SECTION 1A7 - SEAT & SEAT BELT ASSEMBLIES

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will

consist of either seat belt pre-tensioners and a driver's side air bag, or seat belt pre-

tensioners and a driver's and front passenger's side air bags. Refer to CAUTIONS,

Section 12M, before performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deployment, resu lting in possible perso nal in jury or u nnecessary

SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of

safety, the LPG fuel system should be isolated by turning 'OFF' the manual service

valve and then draining the L PG service lines, before any service w ork is carried out

on the vehicle. Refer to the LPG leaflet included with the Owner's Handbook for

details or LPG Section 2 for more specific servicing information.

1. GENERAL DESCRIPTI ON

A four-way electric adjustable drivers seat (front up and down, and rear up and down) is fitted to all VT Series

Models except Calais Models. Calais models are fitted with an eight-way electric adjustable front passenger and

drivers seat (front up and down, rear up and down, forward and rearward (fore/aft), and reclining).

The four-way electric driver’s seat contains two electric, reversible motors. The front and rear heights of the seat are

controlled by separate lift motor and gearbox assemblies. Each motor can be operated independently of each other,

or operated together to raise or lower the seat.

The eight-way driver and passenger seats have two additional electric, reversible motors fitted. A separate fore and

aft movement motor and gearbox assembly controls the seats forward and rearward positioning. The fourth motor

controls the seat back reclining position.

A driver’s seat lumbar support is standard on all models, while a front passenger seat lumbar support is standard on

Acclaim, Berlina, S, SS and Calais models.

Front seat belt height adjusters provide the ability to raise and lower the seat belt from the shoulder for additional

comfort and are fitted as standard equipment on Calais.

The front seat belts also come, as standard equipment, with pyrotechnic seat belt pre-tensioners. These pre-

tensioners are connected into the SRS and are designed to restrain potentially fatal body movements upon impact

in a collision. Seat belt pre-tensioners work in conjunction with standard inertia reel seat belt retractors with webbing

clamps. For principles of operation and diagnosis of the seat belt pre-tensioner system, refer to

Section 12M SUPPLEMENTAL RESTRAINT SYSTEM.

NOTE:

If a seat belt pre-tensioner is deployed, the seat belt pre-tensioner assembly together with the seat adjuster,

guide rail assembly and control module (SDM) must be replaced.

The seat covers (except leather trim option) for the front seat back and cushion, and rear seat back and cushion

are bonded to the pad material. If the there is a need to replace the seat cover on any of these components, they

must be replaced as a cover and pad assembly. Only the covers for the rear seat armrests are replaceable as sub-

assemblies (separate cover and pad assembly).

All models feature access to the rear compartment through the rear seat back, either when the fold down tray is

lowered for sedans or via the 60/40 split rear seat on wagon models.

Techline

Techline

Techline

Techline

Techline

Techline

1.1 ELECTRIC SEAT ADJUSTMENT

WARNING:

For reasons of personal safety, the vehicle

must only be driven when the seat is adjusted

to the correct driving position. Do not adjust

the driver’s seat when the vehicle is moving as

the seat could move away from the driving

position, causing loss of control.

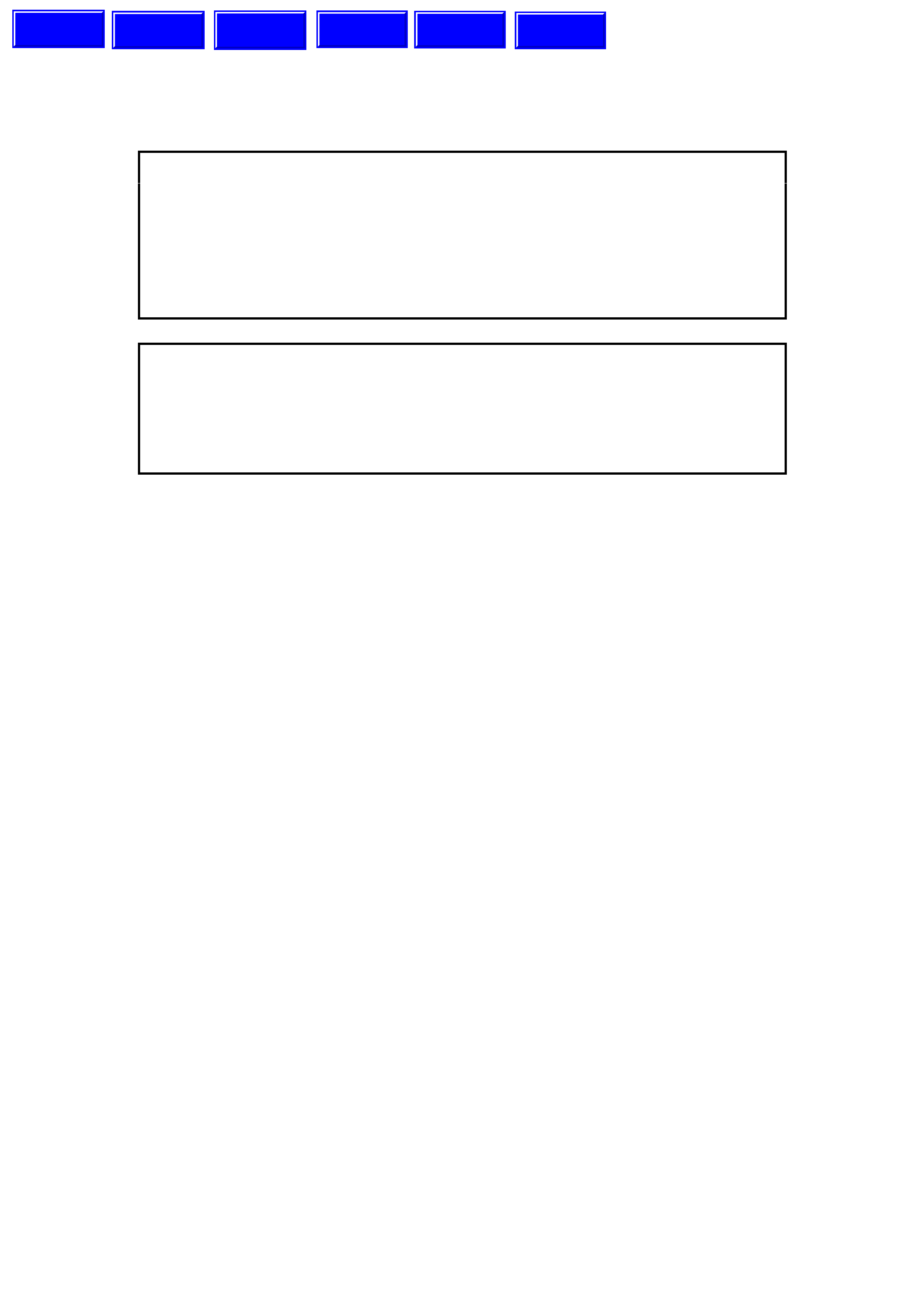

SEAT CONTROL ADJUSTMENT SWITCH ASSEMBLY

A seat control adjustment switch is fitted to the

outside of eac h seat fr am e where electric seats are

fitted. This switch assembly provides independent

control of:

1. Horizontal switch - f ront and rear height (up and

down movement) of seat, and on vehicles with

the eight way electric seats, this switch also

provides fore/aft movement.

2. Vertical switch (eight-way electric seats only) -

seat recliner angle.

Figure 1A7-1

To control the seat front and rear heights, and the

fore and aft movements, the appropriate electric

mo tor and gear box ass embly is driven which dr aws

in or extends out a mating worm shaf t which in turn

operates either the cross bar, for up and down

movement, or the seat guide rail for fore/aft

movem ent. By reversing the polarity of each of the

motors terminals, causes the motor to drive in the

reverse direction and therefore the seat will move

in the opposite direction.

The seat back recliner angle on Calais models is

adjusted by a recliner motor attached to the inner

seat back f ram e. T he m otor has a drive gear which

is meshed with a driven gear attached to the seat

back frame. Motor operation causes the rotation of

the drive gear which turns the driven gear and seat

back frame, thereby altering the seat back recliner

angle. Reversing the polarity of the recliner motor

terminals causes the motor to drive in the reverse

direction and the seat back moves in the opposite

direction.

2. SERVICE OPERATIONS

2.1 FRONT BUCKET SEAT ASSEMBLY

REMOVE

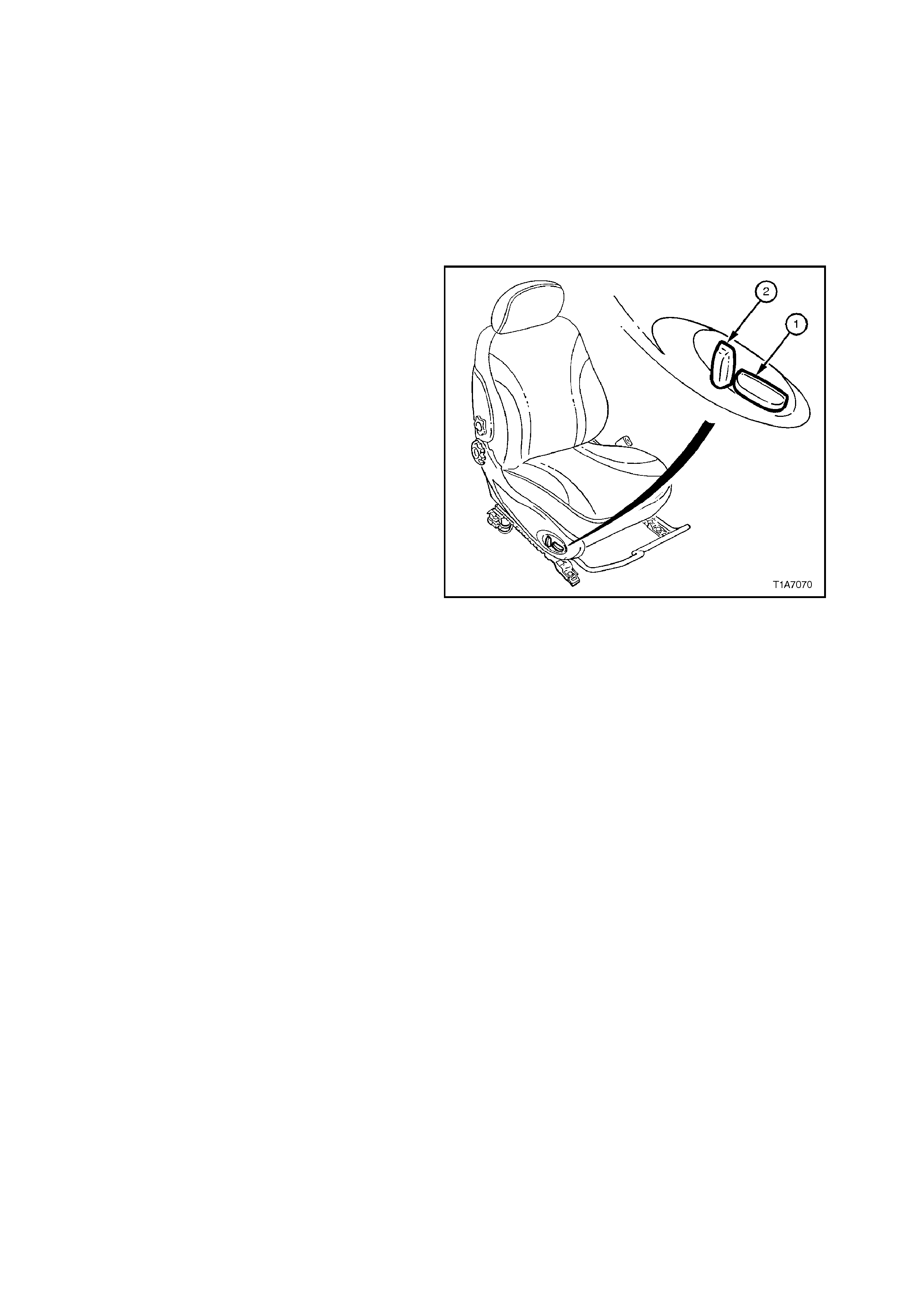

1. Position seat for easiest access to the four

seat retaining bolts and, if possible, the seat

should be fully raised and reclined fully

forward.

2. Disconnect battery earth lead.

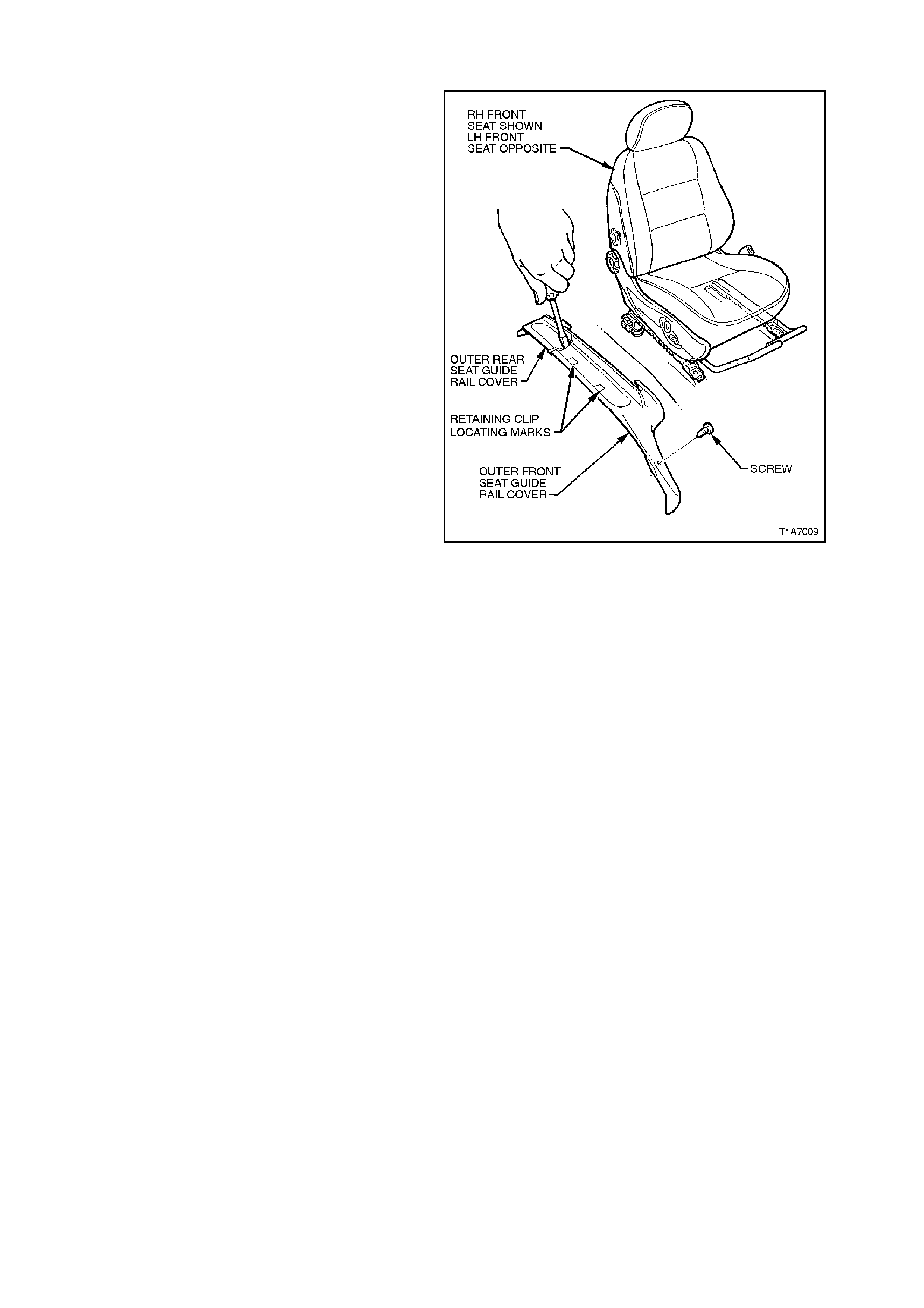

3. If removing the driver’s seat, remove the

retaining screw from the driver’s side outer front

guide rail cover, refer to Fig. 1A7-2.

4. Remove the front outer guide rail covers, refer to

2.2 FRONT SEAT GUIDE RAIL COVERS in this

Section.

On driver’s seat, lift the outer front seat guide

rail cover over fuel filler door release lever.

5. Lift the two rear guide rail covers up and off the

guide rails.

6. Disconnect seat and seat belt wiring harness

connectors from outer side of seat.

7. Remove the f our bolts securing the front seat to

the floor and remove seat.

REINSTALL

Installation is the reverse of the rem oval operation,

noting the following:

1. Tighten all bolts to the correct torque

specification.

FRONT SEAT TO FLOOR SECURING 35 - 50

BOLT TORQUE SPECIFICATION Nm

2. Refer to Section 2.2 FRONT SEAT GUIDE

RAIL COVERS for procedure on how to

reinstall front seat guide rail cover.

3. Check operation of front seat mechanical and

electrical adjustments.

Techline

Techline

Techline

Figure 1A7-2

2.2 FRONT SEAT GUIDE RAIL COVERS

REMOVE

1. On drivers side, remove the retaining screw

from the drivers side outer front guide rail

cover, refer to Fig. 1A7-3.

2. Using a small screwdriver, push in the centre

of the front and rear outer seat guide rail

covers where the two parts meet, refer to Fig

1A7-3.

3. Remove the front outer guide rail covers by

lifting the outer edge of the front cover up and

pulling it forward. Lift driver’s outer front seat

guide rail cover over fuel filler door release

lever.

4. Lift the two rear guide rail covers up and off

the guide rails.

REINSTALL

1. Align the outer front seat guide rail c over’s two

retaining clips and push firmly to engage.

NOTE:

The two retaining clips on the side can be aligned

by using the alignment marks on the upper side of

the cover, refer to Fig. 1A7-3.

2. Push the front of the outer front s eat guide rail

cover down to engage cover with front of seat

rail.

3. On driver’s side, reinstall the retaining screw at

the front of the outer front seat guide rail

cover.

4. Install the outer rear seat guide rail cover

lower rear retainer over seat guide rail and

push outer rear seat guide rail cover forward to

engage with outer front seat guide rail cover.

Figure 1A7-3

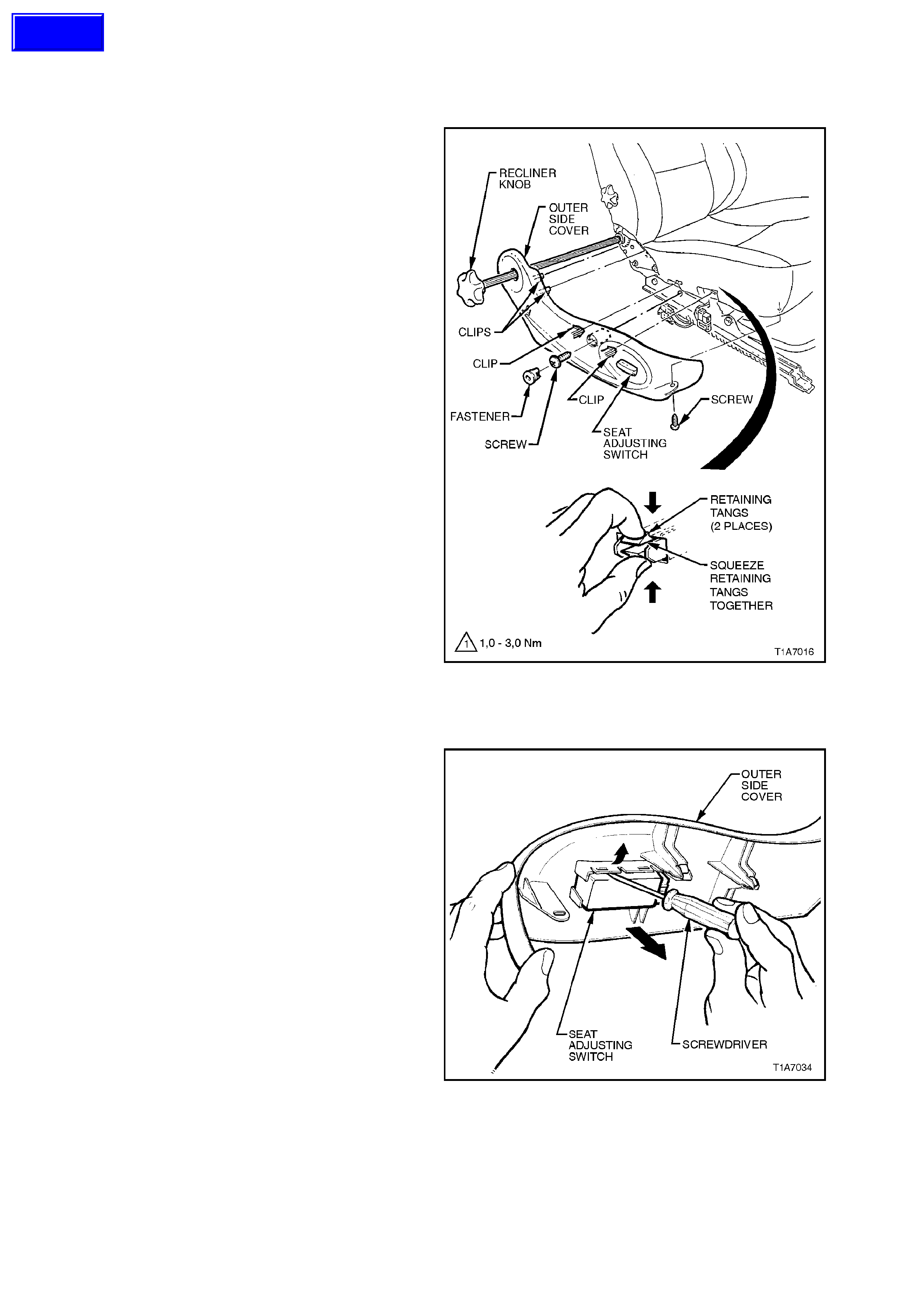

2.3 FRONT SEAT OUTER SIDE COVER AND SEAT ADJUSTING SWITCH ASSEMBLY

REMOVE

1. On a four- way seat, remove front seat inner

side cover, refer to Section 2.4 FRONT

SEAT INNER SIDE COVER.

2. On a four-way seat, from the inner side of the

seat assembly, gently tap the recliner shaft

towards the outer side of the seat assembly

(approximately 1 - 2 cm) using a pin punch.

3. On a four-way seat, fully withdraw the seat

back reclining knob and recliner shaft

assembly from the seat assembly.

4. Remove the screw from the front of the outer

side cover.

5. Remove the front seat outer side cover

fastener by rotating fastener anti-clockwise

(one quarter turn) and remove the screw

located behind this fastener .

6. Adjust the seat assembly to its highest

position.

7. Gently pull outer cover away from seat back

recliner (clip either side of recliner frame).

8. Reach up under the seat assembly and

squeeze the retaining tangs together (2

positions) on the inner side of the outer cover,

refer to Fig. 1A7-4 while gently pulling the

outer cover.

NOTE:

Only remove outer c over far enough away fr om the

seat cushion assembly to gain access to the seat

adjusting switch wiring harness.

9. Disconnect seat adjusting switch wiring

harness at the switch and rem ove outer cover

and switch assembly.

Figure 1A7-4

10 Remove the knob/s from the seat adjusting

switch by simply pulling them straight off.

11. On a four-way seat, gently pry the seat

adjusting switch f rom the outer side c over with

the aid of a screwdriver, refer Fig. 1A7-5.

On a eight-way switch, remove the three

screws securing the seat adjusting switch to

outer side cover and remove seat adjusting

switch.

NOTE:

Fig. 1A7-5 shows a four-way switch assembly.

Figure 1A7-5

Techline

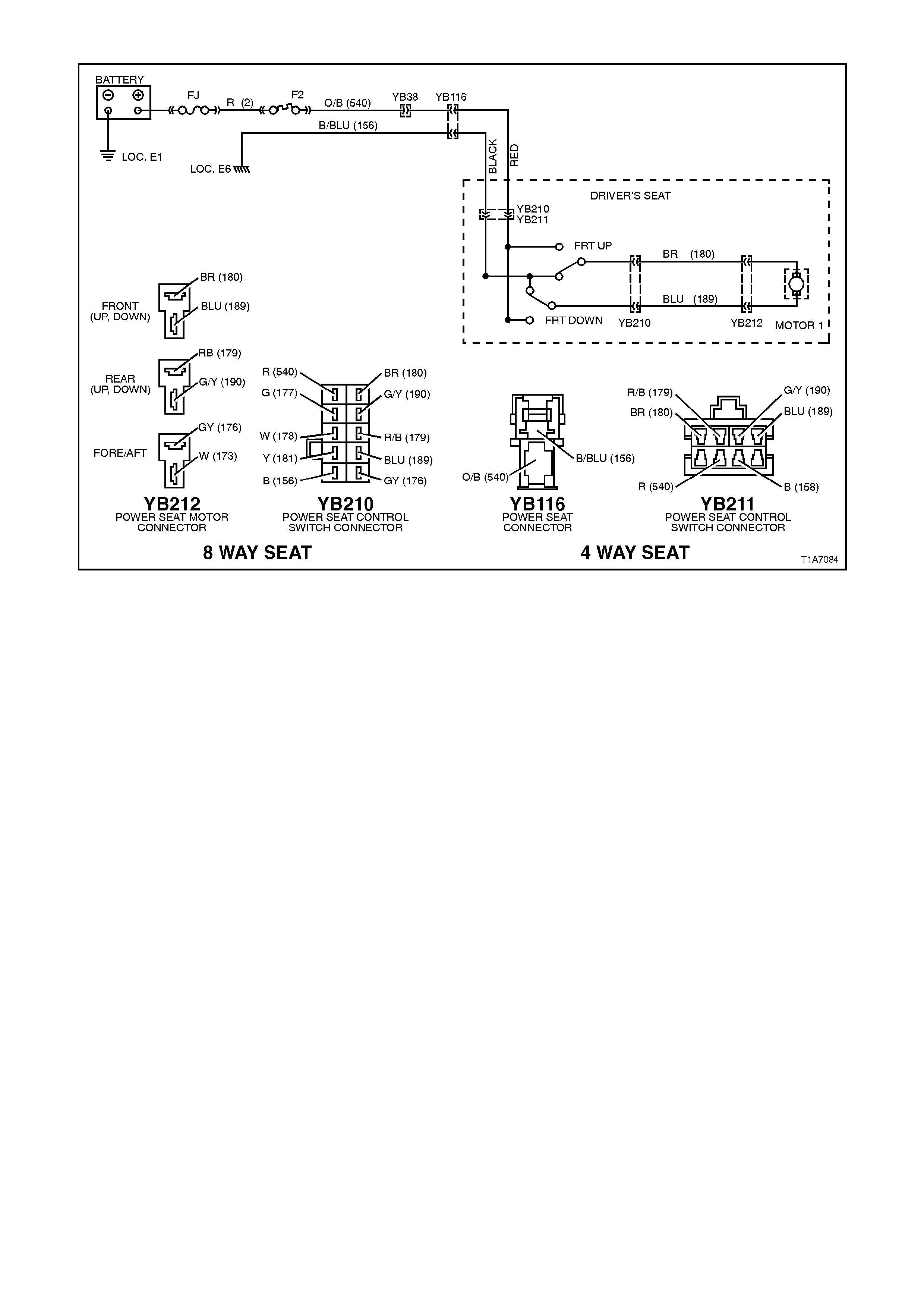

TEST

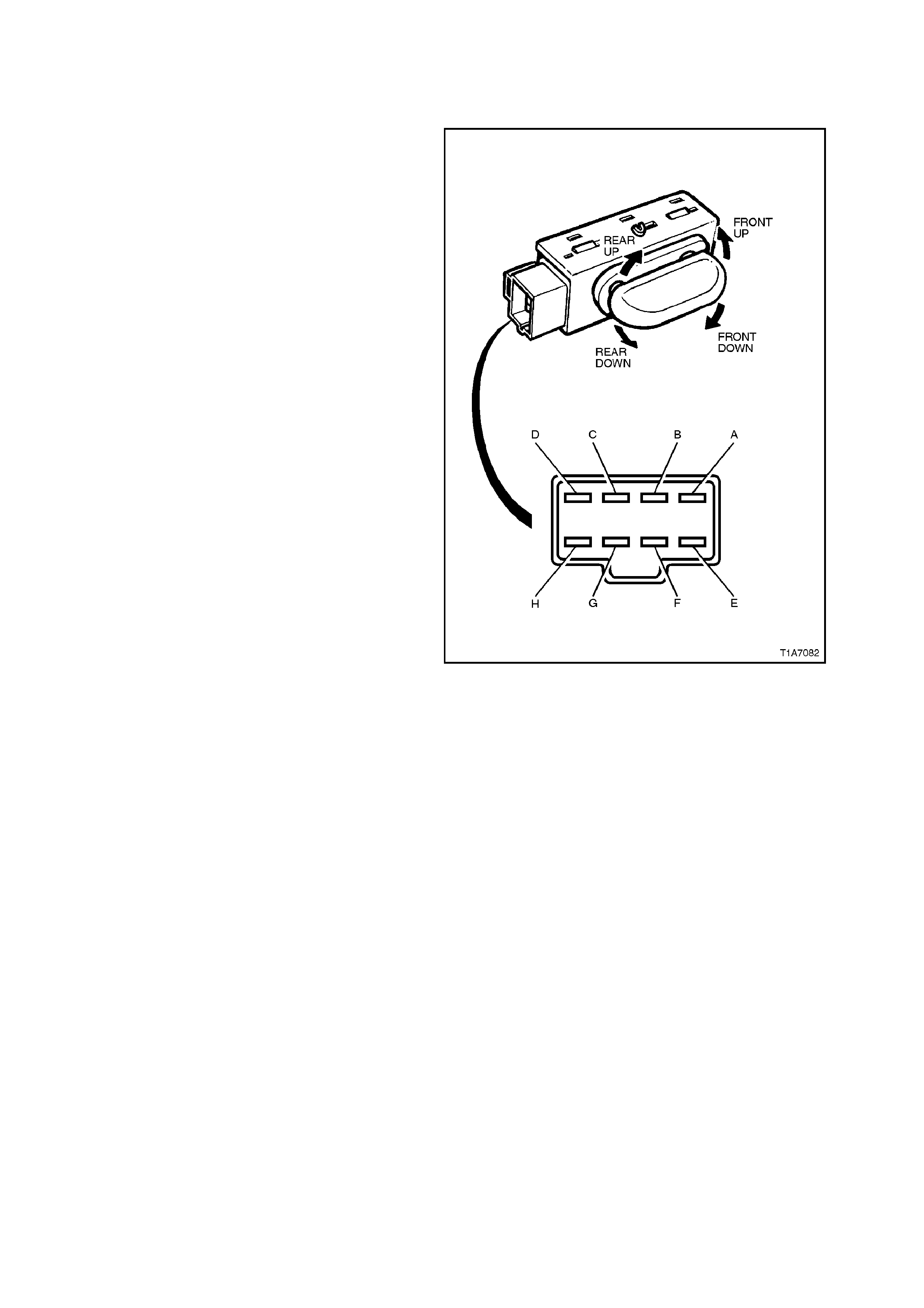

FOUR-WAY SEAT ADJUSTING SWITCH (UP

AND DOWN ONLY)

The four way seat adjusting switch assembly

contacts c an be check ed f or continuity between the

various term inals by referring to the following char t,

while referring to Fig. 1A7-6.

1. Attach Ohmmeter probes (using connector

leads from KM-609) to the appropriate switch

terminals nominated in the following chart.

2. Hold the switch in the nominated function

position as per the following chart while

referring to Fig. 1A7-6.

NOTE:

If any of the readings are not as specified, replace

the switch assembly.

