SECTION 6C2-2A - DIAGNOSTIC CHARTS

CAUTION

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS

will consist of either seat belt pre-ten sioners and a driv er’s side air bag, or seat b elt

pre-tensioners and a driver’s and front passenger’s side air bags. Refer to

CAUTIONS, Section 12M, before performing any service operation on or around SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deployment, resulting in possible personal injury or

unnecessary SRS system repairs.

SYSTEM COMPONENT LOCATIONS

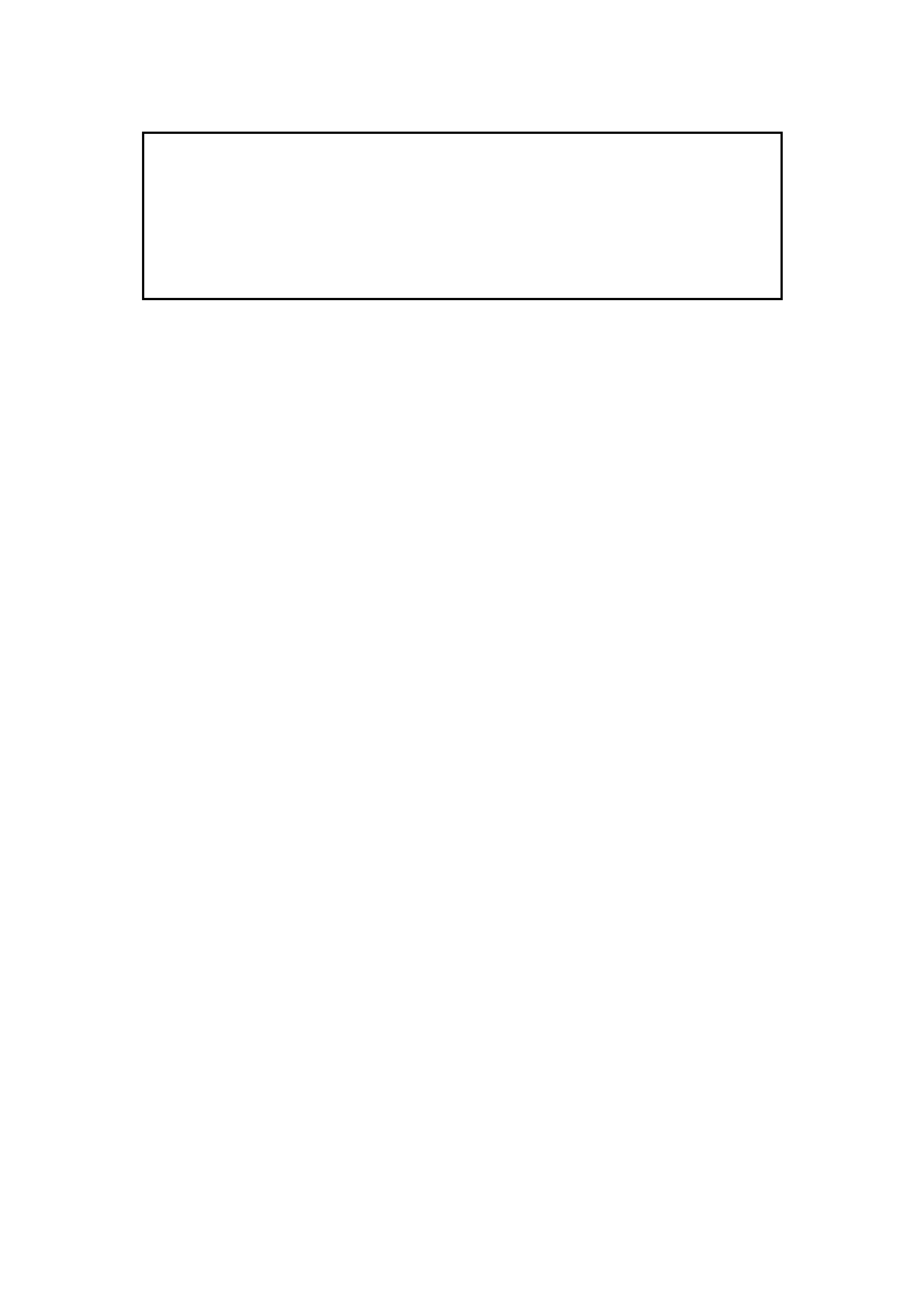

Figure 6c2-2A-1 Engine Compartment Component Locations

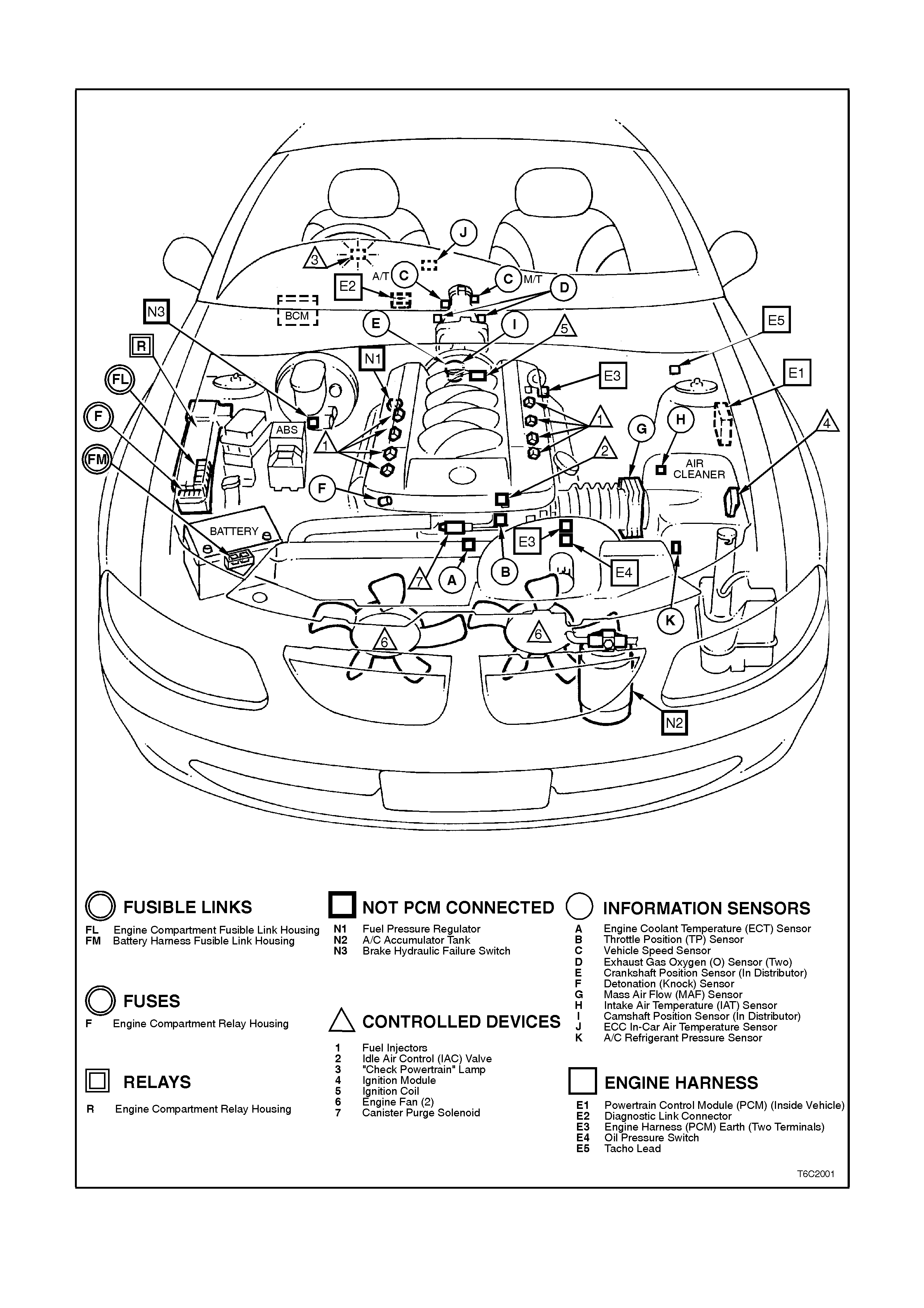

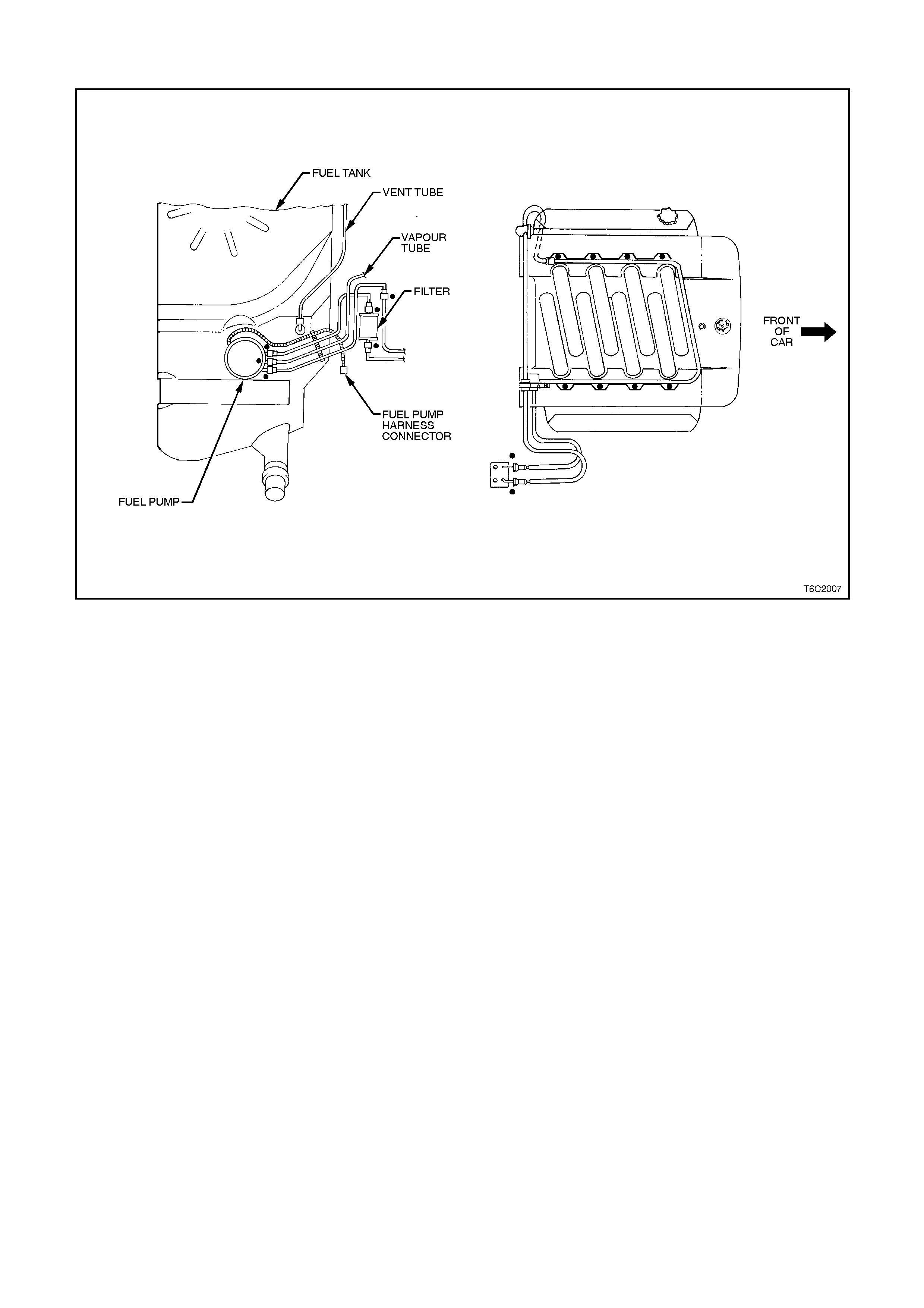

Figure 6C2-2A-2 System Component Locations

Figure 6C2-2A-3 Power Distribution Center

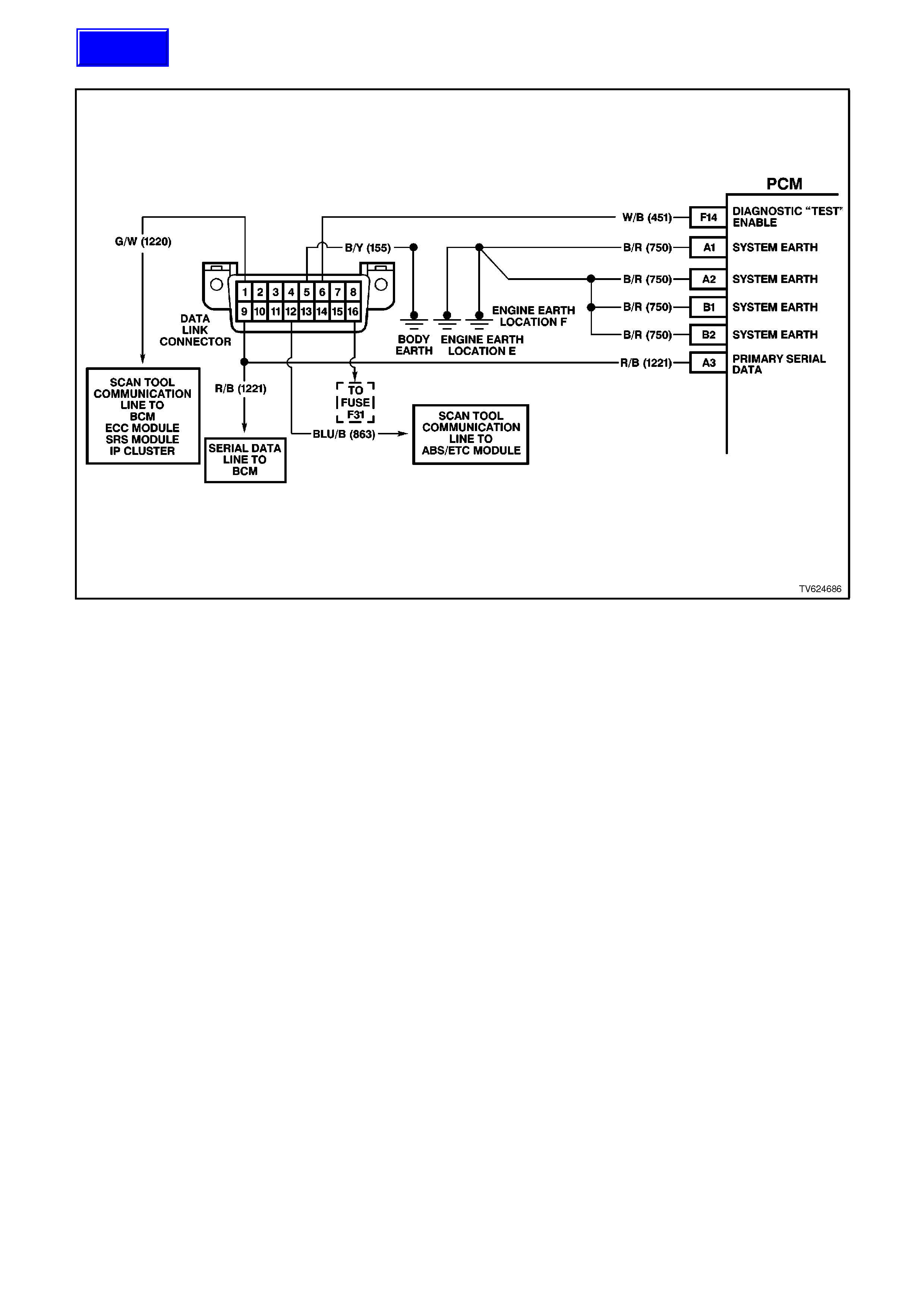

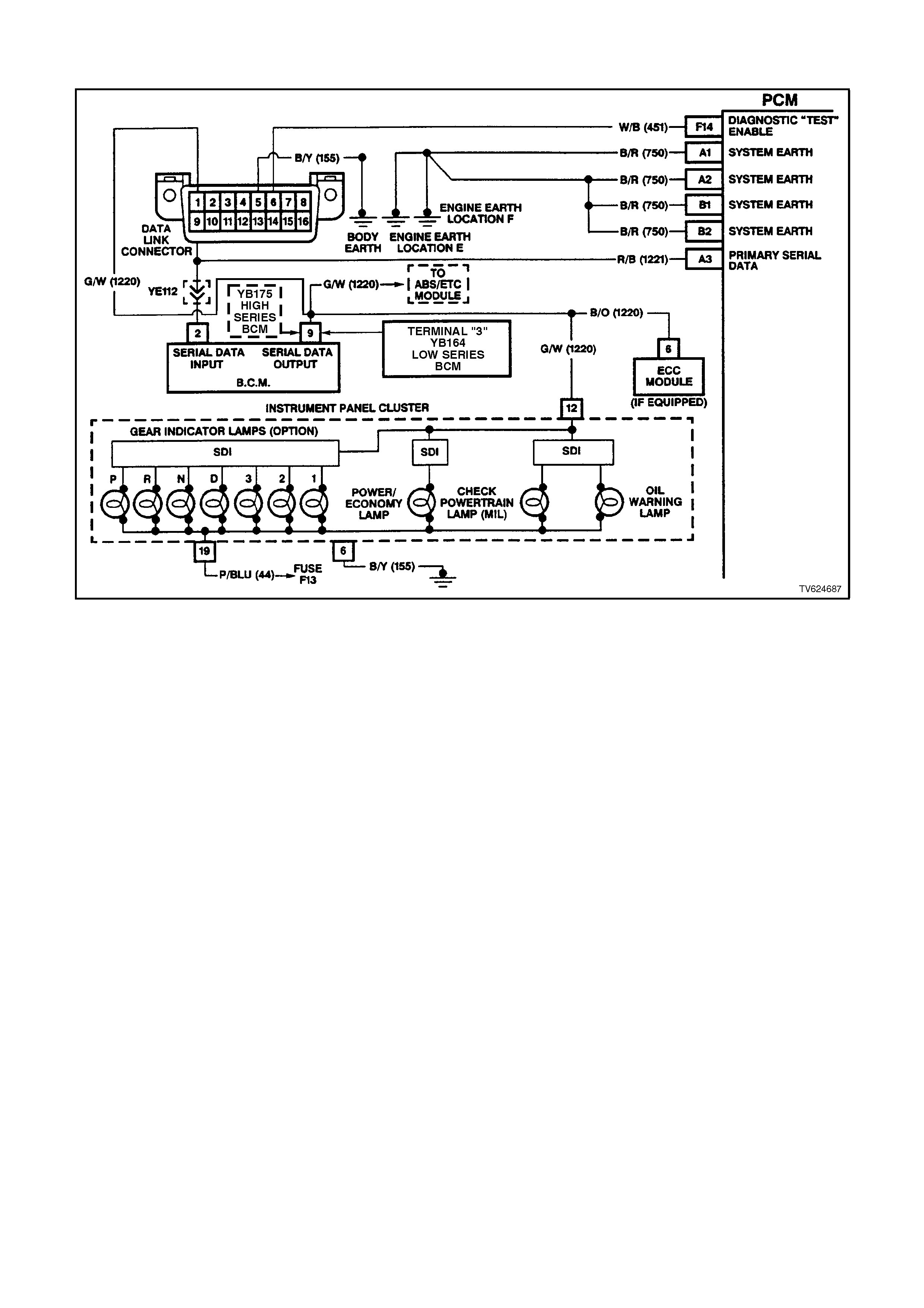

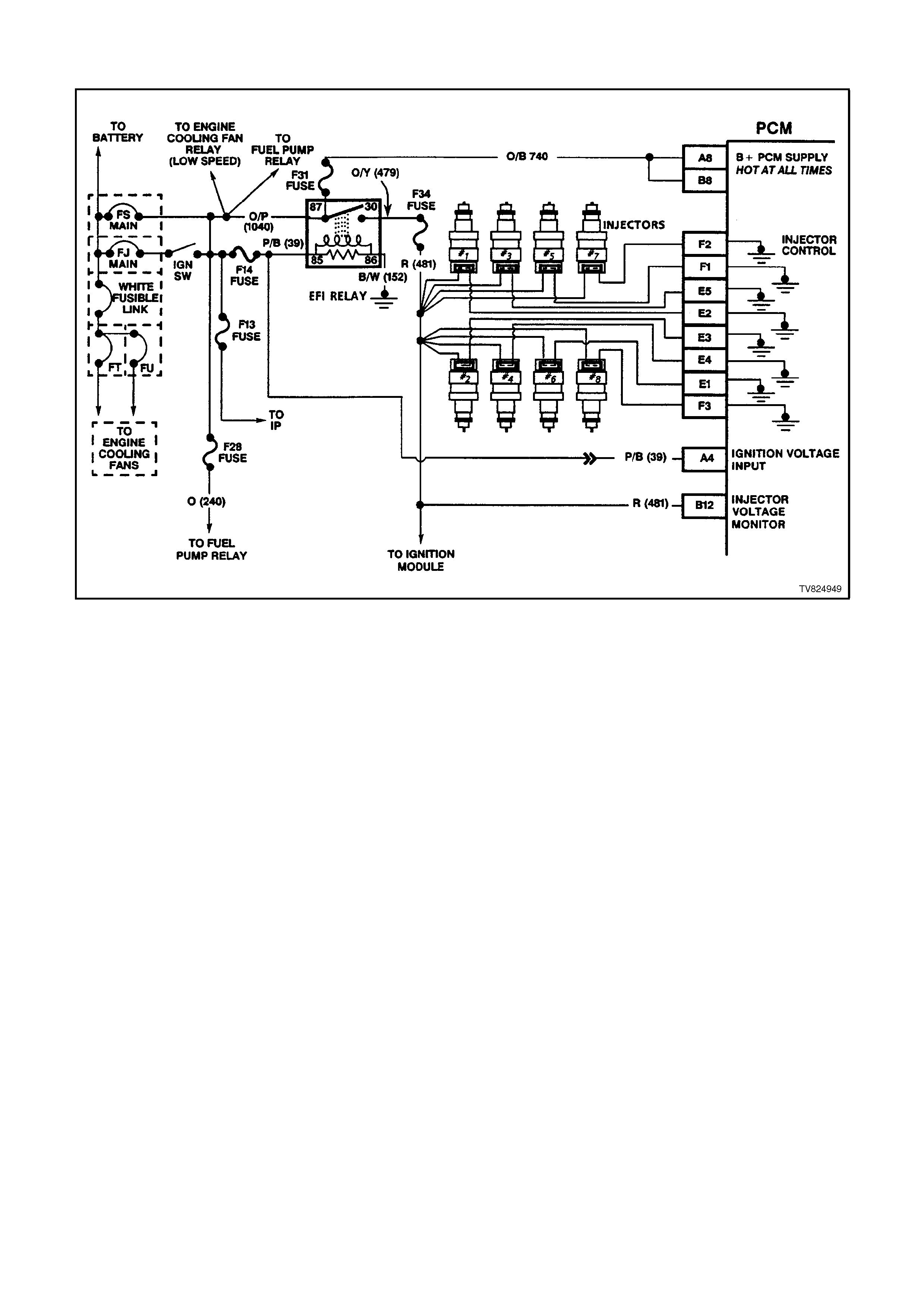

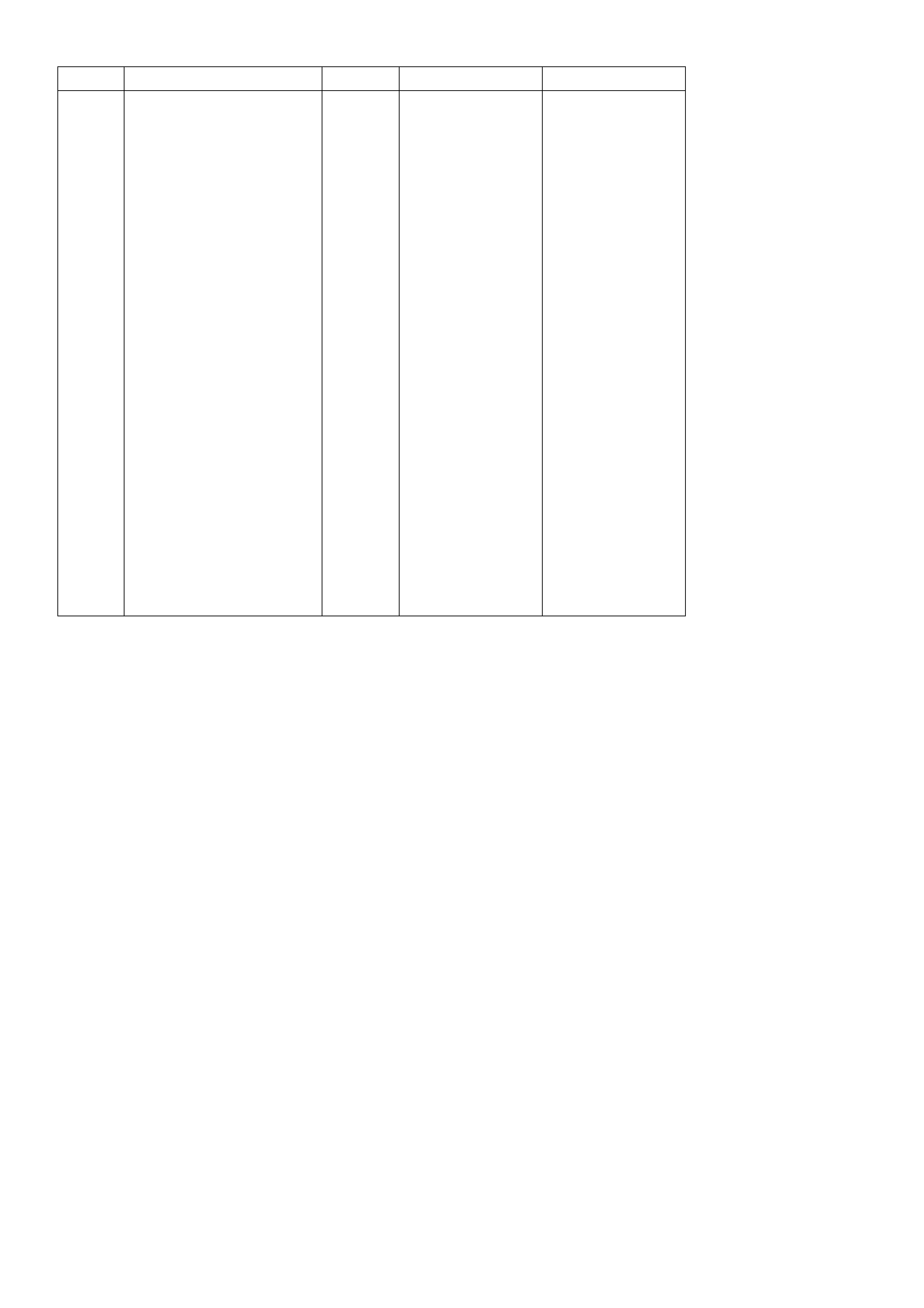

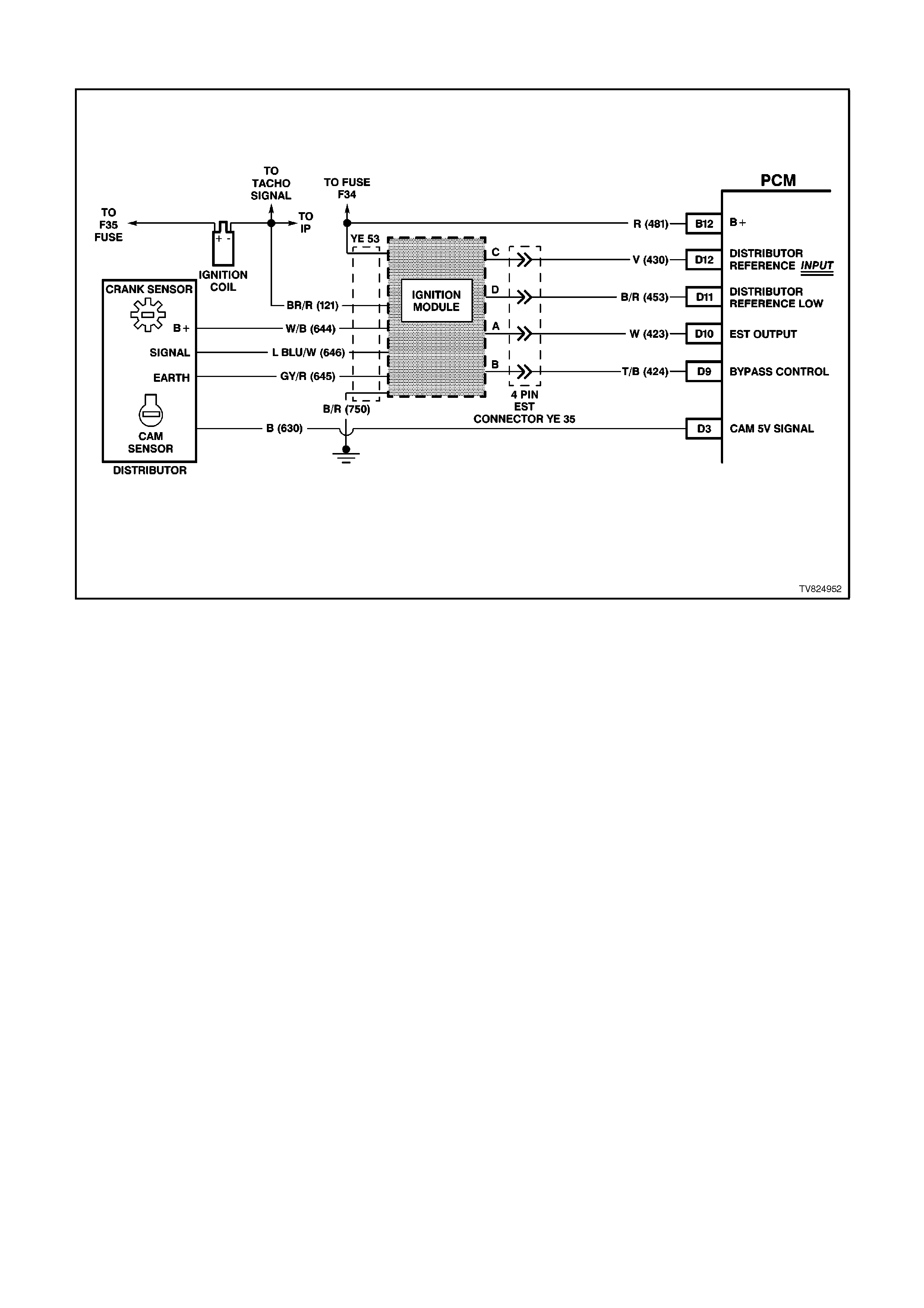

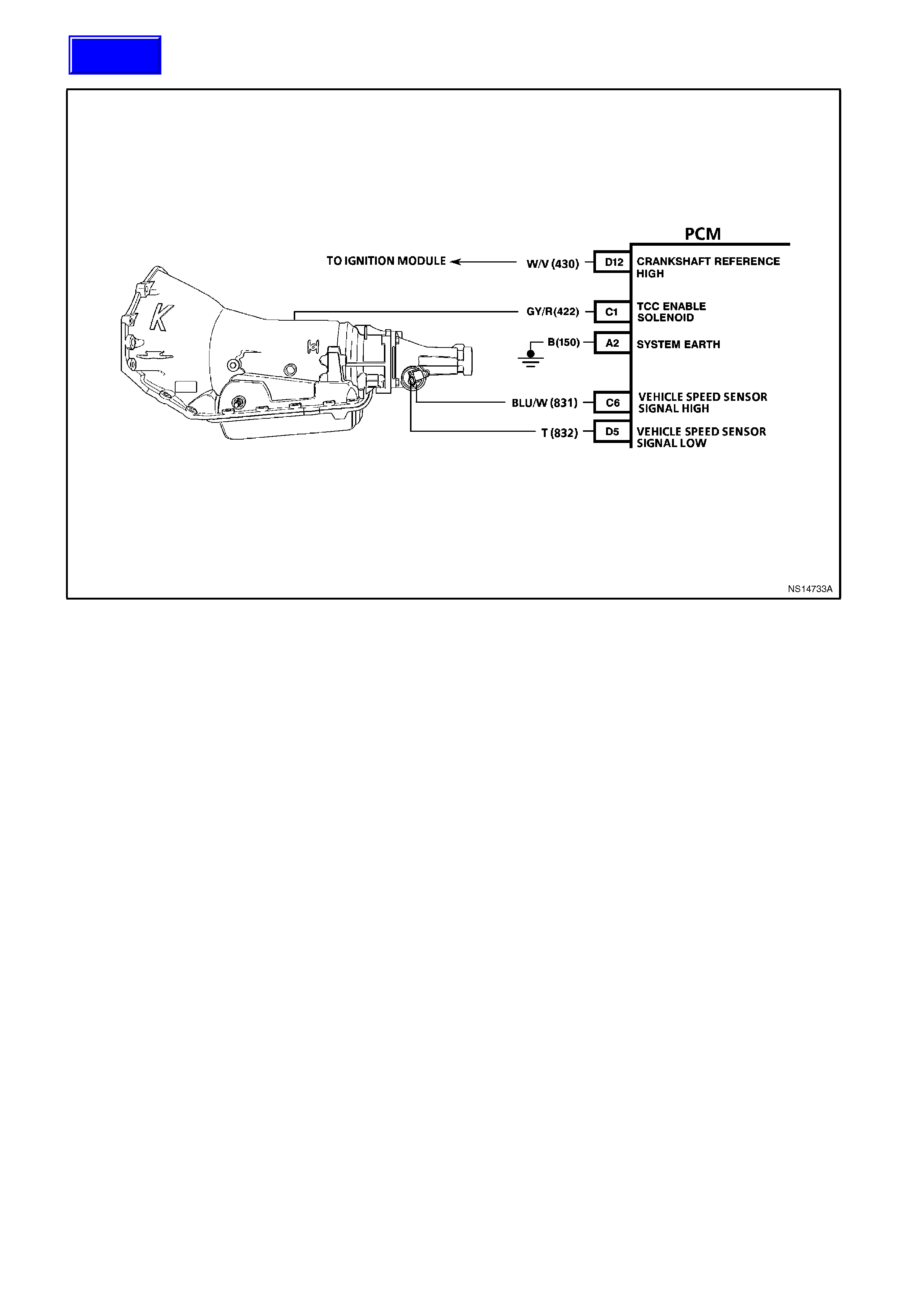

PCM WIRING DI AGRAMS

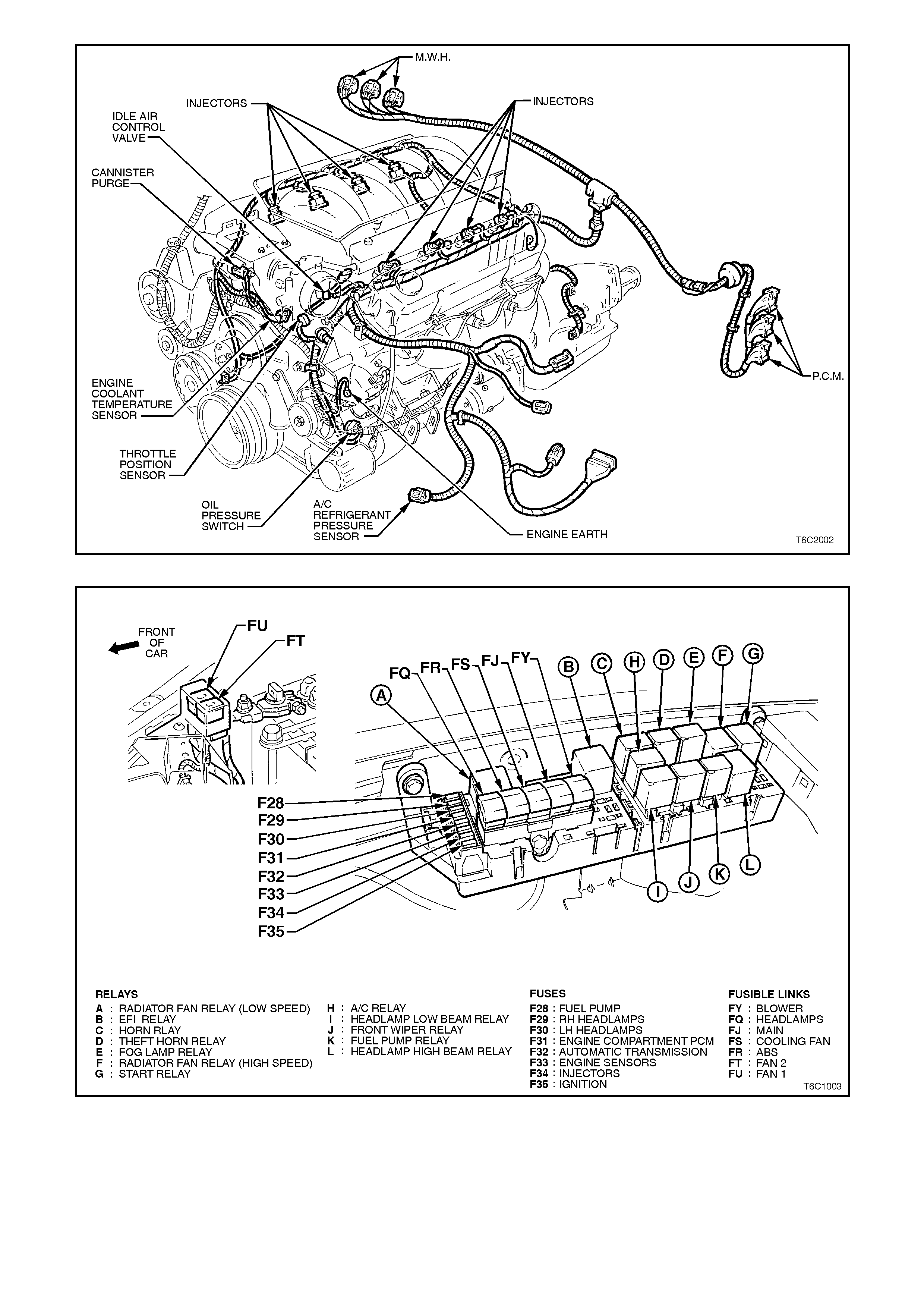

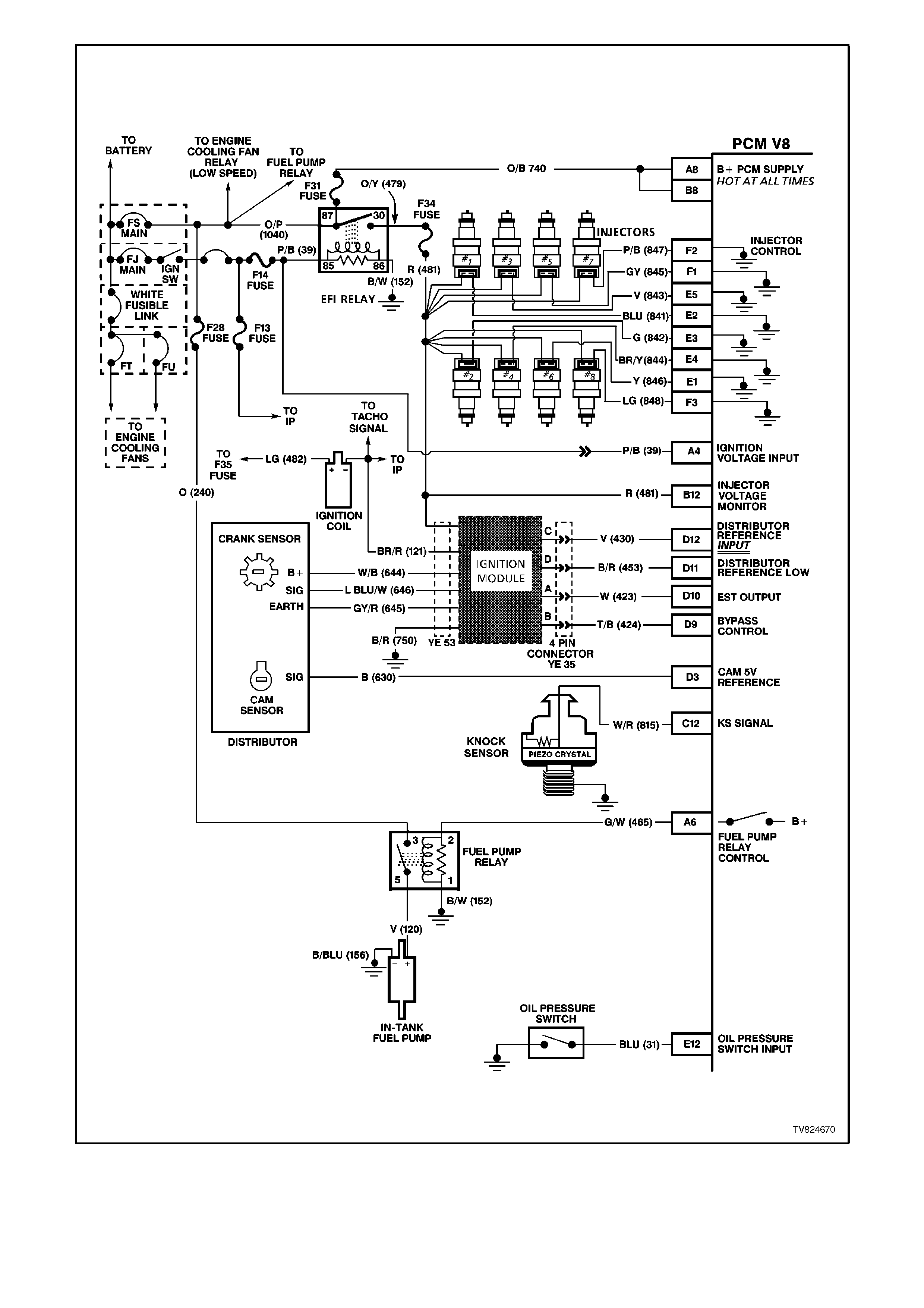

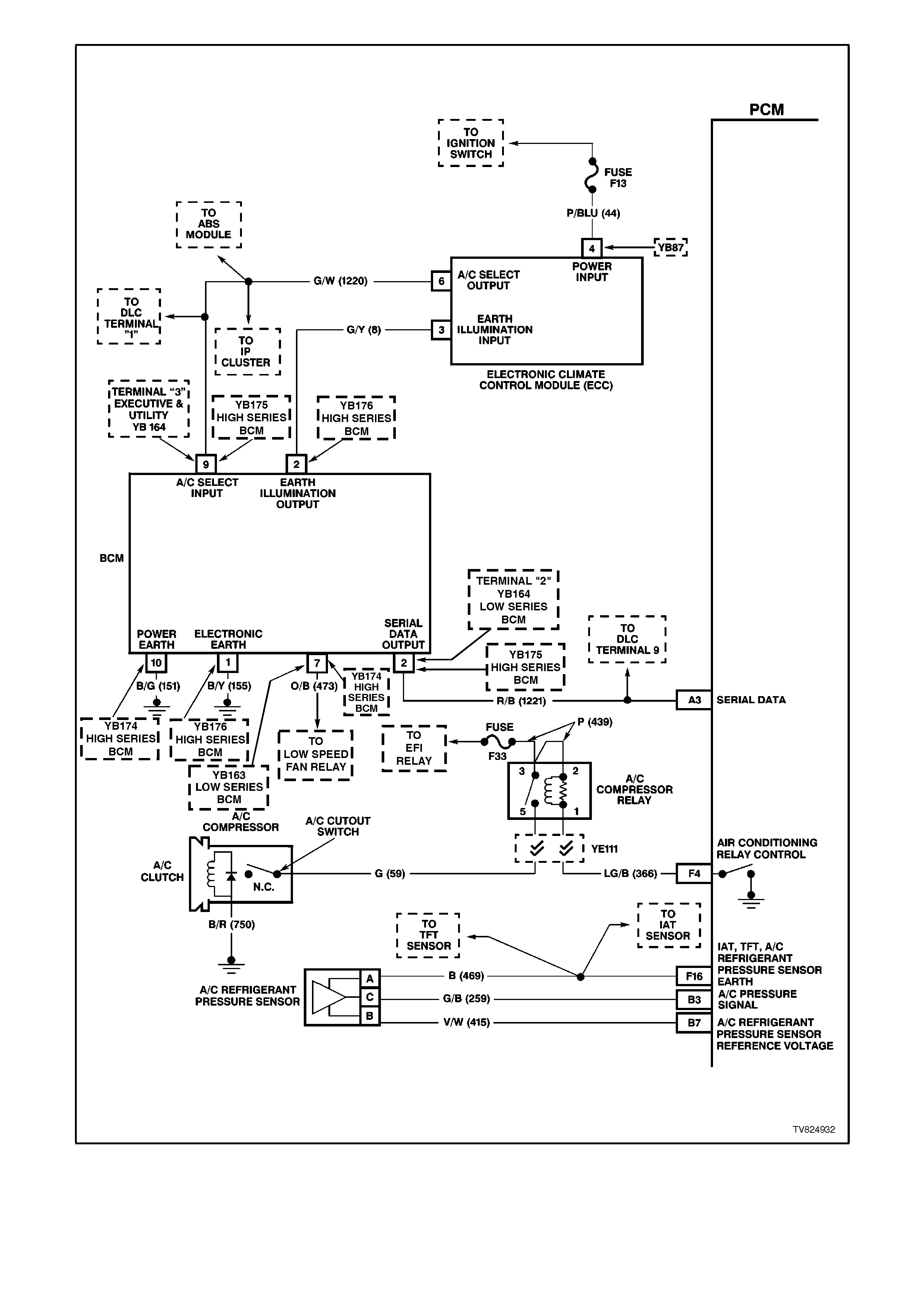

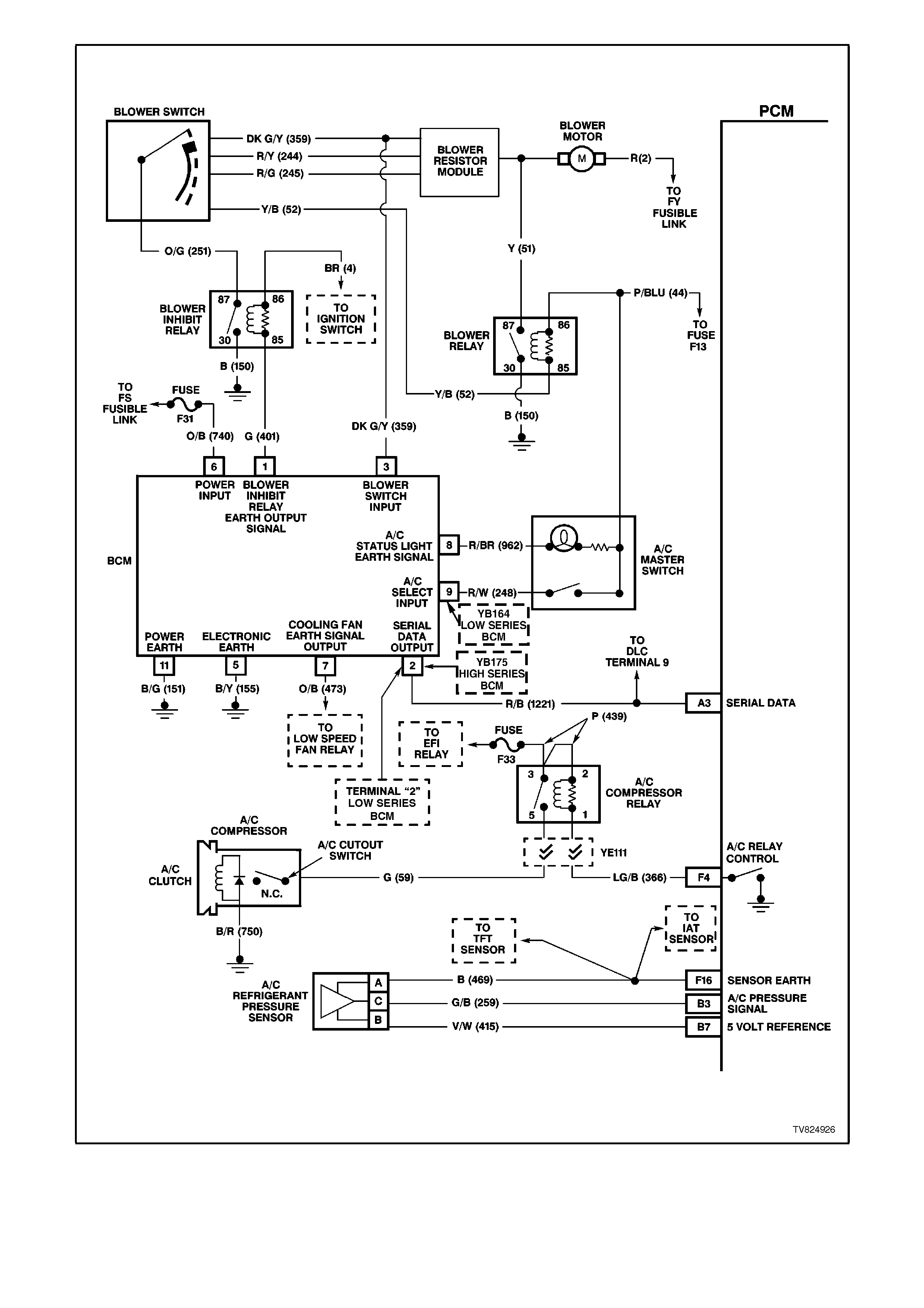

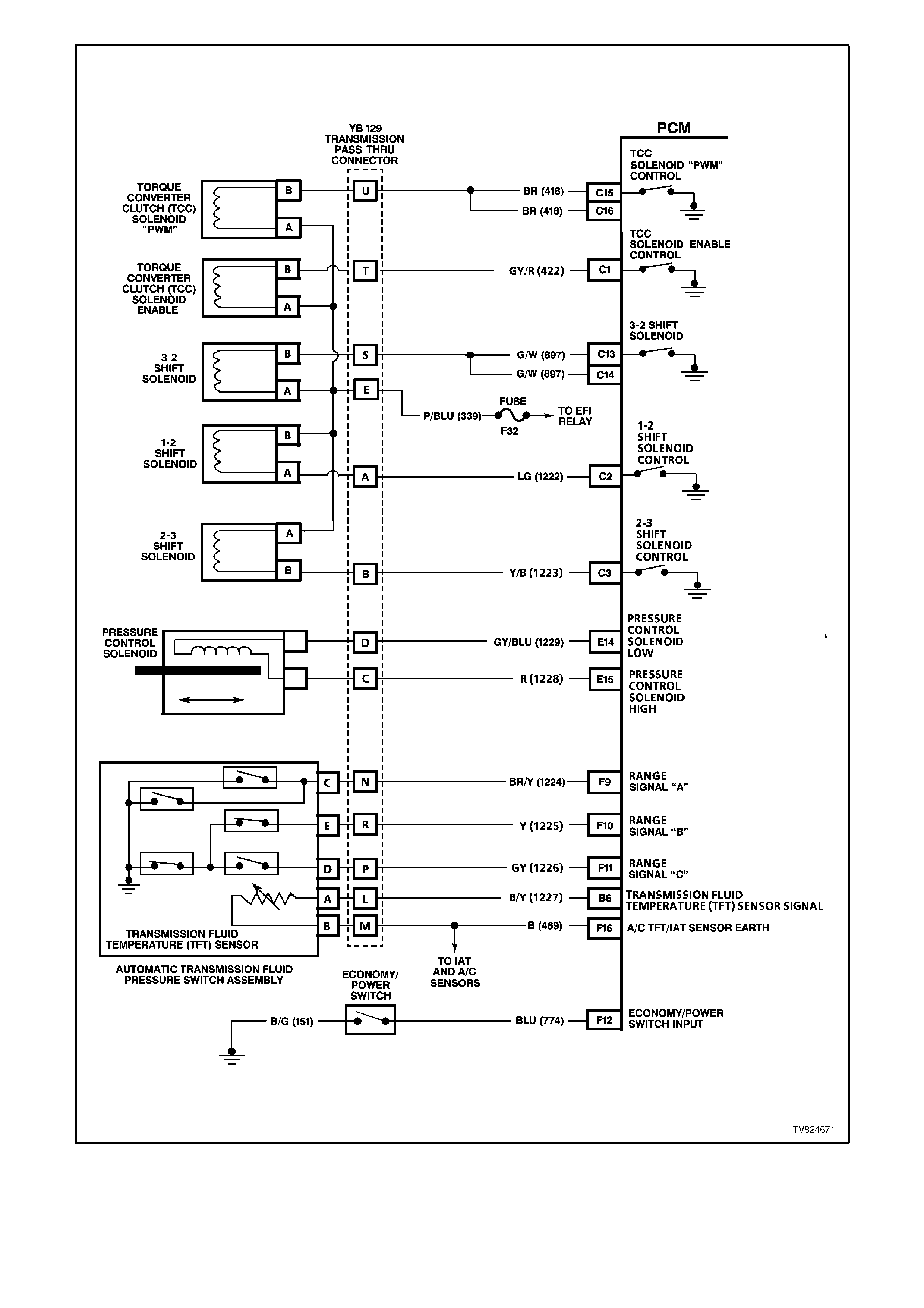

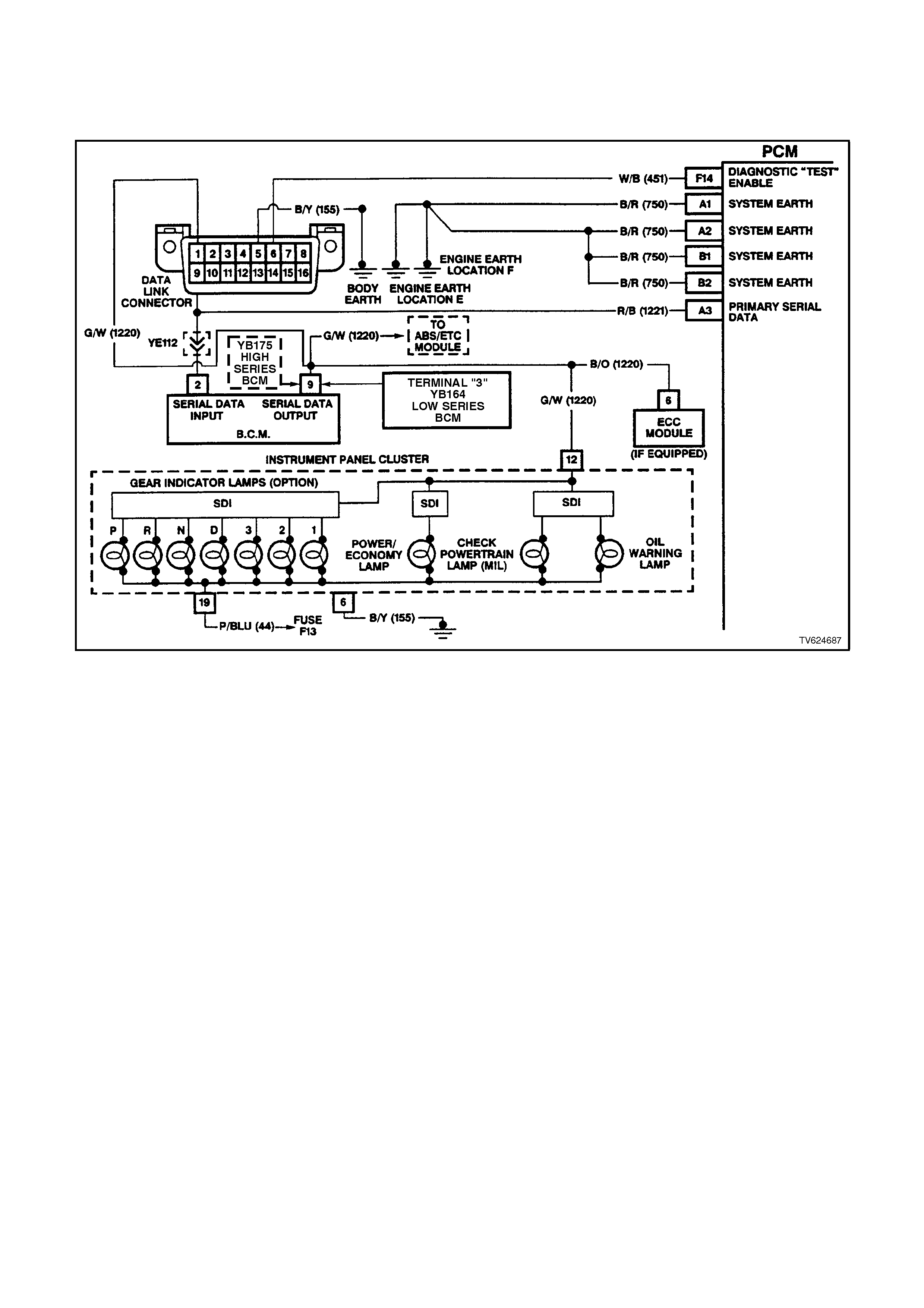

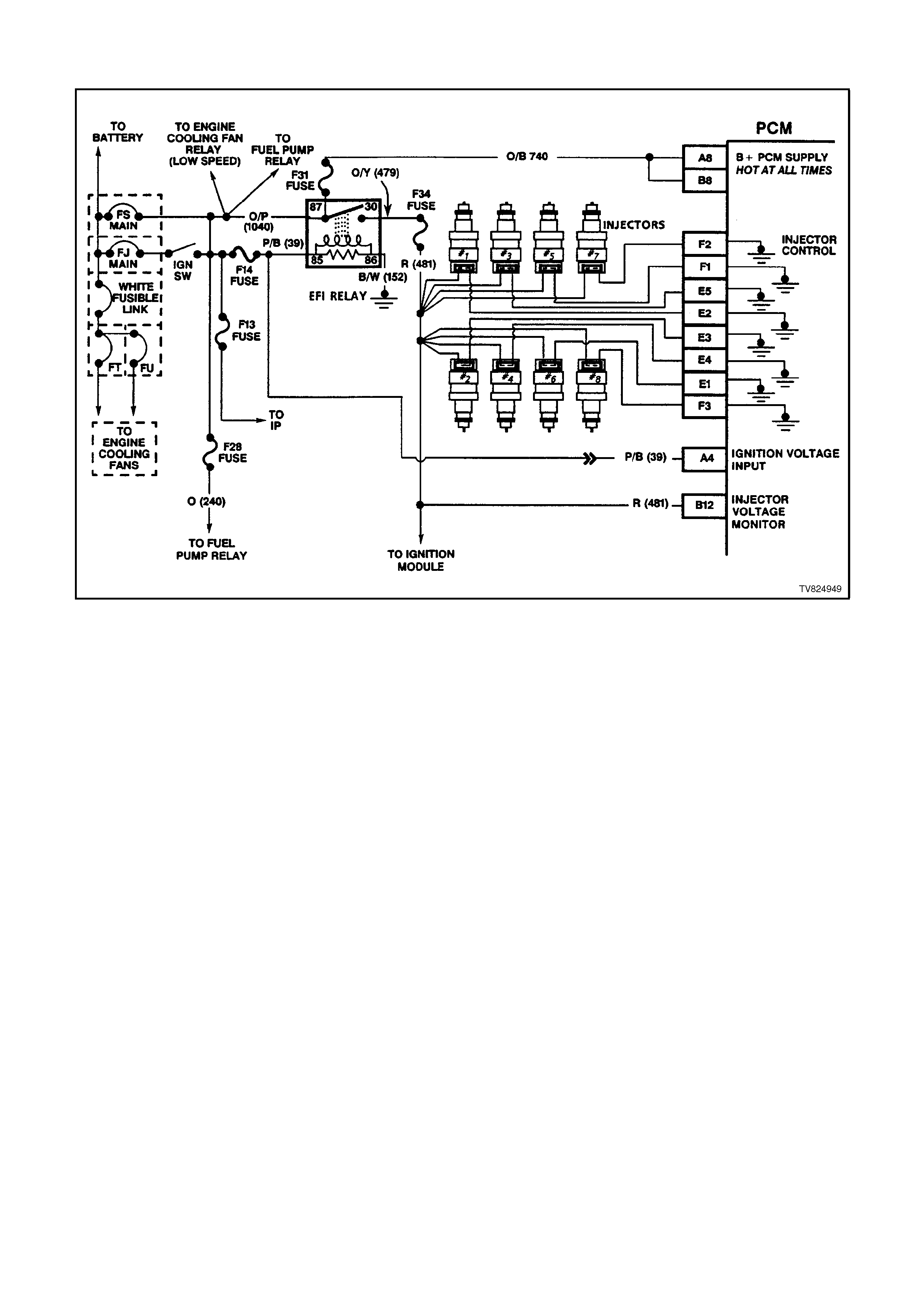

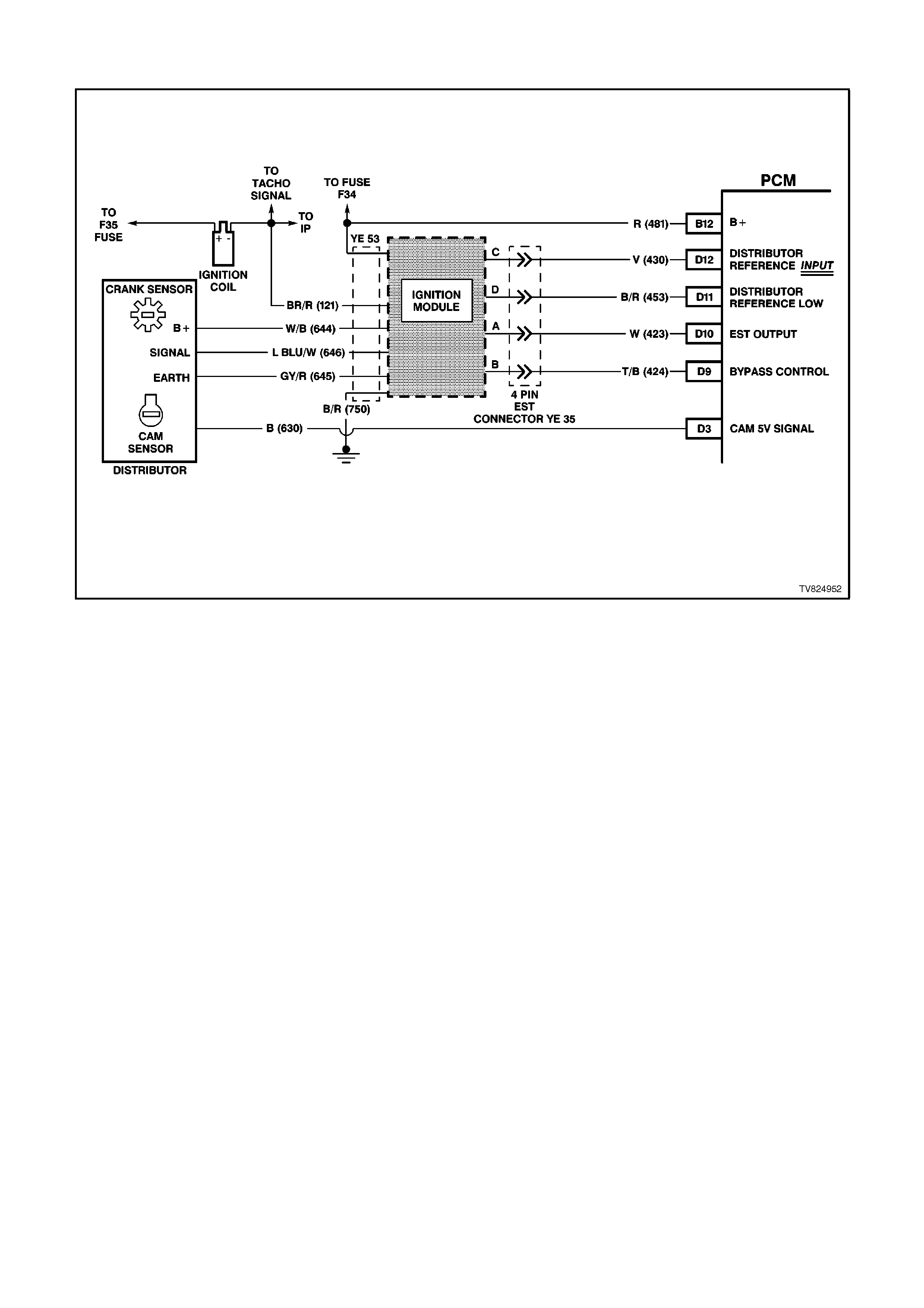

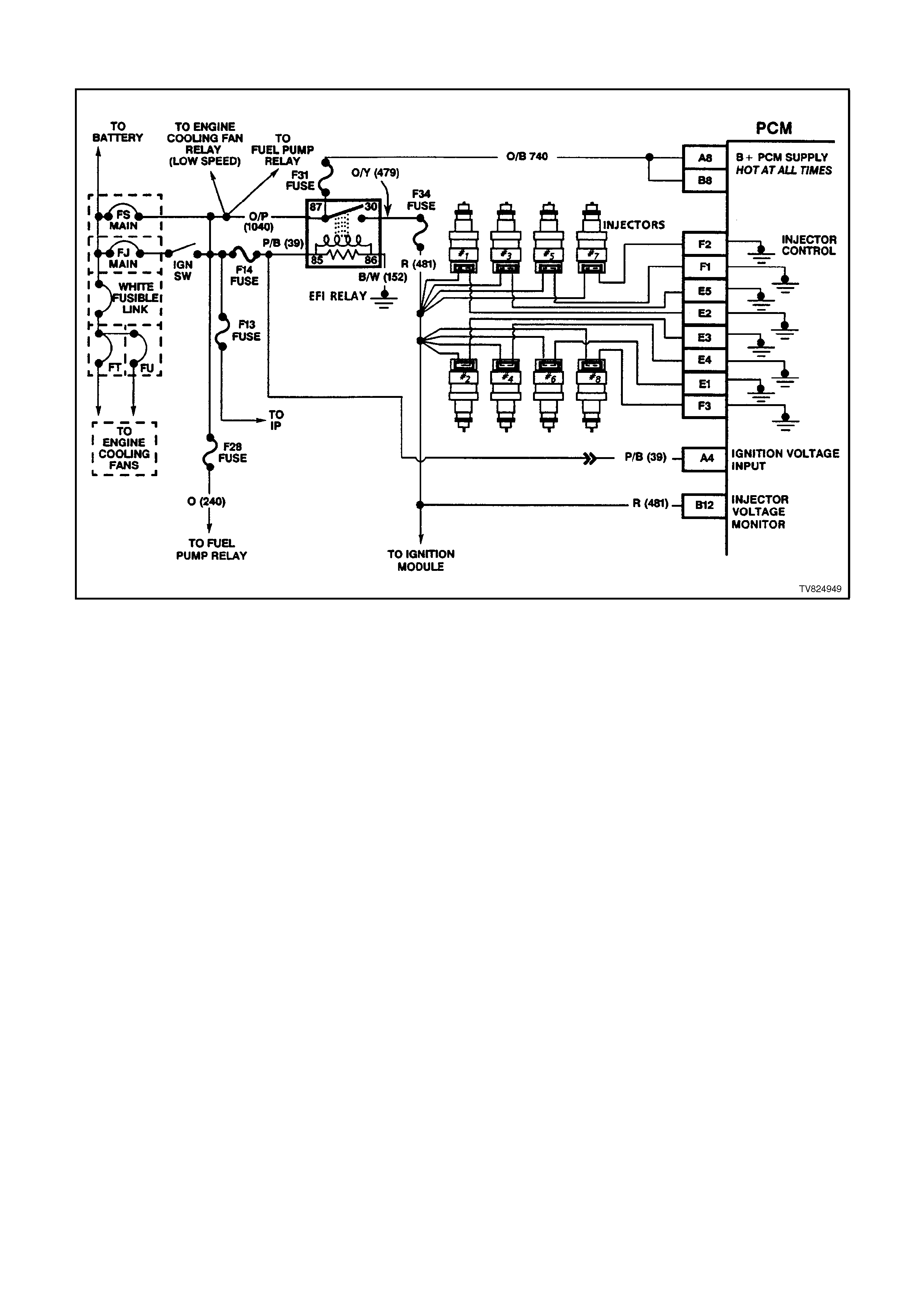

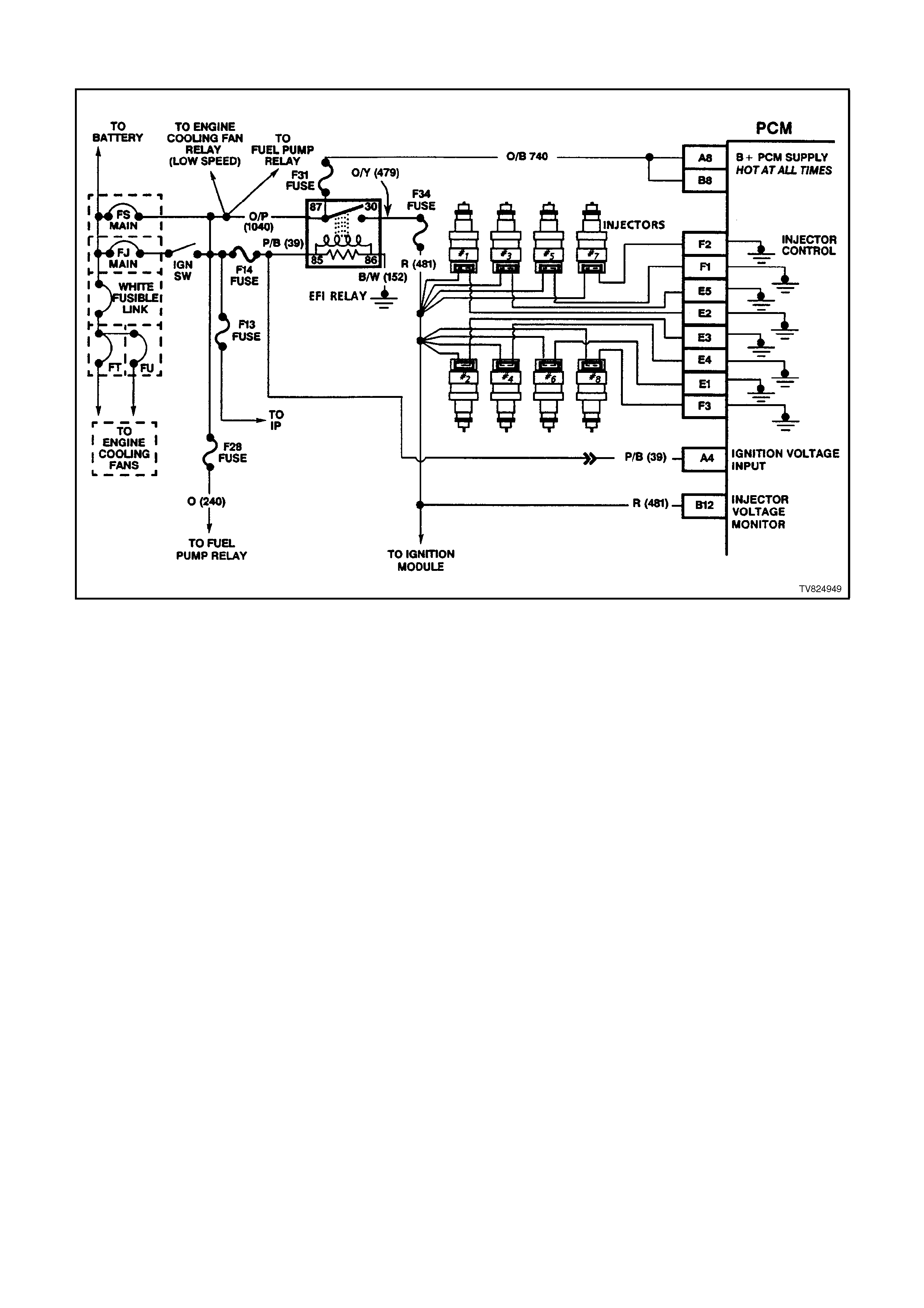

Figure 6C2-2A-4 PCM wiring diagram 1 of 8

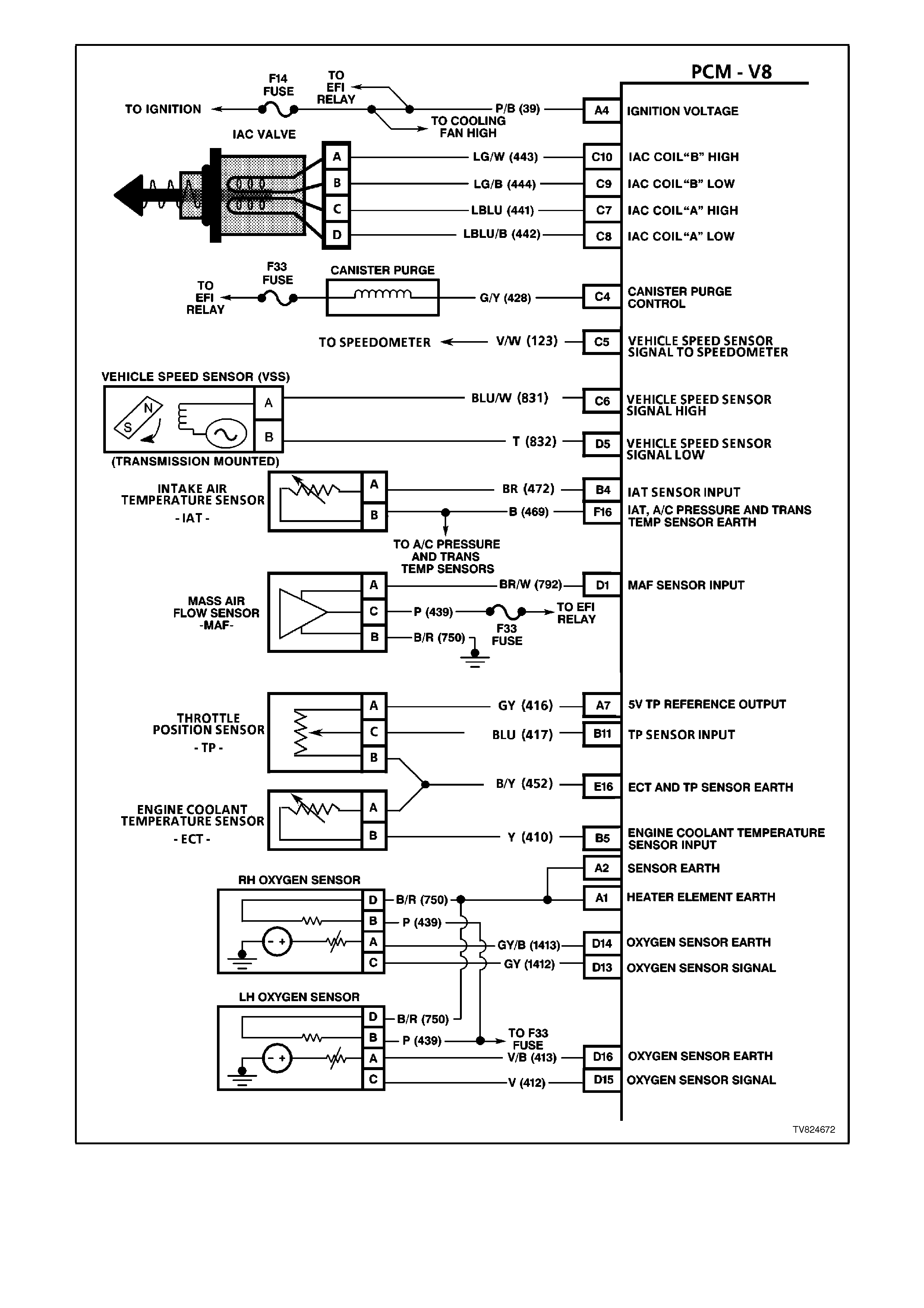

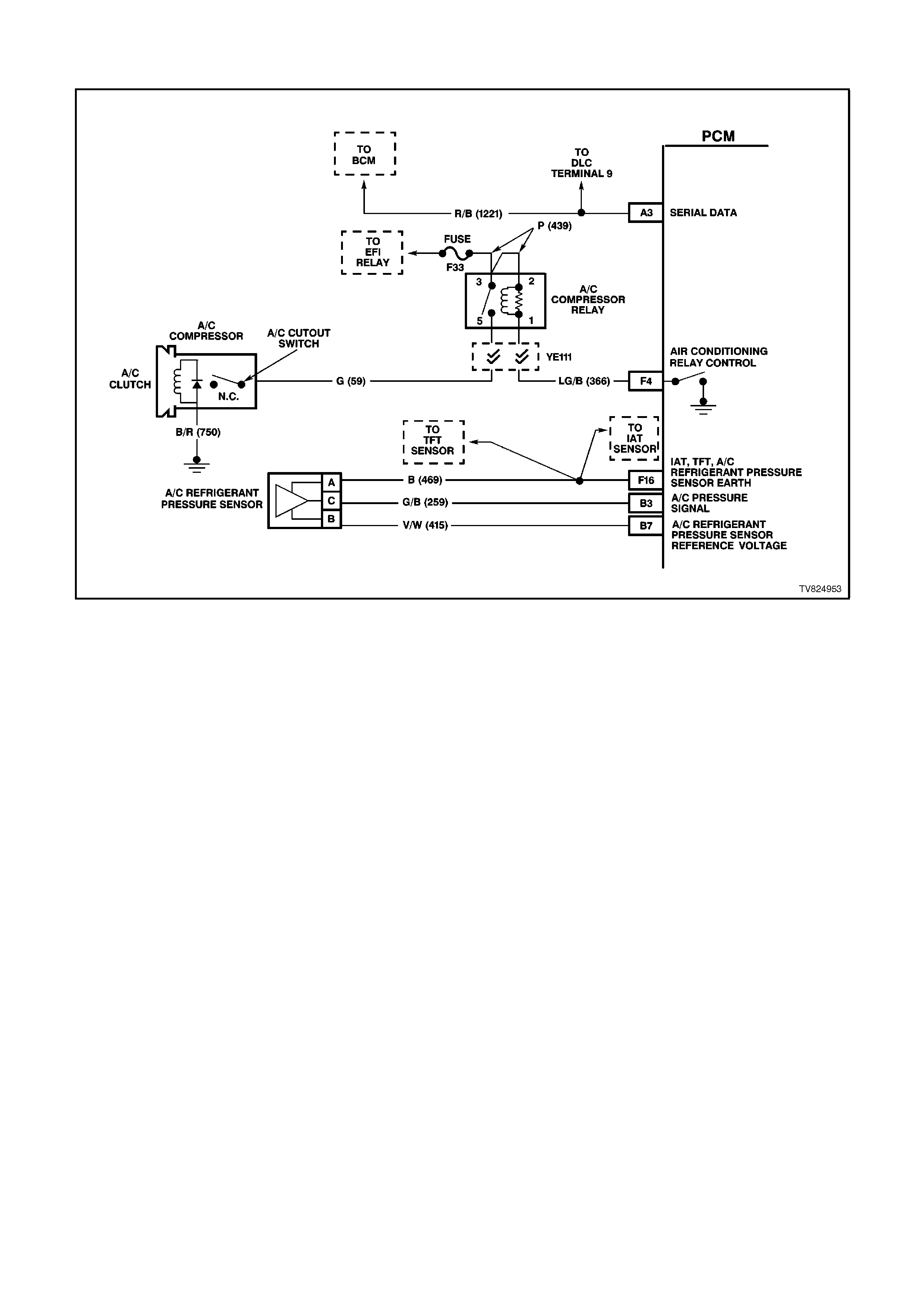

Figure 6C2-2A-5 PCM Wiring Diagram 2 of 8

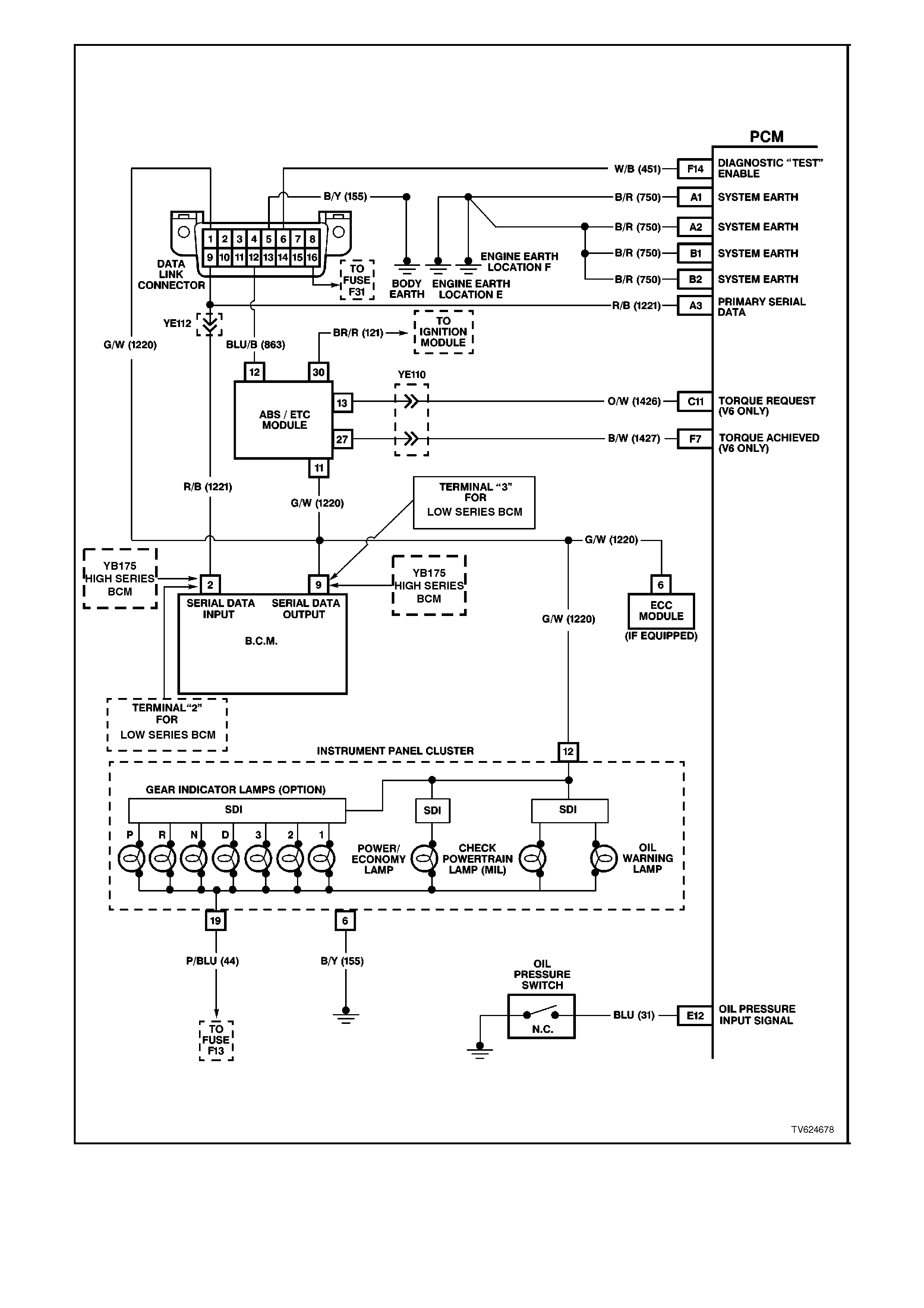

Figure 6C2-2A-6 PCM Wiring Diagram 3 of 8

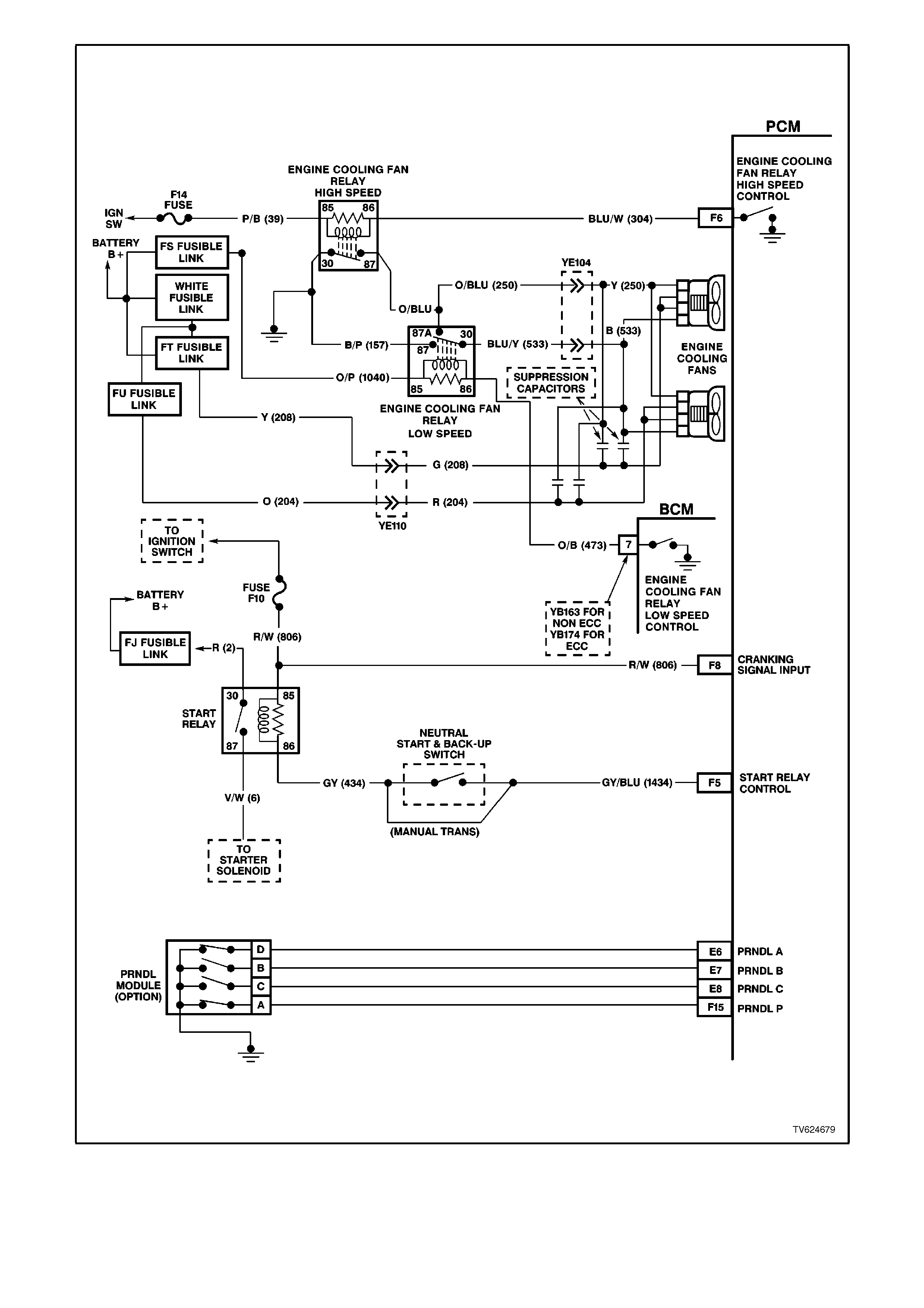

Figure 6C2-2A-7 PCM Wiring Diagram 4 of 8

Figure 6C2-2A-8 PCM Wiring Diagram 5 of 8

Figure 6C2-2A-9 PCM Wiring Diagram 6 of 8

Figure 6C2-2A-10 PCM Wiring Diagram 7 of 8

