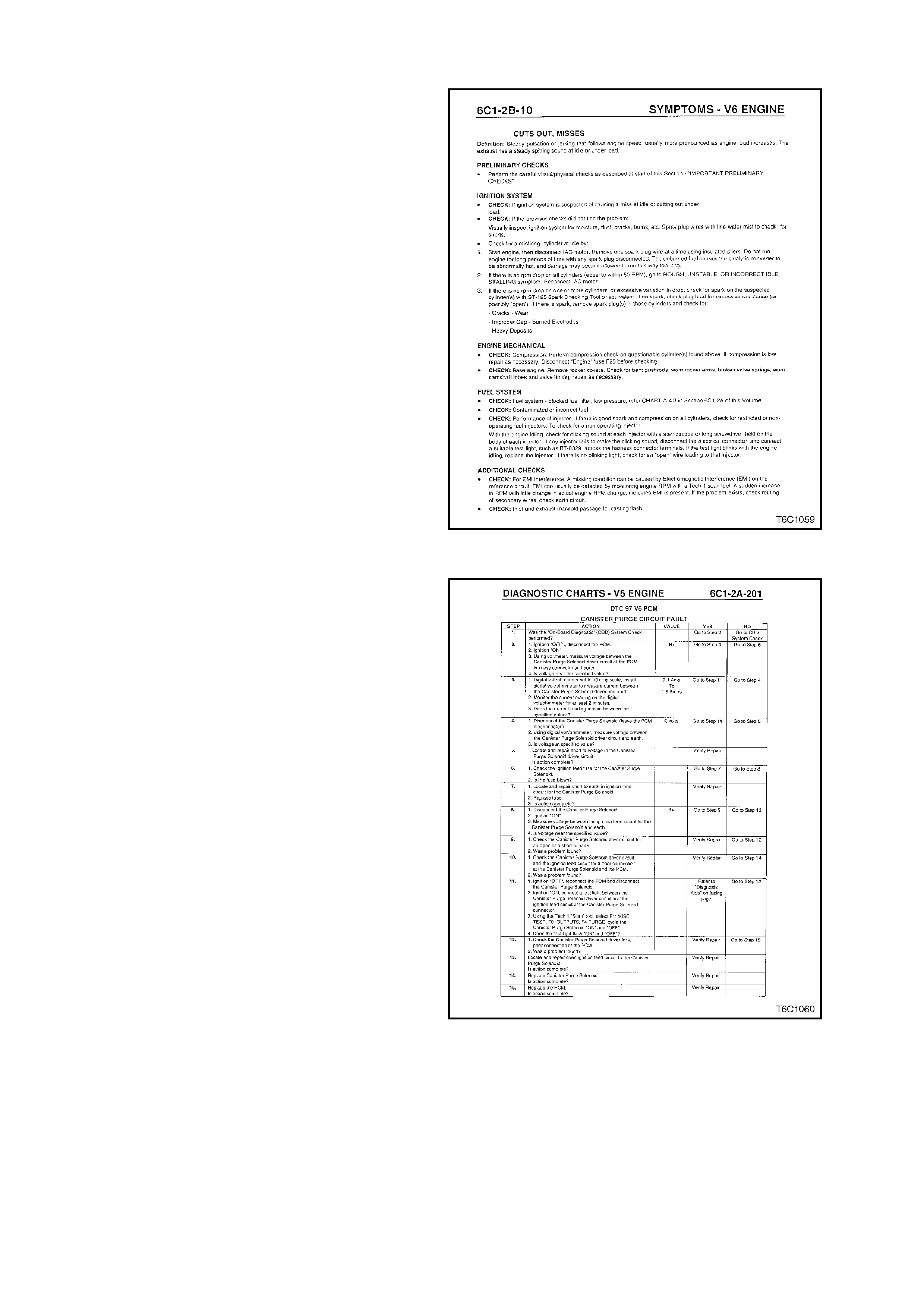

SECTION 6C2-2 - DIAGNOSIS - V8 ENGINE

CAUTION

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS

will consist of either seat belt pre-ten sioners and a driv er’s side air bag, or seat belt

pre-tensioners and a driver’s and front passenger’s side air bags. Refer to

CAUTIONS, Section 12M, before performing any service operation on or around SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deployment, resulting in possible personal injury or

unnecessary SRS system repairs.

This is where to start all driveability and emissions diagnosis, once you read and understand

Section 6C2-1 GENERAL INFORMATION. The beginning of Section 6C2-2A DIAGNOSIS CHARTS contains

reference material: wiring diagrams, control module terminal end views and normal voltages, and engine

component locations. Remember, this information is for reference; do not start diagnosis using these charts. Alway s

start diagnosis with “On-Board Diagnostic System Check”. This check verifies that the diagnostic circuits are

operating properly. Then sends you to the correct service chart for diagnosis.

If the initial steps in the On-Board Diagnostic System Check reveal a problem, or if the engine does not start, you

will be using one or more "A" charts for diagnosis. The On-Board Diagnostic System Check will send you to the

correct chart. These charts follow the On-Board Diagnostic System check and problems that prevent the engine

from starting.

If the On-Board Diagnostic System Check shows that diagnostic trouble codes have been stored, proceed to the

appropriate Diagnostic Trouble Code (DTC) diagnosis charts. If more than one diagnostic trouble code has been

stored, always start diagnostic trouble code diagnosis with the lowest diagnostic trouble code number and work

upward. Diagnostic trouble code diagnosis charts start immediately after the "A" charts.

DIAGNOSTIC PRECAUTIONS

The following requirements must be obse rved when working on vehicles.

1. Before removing any PCM system component, disconnect the battery earth lead.

2. Never start the engine without the battery being solidly connected.

3. Never separate the battery from the on board electrical system while the engine is running.

4. When charging the battery, disconnect the battery from the vehicle's electrical system.

5. Never subject the PCM to tem peratures above 80 degrees C i.e. paint oven. Always rem ove contr ol unit first if

this temperature is to be exceeded.

6. Ensure that all cable harness plugs are connected solidly and that battery terminals are thoroughly clean.

7. The engine and transmission management system harness connectors are designed to fit in only one way;

there are indexing tabs and slots on both halves of the connector. Forcing the connector into place is not

necessa ry if it is being installed with the proper orientation. F ailure to tak e care to matc h the indexing tabs and

slots to ensure the connector is being installed correctly can cause damage to the connector, the module, or

other vehicle components or systems.

8. Never connect or disconnect the cable harness plug at the PCM when the ignition is switched "ON."

9. Before attempting any electric arc welding on the vehicle, disconnect the battery leads and the PCM

connectors.

10. When steam cleaning engines, do not direct the steam cleaning nozzle at PCM system components. If this

happens, corrosion of the terminals can take place.

11. Use only the test equipment specified in the diagnostic charts, since other test equipment may either give

incorrect results or damage good components.

12. All voltage measurements using a voltmeter must use a digital voltmeter with an internal impedance rating of at

least 10 million ohms per volt (10 mega ohms)

