SECTION 1D - BUMPER BARS

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will

consist of either seat belt pre-tensio ners and a driver’s side air bag , or seat belt pre-

tensioners and a driver’s and front passenger’s side air bags. Refer to CAUTIONS,

Section 12M, before performing any service operation on or around SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deplo yment, resulting in possible p ersonal injury or unnecessary

SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of

safety, the LPG fuel system should be isolated by turning 'OFF' the manual service

valve and then draining the LPG serv ice lines, before any service w ork is carried out

on the vehicle. Refer to the LPG leaflet included with the Owner's Handbook for

details or LPG Section 2 for more specific servicing information.

1. GENERAL INFORMATION

Front and rear bumper bar assemblies fitted to VT Series models are of polypropylene material. The centre of the

front bumper bar facia is attached to a steel bumper support beam which, in turn, is attached to longitudinal frame

members and to the front fender sheet metal on each side. The rear bumper bar facia is attached to the body at the

sides and at the rear. Steel bumper support beam is attached to rear longitudinally.

2. SERVICE OPERATIONS

2.1 PAINT SYSTEM

The paint system for the bumper bar facias is relatively straightforward as long as the correct materials are used.

Normal refinish lacquers will not adhere to polypropylene/EPDM bumpers.

CAUTION:

Thorough cleaning and the use of Holden’s approved paint and additives is required. Other ma terials and

methods may damage the plastic or lead to premature pa int failure.

The following service recommendations are compiled to guide Dealerships on the correct materials and methods to

be employed when refinishing bumper bars and also preparing new parts for service installation.

RECOMMENDED MATERIALS

Front and rear bumper bars installed on VT Series models are made from high impact strength

Polypropylene/EDPM plastic.

It is essential that only Holden’s approved methods, materials, paints etc; be employed when paint repair operations

are performed and when preparing new parts for installation to the vehicles.

The Holden’s approved materials are:

-Dulux* Bodykleen 920-30509

-Dulux* Plastpak Universal Anti Static Cleaner 920-39237

-Dulux* Plastpak Universal Primer 499-38571

-Dulux* Plastpak Flexible Additive for Two Component Products 499-35484

-Dulux* Cobra Basecoat - Colour 534 Line

-Dulux* Basecoat Thinner 920-34926

-Dulux* 2K Clearcoat 455-30900

-Dulux* 2K Acrylic Enamel Solid Colour 426 Line

-Dulux* 2K MS Hardener Normal 980-35239

-Dulux* 2K Reducer Fast 920-19148

* Dulux is a trademark of Dulux Australia.

COLOUR FINISHING OF REPLACEMENT PARTS

Spare parts require priming and coating with approved topcoat colour before installation to the vehicle.

1. Order part and paint materials.

2. Read Safe Handling instructions further in this Section and obtain the required respirator.

3. Cleaning. Wash unpainted polypropylene bumper bar all over with a made-up solution of 9 parts fresh water: 1

part Dulux Bodykleen 920-30509. Apply with a clean non-metallic pad (recommended Scotchbrite 448) to scuff

the surface.

4. Rinse with fresh cold water.

5. Using a clean cloth saturated with Dulux Plastpak Universal Anti-static cleaner 920-39237, wash the entire

part, allowing contact for a minimum 15 seconds.

6. Dry thoroughly using a separate, clean, dry cloth.

7. Repeat steps 5 and 6 another 3 times. Each time using a separate clean dry cloth.

NOTE:

If a static charge has built up on the bumper surface (after completing all cleaning operations) dampen the surface

with the Plastpak Universal Anti-static cleaner and allow to evaporate dry. This will impart full anti-static properties to

the bumper.

8. Priming: Apply one light double (approximately 3 - 8 µm D.F.B.) coat (uniformly wet) of Dulux Plastpak

Universal primer 499-38571 to all the bumper surface intended for topcoat. Recommended air pressure range

of 320 - 420 kPa.

9. Allow to air dry 15-20 minutes @ 20° C. DO NOT SAND.

** Scotchbrite is a trademark of 3M Co.

PAINT

Solid Colour

To the matched colour, add Flexible Additive then Hardener and Reducer in the following ratios:

-426 line colour - 5 parts by volume

-Flexible Additive 499-35484 - 1 part by volume

-2K MS Hardener 980-35239 - 3 parts by volume

-2K Reducer 920-19148 - 10-20% by volume

Stir thoroughly and strain. Put on the air supplied respirator. Using a 1.4 - 1.8 mm fluid nozzle on a standard spray

gun, apply one medium wet coat. Apply a further one or two coats to achieve coverage allowing a 3 - 5 minutes

flash-off time between coats. If low baking, this can be done immediately (no more than 5 minutes flash-off) at 60°C

for 40 minutes. If air drying, allow 16 hours to dry (correct film thickness is 40 - 50 microns).

Cobra Basecoat, Metallic, Pearl or Solid Colour

Thin the matched basecoat colour with Cobra Basebuilder, 920 line at a 1:1 mix ratio and stir thoroughly, strain

material, and using a 1.4 - 1.6 mm gravity feed spray gun, apply one medium wet even coat. Allow to flash off for

5 minutes before applying the next coat.

Apply one or two further coats to achieve a uniform and even coverage with 5 minutes flash-off between coats.

Allow 10 - 20 minutes drying before applying clearcoat.