Figure 6C2-2A-11 PCM Wiring Diagram 8 of 8

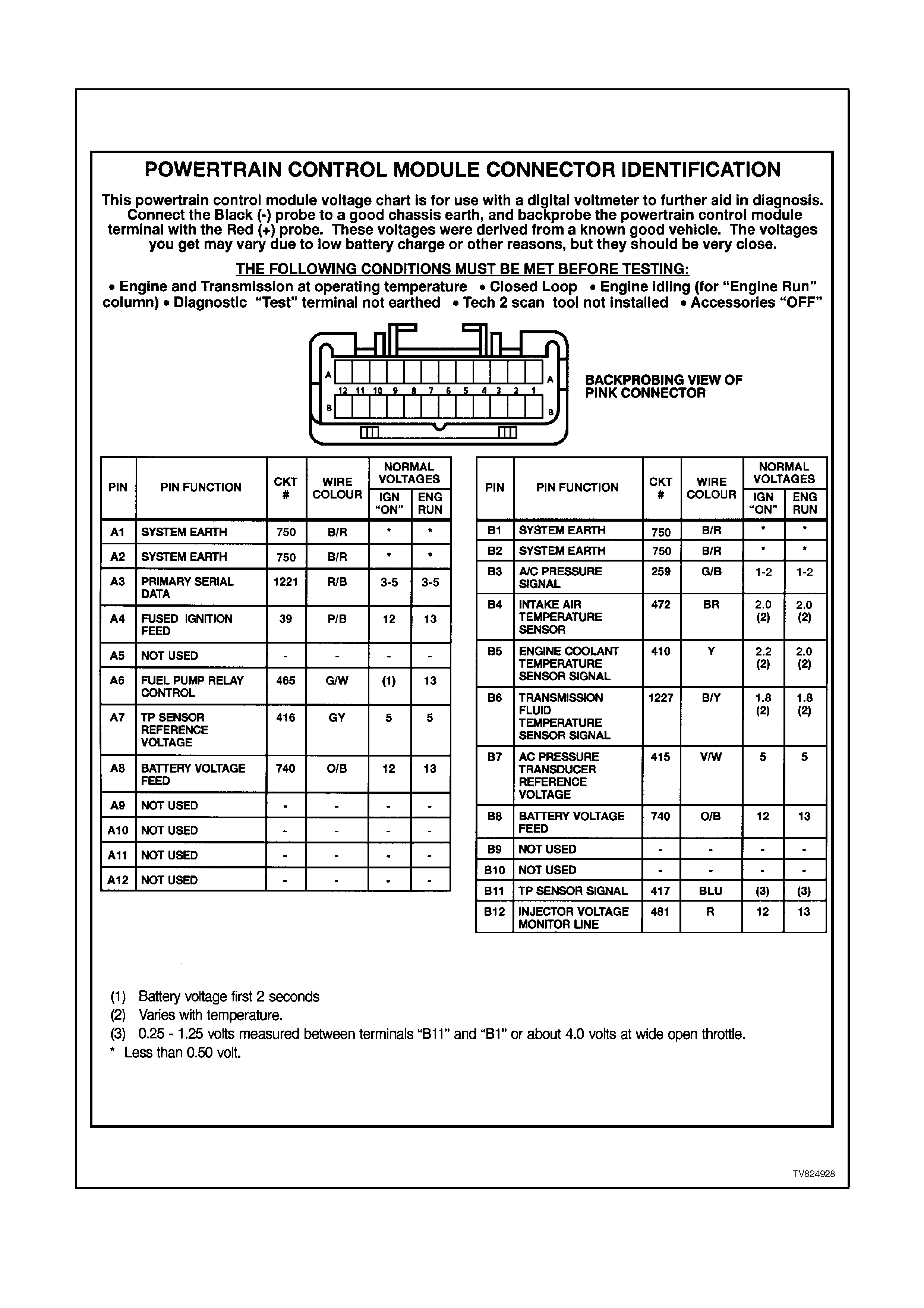

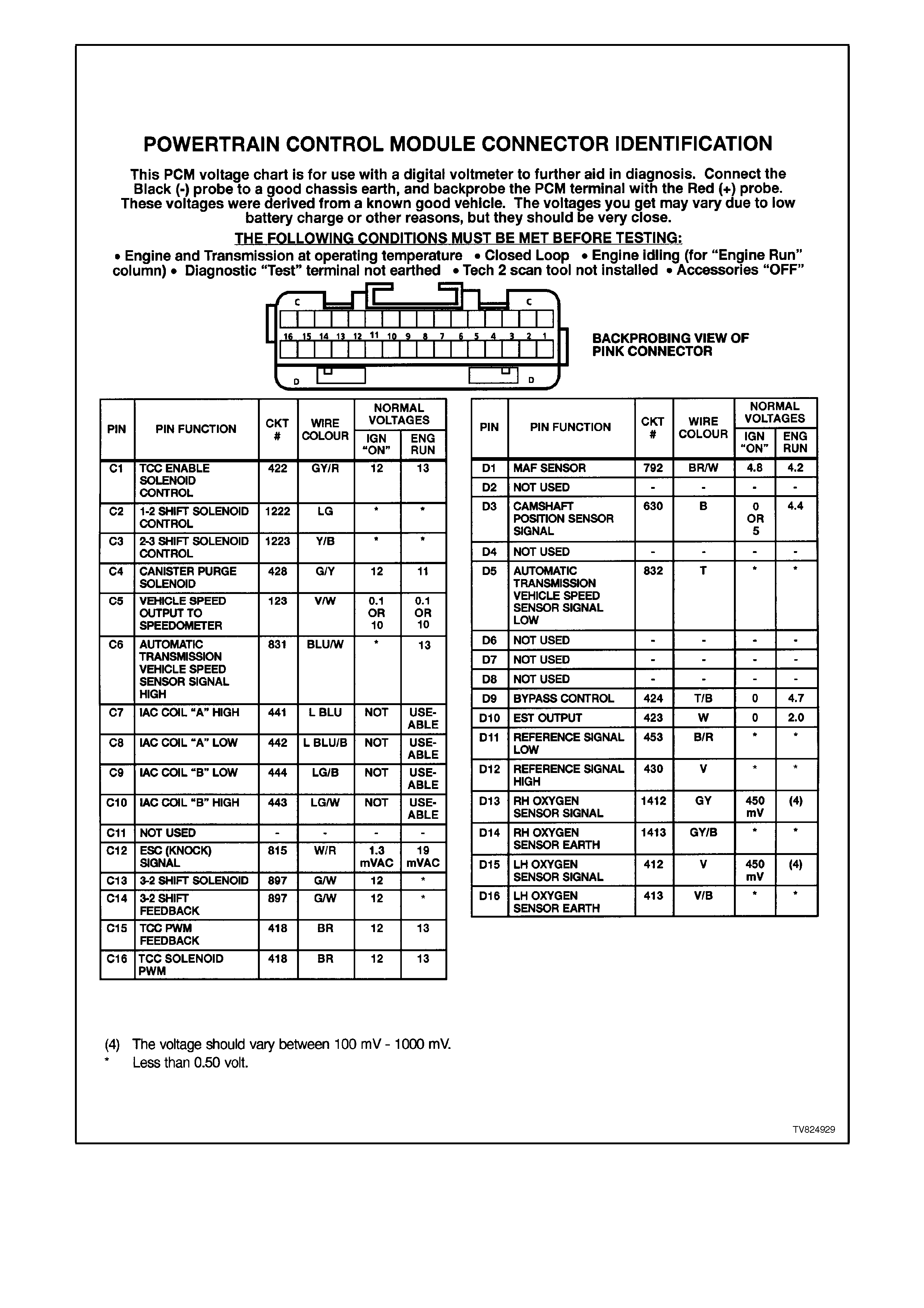

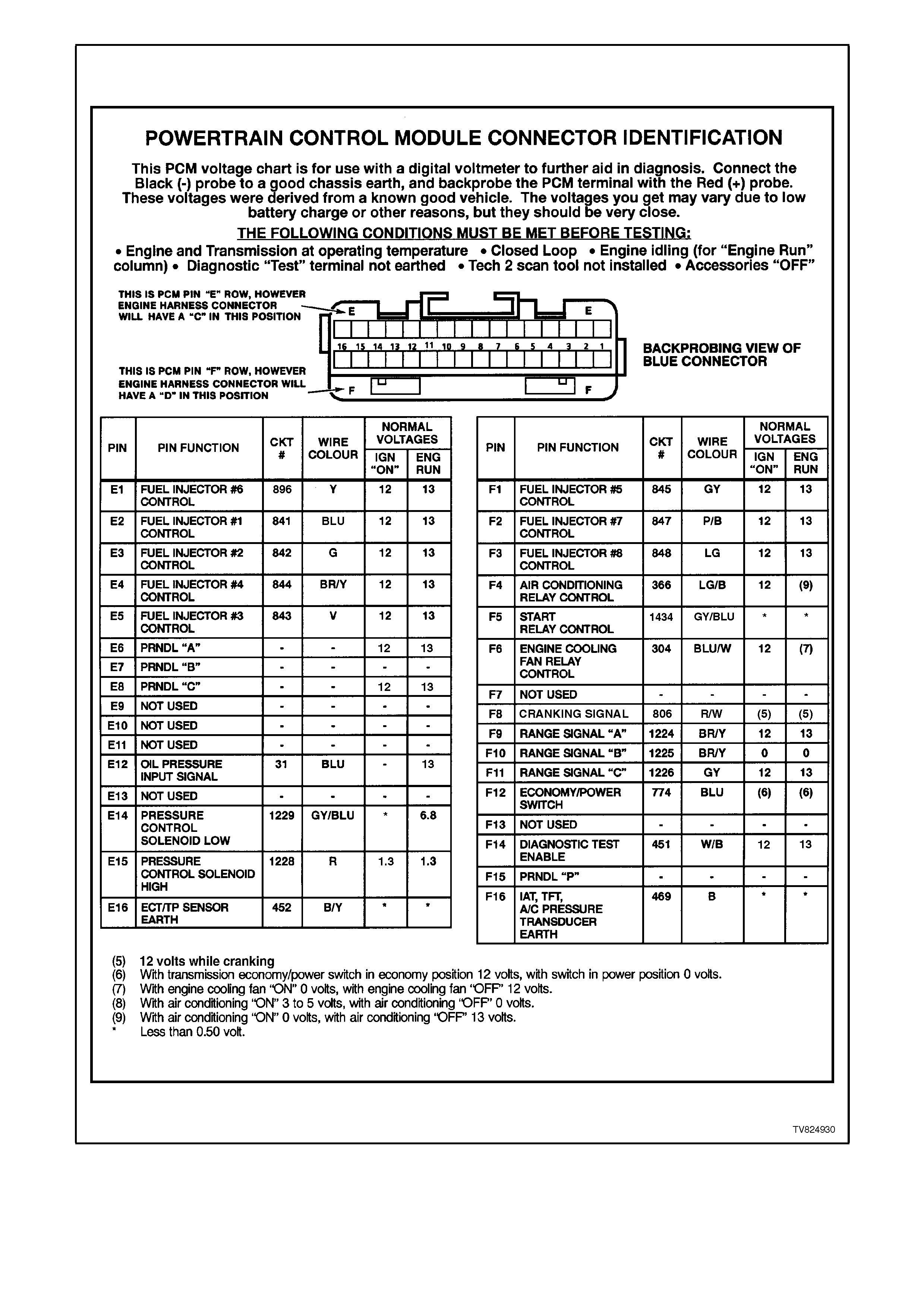

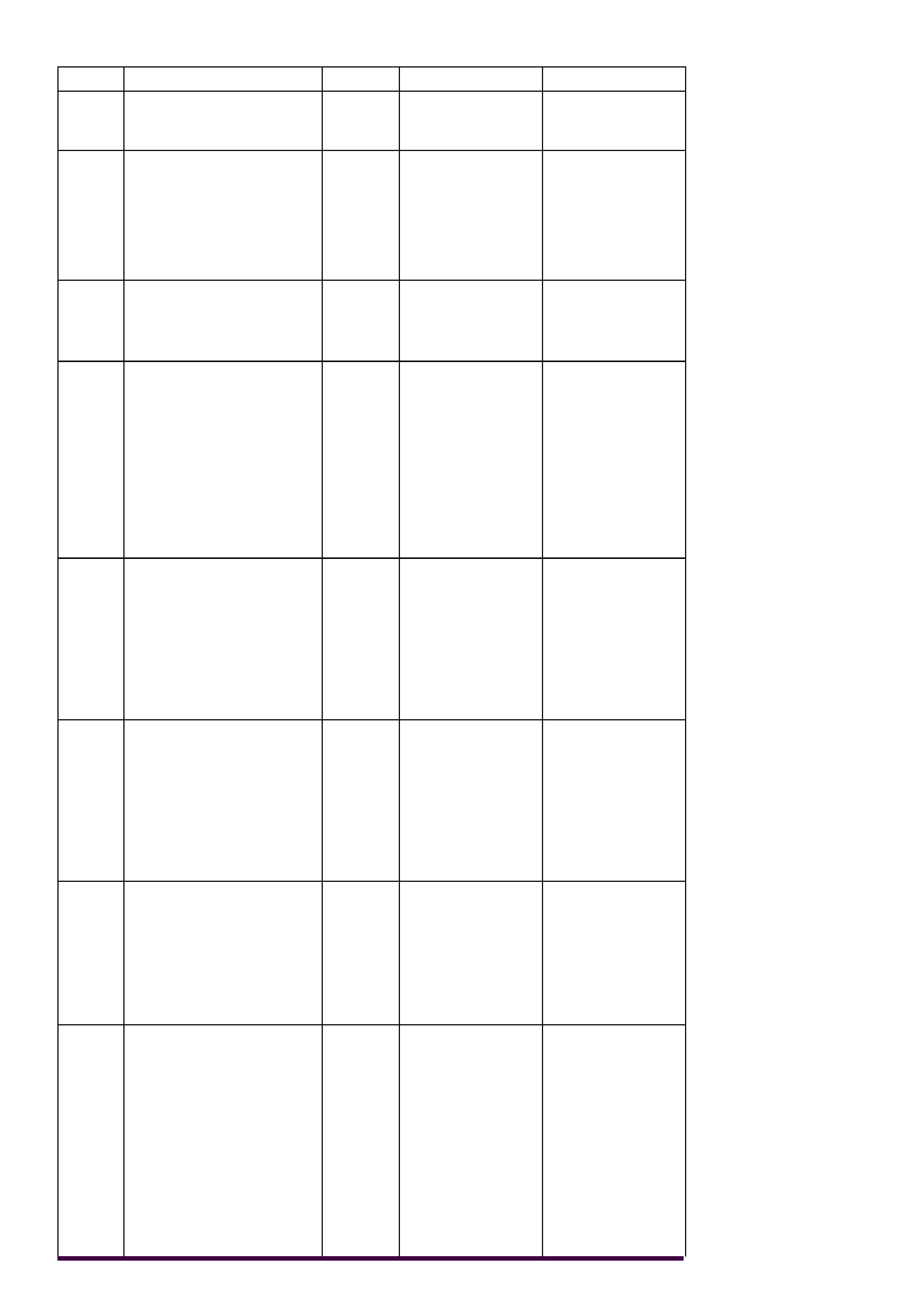

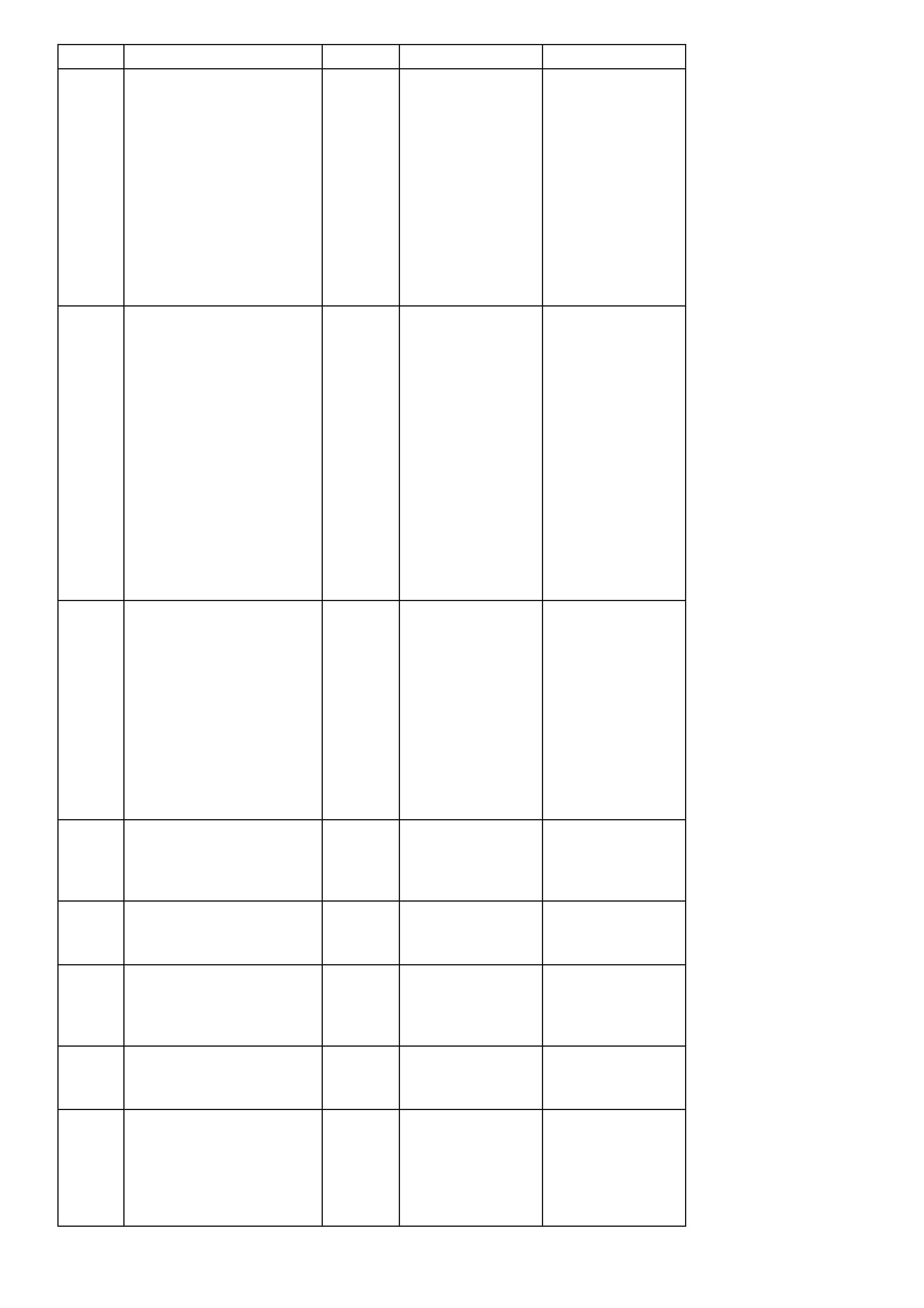

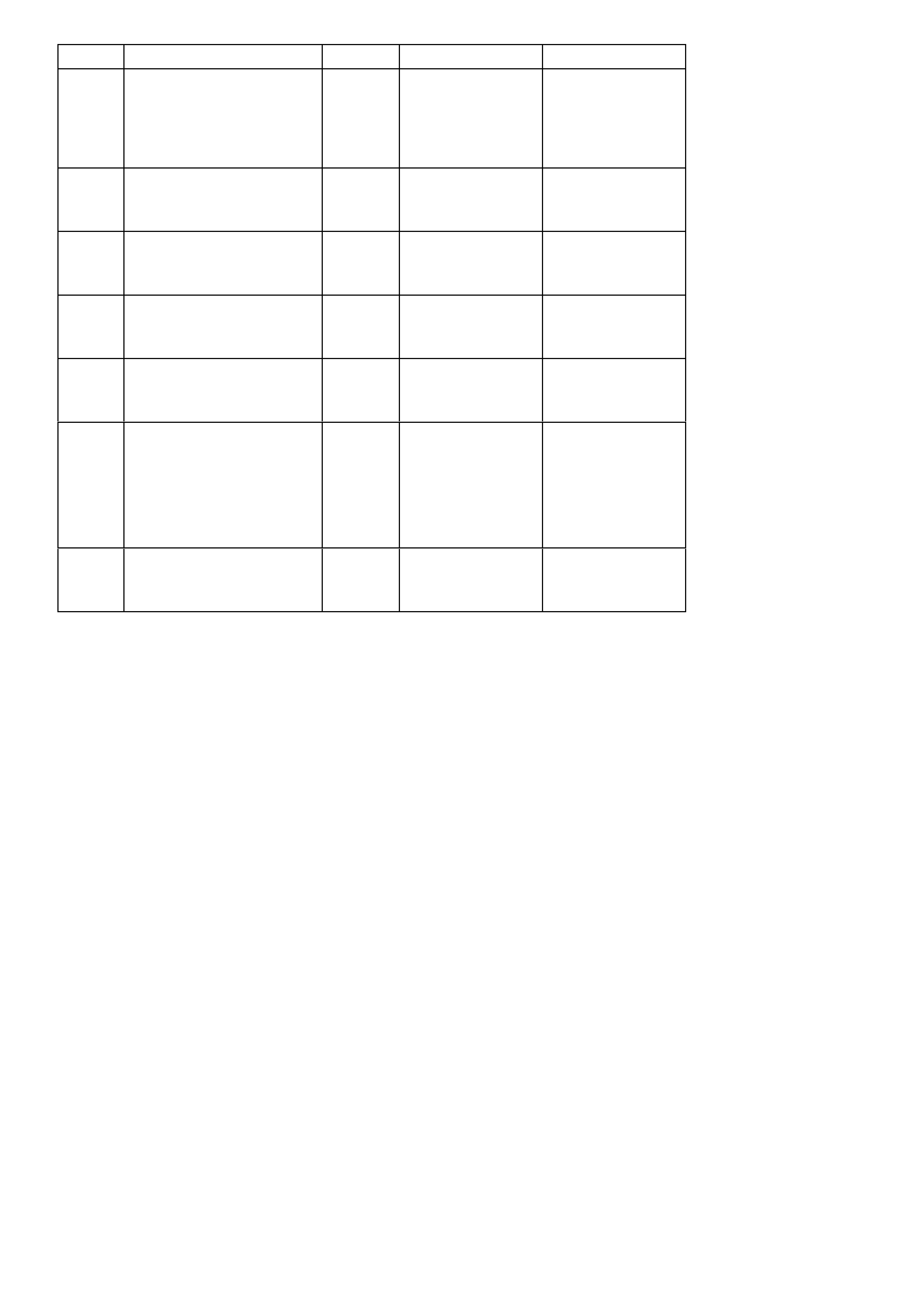

PCM CONNECTOR IDENTIFICATION AND VOLTAGES

Figure 6C2-2A-12 PCM Connector Identification and Voltages 1 of 3

Figure 6C2-2A-13 PCM Connector Identification and Voltages 2 of 3

Figure 6C2-2A-14 PCM Connector Identification and Voltage 3 of 3

PCM CONNECTOR TERMI NAL DEFINITIONS

PINS A1 - A12

A1 SYSTEM EARTH - This terminal should have zero volts. This circuit is connected directly to the engine earth.

A2 SYSTEM EARTH - This terminal should have zero volts. This circuit is connected directly to the engine earth.

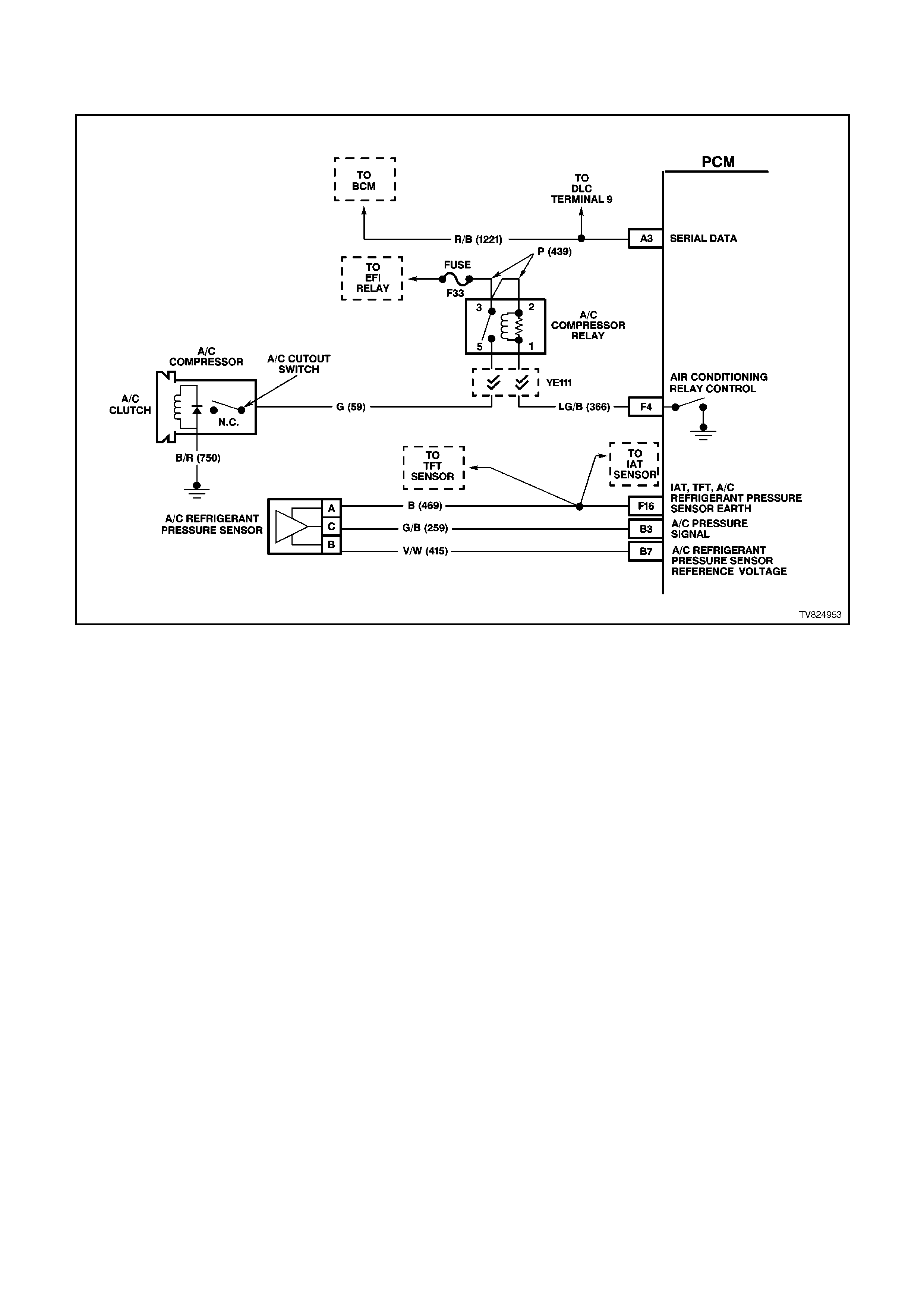

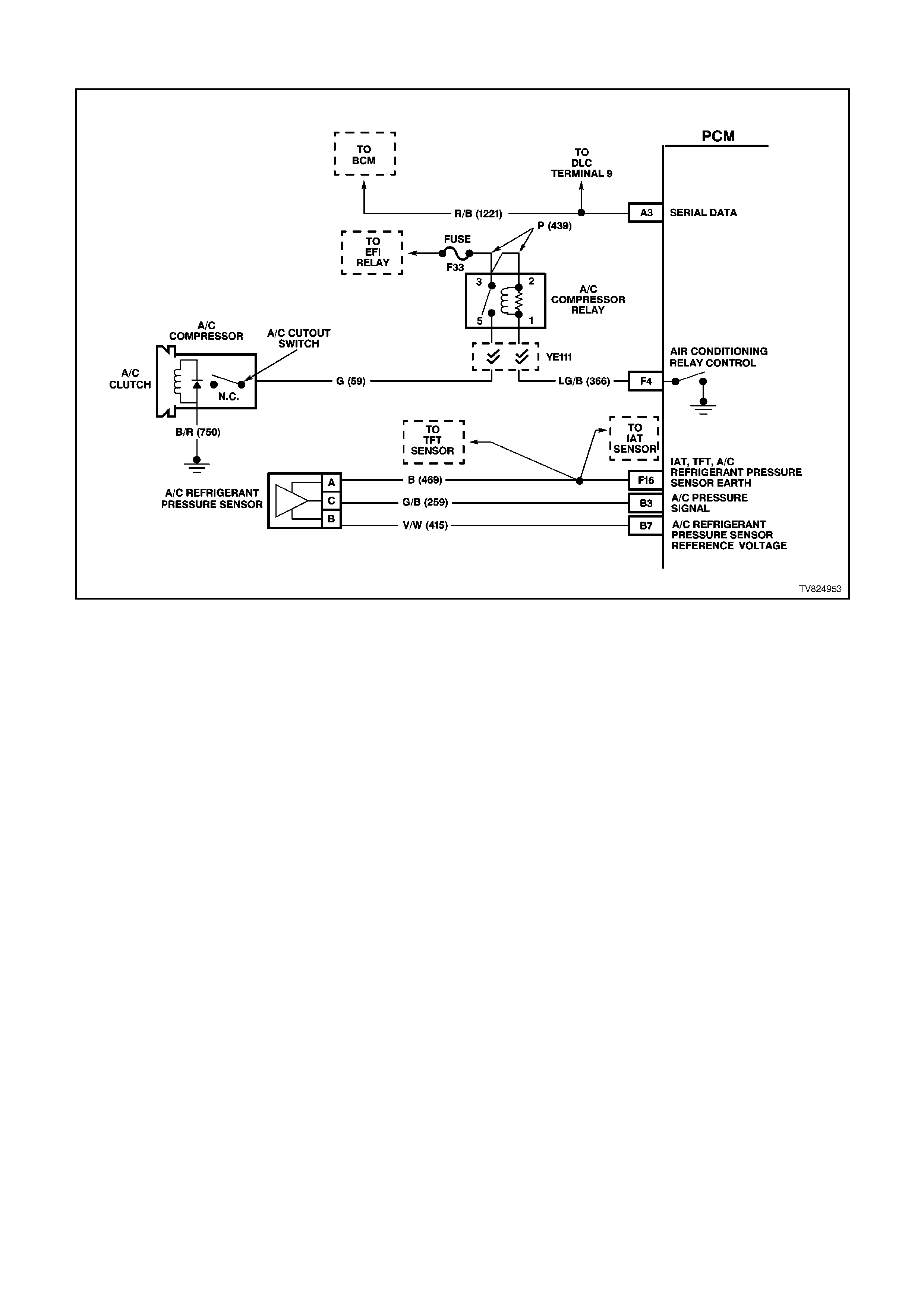

A3 SERIAL DATA - This is a dedicated line for the Tech 2 scan tool communications. The circuit connects the

PCM, the ABS and the BCM together. The Tech 2 scan tool communicates to these modules by sending a

message to the module and requesting the module to respond. The normal voltage on this circuit is about 5

volts. When the Tech 2 scan tool is communicating with a module the voltage will be around 2.5V.

A4 IGNITION FEED - This is the ON signal to the PCM from the ignition switch circuit. The ignition feed is not the

"power supply" to the PCM. The ignition feed only tells the PCM that the ignition switch is "ON." The voltage

should be equal to the battery voltage when the key is in either the "run" or the "crank" position.

A5 NOT USED

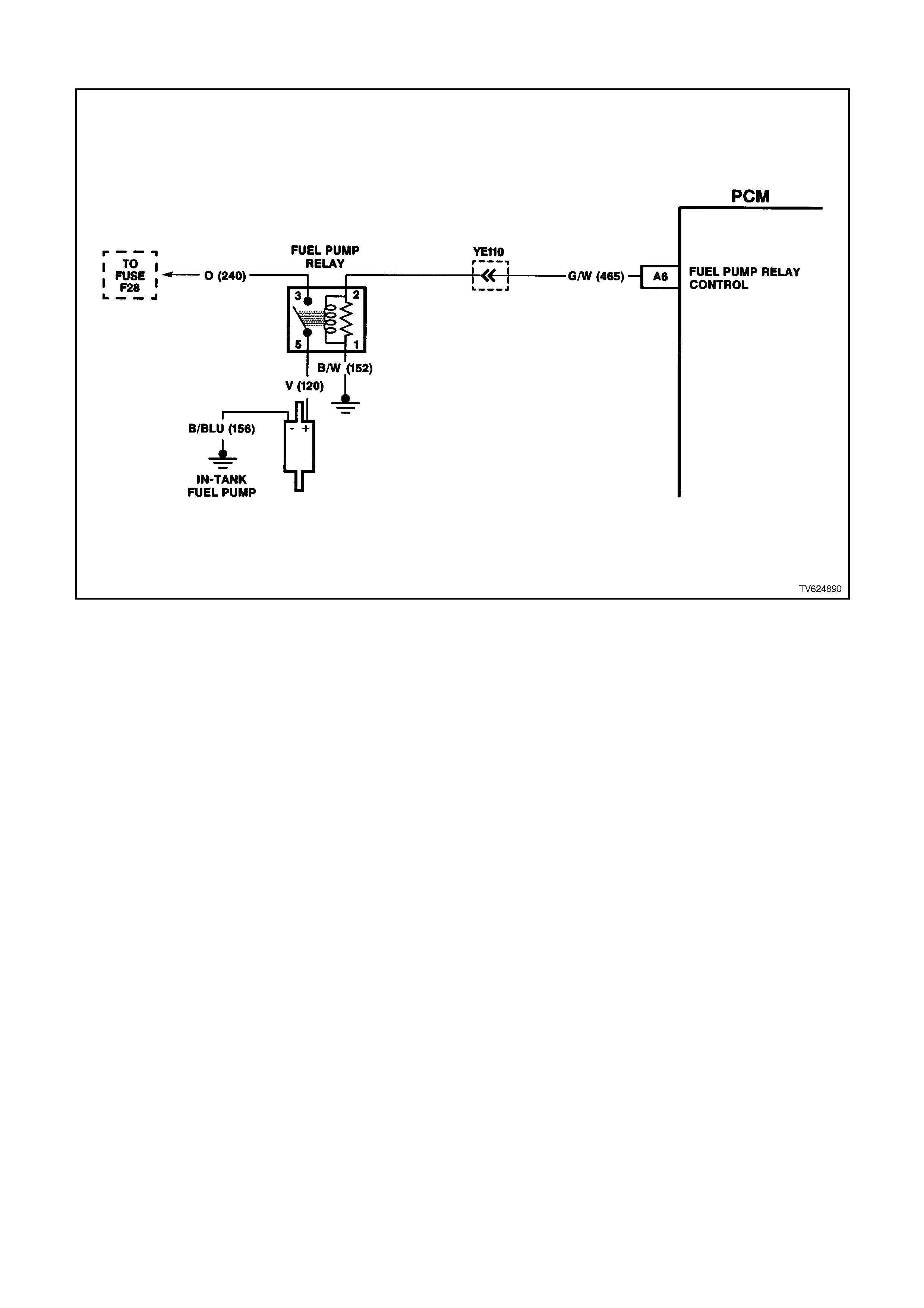

A6 FUEL PUMP RELAY CONTROL - Whenever the ignition is turned ON the PCM energises the fuel pump

relay. If no crankshaft reference input pulses are received, the PCM turns OFF the relay. As soon as the PCM

receives crankshaft reference pulses, the PCM will turn the fuel pump relay back on.