13. When a test light is specified, a "low-power" test light must be used. Do not use a high - wattage test light.

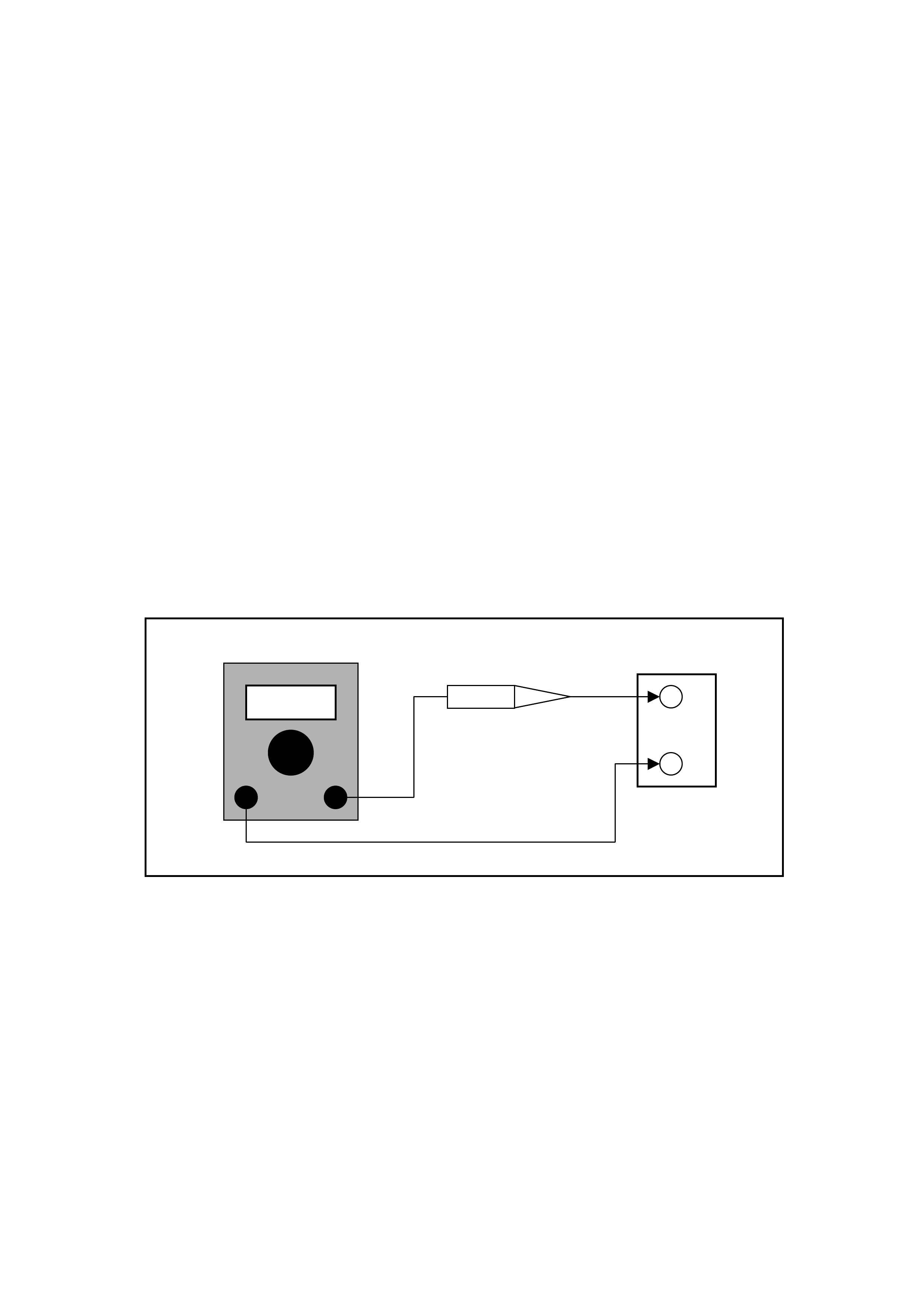

W hile a particular brand of test light is not suggested, a simple tes t on any test light will ensure it to be OK f or

PCM circuit testing. Connect an accurate ammeter (such as the high-impedance digital multimeter) in series

with the test light being tested, and power the test light-ammeter circuit with the vehicle battery.

If the ammeter indicates less than 3/10 amp current flow (0.3 A or 300 ma), the test light is OK to use.

If the ammeter indicates more than 3/10 amp current flow (0.3 A or 300 ma), the test light is NOT OK to use.

DC AMPS +

-

BATTERY

TEST LIGHT

BLOCKING DRIVE WHEELS

The vehicle drive wheels always should be blocked and the parking brake firmly set while checking any sy stem.

VISUAL/PHYSICAL INSPECTION

A caref ul vis ual and physical inspection mus t be per f or med as par t of any diagnostic pr oc edure. This can often lead

to fixing a problem without further steps. Inspect all the wires in the engine compartment for bad connections,

burned or chafed spots, pinched wires, or contact with sharp edges or hot exhaust manifolds. Also, inspect all the

wires. Check beneath the air cleaner, the compressor, the generator, etc. This visual/physical inspection is very

important. The inspection must be done carefully and thoroughly.

BASIC KNOWLEDGE AND TOOLS REQUIRED

To us e this service CD-RO M mos t eff ectively, a general unders tanding of basic electrical cir cuits and circuit testing

tools is required. You should be familiar with wiring diagrams, the meaning of voltage, ohms, amps, the basic

theories of electricity, and understand what happens in an open or shorted circuit.

To perform sy stem diagnosis, the following tools are required.

• A Tech 2

• A test light

• A digital volt-ohmmeter with 10 megaohms impedance

• A vacuum gauge

Familiarise yourself with the tools and their uses before attempting diagnosis. Special tools that are required for

system service and the ones described above are illustrated in Section 6C2-6 SPECIAL TOOLS.

ELECTROSTATIC DISCHARGE DAMAGE

Electronic components used to control the systems are often designed to carry very low voltage. They are very

susc eptible to damage caused by electrostatic dis charge. It is possible f or less than 100 volts of static electr icity to

cause damage to some electronic components. By comparison, it takes as much as 4,000 volts for a person to

even feel the zap of a static discharge.

There are several ways for a person to becom e statically charged. T he most com mon m ethods of charging are by

fric tion and by induction. An example of c harging by friction is a pers on sliding acros s a car seat, in which a c harge

of as much as 25,000 volts can build.

Charging by induction occurs when a person with well-insulated shoes stands near a highly charged object and

momentar ily touches earth. Charges of the s ame polarity are drained off , leaving the pers on highly charged with the

opposite polarity. Static charges of either type can cause damage, therefore, use care when handling and testing

the electronic components.

NOTE:

To prevent possible Electrostatic Discharge damage:

• Do Not touch the PCM connector pins or soldered components on the PCM circuit board.

• When handling a PROM, Do Not touch the component leads, and Do Not remove integrated circuit from

carrier.

DIAGNOSTIC INFORMATION

The diagnostic charts and functional checks are designed to locate a faulty circuit or component through logic

based on the process of elimination. The charts are prepared with the understanding that the vehicle:

• Functioned correctly at the time of assembly.

• There are no multiple faults.

• The problem currently exists.

The PCM perf orm s a continual s elf-diagnos is on cer tain control f unctions . This diagnostic capability is supported by

the diagnostic procedures. The PCM indicates the source of a fault through the use of Diagnostic Trouble Codes

(DTCs). The DTC’s are two digit numbers. W hen a fault is detected by the PCM, a diagnostic trouble code will set

and the Malfunction Indicator Lamp (MIL) "Check Powertrain" lamp will illuminate.

SELF-DIAGNOSTICS

The PCM perf orms the system self diagnostics . The PCM can detect and of ten isolate system faults. W hen a f ault

is detected, the PCM sets a DTC that represents the area of the fault. The PCM may or may not turn ON the

"Check Powertrain" Lamp.

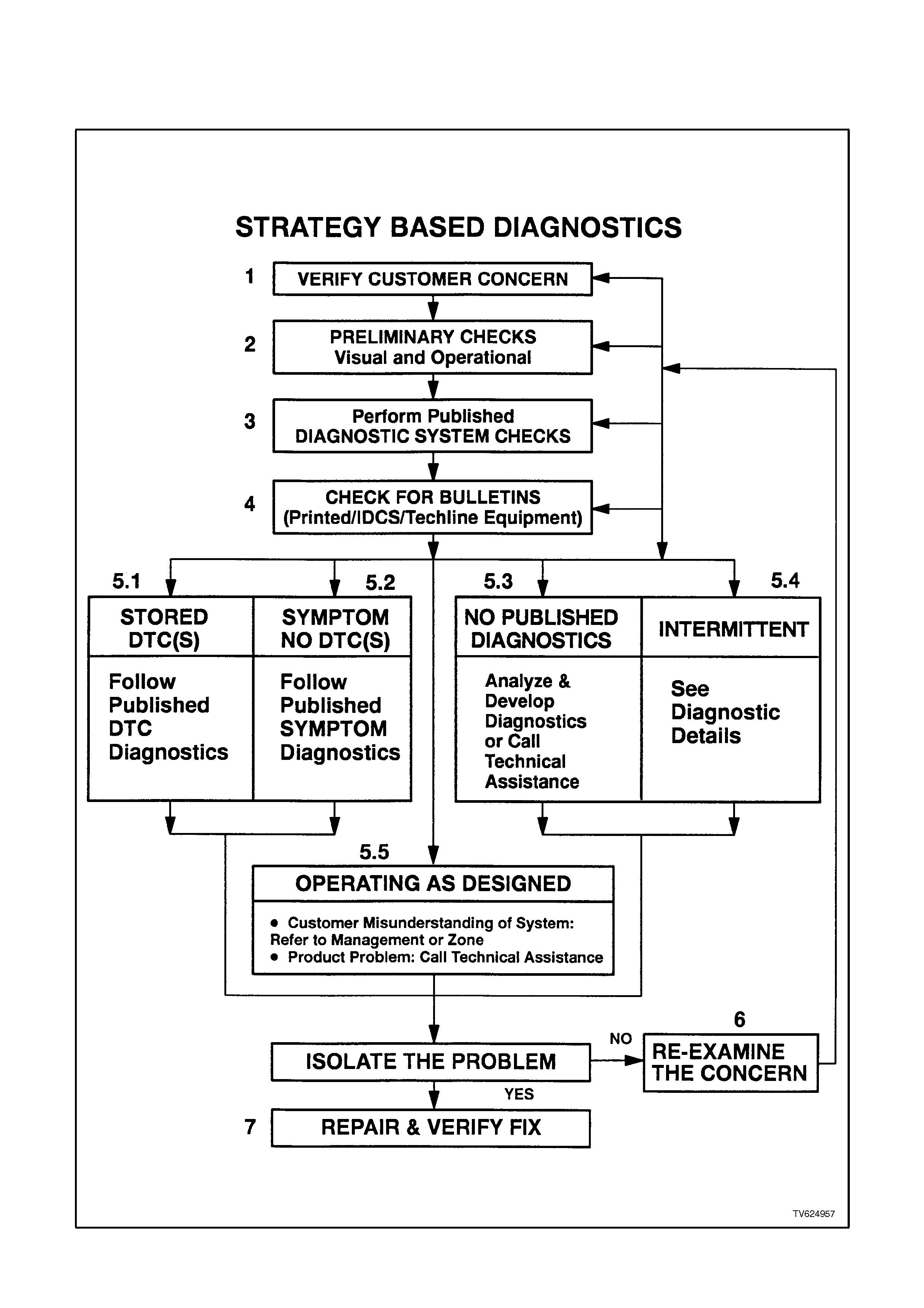

Figure 6C2-2-1 - Strategy Based Diagnostics

MALFUNCTION INDICATOR LAMP (MIL) "CHECK P O WERTRAIN" LAMP

This MIL is located on the instrument panel and

performs the following functions.

