SECTION 7C4 - HYDRA-MATIC 4L60-E AUTOMATIC

TRANSMISSION: ON-VEHICLE SERVICING

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). An SRS

will consist of either seat belt pre-tensioners and a driver's side air bag, or seat belt

pre-tensioners and a driver's and front passenger's side air bags. Refer to

CAUTIONS, Section 12M, before performing any service operation on or around any

SRS components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deplo yment, resulting in possible p ersonal injury or unnecessary

SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas. In the interests of

safety, the LPG fuel system should be isolated by turning ‘OFF’ the manual service

valve and then draining the LPG serv ice lines, before any service w ork is carried out

on the vehicle. Refer to the LPG leaflet included with the Owner's Handbook for

details or LPG Section 2 for more specific servicing information.

CAUTION:

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is

disturbed during Service Operations, it is vital that the complete ABS or ABS/ETC

system is checked, using the procedure as detailed in 4. DIAGNOSIS, ABS or

ABS/ETC FUNCTION CHECK, in Section 12L ABS & A BS/ETC.

1. GENERAL INFORMATION

As detailed in 7C1, material contained within this Section, details service operations that can be carried out on a

transmission while it is still installed in the vehicle, as well as the procedures required to remove and reinstall the

transmission assembly from/to the vehicle.

General servicing information is also included in this Section and it is recommended that this material be read and

followed, whenever servicing operations are to be carried out, on this transmission.

1.1 GENERAL SERVICE PRECAUTIONS

RECOMMENDATIONS

When servicing the transmission, all parts should be cleaned and inspected as outlined under 'Clean and Inspect',

in these recommendations. Individual units should be reassembled before disassembly of other units to avoid

confusion and interchanging of parts.

1. Thoroughly clean the transmission exterior before removal of any component.

2. Disassembly and reassembly must be made on a clean work bench. Cleanliness is of the utmost importance.

The bench tools, and parts must be kept clean at all times.

3. Before installing screws and other fasteners into aluminium parts, DIP SCREWS INTO TRANSMISSION

FLUID (Only use DexronÒ III) to prevent galling aluminium threads and to prevent screws from seizing.

4. To prevent thread stripping, always use a torque wrench when installing screws.

5. If threads in aluminium parts are stripped or damaged, the part can be made serviceable by the use of

commercially available, thread inserts.

6. Protective tools must be used when assembling seals to prevent damage. The slightest flaw in the sealing

surface of the seal can cause an oil leak.

7. Aluminium castings and valve parts are very susceptible to nicks, burrs, etc., and should be handled with care.

8. Internal snap rings should be expanded and external snap rings compressed if they are to be re-used. This will

ensure proper seating when reinstalled.

9. O-rings, gaskets and oil seals that are removed should not be re-used.

10. Teflon oil seal rings should not be removed unless damaged.

11. During assembly of each unit, all internal moving parts must be lubricated with transmission fluid.

Techline

Techline

Techline

OIL COOLER PIPES

If replacement of transmission steel tubing cooler pipes is required, use only double wrapped and brazed steel

tubing meeting Holden Specification 123M or equivalent. Under no circumstances is copper or aluminium tubing to

be used to replace steel tubing. These materials do not have satisfactory fatigue durability to withstand normal car

vibrations.

Steel tubing should be flared using the double flare method.

CLEAN AND INSPECT

After complete disassembly of a component, wash all metal parts in a clean solvent and dry with compressed air.

Blow oil passages out and check to make sure they are not obstructed. Small passages should be checked with tag

wire. All parts should be inspected to determine which parts are to be replaced.

Pay particular attention to the following:

1. Inspect linkage and pivot points for excessive wear.

2. Bearing and thrust surfaces of all parts should be checked for excessive wear and scoring.

3. Check for broken seal rings, damaged ring lands and damaged threads.

4. Inspect seal and O-rings.

5. Mating surfaces of castings should be checked for burrs. Irregularities may be removed by lapping the surface

with emery paper. The emery paper is laid on a flat surface, such as a piece of plate glass.

6. Castings should be checked for cracks and porosity.

NOTE:

Do not use solvents on neoprene seals, composition faced clutch plates or thrust washers as damage to parts may

occur.

2. MAINTENANCE AND GENERAL INFORMATION

2.1 FLUID LEVEL CHECK

GENERAL INFORMATION

When adding or changing the transmission fluid, use only Dexron® III (to Holden’s Specification HN2126). Refer to

the VT Series Owner's Handbook for servicing intervals.

Because this transmission fluid changes colour and smell very early in its life, these indicators should not

necessarily be relied upon to diagnose either transmission internal condition nor fluid deterioration.

Reference to the Fluid Checking Procedure shows that a dark brown fluid colour, coupled with a delayed shift

pattern, may only indicate that the fluid requires replacement and alone, is not a definite indication of a potential

transmission failure.

NOTE:

Do not overfill the transmission. Overfilling will cause foaming of the fluid, loss of fluid, shift complaints and possible

damage to the transmission.

TRANSMISSION FLUID COLOUR

Transmission fluid colour when new and unused, is red. A red dye is added so that it can be distinguished from

other oils and lubricants. The red dye is not an indicator of fluid quality and is not permanent. As the vehicle is

driven, the transmission fluid will quickly begin to look darker in colour. The colour will then appear light brown. A

DARK brown colour with a distinctively burnt odour MAY indicate fluid deterioration and a need for the fluid to be

changed.

TRANSMISSION FLUID CHECKING PROCEDURE

1. Start engine and drive vehicle for a distance of 24 km, or until transmission normal operating temperature is

reached.

NOTE:

As temperature greatly affects transmission fluid levels, this operation must only be carried out with the

transmission at normal operating temperature (82 - 94° C). If the vehicle is not at normal operating temperature,

and the proper checking procedures are not followed, the result could be a false reading of the fluid level on the

dipstick.

2. Park vehicle on level ground.

3. Move gear selector to 'PARK' position.

4. Apply park brake.

5. Let engine idle for 3 minutes with accessories turned off.

6. Lift the locking lever on the red coloured dipstick, remove dipstick and check fluid colour, condition and level.

7. If the fluid level is low, add only enough Dexron® III to bring the level into the “HOT” area.

*Inaccurate fluid level readings will result if checked immediately after the vehicle has been operated under any

or all of the following conditions:

a. In high ambient temperatures above 32° C.

b. At sustained high speeds.

c. In heavy city traffic during hot weather.

d. Towing.

e. In commercial use (e.g. taxi).

*If the vehicle has been operated under these conditions, switch the engine off and allow the vehicle to 'cool' for

approximately thirty minutes. After the cool-down period, re-start the vehicle and continue from step 2, above.

4L60-E TRANSMISSION FLUID CHECKING PROCEDURE

STEP ACTION YES NO

1. Check the fluid colour.

Is the fluid colour red?

Go to Step 2 Go to Step 11

2. Is the fluid level satisfactory? Go to Step 20 Go to Step 3

3. Check the fluid.

Is the fluid foamy?

Go to Step 8 Go to Step 4

4. Check the fluid level. The correct fluid level should

be in the middle of the cross-hatch.

Is the level high?

Go to Step 9 Go to Step 5

5. Fluid will be low.

Add fluid to the correct fluid level.

Is the fluid level satisfactory?

Go to Step 6 Go to Step 1

6. Check for external leaks.

Were any leaks present?

Go to Step 7 Go to Step 20

7. Correct the fluid leak condition.

Is action complete?

Go to Step 20

8. Is the fluid level too high? Go to Step 9 Go to Step 10

9. Remove excess fluid to adjust to the correct fluid

level.

Is action complete?

Go to Step 20

10. 1. 1. Check for contaminants in the fluid.

2. Drain the fluid to determine the source of

contamination.

Is action complete?

Go to Step 15

11. Is the fluid colour a non-transparent pink? Go to Step 12 Go to Step 13

12. Replace the leaking cooler.

Is the action complete?

Go to Step 15

13. The fluid colour should be light brown.

Transmission fluid may turn dark with normal use.

This does not always indicate oxidation or

contamination.

Is the fluid colour light brown?

Go to Step 14 Go to Step 1

14. Drain the fluid to determine if the fluid is

contaminated. A very small amount of material in

the bottom of the oil pan is a normal condition, but

larger pieces of metal or other material in the

bottom of the oil pan are not and the transmission

requires an overhaul.

Was the fluid contaminated?

Go to Step 15 Go to Step 18

15. Overhaul the transmission or fit a SRTA unit. Refer

to Section 7C5 Unit Repair.

Is action complete?

Go to Step 16

STEP ACTION YES NO

16. Flush the coolers.

Is action complete?

Go to Step 17

17. Add new fluid.

Is action complete?

Go to Step 19

18. Change the fluid and filter.

Is action complete?

Go to Step 19

19. Is the fluid level satisfactory? If not, correct as

necessary.

Is action complete?

Go to Step 20

20. Refer to Functional Test Procedure, in Section 7C3,

DIAGNOSIS.

Is action complete?

Fluid Checking

Procedure

Completed

2.2 FLUID LEAK DIAGNOSIS AND REPAIR

The cause of most external leaks can usually be located and repaired with the transmission installed in the vehicle.

METHODS FOR LOCATING LEAKS

General Method

1. Verify that the leak is in fact, transmission fluid.

2. Thoroughly clean the suspected leak area.

3. Operate the vehicle for about 24 km or until normal operating temperatures are reached.

4. Park the vehicle over clean paper or cardboard.

5. Switch the engine off and look for fluid spots on the paper.

6. Make necessary repairs.

Powder Method

1. Thoroughly clean the suspected leak area with a suitable cleaning agent.

2. Apply an aerosol type powder (eg foot powder) to the suspected leak area.

3. Operate the vehicle for about 24 km or until normal operating temperatures are reached.

4. Switch the engine off.

5. Inspect the suspected leak area and trace the leak path through the powder to find the source.

6. Make necessary repairs.

Dye and Black Light Method

While the following can be used as a guide, always follow the manufacturer’s recommendations for use of this

equipment.

1. Pour the manufacturer's recommended amount of dye (such as J28431-B) into the transmission.

2. Road test the vehicle under normal operating conditions.

3. Direct the black light (Tool No. J42220) to the suspect area. Any fluid leak will appear as a brightly coloured

path, leading to the source.

NOTE:

The colour of the dyed fluid can be checked on the transmission dipstick.

4. Make the necessary repairs, then re-check that the leak has been rectified.

REPAIRING THE LEA K

NOTE 1:

Once the leak has been located and traced back to its source, the CAUSE of the leak must be determined, for the

repair to be satisfactory.

NOTE 2:

If a gasket is replaced, but the sealing flange is distorted or bent (eg oil pan flange), the new gasket will not stop the

leak. Obvious damage such as this must be rectified before fitting new gaskets, if a satisfactory repair is to be

expected.

NOTE 3:

Before attempting to repair a leaking seal and/or gasket, check to make sure that the following conditions do not

apply:

Gaskets:

Fluid level or pressure is too high.

Blocked or partially blocked vent or drain back holes.

Incorrectly torqued fasteners or dirty/damaged threads.

Warped/bent flanges or sealing surface.

Scratches, burrs or other damage to the sealing surface.

Damaged or worn gasket.

Cracking or porosity of the component or adjacent part.

Improper sealant used (where applicable).

Seals:

Fluid level or pressure is too high.

Blocked or partially blocked vent or drain back holes.

Damaged seal bore (Scratched burred or nicked).

Damaged or worn seal.

Incorrect previous installation.

Cracks in the component.

Manual or output shaft is scratched, nicked or worn.

Loose or worn bearing, causing excess seal wear.

POSSIBLE POINTS OF FLUID LEAKS

1. Transmission and Oil Pan:

Attaching bolts not torqued correctly.

Improperly installed or damaged gasket.

2. Case Leak:

Filler tube multi-lip seal damaged or missing.

Filler tube bracket misaligned.

Speed sensor seal damaged.

Manual shaft seal worn or damaged.

Oil cooler connector fittings loose or damaged.

Propeller shaft oil seal worn or damaged.

Line pressure plug loose or thread damage has occurred.

Porous casting.

3. Leak at End of Converter:

Converter seal damaged.

•Seal lip cut (Check converter hub for damage).

•Bushing has moved forward and/or is damaged.

•Garter spring is missing from seal.

Converter leak in the weld area.

Porous casting (case or pump).

4. Fluid Comes from Vent or Fill Tube:

Overfilled.

Water or coolant in fluid (milky/pink fluid colour).

Case porous.

Incorrect fluid level indicator.

Blocked or partially blocked vent.

Drain back holes blocked.

The alignment of the oil pump to case gasket is incorrect.

CASE POROSITY REPAIR

1. Clean the area with epoxy manufacturer's recommended solvent and air dry.

CAUTION:

Epoxy adhesives may cause skin irritations and eye damage. Read and follow all information on the

product label, as provided by the manufacturer.

2. Mix sufficient amount of epoxy adhesive ('Araldite' or an equivalent product), following the manufacturer's

recommendations.

3. While the transmission case is hot, apply epoxy adhesive with a clean, dry stiff brush.

4. Allow the adhesive to dry for the recommended time before starting the engine and checking the results of the

repair.

5. Repeat the fluid leak diagnosis procedure previously detailed.

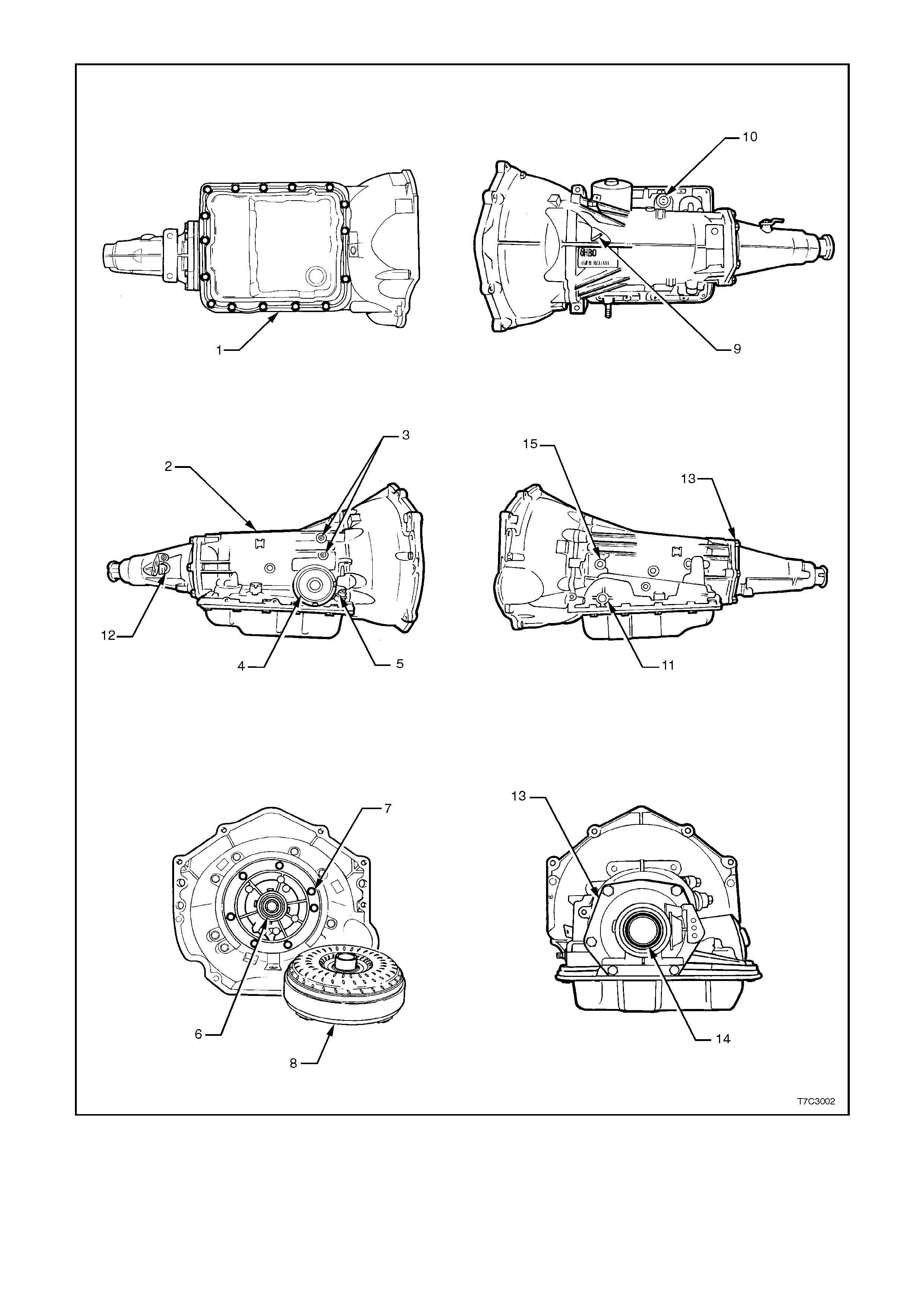

1. Oil Pan Gasket

2. Transmission Main Case

3. Cooler Connections

4. 2-4 Servo Cover Seal

5. Oil Filler Tube Seal

6. Oil Pump Seal Assembly

7. Oil Pump to Case Seal

8. Torque Converter

9. Transmission Vent

10. Pass-through Connector O-ring

11. Manual Shaft Oil Seal

12. Vehicle Speed Sensor O-ring

13. Extension Housing to Case

Seal

14. Extension Housing Oil Seal

Assembly

15. Line Pressure Plug

Figure 7C4-1

2.3 FLEXPLATE AND/OR TORQUE CONVERTER VIBRATION TEST

Should an imbalance condition with either of these

two components be suspected, then the following

procedures should be followed.

EVALUATION

1. Start the engine and run until normal oper ating

temperature is reached.

2. With the engine at idle speed and the

transmission in "PARK" or "NEUTRAL",

observe the vibration condition.

2. Stop the engine.

RECTIFICATION

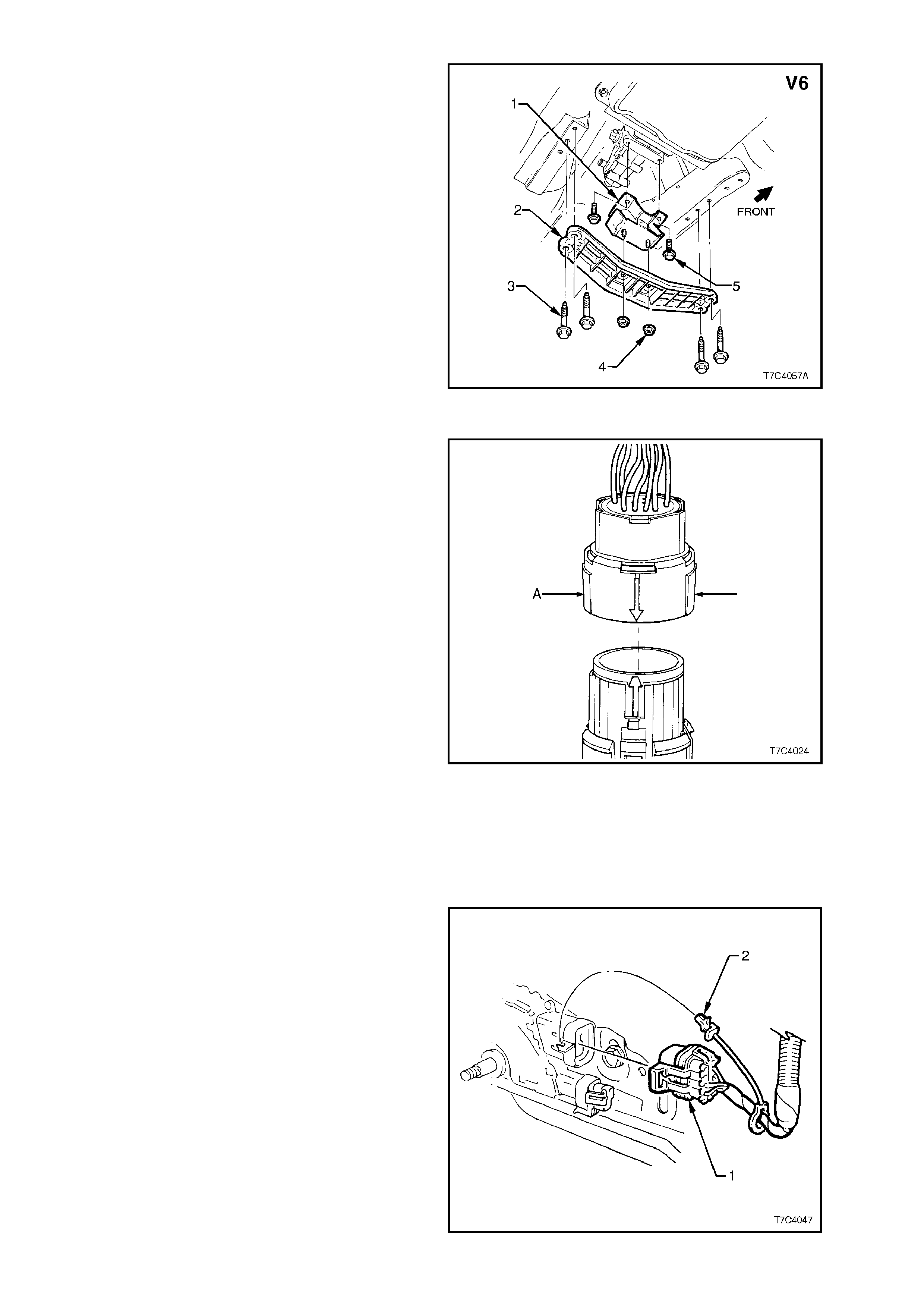

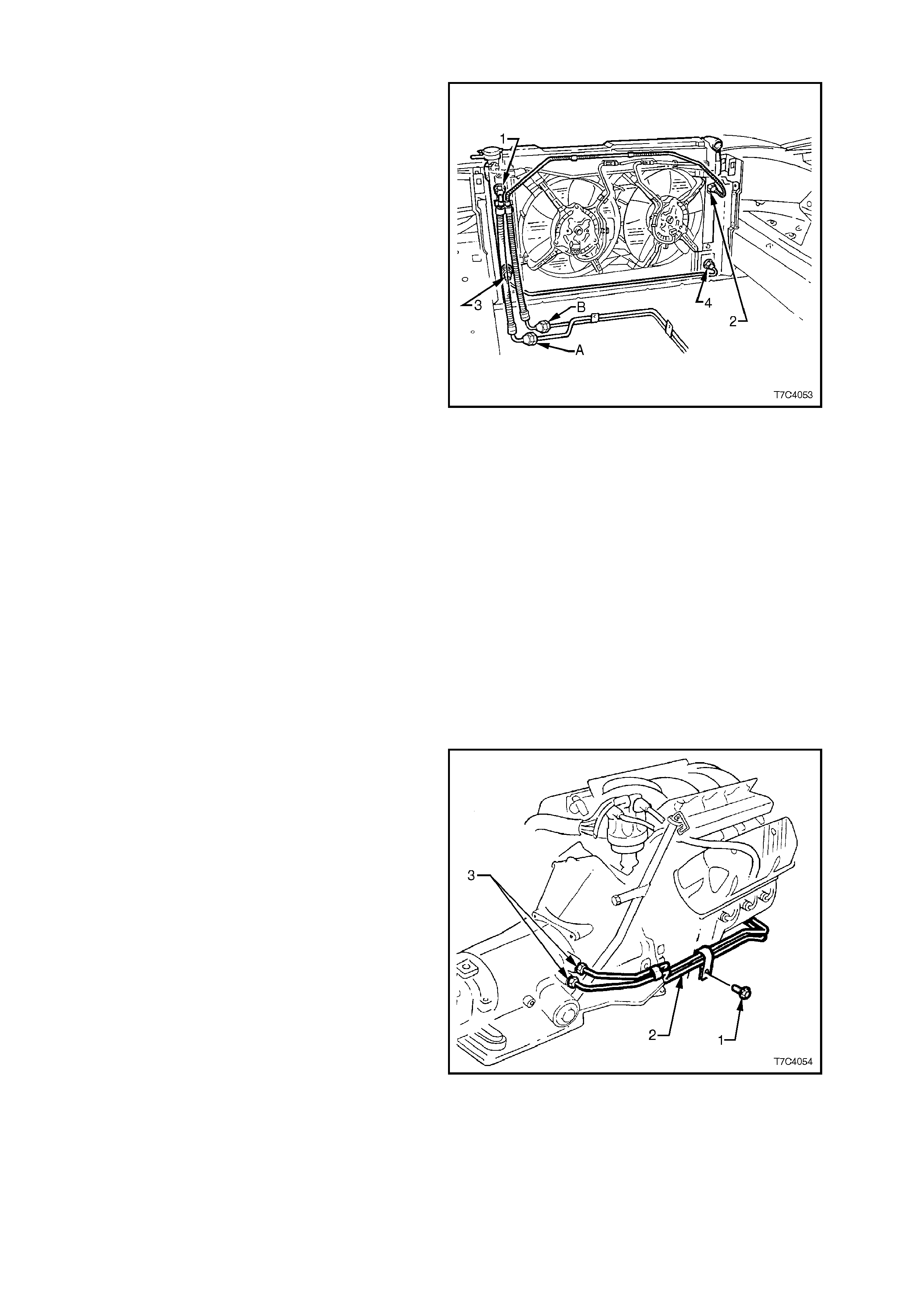

1. Remove the converter cover as follows:

a. Remove the starter motor. Refer to

Section 6D1-2 STARTING SYSTEM V6

ENGINE or to Section 6D2- 2 STARTING

SYSTEM V8 ENGINE, for the necessary

procedure.

b. W hen a V6 engine is fitted to the vehicle,

the beaming braces (4) will need to be

removed, to allow cover removal.

Remove the lower retaining bolts (3),

before the brace to oil pan bolts (1).

Finally remove the two cover retaining

screws (2), and remove the cover from

the front of the transmission.

2. Remove the thr ee torque c onver ter to f lex plate

attaching bolts.

