SECTION 7A - CLUTCH

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). An SRS

will consist of either seat belt pre-tensioners and a driver's side air bag, or seat belt

pre-tensioners and a driver's and front passenger's side air bags. Refer to

CAUTIONS, Section 12M, before performing any service operation on or around any

SRS components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deplo yment, resulting in possible p ersonal injury or unnecessary

SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas. In the interests of

safety, the LPG fuel system should be isolated by turning ‘OFF’ the manual service

valve and then draining the LPG serv ice lines, before any service w ork is carried out

on the vehicle. Refer to the LPG leaflet included with the Owner's Handbook for

details or LPG Section 2 for more specific servicing information.

CAUTION:

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is

disturbed during Service Operations, it is vital that the complete ABS or ABS/ETC

system is checked, using the procedure as detailed in 4. DIAGNOSIS, ABS or

ABS/ETC FUNCTION CHECK, in Section 12L ABS & A BS/ETC.

1. GENERAL INFORMATION

For use with the Type 260 (V6 engine) manual transmission, an hydraulically controlled, diaphragm spring clutch

pressure plate and dual mass engine flywheel are used. From the start of production of VT Series vehicles, this

clutch and manual transmission are fitted as standard equipment on V6 powered, Executive models and optional on

Berlina.

When the Type 290 manual transmission is fitted to the optional V8 engine, the clutch control is also hydraulic,

working a conventional diaphragm spring clutch pressure plate and a solid engine fly wheel.

Techline

Techline

2. GENERAL DESCRIPTI ON

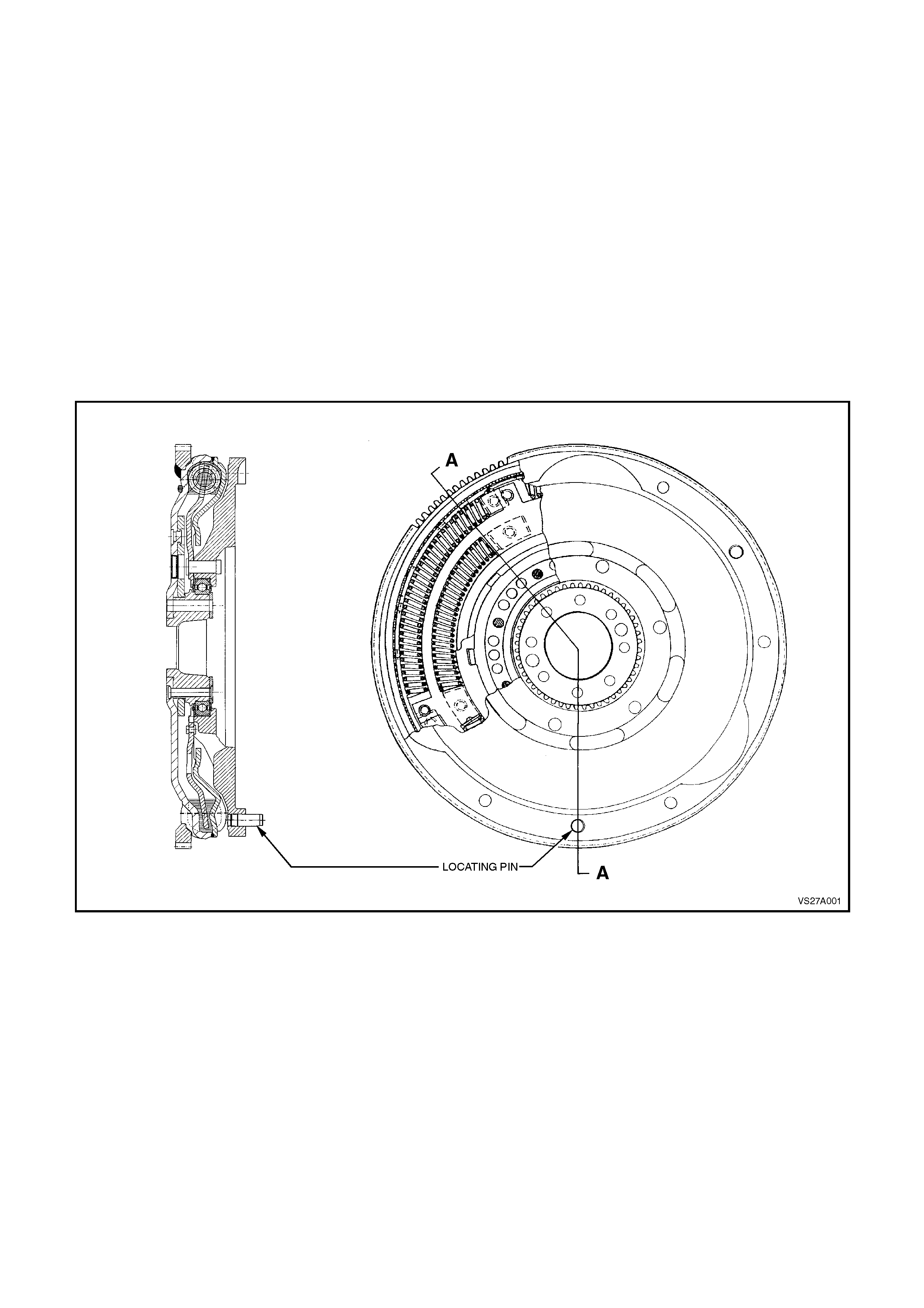

2.1 DUAL MASS FLYWHEEL

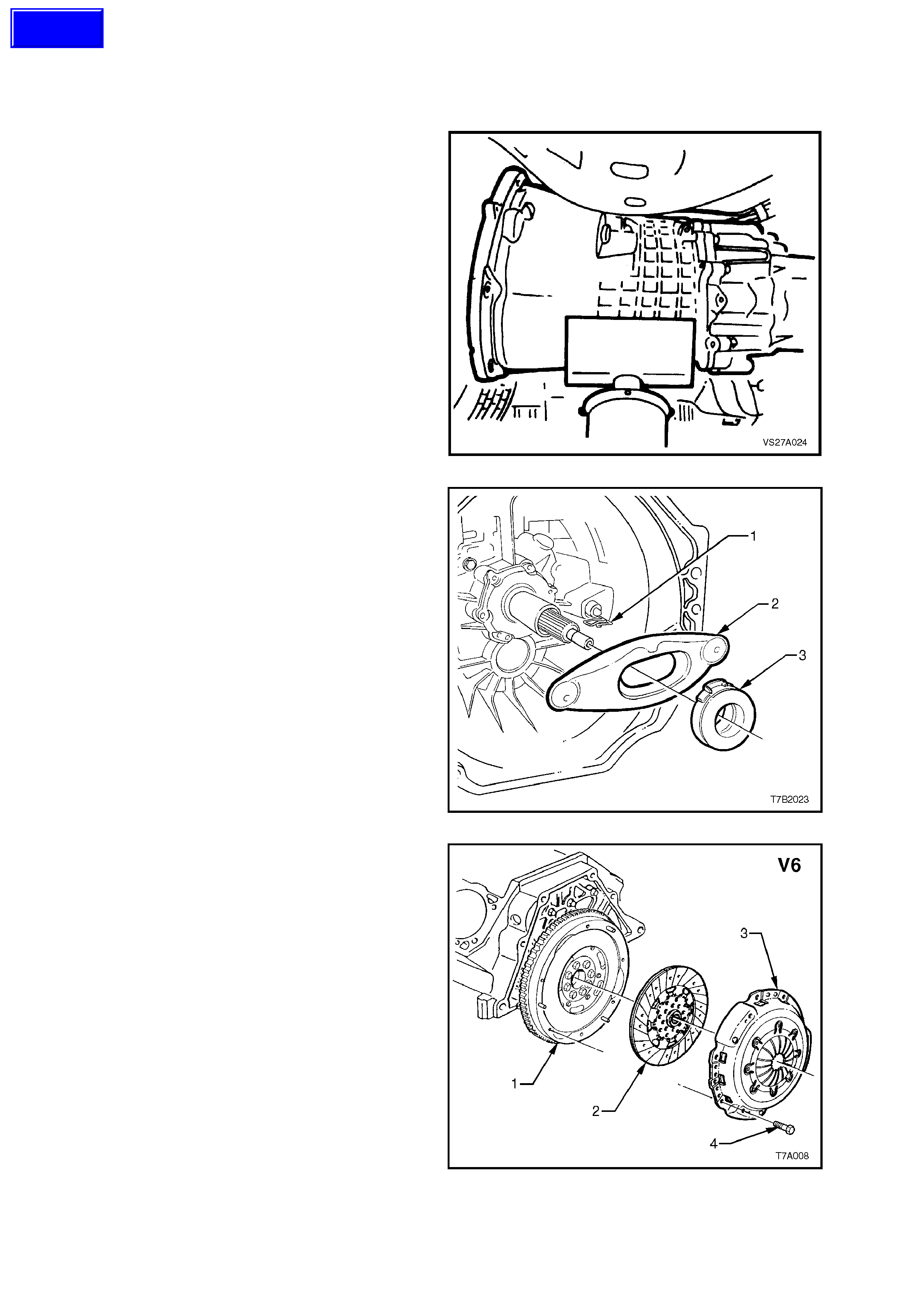

V6 ENGINE

Most engine vibrations caused by the igniting fuel air mixture are absorbed by the engine flywheel and clutch

assembly. However, vibrations that are not absorbed, can travel via the transmission bearings, as far as the

propeller shaft and the vehicle body. Using a dual mass flywheel makes it possible for even these secondary

vibrations to be absorbed at that point.

The fly wheel is divided into two parts that are joined radially by springs. The first half is bolted directly to the engine

crankshaft. A torsion damper consisting of springs and dampening friction systems forms the intermediary

components, while the clutch is bolted to the second half of the fly wheel. The single, dry clutch driven plate is no

longer fitted with torque reaction springs.

The effectiveness of the dual mass flywheel is due to the division of the moments of inertia. The moment of inertia

of the flywheel half on the engine side is reduced and correspondingly increased on the transmission side flywheel

half.

As a result of this sy stem, critical vibrations are only discernible at engine speeds below idle speed. This prevents

body noises and allows smooth gear changing, especially at low temperatures.

Figure 7A-1

SERVICE IMPLICATIONS

Re-surfacing of the clutch driven plate surface, is not possible for the following reasons:

1. As both flywheel masses are able to move independently to each other, it is not possible to effectively clamp

the assembly without the possibility of misalignment.

2. A special balancing procedure is followed at manufacture that involves rotating the flywheel to 6,000 rpm for a

minimum amount of time prior to undertaking balancing at normal speeds.

Because the ring gear is welded to the crankshaft side of the flywheel, ring gear replacement is not possible, as re-

welding could cause distortion and possible burning of the grease used to lubricate the springs.

V8 ENGINE

A conventional, solid flywheel is used for V8 powered applications.

2.2 CLUTCH CONTROL

Hydraulic actuation for the clutch has been adopted

for a number of beneficial reasons;

Noise reduction.

Automatic adjustment.

Constant pedal position.

Constant efficiency factor.

Constant pedal path.

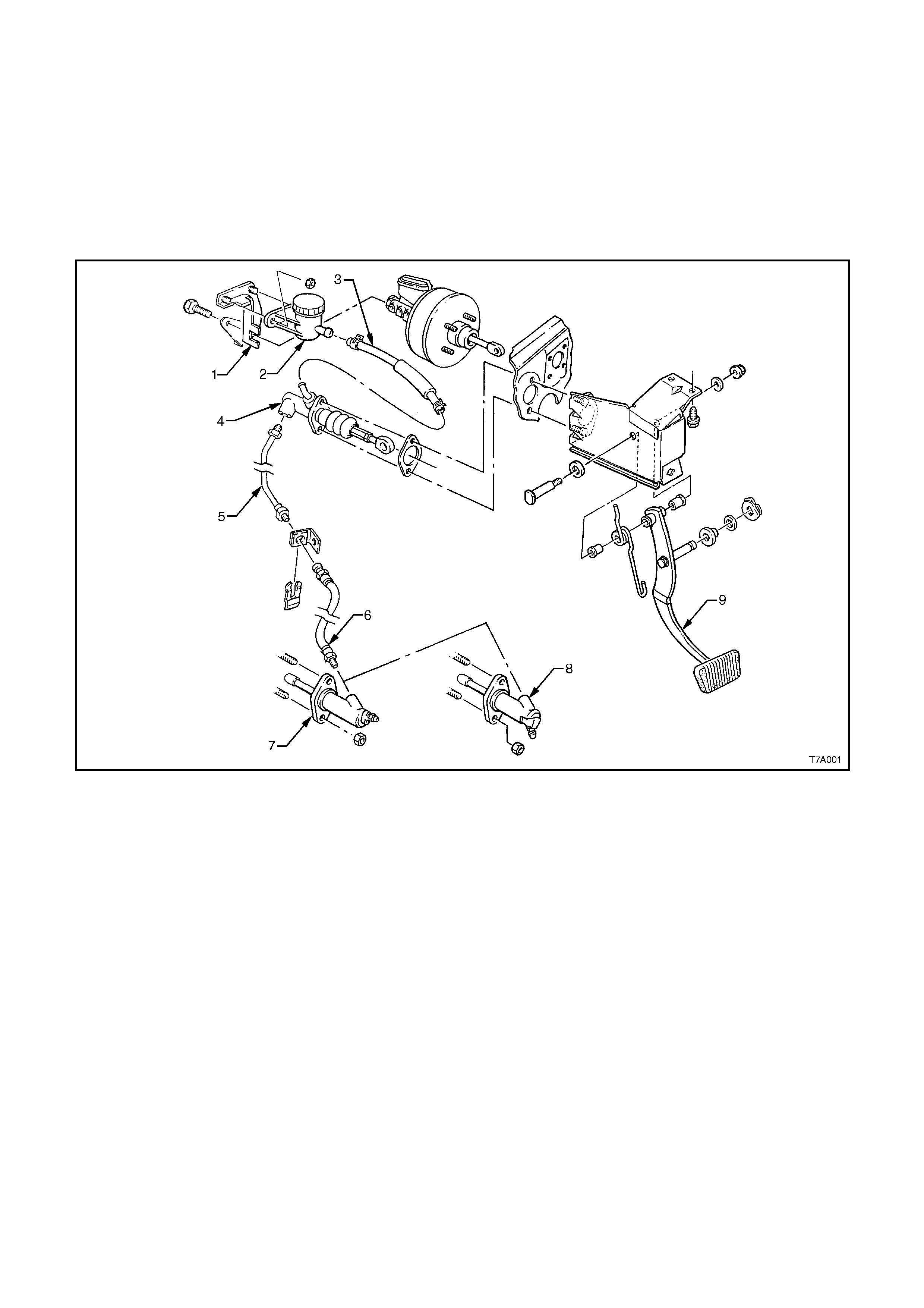

ARRANGEMENT

1. Bracket - Clutch Fluid Reservoir

2. Reservoir - Clutch Fluid

3. Hose - Reservoir to Master Cylinder

4. Master Cylinder

5. Pipe - Master Cylinder to Actuating Cylinder

6. Hose - Pipe to Actuating Cylinder

7. Actuating Cylinder - V8 Engine

8. Actuating Cylinder - V6 Engine

9. Pedal - Clutch

Figure 7A-2 Clutch Control Layout

Brake fluid is fed to the clutch master cylinder from a remote reservoir mounted to a bracket, bolted to the end of

the brake master cylinder. A flexible line connects the two components.

