SECTION 2D - ELECTRONIC CLIMATE CONTROL

(ECC) - DESCRIPTION AND OPERATION

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will

consist of either seat belt pre-tensio ners and a driver’s side air bag , or seat belt pre-

tensioners and a driver’s and front passenger’s side air bags. Refer to CAUTIONS,

Section 12M, before performing any service operation on or around SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deplo yment, resulting in possible p ersonal injury or unnecessary

SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of

safety, the LPG fuel system should be isolated by turning 'OFF' the manual service

valve and then draining the LPG serv ice lines, before any service w ork is carried out

on the vehicle. Refer to the LPG leaflet included with the Owner's Handbook for

details or LPG Section 2 for more specific servicing information.

1. GENERAL DESCRIPTI ON - ECC

The Electronic Climate Control (ECC) System is available in two forms either in Single Zone or Dual Zone.

The Single Zone is standard on Berlina.

The Dual Zone is standard on Calais.

Techline

1.1 DESCRIPTION AND OPERATION

The ECC Module uses a microprocessor to monitor

inputs, process data and thus control outputs.

The inputs used by the ECC are as follows:

• Serial Data information:

• Sunlight level, Priority Key user & Ignition Off

time from BCM, Engine RPM, coolant

temperature, road speed & AC pressure from

PCM.

•In-car temperature sensor.

•Ambient temperature sensor.

•Evaporator temperature sensor.

•Air mix potentiometer (PBR) (2 for dual zone

systems).

•Ignition Voltage.

•Blower Fan Voltage.

•Customer settings by way of the ECC buttons.

The outputs controlled by the ECC module controls

are as follows:

•Serial Data information:

Sunlight level for Instrument dimming of cruise &

Power indicators, AC request to the PCM.

•Air Distribution Mode (demist, foot, foot & face,

face) by controlling the logic of 4 vacuum

solenoids.

•Vent Air Temperature by controlling the position

of the Air mix door (2 for dual zone systems)

(between approx. 5°C (with AC on) and approx.

70°C (with warm engine).

•Air Inlet Mode (i.e. Fresh or Recirculated) by

controlling a vacuum solenoid.

•Blower fan speed by an analogue signal sent to

the Blower speed controller which amplifies this

signal & thus controls the blower voltage.

•Maximum Blower Relay.

•Rear Window Demist relay.

•ECC display and LEDs to indicate ECC status.

RECOMMENDED SETTINGS

The customer should be encouraged to use the

ECC in full Auto mode (gr een Auto LED ON) and a

set temperature of 23°C.

Changing the set temperature to suit different

conditions could cause the ECC to behave

differently from what the customer expects (eg.

setting to 17°C on a hot day could cause the

customer to complain the blower speed is to high

on hot days). This should be discouraged.

EVAPORATOR TEMPERATURE CONTROL

As the A/C system uses a Harrison V5 variable

stroke compressor, there is NO need for an

evaporator temperature sensor in the manual A/C

system. In the ECC system an evaporator air off

sensor does not exist, but is only used to sense

A/C temper ature for ECC software calculations , not

to cycle the compressor on/off. Anti ice-up is

governed by the evaporator pressure control valve

loca ted w ithin the compressor.

BLOWER FAN CONTROL

There are steples s varying blower fan speeds available in the automatic mode and f ive s peeds in the manual mode.

Manual fifth speed is the same as highest automatic blower fan speed.

When the engine is not running, the actual blower speed will not be higher than appr oxim ately fan speed 3, in order

to improve battery life.

AUTOMATIC MODE

The blower speed will vary according to:

• In-car Temperature

• Ambient Temperature

• Sunload

• Drivers Set Temperature

• Coolant Temperature

• Air Distribution Mode

If the cabin is at the required temperature, the blower will be at a minimum. An increase in sunload in these

conditions would cause the blower to increase.

If heating of the cabin is required (eg. After a cold night), the blower would gradually increase as the coolant

temperature increased to approximately 70°C. Then, as the In-car temperature increased, the blower would

decrease.

If extreme cooling of the cabin were required, the blower would increase to maximum speed (over about 15

seconds). Then, as the In-car temperature decreased, the blower would also decrease.

If cooling of the cabin is required, an increase in sunload will cause the blower speed to increase. If heating up of

the cabin is required, an increase in sunload will normally cause the blower speed to decrease.

If the air distribution mode changes, (eg. From Face to Face/Floor) the fan speed may also change.

In order to maintain a constant air flow, the blower voltage compensated for:

• Road Speed

• Air Inlet mode

• Ignition Voltage

AIR DISTRIBUTION CONTROL

There are 5 distribution modes that can be selected either Automatically or manually. These are:

• Demist

• Foot/Demist

• Foot

• Foot/Face

• Face

AUTOMATIC MODE

The air distribution mode selected will vary according to:

• In-car Temperature

• Ambient Temperature

• Sun load

• Drivers Set Temperature

• Start Up conditions

If the cabin is at the desired temperature, the ECC will select either Foot/Face of Face (depending on if the cabin

needed to be warmed up or cooled down).

If cooling of the cabin were required, Foot mode may be selected for a short time (AC purge), followed by Face

mode.

If heating of the cabin is r equired, dem ist m ode would be selec ted until the coolant is warm enough ( Dem ist Delay),

followed by Foot/Demist. Then, as the In-car temperature increased, the mode should change to Foot/Face.

If heating is requires and the coolant is warm, Foot mode may be selected for a short time (Purge), followed by

Foot/Face mode (or Foot/Demist mode depending on conditions).

AIR INLET CONTROL

When recirculate is selected either Manually or Automatically, the ECC will return the Inlet to Fresh Air mode after

approximately 40 minutes. This is to avoid stuffness in the car. The customer can return to recirculate by pressing

the recirculate button.

AUTOMATIC MODE

The Air Inlet mode selected will vary according to:

• In-car Temperature

• Ambient Temperature

• Sun load

• Drivers Set Temperature

• Start Up conditions

• Evaporator Temperature

• AC Pressure

• Coolant Temperature

If the cabin does not require cooling or AC is Off, Fresh air will be selected.

If extreme cooling of the cabin were required, Fresh maybe selected for a short time (Fresh Delay), then Recirc

mode will be selected until the cabin has cooled down sufficiently. Then, Fresh air mode will be selected.

If the cabin needs cooling down, the air mix is at full cold, the Evaporator temperature is high and the AC pressure

is high, Recirc mode may be selected (ie. heavy traffic on a hot day). Then, as the In-car temperature decreases to

a suitable level, Fresh air mode will be selected.

If the coolant temperature gets very high, Recirc may be selected to increase the cooling capacity of the radiator.

VENT AIR TEMPERATURE CONTROL

The vent temperature will vary between approximately 5°C (with AC on and Air mix door at minimum) and

approximately 70°C (with 90°C coolant and Air mix door at maximum).

MANUAL MODE

If the Set temperature is set to C, the air mix door will be set to minimum.

If the Set temperature is set to H, the air mix door will be set to maximum.

AUTOMATIC MODE

When a Set temperature of between 17°C and 30°C is selected, the Vent Air Temperature will be controlled

automatically.

The Vent Air Temperature will vary according to:

• In-car Temperature

• Ambient Temperature

• Sun load

• Drivers or Passengers Set Temperature

When the cabin is at the desired temperature, the average vent air temperature should be approximately the same

as the set temperature.

If the cabin requires cooling, the ECC will try to control the Vent temperature to less than the Set temperature. The

more cooling required, the lower the vent temperature should be.

If the cabin requires heating, the ECC will try to control the Vent temperature to be more than the Set temperature.

The more cooling required, the higher the vent temperature should be.

Generally, the Automatic blower will be at a fairly low level (less than 50%) before the ECC starts to control the

temperature. (eg. When extreme cooling is required, the blower will start on maximum and the Air mix will start at

minimum. As the cabin cools down the blower will decrease gradually, while the Air mix will stay at minimum, then ,

when the blower is approximately 40%, the air mix door maybe opened to turn the water valve on. Then as the

cabin keeps cooling down, the blower is gradually decreased as the vent temperature is increased).

Increasing the Set temperature will increase the vent temperature (provided air mix is not at maximum).

Decreasing the Set temperature will decrease the vent temperature (provided air mix is not at minimum).

As the In-car temperature increases the vent temperature will decrease.

As the In-car temperature decreases the vent temperature will increase.

As the Sun load increases the vent temperature will decrease.

As the Sun load decreases the vent temperature will increase.

As the Ambient temperature increases the vent temperature will decrease.

As the Ambient temperature decreases the vent temperature will increase.

The ECC controls the Air mix position to achieve the required vent temperature, compensating for:

• Evaporator Temperature

• Coolant Temperature

• Inlet Mode

• Air Distribution Mode

ECC COLD START-UP ROUTINES

There are four cold start-up routines incorporated in the ECC system logic to cater for various conditions on first

starting the vehicle, typically at low ambient temperatures.

Each routine has its own respective set or criteria to satisfy before the routine is executed:

Recirculation delay: Automatically defaults to recirculation mode to prevent cold air from entering the vehicle

interior.

Demist delay: To eliminate cold air at floor during warm-up and prevents drivers breath from fogging front

windscreen.

Purge: Allows coolant to heat-up the heater core and avoid humidity to face/windscreen when the blower fan is

activated.

A/C Purge: To avoid hot air blowing on face when the blower fan is activated.

Fresh delay: Uses cooler outside air to purge hot air from the vehicle.

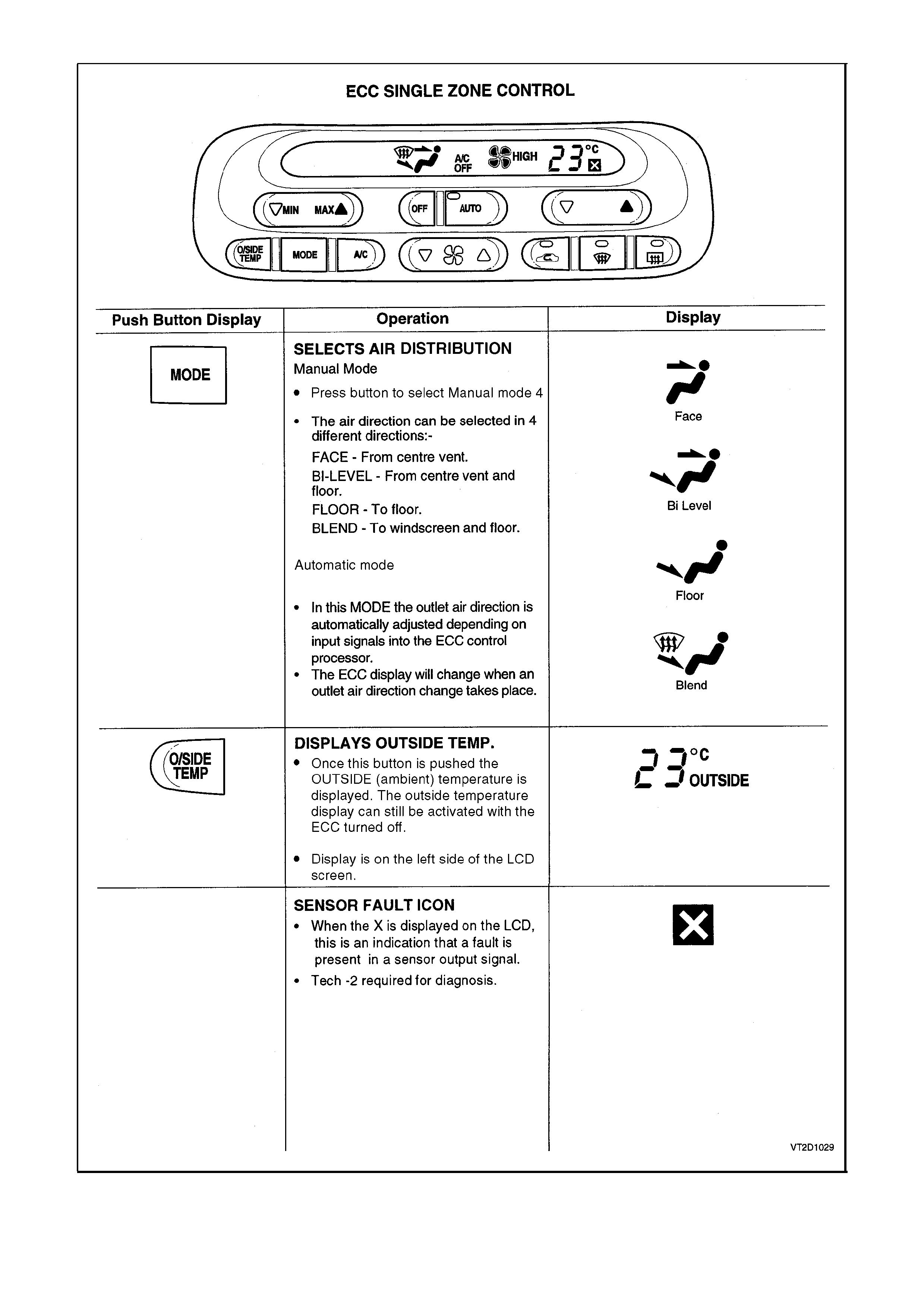

SENSOR MALFUNCTION INDICATOR

If a sensor open circuits due to an electrical connector disconnection or damaged wiring, an X will appear on the RH

side of the ECC Module LCD display. This X will disappear once the problem has been rectified.

