SECTION 12M - SUPPLEMENTAL RESTRAINT

SYSTEM (VERSION 6.2)

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will

consist of either seat belt pre-tensioners and a driver's side air bag, or seat belt pre-

tensioners and a driver's and front passenger's side air bags. Refer to CAUTIONS,

Section 12M, before performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deplo yment, resulting in possible p ersonal injury or unnecessary

SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of

safety, the LPG fuel system should be isolated by turning 'OFF' the manual service

valve and then draining the LPG serv ice lines, before any service w ork is carried out

on the vehicle. Refer to the LPG leaflet included with the Owner's Handbook for

details or LPG Section 2 for more specific servicing information.

1. GENERAL INFORMATION

The Supplemental Restraint System (SRS) with driver's and front passenger's air bags, is standard fitment to VT

Series Acclaim, Berlina and Calais models. Driver's air bag only, is standard equipment on all other VT Series

Models.

The fitment of front passenger's air bags is available on other VT Series Models, refer to Holden's Sales Information

for option availability.

The SRS is intended as a supplement to the protection offered by the driver and front passenger seat belts by

deploying an air bag from the centre of the steering wheel and (when fitted) a passenger’s side air bag from the top

left hand side of the instrument panel pad assembly during certain frontal crashes. Seat belt pre-tensioners are also

activated.

Deployment of the air bag/s and seat belt pre-tensioners is automatic, making the SRS a passive restraint. The

driver does not control the operation or activation of the system. The system operates if the vehicle is involved in

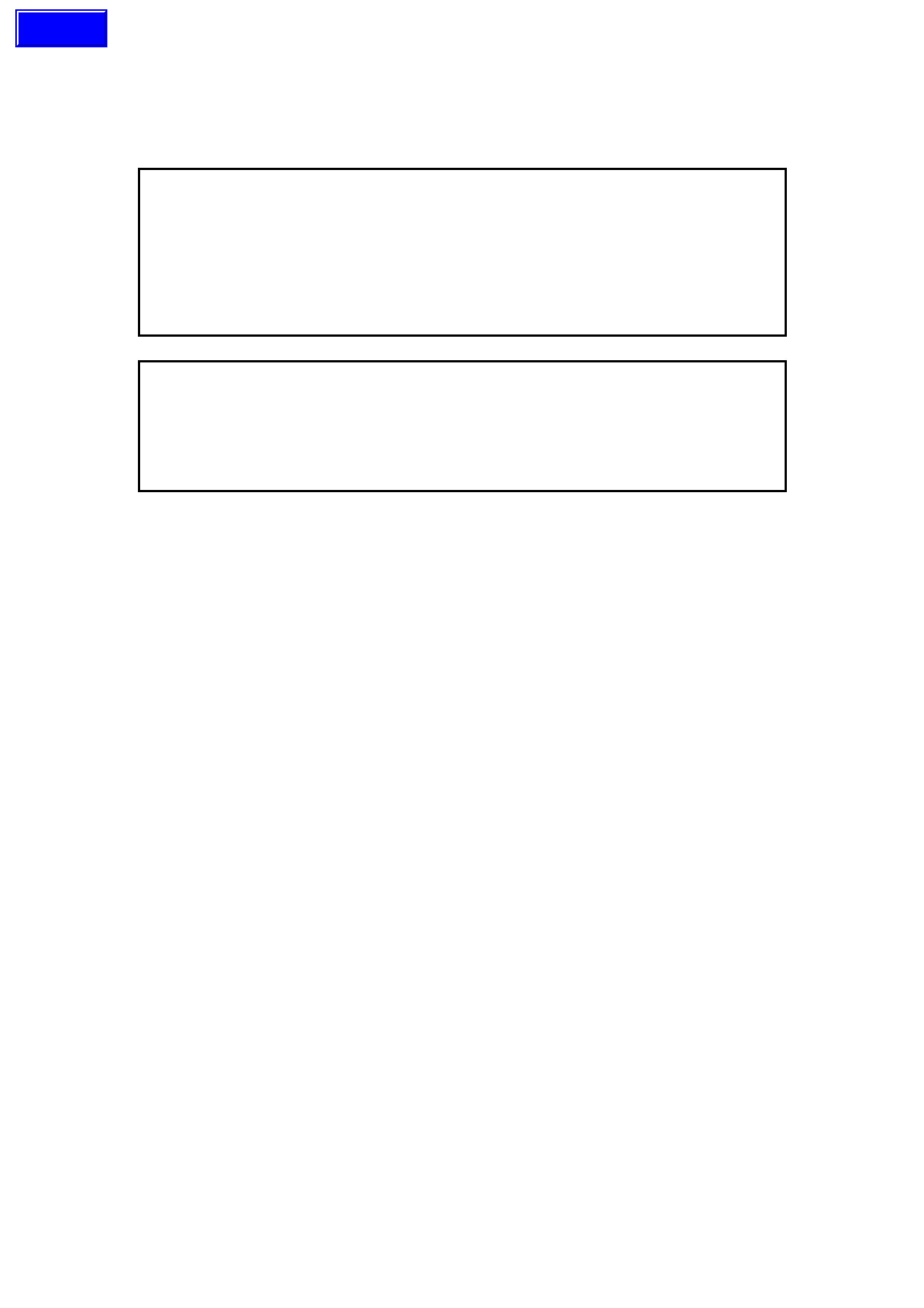

certain frontal (or near frontal) impacts. The frontal impact would normally be within a 60 degree window, occurring

up to 30 degrees off the centre line of the vehicle, refer to Fig. 12M-2. The SRS has the ability to command the

deployment of the seat belt pre-tensioners only or the deployment of all restraint devices. Activation is not designed

to occur in rollovers, side impacts, or rear impacts, where air bag inflation would not provide any driver/front

passenger protection benefit.

Techline

The following pre-conditions determine the operation of the SRS system:

NOTE:

The figures quoted below are the minimum required for the SRS to deploy and are the equivalent of a head on

contact between the vehicle and a barrier or other immovable object.

In most accident scenarios, the vehicle speed required to activate the pre-tensioners and air bags would be

much greater than these values.

Pre-

tensioner Air Bag/s

No Deployment 15 km/h* 20 km/h**

Complete

Deployment 20 km/h* 28 km/h**

Inflation/Tension

Time 5 m/sec 30 m/sec

Max. Displacement

Free Moving Mass 3.0 cm 12.5 cm

* If the vehicle is travelling below 15 km/h and is involved in a frontal (or near frontal) collision, the seat belt pre-

tensioner will not deploy, between 15 and 20 km/h, the pre-tensioner may or may not deploy, and over 20 km/h, the

pre-tensioners will deploy.

** If the vehicle is travelling below 20 km/h and is involved in a frontal (or near frontal) collision, the air bag/s will not

deploy, between 20 and 28 km/h, the air bag/s may or may not deploy, and over 28 km/h, the air bag/s will deploy.

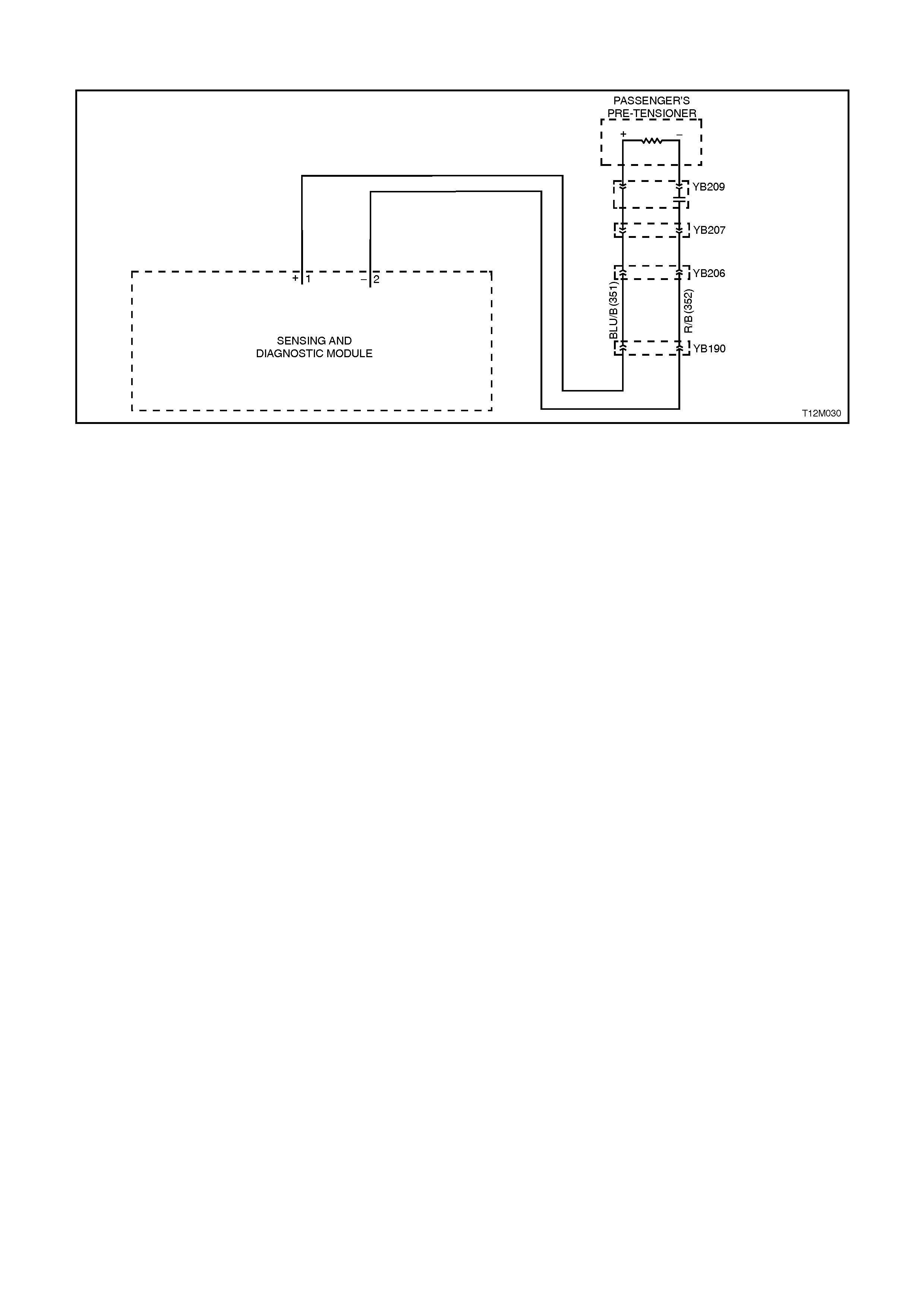

Figure 12M-1

Figure 12M-2

For deployment to occur, numerous factors must be taken into account. For instance, the crush area of the other

vehicle (if involved in the crash), its mass and speed would all contribute to raising or lowering the force required for

deployment to occur as designed. Also, the angle of impact force may not be within the 60 degree window for SRS

deployment to occur, although the physical damage to the vehicle may appear that it was.

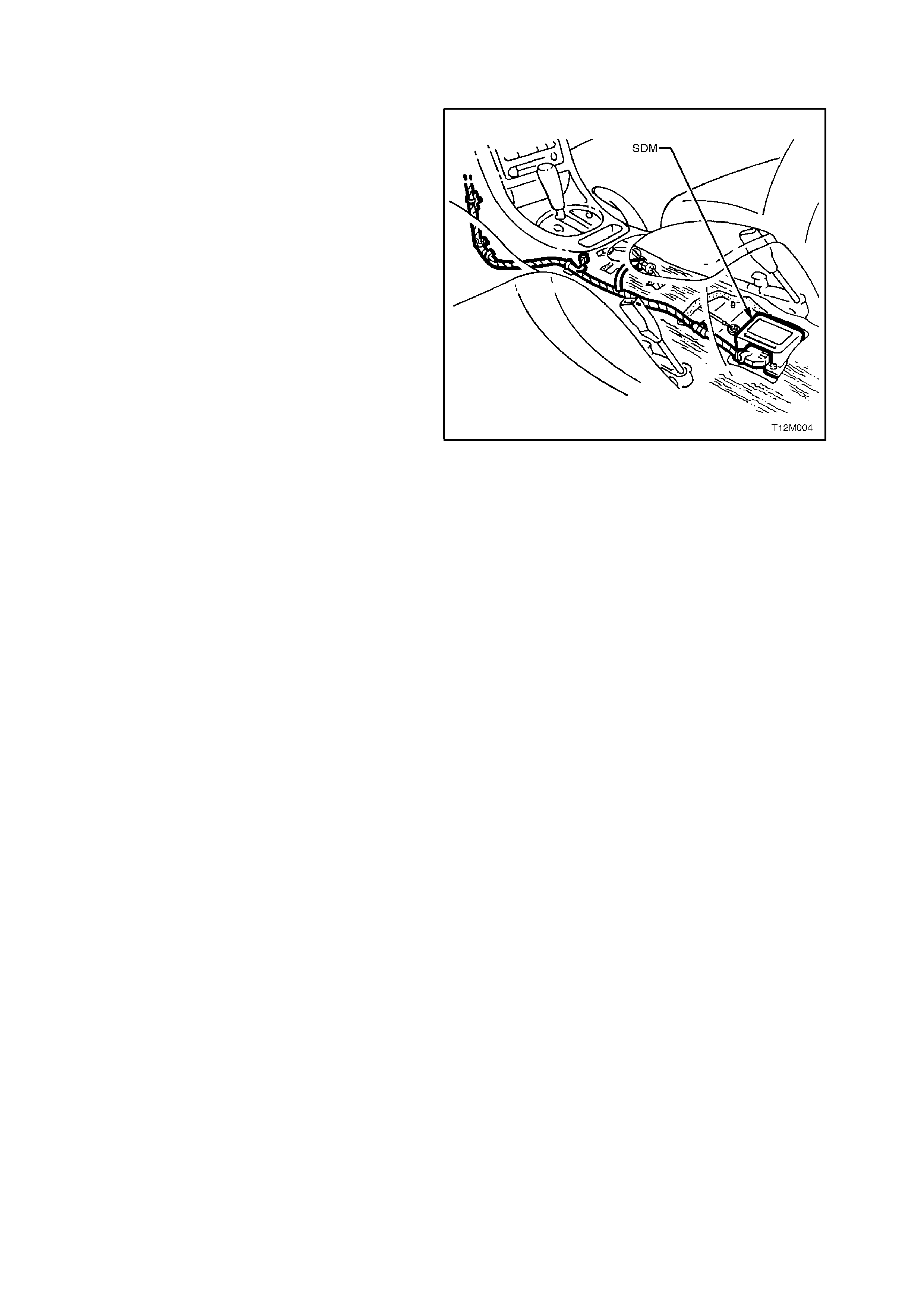

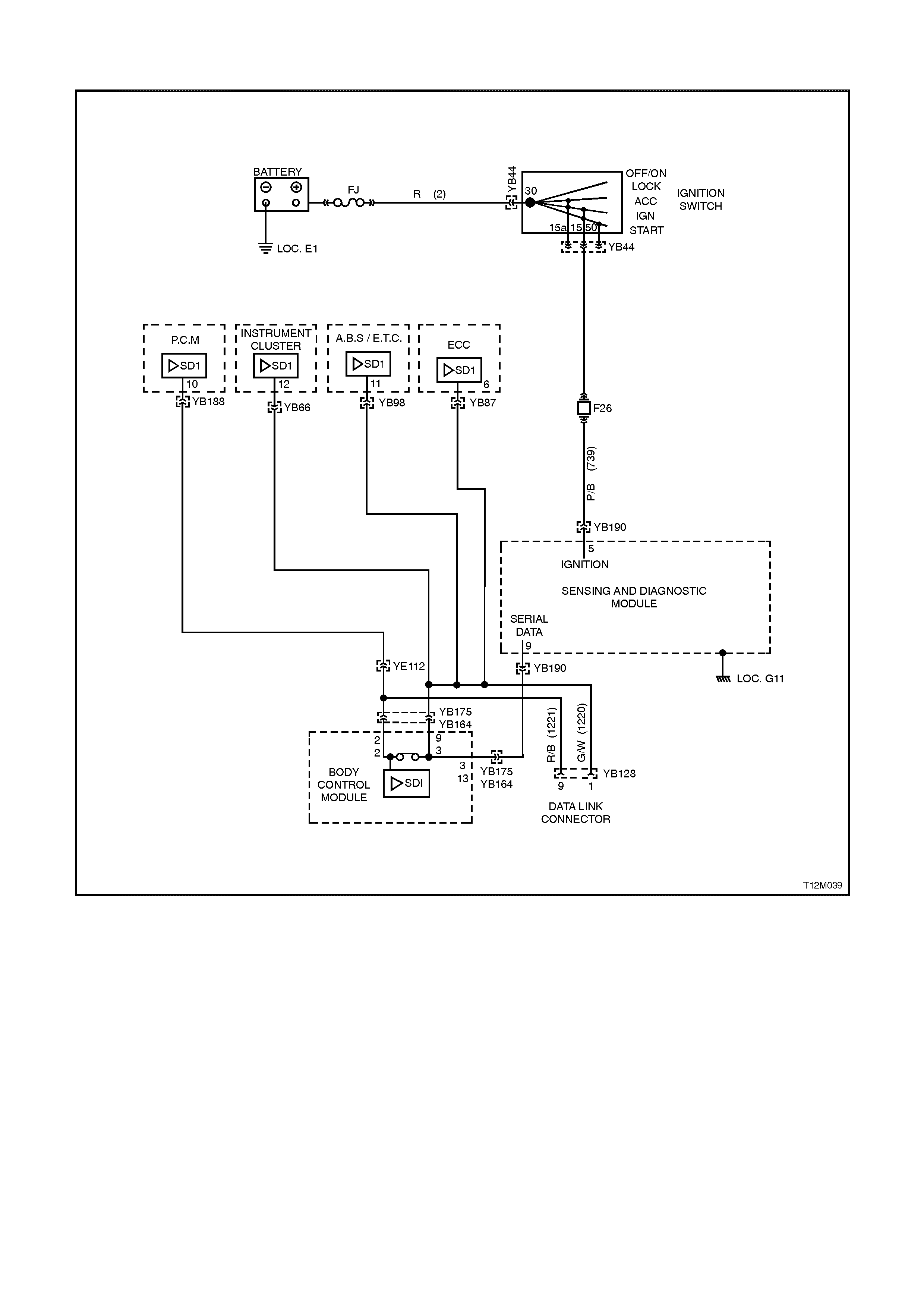

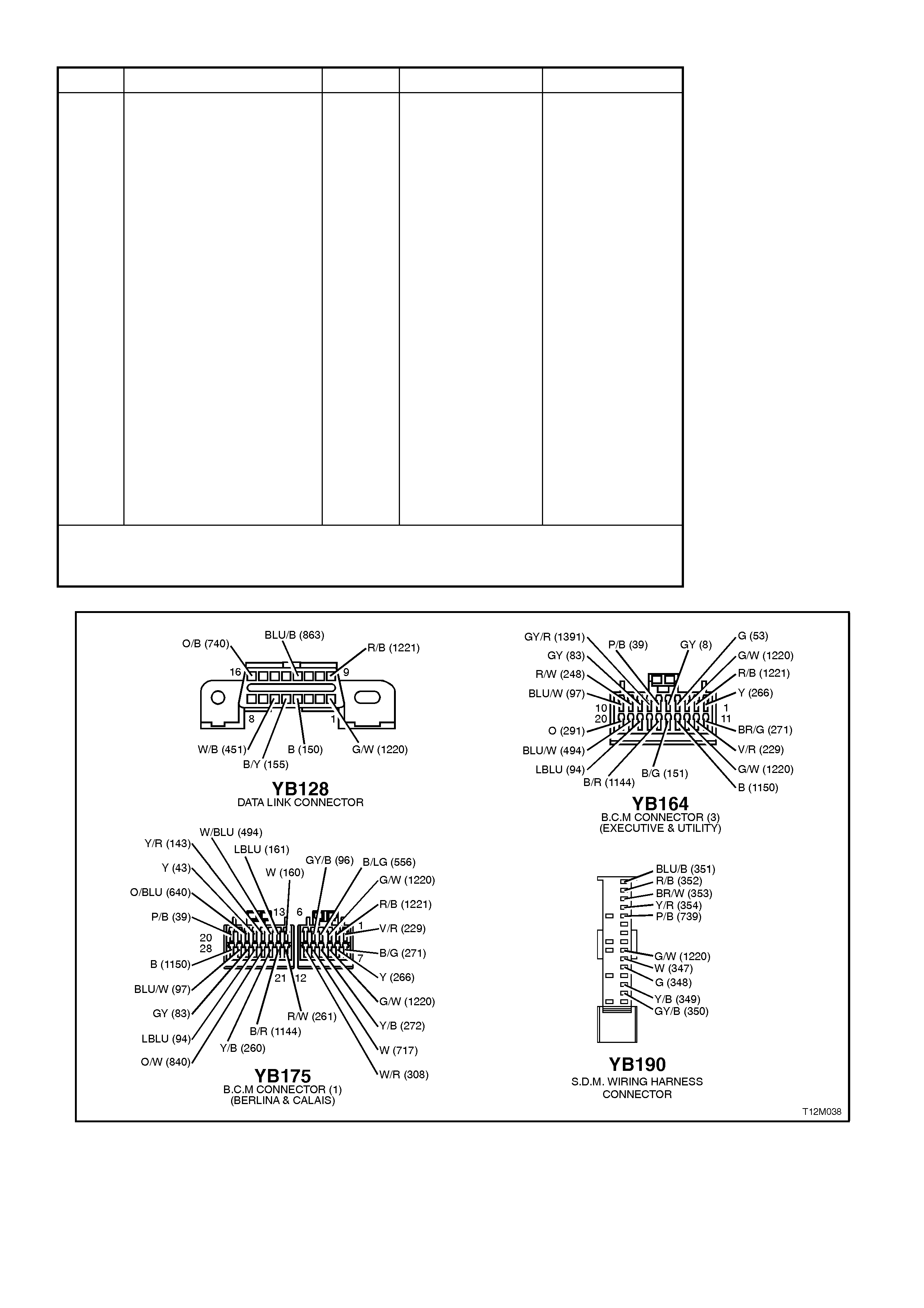

The sensors that control the air bag and seat belt pre-tensioner deployment are incorporated in the Sensing and

Diagnostic Module (SDM), located beneath the centre console.

Regular maintenance of SRS is not required. If at anytime the SRS warning lamp comes on whilst driving or does

not come on when the vehicle is started, there is a system fault and this must be rectified as soon as possible.

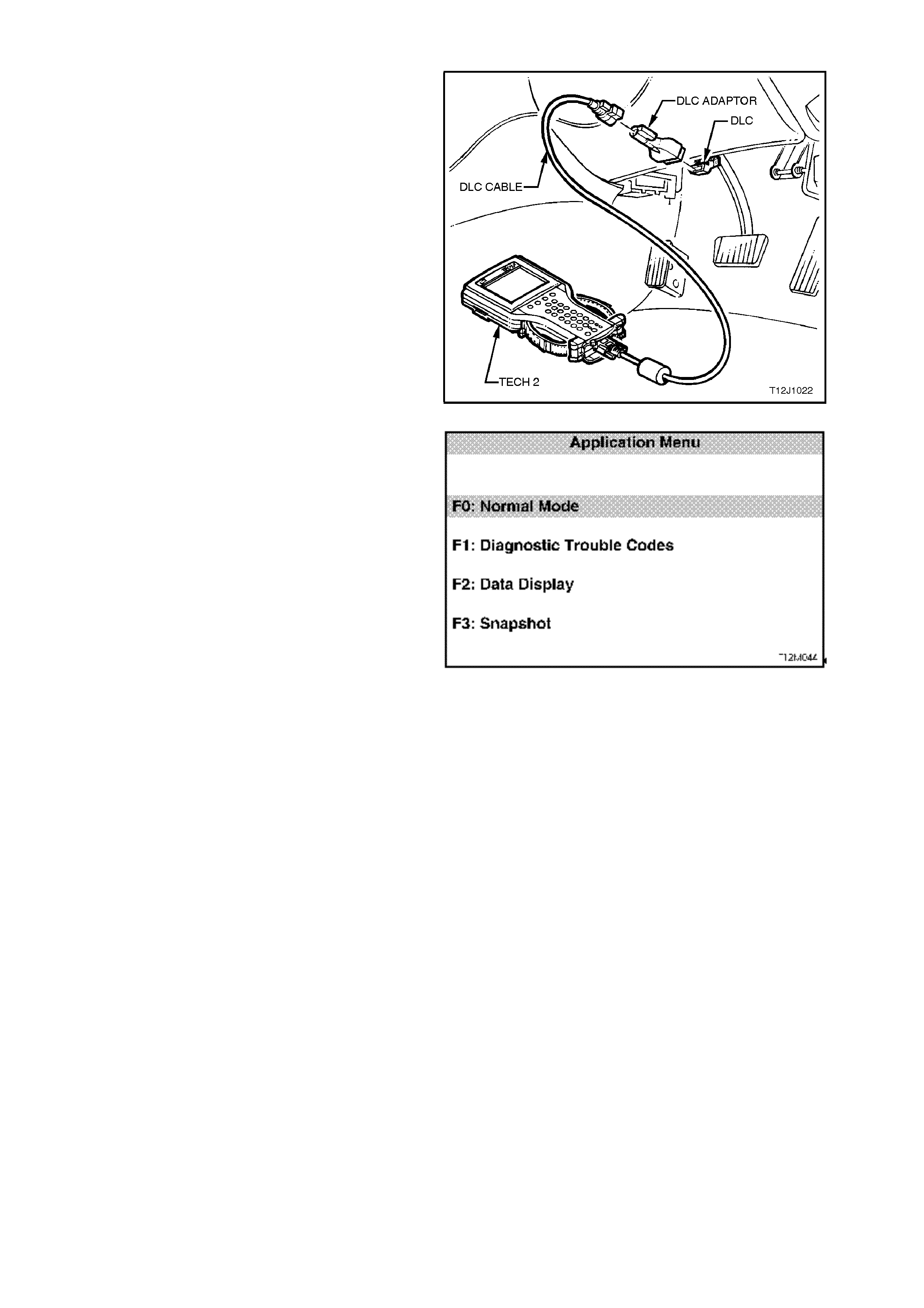

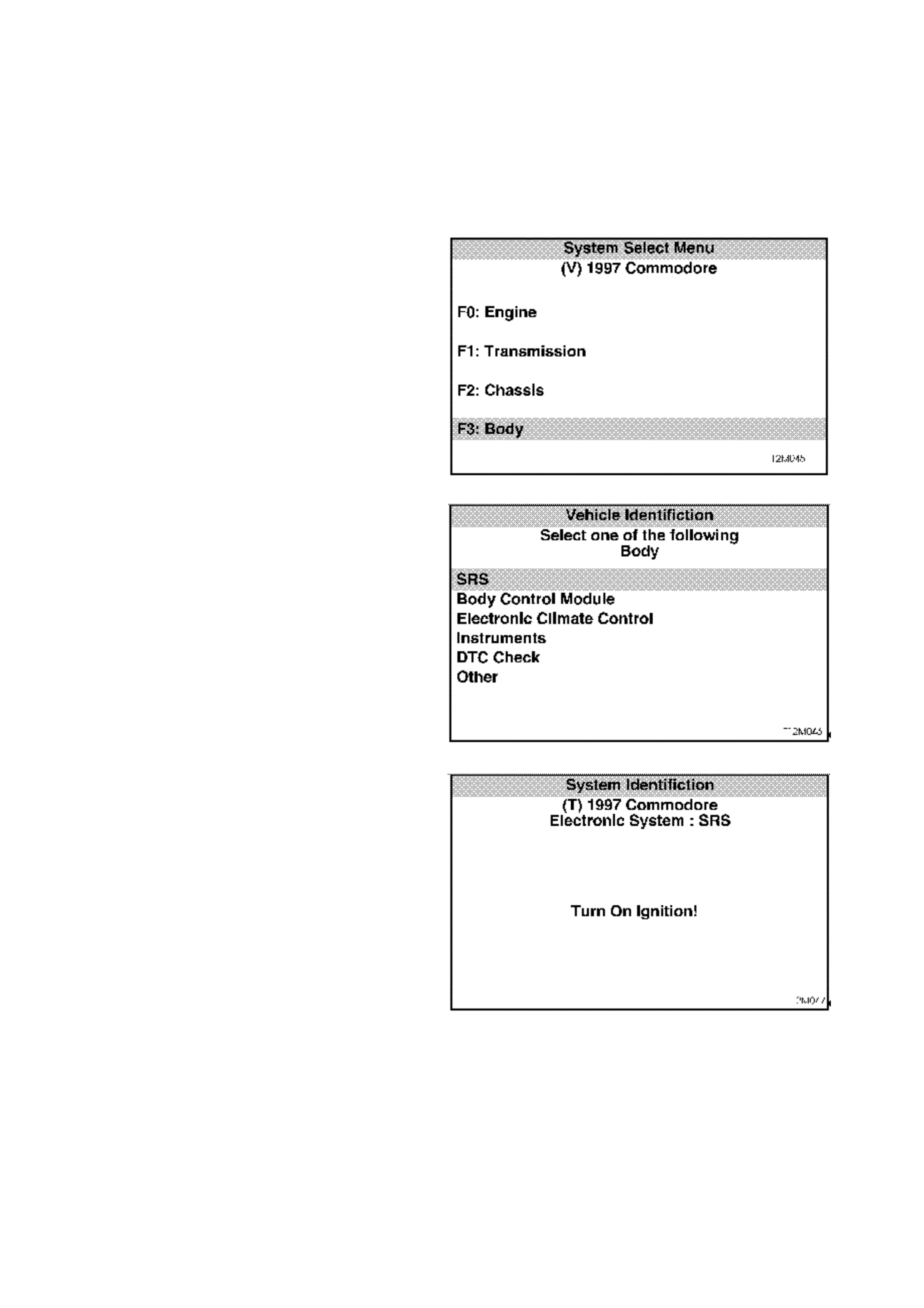

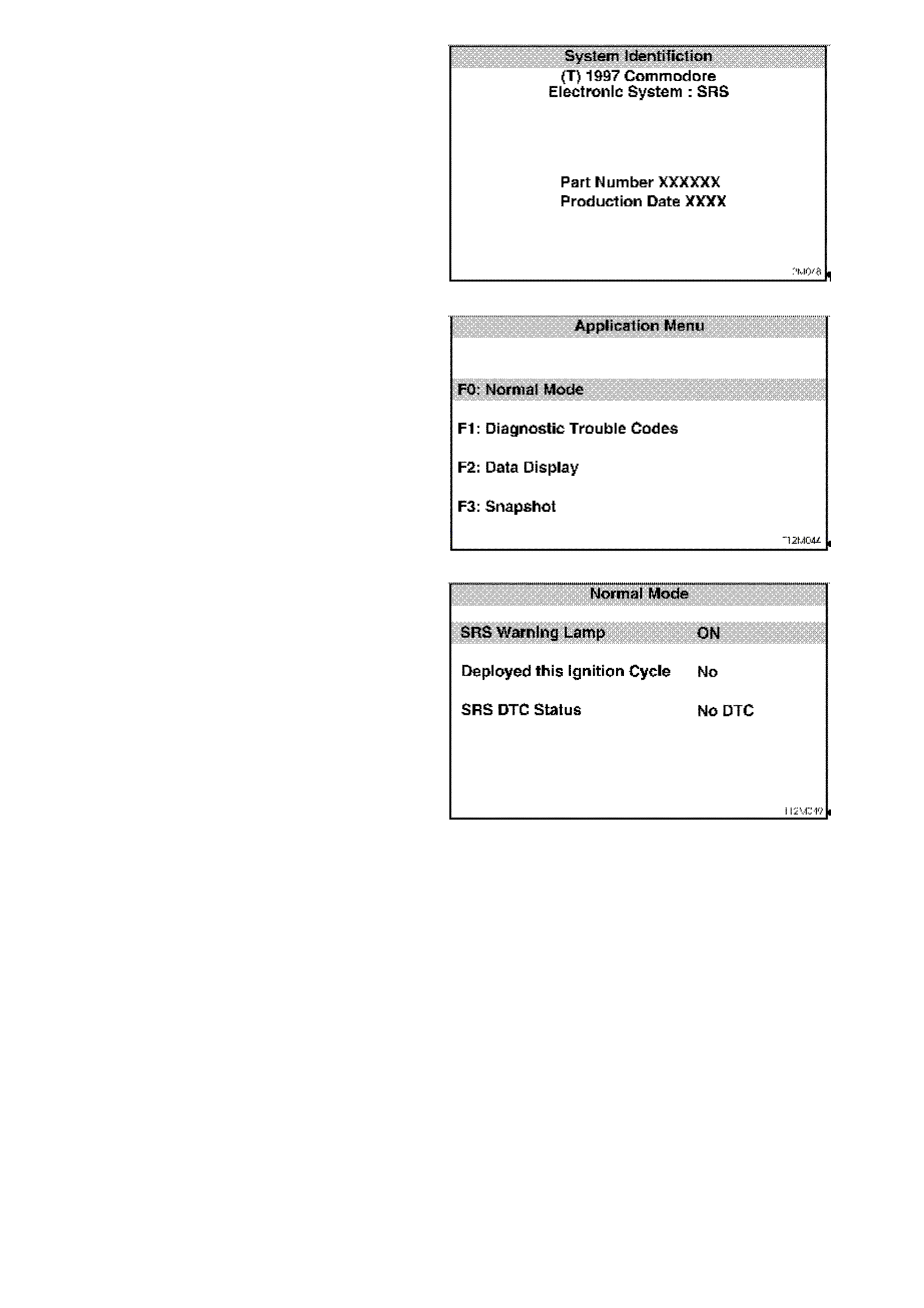

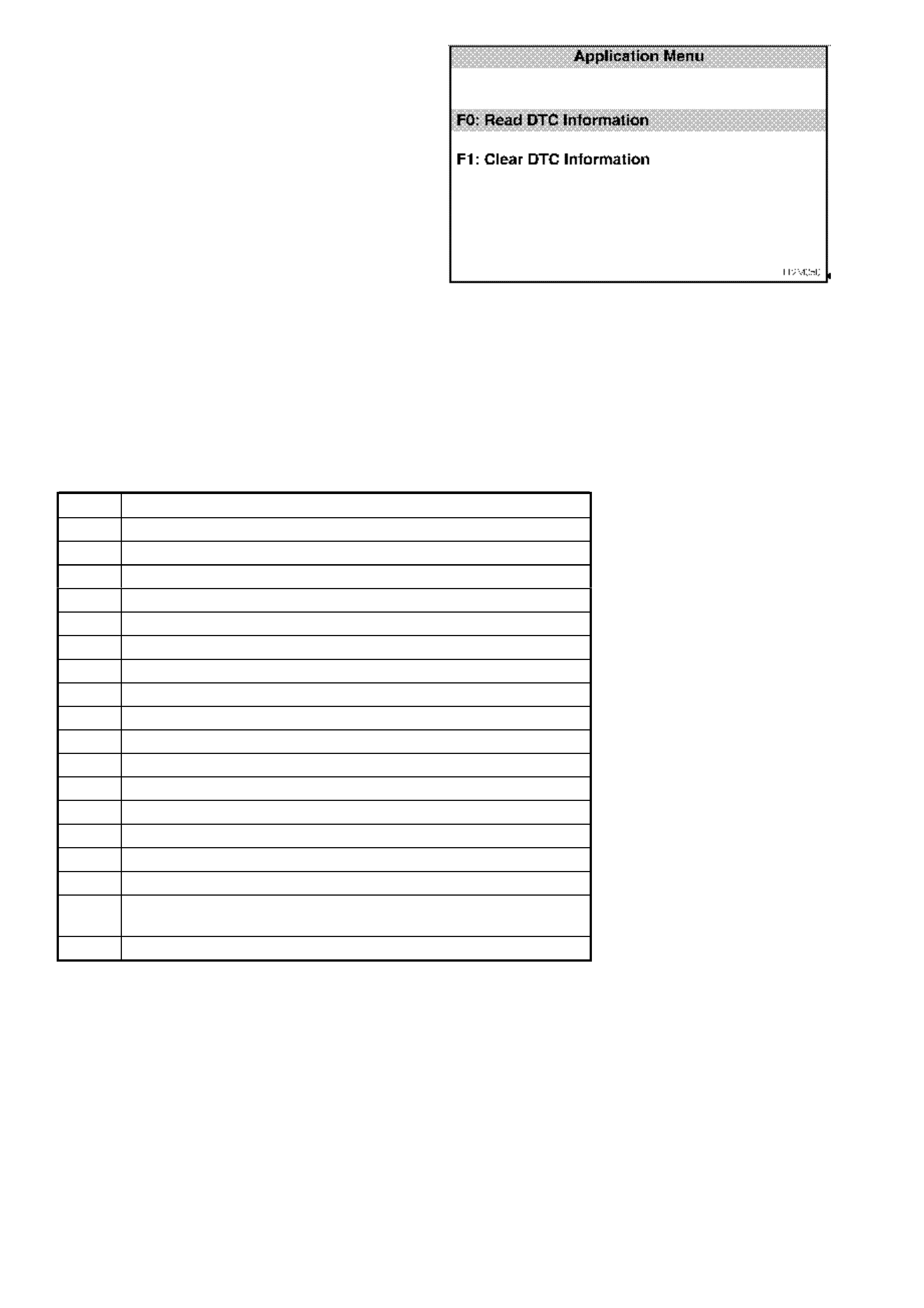

The TECH 2 diagnostic scan tool is programmed to assist with VT electrical diagnosis and problem solving,

including SRS.

TECH 2 connects to the SRS serial data communication information via the Data Link Connector (DLC), attached to

the instrument panel lower right hand trim, to the right of the steering column. For additional information on DLC

location and system diagnosis, refer to 3. DIAGNOSTICS in this Section. For additional and more comprehensive

information regarding TECH 2, refer to Section 0C TECH 2.

IMPORTANT:

Accessory type or after market bull bars or such devices not approved by Holden's and fitted to a vehicle

with SRS may adversely affect the vehicles desired threshold characteristics for SRS deployment.

On vehicles with front passenger's air bag, accessory type or after market type dash panel carpet covers,

or the like MUST NOT be installed, as this will greatly inhibit the performance of the air bag and front

passenger's safety in the event of an air bag deployment.

Fitting of accessories such as drink holders, cassette racks additional mirrors, etc. are not permitted in the

immediate deployment area of the front passenger's air bag as these may be ripped off and propelled

towards the vehicle's occupants when the air bag is deployed.

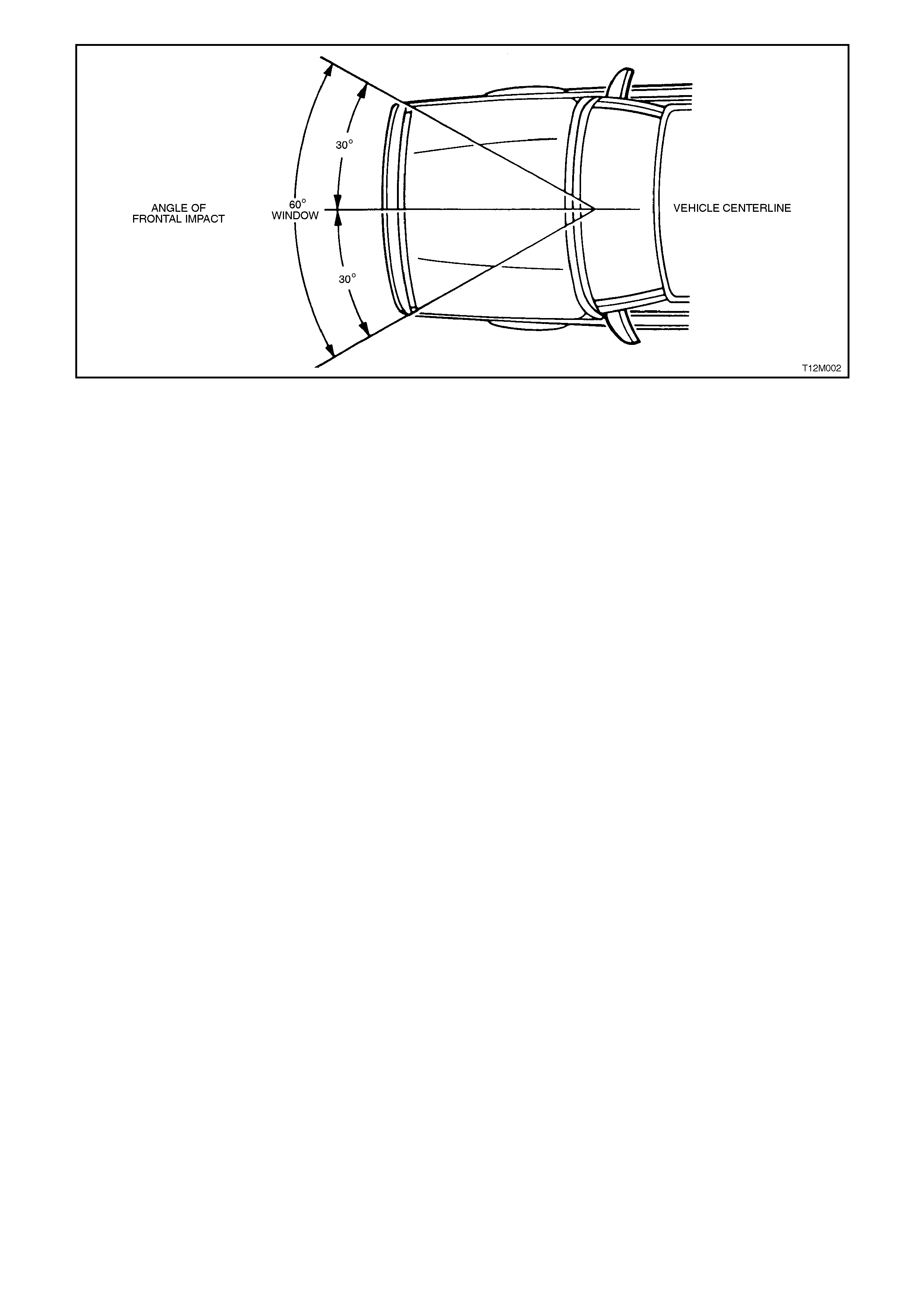

Figure 12M-3, below, illustrates the locations within the passenger compartment of the SRS components.

