SECTION 12J-2 - HIGH SERIES BODY

CONTROL MODULE

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will

consist of either seat belt pre-tensioners and a driver's side air bag , or seat belt pre-

tensioners and a driver's and front passenger's side air bags. Refer to CAUTIONS,

Section 12M, before performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS d eployment, resultin g in po ssible personal in jury or unnecessary

SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of

safety, the LPG fuel system should be isolated by turning 'OFF' the manual service

valve an d then draining t he LPG service lines, befo re any service w ork is carried out

on the vehicle. Refer to the LPG leaflet included with the Owner's Handbook for

details or LPG Section 2 for more specific servicing information.

1. GENERAL DESCRIPTI ON

A Body Control Module (BCM) combines into one central module, the control or assist of various vehicle electrical

systems or features, rather than having individual modules for each system or feature.

High Series Australian Arrow BCM’s are fitted as standard equipment on all VT Series Berlina and Calais Models.

NOTE:

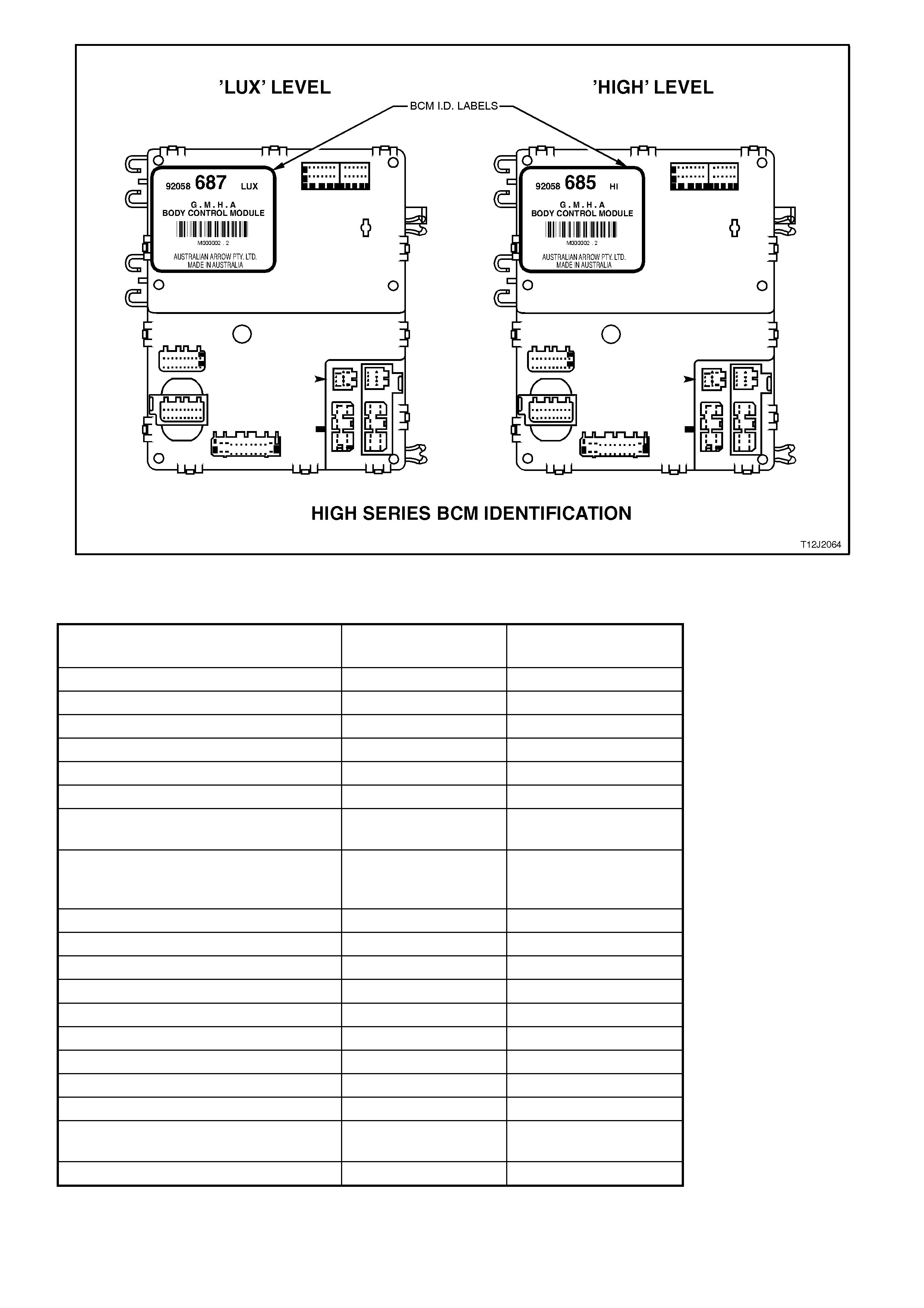

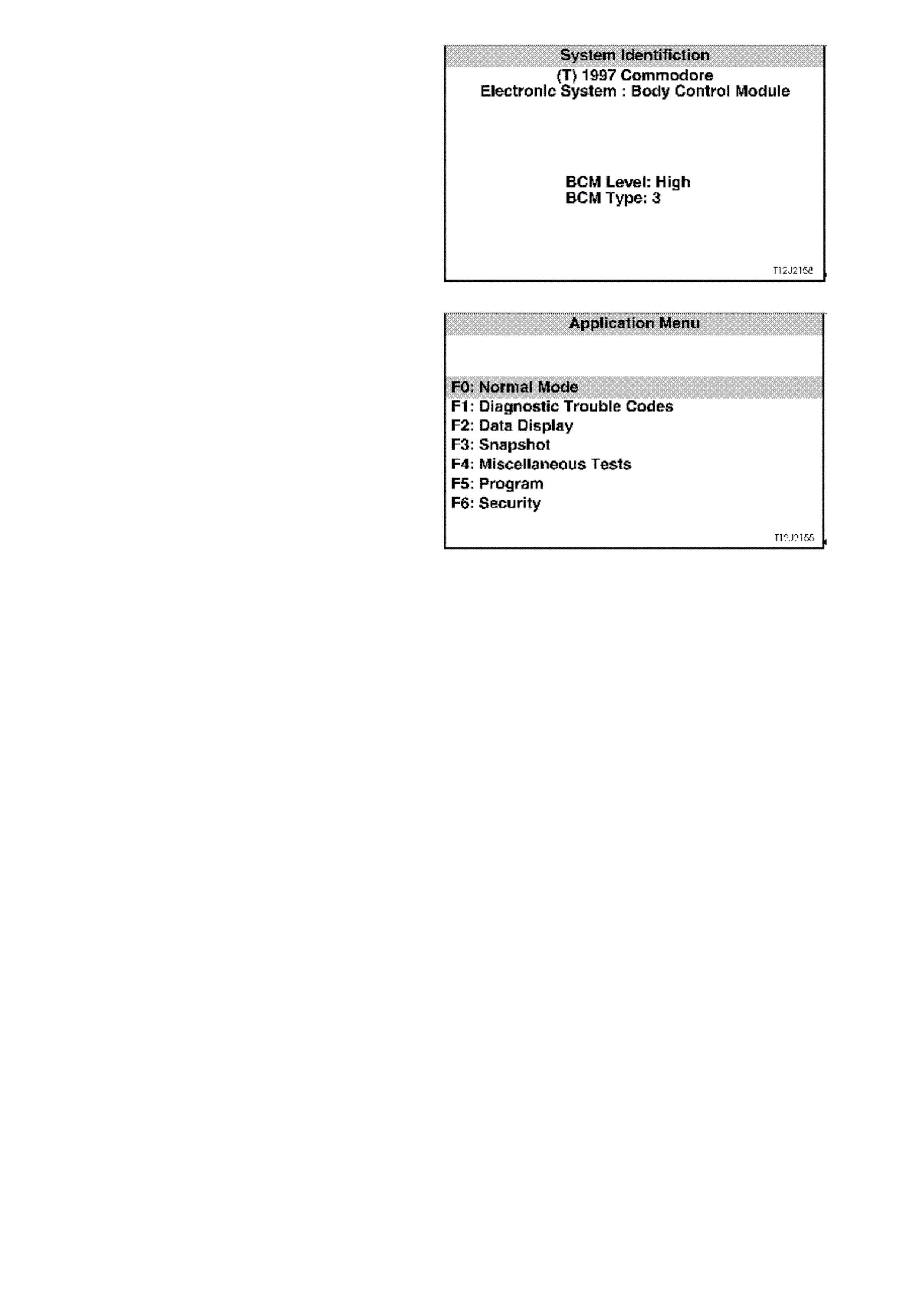

Two levels of High Series Australian Arrow BCM’s have been released, a LUX level for Berlina Models and the HI

level for Calais. If a service operation or diagnostic procedure requires that a High Series BCM must be replaced,

ensure that the correct BCM level is reinstalled for the particular level of vehicle.

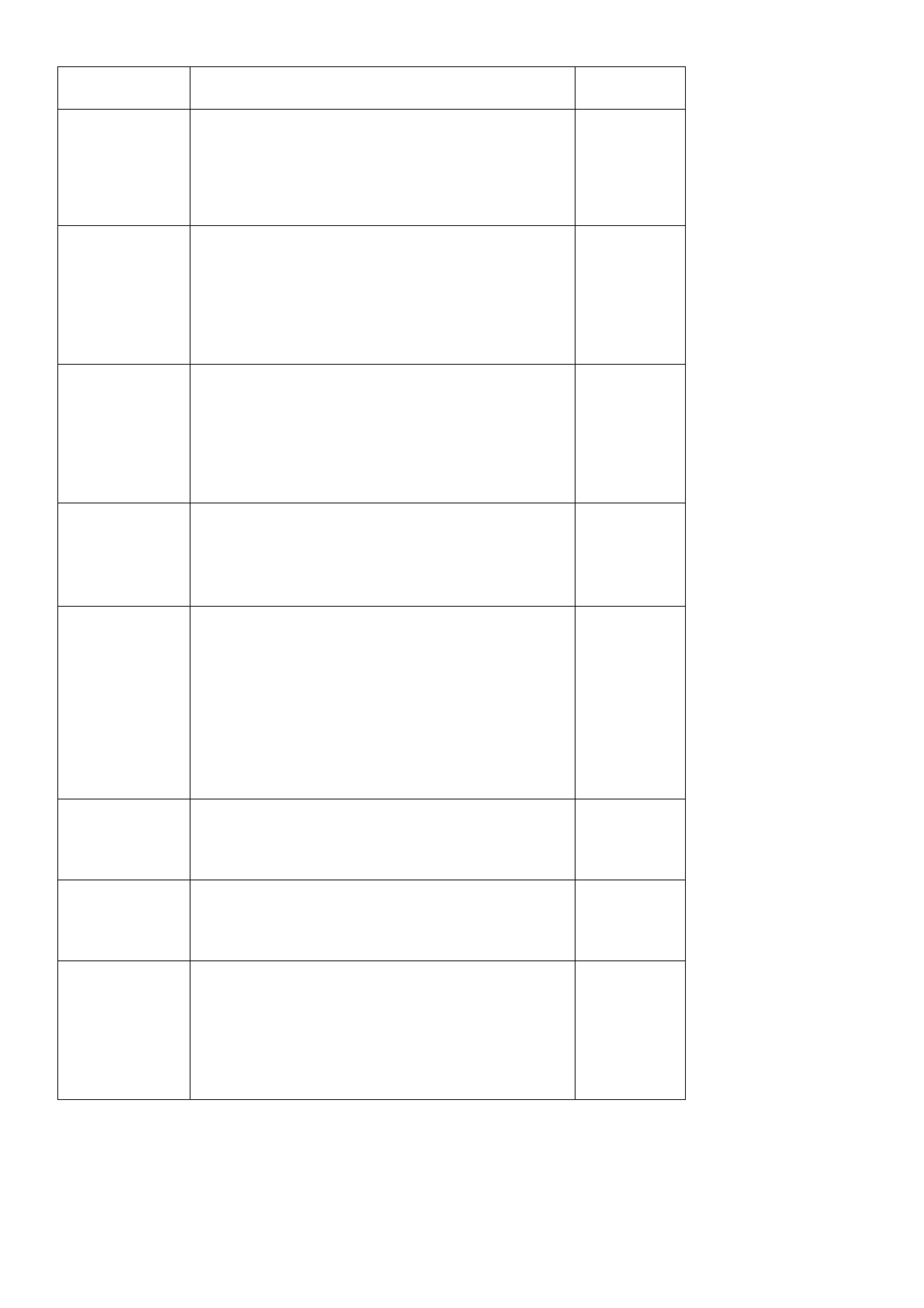

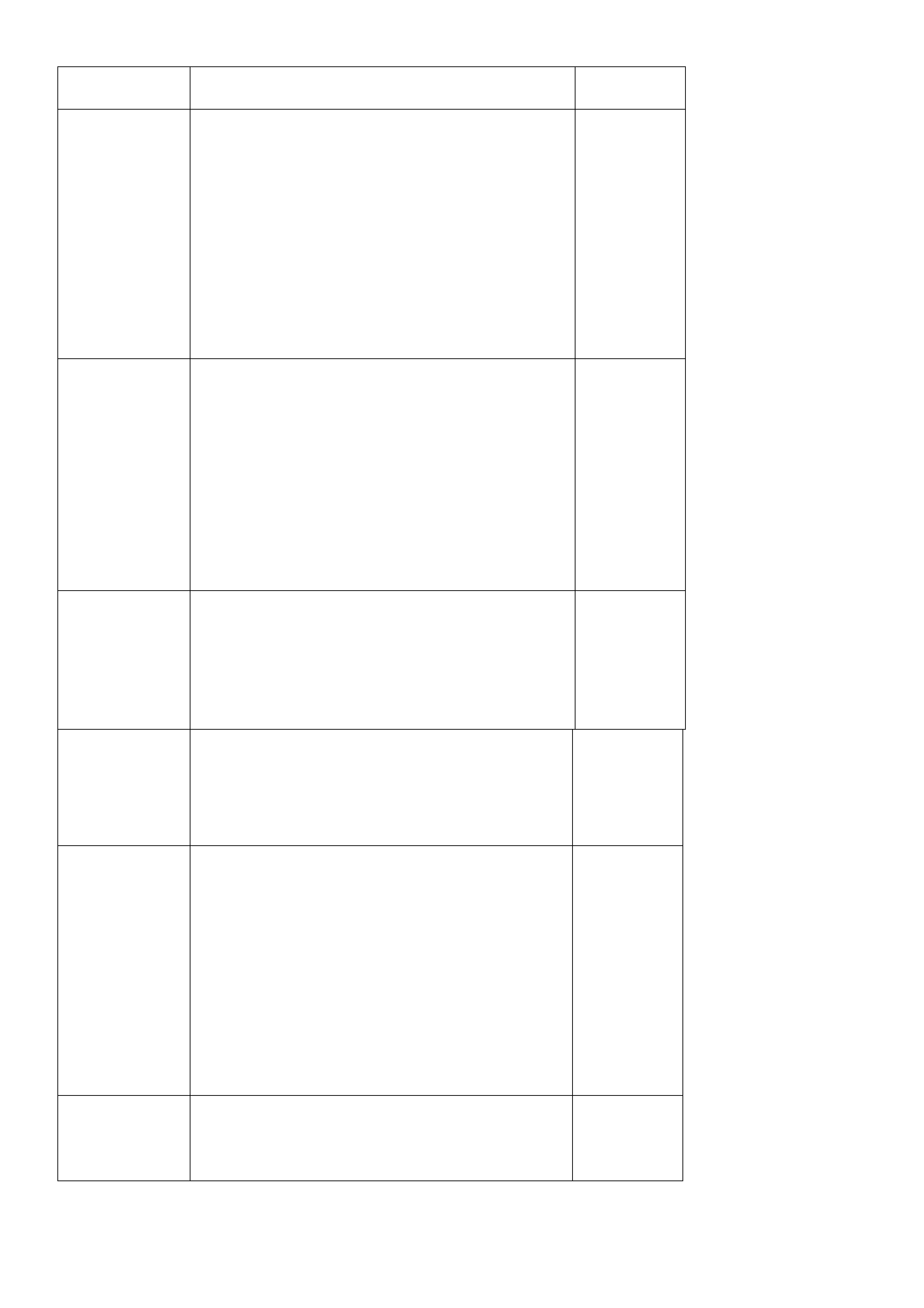

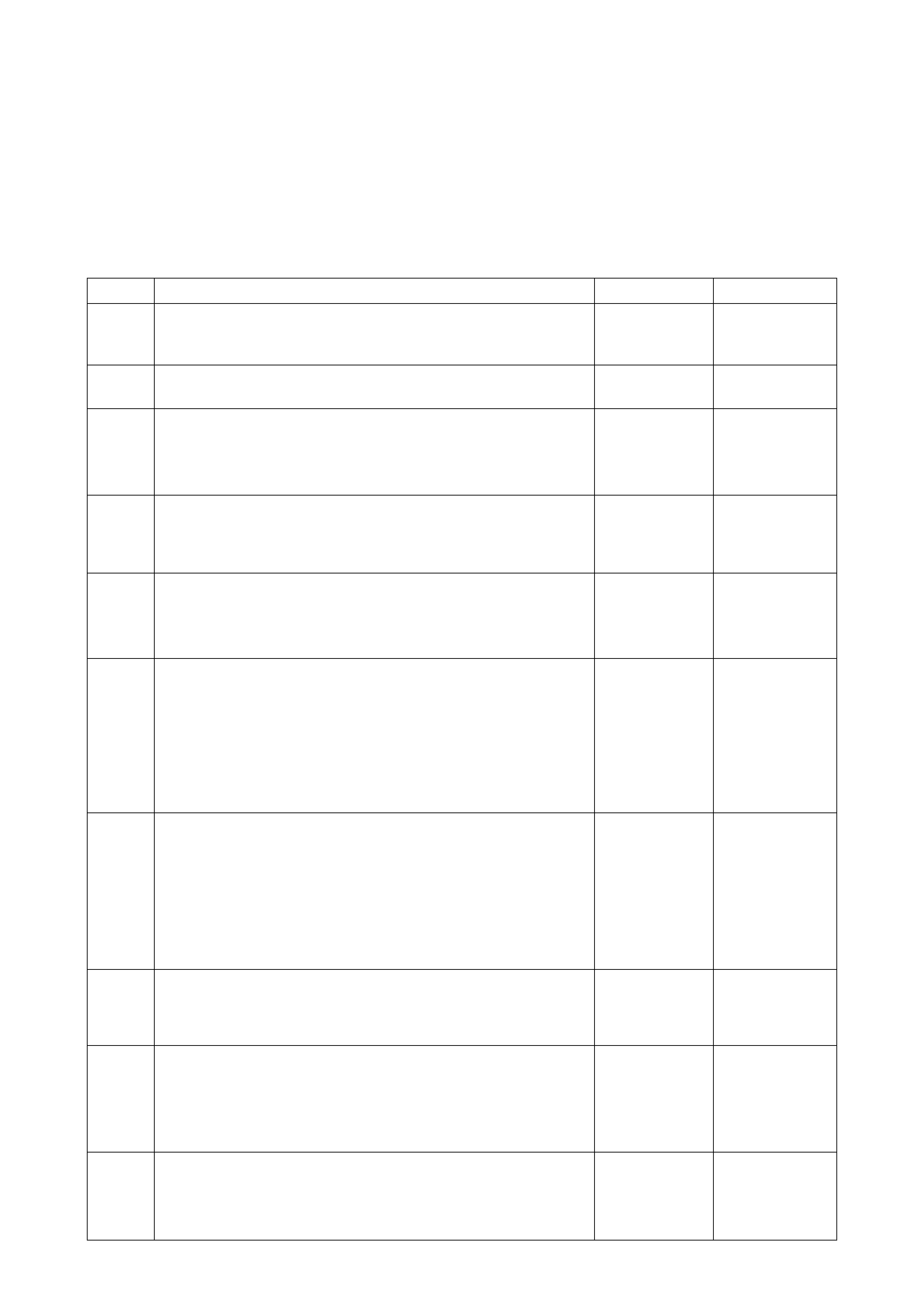

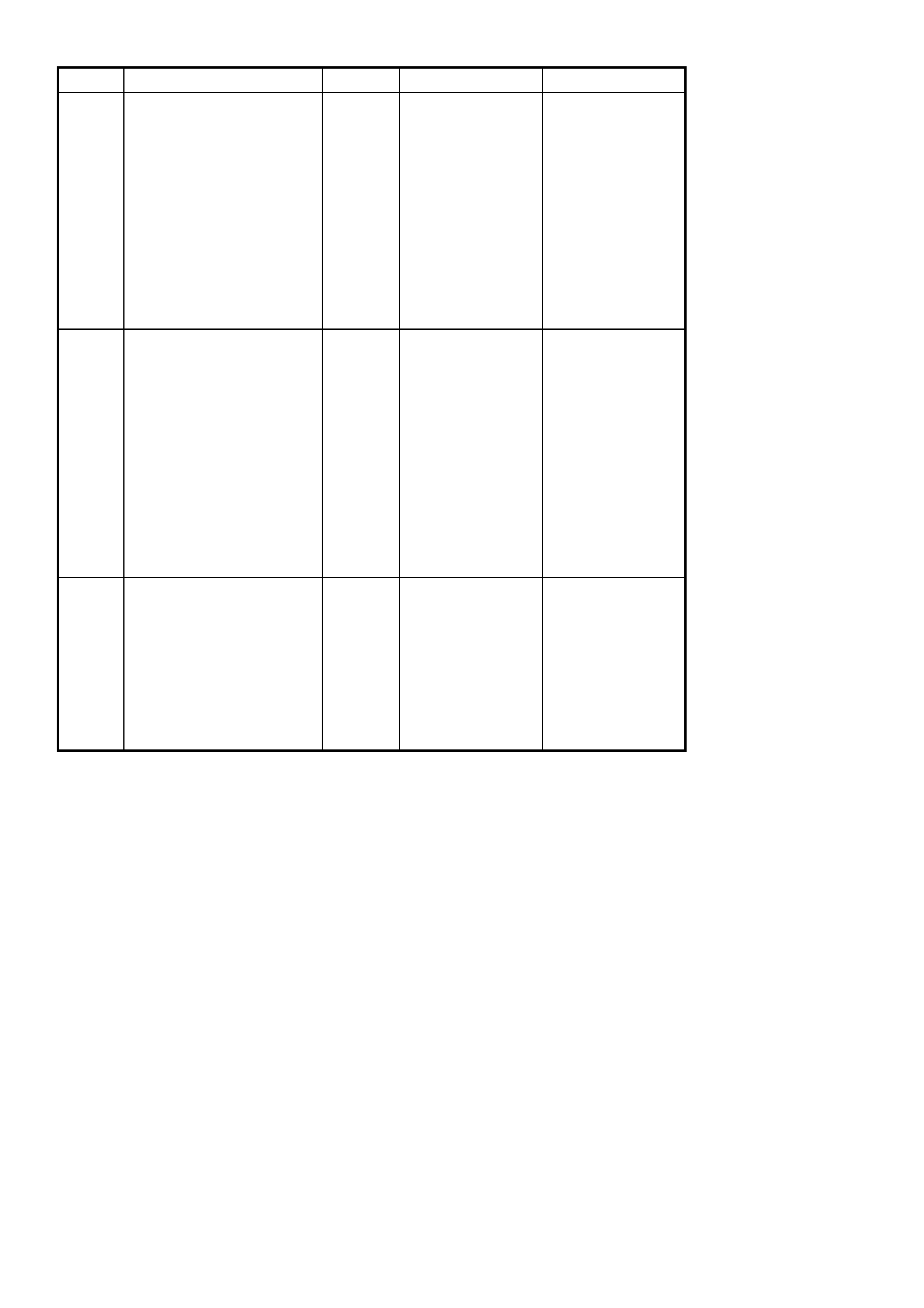

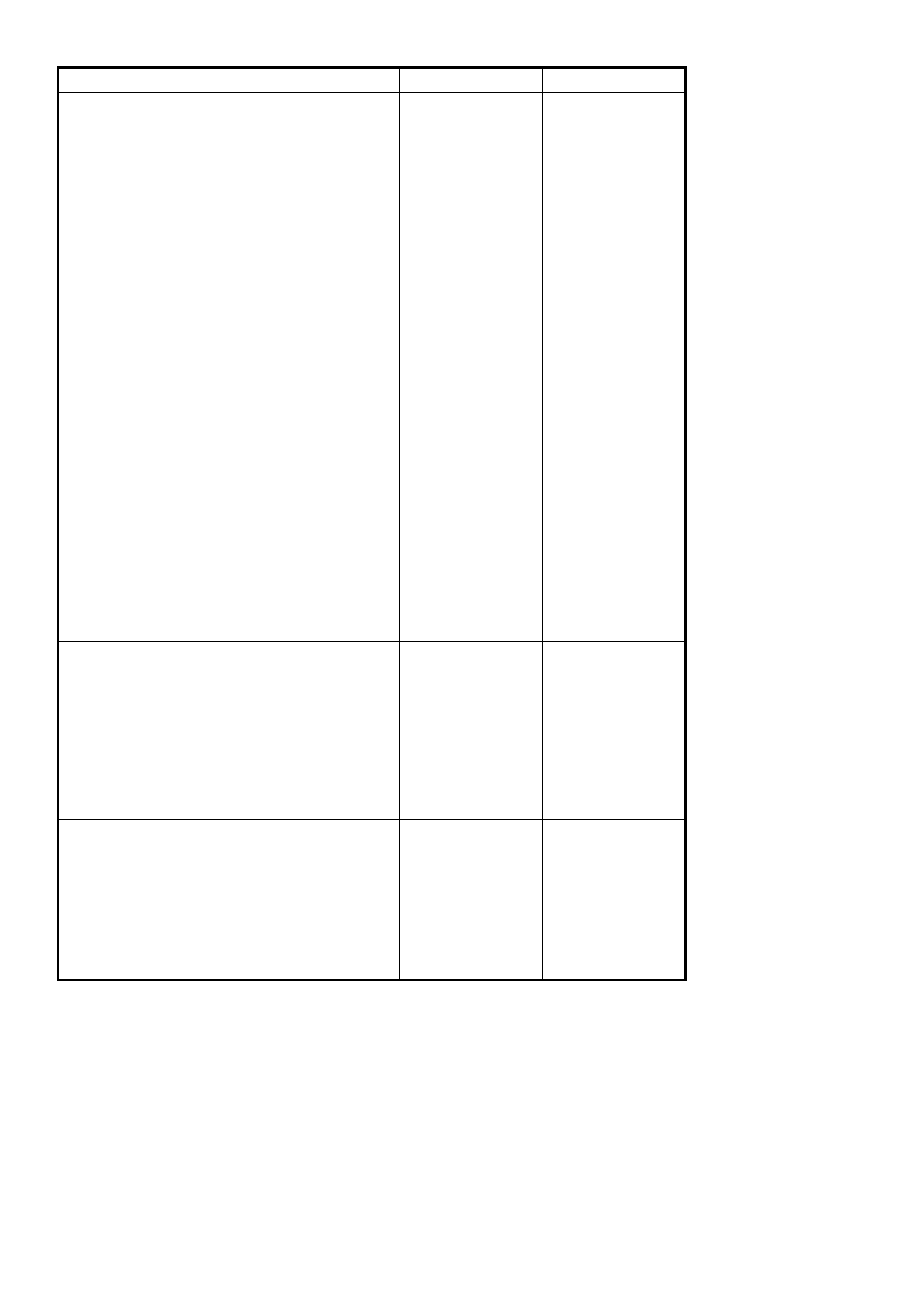

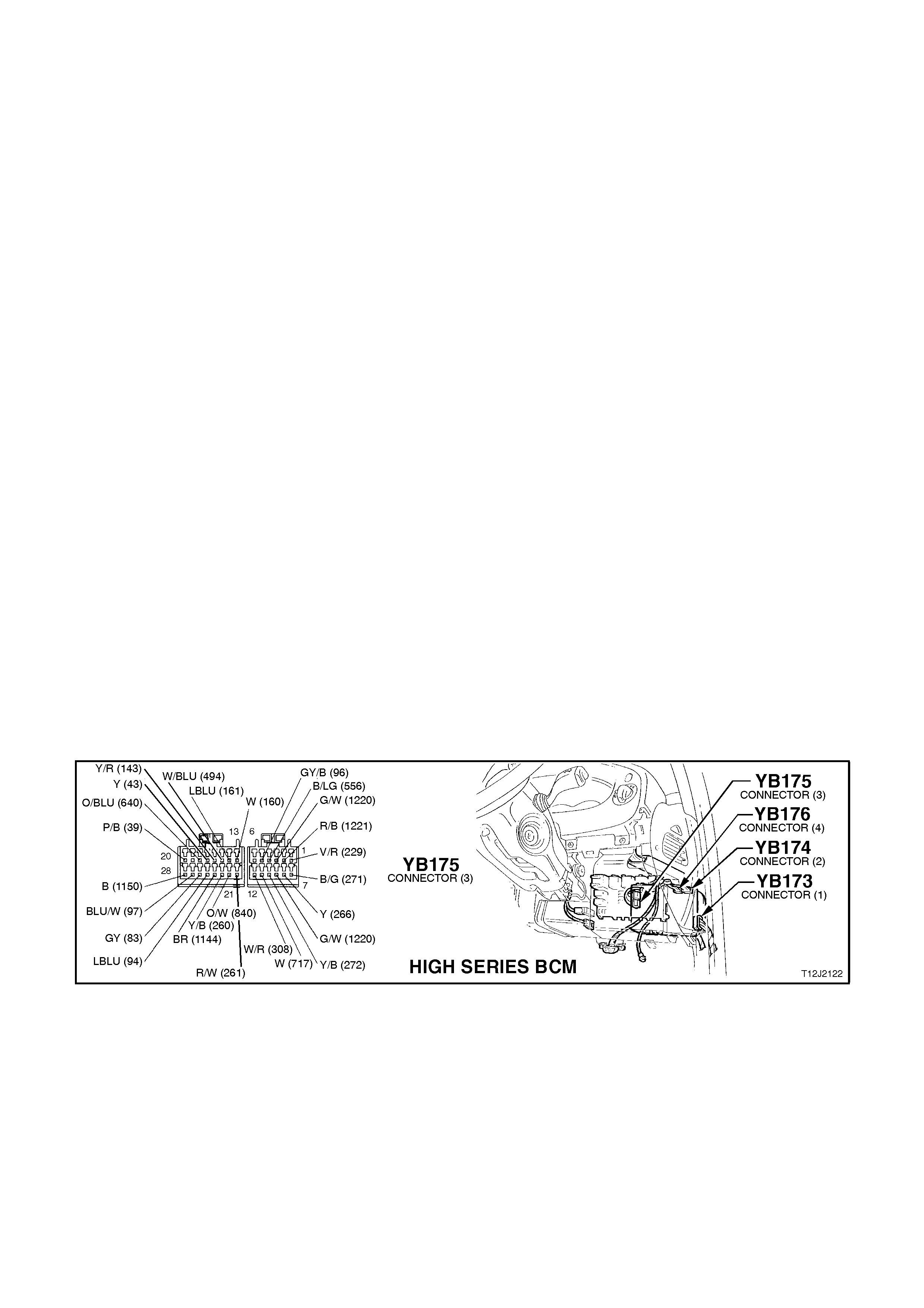

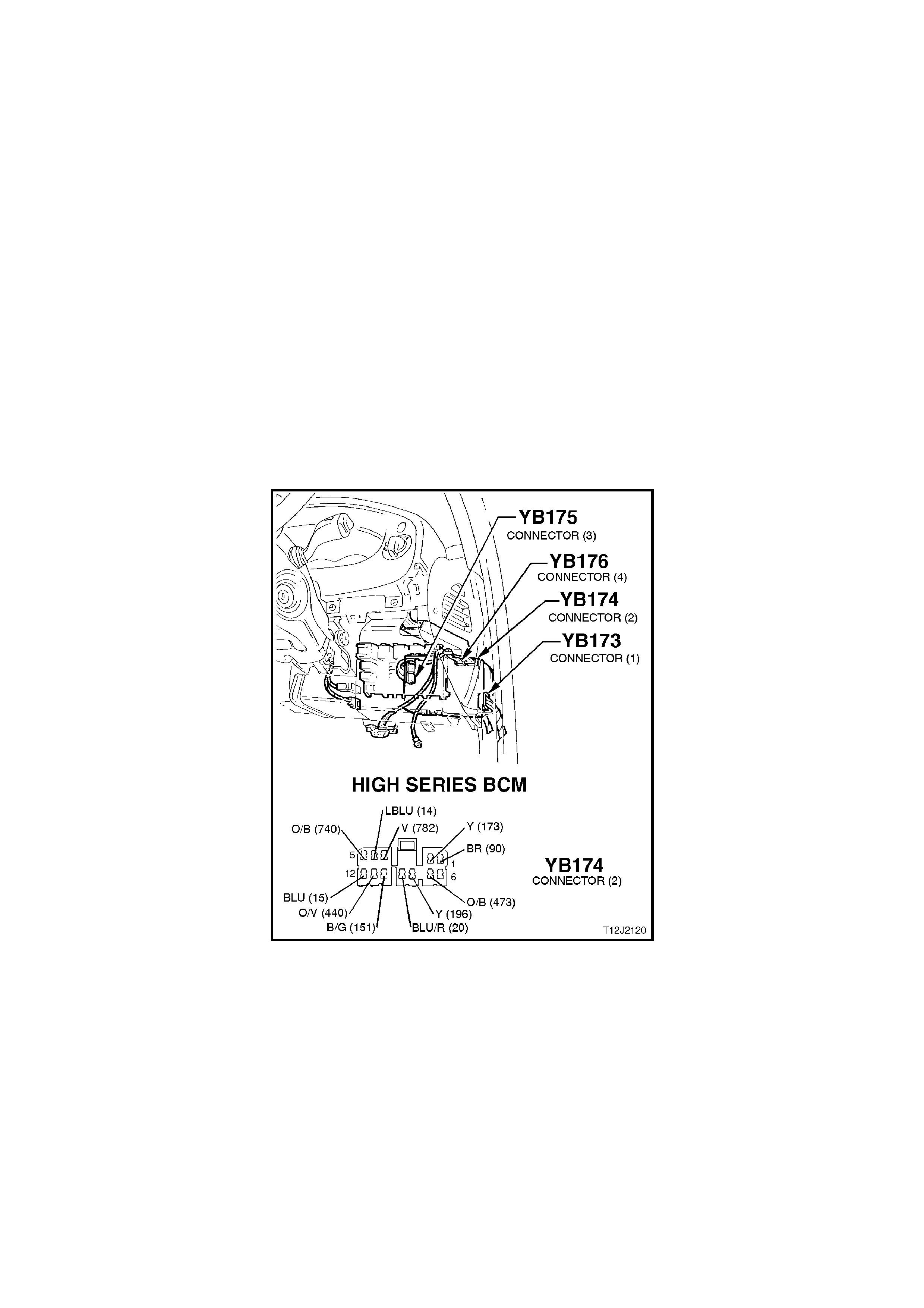

Figure 12J-2-1 illustrates the identification details for the High Series BCM. External identification can be made by

referring to the last three digits of the BCM part number.

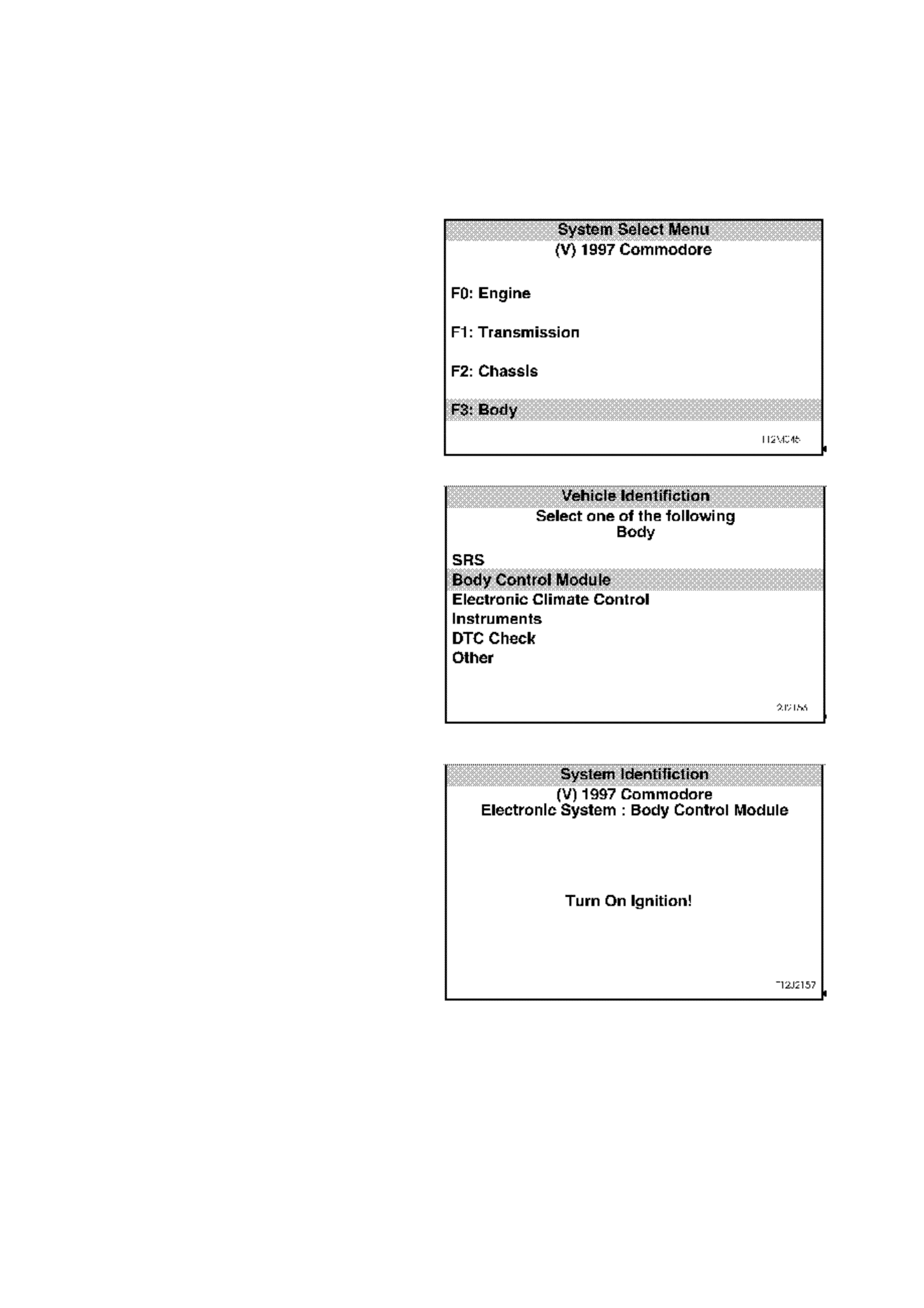

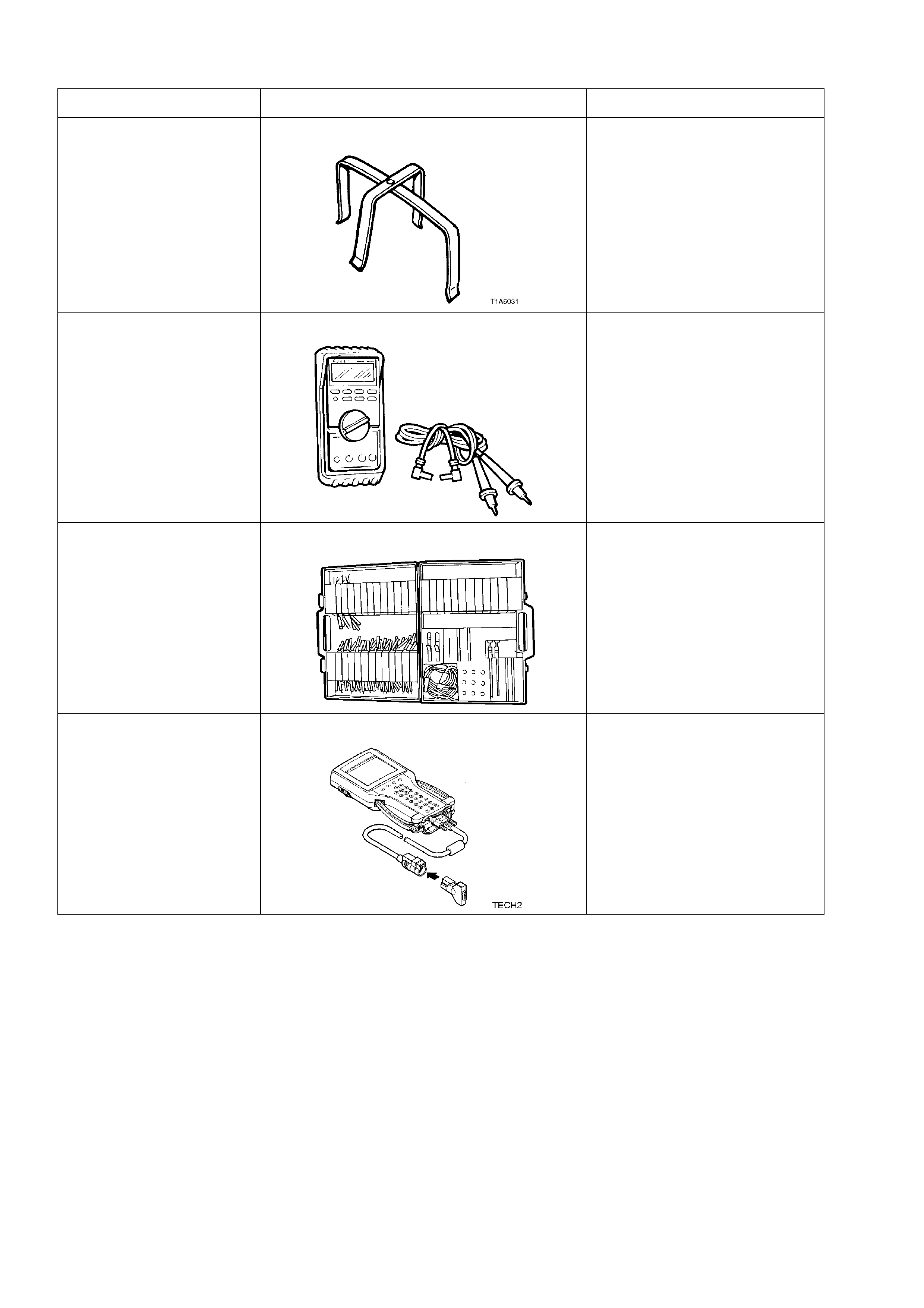

Specific TECH 2 software has been developed f or use with the TECH 2 diagnostic scan tool to assist with various

vehicle electrical system fault finding, including the various BCM functions and controls.

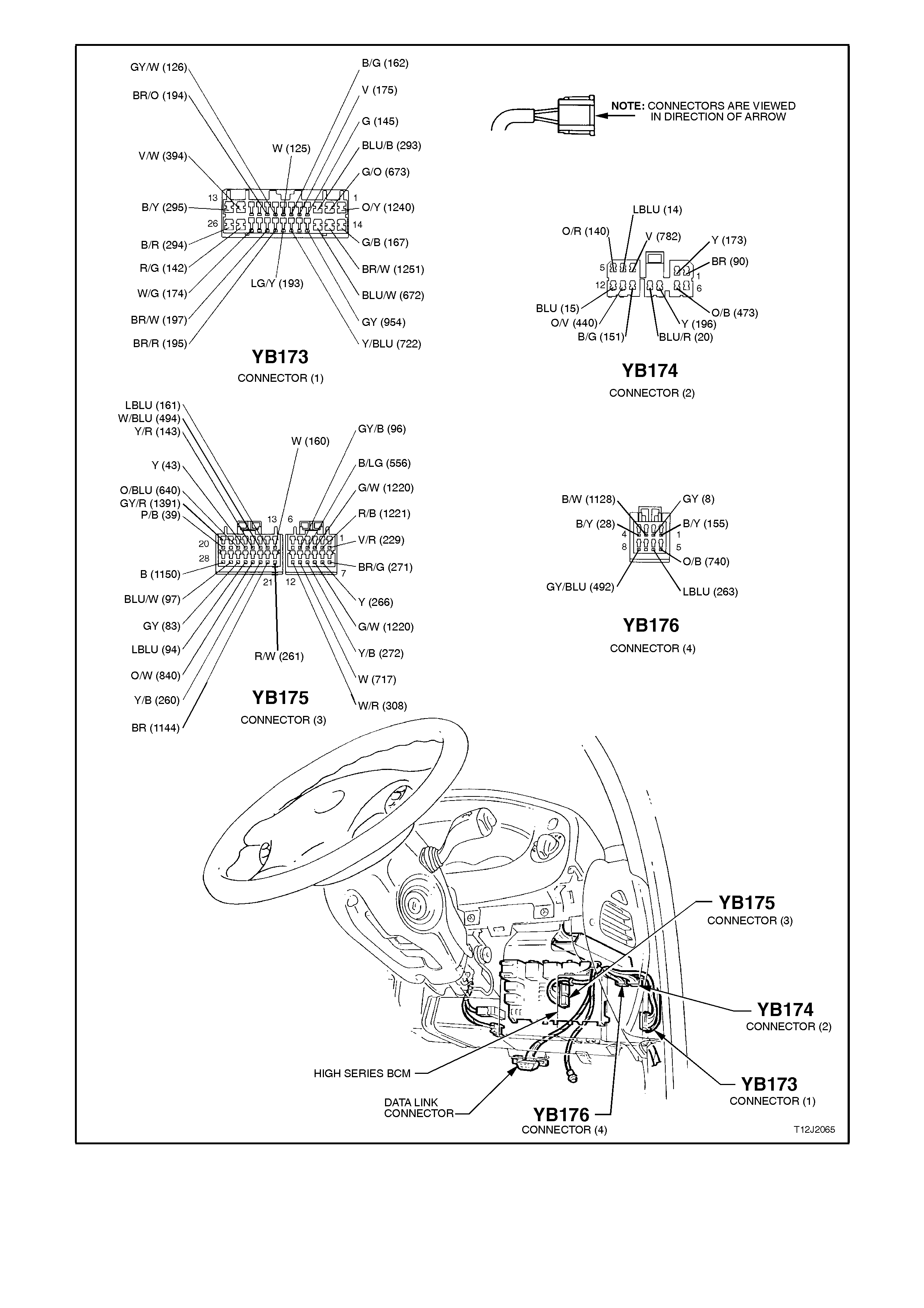

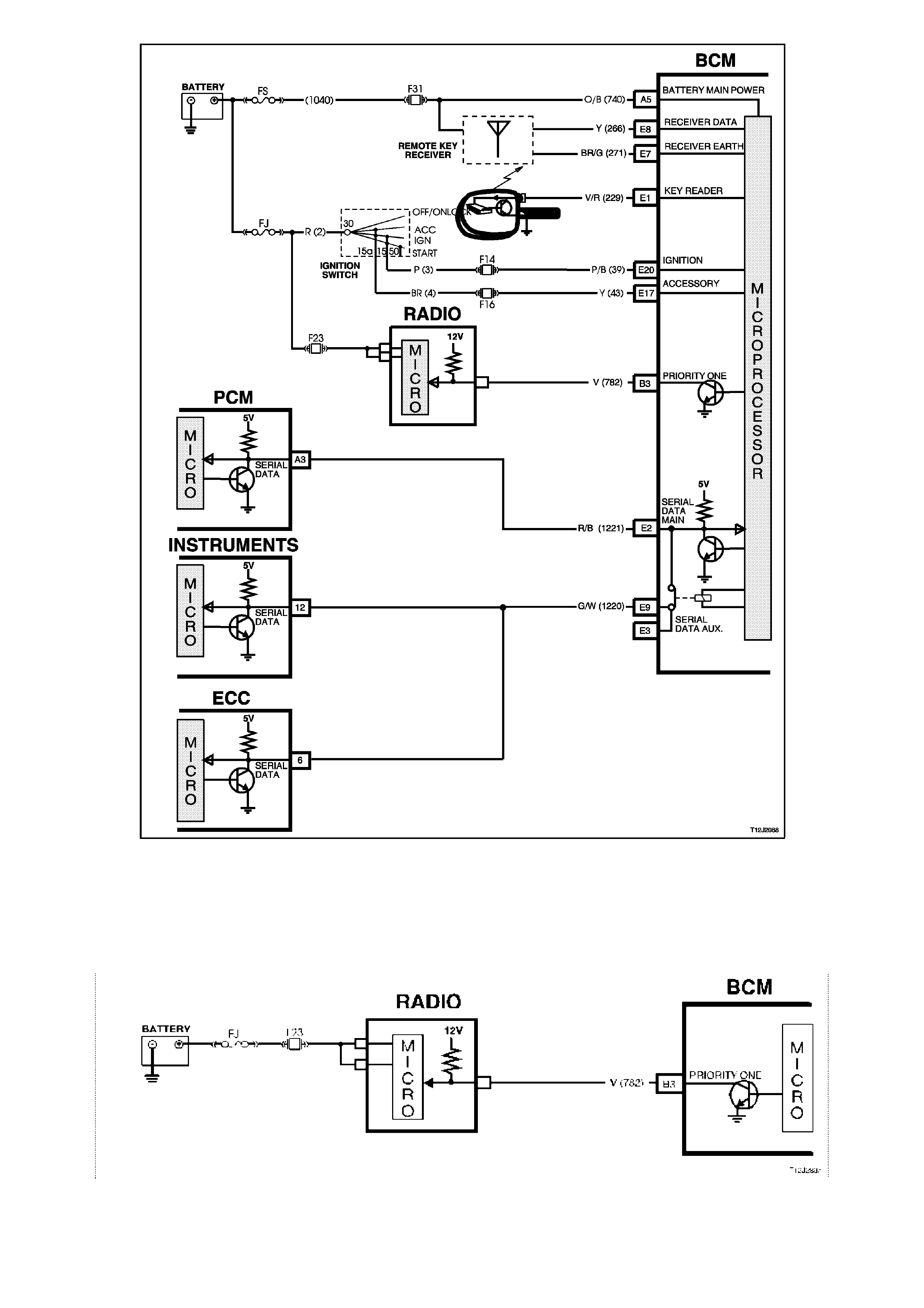

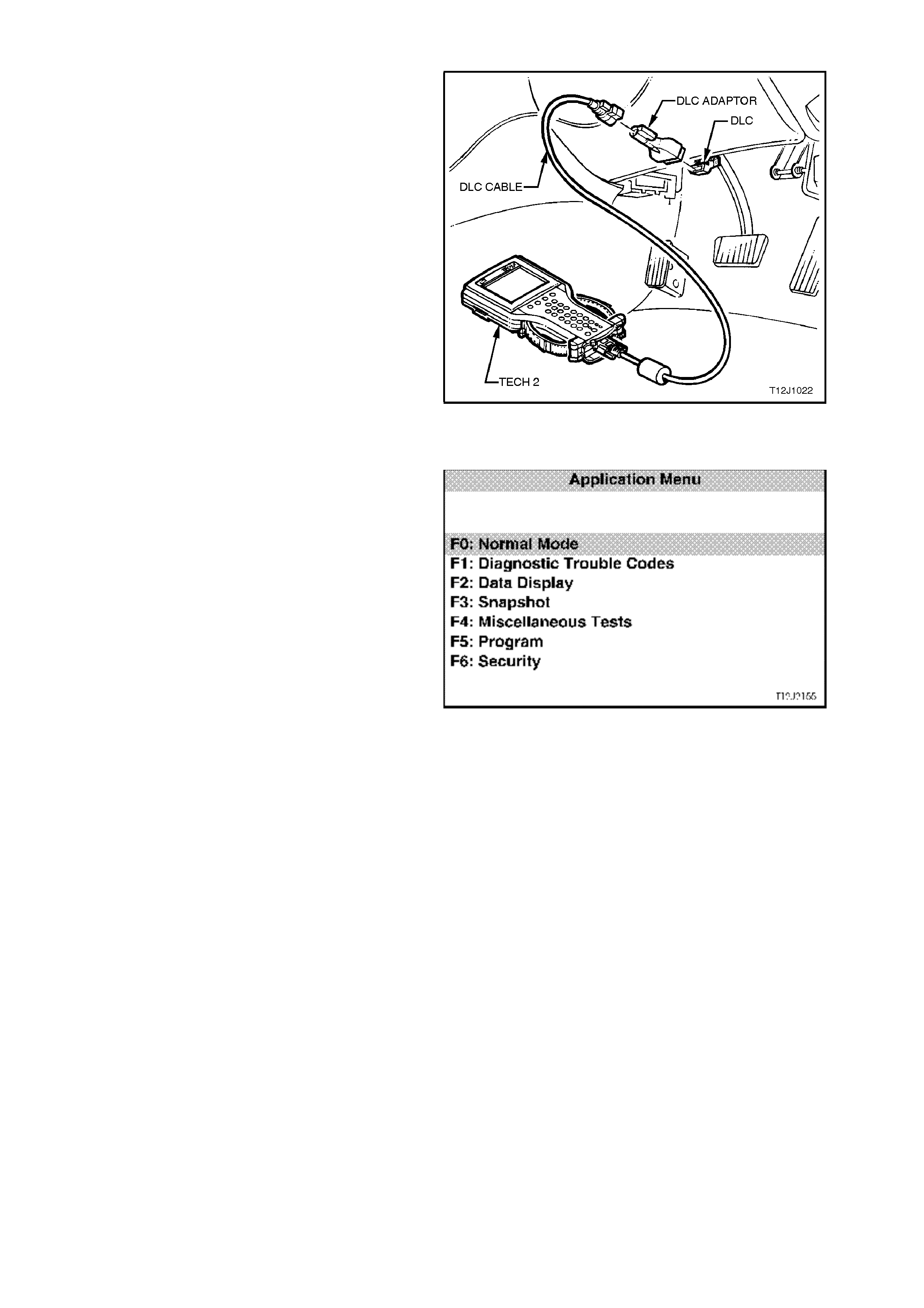

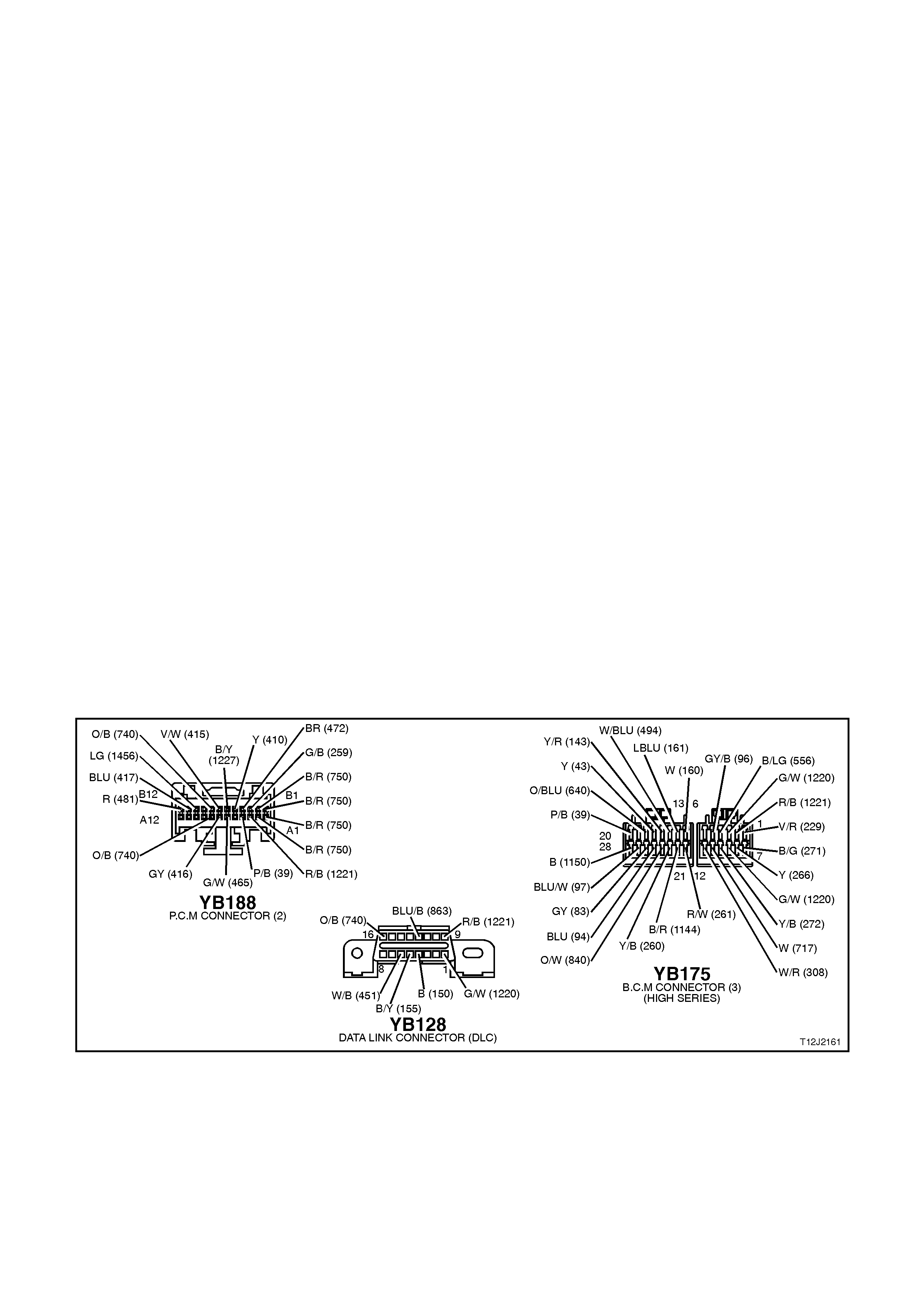

The connection for TECH 2 for the High Series Australian Arrow BCM serial data communication is via the Data

Link Connector (DLC), attached to the instrument panel lower right hand trim, to the left of the steering column,

refer Fig.12J-2-2.

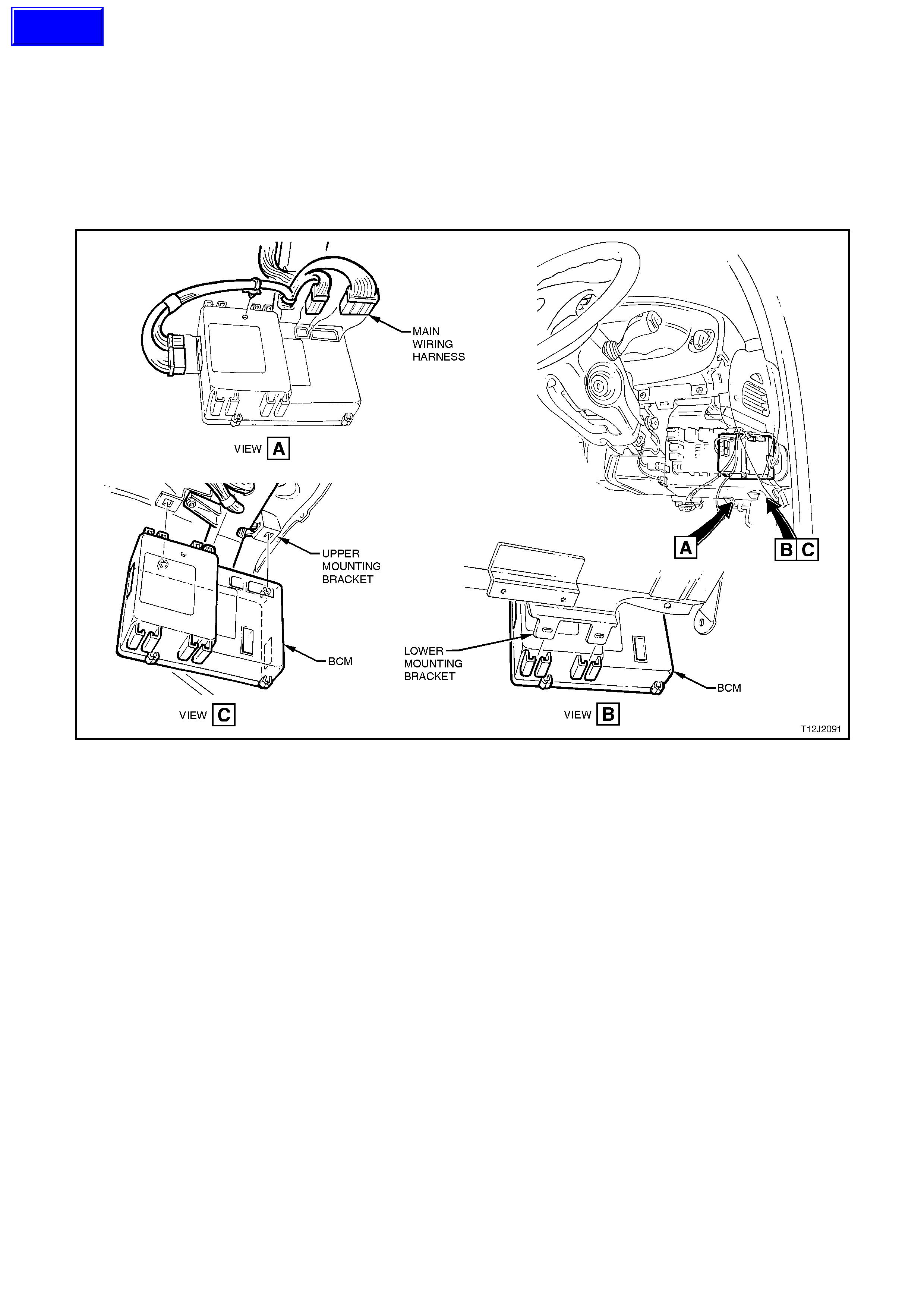

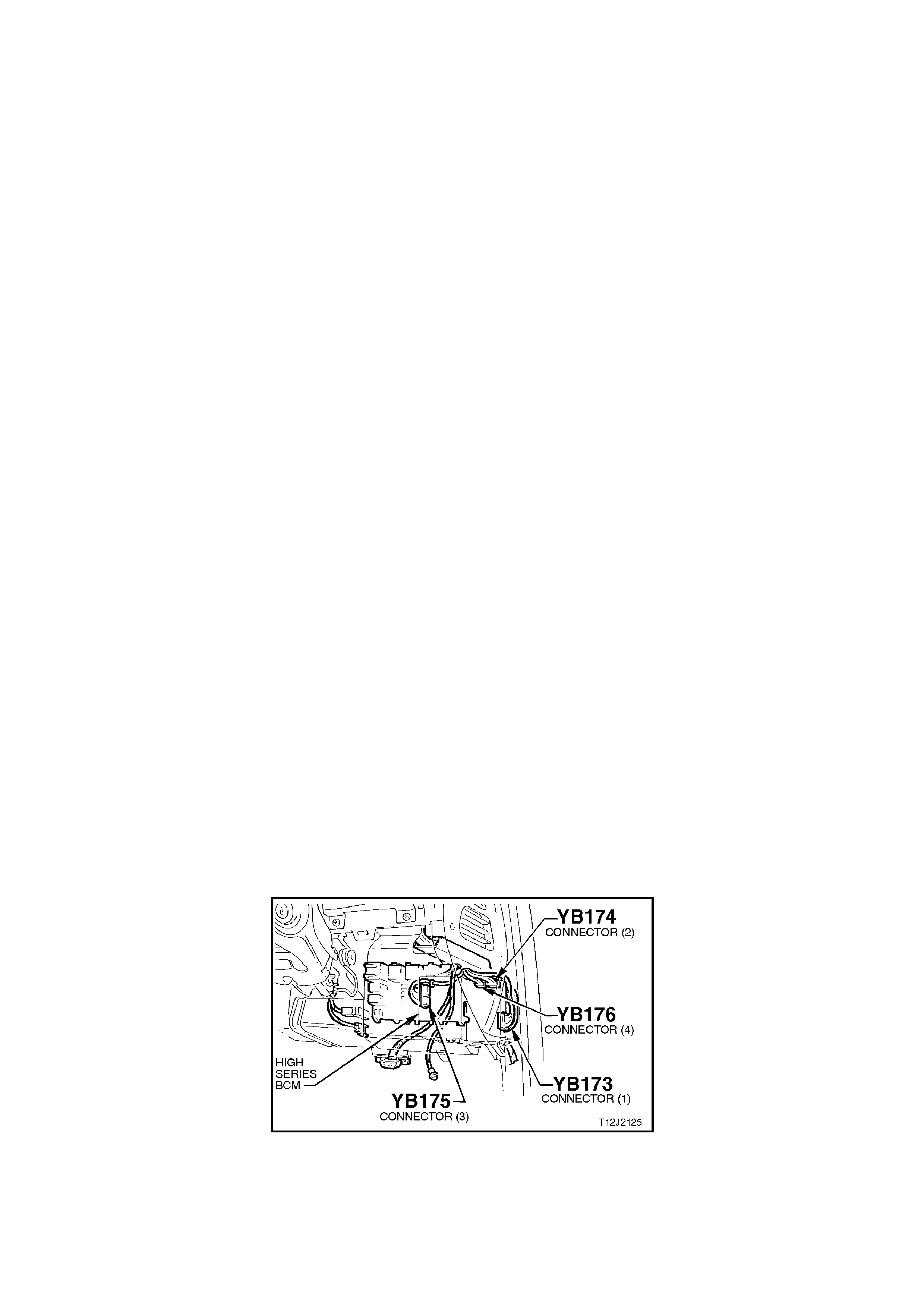

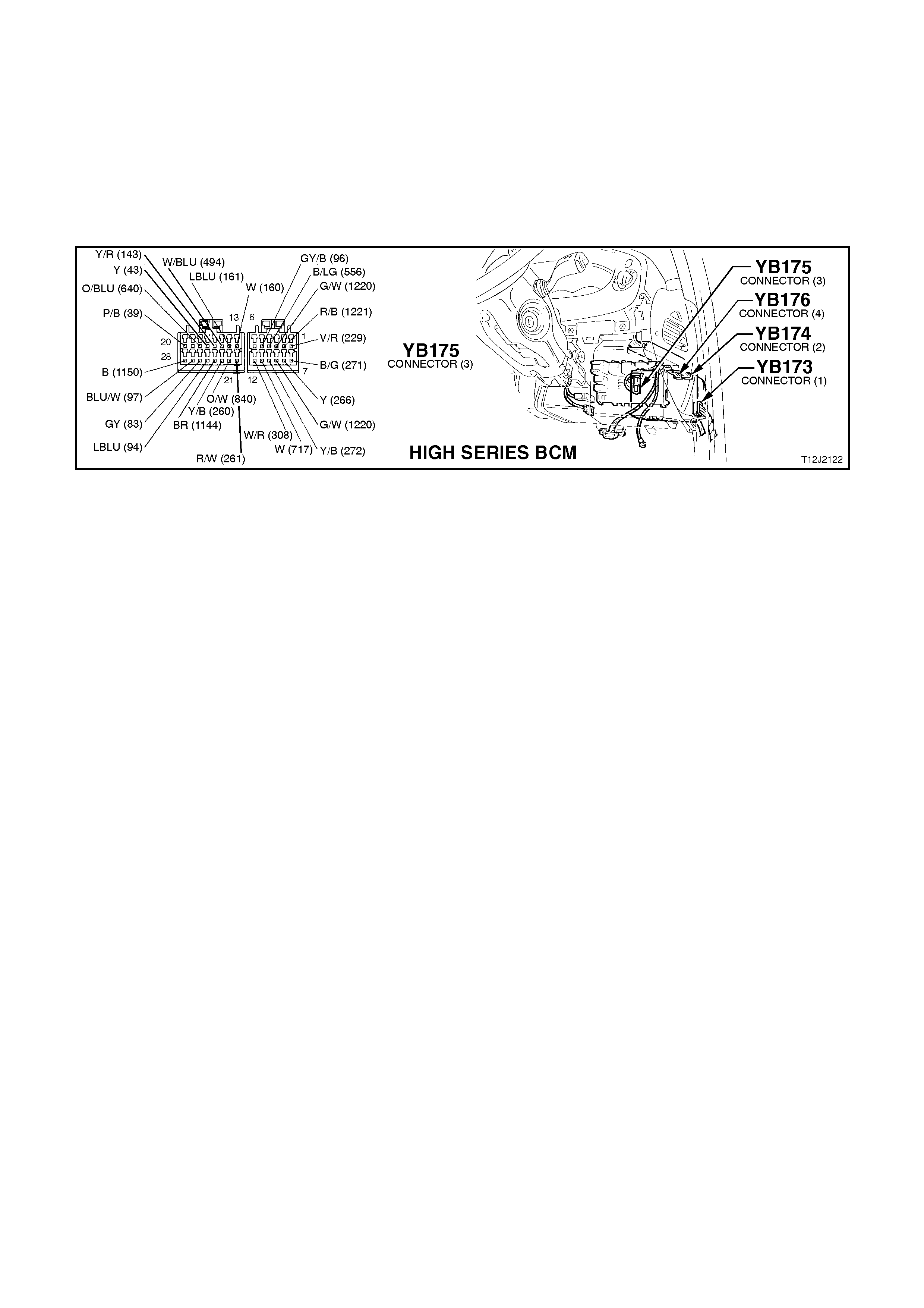

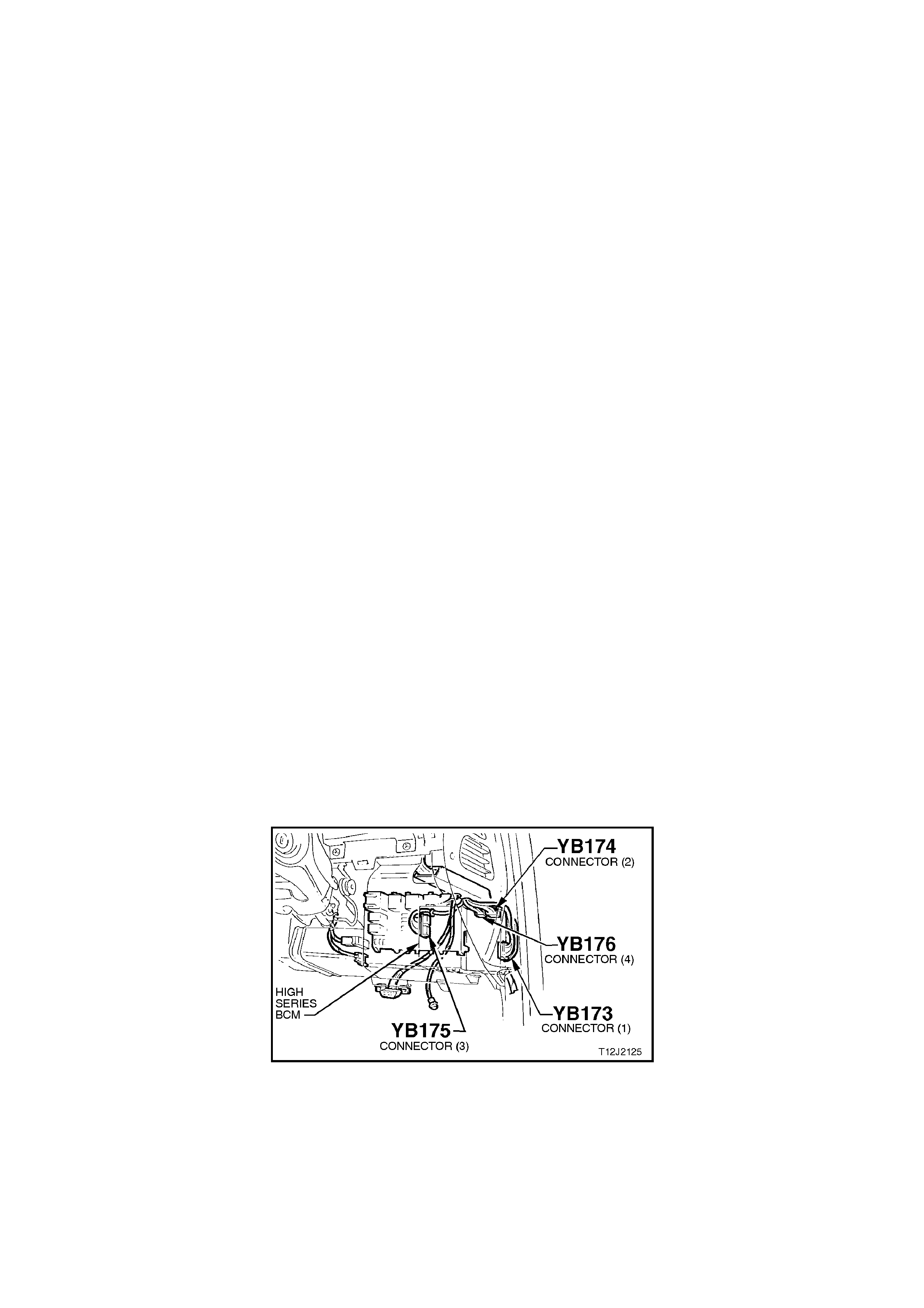

The Australian Arrow High Series BCM is located beneath the instrument cluster, to the right of the steering column,

refer to Fig. 12J-2-2.