3. Rotate the torque converter through 1/3 turn and

install the attaching bolts, after having cleaned

the threads an applying a thread sealant such

as Loctite 242 or equivalent to Holden’s

Specification HN1256, Class 2, Type 2. Tighten

bolts to the correct torque specification.

TORQUE CONVERTER TO

FLEX PLATE BOLT 60 - 70 Nm

TORQUE SPECIFICATION

Figure 7C4-2

4. Reinstall the torque converter housing cover

and beaming braces (V6 engine), tightening

bolts to the correct torque specification.

NOTE:

When installing the beaming braces (V6 engine),

first tighten the brace to oil pan bolts ( 1) f inger tight,

to ensure correct alignment, torque the

transmission to brace bolts (3), then the oil pan

bolts.

LOWER COVER ATTACHING All Engi nes:

SCREW TORQUE SPECIFICATION 3 - 5 Nm

BEAMING BRACE TO OIL PAN V6 Engine:

BOLT TORQUE SPECIFICATION 20 - 35 Nm

BEAMING BRACE TO TORQUE

CONVERTER HOUSING BOLT V6 Engine:

TORQUE SPECIFICATION 50 - 85 Nm

5. Install the starter motor, by following the

procedure detailed in Section 6D1-2

STARTING SYSTEM - V6 ENGINE or

Section 6D2-2 STARTING SYSTEM - V8

ENGINE.

STARTER MOTOR ATTACHING All Engines :

TORQUE SPECIFICATION 40 - 60 Nm

STARTER MOTOR BRACE BOLT 12 - 16

(V8) TORQUE SPECIFICATION Nm

6. Start the engine and check for vibration.

Repeat the above procedure until the best

possible balance is obtained.

Figure 7C4-2

2.4 TRANSMISSION COOLER REVERSE FLUSH AND FLOW RATE CHECK

IMPORTANT:

It is essential that a reverse flush and oil cooler

flow rate check is performed, after ANY of the

following situations:

•Transmission replacement.

•If fluid contamination is suspected.

•Whenever the oil pump and/or torque

converter is replaced.

NOTE:

The reverse flush must be completed prior to

conducting a flow rate check.

REVERSE FLUSH

The recommended procedure for reverse flushing

the transmission cooler and lines, particularly after

an overhauled or replaced transmission has been

installed into the vehicle, is as follows:

1. Disconnect both cooler lines at the

transm ission and at the radiator cooler. Use a

back-up spanner to hold unions, to prevent

damage to the lines.

2. Carefully check the cooler inlet fitting (lower

right hand side) to see whether any material is

evident at this point. If so, dislodge and

remove with a suitable tool and/or

compressed air blown in the reverse direction

through the cooler.

3. Using a com mer c ially available pressure s pr ay

gun and clean solvent, such as white spirit:

a. Back flush through both cooler lines.

b. Back flush through the coolers, including

the external cooler (if fitted).

c. Blow compressed air through return and

inlet pipes to remove solvent.

d. Flush pipes with transmission fluid.

4. Reconnect cooler lines to the transmission

and cooler but leave the cooler return line to

transmission connection open.

5. Conduct a flow rate test as described below,

to ensure that any restriction has been

cleared.

6. If f low rate is satisf actory, reconnect the return

line to the transmission, tightening all fittings

to the specified torque.

OIL COOLER LINES

AND FITTINGS 15 - 18 Nm

TORQUE SPECIFICATION

7. Lower vehicle and check f luid level as detailed

in 2.1 FLUID LEVEL CHECK, in this Section.

FLOW RATE CHECK

CAUTION:

Do not run engine any longer than absolutely

necessary, as too low a fluid level can cause

aeration and foaming.

1. When installing the transmission assembly,

leave the cooler return line disconnected from

the transmission (lower fitting).

2. Ensure that the fluid level is to the

recommended level, as detailed in

2.1 FLUID LEVEL CHECK, in this Section.

3. Place a container underneath the

disconnected cooler line.

4. W ith the selector lever in the Neutral position,

start the engine and observe the f luid flow into

the container, after all air bubbles have

ceased and a steady flow is evident. Measure

the flow rate.

RESULT:

The fluid flow rate should be approxim ately 1.2 litre

in a 20 second period.

If the flow rate is less than this specification, the

source of the restriction must be located and

rectif ied. Poss ibilities are either r adiator tank cooler

and/or external cooler (if fitted).

5. Reinstall the cooler return line and tighten all

fittings to the specified torque.

OIL COOLER LINES AND FITTINGS 15 - 18

TORQUE SPECIFICATION Nm

3. ON-VEHICLE SERVICE OPERATIONS

3.1 FLUID CHANGE AND FILTER REPLACEMENT

NOTE:

To avoid personal injury from accidental hot oil

spillage, perform fluid change only when

transmission fluid is cold.

1. Raise vehicle and support on safety stands.

Refer to Section 0A, GENERAL

INFORMATION for location of the

recommended jacking points.

2. Clean all dirt from around oil pan and

transmission case.

3. Place drain tray under transmission.

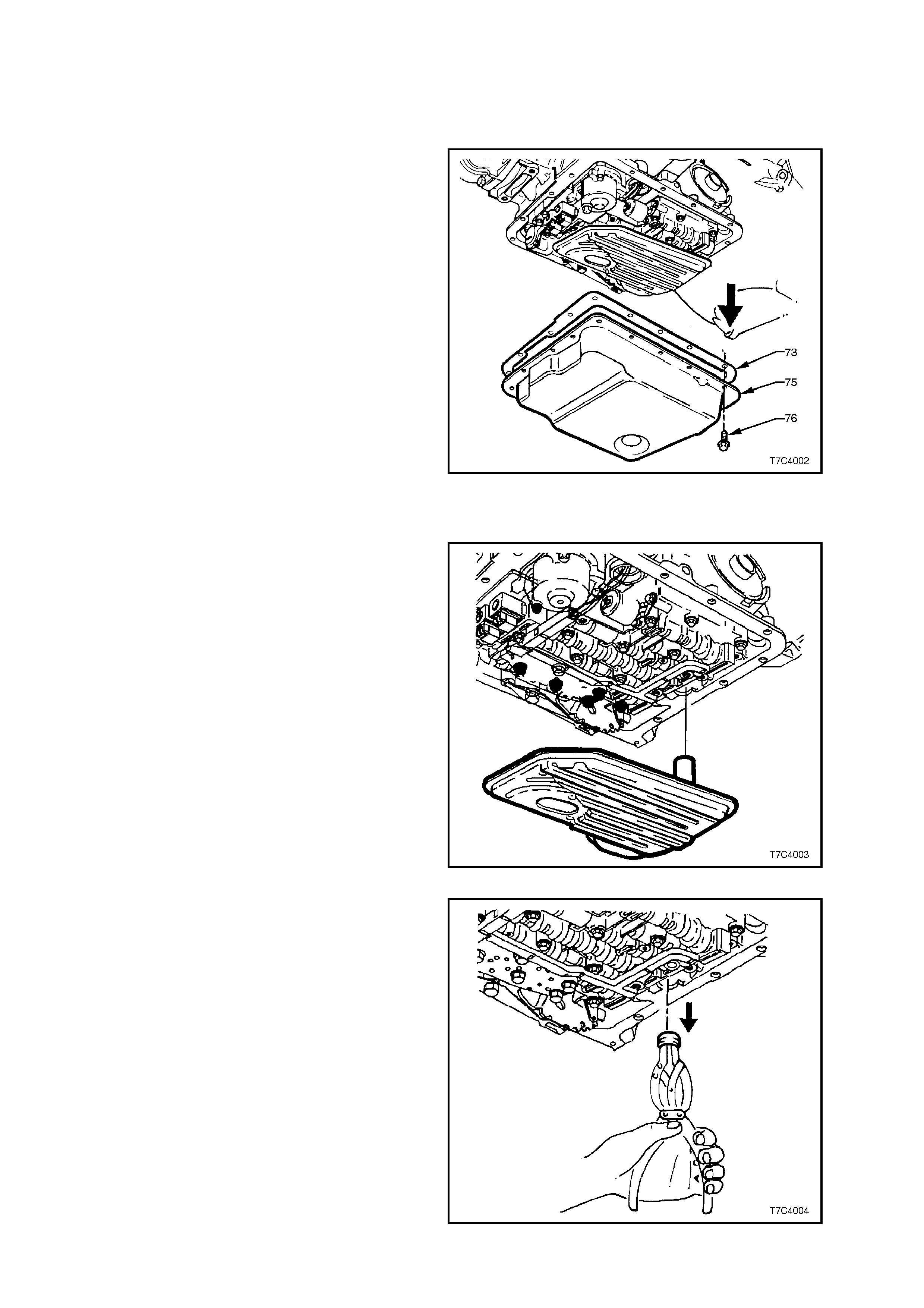

4. Hold oil pan in place and, remove the oil pan

bolts from the front and both sides.

5. Loosen the rear oil pan bolts by about 4 turns

each and, while still supporting the oil pan,

lightly tap the sides with a rubber hammer to

break the gasket seal.

6. Lower the front of the oil pan and drain the

fluid into a suitable c ontainer, then r emove the

oil pan from the transmission.

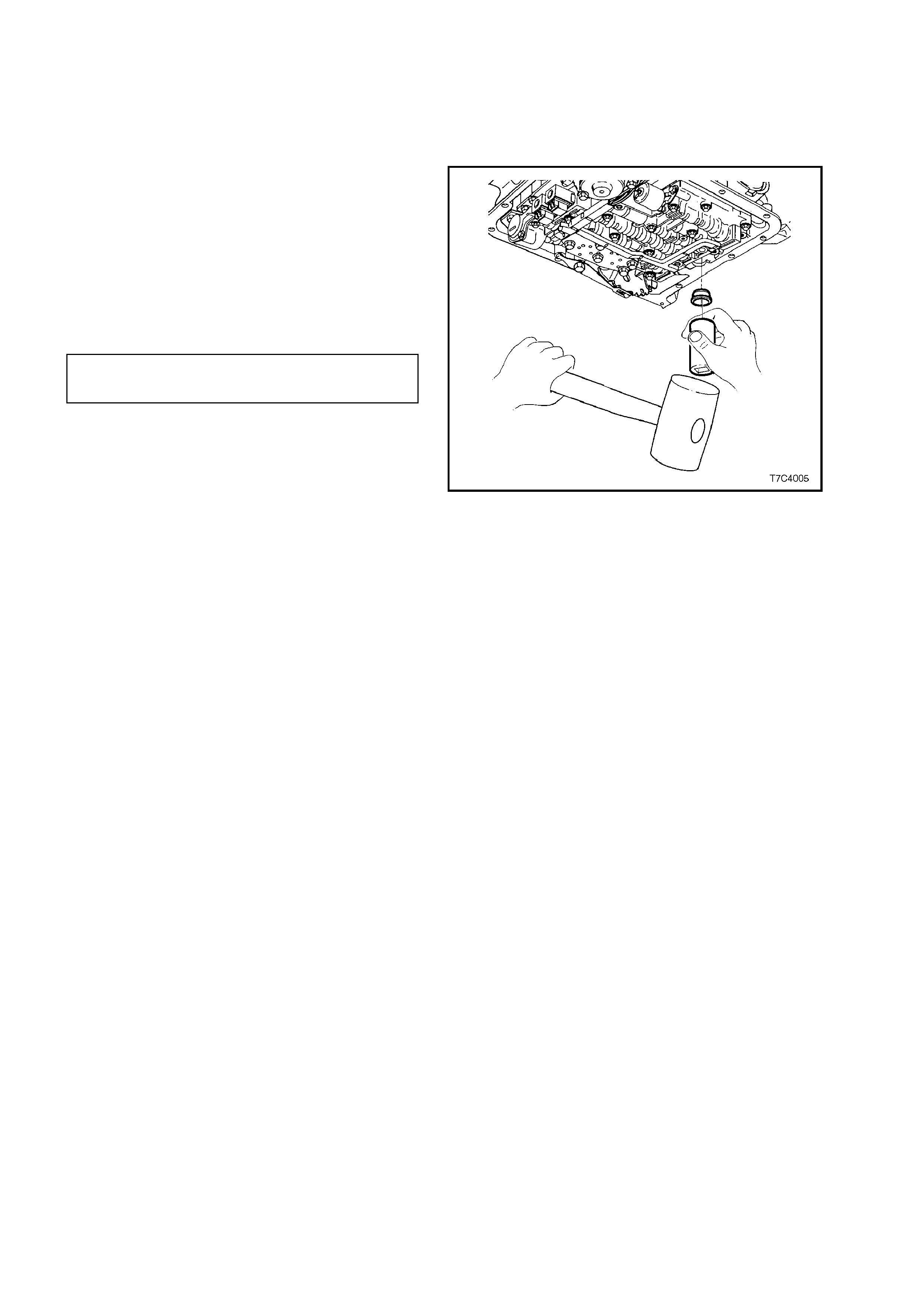

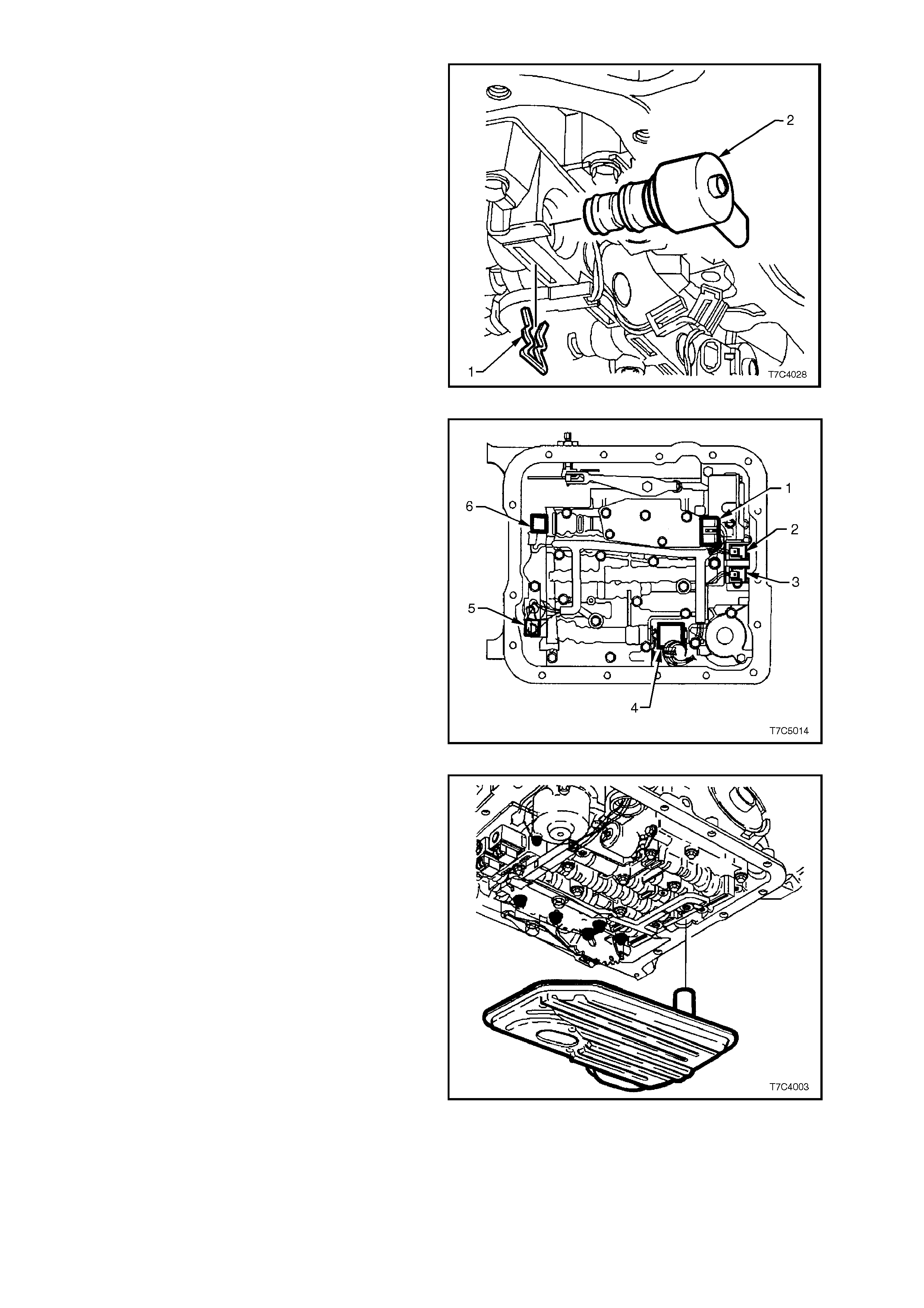

Figure 7C4-3

7. Pull down and twist the filter to rem ove it from

the transmission case.

8. Open the filter by prying the metal crimping

away from the top of the filter and pull apart.

Inspect the f ilter mater ial for particles that may

indicate evidence of a potential transmission

problem. Examples of the type of material to

look for, are;

- Clutch friction material.

- Bronze slivers, indicating bush wear.

- Steel particles.

Figure 7C4-4

9. Using suitable circlip pliers or a two legged

puller ane slide hammer, such as Litchfield

E6668 or other commercial equivalent,

rem ove the f ilter seal. Tak e c ar e not to sc r atch

the oil pump bore during the process.

NOTE:

If scratched, fluid leakage could occur from this

point, once the vehicle has been put back into

service.

Figure 7C4-5

10. Remove old oil pan gasket and discard.

11. Clean the transmission case, oil pan and oil

pan gasket surface, drying with compressed

air. Ensure that all tr aces of the old gask et are

removed.

12. Lubricate a new filter seal with petroleum jelly

(Vaseline or equivalent) and install into the oil

pump bore, using a suitable sized socket or

piece of tubing.

13. Install a new filter into the transmission case.

14. Check that magnet is functional and located in

the designated position in the oil pan. Install

new gasket and reinstall oil pan. Tighten bolts

to specified torque.

OIL PAN BOLT 9.5 - 13.8

TORQUE SPECIFICATION Nm

15. Lower vehicle and add approxim ately 4.8 litres

(V6 engine) or 5.0 litres (V8 engine) of

DexronÒ III automatic transmission fluid.

16. Operate the vehicle for about 24 km or until

normal operating temperatures are reached.

Check that there are no fluid leaks from the oil

pan area.

17. Check transmission fluid level, refer

2.1 FLUID LEVEL CHECK in this Section.

Figure 7C4-6

3.2 SELECTOR LINKAGE

REMOVE

1. Set transmission selector lever to 'PARK'

position.

2. Raise front of vehicle and place on safety

stands Refer to Section 0A GENERAL

INFORMATION for location of the

recommended jacking points.

3. Remove locking bolt (1), dished washer (2),

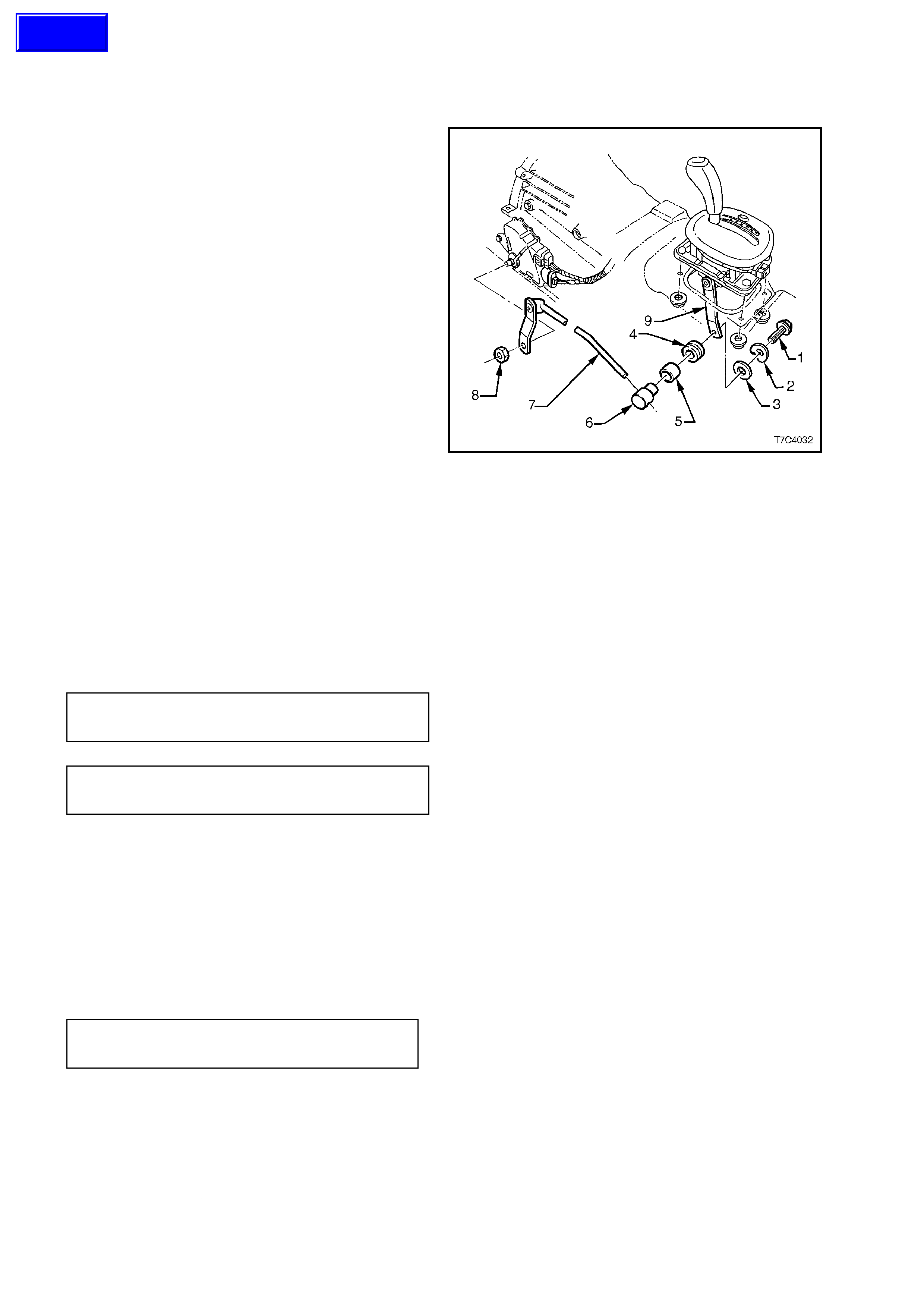

flat washer (3), insulator (4) and sleeve (5)

from lower end of selector lever (9).

4. Slide trunnion (6) from selector rod (7).

5. While holding the transmission selector lever

with an adjustable wrench, remove retaining

nut (8), rod and lever assembly (7) from

transmission manual shaft.

Figure 7C4-7

INSPECT

Check all items for wear and/or damage, replace

all worn or damaged items.

REINSTALL

Installation is the reverse of the r emoval proc edur e.

Tighten the selector lever retaining nut to the

specified torque. Adjust linkage as described

below.

MANUAL SHAFT LEVER NUT 15 - 35

TORQUE SPECIFICATION Nm

SELECTOR LEVER LOCKING 15 - 35

BOLT TORQUE SPECIFICATION Nm

ADJUST

Refer to Figure 7C4-7.

1. Loosen locking bolt at selector lever.

2. Position transmission selector lever in the

'PARK' position.

3. Position gearshift lever in the 'PARK' position,

then tighten the locking bolt at the selector

lever, to the specified torque.

SELECTOR LEVER LOCKING 15 - 35

BOLT TORQUE SPECIFICATION Nm

4. Lower vehicle and test that the vehicle

operates correctly.

5. Ensure that engine can be started only in

'PARK' and 'NEUTRAL'. If required, adjust

the Neutral Start and Back-up Lamp switch

as detailed in 3.4 NEUTRAL START AND

BACK-UP LAMP SWITCH, in this Section.

Techline

3.3 SELECTOR CONTROL LEVER ASSEMBLY

REMOVE

1. Raise vehicle and place on safety stands.

Refer to Section 0A GENERAL

INFORMATION for the location of

recommended jacking points.

2. Remove centre console insert (refer Section

1A3 INSTRUMENT PANEL AND CONSOLE).

3. Disconnect the wiring harness connector (1)

from the control lever assembly patch

harness.

4. From beneath vehicle, disconnect rod from

selector lever by removing bolt securing

trunnion to lever (refer to 3.2 SELECTOR

LINKAGE in this Section).

5. Remove the four nuts securing the control

lever assembly to the floor pan.