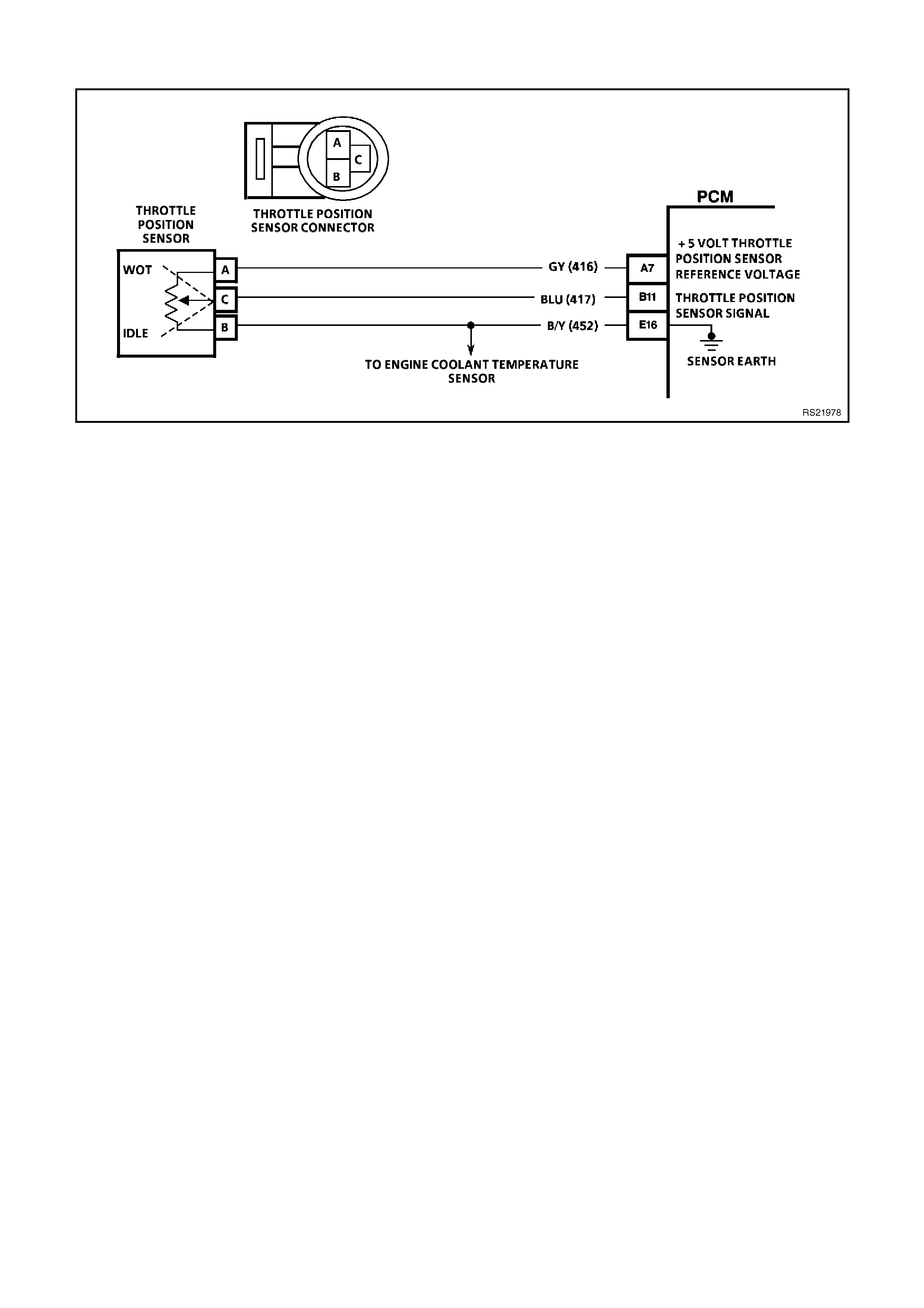

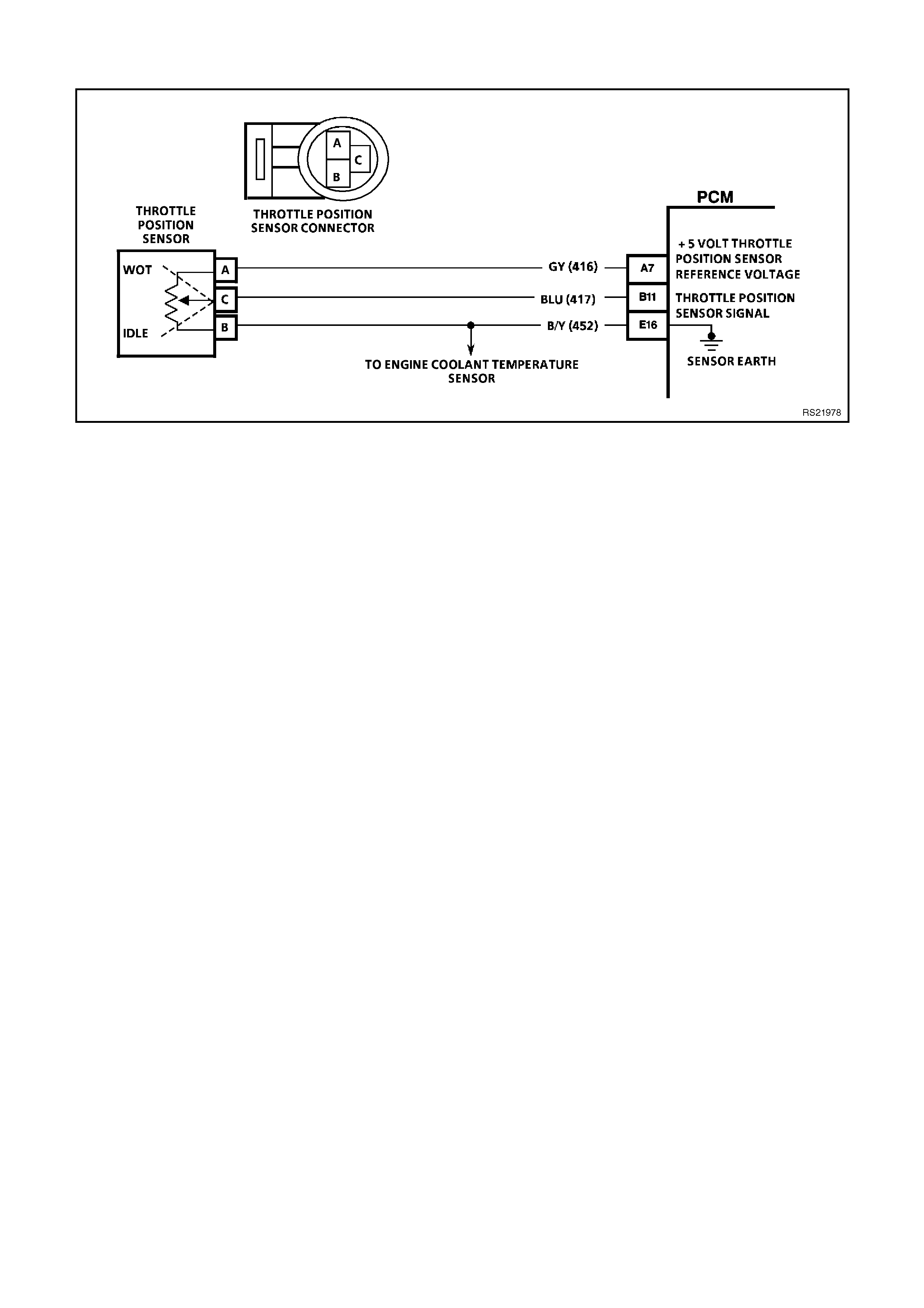

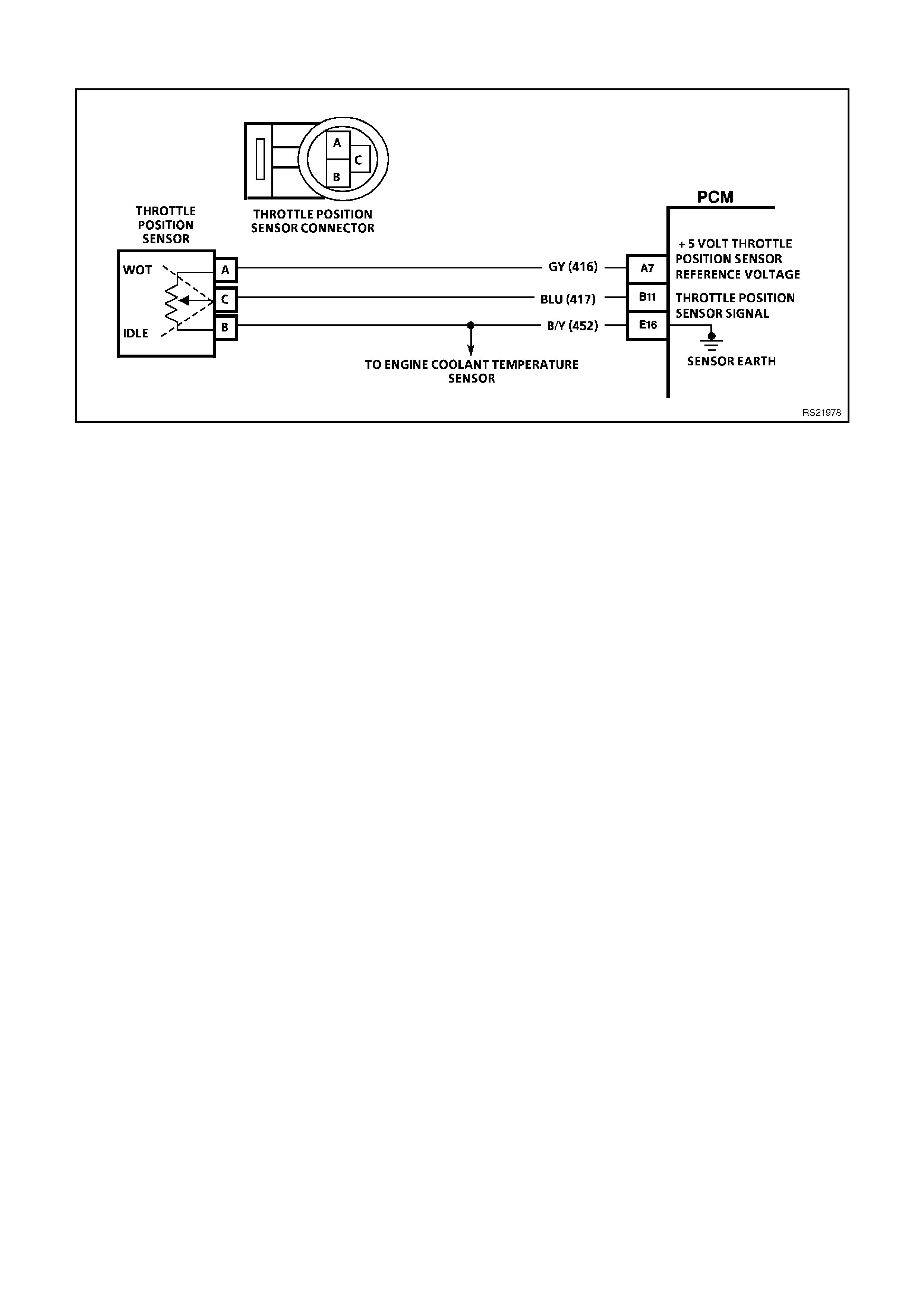

A7 TP SENSOR 5V REFERENCE VOLTAGE - This voltage should always be 5 volts whenever the ignition is

"ON." The reference voltage is a regulated voltage from the PCM, and supplies 5 volts to the TP sensor.

A8 BATTERY VOLTAGE FEED - This supplies the PCM with full-time B+ volts. This circuit stays hot even when

the ignition is turned off. The battery voltage feed circuit receives it's voltage from the ENGINE fuse circuit.

A9 NOT USED

A10 NOT USED

A11 NOT USED

A12 NOT USED

PINS B1 - B12

B1 SYSTEM EARTH - This terminal should have zero volts. This terminal is connected directly to the engine

earth.

B2 SYSTEM EARTH - This terminal should have zero volts. The terminal is connected directly to the engine earth.

B3 A/C PRESSURE TRANSDUCER INPUT SIGNAL - The signal that is sent from the pressure transducer to the

PCM indicates to the PCM what the A/C pressure is. Depending on the A/C pressure, this signal will indicate

to the PCM if the A/C pressure is to low or to high.

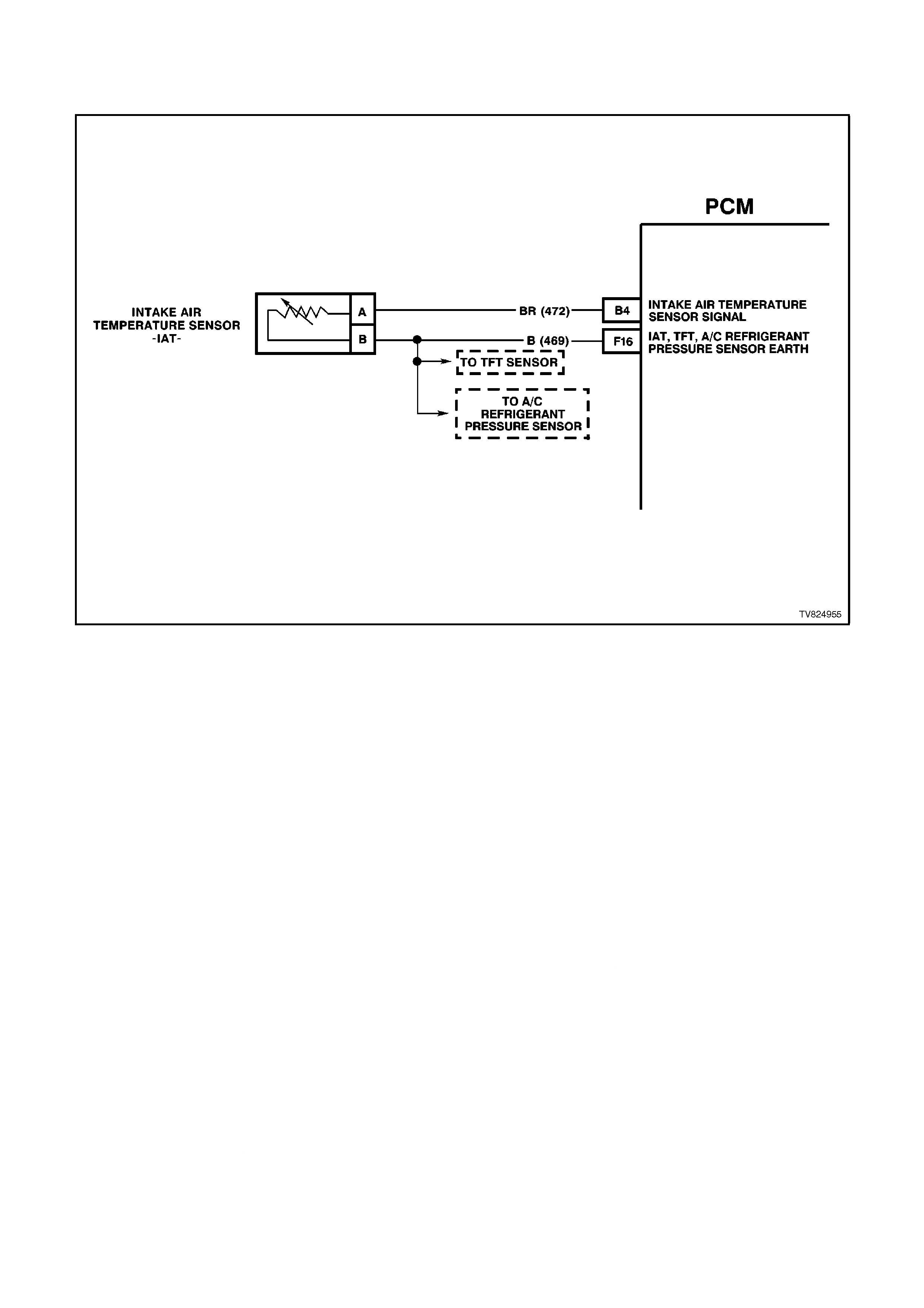

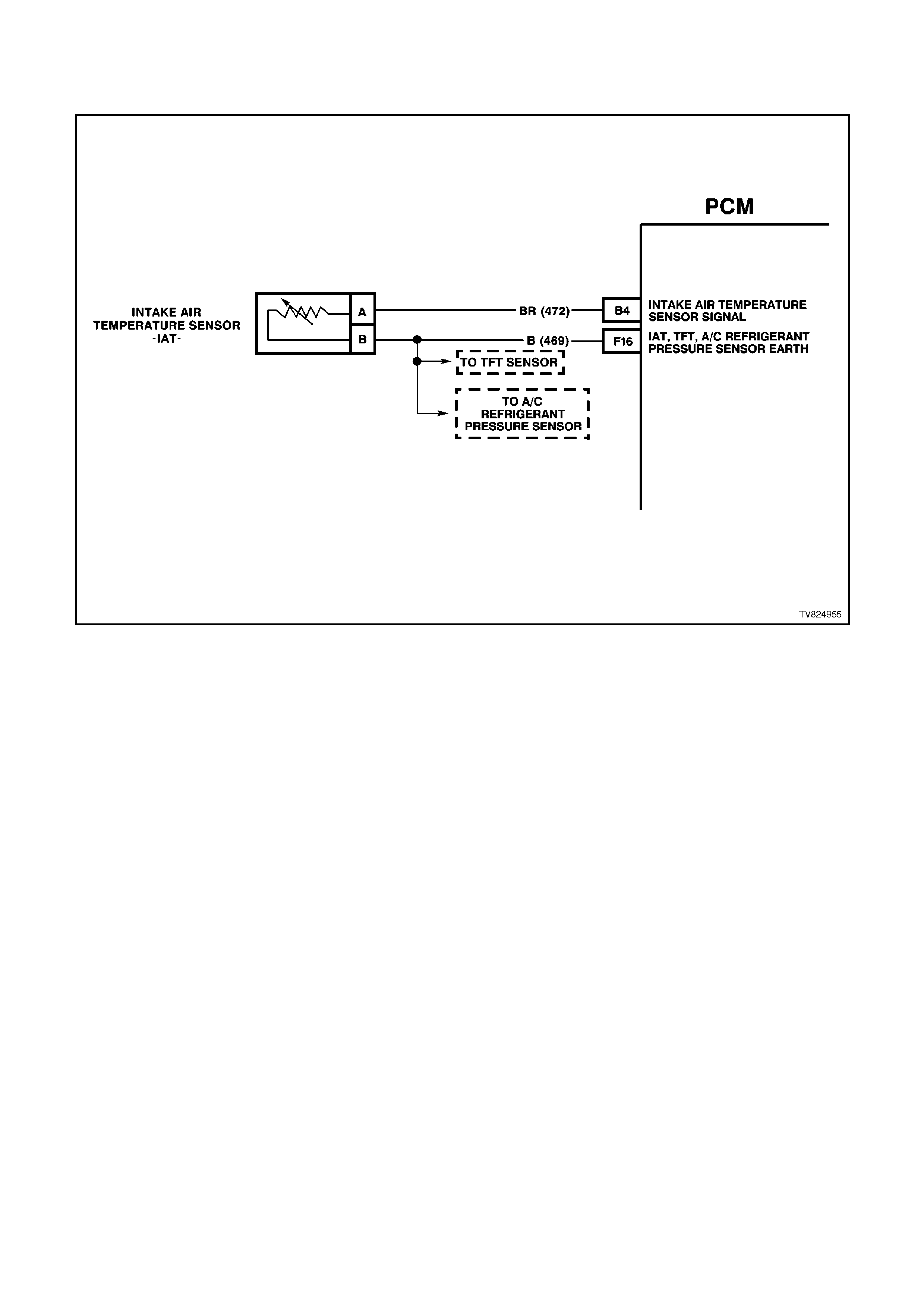

B4 IAT SENSOR SIGNAL INPUT - The PCM sends a 5 volt reference to the IAT sensor. The sensor is connected

to earth. The signal voltage will vary according to incoming air temperature.

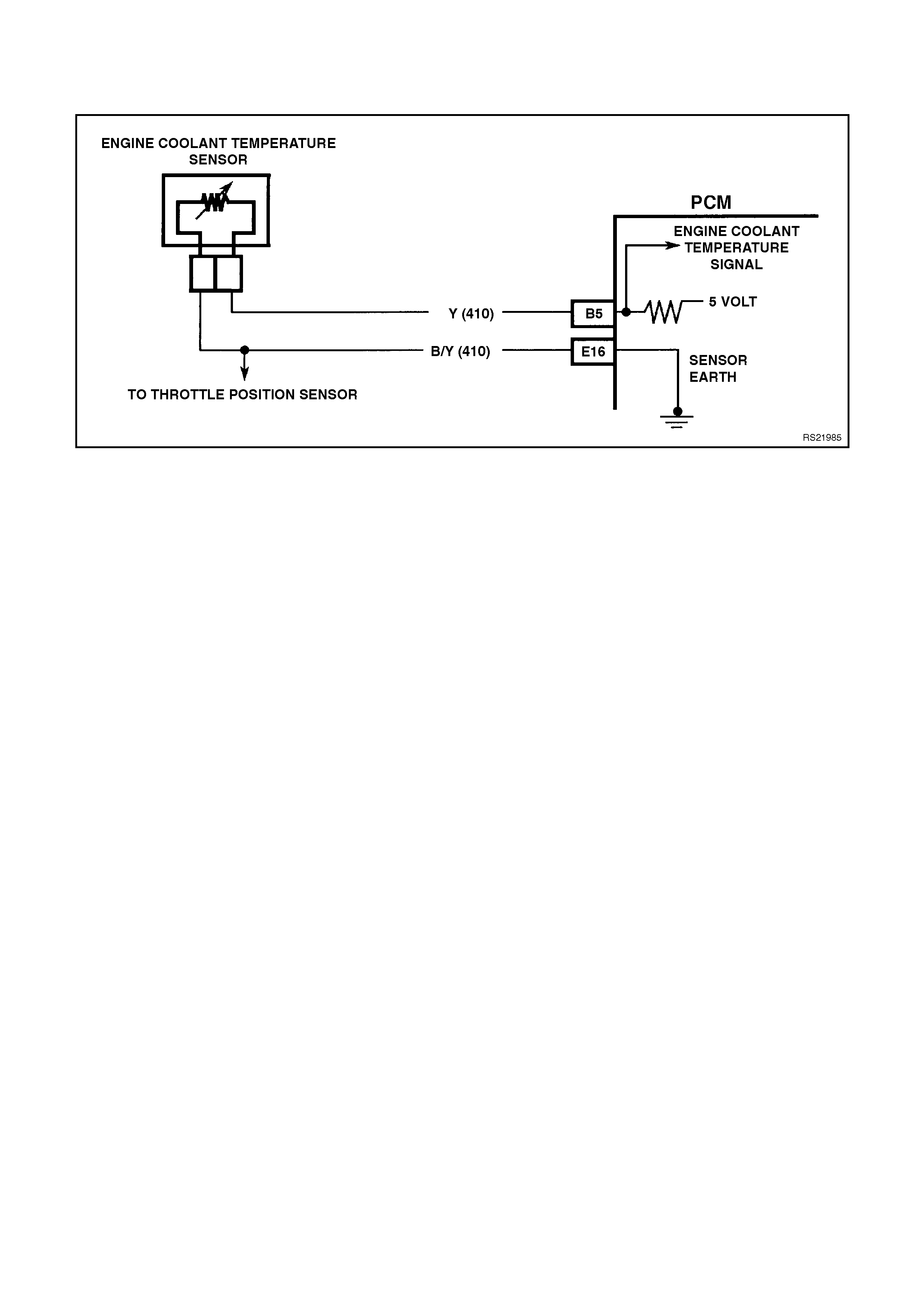

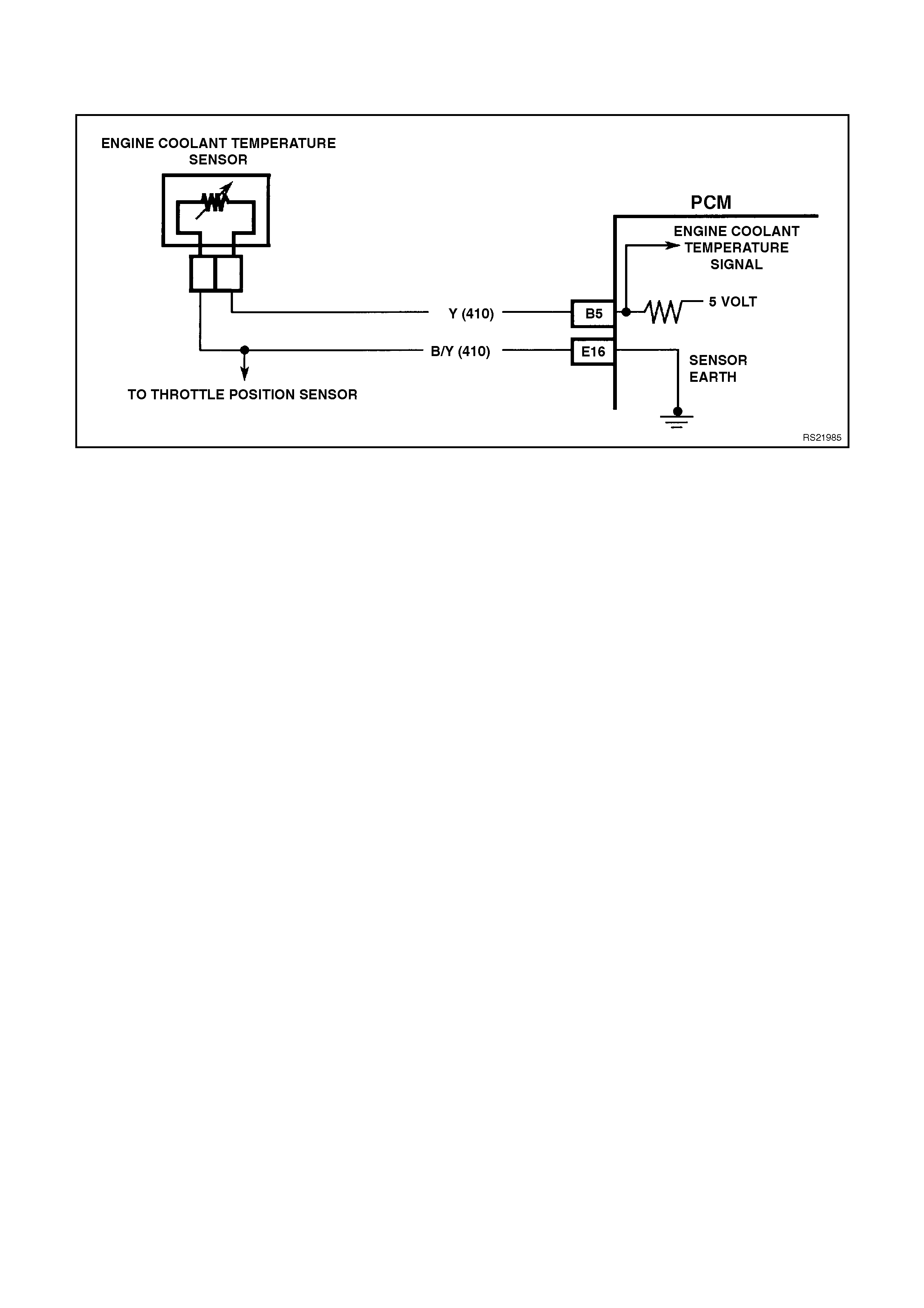

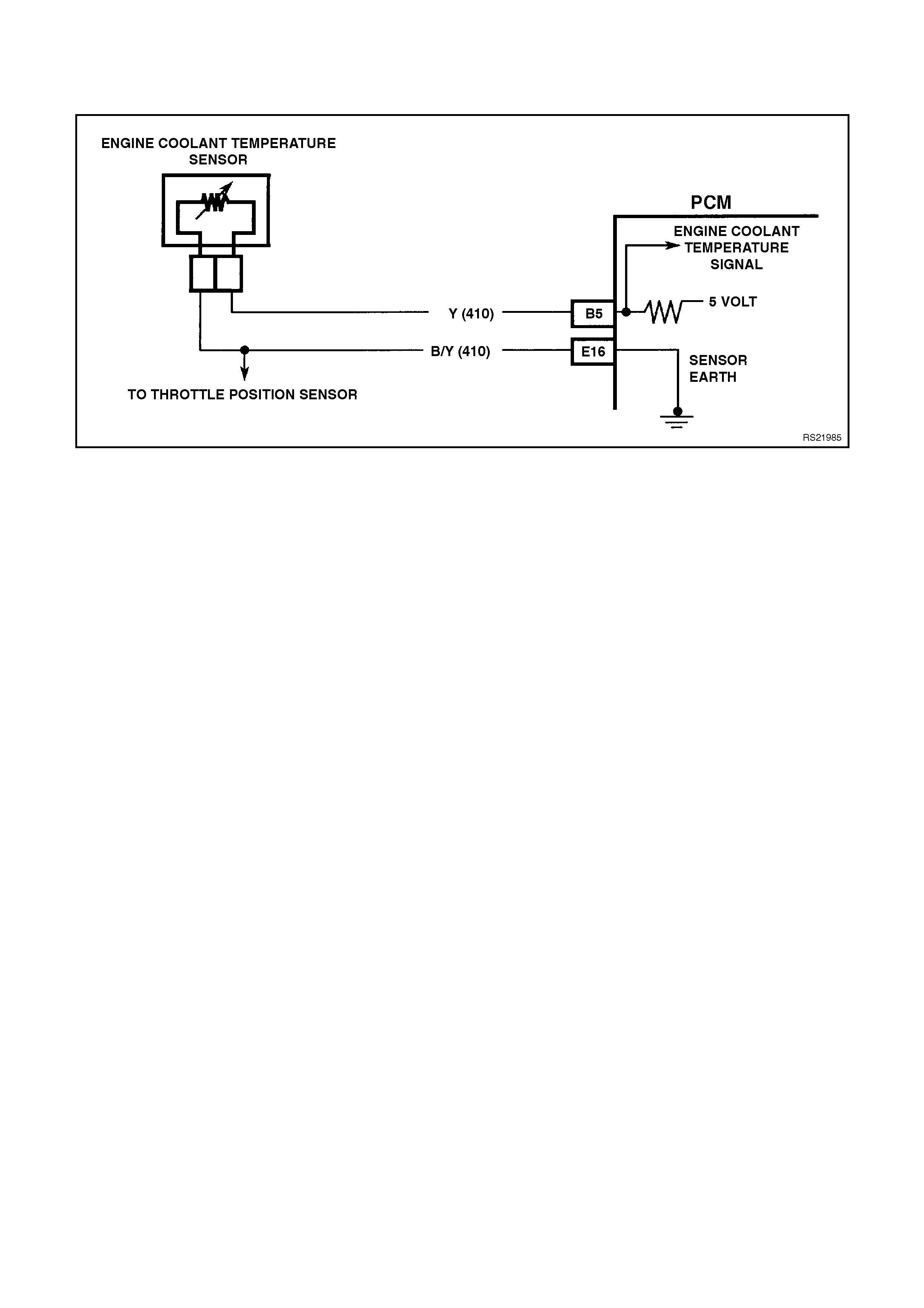

B5 ENGINE COOLANT TEMPERATURE SENSOR SIGNAL INPUT - The PCM sends a 5 volt signal voltage to

the engine coolant temperature sensor. The ECT sensor is also connected to earth. The voltage will vary with

engine coolant temperatures.

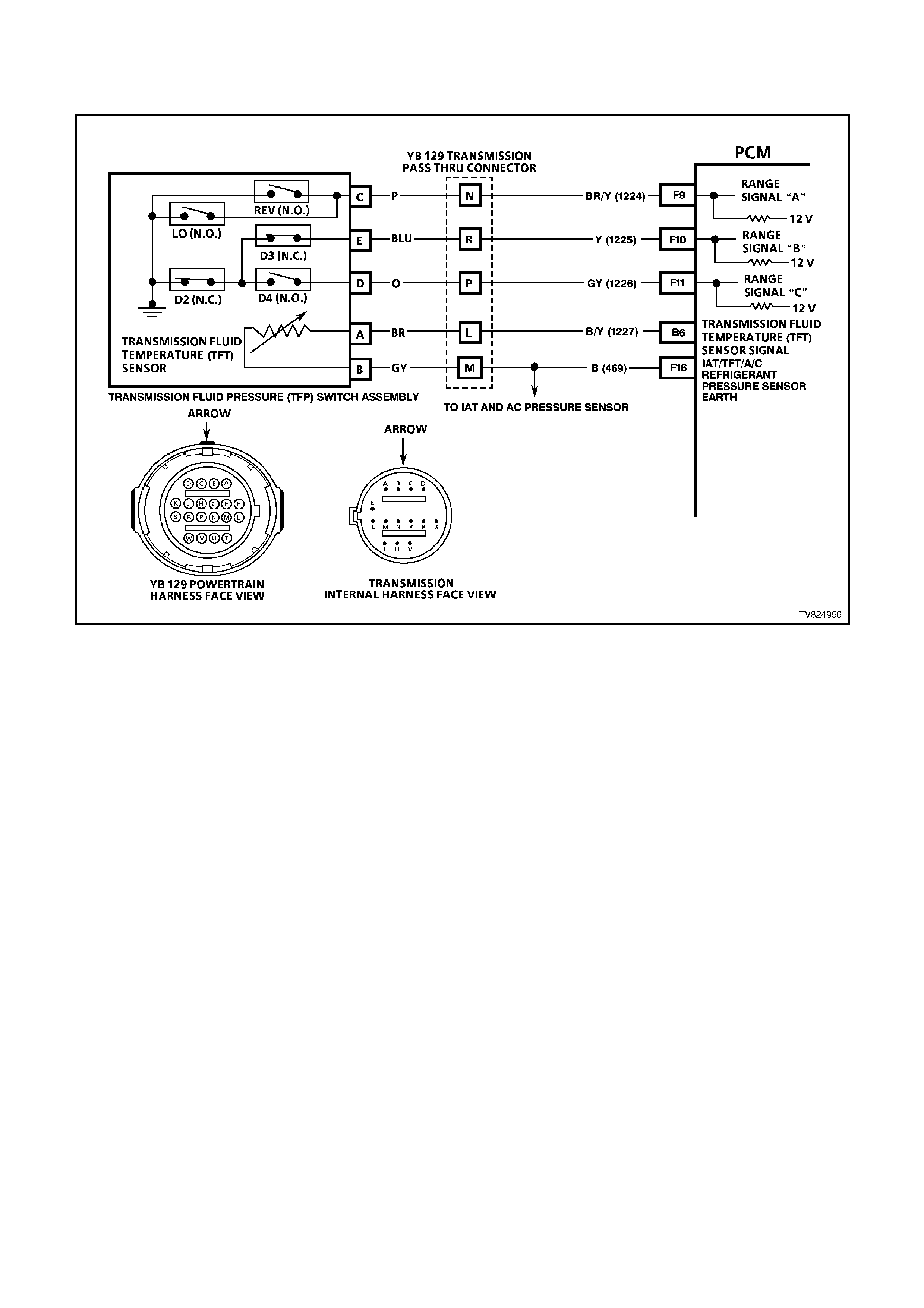

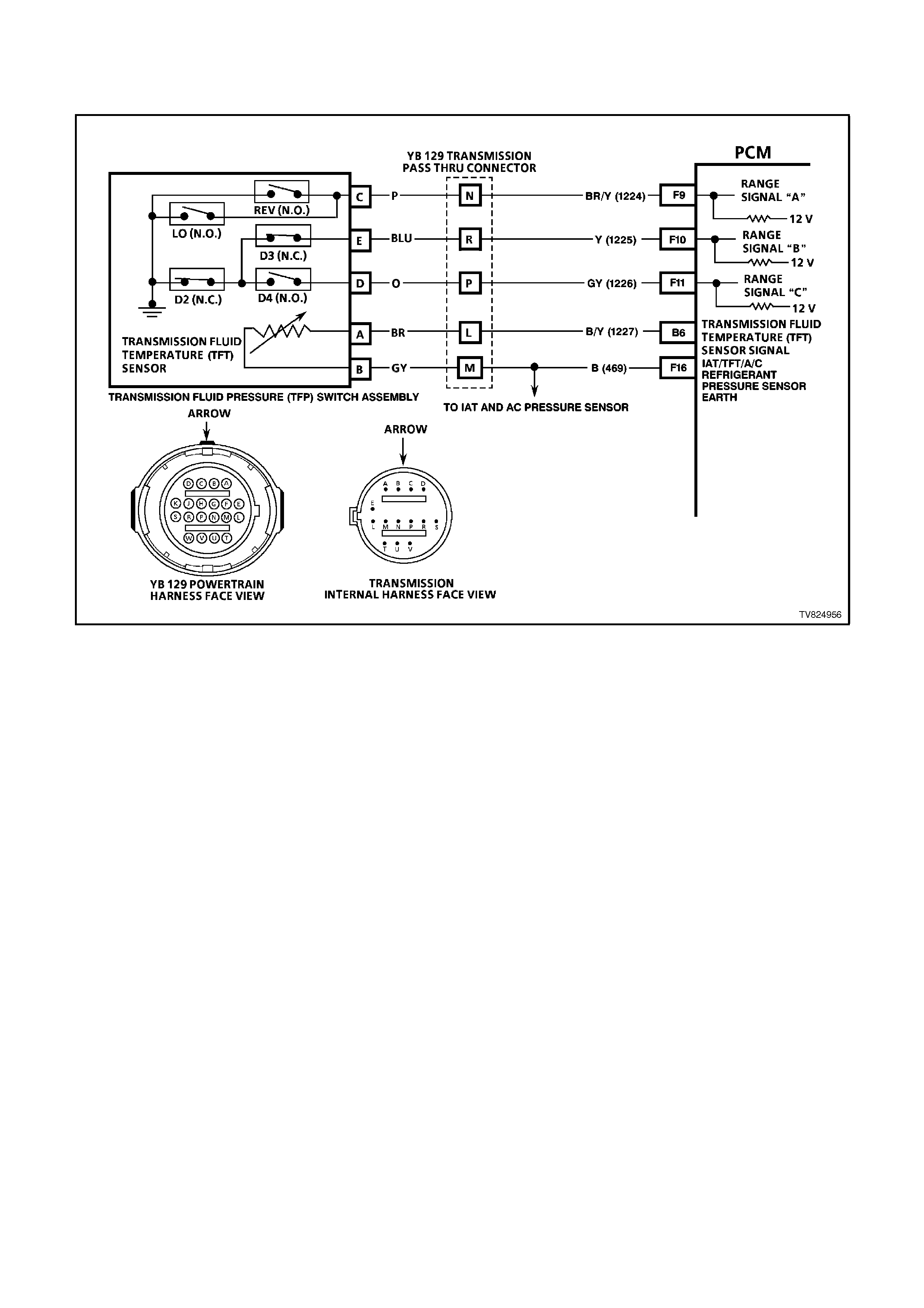

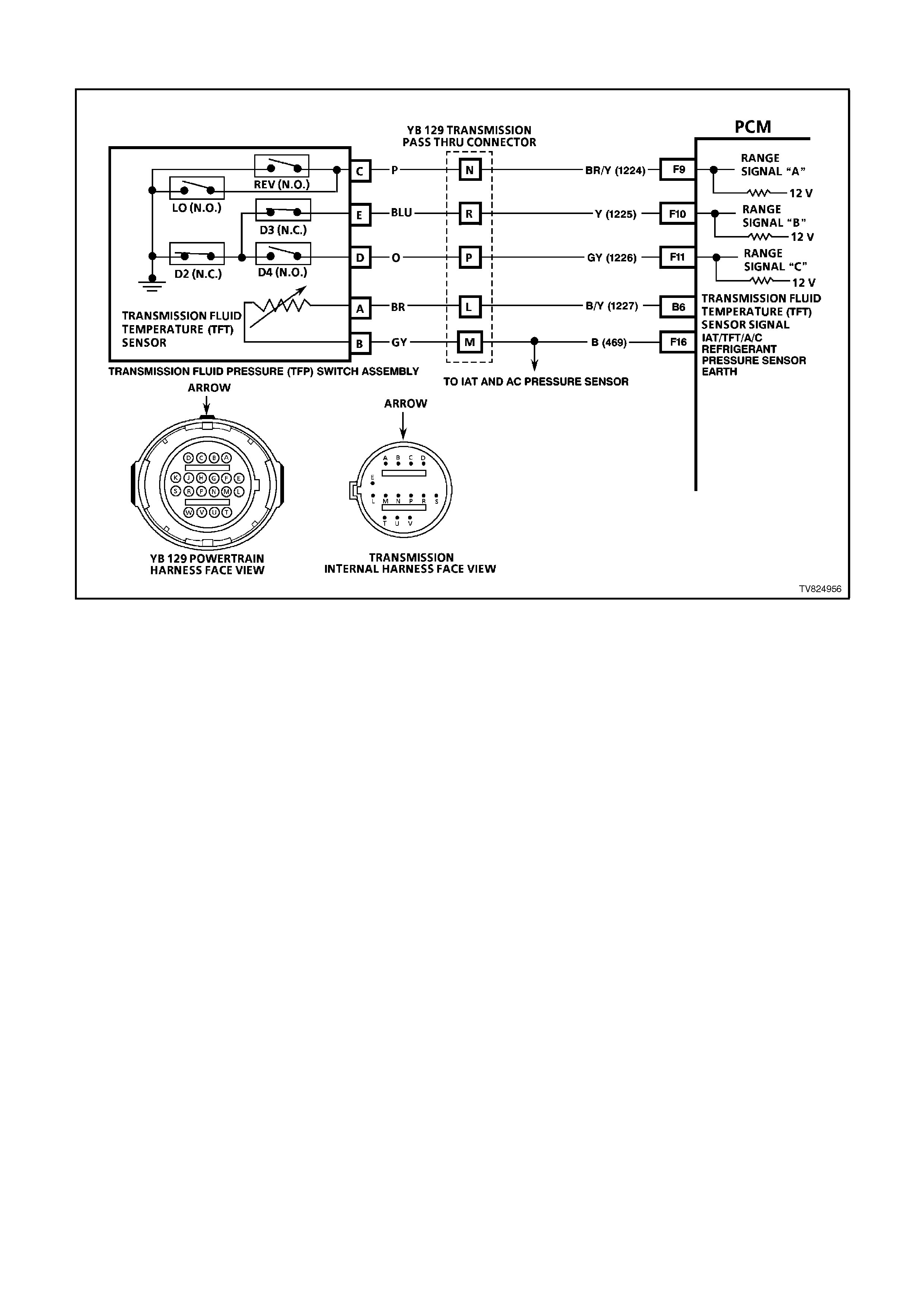

B6 TRANSMISSION FLUID TEMPERATURE (TFT) SENSOR SIGNAL - The PCM sends out a 5 volt signal

voltage to the transmission fluid temperature sensor. The sensor, being also connected to earth, will cycle the

voltage according to transmission fluid temperature. As the fluid temperature increases, the voltage seen on

terminal D15 will decrease.

B7 A/C SENSOR 5V REFERENCE VOLTAGE - This voltage should always be 5 volts whenever the ignition is

ON. It is a regulated voltage output from the PCM, and supplies 5 volts to the A/C sensor.

B8 BATTERY VOLTAGE FEED - This supplies the PCM with full time B+. This circuit stays hot even when the

ignition is turned off. It receives its voltage from the "ENGINE" fuse circuit.

B9 B10 - NOT USED

B11 TP SENSOR SIGNAL INPUT - The TP Sensor input voltage varies from 0 to 5 volts. Typically the voltage is

less than 1.25 volt at idle, and greater than 4-volts at wide open throttle.

B12 INJECTOR VOLTAGE MONITOR LINE - The injector voltage monitor line is used so that the PCM will know

the exact voltage that the fuel injectors are operating. This voltage is used to control the pulse width modulation

of the fuel injectors.

PINS C1 - C16

C1 NOT USED

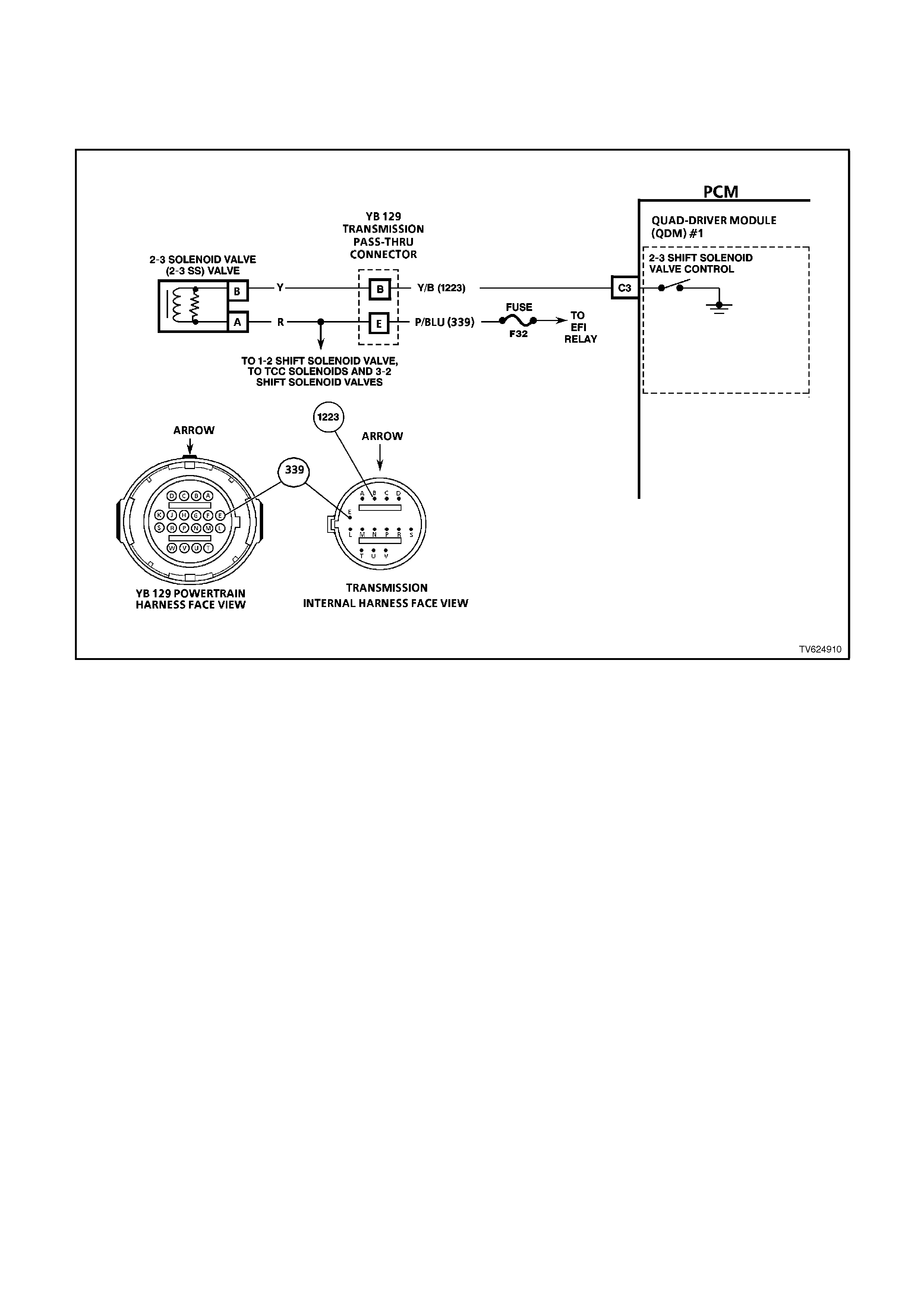

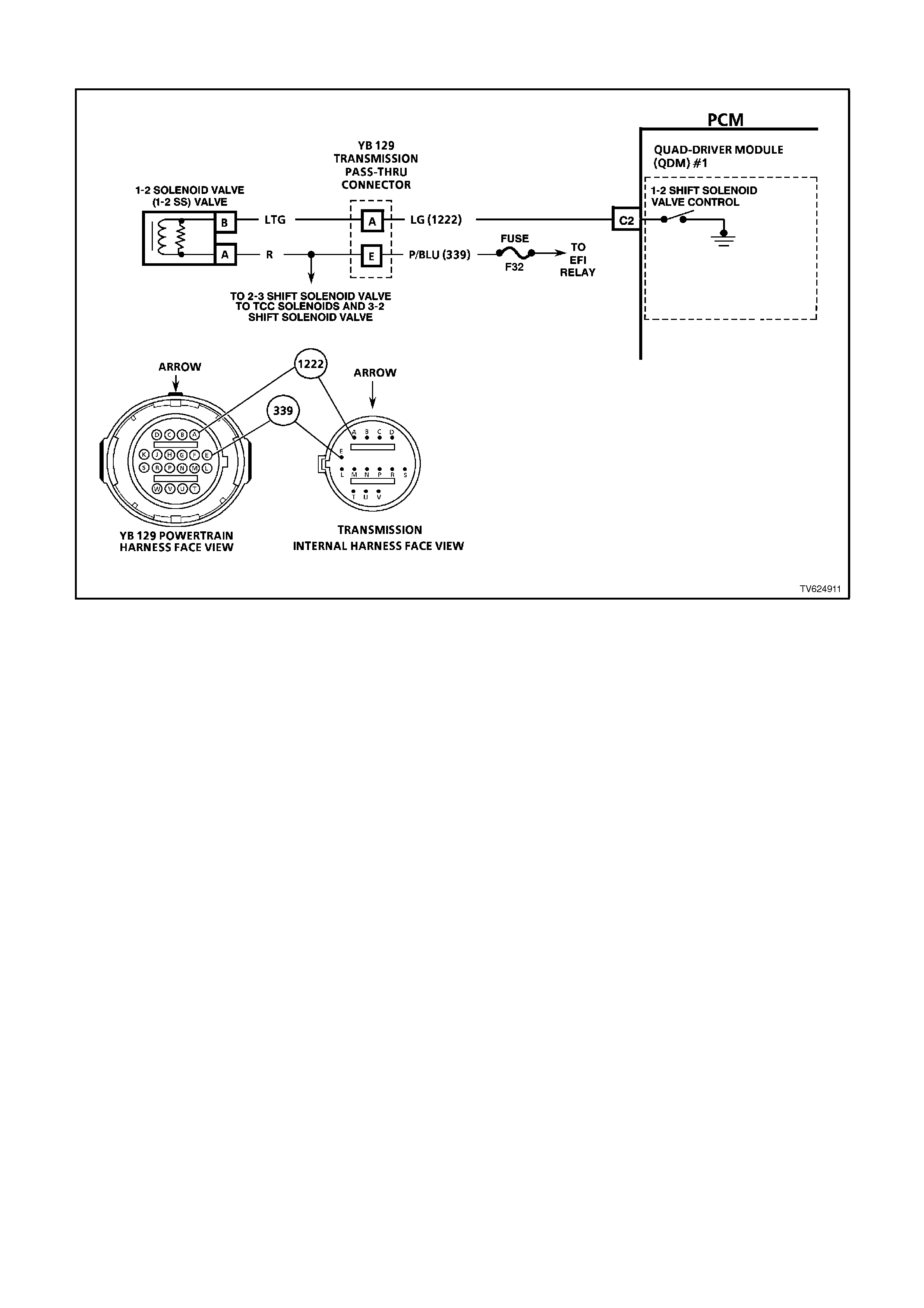

C2 1-2 SHIFT SOLENOID CONTROL - The PCM either opens or earths the 1-2 shift solenoid. When the PCM

provides a path to earth, the 1-2 shift solenoid is considered ON and the voltage should read 0 volts.

C3 2-3 SHIFT SOLENOID CONTROL - The PCM either opens or earths the 2-3 shift solenoid. When the PCM

provides a path to earth, the 2-3 shift solenoid is considered ON and the voltage should read 0 volts.

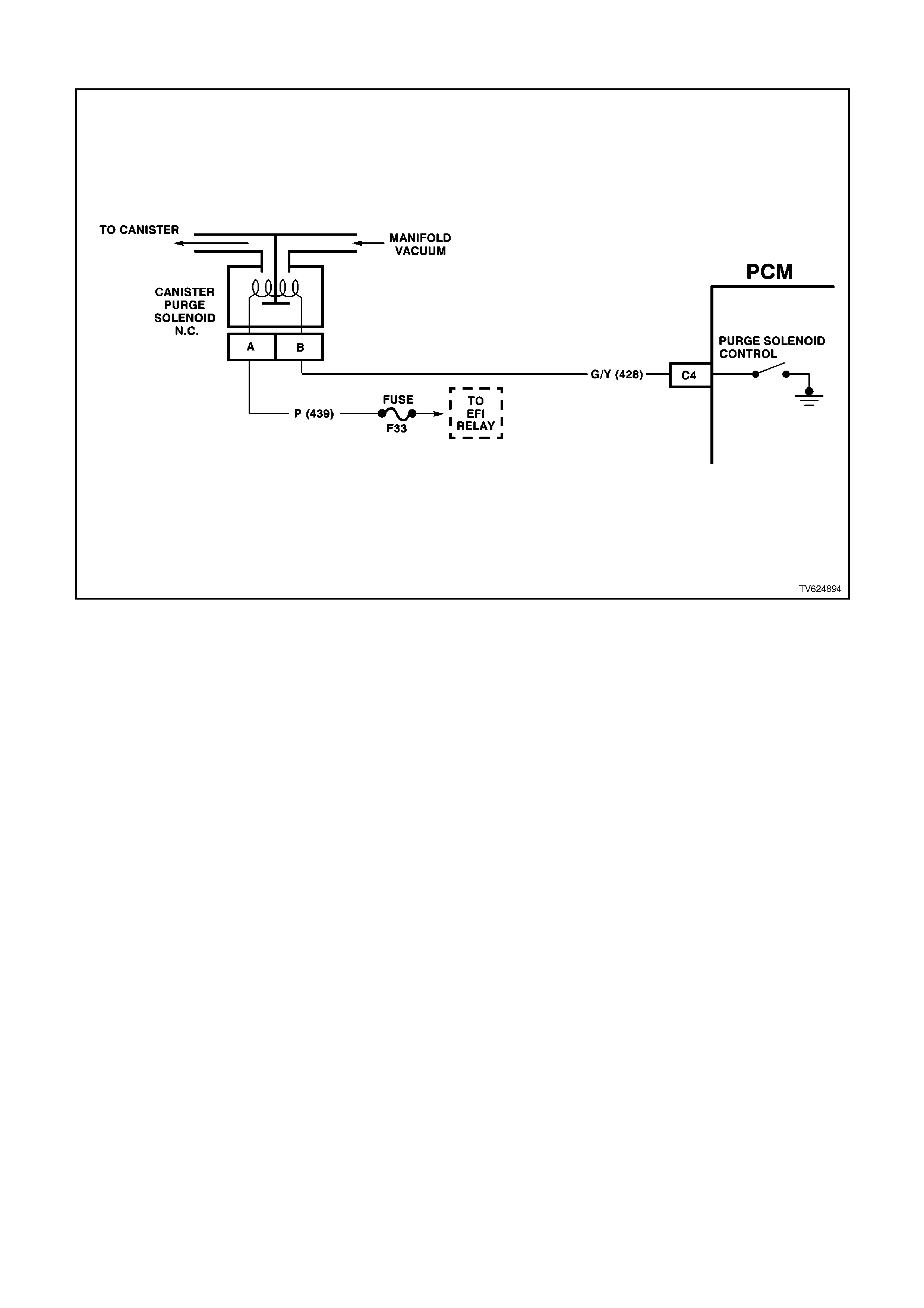

C4 CANISTER PURGE - Grounds the canister purge valve circuit to enable the purging of the canister.

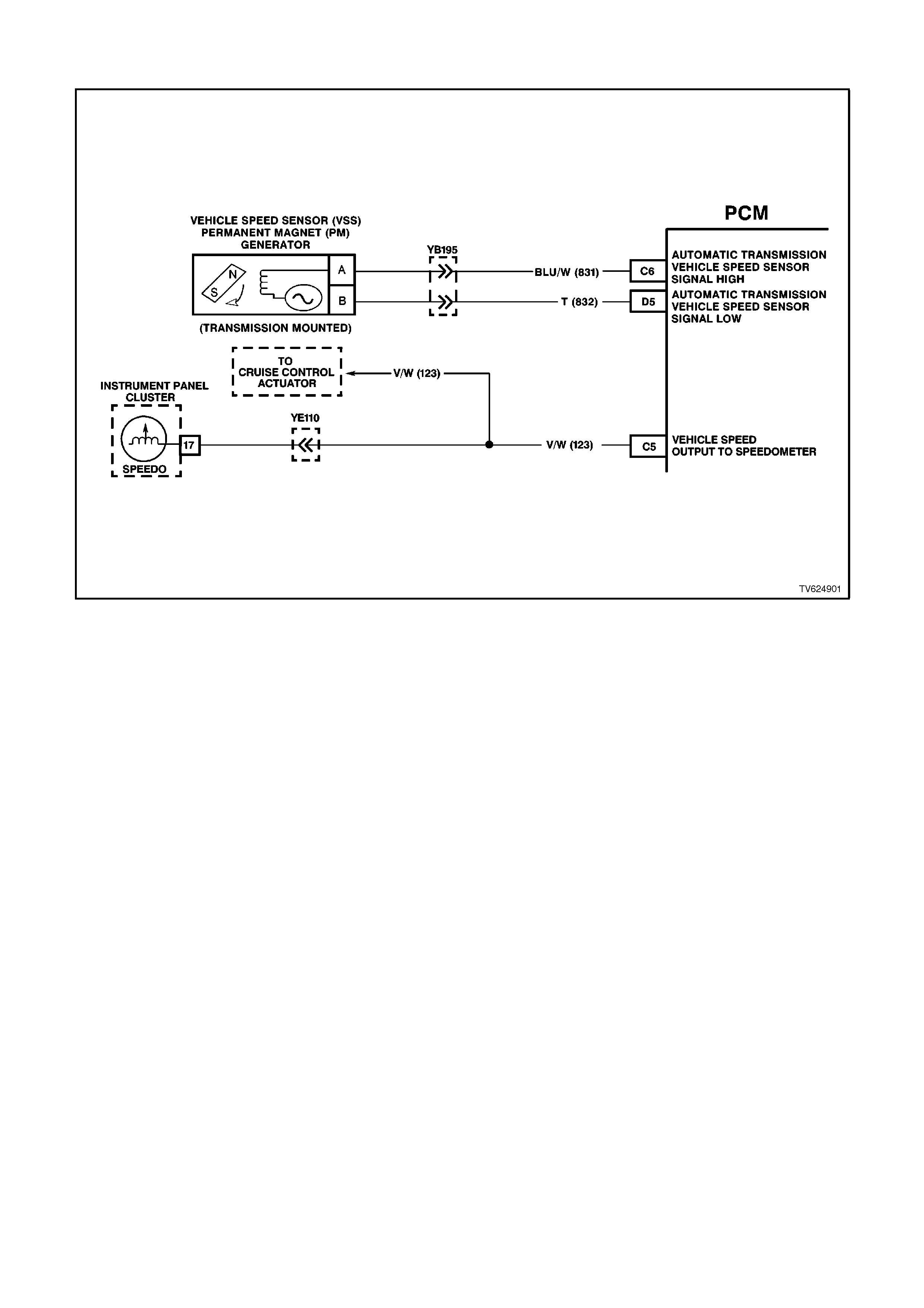

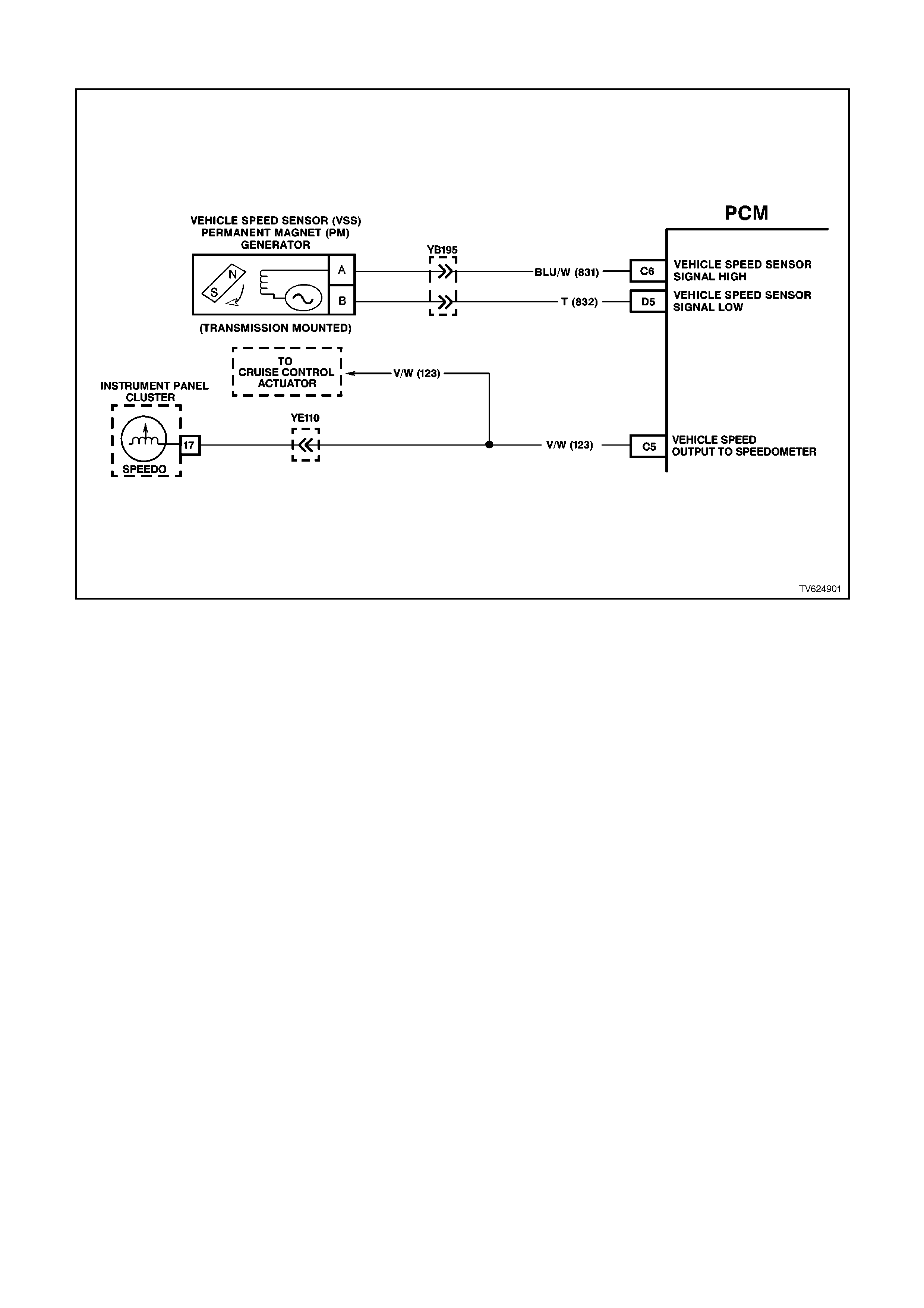

C5 VEHICLE SPEED SENSOR SIGNAL - The PCM alternately earths this signal when the drive wheels are

turning. This pulsing action takes place about 6250 times per kilometre. The speedometer, the BCM and the

trip computer will calculate the vehicle speed based on the time between pulses.