SWITCH POSITION TERMINALS VALUE

REST C - E, F, G, H CONTINUITY

FRONT DOWN B - H CONTINUITY

FRONT UP B - E CONTINUITY

REAR DOWN B - G CONTINUITY

REAR UP B - F CONTINUITY

Figure 1A7-6

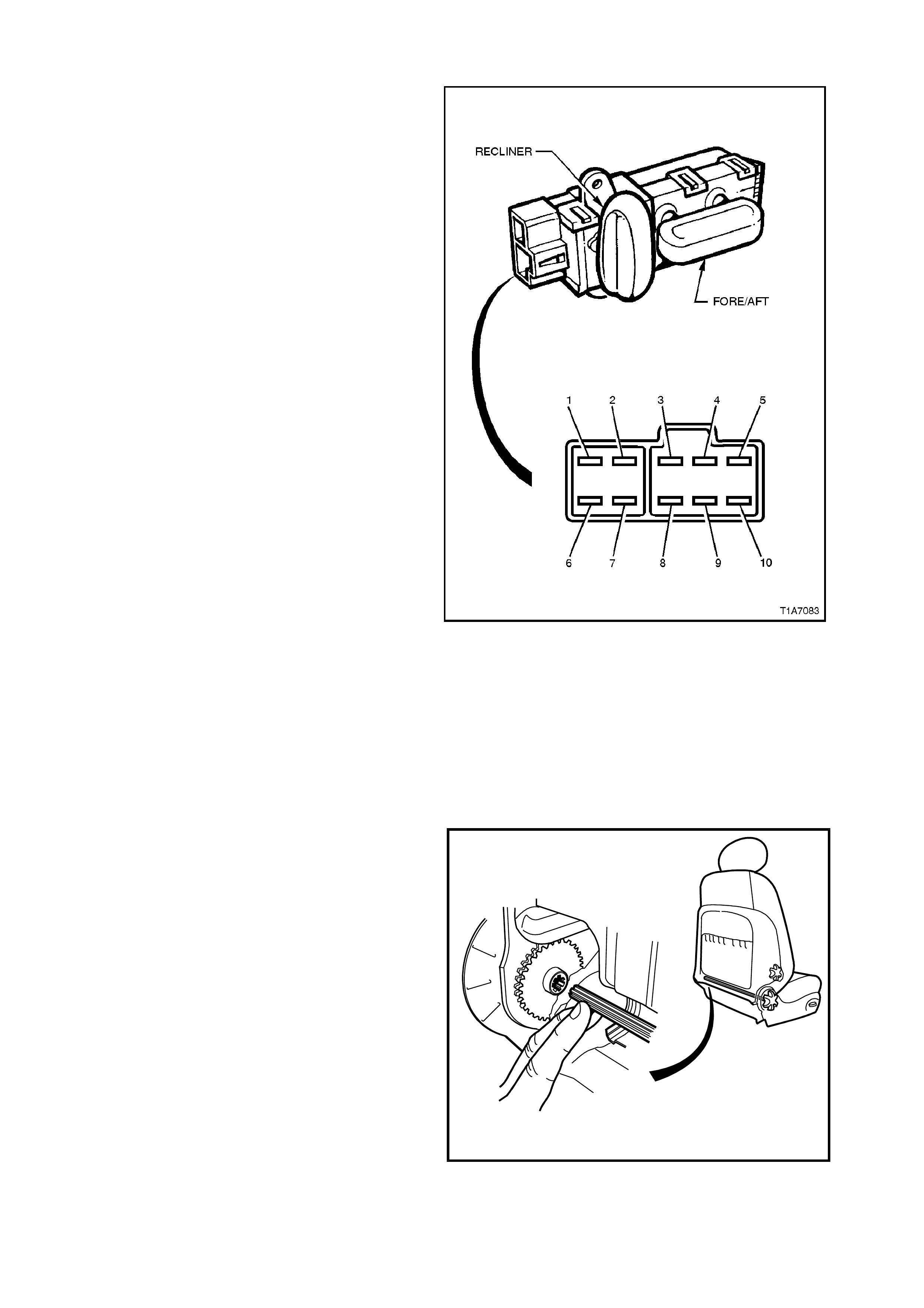

EIGHT-WAY SEAT ADJUSTING SWITCH (UP, DOWN, FORE/AFT AND RECLINE)

The eight-way seat adjusting switch assembly

contacts c an be check ed f or continuity between the

various term inals by referring to the following char t,

while referring to Fig. 1A7-7.

1. Attach ohmmeter probes (using connector

leads from KM-609) to the appropriate switch

terminals nominated in the following chart.

2. Hold the switch in the nominated function

position as per the following chart while

referring to Fig. 1A7-7.

NOTE:

If any of the readings are not as specified, replace

the switch assembly.

SWITCH

POSITION TERMINALS VALUE

REST 1 - 5 CO NTINUITY

RECLINER

(BACK) 1 - 2 CO NTINUITY

RECLINER

(FORWARD) 1 - 4 CONTINUITY

TRACK BACK

(AFT) 1 - 3 CONTINUITY

TRACK FORWARD

(FORE) 1 - 10 CONTINUITY

RH FRONT DOWN 1 - 9 CONTINUITY

LH FRONT DOWN 1 - 6 CONTINUITY

RH FRONT UP 1 - 6 CONTINUITY

LH FRONT UP 1 - 9 CONTINUITY

RH REAR DOWN 1 - 8 CONTINUITY

LH REAR DOWN 1 - 7 CONTINUITY

RH REAR UP 1 - 7 CONTINUITY

LH REAR UP 1 - 8 CONTINUITY

Figure 1A7-7

REINSTALL

Installation of the front seat outer side cover and

seat adjusting switch is the reverse of the removal

procedure, noting the following:

When reinstalling the front seat recliner shaft and

knob assem bly, ensure the s plines on the shaft are

aligned correctly, as per the following procedure:

NOTE: Do not force the recliner shaft into the

recliner shaft sleeve until the splines are aligned

correctly as this will damage the plastic recliner

shaft sleeve.

1. With your fingers inserted between the seat

back cover and the seat back, on the inboard

side of the front seat, align the splines by

guiding the recliner shaft into the recliner shaf t

sleeve.

2. With the recliner shaft aligned and seated in

the recliner shaft sleeve, firmly press on the

recliner knob until the recliner knob snaps into

position (a click will be heard).

T21A7501

Figure 1A7-8

2.4 FRONT SE AT INNER SIDE COVER

REMOVE

1. Remove front seat assembly, refer to

2.1 FRONT BUCKET SEAT ASSEMBLY in

this Section.

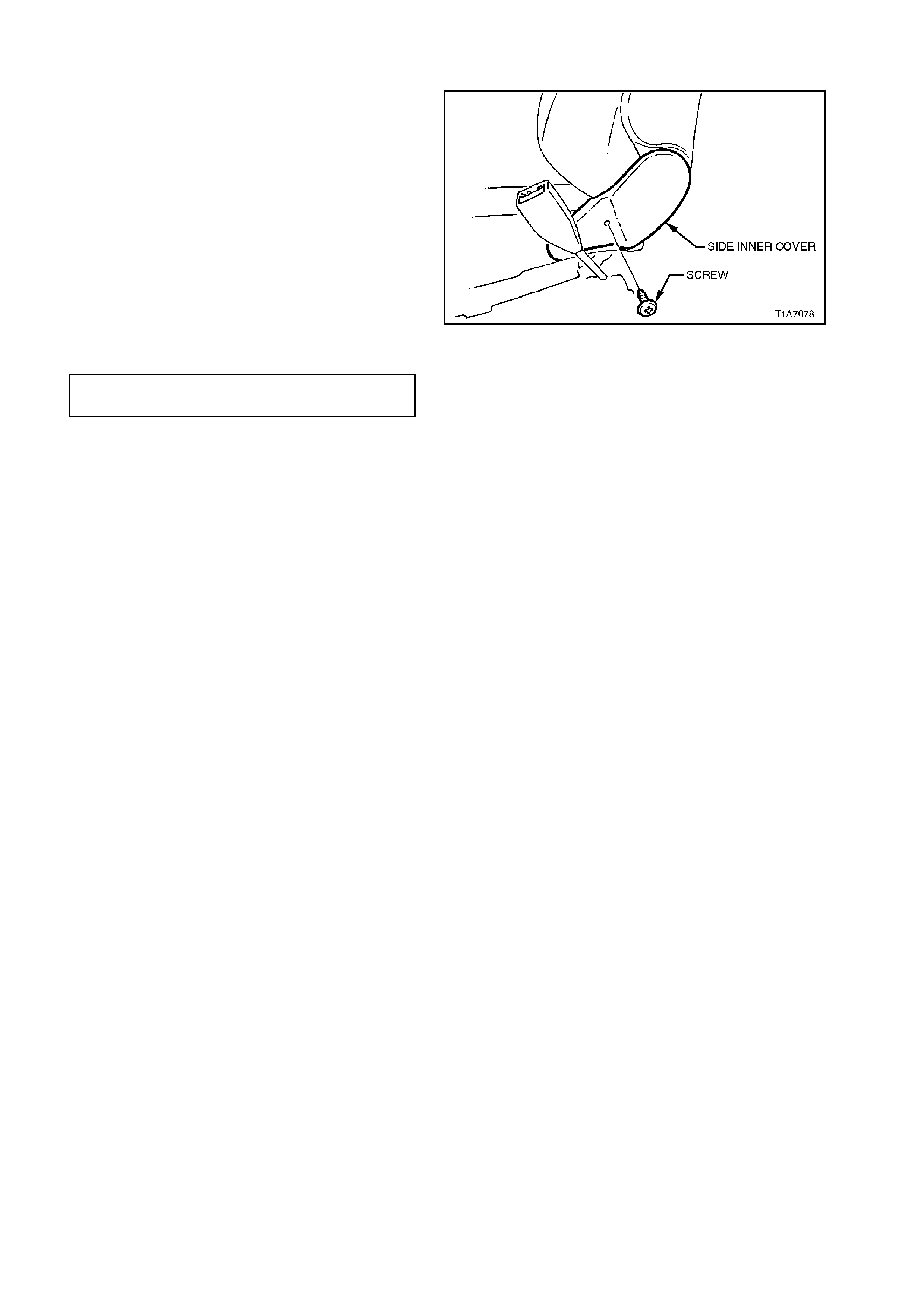

2. 2. Remove sc rew securing side inner c over to

seat and remove inner side cover.

REINSTALL

Installation of the inner side cover is the reverse of

the removal operation, noting the following:

Ensure all fasteners are tightened to the correct

torque specification.

SIDE INNER COVER RETAINING 1.0 - 3.0

SCREW TORQUE SPECIFICATION Nm

Figure 1A7-9

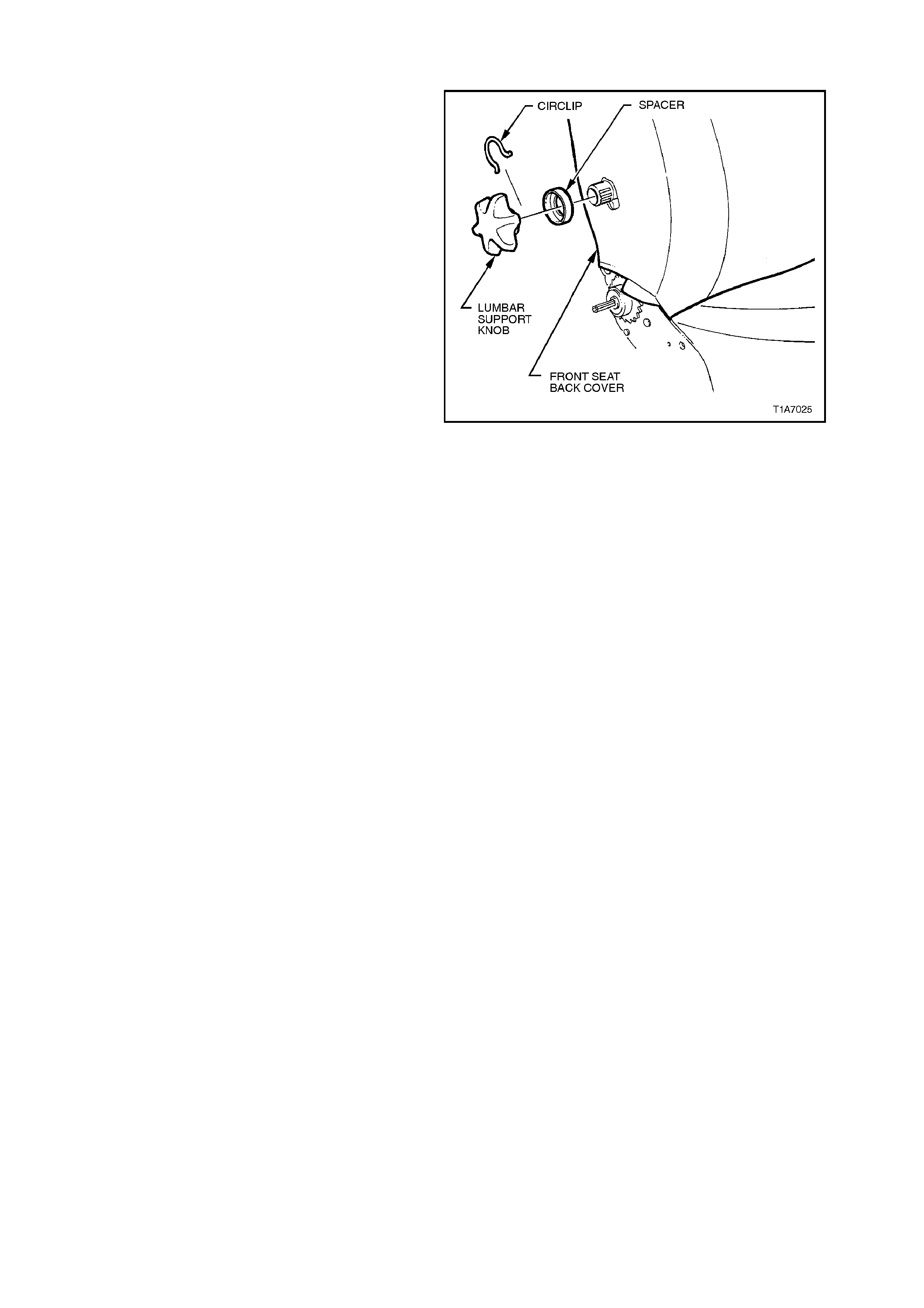

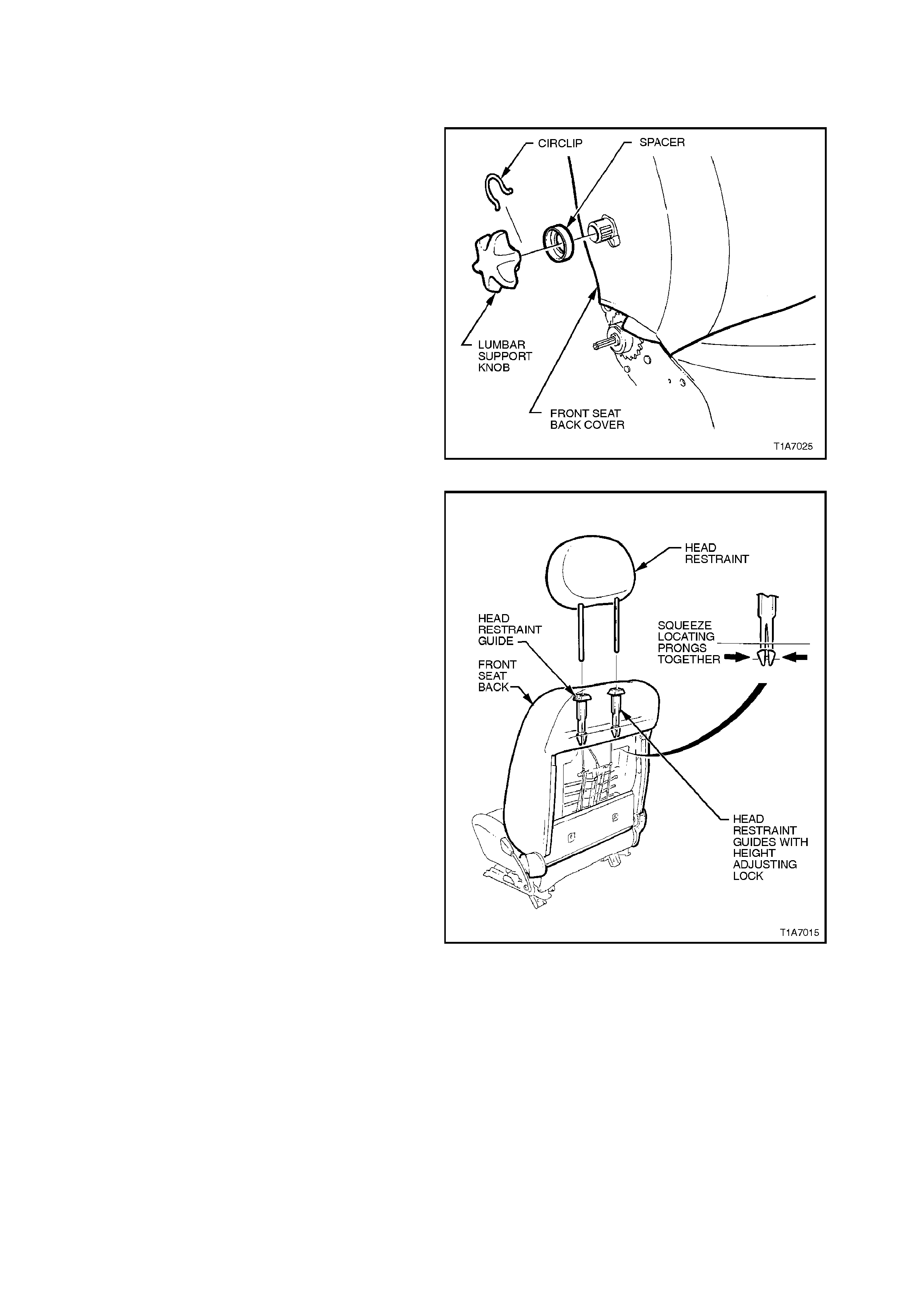

2.5 LUMBAR SUPPORT ADJUSTER KNOB

REMOVE

Remove lumbar support knob by pushing seat back

cover in far enough to expose circlip, remove circlip

and remove lumbar support adjusting knob, refer

Fig. to 1A7-9.

REINSTALL

1. Install circlip onto lumbar support adjusting

knob.

2. Ensure splines of lumbar support are correctly

aligned and push adjusting knob onto lumbar

adjuster shaft until circlip locks adjusting knob

into place.

Figure 1A7-10

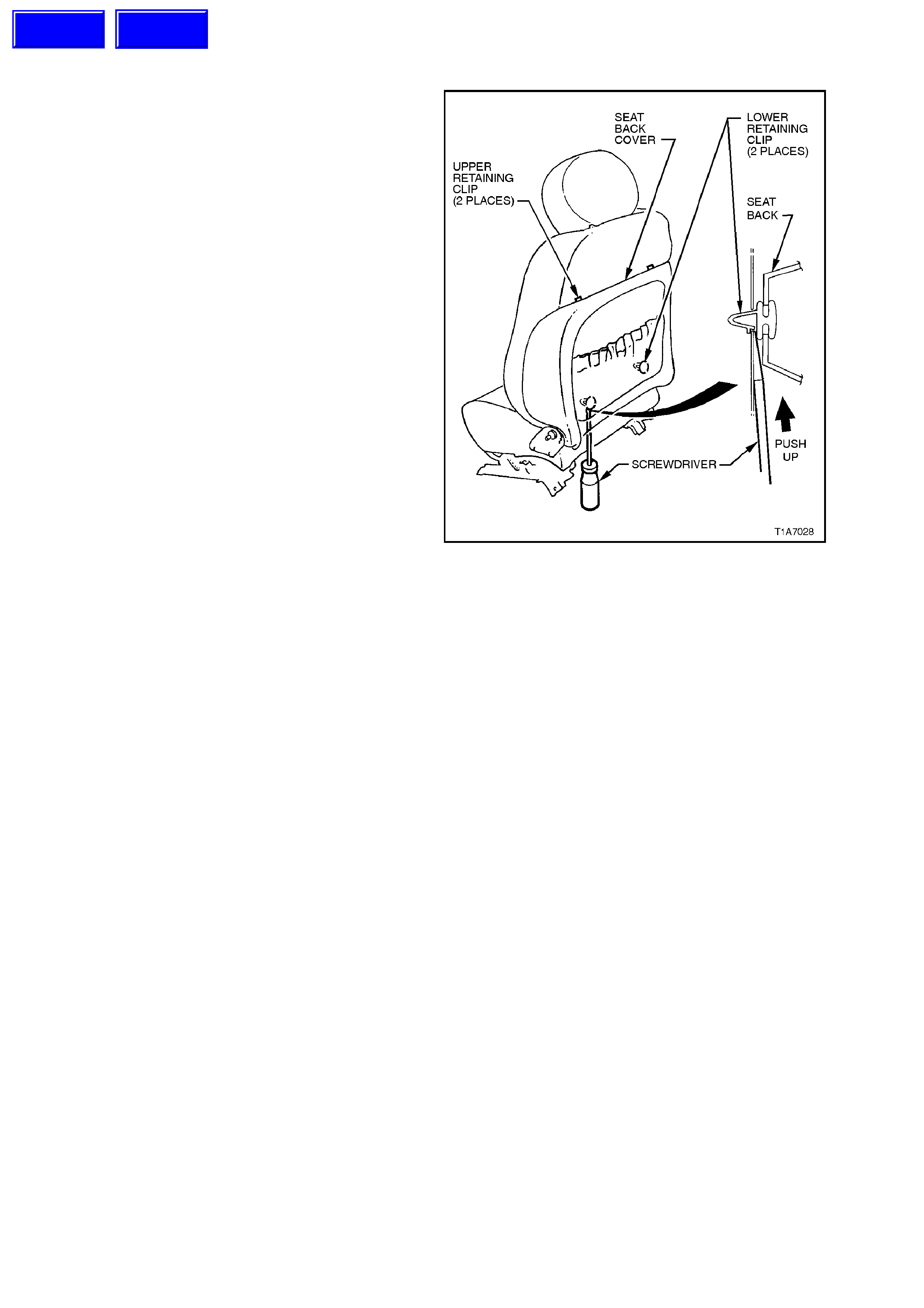

2.6 FRONT SE AT BACK COVER

REMOVE

1. Remove lumbar support adjusting knob, refer

to previous operation 2.5 LUMBAR SUPPORT

ADJUSTER KNOB in this Section.

2. Insert a screwdriver between the seat back

cover and seat back and push up on the

retaining clip (2 places) while pulling the

bottom of the back cover out, away from seat,

to release lower retaining clips, and then pull

back cover down to release top retainers.

Remove seat back cover.

REINSTALL

Installation of the front seat back cover is the

reverse of the removal operation.

Figure 1A7-11

Techline

Techline

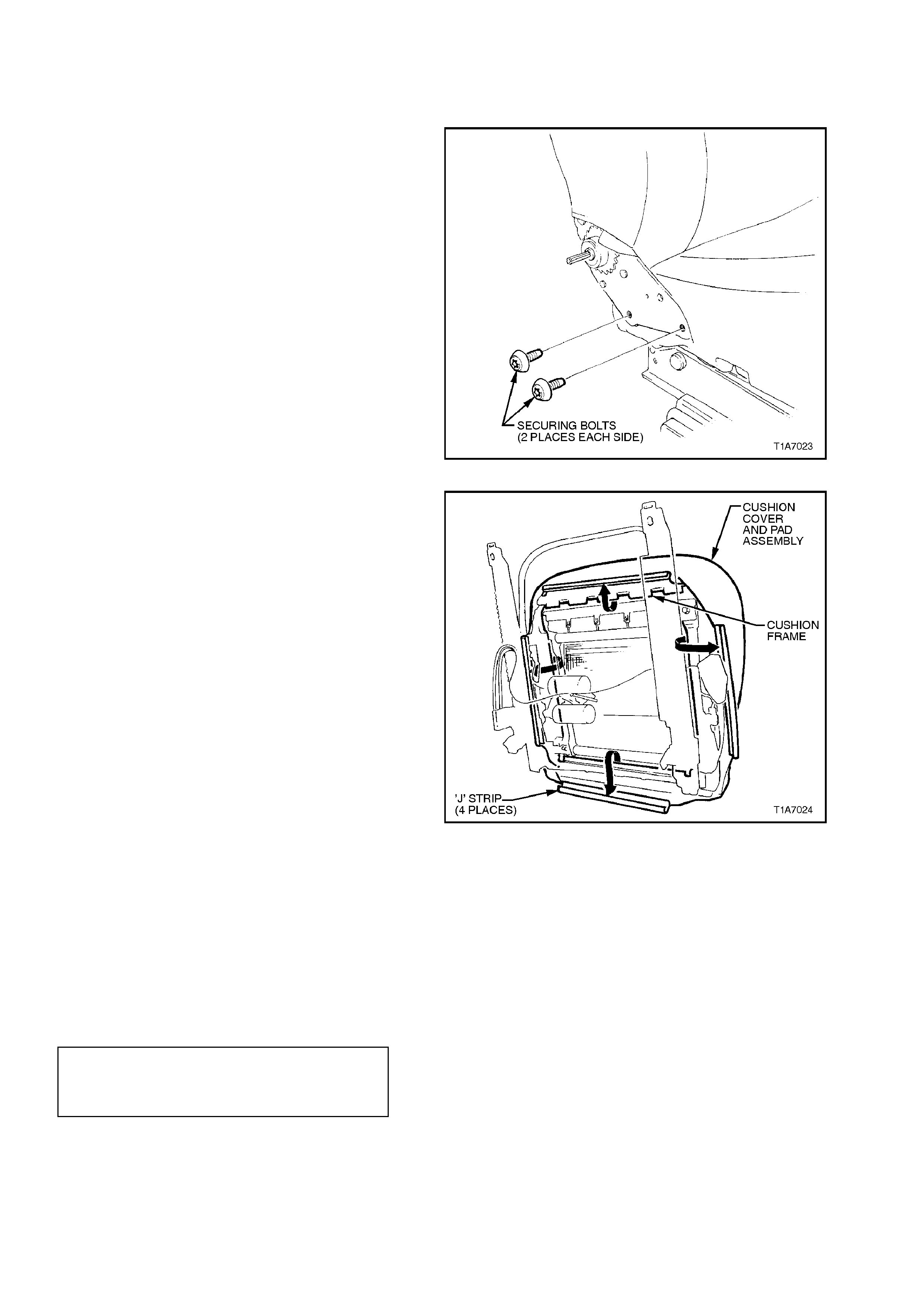

2.7 FRONT SEAT CUSHION PAD AND COVER ASSEMBLY

REMOVE

1. Remove front seat assembly, refer to

2.1 FRONT BUCKET SEAT ASSEMBLY in

this Section.

2. Remove inner and outer side cover

assemblies, refer to

2.3 FRONT SEAT OUTER SIDE COVER AND

SEAT ADJUSTING SWITCH ASSEMBLY in

this Section.

3. On seats with electric recliner assemblies,

disconnect wiring harness connector for

recliner motor (located under rear of the front

seat assembly).

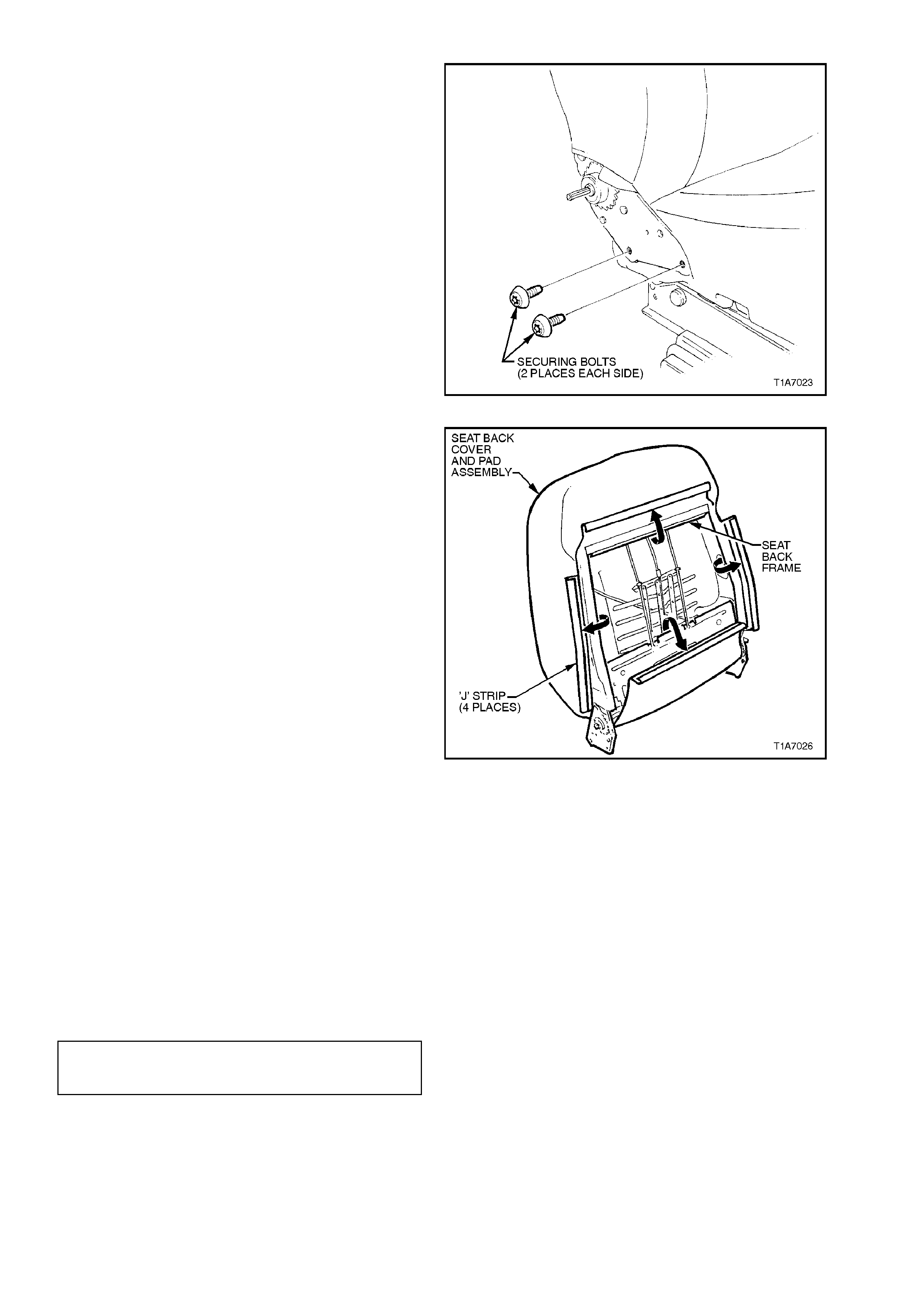

4. Remove the four Torx bolts securing the seat

back assembly to the seat adjuster and guide

rail assembly, remove seat back assembly.

Figure 1A7-12

5. From under seat cushion, pull the front and

side ‘J’ strips away from the seat frame.

6. Lift cover and pad assembly away from seat

frame and then release the rear ‘J’ strip.

Figure 1A7-13

REINSTALL

Installation is the reverse of the rem oval operation,

noting the following:

1. W hen installing the seat bac k assem bly to the

seat adjuster and guide rail assembly, ensure

there is a metal to metal contact of parts (no

trim material caught between).

2. Ensure all fasteners are tightened to the

correct torque specification.

SEAT BACK TO SEAT ADJUSTER

AND GUIDE RAIL ASSEMBLY

SECURING BOLT

TORQUE SPECIFICATION 27 Nm

2.8 FRONT SEAT BACK PAD AND COVER ASSEMBLY

REMOVE

1. Remove front seat assembly, refer to

2.1 FRONT BUCKET SEAT ASSEMBLY in

this Section.

2. Remove inner and outer side cover

assemblies, refer to

2.3 FRONT SEAT OUTER SIDE COVER AND

SEAT ADJUSTING SWITCH ASSEMBLY in

this Section.

3. On seats with electric recliner assemblies,

disconnect wiring harness connector for

recliner m otor (located under r ear of f ront seat

assembly).

4. Remove lumbar support knob by pushing seat

back cover in far enough to expose circlip,

remove circlip and remove lumbar support

adjusting knob, refer to Fig. 1A7-13.

Figure 1A7-14

5. Remove the front seat back cover assembly,

refer to 2.6 FRONT SEAT BACK COVER in

this Section.

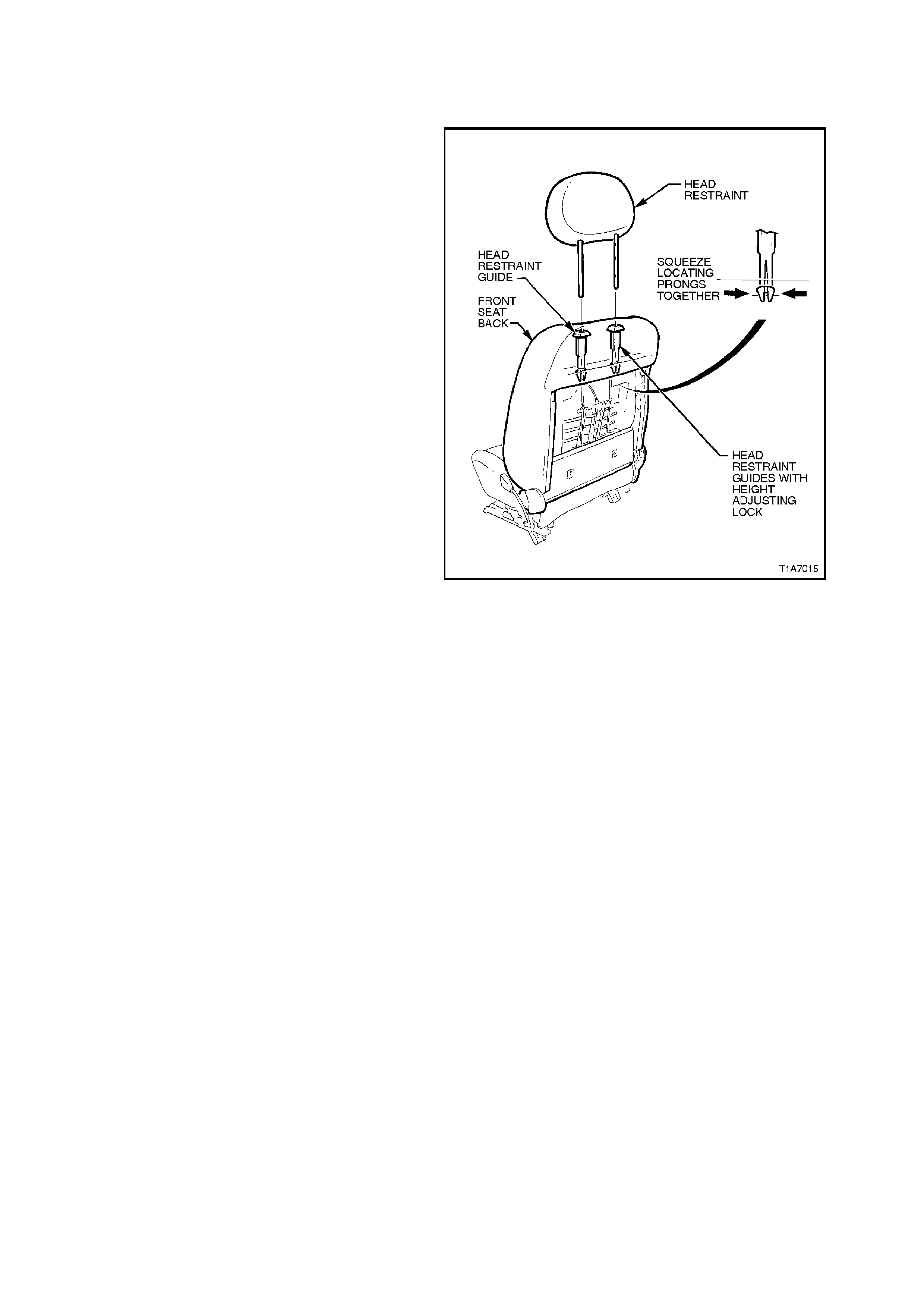

6. While holding head restraint height adjuster

lock in, pull head restraint completely out of

guide.