6. From inside the vehicle, lift the control lever

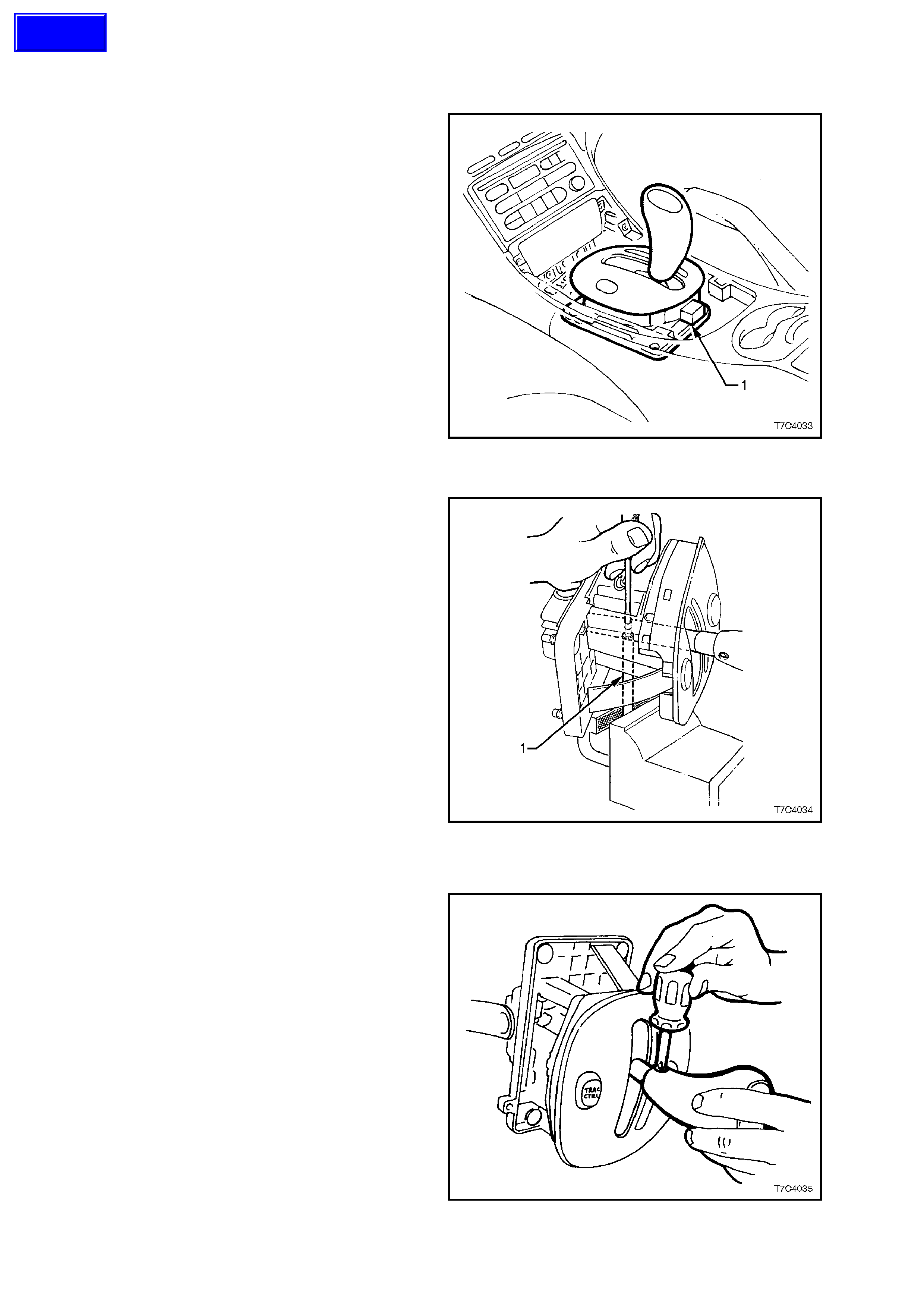

assembly from the floor pan. Figure 7C4-8

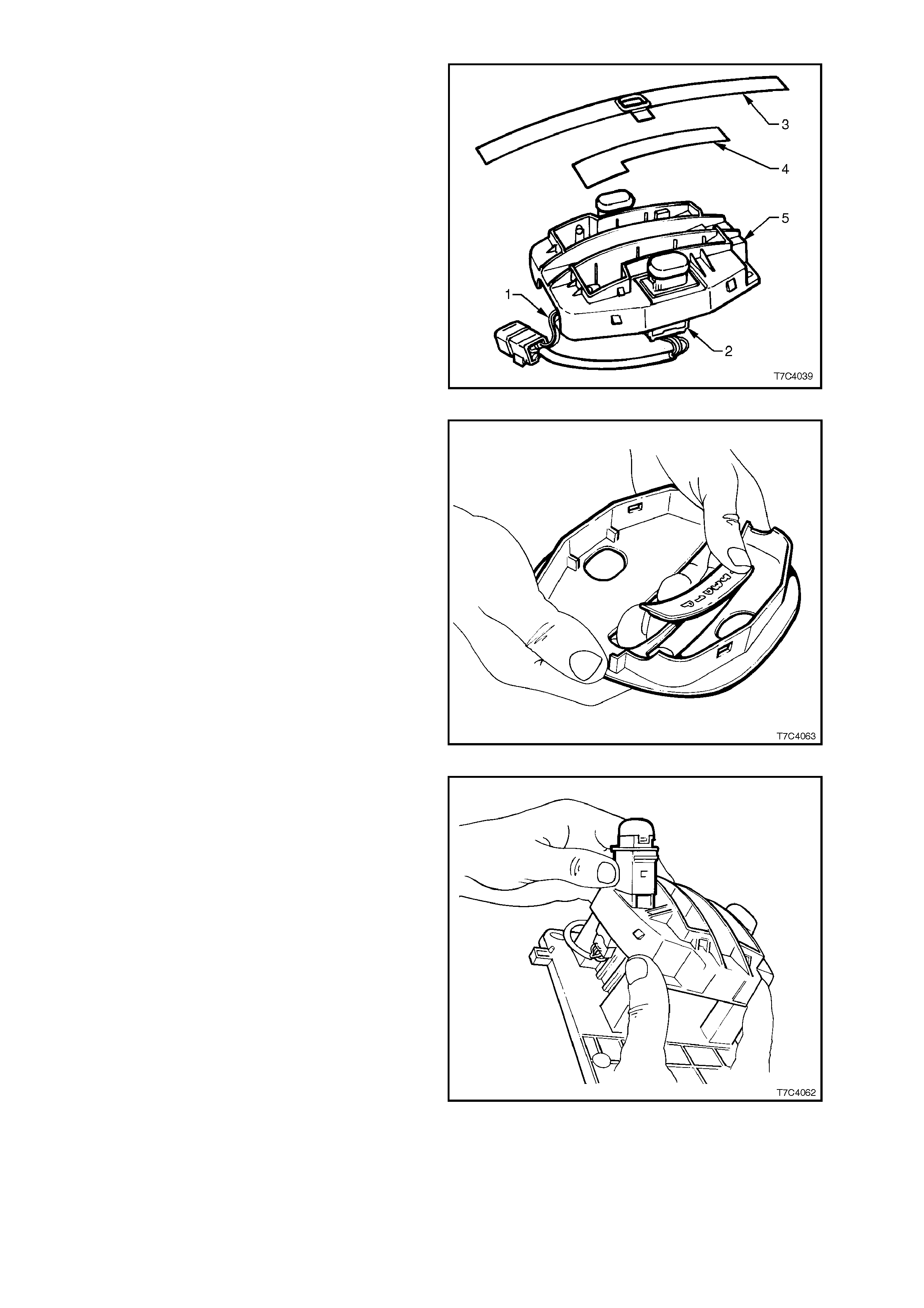

DISASSEMBLE

NOTE: During manufacture, the lower housing is

attached to the base with a solvent adhesive, as an

aid to production installation. For service

replacement, while the lower housing is only

serviced as a complete assembly, the upper

housing is available separately. On installation, the

four retaining clips on a replacem ent upper housing

provide sufficient retention, without the need for

solvent to be used.

If required, the upper components and switches

can be serviced without needing to separate the

two fused components.

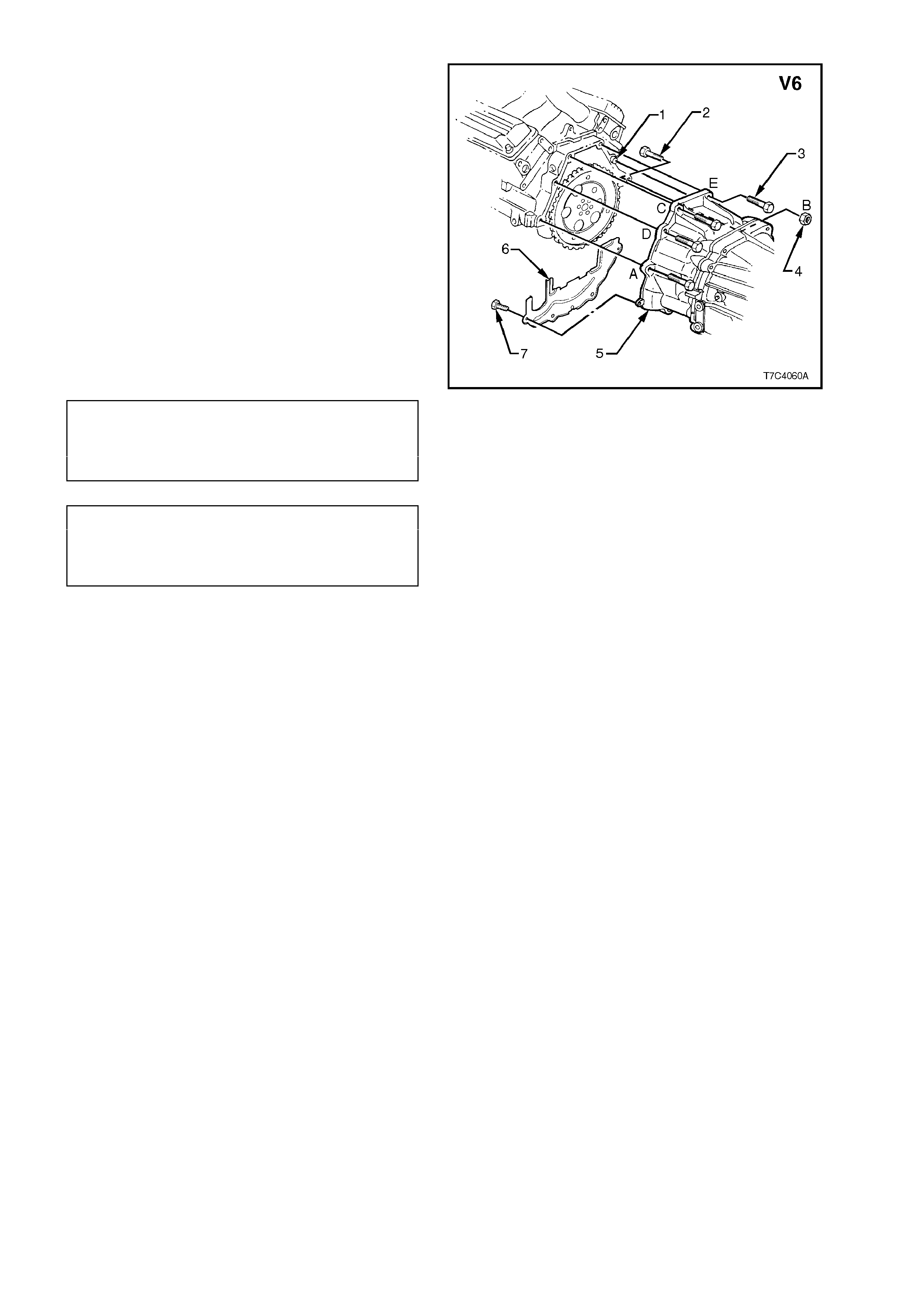

1. Clamp a 100 mm length of suitable diameter

tubing (1), vertically in a bench vice, as shown.

2. Locate the protruding end of the selector lever

roll pin, over the tubing, then remove the pin,

using a suitable sized pin punch and hammer.

3. Remove the button slider and spring from the

selector handle. Take care not to lose the

lower slider guide and spring from the shift

lever.

Figure 7C4-9

4. Remove the selector handle securing screw.

Figure 7C4-10

Techline

5. With the lower selector lever clamped in a

vice, hold the selector knob as shown and

remove by rocking back and forth while firmly

pulling on the handle.

Figure 7C4-11

6. Carefully prise the upper housing from the

lower, freeing the four locating tangs.

NOTE:

The selector lever and base cannot be further

dismantled, without breaking the base and/or base

side plate. These parts are only serviced as a sub-

assembly.

Figure 7C4-12

7. Remove the selector indicator globe and

holder from the lower housing and the patch

harness connector/s from the switch/es.

Release the harness connector f rom the lower

housing and remove the patch harness from

the selector lever mechanism.

Figure 7C4-13

8. Remove the selector slide indicator (3) and

globe diffuser (4) from the lower housing (5).

Figure 7C4-14

9. If required, the selector indicator lens can be

removed from the upper housing by pressing

from the outside, inwards.

Figure 7C5-15

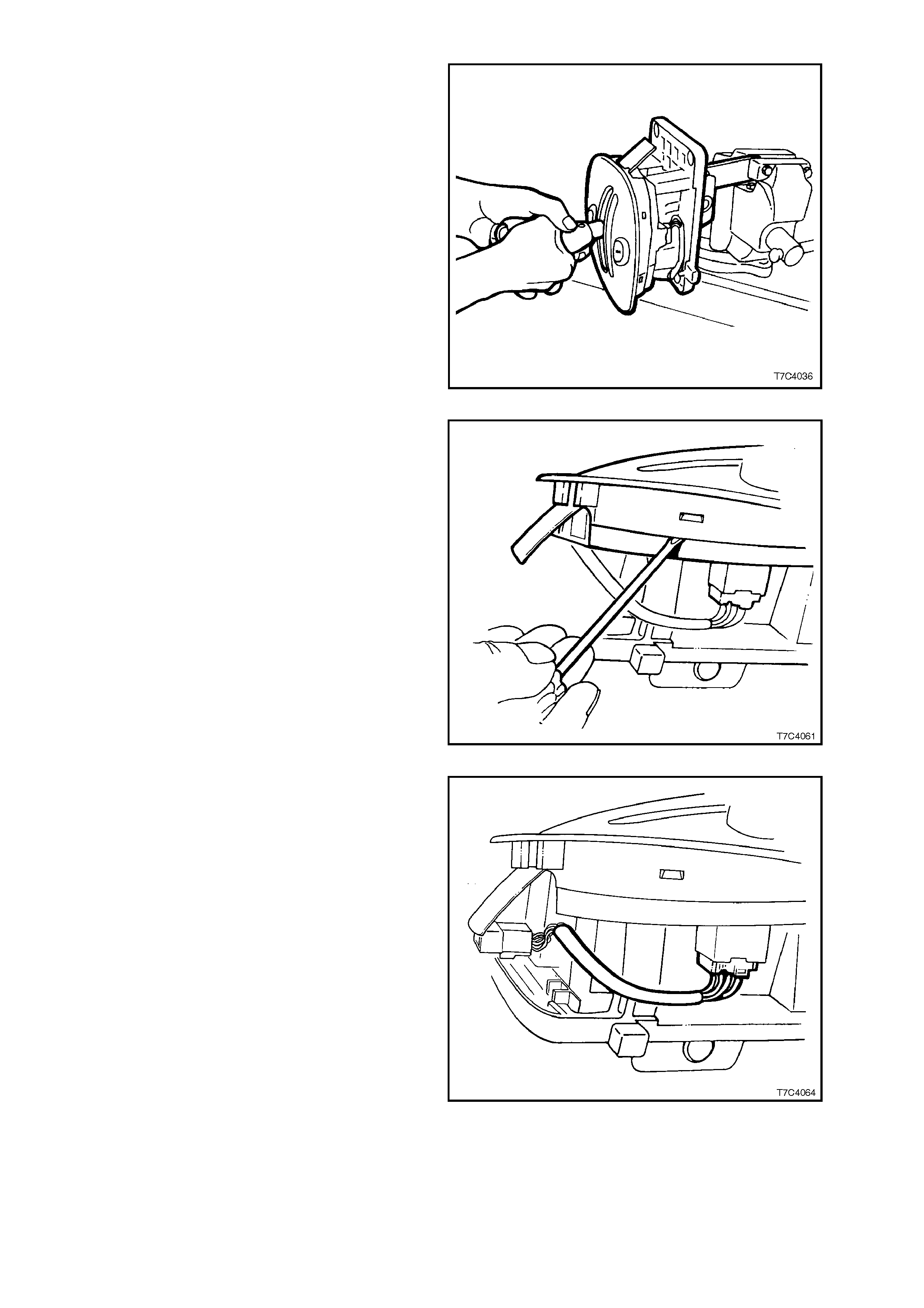

11. To remove the ‘POWER’ switch or

‘TRACTION’ switch (if fitted), use a small

bladed screwdriver and lever one of the

locating tangs under the lower housing to free

the switch. Remove from above, as shown.

Figure 7C4-16

REASSEMBLE

Reassembly is the opposite of the disassembly

process, noting the following points:

1. Testing of either switch can be undertaken by

reference to Section 12L, ABS & ABS/ETC,

as both switches are the same.

2. When installing the r oll pin to the button s lider,

it will be helpful to use a guide pin to assist

with hole alignment.

IMPORTANT:

Careful alignment of the selector handle and the

button slider is required, if irrepairable damage to

the button slider is to be avoided.

3. Install the pin sufficient to engage each of the

moulded selector detents in the base (arrow).

Figure 7C4-17

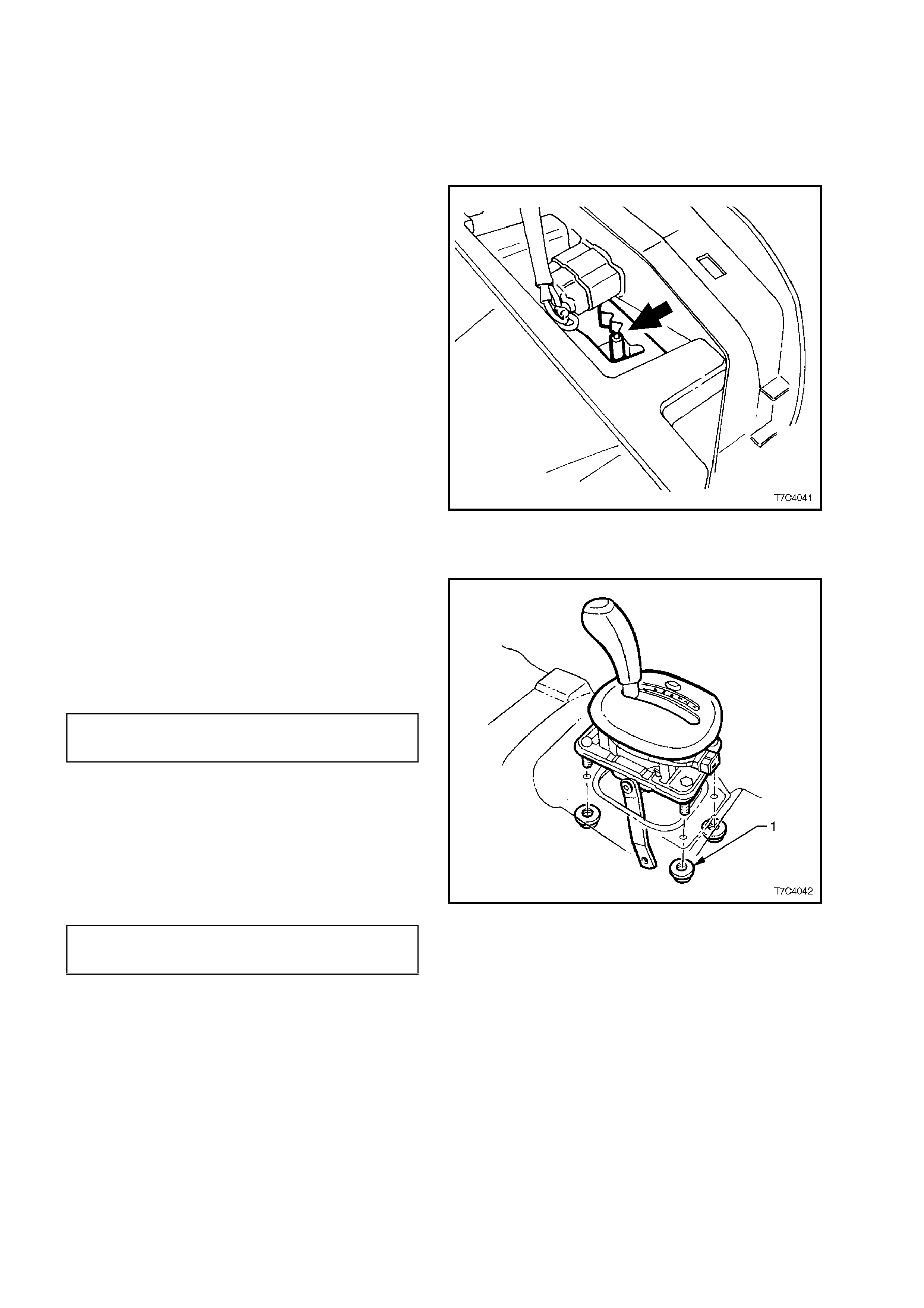

REINSTALL

1. Clean mating surf aces of f loor pan and inspec t

the base seal for damage, replacing if

necessary.

2. Reinstall selector lever assembly to the floor

pan, install the four retaining nuts (1) and

tighten to the correct torque specification.

SELECTOR BASE RETAINING 12 - 18

NUT TORQUE SPECIFICATION Nm

3. The rem ainder of the installation is the r everse

of the removal procedure.

4. Adjust shift linkage as detailed in

3.2 SELECTOR LINKAGE in this Section,

tightening the selector rod locking bolt to the

correct torque specification.

SELECTOR LEVER LOCKING 15 - 35

BOLT TORQUE SPECIFICATION Nm

Figure 7C4-18

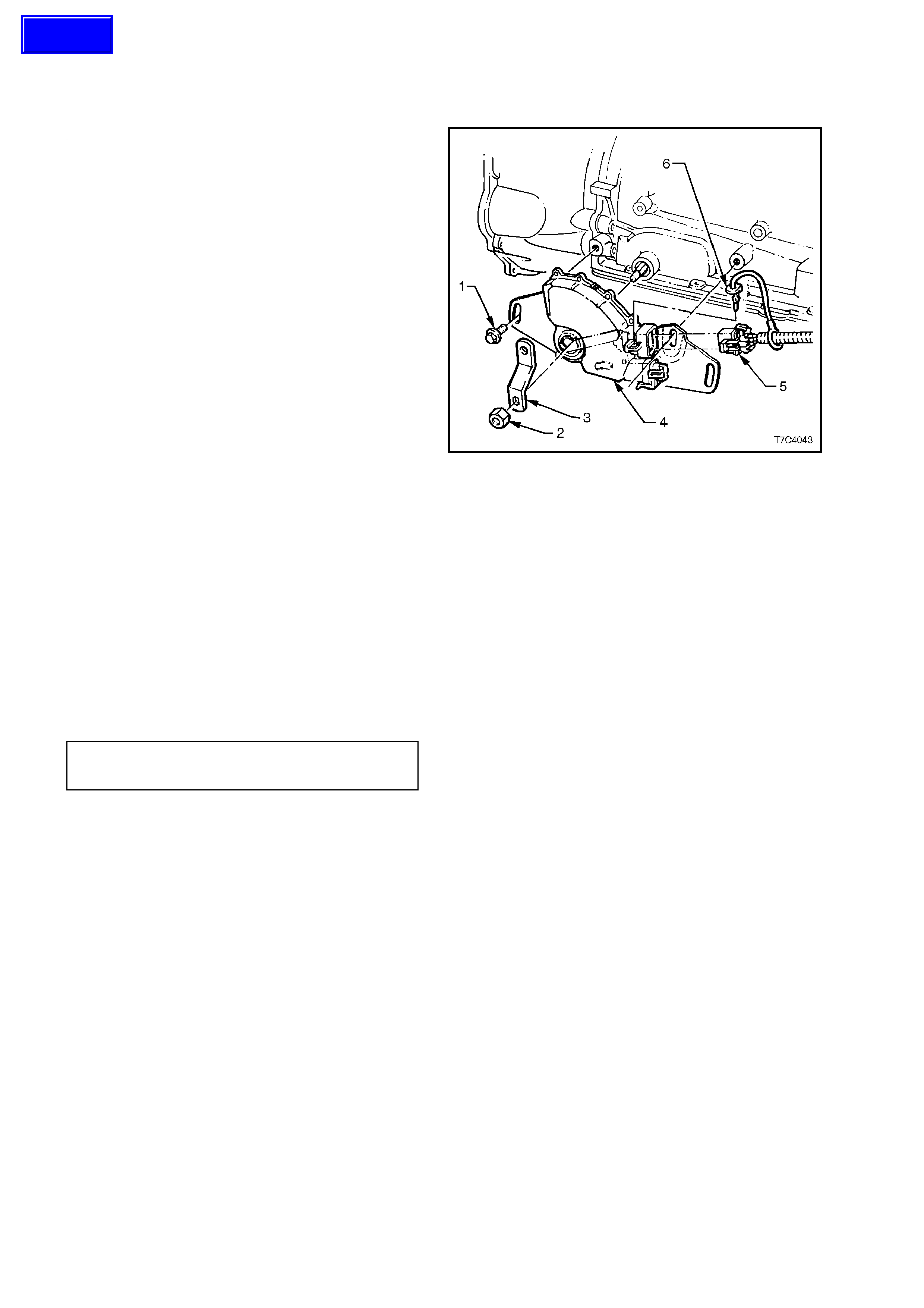

3.4 NEUTRAL START AND BACK-UP LAMP SWITCH

REMOVE

1. Raise the front of the vehicle and place on

safety stands. Refer to Section 0A,

GENERAL INFORMATION for the location of

recommended jacking points.

2. W hile holding the lower selector lever (3) with

an adjustable wrench, remove the retaining

nut (2).

3. Carefully remove the lever from the

transmission manual shaft.

4. Prise the wiring harness connector CPA

(Connector Position Assurance) securing pin

(6) from the neutral start and back-up lamp

switch (4), taking care not to break the pin.

Disconnect the wiring harness connector (5)

from the switch assembly (4).

5. Remove the two switch retaining screws (1),

then slide the switch assembly (4) over the

manual shaft and remove from the vehicle. Figure 7C4-19

REINSTALL

Installation of the neutral start and back-up lamp

switch is the reverse of the removal procedure

except for the following:

1. When installing the two switch securing

screws, leave them finger tight, until the

adjustment process has been completed.

2. After installing the selector lever and retaining

nut, hold the lever with an adjustable wrench

and tighten the nut to the correct torque

specification.

SELECTOR LEVER RETAINING 15 - 35

NUT TORQUE SPECIFICATION Nm

3. Following the neutral start and back-up lamp

switch adjustment procedure, check that the

engine can only be started when the gearshift

lever is either in the ‘P’ (Park) or ‘N’ (Neutral)

positions.

ADJUST

1. Select Reverse range, using the gear selector

control lever.

2. With the vehicle raised and the ignition

switched to the ON position, rotate the neutral

start and back-up lamp switch back and forth

until the best ‘neutral’ position is attained,

where the vehicle’s back-up lamps are

illuminated.