C6 VEHICLE SPEED SENSOR - OUTPUT SHAFT SPEED INPUT SIGNAL HIGH

The transmission has an output shaft speed sensor used by the PCM to calculate vehicle speed, and to help

determine various automatic transmission shifting functions. It is a magnetic inductive sensor that generates an

AC voltage signal sent to the PCM. If measured with the digital AC voltmeter, no voltage will appear until the

output shaft begins turning.

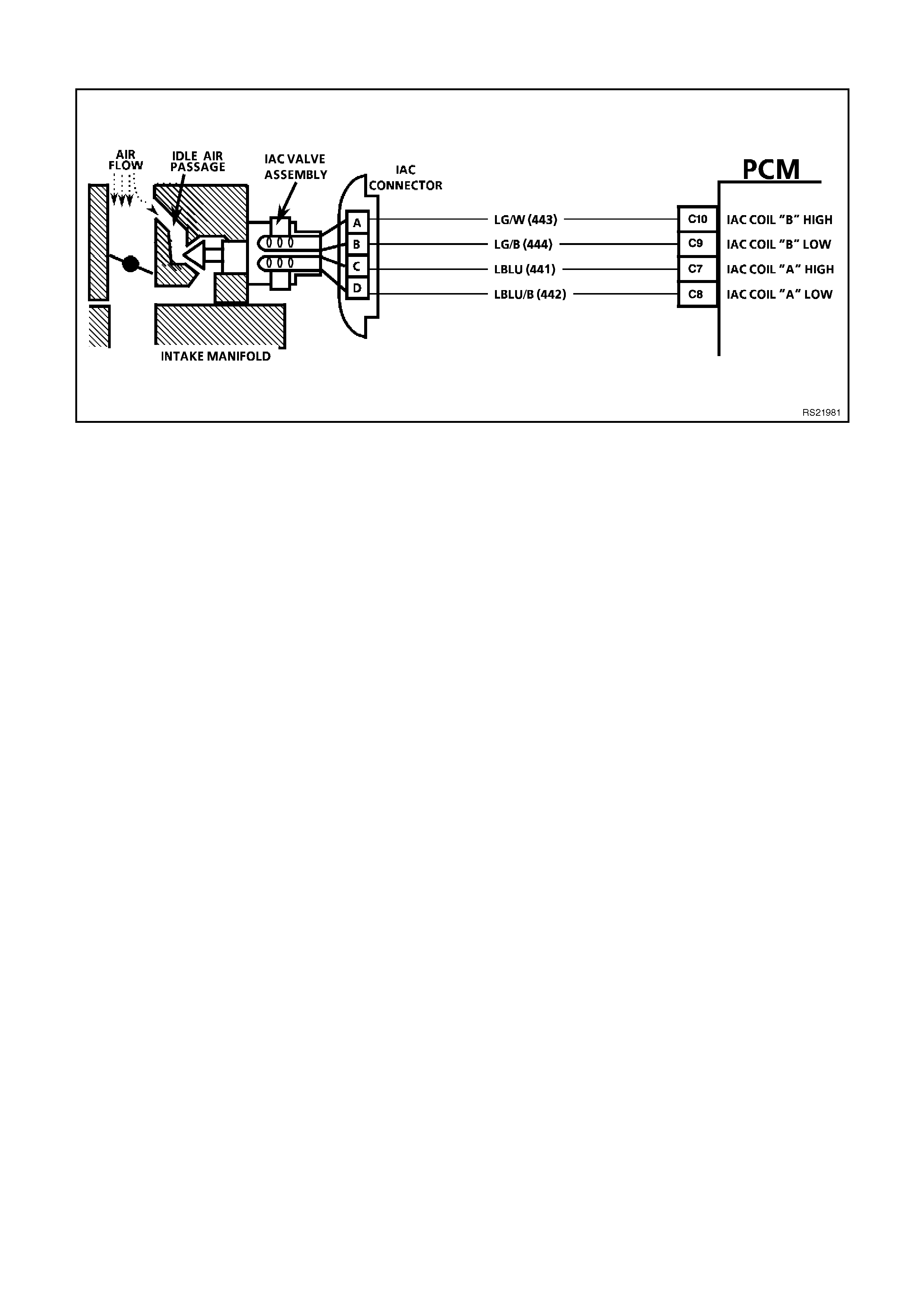

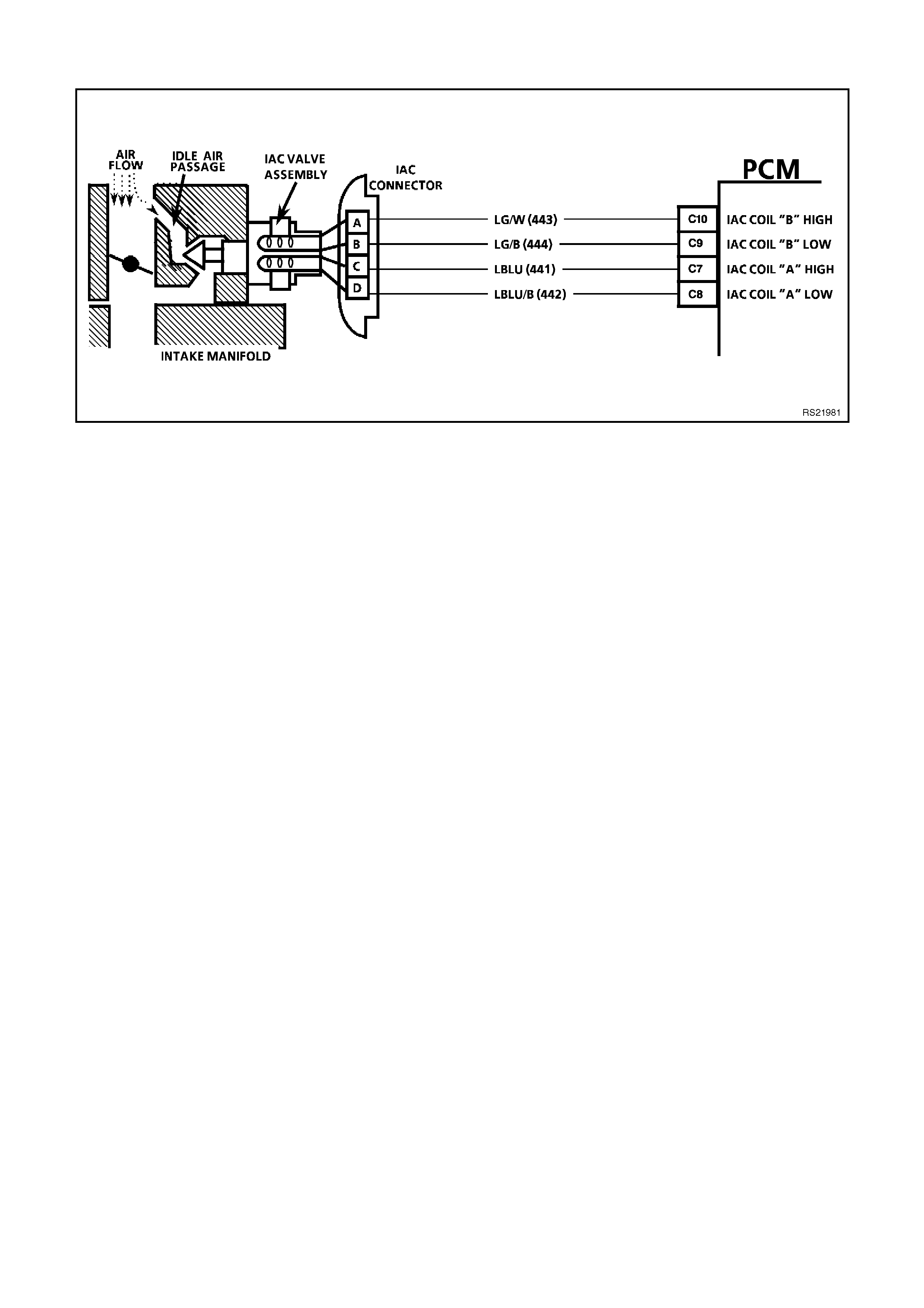

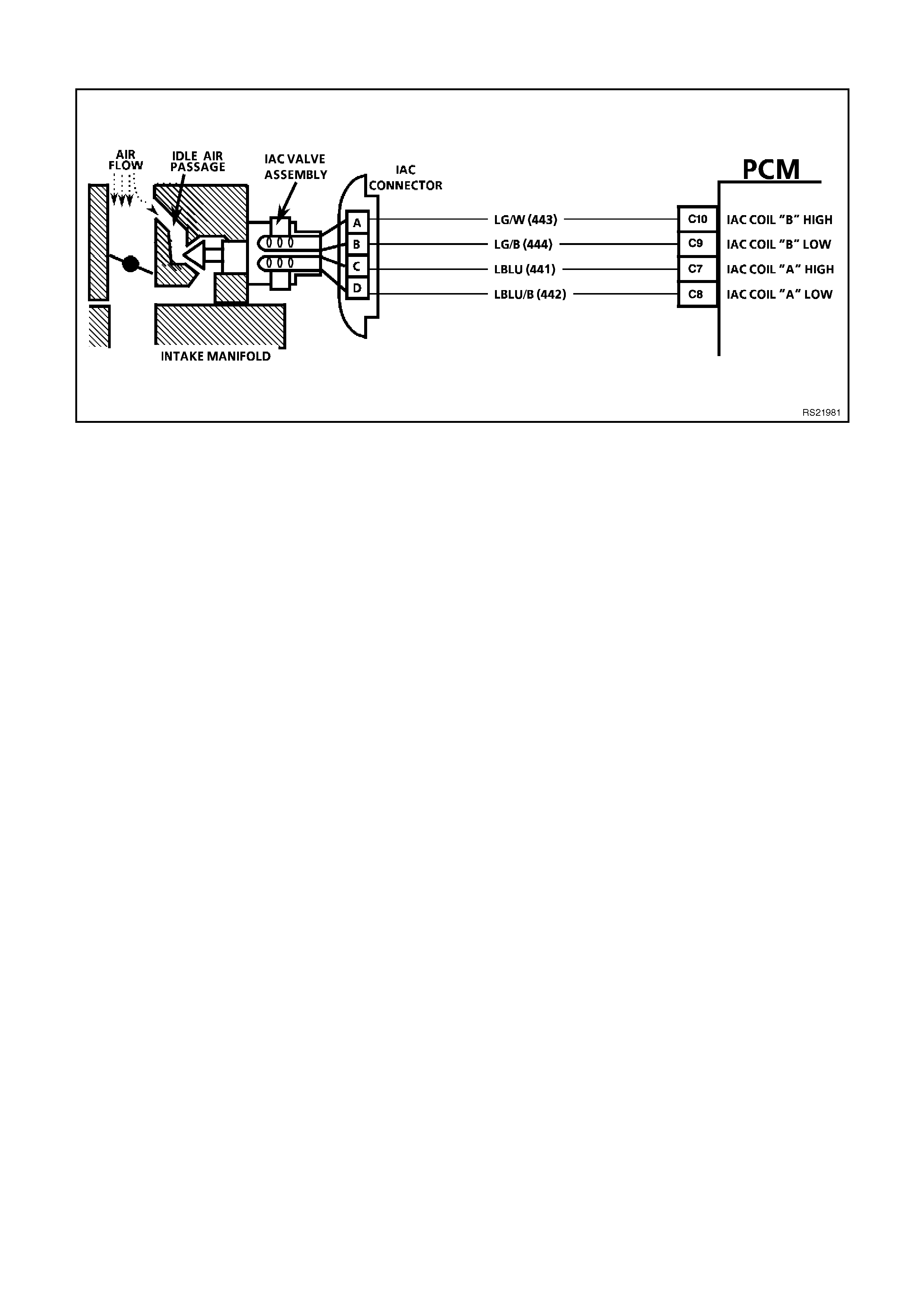

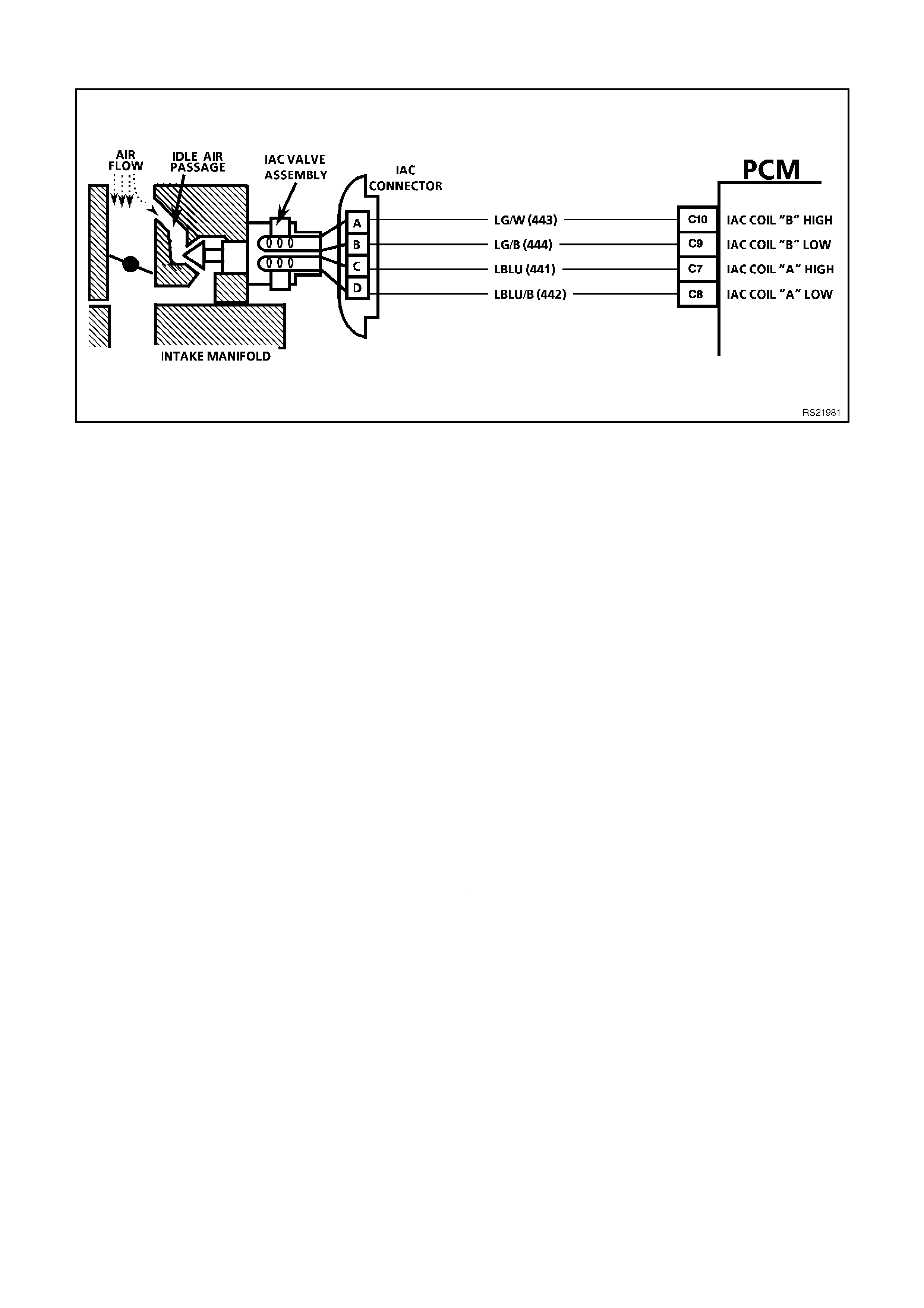

C7, C8, C9,C10

IDLE AIR CONTROL (IAC) VALVE - These circuits control the positioning of the pintle valve which is located

inside the IAC valve. The voltage on this circuit is difficult to predict because of so many variables.

C11 NOT USED

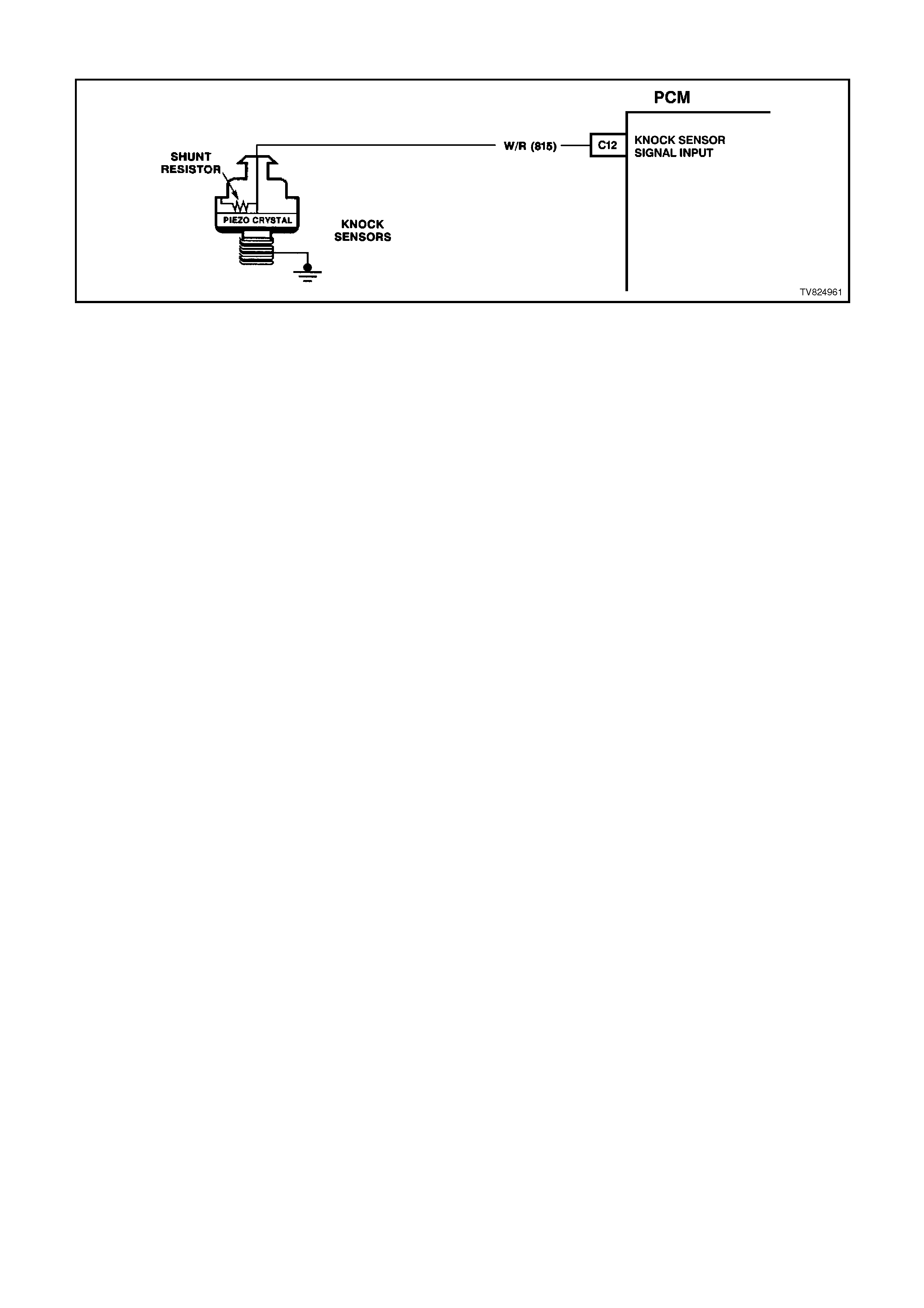

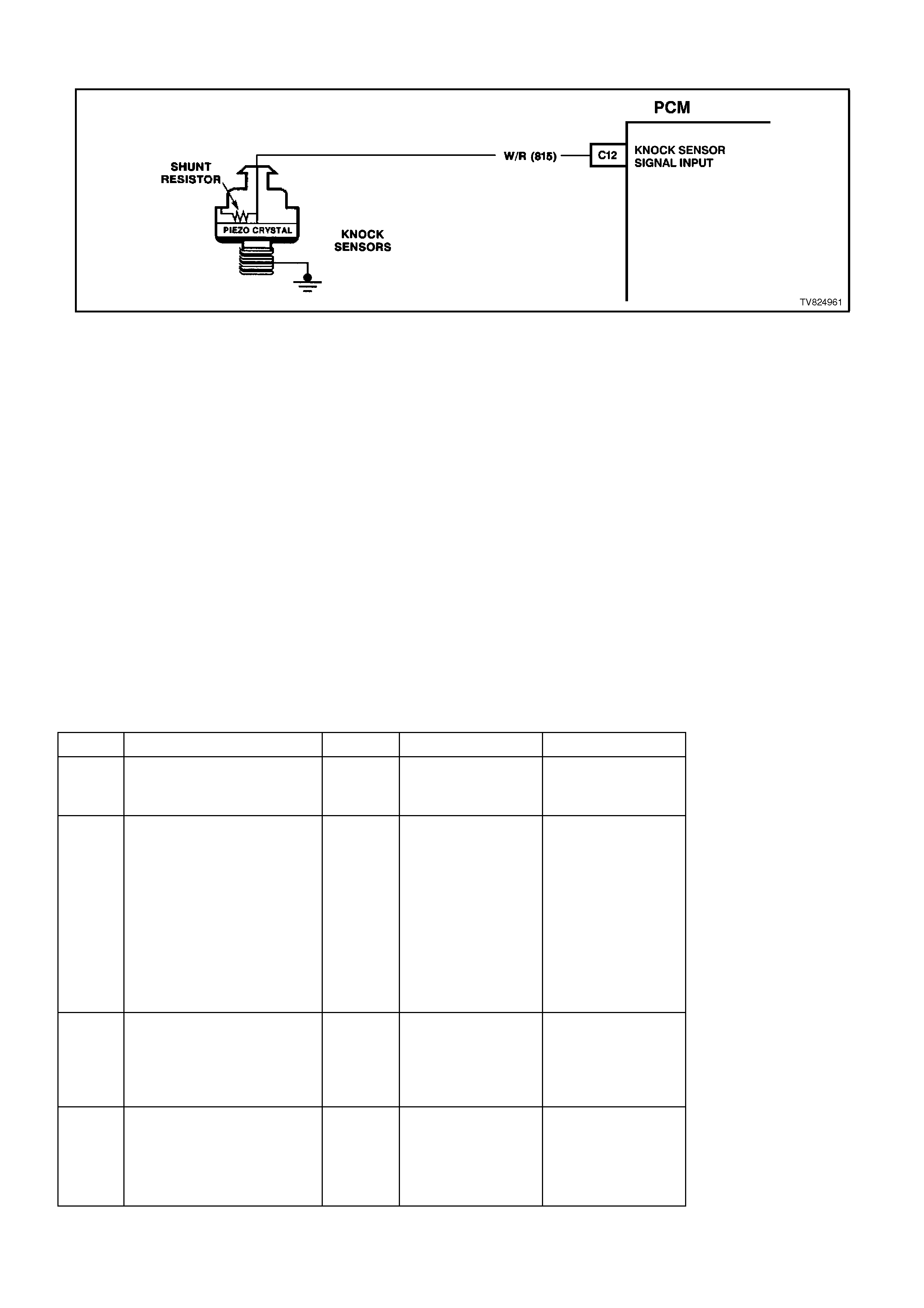

C12 ESC (KNOCK) SIGNAL - The knock sensor is used to detect engine detonation, and the PCM will retard the

Electronic Spark Timing (EST) based on the signal being received.

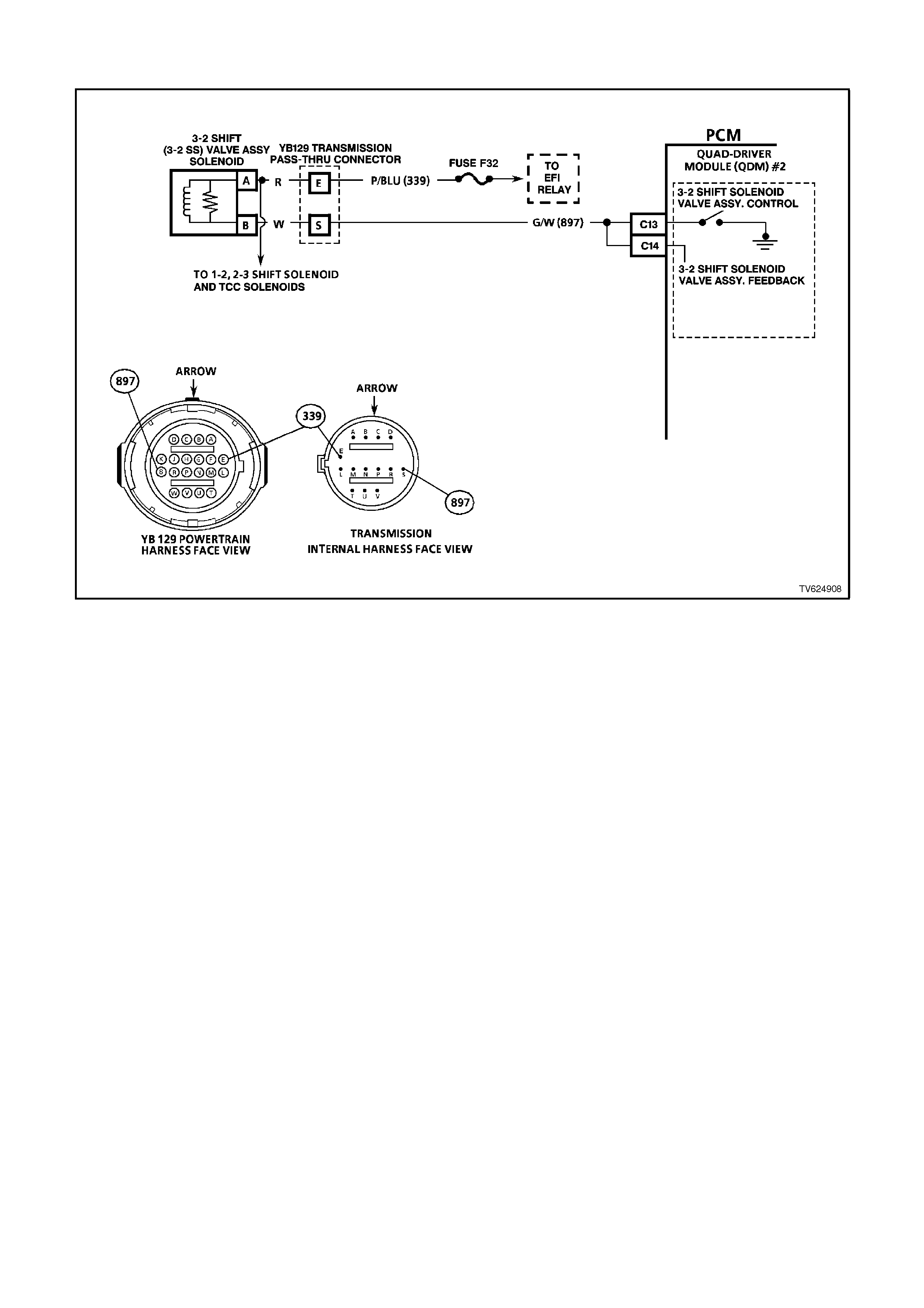

C13 3-2 SHIFT SOLENOID - The 3-2 shift solenoid is normally closed, and is pulse width modulated. The 3-2

control solenoid controls the 3-2 down shift. The PCM operates the 3-2 shift solenoid at a frequency of 50 Hz.

The solenoid is constantly fed B+ voltage. The PCM controls the time the path to earth is closed or opened.

C14 3-2 SHIFT SOLENOID FEEDBACK CIRCUIT The 3-2 shift solenoid is a normally closed solenoid which is

used to control the 3-2 down shift. The solenoid is constantly fed B+ and the PCM controls the time the path to

earth is closed. The PCM does this to provide a smooth 3-2 down shift. If the PCM senses an incorrect voltage

on this circuit when controlling the 3-2 down shift solenoid (i.e. - 0 volts with the solenoid OFF, or 12 volts with

the solenoid ON) a DTC 66 will set.

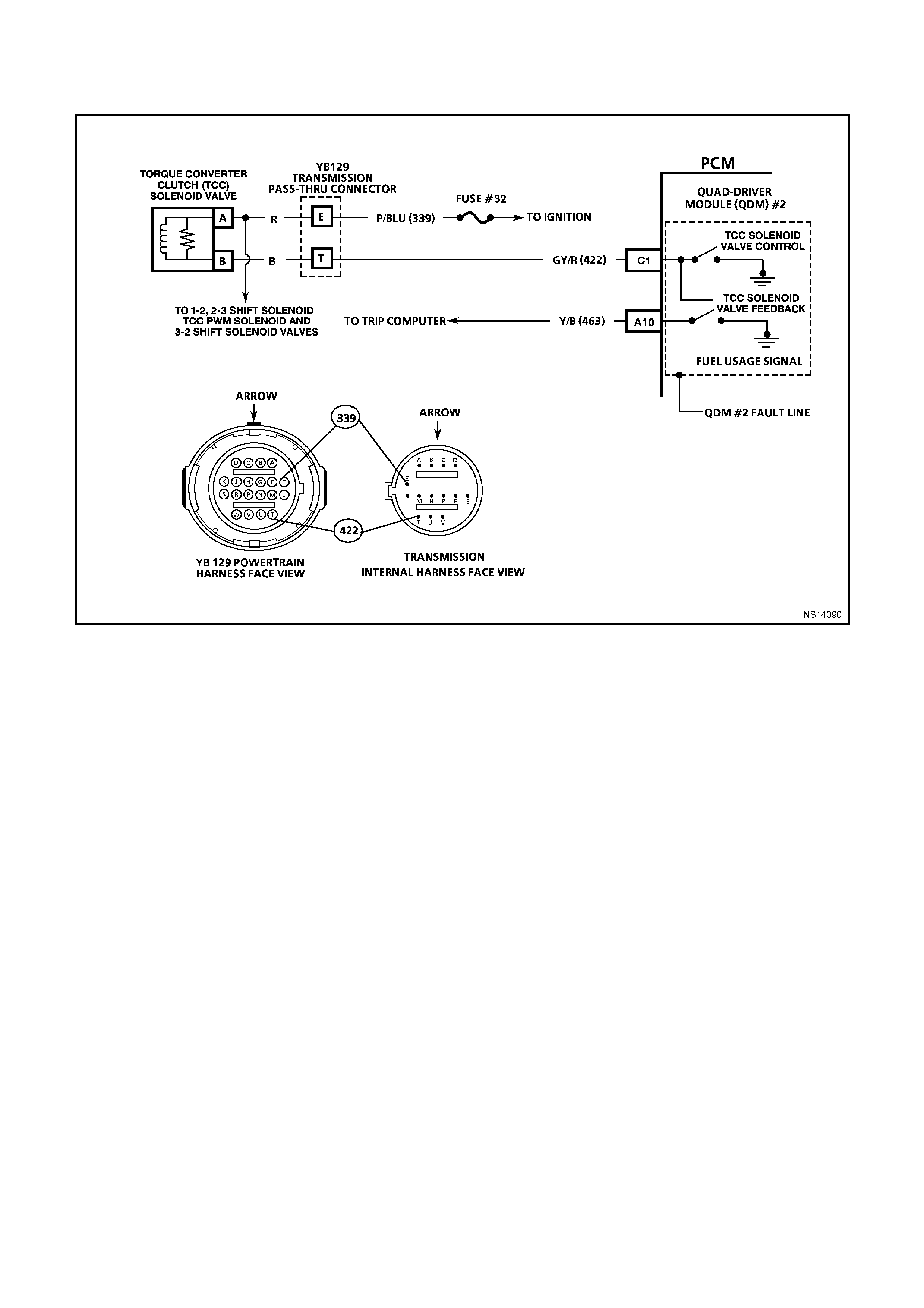

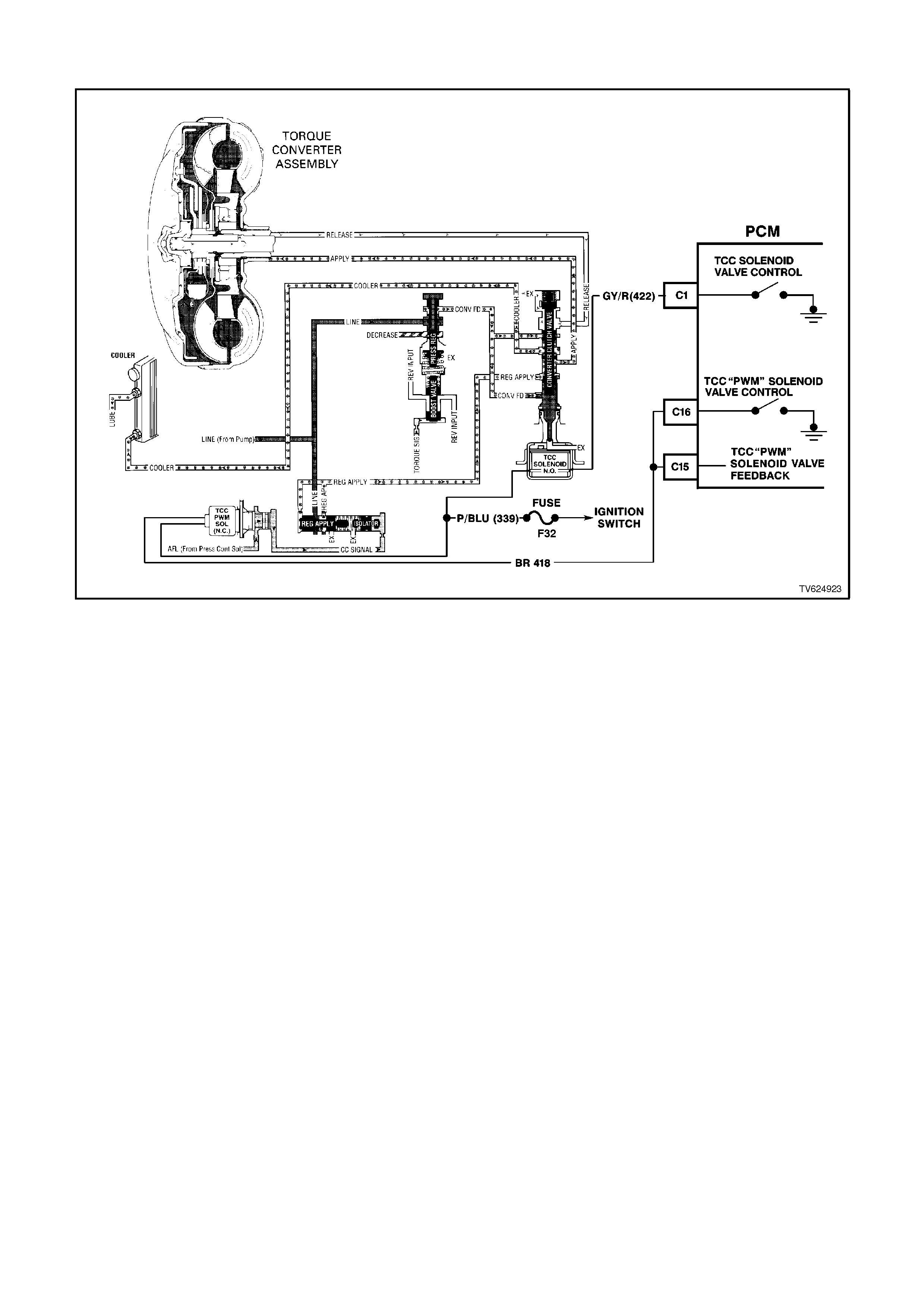

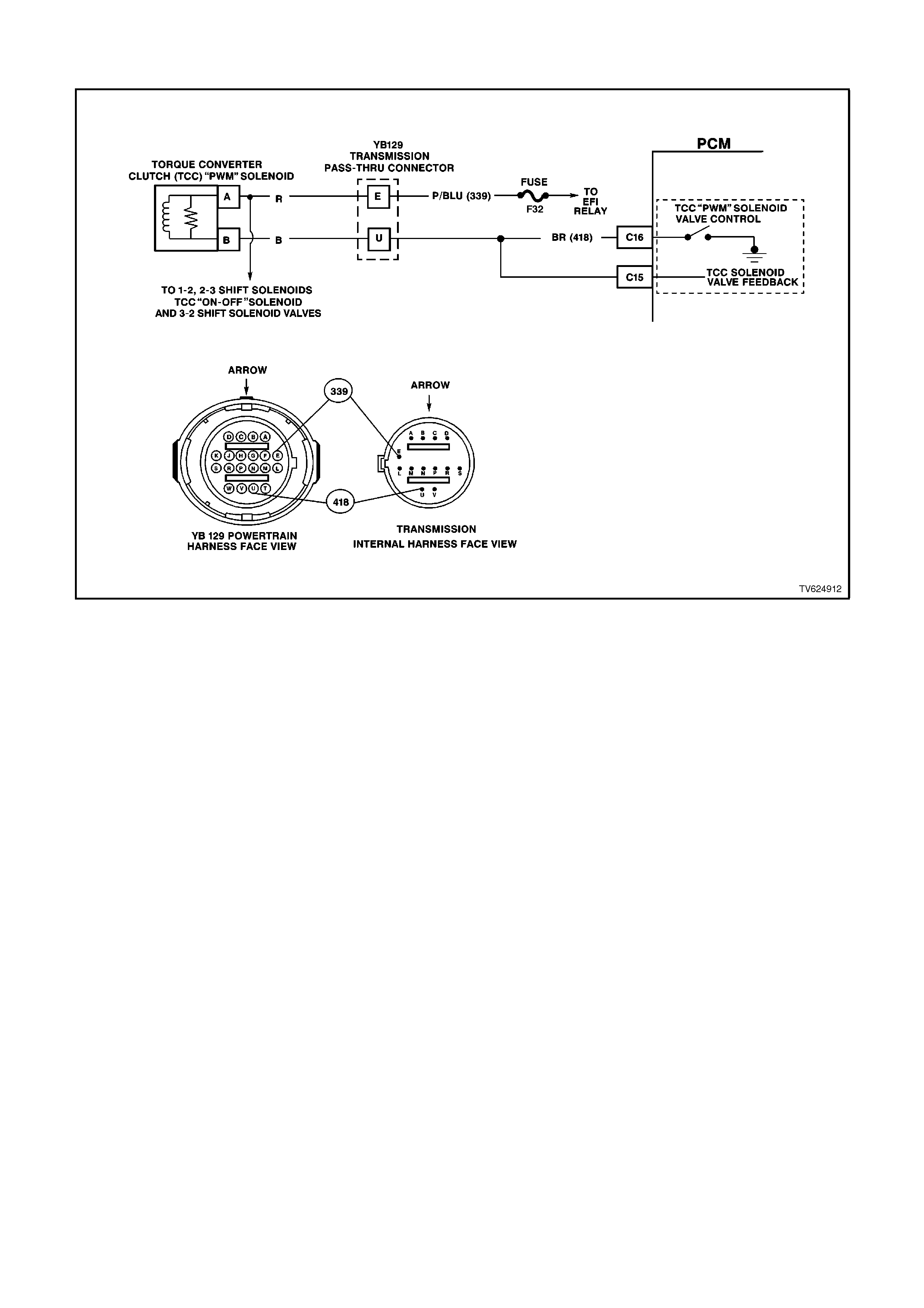

C15 TORQUE CONVERTER CLUTCH ENABLE SOLENOID - The Torque converter clutch apply solenoid is used

to smoothly engage the torque converter clutch. By varying the solenoids duty cycle, the PCM can slowly

engage the torque converter clutch, which allows a smooth TCC engagement. If the PCM senses an incorrect

voltage on this circuit when controlling the TCC PWM solenoid (i.e. - 0 volts with the solenoid OFF, or 12 volts

with the solenoid ON) a DTC 83 will set.

C16 TORQUE CONVERTER CLUTCH - PULSE WIDTH MODULATED APPLY SOLENOID CONTROL

AUTO TRANS ONLY

The PCM uses the pulse width modulated TCC apply solenoid to smoothly engage the torque converter clutch,

after the TCC enable solenoid is energised. By varying the duty cycle pulse width modulation, the PCM can

slowly engage the torque converter clutch, allowing very smooth TCC engagement.

PINS D1 - D16

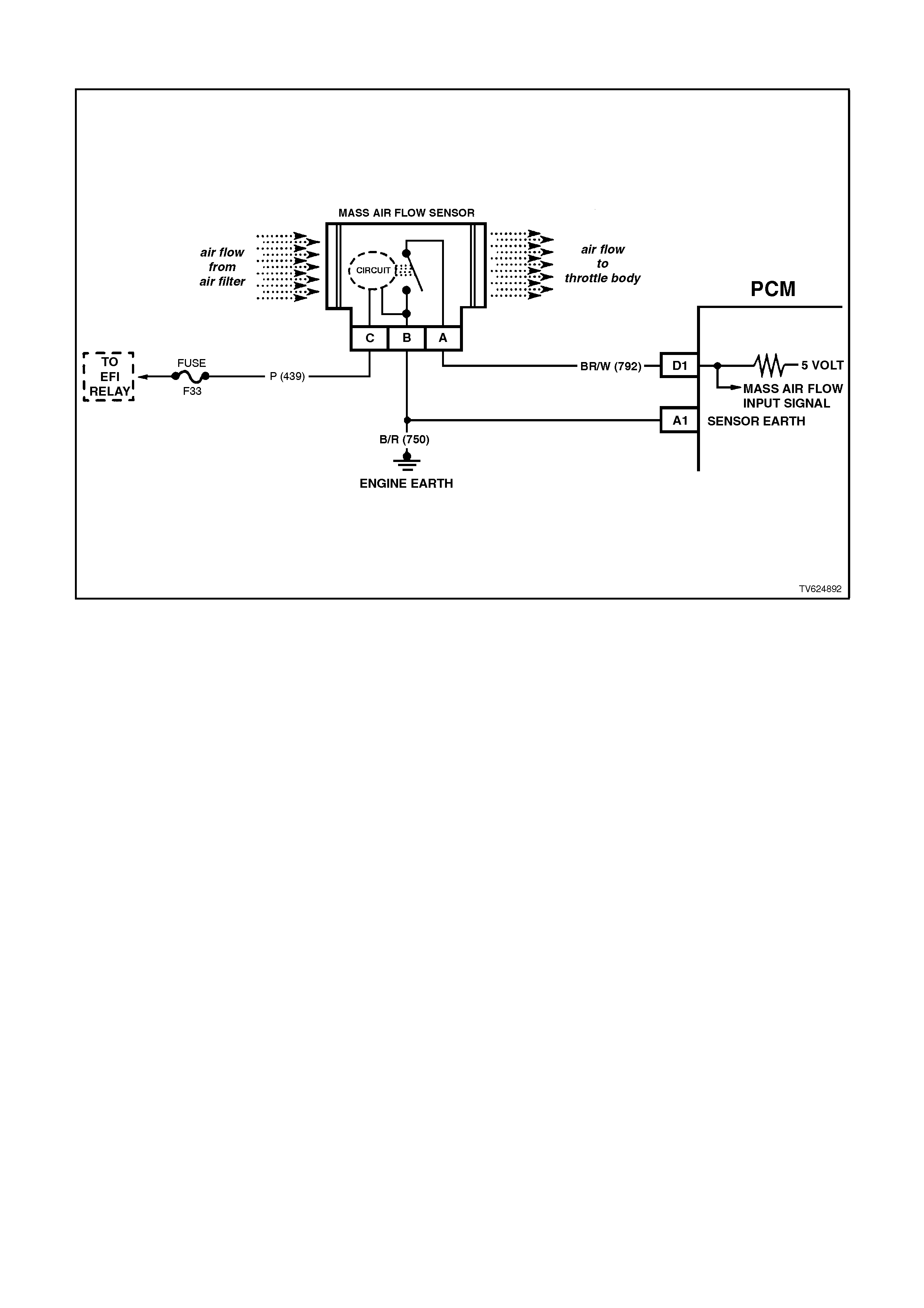

D1 MASS AIR FLOW (MAF) INPUT SIGNAL -

The PCM supplies a 5-volt signal voltage to the mass air flow sensor on this circuit. The mass air flow sensor

pulses the 5-volt signal to earth. These ground pulses occur at a very fast rate - from less than 500 per second

(500 Hz) with no airflow through the sensor, to upwards of many thousands of pulses per second at high air

flow rates such as during acceleration. If measured, the voltage seen will be between 0.5 and 4.5 volts,

depending on air flow through the sensor.

D2 NOT USED

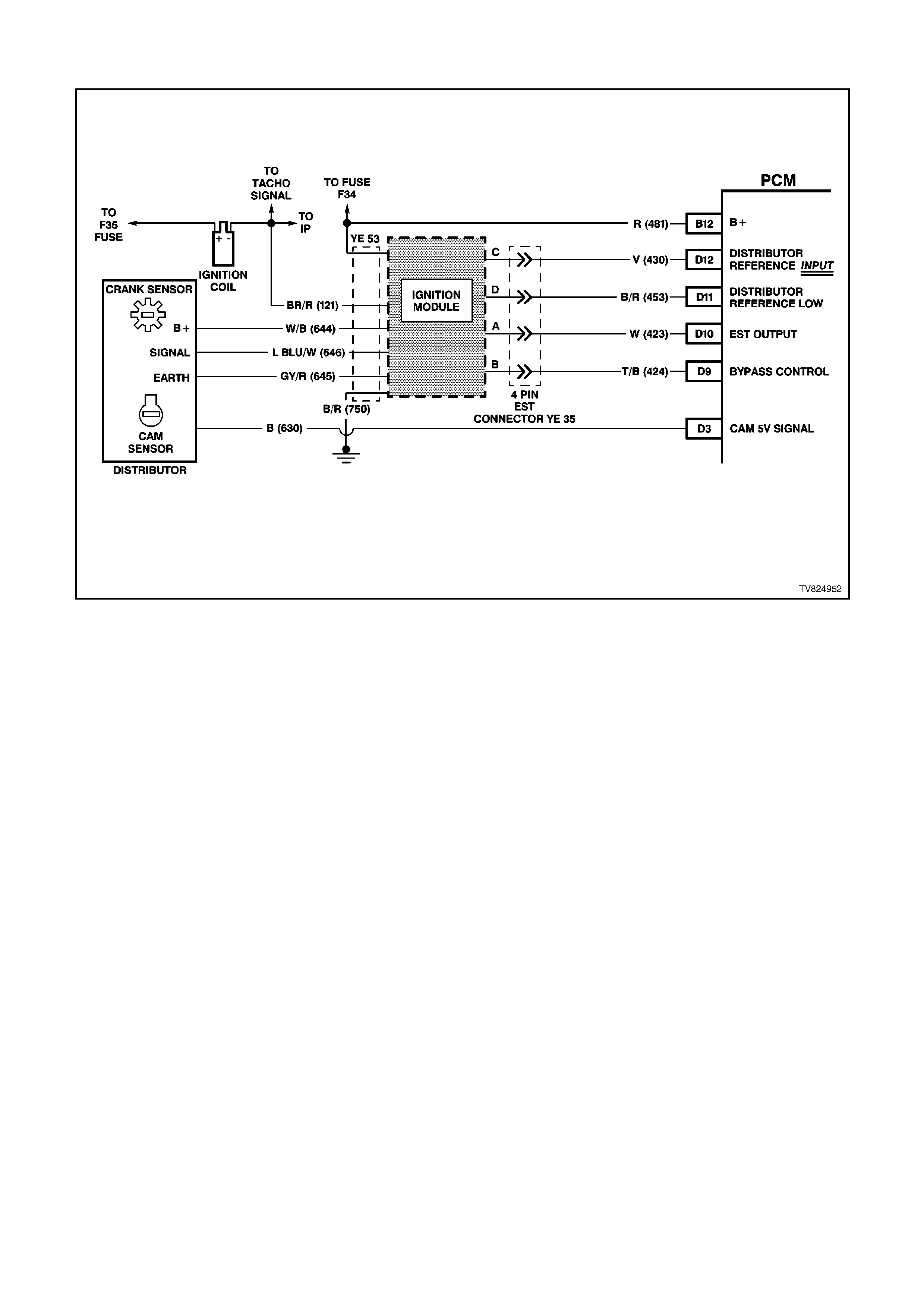

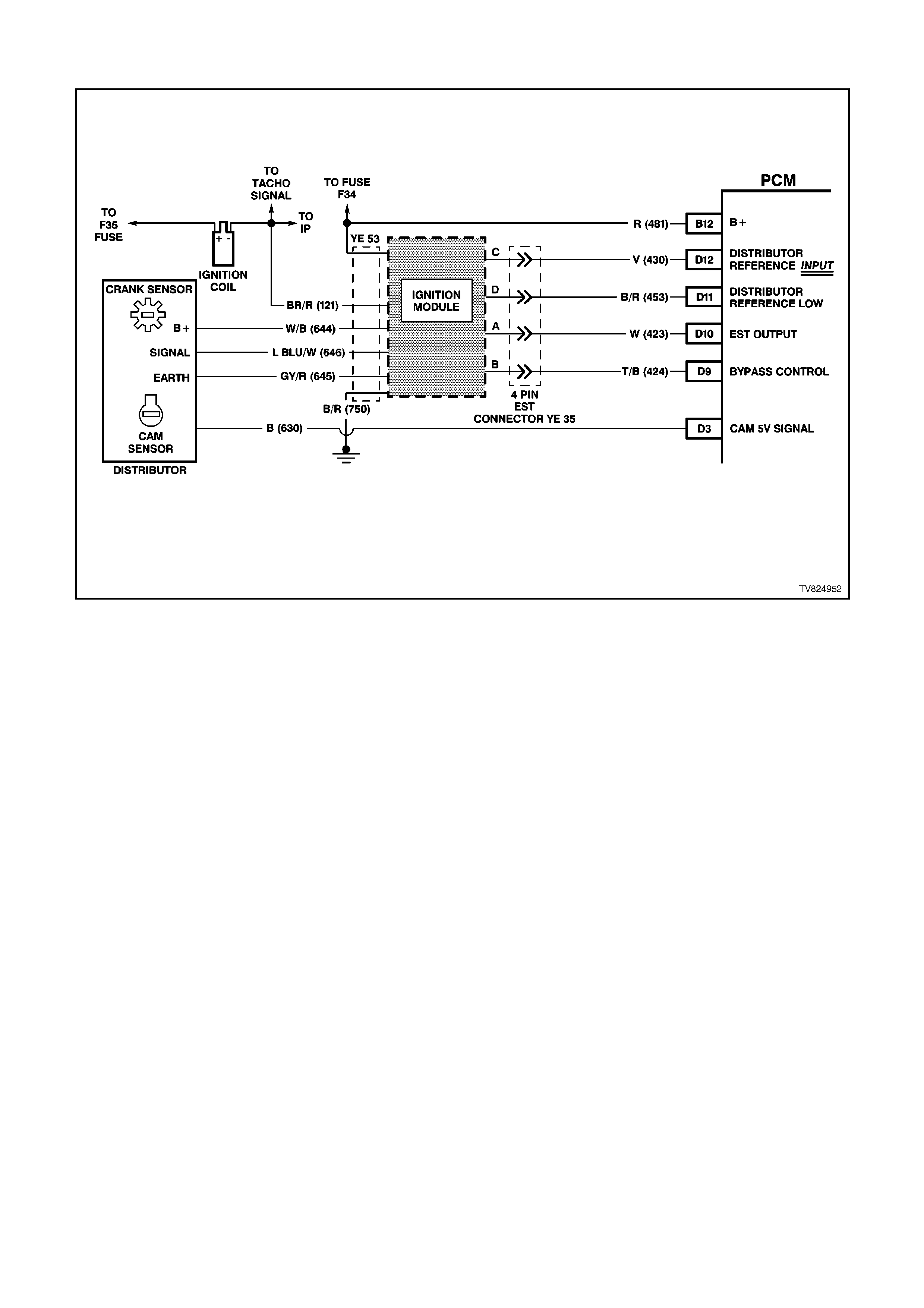

D3 CAMSHAFT POSITION INPUT SIGNAL -

This signal is used by the PCM to sequence the fuel injectors, similar to the firing order of an engine. This

allows the PCM to operate the fuel injectors in a sequential fuel injection mode.

D4 NOT USED

D5 VEHICLE SPEED SENSOR - OUTPUT SHAFT SPEED INPUT SIGNAL LOW -

The transmission has an output shaft speed sensor used by the PCM to calculate vehicle speed, and to help

determine various automatic transmission shifting functions. It is a magnetic inductive sensor that generates an

AC voltage signal sent to the PCM. If measured with the digital AC voltmeter, no voltage will appear until the

output shaft begins turning.

D6 NOT USED

D7 NOT USED

D8 NOT USED

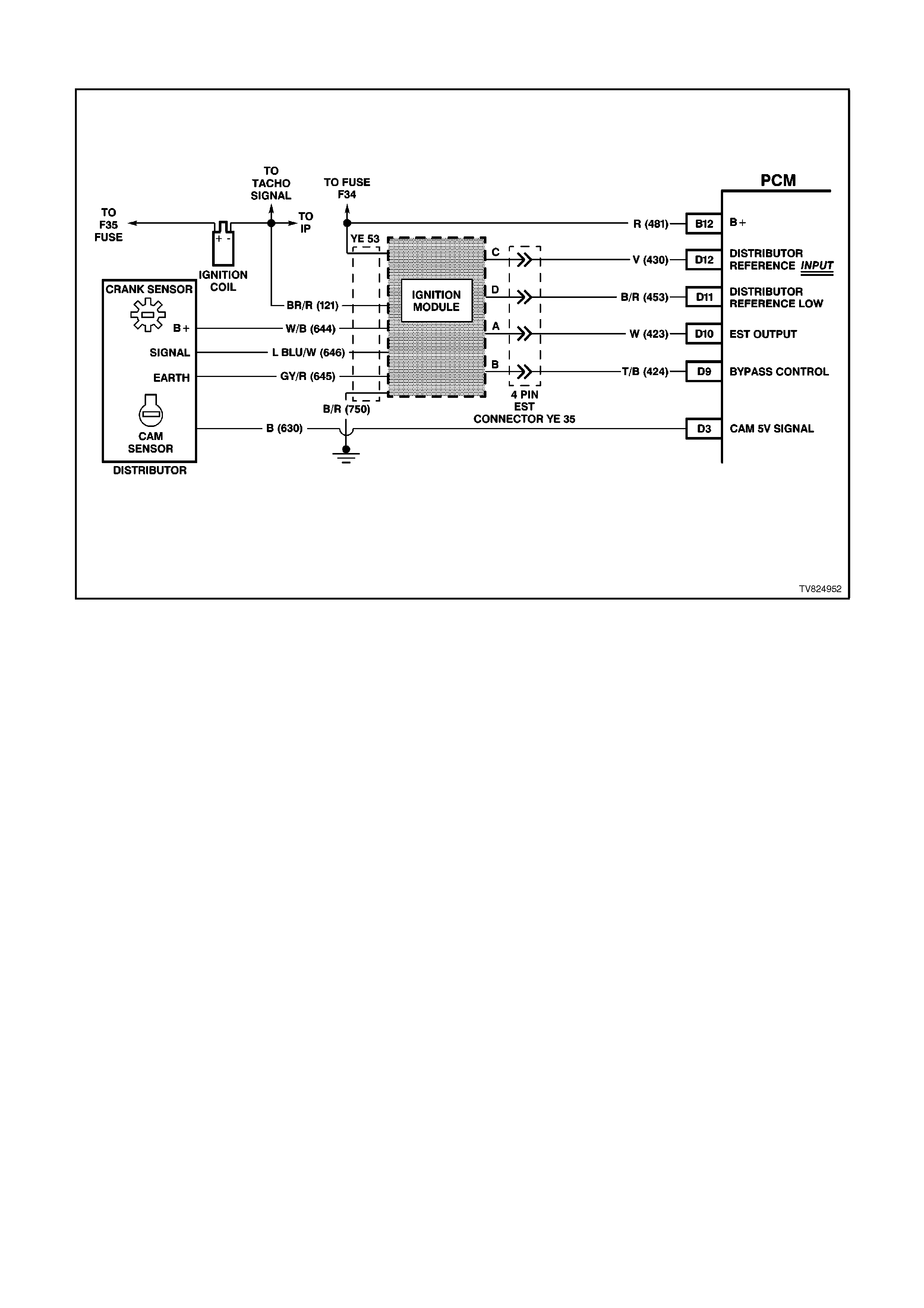

D9 IGNITION MODULE BYPASS CONTROL - With the ignition ON and the engine OFF this terminal will have

very low voltage. As soon as the PCM receives engine RPM over 450 RPM (engine "run" threshold) the PCM

twill send 5 volts to the Ignition Module Bypass Circuit.

D10 ELECTRONIC SPARK TIMING (EST) OUTPUT - This terminal will have very low voltage with the ignition ON

and engine OFF. With the engine at idle, the voltage should be slightly more than 1 volt. As the engine RPM

increases, this voltage will also increases.

D11 REFERENCE SIGNAL LOW - This terminal should always be zero volts. This circuit is connected through the

ignition module to engine earth.

D12 REFERENCE SIGNAL HIGH - This terminal could be called the tach input. It provides the PCM with RPM and

crankshaft position information. With the ignition ON and engine OFF, the voltage will be either high or low,

depending on crankshaft position. As the crankshaft turns, the voltage will be an average of the two readings.