The master cylinder is attached to the firewall in the engine compartment.

The clutch pedal is mounted in the clutch/brake pedal support bracket, bolted to the dash panel.

The clutch master cylinder piston is connected to the clutch pedal by an adjustable push rod, that is bushed and

retained by a spring clip.

No clutch adjustments are required. Although the clutch master cylinder push rod does feature an adjustment, it is

only for production purposes and is not to be tampered with, in service.

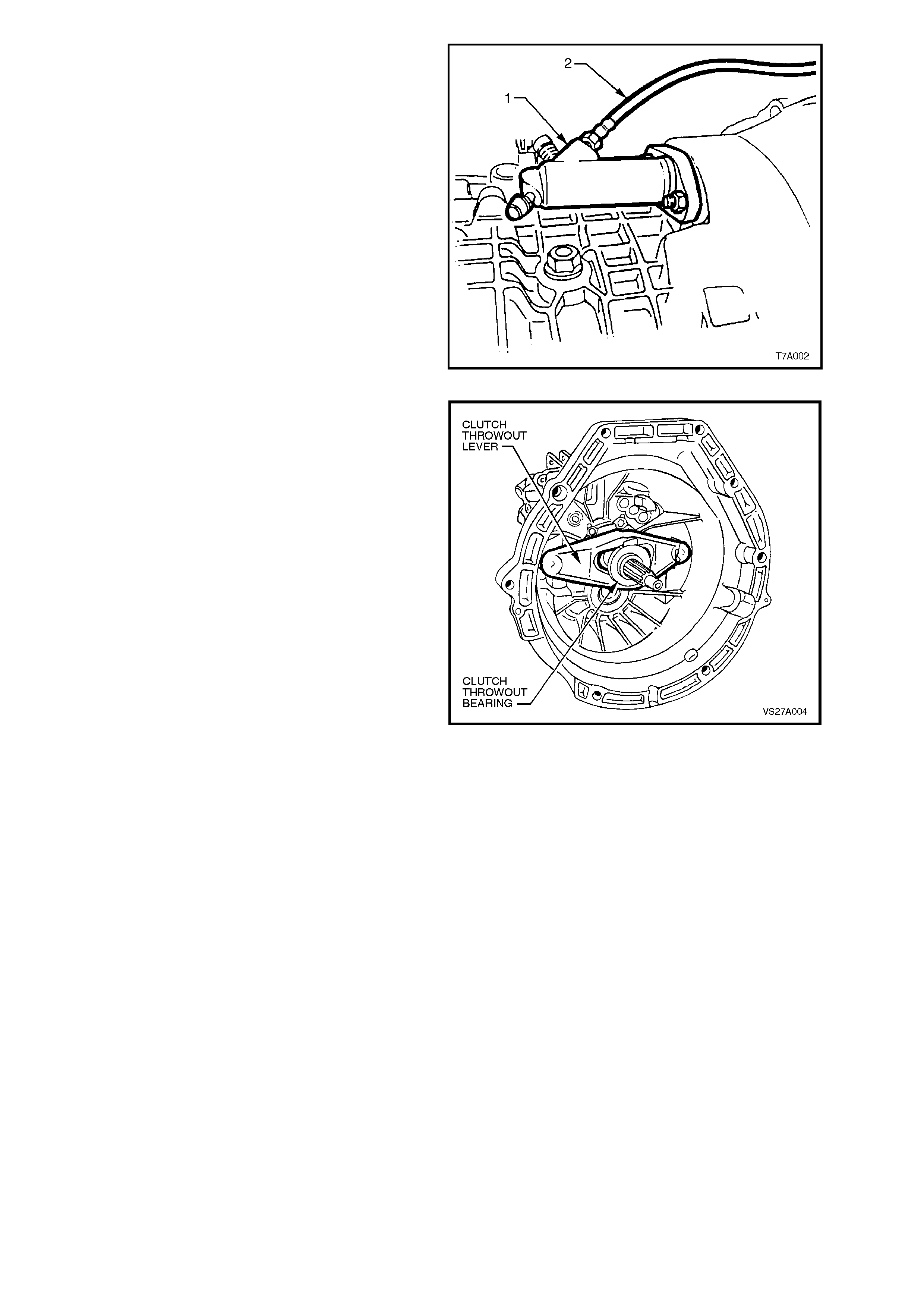

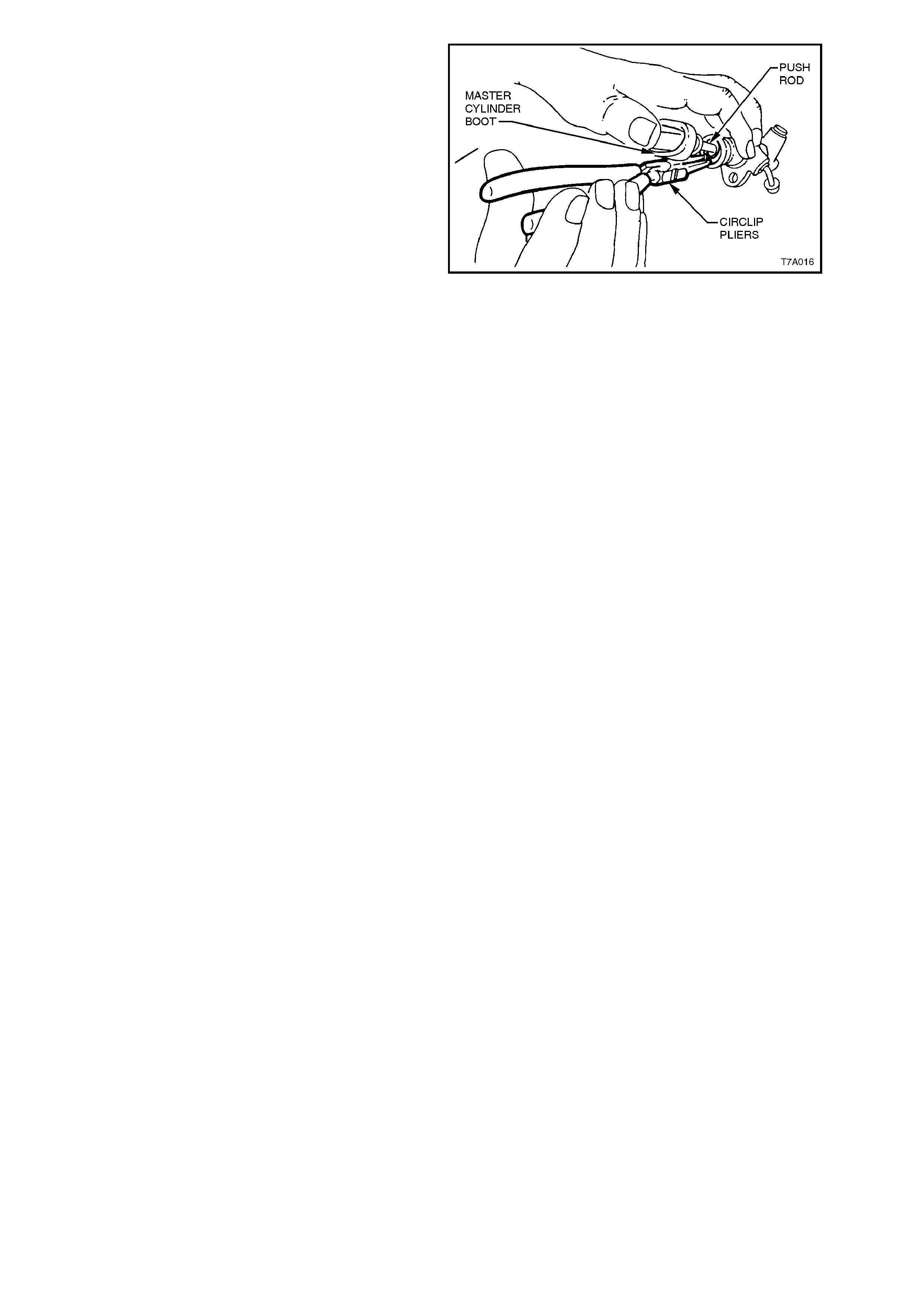

Stroking of the clutch throwout bearing is achieved

by using an hydraulic clutch actuating cylinder (1)

mounted on the r ight hand side of the transm ission

clutch housing.

Hydraulic connection to the master cylinder is by a

flexible hose (2) and steel piping.

The actuating cylinder is fitted with a bleed valve to

assist in removal of air from the hydraulic system.

NOTE:

Apart from the slight change to the actuating

cylinder design used for the V8 application, the

operation is the same as this V6 engined

description.

Figure 7A-3

The c lutch throwout bearing is a sealed-for-life, ball

race type, that is in constant contact with the clutch

pressure plate diaphragm spring.

The throwout bearing is actuated by a pressed

steel clutch throwout lever, that is retained by a

spring clip and pivots at one end, while the stroking

of the clutc h actuating c ylinder piston and pus h rod,

moves it at the other.

NOTE:

While the V6 transmission and clutch release

mechanism is shown, the V8 arrangement is the

same.

Figure 7A-4

2.3 CLUTCH MASTER CYLINDER/ ACTUATING CYLINDER OPERATION

CLUTCH RELEASED

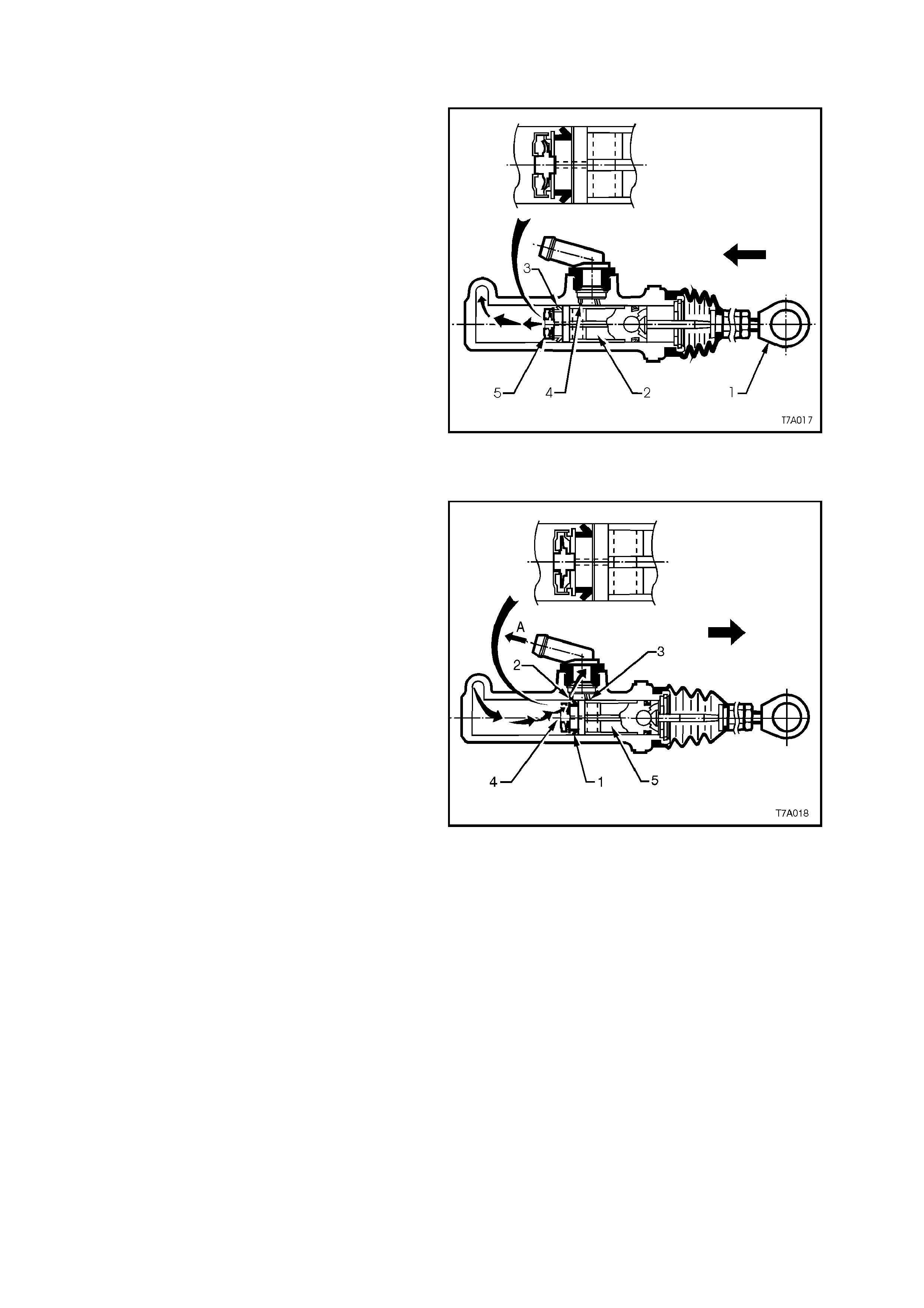

As the clutch pedal is depressed, force is

transm itted via the clutch pedal push r od (1), to the

clutch master cylinder piston (2), moving it down

the cylinder bore. When the piston starts to move,

the primary seal (3) covers the compensating port

(4) and the res ultant build-up in pr essure, seats the

relief valve (5) in the end of the piston.

As hydraulic pressure develops, the fluid is

displaced and moves the piston in the clutch

actuating cylinder against the return spring and

clutch pressure plate diaphragm spring forces, to

stroke the actuating cylinder push rod. In turn, this

action moves the clutch throwout lever and bearing,

releasing the clutch pressure plate.

Figure 7A-5

CLUTCH APPLIED

As the depressed clutch pedal is raised, the clutch

pressure plate diaphragm spring force moves the

fluid back through hydraulic system, to the master

cylinder. As the clutch pedal is lifted to the point

where the pedal is fully released, the master

cylinder, primary piston seal (1) uncovers the

compensating port (2). Once this occurs, excess,

pressurised fluid (arrows) returns to the fluid

reservoir, via ‘A’.

If the clutch pedal is released very quickly, the

combined forces of the clutch pressure plate

diaphragm spring, the return s pring in the actuating

cylinder and the clutch pedal return spring, return

both the pistons quicker than the fluid can return to

the reservoir through the relatively small

compensating port (2).

This cr eates a partial vac uum c ondition that c auses

atmospheric pressure acting on the reservoir fluid,

to force fluid through the recuperating port (3),

unseating the relief valve (4) in the end of the

master cylinder piston equalising fluid pressure.

Should any excess fluid build up in front of the

master cylinder piston (5), it can then return to the

reservoir via the compensating port (2).

Figure 7A-6

3.2 CLUTCH HYDRAULIC SYSTEM, BLEED

The clutch hydraulic system must be bled

whenever the hydraulic line has been

disconnected, or when a leak has allowed air to

enter the system. Air trapped in the system can

prevent full disengagement of the clutch.

