SECTION 0C - TECH 2

Click on the button for more information. CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will

consist of either seat belt pre-tensioners and a driver's side air bag, or seat belt pre-

tensioners and a driver's and front passenger's side air bags. Refer to CAUTIONS,

Section 12M, before performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deplo yment, resulting in possible p ersonal injury or unnecessary

SRS system repairs.

CAUTION:

This vehicle may be equipped w ith LPG (Liquefied Petroleum Gas). In the interests of

safety, the LPG fuel system should be isolated by turning 'OFF' the manual service

valve and then draining the L PG service lines, before any servi ce work is carried out

on the vehicle. Refer to the LPG leaflet included with the Owner's Handbook for

details or LPG Section 2 for more specific servicing information.

1. GENERAL INFORM ATION

The Tech 2 is a hand-held diagnostic computer designed specifically to help you diagnose and repair electronic

systems used on holden vehicles.

When the TECH 2 is attached to a vehicle it can be a very versatile tool. With its large, easy-to-read display, the

TECH 2 guides you step-by-step through the testing procedures. You respond to the TECH 2 through the keyboard

commanding it to:

• Conduct the test you want to run

• Retrieve the diagnostic data you want

• Control the function you want to monitor

The TECH 2 gets its power from the vehicle to be tested and communicates or interfaces with the vehicle electronic

systems through the Data Link Connector (DLC). TECH 2 can communicate with the following control modules, if

the vehicle is equipped with these systems.

• Body Control Module (BCM).

• Powertrain Control Module (PCM).

• Instrument (INS).

• Supplemental Restraint System (SRS).

• Antilock Braking System / Electronic Traction Control System (ABS/ETC).

When connected to the DLC, the TECH 2 can read Diagnostic Trouble Codes (DTC) and diagnostic data.

Depending on the application selected, TECH 2 can also control some systems for troubleshooting or automatic

testing.