DEFAULT MODE: VACUUM

When a leak is apparent in the vacuum system, the air direction will automatically default to demist and fresh air.

AUTOMATIC OPERATION

In fully automatic mode, the microprocessor uses the sunlight, In-car temperature, ambient temperature, evaporator

temperature & customer set temperature to decide & control the amount of blower voltage, and the air inlet mode.

• The Auto button contains a Green LED.

Auto LED ON: indicates the ECC is in full Auto mode (i.e. all functions are controlled automatically).

• The Auto LED OFF: indicates the ECC is in part Manual mode (i.e. at least one function is not being controlled

automatically).

Any or the Auto functions can be manually overridden by pressing the appropriate button.

NOTE:

If one function has been selected manually, other functions still operate automatically.

The ECC uses the in-car temperature sensor, the ambient temperature sensor, the sun load input from the BCM

and the ‘set’ temperature to determine if the cabin needs to be warmed, cooled or maintained. The following tables

provide examples of what the ECC system will attempt under various conditions:

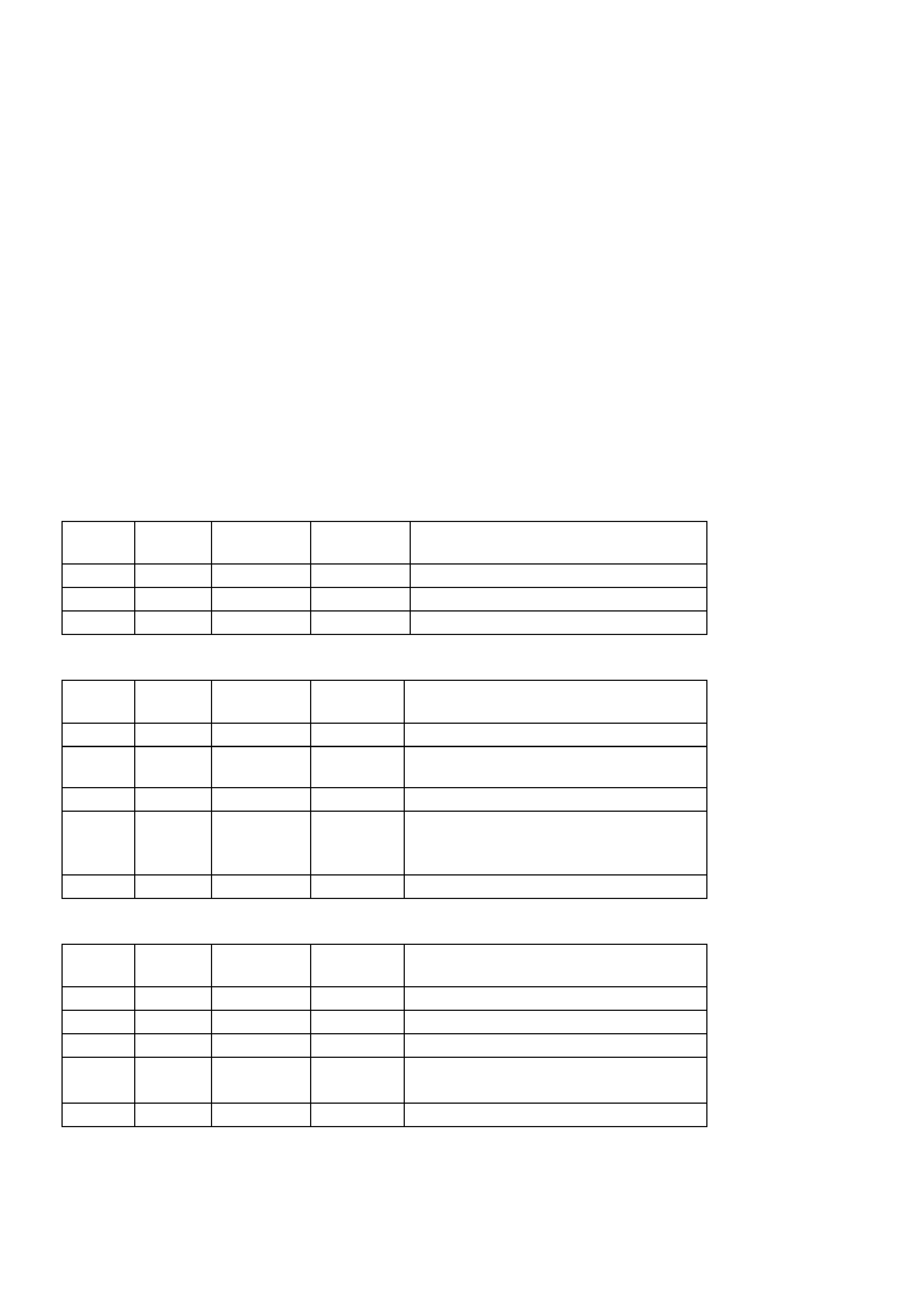

If the cabin is ‘Just Right’, the ECC will try to maintain the cabin temp in the following situations:

SET

TEMP IN-CAR

TEMP AMBIENT

TEMP SUN LOAD TYPICAL SITUATION

23 25 23 Low Driving for a while on a warm night

23 27 12 Low Driving for a while on a cold night

23 23 23 Medium Driving for a while on a spring afternoon

The ECC will try Cooling Down the cabin in the following situations

SET

TEMP IN-CAR

TEMP AMBIENT

TEMP SUN LOAD TYPICAL SITUATION

23 40 23 Low Dusk, car has been sitting in the sun

23 23 23 High Been driving for a while in early afternoon

sun

23 23 30 Low Been driving for a while on a hot night

23 55 30 High Car has been sitting in sun on a hot

summers day

Extreme cooling is required

17 23 23 Low Driver wants to cool down quickly.

The ECC will try Heating Up the cabin in the following situations

SET

TEMP IN-CAR

TEMP AMBIENT

TEMP SUN LOAD TYPICAL SITUATION

23 15 15 Medium Morning drive after a cool night

23 20 20 Low Early morning drive after a mild night

23 23 10 Low Been driving for a while on a cold night

23 5 5 Low Morning drive after a cold night

Extreme heating is required

30 25 20 Low Driver wants to warm up quickly.