3. Tighten the switch retaining bolts but not fully

at this stage.

4. Select P (Park ), R (Rever se) then N (Neutral),

checking that the back-up lamps are only

illuminated when R (Reverse) is selected.

Techline

5. Tighten the two switch assembly securing

screws to the correct torque specification.

NEUTRAL START & BACK-UP

LAMP SWITCH RETAINING 15 - 35 Nm

TORQUE SPECIFICATION

6. Lower the vehicle to the ground and check the

operation of the neutral start and back-up

lamp switch. The vehicle should only start in

either ‘P’ (Park) or ‘N’ (Neutral) ranges and the

reverse lam ps s hould only illum inate when the

‘R’ (Reverse) range is selected.

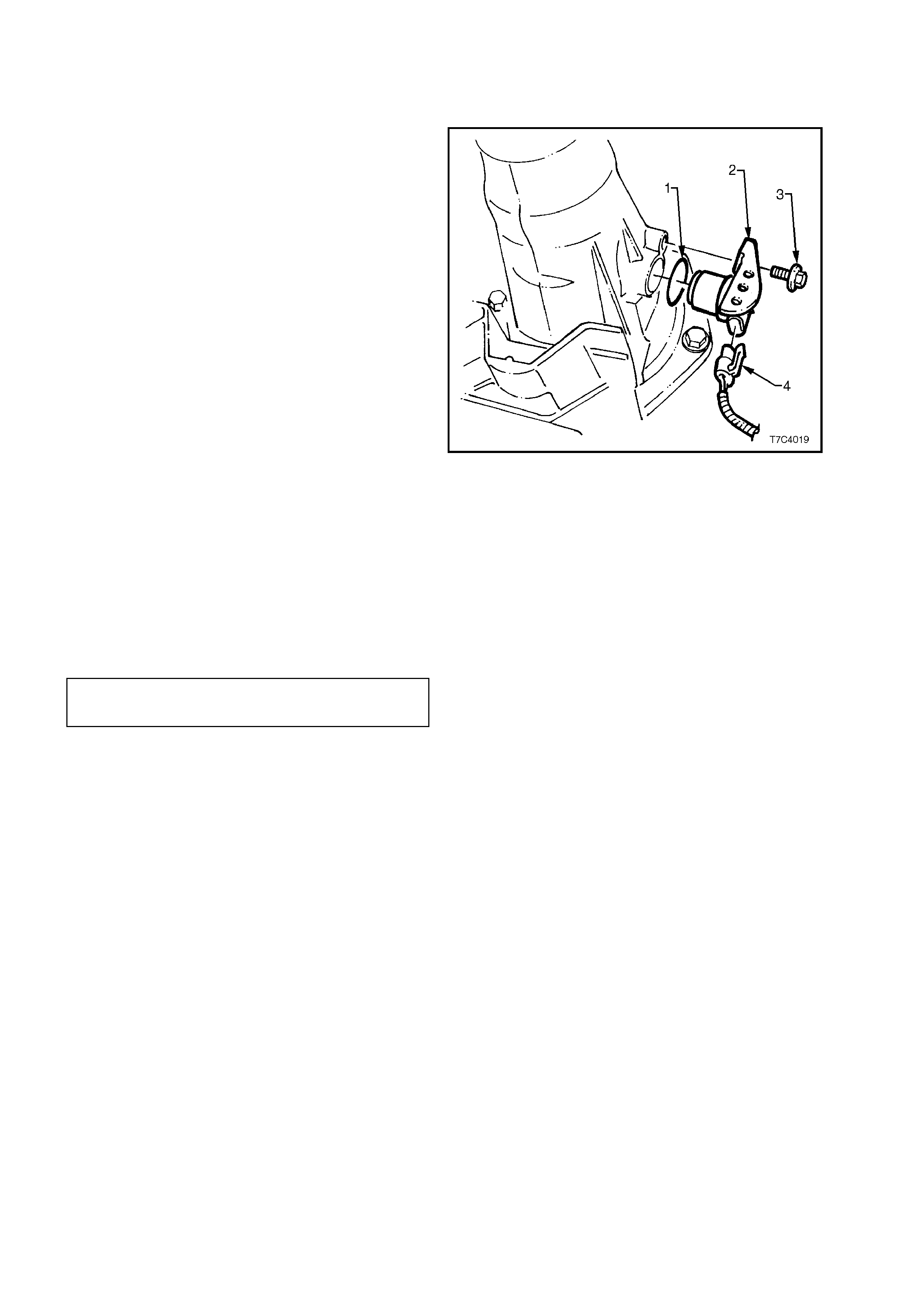

3.5 VEHICLE SPEED SENSOR

REMOVE

1. Raise rear of vehicle and place on safety

stands. Refer Section 0A GENERAL

INFORMATION for location of the

recommended jacking points.

2. Place drip tray beneath speed sensor.

3. Disconnect electrical connector (4) from the

vehicle speed sensor (2).

4. Unscrew vehicle speed sens or retaining scr ew

(3).

5. With a pulling/turning motion, remove vehicle

speed sensor as sembly (2) and O-r ing seal ( 1)

from the transmission extension housing.

Figure 7C4-20

REINSTALL

1. Lubricate a new O -ring s eal (1) with petroleum

jelly (Vaseline or equivalent) and install on the

vehicle speed sensor (2).

2. Install the speed sensor (2) into the

transmission extension housing.

3. Reinstall retaining s crew (3) and tighten to the

specified torque.

SPEED SENSOR RETAINING 10.5 - 13.5

SCREW TORQUE SPECIFICATION Nm

4. Reinstall the wiring harness connector (4) to

the speed sensor (2).

5. Lower vehicle and check fluid level. Refer

2.1 FLUID LEVEL CHECK in this Section.

3.6 CASE EXTENSION OIL SEAL

REPLACE

1. Raise rear of vehicle and place on safety

stands. Refer to Section 0A GENERAL

INFORMATION for location of the

recommended jacking points.

2. Place a drip tray beneath rear of transmission.

3. Remove propeller shaft assembly, refer to

Section 4C PROPELLER SHAFT AND

UNIVERSAL JOINTS.

4. Using a suitable tool such as E308 or

equivalent, remove the oil seal from rear of

case extension.

5. Thoroughly clean around seal bore in case

and ensure there are no burrs.

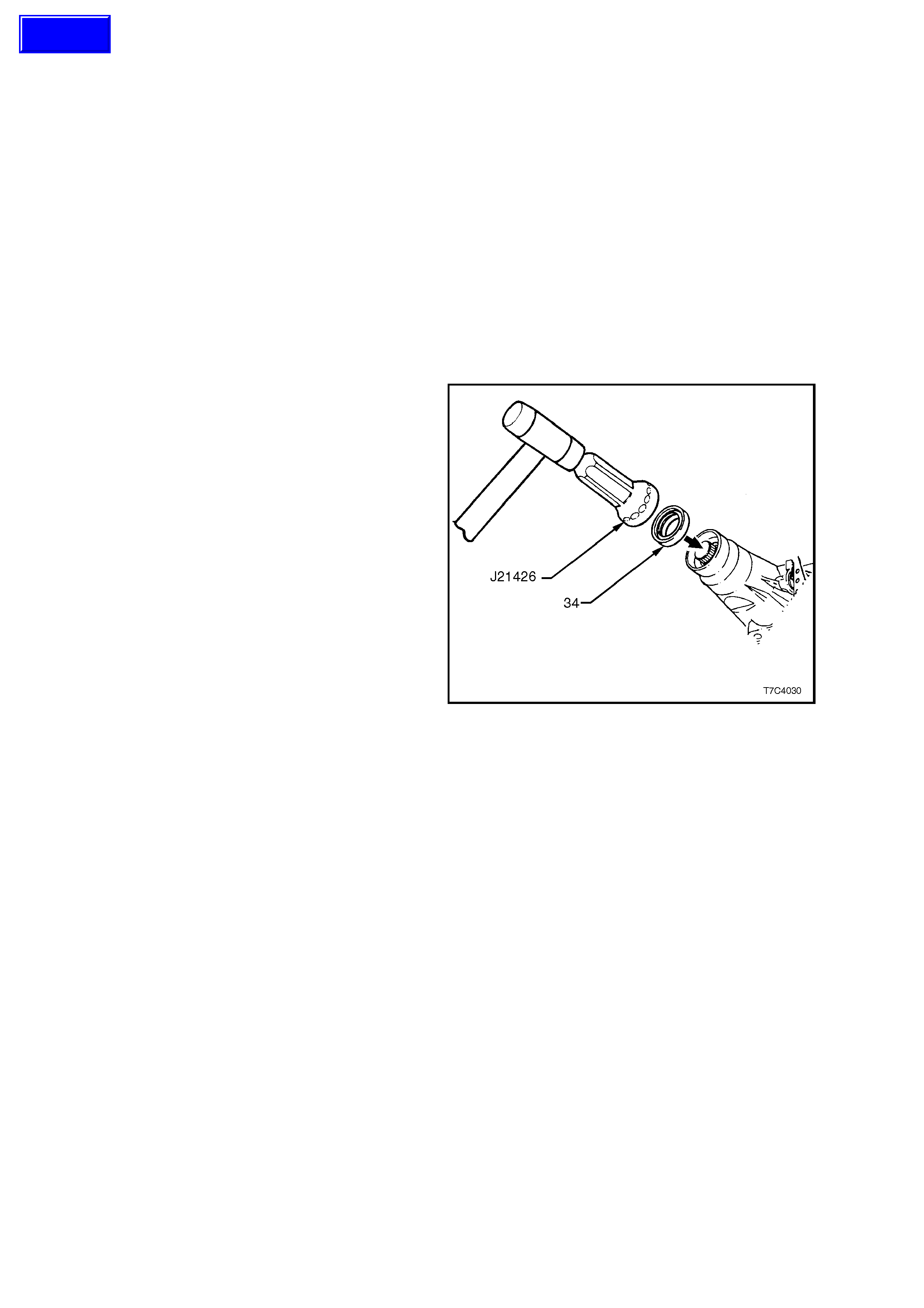

6. Tap new seal (34) into place with Tool No.

J21426.

7. Reinstall propeller shaft.

8. Check fluid level, refer to 2.1 FLUID LEVEL

CHECK in this Section.

Figure 7C4-21

Techline

3.7 EXTENSION HOUSING AND/OR BUSH

REPLACE

1. Raise vehicle and place on safety stands.

Refer to Section 0A GENERAL

INFORMATION for location of the

recommended jacking points.

2. With vehic les fitted with the naturally aspirated

V6 engine, remove the twin exhaust pipe and

catalytic converter assembly. For those

vehicles f itted with either the V6 s upercharged

or V8 engines, remove the exhaust system

from the rear of both catalytic converters

rearwards. Refer to Section 8B EXHAUST

SYSTEM.

3. Place drip tray beneath case extension.

4. Remove propeller shaft, refer to Section 4C

PROPELLER SHAFT AND UNIVERSAL

JOINTS.

5. Use a sharp s criber to m ark the ex act location

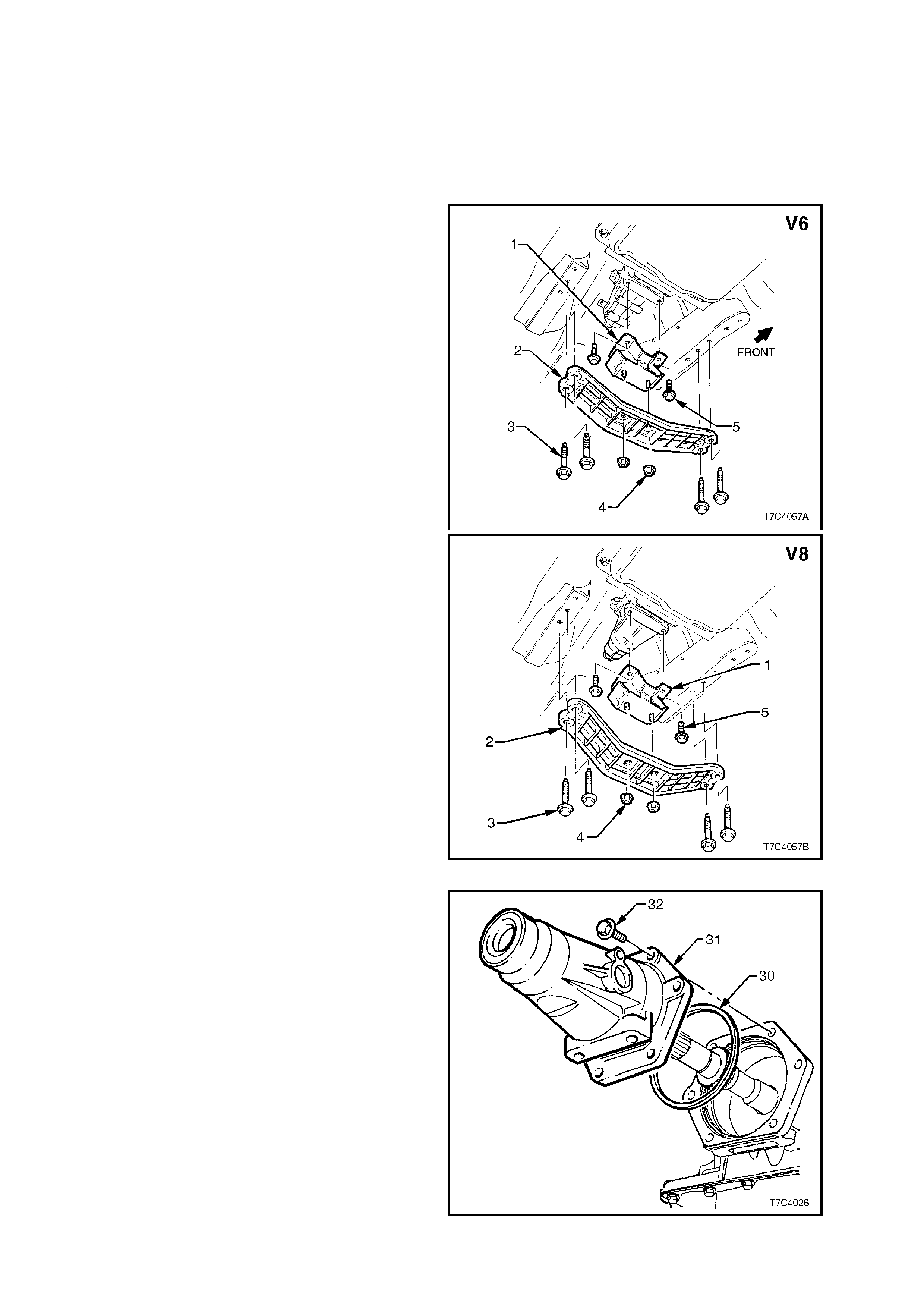

of the crossmember (2) to the side frame,

before loosening any of the four c rossm ember

to side frame attaching bolts (3).

IMPORTANT:

This step is critical to the correct powertrain

alignment on reassembly. If not carried out, then

vehicle vibration and/or handling problems could

result!

6. Remove two bolts (5) securing rear engine

mount to transmission.

7. Support transm iss ion with a jack . Do not place

the support beneath case extension or oil pan.

8. Remove the four crossmember to side frame

bolts (3) and remove crossmember (2) and

rear engine mount (1) from the vehicle.

Figure 7C4-22

9. Remove vehicle speed sensor assembly

wiring harness connector, then remove the

sensor from the extension housing. Refer to

3.5 VEHICLE SPEED SENSOR in this Sect ion

for details.

10. Remove six bolts securing case extension to

transmission case.

11. Remove case extension and seal assembly

from the rear of the transmission case.

Figure 7C4-23

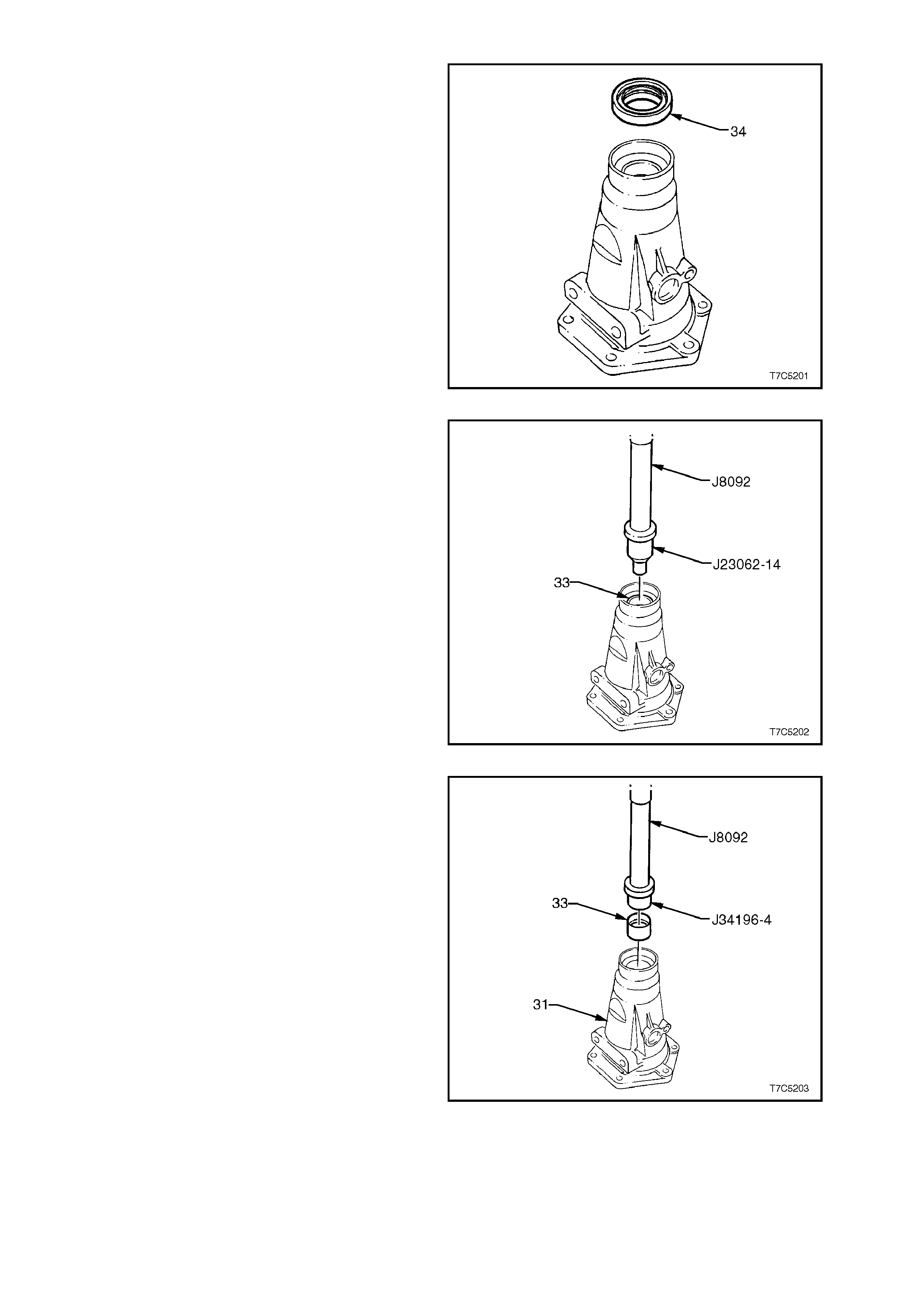

12. If bush is to be replaced, remove the case

extension oil seal, using a removing tool such

as Tool E308 or commercial equivalent.

Figure 7C4-24

13. Using bush remover, Tool J23062-14 and

driver handle J8092, press the bush (33) f rom

the extension housing.

NOTE:

Take note of the orientation of the split in the bush

for installation purposes.

Figure 7C4-25

14. Lubricate the outside of a new bush with

automatic transmission fluid to reduce the

chance of material pick-up.

15. Install a new bush (33) into the extension

housing (31), using installer J34196-4 and

driver handle J8092, ensuring that the split in

the bush is in the same orientation as the

original.

Figure 7C4-26

Installation of c omponents is in the rever se or der to

removal (Steps 1 to 10 above), taking note of the

following points.

16. Lubricate the seal lips of a new case

extension oil seal and install, using Tool No.

J21426.

17. Lubricate a new extension housing to case

seal ring with automatic transmission fluid,

then install to the extension housing. Reinstall

the housing to the transmission case and

tighten the six bolts to the correct torque

specification.

EXTENSION HOUSING TO CASE 42 - 48

BOLT TORQUE SPECIFICATION Nm

18. Lubricate a new vehicle speed sensor O-ring

with automatic transmission fluid, then install

to the sensor. Reinstall the sensor to the

extension housing and tighten the retaining

screw to the correct torque specification.

SPEED SENSOR RETAINING 10.5 - 13.5

SCREW TORQUE SPECIFICATION Nm

19. If removed, reinstall the rear engine mounting

to the crossmember, after noting the

orientation of the rear cross mem ber relative to

the installed engine.

20. Tighten the engine mounting nuts to the

correct torque specification.

REAR ENGINE MOUNTING TO

CROSSMEMBER NUT 20 - 30 Nm

TORQUE SPECIFICATION

21. Reinstall the rear crossmember, ensuring that

it is aligned with the scribe lines m ade prior to

removal, before tightening the attaching bolts

to the correct torque specification.

REAR ENGINE MOUNTING TO

EXTENSION HOUSING BOLT 50 - 65 Nm

TORQUE SPECIFICATION

REAR CROSSMEMBER TO SIDE

RAIL ATTACHING BOLT 50 - 65 Nm

TORQUE SPECIFICATION

Figure 7C4-27

22. For installation of the exhaust pipes and

catalytic converter on naturally aspirated V6

powered vehicles, refer to Section 8B

EXHAUST SYSTEM.

23. Refer to Section 4C PROPELLER SHAFT

AND UNIVERSAL JOINTS for installation of

the propeller shaft.

24. Lower vehicle and check transmission fluid

level (Refer to 2.1 FLUID LEVEL CHECK, in

this Section).

3.8 1-2 ACCUMULATOR ASSEMBLY

REMOVE

1. Remove oil pan and filter, refer

3.1 FLUID LEVEL CHANGE AND FILTER

REPLACEMENT in this Section.

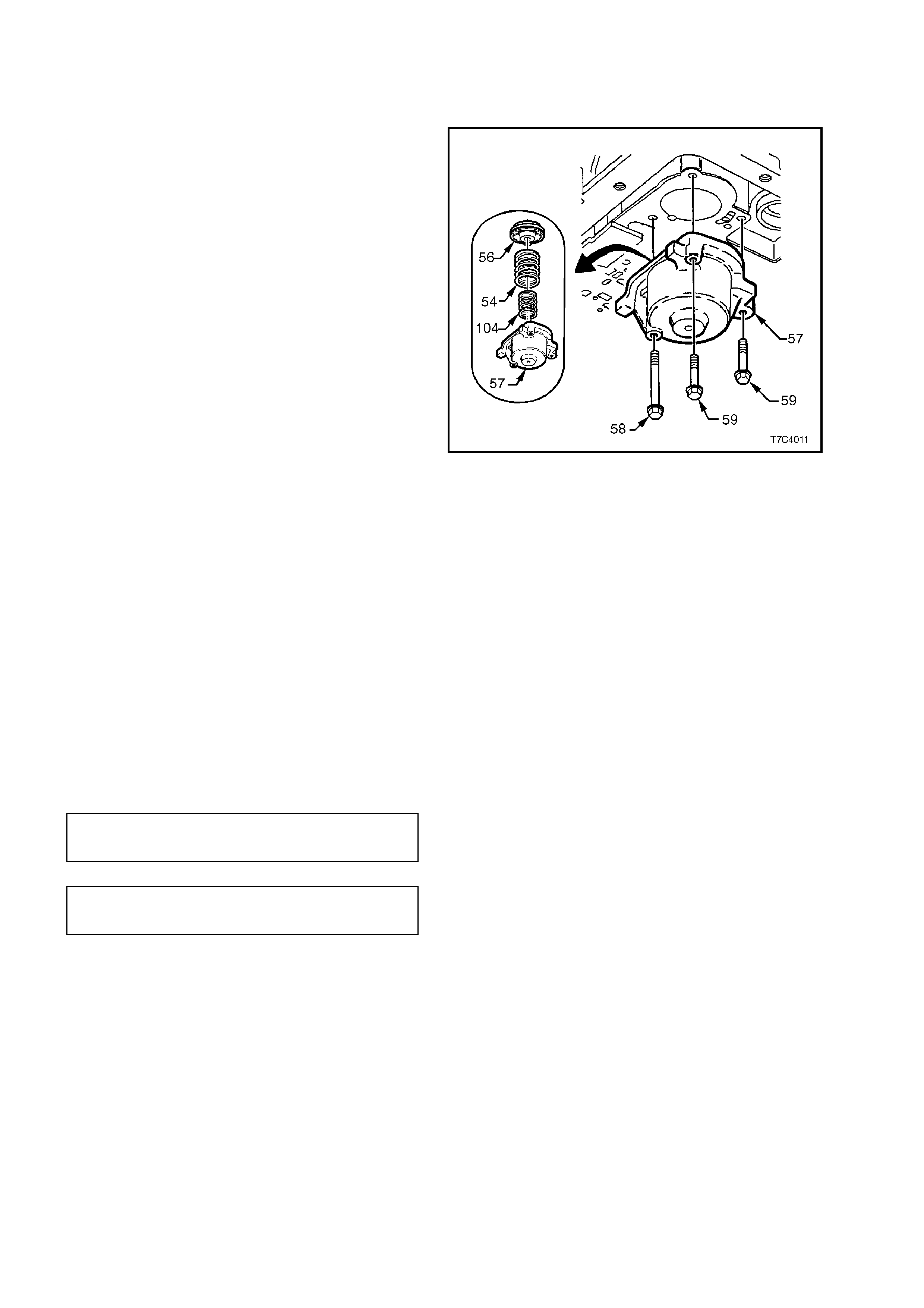

2. Progressively loosen, then remove the three

accumulator c over bolts ( 58 and 59), the c over

(57) and pin assembly, piston and seal

assembly (56) and the two springs (54 and

104), from the control valve body spacer plate.