Mix 2K Clearcoat with Flexible Additive then Hardener and Reducer in the following ratios:

-2K Clearcoat 455-30900 - 5 parts by volume

-Flexible Additive 499-35484 - 1 part by volume

-2K MS Hardener 980-35239 - 3 parts by volume

-2K Reducer 920-19148 - 20% by volume

Stir thoroughly and strain. Put on the air supplied respirator. Using a 1.4 - 1.8 mm fluid nozzle spray gun set-up,

apply one medium wet coat to the basecoat (after allowing the Basecoat 10 - 20 minutes drying time). Apply a

further one or two wet coats after a 3 - 5 minutes flash-off between coats. If low baking, this can be done

immediately after the last coat but do not allow more than 5 minutes flash-off. Bake at 60°C for 40 minutes or, if air

drying, allow 16 hours.

REPAIRING COLOUR COAT

Superficial damage to the paint film and/or plastic surfaces may be rectified by sanding and repainting. Parts having

deep gouges in the plastic surface should be replaced because repair methods using filling materials and thinning

down of the plastic section may reduce overall impact strength.

For shallow paint damage, follow the procedure listed under “Colour finishing of replacement parts”, using P800

paper to sand down imperfections and using, e.g. Scotchbrite 448 pad or P1200 paper, scuff and key existing

paintwork.

Basecoat and Clearcoat can be spot repaired by blending away the basecoat colour but spraying the complete

bumper with Clearcoat coats. Solid colours are best sprayed as complete panels. If the damage extends to the

plastic surface, this must be primed with Plastpak Universal primer after the correct cleaning procedure.

CAUTION:

Drying of all products may be accelerated by heat, but to avoid distortion, unsupported bumpers should

not be heated in an oven or by lamp above 60°

°°

°C.

SAFE HANDLING OF ALL PAINTS CONTAINING DULUX 2K MS HARDENER

Dulux 2K MS Hardener contains not more than 0.3% free isocyanate monomer.

FOR AUTOMOTIVE AND INDUSTRIAL USE ONLY. This product requires professional equipment and experience

for safe handling. Not for use by the general public.

Read and understand the instructions and warnings contained in data sheets and on the label of the can containing

the base product before opening the can. Follow all directions and warnings carefully, otherwise DO NOT use this

product.

Warnings and precautions on the label also apply to the mixture of hardener and base.

Breathing of vapour, spray mist and dust from sanding is harmful and may cause lung irritation and allergic

respiratory reaction. Irritates skin and eyes.

When mixed with the appropriate base, apply in a spray booth fitted with an effective exhaust system. Comply with

local legislation applicable to spray painting of motor vehicles. Wear a positive pressure air supplied full face

respirator (complying w ith Australian Standard 1716 - 1984) and gloves while spraying and during all subsequent

use. The spray booth area should be isolated from other people while spraying is in progress and until all spray mist

has been effectively dispersed.

FIRST AID:

If affected by inhalation of vapour or spray mist, remove to fresh air. If breathing difficulty persists or occurs later,

consult a doctor and have label information available. In case of eye contact, flush immediately with plenty of water

for 15 minutes; call a doctor. In case of skin contact, remove contaminated clothing and wash skin thoroughly with

soap and water. Immerse contaminated clothing in water for 24 hours and do not re-use until it has been laundered.

In case of spillage, absorb onto dry sand or earth, remove from the work area, cover with water for 24 hours before

disposal. Treat empty hardener cans in the same manner.

