SECTION 0A - GENERAL INFORMATION

ck on the button for more information. CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will

consist of either seat belt pre-tensio ners and a driver’s side air bag , or seat belt pre-

tensioners and a driver’s and front passenger’s side air bags. Refer to CAUTIONS,

Section 12M, before performing any service operation on or around SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deplo yment, resulting in possible p ersonal injury or unnecessary

SRS system repairs.

CAUTION:

This vehicle may be equipped w ith LPG (Liquefied Petroleum Gas). In the interests of

safety, the LPG fuel system should be isolated by turning 'OFF' the manual service

valve and then draining the L PG service lines, before any servi ce work is carried out

on the vehicle. Refer to the LPG leaflet included with the Owner's Handbook for

details or LPG Section 2 for more specific servicing information.

1. GENERAL INFORM ATION

The VT Series features new design front and rear end sheet metal, tail lamps, adjustable tilt/reach steering column,

supplemental inflatable restraint, four speed electronic automatic transmission, revised front suspension,

Independent rear suspension as standard on all models, Body Control Module on all models, ABS braking system

and a new instrument panel design.

NOTE:

VT vehicles must be operated only on unleaded fuel with a minimum research octane rating of 91.

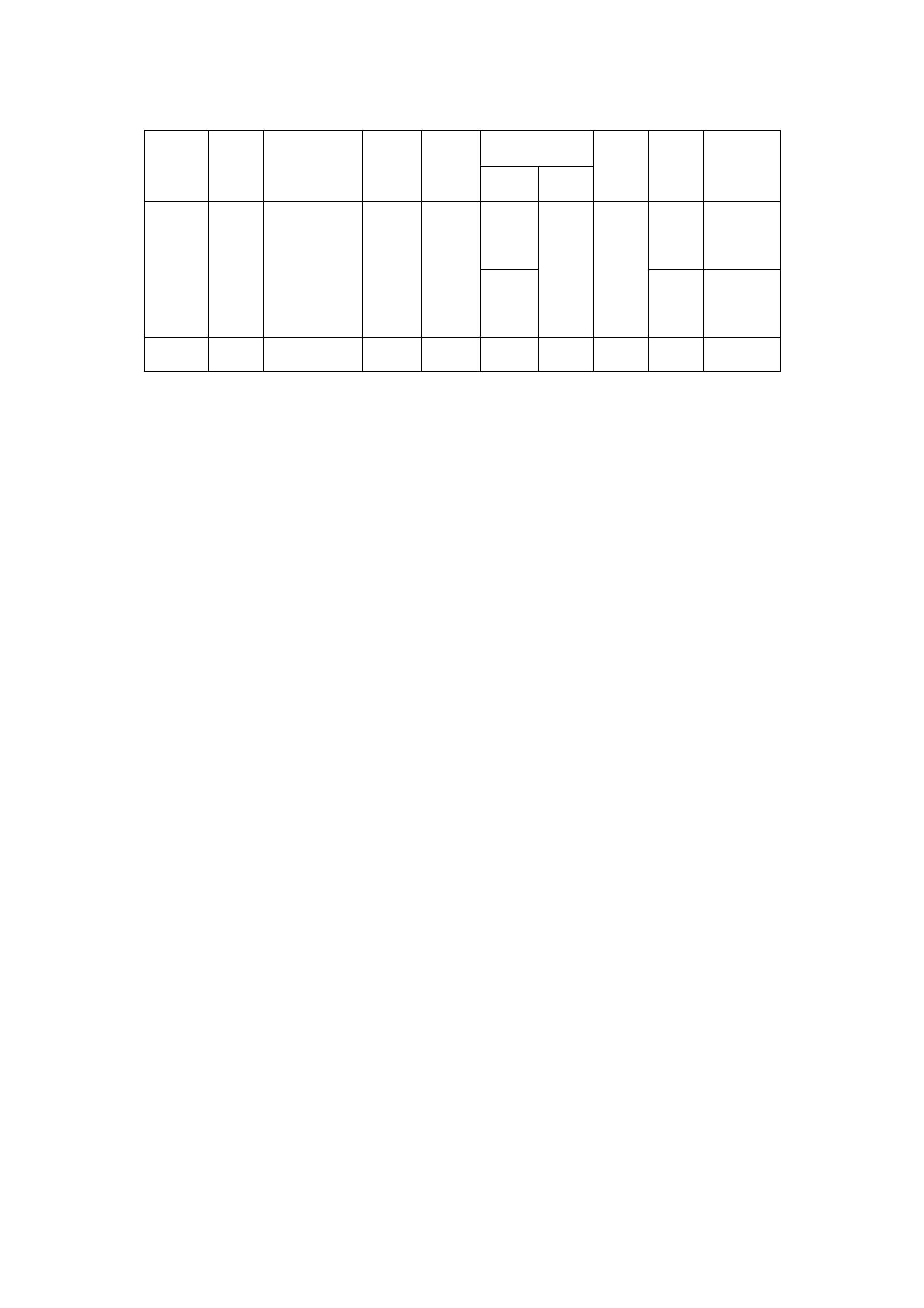

The following charts provide model availability, power train combinations, transmission ratios, engine data and

exterior dimensions for VT Models.

A four speed electronically controlled automatic transmission is standard equipment on Berlina and Calais models.

Manual transmission is standard equipment on Executive models and available as an option on Berlina and Calais

models.

NOTE:

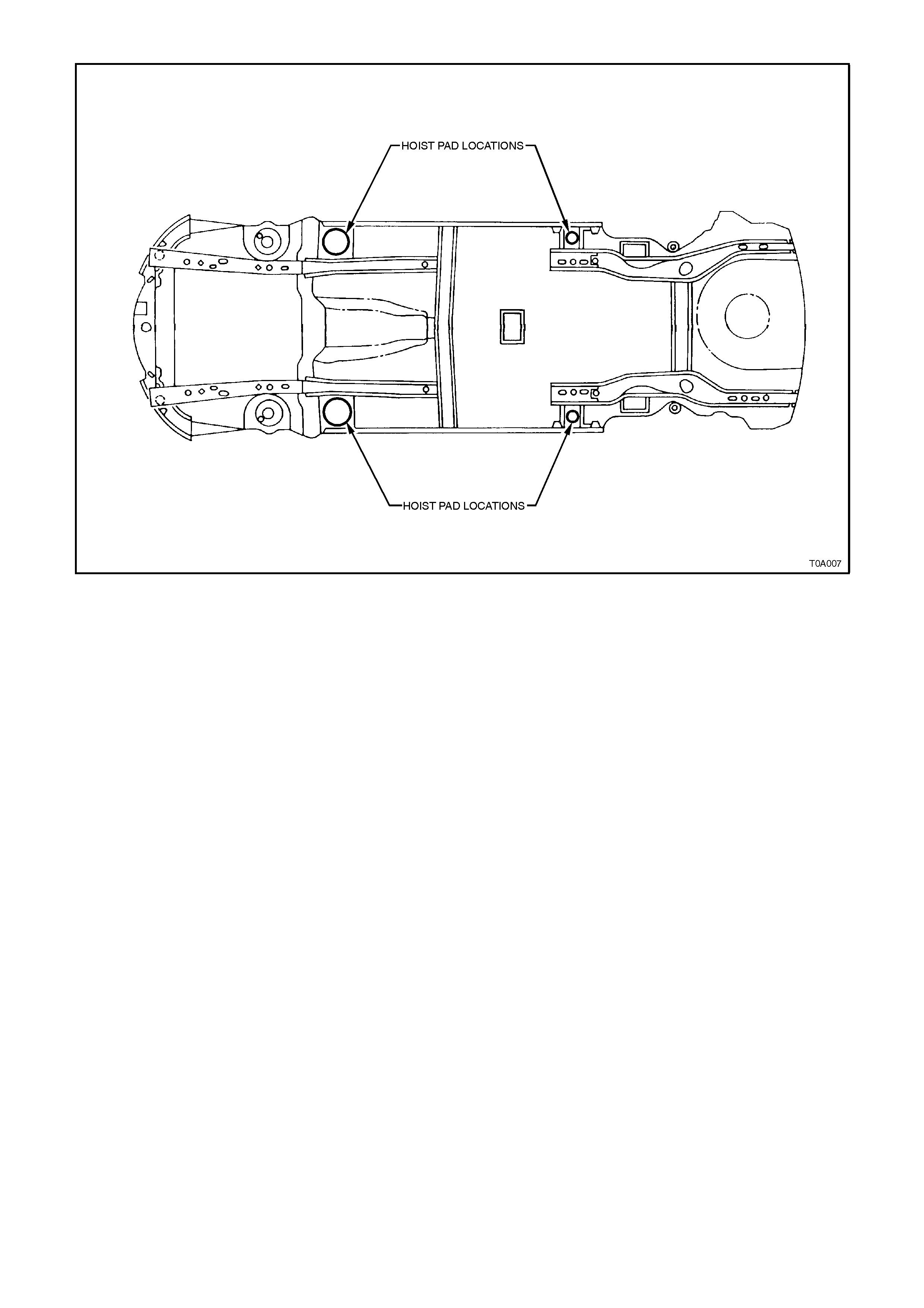

When using a trolley jack to raise the vehicle it is important that the jack be positioned under the suspension cross

member or hoist pad locations. Do not jack under the suspension control arm. The vehicle should always be

supported by jack stands at the hoist pad locations when raised (see following illustration).