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

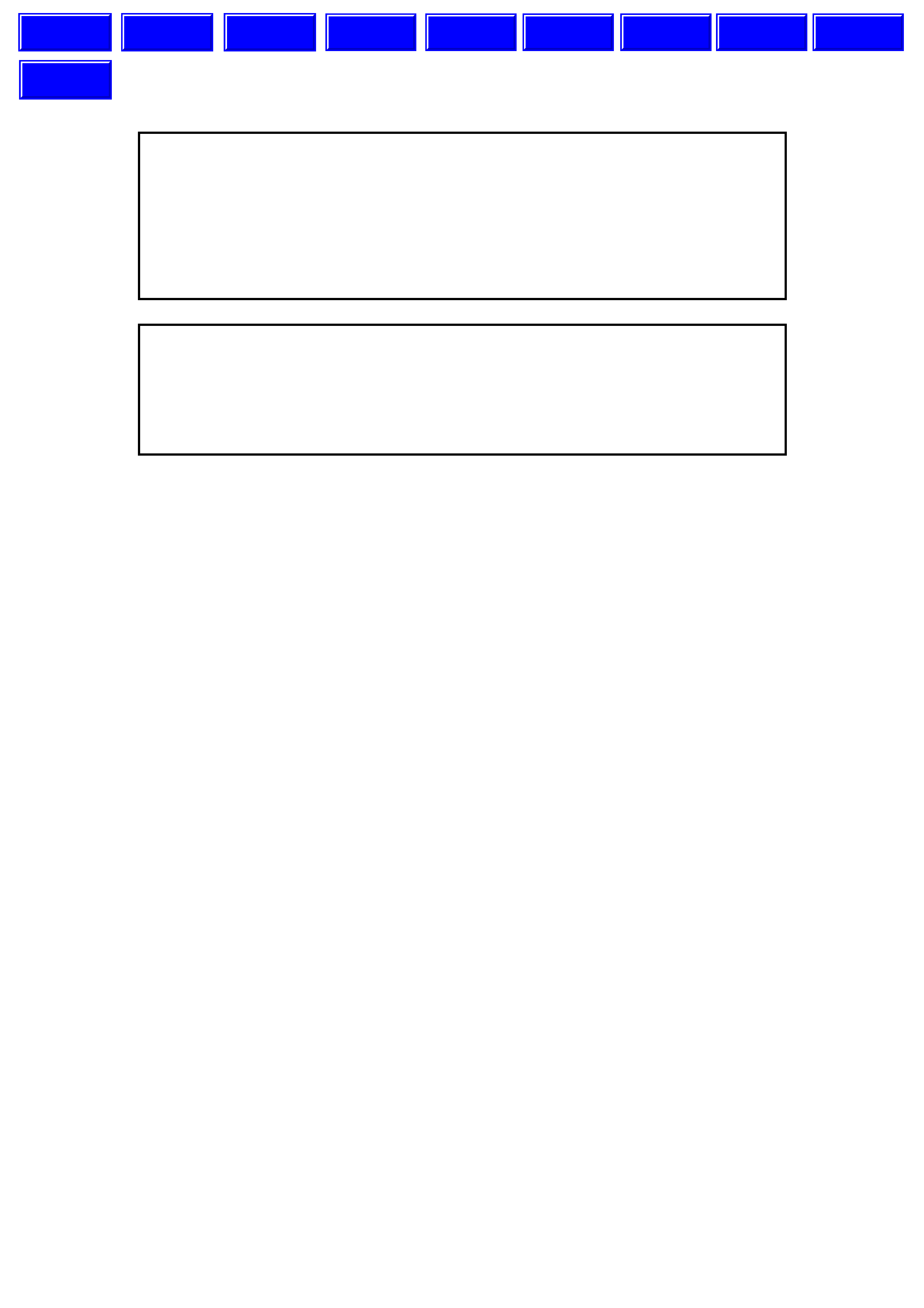

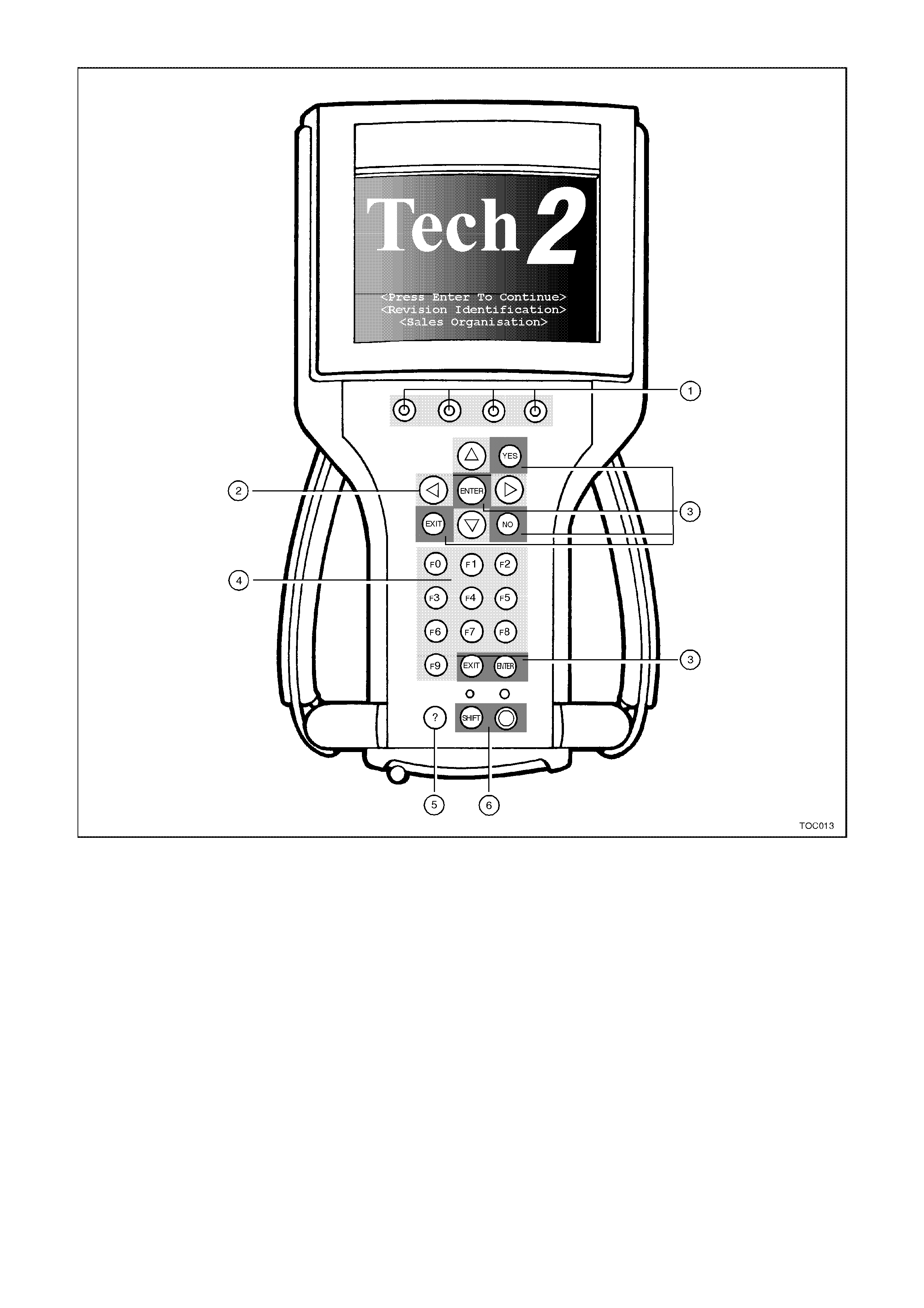

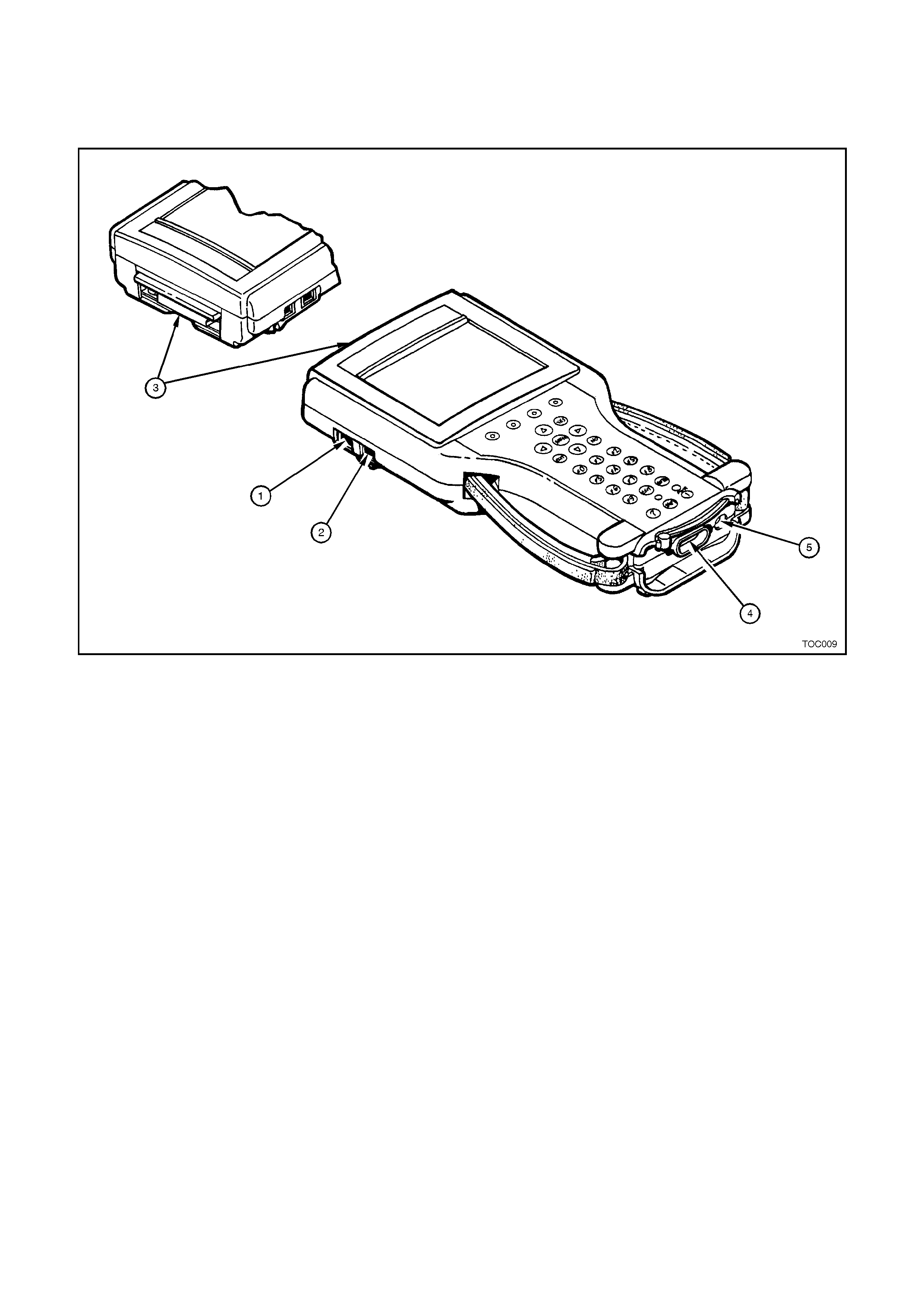

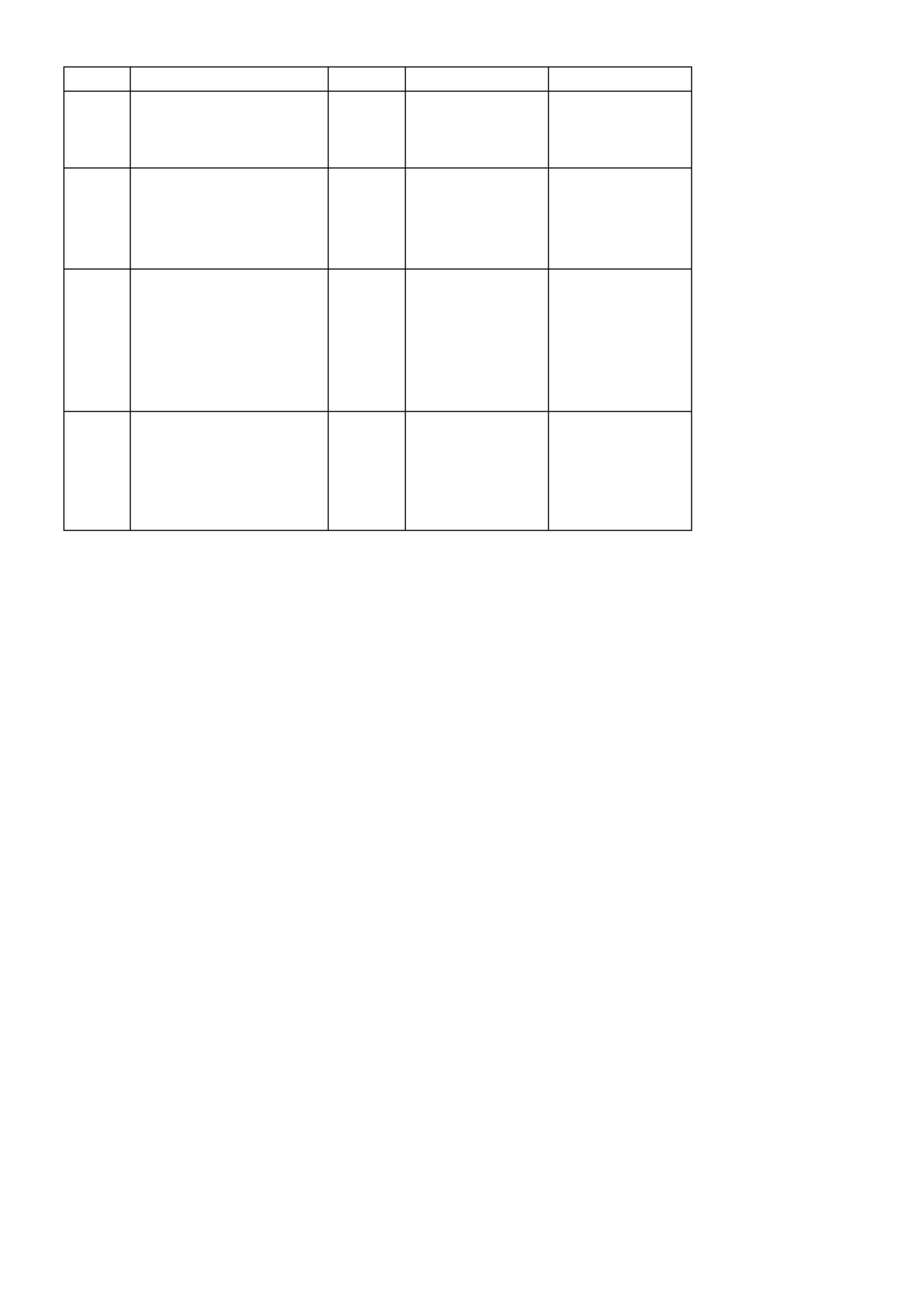

Figure 0C-1 TECH 2

1.1 FEATURES OF THE TECH 2

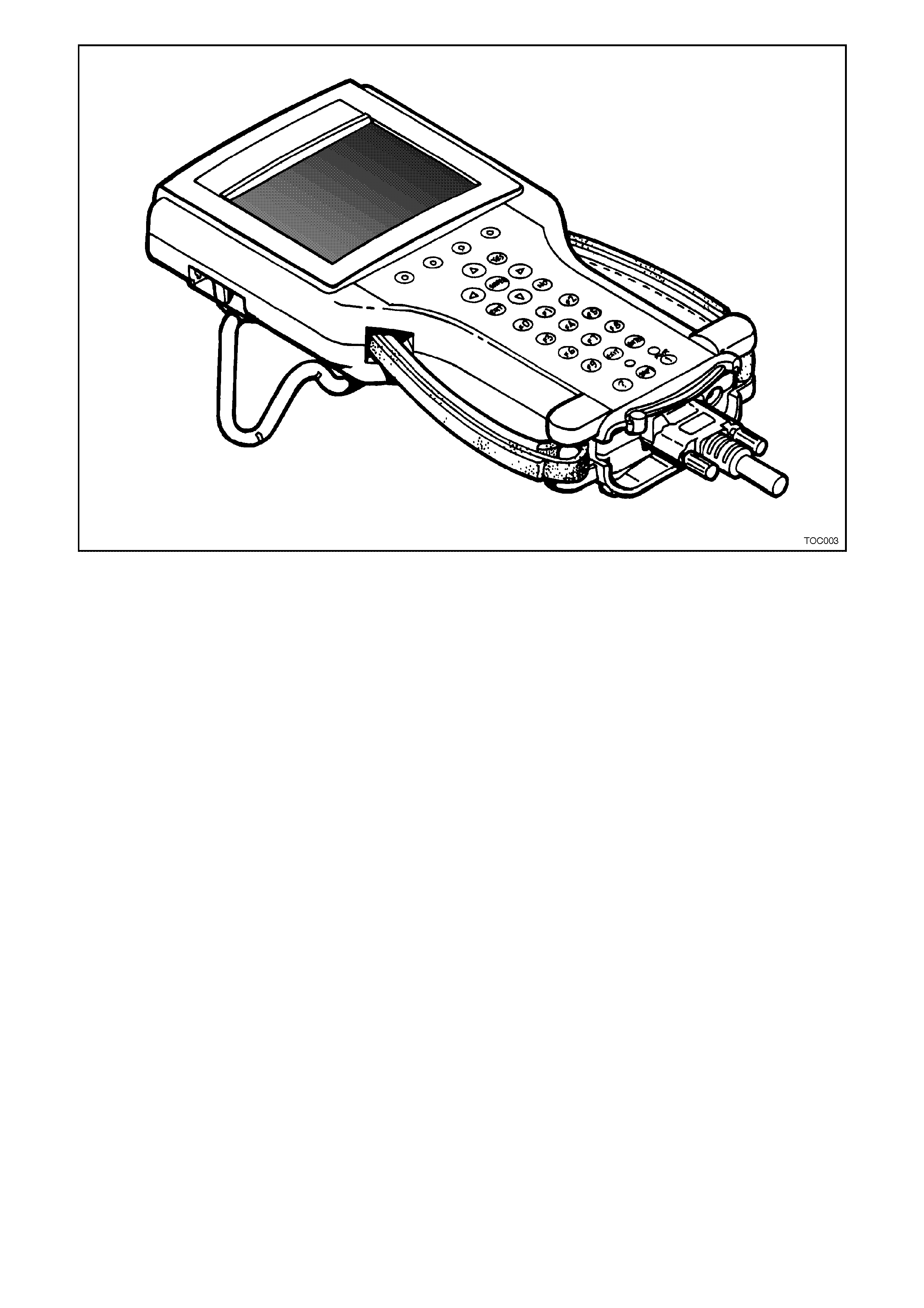

Figure 0C-2 Features of TECH 2

1. Tilt Stand 2. Display 3. Soft Keys

4. Keypad 5. Adjustable Hand Strap 6. Vehicle Communication Interface (VCI)

7. VCI Latching Lever 8. DLC Connector 9. Power Jack

10. PCMCIA Cover 11. PCMCIA Release Button 12. RS-232 Communication Port

13. RS-485 Communication Port

SIZE

The TECH 2 is 305 mm x 152.5 mm x 50.8 mm and weighs approximately 1 kg. This weight is about the same as

the Tech 1.

POWERFUL

The TECH 2 is a tool that is designed to work for many years to come. Because it is extremely more powerful than

the Tech 1, the TECH 2 will be able to help you diagnose vehicles for the foreseeable future.

In the past, as communication from the various microprocessors has evolved, either new tools were created or

adapters were created. The TECH 2 is designed to evolve with the vehicle. Because it uses a Vehicle

Communication Interface (VCI) as an adapter to the DLC, the tool can be updated by a simple change of the VCI

module. This allows hardware updating of the TECH 2 without requiring adapters such as the Switched Adapter

which was used by the Tech 1.

DISPLAY

A large screen, Monochrome Liquid Crystal Display (LCD) which measures 100 x 76 mm is used on the TECH 2.

This allows nine parameters to be seen on screen at the same time. The screen has graphics capabilities which

allow graphs to be plotted on the screen to aid diagnosis. The tool may, in the future, allow some additional graphic

images to be displayed which will help diagnose vehicle systems.

The TECH 2 has an adjustable contrast control to allow the user to change brightness and contrast of the display.

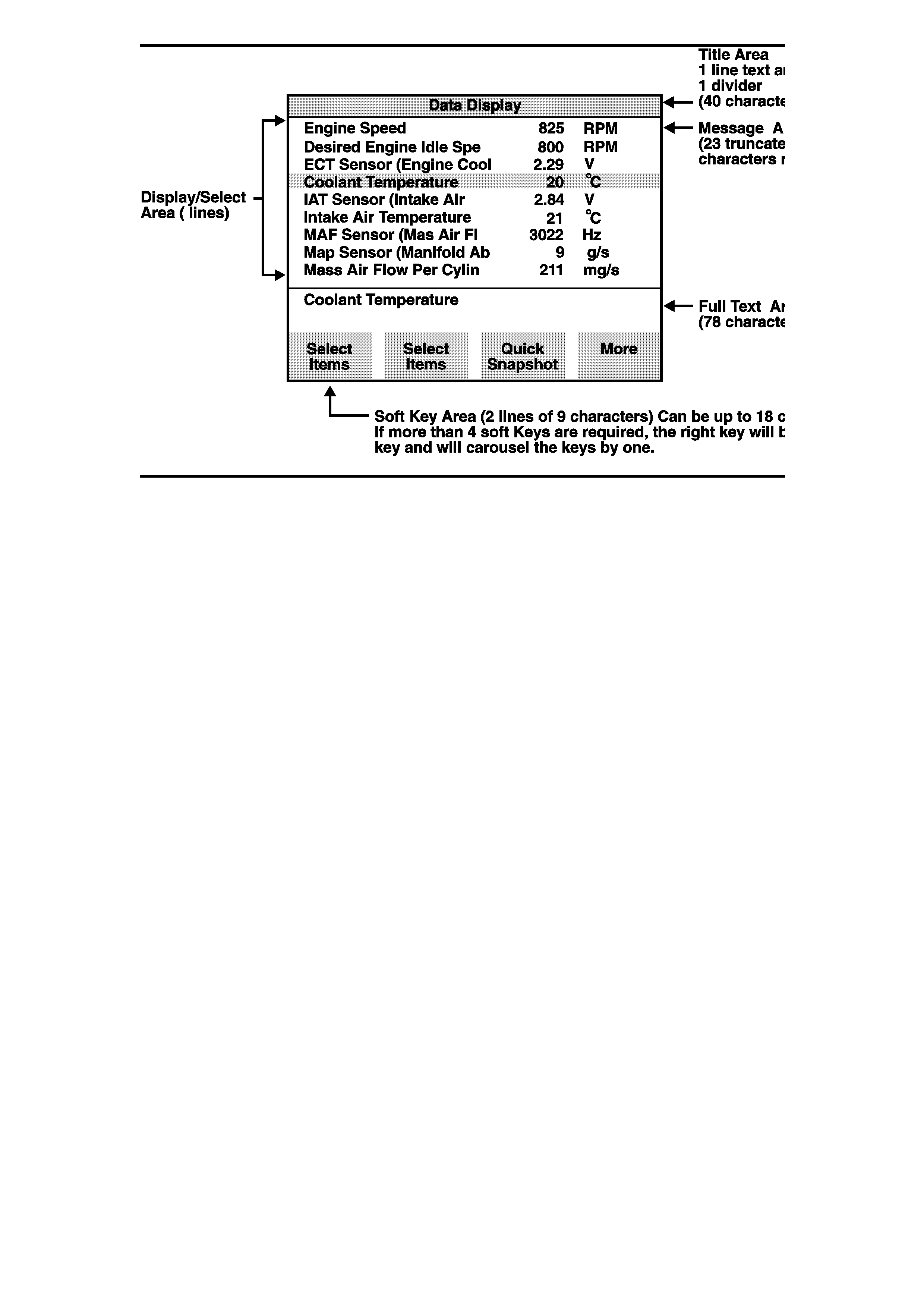

Figure 0C-3 TECH 2 Display

SCREEN AREAS

The screen is broken down into five areas. By looking at the information which is displayed in each area, the user

may use the tool more efficiently.

• Title area

• Message area

• Display/select area

•Full text area*

• Soft key area

*The "full text" area is always a complete description of the highlighted line in the "display/select" area.

Figure 0C-4 TECH 2 Screen Areas

KEYPAD

Figure 0C-5 Keypad

1. Soft Keys 2. Selection Keys 3. Action Keys

4. Function Keys 5. Help Key 6. Control Keys

KEYP AD LAYOUT

The keypad of the TECH 2 contains 27 keys. Within these keys are 23 keys which are pre-defined and four keys

which are referred to as soft keys. The soft key usage will change depending on which part of an application is

being used. Following is a definition of the key usage for the pre-defined keys.

SOFT KEYS

There are four keys on the TECH 2 which will have changing usage within an application. Soft key functions are

software driven. This means that the soft key function may change in different areas of the software. The left most

soft key at the Main Menu will be used to Clear Vehicle, while in Snapshot the same key position may change Units.

The ability of the soft keys to perform different tool operations at different times increases the versatility of the TECH

2.

SELECTION KEYS

The arrow keys are used for screen movement to make a selection. There are four arrow keys. The Up and Down

arrows move the highlight bar one line at a time. If they are held, the highlight bar will scroll. The Left and Right

arrow keys will move the highlight a page at a time. Left arrow moves the highlight up (previous page) and Right

arrow moves the highlight down (next page). The arrow keys are used to move the highlight bar to a position to

make a selection, or to move the display to allow more information to be viewed.

ACTION KEYS

There are a group of keys which are referred to as Action keys. As the name implies, action keys will make an

action take place on the TECH 2 tool. The action keys are YES, NO, ENTER, and EXIT.

YES — Confirms a positive response to a question.

NO — Confirms a negative response to a question.

ENTER (2 keys) — Indicates a selection has been made.

EXIT (2 keys) — Returns user to a previous menu selection.

FUNCTION KEYS

The function keys (F0 - F9) allow direct selection of a choice from a menu.

Help Key

Help (?) accesses a tool help function which is specific to the current operation of the TECH 2.

CONTROL KEYS

There are two keys which are used to control the TECH 2 itself. These are the SHIFT and PWR (Power) key s. The

SHIFT key will access screen contrast control. To adjust contrast during the current power cycle of the TECH 2, use

the following procedure.

Press the SHIFT key (The yellow light will turn on).

Use the Up arrow to Increase screen brightness and contrast or the Down arrow to Decrease screen brightness

and contrast.

Press the SHIFT key (the yellow light will turn off).

This procedure will only adjust the contrast for the duration of this power cycle of the TECH 2. If the power is turned

off and then back on again, the contrast will change to a default value. The default setting is covered in the TECH 2

User’s Guide.

Be aware that if the yellow SHIFT light is on, only the Up/Down arrow keys and the EXIT keys are active.

There is a PWR (Power) switch for TECH 2 which will control turning the TECH 2 on and off. A green indicator will

illuminate when the TECH 2 is switched on.

THUMB ACTION

The TECH 2 is designed for one handed operation. The unit is balanced to allow one hand to comfortably hold and

operate the tool. Straps on the sides of the tool are adjustable to help hold the TECH 2 in one hand. The keypad

configuration is designed for thumb usage while holding the tool in either the left or right hand. It is suggested to use

the selection and action keys instead of the function keys as some TECH 2 screens require making selections from

a list on screen. In these cases there may not be a function key equivalent.