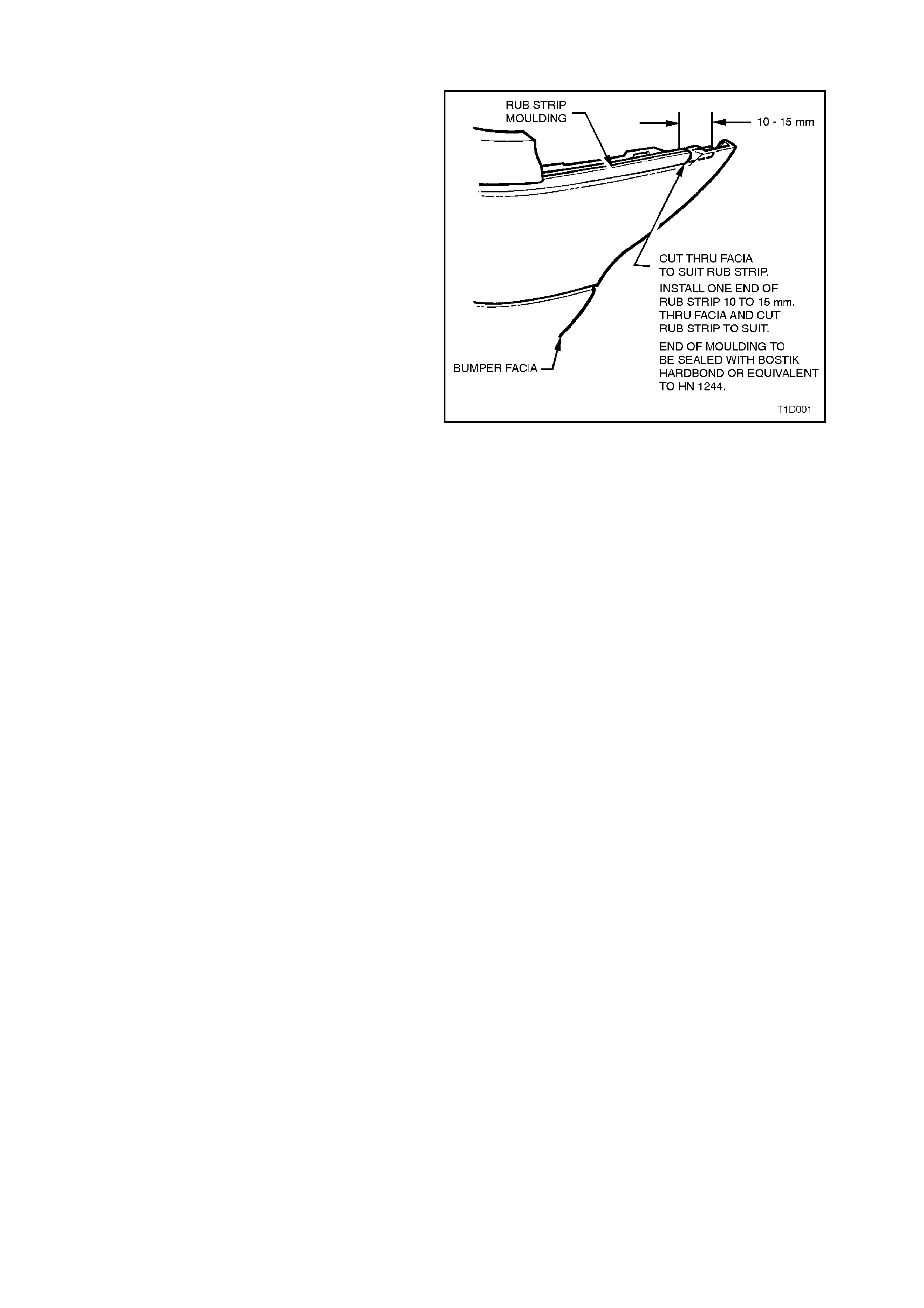

2.2 BUMPE R RUB S T RIP MOULDING

REMOVE

1. Carefully remove the rub strip moulding from

the bumper bar, taking car e not to damage the

bumper bar paint finish.

CAUTION:

Ensure all remains of insert and adhesive are

removed before proceeding.

REINSTALL

1. Warm rub strip moulding until flexible and

adhesive becomes tacky.

2. While still warm and flexible place insert into

one end of bumper bar recess and smooth

down into place working across the bumper

bar face.

NOTE:

Use a clean shop rag to exert pressure while

applying insert.

3. Once installed, trim insert to length and seal

both ends of insert with Bostik Hardbond or

equivalent to specification HN 1244.

NOTE:

Failure to seal ends of insert will result in

discolouration.