Techline

Techline

Techline

Techline

Techline

Techline

Figure 0A-1

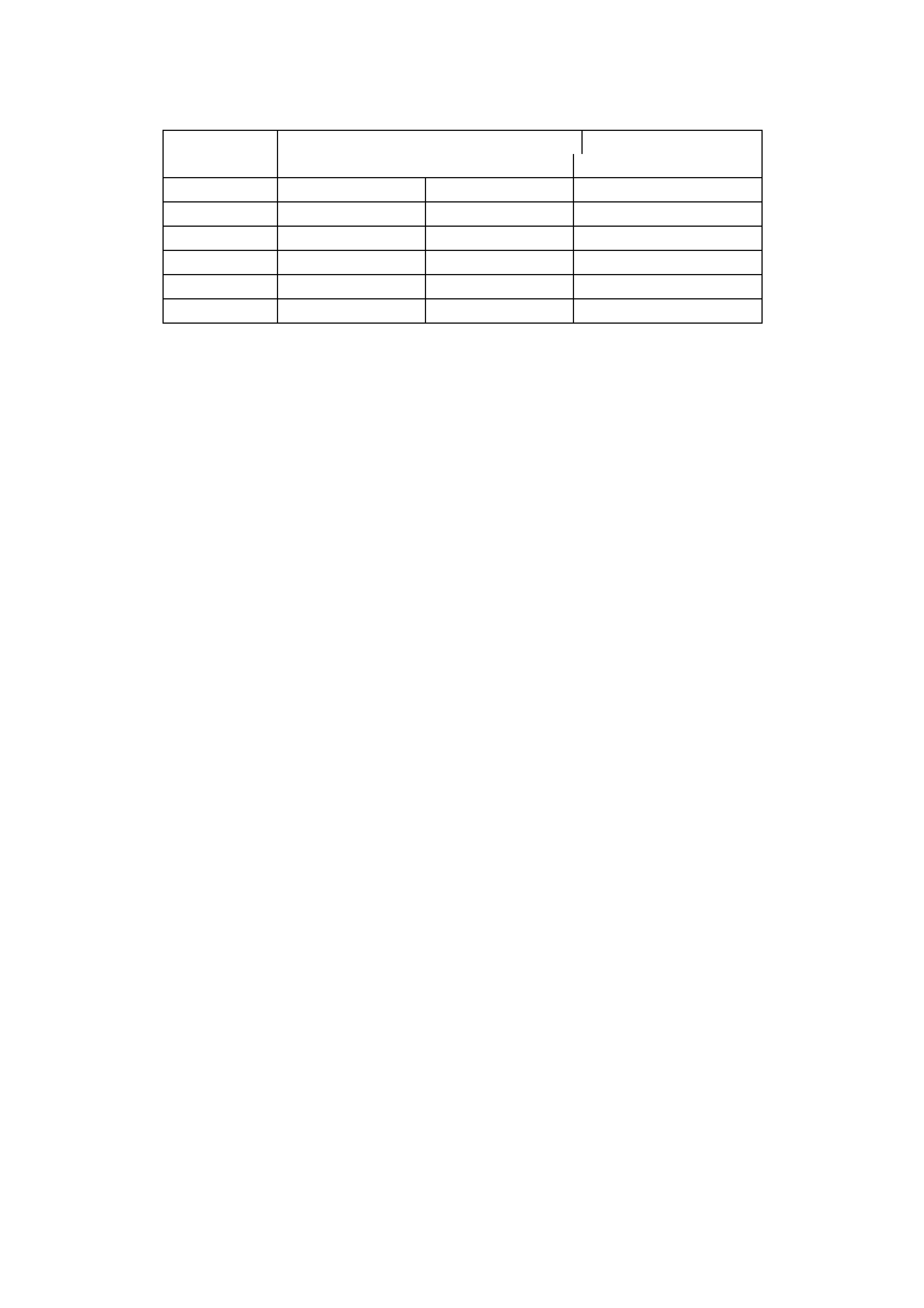

2. MODEL AVAILABILITY AND BASE EQUIPM ENT

BODY MODEL NO.OF TRANSMISSION REAR

AXLE

STYLE NO. MODEL NAME DOORS ENGINE TYPE SHIFT

LOC. RATIO

:1 TYRES WHEELS

Sedan

S/Wagon

8VK69

8VK35

Commodore

Executive

Commodore

Executive

4

5

3.8 PFI 5 Speed

Manual Floor 3.08 205/ 65

R15 6.0J x 15

Steel

Sedan

S/Wagon

8VL69

8VL35

Commodore

Berlina

Commodore

Berlina

4

54 Speed

Auto Floor 3.08 205/ 65

R15 6.0J x 15

Alloy

Sedan 8VX69 Calais 4 3.8 PFI 4 Speed

Auto Floor 3.08 215/60

R16 95H 7.0J x 16

Alloy

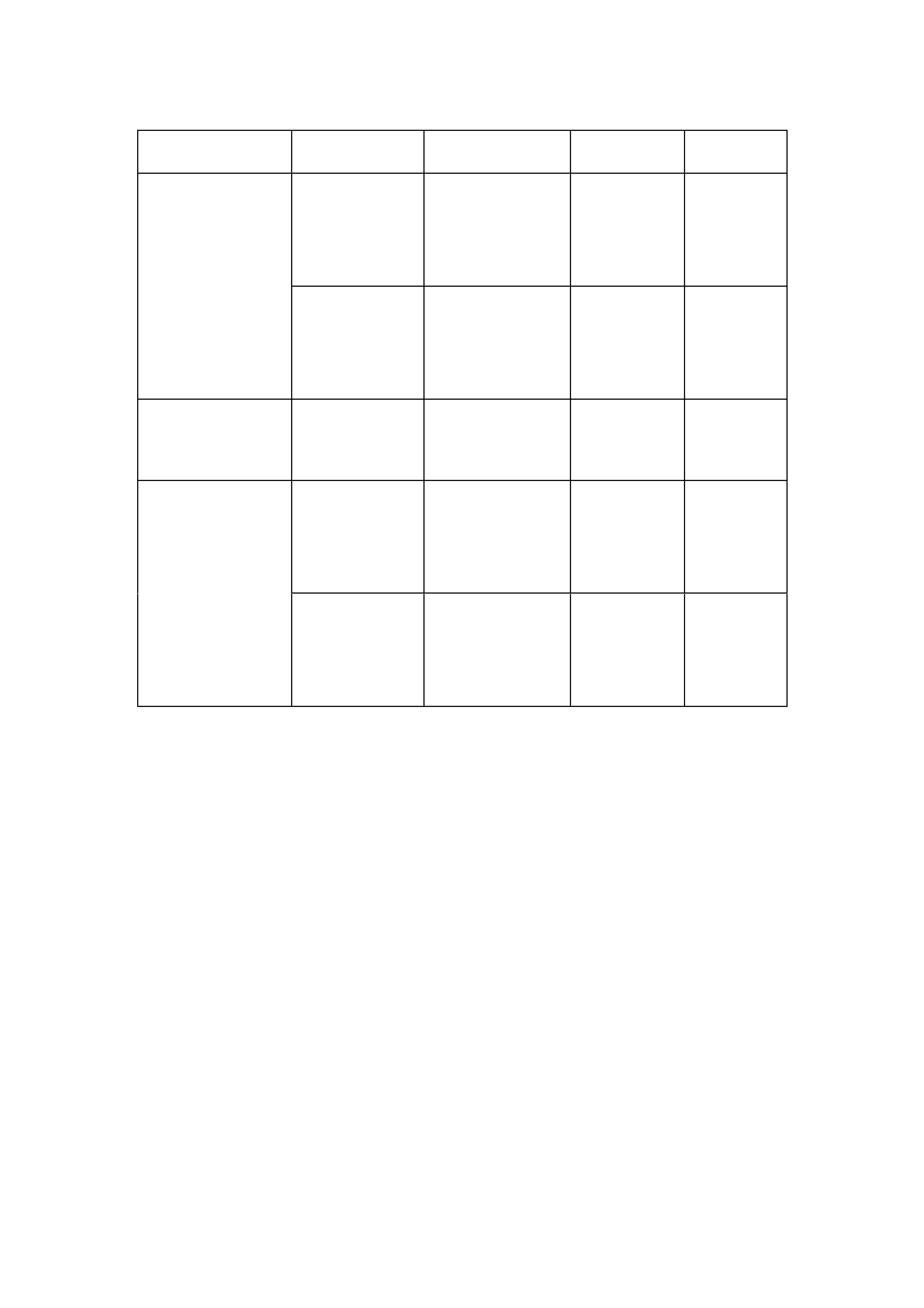

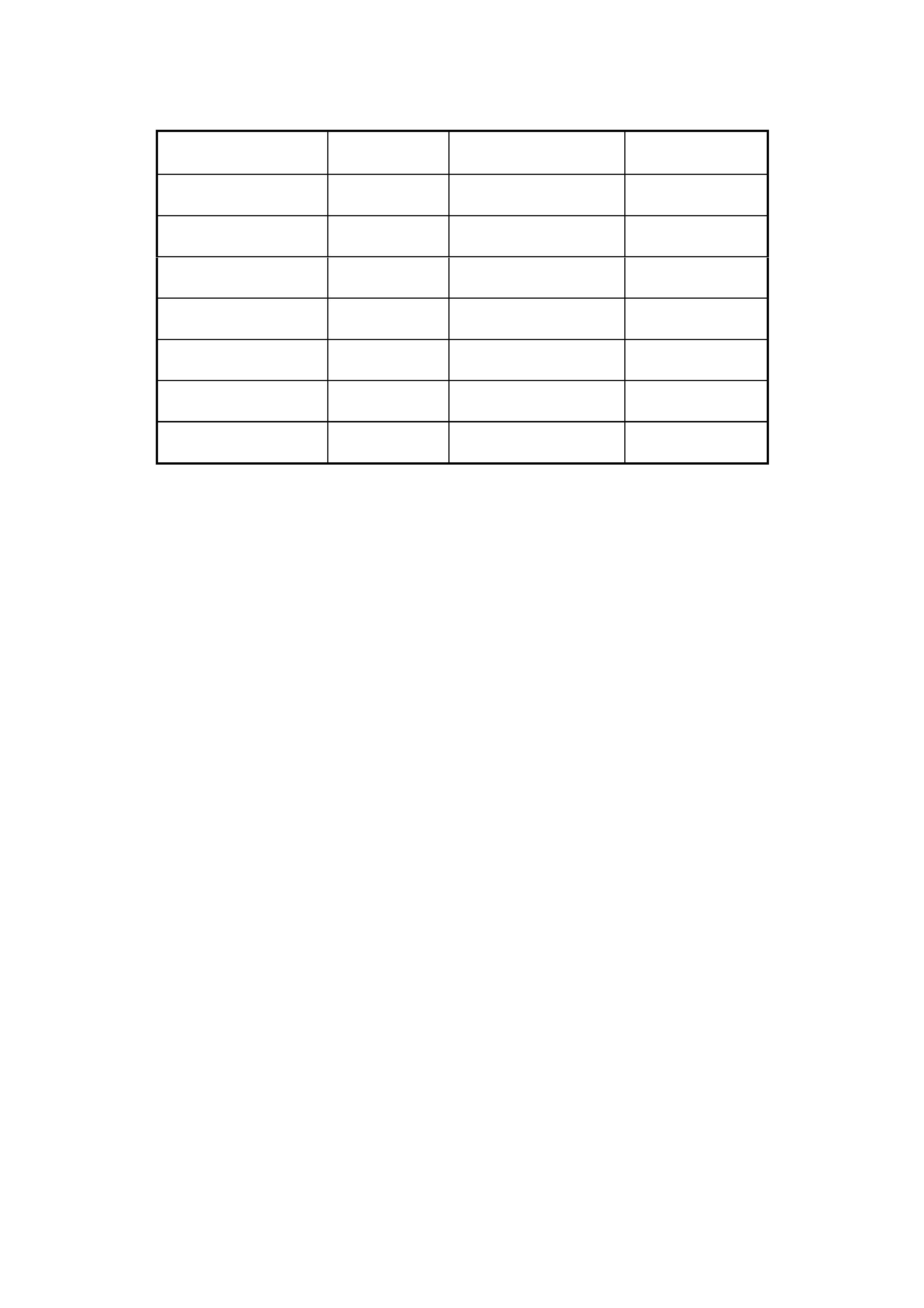

3. POWERTRAIN COMBINATIONS

ENGINE TRANSMISSION

TYPE MODEL

AVAILABILITY FIRST GEAR

RATIO REAR AXLE

RATIO :1

3.8 LITRE

PFI 5 Speed

Manual Exec. Sedan

Exec. Wagon

Berlina Sedan

Berlina Wagon

Calais Sedan

3.829:1 3.08:1

4 Speed

Automatic Exec. Sedan

Exec. Wagon

Berlina Sedan

Berlina Wagon

Calais Sedan

3.06:1 3.08:1

LITRE

PFI

SUPERCHARGED

4 Speed

Automatic Calais Sedan 3.06:1 3.08:1

5.0 LITRE

PFI 5 Speed

Manual Exec. Sedan

Exec. Wagon

Berlina Sedan

Berlina Wagon

Calais Sedan

3.553:1 3.08:1

4 Speed

Automatic Exec. Sedan

Exec. Wagon

Berlina Sedan

Berlina Wagon

Calais Sedan

3.06:1 3.08:1

3.8

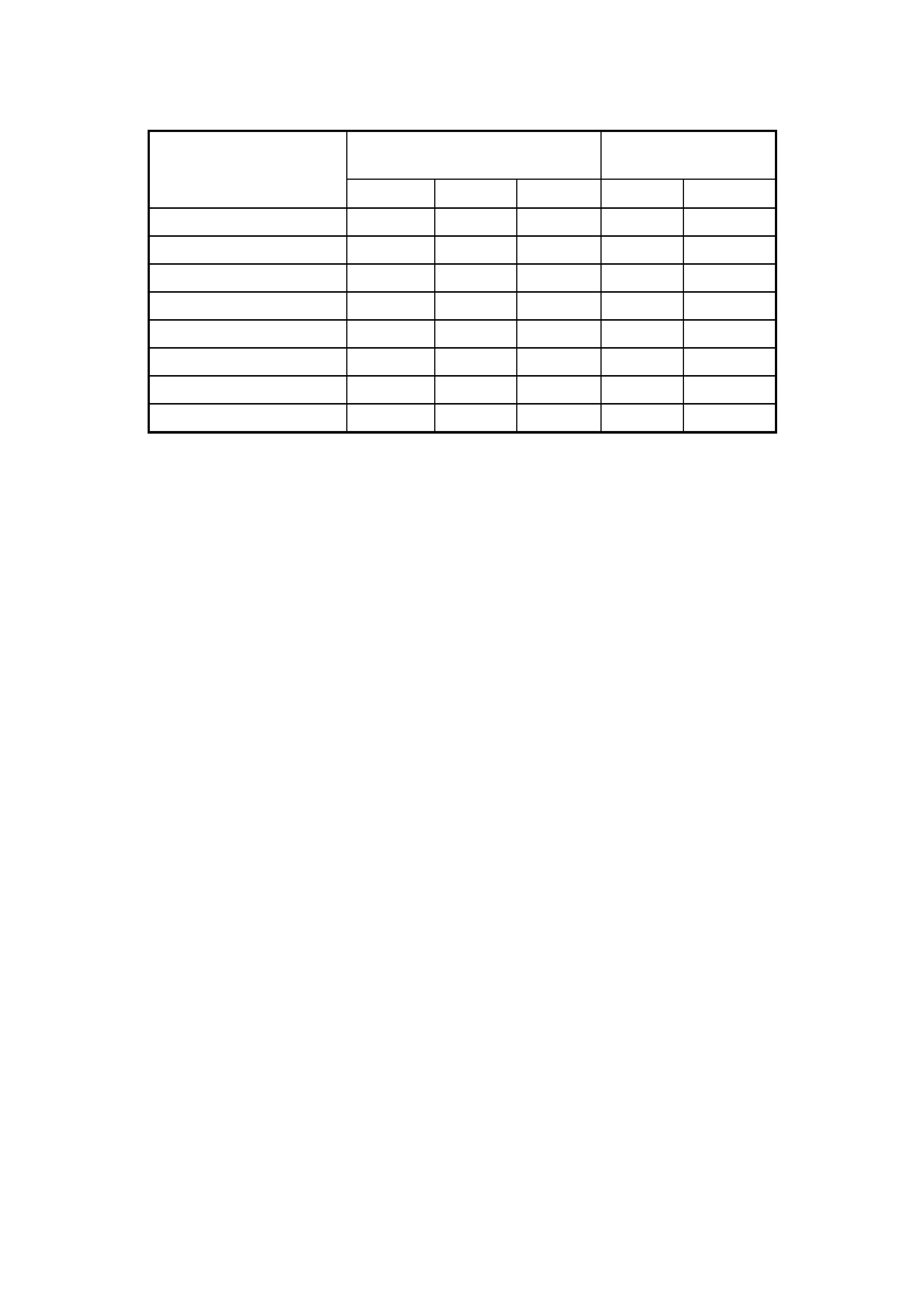

4. TRANSM ISSION RATIOS

5 SPEED MANUAL 4 SPEED AUTOMATIC

V6 V8

1ST 3.829:1 3.553:1 3.06:1

2ND 2.199:1 2.041:1 1.63:1

3RD 1.401:1 1.400:1 1.000:1

4TH 1.000:1 1.000:1 0.7:1

5TH 0.809:1 0.755:1 -

REV 3.456:1 3.553:1 2.3:1

5. ENGINE DATA

ENGINE

DESIGNATION 3.8 LITRE

PFI 3.8 LITRE

SUPERCHARGED 5.0 LITRE

PFI

Piston Displacement

Nom. - cm33791 3791 4987

Compression

Ratio 9.35:1 8.5:1 8.8:1

Number of

Cylinders 6 6 8

Bore x Stroke - mm 96.5 X

86.3 96.5 X

86.3 101.6 X

76.835

Taxable H.P.

RAC OR SAE 34 34 51

Power kW

DIN @ RPM 147 kW

@ 5200 171 kW

@ 5200 179 kW

4600

Torque Nm

DIN @ RPM 304 Nm

@ 3600 375 Nm

@ 3000 400 Nm

@ 3600

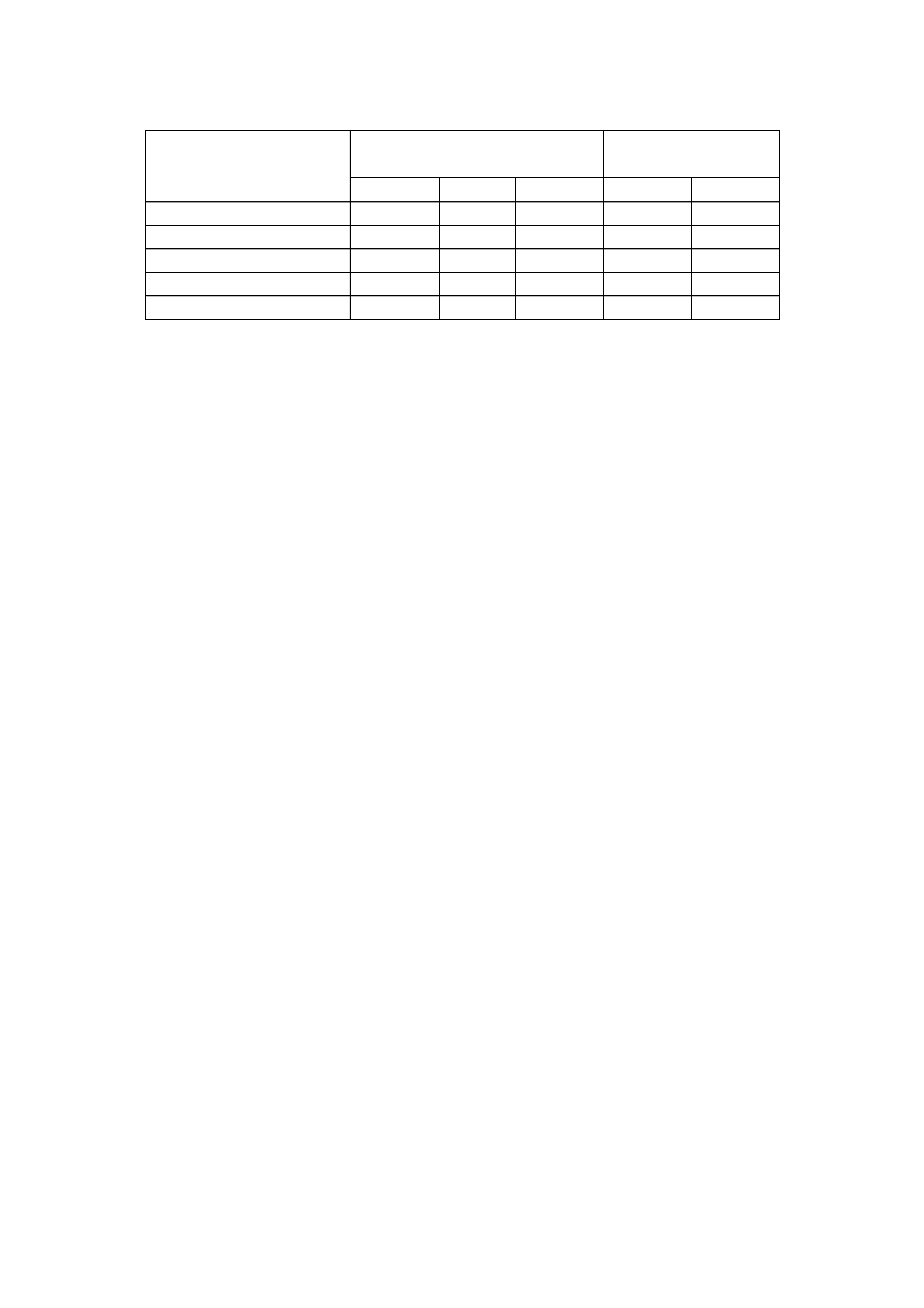

6. EXTERIOR DIM E NSI O NS

STATION WAGON

BODY SEDAN MODELS MODELS

DIMENSIONS 8VK69 8VL69 8VX69 8VK35 8VL35

VEHICLE LENGTH 4882 4882 4882 5040 5040

VEHICLE WIDTH 1824 1824 1824 1824 1824

VEHICLE HEIGHT 1425 1422 1420 1424 1468

WHEELBASE 2788 2788 2788 2938 2938

OVERHANG - FRONT 930 930 930 930 930

OVERHANG - REAR 1164 1164 1164 1174 1174

TREAD - FRONT 1568 1568 1558 1568 1568

TREAD - REAR 1582 1582 1572 1582 1582

7. VEHICLE WEIGHTS

STATION WAGON

VEHICLE SEDAN MODELS MODELS

WEIGHTS 8VK69 8VL69 8VX69 8VK35 8VL35

KERB MASS V6 1551 1605 1642 1612 1672

KERB MASS V8 1643 1672 1748 1704 1754

REAR AXLE LOAD V6 1230 1230 1230 1230 1230

REAR AXLE LOAD V8 1230 1230 1230 1230 1230

PAYLOAD (5 Pass. + Cargo) 408 408 408 480 480

NOTE:

All figures are estimates only.

Payload figures must include luggage, goods, passengers, roof rack load and a full tank of fuel. If you are towing,

then the weight on the tow bar ball must also be included.

Maximum Rear Axle Load is maximum for all conditions.

8. SERIAL NUMBERS

The complete vehicle and various components of

the vehicle are identified by number plates or

numbers stamped into the part. It is essential that

when compiling warranty claims or product and

field reports, the vehicle identification number (VIN)

is quoted in conjunction with the identification

number of the component affected.

The VIN plate is secured to the body by unique

rosette headed rivets.

8.1 LOCATION OF IDENTIFICATION PLATES

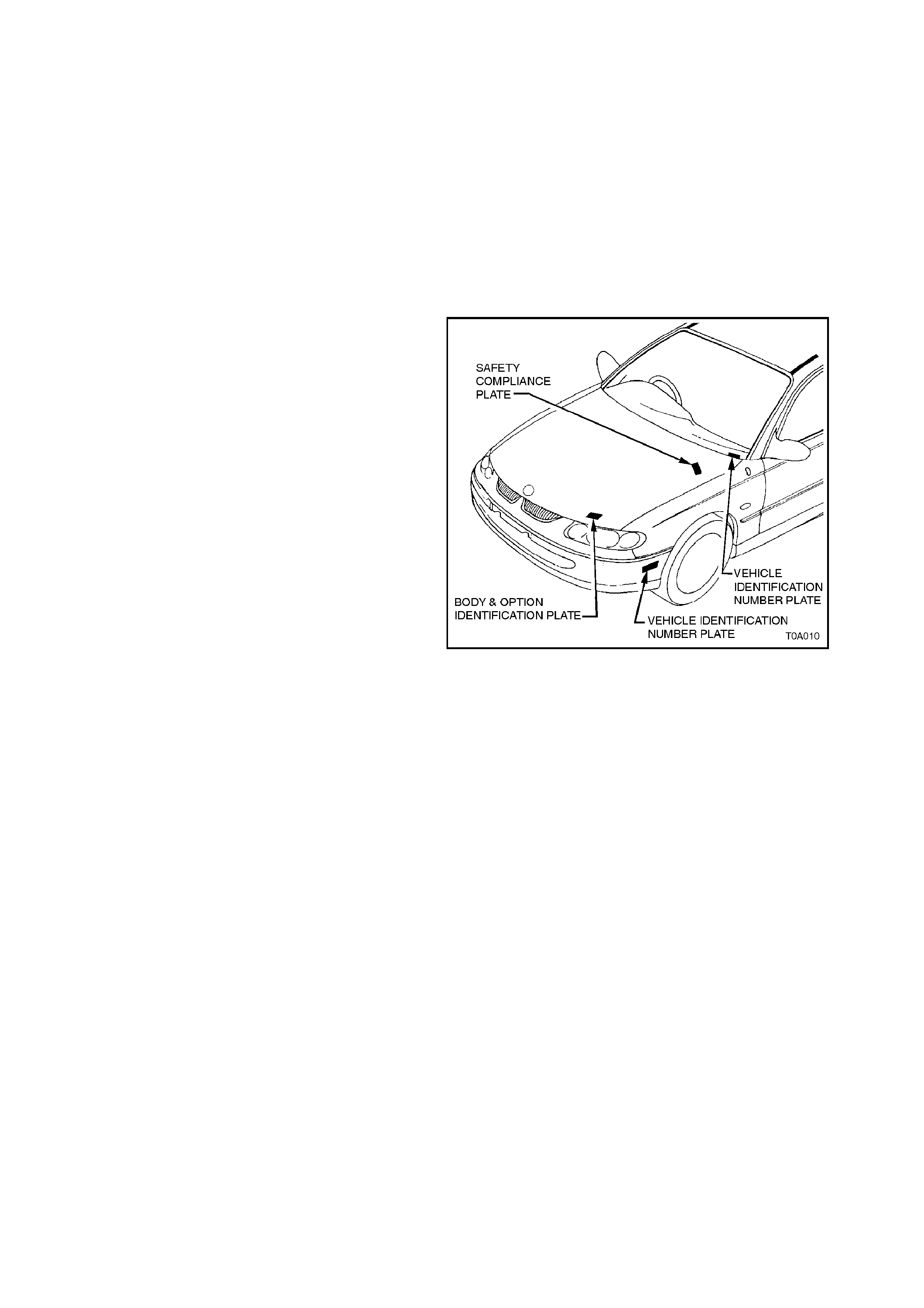

Identification plates are attached to the upper right

side of the dash panel, front radiator s upport panel,

behind the bumper facia, and under the windshield

lower left corner, refer to Fig. 0A-2.