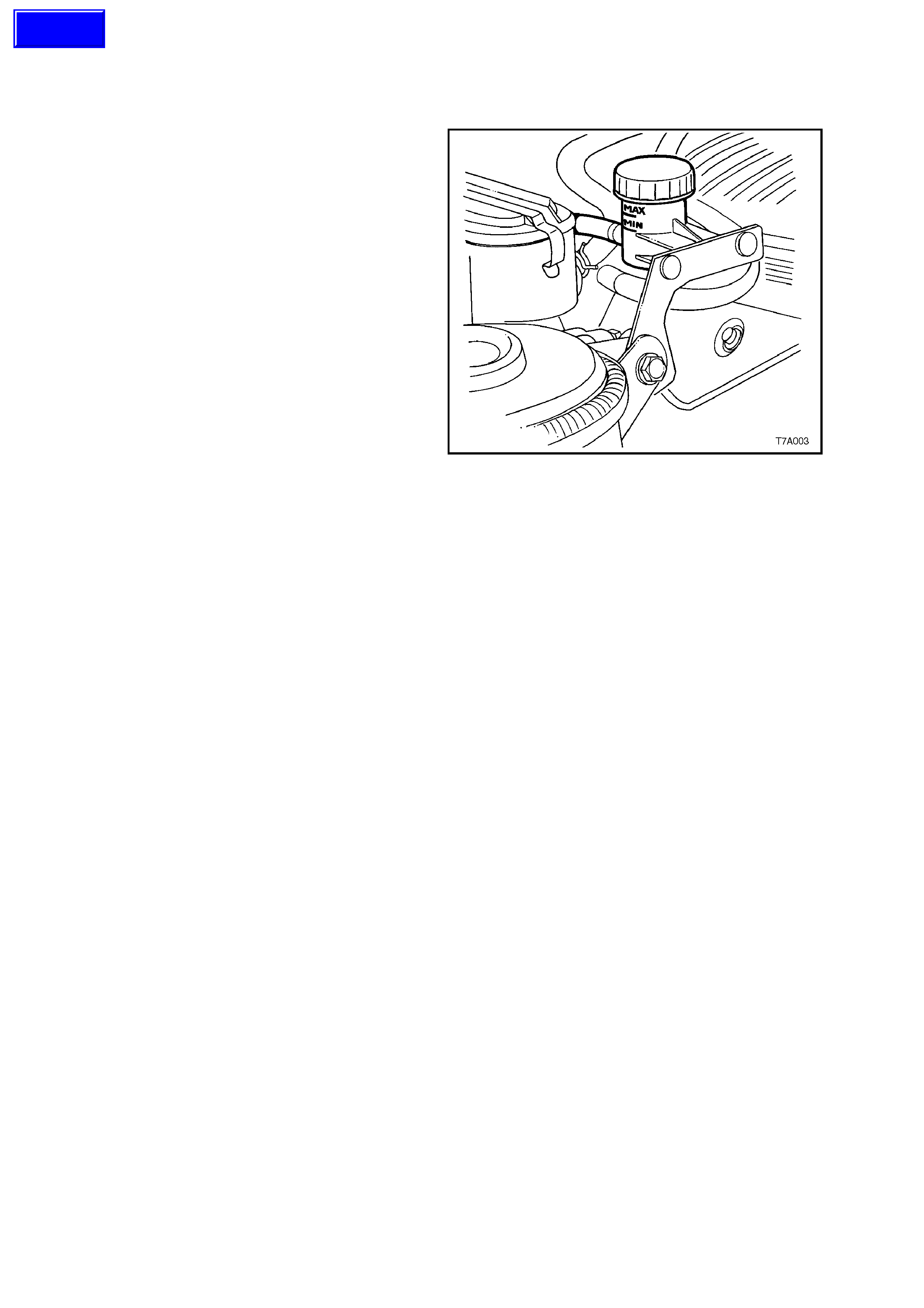

During bleeding operations, the master cylinder

reservoir must be kept at least half full with

hydraulic brake fluid.

1. Carefully clean any dirt from around the

reservoir cap.

2. Remove the filler cap and top up reservoir as

required, with heavy duty hydraulic brake fluid

to Holden’s Specification HN 1796.

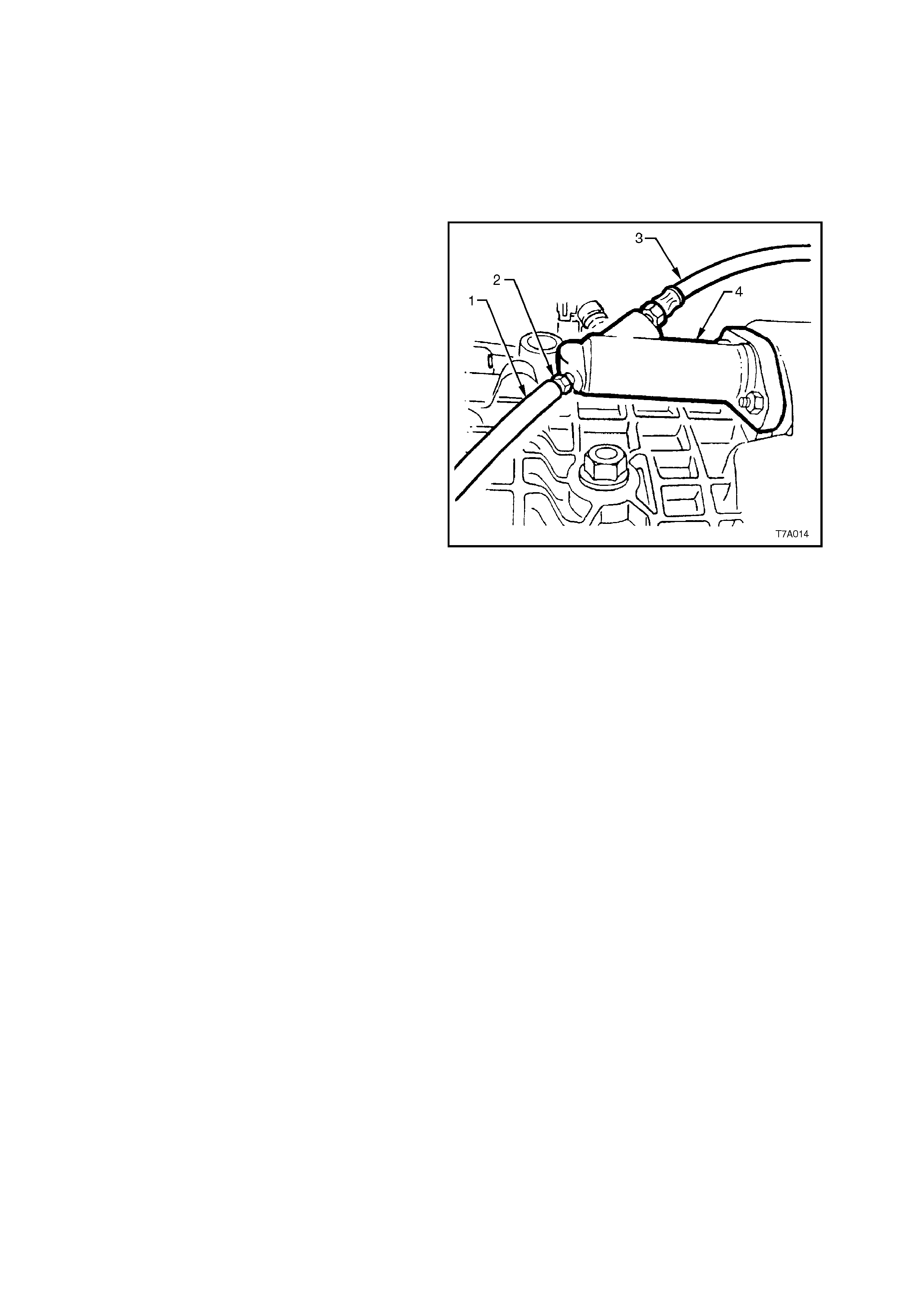

3. Slip the end of a bleeder hose (1) over the

bleeder screw (2) on the clutch actuating

cylinder (4) and insert the other end into a

clean glass container such as a jar, that has

been partially filled with new brake fluid. (V6

version is shown - the V8 arrangem ent is very

similar). Ensure that the end of the hose

always remains submerged in the brake fluid

during bleeding operations.

4. Loosen the bleeder screw ½ to ¾ turn.

5. Fully depress the clutch pedal by hand, then

allow it to return slowly. Continue this slow

pumping motion, forcing fluid and air through

the hydraulic system until all bubbles cease to

appear at the end of the bleeder hose.

6. While depressing the pedal, tighten the

bleeder screw, then remove the bleeder hose

from the actuating cylinder bleeder screw.

7. Once all bleeding operations have been

completed, ensure that the fluid level in the

reservoir is correct.

Figure 7A-8

3.3 CLUTCH MASTER CYLINDER

REMOVE

CAUTION:

Disable the SRS (Air Bag). Refer to Section 12M

DISABLING THE SRS.

1. Disconnect the battery earth cable.

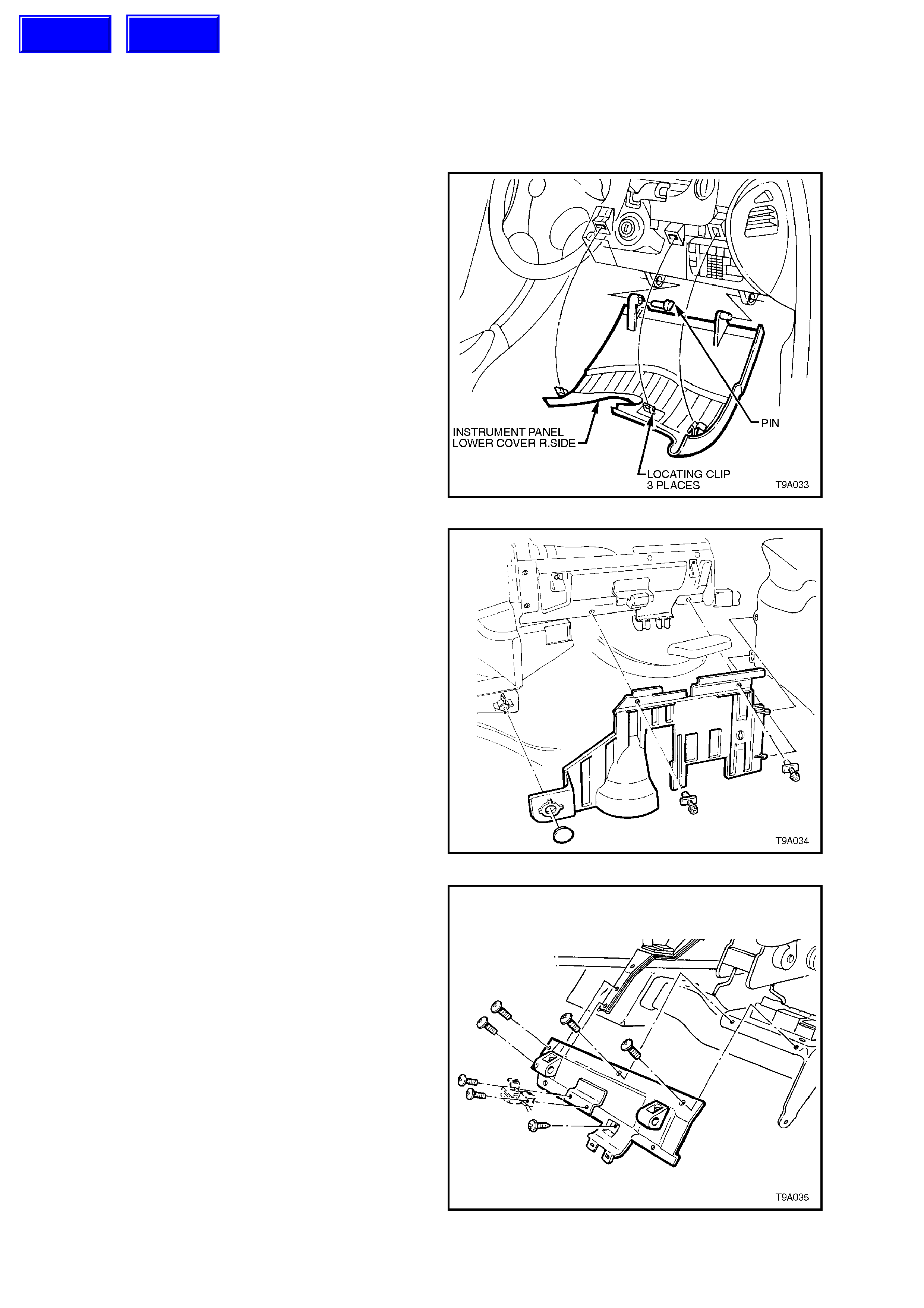

2. From inside the passenger compartment,

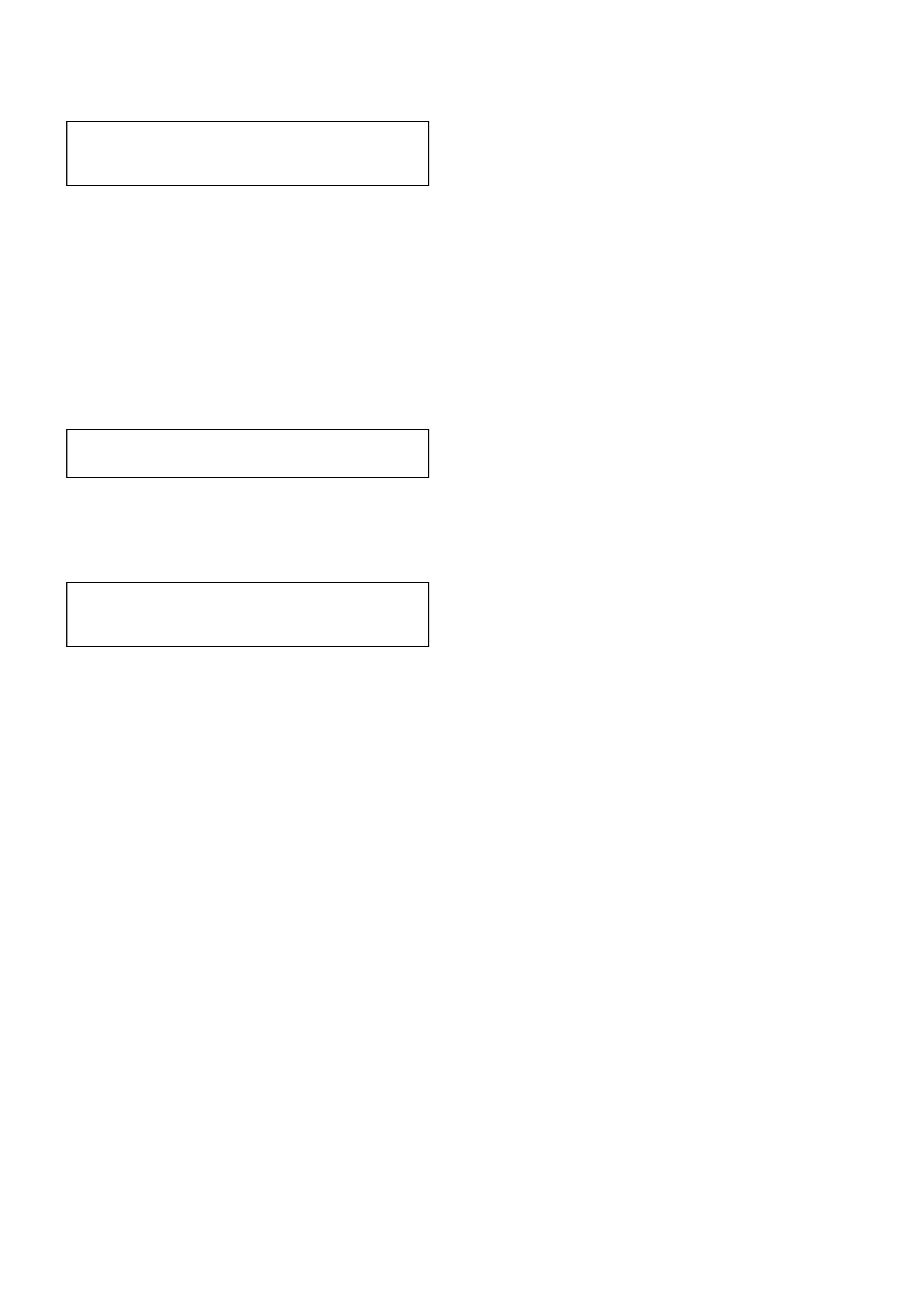

rem ove the lower inst rument panel, r ight hand

cover assembly, as follows;

Grasp the top edge of the c oveer on each s ide

of the steering column with the finger tips and

pull outwards, to free the retaining lugs from

the clips.

