SECTION 6E1 EMISSION CONTROL - V6 ENGINE

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will

consist of either seat belt pre-tensioners and a driver's side air bag, or seat belt pre-

tensioners and a driver's and front passenger's side air bags. Refer to CAUTIONS,

Section 12M, before performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deplo yment, resulting in possible p ersonal injury or unnecessary

SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of

safety, the LPG fuel system should be isolated by turning 'OFF' the manual service

valve and then draining the LPG serv ice lines, before any service w ork is carried out

on the vehicle. Refer to the LPG leaflet included with the Owner's Handbook for

details or LPG Section 2 for more specific servicing information.

1. GENERAL INFORMATION

VT Series Models fitted with V6 engines are designed to comply with the requirements of Australian Design Rule,

ADR 37. In order to meet the low exhaust emission levels specified in ADR 37, these vehicles operate on unleaded

petrol and are fitted with a catalytic converter in the exhaust system. These vehicles also feature electronically

controlled fuel injection and direct ignition system.

In addition, these vehicles are fitted with the following emission control systems:

V6 NON SUPERCHARGED V6 SUPERCHARGED

ENGINE VENTILATION ENGINE VENTILATION

EVAPORATIVE EMISSION CONTROL EVAPORATIVE EMISSION CONTROL

THREE WAY CATALYTIC CONVERTER THREE WAY CATALYTIC CONVERTER

EXHAUST GAS RECIRCULATION

1.1 VEHICLE EMISSION CONTROL INFORMATION LABEL

The Vehicle Emission Control Information Label, is

located in the engine compartment as shown in

Figure 6E1-1. The label contains important engine

tune conditions to achieve the correct emission

levels, and should be ref err ed to bef ore making any

adjustments. Refer to Figure 6E1-2 for the V6

engine or 6E1-3 for the V6 supercharged engine.

Figure 6E1-1

Figure 6E1-2

Figure 6E1-3

1.2 EMISSIONS MANAGEMENT

All aspects of engine air/fuel ratio and spark timing are controlled by the Powertrain Control Module (PCM). The

mixture control is a closed loop system which incorporates dual oxygen sensors in the exhaust system engine pipe.

The Engine Ventilation system is not controlled by the PCM. How ever the Evaporative Emission Control system is

now controlled by the PCM through a canister purge solenoid valve. The PCM and its associated systems are

described in Section 6C1 POWERTRAIN MANAGEMENT - V6 ENGINE.

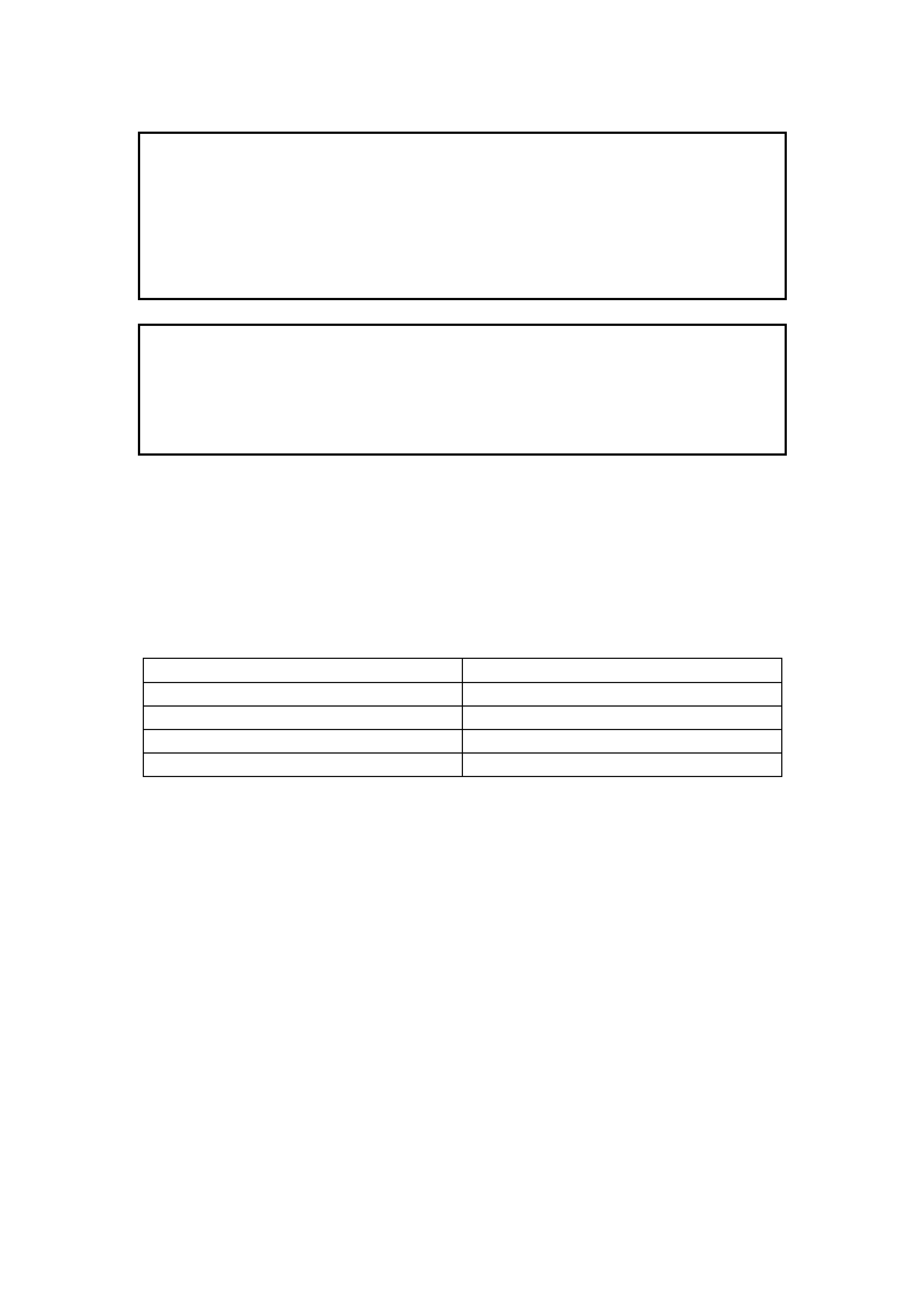

1.3 ENGINE VENTILATION

The engine ventilation system uses a Positive

Crank case Ventilation (PCV) valve whic h is located

in the inlet manifold.

During normal driving conditions, crankcase

vapours are drawn into the inlet manifold via a PCV

valve.

Vapours are then delivered through the plenum

chamber of the inlet manifold into the combustion

chamber, to be burnt with the air/fuel mixture.