7. From the back of front seat, squeeze the

lock ing prongs of head restraint guide together

while pulling top of guide out of seat back

assembly, refer to Fig 1A7-14

Figure 1A7-15

8. Remove the four bolts (two on each side)

securing the seat back assembly to the seat

height adjuster, remove seat back assembly.

Figure 1A7-16

9. Pull the four ‘J’ strips away from the seat

frame.

10. Lift cover and pad assembly away from seat

back frame.

Figure 1A7-17

REINSTALL

Installation is the reverse of the rem oval operation,

noting the following:

1. When installing the lumbar support adjusting

knob, ensure s plines are correc tly aligned and

circlip is installed onto adjusting knob before

inserting adjusting knob onto shaft.

2. Ensure the head restraint guide with adjusting

lock is installed on the correct side, ie. side

with notches on the head restraint.

3. Ensure all fasteners are tightened to the

correct torque specification

SEAT BACK TO SEAT HEIGHT

ADJUST ASSEMBLY SECURING

BOLT TORQUE SPECIFICATION 27 Nm

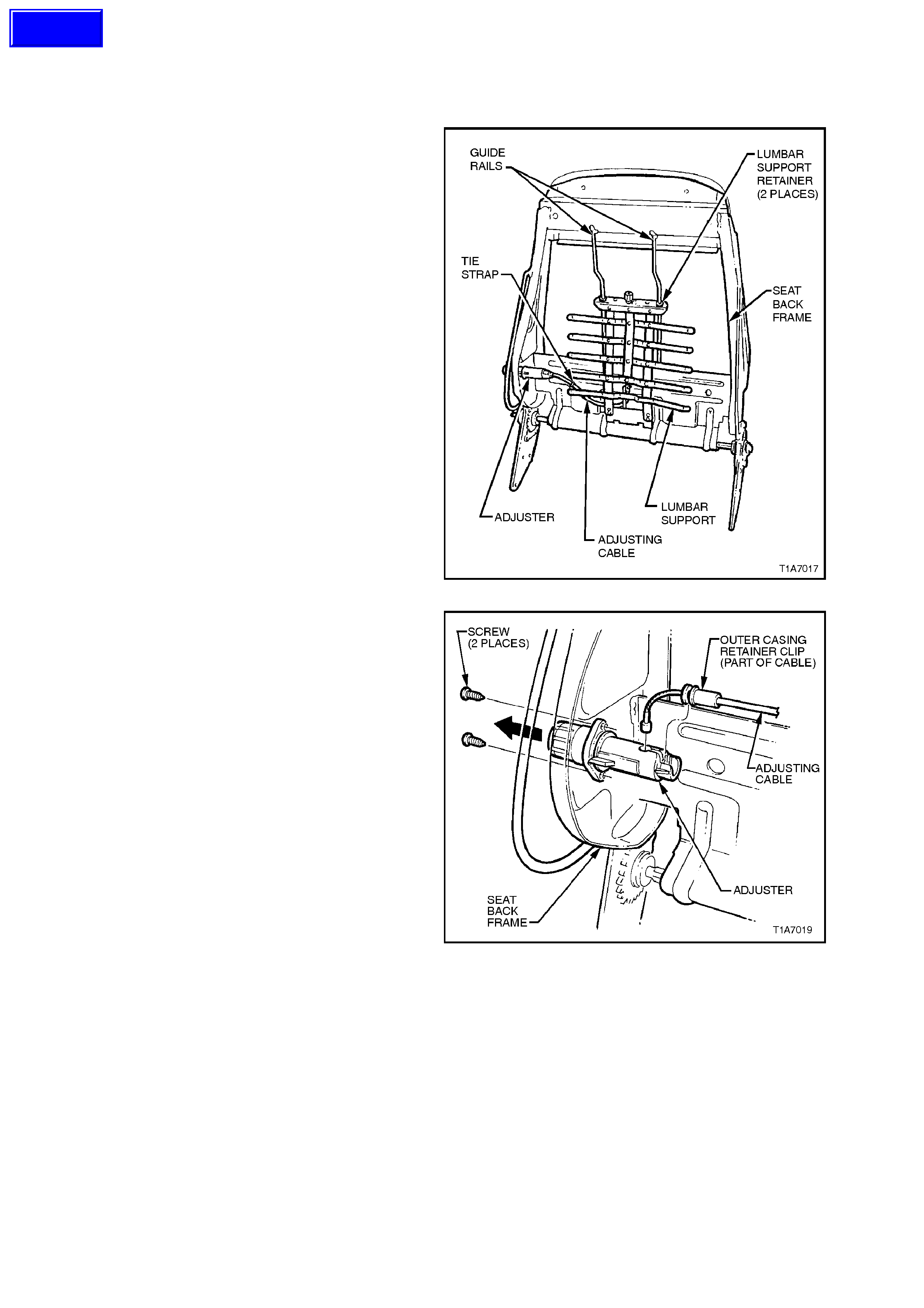

2.9 FRONT SEAT BACK FRAME, LUMBAR SUPPORT AND ADJUSTER ASSEMBLY

REMOVE

NOTE:

The lumbar support is part of the seat back frame

and can only be replaced as an assembly.

1. Remove front seat back cover and pad

assembly, refer to 2.8 FRONT SEAT BACK

PAD AND COVER ASSEMBLY in this

Section.

2. From the back of the front seat back frame,

disengage the lumbar support adjuster cable

wire tie clip by squeezing the tangs on the wire

tie retaining clip together and pushing wire tie

retaining clip through seat back frame.

3. Push the top of the lumbar support to

disengage the two retainers from the guide

rails on the seat bac k , allowing lumbar support

to swing freely.

4. While slightly compressing lumbar support

assembly by hand to release cable tension,

disengage adjuster cable from the top of the

lumbar support.

Figure 1A7-18

5. Remove adjusting cable from adjuster by

unclipping outer casing of cable from adjuster

and removing cable assembly.

6. Remove the two screws securing the

lumbar support adjuster to the seat back

frame and remove adjuster.

Figure 1A7-19

REINSTALL

Installation is the reverse of the rem oval operation,

noting the following:

Align hole in adjuster for adjusting cable ball by

turning the adjuster until access hole lines up,

insert cable into adjuster and push outer casing of

cable into locking seat of adjuster until it clicks.

Techline

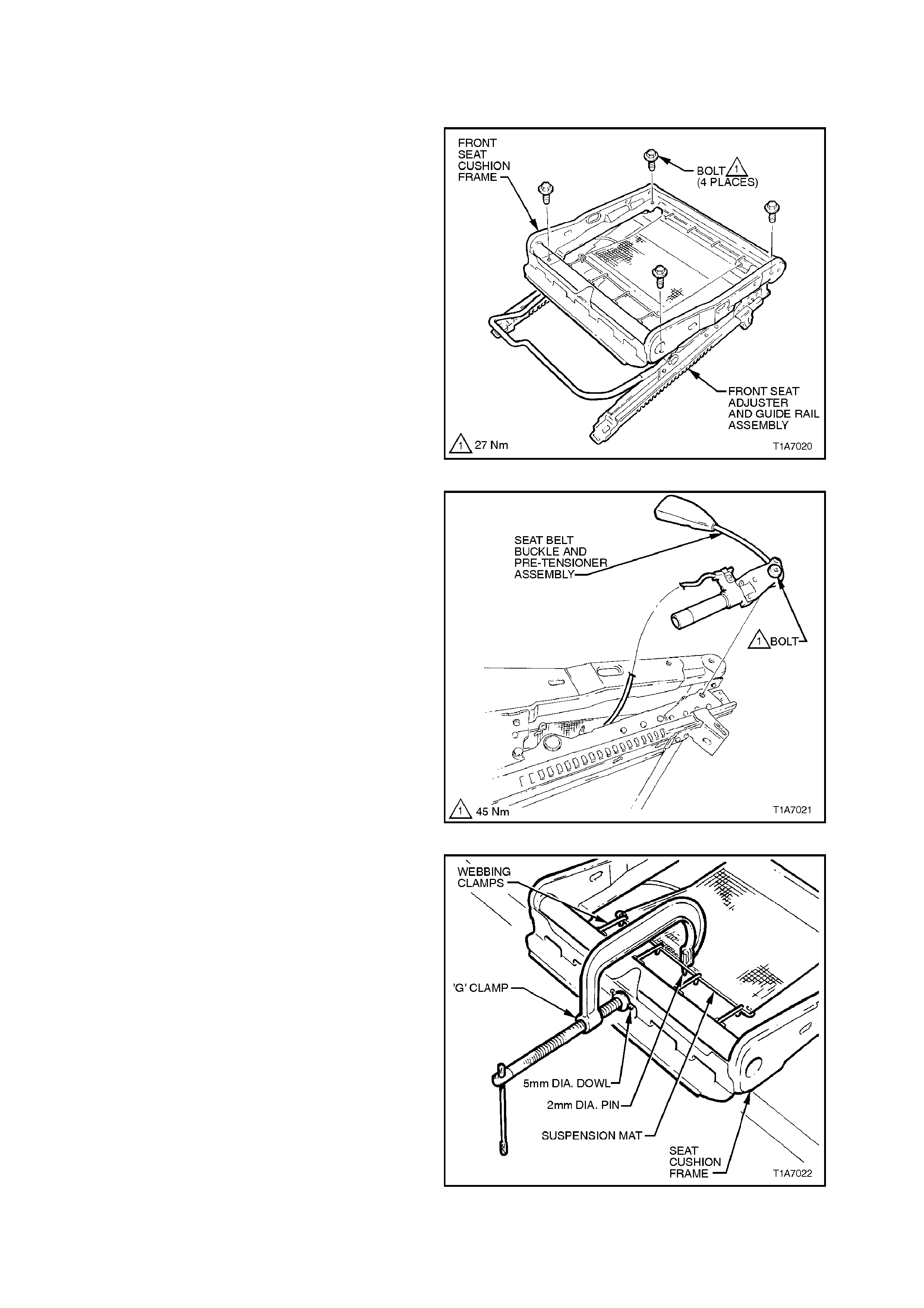

2.10 FRONT SEAT CUSHION FRAME ASSEMBLY

REMOVE

1. Remove front seat cushion cover and pad

assembly, refer to 2.7 FRONT SEAT

CUSHION PAD AND COVER ASSEMBLY in

this Section.

2. Remove the four bolts securing the front seat

cushion to adjuster and guide rail assembly.

Figure 1A7-20

NOTE:

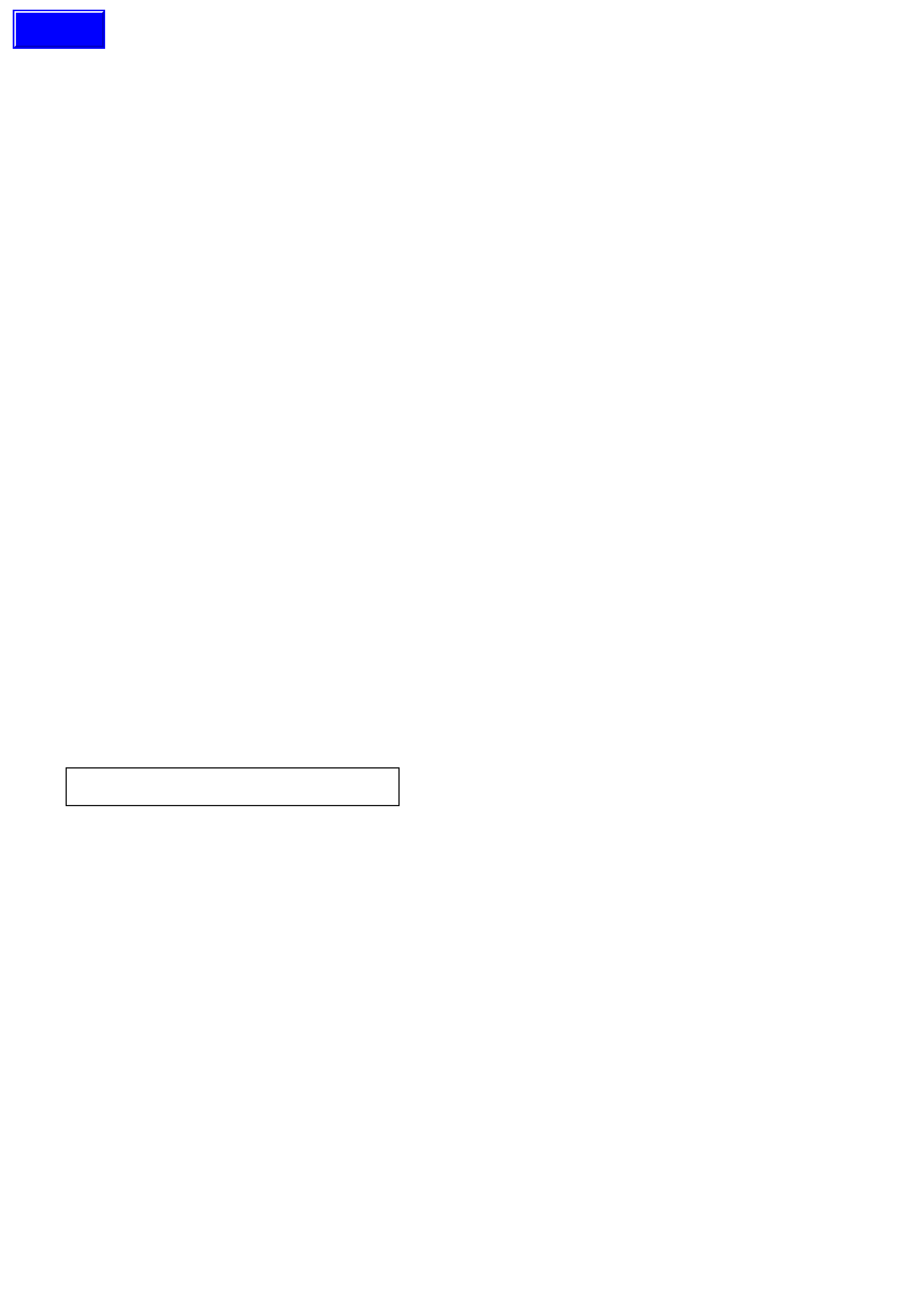

Before disconnecting pre-tensioner wiring harness

connector, take note of wiring harness routing.

3. Disconnect seat belt pre-tensioner wiring

harness from seat frame.

4. Remove bolt securing seat belt buckle and

pre-tensioner assembly to frame and remove

seat belt buckle and pre-tensioner assembly.

Figure 1A7-21

5. Using a pre-fabricated tool:

‘G’ clamp with 5mm diameter metal dowel

welded to one end, approximately 40mm long

and a 2mm diam eter pin approx imately 20mm

long welded to the other end.

Using pre-fabricated tool, stretch the

suspension mat far enough to allow for

webbing clamps to be removed from seat

frame. Back ‘G’ clamp load off and remove

suspension mat.

NOTE:

When using pre-fabricated tool, use existing holes

in suspension mat to ensure that mat deformation

does not occur.

Figure 1A7-22

REINSTALL

Installation is the reverse of the rem oval operation,

noting the following:

1. Ensure all fasteners are tightened to the

correct torque specification.

FRONT SEAT CUSHION FRAME TO

SEAT GUIDE RAIL AND ADJUSTER

BOLT TORQUE SPECIFICATION 27 Nm

SEAT BELT BUCKLE AND

PRE- TENSIONER ASM. BOLT

TORQUE SPECIFICATION 45 Nm

2. Ensure the pre-tensioner and seat adjuster

motor wiring harness is routed correctly and

retained by wiring ties at each red spot tape

location.

3. When installing seat belt buckle and pre-

tensioner assembly ensure that the front

locating pin on the pre-tensioner assembly

aligns with seat frame.

2.11 FRONT SEAT ADJUSTER ASSEMBLIES

The front seat adjuster and guide rail assembly for non-electric seats are not serviceable due to safety restraints.

The front seat adjuster assembly on electric seats is also a non-serviceable item except for the drive motors and

(on eight-way electric seats) the drive shafts on the fore/aft motor.

If the adjuster assembly, drive motors or drive shafts need to be removed or replaced, refer to the individual service

operation for removing the seat cushion frame and drive motors from the adjuster assembly in this Section.

2.12 FRONT SEAT LIFT MOTORS

REMOVE

NOTE:

Illustrations for this ser vice operation s how the s eat

adjuster assembly removed from the seat

assembly. To perform this service operation, the

seat adjuster assembly does not have to be

removed from the seat assembly.

CAUTION:

When replacing front seat lift motors always

use new small and large clevis pins.

1. Remove front seat assembly, refer to

2.1 FRONT BUCKET SEAT ASSEMBLY in

this Section.

2. Disconnect lift motor wiring harness

connectors and cut wiring harness retaining

straps sec uring the lift m otor wiring harness to

the guide rails (note position of retaining

straps).

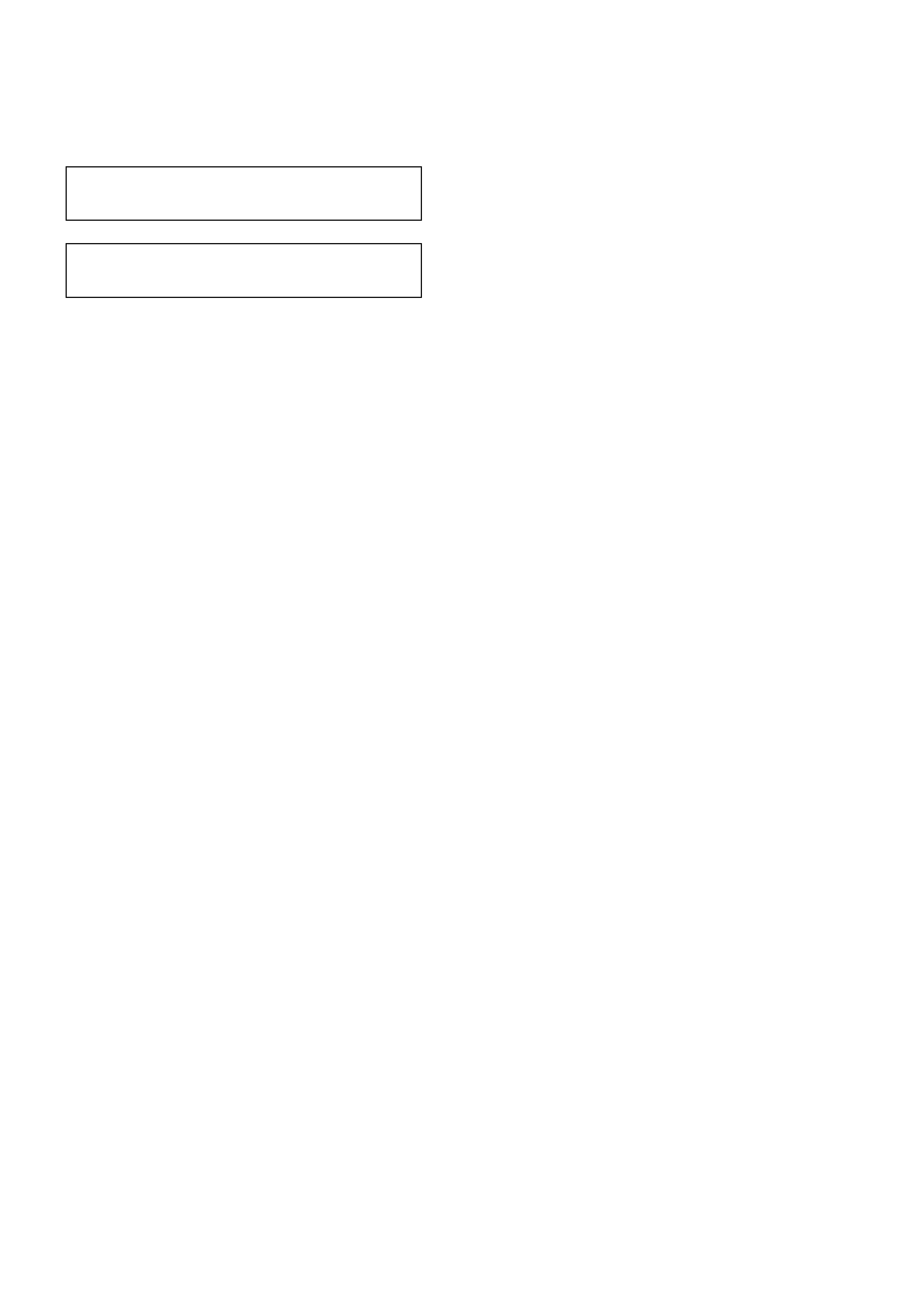

3. On the appropriate lift motor, file the retaining

burrs of f the large clevis pin, r efer to Fig. 1A7-

22, and gently tap the clevis pin out.

Figure 1A7-23

4. Using clevis pin removal punch AU461, tap the

sm aller clevis pin through the c ross br ace and

motor assembly, refer to Fig. 1A7-23.

5. Remove lift motor.

Figure 1A7-24

REINSTALL

Installation of the lift motor/s is the reverse of the

removal procedure, noting the following:

CAUTION:

Always use new small and large clevis pins.

1. Screw the yoke either in or out of lift motor

worm shaft to align the yoke with the cross

brace assembly.

2. Insert new large clevis pin and, using a centre

punch, burr the end of the clevis pin to pr event

it from coming out, refer Fig. to 1A7-24

(approx. 3 places).

3. Using new retaining straps secure seat

adjusting motor wiring harness to the seat

adjuster assembly in previously noted

positions (red spot tape).

Figure 1A7-25

Campaign

2.13 FRONT SEAT FORE/AFT MOVEMENT MOTOR

REMOVE

NOTE:

Illustrations for this ser vice operation s how the s eat

adjuster assembly removed from the seat

assembly. To perform this service operation, the

seat adjuster assembly does not have to be

removed from the seat assembly.

1. Remove front seat assembly, refer to

2.1 FRONT BUCKET SEAT ASSEMBLY in

this Section.

2. Disconnect fore/aft motor wiring harness

connector (located under front seat assembly).

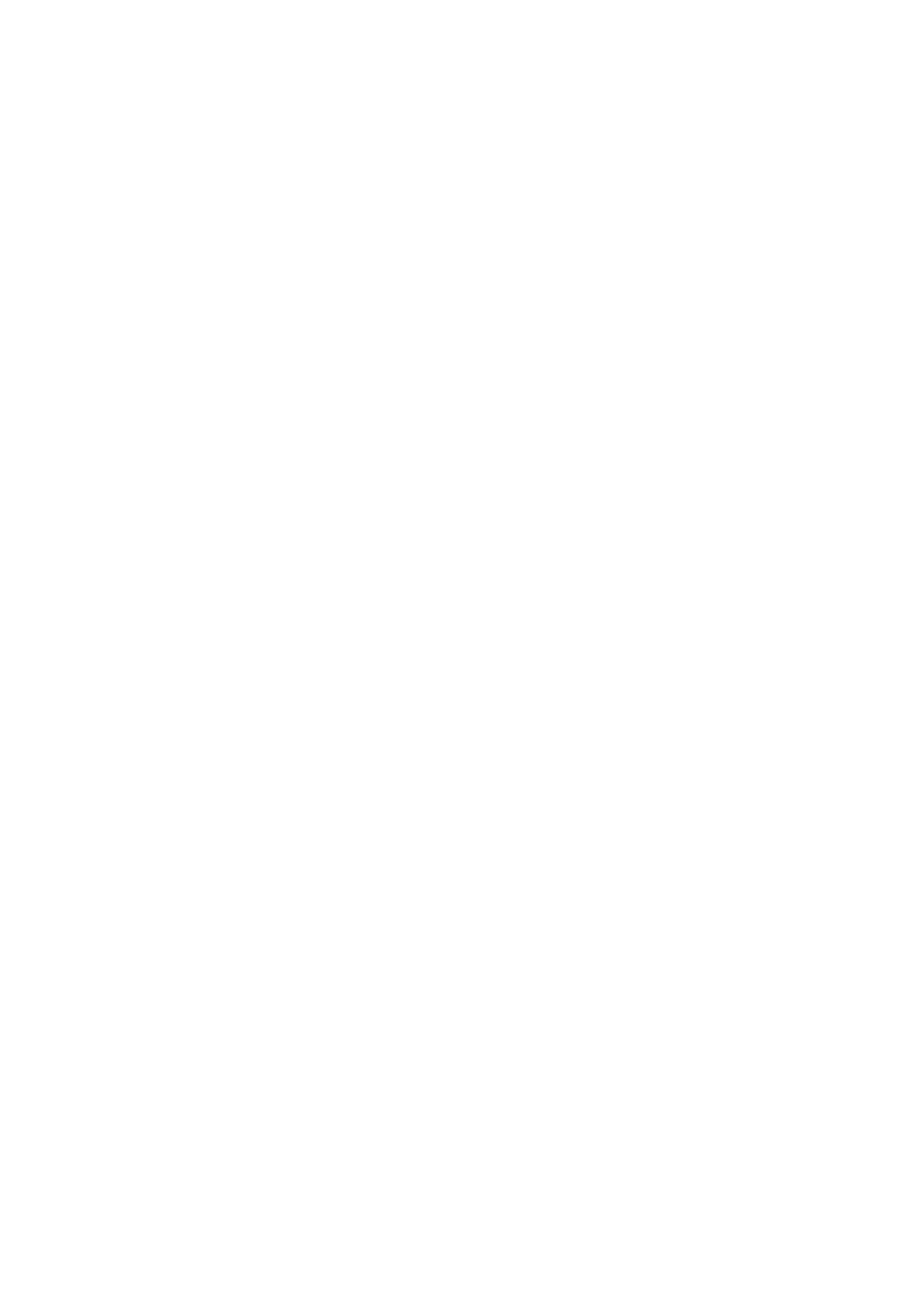

3. Using a screwdriver, gently lever the two

retaining tangs out of the seat adjuster frame

assembly, refer to Fig. 1A7-25 Figure 1A7-26

4. Using a scr ewdriver, lever f ore/aft m otor out of

seat adjuster frame assembly with both drive

shafts still attached.

NOTE:

Remove fore/aft motor far enough to remove drive

shafts taking care not to bend drive shafts any

more than necessary.

5. Remove drive shafts from fore/aft motor and

remove fore/aft motor.

Figure 1A7-27

REINSTALL

Installation of the fore/aft motor is the reverse of

the removal procedure, noting the following:

Insert drive shafts into fore/aft motor first, then

install drive shafts into gearbox and worm drive

assemblies while taking care not to bend drive

shafts any more than is necessary.

2.14 FRONT SEAT RECLINING MOTOR AND GEARBOX ASSEMBLY

REMOVE

1. Remove front seat back cover and pad

assembly, refer to 2.8 FRONT SEAT BACK

PAD AND COVER ASSEMBLY in this

Section.

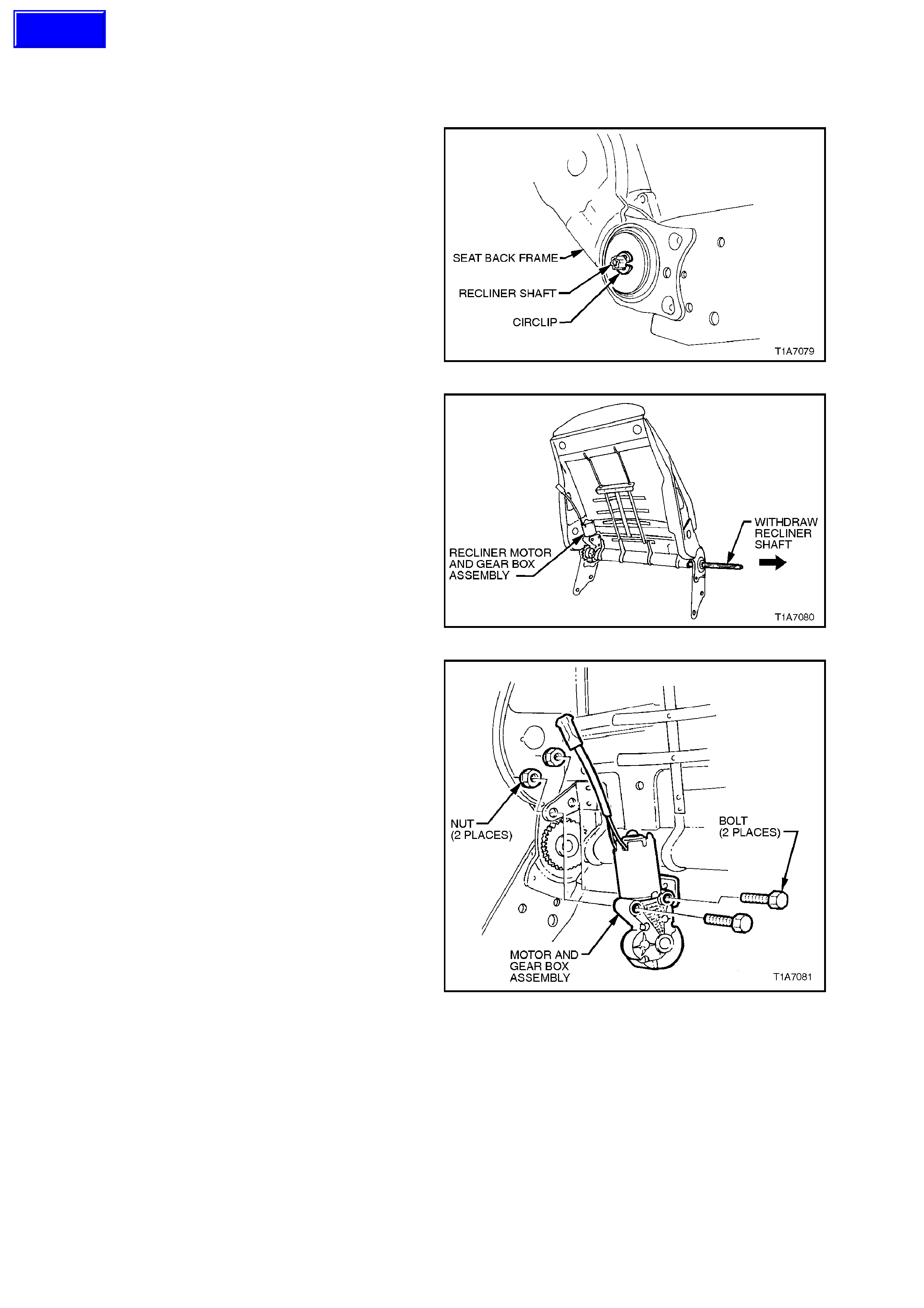

2. Remove one of the two circlips retaining the

recliner drive shaft to the seat back frame at

the reclining m otor and gear box ass embly side

of the seat back frame.

Figure 1A7-28

3. Withdraw recliner drive shaft from seat back

frame far enough to disengage motor and

gearbox assembly.

Figure 1A7-29

4. Remove the two bolts and nuts securing the

recliner motor and gearbox assembly to the

seat back frame and remove motor and

gearbox assembly.