Figure 12M-3

1. Front passenger’s side air bag inflator assembly.

2. Passenger Air Bag (PAB) door.

3. Clock spring coil assembly.

4. SRS wiring harness (part of main wiring harness).

5. Horn bar and driver’s side air bag inflator module.

6. Sensing and Diagnostic Module (SDM).

7. Seat belt pre-tensioner assembly.

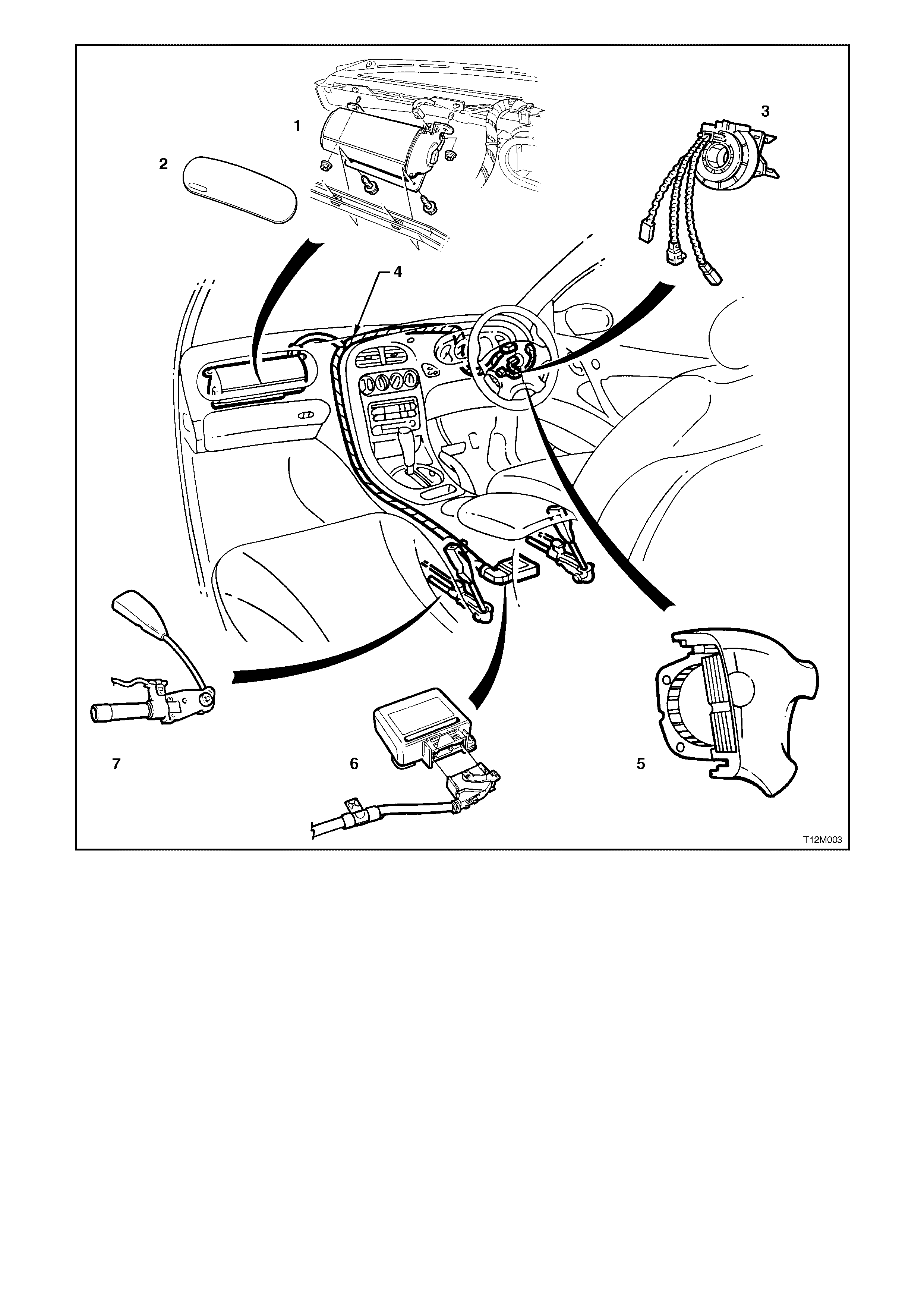

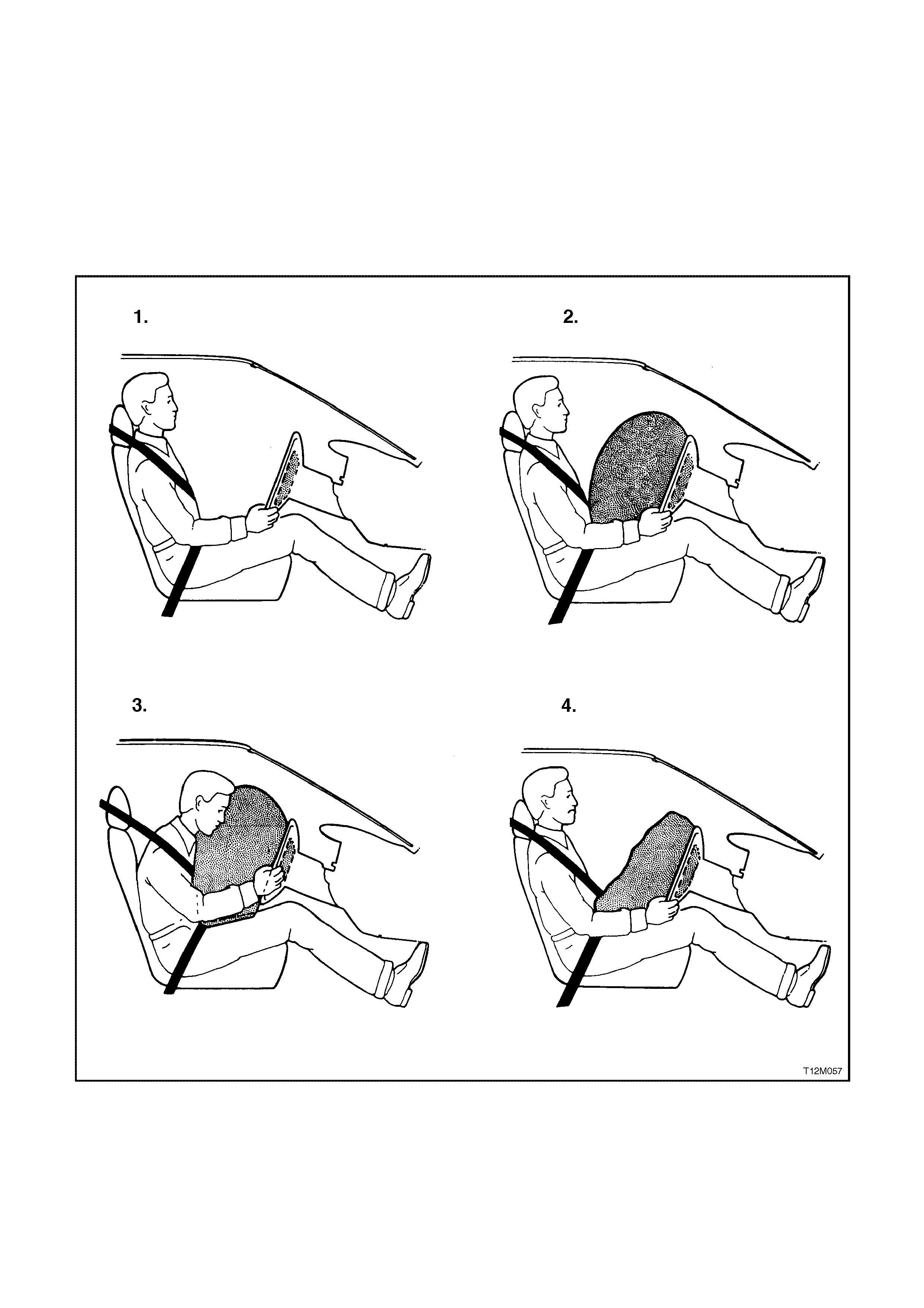

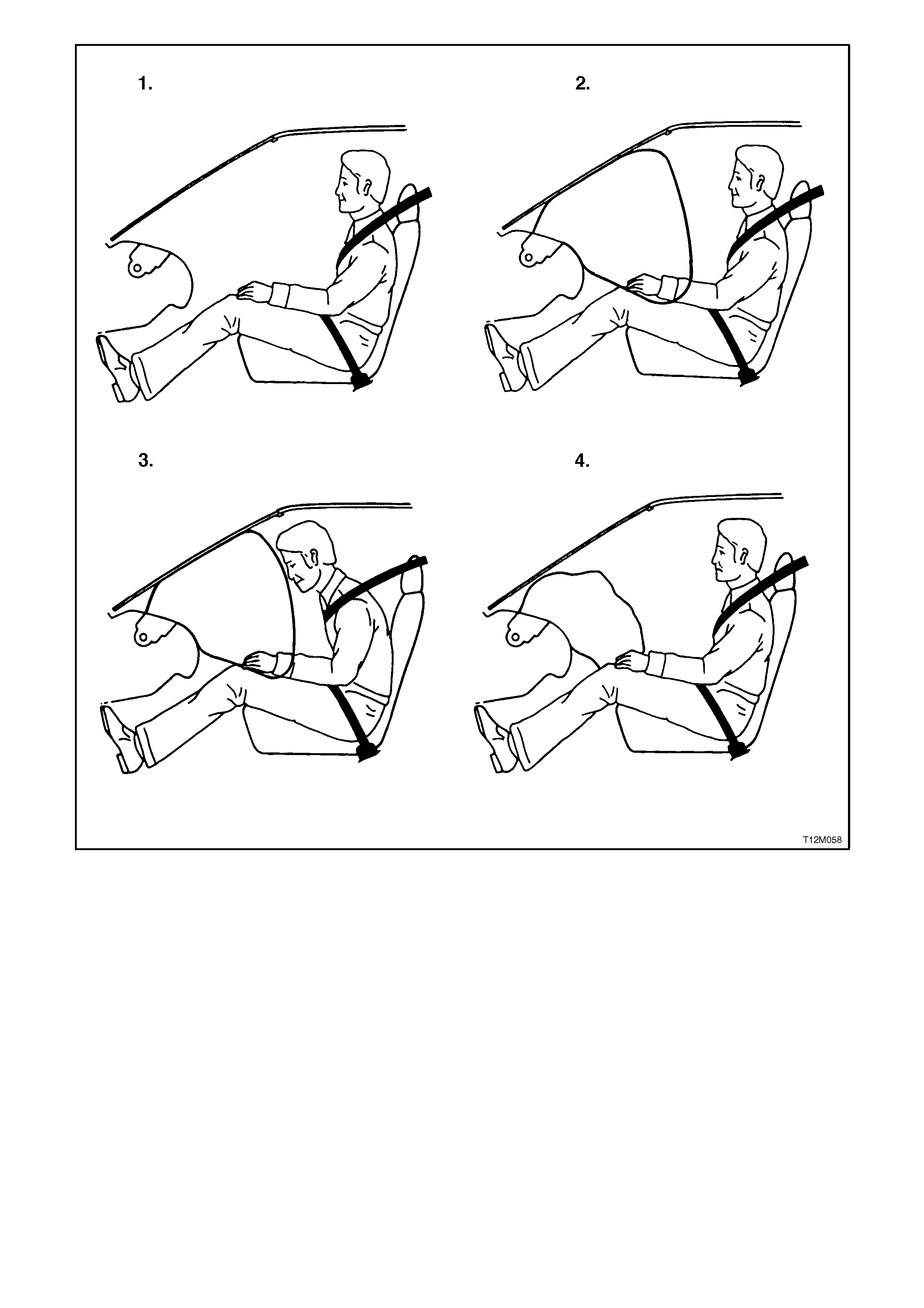

The SRS system operates the air bag inflator module/s in four stages (refer to Figs. 12M-4 and 12M-5) to protect

the driver and front seat passenger (if front passenger side air bag is installed) during a crash.

NOTE:

If air bags are deployed, they will both deploy simultaneously.

1. Before Deployment: The SRS is in a state of readiness, unless the Sensing and Diagnostic Module (SDM)

detects a fault and alerts the vehicle driver via the SRS warning lamp in the instrument cluster warning lamp

panel.

2. Fully Deployed: The air bag/s are inflated and the SDM records the data related to the SRS conditions and

operation.

3. During Restraint: The force of the crash causes the head and upper torso of the front passenger and/or driver

to move forward into the inflated air bag/s.

4. End of Crash: The air bag/s deflate within several seconds after deployment.

Figure 12M-4

1. Before deployment 3. During restraint

2. Fully deployed 4. End of crash

Figure 12M-5

1. Before deployment 3. During restraint

2. Fully deployed 4. End of crash

1.1 SYSTEM COMPONENTS

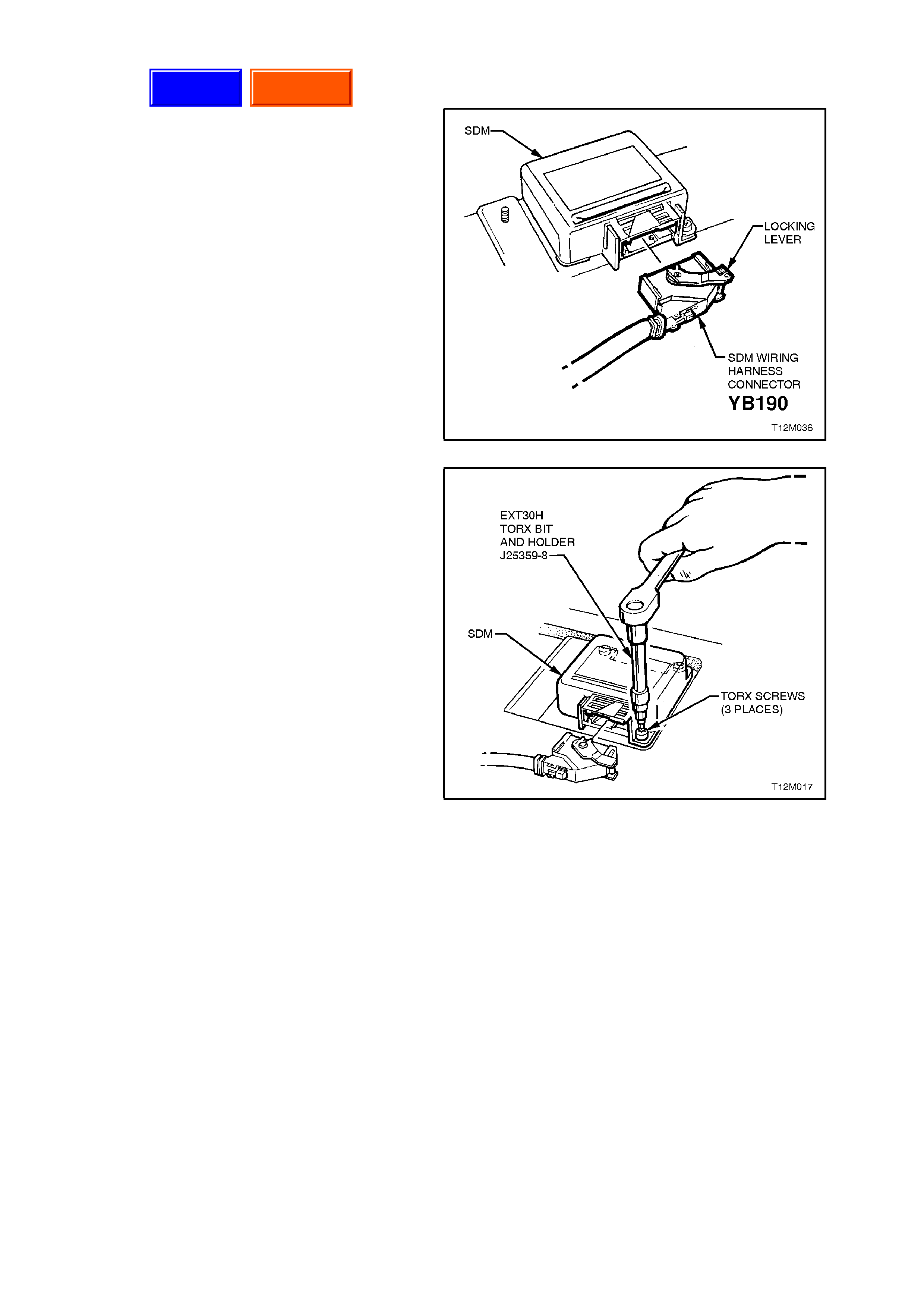

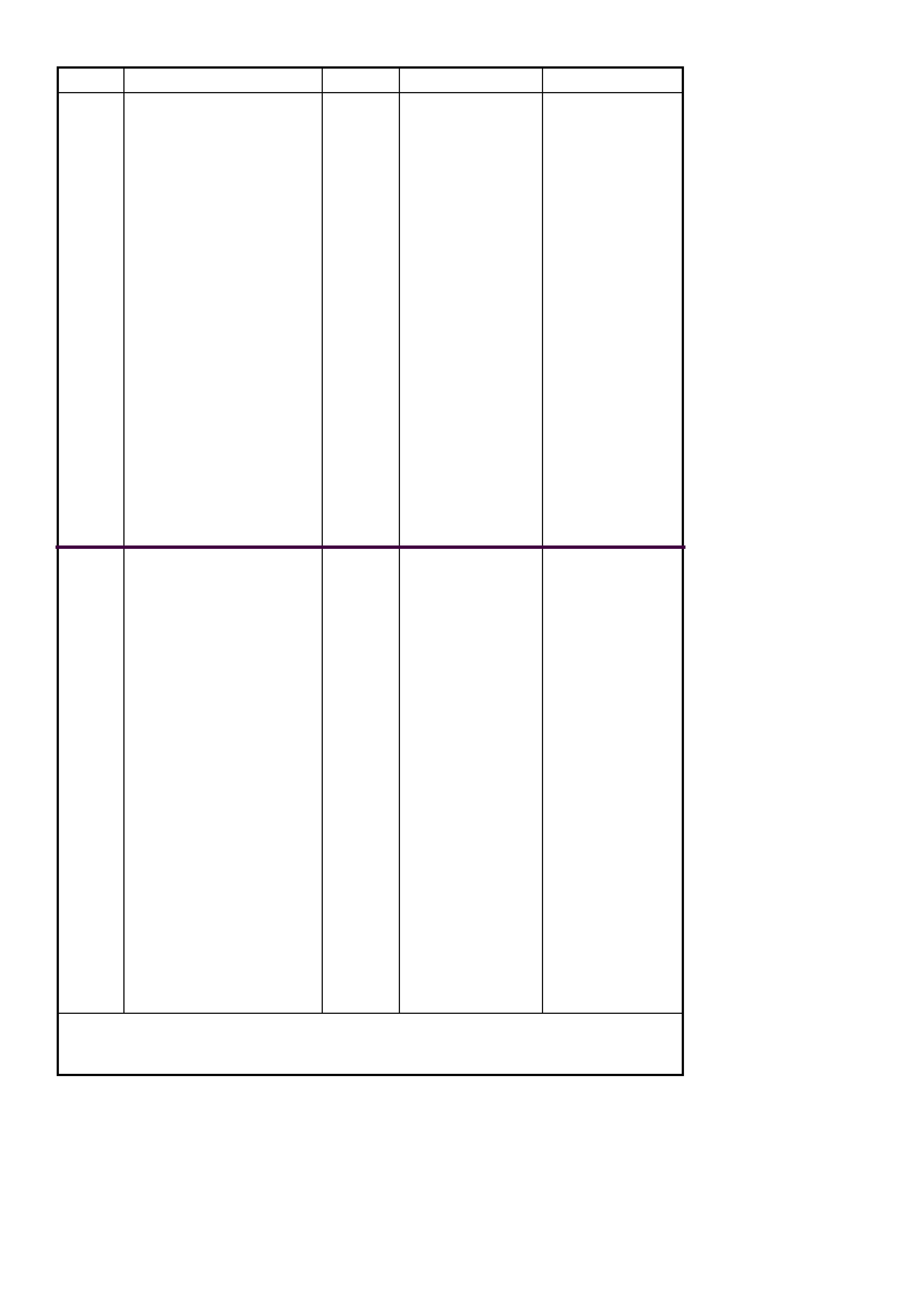

SENSING AND DIAGNOSTIC MODULE

The Sensing and Diagnostic Module (SDM), which

is mounted under the centre console assembly,

consists of an electronic acceleration sensor

system, electronic control system, energy storage

devices, self diagnostics, fault memory and crash

event recording facility.

The primary function of the SDM, as part of the

SRS, is to sense crash events and discriminate

between non-deployment and required deployment

events.

The SDM is a centralised, self contained crash

sensing and triggering system that requires no

additional external sensing inputs. The SDM also

performs continual tests on the pre-tensioners and

air bag circuits for the front seat belt pre-tensioners,

the driver's air bag and (if fitted) front passenger's

air bag.

In the case of a deployment event, the function of

the sensing system is to initiate the pre-tensioners

or pre-tensioners and air bag/s in a timely manner

in order to protect the vehicle occupant/s.

Secondary to this, the SDM can diagnose system

faults which may prevent air bag deployment or

increase the probability of an inadvertent

deployment and warn the driver in the case of a

system fault.

The SDM is designed for a one time deployment

use only, and must be replaced after a

deployment. If deployment occurs and the SDM

is not replaced, the SRS warning lamp in the

instrument cluster will be continually

illuminated.

Figure 12M-6

Integrated in the SDM are two piezoelectric sensors

(crash sensor) that constantly monitor the

acceleration data of the vehicle. Microprocessors

within the SDM com par e the signals f rom thes e two

sensors to a set of values stored in the processor

memory. If the processed values exceed their set

of stored values, the SDM provides an AC output

signal to ignite the pyrotechnic gas generators in

the pre-tensioners or the pre-tensioners and air

bag/s.

An energy reserve (capacitor) in the SDM stores

sufficient energy to activate the air bag/s in the

event of the electrical system being damaged by

the impact.

The electronic diagnostic facility within the SDM

constantly monitors the electrical circuits and the

firing circuit. Faults that occur in the system are

stored in the m em or y and the SRS warning lam p in

the instrument cluster warning lamp panel will be

switched on.

The SDM performs the following functions:

It continuously monitors the SRS electrical circuits.

It controls the SRS warning lamp in the instrument

cluster to alert the vehicle driver of a detected

system fault.

It has an energy reserve that provides back-up

power (in case the vehicle system power lost

during a crash) to operate the air bag inflator

module/s.

NOTE:

Due to the presence of energy storage devices

within the SDM, servicing of any SRS component

should not be attempted within 10 seconds after

disabling the system.

During deployment, it records and stores SRS and

crash event information:

- Diagnostic Trouble Codes (DTCs) for

detected faults.

- SRS warning lamp operation data.

It comm unic ates diagnostic information thr ough the

Data Link Connector (DLC) for the following

purposes:

- System checks at the vehicle assembly plant.

- Service diagnosis (using TECH 2).

- Transm itting of c rash event rec ording data f or

post Crash analysis.

For details on connecting TECH 2 to the DLC, ref er

to 3.4 TECH 2 DIAGNOSTICS in this Section, or

for more detailed information regarding TECH 2,

refer to Section 0C TECH 2.

Additionally, in the event of SRS deployment, the

SDM will send serial data via the auxiliary serial

data bus (circuit 1220) to advise various vehicle

systems to take appropriate shutdown action.

The PCM monitors this serial data and performs a

vehicle shutdown once the appropriate data is

identified and the vehicle speed is zero for more

than 10 seconds.

The BCM also monitors this serial data and

performs the f ollowing actions onc e the appr opriate

data is identified and the vehicle speed is zero for

more than 10 seconds:

Turn the dome lamp on continuously.

Unlock all doors.

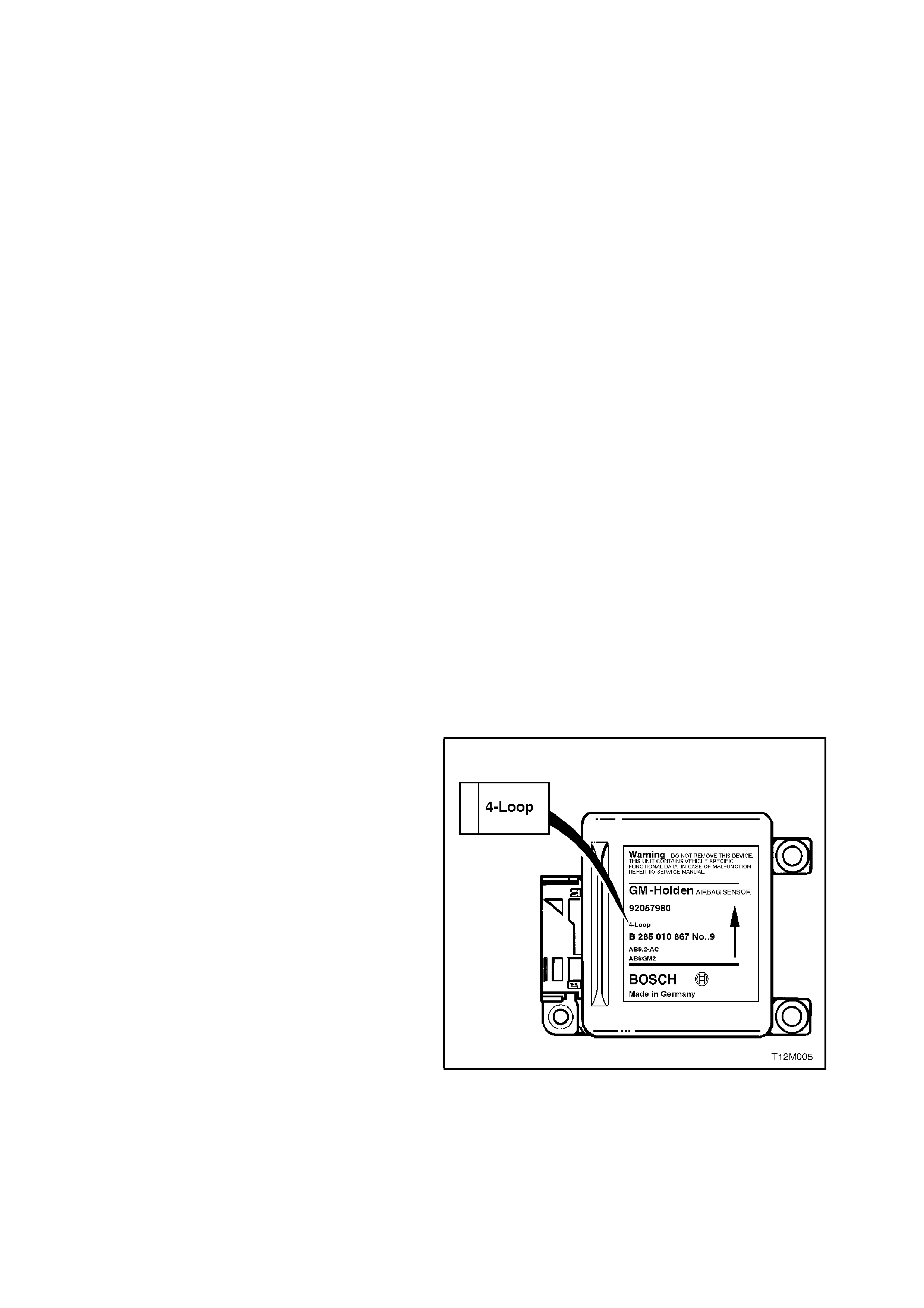

For VT Series Models, two different and non

interchangeable SDMs are released:

• 3-Loop system - for pre-tensioners and driver's

air bag only.

• 4-Loop system - for pre-tensioners, driver's air

bag and front passenger's air bags.

To identify the different SDMs, refer to the

identification label on the top of the SDM. Figure

12M-7 shows the identification label for the 4 loop

system.

NOTE:

Always refer to the latest VT spare parts

microfiche/Part Finder information for the latest part

numbers when ordering SRS components.

Figure 12M-7

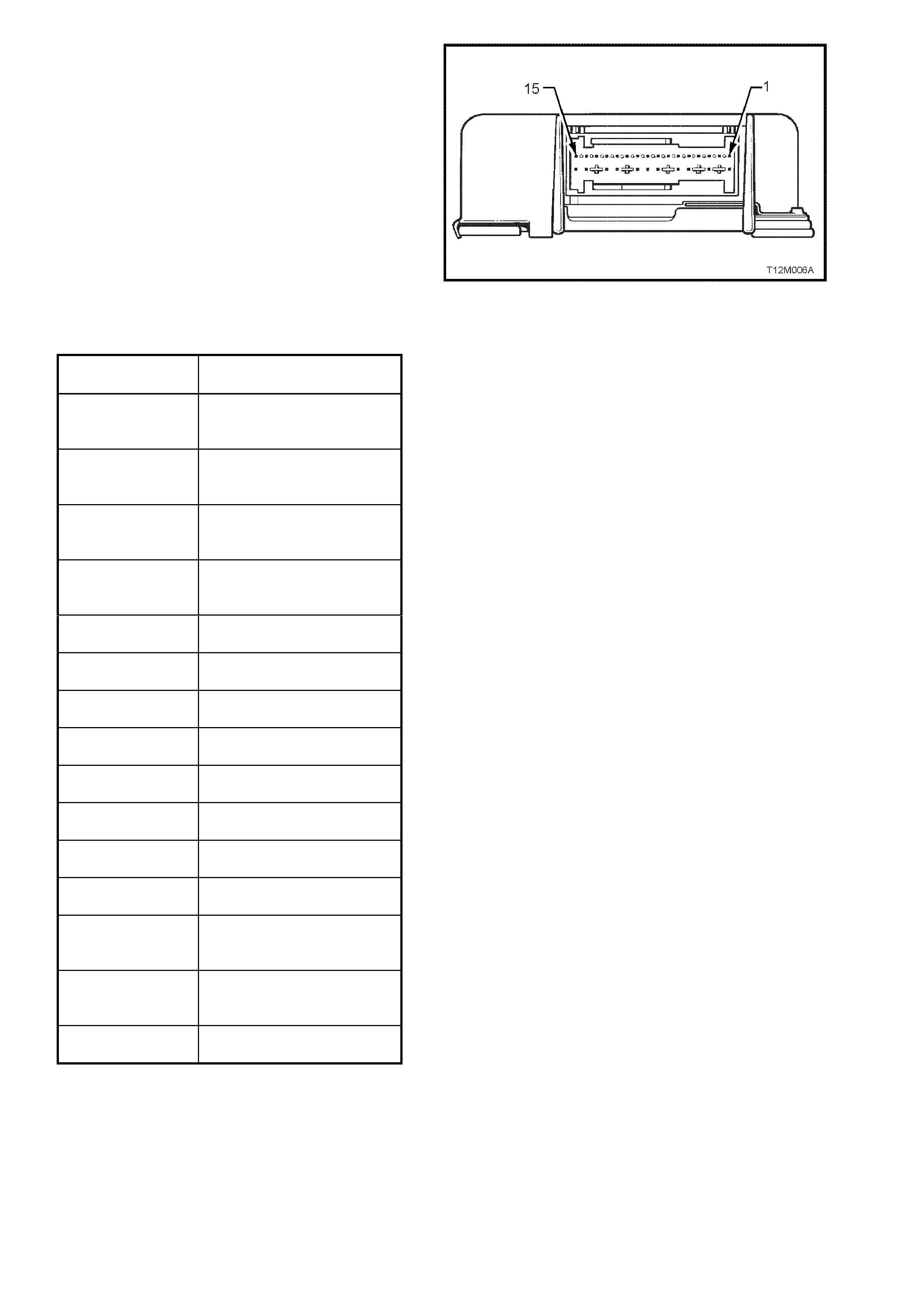

Figure 12M-8

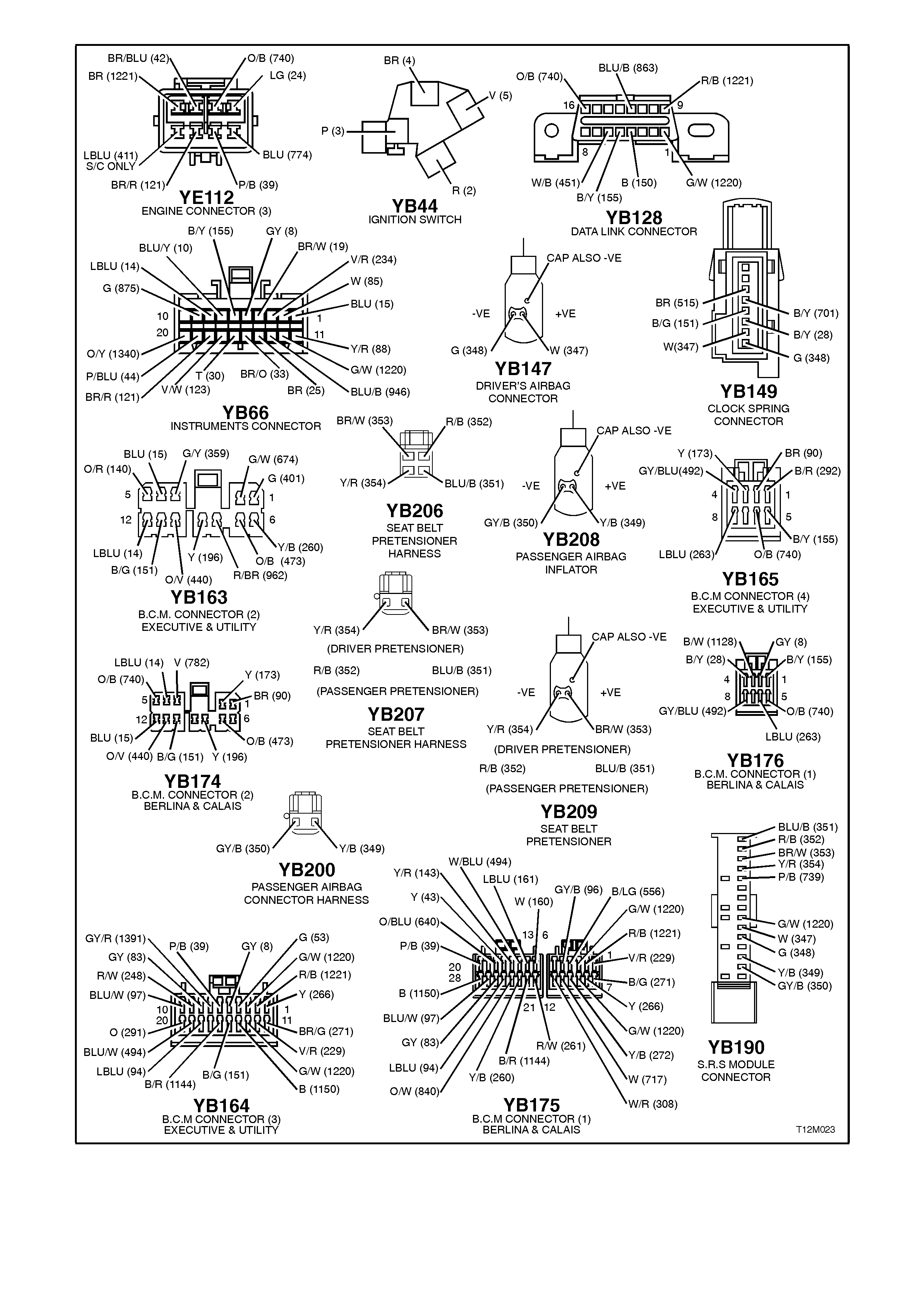

SDM Terminal Assignments

TERMINAL NO. FUNCTION

1 Left hand pre-tensioner,

plus

2 Left hand pre-tensioner,

minus

3 Right hand pre-tensioner,

plus

4 Right hand pre-tensioner,

minus

5 Ignition

6 Not used

7 Not used

8Earth

9 Serial data

10 Driver’s air bag, plus

11 Driver’s air bag, minus

12 Not Used

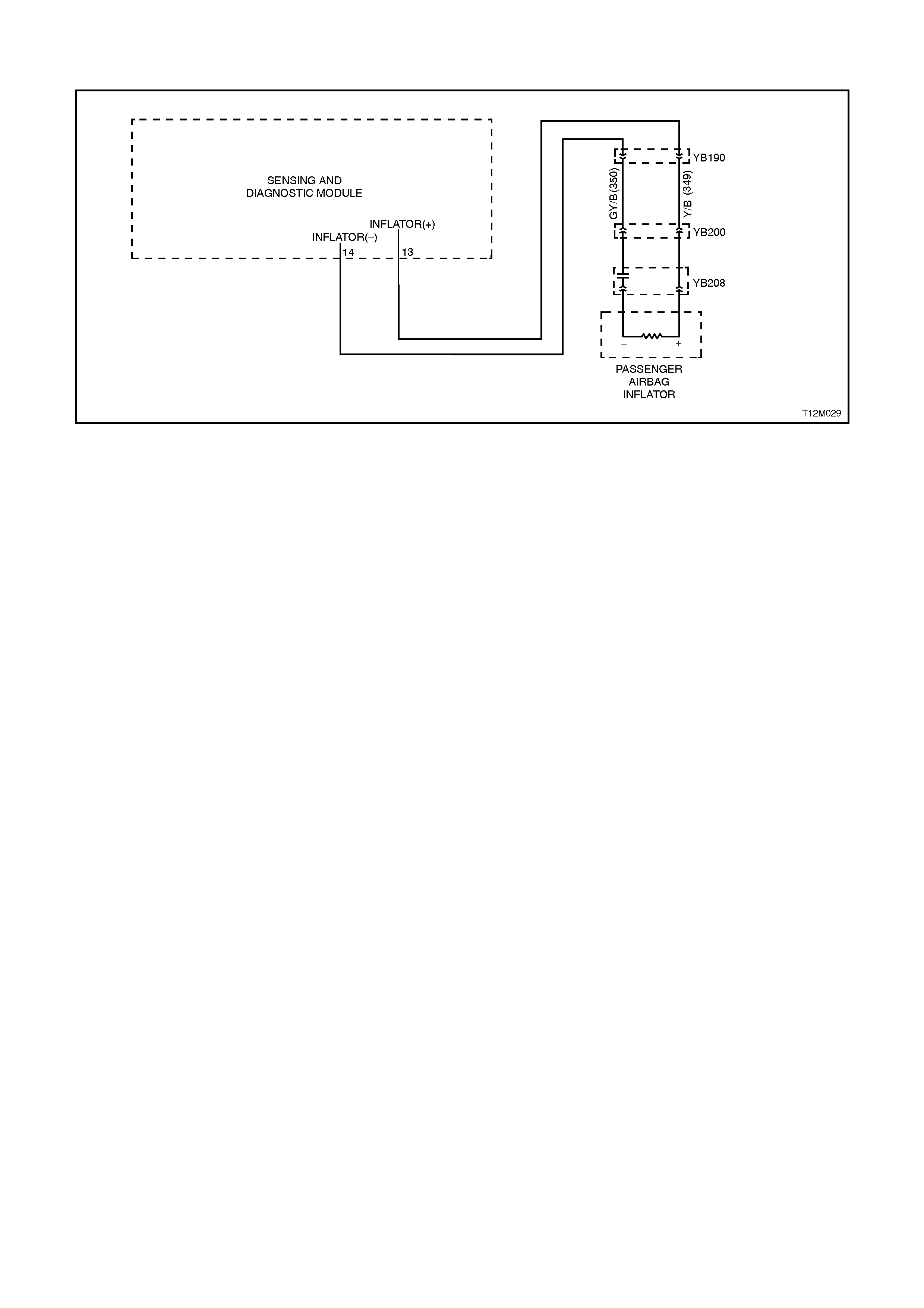

13 Front passenger’s air bag,

plus

14 Front passenger’s air bag,

minus

15 Not Used

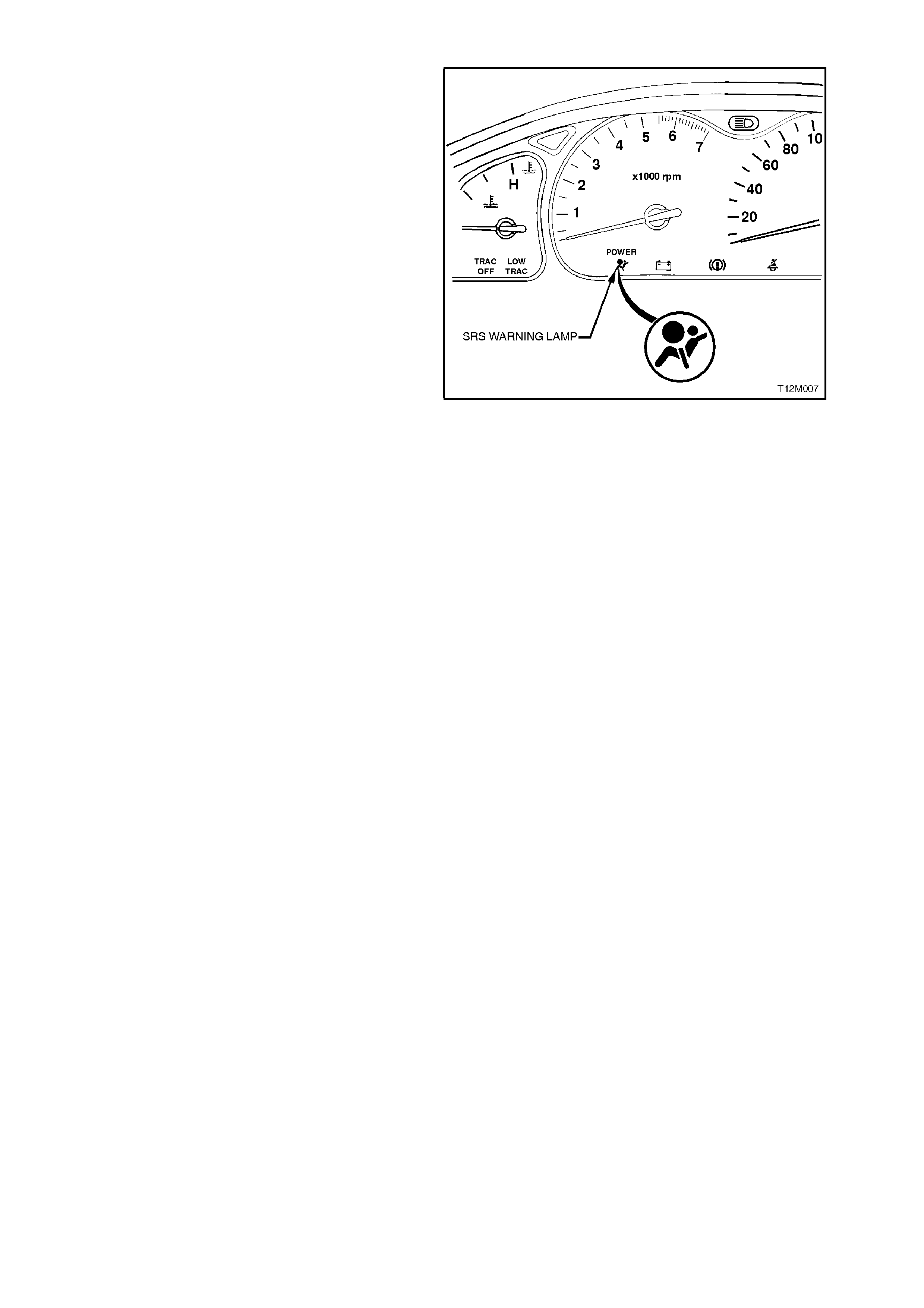

SRS WARNING LAMP

The SRS warning lam p is located in the instrum ent

cluster warning, refer to Fig. 12M-9.