Techline

Techline

Techline

Techline

Techline

Techline

Techline

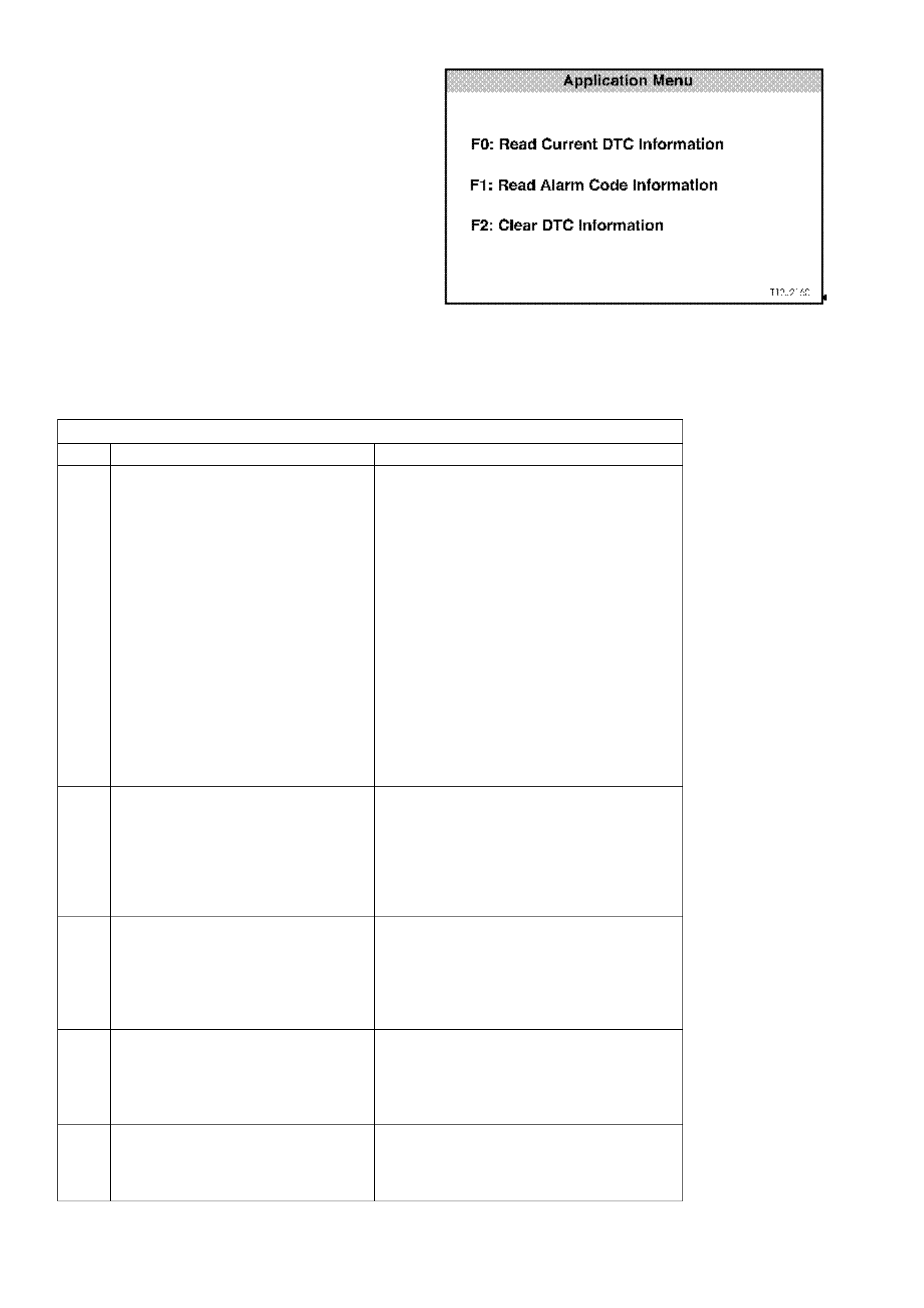

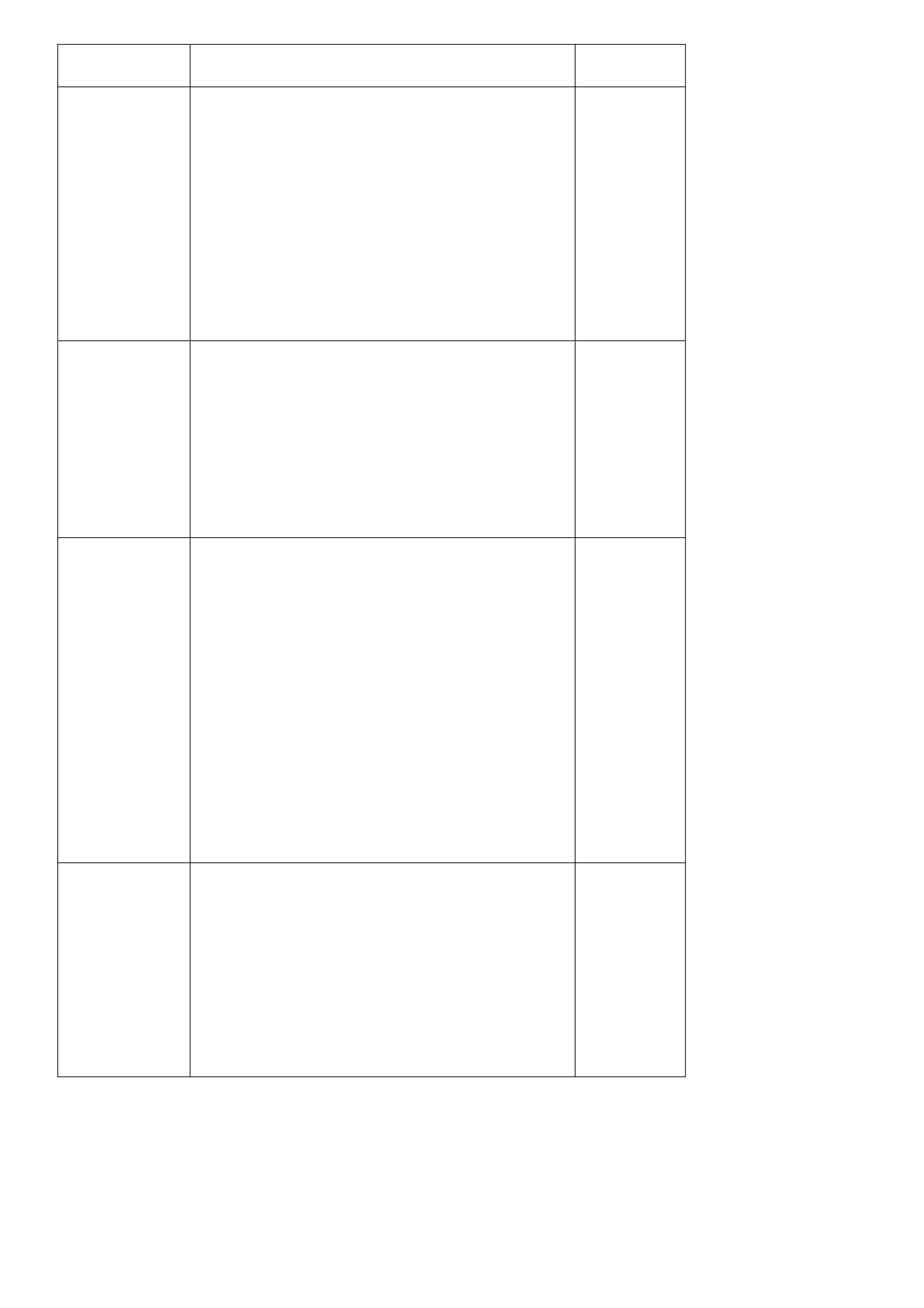

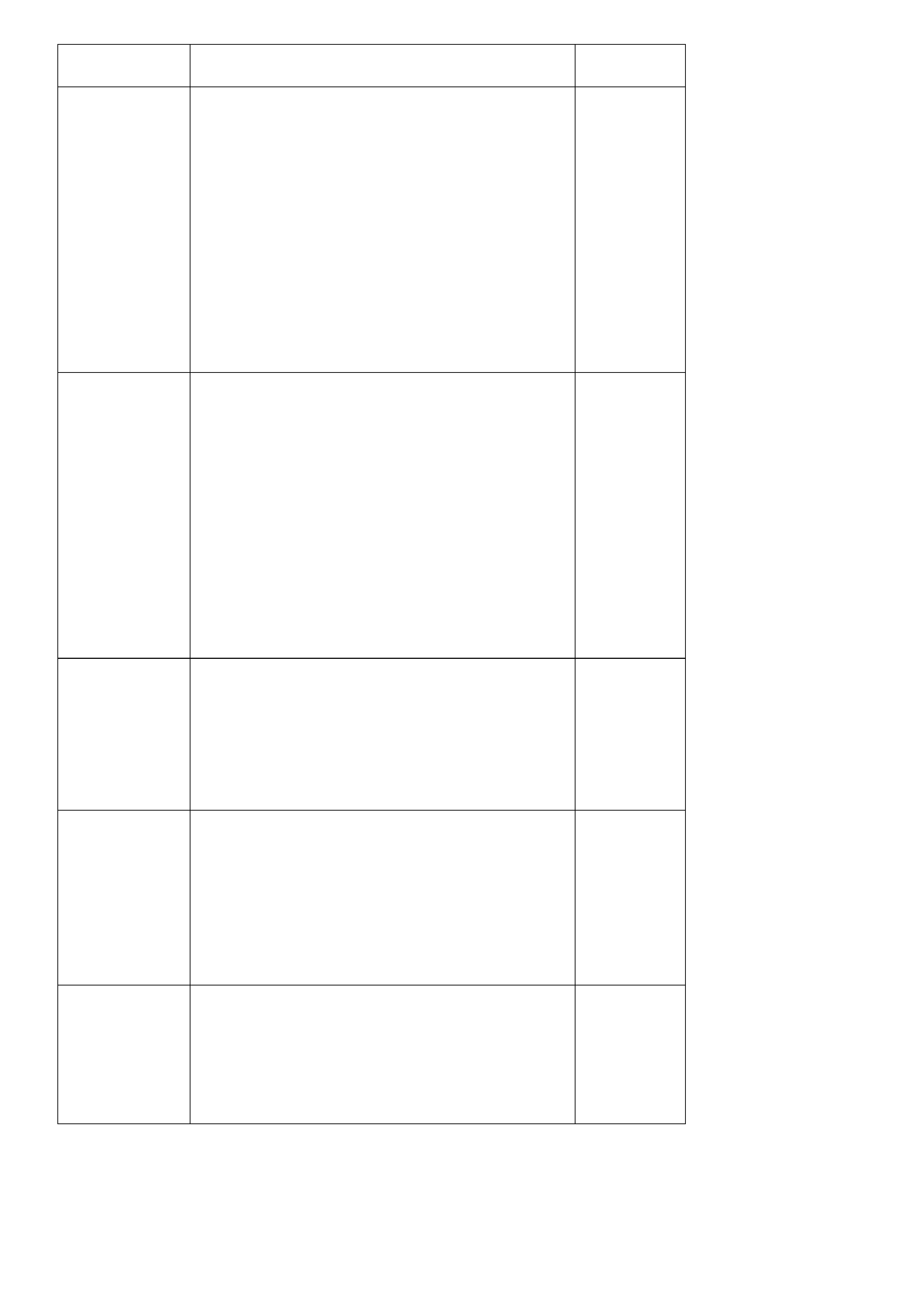

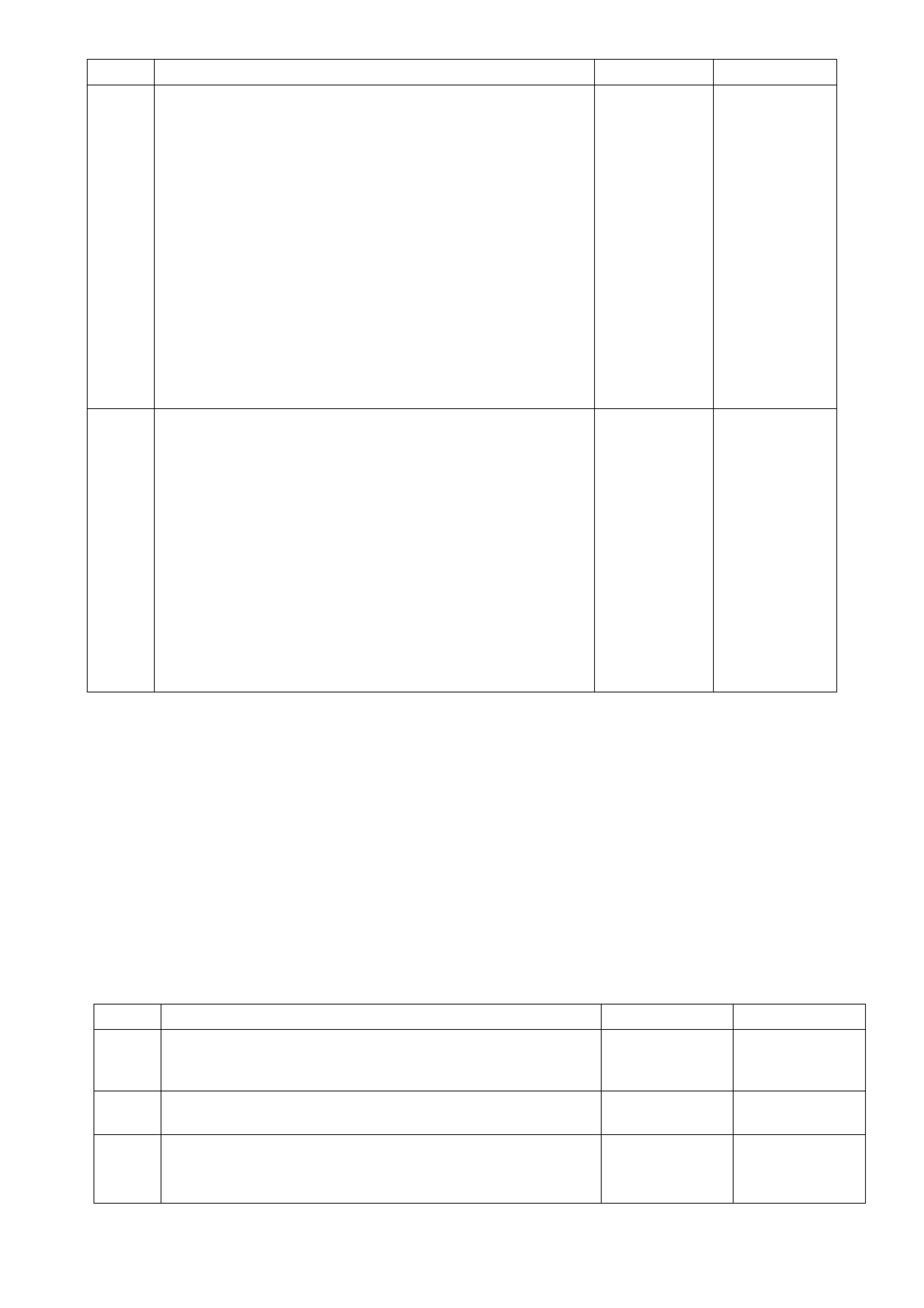

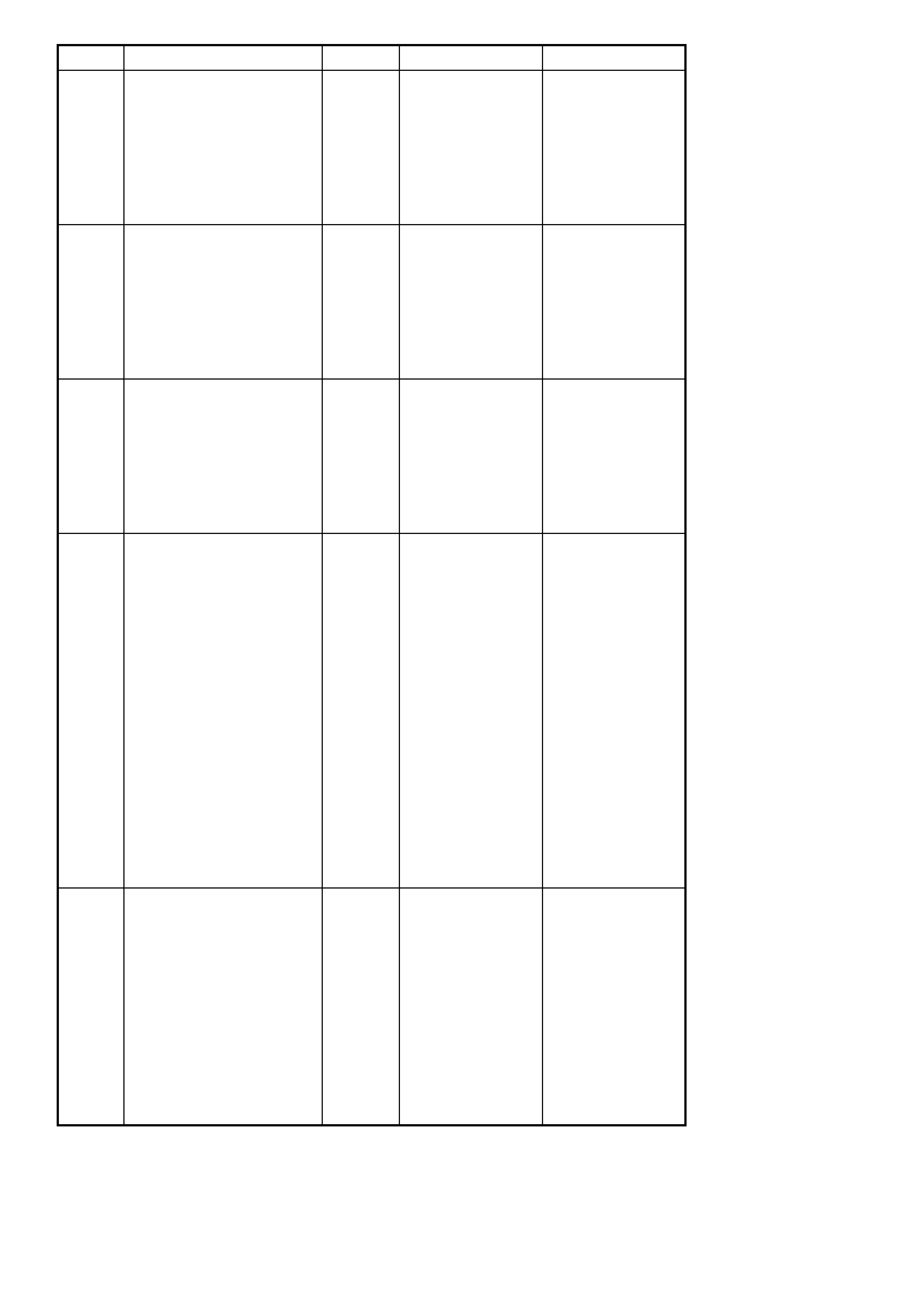

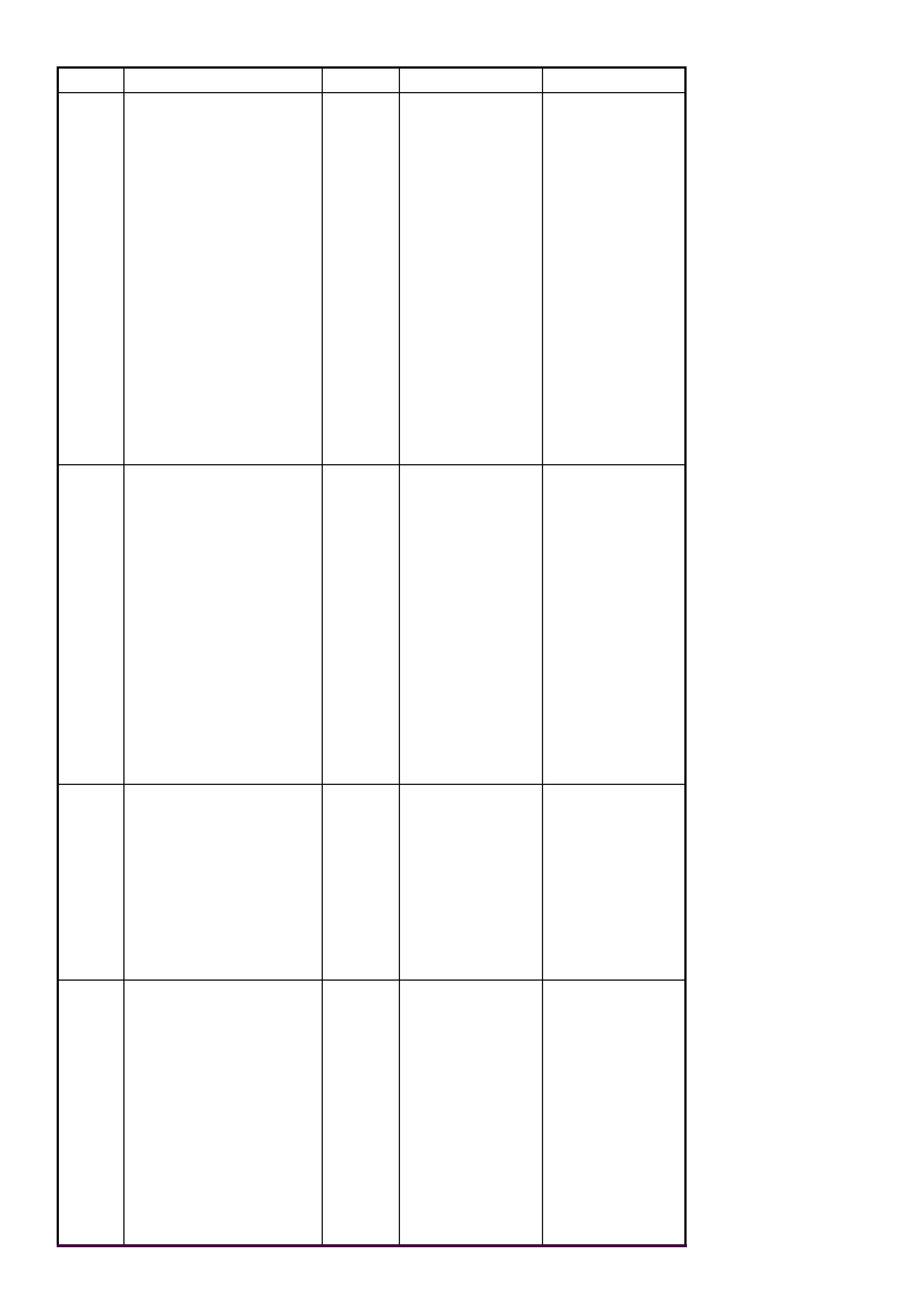

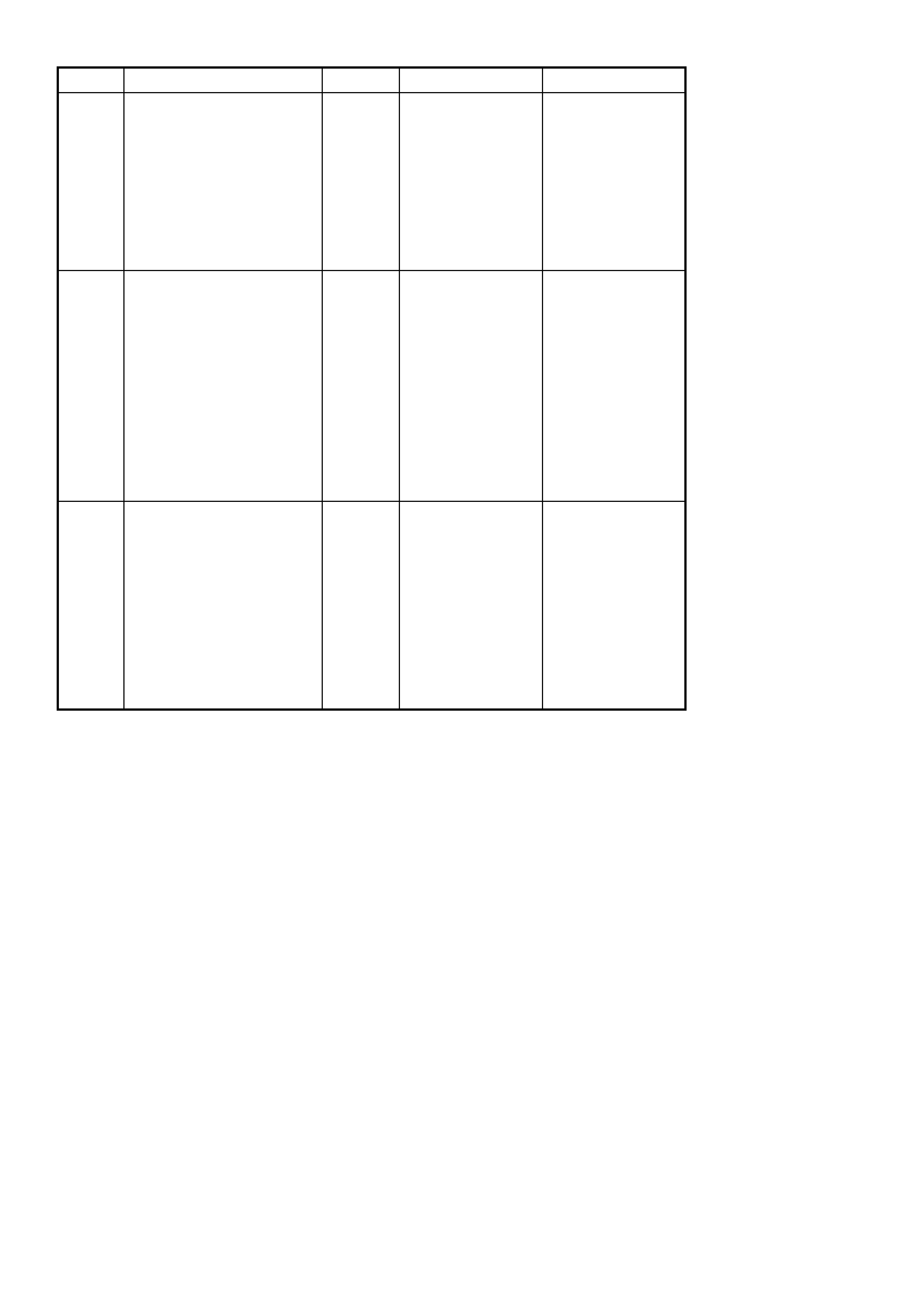

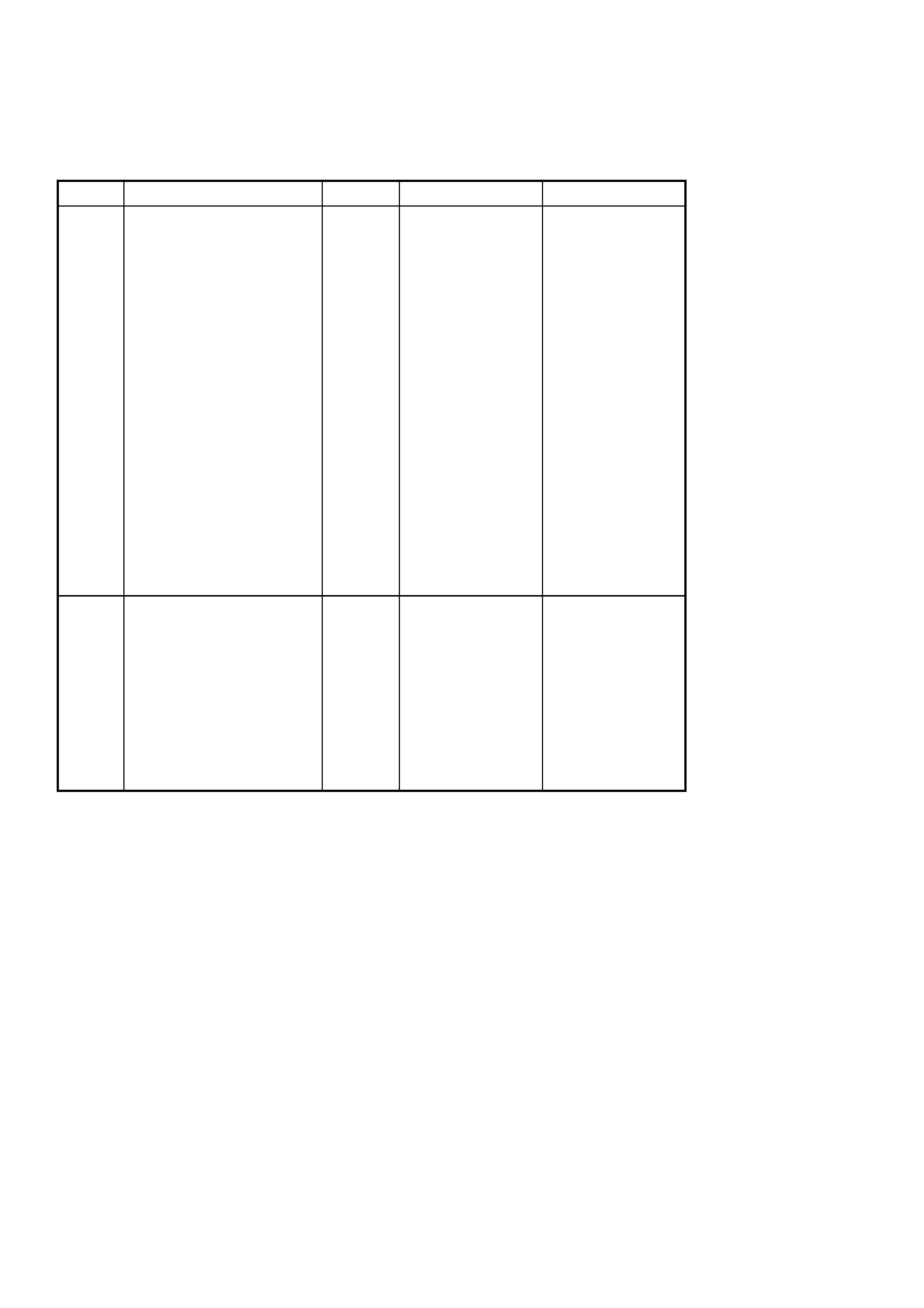

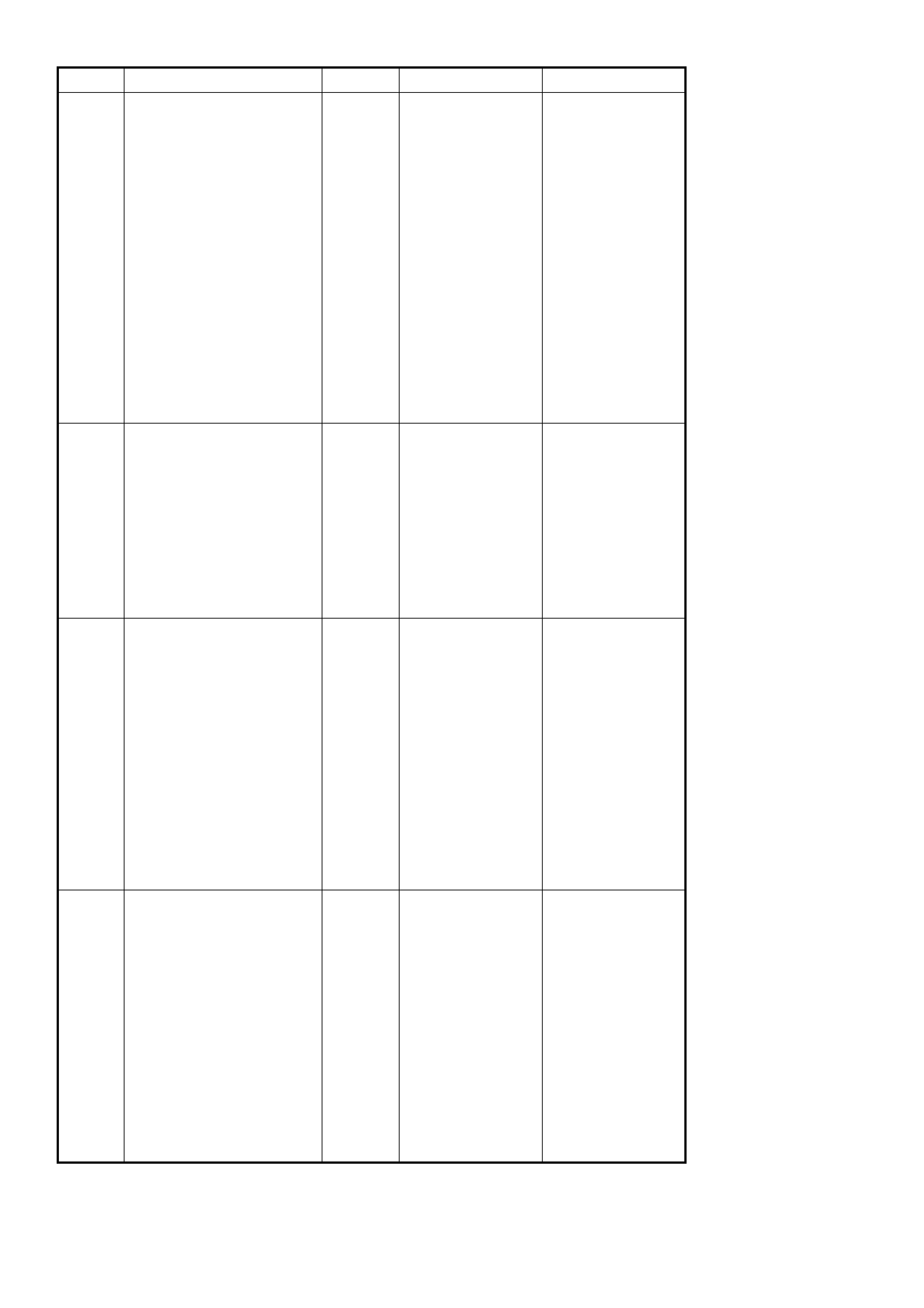

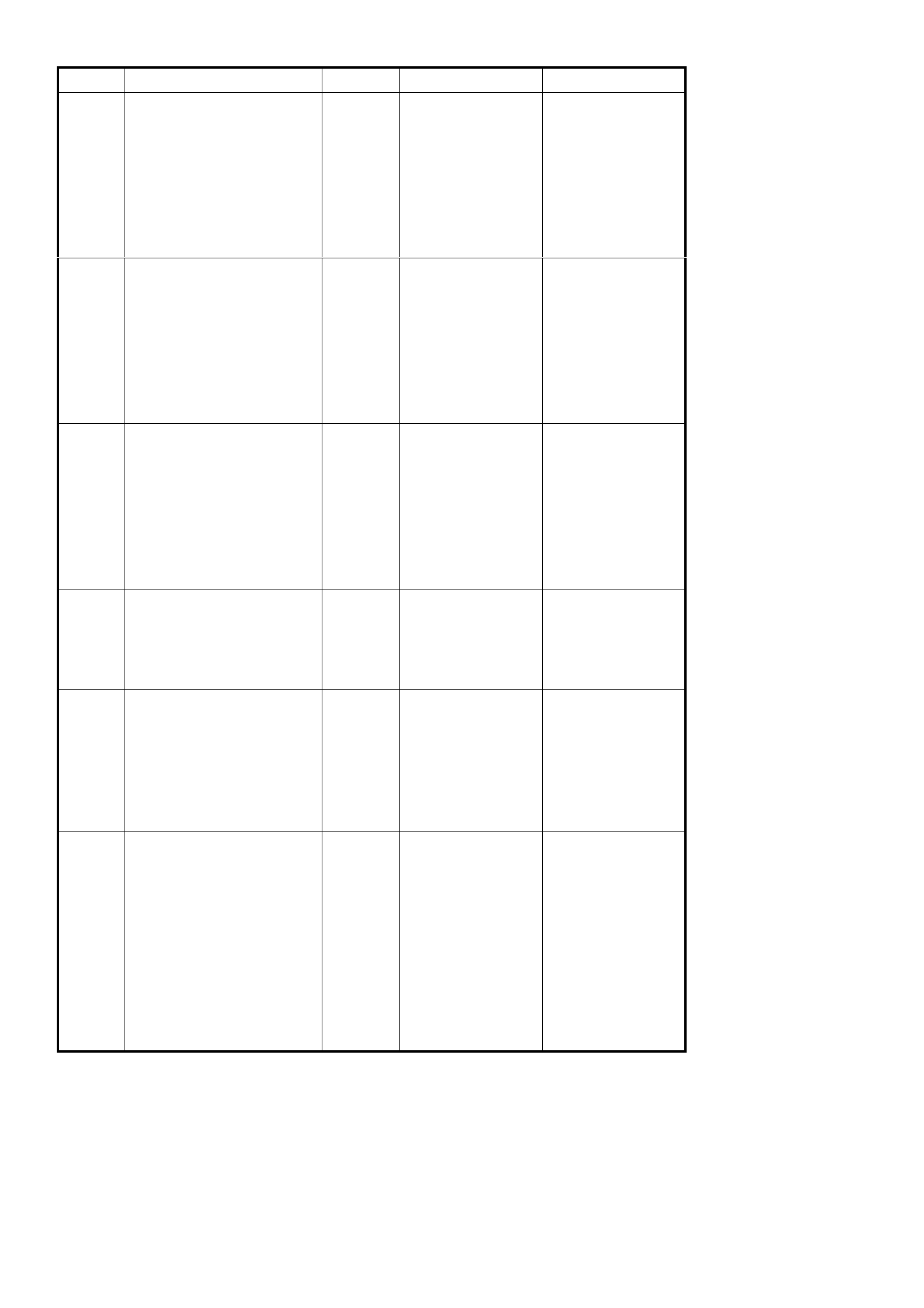

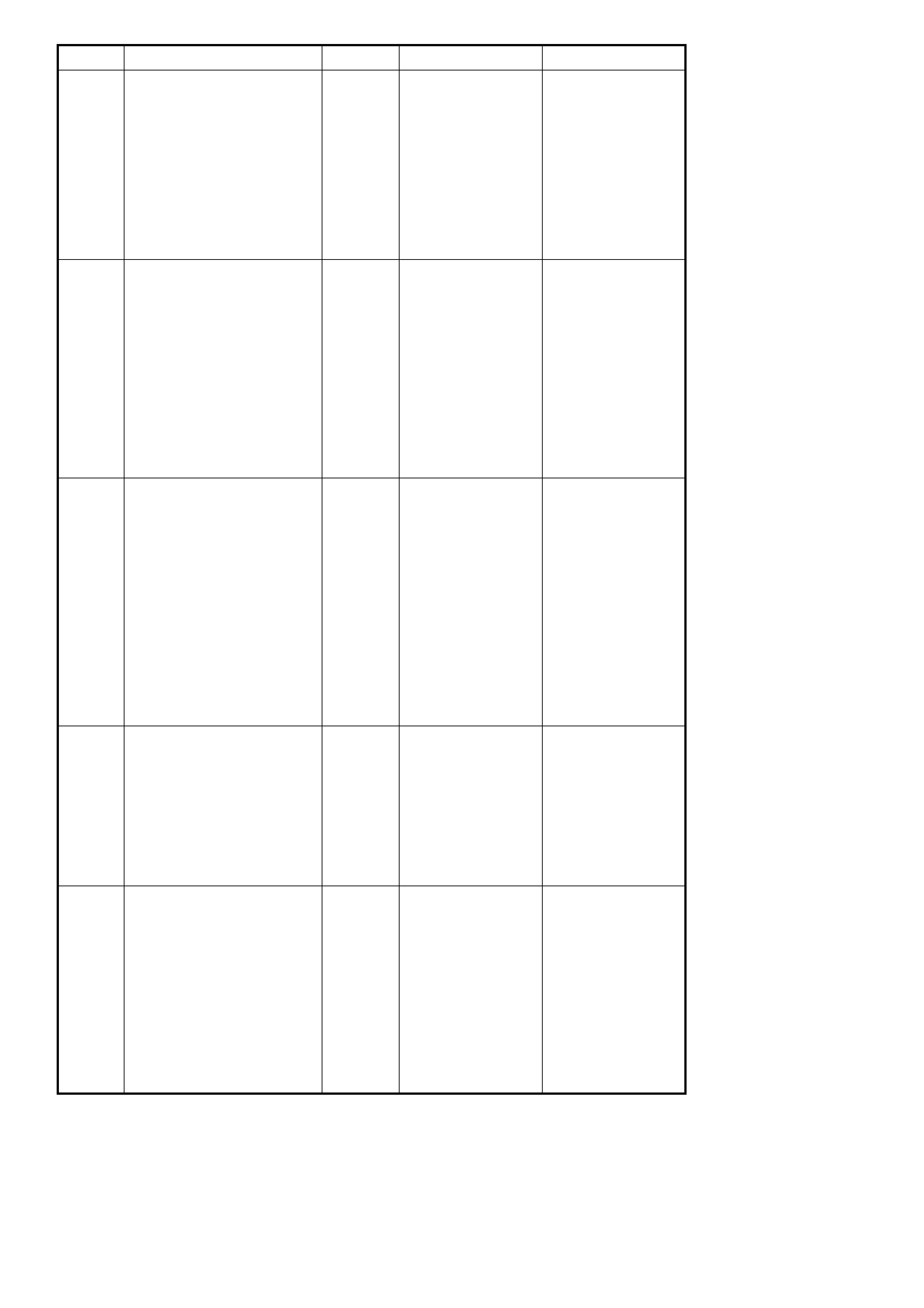

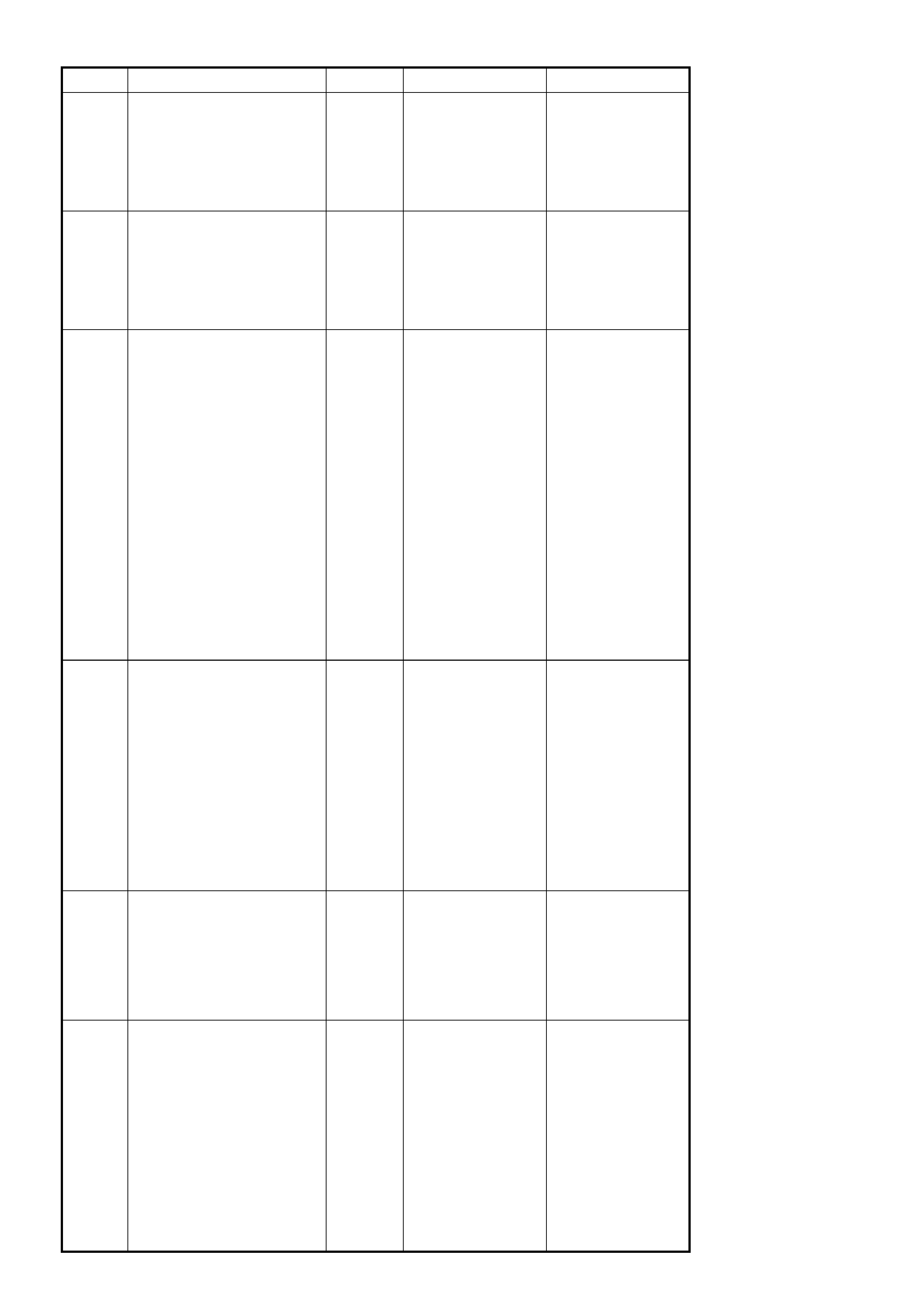

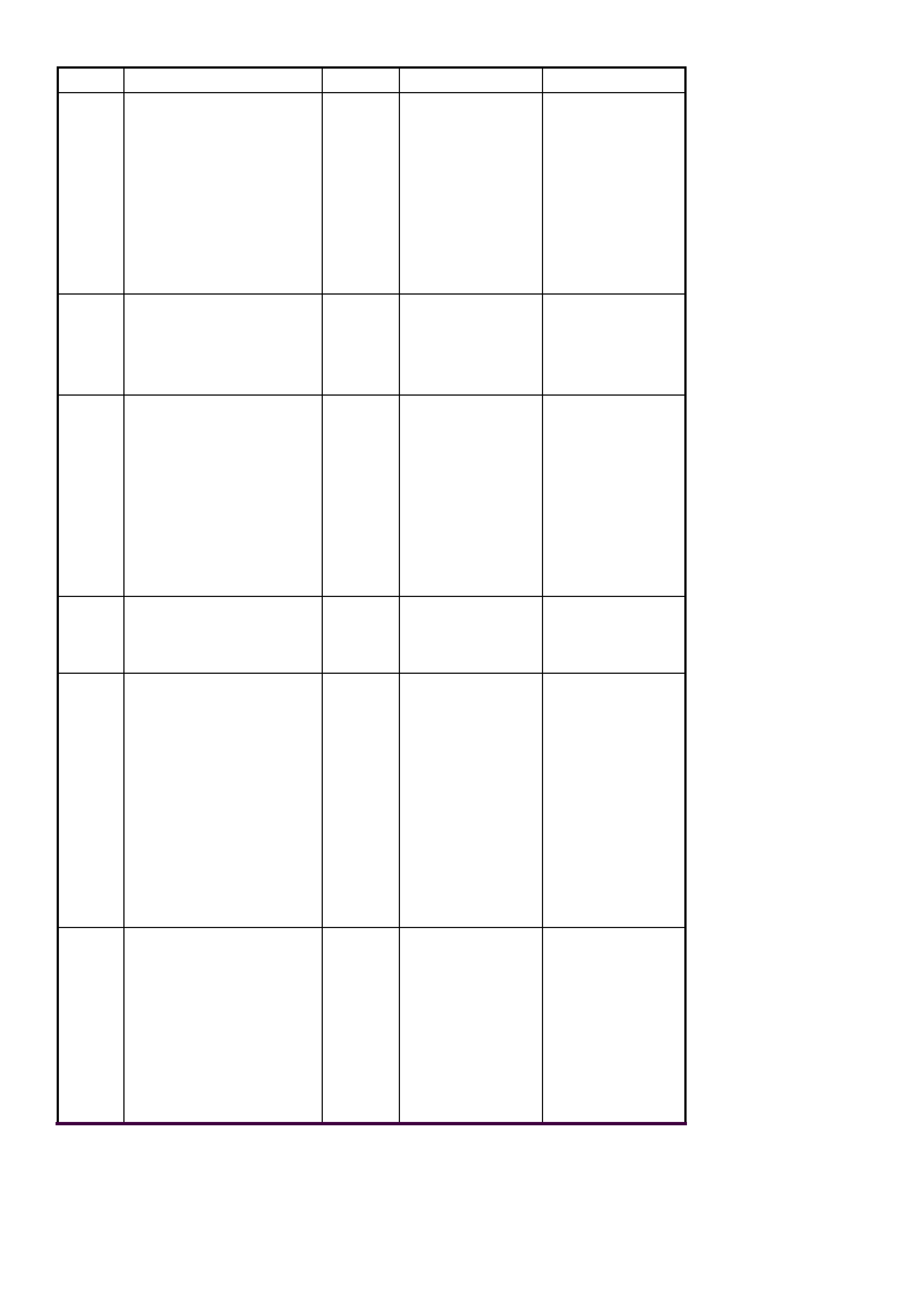

Figure 12J-2-1

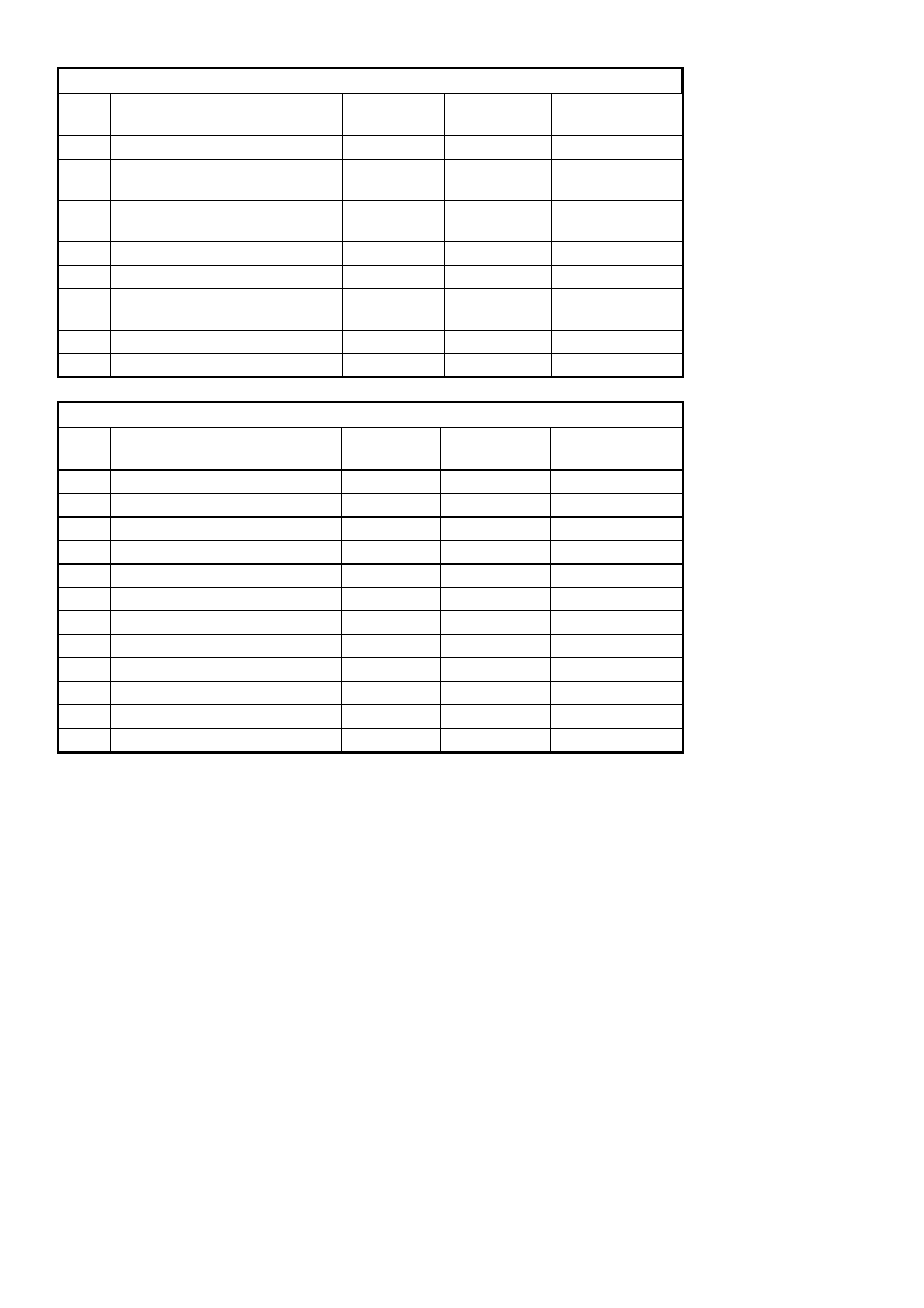

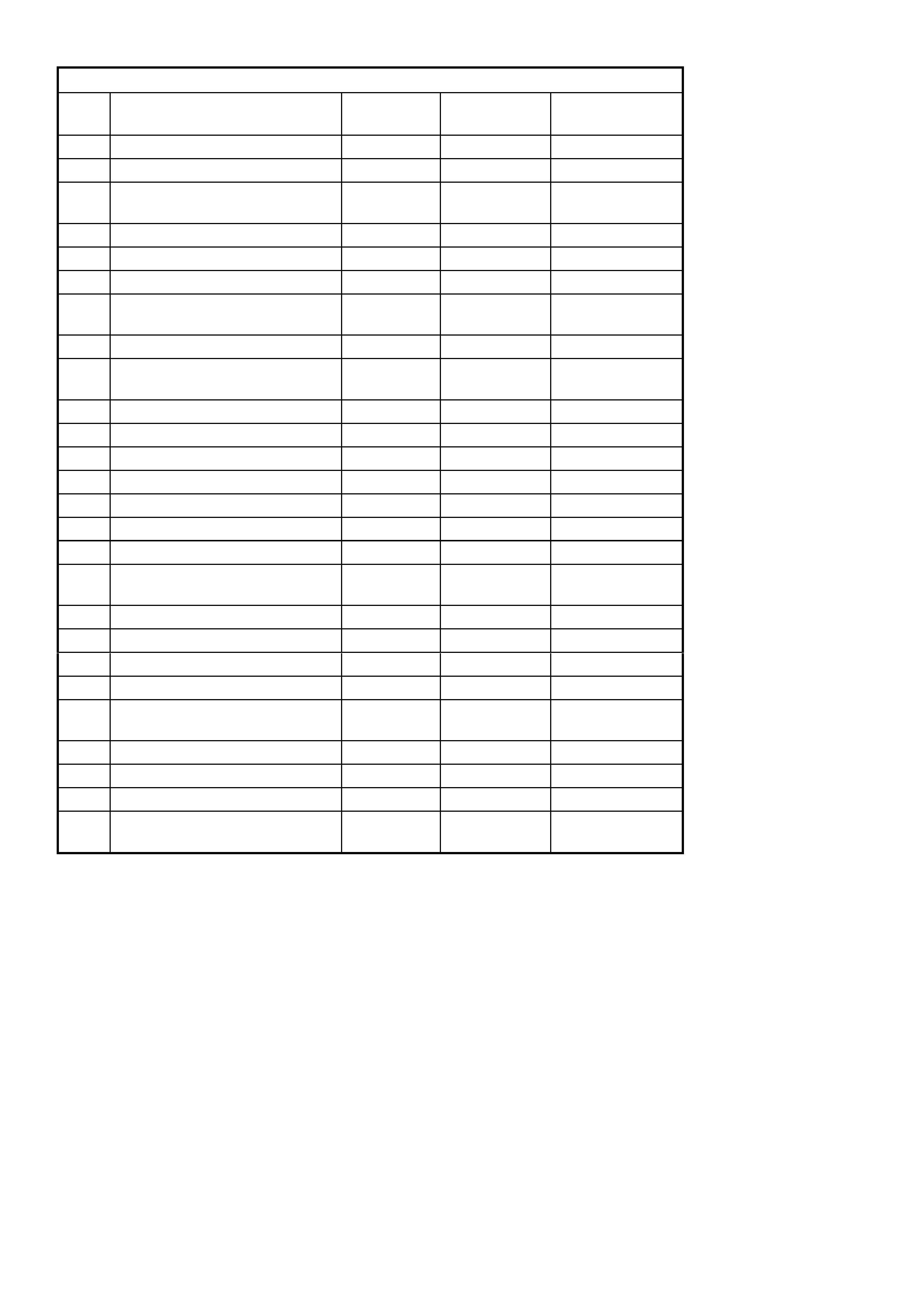

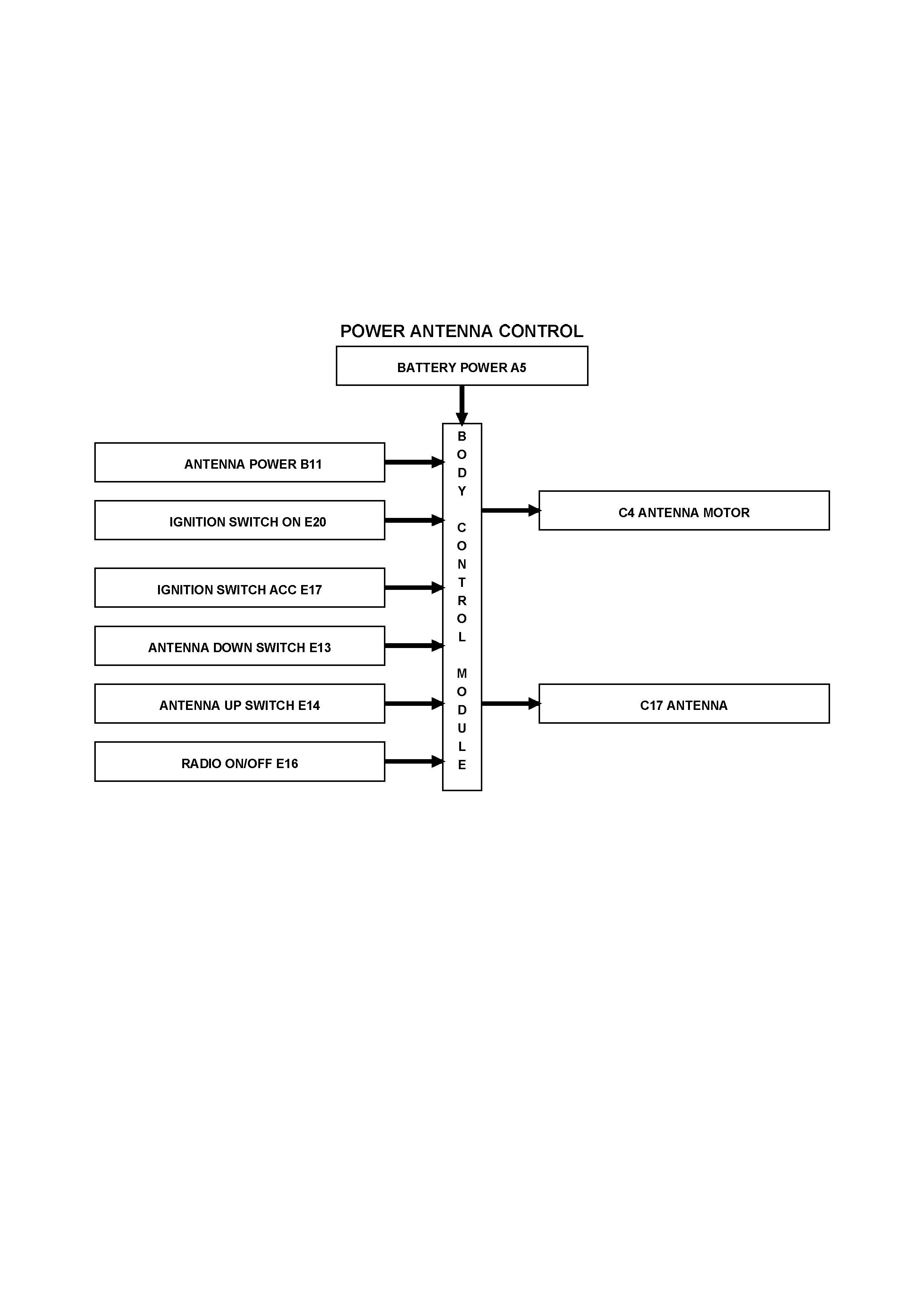

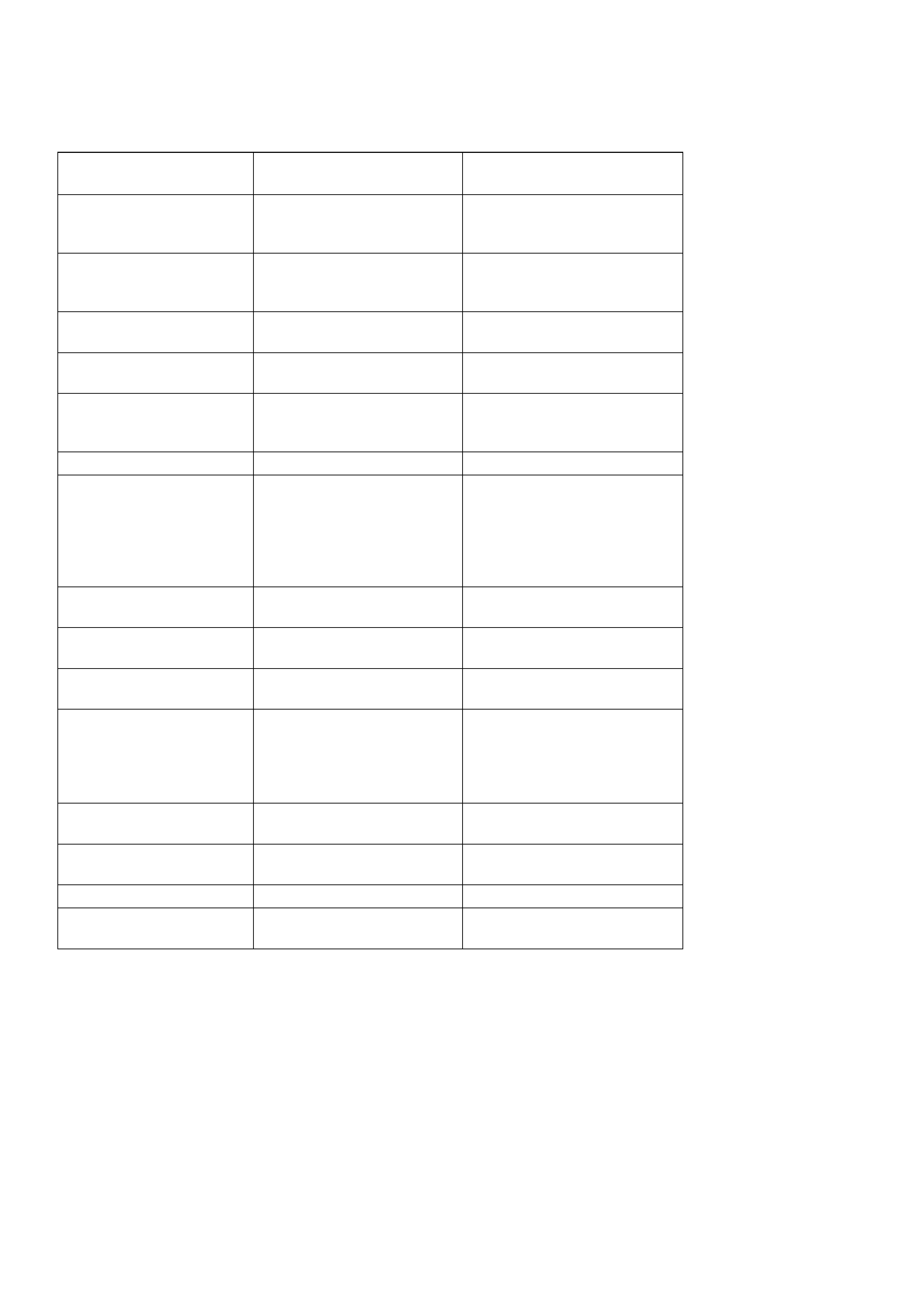

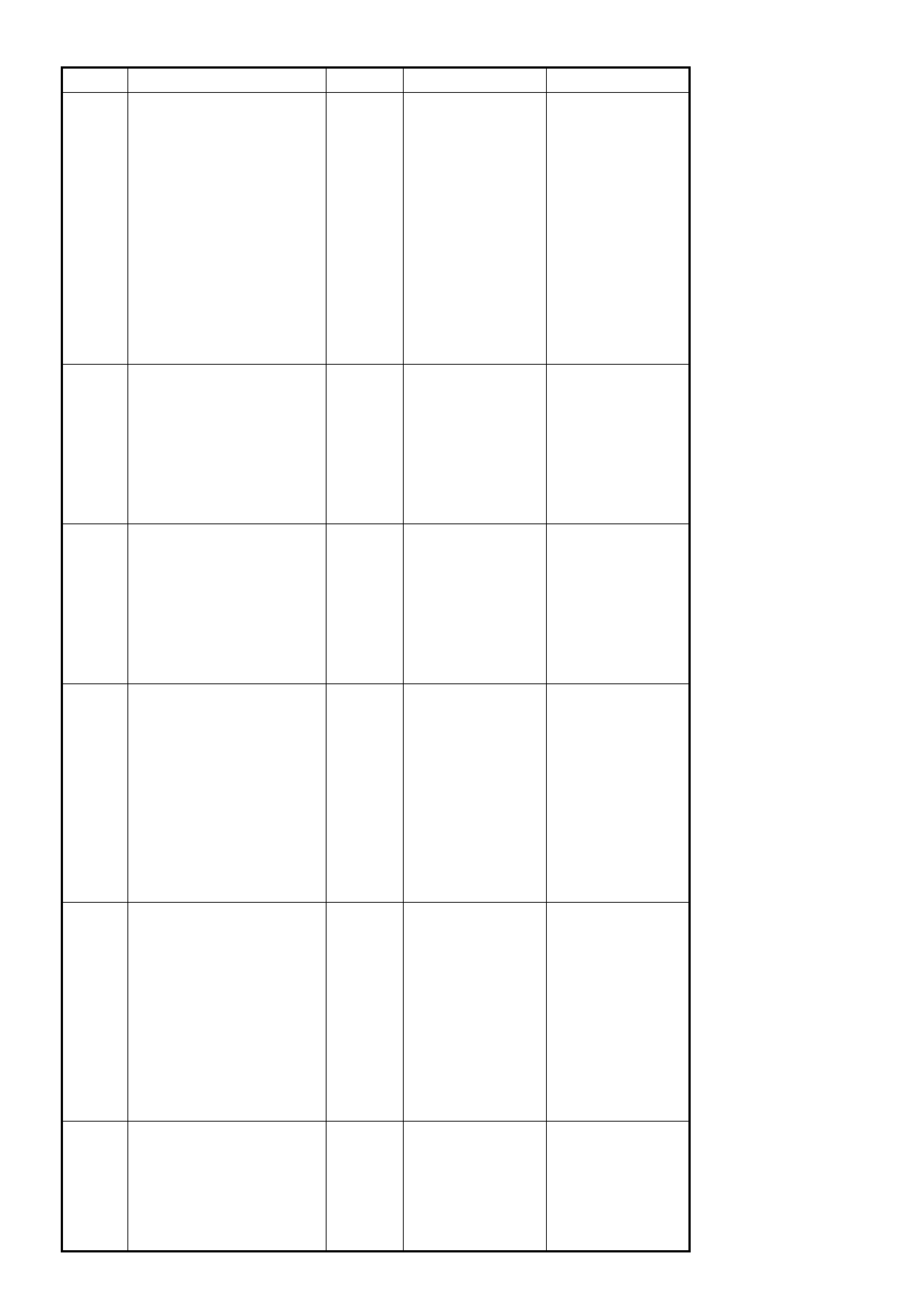

BODY CONTROL MODULE FEATURES

BCM FEATURE LEVEL 2 (BERLINA)

LUX - 687 LEVEL 3 (CALAIS)

HI - 685

Central door locking A A

Boot release with speed interlock A A

Power window system A A

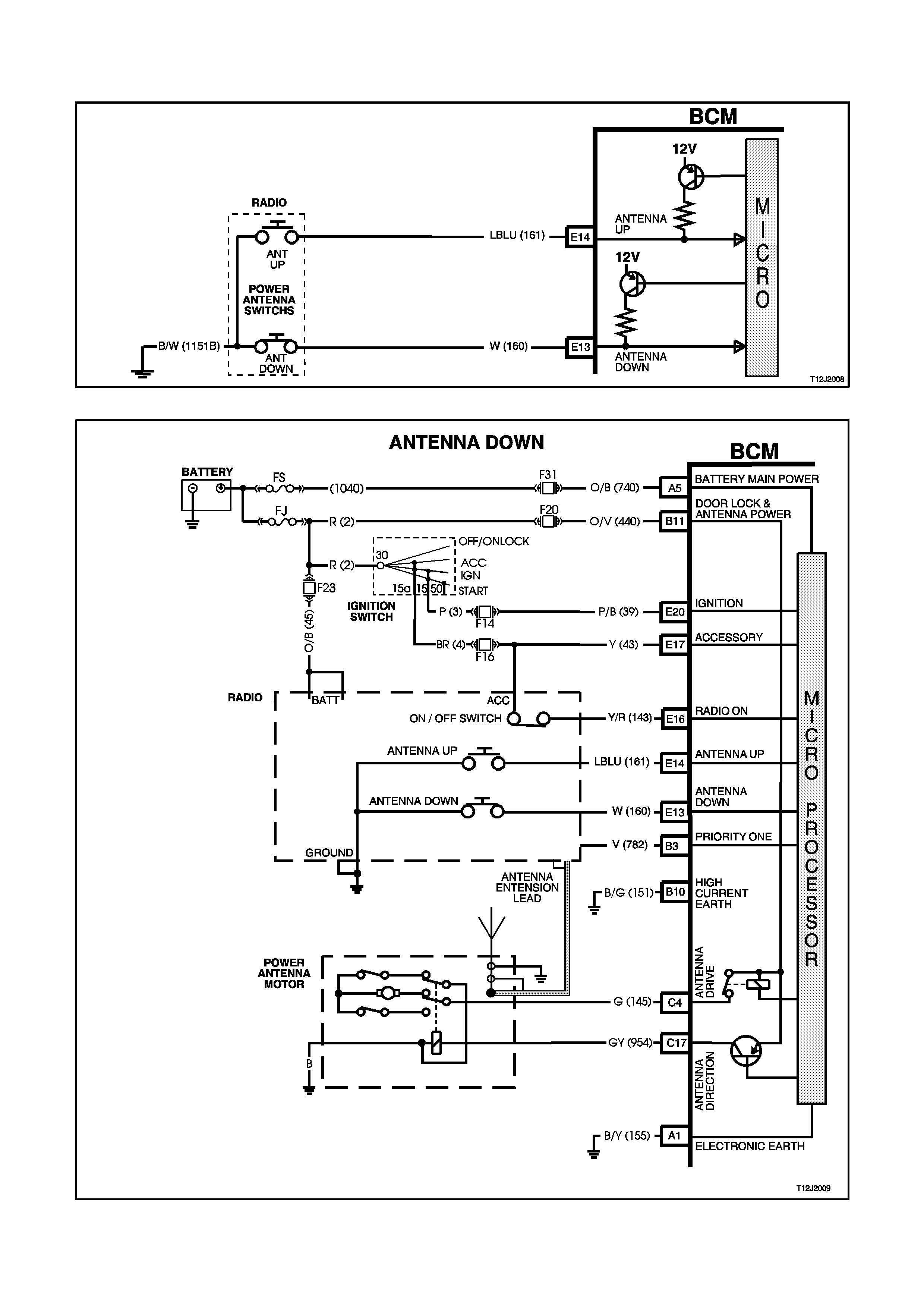

Power antenna control A A

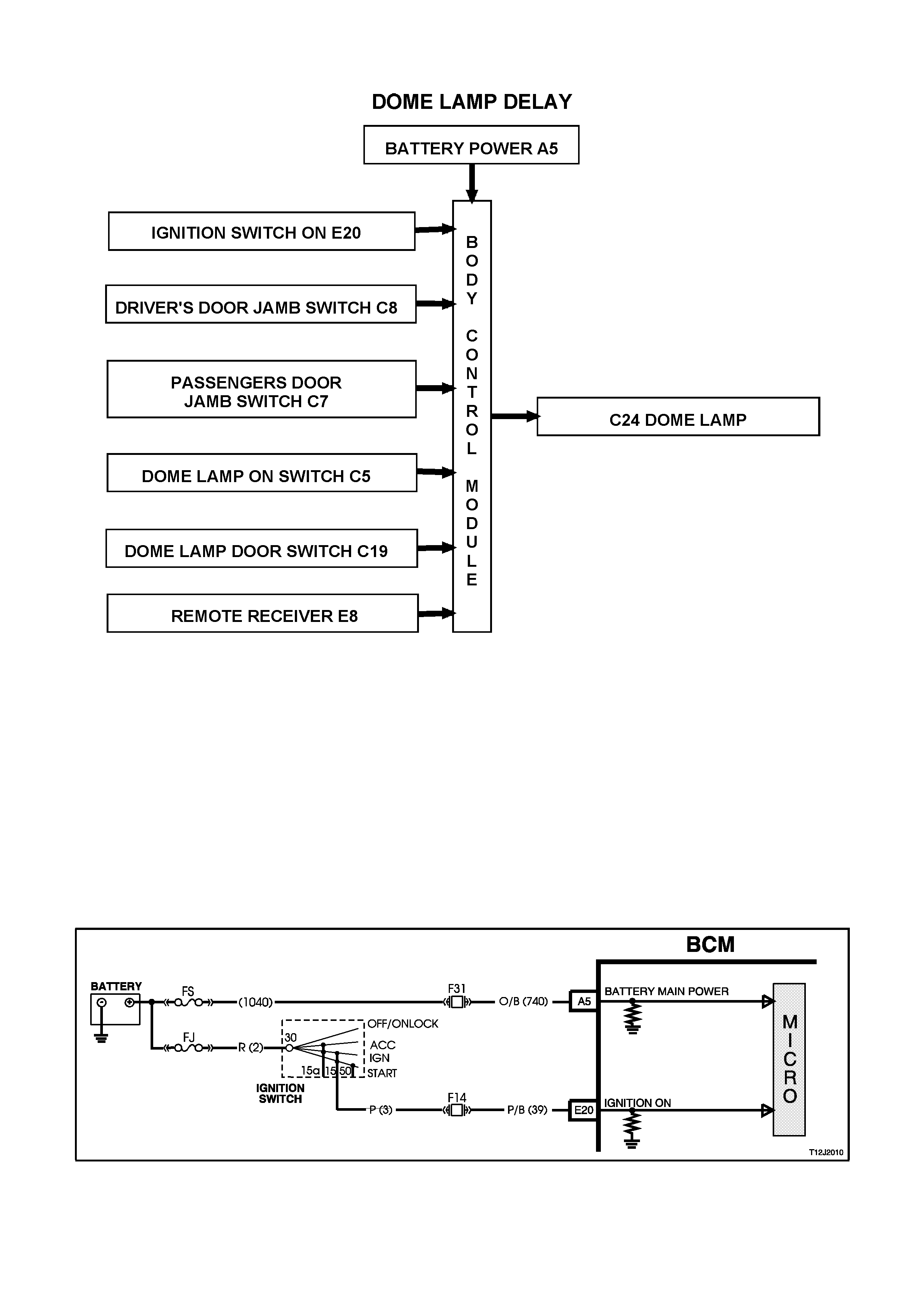

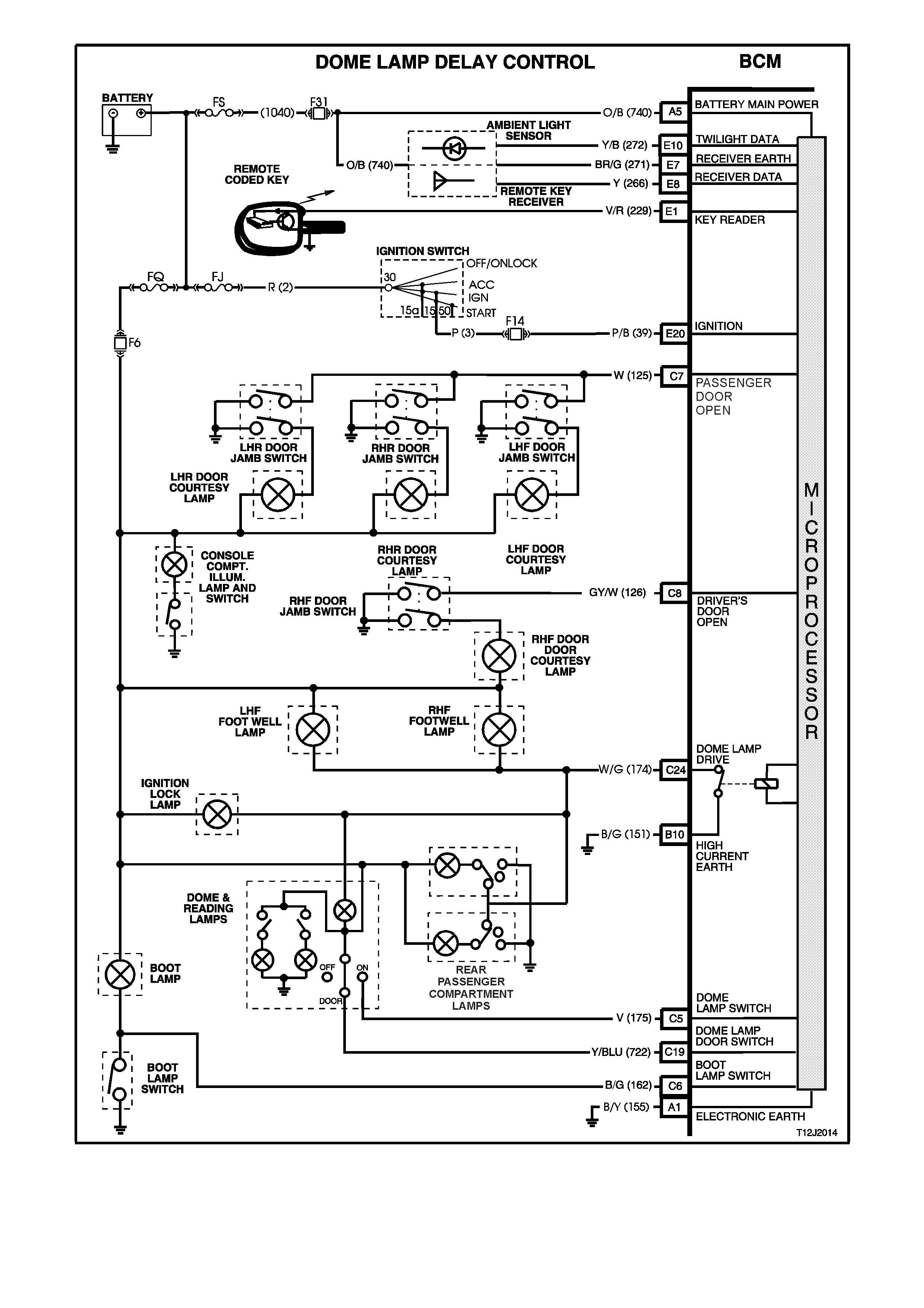

Dome lamp delay control A A

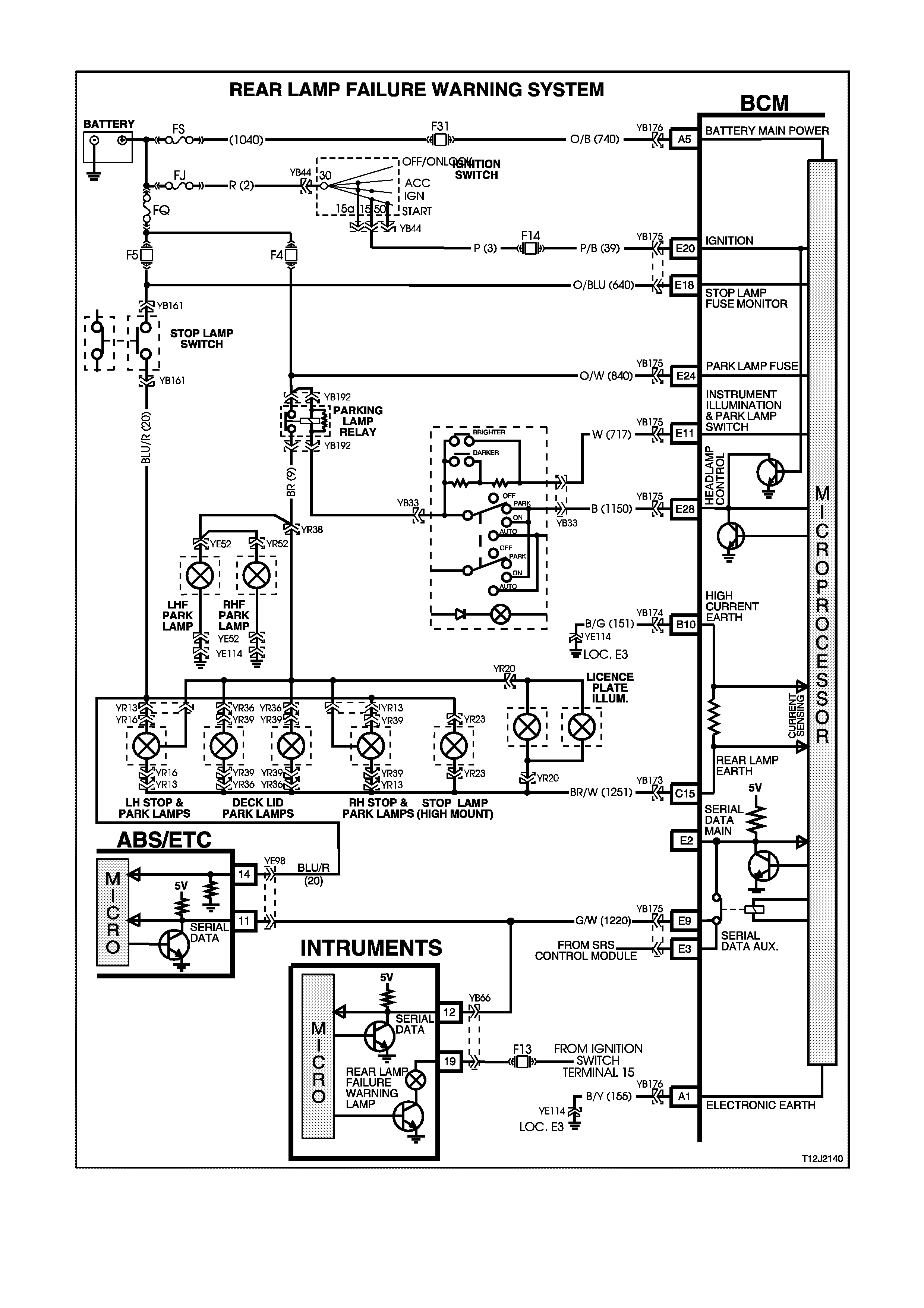

Rear lamp failure warning lamp control N/A A

Road speed dependent and variable

dwell wiper control - front AA

Intermittent and synchronised to front

rear wiper control with full wipe in

reverse gear (wagon only)