Prise out the left hand hinge pin with a

screwdriver or similar tool.

Tilt the panel down on the left hand side and

disengage the right hand side hinge pin.

Figure 7A-9

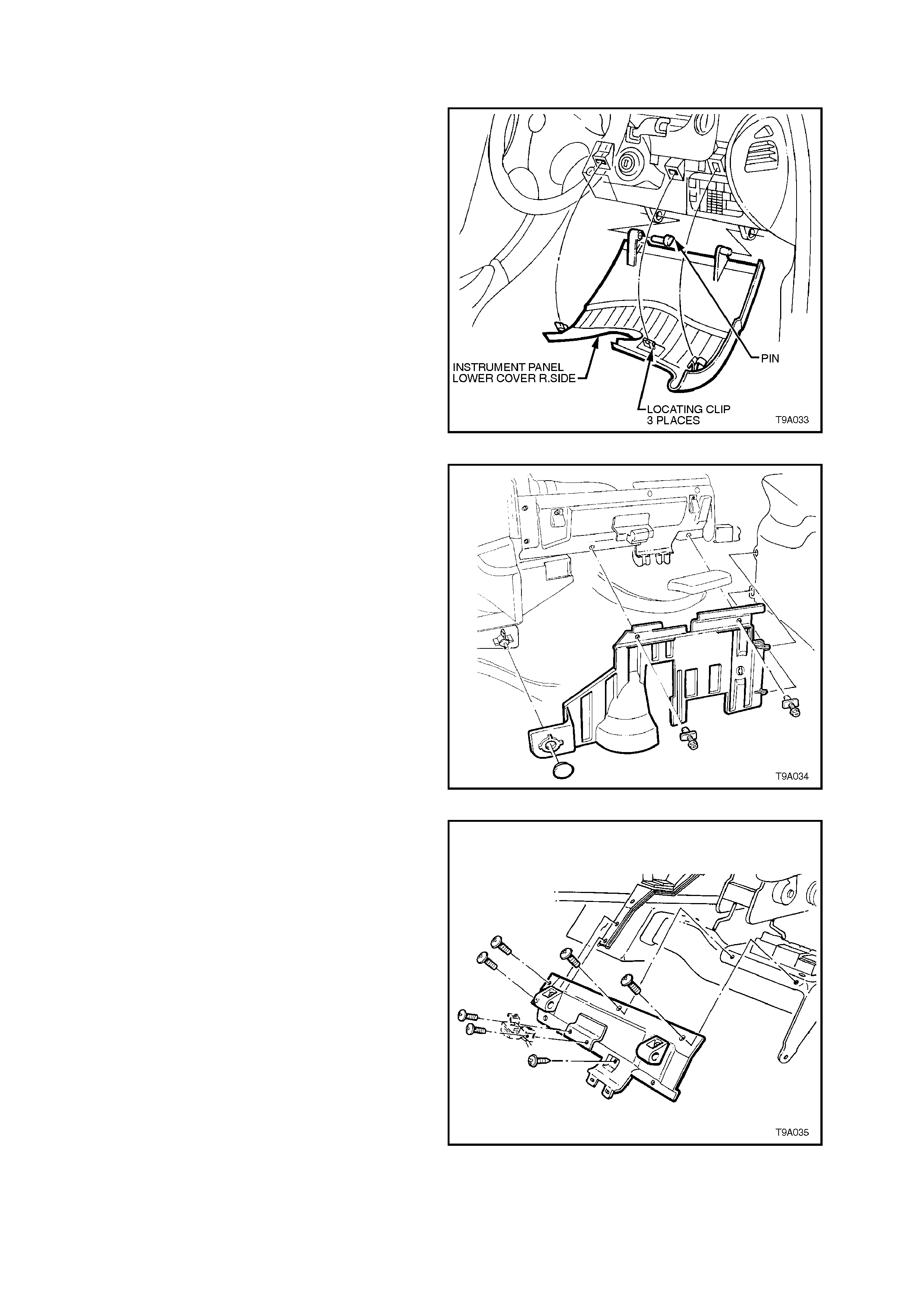

3. Remove the instrument panel lower trim by

removing the two fasteners and retainer.

Lower the panel sufficiently to gain access to

the footwell illum ination lam p holder, then twist

the lamp holder to remove from the trim.

Figure 7A-10

4. Remove screws attaching the fuse and Body

Control Module (BCM) panel to the dash

panel. Leaving the Data Link Connec tor (DLC)

attached to the panel, swing the panel to one

side and secure with tie wire or similar.

Figure 7A-11

Techline

Techline

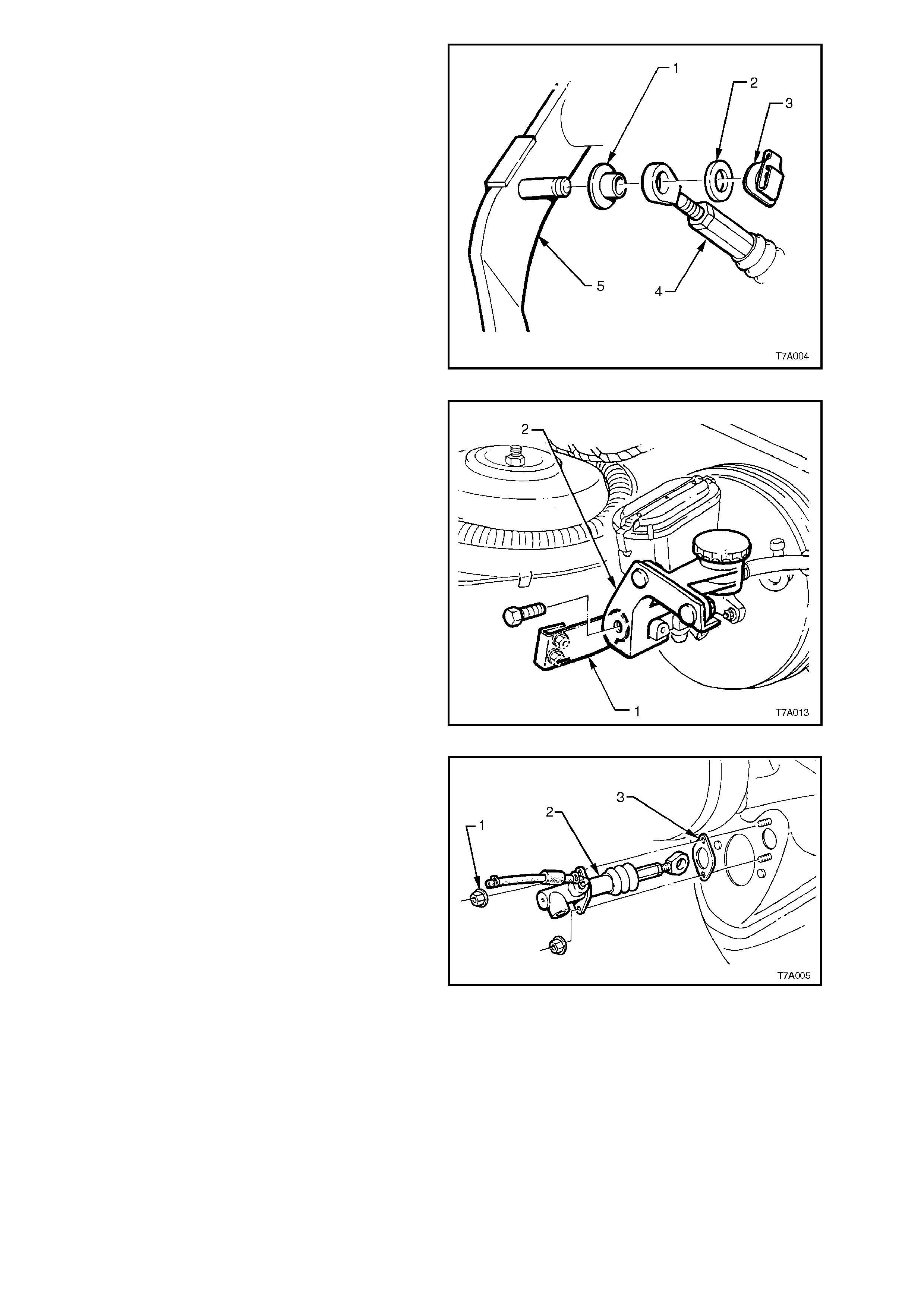

5. Disconnect the clutch master cylinder push

rod by removing the spring clip (3) and metal

washer (2) from pin on the clutch pedal (5).

Disconnect the master cylinder push rod (4)

from the inner bush (1).

Figure 7A-12

6. Remove the clutch master cylinder fluid

reservoir and bracket (2) as an assembly by

removing the bolt from the end of the brake

master cylinder end brace (1). Support the

clutch reservoir to prevent fluid spillage.

Figure 7B2-13

6. Remove the hydraulic steel pipe (not shown)

from the c lutch m aster cylinder, then plug both

the open pipe end and the master cylinder

opening to prevent dirt entry and fluid loss.

7. Remove the two clutch master cylinder

retaining nuts (1) from the engine bay side of

the cockpit module and remove the master

cylinder (2) and reservoir assembly from the

vehicle. Also remove the gasket (3).

Figure 7A-14

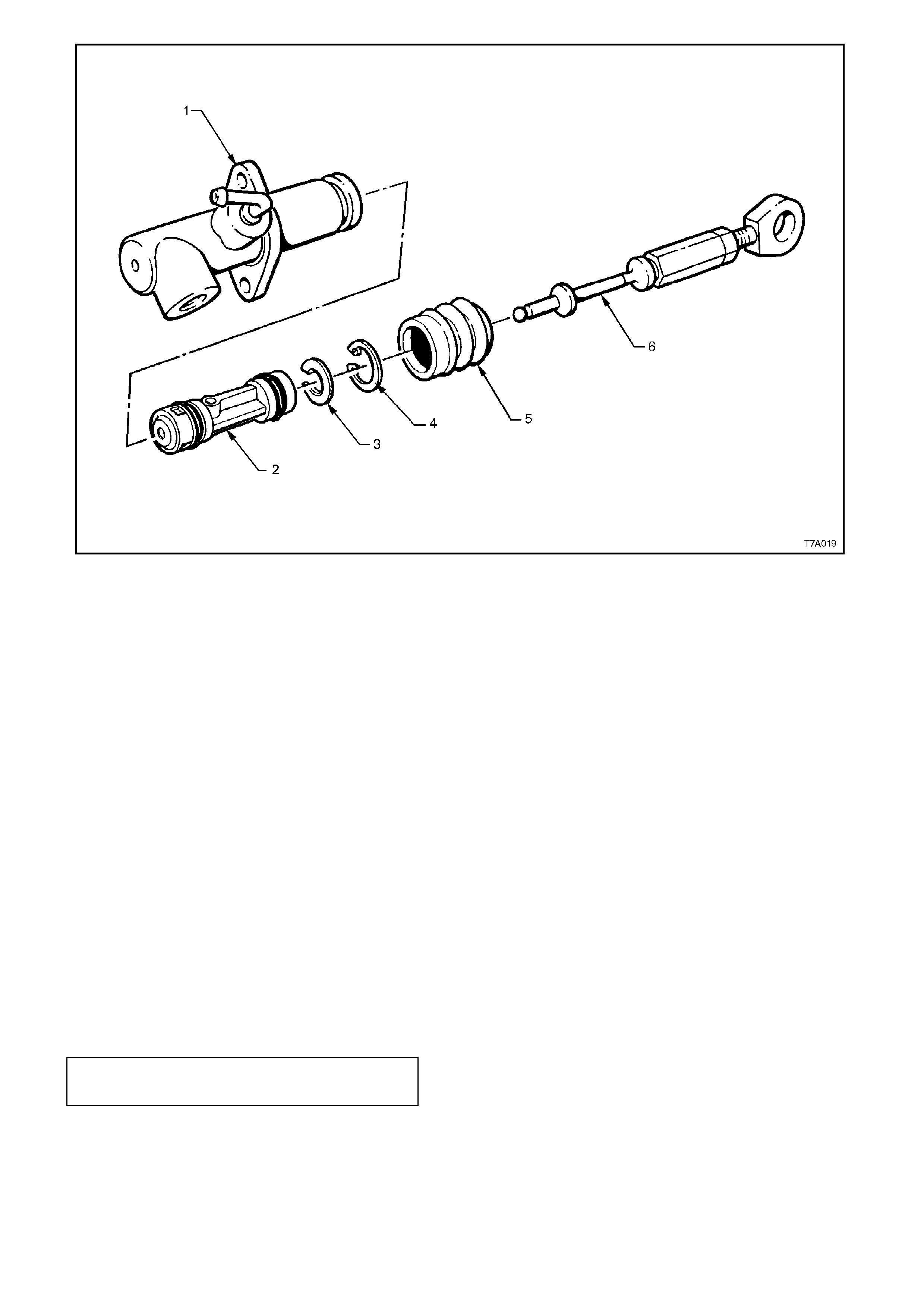

DISASSEMBLE

1. Drain the brake fluid from the reservoir into a

suitable container. Discard the collected fluid.

2. Disconnect the flexible hose from the master

cylinder and set to one side, with the reservoir.

3. Remove the boot from the cylinder groove and

pull back over the eyelet shaped end of the

push rod.

4. Using the master cylinder push rod, depress

the master cylinder piston sufficient to relieve

pressure on the circlip. Then, using suitable

circlip pliers, remove the circlip from the

master cylinder body.

5. As the push rod is secured to the piston,

gently pulling on the push rod will remove the

piston assembly and retaining washer from the

master cylinder bore.

6. As the repair kit supplies all of the removed

components as a complete assembly, no

further dismantling is required.

IMPORTANT:

While the push rod appears to be adjustable, the

push rod length is set by the manufacturer and is

not to be disturbed!

Figure 7A-15

CLEAN AND INSPECT

IMPORTANT: Do not wash hands in petrol or oil

before cleaning or handling master cylinder parts;

always use a soap and water based hand cleaning

product.

Hands m ust be clean bef ore hydraulic c omponents

are handled and washed, as the slightest trace of

mineral based grease or oil in the cylinder or on

components, can cause excessive swelling and/or

destroy rubber based parts.