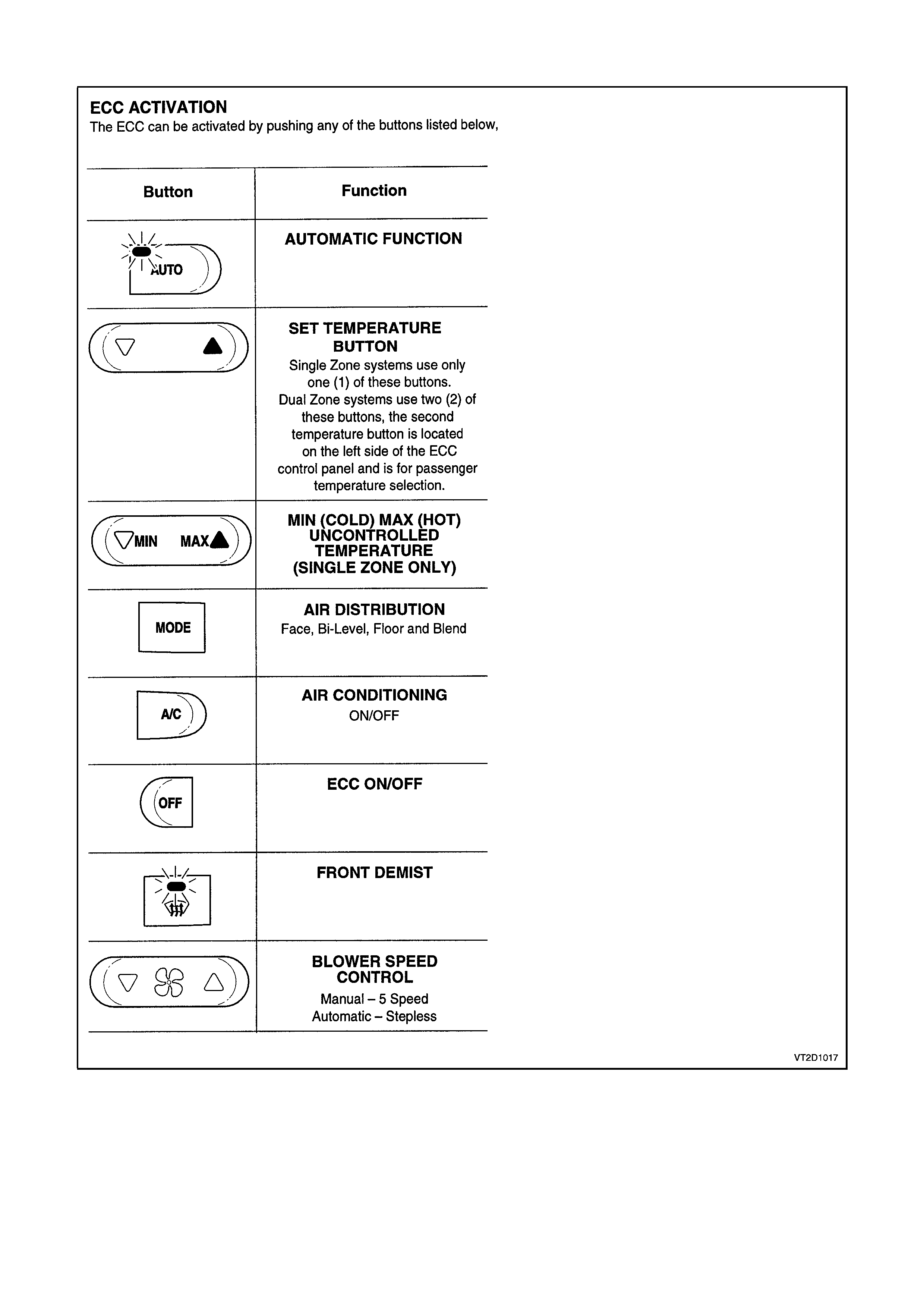

ECC ACTIVATION

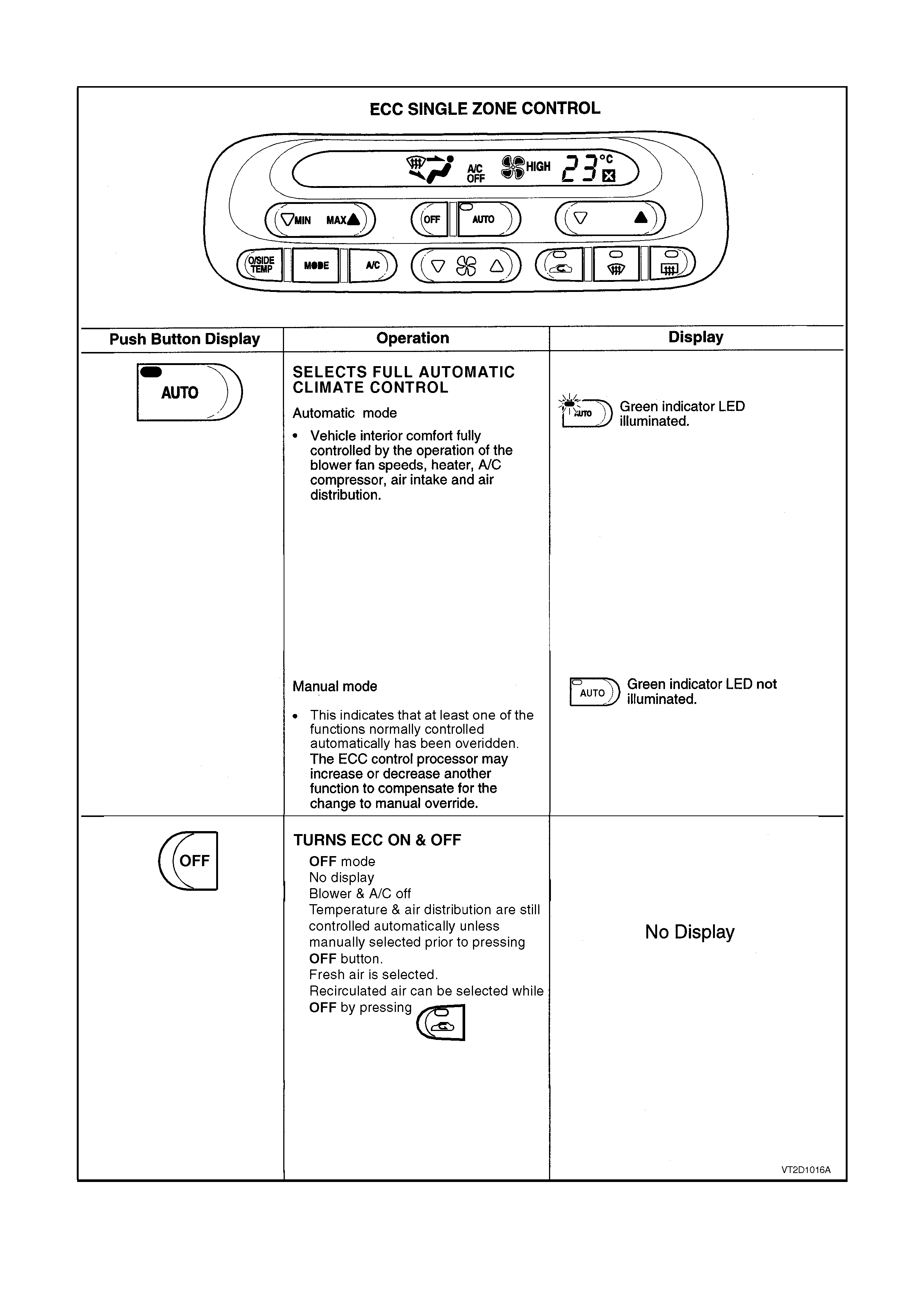

Figure 2D-1

ECC SINGLE ZONE OPERATION

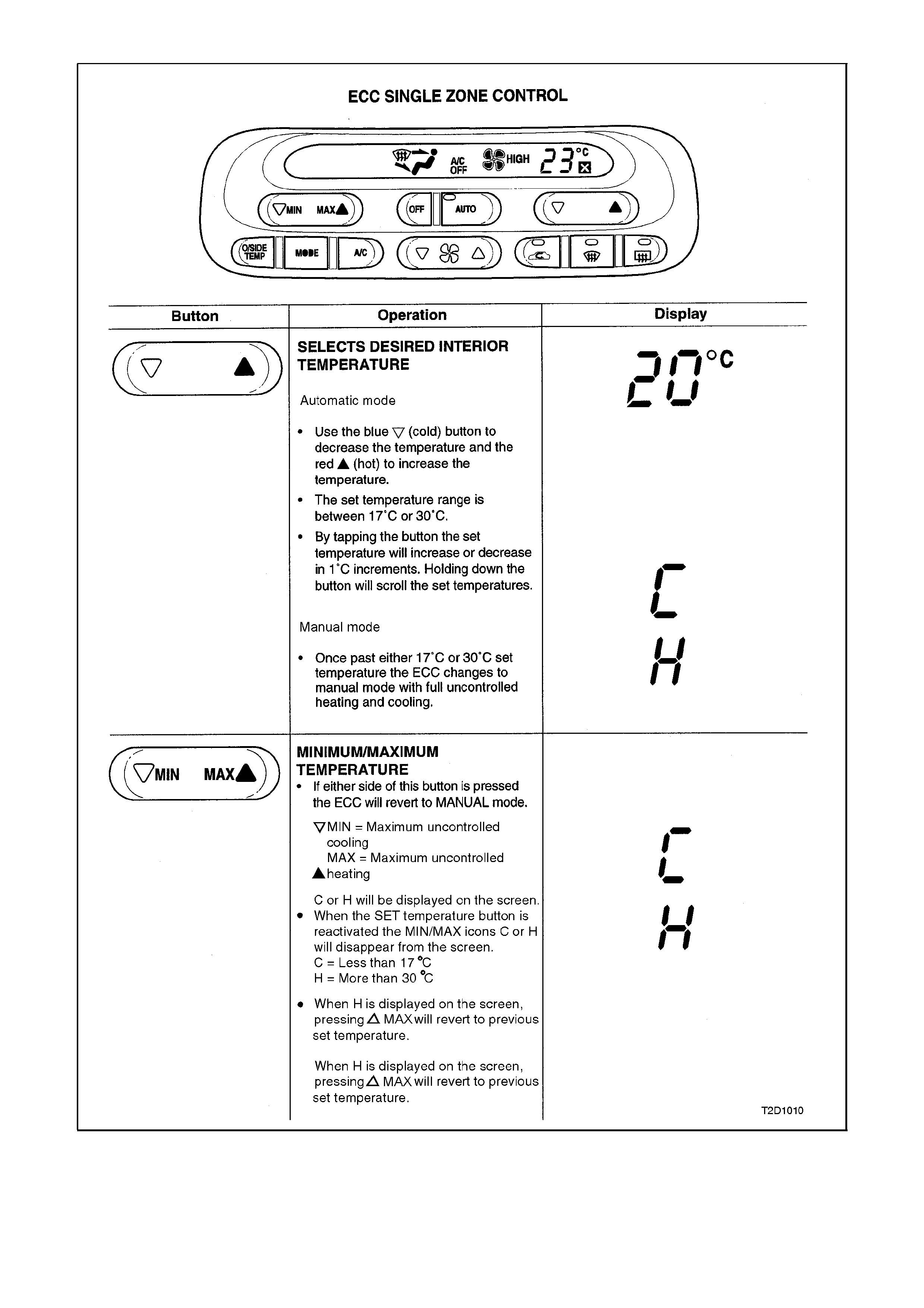

Figure 2D-2

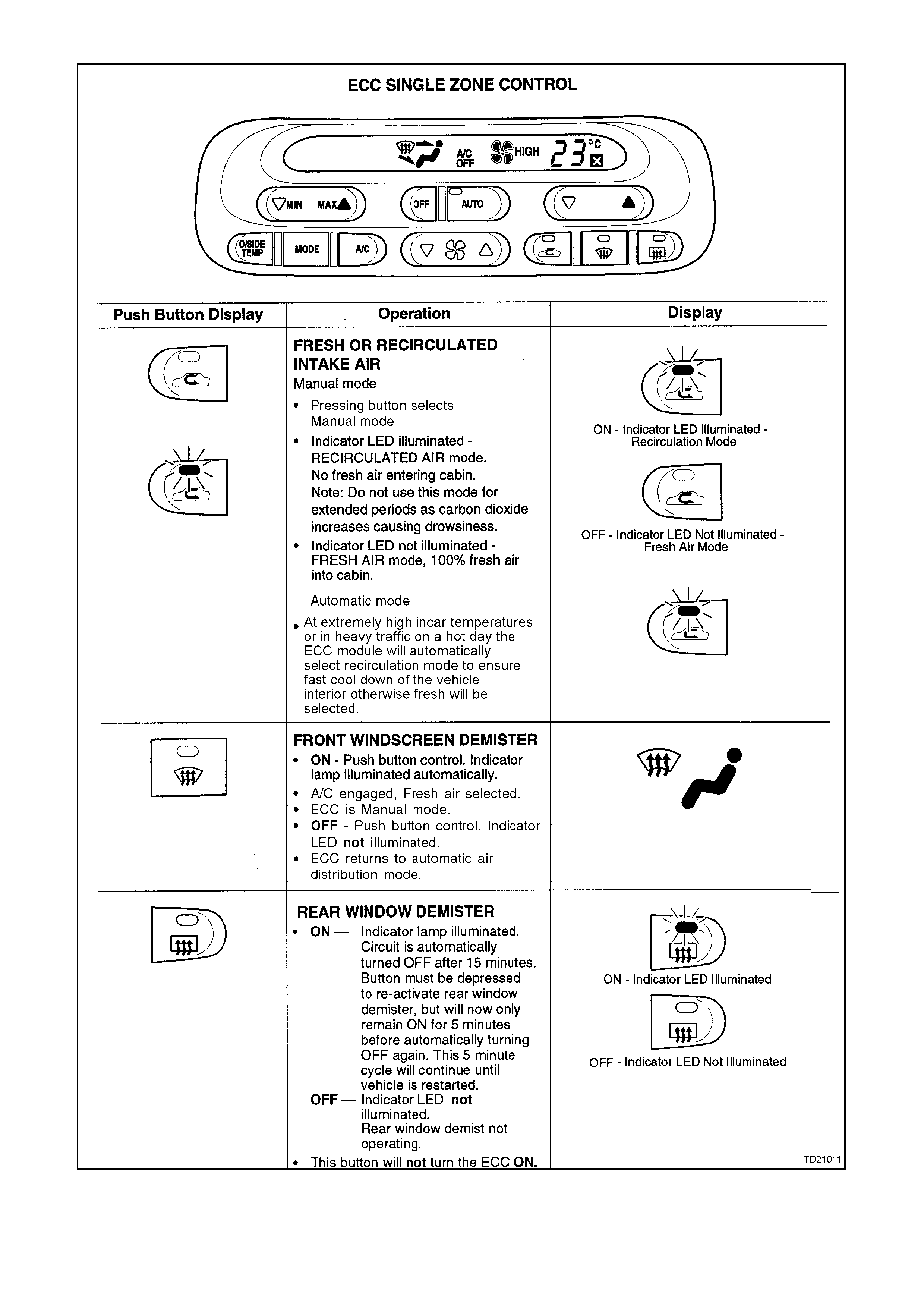

Figure 2D-3

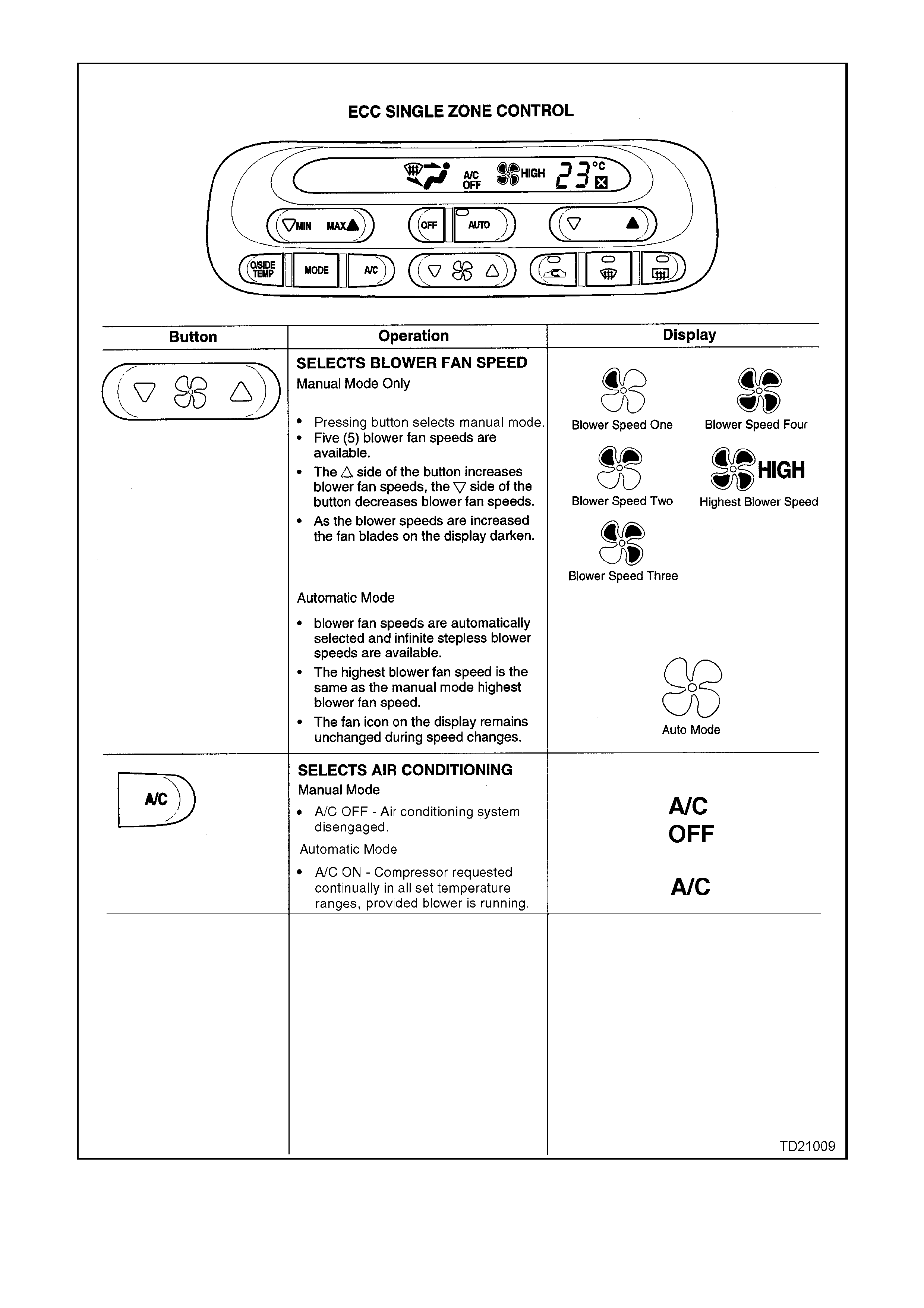

Figure 2D-4

Figure 2D-5

Figure 2D-6

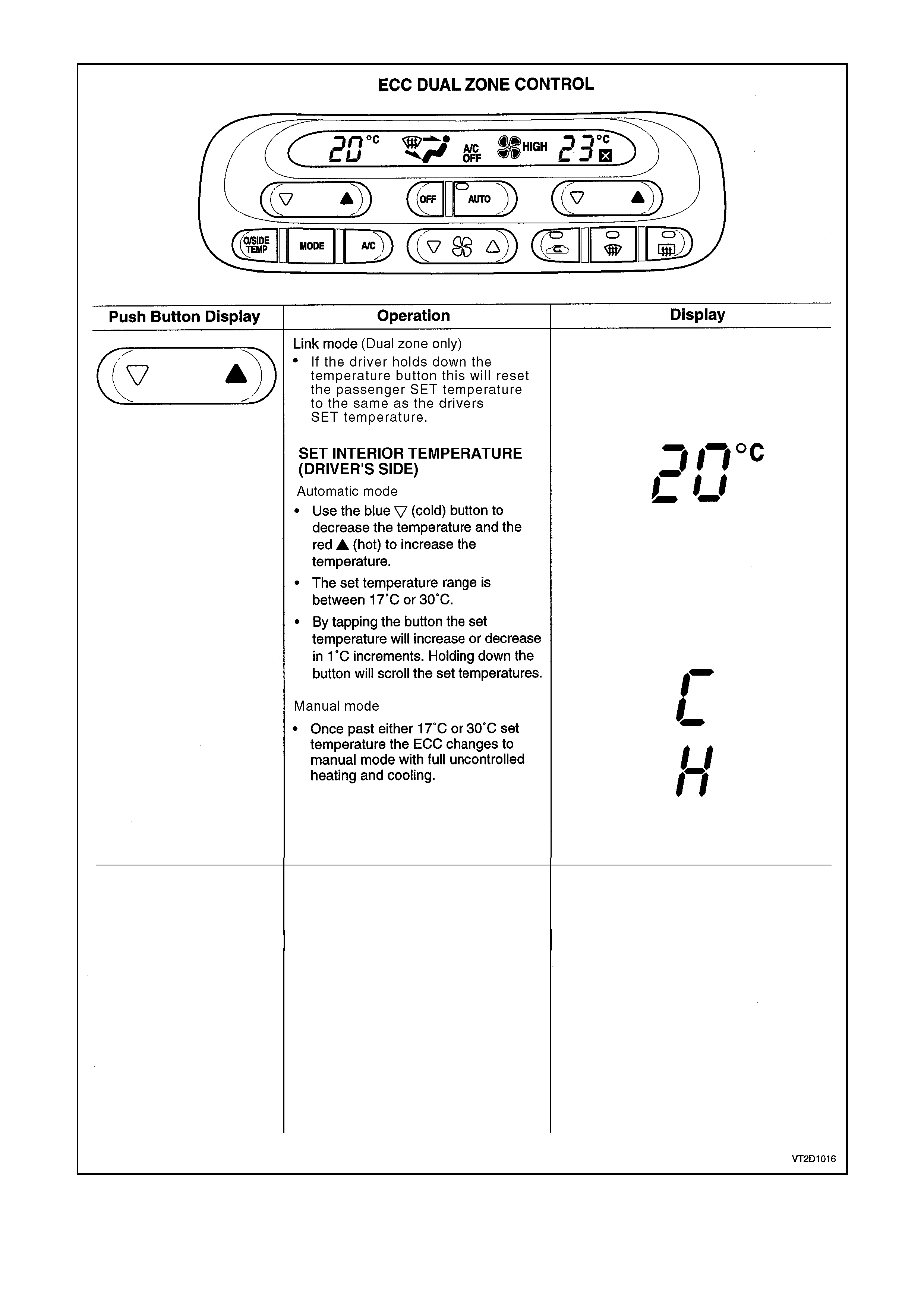

ECC DUAL ZONE OPERATION

General Information

The operation of the Dual Zone ECC system is the same as the Single Zone ECC system noting the following:

Link mode

The link mode refers to the mode when the operation of both the passenger and driver air mix motors are

synchronised.

When the driver ‘set’ temperature is changed, likewise the passenger ‘set’ temperature changes to the same value.