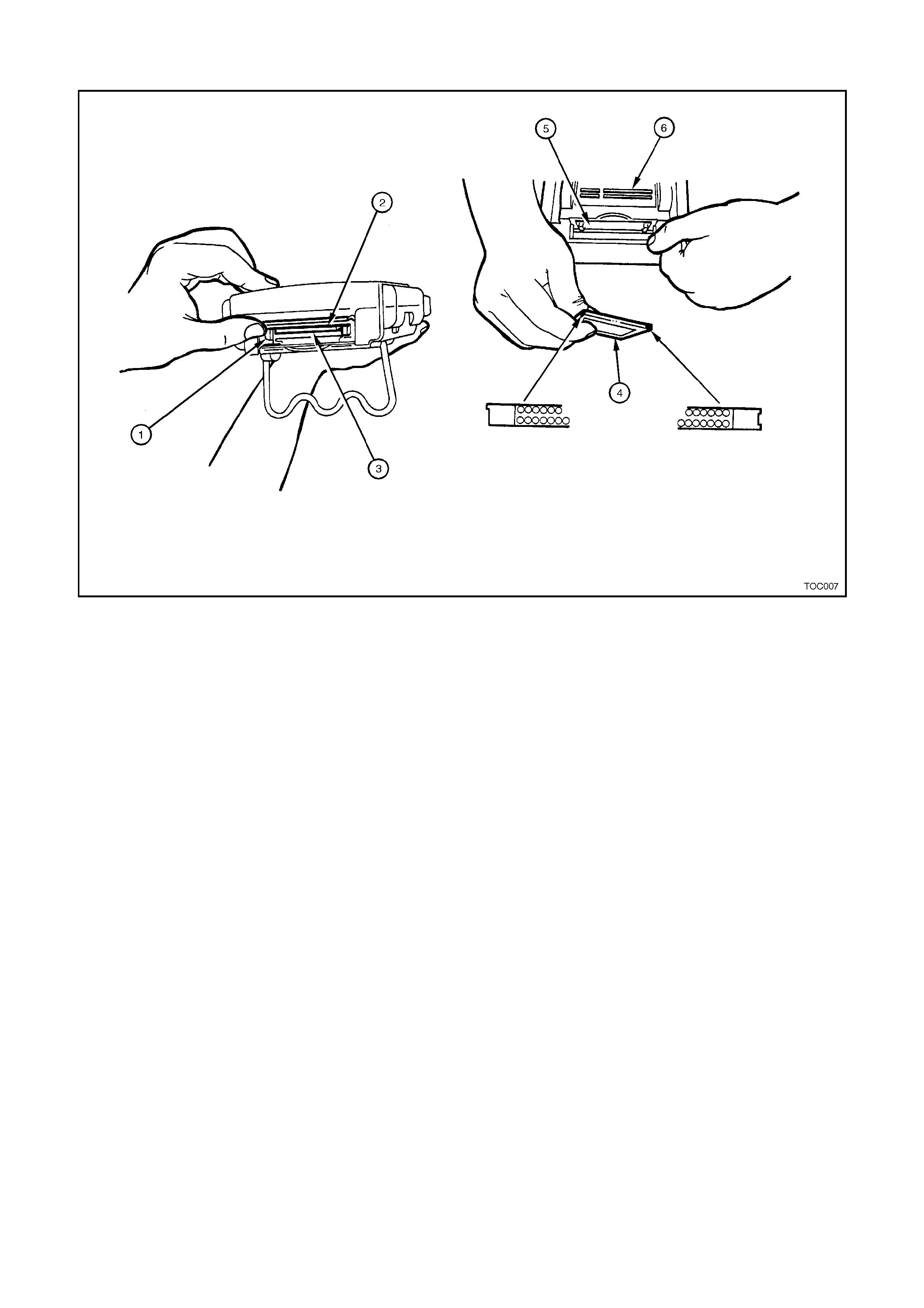

PCMCIA CARD

Figure 0C-6 PCMCIA Card

1. PCMCIA Release Button 2. In Use Upper PCMCIA Slot 0 3. Empty Lower PCMCIA Slot 1

4. TECH 2 PCMCIA Card 5. PCMCIA Cover 6. Underneath Side of TECH 2

The TECH 2 uses a Personal Computer Memory Card Industry Association (PCMCIA) standard memory card for

storage of diagnostic functions and applications. The memory card has a capacity of 10 Megaby tes which is ten

times the amount of memory of the Tech 1 Mass Storage Cartridge (MSC). Because there is more memory, there is

storage capability for two snapshots. This will allow comparison of before/after type conditions on a vehicle being

serviced.

The PCMCIA card is accessed through a door on top of the unit, and should not normally require removal. The card

is ejected by pushing the arrow button pointing to card to be removed. Cards are notched to allow insertion only one

way. When re-inserting the card make sure that it fully seats into the TECH 2. The PCMCIA card fits into slot zero

which is closest to the screen. There is a second slot for possible future expansion. The second slot is identified as

slot one.

NOTE:

The PCMCIA card is sensitive to magnetism and static electricity so care should be taken in the handling of

the card.

A write protect slide mechanism is on the top edge of the card. The correct position is to the middle of the card

(unlocked). If the write protect is in the locked position, snapshots will not be able to be stored, and Service

Programming will not work.

TECH 2 and PCMCIA card will be updated by connecting to a Technical Information System (TIS).

The software that operates the TECH 2 is stored on the PCMCIA card. The contents of the card are not distinct

applications. All of the applications share a single database of information on the TECH 2's PCMCIA card.

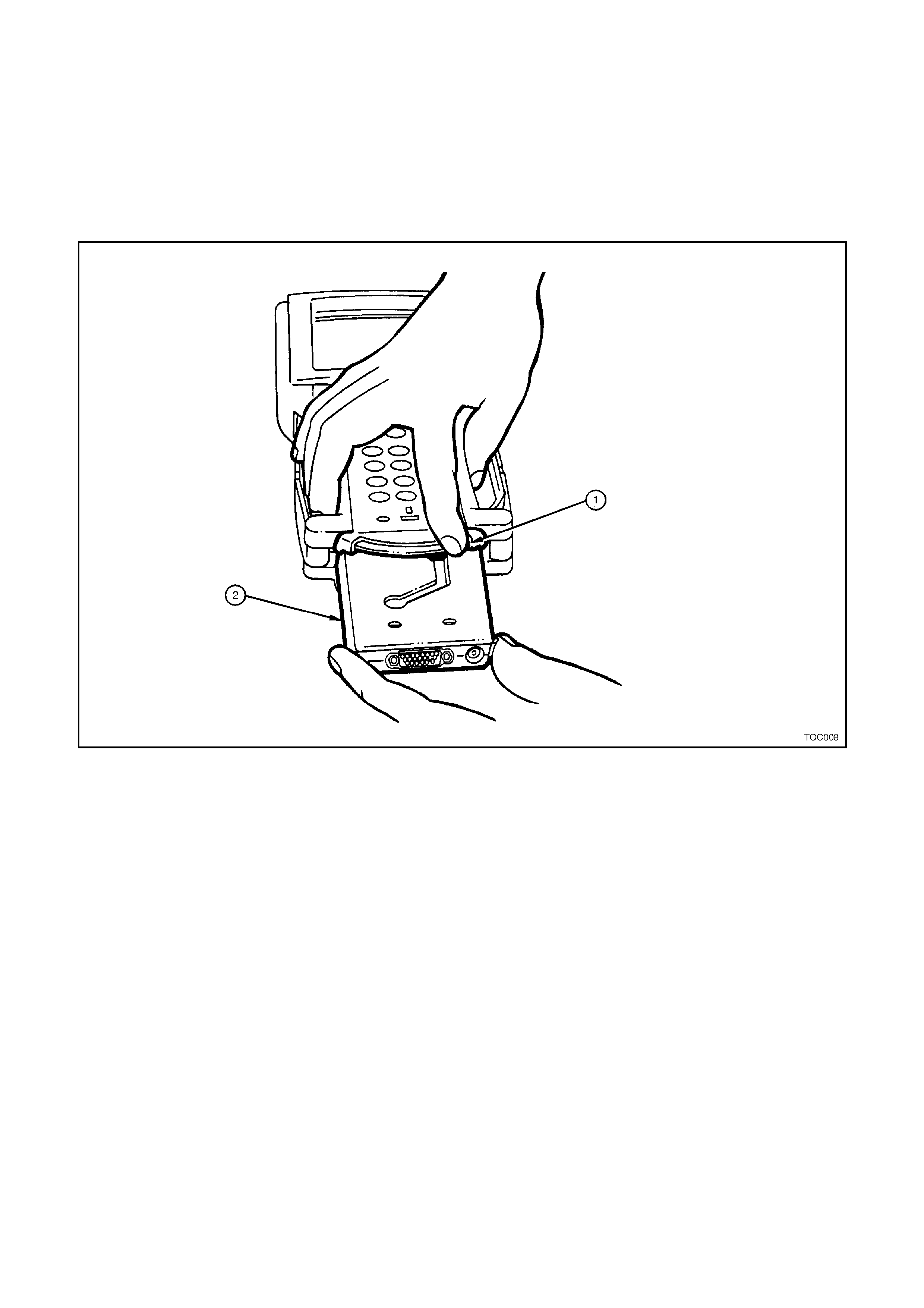

VEHICLE COMMUNICATION INTERFACE MODULE

The TECH 2 uses a Vehicle Communication Interface (VCI) module, located in the bottom of the unit to act as an

interface between the vehicle and the internal workings of the TECH 2. This allows the TECH 2 to communicate to

many different types of data systems on vehicles.

Data is transmitted between the vehicle and the TECH 2 through the DLC cable. Power for the TECH 2 is also sent

through the VCI module. Power can either come through the DLC cable or from the power jack on the bottom of the

VCI module. Internally, the VCI module protects the TECH 2 against reverse polarity power connections.

During normal usage of the TECH 2, there is no reason to remove the VCI module. In the future, if different types of

data communication are used on the vehicle, the VCI module could be changed to extend the useful life of the

TECH 2 even further. To remove the VCI module, refer to the TECH 2 User's Guide.

Figure 0C-7 VCI Module

1. VCI Module Lever (moved all the way to the right) 2. VCI Module

SERIAL PORTS

TECH 2 also has two serial port connections for communication to other computers such as TIS. These ports are

the RS-232 and the RS-485. The RS-232 is used for connecting to TIS for updating the contents of applications on

the TECH 2. To perform Service Programming with the TECH 2 the RS-232 port is also used.

The RS-485 is currently not used, but may in the future allow for other tool capabilities.

Figure 0C-8 Serial Ports

1. RS-485 Port 2. RS-232 Port 3. PCMCIA Slots

4. DLC Connector 5. Power Jack Connector

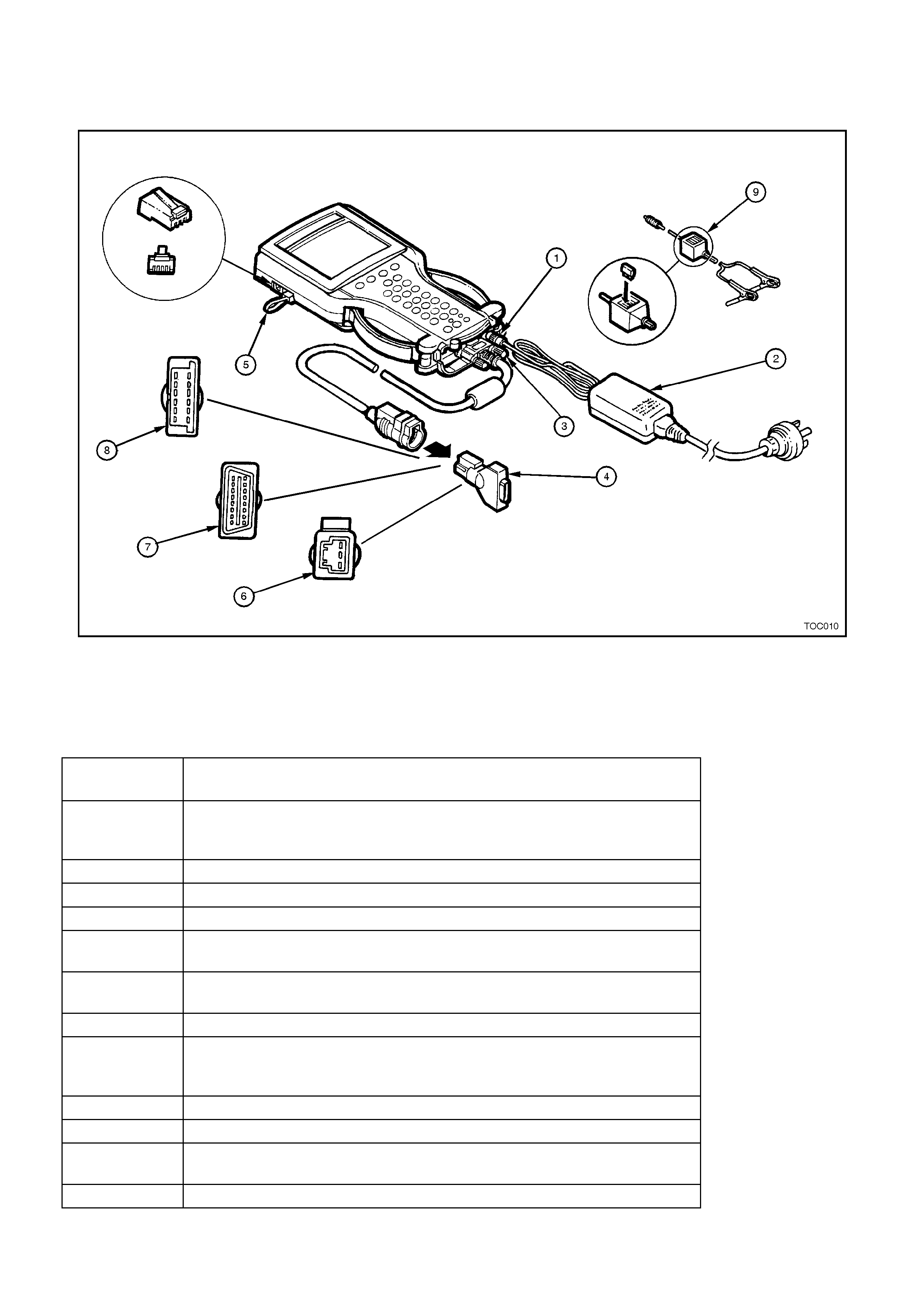

ADAPTERS FOR TECH 2

The TECH 2 includes a selection of cables and adapters to accommodate a variety of operating conditions and

functions.

Figure 0C-9 Adapters for TECH 2

1. Power Jack 2. Power Supply 3. DLC Cable

4. DLC Loopback Connector 5. RS-232 Loopback Connector 6. Opel/Isuzu/Geo 3/19 Pin Adapter

7. SAE 16/19 Pin Adapter 8. NAO 12/19 Pin Adapter 9. Battery Power Cable

PRODUCT

NUMBER PRODUCT NAME

3000115 Universal 100 - 240 Volt AC power supply with 3000114 w all socket

cable. This adapter should only be used for powering the TECH 2 while

away from the vehicle such as while connected to a TIS.

3000095 DLC Cable.

3000096 Cigarette Lighter Power Cable - Supplies 12V power to the TECH 2.

3000097 Battery Power Cable - Supplies 12V power to the TECH 2.

3000098 SAE 16/19 Pin Adapter - Connects the TECH 2 to some 1995 vehicles,

and most 1996 and newer vehicles.

3000099 NAO 12/19 Adapter - Allows the TECH 2 to connect on vehicles built

prior to 1996.

3000102 Opel/Isuzu/Geo 3/19 Adapter.

3000109 DLC Loopback Connector - Used to diagnose the DLC capability of the

TECH 2. It can either be connected to the end of the DLC cable or to the

DLC cable connection point on the tool.

3000110 RS-232 Cable.

3000111 RS-232 DB9 Adapter.

3000112 RS-232 Loopback Connector - Used to diagnose the RS-232 function of

the TECH 2.