Figure 0A-2

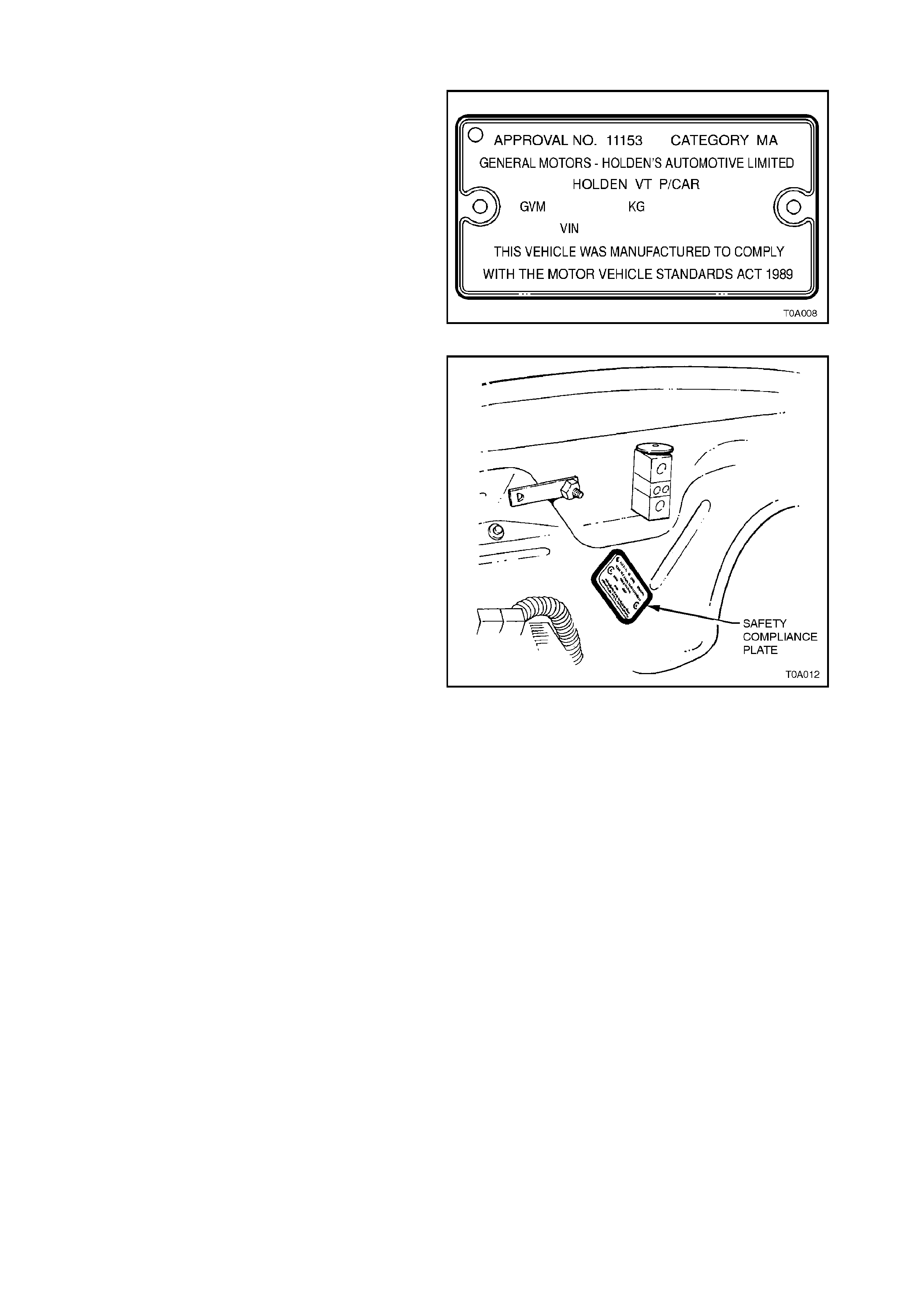

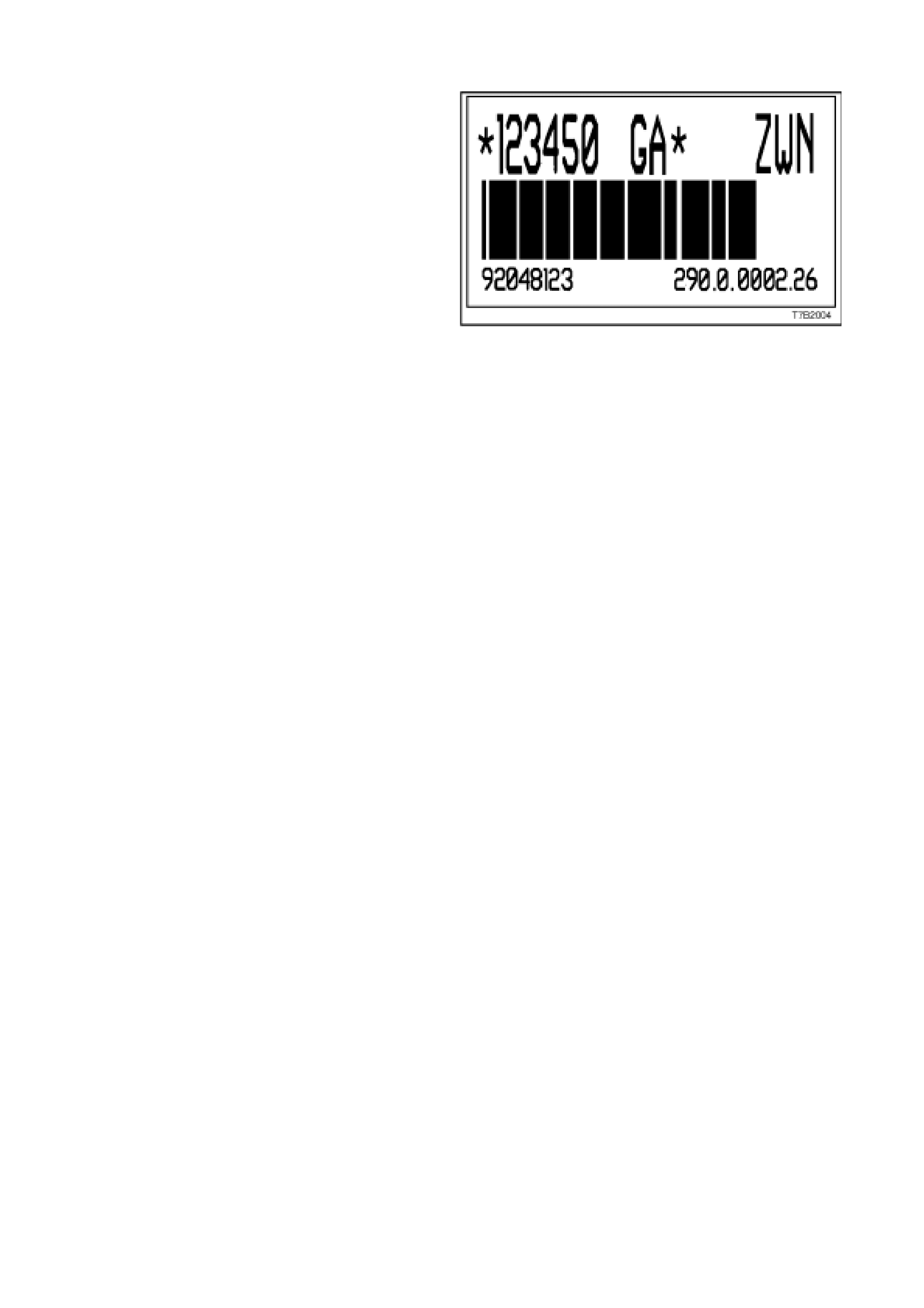

8.2 SAFETY COMPLIANCE PLATE (NOT APPLICABLE TO EXPORT)

Plate stamped with the following information:

Refer to Fig. 0A-3.

COMPLIANCE PLATE APPROVAL NUMBER.

VEHICLE CATEGORY CODE.

NAME APPEARING ON COMPLIANCE PLATE

APPROVAL.

MAKE/MODEL.

SEATING CAPACITY.

DATE OF MANUFACTURE (* Variable

information).

VEHICLE IDENTIFICATION NUMBER (* Variable

information). Figure 0A-3

Figure 0A-4

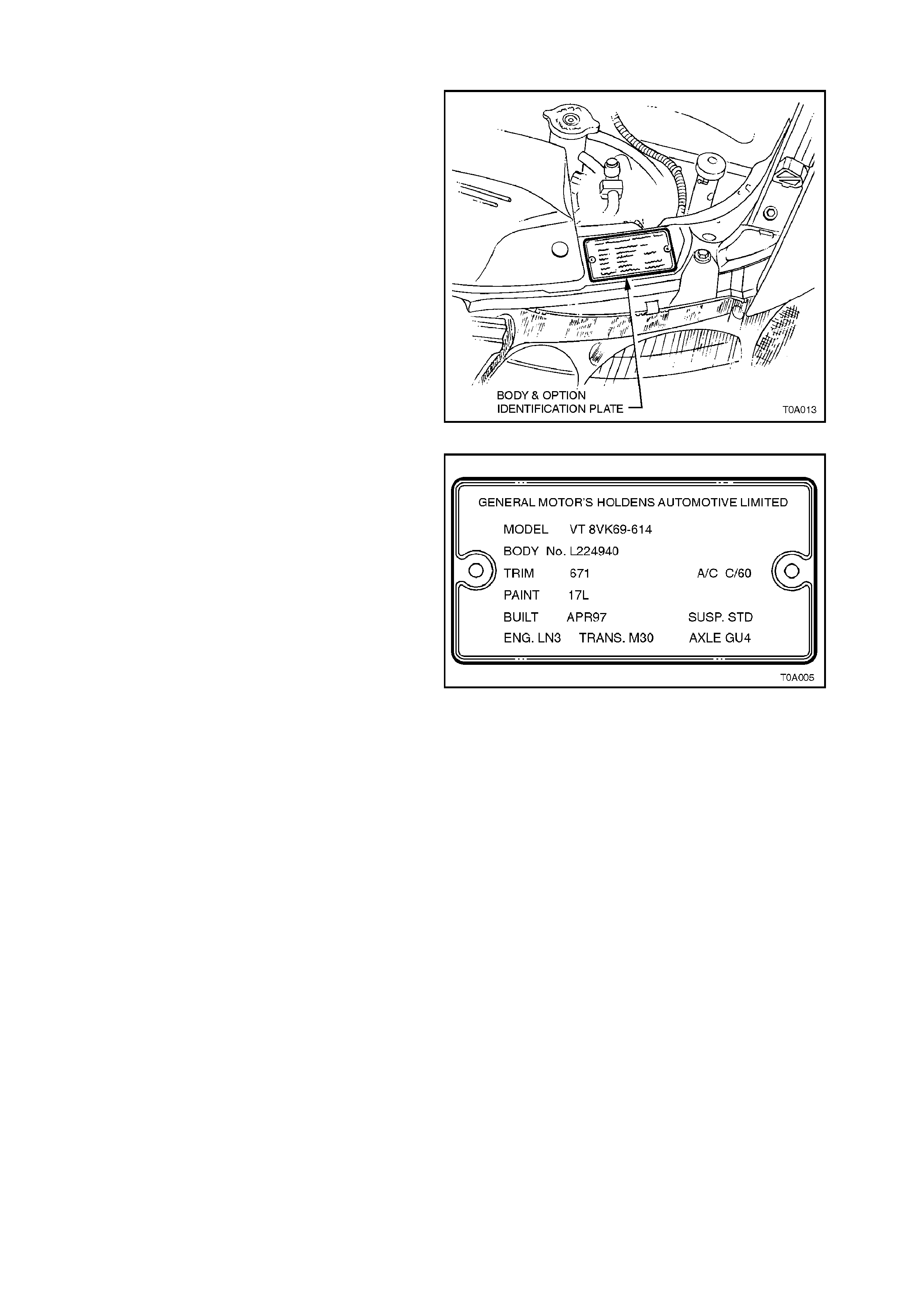

8.3 BODY AND OPTION IDENTIFICATION PLATE

Plate stamped with the following information, refer

to Fig. 0A-6

Figure 0A-5

MODEL

Combination of letters and numbers identifying the

body, model and style.

TRIM

Exterior paint colour and trim combination.

PAINT

Exterior paint material and colour identification.

BUILT

The date of manufacture by calendar month and

year in which the body shell and power train are

conjoined and the vehicle is driven or moved from

the production line.

SUSP

Suspension option code identification number, i.e.

FE2.

ENGINE, TRANSMISSION AND AXLE

Identification option codes for specific engine,

transmission and rear axle.

A/C

Identification option code C60 is used for vehicles

fitted with air conditioning. C61 Identifies vehicles

fitted with Electronic Climate Control air

conditioning.