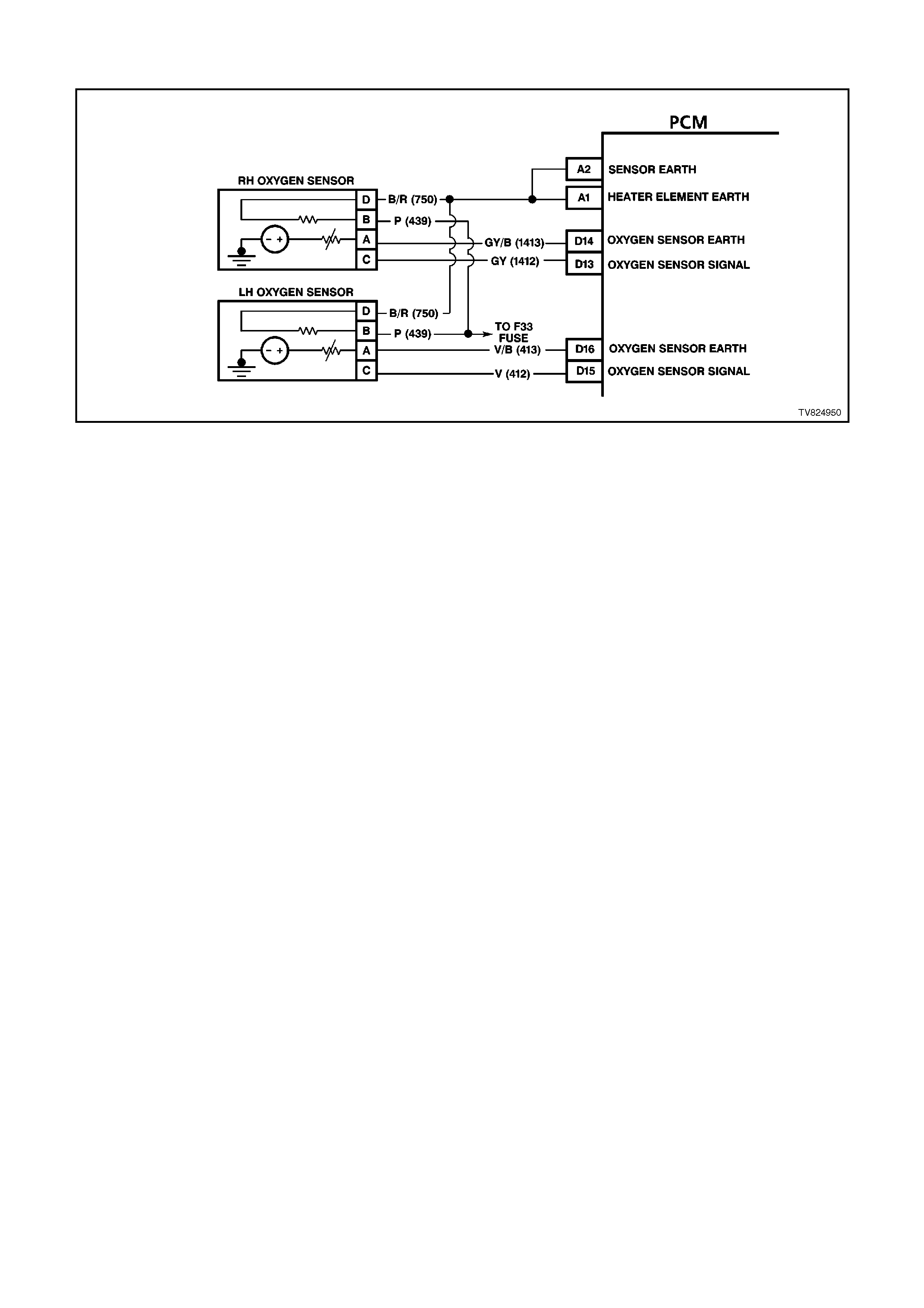

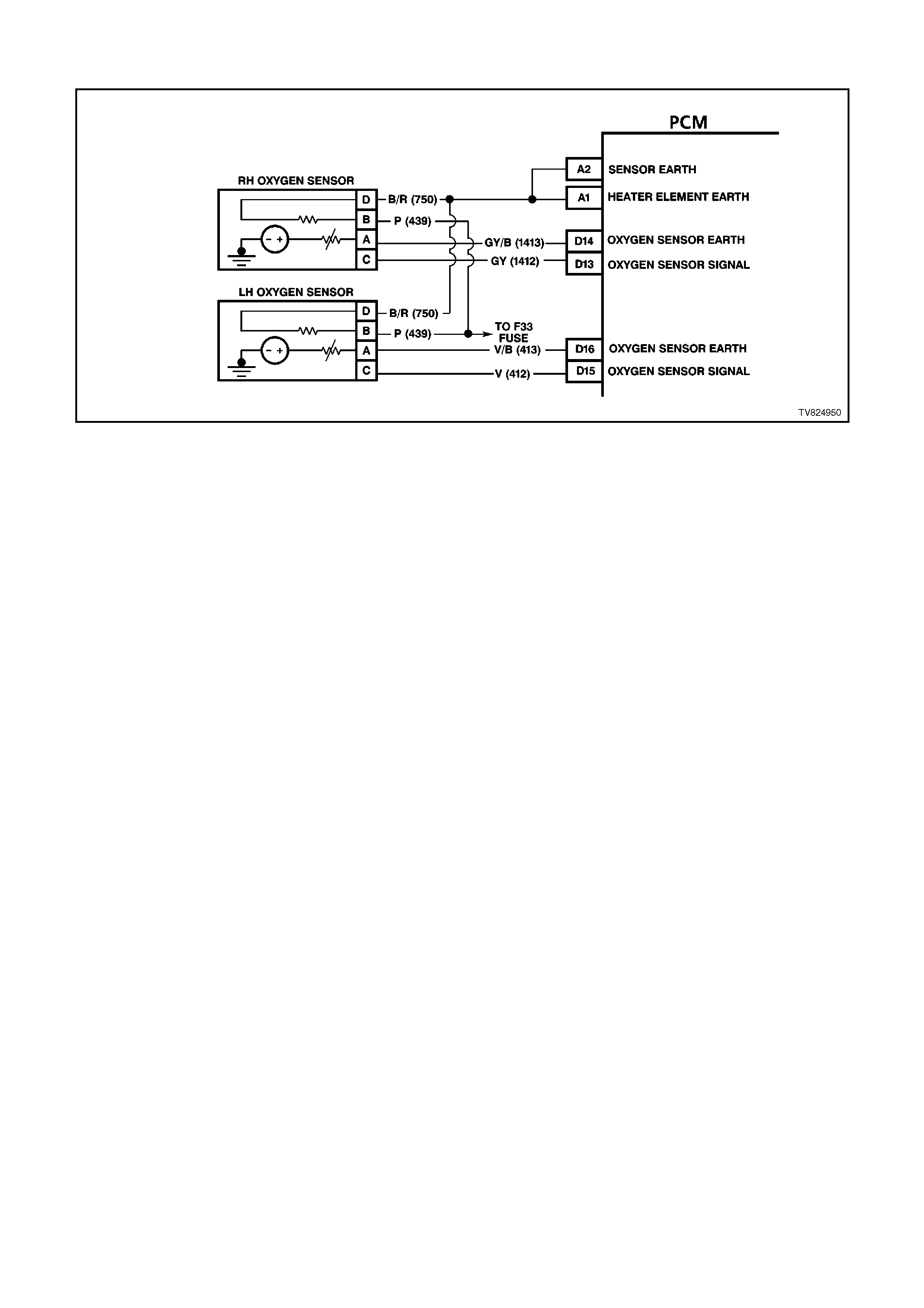

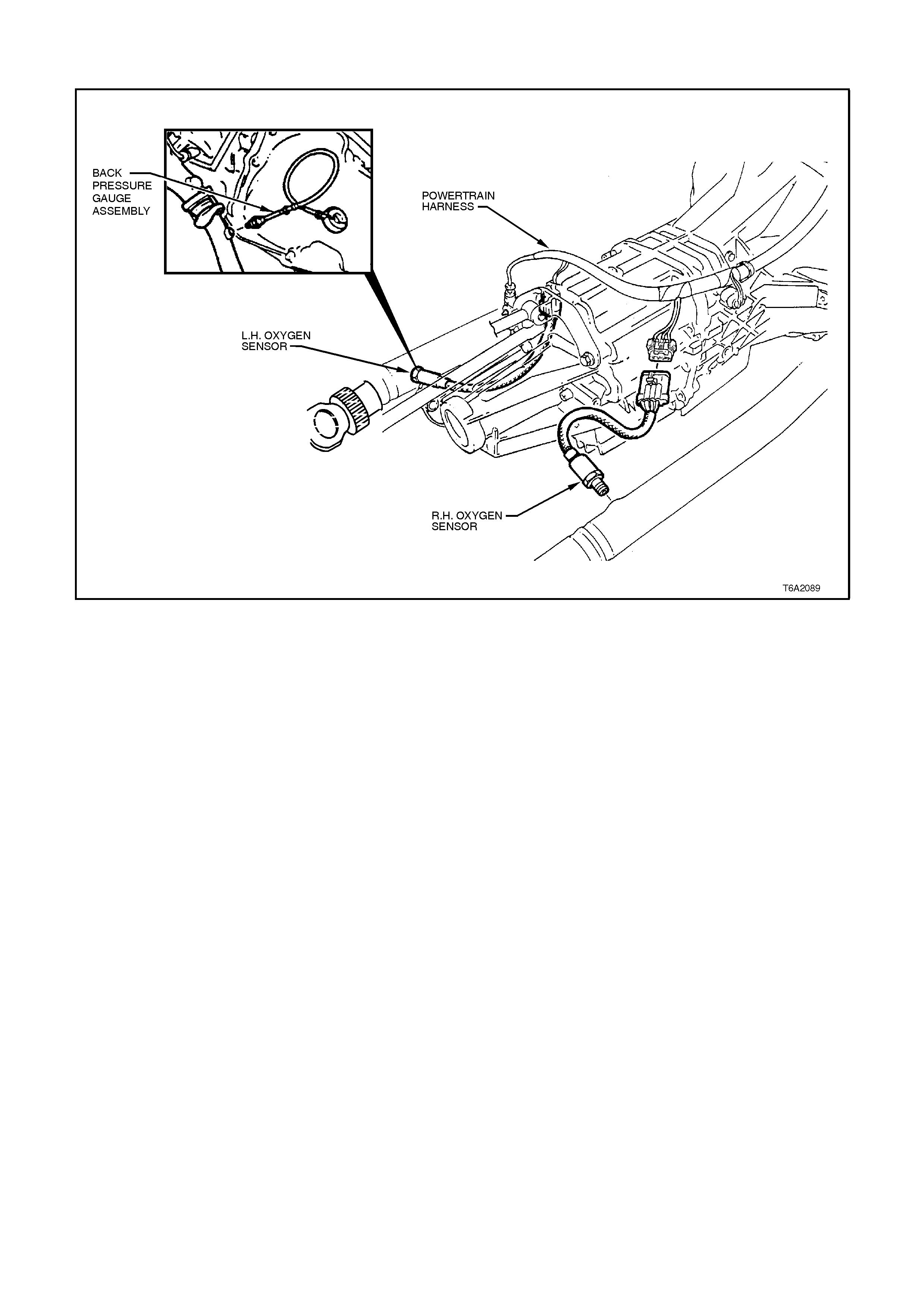

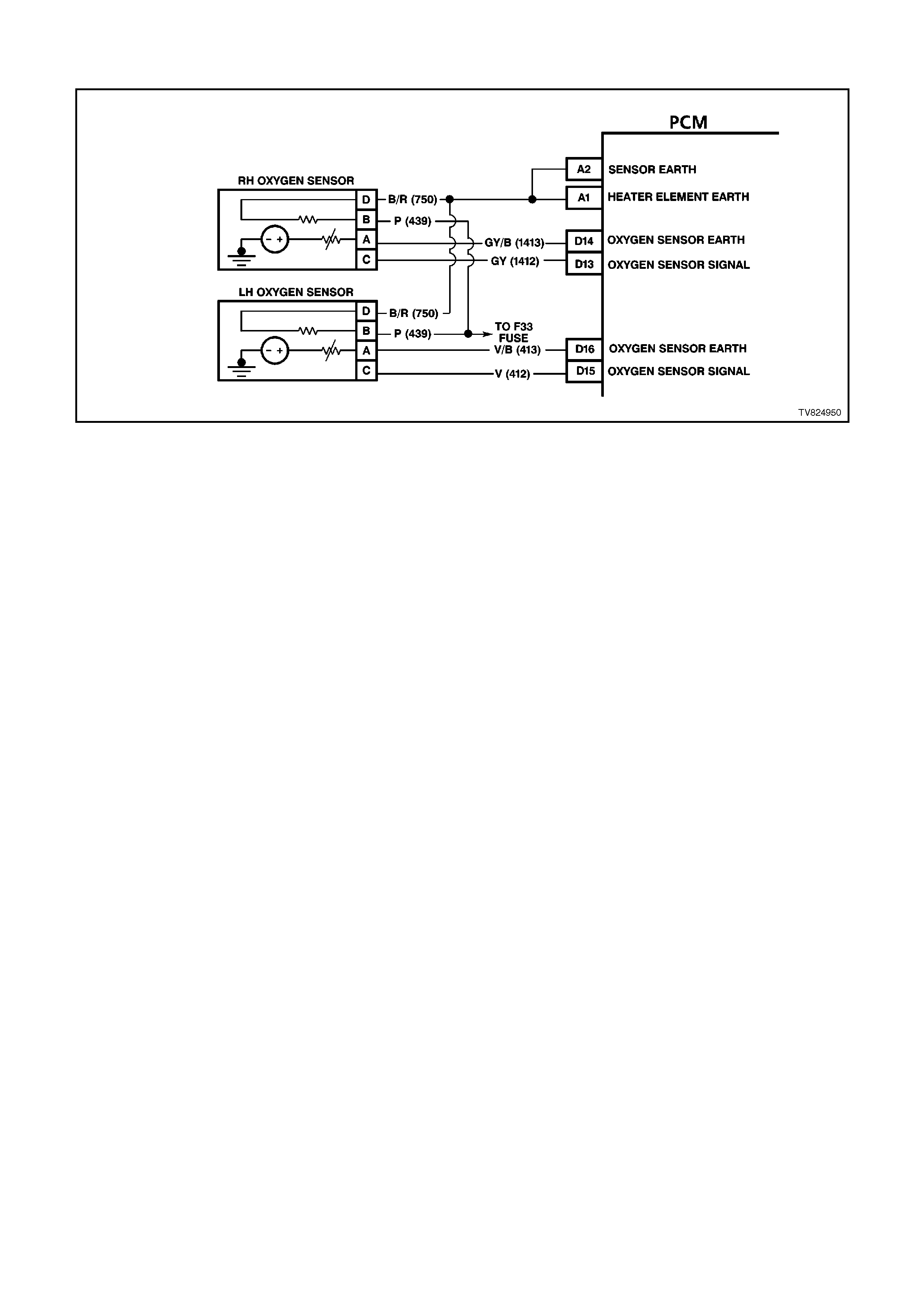

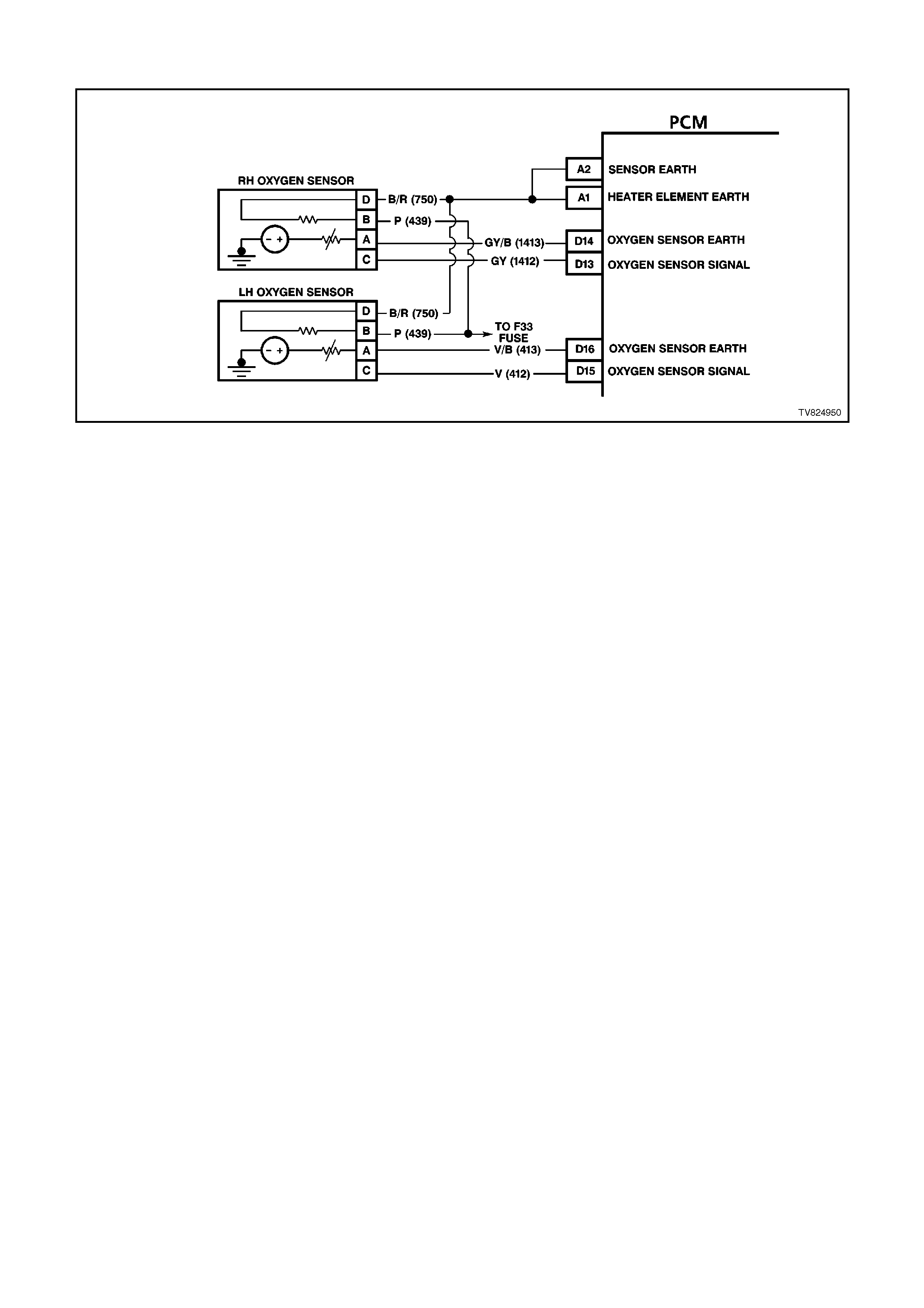

D13 R/H OXYGEN SENSOR SIGNAL INPUT - With the ignition ON and the engine OFF, the voltage should be

between 350 and 450 millivolts (.350 -.450 volts). This is the PCM-supplied O2 circuit "bias" voltage. With the

engine running and the O2 sensor in closed loop, the voltage should be changing between 10 - 1000 millivolts

(.010 - 1.000 volt).

D14 R/H OXYGEN SENSOR EARTH CIRCUIT - This terminal should have zero volts. This circuit is connected

directly to the engine earth. This terminal earths the PCM circuitry for the O2 voltage inside the PCM.

D15 L/H OXYGEN SENSOR SIGNAL INPUT - With the ignition ON and the engine OFF, the voltage should be

between 350 and 450 millivolts (.350 -.450 volts). This is the PCM-supplied O2 circuit "bias" voltage. With the

engine running and the O2 sensor in closed loop, the voltage should be changing between 10 - 1000 millivolts

(.010 - 1.000 volt).

D16 L/H OXYGEN SENSOR EARTH CIRCUIT - This terminal should have zero volts. This circuit is connected

directly to the engine earth. This terminal earths the PCM circuitry for the O2 voltage inside the PCM.

PINS E1 - E16

E1 FUEL INJECTOR CONTROL - With the engine OFF and the ignition ON, the voltage should be B+. With the

engine running at idle, the charging system increases the battery voltage slightly, so this voltages will increase.

With higher engine RPM or more engine load, the resulting increase in injector pulse frequency or injector

pulse width will cause this voltage to become slightly less.

E2 SAME AS E1

E3 SAME AS E1

E4 SAME AS E1

E5 SAME AS E1

E6 RANGE SIGNAL "A" - The PCM sends out a buffered B+ signal to the pressure switch assembly. The B+

signal must pass through a series of switches to earth. When the switch(es) are closed, the voltage should be

near 0. The PCM monitors this voltage to calculate the position of the manual valve.

E7 RANGE SIGNAL "B"- SAME AS E6

E8 RANGE SIGNAL "C"- SAME AS E6

E9 NOT USED

E10 NOT USED

E11 NOT USED

E12 OIL PRESSURE SWITCH - This is a earth input to the PCM from the Oil Pressure Switch indicating proper oil

pressure when the engine is running. If oil pressure is lost while the engine is running, the oil switch will open

its contacts and the earth signal to the PCM will be removed. When the PCM sees this loss of earth signal, the

PCM will command the oil lamp ON.

E13 NOT USED

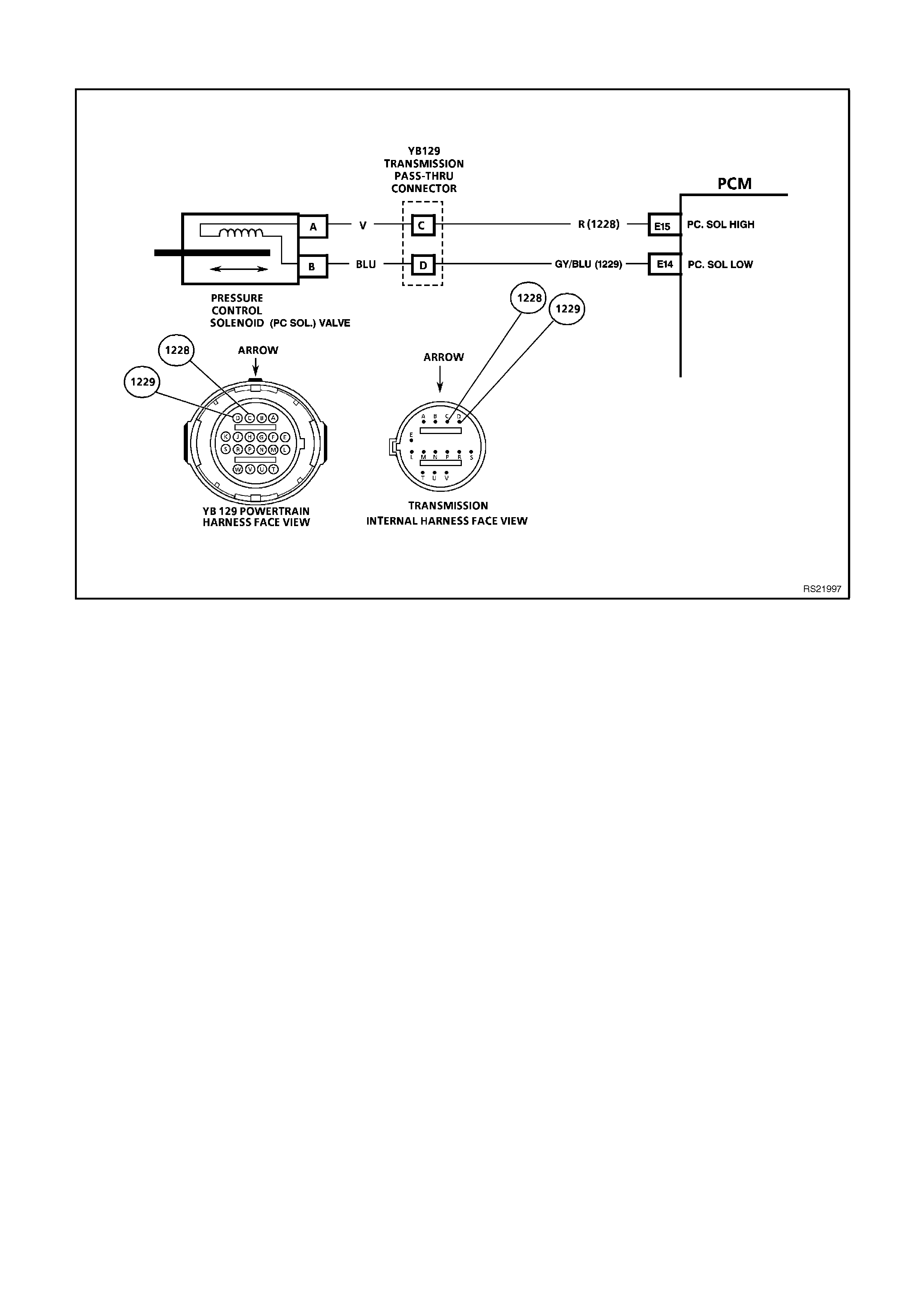

E14 TRANSMISSION PRESSURE CONTROL

SOLENOID (PCS) - LOW

AUTO TRANS ONLY

The 4L60-E automatic transmission uses an electrical solenoid to control hydraulic pressure inside the

transmission. This electrical solenoid allows the PCM to control "line pressure", similar to other automatic

transmissions that use a "throttle valve" cable or vacuum modulator. The duty cycle, and amount of current

flow to the PCS, are both controlled by the PCM. By monitoring this line, the PCM can determine if the

commanded amperage has gone to the PCS and returned to the PCM.

E15 TRANSMISSION PRESSURE CONTROL

SOLENOID (PCS) - HIGH

AUTO TRANS ONLY

The duty cycle, and amount of current flow to the PCS, are controlled by the PCM. This circuit is the B+ supply

line from the PCM to the PCS. The duty cycle and amperage are controlled by the PCM.

E16 ECT/TP SENSOR EARTH - This terminal should be zero volts. This circuit is connected through the PCM to

the engine earth.

PINS F1 - F16

F1 FUEL INJECTOR CONTROL - With the engine OFF and the ignition ON, the voltage should be B+. With the

engine running at idle, the charging system increases the battery voltage slightly, so this voltages will increase.

With higher engine RPM or more engine load, the resulting increase in injector pulse frequency or injector

pulse width will cause this voltage to become slightly less.

F2 SAME AS F1

F3 SAME AS F1

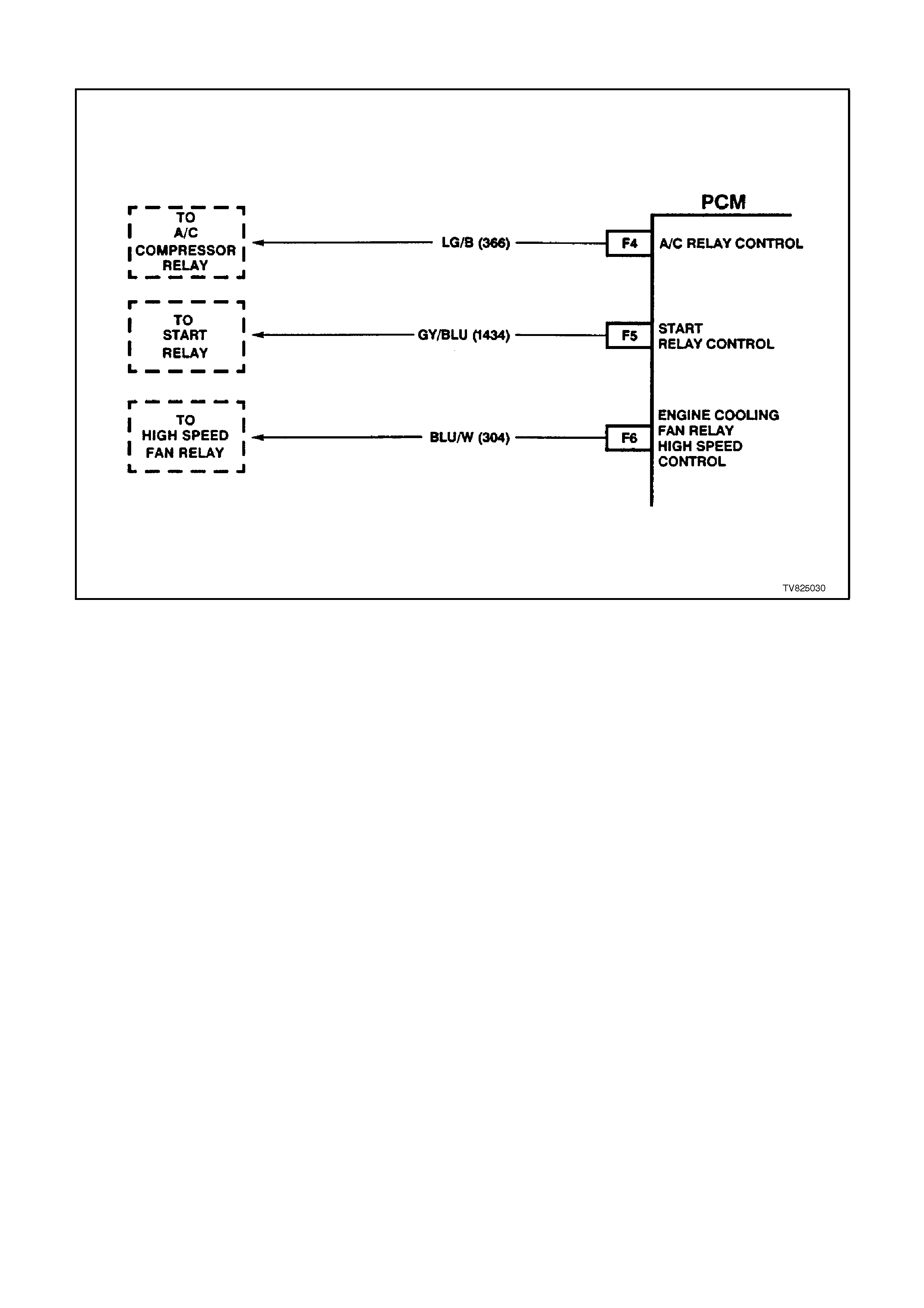

F4 AIR CONDITIONING RELAY CONTROL -

When the A/C is requested, the BCM will communicate to the PCM via the serial data line, requesting A/C. The

PCM supplies the earth path on this terminal to energise the A/C control relay. The voltage will be less than 1

volt when the PCM energises the relay. When the PCM does energise the A/C control relay, the voltage will be

more than 0.1, but less than 1 volt.

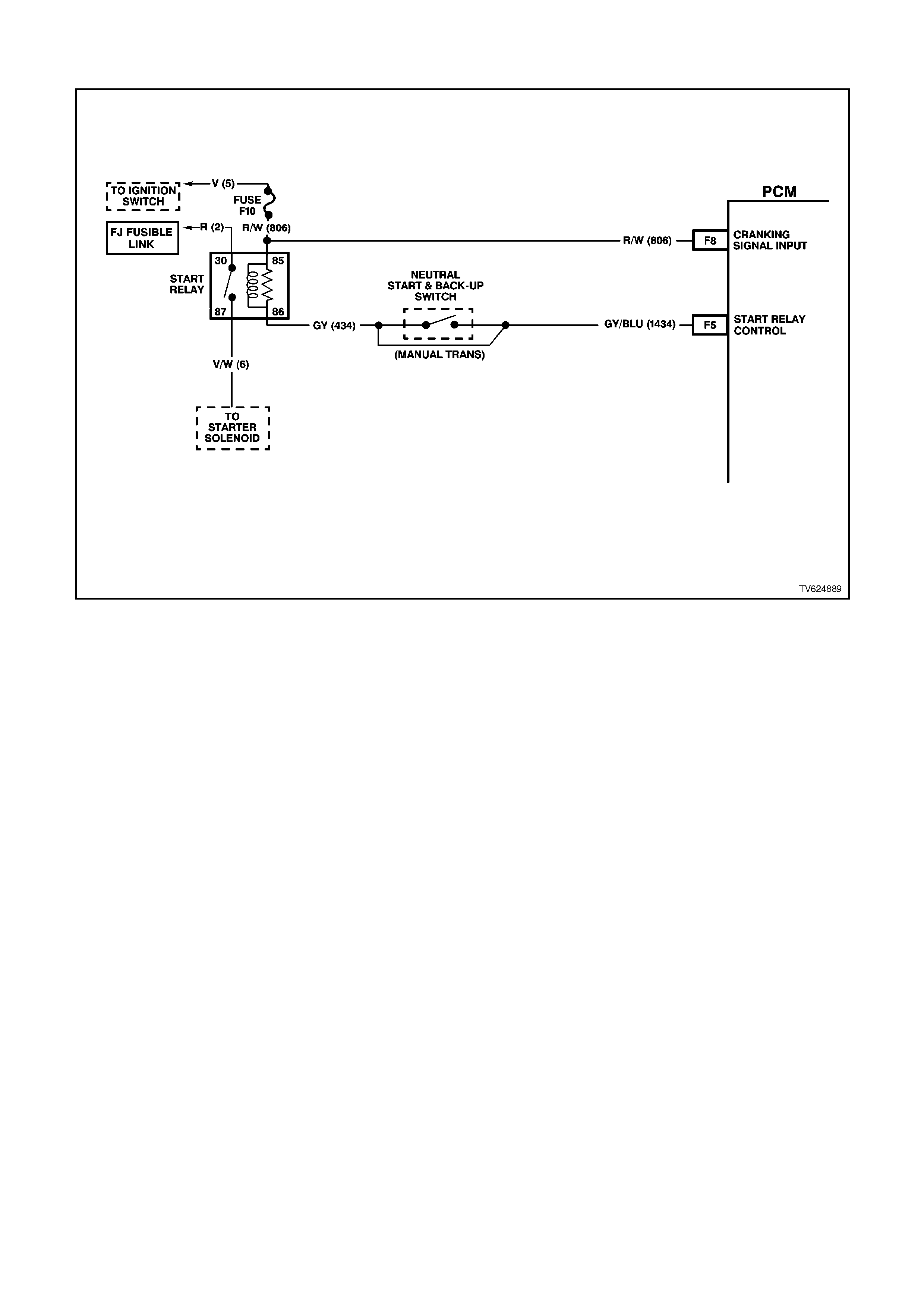

F5 START RELAY CONTROL - When the PCM receives the ignition voltage from the Cranking Signal Input

circuit, the PCM will then supply the earth signal needed to energise the Start Relay Control. Once this Start

Relay Control is energised, power is supplied to the starter.

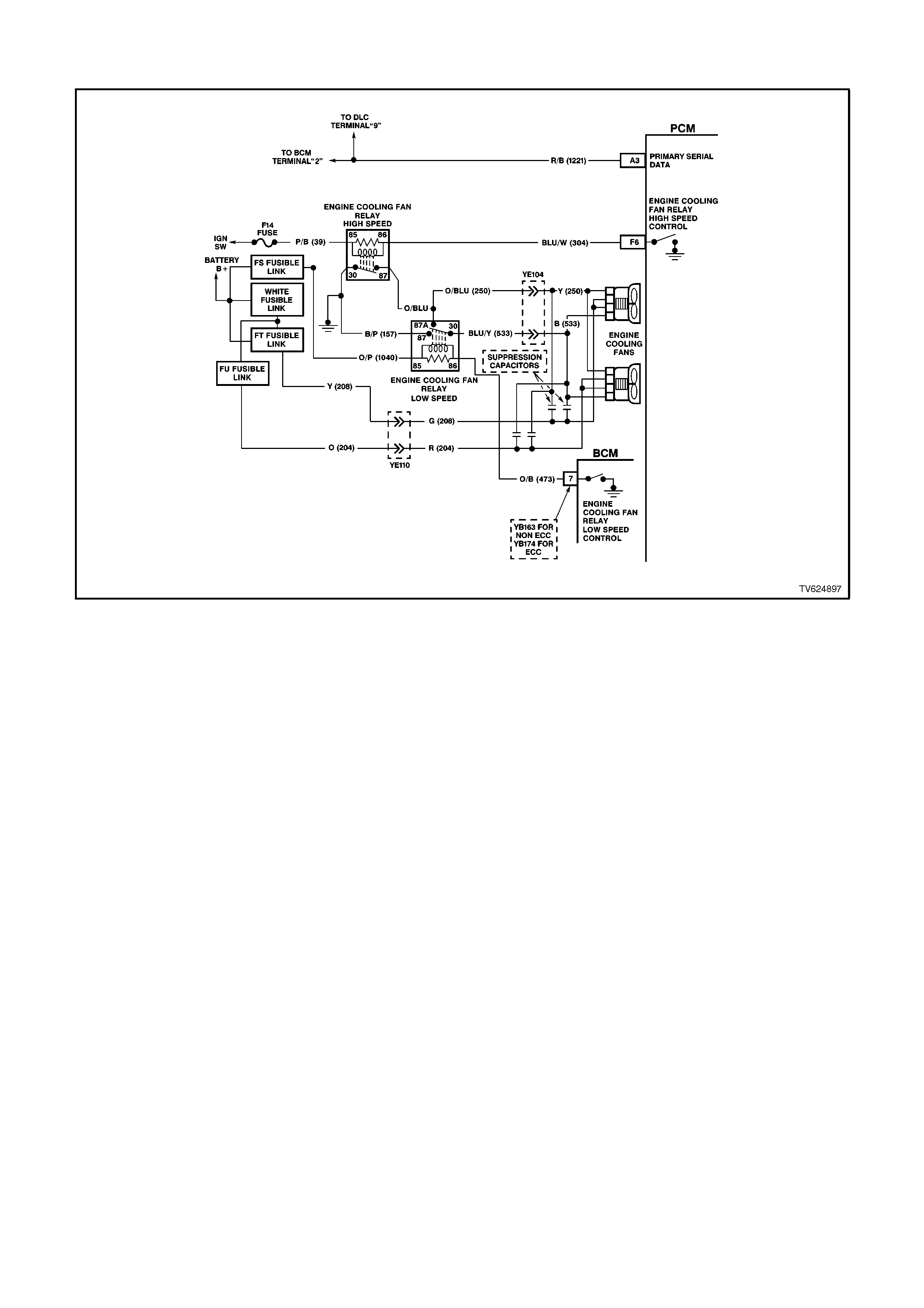

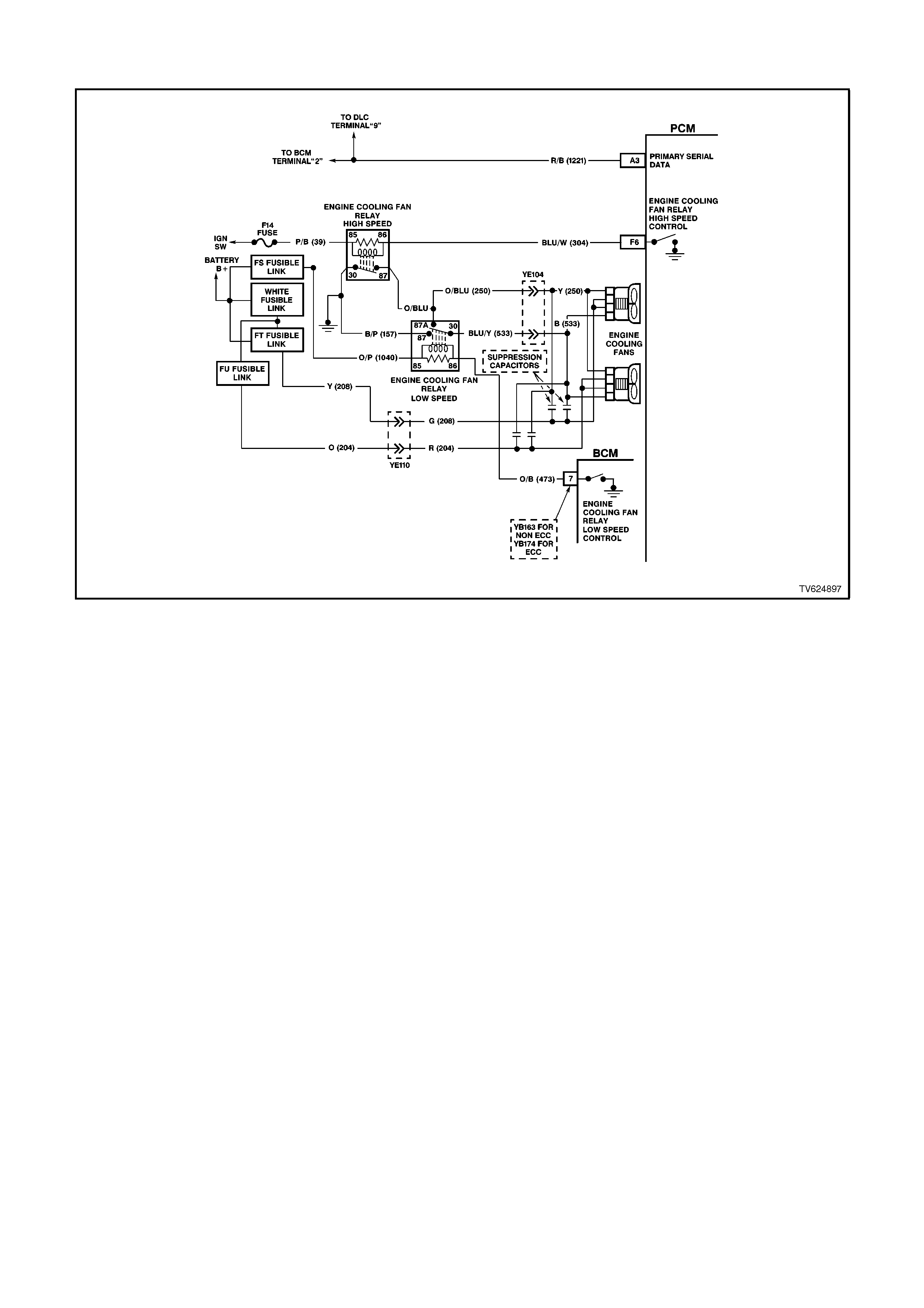

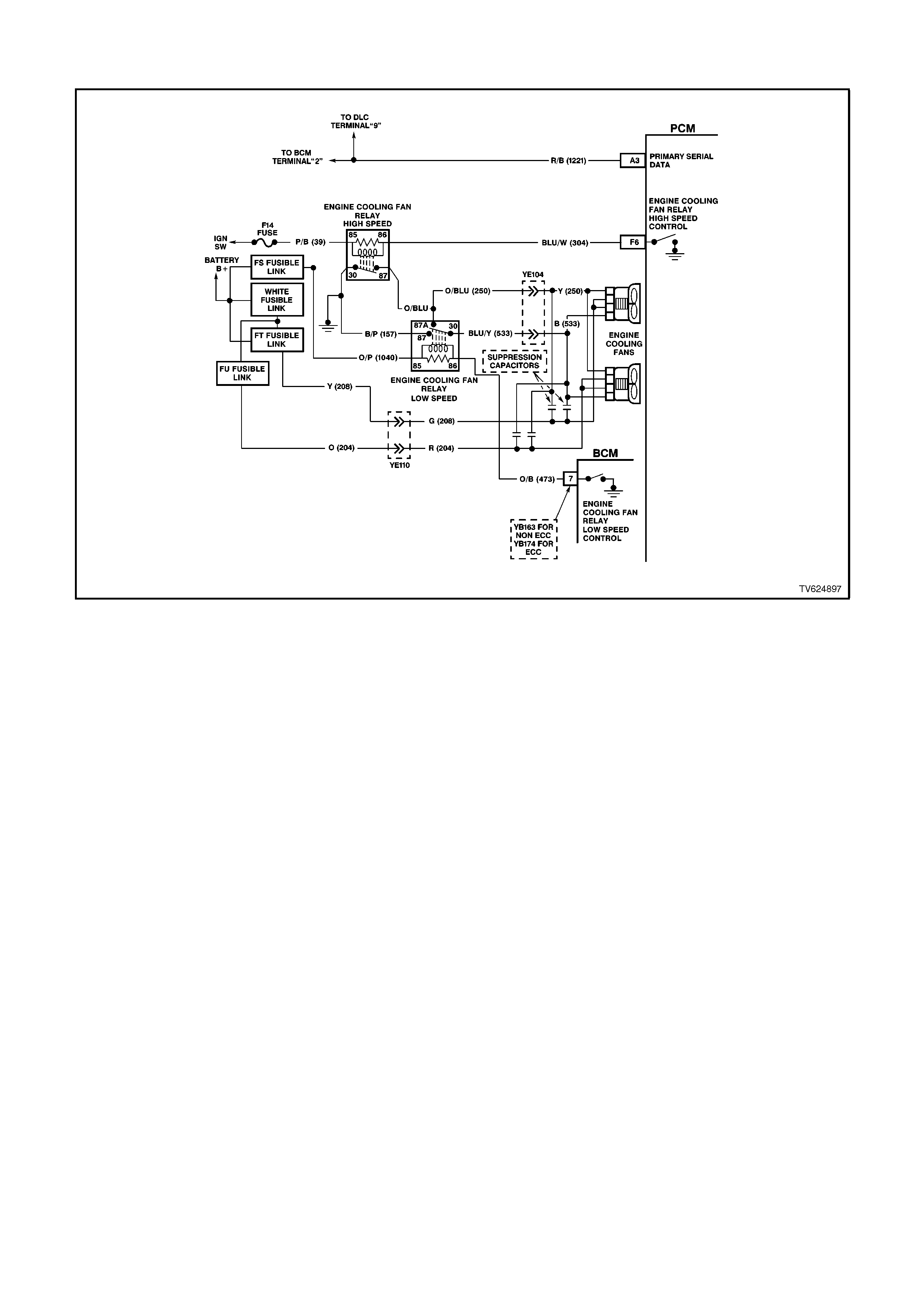

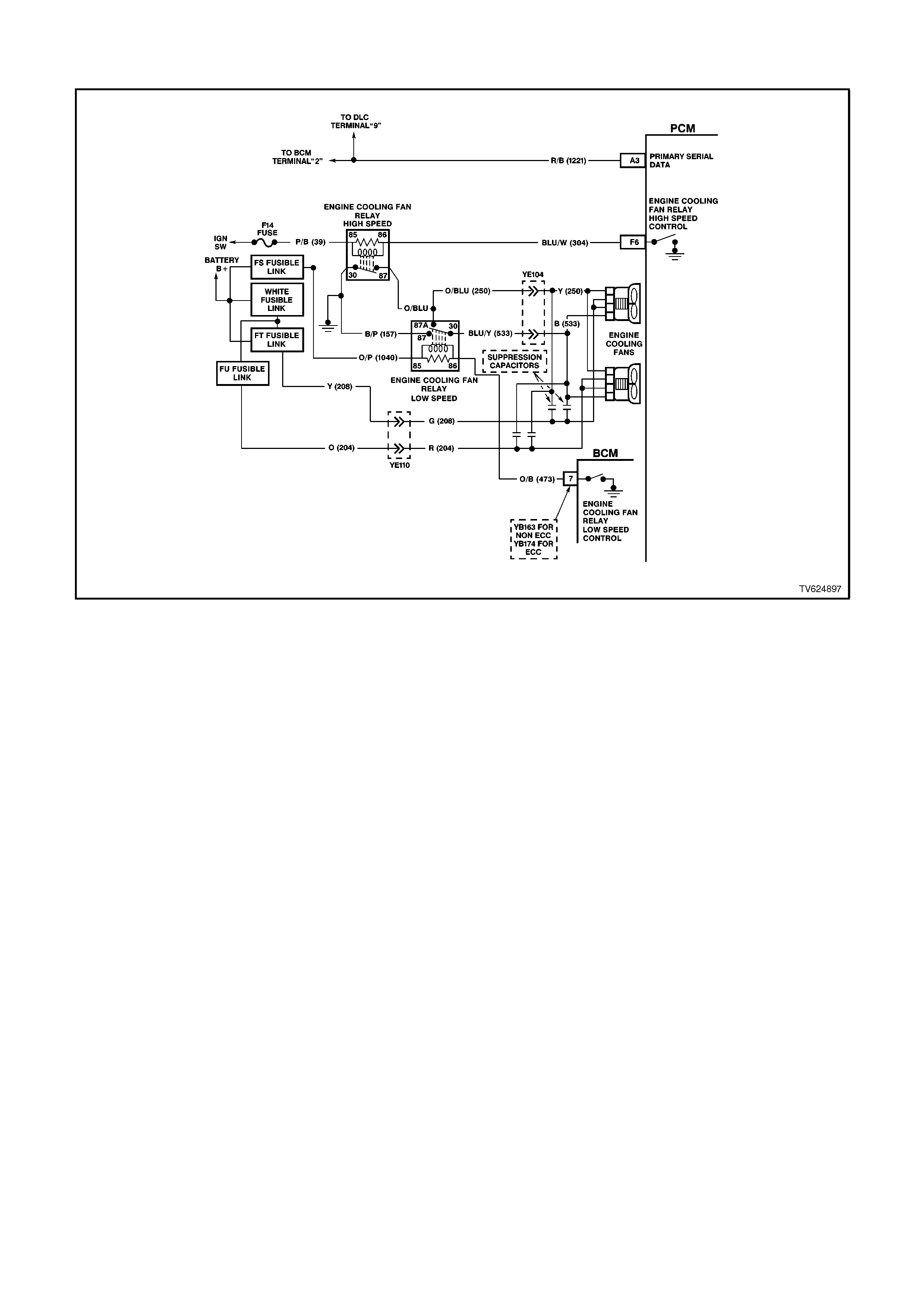

F6 ENGINE COOLING FAN - HIGH SPEED RELAY CONTROL -This terminal will have B+ until the PCM

energises the high speed cooling fan relay. The input that causes the PCM to energise the high speed fan relay

is the engine coolant temperature sensor. The PCM will also energise the high speed fan relay in the

Diagnostic Mode - i.e., ignition ON, engine stopped, and DLC diagnostic "test" enable terminal earthed.

F7 NOT USED

F8 NOT USED

F9 RANGE SIGNAL A INPUT SIGNAL

F10 RANGE SIGNAL B INPUT SIGNAL

F11 RANGE SIGNAL C INPUT SIGNAL

AUTO TRANS ONLY

Range signal "A", "B" and "C". The PCM sends out a buffered 12 volt signal to the pressure switch assembly,

located in the automatic transmission valve body. The 12 volt signal must pass through either a normally open

or normally closed switch to reach earth. When the switch(es) are closed, the signal should be near 0 volts.

The PCM monitors the status of these signals to determine which gear servo is actually receiving hydraulic

apply pressure.

F12 NORMAL / ECONOMY INPUT SIGNAL

AUTO TRANS ONLY

The PCM sends a signal of about 12 volts, and monitors the status of this circuit. In the ECONOMY position

the switch is open, the PCM voltage status signal remains high - about 12 volts, and the PCM does not allow

shift point changes. When the transmission switch is pressed to the POWER position the switch is closed and

the PCM voltage status signal is pulled low - about 0 volts. The PCM senses the zero voltage signal, and

enables power mode shifting only if other criteria are met. These criteria include throttle position and engine

speed.

F13 NOT USED

F14 DIAGNOSTIC TEST ENABLE INPUT - This terminal is connected to the DLC. When the diagnostic test

terminal is not earthed, this terminal will read 5 volts. When the DLC diagnostic test enable terminal is earthed,

the resulting zero voltage at the PCM will cause the PCM to operate in the Diagnostic Mode.

F15 PRNDL P - This circuit along with PCM circuits E6, E7, E8 indicate to the PCM what transmission gear the

driver has selected. The PCM will then send a command via the serial data line to the instrument panel cluster

to indicate to the driver what gear has been selected.

F16 INTAKE AIR TEMPERATURE / TRANSMISSION FLUID TEMPERATURE /A/C PRESSURE SENSOR

EARTH CIRCUIT - This terminal should be zero volts. It is connected through the PCM circuitry to engine

earth.

TECH 2 SCAN ENGINE DATA

The Tech 2 scan Data listed in the table may be used for comparison

1. After completing the " ON-BOARD DIAGNOSTIC SYSTEM CHECK"

2. Finding the on-board diagnostics are functioning properly and

3. No diagnostic DTCs are displayed.

A TECH 2 SCAN TOOL THAT DISPLAYS FAULTY DATA SHOULD NOT BE USED, AND THE PROBLEM

SHOULD BE REPORTED TO THE MANUFACTURER. THE USE OF A FAULTY TECH 2 SCAN TOOL CAN

RESULT IN MISDIAGNOSIS AND UNNECESSARY PARTS REPLACEMENT.

Only the parameters listed are used in this Volume for diagnosis. For more description on the values and use of the

Tech 2 scan tool to diagnosis PCM inputs, refer to the applicable diagnosis chart in this Section. If all values are

within the range illustrated, refer to "Symptoms" Charts in Section 6C2-2B.

TEST DESCRIPTION:

Number(s) below refer to number(s) on the Tech 2 Scan Data Engine Stream chart.

1. The Tech 2 scan tool "FO: DATA LIST" will display scan position's that will be displayed in order. The Tech 2

can tool will display nine (9) scan position parameters at a time. The "DOWN ARROW" button will scroll down

through all of the scan positions one at a time. After "Time From Start" parameter is displayed, pressing the

"DOWN ARROW" button again, will display scan position parameters starting at the top of the list again.

2. "Units Displayed" are the available ways of displaying what each parameter is currently operating in, or a value

that is being sensed or being output by the PCM.

3. "Typical Data Value" is separated into two parts. These displayed values are typical of a normally operating

vehicle. The ignition "ON" comparison should be performed first as this may lead to a quick identification of a

failure. The engine running data should be compared to the ignition "ON" data as a diagnostic check to make

sure the component or system is operating properly.

4. Ignition "ON" values are the typical values that should be seen on the Tech 2 scan tool with the ignition "ON,"

and engine stopped. Temperature sensors should be compared to the actual temperatures by letting the

sensor sit overnight and then comparing their values. A difference of 3-5 degrees C from the actual

temperature may indicate a problem with the sensor. Use the diagnostic aids chart for that sensor to compare

the resistance to temperature values.

5. "ENGINE RUNNING" typical data values are an average of display values recorded from normally operating

vehicles at normally operating temperature. They are intended to represent what a normally functioning system

would typically display.