The SRS warning lamp is controlled by the SDM,

via the serial data circuit and will illuminate to warn

the driver that the system has been disabled or

there is a fault in the system.

The SRS warning lamp will illuminate when :

The ignition is switched ON, the SRS warning

lamp will be illuminated for approximately 5

seconds to indicate the system start-up

sequence. During this period the SDM

performs a system wiring and self check. If no

system faults are detected, the SRS warning

lamp will be switched OFF.

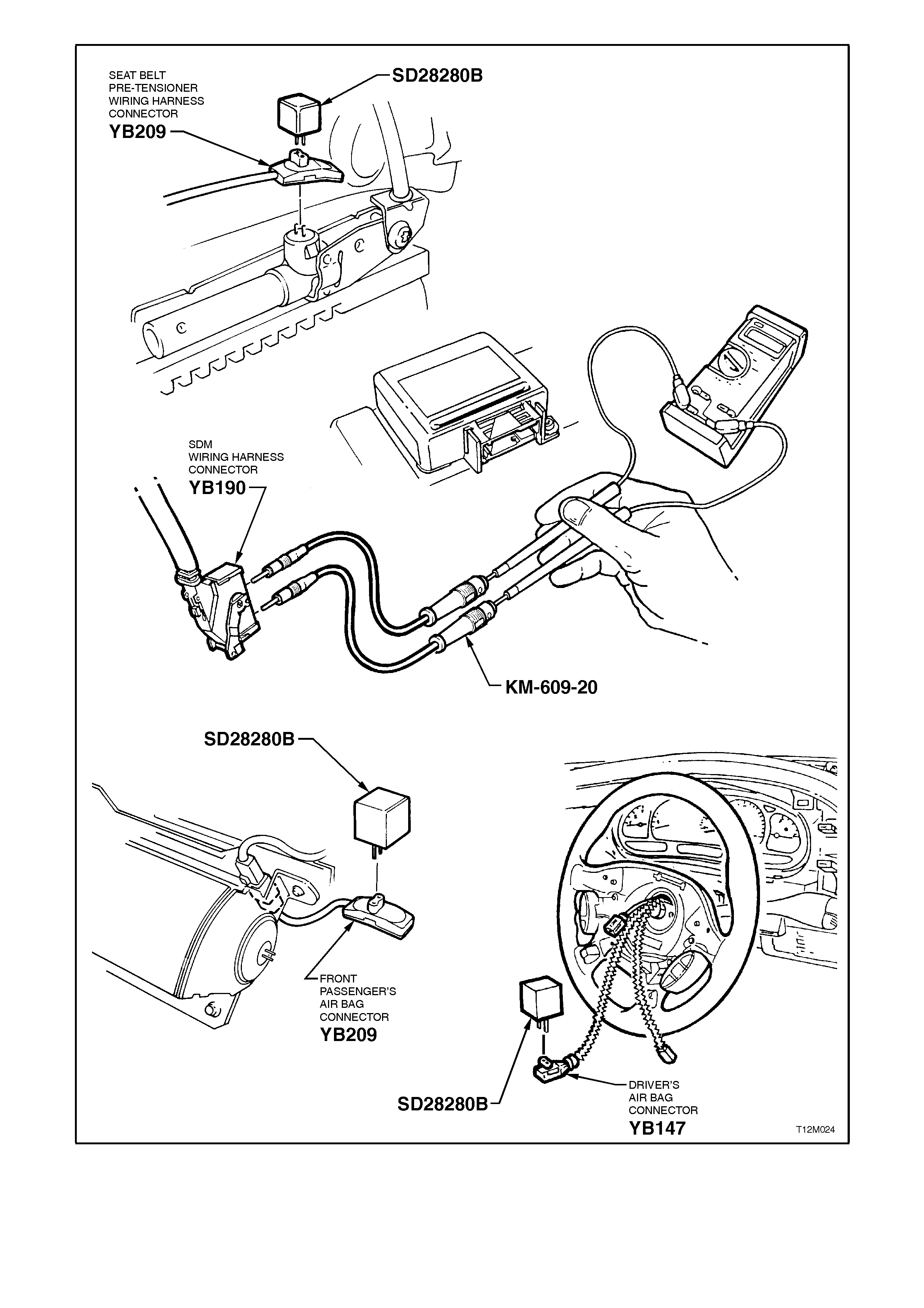

If communication is lost between the SDM and

the instruments (for example SDM wiring

harness YB190 disconnected or no BCM poll)

the SRS warning lamp will be illum inated when

the ignition is first switched ON, it will then be

turned OFF for approximately 2 seconds and

then commanded ON constantly until the fault

is remedied (communication resumed) (No

DTC will be set).

If battery voltage is below 9 volts or above 20

volts the SRS warning lamp will be illuminated

and remain illuminated until the problem is

resolved (No DTC will be set).

If the SRS is deployed, the SRS warning lamp

will be illuminated until the problem is resolved

(No DTC will be set).

If one or more current or history Diagnostic

Trouble Codes (DTC's) are detected when the

ignition is switched ON, the SRS warning lamp

will illuminate and remain illuminated until the

DTC is cleared. Additionally, 3 seconds after

the ignition is switched ON, an audible warning

chime will sound.

During an ignition cycle, if the SDM detects a

current DTC, the SRS warning lamp will be

illuminated. If dur ing this cycle, the current DTC

fault condition clears, a history DTC will be

logged in the SDM and the SRS warning lamp

will still remain illuminated.

When TECH 2 is communicating with the SDM,

the SRS warning lamp will be illuminated and

the SRS will be disabled.

For all DTC details, refer to 3 DIAGNOSTICS in

this Section.

Figure 12M-9

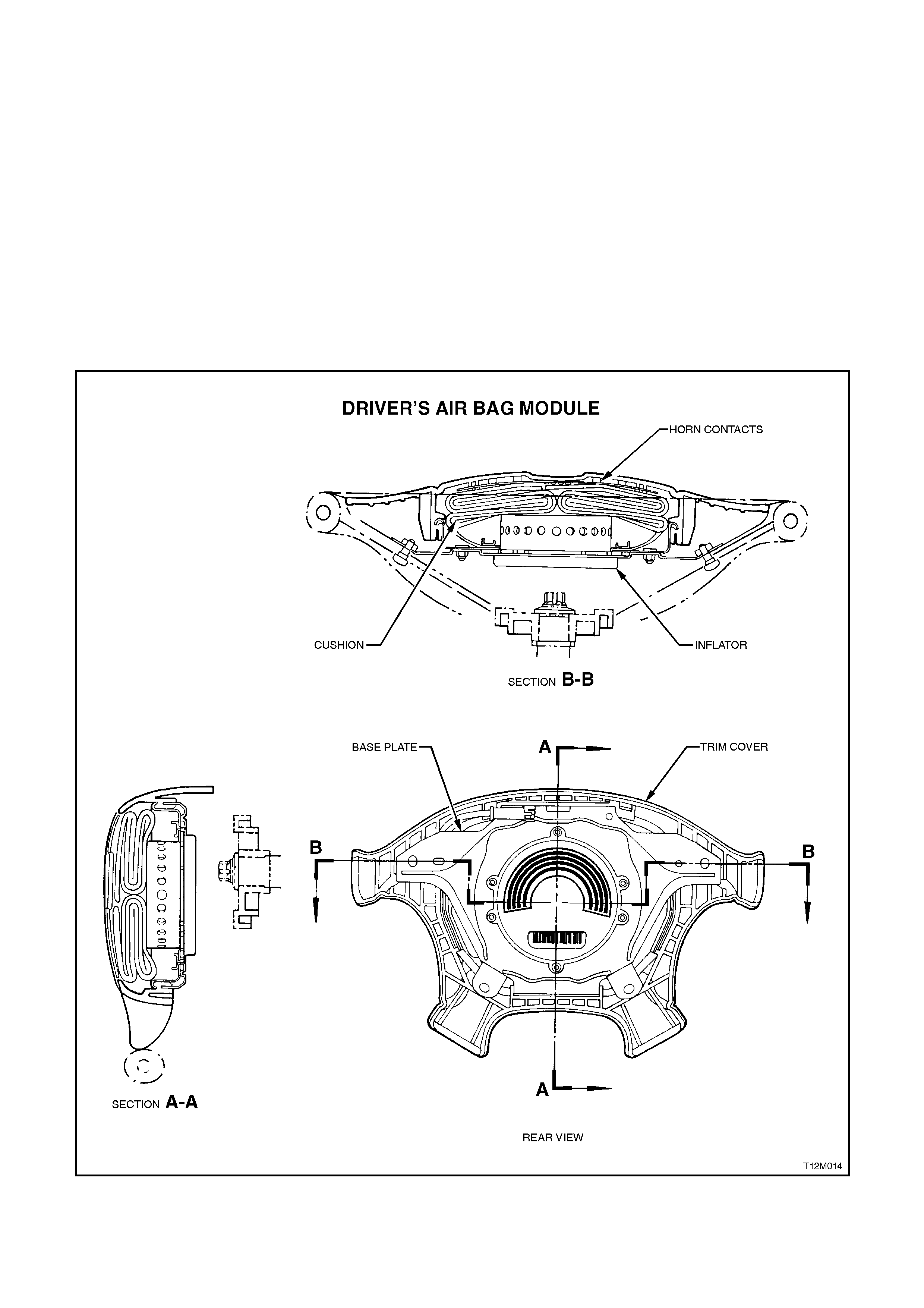

HORN BAR AND AIR BAG INFLATOR MODULE ASSEMBLY

The horn pad is incorporated into the air bag inflator module.

The horn bar (which is incorporated into the air bag inflator module) and air bag inflator module assembly contain

the following parts:

A trim cover with seams for separation during inflation.

A horn contact which is attached to the underside of the trim cover.

A cloth cushion mounted to the base plate and folded.

An electro-chemical module.

A base plate, fastened to the steering wheel with four tamper proof Torx screws

IMPORTANT:

THE HORN BAR AND AIR BAG MODULE ASSEMBLY COMPONENTS ARE NOT REPAIRABLE.

UNDER NO CIRCUMSTANCES ARE THE COMPONENTS OF THE HORN BAR AND AIR BAG MODULE

ASSEMBLY TO BE DISASSEMBLED. THE ASSEMBLY CONTAINS A PYROTECHNIC GAS GENERATOR AND

THE AIR BAG FOLD IS CRITICAL TO AIR BAG PERFORMANCE AND DRIVER SAFETY.

Figure 12M-10

The air bag inflator module (inflator) contains several components (refer to Fig. 12M-11 which shows a ty pical

inflator assembly):

An Electro Explosive Device (EED), with:

An electrical heating element (called an initiator).

A small amount of Lead Styphnate covered with a mixture of Titanium Hydride and Potassium Perchlorate.

An enhancer pack with approximately 3 grams of Baron Potassium Nitrate.

A propellant based on Sodium Azide.

During deployment, the air bag inflator module operates in the following sequence:

The EED initiator receives current from the SDM and begins the chemical reaction by igniting the Lead Styphnate

and the mixture of Titanium Hydride and Potassium Perchlorate.

The EED ignites the Baron Potassium Nitrate in the enhancer pack.

The enhancer's pack chemical reaction causes the Sodium Azide propellant to rapidly produce Nitrogen gas.

The Nitrogen gas pushes the air bag, which separates the steering wheel horn bar trim cover and inflates.

As the air bag inflates, some of the Nitrogen begins to exit into the passenger compartment through vent holes of a

calibrated size. (Allowing the gas to escape in this manner allows for deflation and also enhances the cushioning

effect).

After deployment, the surface of the cushion may contain a powdery residue. This powder consists primarily of corn

starch (used to lubricate the cushion) and by-products of the chemical reaction. Sodium Hydroxide dust is produced

as a by-product of the deployment reaction.

The Sodium Hydroxide then quickly reacts with atmospheric moisture and is converted to Sodium Carbonate and

Sodium Bicarbonate (baking soda). Therefore, it is unlikely that Sodium Hydroxide will be present after deployment.

As a precaution however, gloves and safety glasses are recommended when handling a deployed air bag to prevent

any possible irritation of the skin or eyes.

Figure 12M-11

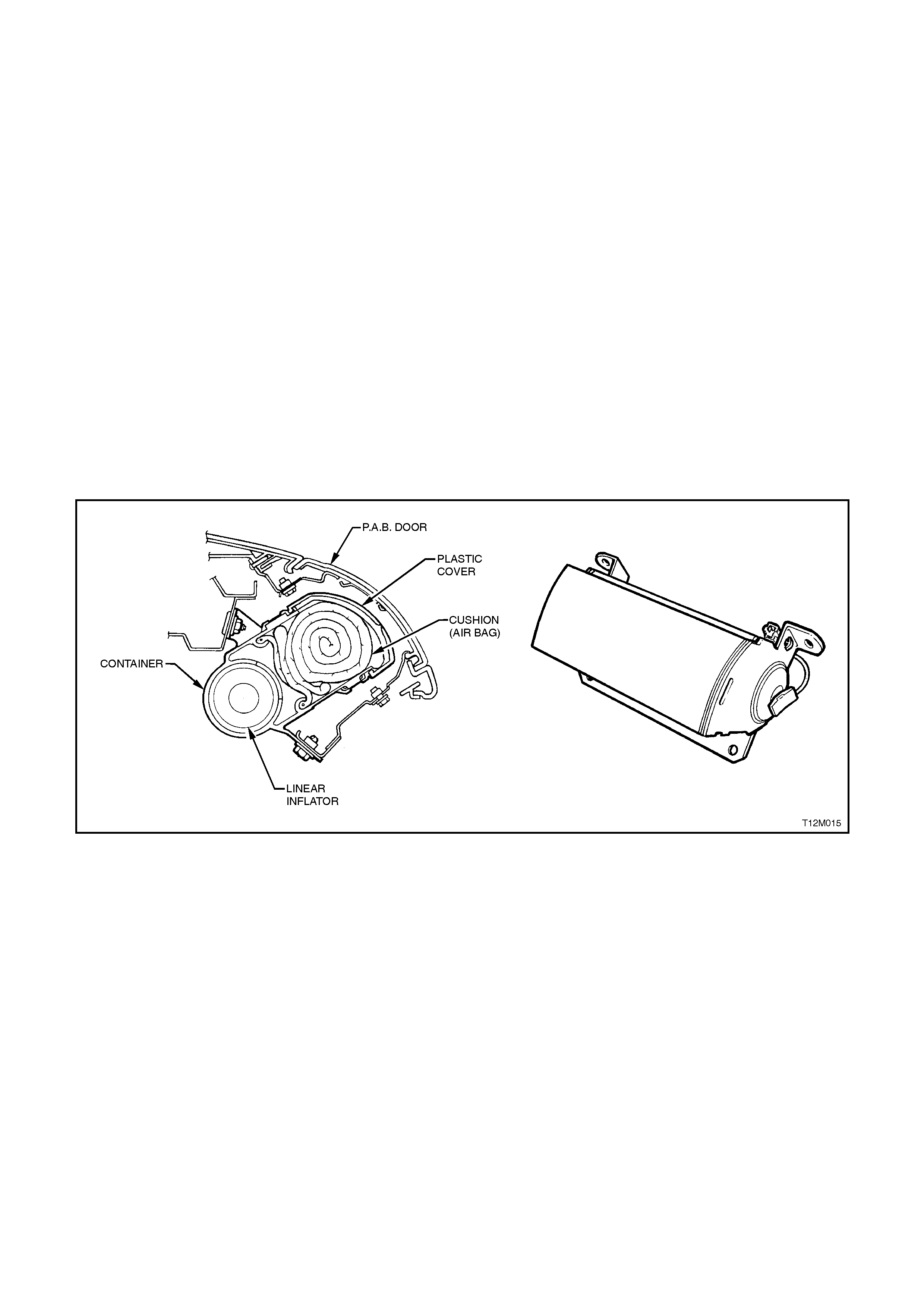

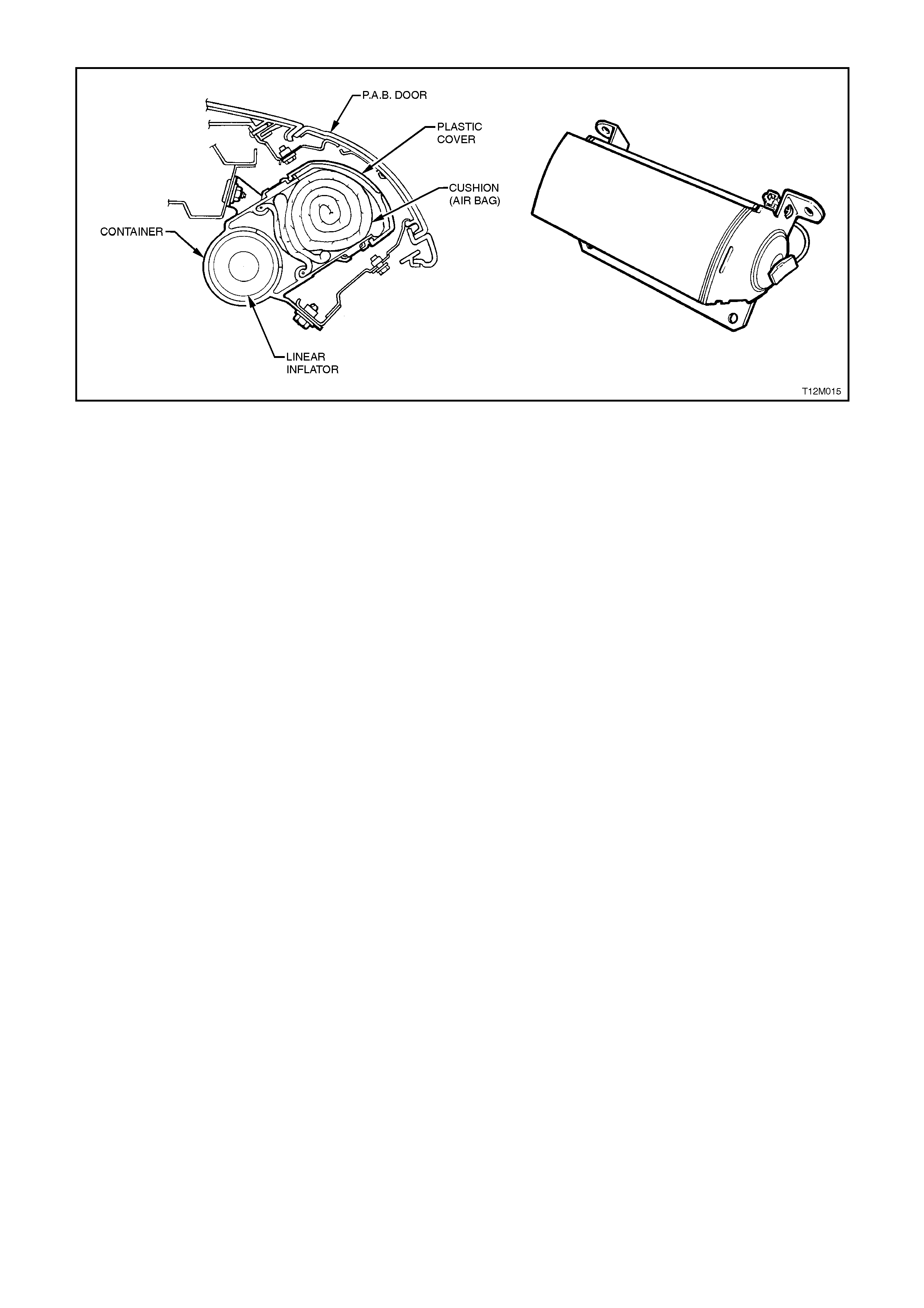

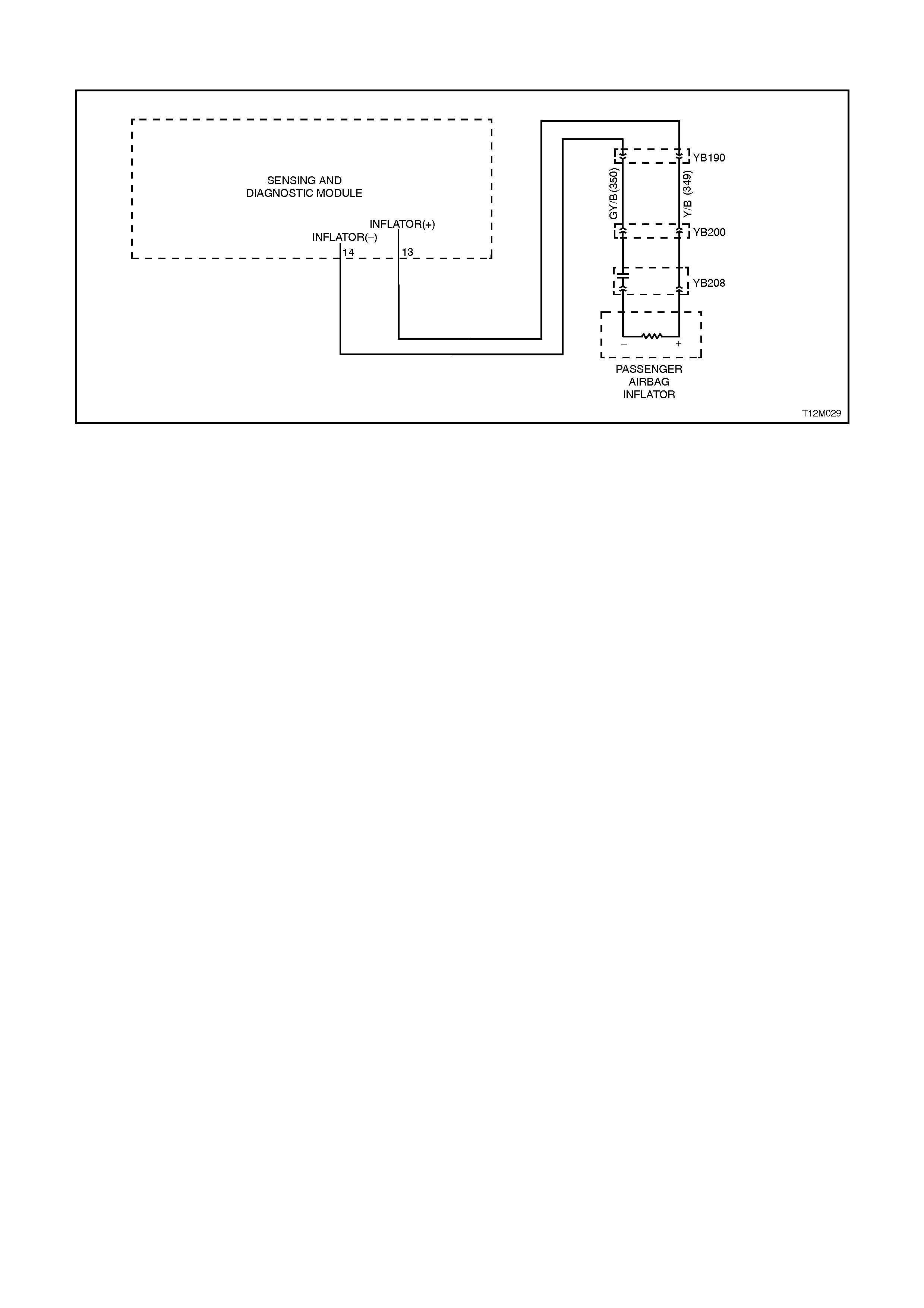

FRONT PASSENGER'S INFLATOR MODULE A SSEMBLY

The front passenger inflator module assembly contains the following parts:

A container, fastened to the dash panel with stud nuts and bolts.

A cloth cushion mounted in the container and folded.

A protective plastic cover over the cushion and hinged to the container to allow the cushion to expand during

inflation.

An electro-chemical module.

The front passenger's air bag deploys through a cut out in the instrument panel pad assembly substrate and a

Passenger Air bag (PAB) door. The PAB door assembly is a skin and foam laminate over an injection moulded

plastic insert with a sheet metal hinge heat staked to the rear surface. This assembly is then attached, using four

screws, to the instrument panel pad assembly.

WARNING:

COMPONENTS OF THE FRONT PA SSENGER'S SIDE AIR BAG INFLATOR MODULE ARE NOT REPAIRABLE.

UNDER NO CIRCUMSTANCES ARE THE COMPONENTS OF THE FRONT PASSENGER'S AIR BAG

INFLATOR MODULE TO BE DISASSEMBLED. THE AIR BAG INFLATOR MODULE CONTAINS A

PYROTECHNIC GAS GENERATOR AND THE AIR BAG FOLD IS CRITICAL TO AI R BAG PERFORMANCE

AND FRONT PASSENGER SAFETY.

Figure 12M-12

The linear inflator contains several components (refer to Fig. 12M-13 which shows a typical inflator assembly):

An Electro Explosive Device (EED), with:

An electrical heating element (called an initiator) and a fuse.

A small amount of Lead Styphnate covered with a mixture of Titanium Hydride and Potassium Perchlorate.

An enhancer pack with Boron Potassium Nitrate.

A propellant based on Sodium Azide.

During deploy ment, the front passenger's air bag inflator module operates in three stages:

The EED initiator receives current from the SDM and begins the chemical reaction by igniting the Boron Potassium

Nitrate in the enhancer pack.

The enhancer pack's chemical reaction causes the Sodium Azide propellant to rapidly produce Nitrogen gas.

The Nitrogen gas pushes the air bag, which separates the protective cover, pushes the hinged PAB door and

inflates.

As the air bag inflates, some of the Nitrogen begins to exit into the passenger compartment through vent holes of a

calibrated siz e.

Internal tethering controls the fill and placement of the air bag, to maximise the benefits to the front passenger.

In some deployment conditions, the windshield may be broken by the opening of the Passenger Air bag Door when

the air bag deploys.

As with the drivers' side air bag, the surface of the front passenger's air bag may contain a powdery residue after

deployment. This powder consists primarily of corn starch (used to lubricate the cushion as it inflates) and by-

products of the chemical reaction. Sodium Hydroxide dust is produced as a by-product of the deployment reaction.

The Sodium Hydroxide then quickly reacts with atmospheric moisture and is converted to Sodium Carbonate and

Sodium Bicarbonate (baking soda). Therefore, it is unlikely that Sodium Hydroxide will be present after deployment.

As a precaution however, gloves and safety glasses are recommended when handling a deployed air bag to prevent

any possible irritation of the skin or eyes.