3. Using LOW pres s ur e air, apply to the drilling in

the cover to remove the 1-2 accumulator

piston (56). Remove and discard the piston

seal.

4. Remove the two 1-2 accumulator springs (54

and 104).

Figure 7C4-28

CLEAN AND INSPECT

1. Clean com ponents with a suitable solvent and

air dry.

2. Check that springs are not distorted, or

broken.

3. Lubricate new seal with petroleum jelly and

install on piston. Check that piston seal does

not bind in the piston groove.

4. Check all machined surfaces for damage or

wear.

REINSTALL

Installation is the reverse of the r emoval proc edur e.

Use a new oil pan gasket and tighten all fasteners

to specified torque settings.

1 - 2 ACCUMULATOR COVER 8 - 14

BOLTS TORQUE SPECIFICATION Nm

OIL PAN BOLT 9.5 - 13.8

TORQUE SPECIFICATION Nm

3.9 CONTROL VALVE BODY AND W I RING HARNESS

REMOVE

1. Remove oil pan and filter, refer

3.1 FLUID LEVEL CHANGE AND FILTER

REPLACEMENT in this Section.

2. Disconnect wiring harness connectors from all

electrical components, except the Torque

Converter Clutch (TCC) Solenoid.

3. Remove two bolts ( 68) securing T CC solenoid

assembly.

4. Withdraw TCC solenoid assembly from pump.

5. Swing the wiring harness and TCC s olenoid to

one side and tie up with a piece of tie wire to a

suitable place on the underneath of the

vehicle.

Figure 7C4-29

6. Remove the Transmission Pressure Switch

Assembly retaining bolts, then remove the

Pressure Sw itch Assembly.

Figure 7C4-30

7. Remove the bolt (64) securing the manual

detent spring (63).

Figure 7C4-31

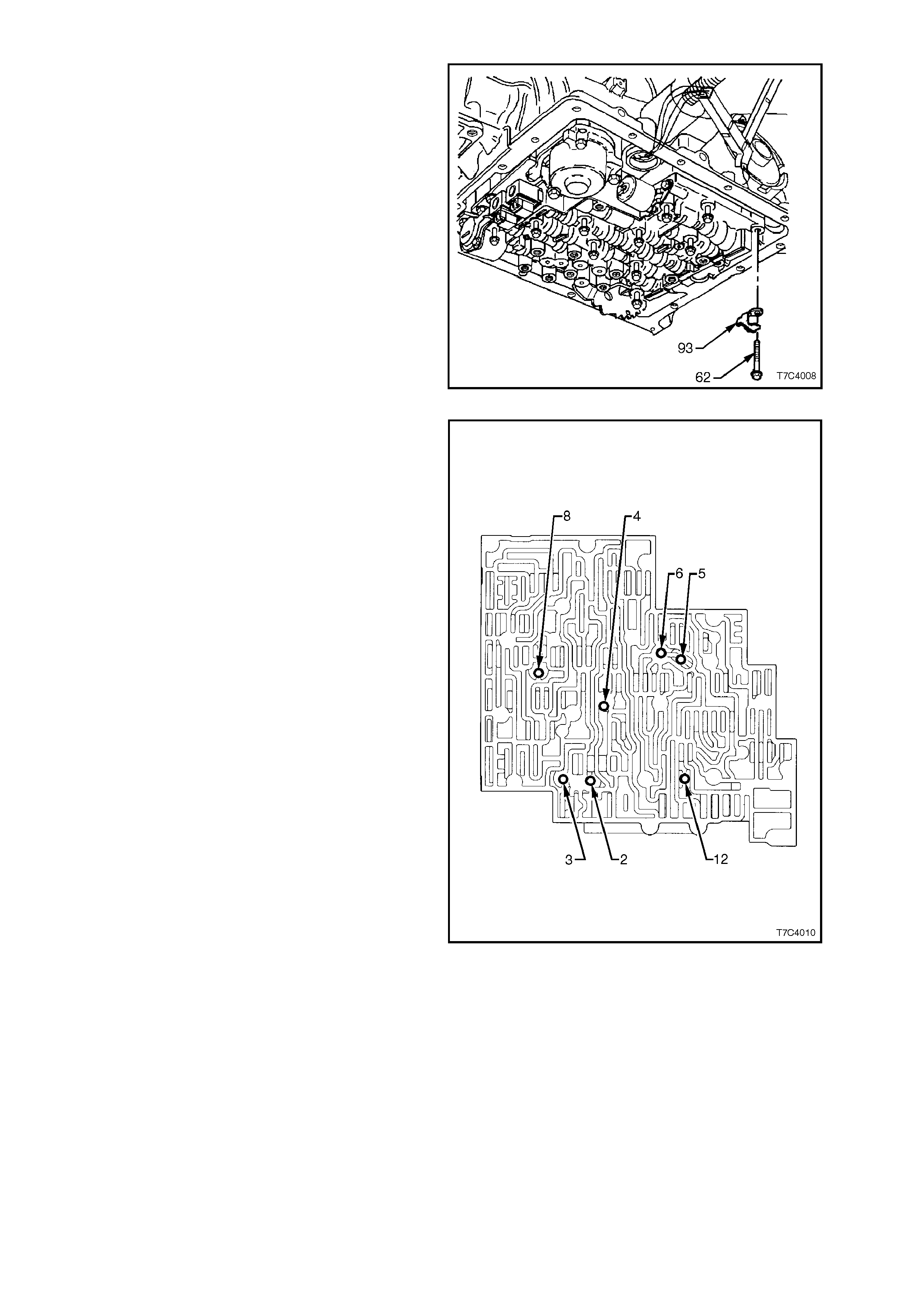

8. Remove the control valve body retaining bolt

(62) securing the dipstick stop bracket (93).

9. Remove remaining control valve body bolts.

9. Remove control valve body assembly by

supporting at the rear with one hand, while

holding the manual valve with the other. As the

valve body is being lowered, rotate it slightly to

release the m anual valve link fr om the m anual

valve.

10. Remove manual valve link from inner detent

lever.

Figure 7C4-32

NOTE:

Take care not to lose the seven check balls that

are located under the control valve body. Locations

for the seven check balls are as shown.

Figure 7C4-33

DISASSEMBLE, CLEAN, INSPECT AND REASSEMBLE

For these Operations, refer to 2.16 CONTROL

VALVE BODY in 7C5, AUTOMATIC

TRANSMISSION - UNIT REPAIR.

REINSTALL

1. Ensure spacer plate gasket is in satisfactory

condition. If gasket needs to be r eplaced, r ef er

to 3.10 SPACER PLATE, CHECK BALLS,

FILTER SCREENS AND 3-4

ACCUMULATOR in this Section.

2. Reinstall check balls in control valve body as

shown in Figure 7C4-34 and secure with

petroleum jelly.

3. Install the manual valve link into the inner

detent lever.

4. While supporting the manual valve link in one

hand and the valve body in the other, rotate

the valve body slightly and connect the link

with the manual valve. Move the m anual valve

forward to retain the link connection and

carefully offer the valve body up, into position.

NOTE:

Be careful not to damage the two filter screens

attached to the spacer plate, during this operation.

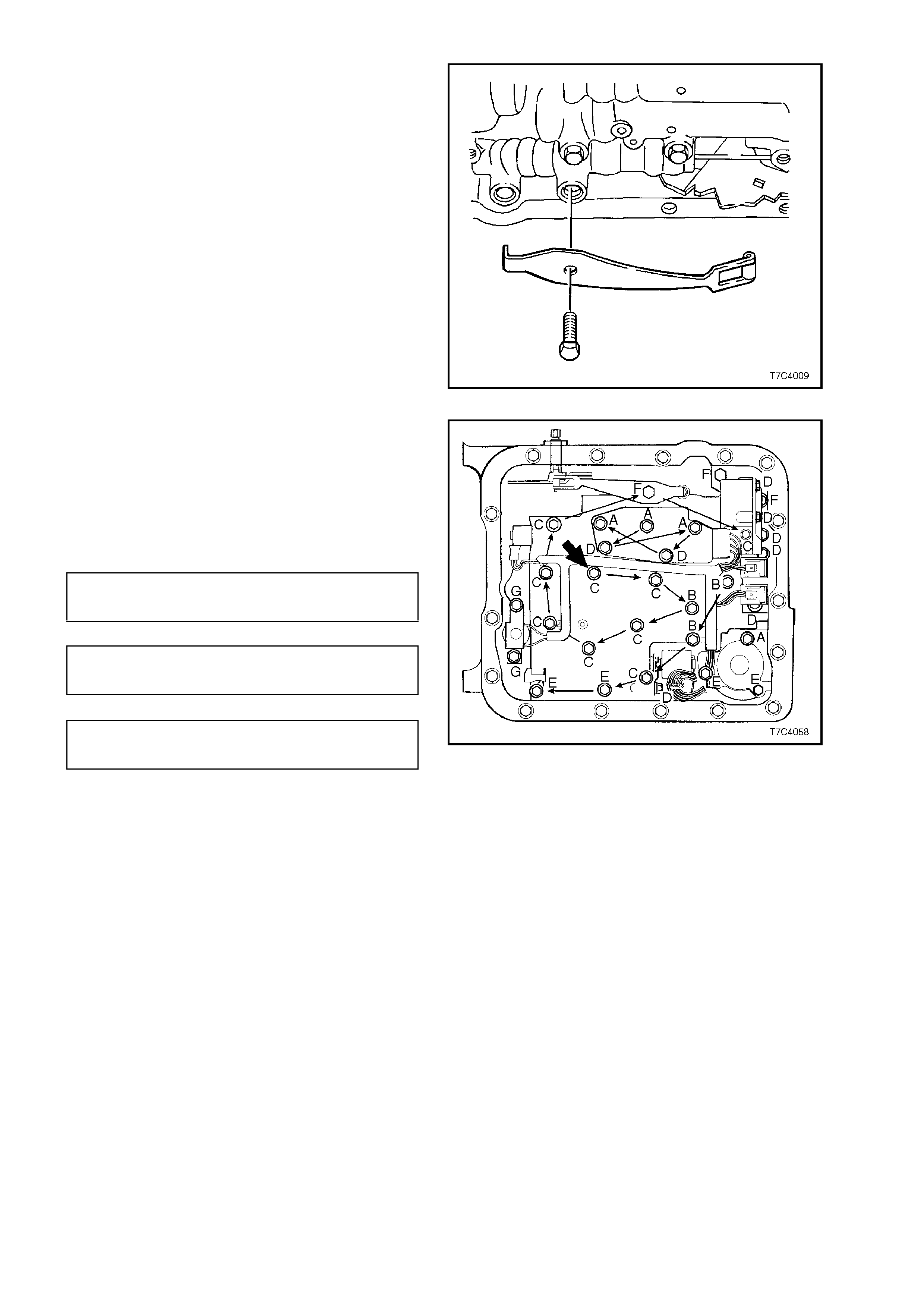

Figure 7C4-34

5. Reinstall bolts to the transmission range

pressure switch assembly (PSA), but do not

tighten.

Figure 7C4-35

6. Install the dipstick stop bracket (93) and

retaining bolt (62). Do not tighten at this time.

7. Loosely install the remainder of the control

valve body bolts.

Figure 7C4-36

8. Reinstall the manual detent spring assembly

retaining bolt.

Figure 7C4-37

9. Coat a new TCC solenoid O-ring with

petroleum jelly and install on solenoid, then

reinstall TCC solenoid assembly into the oil

pump body.

10. Tighten all bolts to the specified torque

specification, starting from the center (bold

arrow), in the order shown.

CONTROL VALVE BODY and PSA 8 - 14

TORQUE SPECIFICATION Nm

MANUAL DETENT SPRING 20 - 27

BOLT TORQUE SPECIFICATION Nm

TCC SOLENOID BOLT 8 - 14

TORQUE SPECIFICATION Nm

IMPORTANT:

The control valve body bolts must be tightened in

an outward spiral from the centre (bold arrow), as

shown. Failure to f ollow this pattern m ay dis tort the

valve body, causing valves to jam in their bores.

NOTE:

There are 7 different bolt sizes used. The letters

shown, relate to the following bolt sizes.

Control Valve Body Fastener Specifications

A-M6 x 1.00 x 65.0

B-M6 x 1.00 x 54.4

C-M6 x 1.00 x 47.5

D M6 x 1.00 x 18.0

E-M6 x 1.00 x 35.0

F-M8 x 1.25 x 20.0

G-M6 x 1.00 x 12.0

Figure 7C4-38

11. Coat a new TCC PWM solenoid O-ring with

petroleum jelly, install on the solenoid (2).

Then reinstall the solenoid into the control

valve body, securing with retaining clip (1).

Figure 7C4-39

12. Reinstall electrical wiring harness clips to

secure the harness to the control valve body

and install the wiring harness connectors as

shown, and identified below.

Electrical Connector Identification

1. Pressure Switch Assembly (PSA).

2. 1-2 Shift Valve Solenoid

3. 2-3 Shift Valve Solenoid

4. Pressure Control Solenoid (PCS)

5. TCC Pulse Width Modulated (T CC PWM)

Solenoid

6. 3-2 Control Solenoid

Figure 7C4-40

13. Reinstall oil filter into the oil filter seal.

Figure 7C4-41

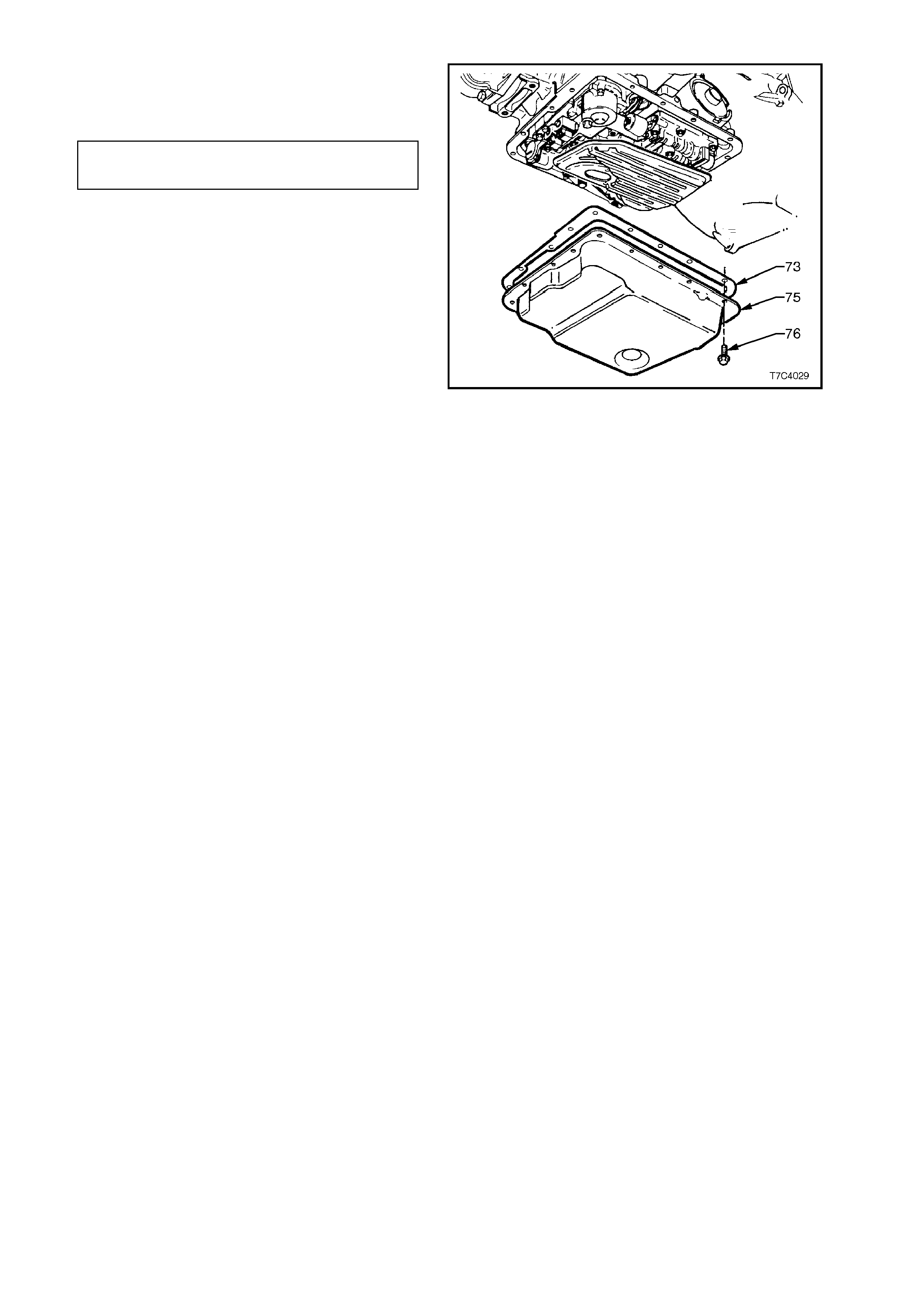

14. Install a new oil pan gasket (73), then reinstall

the oil pan (75), tightening the bolts (76) to the

correct torque specification.

OIL PAN BOLT 9.5 - 13.8

TORQUE SPECIFICATION Nm

15. Fill transmission with DexronÒ III automatic

transmission fluid, as detailed in

Operation 3.1, in this Section.

16. Lower vehicle and road test until the

transmission has reached operating

temperature.

17. Re-check fluid level (see Operation 2.1, in

this Section) and c heck f or f luid leaks fr om the

oil pan area.

Figure 7C4-42

3.10 S PACER PLATE, CHECK BALLS, FILTER SCREENS AND 3-4 ACCUMULATOR

REMOVE

1. Remove control valve body as described in

3.9 CONTROL VALVE BODY AND WIRING

HARNESS in this Section.

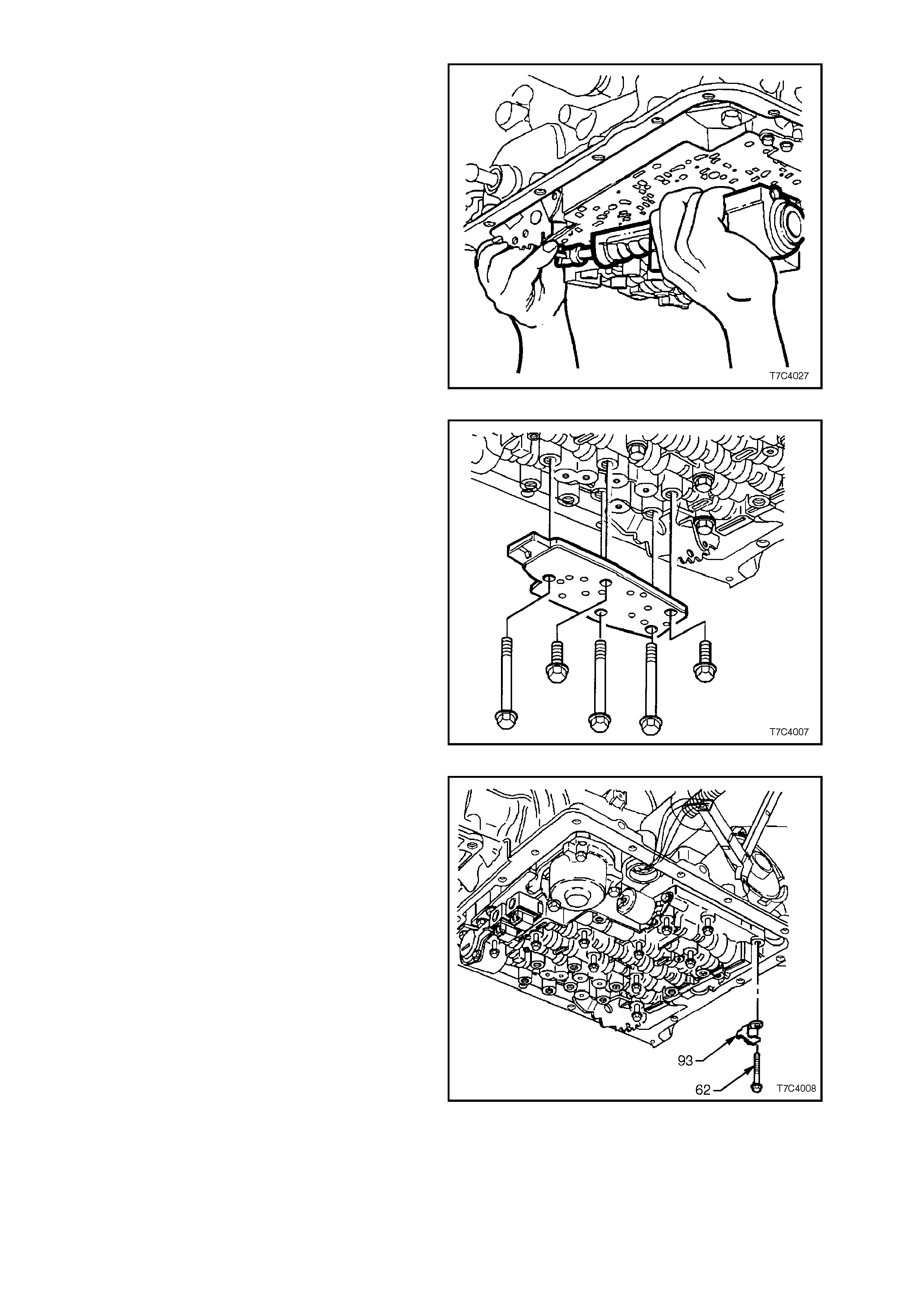

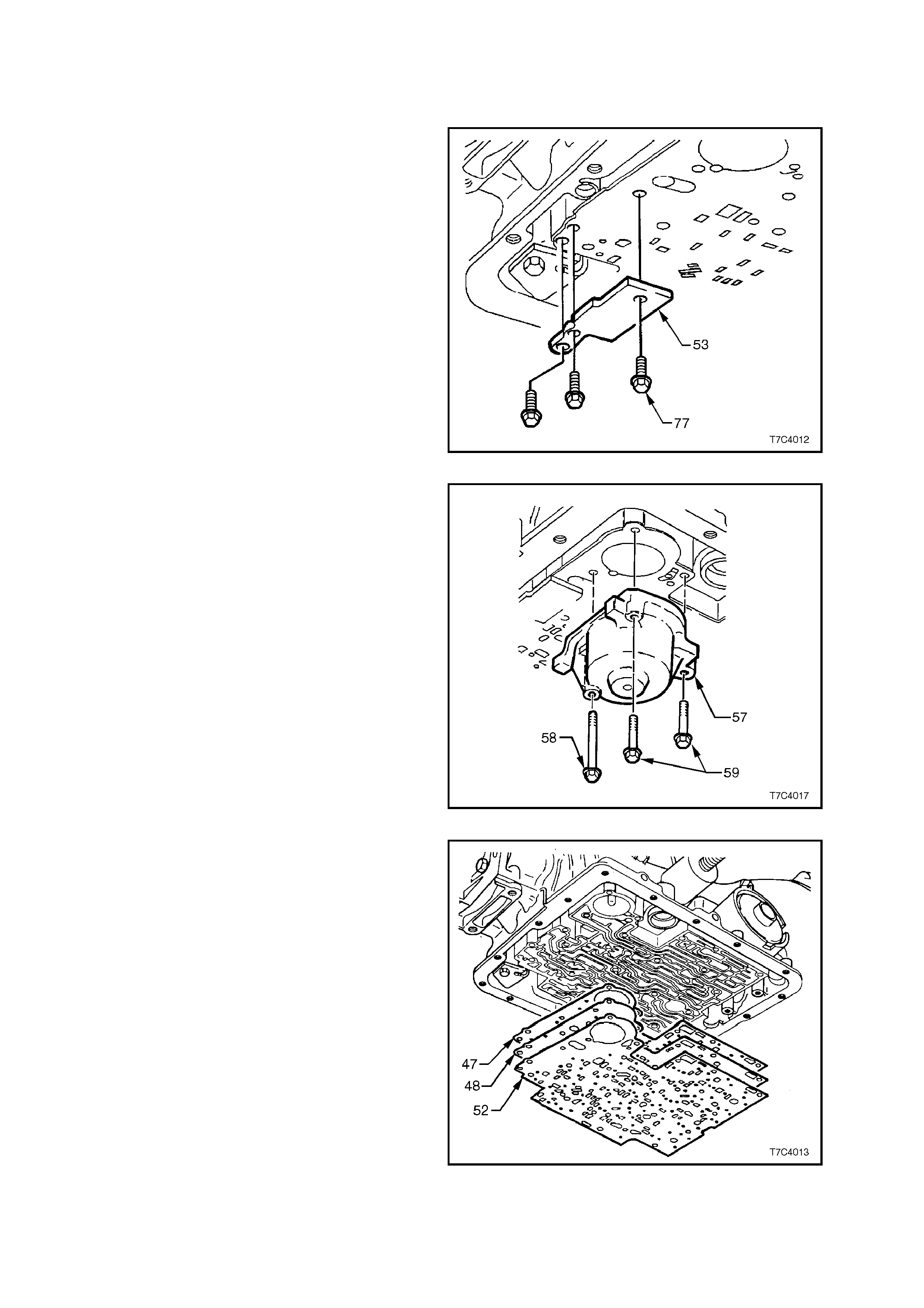

2. Remove the three spacer plate retaining plate

bolts (77) and plate (53).

Figure 7C4-43

3. W hile s upporting the spacer plate, remove 1- 2

accumulator assembly retaining bolts (58 and

59), then carefully lower the accumulator

assem bly from the spacer plate and set to one

side, assuming that removal of the piston and

springs is not required.

NOTE:

The 3-4 accumulator spring may push the spacer

plate away from transmission case when the

accumulator cover is removed.

Figure 7C4-44

4. Remove the spacer plate (48) and two spacer

plate gaskets (47 and 52) from the

transmission case.