AN/A

Speed sensitive power steering N/A A

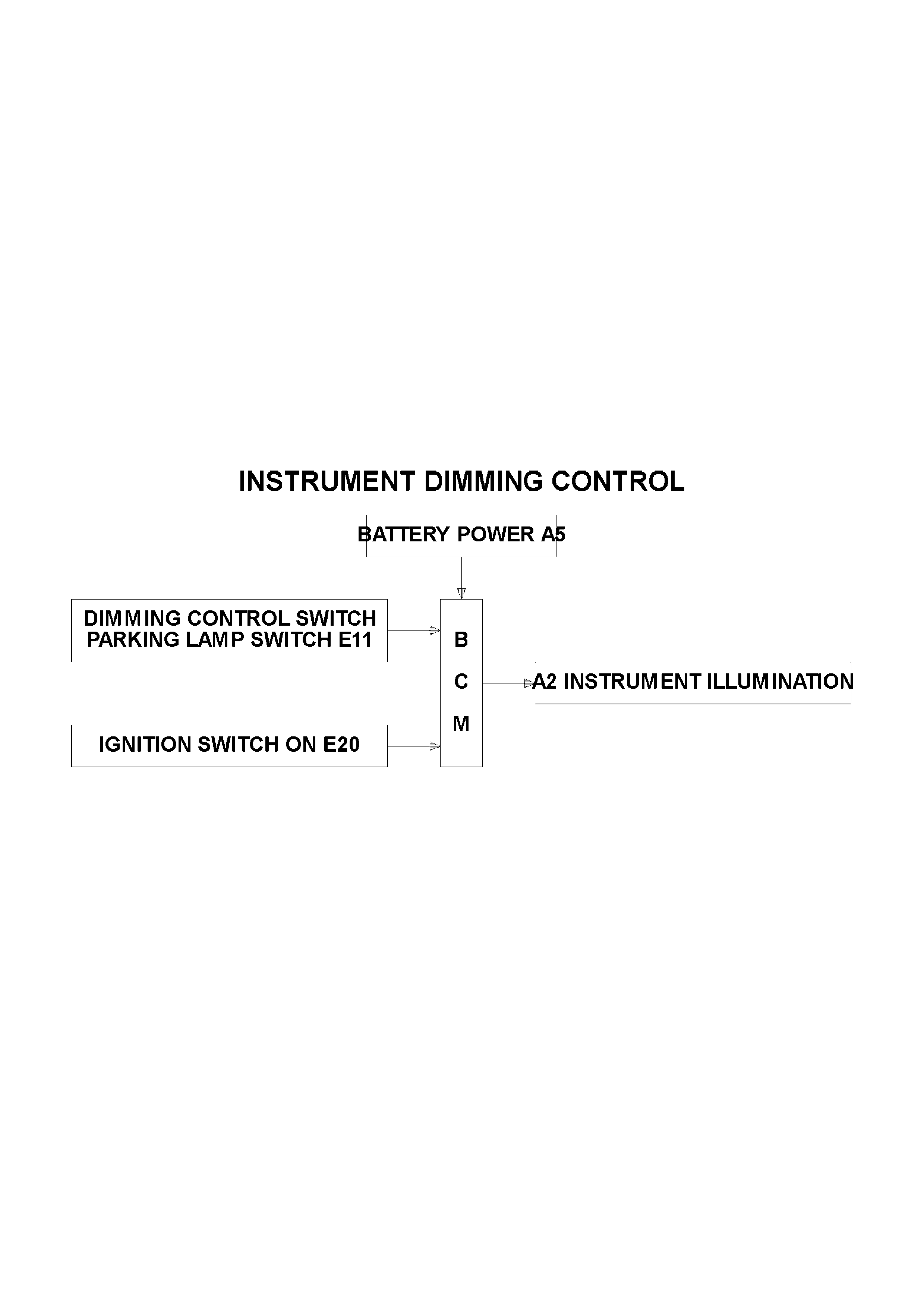

Instrument dimming control A A

Automatic lights OFF (variable) A A

Automatic lights ON - twilight sentinel N/A A

Engine disable A A

Alarm A A

Engine cooling low speed fan control A A

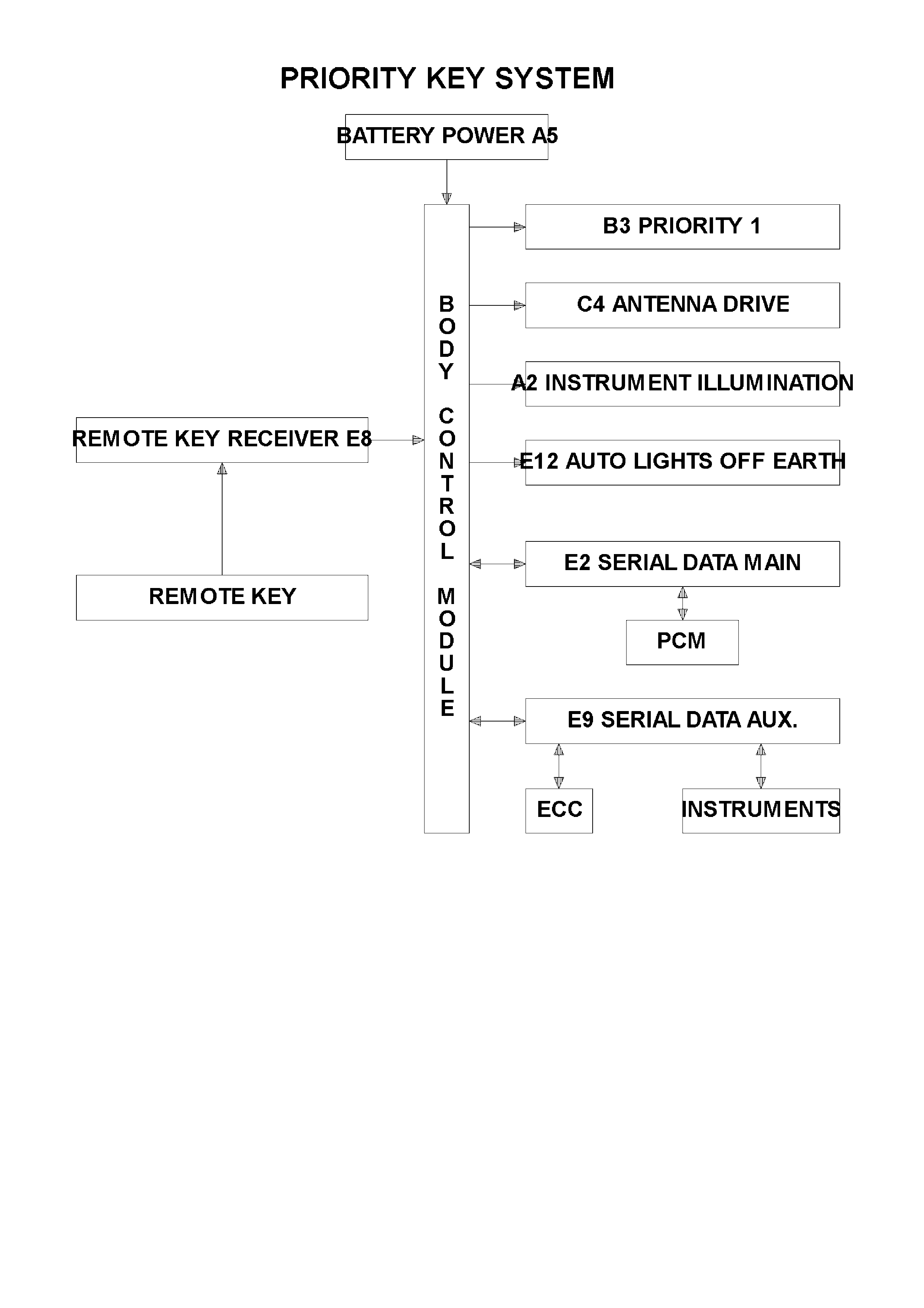

Priority key system N/A A

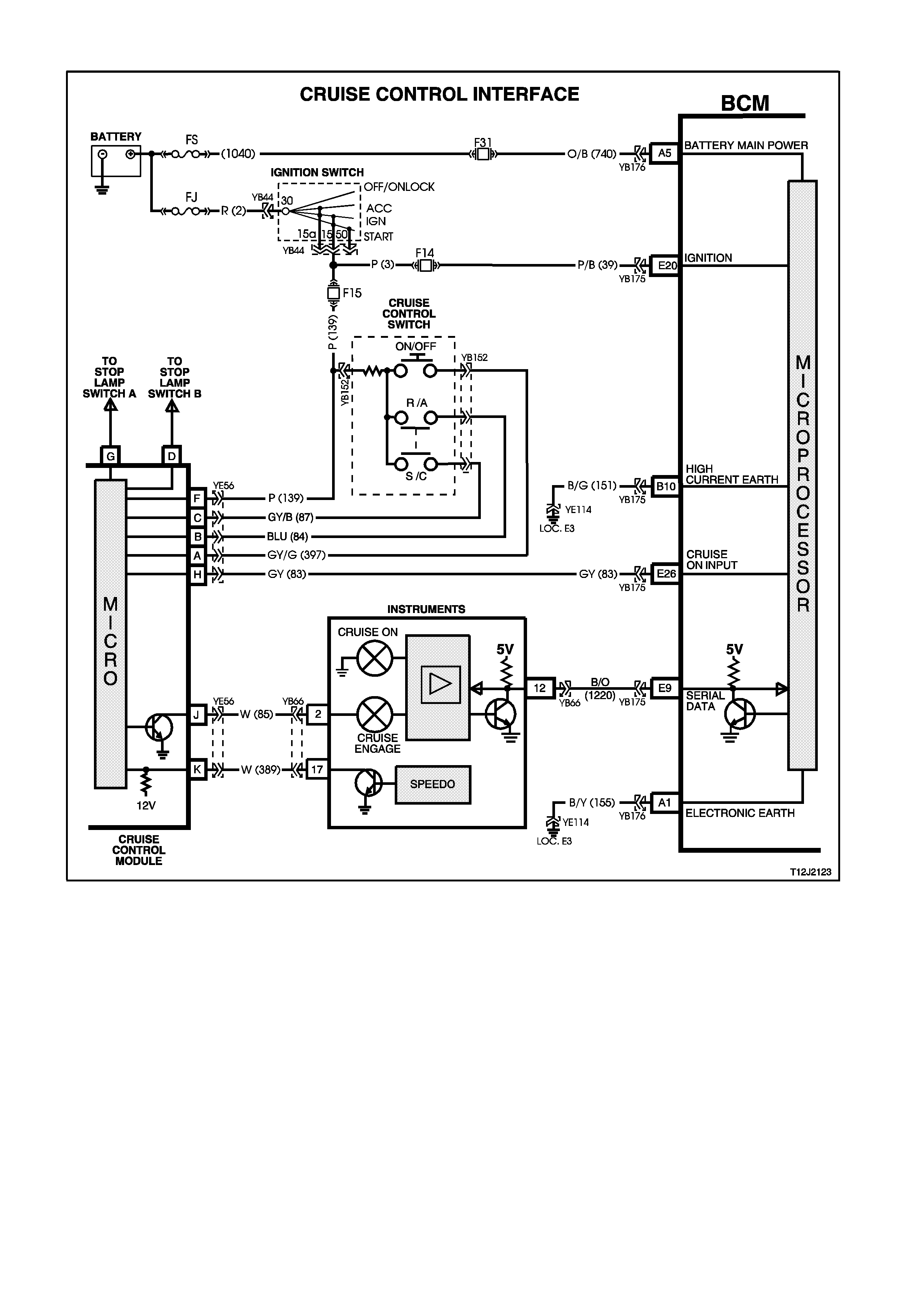

Cruise control interface A A

SRS (air bag) deployment vehicle

shutdown AA

Serial data interface A A

N/A = NOT AVAILABLE

A = AVAILABLE

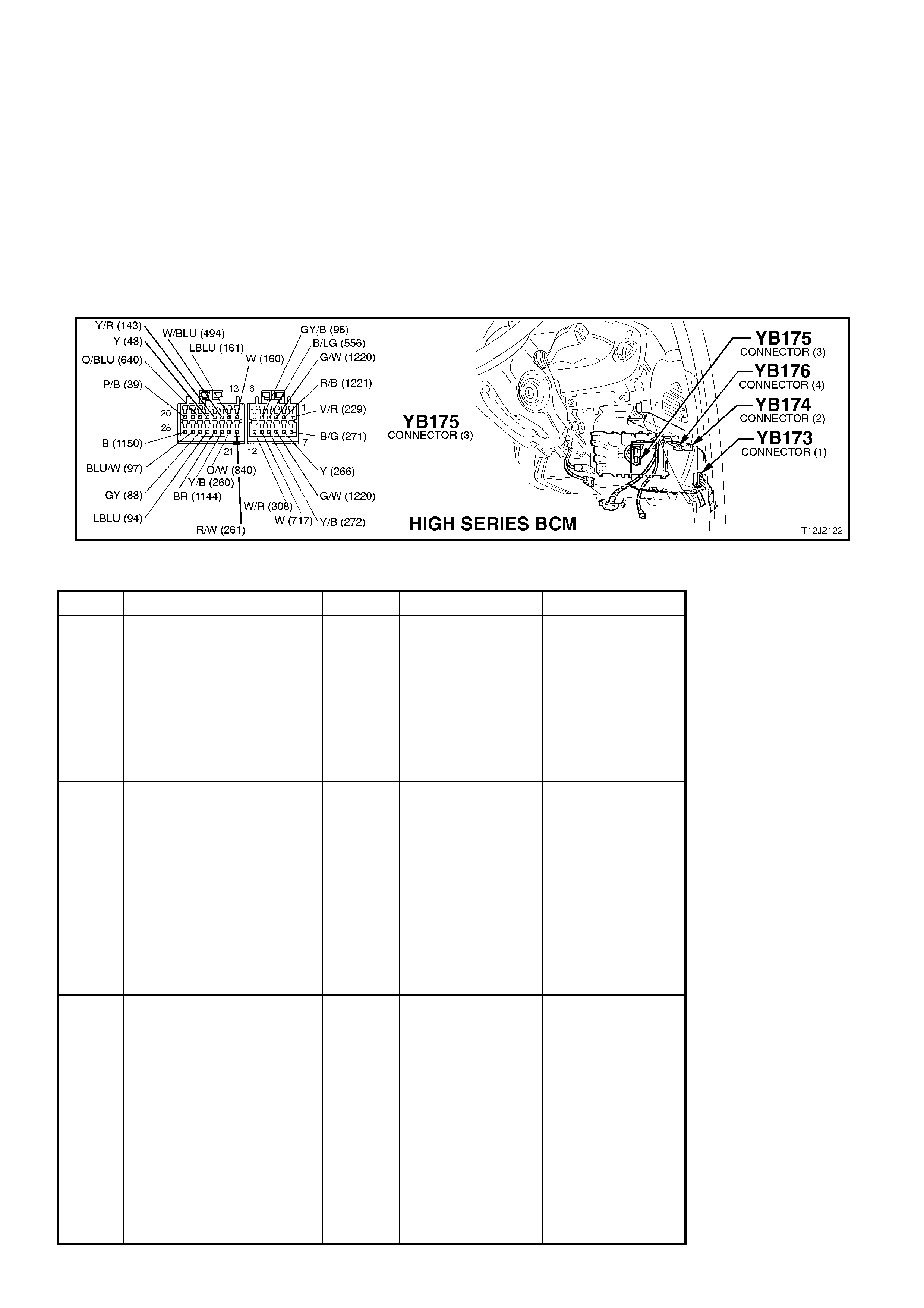

Figure 12J-2-2

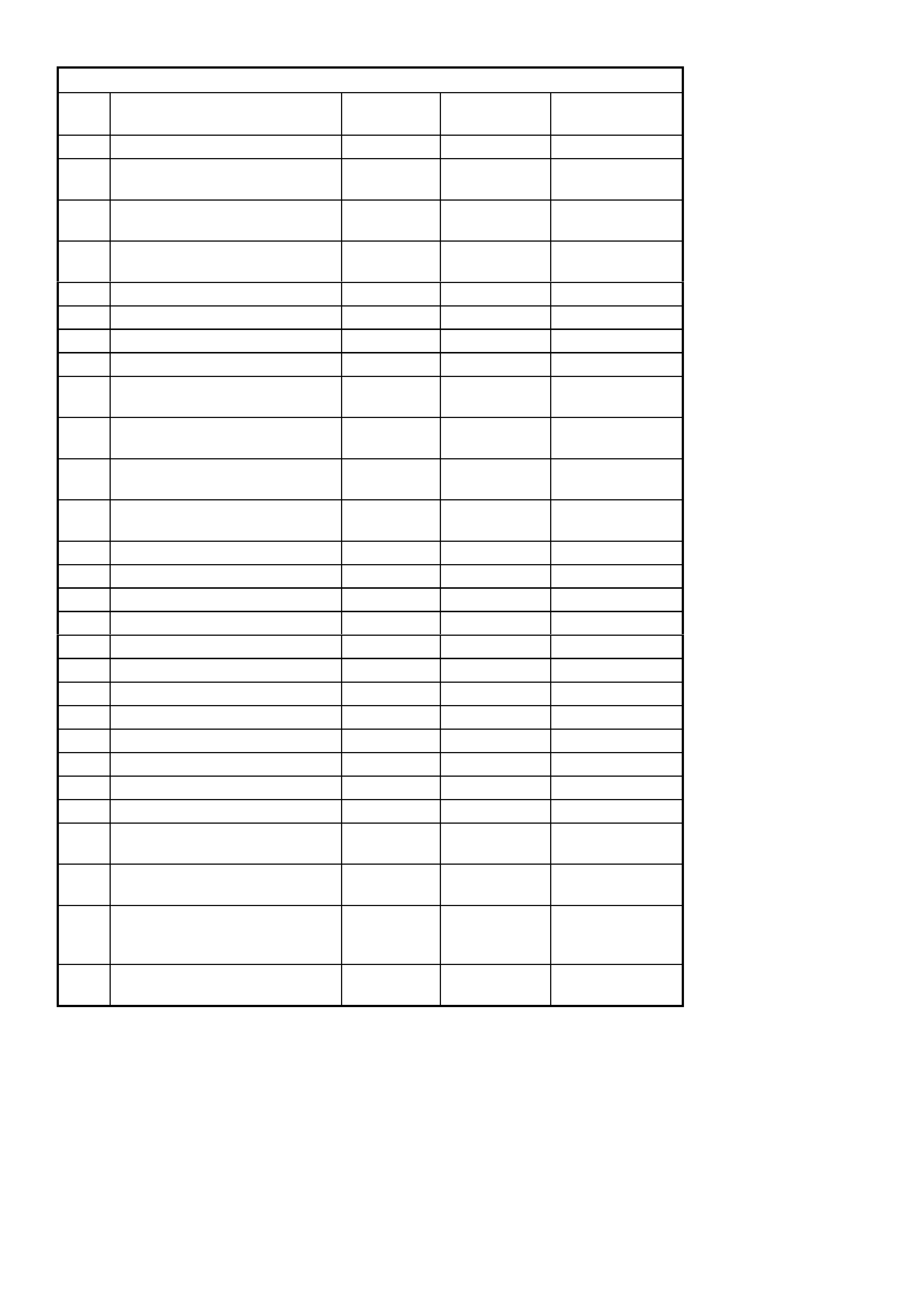

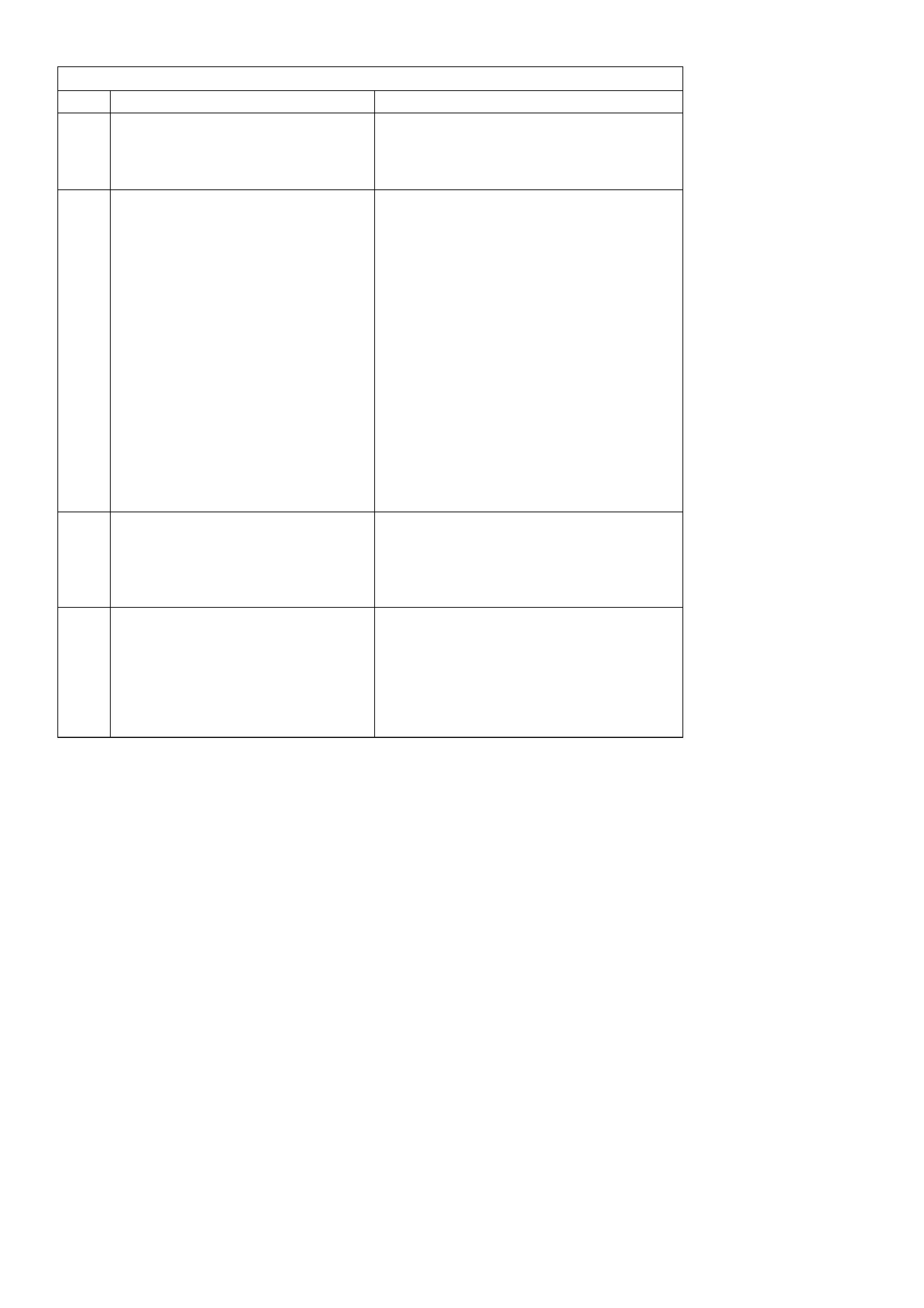

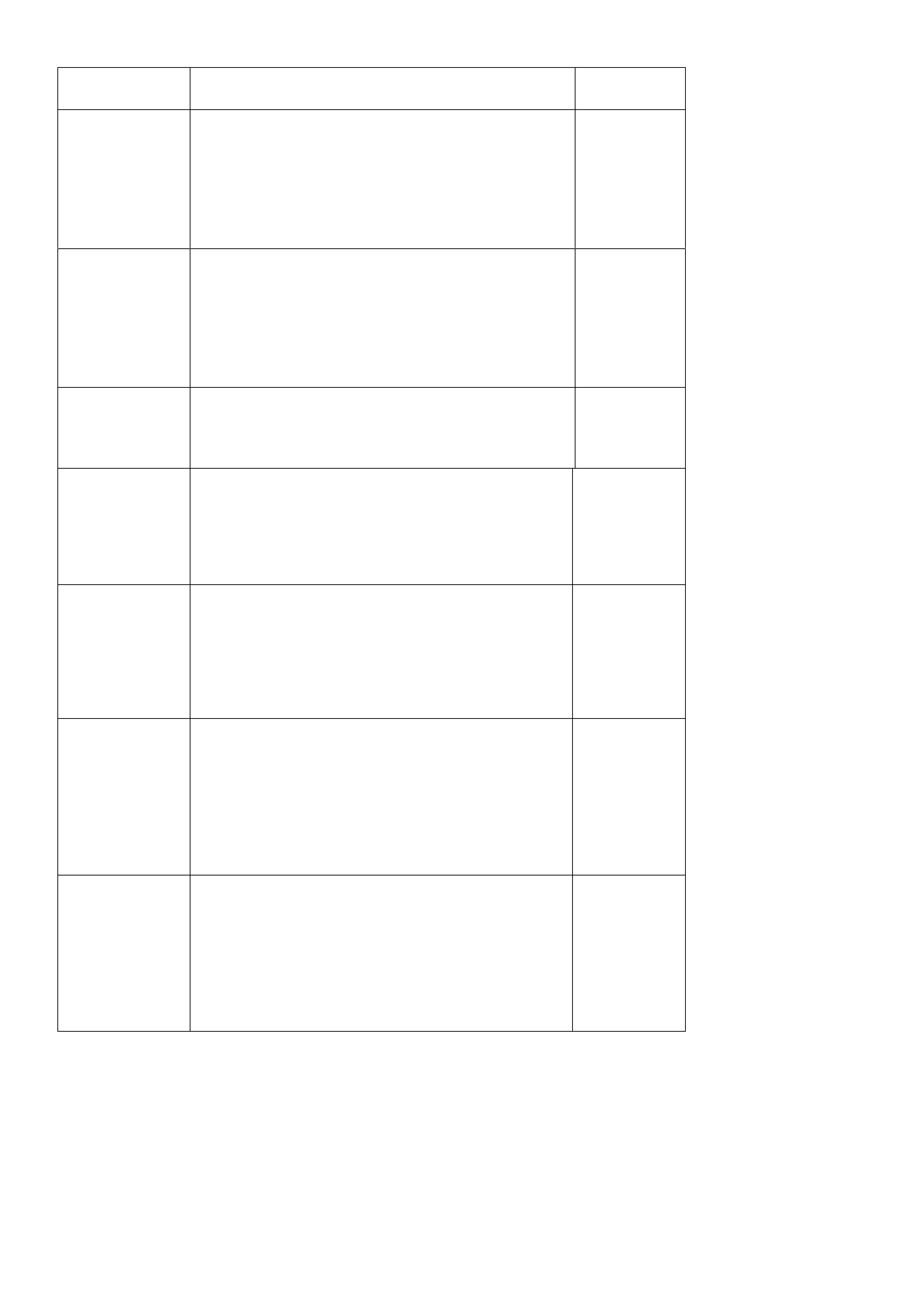

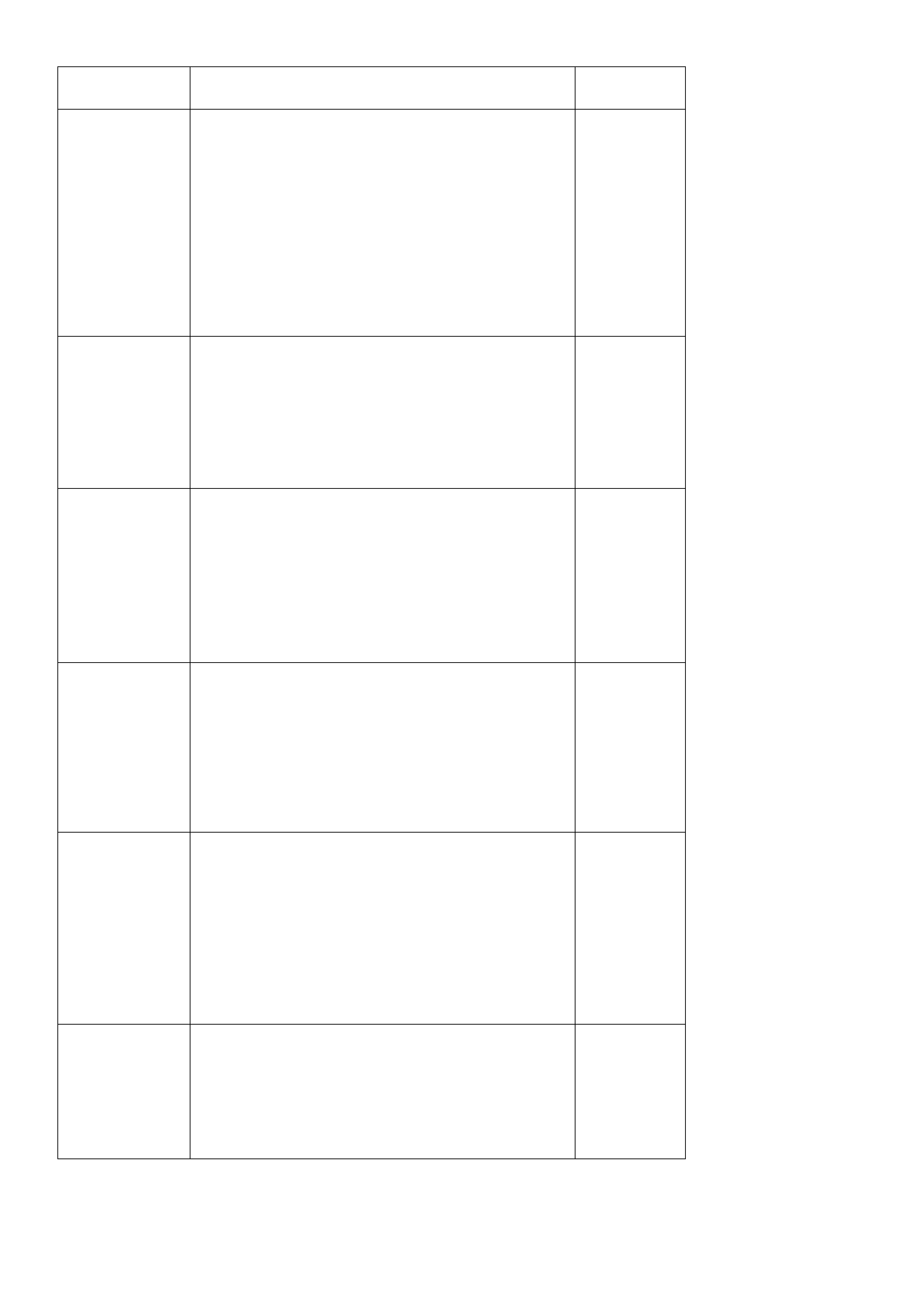

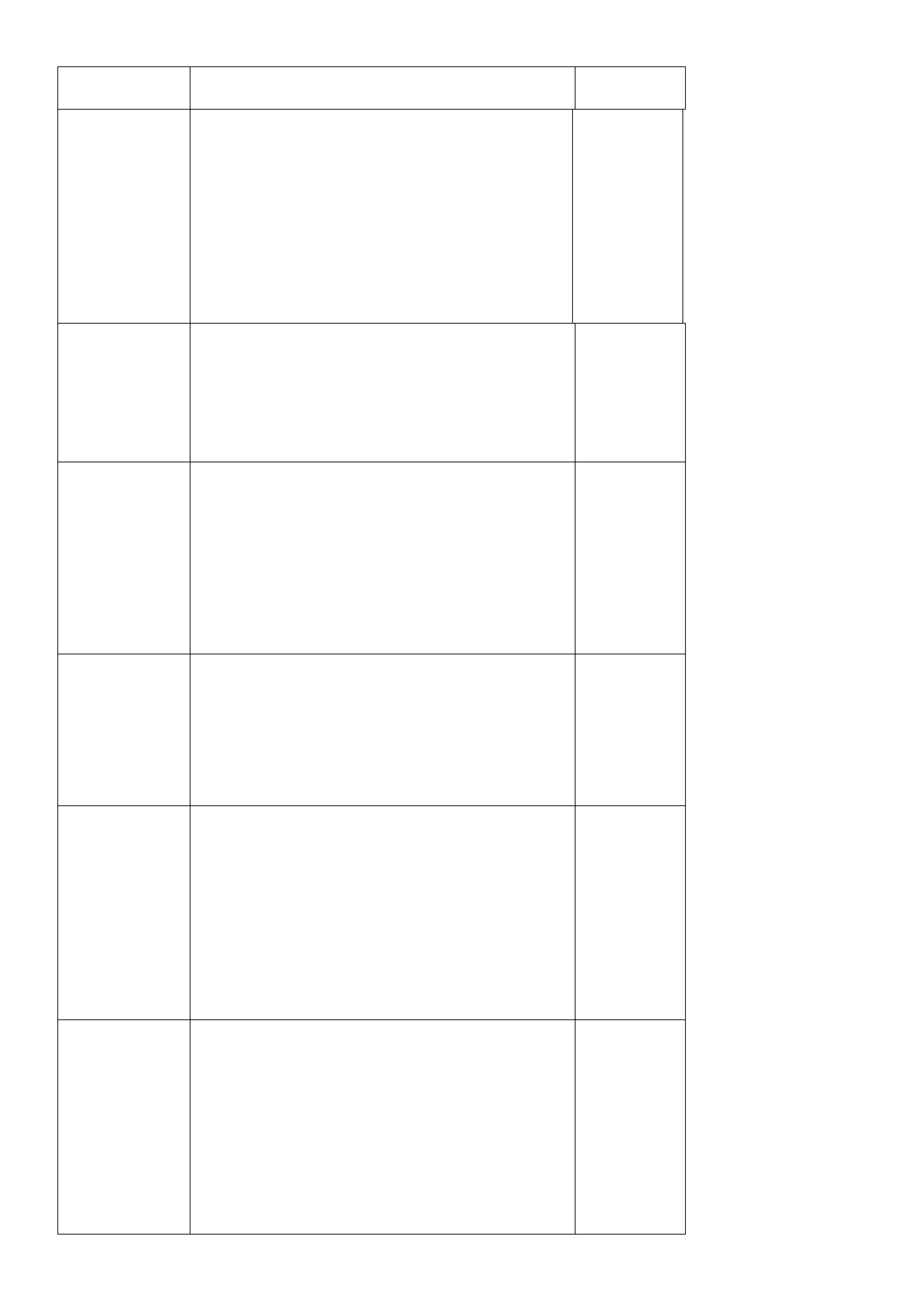

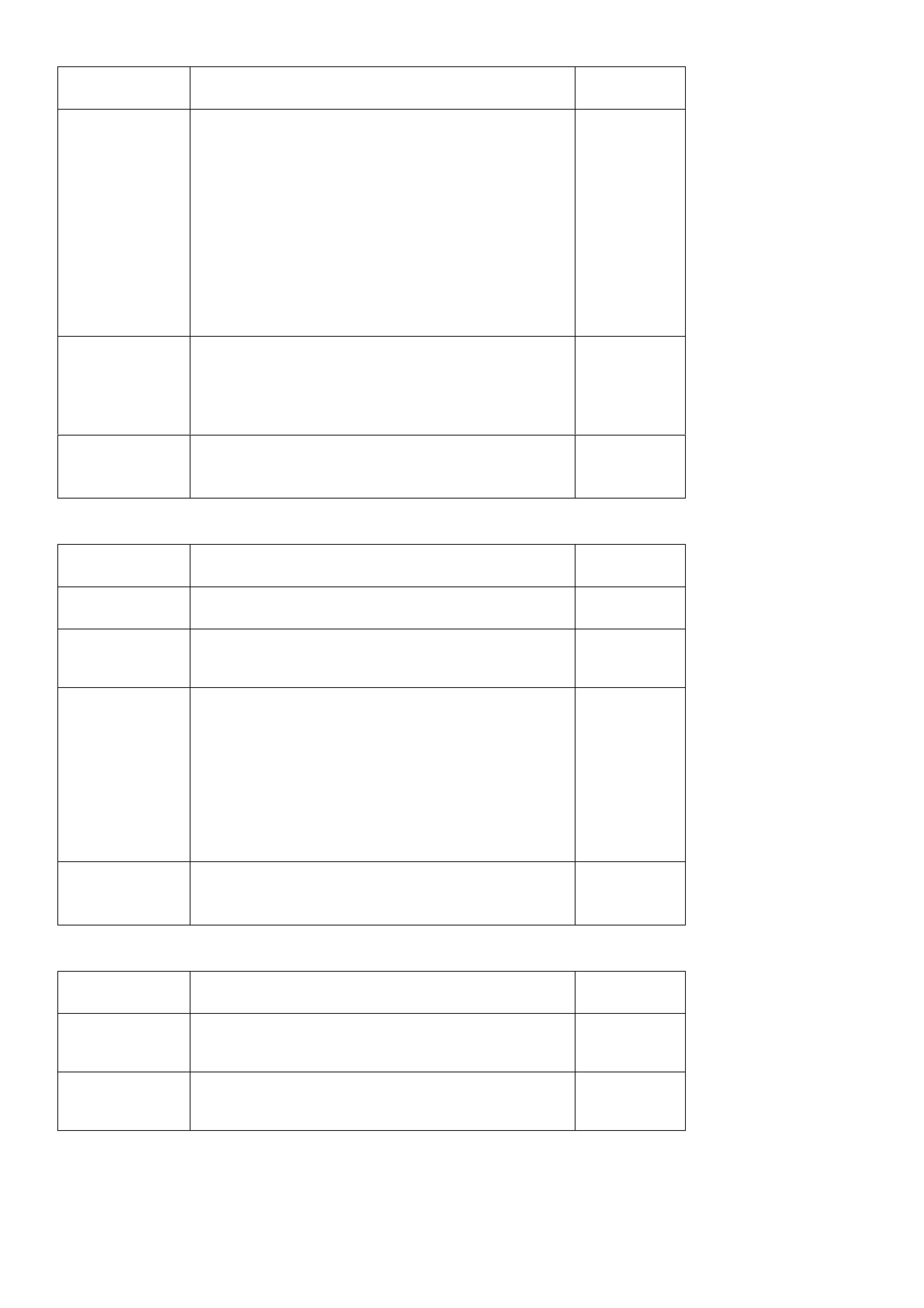

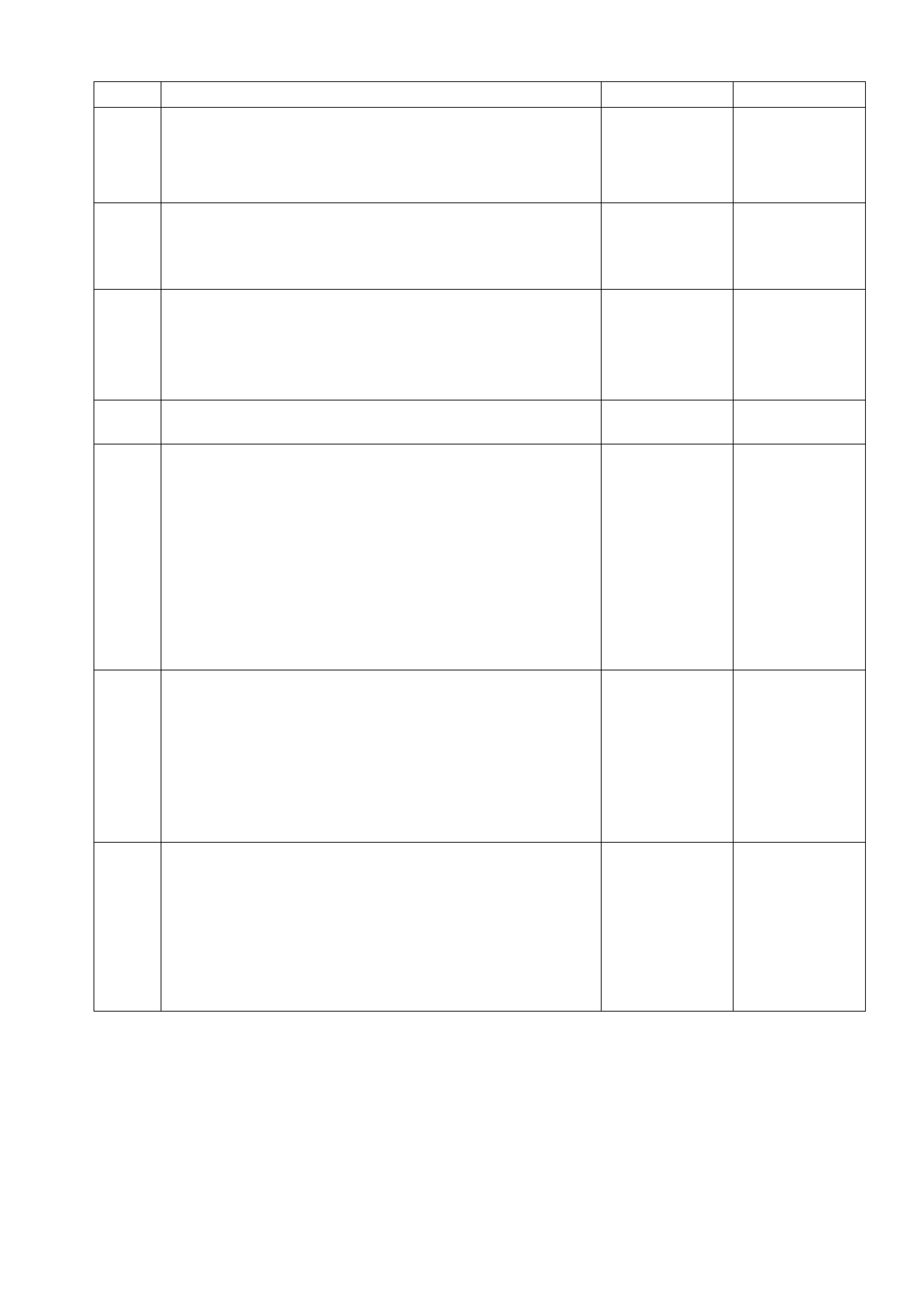

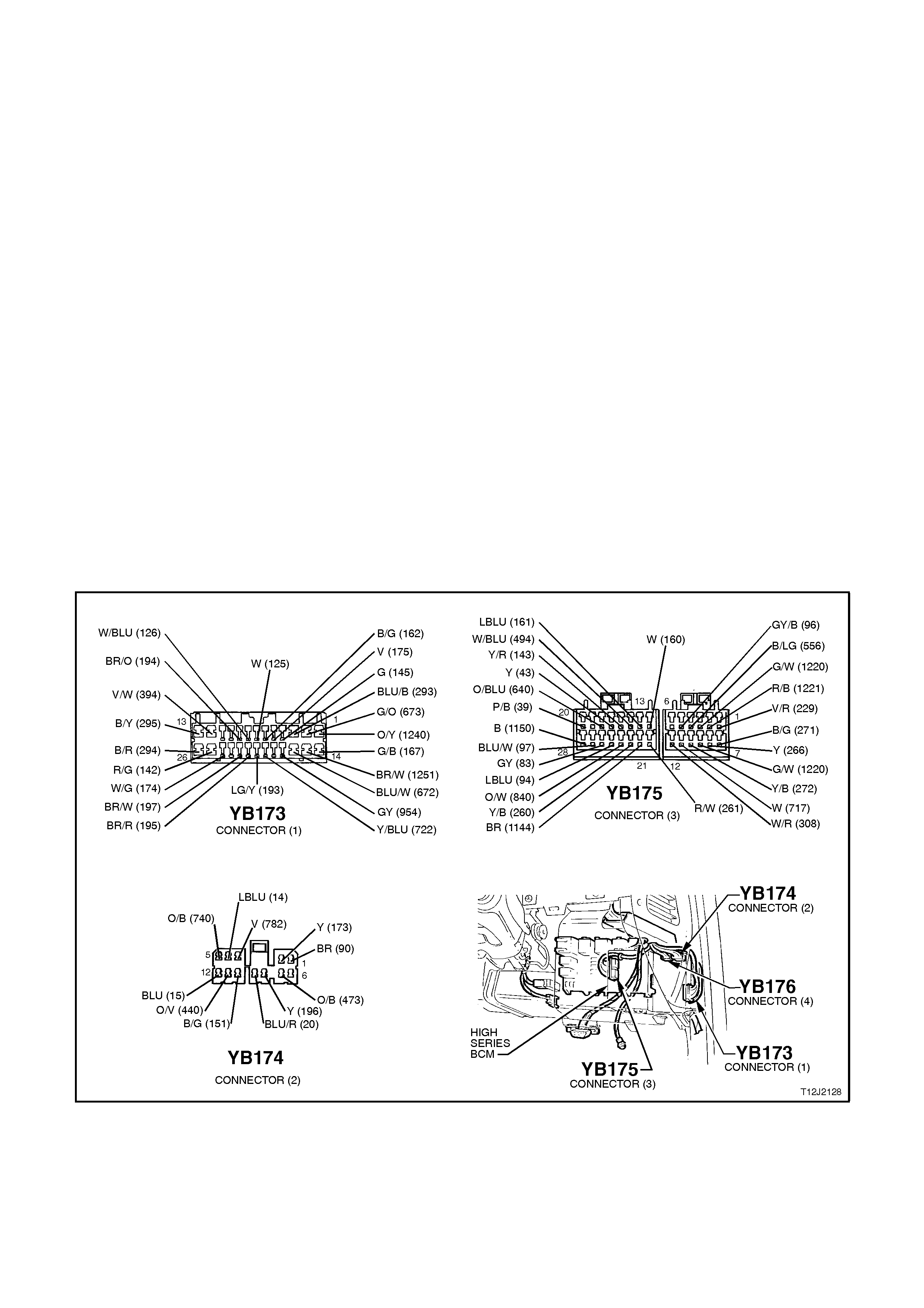

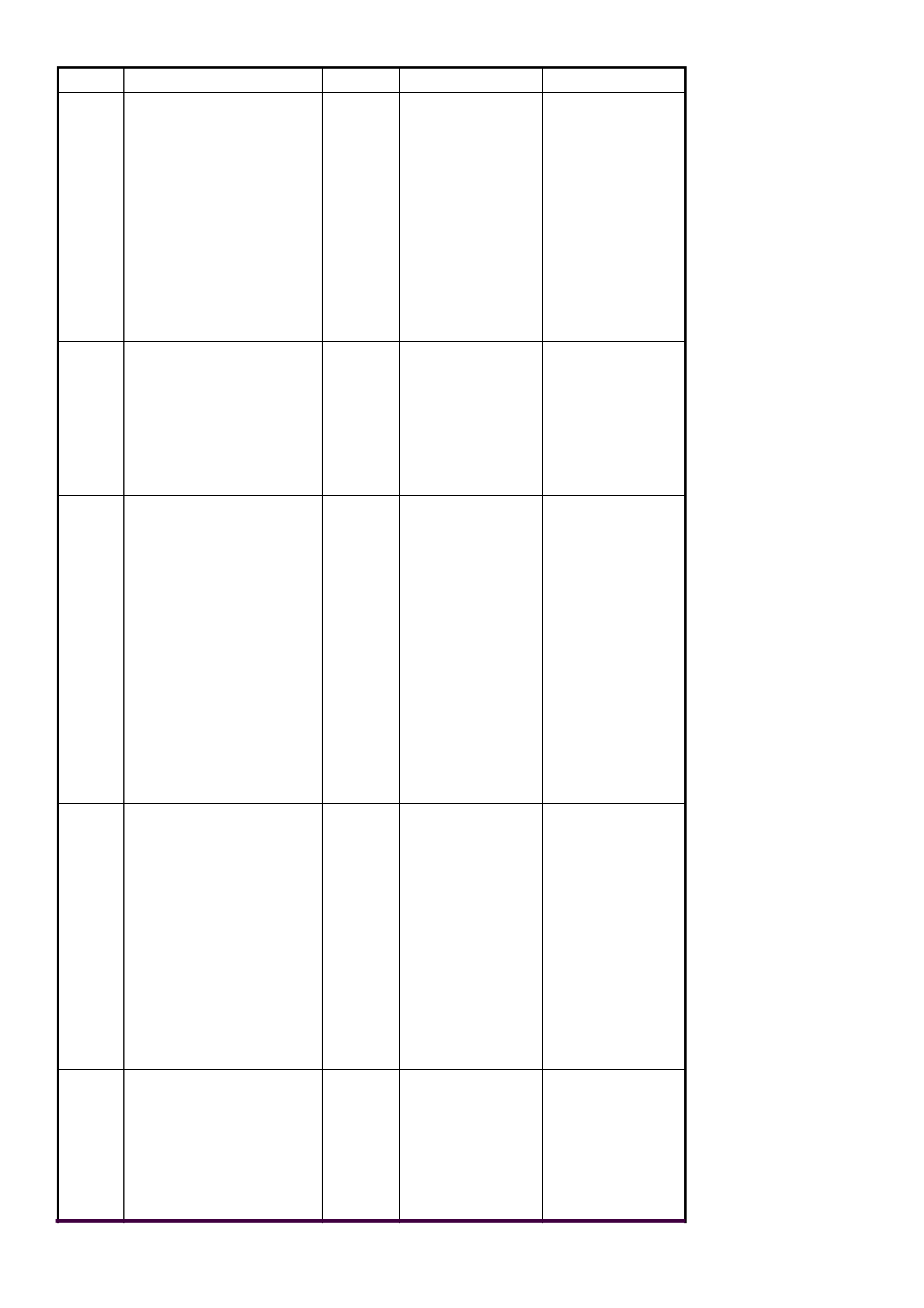

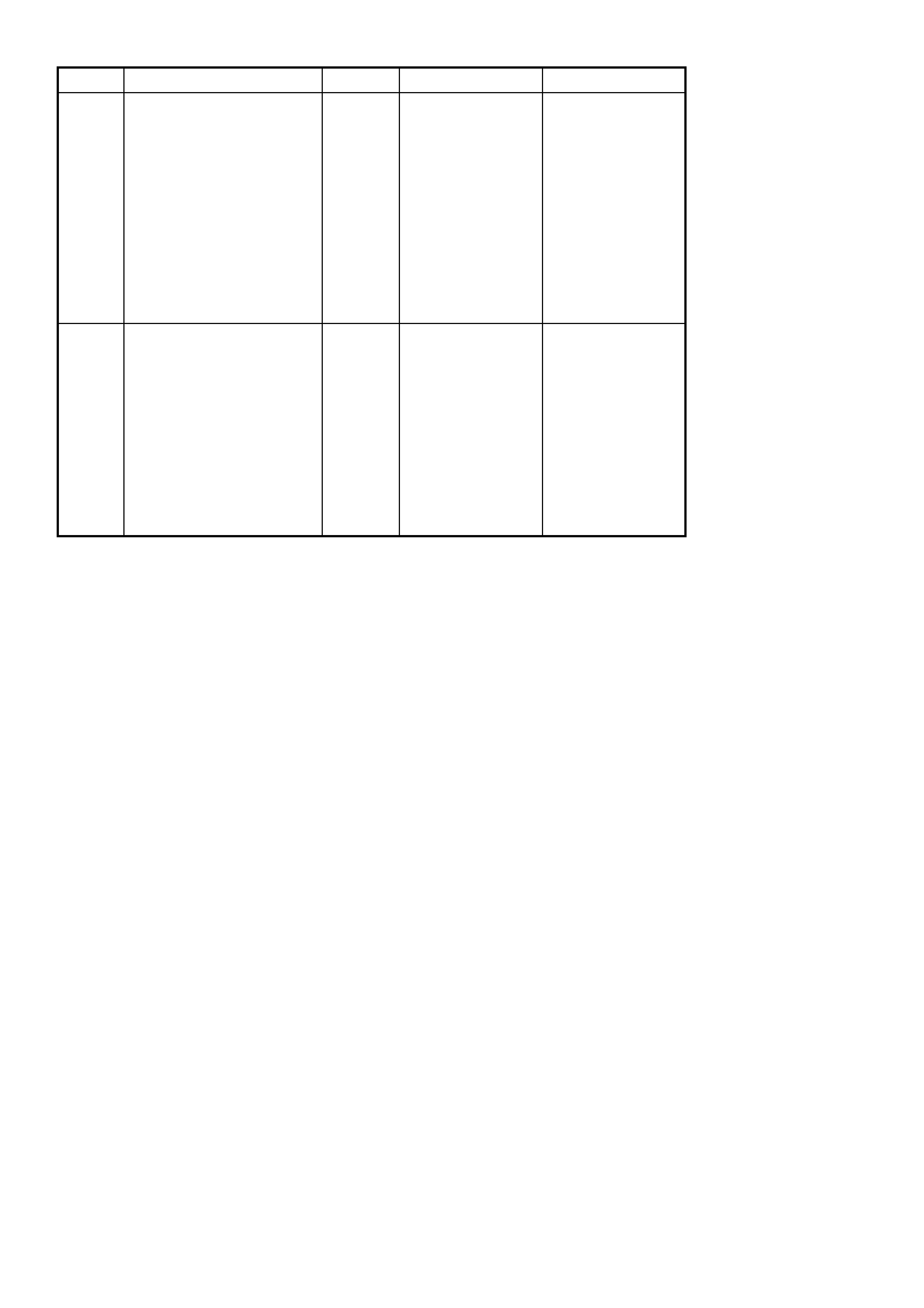

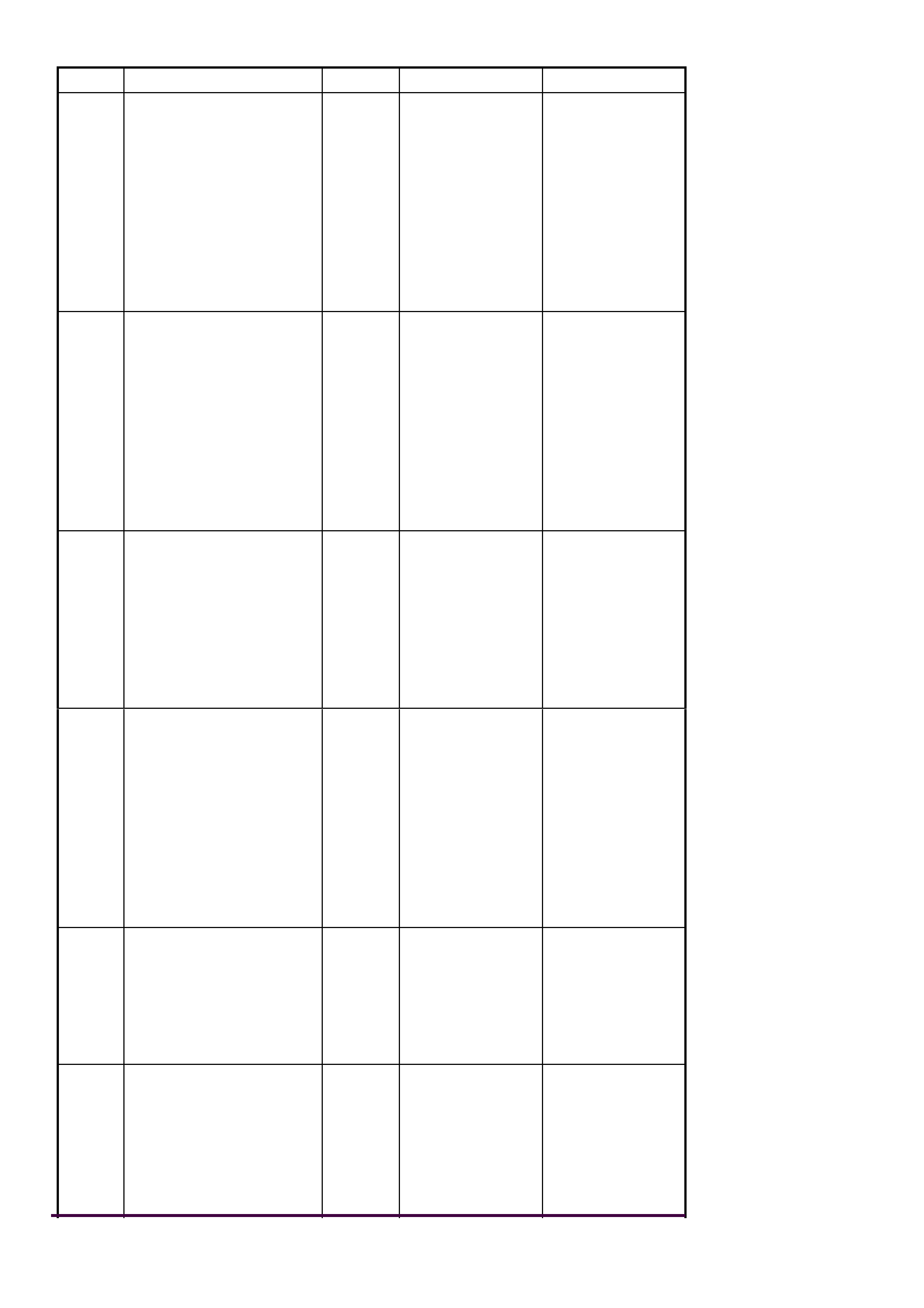

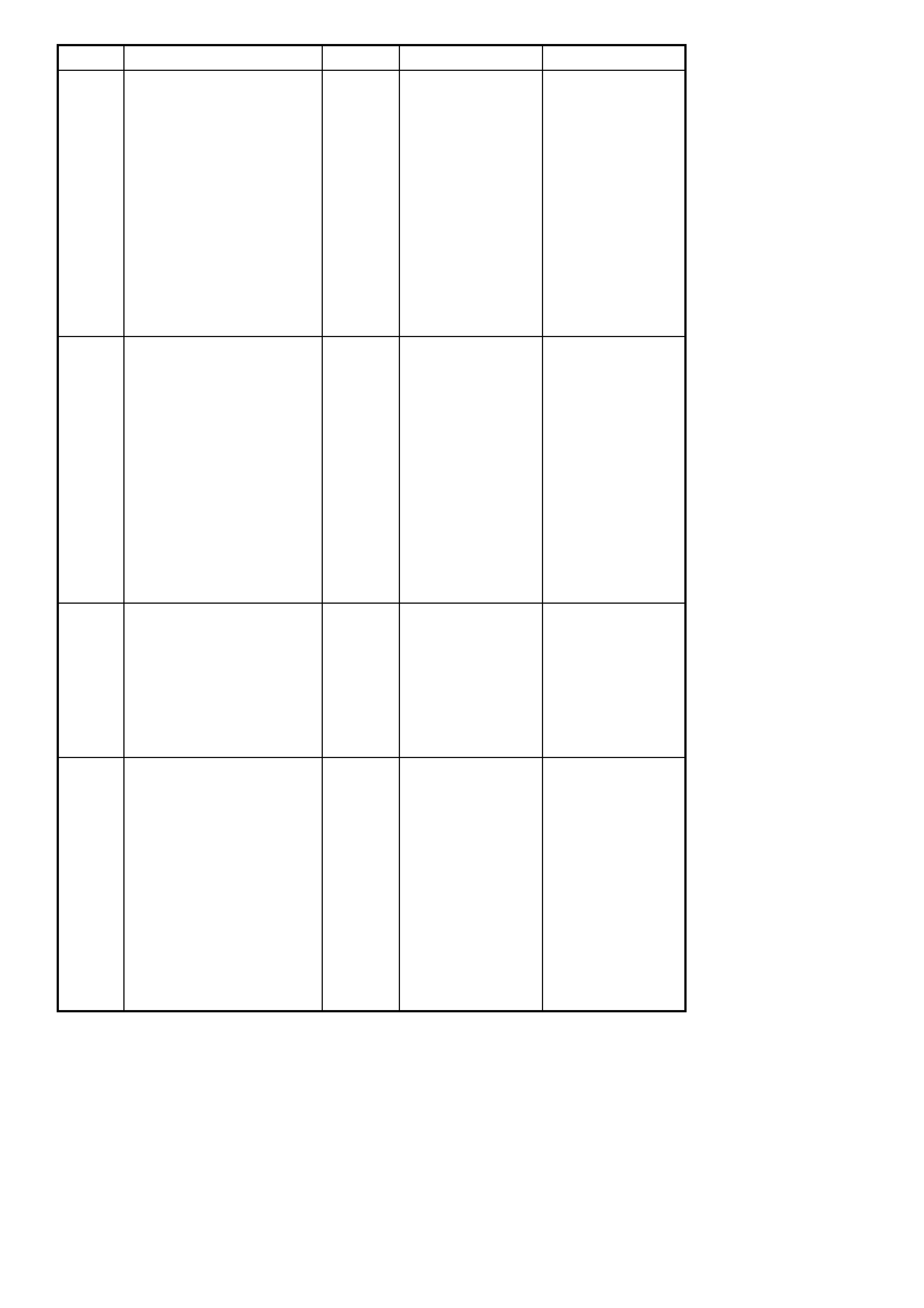

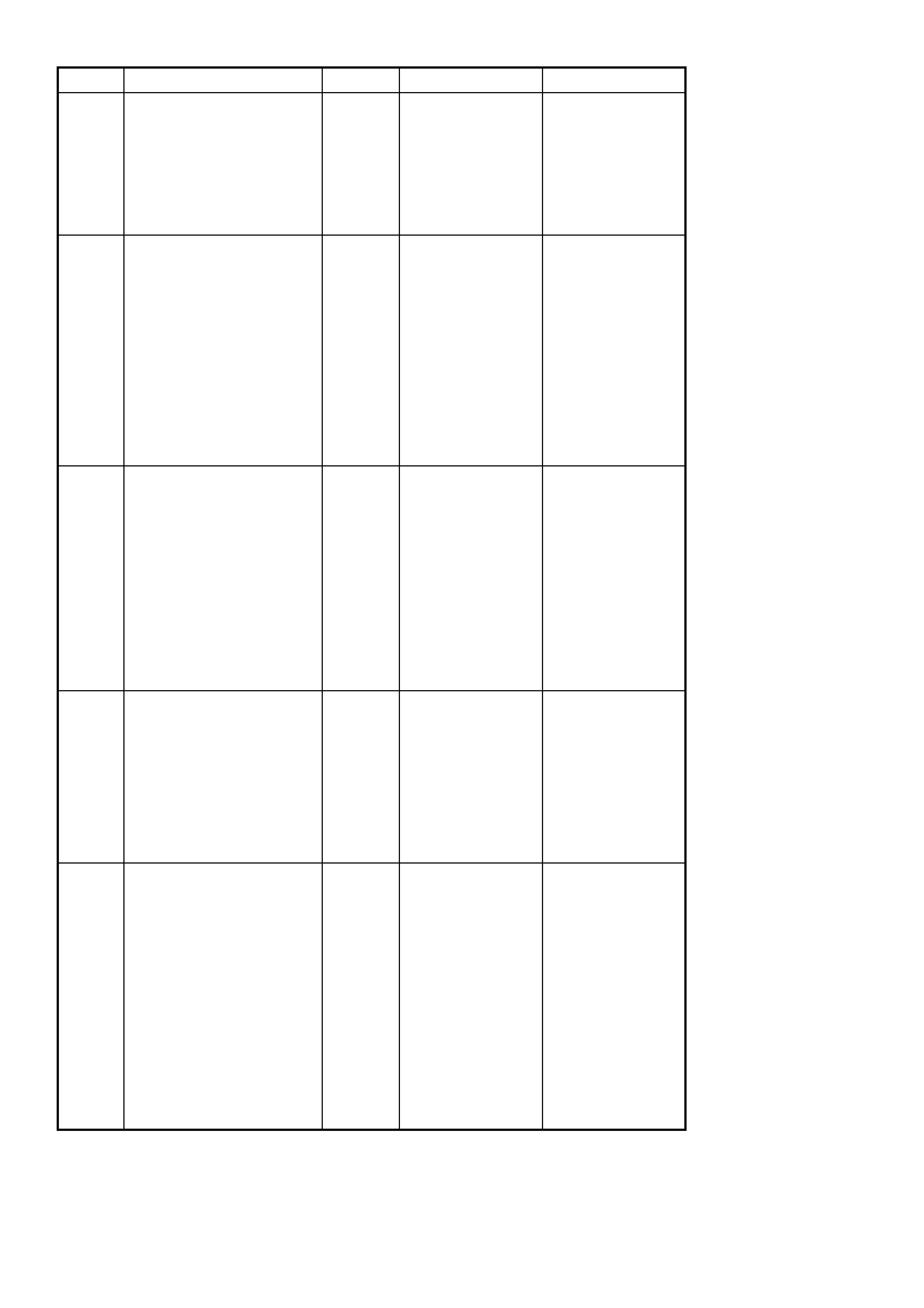

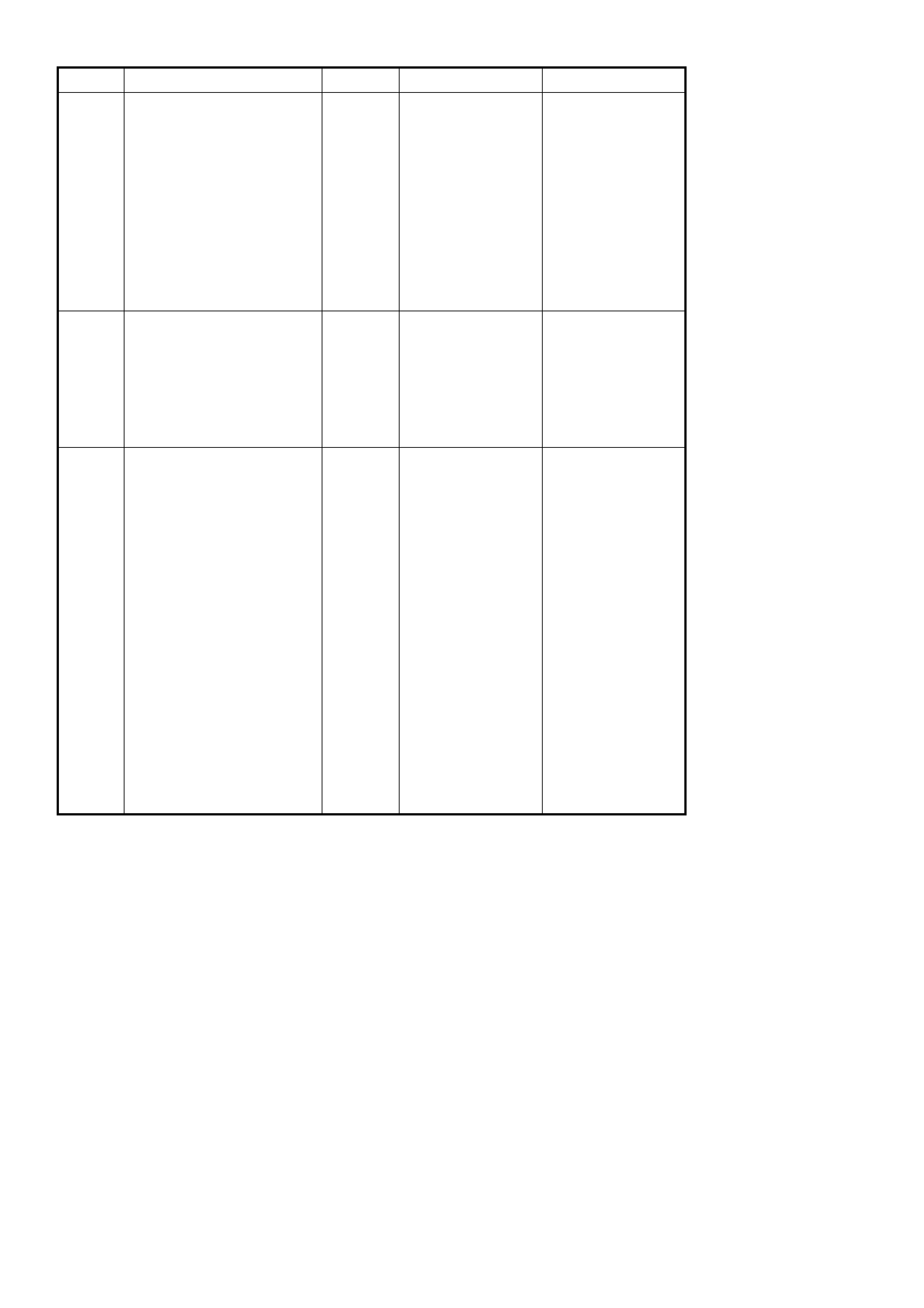

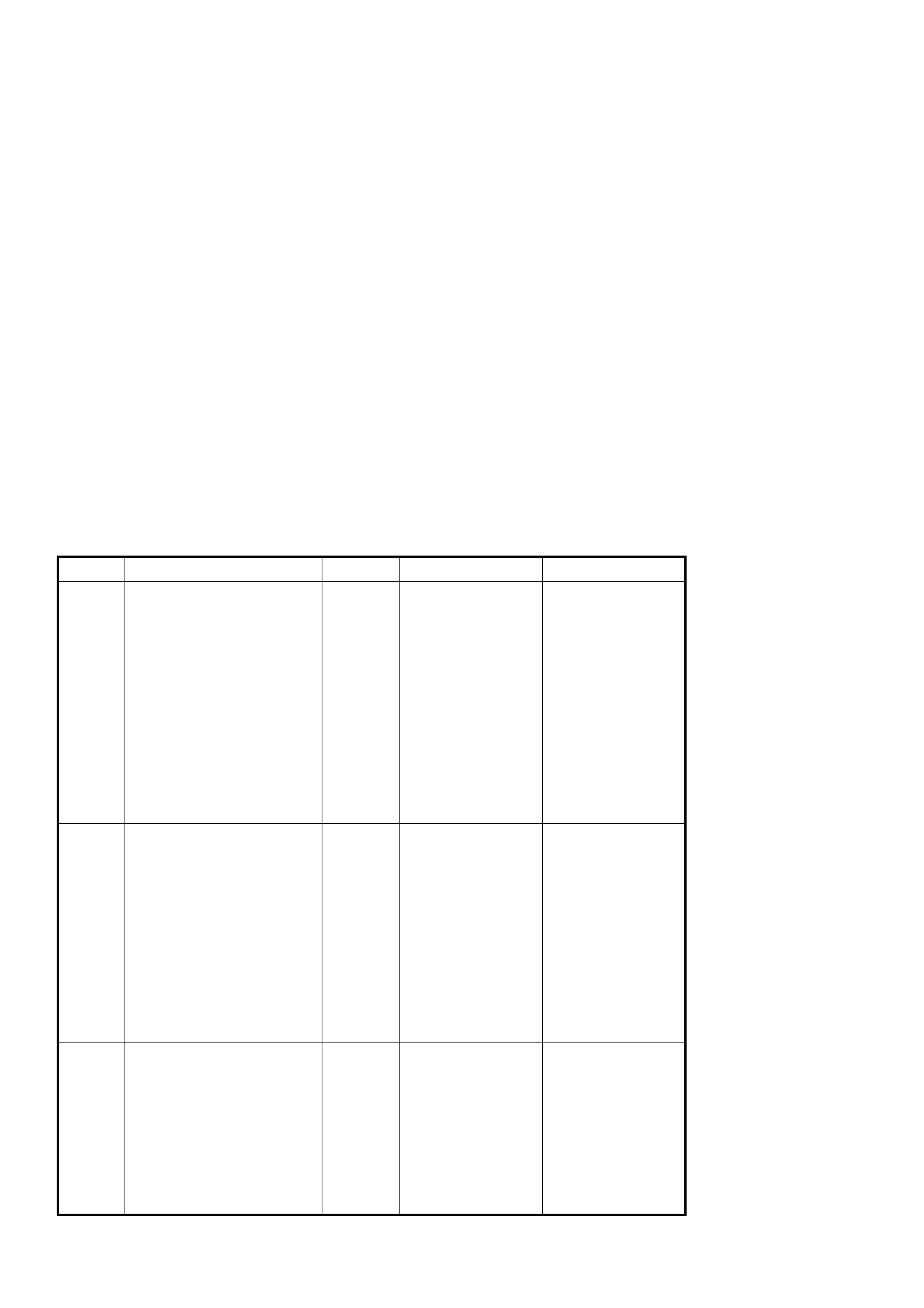

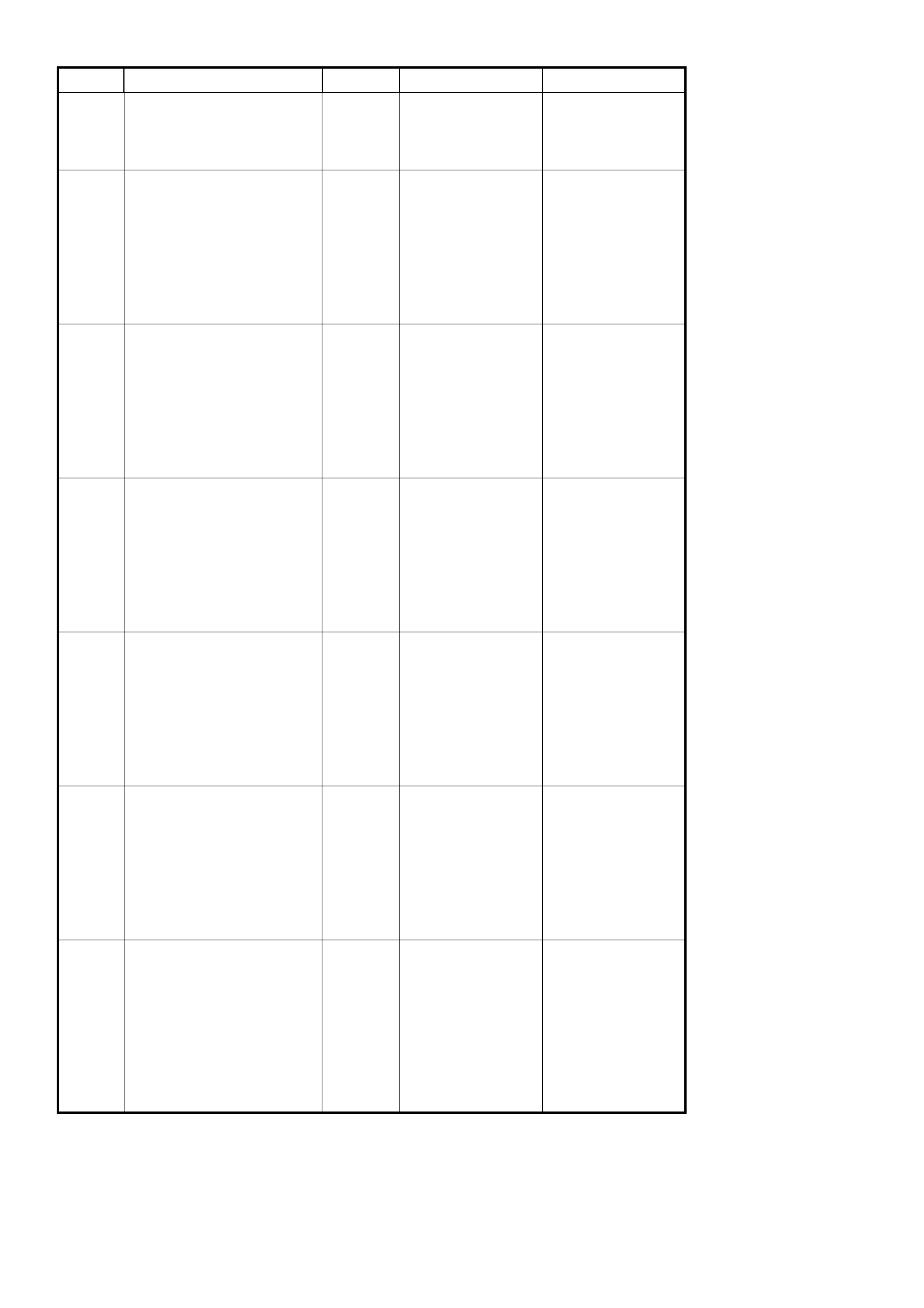

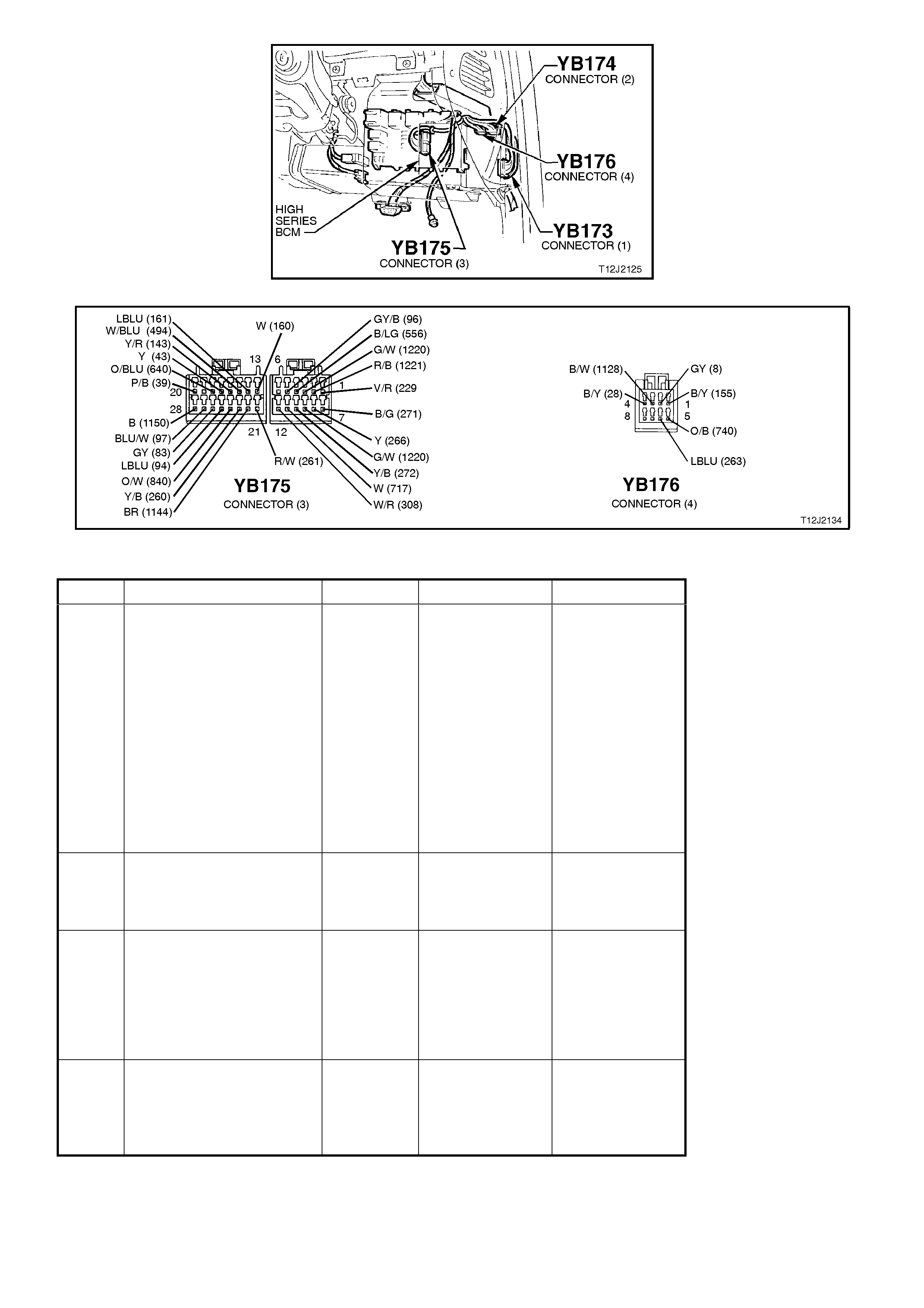

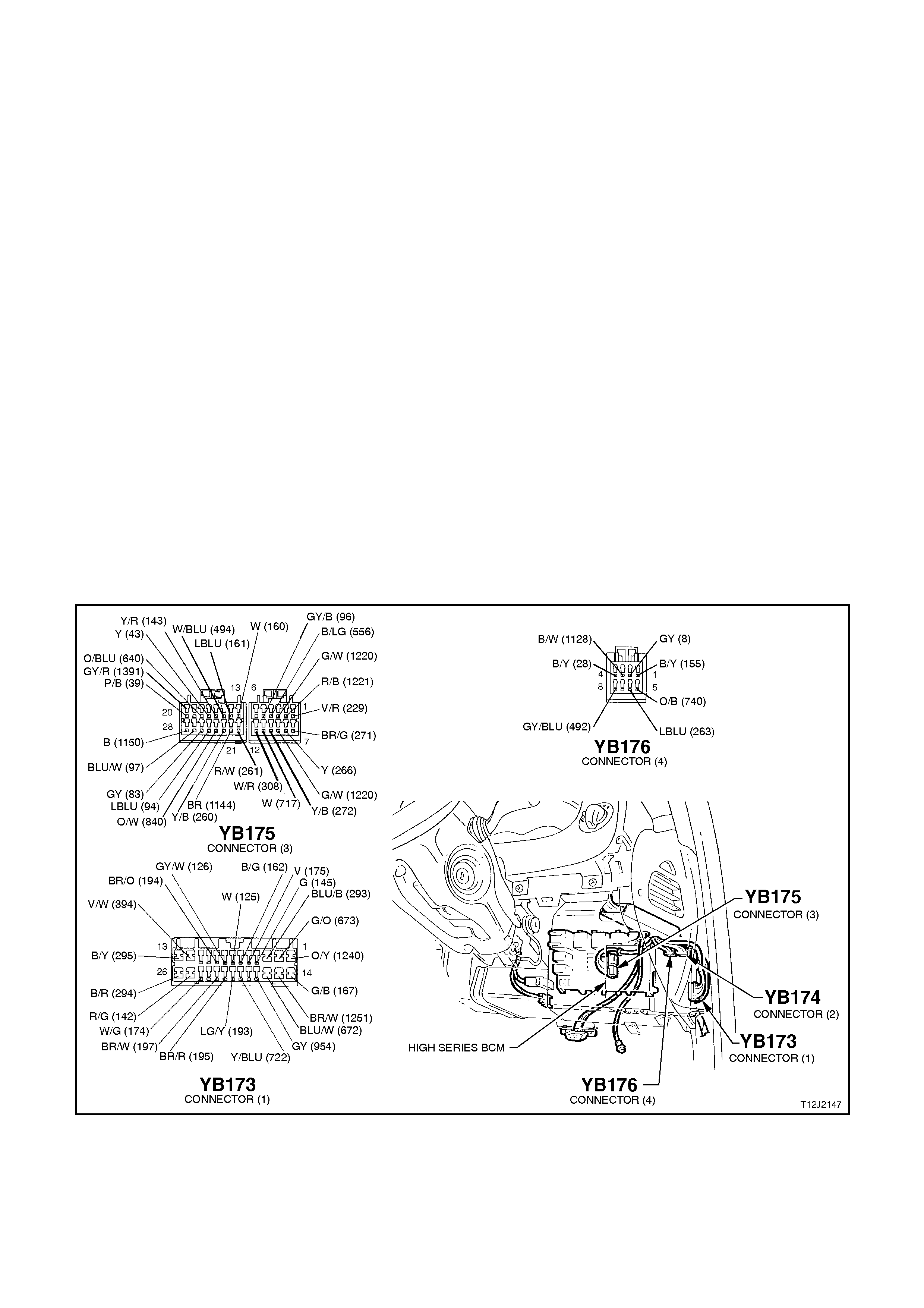

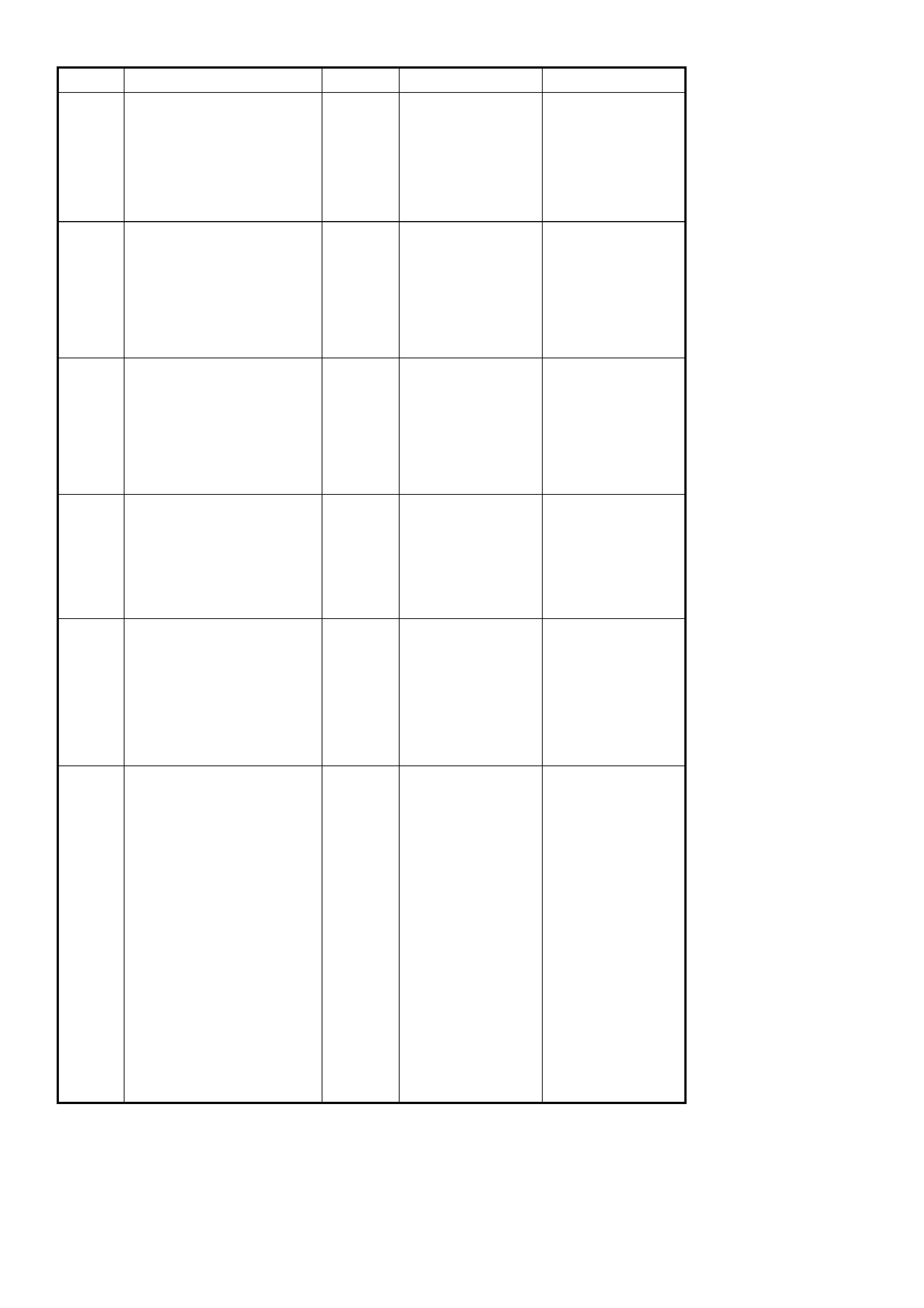

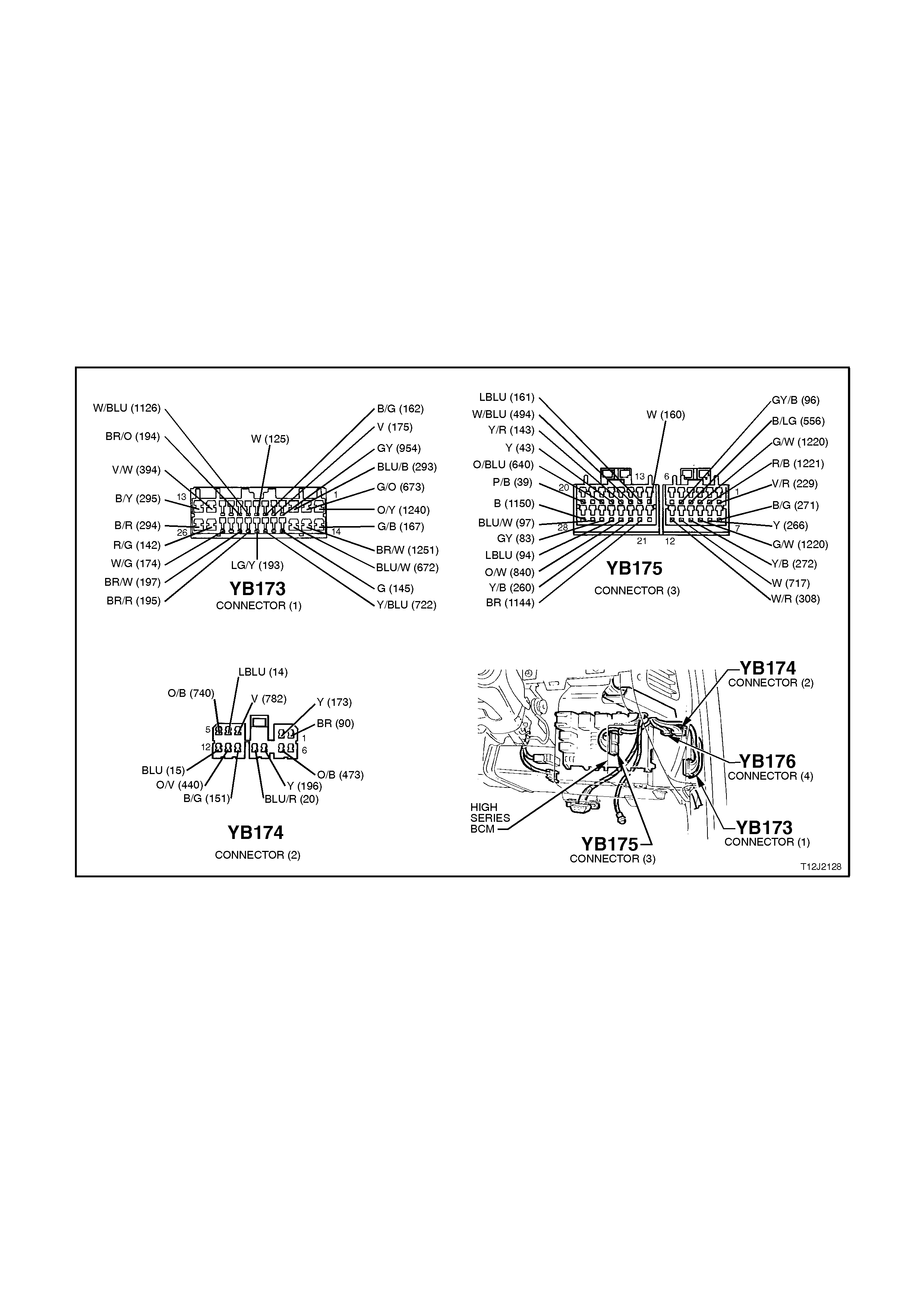

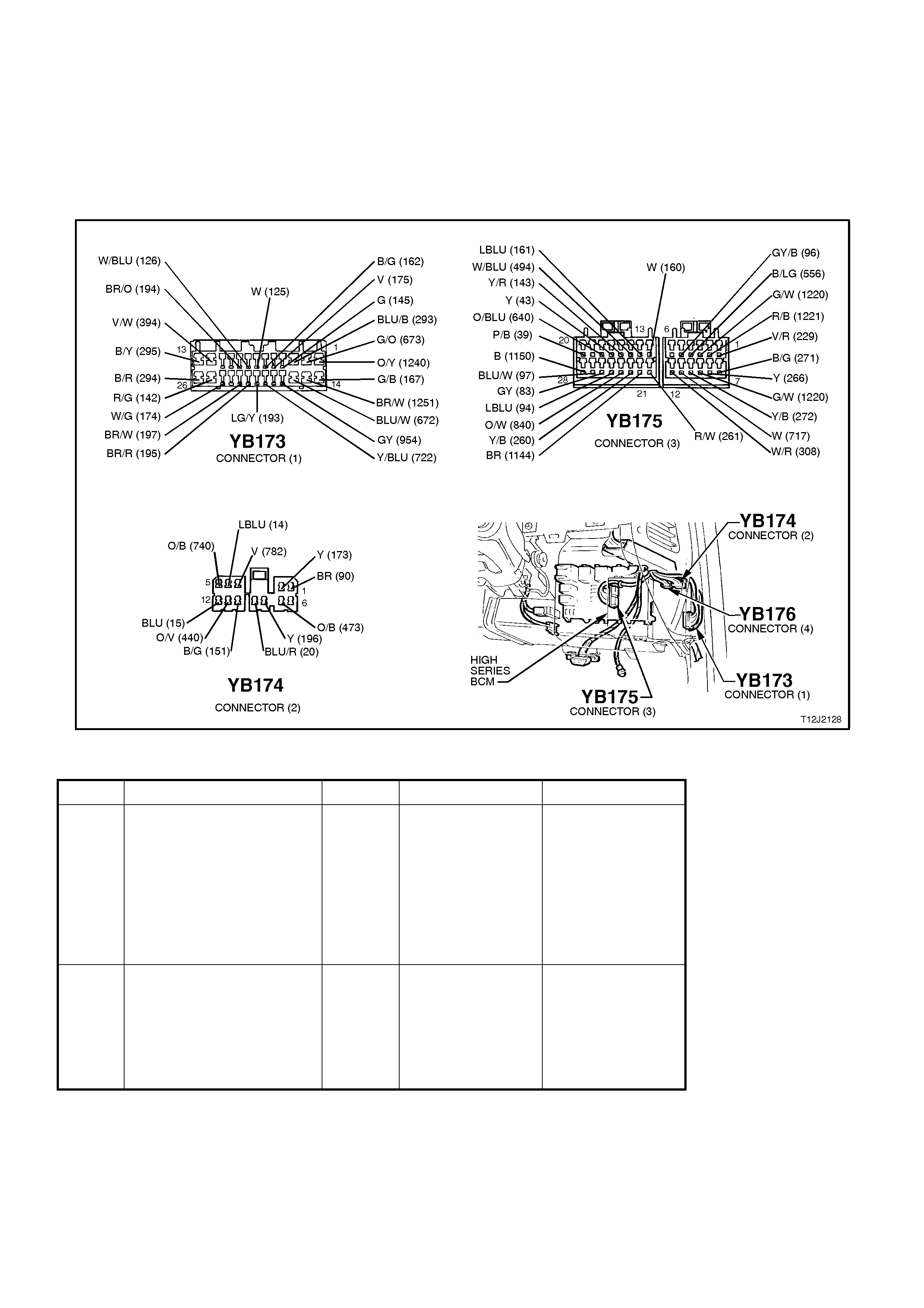

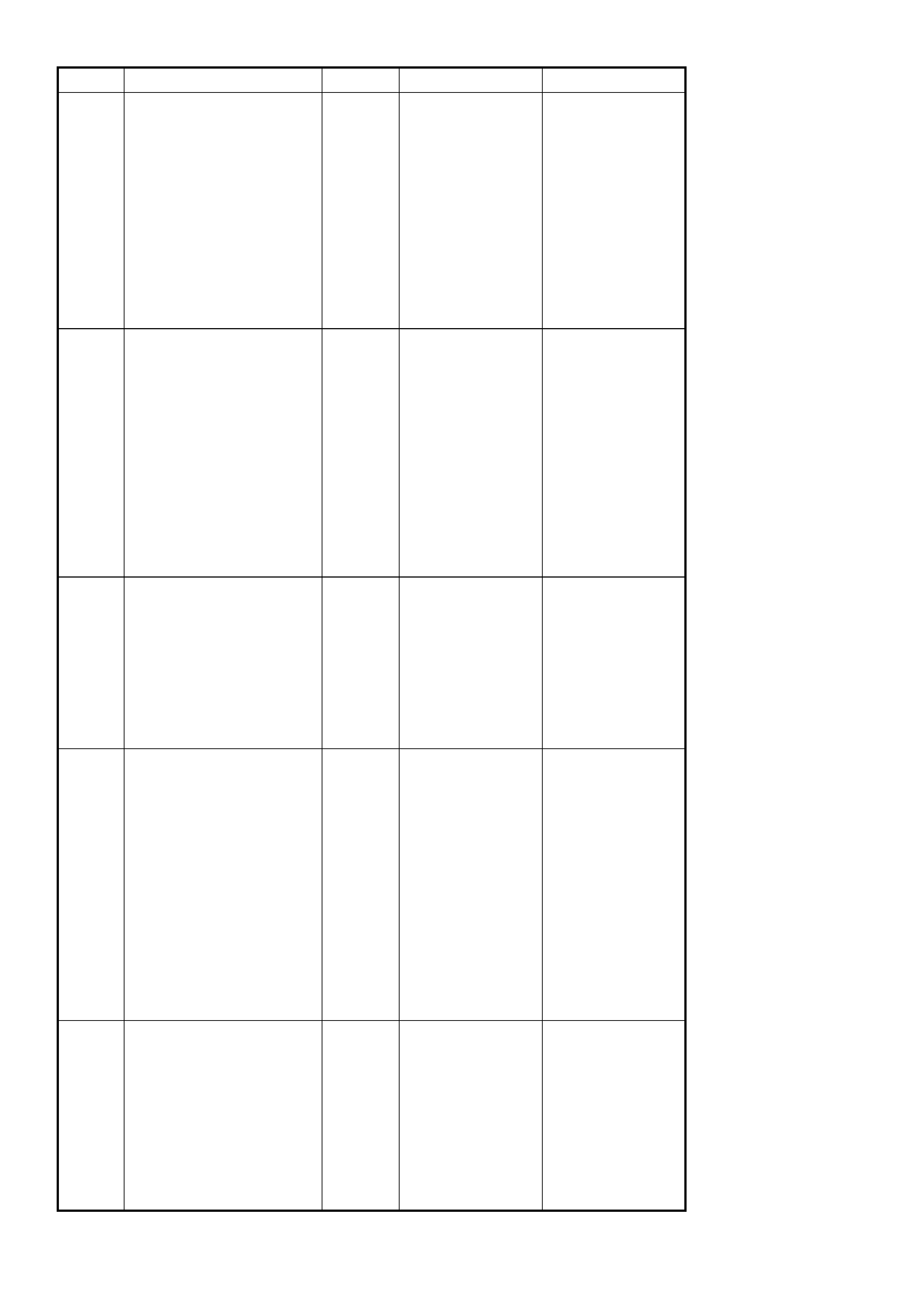

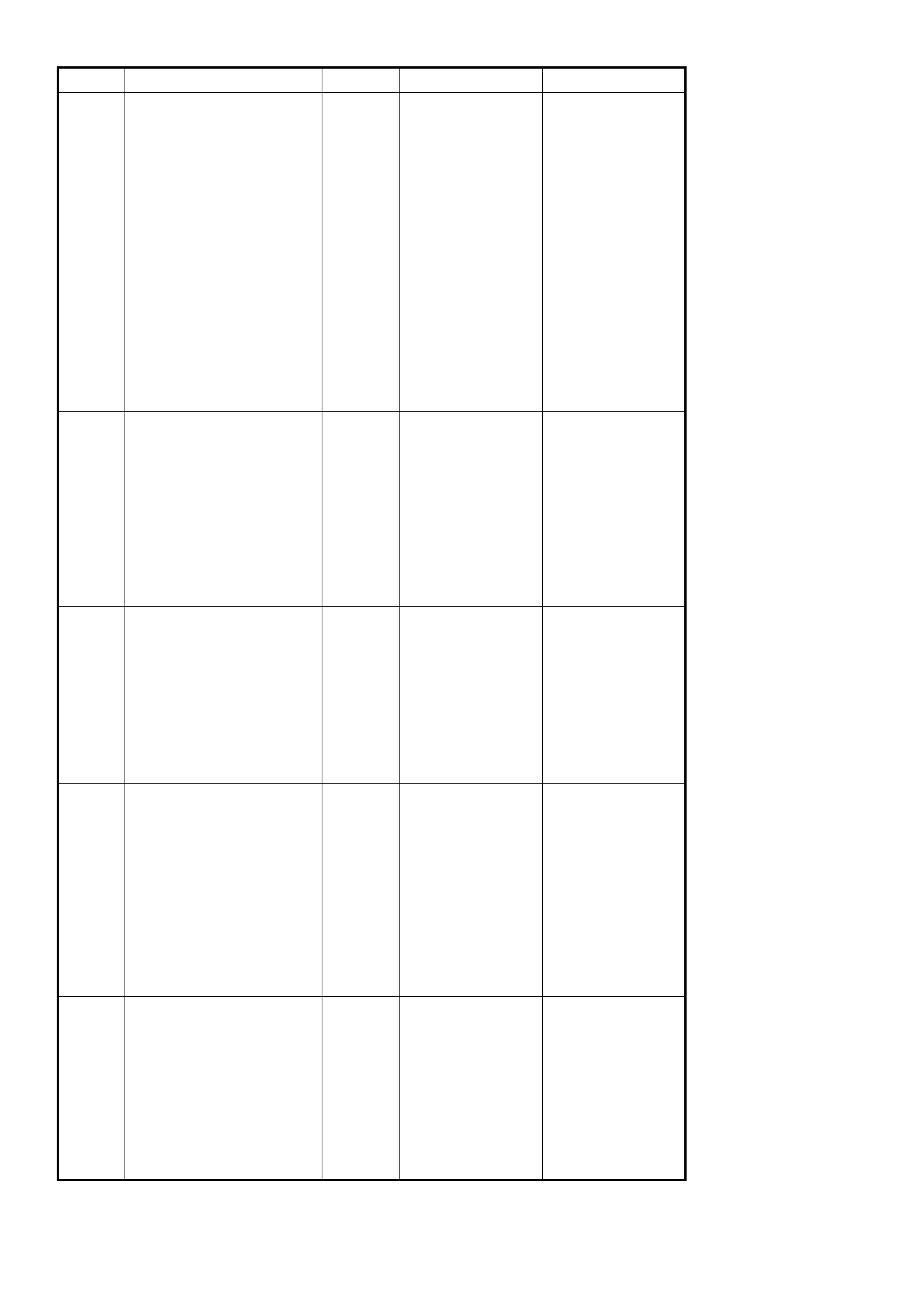

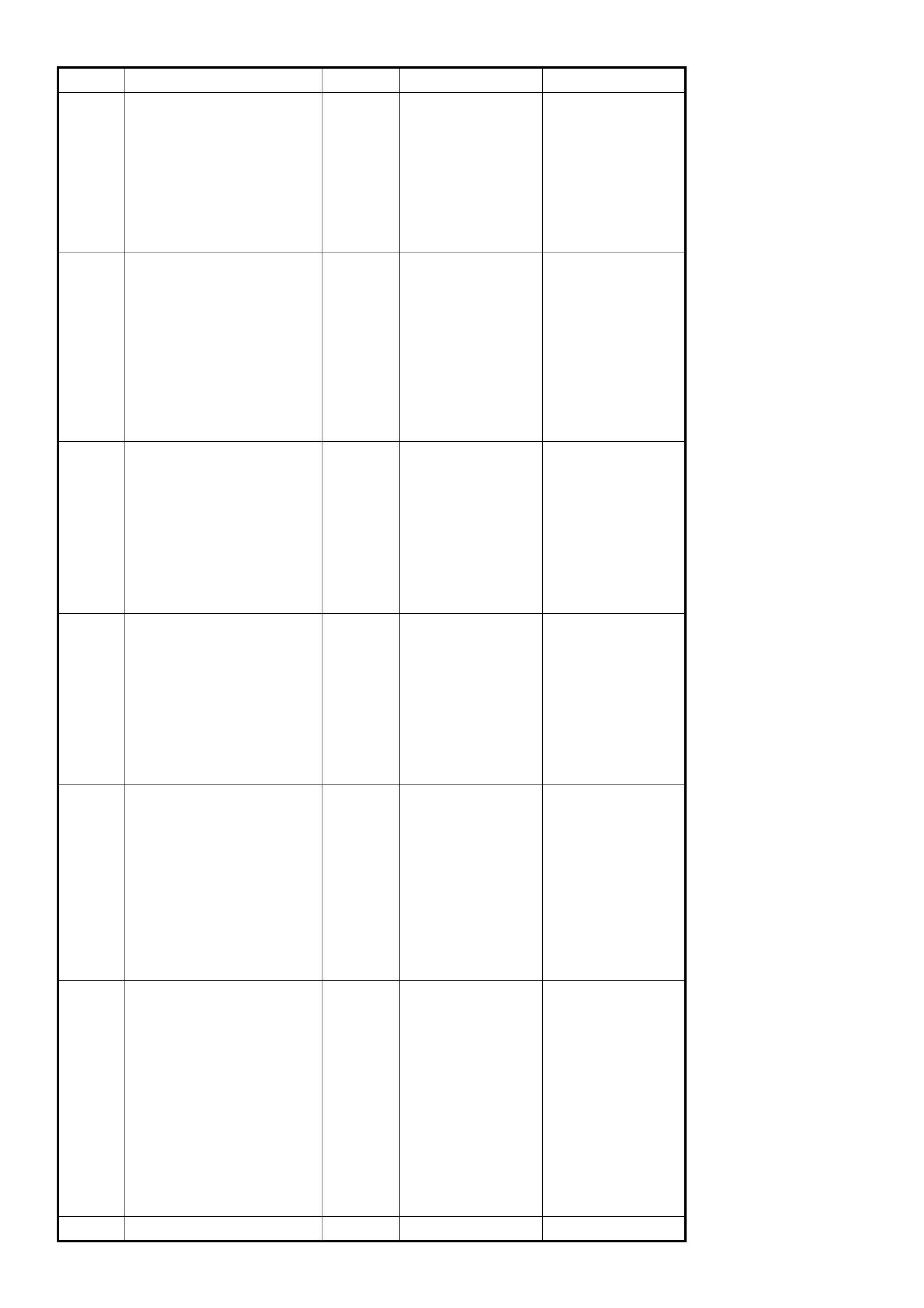

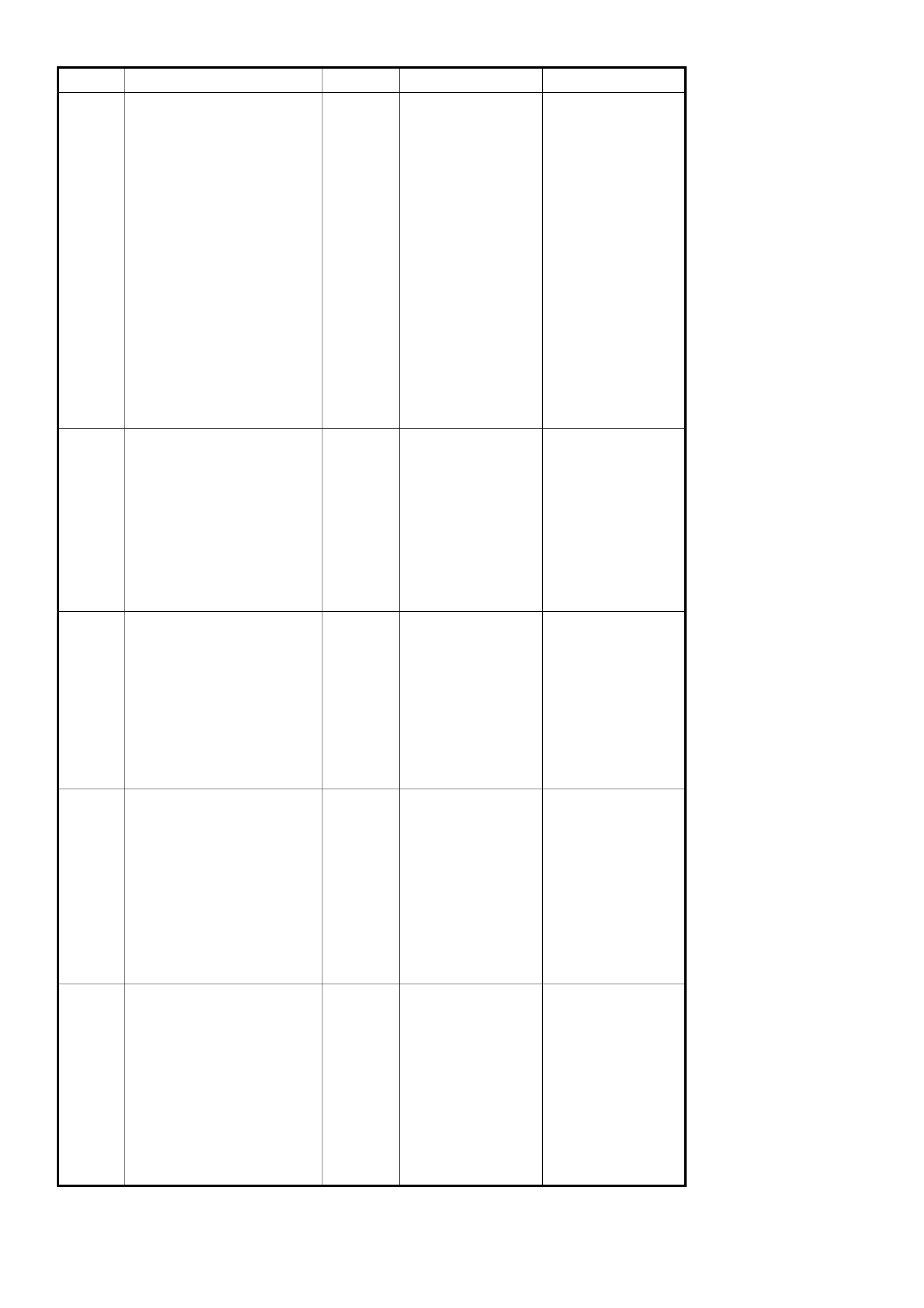

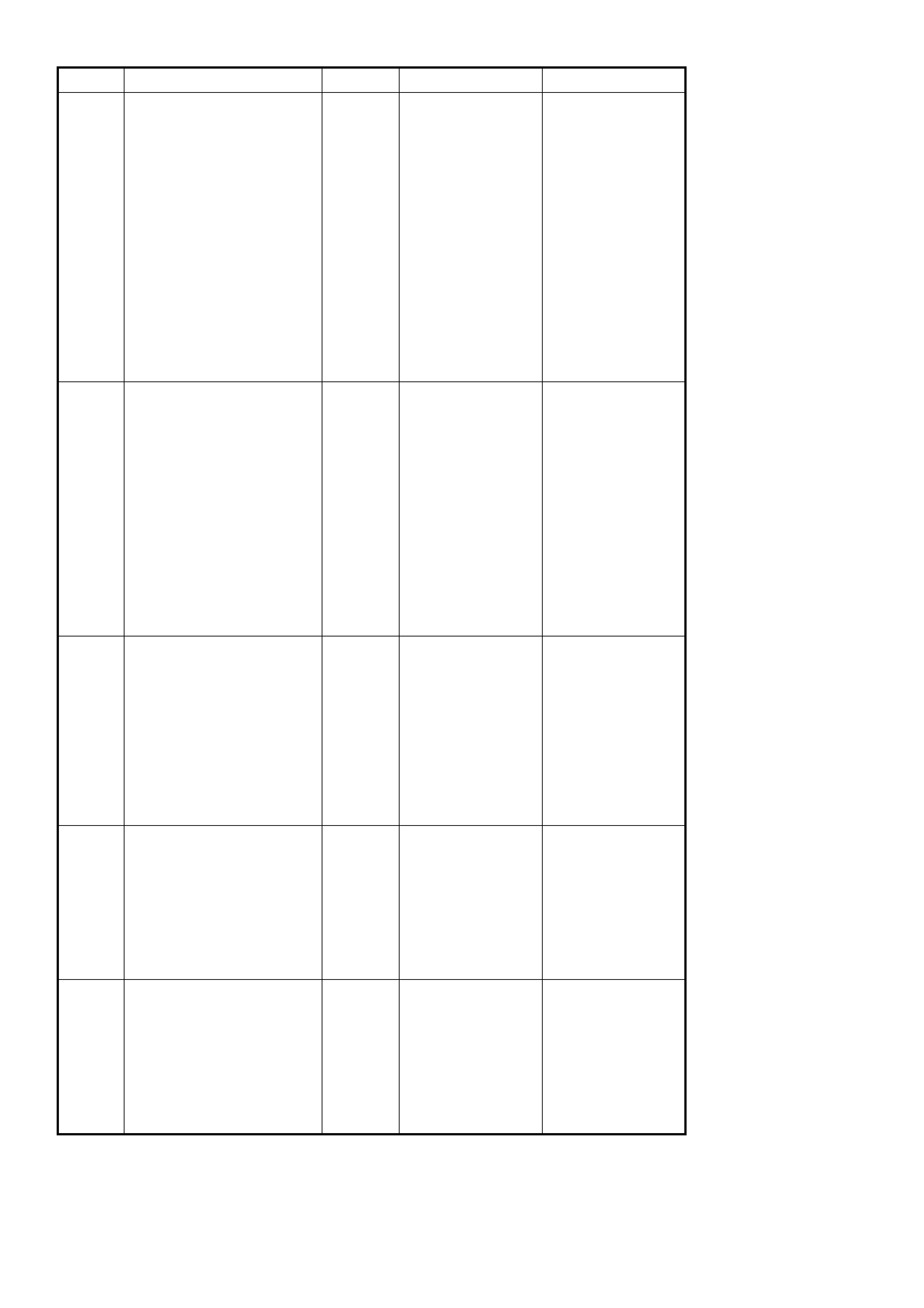

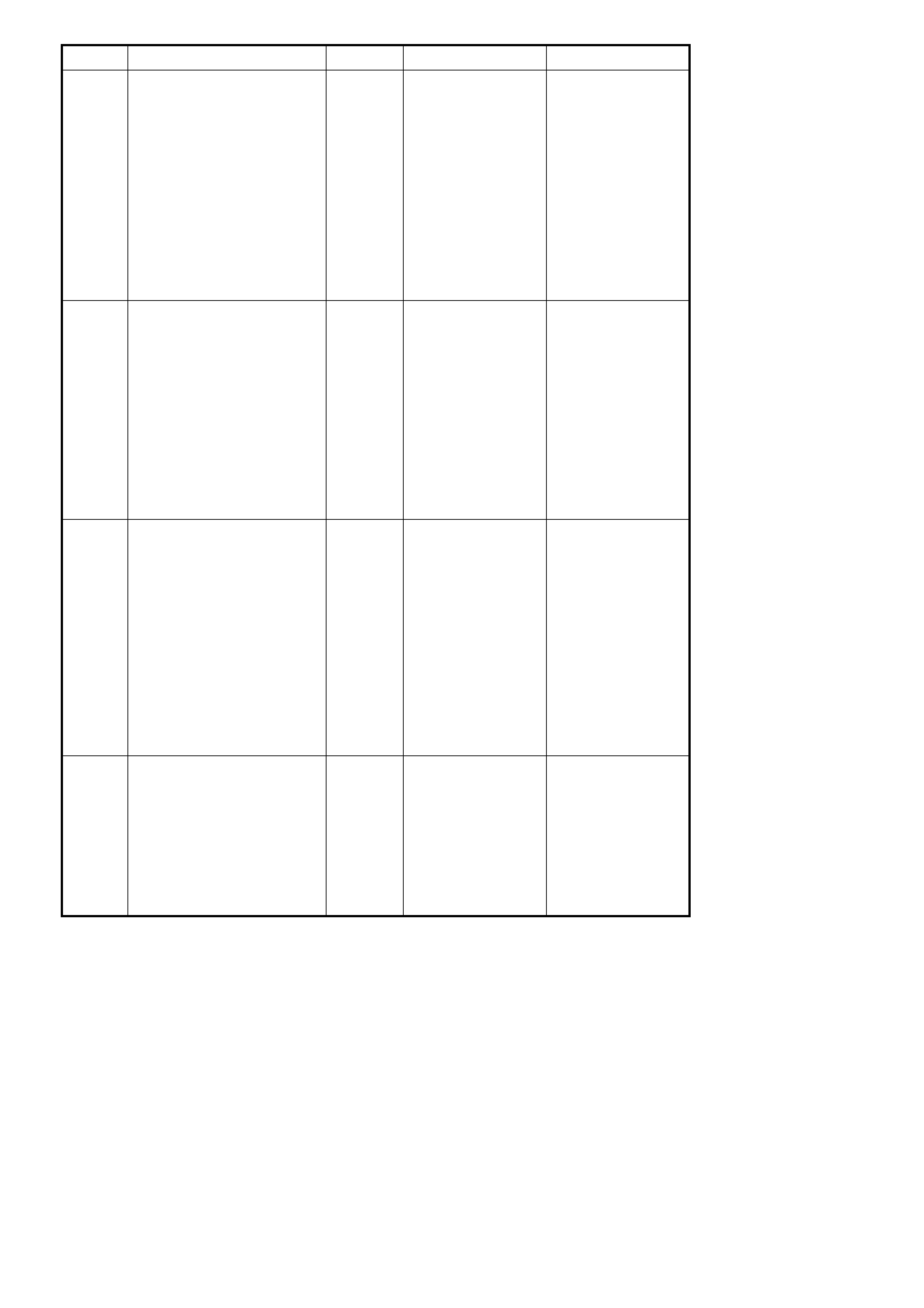

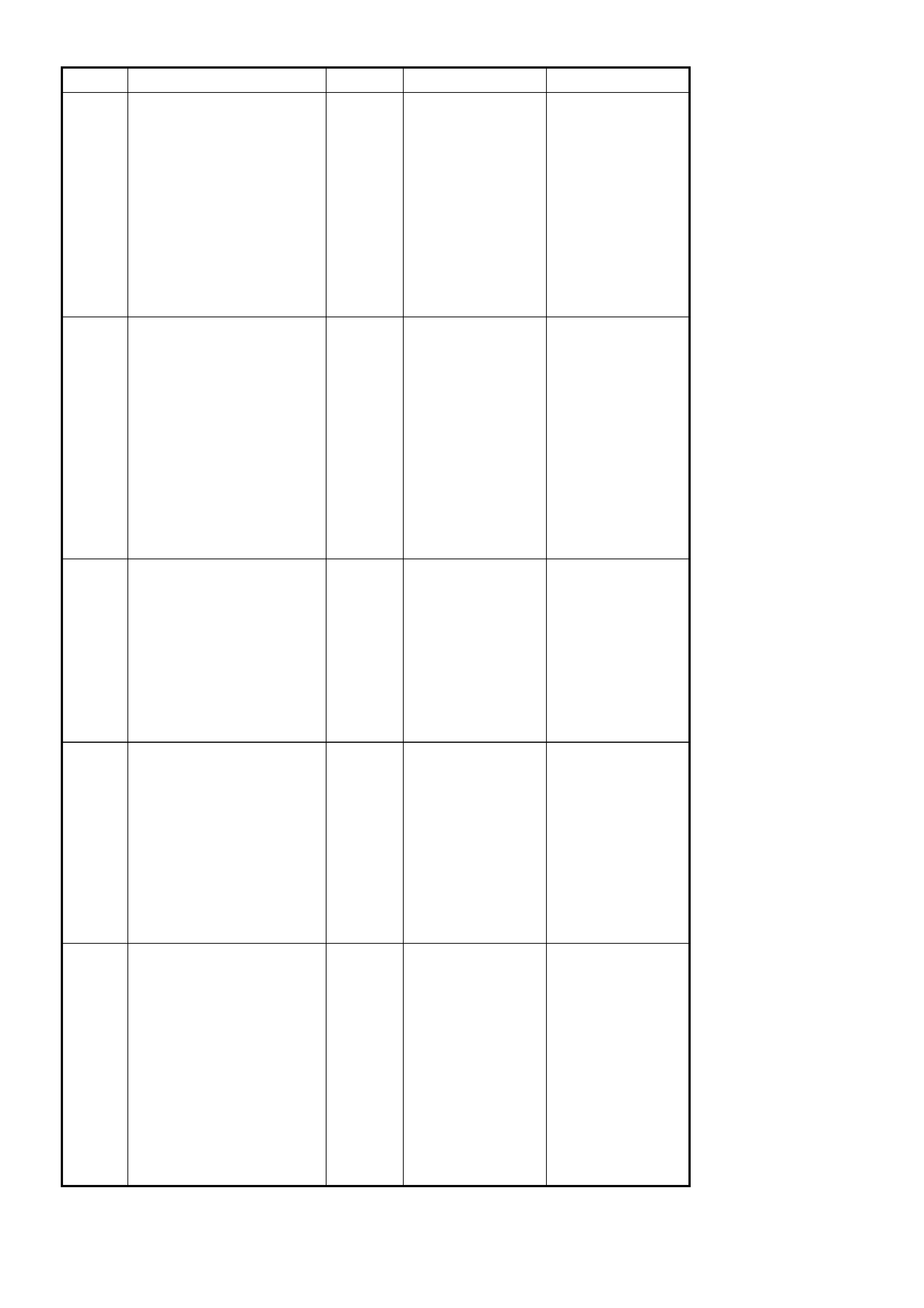

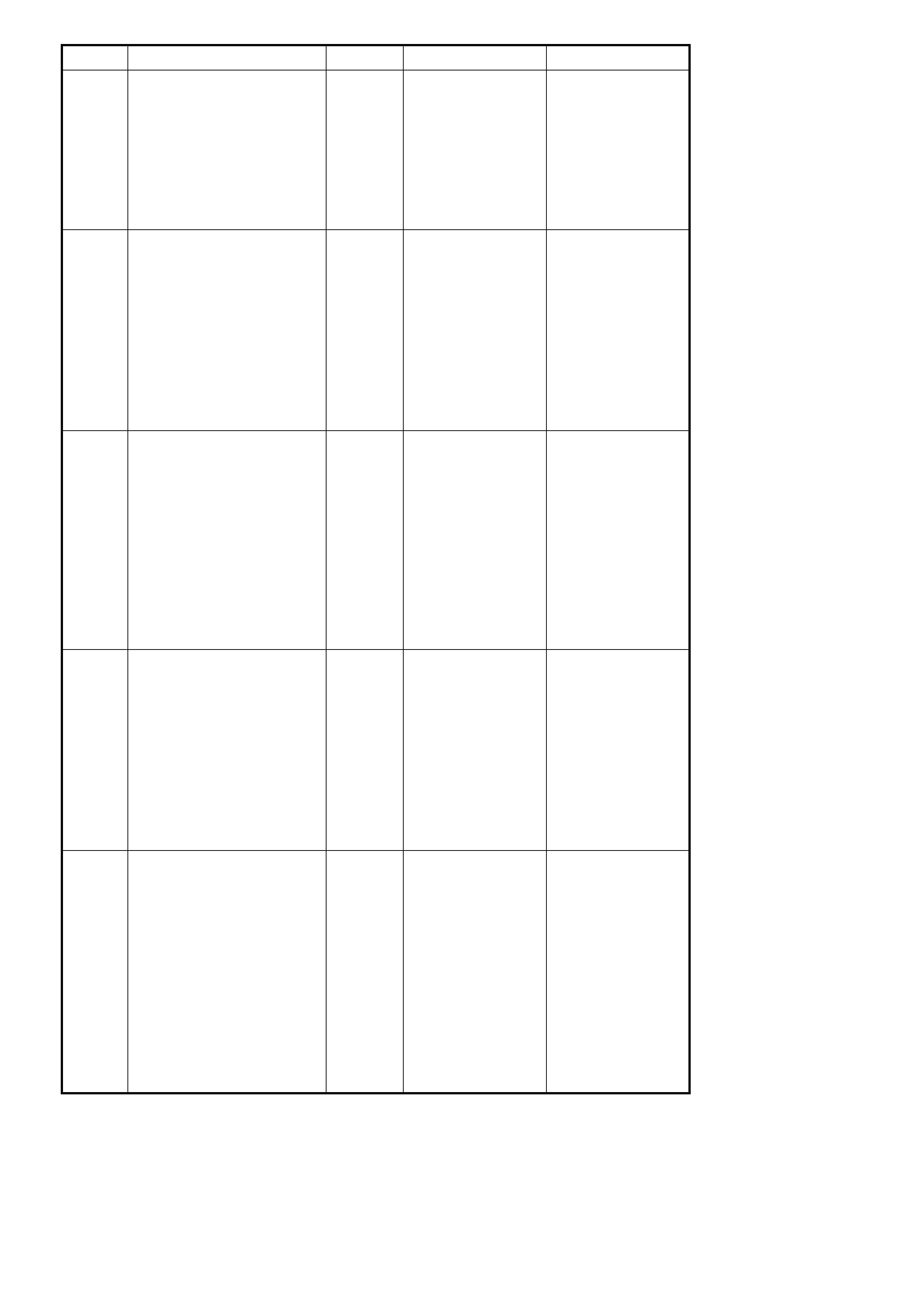

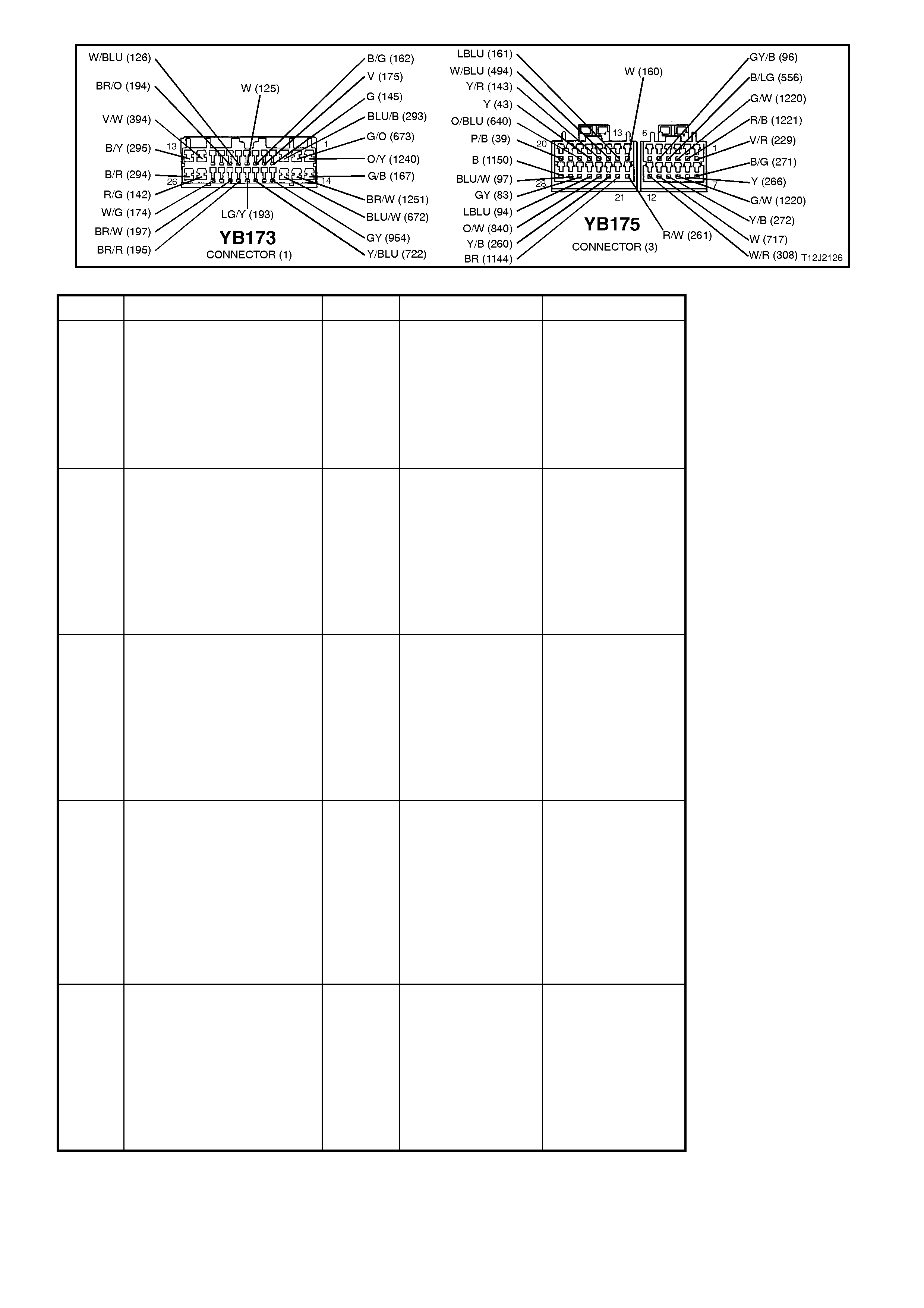

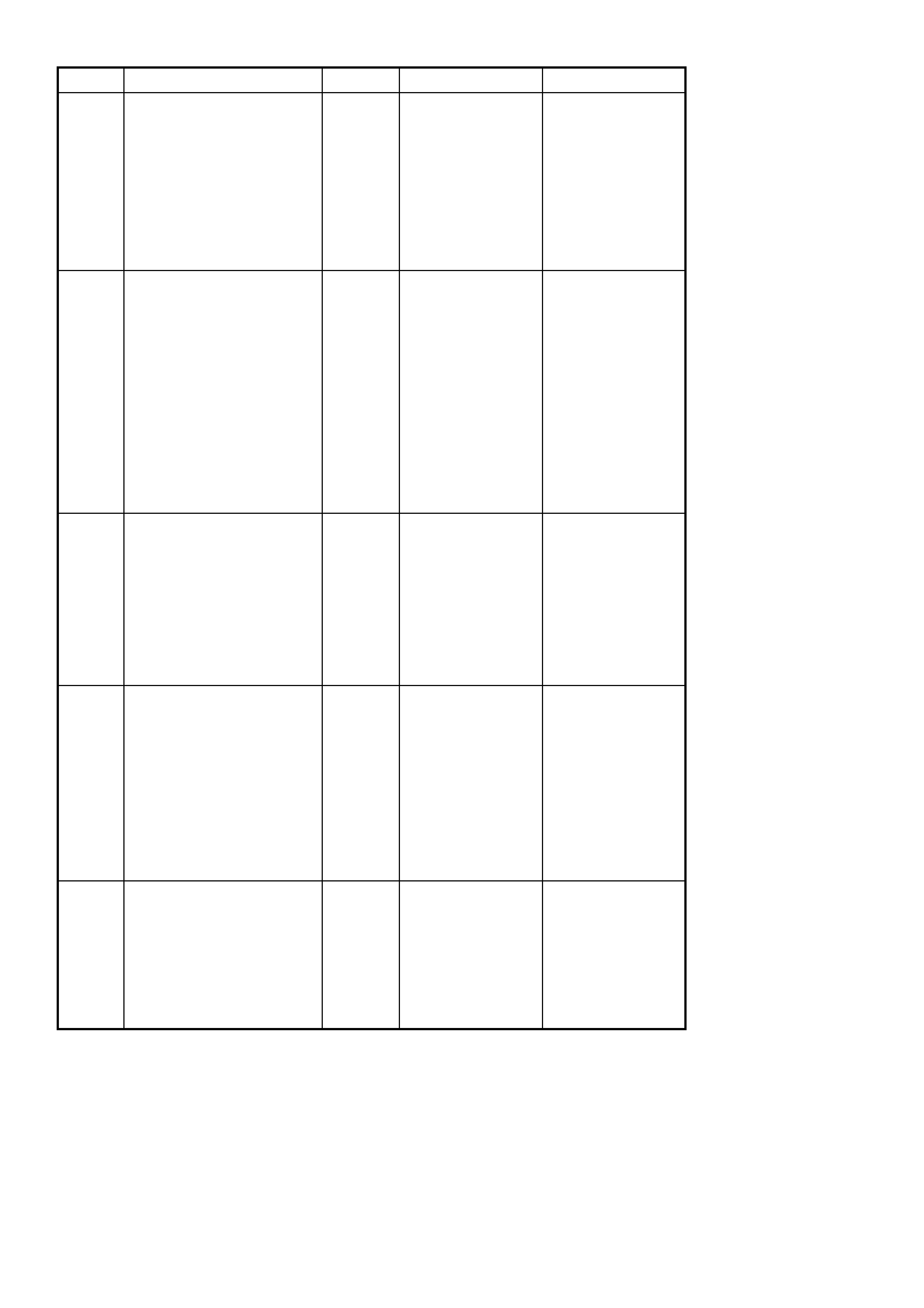

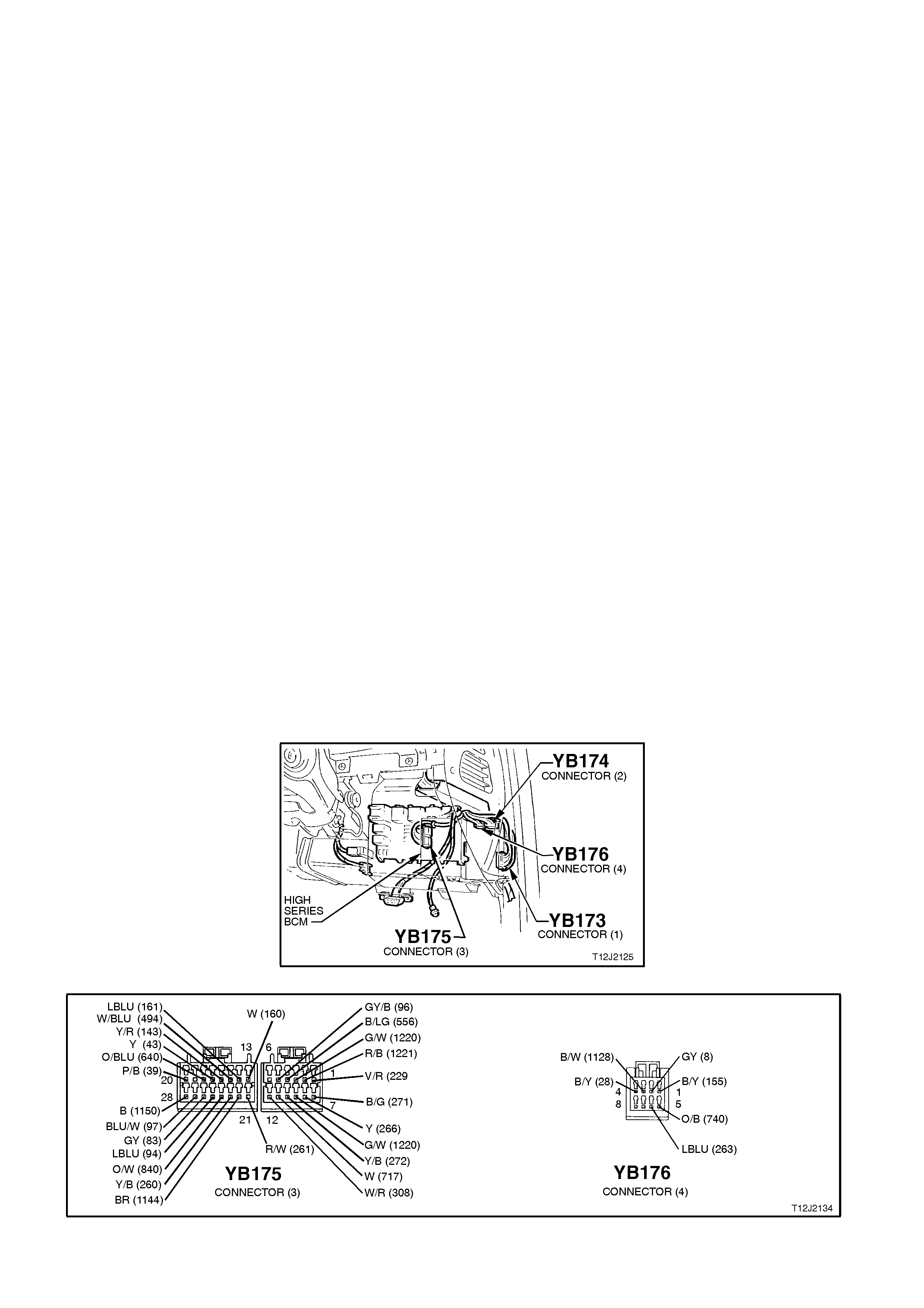

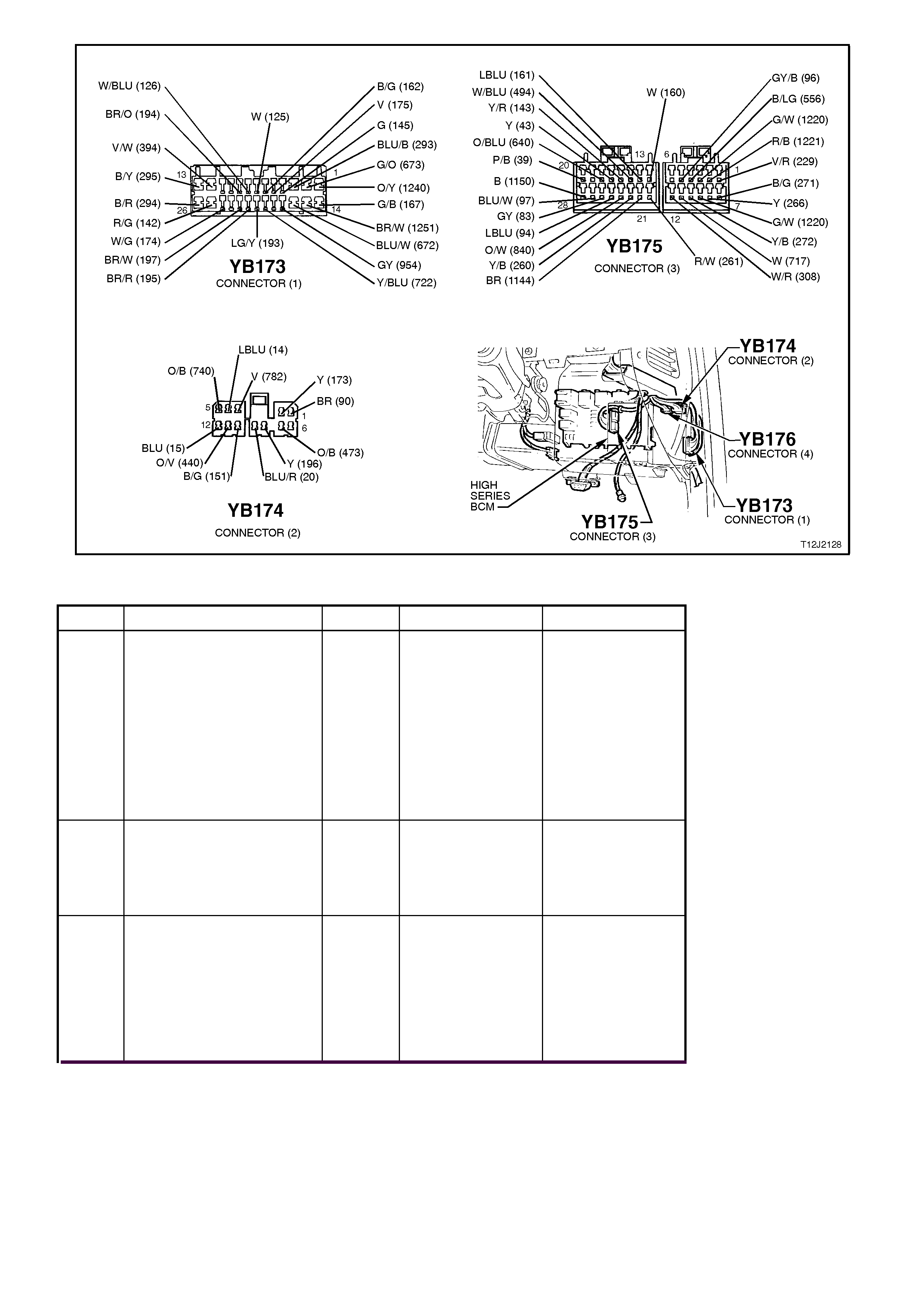

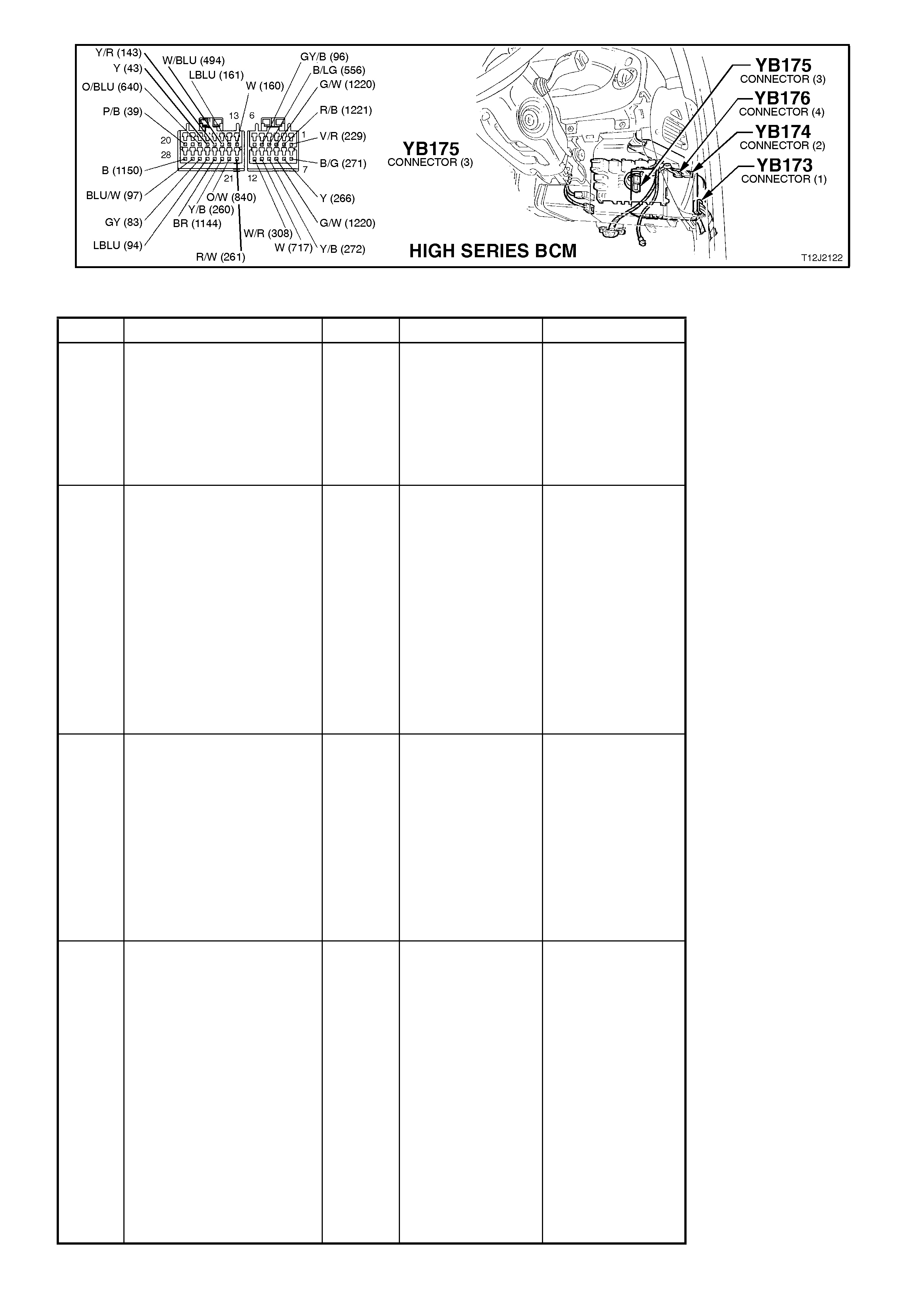

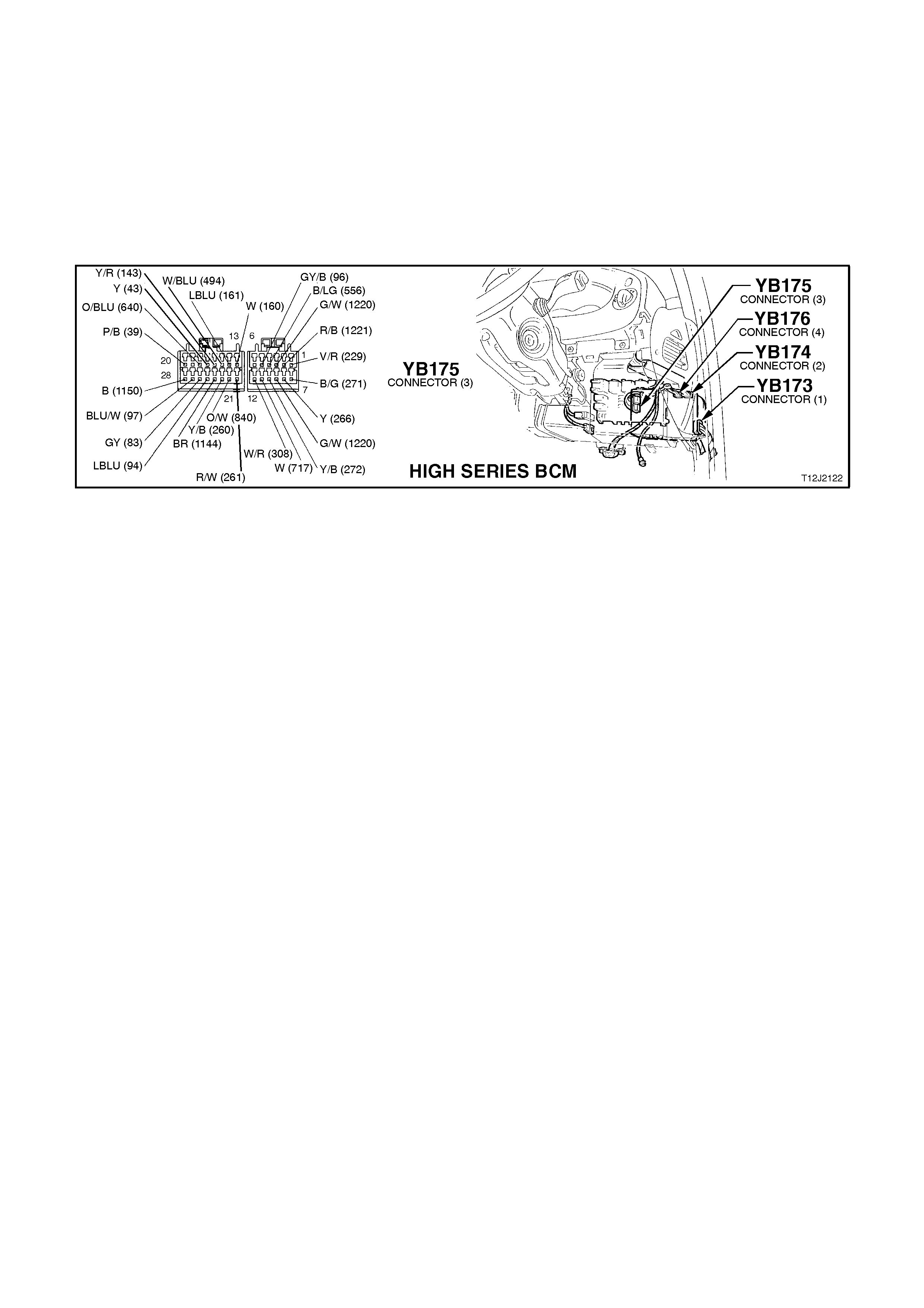

HIGH SERIES BCM TERMINAL IDENTIFICATION

YB176 CONNECTOR 4

PIN

NO. DESCRIPTION CIRCUIT WIRE

COLOUR CIRCUIT TYPE

A1 EARTH (ELECTRONIC) 155 B/Y E

A2 INSTRUMENT ILLUMINATION

OUTPUT 8GYO

A3 THEFT DETERRENT HORN

OUTPUT 1128 B/W O

A4 HORN OUTPUT 28 B/Y 0

A5 BATTERY POSITIVE 740 O/B P

A6 THEFT DETERRENT LED

OUTPUT 263 LBLU O

A7 NC

A8 REAR WIPER OUTPUT 492 GY/BLU O

YB174 CONNECTOR 2

PIN

NO. DESCRIPTION CIRCUIT WIRE

COLOUR CIRCUIT TYPE

B1 WIPER OUTPUT 90 BR O

B2 POWER WINDOW OUTPUT 173 Y O

B3 PRIORITY KEY ONE OUTPUT 782 V O

B4 LEFT INDICATOR OUTPUT 14 LBLU O

B5 INDICATOR POWER 140 O/R P

B6 NC

B7 LOW FAN SPEED OUTPUT 473 O/B O

B8 WIPER PARK INPUT 196 Y PD/O

B9 NC

B10 POWER EARTH 151 B/G E

B11 DOOR LOCK POWER 440 O/V P

B12 RIGHT INDICATOR OUTPUT 15 BLU O

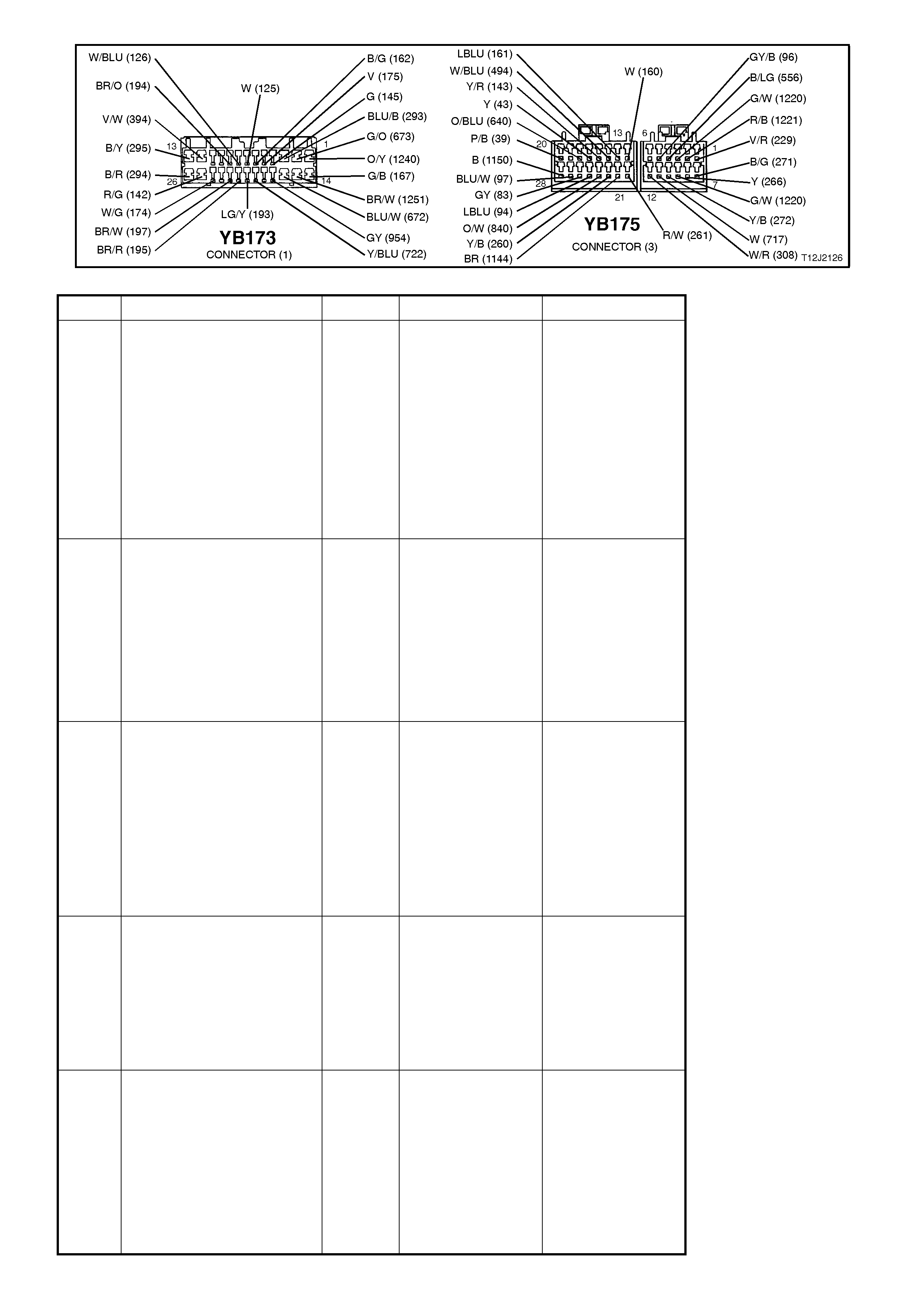

YB173 CONNECTOR 1

PIN

NO. DESCRIPTION CIRCUIT WIRE

COLOUR CIRCUIT TYPE

C1 WINDOW POWER INPUT 1240 O/Y P

C2 WINDOW MOTOR OUTPUT 673 G/O O

C3 DRIVERS DOOR UNLOCK

OUTPUT 293 BLU/B O

C4 ANTENNA DRIVE OUTPUT 145 G O

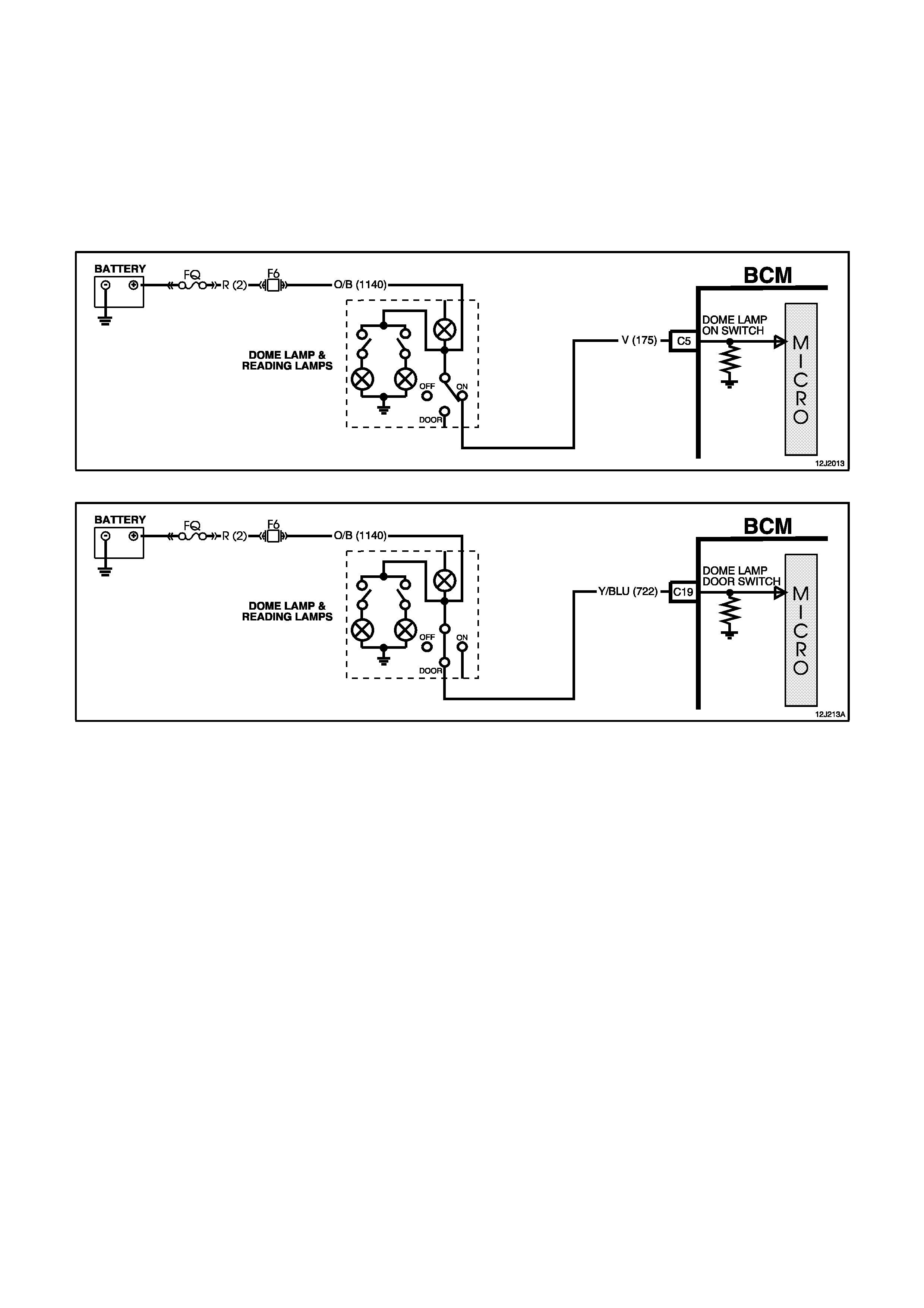

C5 DOME ON INPUT 175 V PD

C6 BOOT LAMP INPUT 162 B/G PPU

C7 PASSENGER DOOR AJAR

INPUT 125 W PPU

C8 DRIVERS DOOR AJAR INPUT 126 GY/W PPU

C9 PASSENGERS DOOR

UNLOCK INPUT 194 BR/O PU

C10 NC

C11 NC

C12 DEADLOCK OUTPUT 394 V/W O

C13 ALL DOORS, LOCK OUTPUT 295 B/Y O

C14 WINDOW DOWN INPUT 167 G/B PD

C15 STOP/TAIL SENSE INPUT 1251 BR/W I

C16 WINDOW UP INPUT 672 BLU/W PD

C17 ANTENNA DIRECTION

OUTPUT 954 GY O

C18 NC

C19 DOME - DOOR INPUT 722 Y/BLU PD

C20 UNLOCK INPUT 193 LG/Y PPU

C21 LOCK INPUT 195 BR/R PPU

C22 DEADLOCK REQUEST

INPUT 197 BR/W PPU

C23 NC

C24 DOME LAMP OUTPUT 174 W/G O

C25 BOOT OUTPUT 142 R/G O

C26 PASSENGER DOOR

UNLOCK OUTPUT 294 B/R O

YB175 CONNECTOR 3

PIN

NO. DESCRIPTION CIRCUIT WIRE

COLOUR CIRCUIT TYPE

E1 SLIP RING 229 V/R I/O

E2 SERIAL DATA INTERFACE

MAIN BUS 1221 R/B I/O

E3 AIRBAG SERIAL DATA

INTERFACE BUS 1220 G/W I/O

E4 POWER STEERING

SOLENOID OUTPUT 556 B/LG O

E5 WIPER DWELL INPUT 96 GY/B PU

E6 NC