Figure 12M-13

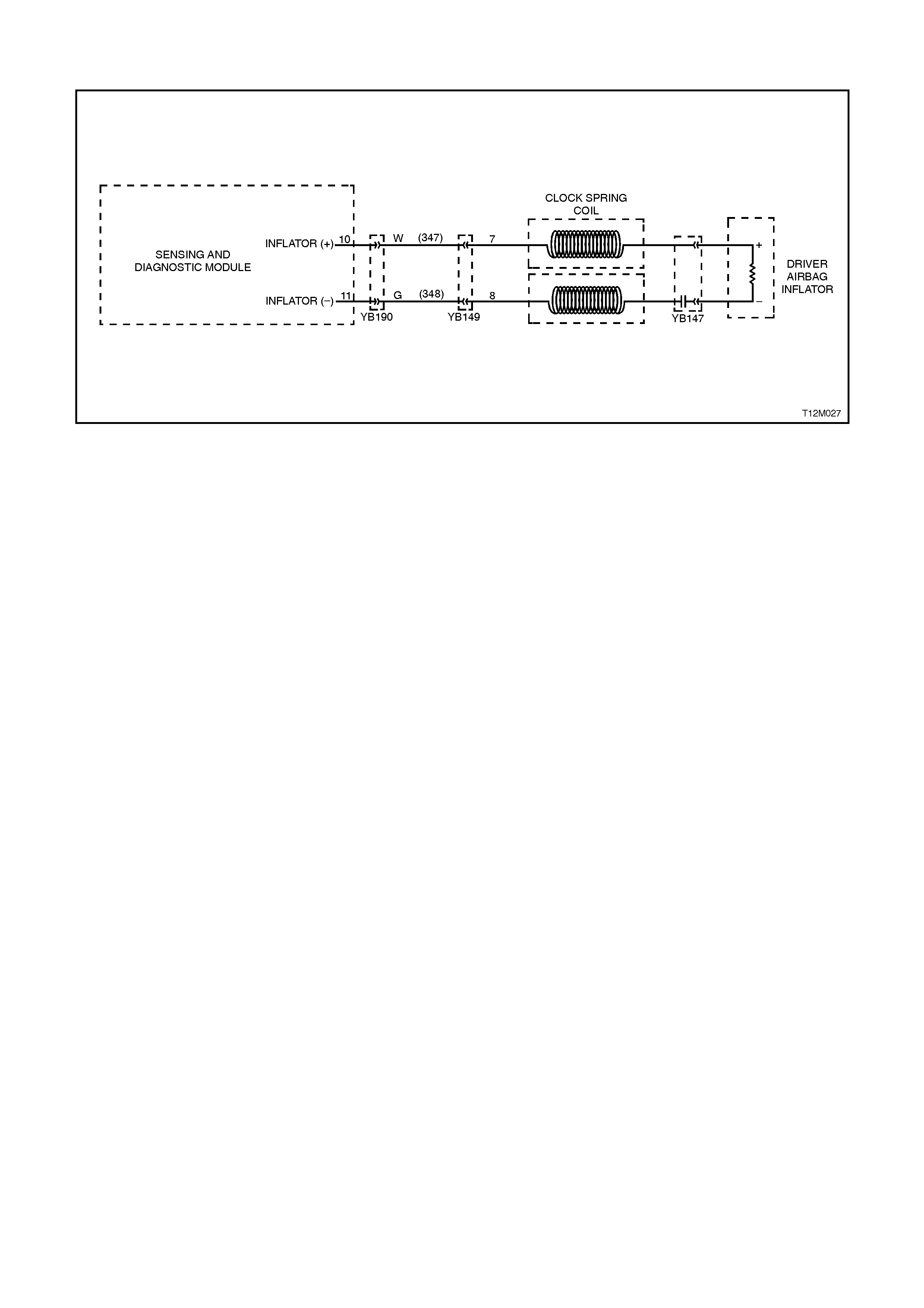

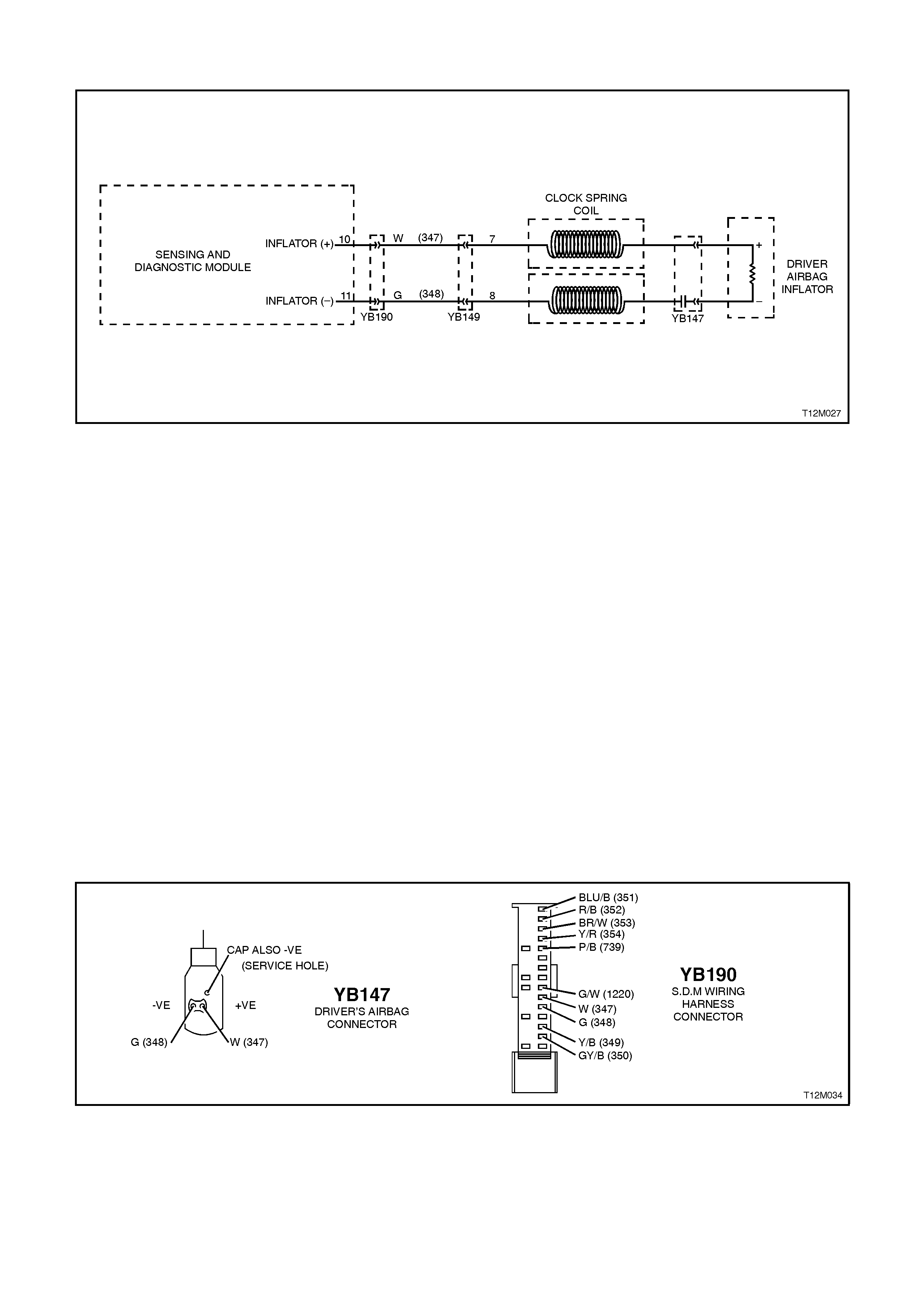

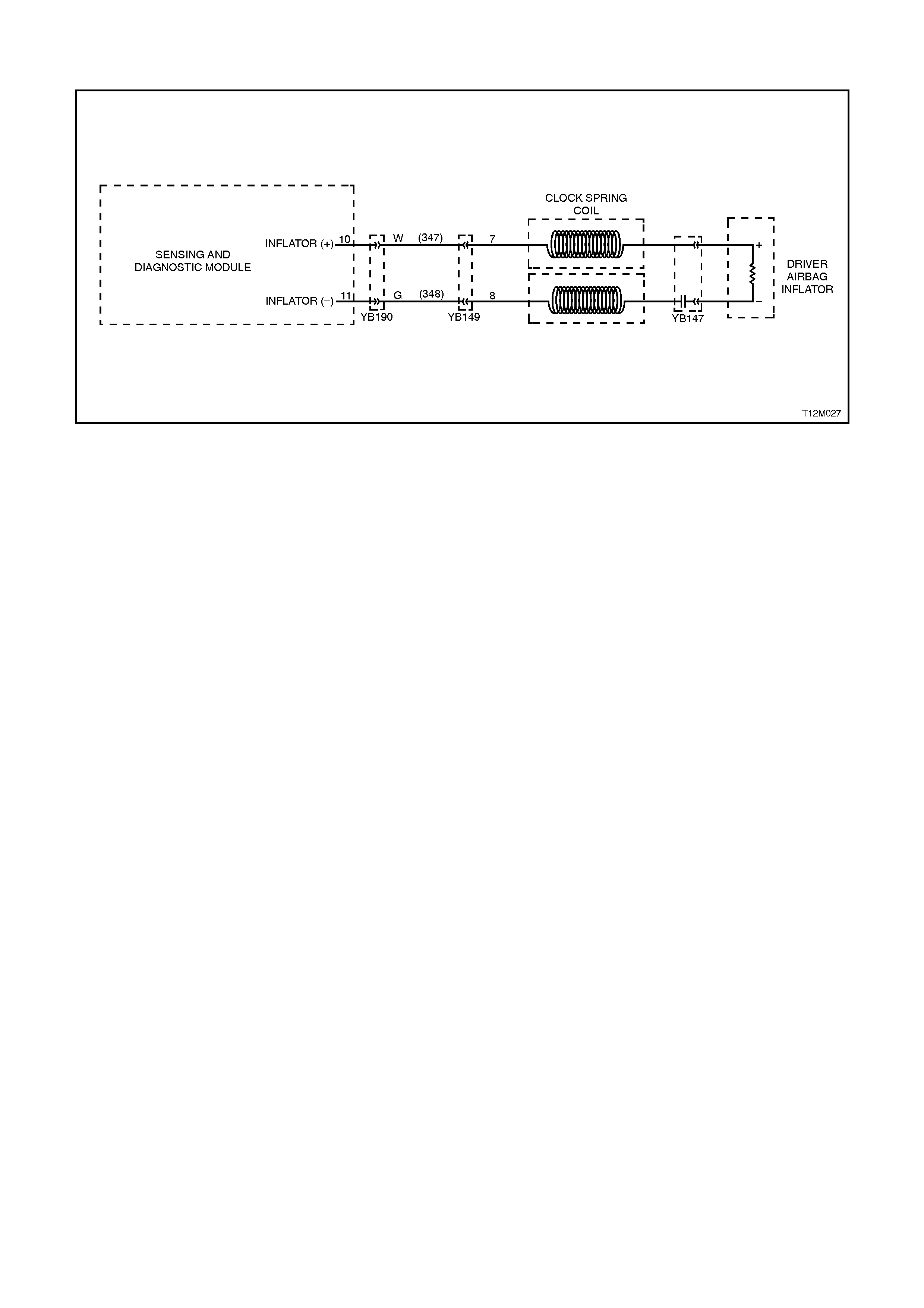

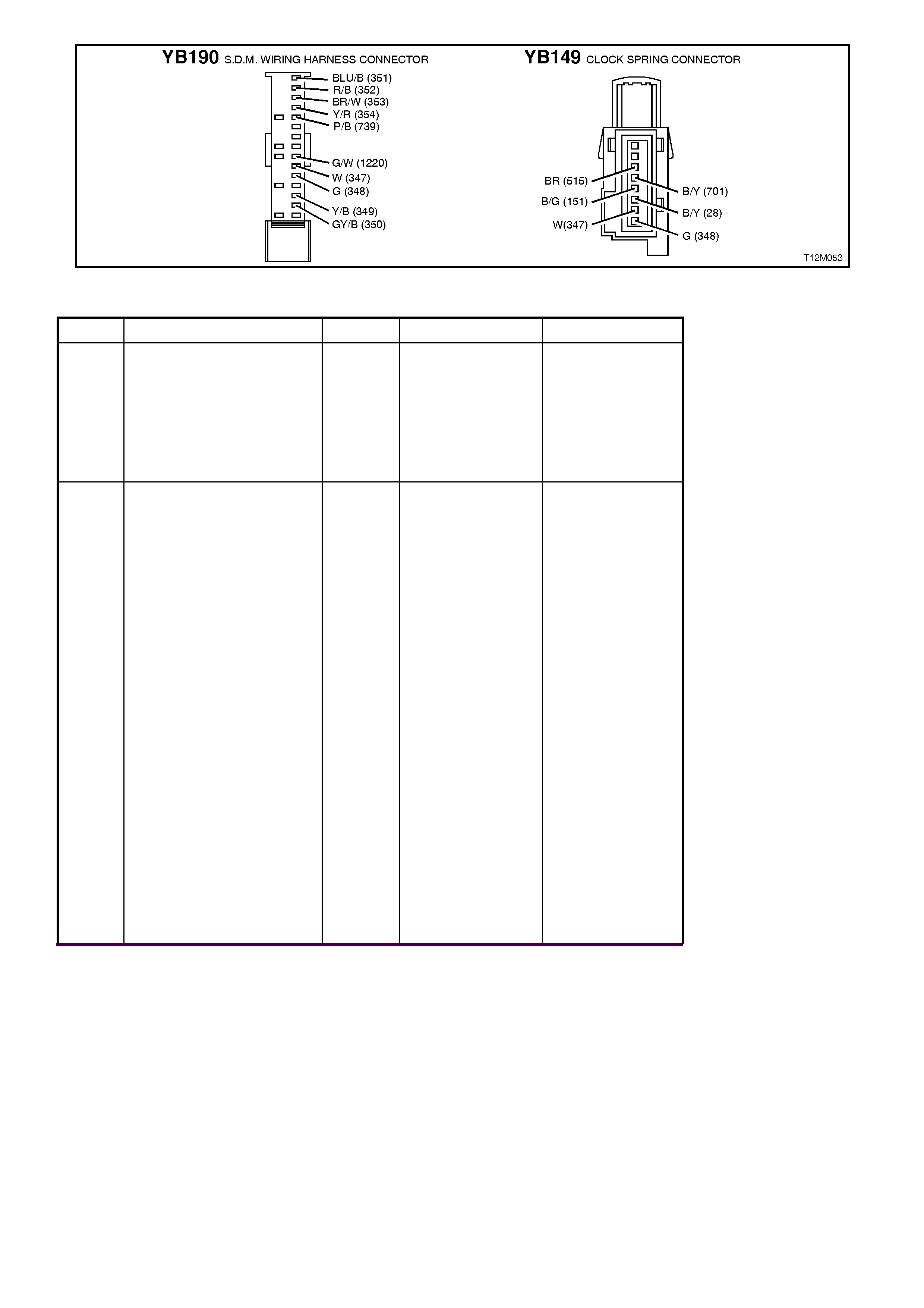

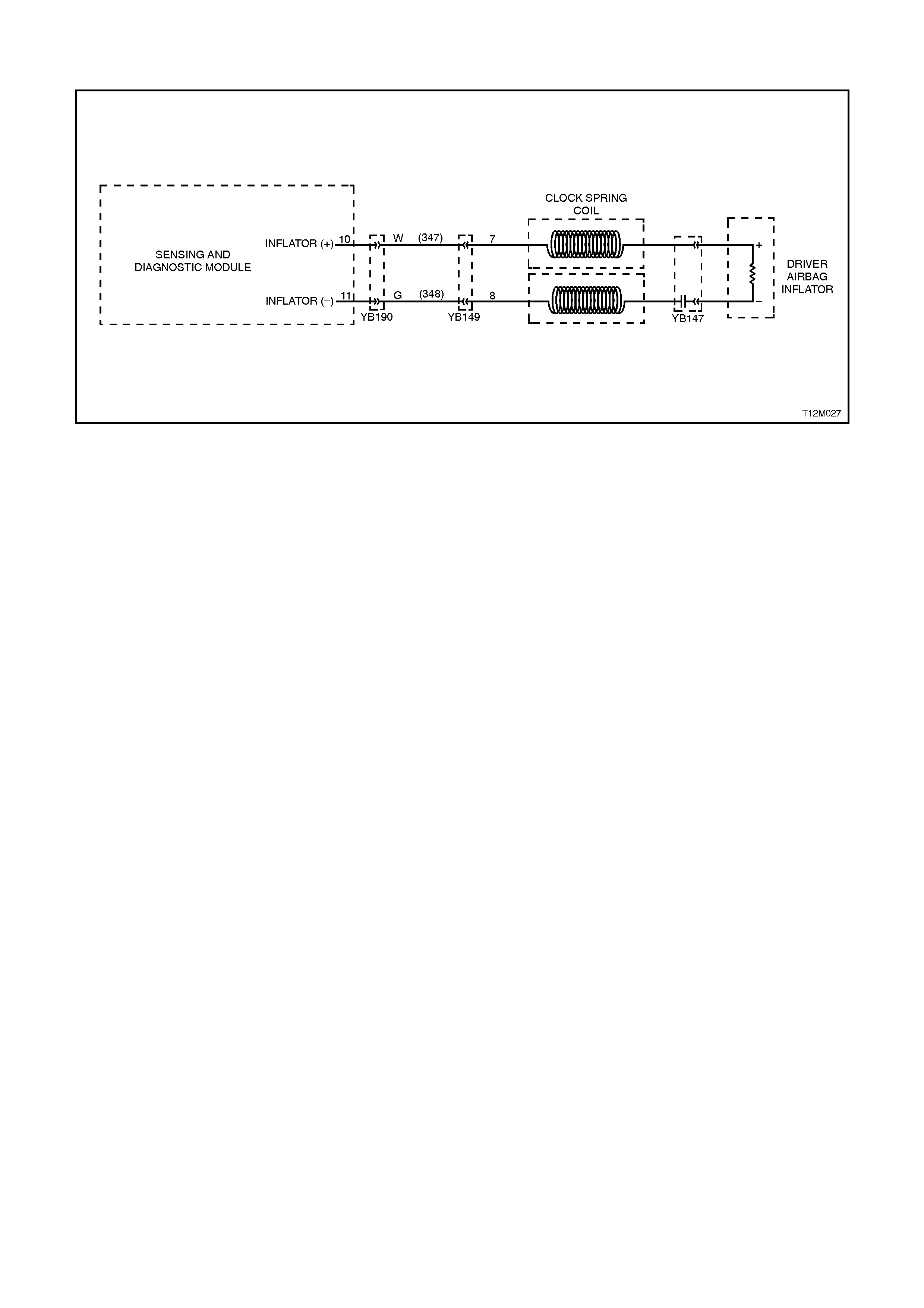

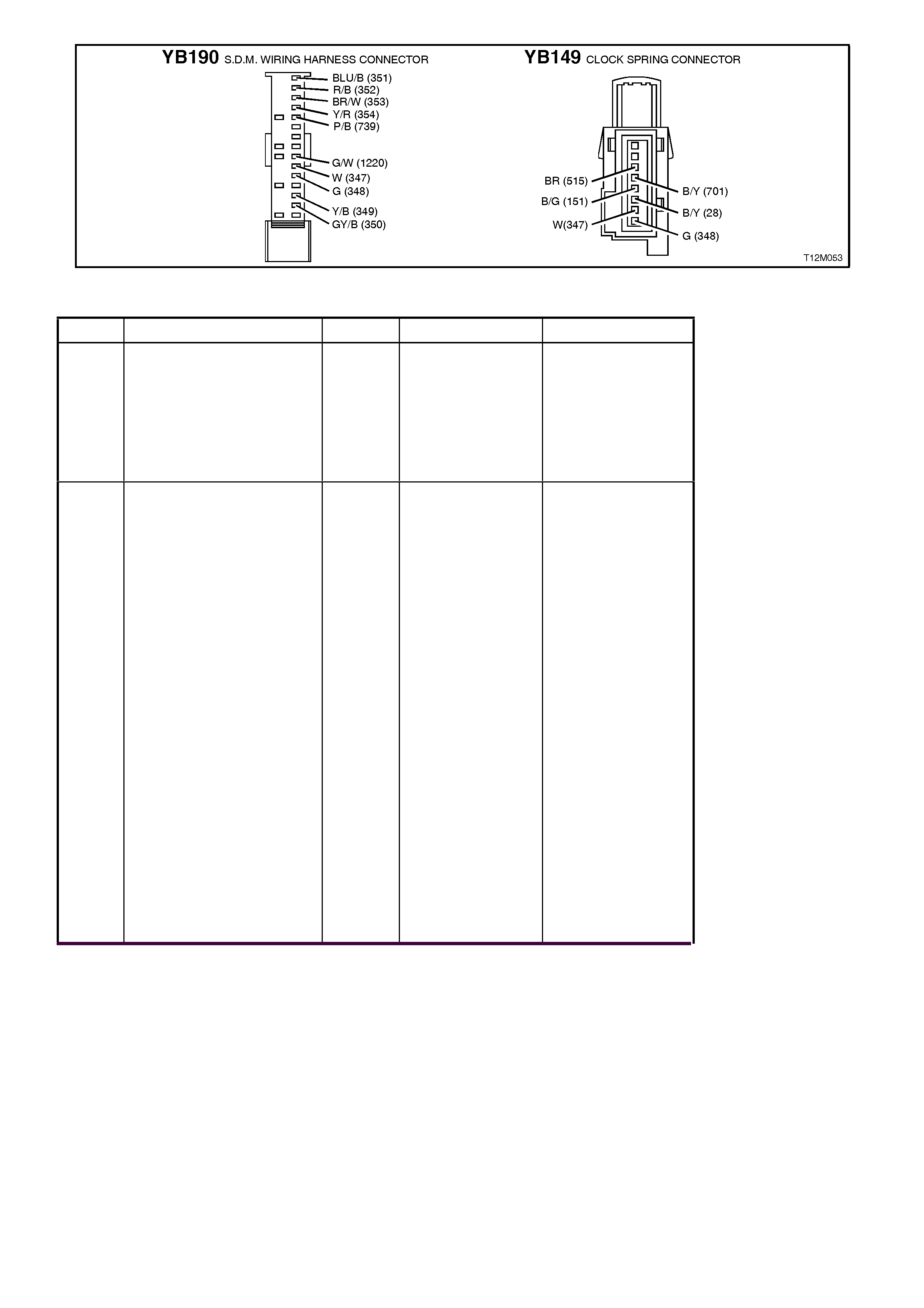

CLOCK SPRING COIL ASSEMBLY

The clock spring coil assembly has the following

parts:

1. A pigtail wiring harness that connects to the air

bag inflator module at the top of the steering

column (connector YB147).

2. A lower wiring harness connector which is

incorporated with the clock spring coil outer

housing assembly.

3. A rotating inner hub which engages with the rear

of the steering wheel.

4. A ribbon wire assembly that provides an

unbroken connection between the SDM and air

bag inflator module as the steering wheel is

rotated during vehicle operation.

5. The coil assembly also has pigtail wiring

harnesses and wires in the ribbon wire

assembly for the horn contacts in the steering

wheel horn bar and, if fitted, the remote audio

controls (not shown).

Figure 12M-14

The coil assembly operates in the following

manner:

When the steering wheel is in the straight-ahead

position, the inner hub and outer housing are

aligned to provide approximately 2.5 turns of the

steering wheel in either direction.

When the steering wheel is turned in a clockwise

direction (r ight turn), the inner hub winds the ribbon

wire as it rotates with the steering wheel.

When the steering wheel is turned in an anti-

clockwise direction (left turn), the inner hub

unwinds the ribbon wire as it rotates with the

steering wheel.

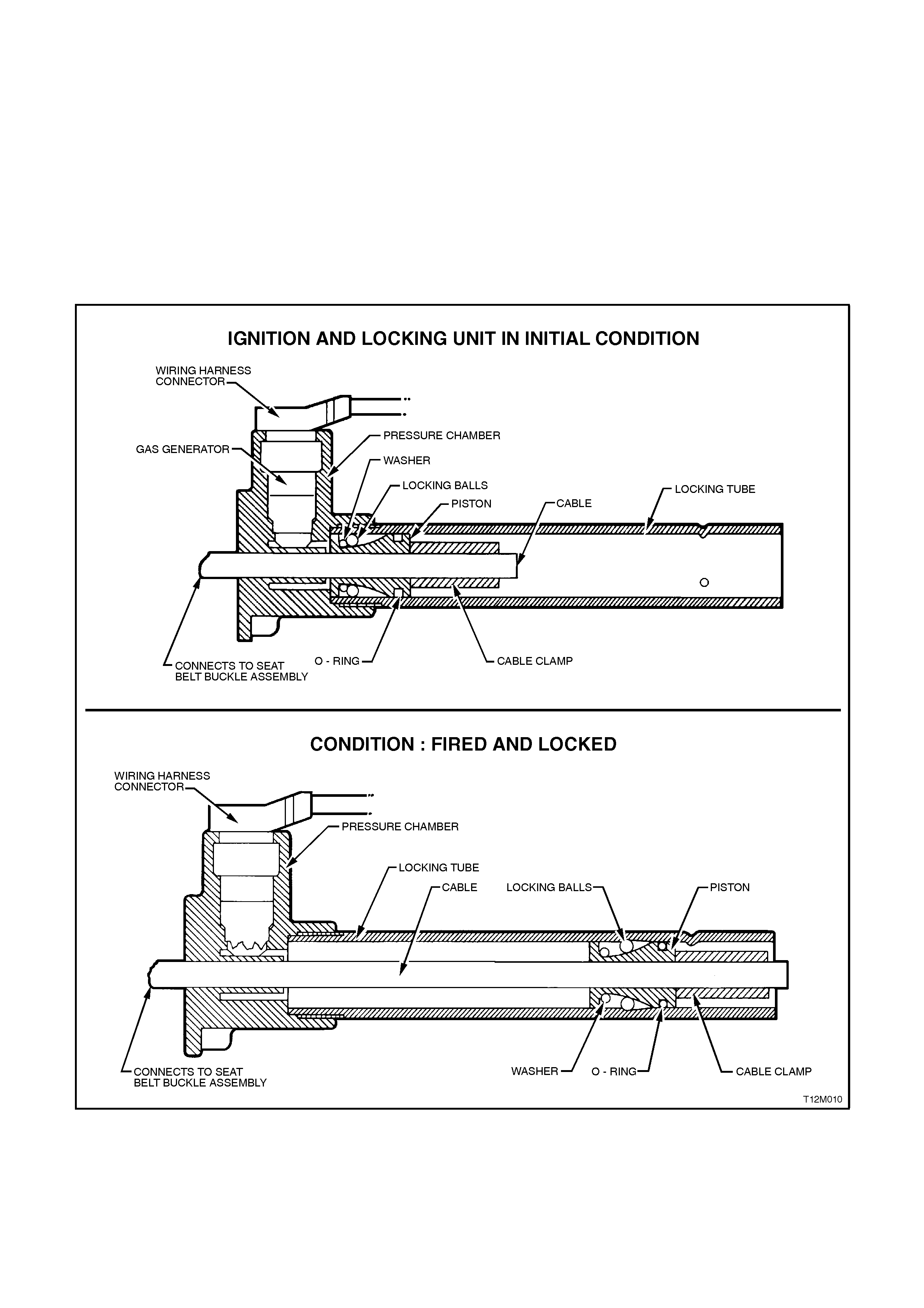

SEAT BELT PRE-TENSIONERS

The driver and front seat passenger seat belts are equipped with a pyrotechnical seat belt pre-tensioner. The

purpose of these pre-tensioners is in the case of a frontal collision, to remove all webbing slack from the seat belt

before the occupant has moved, relative to the vehicle.

The seat belt pre-tensioners have a gas generator complete with an igniter connected to a cylinder. Inside the

cylinder is a piston connected to a cable, the other end of which is connected to the belt buckle assembly.

When an ignition signal from the SDM is sent to the igniter, the gas generator is activated driving the piston down

the cylinder. This action tightens the cable around a roller which pulls the buckle towards the seat taking up the

slack in the seat belt. The tensioner can take up about 9 cm of slack. The outer plastic tube on the buckle assembly

is destroyed during activation. The piston is prevented from moving back up the cylinder by a series of locking balls

once the piston has taken up all the slack in the seat belt.

Figure 12M-15 shows the pre-tensioner assembly before and after the pre-tensioner has been fired.

Figure 12M-15

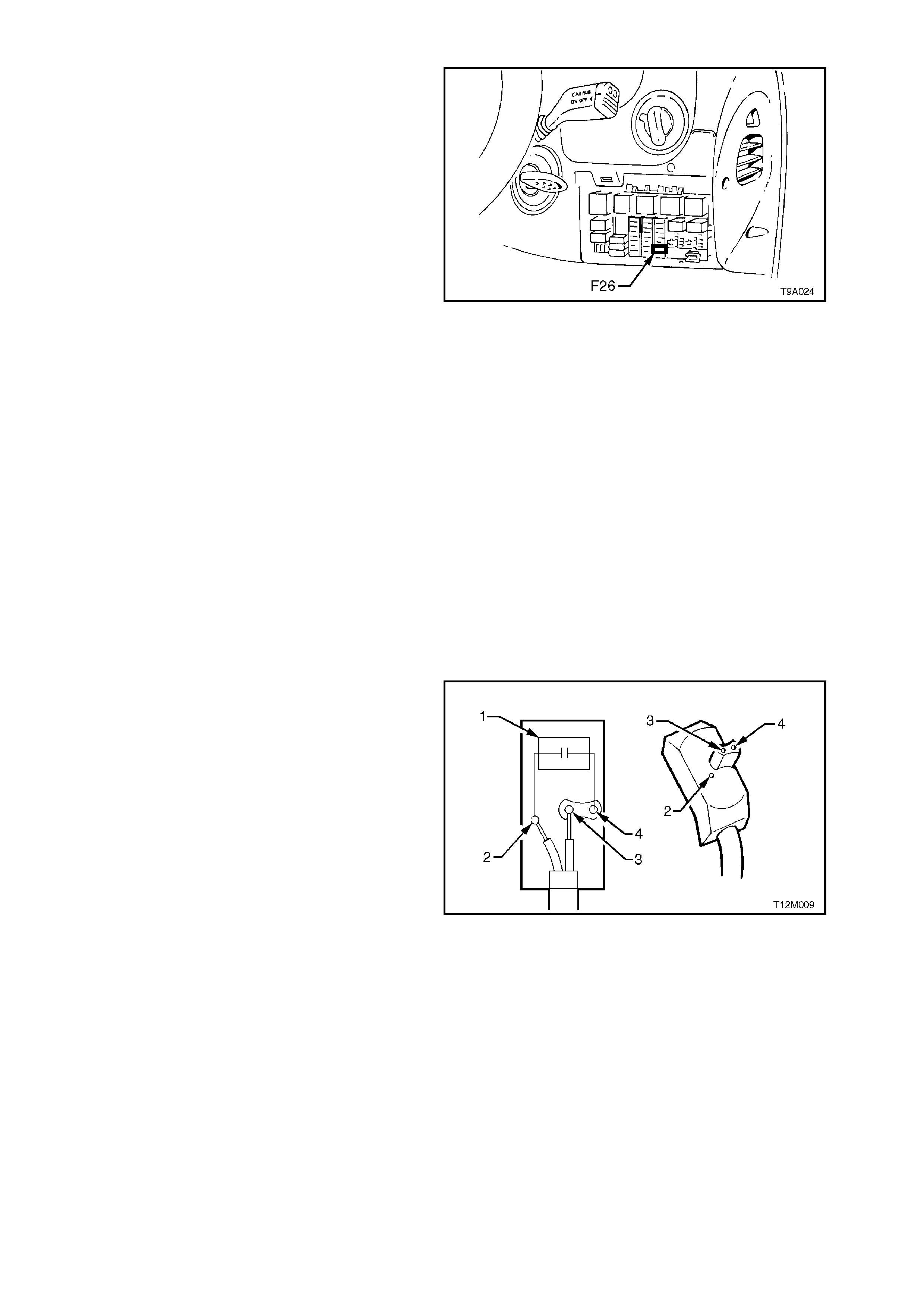

SRS FUSE

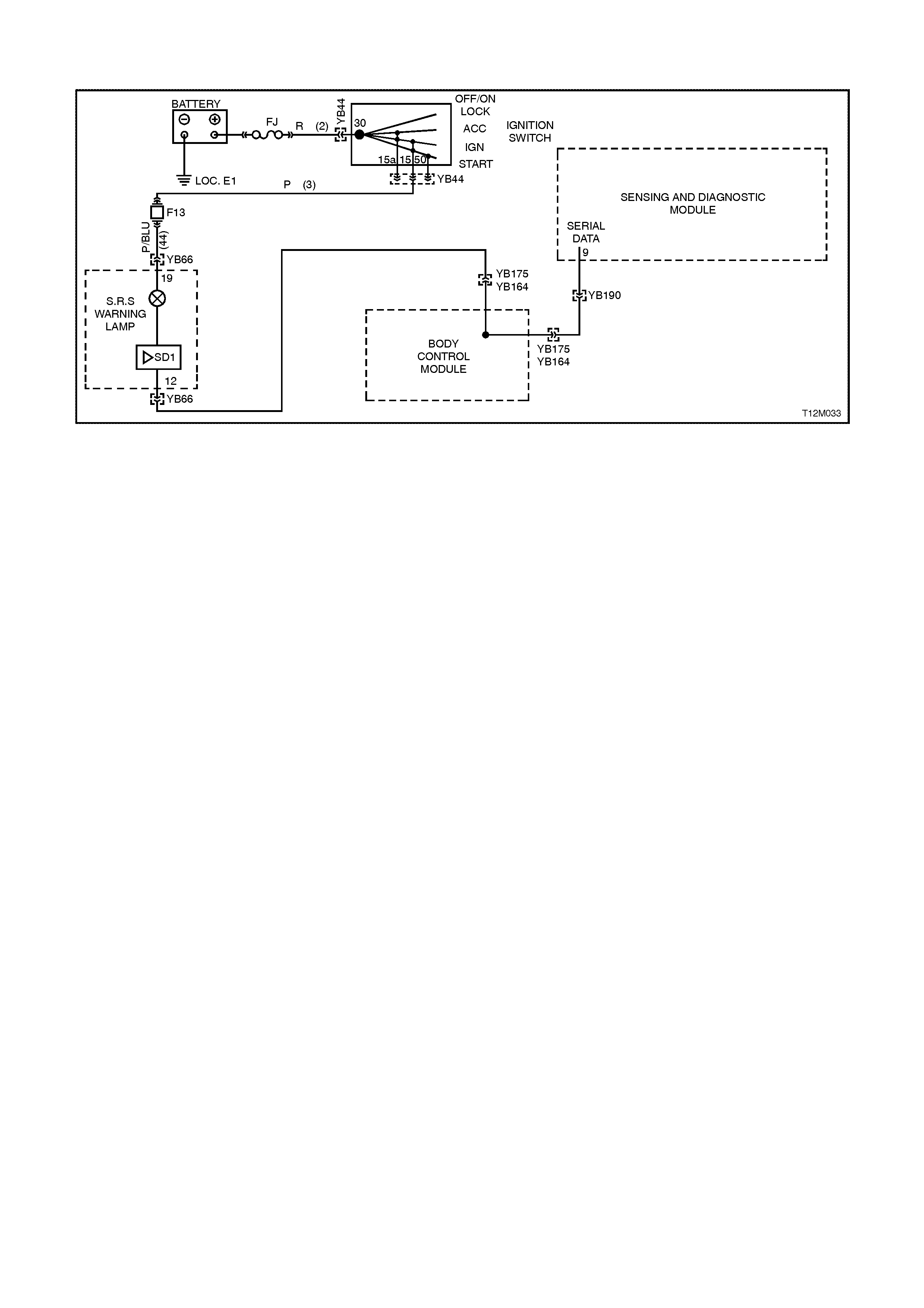

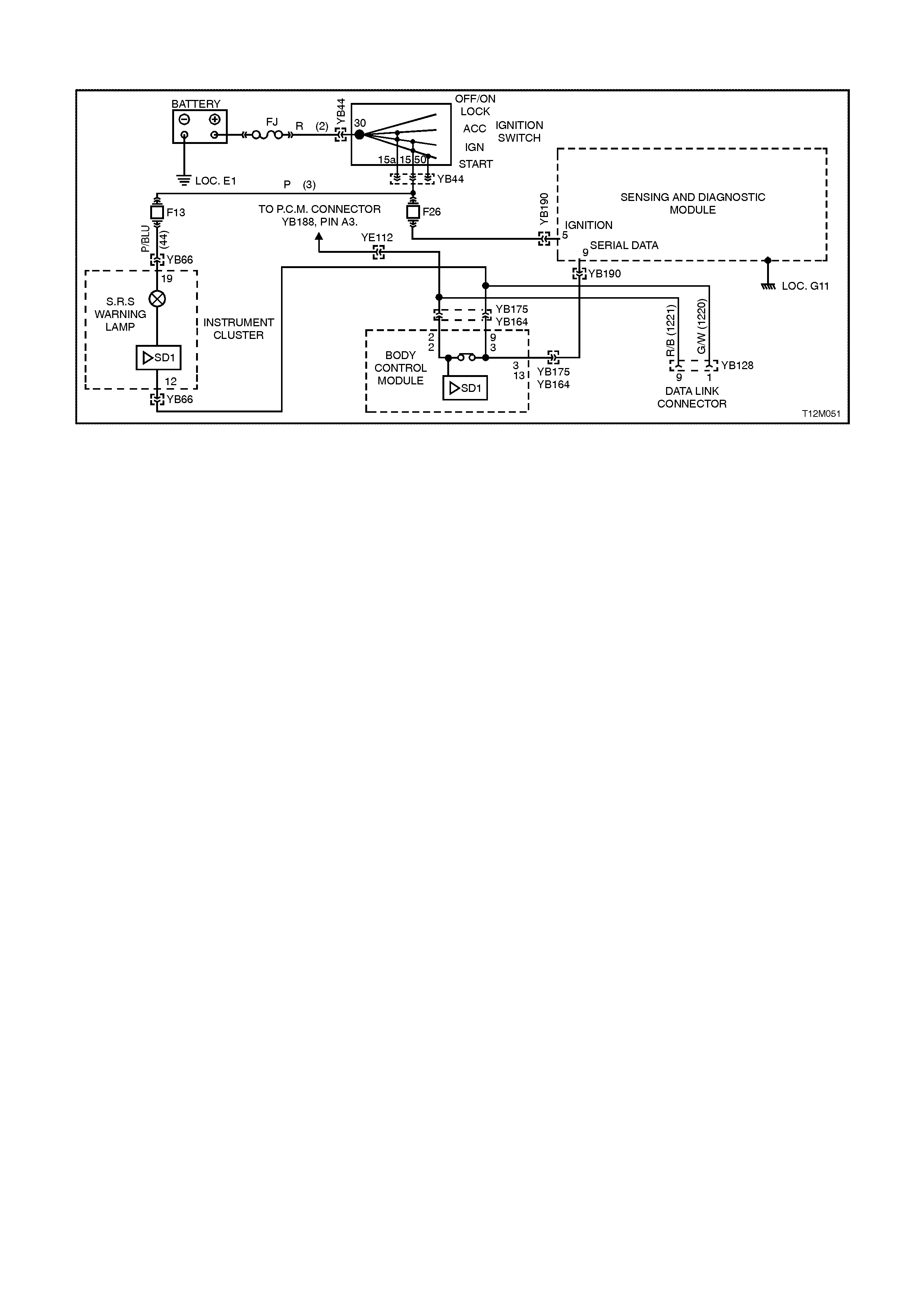

The SDM is supplied voltage from the ignition

switch, via fuse F26, located in the passenger

compartment fuse panel.

Access to this fuse panel is by grasping the top

edge of each side of the instrument panel right

hand cover with the finger tips and pulling the top

edge out, to free the retaining lugs from the clips.

NOTE:

Fuse F13 (instrument fuse), located in the

passenger compartment fuse panel, is also used

for the SRS warning lamp circuit.

