problem.

7. This test checks if the service line is blocked. If the service line is not blocked then the manual service valve or

the LPG cylinder pick up must be blocked.

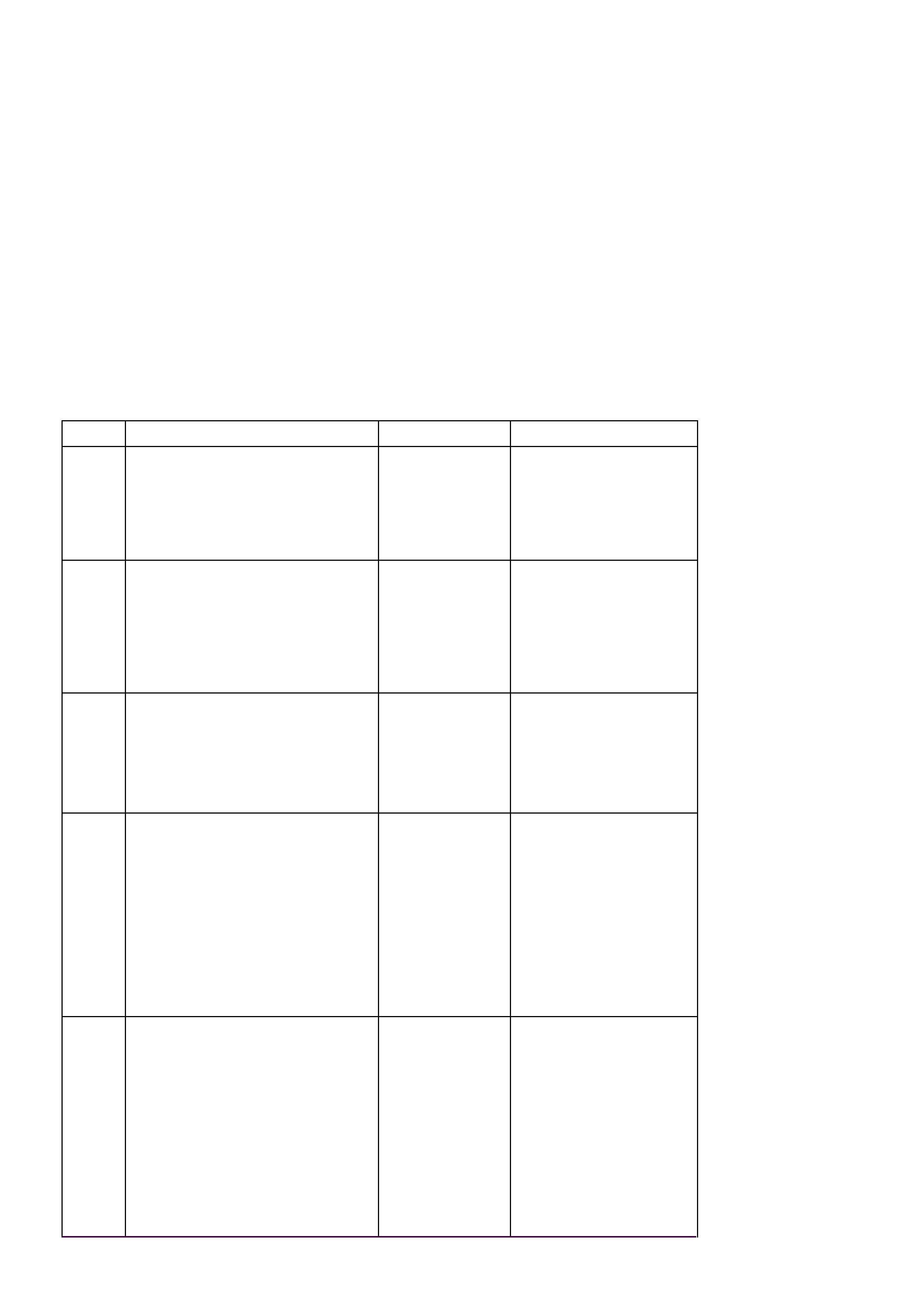

STEP ACTION YES NO

1. 1. Is primary converter pressure

below specification? Go to Step 4. Go to Step 2.

2. 1. Is primary converter pressure

above specification? Repair converter,

refer 2.15

CONVERTER in

Section 2, of

VT Sedan With

Production LPG.

Recheck starting

on LPG.

Go to Step 3.

3. 1. If primary converter pressure

is within specification, is the

secondary converter pressure

out of specification?

Repair converter,

refer 2.15

CONVERTER

Section 2, of

VT Sedan With

Production LPG.

Recheck starting

on LPG.

Go to step 4.

4. 1. Ignition OFF.

2. Close manual service valve.

3. Remove the solenoid valve

from the manual service valve

assembly and reinstall

solenoid sleeve, refer 2.8

SMART UNIT AND

SOLENOID VALVE in Section

2, of VT Sedan With

Production LPG (Sedan) or

Section 2A, in this Section

(Wagon).