IMPORTANT:

As the spacer plate and gaskets are lowered from

the transmission, a check ball and the 3-4

accumulator spring will also come away. Do not

lose the check ball.

Figure 7C4-45

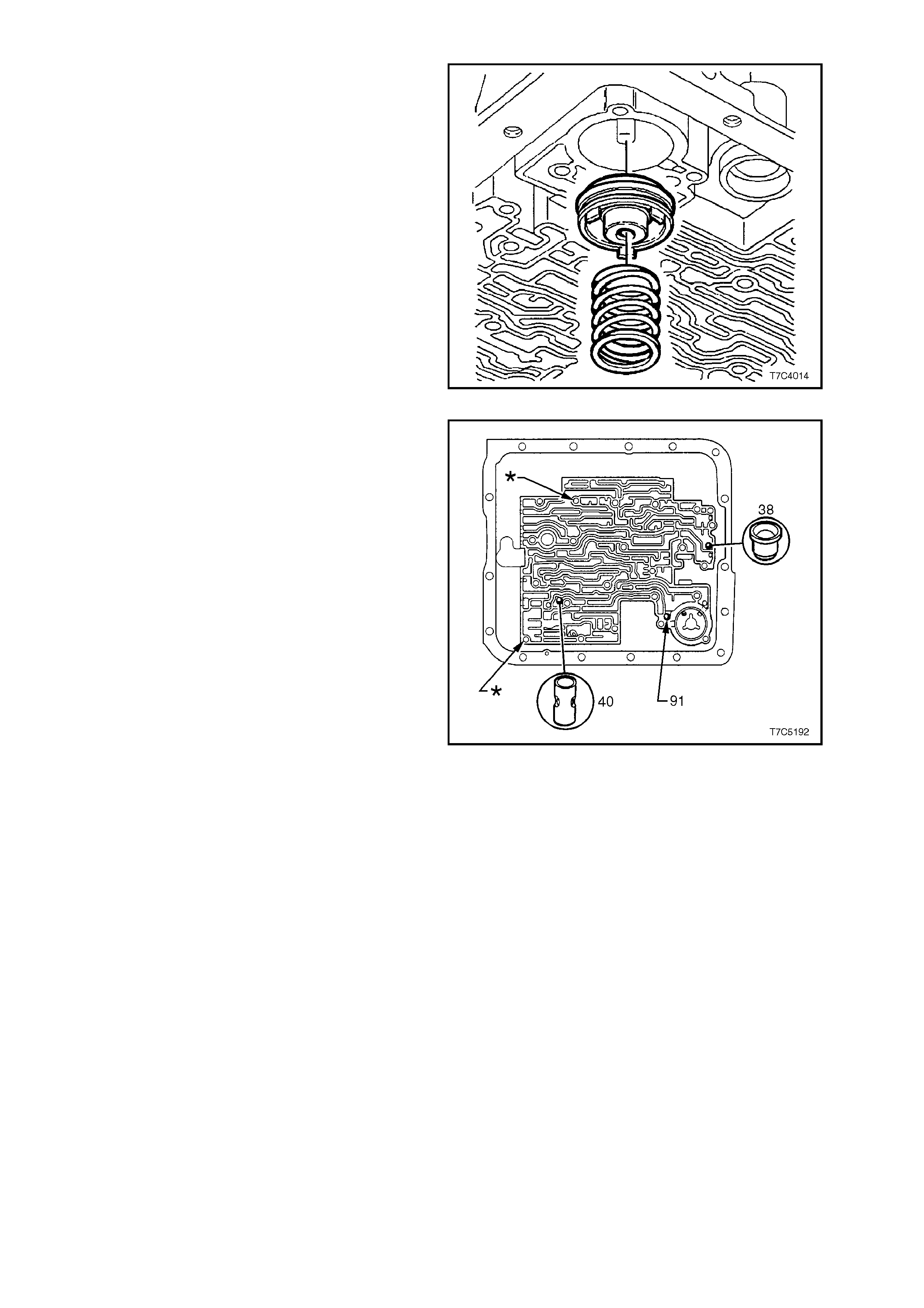

5. If removal of the 3-4 accumulator piston is

required, use snap ring pliers and rotate the

piston while pulling it from the case. Remove

and discard the piston seal.

Figure 7C4-46

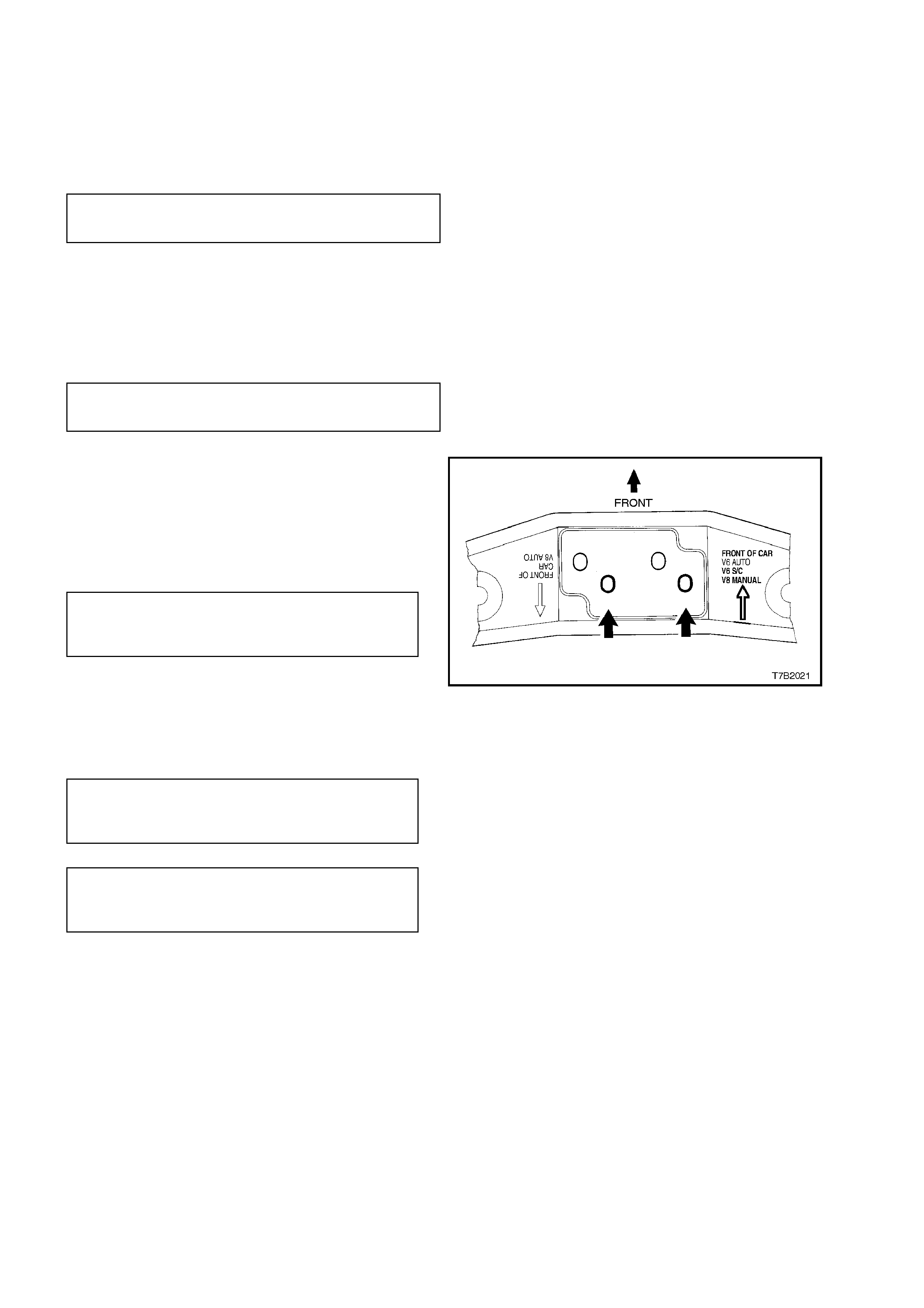

6. The location of the checkball (91), 3rd

accumulator check ball assembly (40) and

orifice cup plug (38) in the transmission case,

are as shown.

NOTE:

The locations marked as (Q) are for two guide

studs to be inserted for reassembly.

Figure 7C4-47

CLEAN AND INSPECT

1. Wash components in clean solvent.

2. Dry with compressed air.

3. Inspect piston for porosity, ring groove

damage or pin hole damage.

4. Check spring for distortion or damage.

5. Inspect accumulator bore for wear or damage.

6. Check spacer plate, filter screens and check

balls for damage.

REINSTALL

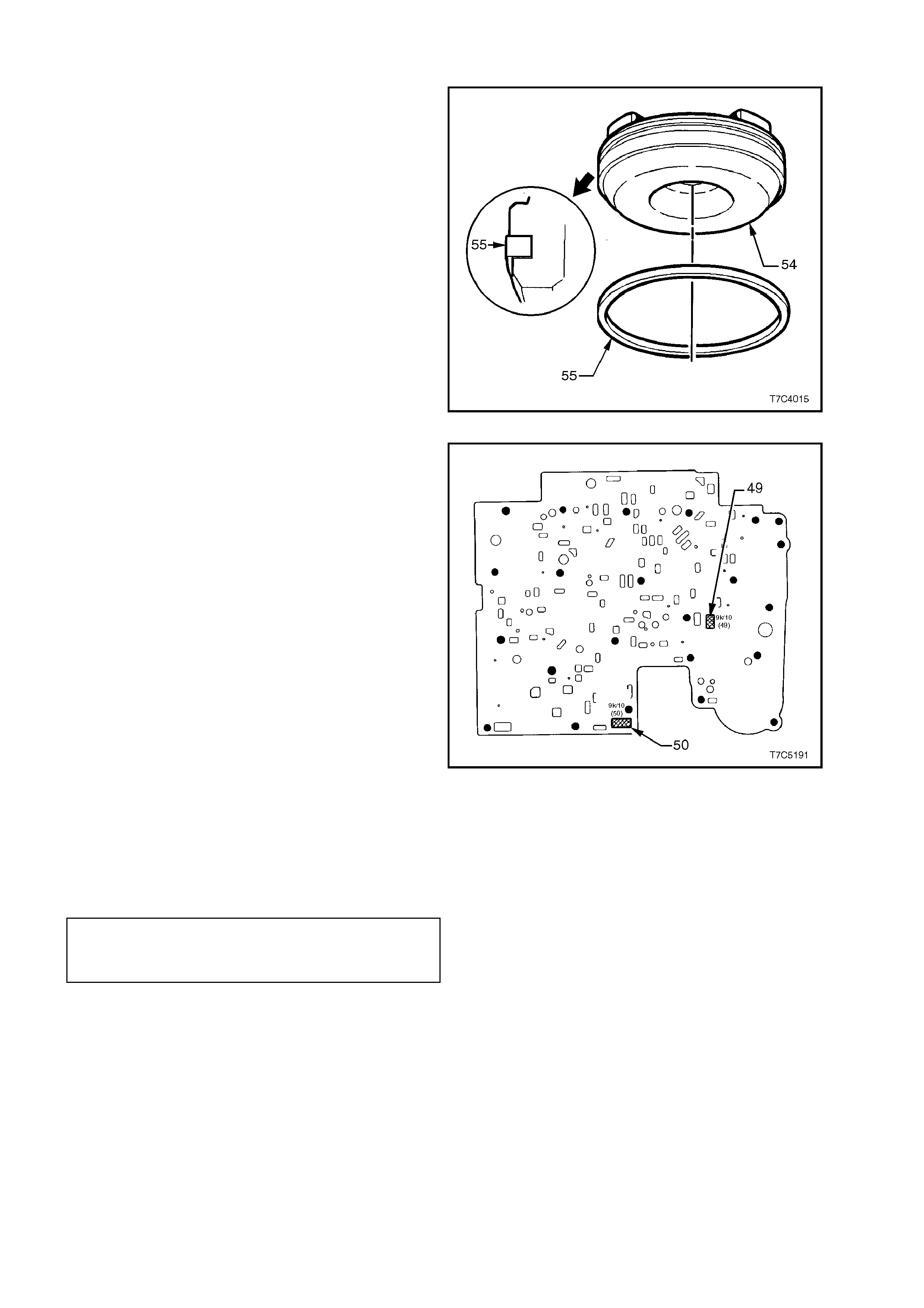

1. Lubricate new seal (55) with petroleum jelly

and install on 3-4 accumulator piston (54).

2. Reinstall pin in case.

3. Reinstall piston onto pin s o that the pis ton s ide

with three lugs, faces out of bore (Refer to

Figure 7C4-48).

4. Install guide pins (J25025-1) into transmission

case in the locations shown in Figure 7C4-47.

NOTE:

Ensure that the guide pins are f ully installed s o that

no thread is visible. Otherwise the spacer plate

gasket could become caught in a thread during

installation, resulting in incorrect alignment.

5. Reinstall the check ball in the transmission

case as shown (Figure 7C4-47) and use

petroleum jelly to hold the ball in place.

6. Reinstall 3-4 accumulator spring. Figure 7C4-48

7. If a new spacer plate is to be installed, it will be

necessary to fit two filter screens (49 and 50)

to the spacer plate bef or e f itment. Locations of

these screens are as shown.

8. Reinstall spacer plate with new gaskets that

have been smeared with petroleum jelly and

hold in place until accumulator is reinstalled.

NOTE:

Gasket marked 'C' is fitted between spacer plate

and transmission case and gasket marked 'V' is

located between spacer plate and control valve

body.

Figure 7C4-49

9. Reinstall accumulator. Refer to 3.8 1-2

ACCUMULATOR in this Section.

10. Install spacer plate support plate (53) and

retaining bolt (77), tightening to the correct

torque specification.

SPACER PLATE SUPPORT

PLATE RETAINING BOLT 8 - 14 Nm

TORQUE SPECIFICATION

10. Remove guide pins (J25025-1) from the

transmission case.

11. Reinstall control valve body. Refer to

3.9 CONTROL VALVE BODY AND WIRING

HARNESS in this Section.

12. Reinstall filter and oil pan. Refer to 3.1 FLUID

CHANGE AND FILTER REPLACEMENT in this

Section.

3.11 MANUAL SHAFT SEAL

REPLACE

1. Disconnect selector linkage from

transmission. Refer to 3.2 SELECTOR

LINKAGE in this Section.

2. Remove oil pan and filter, refer to

3.1 FLUID CHANGE AND FILTER

REPLACEMENT in this Section.

3. Remove bolt s ecuring manual detent spring to

control valve body and remove spring

assembly.

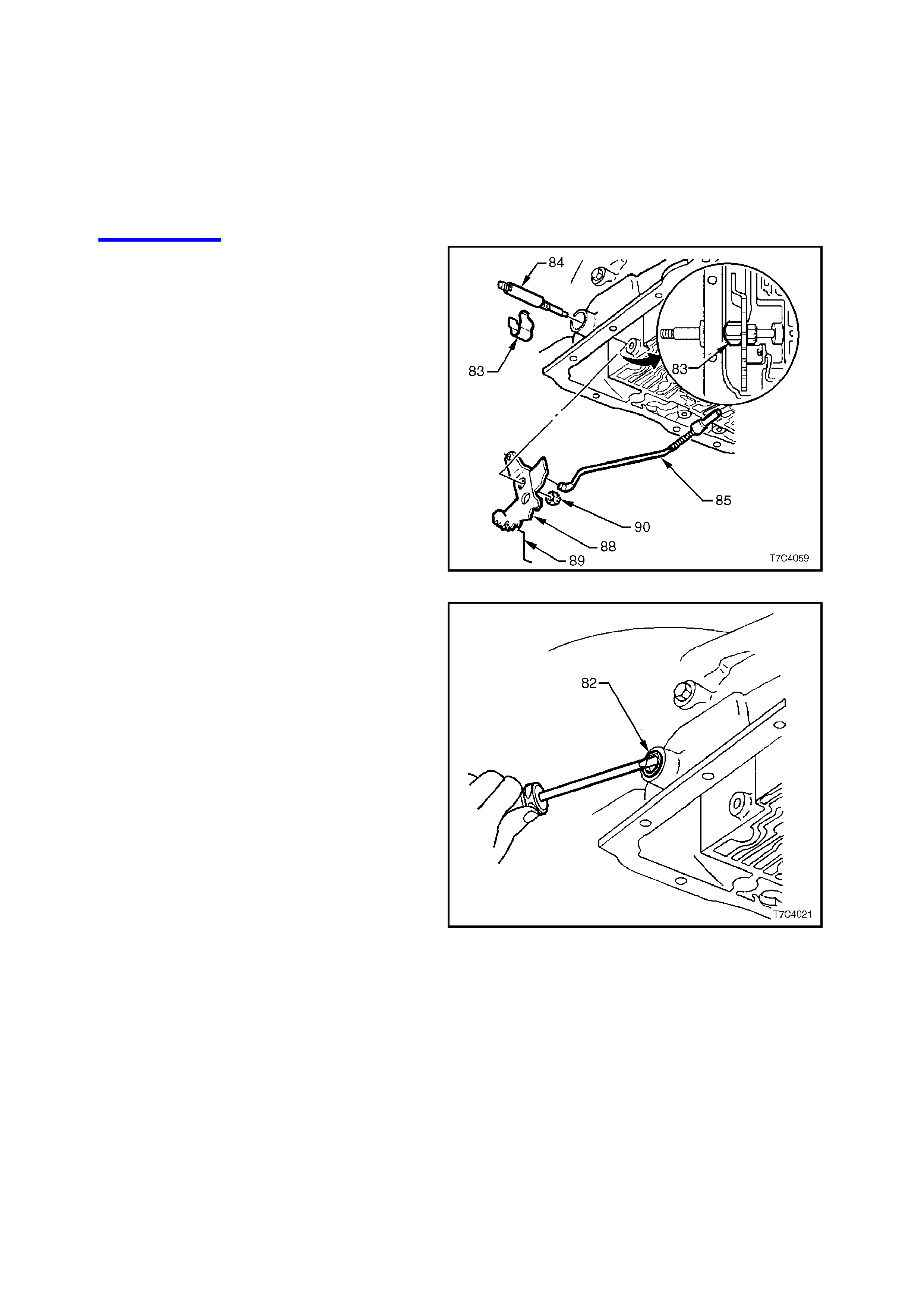

4. Remove nut (90) securing inner detent lever

(88) to manual shaft (84).

5. Remove retaining clip (83) from manual shaft

(84).

6. Withdraw manual shaft from transmission

case.

NOTE:

It may be necessary to first remove burrs from the

shaft, caused by the inner detent lever.

Figure 7C4-50

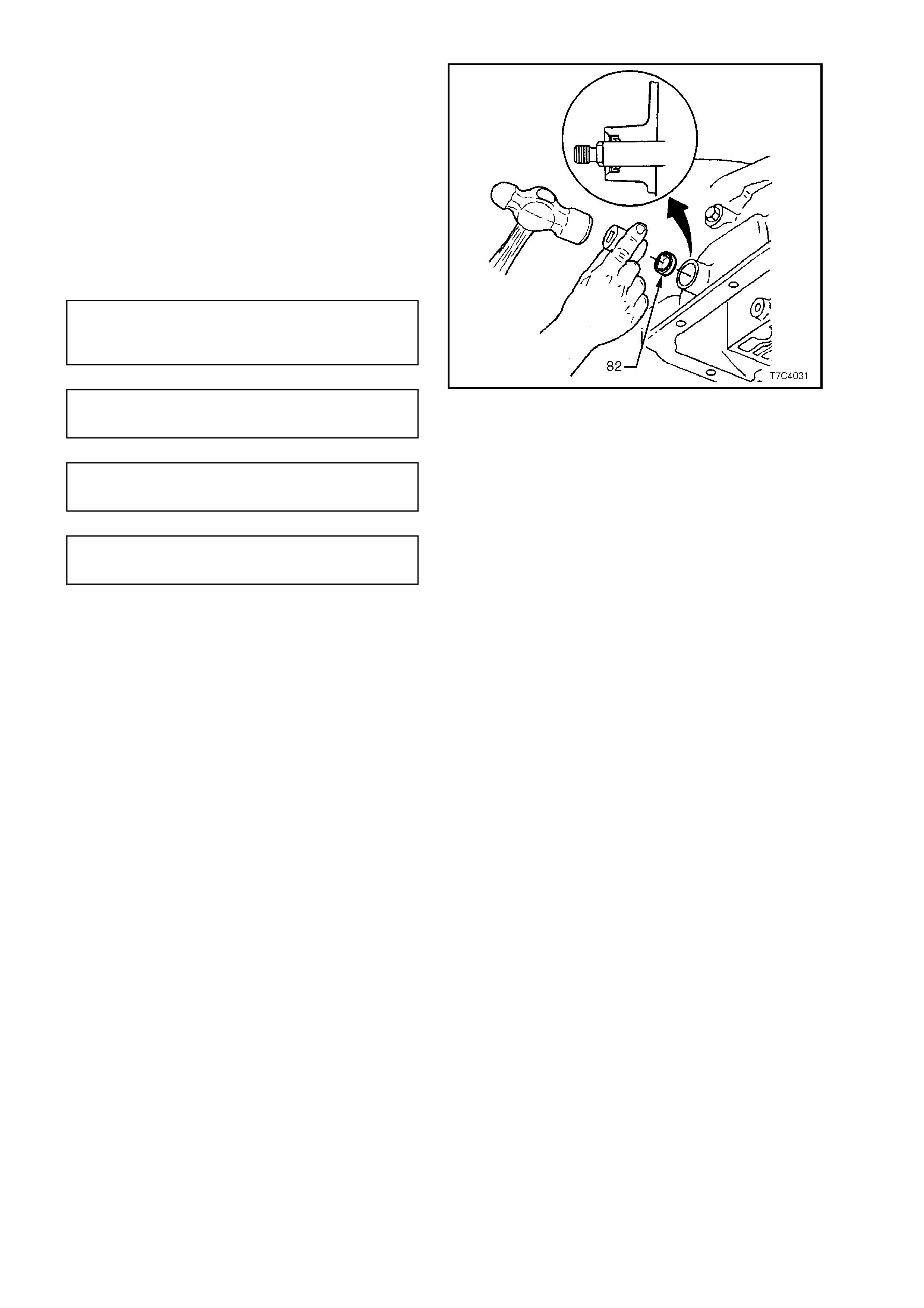

7. Prise manual shaft seal (82) from transmission

case with suitable tool such as a screwdriver.

Figure 7C4-51

8. Tap new seal into place with a 14 mm socket.

Seal lip faces inwards.

9. Reinstall components in reverse order of

removal (steps 1 to 6 above). Tighten nuts and

bolts to specified torques.

NOTE:

If the selector lever was removed from the manual

shaft in the disassembly process (not a necessary

step), then the lever must be held with an

adjustable wrench when tightening the retaining nut

to the specified torque.

MANUAL SHAFT TO INNER

DETENT LEVER NUT 27 - 34 Nm

TORQUE SPECIFICATION

MANUAL DETENT SPRING BOLT 20 - 27

TORQUE SPECIFICATION Nm

MANUAL SHAFT LEVER NUT 15 - 35

TORQUE SPECIFICATION Nm

SELECTOR LEVER LOCKING 15 - 35

BOLT TORQUE SPECIFICATION Nm

Figure 7C4-52

3.12 FILLER TUBE

REPLACE

1. Disconnect the battery earth lead.

2. Remove the transmission dipstick (1 or 5).

3. Remove the bolt securing transmission filler

tube to converter housing (V8 engine) (7) or

right hand cylinder head (V6 engine) (3).

4. Using a twisting/pulling motion, remove filler

tube (2 or 6) from transmission case seal (4)

and withdraw from engine compartment.

5. Replace the filler tube seal (4), lubricate with

transmission fluid and install into transmission

case.

6. Reinstall the filler tube (2 or 6) in the reverse

order to removal, routing the transmission

breather hose into the correct position.

7. Tighten the filler tube bracket retaining bolt (3

or 7) to the correct torque specification.

FILLER TUBE V6 Engine:

RETAINING 20 - 35 Nm

BRACKET BOLT V8 Engine:

TORQUE SPECIFICATION 30 - 45 Nm

Figure 7C4-53

3.13 TRANSMISSION ASSEMBLY

REMOVE

1. Disconnect the battery earth lead.

2. Raise vehicle and place on safety stands.

Place drip tray beneath transmission.

3. Remove filler tube as detailed above.

4. Plug filler tube hole to prevent dirt entry.

5. Remove propeller shaft assembly: Refer to

Section 4C PROPELLER SHAFT AND

UNIVERSAL JOINTS.

6. Disconnect electrical connectors from vehicle

speed sensor and oxygen sensors.

7. If not already removed in Step 5, remove

exhaust pipes from the exhaust manifolds to

the rear of the catalytic converter (only

required for the naturally aspirated V6 engine).

8. Hold the transmission selector lever with an

adjustable wrench while loosening the

retaining nut. Remove the selector lever from

the manual shaft.