E7 RECEIVER EARTH 271 BR/G E

E8 RECEIVER DATA 266 Y I

E9 SERIAL DATA INTERFACE

AUXILIARY BUS 1220 G/W I/O

E10 TWILIGHT INPUT (AMBIENT

LIGHT SENSOR) 272 Y/B I

E11 INSTRUMENT DIMMER

INPUT 717 W PU

E12 AUTO LIGHTS EARTH

OUTPUT 308 W/R O

E13 ANTENNA DOWN INPUT 160 W PPU

E14 ANTENNA UP INPUT 161 LBLU PPU

E15 REAR WASHER INPUT 494 W/BLU PD

E16 RADIO ON INPUT 143 Y/R PD

E17 ACCESSORIES INPUT 43 Y PD, P

E18 STOP LAMP FUSE INPUT 640 O/BLU PD

E19 REAR WIPER INPUT 1391 GY/R PD

E20 IGNITION INPUT 39 P/B PD, P

E21 BONNET SWITCH INPUT 261 R/W PPU

E22 BOOT RELEASE INPUT 1144 B/R PPU

E23 BONNET SWITCH INPUT 260 Y/B PD

E24 PARK LAMP FUSE INPUT 840 O/W PD

E25 FRONT SCREEN

WASH/WIPE INPUT 94 LBLU PU

E26 CRUISE CONTROL ON

INPUT 83 GY PD

E27 FRONT SCREEN

INTERMITTEN T AUTO WIPE

INPUT

97 BLU/W PD

E28 LIGHTS OFF EARTH

OUTPUT 1150 B O

GLOSSARY

E – Earth O – Output P - Power

PU - Pull up PPU - Pulsed pull up PD - Pull down

I – Input I/O - Input / Output NC - No circuit

B - Black W - White R - Red P - Pink

O - Orange Y - Yellow V - Violet BLU - Blue

G - Green LG - Light green BR - Brown GY - Grey

T - Tan LBLU - Light blue DKBLU - Dark blue

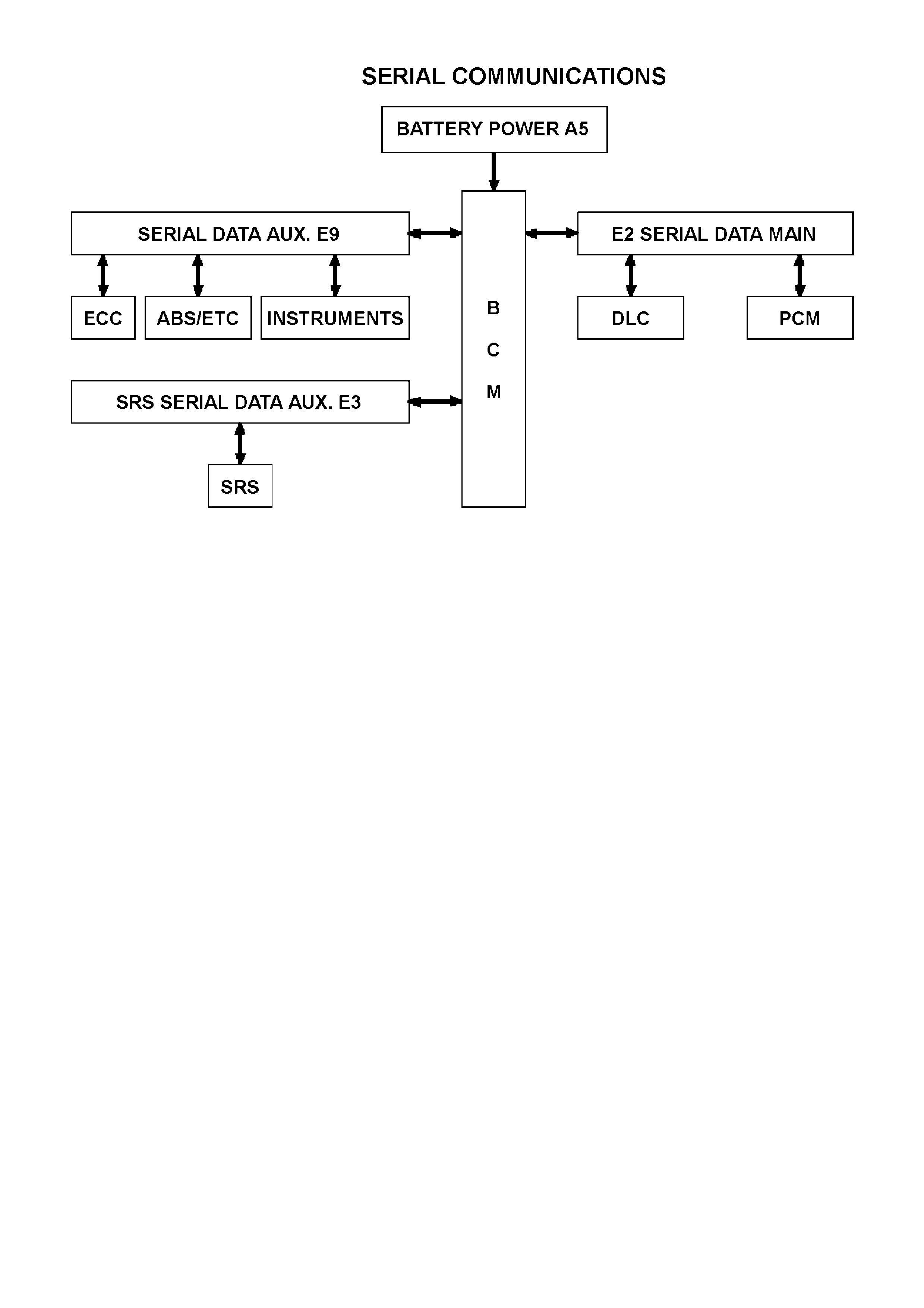

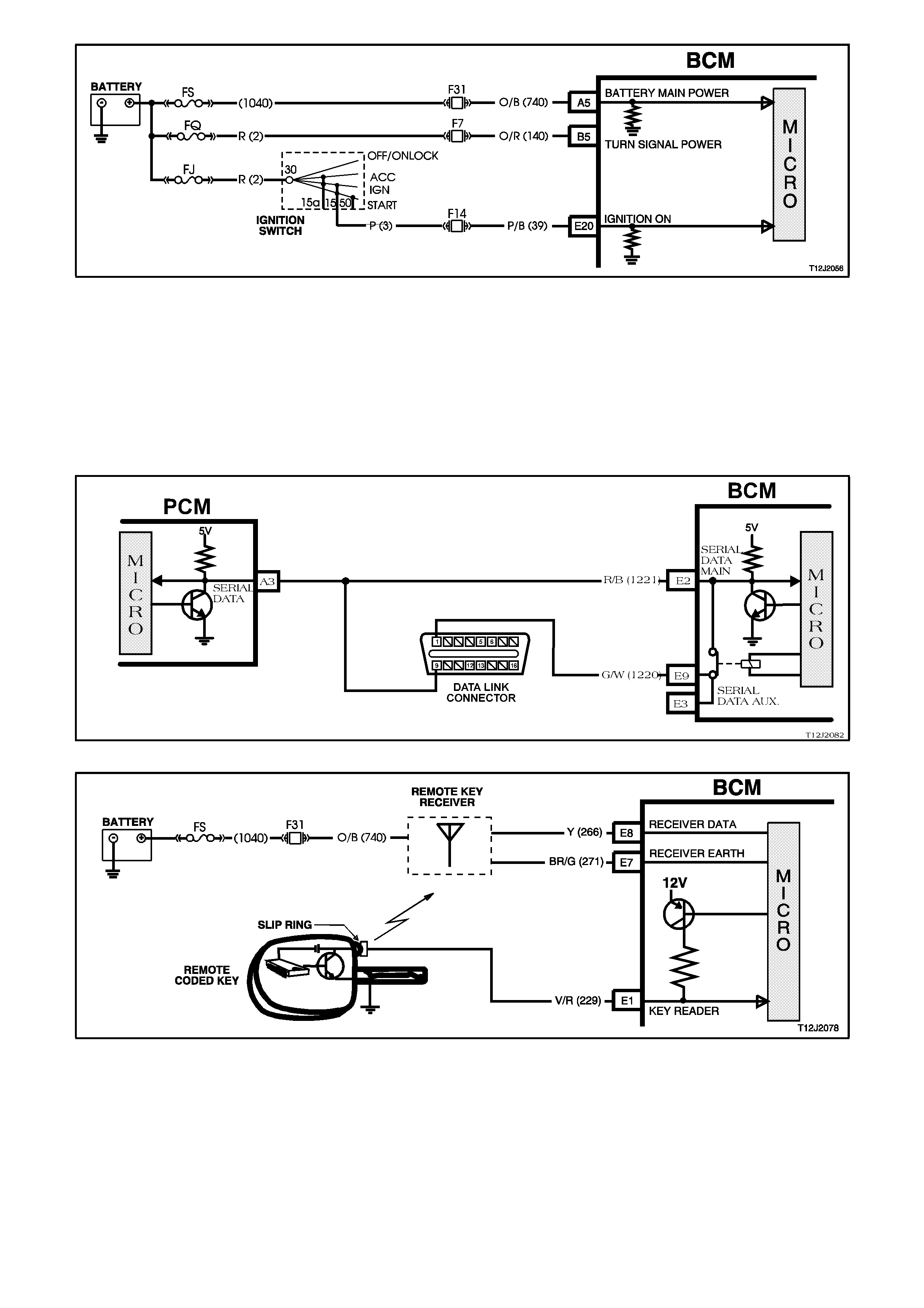

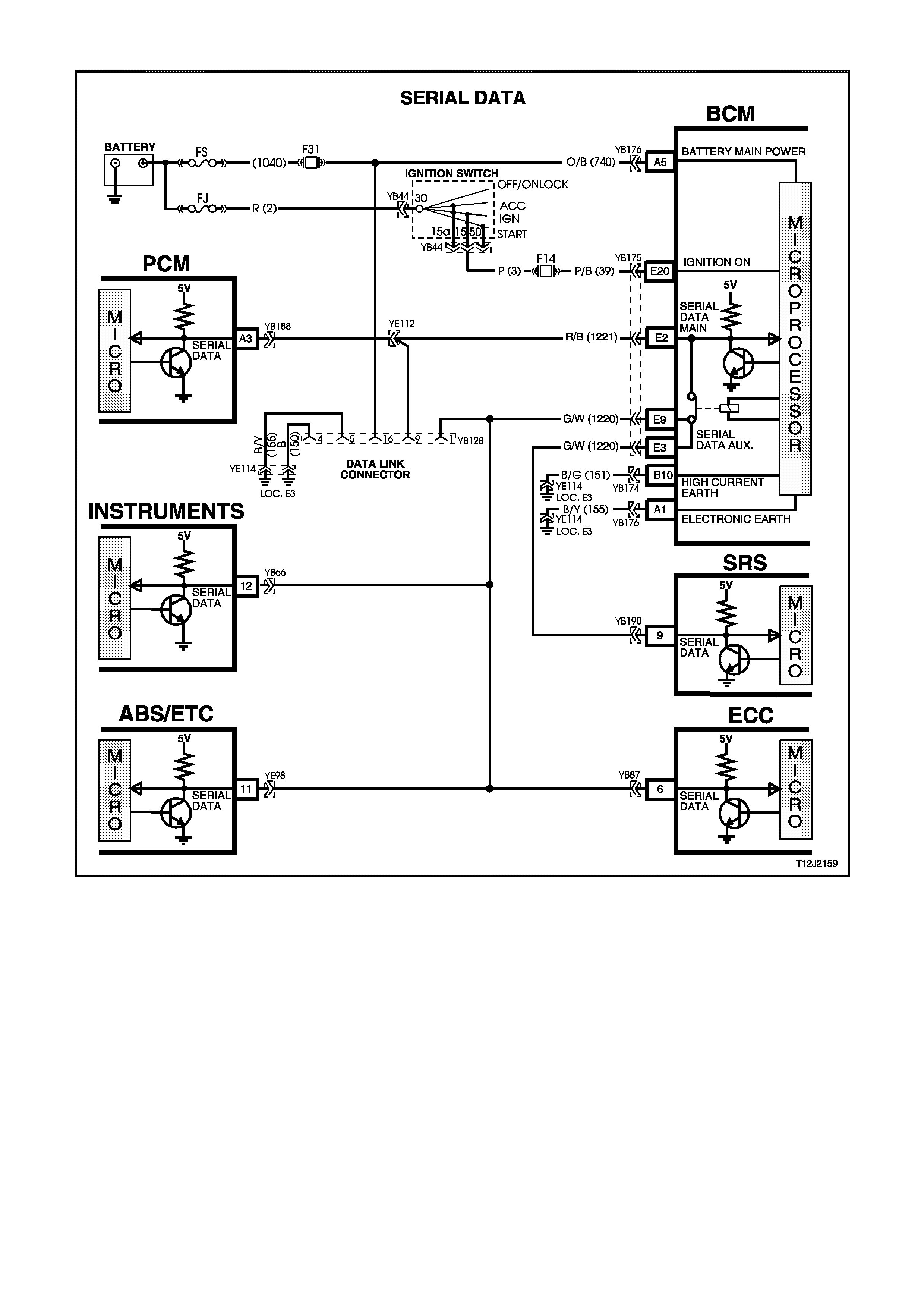

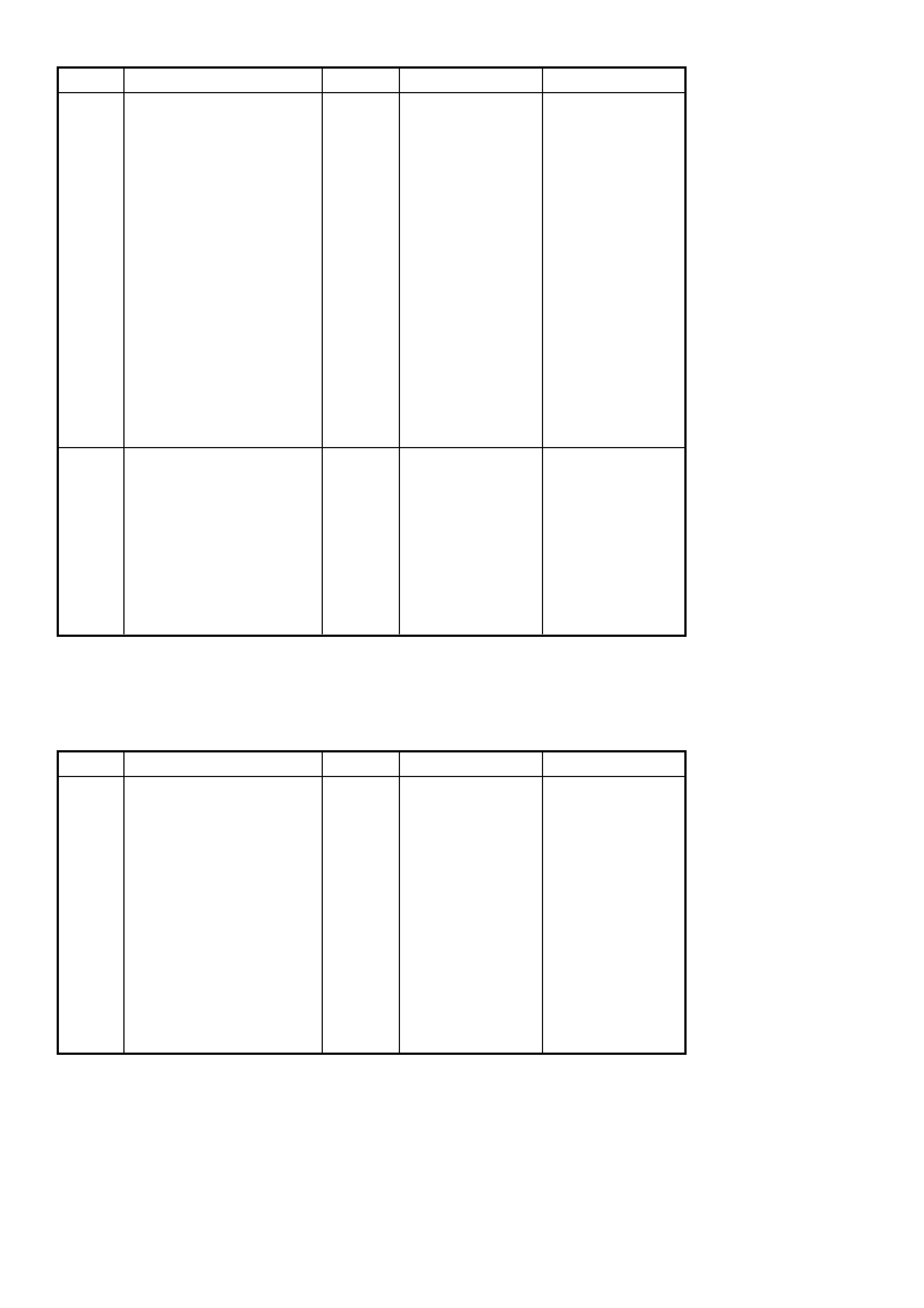

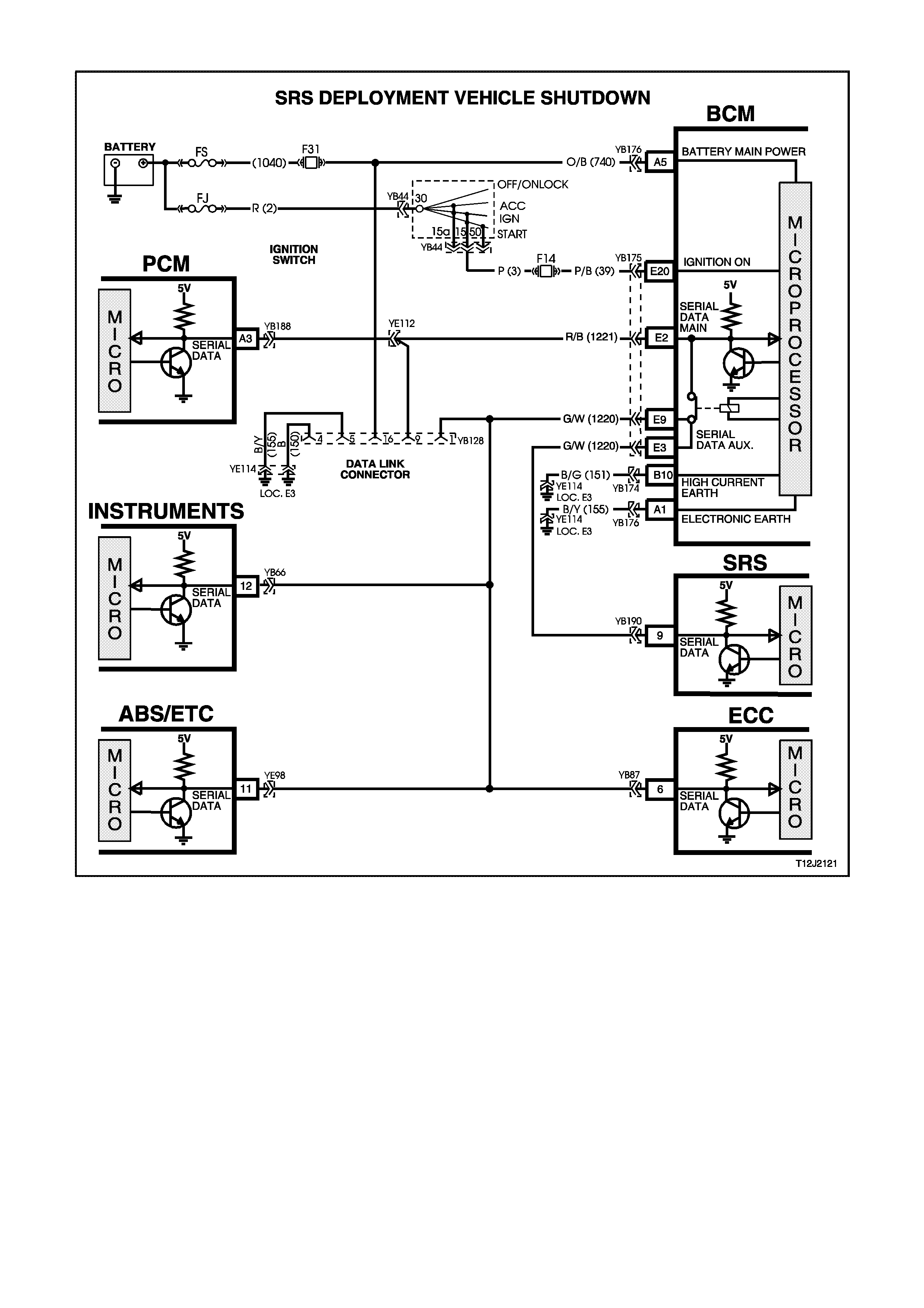

1.1 SE RIAL DATA COMMUNICATION (BUS MASTER)

GENERAL INFORMATION

The VT Series Model uses a BUS MASTER communication system, where the BCM is the bus master.

The BCM periodically polls (surveys) each device on the bus and requests status data.

The devices connected to the bus are:

• Body Control Module (BCM)

• Powertrain Control Module (PCM)

• Electronic Climate Control (ECC)

• Instrument cluster (INS)

• Antilock Brake/Electronic Traction Control System (ABS/ETC)

• Supplemental Restraint System (SRS)

• External diagnostic tool (TECH 2)

The data provided by each device may be utilised by any device connected to the bus.

Each device has a unique response Message Identifier Word (MIW) for ease of identification.

The bus master (BCM) polls each control module with a serial data message which includes that control modules

MIW. The polled control module responds by putting a serial data message onto the bus which includes its own

MIW and data, which is retrieved and utilised by any control module requiring it.

The BCM polls each device for a status update, once every 300 milliseconds. The exception to this being the PCM

which is polled twice every 300 milliseconds.

When the ignition switch is turned from the OFF position to the ON position, the BCM will communicate with the

PCM for antitheft purposes. If the BCM does not receive a message OK TO START from the PCM within 0.5

seconds of the ignition being switched on, the auxiliary bus is isolated via switching within the BCM.

The isolation of the auxiliary data bus during this period eliminates the possibility of a device failure other than the

BCM or PCM causing a problem on the bus and inhibiting antitheft communications.

This period is known as ‘Short Loop Time’, continues until the PCM responds with an acknowledgment or a

maximum period of 5 seconds, after which the BCM will switch to the standard poling sequence.

Following successful antitheft communications, the BCM begins sequential polling of devices on the bus and normal

system operation is established.

When the ignition switch is in the OFF position, the BCM continues to poll, allowing for TECH 2 communications

and external control of the bus prior to the ignition being switched on.

NOTE:

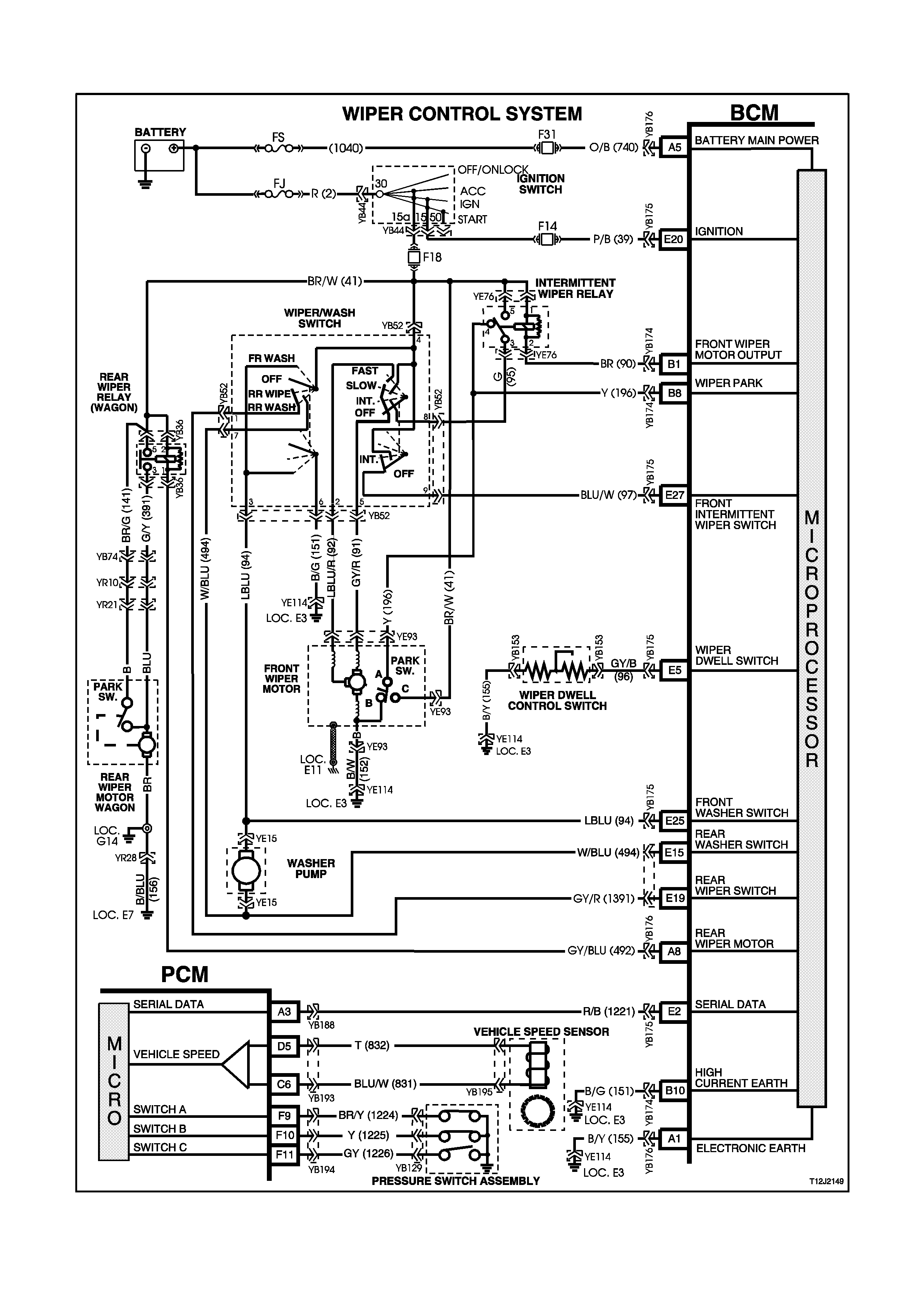

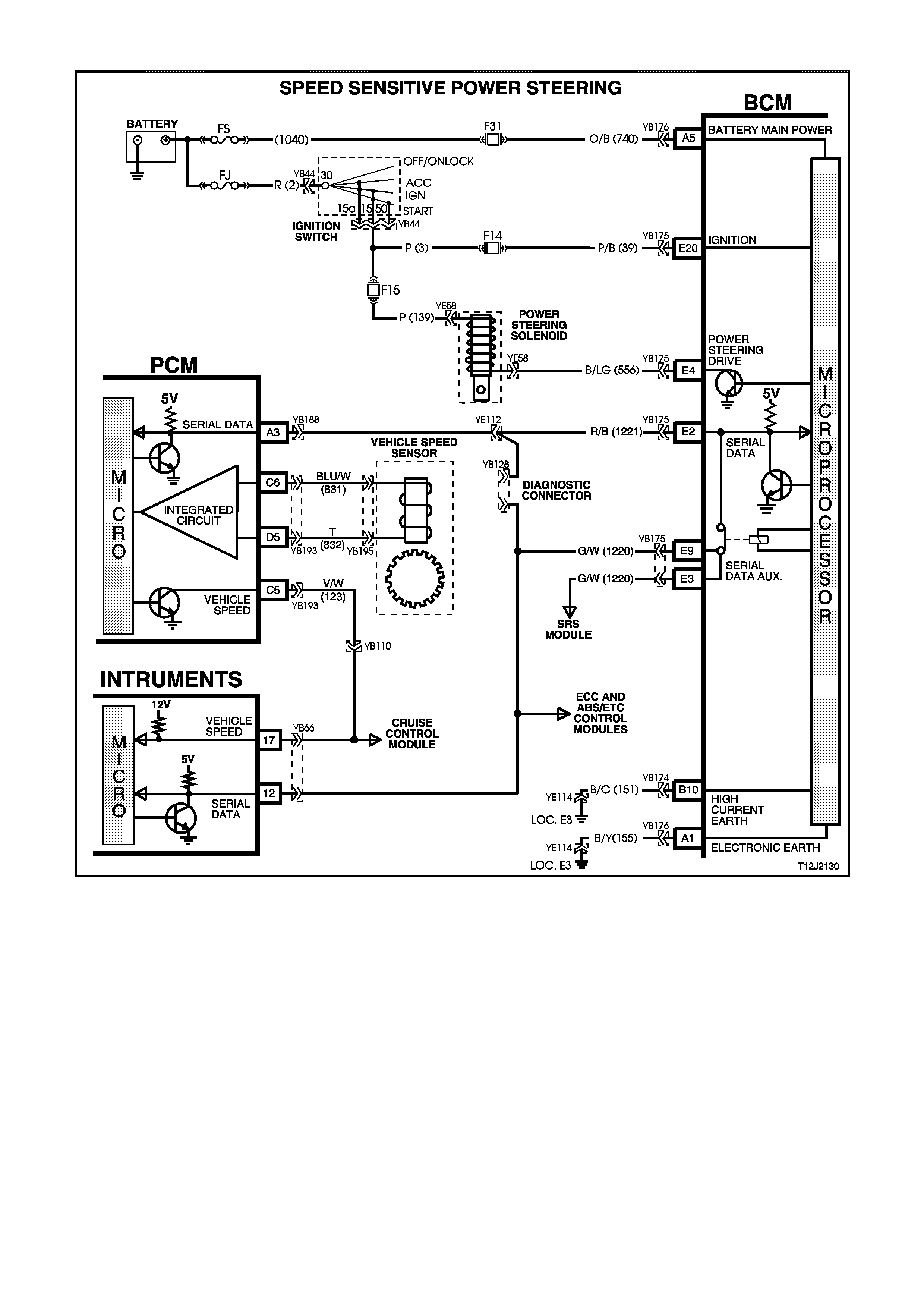

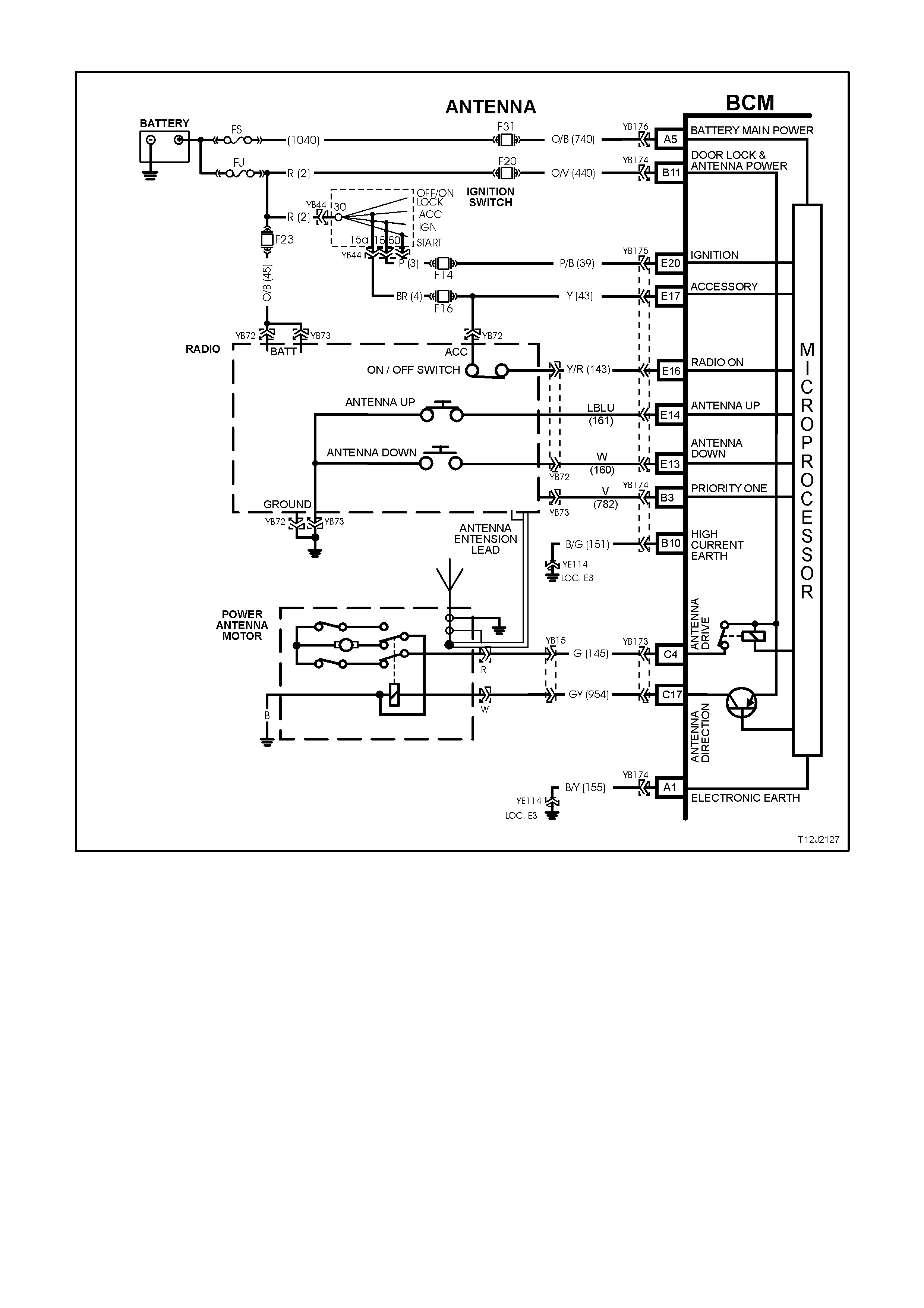

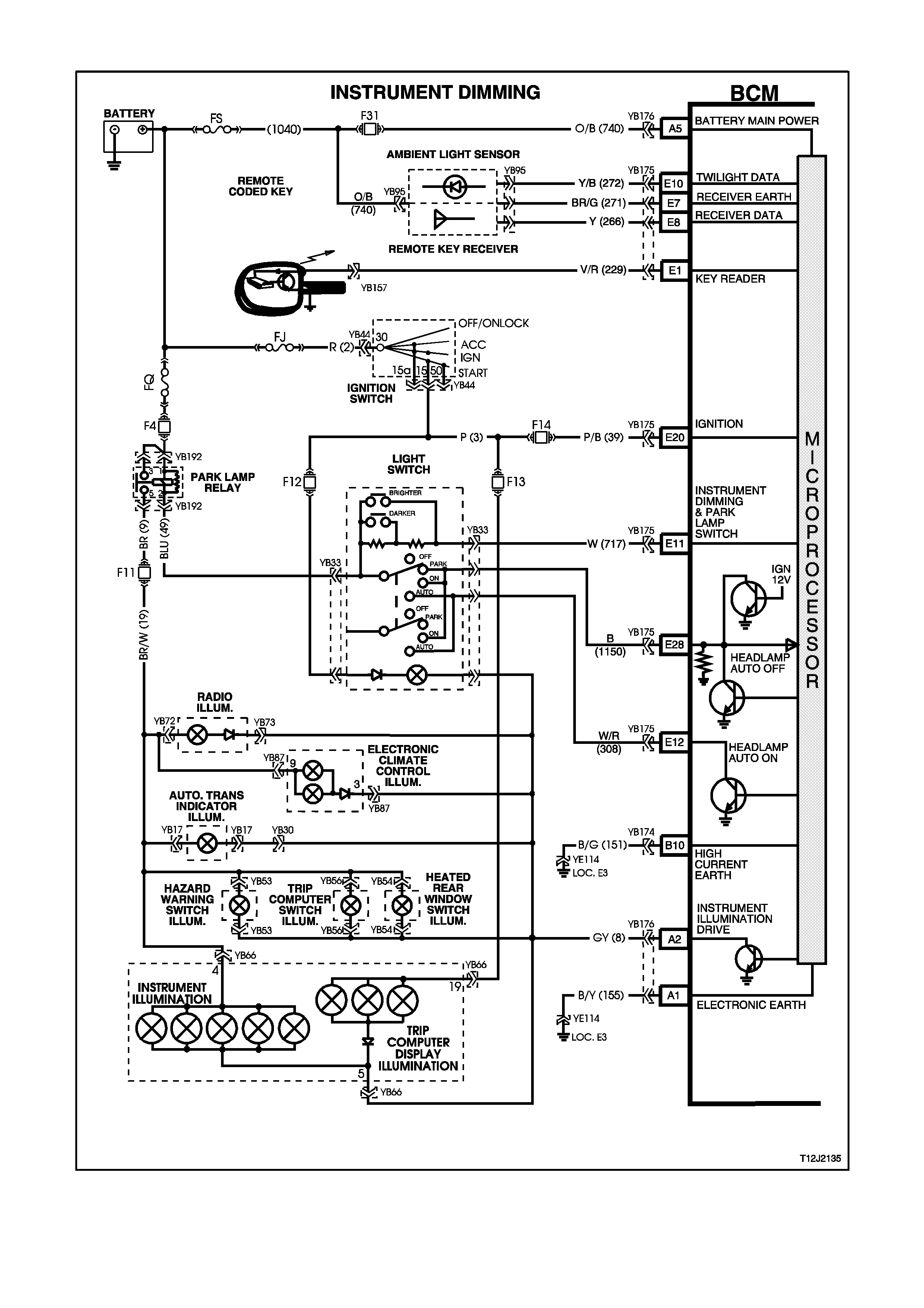

The circuit diagrams shown in this General Description Section are to aid in interpreting the operation of the circuit

and therefore, only the main connectors and wiring colours are shown. For complete circuit details, refer to either

the relevant diagnostic section or Section 12P WIRING DIAGRAMS.

