SECTION 1A9 - EXTERIOR ORNAMENTATION

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will

consist of either seat belt pre-tensioners and a driver's side air bag, or seat belt pre-

tensioners and a driver's and front passenger's side air bags. Refer to CAUTIONS,

Section 12M, before performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deplo yment, resulting in possible p ersonal injury or unnecessary

SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of

safety, the LPG fuel system should be isolated by turning 'OFF' the manual service

valve and then draining the LPG serv ice lines, before any service w ork is carried out

on the vehicle. Refer to the LPG leaflet included with the Owner's Handbook for

details or LPG Section 2 for more specific servicing information.

1. GENERAL DESCRIPTI ON

Exterior ornamentation on VT Series Models includes:

• Body side mouldings for all model variants except ‘S’ and ‘SS’ models.

• Various name plates, emblems and decals depending on model variant.

• A windshield moulding cover.

• An air deflector for station wagons and an air spoiler for ‘S’ and ‘SS’ models.

• Door frame opening mouldings.

• ‘B’ pillar and quarter panel to roof mouldings.

• Roof finisher and side mouldings.

• Rocker panel skirts.

Exterior ornamentation components are secured to the body using various fasteners, double sided tape and

polyurethane adhesive.

Techline

Techline

2. SERVICE OPERATIONS

2.1 SERVICE NOTES

Numerous clips, fasteners, retainers, bushes, screws, nuts and contact adhesives are used to secure the various

exterior ornamentation components to the vehicle body. To locate the service information applicable a to a

particular component, refer to 2.2 PICTORIAL INDEX in this Section.

When removing, handling or installing exterior ornamentation components, the following care should be exercised:

1. Finishers adjacent to the component being removed should be covered with masking tape to prevent damage

to panels and paint work.

2. Removal of adhesive bonded nameplates and emblems is more easily achieved with the aid of a heat lamp

positioned adjacent to the part to be removed.

NOTE:

Ensure that the heat lamp is not too close to the body, or the heat to intense to adversely affect the paint finish.

3. Holes in body panels for screws, bolts, clips, etc. that could permit water entry into the body must be

adequately sealed with either a non-hardening sealer or presealed screws, clips, etc.

4. Using a clean cloth, clean the area of body surface where emblems, mouldings, etc. are to be applied with

‘Prepsol’ solvent or equivalent.

5. It is essential that the body temperature of the vehicle be at least 21°C before adhering adhesive bonded

components to the vehicle.

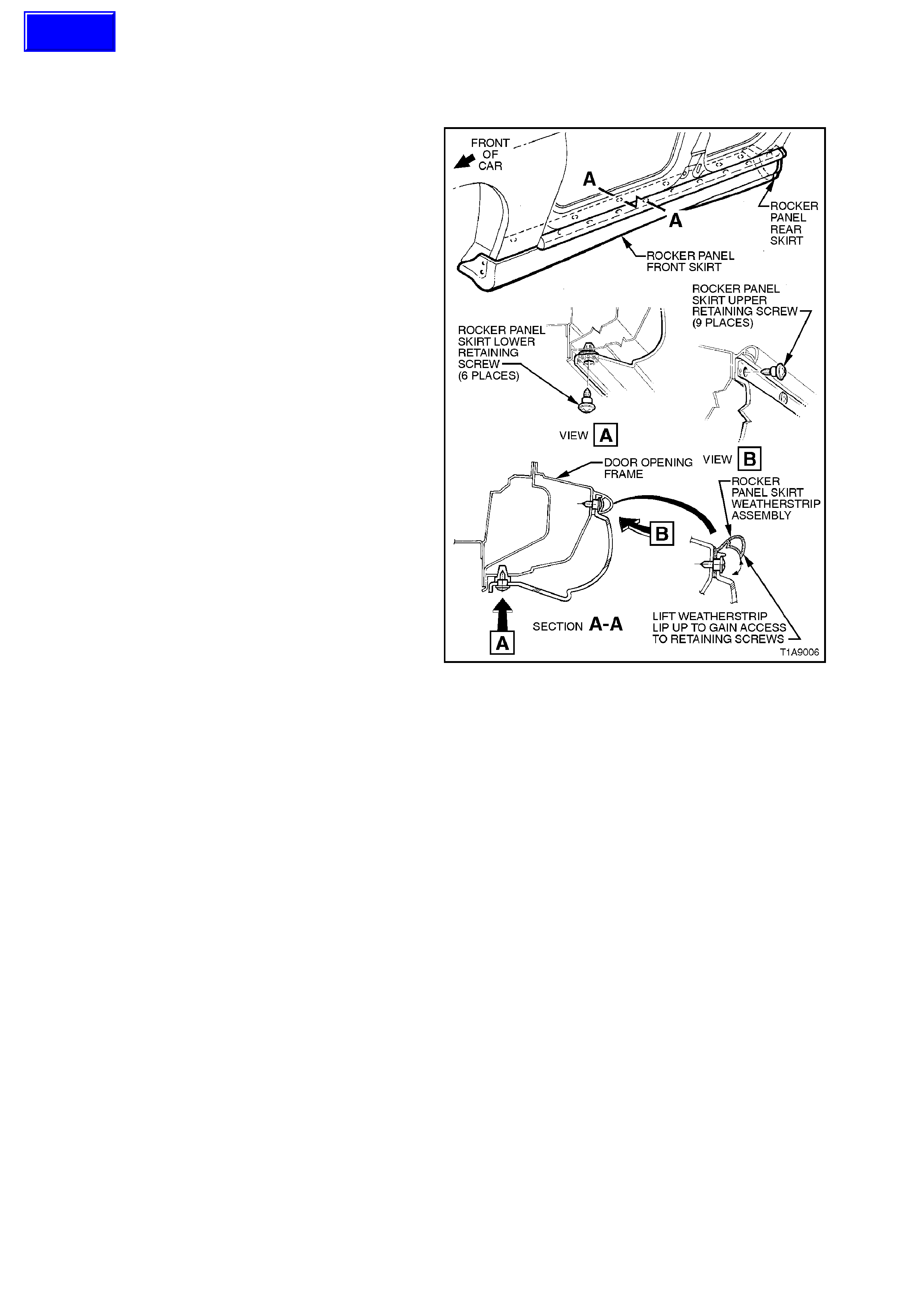

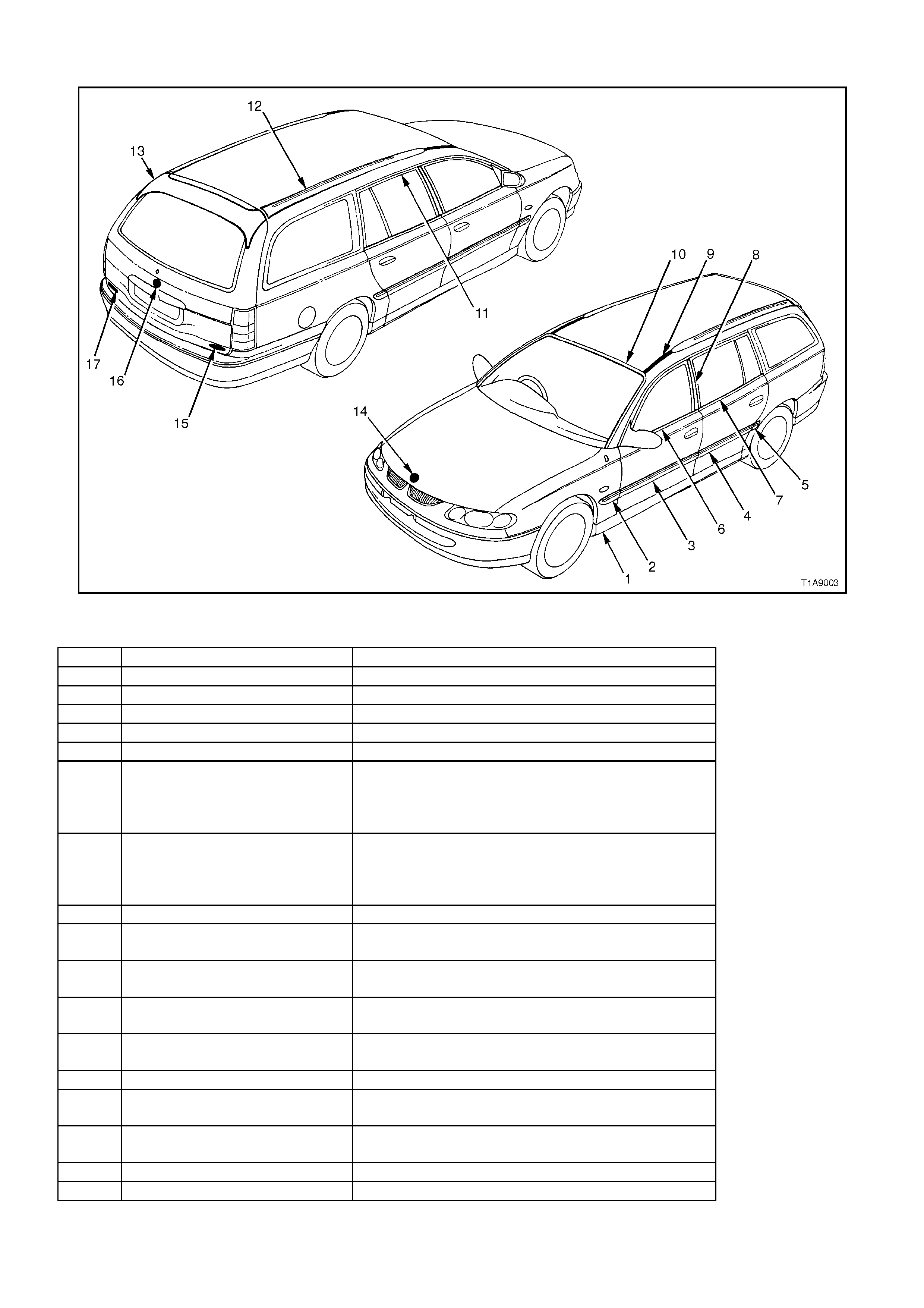

2.2 PICTORIAL INDEX

The following pictograph indexes provide a quick guide to finding the correct service procedure for the applicable

exterior ornamentation component. Within this Section, simply locate the appropriate component in Fig. 1A9-1, 2 or

3 and cross reference it in the table below the Figure.

SEDAN - EXCLUDING 'S' & 'SS'

Figure 1A9-1

ITEM DESCRIPTION REFERENCE

1 Rocker panel skirt 2.3 ROCKER PANEL SKIRT in this Section

2 Front fender side moulding 2.4 BODY SIDE MOULDINGS in this Section

3 Front door side moulding 2.4 BODY SIDE MOULDINGS in this Section

4 Rear door side moulding 2.4 BODY SIDE MOULDINGS in this Section

5 Front door belt moulding 2.16 FRONT AND REAR DOOR BELT

WEATHERSTRIP AND MOULDING ASSEMBLY

in Section 1A5 FRONT AND REAR DOOR

ASSEMBLIES.

6 Rear door belt moulding 2.16 FRONT AND REAR DOOR BELT

WEATHERSTRIP AND MOULDING ASSEMBLY

in Section 1A5 FRONT AND REAR DOOR

ASSEMBLIES.