•The MIL is used as a bulb check, the MIL will

come ON with the ignition ON and the engine

OFF.

• The MIL informs the driver that a fault has

occurr ed and that the vehicle should be tak en in

for service as soon as reasonably possible.

• The MIL will display Diagnostic Trouble Codes

stored by the PCM.

• The MIL indicates "Open Loop" or "Closed

Loop" operation of the engines fuel control

system.

As a bulb and system check, the Malfunction

Indicator Lamp (MIL) "Check Powertrain" lamp will

com e ON with the ignition ON and the engine O FF.

When the engine is started, the (MIL) "Check

Powertrain" lamp will turn OF F . Not all of the DTC's

will turn ON the "Check Powertrain" Lamp. If the

"Check Powertrain" lamp remains ON, the self-

diagnostic system has detected a problem. If the

problem goes away, the "Check Powertrain" lamp

will go out in most cases after 10 seconds, but a

diagnostic trouble code will remain stored.

When the "Check Powertrain" lamp remains ON

while the engine is running, or when a fault is

suspected due to a driveability or emissions

problem, perform the "On-Board Diagnos tic System

Check". The proc edur es f or thes e chec ks ar e given

in Section 6C2-2A DIAGNOSIS CHARTS. These

checks will help identify faults which may not be

detected if other diagnostics are performed.

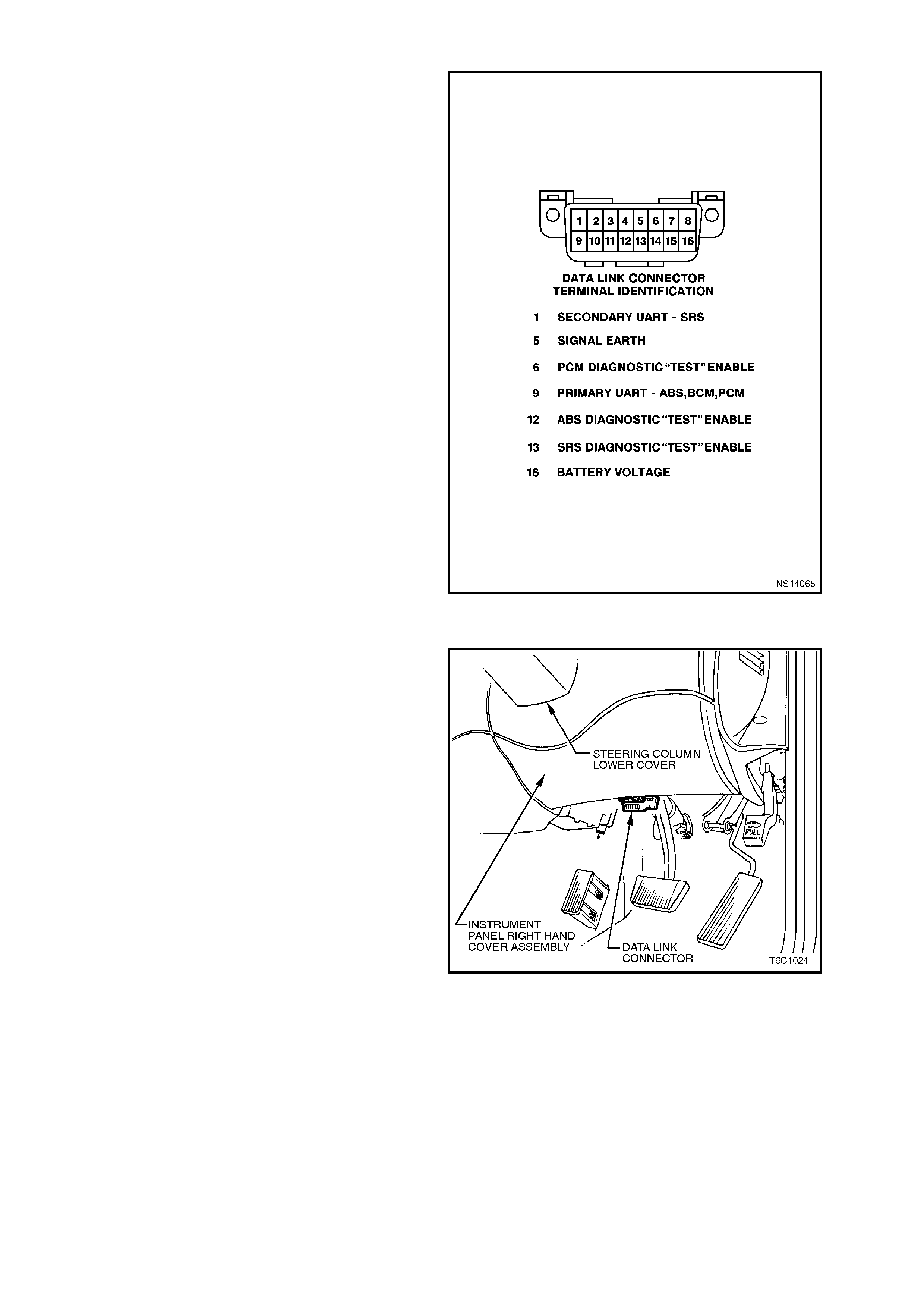

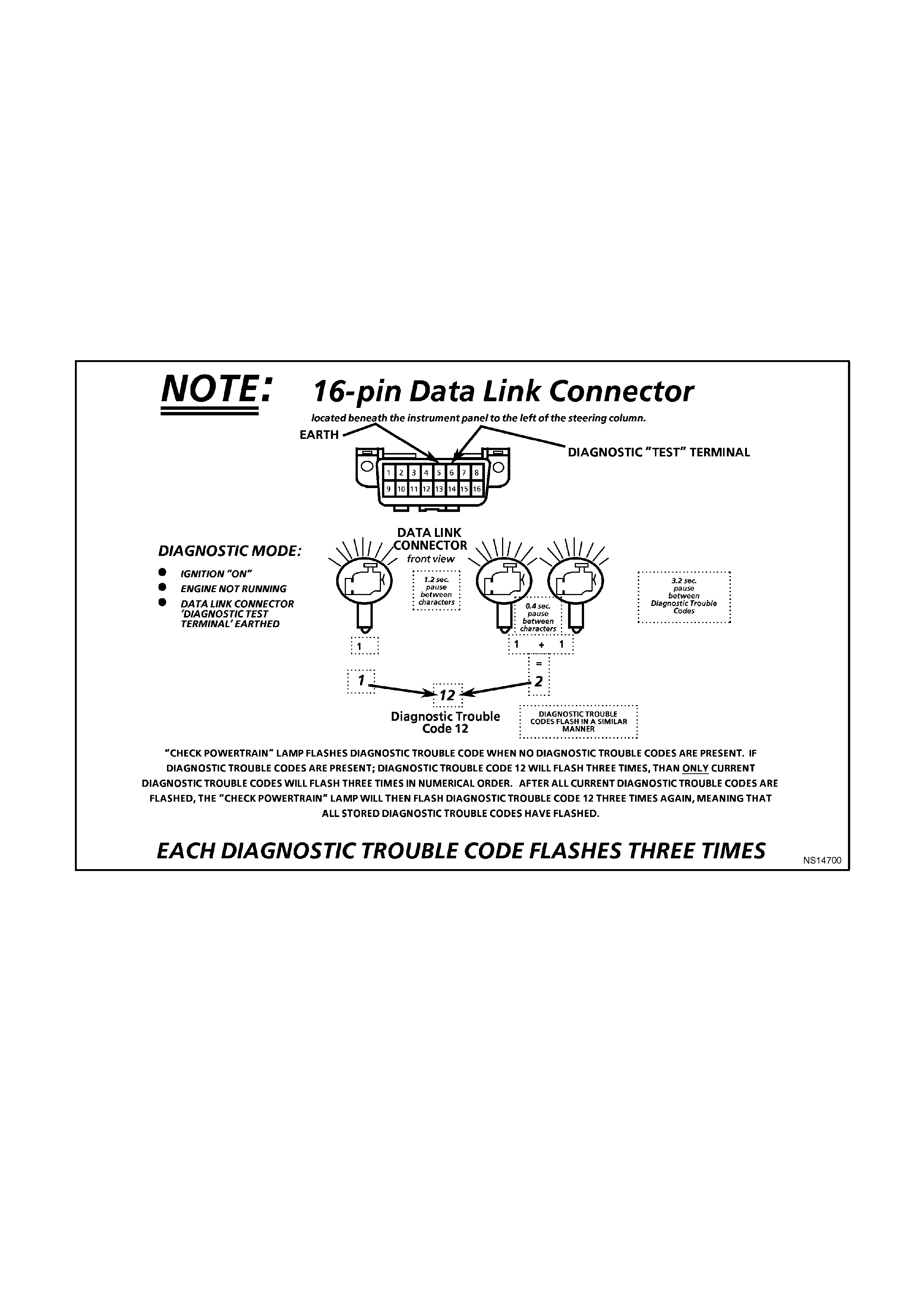

Figure 6C2-2-2 Data Link Connector (DLC)

Figure 6C2-2-3 Data Link Connector (DLC) Location

INTERMITTENT (MIL) "CHECK POWERTRAIN" LAMP

In the case of an "interm ittent" problem , the "Check

Powertrain" lamp may light for ten seconds and

then go out. The corresponding diagnostic trouble

code will be stored. The DTC will remain stored

until the battery voltage to the PCM has been

disconnected, or until it is erased using the Tech 2

scan tool. When unexpected diagnostic trouble

codes appear, chances are that these diagnostic

trouble codes were set by an intermittent fault.