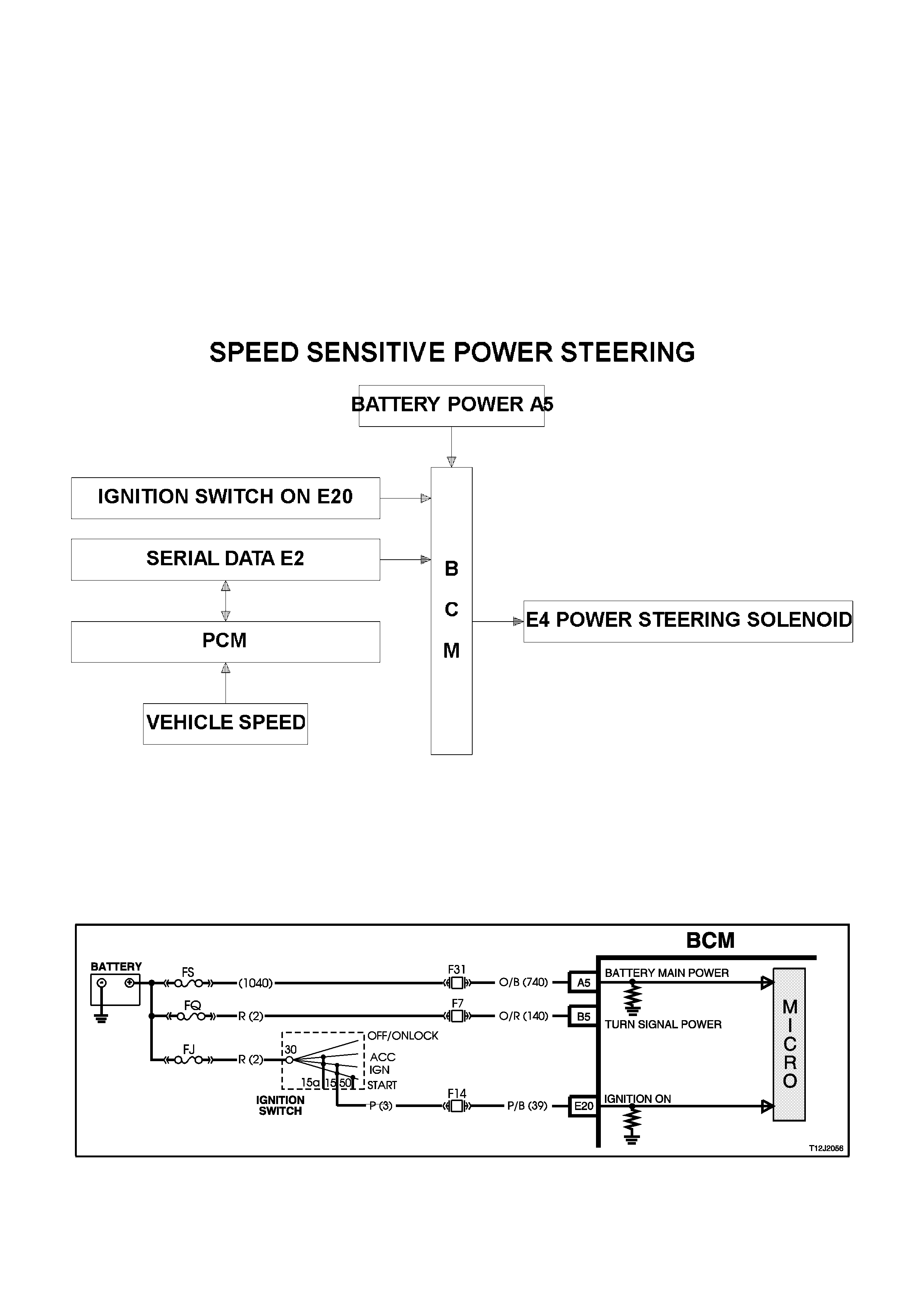

SYSTEM OVERVIEW

INPUTS / OUTPUTS

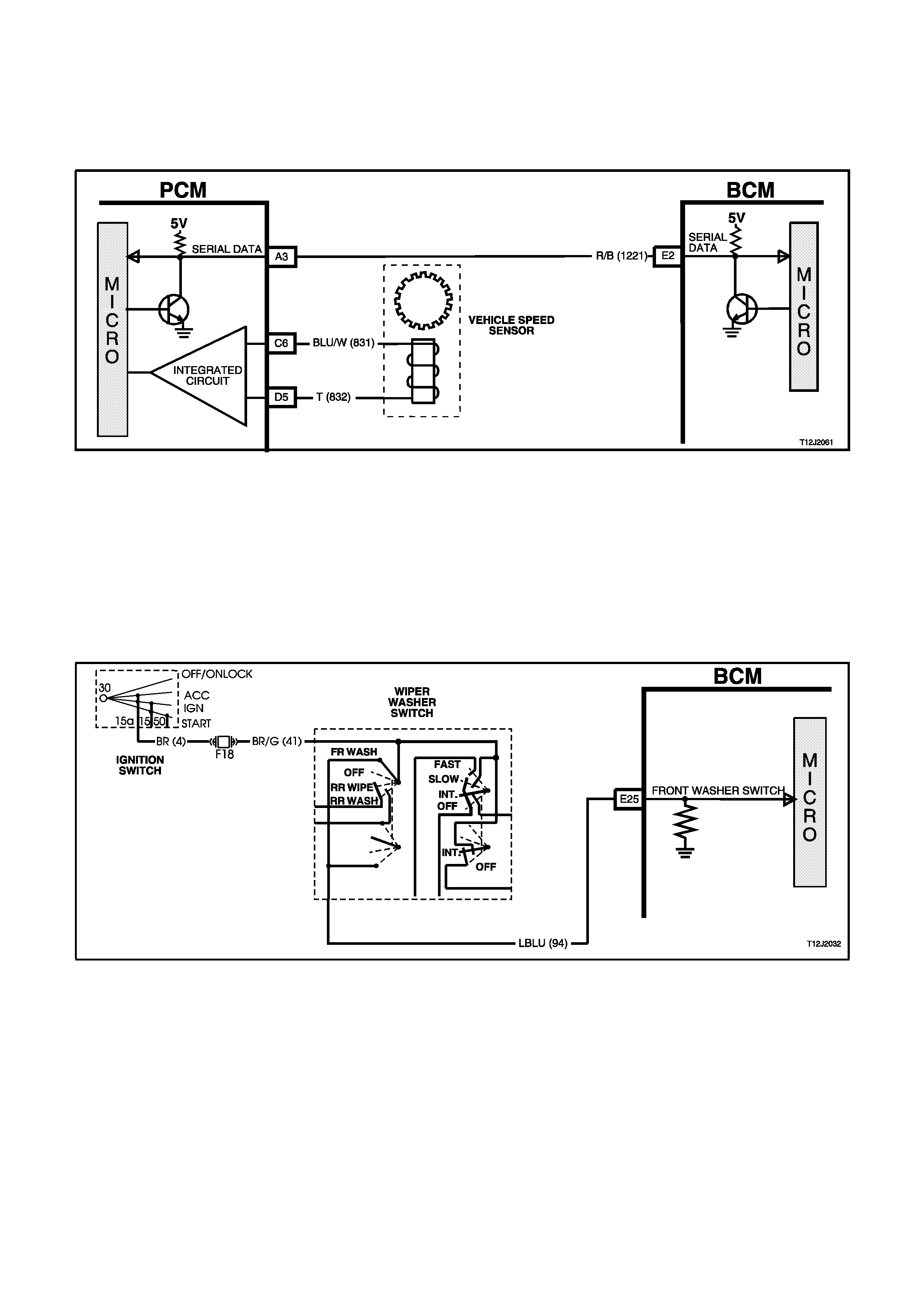

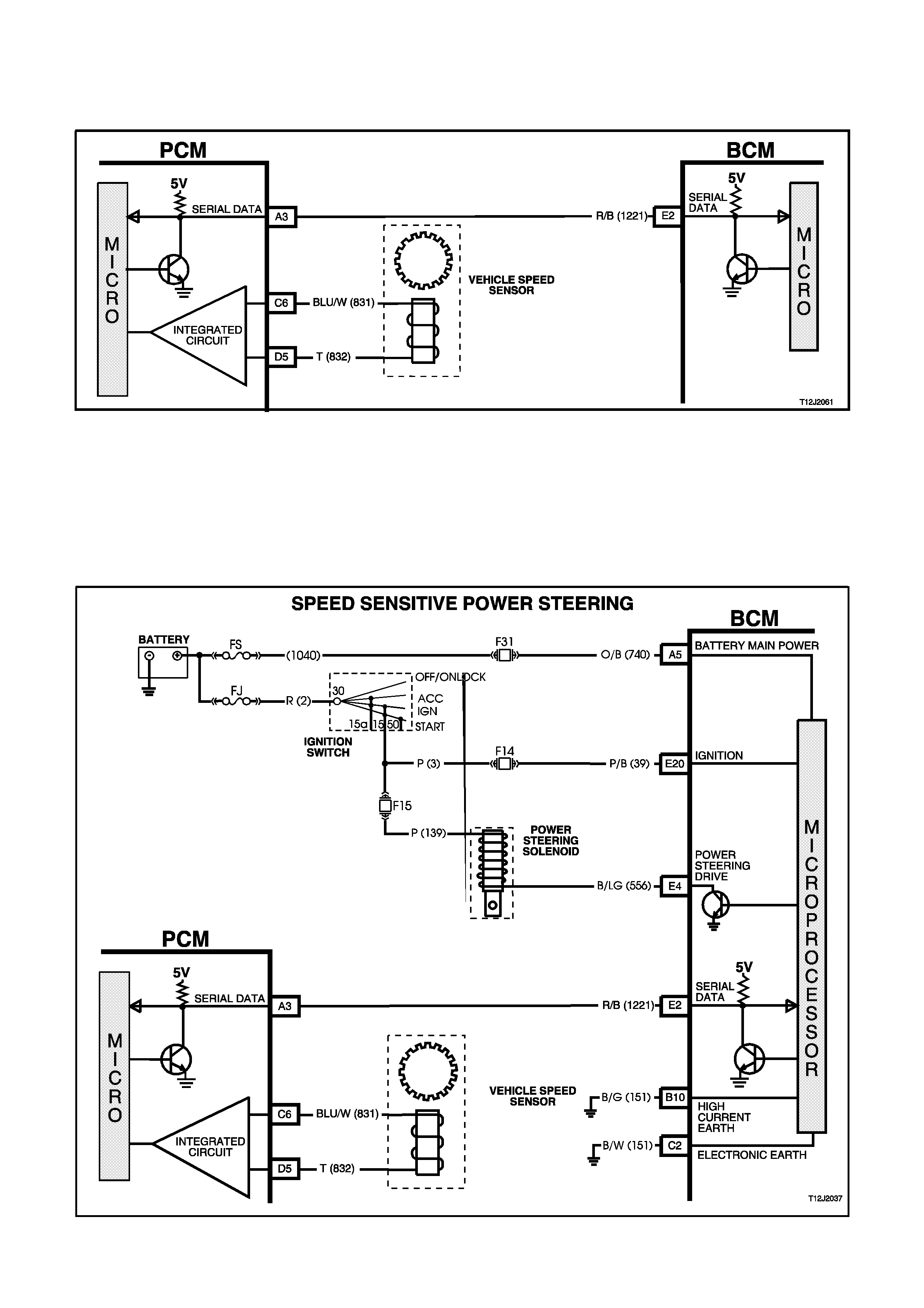

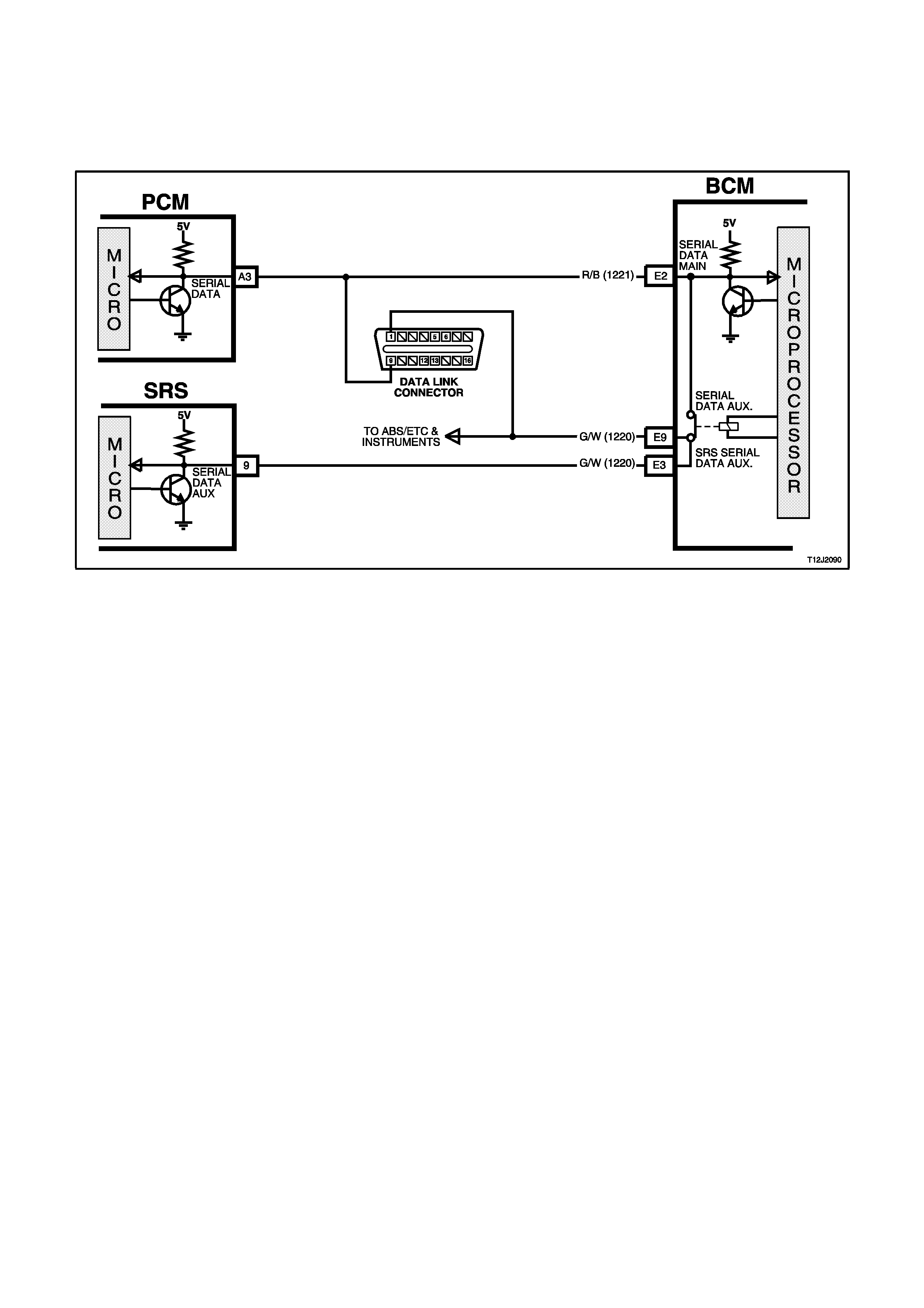

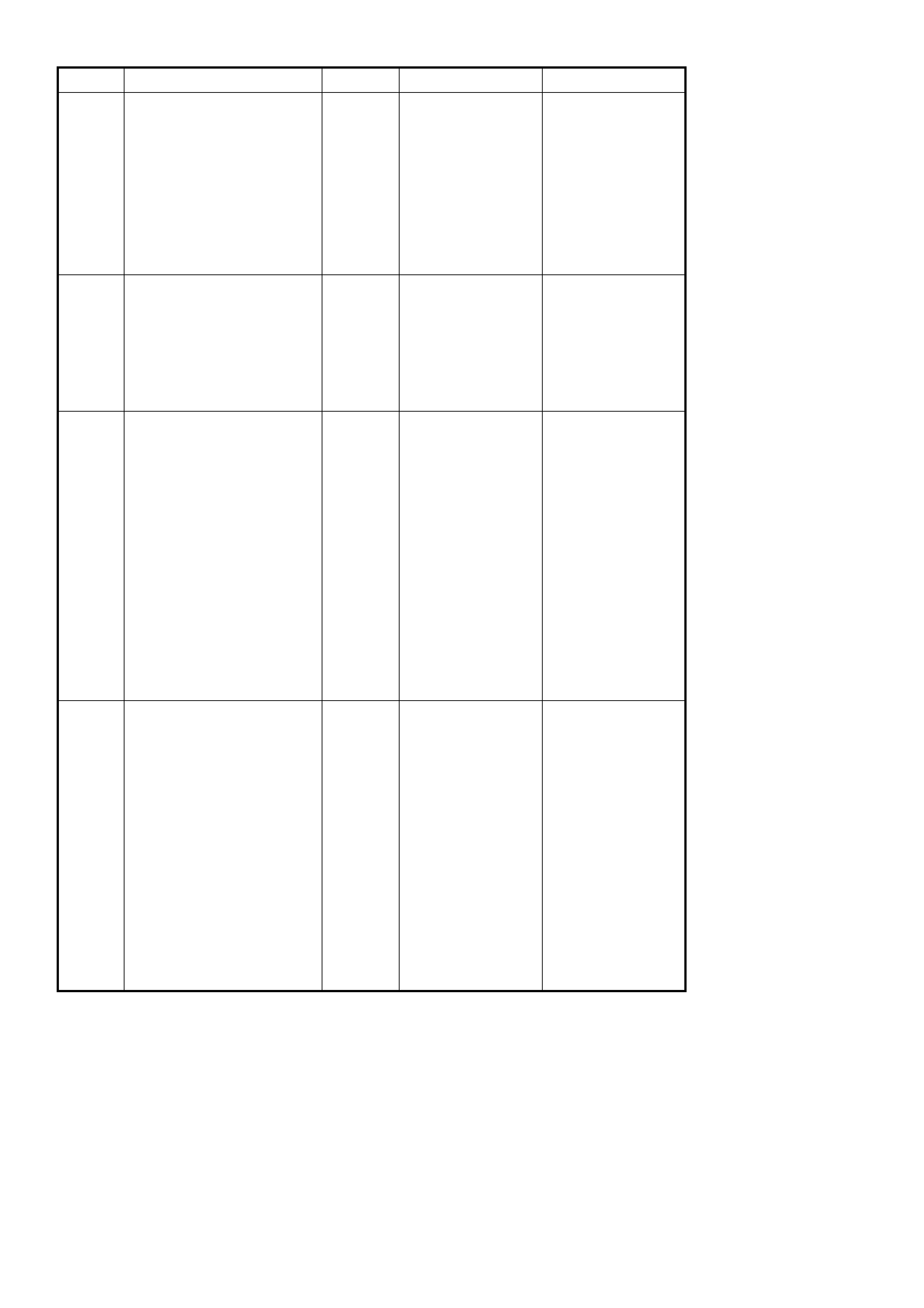

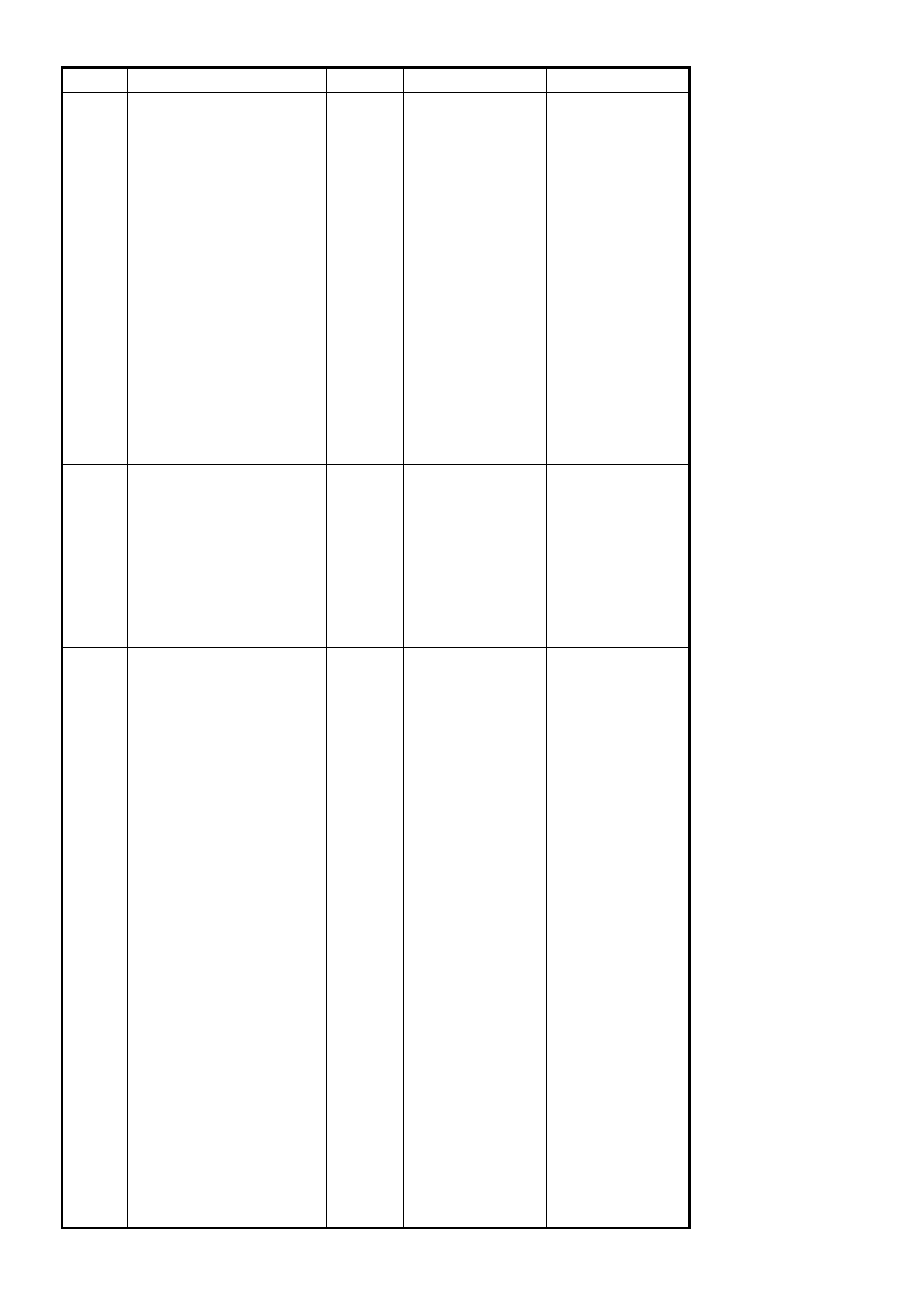

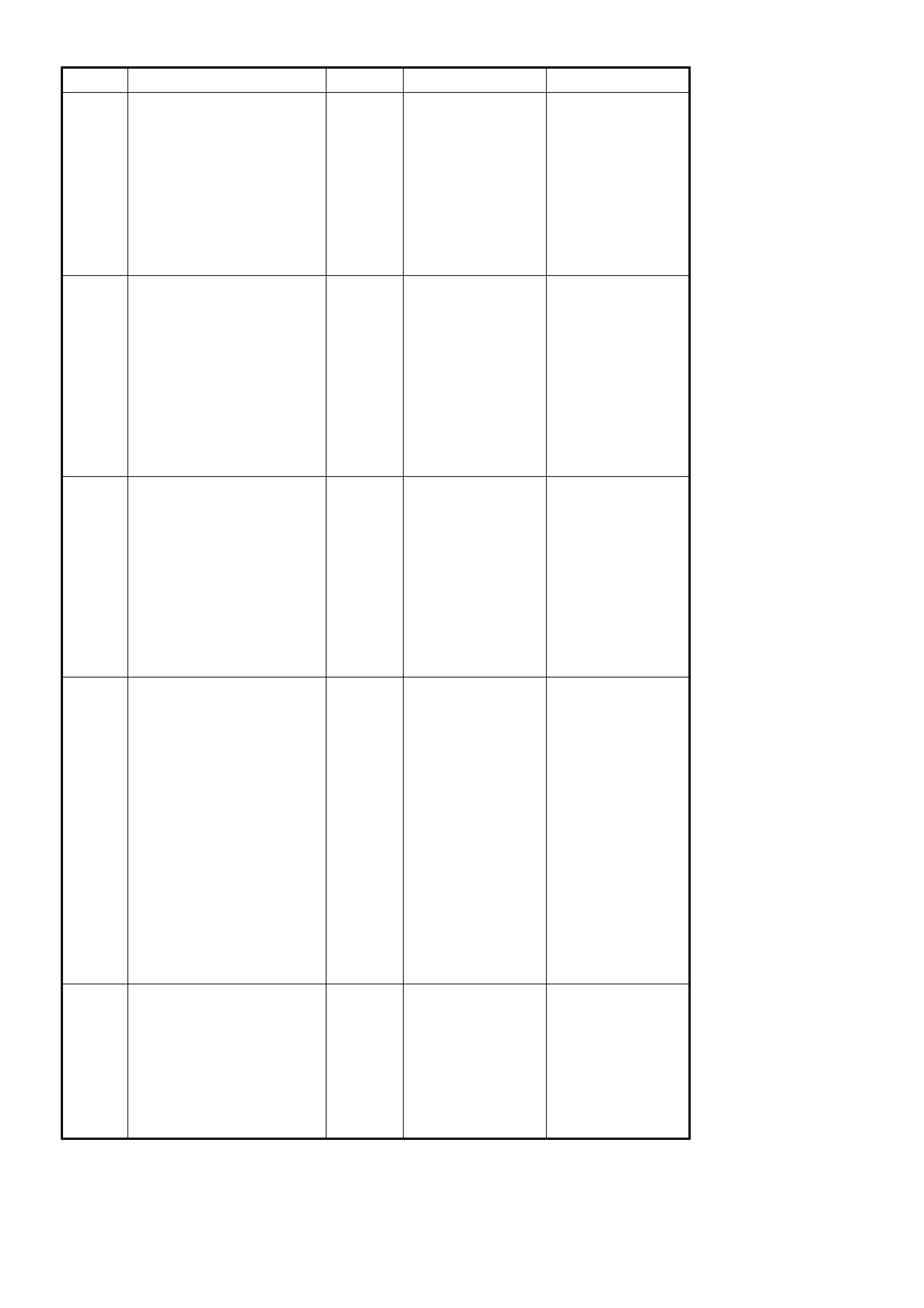

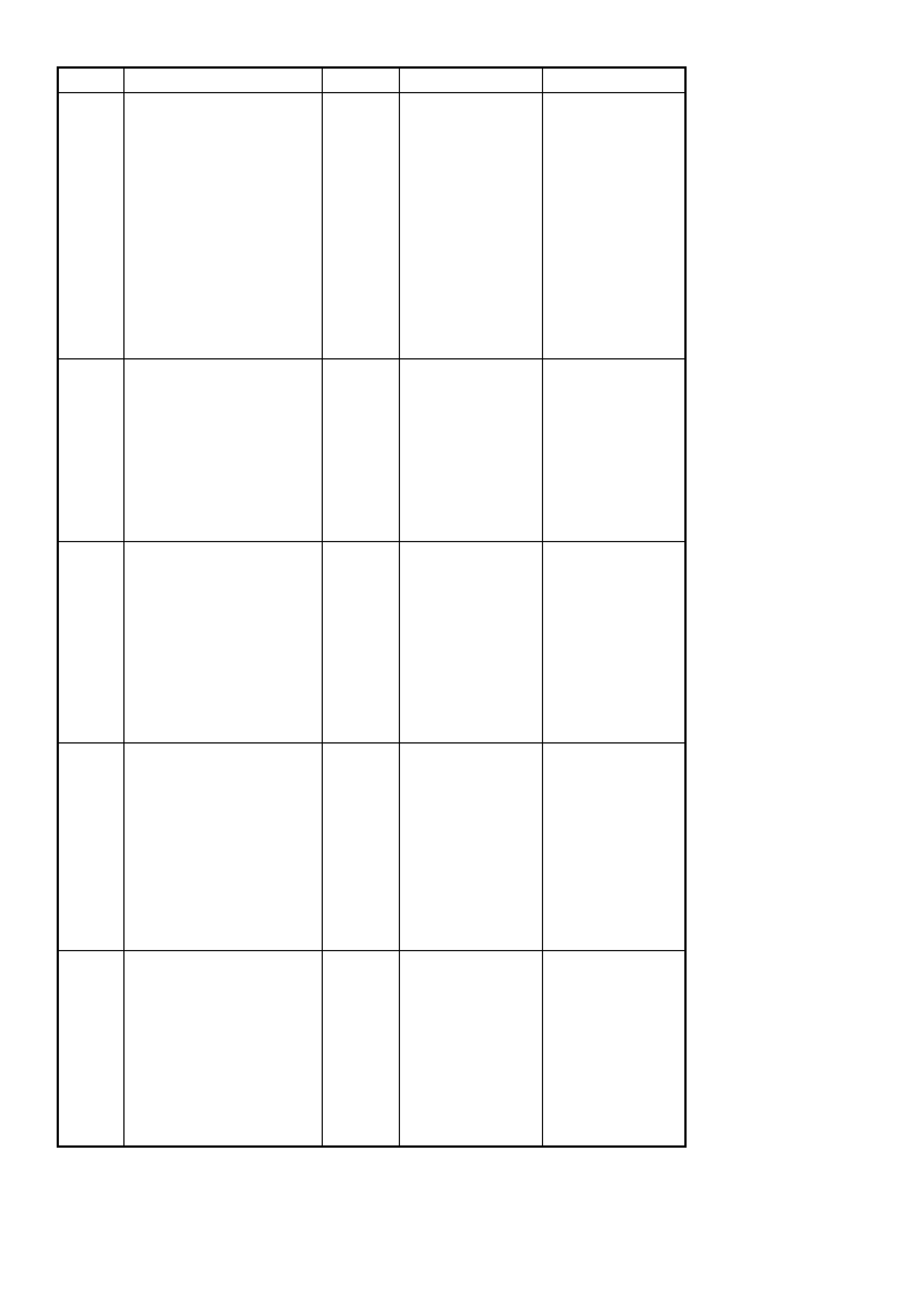

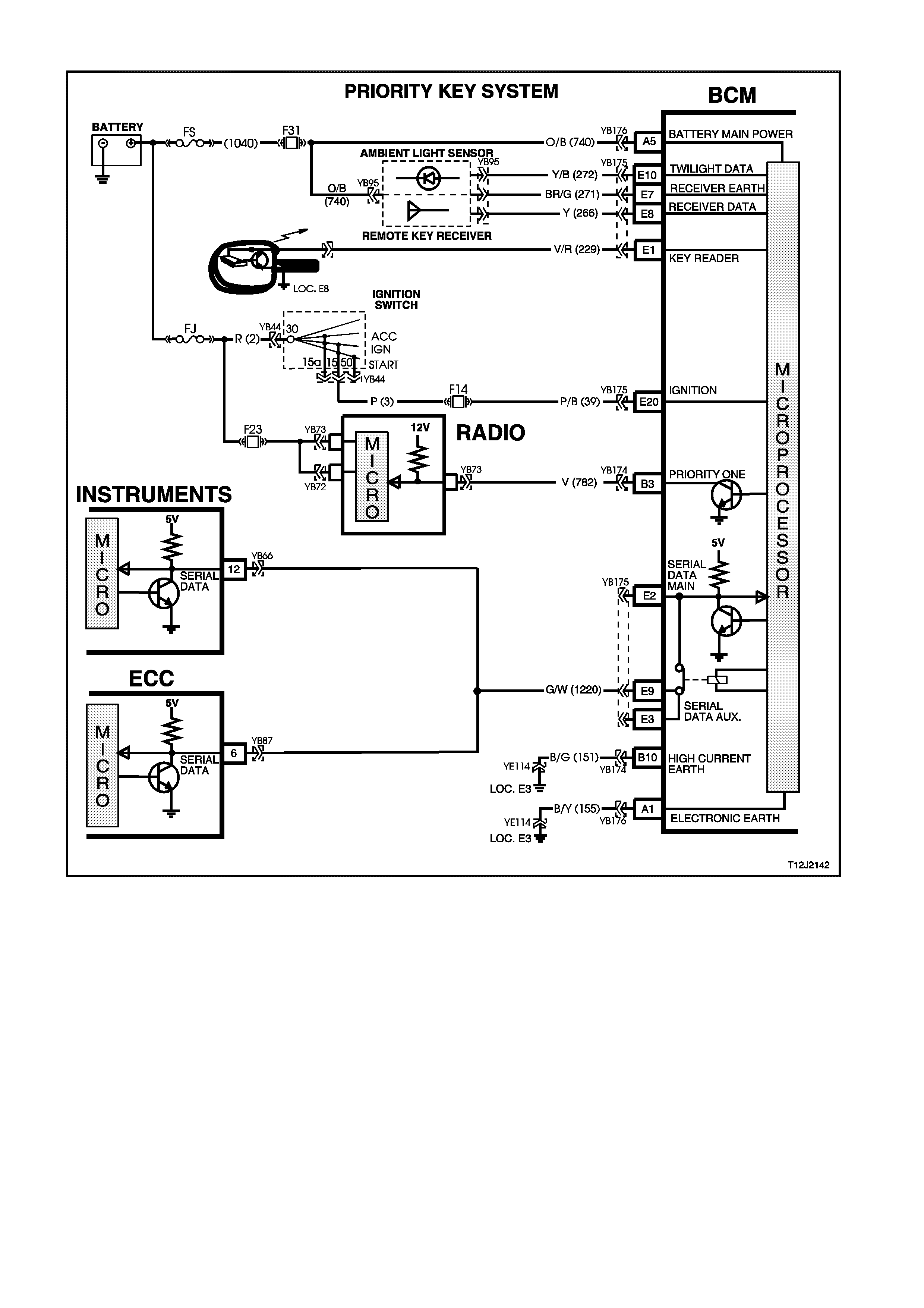

SERIAL DATA SIGNAL - MAIN

BCM terminal E2, serial data signal - main, refer Fig. 12J-2-3, is connected to the PCM and DLC via circuit 1221

(Red/Black wire). It is via this line that the BCM communicates with the PCM and external devices connected to the

DLC, at all times.

SERIAL DATA SIGNAL - AUXILIARY

BCM terminals E9 and E3, serial data signal - auxiliary, refer Fig. 12J-2-3, is connected to the INS, ABS/ETC and

SRS modules via circuit 1220 (Green/White wire). It is via this line that the BCM communicates with these devices,

after successful anti theft communications between the PCM and BCM (via the serial data - main line when the

ignition switch is turned from the OFF to ON position).

During anti theft communications, the serial data - auxiliary line is isolated from the serial data - main line via

switching within the BCM, if the BCM does not receive an OK TO START message from the PCM within 0.5

seconds of the ignition being switched on.

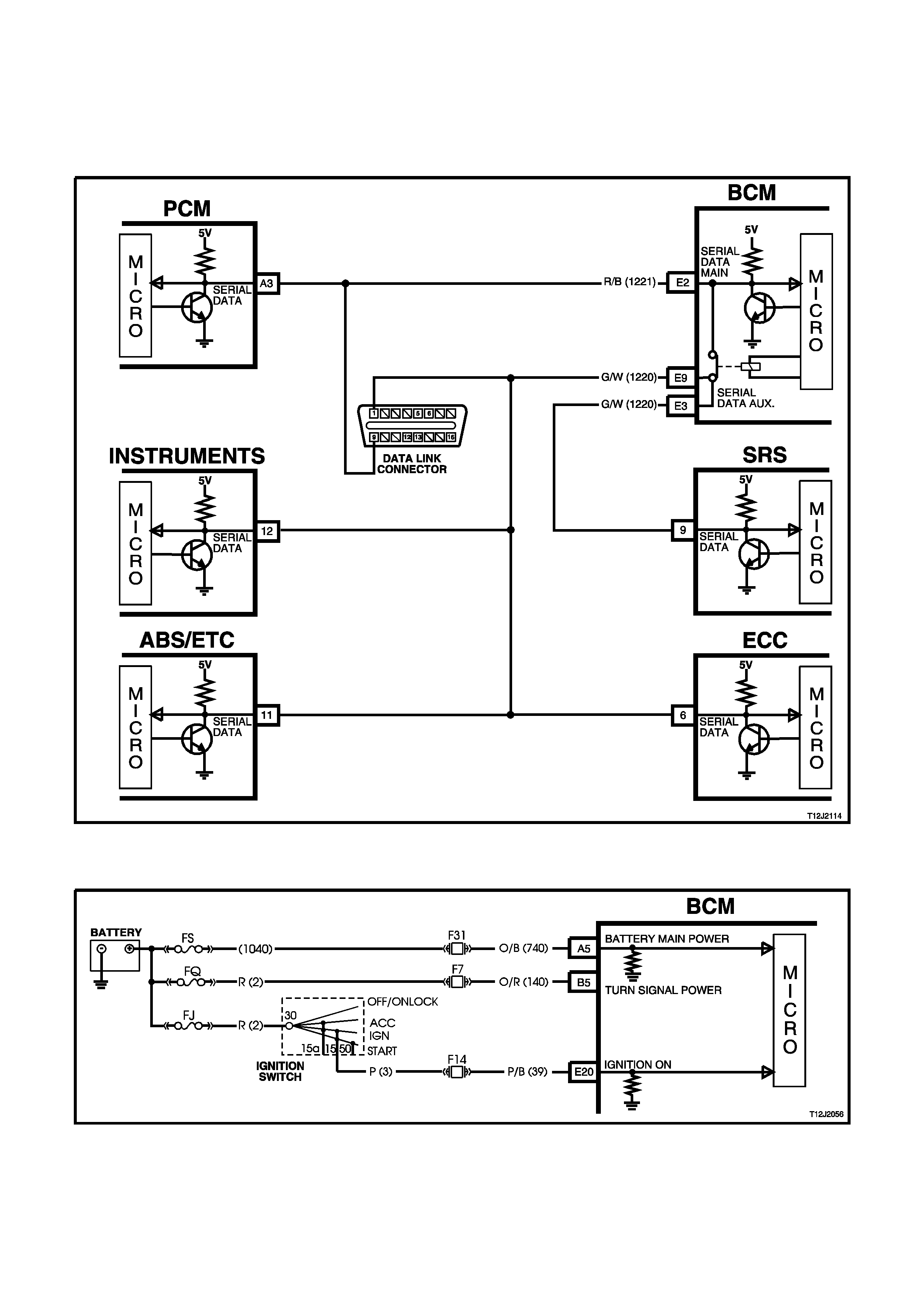

INPUTS

IGNITION SWITCH ON INPUT SIGNAL

The BCM uses this input signal to determine when the ignition switch is in the IGN or START position. When the

ignition switch is in the IGN or START position, battery voltage is applied to the BCM terminal E20 from the ignition

switch and fuse F14 via circuit 39 (Pink/Black wire), Refer to Fig. 12J-2-4.

Figure 12J-2-3

Figure 12J-2-4

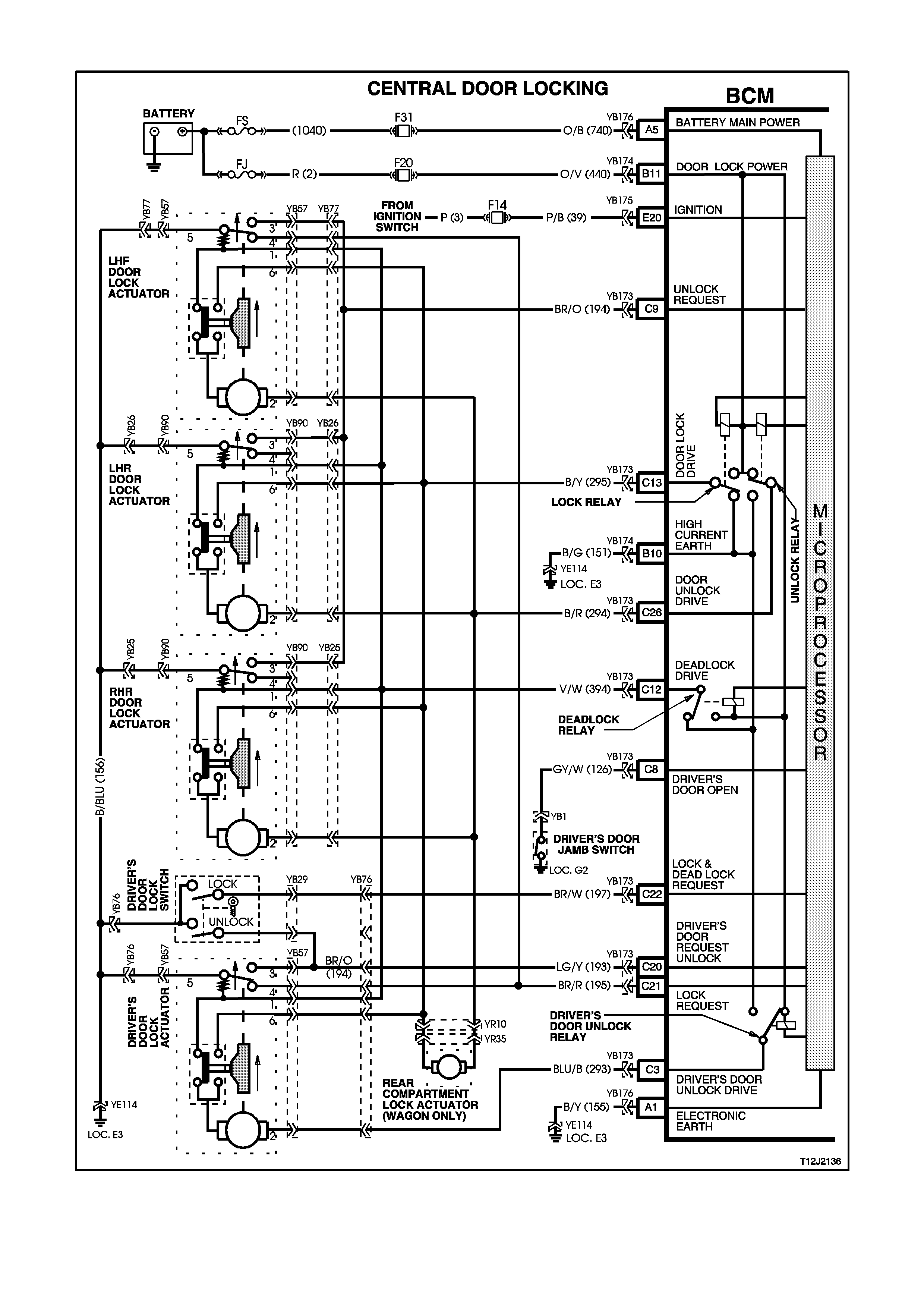

1.2 CENTRAL DOOR LOCKING SYSTEM

GENERAL INFORMATION

NOTE:

The circuit diagrams shown in this General Description Section are to aid in interpreting the operation of the circuit

and therefore, only the main connectors and wiring colours are shown. For complete circuit details, refer to either

the relevant diagnostic section or to Section 12P WIRING DIAGRAMS.

The central door locking system provides for locking and unlocking of all doors and tailgate (station wagon models)

as well as enhanced locking or 'deadlock' (doors only).

The system incorporates the following functions:

1. 1. Door and tailgate locking activated via:

Driver's door lock actuator (mechanically linked to door interior snib and door latch).

Left hand front passenger’s door lock actuator (mechanically linked to interior snib button).

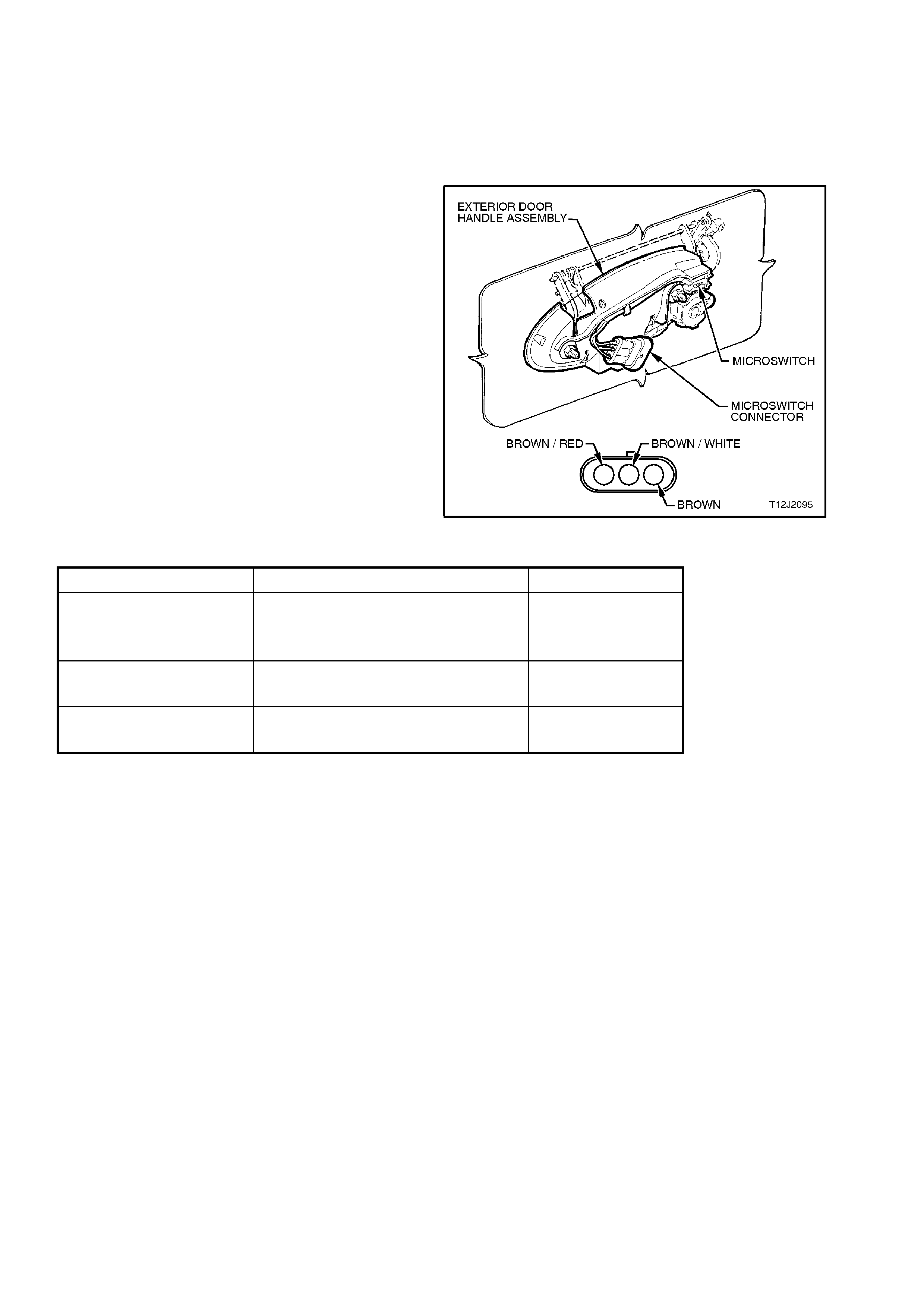

Driver’s door key barrel micro switches, which are also mechanically linked to the door latch, and therefore

linked to the actuators. VT Series Models require micro switch activation to force lock (and unlock) without

moving the actuator.

Pressing the lock button on remote coded key (provided all doors are closed).

2. 2. Door and tailgate unlocking via:

All door lock actuators (mechanically linked to door interior snib).

Micro switch in driver’s door.

Pressing the unlock button on remote coded key.

The driver’s door key barrel can also be moved independently of the actuator, allowing unlocking of the driver’s

door latch in the case where the actuator is stuck down, ie. deadlock when the battery is discharged.

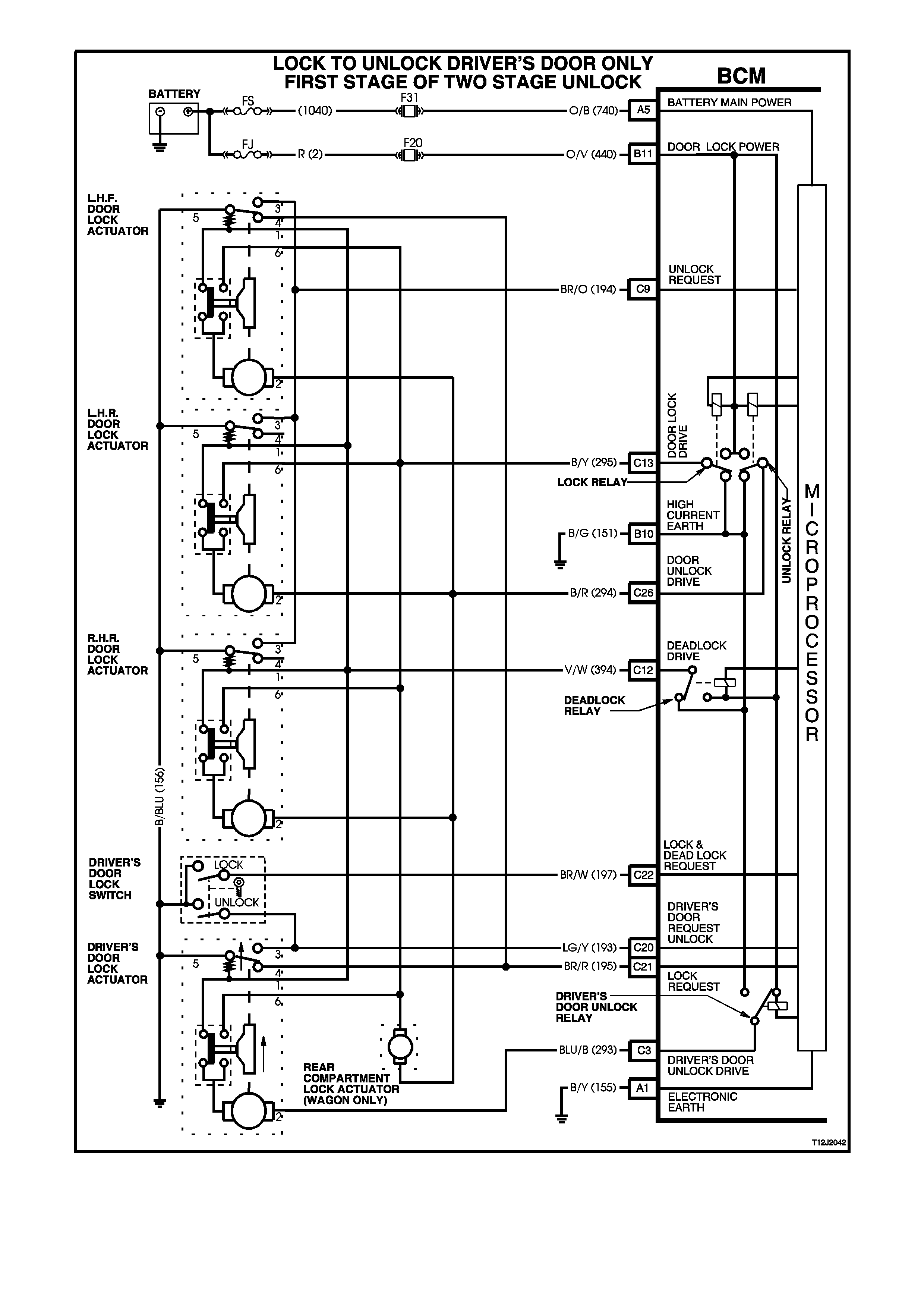

3. Single and Two Stage Unlocking

The BCM is capable of operating in either of two unlock modes, either two or single stage unlock. The BCM, as

fitted to the vehicle is programmed to operate the central door locking system in the two stage unlock mode.

TWO STAGE UNLOCK

In the two stage unlock mode, when the remote coded key unlock button is depressed for 0.25 seconds, the BCM,

on receiving the unlock request from the remote coded key, via the remote receiver, will unlock the driver’s door

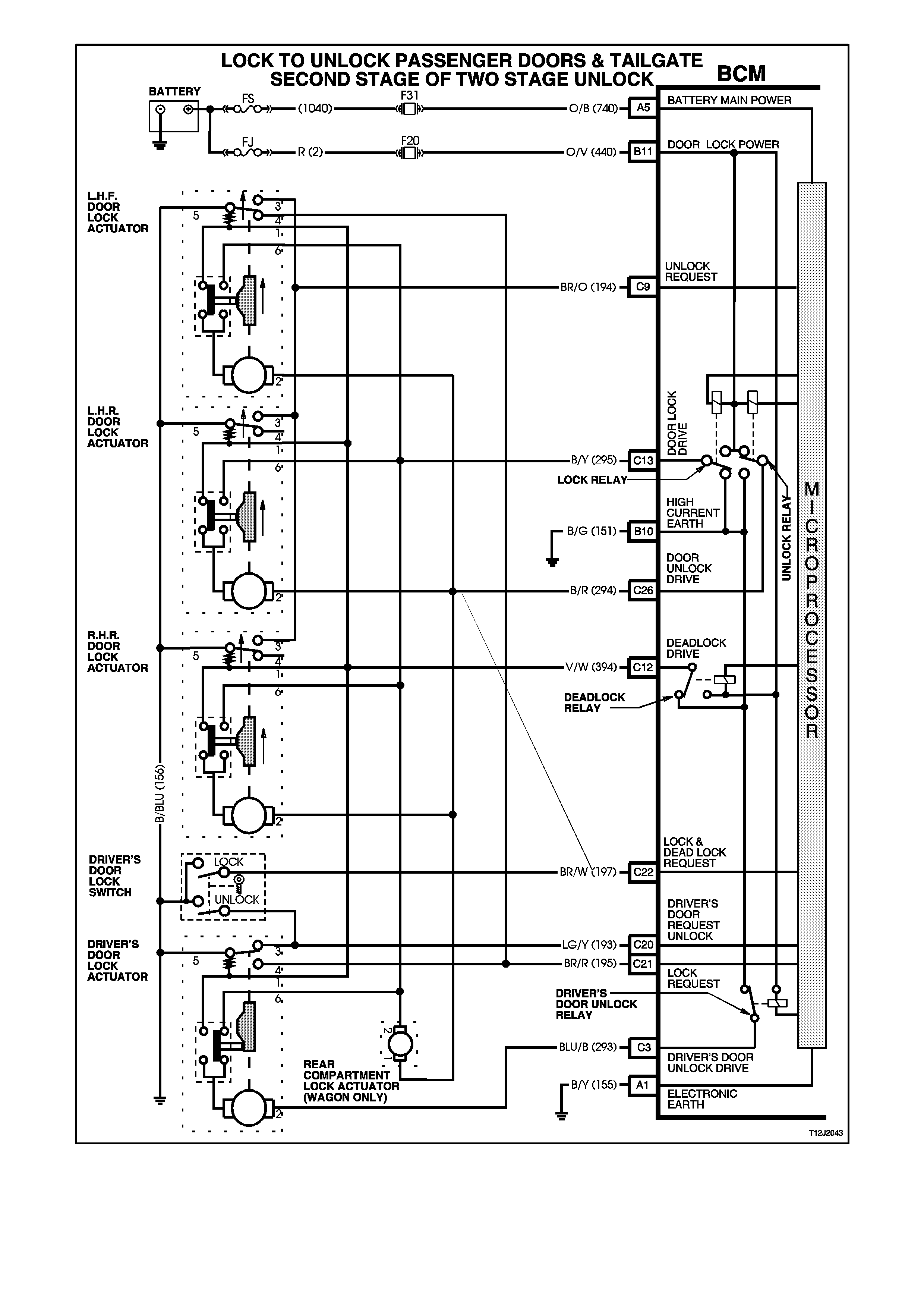

only. If the remote coded key unlock button is depressed again for 0.25 seconds the BCM, on receiving the second

unlock request from the remote coded key, will unlock all passenger doors.

Or alternatively, if the remote coded key is depressed continuously for 0.5 seconds, the BCM, on receiving the

unlock request from the remote coded key, will unlock all doors, first the driver’s door, then all passenger doors.

SINGLE STAGE UNLOCK

In single stage unlock mode, when the remote coded key unlock button is depressed for 0.25 seconds or longer,

the BCM on receiving the unlock request from the remote coded key, via the remote receiver, will unlock all doors

simultaneously.

With TECH 2, the BCM can be programmed to operate in either two stage or single stage unlock (depending on the

vehicle’s owner or operator requirements).

If a short circuit exists on either the lock or unlock signal inputs, the opposing input is still able to perform its

function. This enables the doors to be unlocked when a short circuit exists on the lock input or vice-versa.

To protect the motors used in the door and tailgate lock actuators, in the event of multiple activation's within a

defined time period, the system will 'time-out' and protect the motors from damage. After a fixed time delay, the

system will re-activate as normal.

The deadlock feature provides for mechanical jamming of the door lock actuators. This is achieved electrically via

the driver's door key barrel micro-switch.

NOTE:

Deadlock is inhibited whilst the ignition is switched ON.

Operation of the Central Door Locking System is also affected by the Theft Deterrent System, refer to 1.3 THEFT

DETERRENT SYSTEM in this Section.

SYSTEM CHECK

The operation of the Central Door Locking System

is independent of the ignition being switched ON or

OFF.

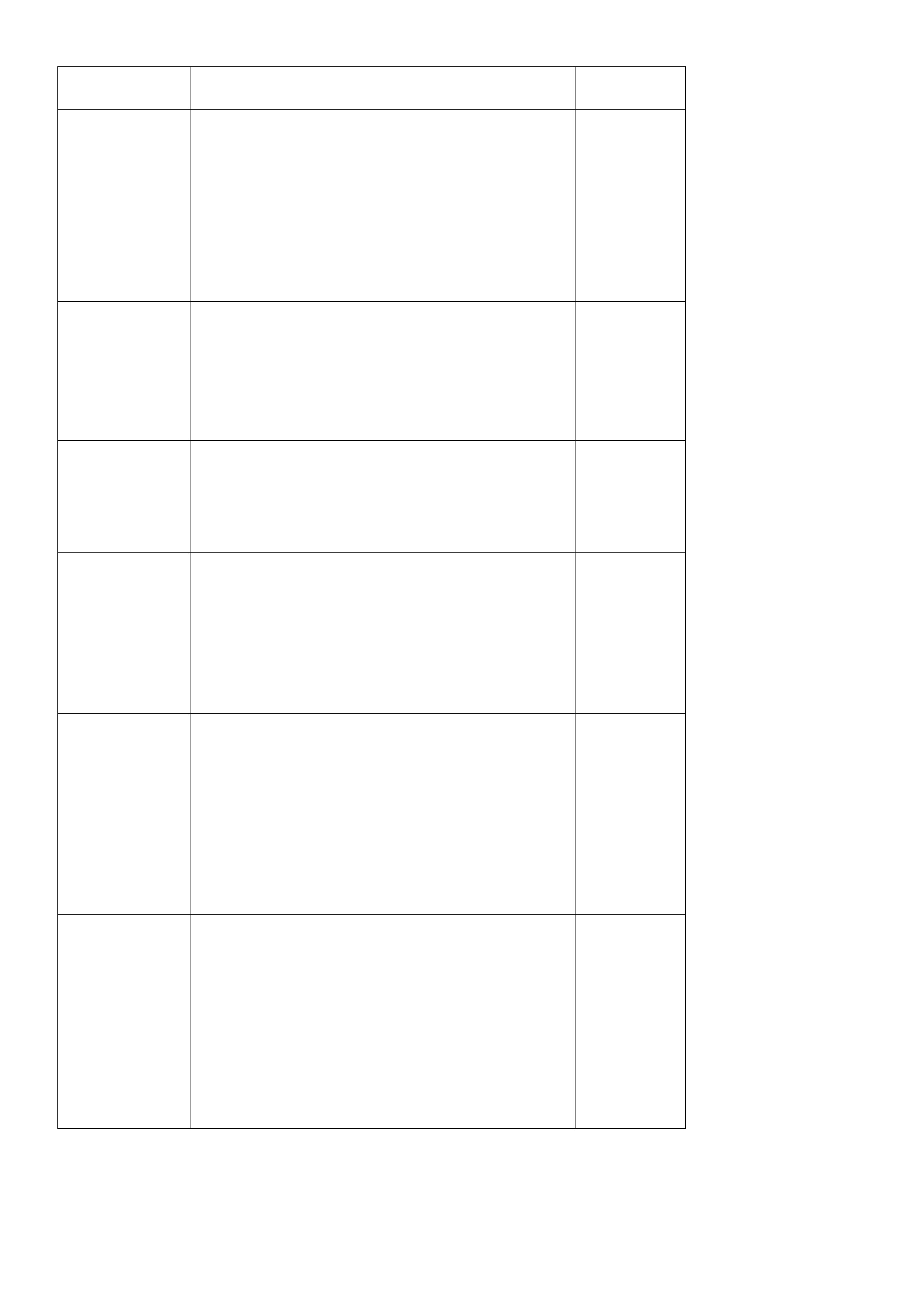

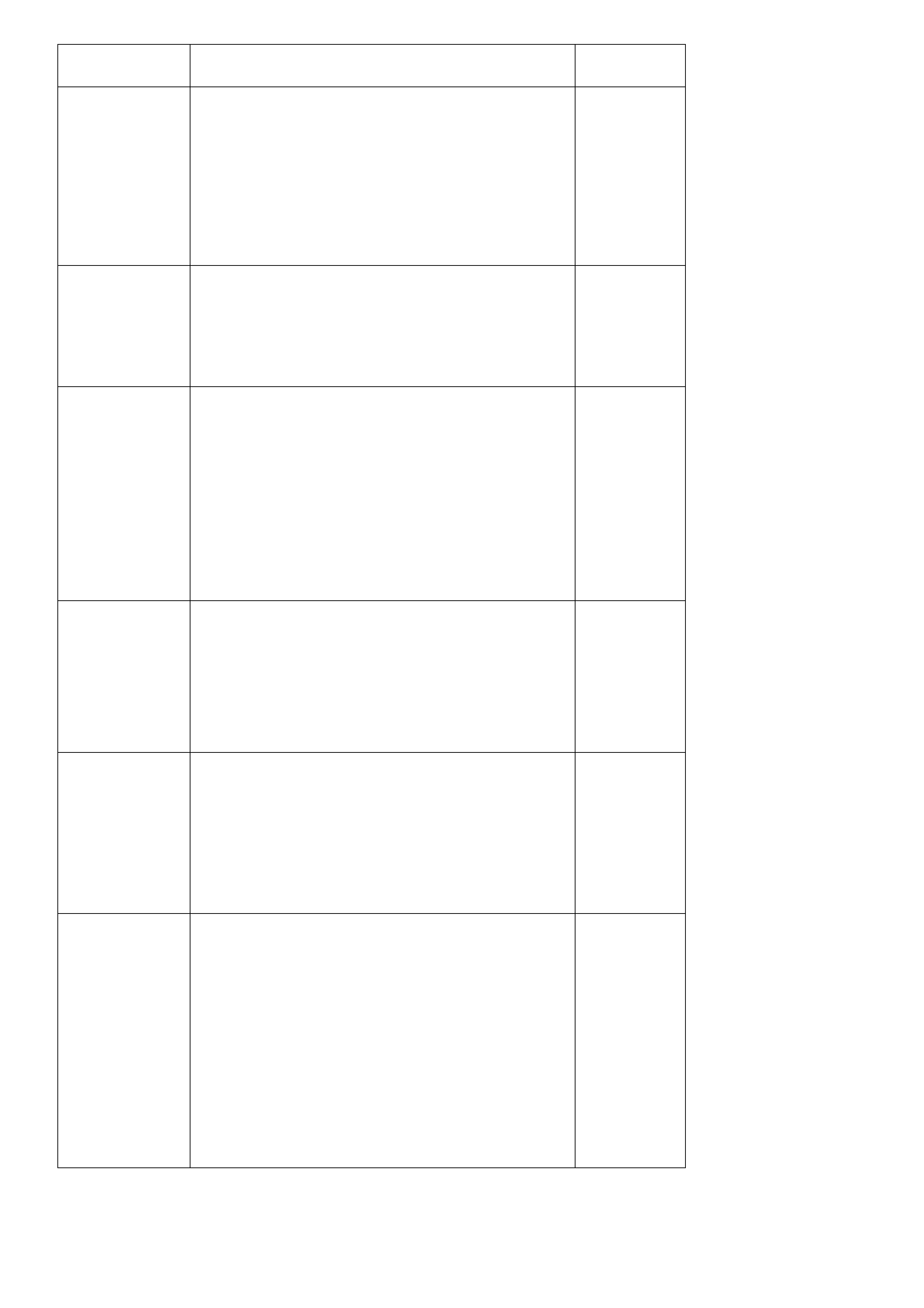

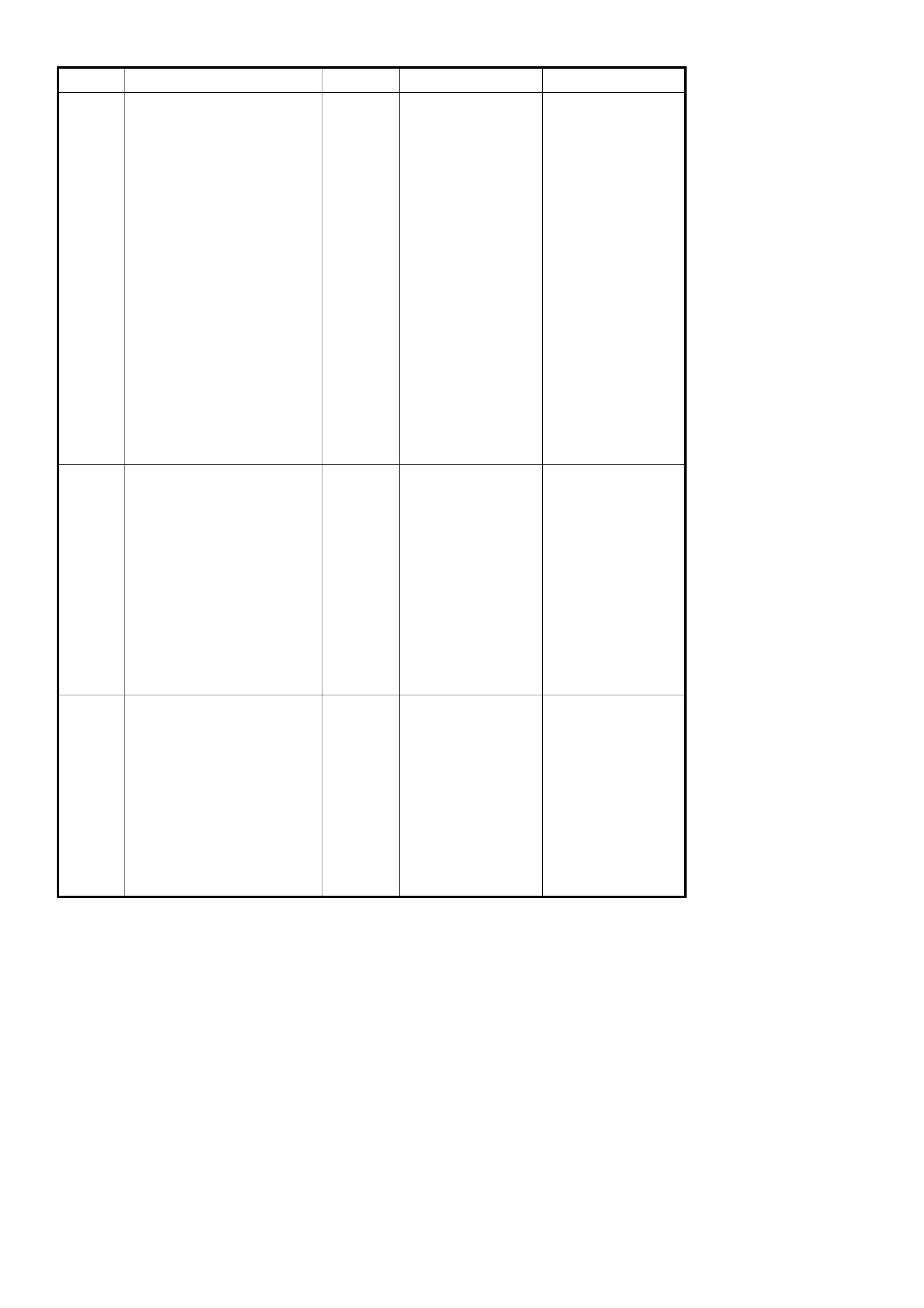

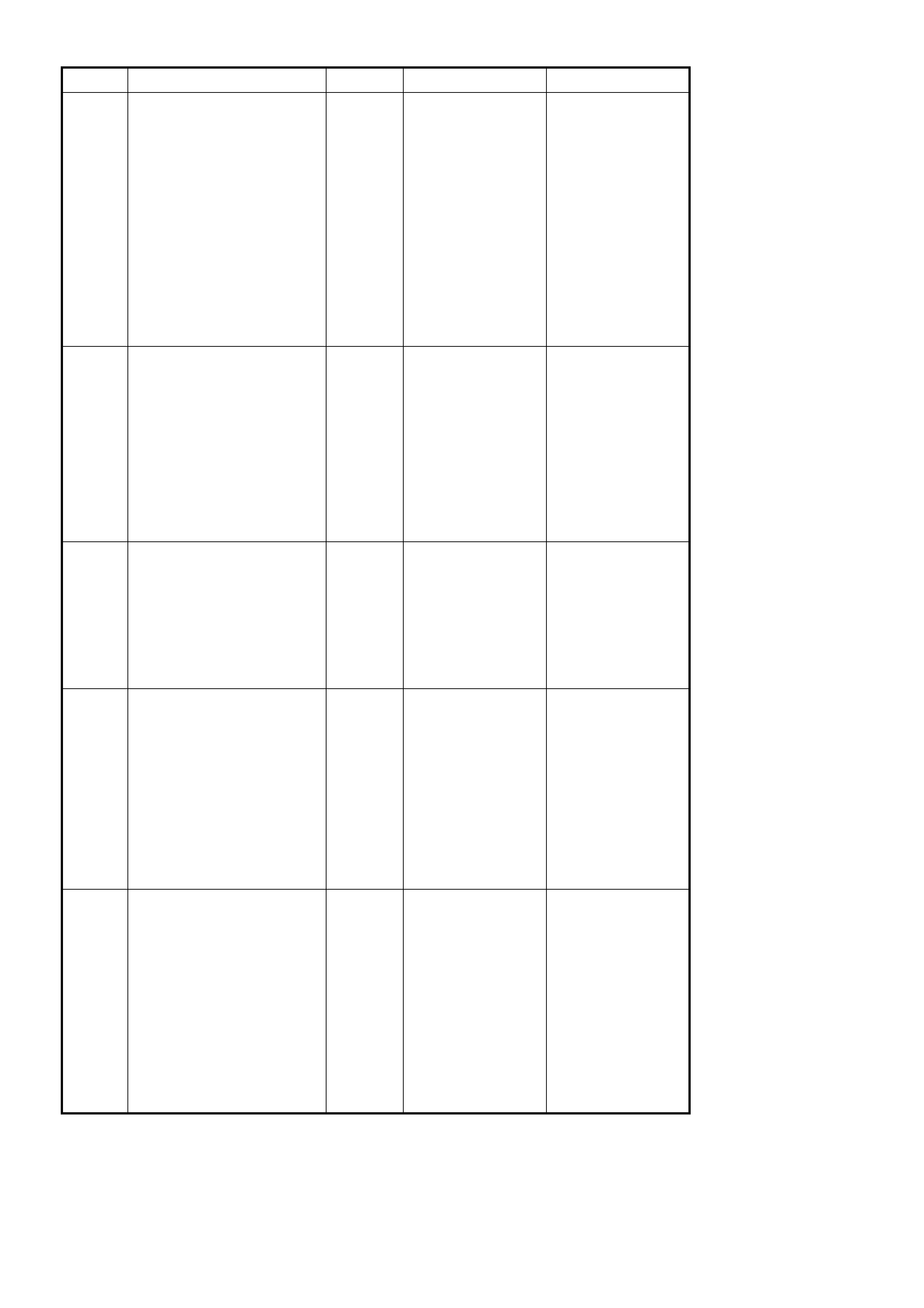

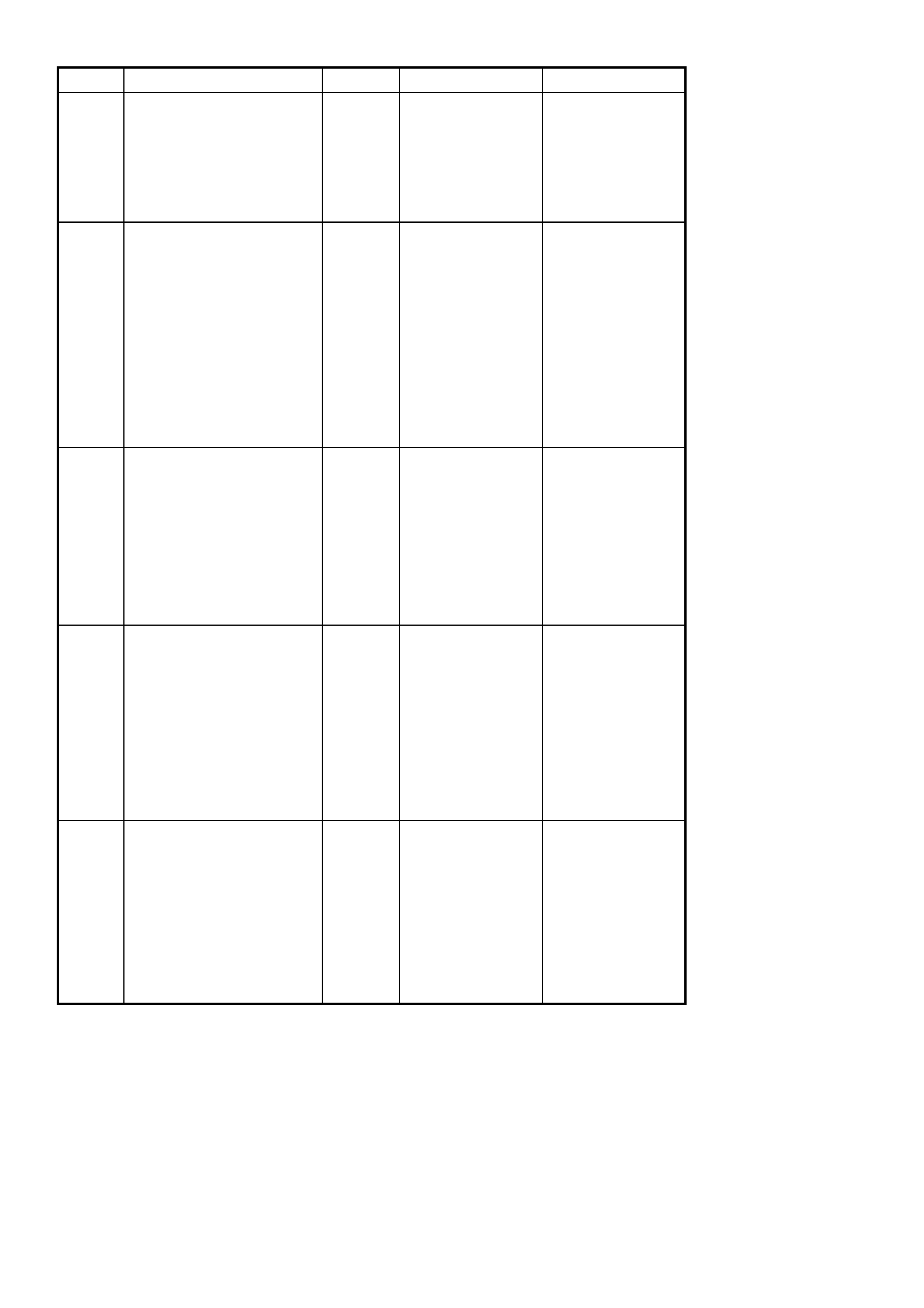

Figure 12J-2-5 shows the key positions on the

driver’s door for the various key locking functions.

Deadlock refers to the electrical m eans that c an be

activated to ensure vehicle security by inhibiting

door lock operation.

Even though the electronic theft deterrent system,

via the remote coded key, can activate the door

locks, it does not engage the electrical 'block ing' of

the doors (deadlocking).

Figure 12J-2-5

CENTRAL LOCKING AND UNLOCKING

Operation of this system can be effected as

follows;

1. Driver’s door, outside key and inside locking

(snib) button.

2. Left hand front passenger door inside locking

(snib) button (locking and unlocking)

3. Rear passenger doors inside locking (snib)

button (only unlocking is possible).

DEADLOCK

The deadlocking feature applies to all four doors,

but not to the luggage compartment lid or tailgate.

After the deadlocking feature device has been

engaged, unlocking is possible at the driver’s door

from outside, by inserting the key into the driver’s

door lock c ylinder and turning the k ey to the unlock

position or activating the unlock button on the

rem ote key unlocks the deadlocks on all doors, but

only unlocks the driver’s door (only if 2 stage

unlocking has been enabled).

To ensure access to the vehicle if the electrical

system should fail (discharged battery), after the

system has been engaged, the driver’s door key

barrel can be m oved independently of the actuator

and therefore allowing unlocking of the driver’s

door latch.

The rear compartment lid or tailgate can be

locked/unlocked with the key when the mechanical

deadlocking feature is actuated, while leaving the

doors secured. However, if the theft deterrent

system has been activated, the alarm will sound

when the rear compartment lid is raised (sedans

only).

NOTE:

Deadlocking is not possible with the ignition on.

REMOTE CODED KEY CHECK

Check that the BCM locks all doors when the

remote coded key lock button is pressed, at a

distance within 4 metres from the driver’s side B

pillar.

When the remote coded key unlock button is

pressed the driver's side should unlock (vehicles

programmed for two stage unlock). Pressing the

unlock button again and all passenger doors (and

tailgate on station wagon models) should be

unlocked.

On vehicles programmed for single stage unlock,

the single press of the unlock button will unlock all

doors and tailgate on station wagon models.

If this test does not prove satisfactory, refer to

2.3 REMOTE CODED KEY in this Section for a

more detailed diagnosis before continuing with the

central locking system check.

Figure 12J-2-6

CHECKING THE DEADLOCK FEATURE

Open all windows.

Close all doors.

Actuate the deadlock feature f rom the dr iver’s door

with the key.

Check that all door lock buttons cannot be pulled

up. They are electrically blocked.

NOTE:

The door lock (snib) buttons can be pulled up

slightly, but they will be under tension.

OVERHEATING PREVENTION

In the event of multiple activations within a defined

time period, the central door locking system will be

deactivated and remain inoperative for a defined

time period to prevent the door actuators from

overheating. After a fixed time delay, the system

will re-activate and operate as normal.

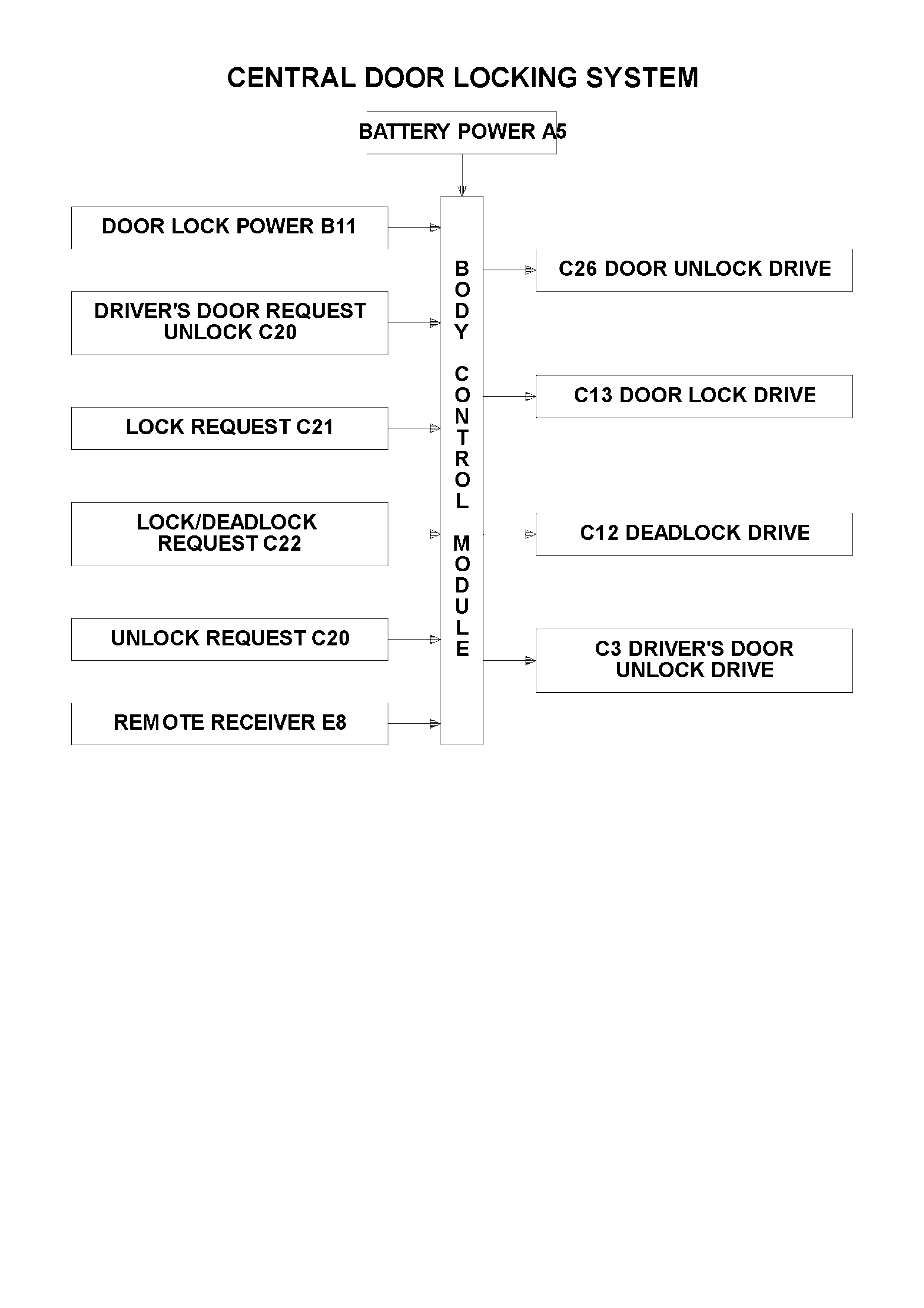

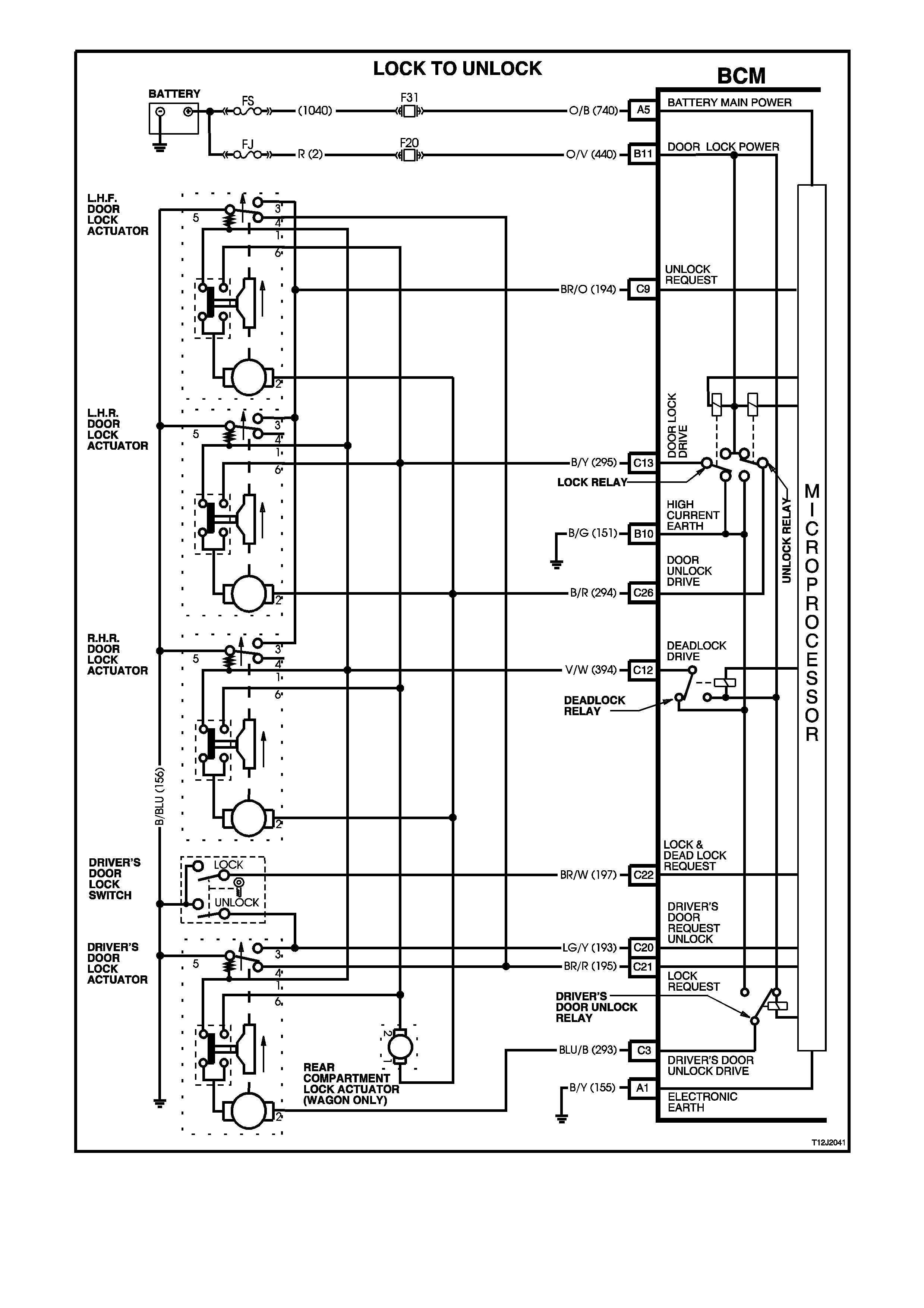

SYSTEM OVERVIEW

CIRCUIT OPERATION

The door and tailgate locks are operated by reversible motors that receive voltage from relays within the BCM.

These relays operate the motors by applying battery voltage to one side of each motor and earth to the other side.

The central door locking system has four operational phases as follows:

1. Lock to Unlock

2. Unlock to Lock

3. Lock to Deadlock

4. Deadlock to Unlock

The circuit operation of each of these four phases is described as follows:

LOCK TO UNLOCK OPERATION

(Refer to Fig. 12J-2-10)

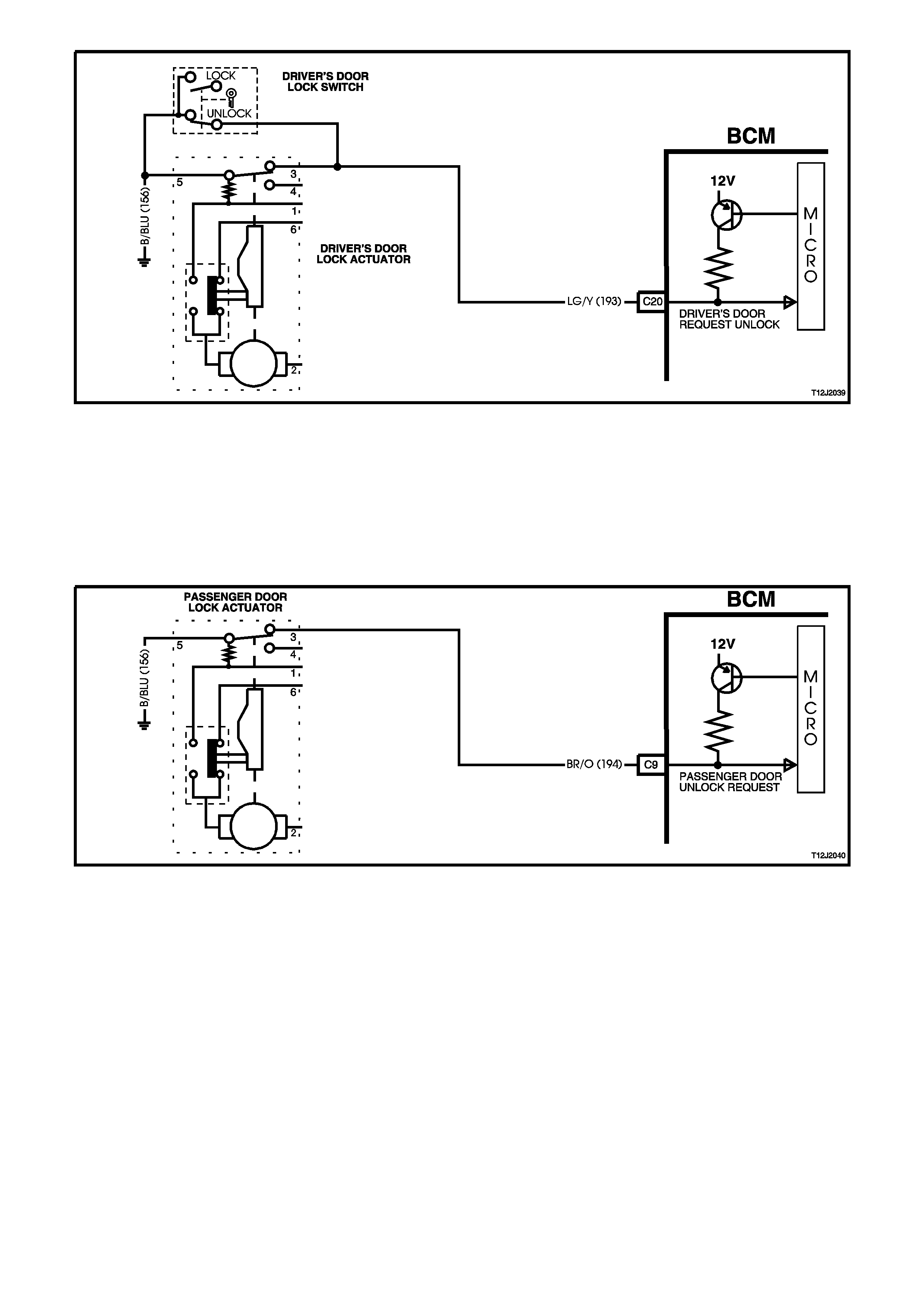

DRIVER’S DOOR REQUEST UNLOCK INPUT SIGNAL

(Refer to Fig. 12J-2-7)

When unlocking the doors and tailgate via the right hand front door lock cylinder barrel microswitch or interior snib

button, BCM terminal C20 (driver's door request unlock signal), is connected to earth by the driver’s door lock

actuator switch contacts changing position from terminals 4-5 to 3-5 or in the case of the driver’s door cylinder

barrel micro switch, C20 is connected to earth via the microswitch contacts, unlock position circuit 156 (Black/Blue

wire). This action causes the voltage on terminal C20, circuit 193 (Light Green/Yellow wire), to be pulled low, less

than 0.2 volt (Driver’s door unlocked). This low voltage at terminal C20 is seen by the BCM as a driver’s door

request unlock signal.

NOTE:

Manually activating any unlock request line will cause all doors to be unlocked.

Figure 12J-2-7

PASSENGER DOOR UNLOCK REQUEST INPUT SIGNAL

(Refer to Fig. 12J-2-8)

When unlocking the doors via any passenger door interior snib button, BCM terminal C9 (passenger door unlock

request signal) is connected to earth by the activated passenger door lock actuator switch contacts, terminals 3,

circuit 194 (Brown/Orange wire) and 5, circuit 156 (Black/Blue wire). This action causes the voltage on terminal C9,

circuit 194 to be pulled low, less than 0.2 volt (doors unlocked). This low voltage at terminal C9 is seen by the BCM

as a passenger door unlock request signal.

A low voltage at terminal C20 or C9 is seen by the BCM as a system unlock request. This then enables the BCM to

energise the internal unlock relays for approximately 0.75 seconds. This causes the unlock relay contacts to close

and battery voltage is applied, via fuse F20, circuit 440 (Orange/Violet wire) and BCM terminals B11 and C26, to

terminal 2 of each of the passenger door lock actuators and to the tailgate lock actuator (station wagon models),

circuit 294 (Black/Red wire). Battery voltage is also applied, via fuse F20, circuit 440 (Orange/Violet wire) and BCM

terminals B11 and C3, to terminal 2 of the driver’s door lock actuator, via circuit 293 (Blue/Black wire).

The opposite terminal of the door lock actuators (terminal 1) is connected to earth via BCM terminal C12, circuit 394

(Violet/White wire) through the BCM internal deadlock relay contacts and BCM terminal B10, circuit 151

(Black/Green wire). This causes the door lock actuator motor armatures to rotate from the lock to the unlock

position, and the door lock actuator switch contacts to change from terminal 1 to 6. The rotation of the passenger

door lock actuator motor armatures also causes the door lock switch contacts to change from the lock to the unlock

position. The tailgate lock actuator motors are earthed via the BCM terminal C13, circuit 295 (Black/Yellow wire),

through the BCM internal lock relay contacts and BCM terminal B10 and circuit 151 (Black/Green wire).

REMOTE CODED KEY OPERATION

(Refer to Fig. 12J-2-9 for the remote receiver/key, Fig. 12J-2-11 for first stage of two stage unlock and Fig. 12J-2-12

for the second stage of two stage unlock)

TWO STAGE UNLOCK

If the BCM is operating in the two stage unlock mode and the remote coded key unlock button is depressed for 0.25

seconds, the BCM, on receiving the unlock request from the remote coded key, via remote receiver, activates the

microprocessor within the BCM, causing the driver’s door unlock relay to toggle to the unlock state, unlocking the

driver’s door only as described previously.

If the remote coded key unlock button is depressed again for 0.25 seconds, the microprocessor within the BCM, on

receiving the second unlock request from the remote coded key, will toggle the unlock relay contacts to the unlock

state and the passenger doors (and tailgate) will unlock as described previously.

If the remote coded key is depressed continuously for 0.5 seconds, the microprocessor within the BCM, on

receiving the unlock request from the remote coded key will unlock all doors, first the driver’s door, then all

passenger doors (and tailgate), as described previously.

SINGLE STAGE

If the BCM is operating in the single stage unlock mode and the remote coded key unlock button is depressed for

0.25 seconds, the microprocessor within the BCM, on receiving the RF unlock request from the remote coded key,

causes the unlock relay contacts to toggle to the unlock state, all doors (and tailgate) will then unlock as described

previously.

Figure 12J-2-9

Figure 12J-2-10

Figure 12J-2-11

Figure 12J-2-12

UNLOCK TO LOCK OPERATION

(Refer to Fig.12J-2-15)

LOCK REQUEST

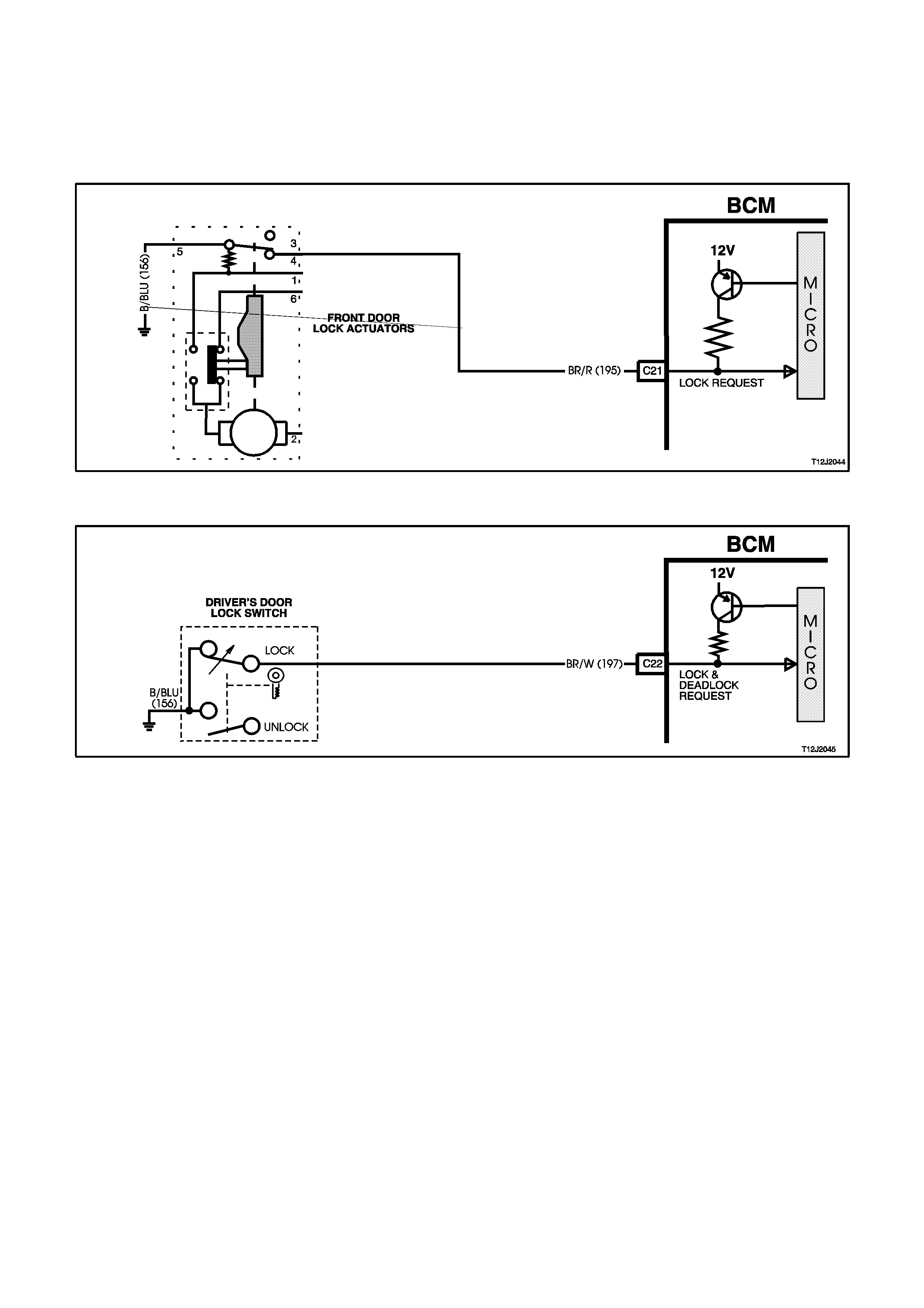

(Refer to Fig. 12J-2-13)

When locking the doors and tailgate via the driver’s or front passenger’s door interior snib button, the BCM terminal

C21, circuit 195 (Brown/Red wire), is connected to earth, circuit 156 (Black/Blue wire) by the driver’s or front

passenger’s door lock actuator key switch contacts changing over from terminals 3-5 to 4-5.

This action causes the voltage on terminal C12, circuit 195 (Brown/Red wire), to be pulled low, less than 0.2 volt

(doors locked).

This low voltage at terminal C21 is seen by the BCM as the system lock request.