Figure 12M-16

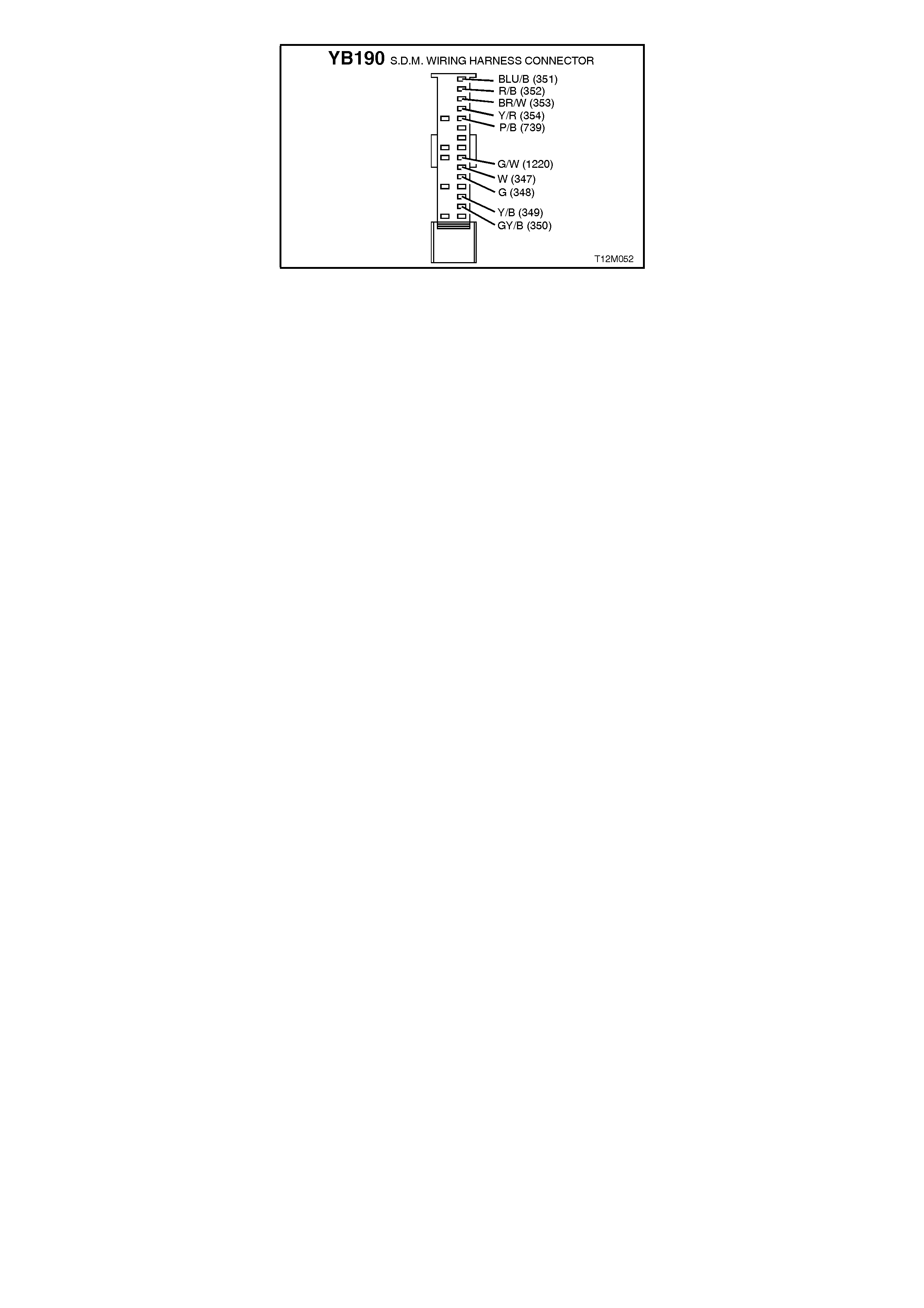

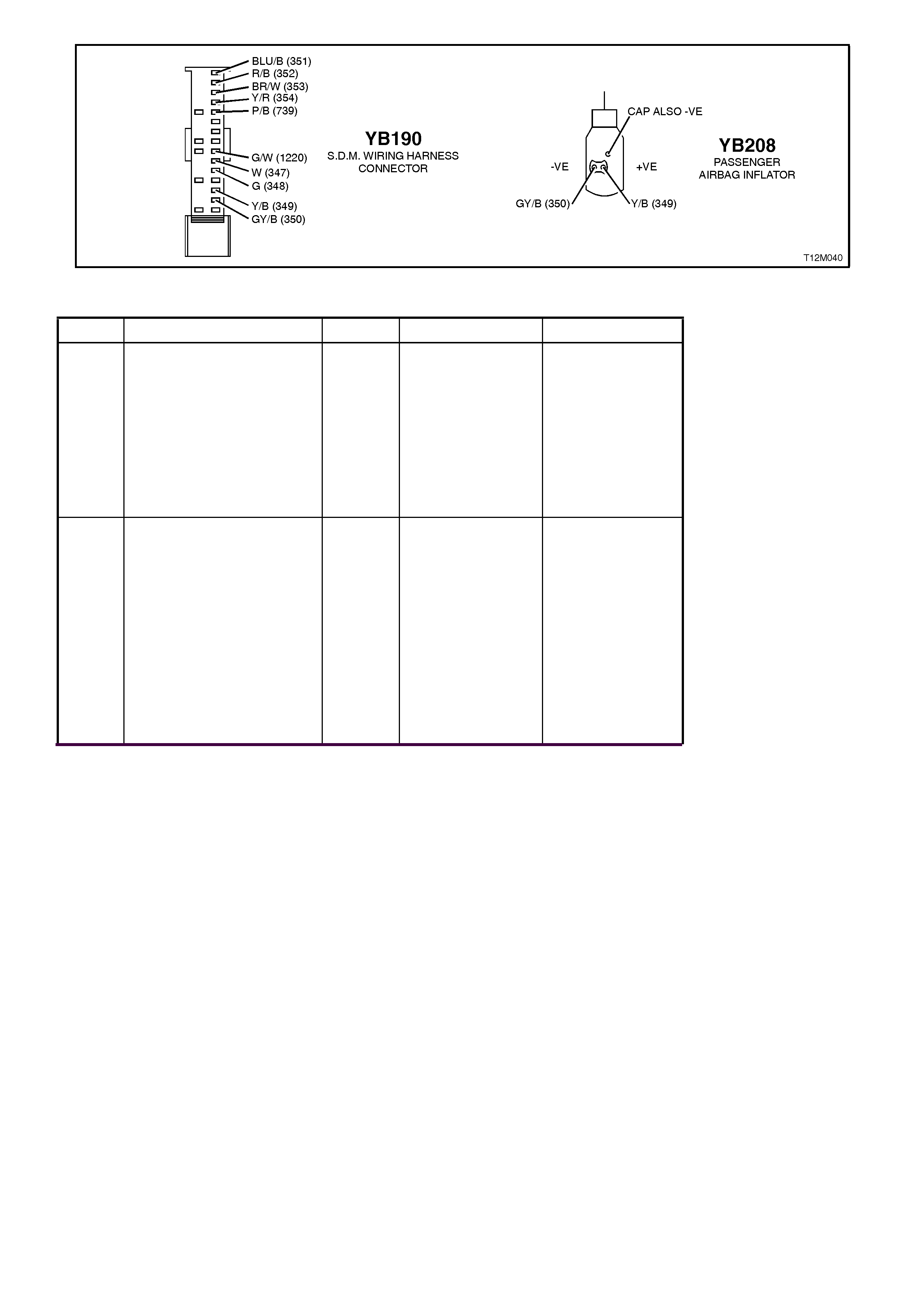

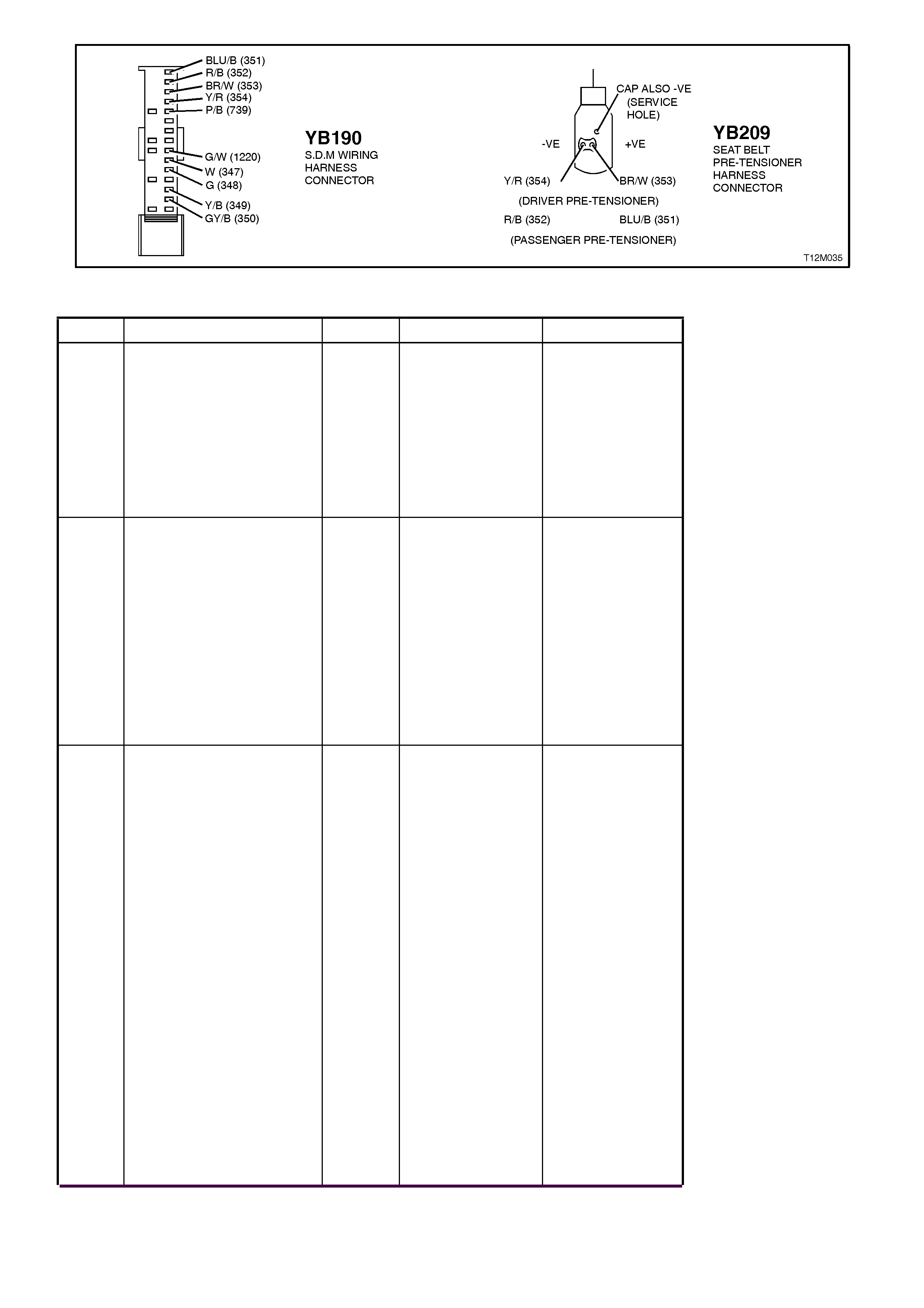

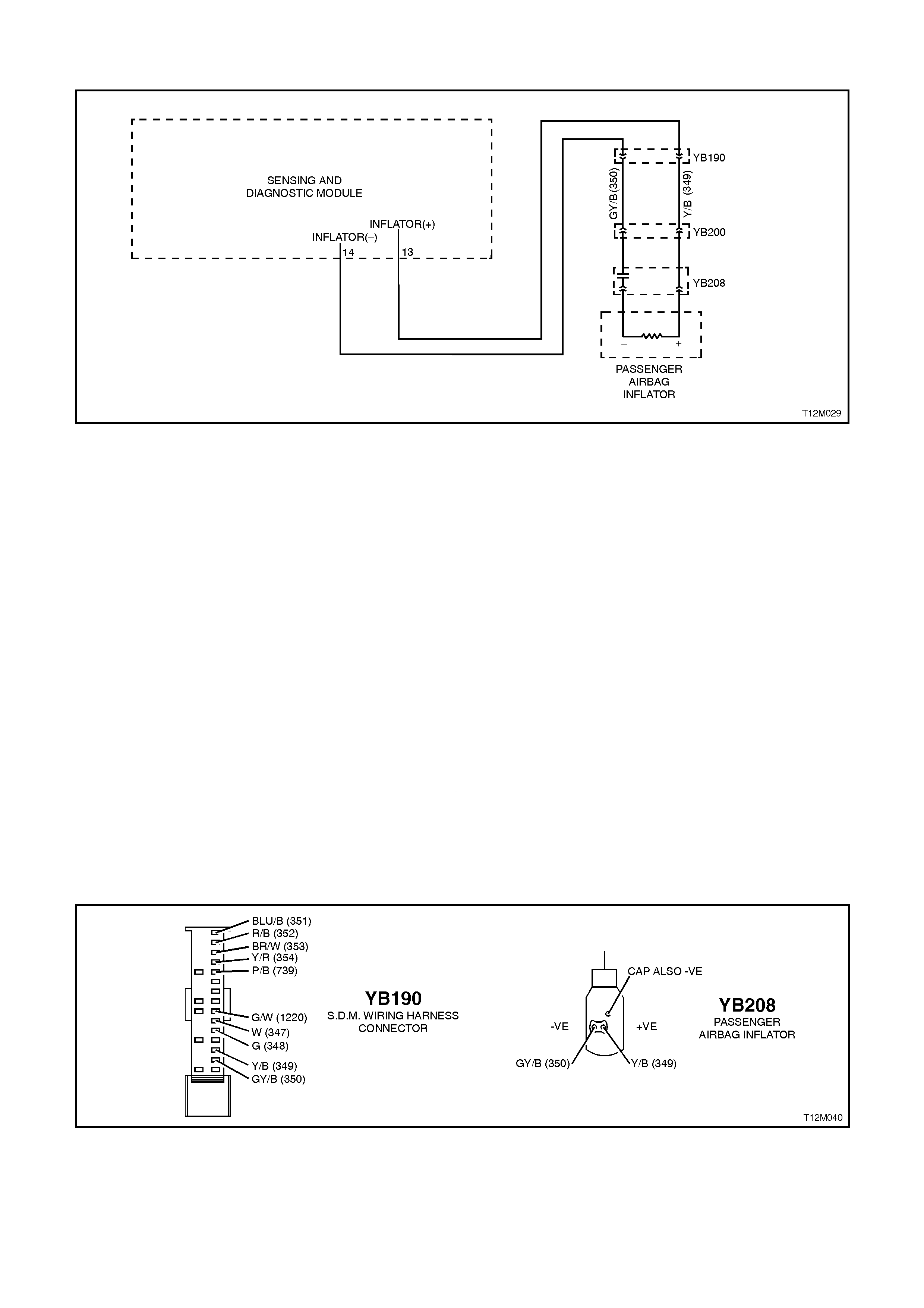

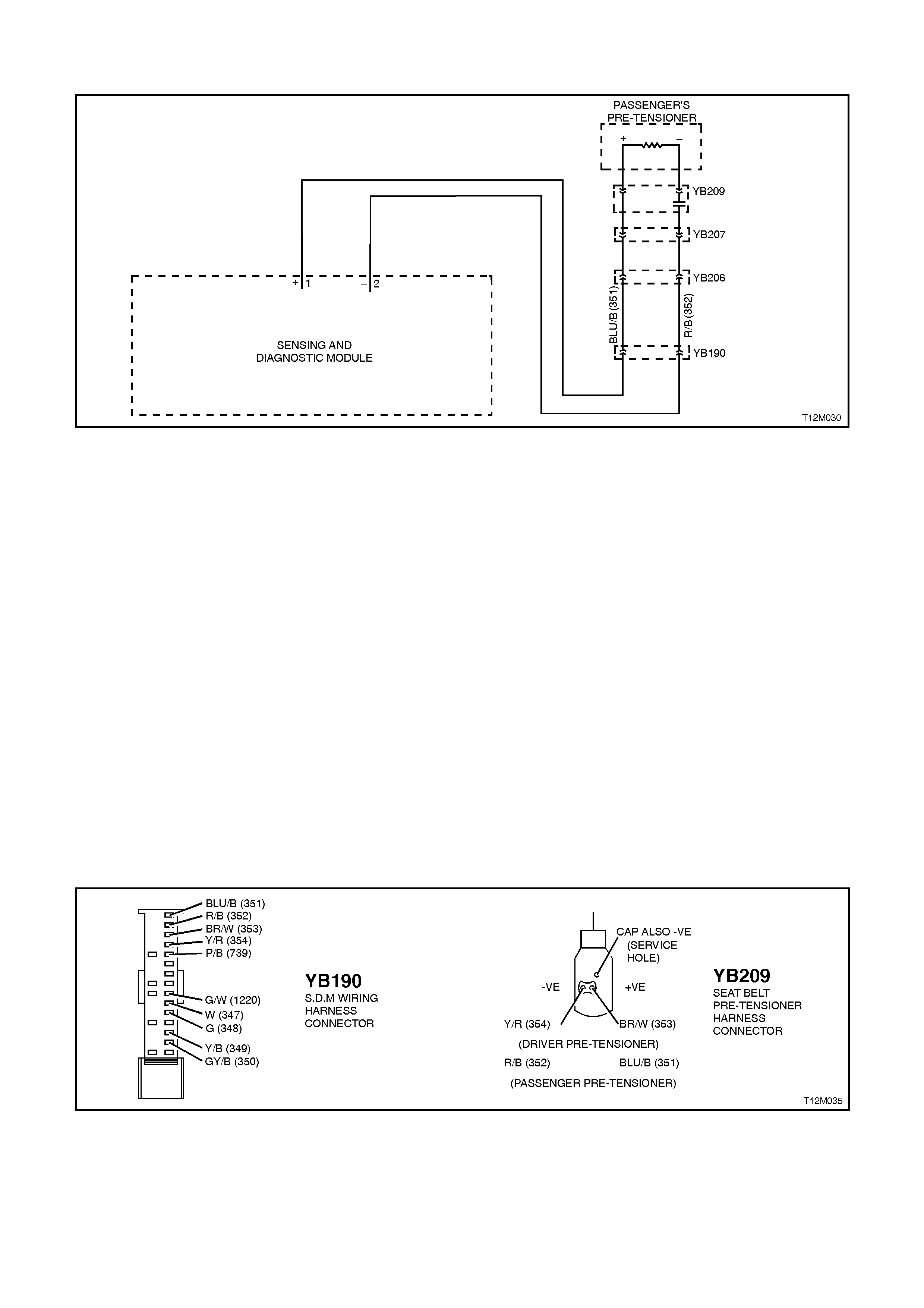

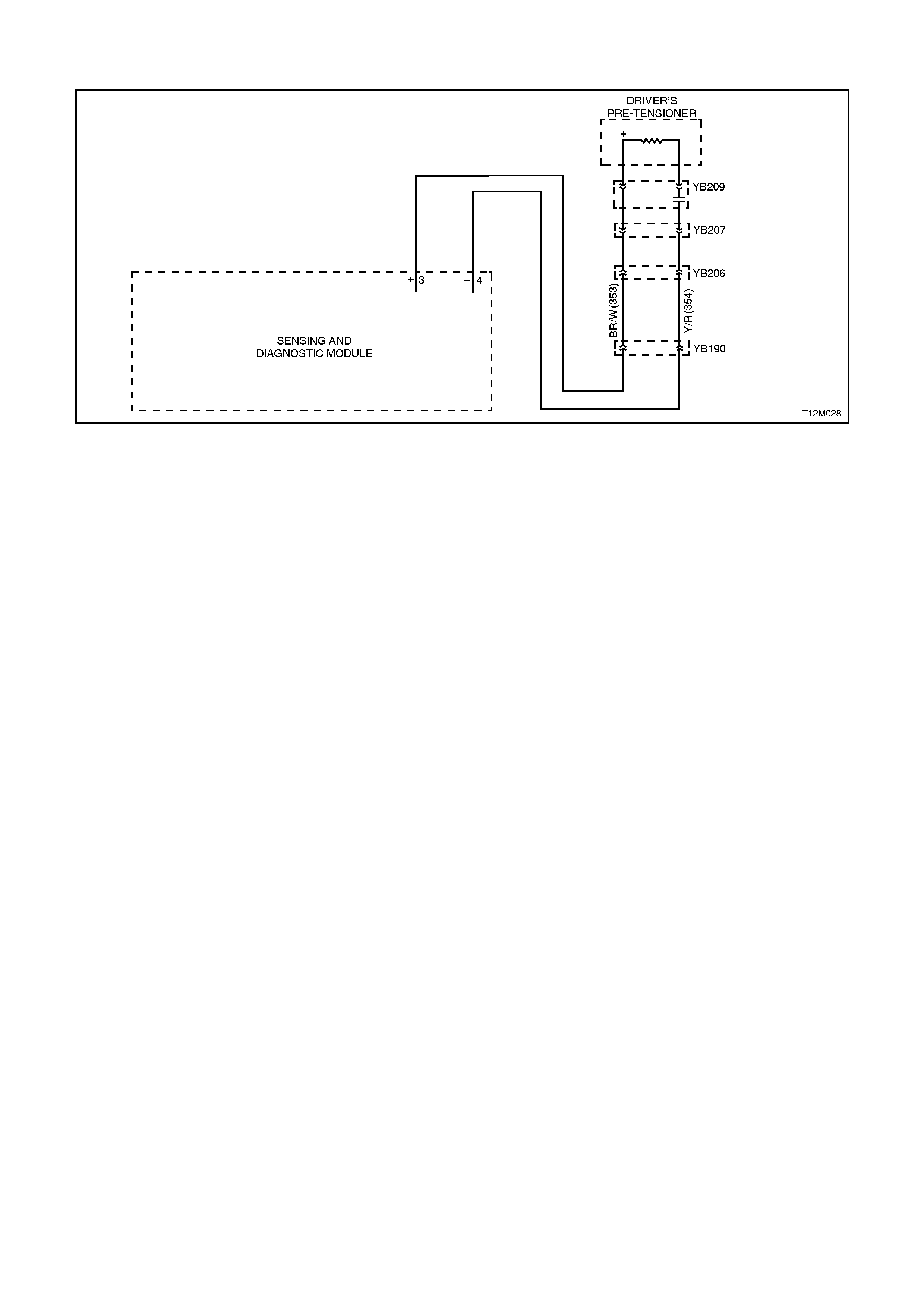

WIRING HARNESS

The SRS wiring harness is incorporated with the

main wiring harness and contains the necessary

wiring to interconnect the various system

components.

There is no specific wiring harness for vehicles

without a passenger side air bag, rather, the

additional wire for this connection is taped back to

the SRS wiring harness.

Although the SRS harness is incorporated with the

main wiring harness, it can still be identified by the

yellow PVC tubing or yellow tape covering the

harness wiring. The majority of the specific SRS

wiring harness connectors are either coloured

yellow or have a yellow retaining clip or slide to

identify them as SRS connec tors. O ne exception to

this is the wiring harness connector YB190 for the

SDM, which is coloured orange.

The connectors on the SRS wiring harness which

interface with the igniters have an in-built capacitor

which is connected in series with the trigger circuit.

The purpose of the capacitor is to prevent

unintentional triggering of the SRS by blocking any

Direct Current (DC) in the circuit.

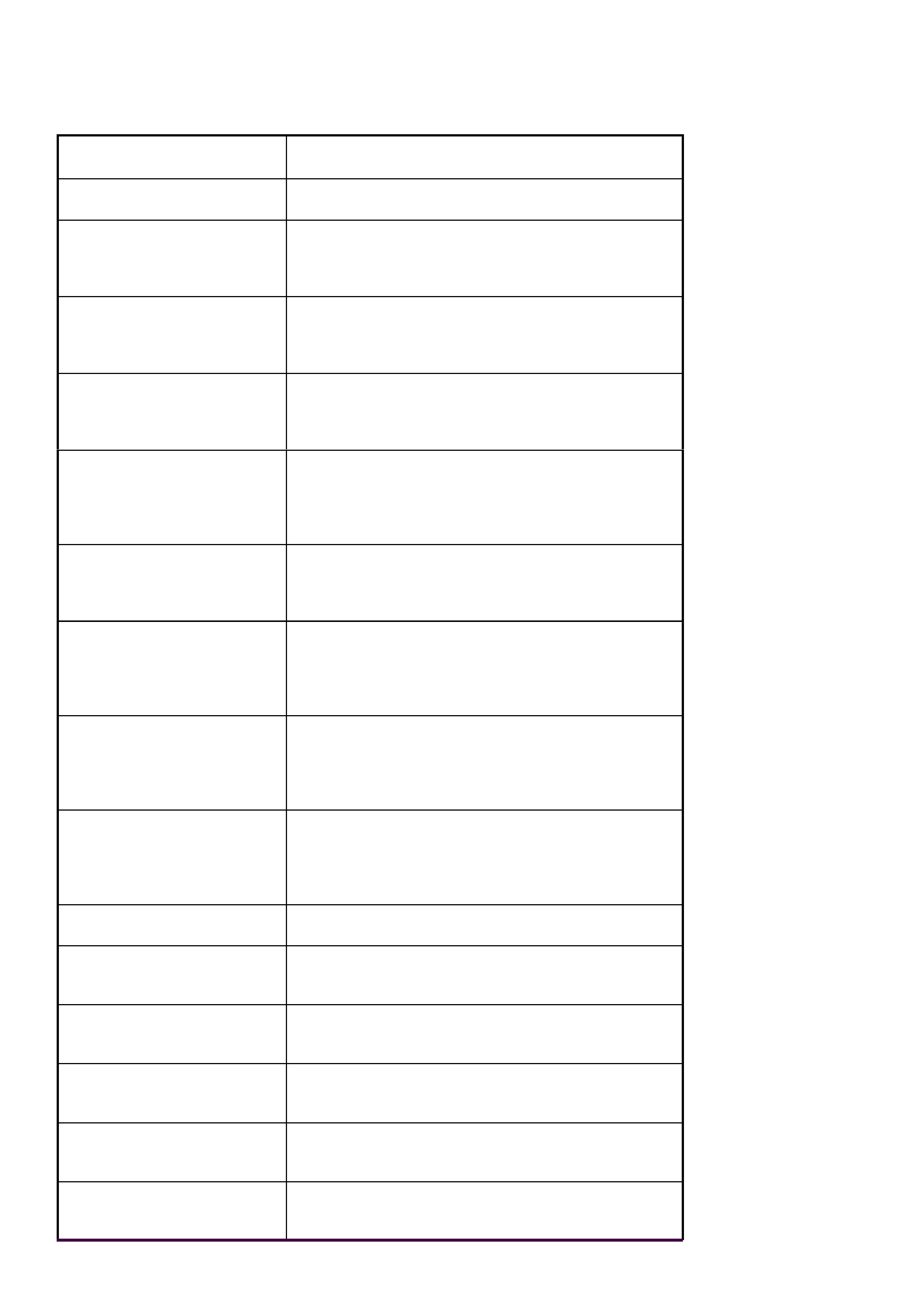

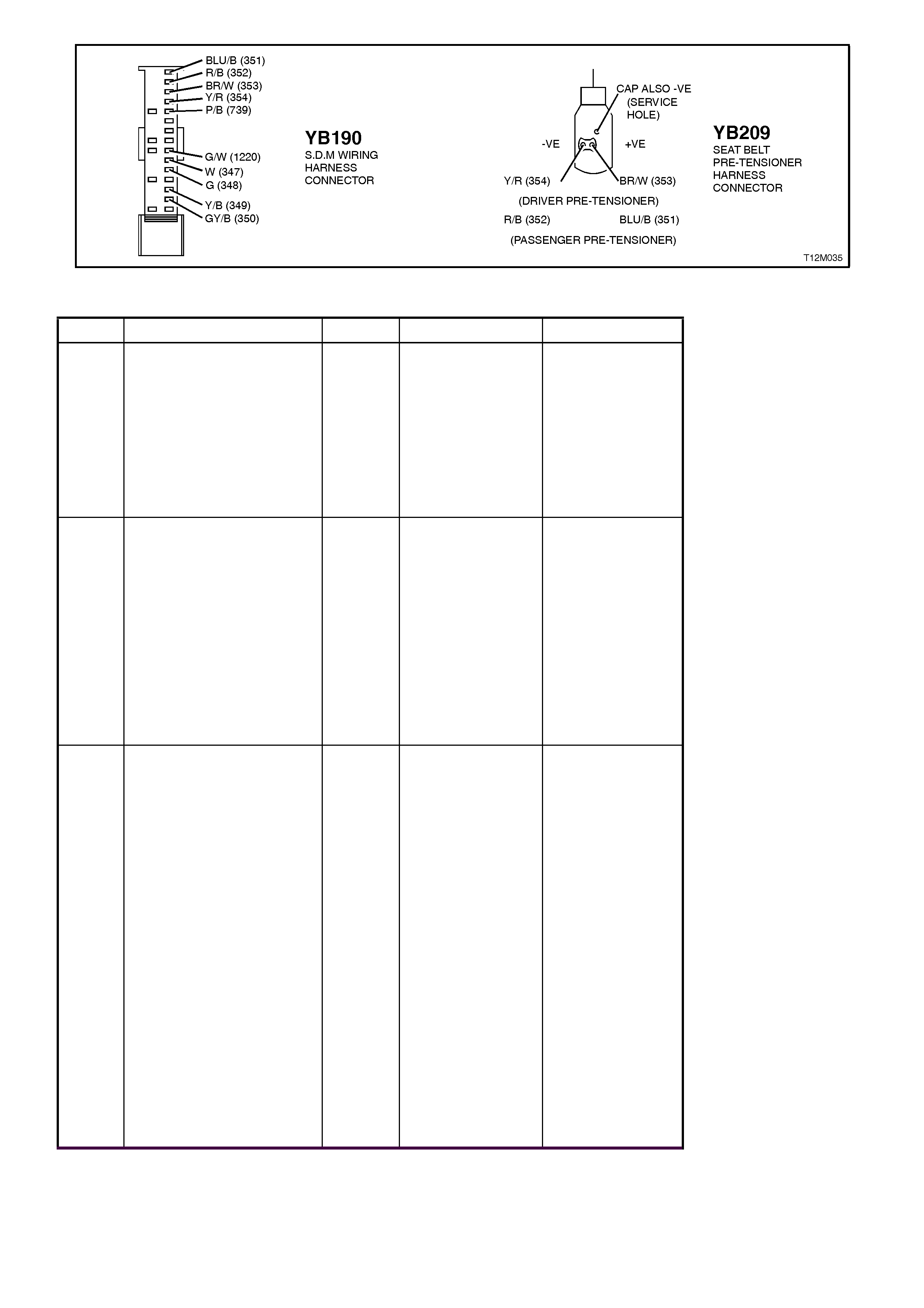

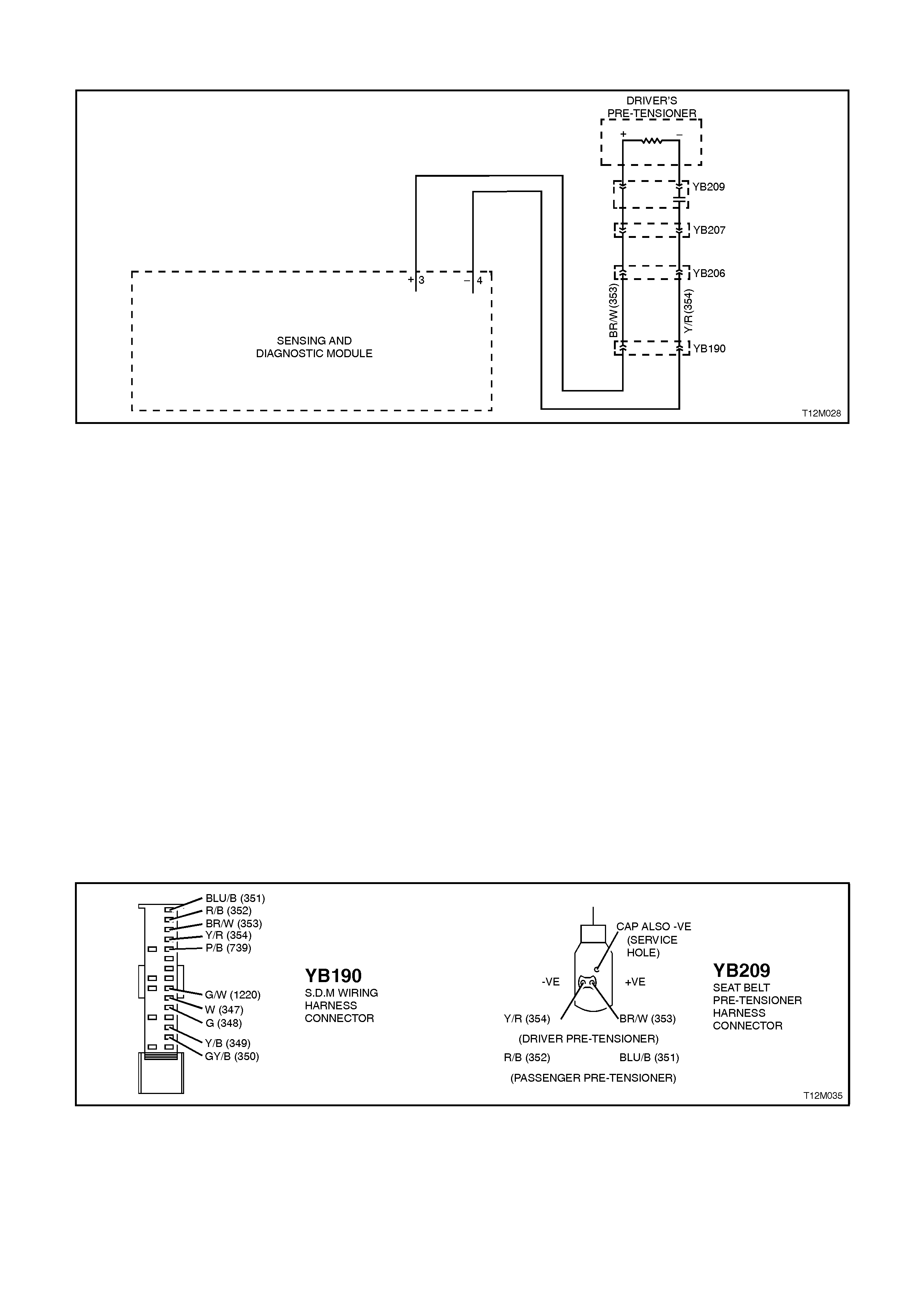

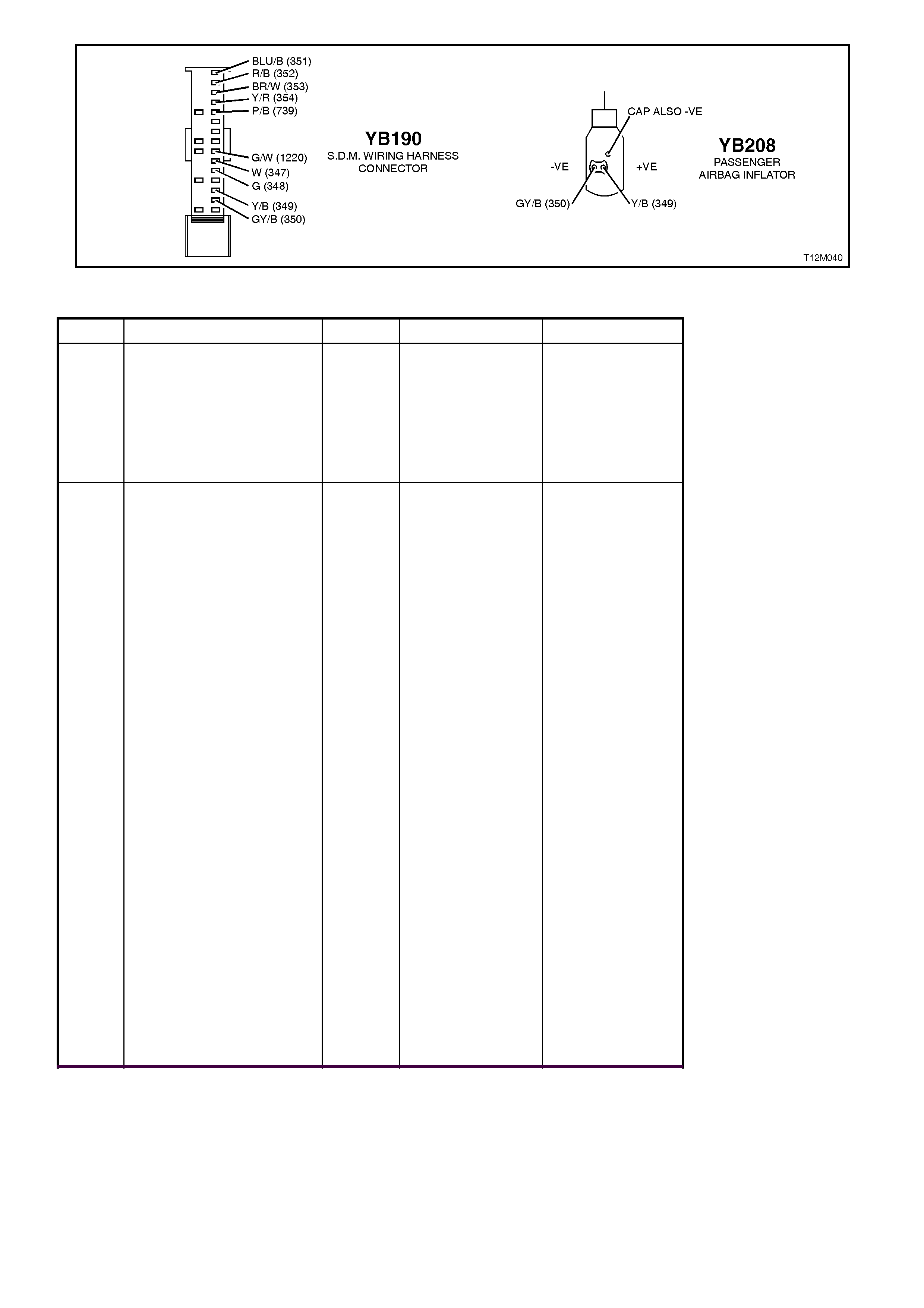

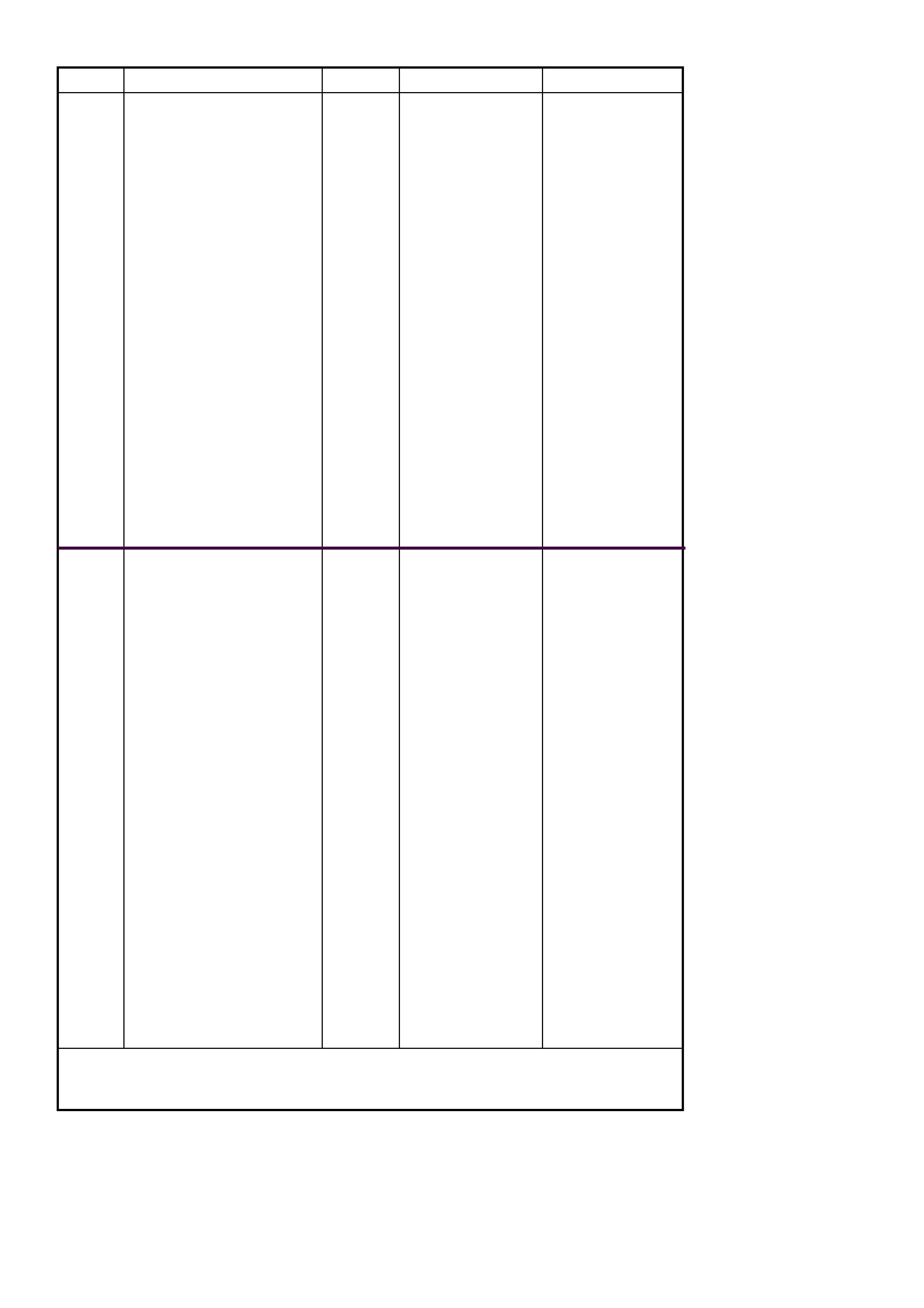

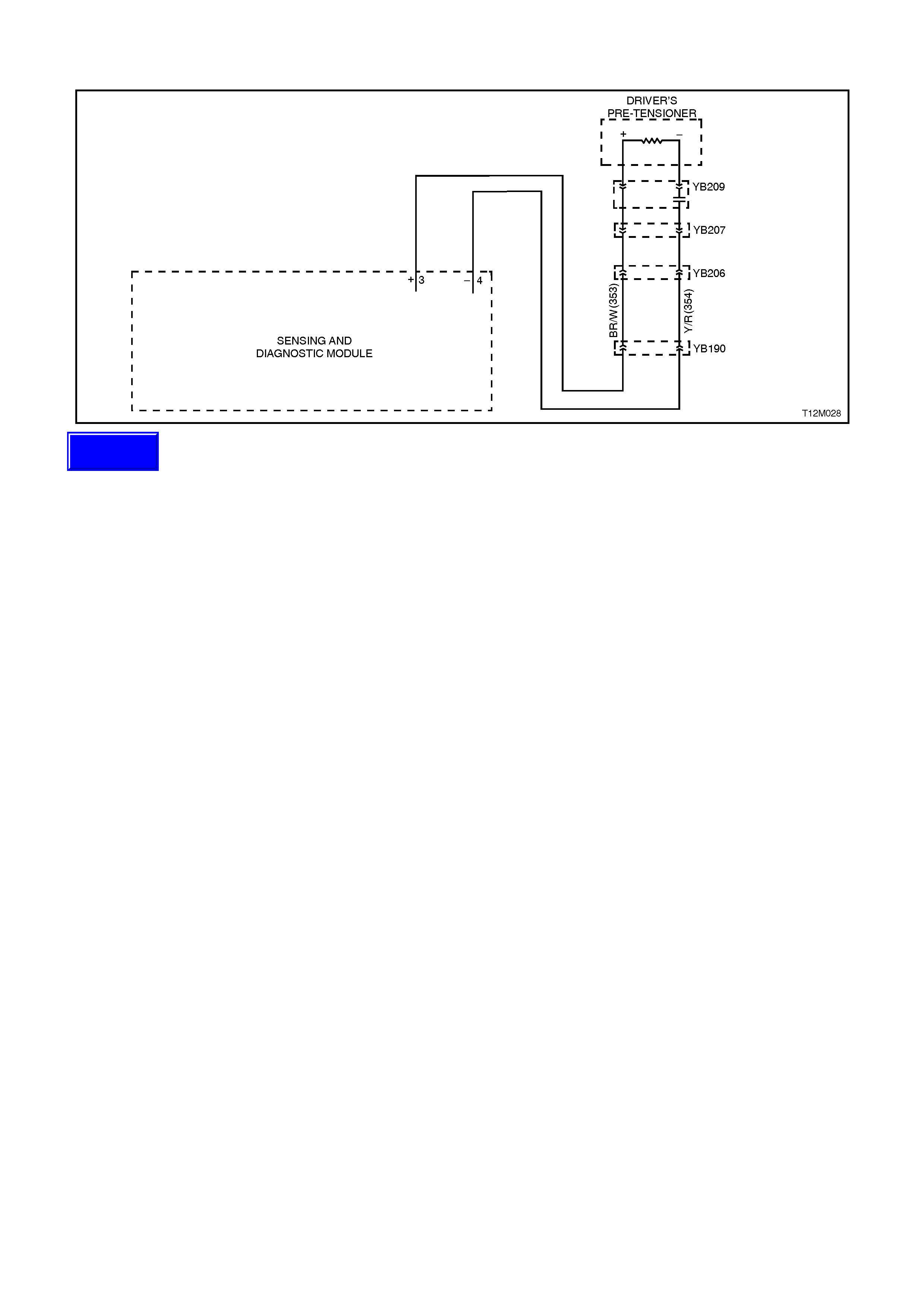

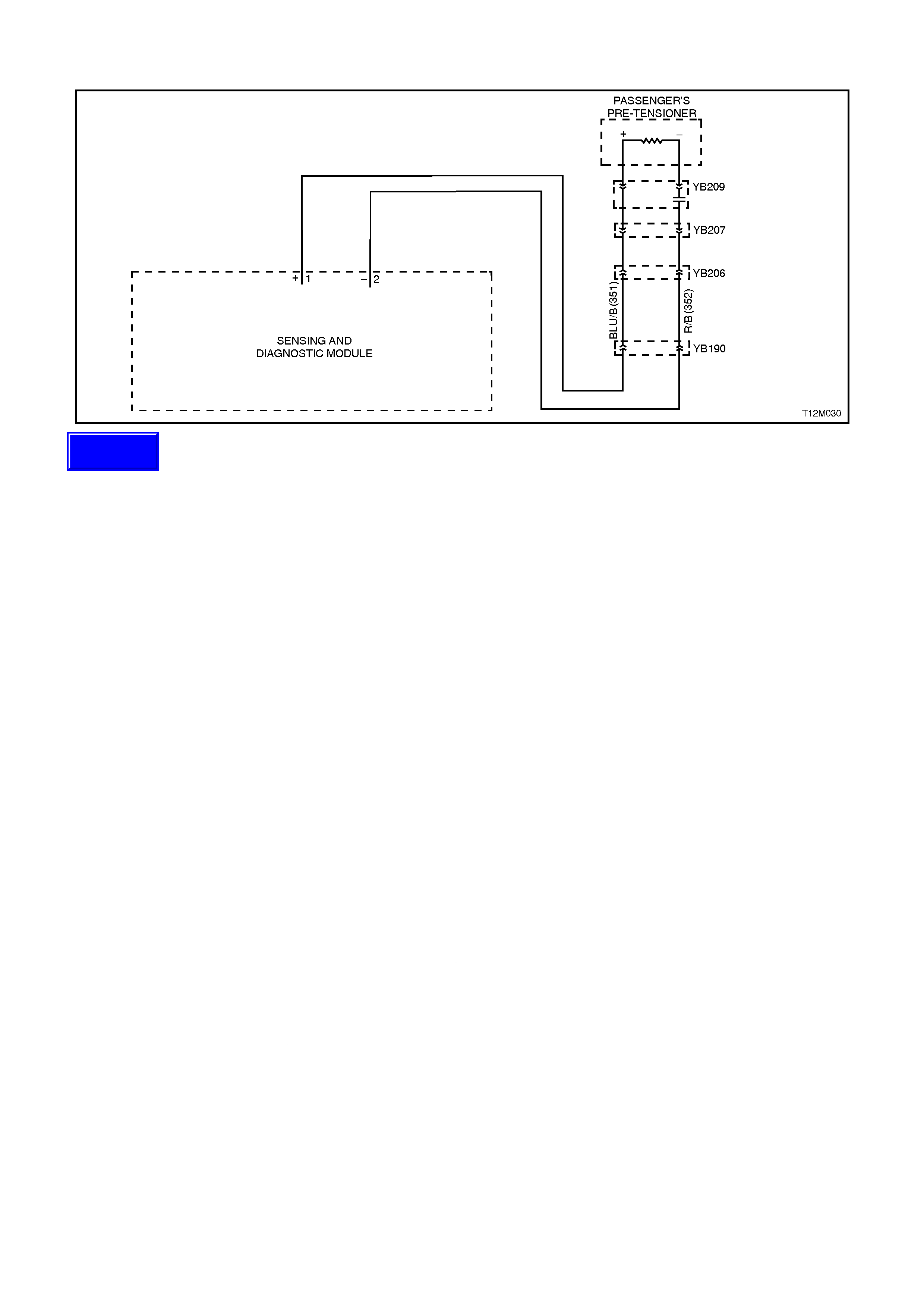

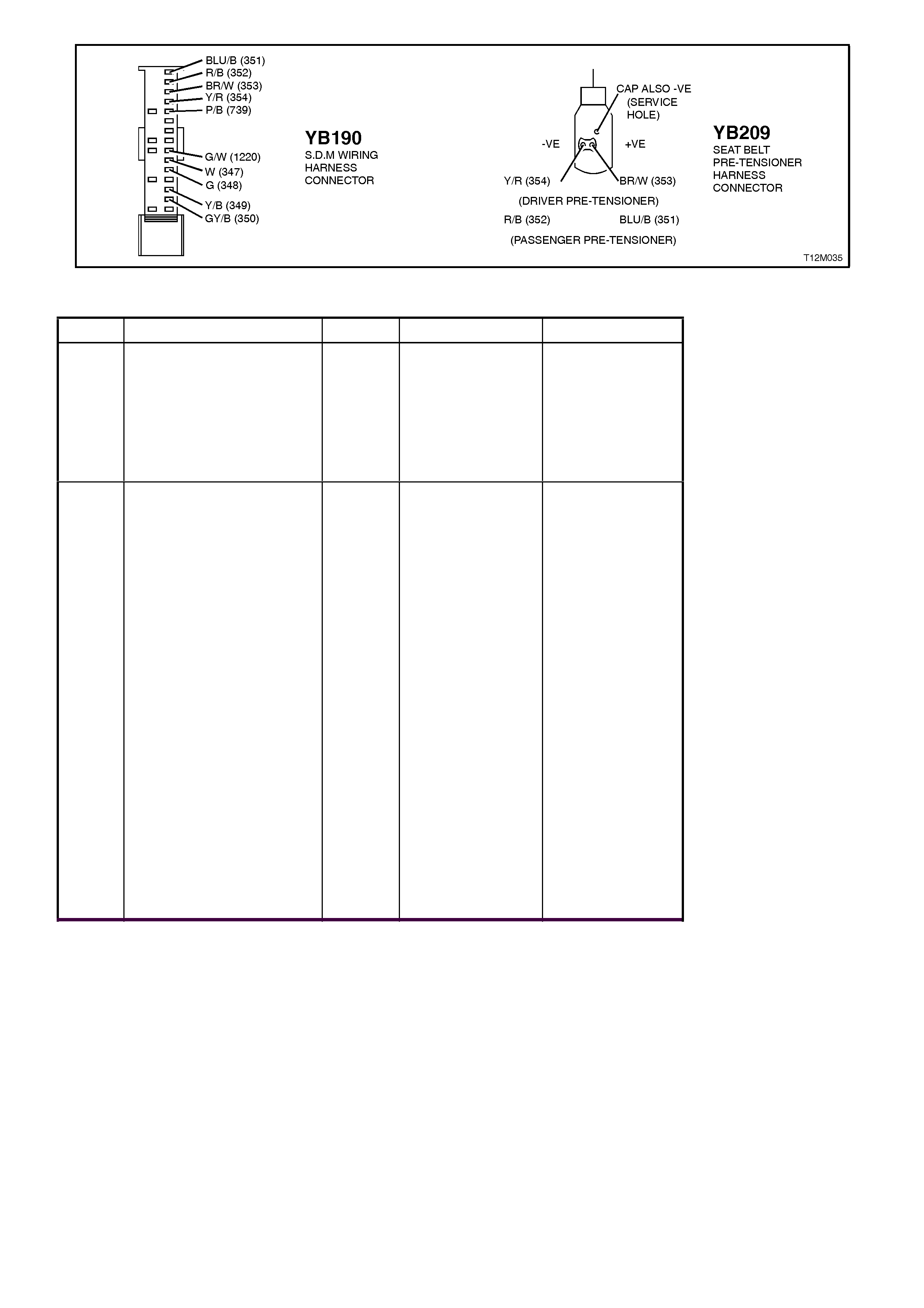

Figure 12M-17 illustrates the SRS wiring harness

connector with an in-built capacitor. The connector

consists of:

1. Capacitor.

2. A “Service Hole” to aid in diagnosis of the

system.

3 & 4. Terminals.

Special wiring repair procedures have been

developed for use on the SRS due to the sensitive

nature of the circuitry. The procedures described in

2.8 SRS WIRING REPAIR in this Section is the

only recommended and approved SRS wiring

repair m ethod. No alternative repair methods are

to be used.

Figure 12M-17

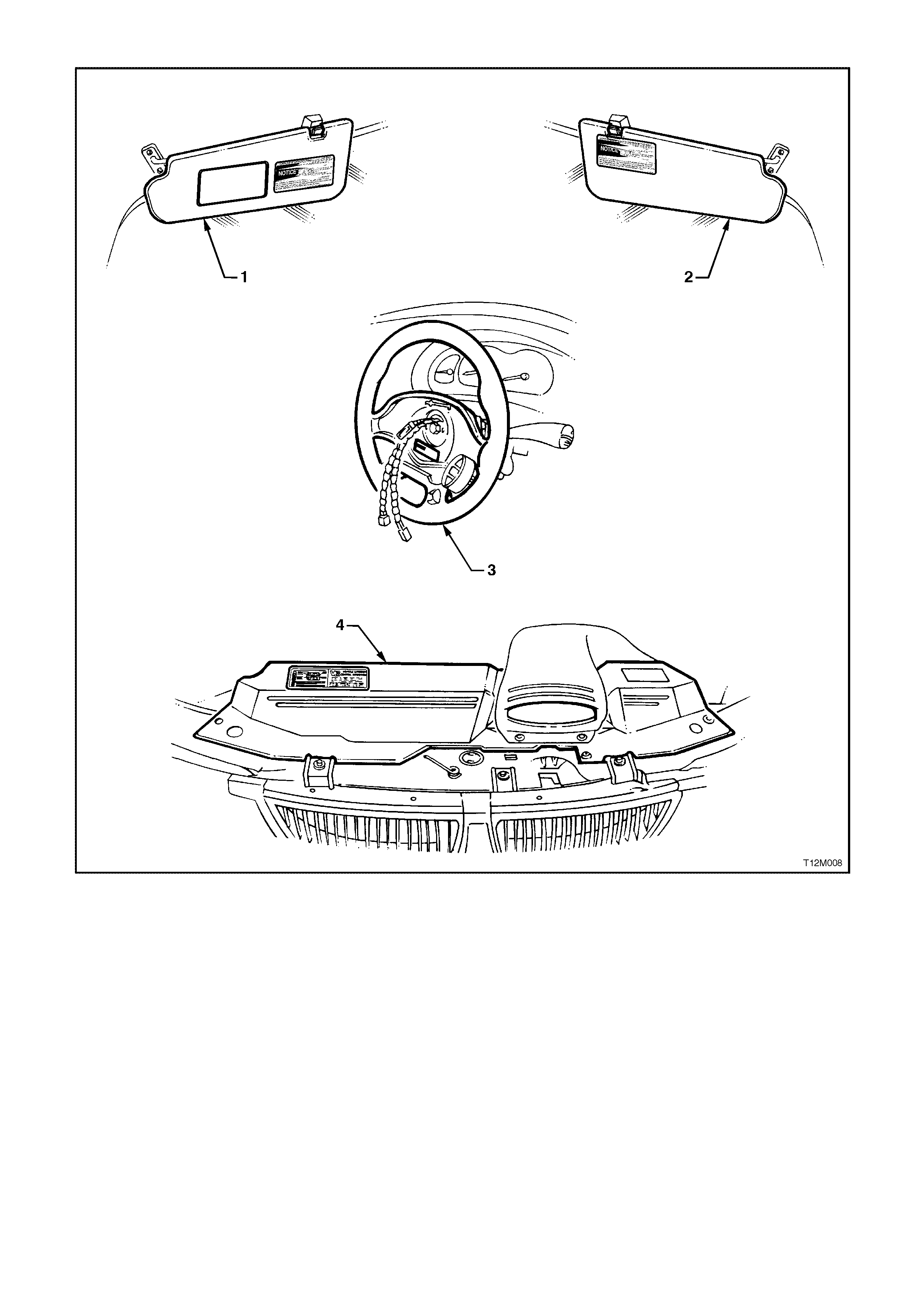

WARNING LABELS

In order to provide adequate warning of the SRS operation and service requirement to the vehicle's owner or driver

and service technicians, SRS warning labels are located on the driver's side sun visor, front passenger's side sun

visor (vehicles with front passenger's air bag), in the engine compartment (engine cooling fan shroud), and on the

steering wheel hub, refer to Fig. 12M-18.