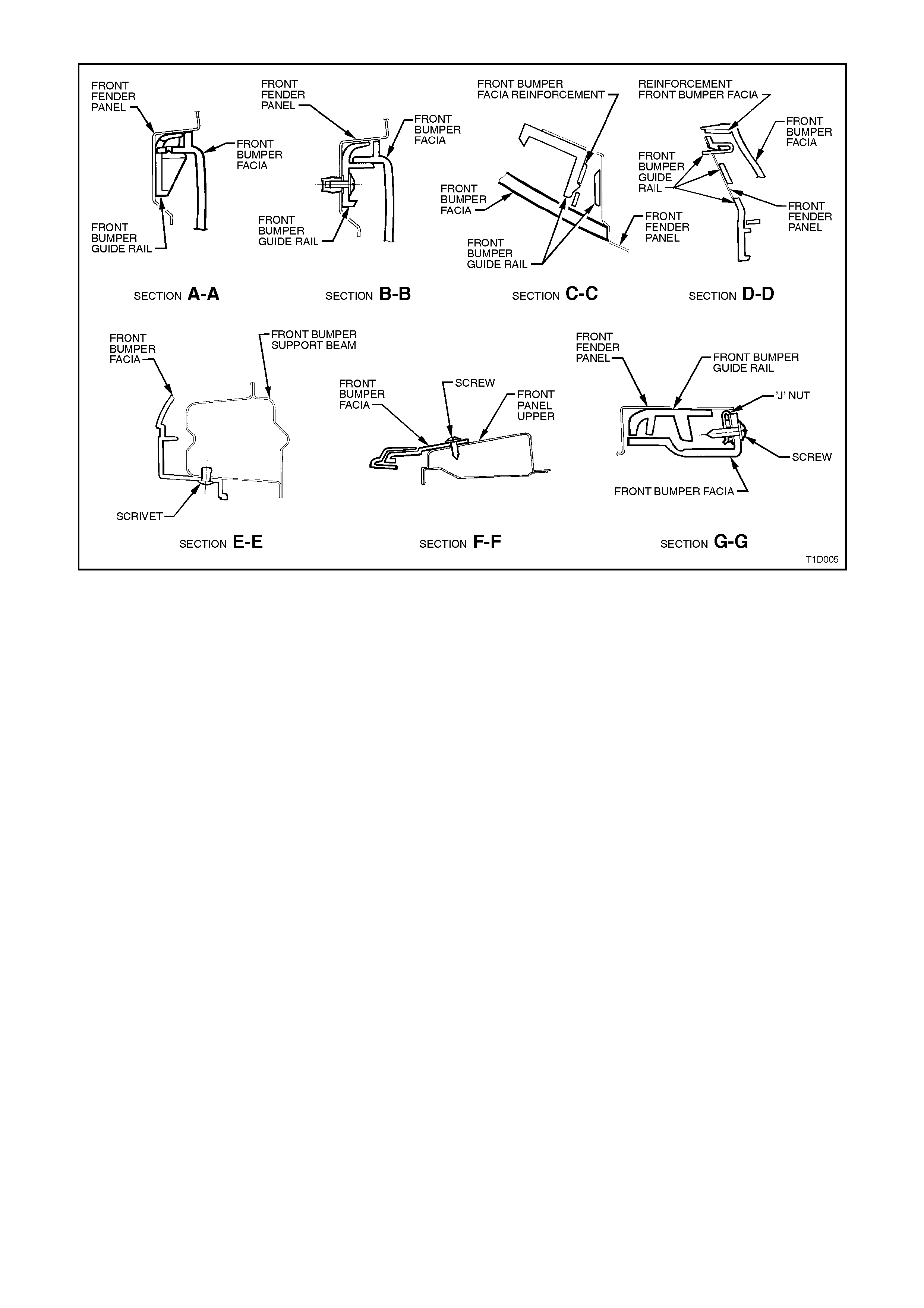

Figure 1D-1

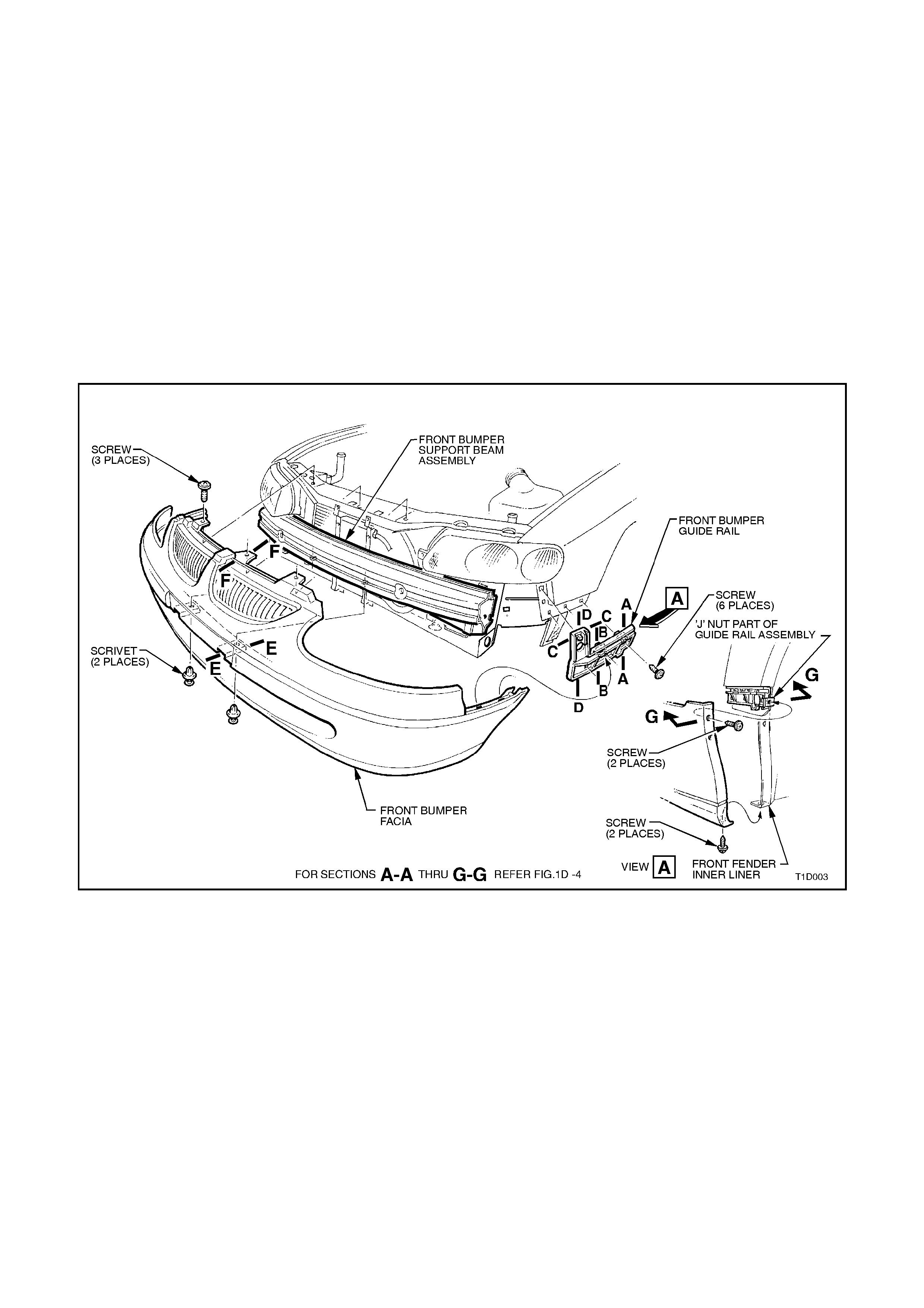

2.3 FRONT BUMPER BAR ASSEMBLY

REMOVE

1. Remove scrivets (two) from behind number

plate.

2. Remove screws securing facia sides to front

fender wheelarch opening and radiator suppor t

upper panel.

3. With the facia supported, pull the facia side

members out, disconnect the facia side

supports, then slide the facia forward removing

the facia assembly, refer to Fig. 1D-2.

NOTE:

Support beam should not be removed unless

damaged, refer to Section 1A2 BODY

DIMENSIONS for alignment details.