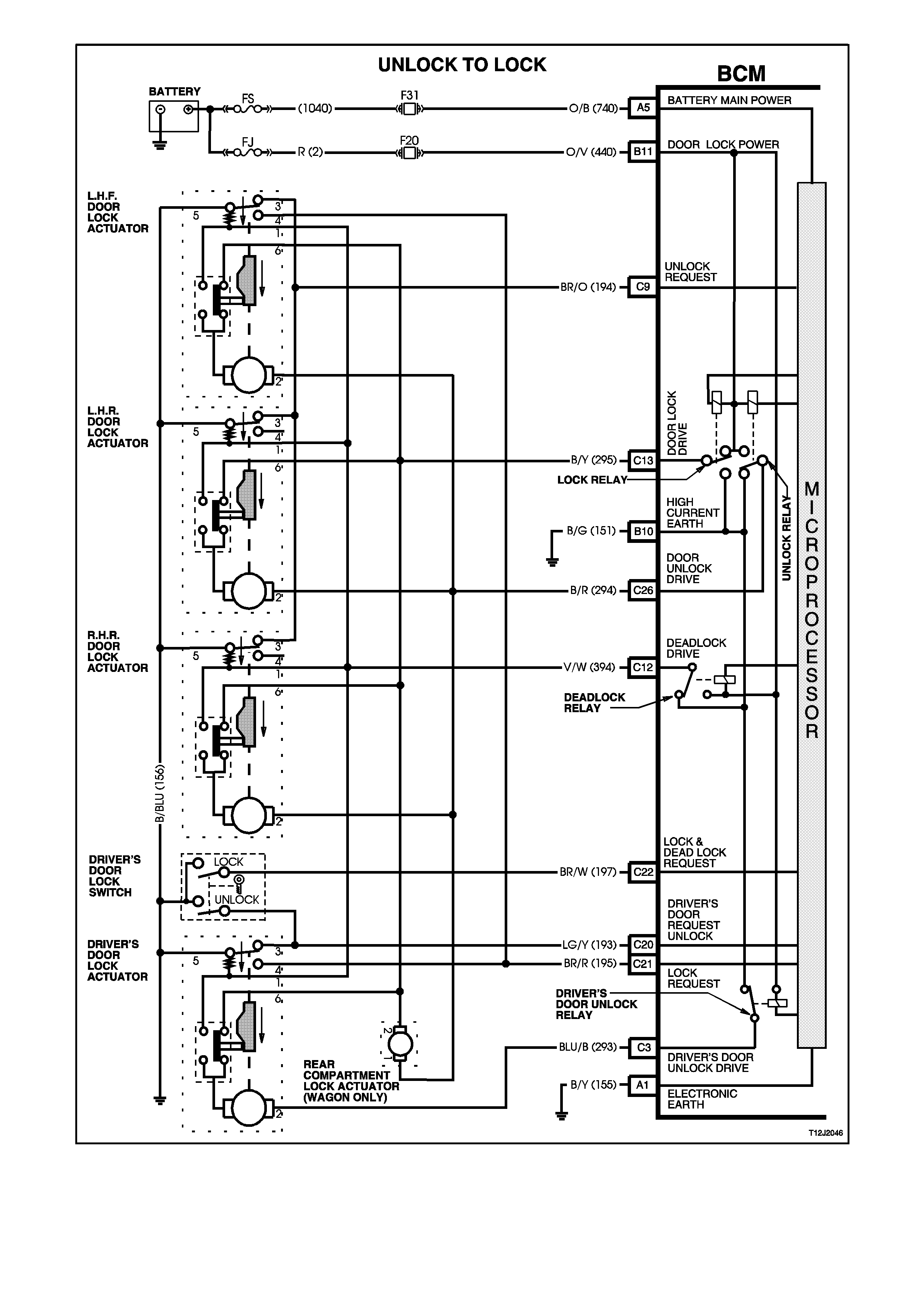

LOCK AND DEADLOCK REQUEST

(Refer to Fig. 12J-2-14)

When locking the doors and tailgate via the driver’s door cylinder barrel microswitch, BCM terminal C22

(lock/deadlock request signal) is connected to earth via the microswitch contacts, lock position, circuit 156

(Black/Blue wire). This action causes the voltage on terminal C22, circuit 197 (Brown/White wire) to be pulled low,

less than 0.2 volt (door locked). This low voltage at terminal C22 is seen by the BCM as the system lock request

(only if driver’s door is closed).

Either of these lock requests, via driver’s or front passenger’s snib buttons and driver’s door microswitch, then

enable the BCM to energise the internal lock relay for approximately 0.75 seconds, the lock relay contacts close and

battery voltage is applied, via fuse F20, circuit 440 (Orange/Violet wire) and BCM terminals B11 and C13, to

terminal 6 of each door lock actuator and to the tailgate actuator, circuit 295 (Black/Yellow wire).The opposite

terminal (terminal 2) of the passenger doors and tailgate door lock actuator motors is connected to earth through

BCM terminal C26, circuit 294 (Black/Red wire), the internal unlock relay contacts and through BCM terminal B10 to

earth, circuit 151 (Black/Green wire). The opposite terminal (terminal 2) of the driver’s door lock actuator motor is

connected to earth through BCM terminal C3, circuit 293 (Blue/Black wire), the internal driver’s door unlock relay

contacts and through BCM terminal B10 to earth, circuit 151 (Black/Green wire).

This allows the door lock actuator motor armatures to rotate to the lock position and causes the door lock actuator

switch contacts to change from terminals 6 to 1. This action disconnects the voltage supply to the door lock actuator

motor armatures, the armatures now have earth connection on both sides, with actuator terminals 6 earthed

through the deadlock relay terminals and through BCM terminal B10 to earth circuit 151 (Black/Green wire). This

causes an instantaneous halt to door lock actuator motor armature rotation.

This rotation of the passenger door lock actuator motor armatures also causes the passenger door lock switch

contacts to change to the lock position.

After approximately 0.75 seconds, the power to all the actuators via BCM terminal C13 circuit 295 (Black/Yellow

wire) is disconnected by the opening of the internal lock relay contacts.

REMOTE CODED KEY OPERATION

When locking the doors via the remote coded key, the RF output signal from the key (via remote receiver) activates

the microprocessor within the BCM, causing the door lock relay to be energised locking all doors (and tailgate) as

described previously. If any door does not lock either BCM terminal C20 (driver’s door request unlock) or C9

(Unlock request) will remain low, this low voltage is seen by the BCM as an unsuccessful attempt to lock all doors

and the BCM will cause the theft deterrent horns to sound momentarily (driver’s door must be closed).

Figure 12J-2-13

Figure 12J-2-14

Figure 12J-2-15

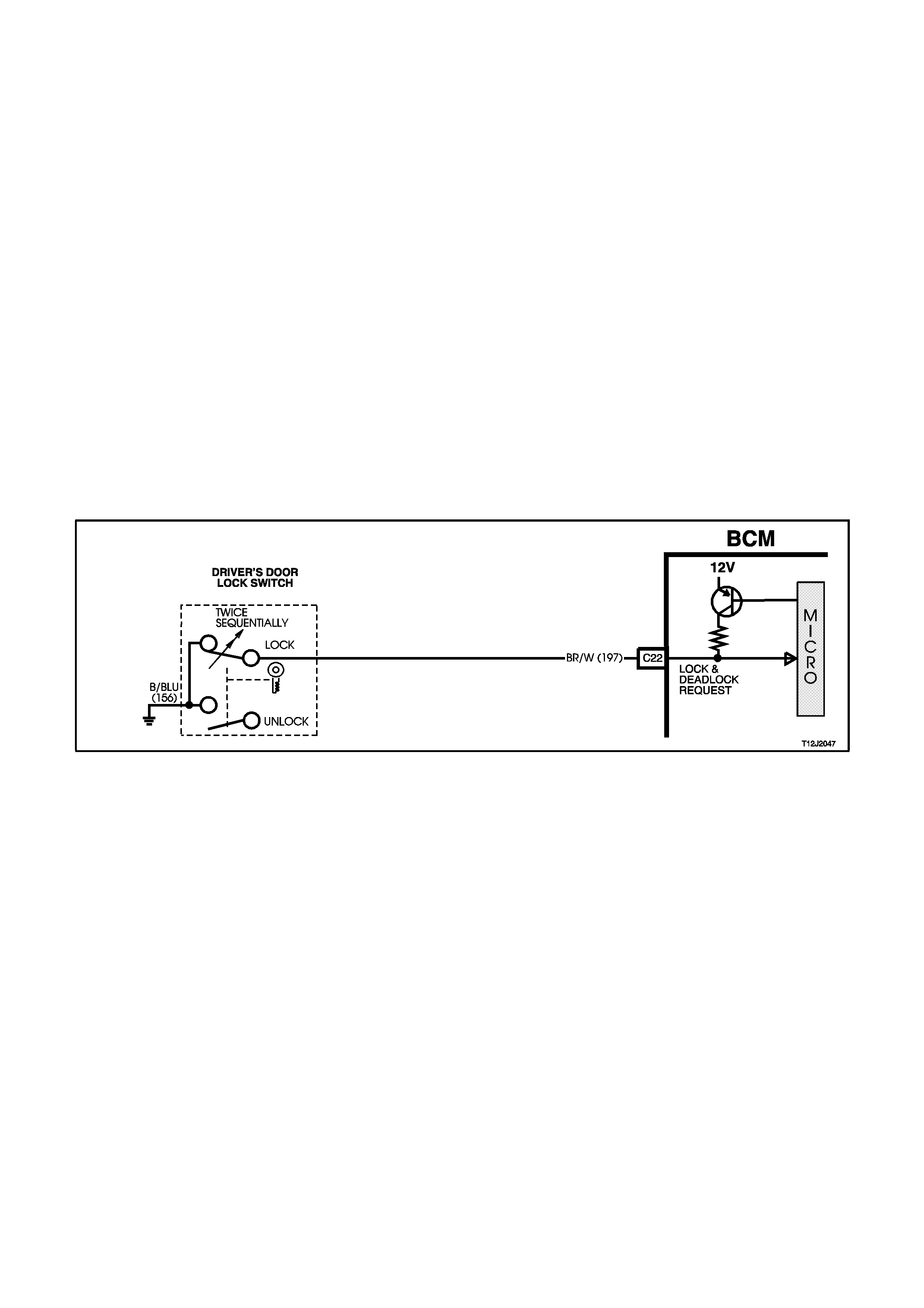

UNLOCK TO DEADLOCK OPERATION

(Refer to Fig.12J-2-17)

LOCK / DEADLOCK REQUEST INPUT SIGNAL

(Refer to Fig.12J-2-16)

Deadlocking is activated after two sequential lock activation’s of the driver’s door lock switch. This action causes the

micro-switch contacts to change to the lock position. This connects BCM terminal C22 circuit 197 (Brown/White

wire) to earth via circuit 156 (Black/Blue wire), causing the voltage on terminal C22 to be pulled low, less than 0.2

volt.

This low voltage at terminal C22 is seen by the BCM as the system deadlock request. This enables the BCM to

energise the internal lock and deadlock relays for approximately 0.75 seconds, the lock and deadlock relays

contacts close and battery voltage is applied, via fuse F20, circuit 440 (Orange/Violet wire) and BCM terminals B11,

C13 and C12, circuit 295 (Black/Yellow wire) and 394 (Violet/White wire) to terminals 6 and 1 of each electric door

lock motor.

The opposite terminal (terminal 2) of all the passenger lock actuator motors is connected to earth through BCM

terminal C26, the internal unlock relay contacts and through BCM terminal B10 to earth, circuit 151 (Black/Green

wire). Terminal 2 of the driver’s door lock actuator motors is connected to earth through BCM terminal C3, the

internal driver’s door unlock relay contacts and through BCM terminal B10 to earth, circuit 151 (Black/Green wire).

This causes the door lock actuator motor armatures to rotate in the locking (downward) direction into the deadlock

position. This rotation of the door lock actuator motor armatures also causes the door lock actuator switch contacts

to change from terminals 6 to 1 to 6.

NOTE 1: The tailgate actuator is not designed to go to deadlock.

NOTE 2: Unlock to deadlock operation will only work if the driver’s door is closed and the ignition is off. If driver’s

door is open, door will not lock. If ignition is on, door will not deadlock.

Figure 12J-2-16

Figure 12J-2-17

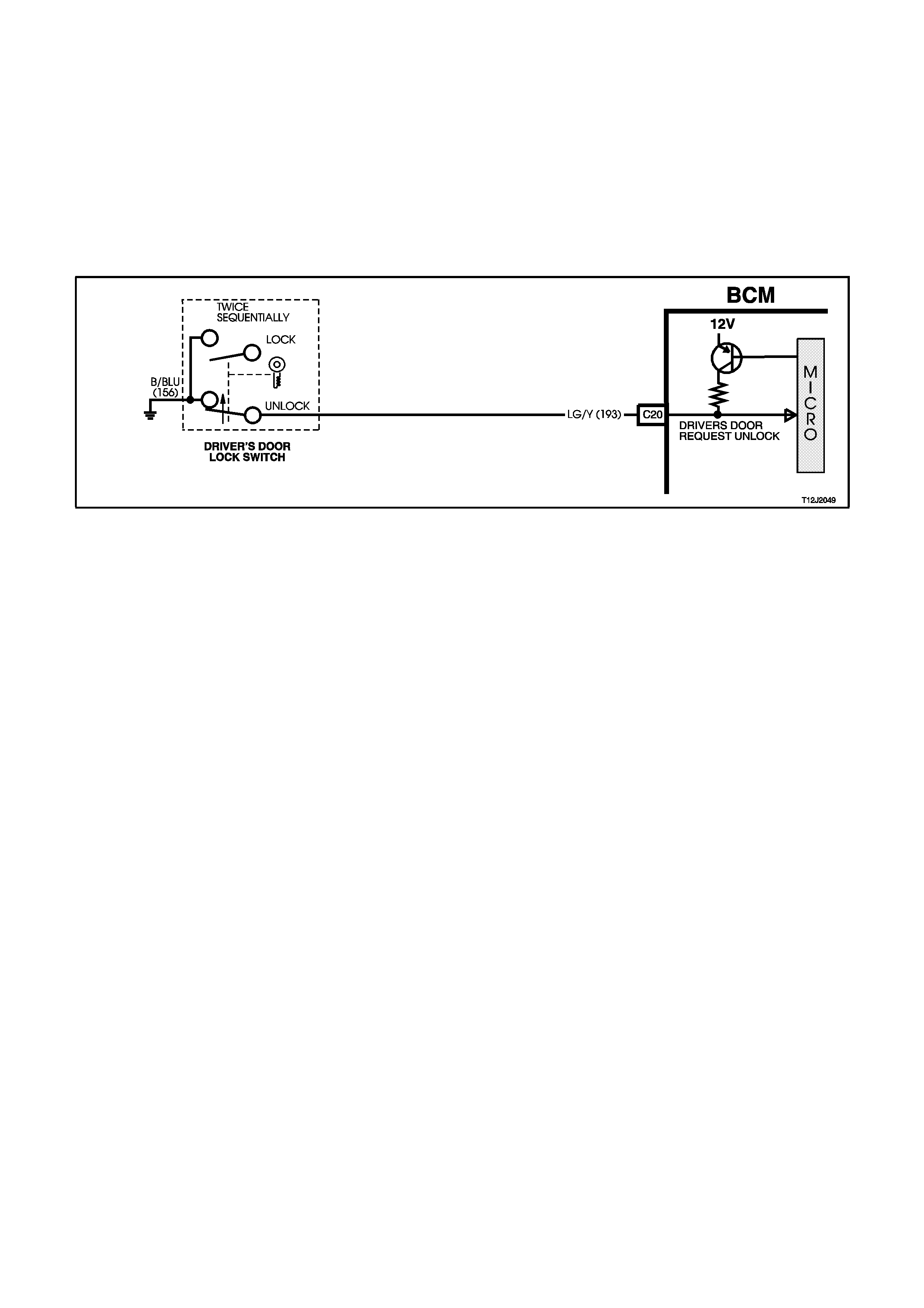

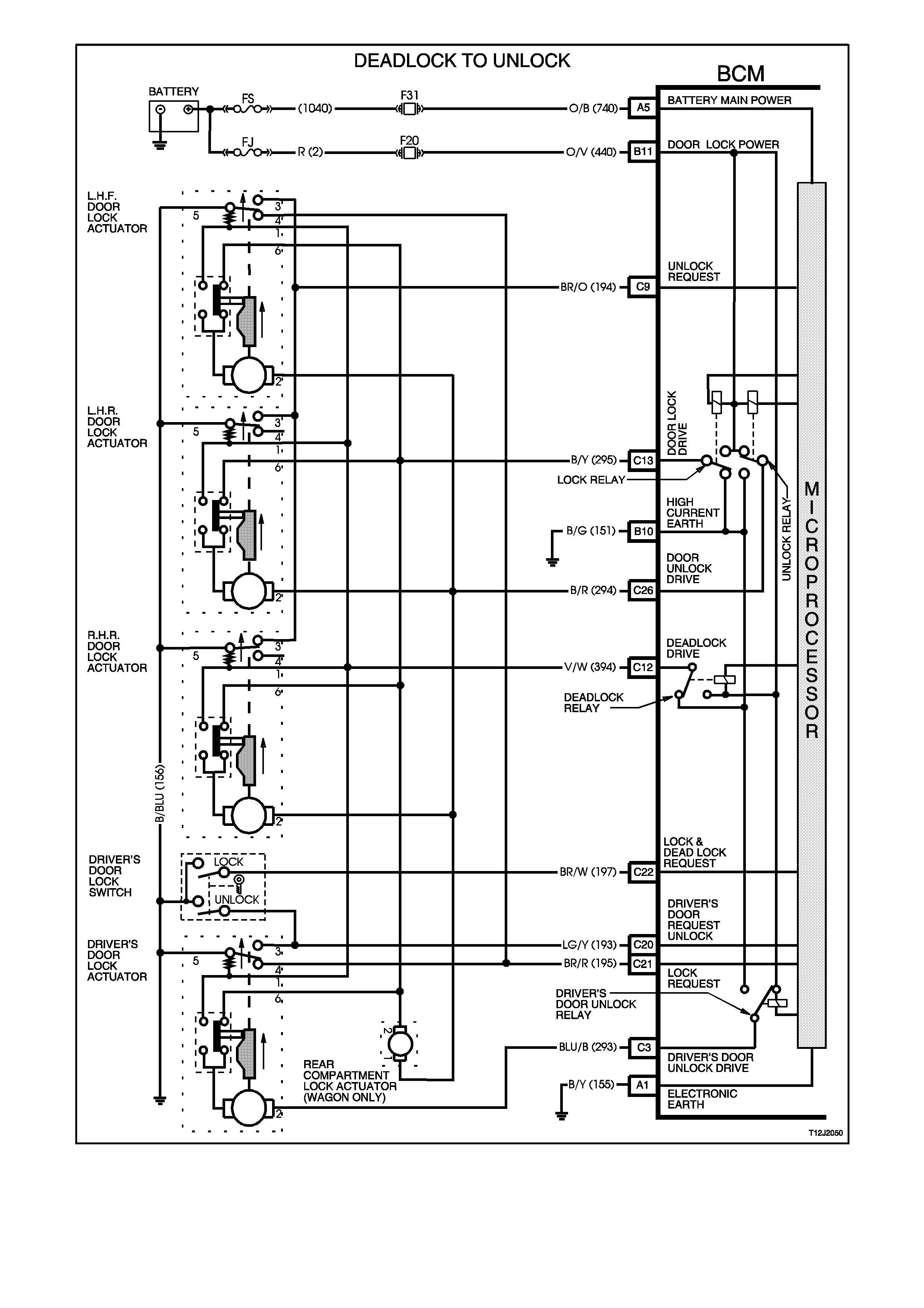

DEADLOCK TO UNLOCK OPERATION

(Refer to Figs. 12J-2-18 and 12J-2-19)

When unlocking the doors from the deadlock position by the driver’s door lock cylinder barrel, by turning to the

unlock position, the microswitch contacts change to the unlock position. This connects BCM terminal C20 circuit

193 (Lt. Green/Yellow wire), to earth via circuit 156 (Black/Blue wire), causing the voltage at terminal C20 to be

pulled low, less than 0.2 volts.

This low voltage at terminal C20 is seen by the BCM as the driver’s door unlock request signal. This then enables

the BCM to energise the internal unlock relays for approximately 0.75 seconds. This causes the relay contacts to

toggle and battery voltage is applied, via fuse F20, circuit 440 (Orange/Violet wire) and BCM terminals B11, C26

and C3 (drivers door unlock, drive, circuit 293 (Blue/Black wire) passenger’s door unlock, drive, circuit 294

(Black/Red wire)) to terminals 2 of each of the door lock actuators and to the tailgate lock actuator, circuit 294

(Black/Red wire).

Figure 12J-2-18

Initially, actuator terminal 6 is connected to earth via circuit 295 (Black/Yellow wire) through the BCM terminal C13,

through the internal lock relay contacts to terminal B10 to circuit 151 (Black/Green wire). This then allows the

passenger door lock actuator motor armatures to rotate from the deadlock toward the unlock position, causing the

passenger door lock actuator switch contacts to change from terminal 6 to 1. As terminal 1 is connected to earth via

circuit 394 (Violet/White wire) through terminal C12 of the BCM, the deadlock relay contacts to terminal B10 to

circuit 151 (Black/Green wire), the door lock actuator motor armatures will continue to rotate further to the unlock

position.

This rotation of the passenger door lock actuator motor armatures causes the door lock actuator switch contacts to

change back to terminal 6. This rotation of the passenger door actuator lock motor armatures also causes the

passenger door lock switch contacts to change to the unlock position.

NOTE:

Provided the ignition is off, the doors may be unlocked from the deadlock position by activating the unlock button on

the remote key. If set for two stage unlock, the drivers door will fully unlock (deadlock to unlock) and the remaining

passenger doors will go from the deadlock position to the lock position. If set for single stage unlock, all doors will

go from the deadlock position to the unlock position.

Figure 12J-2-19

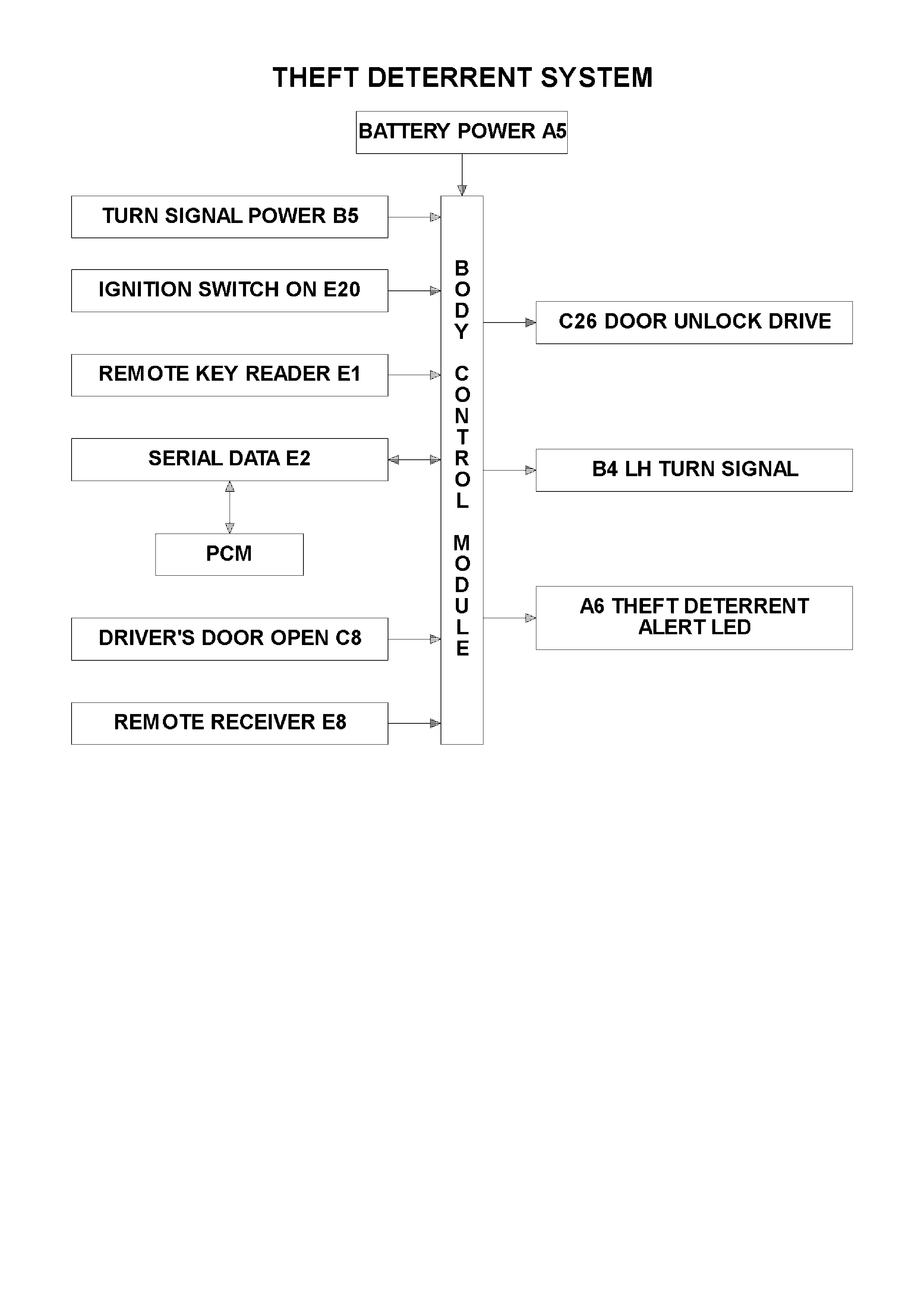

1.3 THEFT DETERRENT SYSTEM

GENERAL INFORMATION

The theft deterrent system on VT Series Models uses a remote coded key to arm and disarm the system, and

where fitted, electrically lock or unlock all doors and tailgate (station wagon), or operate the boot unlock mechanism

(sedan models).

NOTE:

The circuit diagrams shown in this General Description Section are to aid in interpreting the operation of the circuit

and therefore, only the main connectors and wiring colours are shown. For complete circuit details, refer to either

the relevant diagnostic section or Section 12P WIRING DIAGRAMS.

SYSTEM OPERATION

When enabled, there are two modes of theft deterrent operation, armed and disarmed.

Armed

Once the theft deterrent system is enabled, it can be manually armed in one of two ways:

Actively, by pressing the lock button on the remote coded key or,

Passively, as the BCM will automatically arm 30 seconds after the ignition is turned off.

Disarmed

With the system disarmed, the engine management control module is enabled, allowing the engine to be started

when the ignition switch is turned to the run position.

The theft deterrent system can be disarmed in three ways:

1. Pressing the unlock button on the remote coded key. This unlocks the doors, turns the interior dome lamp on

and fully disarms the system for 30 seconds or,

2. By inserting the remote coded key into the ignition switch key barrel and turning the ignition to the ON or RUN

position. This causes the BCM to read a security code serial data output from the remote coded key contact pin

via the remote coded key reader assembly.

3. The system can also be disarmed by turning the ignition switch to the ON position for approximately two hours.

NOTE:

Should the engine crank for a brief period then stop when the ignition switch is turned to the START position (ie.

due to mis-aligned or a faulty remote coded key reader), pressing the unlock button on the remote coded key will

also disarm the theft deterrent system.

The theft deterrent system has a timed override function. The theft deterrent system can be overridden (disabled),

as for example in the event of a remote coded key failure, by turning the ignition switch to the ON position for

approximately two hours. The theft deterrent alert indicator LED will go out once the sy stem has been disabled and

normal starting of the vehicle can take place.

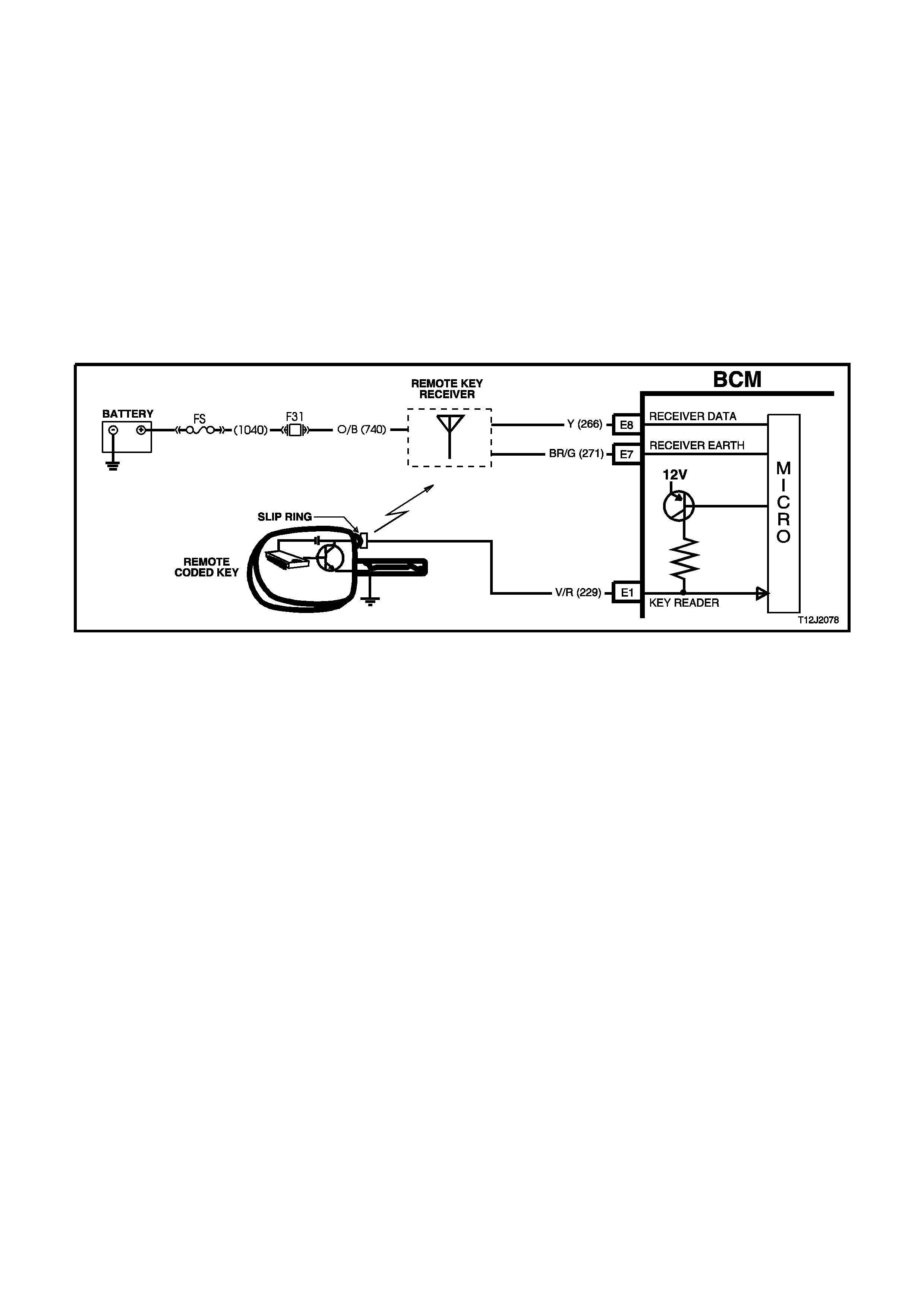

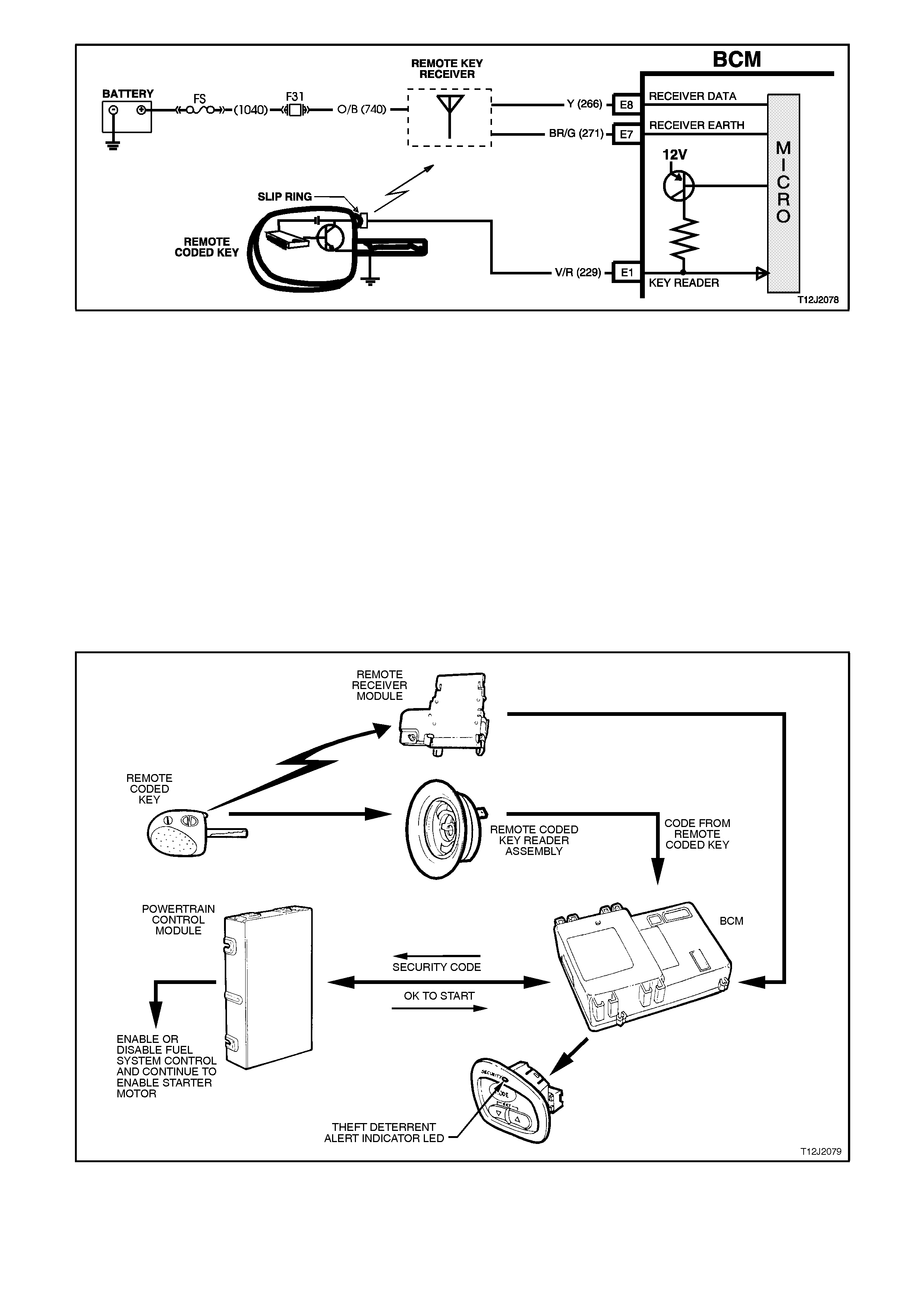

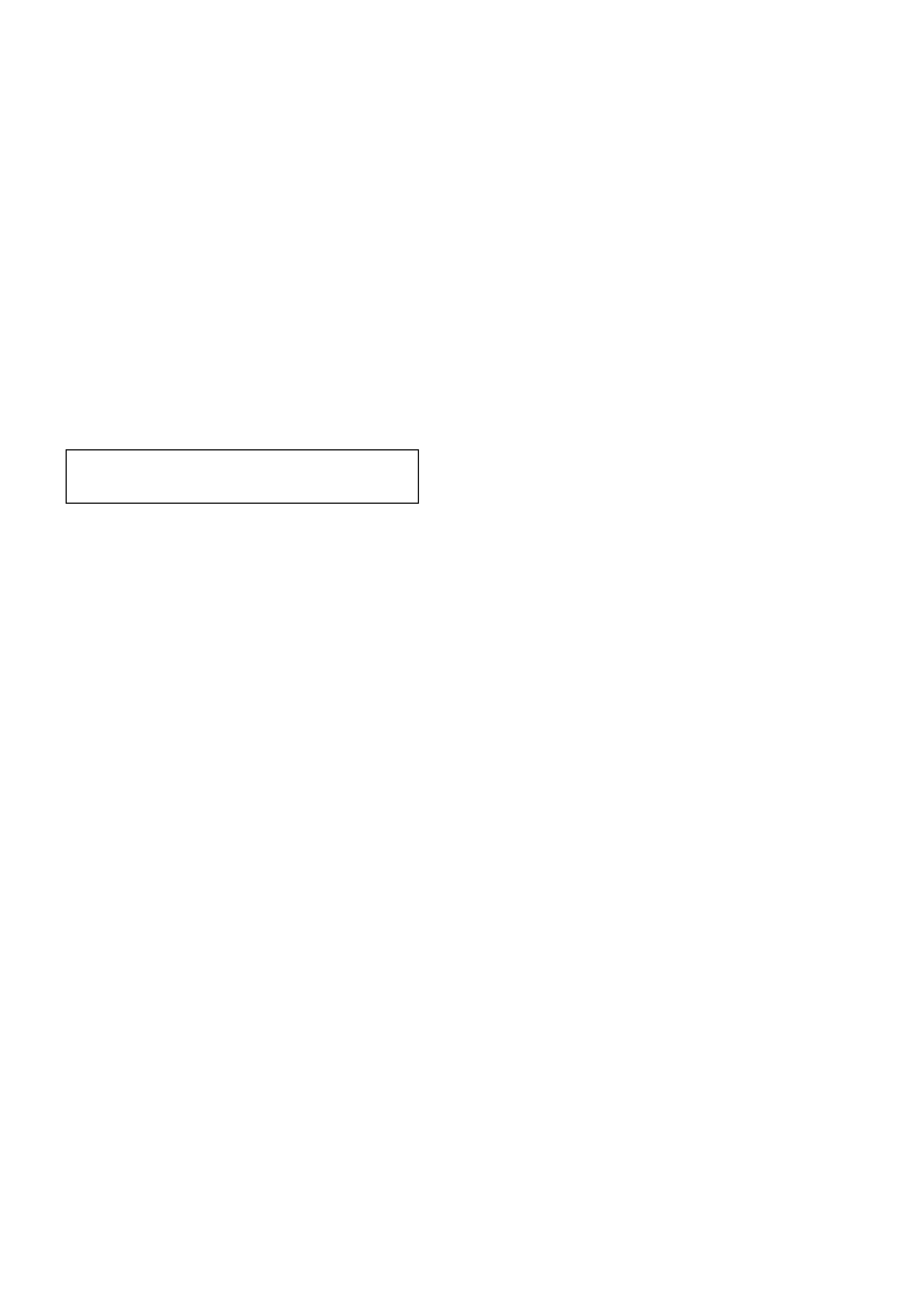

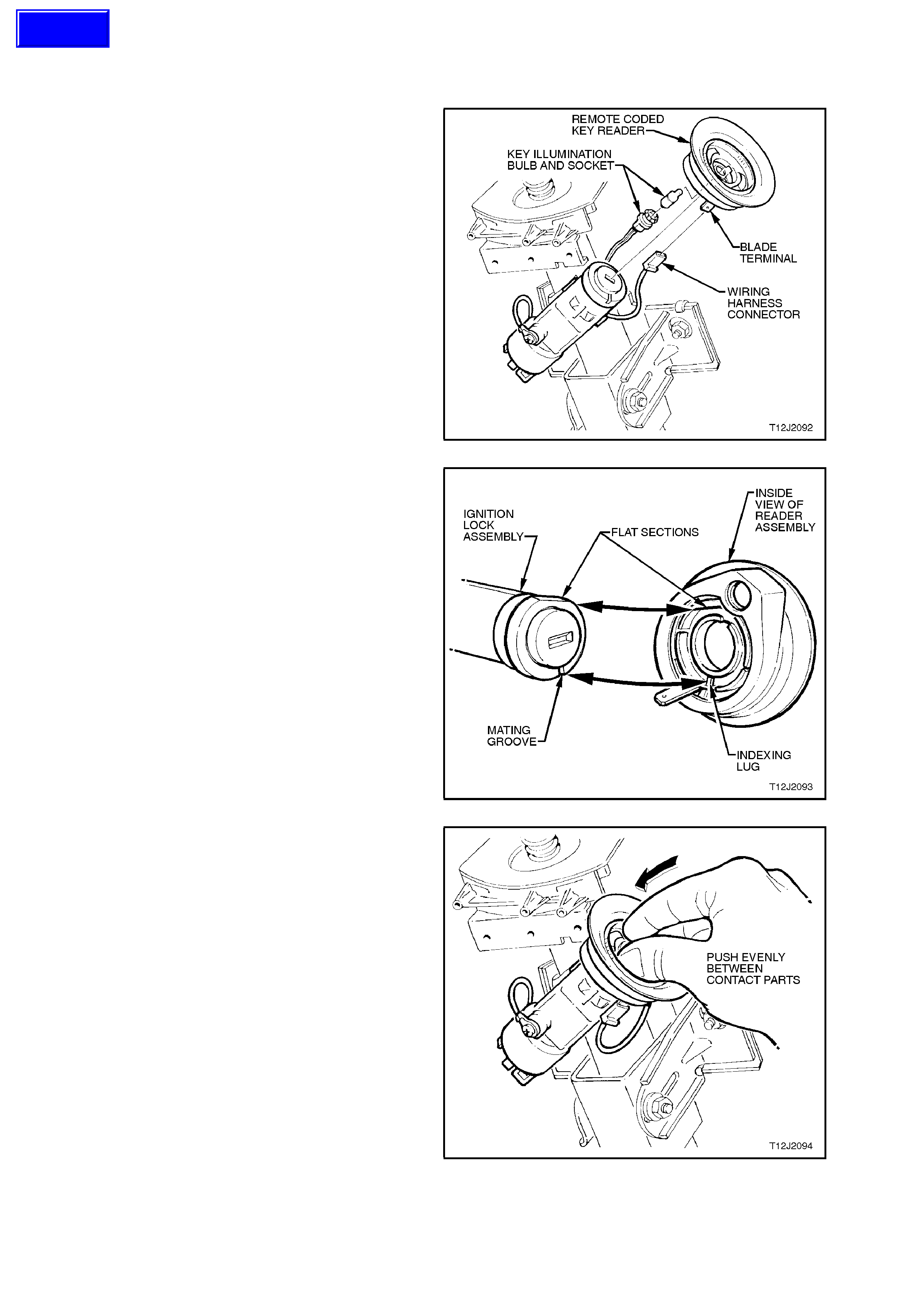

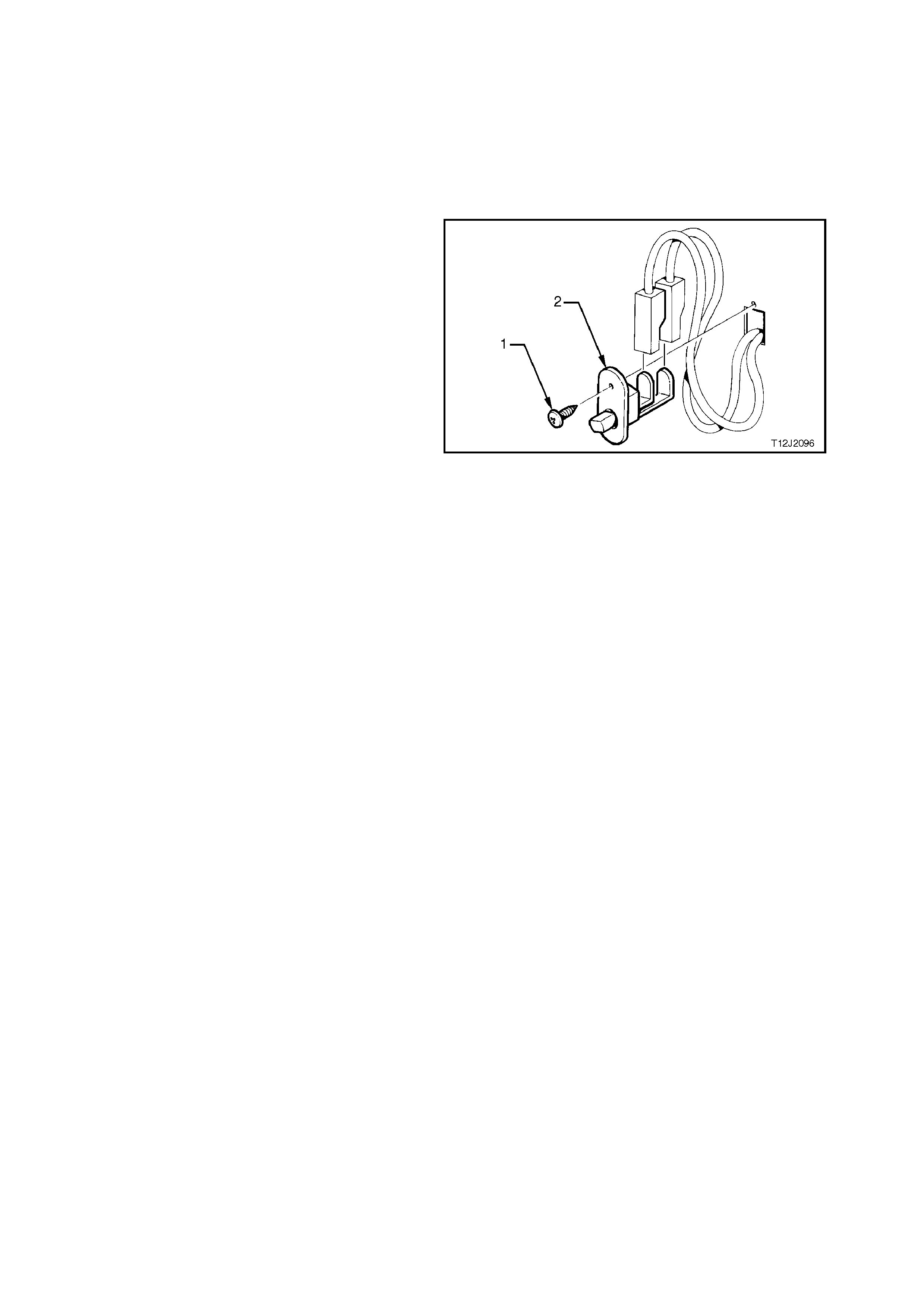

REMOTE CODED KEY

(Refer to Fig. 12J-2-20)

The theft deterrent system uses a remote coded key to arm and disarm the system, and electrically lock or unlock

all doors and tailgate (station wagon), or operate the boot unlock mechanism (sedan models).

The remote coded key is powered by its own internal battery. If its internal battery fails, the remote coded key can

be powered by the remote coded key reader once the key is inserted into the ignition switch key barrel and turned to

the IGN or START position.

The radio frequency transmitted by the remote key is received by the BCM remote receiver, located in the

instrument panel, between the demist ducts.

When the theft deterrent system is armed by pressing the remote coded key lock button, the indicators will flash

once and the theft deterrent alert indicator LED will begin to flash. Disarming the system by pressing the unlock

button will cause the indicators to flash twice and the theft deterrent alert indicator LED will stop flashing.

NOTE:

Passive arming of the system does not automatically operate the door locks or flash the indicators.

Figure 12J-2-20

THEFT DETERRENT ALERT INDICATOR LED

The theft deterrent alert indicator LED is used to indicate the state of the system. A flashing LED indicates that the

system is armed and consequently the vehicle cannot be started. When the LED is turned off, the BCM is disarmed

and the engine can be started.

On VT Series Models, the LED indicator is located in the trip computer switch facia.

OPERATION

(Refer to Fig. 12J-2-21)

When the ignition switch is turned to the ON position, the BCM polls the PCM and sends an encrypted BCM/key

security code. The security code is received by the BCM, via the remote key reader (slip ring) or via the remote

receiver in the event of no slip ring communication.

The PCM compares the received security code with its stored security code and if matched, the PCM will continue

to enable injector fuelling and engine crank.

The PCM will return a Valid Code message (OK TO START), which tells the BCM to jump from the short loop mode

to the long loop mode.

Figure 12J-2-21

SYSTEM OVERVIEW

CIRCUIT OPERATION

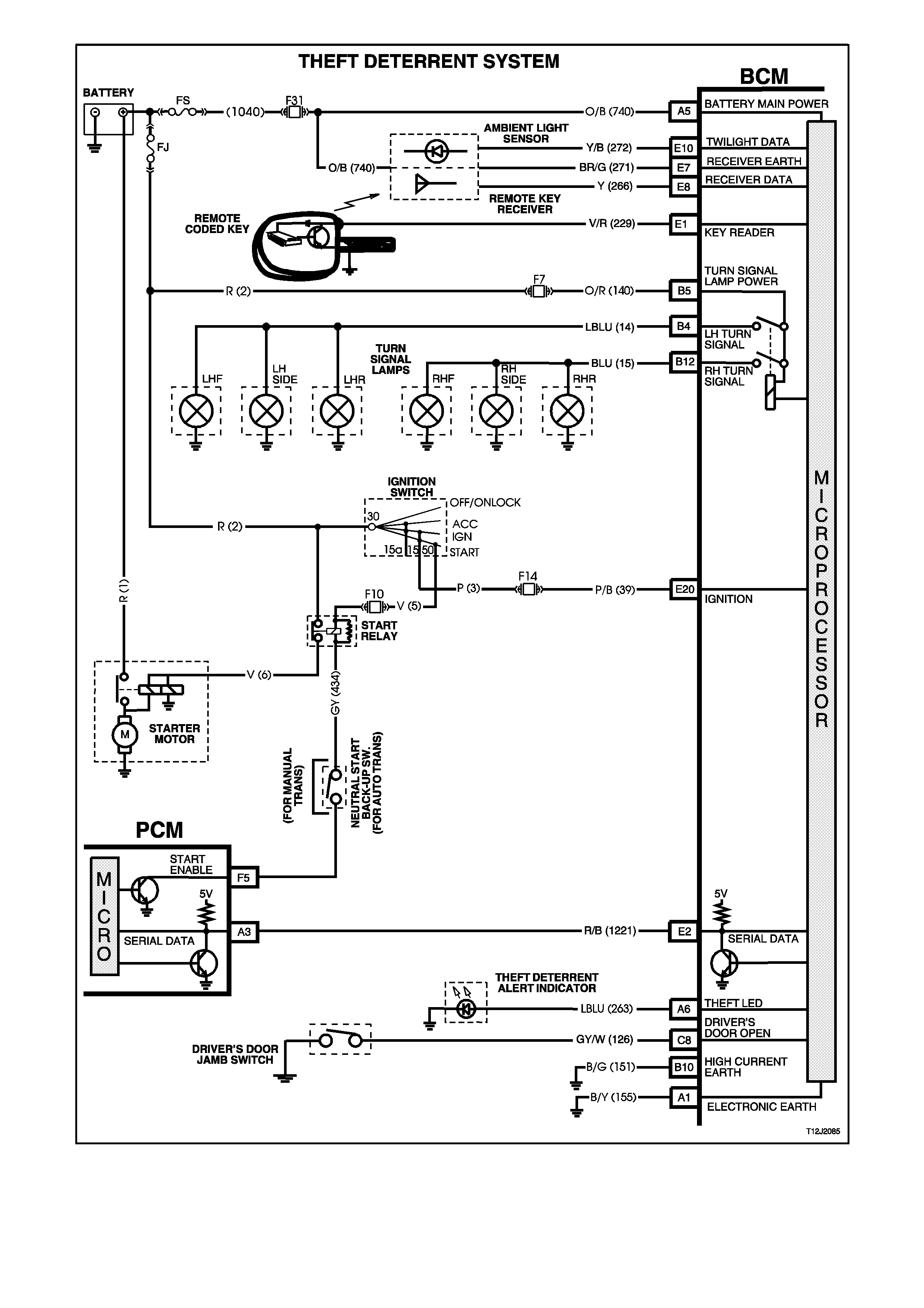

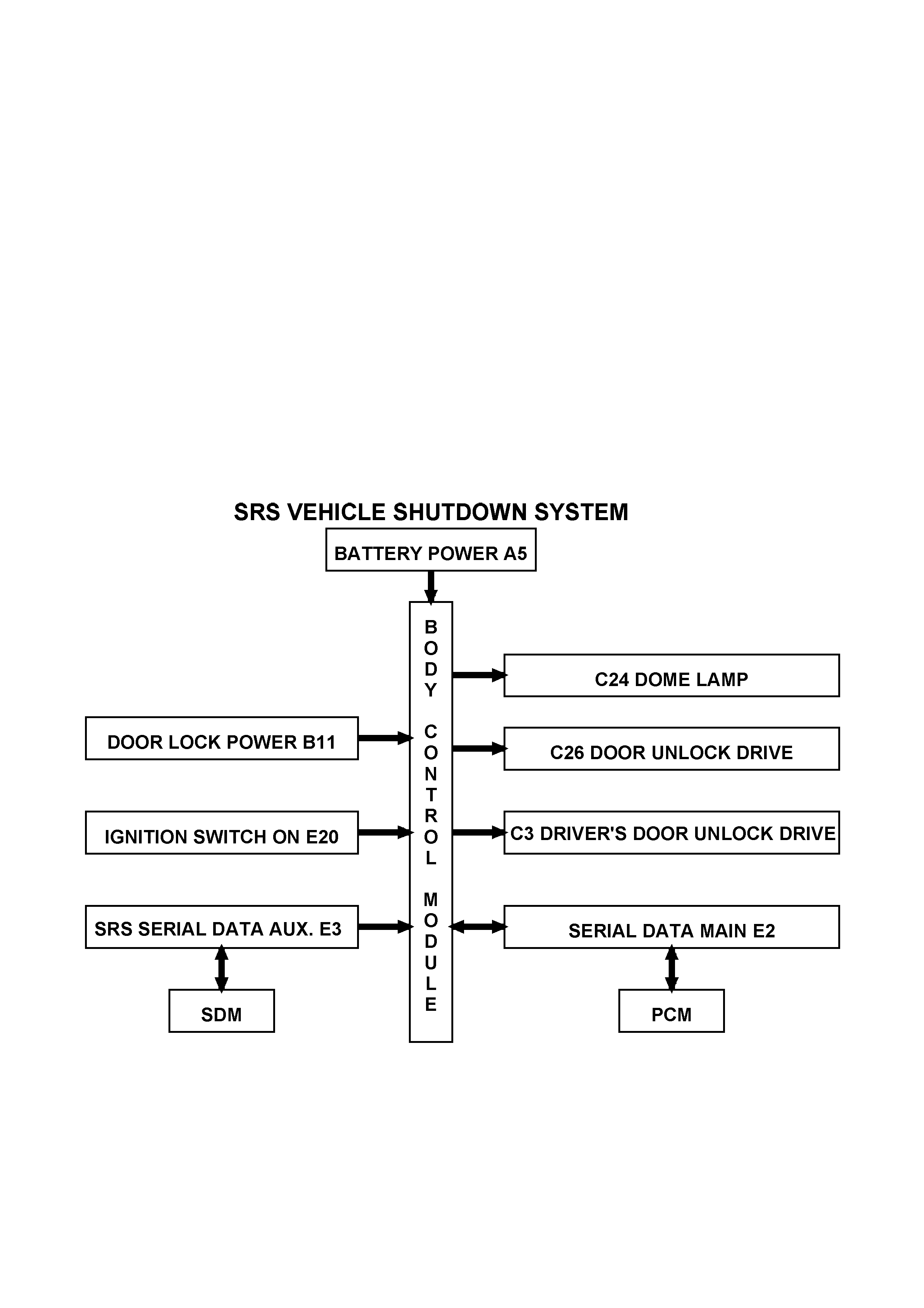

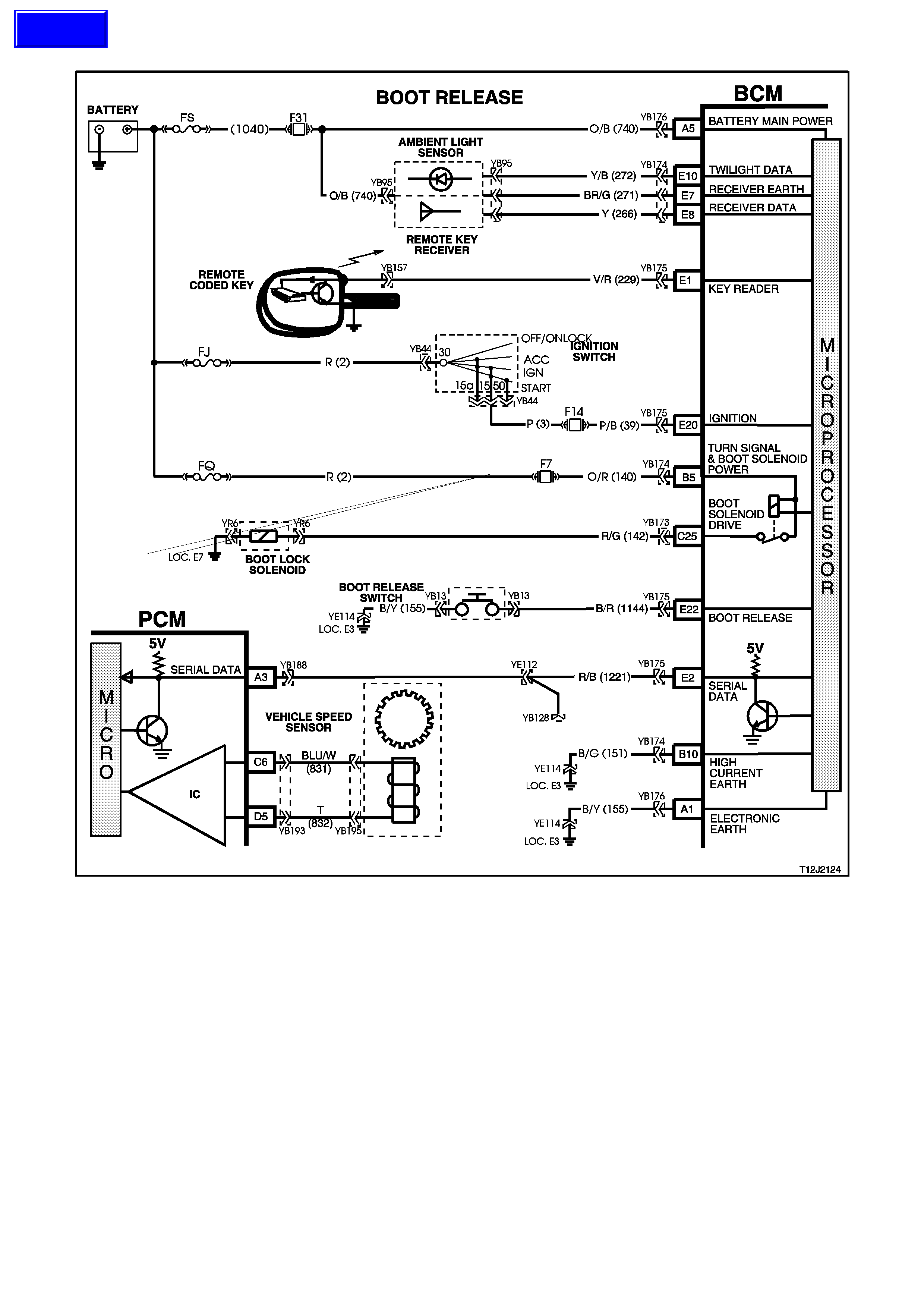

(Refer to Fig. 12J-2-26)

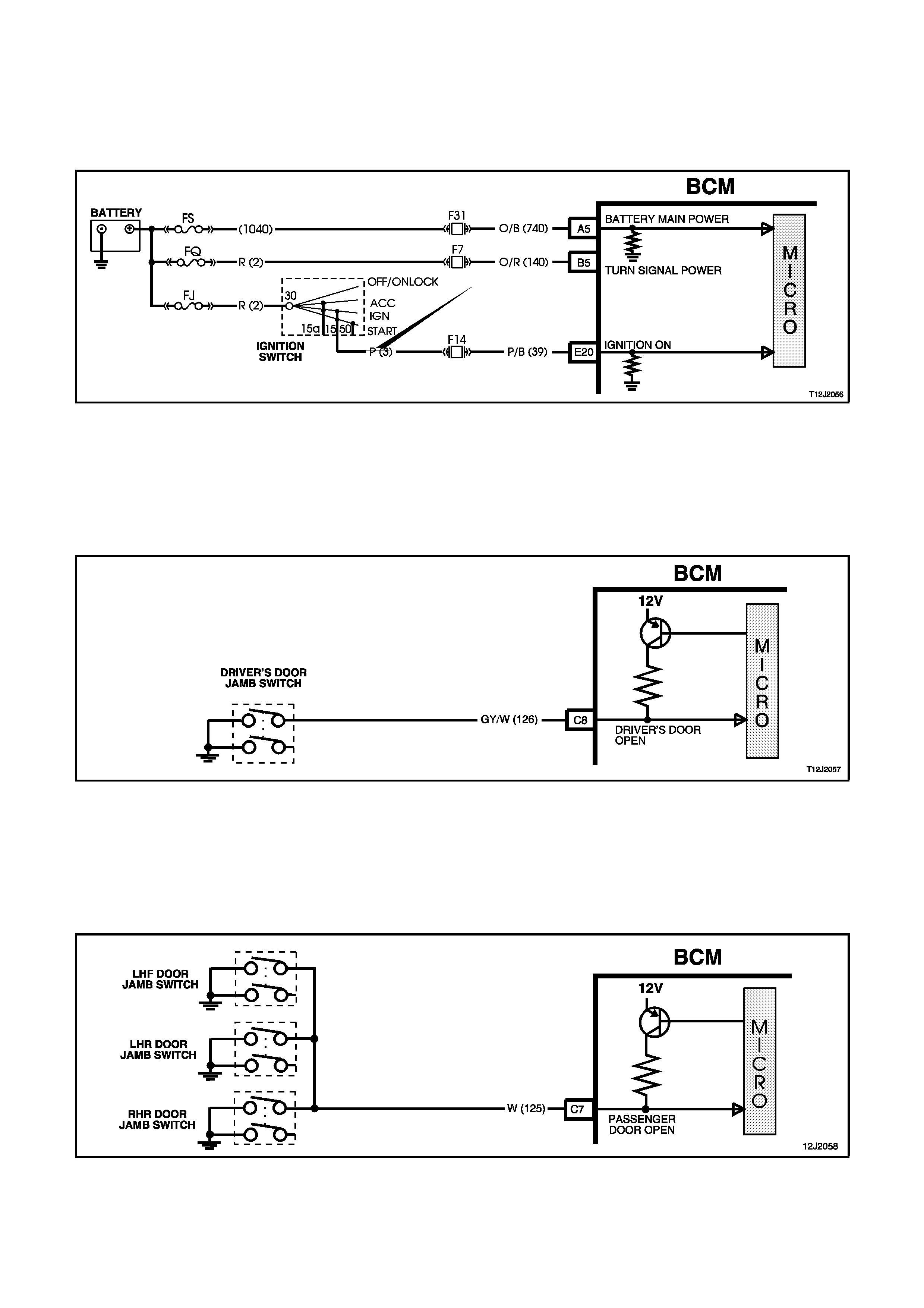

BATTERY POWER

(Refer to Fig. 12J-2-22)

Battery voltage is applied to the BCM microprocessor from terminal A5 at all times from fusible link FS and fuse F31

via circuit 740 (Orange/Black wire).

INDICATORS POWER

(Refer to Fig. 12J-2-22)

Battery voltage is applied to BCM terminal B5 at all times from fusible link FQ and fuse F7 via circuit 140

(Orange/Red wire).

INPUTS

Ignition Switch ON Input Signal

(Refer to Fig. 12J-2-22)

The BCM uses this input signal to determine when the ignition switch is in the IGN or START position. When the

ignition switch is in the IGN or START position, battery voltage is applied to the BCM terminal E20 from the ignition

switch and fuse F14 via circuit 39 (Pink/Black wire).

Figure 12J-2-22

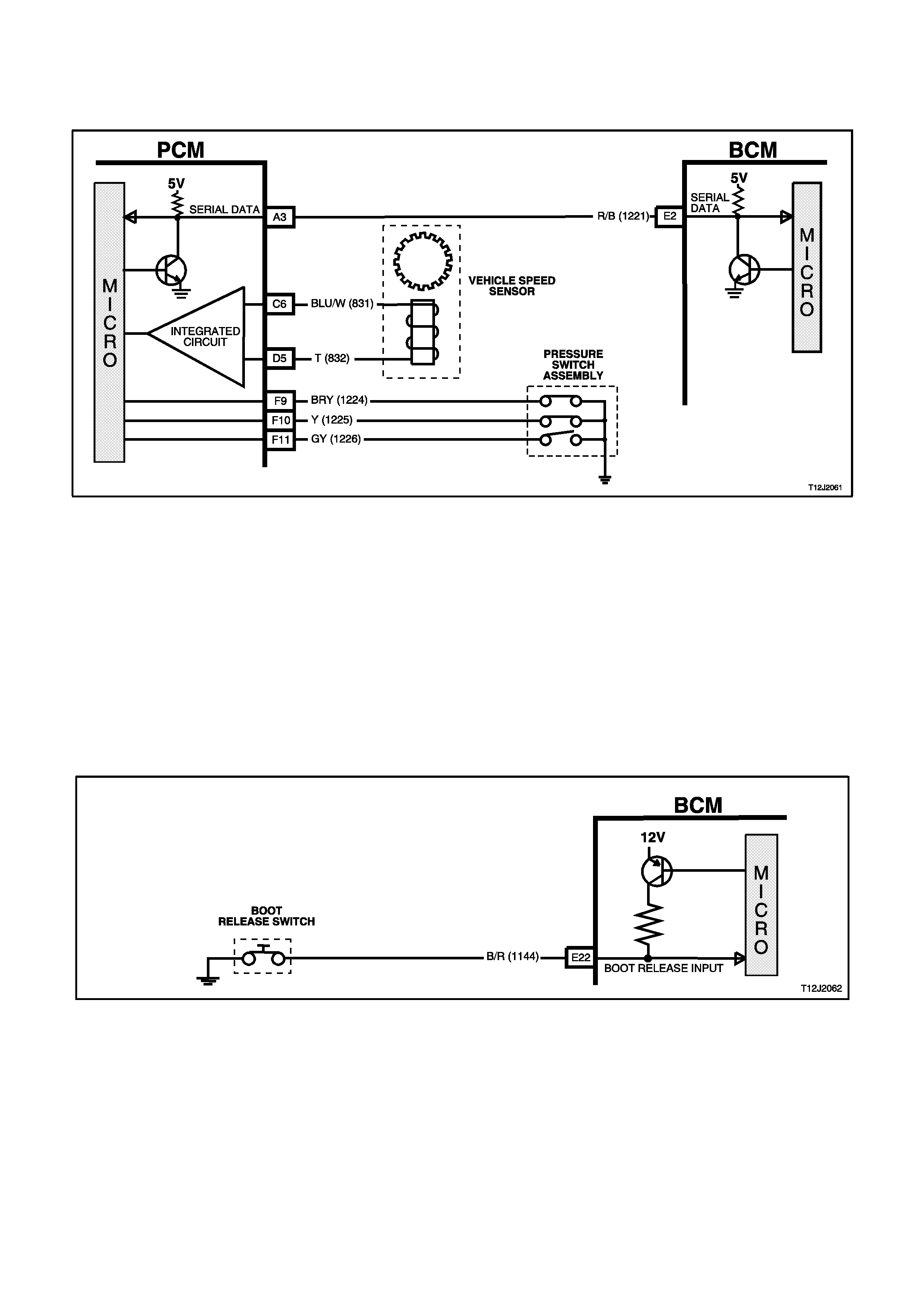

BCM and Engine Control Module Communication (Serial Data)

(Refer to Figs. 12J-2-23 and 12J-2-24)

When the ignition switch is turned to the ON position, and the BCM has received a correct security code from the

key or key reader, the BCM will transmit the security code to the PCM. The PCM will compare that code with its own

stored code. If the security codes are the same, the PCM will continue to enable engine starting and also give the

BCM a ‘Valid Code’ message (OK TO START).

The serial data from the remote coded key is applied to BCM terminal E1, circuit 229 (Violet/Red wire)

Figure 12J-2-23

Figure 12J-2-24

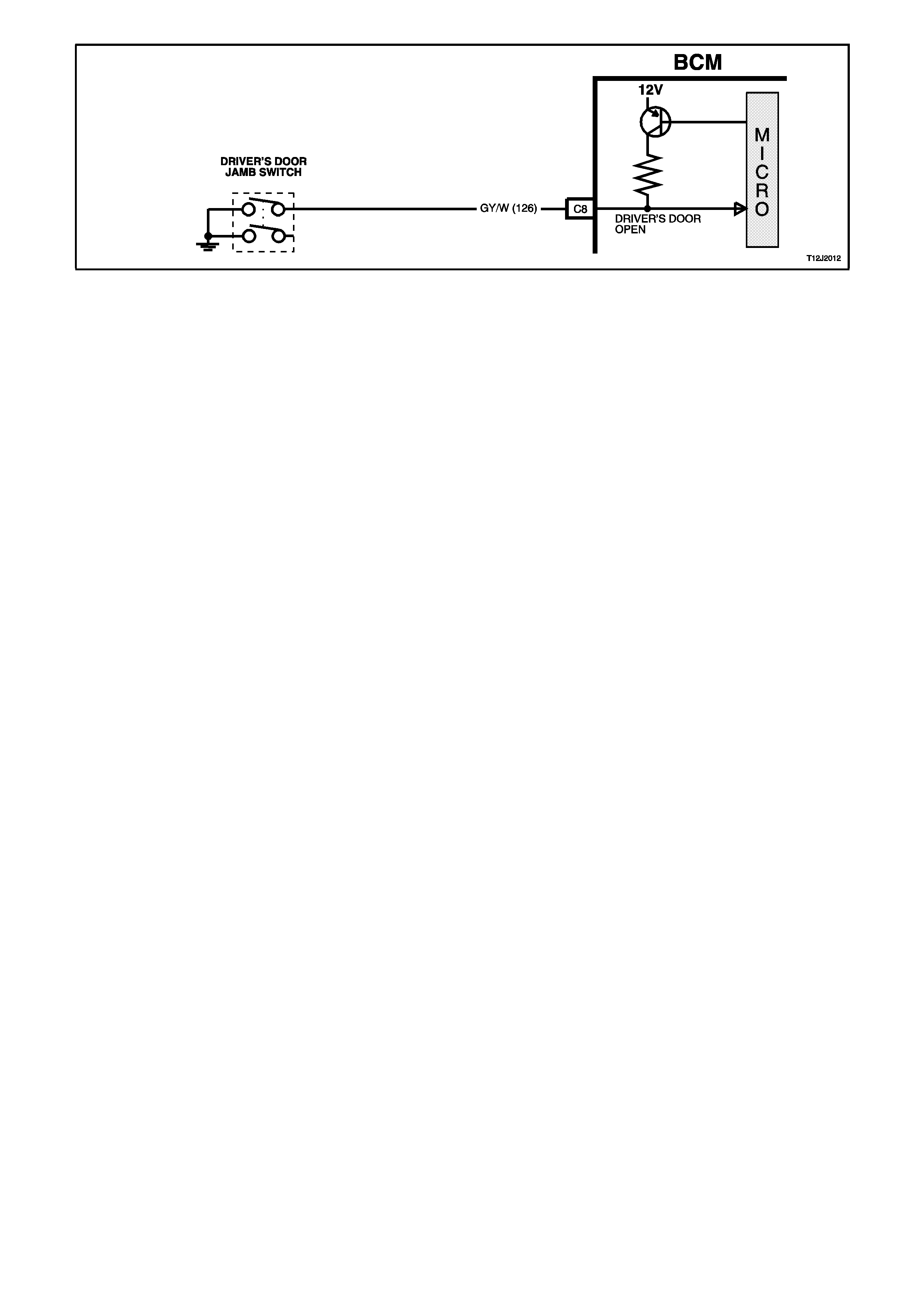

Driver's Door Jamb Switch

(Refer to Fig. 12J-2-25)

The BCM uses this input signal to determine if the driver's front door is opened or closed. The BCM must sense that

the driver's door is closed before the theft deterrent system can be actively armed.

When the door is opened, the jamb switch earths terminal C8 via circuit 126 (Grey/White wire). This causes the

voltage at terminal C8 to be pulled low, less than 0.2 volt (driver's door open). This low voltage at terminal C8 is

seen by the BCM as the driver's door open input signal.

Figure 12J-2-25

OUTPUTS

(Refer to Fig. 12J-2-26)

Left Hand Indicators

The BCM controls the operation of the left hand indicators by pulsing its internal indicator relay. This causes the

indicator relay contacts to close and open a number of times. This allows battery voltage from terminal B5 to be

applied internally to terminal B4, to the left hand indicator lamps via circuit 14 (Light Blue wire).

Right Hand Indicators

The BCM controls the operation of the right hand indicators in the same manner as the left hand indicators. Pulsing

of its internal indicator relay causes the indicator relay contacts to close and open a number of times. This allows

battery voltage from terminal B5 to be applied internally to terminal B12, to the right hand indicator lamps via circuit

15 (Blue wire).

Theft Deterrent Alert Indicator LED

The theft deterrent alert indicator LED will continuously flash on and off whenever the system is armed. The BCM

controls the operation of the theft deterrent alert indicator LED by pulsing an internal switch on and off, which in turn

switches the voltage applied to the theft deterrent alert indicator LED via terminal A6, circuit 263 (Light Blue wire).

Figure 12J-2-26

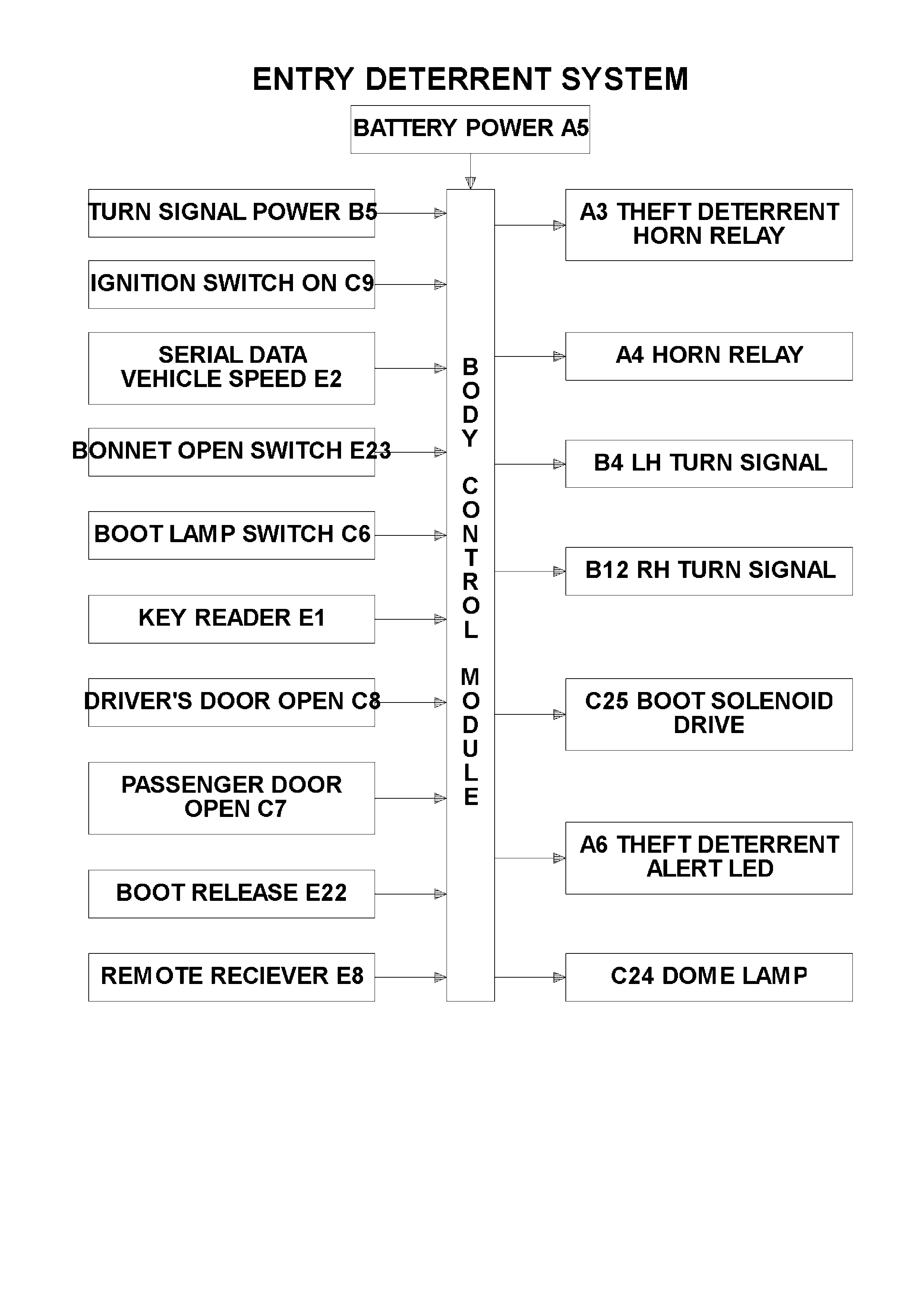

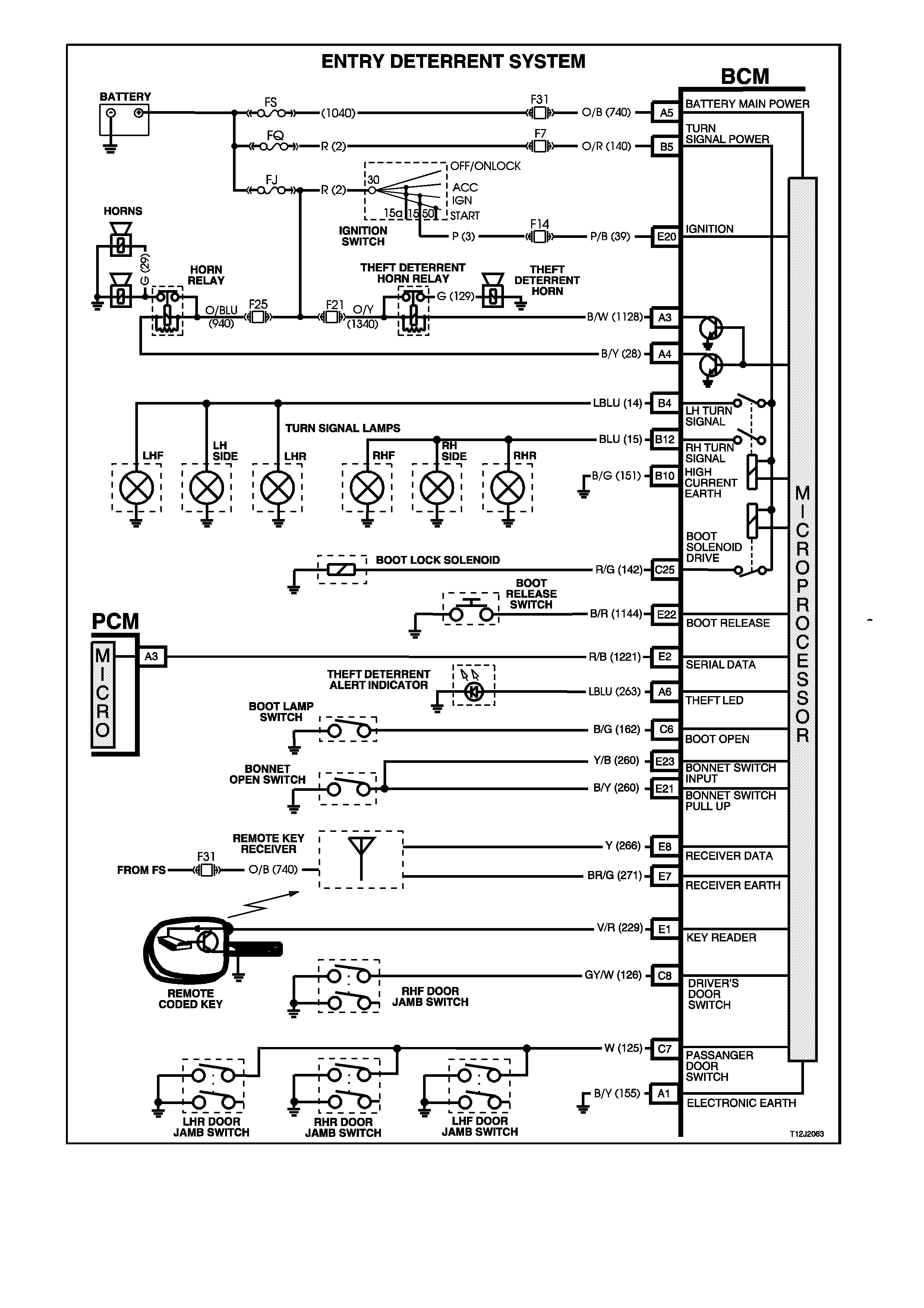

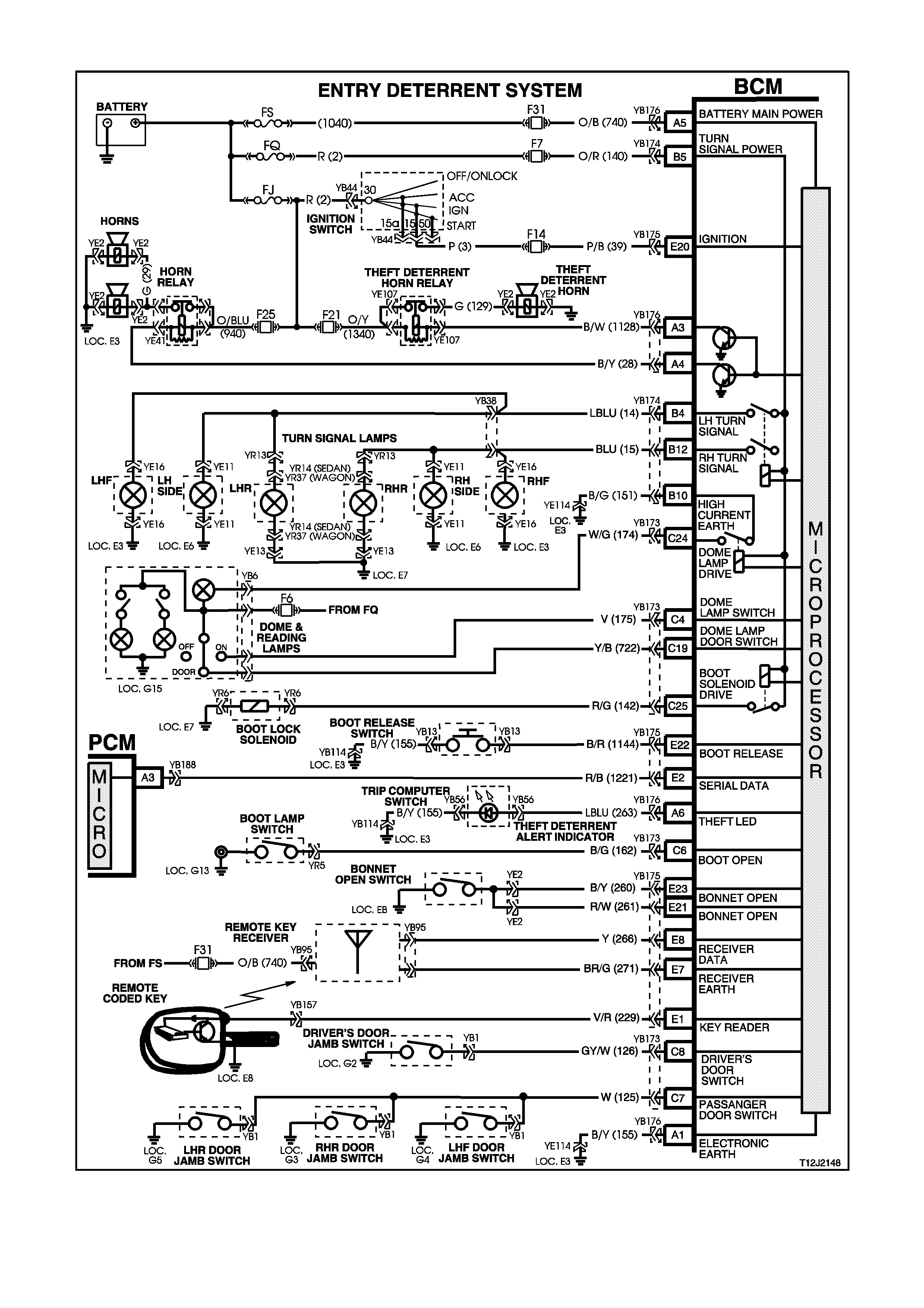

1.4 ENTRY DETERRENT SYSTEM

GENERAL INFORMATION

The entry deterrent system, incorporated in the BCM, is designed to deter unwanted access to the vehicle's

passenger compartment by providing audible and visual warning (alarm) of illegal entry to the vehicle.

Arming of the theft and entry deterrent systems is by pressing the lock button on the remote coded key.

NOTE:

The entry deterrent system does not arm passively.

The remote coded key also incorporates a boot release function button.

An ultrasonic sensor option can also be fitted to the vehicle.

NOTE:

The circuit diagrams shown in this General Description Section are to aid in interpreting the operation of the circuit

and therefore, only the main connectors and wiring colours are shown. For complete circuit details, refer to either

the relevant diagnostic section or Section 12P WIRING DIAGRAMS.

Arming Operation

The entry deterrent system is armed by pressing the lock button on the remote coded key, the output signal from

the key, via the remote receiver, activates the microprocessor within the BCM, providing that the ignition is OFF and

the vehicle road speed input indicates speed is zero. Note that one continuous press of a button on the remote

coded key should cause only one arm/disarm operation. It is not possible to arm the system or remote lock the

doors with the driver's door open.

When the system is armed, the following actions take place:

1. All doors lock (and tailgate on Berlina station wagon).

2. All indicator lamps flash once.

3. The power antenna retracts.

4. The power window system deactivates.

5. The dome lamp is switched off (provided it has not been turned on by another system).

6. The theft deterrent alert indicator LED flashes (refer theft deterrent system operation description).

Triggered Operation

Once the entry deterrent system is armed, it is triggered by any one of the following inputs:

1. The bonnet being opened (or ultrasonic trigger).

2. The boot being opened.

3. Any door being opened.

4. Ignition being switched on.

If any of the previous conditions exist at the time of the system arming, they will be ignored until the fault condition is

cleared.

Once triggered, the system will operate as follows:

1. Flash all indicator lamps at a rate of one flash every two seconds.

2. Pulse all vehicle horns at a rate of one pulse per second.

3. Flash the dome lamp at a rate of one flash every two seconds.

Flashing of the indicators and dome lamp, and sounding of the horn/s will continue for a period of 30 seconds.

Disarming Procedure

The system is disarmed by:

A. Pressing the unlock button on the remote coded key. The RF output signal from remote coded key, via the

remote receiver, activates the microprocessor within the BCM.

Upon disarming the following actions take place:

1. All doors (and tailgate on Berlina station wagon) unlock.

2. All indicators lamps flash twice, however if the system has been triggered since being armed, they will flash

three times.

3. The dome lamp is activated for 30 seconds (normal delay cancellation conditions apply).

4. If the system has been triggered since being armed, the theft deterrent alert indicator LED will flash a code

indicating the triggered source, otherwise it will be turned off. This flashing code will be cancelled once the

ignition is switched on.

B. If the remote coded key is not working (eg. flat battery), turning the ignition on allows the BCM to provide a

power supply to the remote coded key to enable reading of the key security code. (the alarm may trigger

briefly)

Flash Codes

The system triggered flash codes emitted by the theft deterrent alert indicator LED flash at a defined flash rate with

a pause between codes. Pause are 1.5 seconds. Codes are repeated twice before moving to the next code.

Two flashes - bonnet (or ultrasonic sensor)

Three flashes - boot

Four flashes - passenger door

Five flashes - driver's door

Six flashes - ignition on

NOTE:

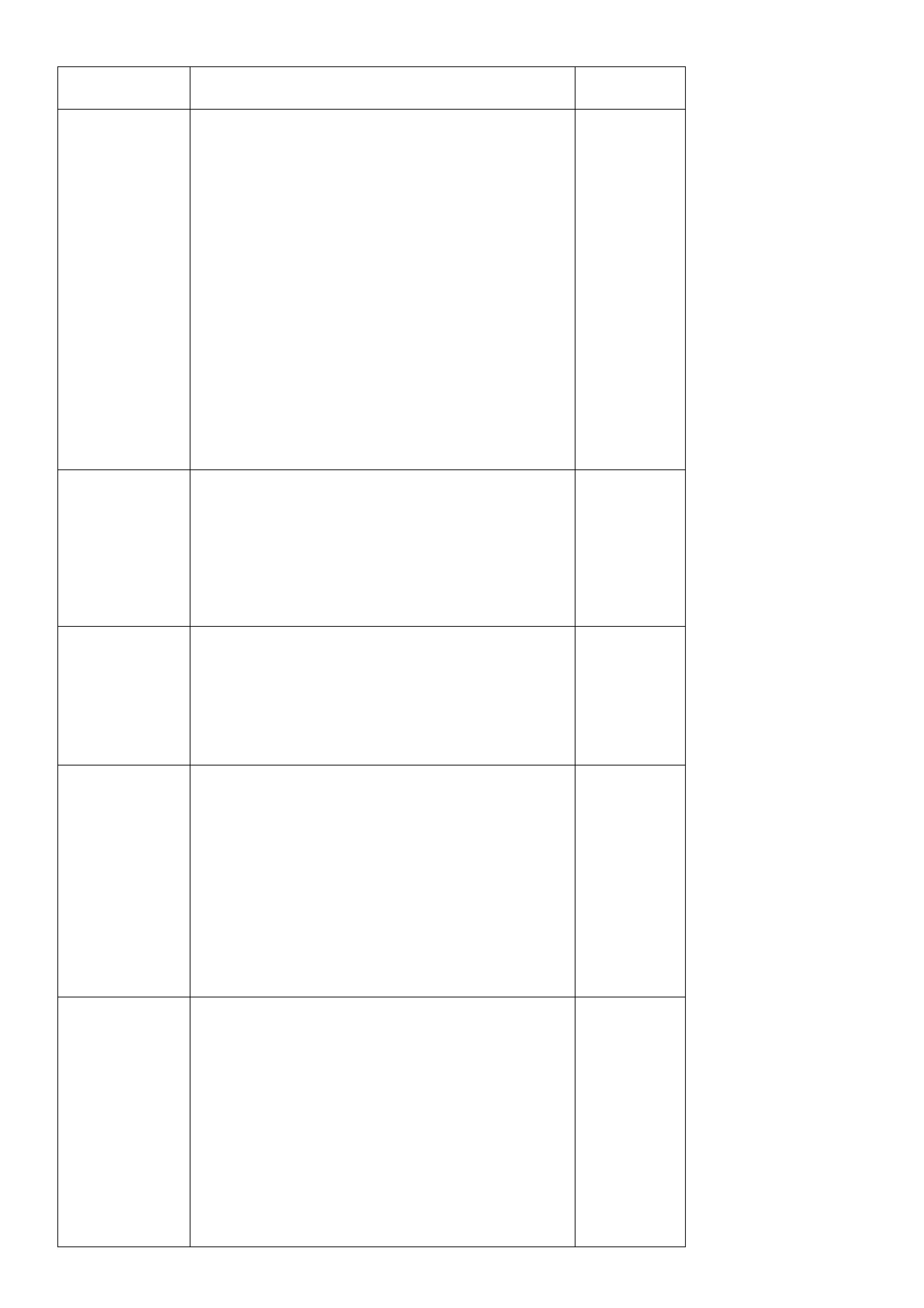

Alarm codes are stored in the BCM until cleared (BCM reset). To access this information, connect TECH 2 to the

DLC and select Body / Body Control Module / Diagnostic Trouble Codes / Read Alarm Code Information.