Figure 1A7-30

Techline

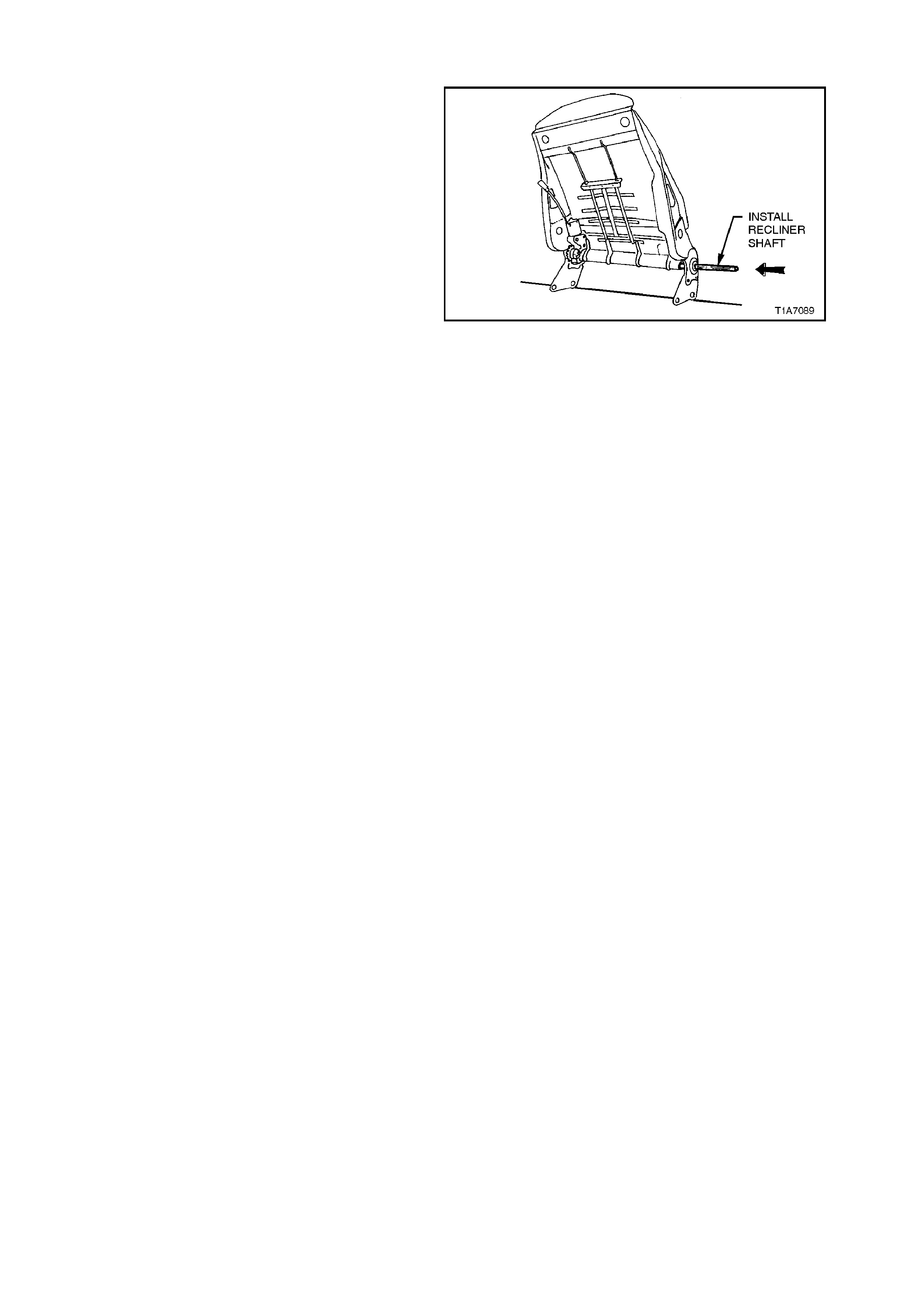

REINSTALL

Installation of the reclining motor and gearbox

assembly is the reverse of the removal procedure

noting the following:

1. Replace the two nylon lock nuts securing the

recliner motor and gearbox assembly to the

seat back frame.

2. W hen installing the rec liner drive shaf t, ensure

the splines are aligned evenly by placing the

bottom of the seat recliner plates on a bench,

refer to Fig 1A7-30.

Figure 1A7-31

2.15. FRONT SEAT HEAD RESTRAINT ASSEMBLY

REMOVE

1. Remove the lumbar support adjusting knob,

where required, refer to 2.5 LUMBAR

SUPPORT ADJUSTER KNOB in this Section.

2. Remove the front seat back cover assembly,

refer to 2.6 FRONT SEAT BACK COVER in

this Section.

3. While holding head restraint height adjuster

lock in, pull head restraint completely out of

guide.

4. From the back of front seat, squeeze the

lock ing prongs of head r est raint guide together

while pulling top of guide out of seat back

assembly, refer to Fig 1A7-32.

REINSTALL

Installation of the front seat head restraint

assembly is the reverse of the removal procedure

noting the following:

When installing head restraint guide, ensure that

locating slots in the s eat bac k align with k ey-way on

the head restraint guide and the head restraint

guide with adjusting lock is installed on the correct

side, ie. align with notches on the head restraint. Figure 1A7-32

2.16 REAR SEAT HEAD RESTRAINT ASSEMBLY - SEDAN

REMOVE

1. Remove rear seat cushion assembly, refer to

2.18 REAR SEAT CUSHION AND BACK

ASSEMBLIES - SEDAN in this Section.

2. Remove appropriate side rear seat back, refer

to 2.18 REAR SEAT CUSHION AND BACK

ASSEMBLIES - SEDAN in this Section.

3. While holding head restraint height adjuster

lock in, pull head restraint completely out of

guide.

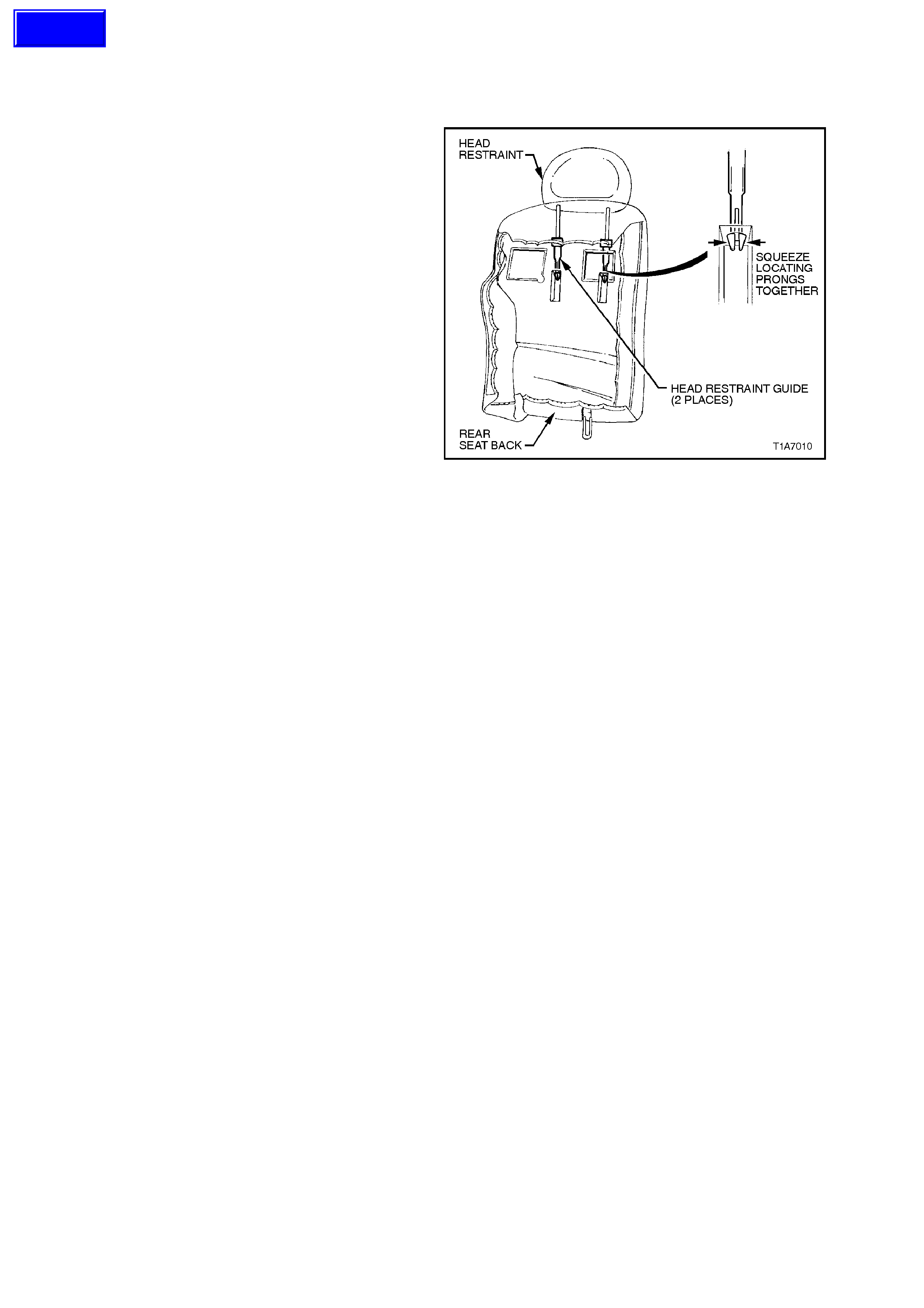

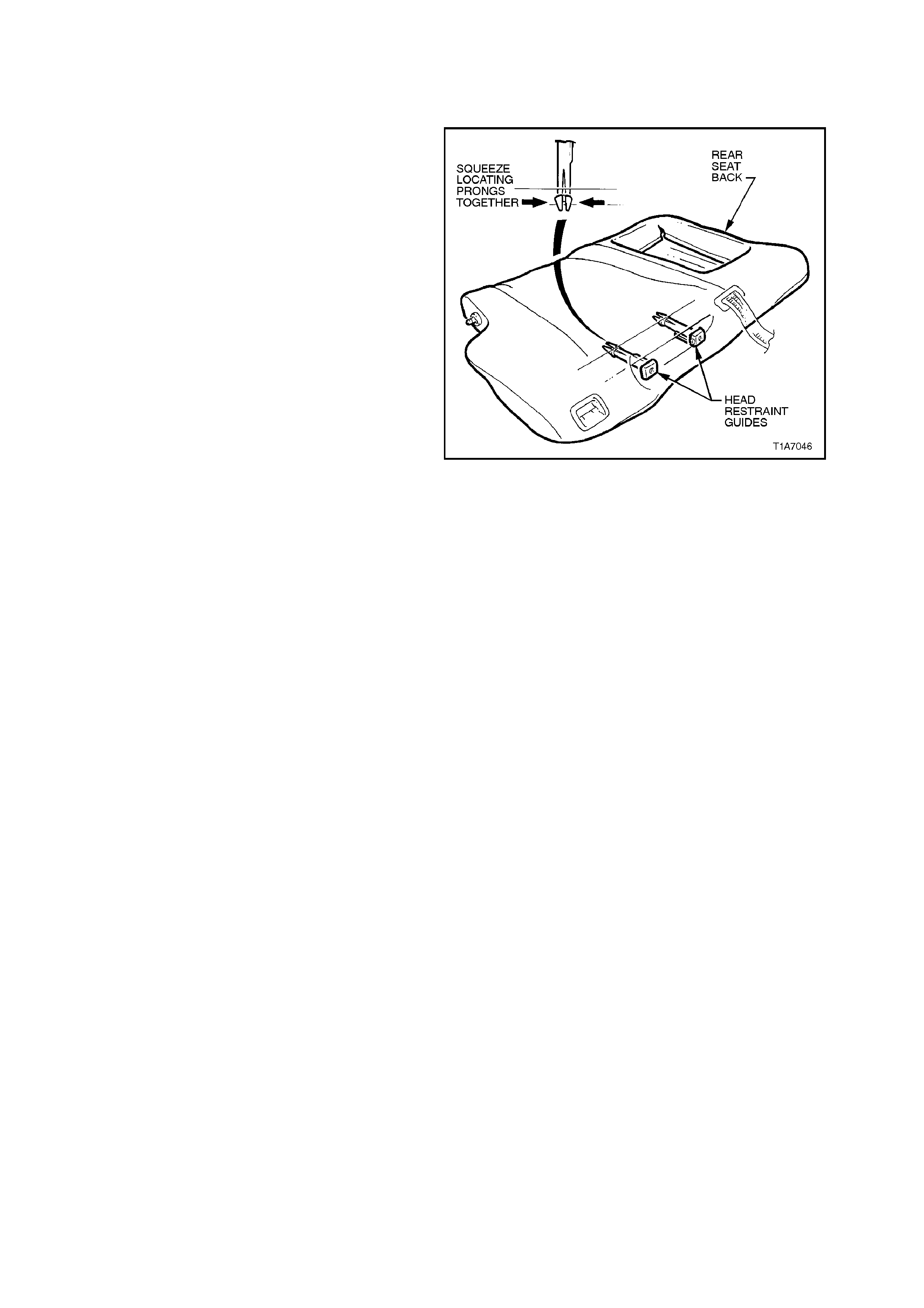

4. From the back of rear seat back (foam side)

squeeze the locking prongs of head restraint

guide together while pulling top of guide out of

seat back assembly, refer to Fig 1A7-33.

REINSTALL

Installation is the reverse of the removal procedure

noting the following:

When installing head restraint guide, ensure that

locating slots in the s eat bac k align with k ey-way on

the head restraint guide and the head restraint

guide with adjusting lock is installed on the correct

side, ie. align with notches on the head restraint.

Figure 1A7-33

Techline

2.17 REAR SEAT HEAD RESTRAINT ASSEMBLY - WAGON

REMOVE

1. While holding head restraint height adjuster

lock in, pull head restraint completely out of

guide.

2. Remove rear seat cover and pad assembly,

refer to 2.27 REAR SEAT BACK COVER

AND PAD ASSEMBLY - WAGON, Steps 1 -

16 in this Section.

3. Remove the head r estraint guides by reaching

in between seat back frame and pad

assembly, squeezing the head restraint guide

locating prongs together and pulling the top of

the guide (from outside of seat) up and out of

the seat back assembly.

REINSTALL

Installation of the r ear seat head r estraint ass em bly

is the reverse of the rem oval procedure, noting the

following:

When installing head restraint guide, ensure that

locating slots in the s eat bac k align with k ey-way on

the head restraint guide and the head restraint

guide with adjusting lock is installed on the correct

side, ie. align with notches on the head restraint.

Figure 1A7-34

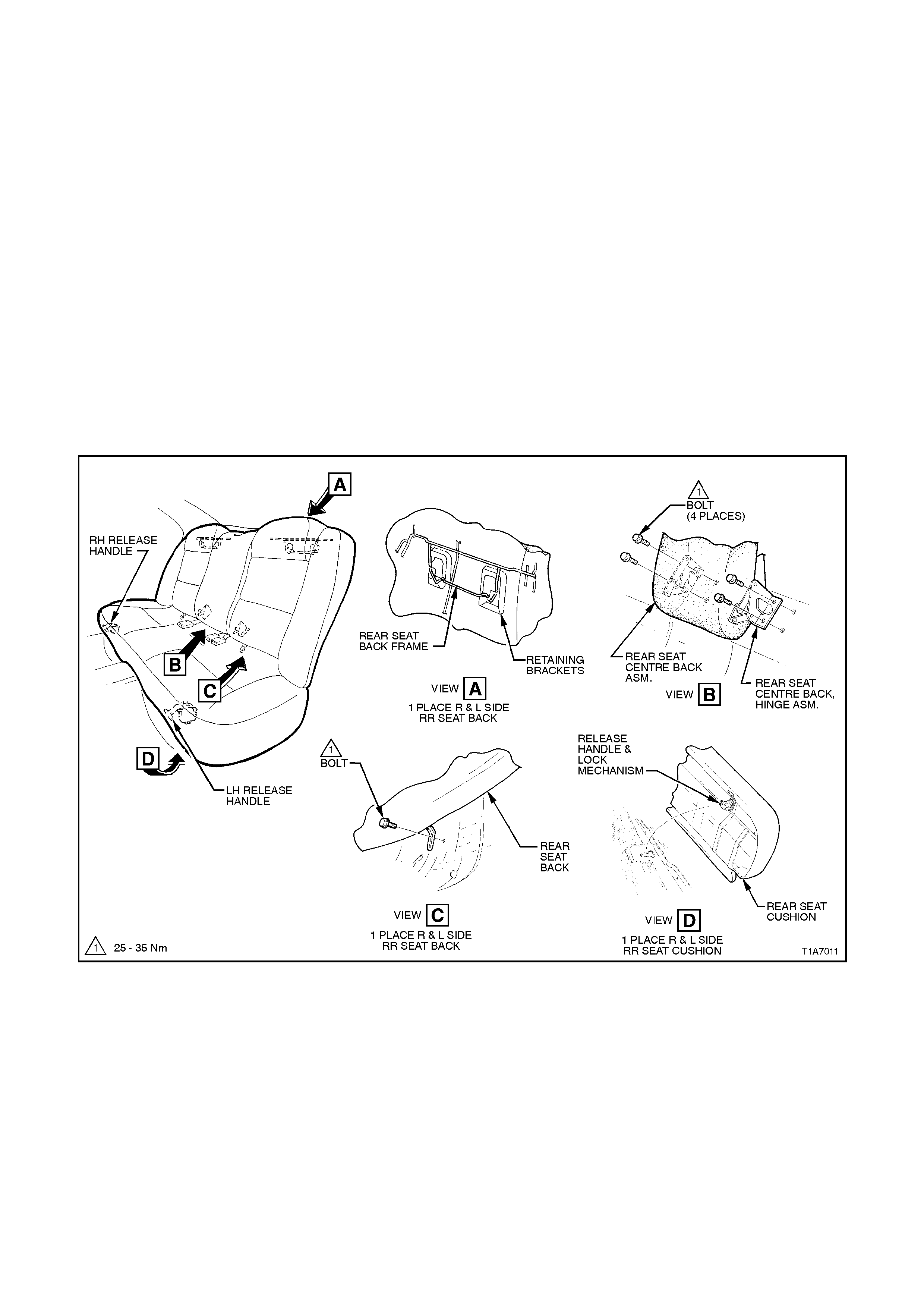

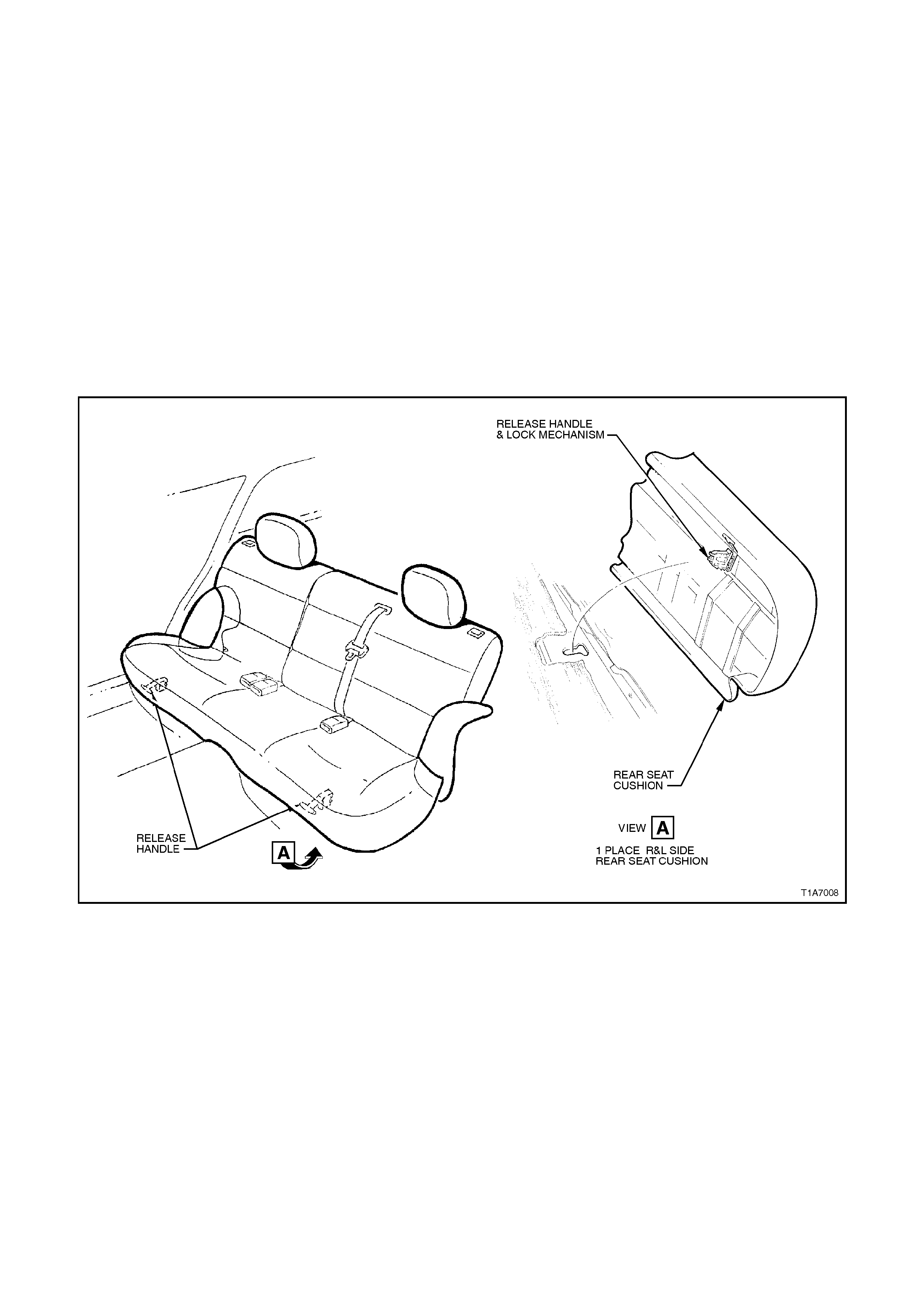

2.18 REAR SEAT CUSHION AND BACK ASSEMBLIES - SEDAN

REMOVE

1. Lift front edge of rear seat cushion slightly to gain access to rear seat cushion release handles, refer to Fig.

1A7 - 35.

2. From either the left or right side of seat, pull release handle downwards towards the floor, while at the same

time lifting the front of the rear seat cushion until lock mechanism is released.

3. Repeat step 2 for opposite side of seat and remove rear seat cushion.

4. Detach and lower rear seat centre back.

5. Remove the two bolts securing the left and right seat back assemblies to the rear floor pan. Lift left and right

seat back assemblies up and out of retaining brackets in the rear compartment front panel. Remove left and

right seat back assemblies.

6. 6. Remove the four bolts securing the rear seat centre back hinge assembly and remove rear seat centre

back assembley.

REINSTALL

Installation of the rear seat cushion and back assemblies is the reverse of the removal operation.

Figure 1A7-35

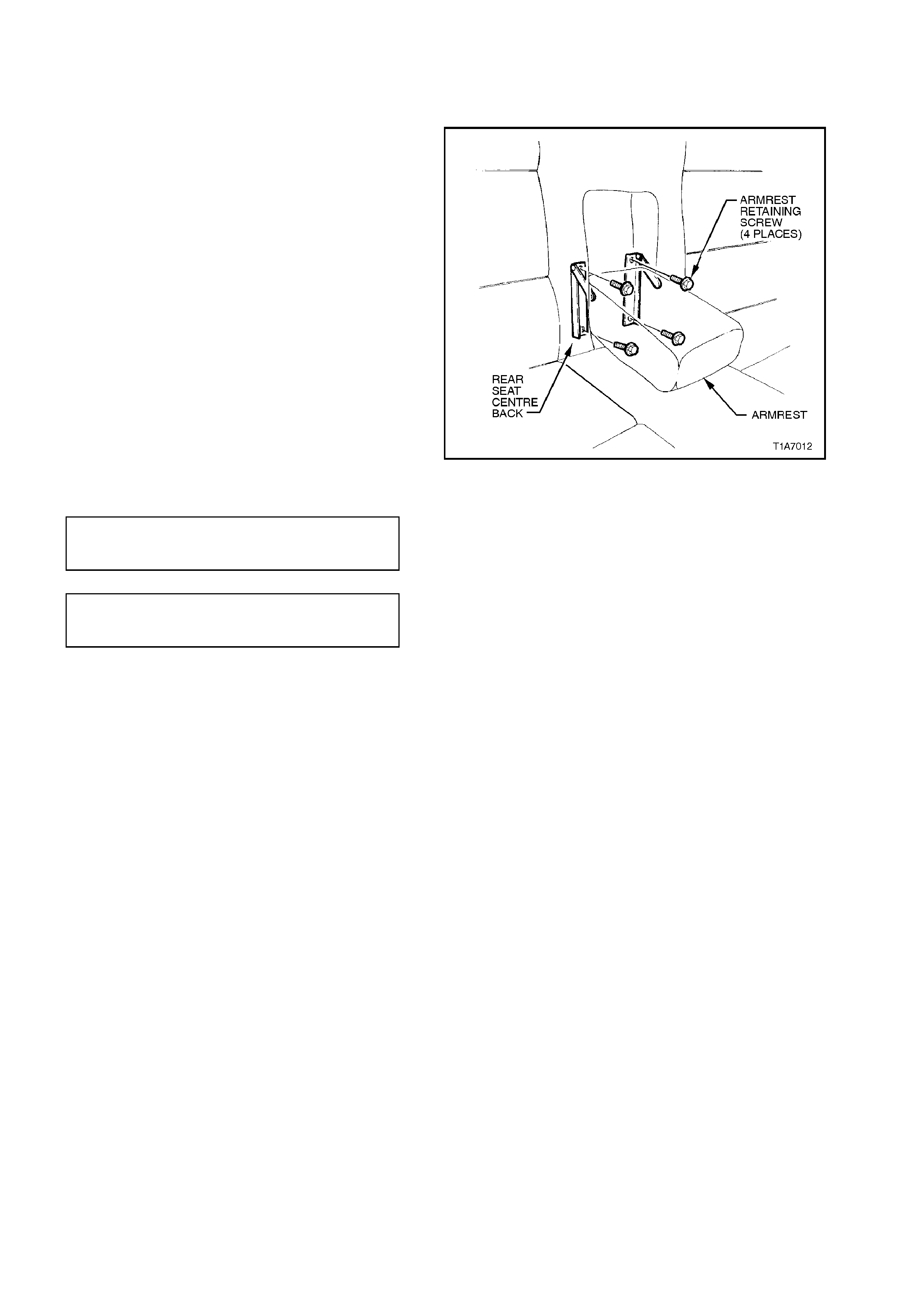

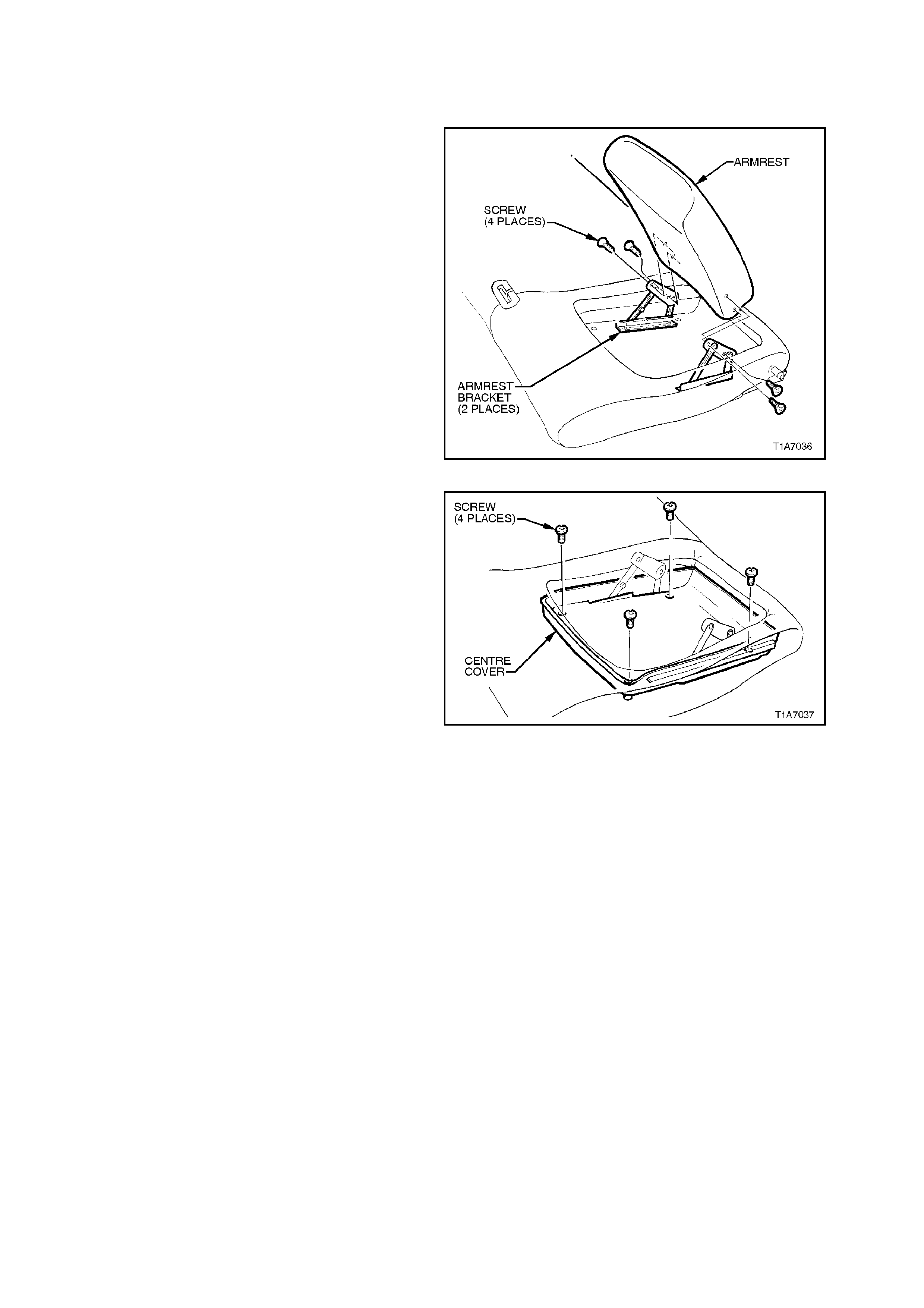

2.19 REAR SEAT BACK FLAP ARMREST - SEDAN

REMOVE

1. Lower armrest and move cloth trim to gain

access to the four armrest retaining screws.

2. Remove the f our ar m rest retaining screws and

remove armrest and hinge assembly.

3. Remove the four screws securing the armrest

to the hinge and remove armrest.

REINSTALL

Installation of the rear s eat back f lap armrest is the

reverse of the removal operation, noting the

following:

Ensure all bolts are tightened to the correct torque

specification

Figure 1A7-36

ARMREST TO HINGE

SECURING SCREWS

TORQUE SPECIFICATION 7 - 10 Nm

HINGE TO REAR SEAT BACK

FLAP RETAINING SCREW

TORQUE SPECIFICATION 3 - 5 Nm

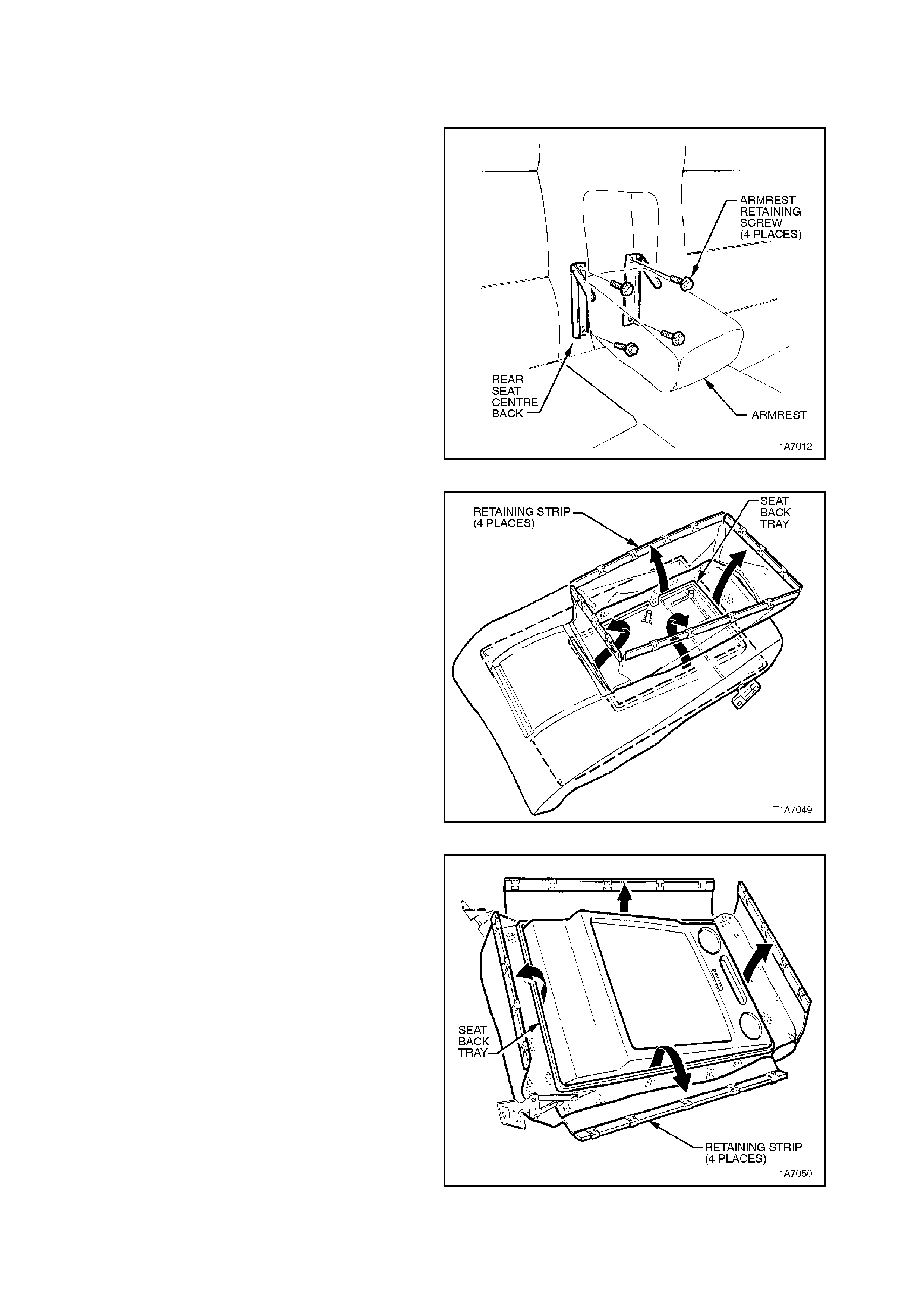

2.20 REAR SEAT BACK CENTRE COVER AND PAD ASSEMBLY - SEDAN

REMOVE

1. Remove rear seat c entre back assem bly, refer

to 2.18 REAR SEAT CUSHION AND BACK

ASSEMBLIES - SEDAN, in this Section.