Figure 0A-6

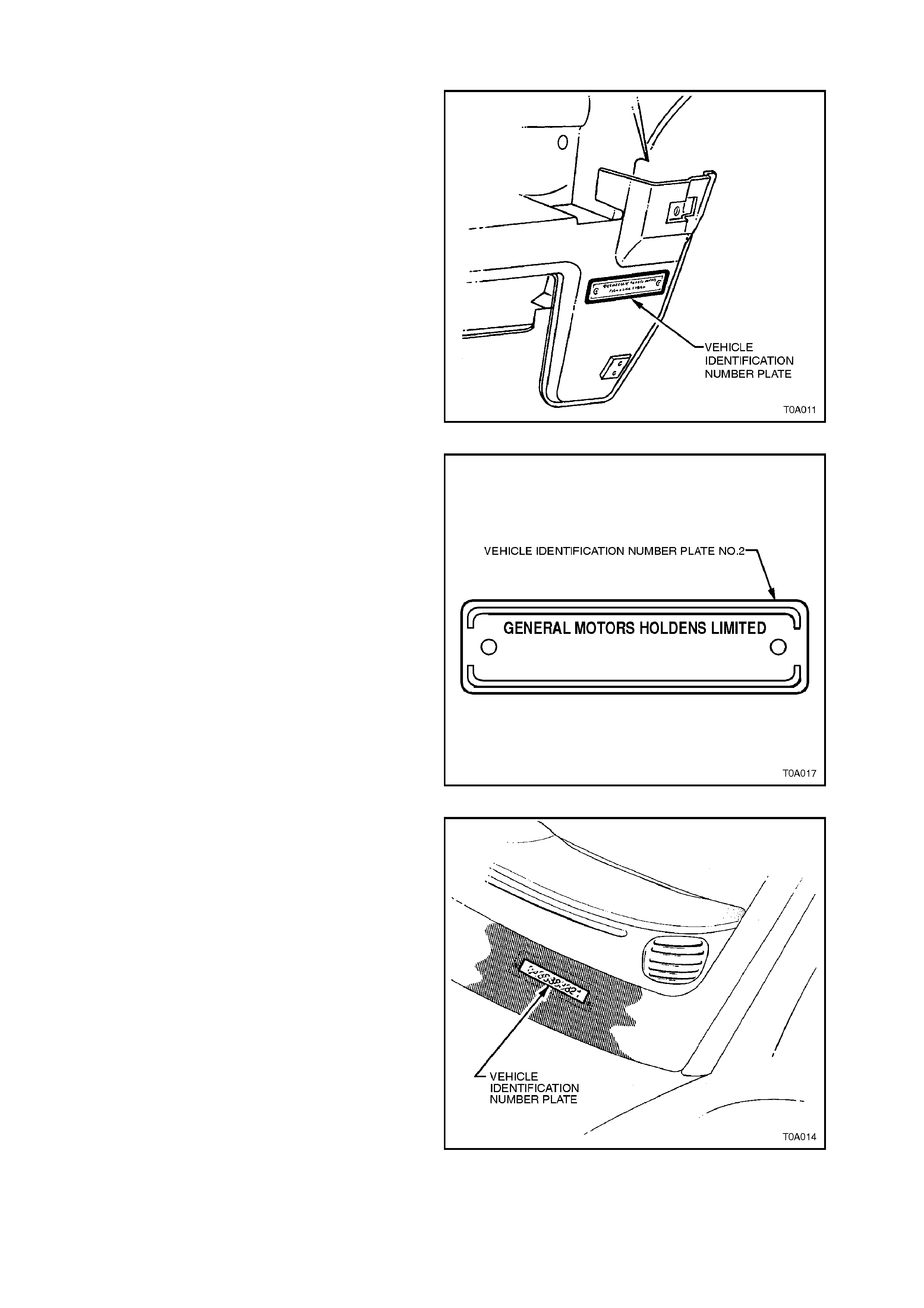

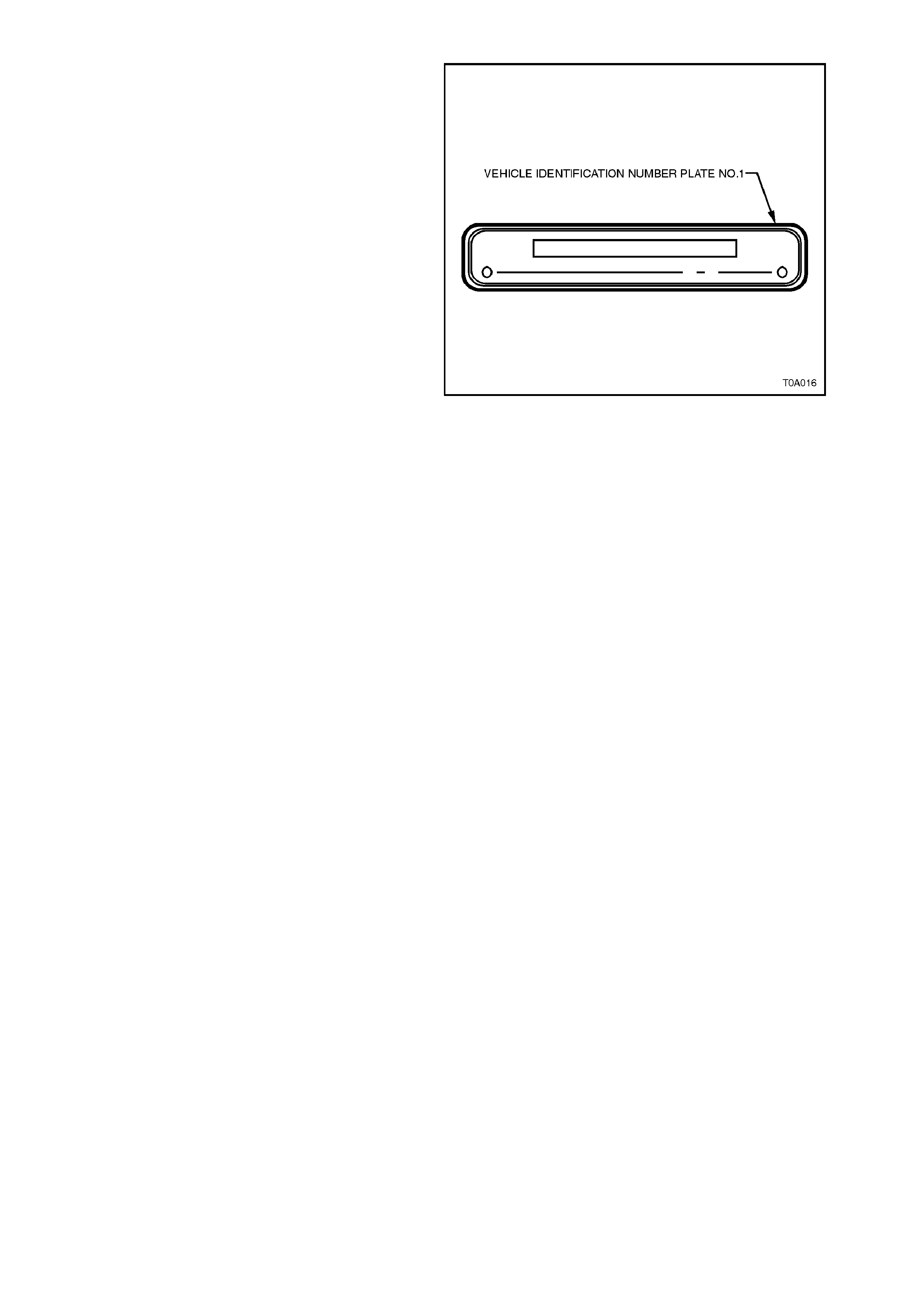

8.4 VEHICLE IDENTIFICATION NUMBER PLATE LOCATION (BODY LOCATION)

The Vehicle Identification Number Plate (Body) is

located under the front bumper on the left hand

side.

Figure 0A-7

Figure 0A-8 shows the Vehicle Identification

Number plate located under the bumper facia.

Figure 0A-8

The Vehicle Identification Number Plate (Body) is

located under the windscreen and is viewed

through the windscreen aperture.

Figure 0A-9

Figure 0A-10 shows the Vehicle Identification

Number plate located under the windscreen

aperture.

Figure 0A-10

VEHICLE IDENTIFICATION NUMBERING SYSTEM

The Vehicle Identification Numbering System (VIN) is based on the uniform Car Model Designation

System. The reason for this is to identify the vehicle in one coded series of Characters.

The significance of these characters or blocks of characters is explained below, using as an example

identification number 6H8 VT X 69 H V L 123456.

MODE L DES IG NATION

WMI Code

Model Series Code

De

g

ree of Luxur

y

BODY S TYLE CODE

ENGINE CODE

MODE L YE AR CODE

ASSEMBLY PLANT CODE

SERIAL SEQUENCE

GENE RAL MOT ORS - HOL DE N' S AUTO M OTIVE

6H8 VT X 69 H V L 123456

MODEL DESIGNATION

WMI Code - 6H8 - World manufacturer's identifier allocated to Holden

Model Series Code - VT = VT Series

Degree of Lux ury - K - COMMODORE "EXECUTIVE"

- L- COMMODORE "BERLINA"

- X - CALAIS

Body Style Code - 69 - Sedan 35 - Station Wagon

ENGINE CODE

Engine Identification Code (H - signifies 3.8 engine, S - signifies 3.8 supercharged engine,

M - signifies 5.0 engine)

MODEL YEAR CODE

V - Identifies Model Year V = 1997

W = 1998

This Letter relates to GM Internal Operation Only.

ASSEMBLY PLANT CODE

Australian Assembly Plant Identification Code:-

L - Adelaide (Elizabeth)

SERIAL (Sequence ) NUMBER

123456 - Sequential Production Serial Number

NOTE: This designates the Serial Unit Number at the Vehicle Plant, starting at

(00001) and continues in Numerical Sequence regardless of vehicle type.

Techline

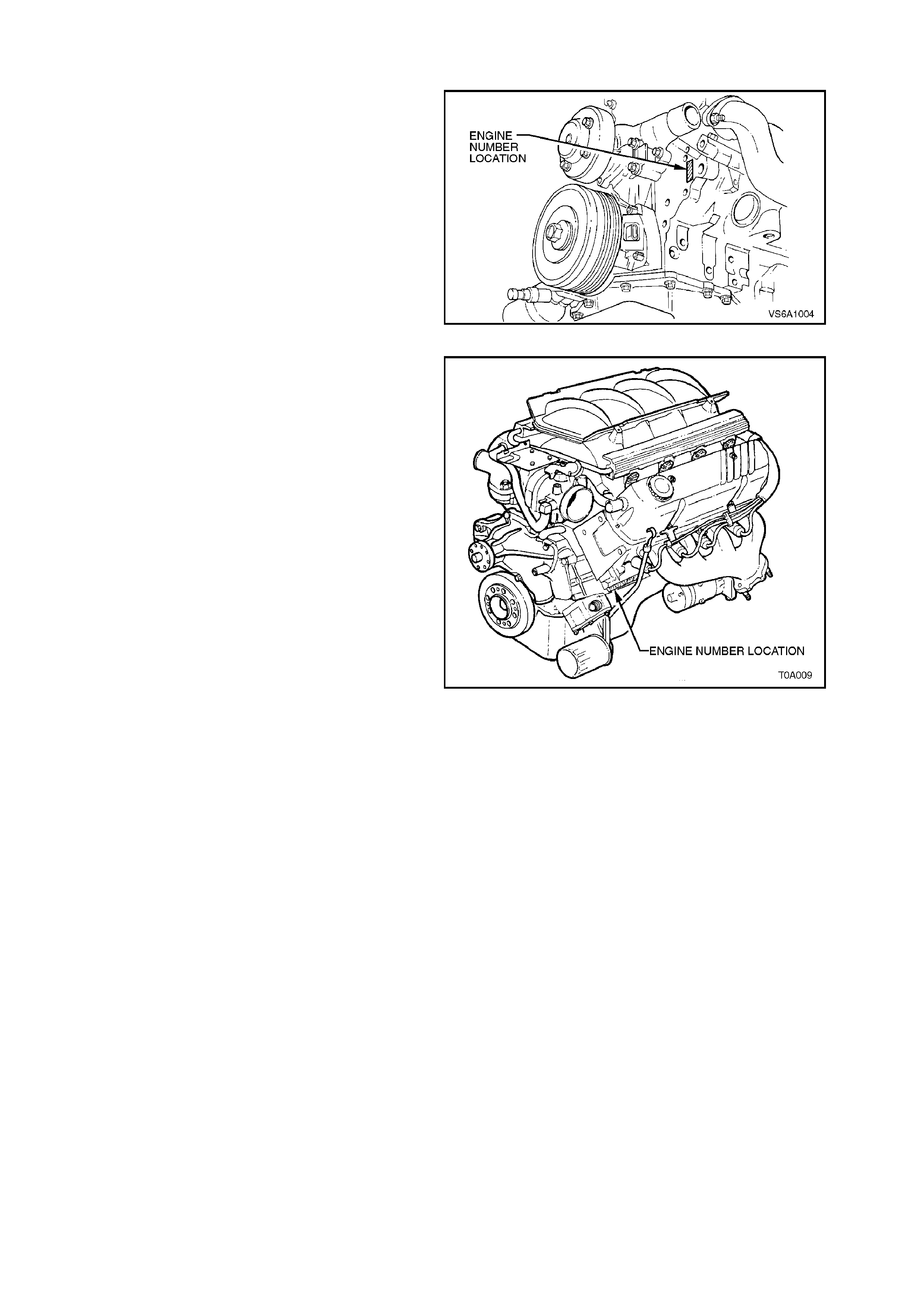

8.6 ENGINE SERIAL NUMBER

The engine number for the 3.8 V6 engine is

stamped on the front face of the engine, below the

ignition coil as illustrated in Fig.0A-12.

Figure 0A-12

The V8 engine number is stamped on a pad

located below number 2 cylinder spark plug. Refer

to Fig. 0A-13.

Figure 0A-13

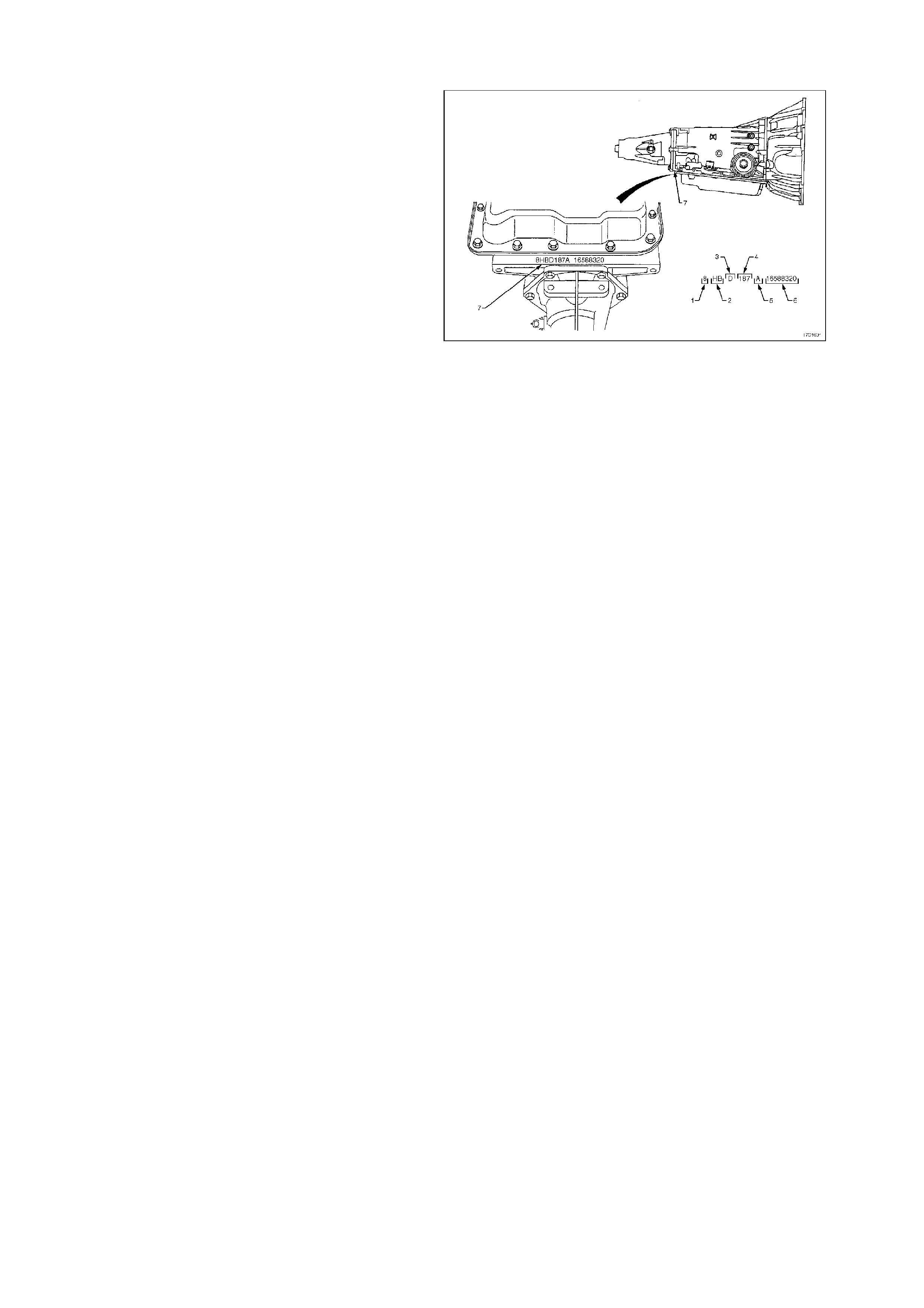

8.7 AUTOMATIC TRANSMISSION SERIAL NUMBER

The automatic transmission serial number is

stamped into a machined surface at the rear

underside of the transmission centre case, refer to

Fig. 0A-14.

1. Model Year (‘8’ = 1998)

2. Model: V8 - 5.0 litre ..................8HBD

V6 - 3.8 litre .........................8HFD

V6 Supercharged - 3.8 litre ..8HND

3. Transmission Model Identifier (D = 4L60-E)

4. Julian Date (or day of year)

5. Shift Built (a, B, J = first shift; C, H, W =

second shift)

6. Individual Transmission Serial Number

7. Transmission Identification Number Location Figure 0A-14

8.8 MANUAL TRANSMISS ION S ERIAL NUMBER

The manual trans miss ion ser ial number is loc ated on a

self adhesive decal attached to the left side of the

transmission front housing. This number provides

coded information which could be significant to parts

interpretation and should be referred to when ordering

replacement components.