7 Quarter panel to roof moulding 2.5 QUARTER PANEL TO ROOF MOULDING

ASSEMBLY in this Section

8 ‘B’ pillar moulding 2.6 ‘B’ PILLAR MOULDING in this Section

9 Windshield moulding cover 2.7 WINDSHIELD MOULDING COVER in this

Section

10 Door frame opening moulding 2.8 DOOR FRAME OPENING MOULDING in this

Section

11 Roof finisher moulding 2.9 ROOF FINISHER MOULDING - SEDAN in this

Section

12 Emblem: ‘Lion’ 2.12 ‘LION’ EMBLEM - ENGINE HOOD in this

Section

13 Name plate: Calais 2.13 NAME PLATES AND DECALS in this Section

14 Name plate: Executive,

Acclaim, Berlina, Calais 2.13 NAME PLATES AND DECALS in this Section

15 Emblem: ‘Lion’ 2.12 ‘LION’ EMBLEM - DECK LID in this Section

16 Name pate: Commodore 2.13 NAME PLATES AND DECALS in this Section

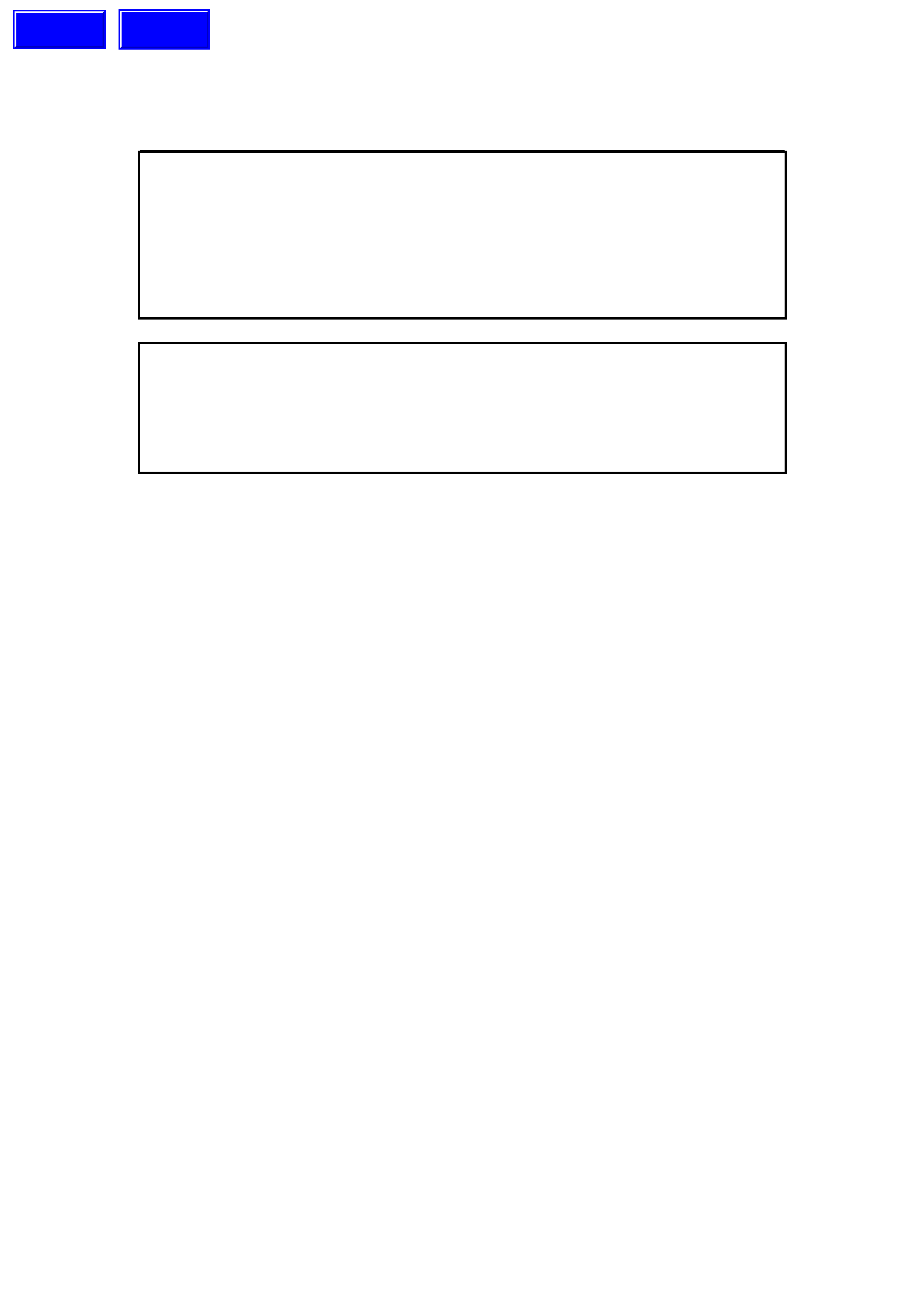

SEDAN - 'S' & 'SS'

Figure 1A9-2

ITEM DESCRIPTION REFERENCE

1 Rocker panel skirt 2.3 ROCKER PANEL SKIRT in this Section

2 Front door belt moulding 2.16 FRONT AND REAR DOOR BELT

WEATHERSTRIP AND MOULDING ASSEMBLY

in Section 1A5 FRONT AND REAR DOOR

ASSEMBLIES.

3 Rear door belt moulding 2.16 FRONT AND REAR DOOR BELT

WEATHERSTRIP AND MOULDING ASSEMBLY

in Section 1A5 FRONT AND REAR DOOR

ASSEMBLIES.

4 Quarter panel to roof moulding 2.5 QUARTER PANEL TO ROOF MOULDING

ASSEMBLY in this Section

5 ‘B’ pillar moulding 2.6 ‘B’ PILLAR MOULDING in this Section

6 Windshield moulding cover 2.7 WINDSHIELD MOULDING COVER in this

Section

7 Door frame opening moulding 2.8 DOOR FRAME OPENING MOULDING in this

Section

8 Roof finisher moulding 2.9 ROOF FINISHER MOULDING - SEDAN in this

Section

9 Emblem: ‘Lion’ 2.12 ‘LION’ EMBLEM - ENGINE HOOD in this

Section

10 Decal ‘SS’ 2.13 NAME PLATES AND DECALS in this Section

11 Name plate: ‘SS’ 2.13 NAME PLATES AND DECALS in this Section

12 Emblem: ‘Lion’ 2.12 ‘LION’ EMBLEM - DECK LID in this Section

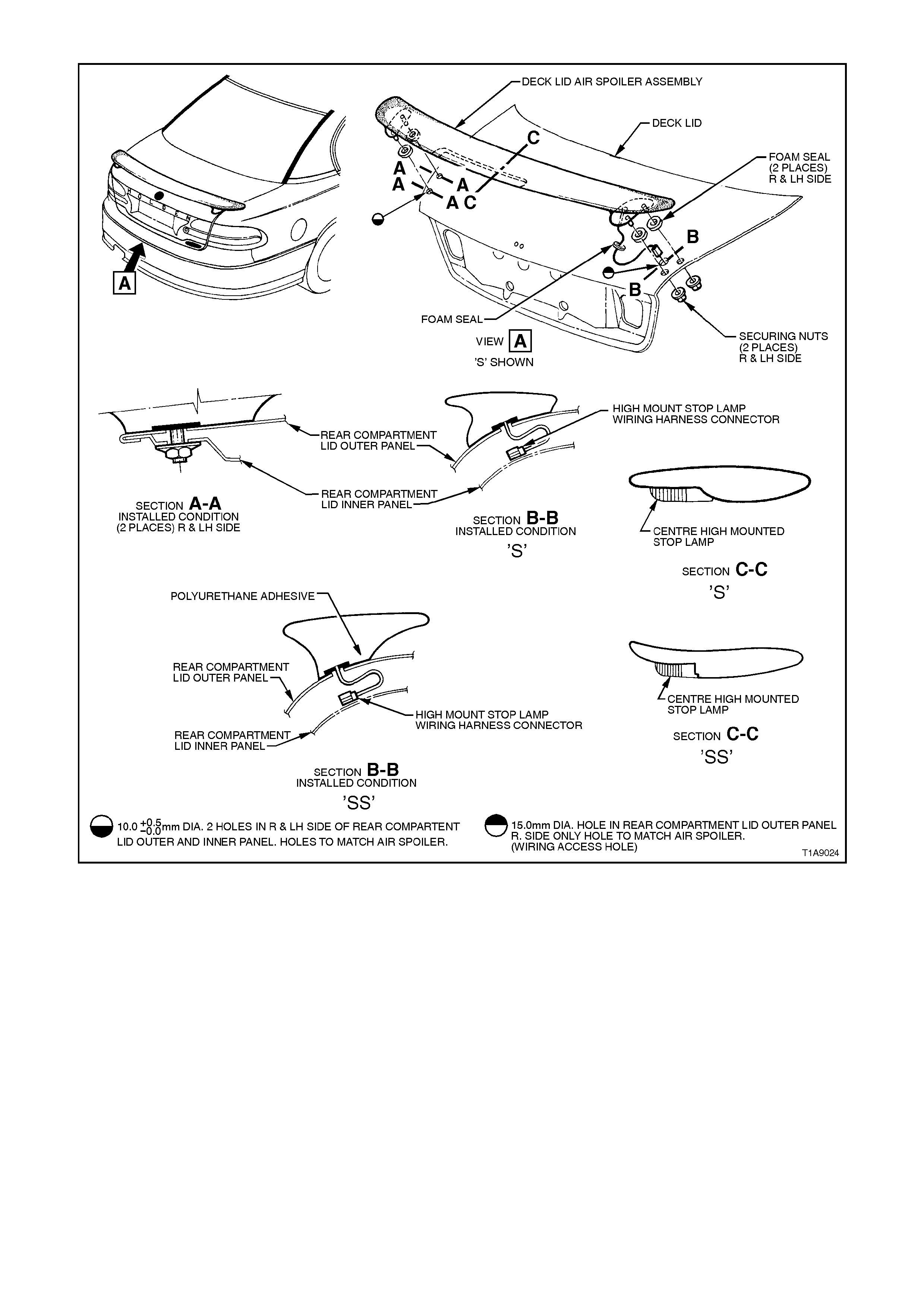

13 Deck lid Air spoiler 2.15 DECK LID AIR SPOILER in this Section

WAGON - EXECUTIVE, ACCLAIM & BERLINA

Figure 1A9-3

ITEM DESCRIPTION REFERENCE

1 Rocker panel skirt 2.3 ROCKER PANEL SKIRT in this Section

2 Front fender side moulding 2.4 BODY SIDE MOULDINGS in this Section

3 Front door side moulding 2.4 BODY SIDE MOULDINGS in this Section

4 Rear door side moulding 2.4 BODY SIDE MOULDINGS in this Section

5 Quarter panel side moulding 2.4 BODY SIDE MOULDINGS in this Section

6 Front door belt moulding 2.16 FRONT AND REAR DOOR BELT

WEATHERSTRIP AND MOULDING ASSEMBLY

in Section 1A5 FRONT AND REAR DOOR

ASSEMBLIES.

7 Rear door belt moulding 2.16 FRONT AND REAR DOOR BELT

WEATHERSTRIP AND MOULDING ASSEMBLY

in Section 1A5 FRONT AND REAR DOOR

ASSEMBLIES.