An intermittent DTC may not re-set. If an

intermittent fault occurs, do not use a Diagnostic

Trouble Code Chart. Consult the "Diagnostic Aids".

The diagnostic chart corresponding to the

intermittent diagnostic trouble code.

Section 6C2-2B SYMPTOMS CHARTS also

covers the topic of "Intermittence." A physical

inspection of the applicable sub-system most often

will resolve the problem. T he Tech 2 s can tool also

has several features which can help in diagnosing

intermittence.

CURRENT DIAGNOSTIC TROUBLE CODES

A current diagnos tic trouble code is a code that is curr ently set. T he current diagnostic trouble code can be flashed

out on the "Check Powertrain" lamp by earthing the data link connector terminal "6". The diagnostic trouble code

can also be displayed on the Tech 2 scan tool.

When the diagnostic trouble c ode is dis played, a code description will also be lis ted on the Tech 2 s c an tool s cr een.

Use of the proper diagnostic trouble code chart will find the cause of the problem.

HISTORY DIAGNOSTIC TROUBLE CODE

A history Diagnos tic Trouble Code (DT C) is a DTC that was a c urrent trouble code. However, the fault that caus ed

the diagnostic trouble c ode to set is no longer pres ent. The way to identify whether a DT C is c urrent or history is to

look at the DTC history information parameter "IGN cycles Since" if the number is 0 the DTC is current, any other

number means the DTC is a history DTC. A history diagnostic trouble code can be flashed on the "Check

Powertrain" lamp by earthing the data link connector term inal "6". The diagnostic trouble c ode c an also be displayed

on the Tech 2. Using the diagnostic trouble code charts to find the cause of a history diagnostic trouble code may

lead to replacement of good components. Whenever a history code is set refer to

Section 6C2-2B, SYMPTOMS CHARTS and also look at the "Diagnos tic Aids " listed beneath the diagnos tic trouble

codes for criteria to set the DTC. History diagnostic trouble codes are usually caused by intermittent conditions.

HOW TO USE THE DTC HIS TORY CODE INFORMATION

Based upon the information that is stored in history, the technician can obtain the DTC criteria when the DTC sets

and should be able to get the DTC to become current again.

HOW DTC HISTORY W ORKS

When a DTC is set, up to ten (10) parameters will also be stored. The first four (4) parameters are:

1 Times occurred, - number (#) of DTC occurrences.

2. "Ignition cycles" - since DTC last appeared.

3. "Engine speed" - RPM when DTC set and,

4. "Times from start" - how long the engine had been running when the DTC set.

Depending upon the DTC, up to 6 additional param eters that are related to this specific DTCs are also stored, for

exam ple, if DTC 22 T P sensor signal voltage high were set, the variable param eters would be: T PS voltage, m ass

air flow, battery voltage, reference voltage and RH LTFT.

READING THE DTC'S

The provision for communicating with the PCM is the Data Link Connector (DLC). The DLC is located below the

instrument panel, to the left of the steering column. The DLC connector is used in assembly plants to receive

information in checking that the engine and transmission are operating properly before they leave the plant. The

diagnostic trouble code(s) stored in the PCM's m emory can be read either with a Tech 2 scan tool, or by counting

the number of flashes of the (MIL) "Check Powertrain" lamp when the diagnostic "test" terminal of the DLC is

earthed. The DLC terminal "6" (diagnostic "test" terminal) is the sixth terminal from the right of the DLC top row. The

terminal is most easily earthed by connecting it to terminal "5" (internal PCM earth), the terminal to the left of

terminal "6" on the top row of the DLC.

After terminals "5" and "6" have been connected together, turn the ignition switch to the "ON" position, with the

engine OFF. At this point, the (M IL) "Check Powertrain" lam p should flash Diagnos tic Trouble Code 12 thr ee times

consecutively. This would be the following flash sequence: "flash, pause, flash-flash, long pause, flash, pause,

flash-flash, long pause, f lash, paus e, f lash-f lash. Diagnostic T rouble Code 12 indicates that are no ref erence puls es

coming to the PCM and that the PCM's diagnostic system is operating properly. If Diagnostic Trouble Code 12 is not

indicated, a problem is present within the diagnostic system, and should be check ed by referring to the "On-Board

Diagnostic System Check" chart in Sections 6C2-2A DIAGNOSIS CHARTS. Following the output of Diagnostic

Trouble Code 12, the (MIL) "Check Powertrain" lamp will indicate a diagnostic trouble code three times if a

diagnostic trouble c ode is present, or it will sim ply continue to output Diagnostic Tr ouble Code 12. If m ore than one

diagnostic trouble code has been stored, the diagnostic trouble codes will be output from the lowest to the highes t.

With each diagnostic trouble code being displayed three times.

CLEARING THE DTCS

To clear a current or a history diagnostic tr ouble code from the mem ory of the PCM, the PCM power feed m ust be

disconnected for at least ten (10) seconds. The battery power feed can be disconnected by:

• Disconnecting the positive battery terminal

• Removing the engine fuse

The Tech 2 scan tool has a special mode that can be used to clear both history and current diagnostic trouble

codes.

NOTE:

To prevent PCM damage, the ignition must be OFF when disconnecting or reconnecting PCM power.

CLEARING THE DTC HISTORY CODE

The Tech 2 scan tool is the only tool capable of clearing the DTC history code. Disconnecting the battery will not

erase DTC history. The Tech 2 scan tool sends a special message to the PCM to erase the DTC's.

IGNITION CYCLE DEFAULT

If the ignition is cycled (OFF and O N) 50 tim es without a particular fault r esetting, that DTC will be cleared f rom the

PCM memory and the ignition cycle counter in the PCM will reset to zero.

PCM SLEEP TEST

After the ignition switch is turned OFF the PCM will continue to operate f or several sec onds. During this shut down,

the PCM will set the IAC valve to a position to be used on the next startup, de-energising all the solenoids and

relays, etc. and go to sleep. The PCM can be c heck ed for this s leep test by m onitoring the voltage of DLC ter minal

"6" it should go from 5 volts to 0 volts. The Tech 2 scan tool will display updated data until the sleep mode is

activated then the PCM will no longer send out serial data and the Tech 2 scan tool will display DLC Data Lost.

DIAG NOS TIC MODE

When the diagnostic "test" terminal is earthed with the ignition ON and the engine stopped, the system will enter

what is called the Diagnostic Mode. In this mode the PCM will;

• Display a Diagnostic Trouble Code 12 by flashing the (MIL) "Check Powertrain" lamp, indicating the system is

operating correctly.

• Display any stored diagnostic trouble codes by flashing the (MIL) "Check Powertrain" lamp. Each code will be

flashed three times, then Diagnostic Trouble Code 12 will be flashed again.

FIELD SERVICE MODE

Whenever the diagnostic test terminal is earthed with the engine running, the system will enter the Field Service

mode. While in the Field Service Mode the Technician can set the ignition base timing.

While the system is in the Field Service Mode, new DTCs cannot be stored in the PCM.

PCM LEARNING ABILITY

The PCM has a "learning" ability which allows the PCM to make cor r ect ions for minor var iations in the engine or the

transmission system to improve driveability.

TRANSMISS ION ADAPT FUNCTION

The HYDRA-MATIC 4L60-E uses a feedback line pressure control system which has the ability to adapt the

system's line pr essur e to com pensate f or nor m al wear of the clutc h plates, seals , springs , etc. T his learning featur e

is similar to what is used for engine fuel control, short term fuel correction, and long term fuel trim.

The HYDRA-MATIC 4L60-E transmission only uses the adapt function for the 1-2 up-shift. The PCM monitors the

engine speed to determine if the shift is occurring too fast (harsh) or too slow (soft). The PCM will adjust the

pressure control solenoid to maintain the correct shift feel. The line pressure can adapt to values ranging from 35

kPa below, to 70 kPa above normal line pressure.

Whenever the battery is disconnected, the "learning" process resets. A change may be noted in the vehicle's

perfor m ance. T o teach the vehicle, res et the IAC valve and ensure that the engine is at operating tem perature. The

vehicle should be driven at part throttle, with moderate acceleration and idle conditions until normal performance

returns.

Diagnostic charts contain diagnosis procedures using a Tech 2 sc an tool whenever possible. The T ech 2 sc an tool'

contains information about what is happening in the engine/transmission management system.