4. Does engine start and run on

LPG?

Replace smart

unit and

solenoid valve.

Recheck starting

on LPG.

Go to Step 5.

STEP ACTION YES NO

5. 1. Ignition OFF.

2. Close manual service valve.

3. With the solenoid valve still

removed from the manual

service valve assembly.

4. Disconnect the front service

line at the LPG lockoff.

5. In accordance with AS-1425,

have a second technician

open the manual service valve

(slowly so that the excess flow

valve doesn’t shut LPG flow

off, if a click is herd at the

manual service valve, the

excess flow valve has closed).

6. Does LPG flow from the front

service line?

Go to Step 6. Go to Step 7.

6. 1. Test LPG lockoff (refer 2.14

LPG LOCKOFF in Section 2,

of VT Sedan With Production

LPG).

2. Is LPG lockoff OK?

Repair converter,

refer 2.14

CONVERTER in

Section 2, of

VT Sedan With

Production LPG.

Recheck starting

on LPG.

Repair LPG lockoff, refer

2.14 LPG LOCKOFF in

Section 2, of VT Sedan

With Production LPG.

Recheck starting

on LPG.

7. 1. Disconnect rear service line at

manual service valve.

2. With front service line still

disconnected, blow air through

service line to check for

blockages

3. Does air flow through service

line?

Check for manual

service valve or

LPG cylinder fuel

pick-up blockage

or fault. Repair or

replace blocked

or damaged

components.

Recheck starting

on LPG.

Check for damaged or

blocked service lines.

Repair or replace blocked

or damaged components.

Recheck starting

on LPG.

3.2 FUEL CONTROL VALVE DOES NOT OPERATE

TEST DESCRIPTION

The numbers below refer to step numbers in the following diagnostic chart.

1. The LPG VEHICLE PRELIMINARY DIAGNOSIS CHECK must be the first step when diagnosing any LPG

system problem.

2. These initial checks are designed to verify that the engine is capable of operating on LPG.

3. If the FCV can be heard operating the ADP is being powered up and pulsing the FCV.

4. This test checks that the ADP is pulsing the FCV.

5. This test checks if power is being supplied to the FCV.

6. This test checks if the ADP is supplying power to circuit 1061 (Blue/Yellow wire).

7. This test checks the continuity of circuit 1062 Green wire.

8. This test checks that battery voltage is being supplied from the LPG relay to the ADP via circuit 1035

(Pink/Blue wire).