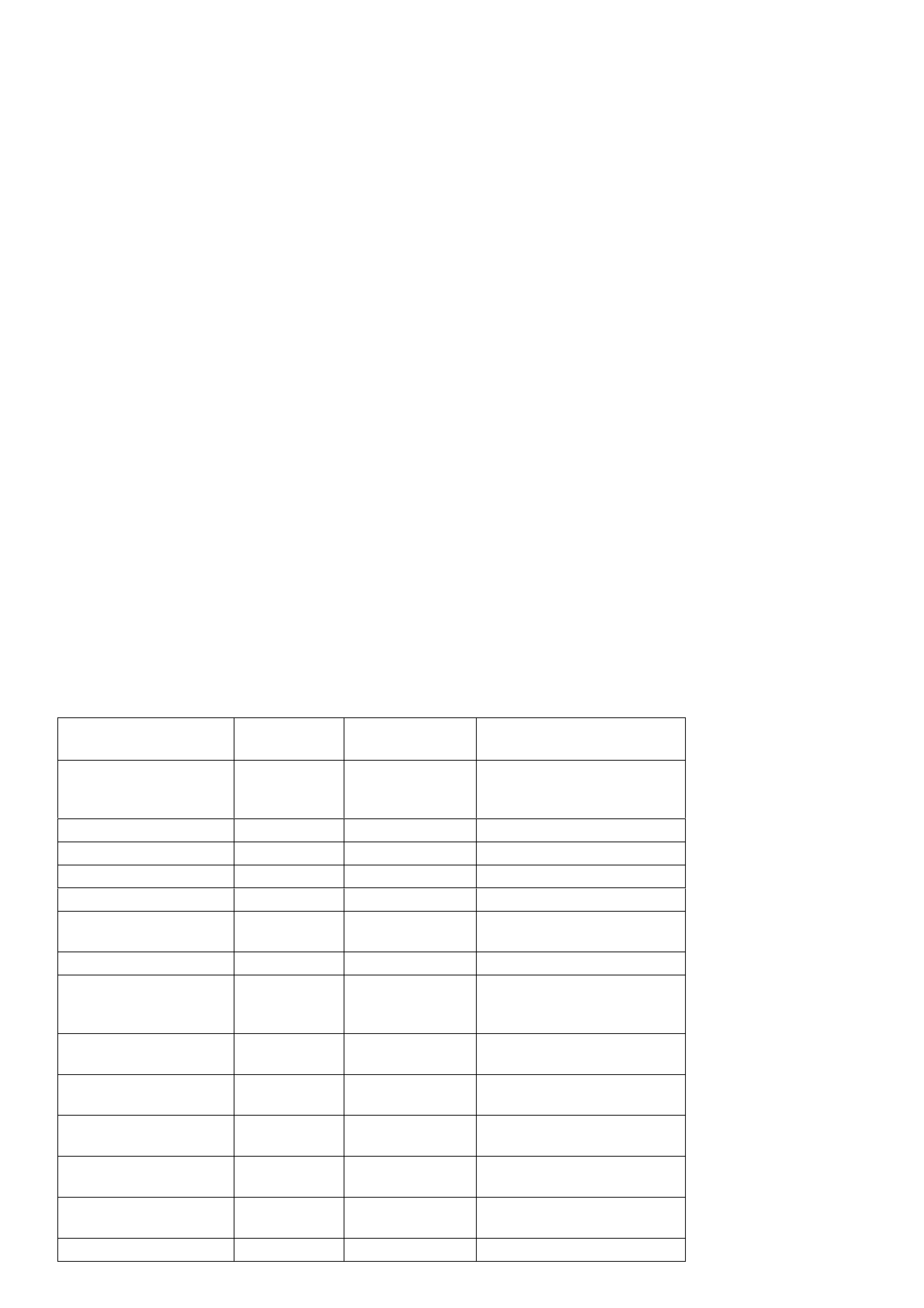

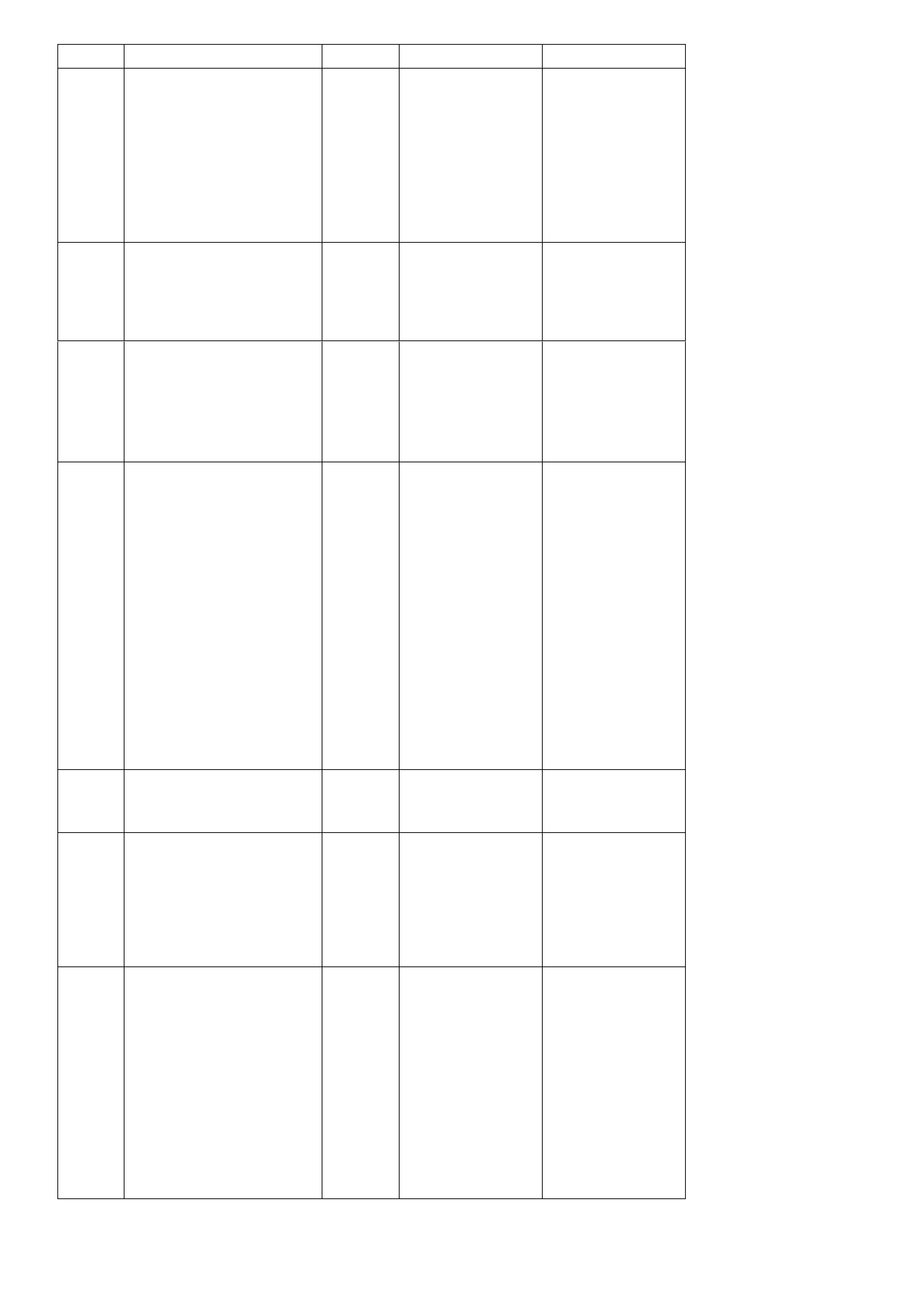

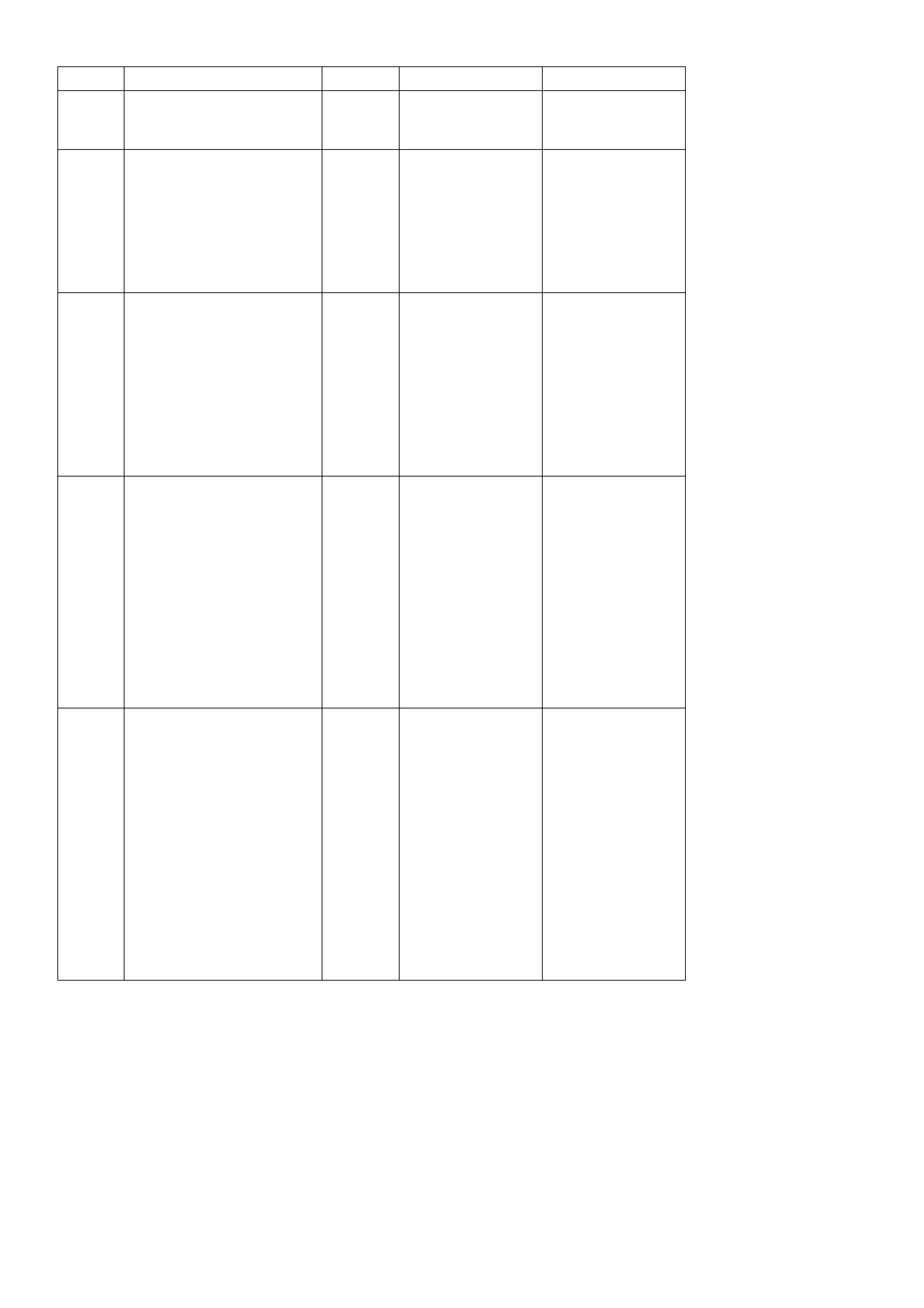

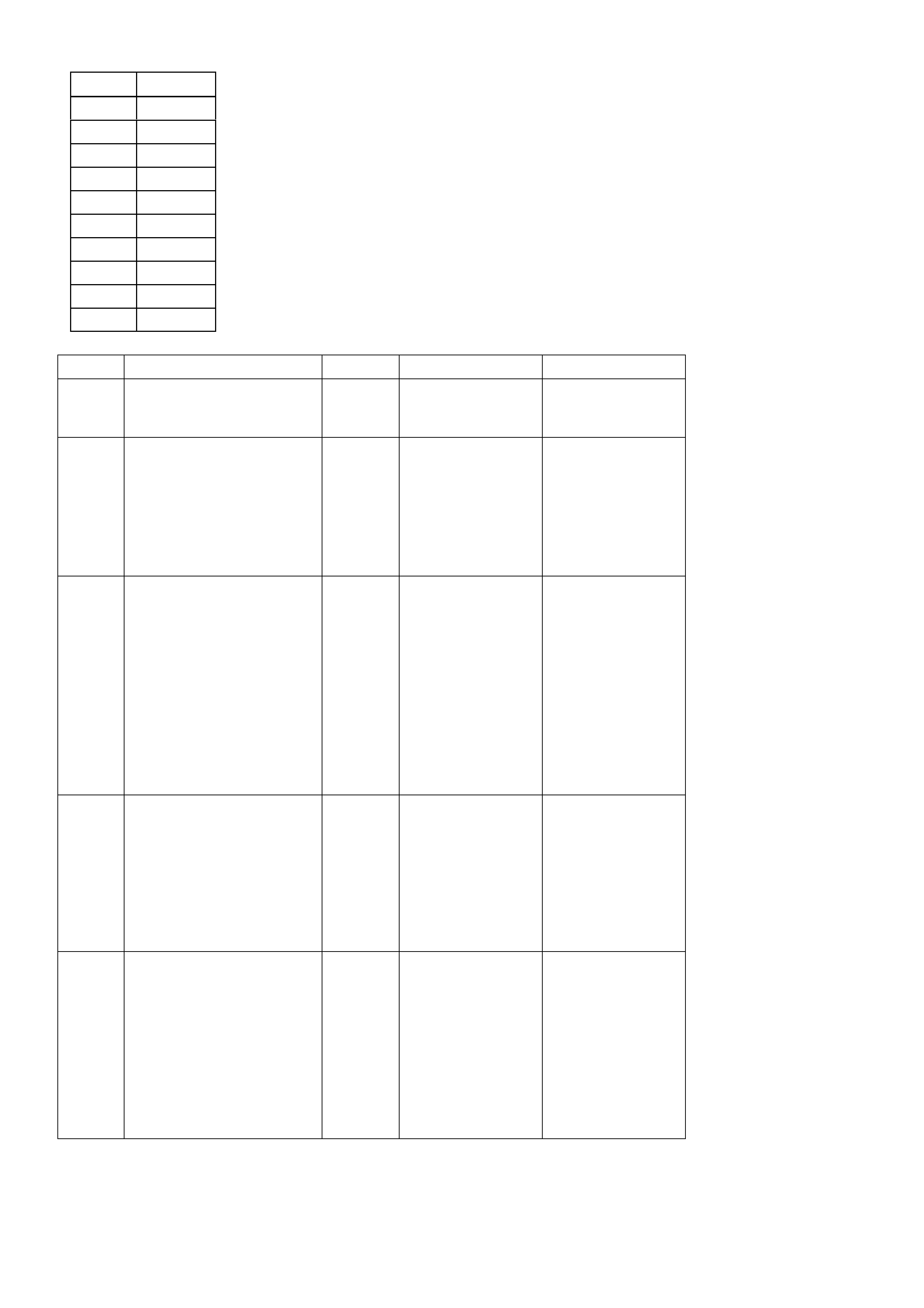

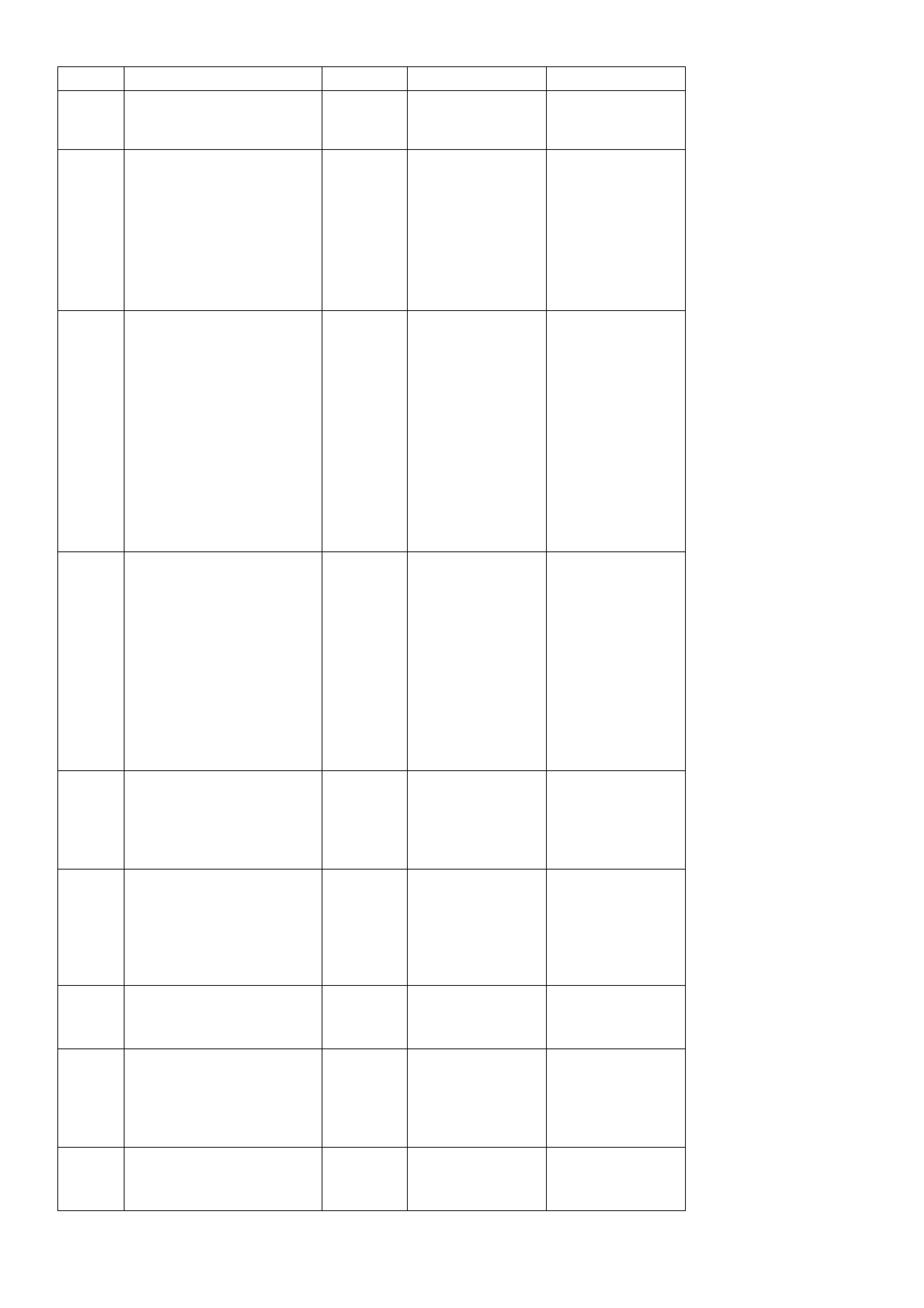

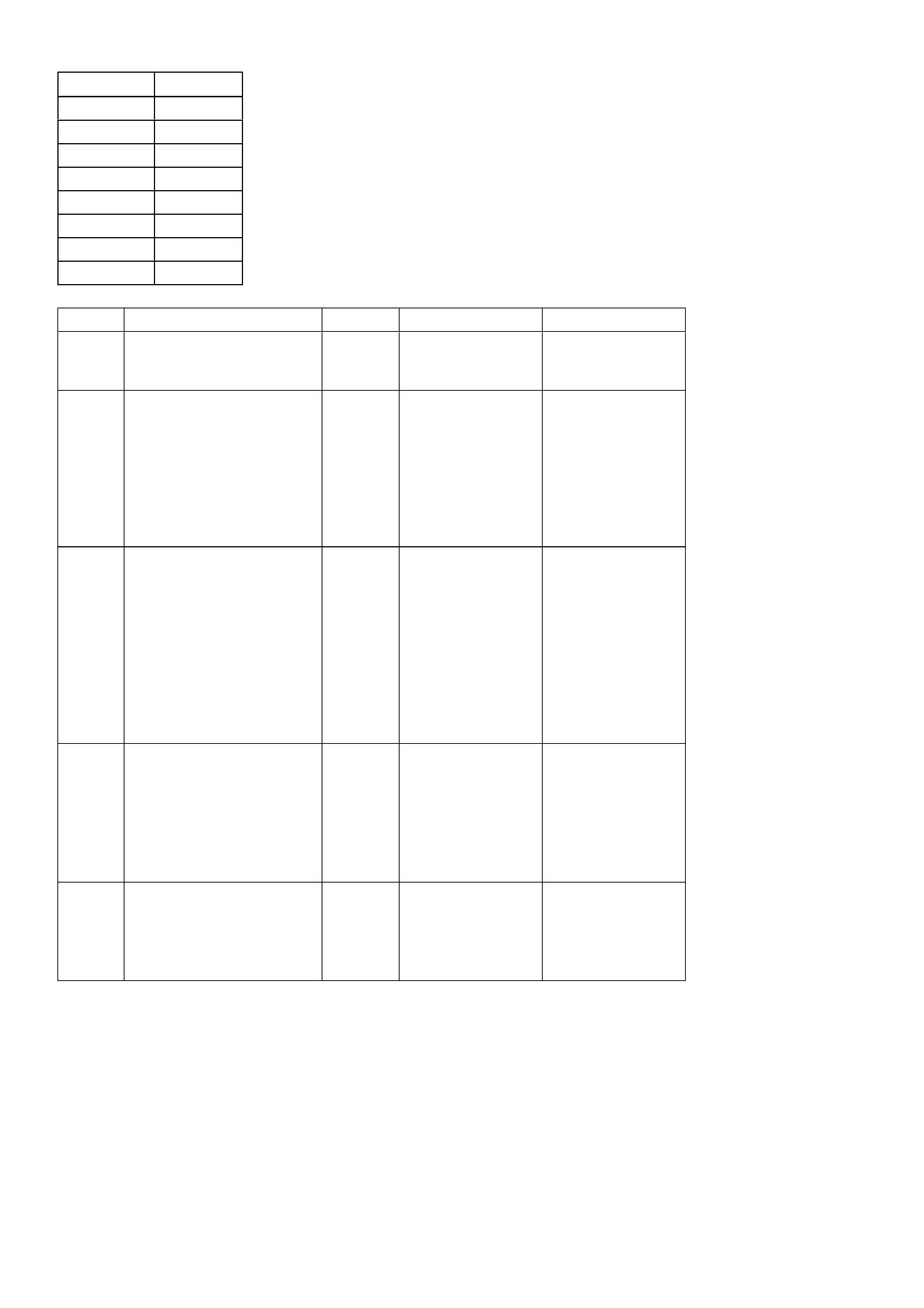

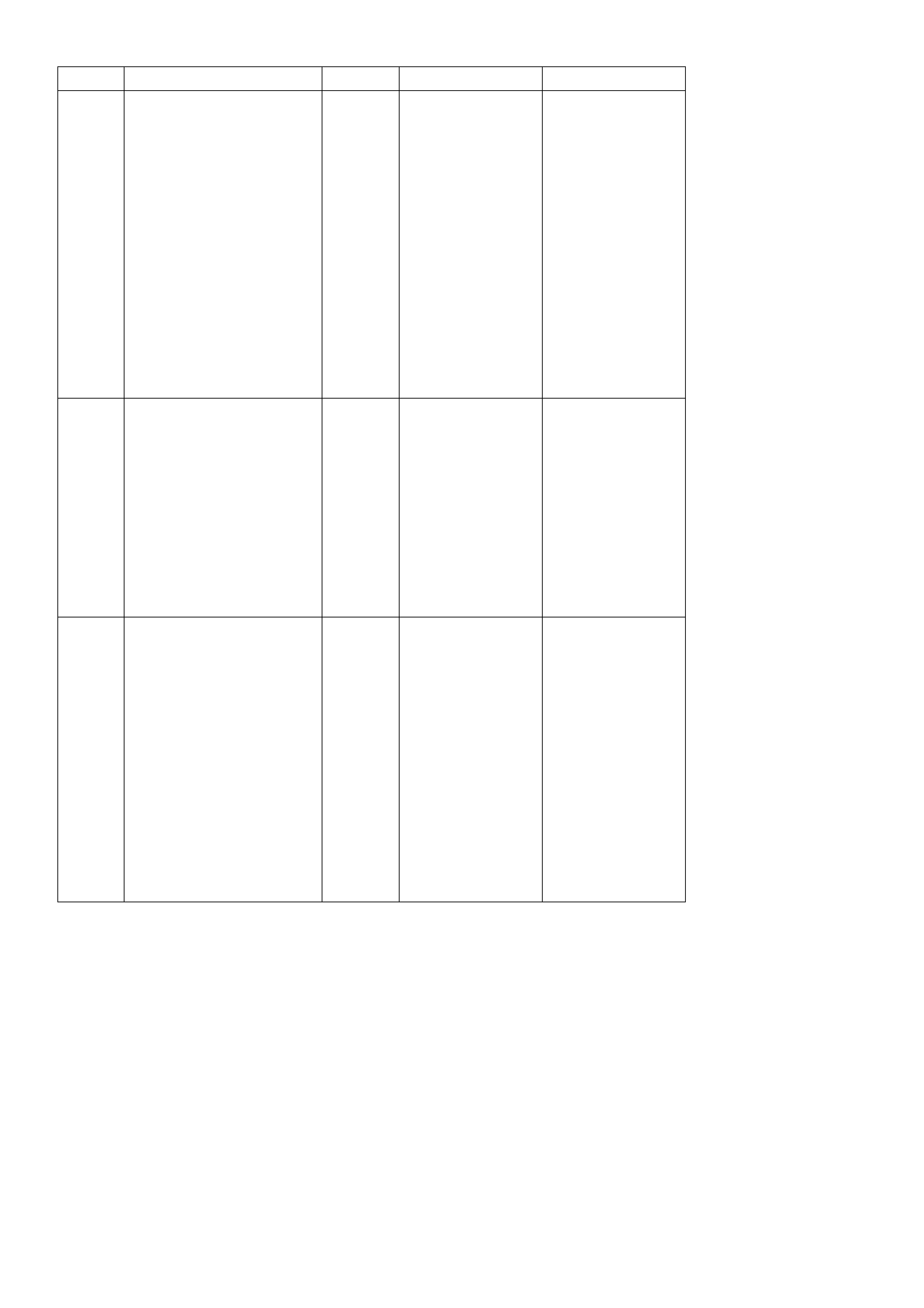

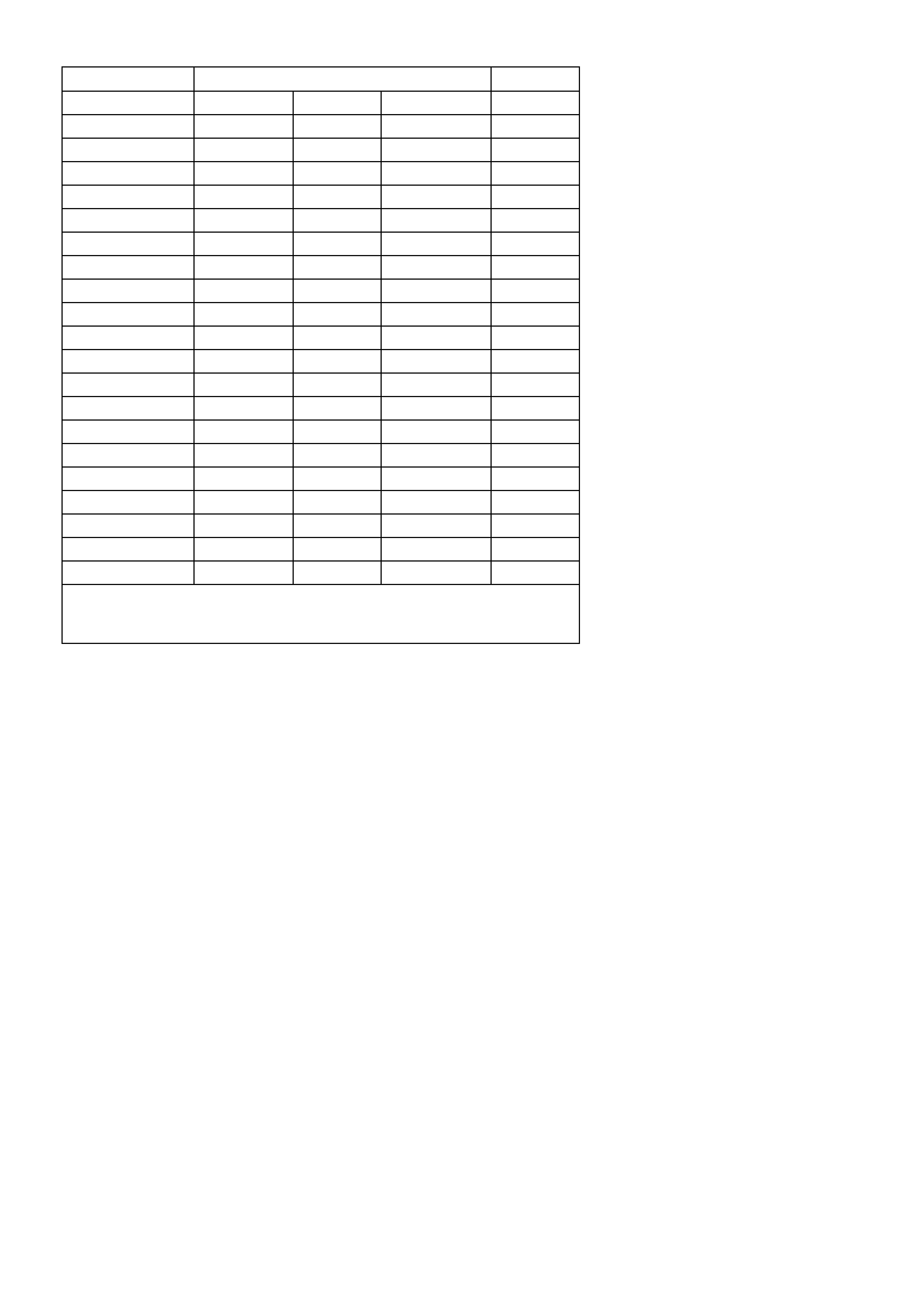

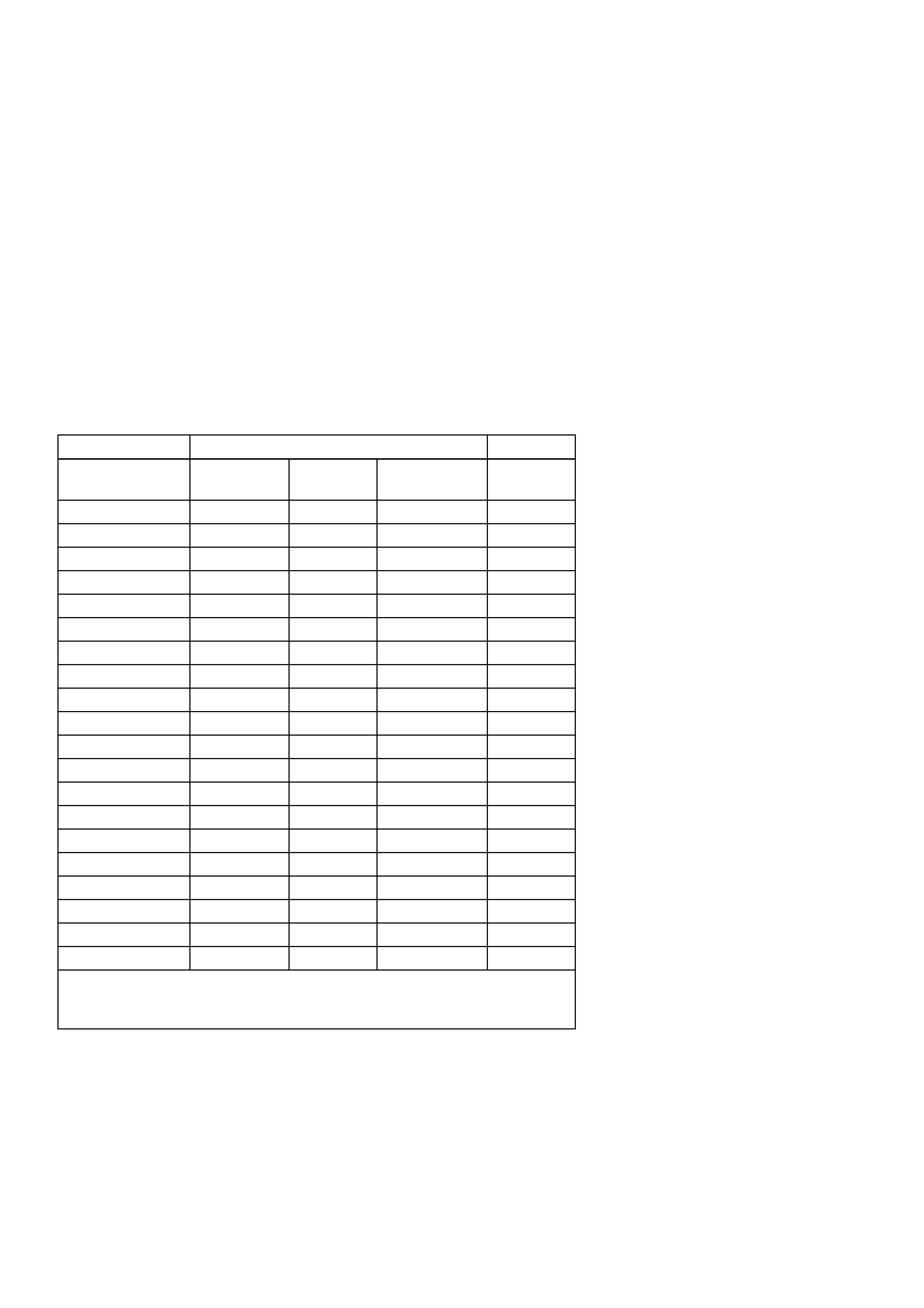

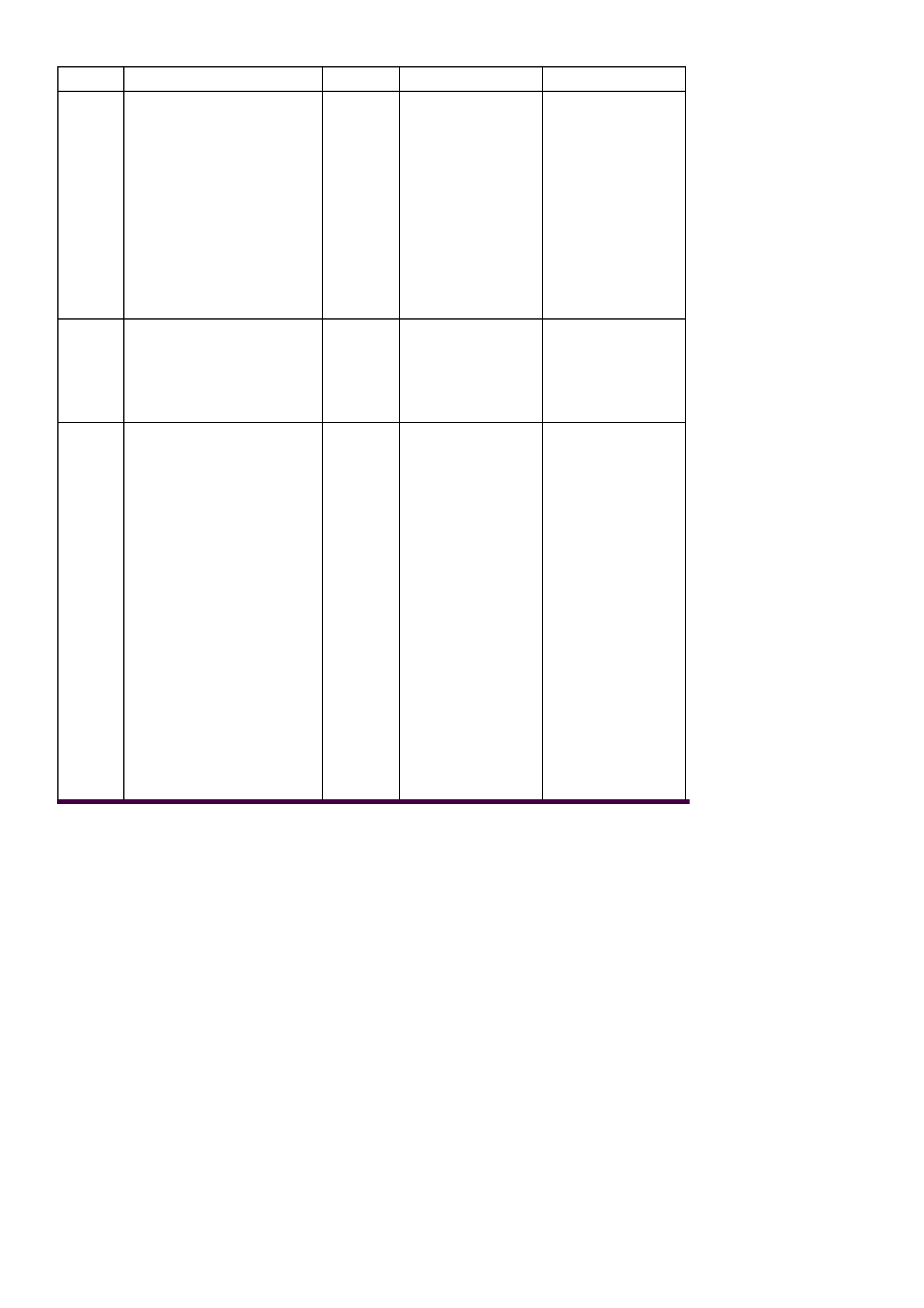

TECH 2 SCAN DATA ENGINE STREAM

TYPICAL DATA VALUE !

!!

!

SCAN POSITION "UNITS

DISPLAYED # IGNITION

"ON" $ENGINE RUNNING %

ENGINE SPEED RPM 0 RPM ± 100 RPM FROM DESIRED

RPM

(± 50 RPM IN DRIVE)

DESIRED IDLE

SPEED RPM 0 RPM PCM IDLE COMMAND

(VARIES WITH

TEMPERATURE)

ECT SENSOR VOLTS VOLTS Varies 1.96 V

ENG. COOLANT

TEMP DEGREES C Varies +96 C

IAT VOLTAGE VOLTS Varies Varies

IAT DEGREES C Varies Varies

MAF SENSOR

FREQUENCY Hz 0 Hz 2600-2900 Hz

MASS AIR FLOW GRAM /SEC 0 G/S 5 -10 G/S

MASS AIR FLW/CYL mG/S 0.0 mG/S 150-170 mG/S

TPS SIGNAL

VOLTAGE VOLTS 0.32 V 0.47 V

TPS ANGLE 0-100 % 0 % 0 %

RH O2 SENSOR

READY YES / NO NO YES

LH O2 SENSOR

READY YES / NO NO YES

RH O2 SENSOR mV 447

mV(varies) 100 - 1000 mV AND

VARYING

LH O2 SENSOR mV 447

mV(varies) 100 - 1000 mV AND

VARYING

ST FUEL TRIM R + 0 - 100 % 0 % + 0 % to 10%

ST FUEL TRIM L + 0 - 100 % 0 % + 0 % to 10 %

LT FUEL TRIM R + 0 - 100 % 0% + 0 % to 10%

LT FUEL TRIM L + 0 - 100 % 0 % + 0 % to 10 %

LTFT ENABLE YES / NO NO NO

FUELLING MODE OPEN /

CLOSED LOOP OPEN LOOP CLOSED LOOP

LTFT CELL CELL # 0 0

RH O2 STATUS RICH / LEAN LEAN Rich

LH O2 STATUS RICH / LEAN LEAN Rich

RH O2 CROSS CNTS COUNTS 0 0

LH O2 CROSS CNTS COUNTS 0 0

STFT DELTA 0 - 100 % 0 % 0 - 10%

LTFT DELTA 0 - 100 % 0 % 0 - 10%

DECEL FUEL CUT-

OFF NO/YES NO NO

INJ. PULSE TIME mS 27.5 mS 3-5 mS

INJECTOR VOLTAGE VOLTS 11.4 V 14.0 V

AIR / FUEL RATIO % 0.0 : 1 14.0 : 1

PURGE PWM % 0 % 0 -15 %

BATTERY VOLTAGE VOLTS 11.3 V 14.0 V

REFERENCE VOLTS VOLTS 4.99 V 4.99 V

CRANK SWITCH CRANKING/OF

FOFF OFF

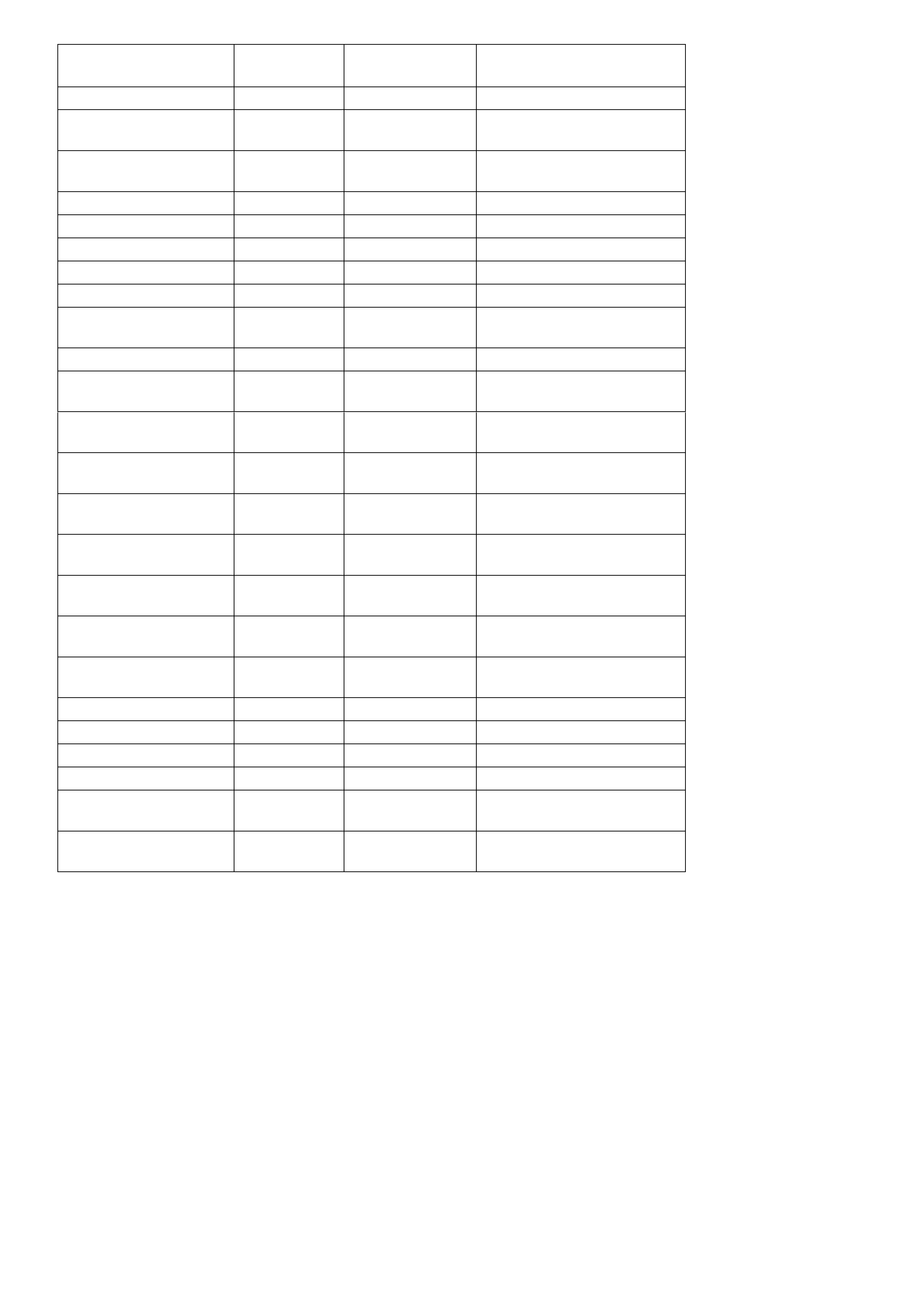

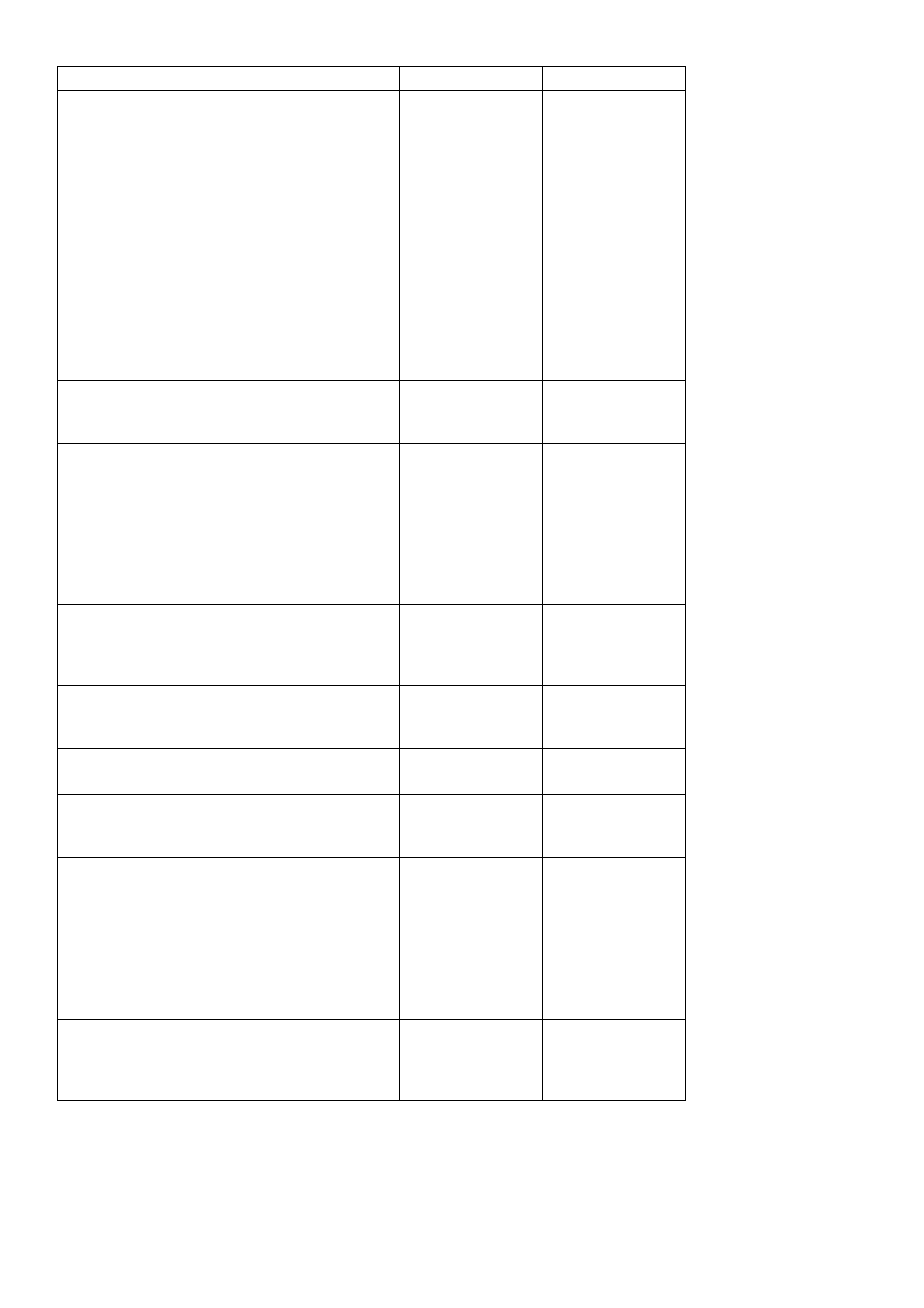

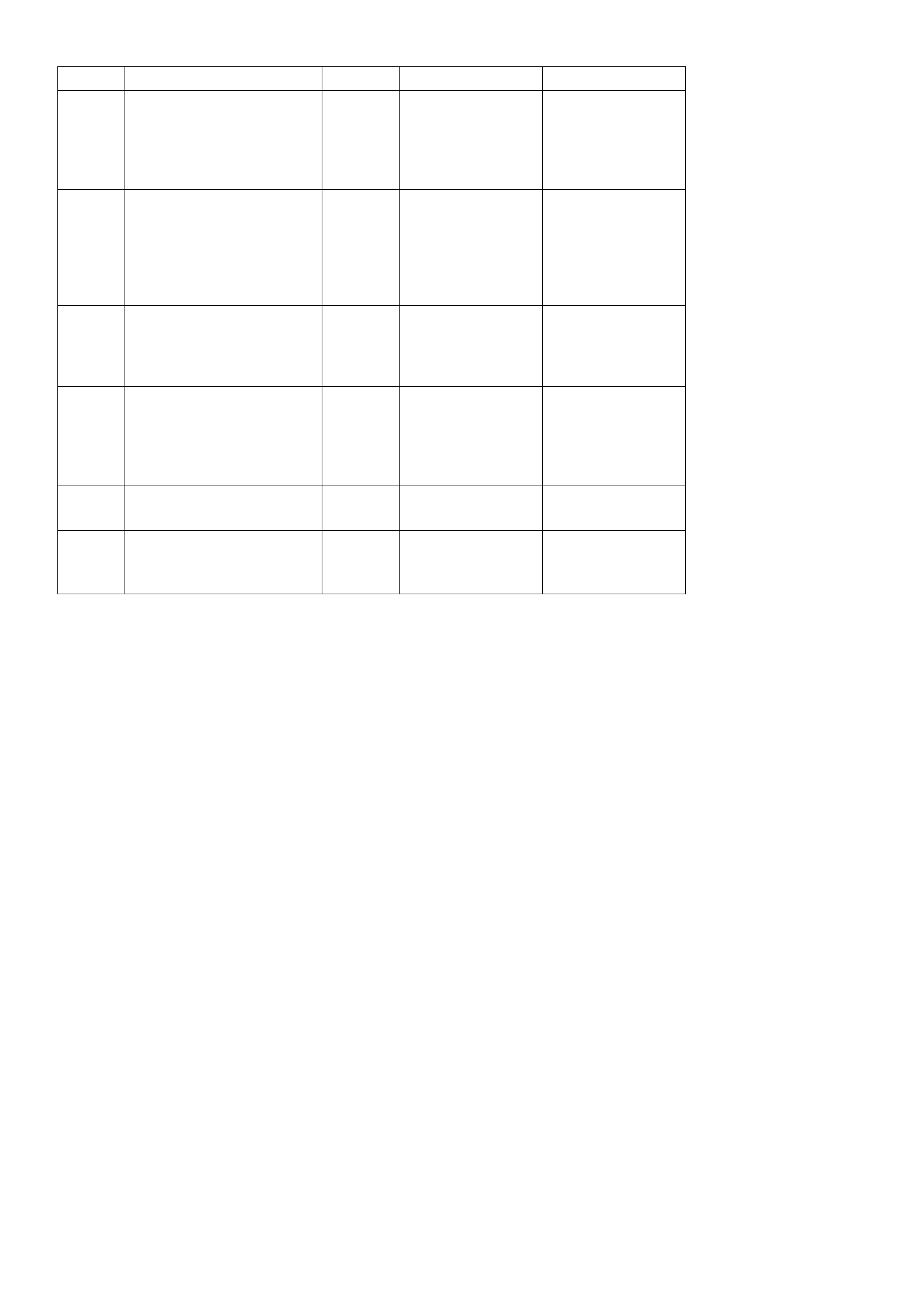

TYPICAL DATA VALUE !

!!

!

CAM SIGNAL MISSING

/PRESENT MISSING PRESENT

IAC POSITION STEPS 30-50

STEPS 25 -50 STEPS

LITRES / Hr LITRES/Hr 00.00 2.50 L/Hour

IDLE RPM VARIANT RPM 0 RPM 9 RPM

SPARK MODE BYPASS/EST BYPASS EST

SPARK ADVANCE DEGREES

BTDC + 0° BTDC + 18 ° BTDC

KNOCK SIGNAL KNOCK/NONE NONE NONE

KNOCK RETARD # OF DEGREES 0 ° 0 °

TCC SOLENOID ON / OFF OFF OFF

VEHICLE SPEED KM / H 0 KM/H 0 KM/H

A/C REQUEST ON /OFF OFF OFF

A/C CLUTCH ON /OFF OFF OFF

A/C PRESSURE

VOLTS VOLTS 1-2 V 1-2 V

A/C PRESSURE kPa 400 - 600

kPa 400 -600 kPa A/C OFF

800 -1000 kPa A/C ON

HIGH SPEED FAN ON / OFF OFF OFF

LOW SPEED FAN

REQUEST ON / OFF OFF ON or OFF

THEFT STATUS NO

START/START START START

STARTER RELAY OFF/ON ON ON

FUEL PUMP RELAY ON / OFF OFF ON

CRANK TIME SEC 0.0 SEC 0.5 SEC

DTC STATUS NO

DTC(s)/DTC(s)

SET

NO DTC(s) NO DTC(s)

TIME FROM START TIME 0:00:00 VARIES FROM START

PROM I.D. FOUR DIGITS Varies with

Prom

Updates

Varies with PROM Updates

CHECK

POWERTRAIN LAMP ON/OFF ON OFF

TECH 2 SCAN ENGINE DATA DESCRIPTIONS

A list of explanations for each data message displayed on the Tech 2 scan tool is listed below. This information will

assist in diagnosing emission or driveability problems. The displays can be viewed while the vehicle is being driven.

Refer to the " On-Board Diagnostic System Check" for additional informational.

ENGINE SPEED - Range 0-9999 RPM - The engine speed is computed by the PCM from the fuel control reference

input. It should remain close to desired idle under various engine loads with engine idling.

DESIRED IDLE SPEED- Range 0-3175 RPM - The idle speed that is commanded by the PCM. The PCM will

compensate for various engine loads to keep the engine at the desired idle speed.

ECT SENSOR VOLTS/ENG COOLANT TEMP- Range -40 degrees to 151 degrees C / 0 - 5 VOLTS - The

Engine Coolant Temperature (ECT) sensor is mounted in the inlet manifold. The ECT sensor measures the engine

temperature. The PCM supplies a 5 volts reference and a earth circuit to the engine coolant temperature sensor.

When the sensor is cold (internal resistance high), the PCM reads a high signal voltage. As the sensor warms

(internal resistance decreases), the voltage signal will decrease.

IAT SENSOR VOLTS/IAT - Range -40 degrees to 151 degrees C / 0 - 5 VOLTS - The PCM converts the

resistance of the intake air temperature sensor to degrees. Intake Air Temp (IAT) is used by the PCM to adjust fuel

delivery and spark timing according to incoming air density.

MAF Sensor - Range 0-10,192 Hz - The signal that is sent from the Mass Air Flow (MAF) sensor to the PCM is in

the form of a frequency output. This frequency output changes as the demand of engine air intake changes.

MASS AIR FLOW - Range 0-246 Grams/Sec. - The Mass Air Flow (MAF) sensor measures the change in the

intake air flow which results from engine load and speed changes. As intake air flow increases, the air in the inlet

manifold also increases and addition fuel is required.

MASS AIR FLOW/CYL - Range 0-1000 mG/S. - Calculated air flow per each cylinder.

TPS VOLTAGE - Range 0-5.10 Volts - Used by the PCM to determine the amount of throttle demanded by the

driver. The TPS voltage should read between 0.25 - 1.25 volts at idle to greater than 4 volts at wide open throttle.

TPS ANGLE - Range 0-100% - Computed by the PCM from the TP sensor voltage. The TP angle should read 0%

at idle to greater than 80% at Wide Open Throttle.

(RIGHT) AND (LEFT) O2 SENSOR READY - Tech 2 display s "YES" or "NO". Indicating if the oxygen sensor has

reached operating temperature.

(RIGHT or LEFT) O2 SENSOR - Range 0-1192 mV - Represents the exhaust sensor output voltage. The O2

sensor voltage should fluctuate constantly between 100 mV (Lean exhaust) and 1000 mV (Rich exhaust) when

operating in "Closed Loop."