CHART A - ON-BOARD DIAGNOSTIC SYSTEM CHE CK

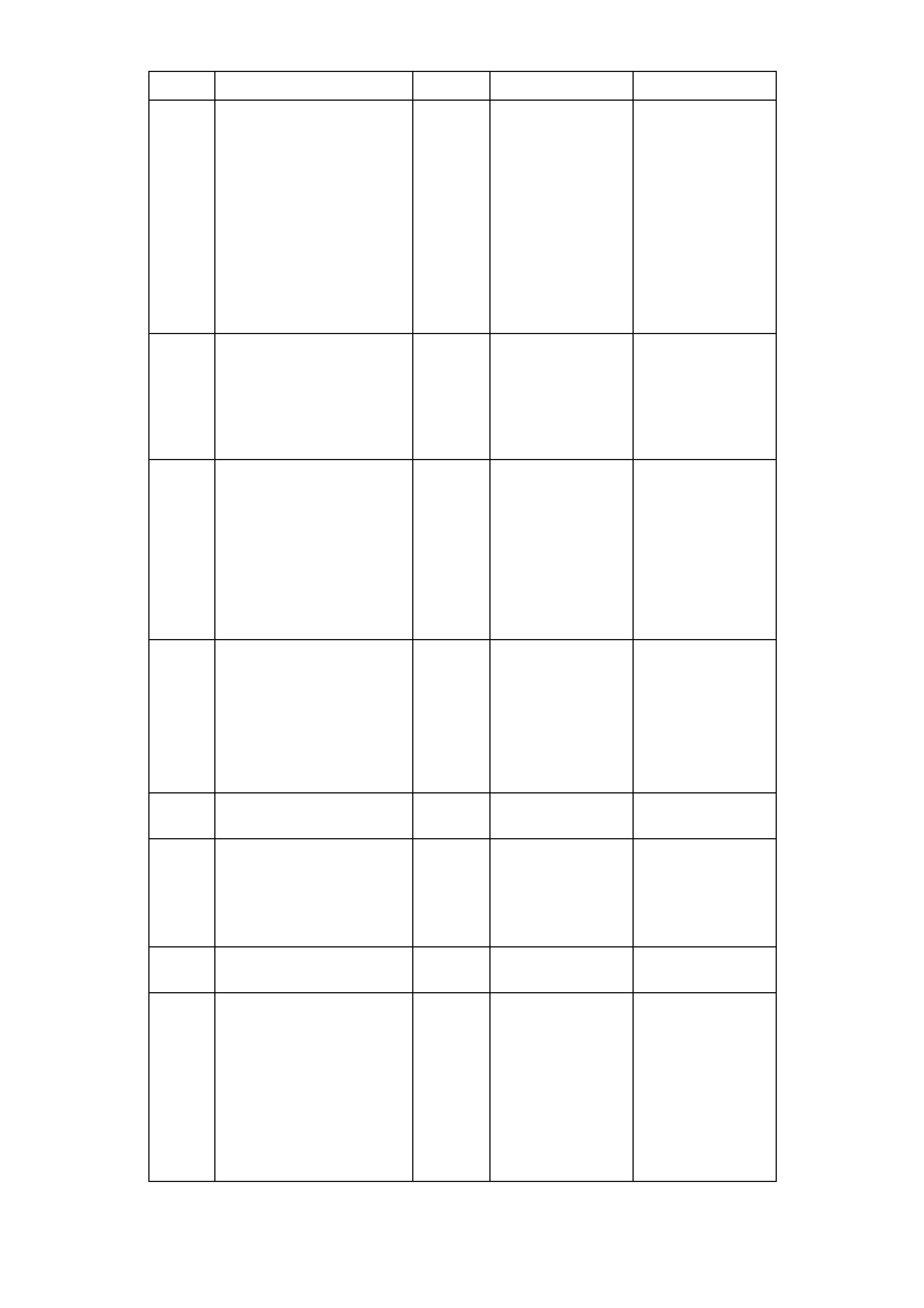

STEP ACTION VALUE YES NO

11. Ignition ON engine

OFF.

2. Observe the "CHECK

POWERTRAIN" lamp.

Is the "CHECK

POWERTRAIN" lamp

"ON" steady?

Go to Step 2 If

No "CHECK

POWERTRAIN"

lamp, Go to Chart

A-1 in this Section

----------------------

If "CHECK

POWERTRAIN"

lamp is flashing

DTC 12, Go to

Step 10

2Jumper the Data Link

Connector terminal "6" to

terminal "5".

Does the "CHECK

POWERTRAIN" lamp

flash DTC 12 ?

Go to Step 3 Go to Chart A-2

in this Section

31. Remove the Data Link

Connector jumper.

2. Install a Tech 2 Scan

tool.

3. Ignition "ON" engine

"OFF".

Does the Scan tool

display PCM serial data?

Go to Step 4 Go to Chart A-2

in this Section

41. Ignition ON engine

OFF.

2. Use the scan tool to

check for any Theft

Deterrent DTC(s).

Are any Theft Deterrent

DTC(s) stored?

Go to the

appropriate DTC

chart

Go to Step 5

5Does the engine crank? Go to Step 6 Go to Chart A-4.0

in this Section

6Use the scan tool to

check for any other

DTC(s).

Are Any Diagnostic

Trouble Codes set?

Refer To

Applicable DTC

Chart in this

Section. Start with

lowest DTC

Go to Step 7

7Does the engine start? Go to Step 8 Go to chart A-3.1

in this Section

81. Ignition ON, engine

OFF.

2. Compare the Tech 2

Scan tool data values

with the typical values

shown on the Tech 2

scan data chart.

Are the values within the

typical ranges?

Go to Step 9 Refer to indicated

Component(s)

System checks in

this Section

STEP ACTION VALUE YES NO

91. Run the engine until

the normal operating

temperature is reached

(90°C).

2. Run the engine at

1500 RPM's for two

minutes, then let the

engine idle.

3. Compare the Tech 2

scan data with the

typical values shown

on the scan data chart.

Are all the values normal

or within their typical

ranges?

Refer to

"Symptom

Diagnosis Charts"

in Section 6C1-2B

Refer to indicated

"Component(s)

System " checks

in this Section

10 Check for an earthed

diagnostic "TEST"

terminal circuit.

Was a problem found?

Verify Repair Go to Step 11

11 Replace the PCM.

Is the action complete?

Verify Repair

Figure 6C2-2-4 - Example Of On-Board Diagnostic System Check

ON-BOARD DIAGNOSTIC SYSTEM CHECK

After the vis ual/physical under hood inspection, the "O n-Board Diagnostic System Check" is the star ting point for all

diagnostic procedures.

All Diagnostic procedures must always begin with the "On-board Diagnostic System Check".

The "On-Board Diagnostic System Check," represents an organised approach in identifying system problems.

The " ON-BOARD DIAGNOSTIC SYSTEM CHECK" makes an initial check of the system, then will direct the

technician to other charts in this Section. The entire section is set up in a specific order, that is, the "ON-BOARD

DIAGNOST IC SYSTEM CHECK" will lead the technician to other charts, and thos e charts m ay lead to other charts.

THE SEQUENCE MUST BE FOLLOWED. The engine/transmission control system uses many input signals and

controls many output functions. If the correct diagnostic sequence is not followed, incorrect diagnosis and

replacement of good parts may happen.

Diagnostic charts incorporate diagnosis procedur es using a T ech 2 "Scan" tool where possible. T his T ech 2 "Scan"

tool is a sm all hand-held com puter in itself. Its j ob is to give inform ation to a technician about what is happening in

the engine/transmission management system.

The Data Link Connector (DLC) is used by the assem bly plant to perf orm end of line tests . T his connec tor c an als o

be used by technician to monitor certain inputs and output as seen by the electronic control module. The Tech 2

"Scan" tool reads and dis plays the inform ation (serial data) supplied to the data link connector f rom the Powertrain

Control Module (PCM).

The correct procedure to diagnose a problem is to follow three basic steps.

1. Are the On-Board Diagnostics working? This is determined by performing the "On-Board Diagnostic System

Check." Since this is the starting point for the diagnostic procedures or finding the cause of a failure, always

begin here.

If the On-Board Diagnostics aren't working, the "On-Board Diagnostic System Check " will lead to a diagnostic

chart in this section to correct the problem. If the On-Board Diagnostics are working correctly, the next step is:

2. Is there a Diagnostic Trouble Code stored? If a diagnostic trouble code is stored, go directly to the num bered

diagnostic trouble code chart in this Section. This will determine if the fault is still present. If no diagnostic

trouble code is stored, then:

3. Observe Serial Data transmitted by the PCM - This involves reading the information available on the Serial

Data Stream with a T ech 2 "Sc an" tool. Inf or mation on this tool and the meaning of the var ious dis plays can be

found in the suc ceeding paragr aphs. T ypical data readings under a particular oper ating condition can be f ound

on the "Tech 2 Scan tool Data" chart.

DLC TECH 2 "SCAN" TOOL

The PCM c an com m unicate a var iety of inf orm ation thr ough DLC connector term inal "9". T his data is tr ansm itted at

a high frequency (8192 Baud Rate) which requires a Tech 2 "Scan" tool for interpretation.

TECH 2 "SCAN" TOOL EXPLANATION

To explain how the Te ch 2 "Scan" tool works, let's think f or a minute about how a television works. A televis ion is an

electronic device that receives and processes information, and sends out information in a form that can be

understood by the person watching it. The television receives a signal (from a transmitting station) that is not

useable to the person.