1. Wash all parts in clean alcohol or methylated

spirits and blow dry with compressed air.

2. Inspect the master cylinder bore for scores,

deep scratches or corrosion. If considered to

be unserviceable, the complete master

cylinder assembly must be replaced.

NOTE:

The master cylinder bore must not be honed.

3. Carefully inspect the piston to ensure that it is

free from burrs and/or sharp edges, which

may cause damage to the master cylinder

wall.

4. Check that the breather c ap ventilation system

on the reservoir is intact and functional.

5. Replace all internal components supplied in

the clutch master cylinder overhaul kit.

REASSEMBLE

1. Dip piston seals and the piston in clean brak e

fluid to Holden’s Specification HN 1796.

2. After lubricating the master cylinder bore with

clean brake fluid to Holden’s Specification HN

1796, install piston, push rod and boot

assembly into the cylinder.

NOTE:

Ensure that neither of the piston seals get caught

or damaged during the installation process.

3. Install the washer (3) and retaining circlip (4).

1. Cylinder - Clutch Master

2. Spring - Return

3. Retainer

4. Seal - Primary

5. Washer

6. Piston

7. Seal - Secondary

8. Washer - Retaining

9. Circlip

10. Boot

11. Rod Assembly - Push

Figure 7A-16 - Clutch Master Cylinder

4. Install the flange of the boot (5) over the end

of the master cylinder bore (1), ensuring that

the boot fits completely into the groove

provided.

5. Install master cylinder reservoir hose to the

mas ter cylinder fitting, ensuring that the clam p

is securely tightened.

6. Plug the master cylinder outlet fitting to

prevent the entry of foreign matter into the

cylinder, during installation operations.

REINSTALL

Installation is the reverse of removal operations

except for the following points:

1. Install master cylinder over studs, fit retaining

nuts and washers and tighten to the correct

torque specification.

CLUTCH MASTER CYLINDER NUT 20 - 30

TORQUE SPECIFICATION Nm

2. Install and tighten hydraulic pipe flare nut to

master cylinder to the correct torque

specification.

HYDRAULIC PIPE FLARE NUT

TO CLUTCH MASTER CYLINDER 8 - 11 Nm

TORQUE SPECIFICATION

3. Bleed the clutch hydraulic system, as detailed

in 3.2 CLUTCH HYDRAULIC SYSTEM,

BLEED, in this Section.

4. Following bleeding operations, check that the

hydraulic fluid level is correct, as detailed in

3.1 FLUID LEVEL CHECK, in this Section.

5. Check clutch operation.

IMPORTANT:

Enable the SRS (Air Bag). Refer to Sectio n 12M

ENABLING THE SRS.

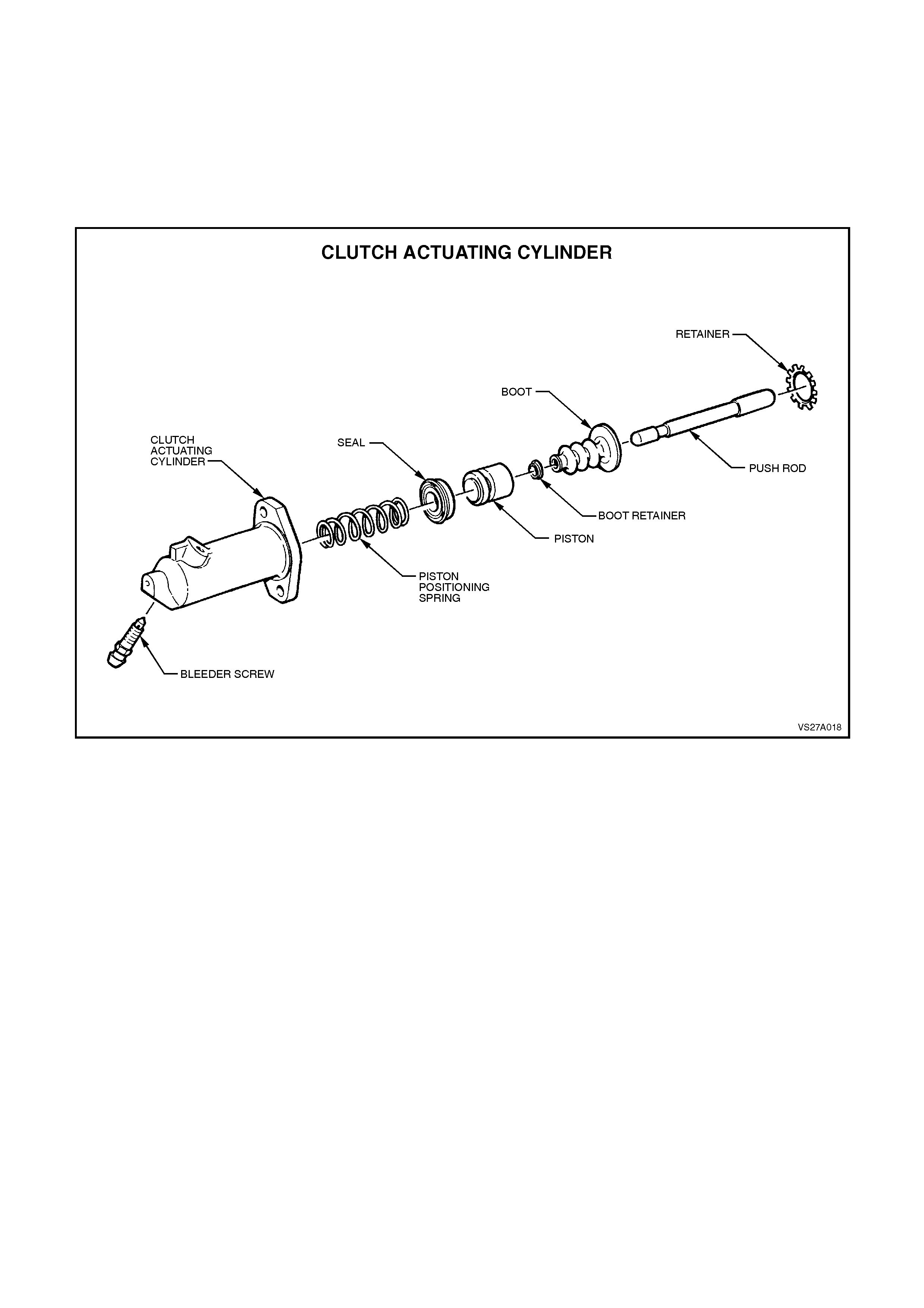

3.4 CLUTCH ACTUATING CYLINDER

REMOVE

1. Raise the vehicle and place on safety stands.

Refer to Section 0B GENERAL

INFORMATION for location of jacking points.

NOTE:

The text and illustrations for this Operation can

refer to either the V6 or V8 clutch system, as the

procedure for both, is identical.

2. Place a suitable, clean container under the

clutch actuating cylinder, then disconnect the

hydraulic pipe from the hydraulic hose, at the

bracket attached to the vehicle sub-frame.

Plug the end of the pipe to block the flow of

brak e fluid from the c lutch mas ter cylinder and

reservoir.

Also plug the hose opening to prevent the

entry of foreign matter during removal

operations.

3. Remove the hose retaining clip with

combination pliers and remove the hose from

the bracket.

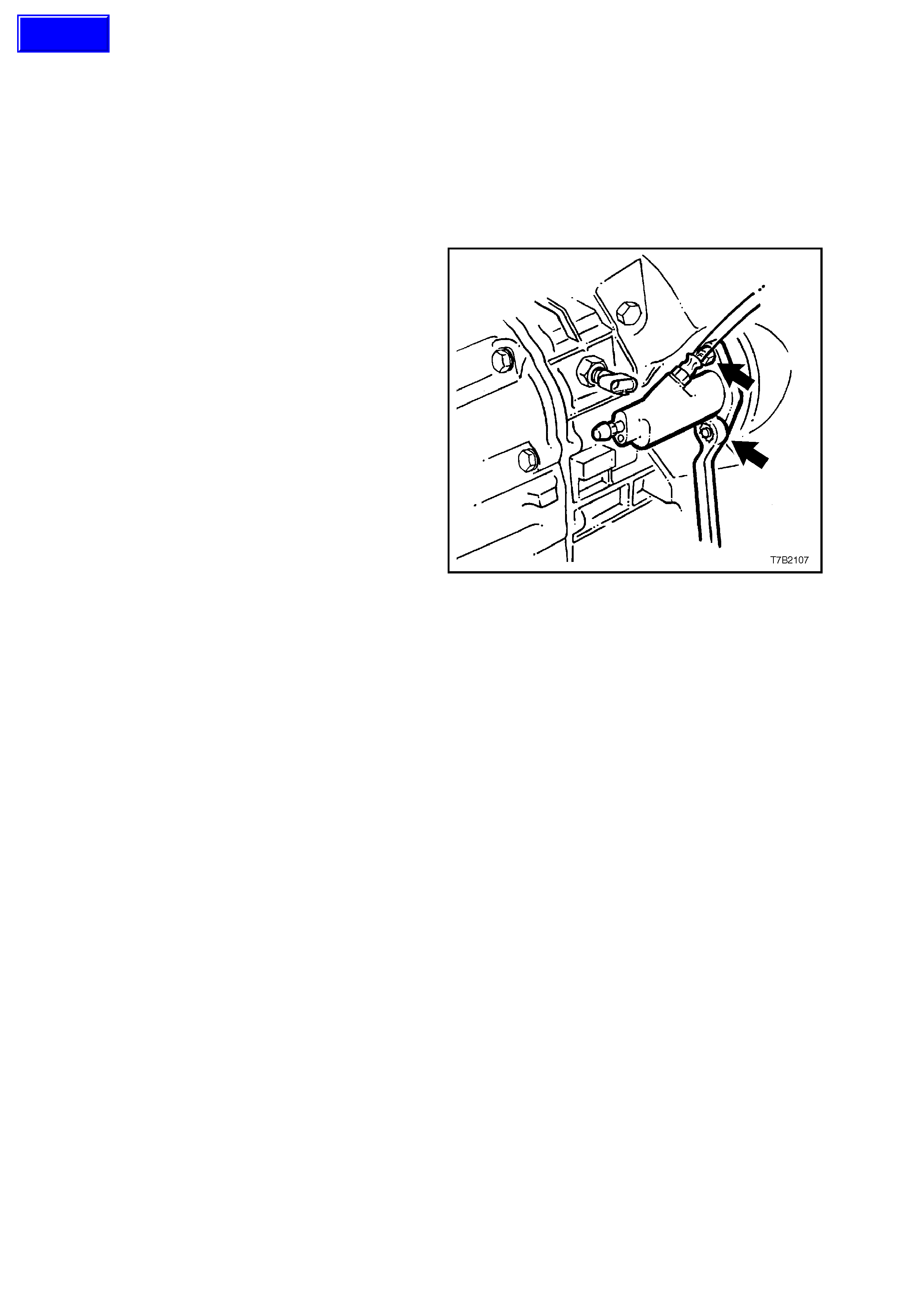

4. Remove the two clutch actuating cylinder

mounting nuts (arrows), then remove cylinder

from the vehicle.

NOTE:

As spring force from the actuating cylinder piston

positioning spring, will push the cylinder out from

the transmission housing, hold the cylinder in,

against this force while removing the mounting

nuts.

Figure 7A-17 - V8 Application

DISASSEMBLE

1. While holding the piston inwards against

spring for ce, prise the retainer from the end of

the actuating cylinder.

2. Release the holding force and remove the

retainer, boot and push rod assembly, piston

and seal, and the spring from the cylinder. It

may be necessary to tap the open end of the

cylinder against a block of wood to dislodge

the piston assembly and spring.

3. Remove the bleeder screw from the cylinder.

4. Prise the seal from the piston and discard.

CLEAN AND INSPECT

IMPORTANT:

Do not wash hands in petrol or oil before cleaning

or handling actuating cylinder parts; always use a

soap and water based hand cleaning product.

Hands m ust be clean bef ore hydraulic com ponents

are handled and washed, as the slightest trace of

mineral based grease or oil in the cylinder or on

components, can cause excessive swelling and/or

destroy rubber based parts.

1. Wash all parts in clean alcohol or methylated

spirits and blow dry with compressed air.

2. Inspect the actuating cylinder bore for scores,

deep scratches or corrosion. If considered to

be unserviceable, the complete cylinder

assembly must be replaced.

Techline

NOTE:

The actuating cylinder bore must not be honed.

3. Carefully inspect the piston to ensure that it is

free from burrs and/or sharp edges, which

may cause damage to the cylinder wall.

4. Check that the bleeder screw thread is

undamaged and that the drilled passage is

clear of debris.

5. Replace all rubber seals and the dust boot.

Figure 7A-18 - Clutch Actuating Cylinder - V6 Engine

REASSEMBLE

1. Dip piston seal and the piston in clean brake

fluid to Holden’s Specification HN 1796, then

install seal over piston land, with the lip facing

away from the push rod end.

2. After lubricating the actuating cylinder bore

with clean brake f luid to Holden’s Spec if ic ation

HN 1796, install the spring and piston

assembly into the cylinder.

3. Install the push rod, boot and retaining

washer, into the cylinder.

4. Using a suitable sleeve such as a deep

socket, install a new retainer into the end of

the cylinder.

5. Install the bleeder screw and tighten finger

tight only, at this time.

6. Plug the actuating cylinder outlet fitting to

prevent the entry of foreign matter into the

cylinder, during installation operations.

REINSTALL

Installation is the reverse of removal operations

except for the following points:

1. Install hydraulic hose to clutch actuating

cylinder and tighten to the correct torque

specification.

HYDRAULIC HOSE TO CLUTCH

ACTUATING CYLINDER 10 - 12 Nm

TORQUE SPECIFICATION

2. Install actuating cylinder over the housing

studs and fit retaining nuts and washers.

NOTE:

During installation, ensure that the actuating

cylinder push rod is correctly located in the clutch

lever. If installed out of position, the push rod and

piston will be pumped out of the cylinder during

bleeding operations, damaging the piston seal.

3. Tighten fasteners to the correct torque

specification.

CLUTCH ACTUATING CYLINDER 20 - 25

NUT TORQUE SPECIFICATION Nm

4. Install and tighten hydraulic pipe flare nut to

actuating cylinder to the correct torque

specification.

HYDRAULIC PIPE FLARE NUT TO

FLEXIBLE HOSE 12 - 14 Nm

TORQUE SPECIFICATION

5. Bleed the clutch hydraulic system, as detailed

in 3.2 CLUTCH HYDRAULIC SYSTEM,

BLEED, in this Section.

6. Following bleeding operations, check that the

hydraulic fluid level is correct, as detailed in

3.1 FLUID LEVEL CHECK, in this Section.

7. Lower vehicle and road test vehicle, to check

clutch operation.

3.5 CLUTCH P EDAL

REMOVE

CAUTION:

Disable the SRS (Air Bag). Refer to Section

12M DISABLING THE SRS.

1. Disconnect the battery earth cable.

2. From inside the passenger compartment,

remove the lower the instrument panel, right

hand cover assembly, as follows;

Grasp the top edge of the cover on each side

of the steering column with the finger tips and

pull outwards, to free the retaining lugs from

the clips.