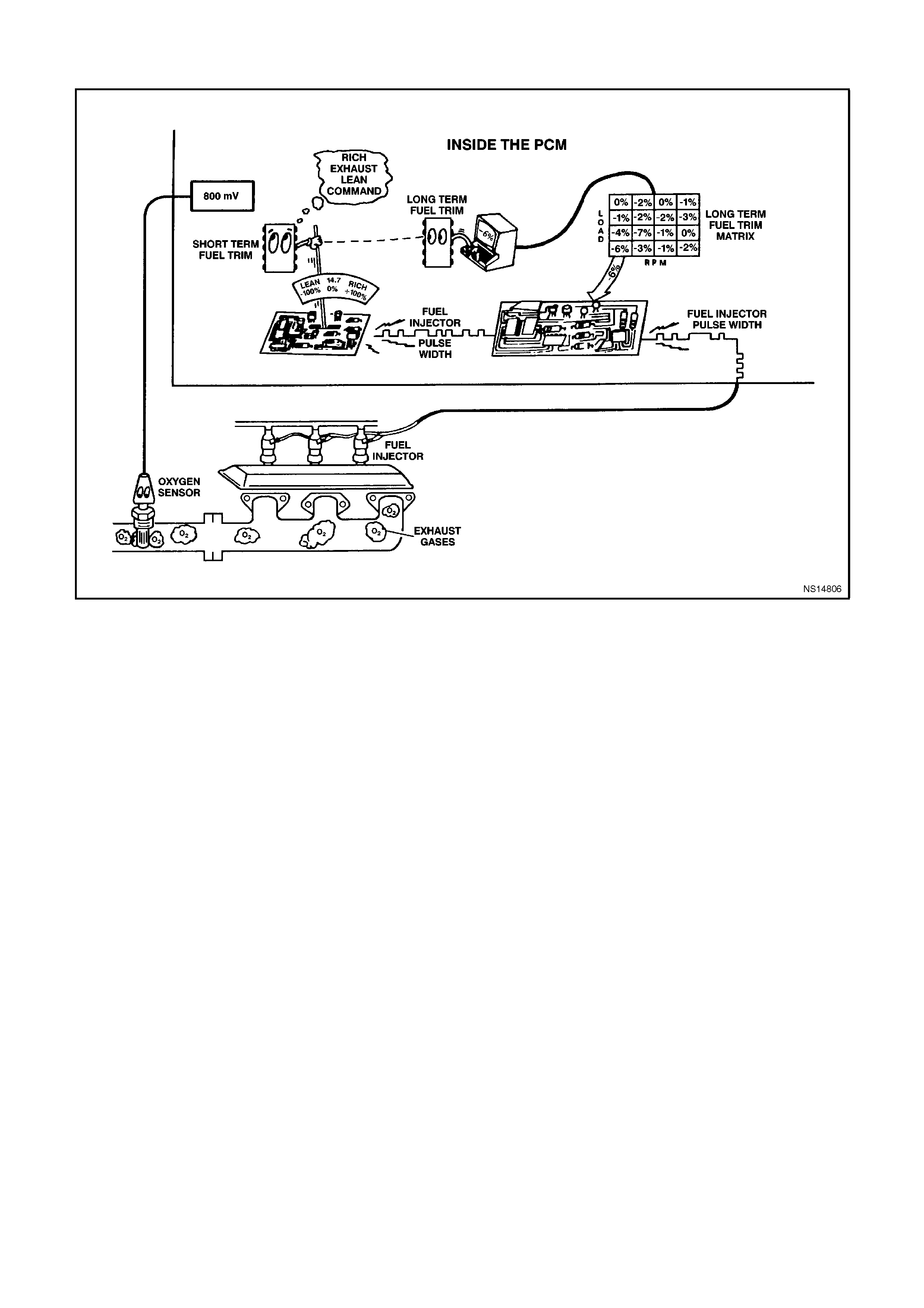

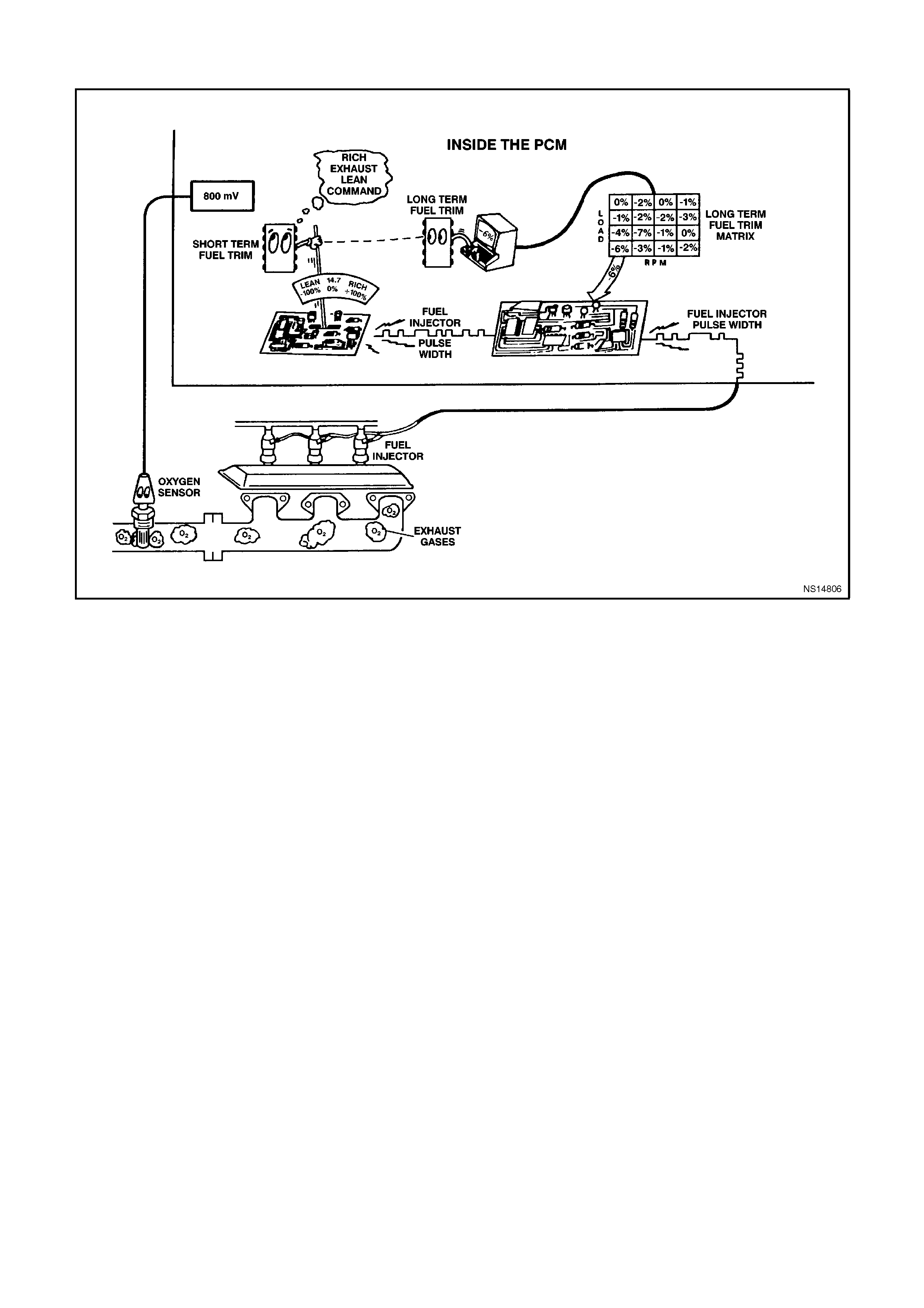

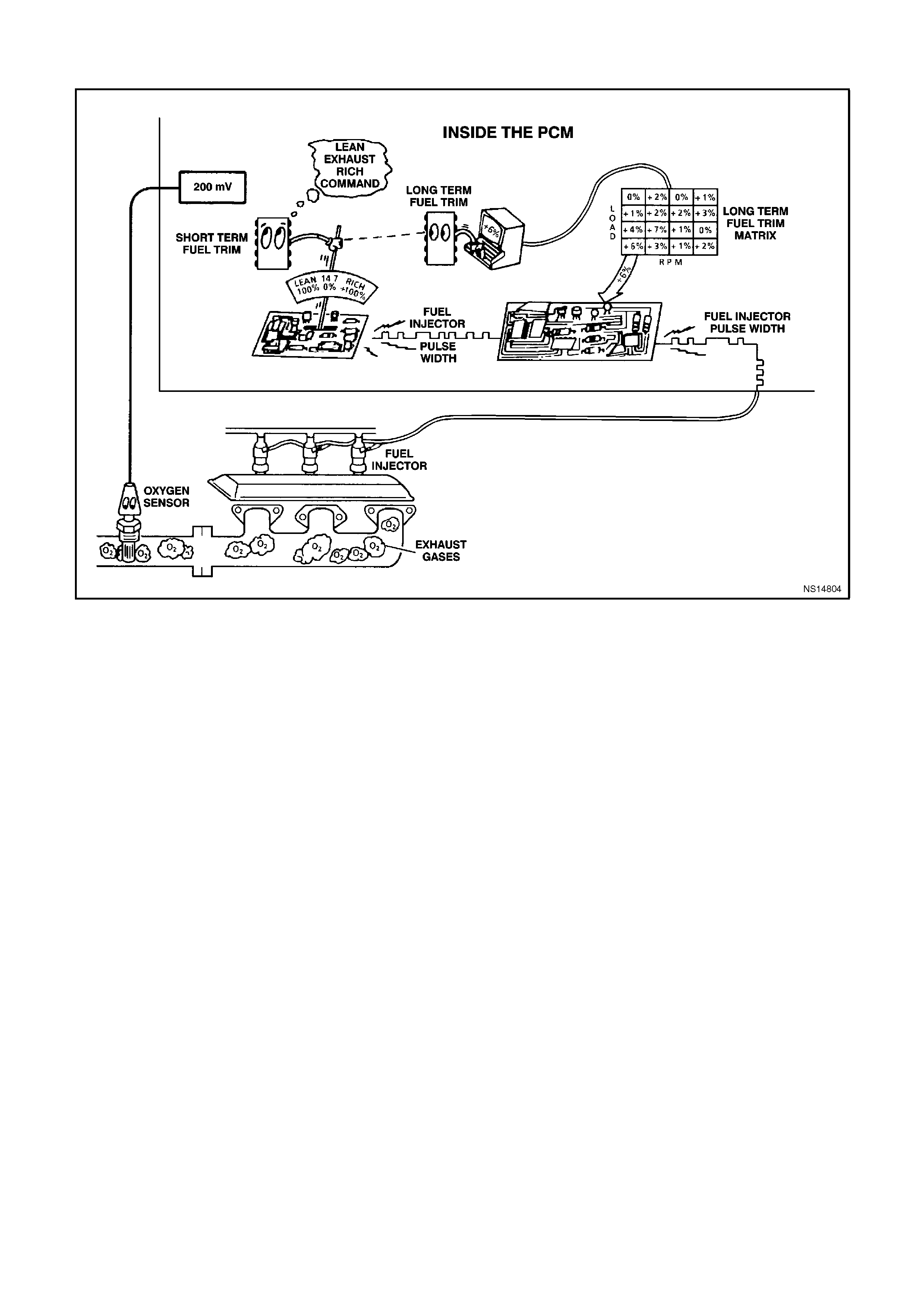

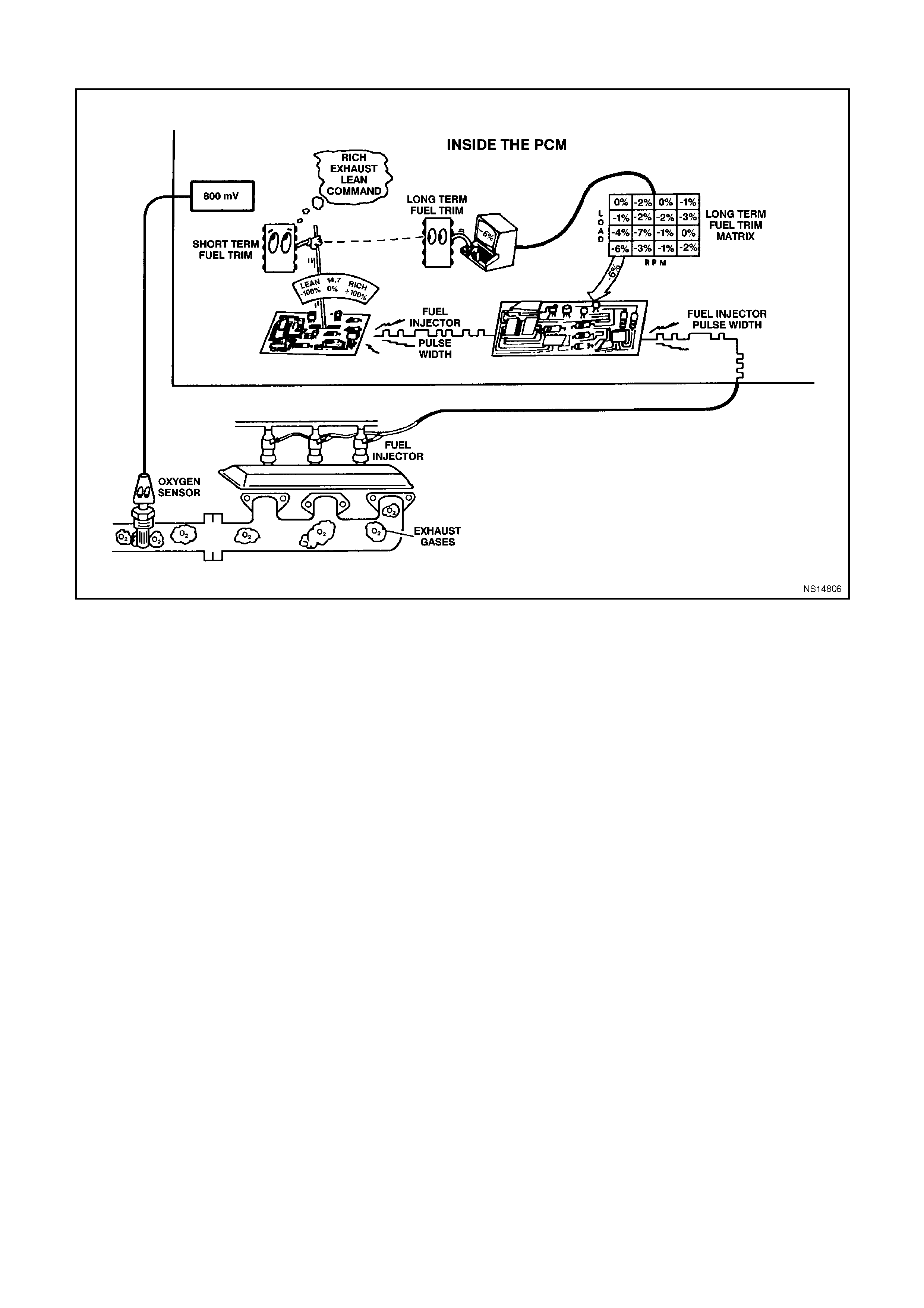

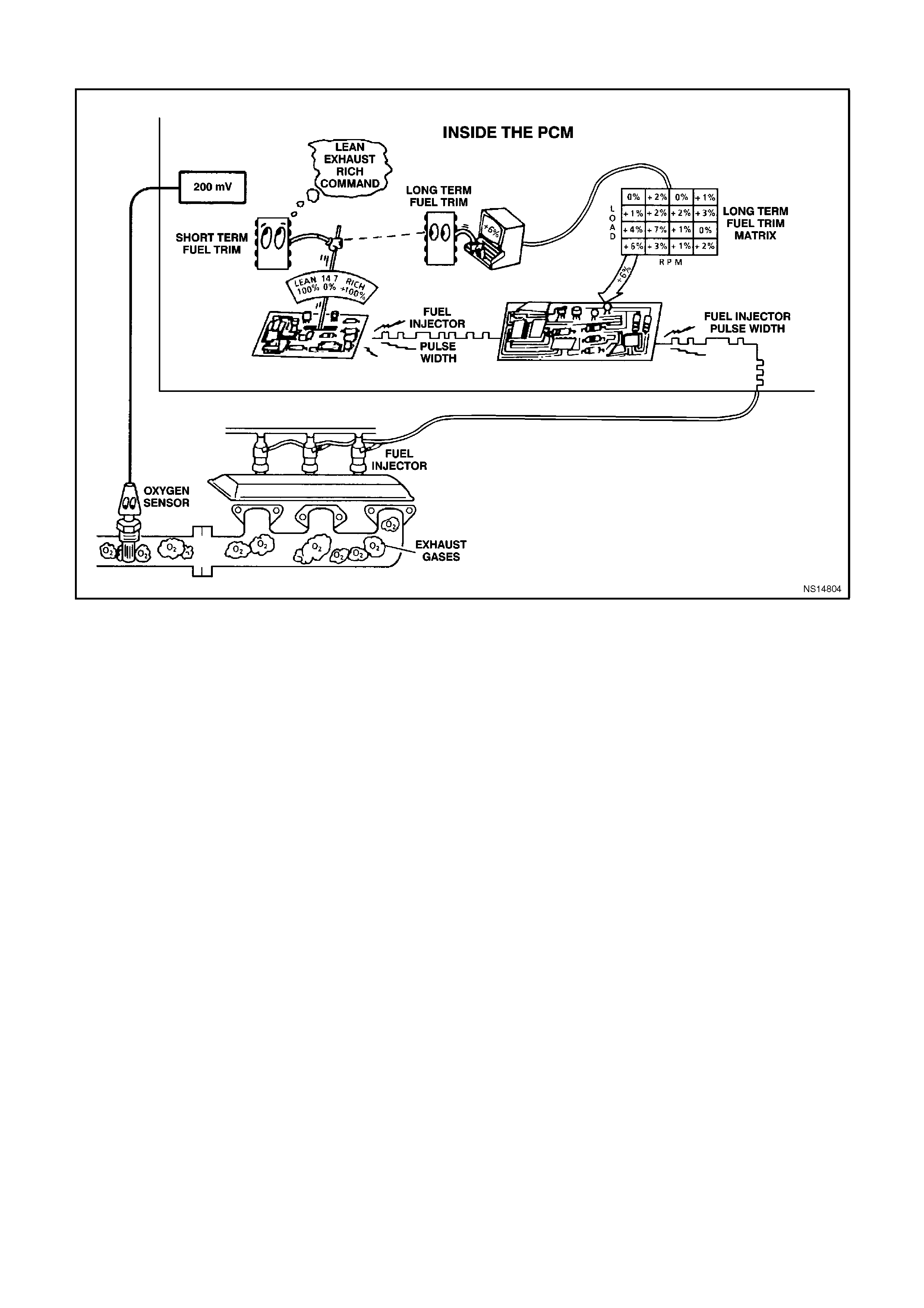

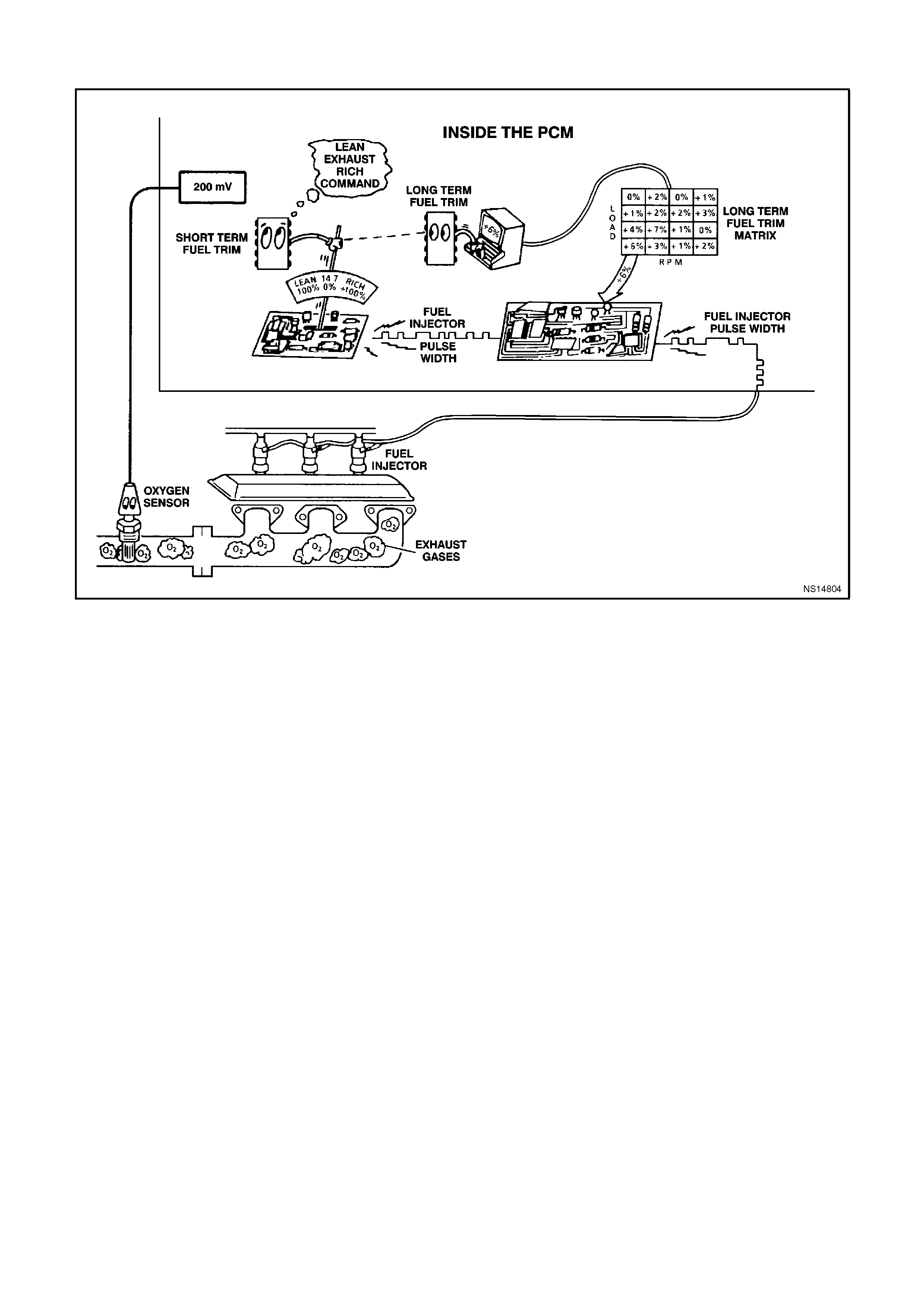

(LEFT or RIGHT) SHORT TERM FUEL TRIM - Range -100% -0% -+ 100% - Short Term Fuel Trim represents a

short-term correction for fuel delivery by the PCM in response to the amount of time the oxygen sensor voltage is

above or below the 450 mV threshold. If the oxygen sensor voltage has mainly been below 450 mV, indicating a

lean air/fuel mixture, STFT will increase to request the PCM to reduce fuel delivery to compensate for the indicated

rich condition. Under certain conditions such as extended idle and high ambient temperatures, canister purge may

cause STFT to read less than -10%.

(LEFT or RIGHT) LONG TERM FUEL TRIM -100% - 0% - +100% - LTFT is derived by the PCM from the STFT

value and is used for long-term correction of fuel delivery. A value of 0% indicates that fuel delivery requires no

compensation to maintain a 14.7:1 air/fuel ratio. A value below 0% means that the fuel system has been rich and

fuel delivery is being reduced decreased injector pulse width to maintain a 14.7 to 1 A/F ratio. A value above 0%

indicates that a lean condition exists and the PCM has been compensating by adding fuel. LTFT tends to follow

STFT.

LTFT ENABLE - Tech 2 Displays "YES" or "NO". - The Long Term Fuel Trim is enable by the PCM when a long

term fuel correction is required. A YES indicates that the LTFT is enabled, a NO indicates that is not.

FUELLING MODE - Displays OPEN or CLOSED- "Closed Loop" displayed indicates that the PCM is controlling

the fuel delivery from the oxygen sensor voltage. In Open Loop, the PCM ignores the oxygen sensor voltage and

bases the amount of fuel to be delivered on TP Sensor, coolant, and the IAT sensor inputs only. At extremely high

temperatures, it is possible for the system to remain in Open Loop to control the catalytic converter temperatures.

LTFT CELL - Range 0-23 - LTFT cell is dependent upon engine speed and mass air flow readings. A plot of RPM

vs MAF is divided into 24 cells. LTFT cell indicates which cell is currently active.

O2 SENSOR STATUS (Left or Right) - RICH or LEAN - Indicates whether the exhaust oxygen sensor voltage is

above (rich) or below (lean) the 450 mV oxygen sensor threshold voltage. This voltage should change constantly

indicating that the PCM is controlling the air/fuel mixture properly.

O2 SENSOR CROSS COUNTS (Left or Right) - Displays the number of times the O2 Sensor voltage switches from

less than 450 mV to greater than 450 mV and then from greater than 450 mV to less than 450 mV.

STFT/LTFT DELTA - Range 0-100%. - The difference (Delta) in % of the STFT/LTFT counts from each bank. This

value is used by the PCM to determine bank to bank fuel trim balance.

DEC. FUEL CUT-OFF - Displays OFF or ON - Indicates if the PCM is in the Decel Fuel Cut-off Mode.

INJ. PULSE WIDTH - Range 0.0 - 999.9 mS. - The ON time of the injector as determined by the PCM.

INJECTOR VOLTAGE - Range 0 - 14.0 Voltage -The voltage commanded from the PCM to open the injector.

AIR FUEL RATIO - Range 0.00 : 99.99 - The reading reflects the commanded value. This should be at or near

14.7. A lower value indicates a richer commanded air fuel mixture while a higher value indicates a leaner mixture.

PURGE PWM - Range 0-100%. The duty cycle of the purge solenoid as being commanded by the PCM.

BATTERY VOLTAGE - Range 0-25.5 volts - This represents the system voltage measured by the PCM at the

ignition No. 1 feed.

REFERENCE VOLTS - Range 0-5 Volts - Indicates the voltage that is supplied to various sensors from the PCM.

CRANK SWITCH - Displays Cranking or OFF. - Indicates that the engine is cranking. The signal is used by the

PCM to prevent backfire.

CAM SIGNAL - Range MISSING/PRESENT- A signal generated by the cam sensor then sent to the PCM. The

PCM then uses this signal for piston positioning for sequential fuelling.

IDLE SPEED VARIANT - RANGE 0-9999 RPM - Indicates the variation in RPM between sampling of engine

speeds.

IAC POSITION - Range 0-255 Counts - Displays the commanded position of the idle air control pintle in counts.

The higher the number of counts, the greater the commanded idle speed. The Idle air control valve should respond

quickly to changes in engine load.

LITRES/100km - Range 0-100 - Indicates fuel consumption per litres per 100 km.

SPARK MODE - Displays "BYPASS" or "EST" - Indicates what mode of ignition timing the vehicle is operating.

SPARK ADVANCE - Range -90 Degrees to +90 Degrees - This displays the spark advance (EST) calculation

which the PCM is programming into the ignition system. The PCM computes the desired spark advance using data

such as engine temperature, engine rpm, engine load, vehicle speed, and operating mode.

KNOCK SIGNAL - Displays "KNOCK" or "NONE" - Indicates whether or not a knock signal is being detected by

the PCM. Should read "NONE" at idle.

KNOCK RETARD - Range 0 Degrees - 90 Degrees - Indicates the amount of spark advance the PCM is removing

from EST in response to the Knock sensor (ESC) signal. Should read 0 degrees at idle.

TCC ENABLE SOLENOID - Displays ON or OFF. - Indicates if the TCC enable Solenoid is commanding the TCC

ON or OFF.

VEHICLE SPEED - Range 0-255 km/h - The vehicle speed sensor signal is converted into kph and mph for

display.

A/C REQUEST - Displays YES or NO - Represents the state of the A/C request serial data input from the BCM.

A/C CLUTCH - Displays ON or OFF - Represents the commanded state of the A/C clutch control relay. Clutch

should be engaged when ON is displayed.

A/C PRESSURE SENSOR - Tech 2 Displays 0.0 - 5.0 Volts - Represents the A/C refrigerant pressure sensor

signal. The amount of pressure indicates the amount of load that the A/C compressor is placing on the engine. The

PCM uses this information to adjust idle speed and to control the cooling fan.

A/C PRESSURE - Range 0 - 3195 kPa - The kPa displayed indicates that the PCM is monitoring an A/C

Refrigerant Pressure signal voltage which is too high or too low to allow the A/C compressor clutch to engage.

HIGH SPEED FAN - Tech 2 Displays "ON" or "OFF - Indicates if the engine cooling fan high speed relay has

been commanded ON or OFF.

LOW SPEED FAN REQUEST - Tech 2 Displays "ON" or "OFF - Indicates if the engine cooling fan low speed

relay has been commanded ON or OFF.

THEFT STATUS - Displays "NO START" or " START". - Indicates the status of the Theft Deterrent System.

FUEL PUMP STATUS - Displays ON or OFF. - Indicates if the fuel pump is ON or OFF.

ENGINE CRANK TIME - Range 0 - 99.9 Seconds. - Indicates the duration of the engine crank time.

DTC STATUS - Indicates if there are any DTC's in

TIME FROM START - Displays 0:00:00. - Indicates the hours, minutes and seconds the engine has been running.

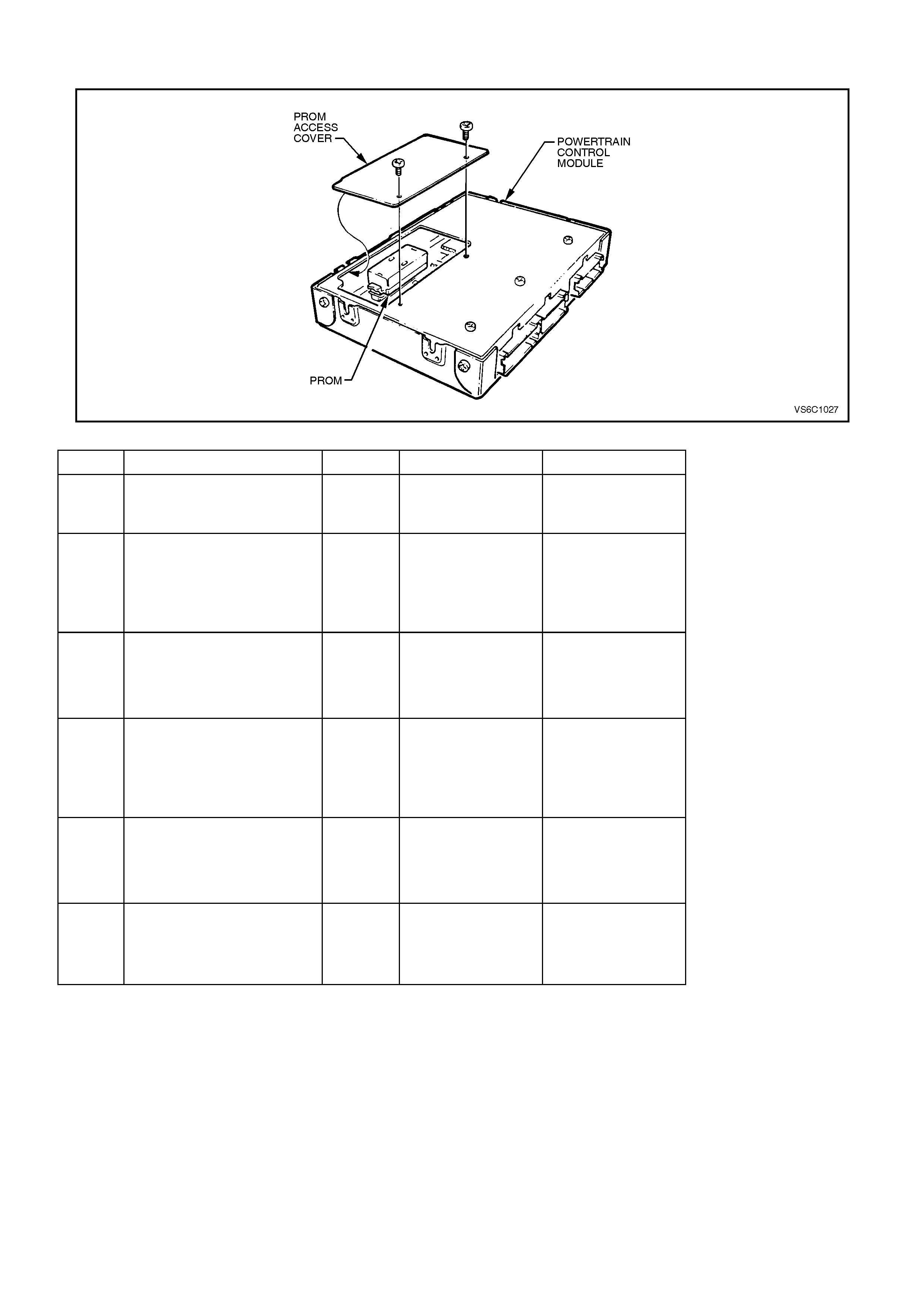

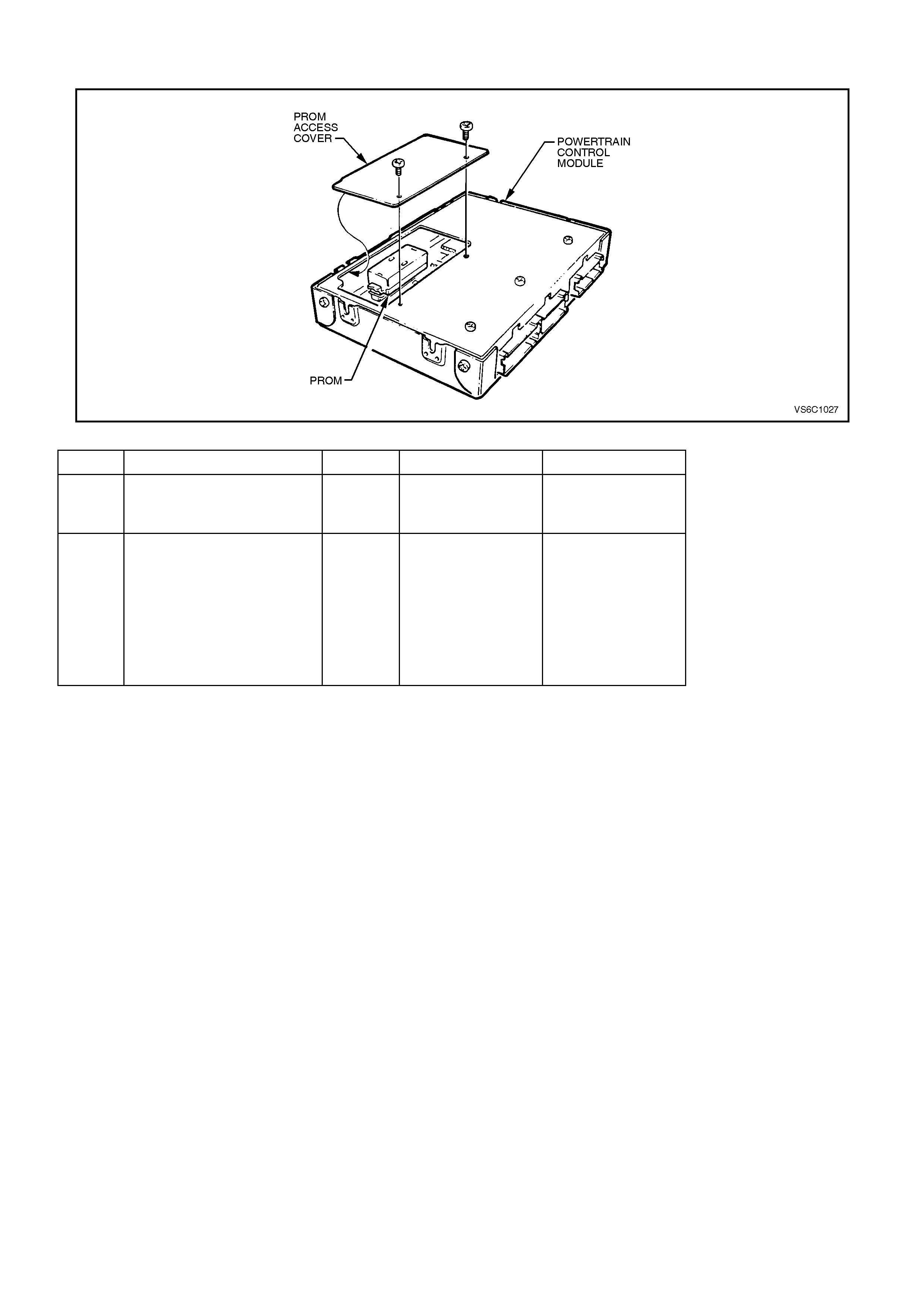

PROM I.D. - Displays a four digit number - Indicates the numerical identification of the PROM stored in the PCM.

TECH 2 SCAN TOOL TRANSM ISSION DATA

The Tech 2 scan Data listed in the table may be used for comparison

1. After completing the " ON-BOARD DIAGNOSTIC SYSTEM CHECK".

2. Finding the on-board diagnostics are functioning properly and

3. No diagnostic DTCs are displayed.

A TECH 2 SCAN TOOL THAT DISPLAYS FAULTY DATA SHOULD NOT BE USED, AND THE PROBLEM

SHOULD BE REPORTED TO THE MANUFACTURER. THE USE OF A FAULTY TECH 2 SCAN TOOL CAN

RESULT IN MISDIAGNOSIS AND UNNECESSARY PARTS REPLACEMENT.

Only the parameters listed are used in this manual for diagnosis. For more description on the values and use of the

Tech 2 scan tool to diagnosis PCM inputs, refer to the applicable diagnosis chart in this Section. If all the values are

within the range illustrated, refer to "Symptoms" Charts in Section 6C2-2B.

TEST DESCRIPTION:

Number(s) below refer to circled number(s) on the diagnostic chart.

1. The scan position refers to the Tech 2 scan tool DATA LIST that will be displayed in order.

2. "Units Displayed" are the available ways of displaying what each parameter is currently operating in, or a value

that is being sensed or being out putted by the PCM.

3. "Typical Data Value" is separated into two parts. These displayed values are typical of a normally operating

vehicle. The ignition ON comparison should be performed first as this may lead to a quick identification of a

fault. The engine running data should be compared to the ignition ON data as a diagnostic check to make sure

the component or the system is operating properly.

4. Ignition ON values are the typical values that should be seen on the Tech 2 scan tool with the ignition ON, and

the engine OFF. The temperature sensors should be compared to the actual temperatures by letting the

sensor sit overnight and then comparing their values. A difference of 3 to 5 degrees C from the actual

temperature may indicate a problem with the sensor. Use the diagnostic aids chart for that sensor to compare

the resistance to temperature values.

Some ON or OFF switches may display an abnormal state. If the chart states this position is abnormal, than

this may be caused by an open or short to earth, depending upon the normal state of the switch. Refer to the

proper Section or more information on diagnosis.

5. "ENGINE RUNNING" typical data values are an average of display values recorded from normally operating

vehicles at normally operating temperature. They are intended to represent what a normally functioning system

would typically display.

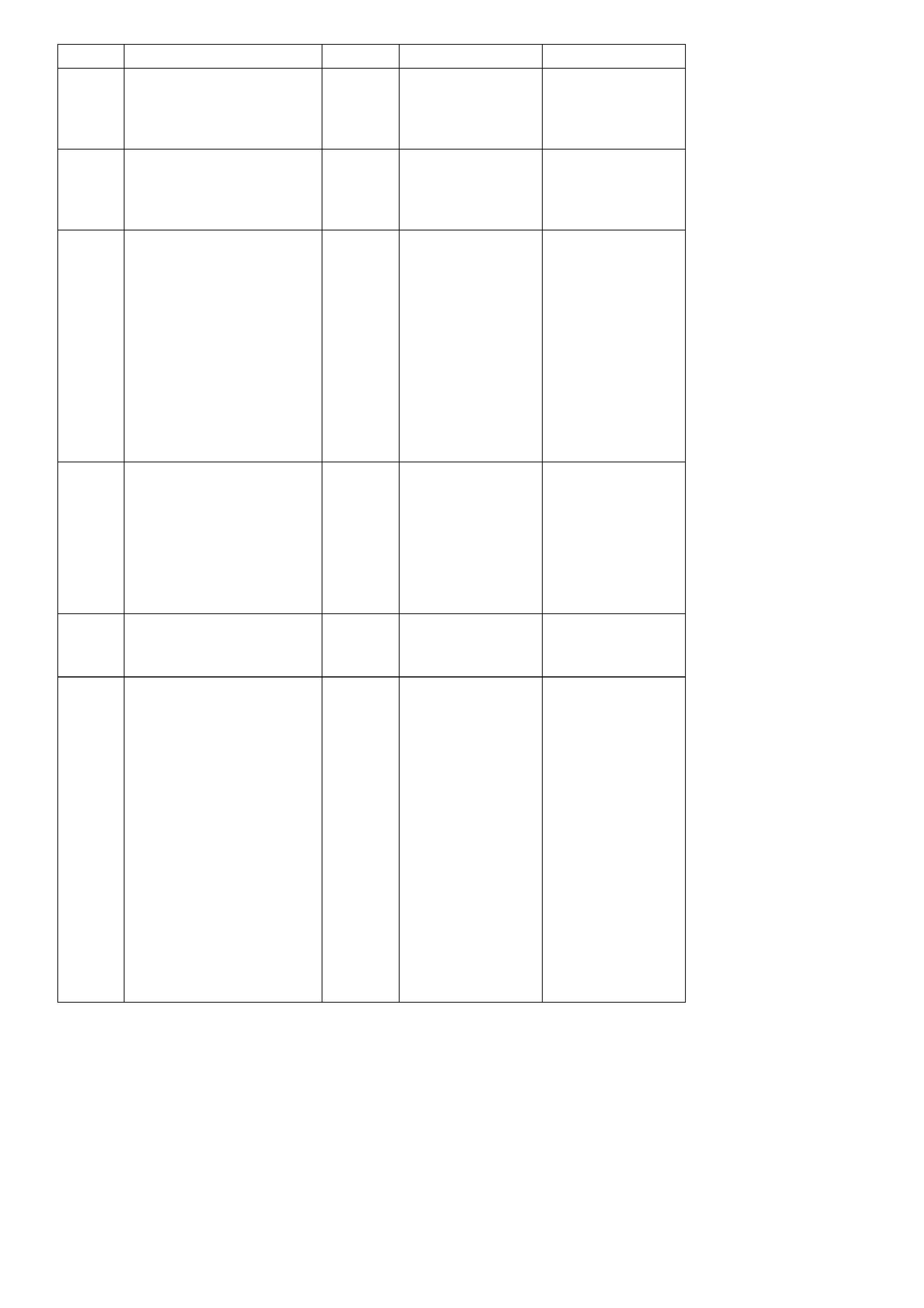

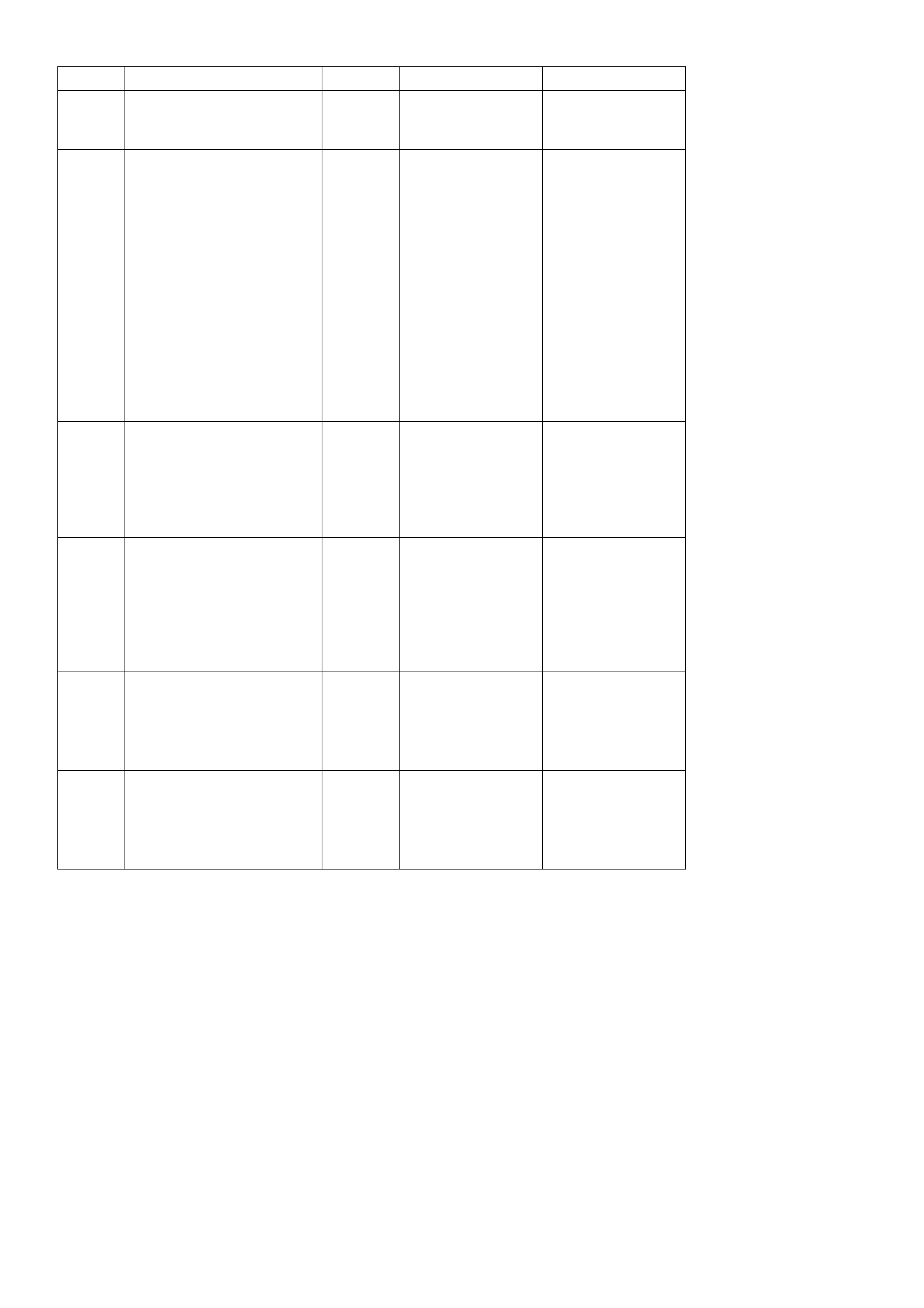

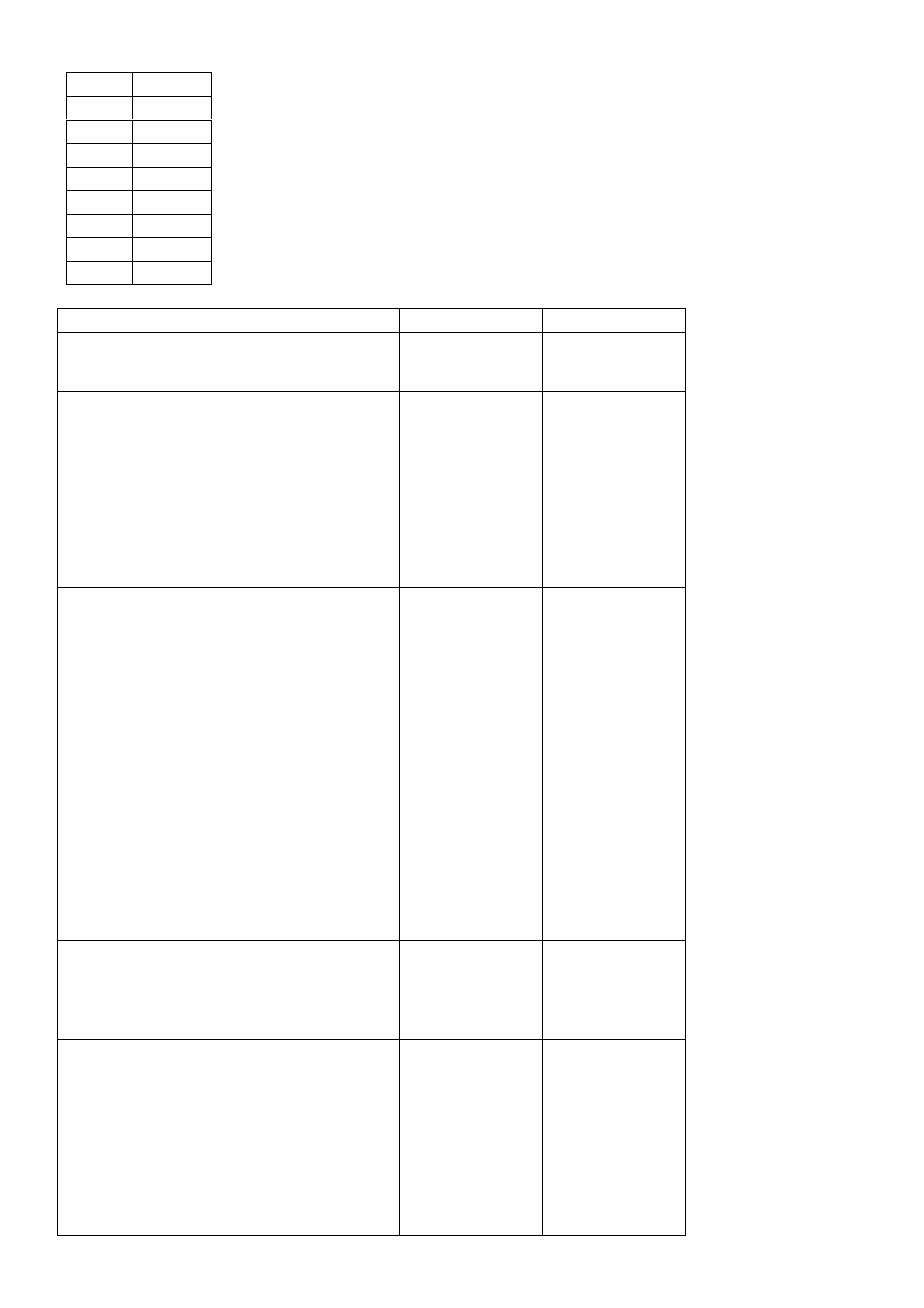

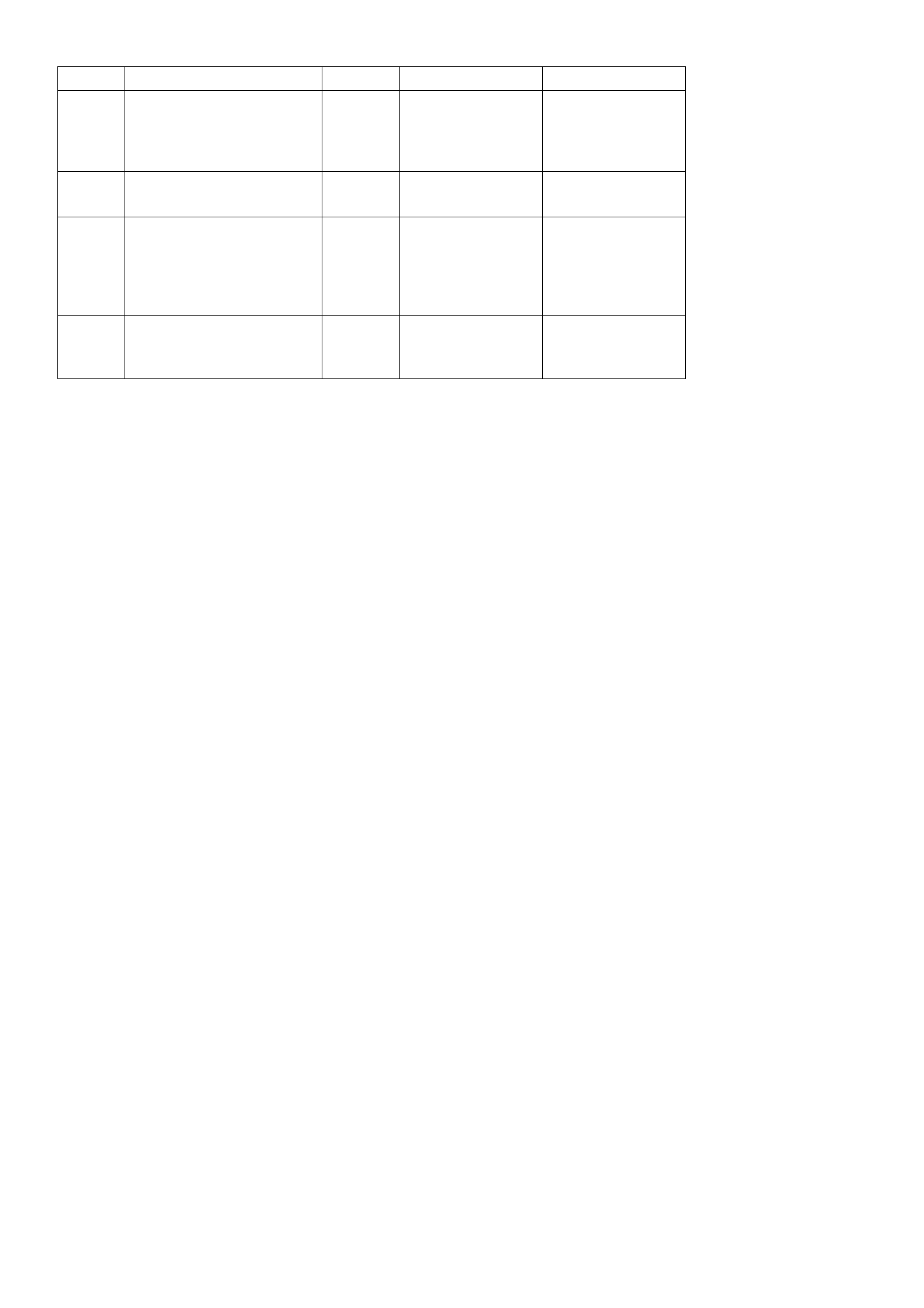

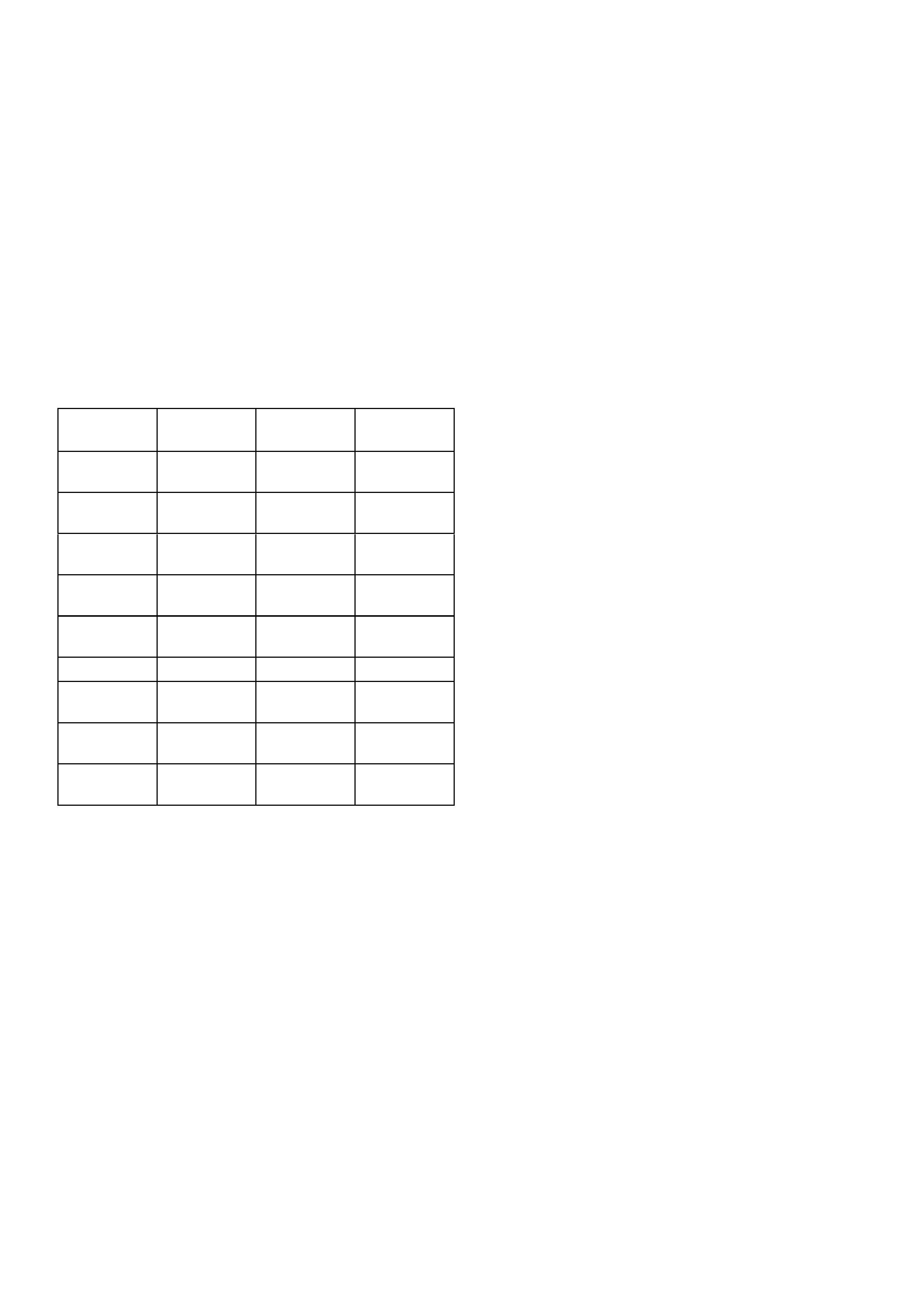

TECH 2 SCAN DATA - TRANSMISSION

DISPLAY POSITION UNITS

DISPLAYED TYPICAL DATA

IGNITION ON TYPICAL VALUE ENGINE

RUNNING

ENGINE SPEED RPM 0 RPM ± 100 RPM FROM

DESIRED RPM

(± 50 RPM IN DRIVE)

VEHICLE SPEED km/h 0 km/h 0 km/h

TPS SIGNAL VOLTS 0.50 V 0.50 V

THROTTLE ANGLE 0-100 % 0 % 0 %

ECT SENSOR V Varies Varies

COOLANT

TEMPERATURE °C Varies 96°C

TFT SENSOR V Varies Varies

TRANSMISSION

FLUID

TEMPERATURE

°C Varies Varies

TFP SWITCH A OPEN/

CLOSED OPEN 12V OPEN 12V

TFP SWITCH B OPEN/

CLOSED CLOSED 0V CLOSED 0V

TFP SWITCH C OPEN/

CLOSED OPEN 12V OPEN 12V

TFP GEAR P-N-

1-2-3-D-RP/N P/N

PRNDL SELECTED

POSITION INVALID/

P-R-N-D-LPP

1-2 SHIFT SOLENOID ON/OFF OFF ON

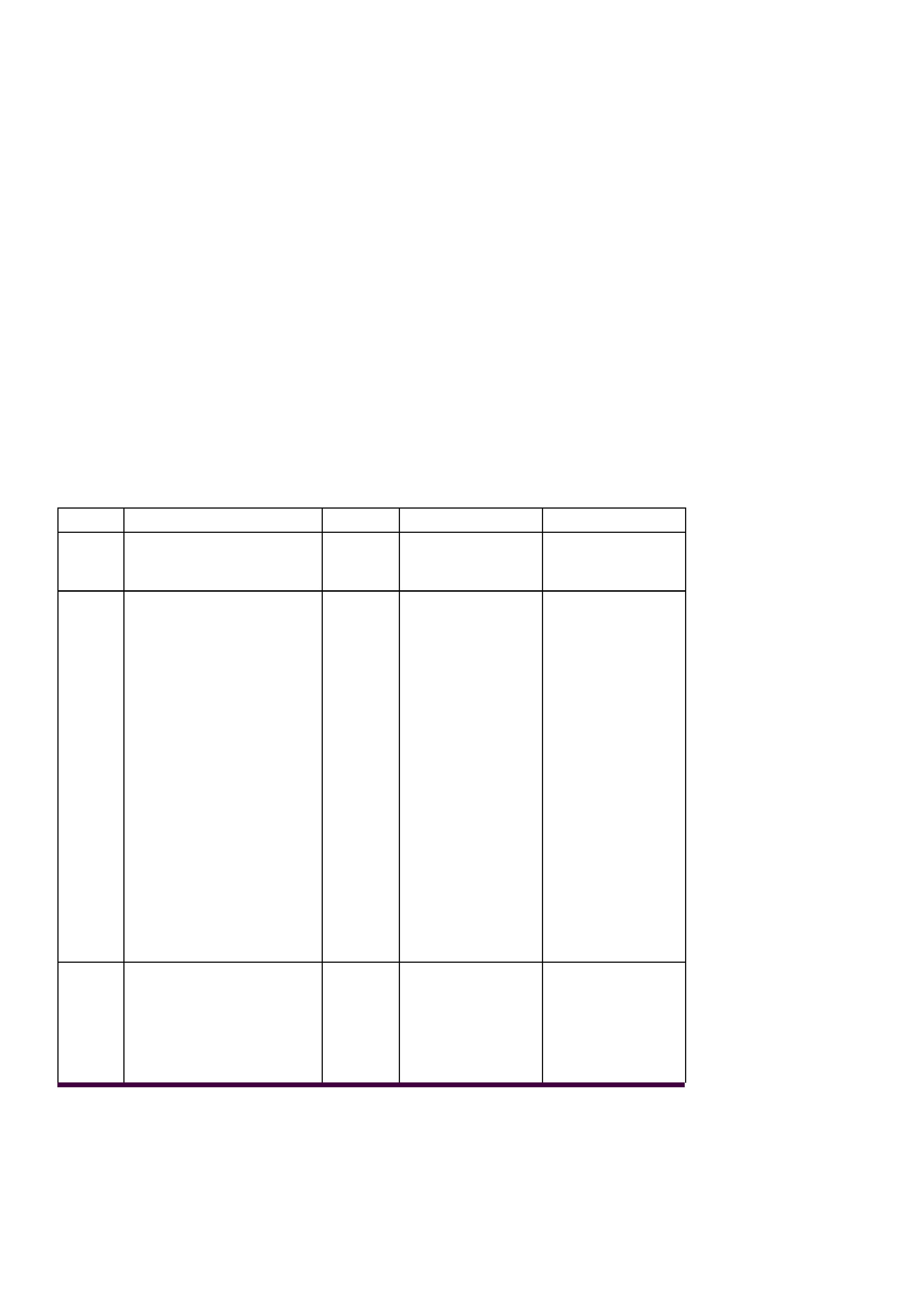

DISPLAY POSITION UNITS

DISPLAYED TYPICAL DATA

IGNITION ON TYPICAL VALUE ENGINE

RUNNING

2-3 SHIFT SOLENOID ON/OFF OFF ON

1-2 SHIFT SOLENOID

FEEDBACK ON/OFF OFF ON

2-3 SHIFT SOLENOID

FEEDBACK ON/OFF OFF ON

1-2 SHIFT TIME sec 0 sec 0 sec

2-3 SHIFT TIME sec 0 sec 0 sec

COMMANDED PCS Ma 0 mA 950 mA

ACTUAL PCS mA 0 mA 950 mA

PCS DUTY CYCLE % 0 mA 60%

TCC ENABLE

SOLENOID ON/OFF OFF OFF

TCC PWM SOLENOID % 0% 0%

TRANSMISSION SLIP

SPEED RPM 0 650 RPM

ECONOMY/POWER

SHIFT SWITCH Economy/

Power Economy Economy

3-2 DOWNSHIFT

ENABLED YES/NO NO NO

3-2 DOWNSHIFT

SOLENOID ON/OFF OFF ON

LONG TERM 1-2

SHIFT ADAPT kPa 0 kPa 0

LONG TERM 2-3

SHIFT SOLENOID kPa 0 kPa 0

SHORT TERM SHIFT

ADAPT kPa 0 kPa 0 kPa

ADAPT SHIFT

STATUS Enabled/

Disabled Enabled Enabled

SHIFT ADAPT CELL 0 0 0

GEAR RATIO :1 1 3.06:1

COMMANDED GEAR 1-2-3-4 3 1

BATTERY VOLTAGE V 12V 12V

TIME FROM START HH:MM:SS Varies with

engine run time Varies with

engine run time

CHECK

POWERTRAIN LAMP OFF/ON ON OFF

TECH 2 SCAN TOOL TRANSM ISSION DATA DESCRIPTIONS

A list of explanations for each data message displayed on the Tech 2 scan tool begins as follows. This information

will assist in tracking emission or driveability problems, since the displays can be viewed while the vehicle is being

driven. Refer to the " On-Board Diagnostic System Chec k " for additional informational.

ENGINE SPEED - Range 0-9999 RPM - Displays the actual engine speed, as received from the reference input

signal. Displays in increments of 1 RPM.

VEHICLE SPEED - Range 0-255 KM/H - Displays the PCM's calculation of vehicle speed as received from the

PCM. Useful for checking speedometer accuracy.

TPS SIGNAL - Range 0-5 VOLTS - This position shows the Throttle Position sensor signal input to the PCM. The

values read will be in voltage. The PCM then will calculate the throttle opening. The TP sensor voltage should be

between 0.25 - 1.25 volts with the throttle closed and greater than 4 volts at Wide Open Throttle .

TPS THROTTLE ANGLE - Range 0-100% - This display is the PCM's calculation of the percentage of throttle

opening. The TPS angle should display zero (0%) with the throttle closed and greater than 80% at Wide Open

Throttle.

ECT SENSOR VOLTS/ENG COOLANT TEMP - Range -40 degrees C to 151 degrees C/0 - 5 Volts - The PCM

supplies 5 volts to the ECT sensor circuit. The sensor is a thermistor which changes internal resistance as

temperature changes. When the sensor is cold (internal resistance high), the PCM receives a high signal voltage

which it interprets as a cold engine. As the sensor warms (internal resistance decreases), the voltage signal will

increase indicating a warm engine.

TFT SENSOR VOLTS/TRANS FLUID TEMP - Range -40 degrees C to 151 degrees C/0 - 5 VOLTS - This

displays the temperature of the fluid in the transmission.. The TECH 2 scan tool will display TFT in voltage and in

degrees Celsius. The TFT sensor reading should read close to the air temperature when the transmission is cold,

and increases as the transmission fluid temperature increases. After the engine is started the temperature should

rise steadily to between 82 degrees C and 94 degrees C then stabilise.

TFP SWITCHES A/B/C RANGE VOLTS - Range 0-12 VOLTS - These values represent the three fluid pressure

switch assembly signals. These lines are normally high and are taken low as the fluid pressure switch interprets the

manual valve position. The sequence of these signals is decoded by the PCM to determine the appropriate gear

range.

PRNDL SELECTED POSITIONS - This value represents the decoded sequence of the Transmission Fluid

Pressure Manual Valve Position Switch Assembly (TFP). The TFP is used to determine the manual valve position.

The manual valve position is an input to the PCM used to control line pressure, TCC, and shift solenoid operation.

1-2 SHIFT SOLENOID, AND 2-3 SHIFT SOLENOID This displays the ON or OFF state of the two shift solenoids.

The shift solenoids are turned OFF or ON to change gears.

1-2 AND 2-3 SHIFT SOLENOID FEEDBACK - These values represent the true electrical state of the solenoids.

The PCM uses this information to set malfunction DTC's.

1-2 SHIFT TIME - This value represents the time taken to shift from first gear to second gear. This information is

only accurate if the shift was adaptable.

2-3 SHIFT TIME - This value represents the time taken to shift from second gear to third gear. This information is

only accurate if the shift was adaptable.

COMMANDED TFP - This value represents the commanded pressure control solenoid current. The commanded

current is determined from the manual valve position, transmission fluid temperature, transmission output speed,

shift solenoid state, TCC, A/C status, engine speed, TCC slip and the throttle position sensor. The commanded

pressure control solenoid current is then used to control the transmission line pressure.

ACTUAL TFP - This value represents the actual transmission fluid pressure control solenoid current. This value

should always be close to the desired pressure control solenoid current.

TFP DUTY CYCLE - This value represents the pressure control solenoid duty cycle. This value is determined by the

desired pressure control solenoid current.

TORQUE CONVERTER CLUTCH (TCC) SOLENOID-

This value represents the status of the Torque Converter Clutch (TCC) solenoid. This status is determined by

throttle position, transmission output speed, transmission range, engine coolant temperature, transmission fluid

temperature, and TCC slip.

TCC PWM SOLENOID - Range 0-100%. This parameter is the commanded percentage of ON time of the TCC

PWM solenoid . Approximately 90% represents an ON (energised) commanded state. Zero percent represents an

OFF (non-energised) commanded state. This commanded state is applied at a vehicle speed between

approximately 0 -16 km/h (0-10 mph).

TRANSMISSION SLIP SPEED - This displays the calculated difference between the engine RPM and the

transmission input shaft RPM. This TCC slip RPM should be within ±30 RPM to the actual engine RPM whenever

the TCC is applied.

ECONOMY/POWER SHIFT SW - This display shows the state of the economy/power switch.

3-2 SHIFT SOLENOID PWM- This value represents the duty cycle of the 3-2 downshift solenoid. This device

regulates the release of the 3-4 clutch and the apply of the 2-4 band. The duty cycle is normally about 90%, except

during a 3-2 downshift when the duty cycle drops. The duty cycle will be 0% in first gear. The duty cy cle is

determined by throttle position, vehicle speed, and the commanded gear.

3-2 SHIFT SOLENOID FEEDBACK - These values represent the true electrical state of the solenoid and circuit.

The PCM uses this information to set a DTC.

ADAPT SHIFT STATUS- This value indicates if the current shift will update the 1-2 adapt tables which are used to

modify line pressure.

SHIFT ADAPT CELL - This value displays the cell that the PCM is operating. There are three cells to adapt the

shift, these cells are: Light throttle, Medium throttle and Full throttle. These three cells are very similar to LTFT cell

used by the engine.

GEAR RATIO - This display represents the gear ratio of the commanded gear. 1st 3.06:1, 2nd 1.63:1, 3rd 1.00:1,

4th 0.69:1, Rev 2.29 :1.

COMMANDED GEAR - The gear that the PCM is commanding the transmission. In Park, the Tech 2 scan tool will

display, the commanded state of the shift.

BATTERY VOLTAGE - Range 0-25.5 VOLTS - This represents the system voltage measured by the PCM at its

ignition No. 1 feed.

TIME FROM START - Tech 2 Displays 0:00:00 - Indicates the hours, minutes and seconds the engine has been

running.

CHECK POWERTRAIN LAMP - ON/OFF - Indicates whether the lamp on the instrument panel is illuminated.