The television processes it, then sends the signal to a screen. The person can then see the information that the

television transmitting station sent out. The Tech 2 "Scan" tool is like the television because it also processes

information, sent to it by the PCM. The information is sent out of the PCM to the Data Link Connector (DLC)

term inal "9". The T ech 2 "Scan" tool plugs into the data link connector , and the infor mation is s ent to the tool on its

cable. The Tech 2 "Scan" tool processes the information, and "sends" the signal to a display screen on the tool. Just

like a television, you can s elect which "station" that you want to see. T he difference is instead of seeing the pic ture

on a television, you "see" the display scr een, and the "stations" that you can select on a T ech 2 "Scan" tool are the

different input and output signals that are being processed by the PCM.

The T ech 2 "Scan" tool cartridge for the VS Commodore has the ability to send m essages back to the PCM to do

diff erent things suc h as switch outputs "OF F" and "ON." This allows the technician to control the PCM. T his c ontrol

only lasts as long as the Tech 2 "Scan" tool is connected.

TECH 2 "SCAN" TOOL USES

The Tech 2 "Scan" tool is a useful and quick way of comparing operating parameters of a poorly operating engine or

transmiss ion with a known good one. For ex ample, a sens or may shift its value but not set a DTC. Comparis on with

a known good vehicle may uncover this problem.

The Tec h 2 "Scan" tool allows a quick check of sensors and switches which ar e inputs to the PCM. T he PCM in the

vehicle sends out information to the Tech 2 "Scan" tool at a very fast rate, and the display on the tool can update

quicker than a digital voltmeter. The Tech 2 "Scan" tool allows a technician to manipulate wiring harnesses or

com ponents under the vehicle while observing the T ech 2 "Sc an" tool readout. T his can help in locating inter m ittent

connections.

After you enter the proper vehicle information, the first display on the Tech 2 will ask for what type of system to

select from. The following is a list of systems the Tech 2 will display:

F0: ENGINE

F1: TRANSMISSION

F3: CHASSIS

F4: BODY

After selecting F0: ENGINE, the scan tool will display:

V6

V6 SUPERCHARGE

V8

DTC CHECK

OTHER

Once the proper engine has been selected, the Tech 2 "Scan" tool will now have seven test modes for diagnosis

and service of the PCM system. The seven test modes are as follows:

MODE F0: NORMAL MODE

In this test mode, the scan tool will display various engine and transmission data and vehicle information.

MODE F1: DIAGNOSTIC TROUBLE CODES

In this test mode, DTC's stored by the PCM maybe displayed or cleared. When entering this mode there are four

mode:

F0. Read Current DTC

F1. Read History DTC

F2. Clear Current DTC

F4. Clear History DTC

MODE F2: DATA DISPLAY

In this test mode, the Tech 2 "Scan" tool continuously monitors system data, such as: engine speed data, engine

coolant temperature etc. When entering this mode, there are three modes;

F0: All Data

Displays all engine input and output data.

F1: Inputs

Displays all input data to the PCM.

F2: Outputs

Displays all output data from the PCM.

MODE F3: SNAPSHOT

In this test mode, the Tech 2 "Scan" tool captures data before and after a snapshot triggering condition which may

or may not set a DTC.

MODE F4: MISC. TESTS

In this test mode, the Tech 2 "Scan" tool performs software override commands of the PCM, to assist in problem

isolation during diagnostics.

F0: OUTPUT TESTS

F0: Fuel Pump

F1: A/C Clutch

F2: CHK PTRN LMP (Check Powertrain Lamp)

F3 High Fan

F4: Purge

F5: Starter Relay

F1: IAC SYSTEM

F0: RPM Control: used to control engine RPM from 600 RPM to 1675 RPM.

F1: IAC Reset: used to reset IAC if the IAC is lost or if IAC has been replaced.

F2: Base Idle: used to set the engine to base idle.

F2: RESET CELLS

Resets all LT Fuel Trim values to 0%

F3: BYPASS SPARK

With the engine running, this command turns on the bypass control circuit.

F4: A/F RATIO

With the engine running, forces air fuel ratio from 11.7 to 17.7.

MODE F5: FUNCTIONS

The Functions Tests mode performs functional tests on the PCM sy stem which help verify proper operation. In this

mode, fault conditions are automatically logged by the Tech 2 "Scan" tool.

The Tech 2 "Scan" tool also has the ability to send commands to the PCM, instructing the PCM to perform various

functions or tasks. This provides a quick way to determine if a device is operational or not.

In the F5 mode, the following tests can be performed:

F0: IAC Circuit

Designed to confirm to IAC motor functions OK and is not losing track of position. Monitor the engine speed.

Repeatedly cycles the IAC motor in and out and then monitors the engine speed. If OK, then ignition "OFF" and

start repeatedly, then stabilise. If the value of final RPM - initial RPM is greater than a calibrated threshold, then

the IAC circuit has failed.

F1: O2 Sensor

Designed to confirm oxygen sensor is functioning OK and not biased or slow responding. Monitors oxygen

sensor voltages and cross counts when in "Closed Loop" and forces rich/lean "Open Loop" operation.

F2: PWR (Power) Balance

Designed to identify low power output from individual cylinders. Automatically cycles each injector "OFF" than

"ON" while monitoring and recording the RPM drop for each cylinder.

F3: Wrng ( Wiring) Harness

Designed to confirm no intermittent open or short circuits exit in selected circuits. Engine is at idle in "N".

Technician should wiggle powertrain harness. The Tech-2 "Scan" tool monitors inputs that should remain

relatively static at idle such as: ECT, IAT, TP Sensor, VSS, CAM signal present, 18X signal present, EST lines,

injector voltage monitor, battery, ignition. If discontinuity occurs, the Tech-1 "Scan" tool logs failure and

prompts technician to check appropriate circuit.

F4: Low Fan

Designed to confirm that the PCM will send a command to the BCM to turn "ON" the low speed fan.

MODE F6: FIELD SERVICE

In this test mode, With the ignition "ON" and the engine OFF, the Tech-2 "Scan" tool will earth the diagnostic "test"

terminal. The system will display a Diagnostic Trouble Code 12 by flashing the (MIL) "Check Powertrain " lamp

(indicating the system is operating correctly). With the ignition "ON" and engine running, the Technician can set

ignition base timing.

MODE F7: STALL DATA

Designed to capture nine (9) particular data values, when the engine is in a stall condition. This is very similar to

snapshot mode. The PCM will store the first stall condition values, then count the number of stalls after the first.

TECH 2 "SCAN" TOOL USE WITH INTERMITTENCE

The Tech 2 "Scan" tool allows manipulation of wiring harnesses or components under the bonnet with the engine

not running, while observing the Tech 2 "Scan" tool readout.

The Tech 2 "Scan" tool can be plugged in and observed while driving the vehicle under the condition when the

"Check Powertrain" lam p turns "ON" m omentar ily or when the engine driveability is momentarily poor. If the problem

seem s to be related to certain parameters that c an be checked on the T ech 2 "Scan" tool, they should be checked

while driving the vehicle. If there does not seem to be any connection between the problem and any specif ic circ uit,

the Tech 2 "Scan" tool can be used to monitor each param eter, watching for a period of time to see if there is any

change in the readings that indicates intermittent operation.

The Tec h 2 "Scan" tool can capture and stor e data when the problem occurs , so it can be played back at a slower

rate to determine what happened to the system. This is called the "SNAPSHOT" mode.

The Tec h 2 "Scan" tool is an easy way to com pare the oper ating par ameters of a poor ly operating engine with those

of a known good one. For example, a sensor may shift in value but not set a DTC. Comparing the sensor's readings

with those of a known good vehicle may uncover the problem.

The Tech 2 "Scan" tool saves time in diagnosis and helps to prevent the replacement of good parts. The key to

using the Tech 2 "Scan" tool successfully is the technician's ability to understand the system being diagnosed, as

well as understanding the Tech 2 "Scan" tool operation and limitations. The technician should read the Tech 2

operators manual to become familiar with the Tech 2 "Scan" tool operation.

With an understanding of the data which the tool displays, and knowledge of the circuits involved, the tool can be

very useful in obtaining information which would be more difficult or impossible to obtain with other equipment.

The Tec h 2 "Scan" tool does not make the us e of diagnos tic c har ts unnec es sar y, nor can it indicate exac tly where a

problem is in a particular circ uit. Diagnostic Charts incorporate diagnosis procedures that require the use of a T ech

2 "Scan" tool.

TECH 2 "SCAN" TOOL LIMITATIONS

The Tech 2 "Scan" tool must receive the signal from the PCM in order to display any useable information. If the

PCM sends no signals to the data link connector, or the connec tion to the Tech 2" Sc an" tool is defective, the T ech

2 "Scan" tool will only display, "WAITING FOR DATA - NO DATA RECEIVED FROM PCM." The "ON-BOARD

DIAGNOSTIC SYSTEM CHECK" instructs the technician what to do if this happens.

The Tech 2 "Scan" tool has a few limitations. If the Tech 2 "Scan" tool is displaying a PCM "output" function, it

displays only the command given by the PCM. That does not mean that the desired action took place. This is

sim ilar to the autom atic tr ansm iss ion dashboard gears hift indic ator. Jus t bec ause the gears hift pointer indicates the

transmission is in "drive" gear does not mean that the transmission is actually in that gear. To be sure, you must

check the linkage and adjustment at the transmission.

When using the Tech 2 "Scan" tool to observe one of the PCM "output" functions, such as idle air control motor,

TCC solenoid, the technician m ust not assum e the indicated is the sam e as the actual. If the Tech 2 "Scan" tool is

displaying TCC solenoid as being "ON," but the wire to power it is disconnected or defective, the PCM in some

cases has no way of knowing it. The display may indicate the command is "ON," but the device may not be

operating!