Figure 0A-15

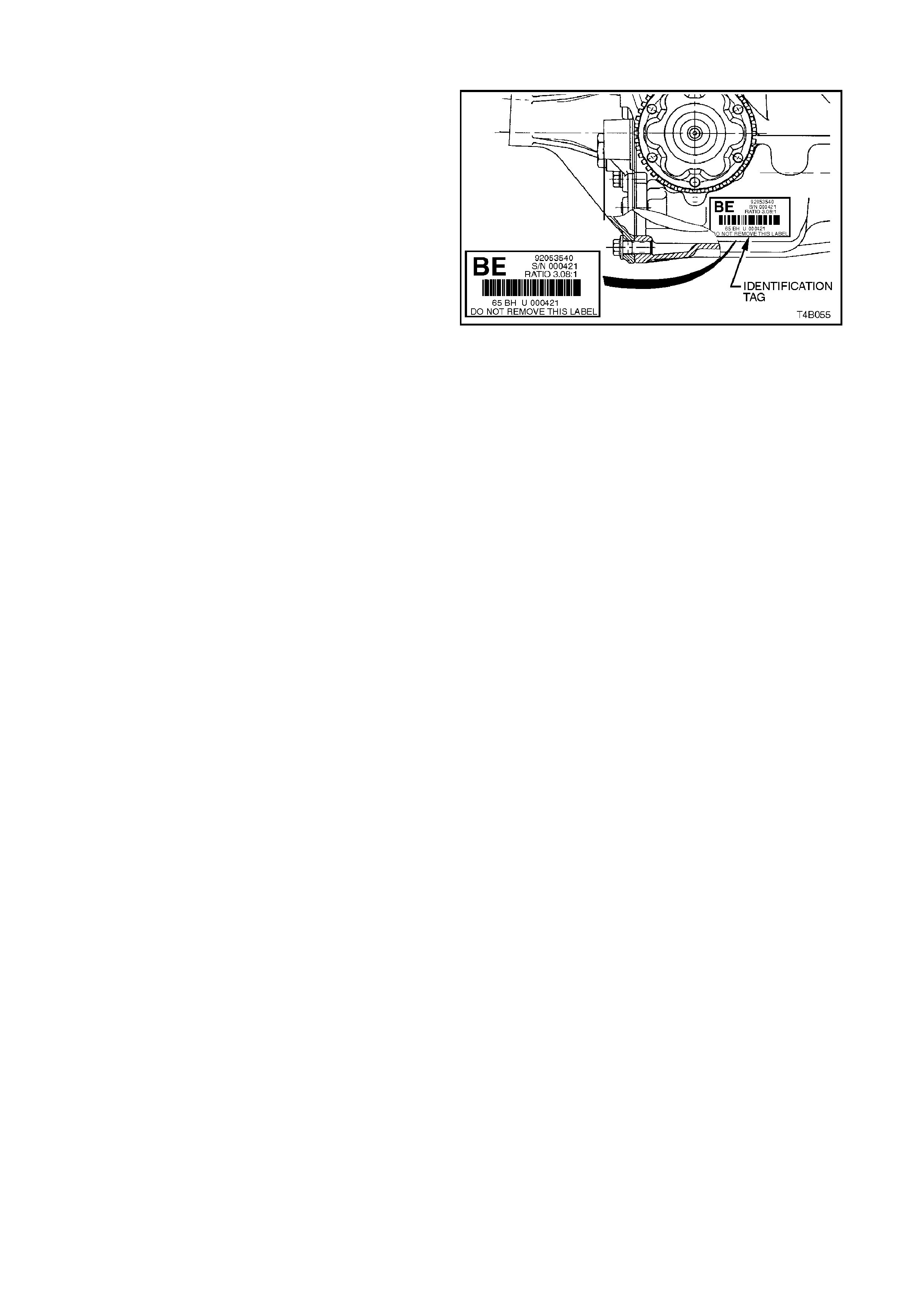

8.9 REAR AXLE IDENTIFICATION

An identification tag is adhered to the final drive

assembly to the RHS of the carrier housing, refer to

Fig. 0A-16. The tag carries the Holden part num ber for

the axle assembly, the final drive ratio and the serial

number of the axle assembly.

Figure 0A-16

9. ADDITIONAL GENERAL INFORMATION

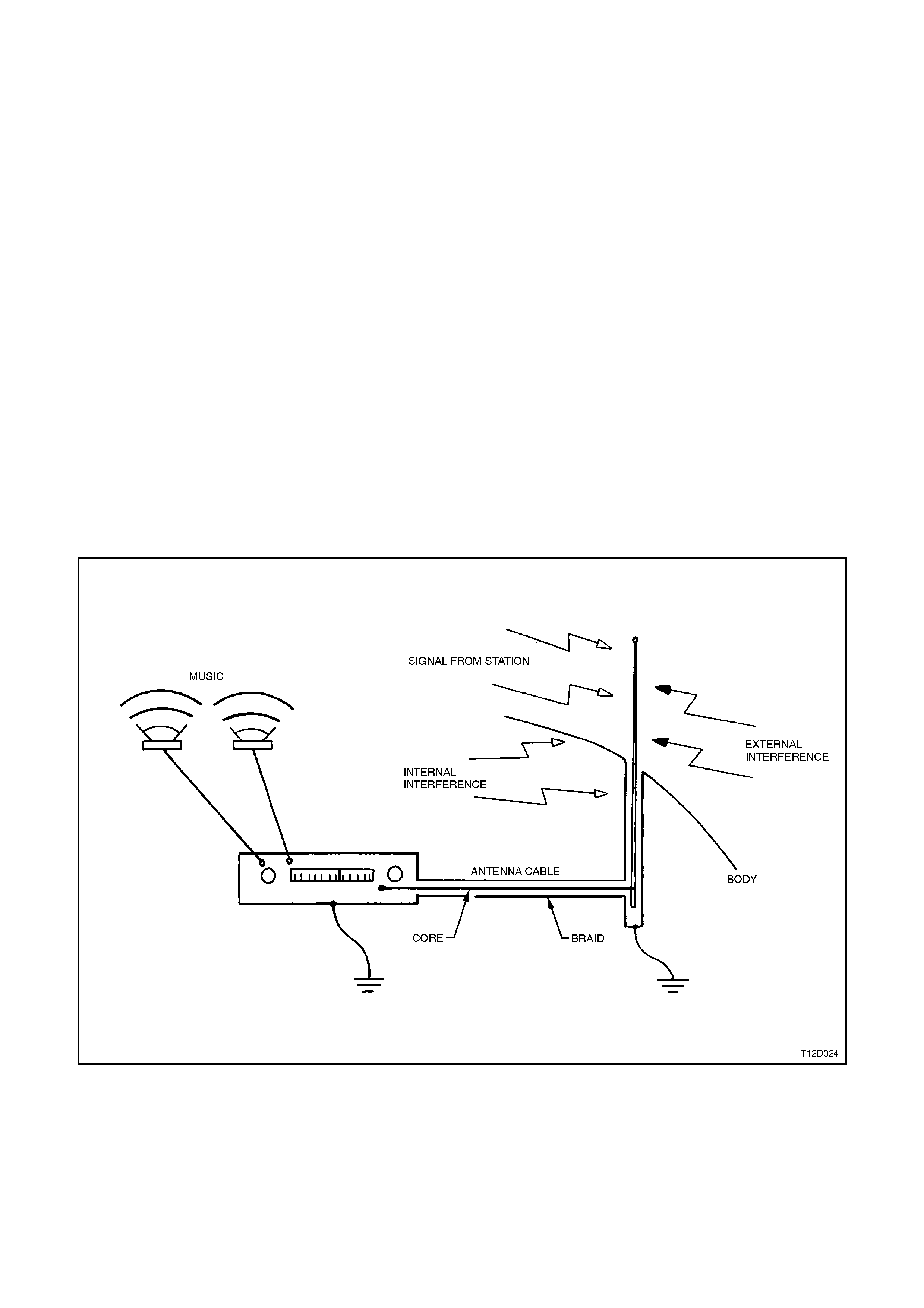

9.1 ELE CTRICAL TRANSIENTS AND RADIO FREQUENCY INTERFERE NCE

Electronic circuits are used in VT Models to perform a number of functions associated with electronic cruise control,

electronic engine and transmission control systems etc. These circuits can be damaged or malfunction as a result

of electrical transients or excessive radio frequency (RF) radiation.

ELECTRICAL TRANSIENTS

Electrical transients are high voltage spikes, produced by the sudden switching or interruption of electric currents.

Older style timing lights and battery chargers can produce serious transients, hence, it is important to use only good

quality equipment suitable for use with electronic systems.

It is also good practice to ensure that the battery is disconnected before using a battery charger.

Indiscriminate fitting of solenoids, indicators or relays can also cause transients.

RADIO FREQUENCY INTERFERENCE

One of the chief sources of RF interference is the ignition system. Other sources include CB radio and radio

telephones. The following are normally used to suppress RF interference.

Resistors e.g. High Tension Cables and Connectors.

Capacitors and Choke Coils.

Metal Braid for screening leads or suppression covers made from conductive material for screening equipment.

To prevent damage to equipment:

Do not replace interference suppressed high tension ignition cables or connectors with unsuppressed types.

Do not remove or reposition interference suppression filters or capacitors.

Figure 0A-17

9.2 STATIC ELECTRICITY

Care should be exercised when handling electronic equipment e.g. the electronic control module (ECM), to avoid

touching the terminals unnecessarily. Static electricity, which is present on every person, can cause damage to

some electronic components.

9.3 PUSH OR TOW STARTING

Do not push or tow start VT Series vehicles. Push or tow starting can result in unburned fuel passing through the

exhaust to the catalytic converter, causing damage to the converter.

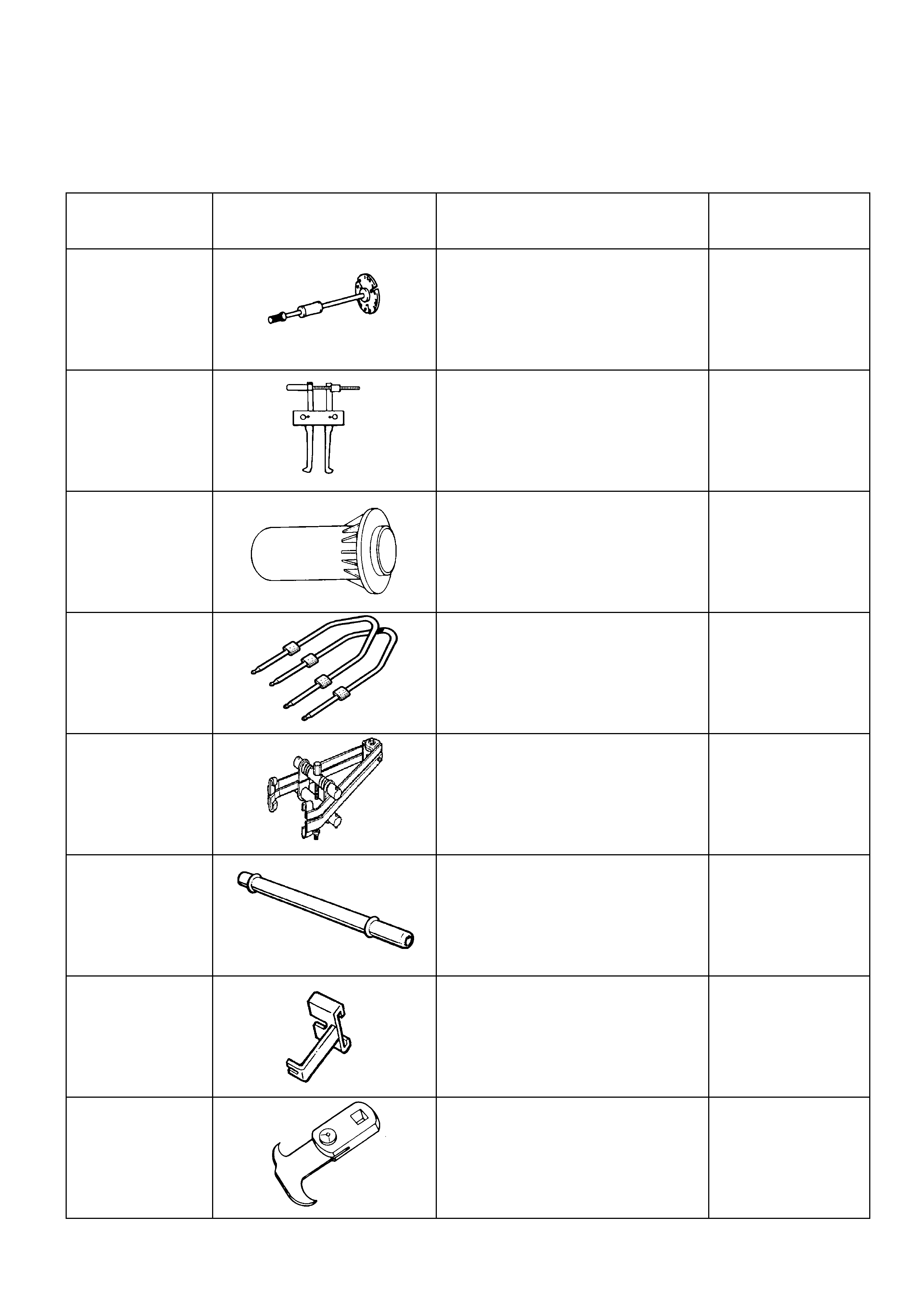

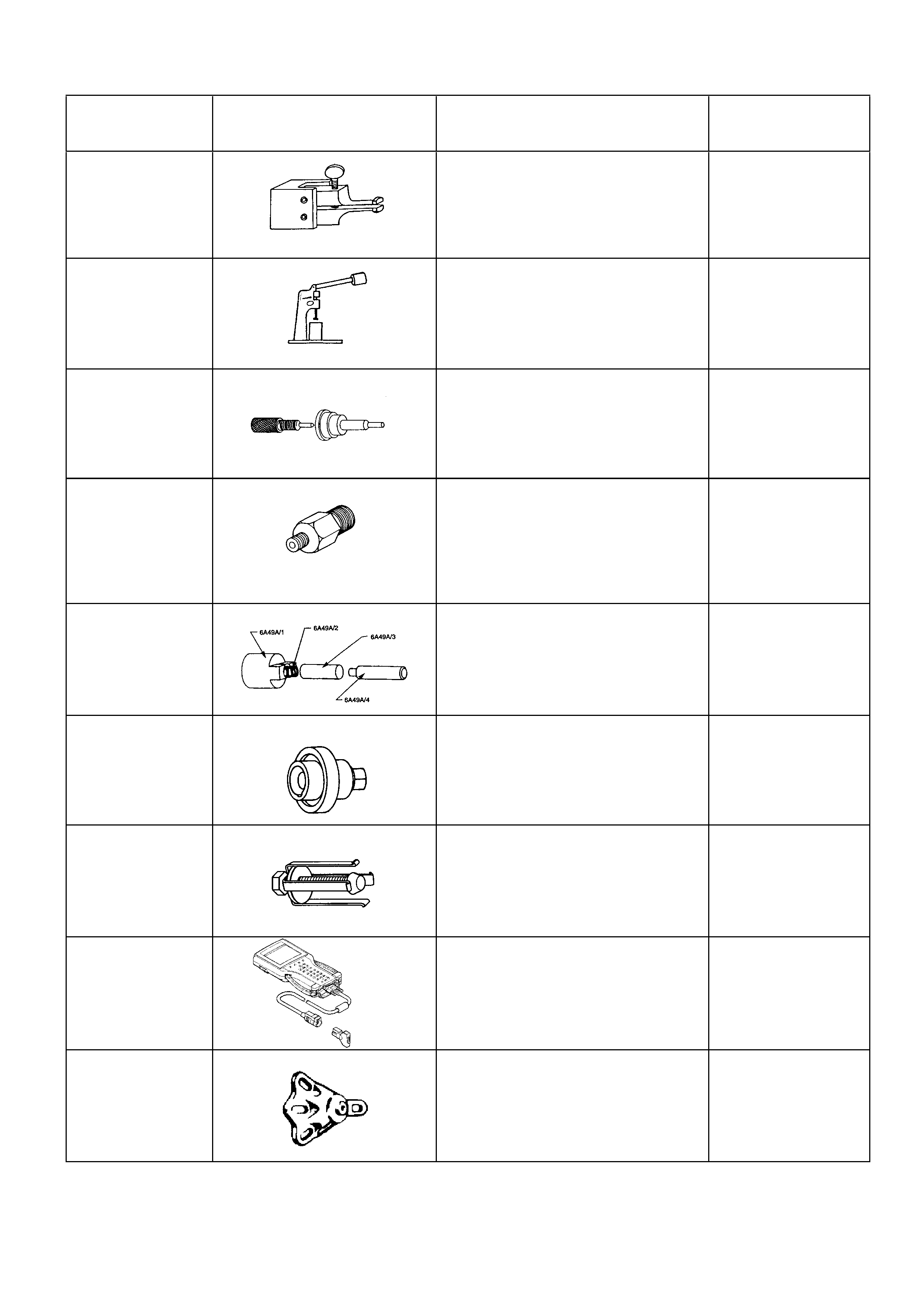

10. CONSOLIDATED TOOL LI ST

The following pages lis t and illustrate all the special se rvice tools required f or use on VT Series Models. The tools

are listed numbered and alphabetical order. The tools are also classified as according to the specification outlined in

the “Holden policy and procedures manual.

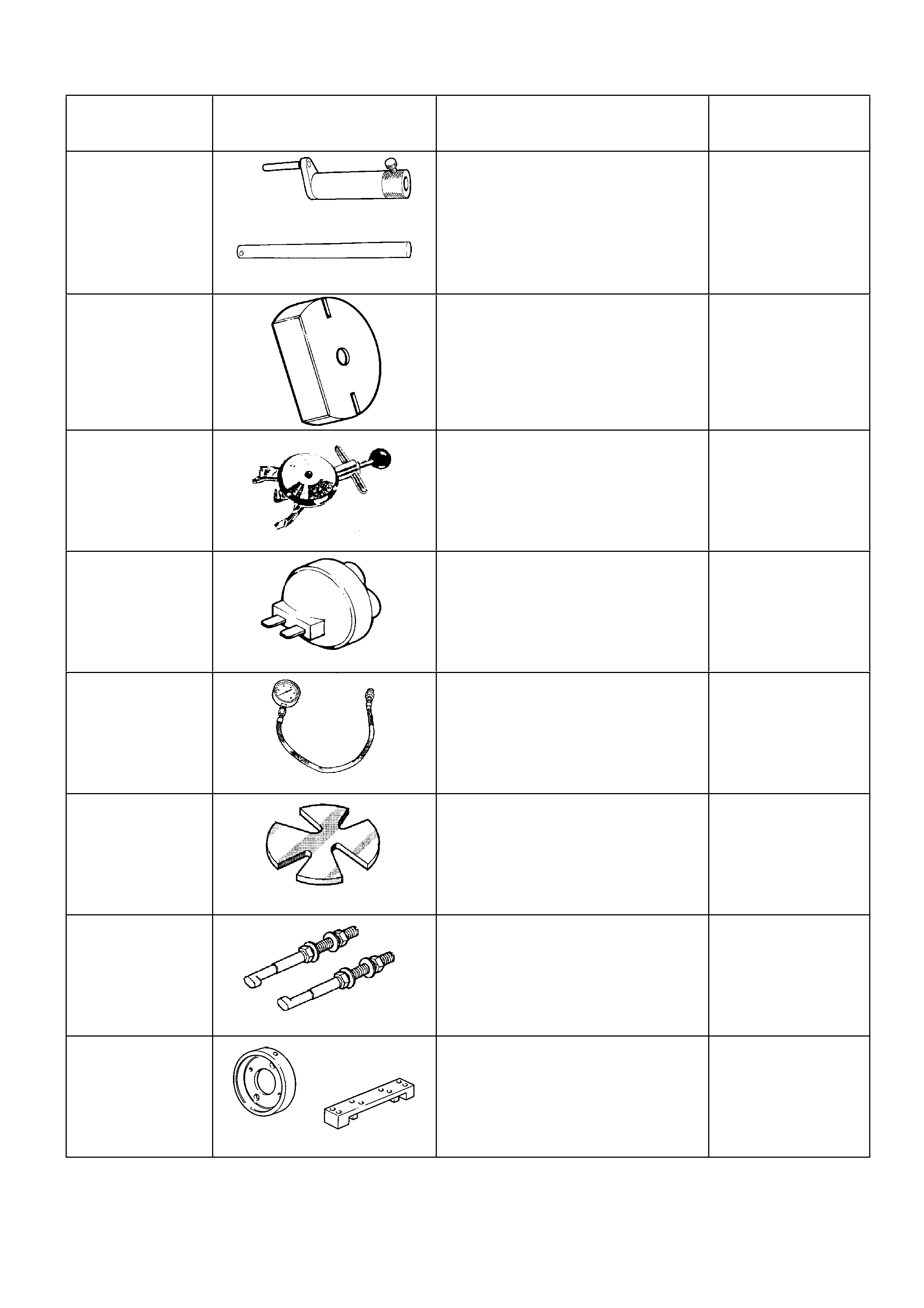

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

09520-32012

SLIDE HAMMER

Used to remove inner axle shafts

from the final drive assembly.