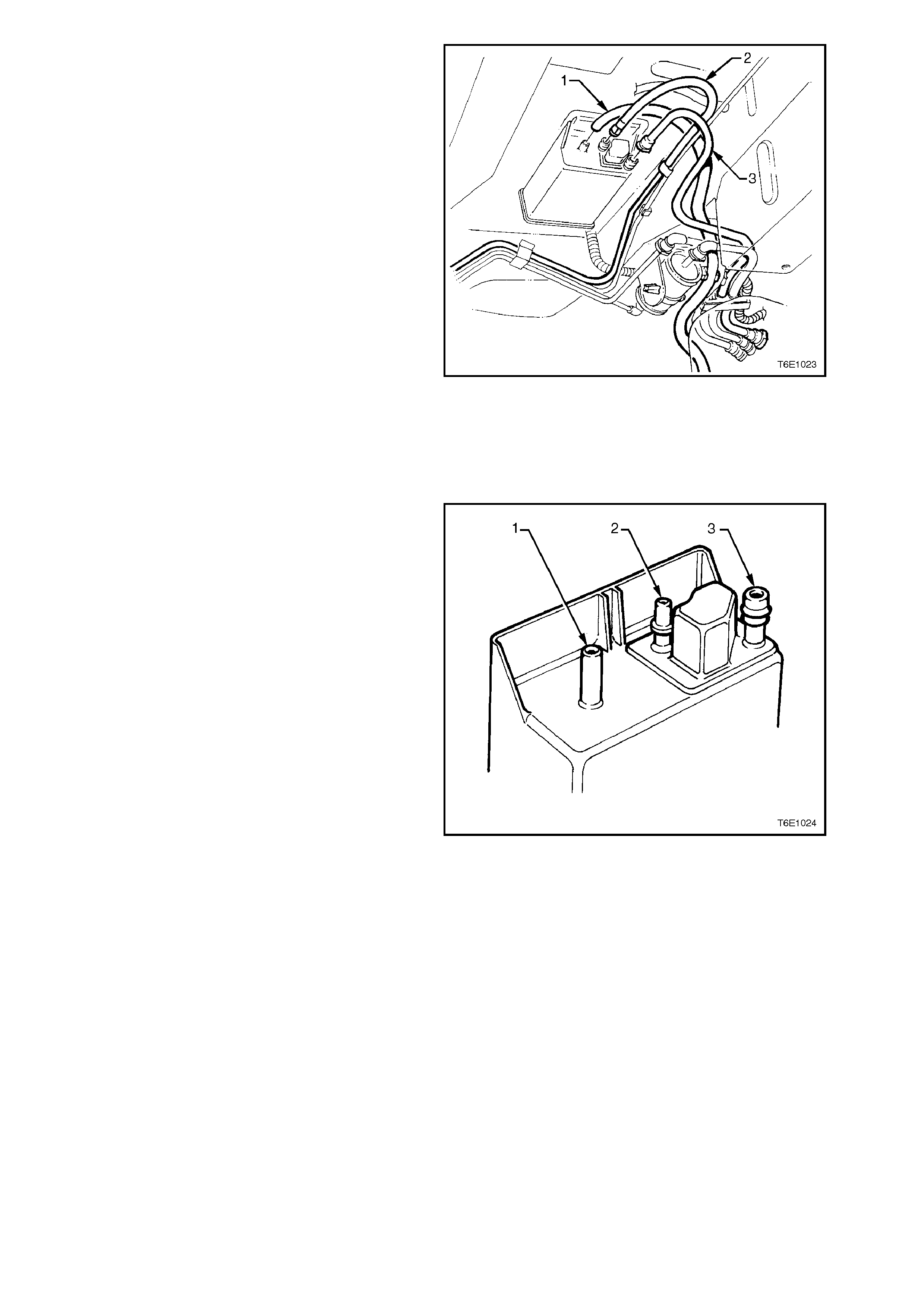

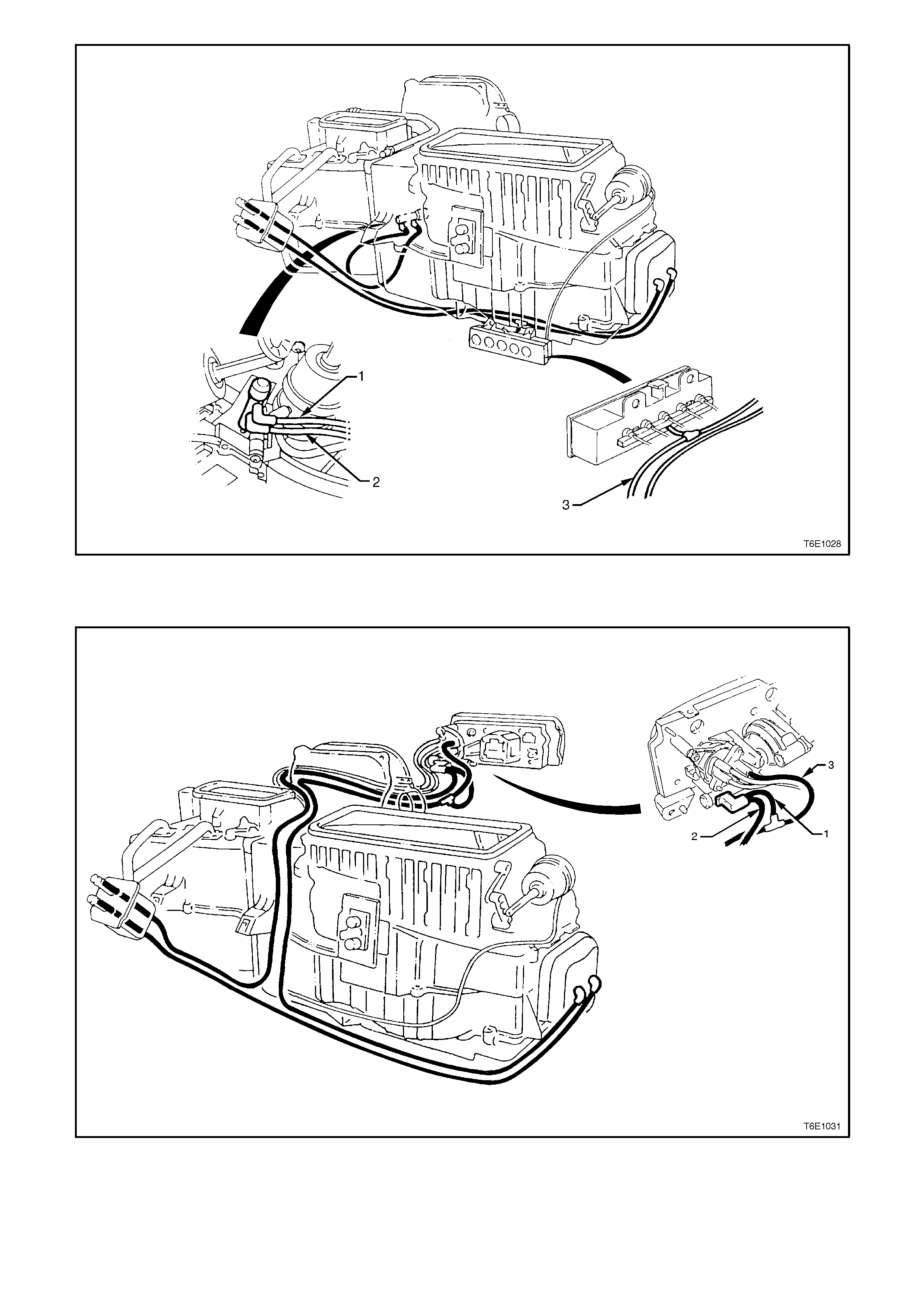

Figure 6E1-4

Figure 6E1-5

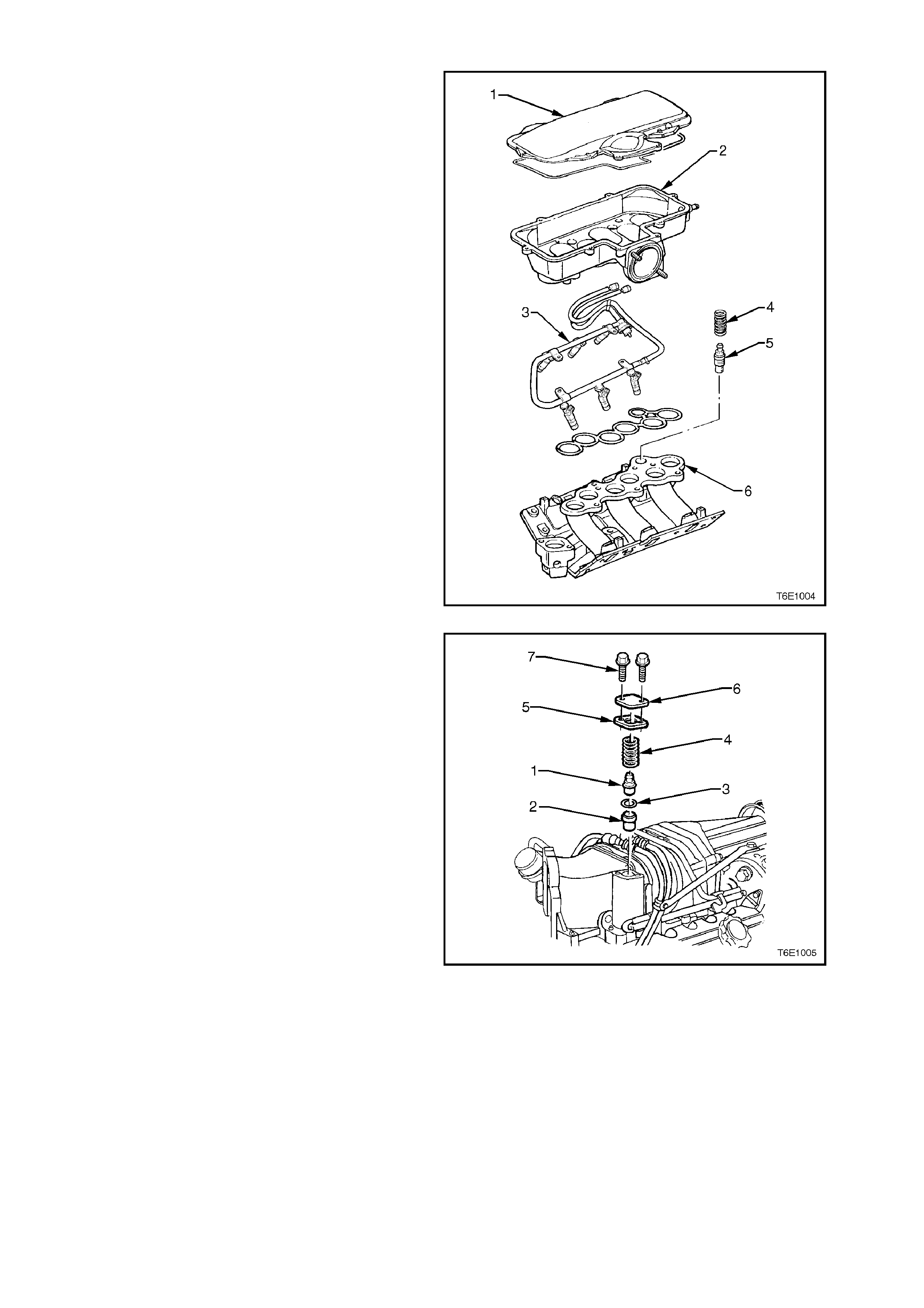

Fresh air is, in turn, drawn into the cr ankcase via a

breather hose (3) which is connected between the

throttle body (1) and a port on the inlet manifold (2).

Figure 6E1-6

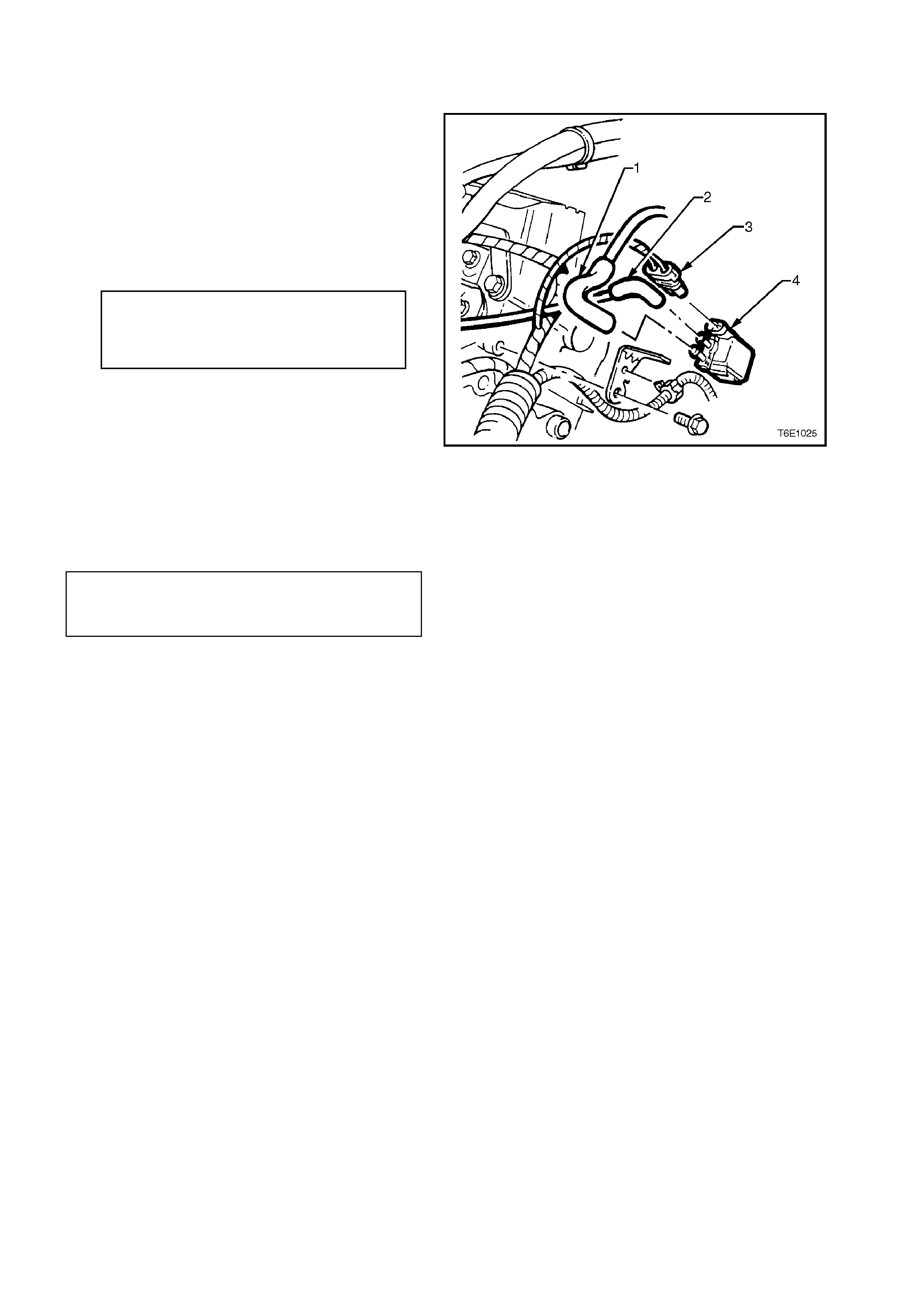

The PCV valve meters the mixture of fresh air and

crankcase vapours into the induction system at a

rate dependant upon manifold vacuum.

To m aintain idle quality, the PCV valve re stricts the

flow when inlet manifold vacuum is high. If

abnormal manifold conditions arise, the system is

designed to allow excessive amounts of crankcase

vapours to flow back through the breather hose (1),

into the throttle body to be consumed by normal

combustion.

Figure 6E1-7

The engine ventilation system must be checked at

the time or distance intervals specified in the VT

Series Owner's Handbook.

The PCV valve is a non-s erviceable item and m ust

be replaced if defective.