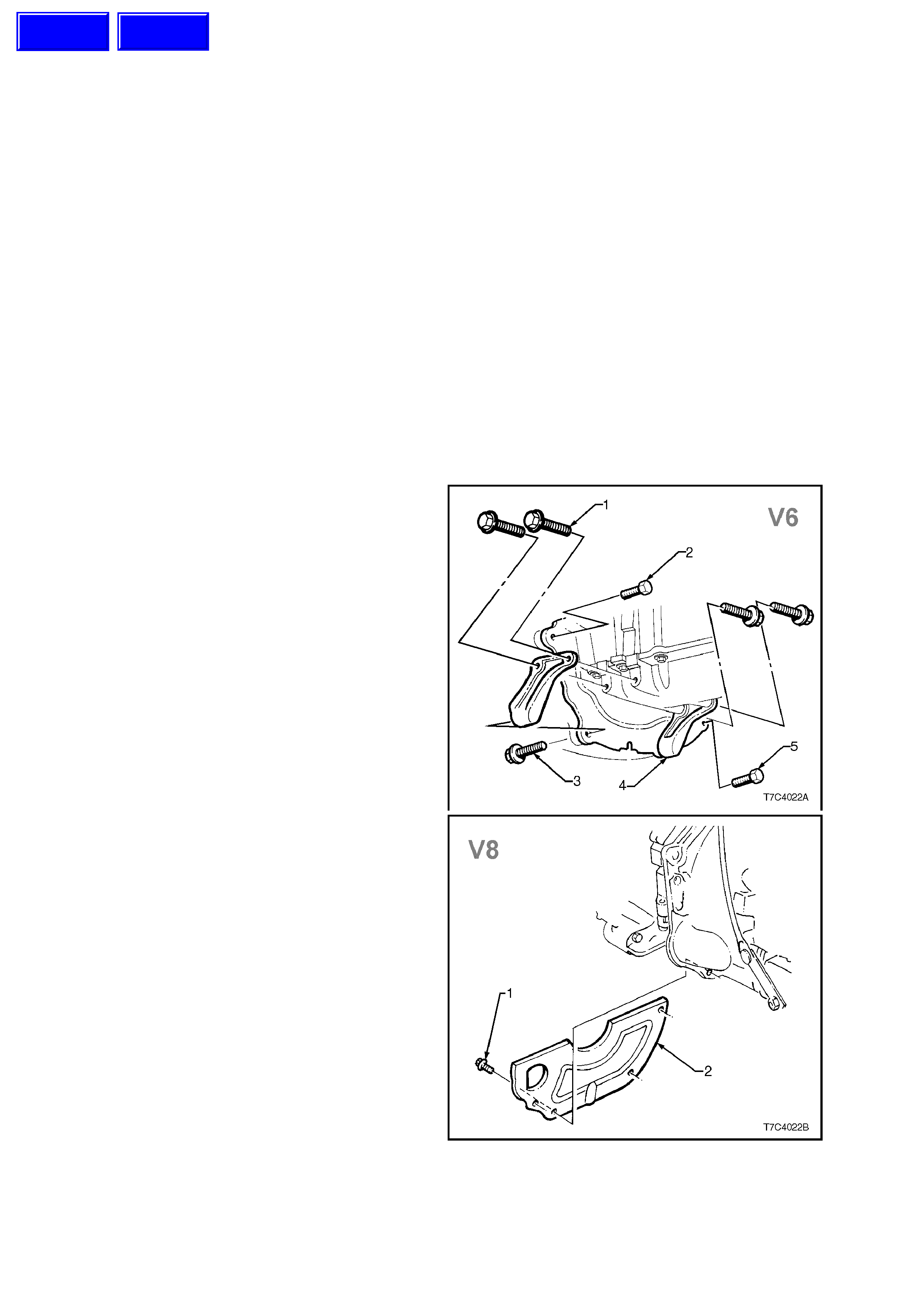

9. Remove converter housing lower cover, as

follows;

a. Remove the starter motor. Refer to

Section 6D1-2, STARTING SYSTEM -

V6 ENGINE or to Section 6D2-2,

STARTING SYSTEM - V8 ENGINE, for

the necessary procedure.

b. W hen a V6 engine is fitted to the vehicle,

the beaming braces (4) will need to be

removed, to allow the transmission lower

cover to be removed. Remove the lower

retaining bolts (3), then the four bolts (1)

securing the br aces to the oil pan. F inally,

remove the two cover retaining screws (2)

and remove the lower transmission cover

from the front of the torque converter

housing.

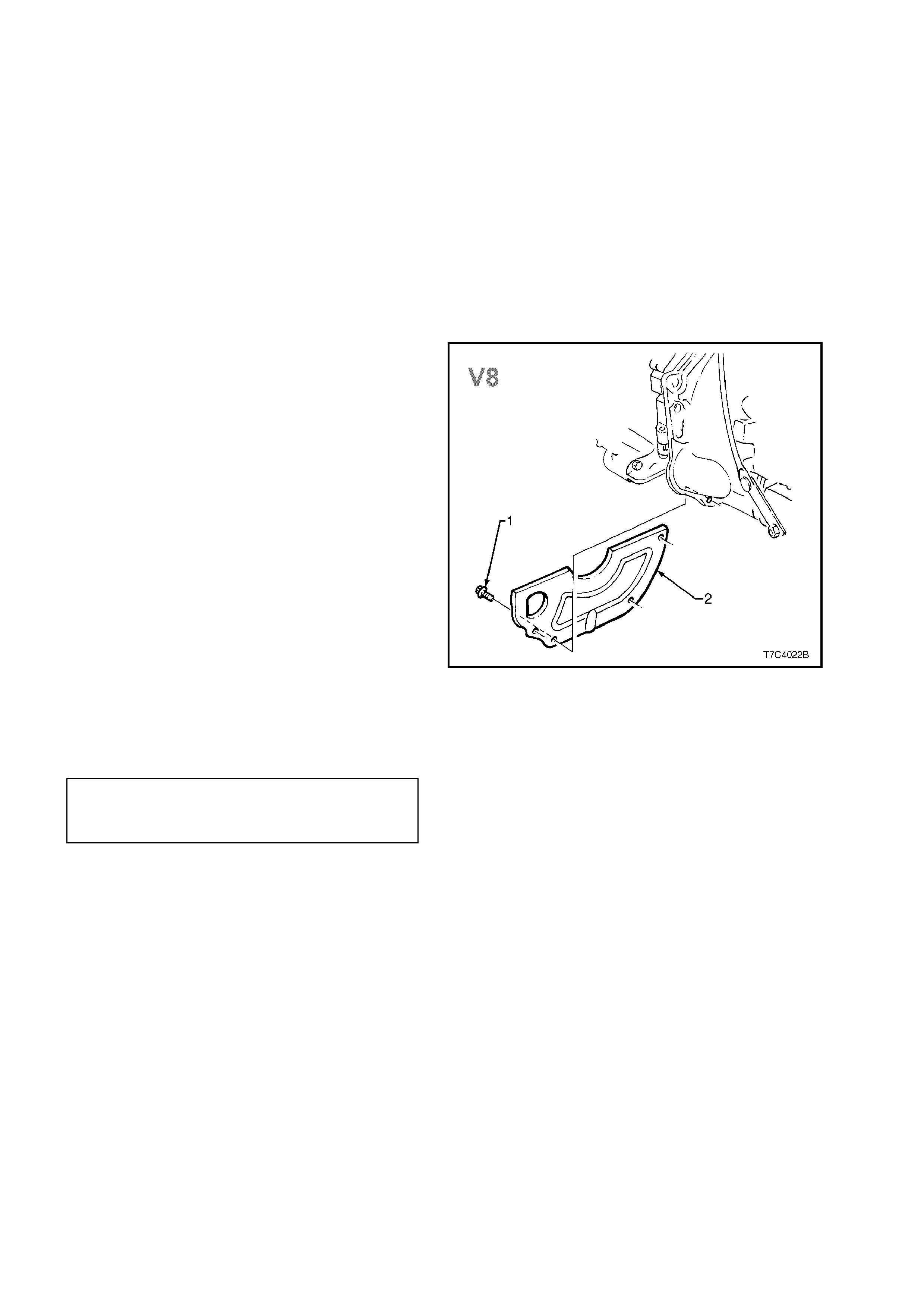

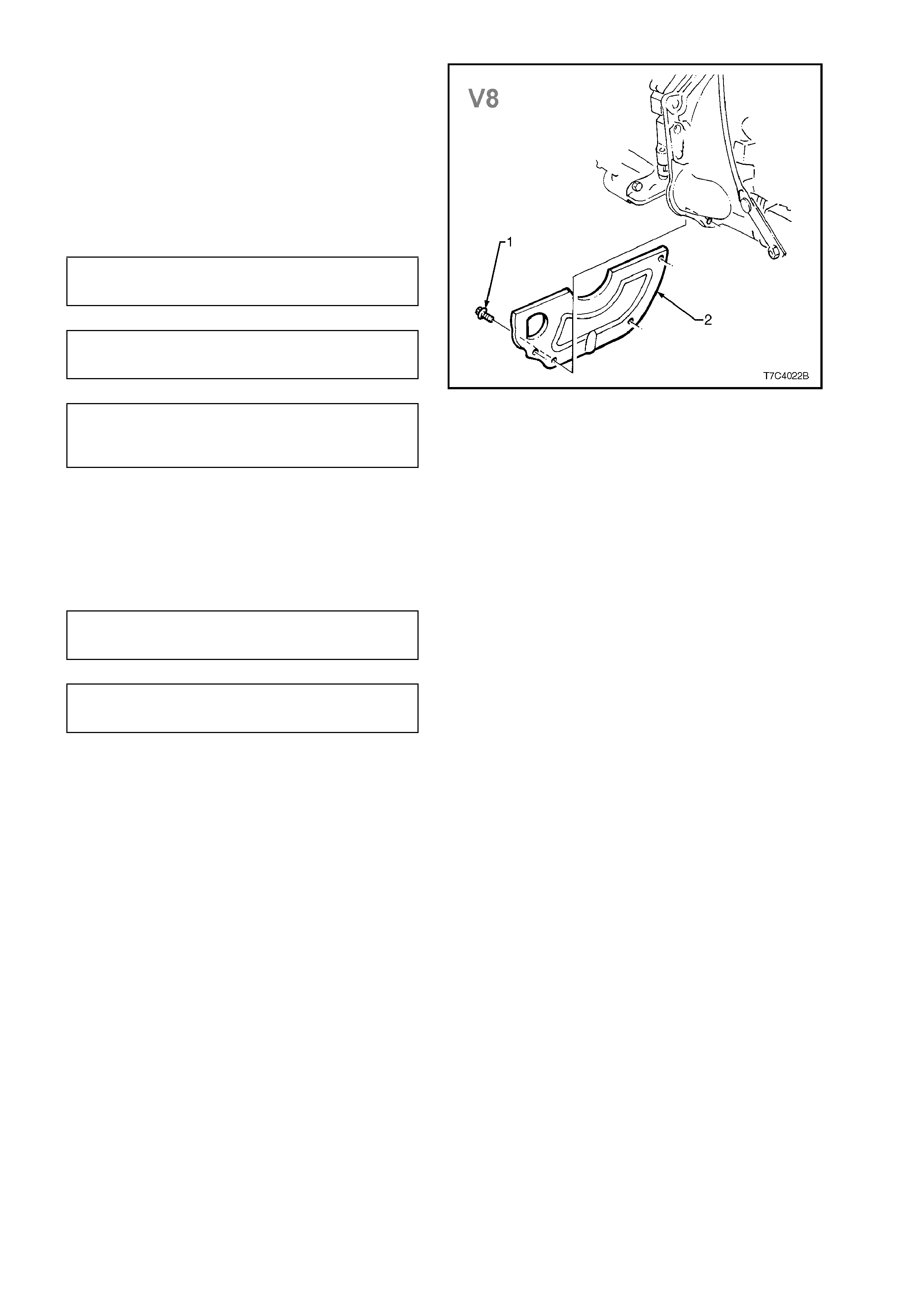

c. With V8 engine, remove the four lower

cover retaining screws (1), then remove

the lower cover (2) from the front of the

torque converter housing.

10. Mark relative position of torque converter and

flexplate, then remove three torque converter

to flexplate attaching bolts. Discard the

removed bolts.

Figure 7C4-54

Techline

Techline

11. Use a sharp s criber to m ark the ex act location

of the crossmember (2) to the side frame,

before loosening any of the four c rossm ember

to side frame attaching bolts (3).

IMPORTANT:

This step is critical to the correct powertrain

alignment on reassembly. If not carried out, then

vehicle vibration and/or handling problems could

result.

12. Remove two bolts (5) securing rear engine

mount to transmission.

13. Support transm iss ion with a jack . Do not place

the support beneath case extension or oil pan.

14. Remove the bolts securing crossmember to

underbody and remove cros s member f r om the

vehicle.

NOTE:

W hile the V6 rear engine mounting arrangement is

shown, the V8 arrangement is similar. Figure 7C4-55

15. Lower rear of transmission to provide sufficient

clearance, without placing any strain on any

electrical wiring and remove electrical

connector from the transmission as follows:

NOTE:

Take care when lowering rear of transmission that

the inlet manifold does not hit the firewall.

· Roll back the dust boot from the connector, to

gain access to the connector.

· Squeeze the widest side of the connector

inwards (A) and PULL DIRECTLY UPWARD.

IMPORTANT:

Do not wriggle the connector from side to side

while removing it! If this situation occurs, there is a

very real possibility of the connector pins being

permanently damaged.

16. Remove the wiring harness clip retaining

screws f rom both the right and lef t sides of the

transmission case .

17. While the rear of the transmission is lowered,

disconnect cooler pipes from tr ansm iss ion and

plug connections, both in the tr ansm iss ion and

the pipe ends themselves, to prevent dirt

entry.

Figure 7C4-56

18. Remove the wiring harness CPA (Connector

Position Assurance) security pin (2) from the

neutral start and back-up lamp switch, then

remove the connector (1) from the switch.

Figure 7C4-57

19. Lower rear of transmission further if

necessary, to gain access to the converter

housing bolts. Then, using a long socket

extension, a univers al joint and a suitable size

socket, remove the remaining converter

housing bolts (and nut, for V6 engine).

20. Support transmission assembly on a suitable

cradle and secure. Also place a suitable

support under engine oil pan rail to support

engine after transmission has been removed.

22. Remove transmission assembly from the

vehicle.

23. Install suitable converter holding tool to

prevent converter becoming dislodged.

REINSTALL

If transmission fluid is contaminated with grit or

foreign material, reverse flush coolers and

connecting pipes as detailed in

2.4 TRANSMISSION COOLER REVERSE FLUSH

AND FLOW RATE CHECK in this Section.

Reinstallation is the reverse of the removal

procedure, noting the following points:

1. Ensure transmission and engine mating

surfaces are clean and free of burrs.

2. Lubricate the torque converter spigot with

wheel bearing grease to Holden’s

Specification HN1227, prior to installation.

3. Ensure locating dowels completely enter

converter housing holes.

4. Prior to reins talling NEW conver ter to f lexplate

bolts, ensure locating marks on converter and

flexplate are aligned.

5. Remove the access hole cover plate in the

lower surface of the torque converter housing

and lever the torque converter forward, prior to

installing and tightening the torque converter

to flexplate attaching bolts. Reinstall the

access hole cover plate.

6. Apply thread sealant such as Loctitie 242 or

equivalent to Holden’s Specification HN1256,

Class 2, Type 2 to the cleaned bolt threads.

Tighten bolts to the correct torque

specification.

TORQUE CONVERTER TO

FLEX PLATE BOLT 60 - 70 Nm

TORQUE SPECIFICATION

7. Oil filler tube seal must be installed into

transmission before installing filler tube to

avoid damage to the seal.

8. The tightening sequence for the transmission

to engine block bolts (and nut (4) f or V6) is as

shown. To avoid confusion the order

suggested, runs from ‘A’ to ‘E’ for V6

applications and f rom ‘A’ to ‘F’ f or V8 powered

vehicles.

NOTE 1:

The bolt (2) and nut (4) loc ation is as shown f or the

V6 transmission.

NOTE 2:

With the V8 transmission, the bolt (4) also holds

the dipstick tube bracket.

Tighten bolts to the correct torque specification.

TORQUE CONVERTER V6 Engine:

HOUSING TO 50 - 60 Nm

ENGINE BOLT V8 Engine:

TORQUE SPECIFICATION 30 - 45 Nm

LOWER TRANSMISSION V6 Engine:

COVER BOLT 30 - 45 Nm

TORQUE SPECIFICATION V8 Engine:

5 - 10 Nm

Figure 7C4-58

9. Prior to installing the wiring harnes s connector

to the transmission, check that all connector

pins and seals are in sound condition. Push

down on the connector body until a 'click' is

heard.

10. Installation of the beaming brace on vehicles

fitted with the V6 engine, is specific and the

procedure detailed in Section 6A1, 2.24

BEAMING BRACE, MUST be followed.

11. Tighten all bolts and nuts to the torque

settings, as specified in

5. TORQUE SPECIFICATIONS, in this

Section.

12. Lower vehicle and check fluid level, refer to

2.1 FLUID LEVEL CHECK, in this Section.

3.14 TRANSMISSION COOLER PIPES

REMOVE

FOR V6 POWERED VEHICLES

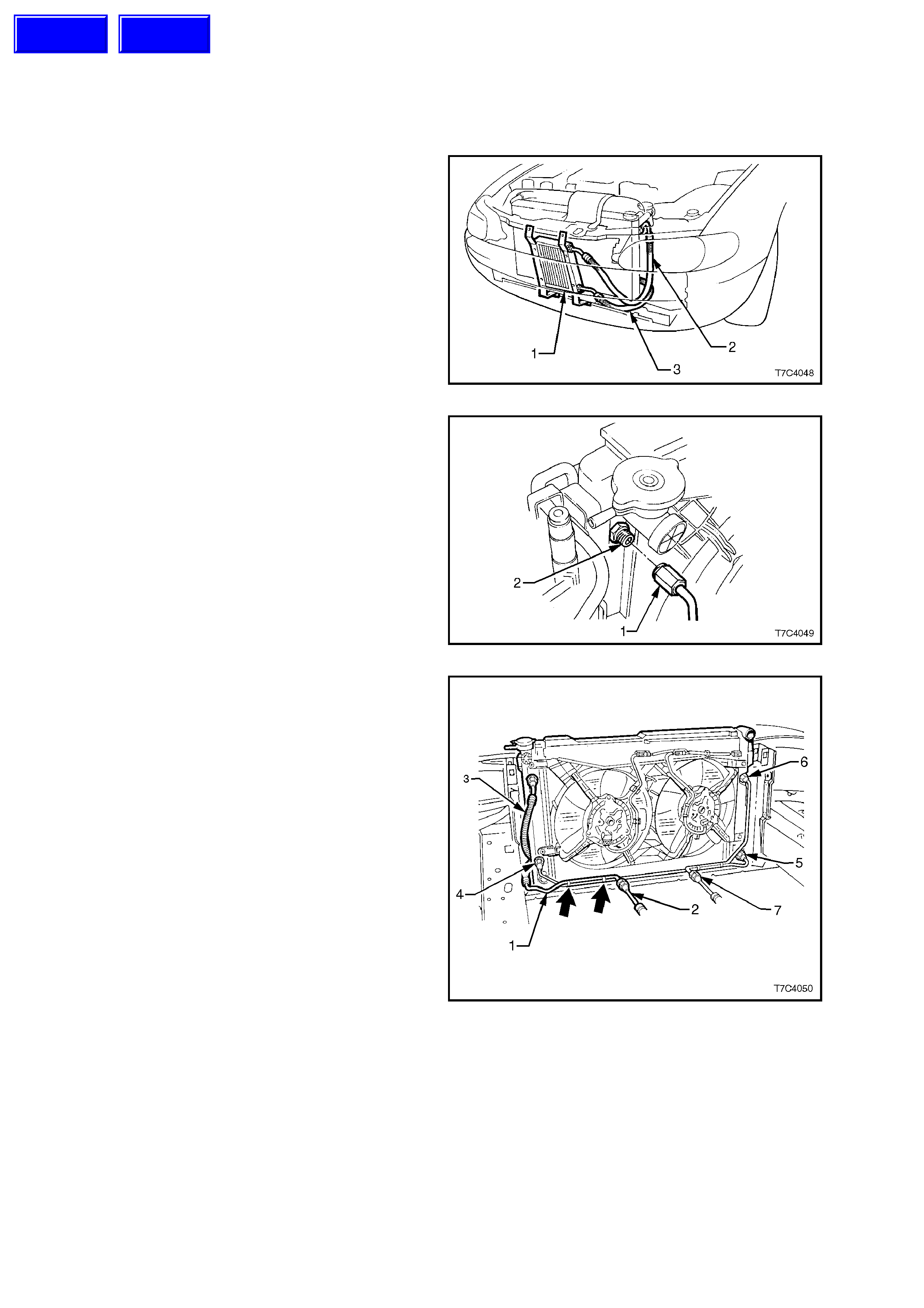

Auxiliary Oil Cooler Hoses

1. Place a drain tray beneath the front of the

vehicle.

2. With the engine hood raised, hold the unions

on the auxiliary oil cooler with a back-up

spanner and disconnect the two transmission

oil cooler hoses (2 and 3), at the auxiliary oil

cooler (1). To prevent foreign matter entry,

plug all open cooler connection points.

NOTE:

Removal of the upper right grille vent will make

access to the fittings, easier. Figure 7C4-59

3. Hold the union (2) at the top lef t of the radiator

tank with a back-up spanner and disconnect

the oil cooler hose (1) from that location.

Figure 7C4-60

4. Remove the clips securing the oil cooler pipes

to each other (arrows).

5. While using a back-up spanner on the

auxiliary oil cooler pipe, disconnect the

transmission return line pipe (2).

6. Remove both auxiliary oil cooler hose

assemblies from the vehicle.

Radiator Cooler P ipes

1. Hold the union at the lower left of the radiator

tank (4) with a back-up spanner and

disconnect the oil cooler pipe from that

location.

2. Repeat this removal operation for the two

pipes on the radiator right hand tank (5 and 6).

3. While using a back-up spanner on the oil

cooler pipe to transmission feed cooler hose

connection (7), disconnect the transmission

feed line hose.

4. Remove the radiator cooler pipes from the

vehicle, separating as required by removing

the pipe clips (arrows).

Figure 7C4-61

Techline

Techline

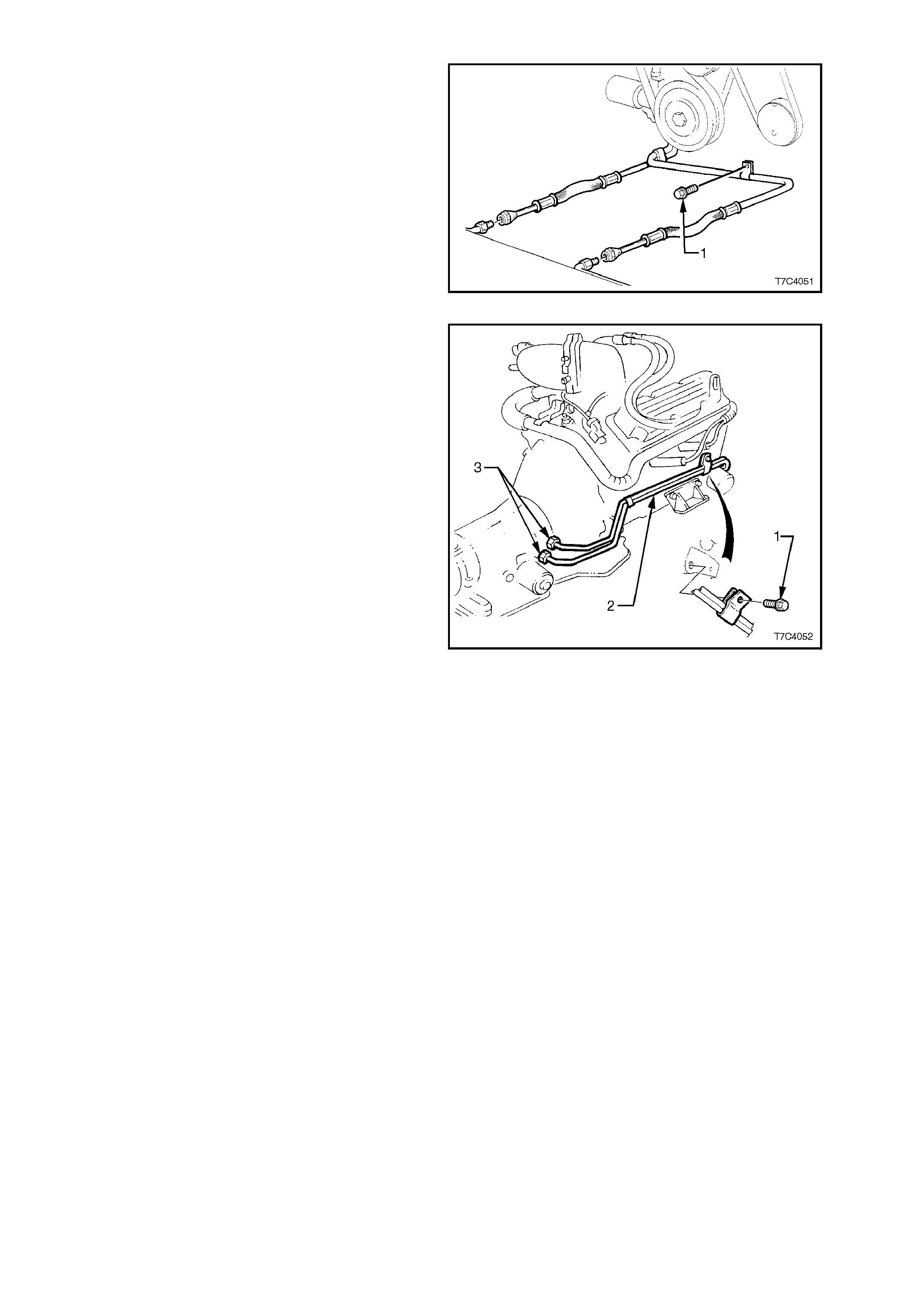

Transmission Oil Cooler Pipes

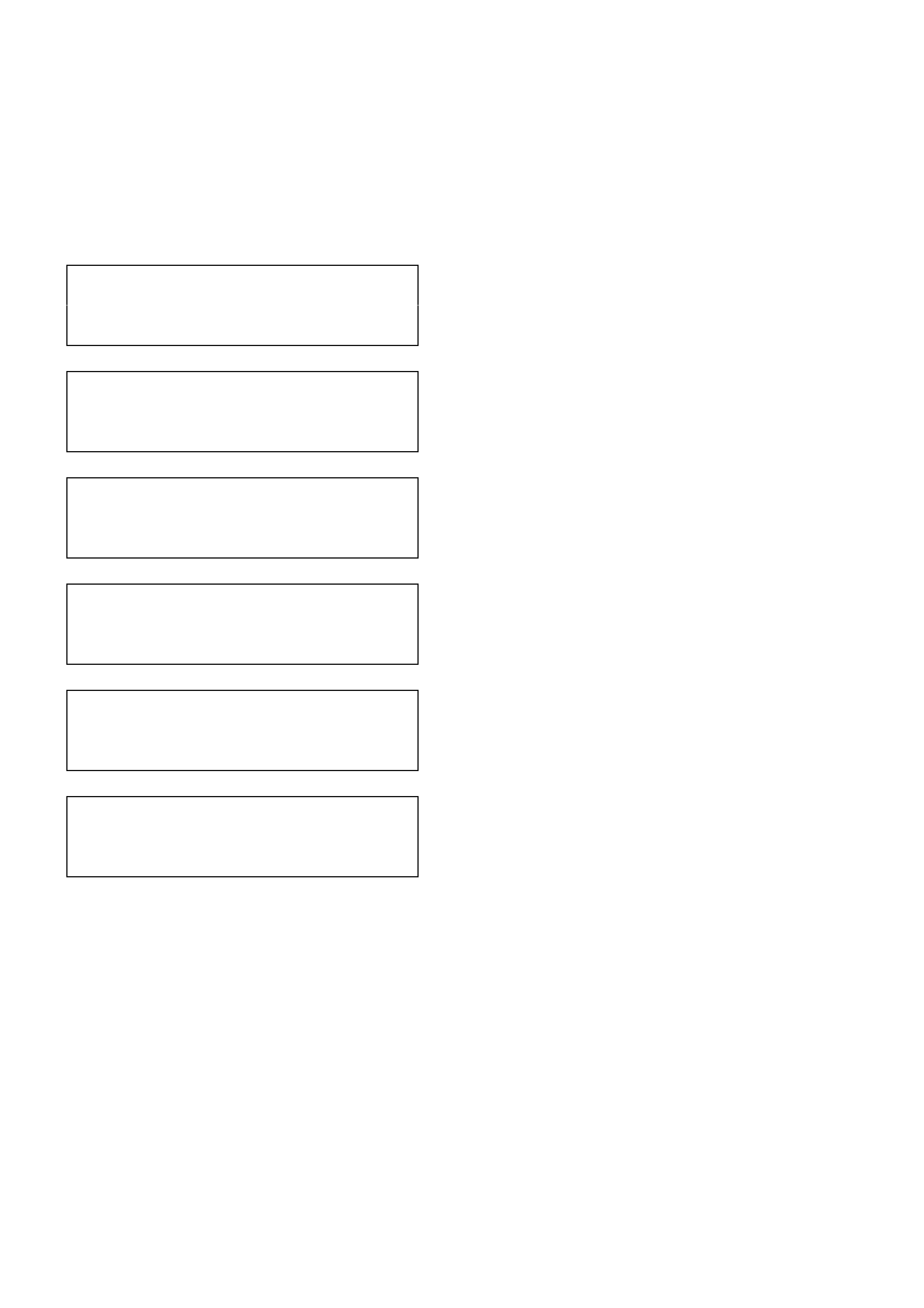

1. Remove the clamp bolt (1) securing the

transm ission return line pipe to the front of the

engine.