To access the ‘link’ mode press and hold the ‘auto’ button for two seconds.

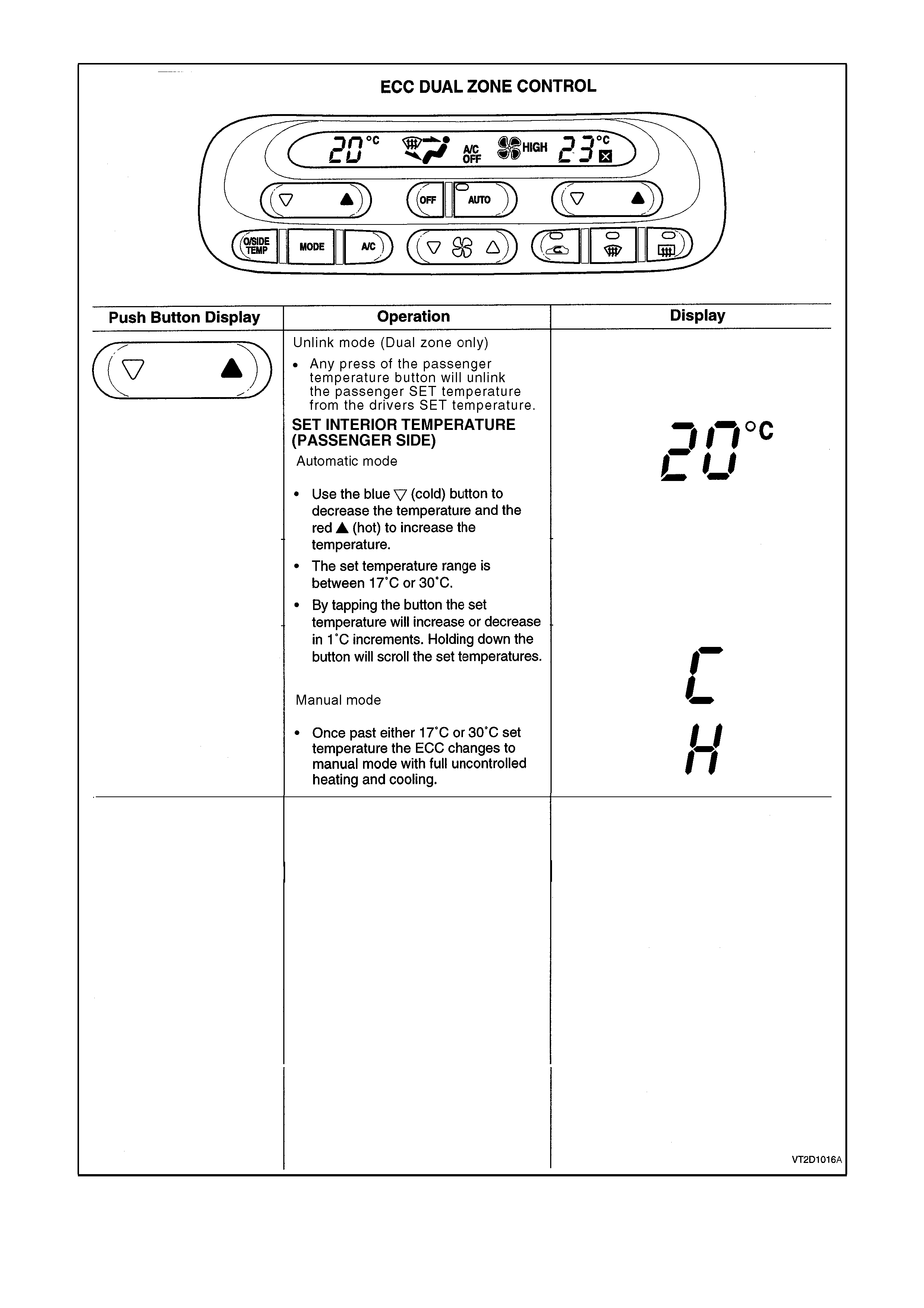

Unlink mode

This mode is when the passenger sets their desired temperature independent of the driver.

To access the ‘unlink’ mode press the passenger side temperature button.

NOTE:

If the ECC was in link mode this will alter to unlink mode.

Mode control

It is NOT possible for the passenger to alter the mode positions such as Floor, Demist, Centre Vent etc. There is no

individual control. Mode positions will be the same for both passenger and driver.

Fan speed control

As with the mode control it is NOT possible for the passenger to alter the blower fan speeds as an individual

function. Once the blower speeds have been selected, blower speeds for both the passenger and driver will be the

same.