1.4 EVAPORATIVE EMISSION CONTROL

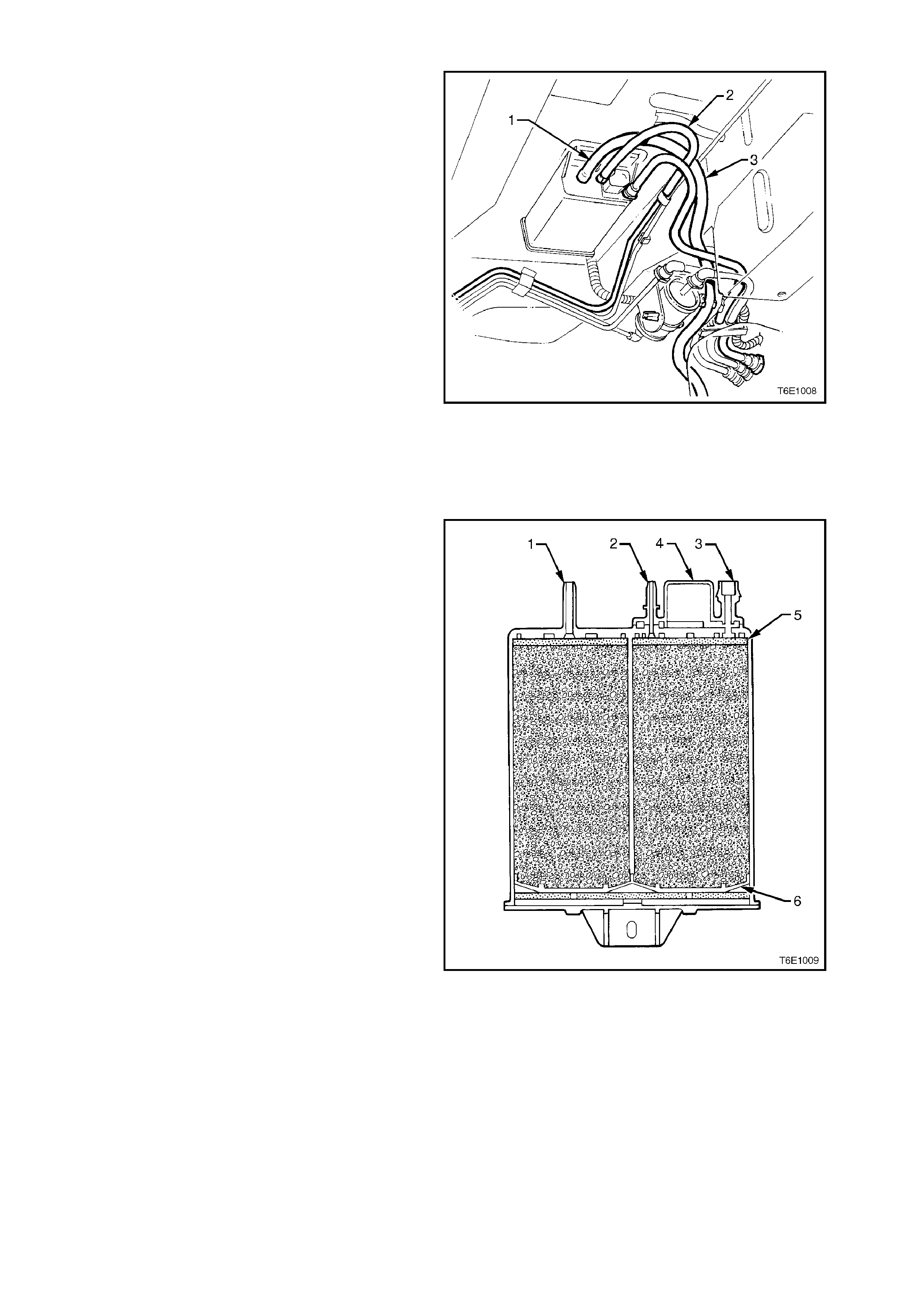

The Evaporative Emission Control System (EECS)

captures fuel vapours, which would normally

escape from the fuel tank and enables them to be

consumed in the combustion process. The EECS

used on VT Series Models is the charcoal canister

storage m ethod. This method transfers fuel vapour

from the fuel tank to an activated car bon (charcoal)

storage canister to hold vapours when the vehicle

is not operating. When the engine is running, the

fuel vapour is purged from the carbon element by

intake air flow and consumed in the normal

combustion process. The fuel tank cap is not

vented to atmosphere, but is fitted with a valve to

allow both pressure and vacuum relief. The

canister is a three port design:

1. Atmospheric port (fresh air inlet)

2. Purge Port

3. Vapour inlet port

The fuel vapour is absorbed by the charcoal in the

canister. When the engine is running, air is drawn

into the canister through the atmospheric port at

the top of the canis ter ass embly. The air mixes with

the vapour and the m ixture is drawn into the intake

manifold via the canister purge line.

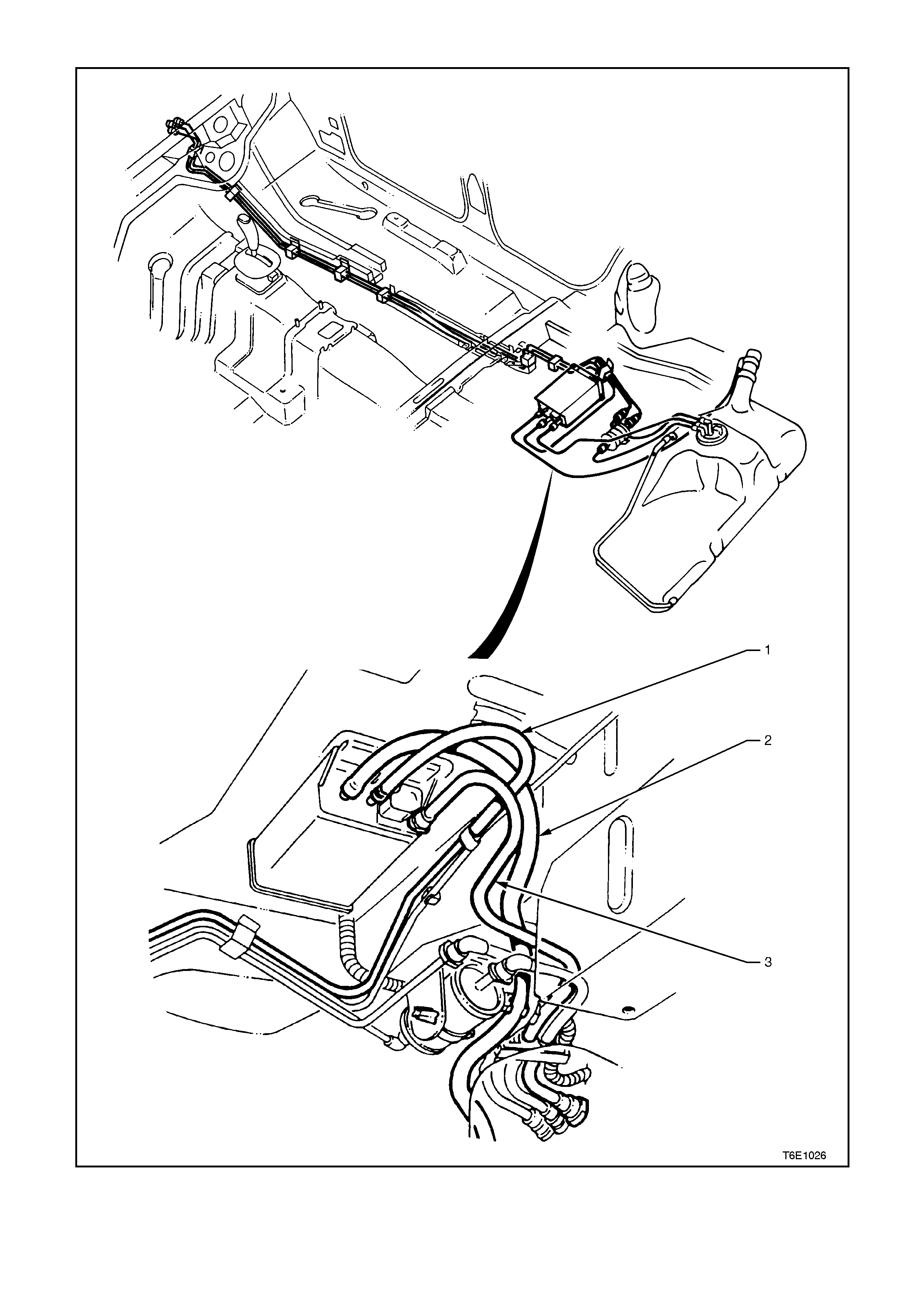

Figure 6E1-8

The purge port (3) on the c anister is controlled by a

PCM activated purge solenoid valve. The solenoid

valve controls the manifold vac uum s ignal from the

throttle body. The vapour inlet port (1) allows fuel

vapour to enter the canis ter from the f uel tank . T he

atmospheric port (1) allows fresh air to be drawn

into the canister.

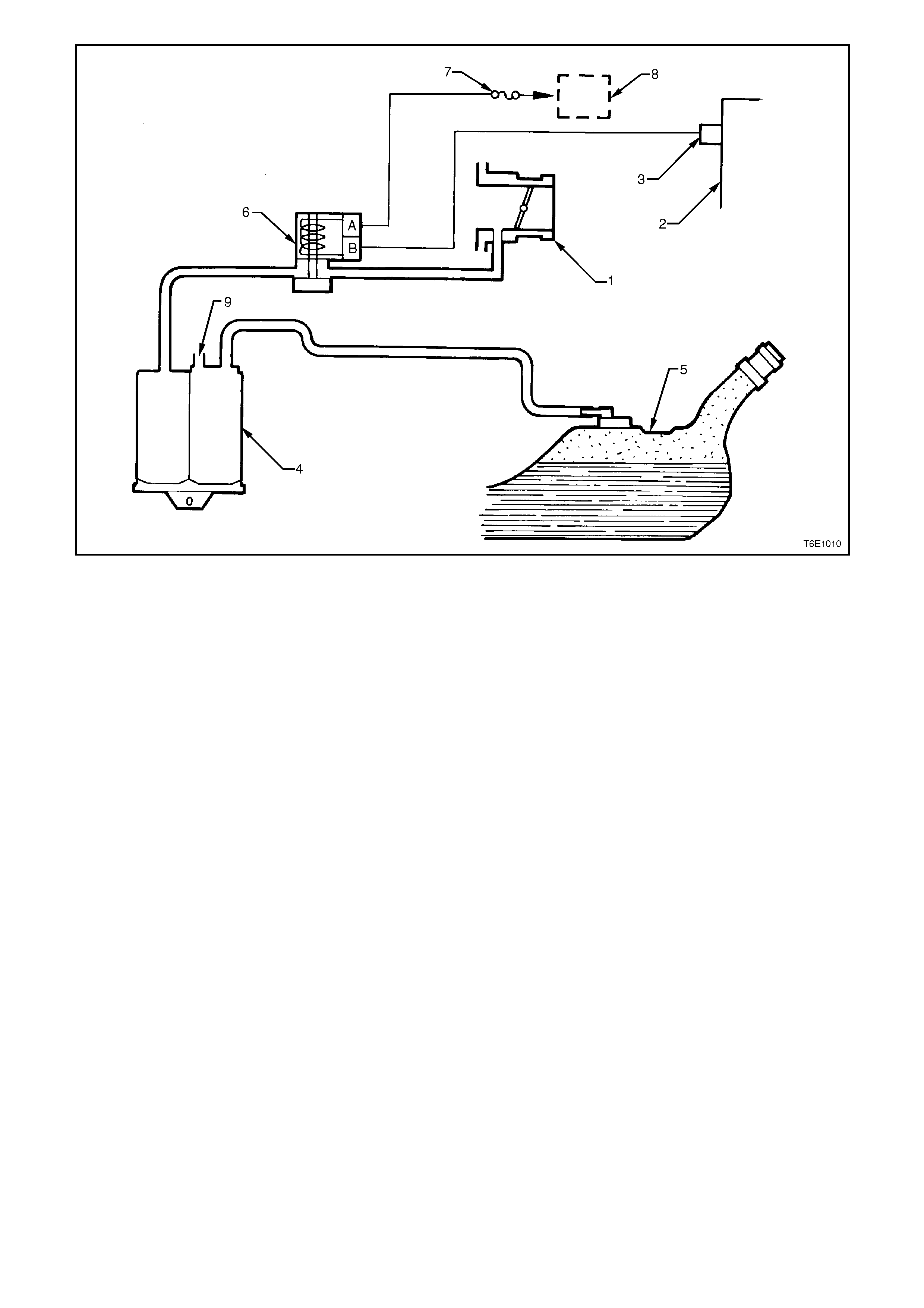

This system has a remote mounted canister purge

control solenoid valve. The PCM operates this

solenoid valve to control vacuum to the canister.