8 ‘B’ pillar moulding 2.6 ‘B’ PILLAR MOULDING in this Section

9 Roof finisher moulding 2.10 ROOF FINISHER MOULDING - WAGON in

this Section

10 Windshield moulding cover 2.7 WINDSHIELD MOULDING COVER in this

Section

11 Door frame opening moulding 2.8 DOOR FRAME OPENING MOULDING in this

Section

12 Roof side moulding 2.11 ROOF SIDE MOULDING - WAGON in this

Section

13 Tailgate air deflector 2.14 TAILGATE AIR DEFLECTOR in this Section

14 Emblem: ‘Lion’ 2.12 ‘LION’ EMBLEM - ENGINE HOOD in this

Section

15 Name plate: Executive,

Acclaim, Berlina 2.13 NAME PLATES AND DECALS in this Section

16 Emblem: ‘Lion’ 2.12 ‘LION’ EMBLEM - TAILGATE in this Section

17 Name plate: Commodore 2.13 NAME PLATES AND DECALS in this Section

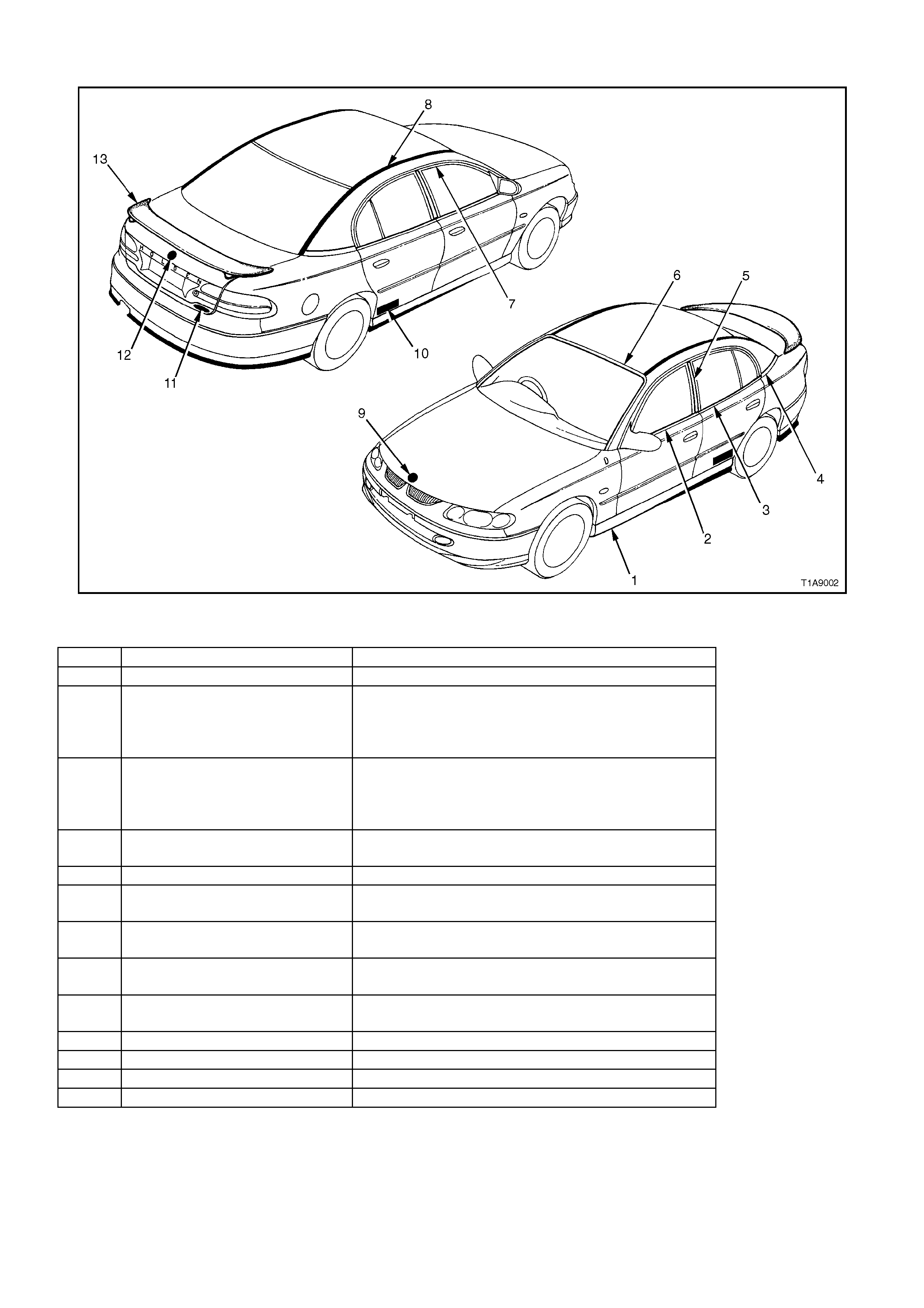

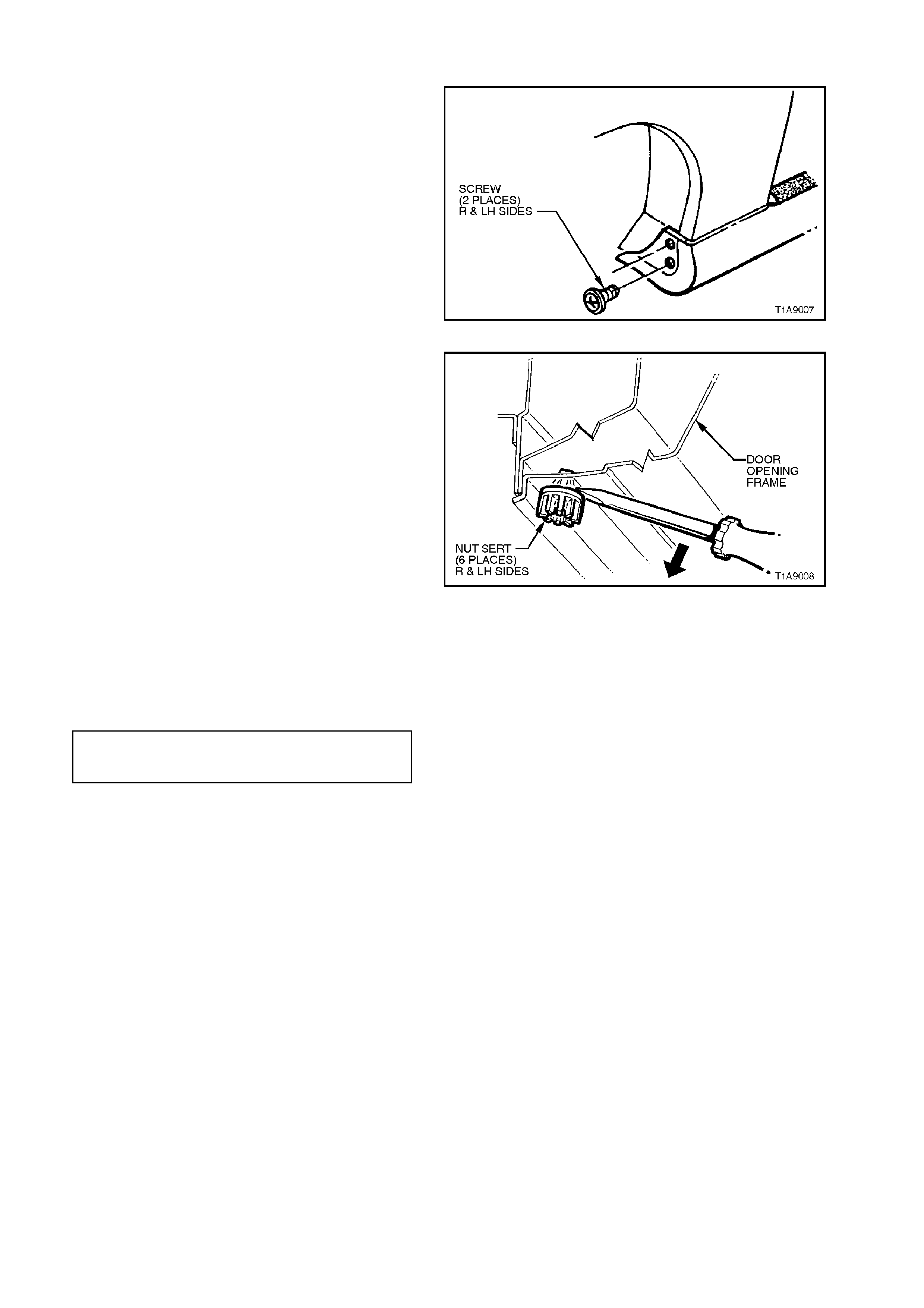

3. Remove the two screws securing the rocker

panel front skirt to the fender liner.

4. Slide rocker panel front skirt forward until it is

free from the rocker panel rear skirt, and

remove rocker panel front skirt.

5. Remove the two screws securing the rocker

panel rear skirt to the body and rem ove rock er

panel rear skirt.

Figure 1A9-5

6. If necessar y, remove the six nuts erts by gently

levering nutsert out from the body, taking care

not to damage paint work, refer to Fig. 1A9-6.

Figure 1A9-6

REINSTALL

Installation of the rocker panel front and rear sk irts

is the reverse of the removal operation, ensuring

that all fastener s are tightened to the c orr ec t torque

specification.

ROCKER PANEL SKIRT

RETAINING SCREWS 1 - 3 Nm

TORQUE SPECIFICATION

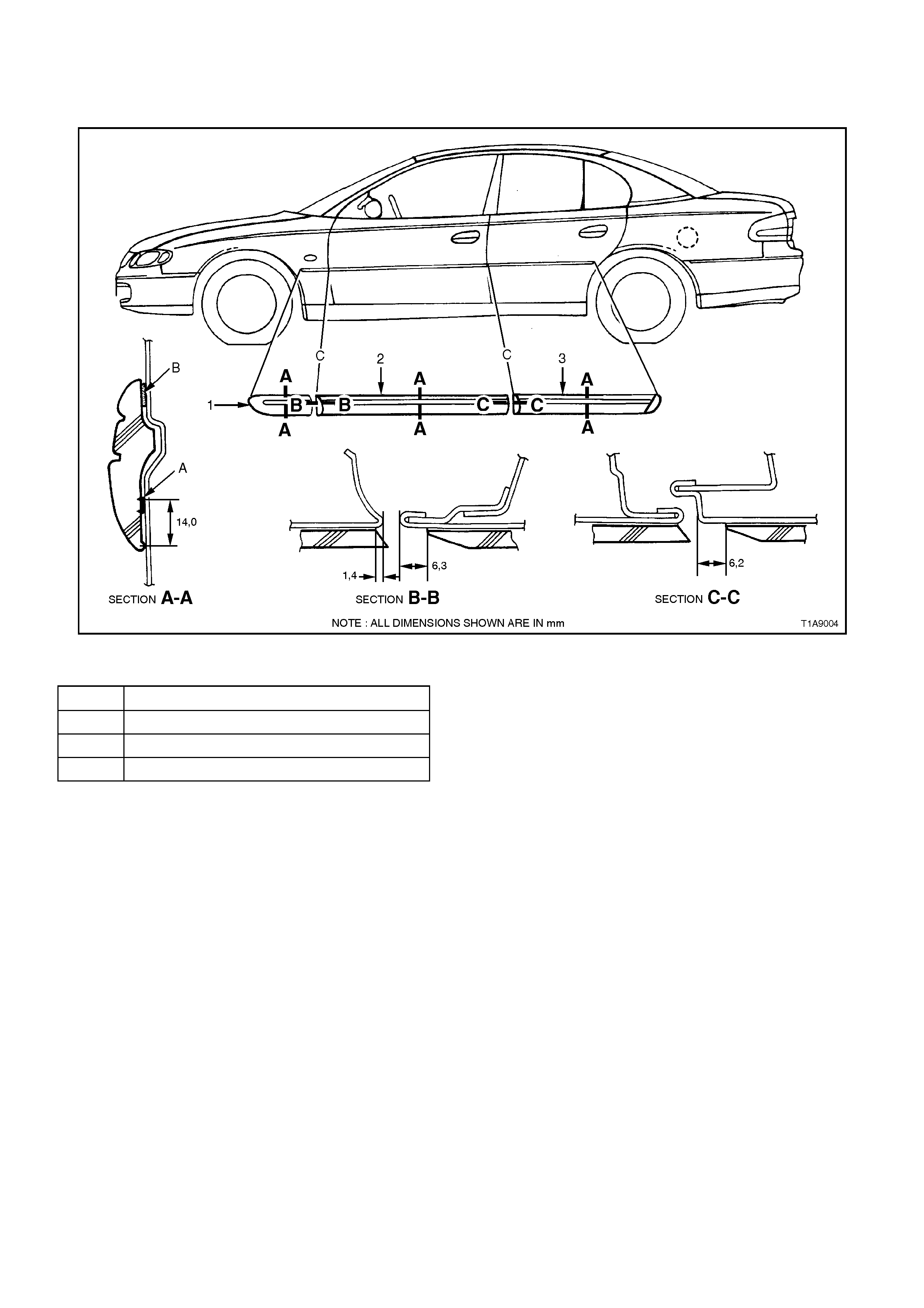

2.4 BODY SIDE MOULDINGS

SEDAN

Figure 1A9-7

ITEM DESCRIPTION

1. Front fender side moulding.

2. Front door side moulding.

3. Rear door side moulding.

SERVICE NOTES:

A Apply a 3.0 mm diameter bead of

polyurethane adhesive such as ‘Expandite

Betaseal 554.02’ or equivalent, to Holden

Specification HN 1890 over entire length of

mouldings.