3000116 Storage Case.

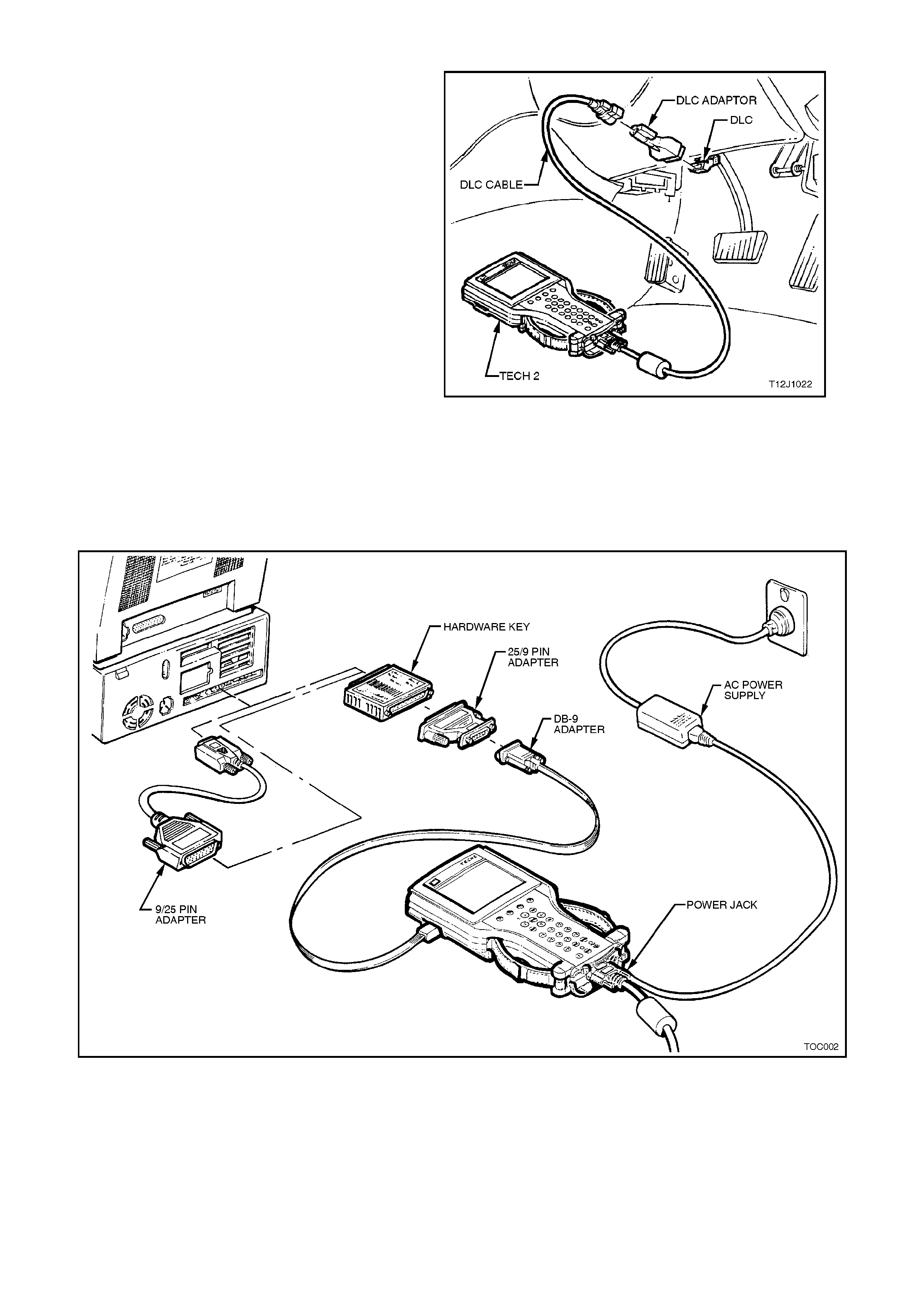

1.2 CONNECTIONS

To use the TECH 2, proper connections will need

to be made. These connections include power and

the DLC. Power for the TECH 2 normally comes

from the DLC. If no power is available at the DLC,

or if using the TECH 2 away from the vehicle,

another source of power should be used. On-

vehicle power connection may also come from the

cigarette lighter adapter or from the battery clip

adapter. When using one of the adapters, connect

to the jack at the back of the DLC cable connection.

The 12V adapters have fuses in them to help

protect the TECH 2 wiring.

The TECH 2 AC power adapter should NOT be

used while the TECH 2 is c onnec ted to a vehicle as

data errors may occur. Instead, the AC power

adapter is designed to be used while away from

vehicle. The TECH 2 will work between 8-20 volts

and about 0.75 amps.

The TECH 2 will also at times be required to be

connected to a Personal Computer (PC) to

communicate with The Technical Information

System (TIS). This connection is m ade via the RS-

232 communication port. A Hardware key is

required when the Service Programming System

(SPS) is being utilised.

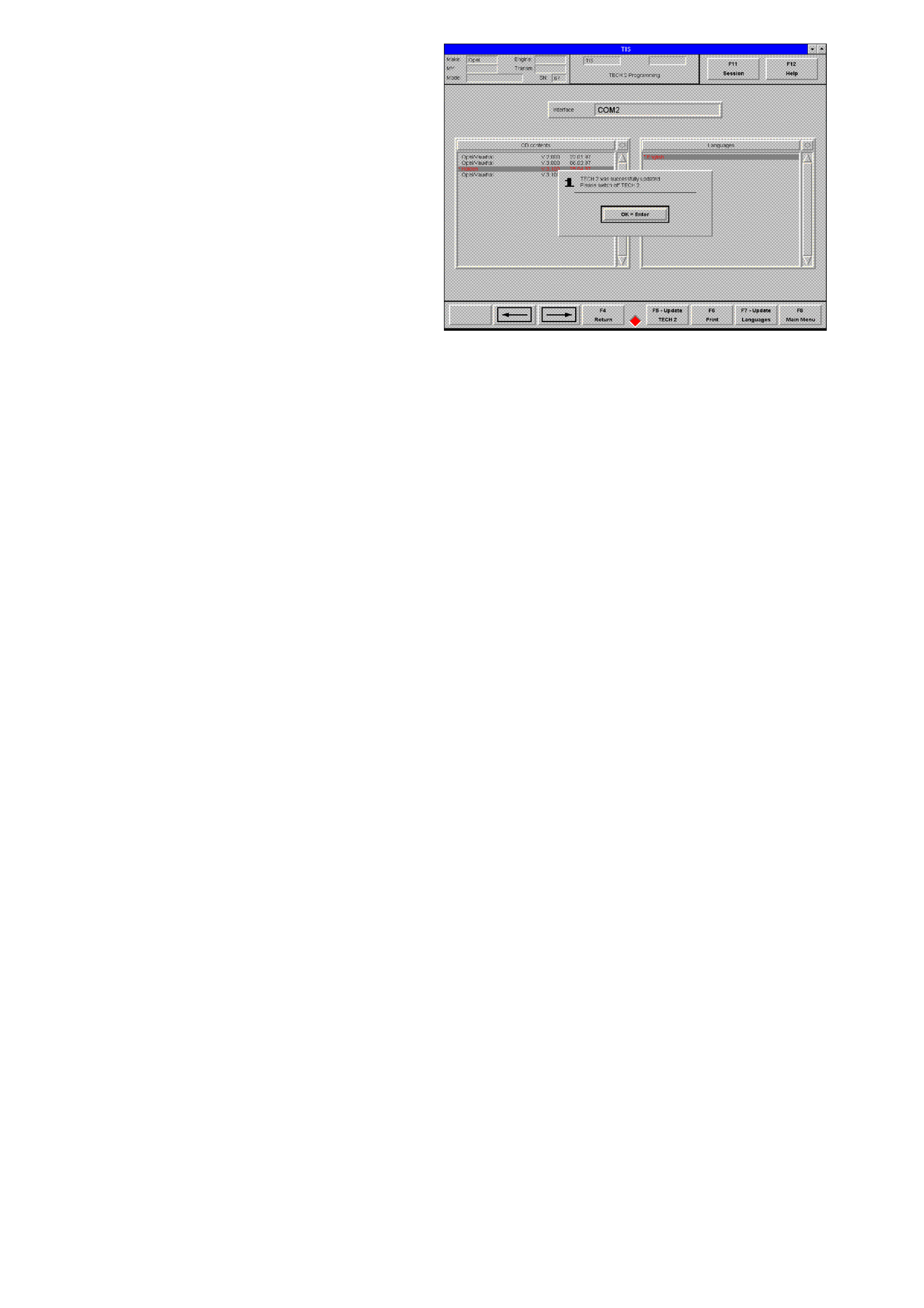

Figure 0C-10 Connecting TECH 2 to the DLC

Figure 0C-10 Connection of Power Jack to TECH 2 DLC Cable and Connection of the RS-232 Serial Communication

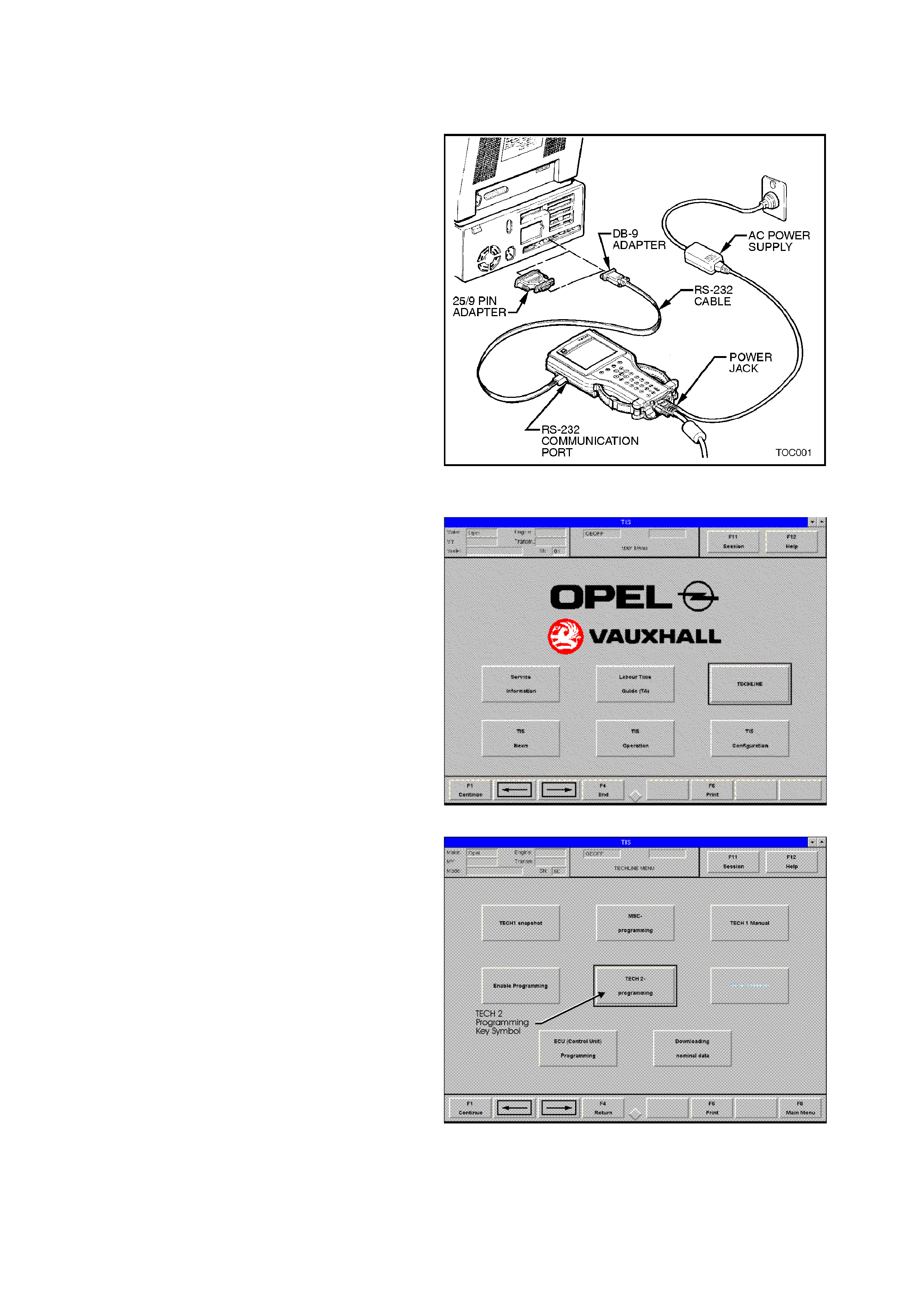

2. PROGRAMMI NG TECH 2

2.1 GENERAL INFORMATION

Before TECH 2 can be used on a vehicle it will

have to be programmed with the latest software.

TECH 2 programming is used to update TECH 2.

The TIS-CD ROM contains the current TECH 2

applications (program) and up to two preceding

versions in various languages. TECH 2 can be

programmed using the following procedure.

1. Connect the RS-232 cable to the TECH 2 RS-

232 communication port.

2. Connect the other end of the RS-232 cable to

the DB-9 and then connect the DB-9 adapter

to the serial communication port of your

computer.

NOTE: If your computer has a 25 pin serial

com munication por t you will need to fit the 25/9 pin

adapter between the 9 pin DB-9 adapter and the

serial communication port.

3. Connect the AC power supply to the TECH 2

power jack.

4. Press the

PWR button to turn on TECH 2. Figure 0C-12 Connecting TECH 2 to the PC

5. From windows double-click the TIS Icon to

begin TIS.

6. Click on

NEW SESSION or press ENTER.

7. Pos ition the selection window with the ←

←←

← or →

→→

→

key on the TECHLINE key symbol.

8. Select

F1 Continue or press ENTER to open

TECHLINE.

Figure 0C-13 TIS Main Menu

9. Position the selection window with the ←

←←

← or

→

→→

→ key on the TECH 2 programming key

symbol.

10. Select F1 Continue or press ENTER to

continue.

Figure 0C-14 Techline Menu

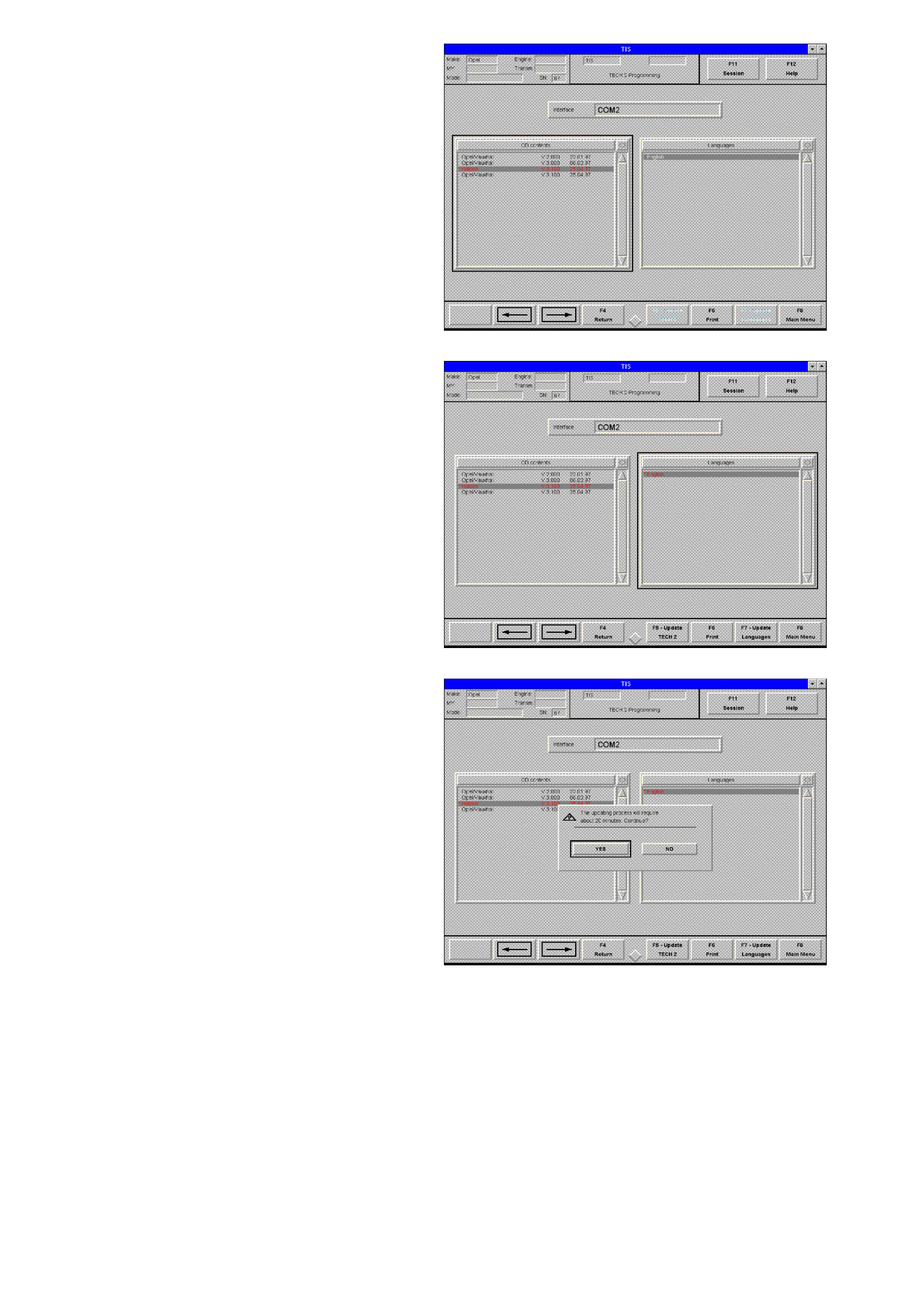

11. Using the ↑

↑↑

↑ or ↓

↓↓

↓ key, move the highlight bar to

the desired Holden TECH 2 application, (you

should select the latest version) and press

ENTER to turn the selection on.