Figure 2D-7

Figure 2D-8

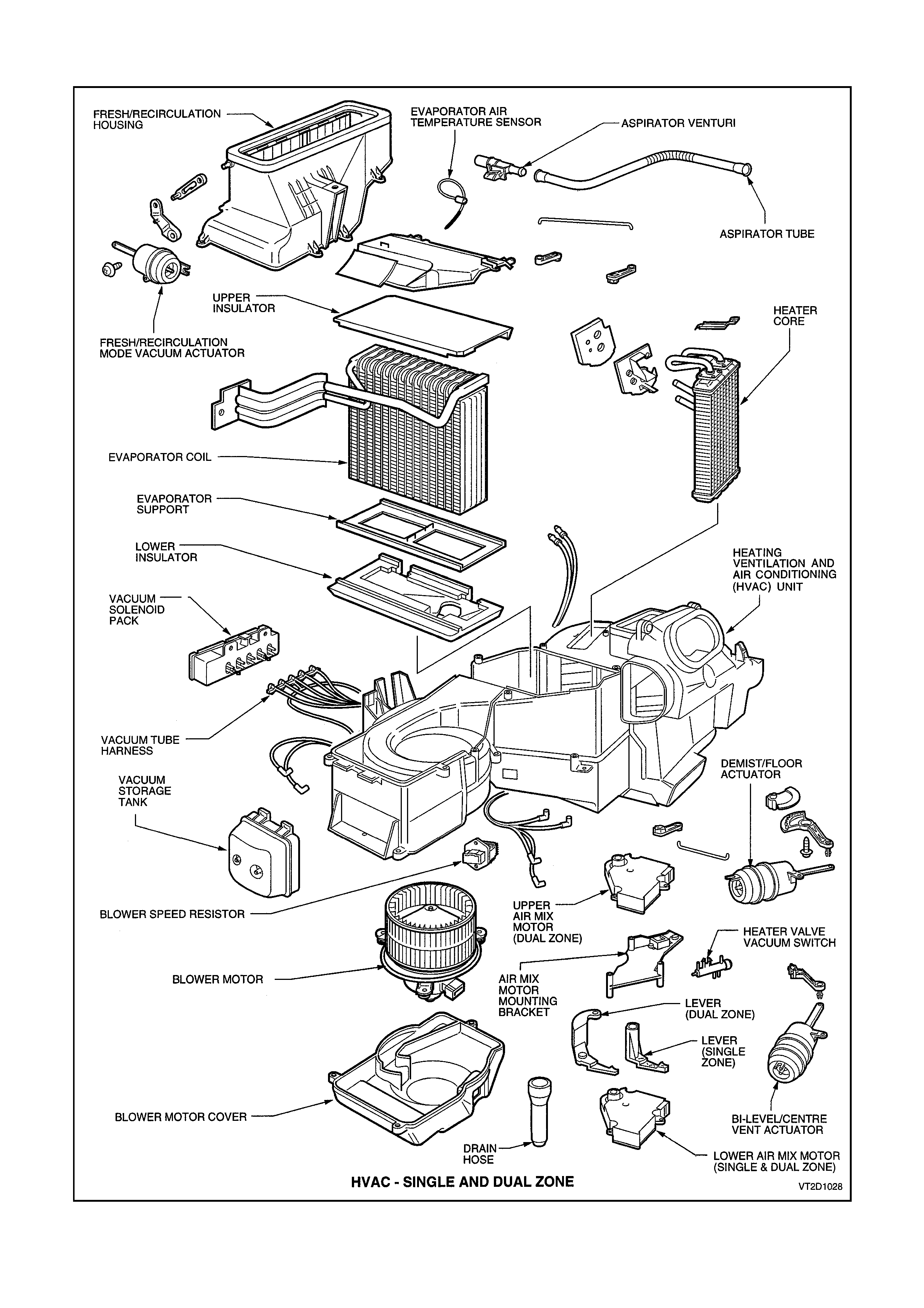

HVAC SYSTEM COMPONENTS

Figure 2D-9

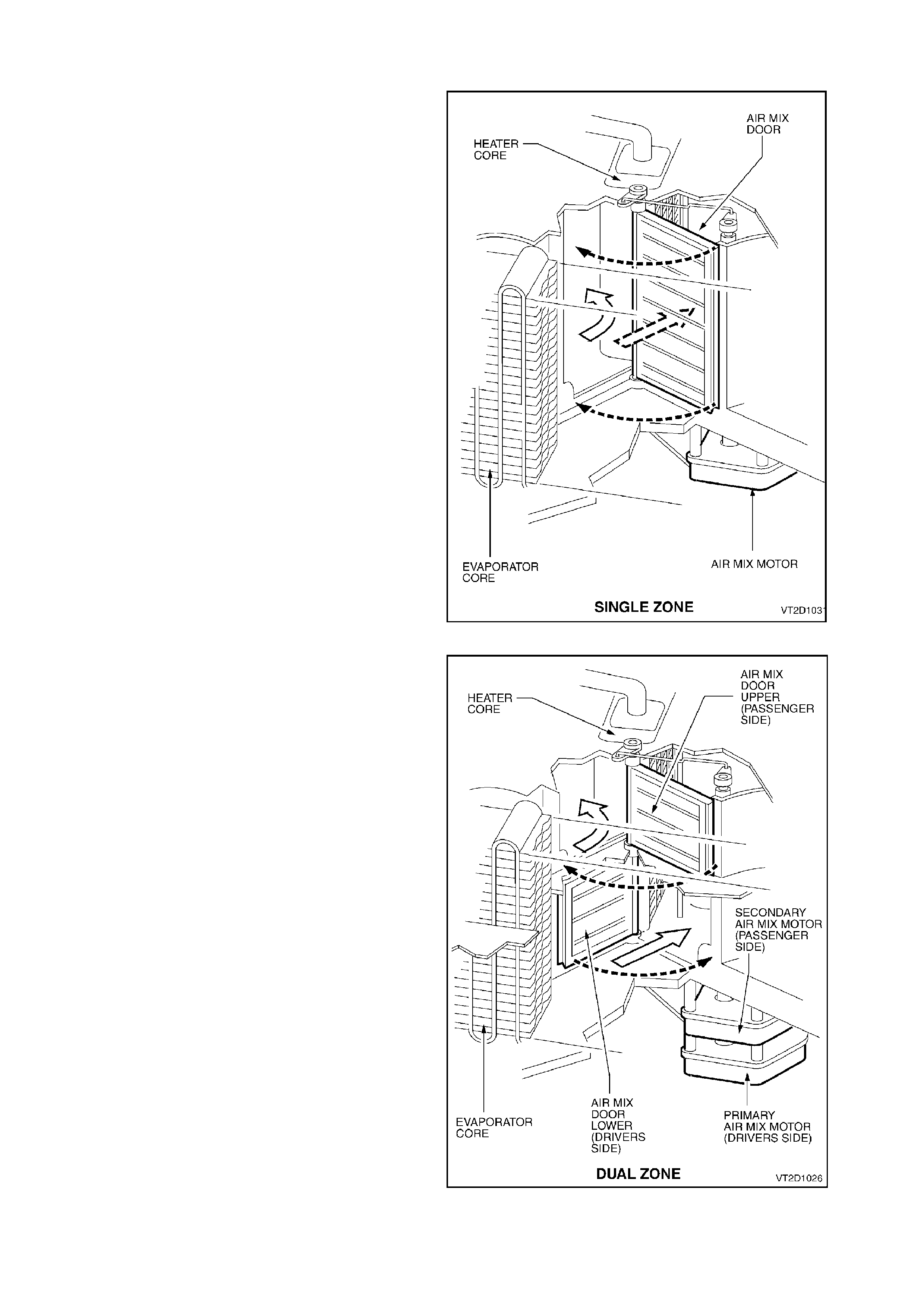

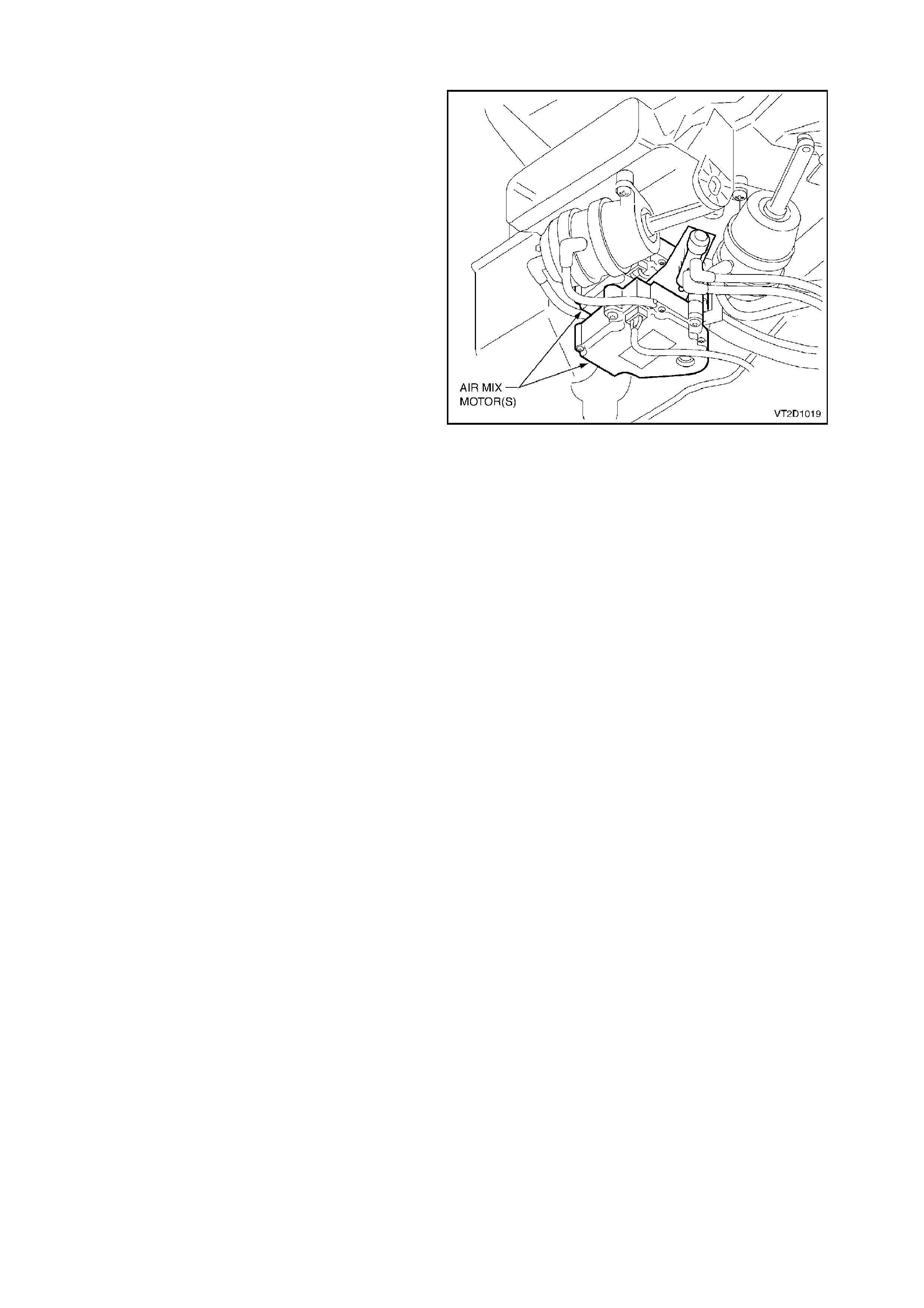

1.2 AIR MIX MOTORS (SINGLE AND DUAL ZONE)

The air mix motor(s), or stepper motor(s) are

located under the HVAC unit. They are used to

operate the air mixing door(s) and are connected

either directly to the air mix door shaft or indirectly

via a rod.

Single Zone (SZ) us es one air mix motor to oper ate

the air mixing door whereas the Dual Zone (DZ)

has two air m ix motors to operate two individual air

mixing doors.

Air mix motor movement is achieved by sending a

12 volt signal between the ECC Module to the air

mix motor. T here is also a 3.5 ± 0.2 volt ‘feedback’

signal from the air mix motor to the ECC Module as

to the location of the air mix door (in relation to air

mix motor drive location).

Figure 2D-10

Figure 2D-11

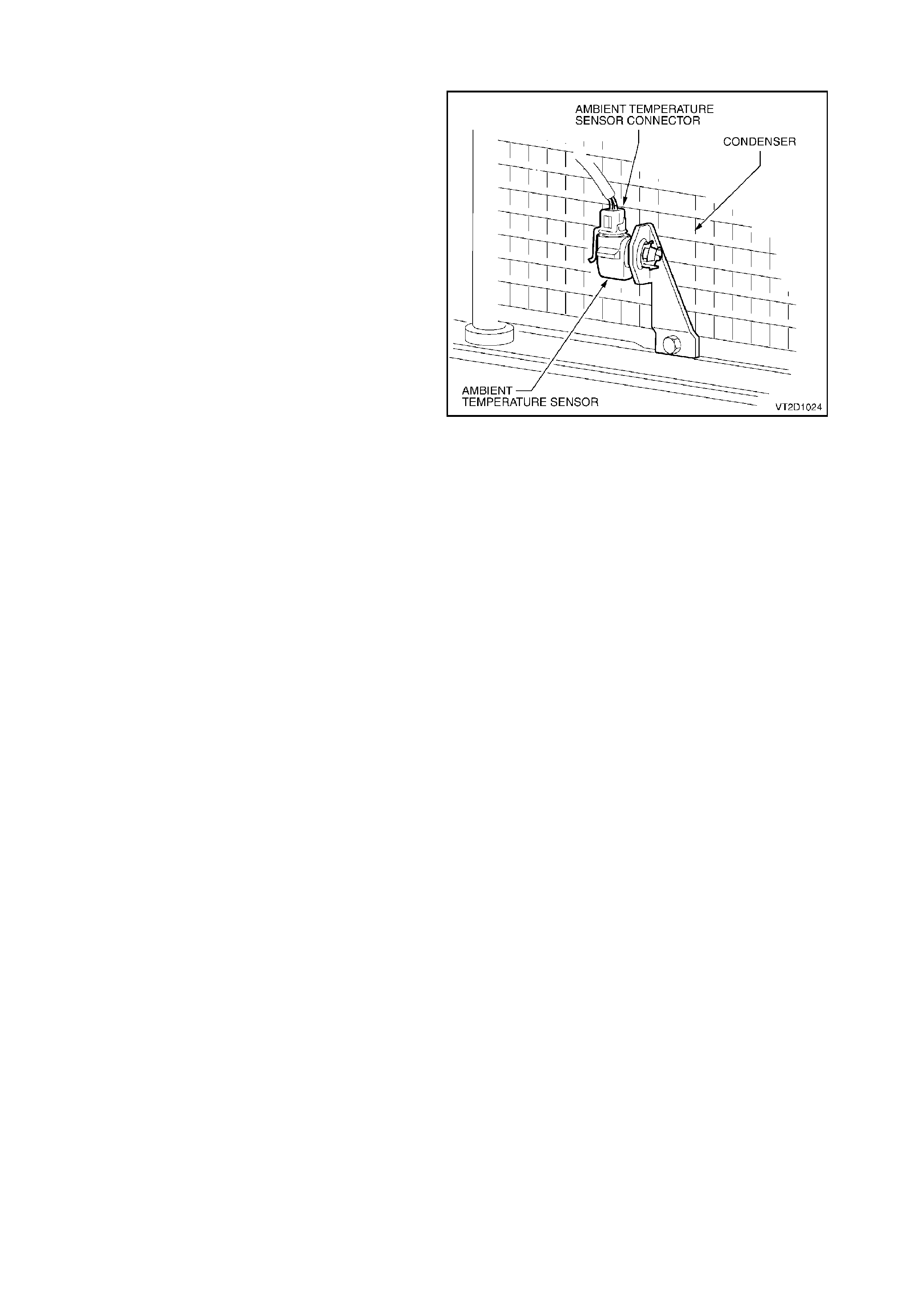

1.3 AMBIENT TEMPERATURE SENSOR

The Am bient T em perature Sensor is loca ted on the

lower driver’s side of the A/C condenser.