9. This test checks the continuity of both of the ADP earth circuits.

10. In this test step circuit 1062 (Green wire) is checked for a short to earth?

11. This test checks the operation of the FCV.

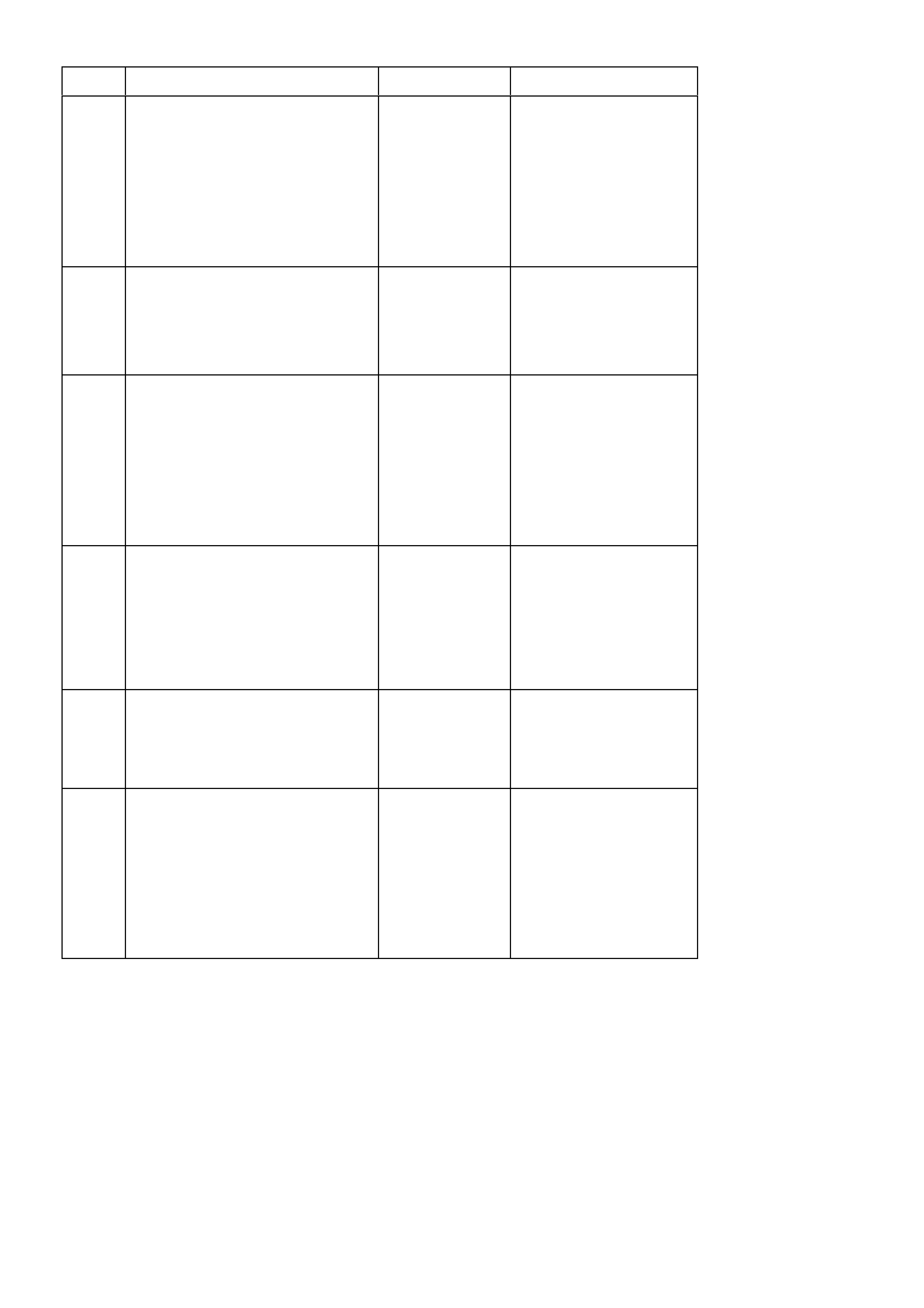

STEP ACTION YES NO

1. 1. Has an LPG VEHICLE

PRELIMINARY DIAGNOSIS

CHECK been performed?

Go to step 2. Perform an LPG

VEHICLE PRELIMINARY

DIAGNOSIS CHECK,

refer Section 3 of

VT Sedan With

Production LPG.

2. INITIAL CHECKS:

1. Has LPG been selected via

the fuel mode switch?

2. Is correct LPG PROM installed

in the PCM?

3. Is fuse F9 OK?

If YES to all, go to

Step 3. Repair any faults.

Verify repair.

3. 1. Ignition ON, select LPG via

fuel mode switch.

2. Can fuel control valve be

heard operating for three

seconds when ignition

switched on?

Go to Step 10. Go to step 4

4. 1. Remove connectors from

FCV.

2. Ignition ON.

3. Check voltage between FCV

circuits 1061 (Blue/Yellow

wire) and 1062 (Black/Blue

wire).

4. Is voltage at least 9 volts for

three seconds when ignition

switched on?

Go to step 10. Go to Step 5.

5. 1. Remove connectors from FCV

terminals.

2. Ignition ON, select LPG via

fuel mode switch.

3. Check for voltage between

connector YE2 circuit 1061

(Blue/Yellow wire) and a

known good earth.

4. Is battery voltage present for

three seconds when ignition

switched on?

Go to Step 7. Go to Step 6.

STEP ACTION YES NO

6. 1. Ignition ON, select LPG via

fuel mode switch.

2. Check for voltage at ADP

connector YB122 circuit 1061

(Blue/Yell ow wire).

3. Is battery voltage present for

three seconds when ignition

switched on?

Repair circuit

1061 (Blue/

Yellow wire).

Verify repair.

Go to Step 7.

7. 1. Check continuity of circuit

1062 (Black/Blue wire)

between FCV terminal YE2

and ADP connector YB122.

2. Is there continuity?

Go to Step 8. Repair open in circuit

1062 (Black/Blue wire)

Verify repair.

8. 1. Ignition ON, and LPG selected

via fuel mode switch.

2. Check for voltage at ADP

connector YB122 circuit 1035

(Pink/Blue wire).

3. Is battery voltage present for

three seconds when ignition

switched on?

Go to Step 9. Repair open circuit 1035

(Pink/Blue wire).

Verify repair.

9. 1. Check continuity of ADP earth

circuits 750 (Black/ Red wire)

and circuit 751 (Black/Blue

wire) from ADP connector

YB122 and a known good

earth.

2. Is there continuity?

Check ADP

connector

terminal

retention if OK,

replace ADP.

Verify repair.

Repair faulty ADP earth

circuit 750 (Black/Red

wire) and 751

Black/Blue Wire.

Verify repair.

10. 1. Check for short to earth in

circuit 1062 (Green wire).

2. Is circuit 1062 (Black/Blue

wire) shorted to earth?

Repair short to

earth in circuit

1062 (Black/

Blue wire).

Verify repair.

Go to step 11.

11. 3. Test operation of FCV, (refer

2.17 FUEL CONTROL

VALVES in Section 2, of VT

Sedan With Production LPG).

4. If FCV operating correctly?

Perform ADP set

up procedure.

(refer 2.23 FUEL

CONTROL

VALVES in

Section 2, of

VT Sedan With

Production LPG).

Verify repair.

Check FCV connector

terminal retention if OK,

replace FCV.

Verify repair.