2. Lower armrest and move cloth trim to gain

access to the four armrest retaining screws.

3. Remove the f our armr est r etaining s crews and

remove armrest and bracket assembly.

Figure 1A7-37

4. Pull the four seat cover retaining strips in the

centre of the seat back up and away from the

inside of the seat back tray, refer to Fig. 1A7-

37.

Figure 1A7-38

5. Pull the four seat cover retaining strips up from

the outer edge of the seat back tray, refer to

Fig. 1A7-39.

6. W hile f eeding the seat cover m aterial over the

release button and esc utcheon ass em bly, peel

the cover and pad assembly away from the

seat back tray.

Figure 1A7-39

REINSTALL

Reinstallation is the reverse of the removal

operation, noting the following:

Ensure all screws are tightened to the correct

torque specification

HINGE TO REAR SEAT FLAP

BACK RETAINING SCREW

TORQUE SPECIFICATION 3 - 5 Nm

2.21 RE AR SEAT BACK TRAY AND LOCK ACTUATOR - SEDAN

REMOVE

1. Remove rear seat back centre cover and pad

assembly, refer to 2.18 REAR SEAT

CUSHION AND BACK ASSEMBLIES -

SEDAN, in this Section.

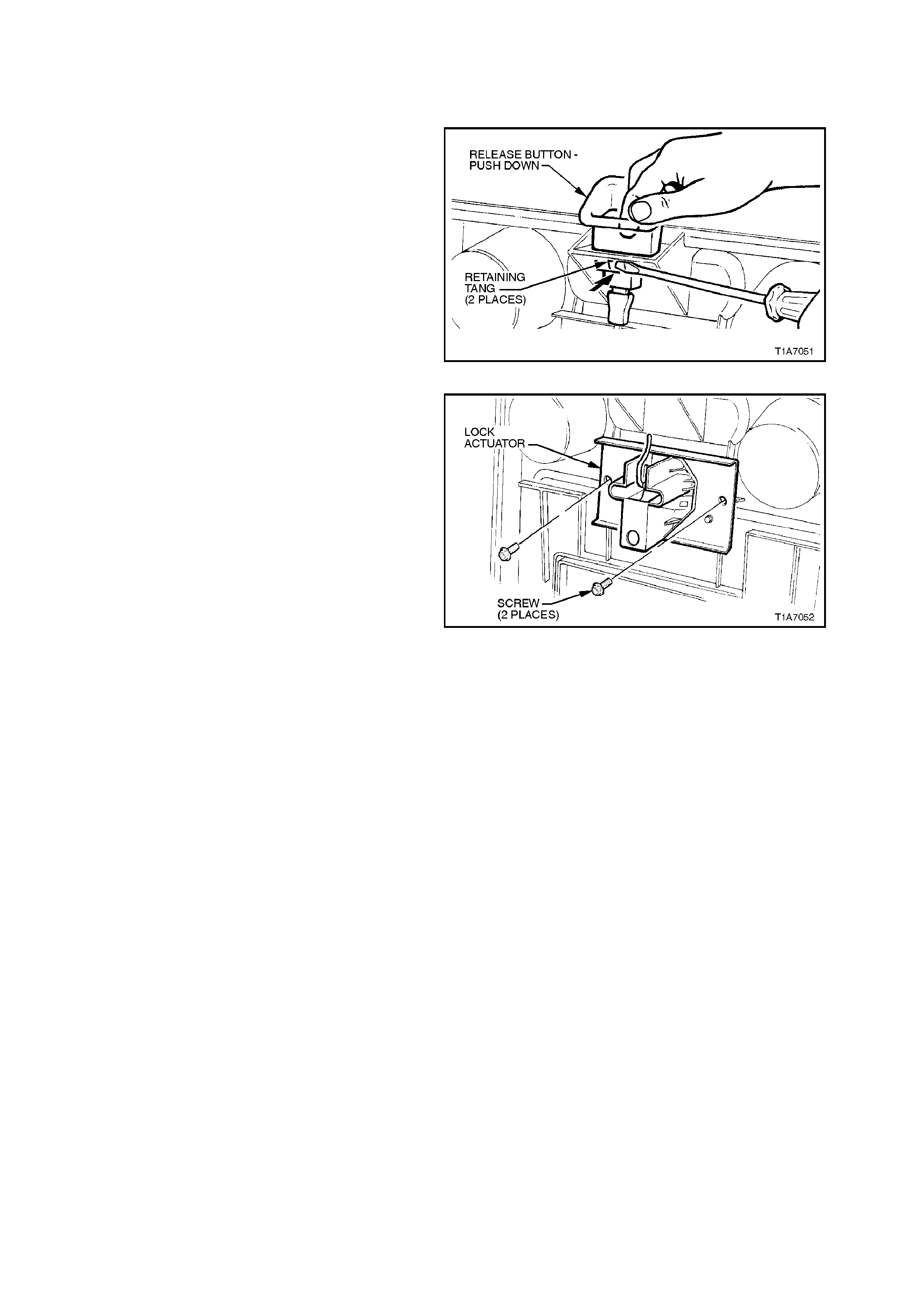

2. Disengage seat release button assembly

retaining tangs by pushing one of the tangs

through the seat back tray while pushing top of

button assembly forward. W hile holding top of

button, to prevent tang f r om r e-engaging, pus h

other tang in to disengage the release button.

Remove release button and escutcheon

assembly.

Figure 1A7-40

3. Remove the two screws securing the lock

actuator to the back tray and remove lock

actuator.

REINSTALL

Installation of the lock actuator is the revers e of the

removal procedure ensuring that the button

assembly and lock actuator rod are correctly

engaged.

Figure 1A7-41

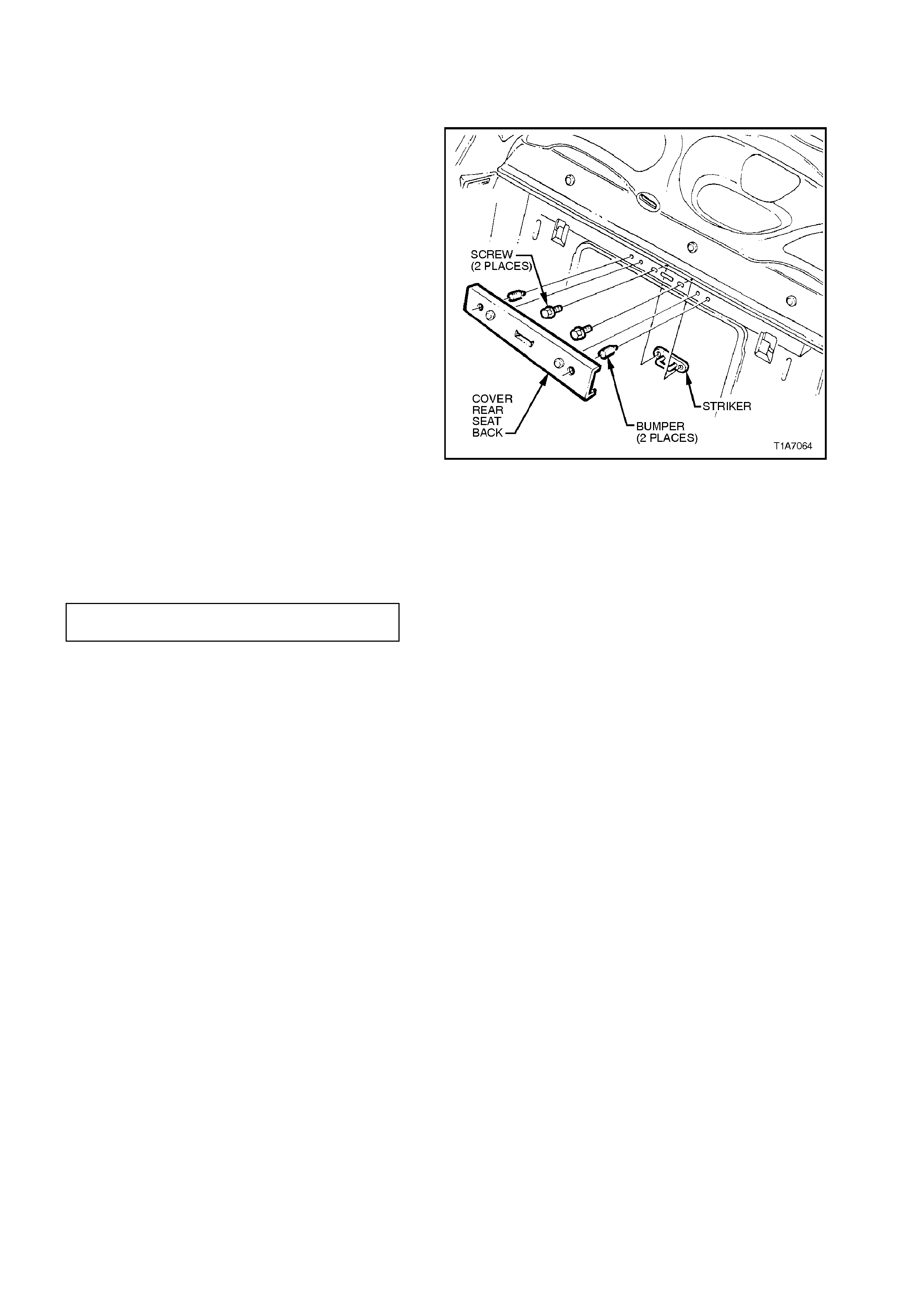

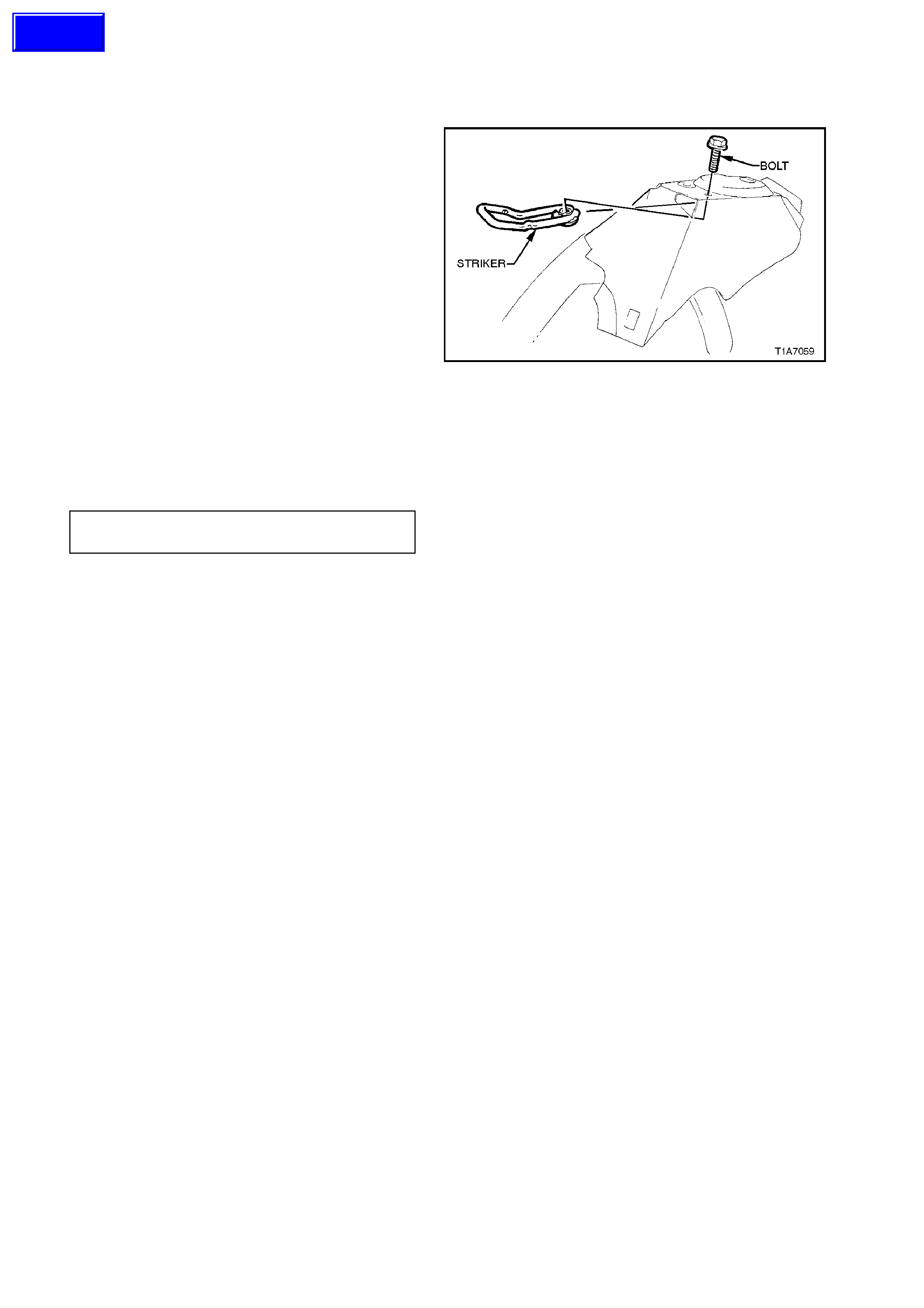

2.22 RE AR SEAT BACK LOCK STRIKER - SEDAN

REMOVE

1. Remove left and right hand rear seat backs,

refer to 2.18 SEAT CUSHION AND BACK

ASSEMBLIES - SEDAN in this Section.

2. With centre seat back detached and lowered,

pry the two retaining clips securing the rear

seat back cover to the parcel shelf and remove

cover.

3. Remove the two sc rews securing the strik er to

the rear panel and remove striker.

Figure 1A7-42

REINSTALL

Installation of the rear seat lock striker is the

reverse of the rem oval procedure ensur ing that the

retaining screws are tightened to the corr ect torque

specification.

STRIKER RETAINING SCREW

TORQUE SPECIFICATION 25 - 35

Nm

2.23 REAR SEAT CUSHION - WAGON

REMOVE

1. Lift front of rear seat cushion slightly to gain access to rear seat cushion release handles, refer to Fig. 1A7-42.

2. From either the left or right side of seat, pull release handle downwards towards the floor, while at the same

time lifting the front of the rear seat cushion until lock mechanism is released.

3. Repeat step 2 for opposite side of seat.

4. Remove rear seat cushion assembly, taking care to pass centre seat belt assemblies through the elastic

retention loops on the rear seat cushion.

REINSTALL

1. Sit rear seat cushion into position and feed seat belt assemblies through the elastic retention loops.

2. Push rear seat cushion into back of seat and push down front of seat until locking mechanisms lock seat

cushion into position.

Figure 1A7-43

2.24 REAR SEAT BOLSTER - WAGON

REMOVE

1. Remove rear seat cushion, refer to

2.23 REAR SEAT CUSHION - WAGON in this

Section.

2. Lower rear seat back assembly.

3. Using a pair of pliers, squeeze tangs of the

upper bolster retaining clip together and pull

the bolster towards the front of the vehicle.

4. Lift bottom of bolster lower retaining tang

up and pull bolster forward, towards front of

vehicle.

REINSTALL

1. Insert bottom retaining tang of bols ter into s eat

back retaining bracket and push upper

retaining tab into retaining bracket.

2. Reinstall rear seat cushion, refer to

2.23 REAR SEAT CUSHION - WAGON in this

Section.

Figure 1A7-44

2.25 REAR SEAT BACK ASSEMBLIES - WAGON

REMOVE

1. Remove rear seat cushion, refer to

2.23 REAR SEAT CUSHION - WAGON in this

Section.

2. Remove rear seat back bolsters, refer to

2.24 REAR SEAT BOLSTER - WAGON in this

Section.

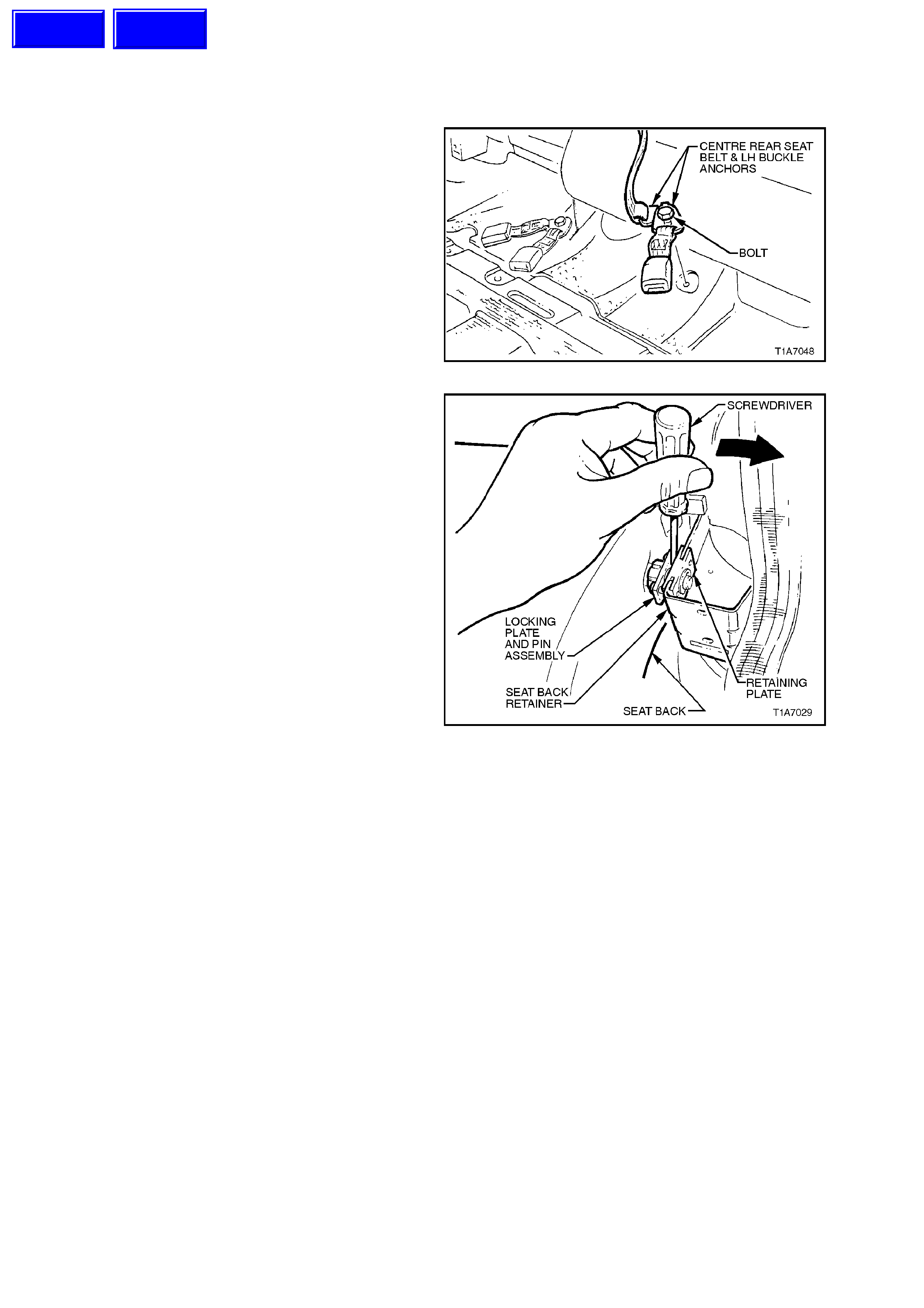

3. Remove the bolt securing the centre rear seat

belt and LH buckle anchors to the floor pan.

Figure 1A7-45

4. Unlatch and lower rear seat back assembly.

NOTE:

If seat back ass embly is not lowered, the seat back

locking plate and pin assembly will be damaged if

Step 5 is attempted.

5. Insert a screwdriver between seat back

retaining plate and locking plate and pin

assembly and gently prise apart to withdraw

pins from retaining plate.

6. Lift outer end of seat up out of seat back

retainer and pull seat back assembly towards

the door, withdrawing it from the seat back

centre hinge assembly.

7. Remove seat back.

Figure 1A7-46

REINSTALL

Installation is the revers e of the rem oval procedure

noting the following:

1. Install seat back in it’s lowered position.

2. Fold seat into upright position and locking

plate and pin assembly will automatically lock.

Techline

Techline

2.26 RE AR SEAT BACK CENTRE SUPPORT - WAGON

REMOVE

1. Remove rear seat cushion assembly, refer to

2.23 REAR SEAT CUSHION - WAGON in this

Section.

2. Remove rear seat back bolsters, refer to

2.24 REAR SEAT BOLST ER - WAGON in this

Section.

3. Remove rear seat back assemblies, refer to

2.25 REAR SEAT BACK ASSEMBLIES -

WAGON in this Section.

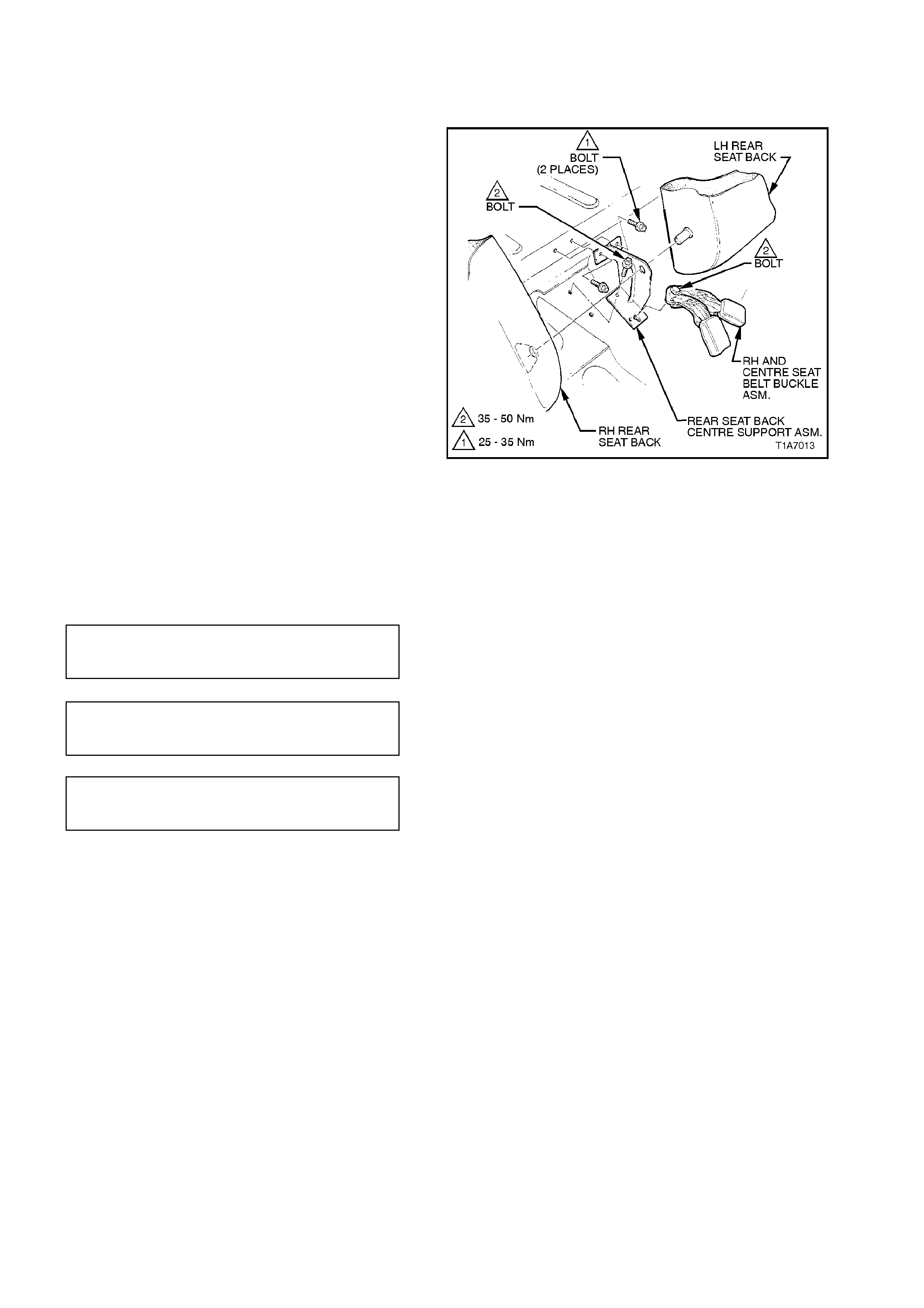

4. Remove the RH and centre seat belt buckle

assembly anchor bolt, refer to Fig. 1A7-47.

5. Remove the four bolts securing the seat back

centre support assembly to the floor pan, refer

1A7-47.

6. Remove centre support assembly.

Figure 1A7-47

REINSTALL

Installation of the rear seat back centre support is

the reverse of the removal operation, noting the

following:

Ensure all bolts are fastened to the correct torque

specifications

SEAT BELT BUCKLE ANCHOR

SECURING BOLT

TORQUE SPECIFICATION 35 - 50 Nm

CENTRE HINGE LOWER

SECURING BOLT

TORQUE SPECIFICATION 35 - 50 Nm

CENTRE HINGE UPPER

SECURING BOLT

TORQUE SPECIFICATION 25 - 35 Nm

2.27 REAR SEAT BACK COVER AND PAD ASSEMBLY - WAGON

REMOVE

NOTE:

When performing this service operation on Berlina

Models, the rear seat centre cover blanking plugs

will become damaged and will need to be replaced.

Therefore, before carrying out this service

operation, order four new blanking plugs from your

authorised Holden parts outlet.

1. Remove rear seat back, refer to

2.25 REAR SEAT BACK ASSEMBLIES -

WAGON in this Section.

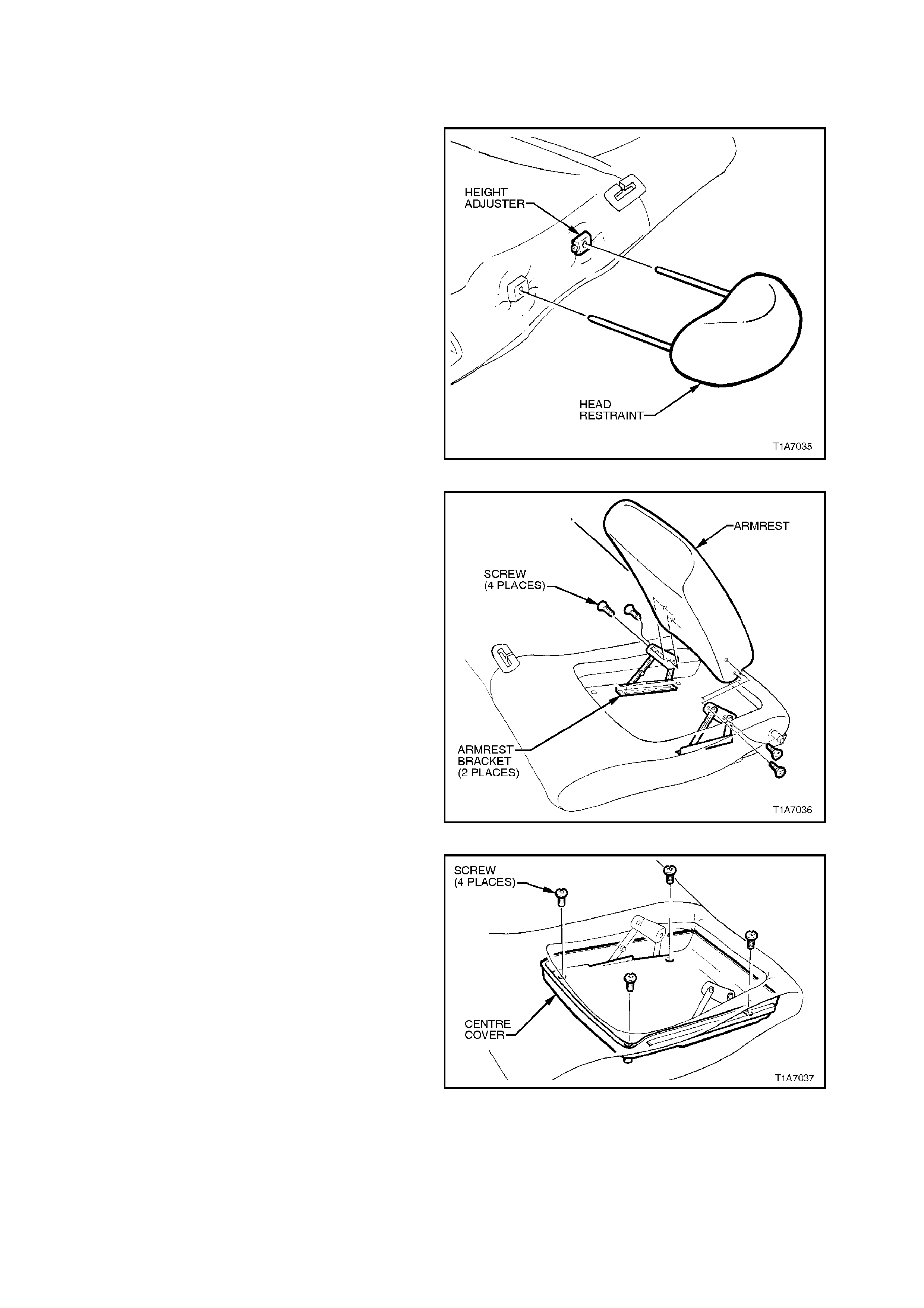

2. While holding the head restraint height

adjuster lock in, pull head restraint completely

out of guide.

Figure 1A7-48

3. On the LH rear seat back, remove the four

screws securing the armrest to armrest

bracket and remove armrest.

Figure 1A7-49

4. Pull the four blank ing plugs from the rear seat

back cover by inserting a scribe or small

screwdriver into the centre of the plug and

pulling them free. Take care not to damage

seat back cover.

NOTE:

The four blanking plugs will be dam aged dur ing this

operation and therefore must be replaced.

5. On the LH rear seat back, remove the four

screws securing the centre cover to the seat

back frame.

Figure 1A7-50

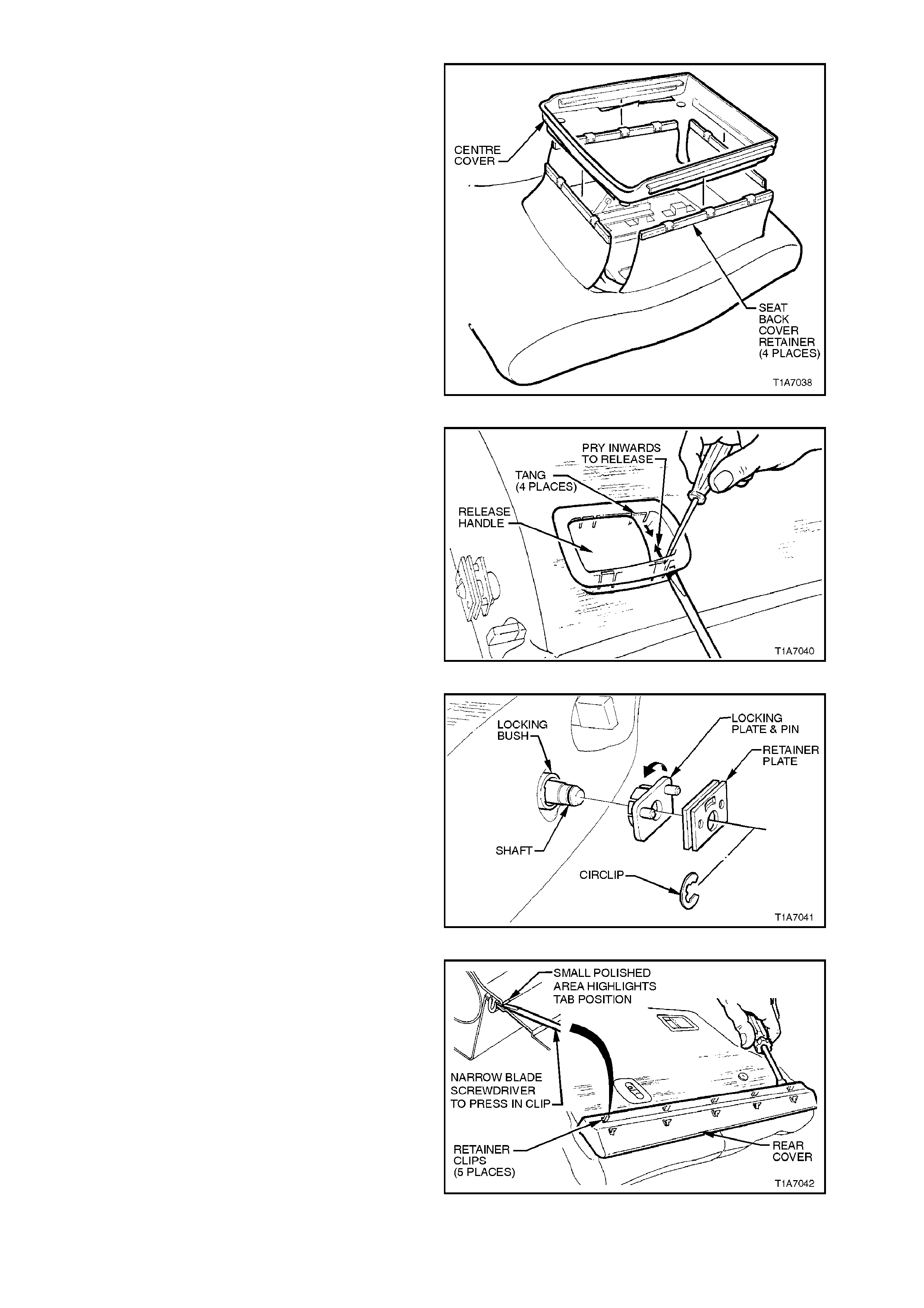

6. On the LH rear seat back , lift the centre cover

up and pull the seat back cover retainer away

from the four s ides of the centre c over , ref er to

Fig. 1A7-51.