IMPORTANT:

If at any time the engine cooling fan shroud, driver's or front passenger's sun visor or steering wheel is replaced,

ensure that the appropriate warning label is applied to the replacement part.

Figure 12M-18

1. Passenger’s side sun visor. 3. Steering wheel (horn bar and air bag inflator

removed)

2. Driver’s side sun visor. 4. Engine cooling fan shroud.

2. SERVICE OPERATIONS

2.1 SAFETY PRECAUTIONS

1. Do not use a fast battery charger for starting the vehicle.

2. Never disconnect the battery from the vehicle's electrical system while the engine is running.

3. Disconnect the battery from the vehicle's electrical system before fast battery charging.

4. Never disconnect or connect the SDM connector with the ignition turned on.

5. After an accident, the individual SRS components must be replaced if the following circumstances apply:

a. Deformation of the SDM. (If the floor pan is deformed where the SDM is mounted, it must be repaired).

b. Pre-tensioners, horn bar and air bag inflator module, front passenger's air bag inflator module that have not

been triggered, but are damaged.

c. Pre-tensioners, horn bar and air bag inflator module, front passenger's air bag inflator module or SDM

assemblies that have been triggered.

In an accident which was severe enough to deploy the pre-tensioners but not severe enough to deploy air

bag/s; any seat belt worn in the accident, the pre-tensioners and the front seat guide rail and adjuster

assemblies must be replaced.

If the horn bar and air bag inflator module or front passenger's air bag inflator module have also deployed;

the steering column, clock spring coil, steering wheel, instrument panel pad, front passenger air bag inflator

support rail assembly, PAB door assembly and instrument panel pad name plate badge.

NOTE:

DAMAGED OR DEFECTIVE COMPONENTS OF THE SYSTEM MUST NOT BE REPAIRED, BUT MUST

ALWAYS BE REPLACED.

7. When fasteners are removed, always reinstall them in the same location from which they were removed. If a

fastener needs to be replaced, use a fastener with the correct part number for that application. If a fastener

with the correct part number is not available, a fastener of equal size and strength (or stronger) may be used.

Fasteners that should not be reused, and those requiring thread locking compound will be identified in this

Section. The correct torque value must be used when installing fasteners that require it. If these conditions are

not adhered to, parts or system damage could result.

8. The windshield plays an active part during the deployment of the front passenger's air bag. The strength of the

windshield and its urethane adhesive is critical to ensure that the front seat passenger is correctly protected

during deployment. Replacement windshield glass and adhesives complying to Holden's specifications may

only be used.

Only use the correct urethane adhesive when installing a windshield to maintain original installation integrity.

Failure to use the correct product will result in poor retention of the glass. For vehicles with front passenger

side air bag, the windshield must be replaced properly so that occupant protection provided by the SRS is

maintained.

9. Sensing and Diagnostic Module.

Take care when handling the SDM. Never strike or jar the module or body structure adjacent to the module in a

manner which could cause deployment of the pre-tensioner’s or air bag/s.

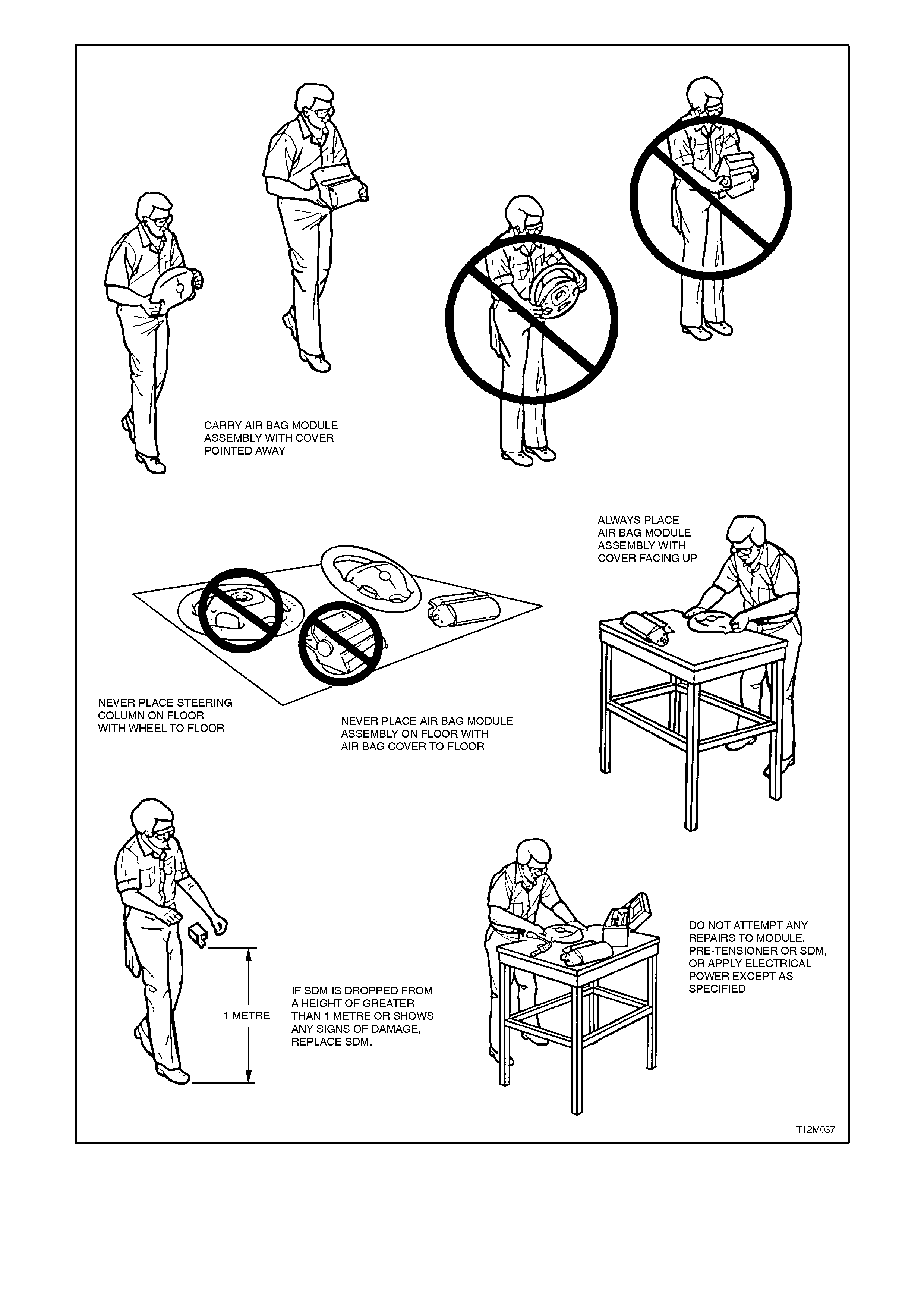

10. Undeployed air bag inflator module.

When carrying a live (undeployed) air bag inflator module, ensure that it is pointed away from you. In case of

an accidental deployment, the air bag will then deploy with minimal chance of injury.

When placing a live air bag inflator module on a bench or other surface, always face the assembly up, away

from the surface. This is necessary in order to provide free space for the air bag to expand, in case of

accidental deployment. Also, never place anything on top of air bag inflator module.

Never carry the driver's air bag inflator module by the horn bar contact wires on the underside of the assembly.

If still connected, never carry the pre-tensioner’s or the front passenger's inflator module by its wiring harness

lead.

Do not apply power to the module except as specified in this Section.

Do not attempt to make any repairs to the module/s. A damaged or defective horn bar and air bag inflator

module or front passenger's air bag inflator module assembly must be replaced.

Do not weld, solder, braze, hammer, machine, drill, or otherwise heat seat belt pre-tensioners or air bag inflator

modules.

11. Deployed air bag inflator module/s.

Always wear gloves and safety glasses when handling a deployed pre-tensioner, horn bar and air bag inflator

module or front passenger air bag inflator module. The surface of these components may contain chemicals

(eg. Sodium Hydroxide) as a result of the gas generated during combustion. This can irritate your skin. Wash

hands with mild soap and water afterwards.

12. Steering column.

During any service operation that requires removal and reinstallation of a steering column fitted with an air bag

inflator module, always carry the steering column with two hands and with the steering wheel away from your

body. Never carry the column by one hand or with steering wheel tow ard you.

Never set a steering column on the floor with the steering wheel toward the floor.

NOTE:

During any service operation that requires removal of a steering column, ensure that the steering shaft is locked to

the column to prevent any possibility of allowing the steering shaft to rotate and possibly damaging the clock spring

coil ribbon wire. For details of locking the steering shaft to the column, refer to Section 9A, STEERING.

CAUTION:

When performing service on or around SRS components or wiring, follow the procedures listed in this

Section to temporarily disable the SRS. Failure to follow these procedures could result in possible SRS

deployment, personal injury or otherwise unnecessary SRS repairs.

7. 7. Disconnecting the battery WILL NOT immediately deactivate the SRS. A residual energy reserve in the

SDM is incorporated to enable the pre-tensioners and air bag/s to deploy in the event of a battery failure. The

SDM has the power to deploy the air SRS for up to 10 seconds after the battery has been disconnected or the

ignition turned off.

8. 8. The SDM can maintain sufficient voltage to cause a deployment for up to 10 seconds after the ignition

switch is turned OFF or the battery is disconnected. Many of the service operations require disconnection of

the battery to avoid an accidental deployment of the pre-tensioners or air bag/s.

9. 9. When carrying out steering gear removal and reinstallation procedures, remove the ignition key from the

ignition lock and ensure that the steering column is locked. If this operation is not carried out and the steering

wheel is spun while the steering gear is removed, the clock spring coil will be destroyed. This will result in the

SDM setting a DTC and non-deployment of the driver’s air bag.

Figure 12M-19

2.2 SYSTEM DISABLING AND ENABLING P ROCEDURE

DISABLING THE SRS

NOTE:

This disabling procedure applies only to VT Series Models which have an AC firing SRS. Conventional SRS

with DC firing such as VS Series Models have a more complex disabling procedure. Always refer to the

appropriate Section for SRS disabling and enabling procedures.

Disconnect both the battery earth and power leads and wait at least 10 seconds before performing any work on the

vehicle.

CAUTION:

The SDM can maintain sufficient voltage to cause SRS deployment for up to 10 seconds after the ignition

switch is turned OFF or the battery is disconnected.

ENABLING THE SRS

NOTE:

Ensure all wiring harness connectors are connected before reconnecting the battery leads.

1. Reconnect both the battery power and earth leads.

2. Switch ignition on, and observe the SRS warning lamp in the instrument cluster. The warning lamp should be

illuminated for approximately 5 seconds. During this period the SDM performs a wiring and self check.

If no system faults are detected, the SRS warning lamp will be switched off. If the warning lamp remains

illuminated and an audible alarm chimes, or the warning lamp illuminates 2 seconds after it was originally

switched off, an SRS fault is present. Refer to 3 DIAGNOSTICS in this Section to rectify fault.

2.3 HORN BAR AND AIR BAG MODULE ASSEMBLY

If conducting the following operation on an air bag

that has deployed, ensure that you are wearing

safety glasses and gloves to pr otect your eyes and

hands from possible irritation when handling the

deployed horn bar and air bag inflator module

assembly.

After the horn bar and air bag inflator module

assem bly has been deployed, the surf ace of the air

bag may contain a powdery residue. This powder

consists primarily of corn starch (used to lubricate

the bag as it inflates) and by-products of the

chemical reaction. Sodium hydroxide dust is

produced as a by-product of the deployment

reaction. T he sodium hydroxide then quick ly r eacts

with atmospheric moisture and is converted to

sodium carbonate and sodium bicarbonate (baking

soda). Therefore, it is unlikely that sodium

hydroxide will be present after deployment. As a

precaution, however, gloves and s af ety glasses are

recommended to prevent any possible irritation of

the skin or eyes.

REMOVE

1. Disable the SRS, refer to

2.2 SYSTEM DISABLING AND ENABLING

PROCEDURE in this Section.

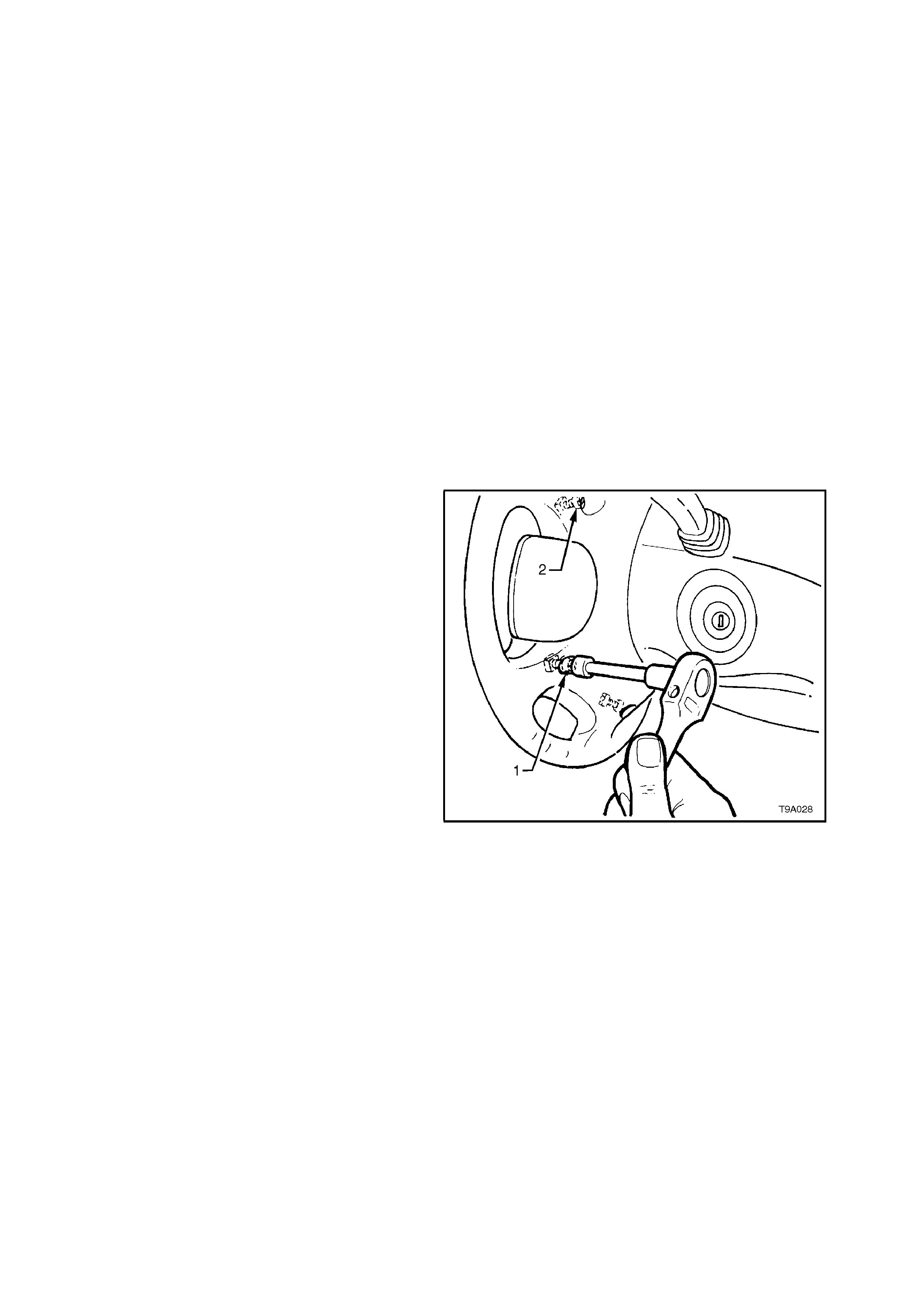

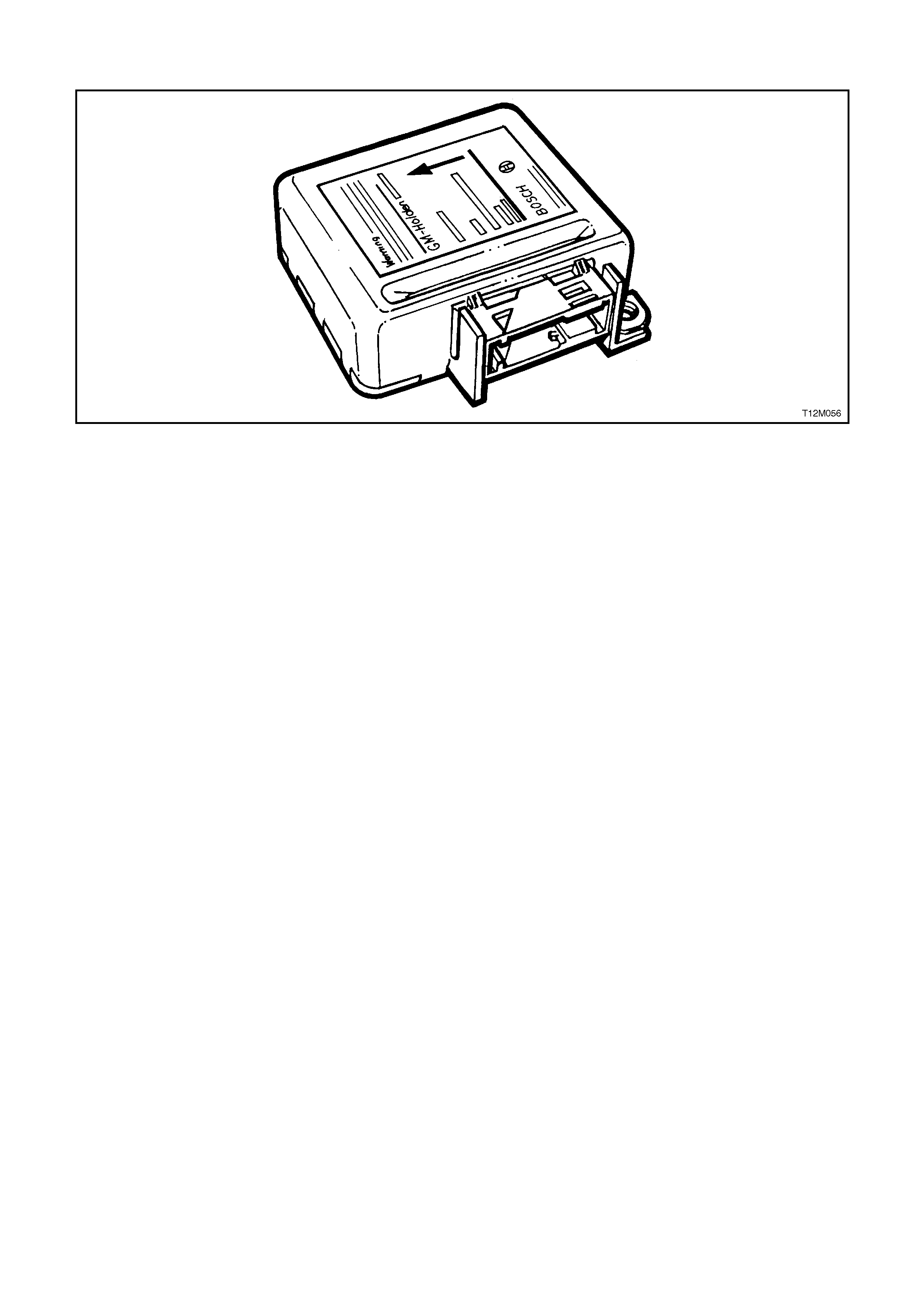

2. Using a number T 30H Torx bit (1) , c ommercially

available or Tool No. ETX30H and a suitable

holder such as Tool No. J25359-8, loosen and

rem ove four sc rews (2) f rom the r ear of s teering

wheel securing the horn bar and air bag inflator

module assembly to the steering wheel.

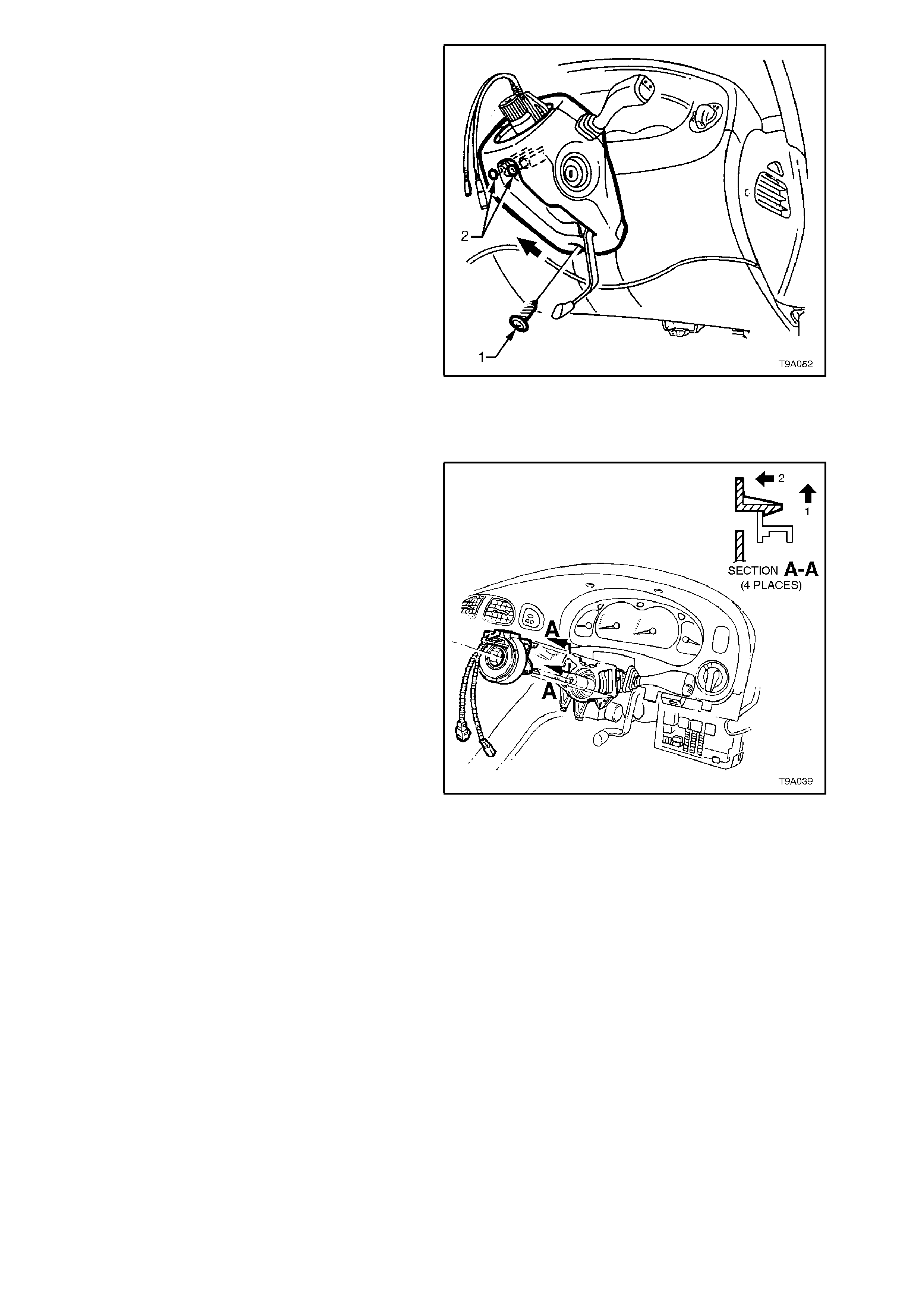

Figure 12M-20

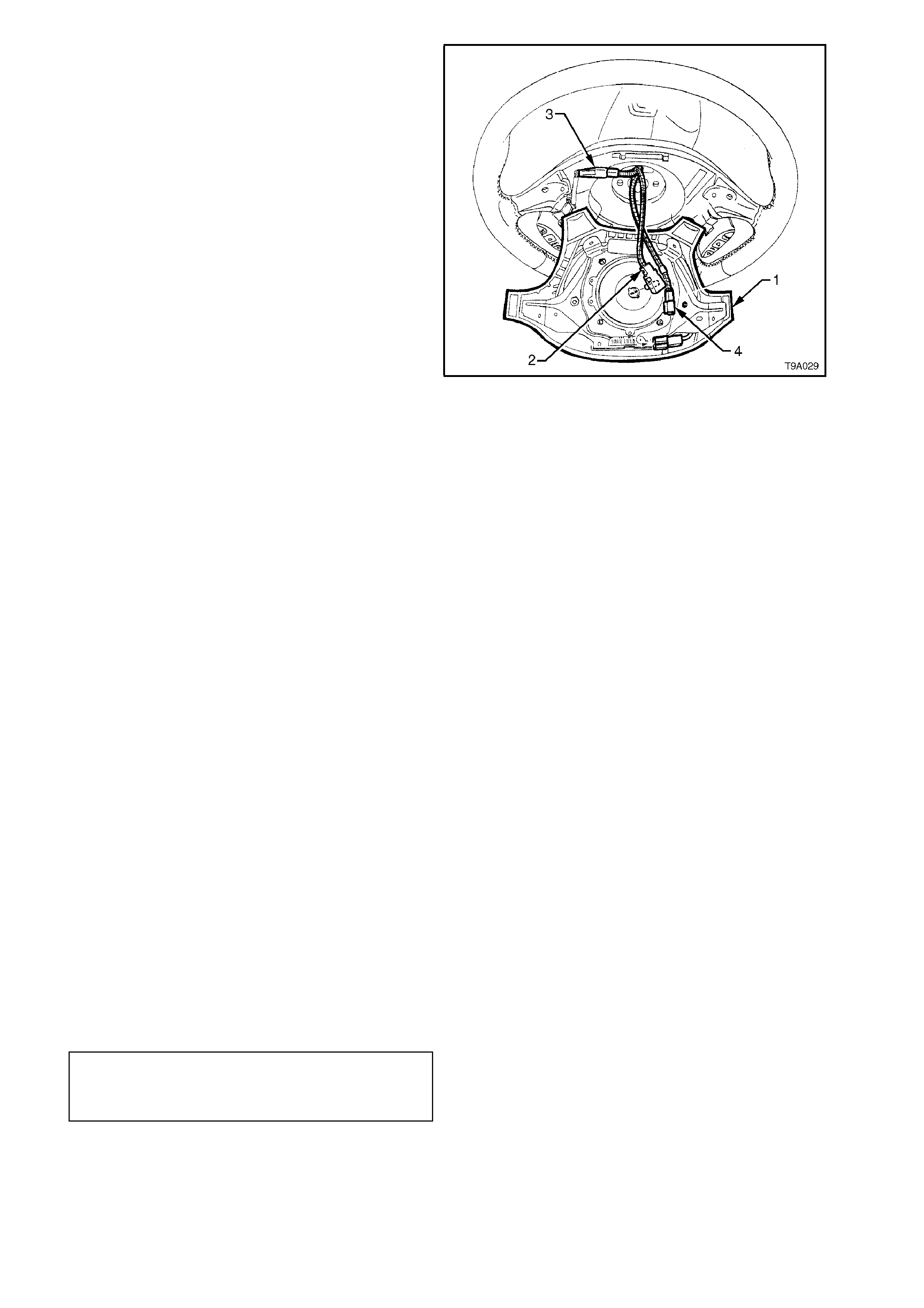

3. Lift up horn bar and air bag inflator module

assembly (1) from the steering wheel, remove

the yellow clock spring to inflator assembly

connection (2) and disconnect wiring harness

connectors (3 and 4) from rear of assembly,

refer to Fig 12M-21.

NOTE:

If removing a horn bar and air bag inflator module

assembly from a steering wheel fitted with stereo

controls (as shown), take extreme care when

disconnecting the left hand horn pad connector (3)

from the stereo control wiring connector otherwise

damage to the stereo control wiring could result.

Remove horn bar and air bag inflator module

assembly.

CAUTION:

When carrying a live (undeployed) horn bar and

air bag inflator module assembly, make sure

the bag opening in the horn bar is pointed away

from you. Never carry the horn bar and air bag

inflator module assembly by the horn bar wires

or connectors on the underside of the

assembly. In case of an accidental deployment,

the bag will then deploy with minimal chance of

injury.

When placing a live horn bar and air bag

inflator module assembly on a bench or other

surface, always face the bag and horn bar up,

away from the surface. Never rest the horn bar

and air bag inflator module assembly with the

horn bar f ace down . This is necessary so th at a

free space is provided to allow the air bag to

expand in the unlikely event of accidental

deployment. Otherwise, personal injury may

result.

Figure 12M-21

REINSTALL

1. Lift horn bar and air bag inflator module

assembly up to steering wheel and reconnect

all wiring harness connectors to rear of

assembly.

2. Seat horn bar and air bag inflator module

assembly on steering wheel, ensuring wiring is

not exposed or trapped between air bag

inflator module and steering wheel hub.

3. Using number T30H Torx bit. Tool No.

ETX 30H and suitable holder such as T ool No.

J25359-8, install and tighten four screws into

rear of steering wheel to secure horn bar and

air bag inflator module assembly to the

steering wheel. Tighten screws to the correct

torque specification.

HORN BAR AND AIR BAG MODULE

ASSEMBLY TO STEERING WHEEL

SECURING SCREW

TORQUE SPECIFICATION 10 - 14 Nm

4. Enable the SRS, refer to

2.2 SYSTEM DISABLING AND ENABLING

PROCEDURE in this Section.

5. Switch ignition on, and observe the SRS

warning lamp in the instrument cluster. The

warning lamp should be illuminated for

approximately 5 seconds. During this per iod of

time the SDM performs a wiring and self

check.

If no system faults are detected, the SRS

warning lamp will be switched off. If the

warning lamp remains illuminated and an

audible alarm chimes, or the warning lamp

illuminates 2 seconds after it was originally

switched off, an SRS fault is pr esent. Ref er to

3 DIAGNOSTICS in this Section to rectify

fault.

HORN BAR AND AIR BA G MODULE ASSEMBLY SCRAPPING PROCEDURE

During the course of a vehicle's useful life, certain

situations may arise which will necessitate the

disposal of a live (undeployed) hor n bar and air bag

inflator m odule assembly. The f ollowing infor mation

covers proper procedures for deploying a live

assembly.

CAUTION:

Failure to follow proper Supplemental Restraint

System (SRS) horn bar and air bag inflator

module assembly disposal procedures can

result in air bag deployment which may cause

personal injury. T he undeployed air bag inflator

module contains substances that can cause

severe illness or personal injury if the sealed

container is damaged during disposal.

In situations which require deployment of a live

horn bar and air bag inflator module assembly,

deployment may only be accomplished outside the

vehicle. The horn bar and air bag inflator module

assembly needs to be removed so the SRS wiring

harness with the capacitor built into the connector

can be removed. Intentional deployment of the

horn bar and air bag inflator module can not be

accomplished using a 12 volt DC supply with the

capacitor in the SRS circuit.

Horn Bar and Air Bag Module Deployment

Outside Vehicle

There m ay be some cir cum stanc es that requir e the

deployment of a horn bar and air bag inflator

module ass em bly befor e a vehicle is to be retur ned

to service. For example, situations in which the

vehicle will be returned to an owner after a

functionally or cosm etically malf unctioning horn bar

and air bag inflator module assembly is replaced.

Deployment and disposal of a malfunctioning air

bag inflator module is, of course, subject to any

required retention period.

For deployment of a live ( undeployed) horn bar and

air bag inflator module assembly outside the

vehicle, the deployment procedure must be

followed exactly. Always wear safety glasses during

the deployment procedure until the assembly is

removed. Before performing the procedure you

should be familiar with servicing the SRS and with

proper handling of the horn bar and air bag inflator

module assembly.

The following must be read fully and understood

before performing the actual procedure.