Prise out the left hand hinge pin with a

screwdriver or similar tool.

Tilt the panel down on the left hand side and

disengage the right hand side hinge pin.

Figure 7A-19

3. Remove the instrument panel lower trim by

removing the two fasteners and retainer.

Lower the panel sufficient to gain access to

the footwell illum ination lam p holder, then twist

the lamp holder to remove from the trim.

Figure 7A-20

4. Remove screws attaching the fuse and Body

Control Module (BCM) panel to the dash

panel. Leaving the Data Link Connec tor (DLC)

attached to the panel, swing the panel to one

side and secure with tie wire or similar.

Figure 7A-21

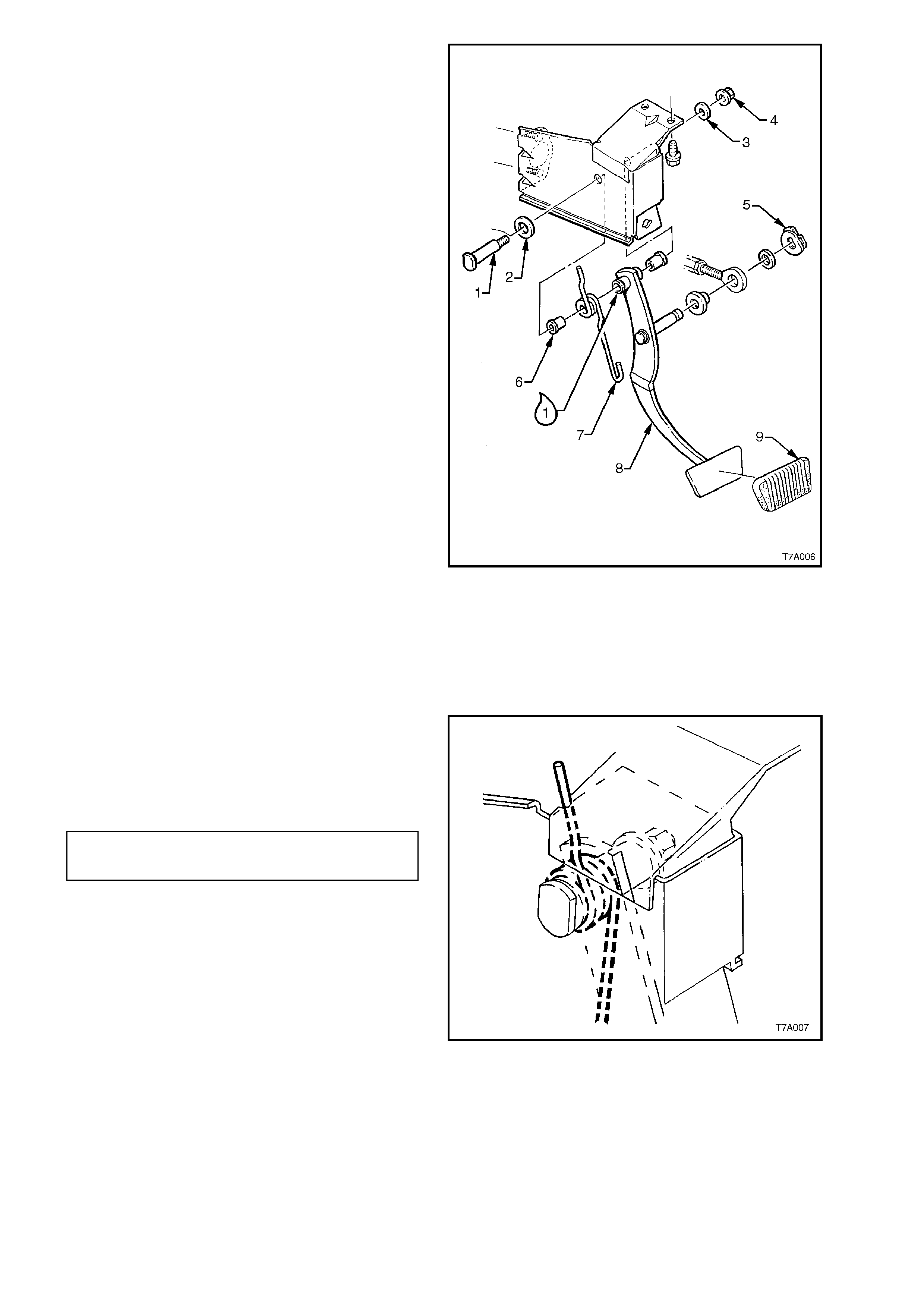

6. Remove the clutch master cylinder push rod

retaining clip (5) and washer from the clutch

pedal pin.

7. Release the end of return spring (7) from

clutch pedal (8) end.

8. Remove clutch pedal pivot retaining nut (4),

washer (3) and pivot bolt (1) and washer (2).

9. Remove the clutch pedal (8) assembly and

spring (7) from the support bracket.

10. Remove return spring (7) and the two bushes

(6) from pedal (8).

Figure 7A-22

REINSTALL

1. Install two pedal bushes into pedal pivot bore.

2. Lubricate bearing surfaces as indicated in

Figure 7A-22 with Molybdenum Disulphide

grease (Holden's Specification HN 1271).

3. Assemble clutch pedal return spring to clutch

pedal, then install pedal to clutch/brake pedal

support.

4. Install clutch pedal pivot bolt (1) and washers

(2 and 3). Install and tighten nut (4) to the

correct torque specification.

CLUTCH PEDAL PIVOT BOLT 12 - 16

TORQUE SPECIFICATION Nm

5. When the return spring is ins talled to the pedal

pin, the upper end will be positioned as shown.

5. Install clutch master cylinder push rod to the

pedal pin, ensuring that the ‘eye’ indexes over

the stepped bush. Install the outer washer and

secure with the clip.

6. Reinstall all removed instrument panel

components in the reverse to removal

operations.

7. Road test vehicle to check clutch operation. Figure 7A-23

IMPORTANT:

Enable the SRS (Air Bag). Refer to Section

12M ENABLING THE SRS.

3.6 CLUTCH DRIVEN P LATE, PRESSURE PLATE AND/OR THROWOUT BE ARING

REMOVE

CAUTION:

Disable the SRS (Air Bag). Refer to Section

12M DISABLING THE SRS.

1. Remove transmission assembly. Refer to

7B1 MANUAL TRANSMISSION - V6 ENG INE

or

7B2 MANUAL TRANSMISSION - V8 ENGINE

Figure 7A-24

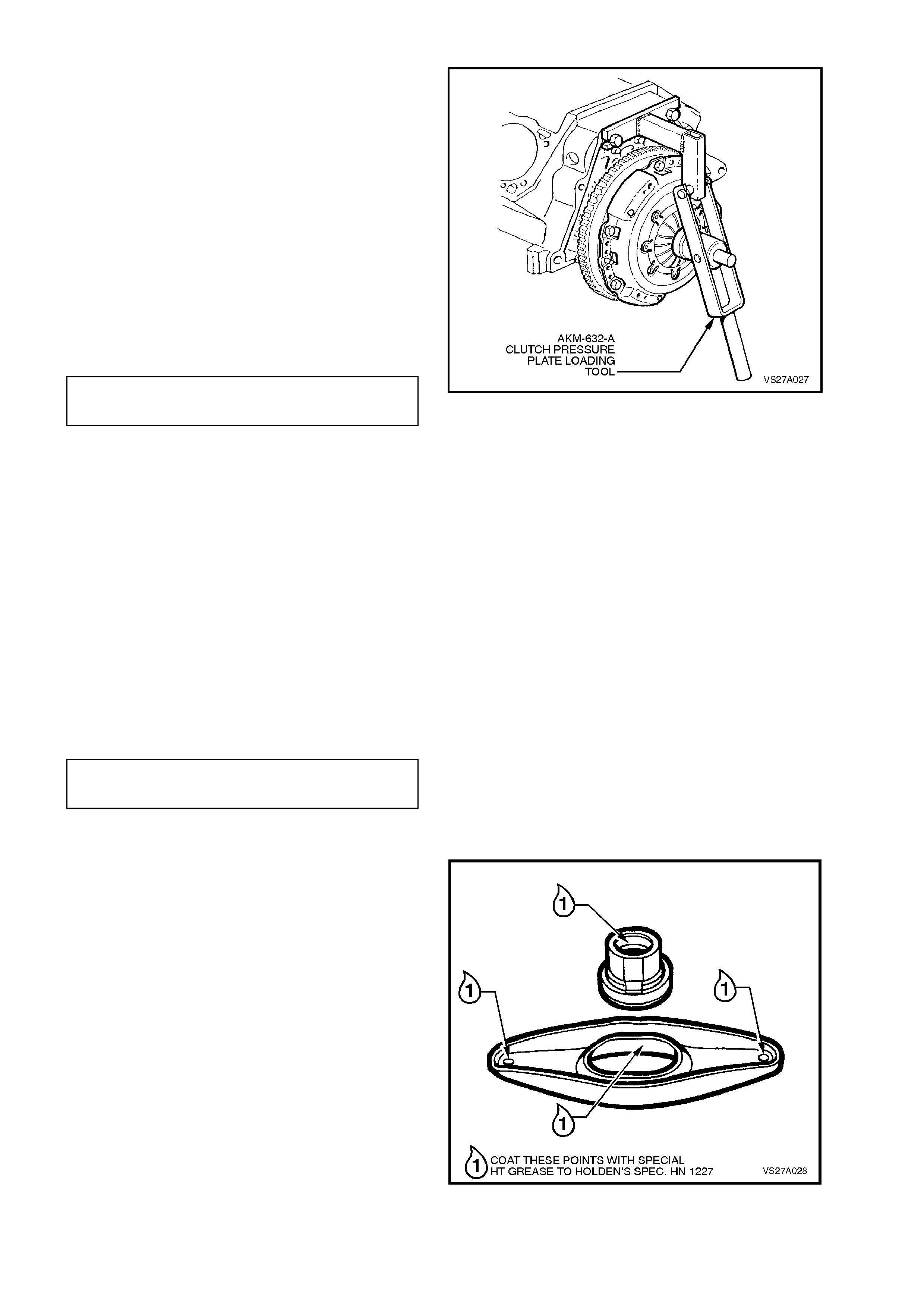

2. Release the clutch throwout lever (2) from the

retaining wire clip (1), then remove the lever

and bearing assembly (3) from the

transmission housing.

Figure 7A-25

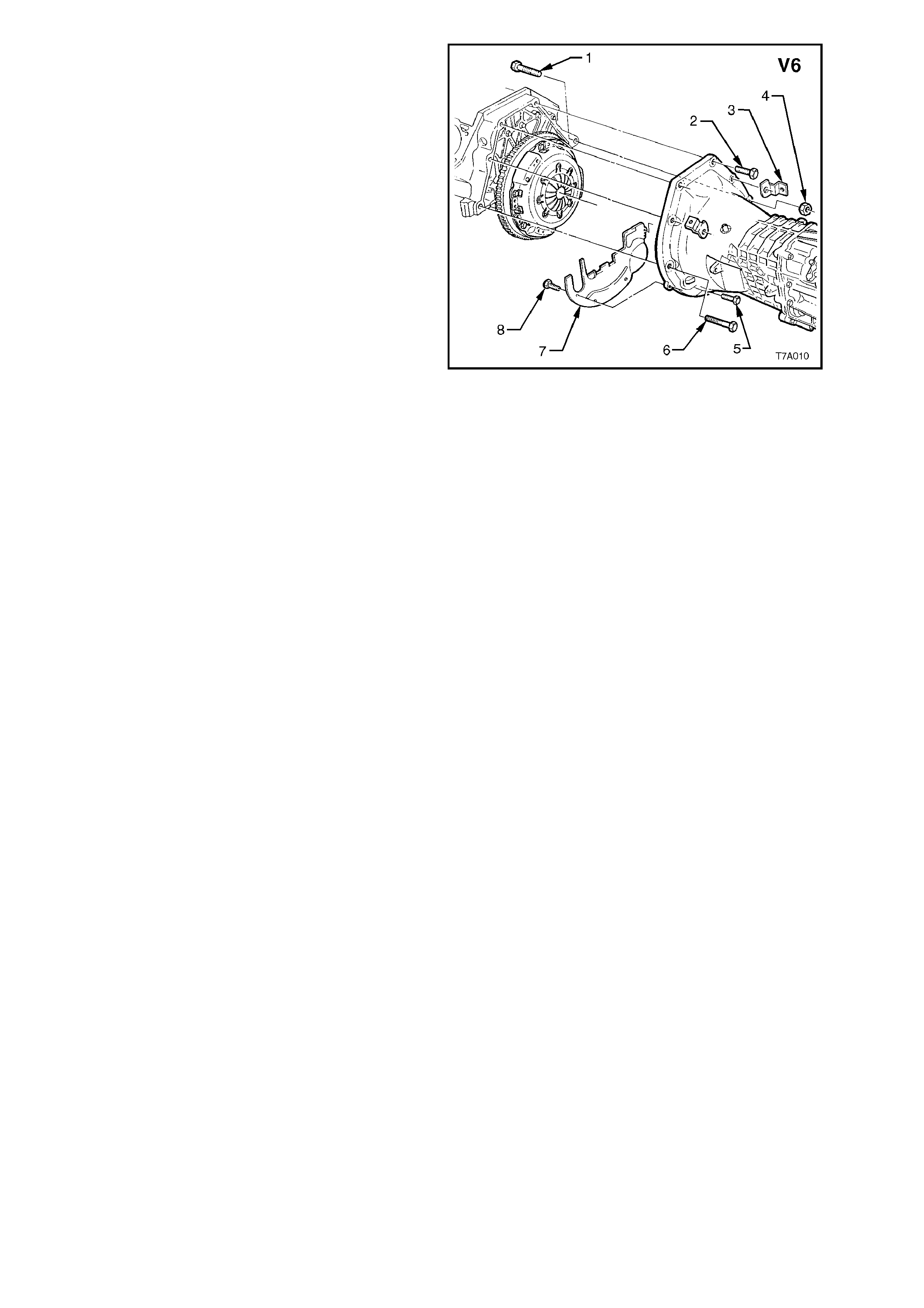

3. Mark the relationship of the clutch pressure

plate to the flywheel, to maintain the correct

balance condition on reassembly.

4. Initially loosen all press ure plate re taining bolts

(4), working from opposite sides, to avoid

distortion of the cover (3).

5. Continue loosening bolts from opposite sides,

until all are rem oved, then lift the c lutch driven

plate (2) and pressure plate (3) assemblies

from the flywheel (1).

Figure 7A-26

Techline

INSPECT

1. W ipe press ure plate and flywheel surfac es clean using a sof t cloth dampened with a suitable cleaning s olvent

(do not use petroleum based products).

NOTE 1:

Do not wash the pressure plate assembly - blow dust out with compressed air after fitting a suitable protective

breathing filter.

NOTE 2:

Do not soak the throw out bearing in cleaning solvent as this will destroy the bearing lubricant.

2. Inspect maindrive gear shaft spigot bush for wear. If necessary, replace the bush as outlined in this Section.

NOTE:

Do not remove the bush unless inspection reveals that it is unserviceable.

3. Inspect clutch lever pivot socket and stud for wear. Replace as required. Check lever retaining spring for

damage or distortion. Spring tension should be sufficient to hold lever in position on the stud. Check clutch

lever for cracks or wear.