It is a thermistor type (NTC) resistor used to

monitor the ambient (outside) temperature. This

sensor is slow reacting due to the dense plastic

housing surrounding it. The ECC takes into account

road speed before updating the temperature

display to avoid false readings in heavy traffic or

extended idle conditions.

Resistance signals are sent directly from the

ambient tem per ature sens or to the ECC Module f or

interpretation.

Figure 2D-12

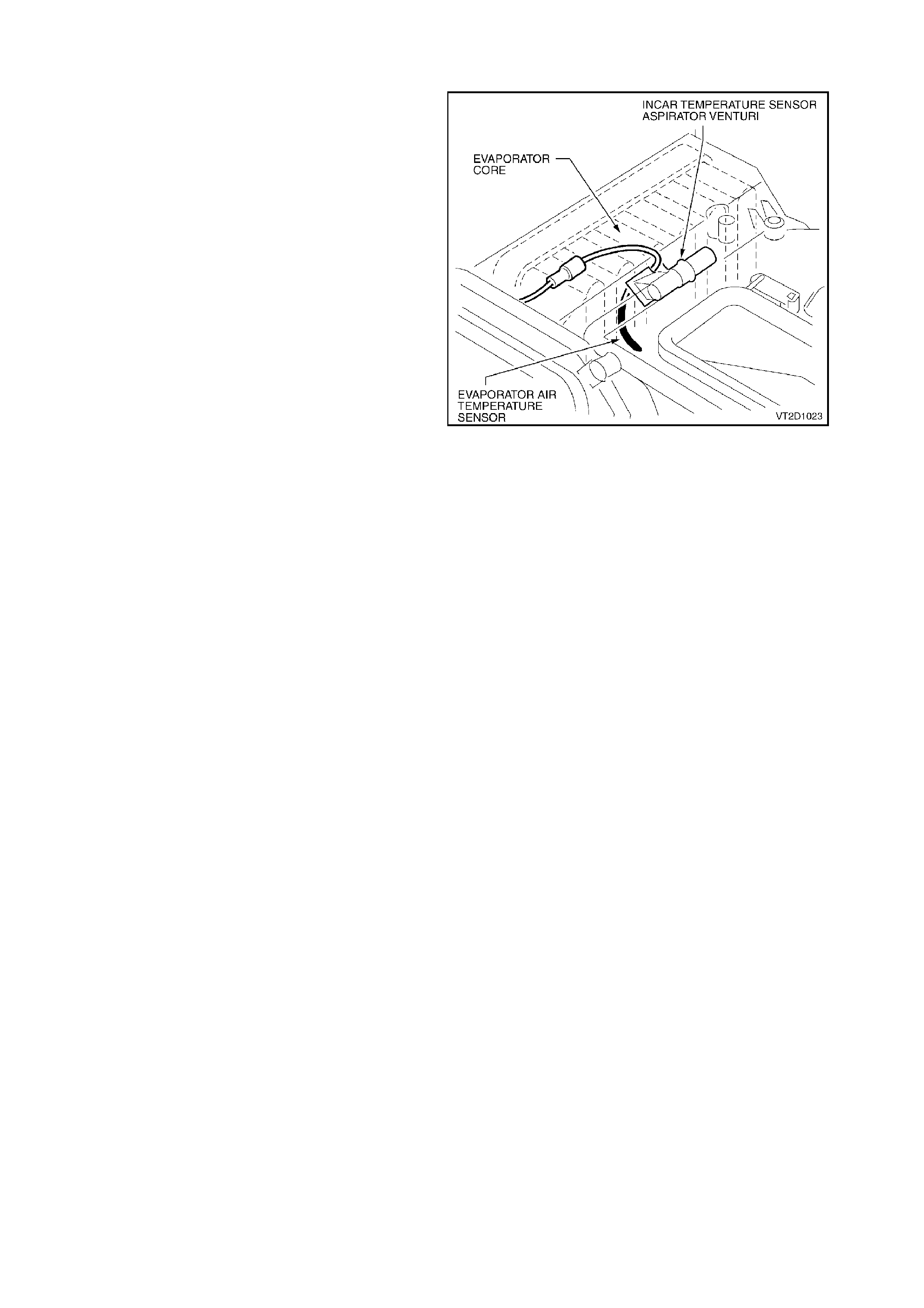

1.4 EVAPORATOR AIR TEMPERATURE SENSOR

The Evaporator Air Temperature Sensor is located

on top of the EBA case near the aspirator venturi.

It is a thermistor type (NTC) resistor used to

monitor the temperature of the air into the HVAC

unit after it has passed through the evaporator coil.

Resistance values are read directly to the ECC

Module for interpretation.

Figure 2D-13

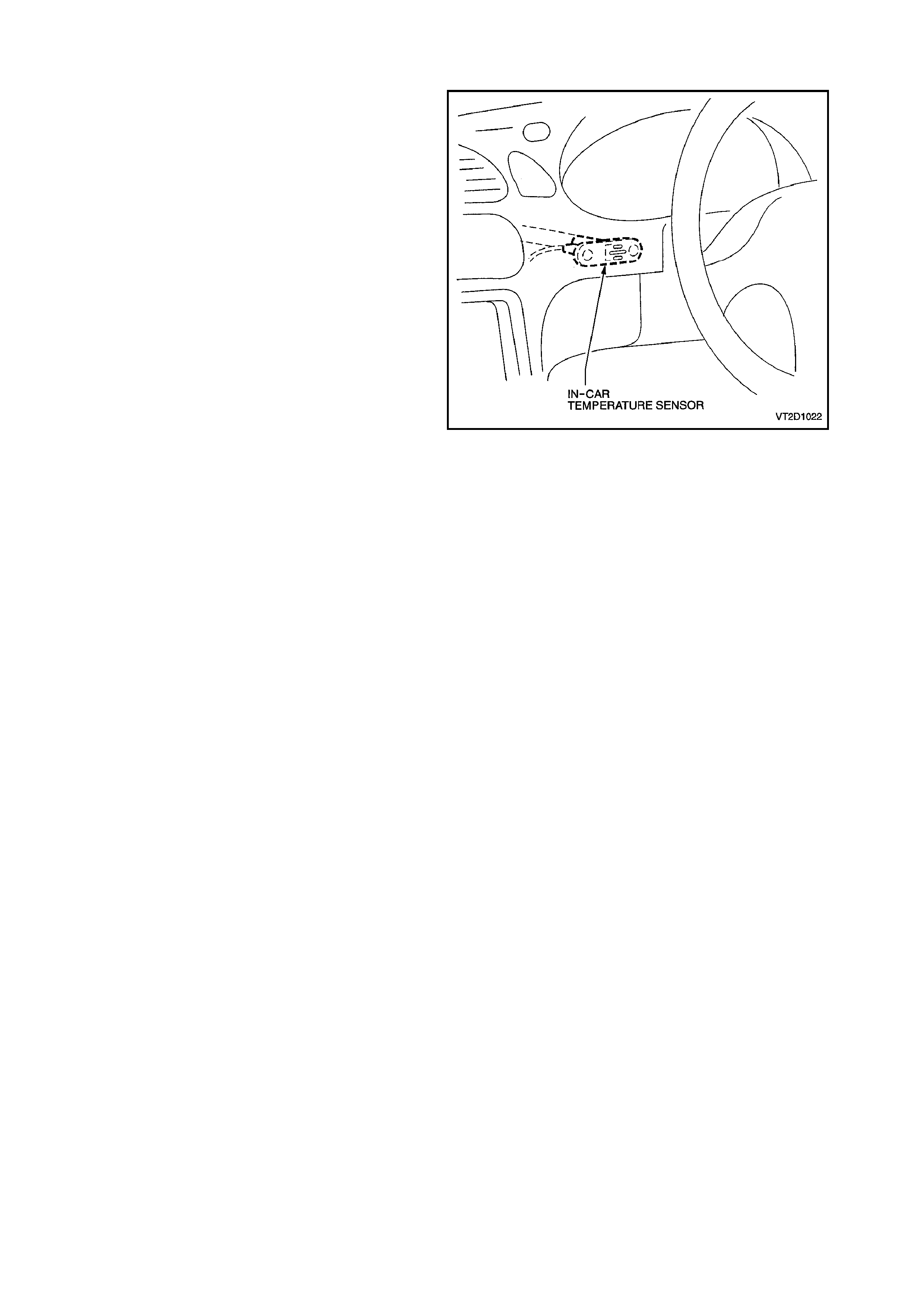

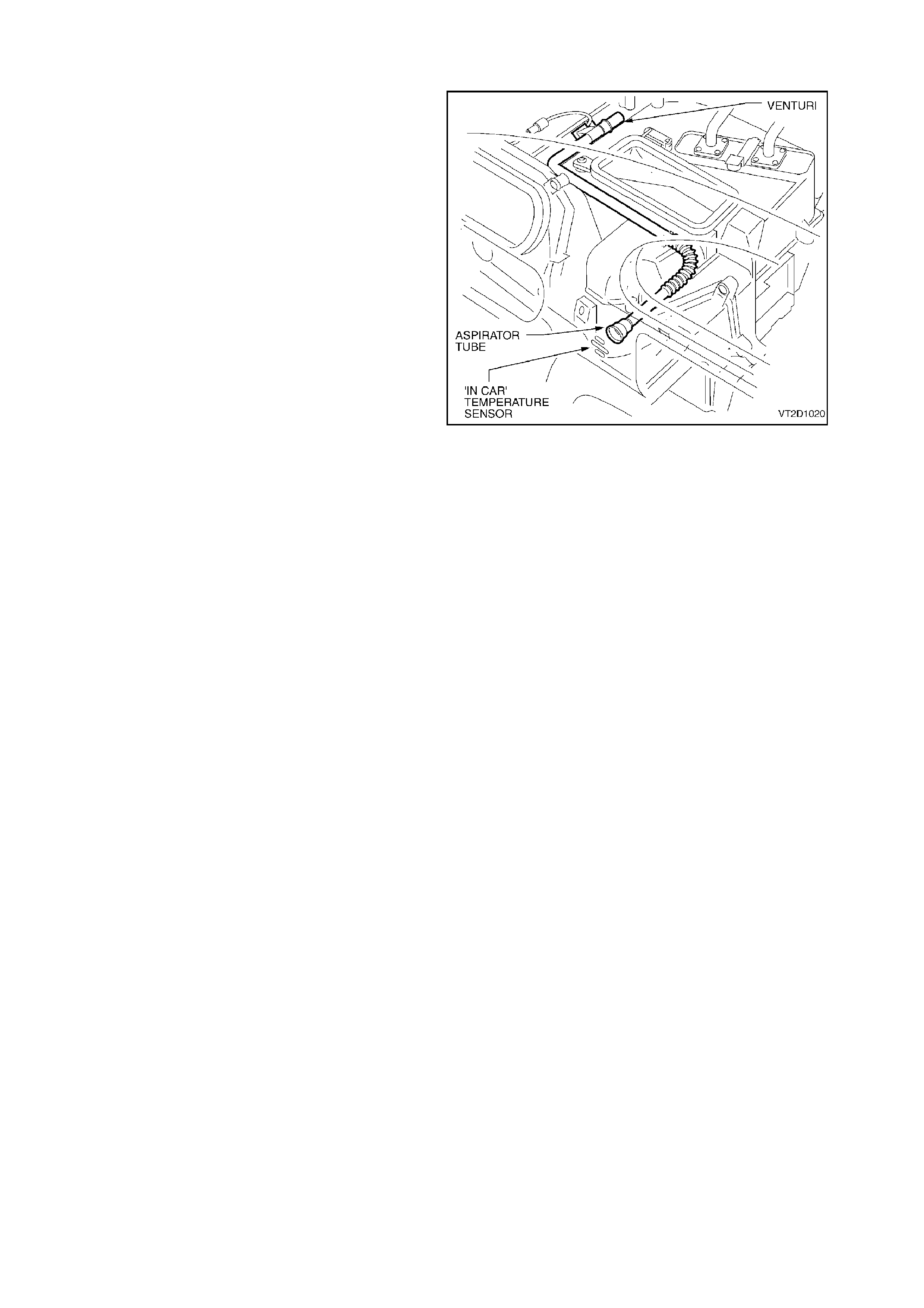

1.5 IN-CAR TEMPERATURE SENSOR

The in-car temperature sensor is located on the

lower driver’s s ide dash panel between the steer ing

wheel and console.