Under cold engine conditions, the solenoid valve is

turned OFF by the PCM, which blocks vacuum to

the canister and prevents purge.

The PCM turns ON the solenoid valve and allows

purge:

• When the engine coolant temperature is less

than 20° C, 3 minutes and 10 seconds after

engine start.

• W hen the engine c oolant temper ature is greater

than 80° C, 5 seconds after engine start.

• Engine is not in Dec el Fuel Cutof f Mode and the

throttle opening is less than 92%.

• Engine is in Closed Loop Fuel Mode.

The canister cannot be repaired, and is serviced

only as an assembly. Periodically check the

canister at the time or distance intervals specified

in the VT Series Owner's Handbook.

1. Atmospheric Port

2. Vapour Inlet Port

3. Purge Port

4. Liquid Trap

5. Volume Compensator and Filter

6. Diffuser

Figure 6E1-9

Figure 6E1-10

1. Throttle Body 4. Carbon Canister 7. Fuse F33

2. PCM 5. Fuel Tank 8. EFI Relay

3. PCM Terminal C4 6. Purge Solenoid Valve 9. Atmospheric Port

1.5 EXHAUST GAS RECIRCULATION

PRINCIPLES OF OPERATION

The Non Superc harged V6 engine is equipped with

an Exhaust Gas Recirculation (EGR) system. The

EGR system is used to lower Oxides of Nitrogen

(NOx) emission levels, caused by high com bustion

temperature.

A linear EGR valve feeds small amounts of exhaust

gas back into the c ombus tion chamber . T his dilutes

the air/fuel mixture and combustion temperatures

are reduced.

The linear EGR valve is designed to accurately

supply exhaust gas to the engine independent of

the intake manif old vac uum. T he valve c ontr ols gas

flow from the exhaust to the intake manifold

through an orifice with a PCM controlled pintle.

During operation, the PCM controls pintle position

by monitoring the pintle position feedback signal.

The linear EGR valve is us ually activated under the

following conditions:

• Warm engine operation.

• Above idle speed.

The PCM monitors actual EGR position and adjusts

the pintle accordingly. The PCM uses information

from the following sensors to control pintle position:

• Engine Coolant Temperature (ECT) sensor.

• Throttle Position (TP) sensor.

• Mass Air Flow (MAF) sensor.

• Engine RPM

Figure 6E1-11

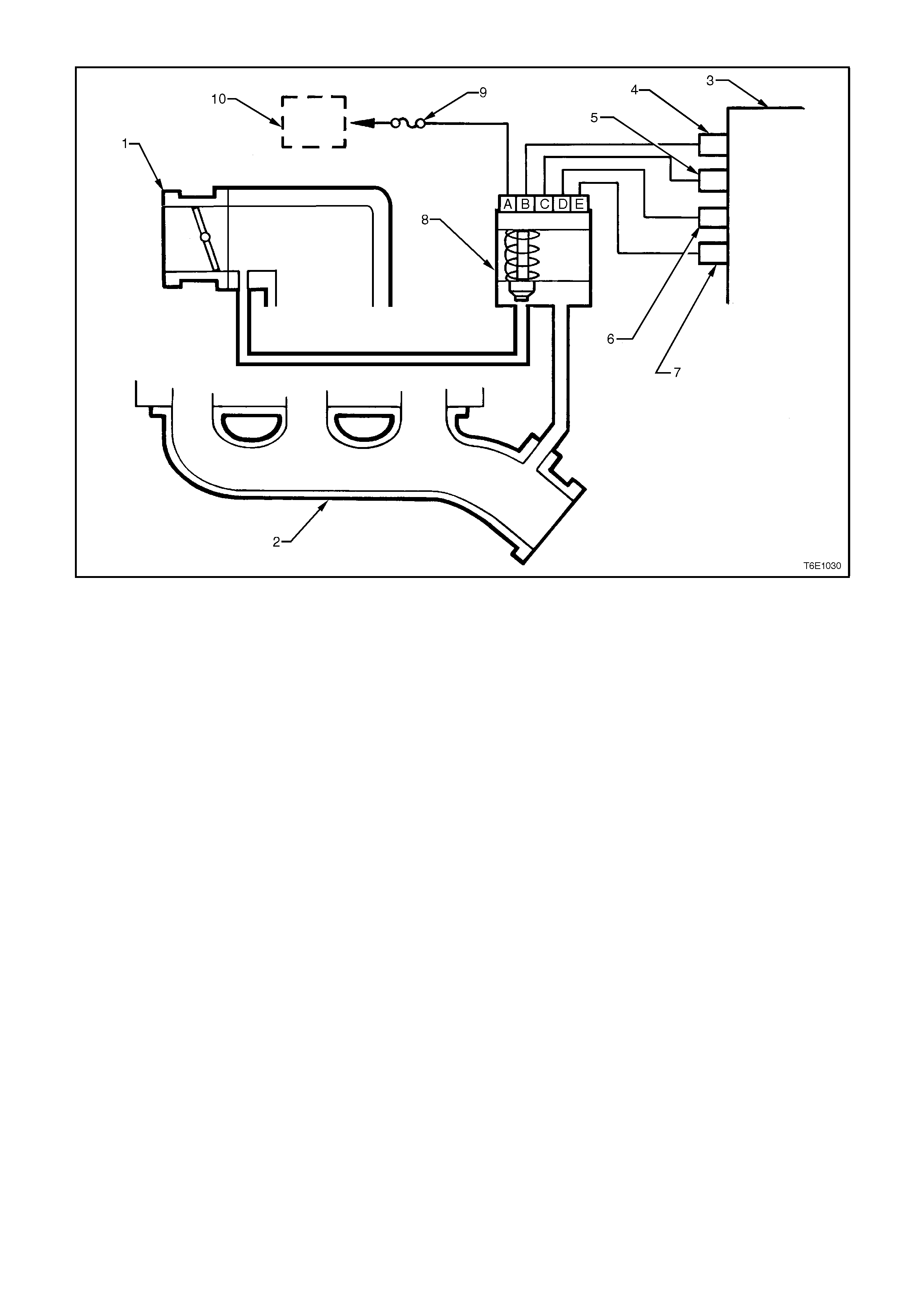

Figure 6E1-12

1. Throttle Body 5. PCM Terminal B10 9. Fuse F33

2. Exhaust manifold 6. PCM Terminal B7 10. EFI Relay

3. PCM 7. PCM Terminal F16

4. PCM Terminal E10 8. Linear EGR Valve

1.6 THREE-WAY CATALYTIC CONVERTER

PRINCIPLES OF OPERATION

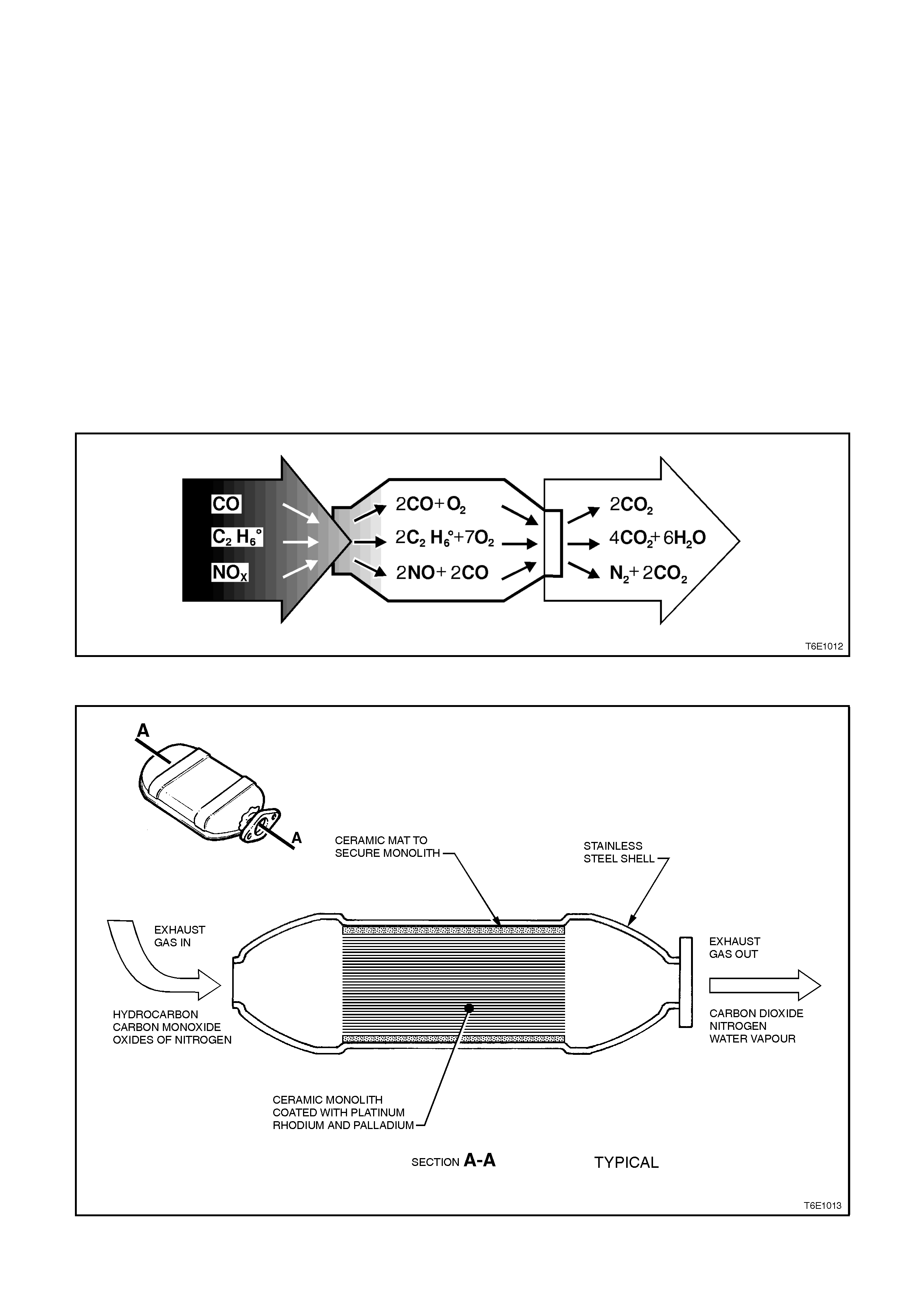

Catalyst is the term used to describe substances which accelerate chemical reactions without themselves changing.