Figure 1A7-51

7. Disengage the corners of the release handle

by inserting a screwdriver under one of the

corners of the release handle assembly while

at the same time prising the retaining tang

towards the centre of the release handle.

8. With one corner of the release handle

disengaged, hold the handle in the release

position (up) and disengage the remaining

three tangs by prising them inwards using a

screwdriver (towards centre of handle).

Remove handle assembly.

Figure 1A7-52

9. Remove the c irclip fr om the s eat back retainer

assembly and remove the r etainer plate ( metal

piece) from shaft.

10. Remove the retainer locking plate and pin by

twisting it off the locking bush.

NOTE:

The locking bush does not have to be removed

unless it is being replaced. This c an be ac hieved by

simply levering it off the shaft.

Figure 1A7-53

11. Remove the rear cover from the rear seat

back by inserting a small screwdriver under

the rear seat back cover and prying cover

away from seat back, refer to Fig. 1A7-54.

Figure 1A7-54

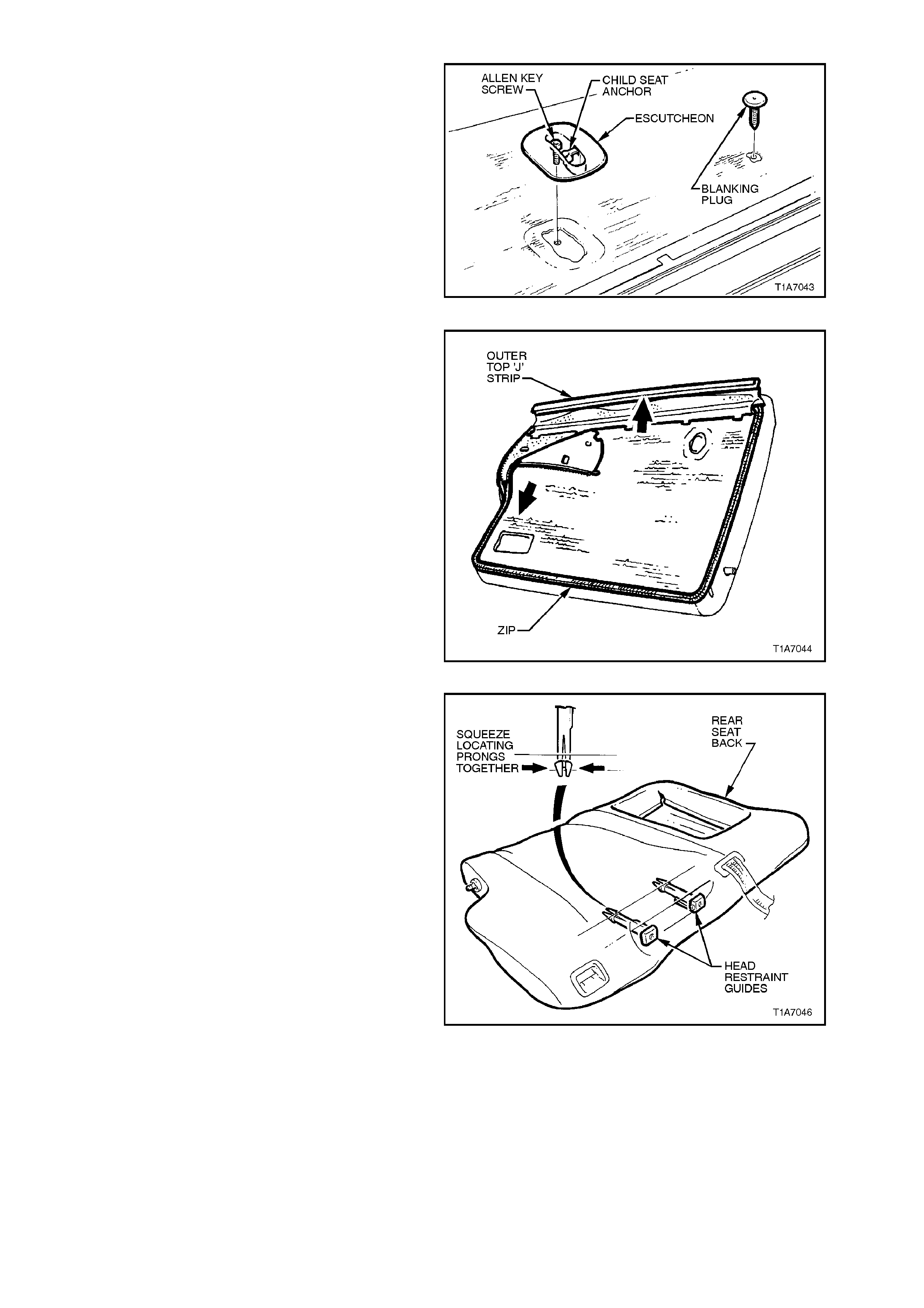

12. On the LH rear seat back, remove the child

seat anchor bolt to the rear seat back and

remove child seat anchor and escutcheon.

13. Prise c hild seat anc hor blanking plug fr om rear

seat back.

Figure 1A7-55

14. Pull the outer top ‘J’ strip from the seat back

frame, refer to Fig. 1A7-55.

NOTE:

To ease in the removal of the top ‘J’ strip, gently

lever strip away from frame using a screwdriver.

15. Unzip seat trim cover.

Figure 1A7-56

16. Rem ove the head restraint guides by reaching

in between seat back frame and pad

assembly, squeezing the head restraint guide

locating prongs together and pulling the top of

the guide (from outside of seat) up and out of

the seat back assembly.

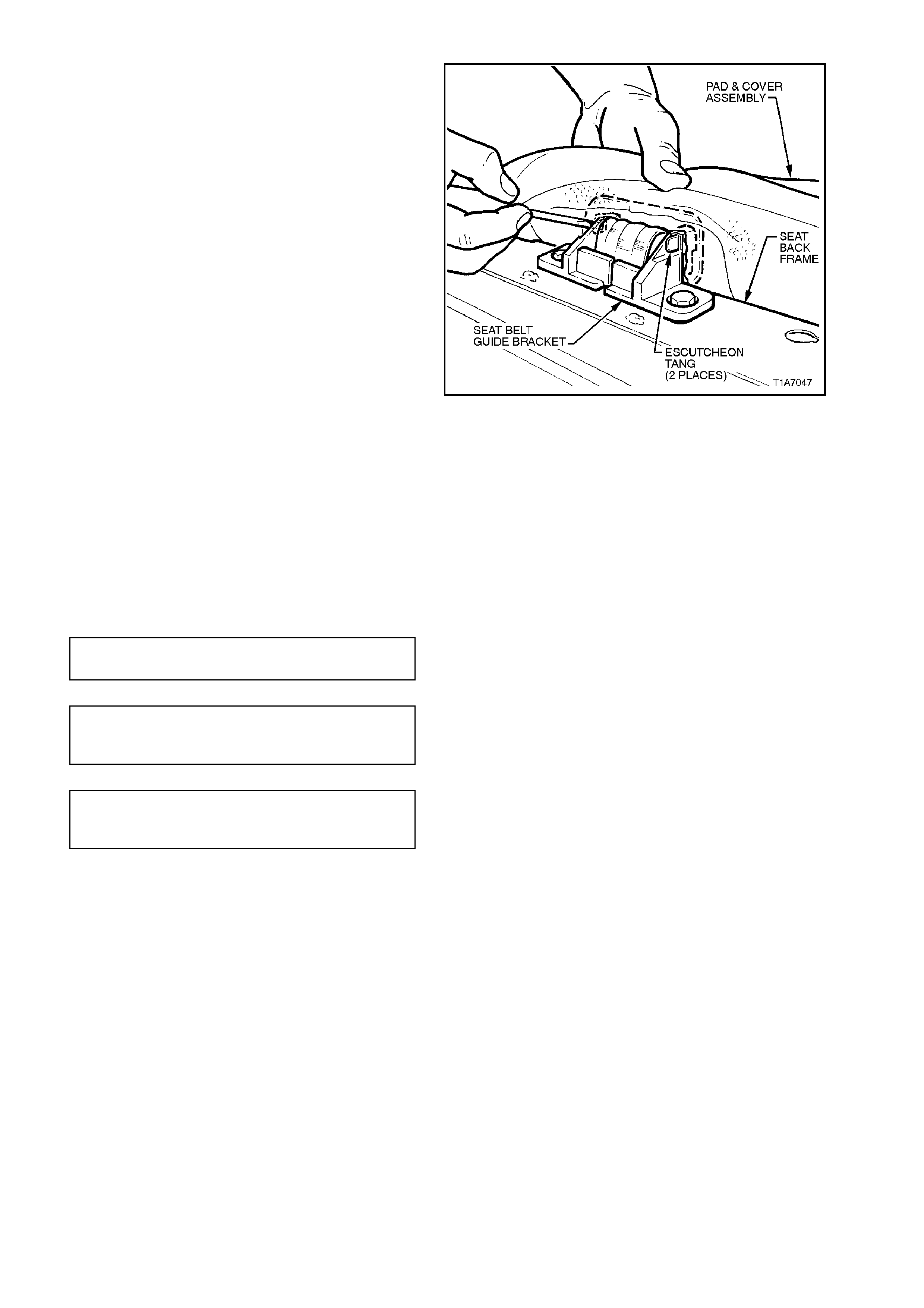

Figure 1A7-57

17. Remove cover and pad away from seat back

frame, noting the following:

Feed the seat back c over material through the

seat back release button and escutcheon

assembly.

On the LH rear seat back , release centre seat

belt escutcheon from inside seat back by

pushing tangs of escutcheon through the seat

belt guide brack et assem bly, refer to Fig. 1A7-

58.

Figure 1A7-58

REINSTALL

Installation of the rear seat cover and pad

assembly is the reverse of the removal procedure,

noting the following:

1. If the locking bush for the seat back retainer

was removed, ensure that the retaining

grooves on the m ating shaft are c lean. (Plast ic

residue on shaft).

2. Tighten all fasteners to the correct torque

specification.

CHILD SEAT ANCHOR BOLT 15.0

TORQUE SPECIFICATION Nm

CENTRE COVER TO FRAME

RETAINING SCREW 2.5 Nm

TORQUE SPECIFICATION

ARMREST TO BRACKET

RETAINING SCREW 4.0 Nm

TORQUE SPECIFICATION

2.28 RE AR SEAT BACK LOCK, ACTUATOR, CABLE AND RELEASE BUTTON - WAGON

REMOVE

1. Remove rear seat back cover and pad

assembly, refer to 2.27 REAR SEAT BACK

COVER AND PAD ASSEMBLY - WAGON in

this Section.

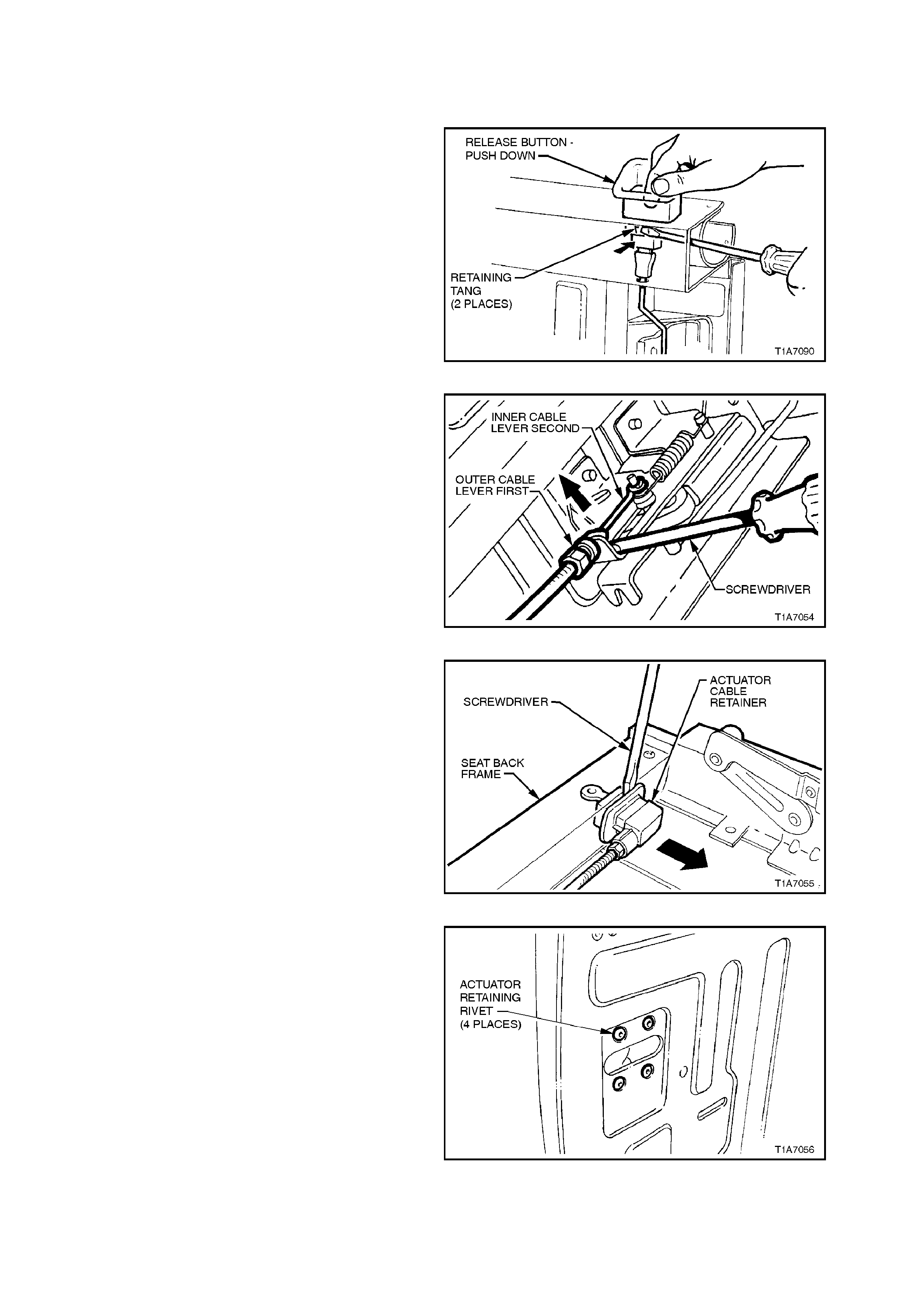

2. Using a screwdriver, depress tangs of release

button and pull release button from seat

frame.

Figure 1A7-59

3. On the LH rear seat back, lever outer part of

actuator cable from actuator and then the

inner part of cable from the actuator using a

small screwdriver.

Figure 1A7-60

4. On the LH rear seat back , lever actuator cable

retainer fr om s eat back f ram e with the aid of a

screwdriver.

NOTE:

When levering the actuator cable retainer f rom s eat

back frame, it is highly possible that the retaining

tangs will be damaged. If this occurs, the actuator

cable must be replaced.

5. On the LH rear seat back, remove tape

securing actuator cable to seat back frame

and remove cable.

NOTE:

Remember location off tape for reinstallation. Figure 1A7-61

6. From the rear side of the seat back, drill the

heads off the four rivets retaining the actuator

to the seat back frame, using a 6mm drill bit.

7. Knock body of rivet through seat back frame

and remove actuator.

Figure 1A7-62

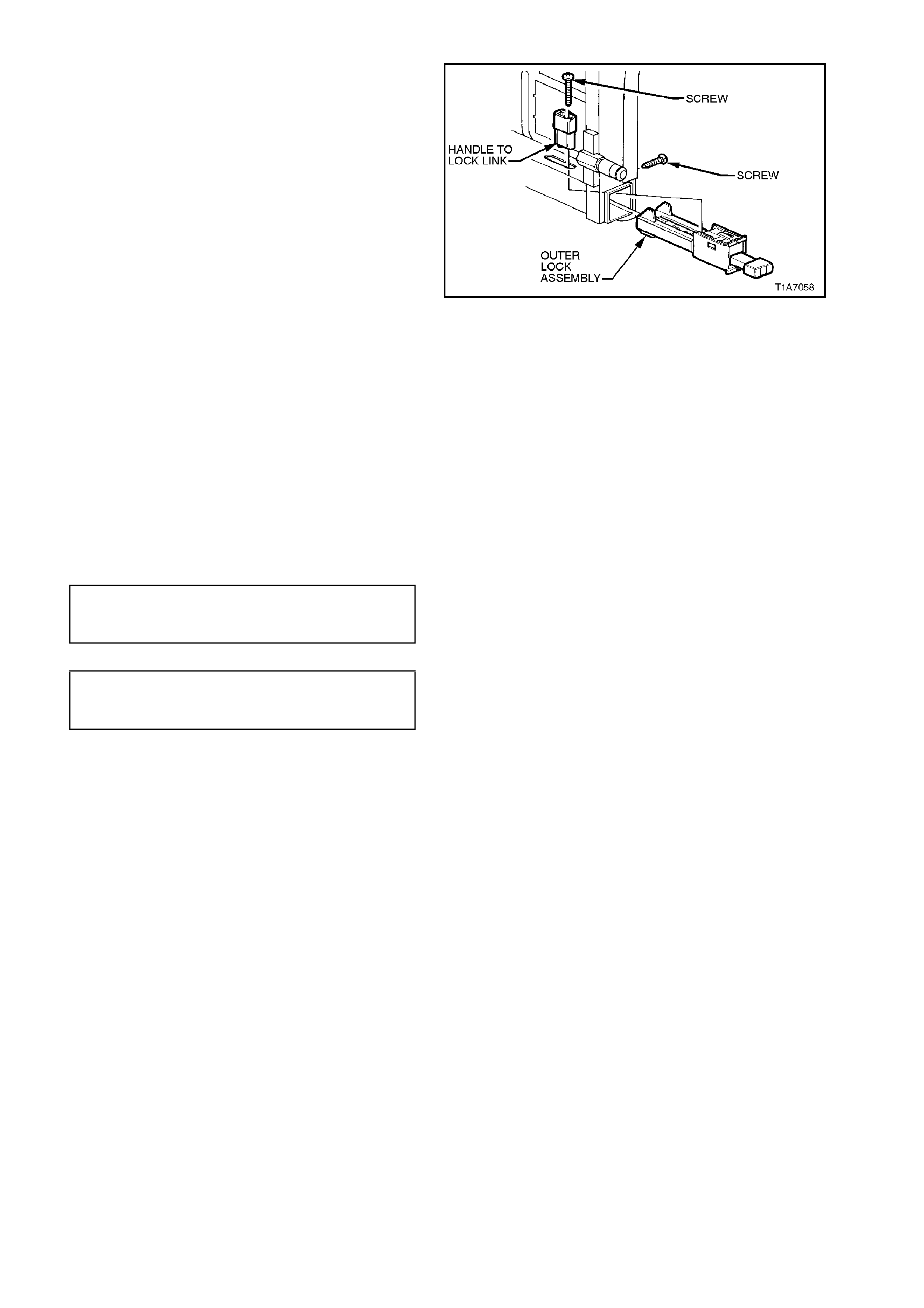

8. Remove the allen key screw from the release

handle to lock link and remove link. Slide lock

out of seat back frame.

Figure 1A7-63

REINSTALL

Installation of the rear seat back actuator, cable

and release button is the reverse of the removal

procedure, noting the following:

1. Use 3/16” steel pop rivets (not aluminium) to

retain the actuator to the seat back.

2. Place the actuator lock in the up position

before connecting the actuator cable.

3. Ensure the release button and the actuator

rod are aligned correctly.

4. Ensure all fasteners are tightened to the

correct torque specification:

SEAT BACK LOCK

ALLEN KEY SCREW 3.0 Nm

TORQUE SPECIFICATION

LH SEAT BACK LOCK

RETAINING SCREW 3.0 Nm

TORQUE SPECIFICATION

5. Check the function of the seat back lock by

operating the seat back lock at least three

times while observing the following:

•Ensure the locking pin on the centre lock

assembly engages fully with the rear seat

back centre s upport ass em bly when it is in the

lock position.

•Ensure the release button, when in the lock

position, sits flush with the escutcheon.

2.29 RE AR SEAT BACK LOCK STRIKER - WAGON

REMOVE

1. Remove carpet from rear quarter inner panel,

refer to Section 1A1 BODY.

2. Remove bolt securing the striker to the rear

quarter inner panel and remove striker and

bumper.

Figure 1A7-64

REINSTALL

Installation is the revers e of the rem oval procedure

noting the following:

Ensure all fasteners are tightened to the correct

torque specifications.

STRIKER RETAINING BOLT 25 - 35

TORQUE SPECIFICATION Nm

Techline

2.30 RE AR SEAT BACK ARMREST - W AGON

REMOVE

NOTE:

When performing this service operation, the rear

seat centre cover blanking plugs will become

damaged and will need to be replaced. Therefore,

before carrying out this service operation, order

four new blanking plugs from your authorised

Holden parts outlet.

1. Remove the four screws securing the armrest

to armrest bracket and remove armrest.

Figure 1A7-65

2. Pull the four blank ing plugs from the rear seat

back cover by inserting a scribe or small

screwdriver into the centre of the plug and

pulling them free. Take care not to damage

seat back cover.

NOTE:

The four blanking plugs will be dam aged dur ing this

operation and therefore must be replaced.

3. On the LH rear seat back, remove the four

screws securing the centre cover to the seat

back frame.

Figure 1A7-66

4. Lift the centre cover up and pull the seat back

cover retainer away from the four sides of the

centre cover, refer to Fig. 1A7-67.

Figure 1A7-67

5. Remove the four screws securing the armrest

brackets to the seat back frame and remove

the armrest brackets.

Figure 1A7-68

REINSTALL

Installation of the rear seat back armrest is the

reverse of the removal procedure, noting the

following:

Tighten all fasteners to the correct torque

specification.

ARMREST BRACKET TO FRAME

RETAINING SCREW 4.0 Nm

TORQUE SPECIFICATION

CENTRE COVER TO FRAME

RETAINING SCREW 2.5 Nm

TORQUE SPECIFICATION

ARMREST TO BRACKET

RETAINING SCREW 4.0 Nm

TORQUE SPECIFICATION

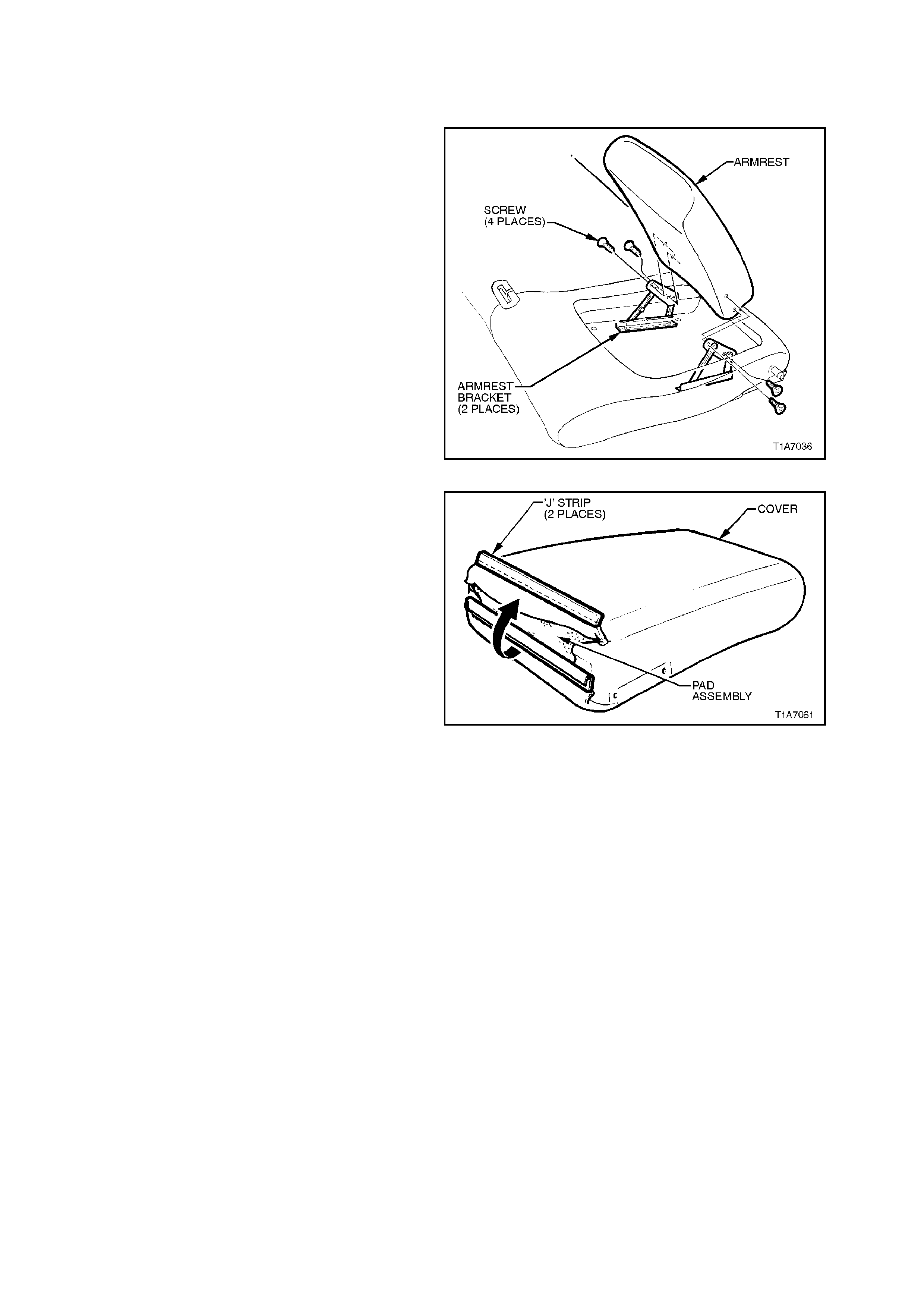

2.31 REAR SEAT BACK ARMREST COVER - WAGON

REMOVE

1. Remove the four screws securing the armrest

to armrest bracket and remove armrest.

Figure 1A7-69

2. At the bottom edge of the armrest, separate

the two ‘J’ strips by pulling the top layer over

the bottom layer of the cover.

3. Peel the armrest cover away from the pad

assembly.

Figure 1A7-70

REINSTALL

Installation of the rear seat back armrest cover is

the reverse of the removal procedure.

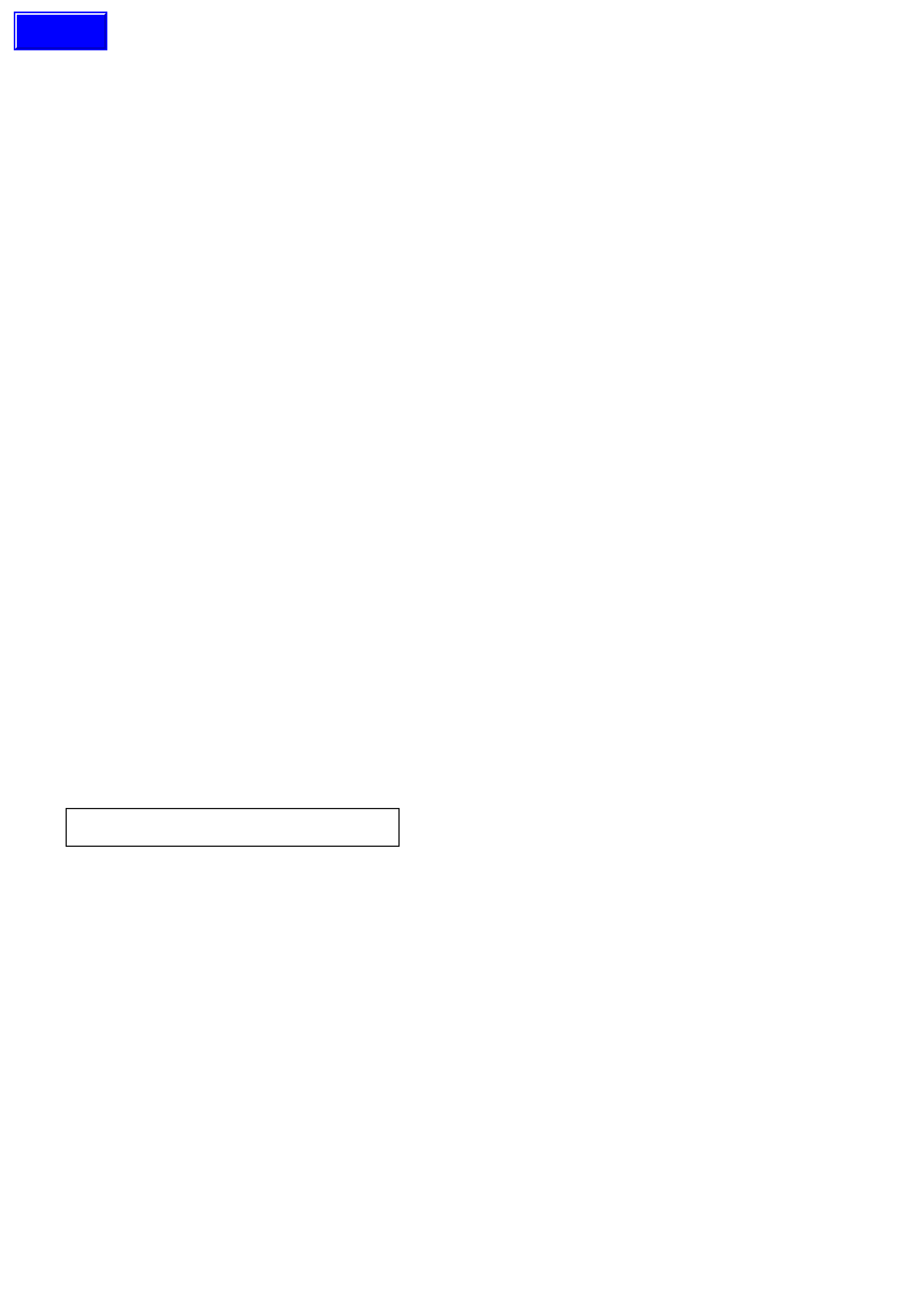

2.32 FRONT SEAT BELT RETRACTOR AND HEIGHT ADJUSTER ASSEMBLY

REMOVE

1. Remove front seat guide rail covers, refer to

2.2 FRONT SEAT GUIDE RAIL COVERS in

this Section.

2. Remove cap and bolt securing the seat belt

lower anchor to the floor pan, refer to Fig.

1A7-70.

3. Remove rocker panel cover, refer to

Section 1A1 UNDERBODY.

4. Remove upper and lower B pillar trims, refer

to Section 1A8, HEADLINING AND REAR

END TRIM. Feed seat belt sash, buckle and

anchor through upper B pillar trim.

5. Remove bolt securing seat belt guide to B

pillar or, on Calais with seat belt height

adjuster, from seat belt height adjuster, refer

to Fig. 1A7-70.

6. Remove the two screws securing the

intermediate wire type sash guide to the B

pillar and remove guide.

7. Remove the bolt securing the front seat belt

retractor assembly to the B pillar and remove

seat belt retractor assembly.

8. Calais only, rem ove the two bolts secur ing the

seat belt height adjuster to the B pillar and

remove height adjuster.

REINSTALL

Installation is the reverse of the rem oval operation,

noting the following:

1. Ensure all seat belt bolts are hand tightened a

minimum of 5 turns before using tools.

2. Tighten all bolts to the correct torque

specification.