Figure 1D-2

Figure 1D-3

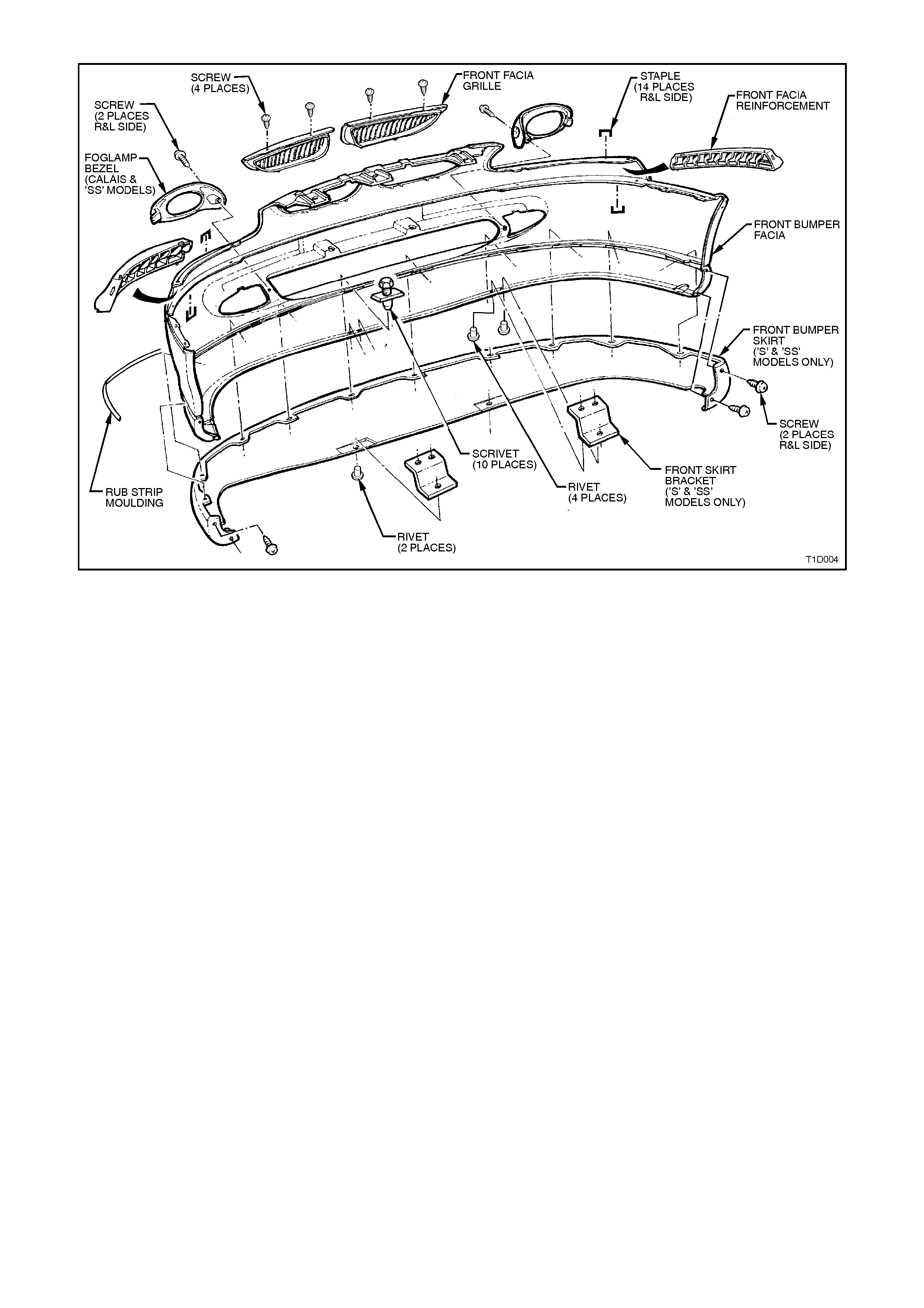

DISASSEMBLE

1. Place the front bumper bar facia assembly face down on a clean protected surface.

2. On Calais and ‘SS’ models, remove screws securing fog lamp bezels (one screw per bezel) and withdraw fog

lamp bezels from front bumper facia.

REASSEMBLE

Reverse disassembly operations.

REINSTALL

Reverse removal operations. Snap the facia onto retainers at guide rails, one side at a time, (refer to section C–C,

Fig. 1D-4) then adjust the facia to ensure correct fender, hood/headlamp clearance.

Figure 1D-4

2.4 FRONT BUMBER SKIRT - 'S' AND 'SS' MODELS ONLY

REMOVE

1. Remove front bumper facia, refer to 2.3 FRONT BUMPER BAR ASSEMBLY in this Section.

2. Remove four screws securing front bumper skirt to front bumper facia.

3. Remove front bumper facia to front bumper skirt retaining scrivets (10 scrivets) and rivets attaching front skirt

bracket to front skirt (one rivet per bracket) and remove front bumper skirt.

REINSTALL

Reverse removal operations, ensuring proper fit of front bumper skirt to front bumper facia.

2.5 REAR BUMPER BAR ASSEMBLY - SEDAN

REMOVE

1. From within the rear compartment remove the rear quarter trim panel, refer to Section 1A8 HEADLINING

AND REAR END TRIM.

2. Remove the four nuts securing the rear bumper assembly to the rear quarter panel (below tail lamps).

3. Remove two screws securing rear bumper facia at each upper wheelarch opening and one screw at the lower

wheelarch opening. Remove six fasteners at the upper edge of facia and two fasteners at lower edge of facia.

4. With the facia supported, pull the facia side members out to disconnect the facia side supports, then slide the

facia rearwards, removing the facia, refer to Fig. 1D-5.

NOTE:

Support beam should not be removed unless damaged, refer to Section 1A2 BODY DIMENSIONS for alignment

details.