Previously released.

Desirable

1150

PULLER

Used with forcing screw E6661S and

adaptor AU412 to remove side

bearing cups from final drive screw

adjusters.

Previously released.

Unique

17-010A

(or E9055)

PINION OIL SEAL INSTALLER

Used to install final drive assembly

pinion oil seal.

Previously released.

Desirable

179 1308 0000

RADIO REMOVAL TOOL

Used for removing VT radio/cassette

unit from it’s mounting location.

New tool for VT.

Mandatory

180

SPRING COMPRESSOR

Used for front spring removal and

reinstallation.

Previously released.

Desirable

216812

TUBE

Used with hose SD28057 and

coupler 7434 and gauge SD28018

(or AU338) for checking fuel system

pressure.

Previously released.

Mandatory

24505373

BY-PASS VALVE ACTUATOR

SETTING TOOL

Used for checking and setting

adjustment of by-pass valve actuator

used with V6 supercharged engine

Previously released.

Desirable

56750

(or E308)

SEAL REMOVER

Used for a wide range of seal

removal applications.

Previously released.

Desirable

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

6A22-2

SPIGOT BEARING REMOVER

Alternatively, use J23907 or E6668

which includes its own slide hammer.

Previously released.

Unique

6A23

VALVE LIFTER TESTER

Used in conjunction with testing fluid

Kent More No. E1151

(previously 361-1-93)

Previously released.

Unique

6A24

VALVE LIFTER ASSEMBLY TOOLS

Used for assembly of valve lifters

during overhaul.

Previously released.

Unique

6A40A

AIR LINE ADAPTOR - 14MM

(CYLINDER INFLATOR)

Used for applying air pressure to

engine cylinder during various

service operations or diagnostic

checks.

Desirable

6A49A

PISTON PIN TOOLS

This tool includes two piston pin

guides: ONLY USE 6A49A/3 for the

5 litre engine.

Previously released.

Unique

6A53

TIMING CASE OIL SEAL

INSTALLER

Used for installing oil on 5 litre

engine.

Previously released

Unique

6A54

TIMING CASE OIL SEAL REMOVER

Used for removing oil seal from

timing case on 5 litre engine.

Previously released

Unique

70000861

TECH 2

DIAGNOSTIC SCAN TOOL

Used for diagnosis of vehicle

electrical system.

Previously released.

Mandatory

7208

REAR AXLE REMOVAL ADAPTOR

Used with E6662B for L.S.D. torque

check.

Previously released.

Desirable

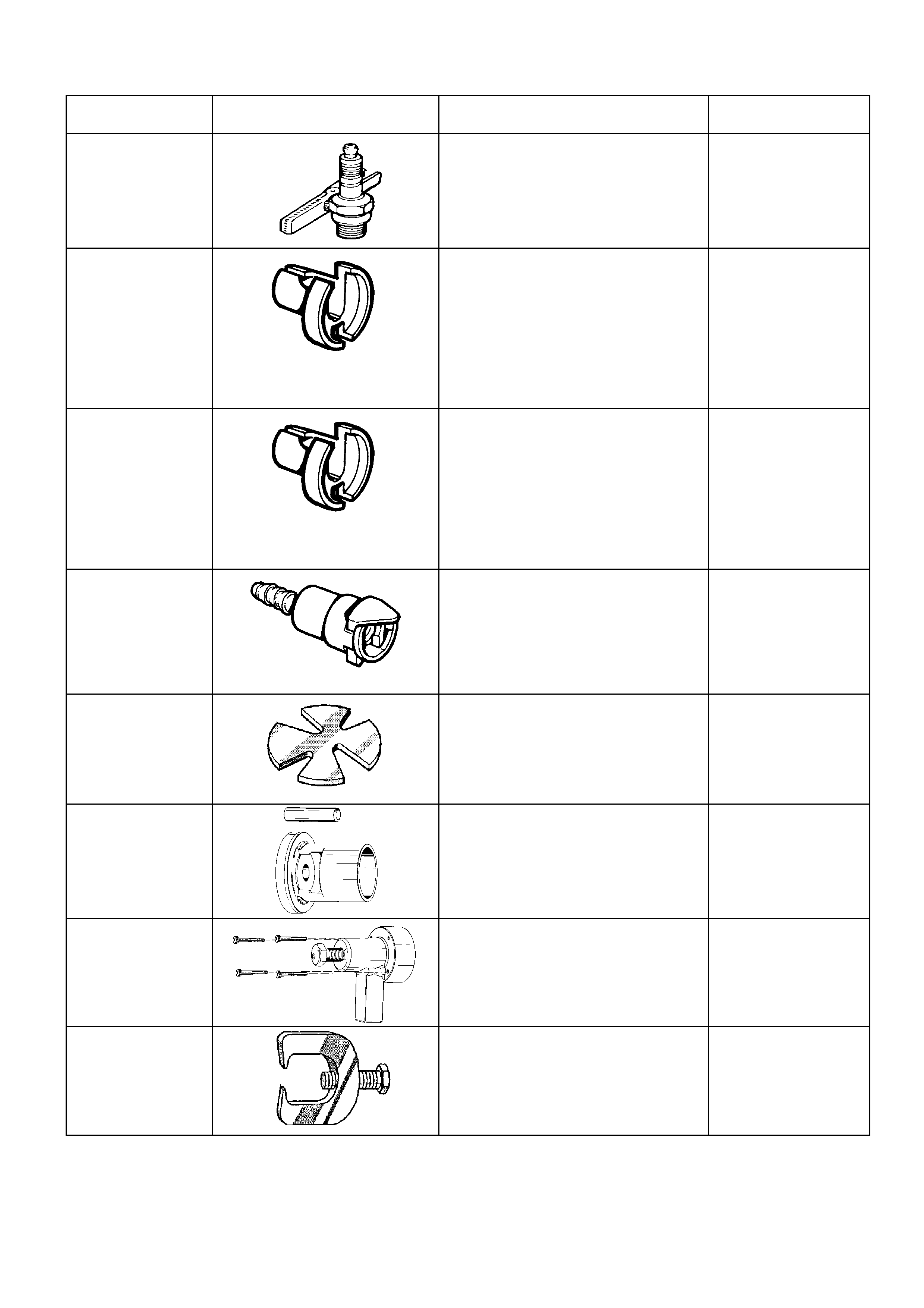

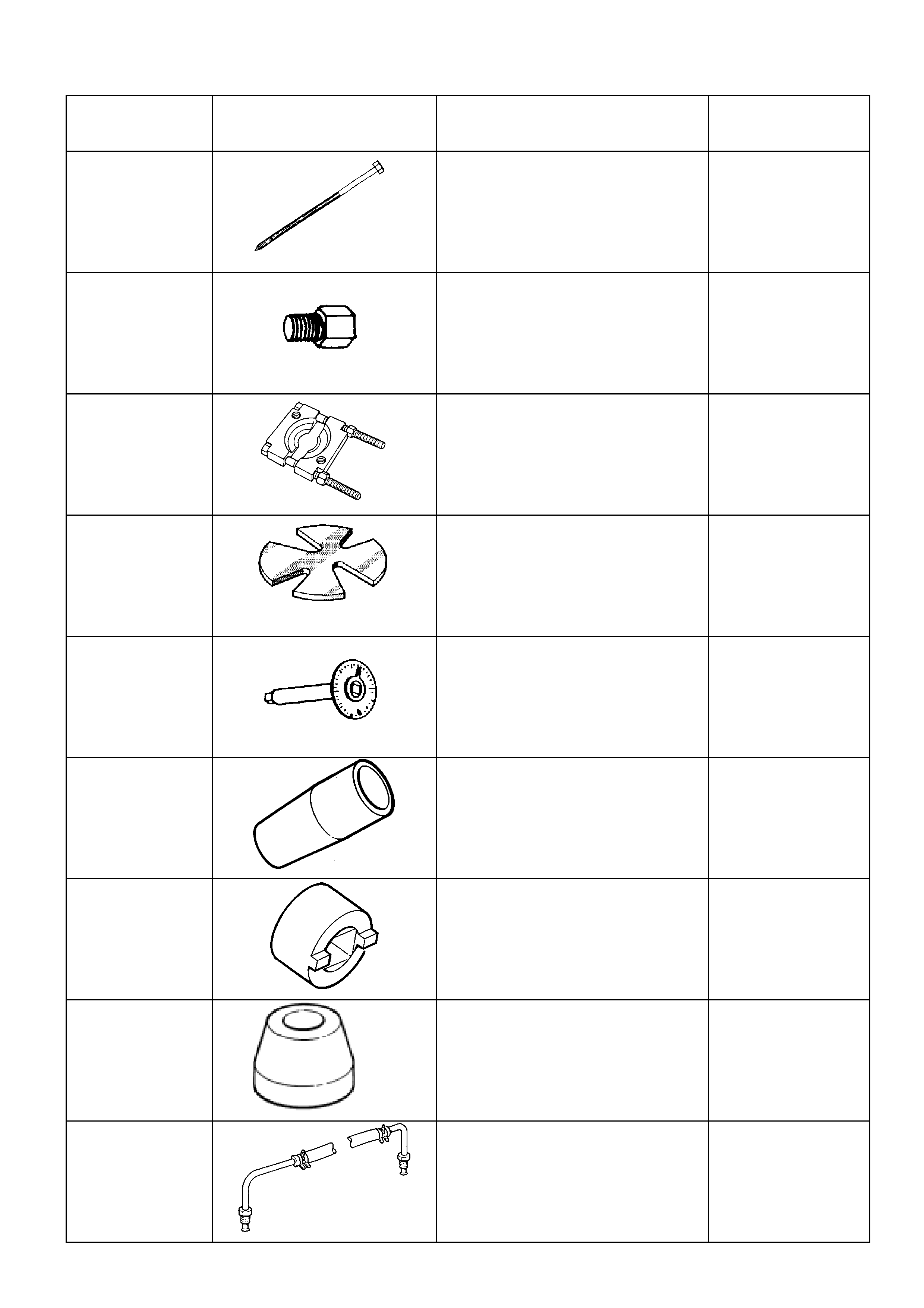

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

7230

(or ST-125)

HEI TESTER

(TEST PLUG)

Used in diagnostic checks with

engine management system.

Previously released.

Mandatory

7370

QUICK CONNECT RELEASE

TOOL, FOR NON

SUPERCHARGED APPLICATION

Used for releasing the fuel return

hose quick connects at the dash

panel and fuel rail connections once

the fuel system has been

depressurised.

Previously released

Mandatory

7371

QUICK CONNECT RELEASE

TOOL, FOR SUPERCHARGED

APPLICATION

Used for releasing the fuel return

hose quick connects at the dash

panel and fuel rail connections once

the fuel system has been

depressurised.

Previously released

Desirable

7434

COUPLER

Used in conjunction with fuel

pressure gauge hose SD28057, tube

216812 and pressure gauge

SD28018 (or AU338) for checking

fuel pressure.

Previously released.

Mandatory

7A42

PRESS PLATES

Used in many applications for

pressing on and off components.

Previously released.

Desirable

9981 066 600

BEARING ASSEMBLY FIXTURE

Used for pressing generator

bearings on at the same time. Tool

available from Robert Bosch

Australia.

New tool for VT.

Unique

9981 066 601

ROTOR BEARING REMOVAL

TOOL

Used for removing rotor from drive

end housing bearing. Tool available

from Robert Bosch Australia.

New tool for VT

Unique

9A10

BALL JOINT

REMOVER

TIE ROD BALL JOINT REMOVER

Used to disconnect steering tie rod

ball joints from steering knuckle.

Previously released.