Remote Boot Release

The rear compartment lock actuator is controlled by pressing the boot button on the remote coded key. The RF

output signal from the remote coded key, via the remote receiver, activates the microprocessor within the BCM.

The rear compartment lock actuator is activated under the following conditions:

1. The boot button on the remote coded key has been pressed continuously for more than 0.5 seconds.

2. The vehicle road speed is less than or equal to fifteen kilometres per hour.

The remote boot release function also operates whilst the entry deterrent system is armed and the system will not

trigger from the remote opening of the boot. Whilst the boot input is inhibited, the bonnet input is similarly inhibited

against triggering the entry deterrent system (this is required for the operation of the ultrasonic sensor option).

After the boot has been closed for 30 seconds, the system will re-arm the boot and bonnet sensing to allow

triggering from the boot and bonnet.

Loss of Vehicle Battery Power

Whenever there is a re-connection of battery power to the BCM, the theft and entry deterrent systems will resume in

the same state as when the battery power was disconnected, except if the system was disarmed. If the system was

disarmed, it will default to passive arm.

SYSTEM OVERVIEW

CIRCUIT OPERATION

(Refer to Fig. 12J-2-34)

Power Supplies

(Refer to Fig. 12J-2-27)

Battery Power

Battery voltage is applied to the BCM microprocessor from terminal A5 at all times from fusible link FS and fuse F31

via circuit 740 (Orange/Black wire).

Turn Signal Power

Battery voltage is applied to BCM terminal B5 at all times from fusible link FQ and fuse F7 via circuit 140

(Orange/Red wire).

INPUTS

(Refer to Fig. 12J-2-27)

Ignition Switch ON Input Signal

The BCM uses this input signal to determine when the ignition switch is in the IGN or START position. When the

ignition switch is in the IGN or START position, battery voltage is applied to the BCM terminal E20 from the ignition

switch and fuse F14 via circuit 39 (Pink/Black wire).

Figure 12J-2-27

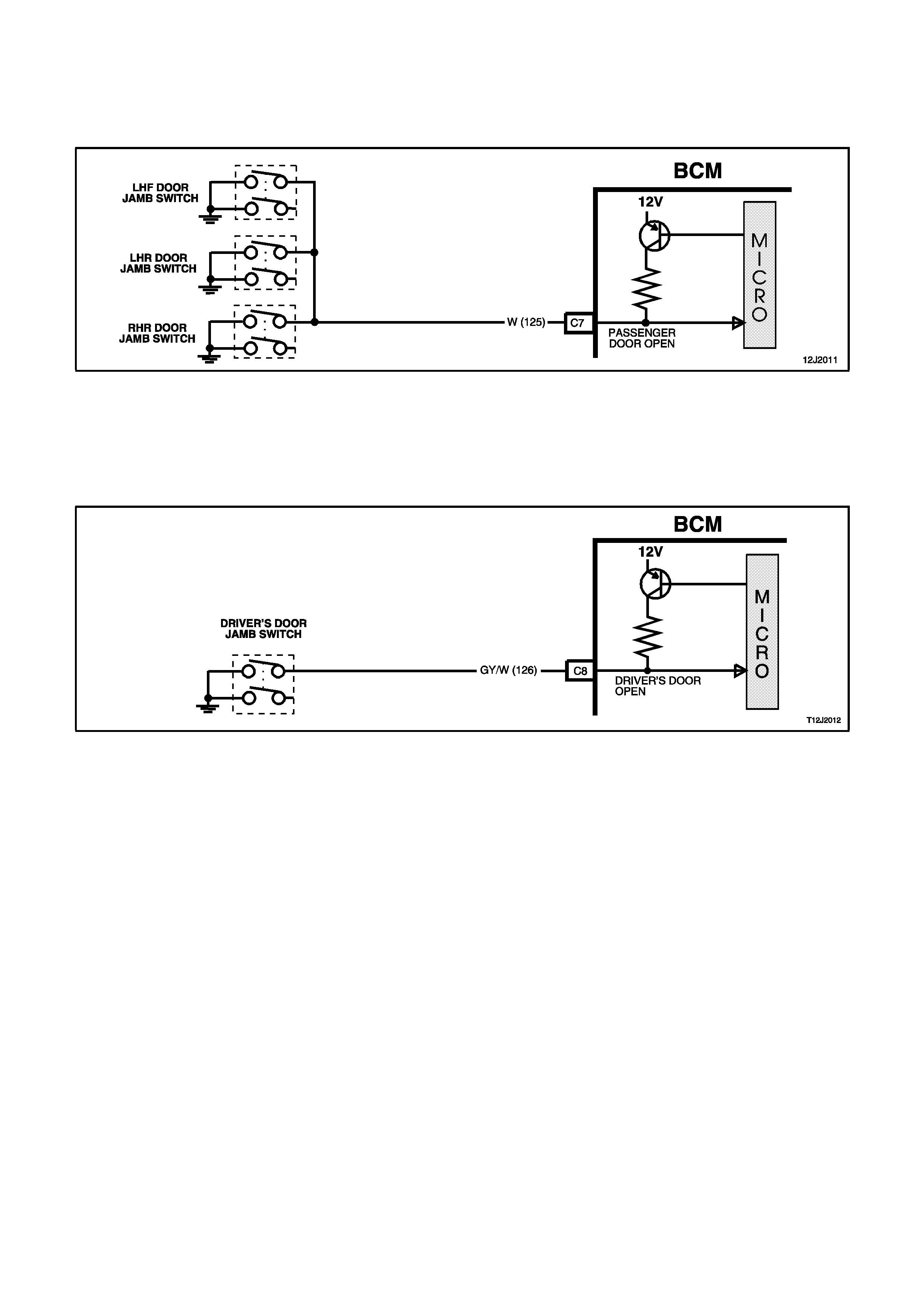

Driver's Door Jamb Switch Input Signal

(Refer to Fig. 12J-2-28)

The BCM uses this input signal to determine if the driver's front door is opened or closed. When the door is opened,

the jamb switch earth’s terminal C8 via circuit 126 (Grey/White wire). This causes the voltage at terminal C8 to be

pulled low, less than 0.2 volt (driver's door open). This low voltage at terminal C8 is seen by the BCM as the driver's

door open input signal.

Figure 12J-2-28

Passenger’s Door Jamb Switch Input Signal

(Refer to Fig. 12J-2-29)

The BCM uses this input signal to determine if any of the passenger doors are opened or if all passenger doors are

closed. If the right hand rear, left hand front or left hand rear door is open, terminal C7 is earthed through circuit 125

(White wire). This causes the voltage at terminal C7 to be pulled low, less than 0.2 volt (if any one of the passenger

doors is opened). This low voltage at terminal C7 is seen by the BCM as the passenger door open input signal.

Figure 12J-2-29

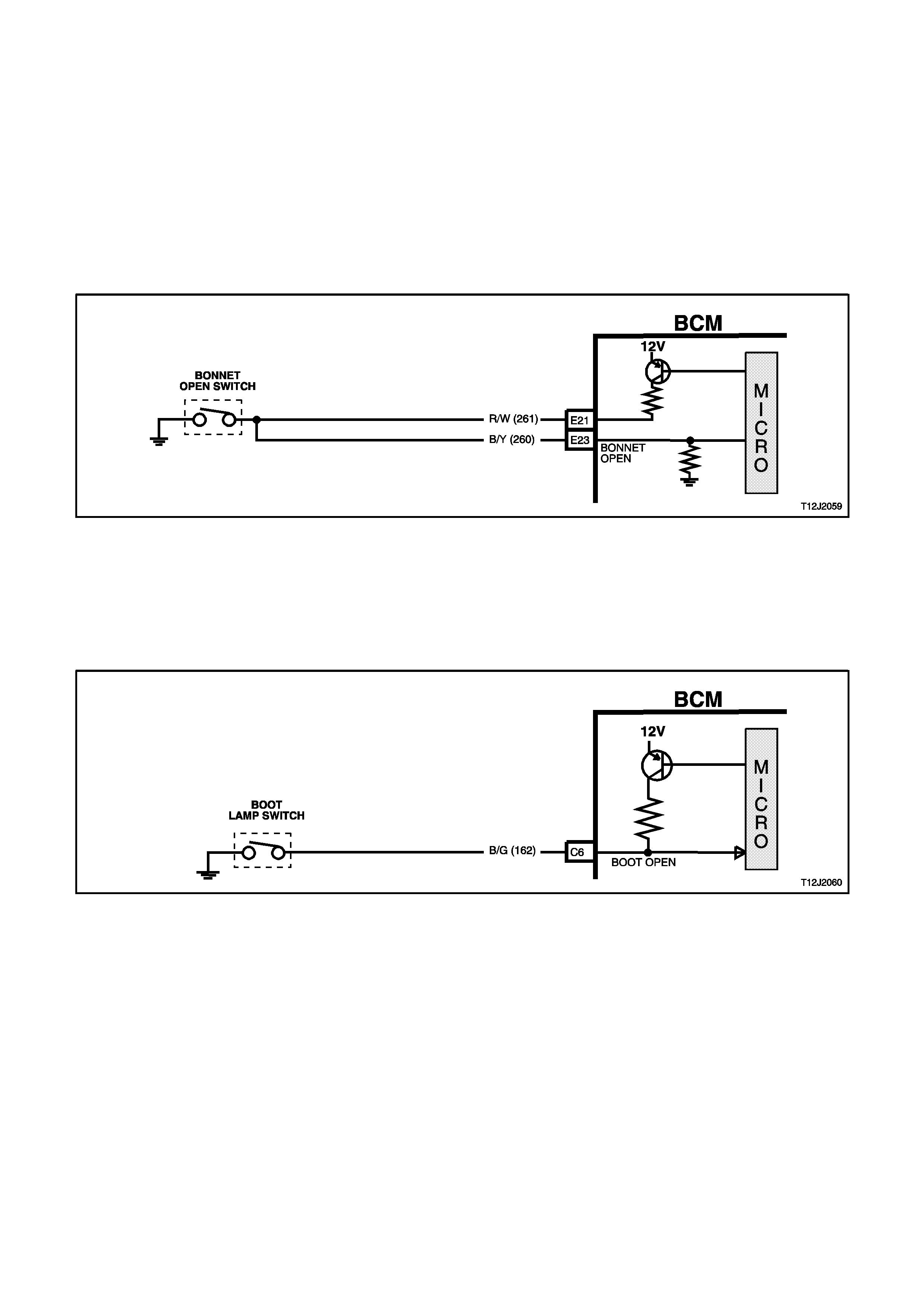

Bonnet Open Switch Input Signal

(Refer to Fig. 12J-2-30)

The BCM uses this input signal to determine if the bonnet is open or closed. When the bonnet is closed, battery

voltage from the BCM, via circuit 261 (Red/White wire) passes through the bonnet switch, via circuit 260

(Yellow/Black wire) and is applied to the BCM terminal E23. This high voltage at the BCM terminal E23 is seen by

the BCM as the bonnet closed input signal. In the event of an open circuit in either circuits 260 or 261, the BCM

internal pull down resistor ensures that the voltage at the input to the microprocessor is less than 0.2 volts. This low

voltage at the microprocessor is seen as the bonnet open signal. This is to ensure that if either of these two circuits

are tampered with, the alarm will be triggered.

When the bonnet is opened, the theft deterrent bonnet open switch closes and earth’s the BCM terminal E23

through circuit 260 (Yellow/Black wire). This action causes the voltage at the BCM terminal E23 to be pulled low,

less than 0.2 volts (bonnet open). This low voltage at BCM terminal E23 is seen by the BCM as the bonnet open

input signal.

Figure 12J-2-30

Boot Lamp Switch Input Signal (Sedan Models Only)

(Refer to Fig. 12J-2-31)

The BCM uses this input signal to determine if the boot is open or closed. When the boot is opened, the boot lamp

switch earth’s BCM terminal C6 through circuit 162 (Black/Green wire). This action causes the voltage at BCM

terminal C6 (Boot Open) to be pulled low, less than 0.2 volt). This low voltage at BCM terminal C6 is seen by the

BCM as the boot open input signal.

Figure 12J-2-31

Vehicle Speed Signal

(Refer to Fig. 12J-2-32)

The BCM terminal E2, receives the vehicle speed from the PCM via the serial data communications bus, circuit

1221 (Red/Black wire).

Figure 12J-2-32

Remote Coded Key RF Signals

When the lock, unlock or boot button on the remote coded key is pressed the remote coded key transmits a Radio

Frequency (RF) signal. The BCM, on receiving any of these RF signals (via remote receiver), determines from the

signal received which button was pressed.

Boot Release input Signals

(Refer to Fig. 12J-2-33)

Pressing the rear compartment lock switch causes the contacts to close, connecting BCM terminal E22 to earth via

circuit 1144 (Black/Red wire). This action causes the voltage at terminal E22 to be pulled low, less than 0.2 volt.

This low voltage at terminal E22 is seen by the BCM as the boot release switch input signal.

NOTE:

The BCM will not activate the rear compartment lock actuator if the vehicle speed is above fifteen kilometres per

hour.

Figure 12J-2-33

OUTPUTS

Theft Deterrent Alert Indicator LED

The theft deterrent alert indicator LED will flash continuously on and off whenever the system is armed. The BCM

controls the operation of the theft deterrent alert indicator LED by pulsing an internal switch on and off, which in turn

allows the switching of the voltage applied to the theft deterrent alert indicator LED via terminal A6, circuit 263 (Light

Blue wire ).

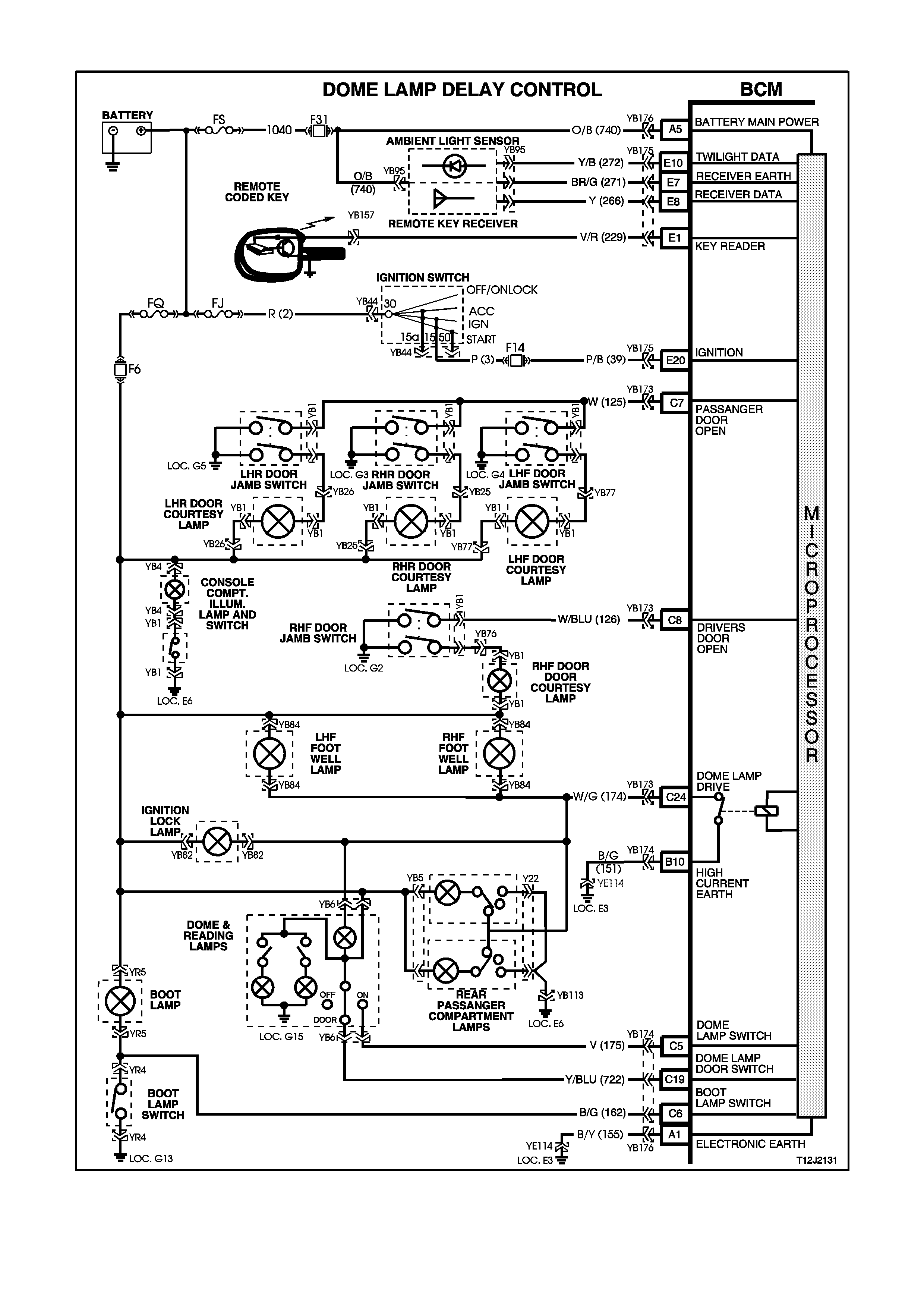

Dome Lamp

Battery voltage is applied to all interior lamps via fuse F6 and circuit 1140 (Orange/Black wire). The opposite side of

the dome lamps are connected to earth via circuit 174 (White/Green wire) and BCM terminal C24. The BCM

controls the operation of the dome lamps connected to this earth circuit by energising its internal dome lamp relay

coil, this causes the internal relay contacts to close completing the circuit to earth.

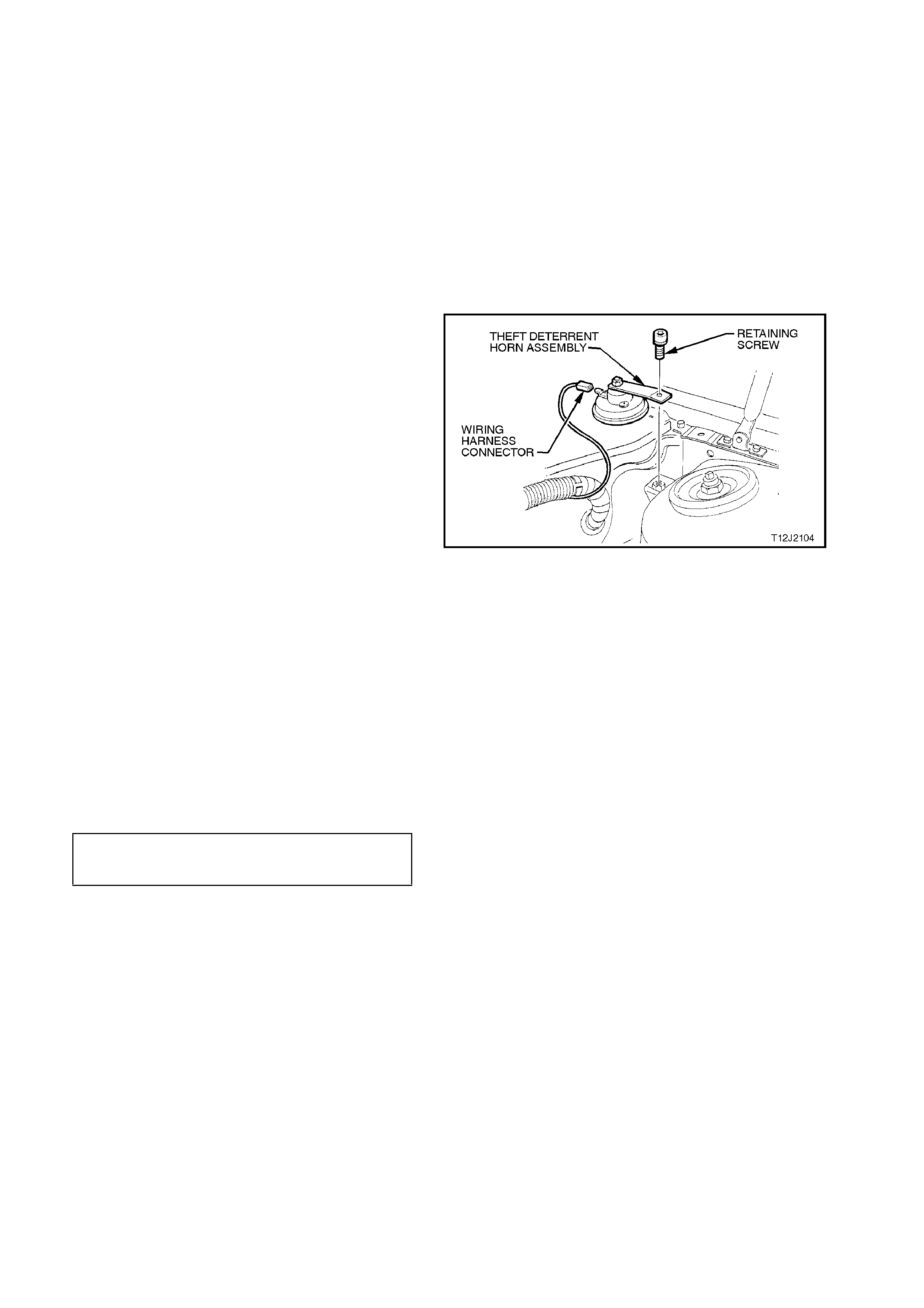

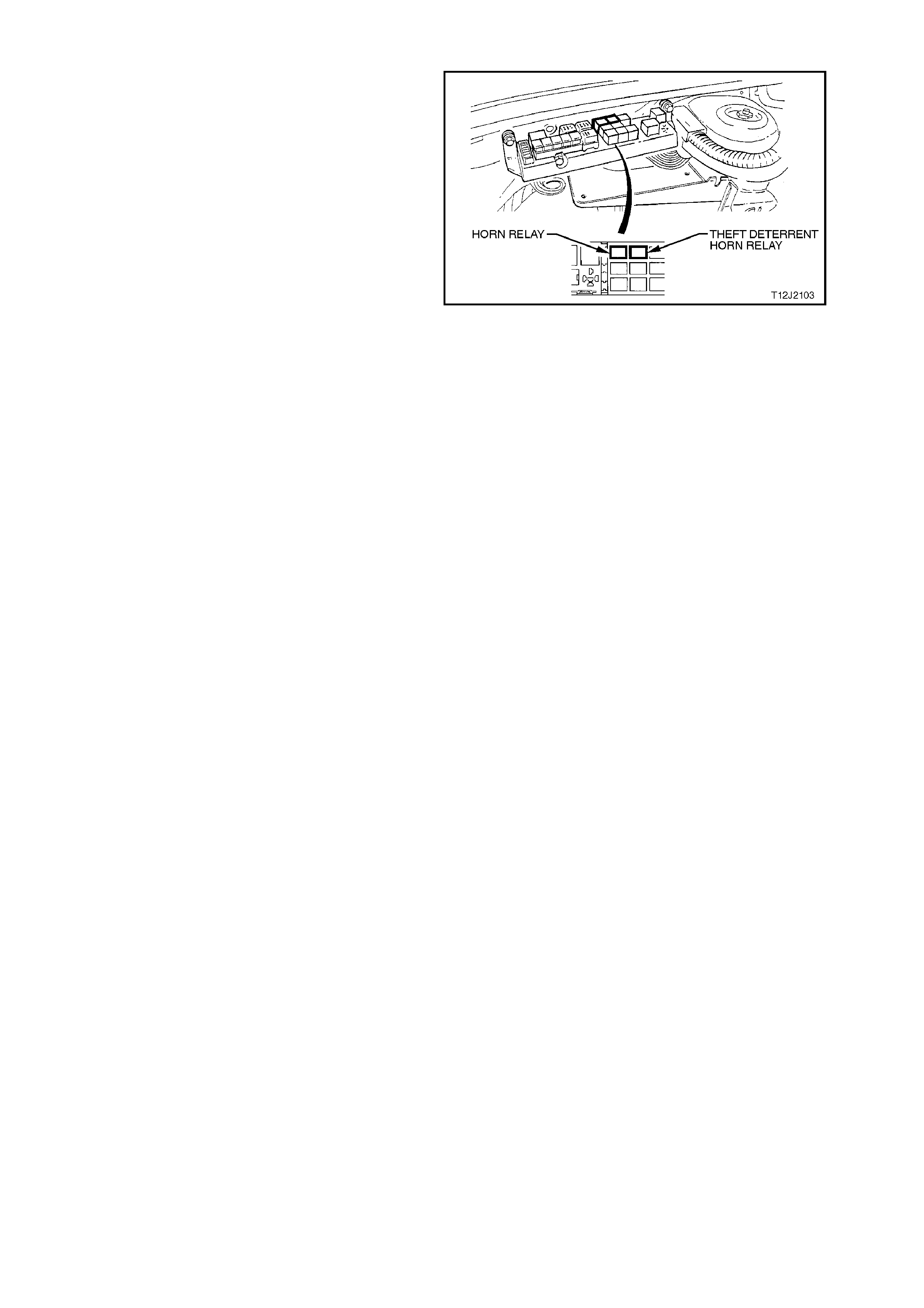

Horn Relay

The BCM can control the operation of the vehicle horn/s by pulsing the horn relay coil to earth through terminal A4,

circuit 28 (Black/Y ellow wire).

Theft Deterrent Horn Relay

The BCM controls the operation of the theft deterrent horn by pulsing the theft deterrent horn relay coil to earth

through terminal A3, circuit 1128 (Black/White wire). The same circuit in the BCM earth’s this circuit and the horn

circuit.

Left Hand Indicators

The BCM controls the operation of the left hand indicators by pulsing its internal indicator relay. This causes the

indicator relay contacts to close and open a number of times. This allows battery voltage from terminal B5 to be

applied to terminal B4, to the left hand indicator lamps via circuit 14 (Light Blue wire).

Right Hand Indicators

The BCM controls the operation of the right hand indicators in the same manner as the left hand indicators. Pulsing

of its internal indicator relay causes the indicator relay contacts to close and open a number of times. This allows

battery voltage from terminal B5 to be applied to terminal B12, to the right hand indicator lamps via circuit 15 (Blue

wire).

Rear Compartment Lock Actuator

The BCM can activate the rear compartment lock actuator by energising its internal boot release relay. This will

apply battery voltage from terminal B5, through the boot release relay contacts and terminal C25 to the rear

compartment release actuator, circuit 142 (Red/Green wire). The earth circuit for the rear compartment solenoid is

via the body and main wiring harness.

Figure 12J-2-34

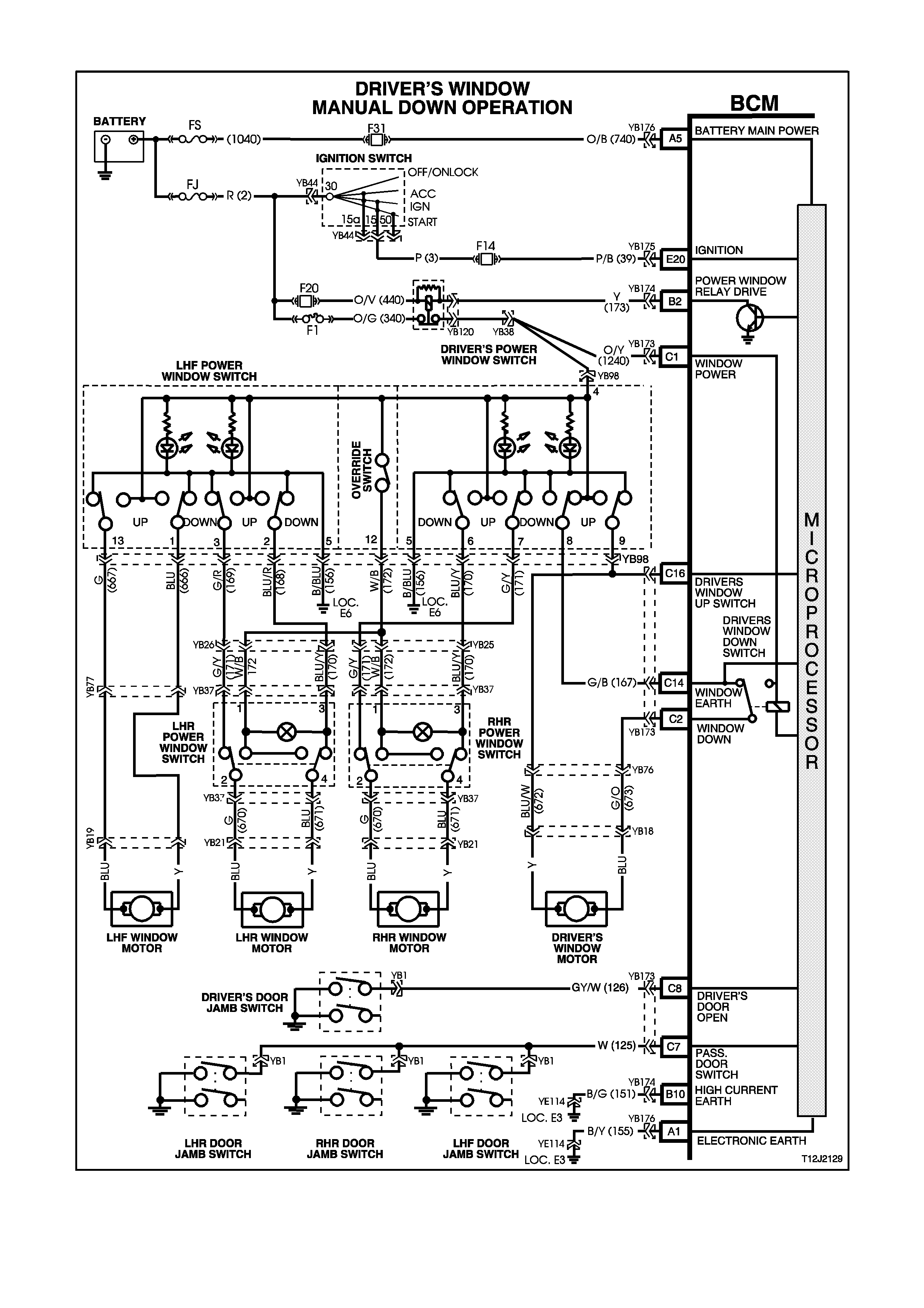

1.5 POWER WINDOW SYSTEM

GENERAL INFORMATION

The BCM controls the following functions of the power window system:

1. Control of positive supply to all door window motors.

2. Automatic down of driver's door window (activated when the driver's power window switch DOWN button is

depressed for more than 0.4 seconds).

Once activated, the automatic down feature is cancelled within 100 ms (0.1 seconds) after:

a. The driver's power window switch UP button is depressed following which the window will move upward or:

b. The driver's power window switch DOWN button is depressed and released. In this case, the window will

remain stationary until another activation (down or up button depressed) takes place.

c. With ignition on, power is supplied continuously to the window system.

d. When ignition is switched OFF and no door has been opened, power is supplied to the window system for a

maximum of 60 minutes.

e. In the event of any door being opened, power is supplied to the system for 45 seconds maximum, timed

from when any door was opened.

When the doors are remotely unlocked (by using the remote coded key) power is supplied to the system for 60

minutes and for a maximum of 45 seconds, once the door has been opened and the ignition has not been turned

ON. The delay is cancelled when the doors are locked by the remote coded key.

NOTE:

The circuit diagrams shown in this General Description Section are to aid in interpreting the operation of the circuit

and therefore, only the main connectors and wiring colours are shown. For complete circuit details, refer to either

the relevant diagnostic section or Section 12P WIRING DIAGRAMS.

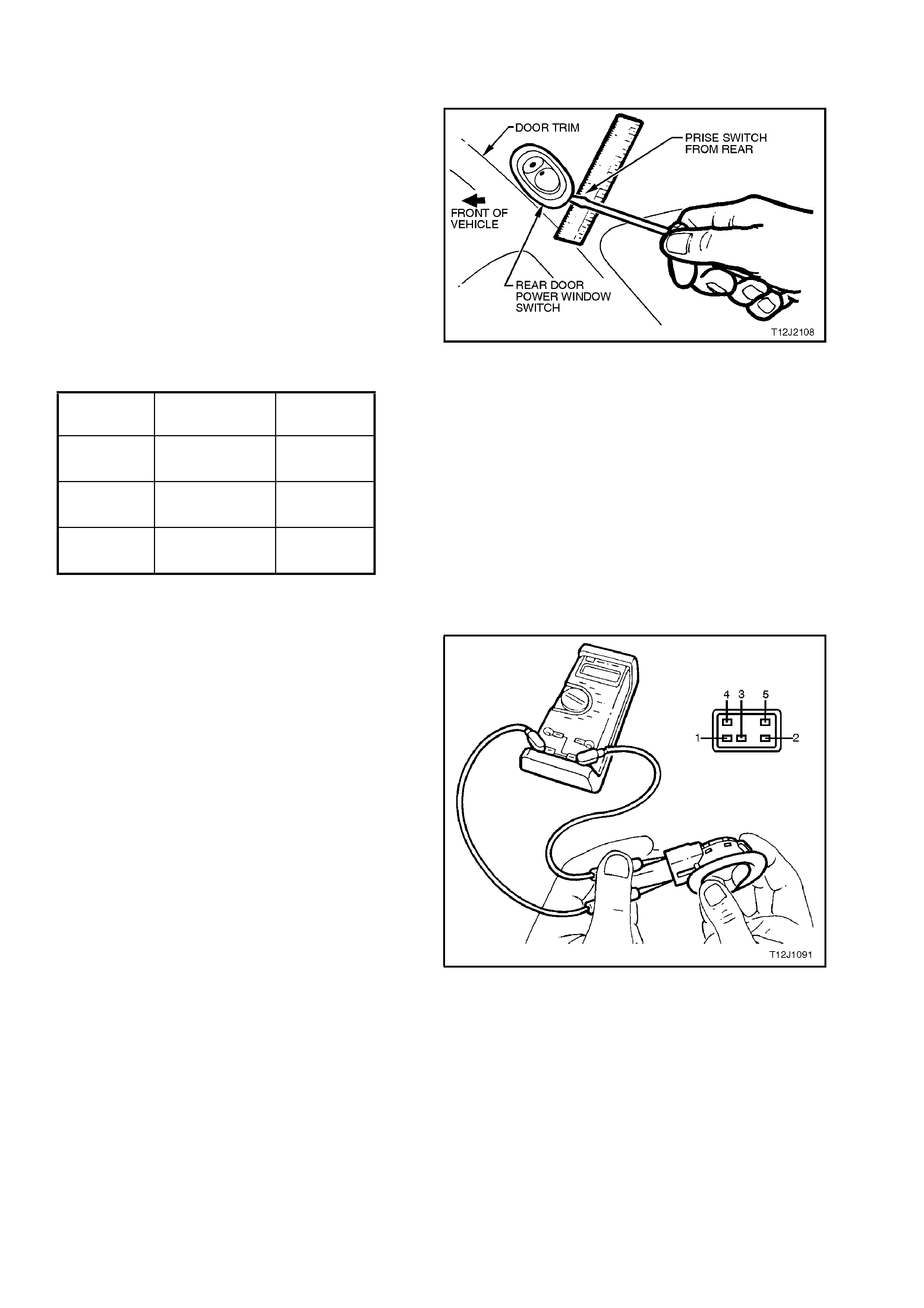

SYSTEM CHECK

Prerequisite Condition

The child saf ety switch must be s witched O FF . T his

will be indicated by the green Light Emitting Diode

(LED) in each of the rear door rocker switches

being illuminated.

System Active

‘System active’ is indicated by the illumination of

the rocker switches.

W hen the ignition switch is turned ON, all switches

are active.

With the ignition switch turned OFF, all switches

will remain active for 45 seconds after any door is

opened. If during this 45 second per iod the driver’s

window switch is activated, the active period will be

extended a further 45 seconds.

With the ignition switch turned OFF, all switches

will remain active for approximately 60 minutes,

PROVIDED THERE ARE NO OPEN DOORS.

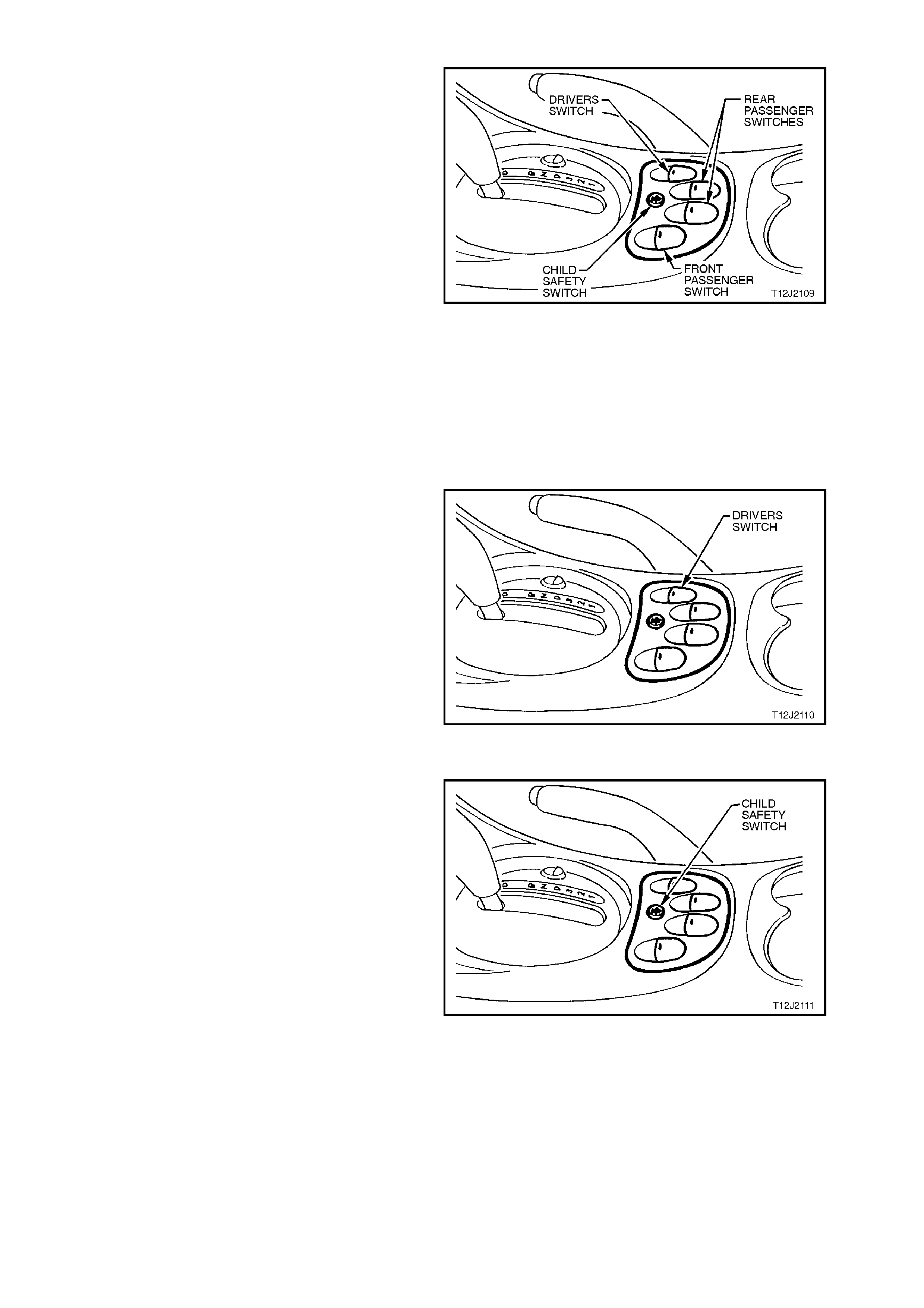

Figure 12J-2-35

System Inactive

Lights are not illuminated

Automatic DOWN Operation of Driver’s Window

With the drivers window in the fully UP position and

the ignition switch turned to ON, press the driver

window switch to the window DOWN position for

more than 0.4 seconds and release.

The window will continue to lower automatically

until the fully DOWN position is reached.

To interrupt this function, press the UP button

momentarily or press and release the down button.

Figure 12J-2-36

Child Safety Switch

When the child safety switch (override switch) is

OFF, the rear windows can be opened or closed

from the centre console switch assembly or the

rocker switches in each of the rear doors.

To check the operation of this feature, proceed as

follows:

1. Ignition switched to ON.

2. Check that the green LED in each of the rear

door rocker switches is illuminated.

3. Open and close the rear door windows using the

rocker switches in the rear doors.

4. Press the child saf ety switch button in the centre

of the switch assem bly in the console as shown

in the Fig. 12J-2-37.

5. Check that the green LED in each of the rear

door rocker switches extinguishes and that the

rear windows can only be raised or lowered

from the switch in the centre console.

Figure 12J-2-37

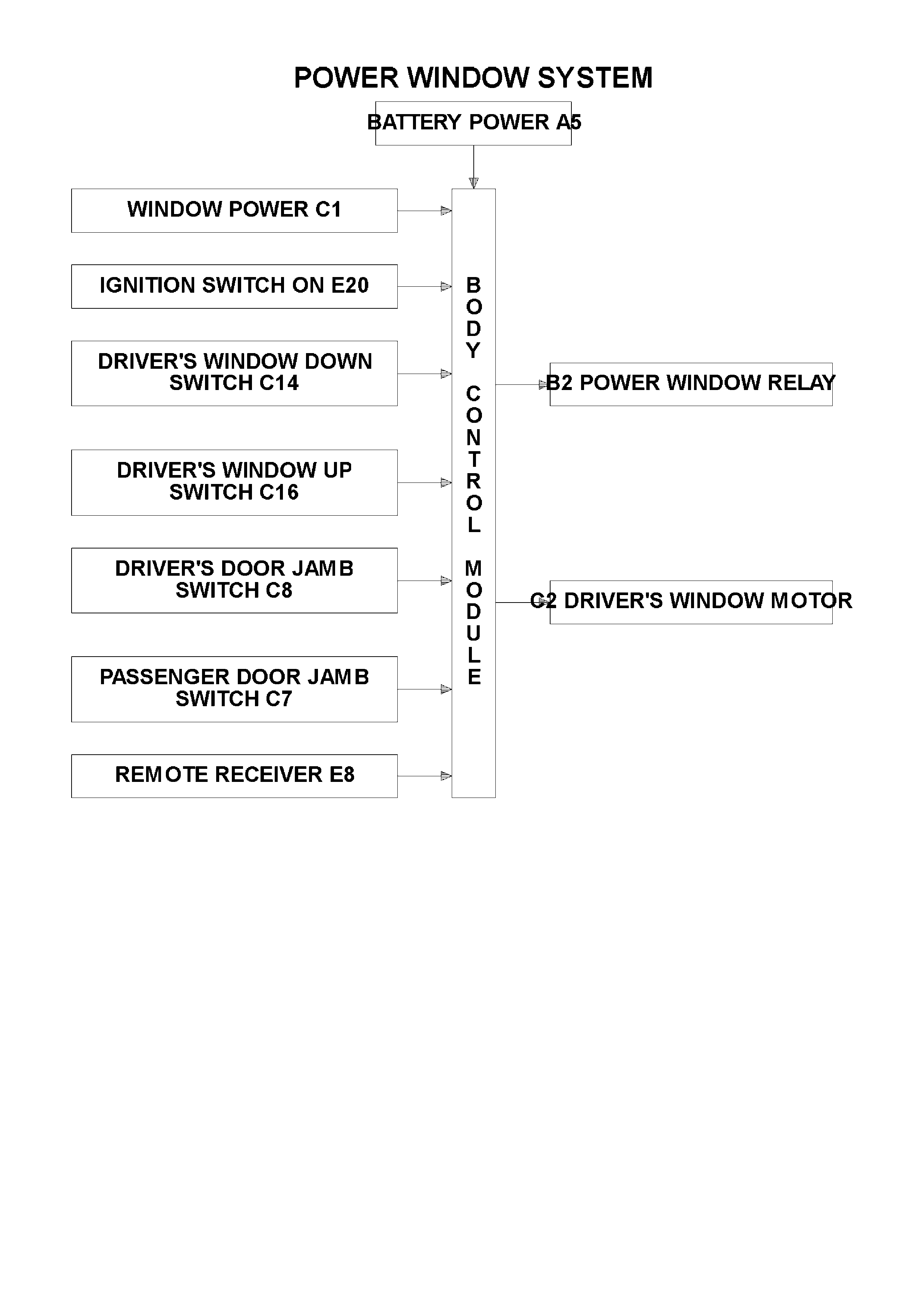

SYSTEM OVERVIEW

CIRCUIT OPERATION

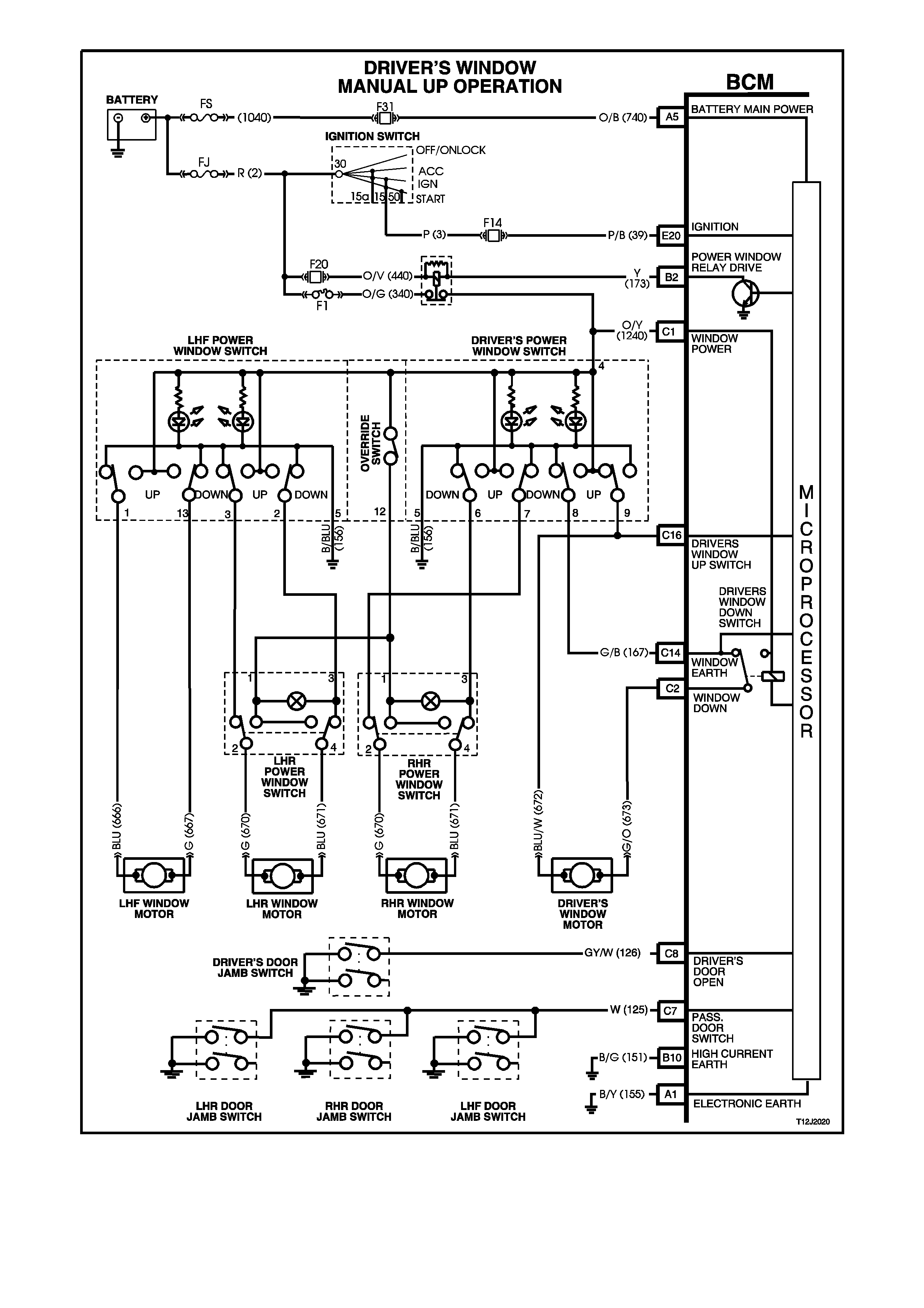

A permanent magnet motor operates each of the power window mechanisms to raise or lower the window glass.

The direction in which the motor turns depends on the polarity of a voltage supplied to its terminals. The power

window switches, located in the centre console, or in the rear doors, control the polarity of the supply voltages.

The BCM has two main control functions in the power window system.

1. To control the operation of the power window relay and hence, power supply to the whole system.

2. To control the operation of the driver's side front window motor.

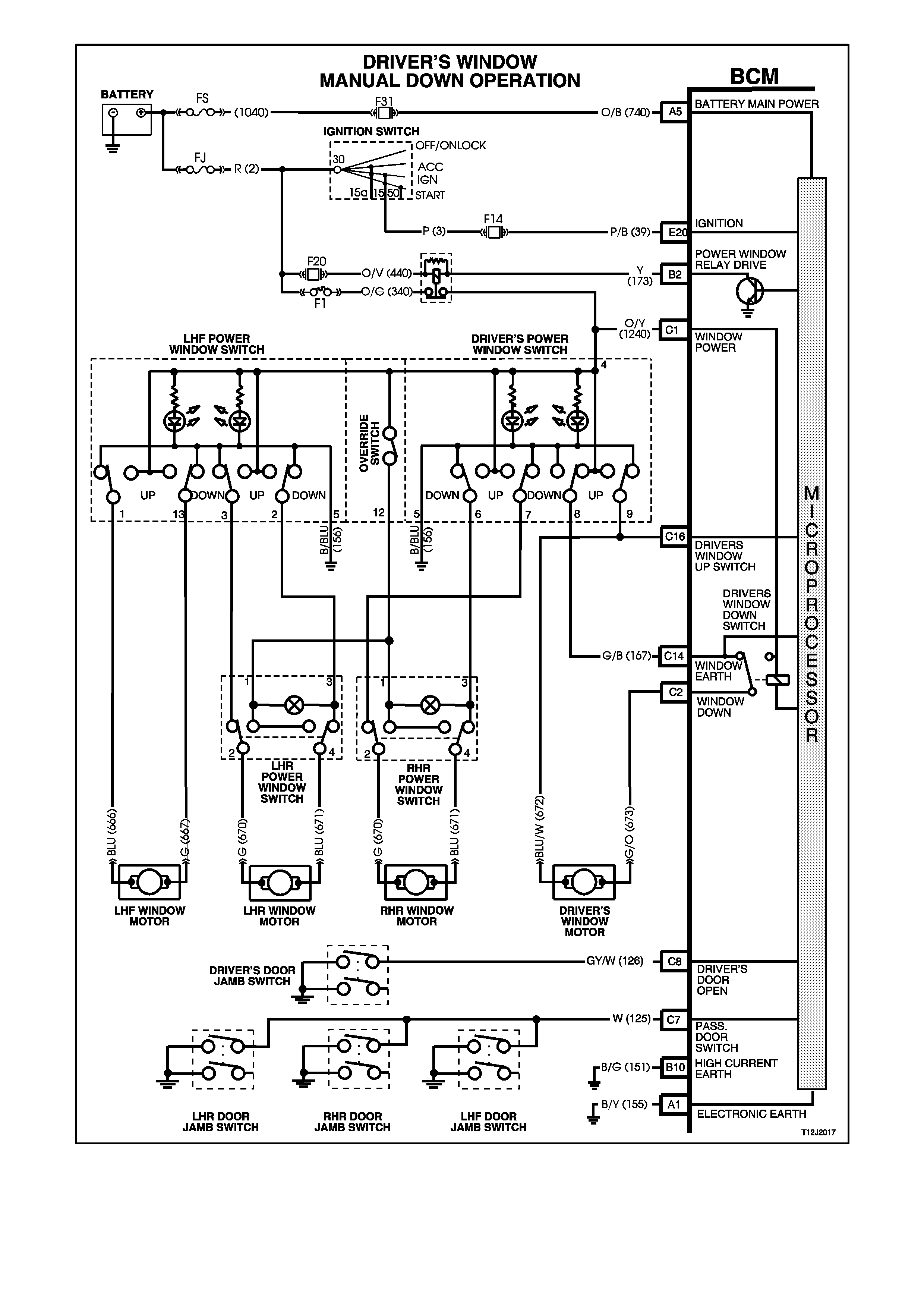

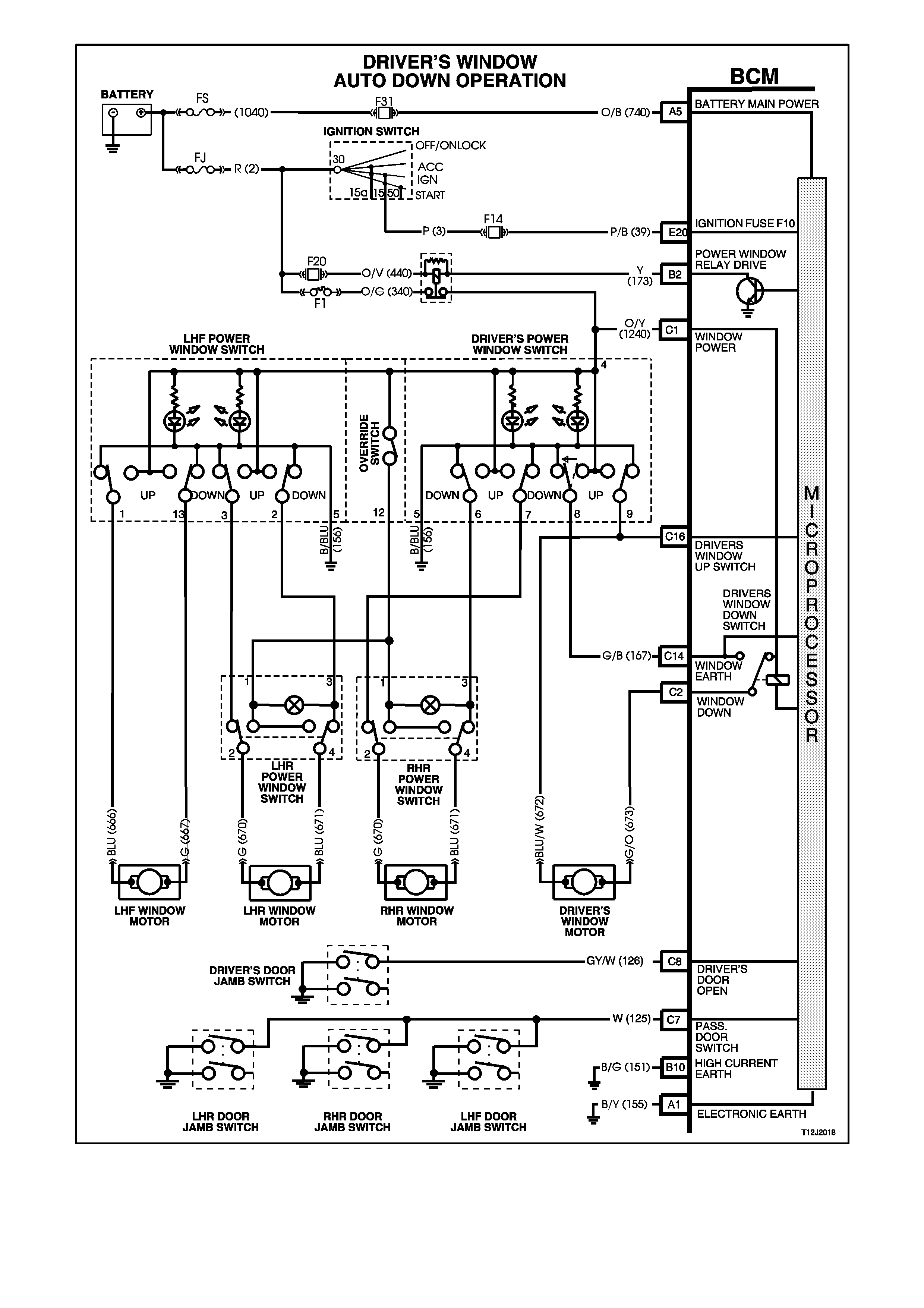

OPENING WINDOW - DRIVER'S DOOR

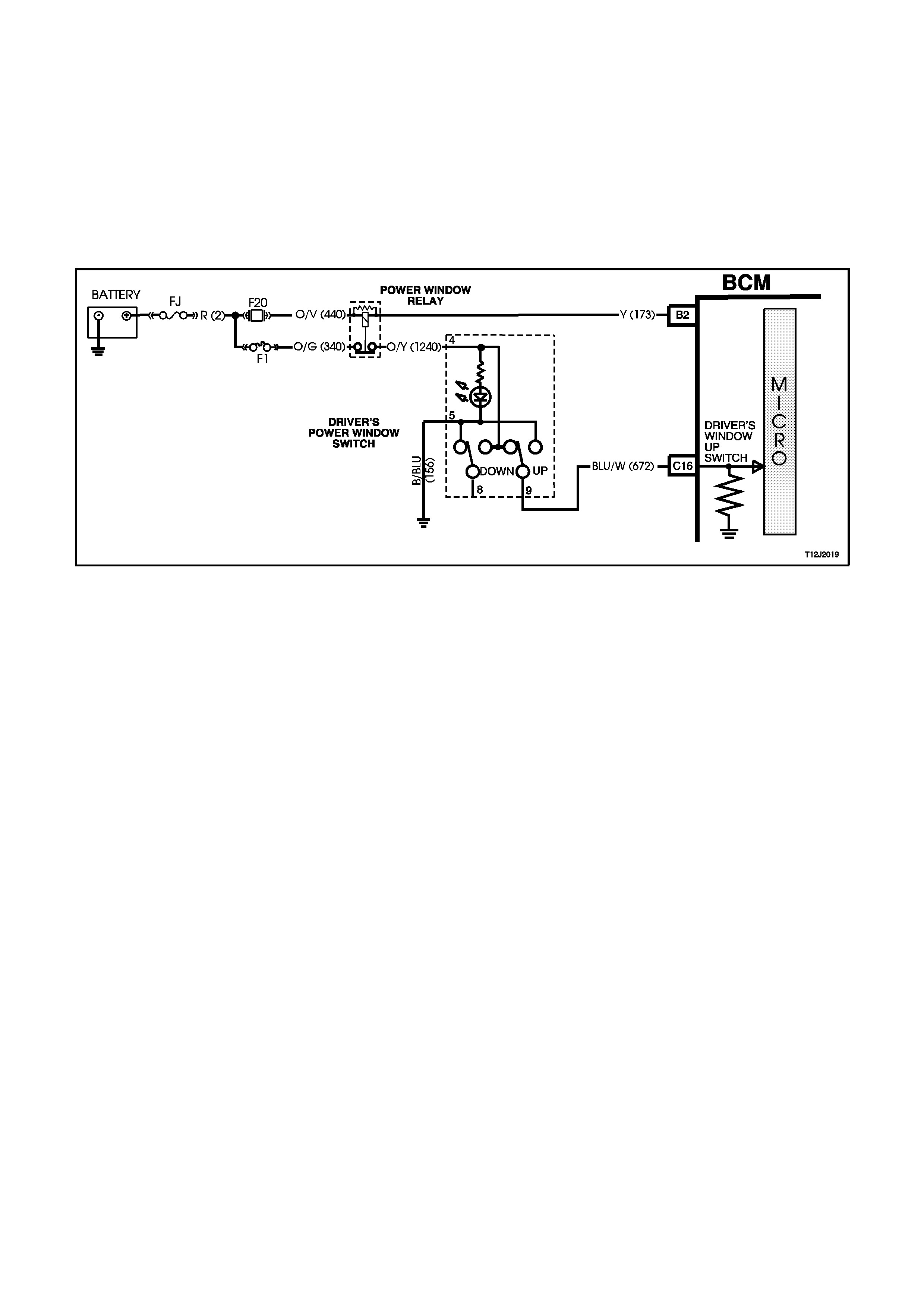

(Refer to Figs. 12J-2-40 and 12J-2-41

Ignition ON Input Signal

(Refer to Fig. 12J-2-38)

The BCM uses this input signal to determine when the ignition switch is in the IGN or START position. When the

ignition switch is in the IGN or START position, battery voltage is applied to the BCM terminal E20 from the ignition

switch and fuse F14 via circuit 39 (Pink/Black wire).

When the BCM receives an ignition ON input it energises the power windows relay (voltage supplied by fuse F20

circuit 440 Orange/Violet wire) by earthing the relay’s pull-in coil via circuit 173 (Yellow wire) and BCM terminal B2.

With the relay coil energised, the relay contacts close and power via fusible link FJ and circuit breaker F1 is applied

to the power window switches and each of the lights of the window switches (for rear door window switches, the

power window override switch in the front power window switch must be off). The opposite side of each light is

connected to earth, therefore the lights are illuminated (system active).

By depressing and releasing the driver's front window switch down button within 0.4 of a second (so as not to

engage the automatic down feature), this allows battery voltage from the power windows relay, circuit 1240

(Orange/Yellow wire), and the power window switch terminal 4, through to terminal 8 and then BCM terminal C14

(window down signal input), through the relay contacts and BCM terminal C2 to one side of the driver's side power

window motor on circuit 673 (Green/Orange wire).

The opposite side of the motor is connected to earth on circuit 672 Blue/White wire via power window switch

terminals 9 and 5 to circuit 156 (Black/Blue wire). This causes the motor armature to rotate, operating the window

regulator to lower the window.

As described under power windows general information, the driver's window will automatically travel fully downward

provided the power window switch down button is depressed for more than 0.4 seconds. The BCM microprocessor

senses the time the down button is depressed via terminal C14 and energises the internal relay so as to allow the

window to lower fully.

Figure 12J-2-38

Driver's Front Window Down Switch Input Signal

(Refer to Fig. 12J-2-39)

With the driver's front window switch down button depressed, battery voltage from the power windows relay, circuit

1240 (Orange/Yellow wire), and the power window switch terminal 4, through to terminal 8 is applied to BCM

terminal C14 (window down signal input).

Figure 12J-2-39

When the BCM receives a driver's front window down switch input signal it energises an internal relay. This causes

the relay contacts to changeover, allowing battery voltage from the power windows relay contacts, BCM terminal C1,

through the BCM internal relay contacts and BCM terminal C2 to one side of the driver's side power window motor

on circuit 673 (Green/Orange wire).

If the window is travelling downward and the down button is again depressed, the BCM microprocessor senses this

(voltage again sensed at BCM terminal C14) and de-energises the internal relay, the contacts open and the motor

stops.

Should the up button be momentarily depressed whilst the window is travelling downward, positive battery voltage is

applied to both sides of the motor armature and the motor stops. If the up button is continuously depressed whilst

the window is travelling downward, the window down function is cancelled. The window will then move upward as

described in the following text.

Figure 12J-2-40

Figure 12J-2-41

CLOSING WINDOW

(Refer to Fig. 12J-2-43)

Driver's Front Window Up Switch Input Signal

(Refer to Fig. 12J-2-42)

By depressing and holding down driver's front window up button, battery voltage from the power windows relay

circuit 1240 (Orange/Yellow wire) is applied, via power window switch terminals 4 and 9, to the driver's side power

window motor circuit 672 (Blue/White wire).

The opposite side to the motor circuit 673 (Green/Orange wire) is connected to earth via BCM terminal C2, through

the BCM internal relay contacts, BCM terminal C14 to switch terminals 8 and 5 to earth on circuit 156 (Black/Blue

wire). This causes the motor armature to rotate, operating the window regulator to raise the window as long as the

power window switch up button is depressed.

Figure 12J-2-42

Window Operation - Passenger Doors

Power is supplied to all the power window switches from the power window relay (to the rear door switches provided

the power window override switch is off). If the power window override switch is on, (contacts between terminals 4

and 12 are open) the power supply to the rear door power window switches is interrupted.

With the switch buttons at rest, all switch contacts are connected to earth circuit 156 (Black/Blue wire). By

depressing the appropriate passenger's window sw itch down or up button, battery voltage from the power windows

relay, is applied to one side of the window motor, via the depressed switch button contact. With the other side of the

motor connected to earth, the motor armature will rotate, operating the window regulator to raise or lower the

window as long as the window switch button is depressed.

Figure 12J-2-43

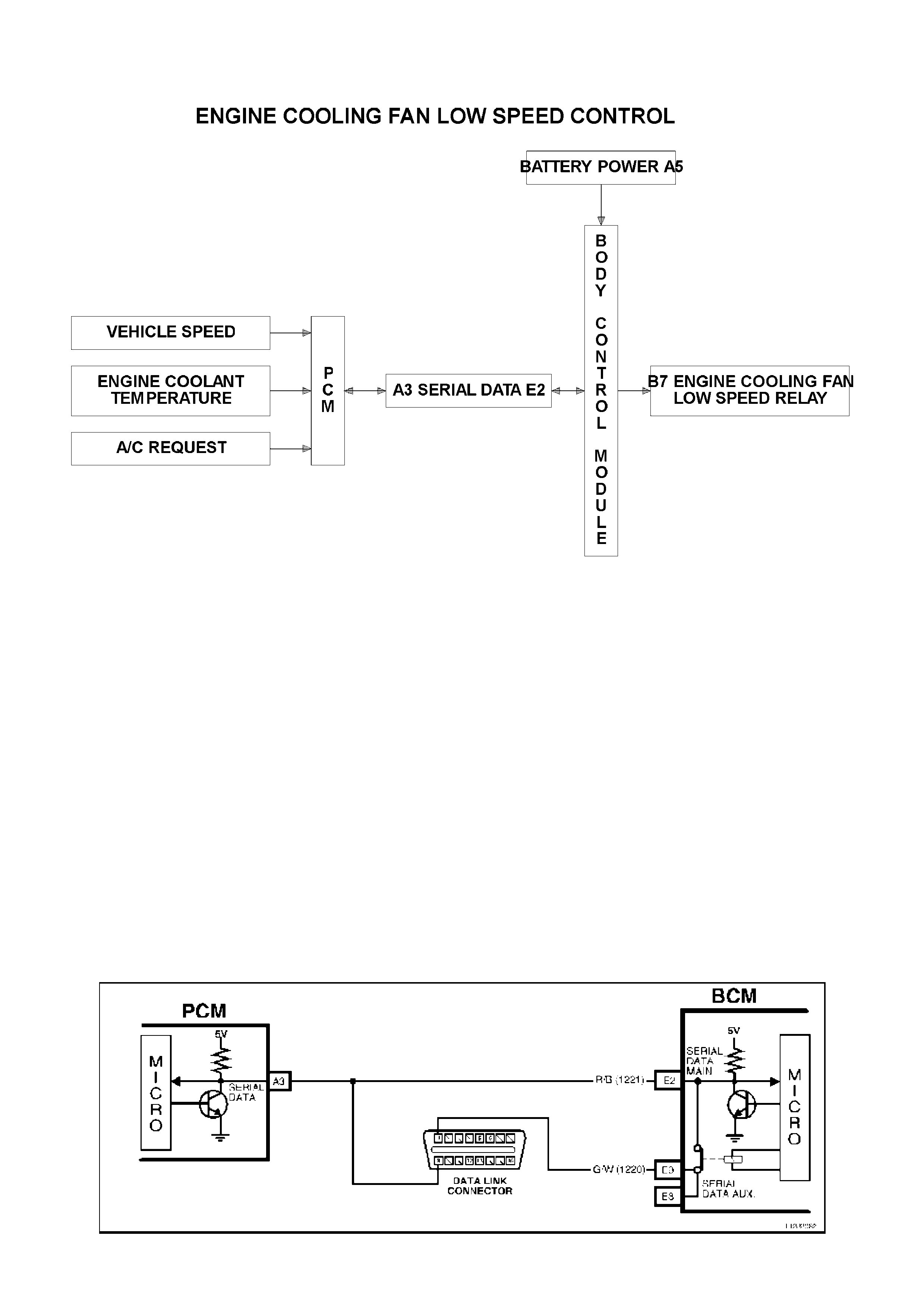

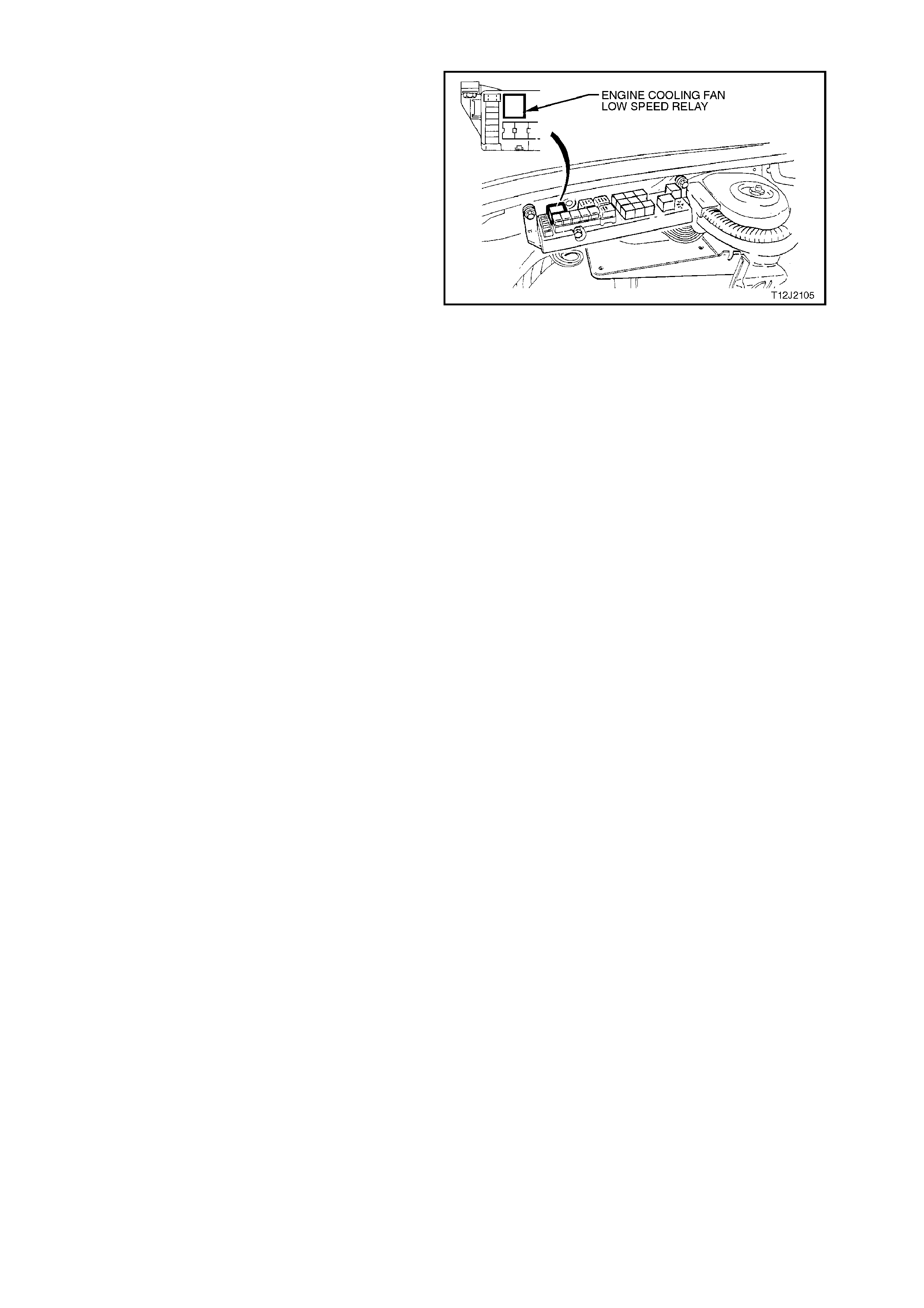

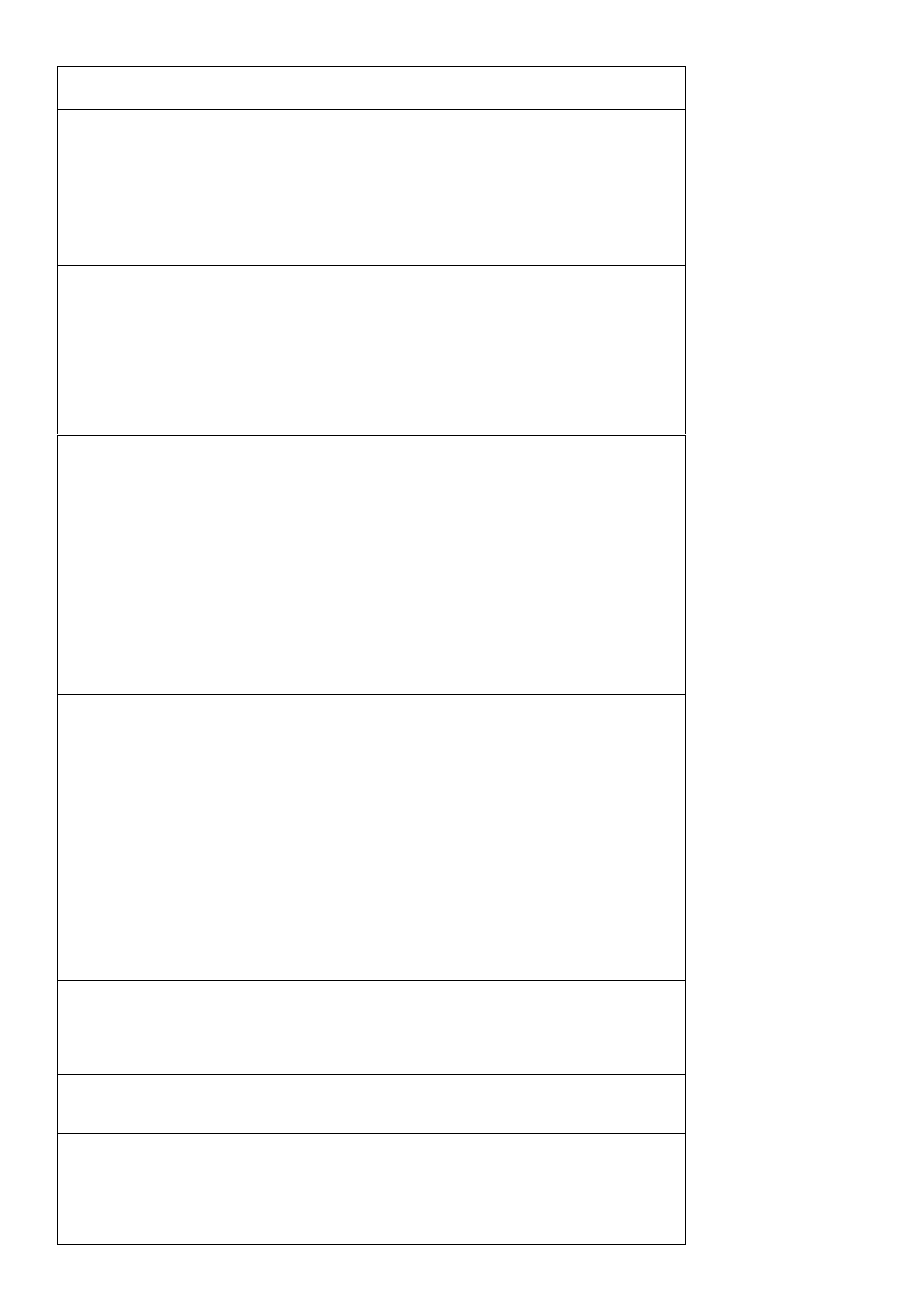

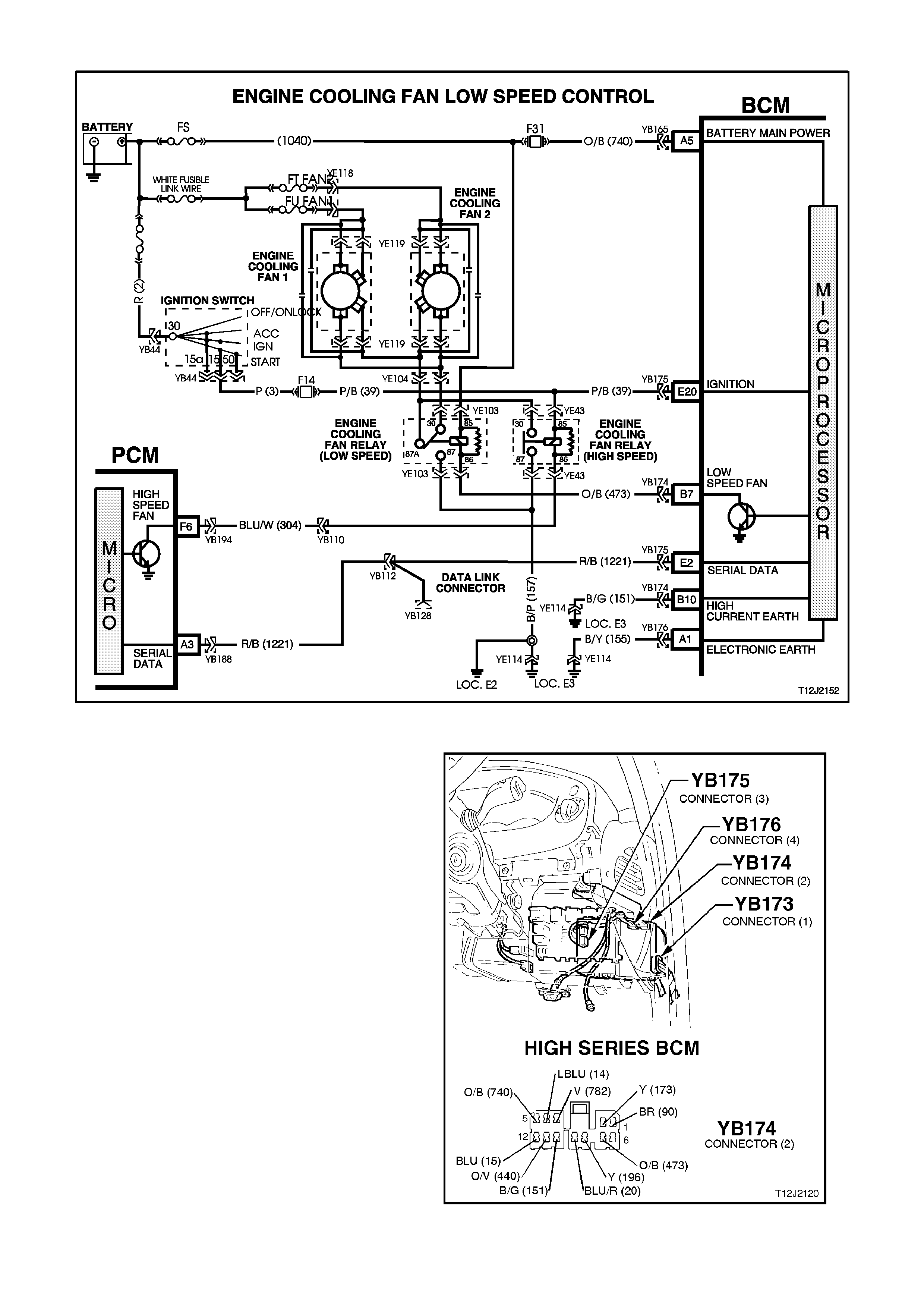

1.6 ENGINE COOLING FAN LOW SPEED CONTROL

SYSTEM OVERVIEW

GENERAL INFORMATION

(Refer to Figs. 12J-2-44 and 12J-2-45)

The engine has a two, two speed electric engine cooling fan assemblies that provide the primary means of moving

air through the engine radiator. These fans are placed between the radiator and the engine and have their own

shroud. These fans are used on all vehicles even if they are not equipped with air conditioning. There is no fan in

front of the A/C condenser.

The two, two speed electric engine cooling fans are used to cool engine coolant flowing through the radiator, and if

fitted, refrigerant flowing through the A/C condenser. The engine cooling fan motors have four terminals, two

negative and two positive terminals. The two positive terminals are permanently connected to battery voltage. When

one of the negative terminals is earthed, the fan motors will operate at low speed. When both negative terminals are

earthed, the fans operate at high speed.

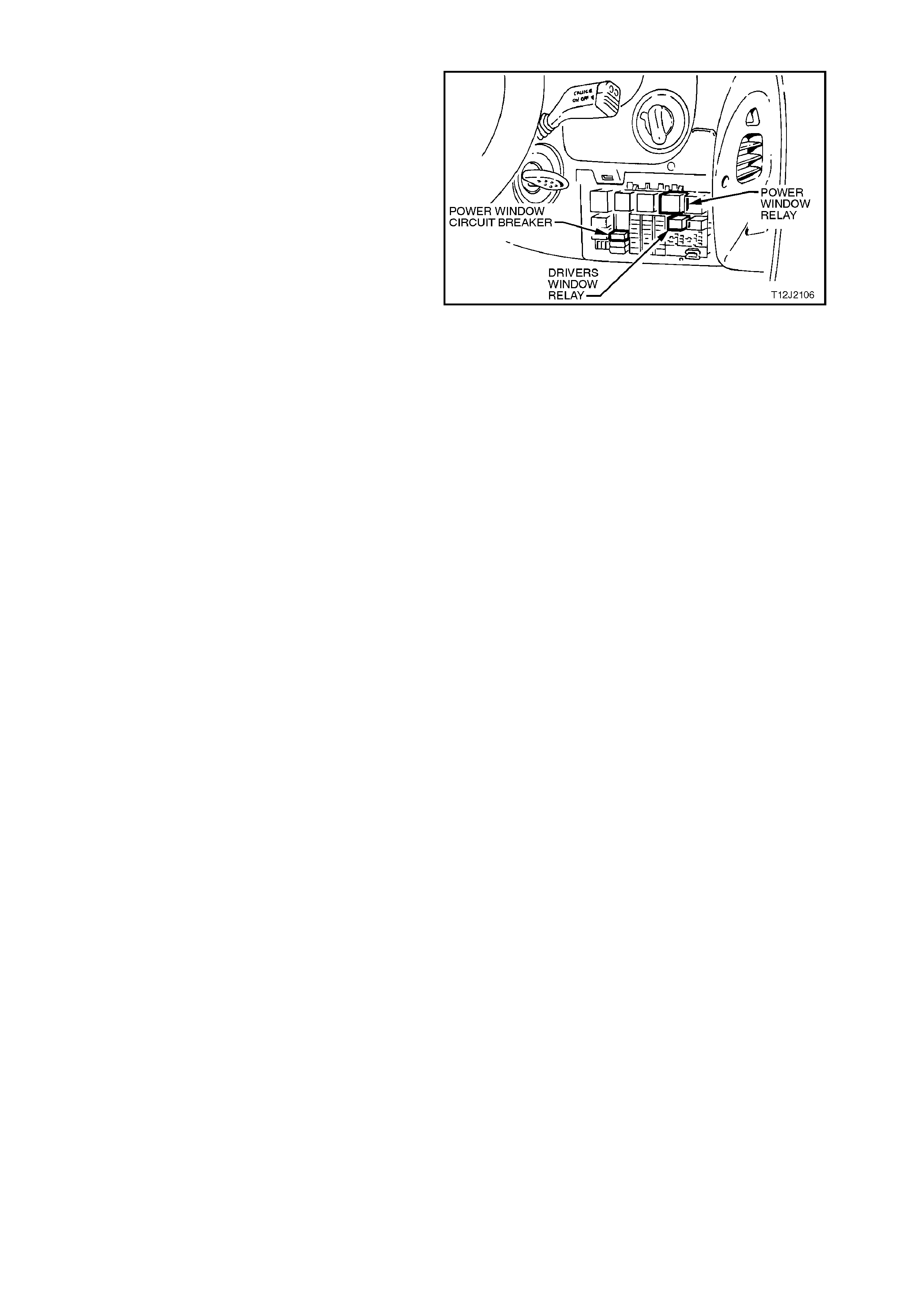

The two speed electric fan's low speed can be enabled when the low speed engine cooling fan micro relay (located

in the engine compartment relay housing, labelled LO FAN) is energised by the BCM via a request from the

Powertrain Control Module (PCM). The PCM will request low speed fan enable and disable via serial data

communication to the BCM on circuit 1221 (Red/Black wire). After the PCM requests a change in the state of the

low speed relay (ie. OFF to ON or ON to OFF), the BCM will send a serial data response message back to the PCM

confirming it received the message. A failure in this response communication will set a PCM DTC 92.

NOTE:

The circuit diagrams shown in this General Description Section are to aid in interpreting the operation of the circuit

and therefore, only the main connectors and wiring colours are shown. For complete circuit details, refer to either

the relevant diagnostic section or Section 12P WIRING DIAGRAMS.

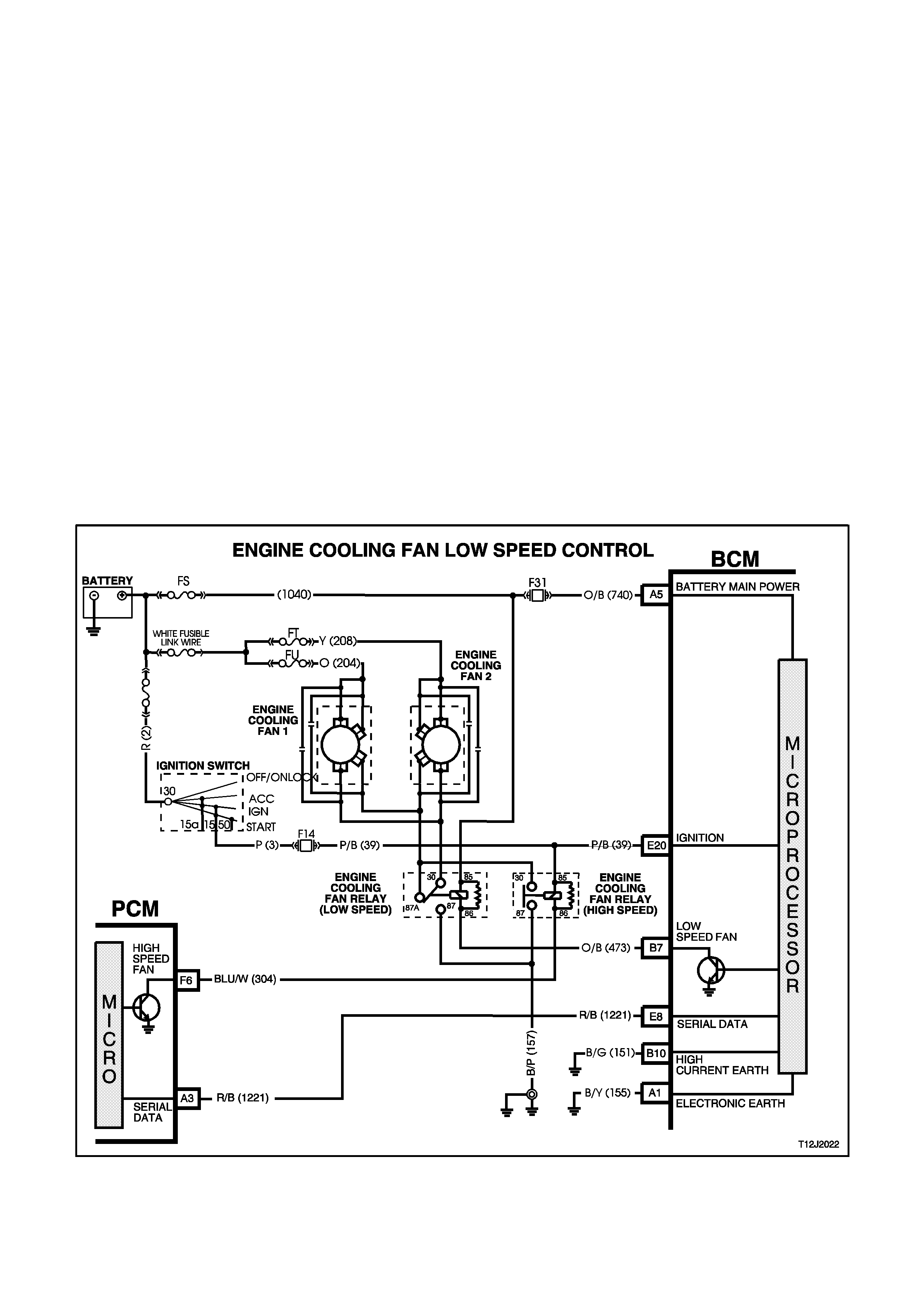

Figure 12J-2-44

The engine cooling low speed fan relay is energised by the BCM earthing terminal B7, circuit 473 (Orange/Brown

wire). This causes the relay contacts to switch over from 30-87A to 30-87 and circuit 157 (Black/Pink wire) is

earthed through the relay and to the low speed fan terminal on circuit 533 (Blue/Yellow wire). The other low speed

fan terminal is connected to battery voltage via circuit 204 (Orange wire) on FAN 1 and circuit 208 (Yellow wire) on

FAN 2.

The engine cooling fan relay is energised by the BCM. The PCM determines when to enable the low speed fan,

based on inputs from the BCM serial data, Engine Coolant Temperature (ECT) sensor and the Vehicle Speed

Sensor (VSS).

The low speed cooling fan relay will be turned ON' when:

A/C request indicated (YES) and either,

the vehicle speed less than 30 km/h.

or

A/C pressure is greater than 1500 kPa.

or

Coolant temperature is greater than 104°C. (V6) or 95°C. (V8)

If the engine coolant temperature is greater than 117°C, when the ignition is switched off, the relay is energised

for approximately 4 minutes. This is known as LOW FAN RUN ON.

An engine coolant temperature sensor fault is detected , such as DTC 14, 15, 16 or 17.

The cooling fan low speed relay will be turned ‘OFF’ when any of the following conditions have been met:

Coolant temperature less than 99°C. (V6) or 90°C. (V8)

A/C request not indicated (NO).

A/C request indicated (YES) and the vehicle speed greater than 50 km/h and A/C pressure is less than 1170

kPa.