In the field of motor vehicle technology, the catalyst has the task of lowering the levels of pollutants, carbon

monoxide (CO), hydrocarbons (HC) and oxides of nitrogen (NOX), in the exhaust gases by converting them into

harmless naturally occurring gases.

CO and HC are converted by oxidation with the oxygen (O2) contained in the exhaust gases into non-poisonous

carbon dioxide (CO2) and water vapour (H2O). To eliminate the oxides of nitrogen (NOX), the harmful carbon

monoxide which binds the oxygen in the exhaust gases is used as a reducing agent. The products of this reaction

are carbon dioxide (CO2) and nitrogen (N2). Together with oxygen, these two gases are components of the air that

we breathe.

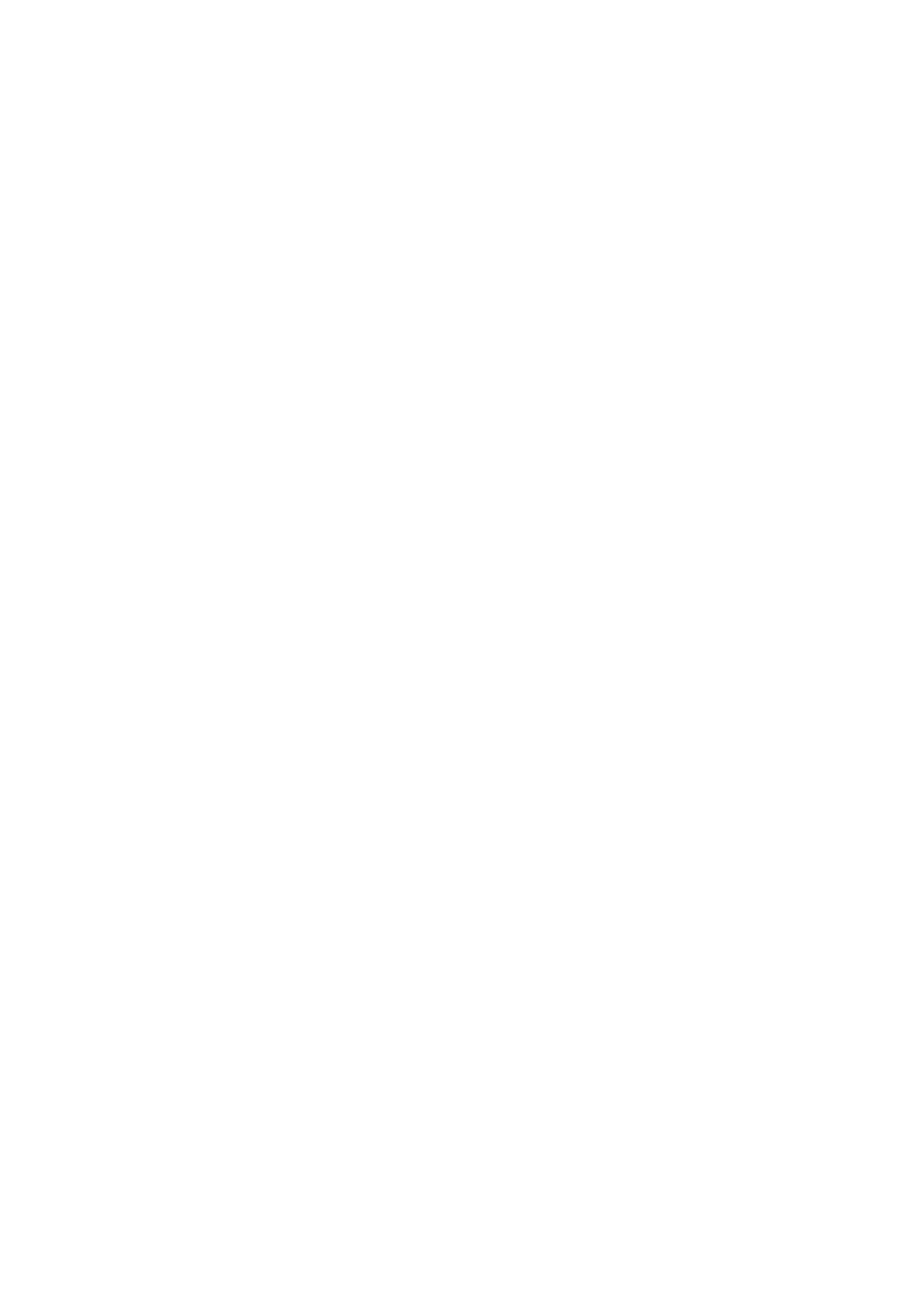

The catalytic converter consists of a stainless steel housing enclosing a ceramic monolith. The monolith is an

extruded core of cordierite, a specially developed high temperature ceramic with approximately 160 cells/sq. cm. in

cross section. This gives the monolith a very large surface area for its mass. Distributed over the monolith surface is

a catalyst consisting of a combination of the precious metals, Platinum, Palladium and Rhodium.

Engine exhaust gases flow over the monolith and reactions with the catalysts occur. The converter is called a three-

way type because it simultaneously converts three components of exhaust gas (CO, HC and NOX) to harmless

natural gases.

Figure 6E1-13

Figure 6E1-14

The catalytic converter can only reduce exhaust

emissions if:-

a. The engine is designed for use with a

catalytic converter and unleaded petrol,

since lead contaminates the catalytic

coating and prevents it from functioning.

b. It is integrated in the exhaust system in

such a way that the exhaust emission

conversion occurs in the most effective

temperature range - in the vicinity of 600

degrees Celsius.

c. The catalysts function effectively within

certain air/fuel ratios only, consequently

the air/fuel ratio supplied to the engine

must be controlled within strict limits for

proper emission conversion and long

converter life. This control is offered by

operating under a closed loop mixture

control system , with dual oxygen sensor s.

For details of the oxygen sensors, ref er to

Section 6C1 POWERTRAIN

MANAGEMENT - V6 ENGINE.

The catalytic converter can be damaged, or

rendered ineffective, if operated outside the limits

of the closed loop mixture control system, or if the

engine burns excessive amounts of oil or if the

exhaust temperature at the converter is too high

(above 850 degrees Celsius).

Figure 6E1-15

SERVICE NOTES

1. Never operate the vehicle with leaded petrol as the lead will contaminate the ceramic monolith.

2. Never drop the catalytic converter, as it will damage the ceramic monolith.

3. Do not allow water, oil or fuel to enter the converter as the ceramic monolith will be contaminated.

4. Do not use any engine additive that is not recommended by Holden. Many additives contain phosphorous,

which will contaminate the ceramic monolith.

5. In order to prevent the catalytic converter from overheating, the following sequence must be followed when

carrying out a cylinder balance test.

a. Maximum time each cylinder may be switched off is 8 seconds.

b. Pause for at least 8 seconds between each switch off.

c. If repeating a cylinder balance test, allow engine to idle for a least 60 seconds before retesting.

6. The vehicle must not be started by pushing or towing, as unburned fuel could reach the catalytic converter and

destroy the ceramic monolith. Always use jumper leads to start vehicle which has a flat or defective battery.

7. When carrying out a compression test, remove the ENGINE fuse, F25, from the engine compartment relay

housing, refer to Section 6A1 ENGINE MECHANICAL - V6 ENGINE. This prevents fuel injection and ignition

during engine cranking.

8. Do not drive vehicle for long periods with engine misfiring or with spark plug leads disconnected, as the

catalytic converter will overheat.

9. Do not coast downhill with engine misfiring or with spark plug leads disconnected.

10. Never re-use catalytic converter flange gaskets.

11. If the catalytic converter housing must be welded, use MIG or TIG with stainless steel wire. Do not use

oxy/acetylene welding, as damage to the monolith may result.

12. The catalytic converter is integrated with the exhaust system. For removal and installation instructions, refer to

Section 8B EXHAUST SYSTEM.

2. SERVICE OPERATIONS

2.1 POS I TIVE CRANKCASE VENTILATION VALVE

REPLACEMENT AND FUNCTIONAL CHECK V6 NON-SUPERCHARGED ENGINE

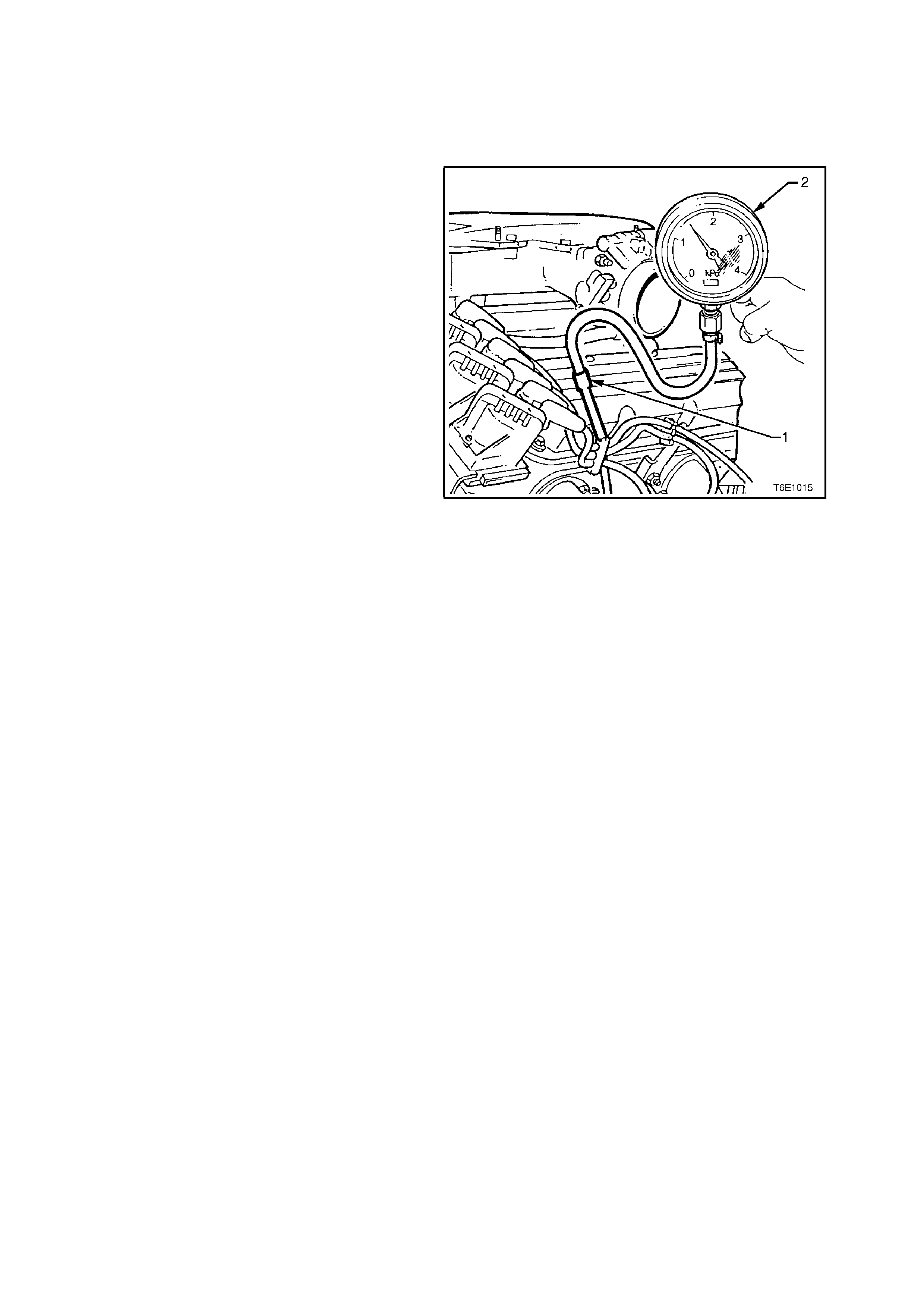

Remove engine oil dipstick. Connect a

commercially available vacuum gauge (2) with a

scale of approximately 0 to -4 kPa (vacuum gauge

must be able to read less than -1 kPa) to the

engine oil dipstick tube (1), ensuring a tight seal.