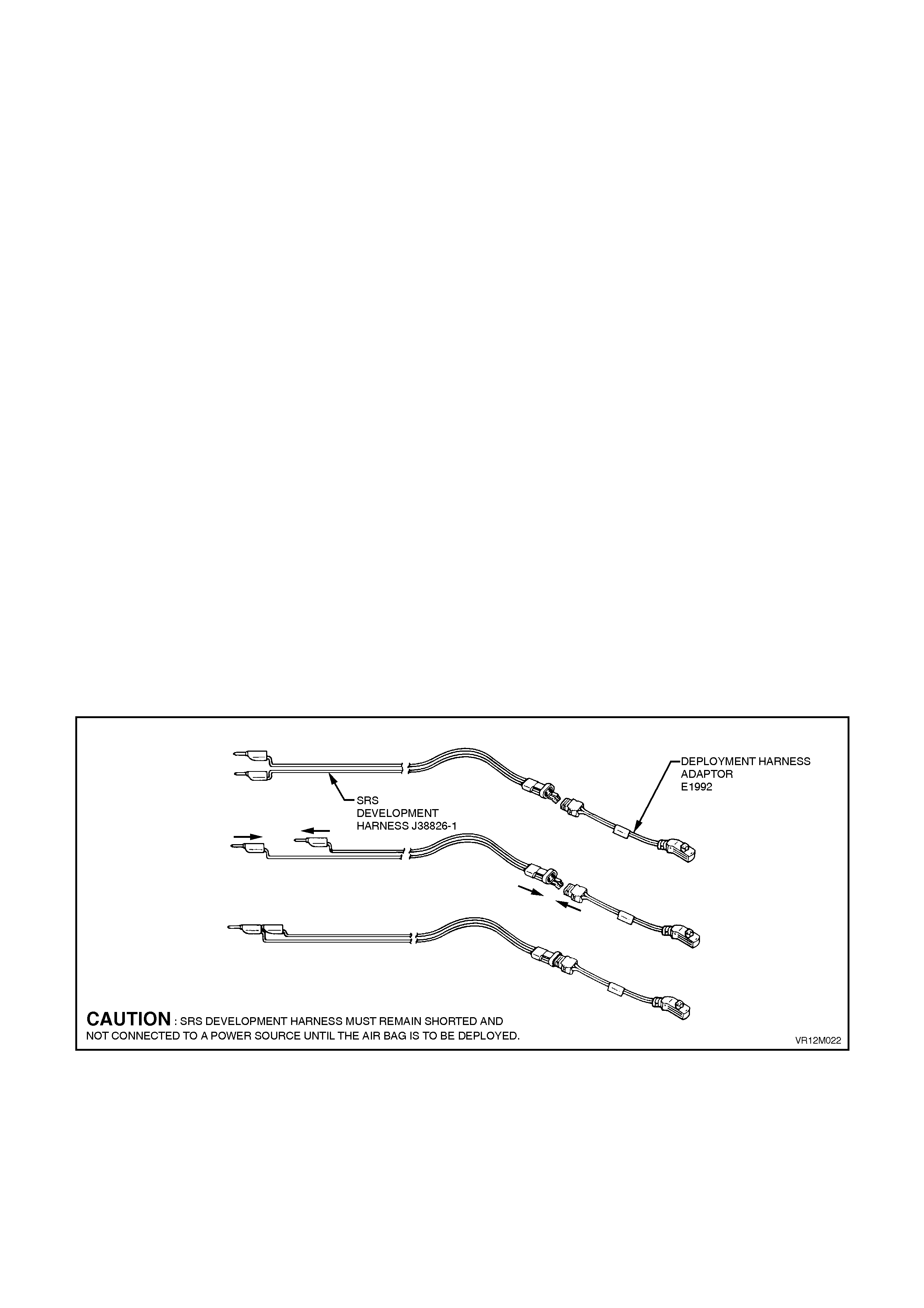

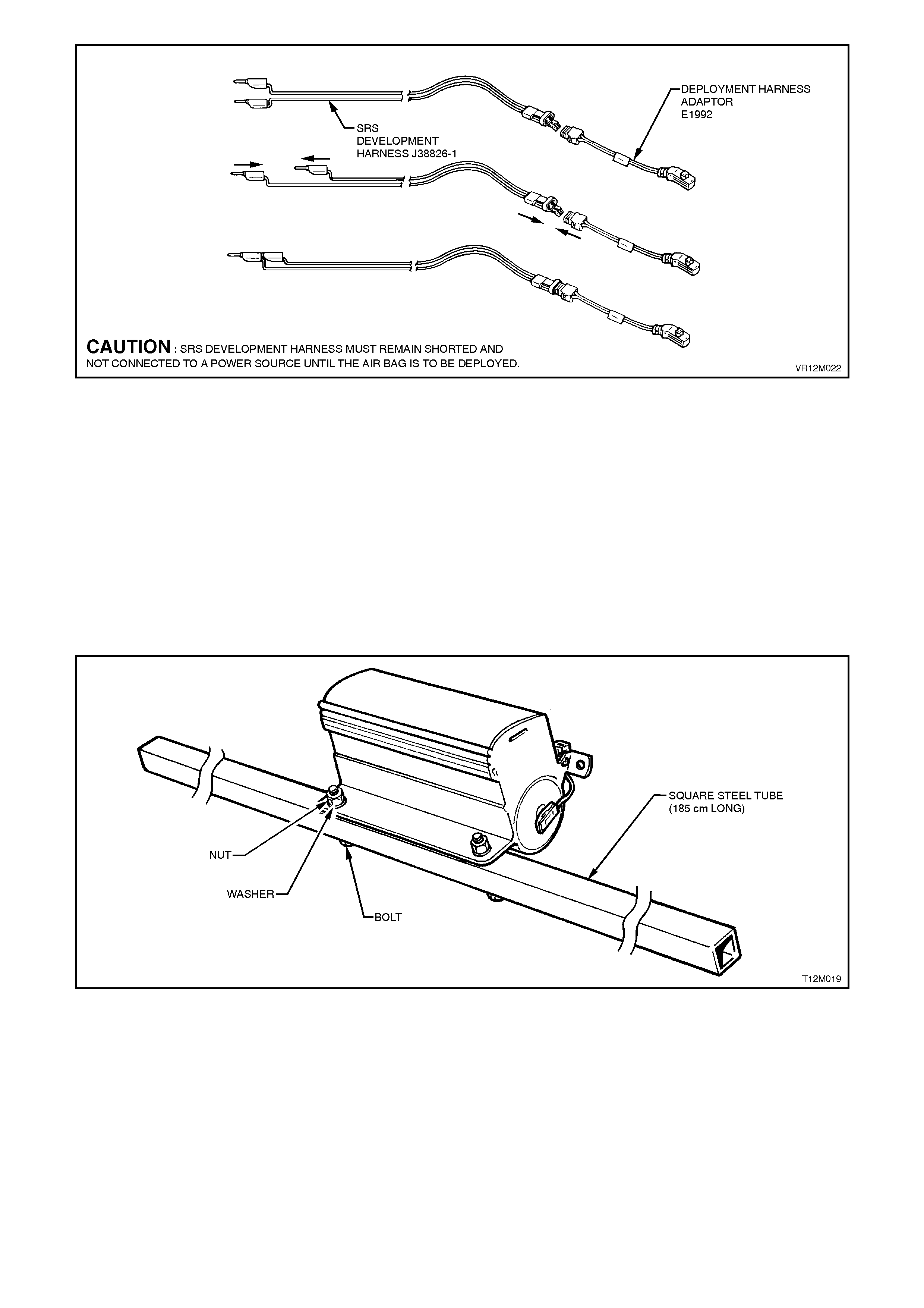

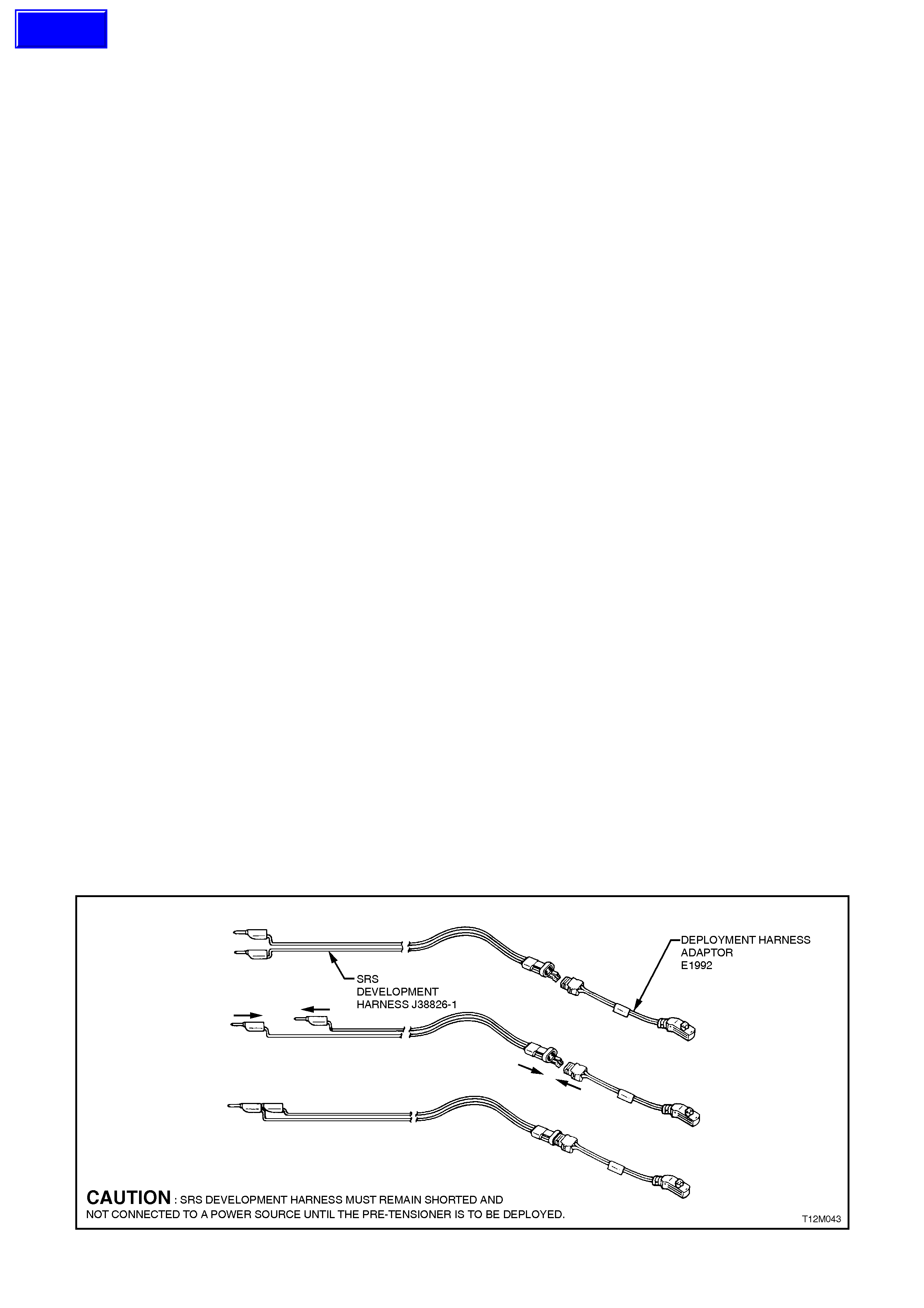

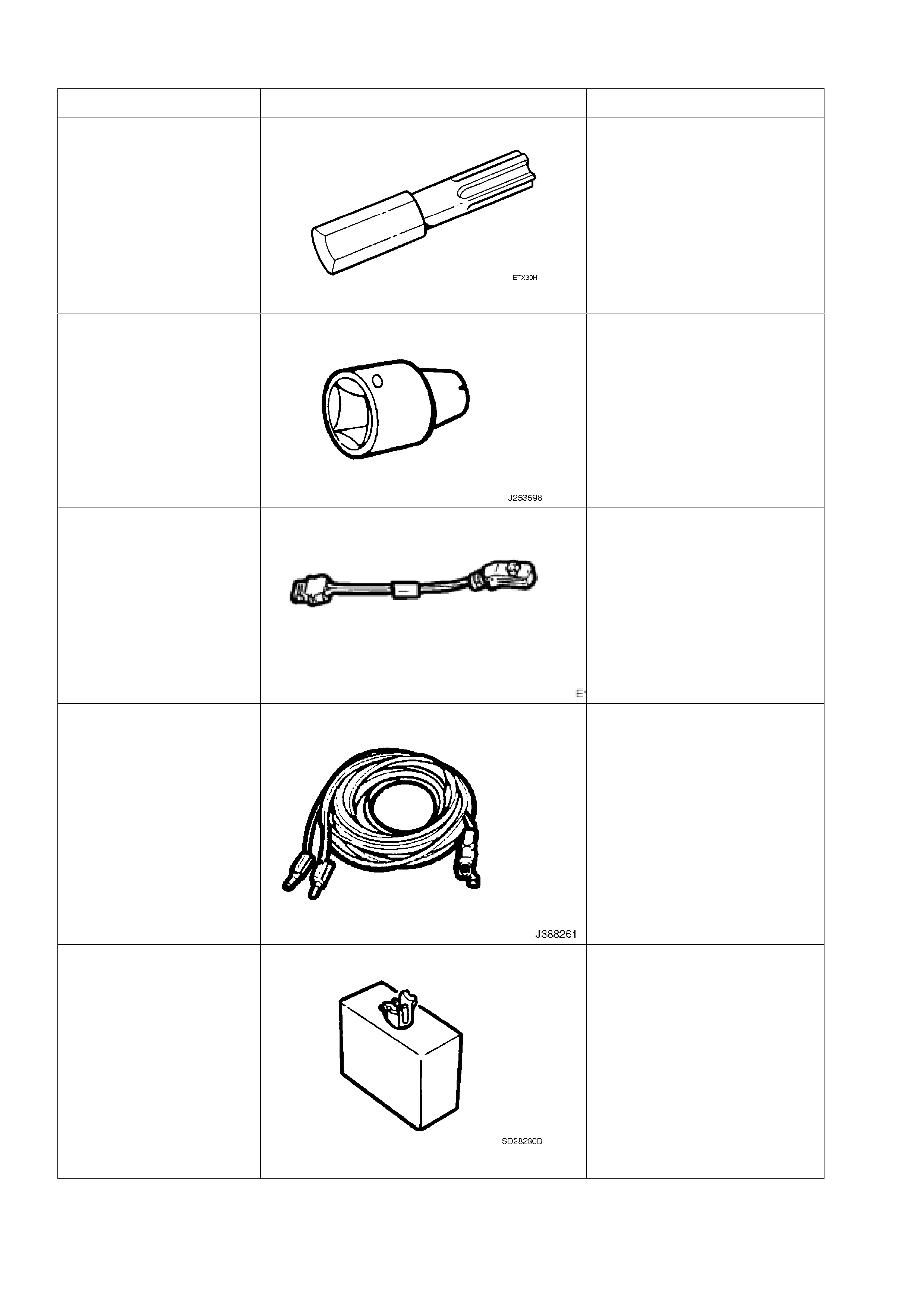

The following procedure requires use of J38826-1

SRS deployment harness with adaptor E1992. Do

not attempt procedure without J38826-1 and

E1992.

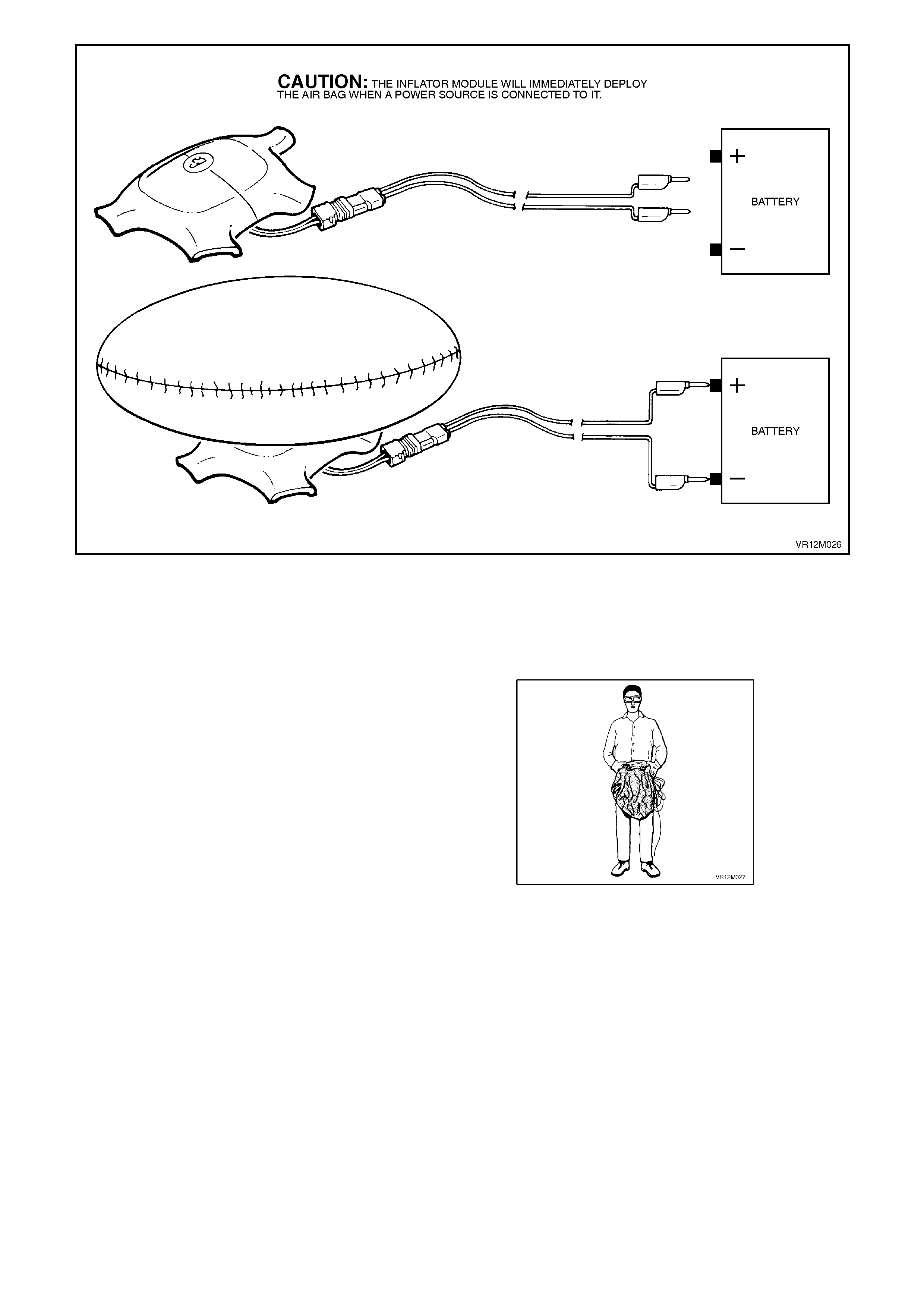

CAUTION:

Failure to follow procedures in the order listed

may result in personal injury. Never connect

deployment harness to any power source

before connecting deployment harness to the

horn bar and air bag inflator module assembly.

The deployment harness must remain shorted

and not be connected to a power source until

the horn bar and air bag inflator module

assembly is ready to be deployed. The module

will immediately deploy the air bag when a

power source is connected to it. Wear safety

glasses and gloves throughout this entire

deployment and disposal procedure.

1. Turn ignition switch OFF and put on safety

glasses.

2. Inspect J38826-1 SRS deployment harness

and adaptor, E1992 for damage. If harness or

adaptor is damaged, discard and obtain a

replacement.

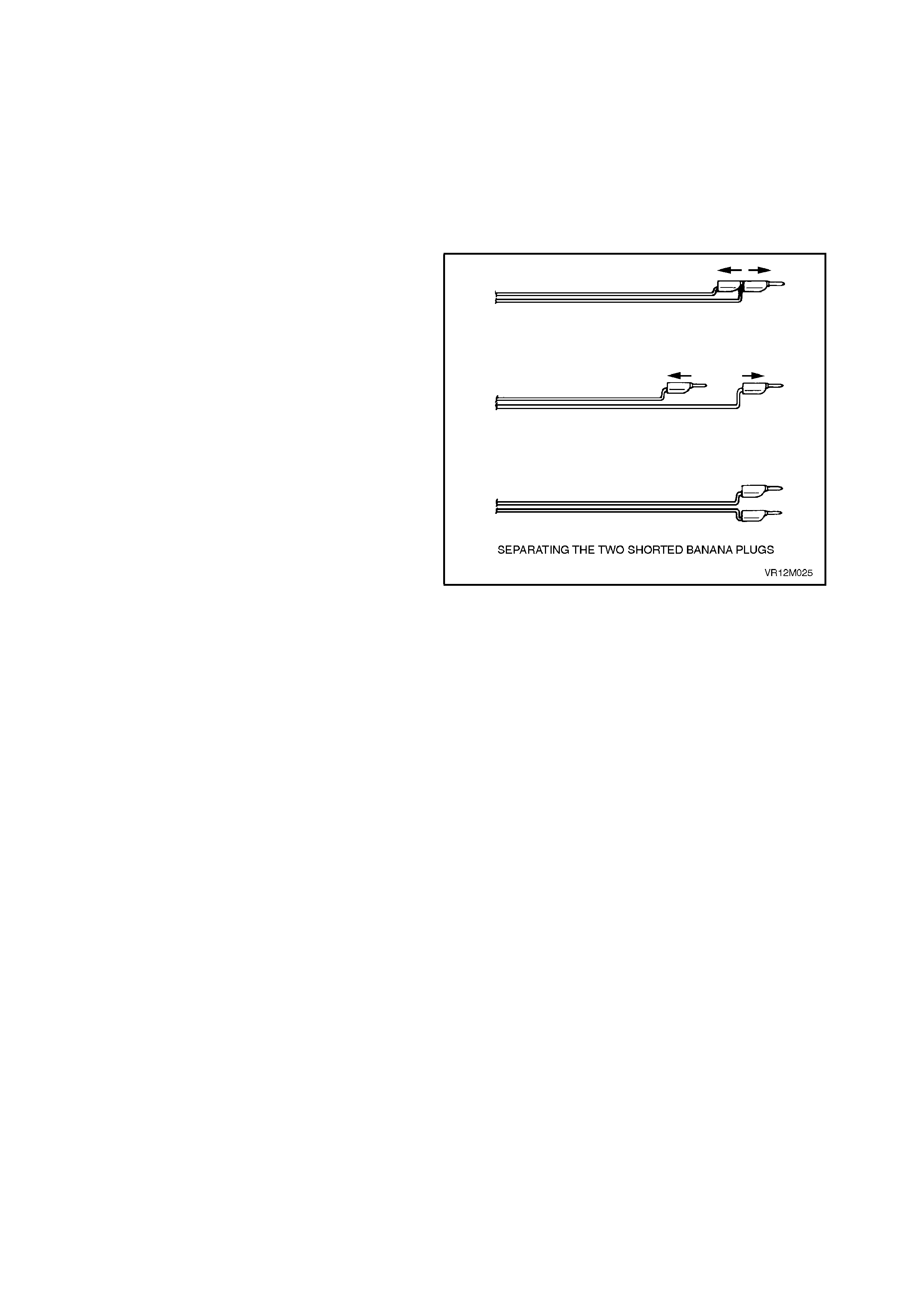

3. Short two SRS deployment harness leads

together by fully seating one banana plug into

the other. SRS deployment harness MUST

remain shorted and NOT connected to a

power source until the air bag is to be

deployed.

4. Connect the appropriate pigtail adaptor to the

SRS deployment harness.

Figure 12M-22

5. Remove horn bar and air bag inflator module

assembly from vehicle, refer to

2.3 HORN BAR AND AIR BAG MODULE

ASSEMBLY in this Section.

CAUTION:

When storing a live horn bar and air bag

inflator module assembly or when leav ing a liv e

assembly unattended on a bench or other

surface, always face the assembly with the

horn bar up and aw ay from the surface. This is

necessary so that a free space is provided to

allow the air bag to expand in th e un likely event

of accidental deployment. Failure to follow

procedures may result in personal injury.

6. Place the assembly on a work bench or other

surface away from all loose or flammable

objects with its horn bar facing up, away from

the surface.

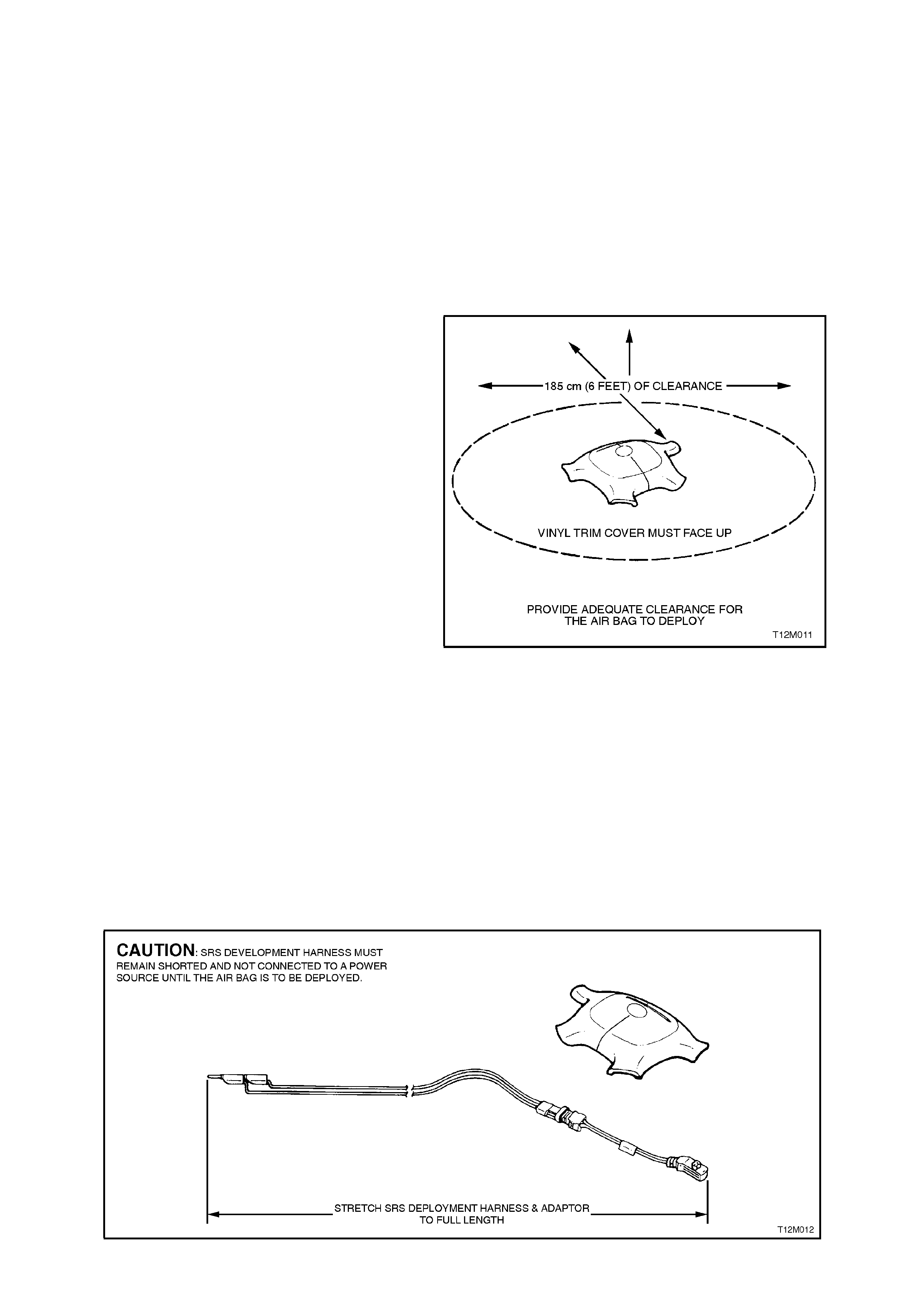

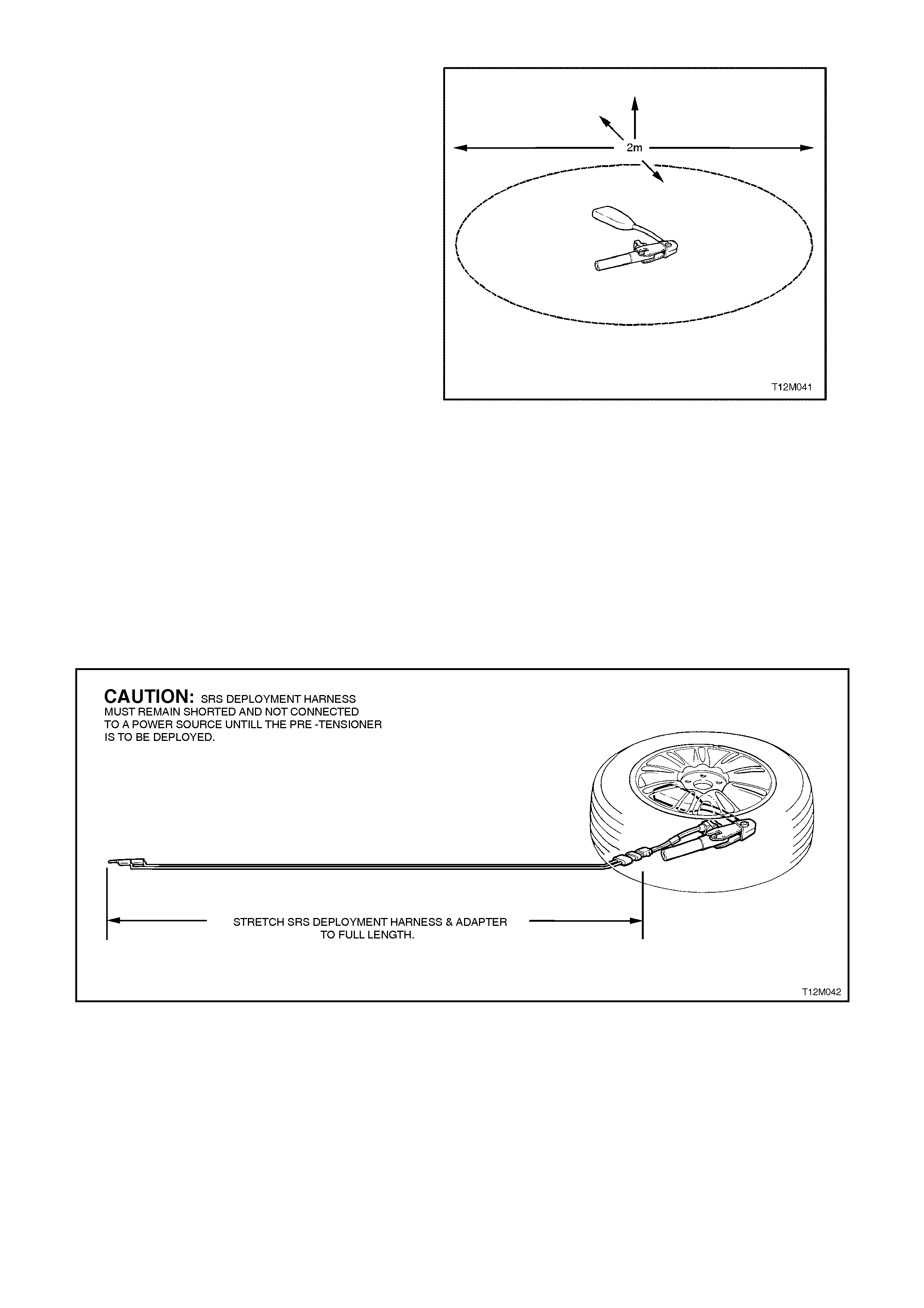

7. Clear a spac e on the ground about 2 metr es in

diameter where the assem bly is to deployed. A

paved, outdoor location where there is no

activity is preferred. If an outdoor location is

not available, a space on the workshop floor

where there is no activity and sufficient

ventilation is recommended. Ensure no loose

or flammable objects are within the

deployment area.

8. Place the assembly, with its horn bar facing

up, on the ground in the space just cleared.

9. Stretch the SRS deployment harness and

adaptor from the horn bar and air bag inflator

module assembly to its full length.

Place a power source near the shorted end of

the SRS deployment harness. Recommend

application: 12 volts minimum, 2 amps

minimum (a vehicle battery is suggested).

Connect the horn bar and air bag inflator

module ass embly to the adaptor E1992 on the

SRS deployment harness.

Figure 12M-23

CAUTION:

The deployment harness M UST remain shorted

and NOT connect ed to a pow er source until th e

air bag is to be deployed. The module will

immediately deploy the air bag when a power

source is connected to it.

Figure 12M-24

12. Verify that the area around the horn bar and

air bag inflator module assem bly is clear of all

people and loose or flammable objects.

13. Verify that the horn bar and air bag inflator

module assembly is resting with horn bar

facing up.

14. Notify all people in the immediate area that

you intend to deploy the horn bar and air bag

inflator m odule assem bly. T he deploym ent will

be accompanied by an explosion which may

startle the uninformed.

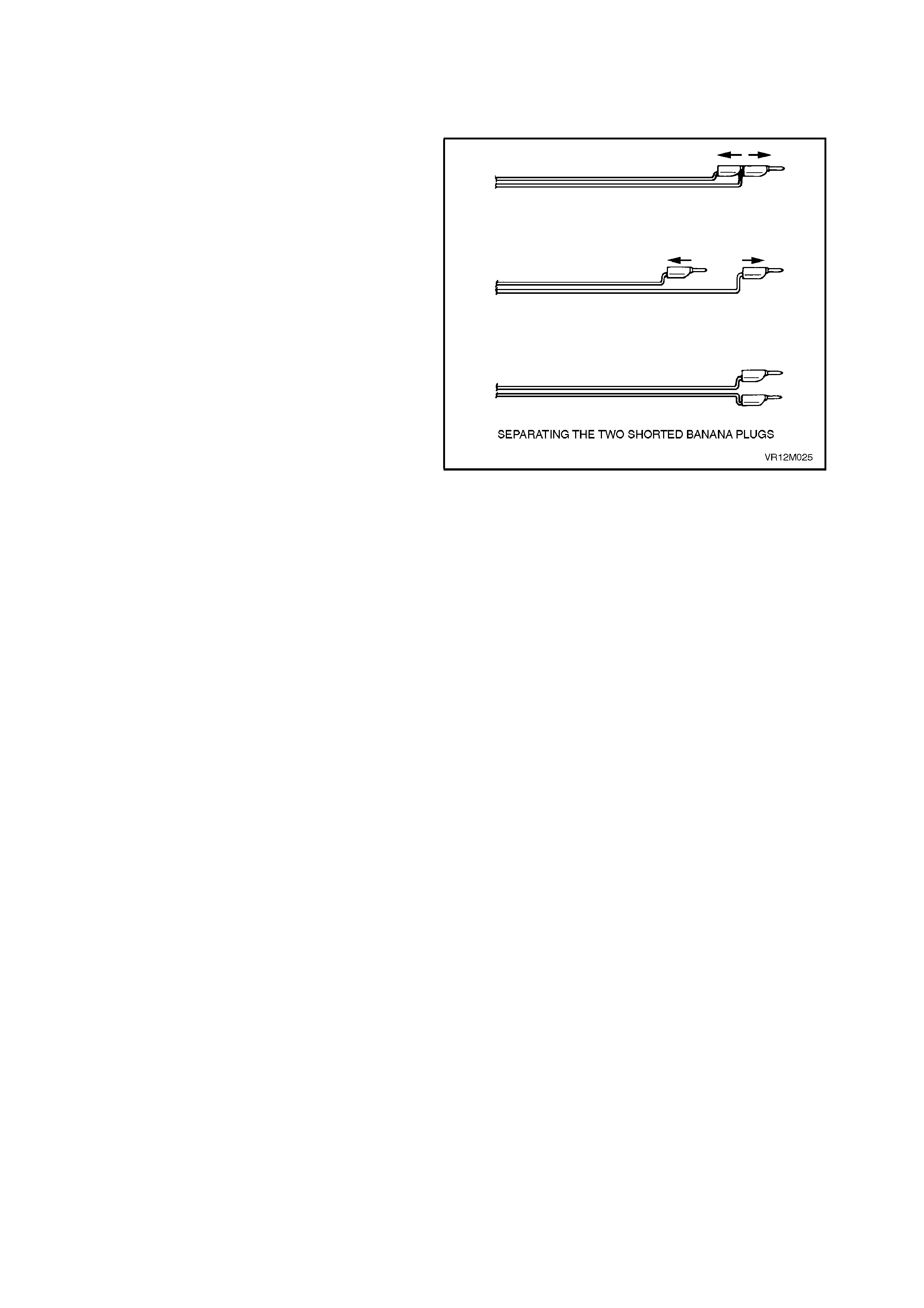

15. Separate the two banana plugs on the SRS

deployment harness.

NOTE:

1. When the air bag deploys, the rapid gas

expansion will create an ex plos ion. Notif y all people

in the immediate area that you intend to deploy the

module.

NOTE:

2. When the air bag deploys, the assembly may

jump about 30 cm vertically. This is a normal

reaction of the module to the forc e of the rapid gas

expansion inside the air bag.

CAUTION:

The deployment harness MUST remain shorted

and NOT connected t o a pow er sou rce until the

air bag is to be deployed. The module will

immediately deploy the air bag when a power

source is connected to it. Connecting the

deployment harness to the power source

should always be the last step prior to

deployment of the air bag. Failure to follow

procedures in the order listed may result in

personal injury.

Figure 12M-25

16. Connect SRS deployment harness leads to

the power source to immediately deploy the

horn bar and air bag inflator module assembly.

Figure 12M-26

17. Disconnect the SRS deployment har ness f rom

the power source.

18. Short the two SRS deployment harness leads

together by fully seating one banana plug into

the other.

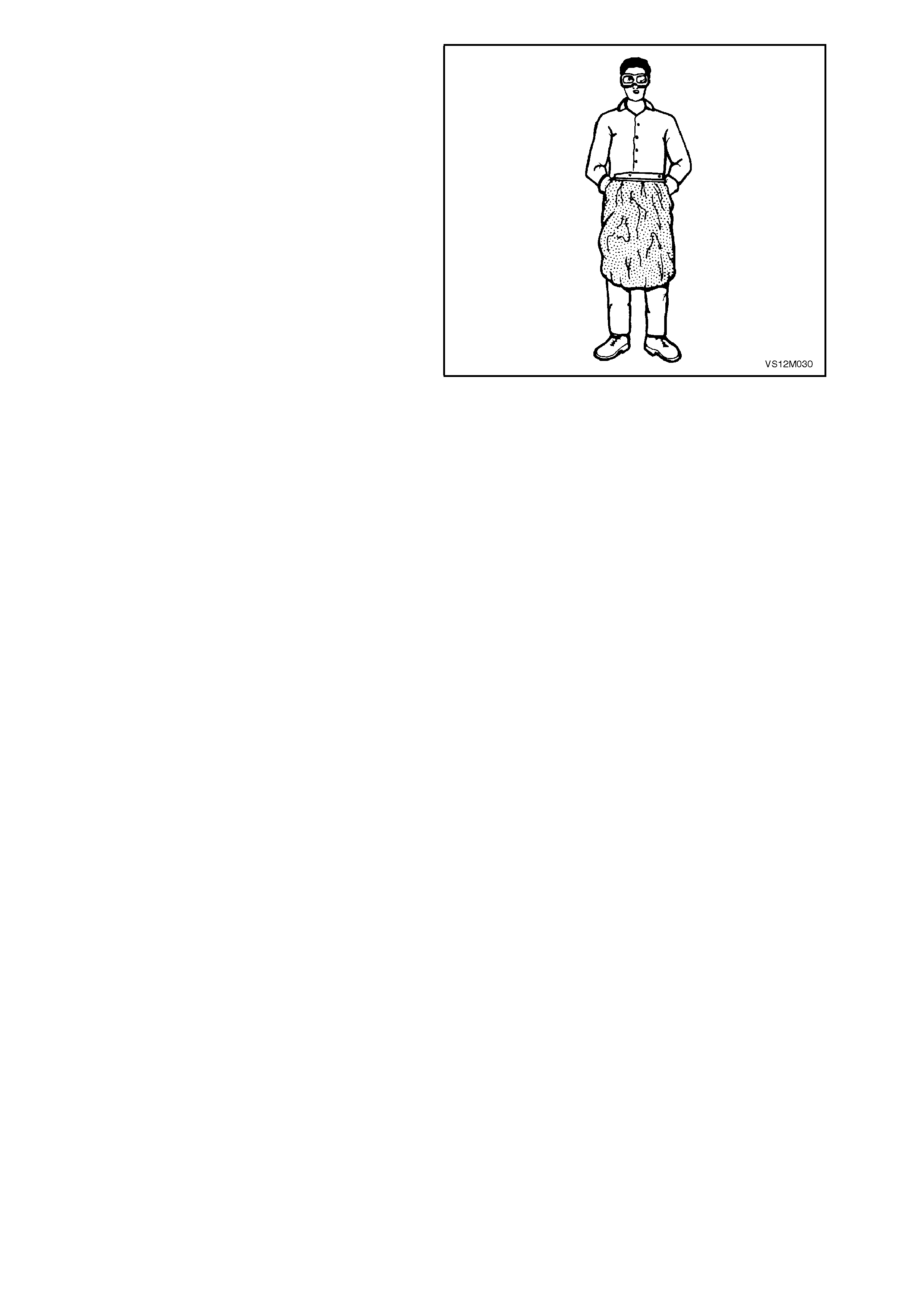

19. Ensure that you are wearing safety glasses

and gloves to protect your eyes and hands

from pos sible ir ritation and heat when handling

the deployed horn bar and air bag inflator

module assembly.

After the horn bar and air bag inflator module

assem bly has been deployed, the surface of the air

bag may contain a powdery residue. This powder

consists primarily of corn starch (used to lubricate

the bag as it inflates) and by-products of the

chemical reaction. Sodium hydroxide dust is

produced as a by-product of the deployment

reaction. The sodium hydroxide then quickly reacts

with the atmospheric moisture and is converted to

sodium carbonate and sodium bicarbonate (baking

soda). Therefore, it is unlikely that sodium

hydroxide will be present after deployment. As a

precaution, however, gloves and saf ety glasses are

recommended to prevent any possible irritation of

the skin or eyes.

Figure 12M-27

CAUTION:

Safety precautions must be observed when

handling a deployed horn bar and air bag

inflator module assembly. After deployment,

the metal surfaces of the module will be very

hot. Do not touch these metal areas of the

module for about 10 minutes after deployment.

Do not p lace the deployed ho rn bar and air bag

inflator module assembly near any flammable

objects. If the deployed horn bar and air bag

inflator module assembly must be moved

before it has cooled, wear gloves and handle by

the air bag or the horn bar.

20. Disconnect the adaptor E1992 from the

module as soon as possible af ter deploym ent.

This will prevent damage to the adaptor or

SRS deployment harness due to possible

contact with the hot module canister. The

adaptor and SRS deployment harness are

designed to be reused. They should, however,

be inspected for damage after each

deployment and replaced if necessary.

21. Dispose of the deployed horn bar and m odule

assembly through normal refuse channels

after it has cooled for at least 10 minutes.

22. Wash your hands with mild soap and water

afterward.

Deployed Air bag Module Handling

After the module has been deployed, the surface of

the air bag may contain a powdery residue. This

powder consists primarily of corn starch (used to

lubricate the bag as it inflates) and by products of

the chemical reaction. Sodium hydroxide dust is

produced as a by product of the deployment

reaction. T he sodium hydroxide then quick ly r eacts

with atmospheric moisture and is converted to

sodium carbonate and sodium bicarbonate (baking

soda). Therefore, it is unlikely that sodium

hydroxide will be present after deployment. As a

precaution, however, gloves and s af ety glasses are

recommended to prevent any possible irritation of

the skin or eyes.

2.4 FRONT PASSENGER'S AIR BAG MODULE ASSEMBLY

If conducting the following operation on an air bag

that has deployed, ensure that you are wearing

safety glasses and gloves to pr otect your eyes and

hands from possible irritation when handling the

deployed air bag inflator module assembly.

After the air bag inflator module assembly has

been deployed, the surface of the air bag may

contain a powdery residue. This powder consists

primarily of corn starch (used to lubricate the bag

as it inflates) and by products of the chemical

reaction. Sodium hydroxide dust is produced as a

by-product of the deploym ent reaction. T he sodium

hydroxide then quickly reacts with the atmospheric

moisture and is converted to sodium carbonate and

sodium bicarbonate (baking soda). Therefore, it is

unlikely that sodium hydroxide will be present after

deployment. As a precaution, however, gloves and

safety glasses are recommended to prevent any

possible irritation of the skin or eyes.

REMOVE

1. Disable the SRS, refer to 2.2 SYSTEM

DISABLING AND ENABLING PROCEDURE

in this Section.

2. Rem ove instrum ent panel pad assem bly, ref er

to Section 1A3 INSTRUMENT PANEL AND

CONSOLE.

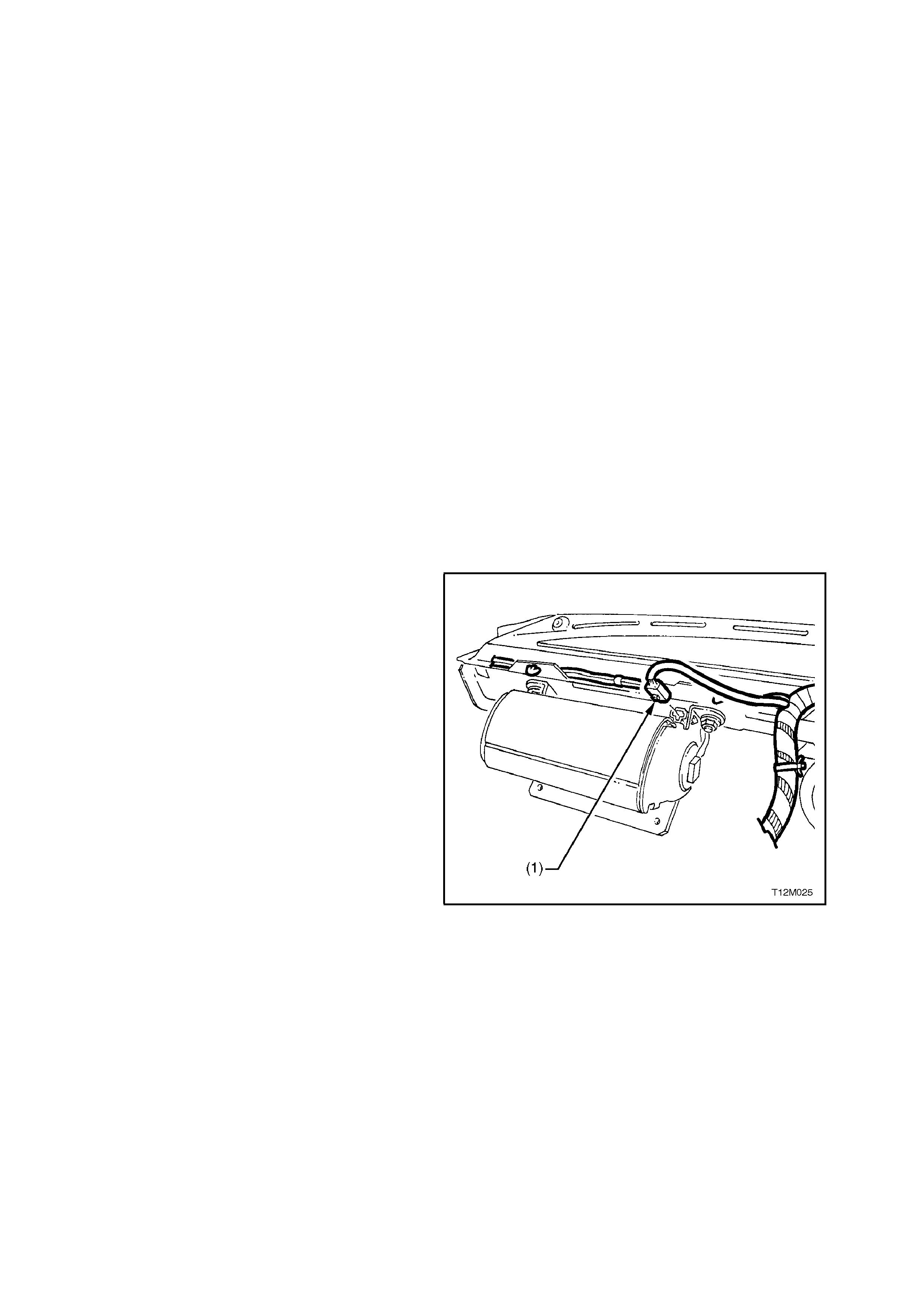

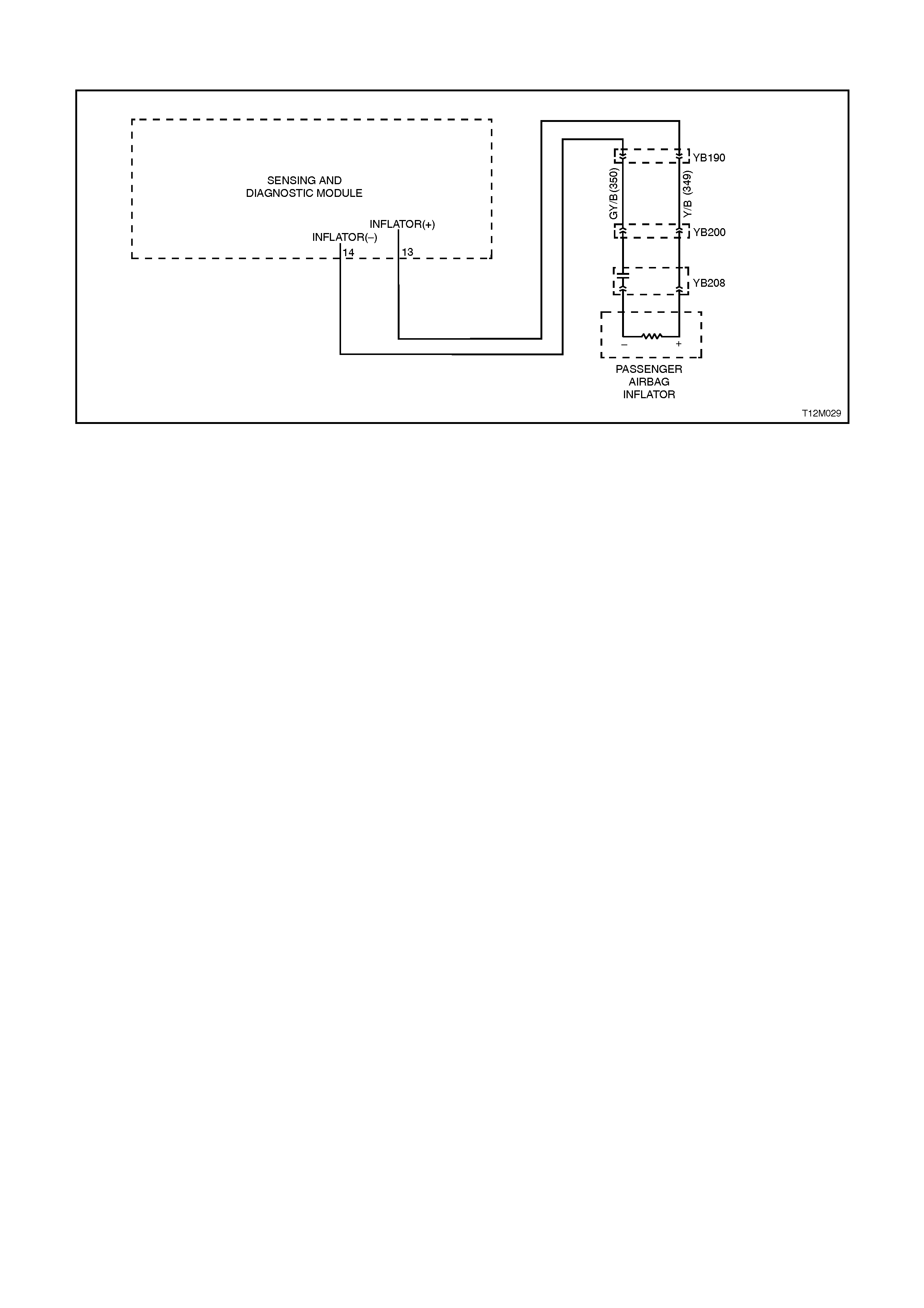

3. Disconnect the passenger’s air bag module

wiring harness connector, YB200 (1) from air

bag module assembly.