B Double sided adhesive foam tape (part of

moulding assembly).

C Top edge of mouldings to be in line.

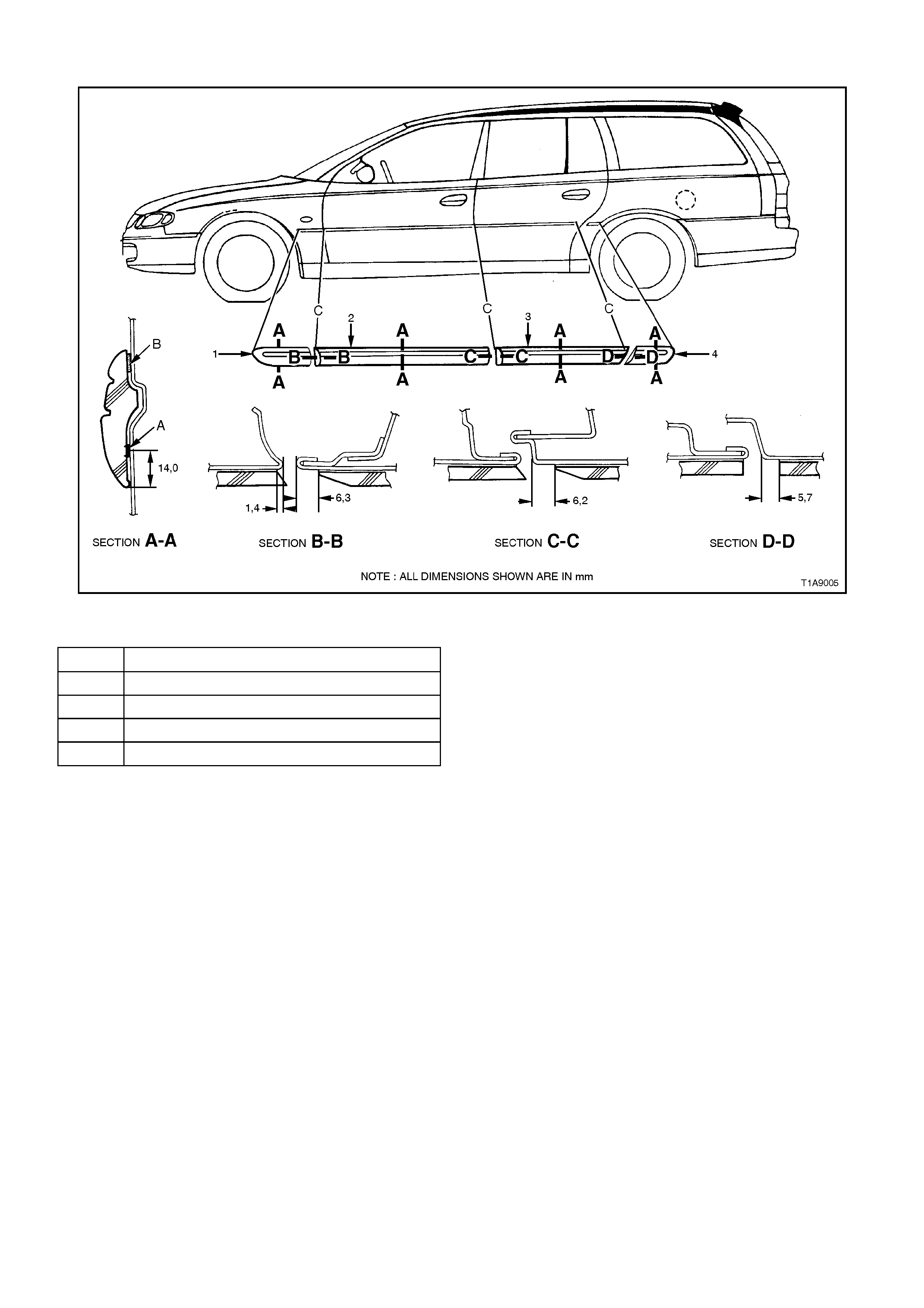

WAGON

Figure 1A9-8

ITEM DESCRIPTION

1. Front fender side moulding.

2. Front door side moulding.

3. Rear door side moulding.

4. Quarter panel side moulding.

SERVICE NOTES:

A Apply a 3.0 mm diameter bead of

polyurethane adhesive such as ‘Expandite

Betaseal 554.02’ or equivalent, to Holden

Specification HN 1890 over entire length of

mouldings.

B Double sided adhesive foam tape (part of

moulding assembly).

C Top edge of mouldings to be in line.

2.5 QUARTER PANEL TO ROOF MOULDING ASSEMBLY

REMOVE

1. Remove ‘C’ pillar trim panel assembly, refer to

Section 1A8 HEADLINING AND REAR END

TRIM, noting the following:

Only remove ‘C’ pillar tr im panel far enough to

gain access to the quarter panel to roof

moulding assembly retaining nut, inside the

quarter panel, refer to Fig. 1A9-9 .

NOTE:

Do not remove seat belt assembly.

2. Remove the quarter panel to roof moulding

retaining nut.

3. Using a piece of piano wire, carefully cut the

two beads of polyurethane adhesive from the

back of the quarter panel to roof moulding at

Section A-A and the double sided tape at

Section B-B in Fig. 1A9-9, noting to remove

and reinsert piano wire to get around locating

stud.

4. Remove quarter panel to roof moulding.

Figure 1A9-9

REINSTALL

Installation of the quarter panel to roof moulding

assembly is the reverse of the removal operation,

noting the following:

1. Apply an 8.0 mm bead of polyurethane

adhesive such as ‘Expandite Betaseal 554.02’

or equivalent, to Holden Specification HN

1890 to the inside of the moulding between

ribs, and for length of ribs in two places for

each moulding, refer to Section A-A,

Fig. 1A9-9

2. To hold the moulding in position while the

polyurethane adhesive cures, apply double

sided adhesive tape, type 5 or equivalent to

Holden Specification HN 2021, on the raised

flat area inside of m oulding (two places), refer

Section B-B Fig. 1A9-9.

3. Tighten all fasteners to the correct torque

specification.

QUARTER PANEL TO ROOF

MOULDING RETAINING NUT 1 -3 Nm

TORQUE SPECIFICATION

2.6 'B' PILLAR MOULDING

REMOVE

1. Open front and rear door on relevant side of

vehicle.

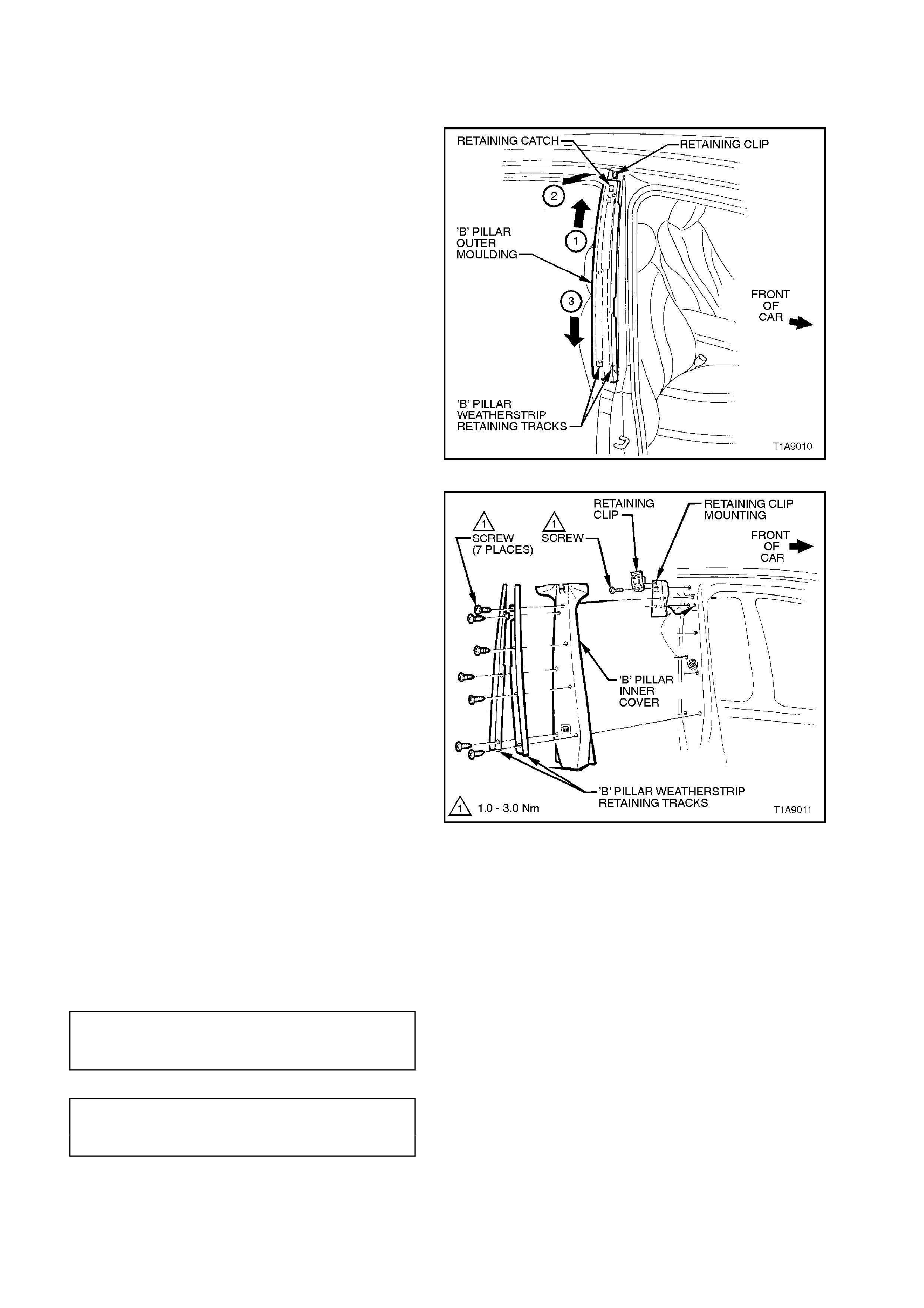

2. To release the outer moulding from the

retaining clip, push the outer moulding up by

hand slightly (1) while gently levering top of

moulding out and away from ‘B’ pillar (2).

3. With top of ‘B’ pillar released from retainer,

hold top of moulding out and slide moulding

down weatherstrip retaining tracks until

moulding rests on rear door hinge assembly

(3).

4. Jiggle outer moulding until it becomes free

from weatherstr ip retaining tr acks, and r emove

outer moulding.

Figure 1A9-10

5. Remove the door frame opening moulding,

refer to 2.8 DOOR FRAME OPENING

MOULDING in this Section.

6. Remove the seven screws securing the ‘B’

pillar weatherstrips retaining tracks to the ‘B’

pillar and remove weatherstrip assemblies.

7. Remove inner cover by pulling cover away

from ‘B’ pillar.

8. Remove the screw securing the moulding

retaining clip and m ounting to the ‘B’ pillar and

remove retaining clip and mounting.

Figure 1A9-11

REINSTALL

Installation of the ‘B’ pillar moulding is the reverse

of the removal procedure, noting the following:

1. Ensure the inner cover is seated correctly,

under door opening weatherstrips.

2. Ensure all fasteners are tightened to the

correct torque specification.

RETAINING CLIP

SECURING SCREW 1 - 3 Nm

TORQUE SPECIFICATION

WEATHERSTRIP ASSEMBLY

SECURING SCREW 1 - 3 Nm

TORQUE SPECIFICATION

3. Slide the outer moulding up and press it in at

the top so that it engages into the retaining

clip.