The Tech 2 "Scan" tool saves time in diagnosis and helps to prevent the replacement of good parts. The key to

using the Tech 2 "Scan" tool successfully for diagnosis is the technician's ability to understand the system being

diagnosed, as well as an understanding of the Tech 2 "Scan" tool's limitations.

With an underst anding of the data the Tec h 2 "Scan" tool disp lays, and k nowledge of the c ircuits involved, the Tec h

2 "Scan" tool is useful in getting information which is difficult or impossible to get with other methods.

The Tech 2 "Scan" tool does NOT make using diagnostic charts unnecessary, nor can it tell you exactly where a

problem is in a circuit. Most diagnostic charts incorporate diagnosis procedures that require the use of a Tech 2

"Scan" tool.

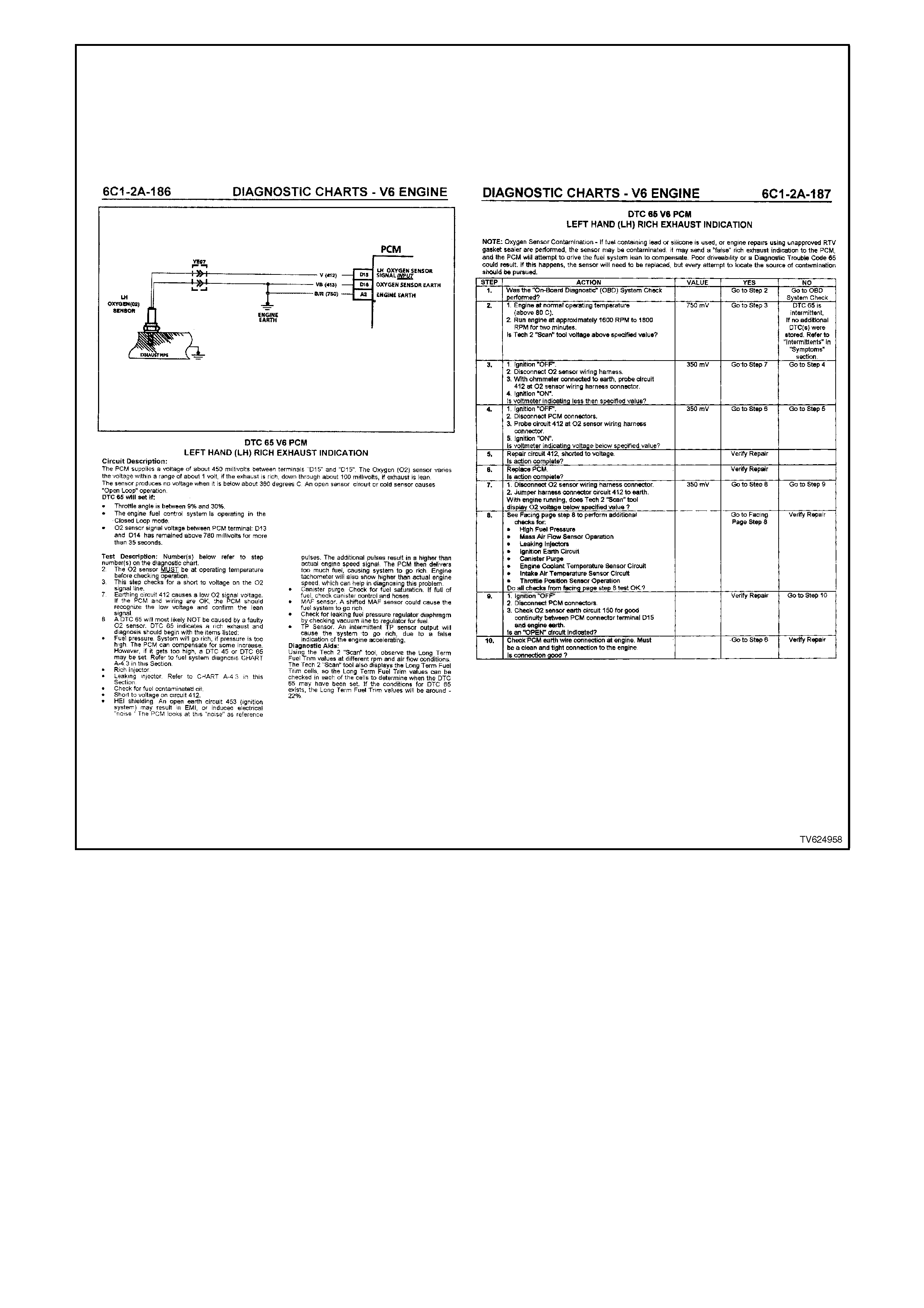

DIAGNOSTI C CHARTS: INTRODUCTION

The diagnostic charts are designed to provide fast and efficient means of fault location for all engine and

transmission functions associated with the PCM. Each diagnostic chart contains 2 parts; diagnosis help charts

located above, and diagnosis tables below. The “help charts" contains pertinent information, including diagnostic

trouble code setting parameters and circuit diagrams . The diagnosis c hart s teps are ex plained by the corresponding

numbered paragraph on the diagnosis help charts.

When diagnosing any problem, always begin with THE ON-BOARD DIAGNOSTIC SYSTEM CHECK! The On-

Board Diagnostic System Check will lead you to the other charts. DO NOT GO DIRECT LY T O A SPECIF IC CHART

or false diagnosis and replacement of good parts could result.

After a fault is corrected and all DT Cs have been cleared, repeat the O n-Board Diagnostic System Check to ass ure

that the proper repairs have been made.

Each DTC displayed consists of a number of flashes representing the first digit followed by a short pause, then a

number of flashes representing the second digit, followed by a longer pause indicating the end of the DTCs.

Each stored DTC is displayed three times before proceeding to the next DTC. After all DTCs stored in memory

have been displayed, the entire flashing sequence is repeated.

Figure 6C2-2-5 Flashing "Check Powertrain" Lamp Diagnostic Mode

The "A" Table and the diagnostic trouble code diagnosis charts are constructed in a similar fashion. A wiring

diagram showing the related components and circuits is displayed at the top of each chart. Immediately below this is

a brief circuit description. Following this is a troubleshooting table for diagnosing the fault. Step numbers on the

right-hand side next to the action boxes in this chart relate to the items in the Test Desc ription above. These item s

provide an explanation of each test in the table.

The steps in any of the troubleshooting tables will instruct you either to make a specific repair or to continue

diagnosing. If further diagnosing is needed, the step will specify where to continue.

The YES and NO column in any diagnostic table will instruct you to go to the next step. If further diagnosis is

needed, the box will specify where to continue.

If the condition is an interm ittent, the troubleshooting table will direct you to the diagnostic aids. This section gives

suggestions for diagnosing intermittent conditions and explains how some faults can occur. Rem ember, charts are

for solving active conditions or diagnostic trouble codes, not intermittent conditions. Use symptom diagnosis for

solving intermittent conditions.