Allow engine to idle and read vacuum gauge. If a

vacuum is present, approximately -0.2 to -1.00 kPa,

the PCV valve and PCV system are functioning

correctly.

If no vacuum or a possible positive pressure is

registered, this can indicate several abnormalities;

• The engine may not be sealed and/or is dr awing

outside air. Check engine crankcase, i.e. valve

cover, oil pan gasket etc. for leaks.

• The engine may be badly worn causing

excessive engine blow-by.

• The PCV valve may be blocked and requires

further investigation using the following

procedure.

1. Remove PCV valve from inlet manifold, refer

2.9 LOWER INLET MANIFOLD, in Section

6A1 ENGINE MECHANICAL - V6 ENGINE.

2. Shake PCV valve and lis ten for rattle of check

valve inside valve housing. If valve does not

rattle, discard and install new PCV valve and

O ring.

3. Install PCV valve with O ring, refer 2.9

LOWER INLET MANIFOLD, in Section 6A1

ENGINE MECHANICAL - V6 ENGINE.

NOTE:

It is possible (and normal) to have a positive

pressure reading at the engine oil dipstick tube

while the vehicle is under driving conditions at wide

open throttle.

CAUTION:

Do not clam p the hos e f rom the PCV valve outlet at

the intake manifold to the throttle body when the

engine is running as this can cause dam age to the

engine.

Figure 6E1-16

REPLACEMENT AND FUNCTIONAL CHECK V6 SUPERCHARGED ENGINE

If an engine is idling rough, check for a clogged

crankcase ventilation valve using the following

procedure:

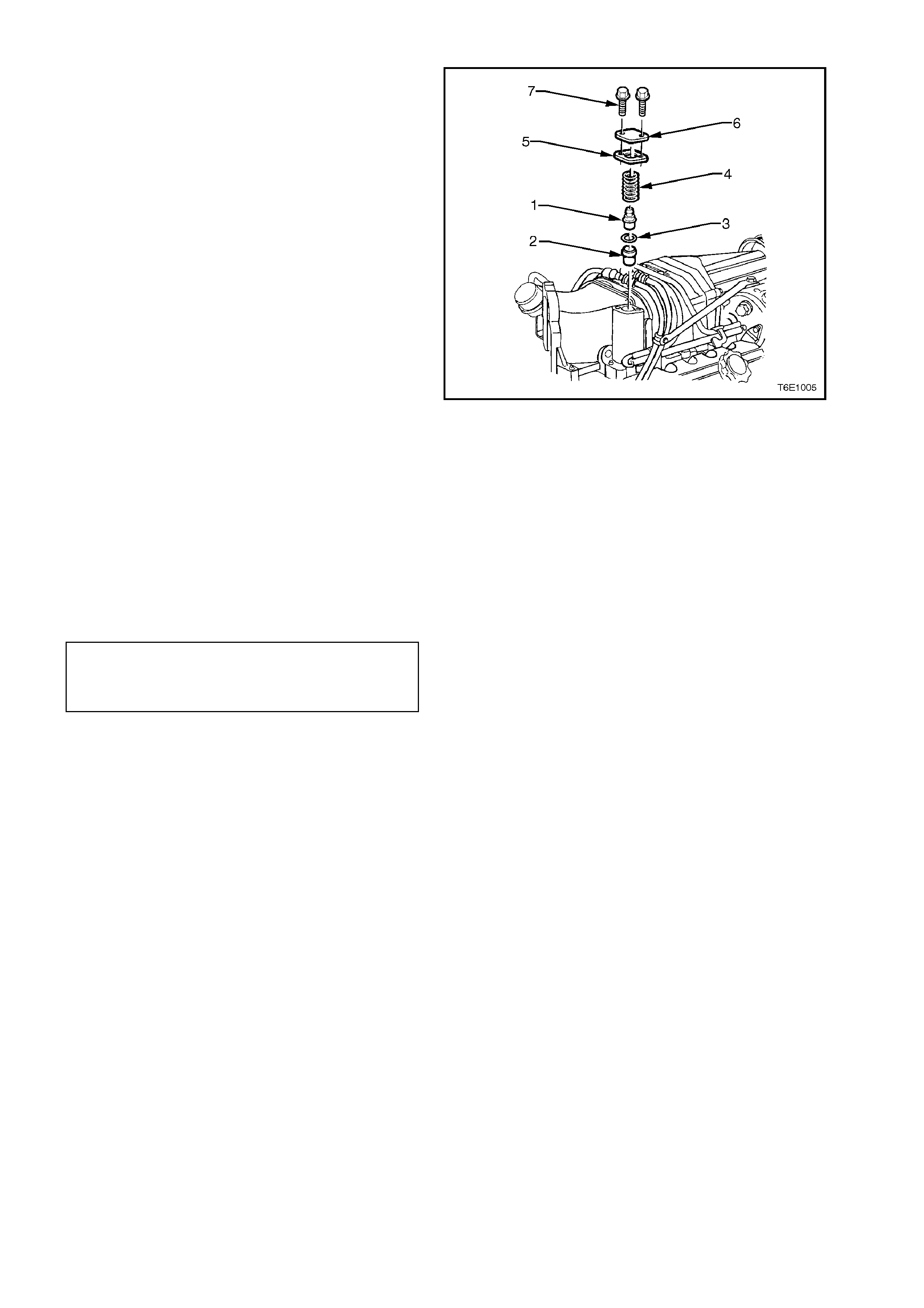

REMOVE

1. Remove the four engine dress cover dome

nuts and remove cover.

2. To overcome spring force, hold down the

positive crankcase ventilation valve cover and

remove the two cover retainer screws.

3. Remove the positive crankcase ventilation

valve cover, gasket, positive crankcase

ventilation valve, spring and O-ring.

4. Shake valve and listen for the rattle of needle

inside valve. If valve does not rattle, replace

valve.

Figure 6E1-17

REINSTALL

Installation of the positive crankcase ventilation

valve is the reverse of the removal procedure,

noting the following:

1. Reinstall positive crankcase ventilation valve

using new O-rings and gasket as necessary.

2. Tighten positive crankcase ventilation valve

cover retaining screws to the correct torque

specification.

POSITIVE CRANKCASE

VENTILATION VALVE COVER

RETAINING SCREW

TORQUE SPECIFICATION

4 - 6

Nm

2.2 EVAPORATIVE EMISSION CONTROL CANISTER

REMOVE

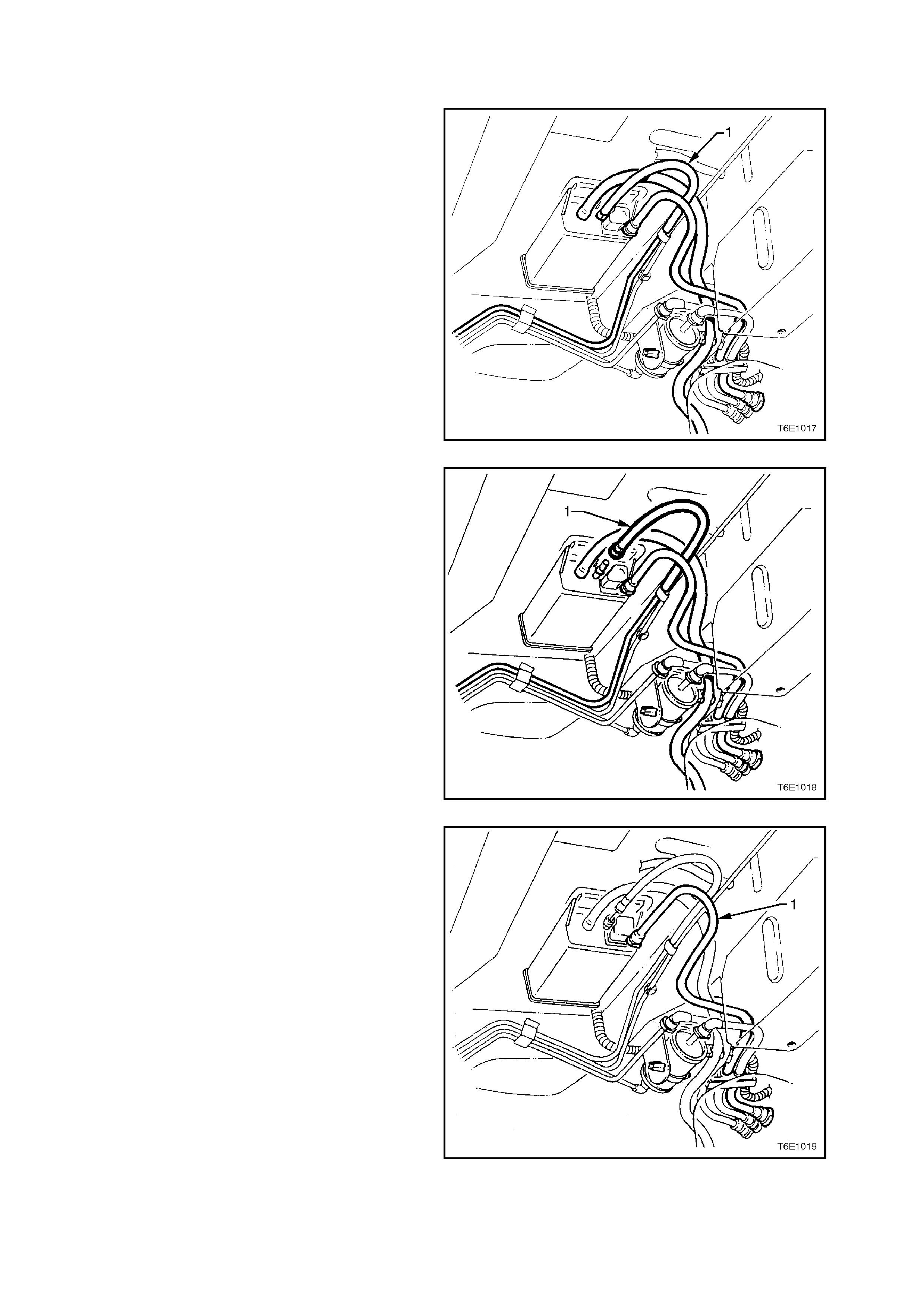

1. Disconnect fuel vapour inlet line (1) by using

the following procedure:

a. Grasp both sides of the quick-connect

fitting. Twist the connector 1/4 turn in

each direction in order to loosen any dirt

within the quick-connect fitting.

CAUTION:

Wear safety glasses when using compressed

air. b. Using compressed air, blow any dirt out

of the quick connect fitting.

Figure 6E1-18

c. Grasp the quick-connect fitting and push

toward the canister

d. Squeeze the quick-connect fitting to

release the retaining tabs, then pull back

on the connector to remove the vapour

fuel line (1) from the canister.

Figure 6E1-19

2. Disconnect f uel vapour purge line (1) by using

the following procedure:

a. Grasp both sides of the quick-connect

fitting. Twist the connector 1/4 turn in each

direction in order to loosen any dirt within

the quick-connect fitting.