Desirable

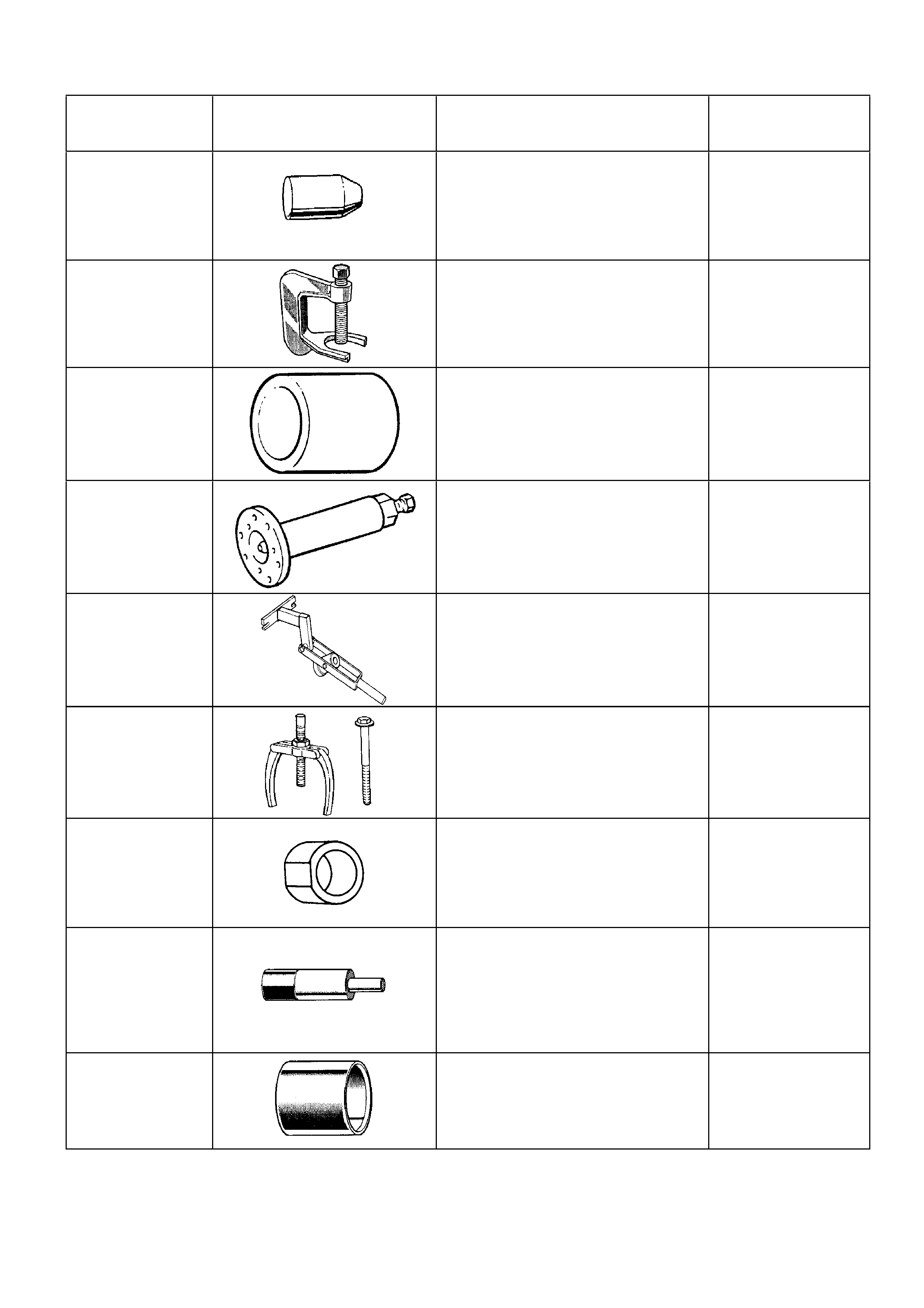

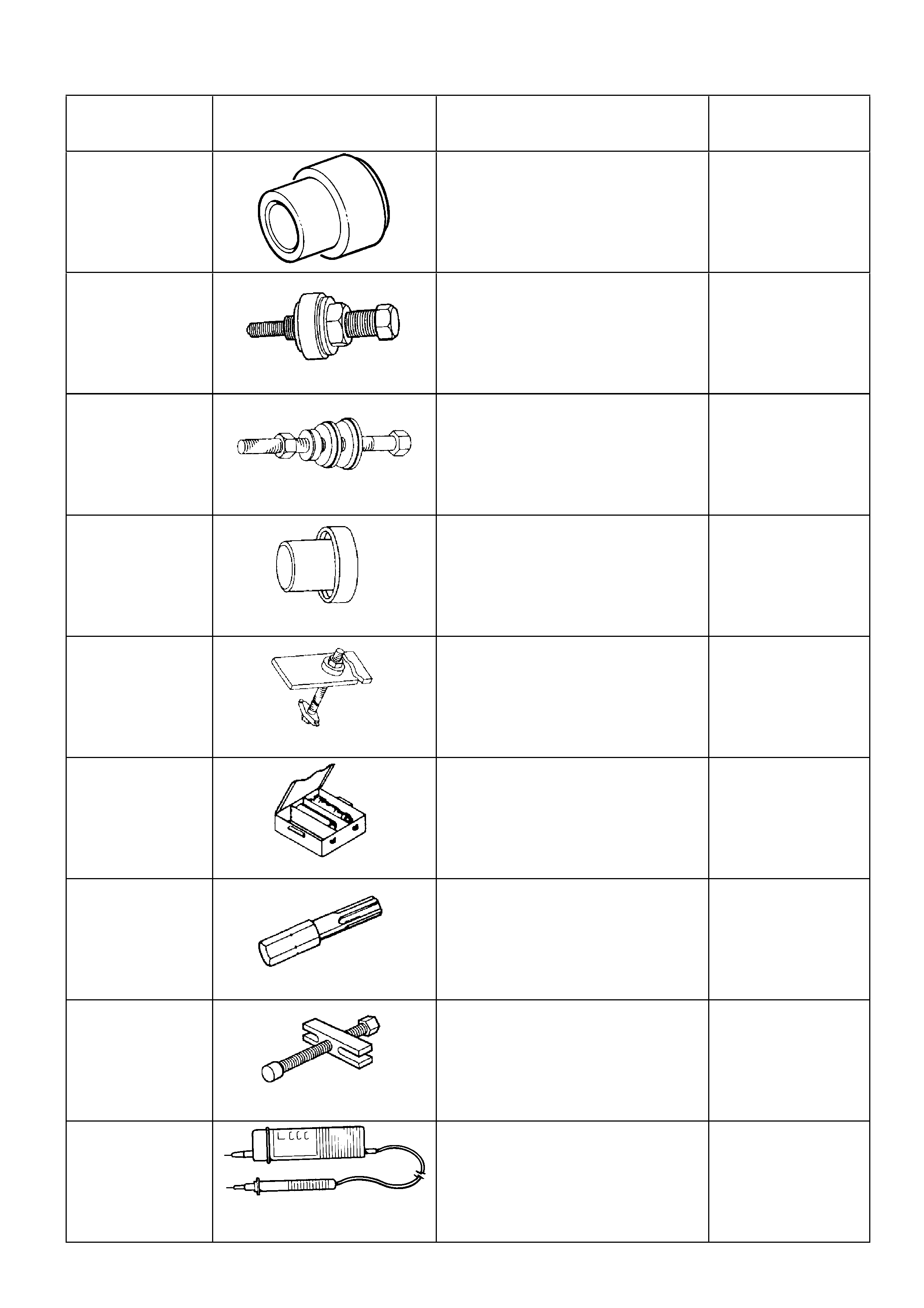

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

9A23

EXPANDER – SLEEVE SEALS

Used for expanding steering gear

rotary valve and sleeve assembly

seals before installation.

Previously released.

Unique

AJ24292-C

PRESS TOOL

Used to remove rear wheel studs

from trunnion assembly

Previously released.

Unique

AKM-500-3

SLEEVE

Used during overhaul of manual

transmission.

Previously released.

Unique

AKM-628-A

EXTRACTOR TOOL

Used to remove the mainshaft flange

and to separate the two transmission

housings (manual transmission) on

disassembly.

Previously released.

Unique

AKM-632-A

CLUTCH PRESSURE PLATE

LOADING TOOL

Used for clutch removal and

reinstallation.

Previously released.

Desirable

AMKM557

PULLER

Used for removing bush from

crossmember front mounting.

Previously released.

Desirable

AU100

REAR MAIN OIL SEAL INSTALLER

Used for 5 litre engine.

Previously released.

Desirable

AU158

CONTROL ARM TENSION ROD

BUSH REMOVER AND INSTALLER

MANDREL

Used with KM158-2 for removing

bush and AU159 and KM157-2 for

installing.

Previously released.

Desirable

AU158-2

CONTROL ARM TENSION ROD

BUSH INSTALLING SUPPORT

SLEEVE

Used with AU158 and AU159

Previously released.

Desirable

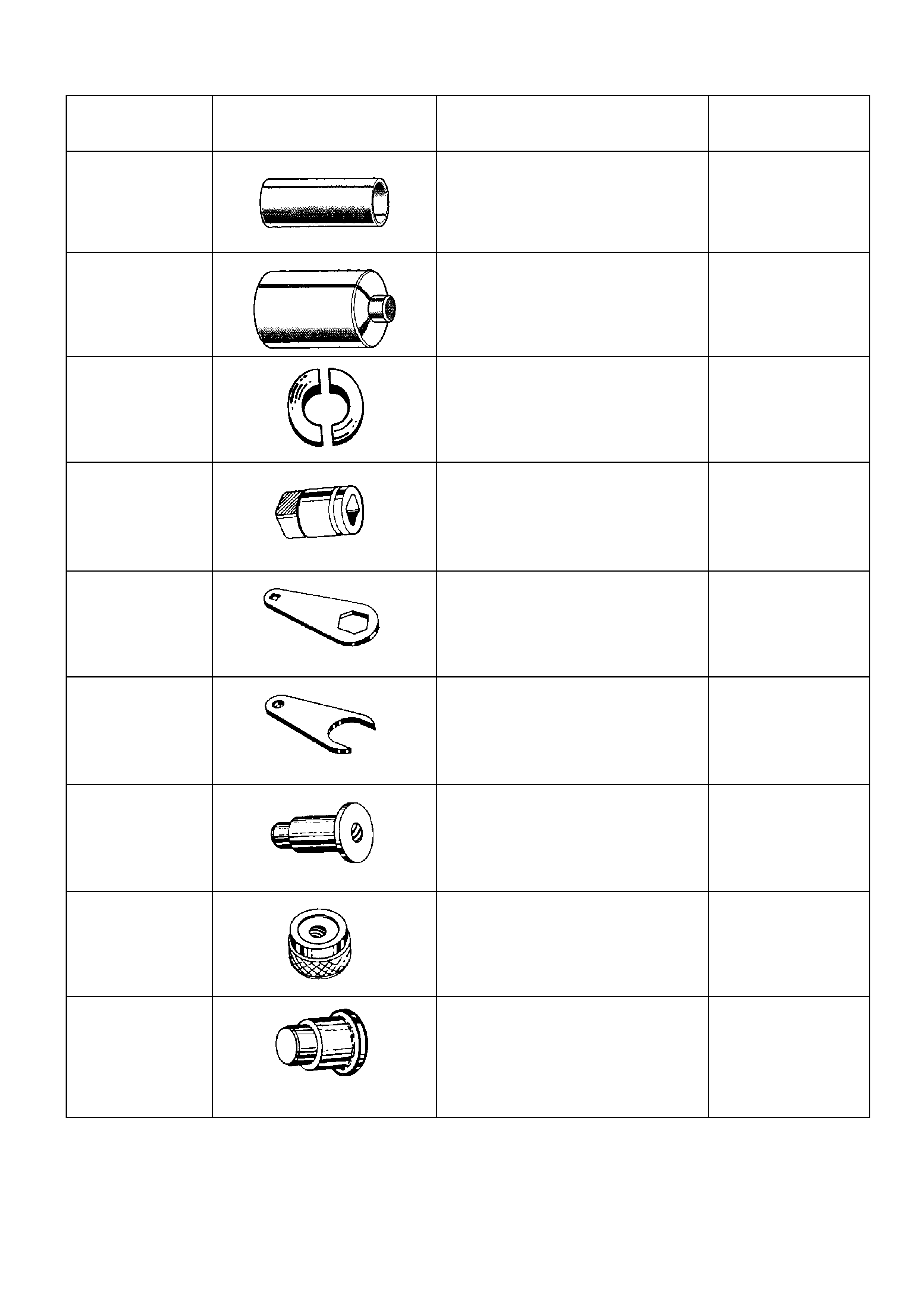

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

AU159

CONTROL ARM TENSION ROD

BUSH REPLACER SLEEVE

Previously released.

Desirable

AU162

CONTROL ARM INNER PIVOT

BUSH REMOVAL MANDREL

Used in conjunction with AU160-1

and KM157-2

Previously released.

Desirable

AU188

PRESS PLATES

Used for removing power steering

pump pulley on vehicles with 5 litre

engine.

Previously released.

AU211-A

RACK PAD ADJUSTING SCREW

WRENCH

Previously released.

Desirable

AU301

RACK PAD ADJUSTING SCREW

LOCK NUT WRENCH

Previously released.

Desirable

AU305

TIE ROD WRENCH

Used for removing/reinstalling tie rod

ball joint housing from steering rack.

Previously released.

Unique

AU306

LOWER PINION BEARING

REMOVER

Used with driver handle AU355-A

(or M523-1) to remove steering gear

pinion lower bearing.

Previously released.

Unique

AU307

PINION LOWER BEARING

INSTALLER

Used to install steering gear pinion

lower bearing.

Previously released.

Unique

AU313

STEERING GEAR UPPER PINION

OIL SEAL INSTALLER

Used to install pinion oil seal during

steering gear overhaul.

Previously released.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

AU314

STEERING GEAR VALVE

HOUSING SEAL AND BEARING

REMOVER

Previously released.

Unique

AU315

STEERING GEAR VALVE

HOUSING SEAL AND BEARING

INSTALLER

Previously released.

Unique

AU316

PRE LOAD ADAPTOR

Used to measure steering gear input

shaft/steering mechanism turning

torque in conjunction with a suitable

torque wrench.

Previously released.

Desirable

AU354

SLIDE HAMMER

Used in conjunction with 6A22-2 to

remove spigot bearing from rear of

crankshaft. To remove rear bearing

cap on V6 engines, two AU354’s

must be used.

Previously released.

Desirable

AU385-4

REMOVER/INSTALLER

Used to remove and install bushes

into rear suspension stabiliser bar.

Previously released.

Desirable

AU384-B

PULLER SCREW

Used in conjunction with AU384-2,

AU384-3, AU384-4, AU384-7 and

AU384-6A. For removal/reinstallation

of the camshaft and balance shaft

bearings on V6 engine.

Previously released.

Desirable

AU385

PISTON PIN REMOVER

Comprises: AU385-1 base; AU385-2

guide; AU385-3 support; AU385-4

mandrel; AU385-5 spring

AU385-6 guide.

Used for pressing gudgeon pins in

and out of V6 connecting rods.

Previously released.

Unique

AU385-4

REMOVER/INSTALLER

Used to remove and install bushes

into rear suspension stabiliser bar.

Previously released.

Desirable

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

AU388

CONNECTING ROD GUIDE TOOLS

Used when removing/reinstalling

connecting rod/piston assemblies

from V6 engine.

Previously released.

Unique

AU390

FABRICATED T HANDLE

WINDSCREEN REMOVAL TOOL

AND PIANO WIRE

Previously released.

Unique

AU390-1

PIANO WIRE

Used in conjunction with T handle

AU390 for windscreen removal.

Previously released.

Unique

AU392

PRESSURE HOSE SET

Comprises of AU392-1 hose with

male end fitting; AU392-2 hose with

female end fitting

Used for checking power steering

system pressures.

Previously released.

Mandatory

AU406

OIL PRESSURE GAUGE

Used for checking engine oil

pressure (as an alternative use

commercially available equivalent).

Previously released.

Mandatory

AU407

SCREW ADJUSTER SOCKET

Used for checking and adjusting

screw adjusters on final drive

assembly during overhaul.

Previously released.

Unique

AU408

DUMMY ARBOR

Used with dummy pinion from

E9300A

To check pinion height on final drive

assembly during overhaul.

Previously released.

Unique

AU409

PRESS FIXTURE

Used for installing needle bearings

and side bearing cup into screw

adjusters on final drive assembly

during overhaul. Used with AU411.

Previously released.

Unique

AU410

SEAL INSTALLER

Used for installing seal into screw

adjusters on final drive assemblies.

Previously released.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

AU411

BEARING AND CUP REMOVER

Used for installing needle bearings

and side bearing cup into screw

adjusters on final drive assembly

during overhaul. Used with AU409.

Previously released.

Unique

AU412

ADAPTOR

Used in conjunction with E66615 and

1150 for removing final drive side

bearing cups from screw adjusters.

Previously released.

Unique

AU415

CONVERSION SCALE

Must be fitted to inclinometer to

enable propeller shaft phase angle of

greater than 30 degrees to be

checked

Previously released.

Mandatory

AU416

TOR X BIT

Used to remove and install brake

backing plate to trailing arm

attaching bolts. (as an alternative,

use commercially available

equivalent).

Previously released

Unique

AU424

CRANKSHAFT BALANCER

PULLER

Used for removal of balancer on V6

engine.

Previously released.

Mandatory

AU425

COOLING SYSTEM FILLER TUBE

Used to ensure coolant level is

correct.

Previously released.

Mandatory

AU435

COOLANT TESTER

Used for testing coolant

concentration.

Previously released.

Mandatory

AU440

CONTRACTOR - SLEEVE SEALS

Used for extracting steering gear

rotary valve and sleeve assembly

seals after installation.

Previously released.

Unique

AU448

CRANKSHAFT BALANCER

HOLDING TOOL

Used to hold V6 engine balancer

while removing/reinstalling retaining

bolt.

Previously released.

Desirable

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

AU453

FUEL PRESSURE GAUGE HOSE

ADAPTOR

Used for checking system fuel

pressure in conjunction with

SD28018.

Previously released.

Mandatory

AU454

GEAR REMOVER PLATES

Used to remove 3rd/4th synchromesh

assembly, 3rd speed gear, 2nd speed

gear and related components from

the manual transmission main shaft.

Previously released.

Unique

AU455

CONNECTOR BODY REMOVER

Mandatory tool used to remove the

door wiring harness connector from

the A and B pillars.

New tool for VT.

Mandatory

AU456

RACK SEAL PROJECTOR-LONG

Used when overhauling steering

gear.

New tool for VT.

Unique

AU457

FRONT CROSSMEMBER

CENTERING TOOL

Used when any service operation

requires removal/reinstallation of

front suspension crossmember , or

when checking front end alignment.

New tool for VT.

Desirable

AU458

REAR CROSSMEMBER

CENTERING TOOL

Used when any service operation

requires removal/reinstallation of rear

suspension crossmember , or when

checking rear end alignment.

New tool for VT.

Desirable

AU460

INSTALLER-INNER RACK SEAL

AND SPACER

Used in conjunction with driver

handle AU355-A when overhauling

steering gear.

New tool for VT.

Unique

AU461

CLEVIS PIN REMOVAL PUNCH

Used for removing clevis pin on

electric adjustable seat assemblies

during repair.

New tool for VT.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

AU462

SELECTOR MECHANISM

LOADING TOOL

Used to preload the selector arm,

spring and associated components

for reassembly into the manual

transmission rear case on V6 and 5

litre applications.

New tool for VT.

Unique

AU463

REAR MAIN OIL SEAL INSTALLER

Used for 5 litre engine.

New tool for VT.

Desirable

BT3373-F

BELT TENSION GAUGE

Used when checking drive and

accessory belt tension and

adjustments.

Previously released.

Desirable

BT-8329

(or ST-8329)

INJECTOR NODE LIGHT TESTER

Used when carrying out engine

management electrical diagnostic

checks.

Previously released.

Mandatory

BT-8515

EXHAUST BACK PRESSURE

GAUGE (WITH ADAPTOR)

Previously released.

Unique

E1312

PRESS PLATES

Used in many applications for

pressing on and off components.

Previously released.

Desirable

E1408

STEERING WHEEL PULLER LEGS

Used in conjunction with a suitable

steering wheel puller such as J1858-

A for removing steering wheel.

Previously released.

Mandatory

E1409

(or 9A6-1)

REAR MAIN SEAL HOUSING

ALIGNING TOOL

Used when aligning rear manual seal

housing on V6 engine. Note:

E1409/11 replaced with J41349.

Previously released.

Desirable

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

E1460-1

POWER STEERING PUMP SHAFT

SEAL INSTALLER

Used for installing power steering

pump shaft front seal

Previously released.

Unique

E1461-1

PRESSURE GAUGE ASSEMBLY

Used when carrying out power

steering system pressure checks in

conjunction with AU392 Pressure

Hose Set

Previously released.

Mandatory

E1673A15

ADAPTOR

Used to remove rear pinion bearing

during final drive overhaul.

Used with E1673MT puller and

E1673B16.

Previously released

Unique

E1673N15

ADAPTOR

Used to remove final drive side

bearings from differential case.

Used with E1673MT puller and

E1673B16.

Unique

E1673B16

STEPPED PLUG

Used with adaptors and puller when

removing bearings in final drive

assembly during overhaul.

Previously released.

Unique

E1673MT

BASIC PULLER

Used with adaptors when removing

bearings from final drive assembly or

manual transmission.

Previously released.

Unique

E1896

(or 56750)

CLAMP PLIERS

Used for securing drive shaft

constant velocity joint boot clamps.