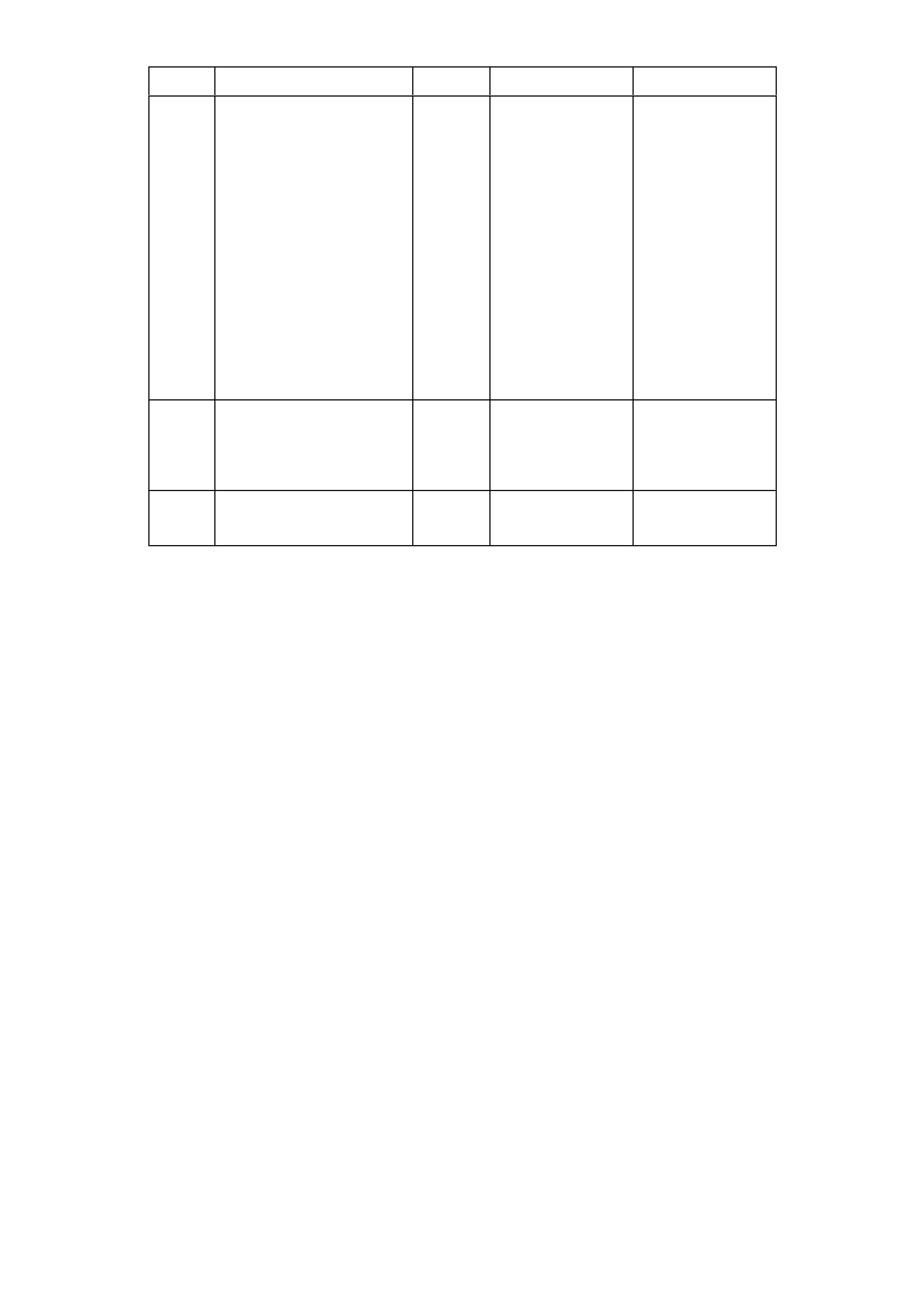

Figure 6C2-2-6 Diagnostic Flow Chart Typical

WRITING THE REPAIR ORDER

The repair order is one of the most important tools

a technician can have. Like his other tools, the

repair order must be highly accurate to give him the

greatest help.

It's up to the service adviser to supply the

technician with this highly accurate tool. Problems

begin for the technician when the repair order is

incomplete or is incorrect.

An incomplete repair order doesn't provide the

technician with a good starting point for the

diagnosis. Consequently, the technician ends up

wasting time, using a shotgun approach to finding

the problem.

An incorrectly written repair order can lead the

technician down the wrong diagnostic path,

preventing him from finding the problem.

Consequently, a service adviser needs to write an

accurate and complete repair order. This is

accomplished by asking the customer these

questions: W HO? W HAT? W HEN? W HERE? and

HOW?

Figure 6C2-2-7 An Incomplete Repair Order

"WHO"? QUESTIONS

"W ho"? is the first question you need to ask. As you begin to fill out the repair order, you need to find out who

was driving the vehicle when the problem occurred and talk directly to that person if at all possible.

This allows you to give firs t-hand inform ation on the problem to the technic ian, which is critical to diagnosing the

problem . If you can't talk direct ly to this person, get their nam e and phone num ber so the tec hnician can call the

customer if needed.

"WHAT"? QUESTIONS

The nex t step is to find out "What"? the pr oblem is .

If it's a driveability problem, and it seems to be

complex, bring the technician who's going to work

on the vehicle into the picture if at all possible.

Allow the technician to question the customer

directly, so he can get the information he needs to

help him diagnos e the problem . Again, this is so he

can get first-hand knowledge of the problem.

If you don't involve the technician with the

customer, you need to ask if the "Check

Powertrain" lamp is ON all the time, coming ON

and OFF during the same key cycle, or is never

ON.

This is important to the technician because this

informs him which diagnostic direction to take.

Either the symptom charts, Fig. 6C2-2-8 or the

diagnostic charts, Fig. 6C2-2-9.

These charts are different from one another. If a

technician is f ollowing the wrong chart, a lot of tim e

is wasted. So, ask the customer questions about

the "Check Powertrain" lamp.

Other good "What"? questions are. Under what

conditions did the problem occur?

Were they accelerating, decelerating, coasting?

Were they driving in the city or on the freeway?

What were the environmental conditions? Was it

raining? snowing? hot? cold? The technician will

need to duplicate these conditions if he is to find

the cause of the problem

Figure 6C2-2-8 Typical Symptomatic

Diagnostic Chart

Figure 6C2-2-9 Typical Diagnostic Table

"WHEN"? QUESTIONS

"W hen"? questions are the next step. If the custom er says the "Check Powertrain" lamp was ON, you need to ask

when the Check Powertrain came "ON" and how long it has been "ON." Is the Check Powertrain "ON" before or

during starting, or when the engine is running?

More impor tant, you need to ask when the problem f irst occ urred. Maybe it began after the vehicle was ser viced f or

a related problem or for something that appears to be totally unrelated.

The technician also needs to know if the problem has got worse. This information may give the technician some

clues as to what the problem may be

"WHERE"? QUESTIONS

"W here"? is the next question. The location where the problem occurs may give the technician an idea as to what

may be contributing to the problem, such as electromagnetic interference from overhead power lines.

"HOW"? QUESTIONS

To round out your questioning, you need to ask the customer "How"? often the problem occurs. This can give the

technician direction as to what ty pe of system may be causing the problem: electrical, mechanical, vacuum, etc.

SUMMARY

In summary, you need to obtain the following information from the customer:

• Who the principal driver is.

• What the problem is.

•When the problem began.

• Where the problem occurs.

• How often the problem occurs.

Complete answers to these questions will aid the technician in diagnosing the problem.

VERIFYING THE COMPLAINT

ENGINE COMPARTMENT INSPECTION

The most important step in diagnosing a driveability complaint is to verify the complaint. This means you have to

duplicate the problem if possible.

Start by performing an engine compartment inspection. Check the integrity of all the electrical connections and

vacuum hoses. Also, check the wire routing for the possibility of Electromagnetic Interference (EMI).

ENTERING THE DIAGNOSTIC MODE

If you didn't find the problem during your engine

compartment inspection, check for stored

diagnostic trouble codes. Use the T ech 2 scan tool

"ON-BOARD DIAGNOSTIC SYSTEM CHECK" to

earth the system into the diagnostic mode.

Don't skip the diagnostic mode and just connect a

Tech 2 scan tool to check for diagnostic trouble

codes.

Figure 6C2-2-10 DLC Terminal Identification

TECH 2 SCAN TOOL INCOMPATIBILITY

If the PCM is equipped with the original PROM, chances are the Tech 2 scan tool will be able to read any stored

diagnostic trouble codes and data accurately.

If the PCM has an after m ark et PROM ins talled, incorrec t data m ay result when using a Tech 2 s can tool. T his data

may include inaccur ate sens or values, s uc h as showing engine RPM at 2,000 when the engine is really not running

at all. This is due to a mismatch between the after market PROM and the programmed information in the Tech 2

scan tool .

The data can include false diagnostic trouble codes. This is where you can get into trouble, diagnosing a problem

that doesn't exist. This is due to a mismatch between the original PROM and the after market PROM.

Verify that the original or updated PROM is correct for the vehicle.

CHECKING FOR STORED DIAGNOSTIC TROUBLE CODES

As you check for diagnostic trouble codes, k eep in m ind that intermittenc e may not store a diagnostic tr ouble code.

So proceed with verifying the complaint, even if no diagnostic trouble codes are stored.

If a diagnostic trouble code is stored, check the service bulletins for the particular vehicle you're working on.

ROAD TESTING THE VEHICLE

This step is optional if the repair order states.

• The driveability problem is intermittent.

• You did not find any problems under the bonnet .

• No diagnostic trouble codes are stored.

Then you need to road test the vehicle in order to recreate the problem.

This is an important step because the problem has to be present in order to repair the problem.

Most intermittent driveability problems are repeatable. That is what road testing is all about.

Before you go on your road test, r eview the vehicle's ser vice histor y. This infor m ation can give you clues as to what

may be causing the driveability problem and what you need to watch.

Read the repair order and think about what systems could possibly cause the problem. This is essential to finding

the problem. Think about how the system or systems in question works, what inputs are needed and what could

cause the problem.

Check all the inputs required f or a circuit, whether the circuit actually has trouble or if you only suspect trouble. All

inputs are needed and m ust be within a "norm al" range. You will want to pay attention to thes e systems and circuits

during and after the road test.

As you're road testing, put the Tec h 2 sc an tool in the s napshot mode s o you can capture the system data when the

problem occurs.

Do not discount the other information the Tech 2 snapshot mode can supply you with.

DON'T FORGET THE BASICS

Whether or not you find anything wrong during the road test, don't forget the basics.

Electrical connections such as power feeds and earths are vital to the operation of almost all of the vehicle systems.

No matter how good the system is, it is still working in combination with the engine. If the engine is not in good

condition, the computer sy stem can't make up for the condition.

Compare performance problems, such as lack of power, with a comparable vehicle. This will let you know if the

customer complaint really is a problem or something that is normal.

If you can't repeat the problem, and you need more information for diagnosing, call the customer who was driving

the vehicle when the problem occurred. This type of professionalism will probably help you diagnose the problem.

PROMS

If a vehicle is just starting to have an intermittent driveability problem and it has accumulated more than 30,000

kilometres, chances are that the PROM is not at fault.

If the vehicle was running properly for such a long time, the original PROM calibrations are not the problem since

the PROM calibrations don't change, the chances of the PROM going bad are rare.

You can tell if the PROM was original to the PCM by comparing their broadcast codes. If the codes are the same,

odds are that they were originally installed on the vehicle and are not the cause of the problem.