CAUTION:

Wear safety glasses when using compressed

air. b. Using compressed air, blow any dirt out of

the quick connect fitting.

Figure 6E1-20

c. Grasp the quick-connect fitting and push

toward the canister

d. Squeeze the quick-connect fitting to

release the retaining tabs, then pull back

on the connector to remove the vapour

purge line from the canister.

3. Remove atmospheric vent line from

atmospheric port.

Figure 6E1-21

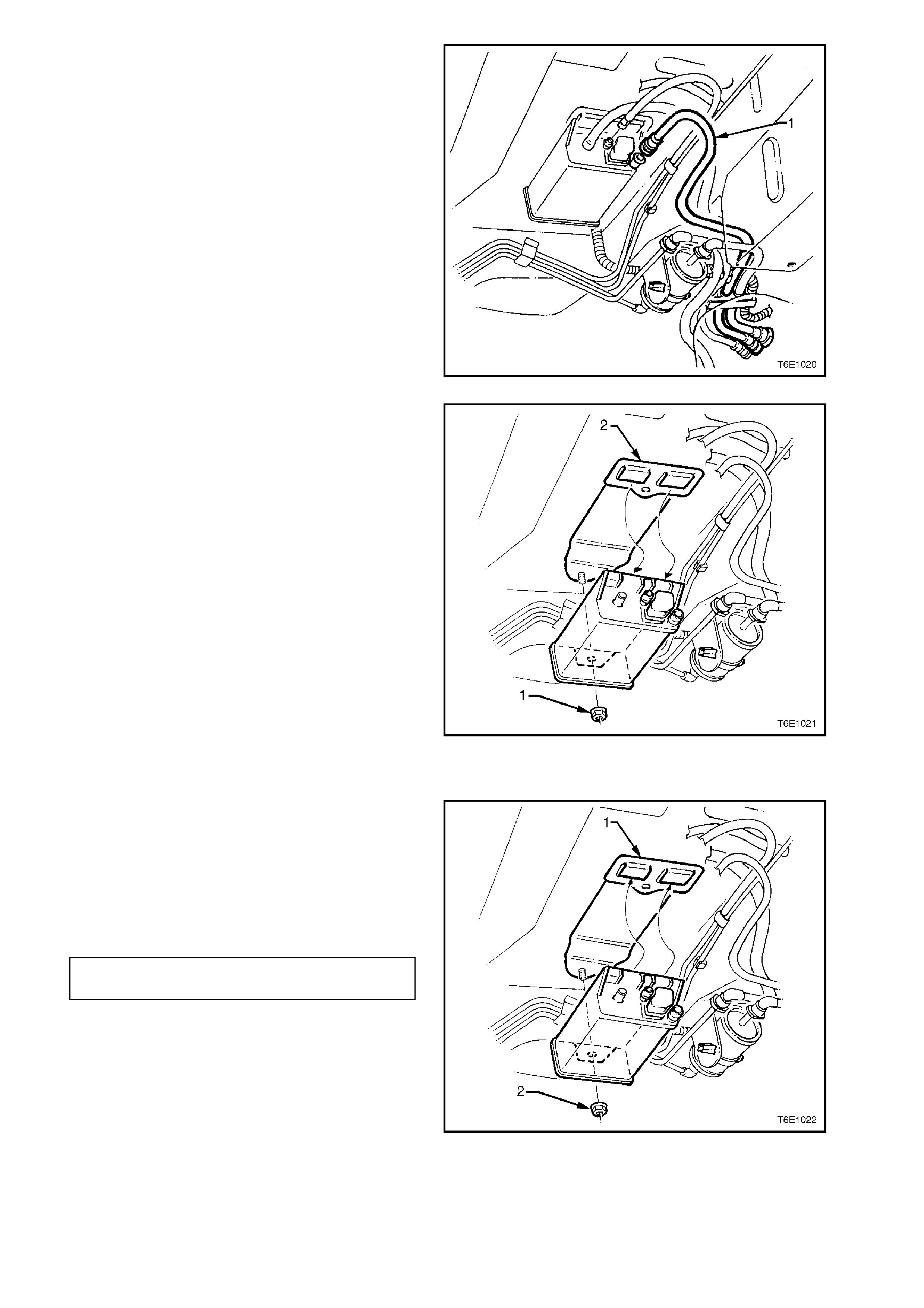

4. Loosen and remove canister retaining nut (1).

5. Remove canister from retaining stud, then

slide canister out of retainer (2).

Figure 6E1-22

REINSTALL

1. Reinstall canister into canister mounting

bracket (1) and over retaining stud.

2. Reinstall canister retaining nut (2) and hand

tighten.

3. Push canister toward centre of vehicle and

tighten canister retaining nut to the correct

torque.

CANISTER RETAINING NUT 2.0 - 5.0

TORQUE SPECIFICATION Nm

Figure 6E1-23

4. Reinstall atmospheric port hose (1).

5. Align fuel vapour purge line quick connector

(2) with fuel vapour purge line port then push

connector firmly onto port.

6. Align fuel vapour inlet line quick connector (3)

with fuel vapour inlet line port then push

connector firmly onto port.

7. Once installed, pull on each quick connect in

order to make sure the connections are secure

and locked in position.

Figure 6E1-24

SERVICE CHECKS

1. Remove canister as previously described.

2. Shake canister. There should be no audible

sound of carbon movement.

3. Using low pressure compressed air (20-35

kPa), blow into the vapour inlet port (2) . Check

that air flows freely from the atmospheric port

(1).

Block the atmospheric port (1) and air should flow

from the purge line port (3).

4. If air flow through the purge line port (3) is

poor, clean the atmospheric filter by blocking

off the vapour inlet port (2) and blowing

compressed air at approximately 300 kPa

through purge line port (3). Recheck air flow

through filter as in Step 3. If air flow through

atmospheric port (1) is still poor, replace

canister.

5. Block the atmospheric port (1) and the purge

line port (3). Apply low pressure compressed

air (20-35 kPa) to the vapour inlet port (2). If

any air leak s f r om canis ter , i.e. around por ts or

seams, canister must be replaced. Figure 6E1-25

2.3 CANISTER PURGE SOLENOID VALVE

REMOVE

1. Disconnect battery earth lead.

2. Mark hoses on canister purge solenoid valve

(top and bottom), and pull hoses from valve.

3. Pull up on solenoid wiring harness connector

retaining tab and pull connector from solenoid

valve.

4. Remove bolt from solenoid bracket. This bolt

attaches to the rear of the right hand cylinder

head, remove solenoid.

1. Vacuum Hose to Carbon Canister.

2. Vacuum Hose from Throttle Body.

3. Canister Purge Solenoid Connector YE99.

4. Canister Purge Solenoid.

Figure 6E1-26

REINSTALL

1. Reinstall canister purge solenoid valve to rear

of cylinder head and install bracket bolt.

Tighten bolt to the correct torque specification.

CANISTER PURGE SOLENOID

VALVE BRACKET TO

CYLINDER HEAD BOLT

TORQUE SPECIFICATION

15 - 20

Nm

2. Reconnect vacuum hoses and wiring harness

connector to canister purge solenoid valve,

ensuring connections are correct.

NOTE:

Apply Loctite 4210 Adhesive to both ends of the

Solenoid to Throttle Body vacuum hose prior to

assembly.

3. Reconnect battery earth.

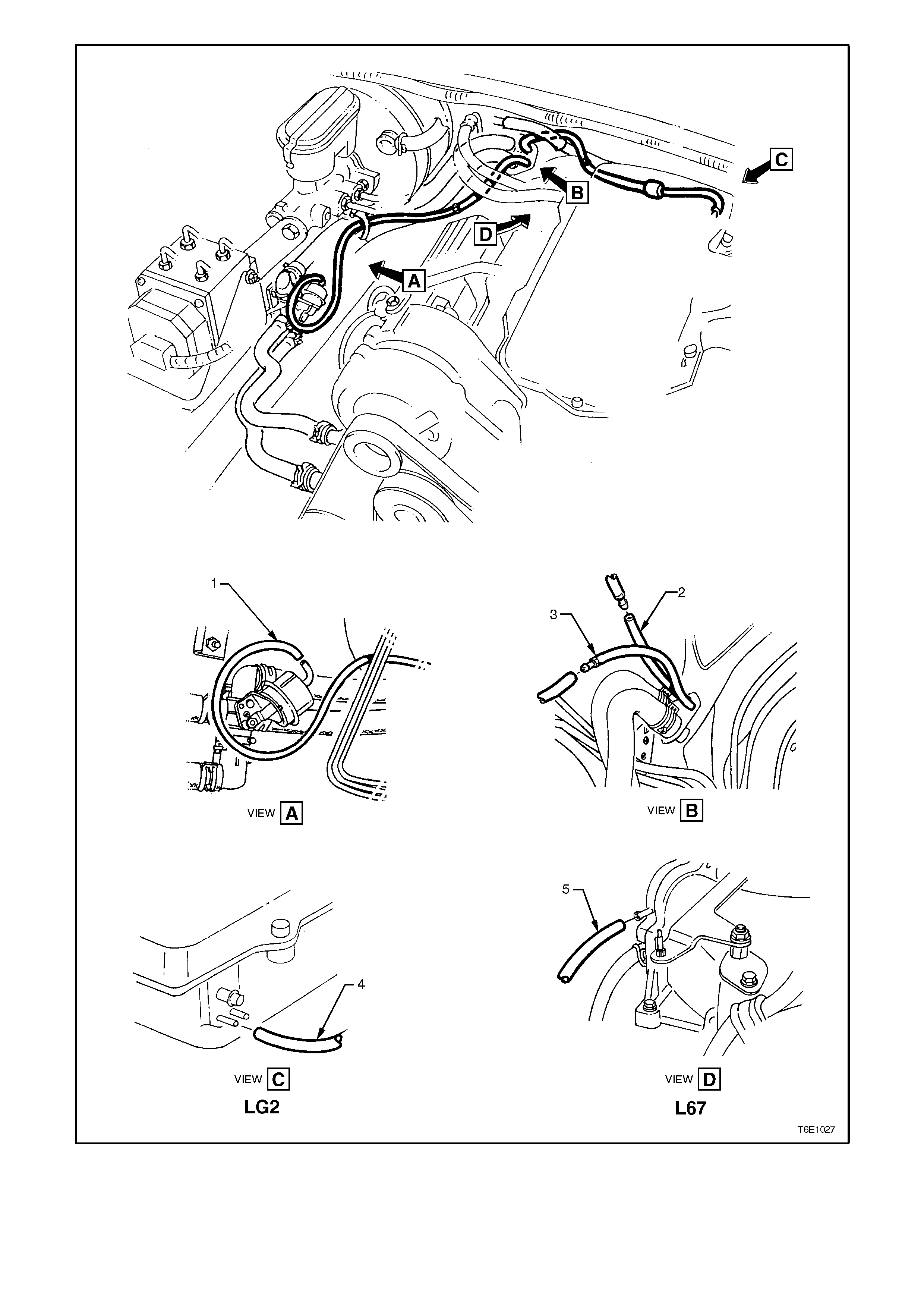

VACUUM HOSE LAYOUT DIAGRAMS

Figure 6E1-27

1. Fuel Vapour inlet line 2. Fuel Vapour Purge Line 3. Atmospheric Vent Line

Figure 6E1-28

1. Vacuum Line

from A/C 2. Vacuum Supply

Line to A/C 3. Vacuum Line to

Water Valve 4. Vacuum Supply

Line to A/C

(LG2)

5. Vacuum Supply

Line to A/C (L67)