Figure 0C-15 Desired TECH 2 Application

12. Position the selection window with the ←

←←

← or

→

→→

→ key on the Languages selection list.

13. Using the ↑

↑↑

↑ or ↓

↓↓

↓ key, move the highlight bar to

the desired language, English and press

ENTER to turn the selection on.

Figure 0C-16 Desired Language

14. Select F5-Update TECH 2 and then YES to

begin the TECH 2 Update.

15. TECH 2 will now be updated to the application

you have selected. The screen display will

indicate the progress of the download as a

percentage. Do not interrupt the connection

until directed.

Figure 0C-17 F5 Update

16. W hen the sc reen opposite is displayed, switch

off TECH 2 and then select OK or press

ENTER.

17. Select F8 M ain Menu, F4 End and then YES

to exit TIS.

18. Disconnect the power s upply from the T ECH 2

power supply jack. Disconnect the RS-232

cable from the TECH 2 RS-232

communication port. Disconnect the RS-232

cable from the serial communication port of

your computer.

19. TECH 2 has been success fully updated and is

now ready for use.

Figure 0C-18 Programming Completed Screen Display

3. USING TECH 2 ON THE VEHICLE

3.1 CONNECTING THE TE CH 2 TO THE VEHICLE

1. Connect TECH 2 to the vehicle DLC, with the

DLC cable and the 16/19 pin adapter.

Figure 0C-19 Connecting the TECH 2 to the Vehicle

2. Switch the unit on by pressing the power

button. A green light should come on

indicating that the tool is receiving power.

NOTE:

At this time the technician should see the Power

On Self Test (POST) run. The POST is a built in

diagnostic self test for the TECH 2 that should find

most common system faults. The POST is run on

every power up to ensure the best operation of the

tool. After the c om pletion of the PO ST, the T ECH 2

unit will briefly show the POST results. If POST

passes, the tool will continue onto the title screen. If

POST fails , results of all test s will be disp layed, and

this should show which test failed. POST failures

may be classified as fatal or non-fatal. A fatal error

will not allow the user to continue using the tool.

Failure of the keypad would be an example of a

fatal error. Non-fatal errors found during the POST

will allow continued use of the TECH 2, but with

some limitations. If either a fatal or non-fatal error

occurs, refer to the Troubleshooting section of the

TECH 2 User's Guide.

1. Power Status Indicator Light

2. PWR (Power) Key

3. SHIFT Key Status Indicator Light

4. SHIFT Key

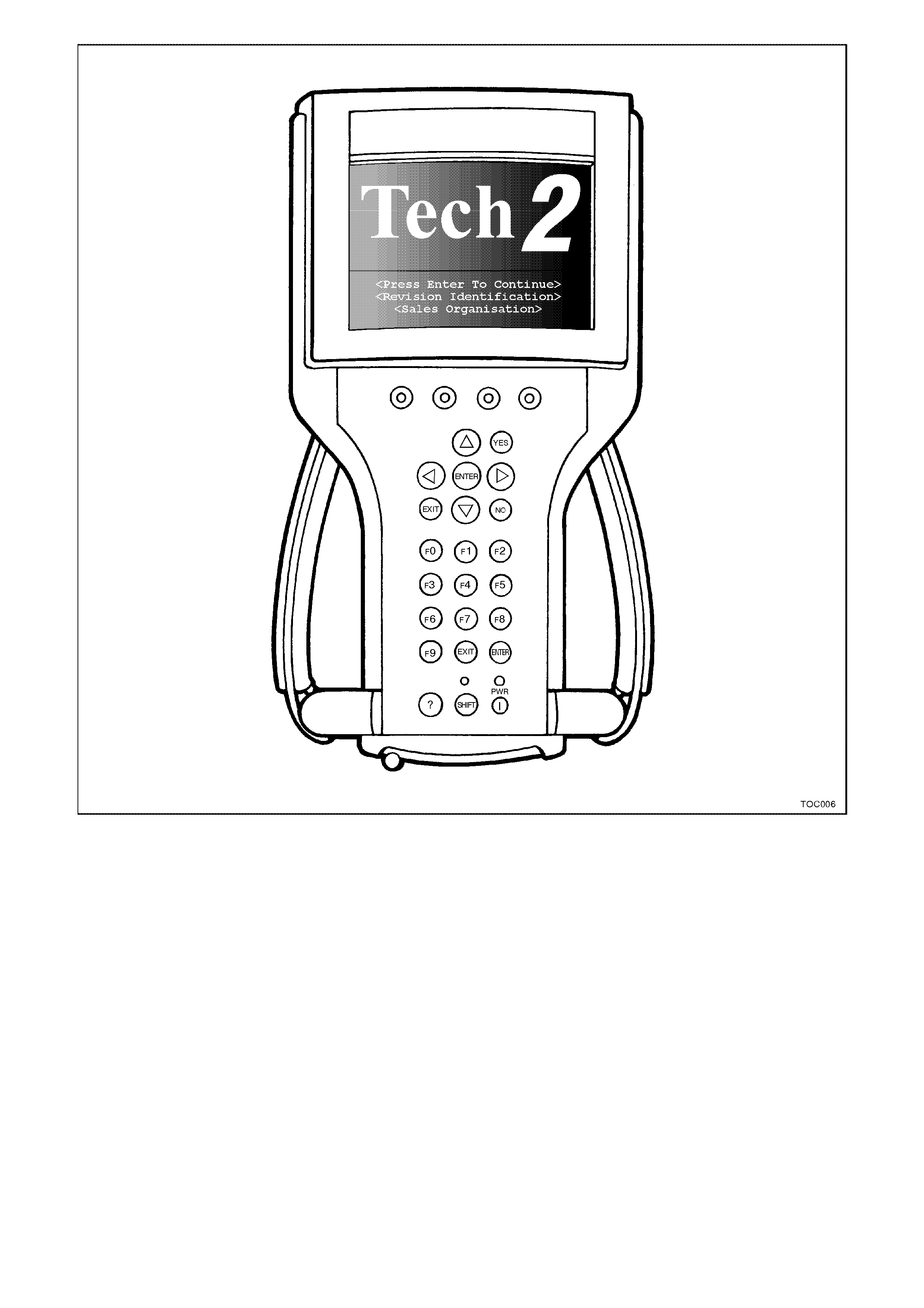

3. At the TECH 2 title screen press the ENTER

key to continue.

Figure 0C-20 TECH 2 PWR and SHIFT Keys

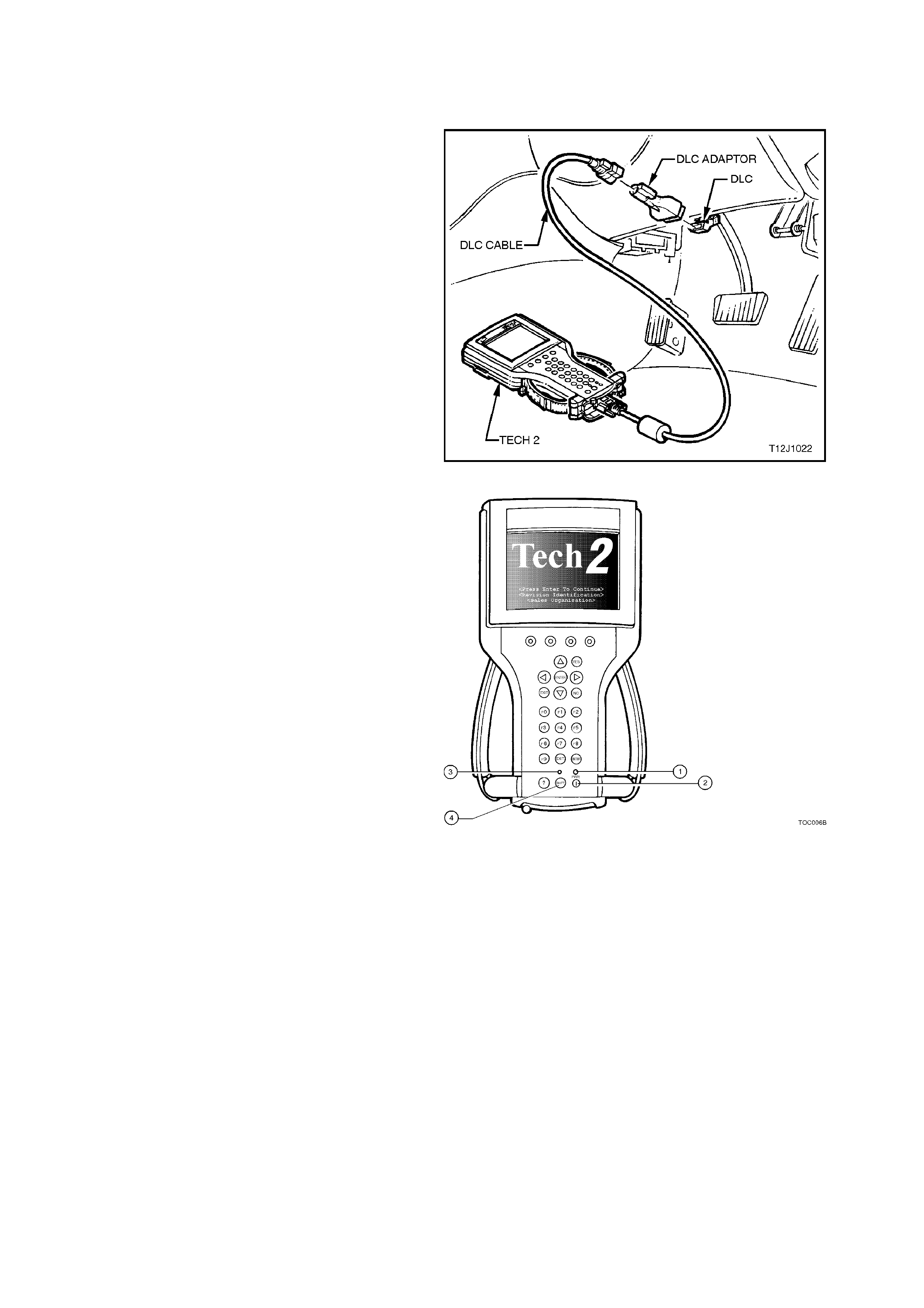

4. A selec tion can be m ade from the Main Menu,

either by using a function key or by using the

arrow keys to highlight a menu choice and

pressing ENTER.

NOTE:

You will then need to supply some additional

information to the T ECH 2. This r equir es navigation

through a series of lists (called picklists). On some

menus or picklis ts, the user can us e a func tion key

to mak e a menu s election, but mos t of the picklis ts

require using the selection and action keys. If a

mistake is made in the selection process, or if a

different application or function is desired, press

EXIT to back up one level. Within an application,

there m ay be sof t keys which are available for use.

These soft keys allow access to additional tool

functions without exiting a current tool function. Soft

keys are made up of sets which will appear

together. To see the next set of soft keys, select

the More soft key.

Figure 0C-21 TECH 2 Main Menu

The TECH 2 Main Menu contains the following:

F0: Diagnostics

Contains all functions to test, diagnose, monitor

and program the different vehicle sy stems.

F1: Service Programming System (SPS)

SPS is used in conjunction with Technical

Information System (TIS) to program vehicle

control units. This feature is not used on the VT

Commodore Series of Vehicles.

F2: View Capture Data

Contains all functions to work with one or two

previously recorded snapshots on one or two

vehicles. This function is to enable the viewing of

captured data without a vehicle.

F3: Tool Options

Contains the TECH 2 self test, set clock , set units,

set screen contrast and Getting Started.

F4: Download/Upload Help

Contains help information on the downloading and

uploading from the TECH 2 to the TIS CD-ROM.

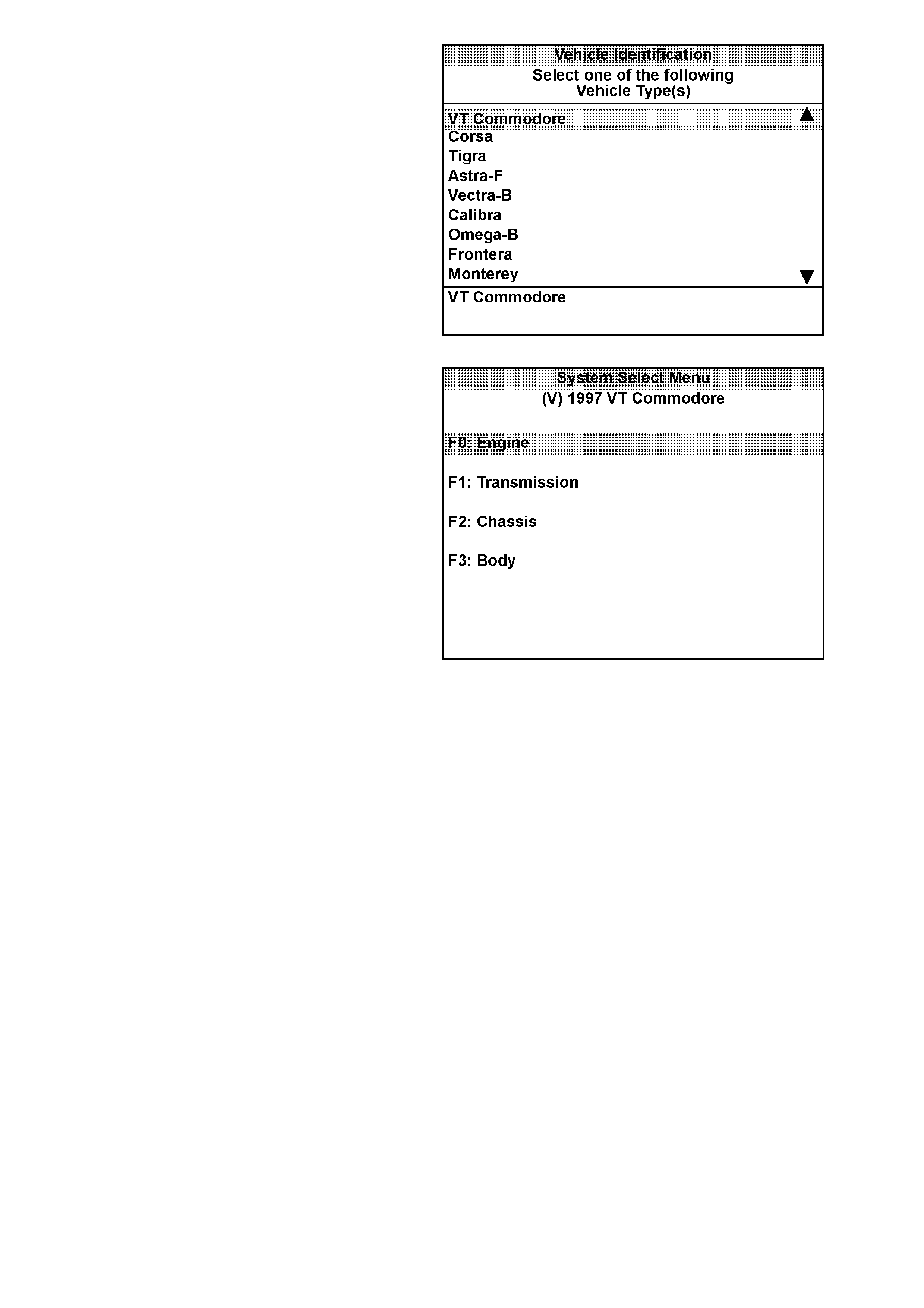

5. Select the correct Model Year with the arrow

keys and the press ENTER. The Vehicle

identification screen will then be displayed.