SEAT BELT SECURING BOLT

TORQUE SPECIFICATION 35 - 50

Nm

Techline

Figure 1A7-71

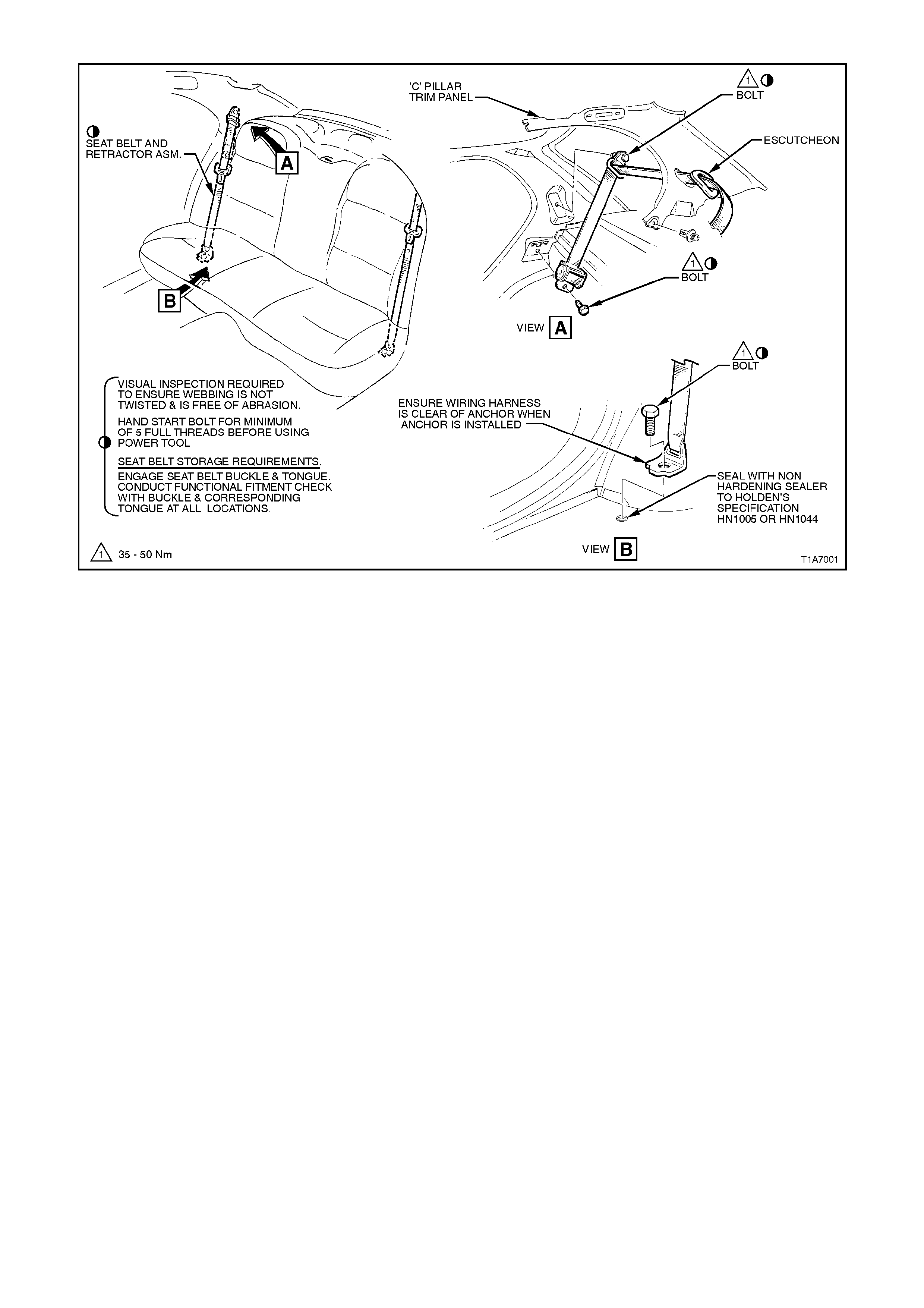

2.33 FRONT SEAT BELT BUCKLE AND PRE-TENSIONER ASSEMBLY

REMOVE

NOTE 1:

If a seat belt pre-tensioner is deployed, the seat

belt pre-tensioner assembly together with the seat

adjuster and guide rail assembly must be replaced.

NOTE 2:

If dispos ing of an undeployed seat belt buck le and

pre-tensioner assembly, refer to the disabling

procedure in Section 12M SUPPLEMENTAL

RESTRAINT SYSTEM.

1. Adjust seat to its rear most position and

disconnect battery.

2. Disconnect wiring harness connector from

seat belt buckle and pre-tensioner assembly.

3. Remove bolt securing seat belt buckle and

pre-tensioner assembly to frame and remove

seat belt buckle and pre-tensioner assembly.

REINSTALL

Installation is the reverse of the removal operation,

noting the following:

1. When installing seat belt buckle and pre-

tensioner assembly, ensure that the front

locating pin is aligned with seat frame.

2. Ensure all bolts are fastened to the correct

torque specifications.

SEAT BELT BUCKLE AND PRE-

TENSIONER ASSEMBLY BOLT 45 Nm

TORQUE SPECIFICATION

Figure 1A7-72

2.34 LEFT AND RIGHT HAND REAR SEAT BELT RETRACTOR ASSEMBLY - SEDAN

REMOVE

1. Remove rear seat cushion and either left or

right hand back seat assembly as applicable,

refer to 2.18 REAR SEAT CUSHION AND

BACK ASSEMBLIES - SEDAN.

2. Remove bolt securing the rear seat belt lower

anchor to the floor pan, refer to Fig. 1A7-72.

3. Remove seat belt escutcheon from C pillar

trim panel by gently prising the lower front of

the escutcheon away from trim.

NOTE:

The seat belt escutcheon may break if the upper

section is pried from the C pillar trim panel.

4. Remo ve C pillar trim panel assem bly, ref er to

Section 1A8 HEADLINING AND REAR END

TRIM. Feed seat belt sash, buckle, anchor

and escutcheon through C pillar panel trim.

5. Remove bolt securing sash guide to the C

pillar, refer to Fig. 1A7-73.

6. Remove bolt securing the rear seat belt

retractor assembly to the rear quarter inner

panel and remove seat belt retractor

assembly, refer to Fig. 1A7-73.

REINSTALL

Reinstallation is the reverse of the removal

operation, noting the following:

1. Ensure all seat belt bolts are hand tightened a

minimum of 5 turns before using tools.

2. Ensure that the threads of all seat belt lower

securing bolts are adequately sealed with a

non hardening sealer, to Holden’s

specification HN 1005 or HN 1044, refer to

Fig. 1A7-73.

3. Tighten all bolts to the correct torque

specification.

SEAT BELT SECURING BOLT

TORQUE SPECIFICATION 35 - 50

Nm

4. When installing the seat belt escutcheon onto

the C pillar, insert the rear upper clips of the

escutcheon into the C pillar then gently push

escutcheon into C pillar.

Techline

Figure 1A7-73

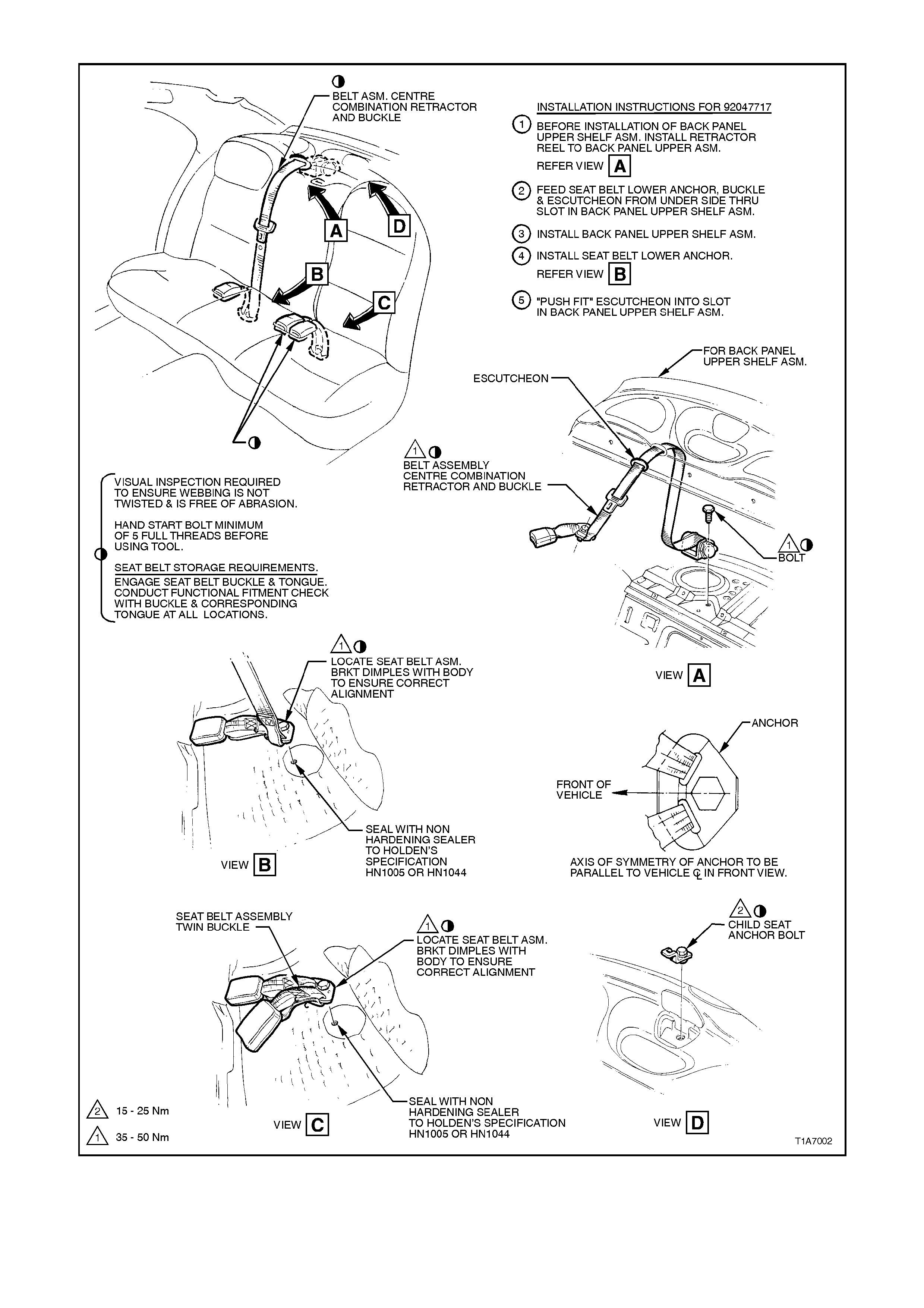

2.35 CENTRE REAR SEAT BELT RETRACTOR ASSEMBLY - SEDAN

REMOVE

1. Remove rear seat cushion, refer to

2.18 REAR SEAT CUSHION AND BACK

ASSEMBLIES - SEDAN in this Section.

2. Remove bolt securing the rear seat belt lower

anchor to the floor pan, refer to Fig. 1A7-73.

3. Detach and lower centre seat back assembly.

4. Gently prise front lower seat belt escutcheon

from parcel shelf.

5. Remove parcel shelf trim, refer to

Section 1A8 HEADLINING AND REAR END

TRIM. Feed seat belt sash, buckle, anchor

and escutcheon through parcel shelf trim.

6. 6. Remove bolt securing the centre seat belt

retractor assembly to the back panel and

remove seat belt retractor assembly, refer

Fig. 1A7-73.

REINSTALL

Installation of the centre rear seat belt retractor

assembly is the reverse of the removal operation,

noting the following:

1. Ensure all seat belt bolts are hand tightened a

minimum of 5 turns before using tools.

2. Ensure that the threads of all seat belt lower

securing bolts are adequately sealed with a

non hardening sealer, to Holden specification

HN 1005 or HN 1044, refer Fig. 1A7-74.

3. Tighten all bolts to the correct torque

specification.

SEAT BELT SECURING BOLT

TORQUE SPECIFICATION 35 - 50

Nm

2.36 LEFT HAND AND CENTRE REAR SEAT BELT BUCKLE ASSEMBLY - SEDAN

REMOVE

1. Remove rear seat cushion, refer to

2.18 REAR SEAT CUSHION AND BACK

ASSEMBLIES - SEDAN in this Section.

2. Remove bolt securing the rear seat belt buckle

anchor to the floor pan, refer to Fig. 1A7-74.

REINSTALL

Installation is the reverse of the rem oval operation,

noting the following:

1. Ensure all seat belt bolts are hand tightened a

minimum of 5 turns before using tools.

2. Ensure that the threads of seat belt buckle

anchor securing bolt is adequately sealed with

a non hardening sealer, to Holden’s

specification HN 1005 or HN 1044, refer Fig.

1A7-74.

3. Tighten all bolt to the correct torque

specification.

SEAT BELT BUCKLE ANCHOR

SECURING BOLT

TORQUE SPECIFICATION 35 - 50 Nm

Figure 1A7-74

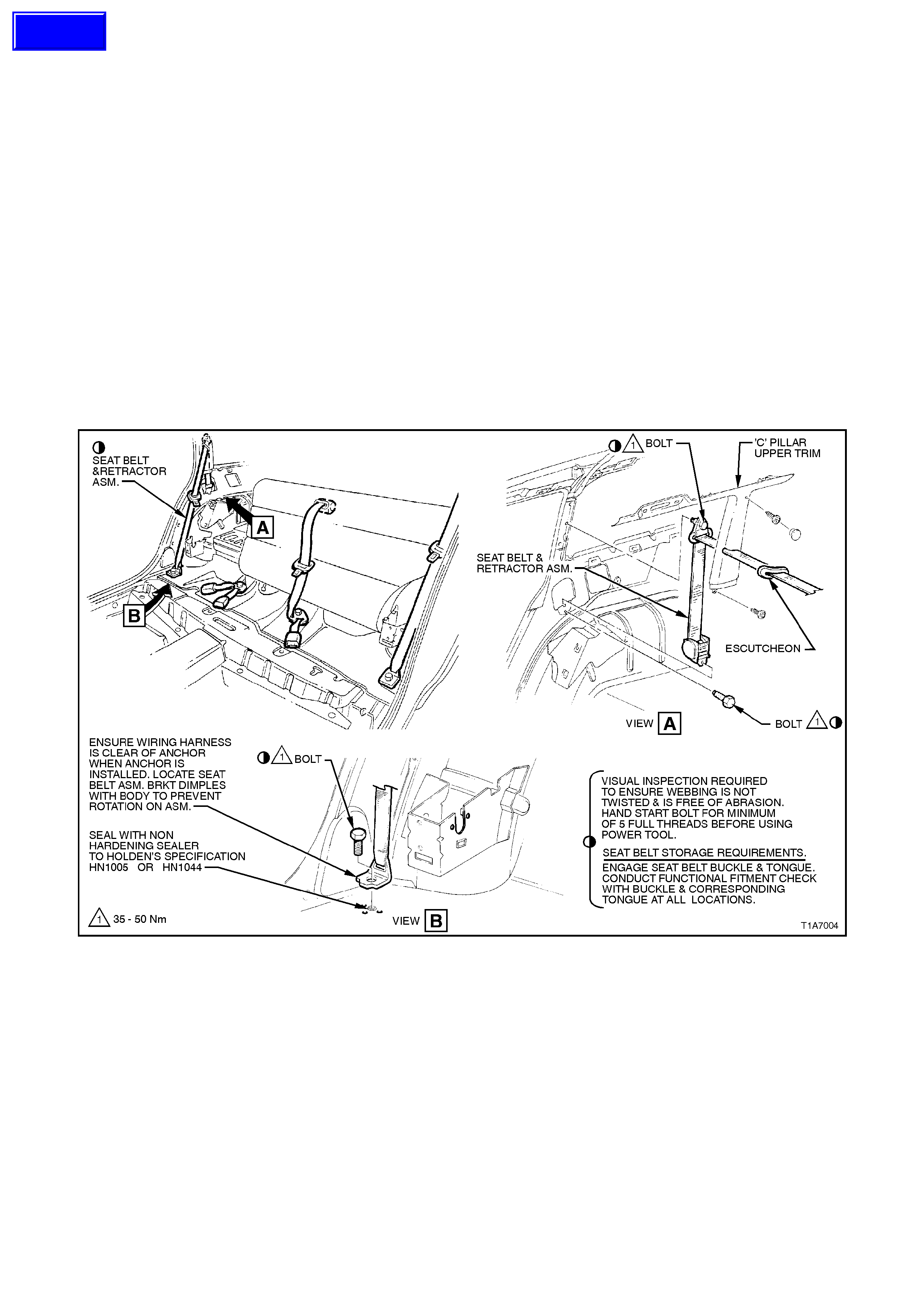

2.37 LEFT AND RIGHT HAND REAR SEAT BELT RETRACTOR ASSEMBLY - WAGON

REMOVE

1. Remove rear seat cushion, refer to 2.23 REAR SEAT CUSHION - WAGON in this Section.

2. Remove rear seat back bolsters, refer to 2.24 REAR SEAT BOLSTER - WAGON in this Section.

3. Remove bolt securing the rear seat belt lower anchor to the floor pan, refer to Fig. 1A7-75.

4. Unlatch and lower rear seat back.

5. Remove escutcheon from upper C pillar upper trim panel by gently prising the lower bottom face of escutcheon

out of trim.

NOTE:

The seat belt escutcheon may break if the upper section is pried from the C pillar upper trim panel.

6. Remove upper and lower C pillar trims, refer to Section 1A8 HEADLINING AND REAR END TRIM. Feed

seat belt sash, buckle, anchor and escutcheon through upper C pillar trim.

7. Remove bolt securing sash guide to the C pillar, refer to Fig. 1A7-75.

8. Remove bolt securing the rear seat belt retractor assembly to the rear quarter inner panel and remove seat belt

retractor and dust cover assembly, refer to Fig. 1A7-75.

Figure 1A7-75

Techline

REINSTALL

Reinstallation of the left and right hand rear seat

belt retractor assemblies is the reverse of the

removal operation, noting the following:

1. Ensure all seat belt bolts are hand tightened a

minimum of 5 turns before using tools.

2. Ensure that the threads of all seat belt lower

securing bolts are adequately sealed with a

non hardening sealer, to Holden’s

specification HN 1005 or HN 1044, refer to

Fig. 1A7-74.

3. Tighten all bolts to the correct torque

specification.

SEAT BELT SECURING BOLT

TORQUE SPECIFICATION 40 - 54

Nm

4. When installing the seat belt escutcheon into

the C pillar, insert the upper two clips of the

escutcheon into the C pillar then gently push

escutcheon into C pillar.

2.38 CENTRE REAR SEAT BELT RETRACTOR ASSEMBLY - WAGON

REMOVE

1. Remove rear seat back cover and pad

assembly, refer to 2.27 REAR SEAT COVER

AND PAD ASSEMBLY - WAGON in this

Section.

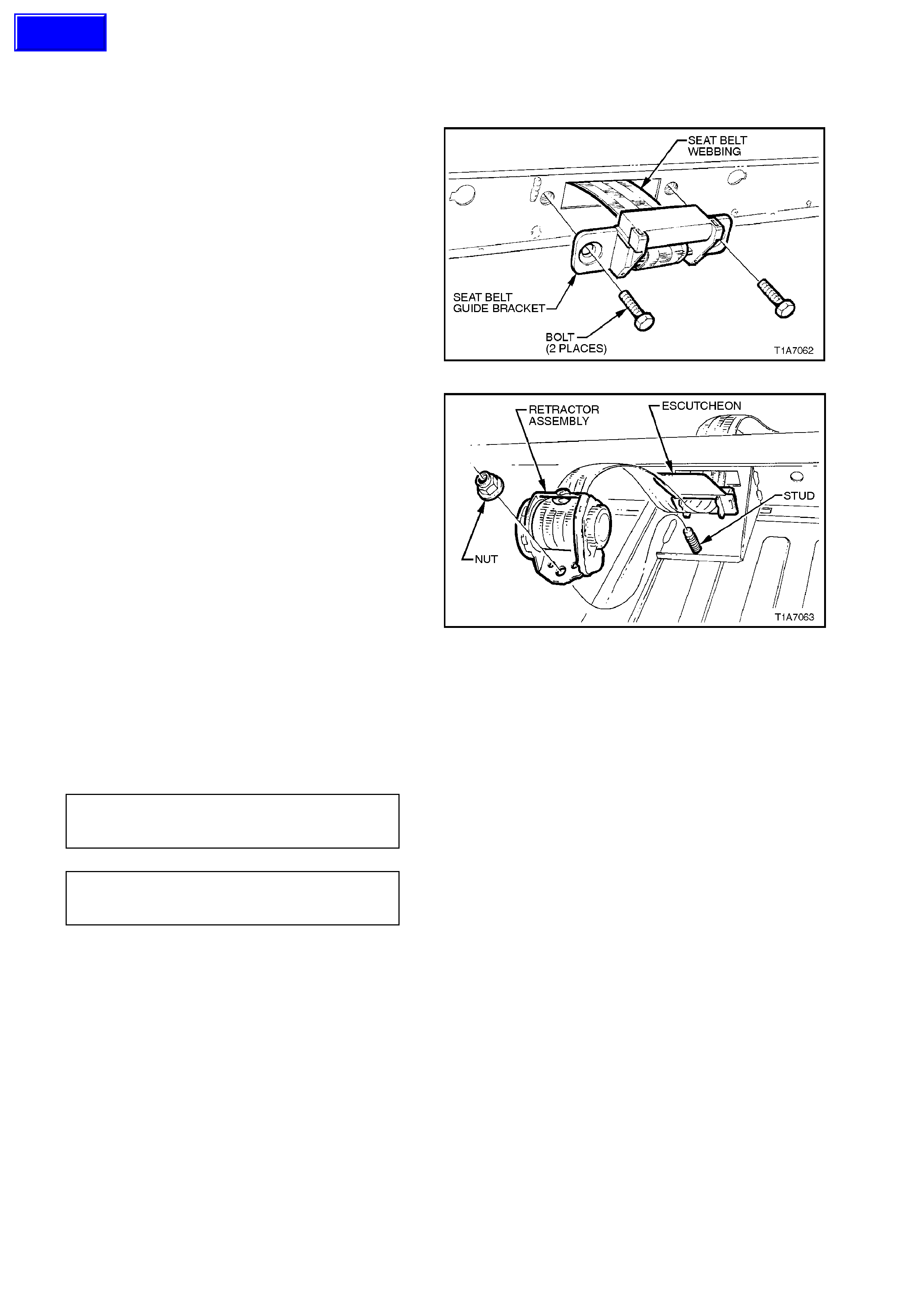

2. Remove the two bolts on the top of the seat

back frame securing the seat belt guide

bracket assembly.

3. Feed seat belt webbing through seat belt guide

bracket and remove seat belt guide bracket.

Figure 1A7-76

4. Remove the nut retaining the seat belt

retractor to the rear seat back frame.

5. Remove seat belt retractor f r om the stud in the

seat back frame.

6. Gently prise escutcheon from seat back

frame, feed seat belt webbing through seat

back frame and remove retractor assembly.

NOTE:

The seat belt retractor will not function unless the

seat back is in an upright position.

Figure 1A7-77

REINSTALL

Installation of the centre rear seat belt retractor

assembly is the reverse of the removal operation,

noting the following:

1. Ensure all fasteners are tightened to the

correct torque specification.

SEAT BELT GUIDE BRACKET

SECURING BOLT

TORQUE SPECIFICATION 20 - 22 Nm

SEAT BELT RETRACTOR

RETAINING NUT

TORQUE SPECIFICATION 35 50 Nm

2. If a new centre rear seat belt retractor

assembly is fitted, ensure the web clip is

removed after the retaining nut is tightened.

Techline

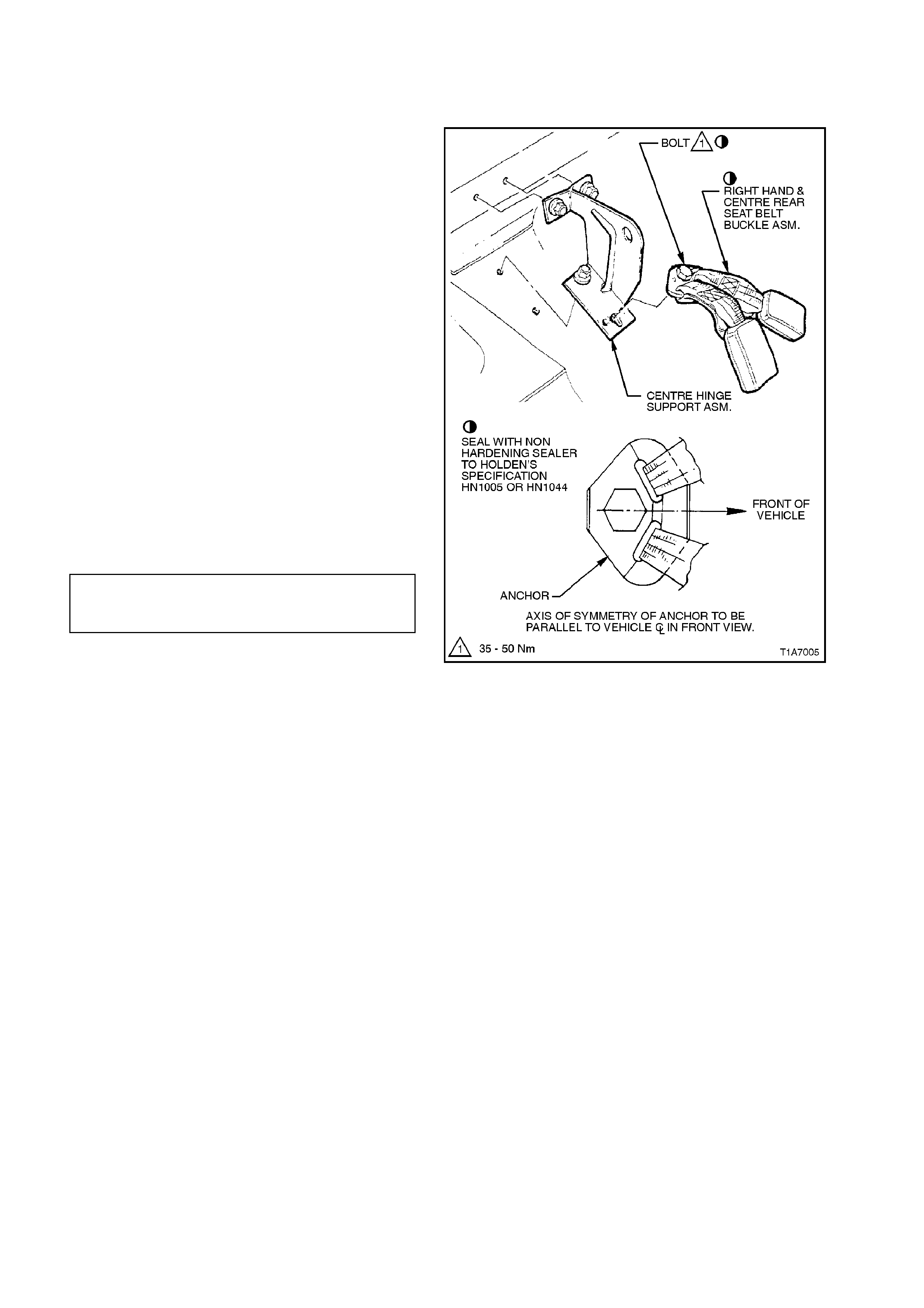

2.39 RIGHT HAND AND CENTRE REAR SEAT BELT BUCKLE ASSEMBLY - WAGON

REMOVE

1. Remove rear seat cushion, refer to

2.23 REAR SEAT CUSHION - WAGON in this

Section.

2. Remove bolt s ec uring the r ear s eat belt buc k le

anchor to the floor pan and seat back bracket,

refer to Fig. 1A7-78.

REINSTALL

Reinstallation of the right hand and centre rear seat

belt buckle assemblies is the reverse of the

removal operation, noting the following:

1. Ensure all seat belt bolts are hand tightened a

minimum of 5 turns before using tools.

2. Ensure that the threads of seat belt buckle

anchor securing bolt is adequately sealed with

a non hardening sealer, to Holden’s

specification HN 1005 or HN 1044, refer to

Fig. 1A7-78.

3. Tighten anchor bolt to the correct torque

specification ensuring that anchor plates are

located correctly, refer to Fig. 1A7-78.

SEAT BELT BUCKLE ANCHOR

SECURING BOLT 35 - 50 Nm

TORQUE SPECIFICATION

Figure 1A7-78

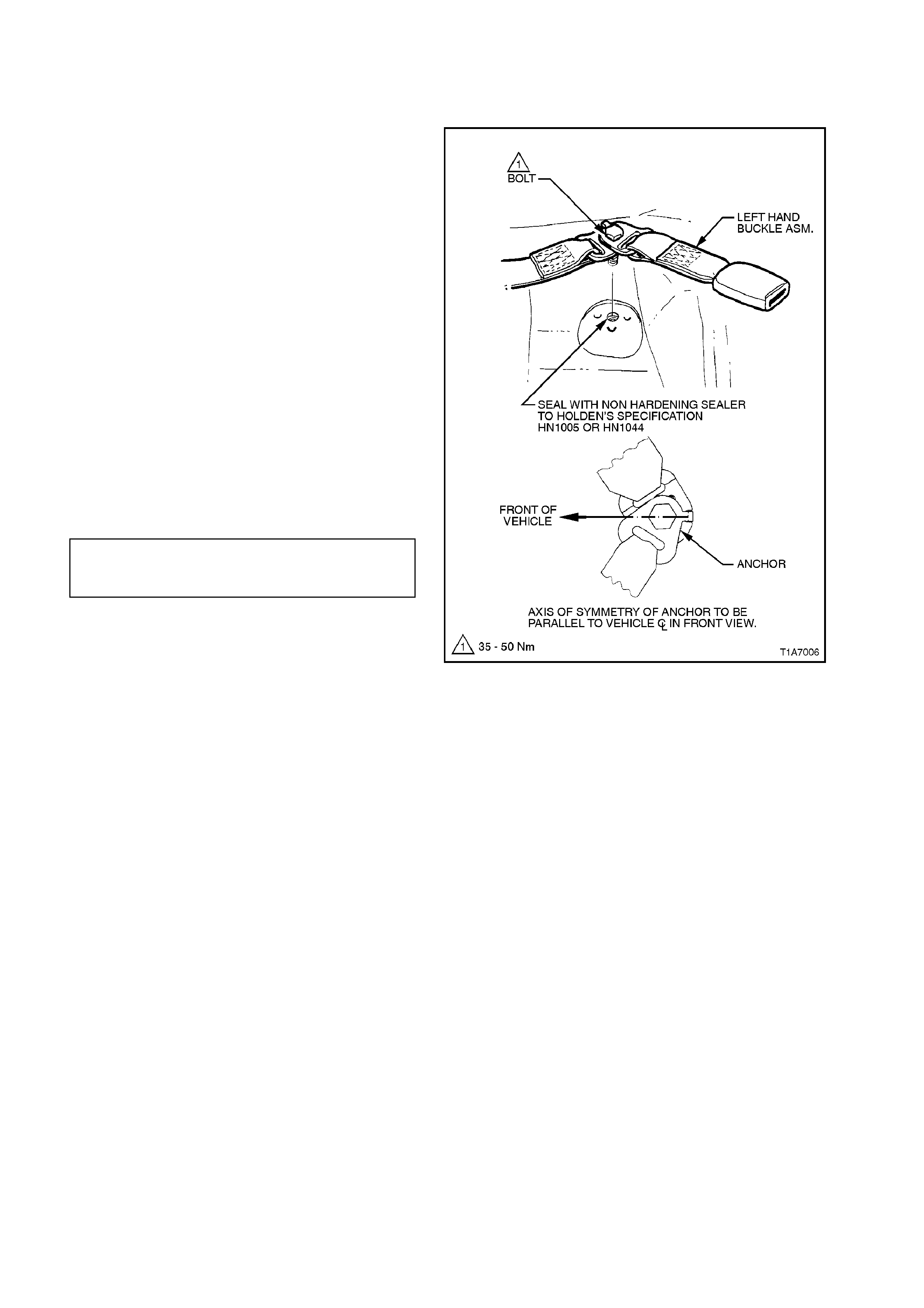

2.40 LEFT HAND REAR SEAT BELT BUCKLE ASSEMBLY - WAGON

REMOVE

1. Remove rear seat cushion, refer to

2.23 REAR SEAT CUSHION - WAGON in this

Section.

2. Remove bolt securing the rear seat belt buckle

anchor to the floor pan, refer to Fig. 1A7-79.

REINSTALL

Installation is the reverse of the removal operation,

noting the following:

1. Ensure all seat belt bolts are hand tightened a

minimum of 5 turns before using tools.

2. Ensure that the threads of seat belt buckle

anchor securing bolt is adequately sealed with

a non hardening sealer, to Holden’s

specification HN 1005 or HN 1044, refer to

Fig. 1A7-79.

3. Tighten anchor bolt to the correct torque

specification ensuring that anchor plates are

located correctly, refer to Fig. 1A7-79.