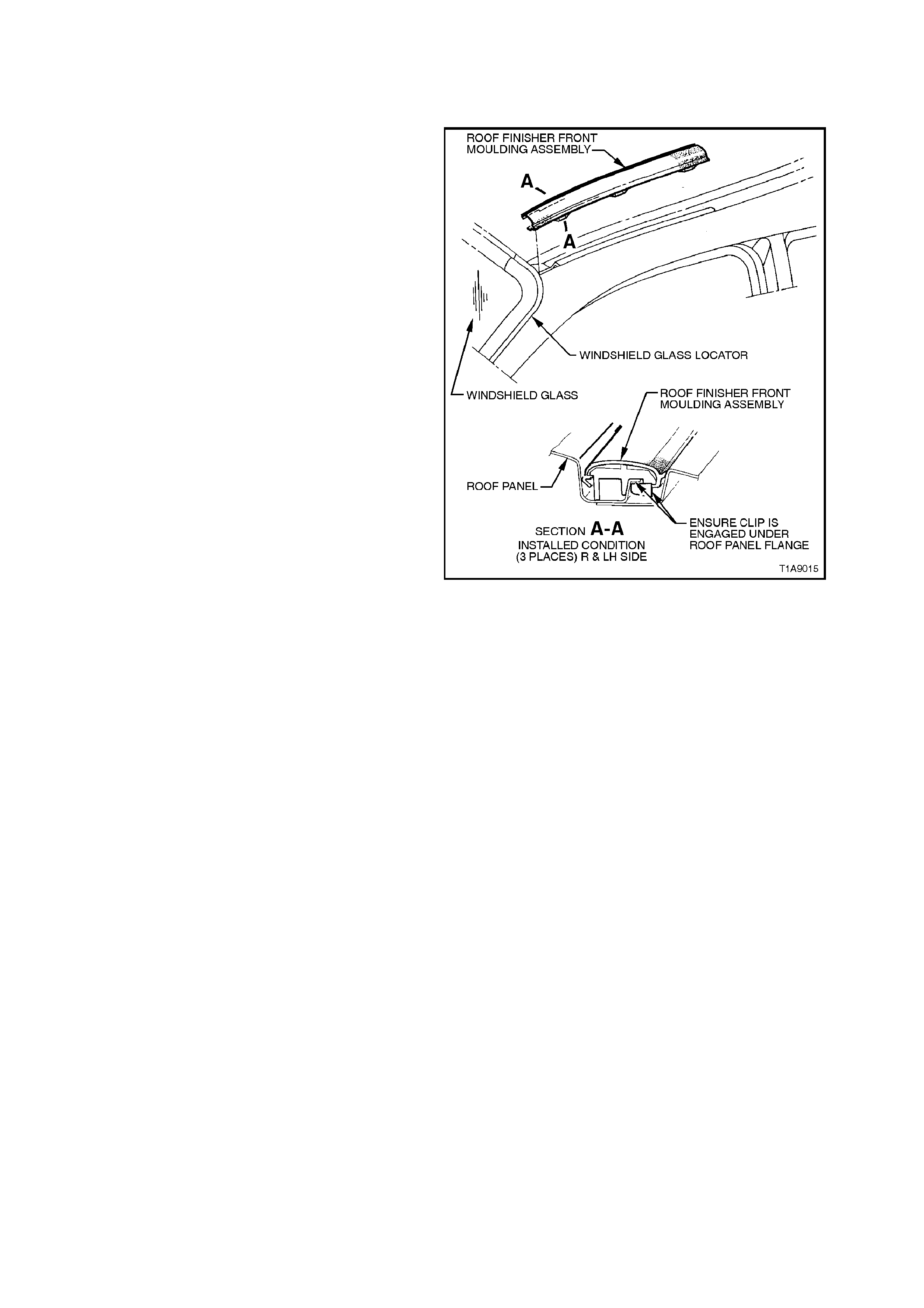

2.7 WI NDSHIELD MOULDING COVER

REMOVE

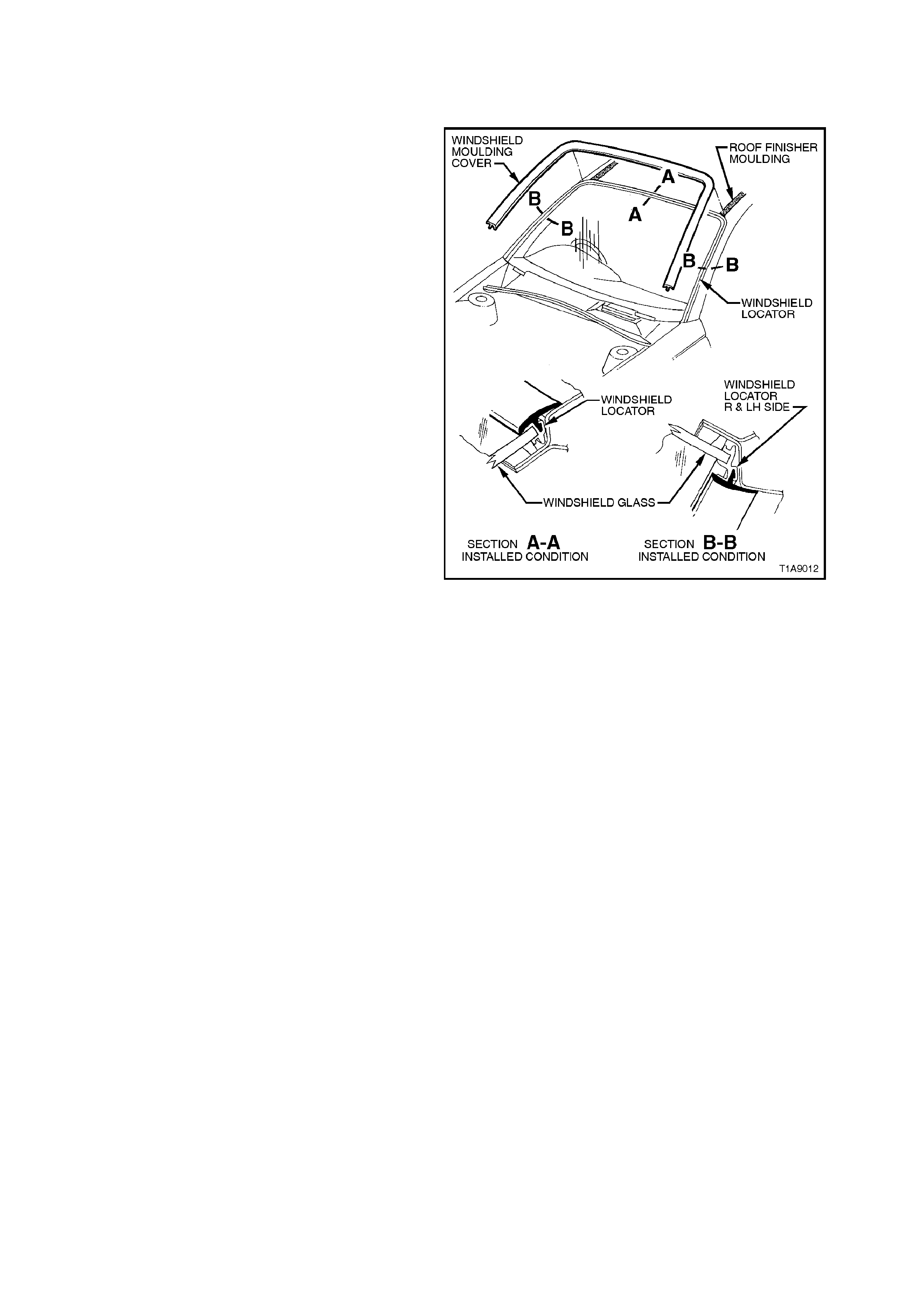

Starting at either corner of the windshield moulding

cover, gently pry windshield moulding cover out of

windshield locator and peel cover away from

windshield locator.

REINSTALL

Sit windshield moulding cover into position (place

each end of cover into locator f irst) and push cover

into windshield locator, ensuring that it is properly

engaged into locators, refer to Fig 1A9-12.

Figure 1A9-12

2.8 DOOR FRAME OPENING MOULDING

REMOVE

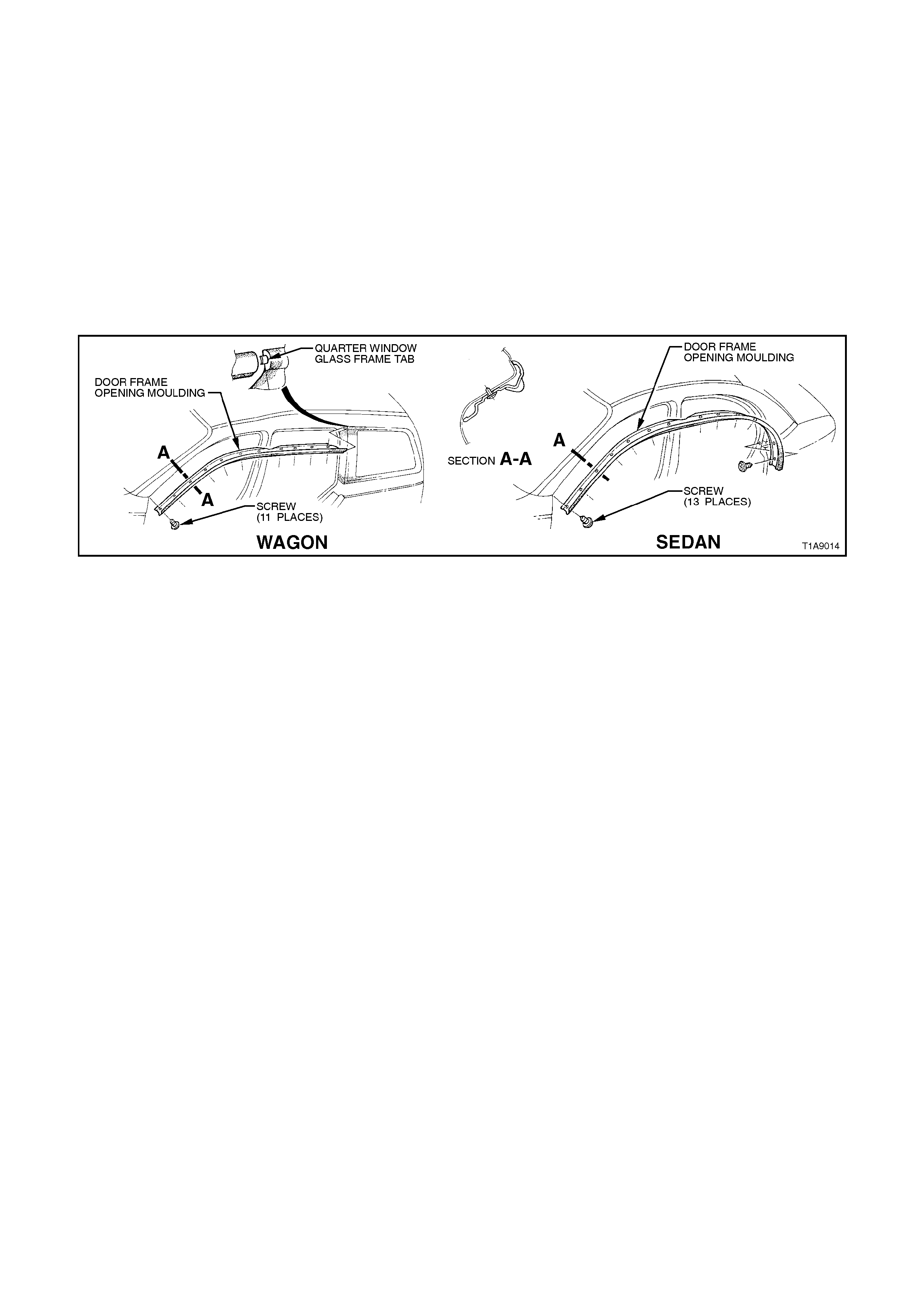

1. Open front and rear door on relevant side of vehicle.

2. Remove the screws (sedan - 13 places, wagon - 11 places) securing door frame opening moulding to body and

remove moulding.

NOTE:

On wagon models, remove moulding from the front first and slide forward slightly to disengage moulding from

quarter window glass frame tab, refer to Fig. 1A9-13.

REINSTALL

Installation is the reverse of the removal procedure.