Figure 0C-22 TECH 2 Vehicle Identification Menu

6. Select the correct Vehicle Type with the arrow

keys and the press ENTER. The System

Select Menu will then be displayed.

Figure 0C-23 TECH 2 Vehicle Identification

7. The desired system can be selected from the

System Select Menu with the function keys or

with arrow keys and then press ENTER.

F0: Engine contains all functions to test,

diagnose, and monitor the engine systems that

communicate with the TECH 2 via the

Powertrain Control Module (PCM).

F1: Transmission contains all functions to

test, diagnose, monitor and program the

transmission systems that communicate with

the TECH 2 via the Powertrain Contr ol Module

(PCM).

F2: Chassis contains all functions to test,

diagnose, monitor and program the vehicles

chassis systems; ABS and Electronic Traction

Control modules.

F3: Body contains all functions to test,

diagnose, monitor and program the vehicles

body systems; Body Control Module,

Electronic Climate Control, Instruments and

Supplemental Restraint System.

Figure 0C-24 TECH 2 System Select Menu

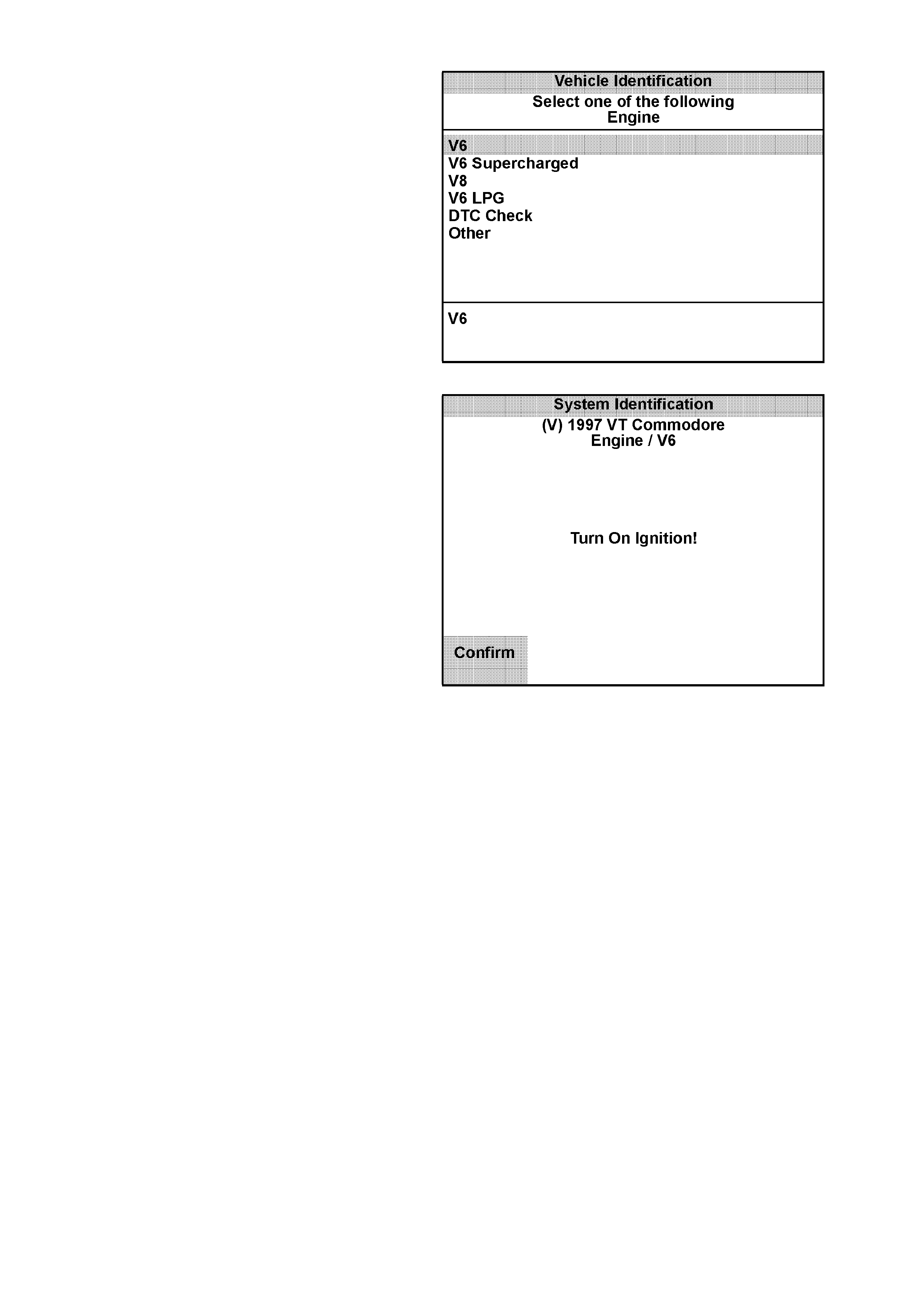

3.2 ENGINE APPLICATION MENU

1. Select the correct engine from the Vehicle

Identification Menu with the arrow keys, then

press ENTER.

Figure 0C-25 Vehicle Identification Menu

2. T urn on the ignition and pres s the Conf irm s of t

key.

Figure 0C-26 System Identification Menu

3. The System Identification screen will then

display the PROM Identification. The PROM

identification will vary with engine type and

software le vel. Press the Confirm soft k ey, the

engine application menu will then be

displayed.

NOTE:

If TECH 2 is able to communicate with the PCM the

PROM Identification will be displayed.

NOTE:

If TECH 2 is unable to communicate with the PCM

a loss of communication screen will briefly be

displayed before TECH 2 returns to the Main Menu.

The following functions can be selected from

the engine application menu:

F0: Normal Mode

F1: Diagnostic Trouble Codes

F2: Data Display

F3: Snapshot

F4: Miscellaneous Tests

F5: Function Tests

F6: Field Service

F7: Stall Data

NOTE:

Functions may vary depending on the application

selected. Refer to Section 6C1 POWERTRAIN

MANAGEMENT V6 or Section 6C2

POWERTRAIN MANAGEMENT V8 for further

information.

Figure 0C-27 System Identification Menu

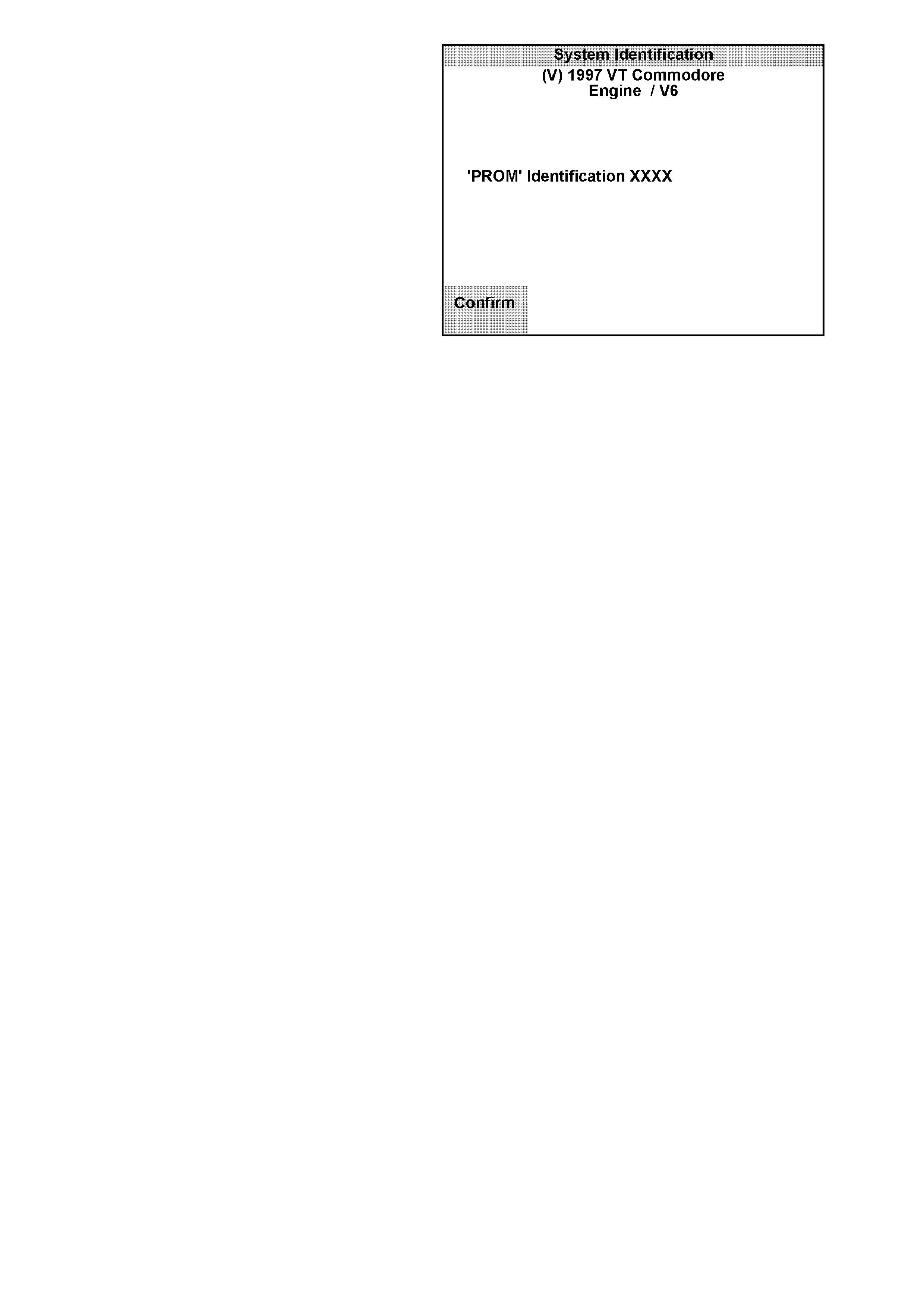

3.3 TRANSMISSION APPLICATION MENU

1. Select the correct transmission from the

Vehicle Identification Menu with the arrow

keys, then press ENTER and follow the sc r een

instructions.

Figure 0C-28 Vehicle Identification Menu

2. T urn on the ignition and pr es s the Confirm sof t

key.

Figure 0C-29 System Identification

3. The System Identification screen will then

display the PROM Identification. The PROM

identification will vary with software level.

Press the Confirm soft key, the transmission

application menu will then be displayed.

The following functions are available in the

transmission application menu:

F0: Normal Mode

F1: Diagnostic Trouble Codes

F2: Data Display

F3: Snapshot

F4: Miscellaneous Tests

F5: Function Tests

F6: Field Service

NOTE:

Functions may vary depending on the application

selected. Refer to Section 6C1 POWERTRAIN

MANAGEMENT V6 or Section 6C2

POWERTRAIN MANAGEMENT V8 for further

information.

Figure 0C-30 System Identification

3.4 CHASSIS APPLICATION MENU

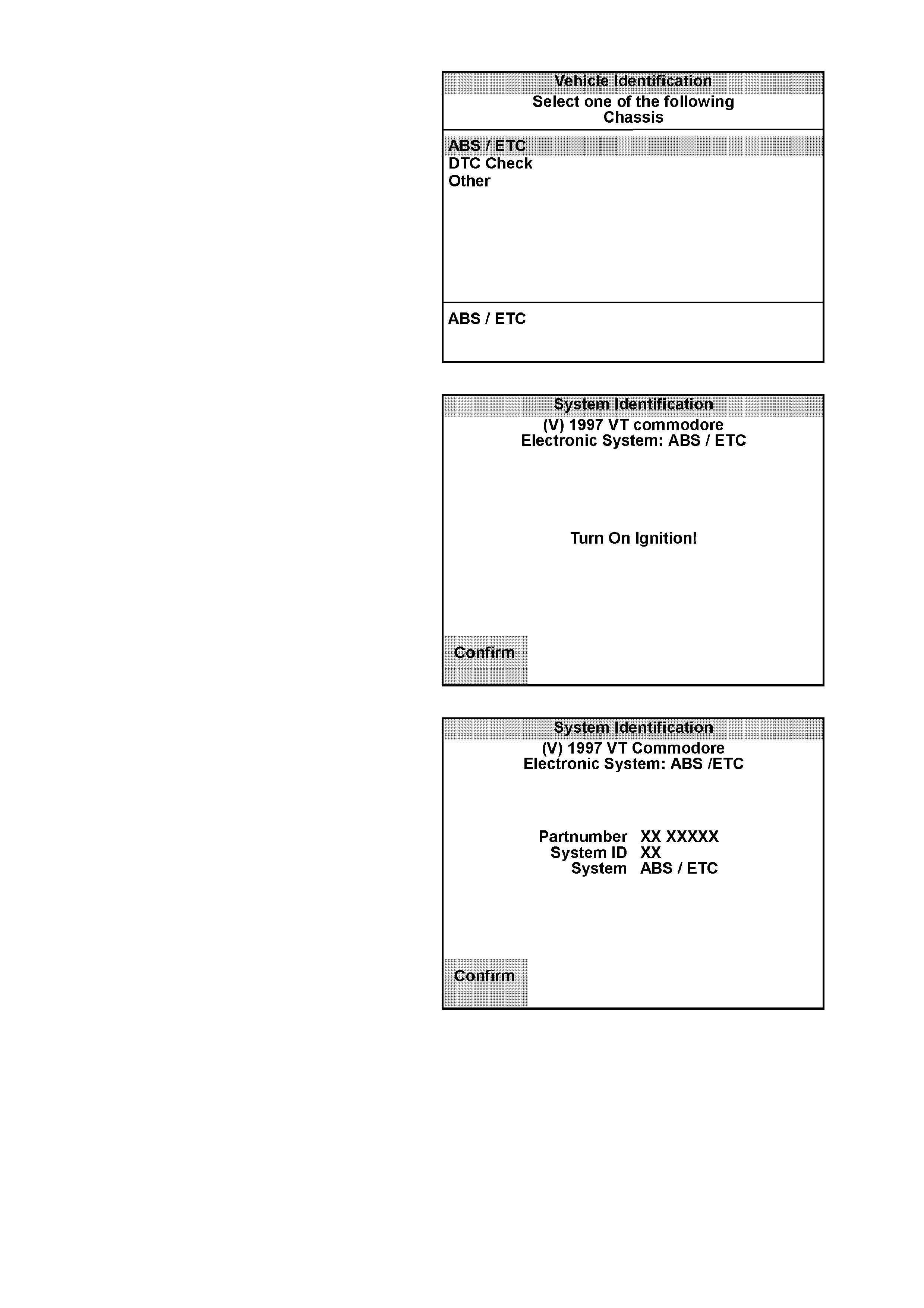

1. Select the correct chassis system from the

Vehicle Identification Menu with the arrow

keys, then press ENTER and follow the

instructions on the screen.

Figure 0C-31 Vehicle Identification Menu

2. T urn on the ignition and pr es s the Confirm sof t

key.

Figure 0C-32 System Identification

The System Identification screen will then

display the control module Partnumber,

System Identification and if the system is an

ABS or an ABS/ETC system.