SEAT BELT BUCKLE ANCHOR

SECURING BOLT 35 - 50 Nm

TORQUE SPECIFICATION

Figure 1A7-79

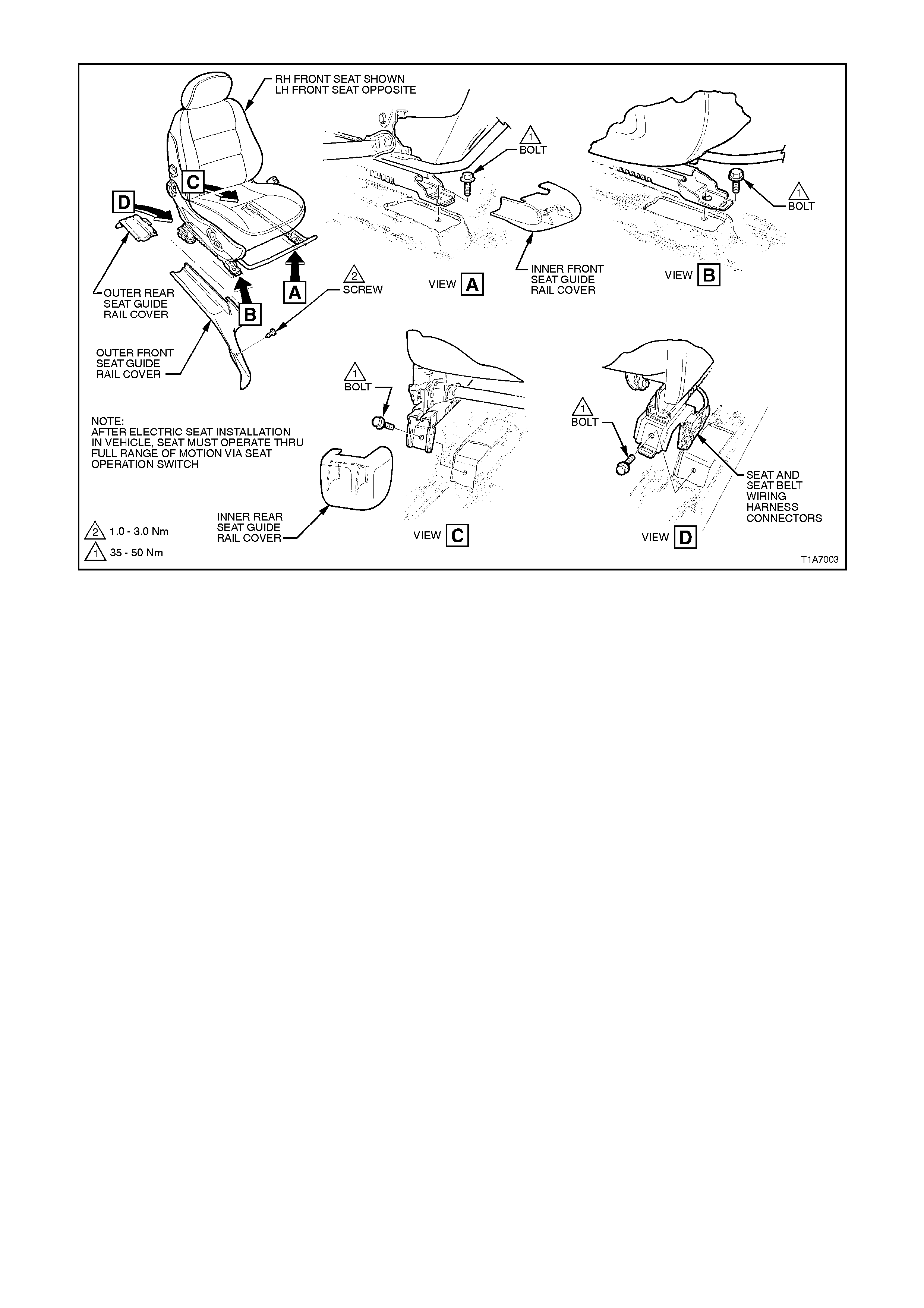

3. DIAGNOSTICS

3.1. PREREQUISITES TO DIAGNOSIS AND TROUBLE SHOOTING

PRELIMINARY SYSTEM REQUIREMENTS

The prerequisites before proceeding with system checks are:

• Fusible link FJ and circuit breaker F2 must be checked before any electrical diagnostic checks are performed.

• Ensure no moisture is present in the main wiring harness to body wiring harness or seat harness connections.

• Ensure that sound earth connections are available for all functioning components.

• Ensure the battery is in good condition and adequately charged (above 11.5 Volts) before carrying out any

electrical checks.

SAFETY REQUIREMENTS

Disconnect the battery when carrying out work which involves the risk of an electrical short circuit.

Do not touch mechanical components during function checks, to avoid the risk of a hand being caught in the

mechanism.

CHECKING EQUIPMENT

An unpowered testlamp with a current draw of less than 3 Amps.

A digital multimeter, with a minimum 10 Megohm impedance MUST be used when undertaking any electrical

checks on these systems.

Exercise care when taking readings from wiring harness connectors. It is preferred that the back probing method

with individual connectors is employed wherever possible, to avoid terminal damage and subsequent connection

failure.

When carrying out wiring checks as directed to by the diagnostic charts, rather than probe terminals and connectors

with incorrect sized multimeter connections, use the adaptors contained in connector test adaptor kit KM-609. This

will prevent any possibility of spreading or damaging wiring harness terminals.

IMPORTANT:

• When checking, the exact order of the test steps should be observed.

• If the required nominal value is not achieved in any stage, then the problem must be rectified before

proceeding further.

• Unless the multimeter being used has an auto ranging function, check that the correct range, as specified, is

selected before the test is carried out.

3.2 VISUAL INSPECTION

When investigating any complaint of an electric seat problem or malfunction, start diagnosis with a visual inspection

of the system.

The visual inspection procedure may quickly identify the cause and illuminate the need for additional diagnosis, in

particular if the problem is a mechanical fault.

If the complaint condition can not be resolved by the visual inspection, proceed to the appropriate diagnostic chart in

this Section.

NOTE:

Diagnostic charts 3.3 to 3.7 in this Section relate to electrical faults only and assume there are no mechanical faults.

ELECTRIC SEAT VISUAL INSPECTION

GENERAL

ITEM INSPECT FOR CORRECTIVE ACTION

Operation of seat (noisy,

slow or no Foreign material causing seat to

bind. Remove foreign material.

operation at all). Dry components, build up of dirt

on moving components. Clean and apply Lithium

based grease (to Holden

specification HN 2073) to

noisy component.

Bent, loose or physically

damaged components. Repair or replace faulty

components.

WIRING CONNECTIONS & CIRCUIT BREAKER

ITEM INSPECT FOR CORRECTIVE ACTION

Seat and switch wiring

harness connectors. Loose connections at individual

motors. Ensure secure connections.

Loose connections at control

switch.

Loose connection at power

supply connector at side of seat

assembly.

Circuit breaker F2. Loose connection or not fitted. Ensure secure connection or

supply new circuit breaker.

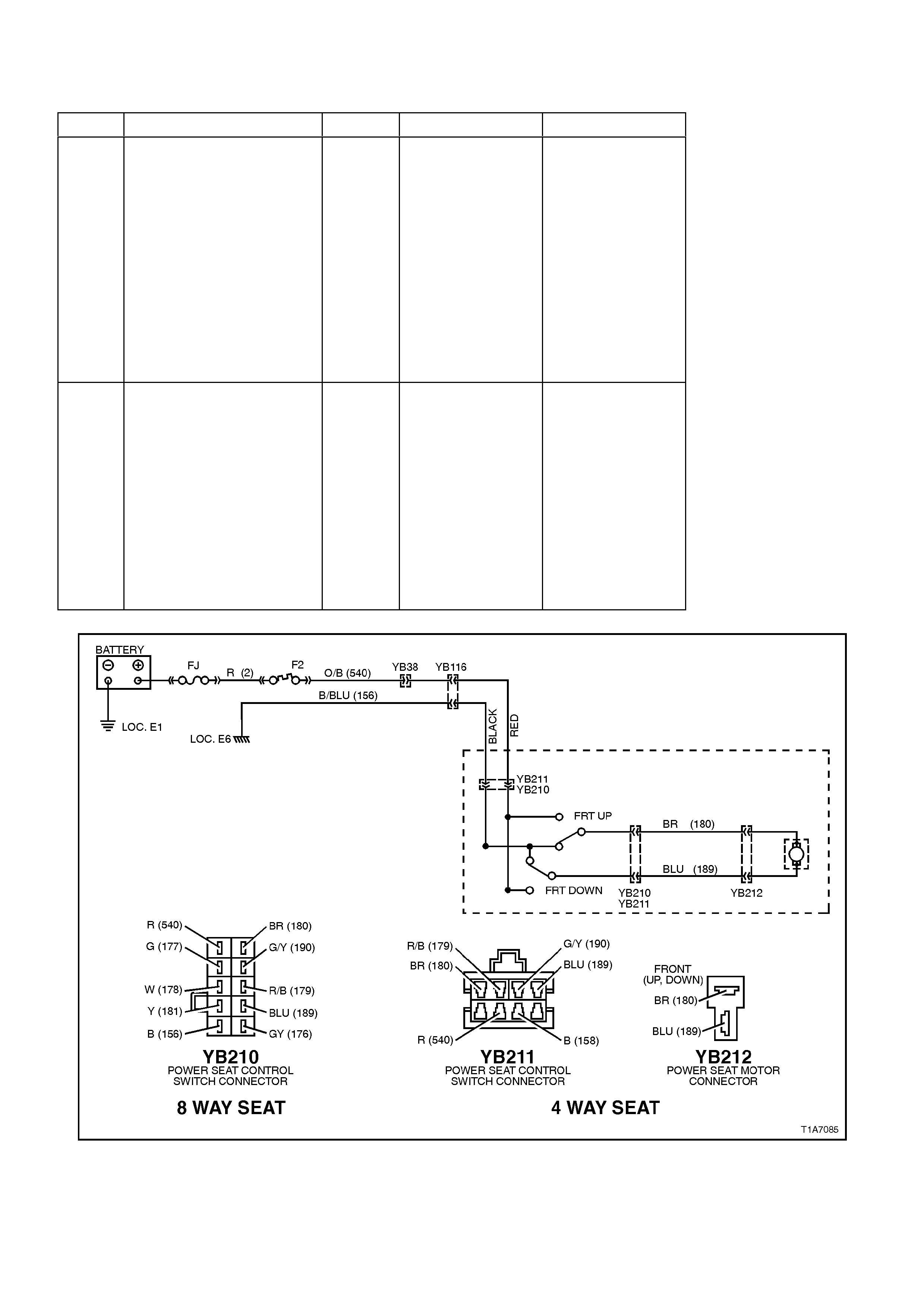

3.3 ELECTRIC SEAT DOES NOT MOVE IN ANY DIRECTION

STEP ACTION VALUE YES NO

1. At the side of the front

seat assembly, back

probe power seat

connector YB116, circuits

540 and 156 with a test

lamp.

Does the test lamp

illuminate ?

Go to Step 4. Go to Step 2.

2. Disconnect body harness

from connector YB116.

Using a voltmeter,

measure voltage at

Orange/Black wire

connection and a sound

earth connection.

Is voltage as specified ?

Battery

+Go to Step 3. Check and repair

open or short in

circuit 540

(including fusible

link FJ and circuit

breaker F2),

recheck and verify

repair.

3. With body harness

connector YB116

disconnected, check for

continuity between

Black/Blue wire

connection and earth

location E6.

Does continuity exist ?

Circuit OK. Check and repair

earth circuit 156,

recheck and verify

repair.

4. Back probe seat switch

connector YB210 (8 way

seat or YB211 (4 way

seat), Red and Black wire

connections with a test

lamp.

Does the test lamp

illuminate ?

Go to Step 5. Check and repair

open in either Red

or Black wire

circuits between

seat switch

connector and

body harness

connector YB116

5. From under front seat

assembly, back probe any

one of the seat adjusting

motors wiring harness

connectors (YB212) with a

test lamp connected to

both sides of the

connector.

Operate the selected seat

adjusting motor.

Does the test lamp

illuminate ?

Replace seat

adjusting motors,

refer to the

appropriate

Service Operation

in this Section.

Replace seat

adjusting switch

assembly, refer to

2.3 FRONT SEAT

OUTER SIDE

COVER AND

SEAT

ADJUSTING

SWITCH

ASSEMBLY in

this Section.

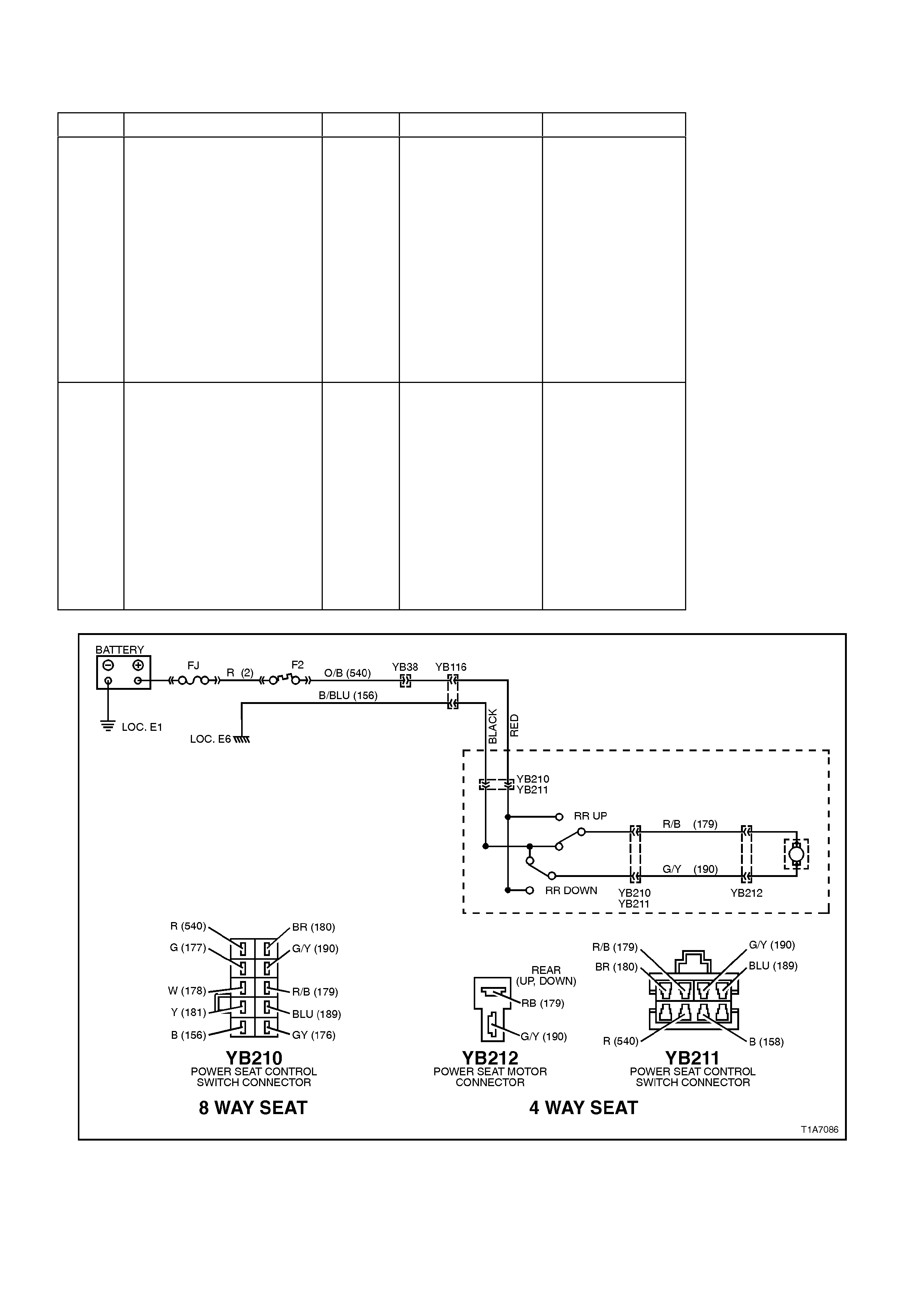

Figure 1A7-80

3.4 ELECTRIC SEAT FRONT UP AND DOWN OPERATION INOPERATIVE

STEP ACTION VALUE YES NO

1. From under front seat

assembly, back probe the

seat front lift motor wiring

harness connector

YB212, between circuit

180 (Brown wire) and

circuit 189 (Blue wire)

connections with a test

lamp.

Operate the seat front lift

motor.

Does the test lamp

illuminate ?

Replace the seat

front lift motor

assembly, refer

2.14 FRONT

SEAT LIFT

MOTOR in this

Section.

Go to Step 2.

2. Back probe seat switch

connector YB210 (8 way

seat) or YB211 (4 way

seat), between circuit 180

(Brown wire) and circuit

189 (Blue wire)

connections with a test

lamp.

Operate the seat front lift

motor.

Does the test lamp

illuminate ?

Check and repair

open in circuits

180 (Brown wire)

or circuit 189

(Blue wire )

between seat

adjusting switch

connector and

seat front lift

motor connector.

Recheck and

verify repair.

Replace seat

adjusting switch,

refer to 2.3

FRONT SEAT

OUTER SIDE

COVER AND

SEAT

ADJUSTING

SWITCH

ASSEMBLY in

this Section.

Figure 1A7-81

3.5 ELECTRIC SEAT REAR UP AND DOWN OPERATION INOPERATIVE

STEP ACTION VALUE YES NO

1. From under front seat

assembly, back probe the

seat rear lift motor wiring

harness connector

YB212, between circuits

179 (Red/Black wire) and

circuit 190 (Green/Yellow

wire) connections with a

test lamp.

Operate the seat rear lift

motor.

Does the test lamp

illuminate ?

Replace the seat

rear lift motor

assembly, refer to

2.14 FRONT

SEAT LIFT

MOTORS in this

Section.

Go to Step 2.

2. Back probe seat adjusting

switch connector, YB210

(8 way seat) or YB211 (4

way seat), circuits 179

(Red/Black wire) and

circuit 190 (Green/Yellow

wire) connections with a

test lamp.

Operate the seat rear lift

motor.

Does the test lamp

illuminate ?

Check and repair

open in circuits

179 (Red/Black

wire) or circuit 190

(Green/ Yellow

wire) between

seat adjusting

switch connector

and seat rear lift

motor connector.

Recheck and

verify repair.

Replace seat

adjusting switch,

refer to 2.3

FRONT SEAT

OUTER SIDE

COVER AND

SEAT

ADJUSTING

SWITCH

ASSEMBLY in

this Section.

Figure 1A7-82

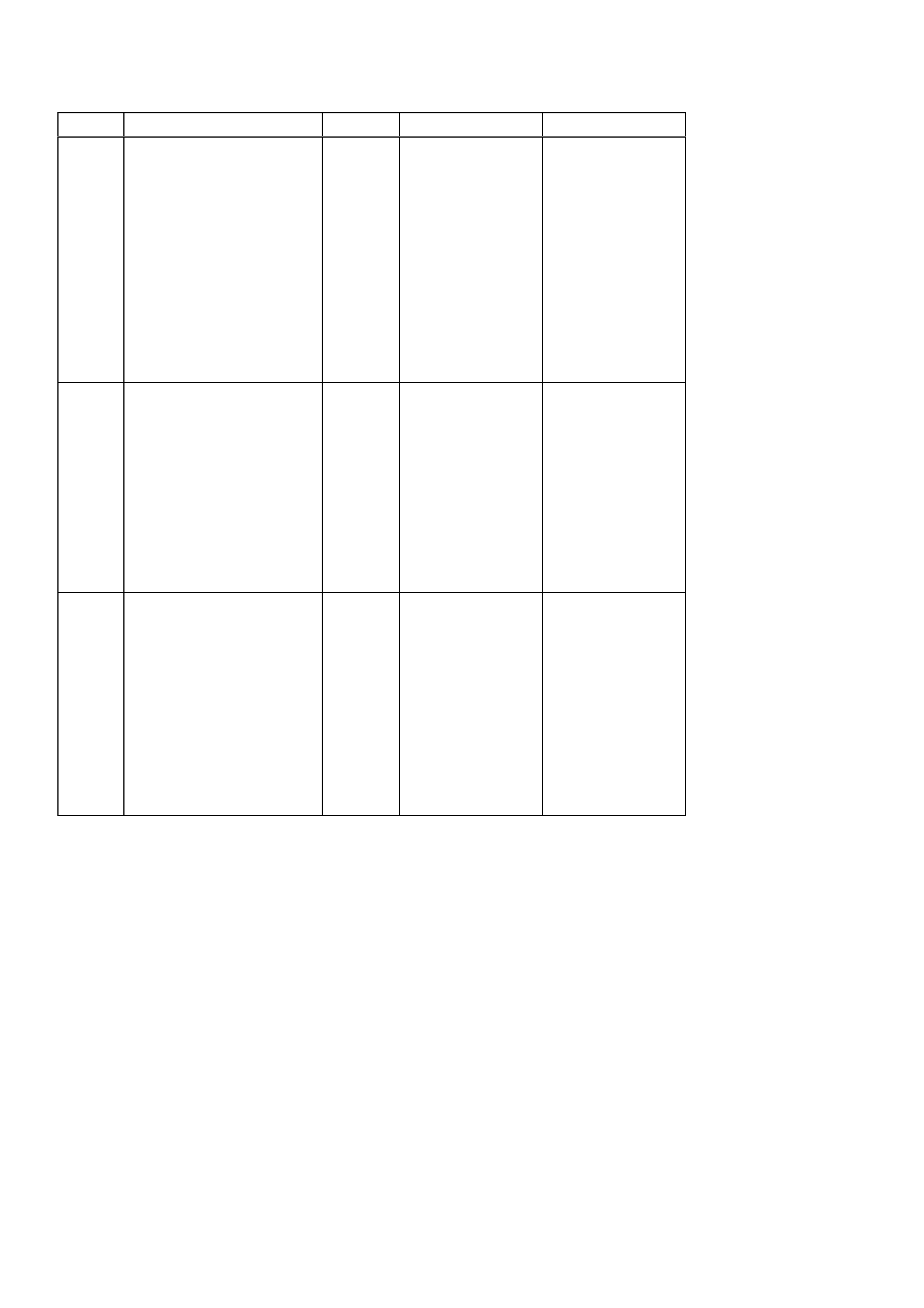

3.6 ELECTRIC SEAT RECLINER INOPERATIVE

STEP ACTION VALUE YES NO

1. From under the front seat

assembly, back probe the

seat reclining motor wiring

harness connector

YB214, between circuits

177 (Green wire) and

circuit 181 (Yellow wire)

connections with a test

lamp.

Operate the seat reclining

lift motor.

Does the test lamp

illuminate ?

Go to Step 3. Go to Step 2.

2. Back probe seat adjusting

switch connector YB210,

between circuit 177

(Green wire) and circuit

181 (Yellow wire)

connections with a test

lamp.

Operate the seat reclining

motor.

Does the test lamp

illuminate ?

Check and repair

open in circuit 177

(Green wire) or

circuit 181 (Yellow

wire) between

seat adjusting

switch connector

and seat reclining

motor connector.

Recheck and

verify repair.

Replace seat

adjusting switch,

refer to 2.3

FRONT SEAT

OUTER SIDE

COVER AND

SEAT

ADJUSTING

SWITCH

ASSEMBLY in

this Section.

3. With seat reclining motor

and gearbox assembly

exposed (seat back cover

and pad removed),

visually inspect reclining

mechanism for cause of

fault, ie. bent drive shaft,

loose motor, etc.

Are there any visible faults

that would cause seat

recliner to be inoperative

?

Repair as

necessary.

Recheck and

verify repair.

Replace seat

reclining motor,

refer to 2.16

FRONT SEAT

RECLINING

MOTOR AND

GEARBOX

ASSEMBLY in

this Section.

Figure 1A7-83

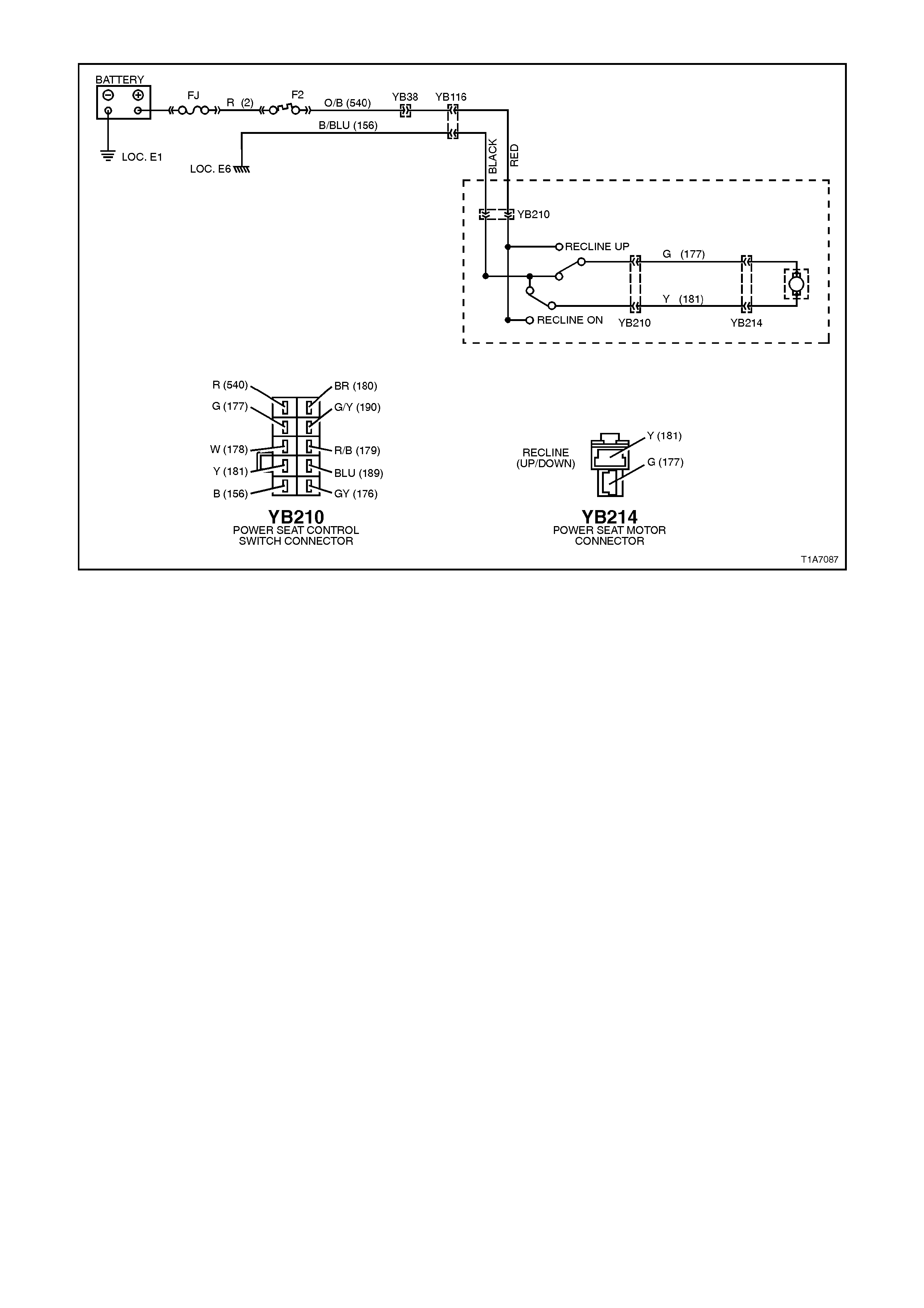

3.7 ELECTRIC SEAT FORWARD AND REARWARD OPERATION INOPERATIVE

STEP ACTION VALUE YES NO

1. Back probe the seat

fore/aft motor wiring

harness connector

YB212, between circuit

176 (Grey wire) and circuit

178 (White wire)

connections with a test

lamp.

Operate the seat fore/aft

motor.

Does the test lamp

illuminate ?

Replace the seat

fore/aft motor

assembly, refer to

2.15 FRONT

SEAT FORE/AFT

MOVEMENT

MOTOR in this

Section.

Go to Step 2.

2. Back probe seat adjusting

switch connector YB210,

between circuit 176 (Grey

wire) and circuit 178

(White wire) connections

with a test lamp.

Operate the seat fore/aft

motor.

Does the test lamp

illuminate ?

Check and repair

open in circuits

176 (Grey wire) or

circuit 178 (White

wire) between

seat adjusting

switch connector

and seat fore/aft

motor connector.

Recheck and

verify repair.

Replace seat

adjusting switch,

refer to 2.3

FRONT SEAT

OUTER SIDE

COVER AND

SEAT

ADJUSTING

SWITCH

ASSEMBLY in

this Section.

Figure 1A7-84

4. TORQUE WRENCH SPECIFI CATIONS

Nm

Armrest Bracket to Frame Retaining Screw 4.0

Armrest to Bracket Retaining Screw 4.0

Armrest to Bracket Securing Bolt - Sedan 7 - 10

B pillar Upper Trim Retaining Screw 1.0 - 3.0

Bracket to Seat Back Retaining Bolt 15 - 25

Centre Cover to Frame Retaining Screw 2.5

Centre Hinge Lower Securing Bolt 35 - 50

Centre Hinge Upper Securing Bolt 25 - 35

Child Seat Anchor Bolt 15 - 25

Front Seat Belt Guide Retaining Screw 2.4 - 3.4

Front Seat Cushion Frame to Seat Guide Railand Adjuster

Asm. Bolt 27

Front Seat to Floor Securing Bolt 35 - 50

Garnish Retaining Screw 2.0

LHR Seat Back Lock Retaining Screw 3.0

Outer Front Seat Guide Rail Cover 1.0 - 3.0

Rear Seat Back to Floor Retaining Bolt 25 - 30

Seat Back Lock Allen Key Screw 3.0

Seat Back to Height Adjuster Asm Securing Bolt 27

Seat Back to Seat Adjuster & Guide Rail Asm Securing Bolt 27

Seat Belt Buckle and Pre-tensioner Asm Bolt 45

Seat Belt Buckle Anchor Securing Bolt 35 - 50

Seat Belt guide bracket securing bolt 20 - 22

Seat Belt Retractor Retaining Nut 35 - 50

Seat Belt Securing Bolt 40 - 54

Side Inner Cover Retaining Screw 1.0 - 3.0

Striker Retaining Bolt - Wagon Seat Back 25 - 35

Striker Retaining Screw - Sedan Seat Back Lock 35

5. SPECIAL TOOLS

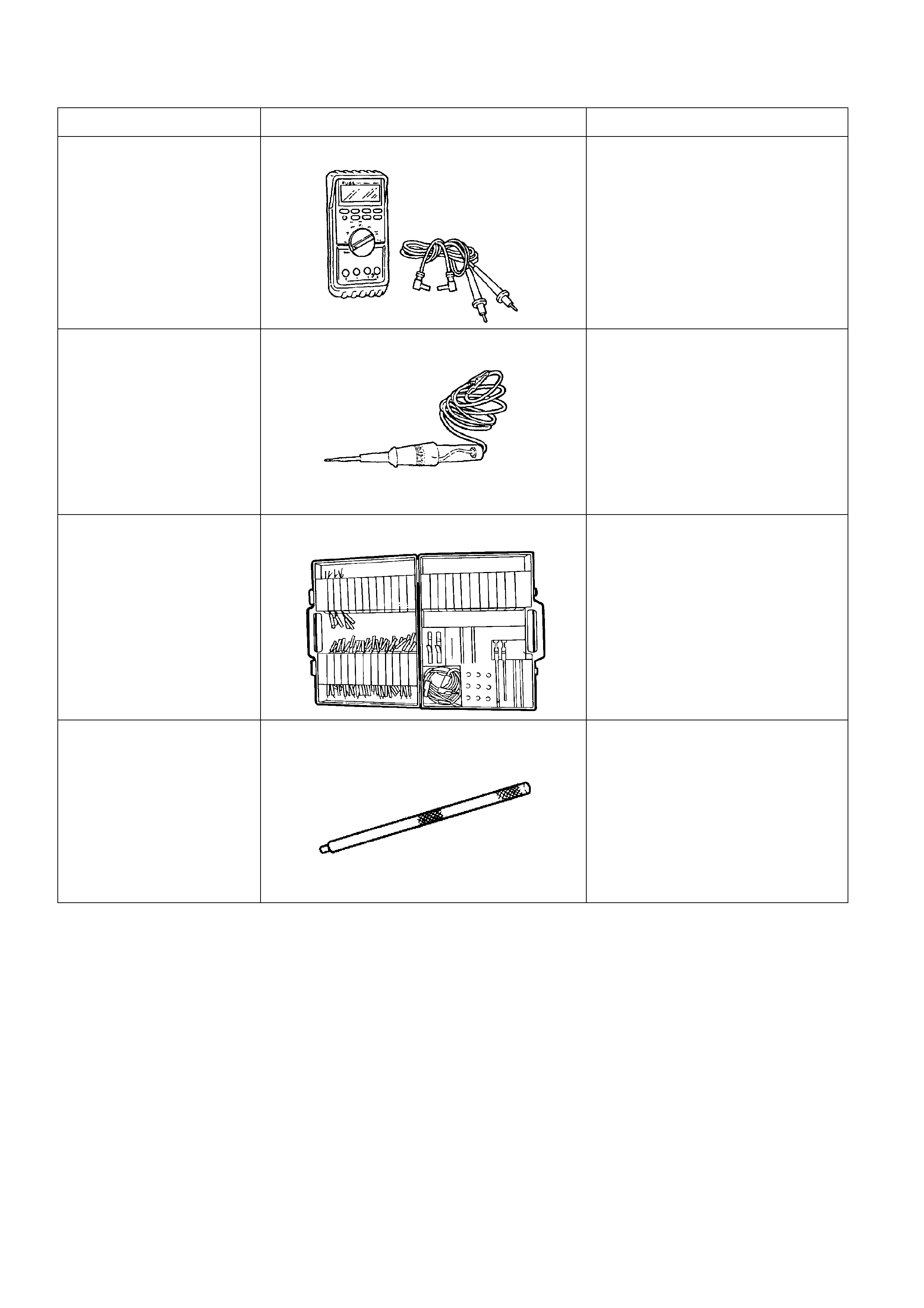

TOOL NO. REF IN TEXT TOOL DESCRIPTION COMMENTS

J39200 DIGITAL MULTIMETER TOOL NO. J39200 PREVIOUSLY

RELEASED, OR USE

COMMERCIALLY AVAILABLE

EQUIVALENT. MUST HAVE 10

MEG OHM INPUT IMPEDANCE

AND BE CAPABLE OF READING

FREQUENCIES

KM-609 ELECTRONIC KIT USED IN CONJUNCTION WITH A

MULTIMETER FOR MEASURING

VOLTAGES AND RESISTANCES

WITHOUT DAMAGING WIRING

HARNESS CONNECTORS

J-34142-B UNPOWERED TEST LIGHT COMMERCIALLY AVAILABLE.

MUST HAVE A CURRENT DRAW

OF LESS THAN 0.3 A

AU461 CLEVIS PIN REMOVAL PUNCH