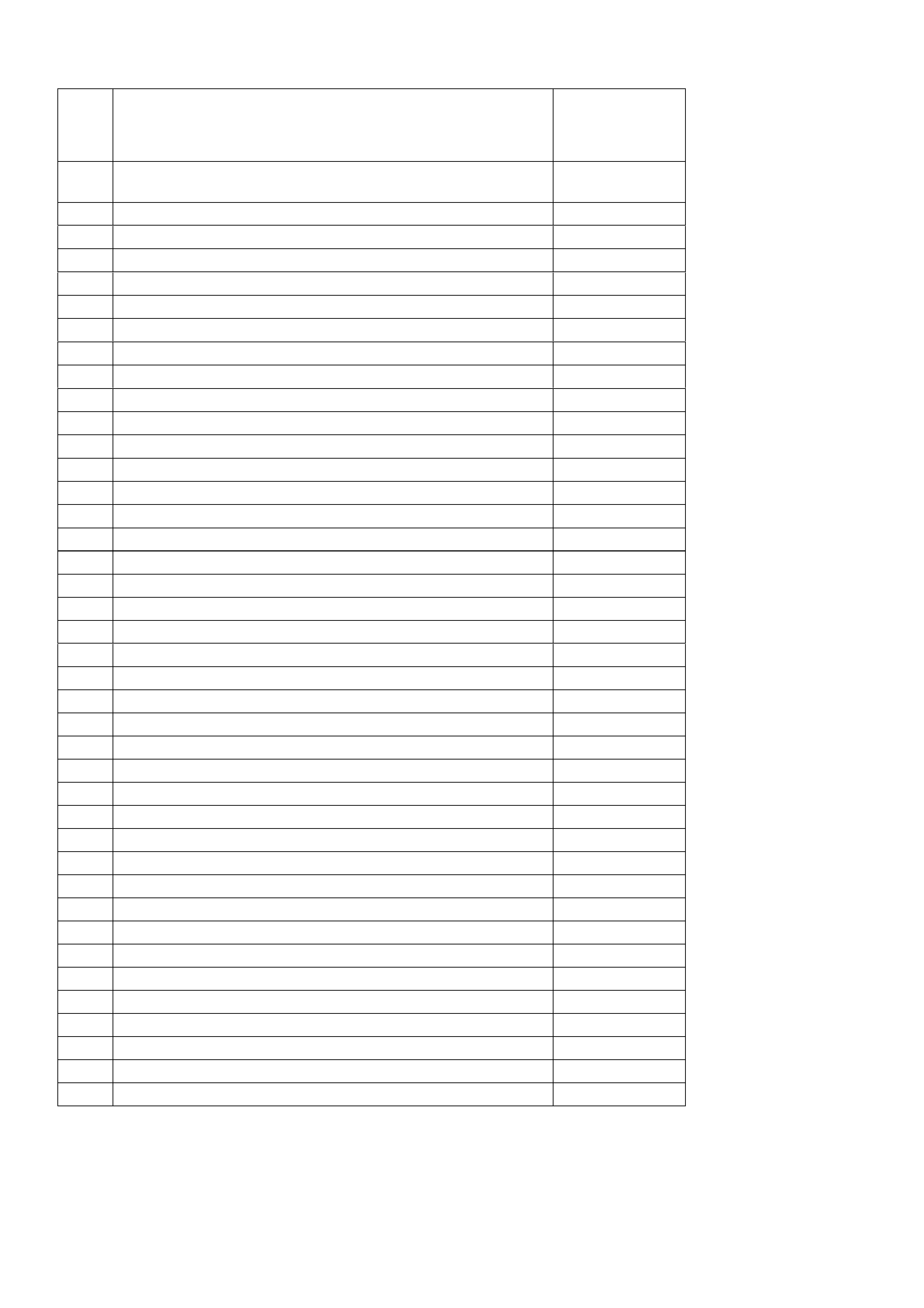

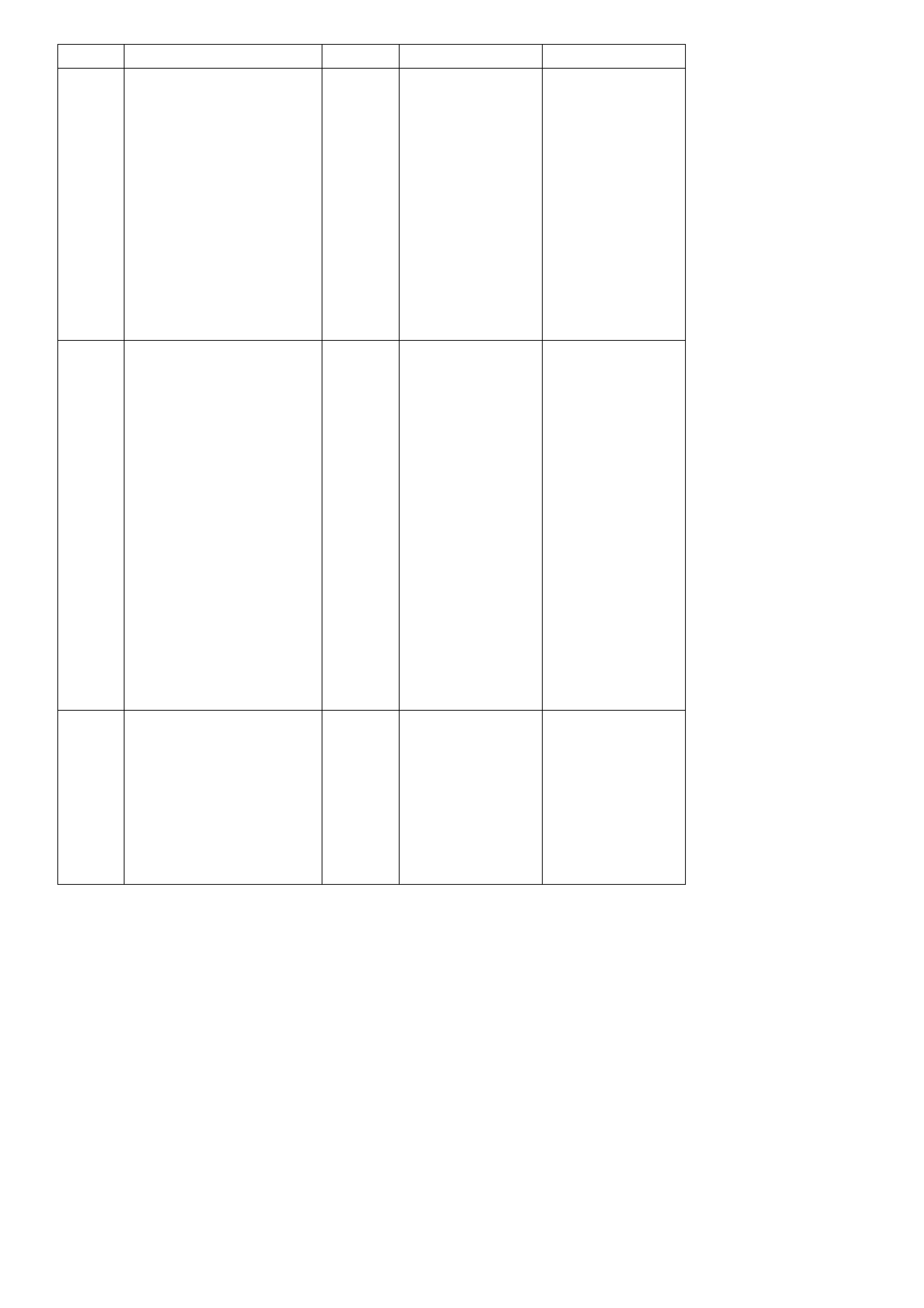

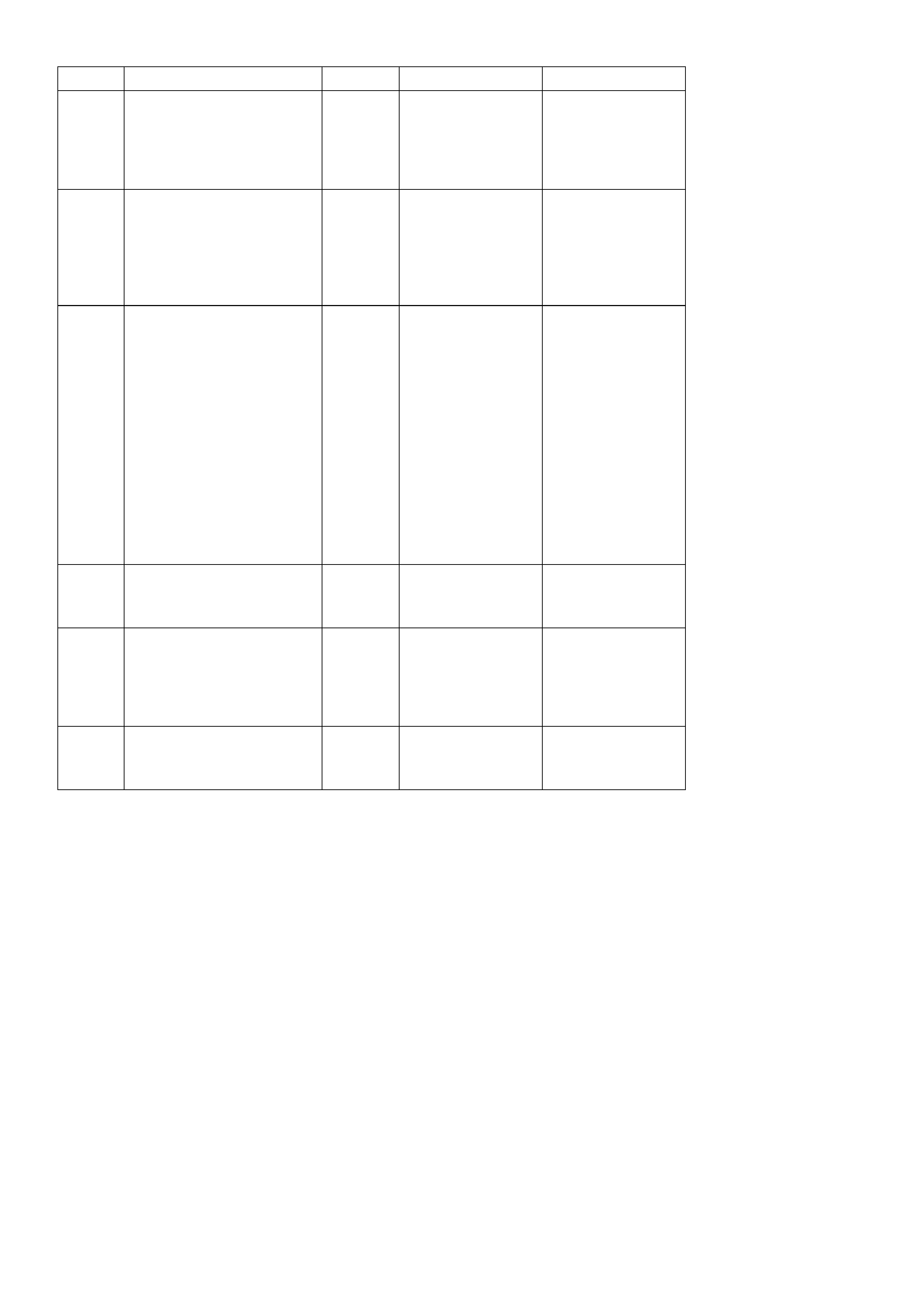

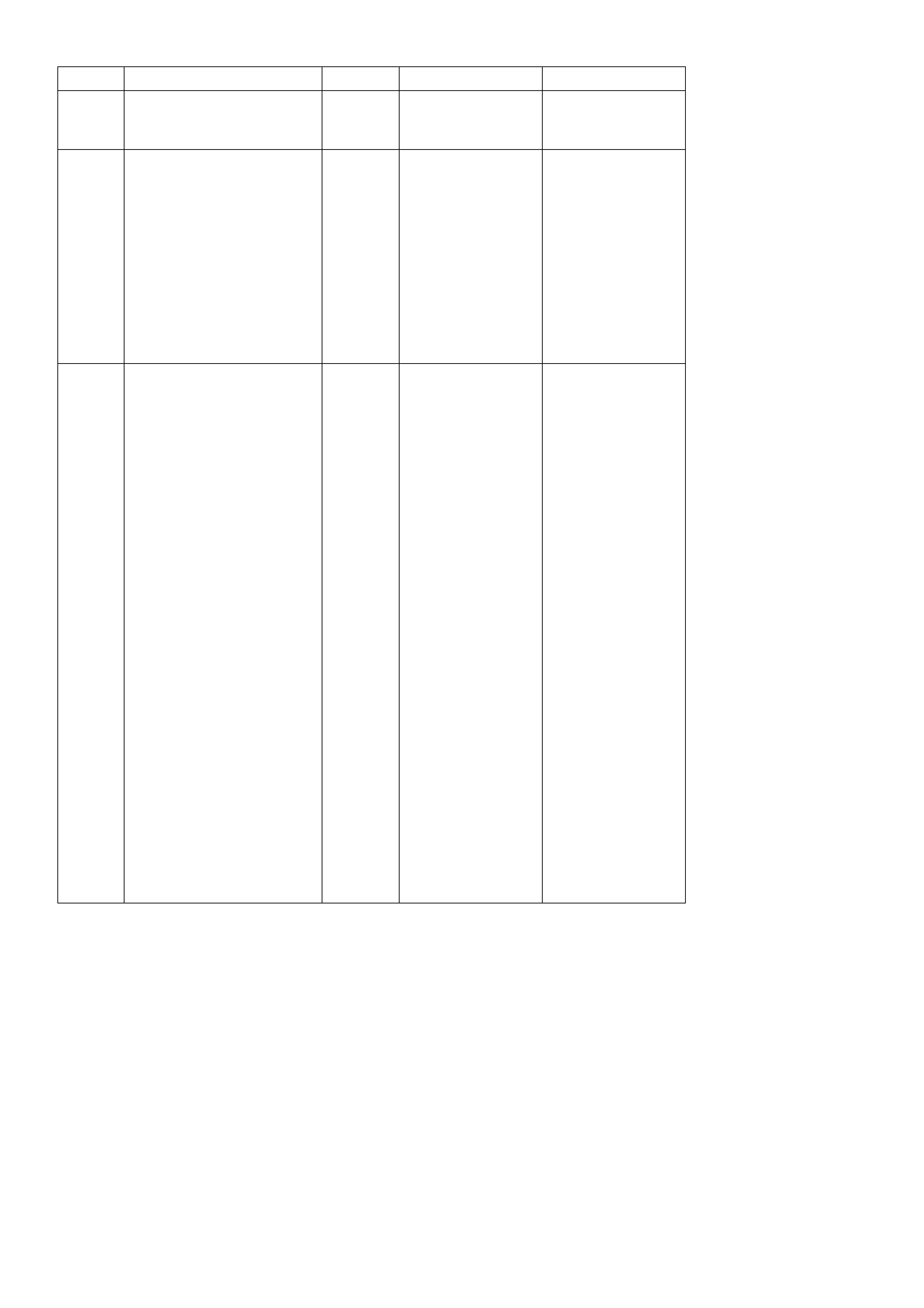

PCM V8 ENGINE DIAGNOSTIC TROUBLE CODES (DTC)

DTC DESCRIPTION ILLUMINATE

“CHECK

POWERTRAIN”

LAMP

12 No revolutions per minute signal - normal when engine is not

running No

13 Right Hand (RH) No Oxygen Sensor Signal Yes

14 Engine Coolant Temperature ECT - Signal Voltage Low Yes

15 Engine Coolant Temperature ECT - Signal Voltage High Yes

16 Engine Coolant Temperature ECT - Signal Voltage Unstable Yes

17 PCM Error - ECT Circuit No

19 Throttle Position (TP) Sensor Stuck No

21 Throttle Position (TP) - Signal Voltage High Yes

22 Throttle Position (TP) - Signal Voltage Low Yes

23 Intake Air Temperature (IAT) - Signal Voltage High No

24 No Vehicle Speed Sensor Signal Yes

25 Intake Air Temperature (IAT) - Signal Voltage Low No

26 Intake Air Temperature (IAT) - Signal Voltage Unstable No

31 Theft Deterrent Signal Missing Yes

32 Mass Air Flow (MAF) Sensor- Out Of Range Yes

35 Idle Speed Error No

36 Vacuum Leak No

41 Ignition Electronic Spark Timing (EST) Circuit Fault Yes

42 Bypass Circuit Fault Yes

43 Knock Sensor Circuit Fault No

44 Right Hand (RH) Lean Exhaust Indication Yes

45 Right Hand (RH) Rich Exhaust Indication Yes

46 No Reference Pulses While Cranking Yes

48 Camshaft Position Sensor Signal Missing No

49 Cam/Crank Sensor Signal Intermittent No

51 PROM Error Yes

54 System Voltage Unstable Yes

55 PCM Analog to Digital (A/D) Conversion Error Yes

57 Injector Voltage Monitor Fault No

63 Left Hand (LH) No Oxygen Sensor Signal Yes

64 Left Hand (LH) Lean Exhaust Indication Yes

65 Left Hand (LH) Rich Exhaust Indication Yes

76 Short Term Fuel Trim (STFT) Delta High No

78 Long Term Fuel Trim (LTFT) Delta High No

91 QDSM (Quad Driver Module) Circuit Fault No

92 Low Speed Fan No BCM Response No

93 SNEF Circuit Fault No

94 No Vehicle Speed Sensor - Manual Transmission Yes

96 A/C Pressure Sensor Circuit No

97 Canister Purge Circuit Fault No

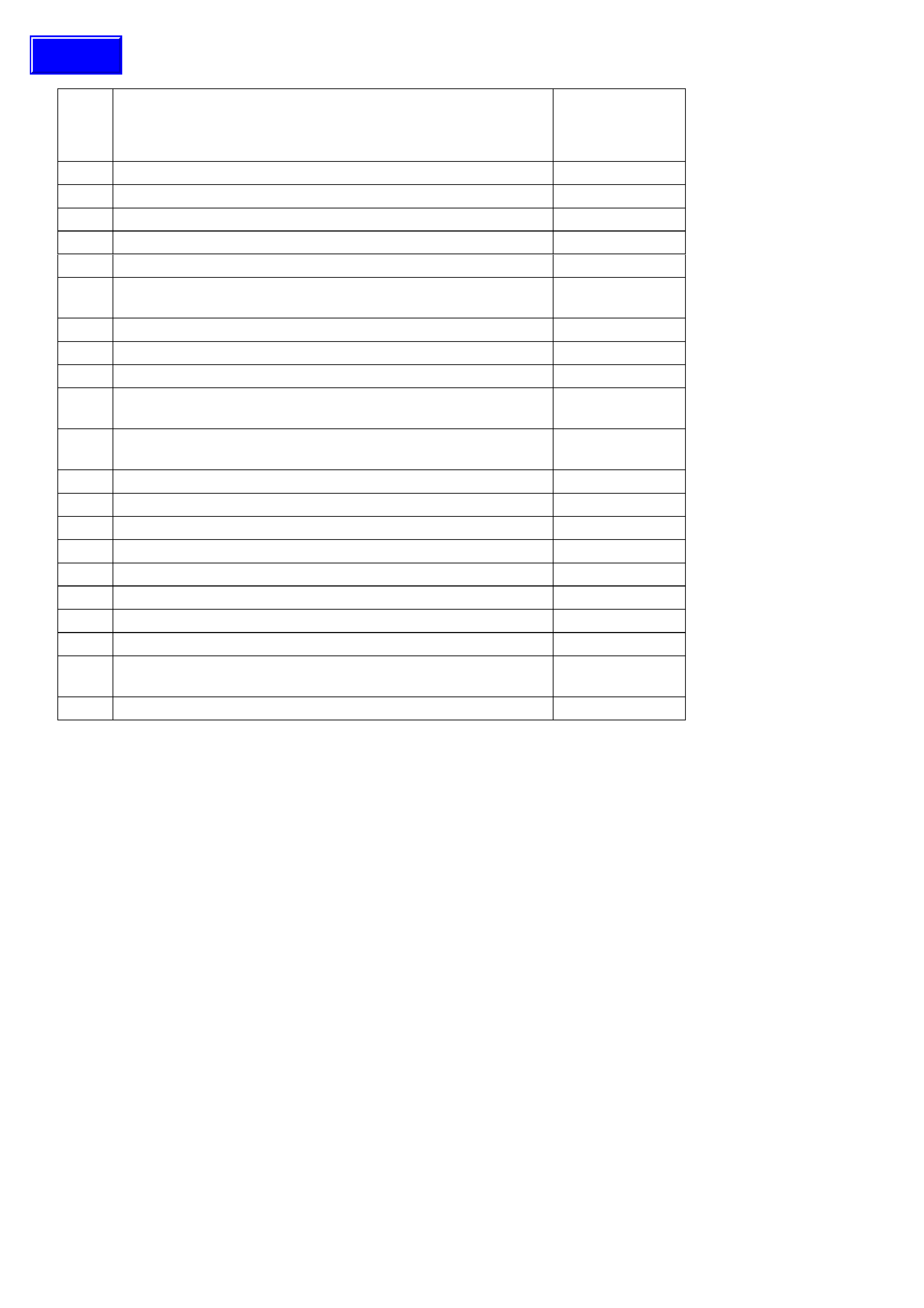

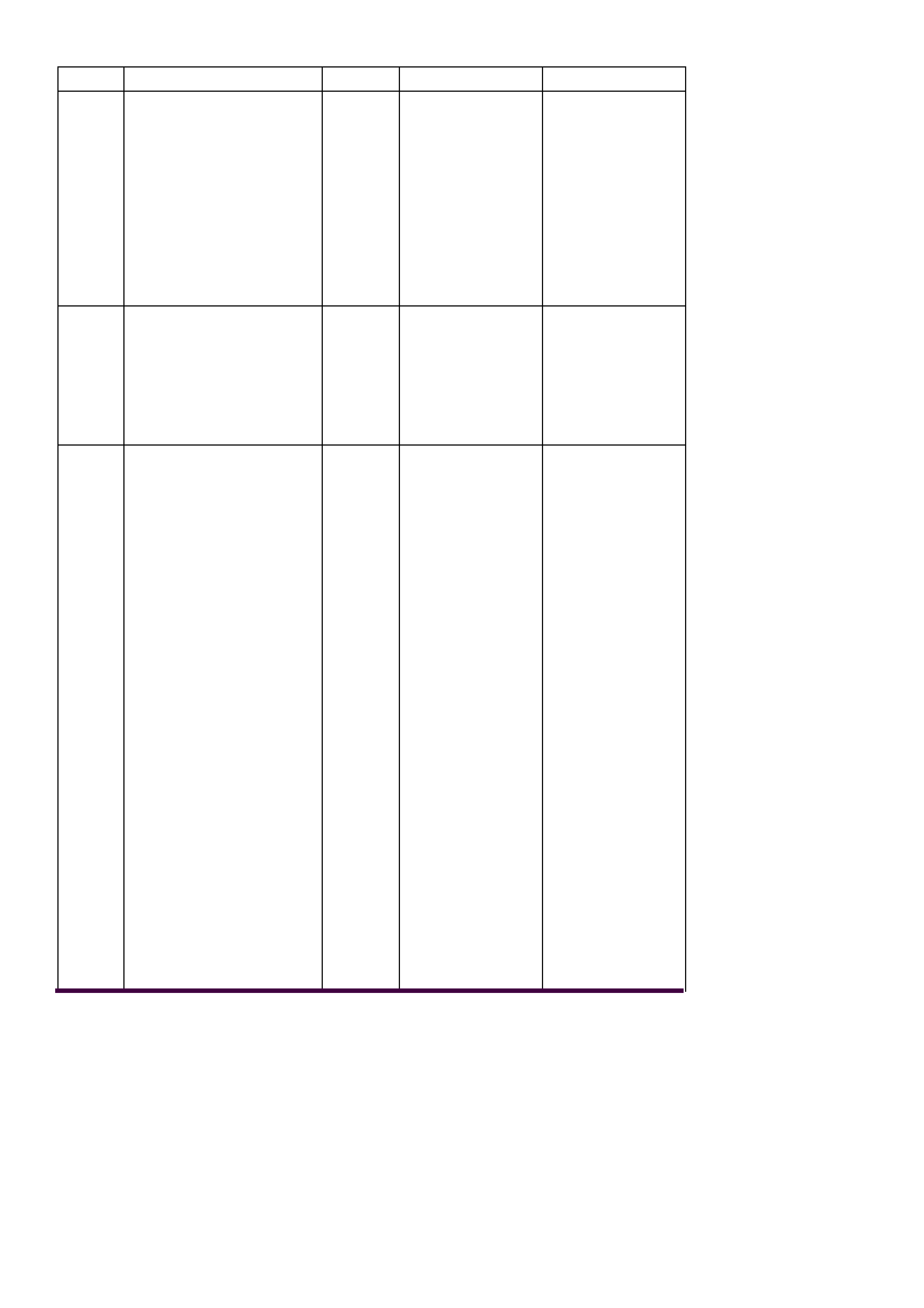

PCM V8 TRANSMISSION DIAGNOSTIC TROUBLE CODES (DTC)

DTC DESCRIPTION ILLUMINATE

“CHECK

POWERTRAIN”

LAMP

14 Engine Coolant Temperature (ECT) - Signal Voltage Low Yes

15 Engine Coolant Temperature (ECT) - Signal voltage High Yes

21 Throttle Position (TP) Signal Voltage High Yes

22 Throttle Position (TP) Signal Voltage Low Yes

24 No Vehicle Speed Sensor Signal Yes

28 Transmission Fluid Pressure Manual Valve Position Switch

Assembly Circuit Yes

52 System Voltage Too High - Long Time Yes

53 System Voltage Too High Yes

55 PROM - Analog - Digital (A/D) Conversion Error Yes

58 Transmission Fluid Temperature (TFT) Sensor Circuit - Low

Input Yes

59 Transmission Fluid Temperature (TFT) Sensor Circuit - High

Input Yes

66 3-2 Downshift Solenoid Circuit - Fault Yes

67 Torque Converter Clutch Enable Solenoid Circuit - Electrical Yes

69 Torque Converter Clutch (TCC) Stuck ON No

73 Pressure Control Solenoid Circuit - Error No

75 System Voltage Low Yes

79 Transmission Fluid Over-Temperature Yes

81 2-3 Shift Solenoid Circuit - Error Yes

82 1-2 Shift Solenoid Circuit - Error Yes

83 Torque Converter Clutch Pulse Width Modulation Solenoid

Circuit No

85 Transmission Component Slipping No

Techline

4L60E TRANSMISSION FLUID CHECKING PROCEDURE

GENERAL INFORMATION

When adding or changing the transmission fluid, use only Dexron III. Refer to the VT Series Owner’s Handbook for

the recommended servicing intervals.

Because Dexron II transmission fluid changes colour and odour very easily, these indicators should not necessarily

be relied upon to diagnose either transmission internal condition or fluid deterioration.

Reference to the table under ‘ Transmission Fluid Checking Procedure” shows that a dark brown fluid colour,

with a delayed shift pattern, may only indicate that the fluid requires replacement and, is not a definite indication of a

potential transmission problem.

NOTE:

Do not overfill the transmission. Overfilling may cause foaming of the fluid, loss of fluid, shift complaints and

possible damage to the transmission.

TRANSMISSION FLUID COLOUR

Transmission fluid colour when new, is red. A red dy e is added so that it can be distinguished from other oils and

lubricants. The red dye is not an indicator of fluid quality and is not permanent. As the vehicle is driven, the

transmission fluid will quickly begin to look darker. The colour will then appear light brown. A dark brown colour with

a distinctively burnt odour may indicate fluid deterioration and a need for the fluid to be changed.

NOTE:

As the temperature affects the transmission fluid levels, this operation must only be performed when the

transmission is at normal operating temperature 82 - 94 followed, the result could be a false reading of the fluid

level on the dipstick. Degrees C. If the vehicle is not at normal operating temperature, and the proper checking

procedures are not

TRANSMISSION FLUID CHECKING PROCEDURE

1. Start the engine and drive the vehicle for a maximum of 24 km, or until the transmission’s normal operating

temperature is reached.

2. Park the vehicle on a level surface.

3. Move the gear selector into PARK.

4. Apply the park brake.

5. Let the engine idle for 3 minutes with all the accessories turned off.

6. Locate the red coloured dipstick in the engine compartment. Lift the locking lever then remove the dipstick.

Check the fluid colour, the fluid condition and the fluid level.

Do not check the fluid levels immediately after the vehicle has been operated under any of the following conditions.

• In high ambient temperatures above 32 °C.

• At sustained high speeds.

• In heavy city traffic during hot weather.

• Towing

• In commercial use (e.g. taxi).

If the vehicle has been operated under these conditions, turn the engine off and allow the vehicle to cool for

approximately thirty minutes. After a cool-down period, re-start the vehicle and continue from step 2.

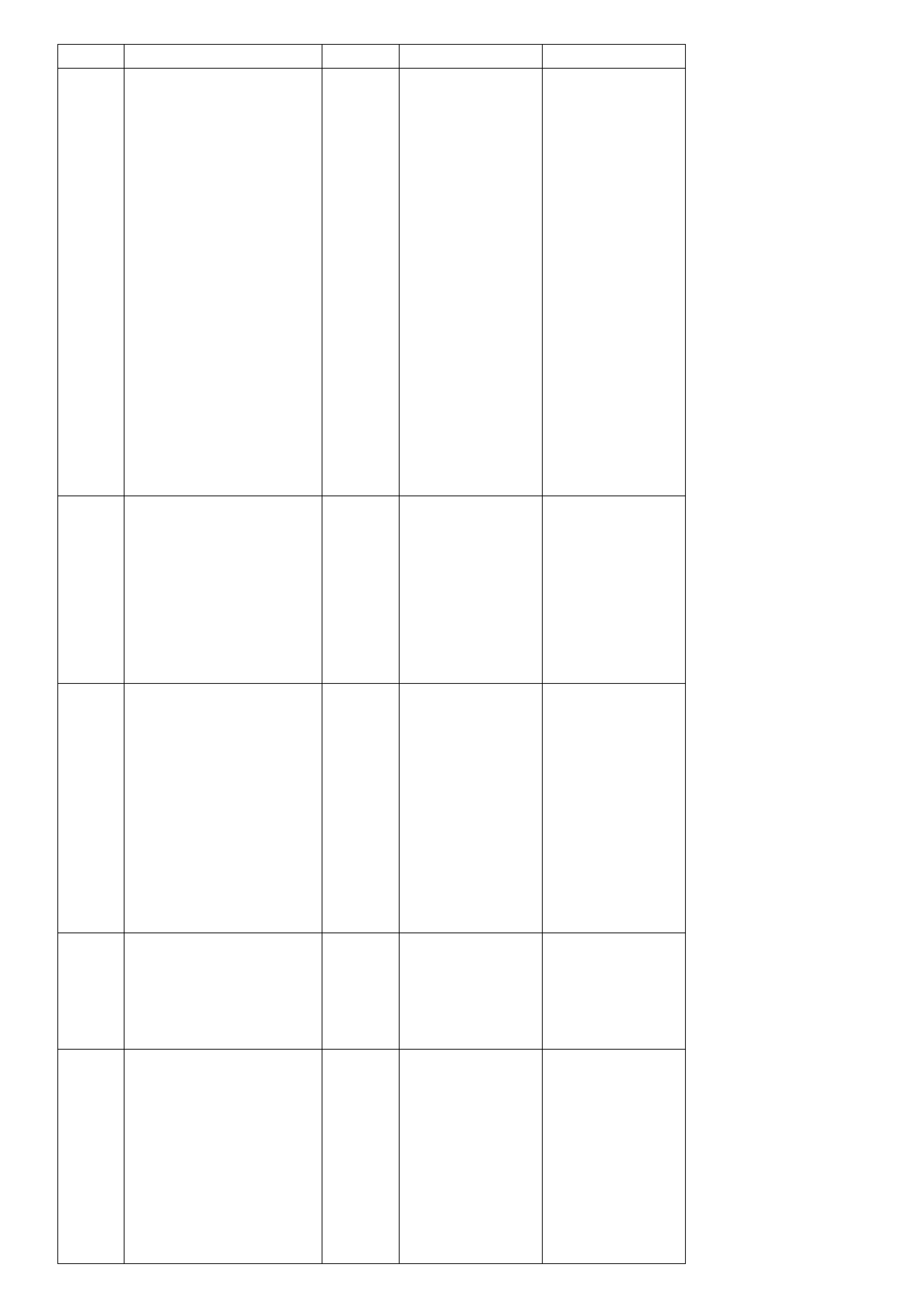

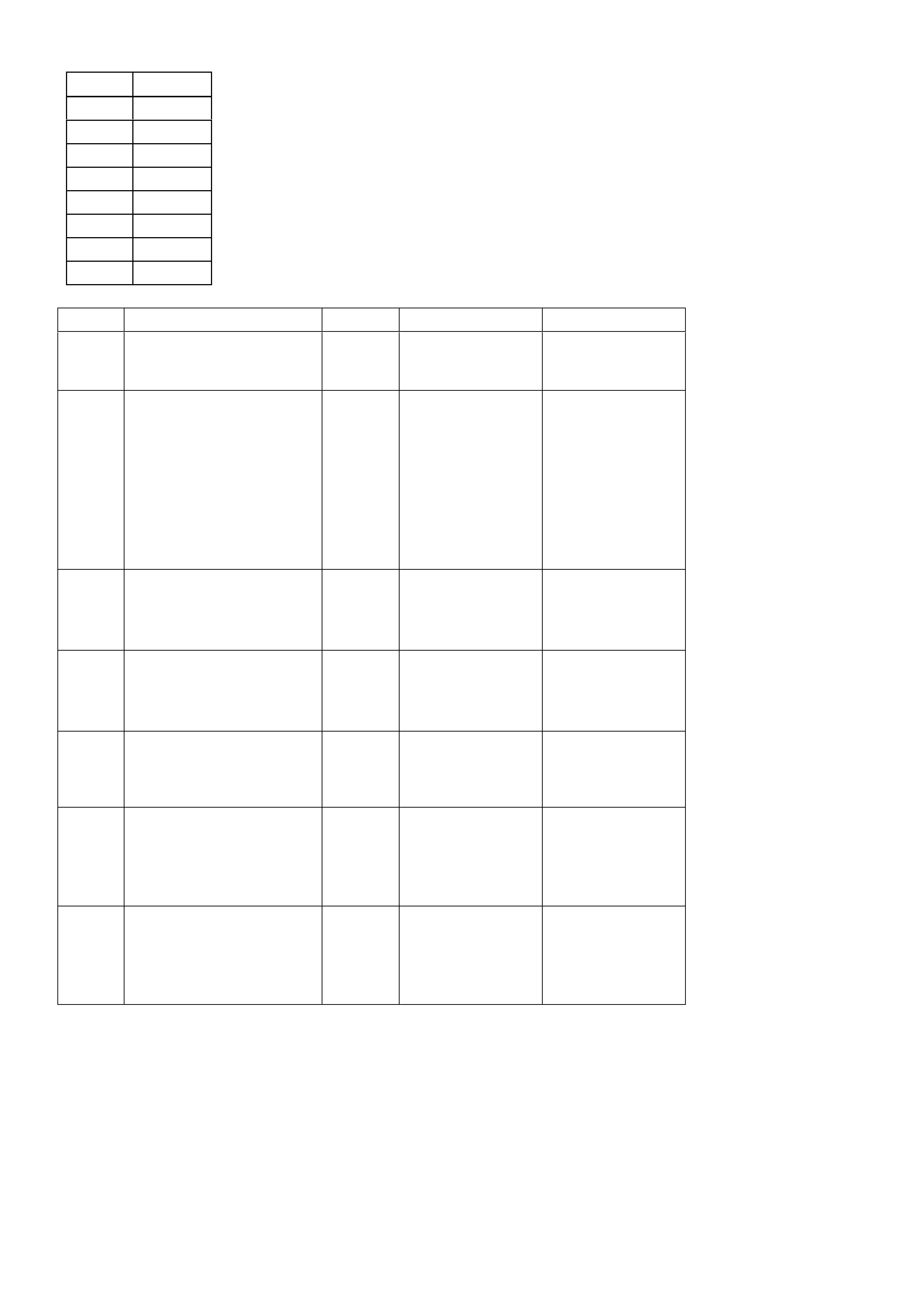

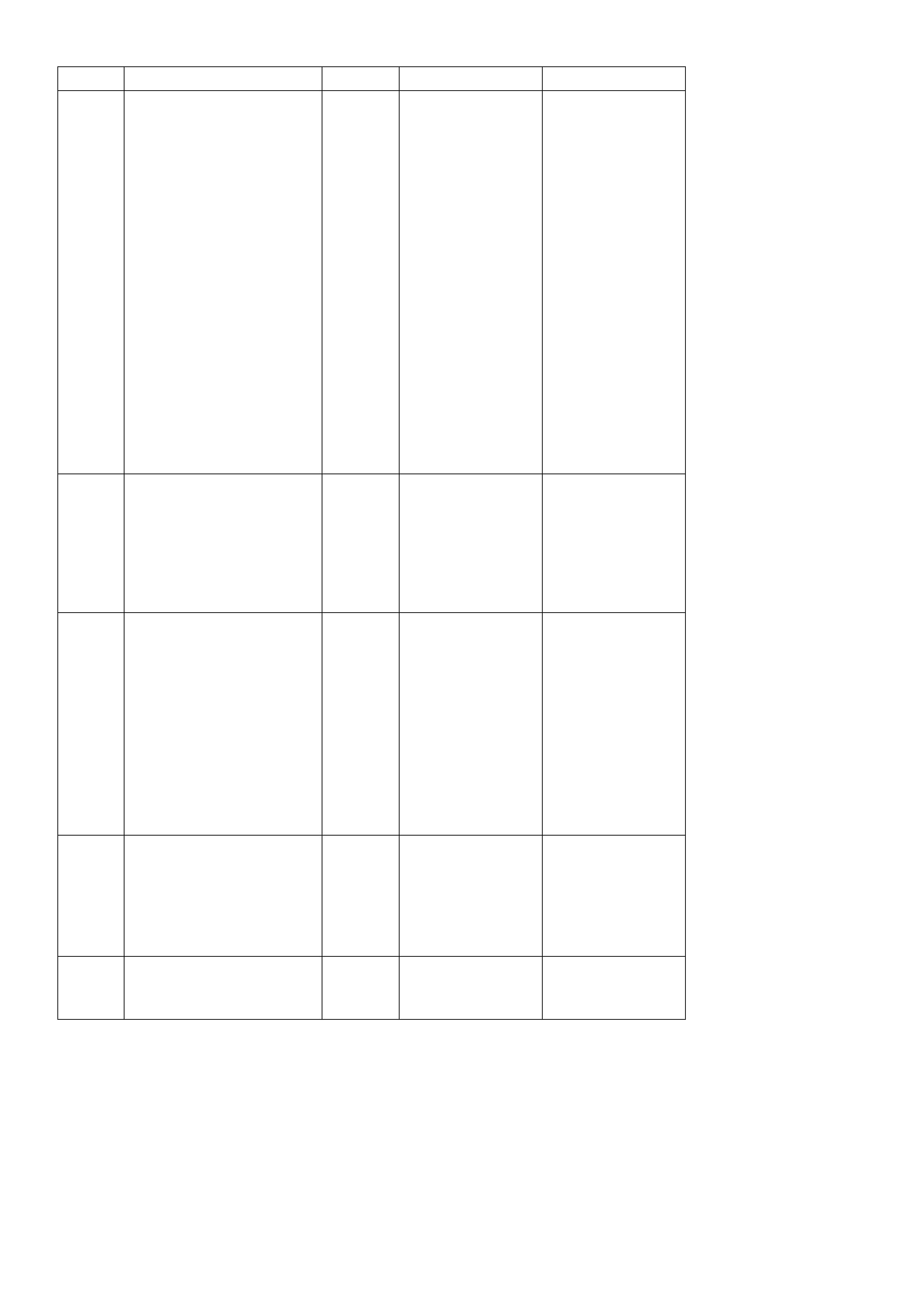

STEP ACTION VALUE YES NO

1Check the fluid colour.

Is the fluid colour red? Go to Step 2 Go to Step 11

2Is the fluid level correct? Go to Step 20 Go to Step 3

3Check the fluid.

Is the fluid foamy? Go to Step 8 Go to Step 4

4Check the fluid level. The

proper fluid level should

be In the middle of the X-

hatch.

Is the fluid level high?

Go to Step 9 Go to Step 5

5Fluid will be low.

Add fluid to the proper

fluid level.

Is the fluid level

satisfactory?

Go to Step 6 Go to Step 1

6Check for external leaks.

Were any leaks found? Go to Step 7 Go to Step 20

7Correct the fluid leak

condition.

Is the action complete?

Go to Step 20

8Is the fluid level too high? Go to Step 9 Go to Step 10

9Remove the excess fluid

to adjust to the proper

fluid level.

Is the action complete?

Go to Step 20

10 1. Check for

contaminants in the

fluid.

2. Drain the fluid in order

to determine the

source of the

contamination.

Is the action complete?

Go to Step 15

11 Is the fluid colour non-

transparent pink? Go to Step 12 Go to Step 13

12 Replace the cooler.

Is the action complete? Go to Step 15

STEP ACTION VALUE YES NO

13 The fluid colour should be

light brown. The

Transmission fluid may

turn dark with normal use.

This does not always

indicate oxidation or

contamination.

Is the fluid colour light

brown?

Go to Step 14 Go to Step 1

14 Drain the fluid in order to

determine if the fluid is

contaminated. A very

small amount of material

in the bottom of the pan is

normal, but large pieces

of metal or other material

in the bottom of the pan

requires a transmission

overhaul.

Was the fluid

contaminated?

Go to Step 15 Go to Step 18

15 Overhaul the

transmission. Refer to

Section 7C5, UNIT

REPAIR.

Is the action complete?

Go to Step 16

16 Flush the cooler.

Is the action complete? Go to Step 17

17 Add the new fluid.

Is the action complete? Go to Step 19

18 Change the fluid and the

filter.

Is the action complete?

Go to Step 19

19 Is the fluid level

satisfactory, If not, correct

as necessary.

Is the action complete?

Go to Step 20

20 Refer to 4L60-E

Transmission Functional

Test Procedure, in

Section 7C3, Diagnosis.

Is the action complete?

Fluid Checking

Procedure

Completed

CHART A - ON-BOARD DIAGNOSTIC SYSTEM CHECK

CIRCUIT DESCRIPTION:

The On-Board Diagnostic System Check is an organised approach in identifying a problem created by a powertrain

control system malfunction. It must be the starting point for any driveability complaint diagnosis, because it directs

the service technician to the next logical step in diagnosing the complaint. Understanding the chart and using it

correctly will reduce diagnostic time and prevent the unnecessary replacement of good parts.

TEST DESCRIPTION:

Number(s) below refer to step number(s) on the diagnostic chart.

1. This step is a check for the proper operation of the "Check Powertrain" lamp (MIL). The PCM should provide

serial data communication path for the "Check Powertrain" lamp, this is a bulb check. The "Check Powertrain"

lamp should be "ON." If it can do this, it confirms that the PCM has power, earth and is capable of some

functions.

If the "Check Powertrain" lamp is "OFF," this indicates a problem in the "Check Powertrain" lamp fuse circuits

or the PCM earth circuits or the PCM's serial data communication circuit or a problem with the PI cluster. Chart

A-1 will check for both ignition feed and constant battery power to the PCM and the PCM earth.

2. This check is done to see if the PCM has the capability of performing internal diagnostics. With the diagnostic

"test" terminal earthed, the "Check Powertrain" lamp, should flash a DTC 12 three times, followed by any

DTC(s) stored in memory. DTC 12 means there is no crankshaft reference signal coming to the PCM, this is

normal because the engine is not running.

3. This check is used to see if the PCM can supply serial data for Tech 2 scan tool use. If a PROM error is

present, the PCM may have been able to flash DTC 12 but not enable serial data.

4. This check is to see there are any Theft Deterrent DTC stored. If Theft Deterrent sy stem is enabled, this may

be the cause of the no crank condition.

5. This test determines if the vehicle is able to crank. If the vehicle will not crank, refer to Chart A-4.0 to diagnosis

starter cranking circuit.

7. This test is used to determine the cause of a "Cranks But Will Not Run," although the PCM is powered up, a

"Cranks But Will Not Run" symptom could exist because of a PCM problem or the vehicle electrical system.

8. Look at all the parameters to determine if one is not in a normal state with just the ignition "ON" and engine

stopped. Look at the ECT value to see if the value is shifted above or below where it should be. If so, refer

"Diagnostic Aid Chart" on DTC 14.

9. Look at all the parameters to determine that all values are within typical ranges for normal operating

temperatures at idle. Keep in mind that a basic engine problem may alter sensor value.

Techline

DIAGNOSTIC AIDS:

If the Serial Data circuit is shorted to voltage or earth, the vehicle will not crank. Check Serial Data circuit from PCM

to BCM, and from BCM to all other controllers.

STEP ACTION VALUE YES NO

11. Ignition ON engine

OFF.

2. Observe the "CHECK

POWERTRAIN" lamp.

Is the "CHECK

POWERTRAIN" lamp ON

steady?

Go to Step 2 If No "CHECK

POWERTRAIN"

lamp, Go to Chart

A-1 in this Section

----------------------

If "CHECK

POWERTRAIN"

lamp is flashing

DTC 12, Go to

Step 10

2Jumper the Data Link

Connector terminal "6" to

terminal "5".

Does the "CHECK

POWERTRAIN" lamp

flash DTC 12?

Go to Step 3 Go to Chart A-1

in this section

31. Remove the Data Link

Connector jumper.

2. Install a Tech 2 Scan

tool.

3. Ignition ON engine

OFF.

Does the Tech 2 tool

display PCM serial data?

Go to Step 4 Go to Chart A-2

in this section

41. Ignition ON engine

OFF.

2. Use the Tech 2 to

check for Theft

Deterrent DTC(s).

Are any Theft Deterrent

DTC(s) stored?

Go to the

appropriate DTC

chart

Go to Step 5

5Does the engine crank? Go to Step 6 Go to Chart A-4.0

in this Section

6Use the scan tool to

check for any other

DTC(s).

Are Any Diagnostic

Trouble Codes set?

Refer To

Applicable DTC

Chart in this

Section.

Start with lowest

DTC Number

Go to Step 7

STEP ACTION VALUE YES NO

7Does the engine start? Go to Step 8 Go to chart A-3.1

in this section

81. Ignition ON, engine

OFF.

2. Compare the Tech 2

Scan tool data values

with the typical values

shown on the Tech 2

scan data page.

Are the values within the

typical ranges?

Go to Step 9 Refer to indicated

Component(s)

System checks in

this Section

91. Run the engine until

the specified operating

temperature is

reached.

2. Run the engine at

1500 RPM's for two

minutes, then let the

engine idle.

3. Compare the Tech 2

scan data with the

typical values shown

on the scan data page.

Are all the values normal

or within their typical

ranges?

85°C Refer to

"Symptom

Diagnosis Charts"

in Section 6C1-2B

Refer to indicated

"Component(s)

System " checks

in this Section

10 Check for an earthed

diagnostic "TEST"

terminal circuit.

Was a problem found?

Verify Repair Go to Step 11

11 Replace the PCM. Refer

to Section 6C2-3 Service

Operations, for Security

Link procedure.

Is the action complete?

Verify Repair

CHART A-1 - NO CHECK POWERTRAIN LAMP

CIRCUIT DESCRIPTION:

There should always be a steady "Check Powertrain" (MIL) lamp with the ignition ON and engine OFF. The Battery

supplies voltage directly to the "Check Powertrain" (MIL) lamp through a fused circuit. The Powertrain Control

Module (PCM) will control the (MIL) over the serial data communication circuit to the Body Control Module (BCM).

When the PCM requests the "Check Powertrain" lamp ON, the PCM will send a message over the serial data circuit

to the BCM requesting that the (MIL) be turned ON. The BCM in return will then send a message through the serial

data circuit to the instrument panel (PI) Cluster. The PI Cluster will then determine what message the BCM is

sending, and will then turn ON the "Check Powertrain" lamp when commanded.

TEST DESCRIPTION:

Number(s) below refer to step number(s) on the diagnostic chart.

2. Fuse F13 supplies the power to the instrument panel cluster. If fuse F13 is open, the instrument panel cluster

lamps will not light.

5. If the Tech 2 scan tool can not communicate with the vehicle, there may be a problem in the serial data line.

Chart A-2 will check the serial data line.

6. If the Tech 2 scan tool is capable of commanding the MIL ON and OFF, the PCM may be at fault.

7. This checks for the proper serial data voltage to the instrument panel (PI) cluster.

STEP ACTION VALUE YES NO

1Was the "On-Board

Diagnostic" (OBD) System

Check performed?

Go to Step 2 Go to OBD

System Check in

this Section

2Check the PI cluster fuse

(F13).

Is the fuse OK?

Go to Step 3 Go to Step 9

31. Ignition OFF.

2. Disconnect the PCM

connectors.

3. Ignition ON engine

OFF.

4. Probe the PCM battery

feed circuits (A8 and

B8) and then the

ignition feed circuit

(A4) with a test light

connected to earth on

the harness side.

Is the test light ON for all

three circuits?

Go to Step 4 Go to Step 15

41. Ignition OFF.

2. Disconnect the PCM

connectors.

3. With a test light

connected to B+,

probe the PCM earth

circuits (A1, A2 , B1,

B2).

Is the test light ON for all

four circuits?

Go to Step 5 Go to Step 16

51. Reconnect the PCM

connectors.

2. Install a Tech 2 scan

tool.

3. Ignition ON, engine

OFF.

Does the Tech 2 scan tool

display PCM serial data?

Go to Step 6 Go to Chart A-2

6With the scan tool still

connected to the DLC,

command the MIL ON

using the scan tool.

Does the MIL turn ON

when commanded ON

with the scan tool?

Go to Step 14 Go to Step 7

71. Ignition OFF.

2. Remove the PI Cluster

from the dash panel.

3. Ignition ON.

4. Using a DVM, probe

the PI Cluster

connector terminal 12

with the DVM

connected to earth.

Does the DVM display

voltage at the specified

value?

4-5 volts Go to Step 8 Go to Step 10

STEP ACTION VALUE YES NO

8Check for poor connection

at the PI Cluster

connector.

Was a problem found?

Verify Repair Go to Step 11

91. Repair the short to

earth in the PI cluster

fuse circuit.

2. Replace the fuse.

Is the action complete?

Verify Repair

10 Repair the open in the

serial data circuit from the

BCM to the PI Cluster.

Is the action complete?

Verify Repair

11 Check the "Check

Powertrain " (MIL) bulb for

an open.

Was a problem found?

Go to Step 12 Go to Step 13

12 Replace the "Check

Powertrain " (MIL) bulb.

Is the action complete?

Verify Repair

13 Replace the instrument

panel cluster.

Is the action complete?

Verify Repair

14 Replace the PCM. Refer

to Section 6C2-3 Service

Operations, for the

Security Link procedure.

Is the action complete?

Verify Repair

15 Check for an open or a

short to earth in the power

circuit that did not light the

test light. Repair as

necessary.

Is the action complete?

Verify Repair

16 Repair the open in the

earth circuit that did not

light the test light.

Is the action complete?

Verify Repair

CHART A-2 - NO SERIAL DATA OR WILL NOT FLASH DTC 12,

MALFUNCTION INDICATOR LAM P (MI L) "CHECK POWERTRAIN" LAMP ON

STEADY

CIRCUIT DESCRIPTION:

There should always be a steady (MIL) "Check Powertrain" lamp when the ignition is ON and the engine is OFF.

The battery voltage is supplied directly to the (MIL) "Check Powertrain" lamp bulb. The Powertrain Control Module

(PCM) will control the "Check Powertrain" lamp and turn ON via the serial data communication circuit.

With the ignition ON, and the engine OFF and the diagnostic test terminal earthed, the "Check Powertrain" lamp

should flash a DTC 12, followed by any diagnostic trouble code(s) that are stored.

With the Tech 2 scan tool connected to the DLC and the ignition switch ON, the scan tool should display serial data.

If the scan tool does not display serial data, then the serial data circuit may be open or shorted.

There are several other control modules that are connected to the serial data circuit (PCM, BCM, ABS module, ECC

module, SRS module and PI cluster). Any one of these controllers could cause a fault in the serial data line. This

fault could result in the scan tool not being able to display serial data.

TEST DESCRIPTION:

Number(s) below refer to step number(s) on the diagnostic chart.

2. This step checks if the PCM will flash a DTC 12.

3. This checks if the Tech 2 scan tool will communicate with the PCM.

4. There should be 4 to 5 volts at the DLC, terminal 9. If the voltage is higher or lower, then serial communication

will be effected. This serial data circuit is also connected to several other controllers. A problem with any one of

these other controllers, may cause serial data communication fault.

DIAGNOSTIC AIDS:

A fault with the serial data circuit, could be caused by one or more of the several controllers connected to this serial

data circuit. Isolate the fault by disconnecting each controller one at a time until the serial data communication is

restored.

STEP ACTION VALUE YES NO

1Was the "On-Board

Diagnostic" (OBD) System

Check performed?

Go to Step 2 Go to OBD

System Check in

this Section.

21. Ignition" ON" engine

stopped.

2. Earth diagnostic

"TEST" terminal No. 6.

Does "CHECK

POWERTRAIN" lamp

flash DTC 12?

Go to Step 3 Go to Step 6

31. Connect Tech 2 scan

tool to DLC.

2. Ignition "ON", engine

stopped.

Does the Tech 2 scan tool

display PCM serial data?

No trouble found Go to Step 4

41. Ignition "ON" engine

stopped.

2. Using DVM, probe

DLC terminal 9 with

DVM connected to

earth.

Does the DVM display

voltage varying between

the

specified value?

3-5 volts Go to Step 5 Go to Step 8

5Check connections

between the DLC and the

PCM. If not OK repair, if

connection are OK,

Replace PCM,

Refer to Section 6C2-3

Service Operations, for

PCM Security link

procedure.

Is the action complete?

Verify Repair

61. Ignition "ON" engine

stopped.

2. Using DVM, probe

DLC terminal 6 with

DVM connected to

earth.

Does the DVM display

voltage at specified

value?

B+ Go to Step 13 Go to Step 12

7Replace the PI cluster.

Is the action complete? Verify Repair

8Is the voltage steady at or

above the specified

value?

5 volts Go to Step 11 Go to Step 9

91. Connect a Tech 2 scan

tool to DLC.

2. Ignition ON, engine

stopped.

Does the Tech 2 scan tool

display BCM serial data?

Go to Step 10 Go to Step 13

STEP ACTION VALUE YES NO

10 Repair the open or the

short to earth in the serial

data circuit between the

PCM and the DLC.

Is the action complete?

Verify Repair

11 Repair the short to voltage

on the serial data circuit.

NOTE:

Assure that none of the

other controllers on the

serial data circuit are

causing this voltage

problem. Unplug each

controller one at a time to

isolate a short to voltage.

Is the action complete?

Verify Repair

12 Check for an open in the

Diagnostic Test circuit

from the PCM to the DLC.

Was a problem found?

Verify Repair Go to Step 5

13 Check for a short to earth,

a short to voltage, or an

open in the serial data

line. Refer to Diagnostic

Aids.

Was a problem found?

Verify Repair Go to Step 7

NOTE:

For additional PCM wiring information refer to PCM Wiring Diagram - 2 of 8 in this section.

CHART A-3.1 - ENGINE CRANKS BUT WILL NOT RUN

CIRCUIT DESCRIPTION:

This is the first of several diagnostic charts that must be followed in order to find the cause of a no-start. These

charts assume, that the cranking motor circuit is in good working order, and that the engine will crank with adequate

RPM. These charts also assume that Diagnostic Trouble Code (DTC) 31 or DTC 46 are not set. The On-Board

Diagnostic System Check is always the starting point for all diagnostic procedures.

TEST DESCRIPTION:

Number(s) below refer to step number(s) on the diagnostic chart.

1. There are a few cases where the PCM could cause a no-start. The On-Board Diagnostic System Check will

uncover any problems in the PCM power circuit and the earth circuit.

4. This is a quick check of the fuel system. The easiest place to install the pressure gauge is where the fuel pipes

come up into the engine compartment. There are 2 hoses, and the gauge must be connected to the hose or

pipe leading directly to the fuel rail. This connection is on the left (passenger) side of the fuel rail. The other

hose or pipe leads to the pressure regulator, and no pressure testing is done there. If the pressure is not as

specified, or continues to drop after the pump stops running, the Fuel System Diagnostic Chart A-4.2 in this

Section must be used.

6. Note that this check is for sufficient voltage at the spark plug wire. If, the spark plug electrodes are wet with fuel

(engine flooded), the engine may not start. A flooded engine is a symptom of some other problem. There is no

normal condition that should ever be able to flood the engine.

NOTE:

Use ST 125 spark checker or equivalent. An ST 125 requires about 25,000 volts (25 kilovolts, or 25 kV) to "spark".

Do not use a spark plug in open air earthed to the engine as an indication of sufficient "spark". Only a few kilovolts

are required to jump the gap of a spark plug outside of the engine, and that would be an inadequate test of the

ignition coil output ability.

8. At this point the Fuel system and the ignition system are OK. Continue to inspect the rest of the PCM input

sensors and outputs. Use the typical scan tool value charts, the functional test charts, and the voltage pin out

charts for additional information.

STEP ACTION VALUE YES NO

1Was the "On-Board

Diagnostic" (OBD) System

Check performed?

Go to Step 2 Go to the OBD

System Check in

this Section

21. Check the power feed

fuses F14, F28, F34

and F35.

2. Check the FS Main

fuse, the FJ main fuse,

and the white fusible

link wire.

Are all of the above circuit

protectors OK?

Go to Step 3 Go to Step 7

31. Install a Tech 2 scan

tool.

2. Ignition ON engine

OFF.

3. Remove the fuel filler

cap.

4. Use the Tech 2 to

command the fuel

pump ON and OFF

while listening at the

fuel filler neck for the

fuel pump to turn ON

and OFF.

Does the fuel pump turn

ON and OFF when

commanded?

Go to Step 4 Go to Chart A-4.1

in this Section

41. Ignition OFF.

2. Remove the EFI relay

from the engine

compartment FUSE

AND RELAY CENTRE,

then crank the engine

for 15 seconds to

relieve the fuel

pressure.

3. Ignition OFF, install a

fuel pressure gauge

(Gauge to be installed

in the pressure line,

between the fuel feed

hose and the fuel inlet

line to the fuel rail, at

left rear of fuel rail.)

4. Reinstall the fuel pump

relay.

5. Turn the ignition ON

for 10 seconds.

Does the fuel pressure

hold steady between the

specified value for two

minutes?

270-350

kPa Go to Step 5 Go to Chart A-4.2

in this Section

STEP ACTION VALUE YES NO

51. Ignition OFF.

2. Disconnect the fuel

injector electrical

connectors.

3. Connect a test light

across the No.1

cylinder fuel injector

harness terminals.

4. Have a helper crank

the engine while you

observe the light.

5. Repeat the test on

cylinders No. 2 through

No. 8.

Did the test light flash on

all eight cylinders while

cranking the engine?

Go to Step 6 Go to Chart A-3.2

in this section

61. Ignition OFF.

2. Remove the spark plug

wire from the No. 1

spark plug.

3. Connect an ST125

spark tester to the No.

1 cylinder (see note

above).

4. Check for spark while

cranking the engine. A

few sparks and then

nothing is considered

no spark.

5. Continue to check for

spark on the remaining

cylinders.

Was their spark on all

eight cylinders?

Go to Step 8 Go to Chart A-8.1

in this Section

71. Repair the short to

earth in the circuit that

the circuit protector

was found open.

2. Replace the open

circuit protector.

Is the action complete?

Verify Repair

STEP ACTION VALUE YES NO

8At this point, the fuel

control system, the fuel

delivery system, and

ignition system are OK.

Check For:

• Fouled spark plugs.

The proper MAF

sensor operation. If the

engine will start with

the MAF sensor

electrical connector

disconnected refer

Chart A-6.1 in this

Section.

The proper TP sensor

circuit operation. Use

the Tech 2 scan tool to

monitor the TP sensor

signal. If the voltage is

over 2.5 volts with the

throttle closed, refer to

Chart A-6.2 in this

Section.

• A restricted exhaust

system. Loosen the

front pipe from the

exhaust manifold(s). If

the engine will start,

refer to Chart A-13 in

this Section.

An improper Engine

Coolant Temperature

(ECT) sensor

resistance. Refer to

DTC 14 DIAGNOSTIC

AIDS to check the

resistance of the ECT

sensor.

• The camshaft timing

chain slipped or

stripped, causing the

camshaft to be out-of-

time.

• Inadequate engine

compression.

• Measure the

resistance across the

terminals of each fuel

injector. Replace any

fuel injector that does

not measures between

14 and 16 Ohms.

Verify Repair

CHART A-3.2 - ENGINE CRANKS BUT WILL NOT RUN

CIRCUIT DESCRIPTION:

These charts assume, that the cranking motor circuit is in good working order, and that the engine will crank with

adequate RPM. These charts also assume that Diagnostic Trouble Code (DTC) 31 or DTC 46 are not set. The On-

Board Diagnostic System Check is always the starting point for all diagnostic procedures.

TEST DESCRIPTION:

Number(s) below refer to step number(s) on the diagnostic chart.

1. Do not use this chart unless sent here from Chart A-3.1. There must be some preliminary checks done before

continuing with this chart. Failure to perform these steps could lead to an incorrect diagnosis.

2. This test both circuits for an open. Repair the open in the circuit that did not light the light.

3. This test CKT 152 for an open in the EFI relay circuit.

6. The Security Link procedure must be performed whenever the PCM or the PROM is replaced. Refer to

Section 6C2-3 SERVICE OPERATION for the Security Link procedures.

STEP ACTION VALUE YES NO

1Was the "On-Board

Diagnostic" (OBD) System

Check performed?

Go to Step 2 Go to the OBD

System Check in

this Section

2From Table A-3.1

1. Ignition OFF.

2. Reconnect the fuel

injector's electrical

connectors.

3. Disconnect the EFI

relay.

4. Ignition ON.

5. With a test light

connected to earth,

probe the EFI relay