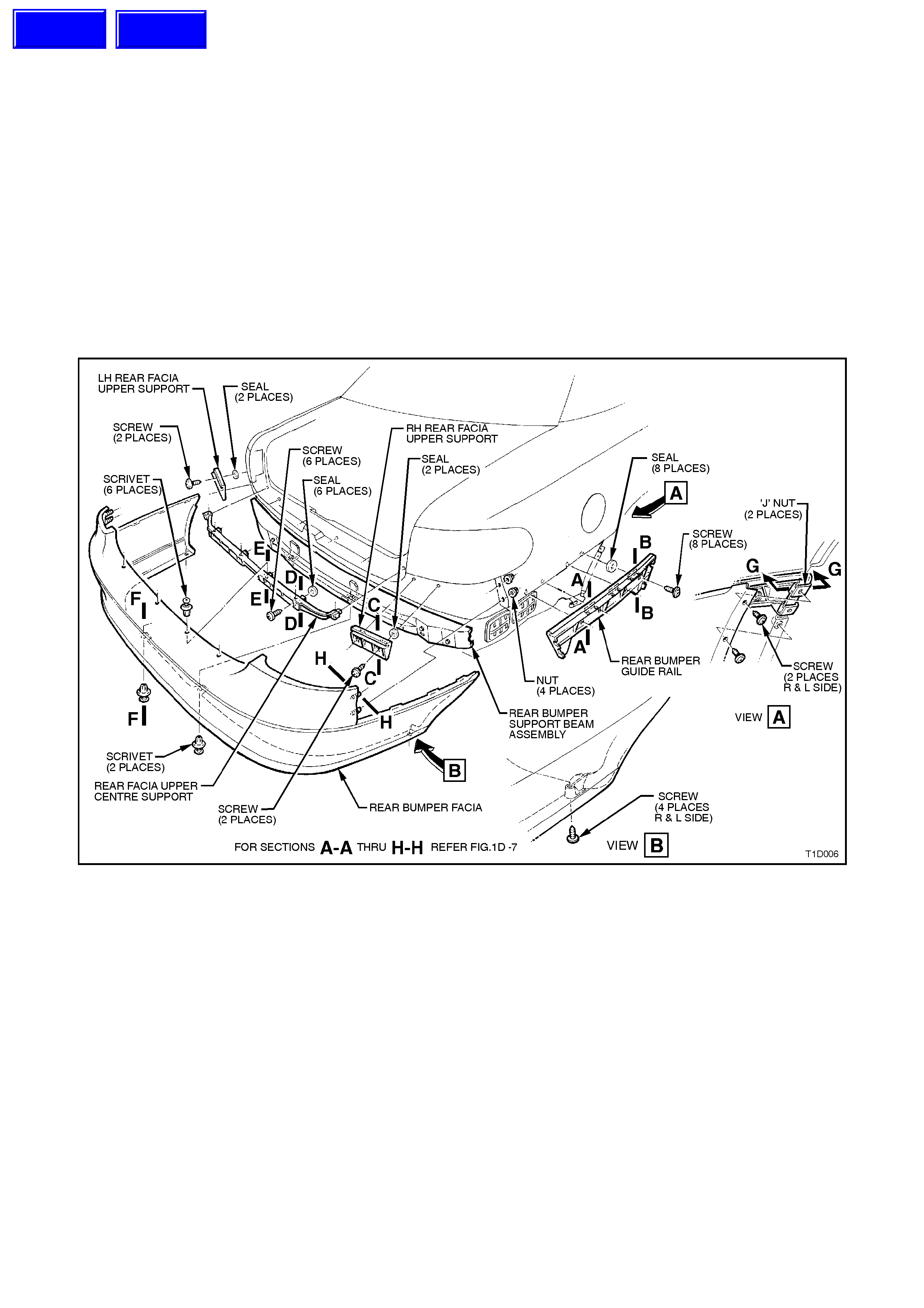

Figure 1D-5

DISASSEMBLE

1. Place the rear bumper bar assembly face down on a clean protected surface.

2. Where fitted, remove the fasteners securing the bumper bar facia skirt to the facia and remove the skirt.

REASSEMBLE

Reverse disassembly operations.

REINSTALL

Reverse removal operations. Locate studs (two each side) on the facia to holes in the rear quarter panel. Snap the

facia onto retainers at the side support, adjust the facia to ensure correct clearance.