3. Press the Confirm soft key, the ABS/ETC

application menu will then be displayed.

The following functions are available in the

ABS/ETC chassis application menu:

F0: Normal Mode

F1: Diagnostic Trouble Codes

F2: Data Display

F3: Snapshot

F4: Miscellaneous Tests

NOTE:

Functions may vary depending on the application

selected. Refer to Section 12L ABS AND

ABS/ETC for further Information.

Figure 0C-33 System Identification

3.5 BODY APPLICATION MENU

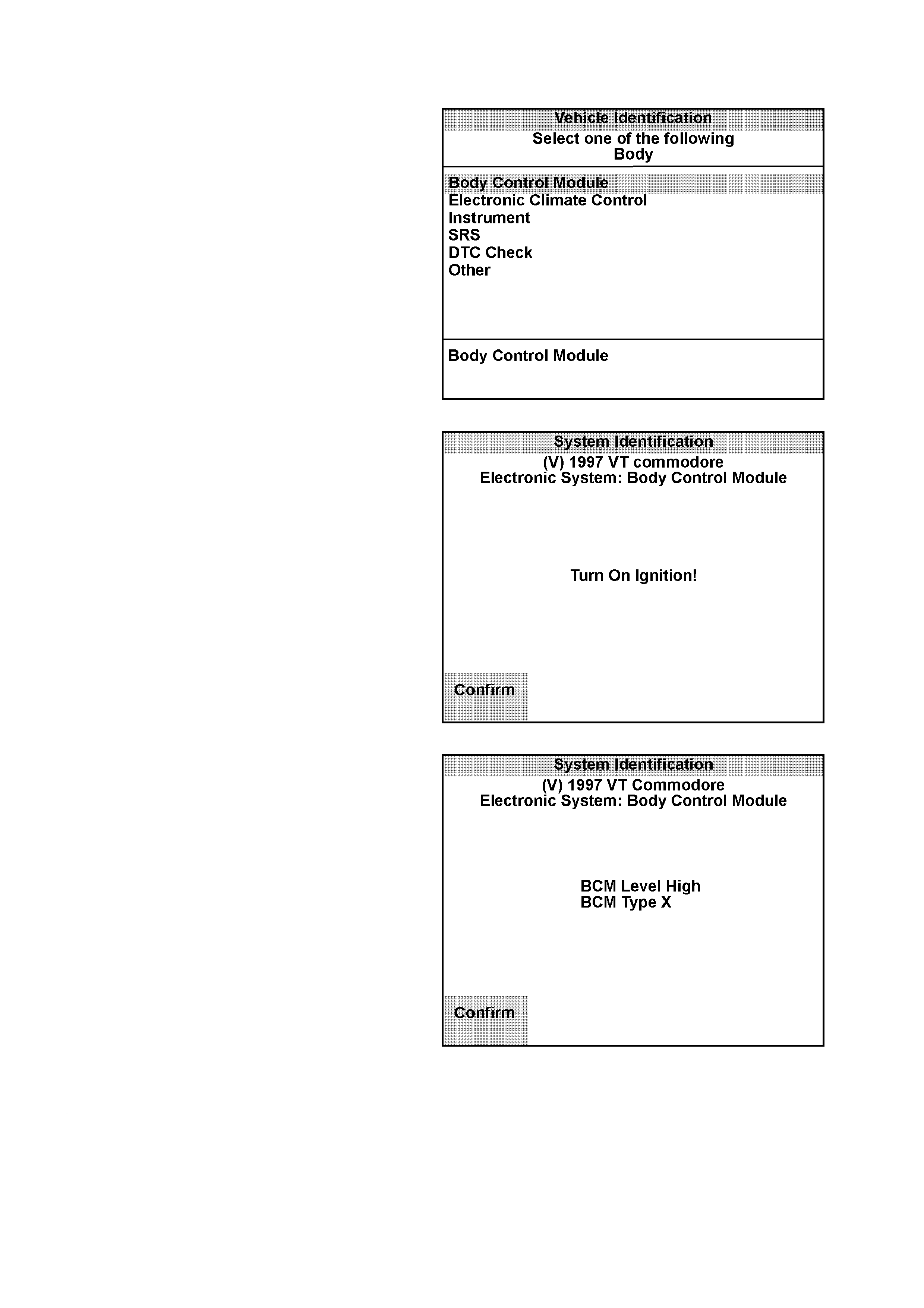

BODY CONTROL MODULE

1. Select Body Control Module from the Vehicle

Identification Menu with the arrow keys, then

press ENTER.

Figure 0C-34 Vehicle Identification Menu

2. Turn on the ignition and press the Confirm

soft key.

Figure 0C-35 System Identification

The System Identification screen will then

display the following information:

BCM Level

BCM Type

3. Press the Confirm soft key, the BCM

application menu will then be displayed.

The following functions are available in the

BCM application menu:

F0: Normal Mode

F1: Diagnostic Trouble Codes

F2: Data Display

F3: Snapshot

F4: Miscellaneous Tests

F5: Program

F6: Security

NOTE:

Functions may vary depending on the application

selected. Refer to Section 12J-1 LOW SERIES

BODY CONTROL MODULE or 12J-2 HIGH

SERIES BODY CONTROL MODULE for further

Information.

Figure 0C-36 System Identification

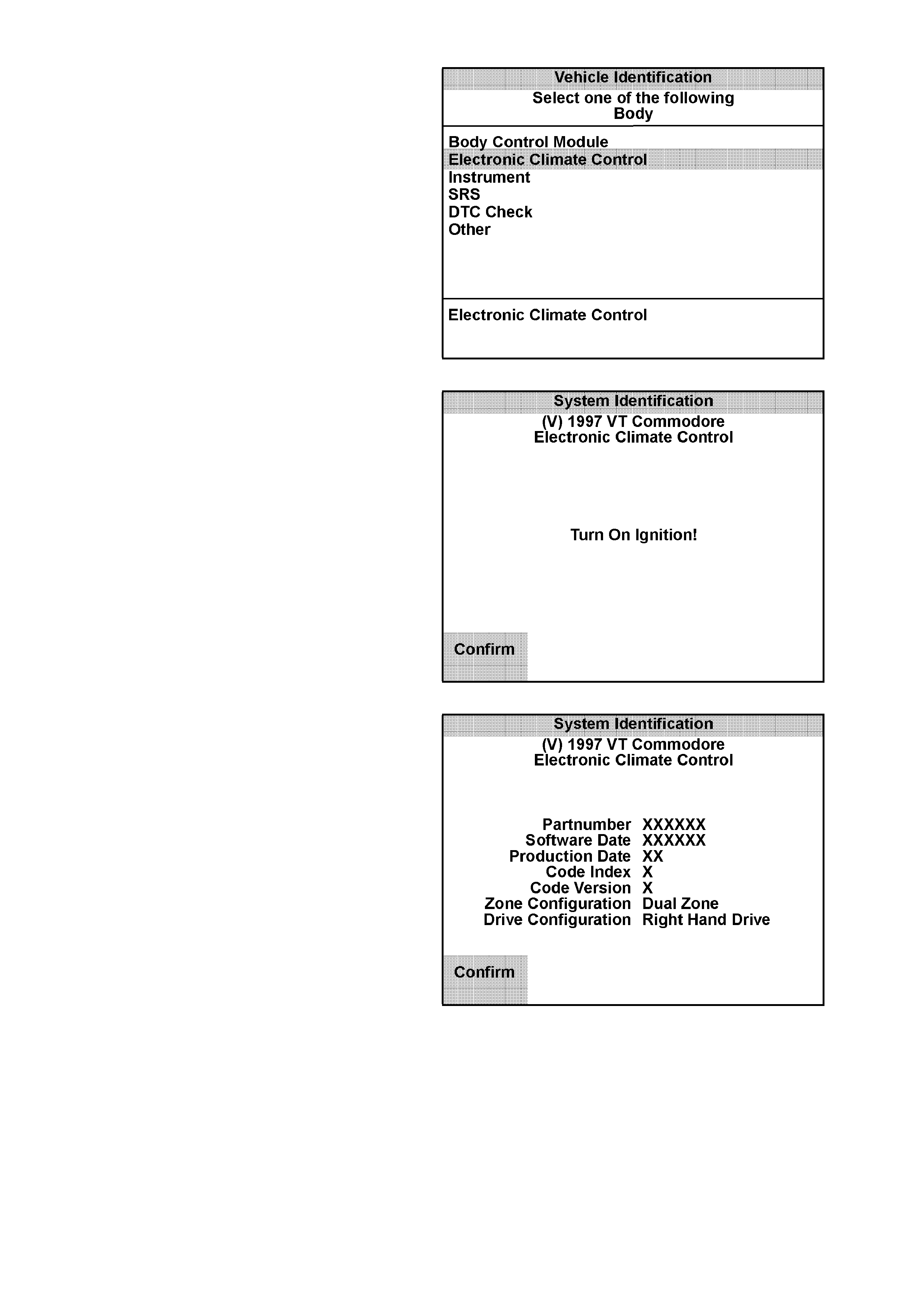

ELECTRONIC CLIMATE CONTROL

1. Select Electronic Climate Control from the

Vehicle Identification Menu with the arrow

keys, then press ENTER.

Figure 0C-37 Vehicle Identification Menu

2. Turn on the ignition and press the Confirm

soft key.

Figure 0C-38 System Identification

The System Identification screen will then

display the following information:

Partnumber

Software Date

Production Date

Code Index

Code Version

Zone Configuration

Drive Configuration

3. Press the Confirm soft key, the engine

application menu will then be displayed.

The following functions are available in the

BCM application menu:

F0: Normal Mode

F1: Diagnostic Trouble Codes

F2: Data Display

F3: Snapshot

F4: Miscellaneous Tests

F5: Program

NOTE:

Functions may vary depending on the application

selected. Refer to the Section 2F AIR

CONDITIONING - ECC DIAGNOSTICS for further

Information.

Figure 0C-39 System Identification

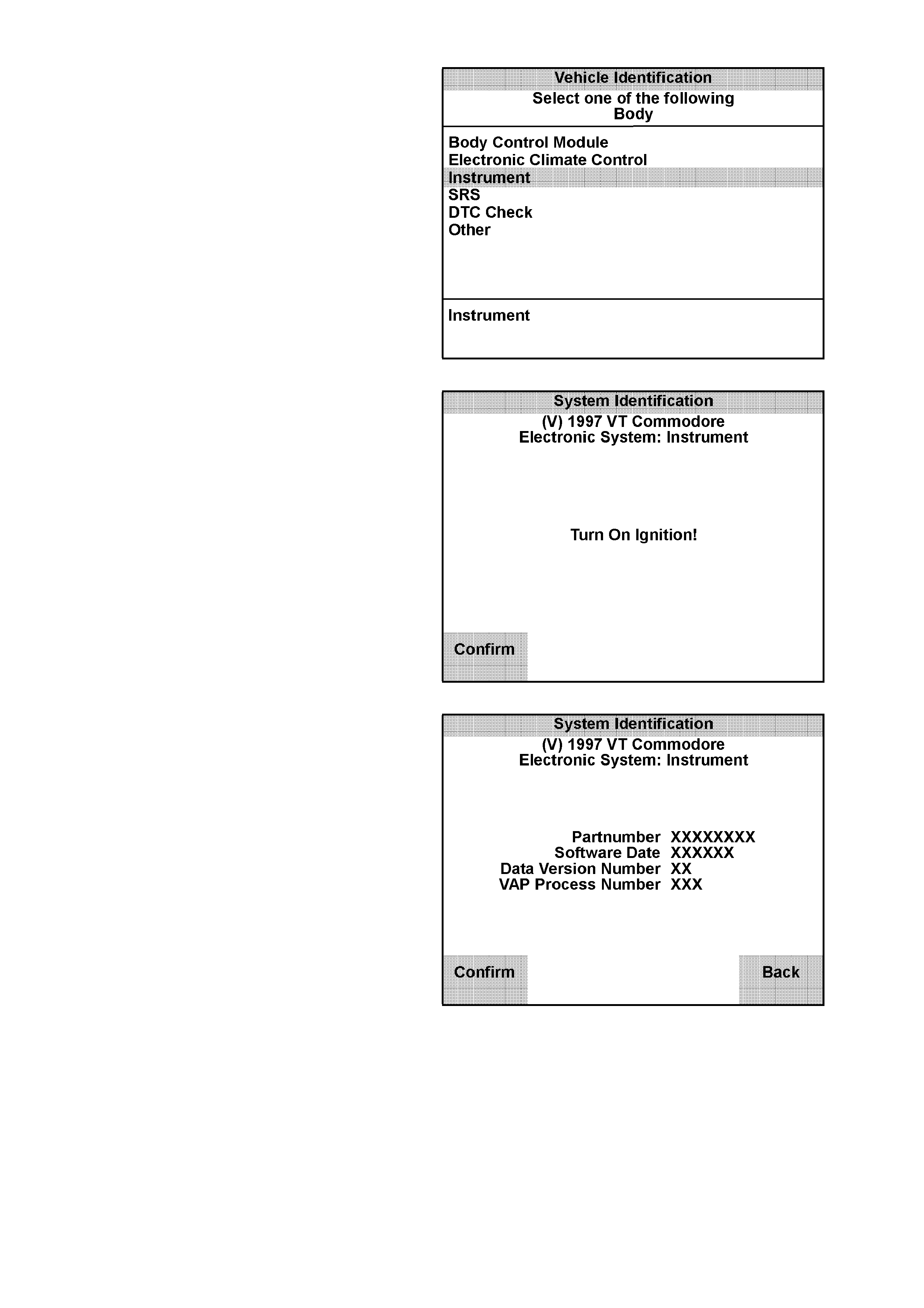

INSTRUMENT

1. Select Instrument from the Vehicle

Identification Menu with the arrow keys, then

press ENTER.