Figure 12J-2-45

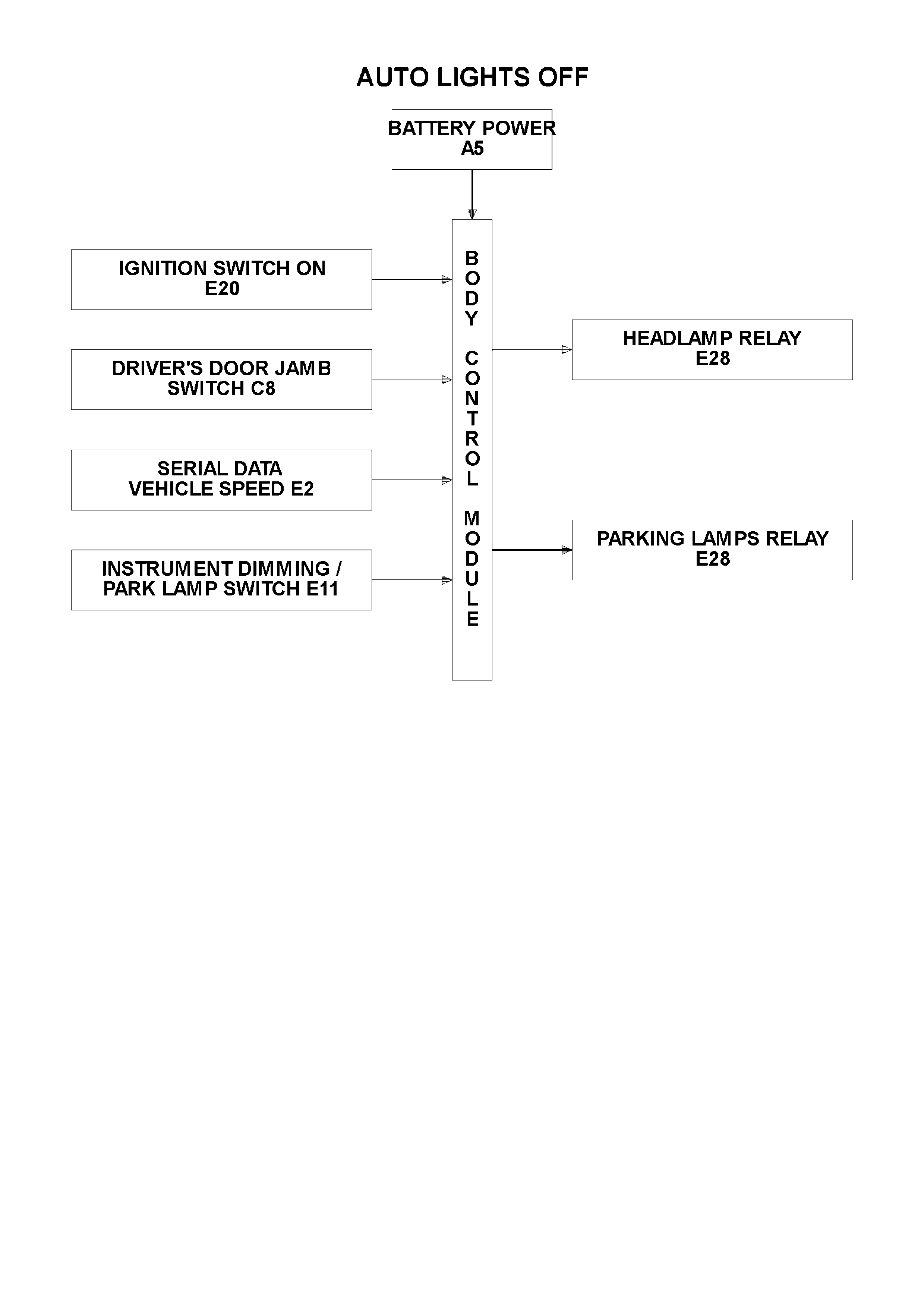

1.7 AUTOMATIC LIGHT CONTROL / AUTOMATIC LIGHTS OFF

(WITHOUT TWILIGHT SENTINEL)

GENERAL INFORMATION

The automatic light control (lights off) feature is designed to automatically switch the headlamps and parking lamps

off when the driver leaves the vehicle.

NOTE:

Since this system is safety related, it is mandatory that in the event of a system failure, the default status of the

BCM light control outputs are in the ON state when the ignition switch is in the IGN position. This will give direct

control of the lights to the headlamp switch.

The sequence of events required to switch the lights off automatically are as follows:

1. The vehicle road speed input to the BCM indicates speed is less than 10 kilometres per hour and there has not

been a sudden loss of speed (ignition being switched off with the vehicle travelling above 10 km/h).

2. The BCM senses that the ignition switch is turned from ON to OFF and remains in the off position.

3. The headlamp switch has not been turned on after the ignition switch was turned off.

4. The BCM senses the driver's door has been opened or that it is already open.

When the ignition switch is turned back to IGN position, the lights will turn back on to the position selected by the

headlamp switch and the mode of headlamps operation (ie. high or low beam or fog lamps [if fitted]) determined by

the position of the relevant switches.

Turning the headlamp switch off deactivates the automatic lights system.

There is a delay period before the automatic lights off feature deactivates the vehicle lights. This time period can be

set by the driver using the following procedure.

1. Turn ignition switch to the 'IGN' position, switch parking lamps on and close the driver's door.

2. Hold the headlamp switch instrument cluster illumination switch control lever in the down position continuously.

3. Turn the ignition switch off.

4. Open the driver's door.

This initiates the start of the time delay period.

5. Wait the required delay time period and release the illumination switch control lever.

This sets the time delay period and switches off the parking lamps.

The delay period adjustment is only possible whilst road speed input to the BCM is zero. A maximum of 180

seconds applies to the time delay period and the default setting is 0 seconds. The time delay period resets to

default value whenever the battery or fuse F31 is disconnected from the vehicle.

This time delay is also dependent on the priority key system. The time delay period can be set for the priority 1

and priority 2 keys. The time delay is recalled when the unlock button on the remote is pressed and is

dependent on whether priority 1 or priority 2 key is used.

NOTE:

The circuit diagrams shown in this General Description Section are to aid in interpreting the operation of the circuit

and therefore, only the main connectors and wiring colours are shown. For complete circuits details, refer to either

the relevant diagnostic section or Section 12P WIRING DIAGRAMS.

SYSTEM OVERVIEW

CIRCUIT OPERATION

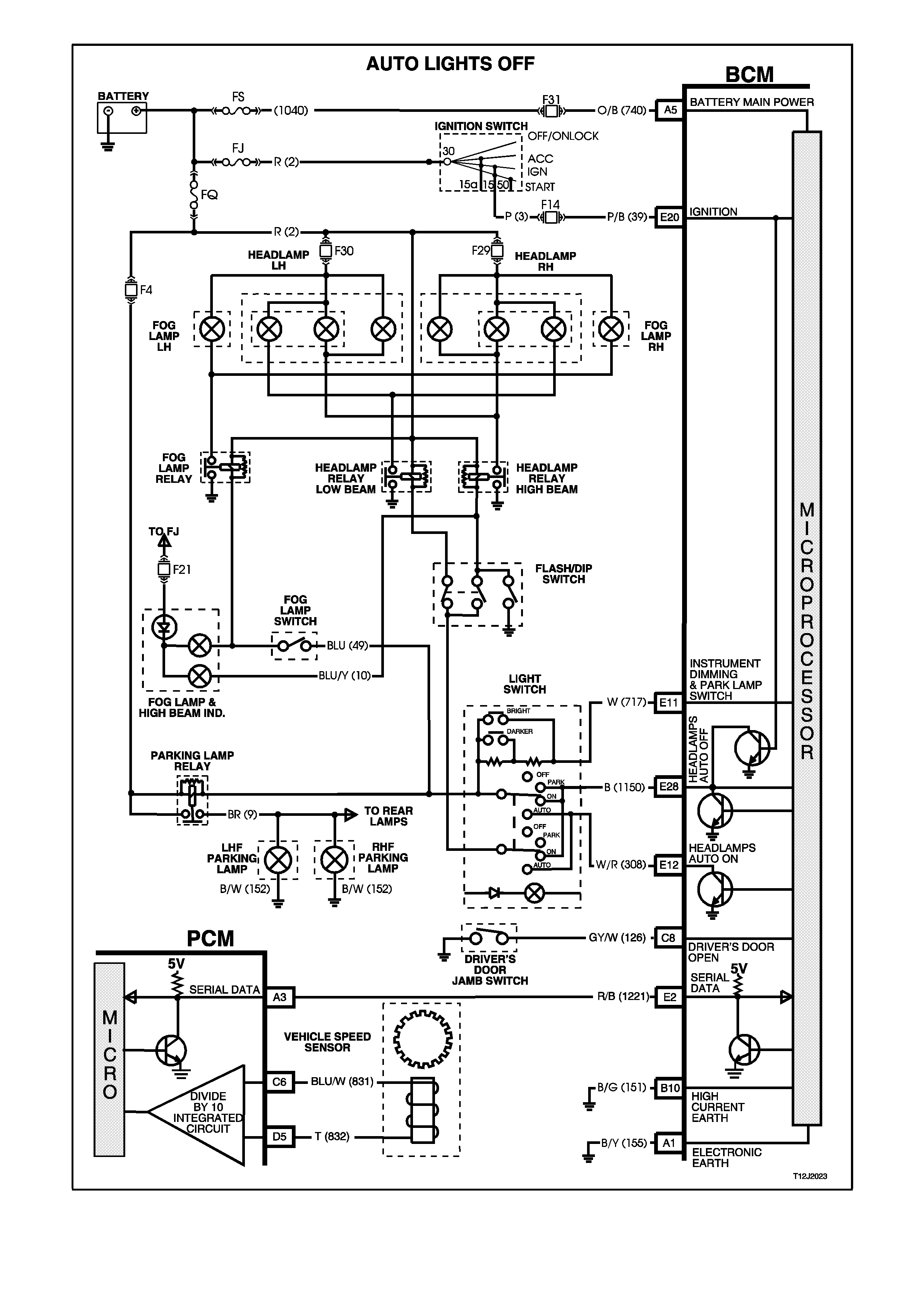

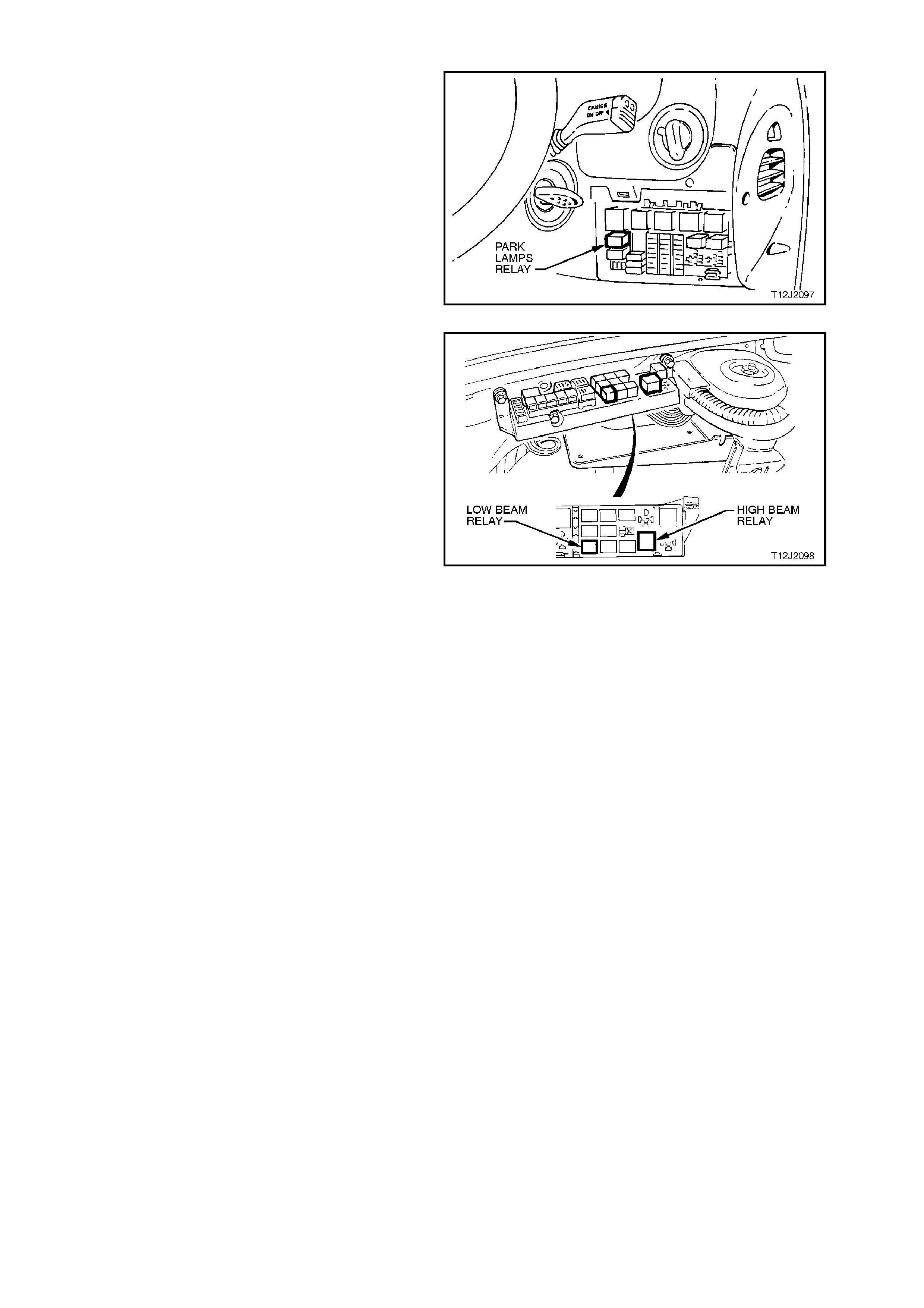

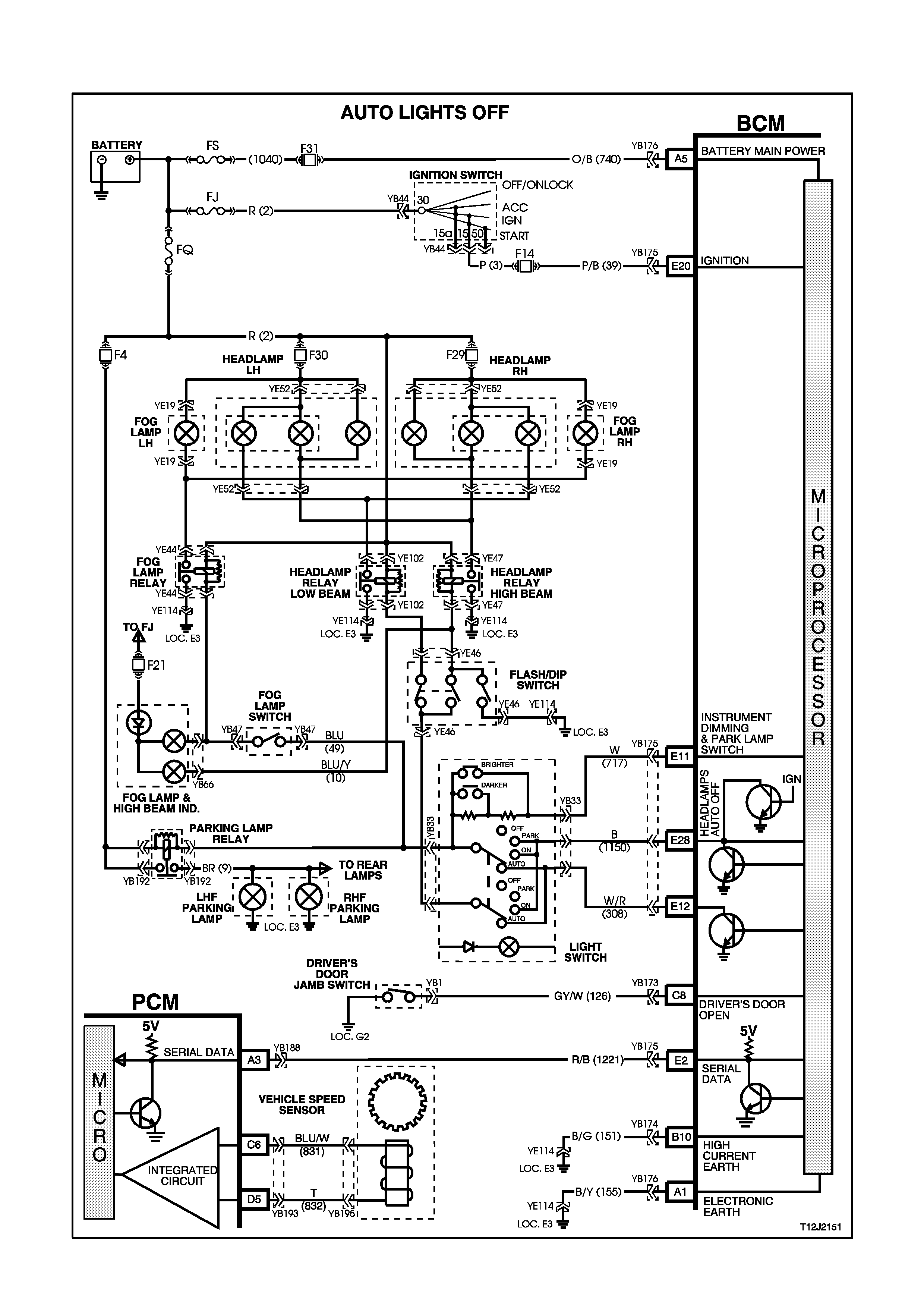

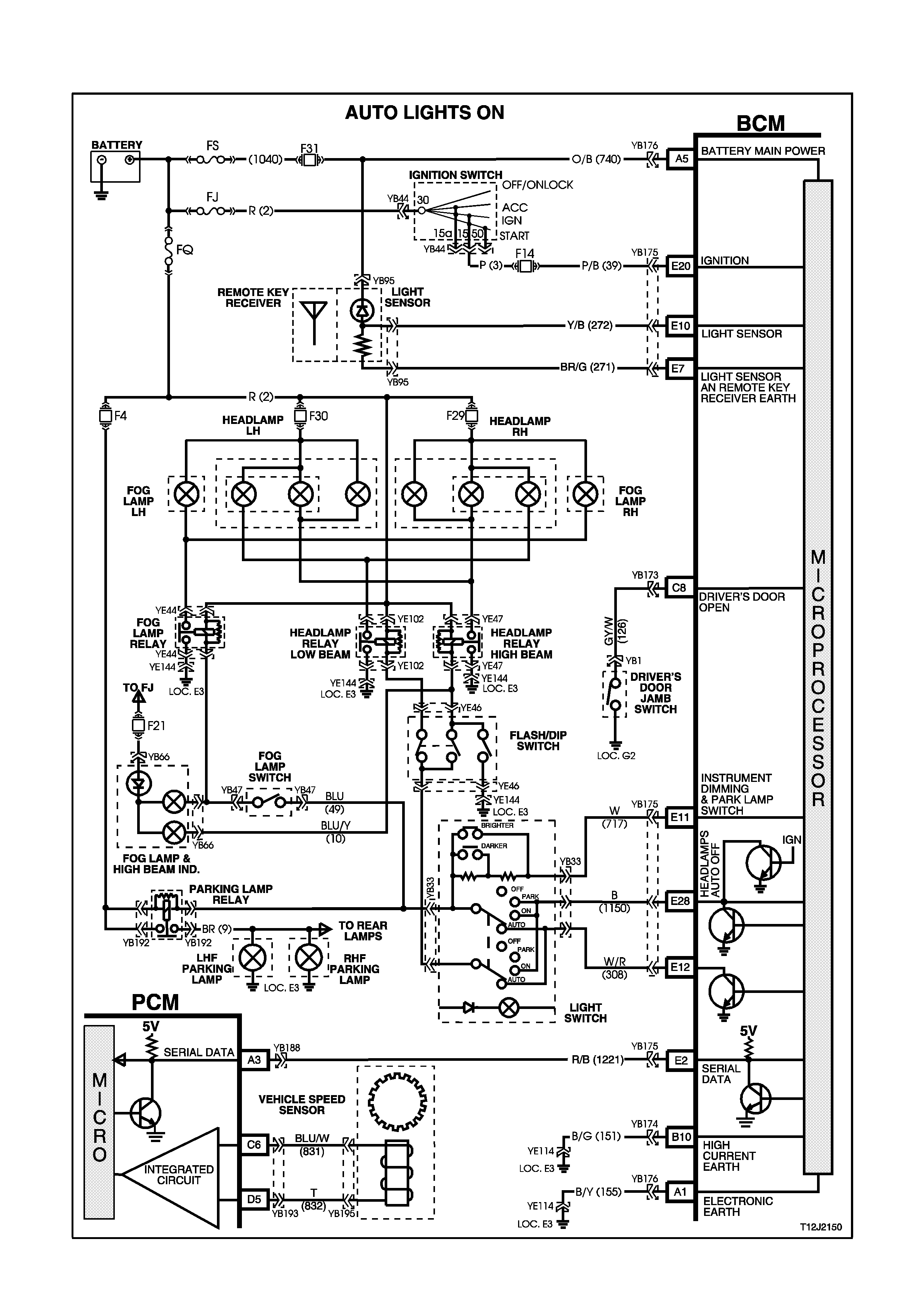

(Refer to Fig. 12J-2-46)

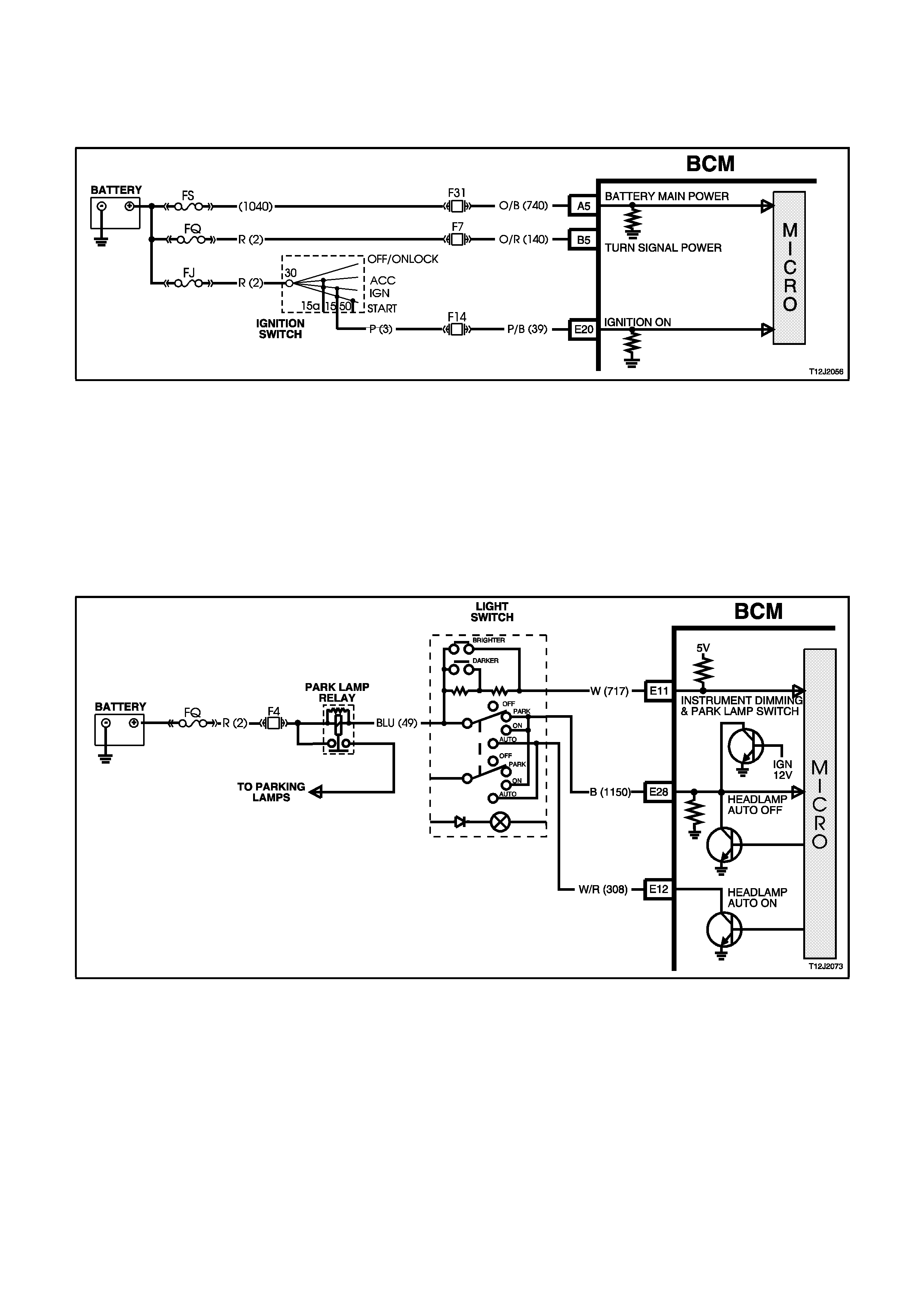

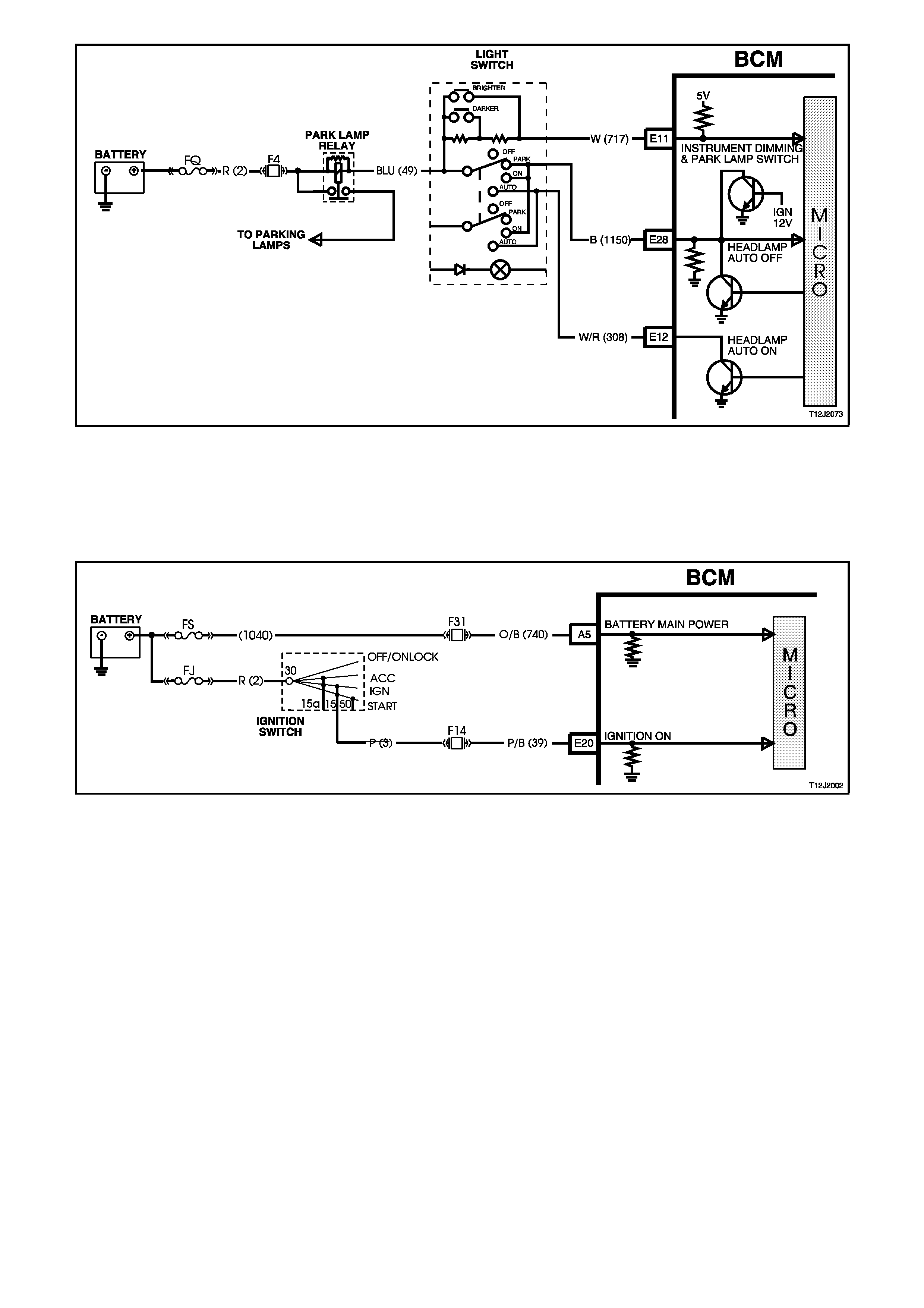

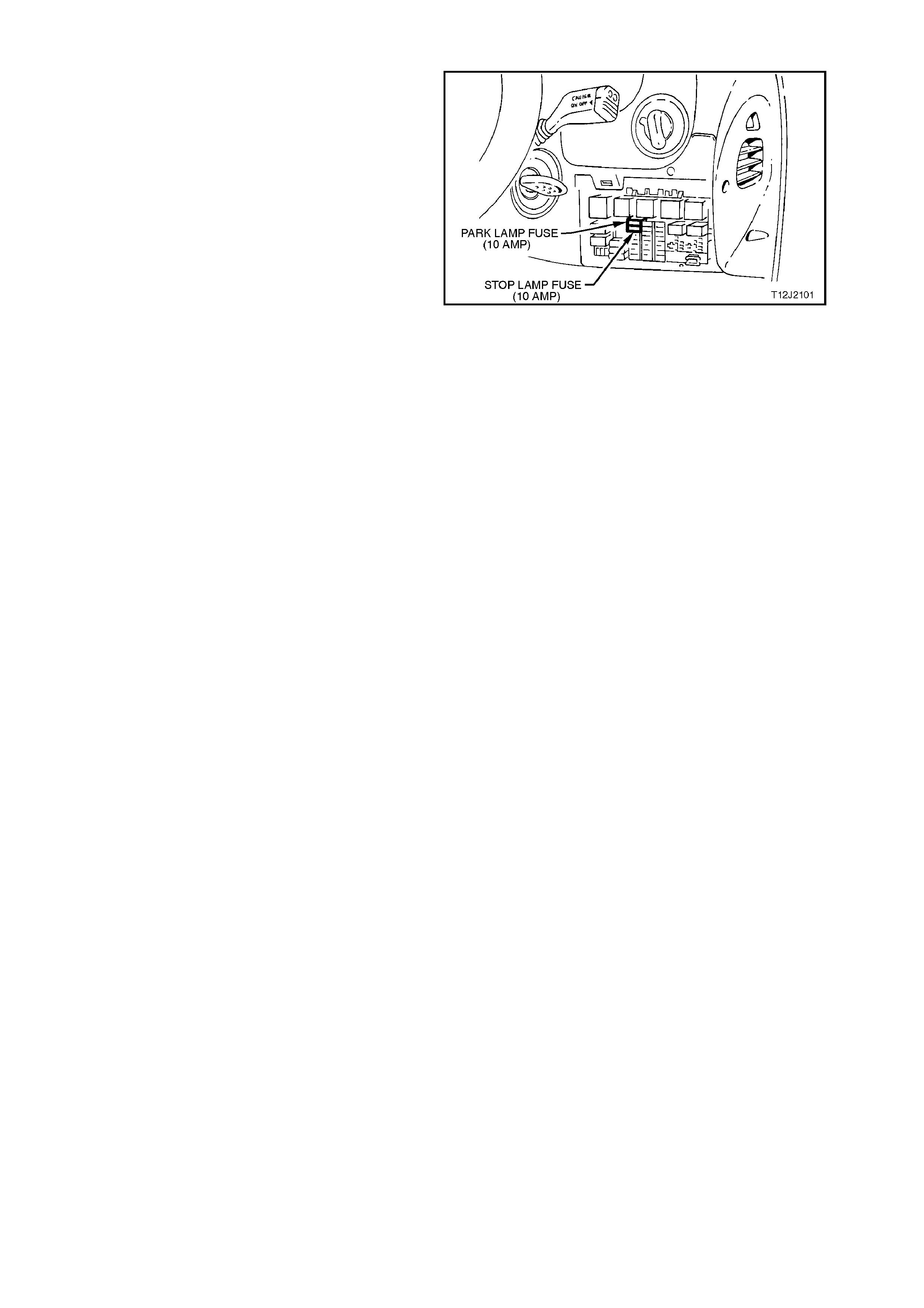

Power Supplies

Battery voltage is applied to the low, high beam and fog lamps (if fitted) relays from fusible link FQ, circuit 2 (Red

wire) and fuses F30 and F29.

Battery voltage is applied to the parking lamps relay from fusible link FQ circuit 2 (Red wire) and fuse F4, circuit 840

(Orange/White wire).

The BCM controls the operation of the exterior light circuits by enabling its internal control circuit, which provides the

earth circuit for the relays.

High Beam Relay Earth Circuit

The earth circuit for the high beam headlamp relay is via circuit 10, (Blue/Yellow wire), through the headlamp and

turn signal control (flash/dip) switch assembly, circuit 147 (White/Black wire), headlamp switch contacts to BCM

terminal E28, circuit 1150 (Black wire) and then to earth through internal switching.

Low Beam Relay Earth Circuit

The earth circuit for the low beam headlamp relay is via 103 (White wire), through the headlamp and turn signal

control (flash/dip) switch assembly, circuit 147 (White/Black wire), headlamp switch contracts to BCM terminal E28,

circuit 1150 (Black wire) and then to earth through internal switching.

Parking Lamps Relay Earth Circuit

The earth circuit for the parking lamps relay is via circuit 49 (Blue wire), the closed parking lamps contacts in the

headlamp switch, through BCM terminal E28, circuit 1150 (Black wire) and then to earth through internal switching.

Figure 12J-2-46

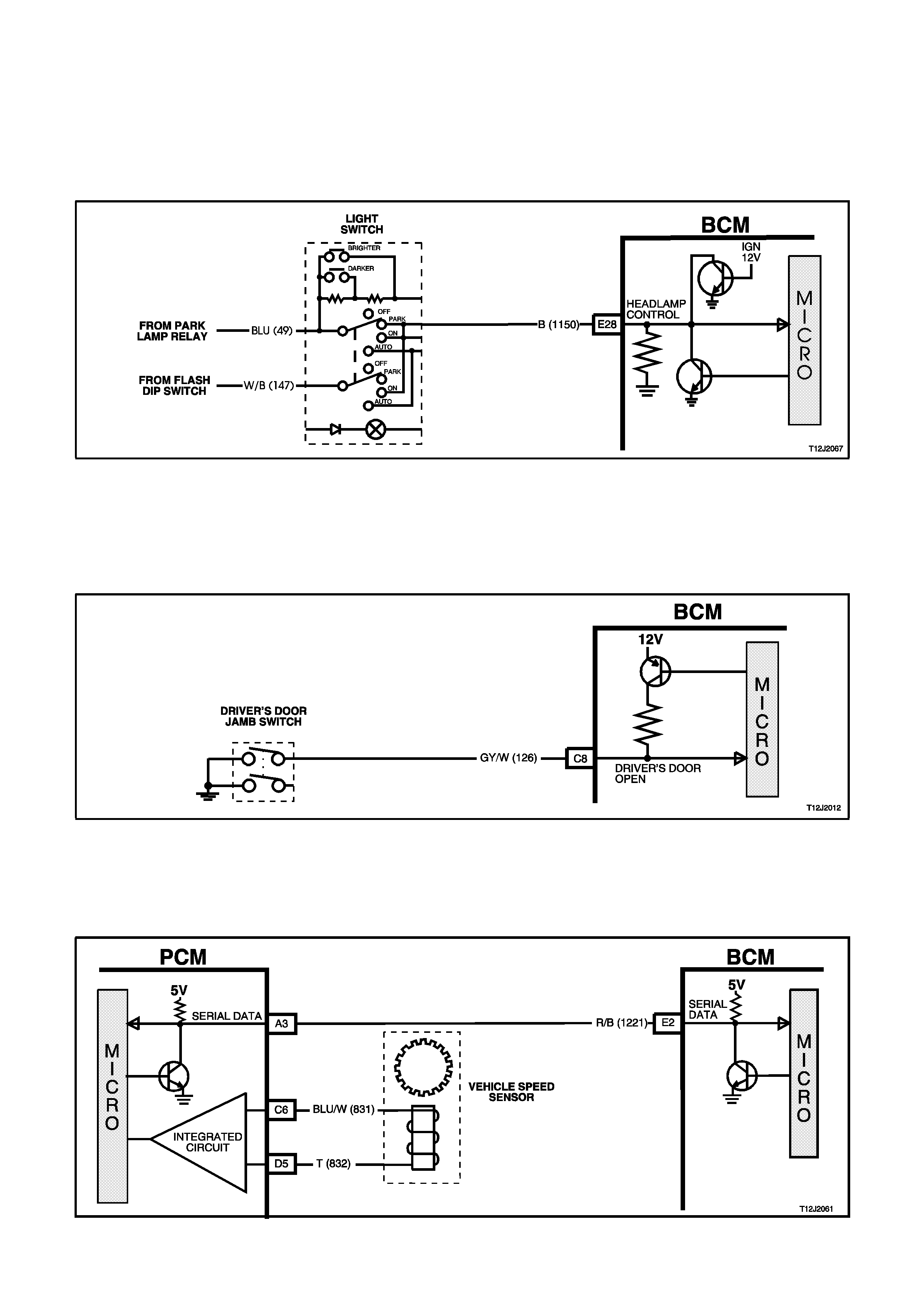

Headlamp Control Input Signal

(Refer to Fig. 12J-2-47)

The BCM monitors the voltage on terminal E28 to determine the position of the headlamp and parking lamp switch.

When the headlamps or parking lamp are on, the voltage at BCM terminal E28 will be less than 0.2 volt. When the

automatic headlamps OFF system has turned the lights off, the voltage at terminal E28 will be 12 volts. If the

headlamp switch is turned off, the voltage at terminal E28 will be less than 0.2 volt. The BCM sees this low voltage

at terminal E28 as a change in status of the headlamp switch and will turn the automatic lights system off. The lights

will then turn back on when a change in position of the switch occurs.

Figure 12J-2-47

Driver’s Door Open Input Signal

(Refer to Fig. 12J-2-48)

When the driver’s door is opened, BCM terminal C8 is connected to earth via circuit 126 (Grey/White wire) and the

driver's door jamb switch. This causes the voltage at terminal C8 to pulled low, less than 0.2 volt (driver's door

open). This low voltage at terminal C8 is seen by the BCM as the driver's door open input signal.

Figure 12J-2-48

Vehicle Speed Signal

(Refer to Fig. 12J-2-49)

The BCM terminal E2, receives the vehicle speed from the PCM via the serial data communications bus, circuit

1221 (Red/Black wire).

Figure 12J-2-49

Ignition Switch ON Input Signal

(Refer to Fig. 12J-2-50)

The BCM uses this input signal to determine when the ignition switch is in the IGN or START position. When the

ignition switch is in the IGN or START position, battery voltage is applied to the BCM terminal E20 from the ignition

switch and fuse F14 via circuit 39 (Pink/Black wire).

Figure 12J-2-50

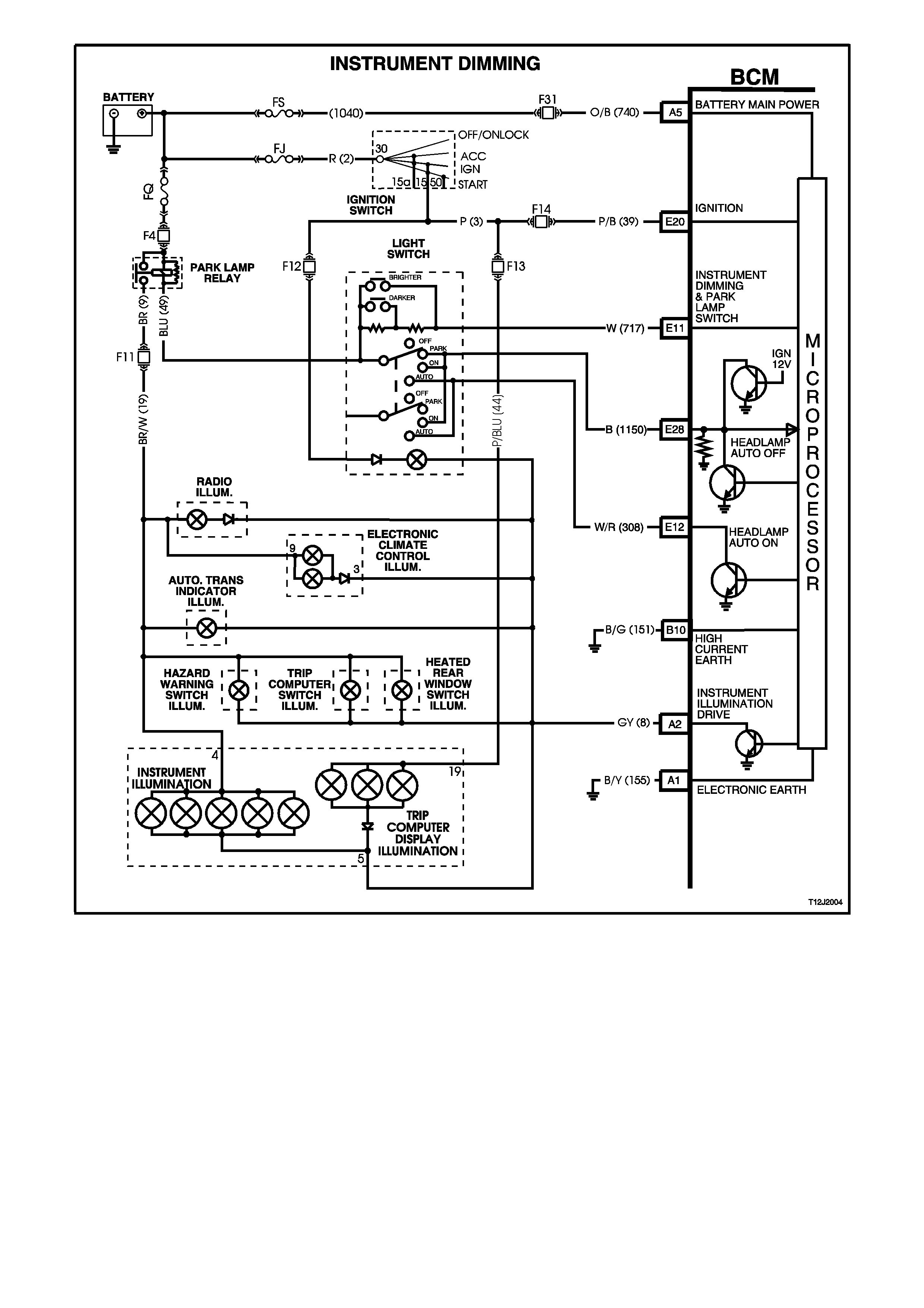

Instrument Illumination Dimmer Switch Input

(Refer to Fig. 12J-2-51)

When the illumination switch lever is in the down position (DIM-), BCM terminal E11 is connected to earth via the

headlamp switch and the 2.7 kilohm resistor in the switch assembly. This causes the voltage at BCM terminal E11

to go from above 5 volts to approximately 1.3 volts. This voltage at BCM terminal E11 is seen by the BCM as the

input signal that determines the delay period for the automatic lights off feature for the period that the voltage is

present.

NOTE:

This circuit will only work while the headlamp switch is in the PARK or ON positions.

Figure 12J-2-51

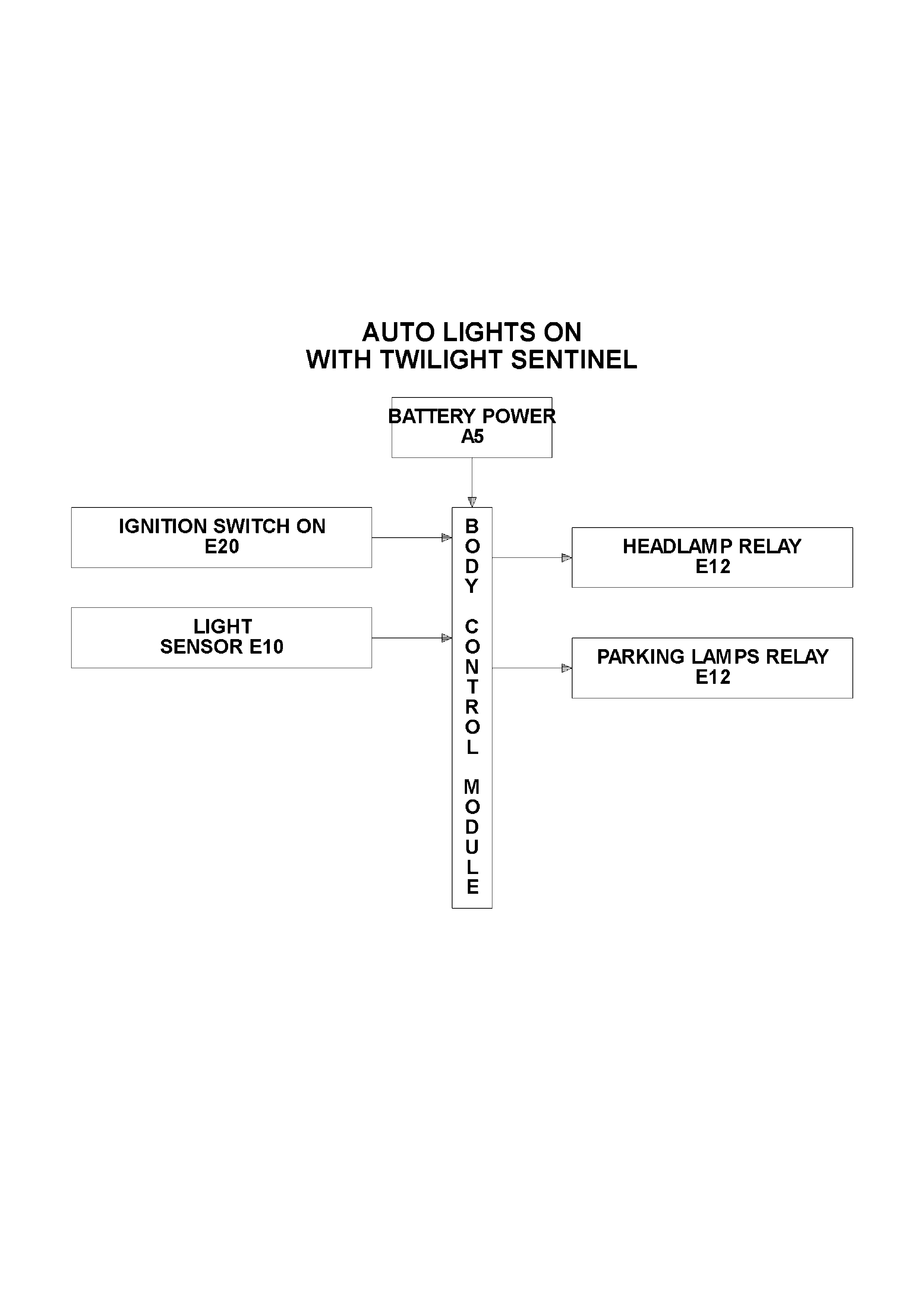

1.8 AUTOMATIC LIGHT CONTROL / AUTOMATIC LIGHTS ON AND OFF

(WITH TWILIGHT SENTINEL)

GENERAL INFORMATION

The automatic light control (lights on and off) feature (with twilight sentinel) turns the vehicle headlamps on and off,

depending on the outside light level. This feature will work only while the headlamp switch is in the Auto position and

the ignition on, the lights will operate as normal in other switch positions.

The operation of the headlamps when the ignition is switched off and the headlamp switch in the Auto position will

be the same as the Auto lights off operation.

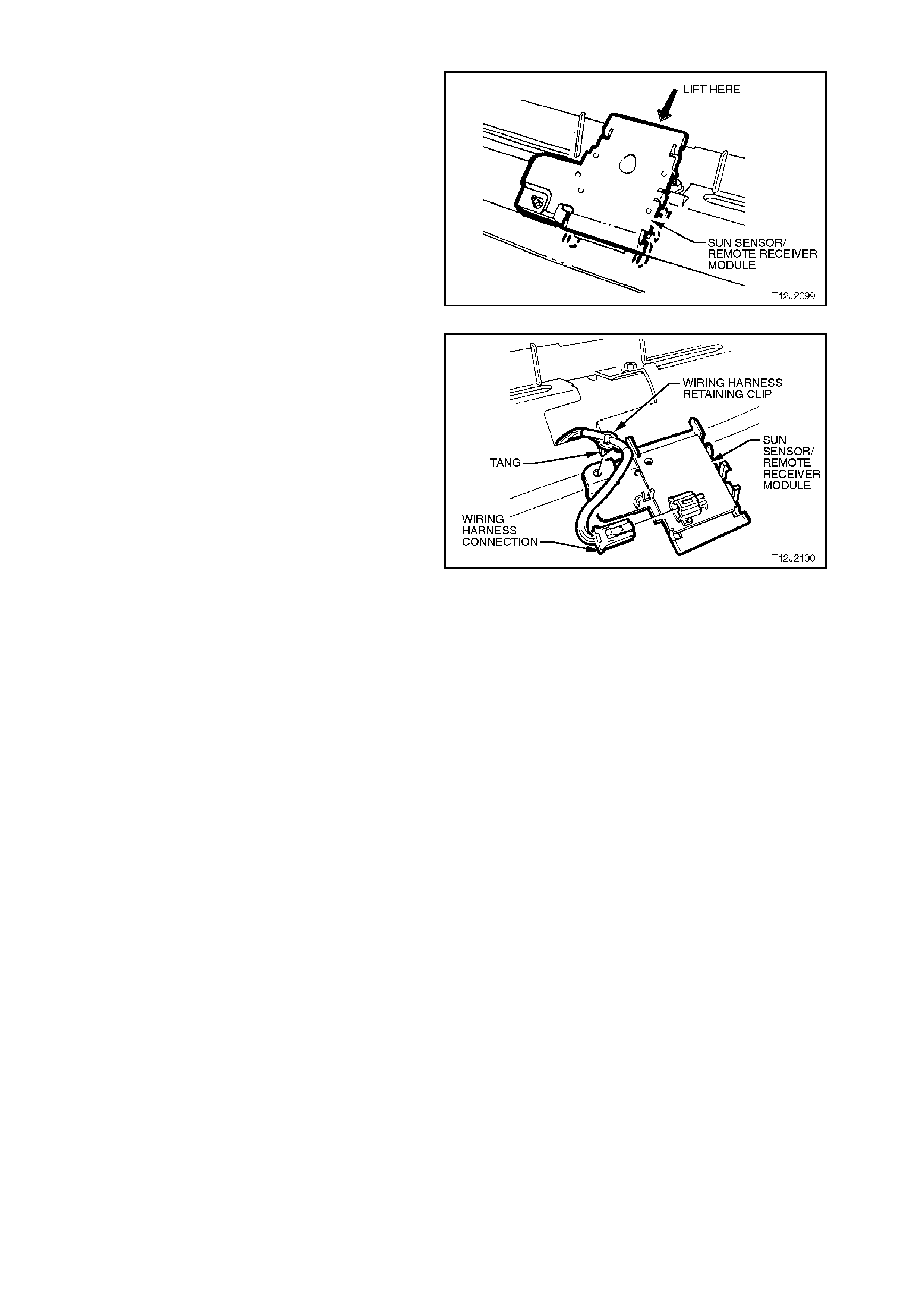

A sensor is mounted in the instrument panel pad of the vehicle to monitor the amount of light in front of the vehicle.

The BCM monitors the output of this sensor and determines when the light levels are low enough to turn them on.

TECH 2 can be used to select several different ON/OFF light levels to suit the customer preferences.

SYSTEM OVERVIEW

CIRCUIT OPERATION

(Refer to Fig. 12J-2-54)

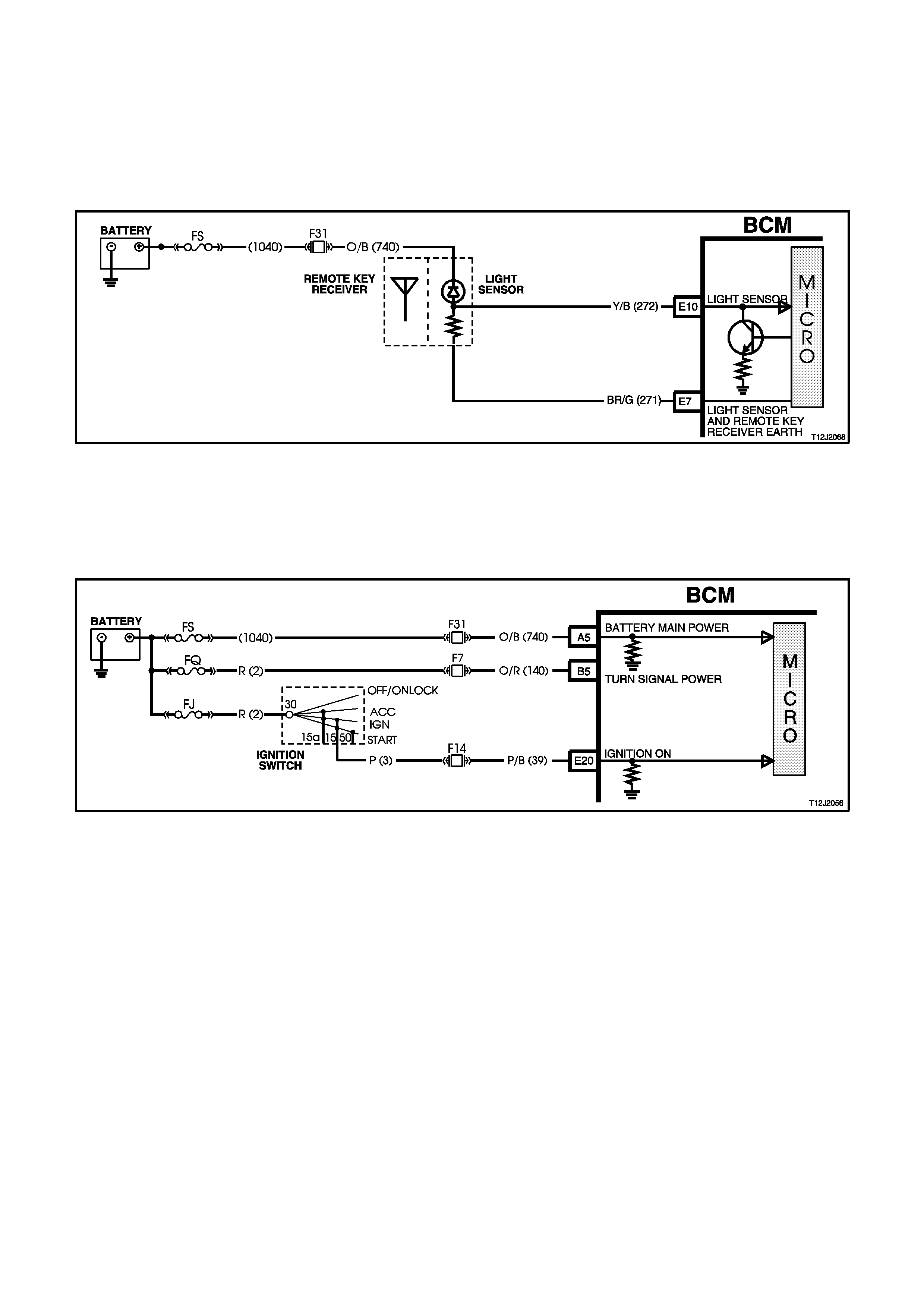

Light Sensor Control Input

(Refer to Fig. 12J-2-52)

The light sensor produces a voltage proportional to the amount of ambient light. This voltage can vary between 0

and 5 volts depending on the amount of light. The BCM determines the light value from the voltage on terminal E10,

circuit 272 (Yellow/Black wire). The BCM reads this input to determine if the headlamps should be on or off. TECH 2

should be used to measure the performance of the light sensor.

Figure 12J-2-52

Ignition Switch ON Input Signal

(Refer to Fig. 12J-2-53)

The BCM uses this input signal to determine when the ignition switch is on or off. When the ignition switch is in the

IGN or START position, battery voltage is applied to the BCM terminal E20 from the ignition switch and fuse F14 via

circuit 39 (Pink/Black wire).

Figure 12J-2-53

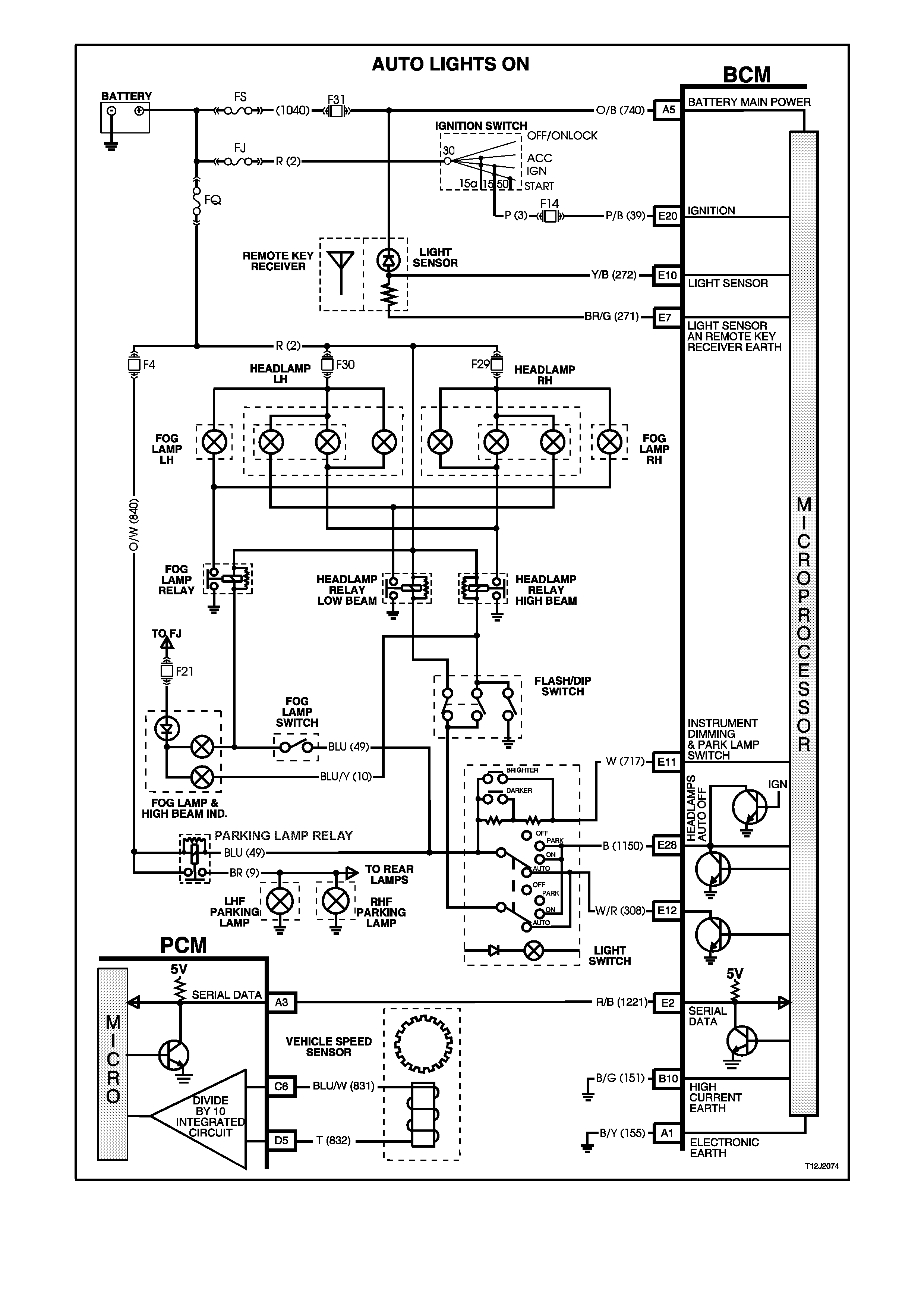

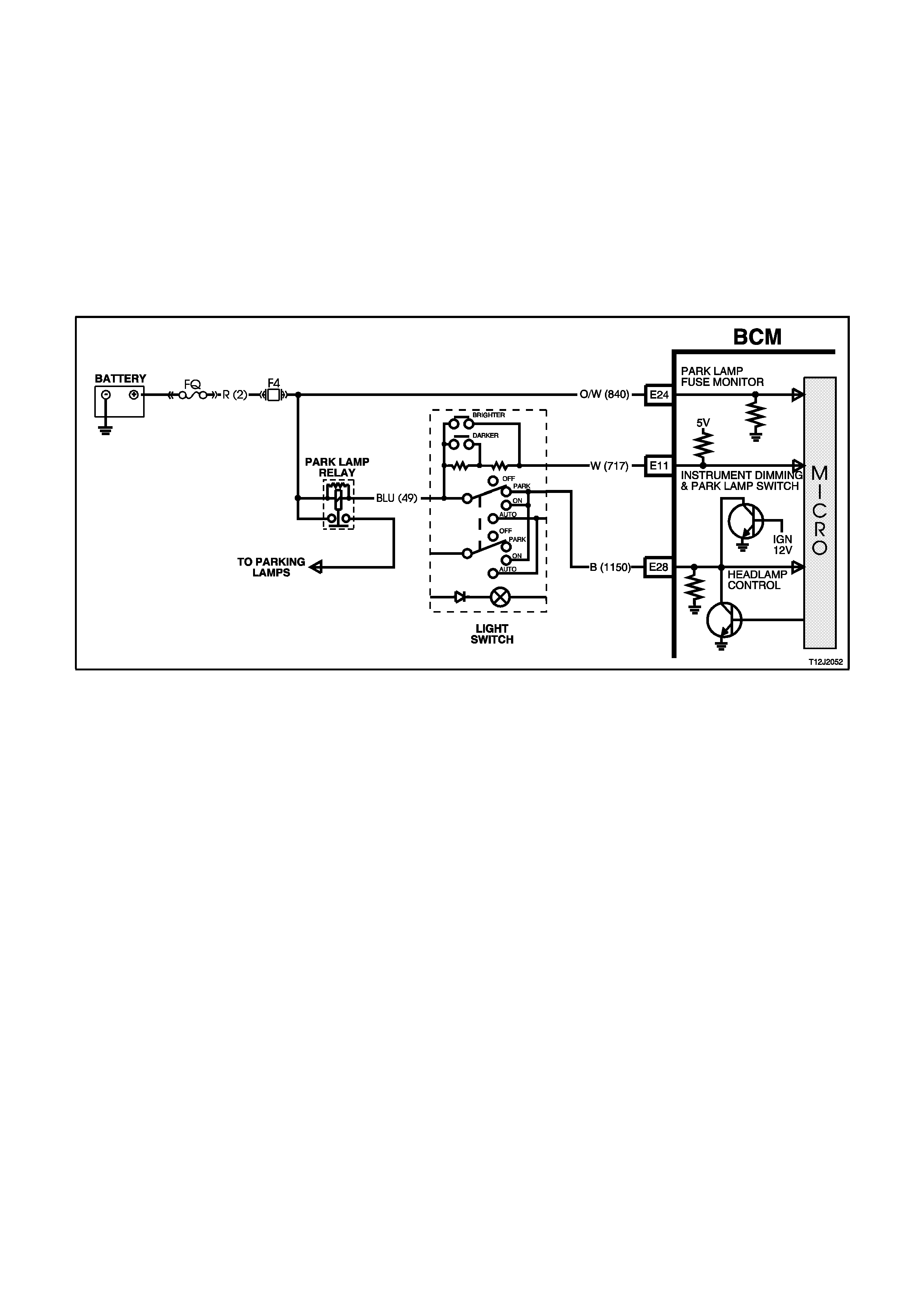

Power Supplies

Battery voltage is applied to the low and high beam relays from fusible link FQ, circuit 2 (Red wire) and fuses F30

and F29. Battery voltage is applied to the parking lamps relay from fusible link FQ, circuit 2 (Red wire) and fuse F4,

circuit 840 (Orange/White wire). The BCM controls the operation of the exterior lights by switching its internal

control circuit, which provides the earth circuit for the relays, on or off. If the ambient light level is low, the BCM will

energise the control circuit, turning the lights on. If the ambient light level is high, the BCM will de-energise the

control circuit, turning the lights off.

High Beam Relay Earth Circuit

The earth circuit for the high beam headlamp relay is via circuit 10 (Blue/Yellow wire), through the headlamp and

turn signal control switch assembly, circuit 147 (White/Black wire), headlamp switch contacts to BCM terminal E12,

circuit 308 (White/Red wire) and then to earth through the internal control circuit.

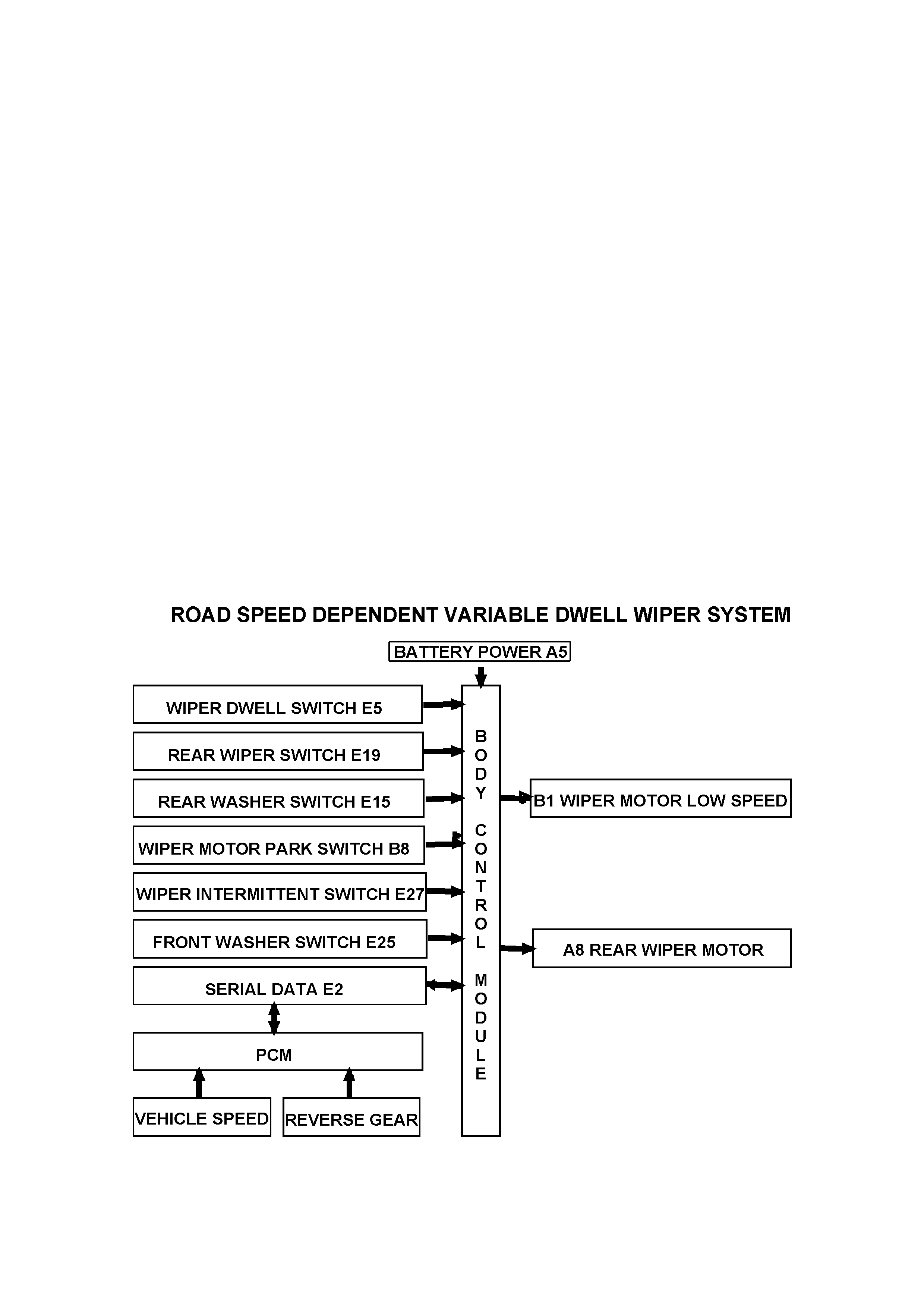

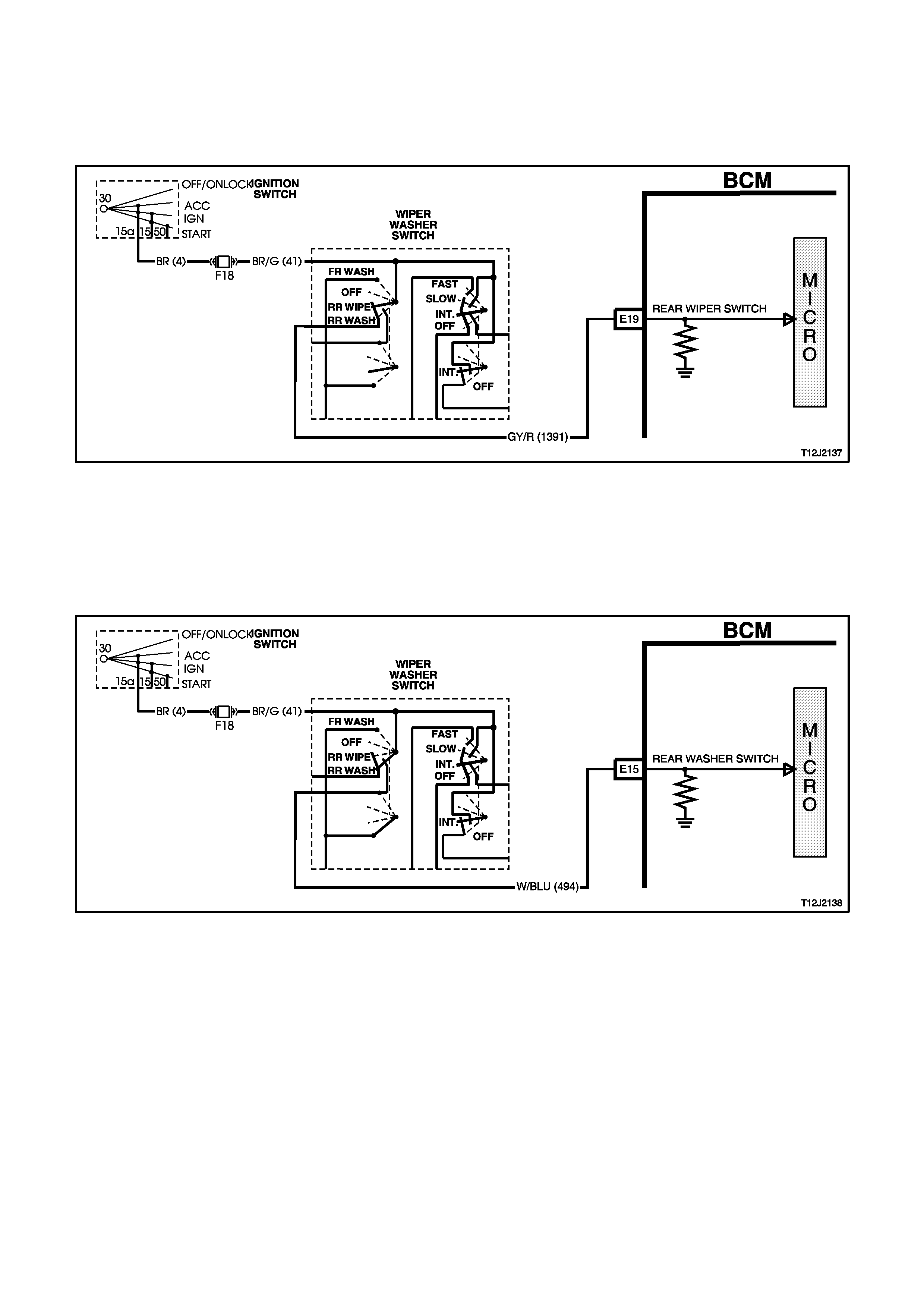

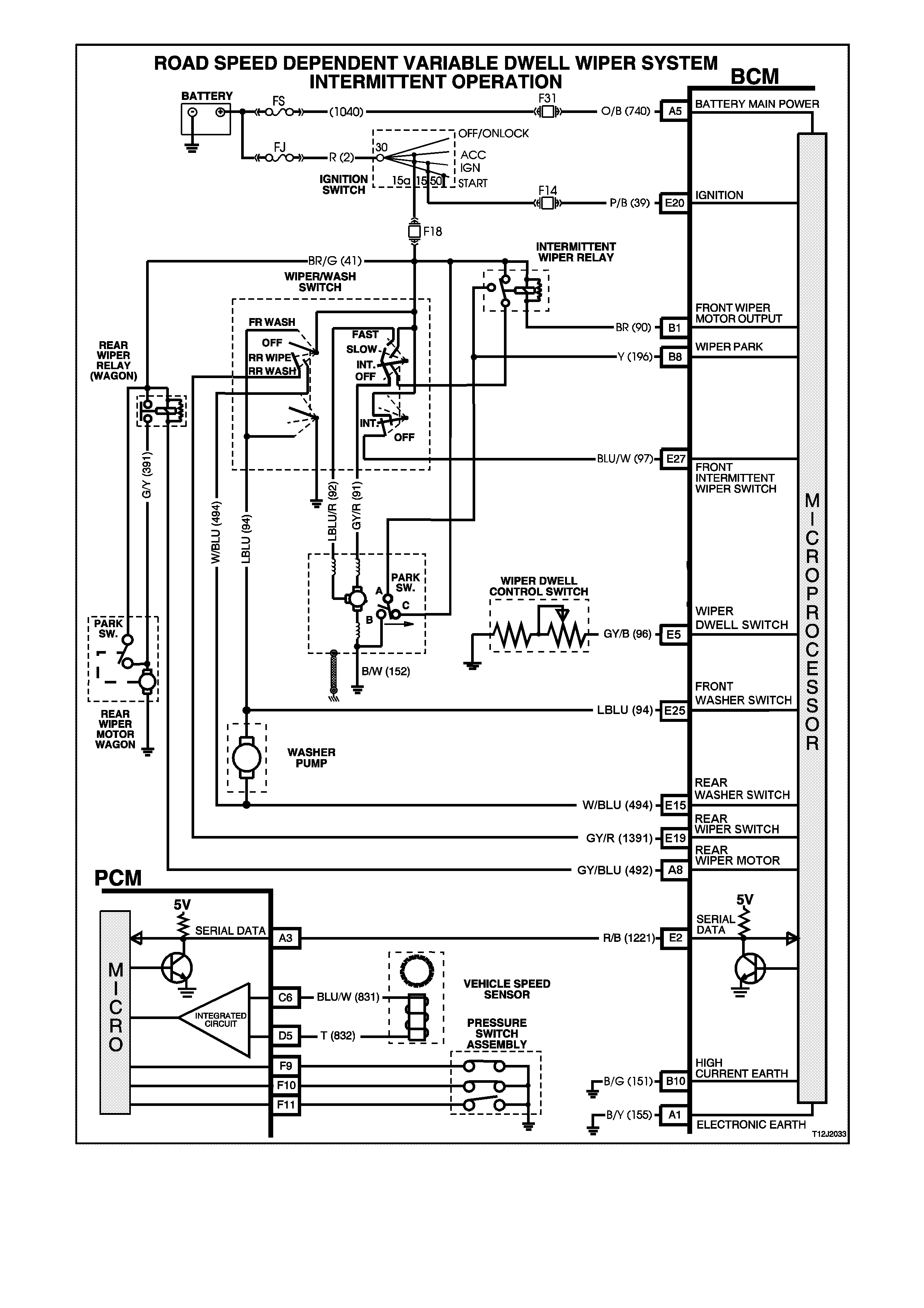

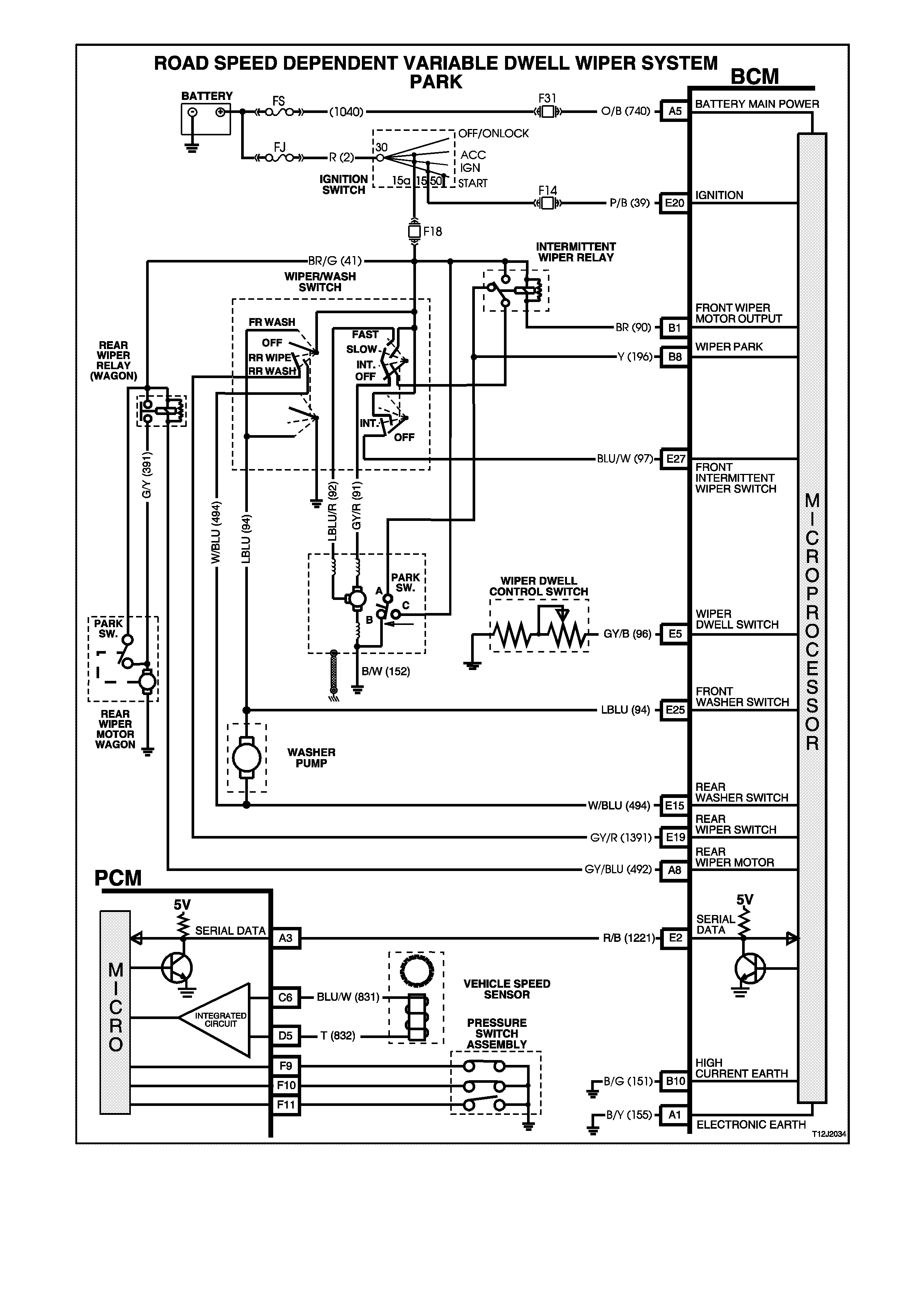

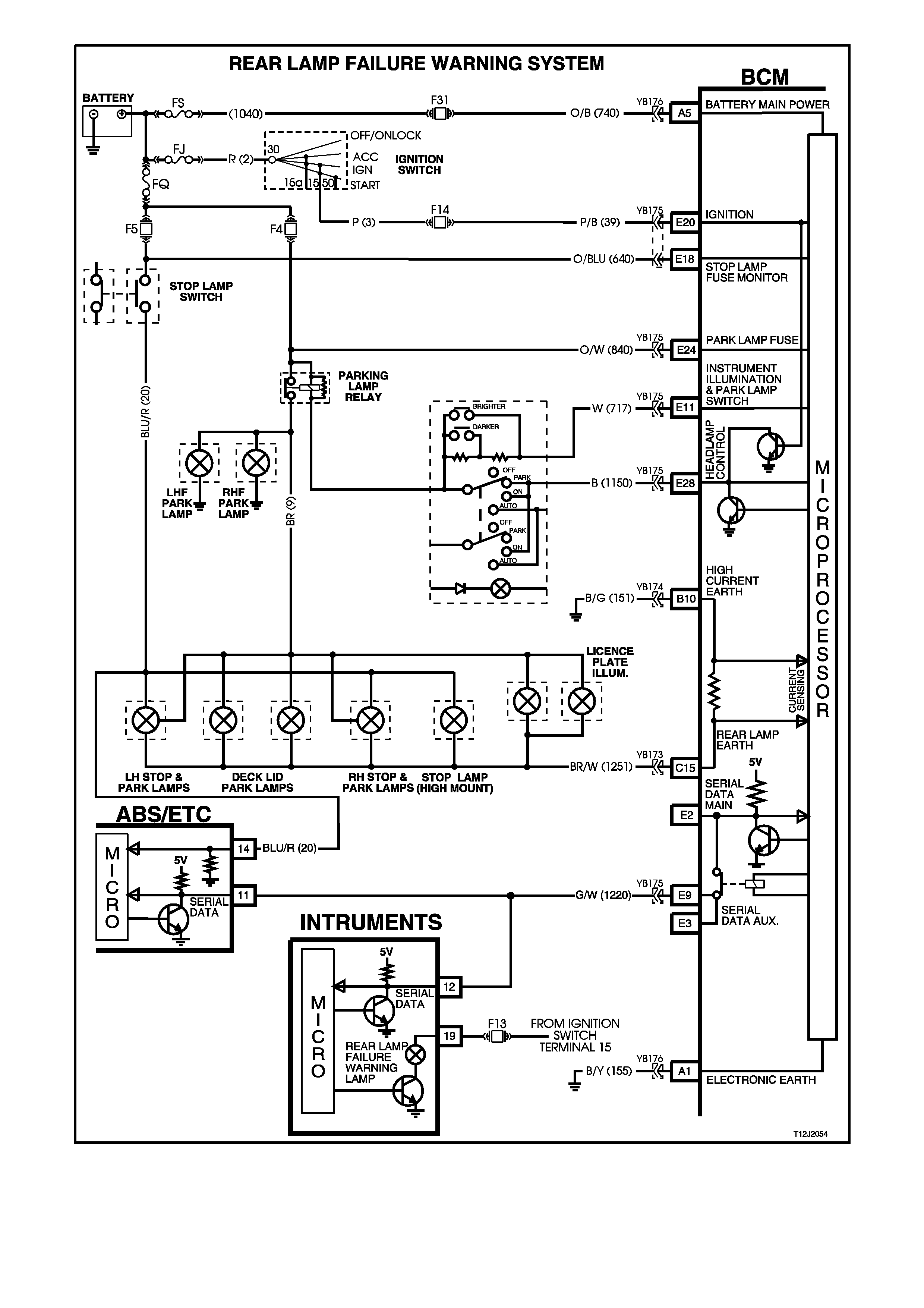

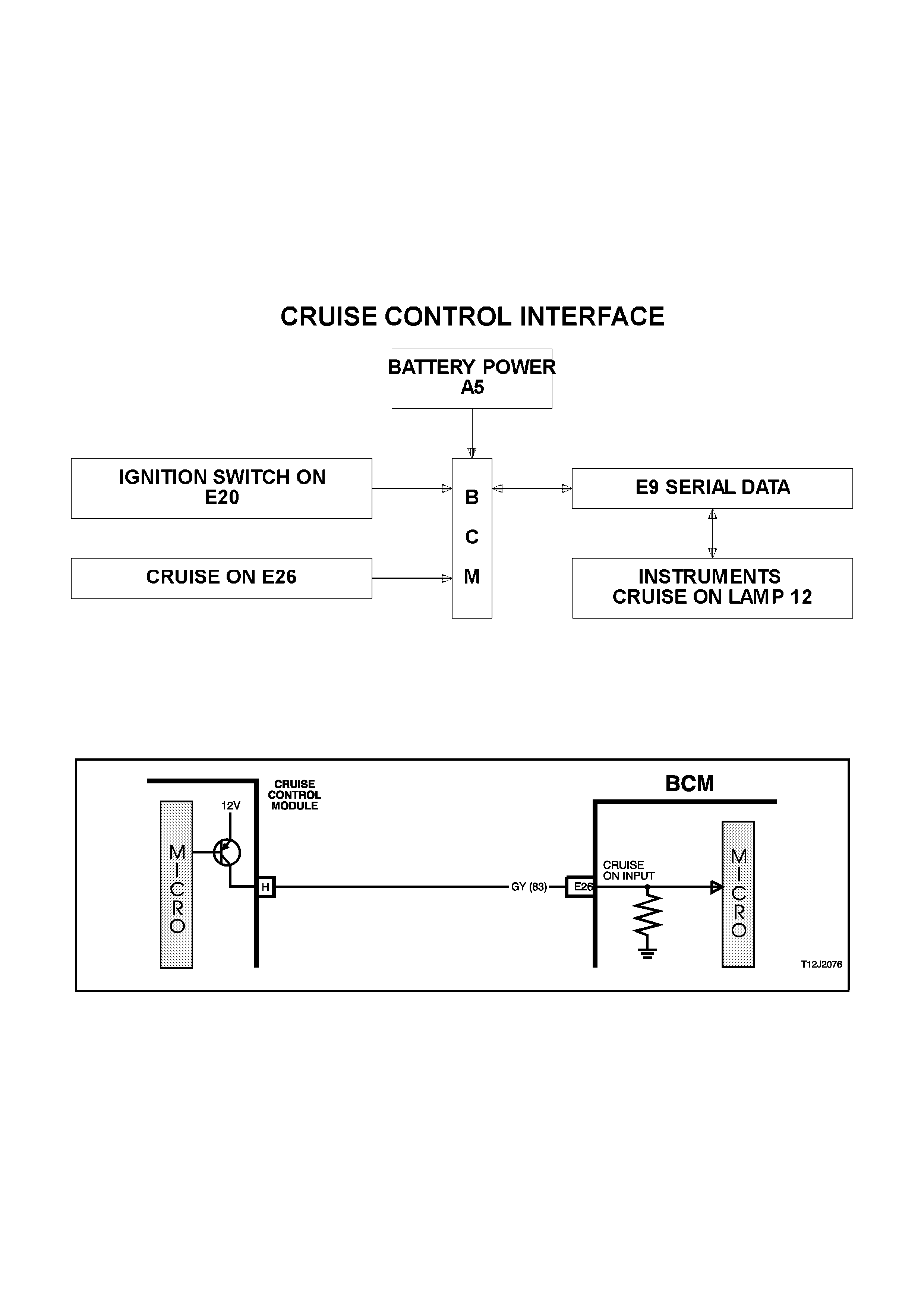

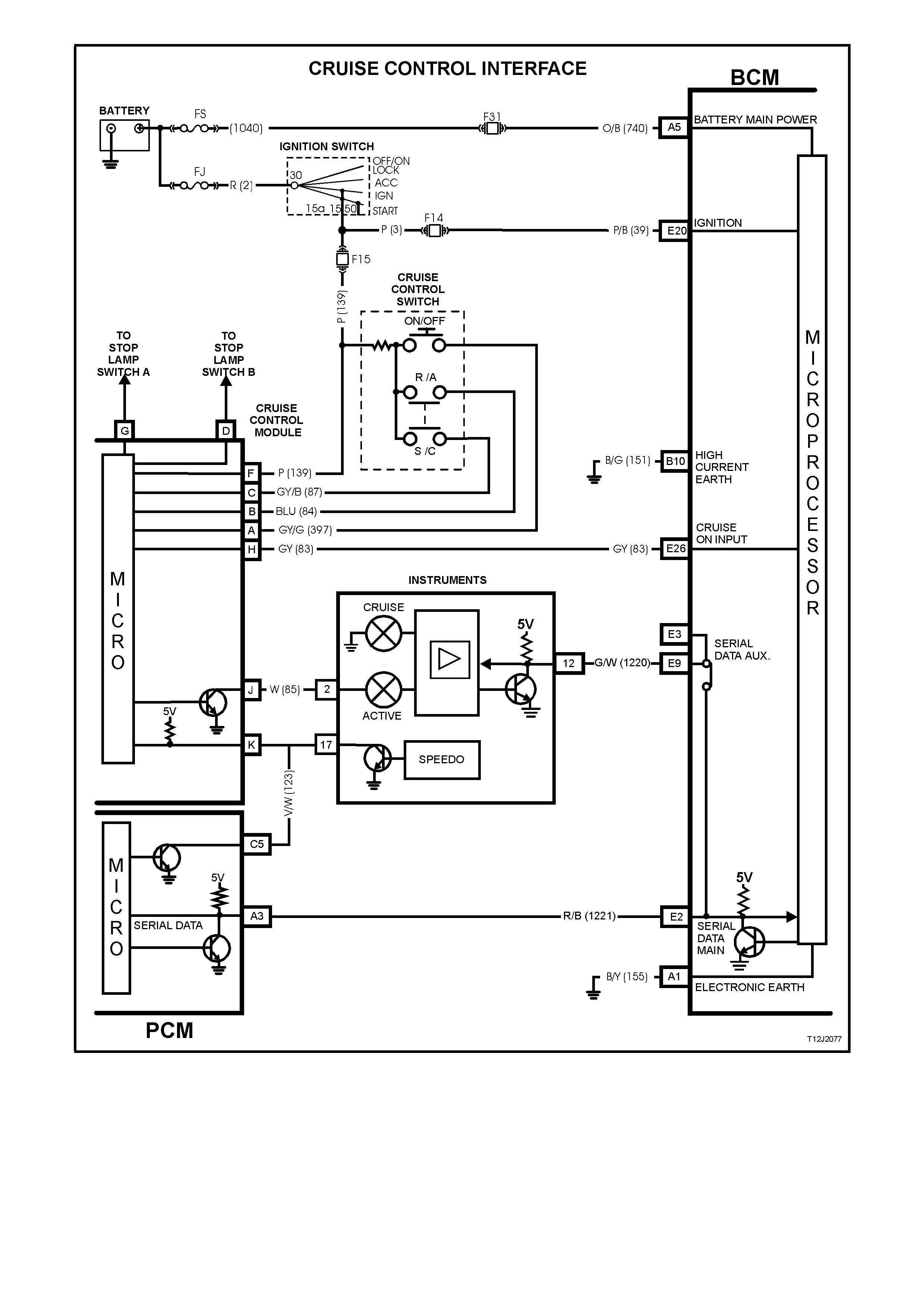

Low Beam Relay Earth Circuit