Previously released.

Desirable

E308

SEAL REMOVER

Used for a wide range of seal

removal applications.

Previously released.

Desirable

E3C10AER

PINION REAR BEARING CONE

REPLACER

Used to install pinion rear bearing

during final drive overhaul.

Previously released.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

E6661S

FORCING SCREW

Used with puller 1150 and adaptor

AU412 to remove side bearing cups

from final drive screw adjusters.

Previously released.

Unique

E6662B

TORQUE WRENCH ADAPTOR

Used with 7208 and a suitable

tension wrench to check L.S.D.

torque

Previously released.

Desirable

E6673

PRESS PLATES

Used for many applications for

pressing on and off components.

Previously released.

Desirable

E7110

PRESS PLATE

Used for supporting stabiliser bar link

while pressing out or installing bush.

Previously released.

Unique

E7115

ANGLE WRENCH

Used to tighten component fasteners

when angle torque is required.

Previously released.

Desirable

E8803-6

RACK SEAL PROTECTOR SHORT

Used during steering gear overhaul.

New tool for VT.

Unique

E8803-7

RACK PISTON TOOL

Used to rotate the end bushing to

remove/install retaining wire clip

during steering gear overhaul.

New tool for VT.

Unique

E8803-9 RACK PISTON SEAL EXPANDER

Used to expand the rack piston seal

prior to installation.

New tool for VT.

Unique

E8803-10

RACK SEAL TEST ADAPTOR

Used in conjunction with hand

vacuum J-23738-A pump to asses

rack seal serviceability.

New tool for VT.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

E8803-11

RACK END SEAL/BUSH

INSTALLER

Used to install rack end seal and

bush during steering gear overhaul.

New tool for VT.

Unique

E9239A

(or J25033-B)

POWER STEERING PUMP PULLEY

RE-INSTALLER

Previously released.

Desirable

E9271

PINION BEARING CUP INSTALLER

Used to install the pinion bearing

cups in the final drive housing.

Previously released.

Unique

E9277

SIDE BEARING INSTALLER

Used to install the side bearings to

the final drive differential case.

Previously released.

Unique

E9293

PINION BEARING CUP REMOVER

Used to remove the pinion bearing

cups in the final drive housing.

Previously released.

Unique

E9300A

PINION HEIGHT SETTING GAUGE

SET

Used with Dummy Arbor AU408 to

check pinion height on final drive

assembly during overhaul.

Previously released.

Unique

ETX30H

T30HTORX BIT

Used to remove screws securing

horn bar and air bag inflator module

assembly to steering wheel and SRS

SDM to floor mounting bracket

Previously released.

Mandatory

J1859-A

STEERING WHEEL PULLER

Used in conjunction with E1408 to

remove steering wheel (or use

commercially available equivalent).

Previously released.

Desirable

J21008-A

SELF POWERED TEST LIGHT

Used during electrical circuit

diagnostic checks (or use

commercially available equivalent).

Previously released.

Mandatory

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J21368

OIL PUMP ALIGNMENT BAND

Used to align automatic transmission

oil pump cover to oil pump body

during transmission overhaul.

Previously released.

Unique

J21426

REAR EXTENSION HOUSING

SEAL INSTALLER

Used to install automatic

transmission/ manual transmission

rear extension housing oil seal.

Previously released.

Unique

J21427-01

PULLER ADAPTOR

Used with puller J8433 to remove

automatic transmission output speed

sensor ring from output shaft.

Previously released.

Unique

J21867

PRESSURE GAUGE AND HOSE

ASSEMBLY

Used for checking automatic

transmission oil pressure during

diagnostic checks.

Previously released.

Mandatory

J22912-01

PRESS PLATES

Used in many applications for

pressing on and off components.

Previously released.

Desirable

J23062-14

BUSH REMOVER

Used in conjunction with driver

handle J8092 to install extension

housing rear bush.

New tool for VT.

Unique

J23327

CLUTCH SPRING COMPRESSOR

Used to compress automatic

transmission clutch assembly springs

during transmission overhaul.

Previously released.

Unique

J23498-A

INCLINOMETER

Used to check propeller shaft phase

and driveline angles. Must be fitted

with AU415 when checking phase

angles of greater than 30 degrees.

Previously released.

Mandatory

J23600-B

(or BT3373-F)

BELT TENSION GAUGE

Used when checking drive and

accessory belt tension and

adjustments.

Previously released.

Desirable

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J23738-A

VACUUM PUMP (20 IN. HG

MINIMUM)

Used for many applications, including

engine, automatic transmission,

steering gear, diagnostic checks.

Previously released.

Mandatory

J23907

SLIDE HAMMER

Used for many functions including

bushing removal during automatic

transmission overhaul

Unique

J24036

BUSH REMOVER

Used during automatic transmission

overhaul.

New tool for VT.

Unique

J25016

OIL PUMP SEAL INSTALLER

Used to install automatic

transmission oil pump seal.

Previously released.

Unique

J25018-A

CLUTCH SPRING COMPRESSOR

ADAPTOR

Used in conjunction with J23327 to

compress clutch springs during

automatic transmission overhaul.

Previously released.

Unique

J25019-9

BUSH INSTALLER

Used in conjunction with driver

handle J8092 to install reverse input

clutch rear bush.

New tool for VT.

Unique

J25019-12

BUSH INSTALLER

Used in conjunction with driver

handle J8092 to install bush during

automatic transmission overhaul.

New tool for VT.

Unique

J25019-14

BUSH REMOVER

Used during automatic transmission

overhaul.

New tool for VT.

Unique

J25019-16

BUSH REMOVER

Used during automatic transmission

overhaul.

New tool for VT.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J25025-B

DIAL INDICATOR STAND AND

GUIDE PIN SET

Used in many applications.

Previously released.

Unique

J25359-8

TOR X BIT HOLDER

Used with ETX30H Torx bit

Previously released.

Desirable

J25359-19

NO. 15 TORX BIT

Used to remove Powertrain Control

Module access cover screws.

Previously released.

Desirable

J25765-A

PRE-LOAD GAUGE

(3/8” DRIVE)

Used for many applications.

Previously released.

Mandatory

J28431-B

PETROL AND DIESEL ENGINE

FLUID AND TRANSMISSION FLUID

DYE

Supplied in packs of 24, 1oz bottles.

Suitable for black light tracing of

engine transmission, power steering

and cooling system fluid leaks.

Previously released.

Desirable

J28540-A

SEAL INSTALLER

Used for installing front cover oil seal

on V6 engines.

Previously released.

Unique

J29369-1

UNIVERSAL BUSH REMOVERS

Used during automatic transmission

overhaul.

Previously released.

Unique

J29369-2

UNIVERSAL BUSH REMOVERS

Used during automatic transmission

overhaul

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J29882

INNER OVERRUN CLUTCH SEAL

PROTECTOR

Used during automatic transmission

overhaul.

Previously released.

Unique

J29883

INNER FORWARD CLUTCH SEAL

PROTECTOR

Used during automatic transmission

overhaul.

Previously released.

Unique

J3289-20

HOLDING FIXTURE BASE

Used in conjunction with J8363-20 to

hold automatic transmission during

overhaul.

Previously released

Unique

J33013B

HUB & DRIVE PLATE

REMOVER/INSTALLER

Used reinstall A/C compressor clutch

pulley and bearing assembly.

Desirable

J33017

PULLEY & BEARING ASSEMBLY

TOOL

Used in conjunction with J33013B to

rein stall A/C compressor clut ch

pulley and bearing assembly.

Desirable

J33023-A

PULLER PILOT

Used in conjunction with J8433-1 to

remove A/C compressor clutch ro tor

and bearing assembly.

Desirable

J33025

CLUTCH COIL PULLER LEGS

Used in conjunction with J8433-1 to

remove A/C compressor clutch ro tor

and bearing assembly.

Desirable

J33027

CLUTCH HUB HOLDING TOOL

Used to hold A/C compressor clutch

hub while removing shaft nut.

Desirable

J33037

2 - 4 BAND APPLY PIN TOOL

Used during automatic transmission

overhaul.

Previously released.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J33095

MICRO PACK TERMINAL

REMOVER

Used for removing wiring harness

terminals from connector body -

PCM.

Previously released.

Unique

J34142-A

UNPOWERED TEST LIGHT

Must have current draw of less than

0.3 A.

Previously released.

Mandatory

J34196

BUSH REMOVER/INSTALLER

Used to remove/install various

bushings in automatic transmission

during overhaul.

New tool for VT.

Unique

J34627

SNAP RING PLIERS

Assists in the removal/replacement

of the output shaft snap ring during

automatic transmission overhaul.

Previously released.

Unique

J35138

TORQUE CONVERTER END PLAY

To be used in conjunction with

commercially available magnetic

stand and dial indicator during

automatic transmission overhaul.

Previously released.

Unique

J35616-A

CONNECTOR TEST ADAPTOR KIT

Used when carrying out electrical

diagnostic circuit charts.

Previously released.

Desirable

J36352

SPEED SENSOR INSTALLER AND

GAUGING TOOL

Used for installing the output speed

sensor ring onto the transmission

output shaft.

Previously released.

Unique

J36400-5

WEATHER PACK TERMINAL

REMOVER

Used for removing wiring harness

terminals from connector body.

Previously released.

Desirable

J36418-B

TURBINE SHAFT SEAL INSTALLER

AND RESIZER

Used during automatic transmission

overhaul.

Previously released.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J36515

J36515-10

ASSEMBLY PALLET AND

ADAPTOR PLATES

Used to pre-assemble the geartrain

and selector components, prior to

assembly into the rear case of 5 litre

manual transmission.

Previously released.

Unique

J36515-15

INPUT SHAFT ADAPTOR

Used in conjunction with J36515 and

J36515-16 when overhauling 5 litre

manual transmission.

New tool for VT.

Unique

J36515-16

CLUSTER GEAR ADAPTOR PLATE

Used in conjunction with J36515 and

J36515-15 when overhauling 5 litre

manual transmission.

New tool for VT.

Unique

J37789-A

OIL PUMP REMOVER

Used to remove the oil pump from

the automatic transmission case

during automatic transmission

overhaul. Used in conjunction with

J39119.

Previously released

Unique

J38196

SEAL INSTALLATION TOOL

Used for installation of the rear main

oil seal on V6 engines. Has been

superseded by J381916-AUS.

Previously released.

Desirable

J38196-AUS

REAR MAIN SEAL INSTALLER

Used on V6 engine.

Previously released.

Desirable

J38735-3

STATOR SHAFT SEALING RING

INSTALLER

Used for installing new stator shaft

dealing rings onto the oil pump

during overhaul procedure.

Previously released.

Unique

J39032

STATIONARY GLASS REMOVAL

TOOL

Used for stationary glass removal (or

use commercially available

equivalent)

Previously released.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J39119

OIL PUMP REMOVER ADAPTOR

Used to remove oil pump in

conjunction with J37789.

Previously released.

Unique

J39200

DIGITAL MULTIMETER

Must have at least 10 MΩ input

impedance and be capable of

reading frequencies.

Previously released.

Mandatory

J39765

MODULAR FUEL SENDER

ASSEMBLY REMOVER/INSTALLER

New tool for VT.

Mandatory

J39775

JUMPER HARNESS

Used for checking automatic

transmission during diagnostic

checks.

Previously released.

Mandatory

J39855-1

STATOR SHAFT SEAL EXPANDER

Expands stator shaft seals for

installation to oil pump. Used in

conjunction with J38735-3.

Previously released.

Unique

J39855-2

STATOR SHAFT SEAL RESIZER

Resizes stator shaft seals after

installation to oil pump.

Previously released.

Unique

J41348

MAIN BEARING CAP PULLER

Used with J6125-B to remove main

bearing caps on V6 engine.

Previously released.

Unique

J41349

REAR MAIN HOUSING ALIGNING

TOOL

Used when checking alignment of

rear seal housing on V6 engine.

Used in conjunction with E1409/112.

Previously released.

Desirable

J41510

#50 TORX PLUS BIT

Used for tightening torque converter

housing to transmission main case

attaching bolts.

New tool for VT.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J41512

VALVE STEM INSTALLATION

TOOL

Used to install valve stem seals on

V6 engines.

Previously released.

Desirable

J41778-1

OIL PUMP BUSH INSTALLER

Used to remove/install automatic

transmission oil pump bush.

Previously released.

Unique

J41778-2

SUPPORT PLATE

Used when installing new oil pump

bush to ensure bush is correctly

installed.

Previously released.

Unique

J42220

BLACK LIGHT LEAK DETECTION

LAMP

Used in conjunction with fluid dye for

checking fluid leaks.

Previously released.

Desirable

J6125-B

SLIDE HAMMER

Used in conjunction with J41348 to

remove main bearing caps on V6

engine.

Previously released.

Unique

J8080

BEARING REMOVER AND

INSTALLER

Used to remove engine bearings

from engine with crankshaft still

installed.

Previously released.

Unique

J8092

DRIVER HANDLE

Used with J34196 to remove/install

bushing in automatic transmission

during overhaul.

New tool for VT.

Unique

J8433

PULLER

Used in conjunction with Puller

Adapter J21427-01 to remove

automatic transmission output speed

sensor ring from output shaft. Also

used for A/C compressor clutch

removal

Desirable

J8681-A UNIVERSAL SHORT FINDER

Used during electrical circuit

diagnostic checks for detecting short

circuits.

Previously released.

Desirable

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J8763-02

HOLDING FIXTURE

Used in conjunction with J3289-20 to

hold automatic transmission during

overhaul.

Previously released.

Unique

KD2078

VALVE SPRING COMPRESSOR

Used to compress valve springs on

V6 engine.

Previously released.

Desirable

KM157-2

CONTROL ARM BUSH INSTALLER

Used with AU158 and AU159.

Previously released.

Desirable

KM328-B

SLIDE HAMMER

Includes cup KM-328-5-A and pin.

Used with KM328-7-A and KM328-9

to remove manual transmission

selector rod front bearing - V6 and 5

litre application .

Previously released.

Unique

KM328-7-A

PULLER LEGS

Used with Spacer KM328-9 and

Puller KM-556-1A to remove manual

transmission cluster gear rear

bearing cup or with KM0328-B to

remove selector rod front bearing .

Previously released.

Unique

KM328-9

SPACER

Used with legs KM-328-7-A and

Puller KM-556-1A to remove manual

transmission cluster gear rear

bearing cup or with KM-328-B to

remove selector rod front bearing -

V6 and 5 litre applications.

Previously released.

Unique

KM409-A

INSTALLER

Used to install the shift rod bearing

into the front of manual transmission

housing - V6 and 5 litre application.

Previously released.

Unique

KM454-A

REMOVER/INSTALLER

Used to remove and install manual

transmission cluster gear bearing

cups - V6 and 5 litre application.

Previously released.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

KM461

INSTALLER

Used to assemble the two manual

transmission housings on

reassembly - V6 and 5 litre

application.

Previously released.

Unique

KM468

HOLDING BAR

Used to hold front wheel hub from

rotating.

Previously released.

Unique

KM480

HOLDING FIXTURE

Modify by drilling two 14mm holes as

shown in the illustration. Used for

holding differential carrier assembly.

Previously released.

Unique

N/A DIFFERENTIAL CARRIER HOLDING

FIXTURE

If KM480 is not

available, fabricate a

holding fixture as

shown

KM508-2

INSTALLING SLEEVE

Used to install new bush in shock

absorber lower mount.

Previously released.

Unique

KM556-1A

PULLER

Part of puller kit KM556-A. Used with

KM328-7-A and KM328-9 to remove

manual transmission cluster gear rear

bearing cup - V6 and 5 litre

applications.

Previously released.

Unique

KM609

CONNECTOR TEST ADAPTOR KIT

Used when carrying out electrical

diagnostic circuit checks.

Previously released.

Desirable

KM609-20

TEST LEADS

Used when carrying out diagnostic

circuit check on VT SRS.

New tool for VT.

Mandatory

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

KM618

INSTALLER

Used for installing new bush into rear

suspension crossmember front

mounting.

Previously released.

Desirable

KM619

REMOVER/INSTALLER

Used to press bushes from and into

rear suspension trailing arms.

Previously released.

Desirable

KM620-1A

FLANGE HOLDING TOOL

Used to hold manual transmission

output flange while removing flange

nut.

Previously released.

Unique

KM620-A

REMOVER/INSTALLER

Used to remove and install trunnion

flange, rear wheel bearing and

trunnion assembly.

Previously released.

Desirable

N/A

CLUTCH CENTERING TOOL

Desirable

N/A

COOLING SYSTEM PRESSURE

TESTER Mandatory

N/A

TECHNICAL INFORMATION

SYSTEM (TIS) 2000 CD ROM

Only available to Holden Dealers

Mandatory

N/A

VACUUM GAUGE

Vacuum gauge with scale of 0 to

-4kPa. Used for checking P.C.V. valve

operation and function.

Previously released.

Mandatory

SD28018

(or AU338)

FUEL PRESSURE GAUGE - HIGH

PRESSURE

Used for checking fuel system

pressure with hose assembly

SD28057.

Previously released.

Mandatory

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

SD28057

FUEL PRESSURE GAUGE HOSE

Used in conjunction with gauge

SD28018 (or AU338), coupler 7434

and tube 216812 for checking fuel

system pressure.

Previously released.

Mandatory

SD28280B

DRIVERS SIDE AIRBAG DUMMY

LOAD

Used when carrying out VT SRS

electronic diagnostic checks.

Previously released.

Mandatory

ST-8329

(or BT-832a)

INJECTOR TEST LIGHT

Used when carrying out engine

management electrical diagnostic

checks.

Previously released.

Mandatory