Figure 7C4-62

2. Remove the clamp bolt (1) securing the

transm ission cooler pipes (2) to the right hand

side of the engine, as shown.

3. Using a pipe spanner, loos en then rem ove the

transmission cooler pipes from the

transmission fittings (3).

NOTE 1:

Use a back-up spanner on the transmission fittings.

NOTE 2:

Applying heat to the pipe spanner and bending it

slightly to modify it, will assist in the loosening

process.

4. Remove the cooler pipes (2) from the vehicle

and separate if required, by rem oving the pipe

clip.

Figure 7C4-63

FOR V8 POWERED VEHICLES:

NOTE:

As an auxiliary oil cooler is not used with the

standard V8 engine, the oil cooler pipe removal

procedures described here, will only reflect this

transmission cooler arrangement.

Oil Cooler Hoses:

1. Hold the union at the top left of the radiator

tank (1) with a back-up spanner and

disconnect the oil cooler hose from that

location.

2. While using a back-up spanner on the

transmission cooler pipe (A), disconnect the oil

cooler hose and remove from the vehicle.

3. Hold the union at the top right of the radiator

tank (2) with a back-up spanner and

disconnect the oil cooler hose pipe from that

location. Remove the cooler pipe clips at the

top of the radiator shroud.

4. While using a back-up spanner on the

transmission cooler pipe (B), disconnect the oil

cooler hose and remove from the vehicle.

NOTE:

To prevent foreign matter entry, plug open

connection points at the radiator and transmission

oil cooler pipe.

Radiator Crossover Cooler Pipe

1. Hold the union at the lower left of the radiator

tank (3) with a back-up spanner and

disconnect the oil cooler pipe from that

location.

2. Repeat this removal operation for the lower

fitting on the radiator right hand tank (4).

3. Remove the radiator cross-over pipe from the

vehicle.

Figure 7C4-64

Transmission Oil Cooler Pipes

1. Remove the clamp bolt securing the

transmission cooler pipes to the front of the

engine (not shown).

2. Remove the clamp bolt (1) securing the

transm ission cooler pipes (2) to the right hand

side of the engine, as shown.

3. Using a pipe spanner, loosen, then remove the

transmission cooler pipes from the

transmission fittings (3).

NOTE 1:

Use a back-up spanner on the transmission fittings.

NOTE 2:

Applying heat to the pipe spanner and bending it

slightly to modify it, will assist in the loosening

process.

4. Remove the cooler pipes (2) from the vehicle

and separate if required, by rem oving the pipe

clip. Figure 7C4-65

REINSTALL

The installation process of the oil cooler

pipes/hoses, is the r everse to rem oval, except

for the following:

1. Ensure that all pipe clamps are fitted correctly

and that pipe/hose routings are as shown in

the removal illustrations.

2. Ensure that all fasteners and fittings are

tightened to the correct torque specifications.

TRANSMISSION OIL COOLER

PIPE BRACKET V6 Engine:

BOLT - V6 ENGINE 20 - 35 Nm

TORQUE SPECIFICATION

TRANSMISSION OIL

COOLER PIPE V6 Engine:

BRACKET SCREW 2.0 - 5.0 Nm

TORQUE SPECIFICATION

TRANSMISSION OIL

COOLER PIPE V8 Engine:

BRACKET SCREWS 5.0 - 8.0 Nm

TORQUE SPECIFICATION

OIL COOLER HOSE

FITTINGS TO V6 Engine:

AUXILIARY COOLER 25 - 30 Nm

TORQUE SPECIFICATION

OIL COOLER

HOSE FITTINGS All Engines:

TO RADIATOR 25 - 30 Nm

TORQUE SPECIFICATION

TRANSMISSION OIL COOLER

PIPE FITTINGS TO All Engines:

RADIATOR PIPES 20 - 23 Nm

TORQUE SPECIFICATION

3. Check for leaks and top up transmission fluid

level as required. Ref er to 2.1 FLUID LEVEL

CHECK in this Section.

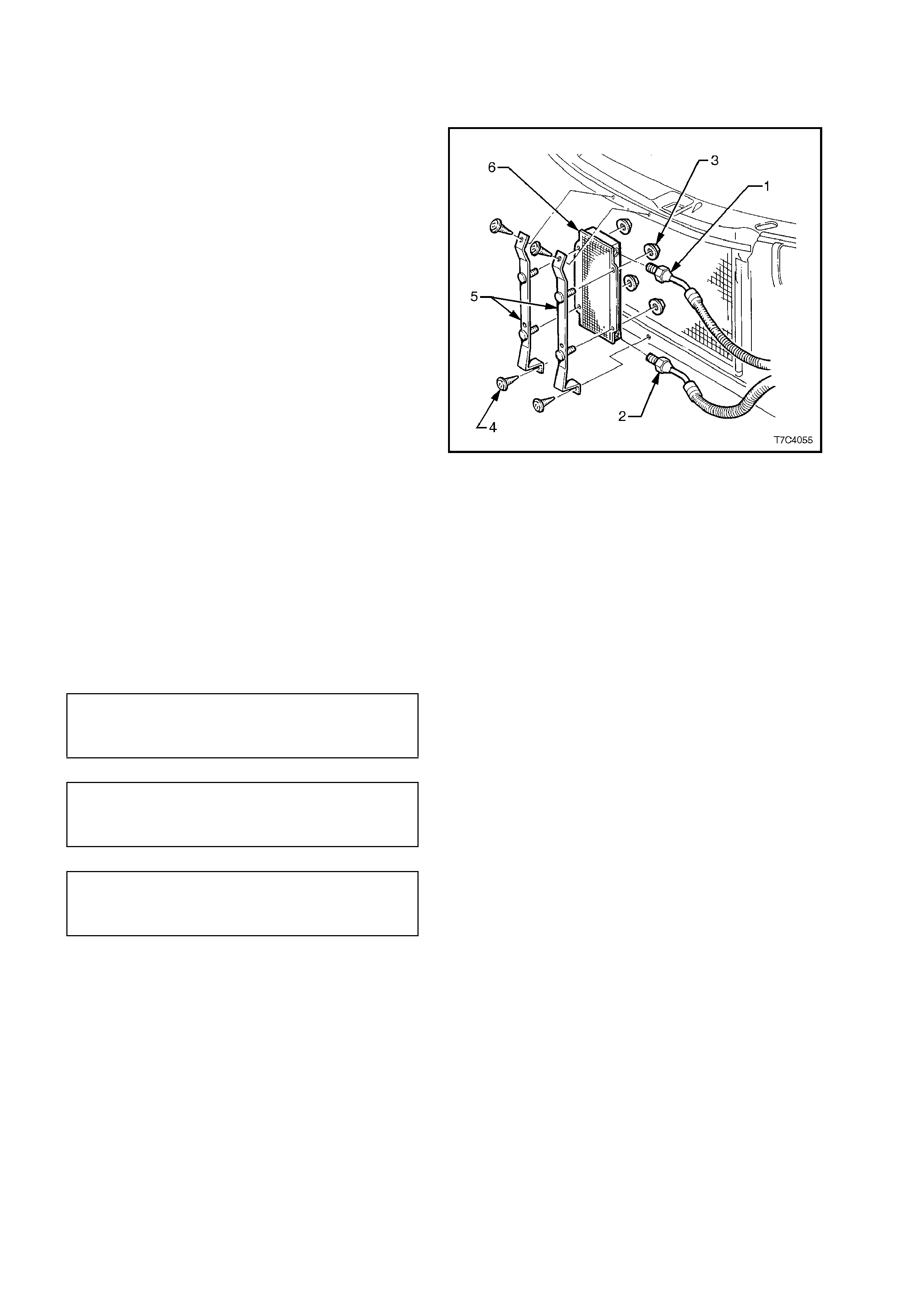

3.15 AUXILIARY OIL COOLER

REMOVE

1. Place a drip tray beneath the auxiliary oil

cooler assembly.

2. With the engine hood raised, hold the unions

on the auxiliary oil cooler (6) with a back-up

spanner and disconnect the two transmission

oil cooler hoses (1 and 2) at the auxiliary oil

cooler (6). To prevent foreign matter entry,

plug all open connections.

NOTE:

Removal of the upper right grille vent will make

access to the fittings, easier.

3. Remove the four auxiliary cooler mounting

bracket retaining nuts (3), then remove the

cooler (6) from the vehicle.

4. If required, remove the four screws (4)

securing the auxiliary cooler mounting

brackets (5), then remove them from the

vehicle.

NOTE:

In order to gain access to the bracket screws, it

will be necessary to remove the front bumper bar.

Refer to Section 1D BUMPER BARS.

Figure 7C4-66

REINSTALL

The installation process of the auxiliary oil cooler, is

the reverse to removal, except for the following:

1. Ensure that all fasteners and fittings are

tightened to the correct torque specifications.

OIL COOLER HOSE FITTINGS TO

AUXILIARY COOLER 25 - 30 Nm

TORQUE SPECIFICATION

AUXILIARY COOLER TO

MOUNTING BRACKET NUTS 5.0 - 12 Nm

TORQUE SPECIFICATION

AUXILIARY COOLER MOUNTING

BRACKET SCREWS 1.5 - 2.5 Nm

TORQUE SPECIFICATION

2. Check for leaks and top up transmission fluid

level as required. Ref er to 2.1 FLUID LEVEL

CHECK in this Section.

4. SPECIFICATIONS

NOTE:

For a complete listing of specifications as they apply to internal components not discussed in this Section, refer to

Section 7C5 HYDRA-MATIC 4L60-E AUTOMATIC TRANSMISSION: UNIT REPAIR.

GENERAL:

Type Hydra-matic 4L60-E

Transmission Code V6 Engine - 8HFD

V6 Supercharged Engine - 8HND

V8 Engine - 8HBD

Special Features Electronically controlled shift pattern, feel and torque

converter clutch operation

Selector Location Floor mounted console

GEAR RATIOS:

Park (P) —

Reverse (R) 2.294:1

Neutral (N) —

Drive (D) 0.696:1

Third (3) 1.000:1

Second (2) 1.625:1

First (1) 3.059:1

SHIFT SPEEDS: Refer to Section 7C3 DIAGNOSIS

OIL PRESSURE: Refer to Section 7C3 DIAGNOSIS

TORQUE CONVERTER:

Number of Elements 3 plus torque converter clutch

Maximum Torque Ratio at Stall V6 Engine - 1.63:1 (k=122)

V6 Supercharged Engine - 1.63:1 (k=133)

V8 Engine - 2.15:1 (k=115)

Nominal Diameter V6 Engine - 245 mm

V6 Supercharged Engine - 258 mm

V8 Engine - 298 mm

LUBRICANT:

Type Recommended DexronÒ III (To Holden's Specification HN2126)

Capacity Nominal Only. Check when transmission

is at operating temperature.

Refill V6 Engine - 4.8 litres

V8 Engine - 5.0 litres

Total (Dry) V6 Engine - 7.9 litres

V8 Engine - 10.6 litres

Fluid Cooling Engine coolant to fluid in both radiator tanks and

externally, air to fluid cooler (where fitted)

2 - 4 SERVO:

Selective Pin Length

1 Groove 65.82 - 66.12 mm

2 Grooves 67.23 - 67.53 mm

No Groove 68.64 - 68.94 mm

5. TORQUE WRENCH SPECIFI CATIONS

NOTE:

For a complete listing of torque wrench specifications as they apply to internal components not discussed in this

Section, refer to Section 7C5 HYDRA-MATIC 4L60-E A UTOMATIC TRANSMISSION: UNIT REPAIR.

Nm

Oil Pan Bolt 9.5 - 13.8

Manual Shaft Lever Nut 15 - 35

Manual Shaft to Inner Detent Lever Nut 27 - 34

Manual Detent Spring Retaining Nut 20 - 27

Selector Lever Locking Bolt 15 - 35

Selector Lever Base Nut 12 - 18

Neutral Start and Back-up Lamp Switch

Bolt 15 - 35

Speed Sensor Retaining Screw 10.5 - 13.5

1 - 2 Accumulator Cover Bolt 8 - 14

Control Valve Body Bolt 8 - 14

Torque Converter Clutch Solenoid Bolt 8 - 14

Spacer Plate Support Plate Bolt 8 - 14

Extension Housing to Case Bolt 42 - 48

Oil Cooler Pipe to Transmission Fitting 15 - 18

Rear Engine Mounting to Transmission

Extension Bolt 50 - 65

Rear Engine Mounting to Crossmember

Nut 20 - 30

Crossmember to Side Rail Attaching Bolt 50 - 65

Starter Motor Attaching Bolt - All Engines 40 - 60

Starter Motor Brace Bolt - V8 Engine 12 - 16

Torque Converter Housing to Engine

Block Bolt - V6 Engine 50 - 60

- V8 Engine 30 -45

Transmission Filler Tube Bracket

Retaining Bolt - V6 Engine 20 - 35

- V8 Engine 30 -45

Torque Converter to Engine Flexplate

Attaching Bolt 60 - 70

Torque Converter Lower Cover Attaching

Screw - All Engines 3.0 - 5.0

Beaming Brace to Engine Oil Pan Bolt - V6 Engine 20 - 35

Beaming Brace to Torque Converter

Housing Bolt - V6 Engine 50 - 85

Transmission Oil Cooler Pipe Bracket Bolt - V6 Engine 20 - 35

Transmission Oil Cooler Pipe Bracket

Screw - V6 Engine 2.0 - 5.0

- V8 Engine 5.0 - 8.0

Transmission Oil Cooler Pipe Fittings to

Oil Cooler Pipes - All 20 - 23

Oil Cooler Hose Fittings to Auxiliary Oil

Cooler - V6 Engine 25 - 30

Oil Cooler Hose Fittings to Radiator - All Engines 25 - 30

Auxiliary Oil Cooler to Mounting Bracket

Nut - V6 Engine 5.0 - 12

Auxiliary Oil Cooler Mounting Bracket

Screws - V6 Engine 1.5 - 2.5

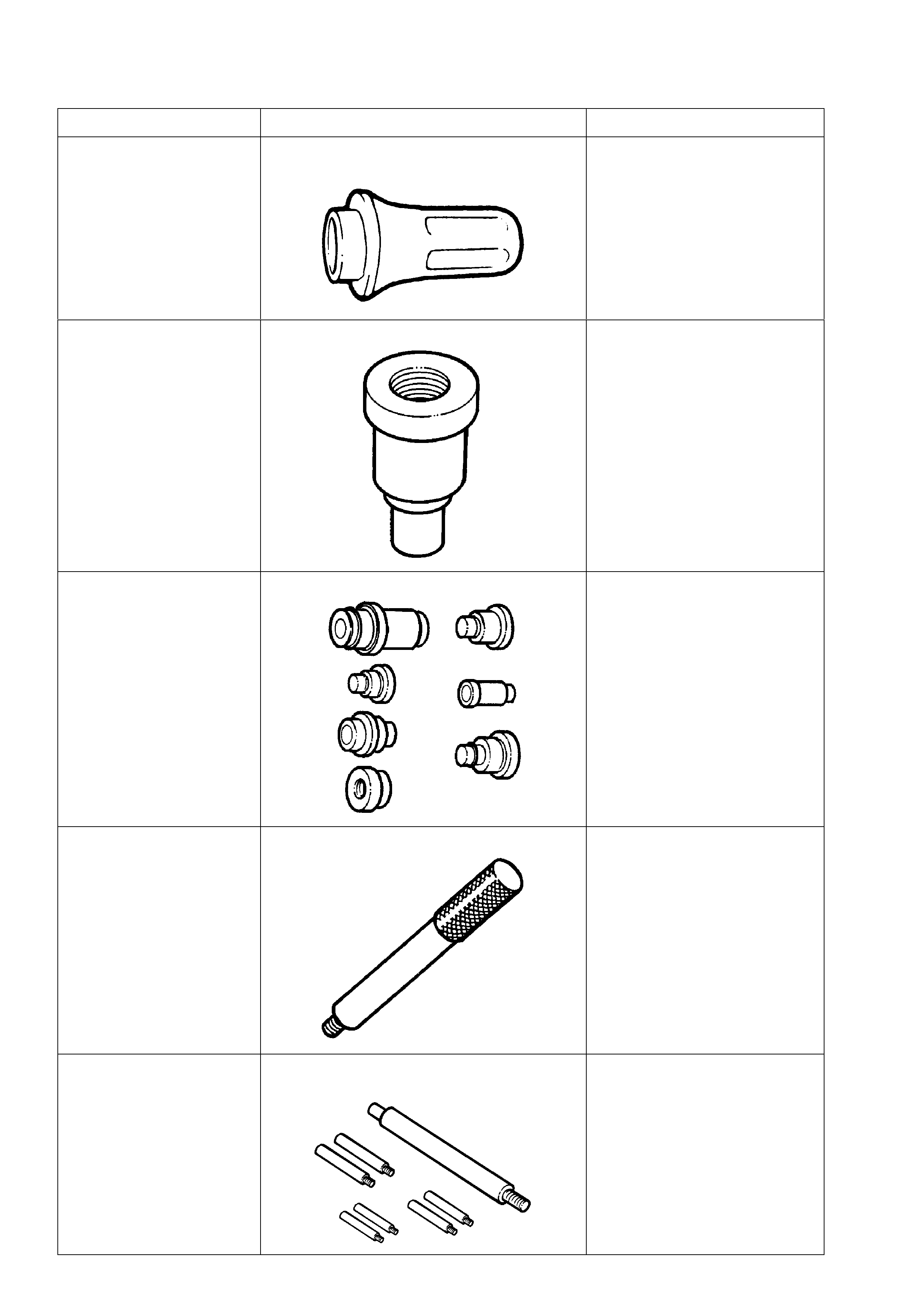

6. SPECIAL TOOLS

TOOL NO. REF IN TEXT TOOL DESCRIPTION COMMENTS

J21426 REAR EXTENSION HOUSING SEAL

INSTALLER PREVIOUSLY RELEASED

FOR TRIMATIC, AS 7AT-6.

J23062-14 BUSH REMOVER NEW RELEASE. USED IN

CONJUNCTION WITH DRIVER

HANDLE J8092.

J34196-B BUSH REMOVER/INSTALLER SET NEW RELEASE. INSTALLER

J34196-4 IS USED TO

INSTALL THE EXTENSION

HOUSING BUSH.

J8092 DRIVER HANDLE PREVIOUSLY RELEASED.

J25025-1 DIAL INDICATOR STAND AND GUIDE PIN

SET PREVIOUSLY RELEASED.

USED HERE FOR THE GUIDE

PINS FOR ALIGNING THE

CONTROL VALVE BODY

SPACER PLATE

TOOL NO. REF IN TEXT TOOL DESCRIPTION COMMENTS

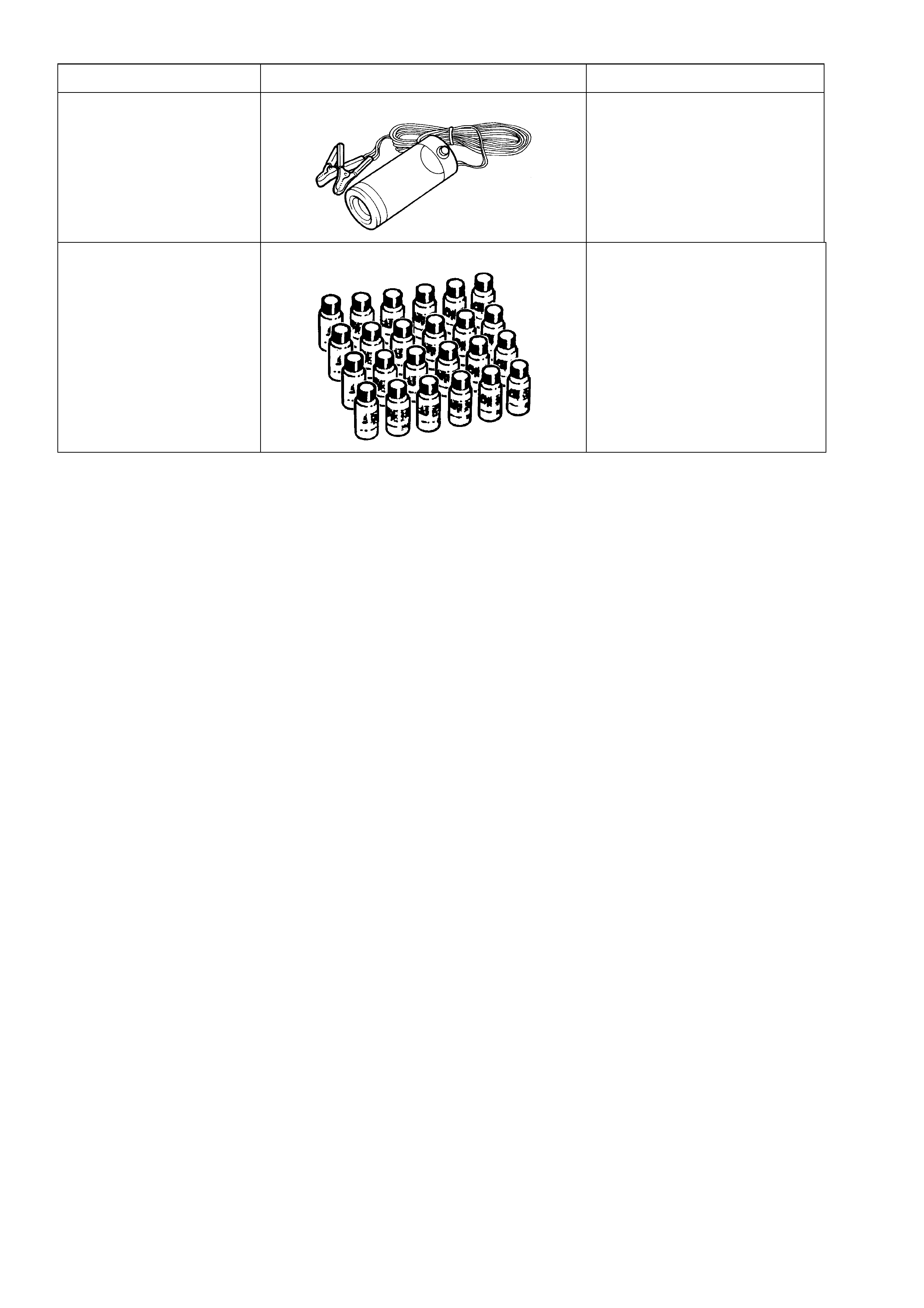

J42220 12 VOLT BLACK LIGHT PREVIOUSLY AVAILABLE

J28431-B

(24 X 1 FLUID OUNCE

BOTTLES)

FLUORESCENT OIL DYE PREVIOUSLY AVAILABLE.

USED IN CONJUNCTION

WITH 12V BLACK LIGHT.

SUITABLE FOR LOCATING

ENGINE TRANSMISSION AND

POWER STEERING FLUID

LEAKS