4. Check throwout bearing for roughness of operation or signs of wear. Replace if necessary.

Examine bearing hub bore for burrs. Any burrs should be removed. If burrs are found, inspect transmission

maindr ive gear bearing r etainer f or s c oring. If s c oring is s light, remove us ing f ine emery cloth. Replace r etainer

if scoring is excessive, refer Section 7B1 MANUAL TRANSMISSION - V6 ENGINE or

7B2 MANUAL TRANSMISSION - V8 ENGINE .

5. Inspect flywheel and clutch pressure plate friction surfaces for burn marks scoring or roughness. Slight

roughness may be smoothed with fine emery cloth.

Scoring of flywheel or pressure plate surfaces will necessitate replacement of damaged component/s.

6. Inspect clutch driven plate for lining wear or other damage.

Examine clutch driven plate linings for oil or fluid contamination.

NOTE:

If oil or fluid is found on the clutch linings, locate and correct the cause of the leak before proceeding with the clutch

repairs.

7. If installing the clutch driven plate, check clutch hub for a free sliding fit on maindrive gear clutch shaft splines.

REINSTALL

1. Lubricate crankshaft spigot bush with a small amount of SAE 90 Gear Oil.

2. Assemble clutch driven plate, together with cover and pressure plate assembly and insert a suitable clutch

centring tool into spigot bearing, through driven plate.

IMPORTANT:

The V6 clutch driven plate is installed with the offset end of the splined hub facing forward. The word “Getriebeseite”

(Gearbox Side) is also stamped on the inner surface on the short hub side. However, the V8 clutch driven plate is

installed with the offset end of the splined hub facing rearwards towards the gearbox. This clutch driven plate has

“Engine Side” stamped on the appropriate side of the plate.

3. Line up marks on pressure plate cover and flywheel, made during disassembly, and install pressure plate over

the locating dowel pins. Loosely install pressure plate to flyw heel bolts.

FOR V6 ENGINED APPLICATIONS:

4. Install the bracket of Tool AKM-632-A, to the

top two gearbox mounting holes, using two of

the gearbox bolts, each with a nut and a flat

washer.

NOTE:

The thread for the nut is 12 mm x 1.75 pitch.

5. Hook the arm of Tool AKM-632-A under the

lugs of the bracket as shown, and apply force

to the arm, depressing the pressure plate by

18 mm, fully releasing the clamping force on

the driven plate.

6. W ith the pr essure plate loaded in this m anner,

tighten the pressure plate bolts to the correct

torque specification, working from opposite

sides.

CLUTCH PRESSURE PLATE BOLT 28 - 35

(V6 ) TORQUE SPECIFICATION Nm

IMPORTANT:

It is critical that the loading tool is used to depress

the pressure plate diaphragm spring, while the

bolts are tightened. If not used, then the pressure

plate cover will be distorted, resulting in an uneven

force being applied to the driven plate and the bolt

torque figures will also be inadequate.

7. Release the force on the lever of Tool AKM-

632-A, when all bolts have been tightened to

the correct specification. Remove Tool

AKM632-A and the bracket.

FOR V8 ENGINED APPLICATIONS:

8. W orking from opposite sides gradually tighten

the pressure plate cover bolts, until the c orrect

torque specification is attained.

CLUTCH PRESSURE PLATE BOLT 41 - 47

(V8) TORQUE SPECIFICATION Nm

ALL APPLICATIONS:

Figure 7A-27

9. Remove the clutch plate centring tool.

10. Lubricate the clutch throwout lever at each of

the points indicated, using special HT Grease

to Holden’s Specification HN 1227.

Use the same lubricant and apply it to the

groove on the inner surface of the throwout

bearing sleeve as shown.

DO NOT OVER-LUBRICATE!

11. Assemble the clutch throwout bearing to the

sleeve, then install the lever and bear ing to the

throwout bearing guide in the transmission.

Secure the pivot end of the lever with the wire

clip and push the actuating cylinder end

inwards, to secure the position of the bearing

to the lever.

Figure 7A-28

12. Reinstall the transm ission assem bly. Refer to

Section 7B1 MANUAL TRANSMISSION, V6

ENGINE or

Section 7B2 MANUAL TRANSMISSION, V8

ENGINE.

NOTE:

When installing the transmission, do not allow it to

‘hang’ on the maindrive gear splines, as the clutch

driven plate will be damaged.

13. Start engine, and check for exhaust leaks

before road testing the vehicle for satisfactory

clutch operation.

IMPORTANT:

Enable the SRS (Air Bag). Refer to Sect ion 12M

ENABLING THE SRS.

Figure 7A-29

3.7 DUAL MASS FLYWHEEL (V6 ENGINED APPLICATIONS ONLY)

CAUTION:

Disable the SRS (Air Bag). Refer to Section

12M DISABLING THE SRS.

NOTE:

Normally this operation would be included with

engine mechanical items (V6 Engine, 6A1) but, as

this component forms an integral part of the clutch

assembly and the driveline, it has also been

included in this Section.

REMOVE

1. Disconnect battery earth lead.

2. Remove manual transmission and the clutch

assembly, refer to 3.6 CLUTCH DRIVEN

PLATE, PRESSURE PLATE AND/OR

THROWOUT BEARING in this Section and

7B, MANUAL TRANSMISSION - V6 ENGINE.

3. Remove the starter motor. Refer

6D1-2 STARTING SYSTEM - V6 ENGINE.

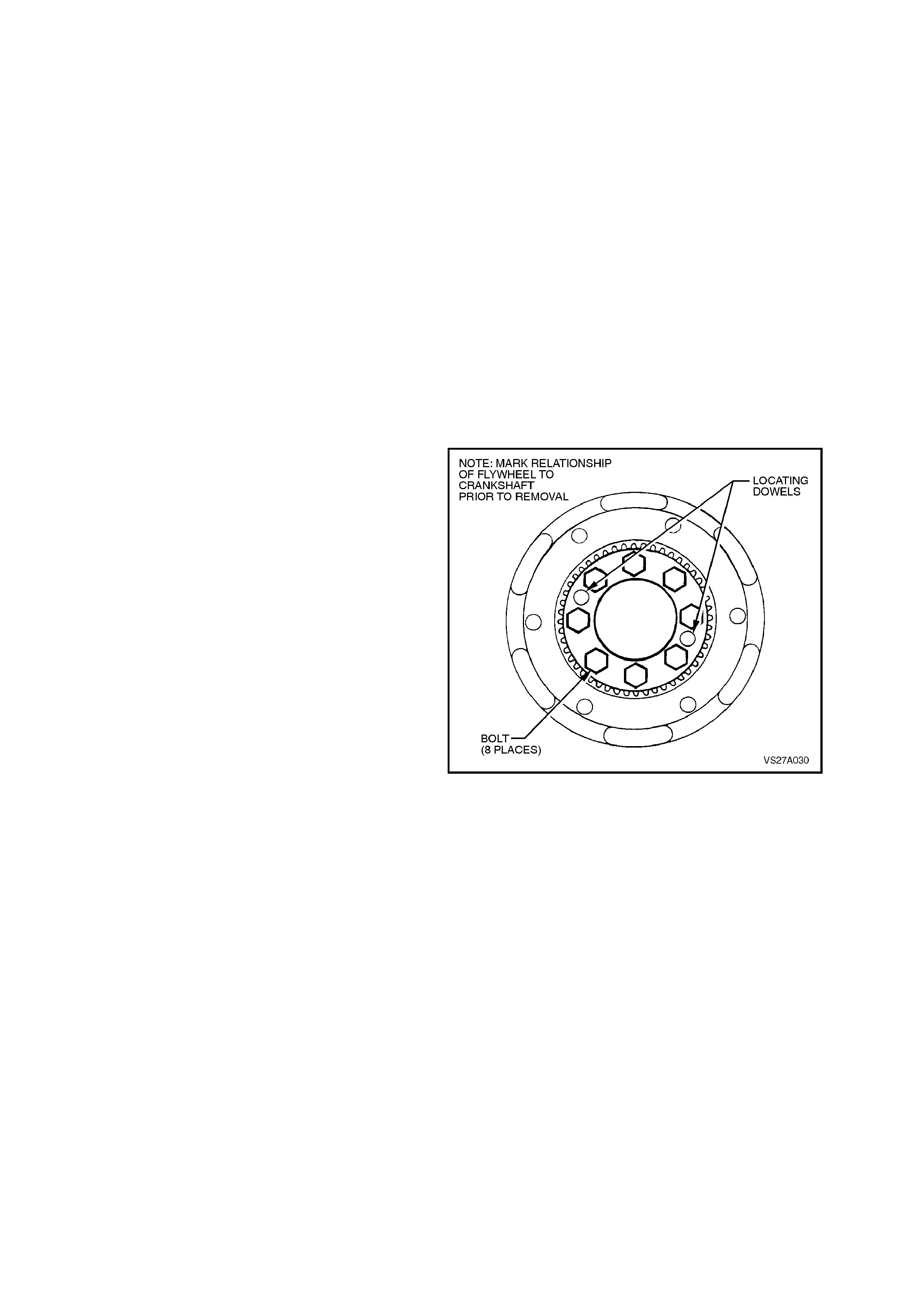

4. To maintain balance conditions, mark the

relative position of the flywheel to the engine

crankshaft.

5. Using a screwdriver or suitable holding tool,

lock the flywheel from turning, while loosening

the eight fastening bolts, working gradually

from opposite sides. Remove flywheel from

the engine crankshaft.

NOTE:

Discard all flywheel attaching bolts once removed,

as new bolts must be used on reassembly.

Figure 7A-30

INSPECT

1. Inspect f lywheel ring gear for crac k s and badly

worn or damaged teeth.

NOTE 1:

If any condition renders the ring gear

unserviceable, the complete dual mass flywheel

MUST be replaced.

NOTE 2:

If ring gear tooth damage is found, the starter

motor pinion gear teeth must also be checked for

damage.

2. Inspect the clutc h driven plate face of the dual

mass flywheel for scoring or excessive heat

damage. W hile som e evidence of heat cracks

can be ignored, should the surface be

considered unserviceable, then the flywheel

MUST be replaced as an assembly .

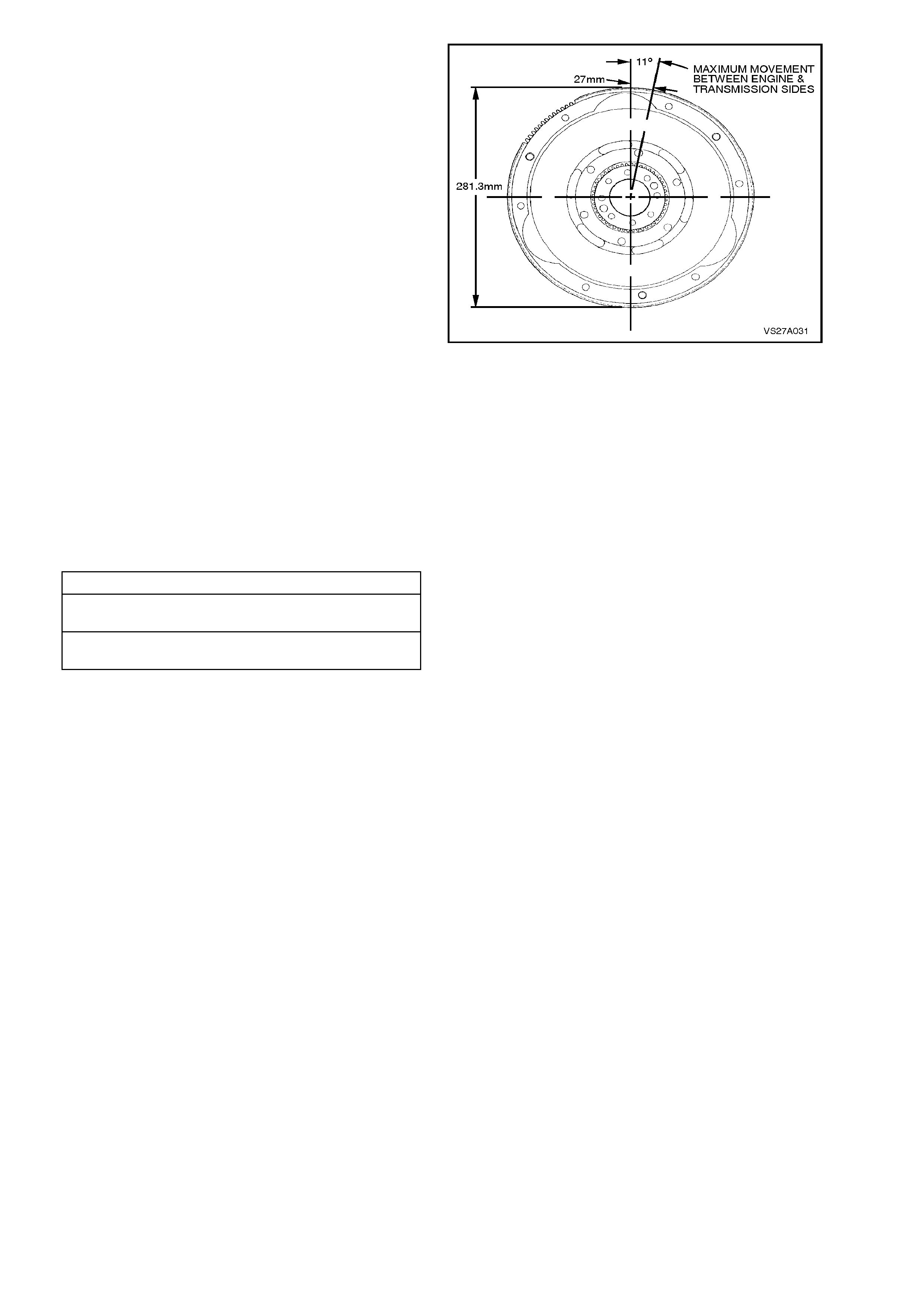

3. Check the rotational free play between the

engine and transmission sides of the dual

mass flywheel. Should the amount of travel

exceed specification, then the flywheel

assembly MUST be replaced as an assembly.

Figure 7A-31

REINSTALL

Installation is the reverse of removal operations

except for the following items.

1. Install flywheel to the engine crankshaft,

aligning with the marks made before removal.

2. Install new bolts and tighten in the

recommended sequence, working from

opposite sides.

FLYWHEEL BOLT TIGHTENING SEQUENCE

STEP 1 TORQUE ALL BOLTS TO

18 - 22 Nm

STEP 2 TIGHTEN ALL BOLTS A FURTHER

80° - 90° TURN ANGLE

3. Reinstall clutch assembly and manual

transmission, refer to 3.6 CLUTCH DRIVEN

PLATE, PRESSURE PLATE AND/OR

THROWOUT BEARING in this Section and

7B, MANUAL TRANSMISSION - V6 ENGINE.

4. Reconnect battery earth lead.

5. Check starter motor operation and road test

vehicle to check transmission and clutch

operation.

IMPORTANT:

Enable the SRS (Air Bag). Refer to Sectio n 12M

ENABLING THE SRS.

3.8 CRANKSHAFT SPIGOT BUSH

REPLACE

CAUTION:

Disable the SRS (Air Bag). Refer to Section

12M DISABLING THE SRS.