Figure 1A9-13

2.9 ROOF FINISHER MOULDING - SEDAN

REMOVE

1. Remove windshield moulding cover, refer to

2.7 WINDSHEILD M OULDING COVER in this

Section.

2. Using a screw driver with a clean shop rag

to prevent paint work damage, pry the front of

the roof finisher moulding out of the roof

channel between the top of the windscreen to

the top of the rear window.

3. Slide the roof finisher m oulding out of the side

moulding retaining channel (between rear

window and quarter panel).

REINSTALL

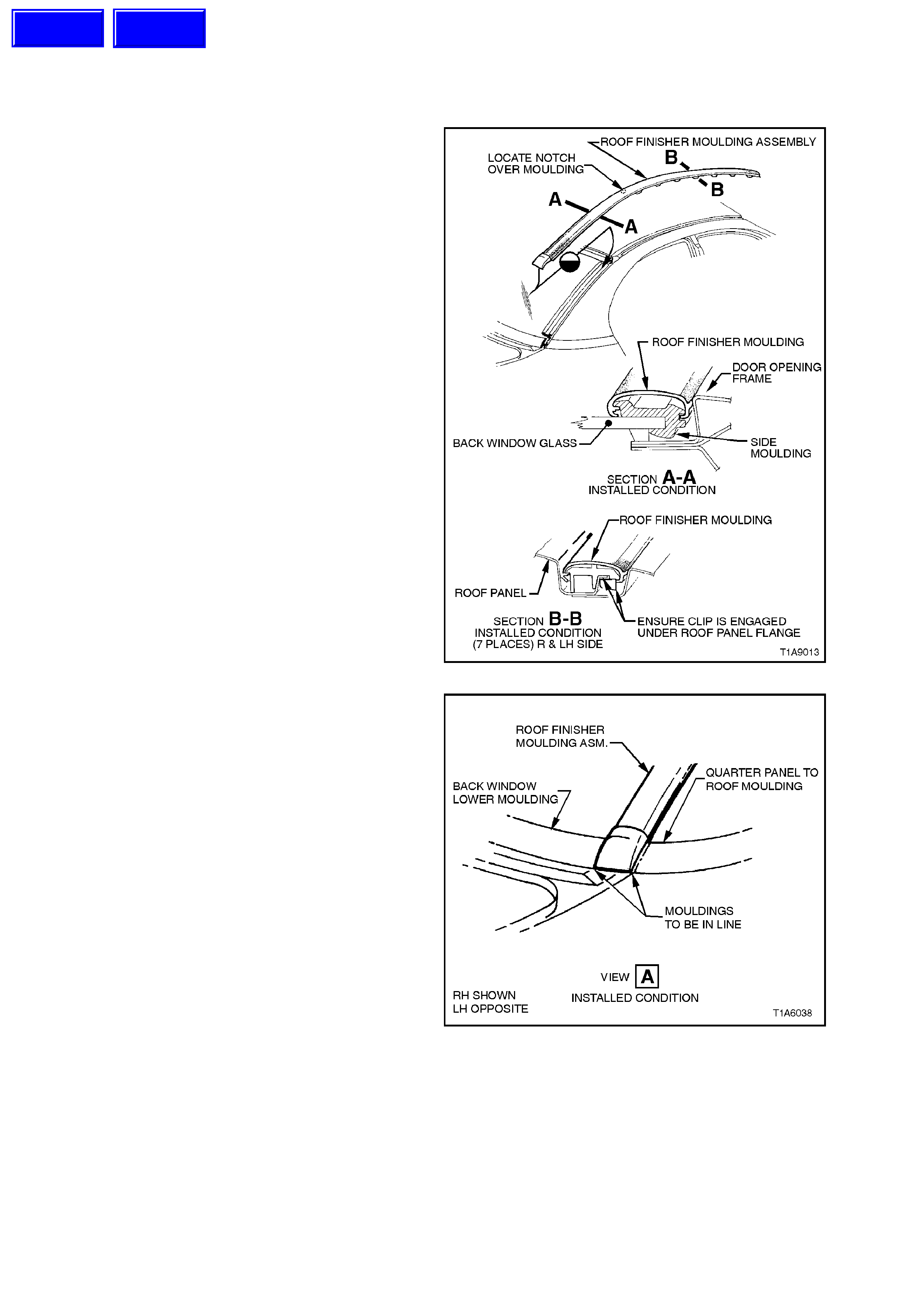

1. Engage roof finisher moulding over side

moulding, refer to Fig 1A9-14, and slide along

until roof finisher moulding is in line with the

quarter panel to roof moulding and the back

window lower moulding, refer to Fig. 1A9-15.

2. Engage roof finisher moulding assembly clips

along roof until roof finisher moulding

assembly sits flush against the roof.

3. Install windshield moulding cover, refer to

2.7 WINDSHIELD M OULDING COVER in this

Section.

NOTE:

The roof finisher moulding must be installed under

the windshield moulding cover.

Figure 1A9-14

NOTE:

Ensure roof finisher moulding end cap is aligned

with quarter panel to roof moulding, refer to Fig

1A9-15.

Figure 1A9-15

Techline

Techline

2.10 ROOF FINISHER MOULDING - WAGON

REMOVE

Starting at the front of the moulding, pry moulding

out of roof channel and remove.

NOTE:

Take care not to damage paint work.

REINSTALL

Push moulding into channel, ensuring that the clip

is engaged under the roof panel flange, r ef er to F ig.

1A9-16.

Figure 1A9-16

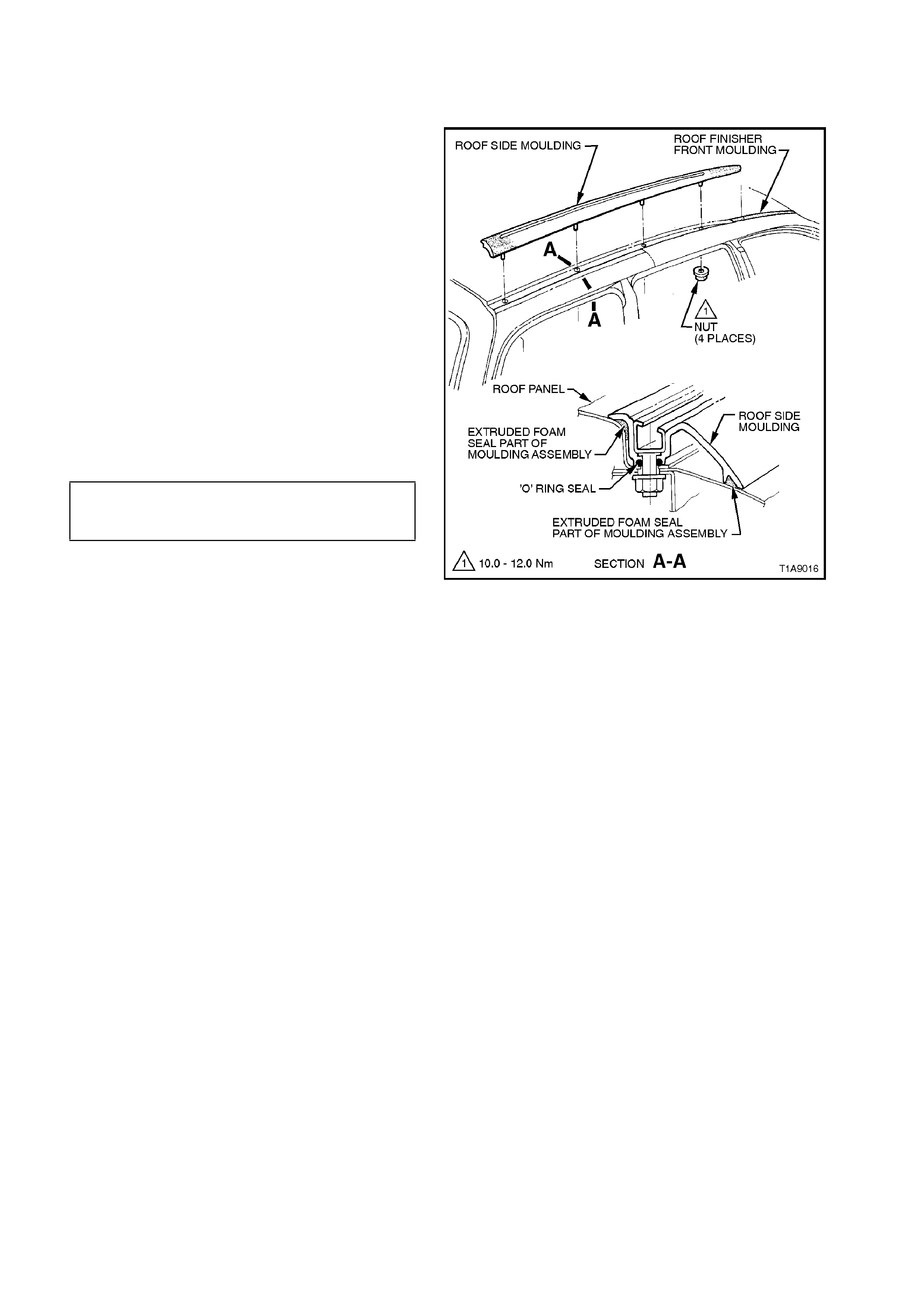

2.11 ROOF SIDE MOULDING - WAGON

REMOVE

1. Remove headlining, refer to

Section 1A8 HEADLINING AND REAR END

TRIM.

2. Loosen and remove the f our nuts securing the

roof side moulding to the roof panel and

remove roof side moulding by lifting roof side

moulding up until s tuds are f ree and then slide

rearward.

REINSTALL

Installation of the roof side moulding is the reverse

of the removal procedure, noting the following:

1. Ensure the O-ring seals are fitted to each of

the roof side moulding studs.

2. Ensure all fasteners are tightened to the

correct torque specification.

ROOF SIDE MOULDING

SECURING NUT 10 - 12 Nm

TORQUE SPECIFICATION

Figure 1A9-17

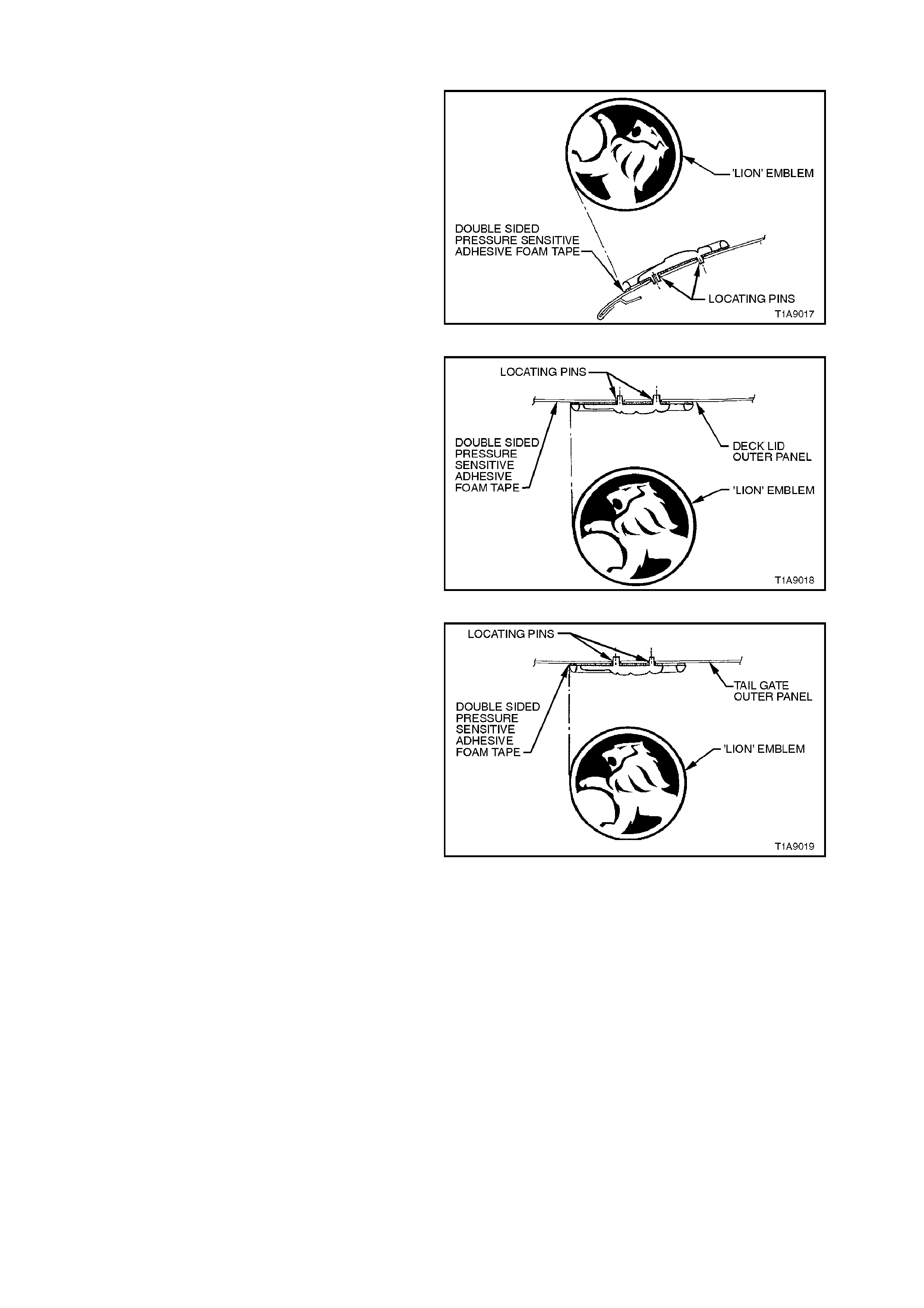

2.12 'LION' EMBLEM

ENGINE HOOD

Service notes

NOTE 1:

Before installation, remove release paper from

adhesive foam tape.

NOTE 2:

After removing release paper from adhesive foam

tape, ensure there is a band of adhesive foam tape

around base of locating pins.

Figure 1A9-18

DECK LID

Service notes

NOTE 1:

Before installation, remove release paper from

adhesive foam tape.

NOTE 2:

After removing release paper from adhesive foam

tape, ensure there is a band of adhesive foam tape

around base of locating pins.

Figure 1A9-19

TAILGATE

Service notes

NOTE 1:

Before installation, remove release paper from

adhesive foam tape.

NOTE 2:

After removing release paper from adhesive foam

tape, ensure there is a band of adhesive foam tape

around base of locating pins.

Figure 1A9-20

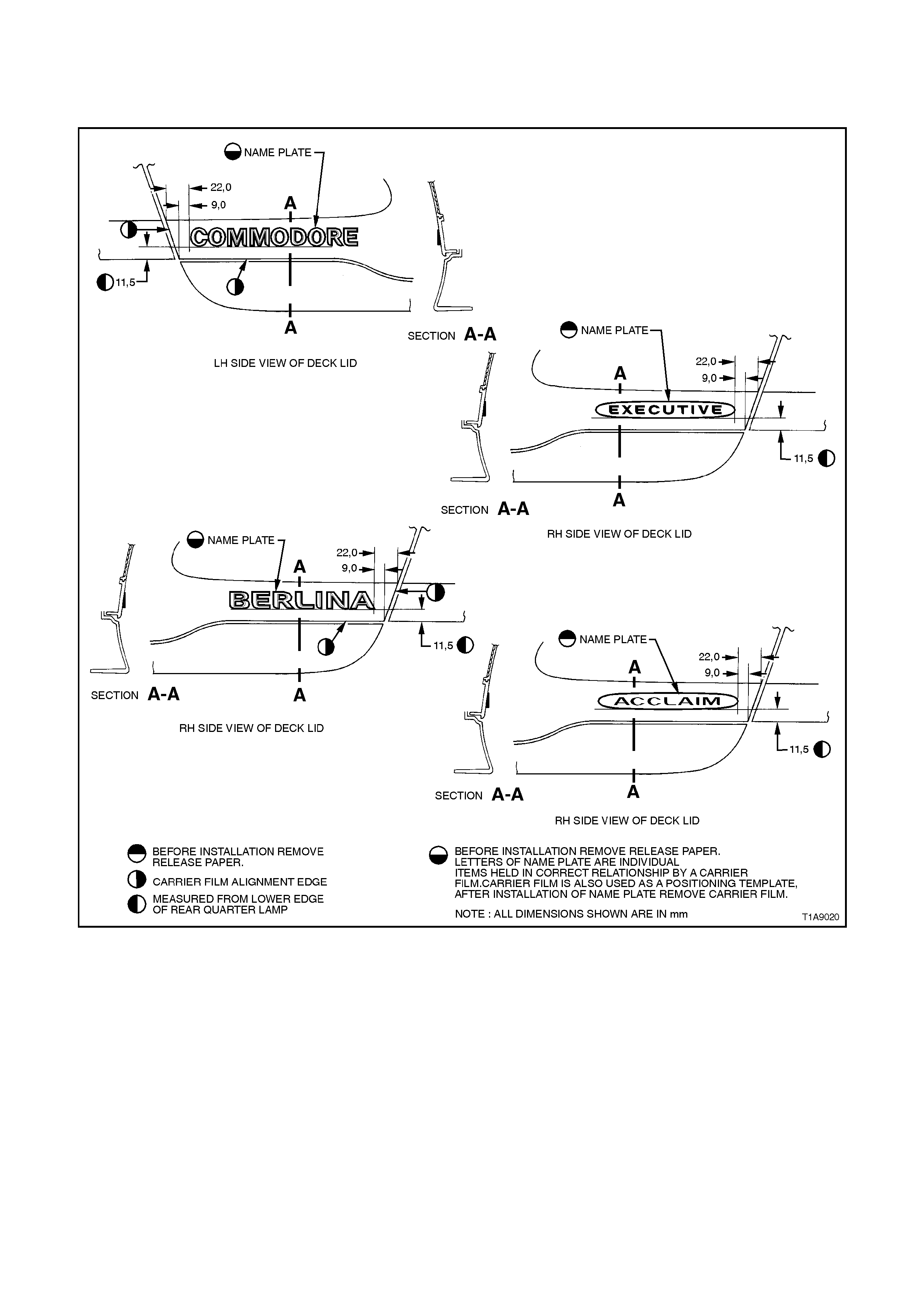

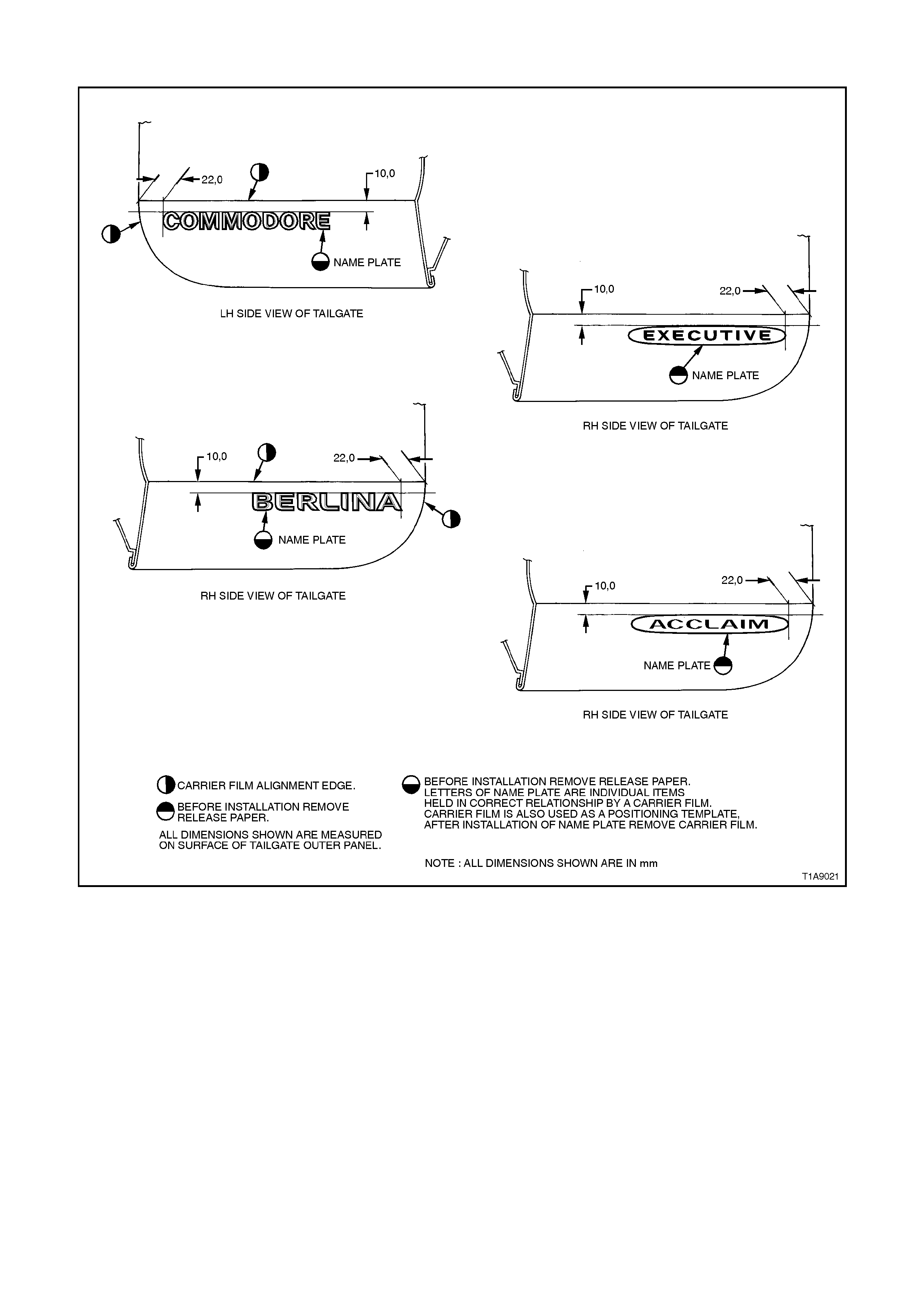

2.13 NAME PLATES AND DECALS

EXECUTIVE, BERLINA & ACCLAIM - SEDAN

Figure 1A9-21

EXECUTIVE, BERLINA & ACCLAIM - WAGON

Figure 1A9-22

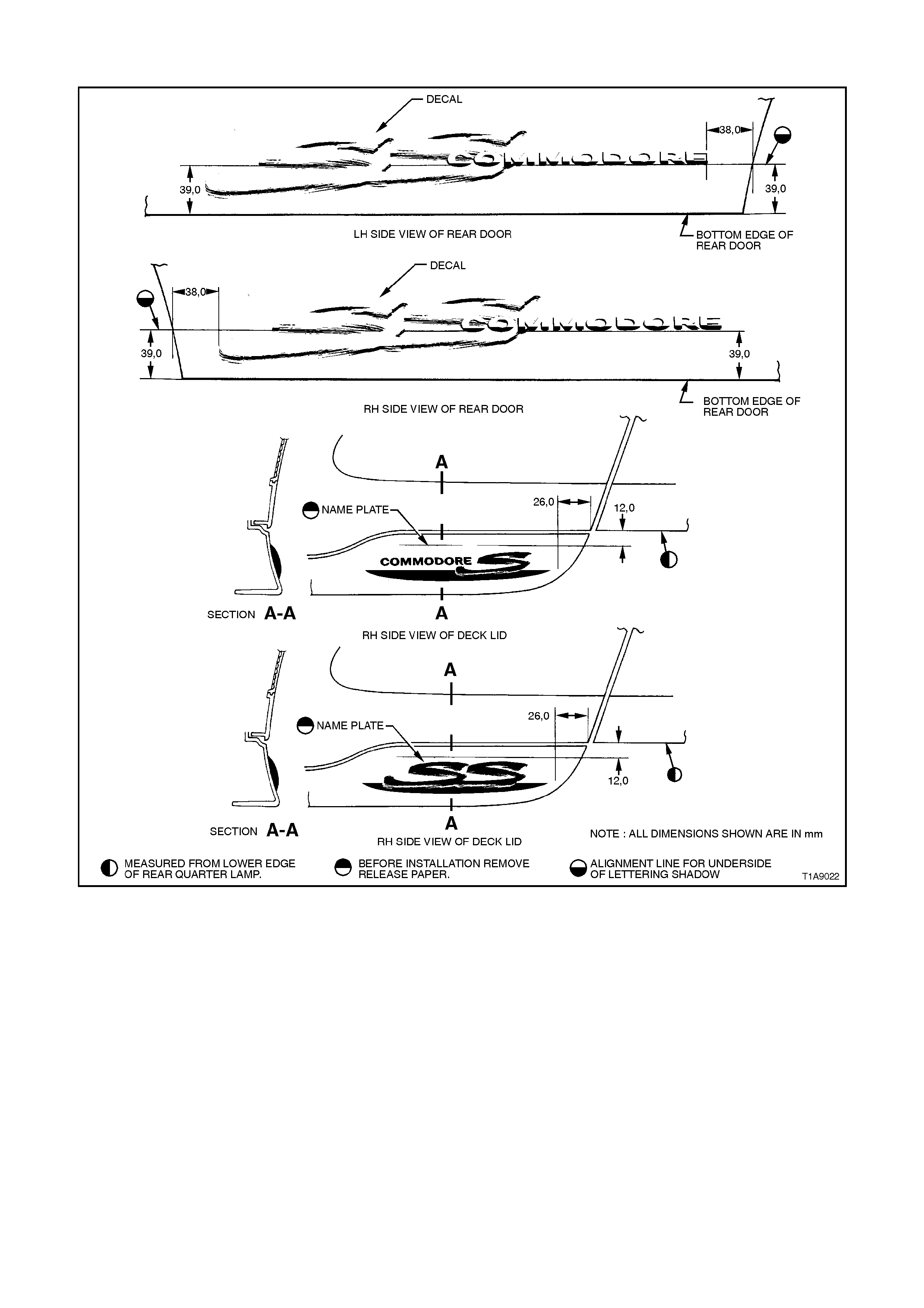

'S' AND 'SS'

Figure 1A9-23

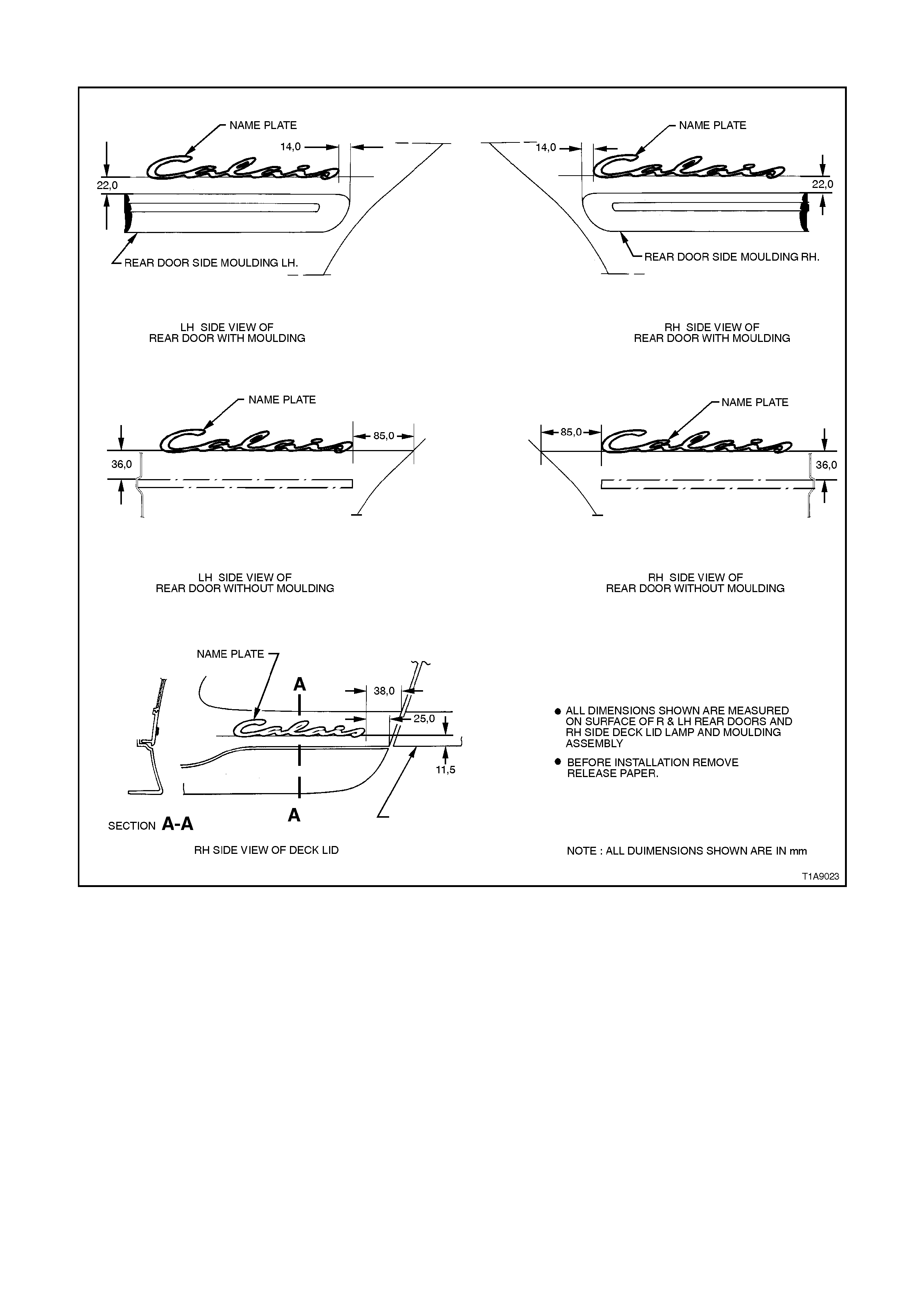

CALAIS

Figure 1A9-24

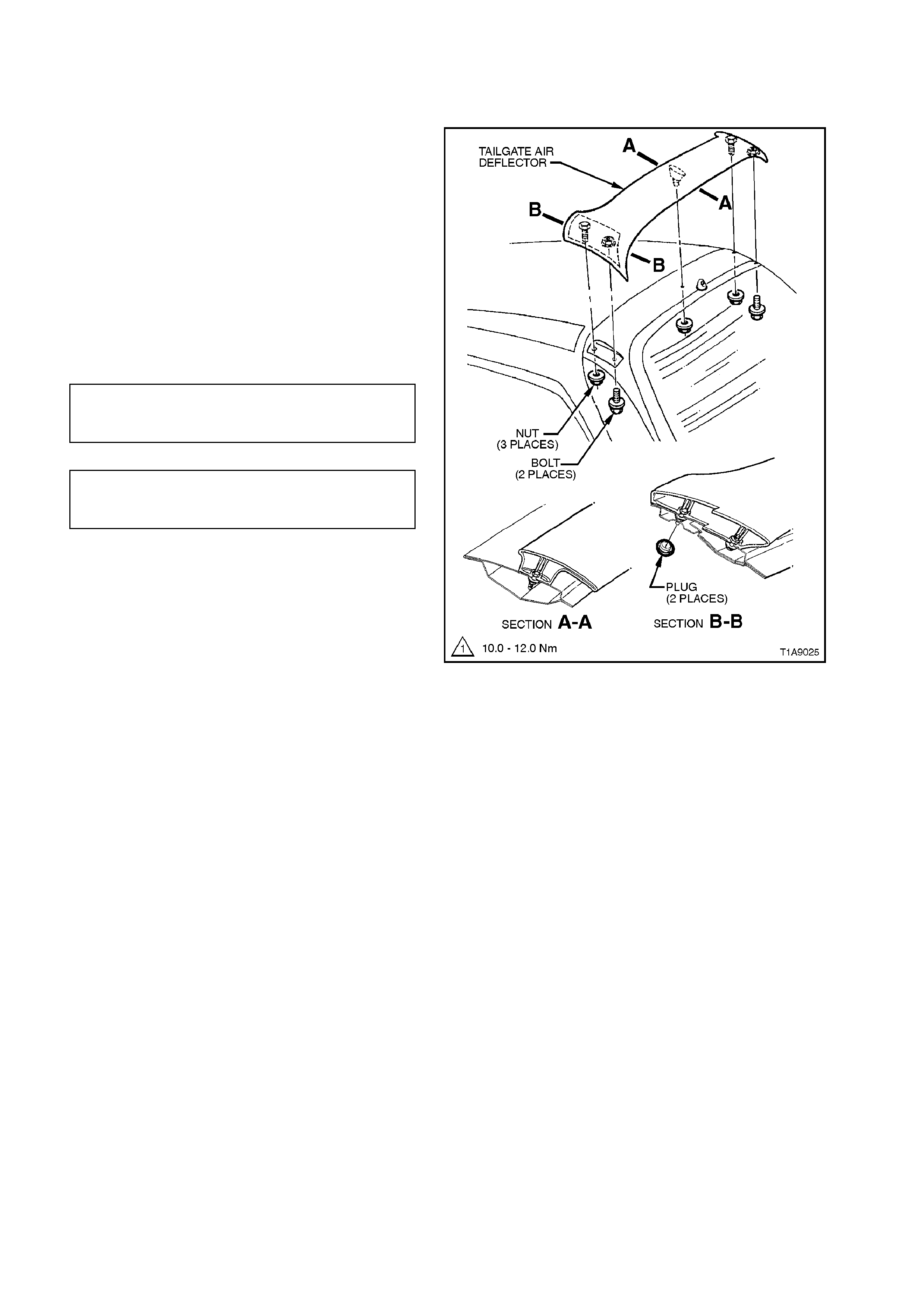

2.14 TAILGATE AIR DEFLECTOR

REMOVE

1. Remove trim panel and blanking plug from

tailgate, refer to Section 1A4 REAR

COMPARTMENT LID AND TAILGATE.

2. Rem ove the three nuts and two bolts securing

the air deflector to the tailgate and remove air

deflector.

REINSTALL

Installation of the tailgate air deflector is the reverse