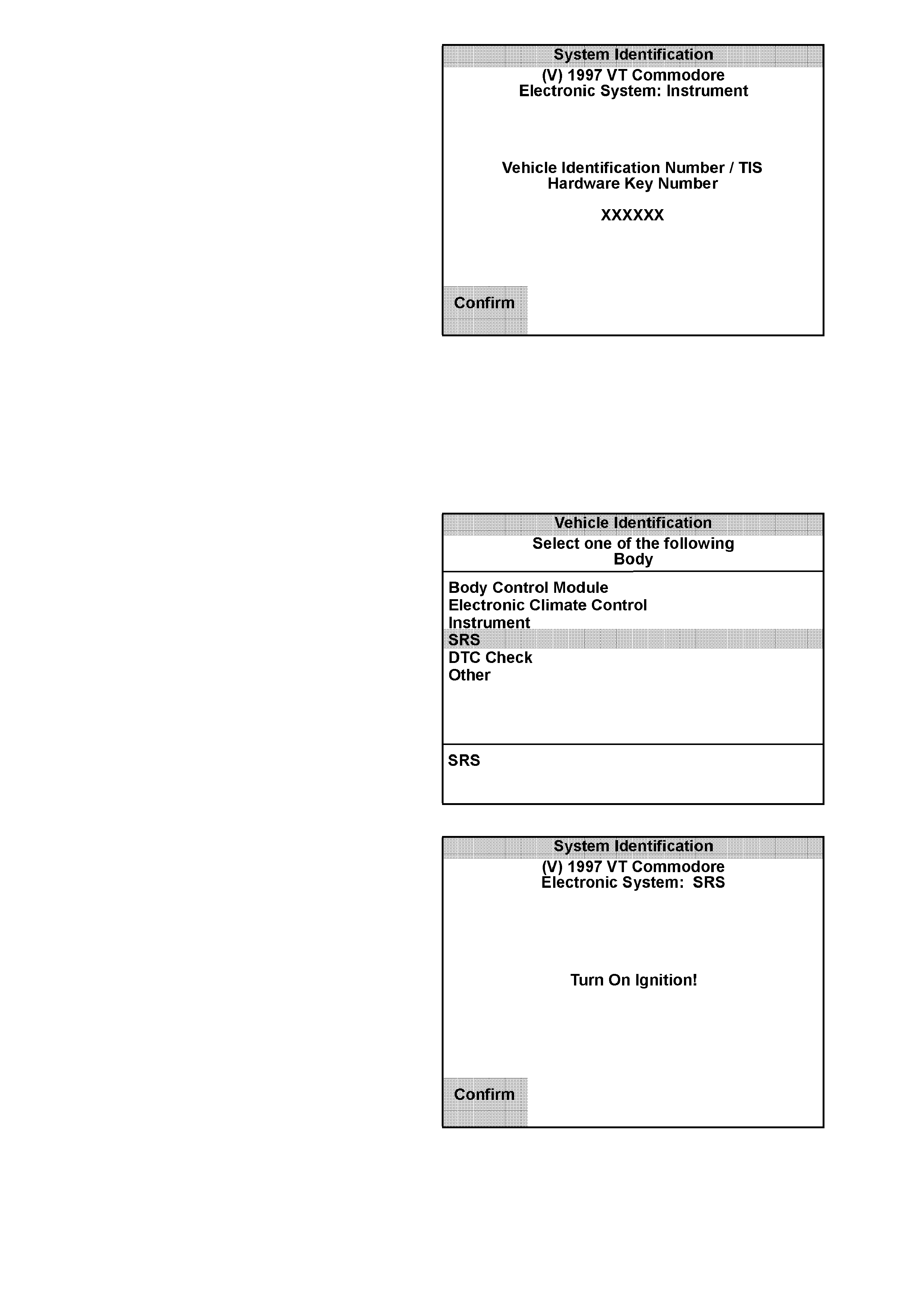

Figure 0C-40 Vehicle Identification Menu

2. Turn on the ignition and press the Confirm

soft key.

Figure 0C-41 System Identification

The System Identification screen will then

display the Partnumber, if the More soft key is

pressed the Software Date, Data Version

Number and the VAP Process Number will

also be displayed.

Figure 0C-42 System Identification

3. Press the Confirm soft key, TECH 2 will then

display either the Vehicle Identification

Number or the TIS Hardware Key Number if

the Odometer has been reset.

4. Press the Confirm soft key again, the

Instrument application menu will then be

displayed.

The following functions are available in the

Instrument application menu:

F0: Normal Mode

F1: Diagnostic Trouble Codes

F2: Data Display

F3: Snapshot

F4: Miscellaneous Tests

F5: Program

NOTE:

Functions may vary depending on the application

selected. Refer to the Section 12C INSTRUMENT

WIPERS, WASHERS AND HORN for further

Information.

Figure 0C-43 VIN or TIS Hardware Key Number

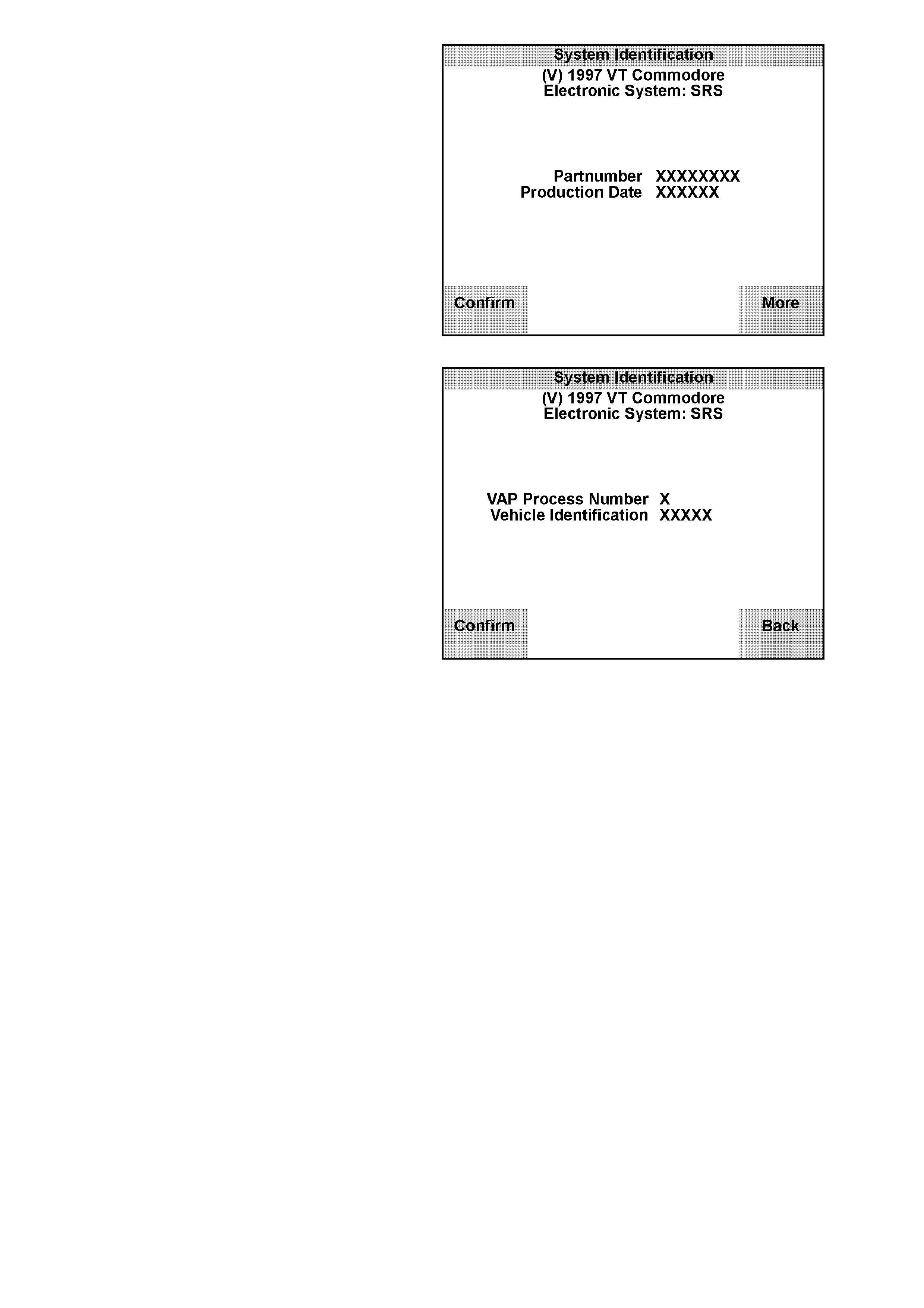

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

1. Select SRS from the Vehicle Identification

Menu with the arrow keys, then press ENTER.

Figure 0C-44 Vehicle Identification Menu

2. T urn on the ignition and pr es s the Confirm sof t

key.

Figure 0C-45 System Identification

The System Identification screen will then

display the following information:

Partnumber

Production Date

Figure 0C-46 System Identification

3. If the More soft key is pressed TECH 2 will

display the VAP Process Number and Vehicle

Identification Number.

4. Press the Confirm soft key, the SRS

application menu will then be displayed.

The following functions are available in the

SRS application menu:

F0: Normal Mode

F1: Diagnostic Trouble Codes

F2: Data Display

F3: Snapshot

F4: Program

NOTE:

Functions may vary depending on the application

selected. Refer to Section 12M SUPPLEMENTAL

RESTRAINT SYSTEM for further Information. Figure 0C-47 VAP Process Number

4. TECH 2 DIAGNOSIS

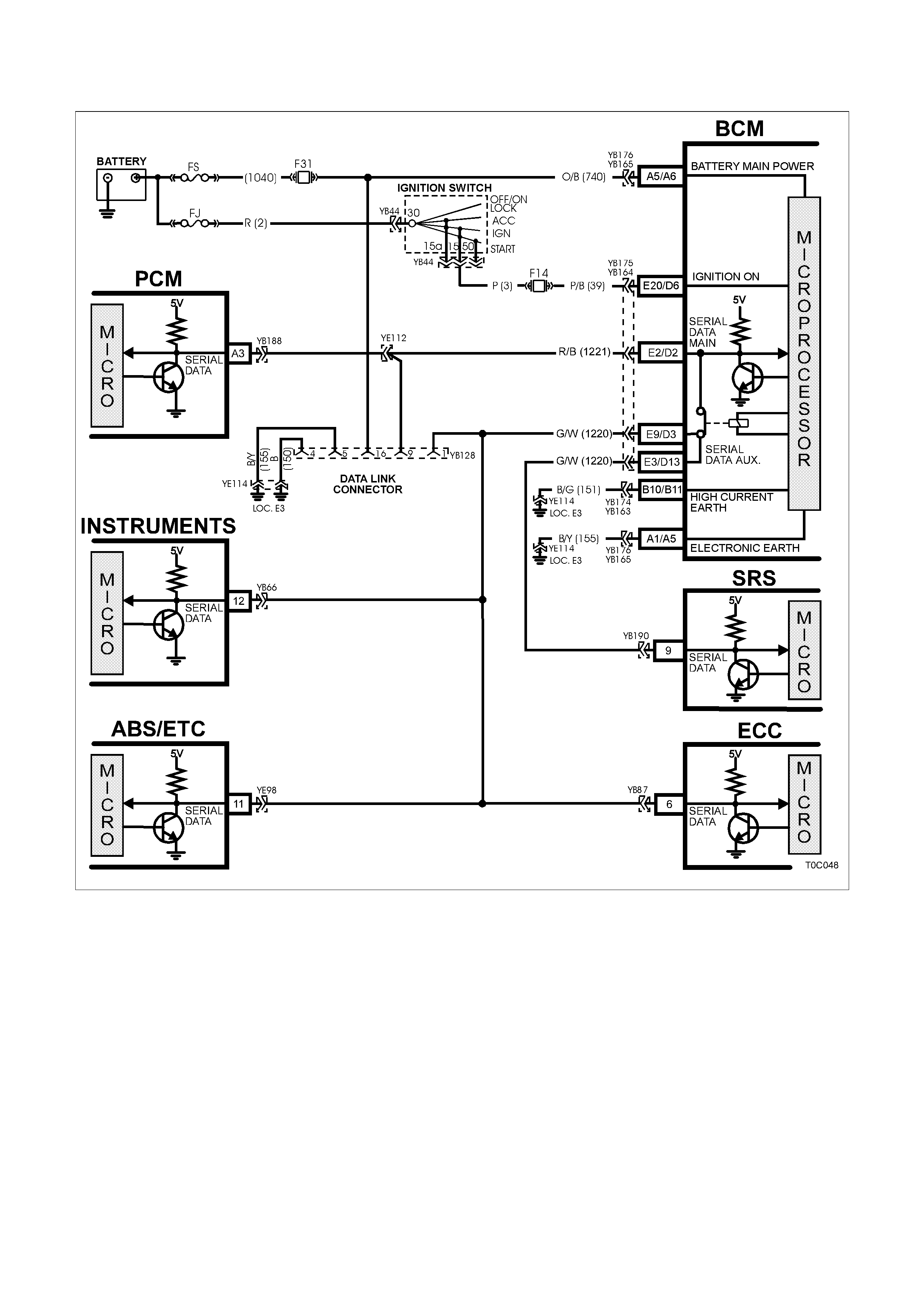

Figure 0C-48 Serial Data Circuit

GENERAL INFORMATION

TECH 2 communicates with the vehicle via the

serial data bus circuit 1221. Circuit 1221 is

connected to terminal 9 of the DLC (YB128) and

the serial data earth circuit is via terminal 5 of the

DLC and circuit 155. The power supply for T ECH 2

is from fuse F31 via circuit 740 to terminal 16 of the

DLC. The earth circuit is via terminal 4 and circuit

150.

TECH 2 can communicate with the following

control modules, if the vehicle is equipped with

these systems.

• Body Control Module (BCM).

• Powertrain Control Module (PCM).

• Instrument (INS).

• Supplemental Restraint System (SRS).

• Antilock Braking System / Electronic Traction

Control System (ABS/ETC).

Test Description

The numbers below refer to step numbers on the

following diagnostic chart.

1. Checks if TECH 2 is being powered up.

2. Check s if TECH 2 is pr ogramm ed with correct

Holden software.

3. Checks if TECH 2 can communicate with BCM

If TECH 2 can communicate with BCM, serial

data circuit 1221 is OK.

4. Checks continuity of serial data earth circuit.

5. Checks if fusible link FS is OK.

6. Checks if fuse F31 is OK.

7. Check if battery voltage is available for TECH

2.

8. Check s if an earth circ uit is available f or T ECH

2.

9. All vehicle circuits have been found to be OK,

fault must be with TECH 2 or an intermitted

fault is causing TECH 2 not to operate

correctly.

STEP ACTION VALUE YES NO

1. • Connect TECH 2 to the

vehicle DLC, with the

DLC cable and the

16/19 pin adapter.

• Switch on TECH 2 by

pressing the PWR

button.

• Does a green light

above the PWR button

come ON?

Go to Step 2. Go to Step 5.

2. • Does TECH 2 display

Title Screen illuminate

and display:

TECH 2

Press [ENTER] To

Continue

Software Version: 3.100

Holden 1997

(Software Version should

be greater than 3.100)

Go to Step 3. Program

TECH 2 PCMCIA

Card refer to

PROGRAMMING

TECH 2 is this

Section.

3. • At the TECH 2 title

screen press the Enter

key.

• Select F0: Diagnostics /

1997 / VT Commodore /

F3: Body / Body Control

Module.

• Turn on ignition and

press the confirm soft

key.

• Does TECH 2 display

the BCM System

Identification Screen?

TECH 2 is

functioning

correctly, refer to

system specific

diagnostics if you

cannot

communicate with a

specific control

module.

Go to Step 4.

4. • Using an ohmmeter

check continuity of

circuit 155

(Black/Yellow wire)

between DLC (YB128)

terminal 5 and a known

good earth.

• Is there continuity?

Go to BCM

diagnosis

SERIAL DATA

COMMUNICATION

Section 12J1 Low

Series,

Section 12J2 High

Series.

Repair open in

circuit 155 between

DLC terminal 5 and

earth LOC. E3.

5. • Is Fusible link FS OK? Go to Step 6. Replace fusible link

and check cause of

blown fusible link.

Verify Repair.

STEP ACTION VALUE YES NO

6. • Is Fuse F31 OK? Go to Step 7. Replace fuse and

check cause of

blown fuse.

Verify Repair.

7. • Check for voltage

between DLC (YB128)

terminals 4 and 16.

• Is voltage at specified

value?

B+ Go to Step 9. Go to Step 8.

8. • Ignition off.

• Check for voltage

between DLC (YB128)

terminals 16 and a

known good earth.

• Is voltage above

specified value?

B+ Repair open in

circuit 150 between

DLC Connector

terminal 4 and earth

LOC. E3.

Verify Repair.

Repair open in

circuit 740 and

1040 between DLC

Connector terminal

16 and fusible link

FS.

Verify Repair.

9. • Perform TECH 2 Self

Test using 240 V AC

power supply. (Refer to

TECH 2 User’s Guide).

• Does TECH 2 pass Self

Test?

Check for incorrect

terminal sizing of

DLC YB128 or

intermittent fault in

DLC circuits.

Send TECH 2 out

for repair.

5. SPECIAL TOOLS

TOOL NO. REF IN TEXT TOOL DESCRIPTION COMMENTS

TECH 2 DIAGNOSTIC SCAN TOOL PREVIOUSLY RELEASED

TECHNICAL

INFORMATION SYSTEM

(TIS)

TIS CD ROM PREVIOUSLY RELEASED