1. Disconnect battery earth lead.

2. Remove manual transmission and the clutch

assembly, refer to 3.6 CLUTCH DRIVEN

PLATE, PRESSURE PLATE AND/OR

THROWOUT BEARING in this Section and

7B, MANUAL TRANSMISSION - V6 ENGINE.

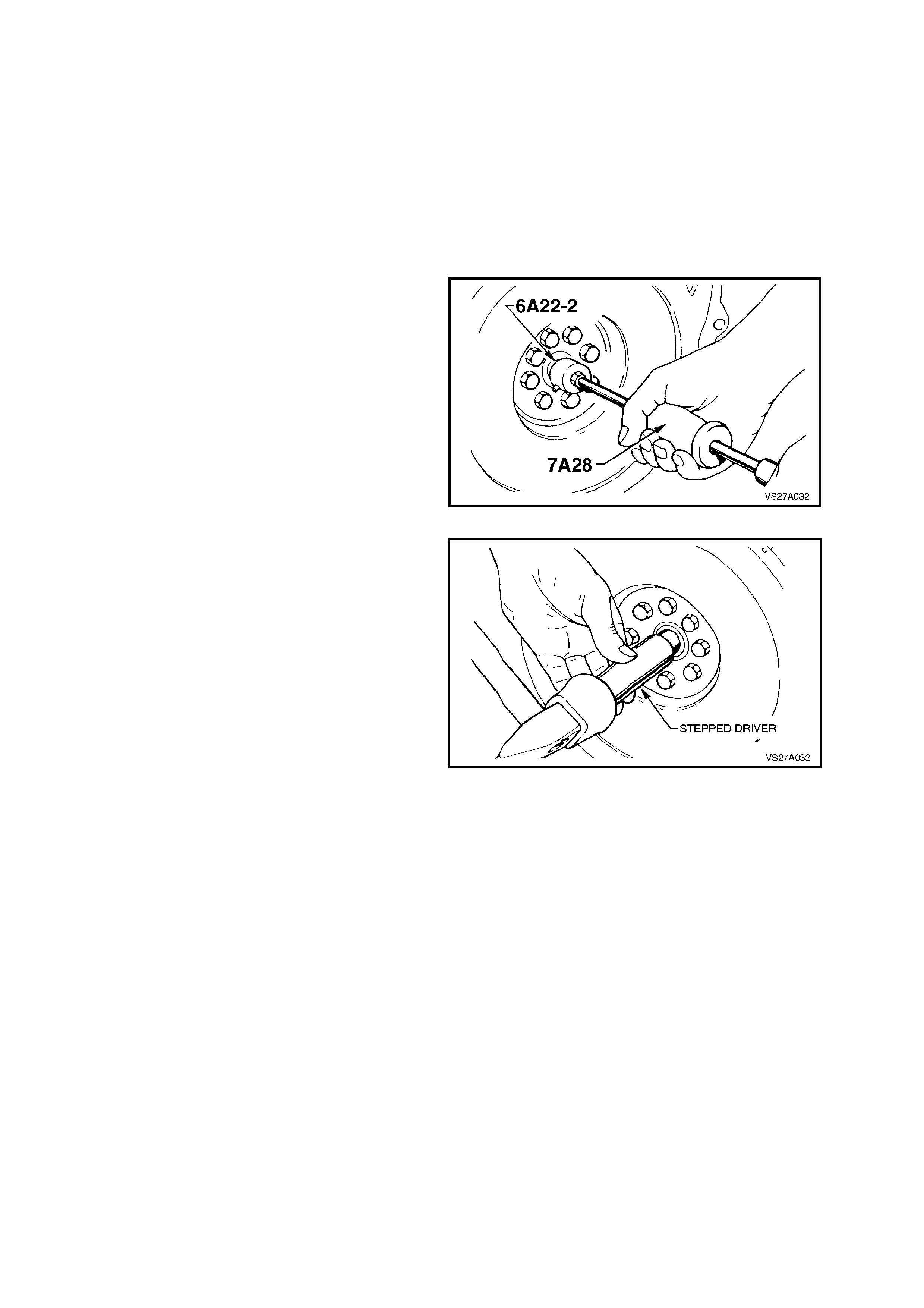

3. Remove bush, using Tool No. 6A22-2, in

conjunction with slide hammer 7A28.

Figure 7A-32

4. To install a new bush, use a stepped driver.

Place a new bush over the smaller diameter of

the fabricated tool, with the radius in the bore

of the bearing agains t the shoulder of the tool.

Drive the bearing into the crankshaft until the

bearing shoulder contacts the crankshaft boss.

Figure 7A-33

5. Lubricate the bearing with a small amount of

SAE 90 gear oil.

6. Reinstall clutch assembly and manual

transmission, refer to 3.6 CLUTCH DRIVEN

PLATE, PRESSURE PLATE AND/OR

THROWOUT BEARING in this Section and

7B, MANUAL TRANSMISSION - V6 ENGINE.

7. Reconnect battery earth lead.

8. Check starter motor operation and road test

vehicle to check transmission and clutch

operation.

IMPORTANT:

Enable the SRS (Air Bag). Refer to Sectio n 12M

ENABLING THE SRS.

4. DIAGNOSIS

CONDITION PROBABLE CAUSE CORRECTIVE ACTION

SLlPPING Worn or oil-soaked lining.

Driven plate sticking on main

drive gear splines.

Weak or broken diaphragm

spring

Master or actuating cylinder

defective

Replace driven plate, correct

oil leak.

Clean splines and apply

special HT Grease, to

Holden’s Specification HN

1227.

Replace pressure plate and

diaphragm assembly. Refer

Operation 3.6 Clutch Driven

Plate, Pressure Plate and/or

Throwout Bearing, in this

Section.

Overhaul defective cylinder as

outlined under 3.3 Master

Cylinder or 3.4 Clutch

Actuating Cylinder, in this

Section.

DRAG OR FAILURE TO

RELEASE Air trapped in hydraulic

system.

Leak In hydraulic system.

Clutch master or actuating

cylinder defective.

Cracked or oil-soaked linings.

Excessive driven plate run-out

or distorted.

Driven plate sticking on

splines.

Main drive gear spigot partially

seized in crankshaft spigot

bush.

Bleed system as outlined

under 3.2 Clutch Hydraulic

System Bleed, in this Section.

Correct leak and bleed

hydraulic system.

Overhaul defective cylinder as

outlined under 3.3 Master

Cylinder or 3.4 Clutch

Actuating Cylinder, in this

Section.

Replace driven plate. Refer

Operation 3.6 Clutch Driven

Plate, Pressure Plate and/or

Throwout Bearing, in this

Section.

Replace driven plate. Refer

Operation 3.6 Clutch Driven

Plate, Pressure Plate and/or

Throwout Bearing, in this

Section.

Clean and free splines and

apply special HT Grease, to

Holden’s Specification HN

1227.

Remove clutch, Iubricate or

replace bush. Refer Operation

3.8 Crankshaft Spigot Bush, in

this Section.

CONDITION PROBABLE CAUSE CORRECTIVE ACTION

GRAB OR CHATTER Oil on linings.

Worn main drive gear splines.

Rough, or grooved, flywheel or

pressure plate.

Loose engine mountings.

Loose or worn universal joints

or loose rear universal joint

flange.

Defective clutch driven plate.

Defective dual mass flywheel.

Replace driven plate, correct

oil leak.

Replace main drive gear.

Replace flywheel or replace

both flywheel and pressure

plate.

Tighten or replace mountings.

Tighten or replace universal

joint/s and/or flange.

Replace clutch driven plate.

Refer 3.6 Clutch Driven Plate,

Pressure Plate and/or

Throwout Bearing, in this

Section

Replace dual mass flywheel.

Refer 3.7 Dual Mass Flywheel,

in this Section

HARD OR STIFF CLUTCH

ACTlON Clutch pedal bush seized or

tight on pedal shaft.

Blockage in fluid hydraulic

pipe.

Replace bushes as detailed in

3.5 Clutch Pedal in this

Section.

Clean lines and bleed

hydraulic system. Refer 3.2

Clutch Hydraulic System Bleed

in this Section.

CLUTCH ENGAGEMENT

TOO SLOW Blockage in fluid hydraulic

pipe.

Clutch master or actuating

cylinder defective.

Incorrect brake fluid used.

Clean lines and bleed

hydraulic system. Refer 3.2

Clutch Hydraulic System Bleed

in this Section.

Overhaul defective cylinder as

outlined under 3.3 Master

Cylinder or 3.4 Clutch

Actuating Cylinder, in this

Section.

Flush and bleed hydraulic

system. Refer 3.2 Clutch

Hydraulic System Bleed in this

Section.

5. SPECIFICATIONS

MASTER CYLINDER: V6 Engine V8 Engine

Type Compensating port.

Bore Size 19.05 mm

Nominal Stroke 30 mm

CLUTCH ACTUATING CYLINDER

Type Flange mounted with side port delivery and end bleed.

Bore Size 22.2 mm 20.6 mm

Available Stroke 25.6 mm 28.8 mm

BRAKE FLUID:

Type To Holden’s Specification HN 1796.

CLUTCH DRIVEN PLATE:

Type Single plate dry disc.

Disc Facing:

Outside Diameter 240 ± 1.0 mm 266 ± 1.0 mm

Inside Diameter 155 ± 1.5 mm 172 ± 1.0 mm

Thickness of disc assembly

with 7,000 N load applied 8.4 ± 0.2 mm 8.23

CLUTCH PRESSURE PLATE:

Type Recessed, with a pressed steel cover plate and a

Belleville diaphragm spring.

CLUTCH THROWOUT

BEARING:

Type Ball race.

Lubrication Sealed with grease for life.

DUAL MASS FLYWHEEL

(V6 EN GINE ONLY):

Type Spring dampened internally; the transmission side

being recessed to accommodate the clutch assembly.

Rotational free play maximum,

including length tolerances and

heat setting losses:

Degrees 11°

Distance 27 mm at the outside diameter (281.3 mm) of the

secondary side of the flywheel assembly.

Serviceability None. Starter motor ring gear is not replaceable and

machining of the clutch facing surface is not permitted.

6. TORQUE WRENCH SPECIFI CATIONS

Nm

Clutch actuating cylinder mounting nut 20 - 25

Clutch flexible hose to clutch actuating cylinder 10 - 12

Clutch master cylinder nut to engine firewall 20 - 30

Clutch pedal pivot bolt 12 - 16

Clutch pressure plate cover to flywheel V6 Engine 28 - 35

V8 Engine 41 - 47

Fly wheel to crankshaft mounting bolts V6 Engine Step 1 18 - 22

Step 2 Turn a further

80 - 90°

V8 Engine 81 - 88

Hydraulic Pipe Flare Nut to Master Cylinder or

Flexible Hose 8 - 11

Lower flywheel cover attaching screw 5 - 10

Starter motor retaining bolt V6 Engine 36 - 50

V8 Engine 24 - 32

Transmission to engine bolt V6 Engine

(and

Beaming

brace bolt)

50 - 85

V8 Engine 30 - 45

7. SPECIAL TOOLS

TOOL NO. REF IN TEXT TOOL DESCRIPTION COMMENTS

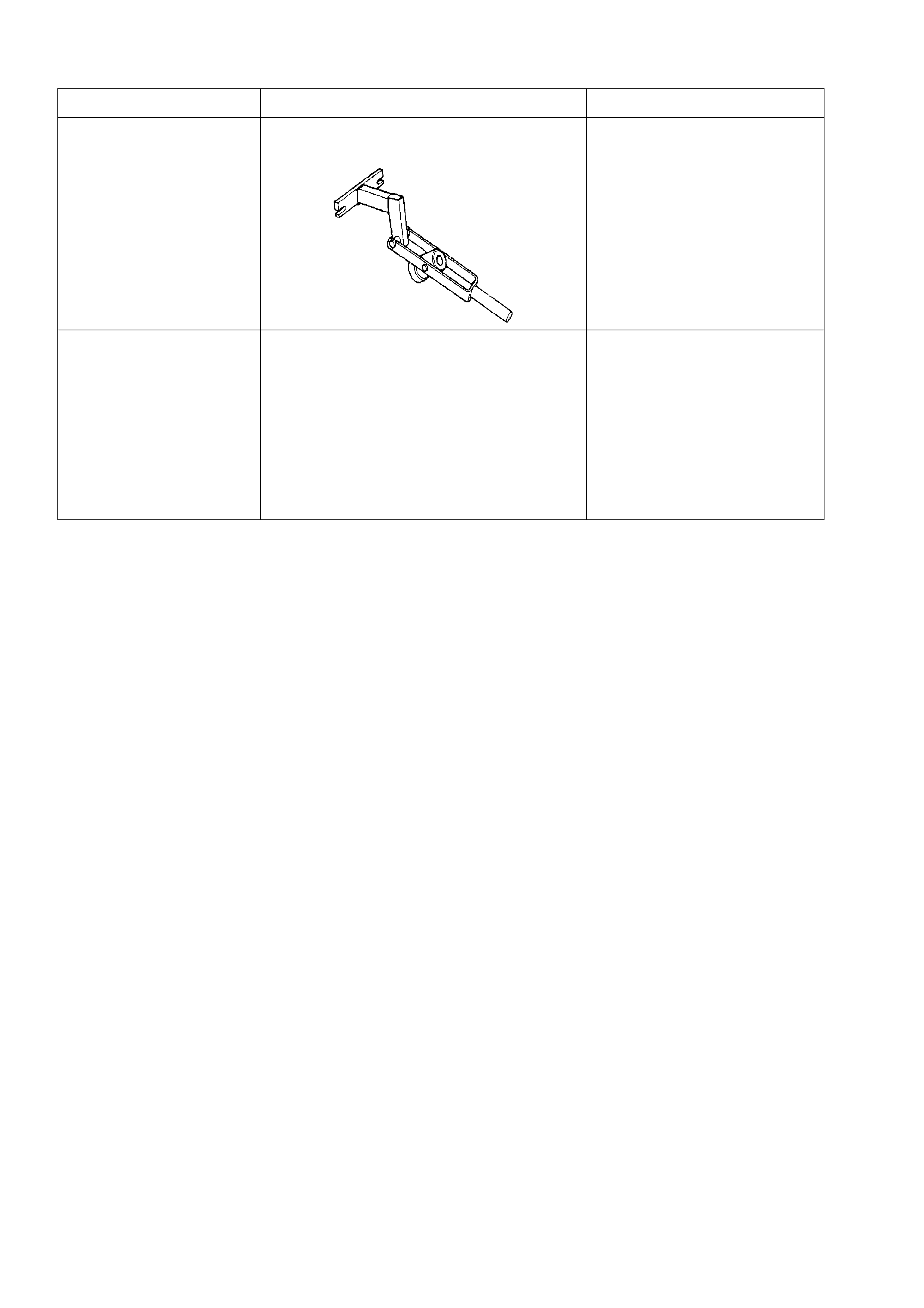

AKM-632-A CLUTCH PRESSURE PLATE LOADING

TOOL USED TO ‘LOAD’ THE

PRESSURE PLATE ON V6

ENGINED VEHICLES, WHILE

TIGHTE NING THE RETAINING

BOLTS.

PREVIOUSLY RELEASED

FOR VS SERIES II.

N/A CLUTCH CENTRING TOOL COMMERCIALLY AVAILABLE.