of the removal procedure, noting the following:

Ensure all fasteners are tightened to the correct

torque specification.

AIR DEFLE CTOR TO TAILGATE

SECURING NUT 2 - 5 Nm

TORQUE SPECIFICATION

AIR DEFLE CTOR TO TAILGATE

SECURING BOLT 2 - 5 Nm

TORQUE SPECIFICATION

Figure 1A9-25

2.15 DE CK LID AIR SPOILER

REMOVE

1. With the deck lid raised, disconnect the

electrical connector to the high mount stop

lamp, refer to View A Fig. 1A9-26.

2. Remove the four nuts securing the spoiler to

the deck lid.

3. While feeding high mount stop lamp wiring

harness through access hole in deck lid,

remove the spoiler assembly.

REINSTALL

Installation of the deck lid spoiler is the reverse of

the removal procedure, noting the following:

1. Ensure the foam seals are installed between

the deck lid spoiler and the deck lid, refer to

Fig 1A9-26.

2. Ensure all fasteners are tightened to the

correct torque specification.

SPOILER ASSEMBLY TO DECK

LID SECURING NUT 2 - 5 Nm

TORQUE SPECIFICATION

Techline

Figure 1A9-26

3. TORQUE WRENCH SPECIFI CATIONS

Nm

Rocker Panel Skirt Retaining Screw 1 - 3

Quarter Panel to Roof Moulding Retaining Nut 1 - 3

‘B’ Pillar Moulding Retaining Clip Retaining Screw 1 - 3

Weatherstrip Assembly Securing Screw 1 - 3

Roof Side Moulding Securing Nut 10 - 12

Spoiler Assembly to Deck Lid Securing Nut 2 - 5

Air Deflector to Tailgate Securing Nut 2 - 5

Air Deflector to Tailgate Securing Bolt 2 - 5