It is also a thermistor type (NTC) resistor used to

monitor the vehicle’s interior temperature.

Resistance signals are read directly by the ECC

Module for interpretation.

It is essential that the aspirator tube (see

1.6 ASPIRATOR TUBE) is connected to give

correct operation.

Figure 2D-14

1.6 ASPIRATOR TUBE

Located on the top of the HVAC unit case to the

rear of the in-car temperature s ensor, the Aspirator

Tube is a convoluted plastic tube attached from a

venturi to the rear of the in-car tem perature sensor

housing. Once any fan speed is selected air from

the vehicle interior is sucked to the in-car

temperature sensor via the aspirator tube and

aspirator venturi. This is used to aid the in-car

temperature to react quickly to any changes taking

place within the vehicle interior.

Figure 2D-15

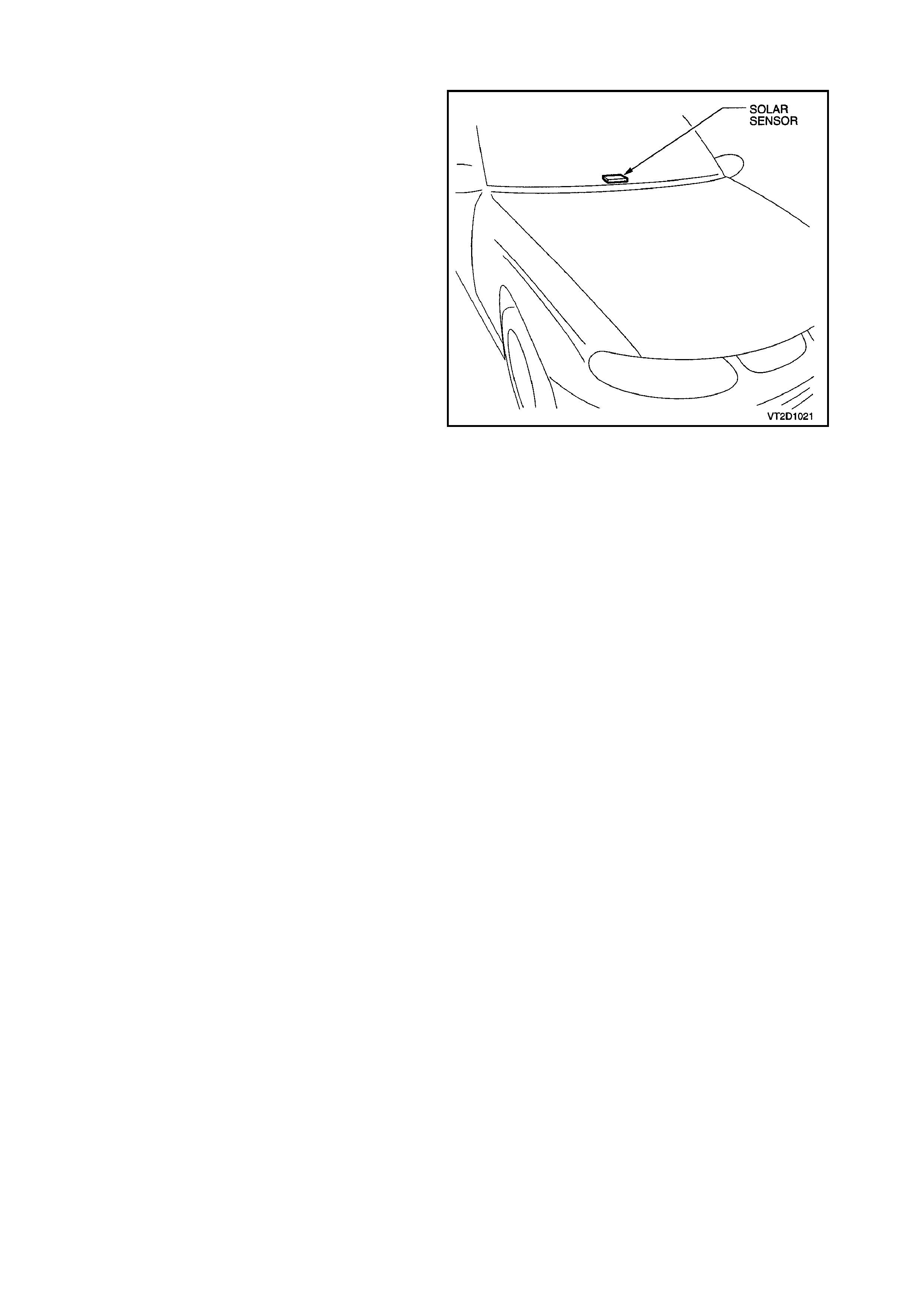

1.7 SOLAR SENSOR

The Solar Sensor (Sun Sensor / Remote Receiver

module) is located in the centre of the Demist panel

and is used to monitor the sun load upon the

vehicle. It is a photochem ical type sensor , m eaning

that a small electrical current will be created

depending on the sun load (str ength) over it. W hen

the sun load is high, a higher blower fan speed and

increased cooling will be selected by the ECC

Module automatically. Likewise, when the sun load

is low, such as going into an underground car park ,

the ECC Module will automatically reduce the fan

speeds and increase heating slightly.

Signals are sent from the solar sensor directly to

the BCM then to the ECC Module via the serial

data.

NOTE:

Solar sensor diagnostics can be found in the BCM

Section.

Figure 2D-16

1.8 AIR MIX MOTOR(S)

Located on the underside of the HVAC unit, the Air

Mix Motor is a small electric m otor used to operate

vent position doors. The motor is sent a voltage

signal of 3.5 ±0.2 volts from the ECC Module

causing the motor to turn and open a door. Motor

direction can be changed to close a door by the

ECC reversing the polarity of the voltage signal.

The air mix motor also uses a potentiometer to

send voltage signals to the ECC Module as to the

position of the air mix motor internally.

Figure 2D-17

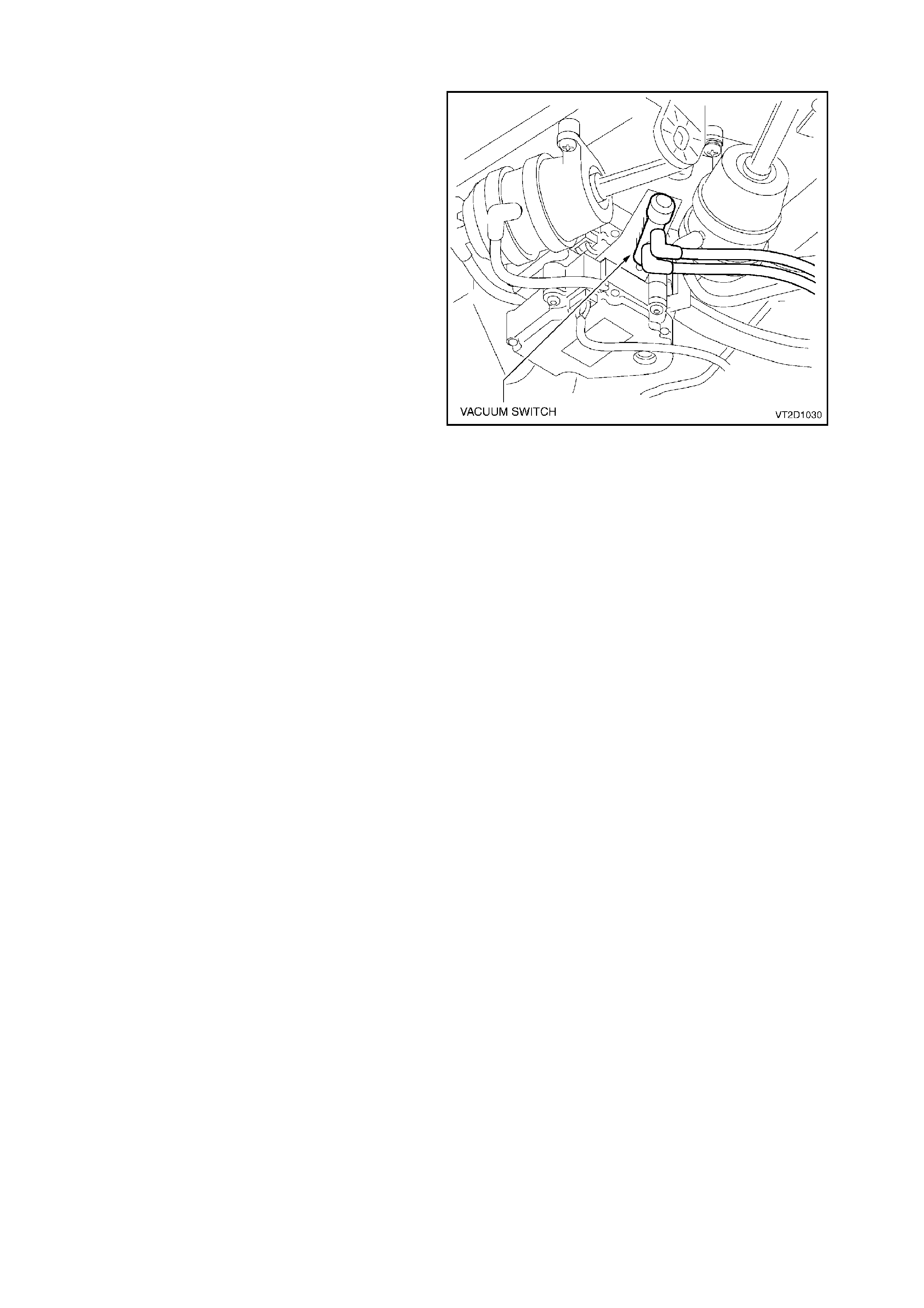

1.9 VACUUM SWITCH

The Vacuum Switch is located on the underside of

the HVAC unit between the vacuum actuators.

The heater water valve is held in the OFF position

by vacuum. A lever attached to the air mix motor

activates a plunger on the vacuum switch. As the

air mix m otor opens the air mix door from full cold,

the vacuum switch plunger is activated and the

vacuum in the heater water valve line is vented

allowing hot water to flow into the heater core.