Techline

Techline

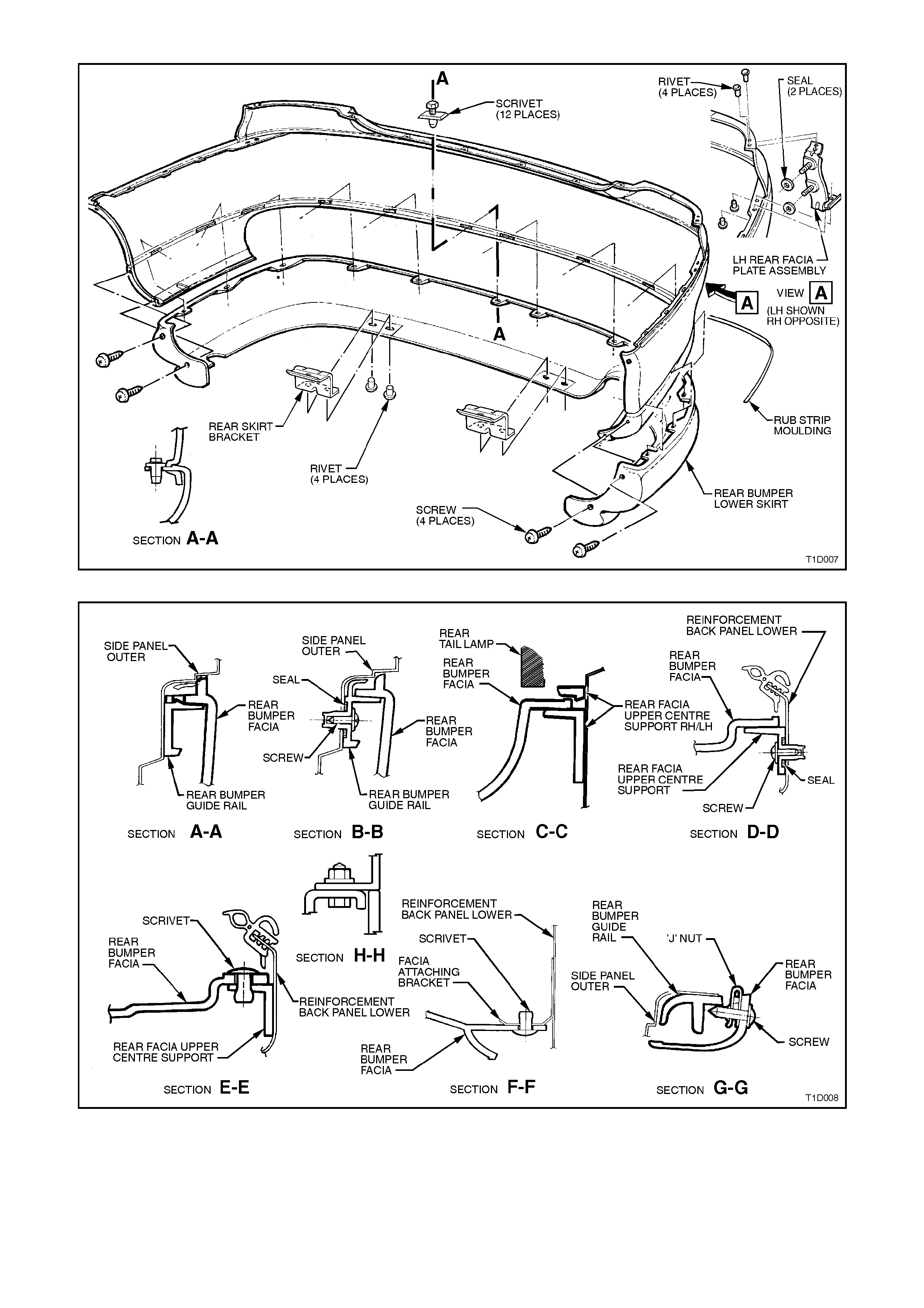

Figure 1D-6

Figure 1D-7

2.6 REAR BUMPER SKIRT - 'S' AND 'SS' MODELS ONLY

REMOVE

1. Remove rear bumper facia, refer to 2.5 REAR BUMPER BAR ASSEMBLY - SEDAN in this Section.

2. Remove four screws securing rear bumper skirt to rear bumper facia.

3. Remove rear bumper facia to rear bumper skirt retaining scrivets (12 scrivets) and rivets attaching rear skirt

bracket to rear skirt (four rivets) and remove rear skirt, refer to Fig. 1D-6.

REINSTALL

Reverse removal operations, ensuring proper fit of front bumper skirt to front bumper facia.

2.7 REAR BUMPER BAR ASSEMBLY- STATION WAGON

REMOVE

1. Remove two screws securing rear bumper facia at each upper wheelarch opening and one screw at the lower

wheelarch opening. Remove six fasteners at the upper edge of facia and two fasteners at lower edge of facia.