NOTE:

Do not disconnect the passenger’s air bag wiring

harness connector YB208.

Figure 12M-28

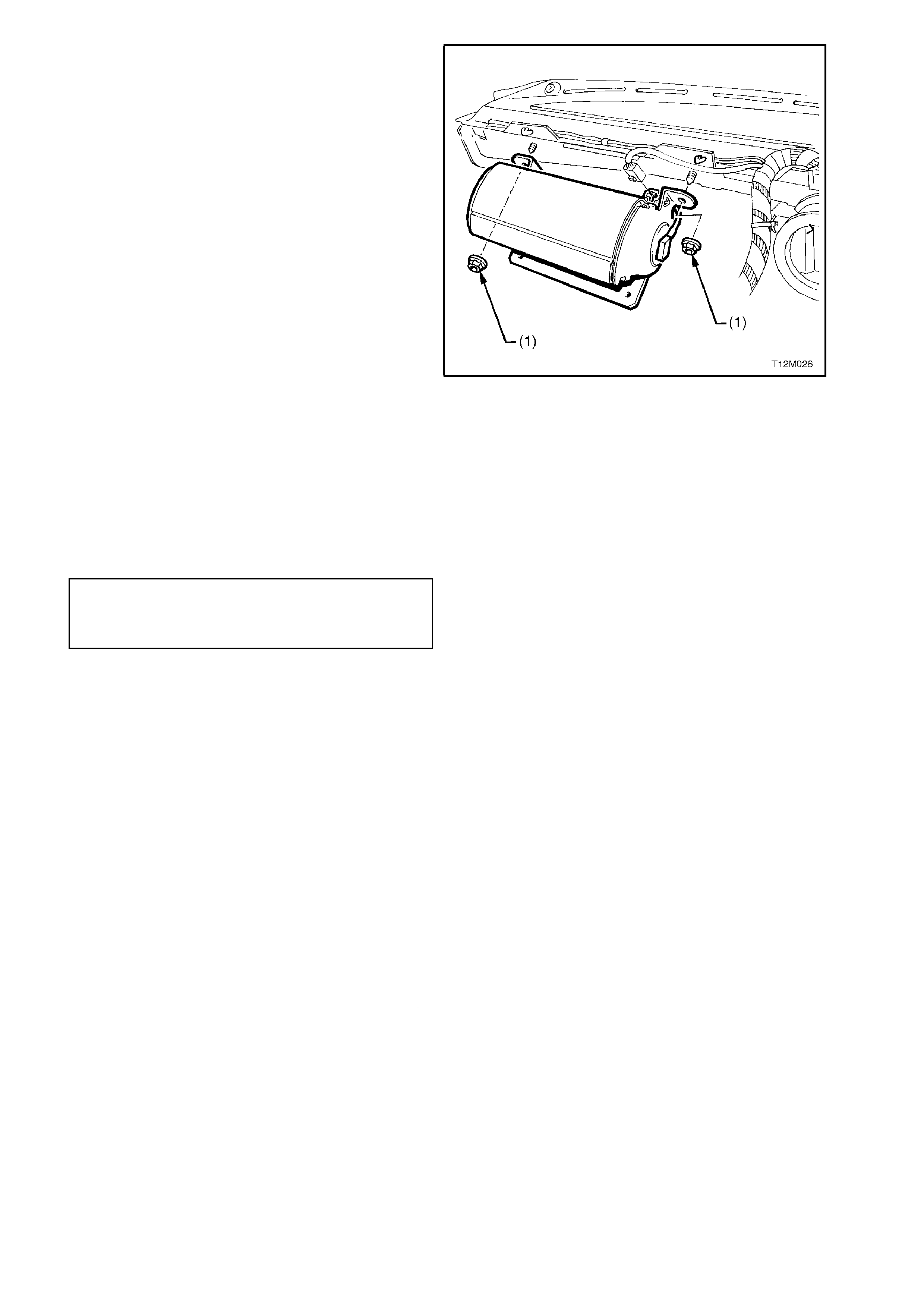

4. Remove passenger’s air bag inflator module

assem bly to dash panel attaching nuts (1) and

remove module assembly.

CAUTION:

When carrying a live (undeployed) front

passenger's air bag inflator module assembly,

make sure the bag opening is pointed away

from you. In case of an accidental deployment,

the bag will then deploy with minimal chance of

injury. When placing a liv e front passenger' s air

bag inflator module assembly on a bench or

other surface, always face with the air bag up,

away from the surface. Never rest the air bag

inflator module assembly with the air bag face

down. This is necessary so that a free space is

provided to allow the air bag to expand in the

unlikely event of accidental deployment.

Otherwise, personal injury may result. Figure 12M-29

REINSTALL

1. Assemble front passenger's air bag inflator

module onto position, over the dash panel

upper two mounting studs.

2. Install air bag inflator module to dash panel

attaching nuts and tighten to the correct

torque specification.

FRONT PASSENGER'S AIR BAG

MODULE TO DASH PANEL

ATTACHING NUT

TORQUE SPECIFICATION 15 - 25 Nm

3. Reinstall ins tr ument panel pad ass embly, ref er

to Section 1A3 INSTRUMENT PANEL AND

CONSOLE.

4. Enable the SRS, refer to 2.2 SYSTEM

DISABLING AND ENABLING PROCEDURE

in this Section.

5. Switch ignition on, and observe the SRS

warning lamp in the instrument cluster. The

warning lamp should be illuminated for

approximately 5 seconds.

During this period the SDM performs a wiring

and self check.

If no system faults are detected, the SRS

warning lamp will be switched off. If the

warning lamp remains illuminated and an

audible alarm chimes, or the warning lamp

illuminates 2 seconds after it was originally

switched off, an SRS fault is pr esent. Ref er to

3 DIAGNOSTICS in this Section to rectify

fault.

FRONT PASSENGER'S AIR BAG MODULE ASSEMBLY SCRAPPING PROCEDURE

During the course of a vehicle's useful life, certain situations may arise which will necessitate the disposal of a live

(undeployed) air bag inflator module assembly. The following information covers proper procedures for deploying a

live front passenger's air bag inflator module assembly.

CAUTION:

Failure to follow proper Supplemental Restraint System (SRS) air bag inflator module assembly disposal

procedures can result in air bag deployment which may cause personal injury. The undeployed air bag

inflator module contains substances that can cause severe illness or personal injury if the sealed container

is damaged during disposal.

In situations which require deployment of a live front passenger’s air bag inflator module assembly, deployment may

only be accomplished outside the vehicle. The passenger’s air bag inflator module assembly needs to be removed

so the SRS wiring harness with the capacitor built into the connector can be removed. Intentional deployment of the

passenger’s air bag inflator module can not be accomplished using a 12 volt DC supply with the capacitor in the

SRS circuit.

Front Passenger's Air bag Module Deployment Outside Vehicle

There may be some circumstance that require the deployment of the front passenger's air bag inflator module

assembly before a vehicle is to be returned to service. For example, situations in which the vehicle will be returned

to an owner after a functionally or cosmetically deficient front passenger's air bag inflator module assembly is

replaced. Deployment and disposal of a malfunctioning air bag inflator module is, of course, subject to any required

retention period.

For deployment of a live (undeployed) front passenger's air bag inflator module assembly outside the vehicle, the

deployment procedure must be followed exactly. ALWAYS wear safety glasses during the deployment procedure

until the assembly is removed. Before performing the procedure you should be familiar with servicing the SRS and

with proper handling of the front passenger's air bag inflator module assembly.

The following must be read fully and understood before performing the actual procedure.

The following procedure requires use of J38826-1 SRS deployment harness with adaptor E1992. Do not attempt

procedure without J38826-1 and E1992.

NOTE:

Adaptor E1992 was previously released as the deployment harness adaptor for the horn bar and air bag module

only. On VT Series Models, this harness adaptor is to be used for the deployment of all SRS components. If the

previously released passenger’s side air bag module, J38826-2 is used for deployment, the procedure will not work

as the SRS wiring harness capacitor would remain in the deployment circuit. If the SRS wiring harness capacitor

remains in the circuit, deployment using a 12 volt DC power supply is not possible.

CAUTION:

Failure to follow procedures in the order listed may result in personal injury. Never connect deployment

harness to any power source before connecting deployment harness to the front passenger's air bag

inflator module assembly. The deployment harness must remain shorted and not be connected to a power

source until the front passenger's air bag inflator module assembly is ready to be deployed. The module

will immediately deploy the air bag when a power source is connected to it. Wear safety glasses and gloves

throughout this entire deployment and disposal procedure .

1. Turn ignition switch OFF and put on safety glasses.

2. Inspect J38826-1 SRS deployment harness and adaptor E1992 for damage. If harness or adaptor is damaged,

discard and obtain a replacement.

3. Short two SRS deployment harness leads together by fully seating one banana plug into the other. SRS

deployment harness MUST remain shorted and NOT connected to a power source until the air bag is to be

deployed.

4. Connect the appropriate pigtail adaptor to the SRS deployment harness.

Figure 12M-30

5. Remove the front passenger's air bag inflator module assembly from vehicle, refer to

2.4 FRONT PASSENGER’S AIR BA G MODULE ASSEMBLY in this Section.

CAUTION:

When storing a live front passenger's side air bag inflator module assembly or when leaving a live

assembly unattended on a bench or other surface, always face the assembly with the air bag up and away

from the surface. This is necessary so that a free space is provided to allow the air bag to expand in the

unlikely event of accidental deployment. Failure to follow procedures may result in personal injury.

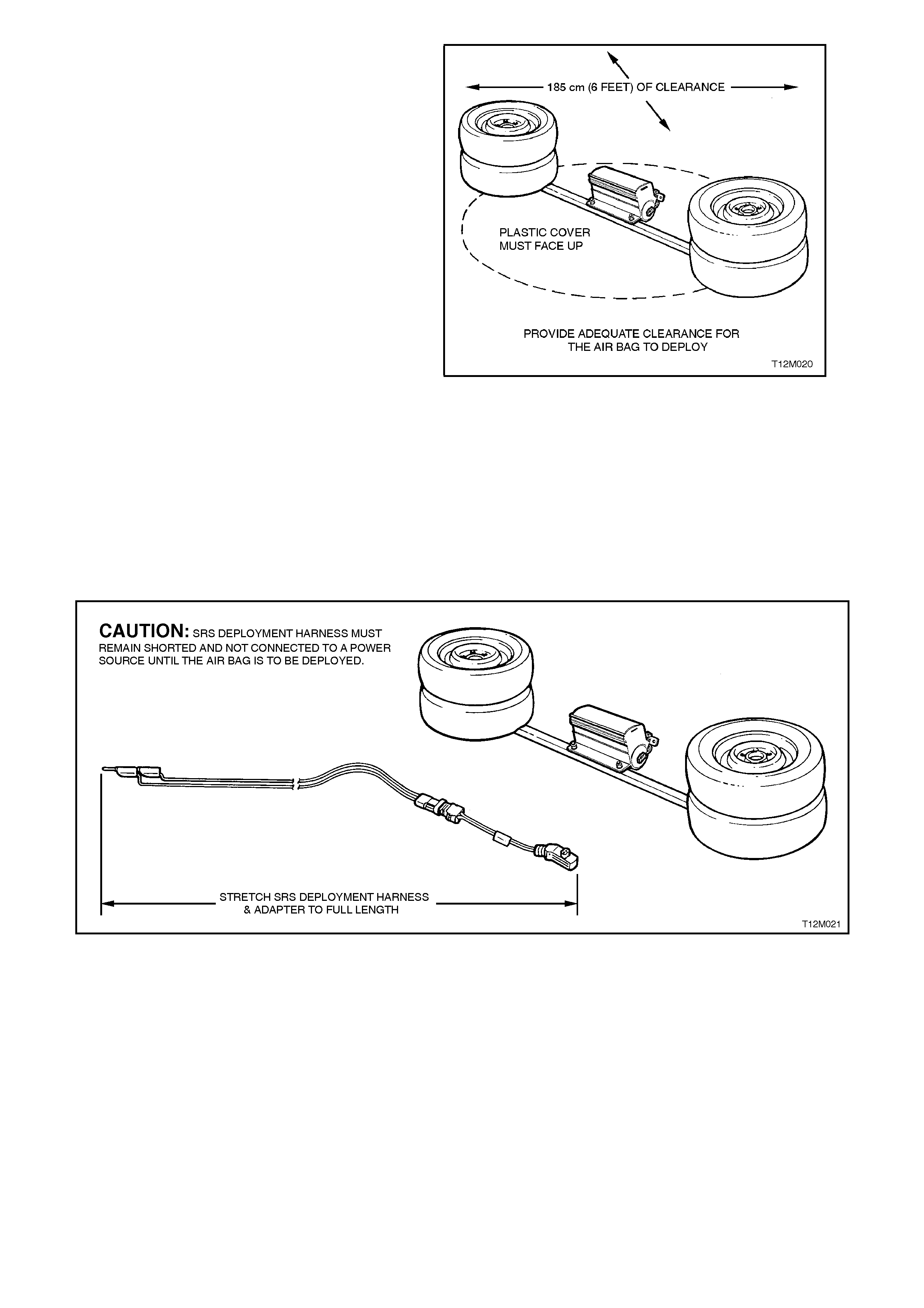

6. Using a 2 metre long square steel tube with suitable sized and positioned holes, bolt the tubing to the lower

bracket of the air bag inflator module assembly as shown in Fig. 12M-31.

7. Position two wheel and tyre assemblies on each end of the tubing as shown in Fig. 12M-32.

Figure 12M-31

8. Clear a spac e on the gr ound about 2 metres in

diameter where the assem bly is to deployed. A

paved, outdoor location where there is no

activity is preferred. If an outdoor location is

not available, a space on the workshop floor

where there is no activity and sufficient

ventilation is recommended. Ensure no loose

or flammable objects are within the

deployment area.

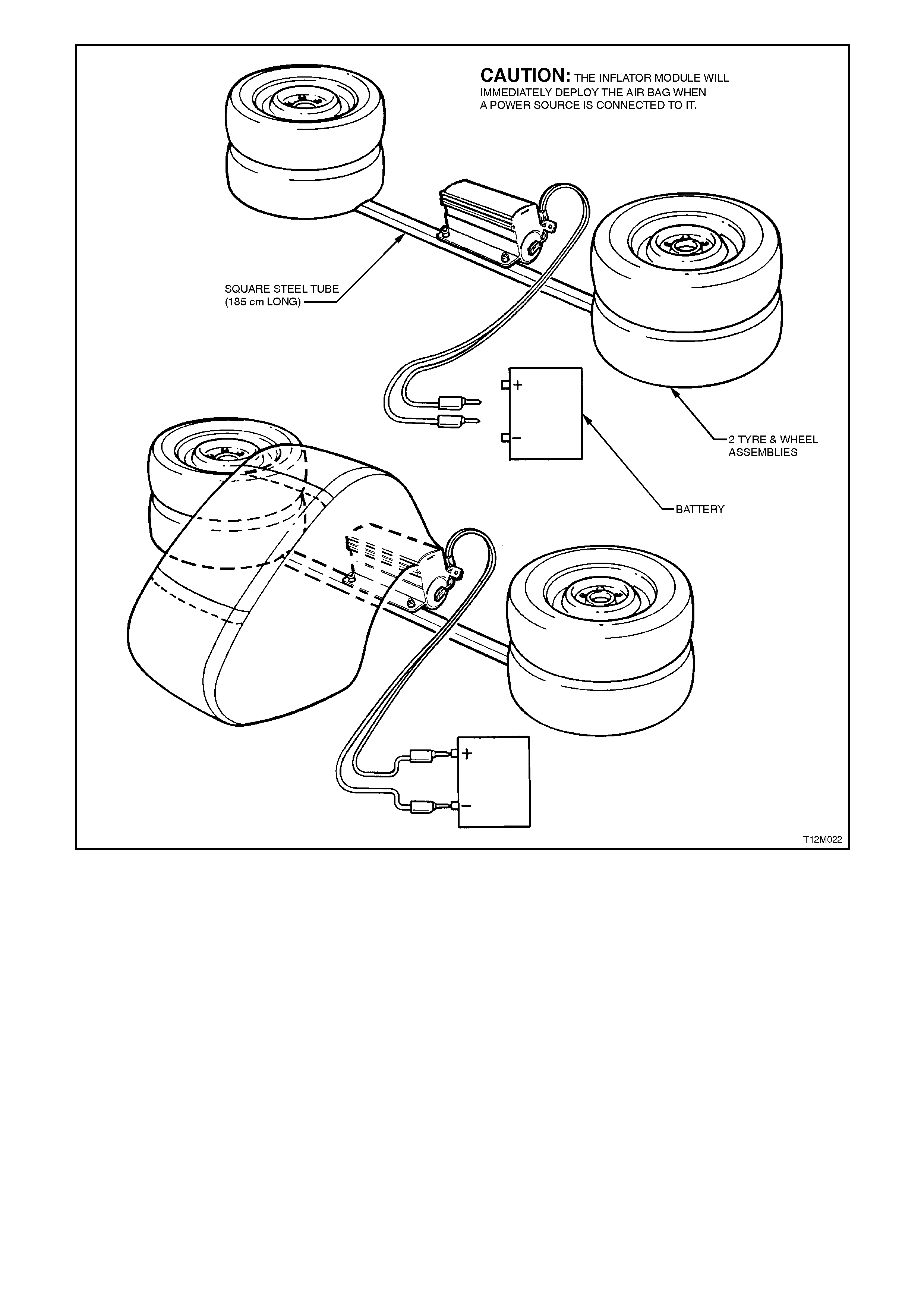

9. Ensure the front passenger's air bag inflator

module assembly is positioned with its air bag

facing up.

10. Stretch the SRS deployment harness and

adaptor from the front passenger's air bag

inflator module assembly to its full length.

Place a power source near the shorted end of

the SRS deployment harness. Recommended

application: 12 volts minimum, 2 amps

minimum (a vehicle battery is suggested).

Connect adaptor E1992 and SRS deployment

harness lead J38826-1 to the front

passenger's air bag inflator module assembly.

Figure 12M-32

CAUTION:

The deployment harness M UST remain shorted

and NOT conn ected to a pow er source until th e

air bag is to be deployed. The module will

immediately deploy the air bag when a power

source is connected to it.

Figure 12M-33

12. Verify that the area around the front

passenger's air bag inflator module assembly

is clear of all people and loose or flammable

objects.

13. Verify that the passenger’s air bag inflator

module assembly is resting with air bag

facing up.

14. Notify all people in the immediate area that

you intend to deploy the air bag inflator

module assembly. The deployment will be

accompanied by an explosion which may

startle the uninformed.

15. Separate the two banana plugs on the SRS

deployment harness.

NOTE:

1. When the air bag deploys, the rapid gas

expansion will create an ex plos ion. Notif y all people

in the immediate area that you intend to deploy the

module.

NOTE:

2. When the air bag deploys, the assembly may

jump vertically. This is a normal reaction of the

module to the force of the rapid gas expansion

inside the air bag.

CAUTION:

The deployment harness MUST remain shorted

and NOT connected t o a pow er sou rce until the

air bag is to be deployed. The module will

immediately deploy the air bag when a power

source is connected to it. Connecting the

deployment harness to the power source

should always be the last step prior to

deployment of the air bag. Failure to follow

procedures in the order listed may result in

personal injury.

Figure 12M-34

16. Connect SRS deployment harness leads to

the power source to immediately deploy the

front passenger's air bag inflator module

assembly.

Figure 12M-35

17. Disconnect the SRS deployment har ness f rom

the power source.

18. Short the two SRS deployment harness leads

together by fully seating one banana plug into

the other.

19. Ensure that you are wearing safety glasses

and gloves to protect your eyes and hands

from pos sible ir ritation and heat when handling

the deployed horn bar and air bag inflator

module assembly.

After the air bag inflator module assem bly has

been deployed, the surf ace of the air bag m ay

contain a powdery residue. This powder

consists primarily of corn starch (used to

lubricate the bag as it inflates) and by -products

of the chemical reaction. Sodium hydroxide

dust is produced as a by-product of the

deployment reaction. The sodium hydroxide

then quickly reacts with the atmospheric

moisture and is converted to sodium

carbonate and sodium bicarbonate (baking

soda). Therefore, it is unlikely that sodium

hydroxide will be present after deployment. As

a precaution, however, gloves and safety

glasses are recommended to prevent any

possible irritation of the skin or eyes. Figure 12M-36

CAUTION:

Safety precautions must be observed when

handling a deployed horn bar and air bag

inflator module assembly. After deployment,

the metal surfaces of the module will be very

hot. Do not touch these metal areas of the

module for about 10 minutes after deployment.

Do not p lace the deployed ho rn bar and air bag

inflator module assembly near any flammable

objects. If the deployed horn bar and air bag

inflator module assembly must be moved

before it has cooled, wear gloves and handle by

the air bag or the horn bar.

20. Disconnect the adaptor E1992 from the

module as soon as possible af ter deploym ent.

This will prevent damage to the adaptor or

SRS deployment harness due to possible

contact with the hot module canister. The

adaptor and SRS deployment harness are

designed to be reused. They should, however,

be inspected for damage after each

deployment and replaced if necessary.

21. Dispose of the deployed air bag assembly

through normal refuse channels after it has

cooled for at least 10 minutes.

22. Wash your hands with mild soap and water

afterward.

Deployed Module Handling

After the module has been deployed, the surface of

the air bag may contain a powdery residue. This

powder consists primarily of corn starch (used to

lubricate the bag as it inflates) and by-products of

the chemical reaction. Sodium hydroxide dust is

produced as a by-product of the deployment

reaction. T he sodium hydroxide then quick ly r eacts

with atmospheric moisture and is converted to

sodium carbonate and sodium bicarbonate (baking

soda). Therefore, it is unlikely that sodium

hydroxide will be present after deployment. As a

precaution, however, gloves and s af ety glasses are

recommended to prevent any possible irritation of

the skin or eyes.

2.5 SEAT BELT BUCKLE AND PRE-TENSIONER ASSEMBLY

REMOVE AND REINSTALL

As the seat belt pre-tensioner assembly is part of the front seat belt buckle assembly, refer to Section 1A7 SEAT

AND SEAT BELT ASSEMBLIES for all Service Operations related to the removal and reinstallation of pre-tensioner

assembly.

PRE-TENSIONER ASSEMBLY SCRAPPING PROCEDURE

During the course of a vehicle's useful life, certain situations may arise which will necessitate the disposal of a live

(undeployed) pre-tensioner assembly. The following information covers proper procedures for deploying a live pre-

tensioner assembly.

CAUTION:

Failure to follow proper Supplemental Restraint System (SRS) pr e-tensioner assembly disposal procedures

can result in pre-tensioner deployment which may ca use personal injury.

In situations which require deployment of a live pre-tensioner assembly, deployment may only be accomplished

outside the vehicle. The pre-tensioner needs to be removed and the SRS wiring harness with the capacitor built into

the connector removed. Intentional deployment of the pre-tensioner assembly can not be accomplished using a 12

volt DC supply with the capacitor in the SRS circuit.

Pre-tensioner Assembly Deployment Outside Vehicle

For deployment of a live (undeployed) pre-tensioner assembly outside the vehicle, the deployment procedure must

be followed exactly. ALWAYS wear safety glasses during this deployment procedure. Before performing the

procedure you should be familiar with servicing the SRS and with proper handling of the pre-tensioner assembly.

The following must be read fully and understood before performing the actual procedure.

The following procedure requires use of J38826-1 SRS deployment harness with adaptor E1992. Do not attempt

procedure without J38826-1 and E1992.

NOTE:

Adaptor E1992 was previously released as the deployment harness adaptor for the horn bar and air bag module

only. On VT Series Models, this harness adaptor is to be used for the deployment of all SRS components.

CAUTION:

Failure to follow procedures in the order listed may result in personal injury. Never connect deployment

harness to any power source before connecting deployment harness to the pre-tensioner assembly. The

deployment harness must remain shorted and not be connected to a power source until the pre-tensioner

assembly is ready to be deployed. The pre-tensioner will deploy immediately a power source is connected

to it. Wear safety glasses and gloves throughout this entire deployment and disposal procedure.

1. Turn ignition switch OFF and put on safety glasses.

2. Inspect J38826-1 SRS deployment harness and adaptor E1992 for damage. If harness or adaptor is damaged,

discard and obtain a replacement.

3. Short two SRS deployment harness leads together by fully seating one banana plug into the other. SRS

deployment harness MUST remain shorted and NOT connected to a power source until the pre-tensioner is to

be deployed.

4. Connect the deployment harness adaptor (E1992) to the SRS deployment harness (J38826-1).

Figure 12M-37

Techline

5. Remove the appropriate pre-tensioner

assem bly from the vehicle, r efer to Section 1A7

SEAT AND SEAT BELT ASSEMBLY.

NOTE:

Leave pre-tensioner to s eat assem bly retaining bolt

installed in the pre-tensioner once removed from

the seat assembly.

6. Clear a space on the ground about 2 metres in

diameter where the pre-tens ioner as sem bly is to

deployed. A paved, outdoor location where there

is no activity is preferred. If an outdoor location

is not available, a space on the workshop floor

where there is no activity and sufficient

ventilation is rec omm ended. Ensure no loose or

flammable objects are within the deployment

area.

7. Stretch the SRS deployment harness and

adaptor from the pre-tensioner assembly to its

full length.

8. Connect adaptor E1992 and SRS deployment

harness lead J38826-1 to the pre-tensioner

assembly.

CAUTION:

The deployment harness MUST remain shorted

and NOT connected to a power source until the

pre-tensioner as sembly is to be deployed. The pr e-

tensioner assem bly will im mediately deploy when a

power source is connected to it.

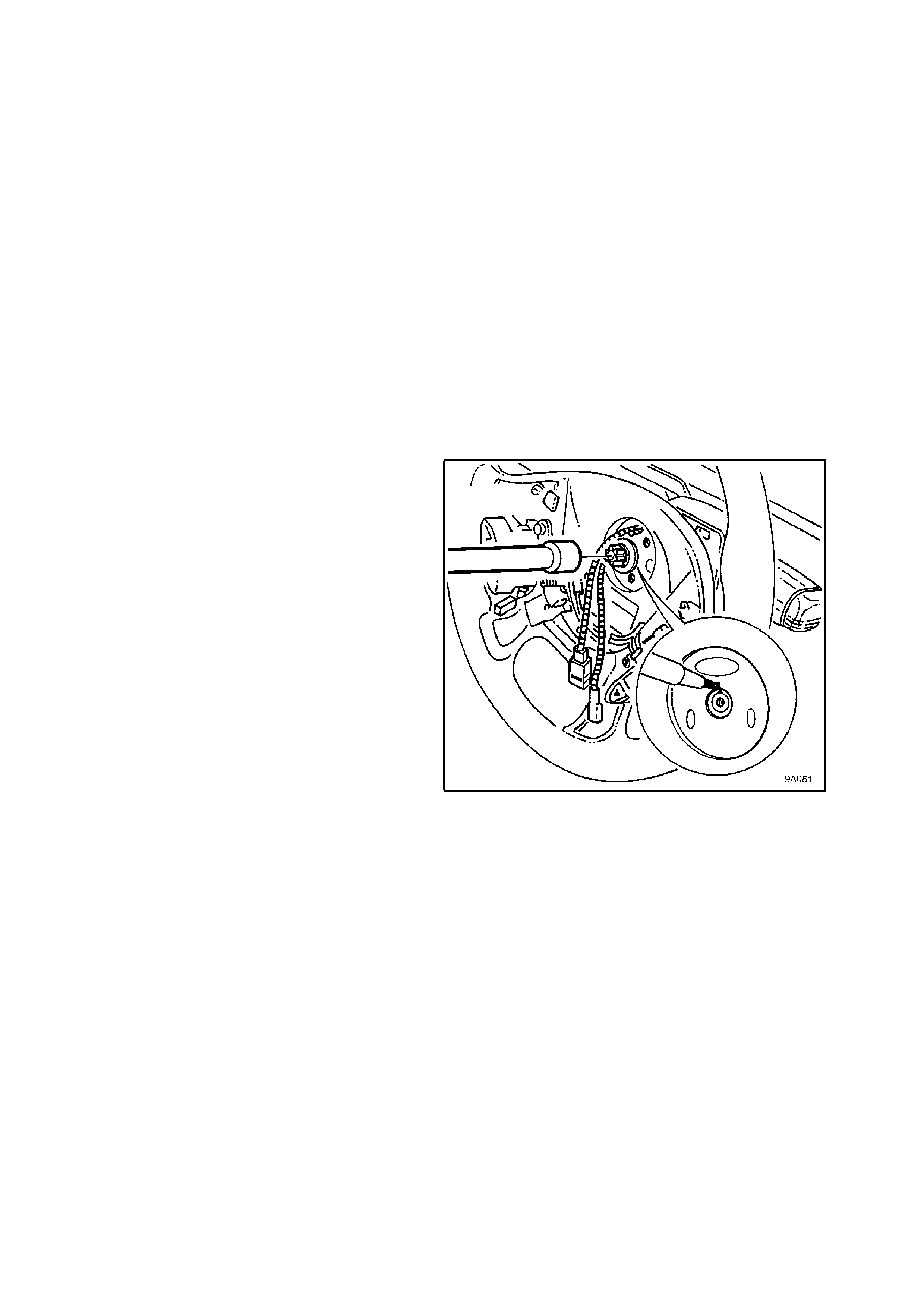

9. Position a wheel and tyre assembly over the

pre-tensioner assembly, refer to Fig. 12M-39.

Figure 12M-38

Figure 12M-39

10. Place a power sourc e near the shorted end of

the SRS deployment harness. Recommended

application: 12 volts minimum, 2 amps

minimum (a vehicle battery is suggested).

11. Verify that the area around the pre-tensioner

assembly is clear of all people and loose or

flammable objects.

12. Notify all people in the immediate area that

you intend to deploy the pre-tensioner

assembly. The deployment will be

accompanied by an explosion which may

startle the uninformed.

15. Separate the two banana plugs on the SRS

deployment harness.

NOTE:

When the pre-tensioner deploys, the rapid gas

expansion will create an ex plos ion. Notif y all people

in the immediate area that you intend to deploy the

pre-tensioner.

CAUTION:

The deployment harness MUST remain shorted

and NOT connected t o a pow er sou rce until the

pre-tensioner is to be deployed. The pre-

tensioner will immediately deploy when a

power source is connected to it. Connecting

the deployment harness to the power source

should always be the last step prior to

deployment of the pre-tensioner. Failure to

follow procedures in the order listed may result

in personal injury. Figure 12M-40

16. Connect SRS deployment harness leads to

the power source to immediately deploy the

pre-tensioner assembly.

17. Disconnect the SRS deployment har ness f rom

the power source.

18. Short the two SRS deployment harness leads

together by fully seating one banana plug into

the other.

19. To prevent damage to the adaptor or SRS

deployment harness, disconnect the adaptor

E1992 from the pre-tensioner as soon as

possible after deployment. The adaptor and

SRS deployment harness are designed to be

reused. They should, however, be inspected

for damage after each deployment and

replaced if necessary.

20. Dispose of the deployed pre-tensioner

assembly through normal refuse channels.

2.6 CLOCK SPRING COIL

IMPORTANT:

Absolutely no wire, connector or terminal repairs

are to be attempted on the clock spring coil If the

clock spring coil is damage in any way, REPLACE

IT.

REMOVE

1. Disable the SRS, refer to

2.2 SYSTEM DISABLING AND ENABLING

PROCEDURE in this Section.

2. Remove horn bar and air bag inflator module,

refer to 2.3 HORN BAR AND AIR BAG

MODULE ASSEMBLY in this Section.

3. Ensure the front wheels and the steering

wheel are in the straight ahead position and

remove keys from ignition switch.

NOTE 1: This is important to ensure that clock

spring coil is locked when the steering wheel is

removed to prevent the steering shaft from being

rotated.

4. To aid the installation of the steering wheel to

it’s original position, sc r ibe an aligning mark on

the steering wheel centre section and steering

shaft. A felt tipped pen could also be used.

NOTE 2:

Do not use a centre punch for this operation.

5. Using a commercially available Torx E20

socket, remove the steering wheel retaining

bolt.

6. Remove the steering wheel from the steering

shaft splines and feed the clock spring coil

wiring and connectors through the steering

wheel aperture.

NOTE 3:

When the steering wheel is removed, check that

the green coloured tang has engaged the inner

clock spring coil member to lock it in the centralised

position.

NOTE 4:

With the increased diameter of the steering shaft

and the angle of the locating bevel, it is not usually

necessary to require a puller to remove the steering

wheel. However, if a puller is required, refer to

Section 9A STEERING.

Figure 12M-41

7. Lower instrument panel right hand cover

assembly (fuse panel cover) by grasping the

top edge on either side of the steering colum n

with the finger tips and pulling the top edge

out, to free the retaining lugs from the clips.

8. Release steering column height adjuster,

completely lower steering column and leave

lever in the release position.

9. Remove the upper steering column cover by

applying a small amount of pressure on the

lower steering column cover (pushing towards

instrum ent cluster ) while lifting the upper cover

upwards and rearwards.

10. Remove screw (1) securing the lower cover to

the steering column.

11. Push the lower steering column cover up

towards the top of the steering c olumn (arr ow)

to release the two retaining tangs (2) on the

steering column, refer to Fig. 12M-42.

12. While feeding the remote coded key reader

outer surround from the lower cover, remove

the lower steering column cover.

Figure 12M-42

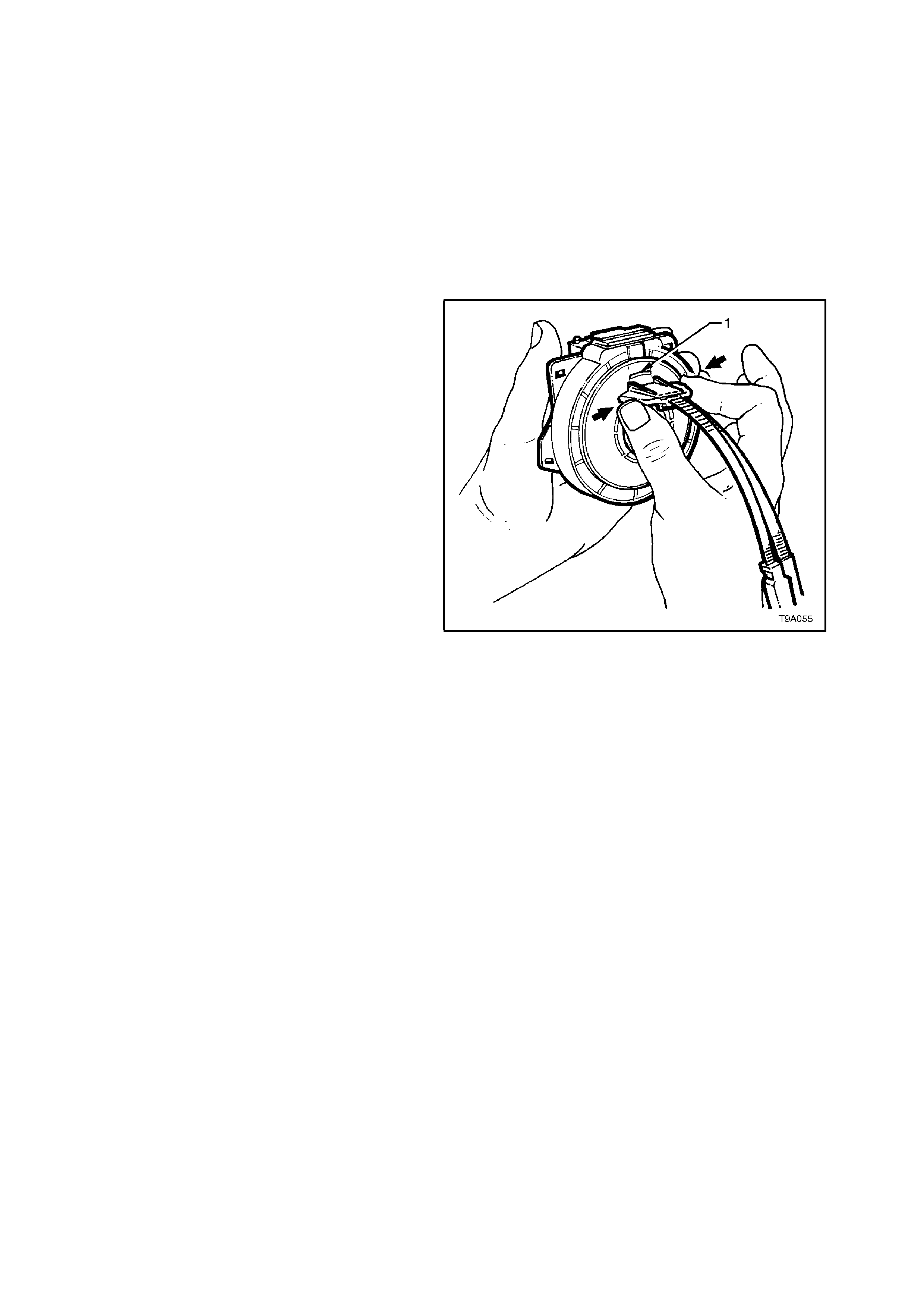

13. Disengage the two top locking tangs on the

clock spring coil assembly by lifting first in

direction (1) then pulling the clock spring coil

assem bly in direction (2), ref er to Fig. 12M-43.

Repeat for the lower two tangs, then remove

clock spring coil assembly from the steering

column.

Figure 12M-43

CENTRING THE CLOCK SPRING COIL

NOTE:

The following procedure must be followed

when reusing a clock spring coil that has been

removed from a steering column without the

steering wheel or clock spring coil being

centred.

1. Ensure that steering gear is in centralised

position before installing the clock spring coil

assembly, otherwise irreparable damage to

the clock spring coil may result. Refer to

Section 9A STEERING for details on

centralising the steering gear.

2. Hold the clock spr ing coil outer hous ing by one

hand while holding each of the two locking

lugs inward with the other hand, refer to Fig.

12M-44.

Rotate the inner member of the clock spring

coil in a clockwise direction until a mechanical

stop is felt.

While still holding the two locking lugs as

before, rotate the inner member of the clock

spring coil in an anti-clockwise direction for

approximately 2.5 turns, until the green

indexing tab (1) is s een in the upper window of

the clockspring coil assembly.

Release the lock ing lugs and the inner rotor of

the clock spring coil assembly should now be

locked to the outer member with the clock

spring coil in the centralised position.

Figure 12M-44

REINSTALL

Installation of the c lock spr ing coil is the reverse of

removal procedures, noting the following points:

1. Ensure that steering gear is in centralised

position before installing the clock spring coil

assembly, otherwise irreversible damage to

the clock spring coil may result. Refer to

Section 9A STEERING for details on

centralising the steering gear.

2. With the clock spring coil assembly locked in

the centralised position, install clock spring

coil ass embly over the end of steer ing c olumn,

indexing the lower locating pins on the clock