Figure 2D-18

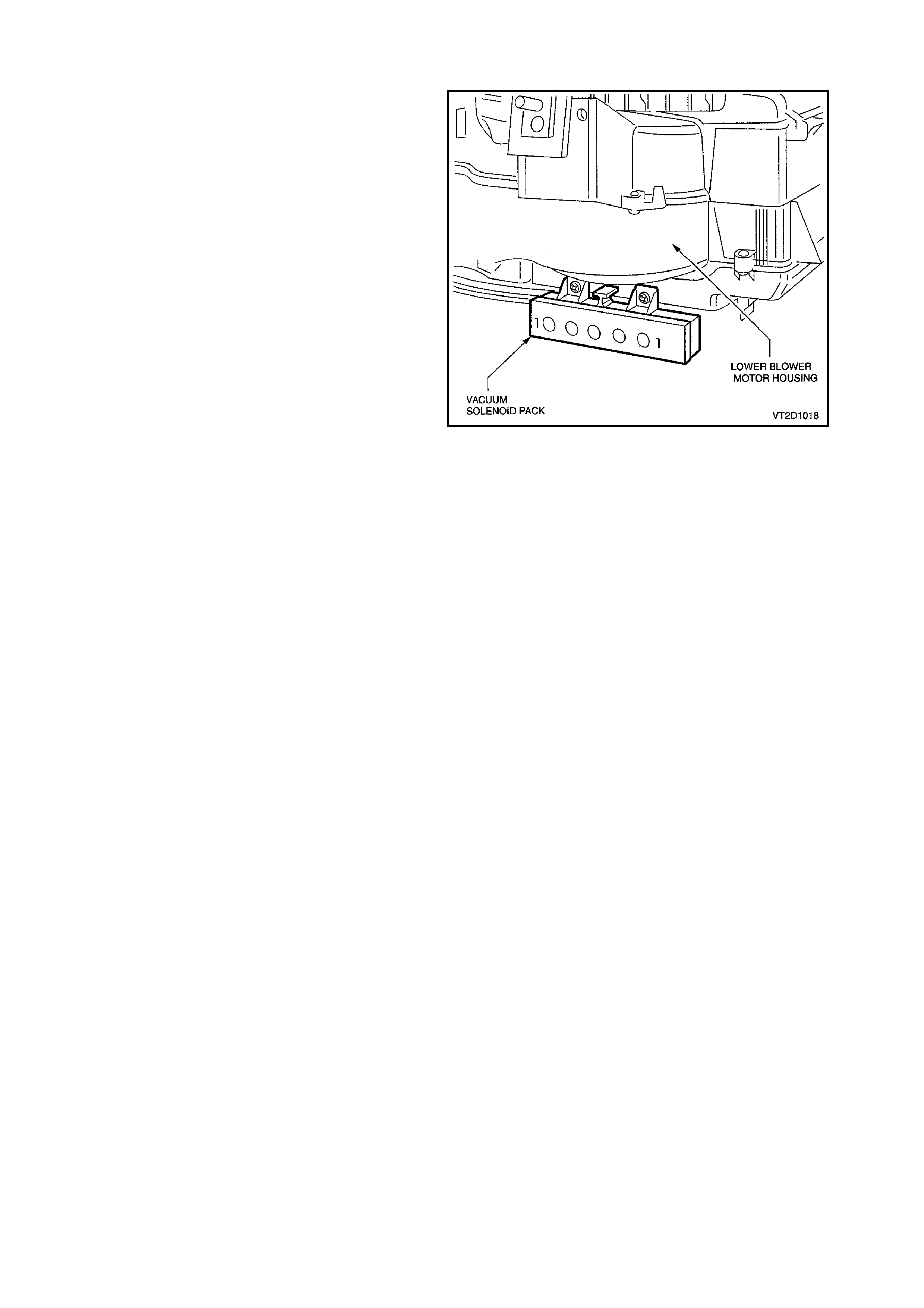

1.10 VACUUM SOLENOID PACK

Located on the lower rear of blower m otor housing,

the Vacuum Solenoid Pack consists of a band of

five electronically activated vacuum solenoids used

to apply or rem ove vacuum to vacuum actuators to

alter air distribution positions.

Power is used to engage these s olenoids and allow

vacuum to flow to an actuator. Removing this

power de-energises the solenoid and allows any

vacuum contained in the actuator and line to vent

through the front section of the solenoid.

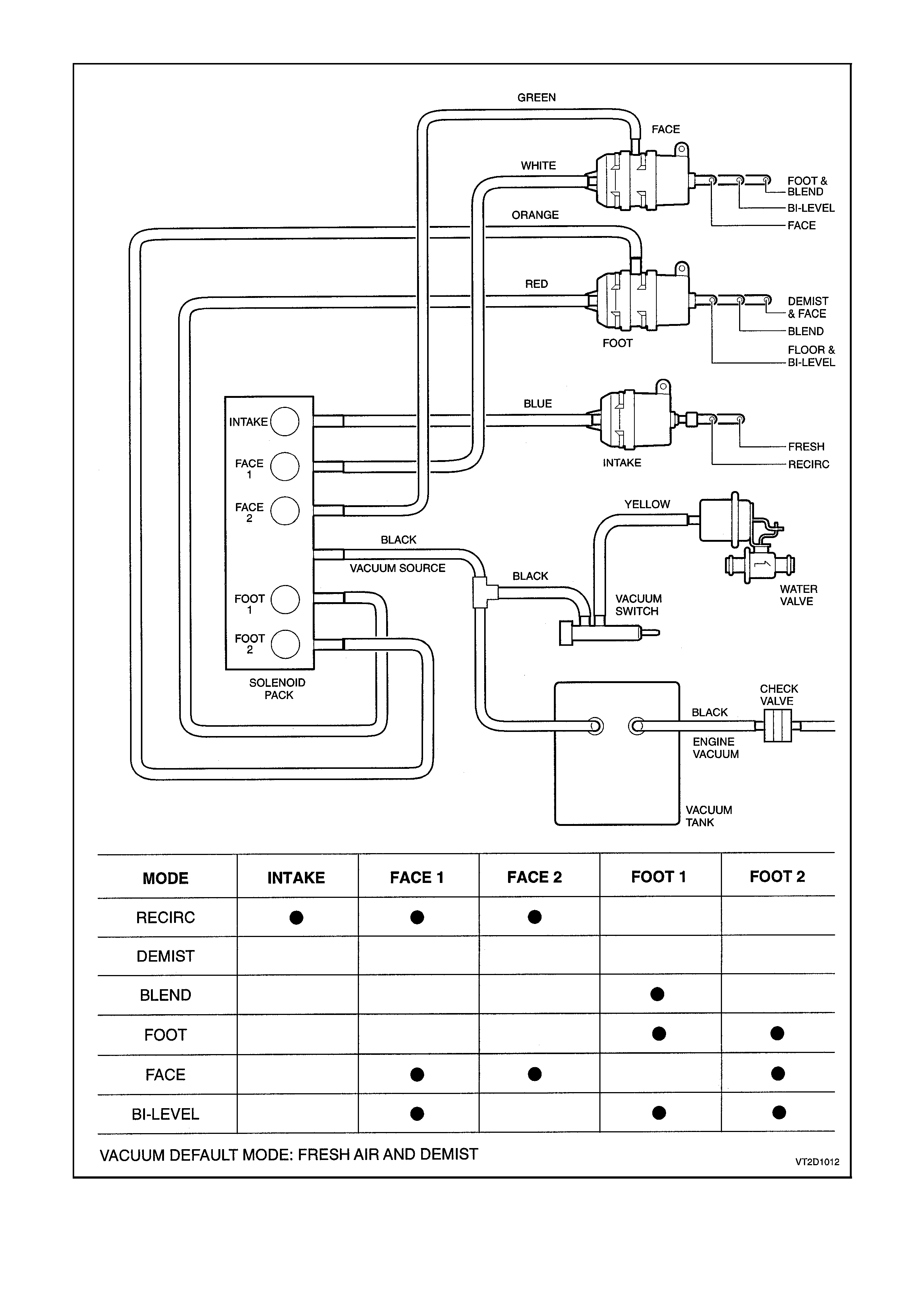

VACUUM CIRCUIT

Vacuum is us ed to control the ON /OFF f unctions of

the vent modes and the heater tap. This vacuum is

provided by the engine.

The engine vacuum moves from the inlet manifold

to a vacuum tank located on the HVAC unit. This

vacuum tank is used to store vacuum in times

when engine vacuum is low such as at full engine

throttle. A check valve is fitted on the supply line

from the engine inlet manifold.

Through a black plastic vacuum tube the vacuum

moves to the vacuum solenoid pack. This black

plastic tube is also teed off to the vacuum control

valve. From the contr ol valve, vac uum moves into a

yellow plastic tube and onto the vacuum operated

heater water valve. Vacuum is used to m aintain f ull

closure of this valve and no hot water can flow.

As the ECC mode switch is selected electronic

solenoids are activated in the solenoid pack

causing vacuum to move to the desired vacuum

actuator through different coloured plastic tubing.

This vacuum will activate the vacuum actuator rod

which then moves a vent position door.

Fig. 2D-20 shows which vacuum actuators are

applied with vacuum in a certain mode.

Vacuum is vented f rom the vac uum actuator/plas tic

tube once the vacuum ECC m ode s witch is us ed to

select a different setting.

Figure 2D-19

Figure 2D-20

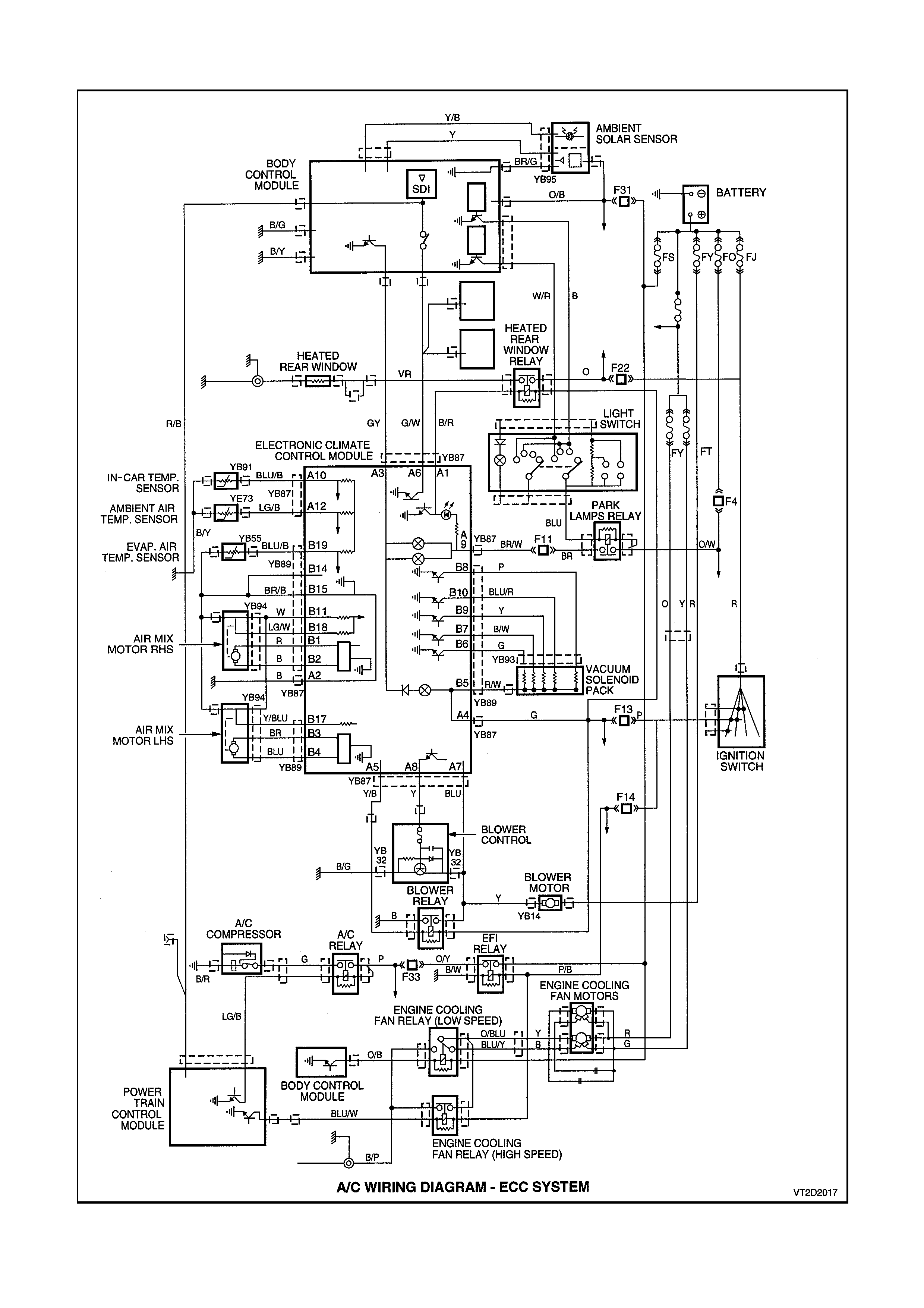

1.11 ECC WIRING DIAGRAM

Figure 2D-21