2. With the facia supported, pull facia side members out to disconnect the facia side supports, then slide the facia

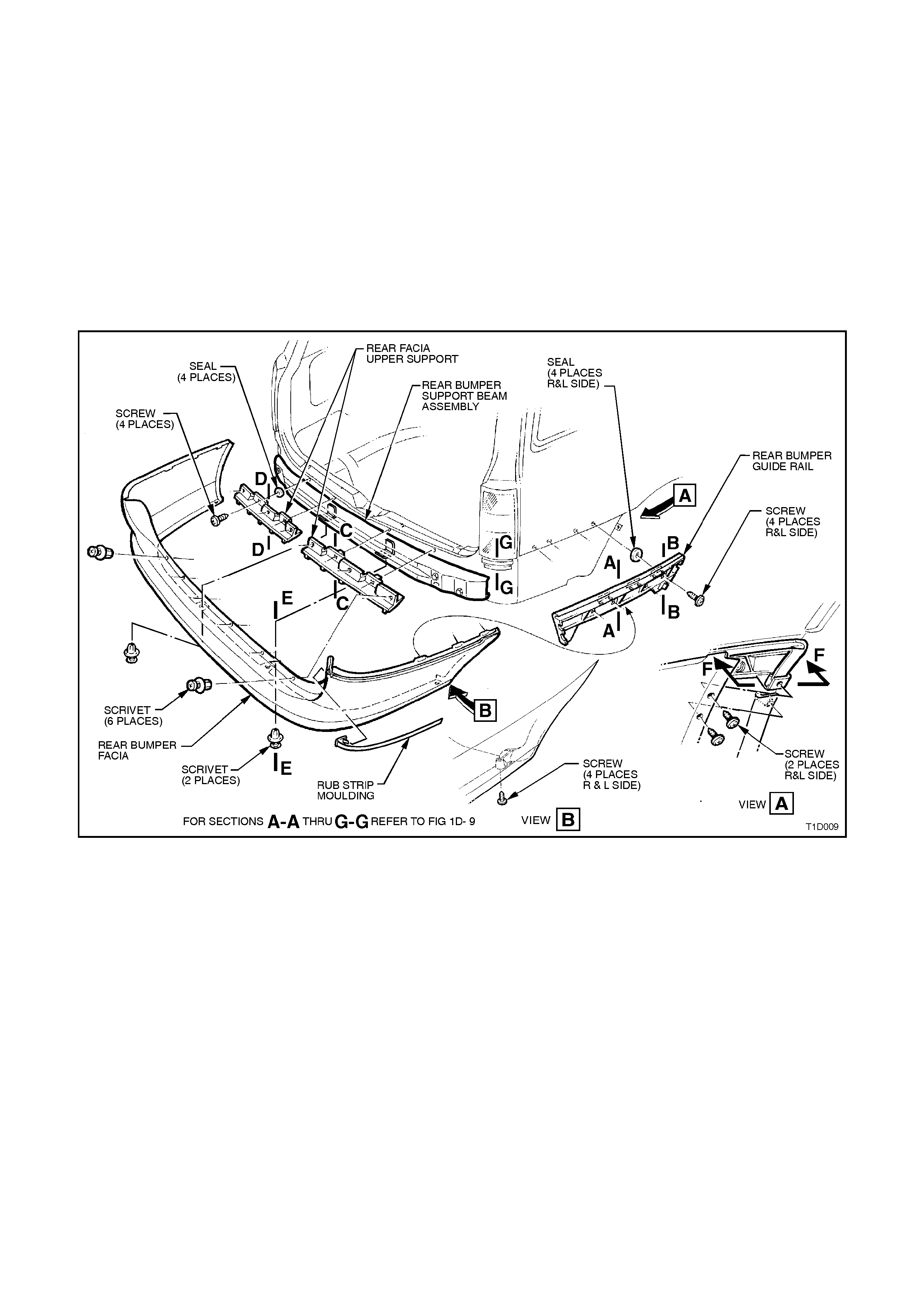

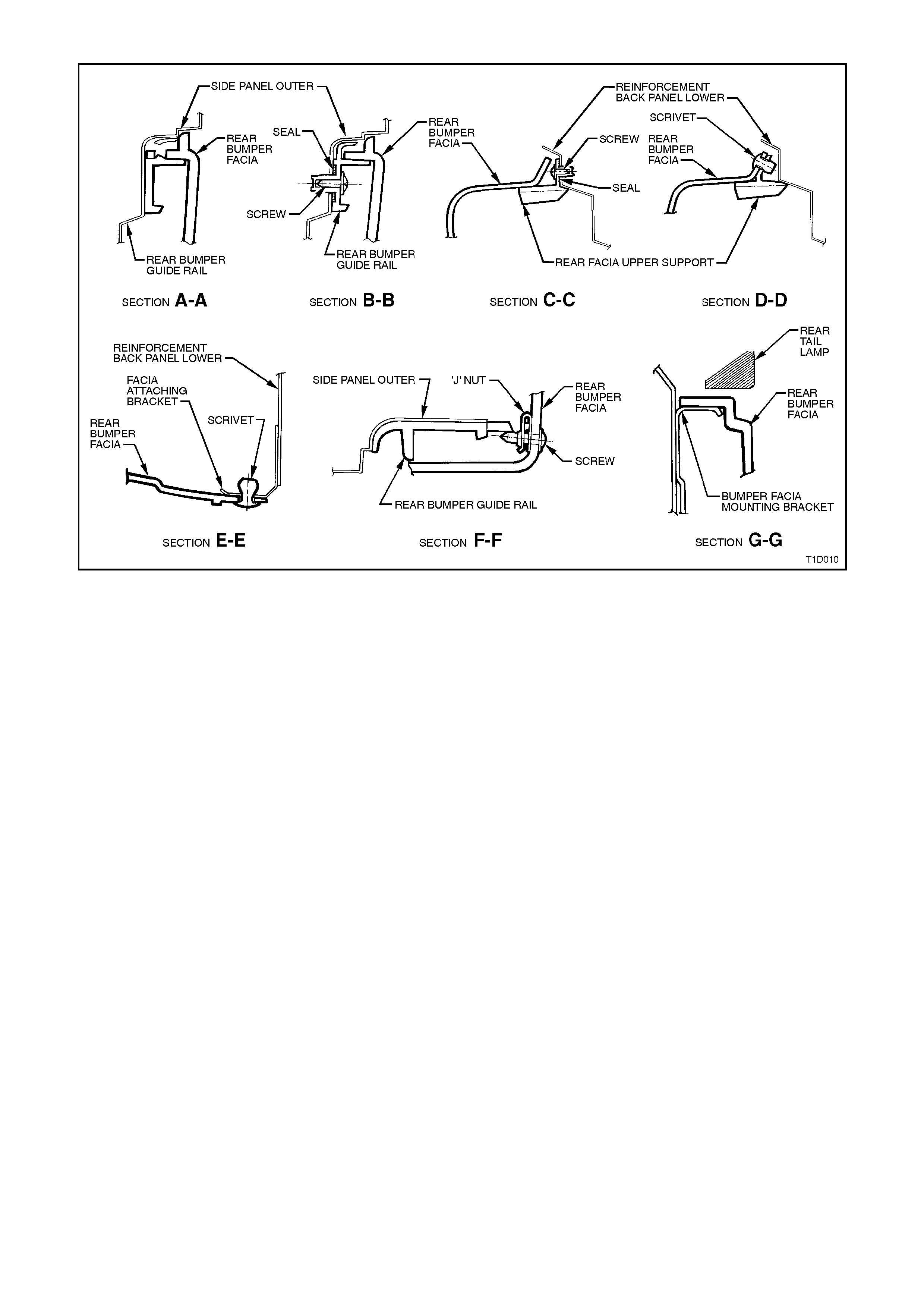

rearwards, removing the facia, refer to Fig. 1D-8.

NOTE:

Support beam should not be removed unless damaged, refer to Section 1A2 BODY DIMENSIONS for alignment

details.

REINSTALL

Reverse removal operations. Snap facia onto retainers at side support, adjust facia to ensure correct clearance.

Figure 1D-8

Figure 1D-9

3. TORQUE WRENCH SPECIFI CATIONS

Nm

Front bumper facia side attaching screws 1.0 - 3.0

Front bumper facia top attaching screws 2.5 - 4.0

Front facia grille securing screws 1.0 - 3.0

Fog lamp bezel attaching screws 1.0 - 3.0

Rear bumper bar assembly attaching nuts 6.0 - 9.0

Rear bumper bar facia securing screws 1.0 - 3.0

Rear bumper skirt securing screws 1.0 - 3.0

Rear bumper facia at wheelarch securing screws 1.0 - 3.0