Figure 6E1-29

1. Vacuum Control Switch Supply 2. Vacuum Line to Water Valve 3. Vacuum Supply

Figure 6E1-30

1. Vacuum Control Switch Supply 2. Vacuum Line to Water Valve 3. Vacuum Supply

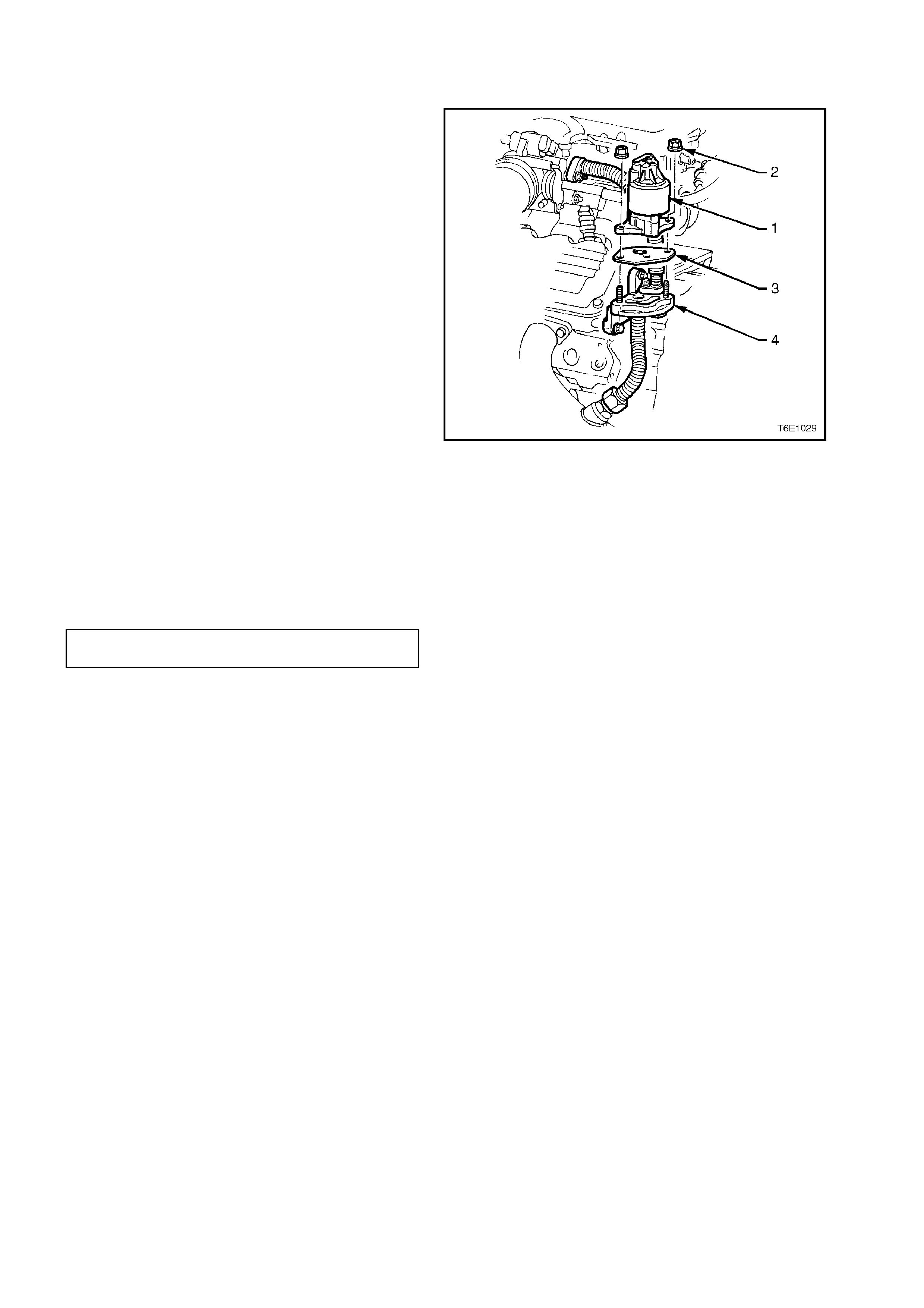

2.4 LINEAR EGR VALVE

REMOVE

1. Disconnect battery earth lead.

2. Remove engine dress cover.

3. Disconnect EGR valve electrical connector.

4. Remove EGR valve retaining nuts (2).

5. Remove EGR valve (1) and gasket (3) from

EGR adaptor assembly (4).

Figure 6E1-31

REINSTALL

1. Install a new EGR adaptor to EGR valve

gasket.

2. Reinstall EGR valve and retaining nuts.

3. Tighten EGR valve retaining nuts to the

correct torque.

EGR VALVE RETAINING NUTS

TORQUE SPECIFICATION 20 - 27

Nm

4. Reinstall engine dress cover.

3. DIAGNOSIS

POSITIVE CRANKCASE VENTILATION

CONDITION PROBABLE CAUSE CORRECTIVE ACTION

Rough, slow idle or stalling PCV valve blocked.

Blocked or damaged

ventilation hose.

Clean valve or replace.

Clean or replace hose.

Rough, fast idle or stalling PCV valve stuck in

intermediate position.

PCV valve leaking.

Clean valve or replace.

Check valve O ring, replace

if necessary.

Check valve installation.

Excessive sludging or

diluting of oil Engine is not being vented. Check for clogged PCV

valve circuit and clogged

ventilation circuit.

EVAPORATIVE EMISSION CONTROL

CONDITION PROBABLE CAUSE CORRECTIVE ACTION

Loss of fuel from filler cap Unsatisfactory sealing

between cap

and filler neck.

Malfunction of filler cap relief

valve.

Replace filler cap.

Replace filler neck if

damaged.

Replace filler cap.

Loss of fuel from fuel lines Loose line connection.

Faulty or leaking vapour

separator.

Secure connection.

Replace.

Loss of fuel from canister Fuel tank overfilled.

When the fuel warms up

during parking or warm

weather operation, excess

fuel is discharged into the

canister, flooding it.

Kinked hoses at filler neck

and vapour separator

reservoir.

Blocked, damaged or

disconnected purge valve at

canister.

Avoid overfilling of tank.

Clean hose. Replace

damaged hose. Install

correctly.

Replace canister

Collapsed fuel tank or

pressure in tank Faulty fuel filler cap

(in high temperature

operating conditions some

pressure may normally be

encountered in the fuel

tank).

Kinked hoses at filler neck

and vapour separator

reservoir.

Blocked or kinked vent line

Defective canister (usually

internal blocked).

Purge solenoid valve is

closed causing canister to

become overloaded.

Replace filler cap.

Clean line. Replace

damaged line

Replace canister.

Refer to 6C1

POWERTRAIN

MANAGEMENT - V6

ENGINE.

Rough idle Improperly routed or

disconnected purge line.

Purge solenoid valve is open

or not receiving power.

Install purge line.

Refer to 6C1

POWERTRAIN

MANAGEMENT - V6

ENGINE.

For diagnosis of faults pertaining to vehicle performance, refer to Section 6C1 POWERTRAIN MANAGEMENT -

V6 ENGINE.

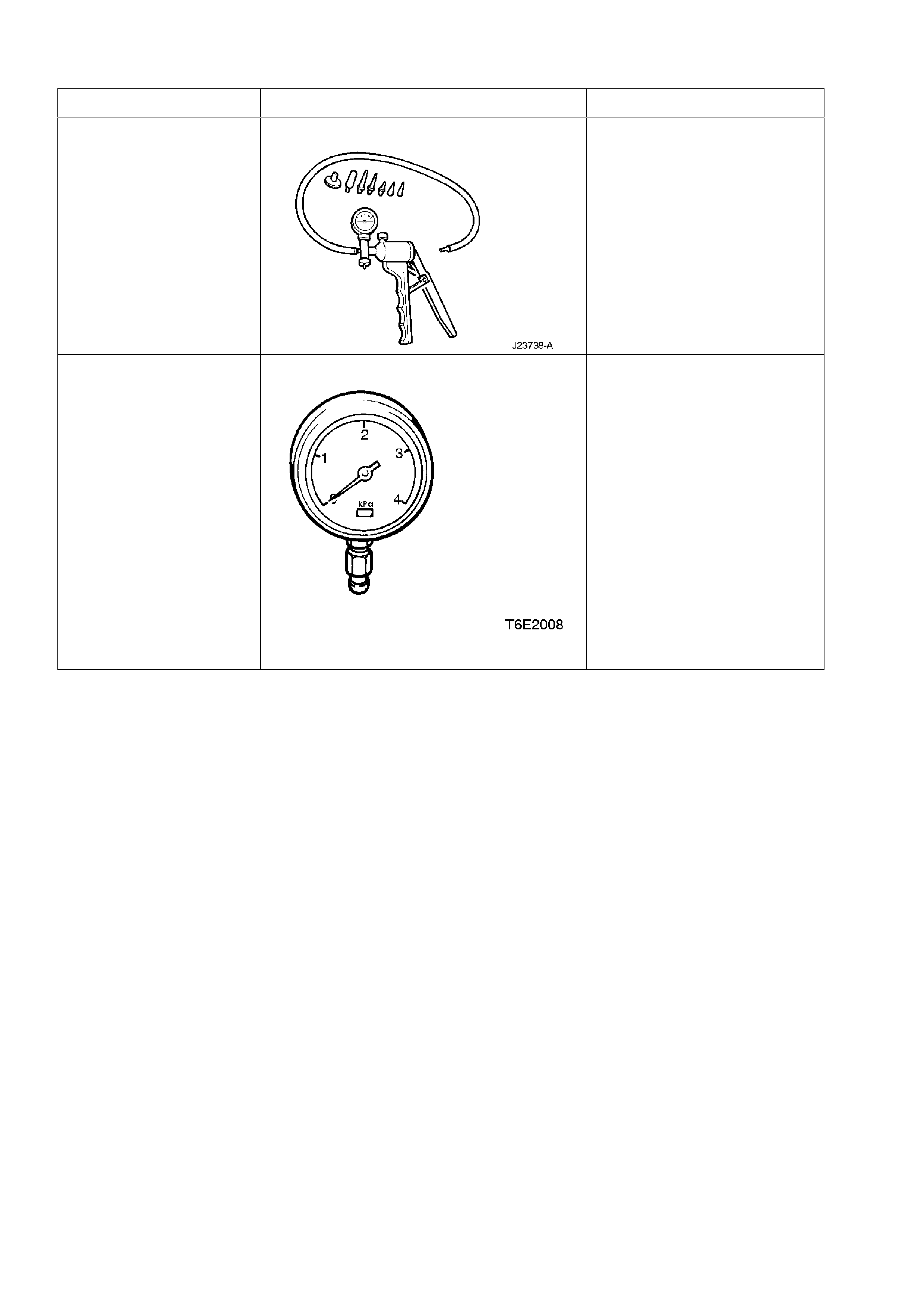

4. SPECIAL TOOLS

TOOL NO. REF IN TEXT TOOL DESCRIPTION COMMENTS

J23738 - A HAND VACUUM PUMP PREVIOUSLY RELEASED

FOR 'V' AND 'J' CARS.

N/A VACUUM GAUGE VACUUM GAUGE WITH

SCALE OF

0 TO -4 KPA

COMMERCIALLY AVAILABLE

SUCH AS "H 68930 30" FROM

:

EXTECH EQUIPMENT

3 WOODBINE COURT

WANTIRNA SOUTH

VICTORIA 3152

PHONE : 03 887 0055

OR

008 338132